Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3518 results about "Crosslinked polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What is a Crosslinked Polymer. Crosslinked polymers are macromolecules that has covalent bonds between polymer molecules. A crosslink is a bond between two polymer chains. These crosslinks can be either ionic bonds or covalent bonds. These crosslinks can be formed either during the process of polymerization or after polymerization.

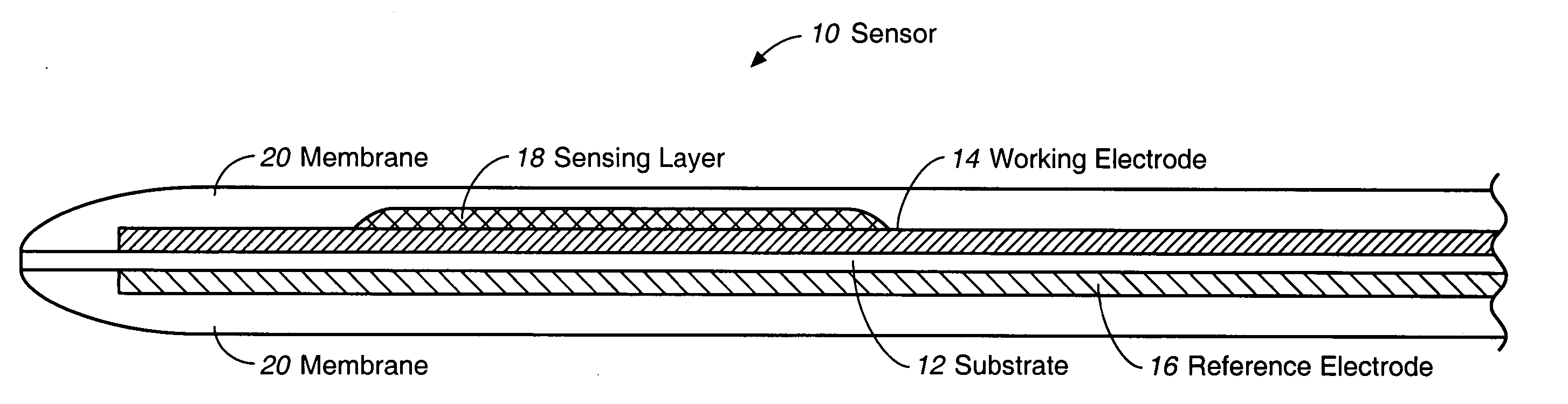

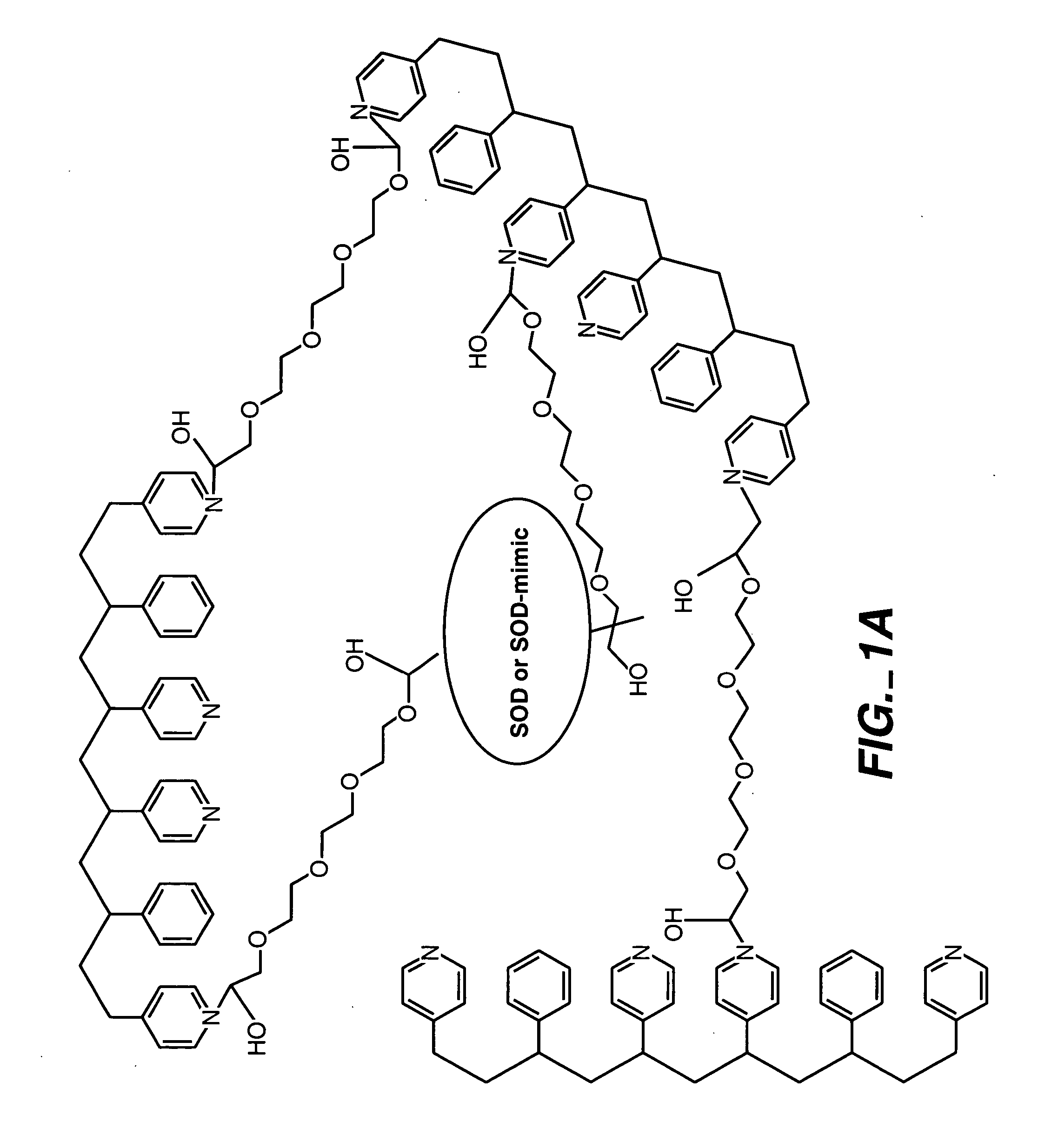

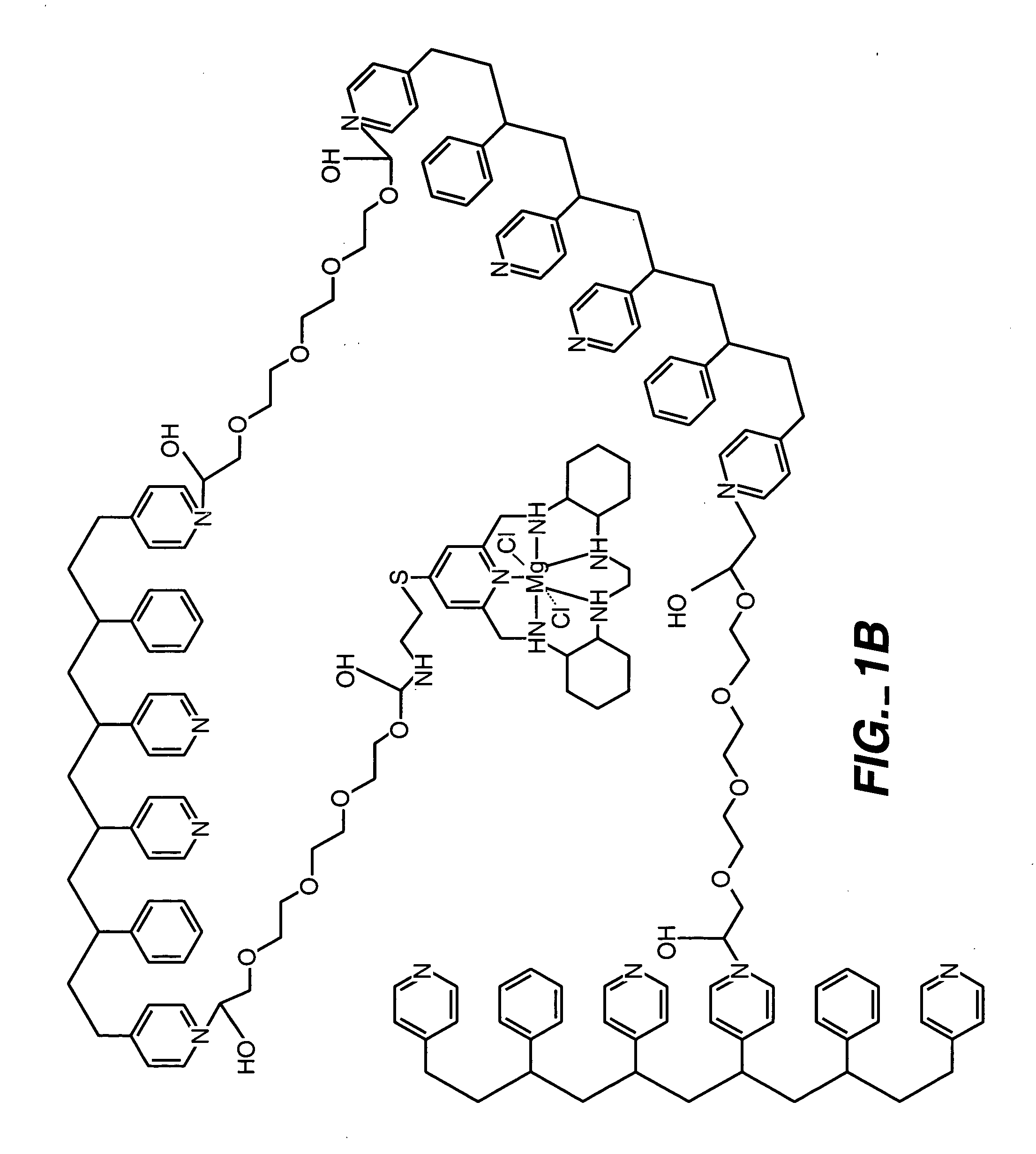

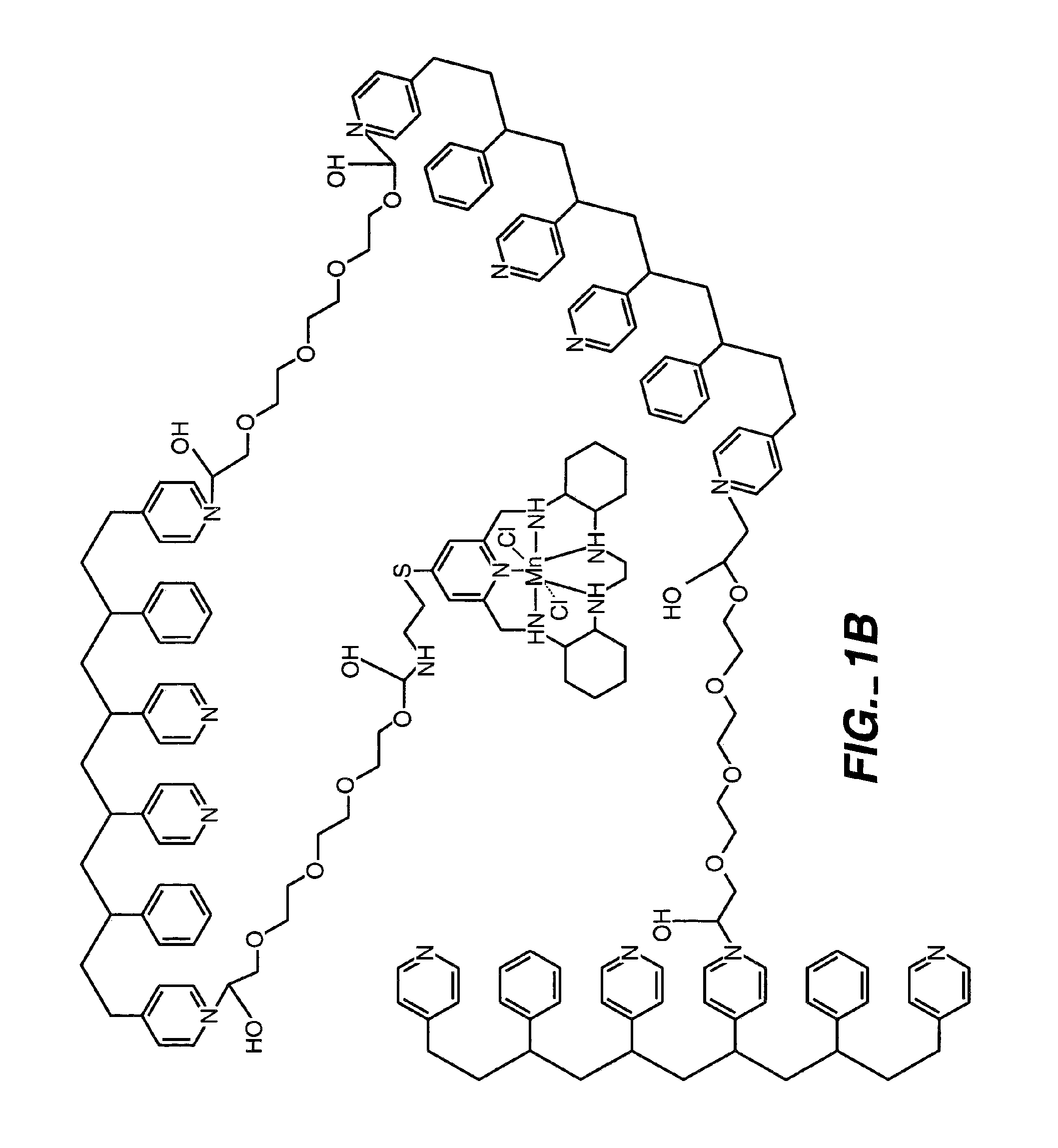

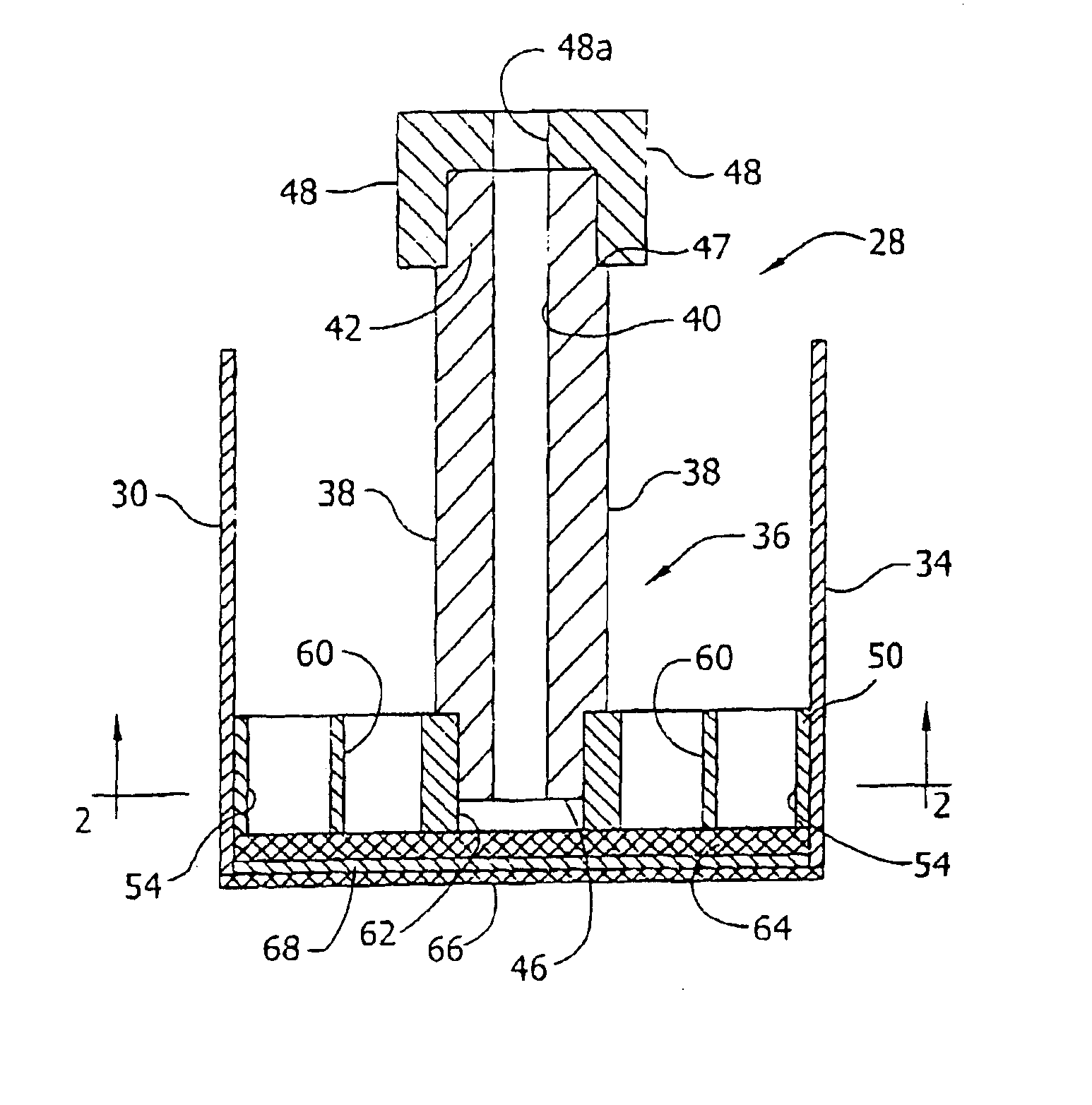

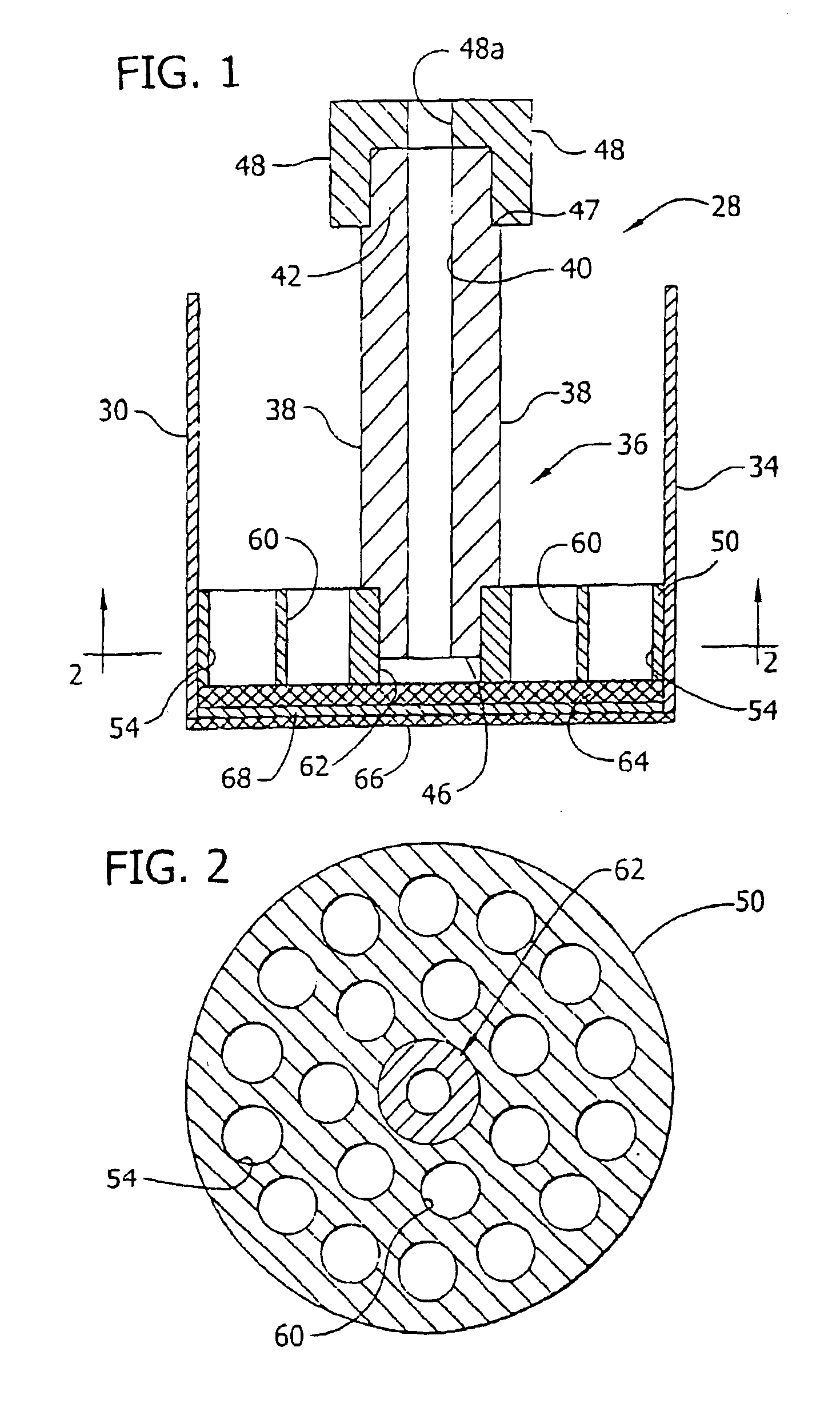

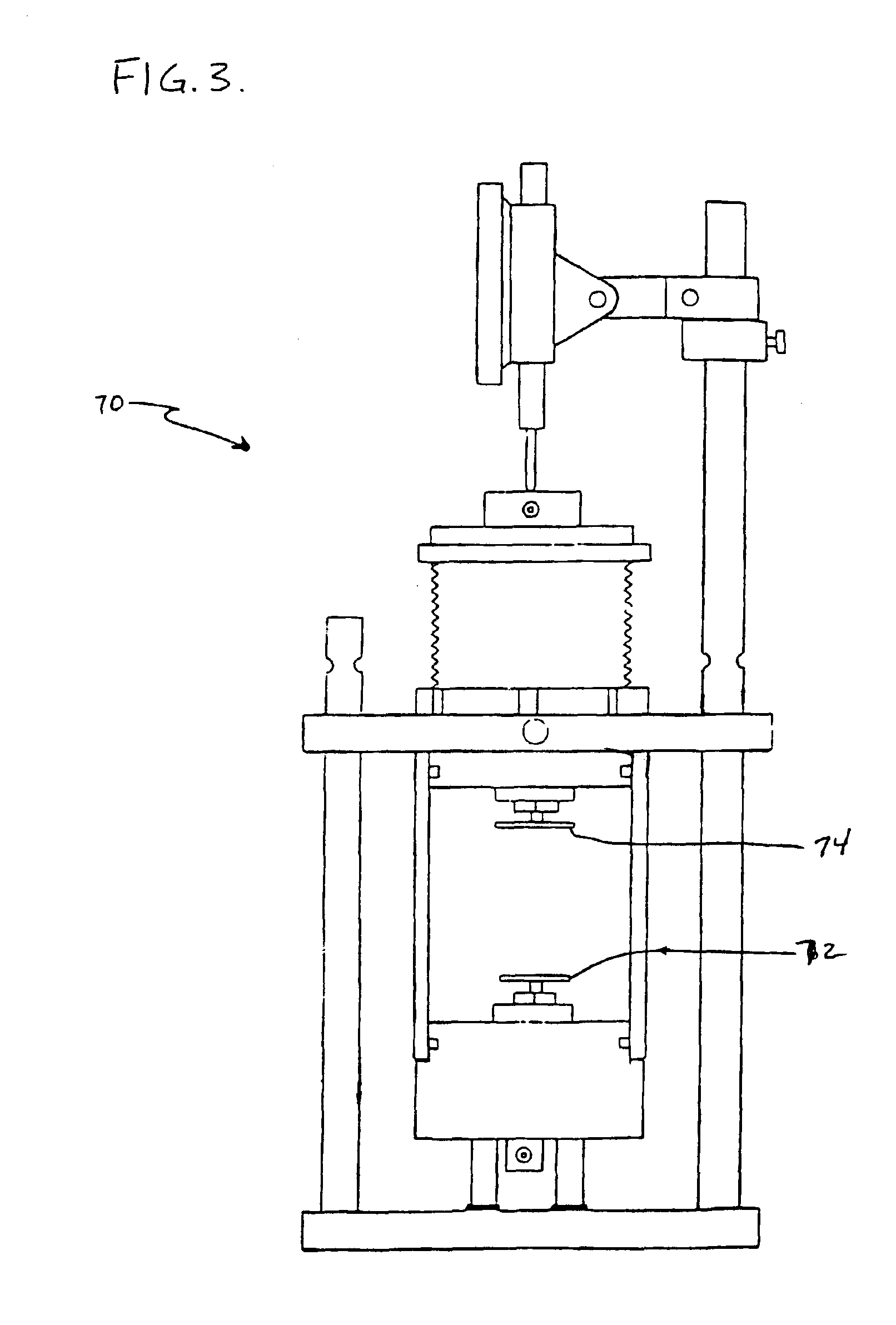

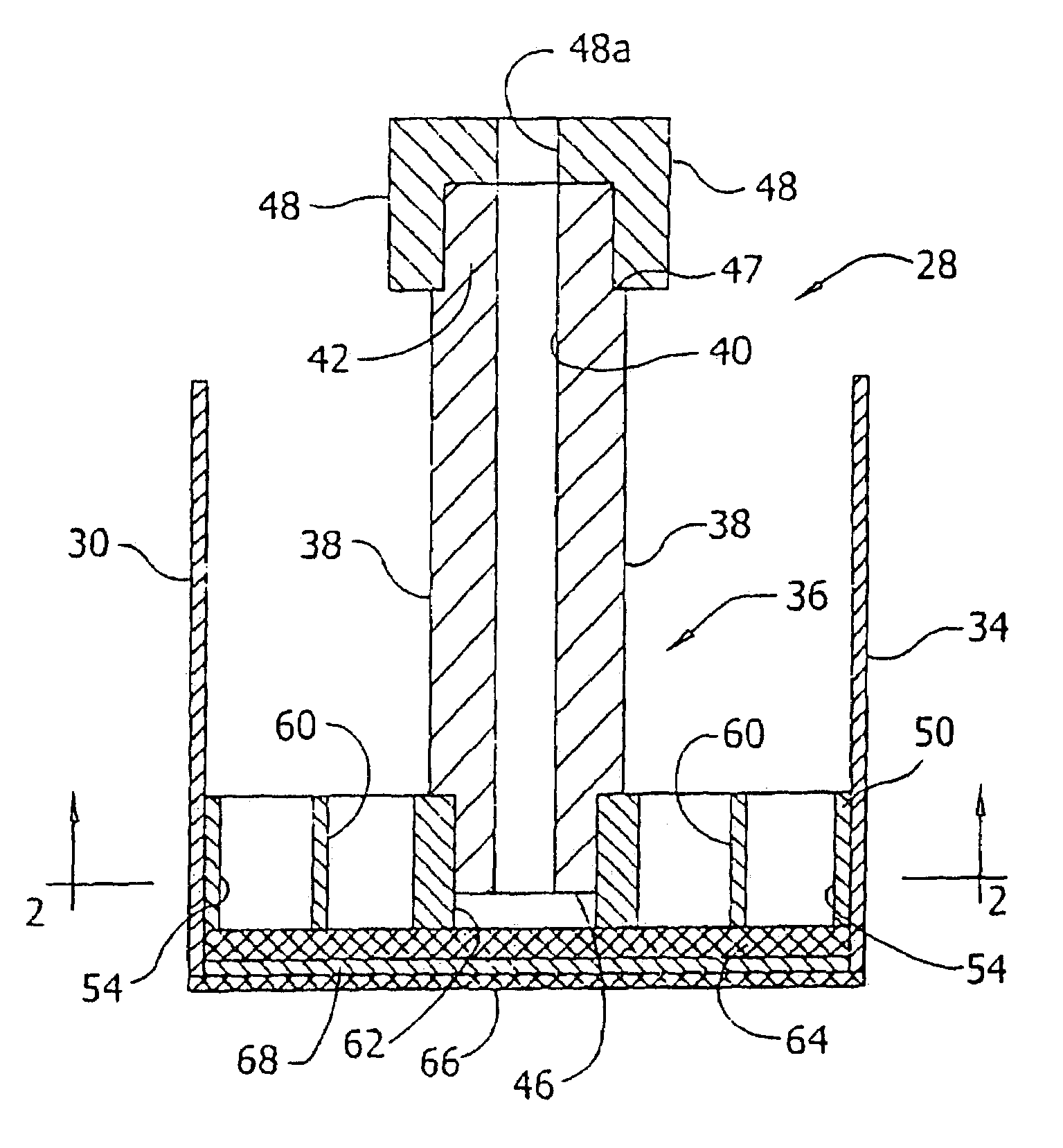

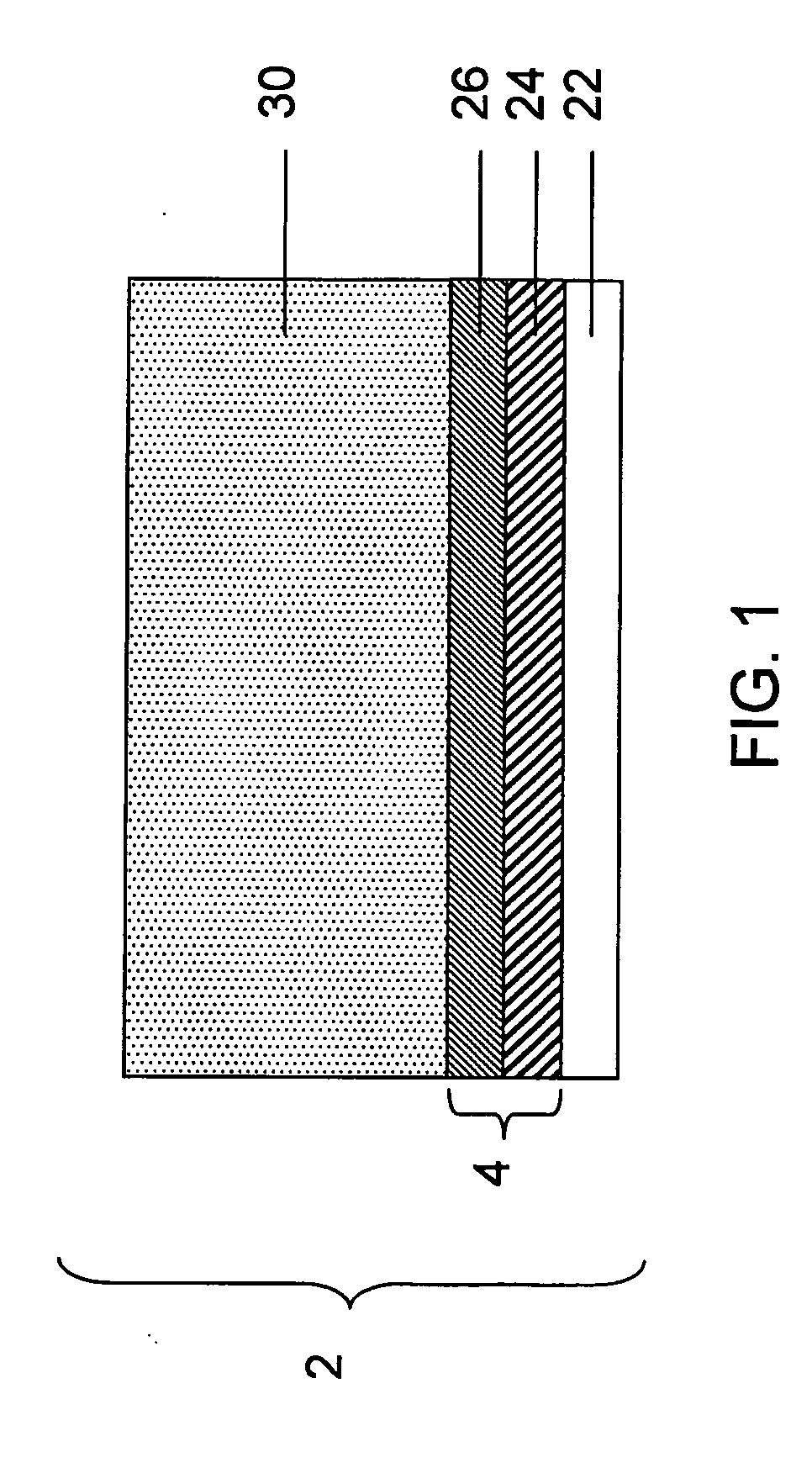

Membrane suitable for use in an analyte sensor, analyte sensor, and associated method

ActiveUS20050173245A1Facilitate linear responsivenessEasy CalibrationImmobilised enzymesBioreactor/fermenter combinationsMetaboliteSuperoxide

