Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6505 results about "Structure based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An articulated structured light based-laparoscope

The present invention provides a structured-light based system for providing a 3D image of at least one object within a field of view within a body cavity, comprising: a. An endoscope; b. at least one camera located in the endoscope's proximal end, configured to real-time provide at least one 2D image of at least a portion of said field of view by means of said at least one lens; c. a light source, configured to real-time illuminate at least a portion of said at least one object within at least a portion of said field of view with at least one time and space varying predetermined light pattern; and, d. a sensor configured to detect light reflected from said field of view; e. a computer program which, when executed by data processing apparatus, is configured to generate a 3D image of said field of view.

Owner:TRANSENTERIX EURO SARL

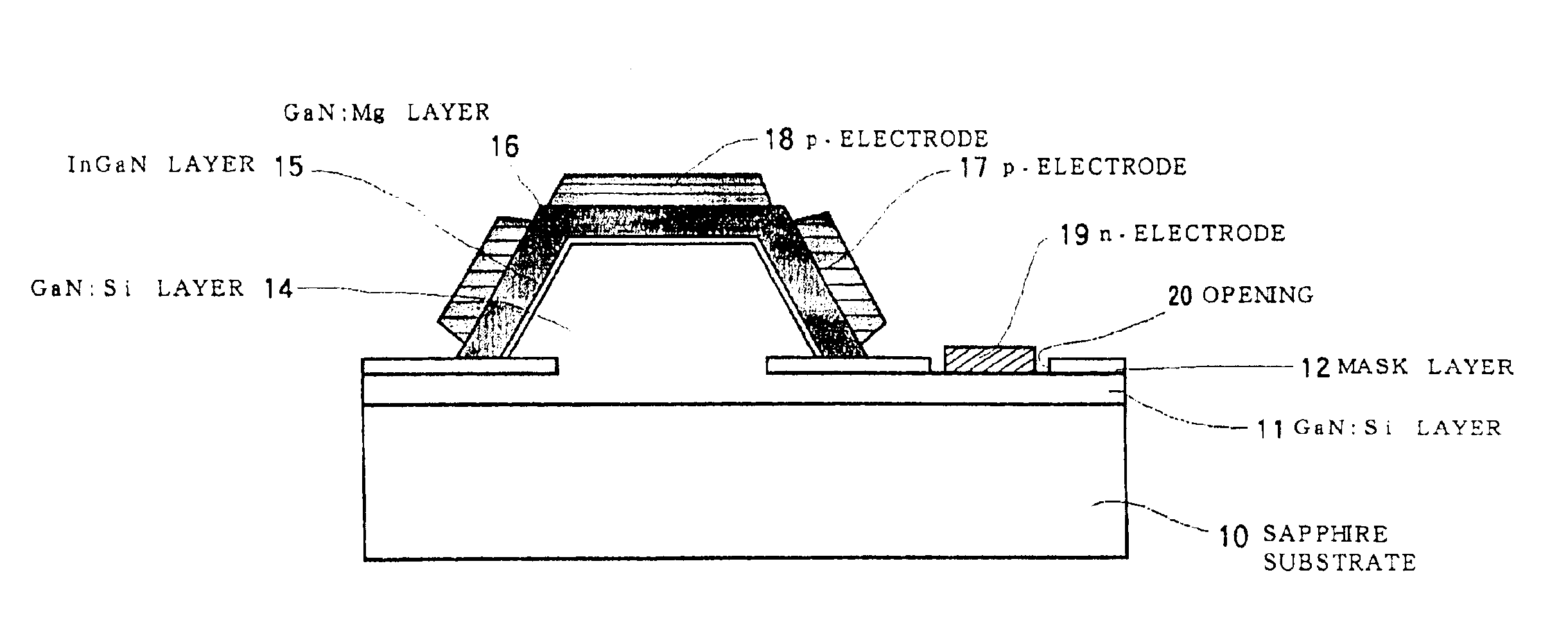

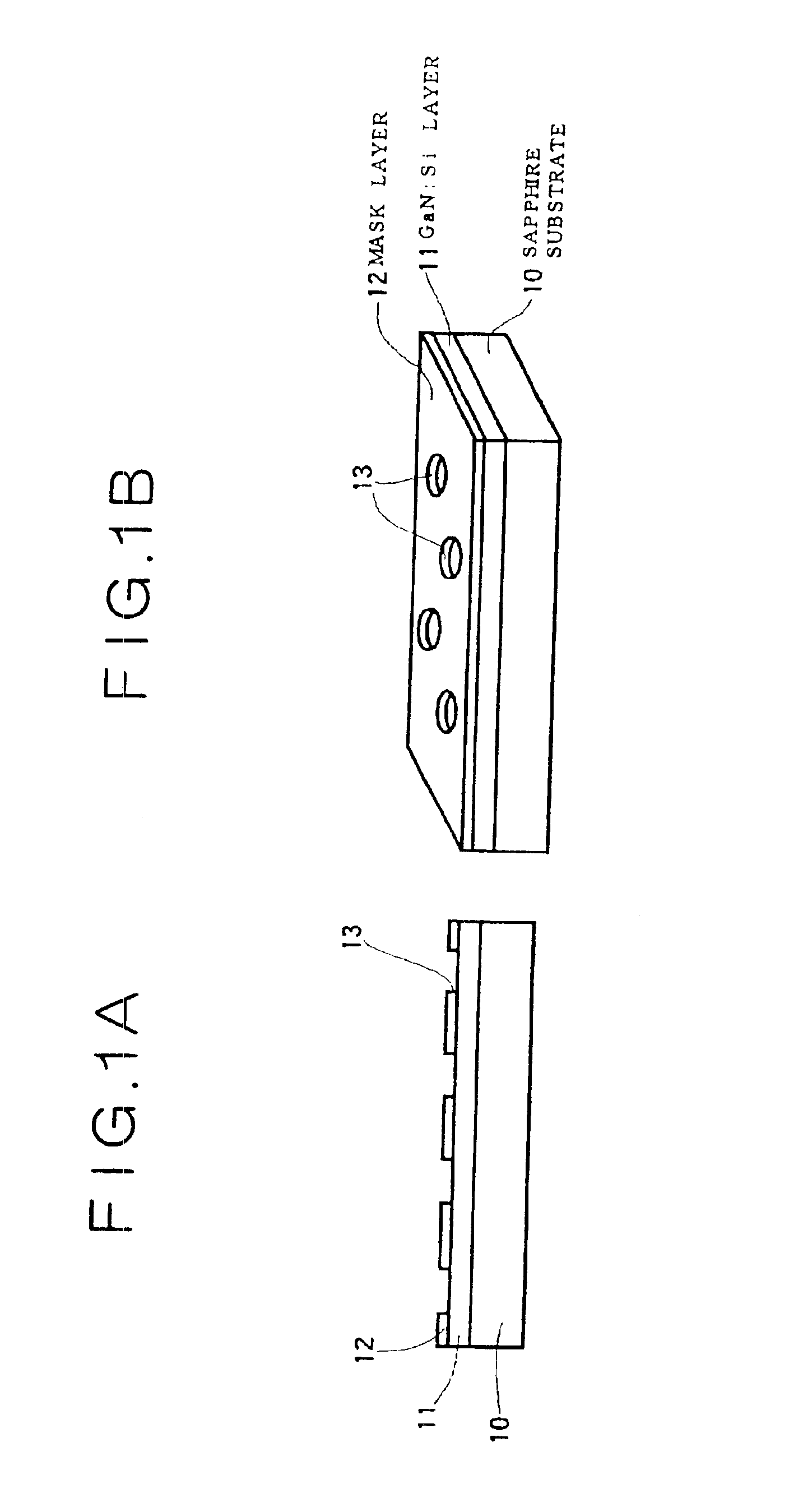

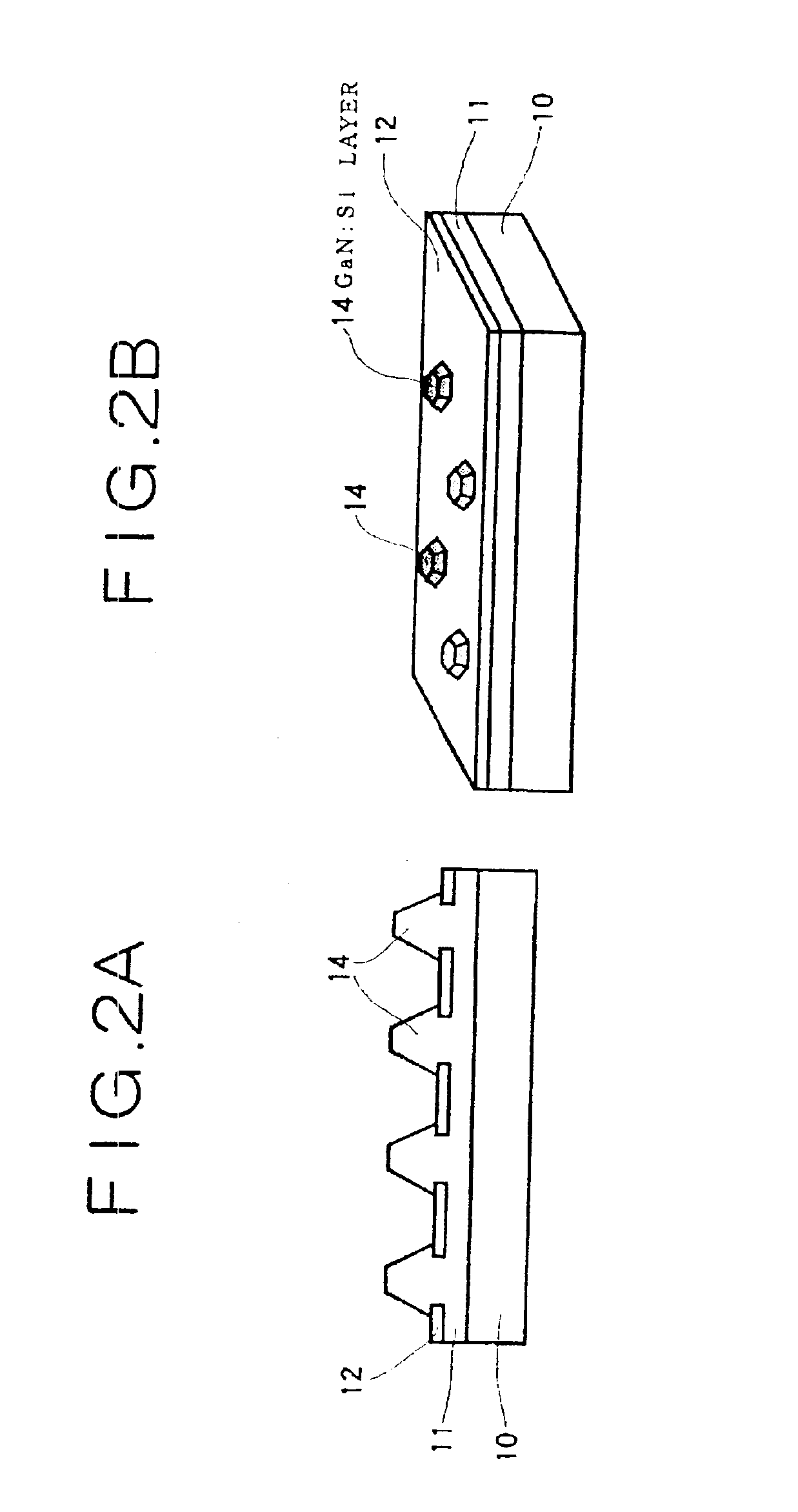

Semiconductor light-emitting device and semiconductor light-emitting device

InactiveUS7087932B2Well formedSolid-state devicesSemiconductor/solid-state device manufacturingCrystal planeCrystallinity

Owner:SAMSUNG ELECTRONICS CO LTD

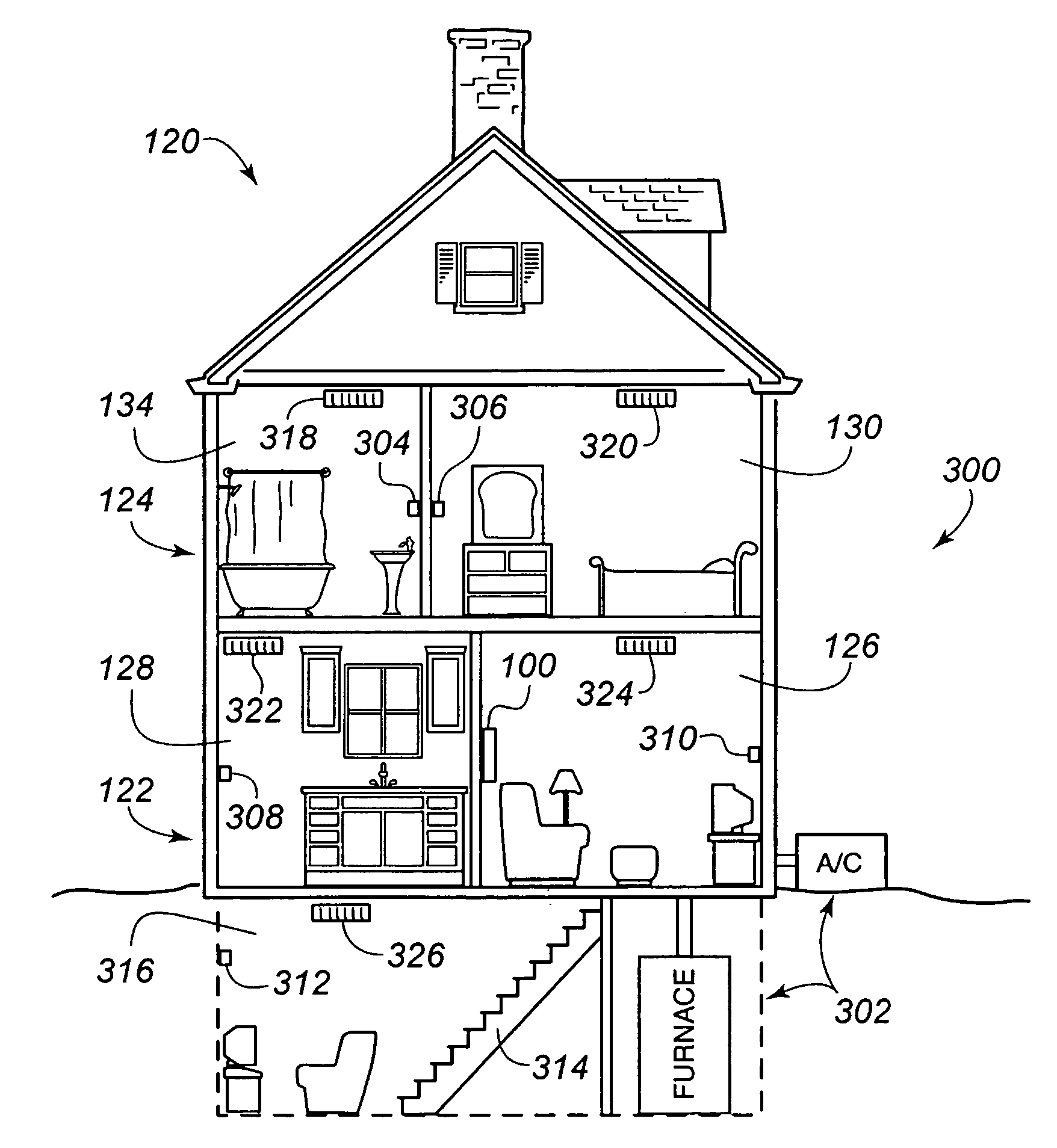

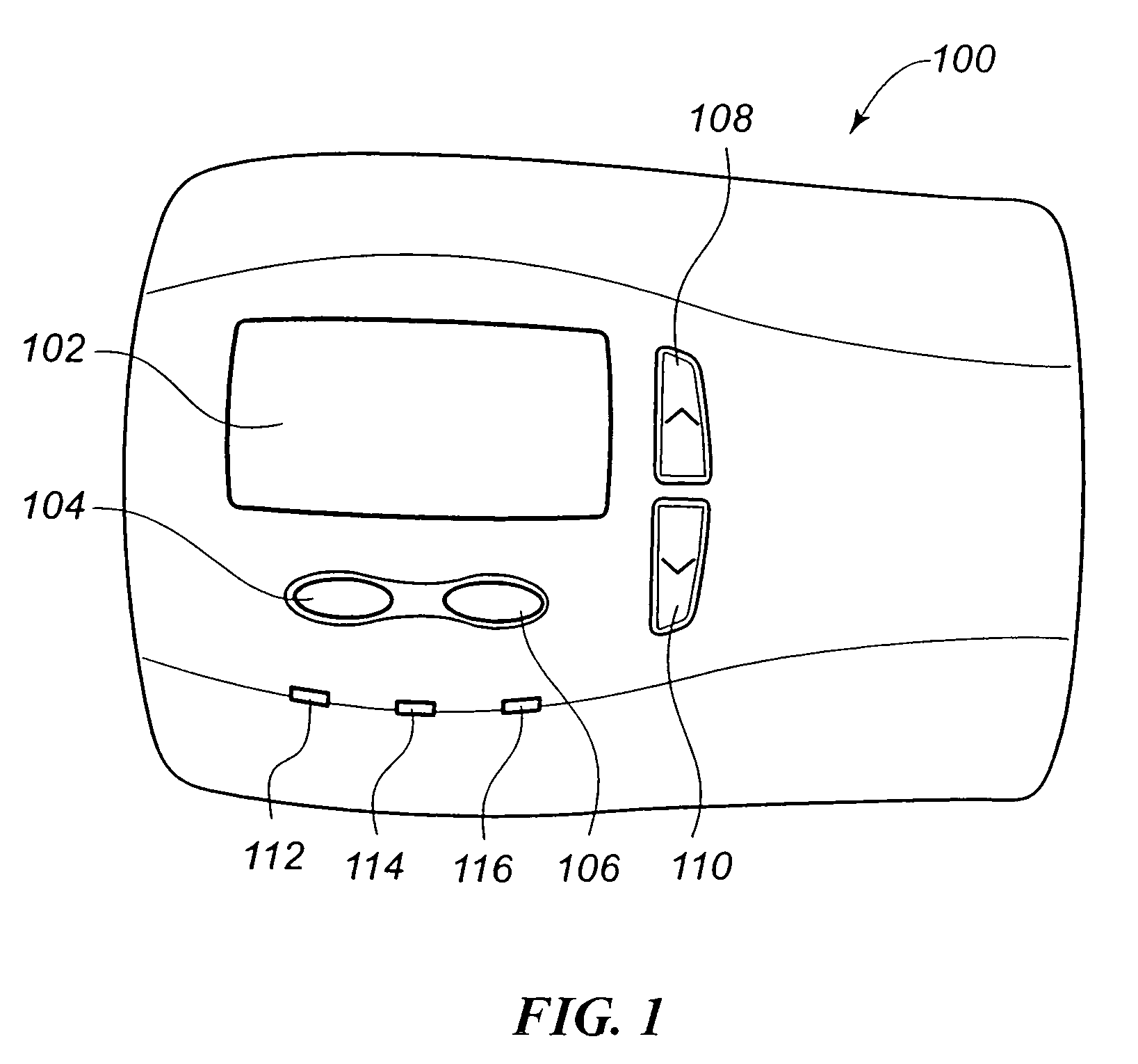

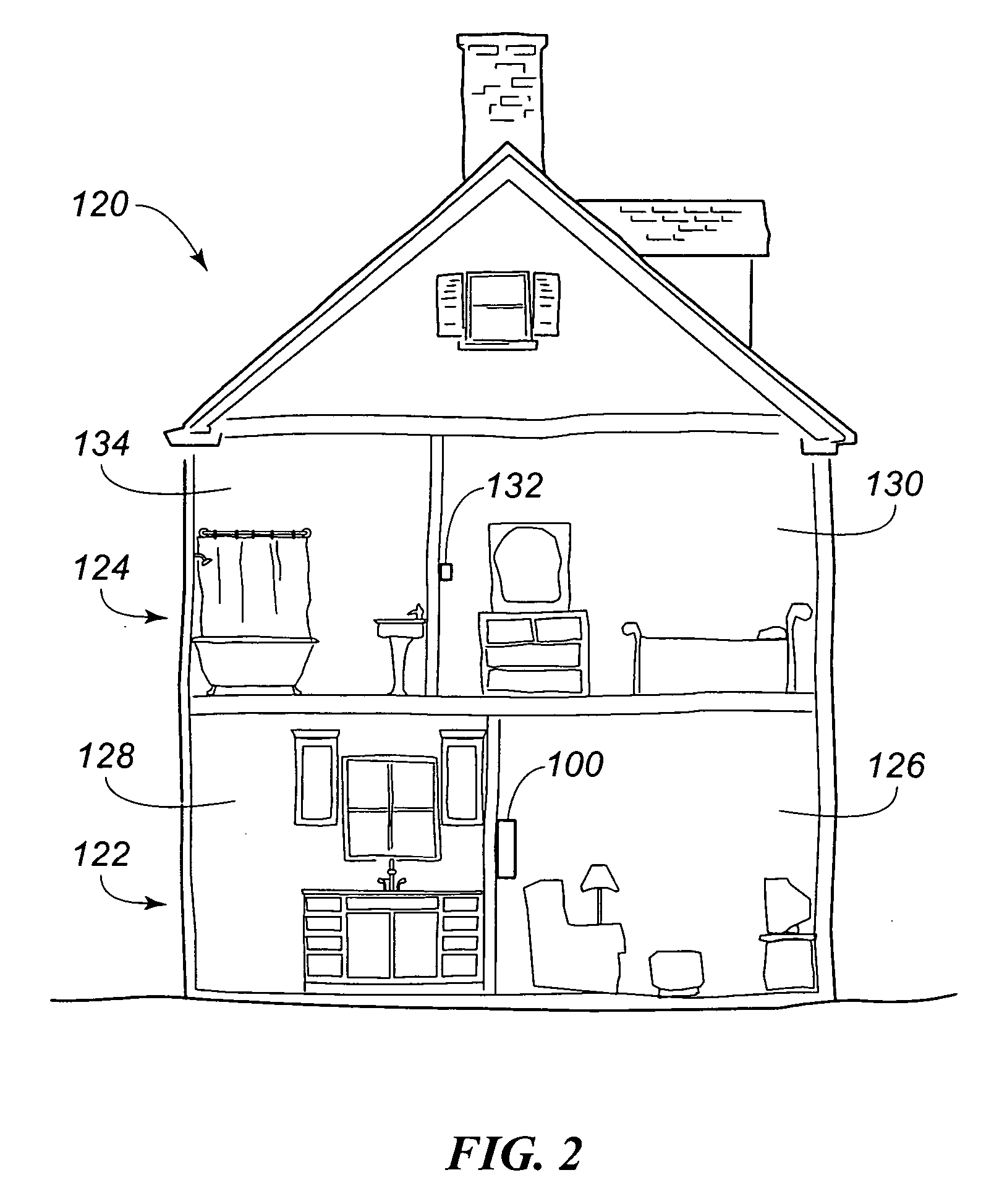

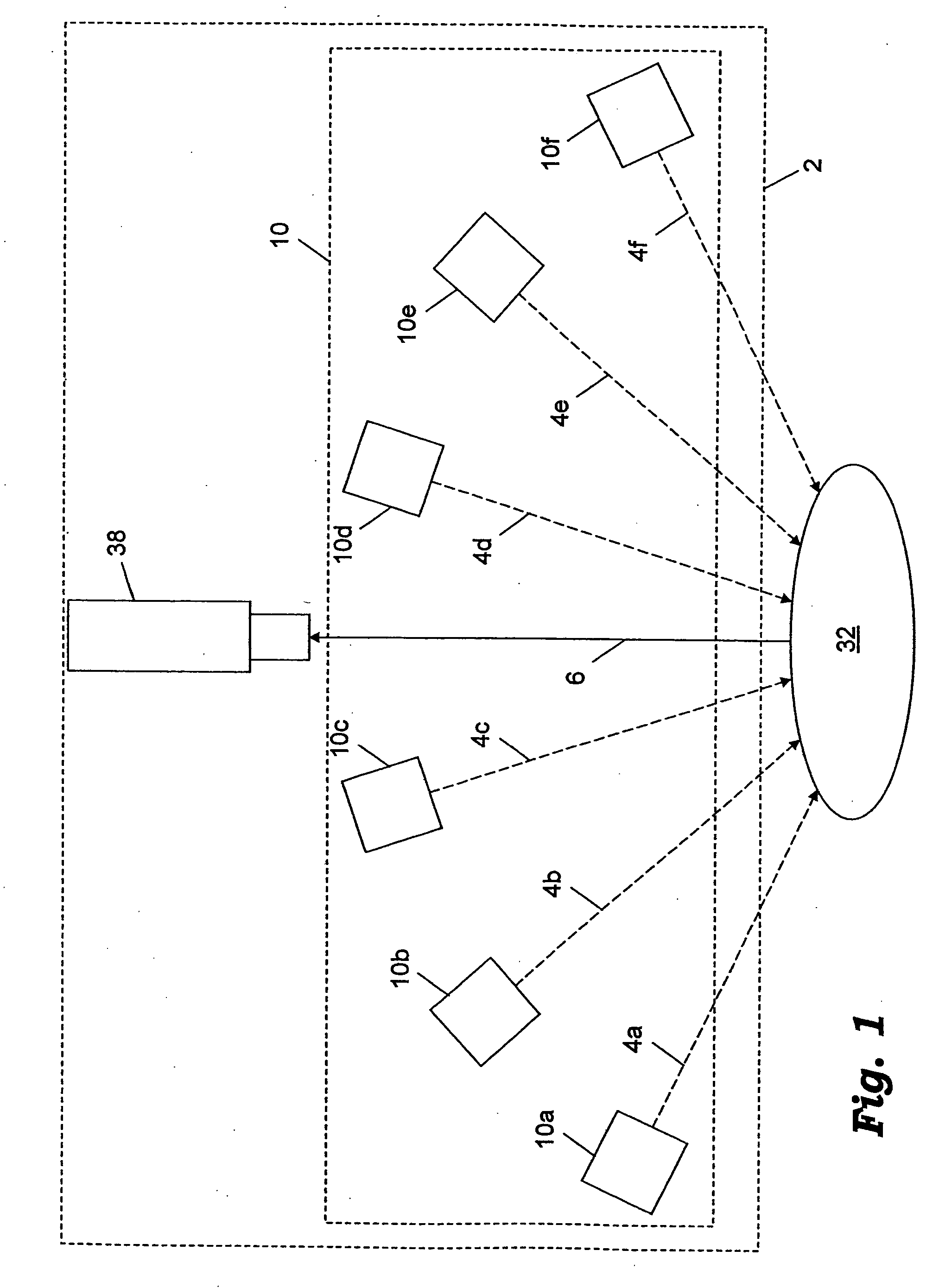

Occupancy-based zoning climate control system and method

InactiveUS20070045431A1Improve comfortImprove energy efficiencyTemperature control without auxillary powerMechanical apparatusControl systemEngineering

A control system for managing a heating, ventilating and air conditioning (HVAC) system based on occupancy of an area is provided. The occupancy may be determined by anticipated programming based on time of day zoning, and / or by actual sensed occupancy. In the later, the control system includes an occupancy sensor that communicates with a programmable thermostat. The occupancy sensor is disposed in the area and senses a state of occupancy of the area. The programmable thermostat instructs the HVAC system to adjust the temperature of the area within the structure based on the state of occupancy of that particular area to enhance occupant comfort and energy efficiency. The thermostat may also include programming modes or scripts that may be run to adjust operational control when abnormal occupancy conditions are sensed. Controllable dampers may also be used by the thermostat to achieve micro zoning control of the HVAC system.

Owner:RANCO OF DELAWARE

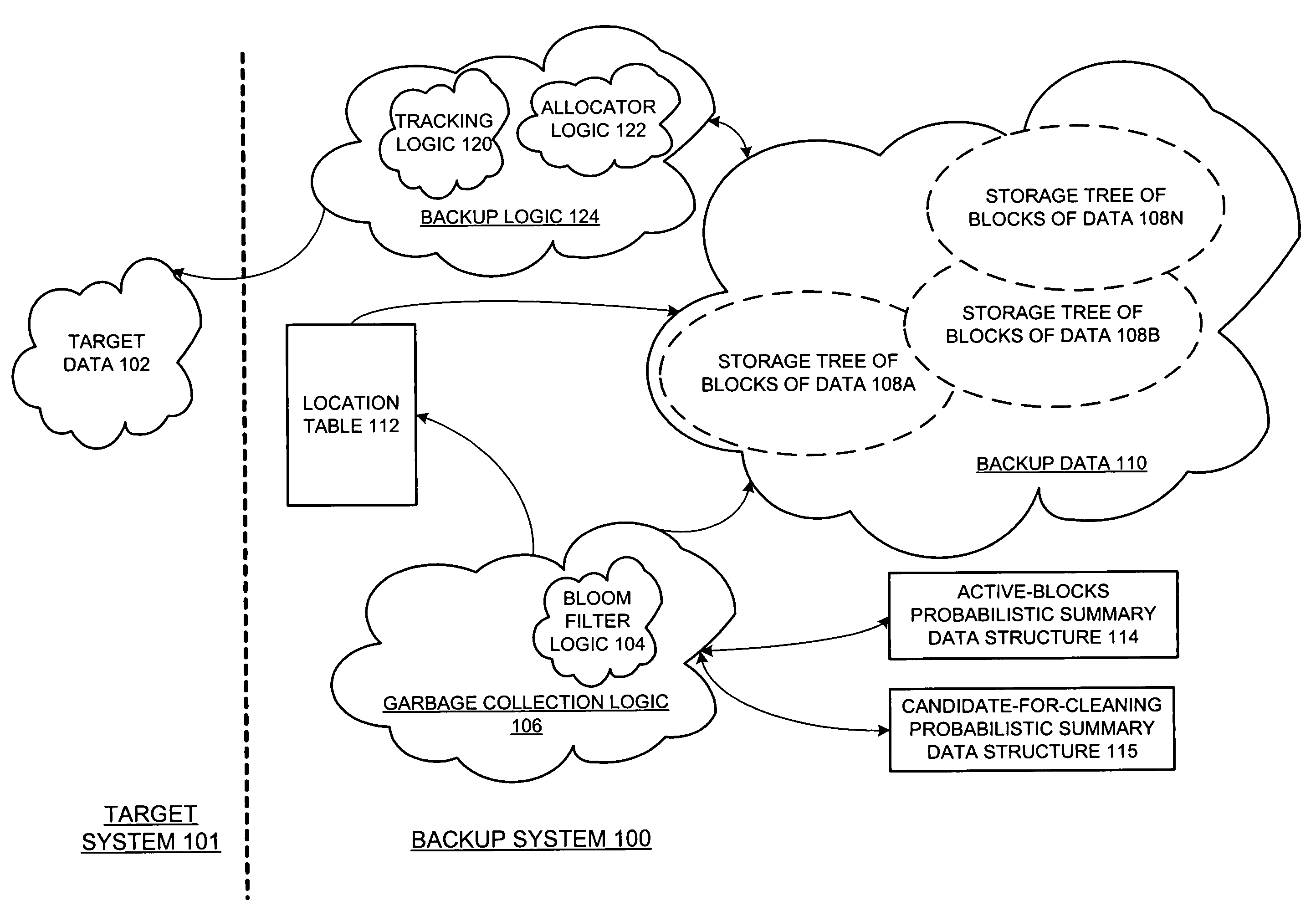

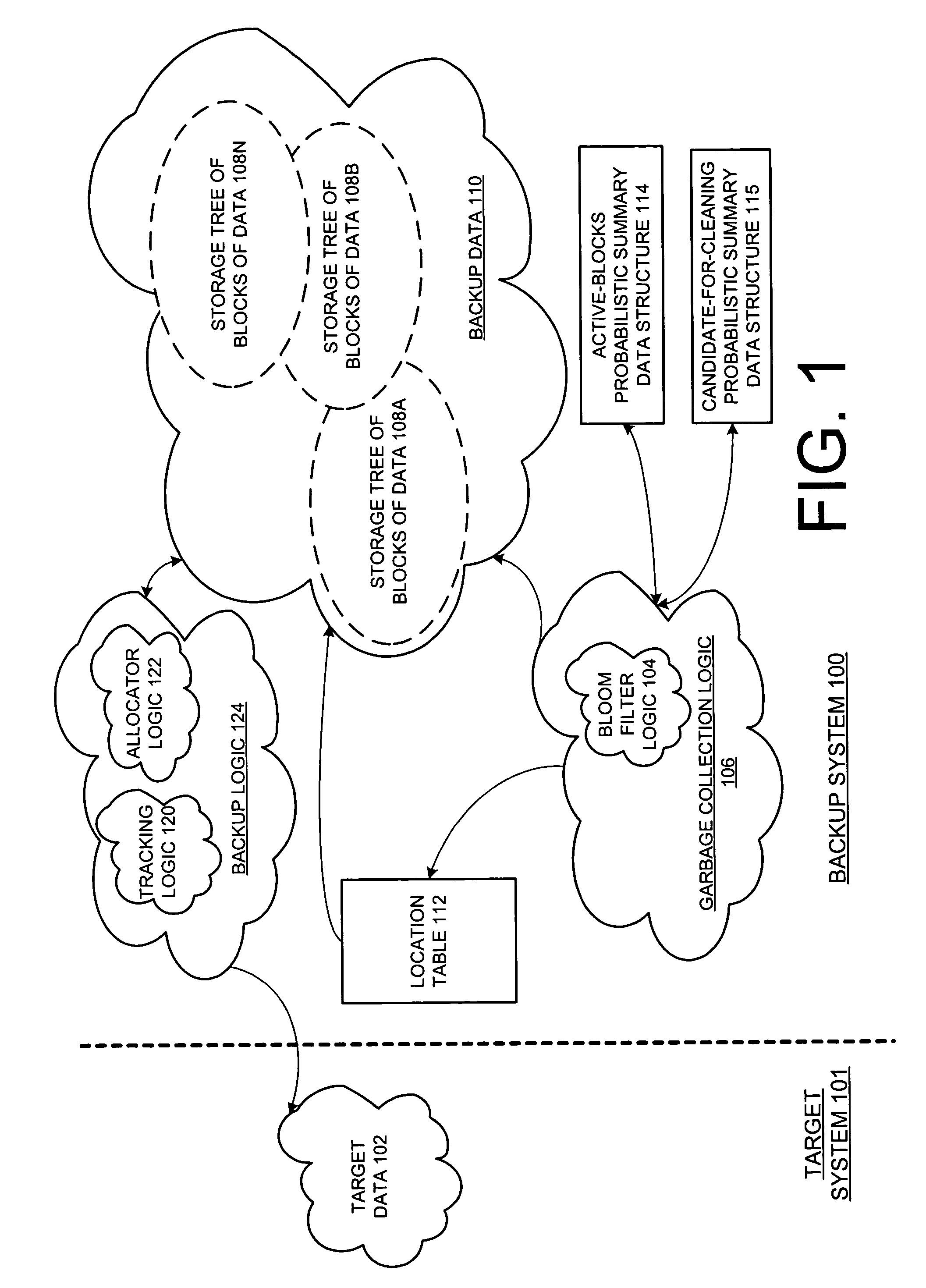

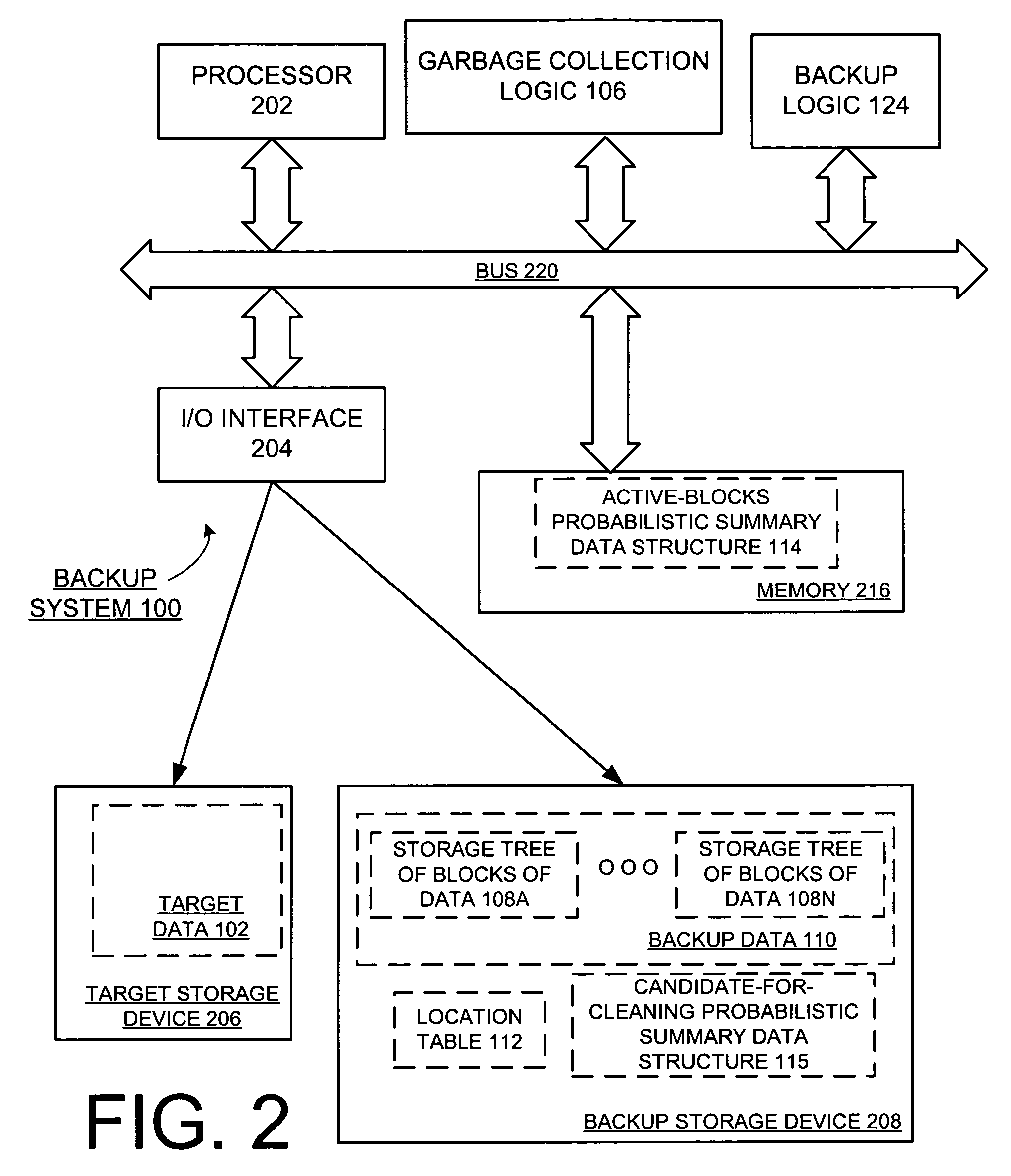

Probabilistic summary data structure based encoding for garbage collection

ActiveUS7424498B1Reduce data volumeIncrease the amount of dataData processing applicationsDigital data processing detailsSummary dataWaste collection

A method and apparatus for different embodiments of probabilistic summary data structure based encoding for garbage collection are described. In one embodiment, a method comprises generating a probabilistic summary data structure that represents active blocks of data within a storage device based on identifications of the active blocks or the data within the active blocks. The method also includes performing garbage collection of at least a portion of the storage device based on the probabilistic summary data structure.

