Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1197 results about "Catalase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

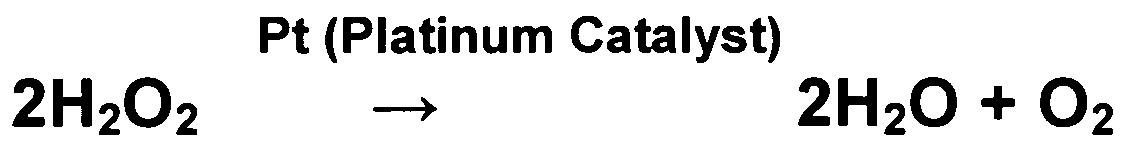

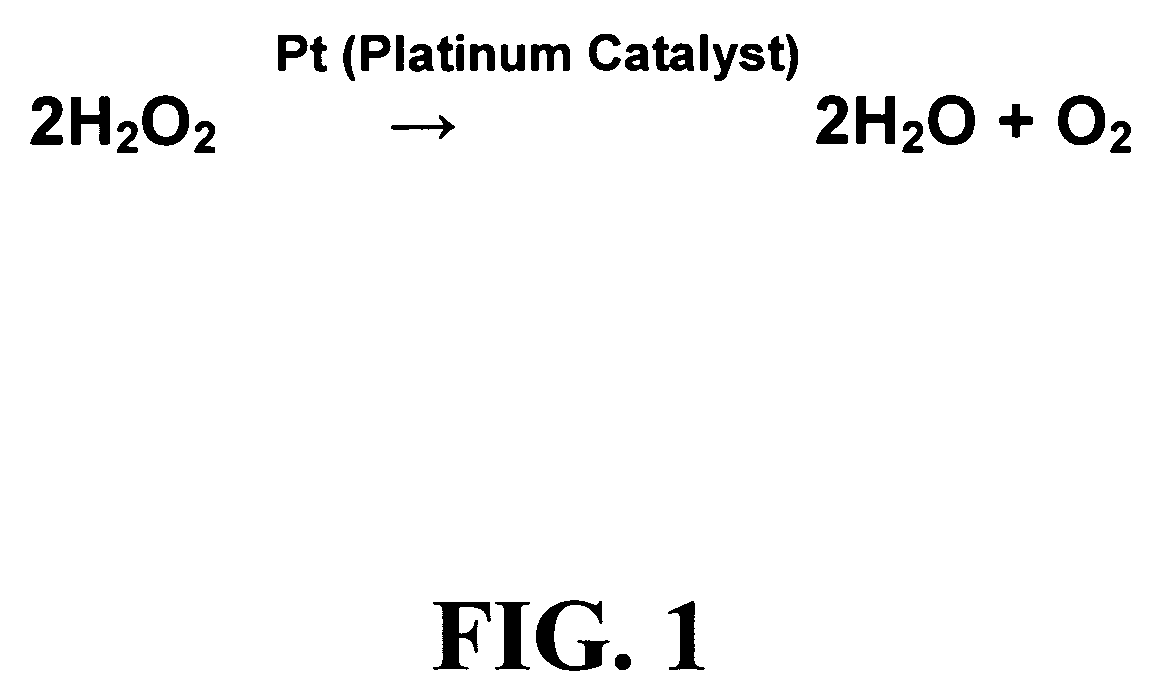

Catalase is a common enzyme found in nearly all living organisms exposed to oxygen (such as bacteria, plants, and animals). It catalyzes the decomposition of hydrogen peroxide to water and oxygen. It is a very important enzyme in protecting the cell from oxidative damage by reactive oxygen species (ROS). Likewise, catalase has one of the highest turnover numbers of all enzymes; one catalase molecule can convert millions of hydrogen peroxide molecules to water and oxygen each second.