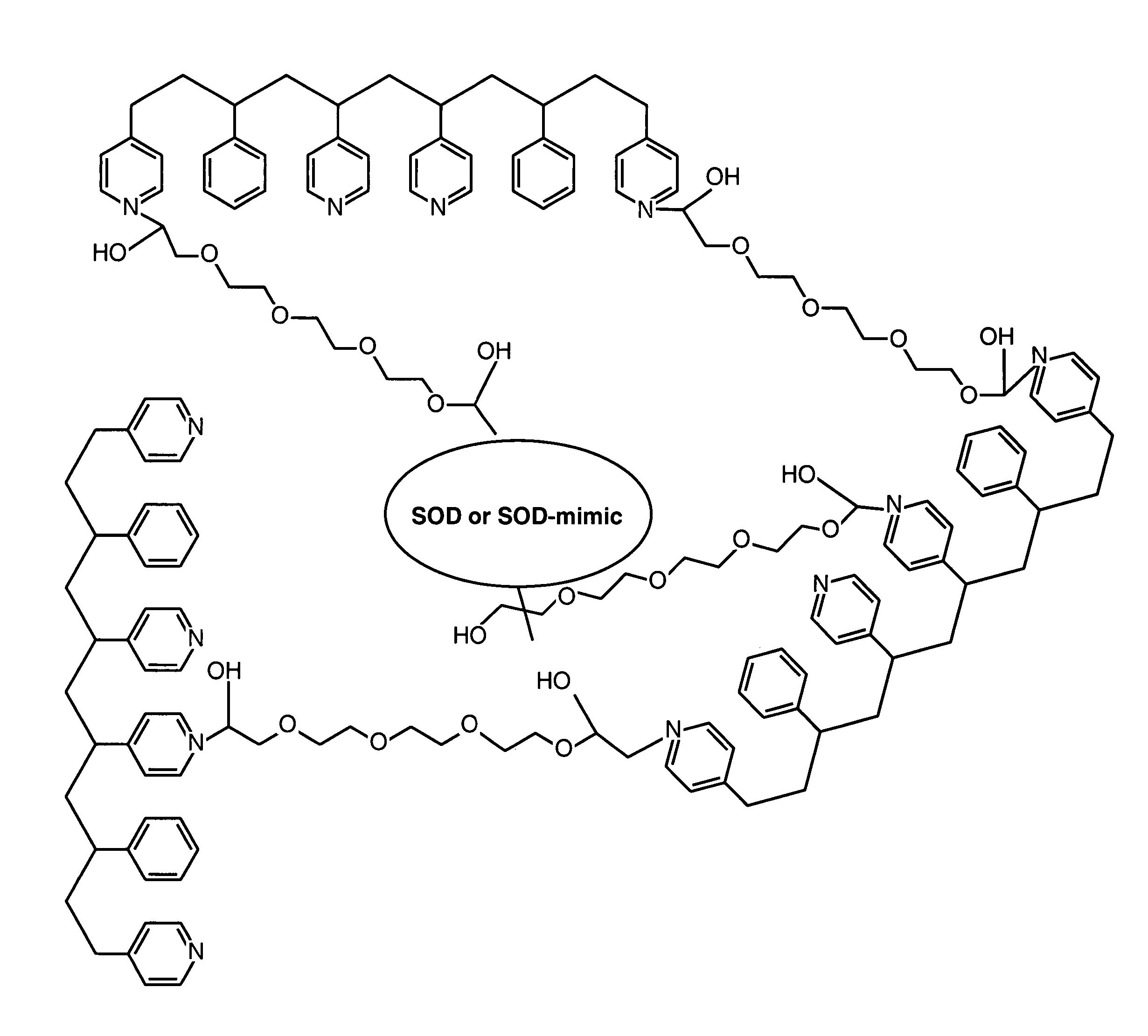

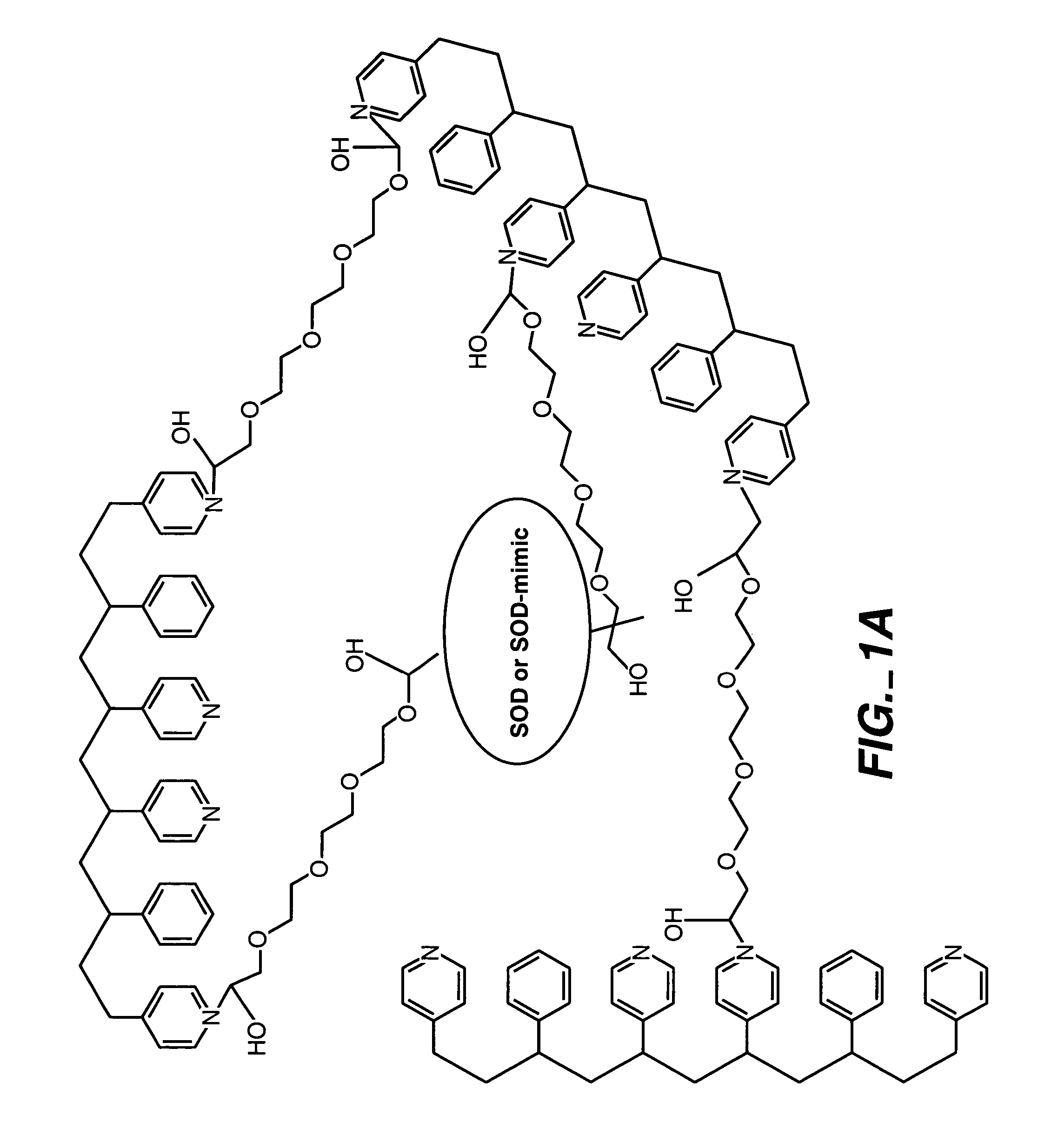

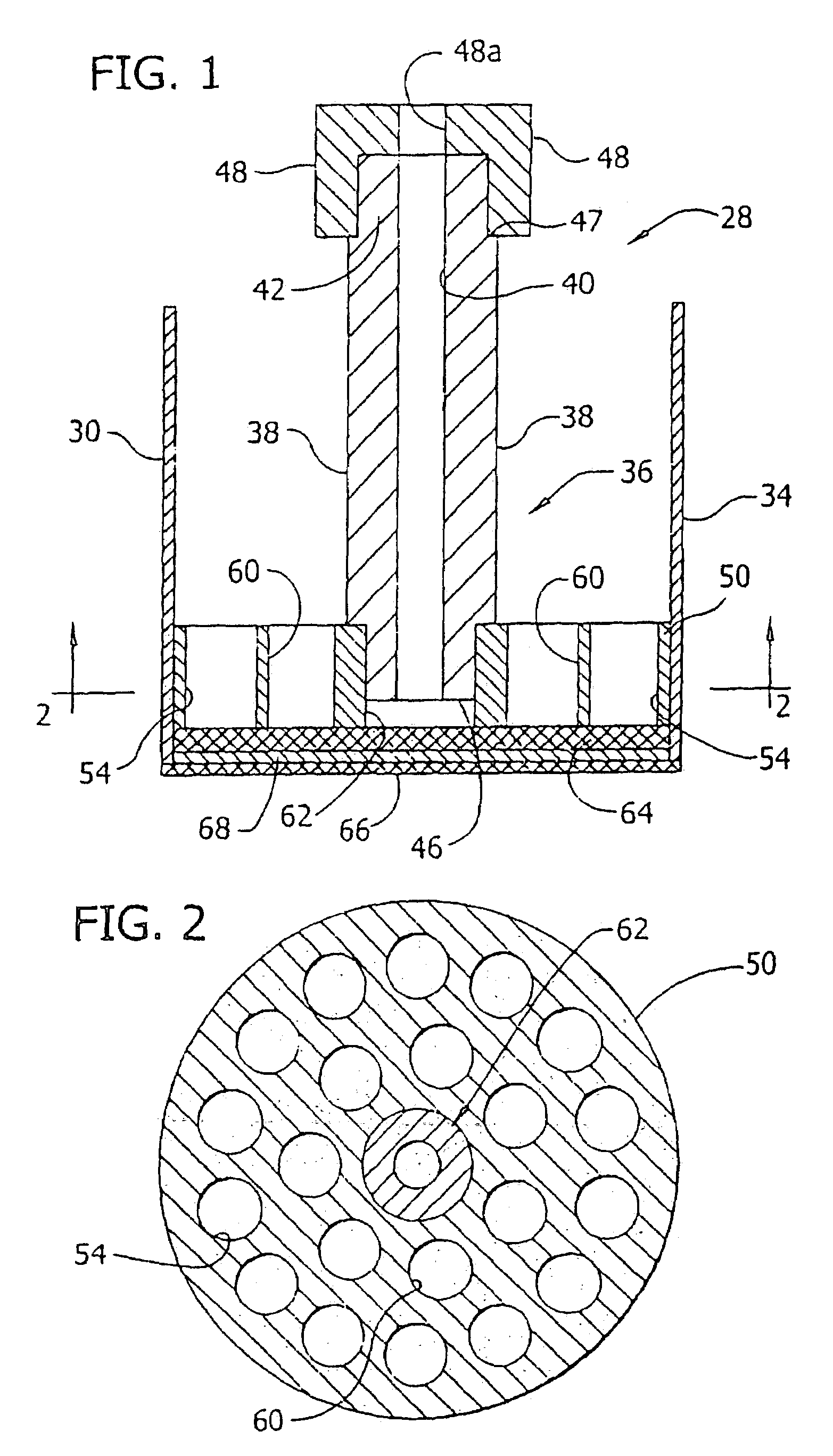

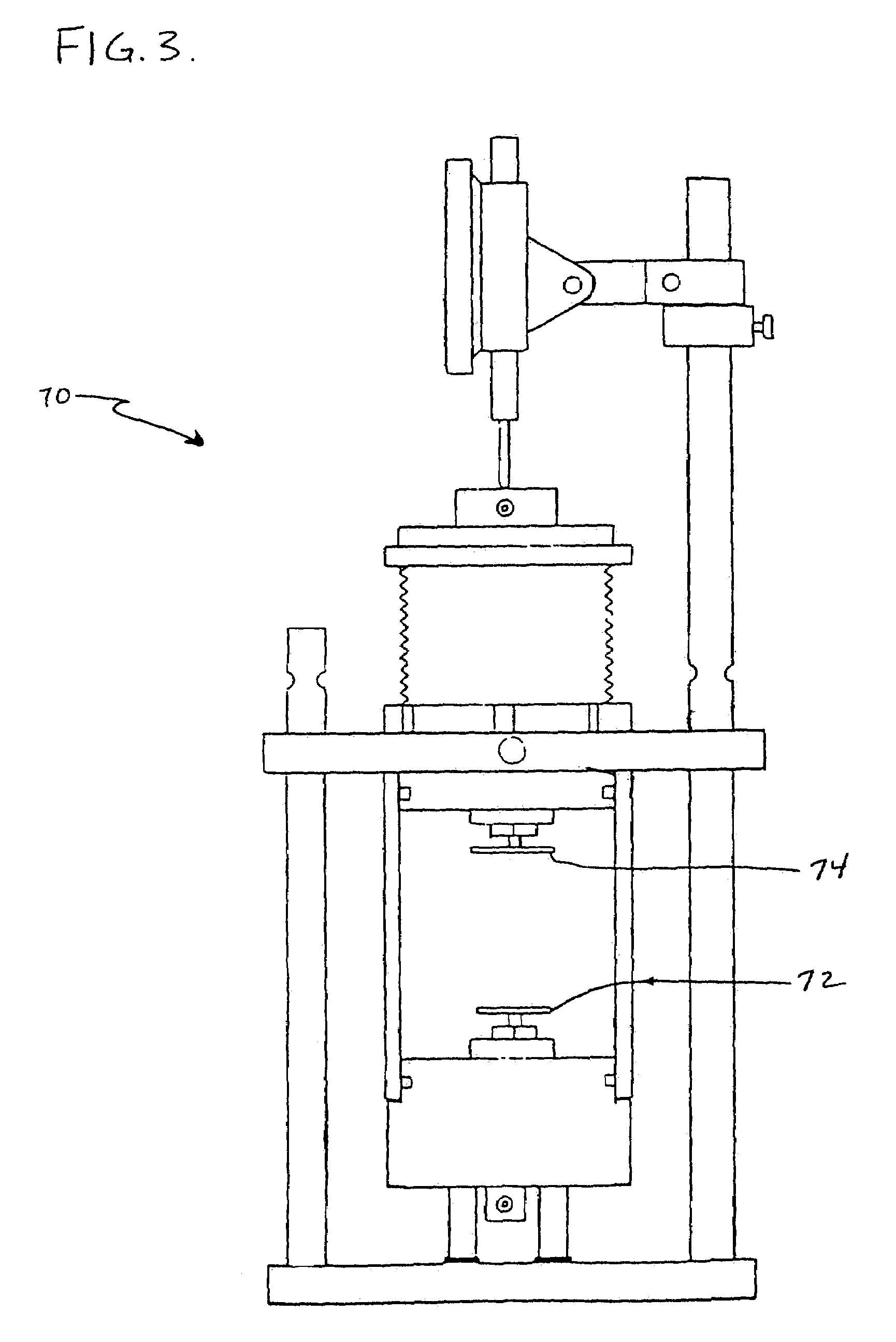

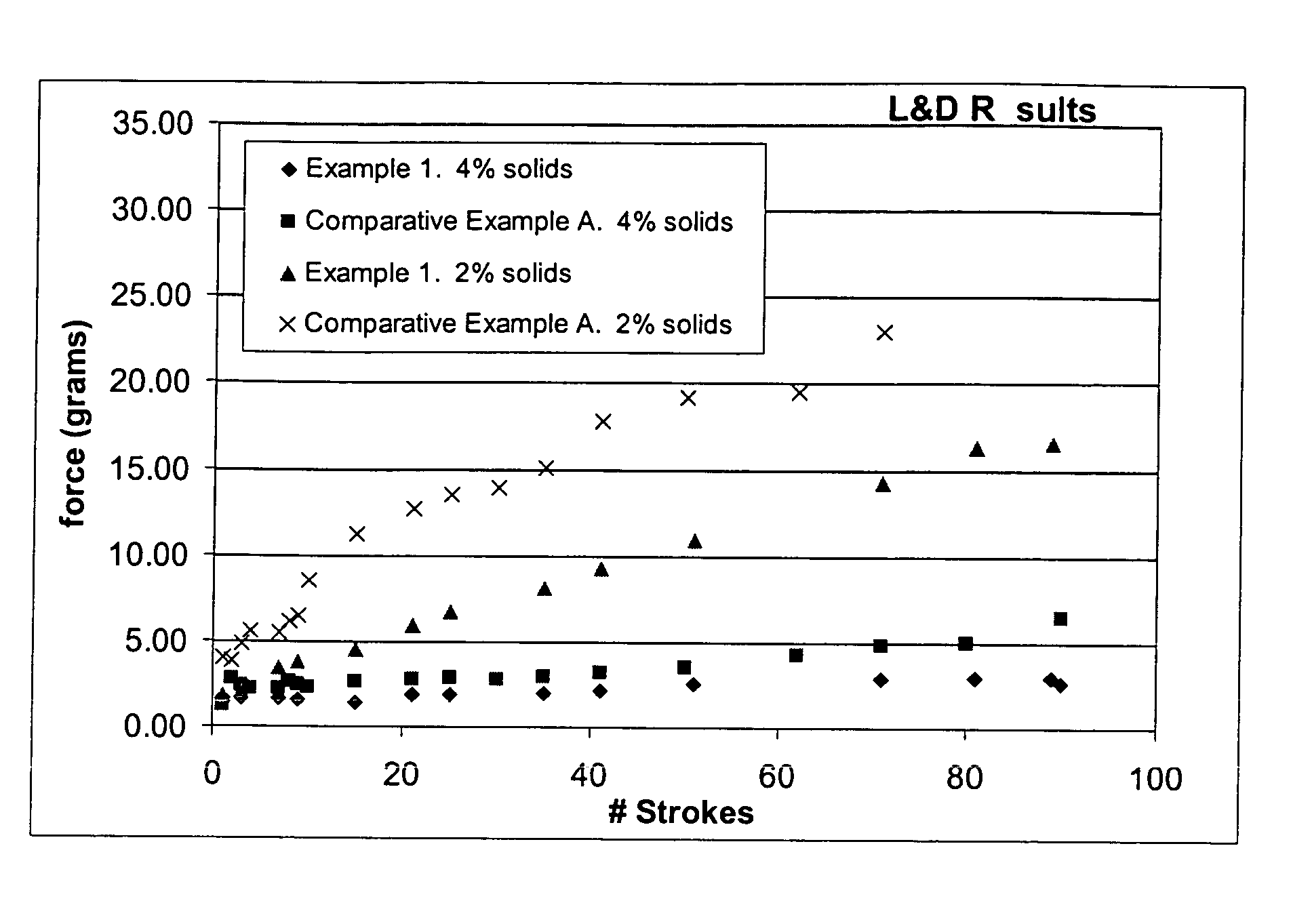

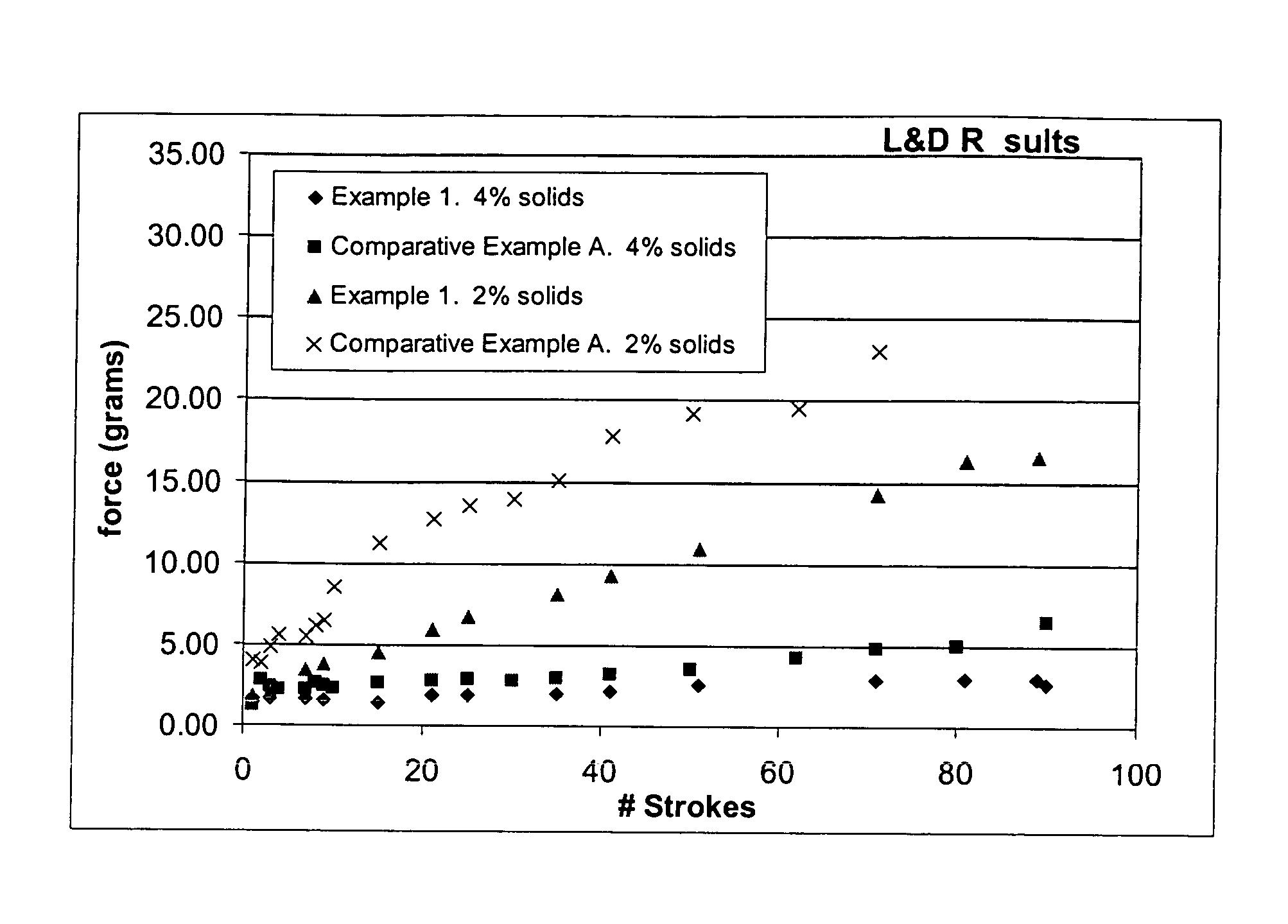

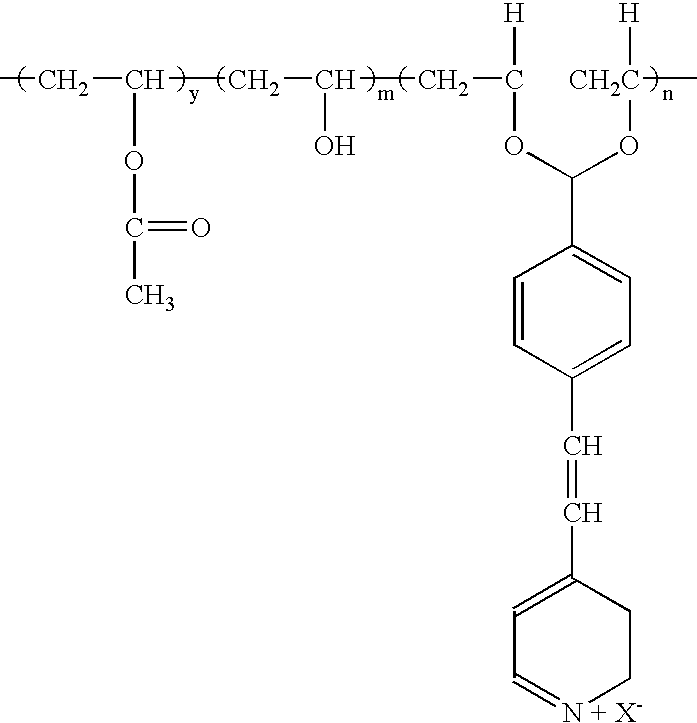

A multifunctional membrane is provided. The multifunctional membrane is suitable for use in an analyte sensor. In a particular application, the multifunctional membrane may be used in connection with an amperometric biosensor, such as a transcutaneous amperometric biosensor. Some functions of the membrane are associated with properties of membrane itself, which is comprised of crosslinked polymers containing heterocyclic nitrogen groups. For example, the membrane, by virtue of its polymeric composition, may regulate the flux of an analyte to a sensor. Such regulation generally improves the kinetic performance of the sensor over a broad range of analyte concentration. Other functions of the membrane are associated with functional components, such as a superoxide-dismutating / catalase catalyst, either in the form of an enzyme or an enzyme mimic, that can be bound to the scaffold provided by the membrane. The effect of any such enzyme or enzyme mimic is to lower the concentration of a metabolite, such as superoxide and / or hydrogen peroxide, in the immediate vicinity of the sensing layer of the biosensor. Lowering the concentrations of such metabolites, which are generally deleterious to the function of the sensor, generally protects or enhances biosensor integrity and performance. The membrane is thus an important tool for use in connection with analyte sensors, amperometric sensors, biosensors, and particularly, transcutaneous biosensors. A membrane-covered sensor and a method for making same are also provided.

Owner:ABBOTT DIABETES CARE INC

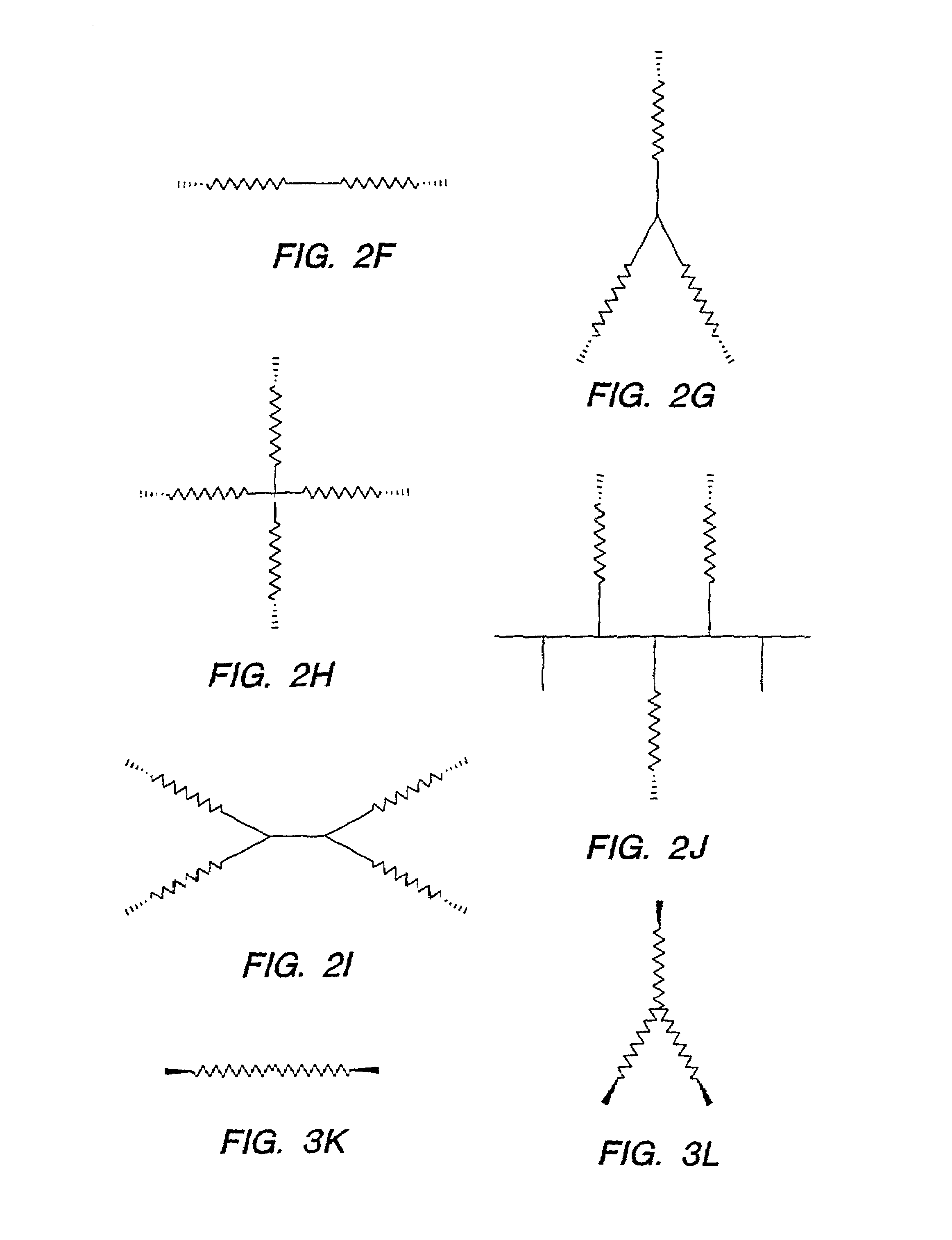

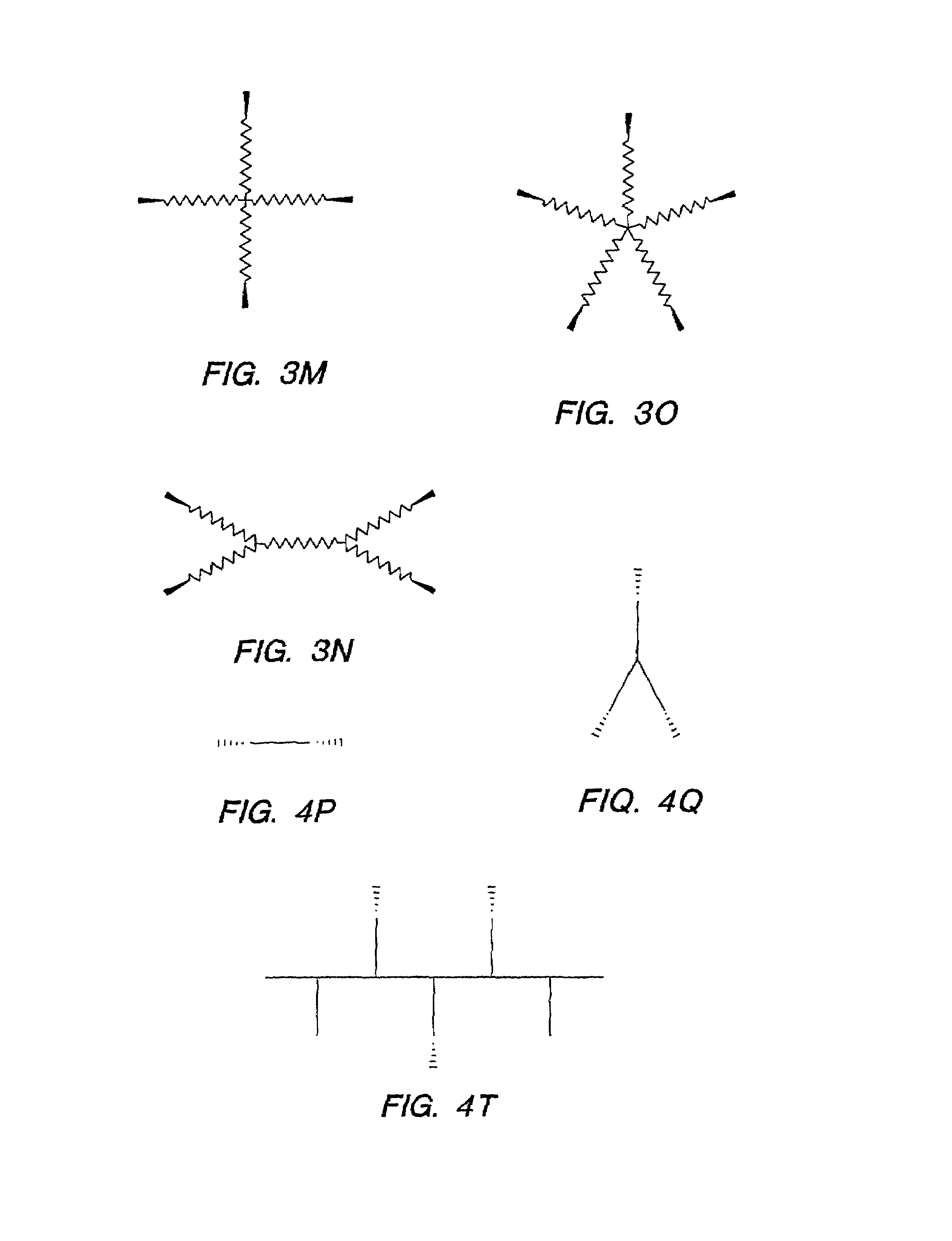

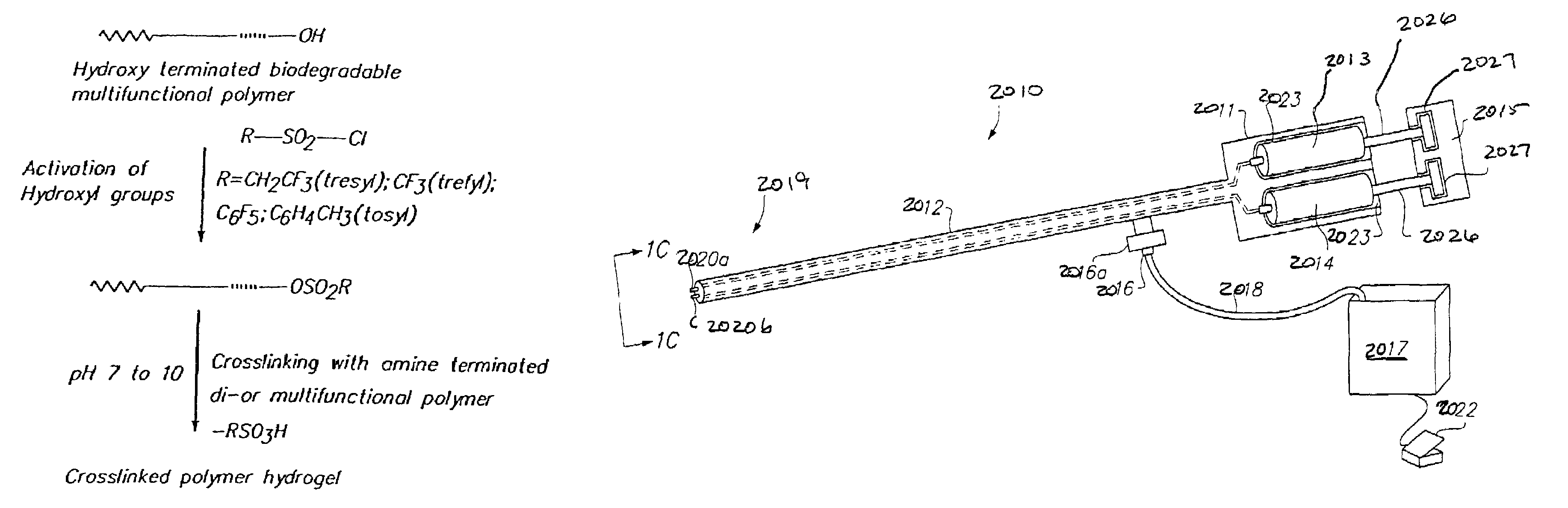

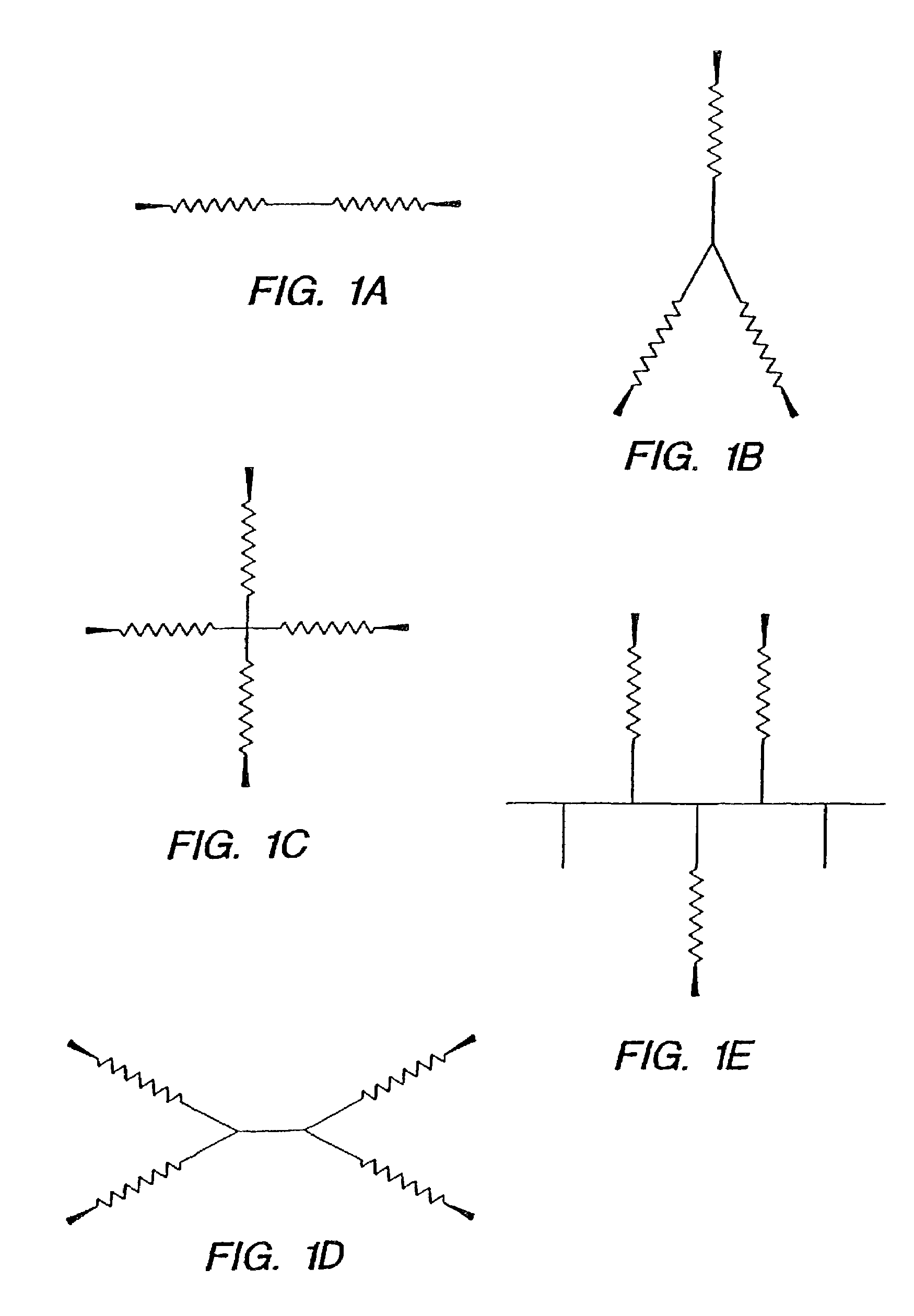

Biocompatible crosslinked polymers

InactiveUS7009034B2Improve performanceImprove visibilityUltrasonic/sonic/infrasonic diagnosticsPowder deliveryWound dressingPost operative