Owner:EMC IP HLDG CO LLC

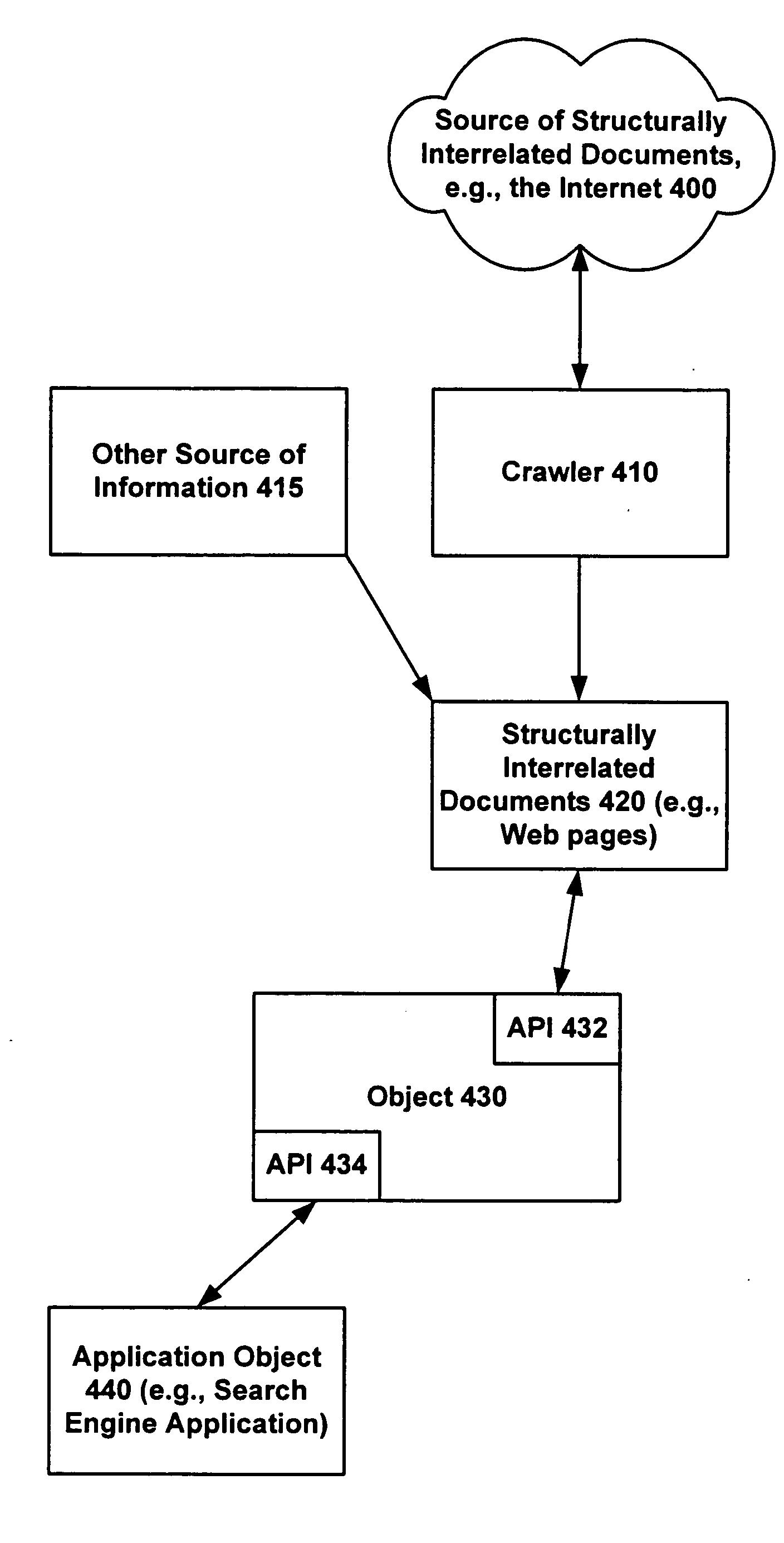

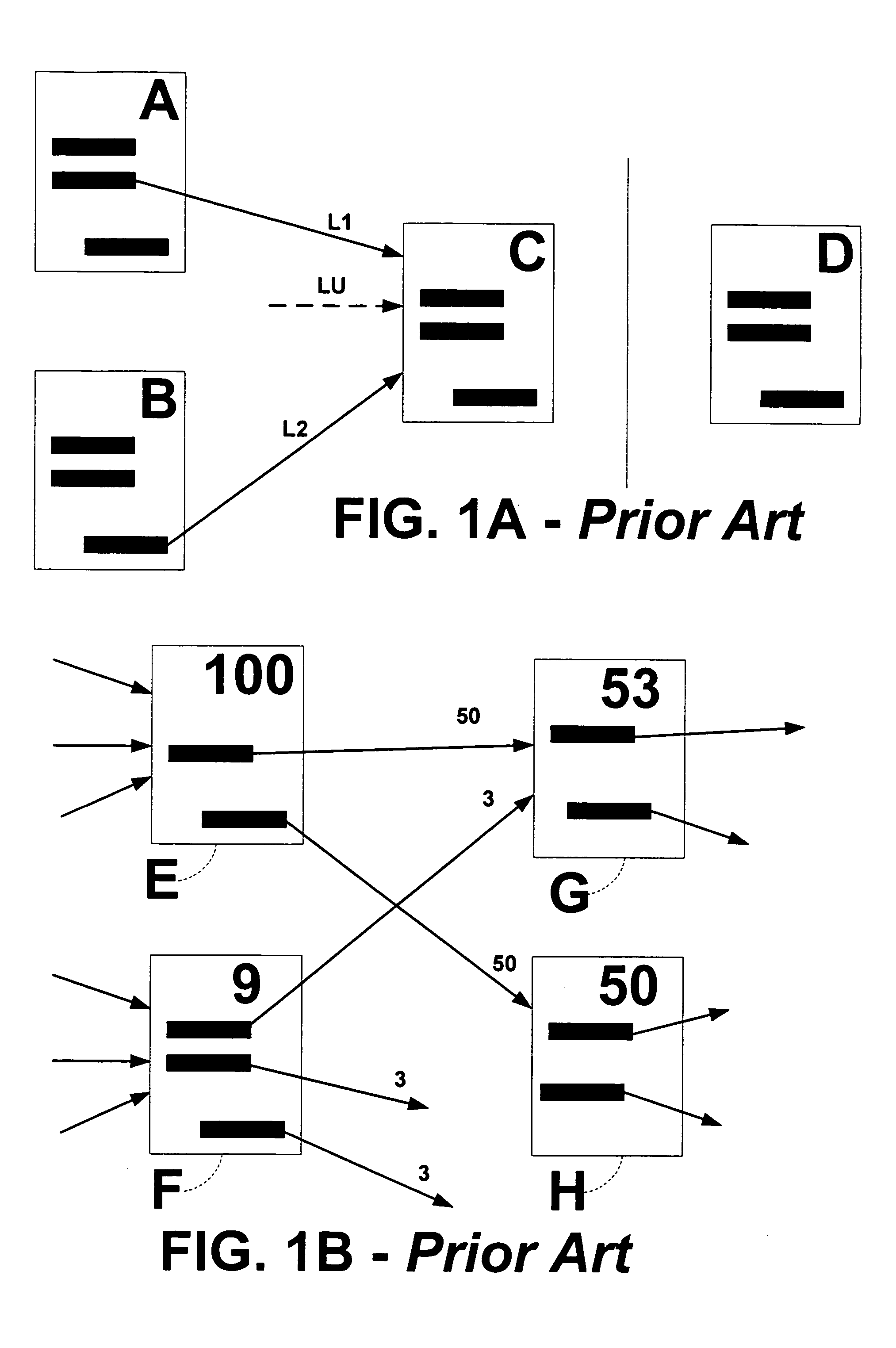

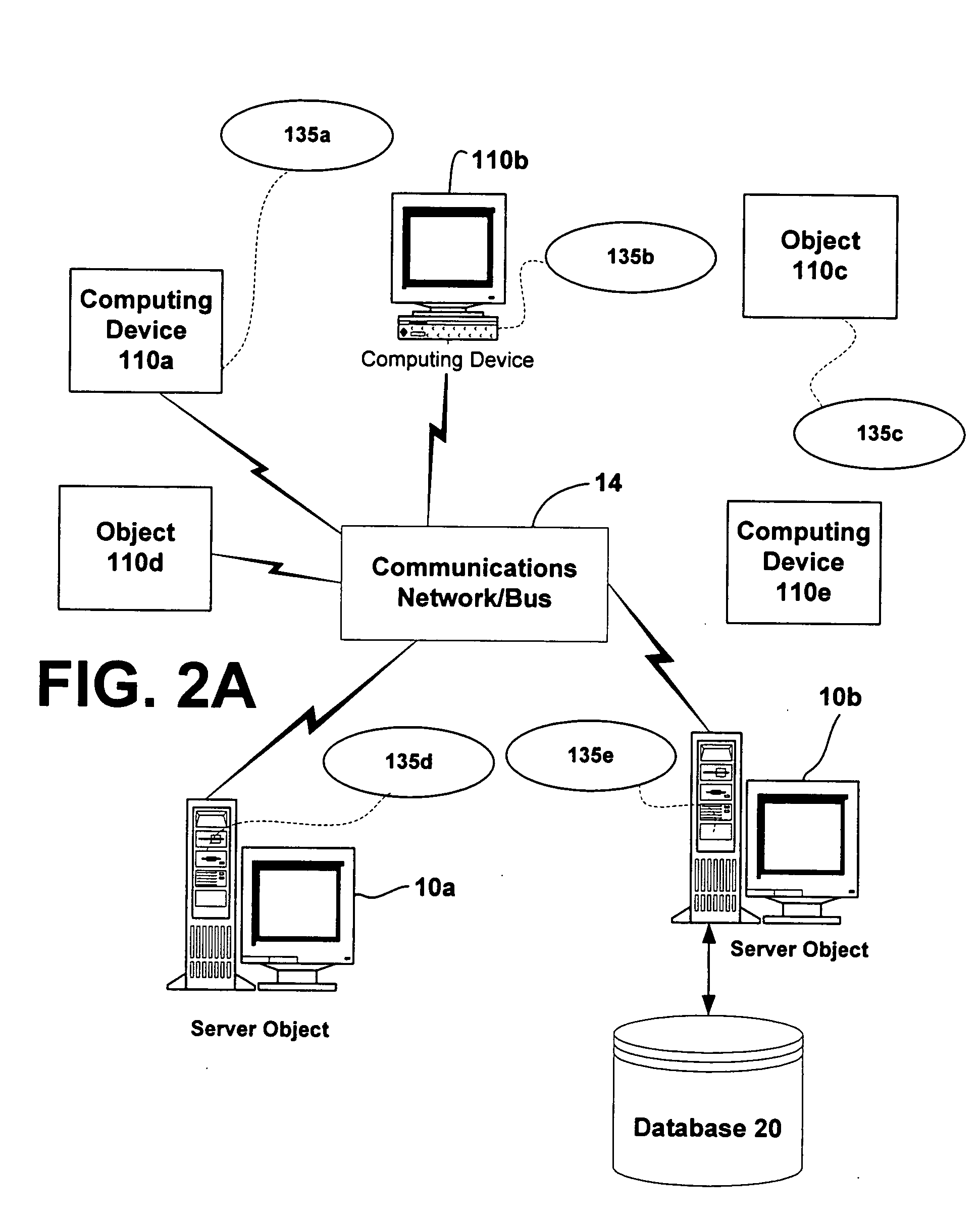

Systems and methods for ranking documents based upon structurally interrelated information

InactiveUS20050060297A1Reduce the impactData processing applicationsWeb data indexingHyperlinkPaper document

Systems and methods for ranking Web pages based on hyperlink information in a manner that is resistant to nepotistic links are provided. In one embodiment, a Web search service is provided for returning quality query results. The vulnerability of existing ranking algorithms, such as PageRank, to Web pages that are artificially generated for the sole purpose of inflating the score of target page(s) is addressed. Intuitively, it is recognized that it is less likely to reach a particular page on a Web server having many pages via a random jump than it is to reach a particular page on a Web server having few pages, which implies that the influence of such a page upon another page by linking to, or endorsing, the other page is diminished. Thus, in various non-limiting embodiments, each Web server, not each Web page, is assigned a guaranteed minimum score. This minimum score assigned to a server can then be divided among all the pages on that Web server.

Owner:MICROSOFT TECH LICENSING LLC

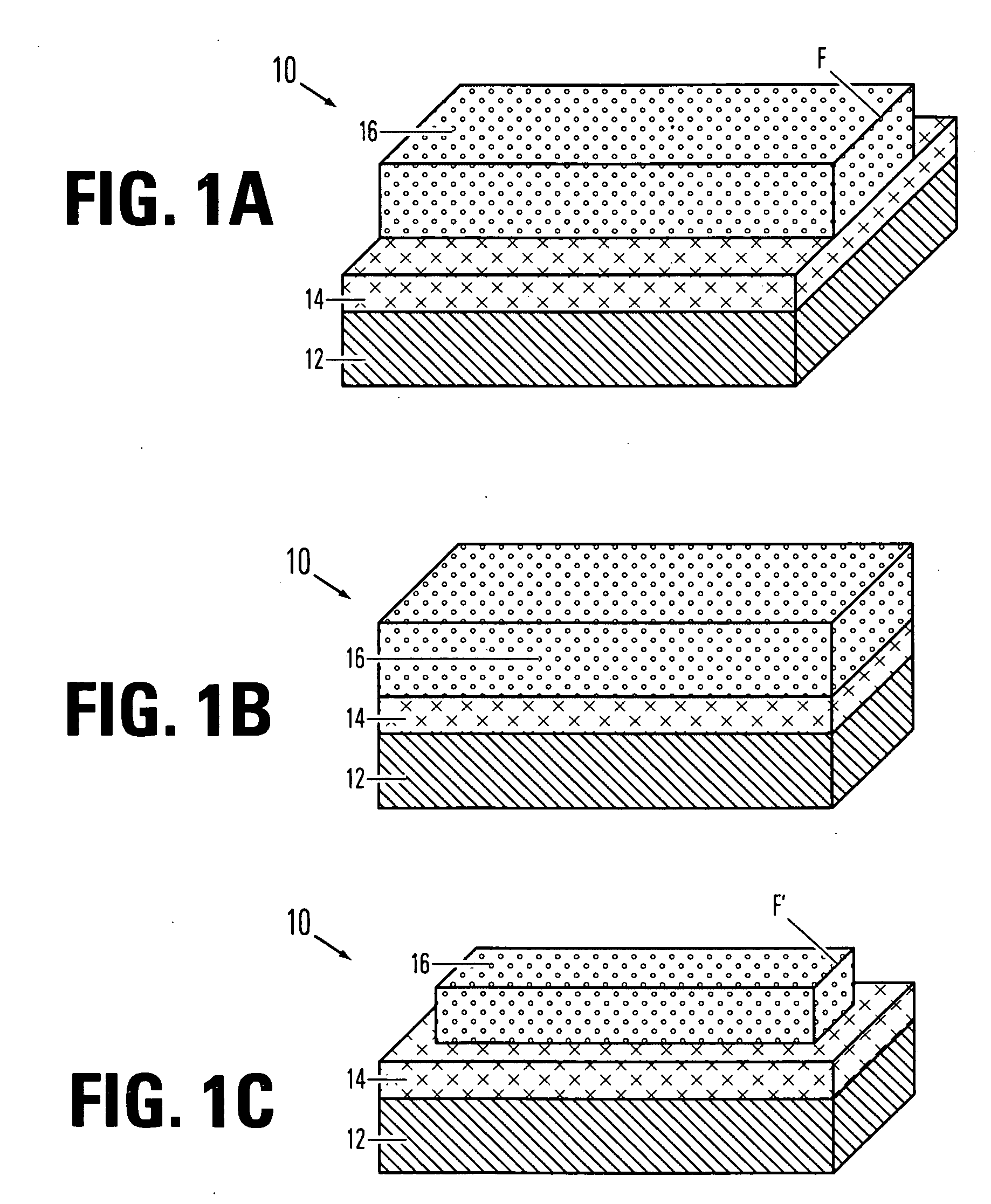

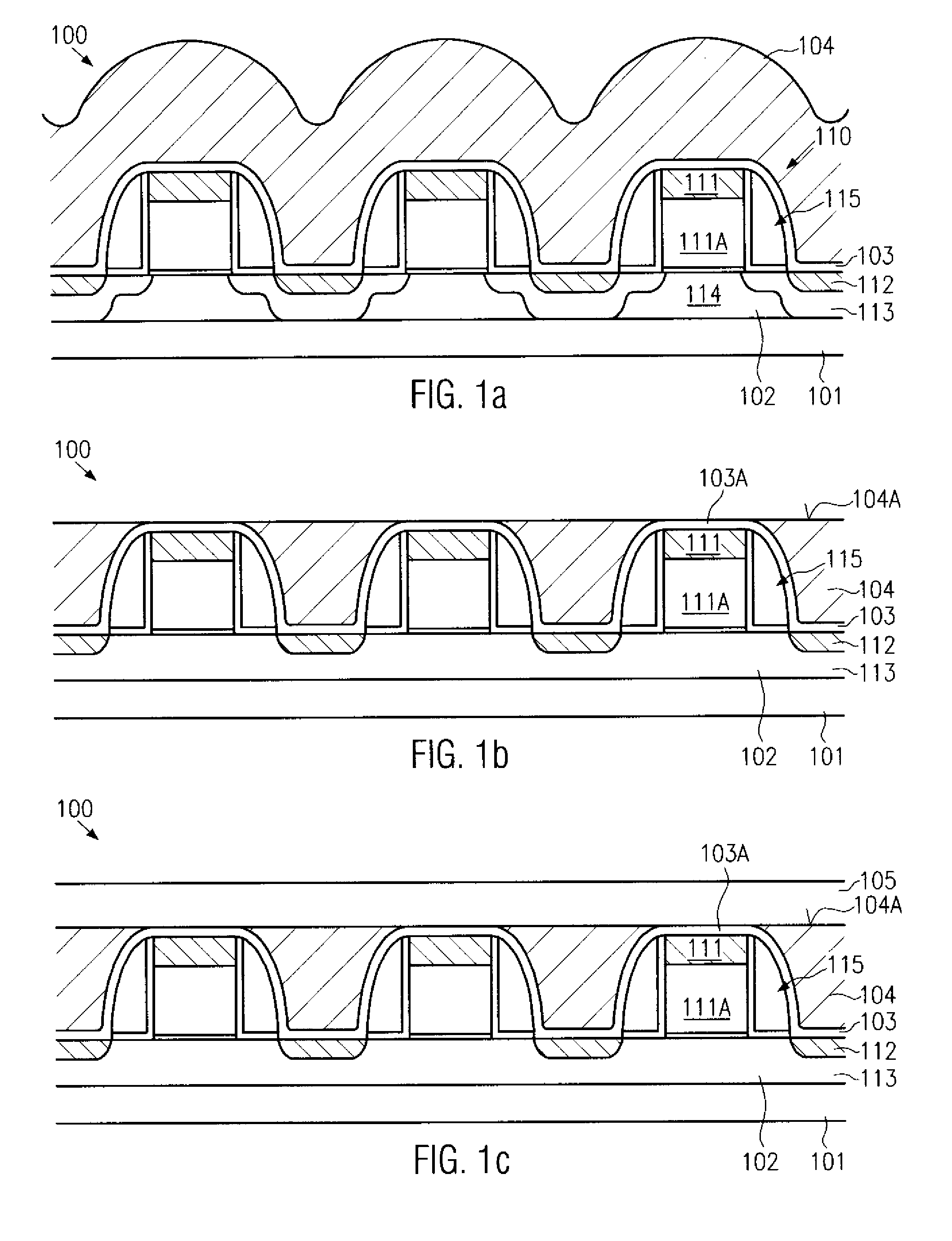

Self-aligned manufacturing method, and manufacturing method for thin film fuse phase change ram

ActiveUS20070173063A1Semiconductor/solid-state device manufacturingDigital storagePhase-change memoryEngineering

A method for manufacturing a self aligned narrow structure over a wider structure based on mask trimming. A method for manufacturing a memory device comprises forming an electrode layer on a substrate which comprises circuitry made using front-end-of-line procedures. The electrode layer includes a first electrode and a second electrode, and an insulating member between the first and second electrodes for each phase change memory cell to be formed. A patch of memory material is formed on the top surface of the electrode layer across the insulating member for each memory cell to be formed. The patch and the first and second electrodes are formed using a self-aligned process based on mask trimming.

Owner:MACRONIX INT CO LTD

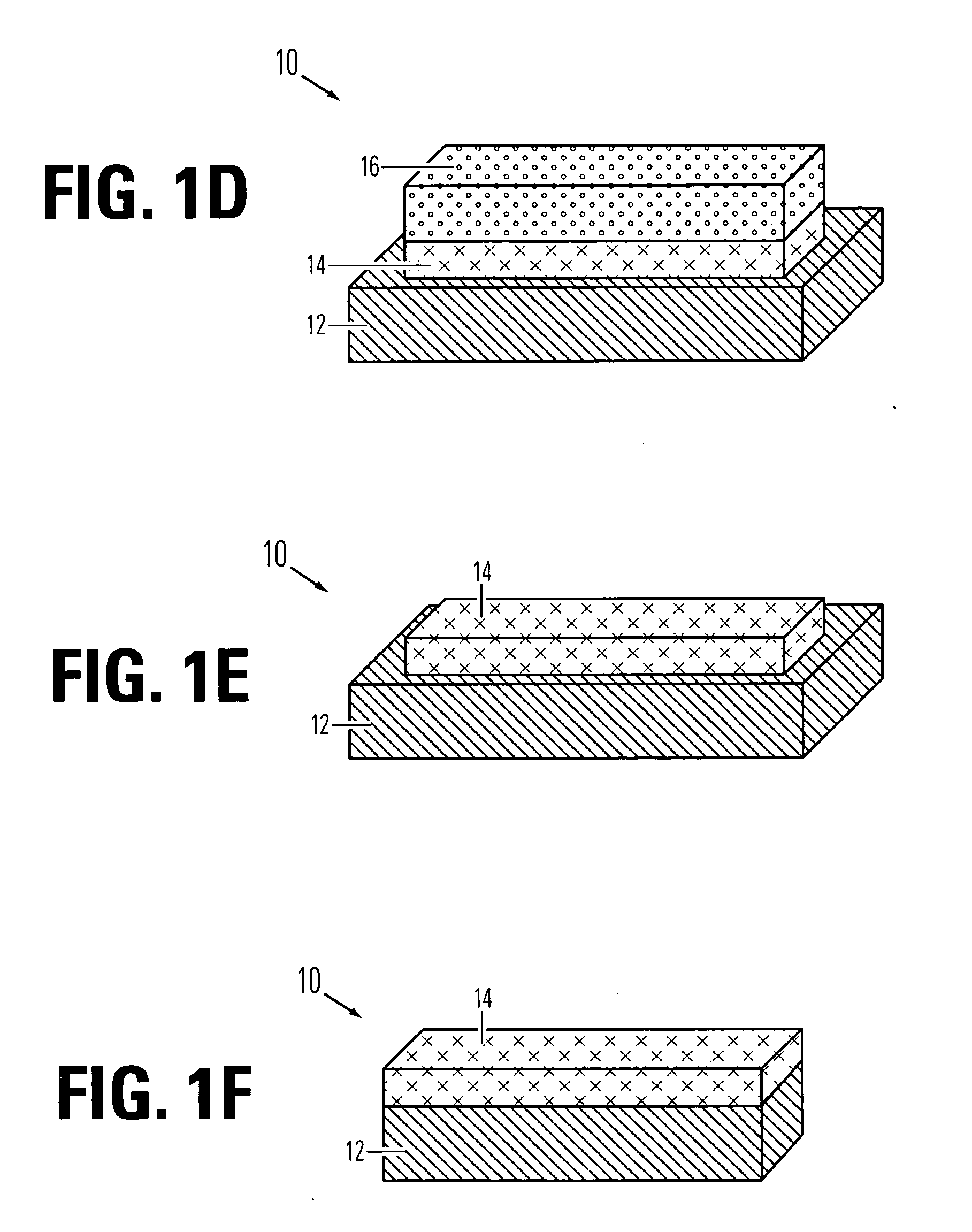

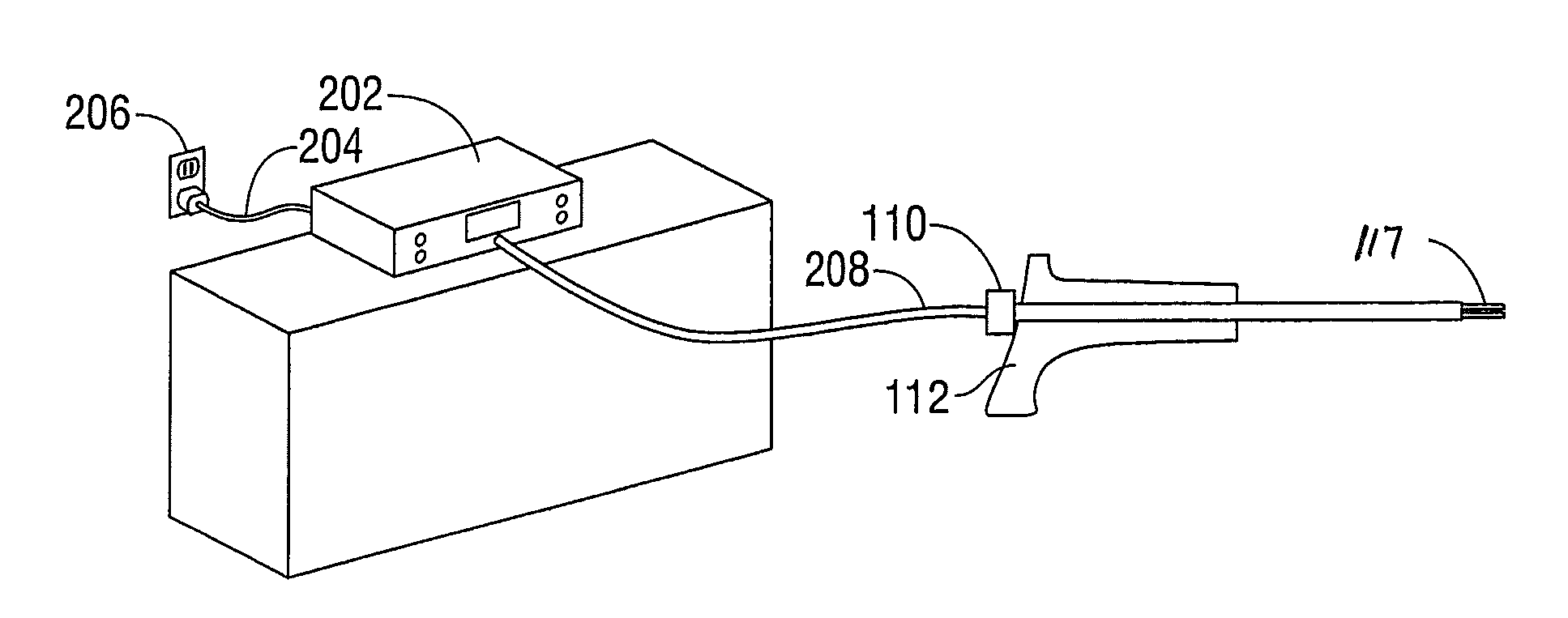

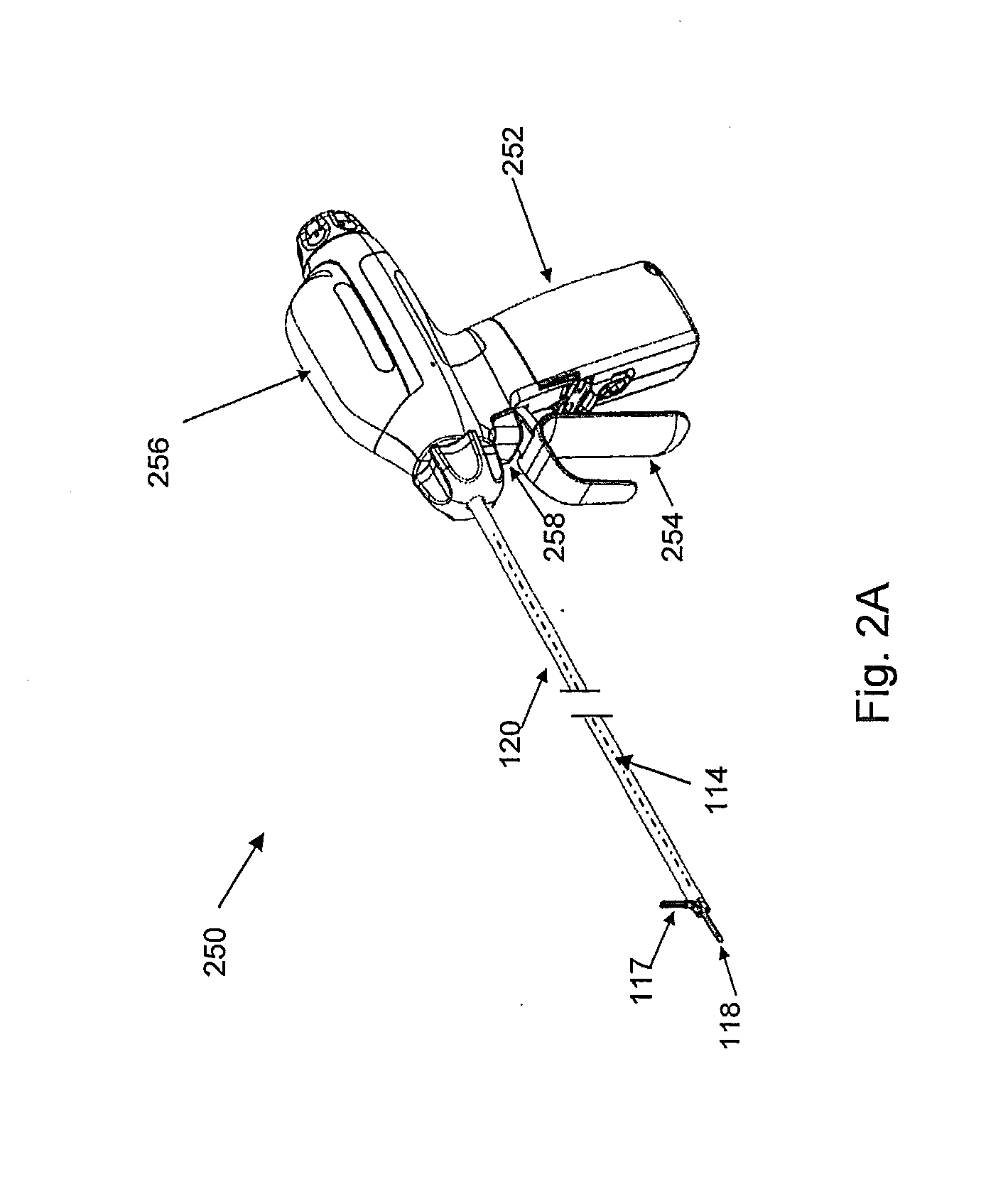

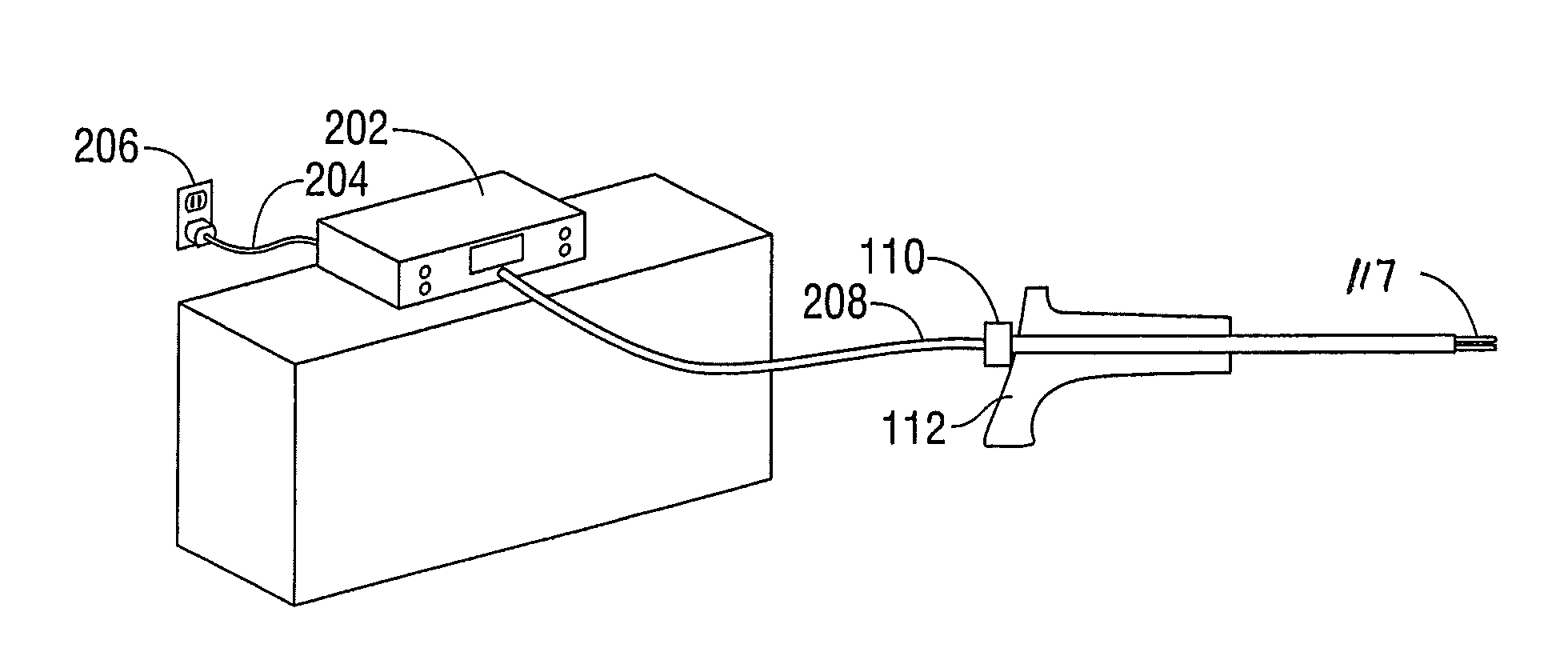

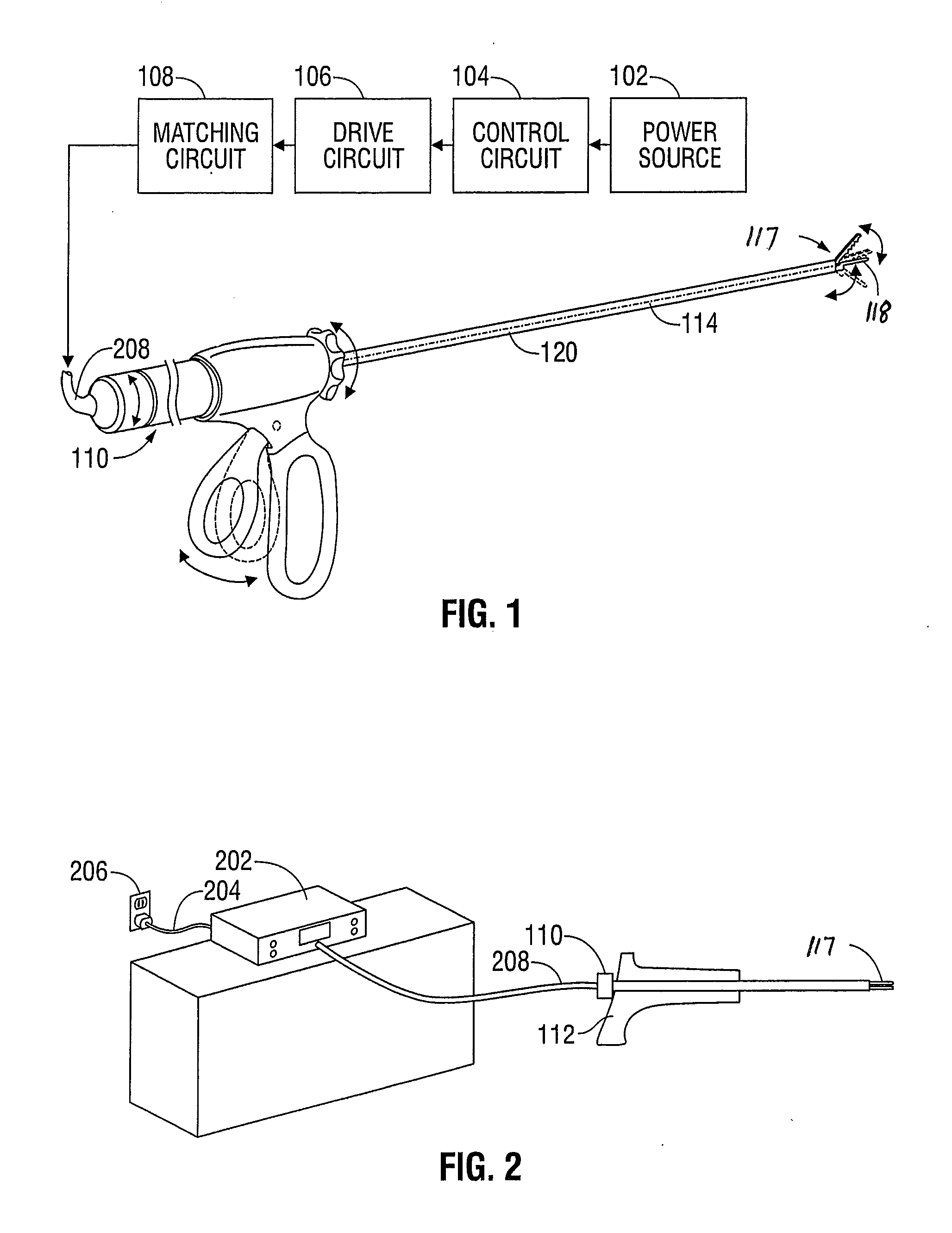

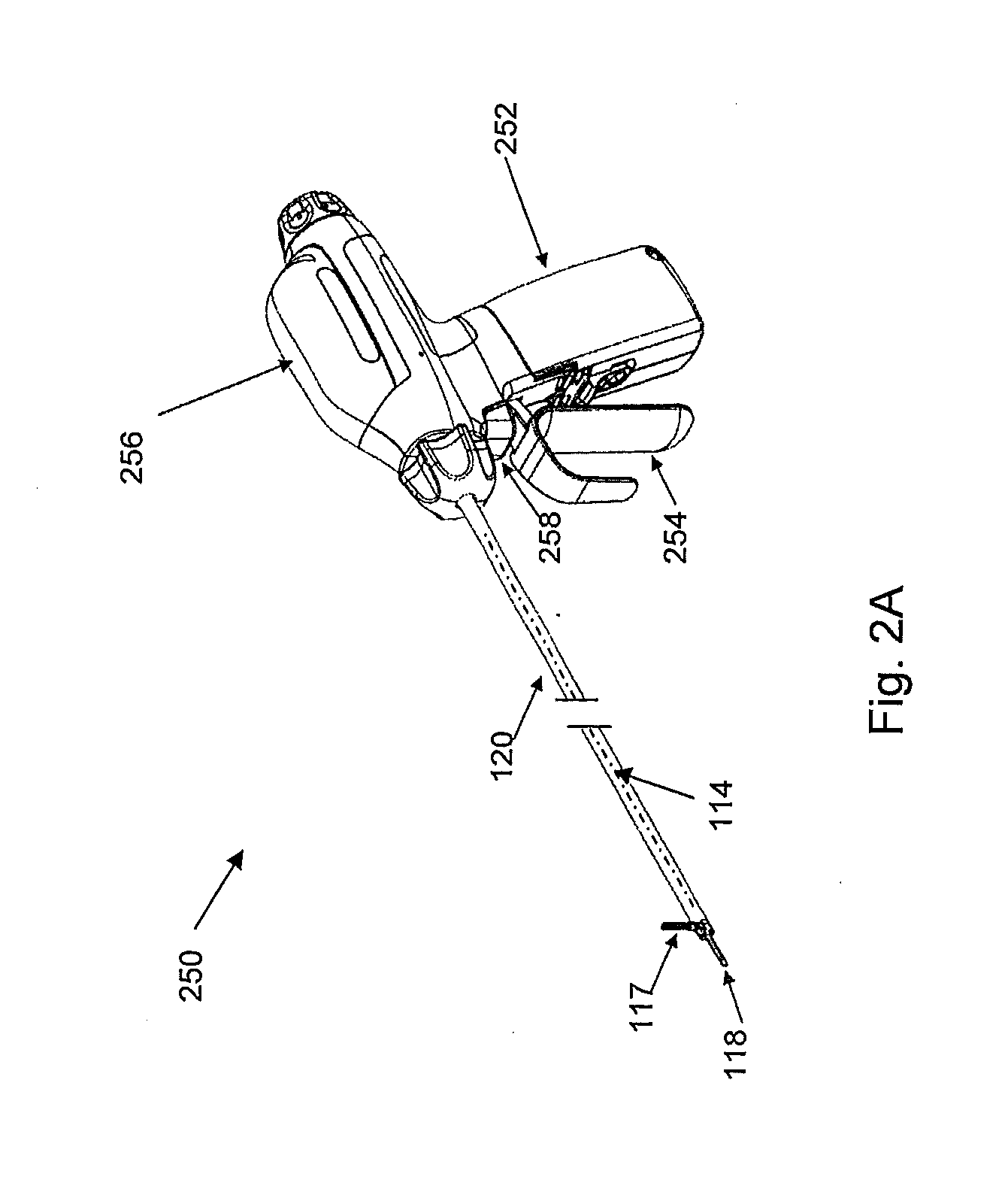

Temperature estimation and tissue detection of an ultrasonic dissector from frequency response monitoring

InactiveUS20130331875A1SurgeryThermometers using physical/chemical changesMicrocontrollerSonification

An ultrasonic surgical apparatus and method of use including a signal generator outputting a drive signal having a frequency, an oscillating structure, receiving the drive signal and oscillating at the frequency of the drive signal, a bridge circuit, detecting the mechanical motion of the oscillating structure and outputting a signal representative of the mechanical motion, and a microcontroller receiving the signal output by the bridge circuit, the microcontroller determining an instantaneous frequency at which the oscillating structure is oscillating based on the received signal, and comparing the instantaneous frequency to a known frequency value and estimating a temperature of the oscillating structure based on the comparison.

