Glass fiber reinforced plastic curing agent composition and glass fiber reinforced plastic composite material prepared by same as well as cable trough

A glass fiber reinforced plastic and curing agent technology, applied in electrical components and other directions, can solve the problems of being easily affected by the external environment, prone to aging and degradation, low mechanical strength, etc., achieving good mechanical strength, inhibiting aging reaction, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

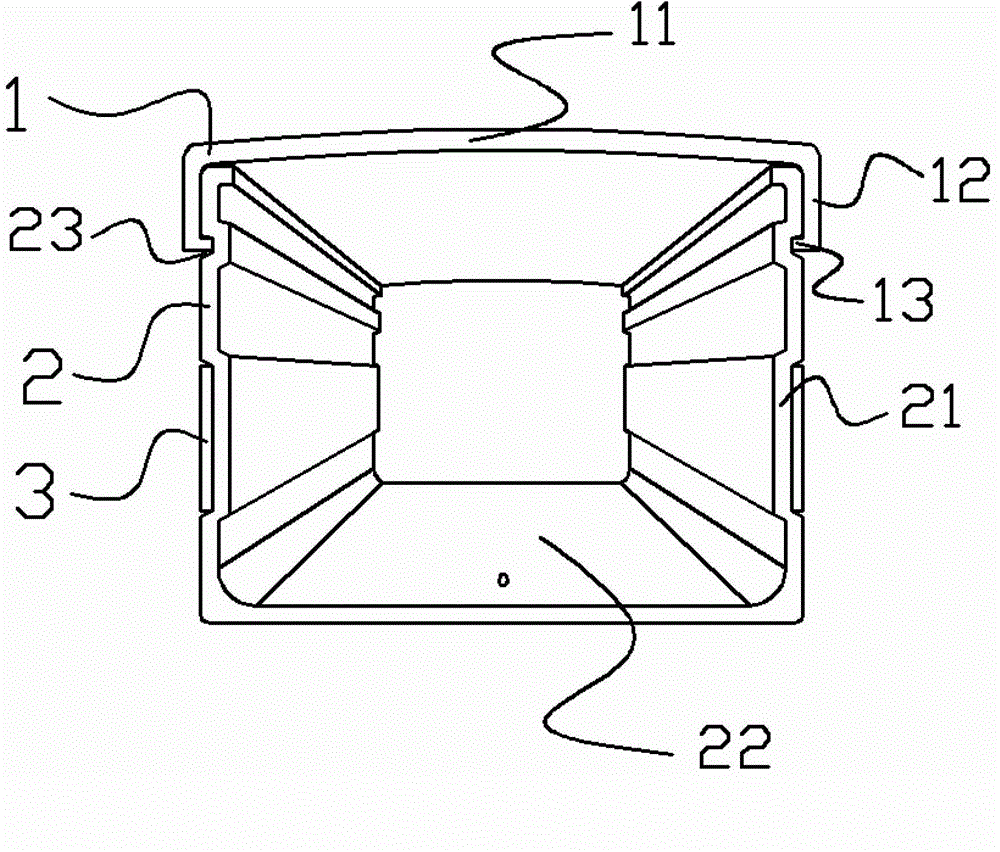

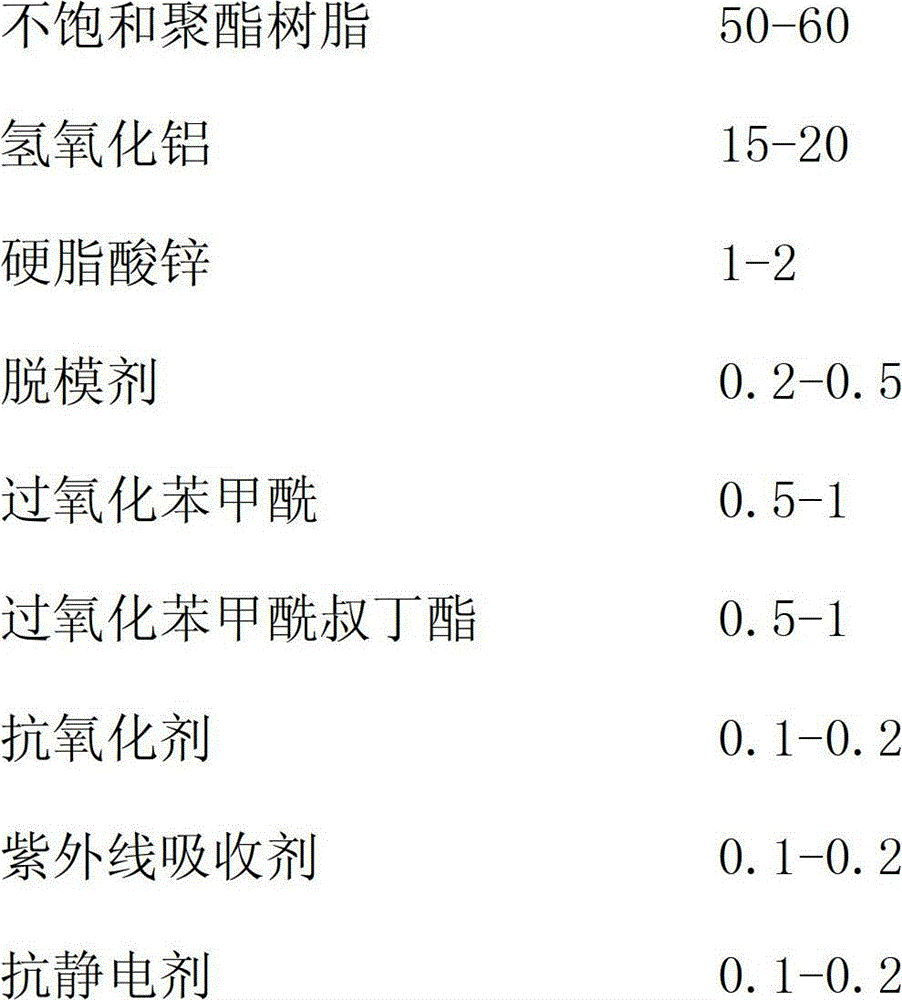

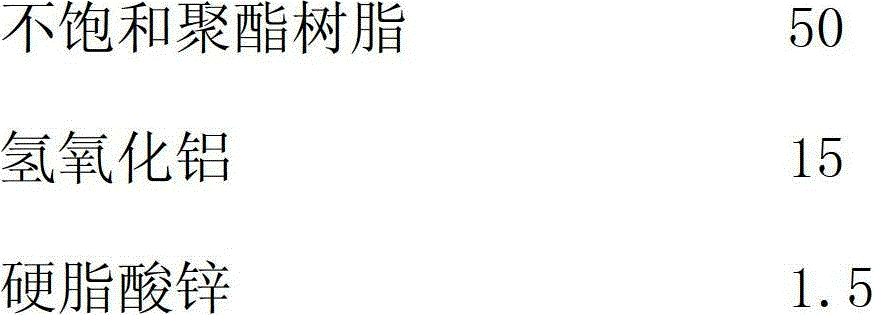

[0050]Weigh the following components: unsaturated polyester resin 50Kg, aluminum hydroxide 15Kg, zinc stearate 1Kg, DA-3 release agent 0.35Kg, benzoyl peroxide 0.6Kg, benzoyl tert-butyl peroxide 0.75 Kg, antioxidant 0.15Kg, ultraviolet absorber 0.15Kg, antistatic agent 0.15Kg. Add the mold release agent to the unsaturated polyester resin, stir with a high-speed disperser at a linear speed of 15m / s for 2 minutes, mix the remaining components evenly, divide them into two equal parts, and add them to the above resin in turn, after each addition Immediately stir 5min with a rotary shear mixer at a linear speed of 20m / s to obtain an unsaturated polyester resin glue; get 1100tex glass fiber untwisted yarn and fully soak it in the above glue, and adopt the existing extrusion molding technology to make The glass fiber untwisted yarn and seam mat soaked in resin glue enter the heated forming mold. The structure of the forming mold is as attached figure 1 , carry out curing molding, th...

Embodiment 2