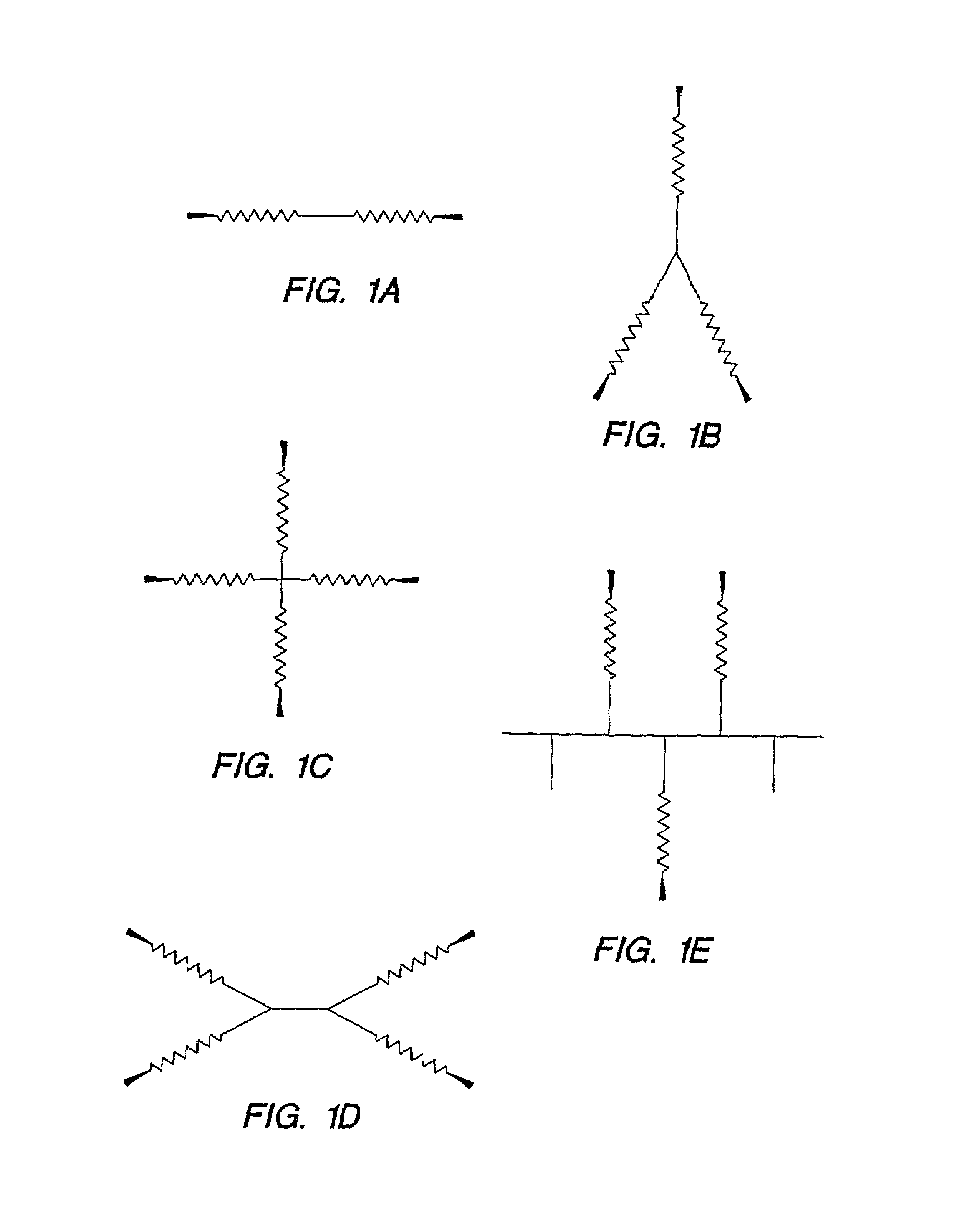

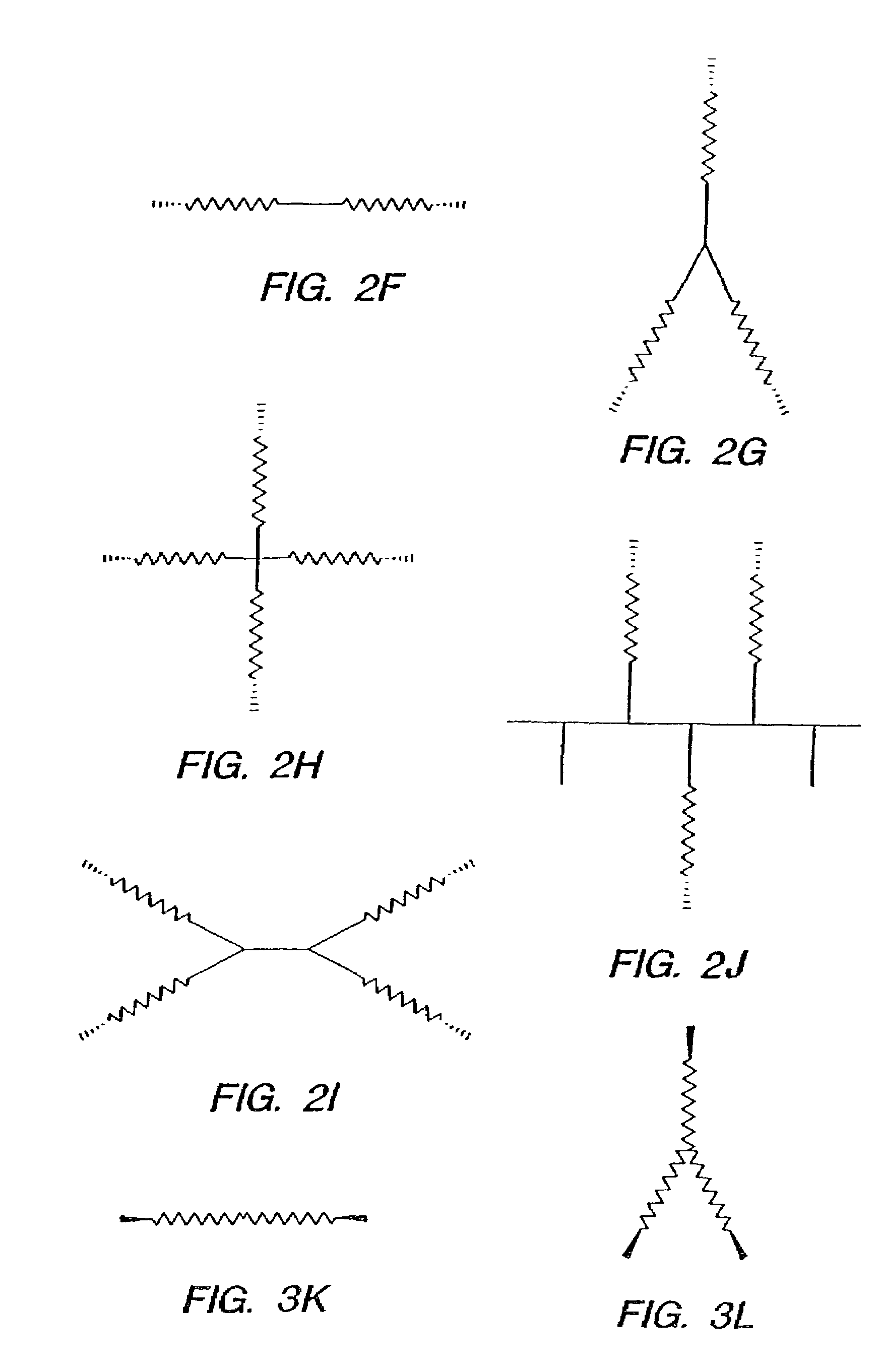

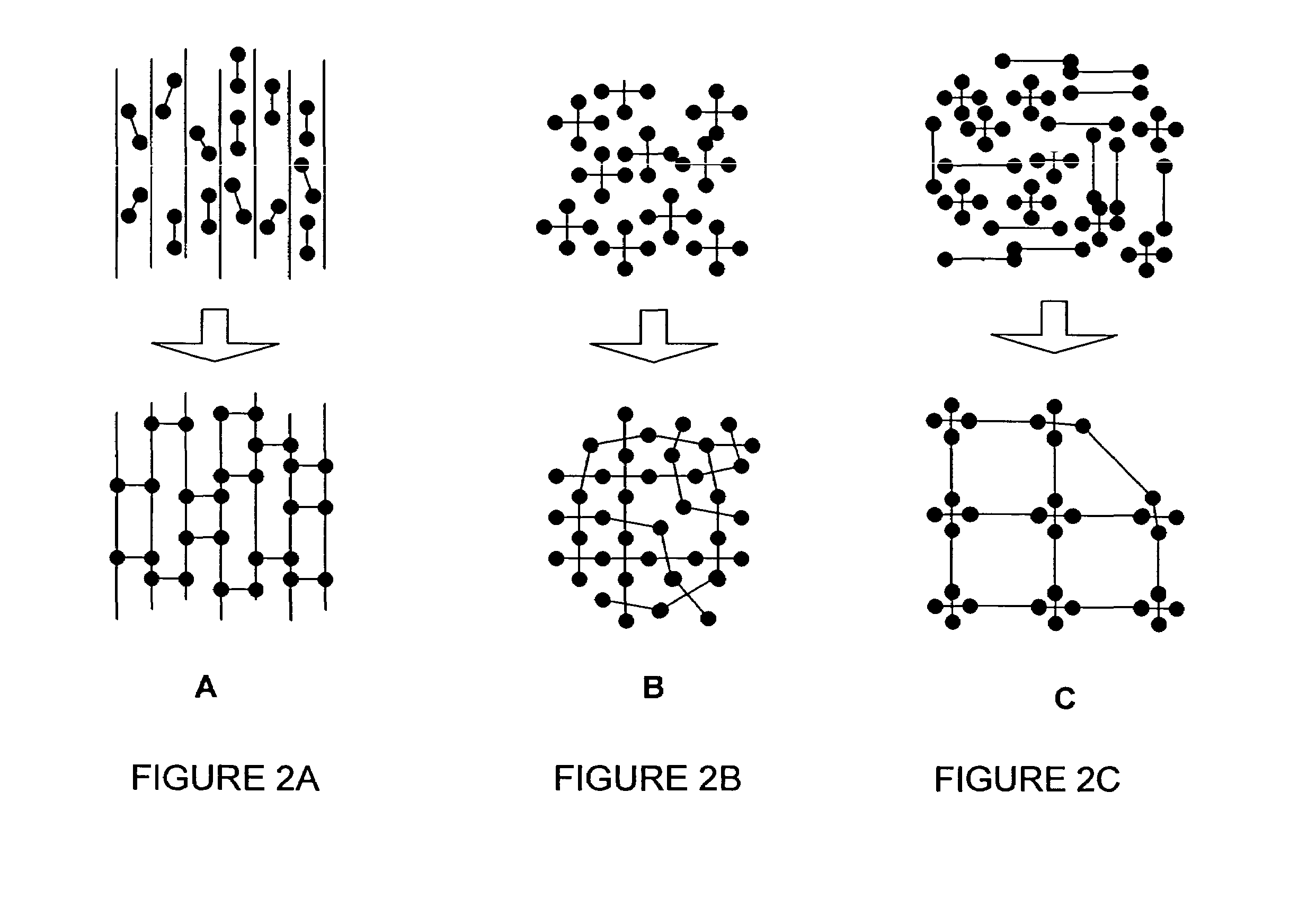

Biocompatible crosslinked polymers, and methods for their preparation and use, are disclosed in which the biocompatible crosslinked polymers are formed from water soluble precursors having electrophilic and nucleophilic functional groups capable of reacting and crosslinking in situ. Methods for making the resulting biocompatible crosslinked polymers biodegradable or not are provided, as are methods for controlling the rate of degradation. The crosslinking reactions may be carried out in situ on organs or tissues or outside the body. Applications for such biocompatible crosslinked polymers and their precursors include controlled delivery of drugs, prevention of post-operative adhesions, coating of medical devices such as vascular grafts, wound dressings and surgical sealants. Visualization agents may be included with the crosslinked polymers.

Owner:INCEPT LLC

Adhesion barriers applicable by minimally invasive surgery and methods of use thereof

Biocompatible crosslinked polymers, and methods for their preparation and use with minimally invasive surgery applicators are disclosed. The disclosure includes compositions and methods for in situ formation of hydrogels using minimally invasive surgical techniques.

Owner:INCEPT LLC

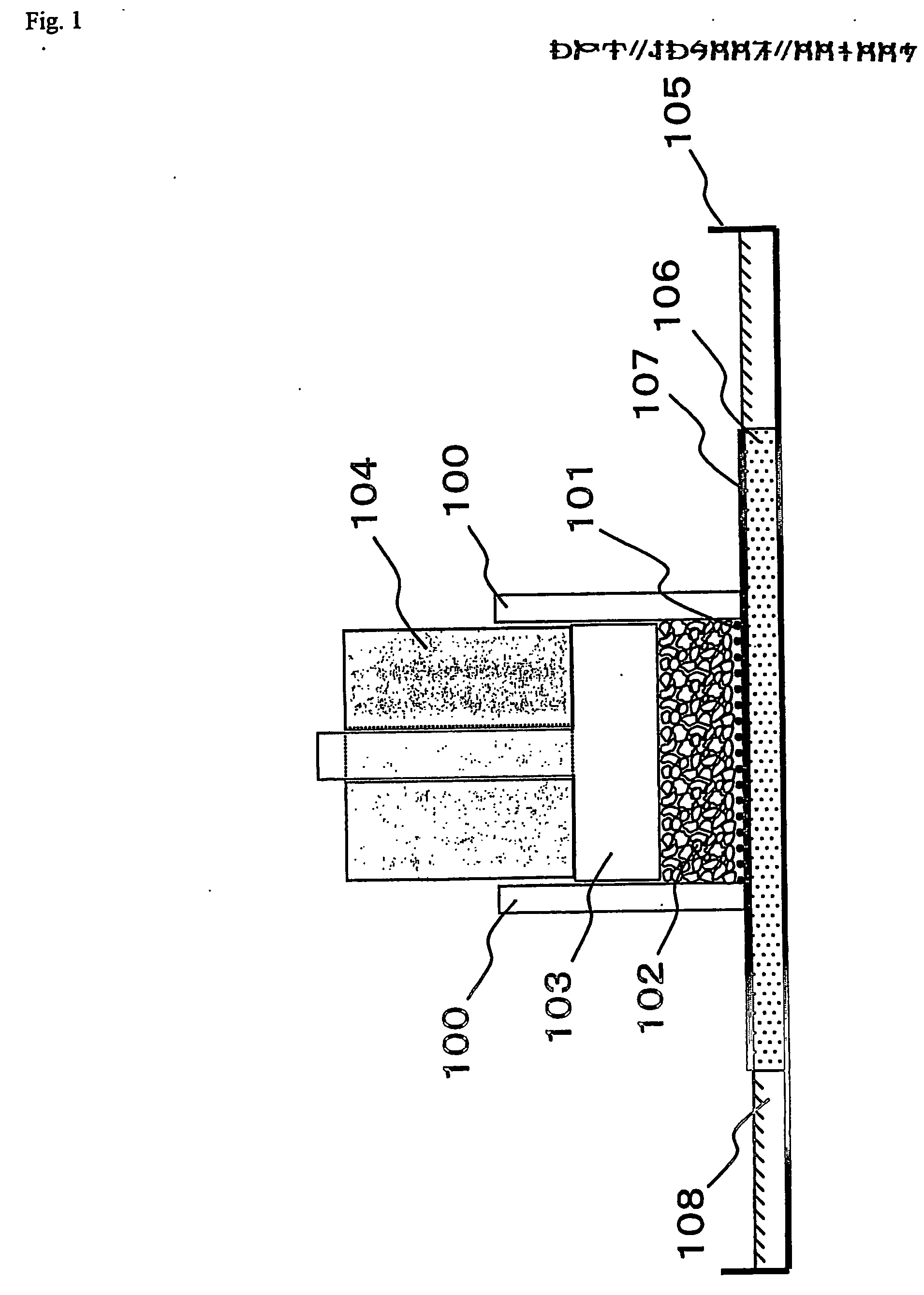

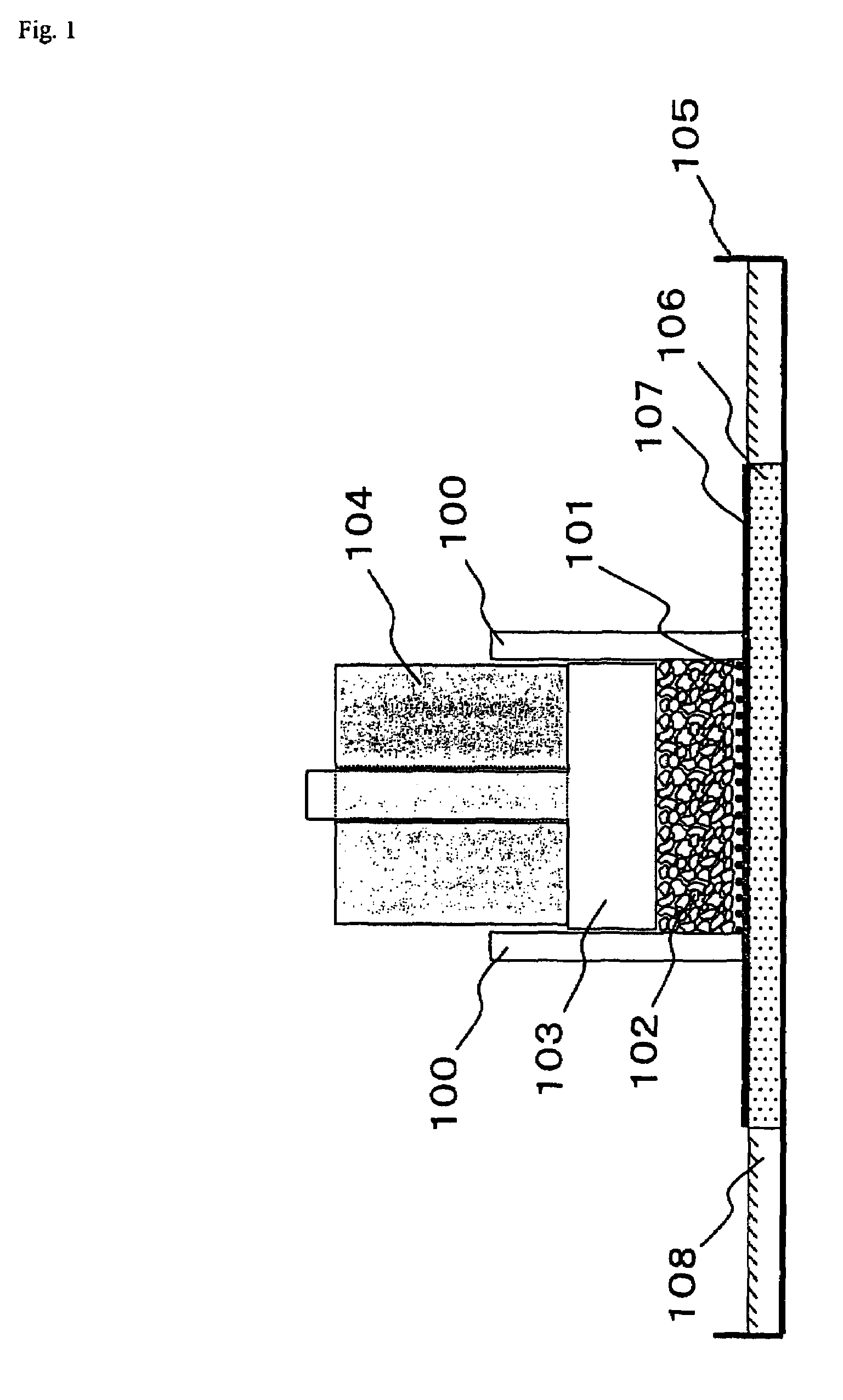

Walter-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σξY) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

Water-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σζ) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