Owner:TYCO HEALTHCARE GRP LP

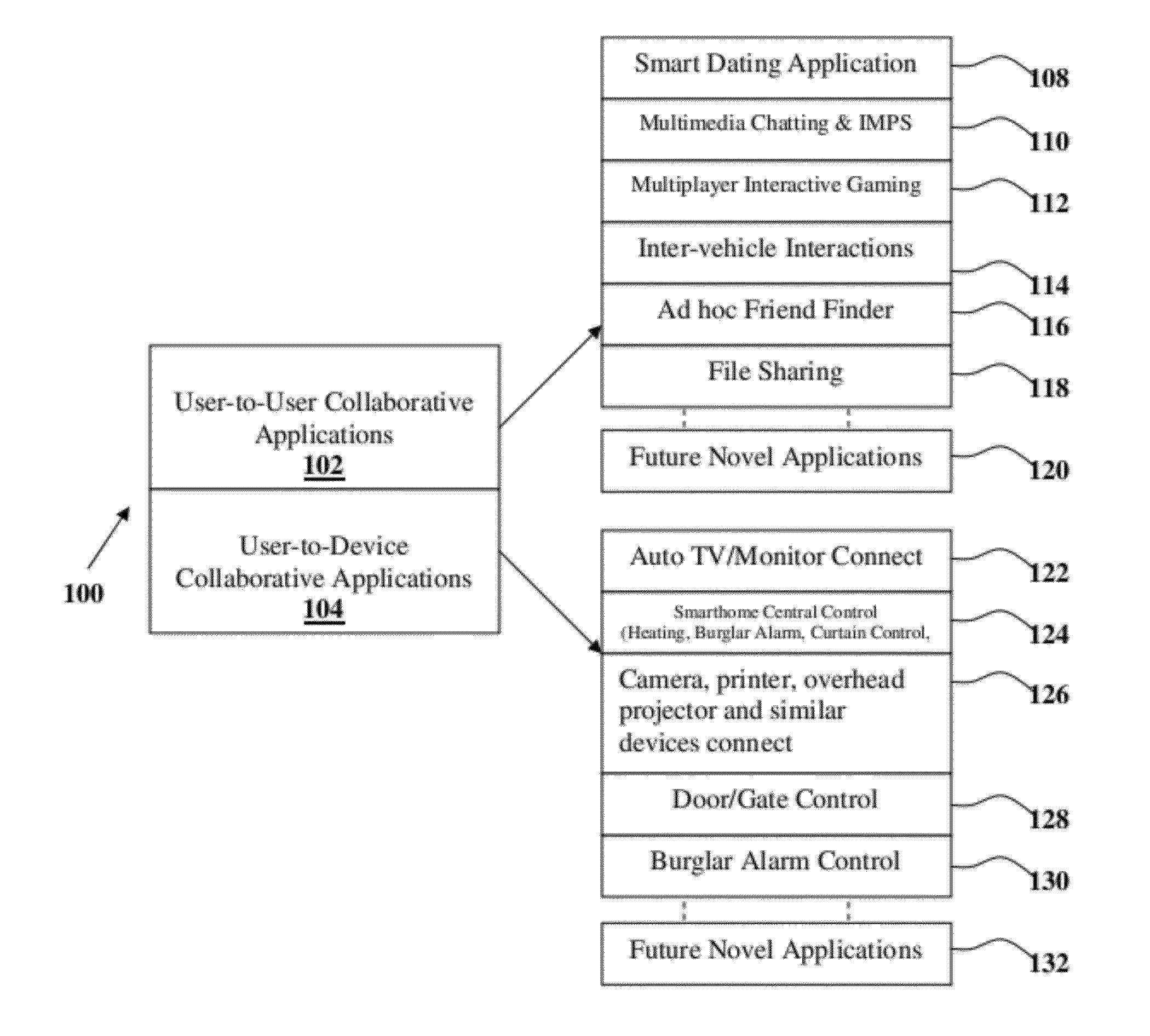

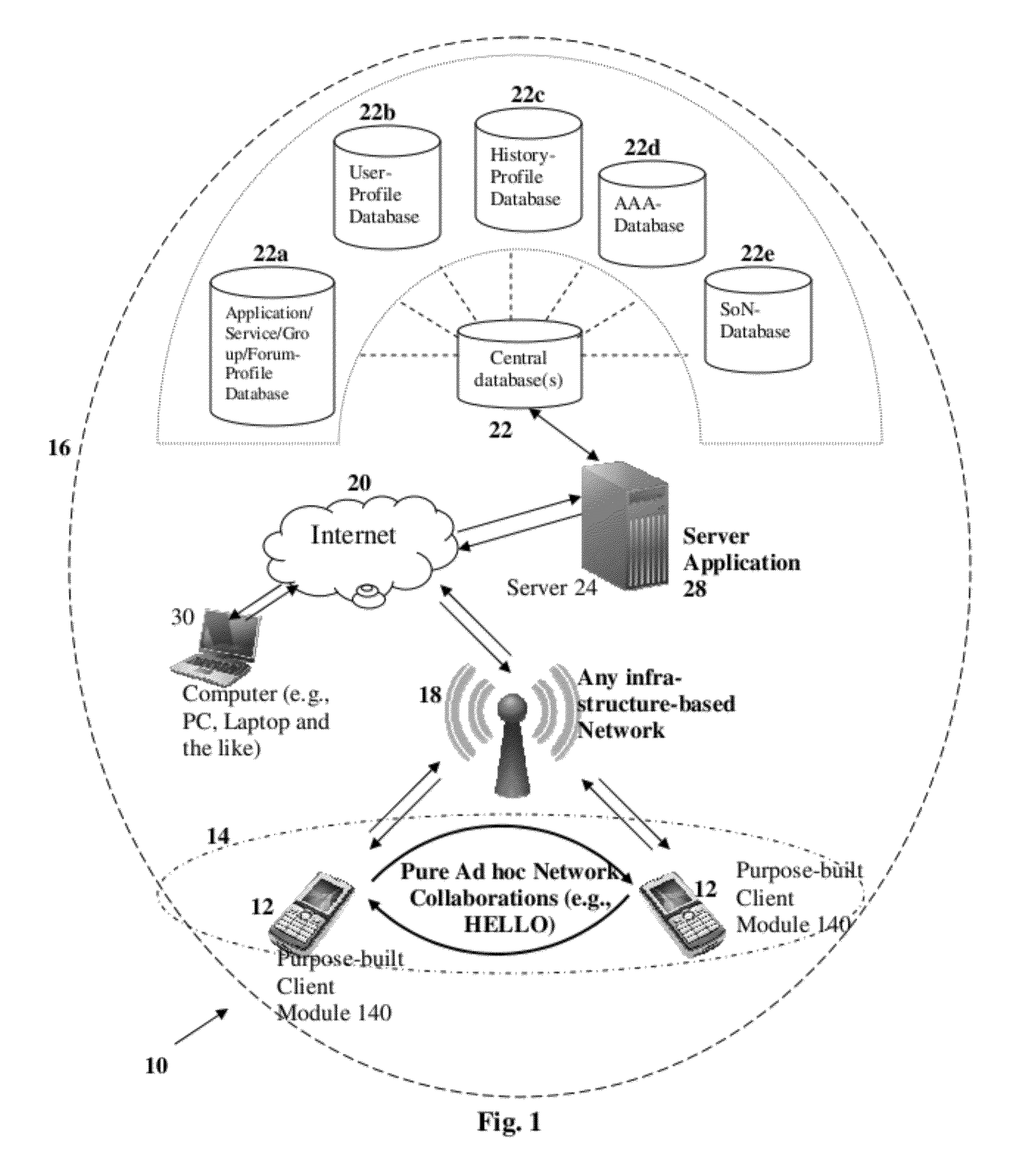

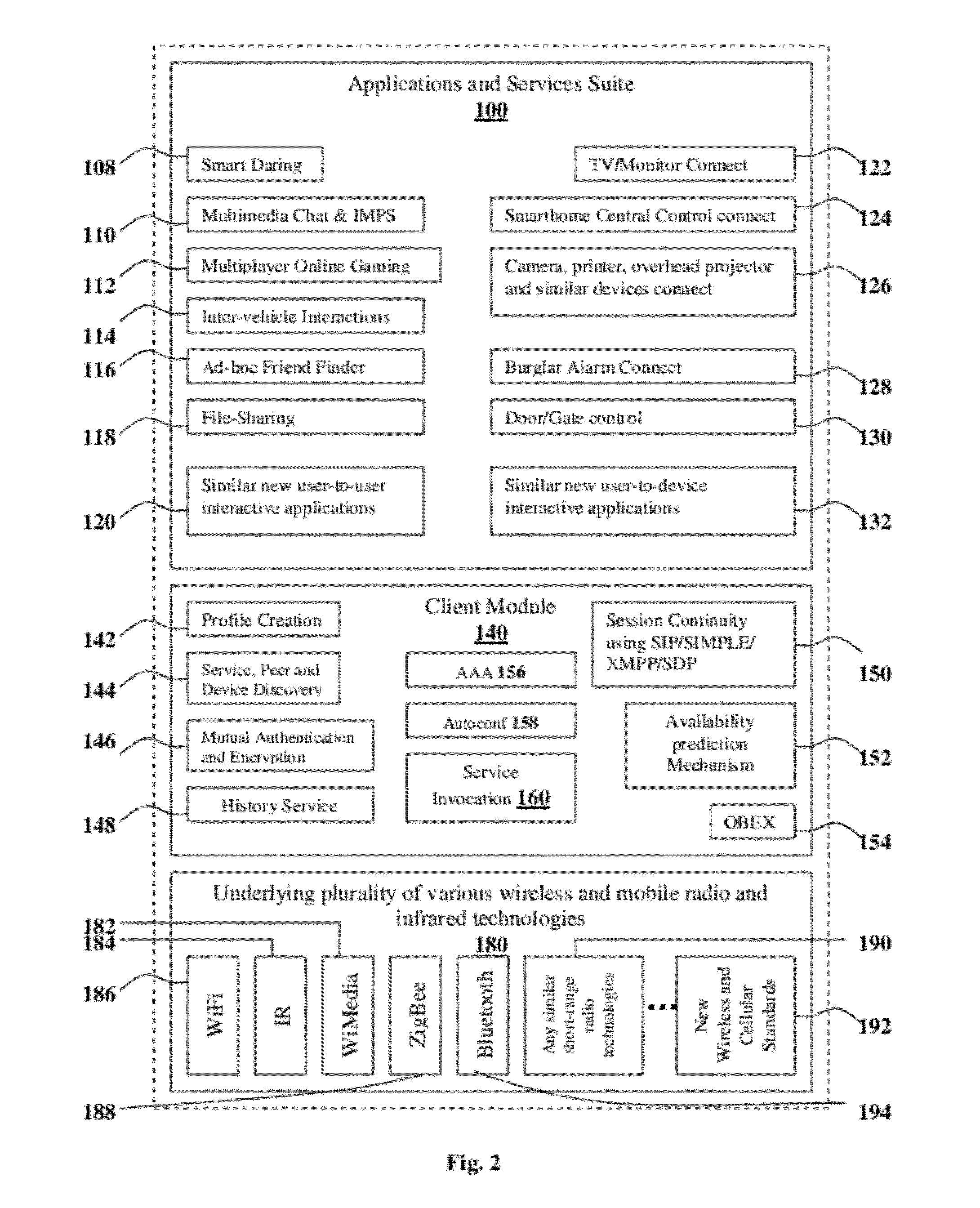

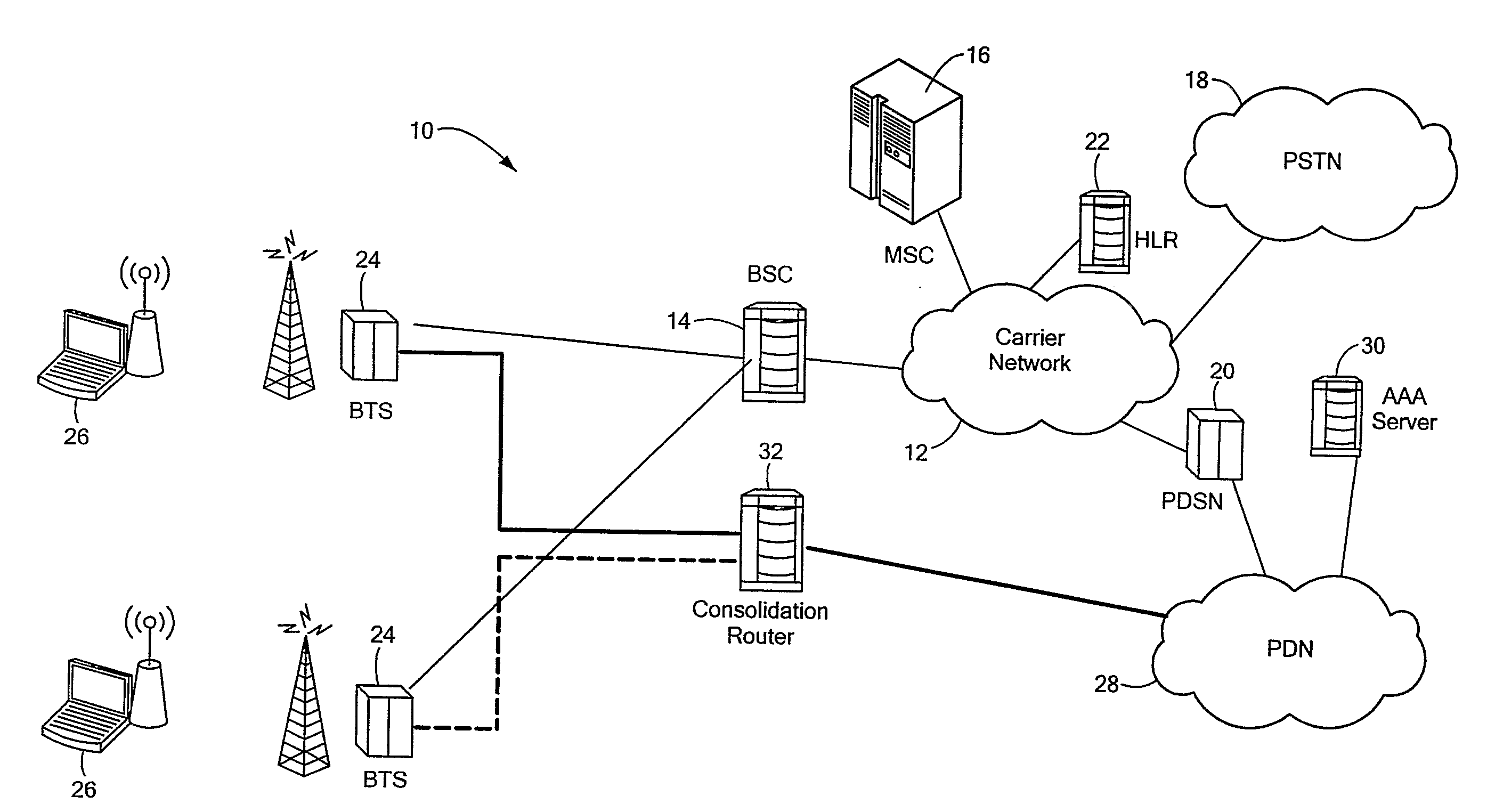

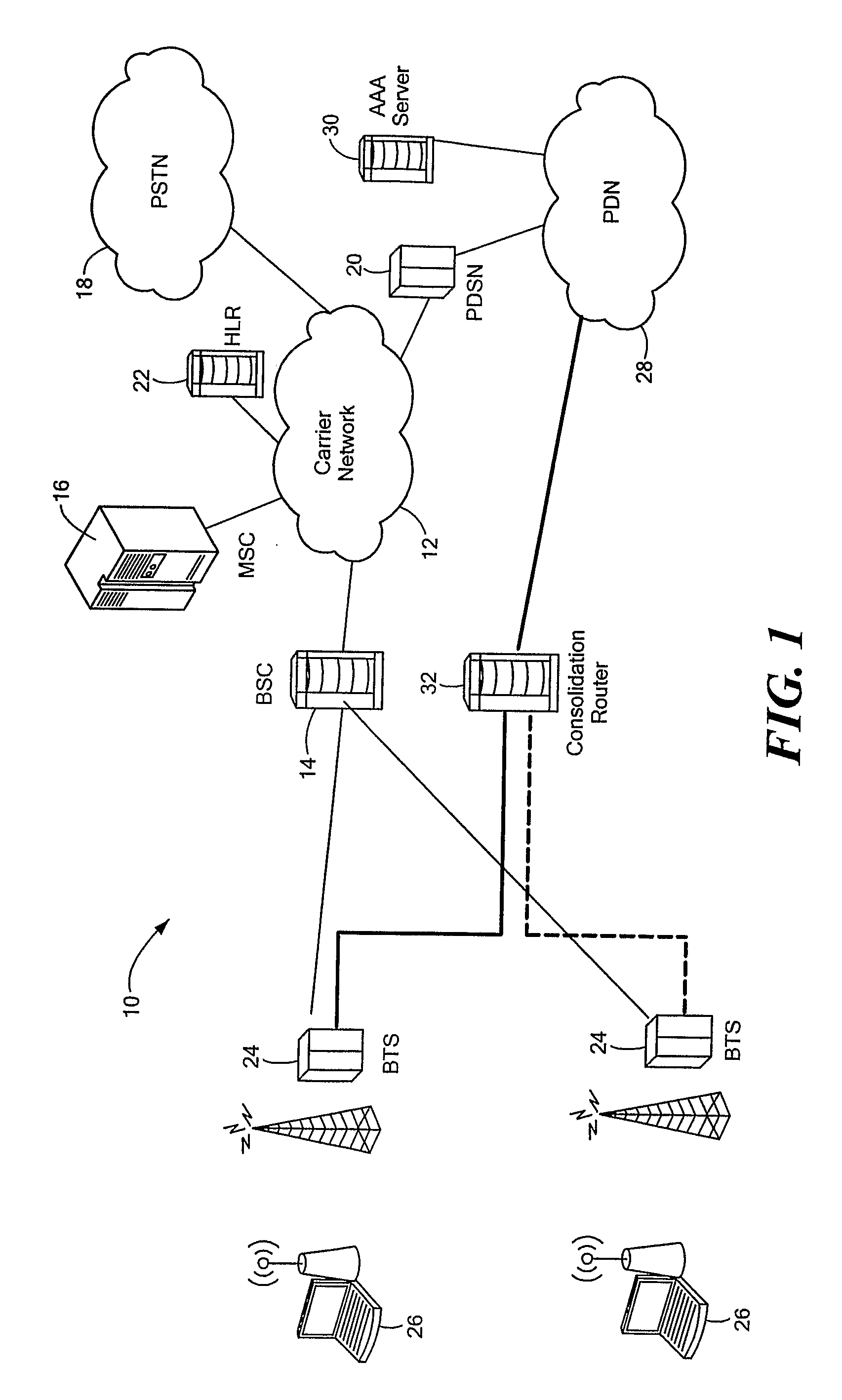

Scalable Secure Wireless Interaction enabling Methods, System and Framework

InactiveUS20120084364A1Avoiding self-configuringConnection securityNetwork topologiesMultiple digital computer combinationsNetwork conditionsOperation mode

The present invention proposes methodologies, a system and a secure spontaneous collaboration framework along with a suitable application and services suite for enabling new paradigm of social networking among users of handheld devices by bridging gab between infra-structure-based networks and mobile ad hoc networks. While supporting three different operating modes for the spontaneous collaboration that suits the user preference and network conditions, the proposed solutions hide the complexity of finding the right peer / device for spontaneous collaboration, self-organising the network to be formed on-demand, mitigating the security threat, being aware of user mobility for service continuity across wide variety of networks. Binding a given user to user's handheld device and specifying the number of applications / services enabling spontaneous collaborations that a given user is interested in are possible through user-profile creations. By taking a holistic view, the proposed solutions enable very practical, scalable, secure and economical spontaneous collaborations.

Owner:SIVAVAKEESAR SIVAPATHALINGHAM

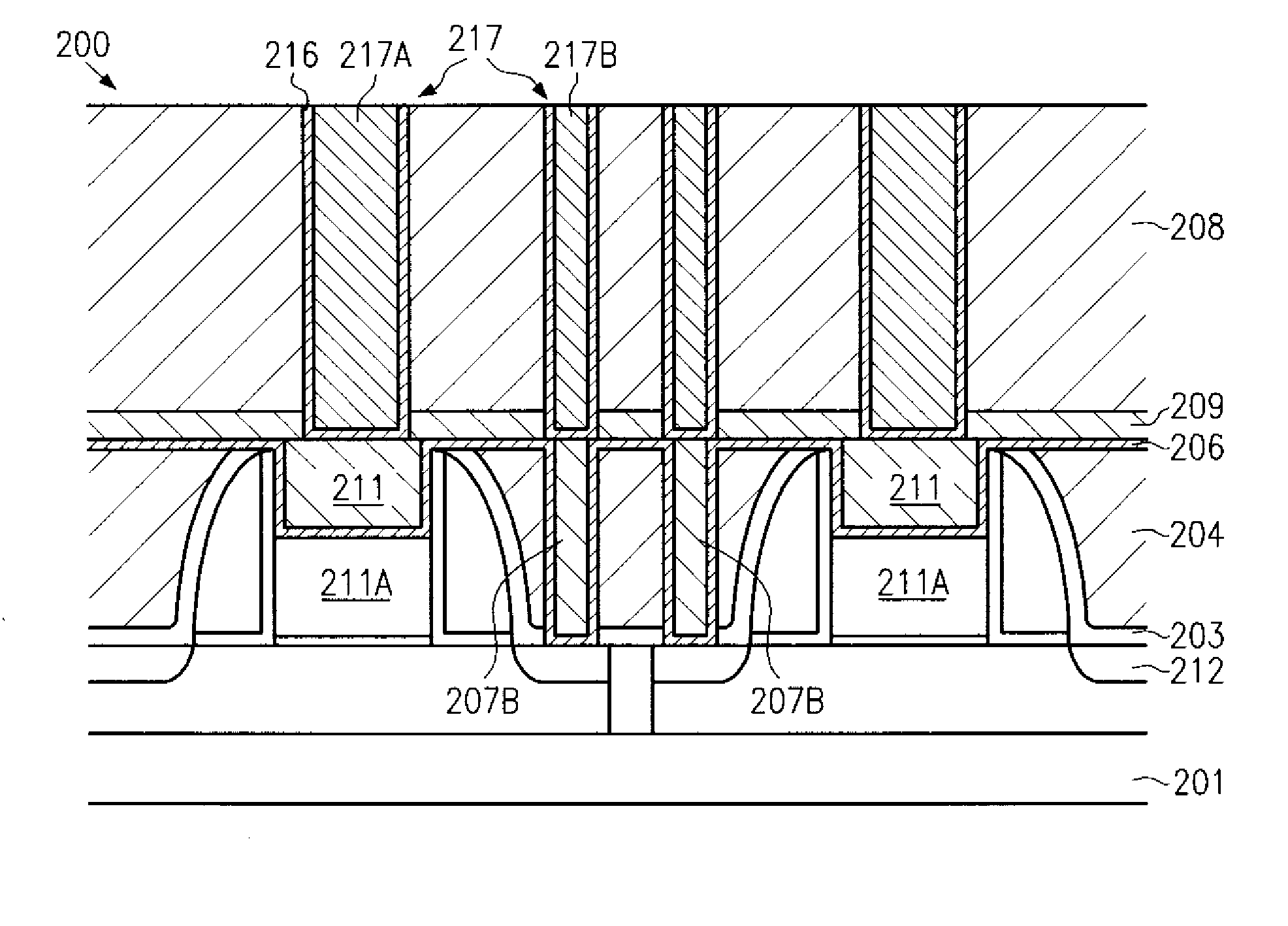

Semiconductor device comprising a contact structure based on copper and tungsten

ActiveUS20070099414A1Reduce resistanceLower resistanceTransistorSemiconductor/solid-state device detailsInter layerDevice material

By providing contact plugs having a lower plug portion, formed on the basis of well-established tungsten-based technologies, and an upper plug portion, which may comprise a highly conductive material such as copper or a copper alloy, a significant increase in conductivity of the contact structure may be achieved. For this purpose, after the deposition of a first dielectric layer of the inter-layer stack, a planarization process may be performed so as to allow the formation of the lower plug portions on the basis of tungsten, while, after the deposition of the second dielectric layer, a corresponding copper-based technology may be used for forming the upper plug portions of significantly enhanced conductivity.

Owner:GLOBALFOUNDRIES US INC

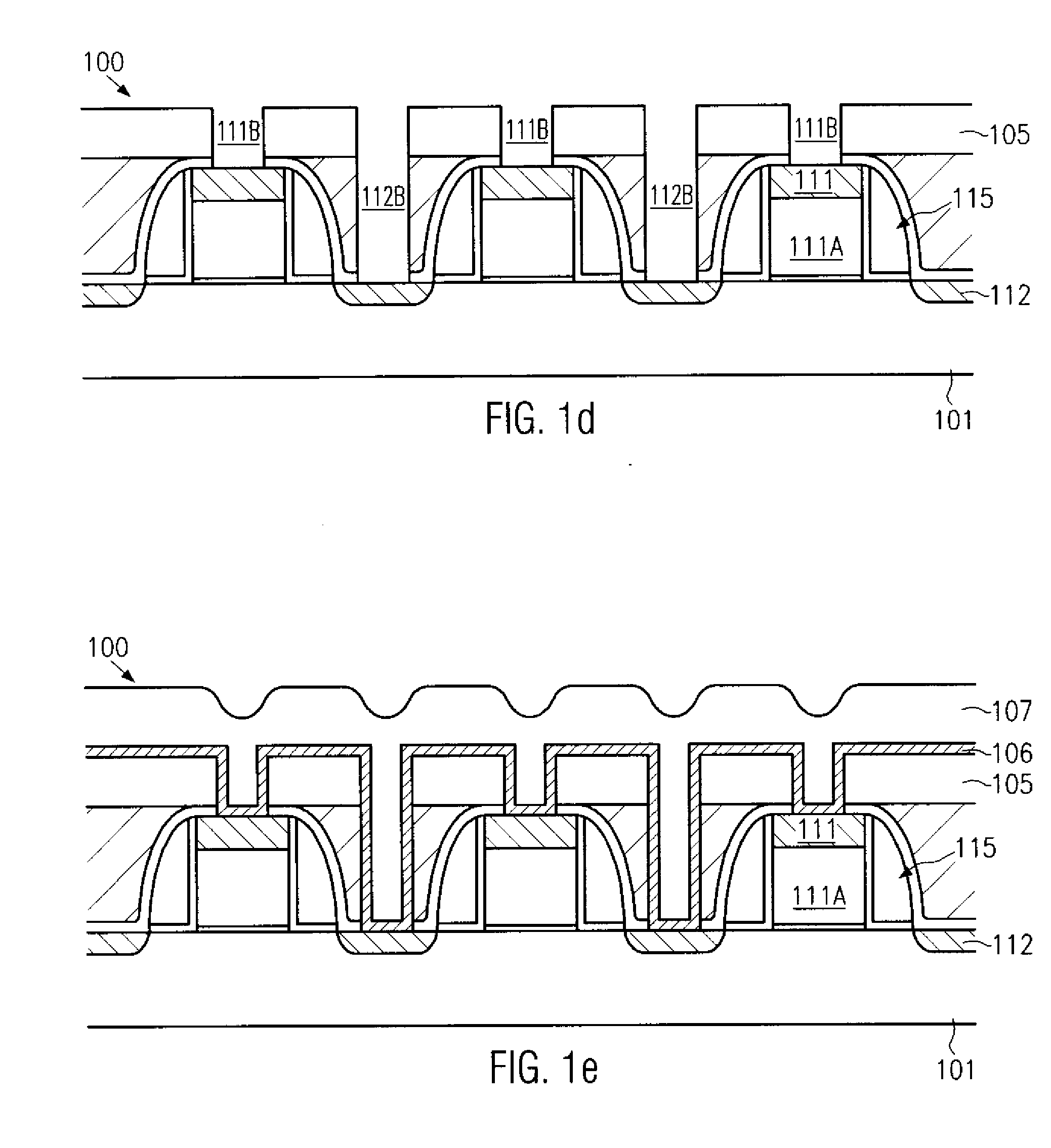

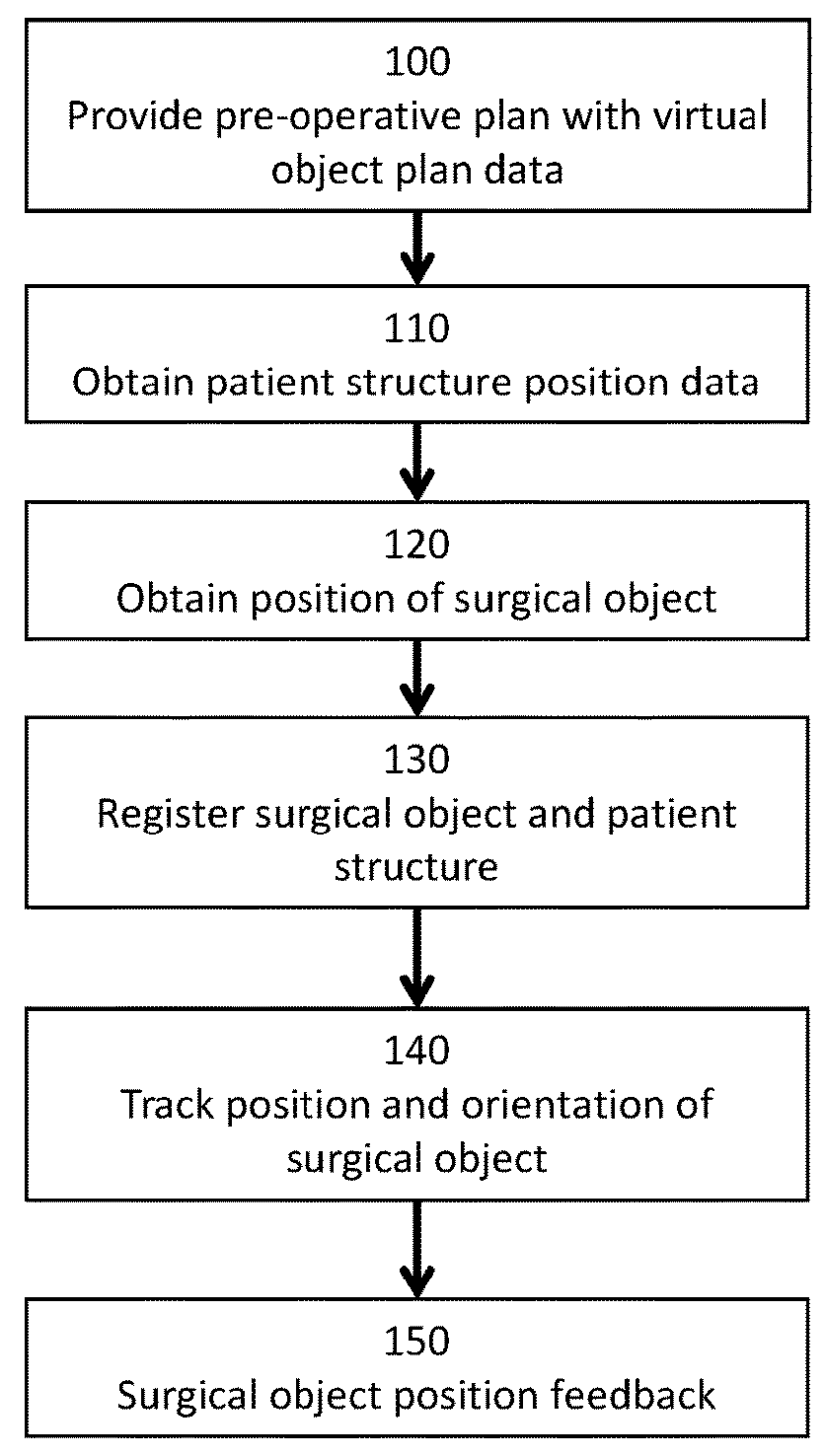

Method and system for computer assisted surgery

A method and system for computer assisted orthopedic feedback of at least one surgical object relative a pre-operative plan are disclosed. The pre-operative plan includes a virtual object, which is the virtual representation of the surgical object, and a virtual structure, which is the virtual representation of the patient structure. The method comprises providing the pre-operative plan including planned position and orientation of the virtual object relative to of the virtual structure; obtaining the position of the patient structure based on a surface of the patient structure using a surgical navigation system; obtaining the position of the surgical object using the surgical navigation system; registering the patient structure to the virtual structure and the surgical object to the virtual object; tracking a current position and orientation of the surgical object using the surgical navigation system; and providing feedback of a current position and orientation of the surgical object relative to the planned position and orientation of the virtual object based on the tracked current position and orientation of the surgical object.

Owner:ORTOMA AB

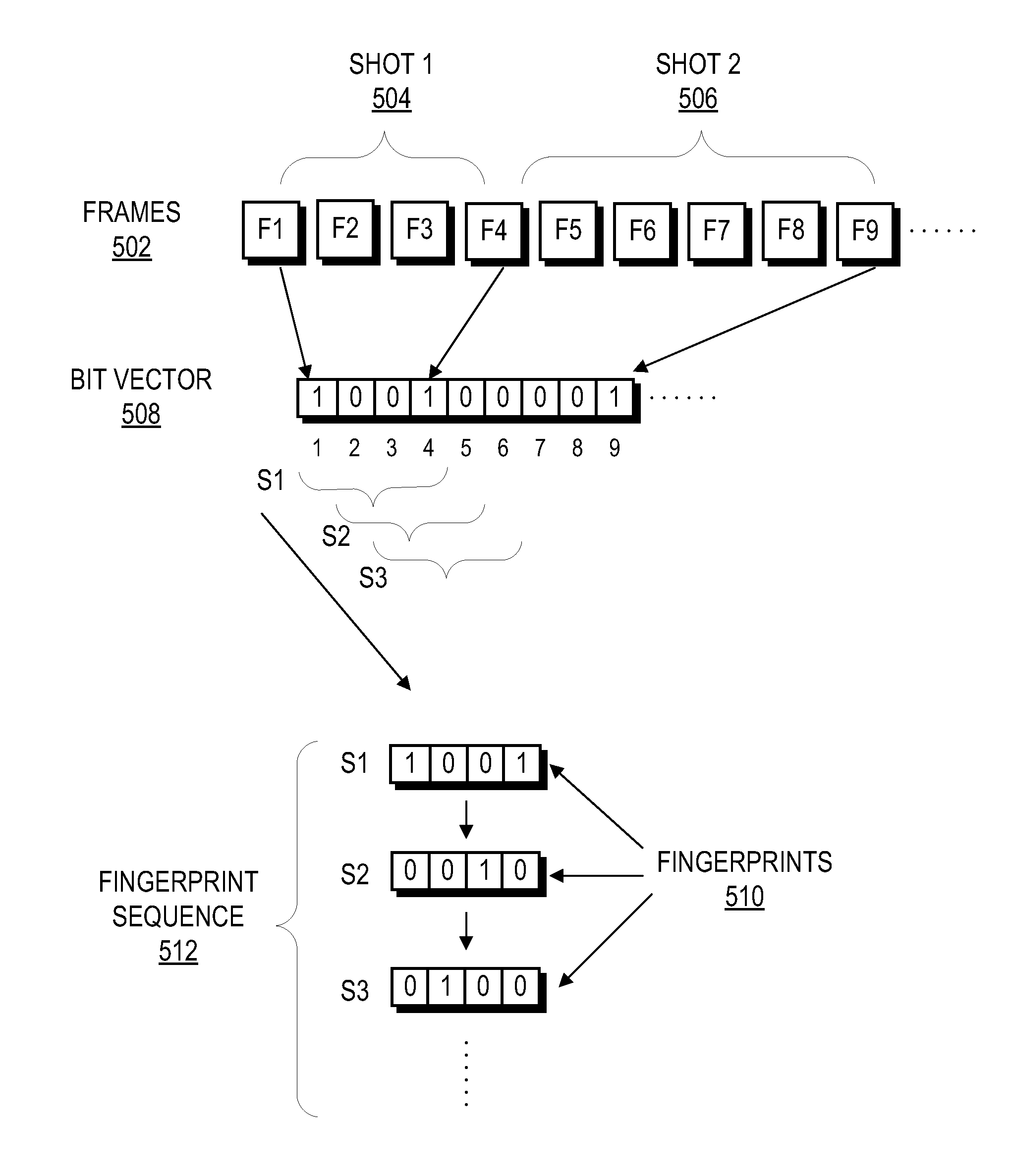

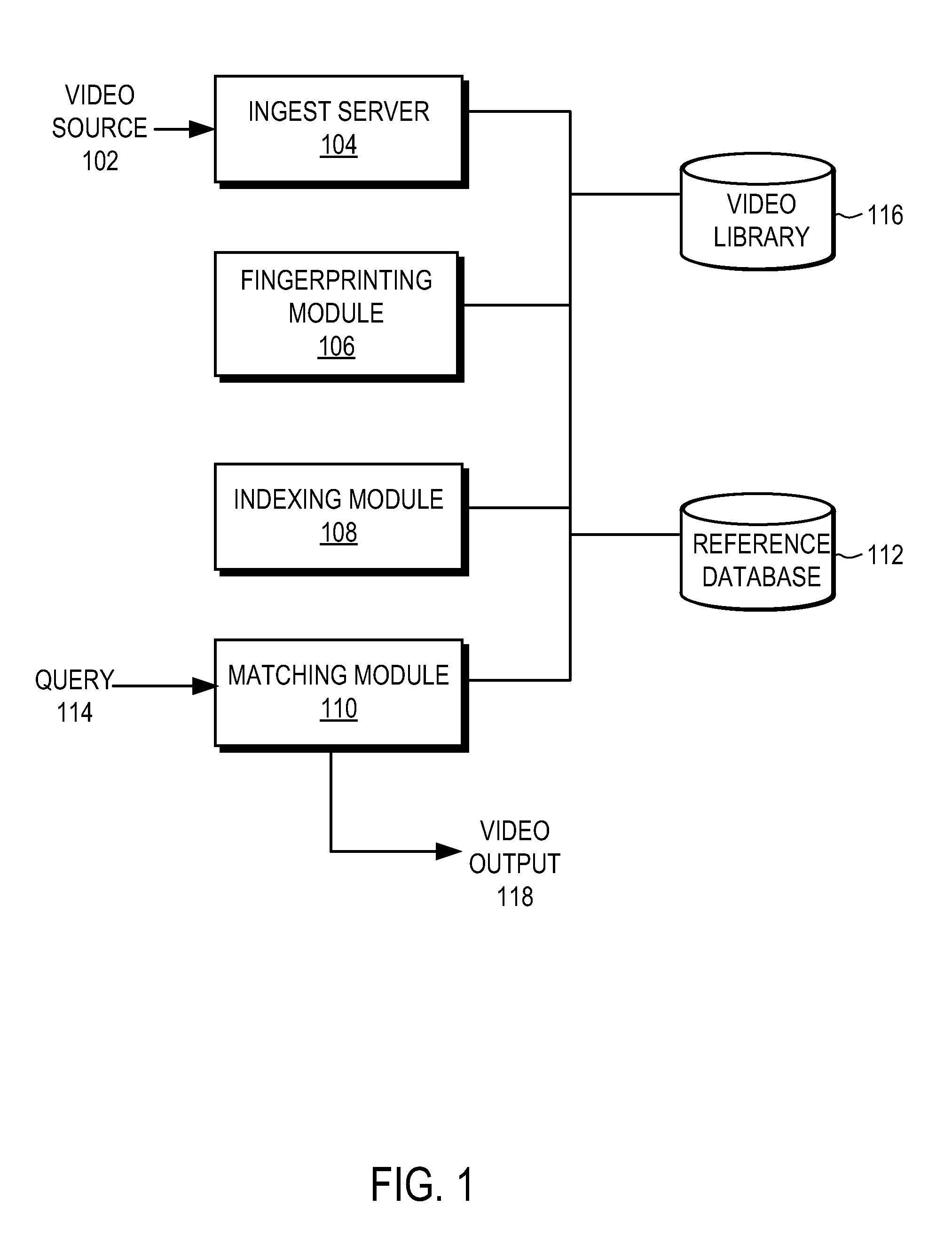

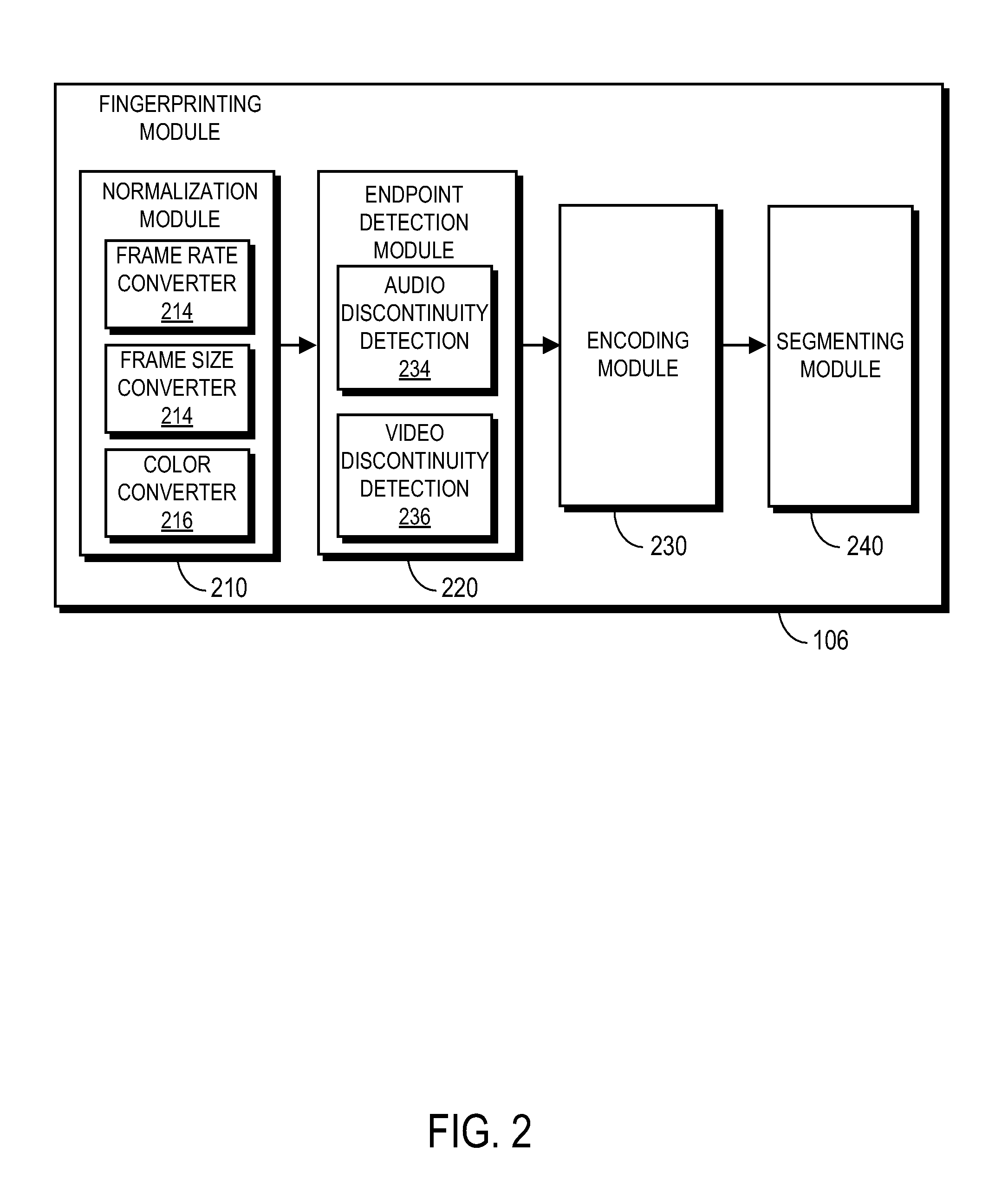

Endpoint based video fingerprinting

ActiveUS8611422B1Quickly and efficiently identifyImprove the display effectPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningFrame sequenceComputer graphics (images)

A method and system generates and compares fingerprints for videos in a video library. The video fingerprints provide a compact representation of the temporal locations of discontinuities in the video that can be used to quickly and efficiently identify video content. Discontinuities can be, for example, shot boundaries in the video frame sequence or silent points in the audio stream. Because the fingerprints are based on structural discontinuity characteristics rather than exact bit sequences, visual content of videos can be effectively compared even when there are small differences between the videos in compression factors, source resolutions, start and stop times, frame rates, and so on. Comparison of video fingerprints can be used, for example, to search for and remove copyright protected videos from a video library. Furthermore, duplicate videos can be detected and discarded in order to preserve storage space.

