Ultra-high strength glass fiber reinforced thermoplastic resin composite plate and preparation method thereof

A technology for strengthening thermoplastics and thermoplastic resins, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., to achieve balanced mechanical properties, good flame retardancy, and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

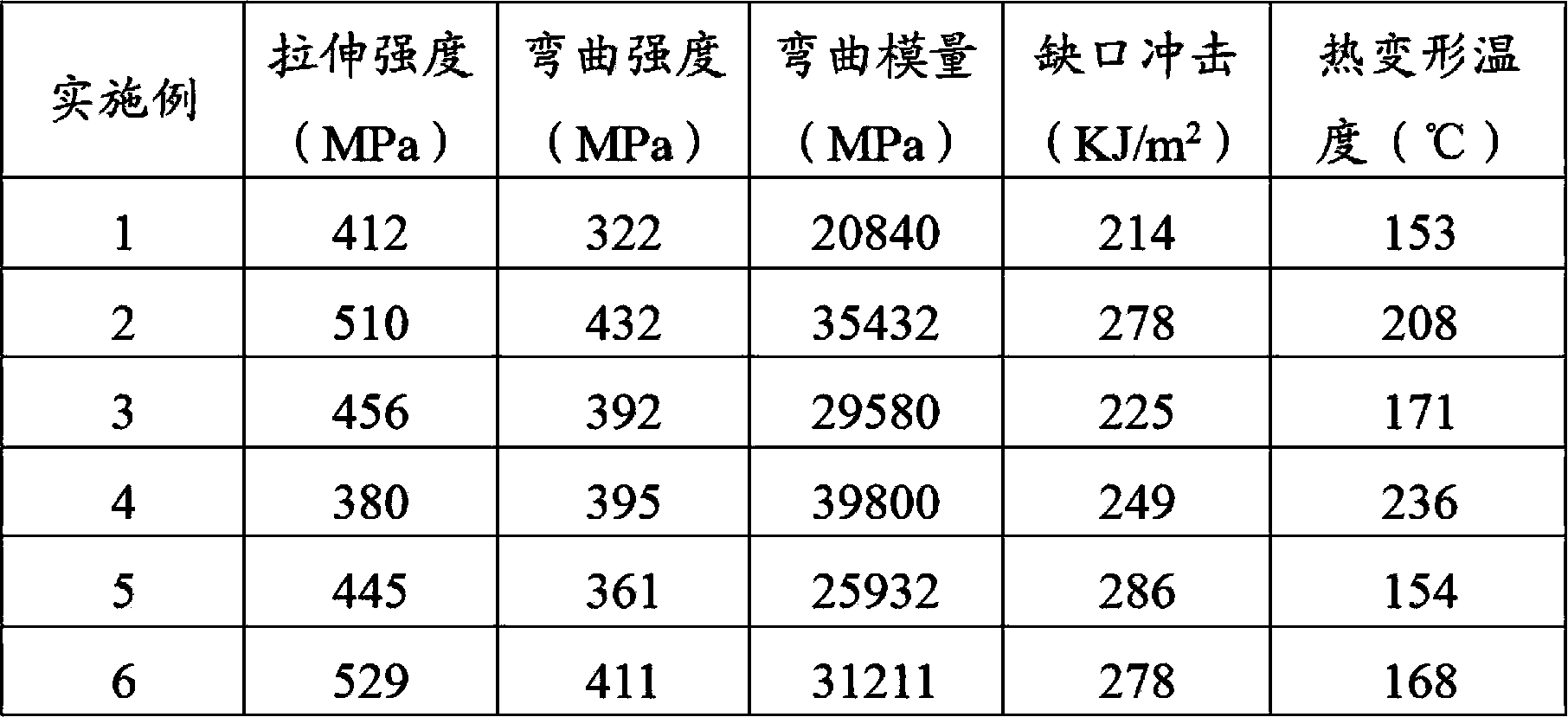

Examples

Embodiment 1

[0035] A bidirectional continuous ultra-high-strength glass fiber reinforced thermoplastic resin composite plate is prepared according to the following method:

[0036] (1) The mixture of 40 parts by weight of polypropylene resin and 0.5 parts by weight of KH540 silane coupling agent is fully mixed in a high-speed mixer and then added to the extruder, through staggered double extrusion Extrude the film from the die head, and arrange 60 parts by weight of continuous ultra-high-strength glass fibers in parallel into a strip through the tension adjustment device, and guide it to the double extrusion die. Contact, impregnate the extruded molten resin at the die head, introduce the impregnated continuous ultra-high-strength glass fiber into the rolling device, roll and cool to obtain continuous ultra-high glass fiber reinforced polypropylene (PP / S-GF ) unidirectional prepreg tape;

[0037] (2) Cut continuous ultra-high-strength glass fiber reinforced polypropylene unidirectional p...

Embodiment 2

[0041] A bidirectional continuous ultra-high-strength glass fiber reinforced thermoplastic resin composite plate is prepared according to the following method:

[0042](1) A mixture of 50 parts by weight of polycarbonate resin and 0.3 parts by weight of KH590 silane coupling agent is fully mixed in a high-speed mixer and then added to the extruder. The coating is extruded from the die, and 50 parts by weight of continuous ultra-high-strength glass fibers are arranged in parallel in a strip through the tension adjustment device, and guided to the double extrusion die. Contact with the die head, impregnate the extruded molten resin at the die head, introduce the impregnated continuous ultra-high-strength glass fiber into the rolling device, roll and cool to obtain continuous ultra-high-strength glass fiber reinforced polycarbonate (PC / S -GF) unidirectional prepreg tape;

[0043] (2) Cut the continuous ultra-high-strength glass fiber reinforced polycarbonate unidirectional prepr...

Embodiment 3

[0047] A bidirectional continuous ultra-high-strength glass fiber reinforced thermoplastic resin composite plate is prepared according to the following method:

[0048] (1) A mixture of 50 parts by weight of polybutylene terephthalate resin and 0.4 parts by weight of SI902 silane coupling agent is fully mixed in a high-speed mixer and then added to the extruder , extrude the coated film through the staggered double extrusion dies, arrange 50 parts by weight of continuous ultra-high-strength glass fibers in parallel into ribbons through the tension adjustment device, and guide them to the double extrusion dies, the two sides of the ribbon continuous fibers They are in contact with the double-extrusion die heads, impregnated with the extruded molten resin at the die heads, and the impregnated continuous ultra-high-strength glass fibers are introduced into the rolling device, rolled and cooled to obtain continuous ultra-high-strength glass fiber reinforced polymers. Butylene tere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com