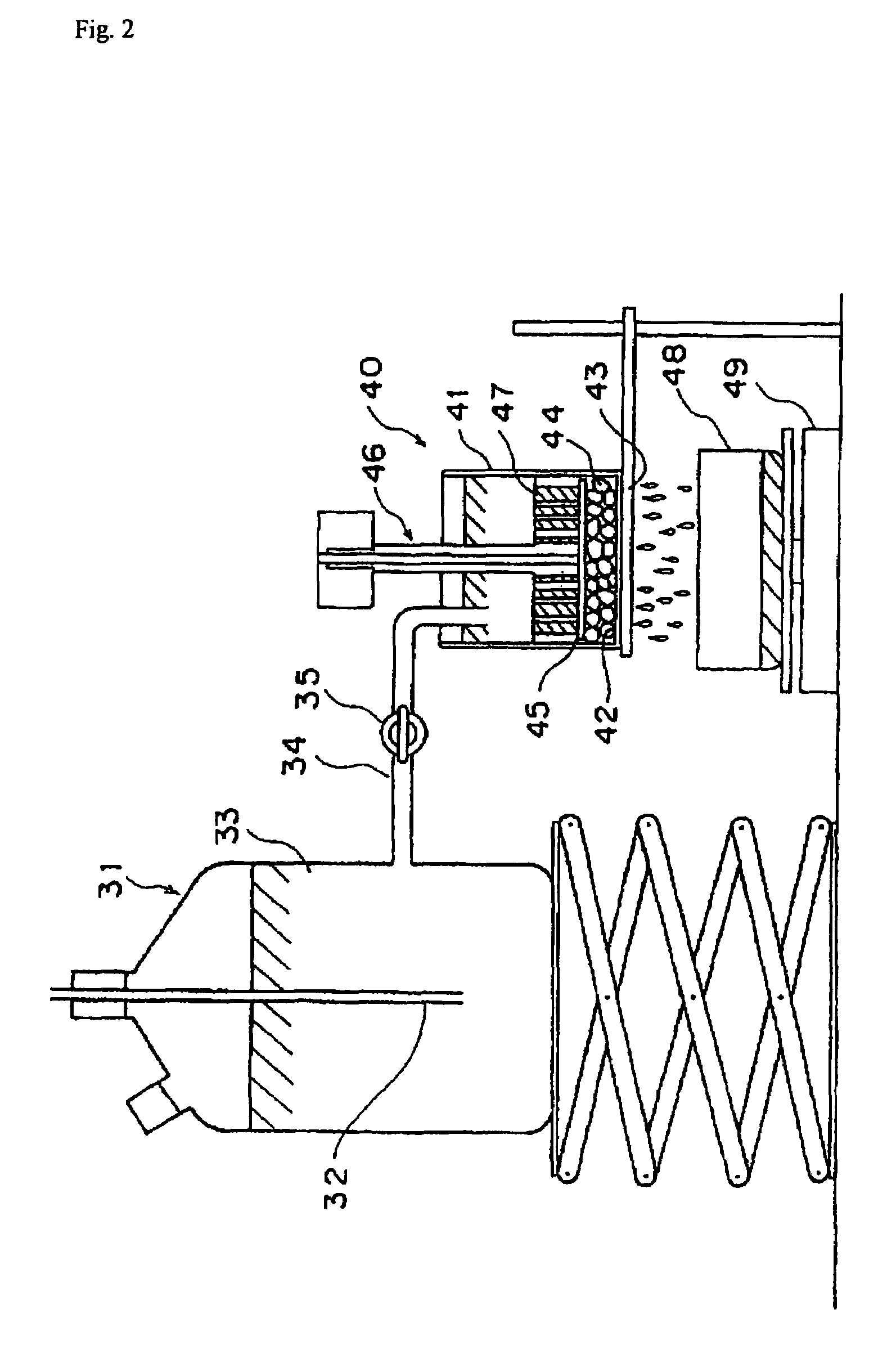

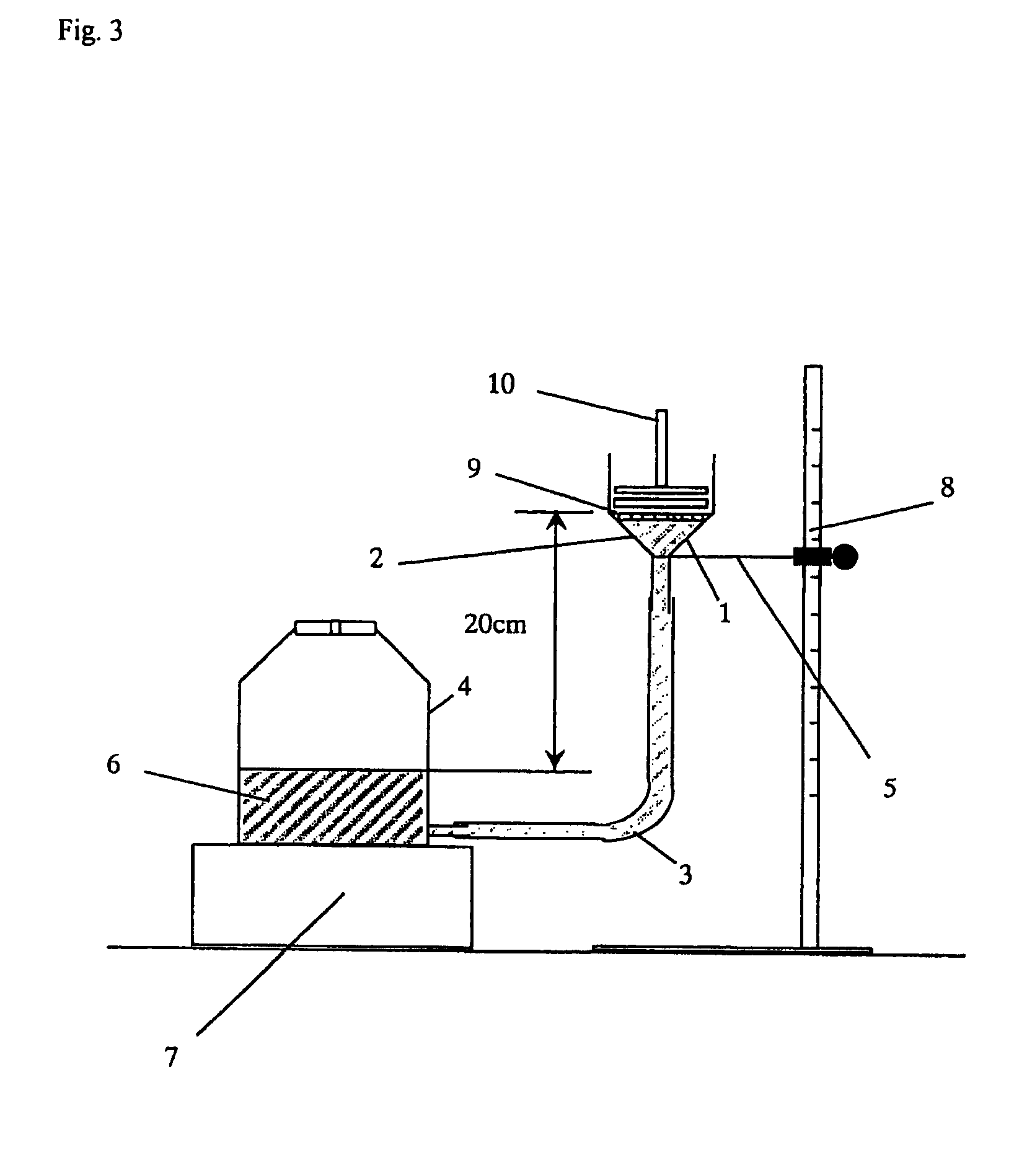

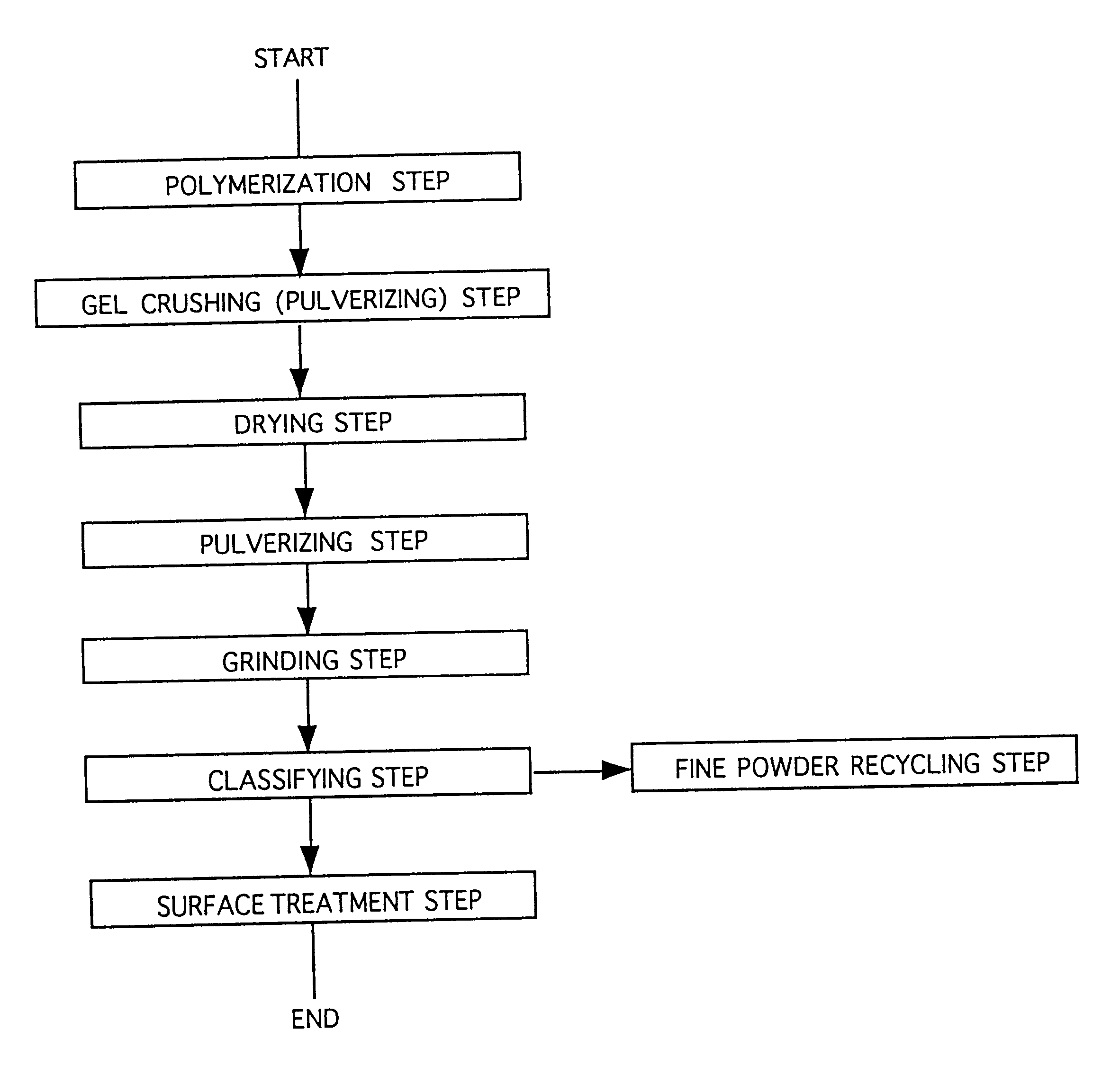

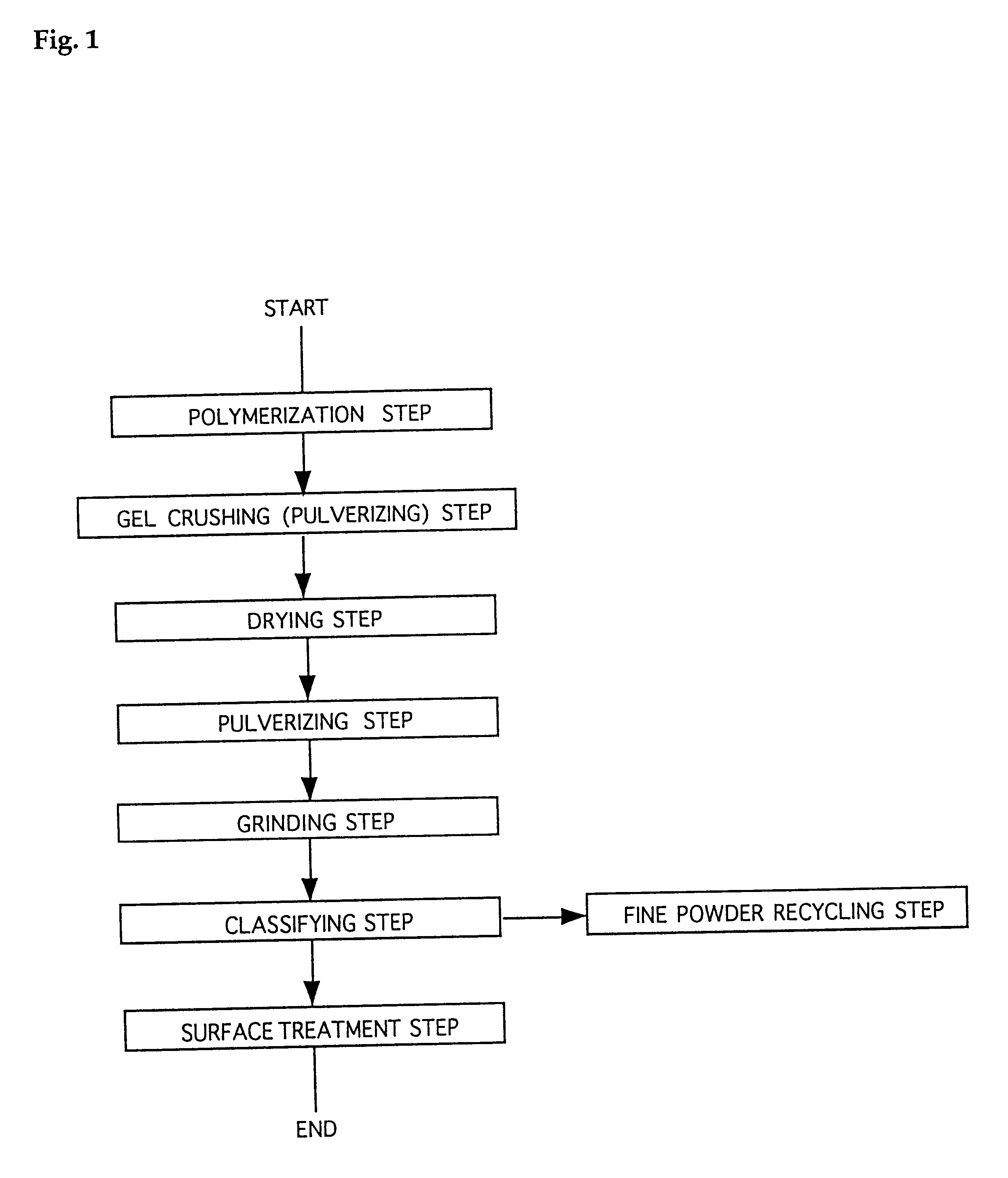

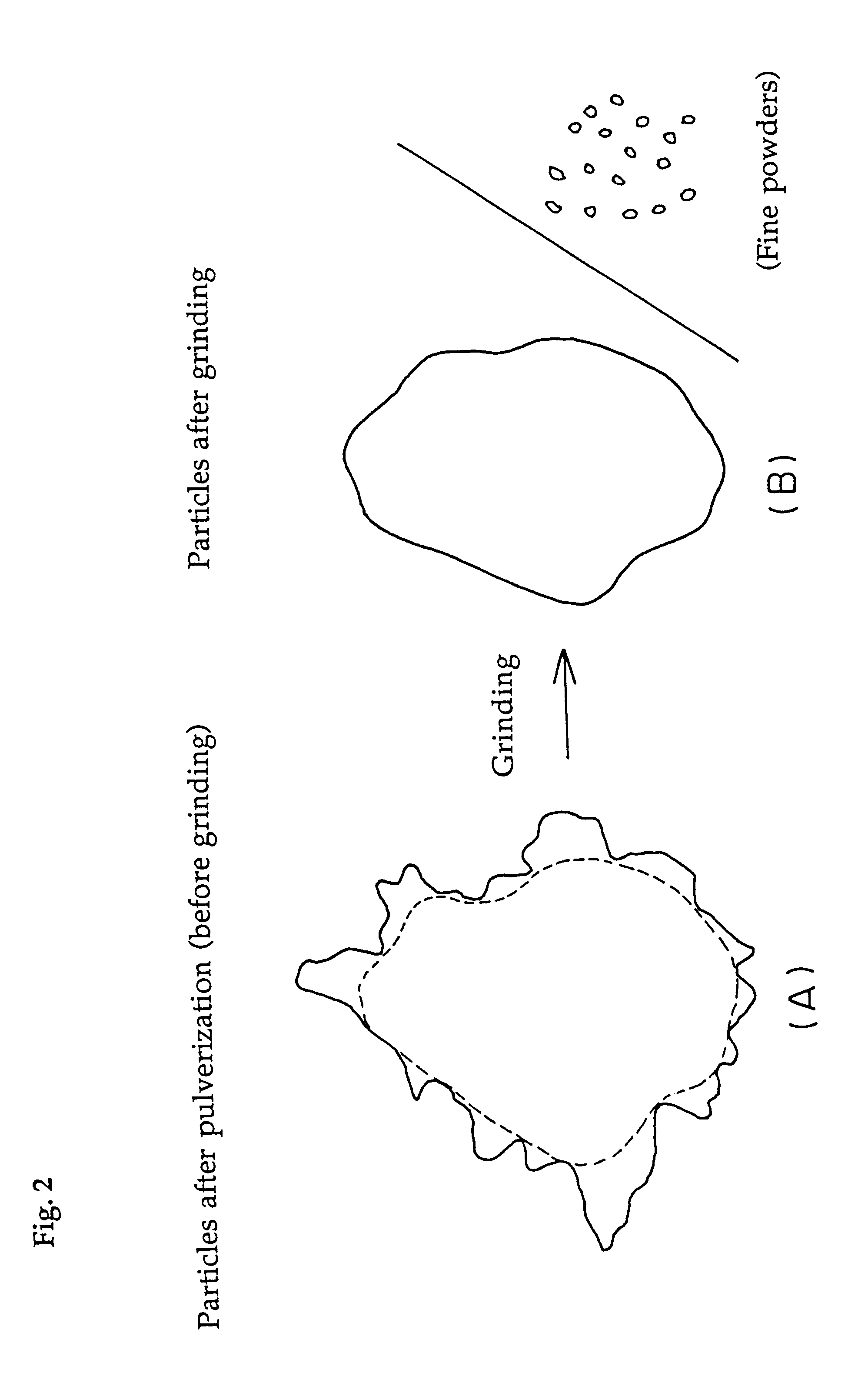

Water-absorbent resin powder and its production process and use

The present invention provides a water-absorbent resin powder and its production process and use, wherein the water-absorbent resin powder has high liquid permeability and high water absorbency. The production process for a water-absorbent resin powder, according to the present invention, comprises the step of obtaining water-absorbent crosslinked polymer particles by an aqueous solution polymerization step, and grinding the resultant crosslinked polymer particles until the bulk density thereof increases to not lower than 0.72 (g / ml). The water-absorbent resin powder is characterized by being arbitrarily pulverized and having a bulk density of not lower than 0.74 (g / ml) and a water absorption capacity of not lower than 20 (g / g) for 0.9 weight % physiological saline under a load of 0.7 psi (4.83 kPa). In addition, the absorbent structure comprises the above water-absorbent resin powder and a fibrous material. The absorbent article comprises an absorbent layer including the above absorbent structure.

Owner:NIPPON SHOKUBAI CO LTD

Process for medical implant of cross-linked ultrahigh molecular weight polyethylene having improved balance of wear properties and oxidation resistance

A medical implant of ultrahigh molecular weight polyethylene having an improved balance of wear properties and oxidation resistance is prepared by irradiating a preform of ultrahigh molecular weight polyethylene, annealing the irradiated preform in the absence of oxygen to a temperature at or above the onset of melting temperature, and forming an implant from the stabilized cross-linked polymer. Implants prepared according to the process of the present invention have comparable oxidation resistance and superior wear performance compared to unirradiated ultrahigh molecular weight polyethylene.

Owner:DEPUY ORTHOPAEDICS INC

Membrane suitable for use in an analyte sensor, analyte sensor, and associated method

ActiveUS7699964B2Facilitate linear responsiveness and calibration and stabilityPreserve and improve performance of sensorImmobilised enzymesBioreactor/fermenter combinationsMetaboliteAmperometric biosensor

A multifunctional membrane is provided. The multifunctional membrane is suitable for use in an analyte sensor. In a particular application, the multifunctional membrane may be used in connection with an amperometric biosensor, such as a transcutaneous amperometric biosensor. Some functions of the membrane are associated with properties of membrane itself, which is comprised of crosslinked polymers containing heterocyclic nitrogen groups. For example, the membrane, by virtue of its polymeric composition, may regulate the flux of an analyte to a sensor. Such regulation generally improves the kinetic performance of the sensor over a broad range of analyte concentration. Other functions of the membrane are associated with functional components, such as a superoxide-dismutating / catalase catalyst, either in the form of an enzyme or an enzyme mimic, that can be bound to the scaffold provided by the membrane. The effect of any such enzyme or enzyme mimic is to lower the concentration of a metabolite, such as superoxide and / or hydrogen peroxide, in the immediate vicinity of the sensing layer of the biosensor. Lowering the concentrations of such metabolites, which are generally deleterious to the function of the sensor, generally protects or enhances biosensor integrity and performance. The membrane is thus an important tool for use in connection with analyte sensors, amperometric sensors, biosensors, and particularly, transcutaneous biosensors. A membrane-covered sensor and a method for making same are also provided.

Owner:ABBOTT DIABETES CARE INC

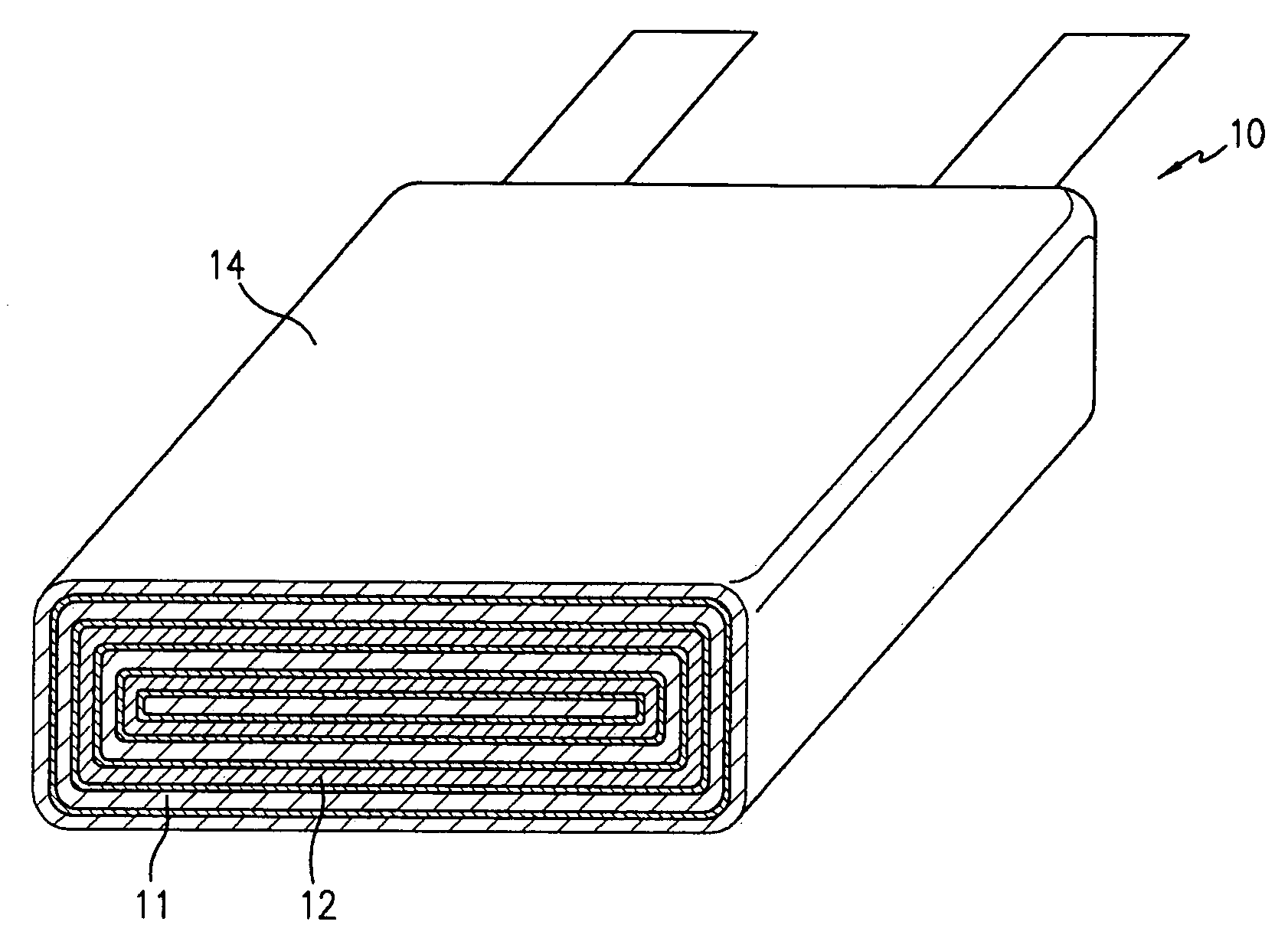

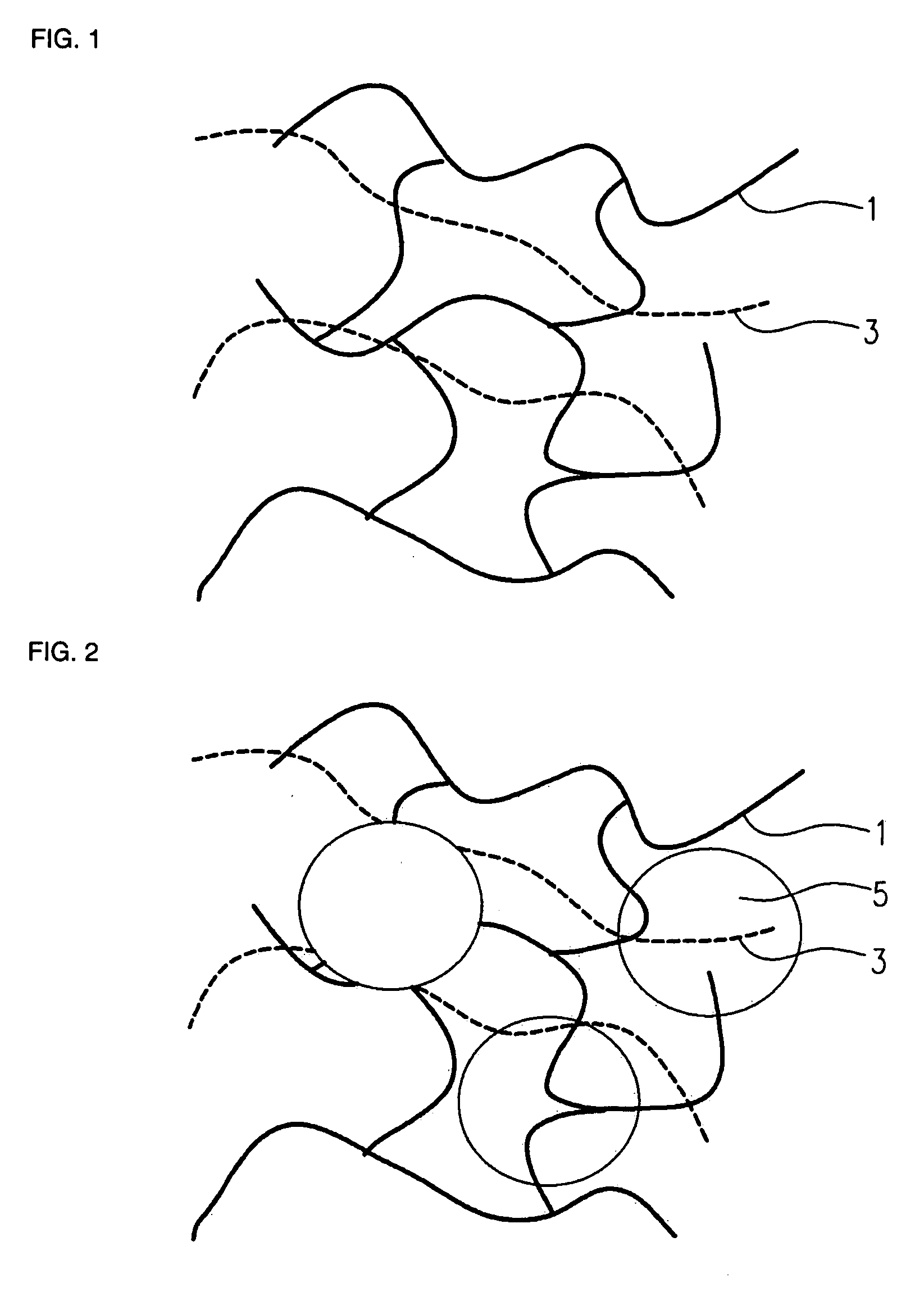

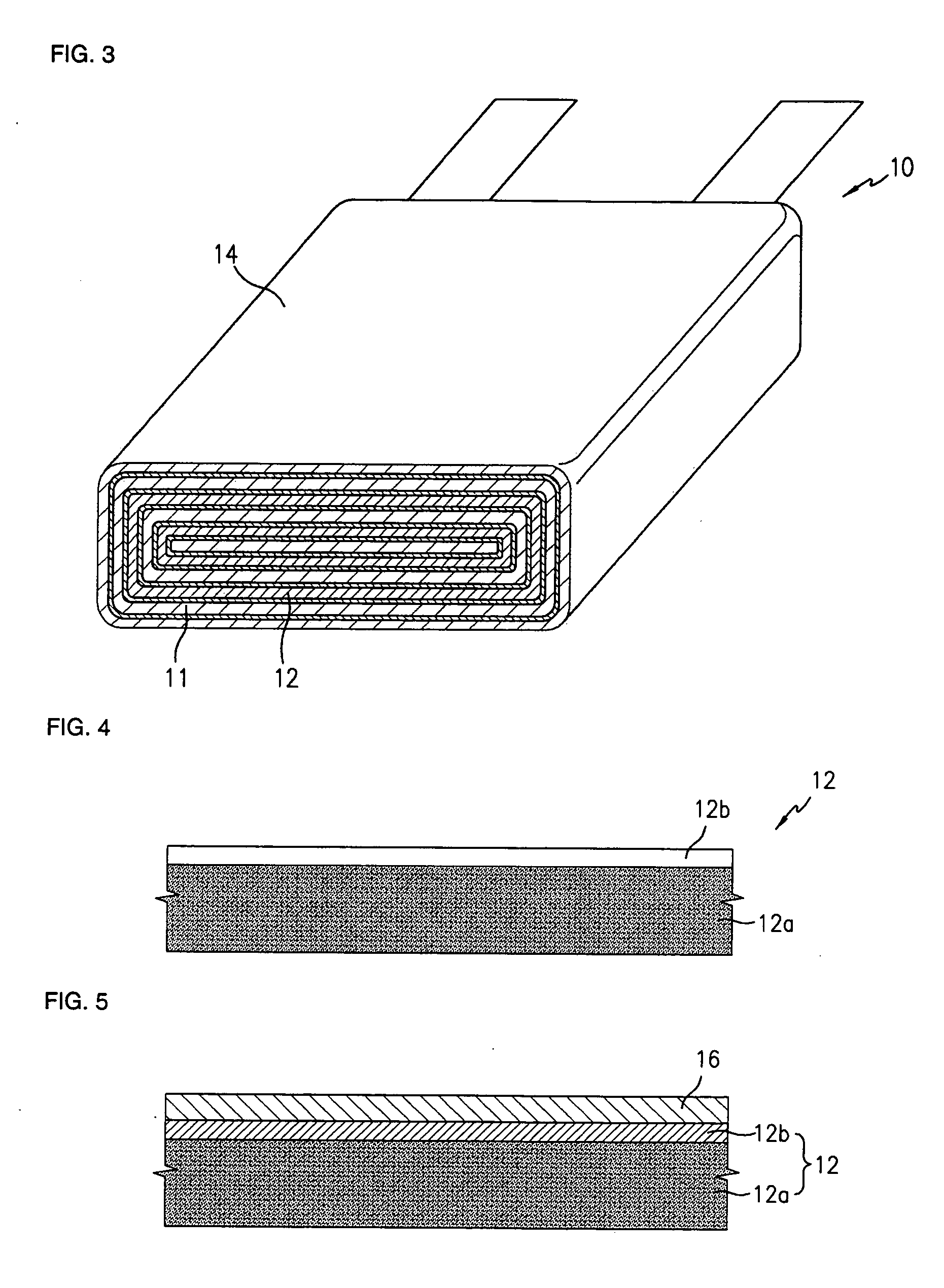

Negative electrode for lithium metal battery and lithium metal battery comprising the same

InactiveUS20050095504A1Improving life-cycle characteristicInhibit side effectsFinal product manufacturePretreated surfacesCross-linkMetallic lithium

The present invention relates to a negative electrode for a lithium metal battery and a lithium metal battery comprising the same. The negative electrode of the present invention comprises a negative active material layer of metallic lithium or a lithium alloy, and a passivation layer formed on the negative active material layer. The passivation layer has a structure comprising a 3-dimensionally cross-linked polymer network matrix penetrated by linear polymers. The passivation layer formed on the surface of the negative electrode reduces reactivity of the negative electrode and stabilizes the surface, so that it offers a lithium metal battery having superior life cycle characteristics.

Owner:SAMSUNG SDI CO LTD

Superabsorbent polymer with high permeability

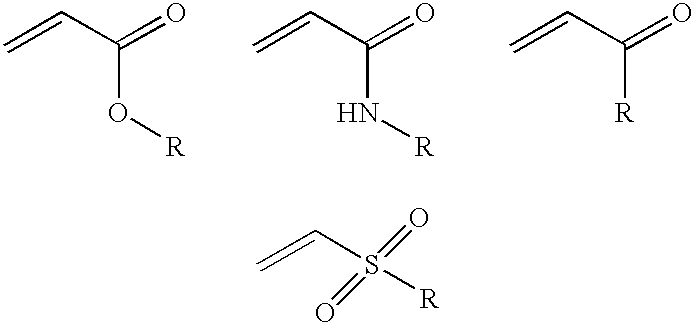

The invention relates to absorptive, crosslinked polymers which are based on partly neutralized, monoethylenically unsaturated monomers carrying acid groups, and have improved properties, in particular in respect of their capacity for transportation of liquids in the swollen state, and which has a high gel bed permeability and high centrifuge retention capacity.

Owner:EVONIK SUPERABSORBER LLC

Superabsorbent polymer with high permeability

Owner:EVONIK SUPERABSORBER LLC

Lubricious coatings for medical device

An ultraviolet curable lubricious coating including at least one lubricious polymer and at least one oxygen-insensitive crosslinkable polymer, methods of making and using the same, and articles coated therewith.

Owner:BOSTON SCI SCIMED INC

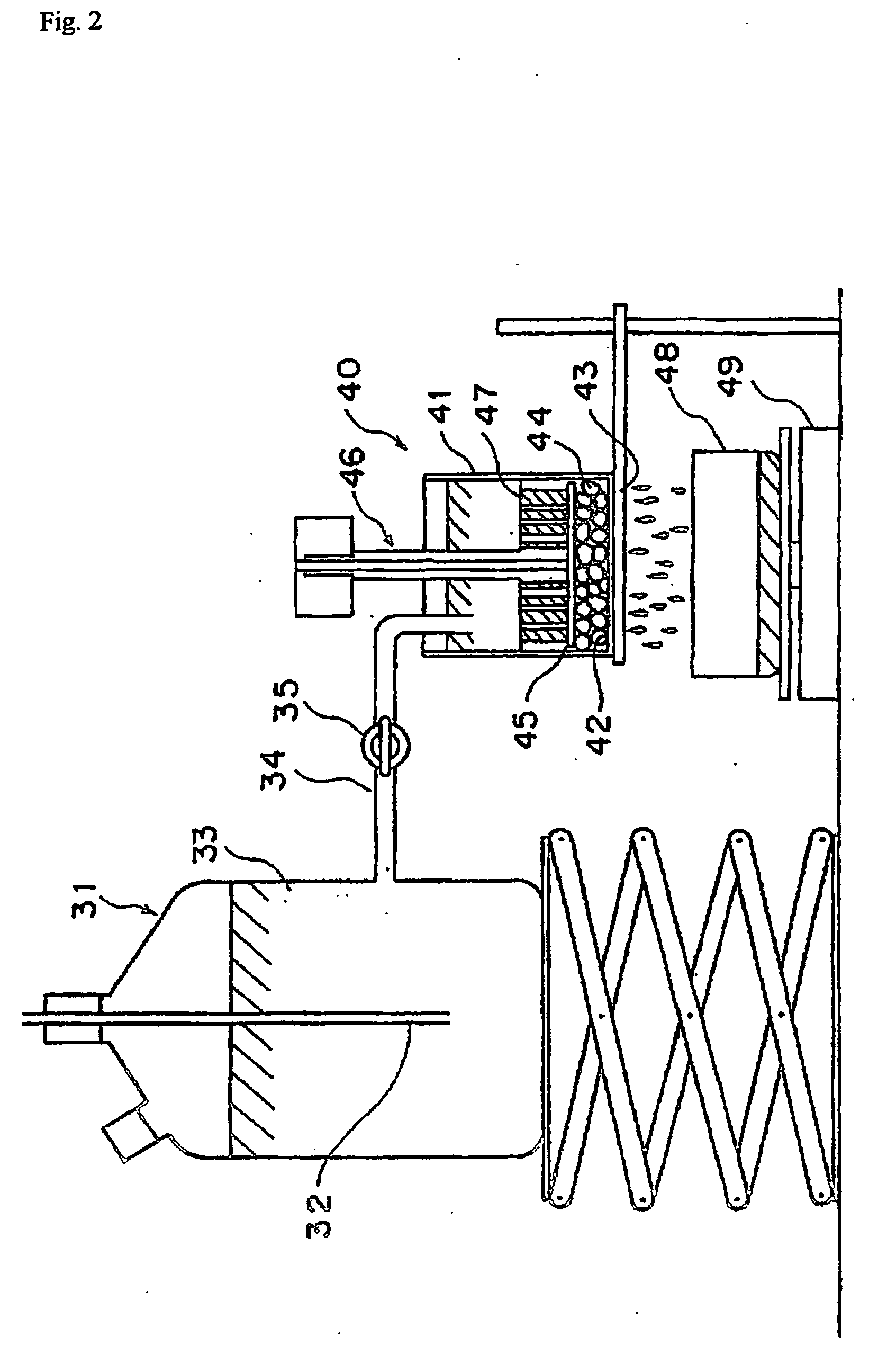

Nanofibers, and apparatus and methods for fabricating nanofibers by reactive electrospinning