Owner:GOOGLE LLC

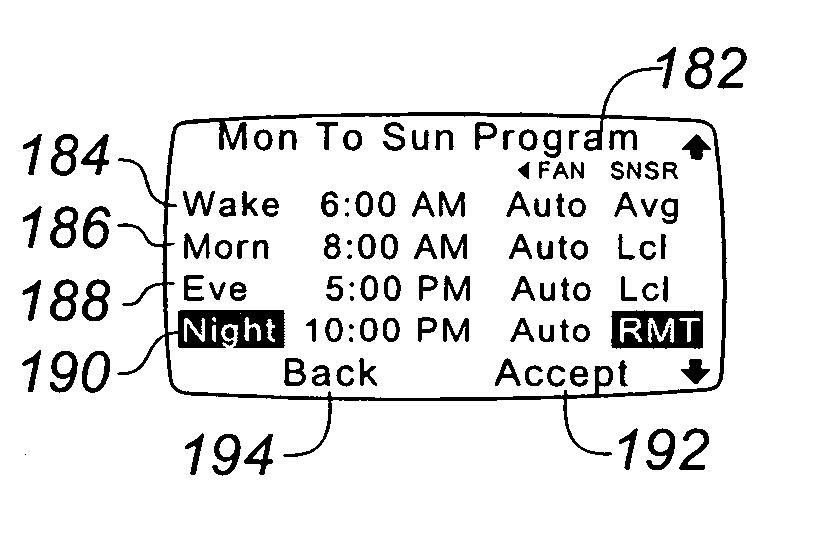

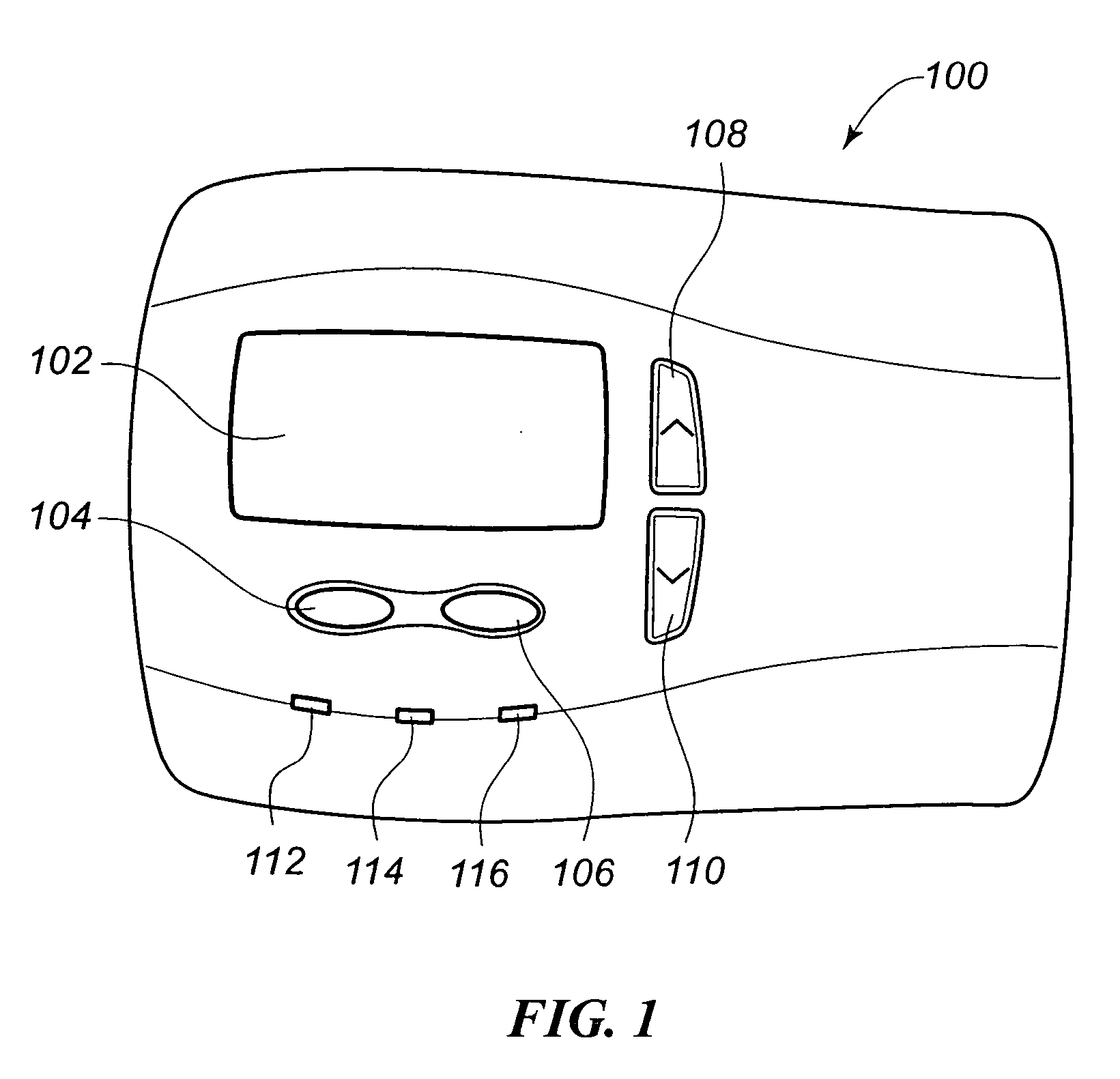

Time of day zoning climate control system and method

InactiveUS20070045429A1Easy to superviseImprove overall occupant comfortTemperature control without auxillary powerMechanical apparatusControl systemMultiple sensor

A time of day zoning control system for a heating, ventilating, and air conditioning system is provided. The system utilizes a programmable thermostat and a number of temperature sensors to control the HVAC system to regulate the temperature in a particular location within a dwelling or structure based on consumer preferences. The regulation control will utilize a temperature sensed by a particular temperature sensor at different times throughout the day to control the temperature in that zone to ensure occupant comfort. A single temperature sensor may be selected to control the HVAC system during these different periods, or multiple sensors may be utilized during the same period. When multiple sensors are used, a weighting factor may be used.

Owner:RANCO OF DELAWARE

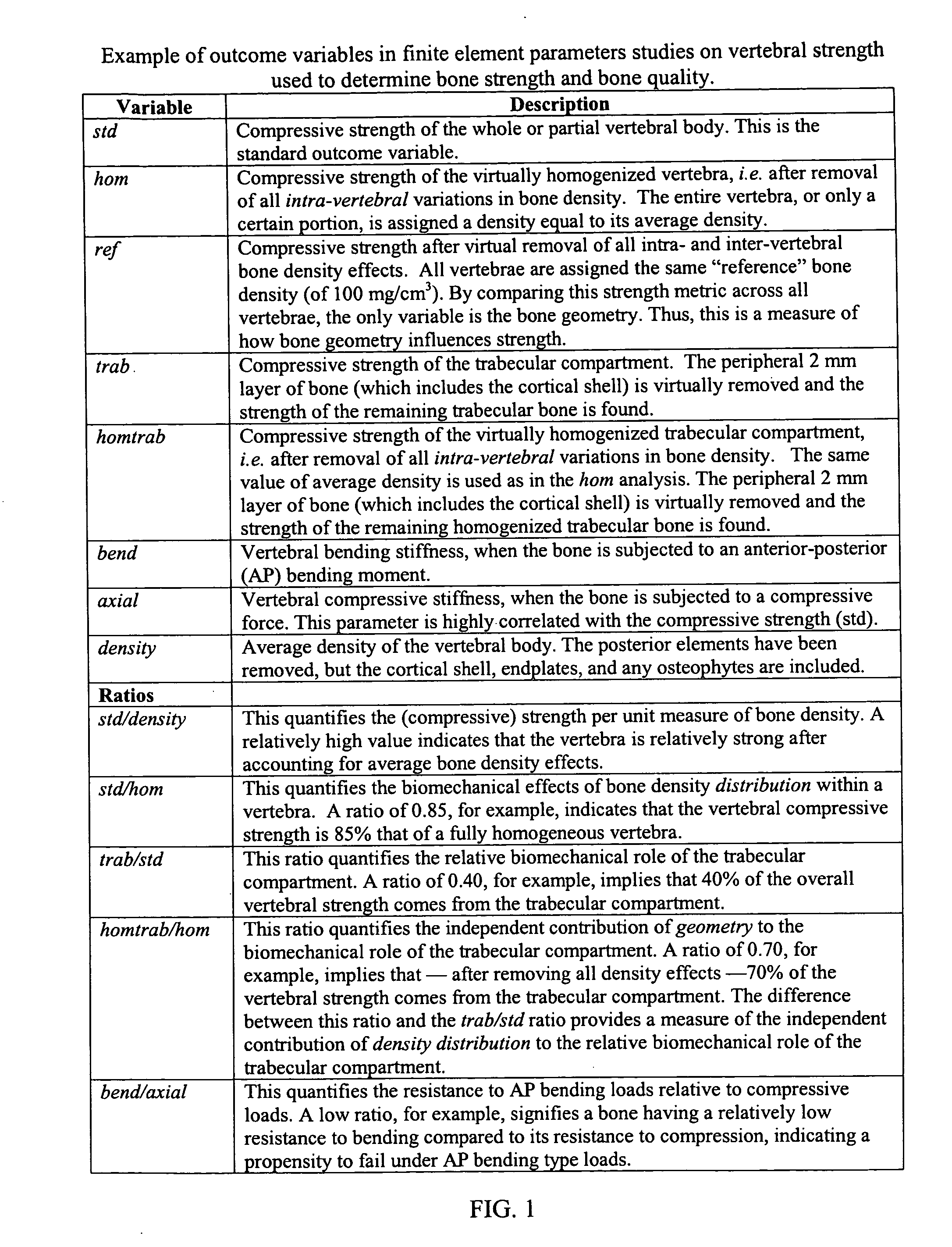

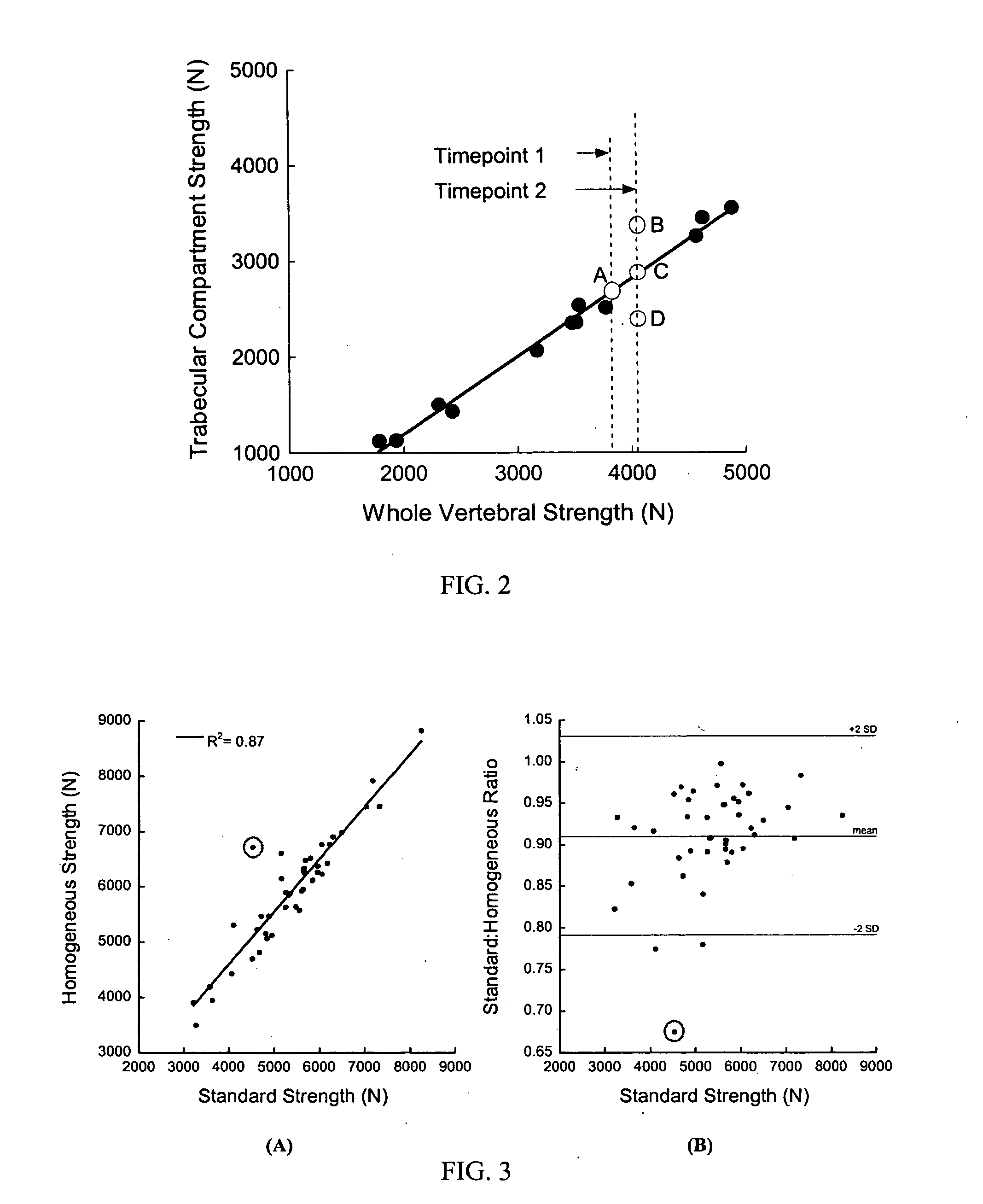

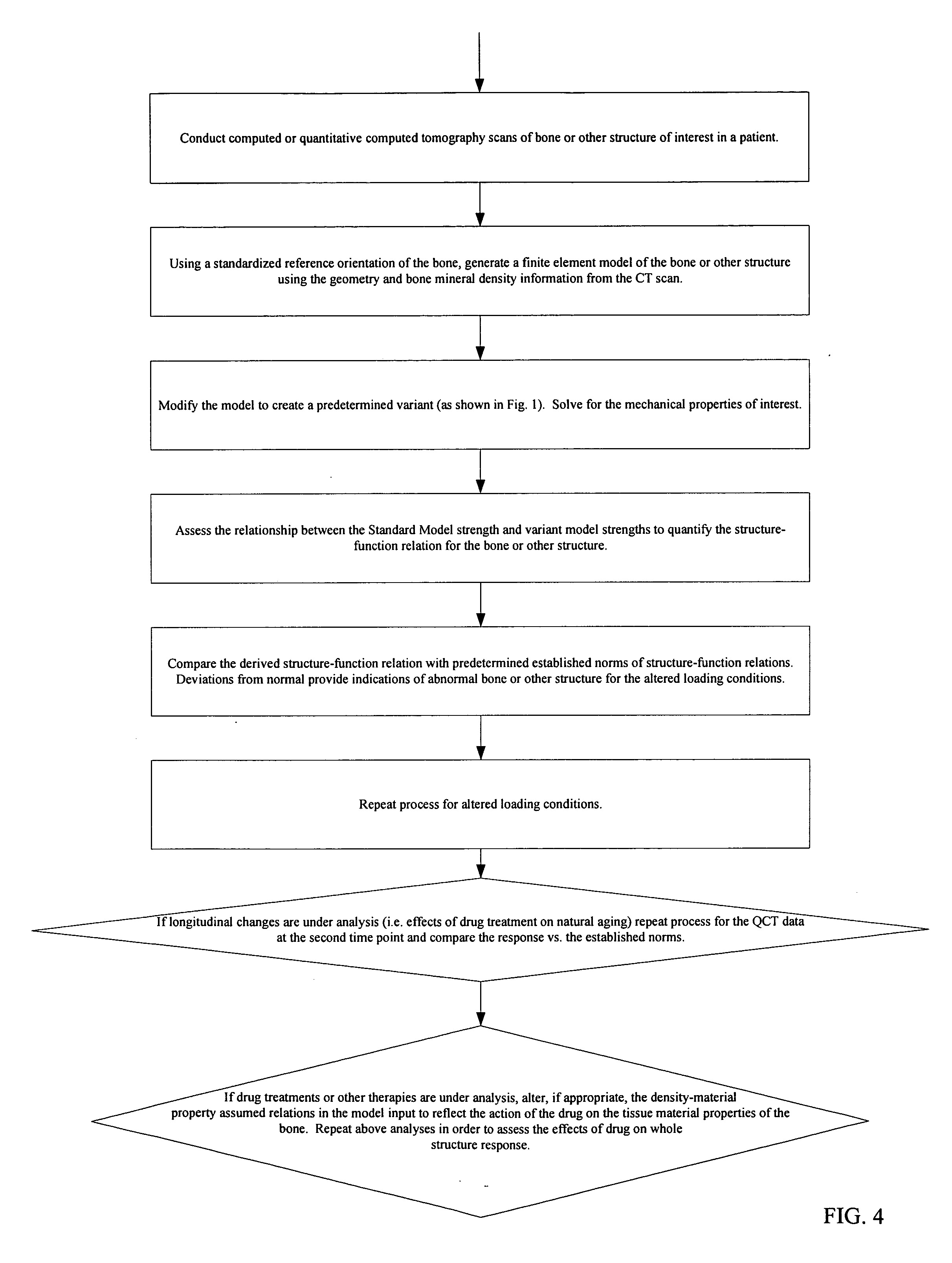

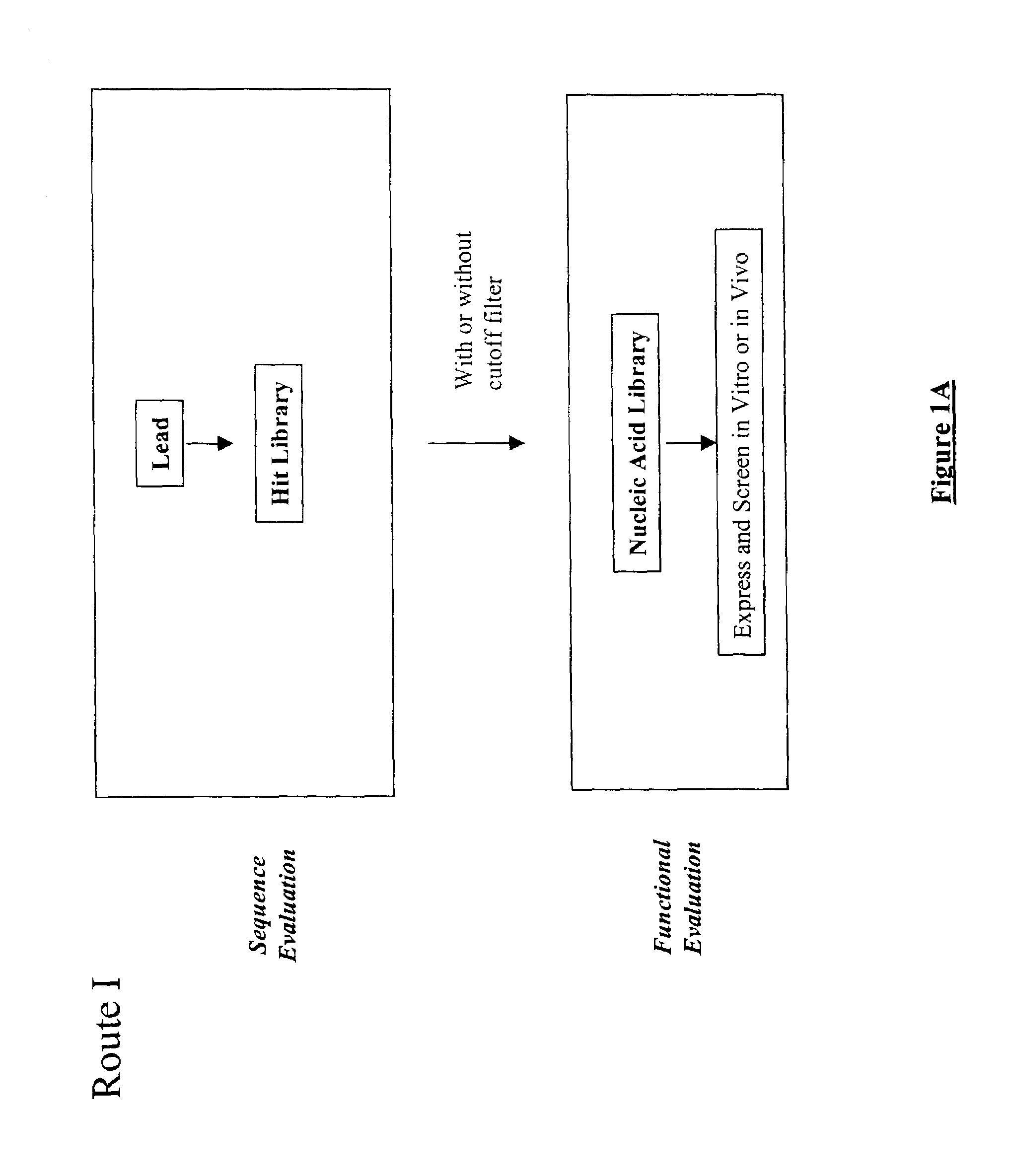

Method for assessment of the structure-function characteristics of structures in a human or animal body

A method for determining one or more structure-function characteristics of a structure in a human or animal body from an image of the structure includes generating a structural model of a structure based on an image of the structure. A first biomechanical quantity is computed based on the structural model. The structural model is varied to create a variant model. A second biomechanical quantity is computed based on the variant model. The first and second biomechanical quantities are compared, in order to assess a structure-function characteristic of the structure.

Owner:RGT UNIV OF CALIFORNIA

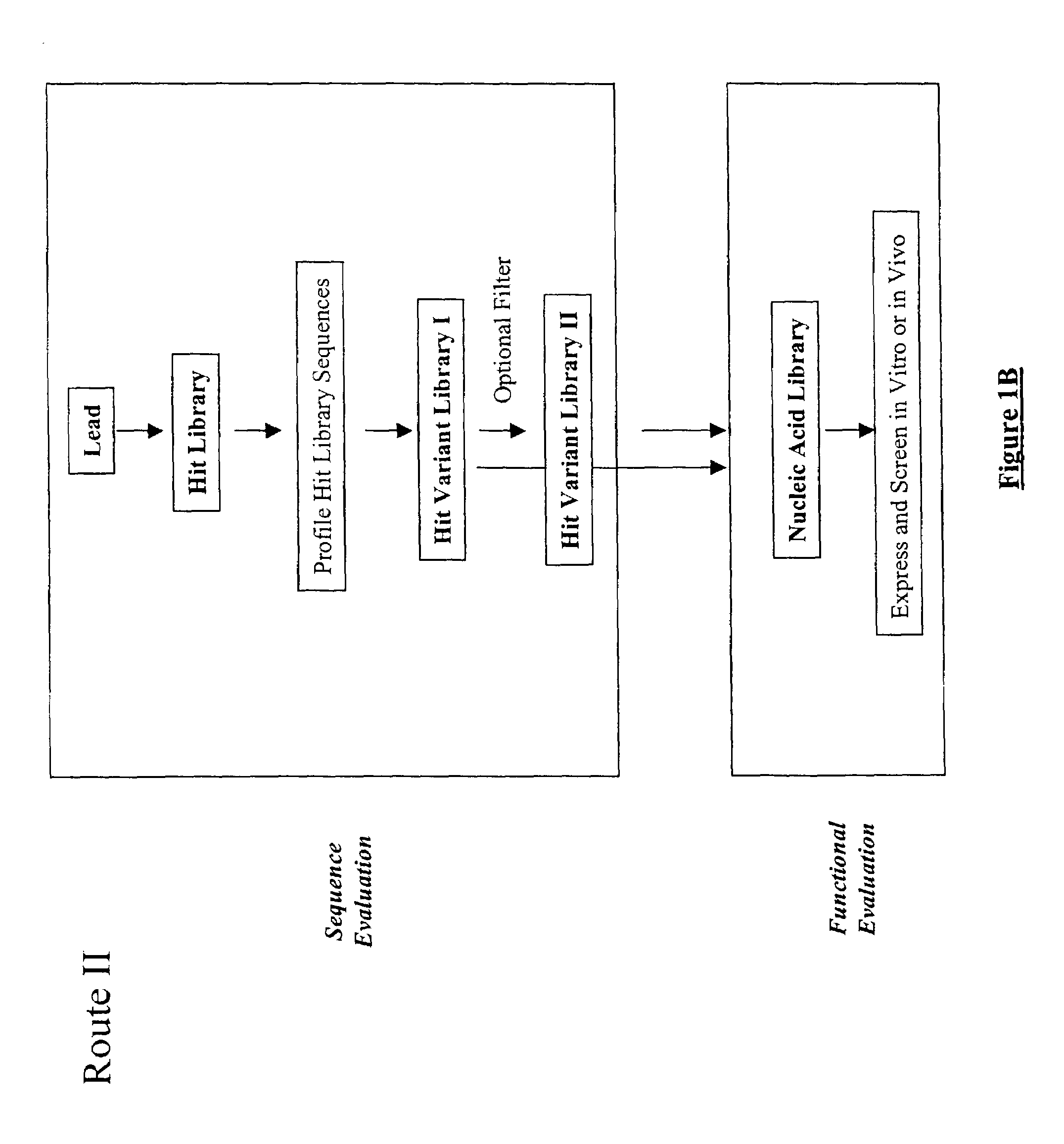

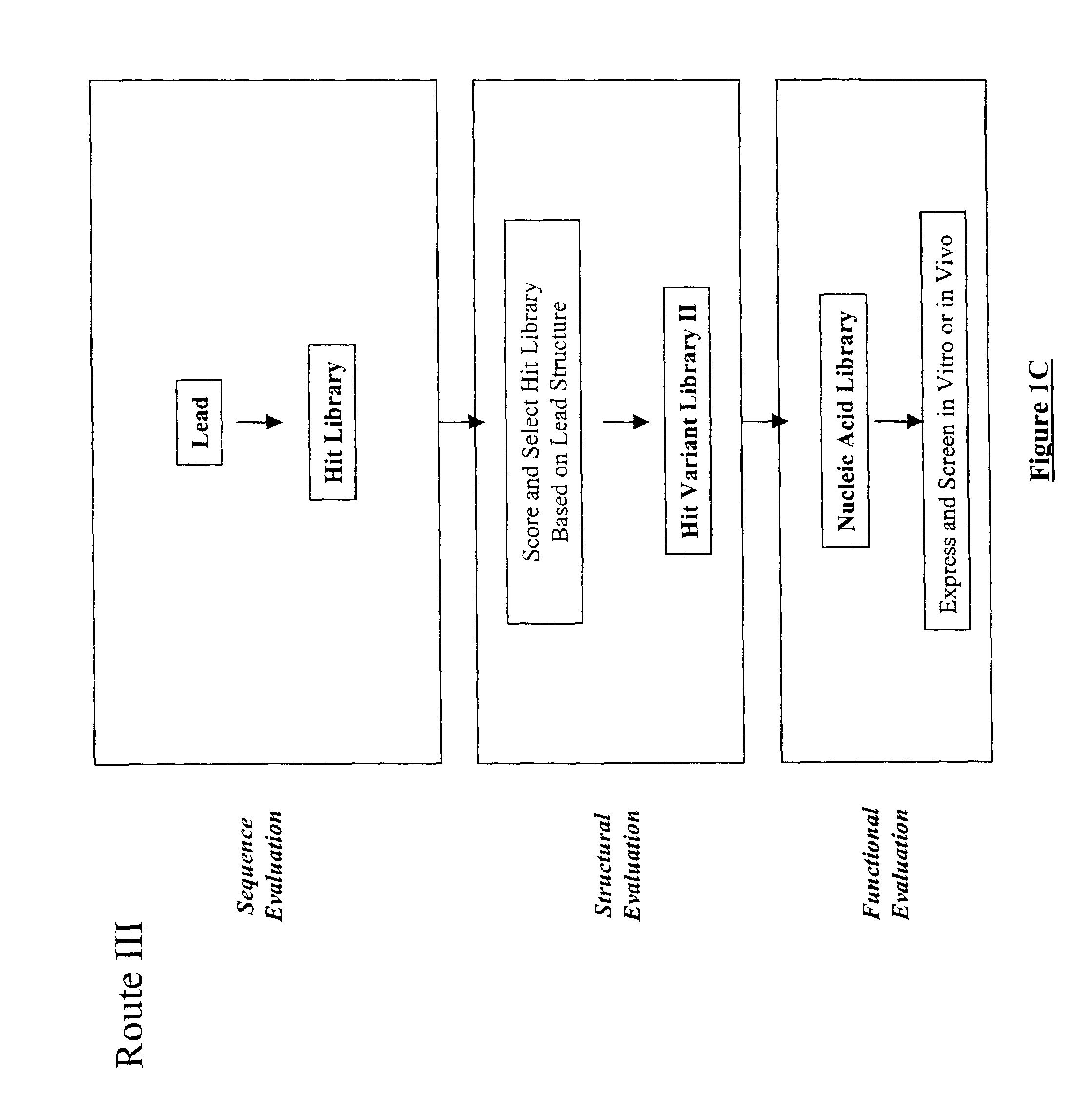

Structure-based selection and affinity maturation of antibody library

InactiveUS7117096B2High affinityImprove throughputPeptide librariesPeptide/protein ingredientsProtein insertionIn vivo

The present invention provides a structure-based methodology for efficiently generating and screening protein libraries for optimized proteins with desirable biological functions, such as antibodies with high binding affinity and low immunogenicity in humans. In one embodiment, a method is provided for constructing a library of antibody sequences based on a three dimensional structure of a lead antibody. The method comprises: providing an amino acid sequence of the variable region of the heavy chain (VH) or light chain (VL) of a lead antibody, the lead antibody having a known three dimensional structure which is defined as a lead structural template; identifying the amino acid sequences in the CDRs of the lead antibody; selecting one of the CDRs in the VH or VL region of the lead antibody; providing an amino acid sequence that comprises at least 3 consecutive amino acid residues in the selected CDR, the selected amino acid sequence being a lead sequence; comparing the lead sequence profile with a plurality of tester protein sequences; selecting from the plurality of tester protein sequences at least two peptide segments that have at least 10% sequence identity with lead sequence, the selected peptide segments forming a hit library; determining if a member of the hit library is structurally compatible with the lead structural template using a scoring function; and selecting the members of the hit library that score equal to or better than or equal to the lead sequence. The selected members of the hit library can be expressed in vitro or in vivo to produce a library of recombinant antibodies that can be screened for novel or improved function(s) over the lead antibody.

Owner:ABMAXIS

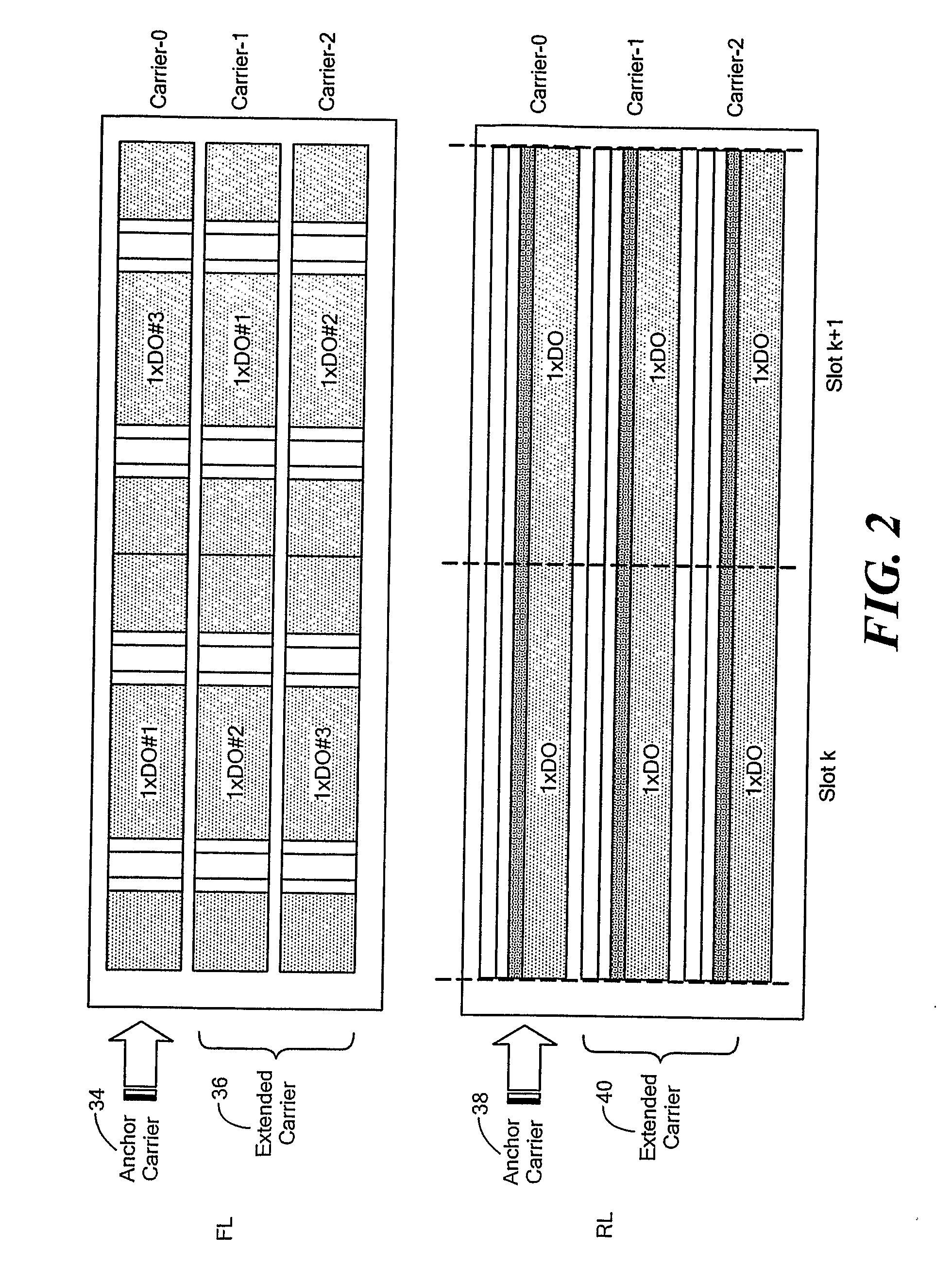

Radio Access System and Method Using Ofdm and Cdma for Broadband Data Transmission

ActiveUS20080151743A1Network traffic/resource managementTransmission path divisionWireless dataBroadband

A method and system for wireless data communication using a first wireless communication technology and a second wireless communication technology. The second wireless communication technology being different from the first wireless communication technology. A transmitter is arranged to transmit data using frame structures based on the first wireless communication technology and the second wireless communication technology in which the frame structure based on the second wireless communication technology has a timing structure, MAC and pilot that are also used with the frame structure of the first wireless communication technology. The transmitter is arranged to selectively change transmission on a frame by frame basis between the first wireless communication technology and the second wireless communication technology.