[0055] Weigh the following components: unsaturated polyester resin 60Kg, aluminum hydroxide 20Kg, zinc stearate 2Kg, CX-2 release agent 0.5Kg, benzoyl peroxide 1Kg, benzoyl tert-butyl peroxide 0.5Kg , antioxidant 0.1Kg, ultraviolet absorber 0.1Kg, antistatic agent 0.19Kg. Add the mold release agent to the unsaturated polyester resin, stir it with a high-speed disperser at a linear speed of 20m / s for 5 minutes, mix the remaining components evenly, divide them into two equal parts, and add them to the above resin in turn. Immediately stir 10min with a rotary shear mixer at a linear speed of 22m / s to obtain an unsaturated polyester resin glue; get 2200tex glass fiber untwisted yarn and fully soak it in the above glue, and adopt the existing extrusion molding technology to make The glass fiber untwisted yarn and seam felt soaked in resin glue enter the heated forming mold for curing and molding, the traction speed is 80cm / min, and the forming mold has three temperature zones: the ...

Embodiment 3

[0060] Weigh the following components: unsaturated polyester resin 55Kg, aluminum hydroxide 15Kg, zinc stearate 1.5Kg, DA-3 release agent 0.2Kg, benzoyl peroxide 0.5Kg, benzoyl tert-butyl peroxide 1Kg, antioxidant 0.2Kg, ultraviolet absorber 0.2Kg, antistatic agent 0.2Kg. Add the mold release agent to the unsaturated polyester resin, stir it with a high-speed disperser at a linear speed of 10m / s for 1min, mix the rest of the components evenly, divide them into two equal parts, and add them to the above resin in turn, after each addition Immediately stir 3min with a rotary shear mixer at a linear speed of 10m / s to obtain an unsaturated polyester resin glue; get 1800tex glass fiber untwisted yarn and fully soak it in the above glue, and adopt the existing extrusion molding technology to make The glass fiber untwisted yarn and seam mat soaked in resin glue enter the heated forming mold for curing and molding, the traction speed is 40cm / min, and the forming mold has three temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com