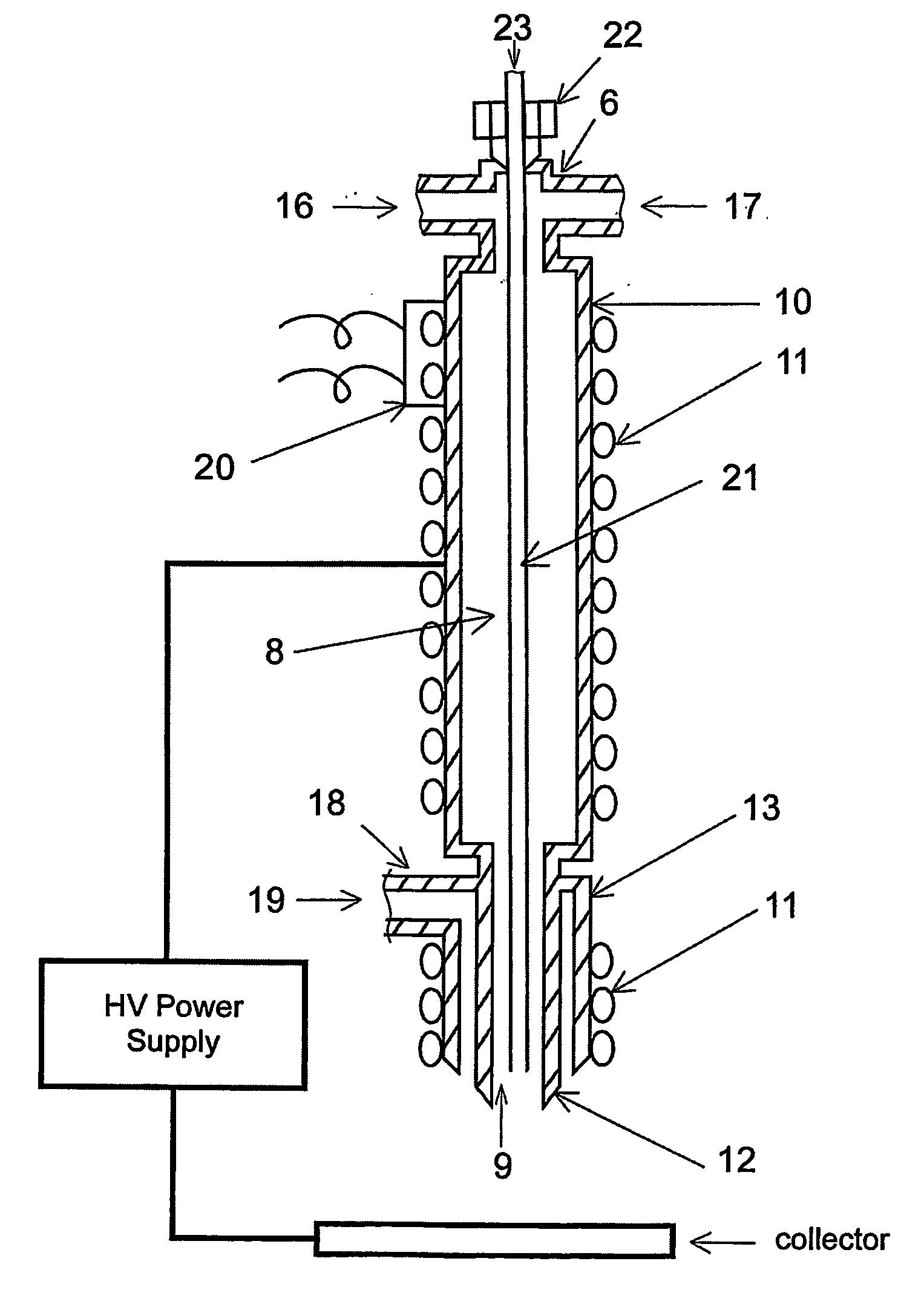

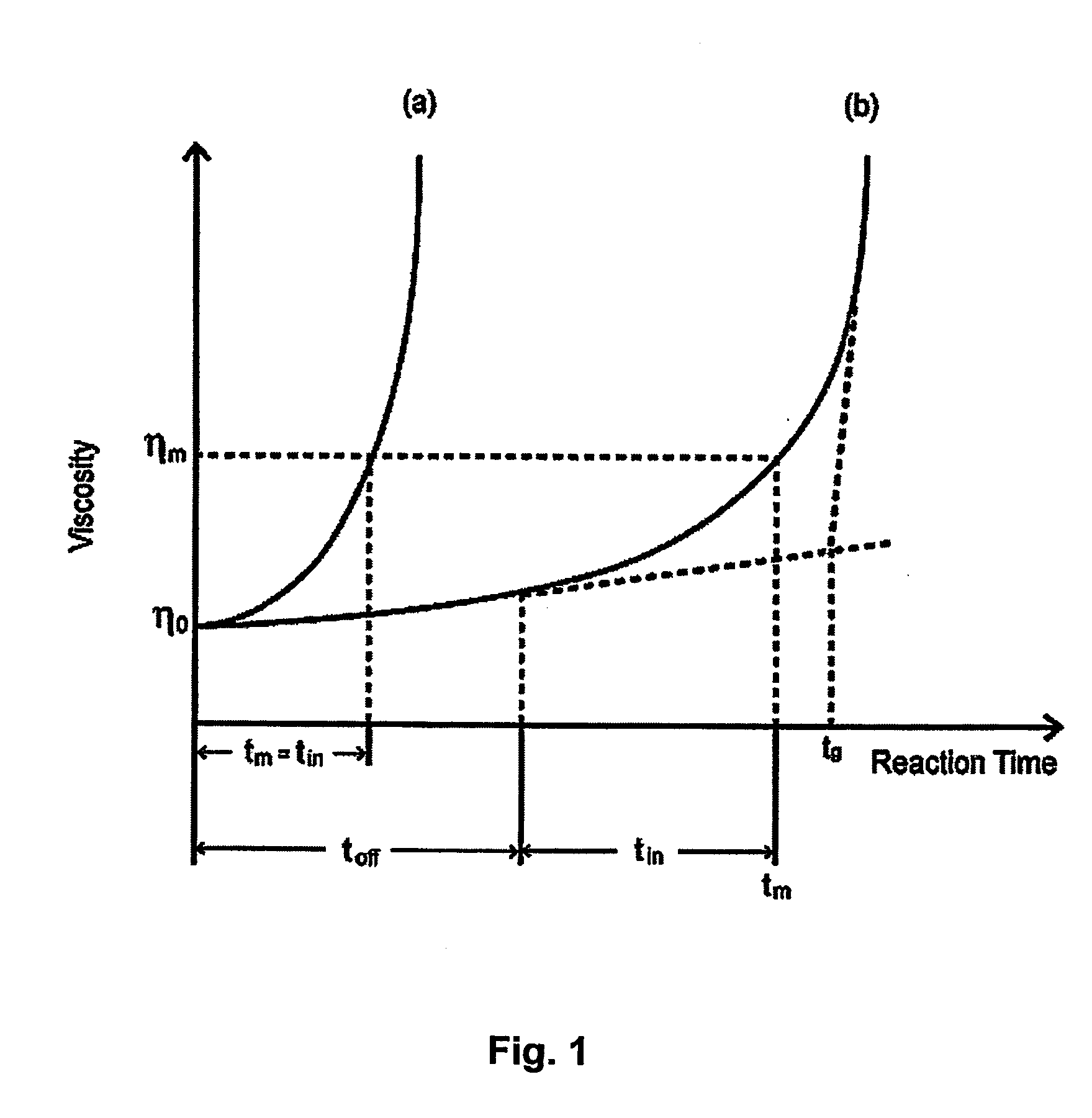

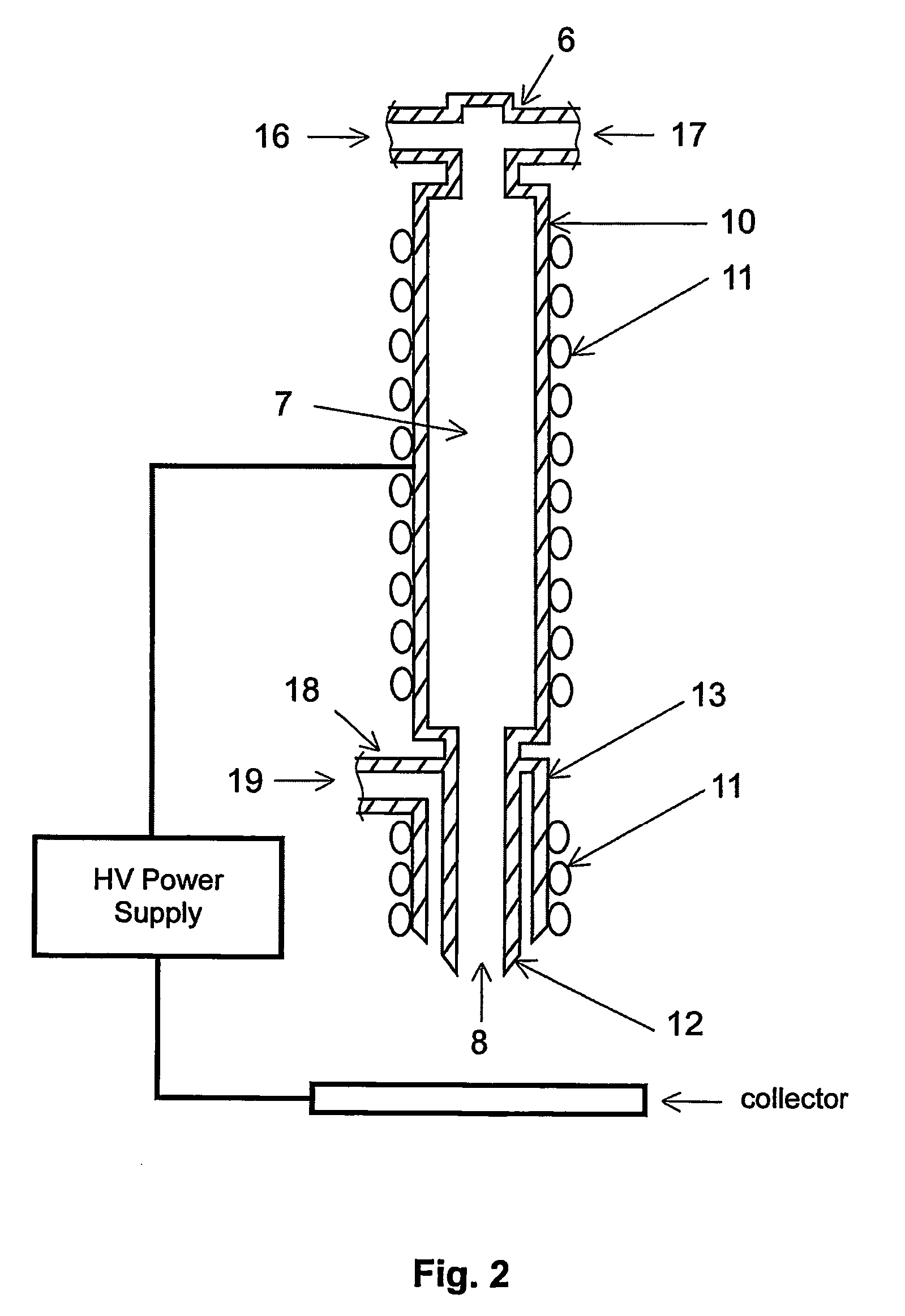

ActiveUS20070018361A1Broaden applicationEasy to controlElectric discharge heatingInorganic material artificial filamentsFiberElectrospinning

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Methods of consolidating formations

InactiveUS6837316B2High mechanical strengthSimple methodLiquid/gas jet drillingFluid removalCross-linkWater soluble

Methods of consolidating formations include drilling a well bore with a drilling fluid that comprises water, a polymeric cationic catalyst which is adsorbed on minerals and rocks in weak unconsolidated zones or formations and then further contacting the unconsolidated formation with a treating fluid comprising a water soluble or dispersible polymer which is cross-linked by a thermoset resin and causes the resin to be hard and tough when cured, and a water soluble or dispersible thermoset resin which cross-links the polymer, is catalyzed and cured by the catalyst and consolidates the weak zone or formation so that sloughing is prevented.

Owner:HALLIBURTON ENERGY SERVICES INC

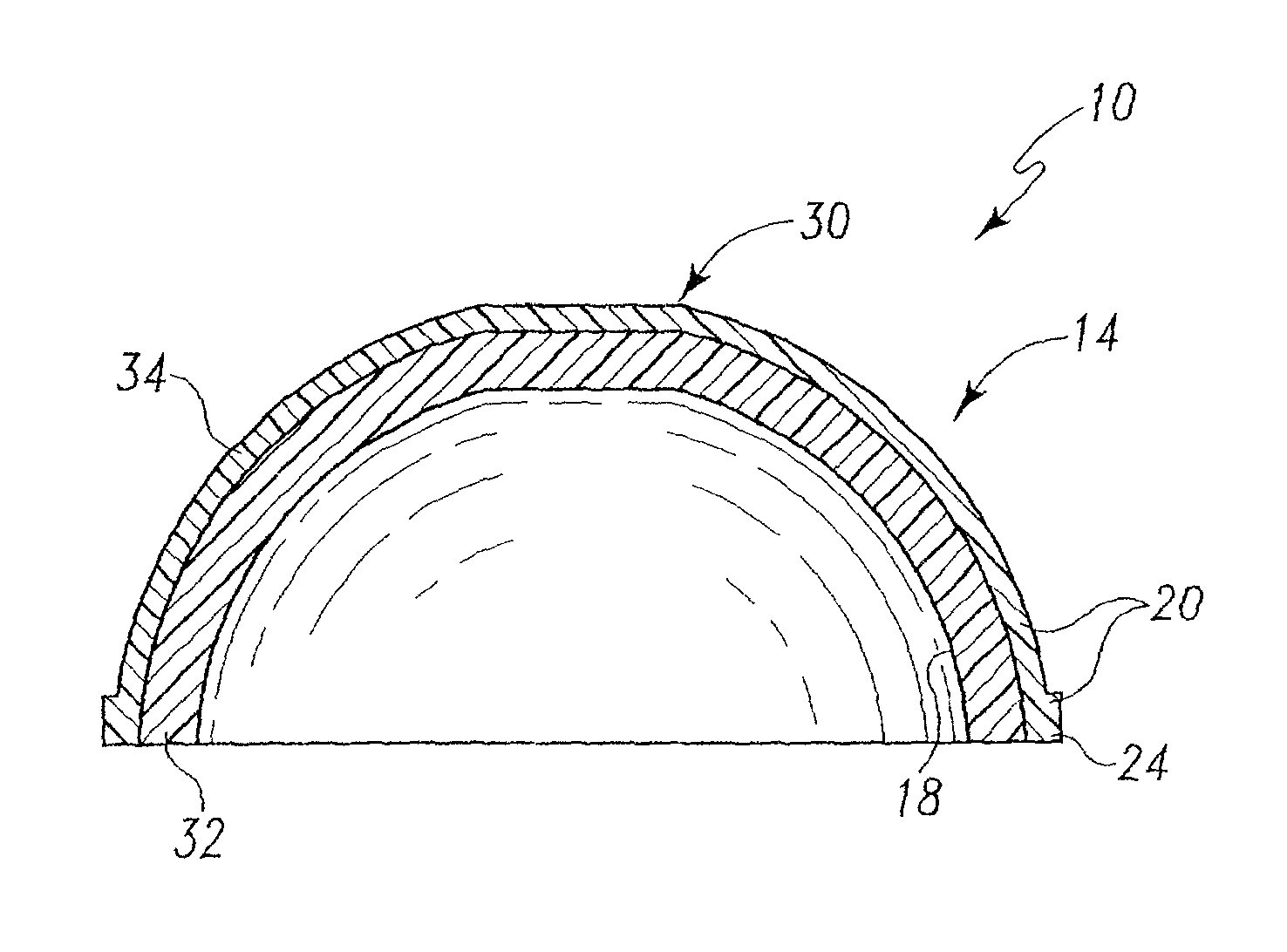

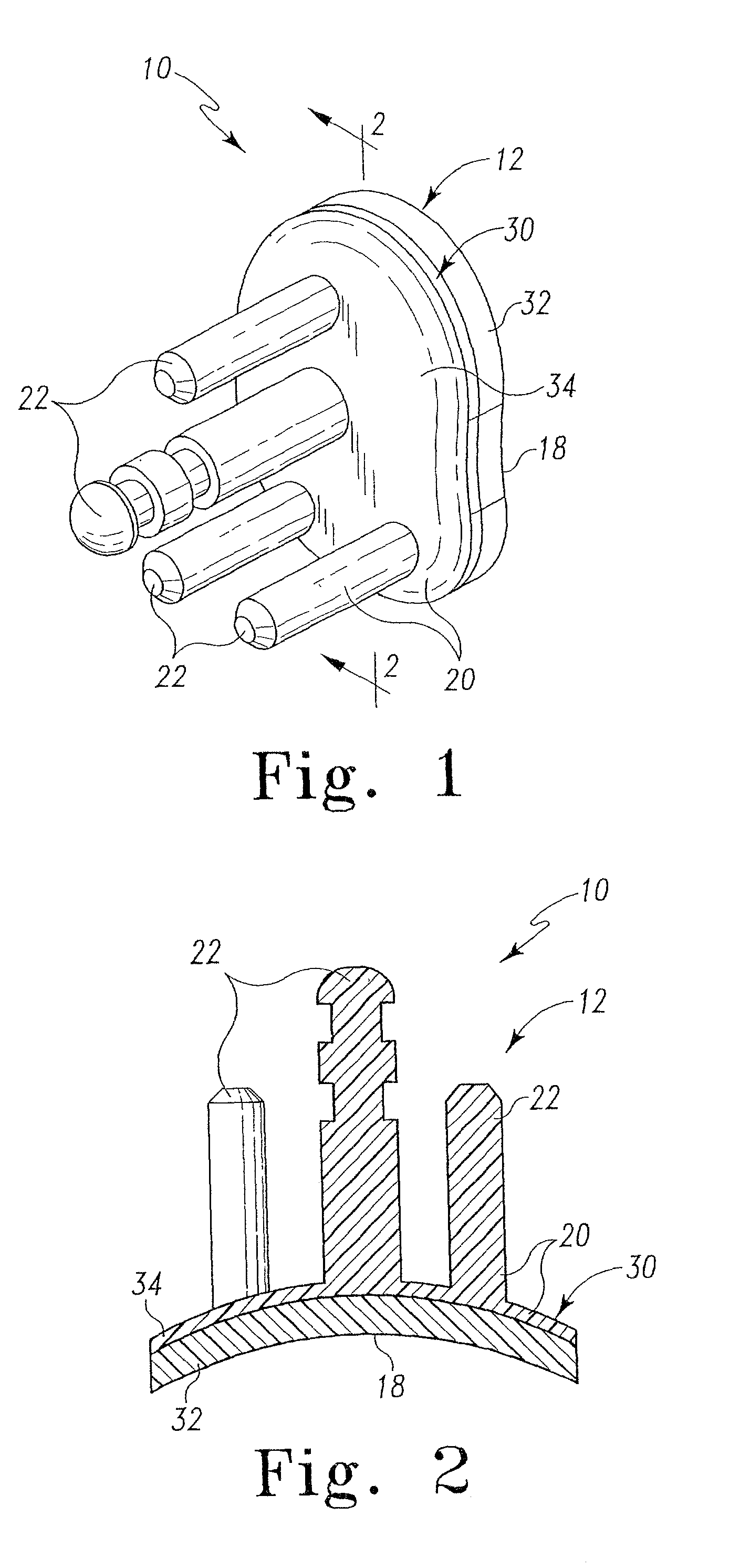

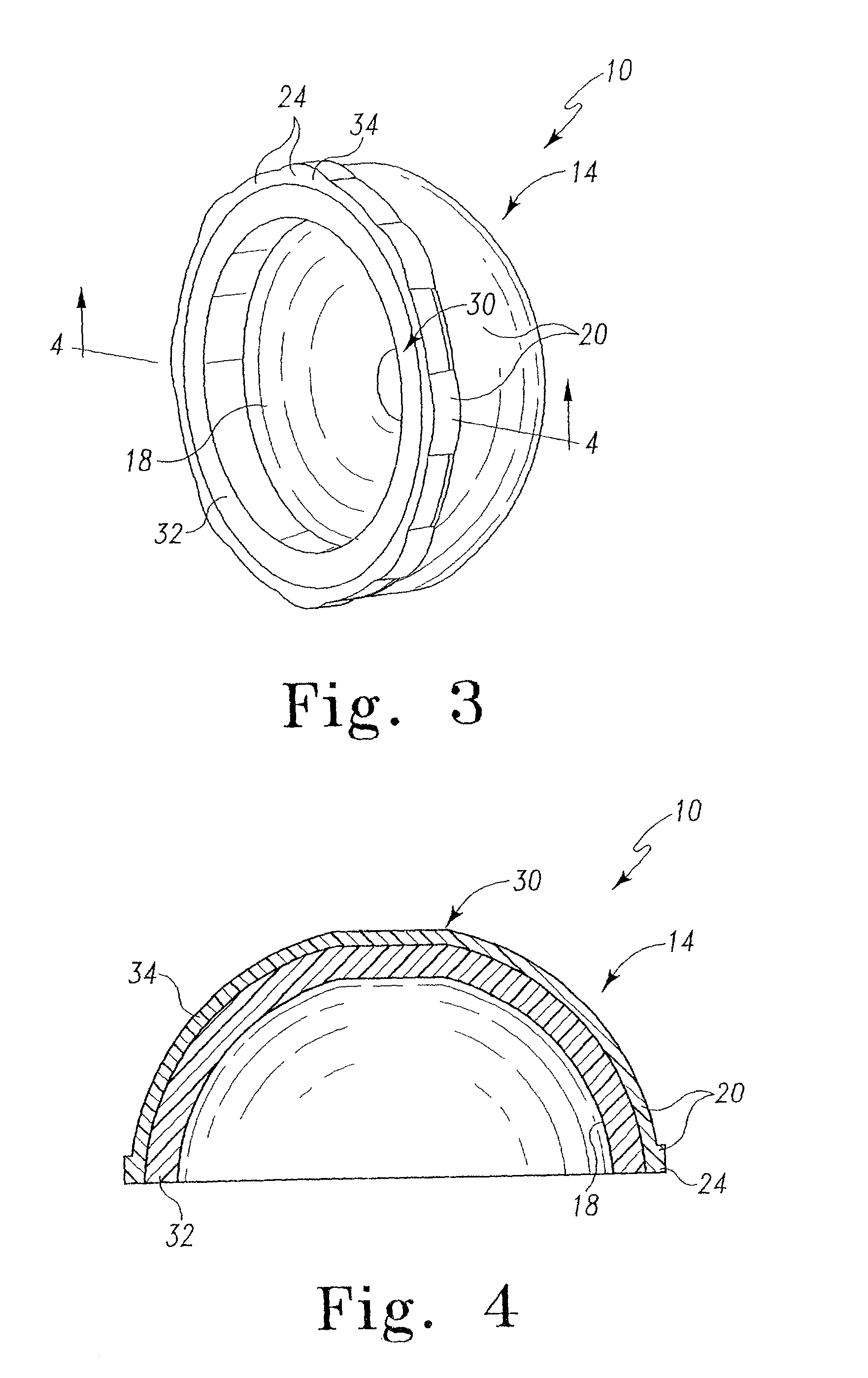

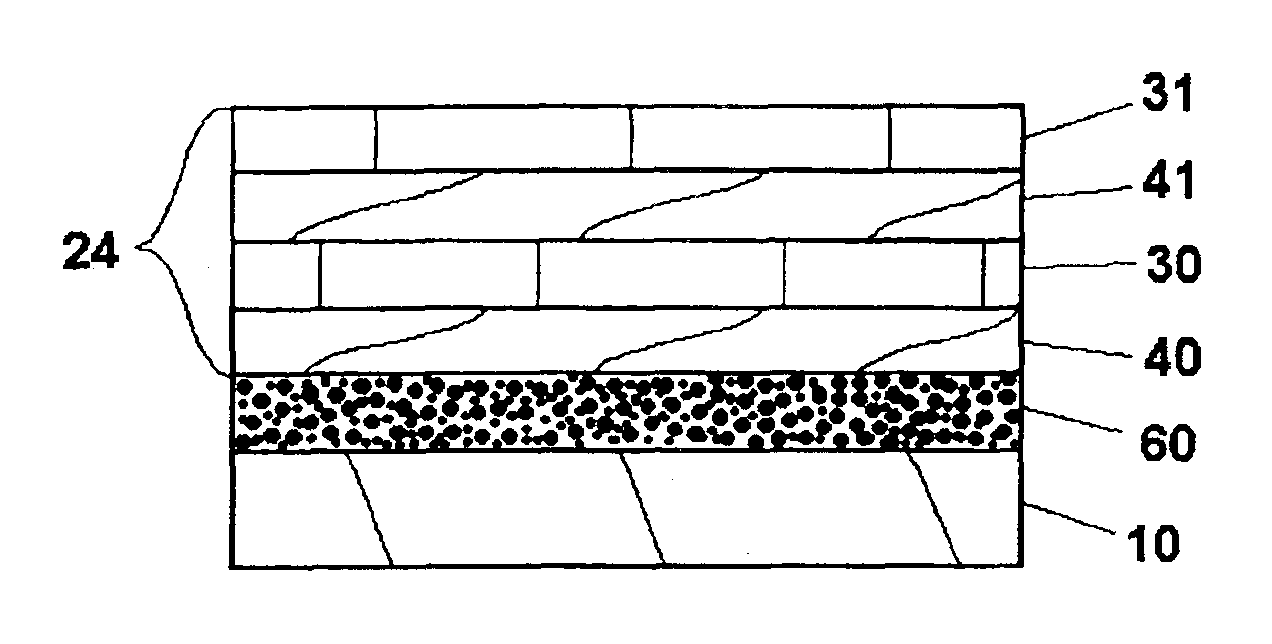

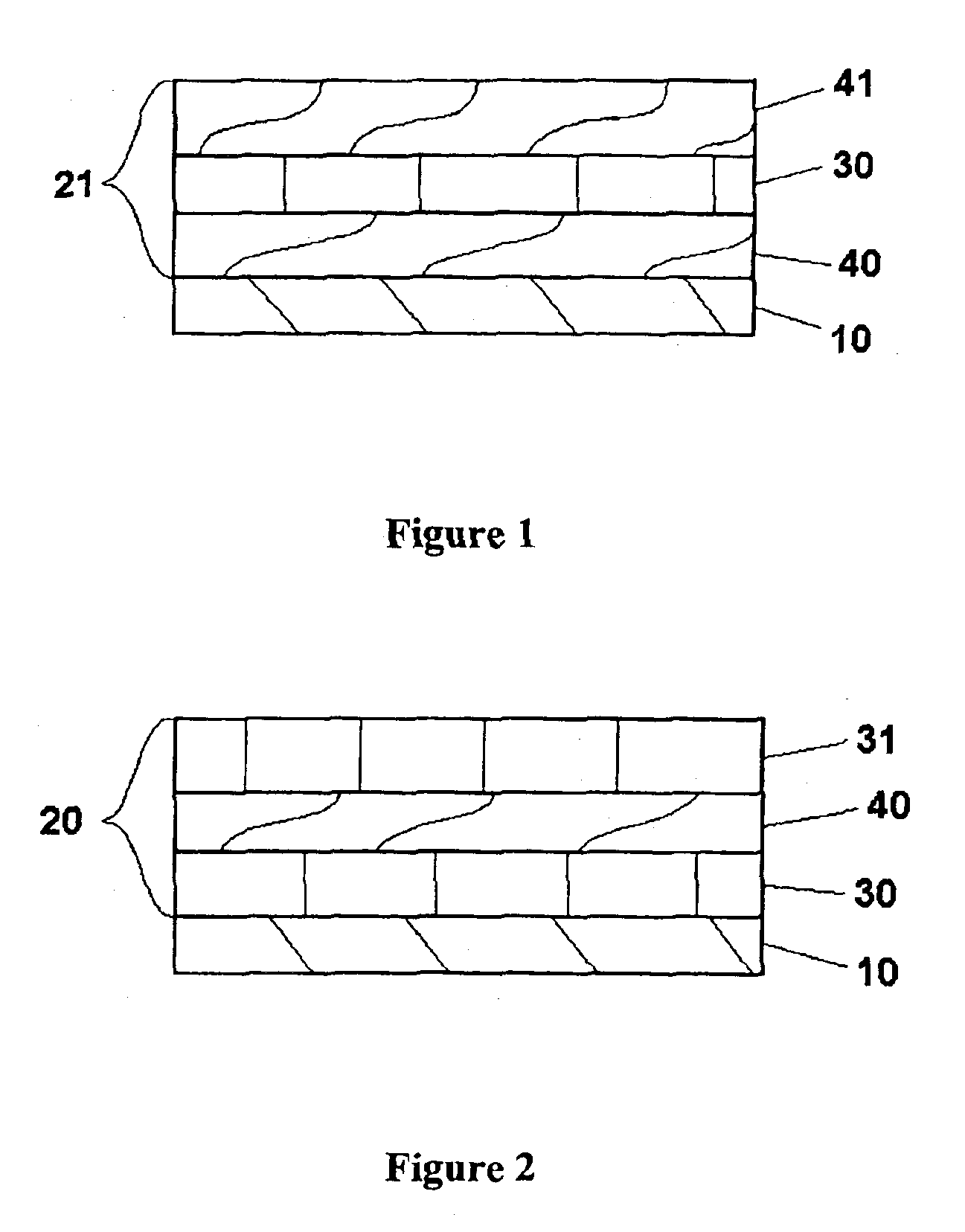

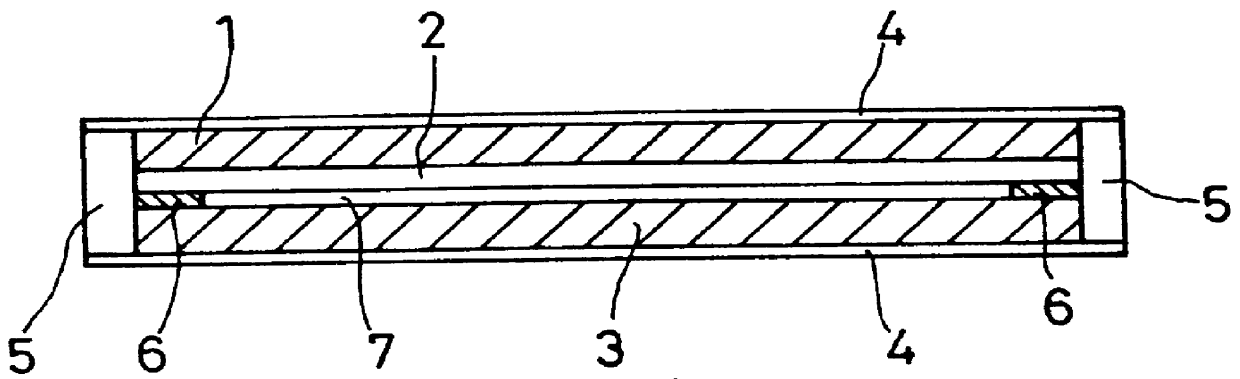

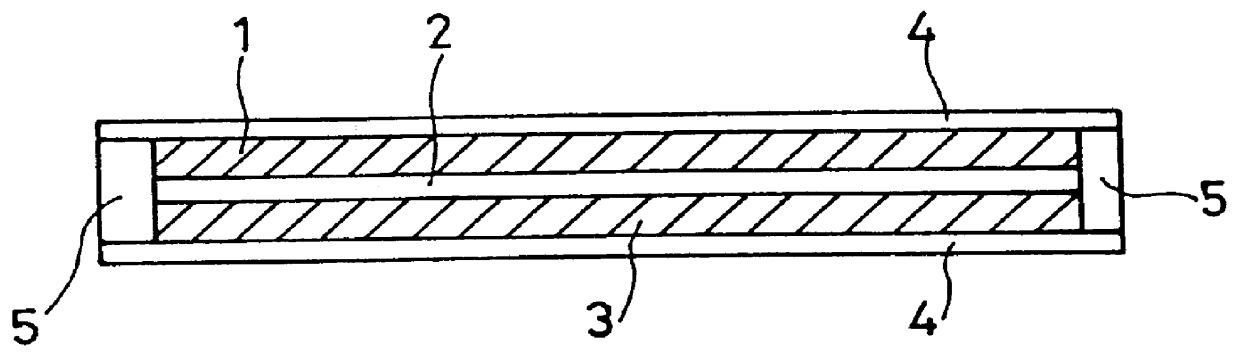

Composite prosthetic bearing having a crosslinked articulating surface and method for making the same

InactiveUS7819925B2Promote oxidationEasy to wearBone implantSynthetic resin layered productsProsthesisCrosslinked polymers

An implantable prosthetic bearing is constructed of a composite material having a first layer and second layer. The first layer has an articulating surface defined therein, whereas the second layer has a engaging surface defined therein for engaging either another prosthetic component or the bone itself The first layer of the implantable prosthetic bearing is constructed of crosslinked polymer such as Ultra-High Molecular Weight Polyethylene, whereas the second layer of the implantable prosthetic bearing is constructed of polymer such as Ultra-High Molecular Weight Polyethylene that is either non-crosslinked or crosslinked to a lesser degree than the first layer. In such a manner, the first layer possesses mechanical properties which are advantageous in regard to the articulating surface (e.g., enhanced wear and oxidation resistance), whereas the second layer possesses mechanical properties which are advantageous in regard to the engaging surface (e.g., high ductility, toughness, and creep resistance). A method of making a prosthetic bearing is also disclosed.