Owner:APPLE INC

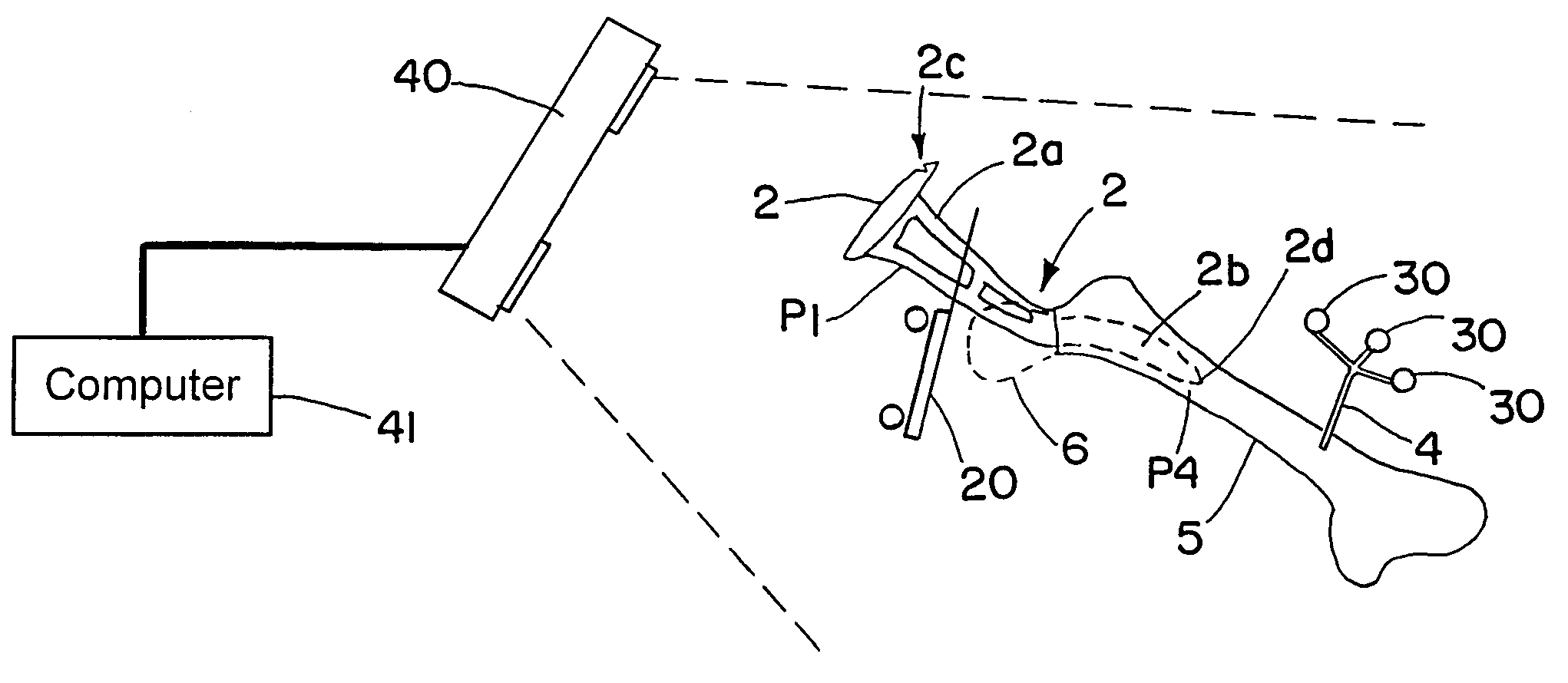

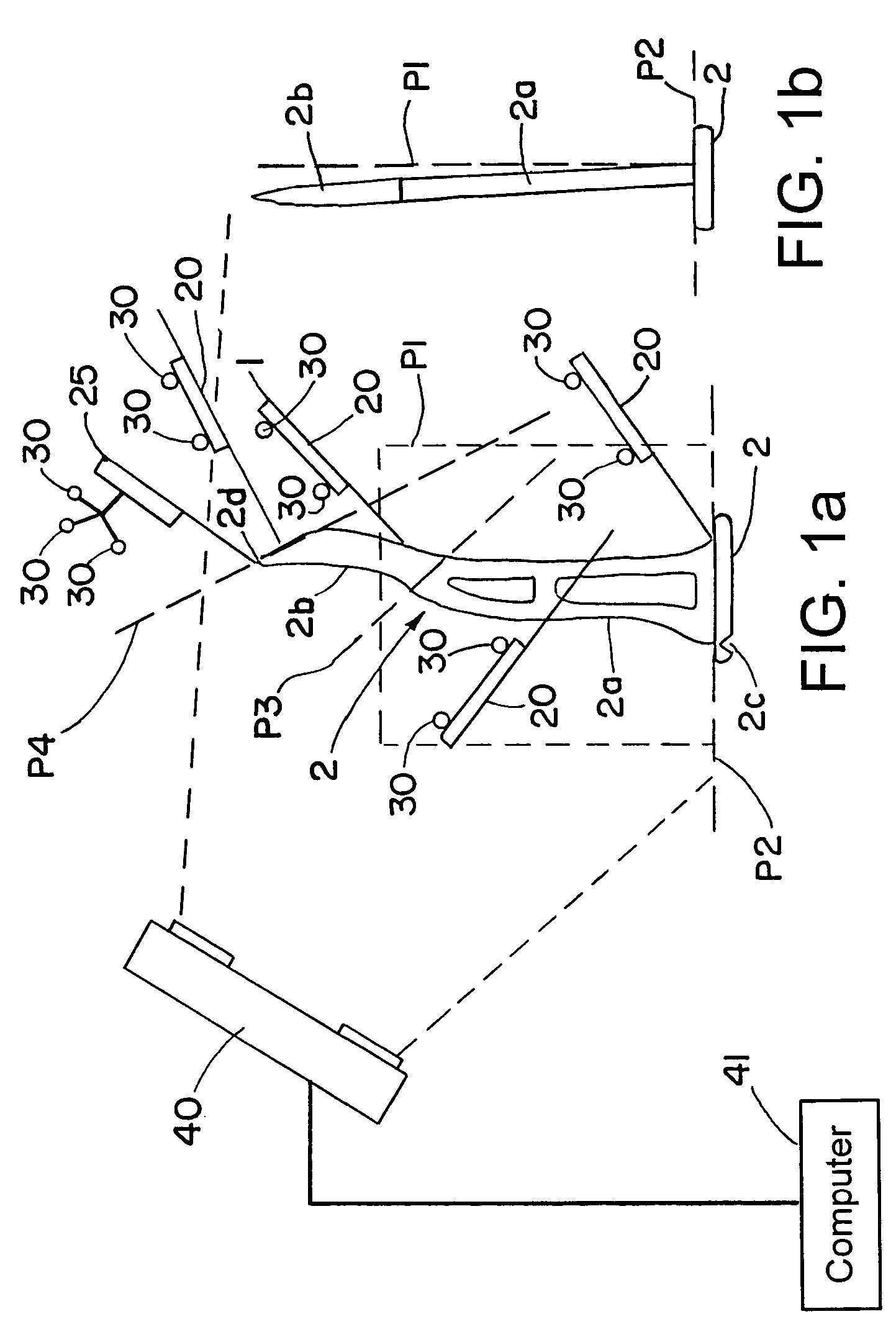

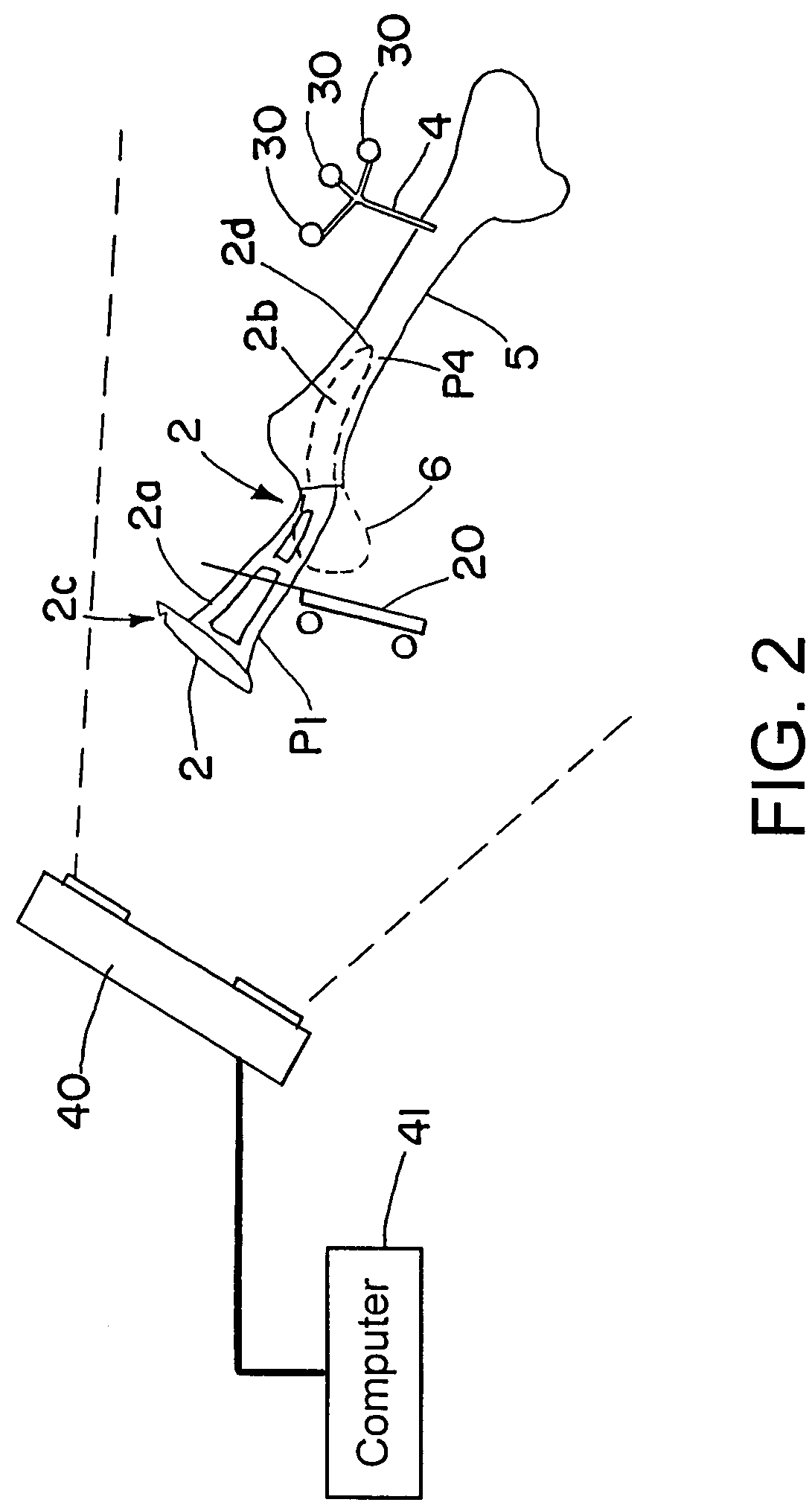

Method and system for determining the location of a medical instrument relative to a body structure

ActiveUS7962196B2Surgical navigation systemsComputer-aided planning/modellingPhysical medicine and rehabilitationArray data structure

A method for determining a location of an object relative to a body structure includes: providing a location of a first part of the object relative to a second part of the object, said second part different from said first part; attaching a marker device to the body structure; detecting a location of the marker device relative to the body structure; positioning the object relative to the body structure; detecting a location of the first part of the object relative to the marker device; and calculating a relative location of the second part of the object relative to the location of the body structure based on the location of the first part relative to the second part, the location of the marker device relative to the body structure, and the location of the first part relative to the marker array.

Owner:SMITH & NEPHEW ASIA PACIFIC PTE LTD +2

Temperature estimation and tissue detection of an ultrasonic dissector from frequency response monitoring

An ultrasonic surgical apparatus including a first signal generator outputting a drive signal at a predetermined voltage and frequency, a first oscillating structure receiving the drive signal and oscillating at the frequency of the drive signal, and a bridge circuit, detecting the mechanical motion of the first oscillating structure and outputting a signal representative of the mechanical motion. The apparatus also includes a second oscillating structure integrally formed within a portion of the first oscillating structure, the second oscillating structure outputting an electrical signal, and a microcontroller receiving the signal output by the bridge circuit and output by the second oscillating structure, the microcontroller determining an instantaneous frequency at which the first oscillating structure is oscillating based on the received signal, comparing the electrical signal from the second oscillating structure with a known signal value and determining the temperature of the second oscillating structure based on a the comparison.

Owner:TYCO HEALTHCARE GRP LP

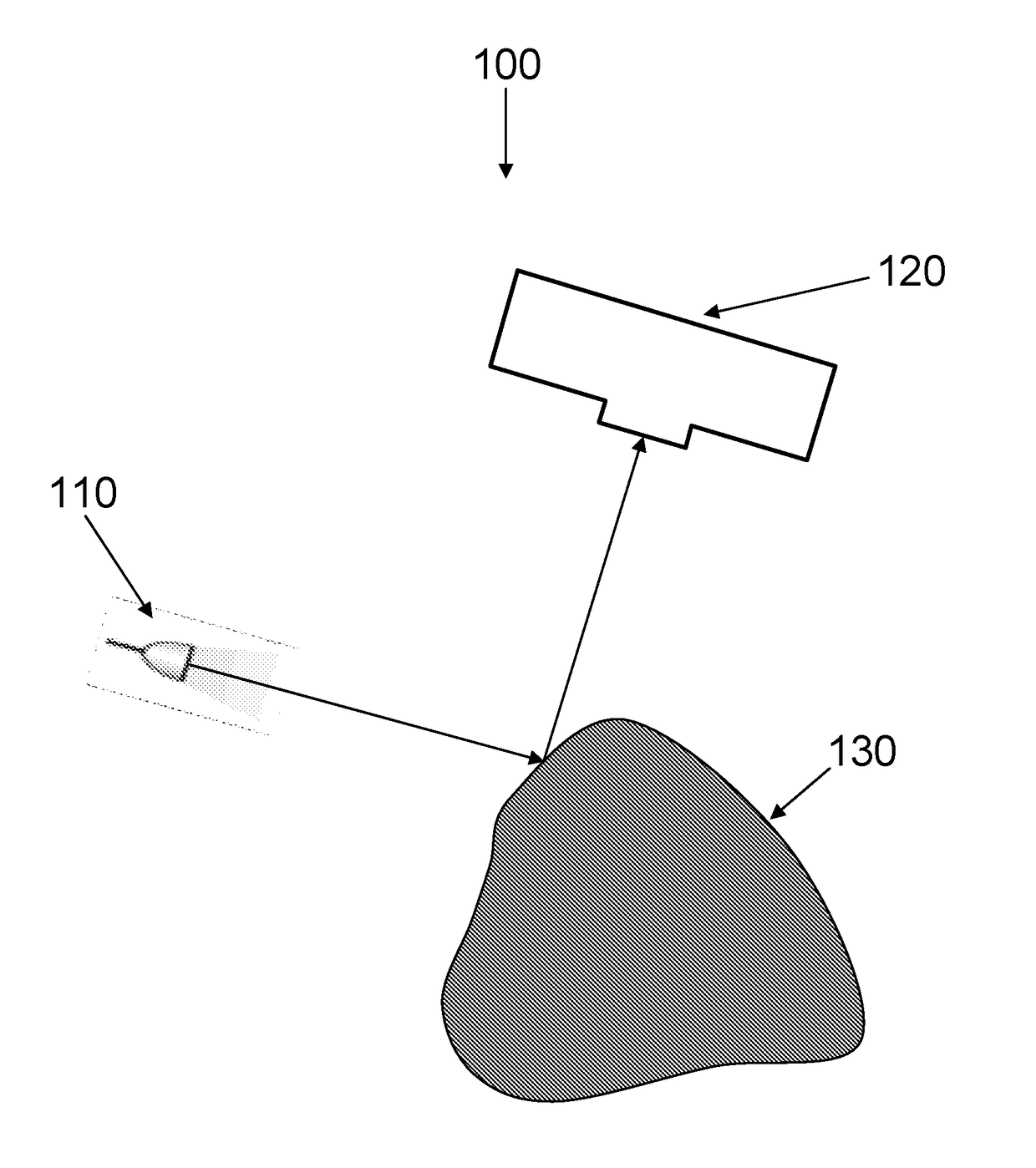

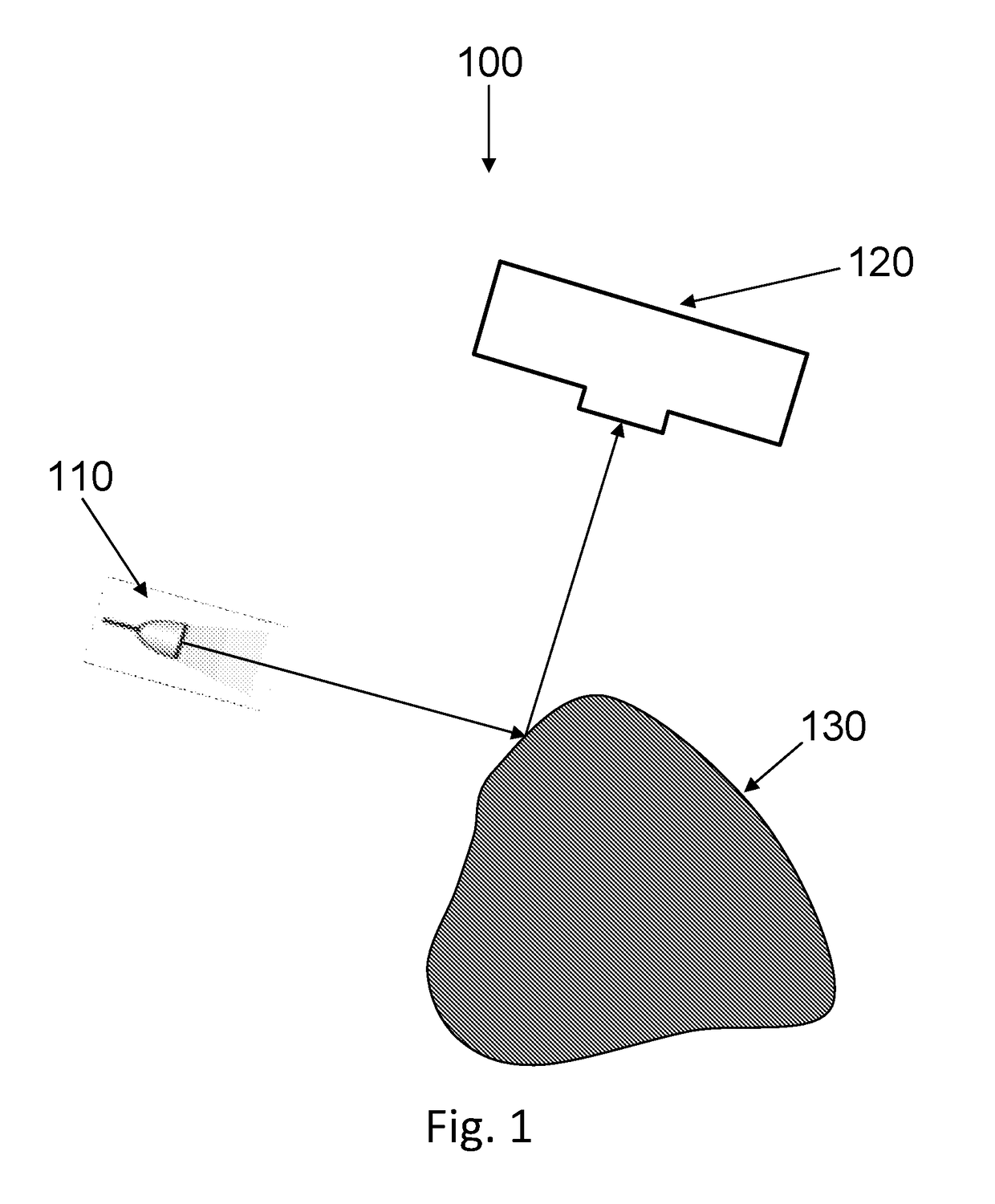

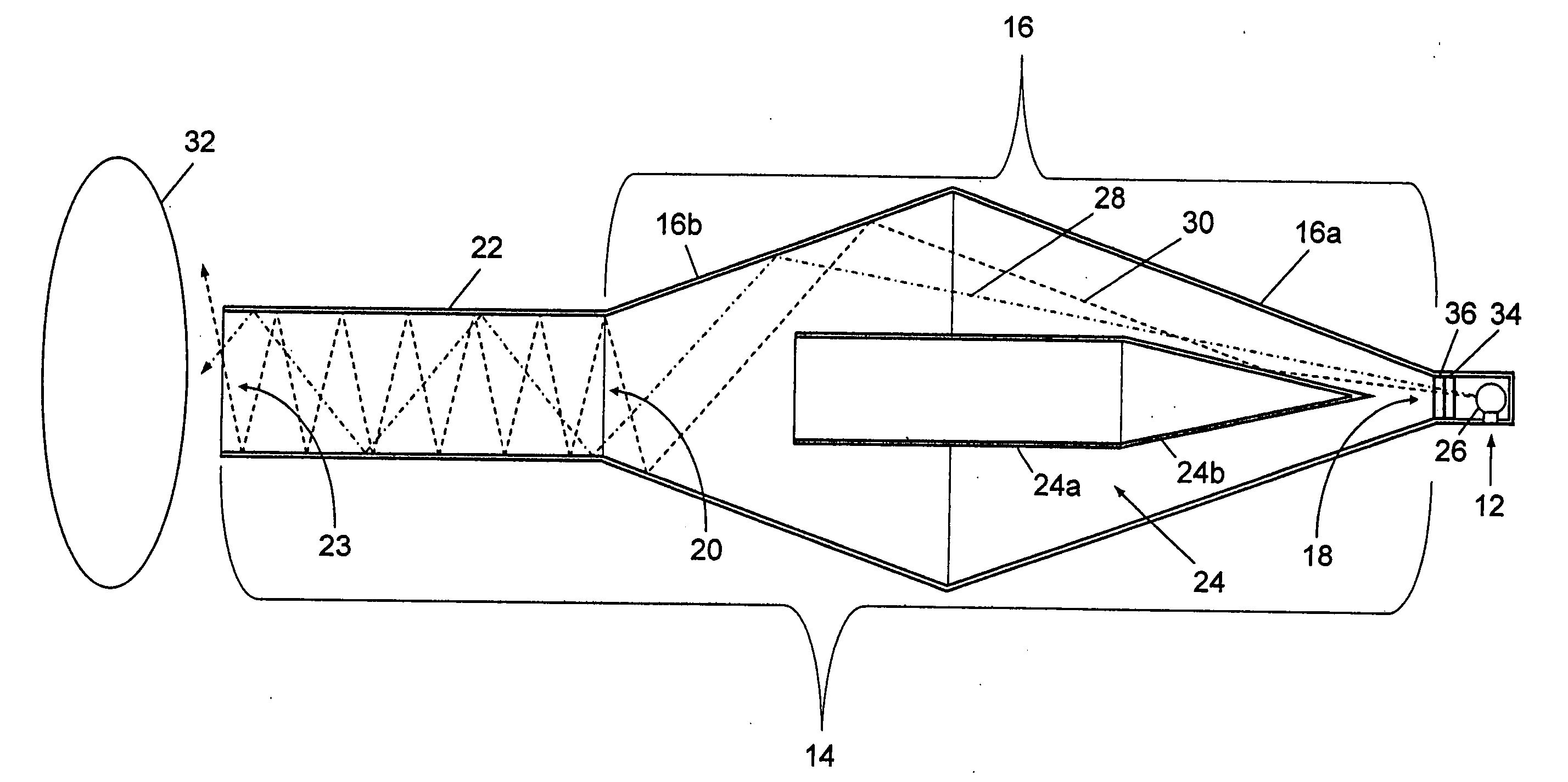

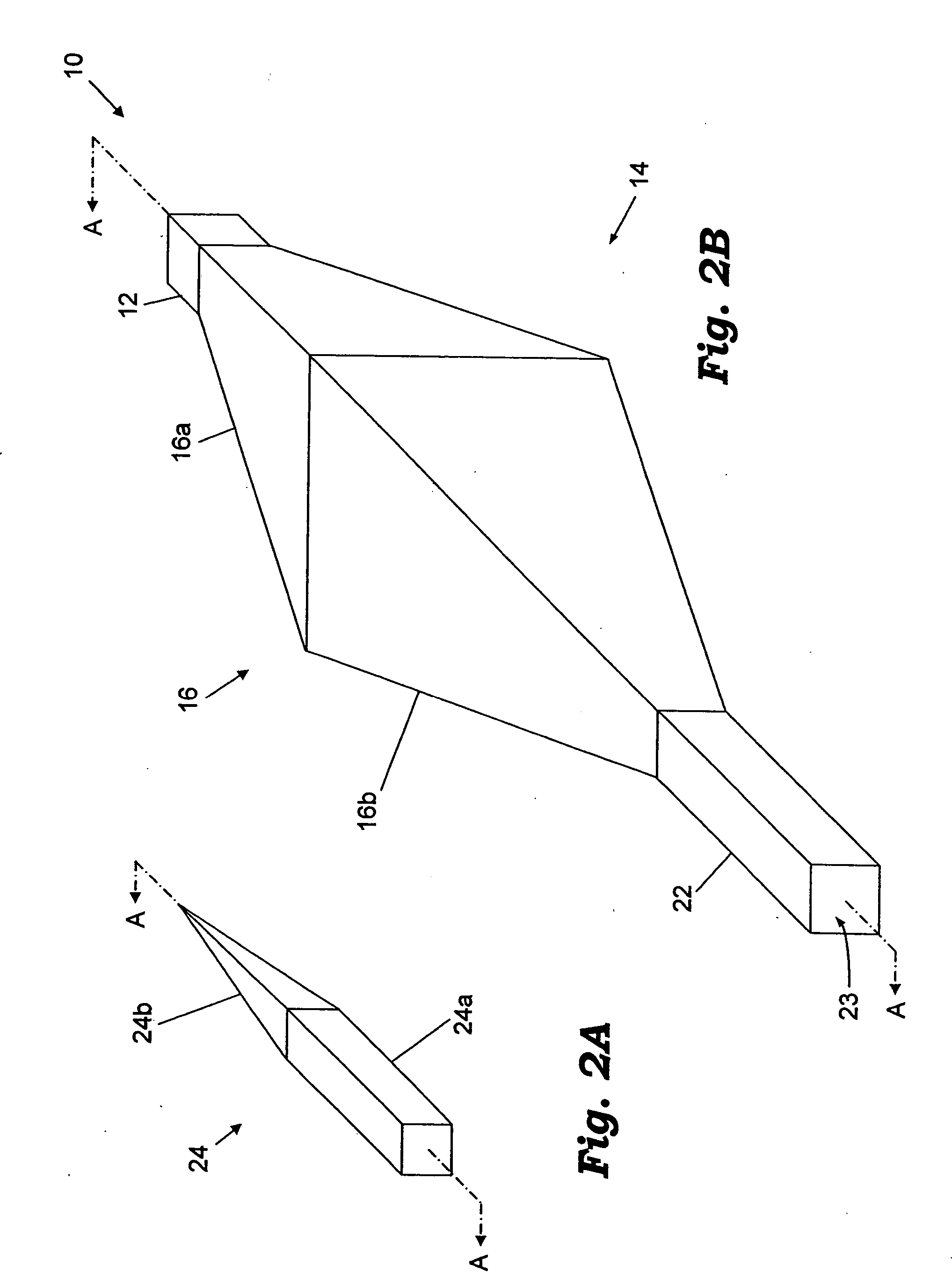

Projection of subsurface structure onto an object's surface

InactiveUS20060122515A1Increase awarenessTelevision system detailsDiagnostics using lightVisibilityVideo image

An imaging system illuminates an object with infrared light to enhance visibility of buried structure beneath the surface of the object, and projects a visible light image of the buried structure onto the surface of the object. The system may include an infrared light source for generating the infrared light and a structure for diffusing the infrared light. The diffusing structure may include one or more layers of diffusing material for diffusing the light. The system further includes a video imaging device for receiving the infrared light reflected from the object and for generating a video image of the buried structure based on the reflected infrared light. The buried structure may be a subcutaneous blood vessel. A calibration procedure is described as well as embodiments for ensuring that the object is maintained in focus at the correct distance.

Owner:CHRISTIE MEDICAL HLDG

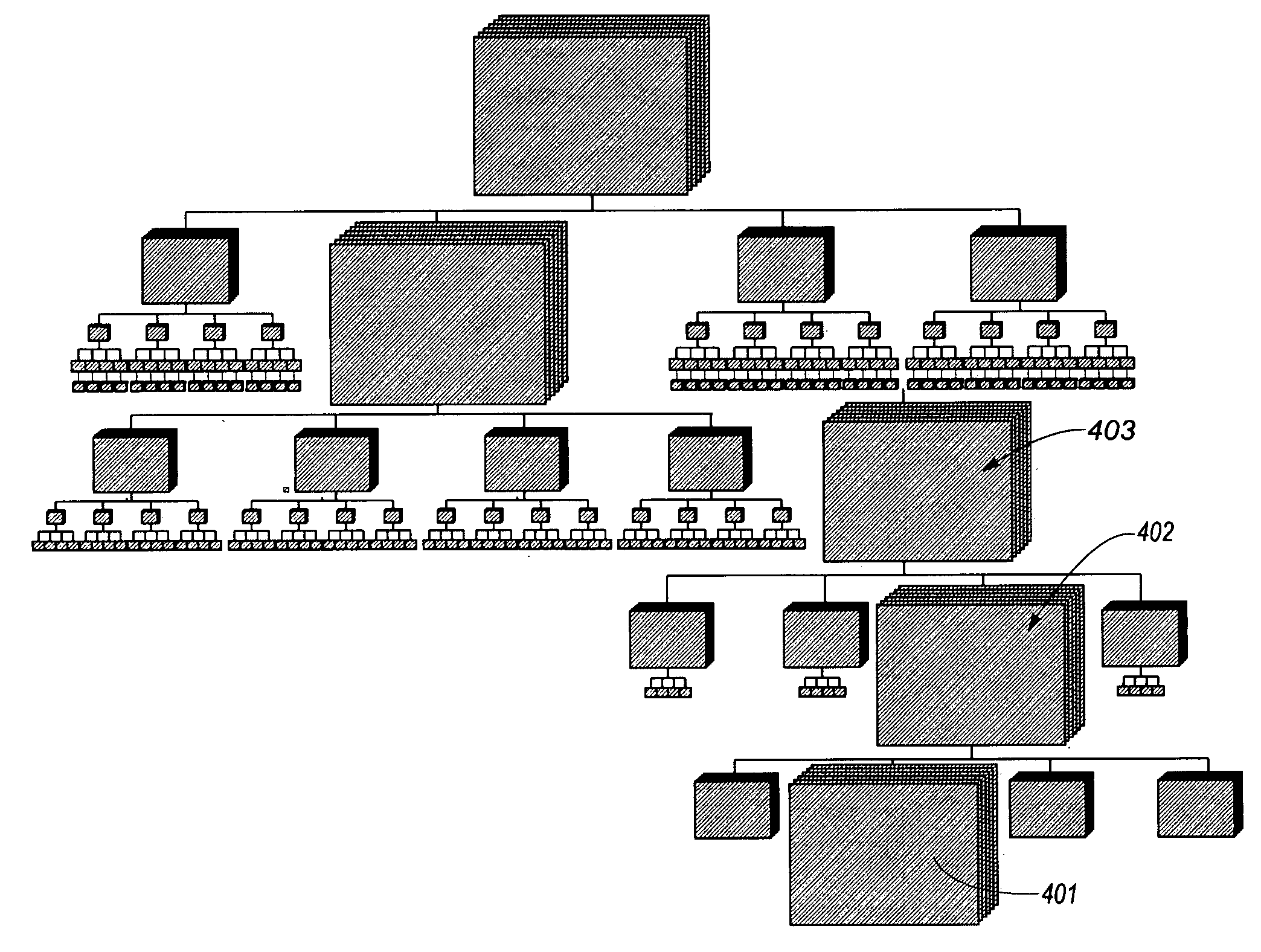

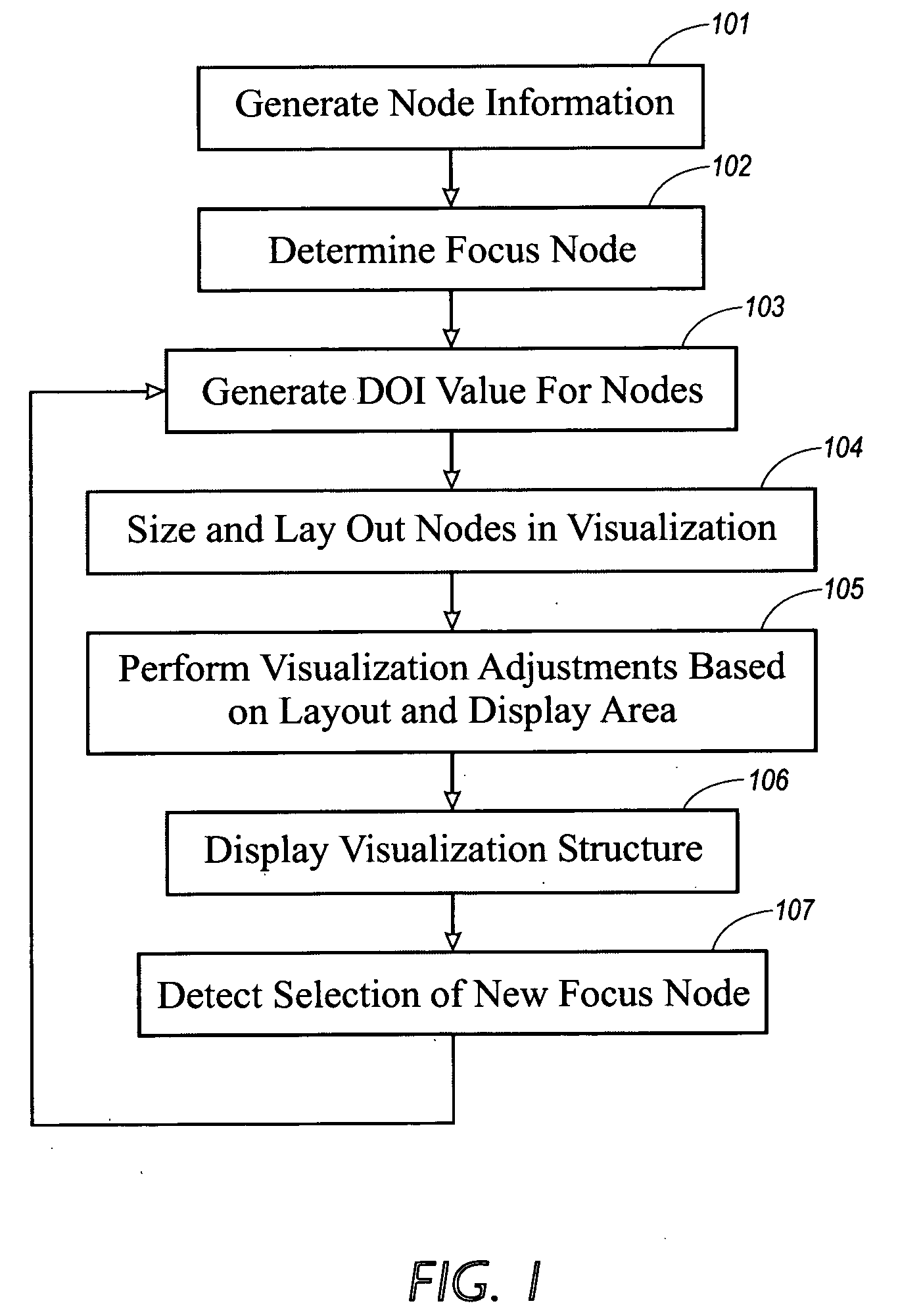

System and method for browsing hierarchically based node-link structures based on an estimated degree of interest

InactiveUS20050273730A1Drawing from basic elementsWeb data navigationDisplay deviceArtificial intelligence

Owner:XEROX CORP

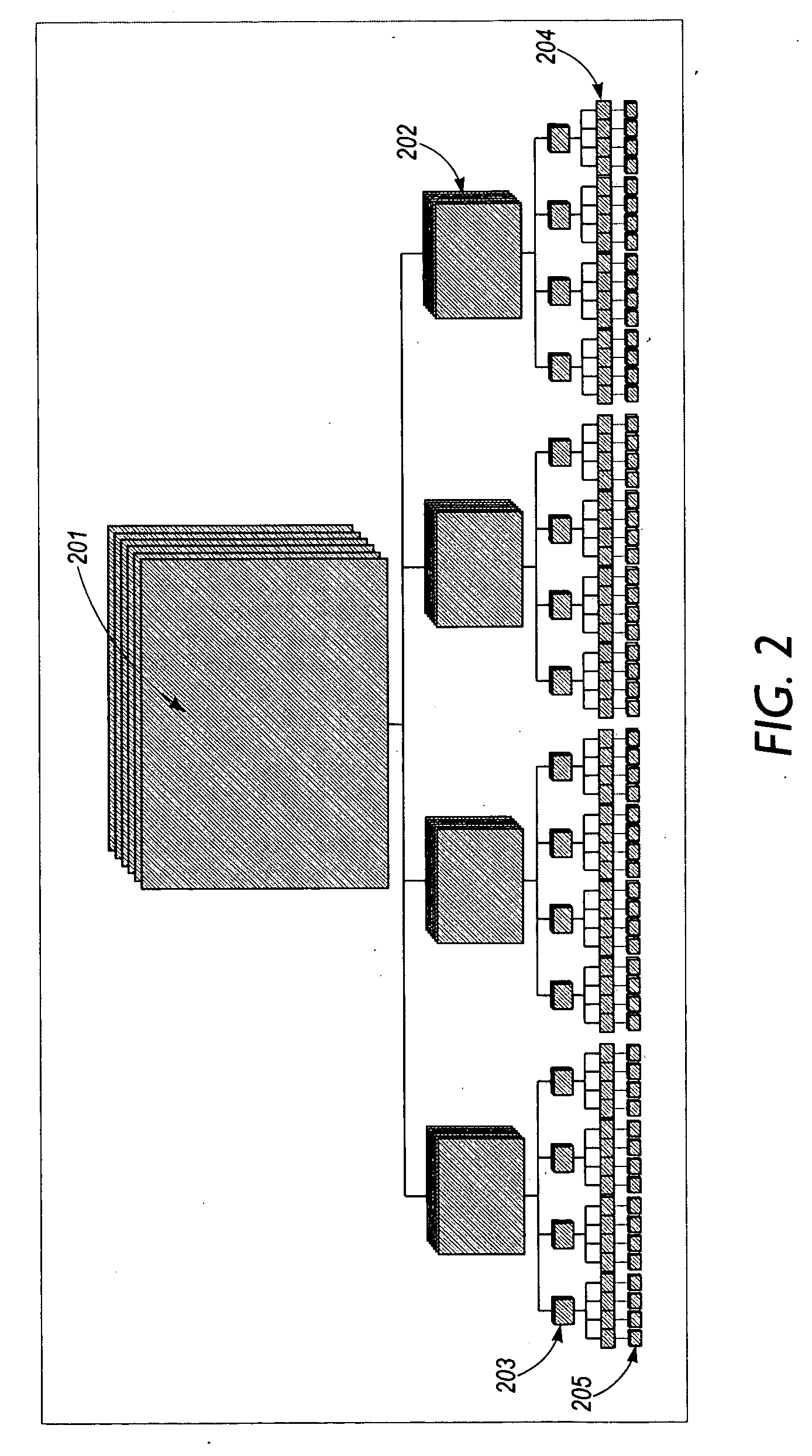

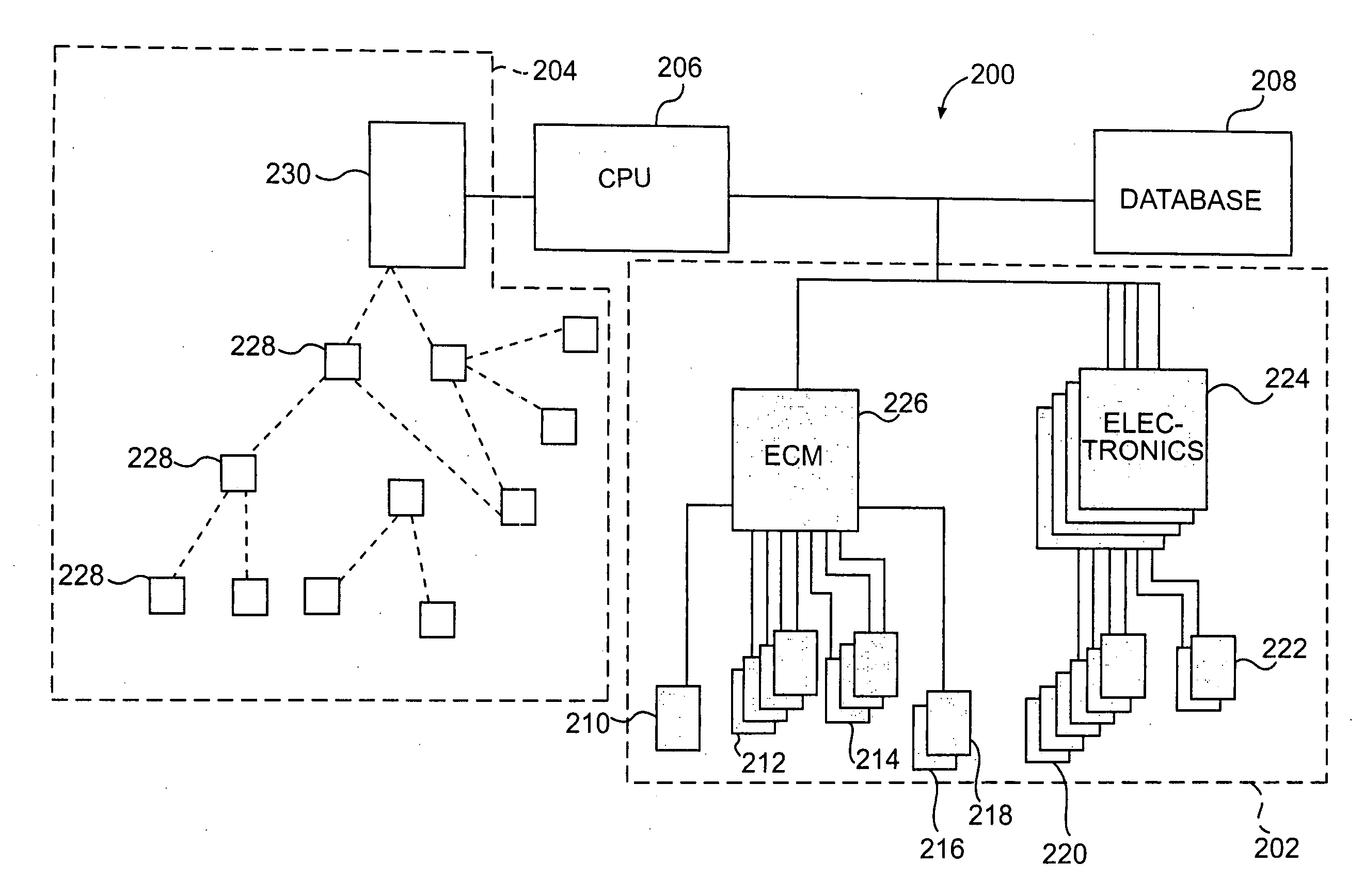

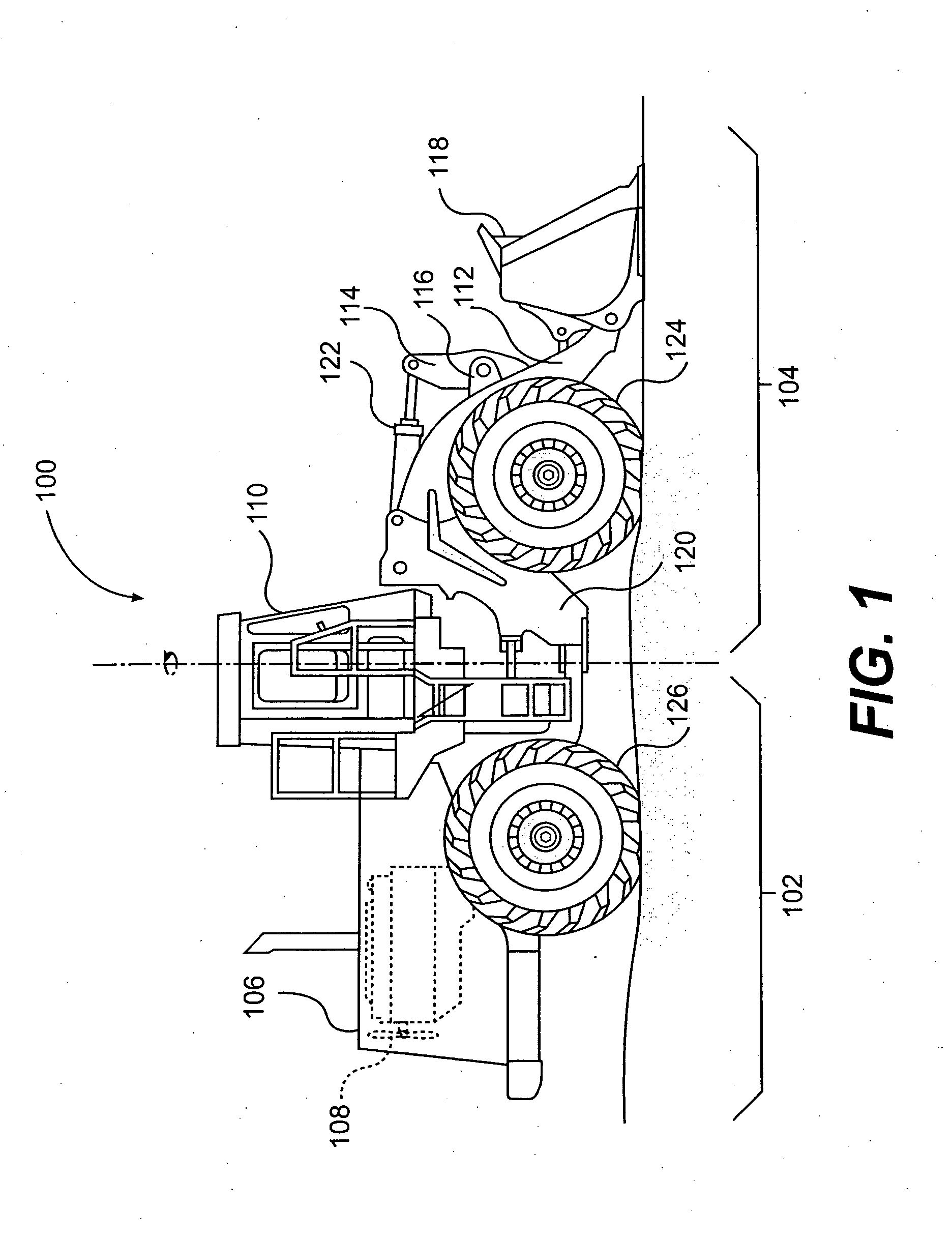

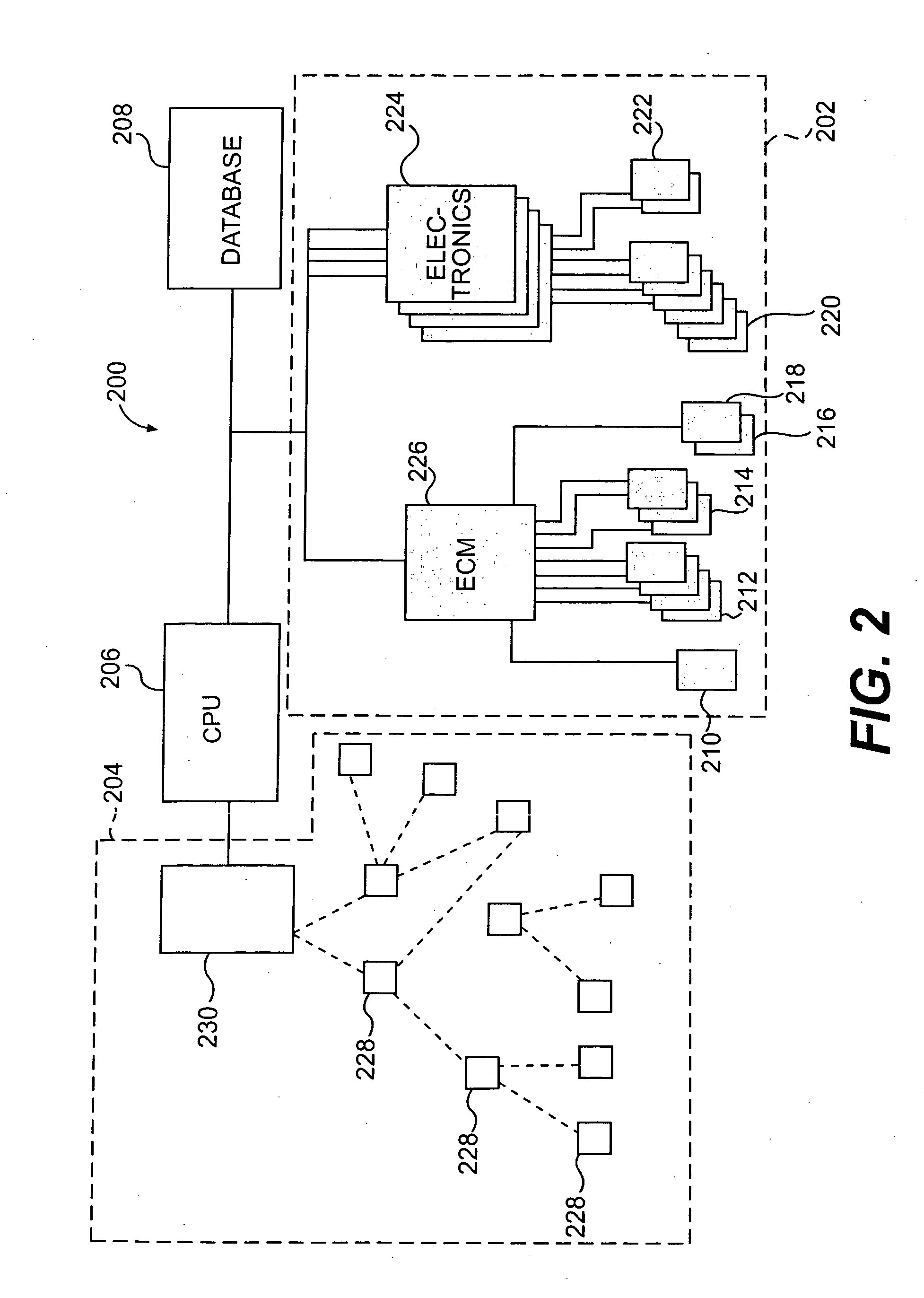

Systems and methods for maintaining load histories

Methods and systems for constructing a load history database for a structure is disclosed. In one embodiment, a method is disclosed that may include detecting a measurable parameter on the structure utilizing a sensor positioned on the structure and determining a value of external loads acting upon the structure based on the detected parameter. Further, the method may include evaluating the value of the external loads against a pre-established factor. Based on the evaluation, the value of the external loads are selectively stored in the load history database.

Owner:CATERPILLAR INC

Coding systems and methods

Disclosed herein are various embodiments of coding systems and methods. In one method embodiment, among others, a coding method comprises receiving input parameters, and providing a packet comprising variable FEC code block sizes throughout the packet structure based on the input parameters.

Owner:INTELLECTUAL VENTURES I LLC

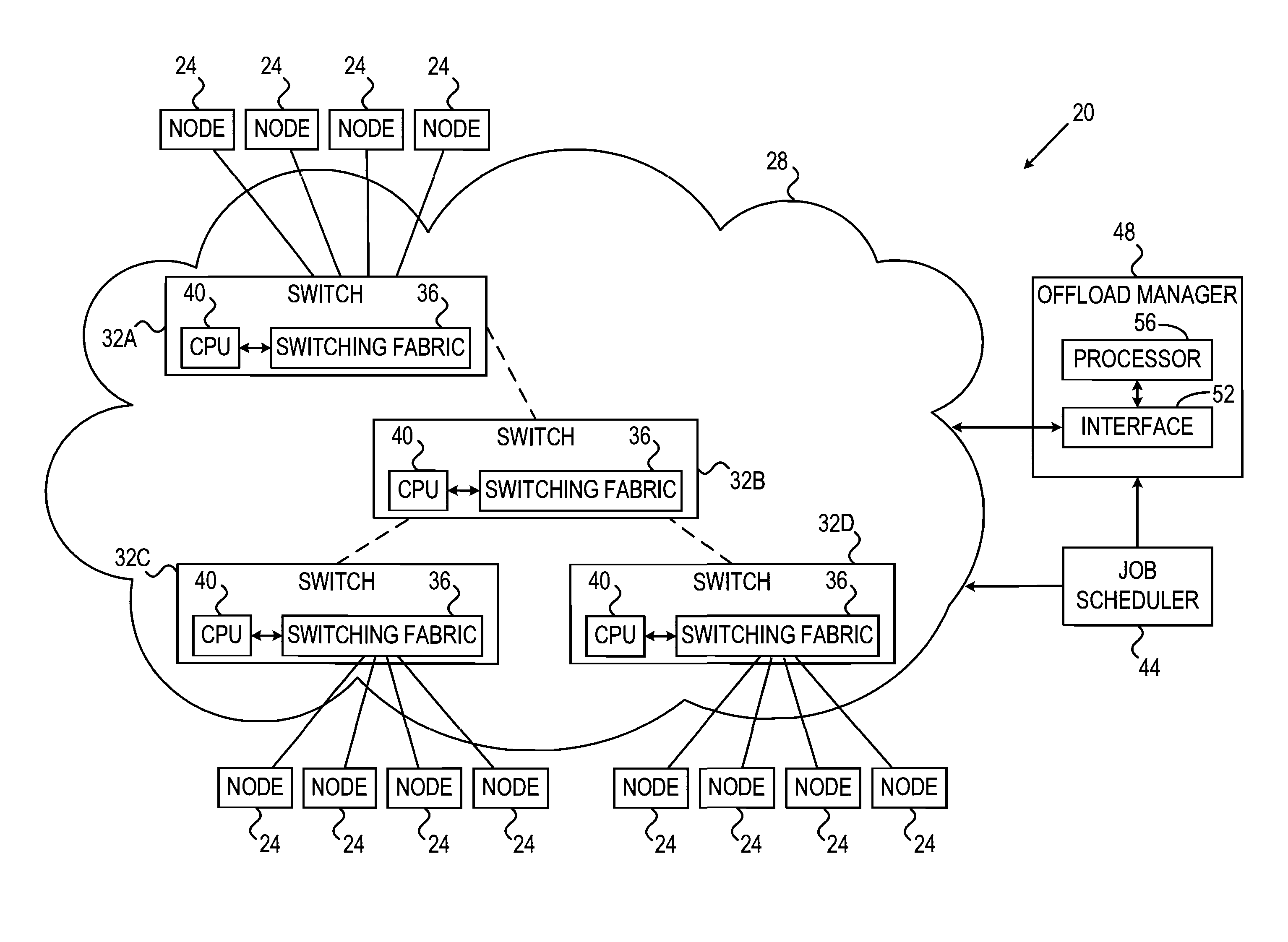

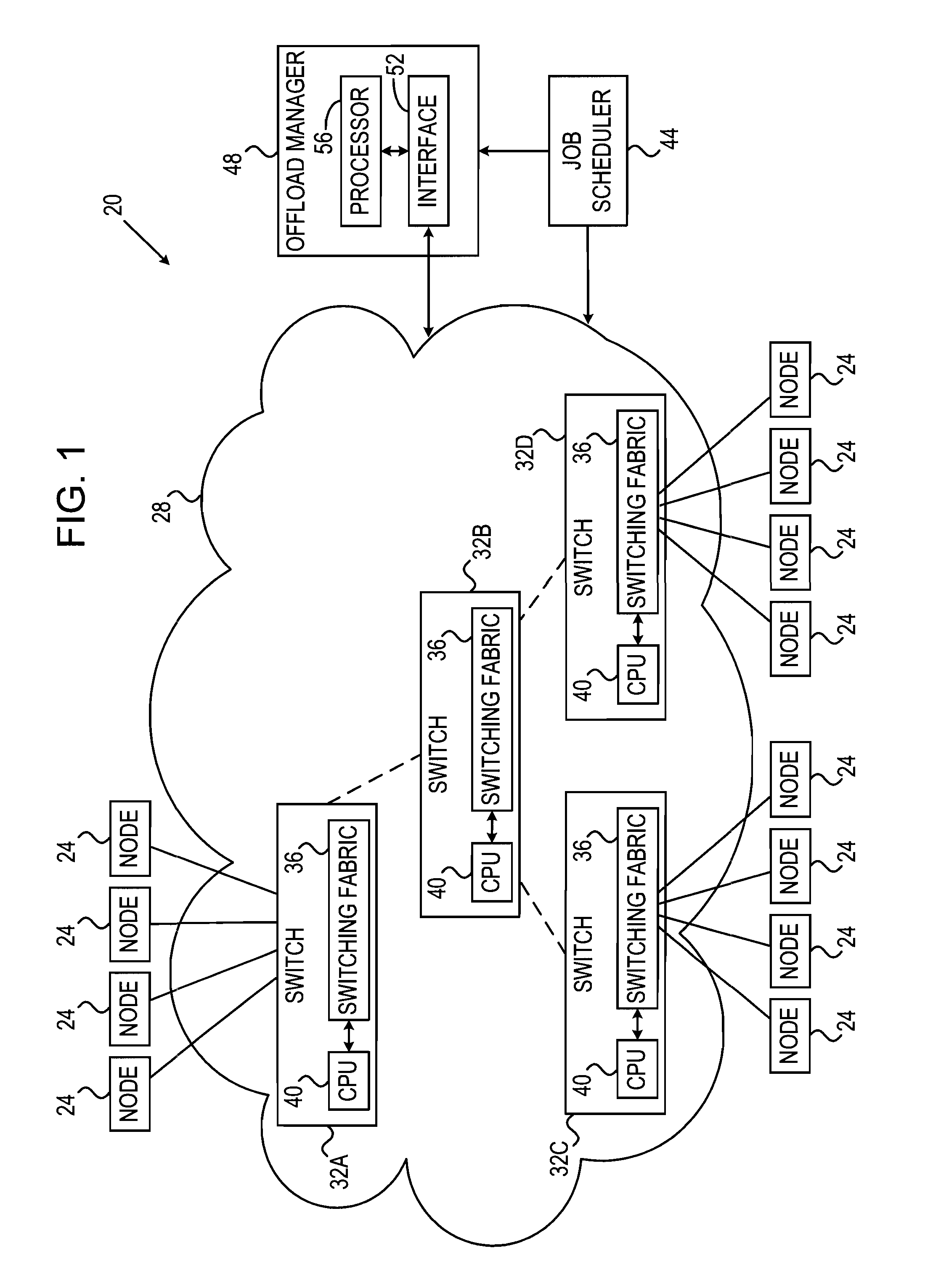

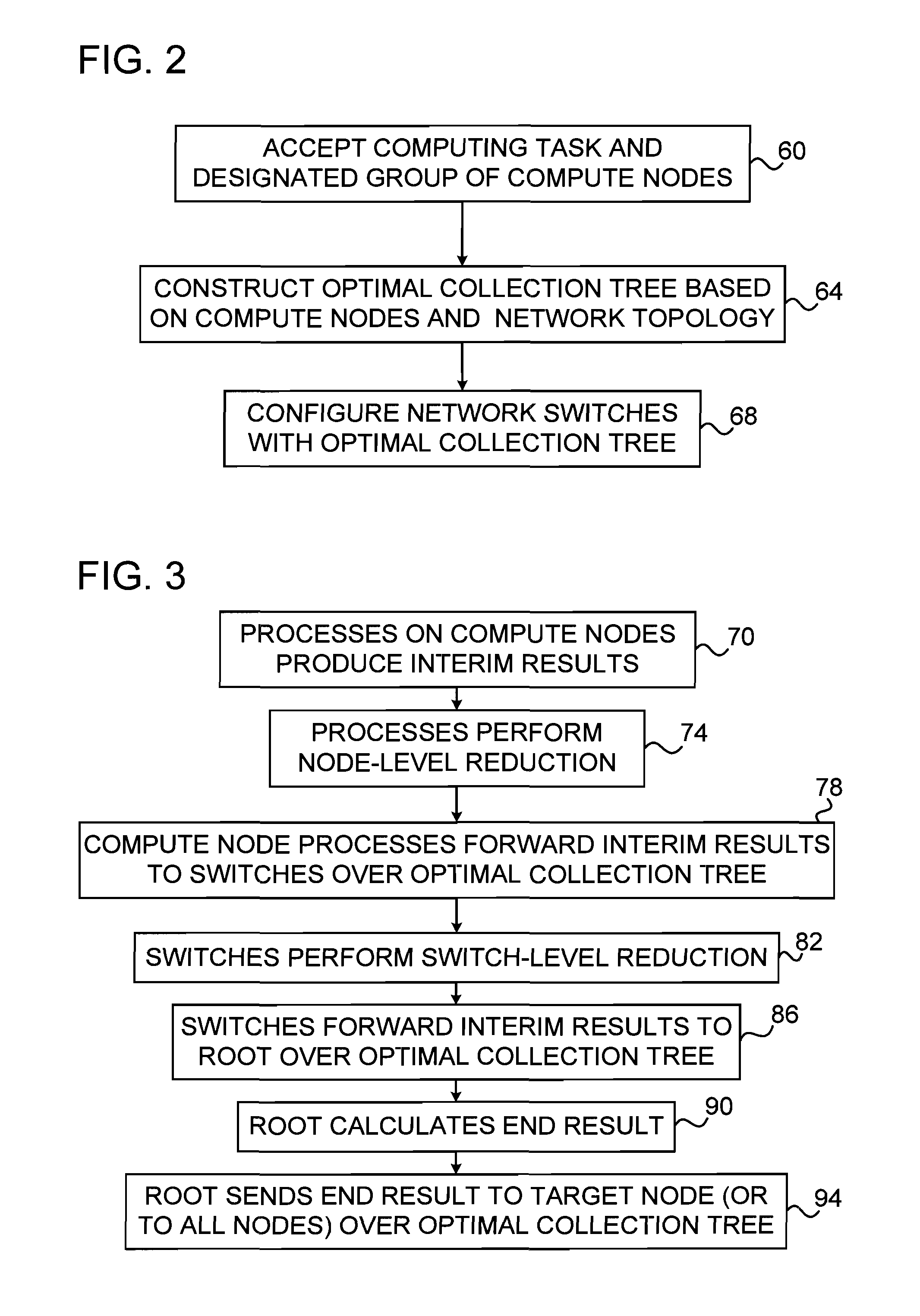

Topology-Aware Fabric-Based Offloading of Collective Functions

ActiveUS20110113083A1Multiple digital computer combinationsTransmissionInterconnectionNetwork switch

A computing method includes accepting a notification of a computing task for execution by a group of compute nodes interconnected by a communication network, which has a given interconnection topology and includes network switching elements. A set of preferred paths, which connect the compute nodes in the group via at least a subset of the network switching elements to one or more root switching elements, are identified in the communication network based on the given interconnection topology and on a criterion derived from the computing task. The network switching elements in the subset are configured to forward node-level results of the computing task produced by the compute nodes in the group to the root switching elements over the preferred paths, so as to cause the root switching elements to calculate and output an end result of the computing task based on the node-level results.

Owner:MELLANOX TECHNOLOGIES LTD

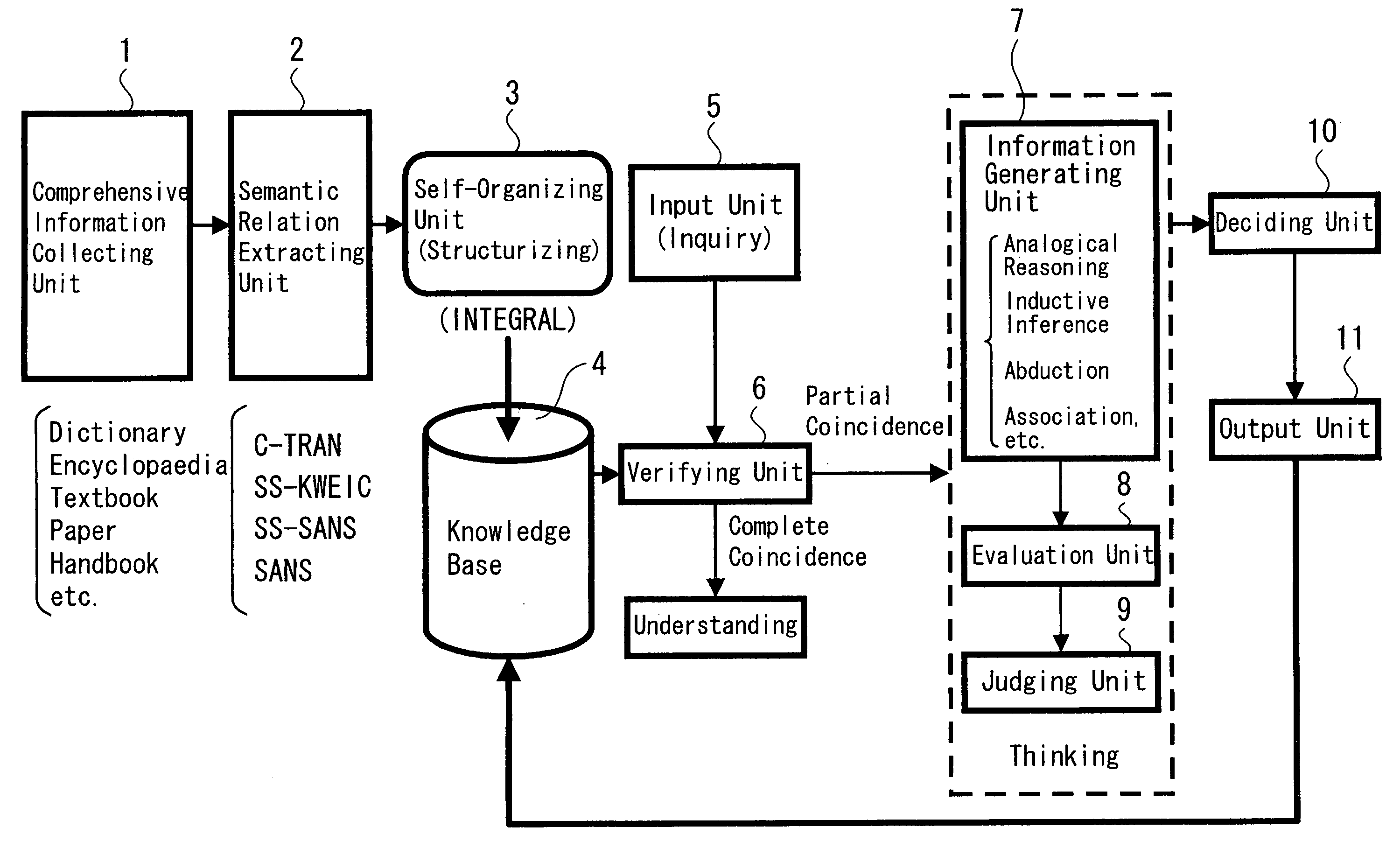

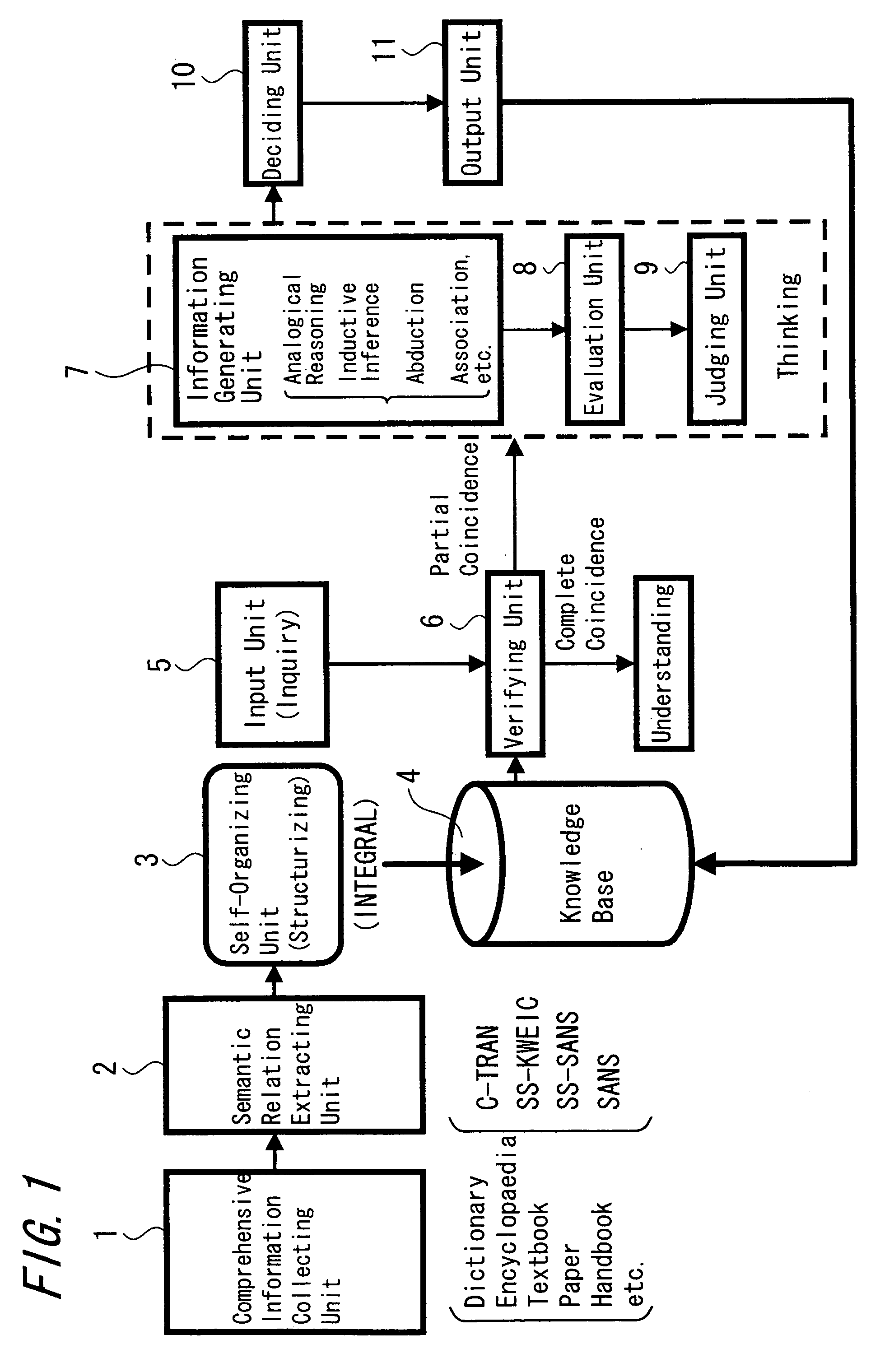

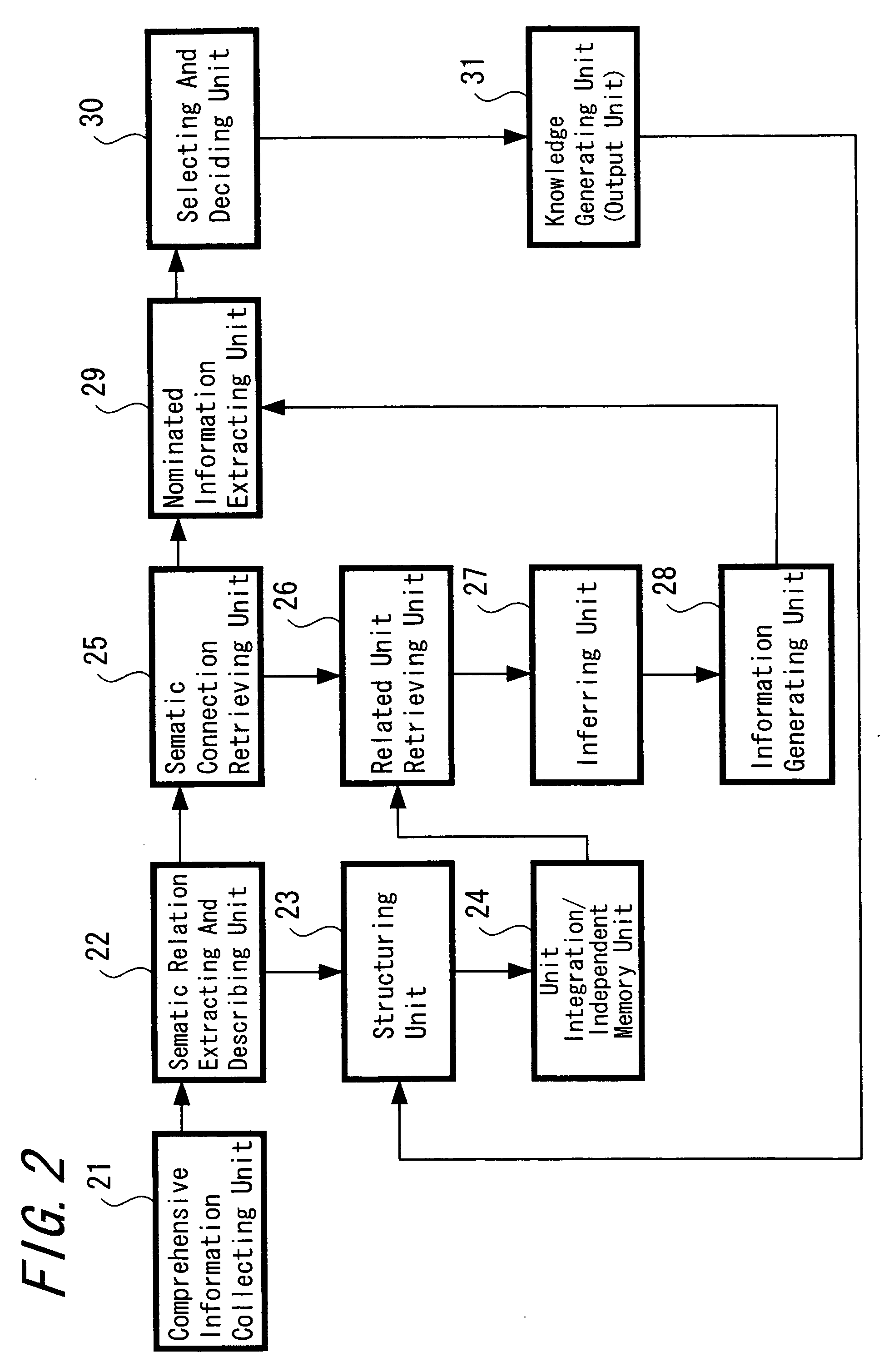

Learning/thinking machine and learning/thinking method based on structured knowledge, computer system, and information generation method

InactiveUS20060217818A1Surpass in accuracySurpass in capacityElectric controllersIgnition automatic controlLearning machineComputerized system

The present invention is to provide a learning machine capable of expressing / accumulating concept and semantic relation by understanding semantic relation of information as a relation between concepts after characteristics, semantic relation and structure of information and the like have been analyzed. The present invention is intended to realize a thinking machine in which information is inclusively collected and stored as knowledge structured based on the semantic relation of the collected information, information is generated by predetermined inference so as to have a new semantic relation in response to an inquiry or request and which can decide an optimal solution to an inquiry and the like by evaluating / deciding new generated information.

Owner:JAPAN SCI & TECH CORP

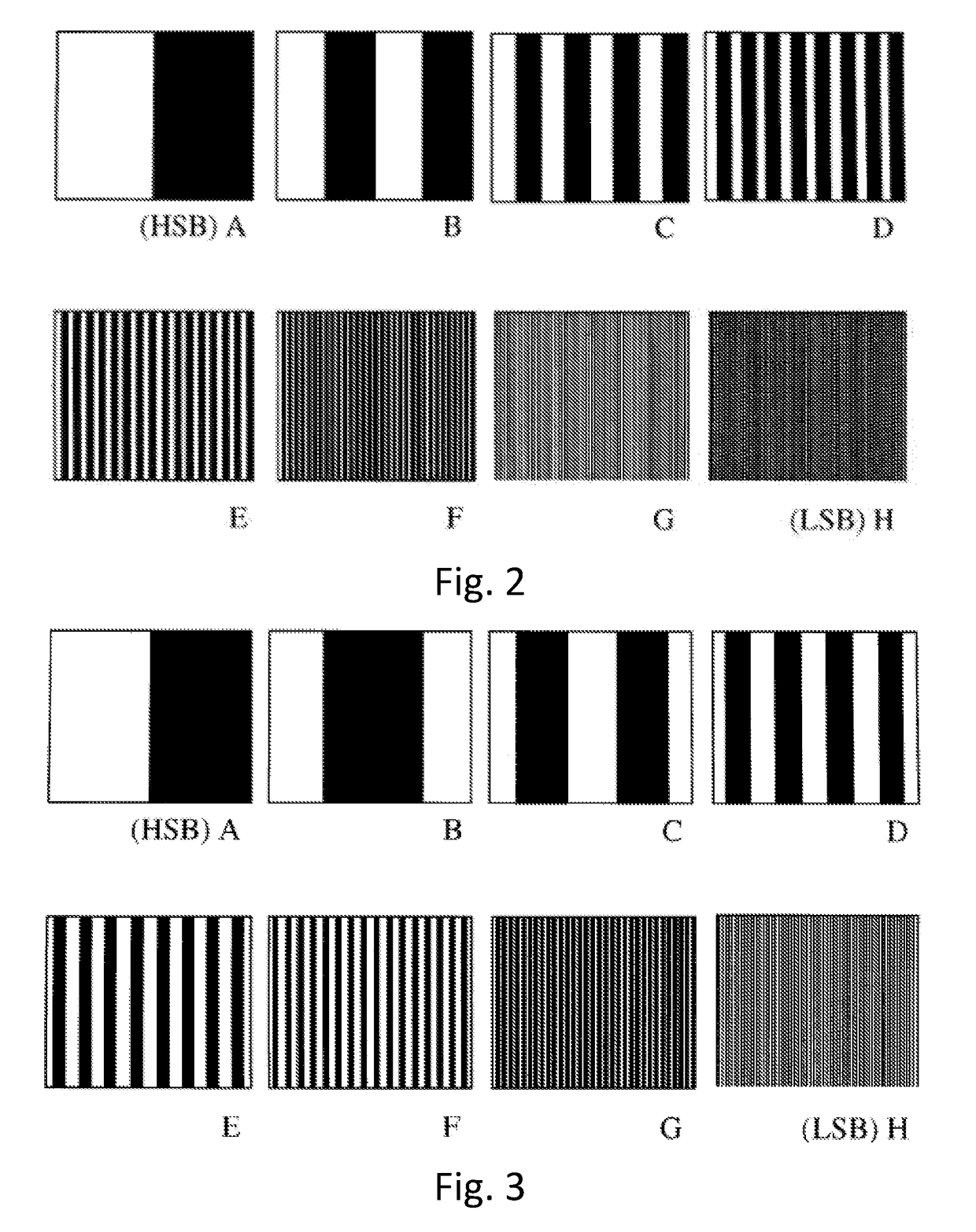

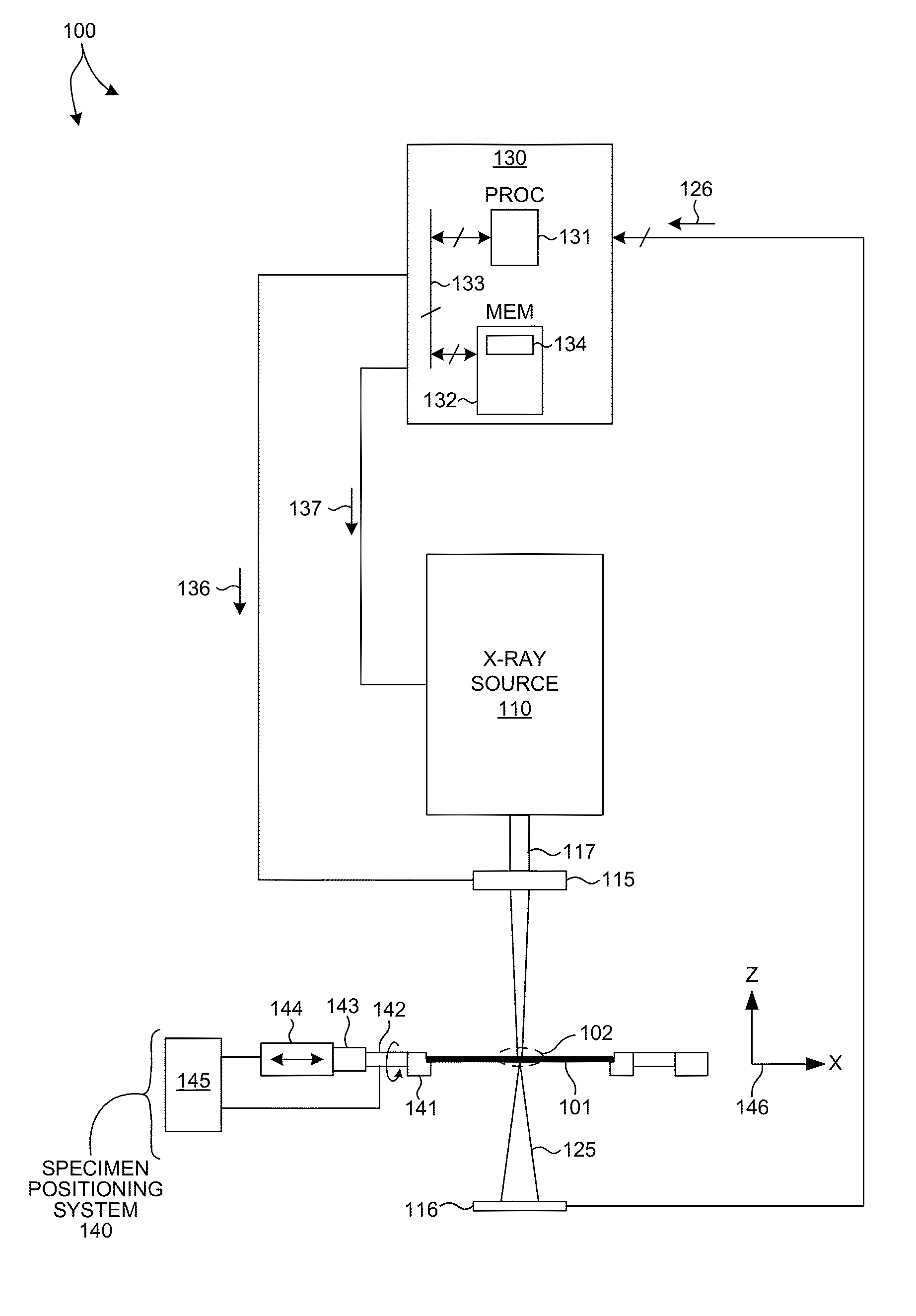

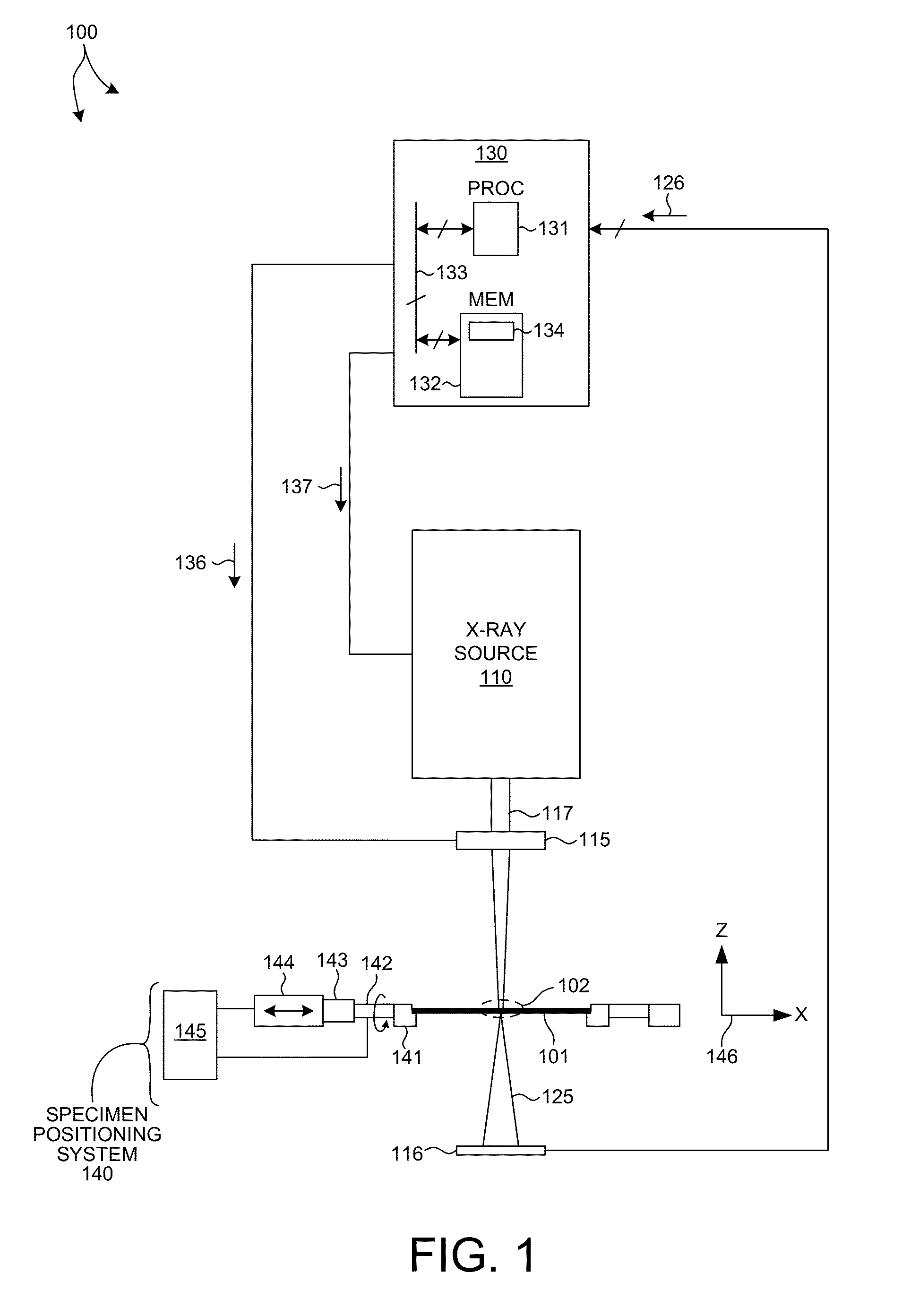

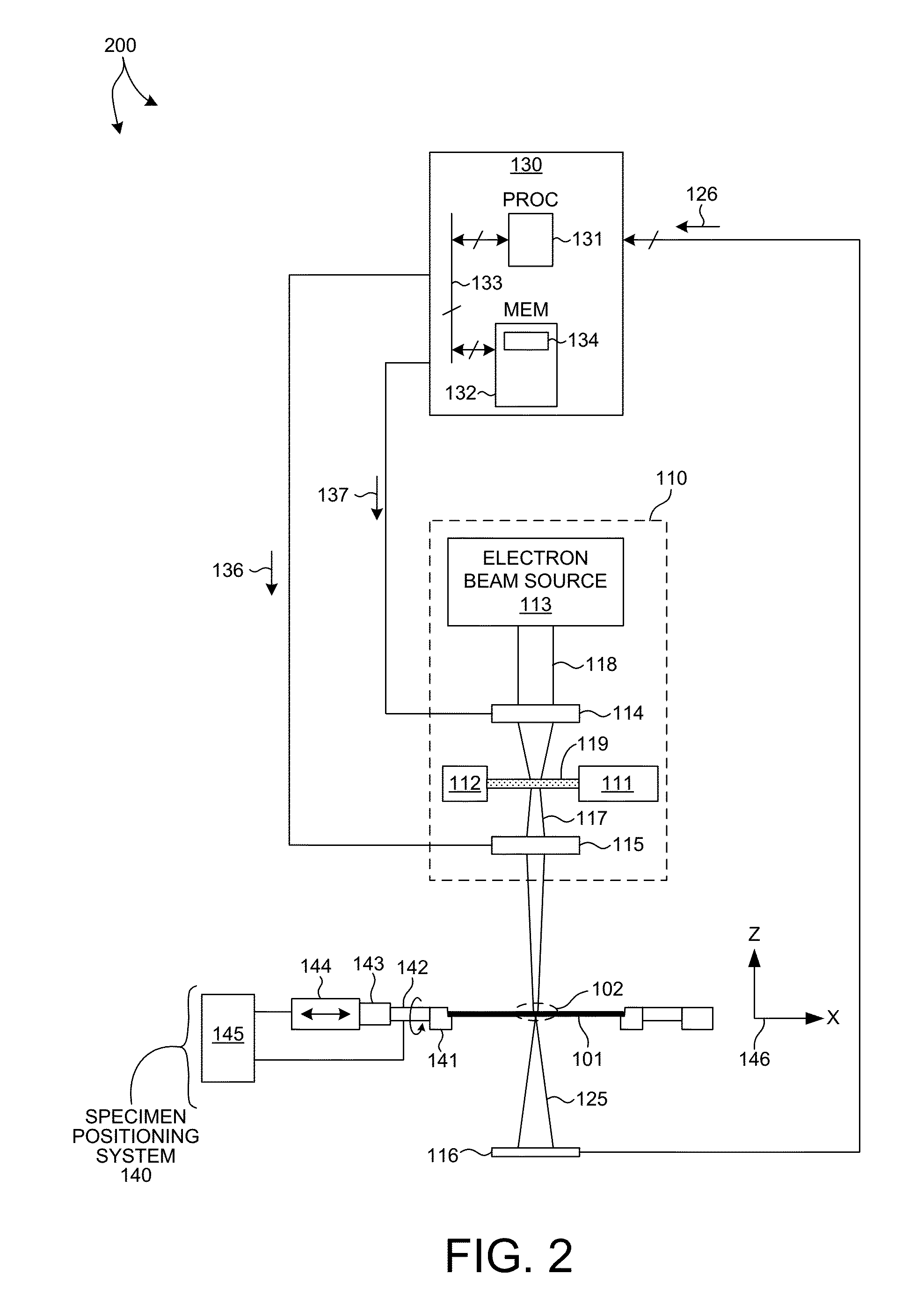

Scatterometry-Based Imaging and Critical Dimension Metrology

ActiveUS20150300965A1Improve the measurement effectMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementDiffraction orderMetrology

Methods and systems for performing measurements of semiconductor structures and materials based on scatterometry measurement data are presented. Scatterometry measurement data is used to generate an image of a material property of a measured structure based on the measured intensities of the detected diffraction orders. In some examples, a value of a parameter of interest is determined directly from the map of the material property of the measurement target. In some other examples, the image is compared to structural characteristics estimated by a geometric, model-based parametric inversion of the same measurement data. Discrepancies are used to update the geometric model of the measured structure and improve measurement performance. This enables a metrology system to converge on an accurate parametric measurement model when there are significant deviations between the actual shape of a manufactured structure subject to model-based measurement and the modeled shape of the structure.