Owner:DEPUY SYNTHES PROD INC

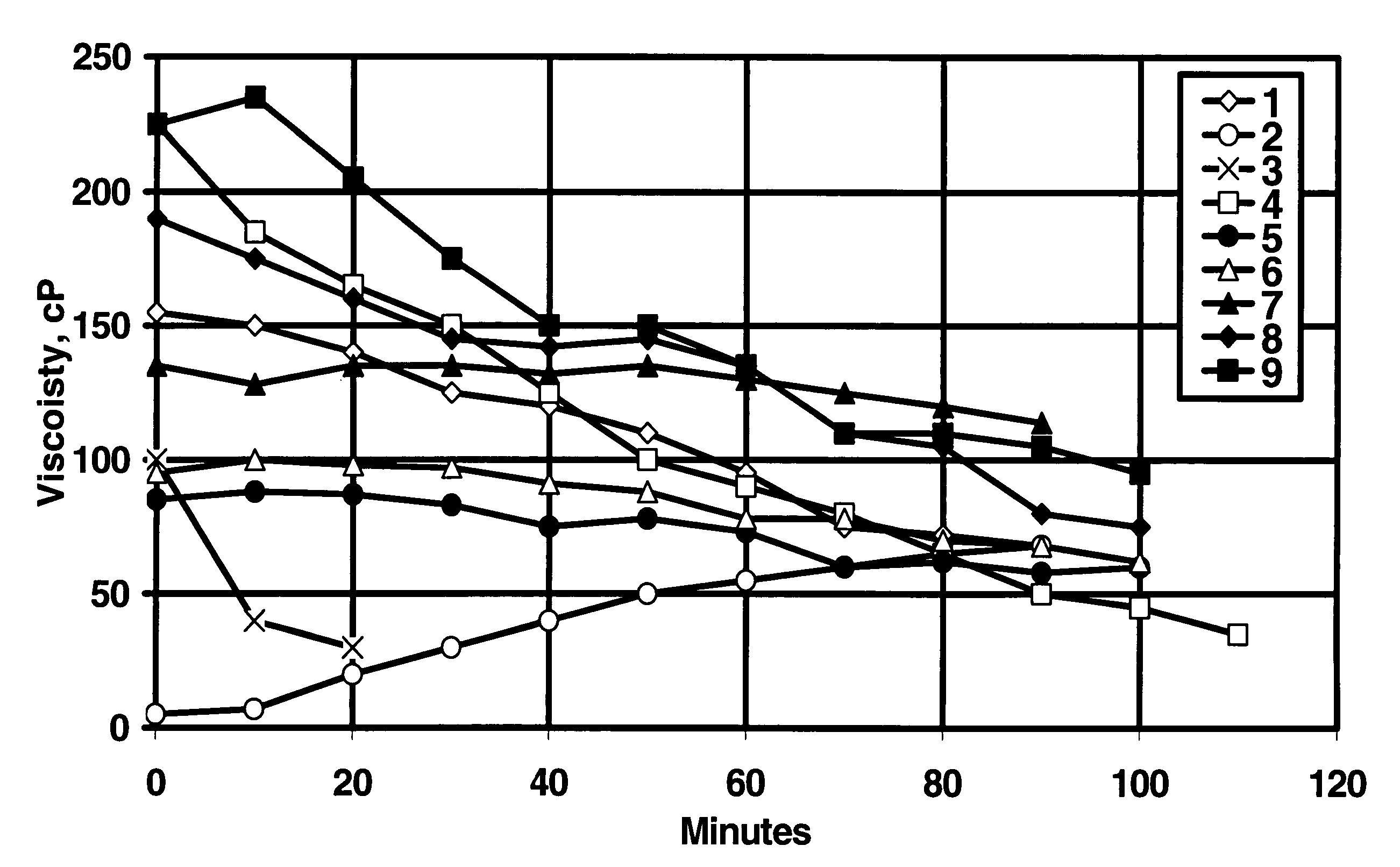

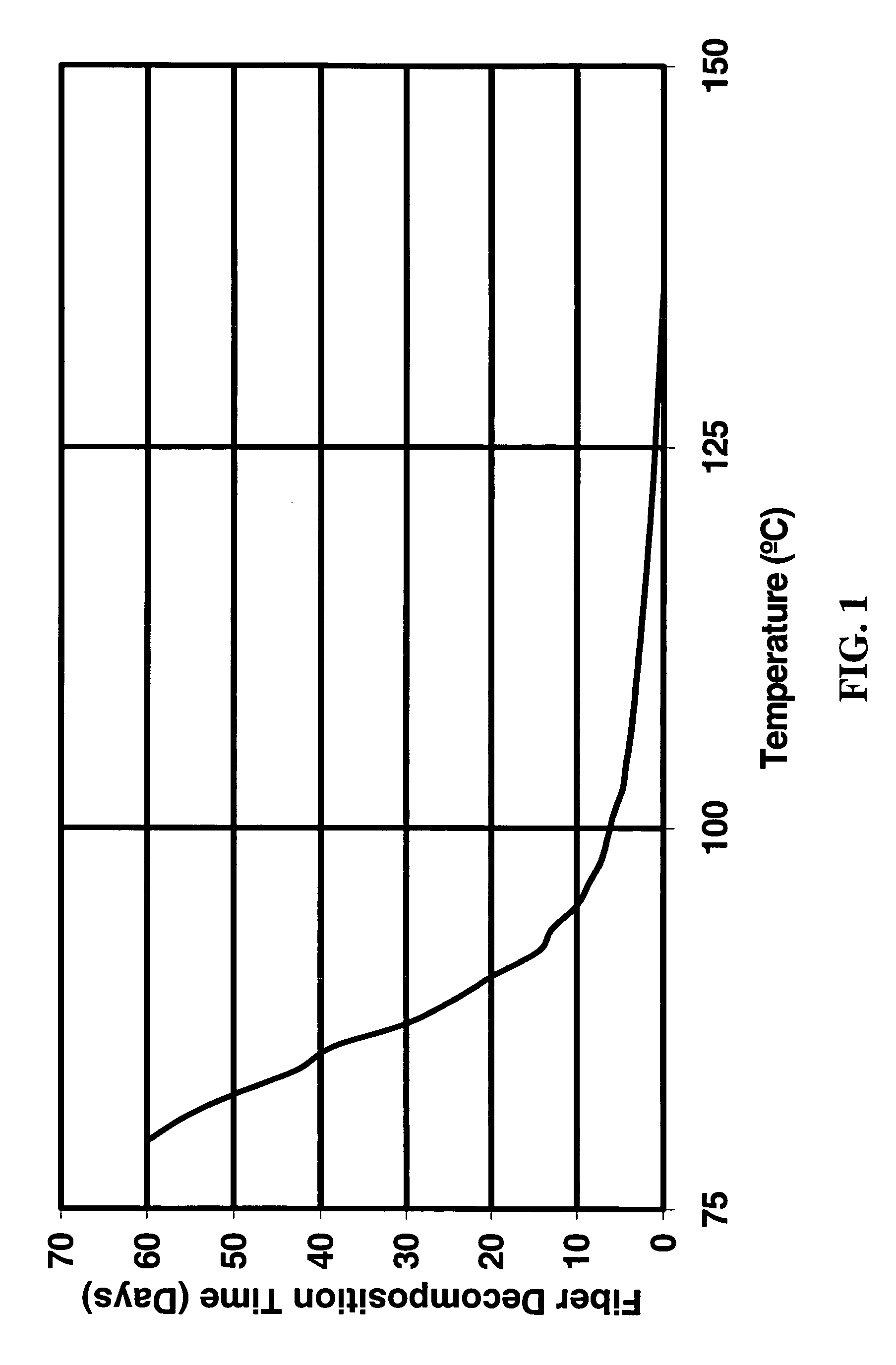

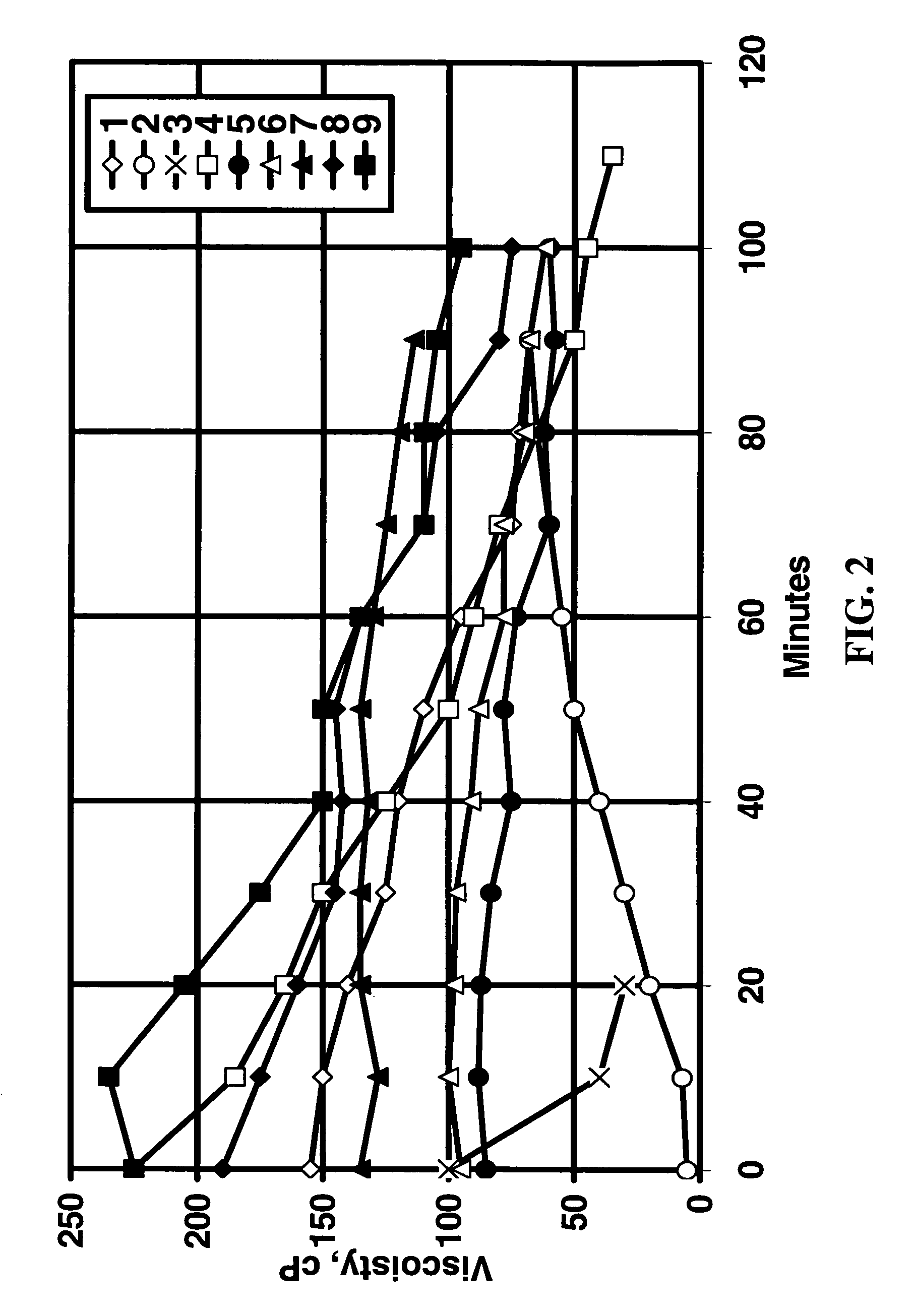

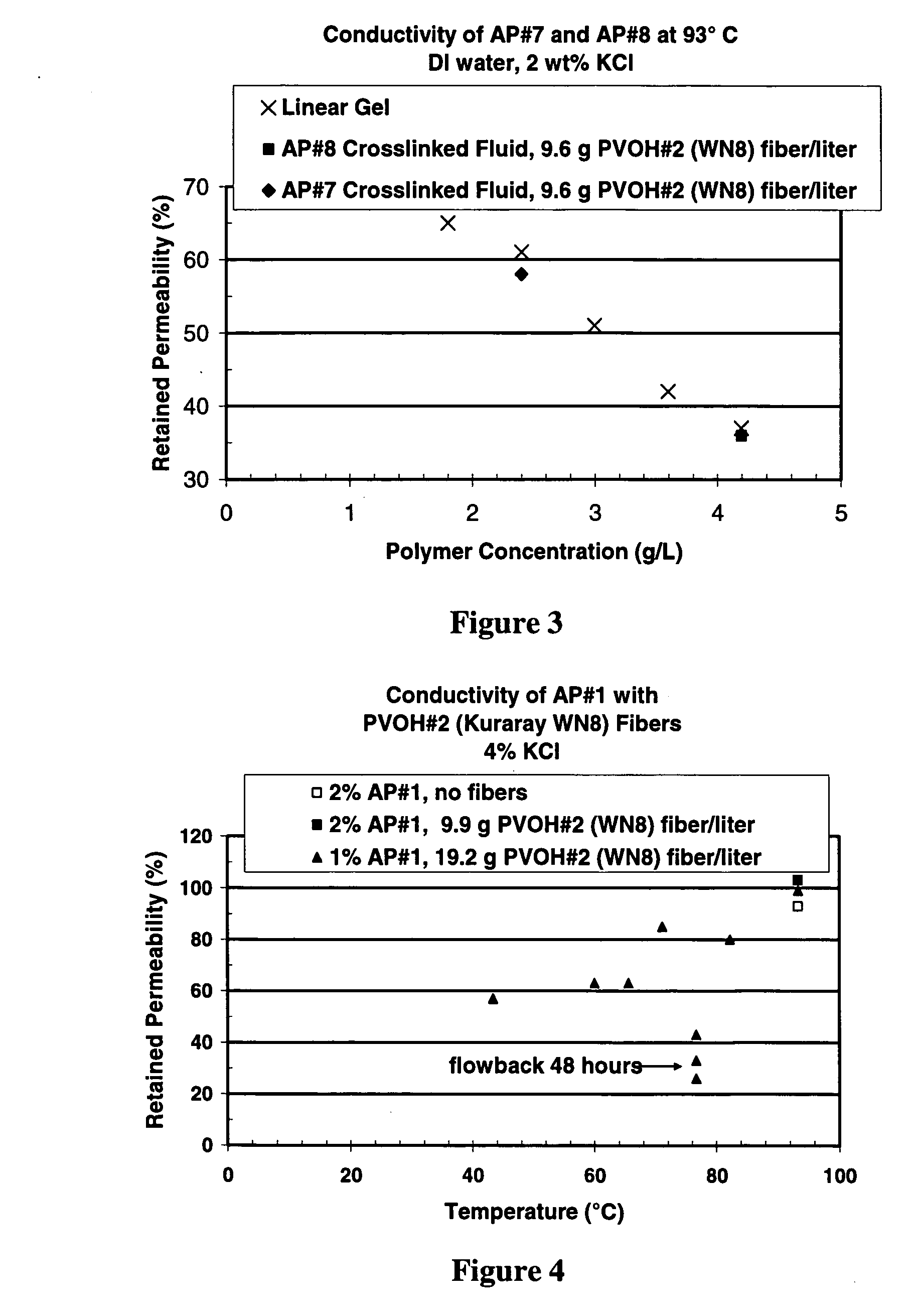

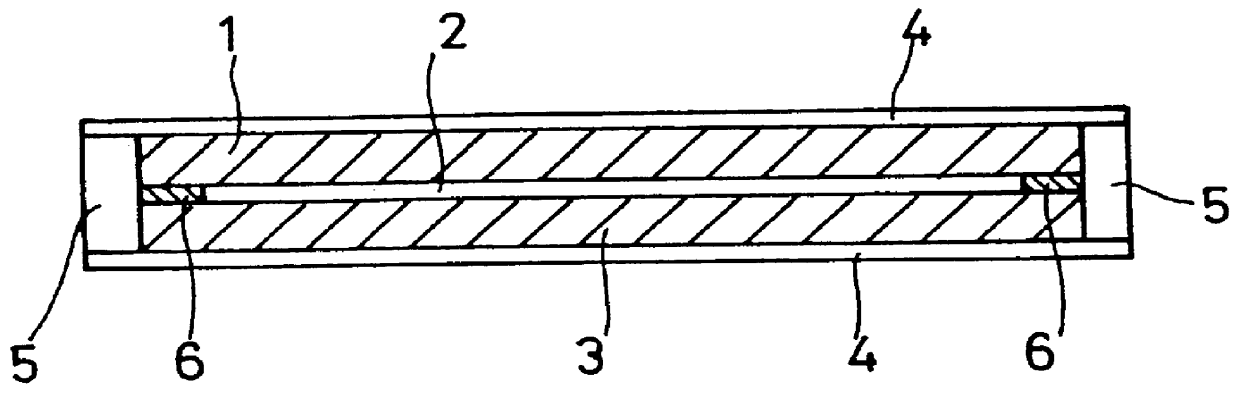

Method of using degradable fiber systems for stimulation

A method for minimizing the amount of metal crosslinked viscosifier necessary for treating a wellbore with proppant or gravel is given. The method includes using fibers to aid in transporting, suspending and placing proppant or gravel in viscous carrier fluids otherwise having insufficient viscosity to prevent particulate settling. Fibers are given that have properties optimized for proppant transport but degrade after the treatment into degradation products that do not precipitate in the presence of ions in the water such as calcium and magnesium. Crosslinked polymer carrier fluids are identified that are not damaged by contaminants present in the fibers or by degradation products released by premature degradation of the fibers.

Owner:SCHLUMBERGER TECH CORP

Lithium anodes for electrochemical cells

InactiveUS6936381B2Cell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsLithium metalCrosslinked polymers

Owner:SION POWER CORP

Cross-linking of low and high molecular weight polysaccharides preparation of injectable monophase hydrogels and polysaccharides and hydrogels thus obtained

A process for the crosslinking of at least one polymer selected from polysaccharides and derivatives thereof, which is carried out in an aqueous solvent by the action of an effective and non-excessive amount of at least one crosslinking agent, characterized in that it is carried out on a mixture containing at least one low-molecular weight polymer and at least one high-molecular weight polymer. A process for the preparation of an injectable monophase hydrogel of at least one crosslinked polymer selected from polysaccharides and derivatives thereof is also disclosed. Crosslinked polymers and injectable monophase hydrogels, respectively, are obtainable by each of said processes.