Owner:KLA TENCOR TECH CORP

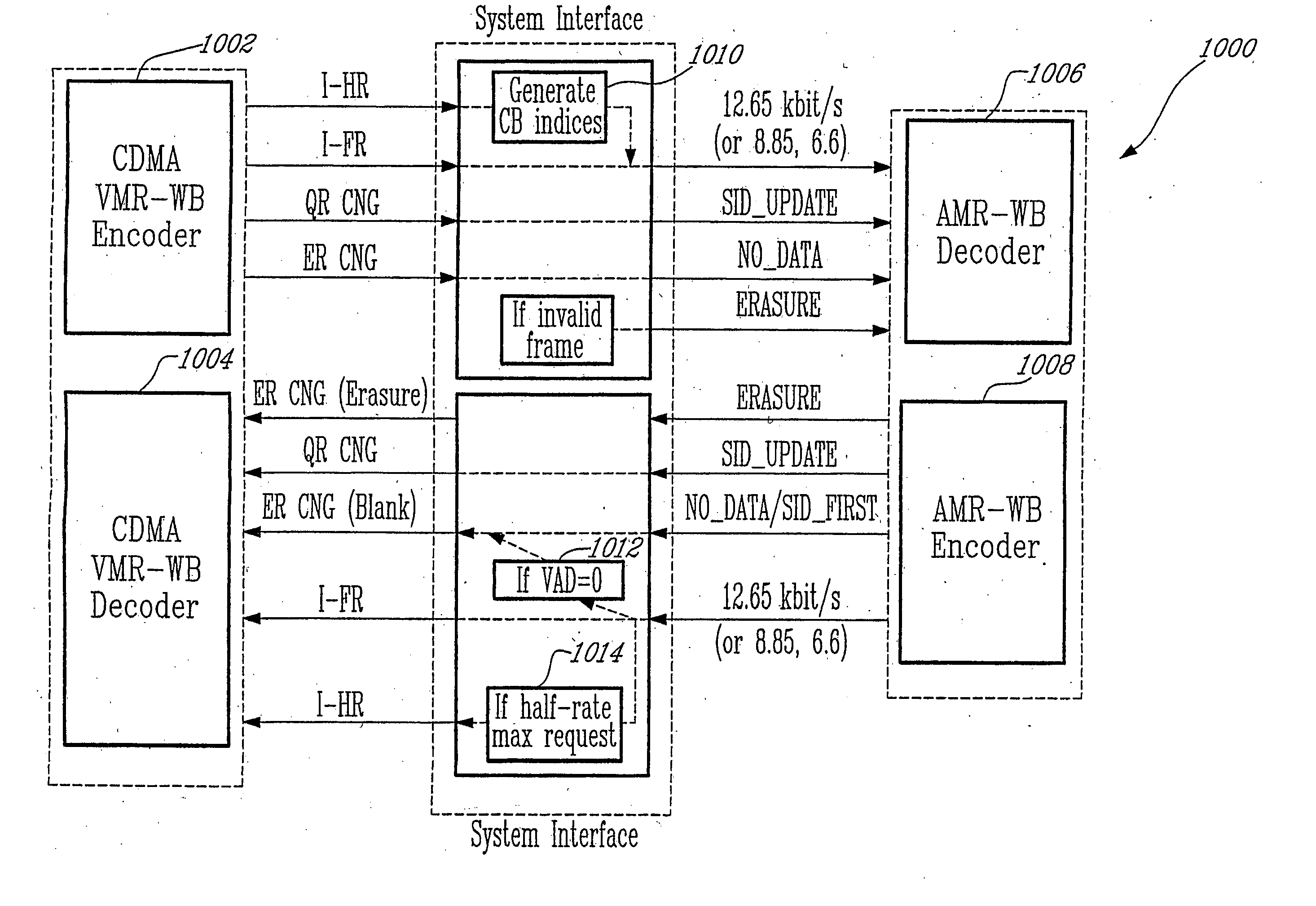

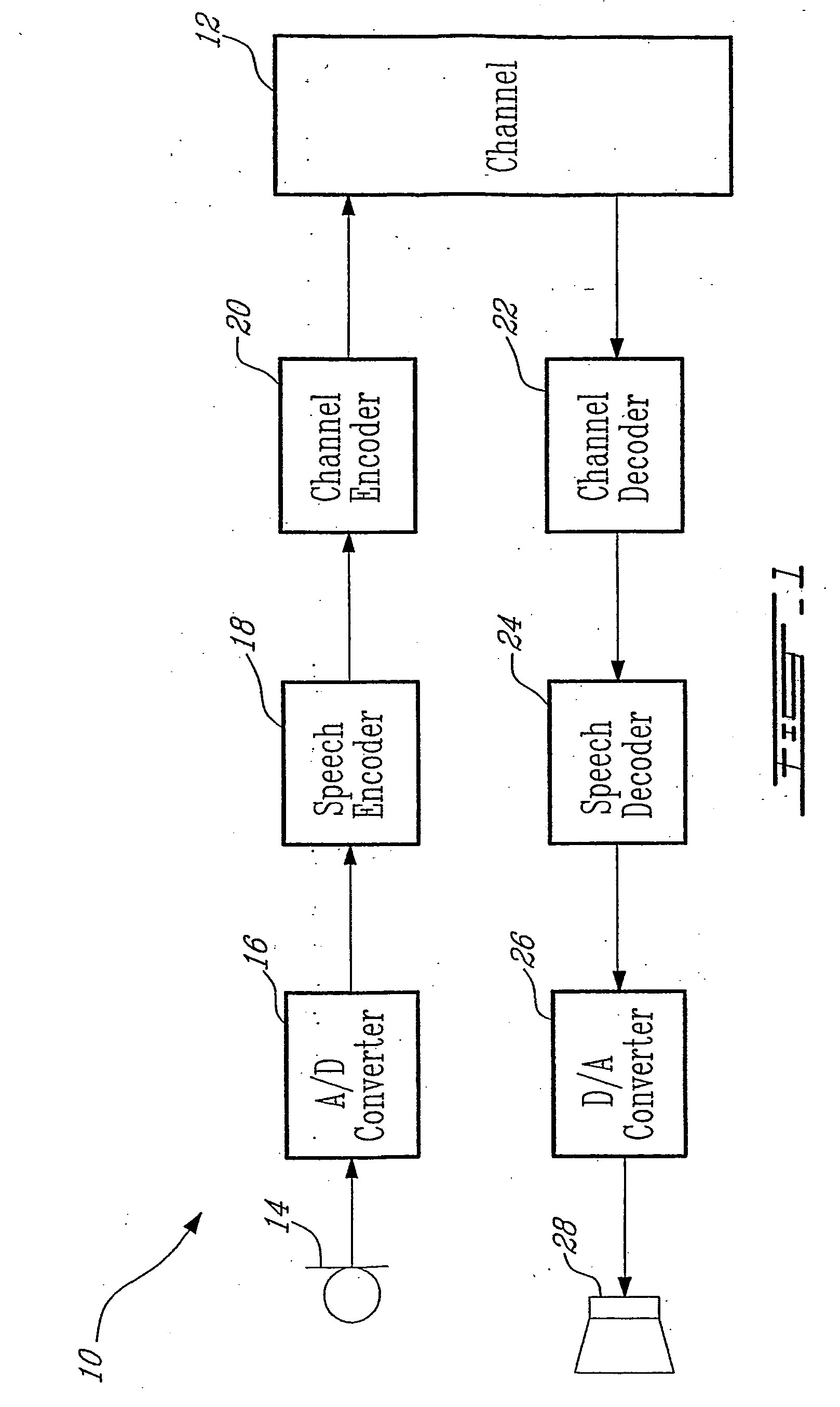

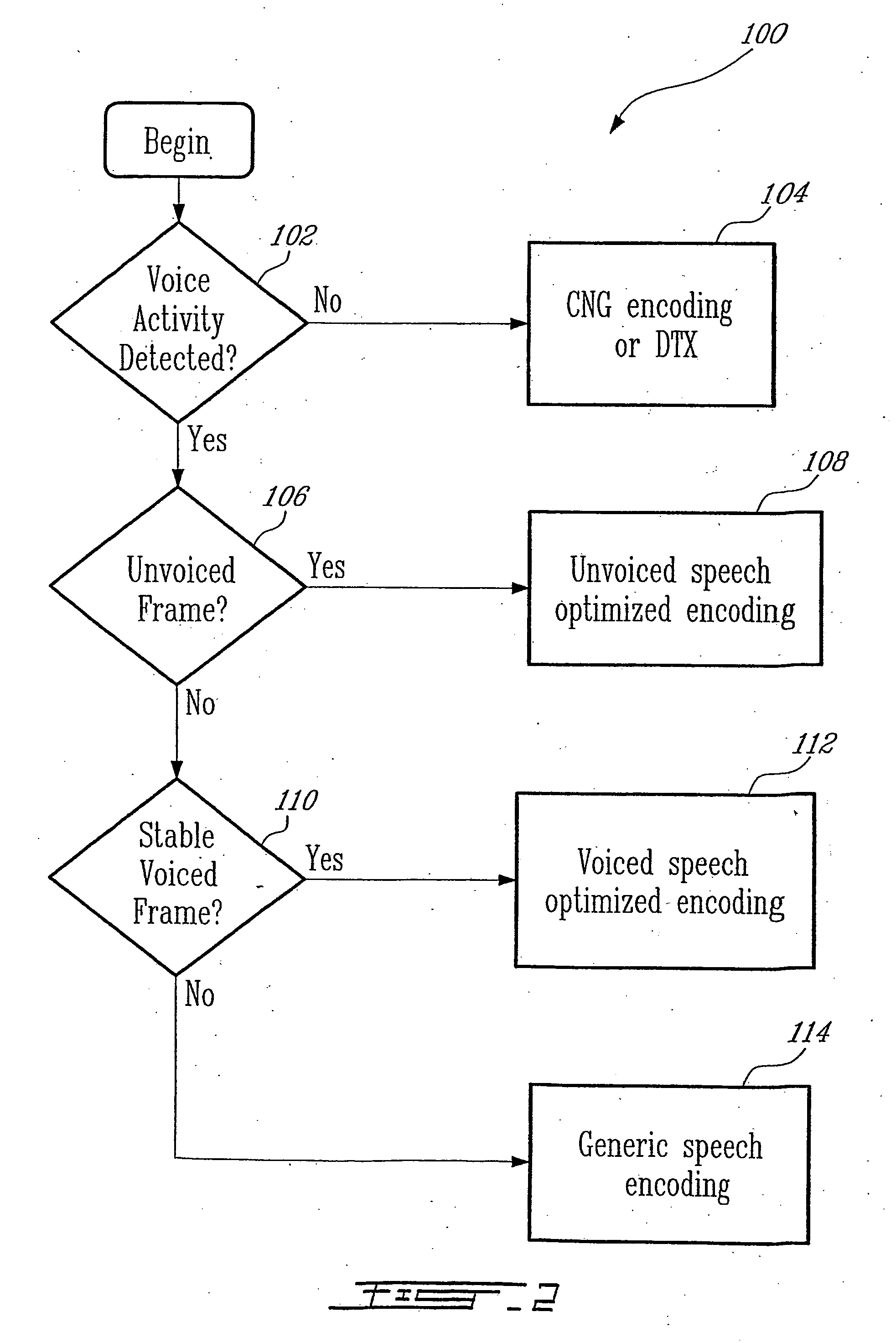

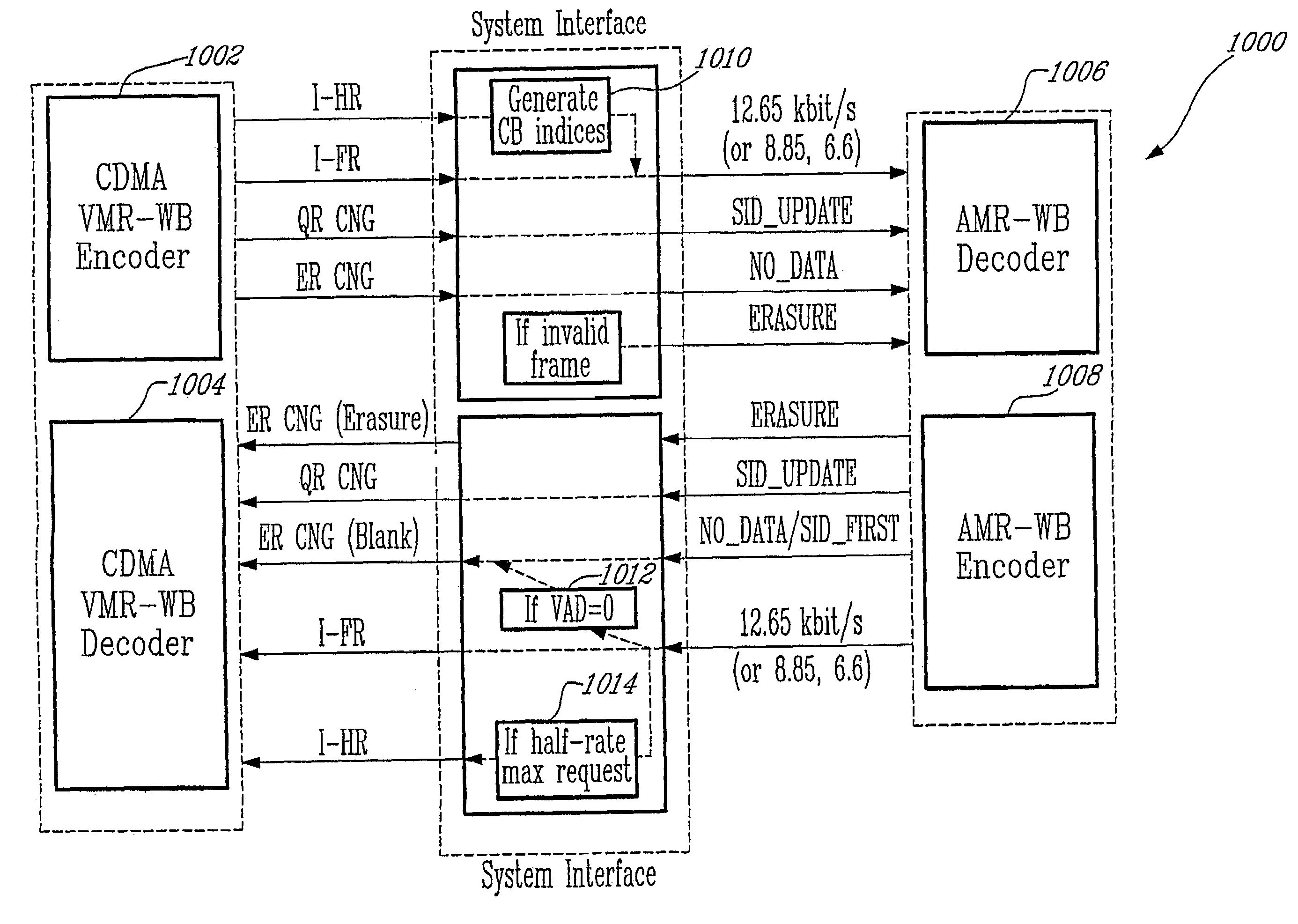

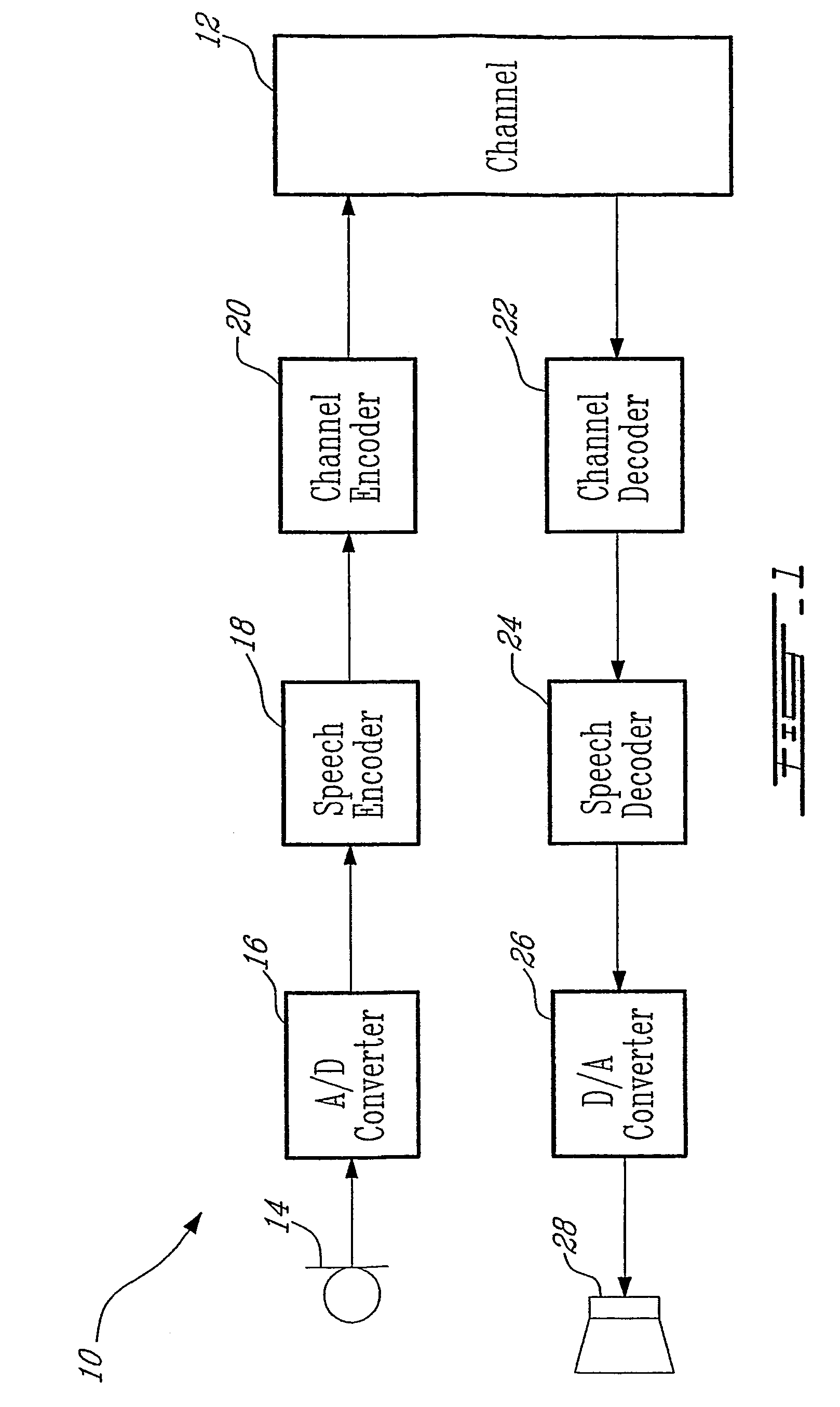

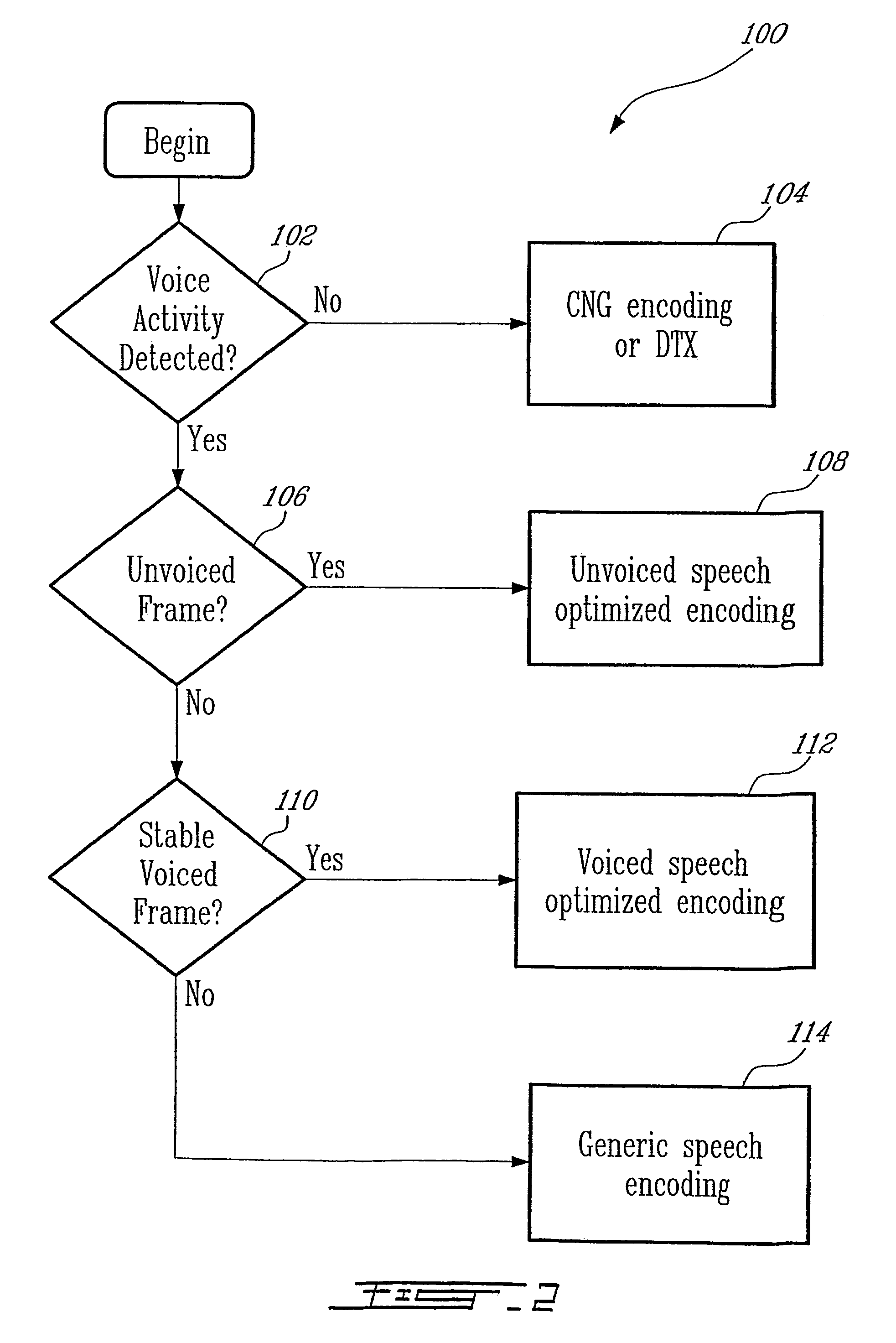

Method for interoperation between adaptive multi-rate wideband (AMR-WB) and multi-mode variable bit-rate wideband (VMR-WB) codecs

ActiveUS20050267746A1Improve classificationImprove methodSpeech analysisFluid pressure measurementBit allocationFull Rate

A source-controlled Variable bit-rate Multi-mode WideBand (VMR-WB) codec, having a mode of operation that is interoperable with the Adaptive Multi-Rate wideband (AMR-WB) codec, the codec comprising: at least one Interoperable full-rate (I-FR) mode, having a first bit allocation structure based on one of a AMR-WB codec coding types; and at least one comfort noise generator (CNG) coding type for encoding inactive speech frame having a second bit allocation structure based on AMR-WB SID_UPDATE coding type. Methods for i) digitally encoding a sound using a source-controlled Variable bit rate multi-mode wideband (VMR-WB) codec for interoperation with an adaptative multi-rate wideband (AMR-WB) codec, ii) translating a Variable bit rate multi-mode wideband (VMR-WB) codecsignal frame into an Adaptive Multi-Rate wideband (AMR-WB) signal frame, iii) translating an Adaptive Multi-Rate wideband (AMR-WB) signal frame into a Variable bit rate multi-mode wideband (VMR-WB) signal frame, and iv) translating an Adaptive Multi-Rate wideband (AMR-WB) signal frame into a Variable bit rate multi-mode wideband (VMR-WB) signal frame are also provided.

Owner:NOKIA TECHNOLOGLES OY

Method for interoperation between adaptive multi-rate wideband (AMR-WB) and multi-mode variable bit-rate wideband (VMR-WB) codecs

InactiveUS7203638B2Improve classificationImprove methodSpeech analysisFluid pressure measurementUltra-widebandBit allocation

A source-controlled Variable bit-rate Multi-mode WideBand (VMR-WB) codec, having a mode of operation that is interoperable with the Adaptive Multi-Rate wideband (AMR-WB) codec, the codec comprising: at least one Interoperable full-rate (I-FR) mode, having a first bit allocation structure based on one of a AMR-WB codec coding types; and at least one comfort noise generator (CNG) coding type for encoding inactive speech frame having a second bit allocation structure based on AMR-WB SID_UPDATE coding type. Methods for i) digitally encoding a sound using a source-controlled Variable bit rate multi-mode wideband (VMR-WB) codec for interoperation with an adaptative multi-rate wideband (AMR-WB) codec, ii) translating a Variable bit rate multi-mode wideband (VMR-WB) codecsignal frame into an Adaptive Multi-Rate wideband (AMR-WB) signal frame, iii) translating an Adaptive Multi-Rate wideband (AMR-WB) signal frame into a Variable bit rate multi-mode wideband (VMR-WB) signal frame, and iv) translating an Adaptive Multi-Rate wideband (AMR-WB) signal frame into a Variable bit rate multi-mode wideband (VMR-WB) signal frame are also provided.

Owner:NOKIA TECH OY

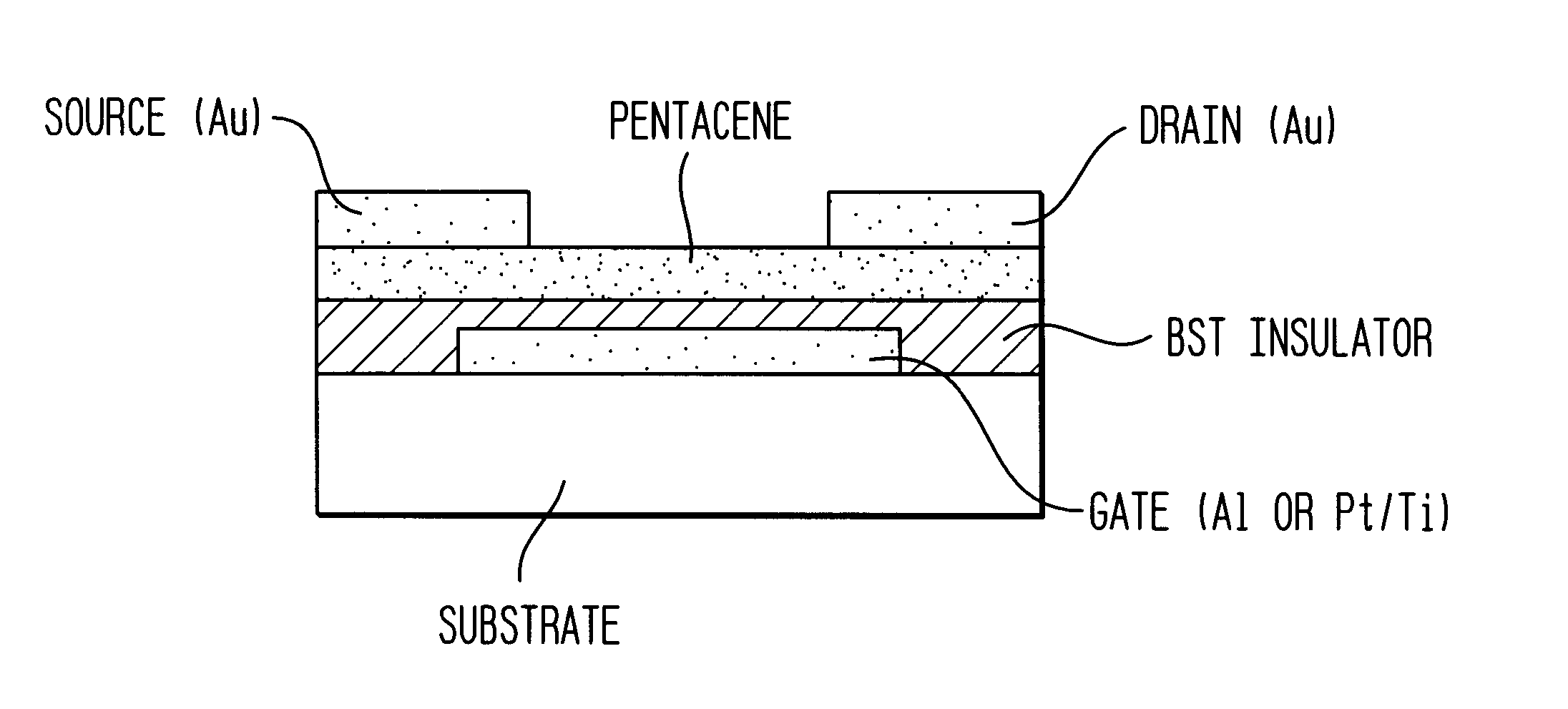

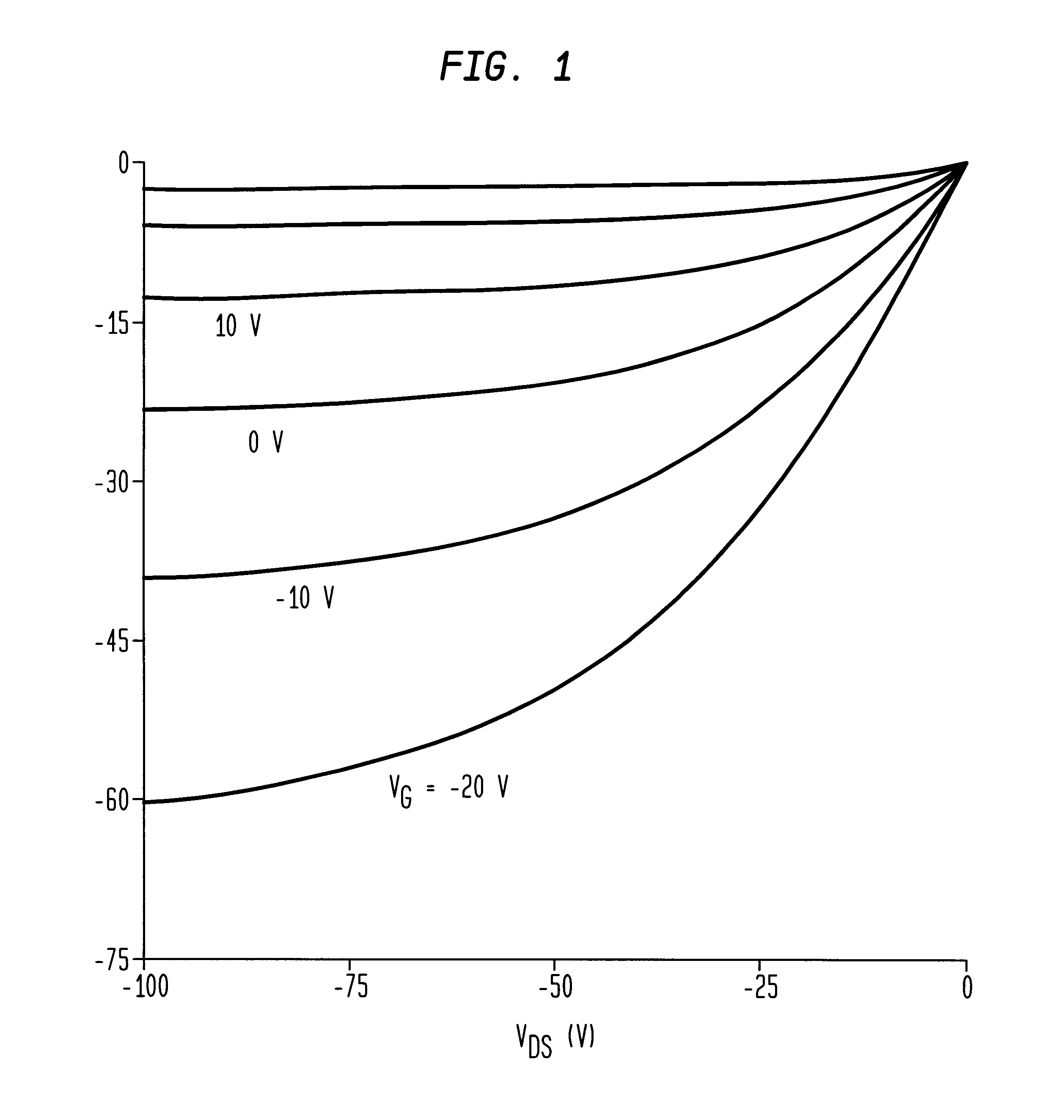

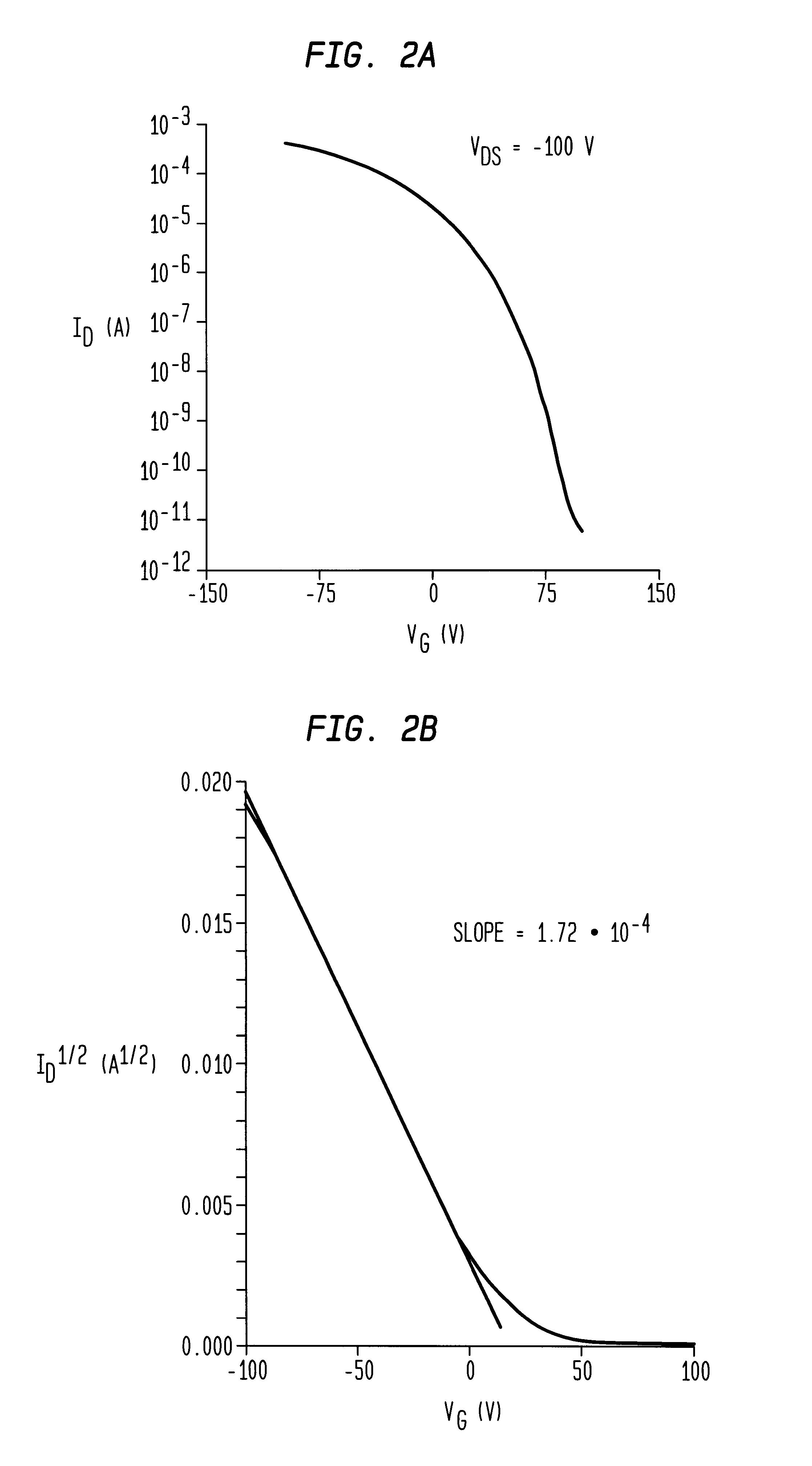

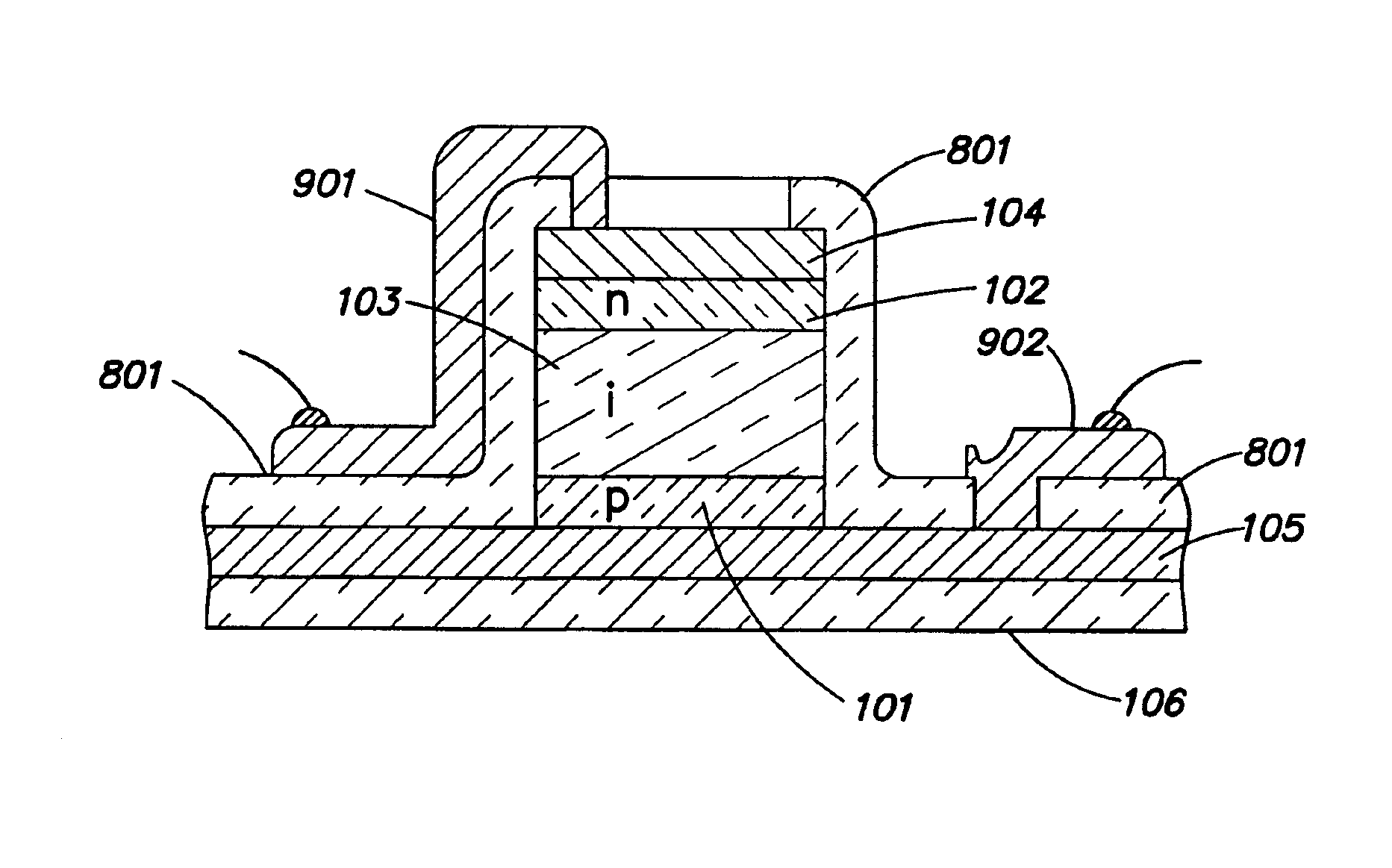

Thin-film field-effect transistor with organic semiconductor requiring low operating voltages

InactiveUS6344660B1Reduce thicknessImprove mobilityTransistorSolid-state devicesDisplay deviceFlat panel display

A thin film transistor (TFT) device structure based on an organic semiconductor material, that exhibits a high field effect mobility, high current modulation and a low sub-threshold slope at lower operating voltages than the current state of the art organic TFT devices. The structure comprises a suitable substrate disposed with he following sequence of features: a set of conducting gate electrodes covered with a high dielectric constant insulator, a layer of the organic semiconductor, sets of electrically conducting source and drain electrodes corresponding to each of the gate lines, and an optional passivation layer that can overcoat and protect the device structure. Use of high dielectric constant gate insulators exploits the unexpected gate voltage dependence of the organic semiconductor to achieve high field effect mobility levels at very low operating voltages. Judicious combinations of the choice of this insulator material and the means to integrate it into the TFT structure are taught that would enable easy fabrication on glass or plastic substrates and the use of such devices in flat panel display applications.

Owner:GLOBALFOUNDRIES INC

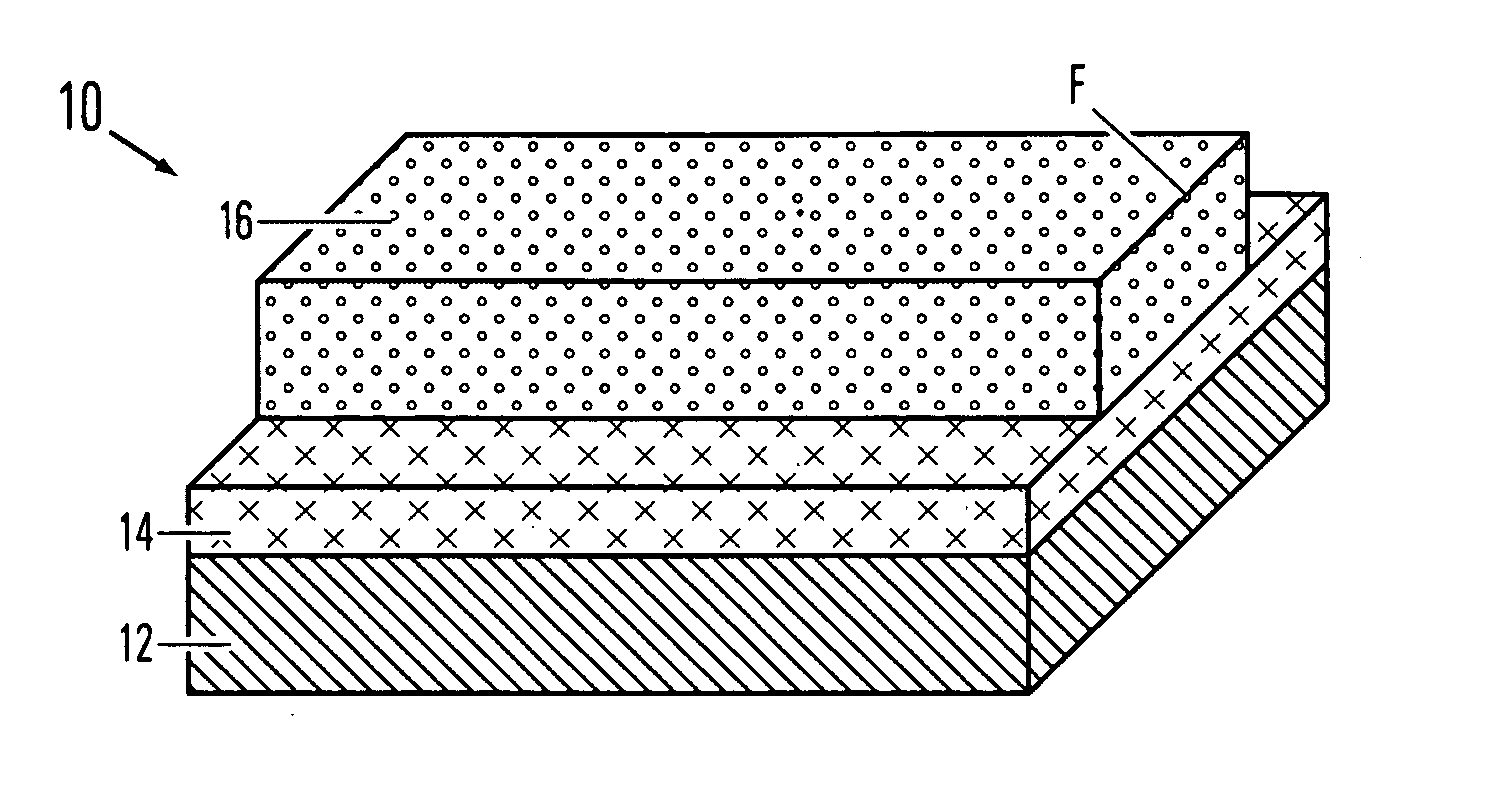

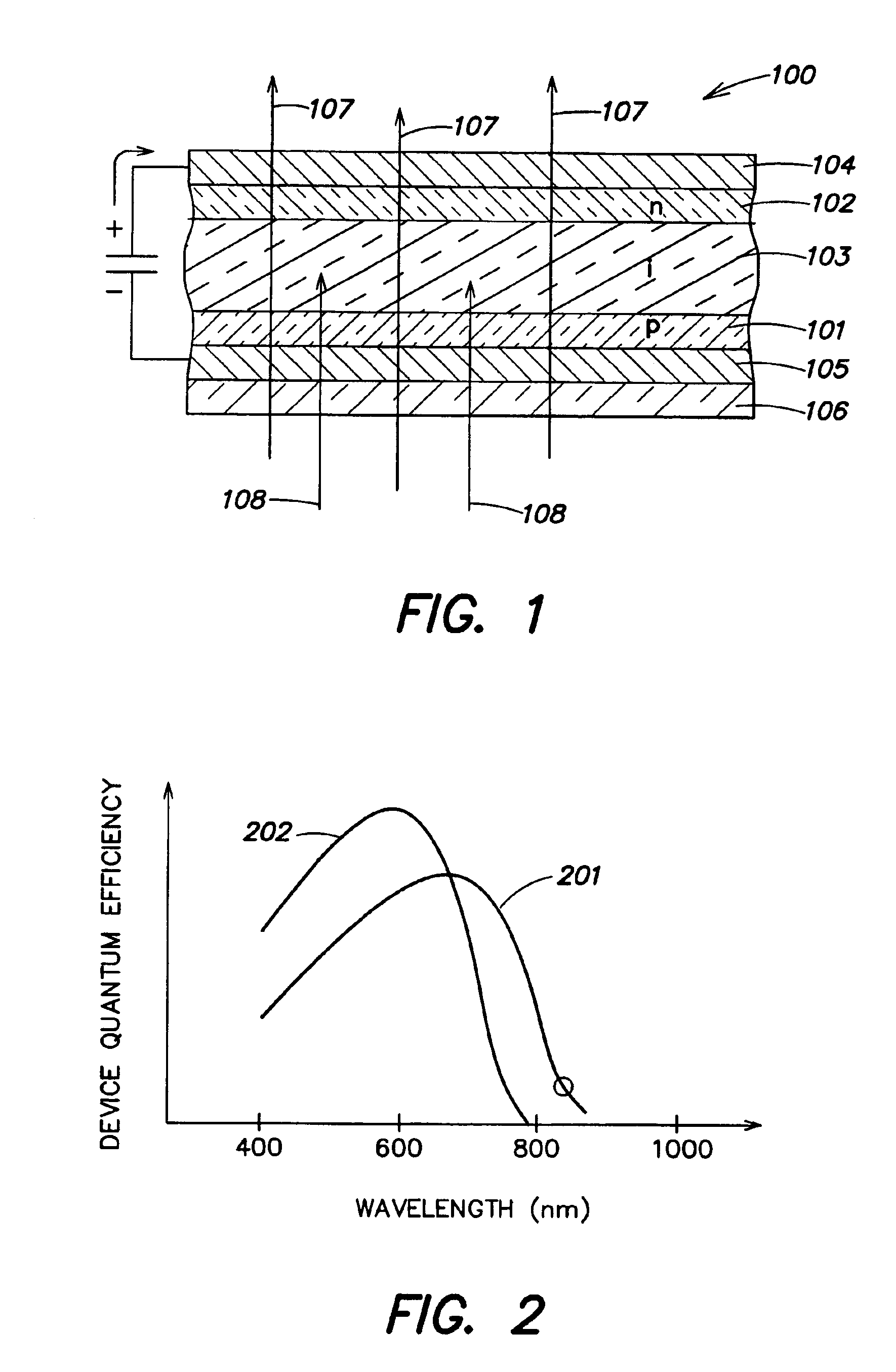

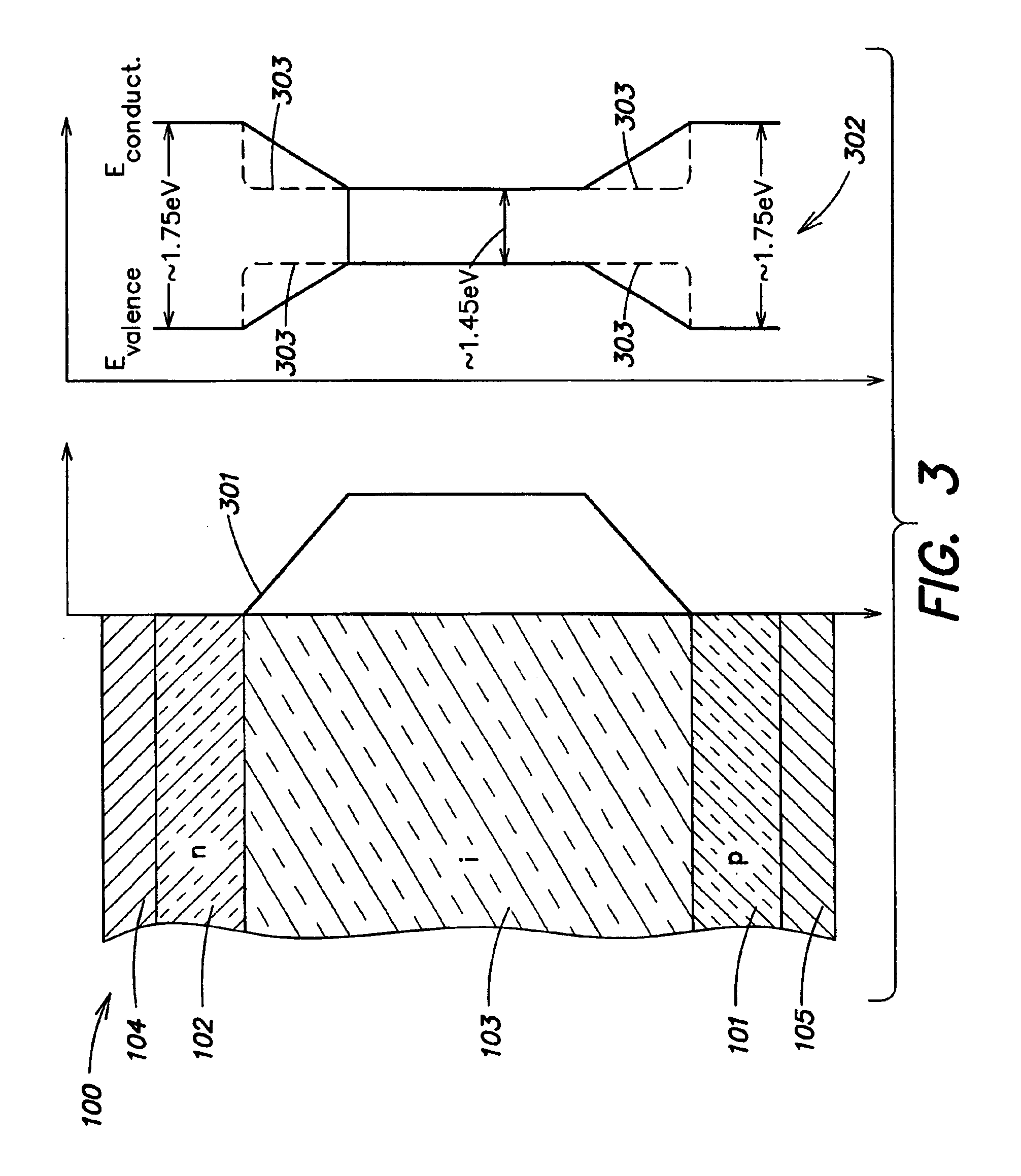

Semitransparent optical detector including a polycrystalline layer and method of making

InactiveUS6879014B2Final product manufactureSolid-state devicesVertical-cavity surface-emitting laserElectrical conductor

Materials suitable for fabricating optical monitors include amorphous, polycrystalline and microcrystalline materials. Semitransparent photodetector materials may be based on silicon or silicon and germanium alloys. Conductors for connecting to and contacting the photodetector may be made from various transparent oxides, including zinc oxide, tin oxide and indium tin oxide. Optical monitor structures based on PIN diodes take advantage of the materials disclosed. Various contact, lineout, substrate and interconnect structures optimize the monitors for integration with various light sources, including vertical cavity surface emitting laser (VCSEL) arrays. Complete integrated structures include a light source, optical monitor and either a package or waveguide into which light is directed.

Owner:II VI DELAWARE INC +1

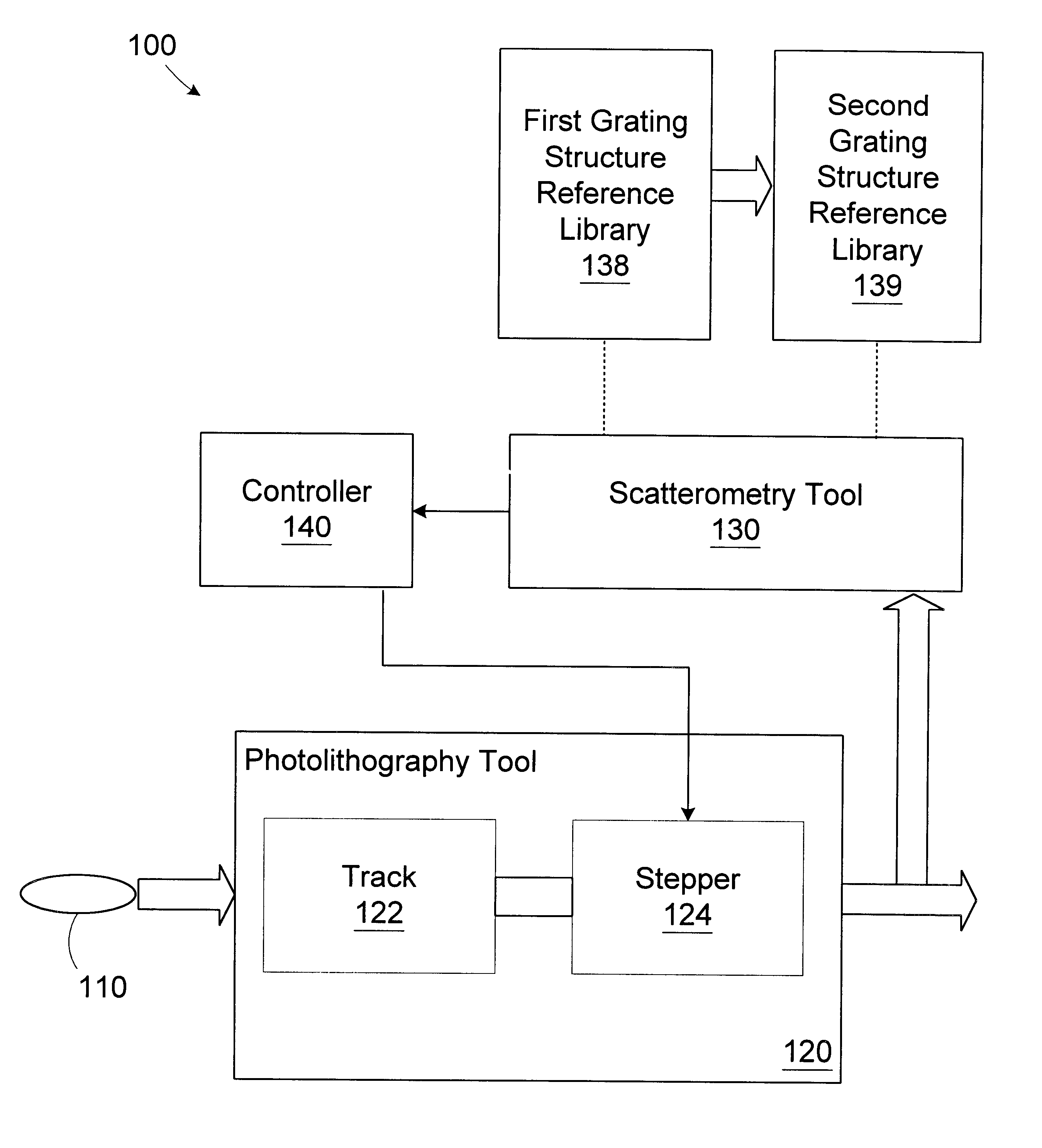

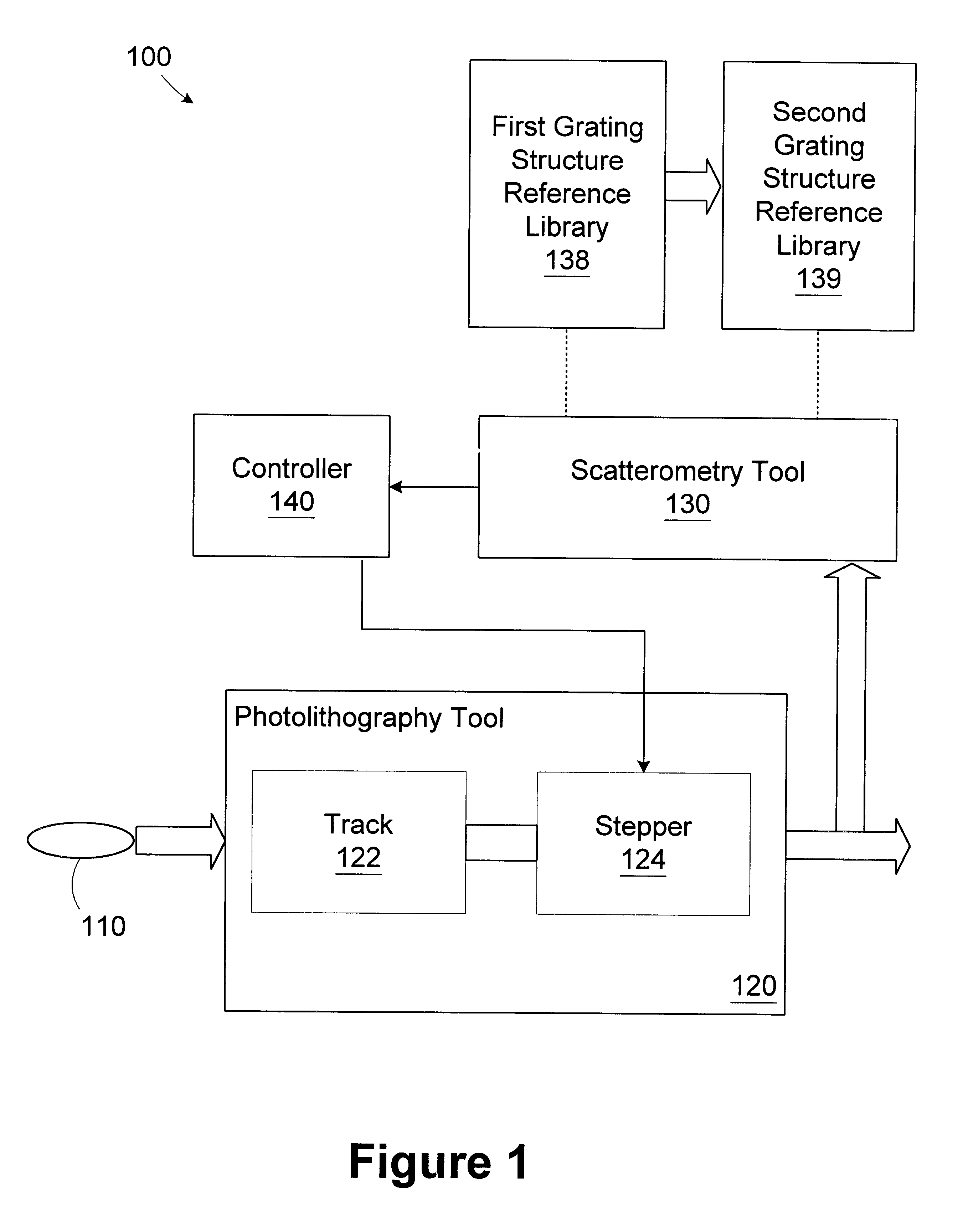

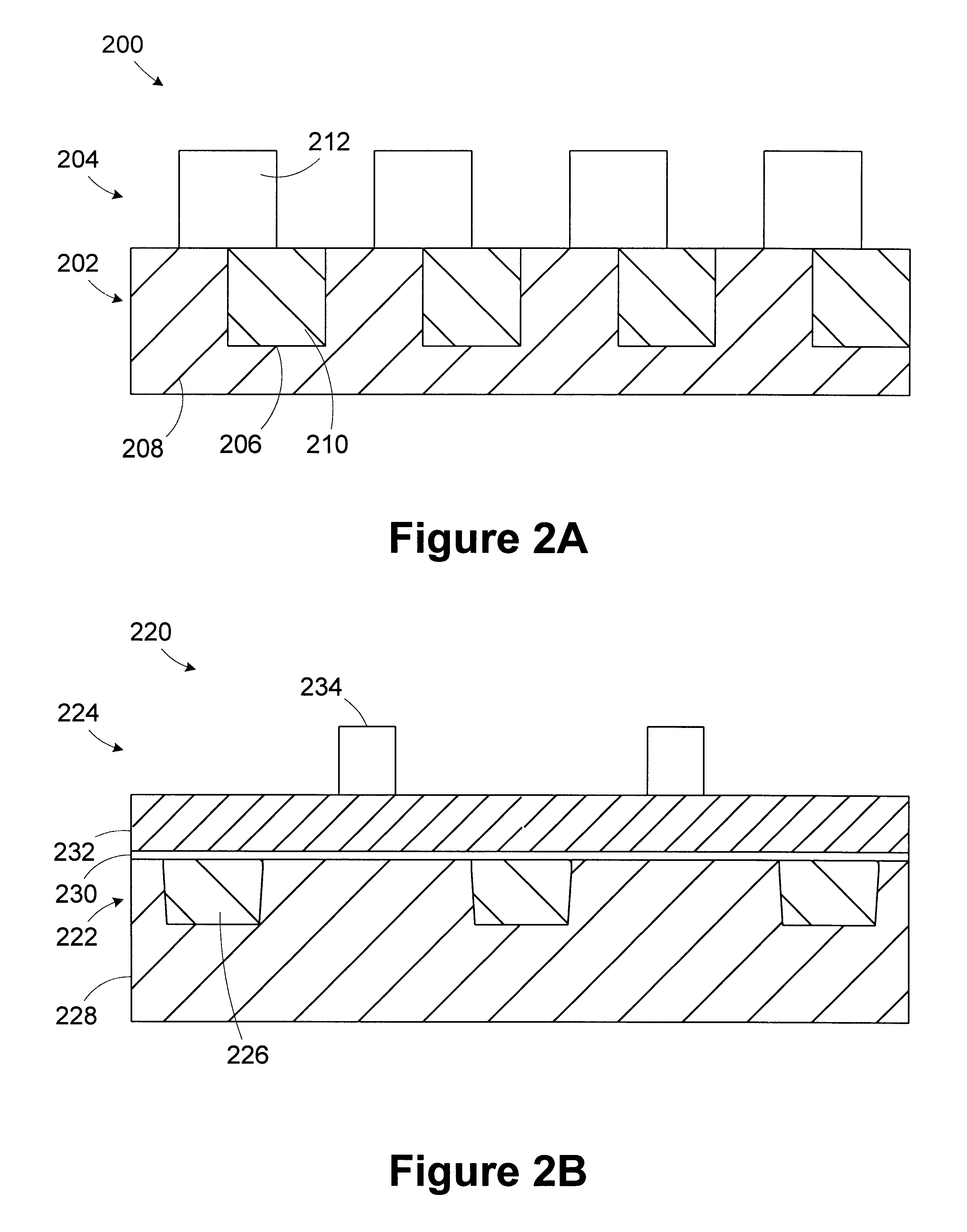

Method and apparatus for controlling photolithography overlay registration

InactiveUS6458605B1Electrolytic capacitorsSemiconductor/solid-state device manufacturingGratingMetrology

A method for controlling a photolithography process includes providing a wafer having a first grating structure and a second grating structure overlying the first grating structure; illuminating at least a portion of the first and second grating structures with a light source; measuring light reflected from the illuminated portion of the first and second grating structures to generate a reflection profile; determining an overlay error between the first and second grating structures based on the reflection profile; and determining at least one parameter of an operating recipe for a photolithography stepper based on the determined overlay error. A processing line includes a photolithography stepper, a first metrology tool, and a controller. The photolithography stepper is adapted to process wafers in accordance with an operating recipe. The first metrology tool is adapted to receive a wafer having a first grating structure and a second grating structure overlying the first grating structure. The metrology tool includes a light source, a detector, and a data processing unit. The light source is adapted to illuminate at least a portion of the first and second grating structures. The detector is adapted to measure light reflected from the illuminated portion of the first and second grating structures to generate a reflection profile. The data processing unit is adapted to determine an overlay error between the first and second grating structures based on the reflection profile. The controller is adapted to determine at least one parameter of the operating recipe of the photolithography stepper based on the determined overlay error.

Owner:FULLBRITE CAPITAL PARTNERS

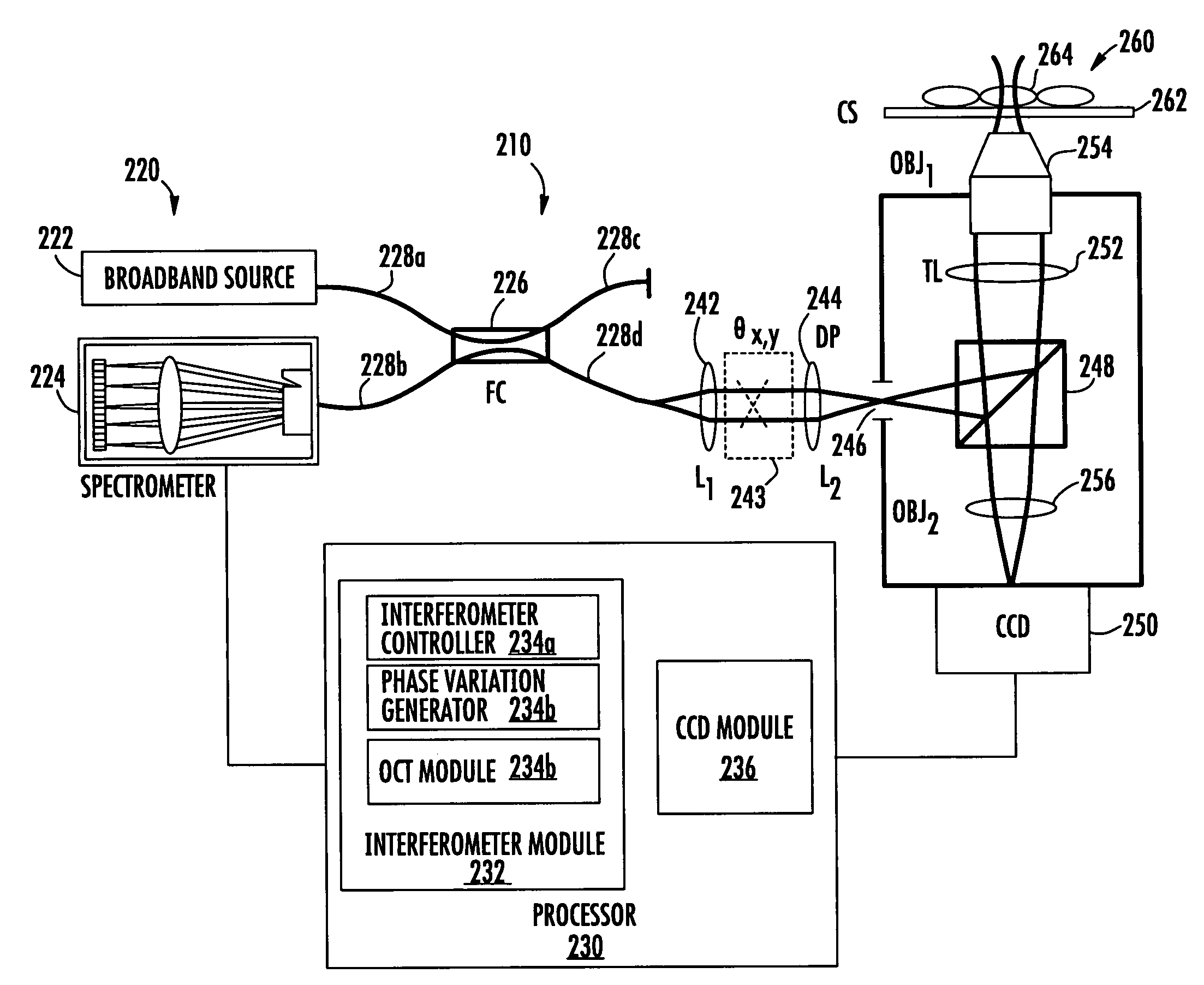

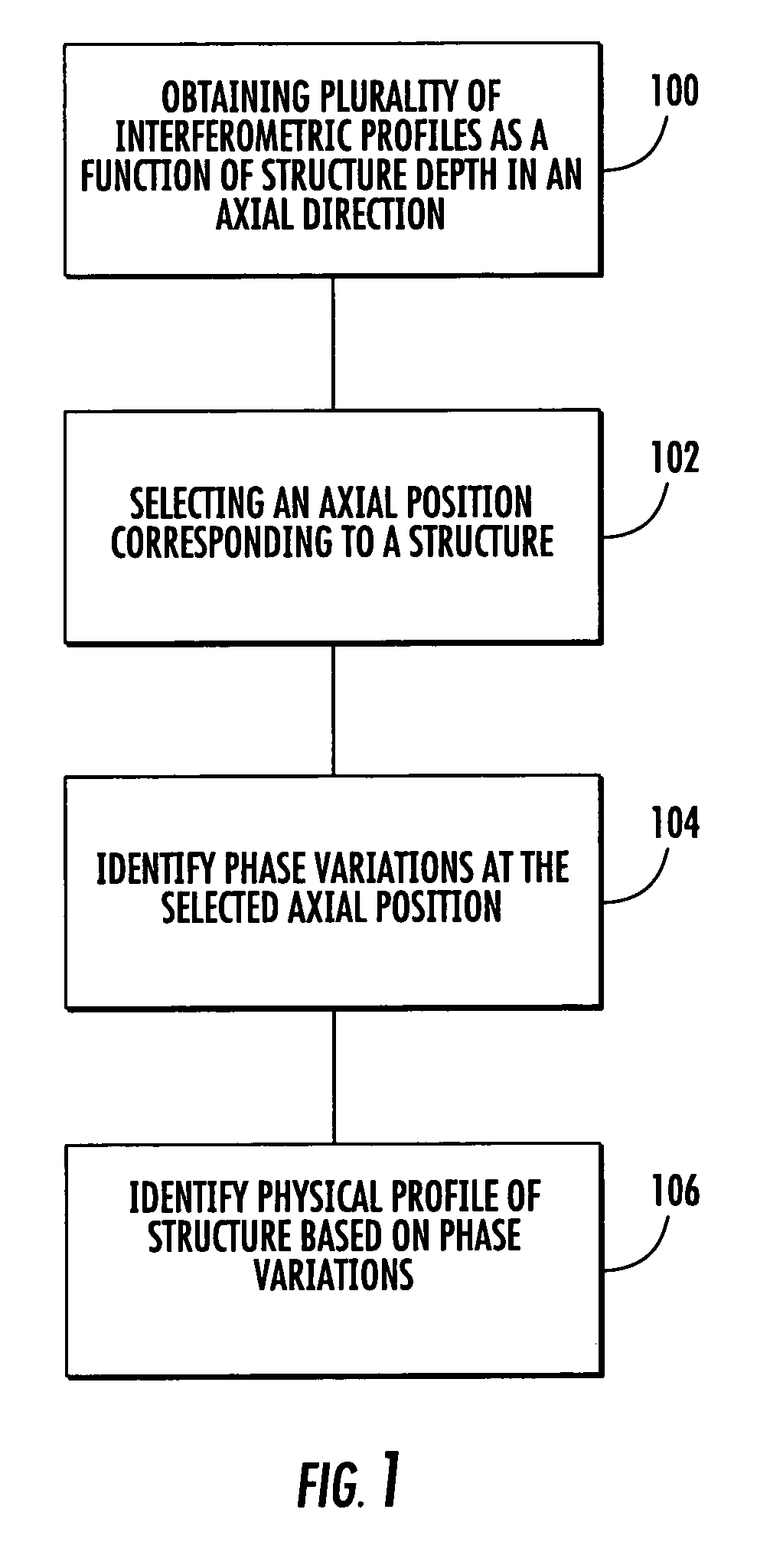

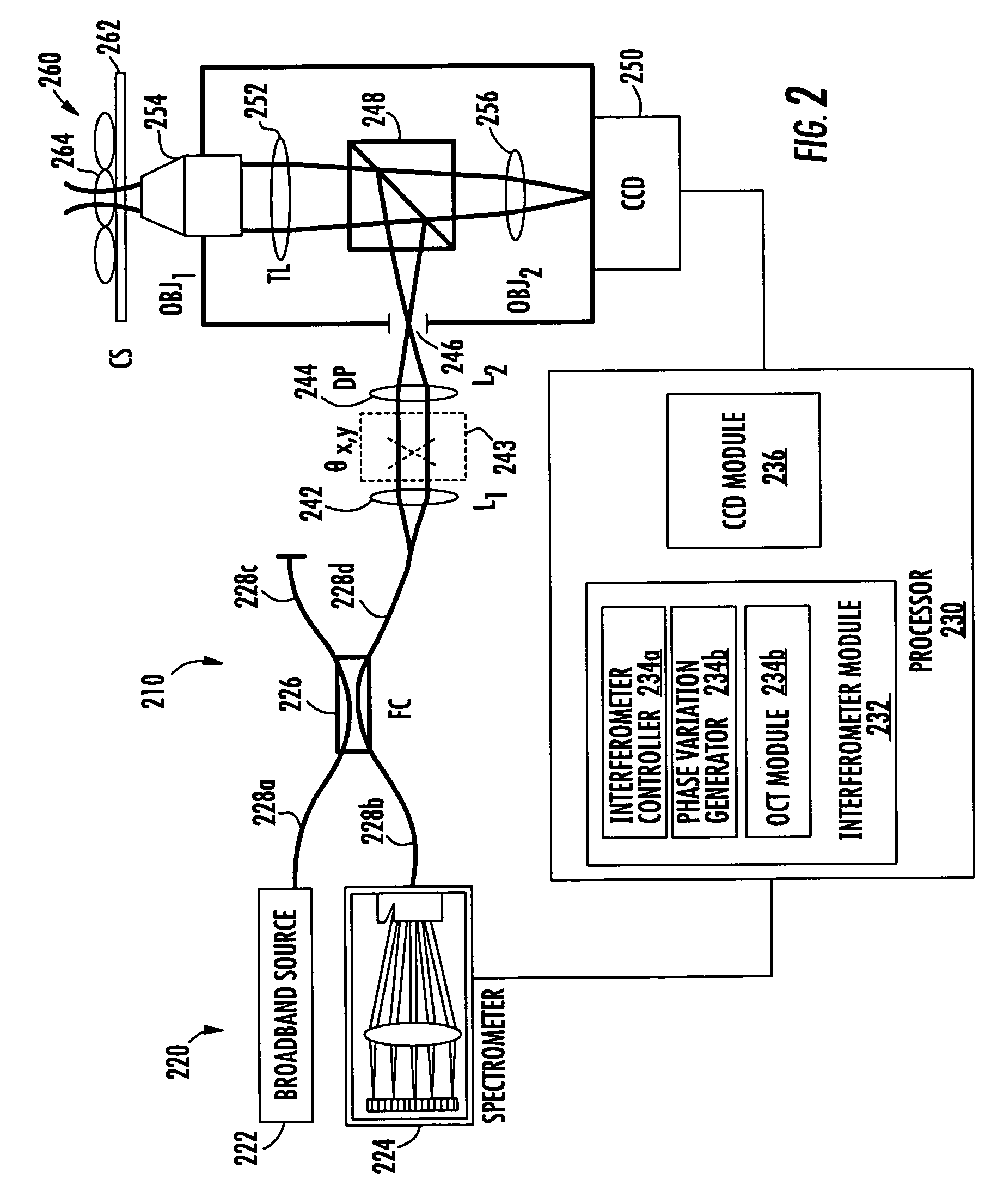

Methods, systems and computer program products for characterizing structures based on interferometric phase data

Structure profiles from optical interferometric data can be identified by obtaining a plurality of broadband interferometric optical profiles of a structure as a function of structure depth in an axial direction. Each of the plurality of interferometric optical profiles include a reference signal propagated through a reference path and a sample signal reflected from a sample reflector in the axial direction. An axial position corresponding to at least a portion of the structure is selected. Phase variations of the plurality of interferometric optical profiles are determined at the selected axial position. A physical displacement of the structure is identified based on the phase variations at the selected axial position.

Owner:DUKE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com