Owner:ALLERGAN IND

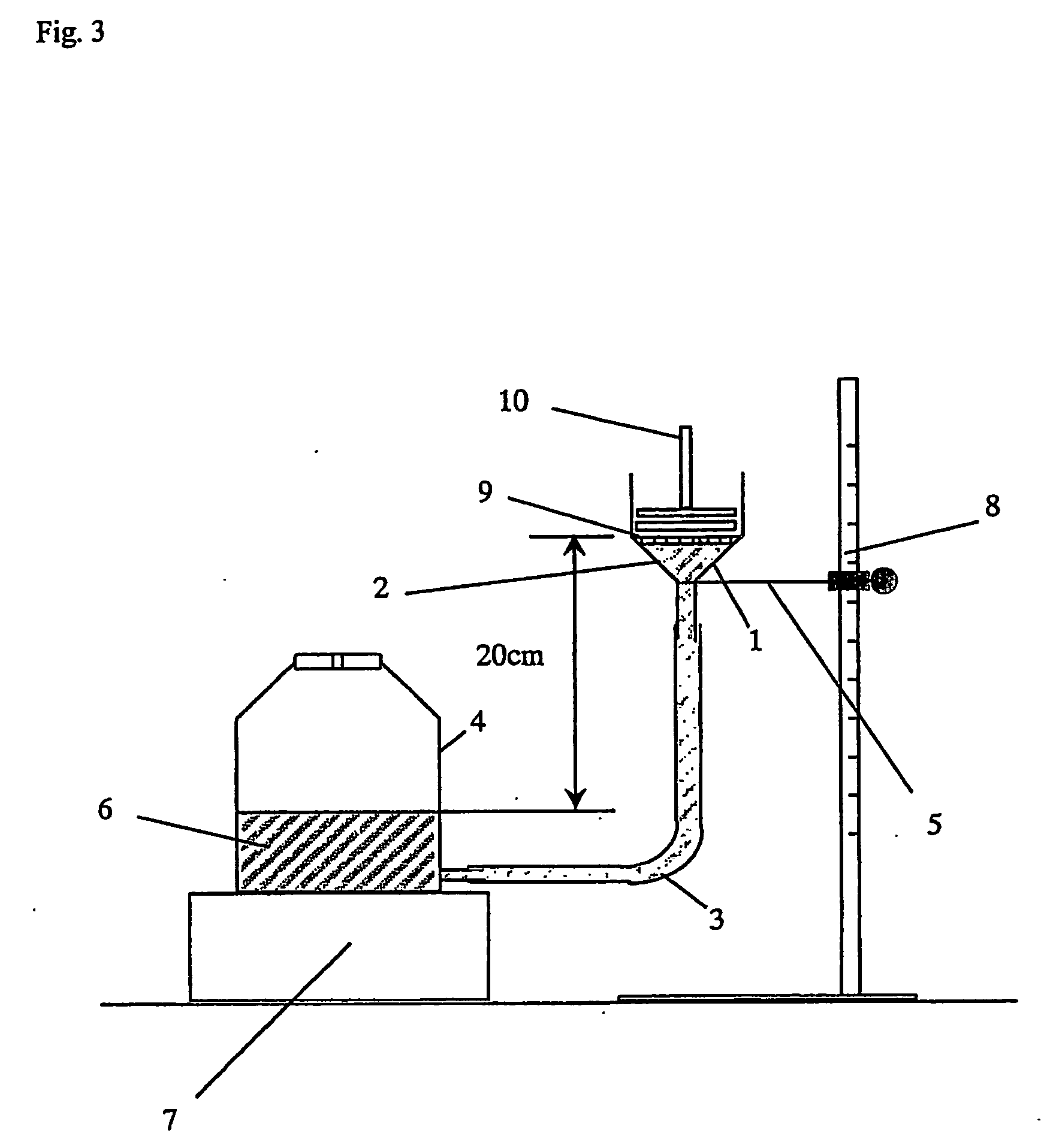

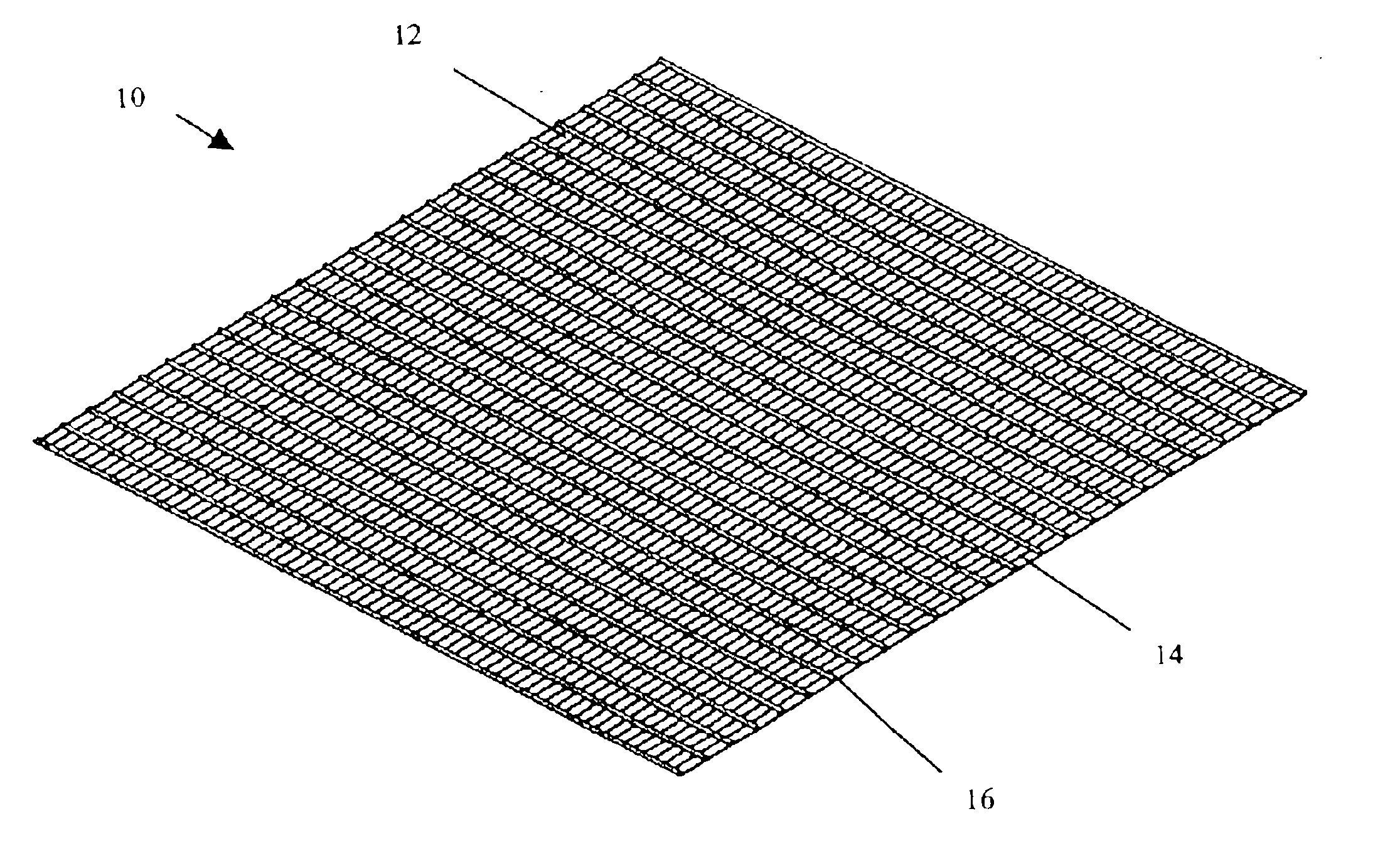

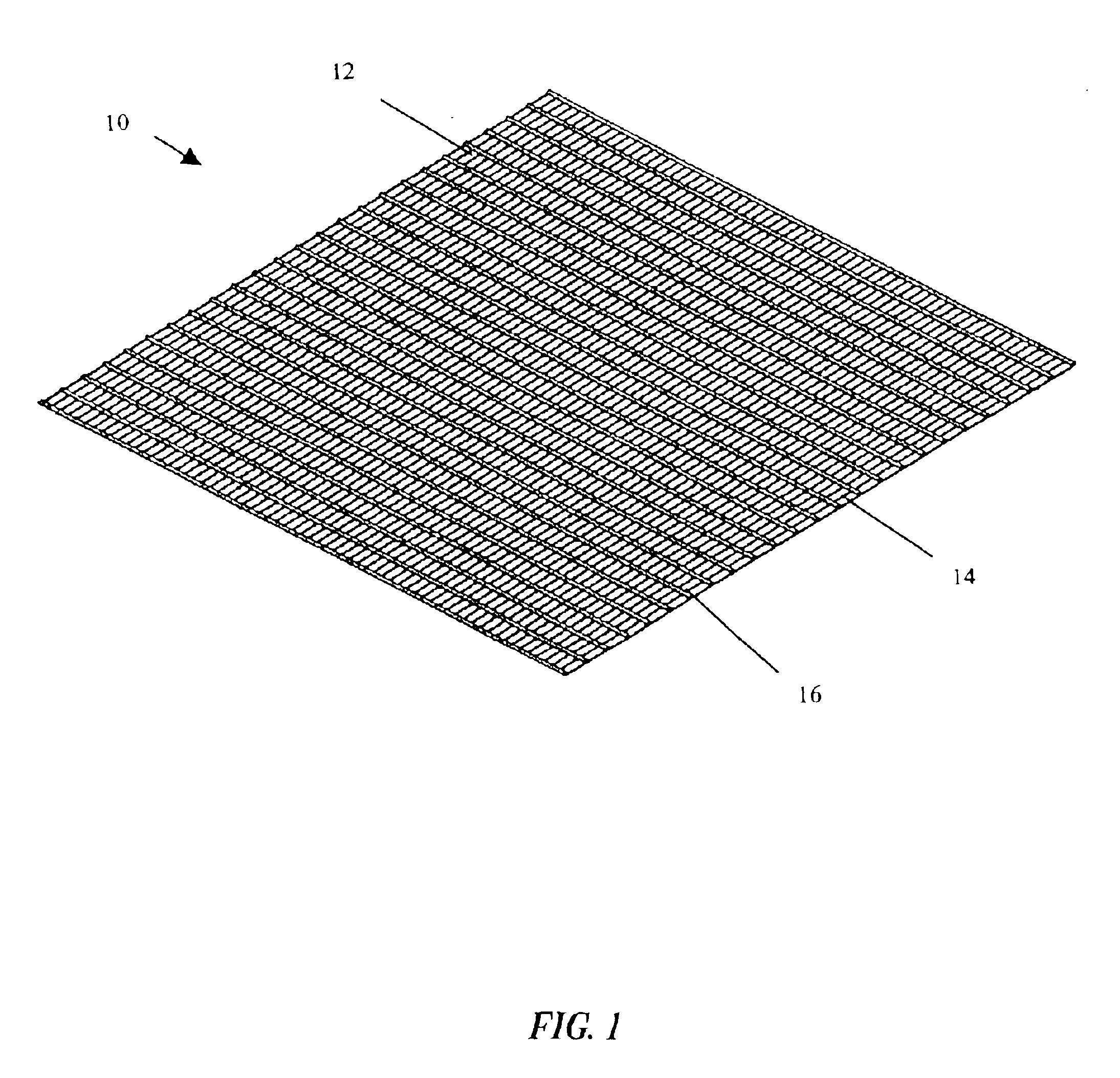

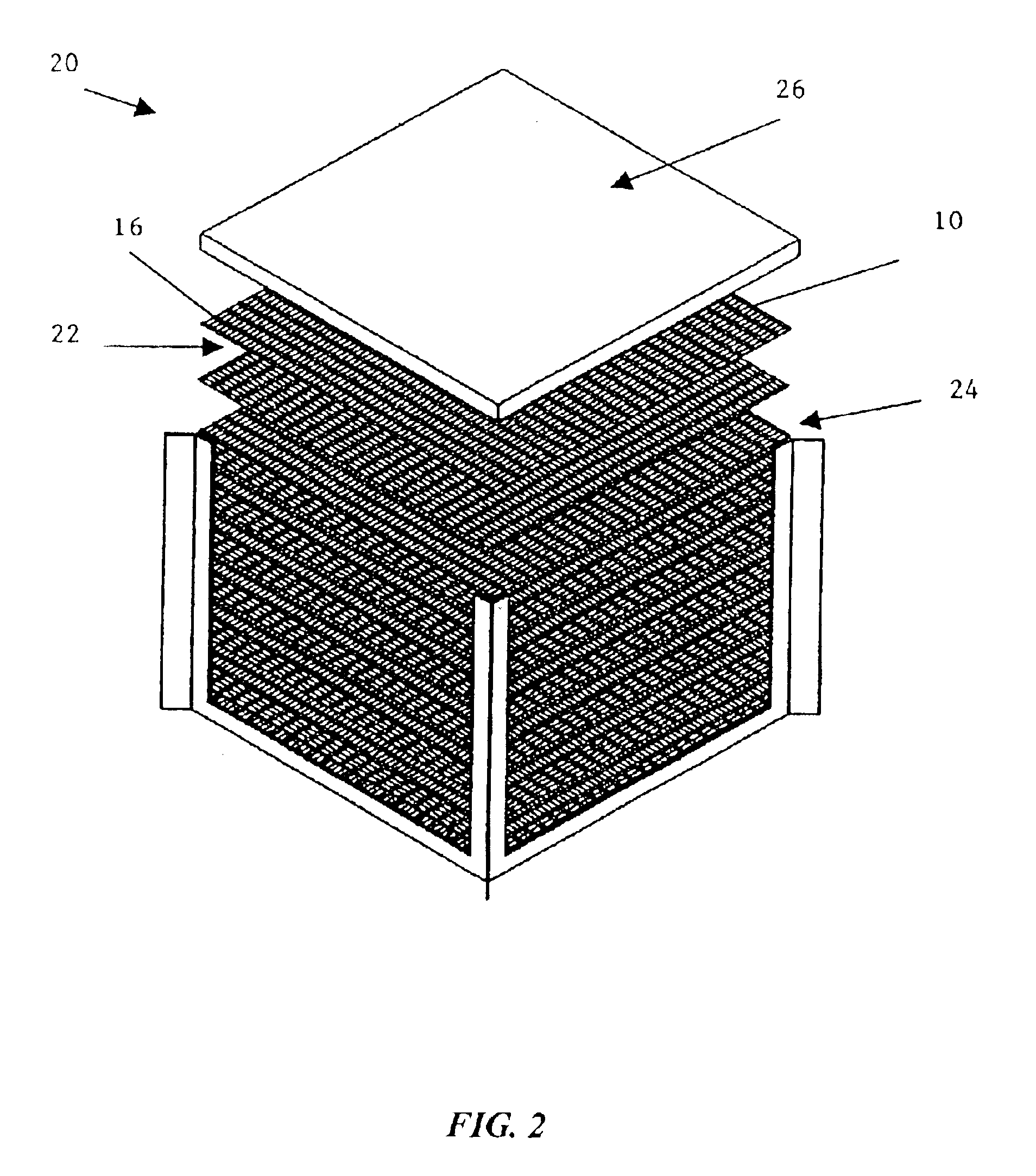

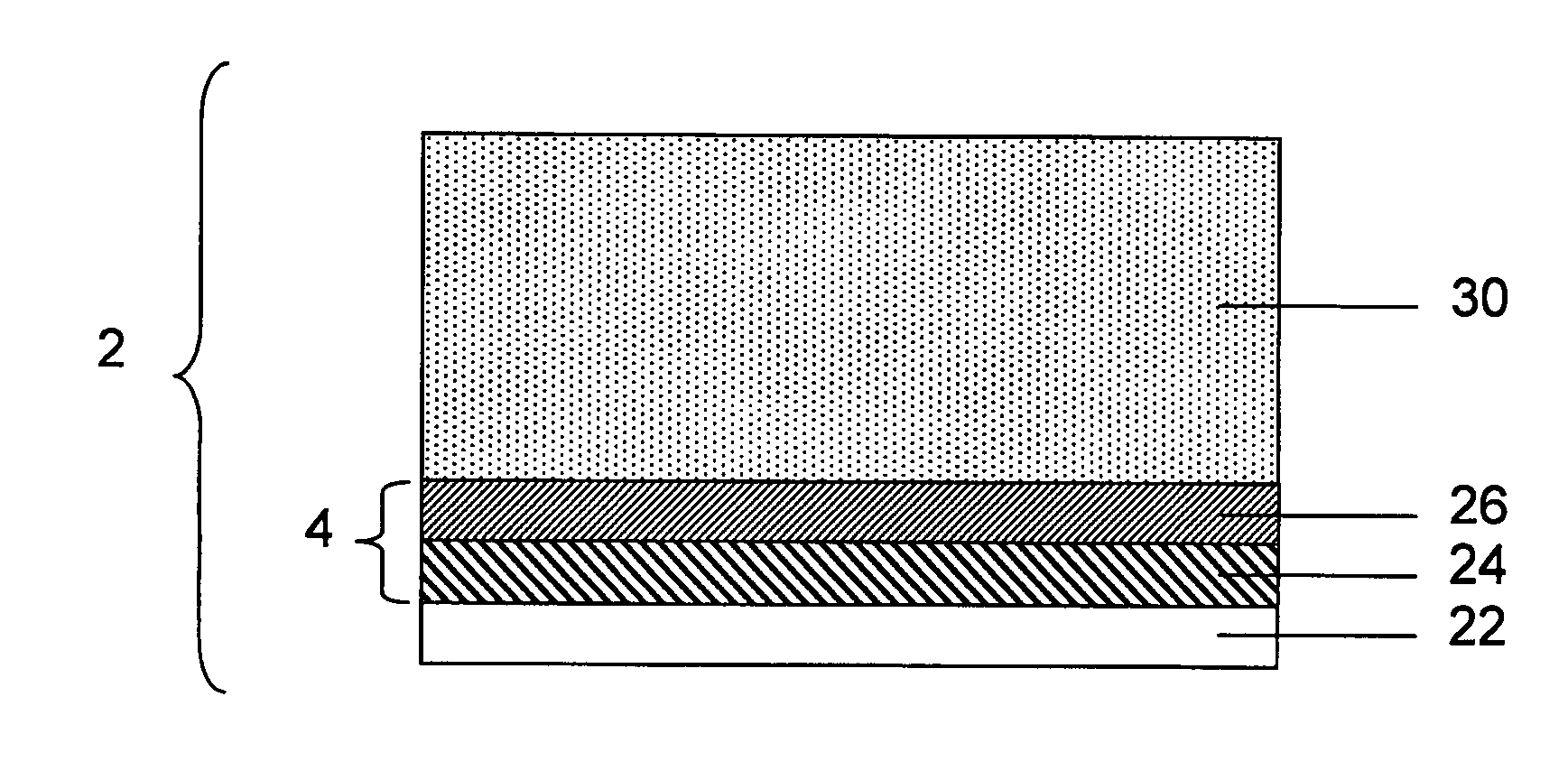

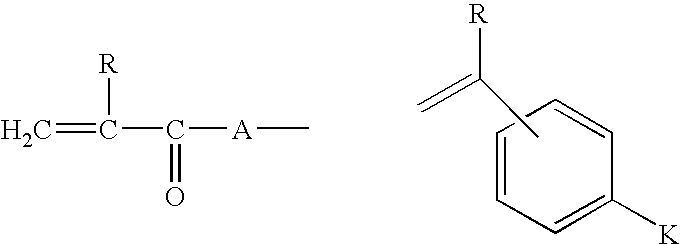

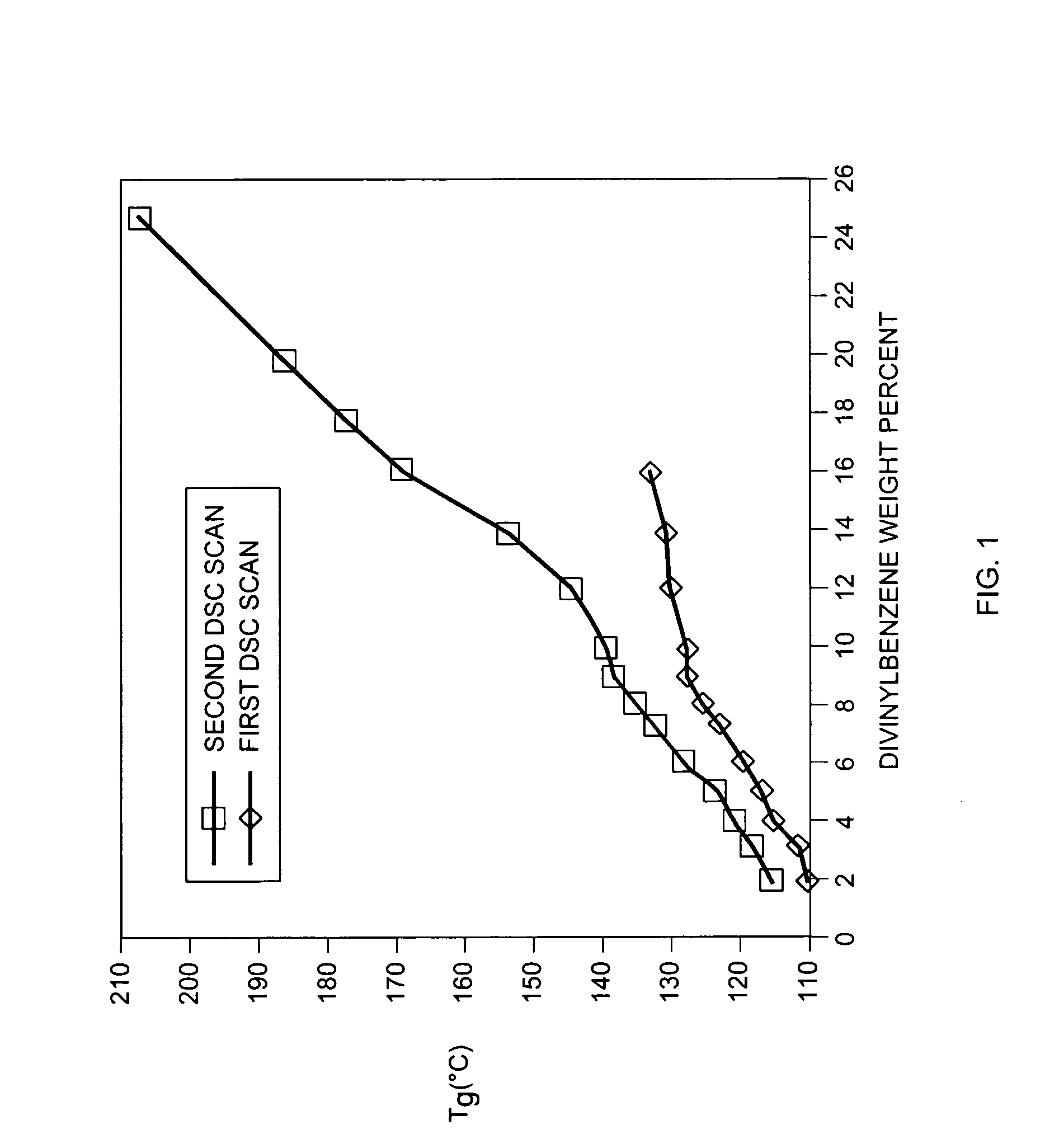

Crosslinked polymer electrolyte membranes for heat and moisture exchange devices

InactiveUS6841601B2Improve permeabilityLow costSpace heating and ventilationIndirect heat exchangersEnergy recoveryMoisture

A unitary humidity exchange cell (HUX) is dislosed that includes at least one composite membrane, disposed between at least one first chamber for flow of the first fluid therethrough and at least one second chamber for flow of the second fluid therethrough. The composite membrane include an at least partially sulfonated humidity-conducting polymer comprising residues derived from at least one arylvinyl monomer; and a reinforcing substrate bonded thereto. The product finds utility in a variety of physical and chemical processes and products whereby moisture or other highly polar liquid or gas transfer, exchange removal or delivery is important. A notable application is the Membrane Energy Recovery Ventilator (MERV) in which both heat, ions and moisture is transferred between two air streams, one intake and one exhaust, from an air-conditioned building.

Owner:TANGREDI PATRICIA

Primer for battery electrode

ActiveUS20100291442A1Electrode carriers/collectorsActive material electrodesPolyvinyl alcoholCrosslinked polymers

Primer arrangements that facilitate electrical conduction and adhesive connection between an electroactive material and a current collector are presented. In some embodiments, primer arrangements described herein include first and second primer layers. The first primer layer may be designed to provide good adhesion to a conductive support. In one particular embodiment, the first primer layer comprises a substantially uncrosslinked polymer having hydroxyl functional groups, e.g., polyvinyl alcohol. The materials used to form the second primer layer may be chosen such that the second primer layer adheres well to both the first primer layer and an electroactive layer. In certain embodiments including combinations of first and second primer layers, one or both of the first and second primer layers comprises less than 30% by weight of a crosslinked polymeric material. A primer including only a single layer of polymeric material is also provided.

Owner:SION POWER CORP

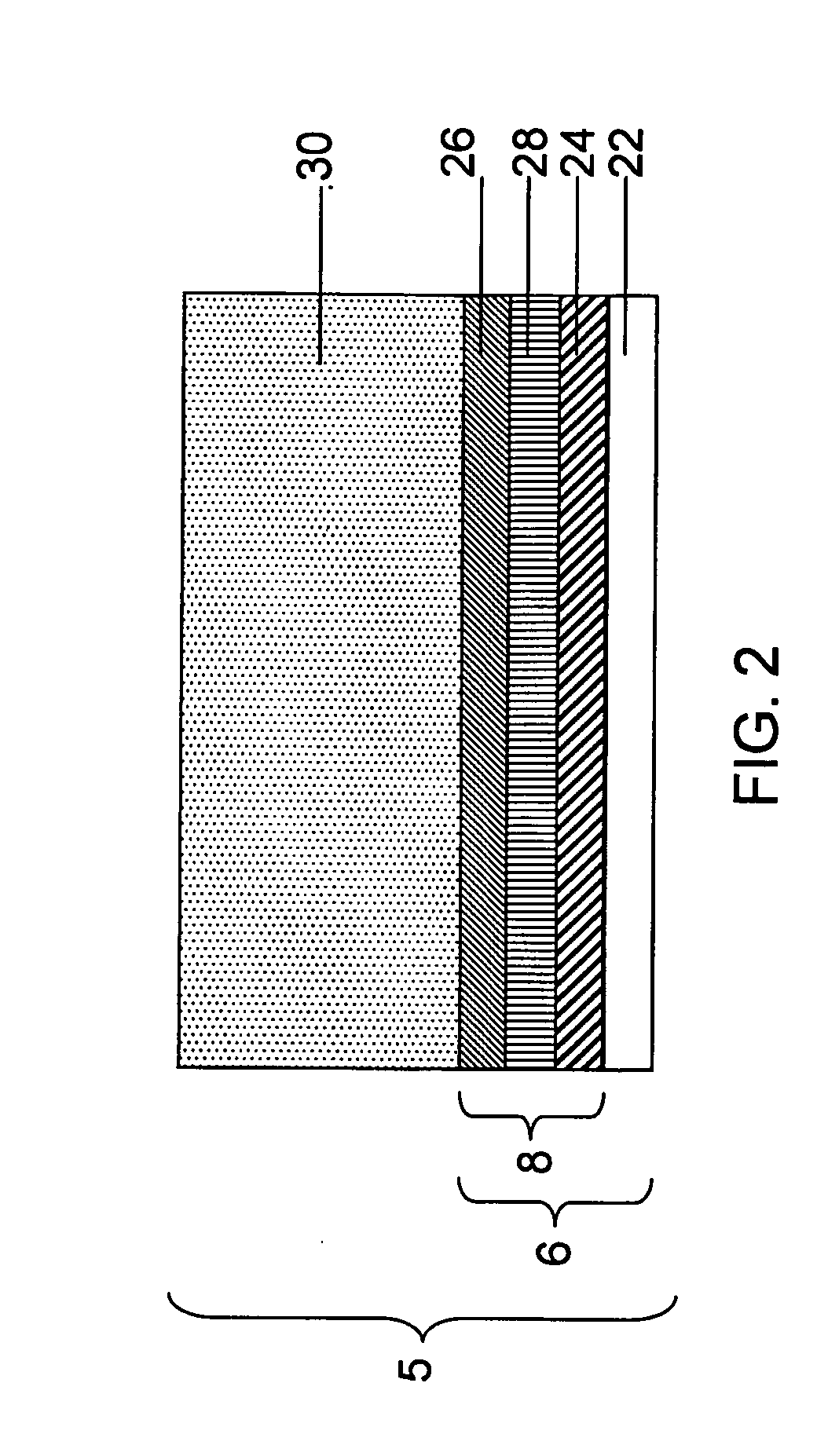

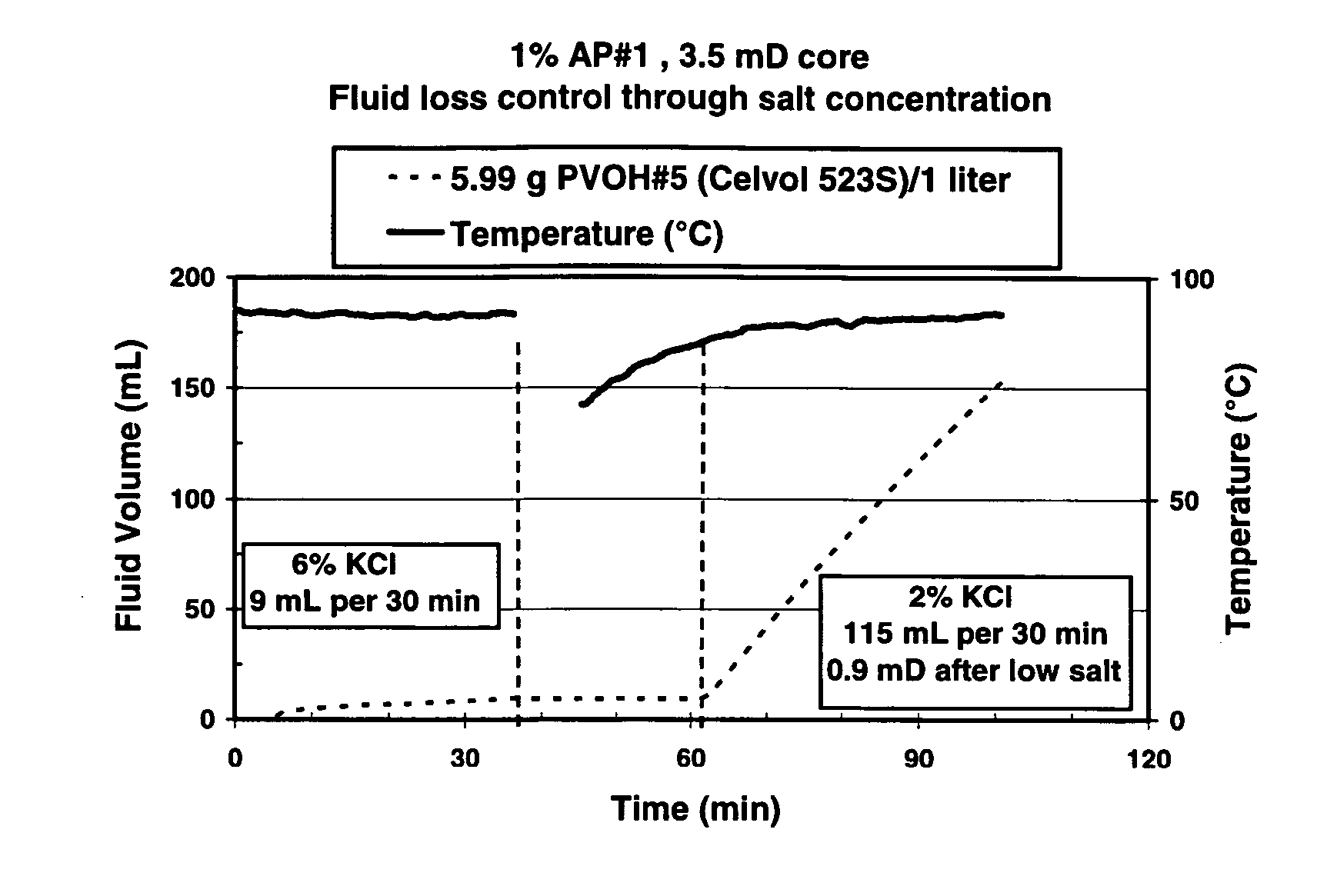

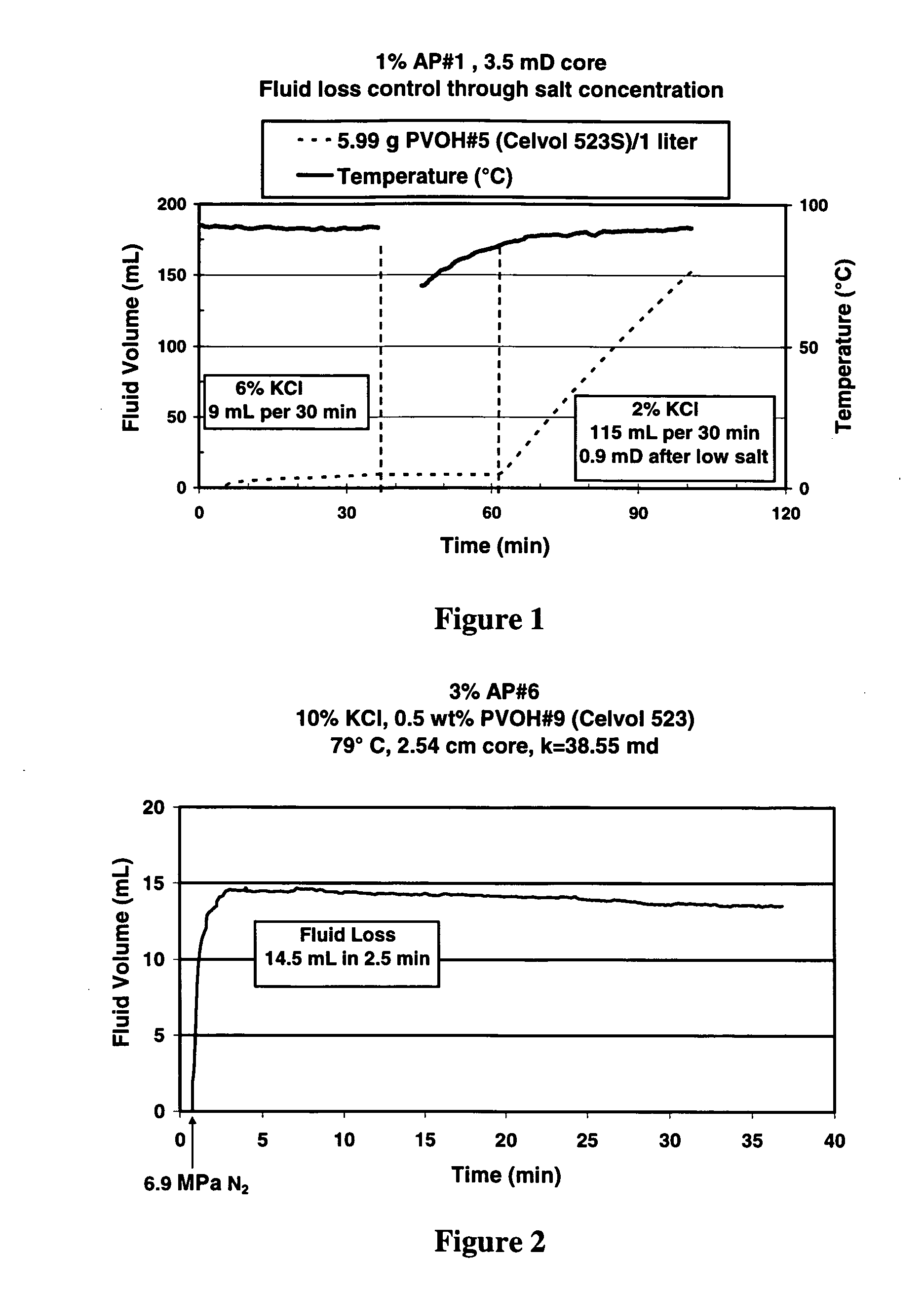

Well treatment with dissolvable polymer

InactiveUS20060157248A1Ease and flexibility for subsequent completion processEasy to processInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

Film for a separator of electrochemical apparatus, and production method and use thereof

InactiveUS6096456AHigh film strengthEasily and uniformly processedElectrolytic capacitorsSolid electrolyte cellsElectrolytic agentCarbamate

This invention provides a film comprising a cross-linked polymer having an oxyalkylene group or a cross-linked polymer having an oxyalkylene group through a urethane bond, as a constituent component, a production method of the film, and an electrochemical apparatus using the film as a separator. The film for separator of an electrochemical apparatus can be easily and uniformly processed, can include an electrolytic solution, exhibits good film thickness and ensures excellent safety and reliability. The electrochemical apparatus is free of leakage of the solution.

Owner:SHOWA DENKO KK

Crosslinked polymers and refractive devices formed therefrom

A polymer is formed of ethylenically unsaturated monomers including a zwitterionic monomer, an aromatic monomer and a cross-linking monomer. Preferably the crosslinking monomer includes at least one a group containing compound and at least one aliphatic group containing compound. The polymer is water-swellable and a hydrogen has optical and mechanical properties rendering it suitable for use as an intraocular refractive device such as an intraocular lens.

Owner:BIOCOMPATIBLES UK LTD

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

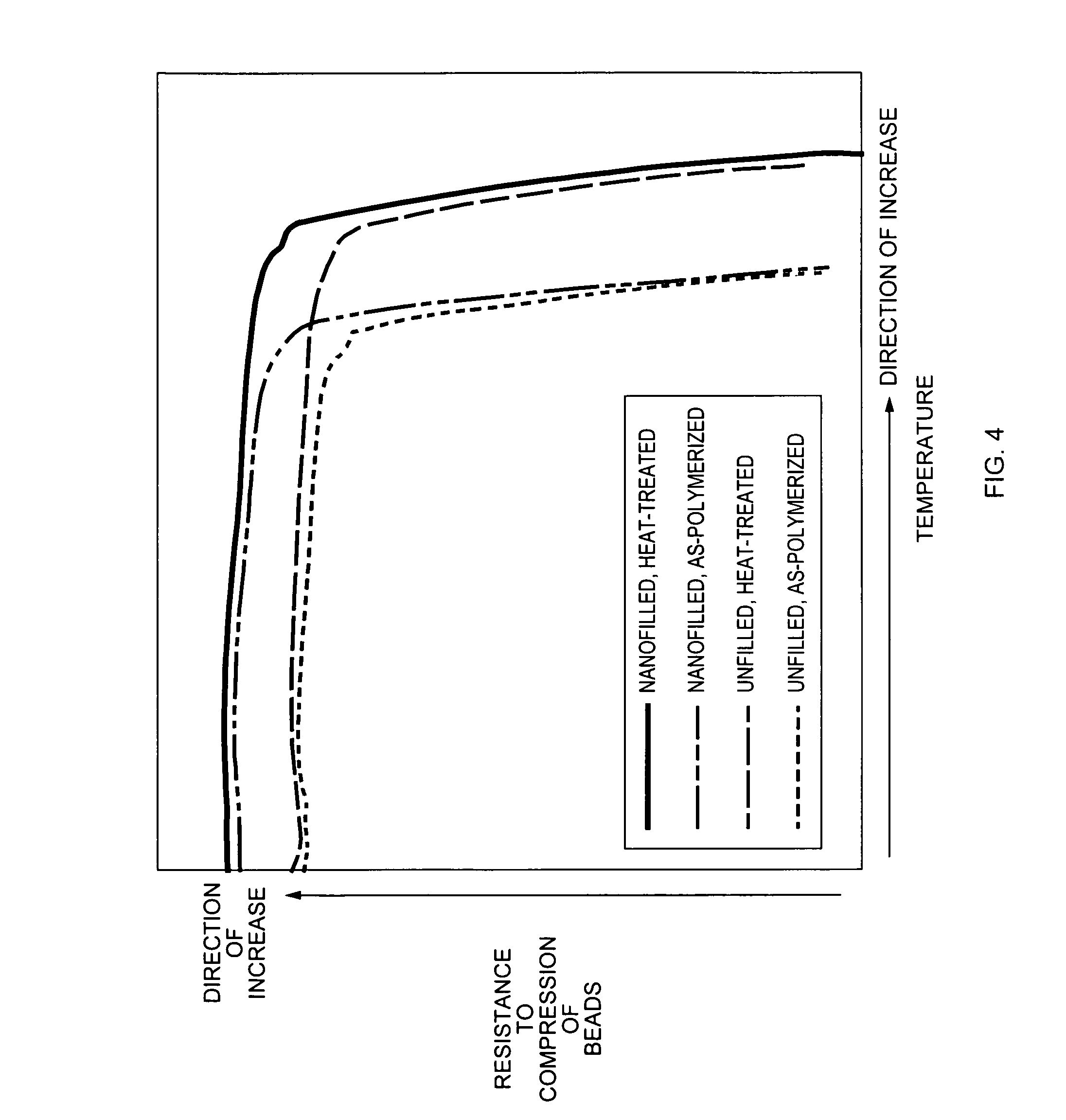

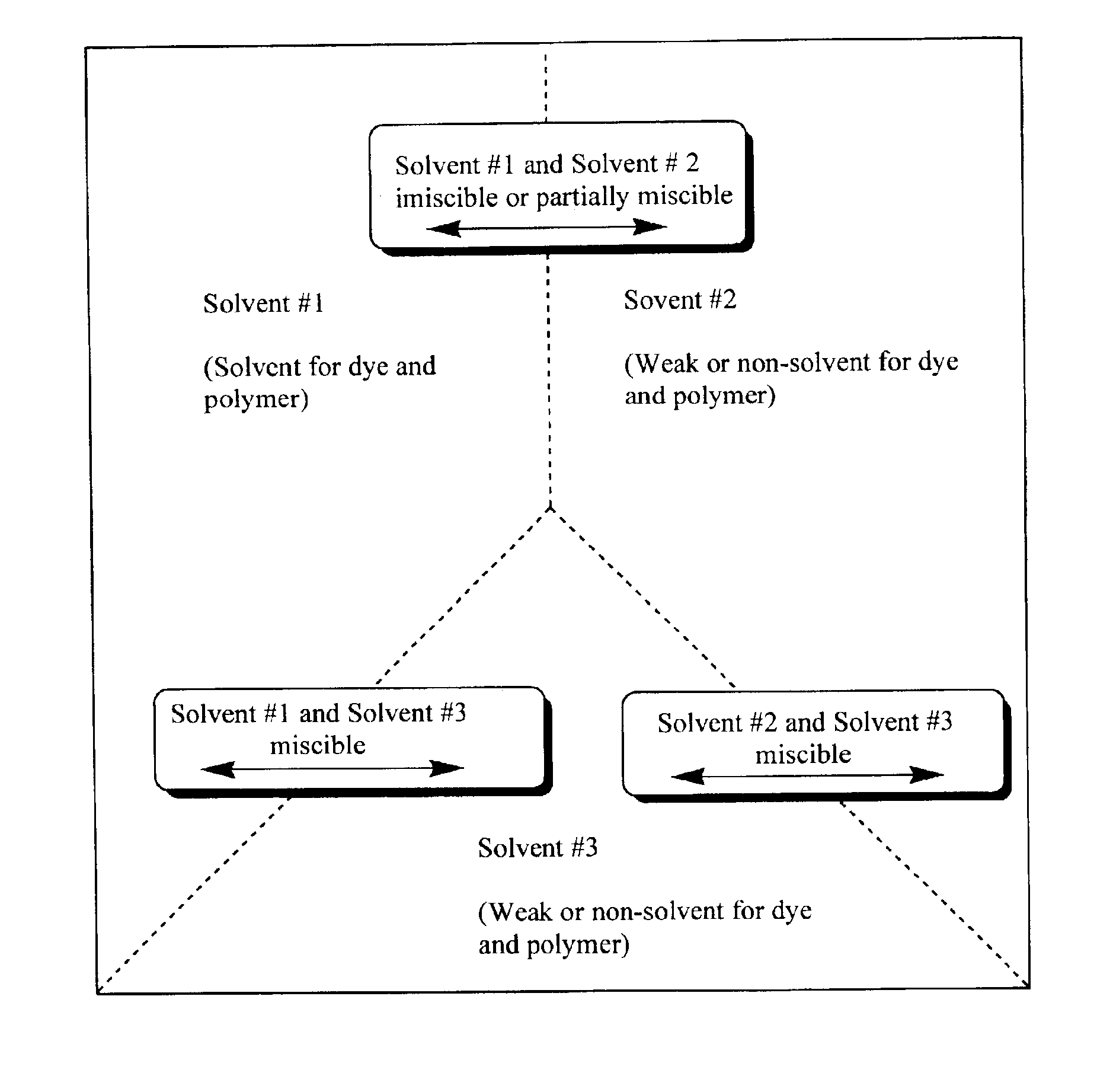

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

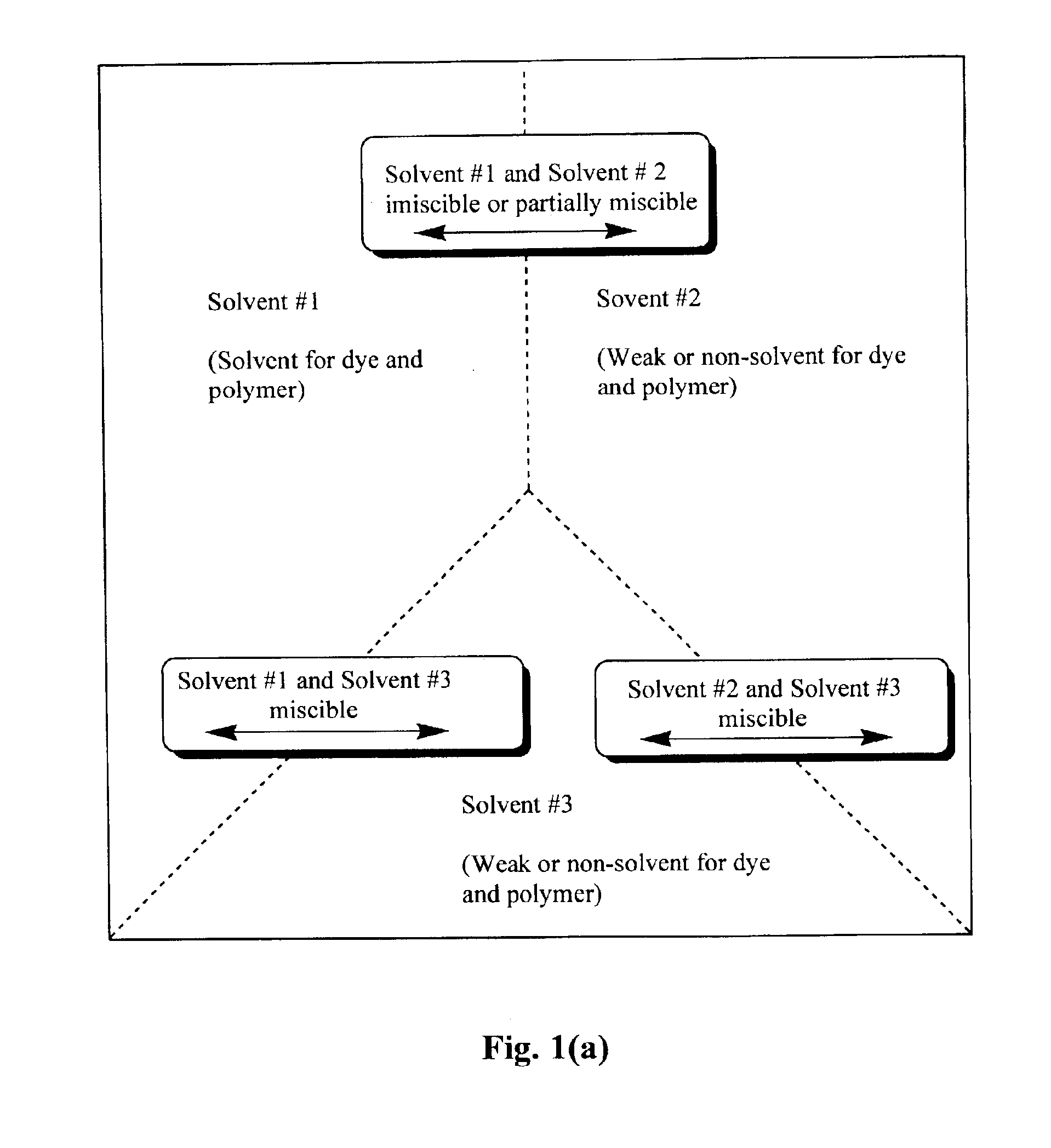

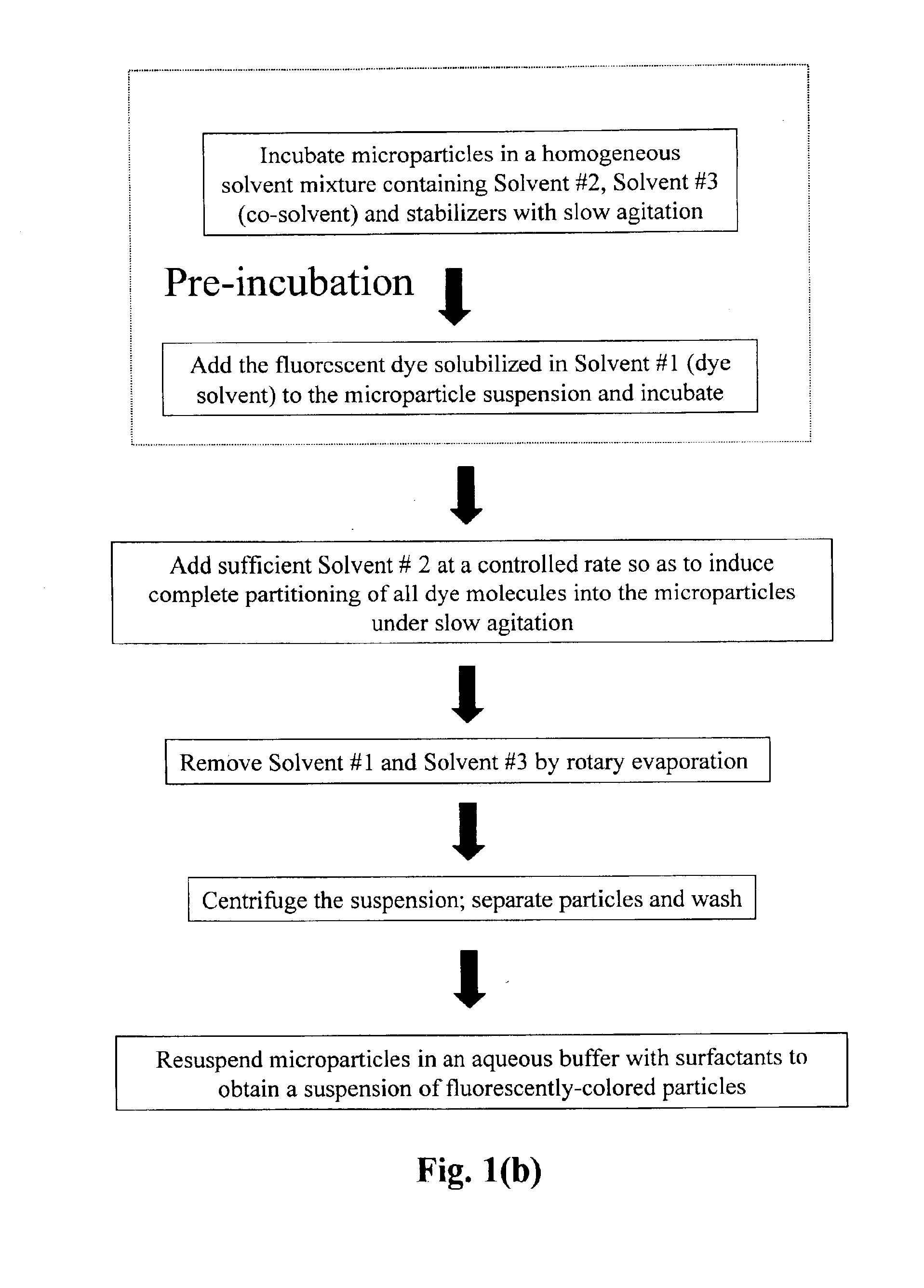

Production of dyed polymer microparticles

A dye, such as a fluorescent dye, is incorporated into polymer microparticles using a solvent system composed of a first solvent in which the dye and the microparticle polymer are soluble, a second solvent in which the dye and the microparticle polymer are not or only weakly soluble, and a third solvent in which the dye and the microparticle polymer are not or only weakly soluble. The first and second solvents are immiscible with each other, or at most partially miscible. The third solvent is miscible with the first and second solvents. The formulation provides substantially complete partitioning of the dye to the microparticles. The method may be used to obtain dyed polymer microparticle formed of cross-linked or non-cross-linked polymers. Libraries are provided comprising two or more sets of microparticles of different dye loadings. Fluorescent core-shell microparticles are produced from a mixture of microparticle cores incorporating one or more fluorescent dyes, a polymerization mixture comprising at least one polymerizable shell monomer, at least one free radical polymerization initiator comprising a water-insoluble oxidizing agent, and at least one water-soluble reducing agent.

Owner:BIOARRAY SOLUTIONS

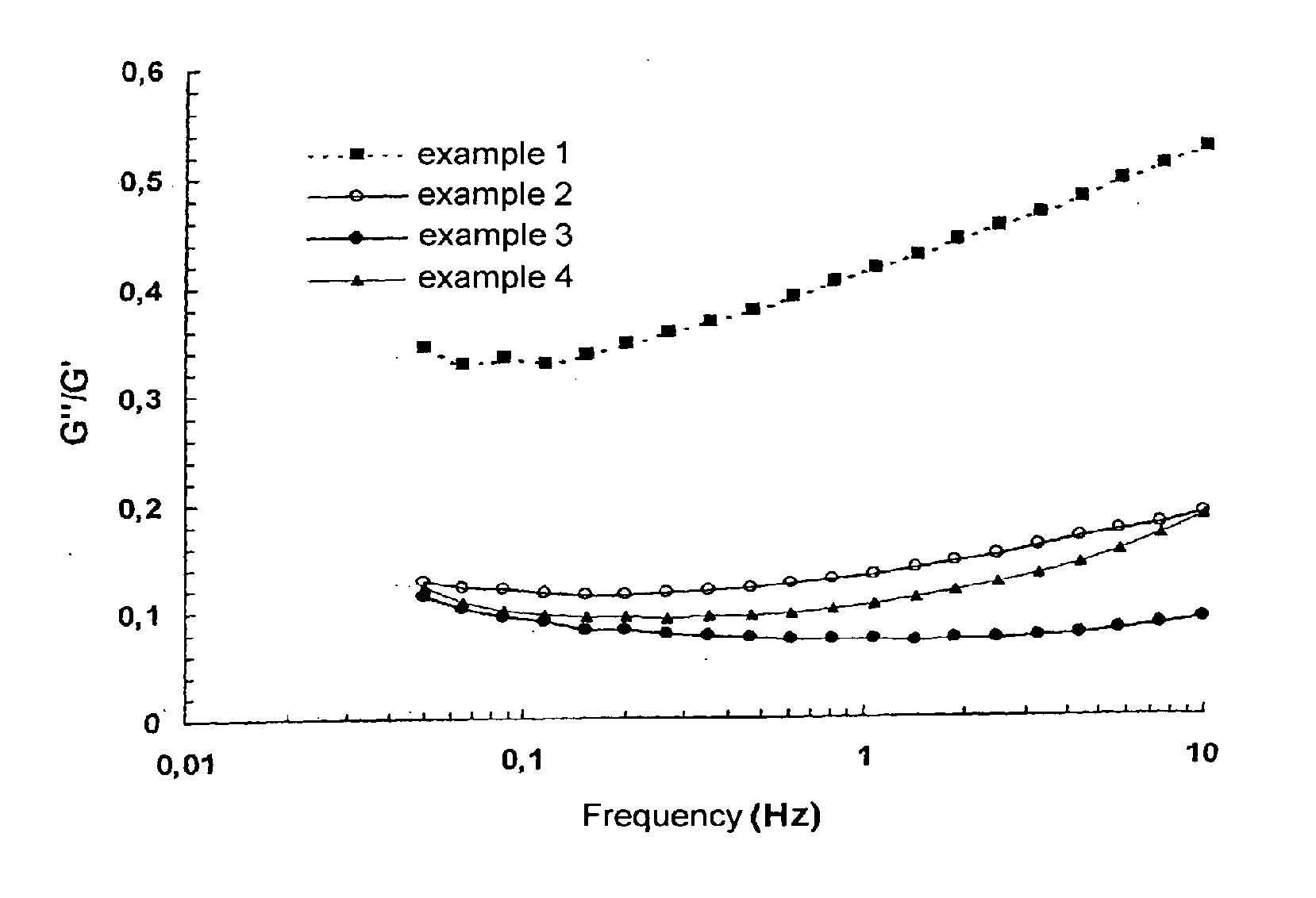

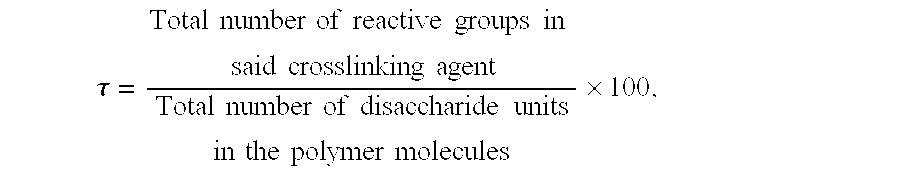

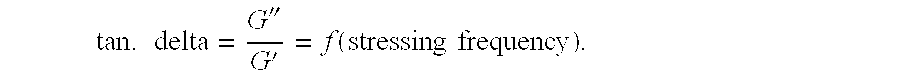

Cross-linking of low-molecular weight and high-molecular weight polysaccharides, preparation of injectable monophase hydrogels, polysaccharides and hydrogels obtained

ActiveUS20100226988A1Good curative effectImproved mechanical and remanence propertyPowder deliveryBiocidePolymer scienceCrosslinked polymers

A process for the crosslinking of at least one polymer selected from polysaccharides and derivatives thereof, which is carried out in an aqueous solvent by the action of an effective and non-excessive amount of at least one crosslinking agent, characterized in that it is carried out on a mixture containing at least one low-molecular weight polymer and at least one high-molecular weight polymer. A process for the preparation of an injectable monophase hydrogel of at least one crosslinked polymer selected from polysaccharides and derivatives thereof. Crosslinked polymers and injectable monophase hydrogels respectively obtainable by each of said processes.

Owner:ALLERGAN INC

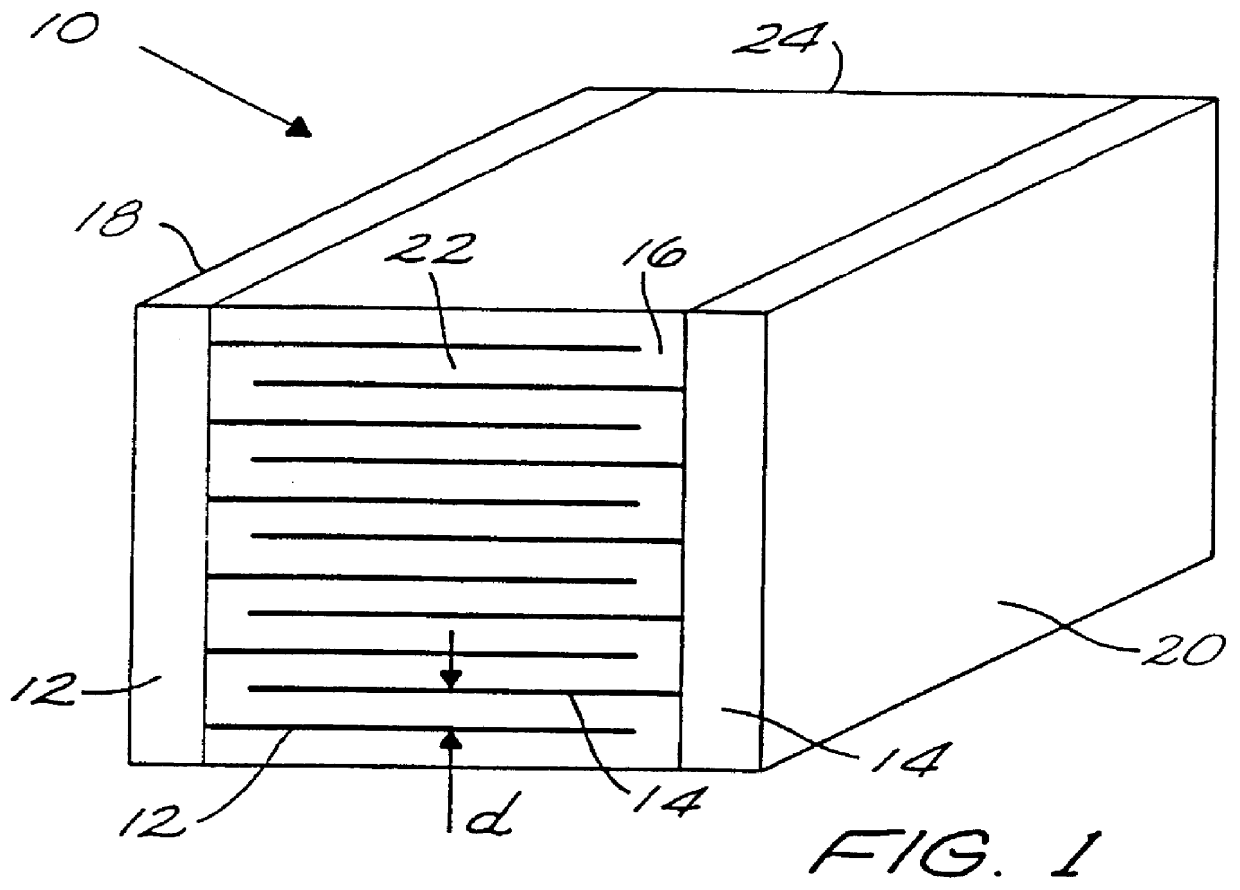

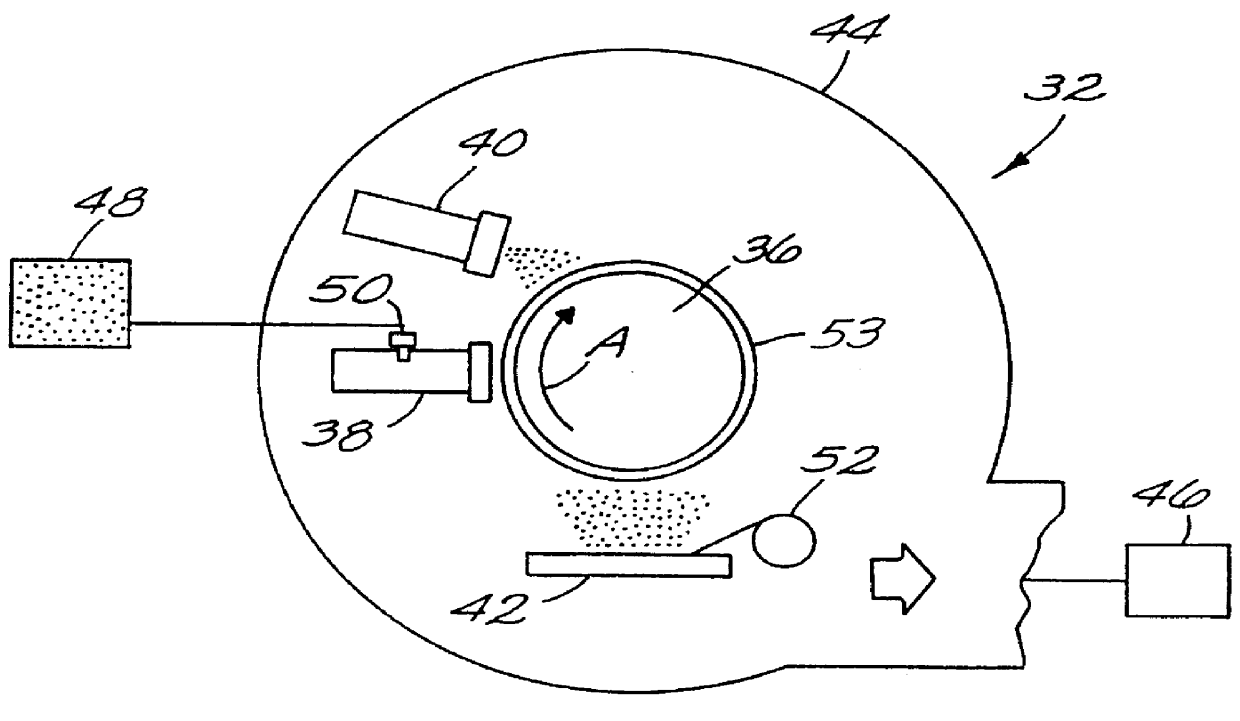

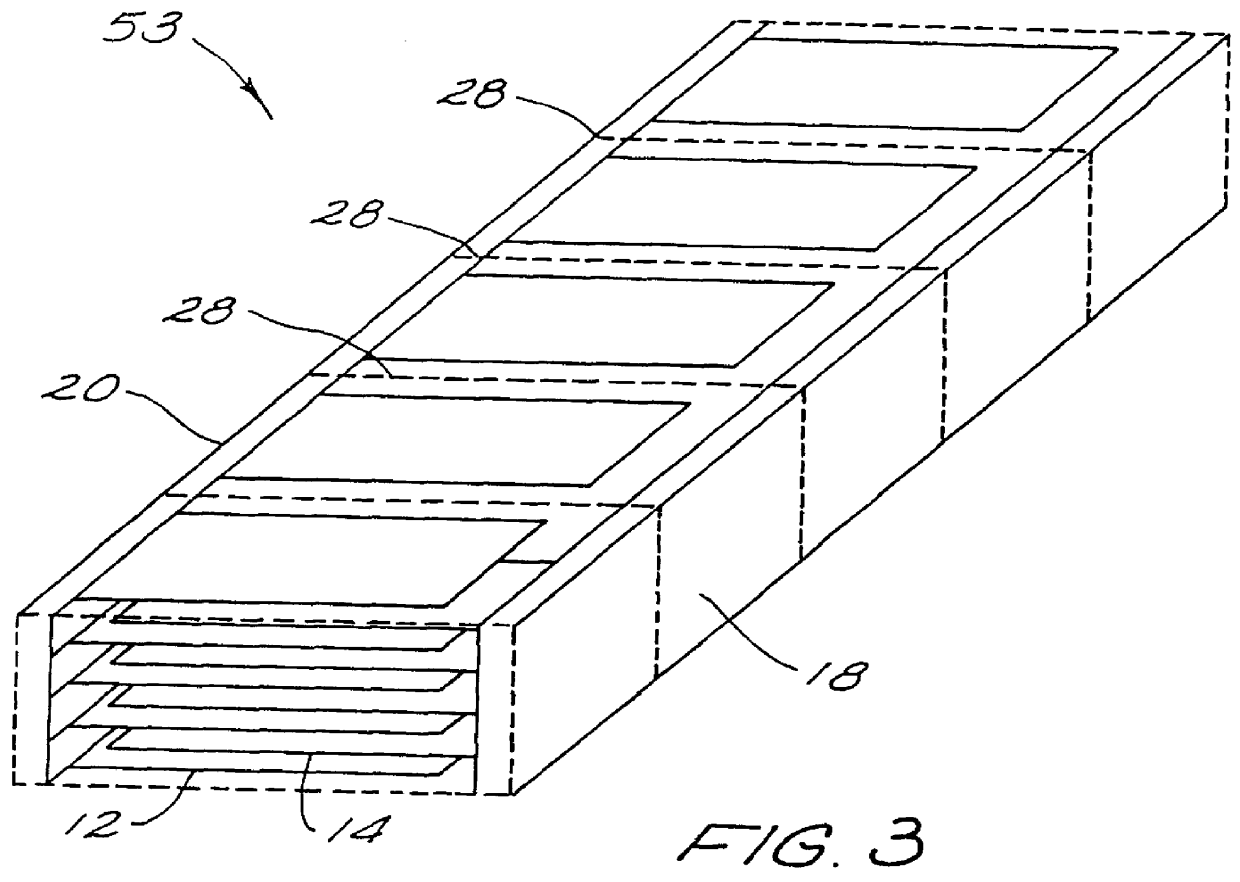

Apparatus for producing metal coated polymers

InactiveUS6106627AHigh breakdown strengthAvoid depositionRadiation applicationsVacuum evaporation coatingCross-linkBreakdown strength

A method of improving the breakdown strength of polymer multi-layer (PML) capacitors is provided and of providing a window in food packaging is provided. The method comprises patterning the aluminum coating, either by selective removal of deposited aluminum or by preventing deposition of the aluminum on selected areas of the underlying polymer film. Apparatus is also provided for patterning metal deposition on polymer films comprising masking for defining regions in which metal is deposited. The apparatus comprises: (a) a rotating drum; (b) a monomer evaporator for depositing a monomer film on the rotating drum; (c) a radiation curing element for curing the monomer film to form a cross-linked polymer film; and (d) a resistive evaporator for depositing a metal film on the cross-linked polymer film. The foregoing elements are enclosed in a vacuum chamber. The masking comprising one of the following: (e1) a web mask provided with openings for depositing the metal film therethrough, the web mask including a portion adapted for positioning between the resistive evaporator for depositing the metal film on the cross-linked polymer film and the rotating drum; or (e2) a rotating element for transferring liquid from a source to the rotating drum, the rotating element adapted to transfer the liquid to the rotating drum after the monomer evaporator for depositing the polymer film and before the resistive evaporator for depositing the metal film.

Owner:SIGMA LAB OF ARIZONE

Oral care composition with cross-linked polymer peroxide

InactiveUS20060045854A1Low costImprove convenienceCosmetic preparationsToilet preparationsCross-linkWhitening Agents

Oral care compositions comprising: (a) a peroxide complex comprising a peroxide component and an N-vinyl heterocyclic polymer (e.g., poly-N-vinyl polylactam, or poly-N-vinyl-polyimide); (b) a whitening agent (e.g., hydrogen peroxide); and (c) an orally acceptable carrier. In one embodiment, the carrier comprises a film forming material. Methods are also provided for making an oral care composition comprising: (a) mixing a whitening agent, silicone adhesive and carrier fluid to form a homogenous mixture; (b) adding a peroxide complex to said homogenous mixture, wherein said complex comprises hydrogen peroxide and an N-vinyl heterocyclic polymer; and (c) mixing under vacuum.

Owner:COLGATE PALMOLIVE CO

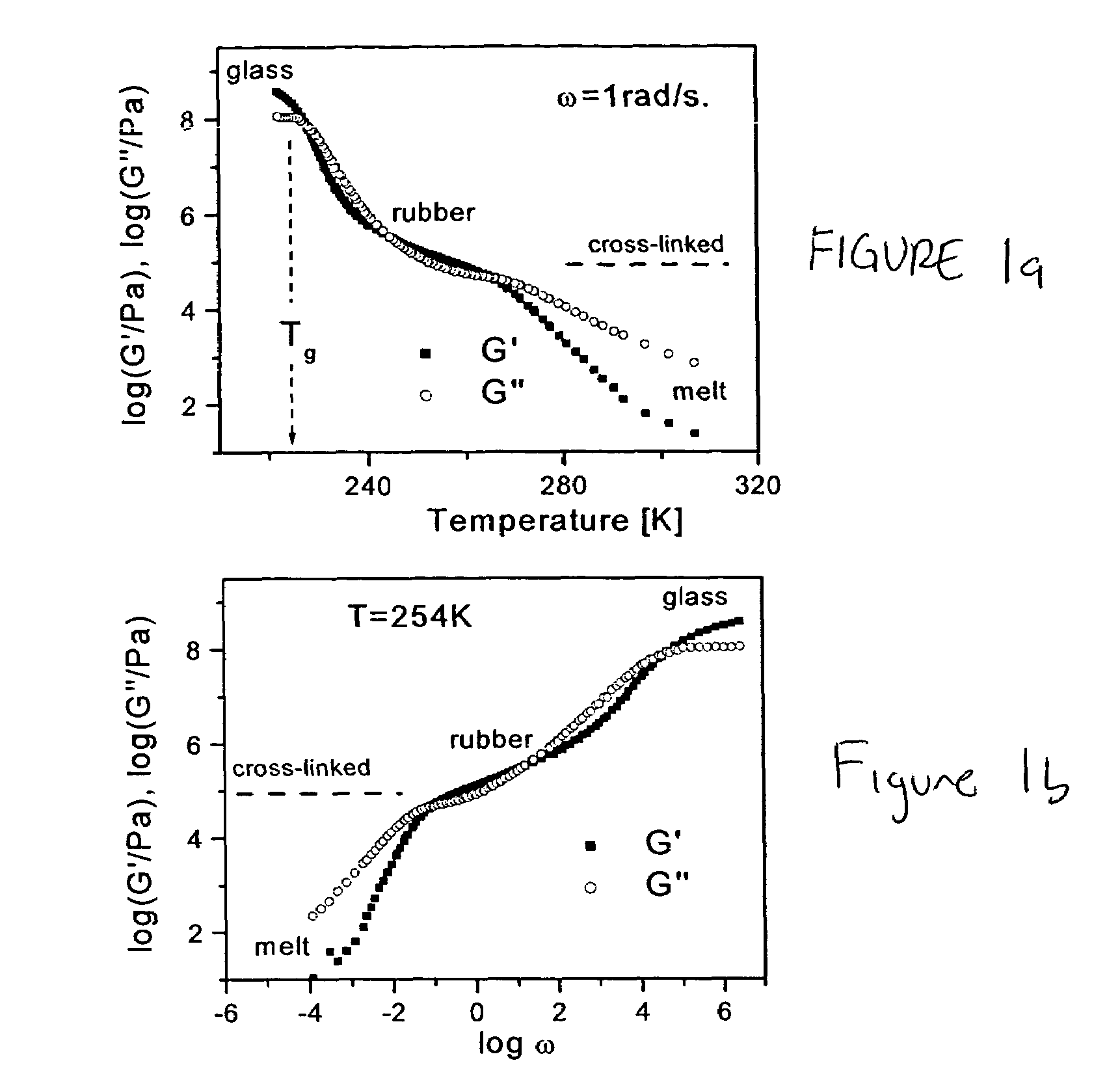

Polymers, supersoft elastomers and methods for preparing the same

Embodiments of the present invention include a material comprising a polymer having a modulus of elasticity less than 105 Pa and a material comprising a polymer having a modulus of elasticity of less than 5×104 Pa. Embodiments also include a material comprising a polymeric network and a multiplicity of side chains attached to the polymeric network. The multiplicity of side chains may have an average molecular weight below the critical molecular weight for entanglements. In certain embodiments it may be advantageous for the side branches to have a glass transition temperature below the use temperature of the material. The polymer network may comprise at least two monomers so that the polymer network is a copolymer. Embodiments of the present invention also include methods of forming a polymer network. Such as, for example, a method of preparing a polymer network comprising cross-linking a polymer, wherein the polymer comprises a multiplicity of side chains. The polymer may be at least one of a polymer brush, a polymer comb, and a nanocomposite material. An additional embodiment may include polymerizing macromonomers in the presence of a crosslinking agent. This embodiment may result in the forming a polymer network, wherein the polymer network comprises a multiplicity of branches attached to the polymer network, wherein the macromonomers may have a molecular weight less than the critical molecular weight for entanglements. Another embodiment of the method of forming a polymer network may comprising polymerizing monomers directly from a crosslinked polymer network. This method may result in forming a branched polymer network, wherein the polymer network comprises a multiplicity of branches attached to the polymer network.

Owner:CARNEGIE MELLON UNIV

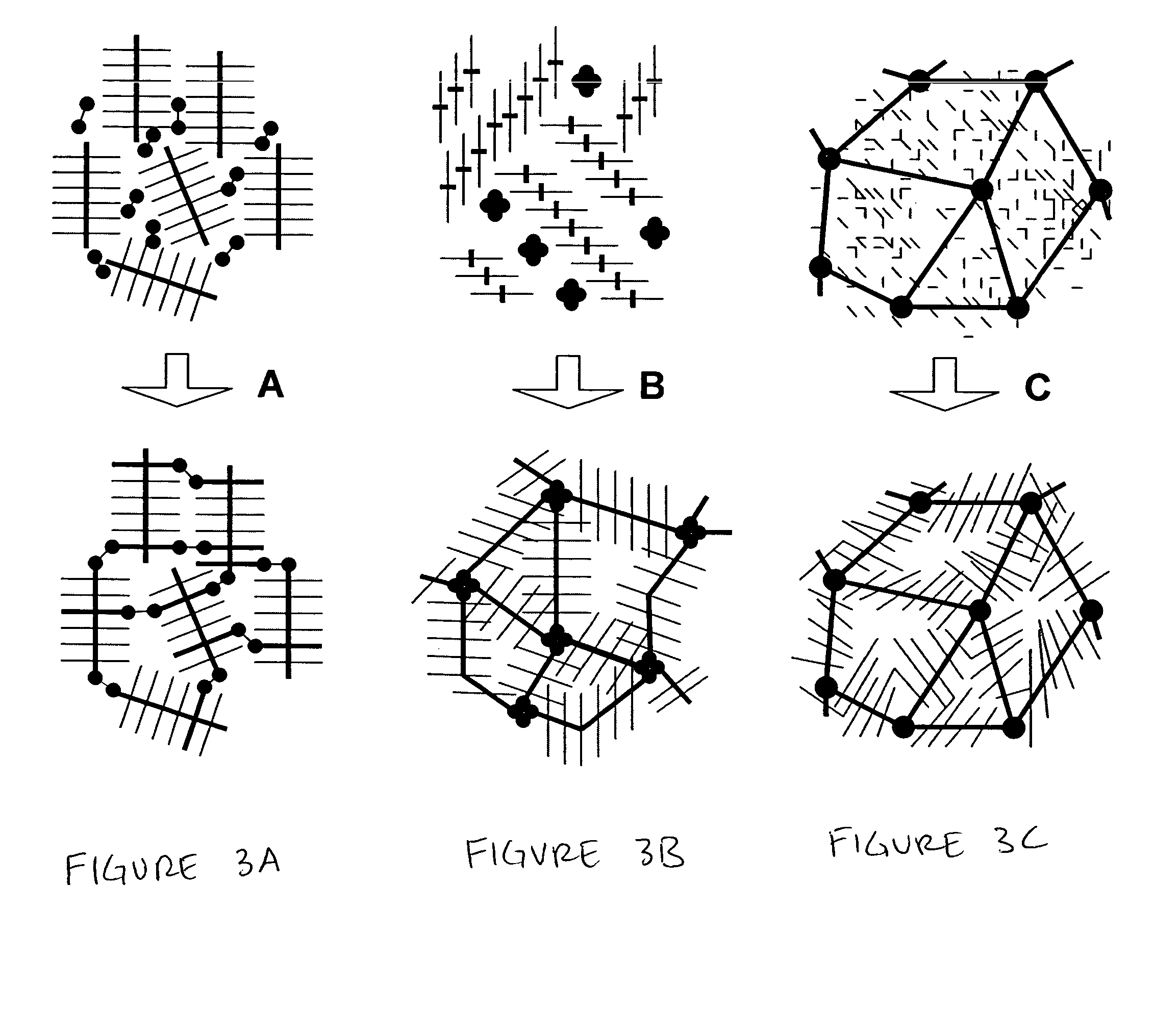

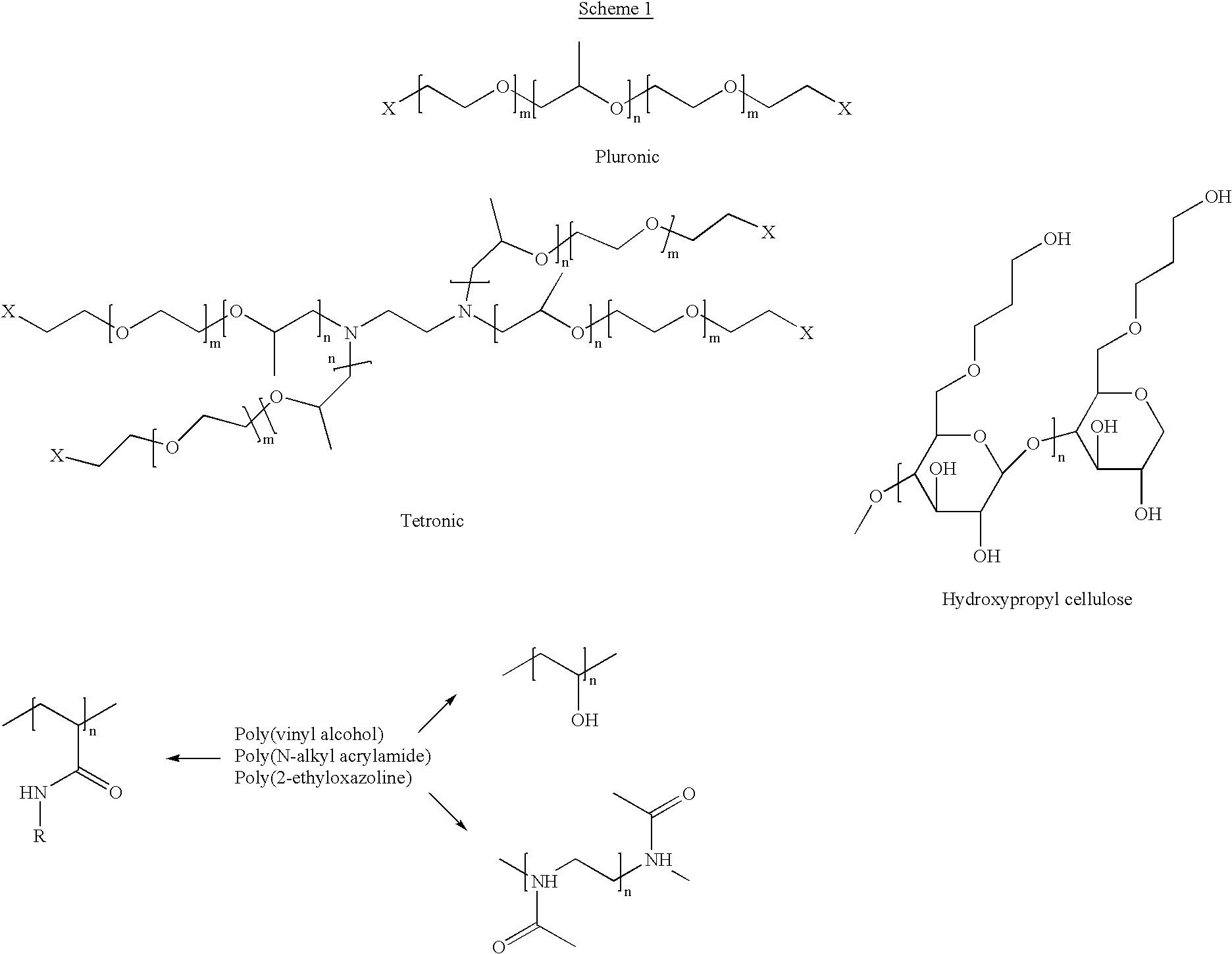

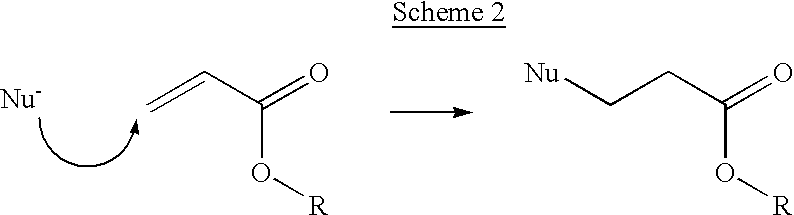

Two-phase processing of thermosensitive polymers for use as biomaterials

InactiveUS20030044468A1Negligible cytotoxicityWithout adversely affecting the activity of these sensitive moleculesPowder deliveryOrganic active ingredientsPolymer scienceThermosensitive polymer

A two-step system for preparing biomaterials from polymeric precursors is disclosed. The method involves (a) shaping the polymeric precursors by inducing thermal gelation of an aqueous solution of the polymeric precursors and (b) curing the polymeric precursors by cross-linking reactive groups on the polymeric precursors to produce a cured material. The curing reaction involves either a Michael-type addition reaction or a free radical photopolymerization reaction in order to cross-link the polymeric materials. The biomaterials produced by this method have a variety of biomedical uses, including drug delivery, microencapsulation, and implantation.

Owner:EIDGENOSSISCHE TECHN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com