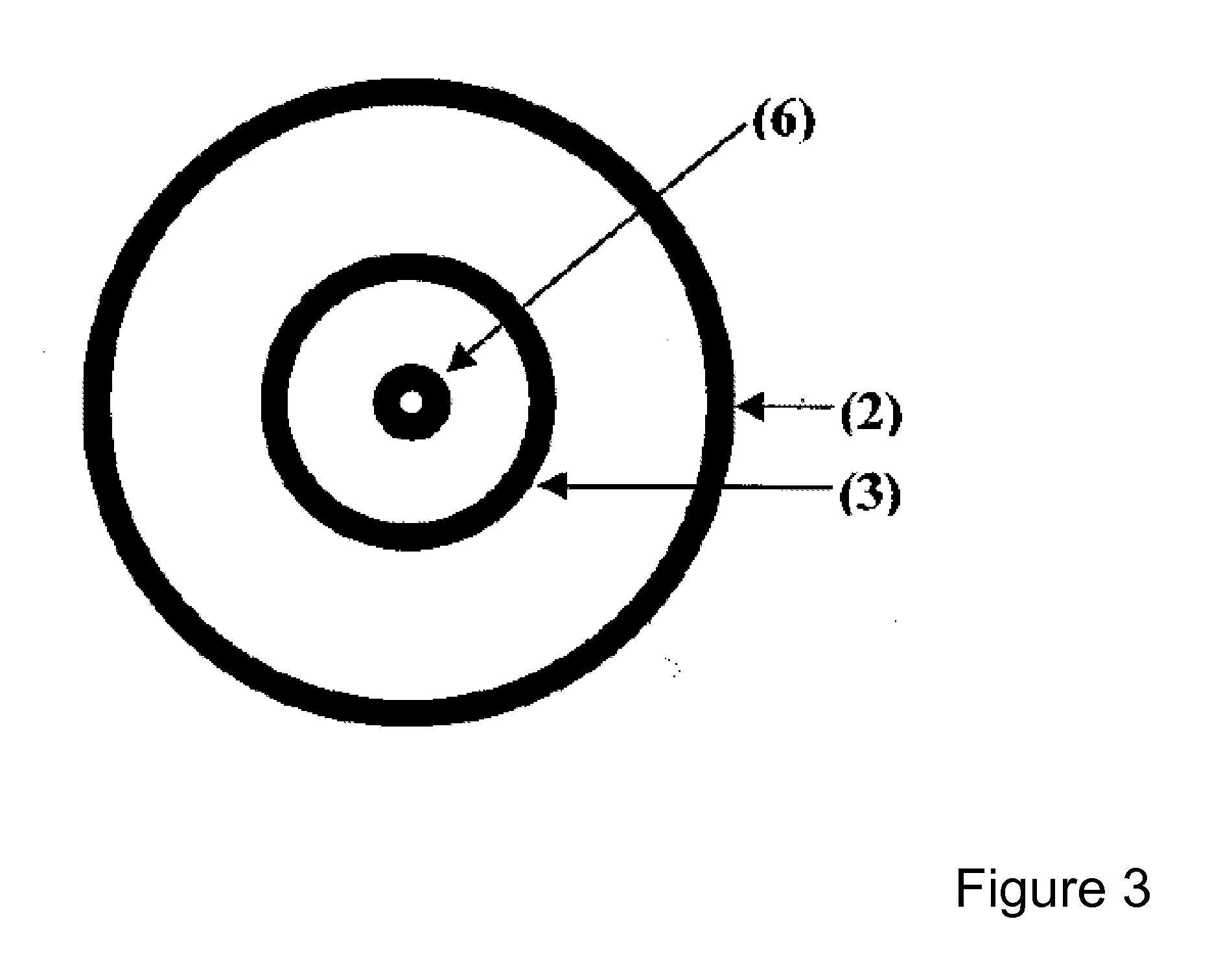

Membrane suitable for use in an analyte sensor, analyte sensor, and associated method

ActiveUS7699964B2Facilitate linear responsiveness and calibration and stabilityPreserve and improve performance of sensorImmobilised enzymesBioreactor/fermenter combinationsMetaboliteAmperometric biosensor

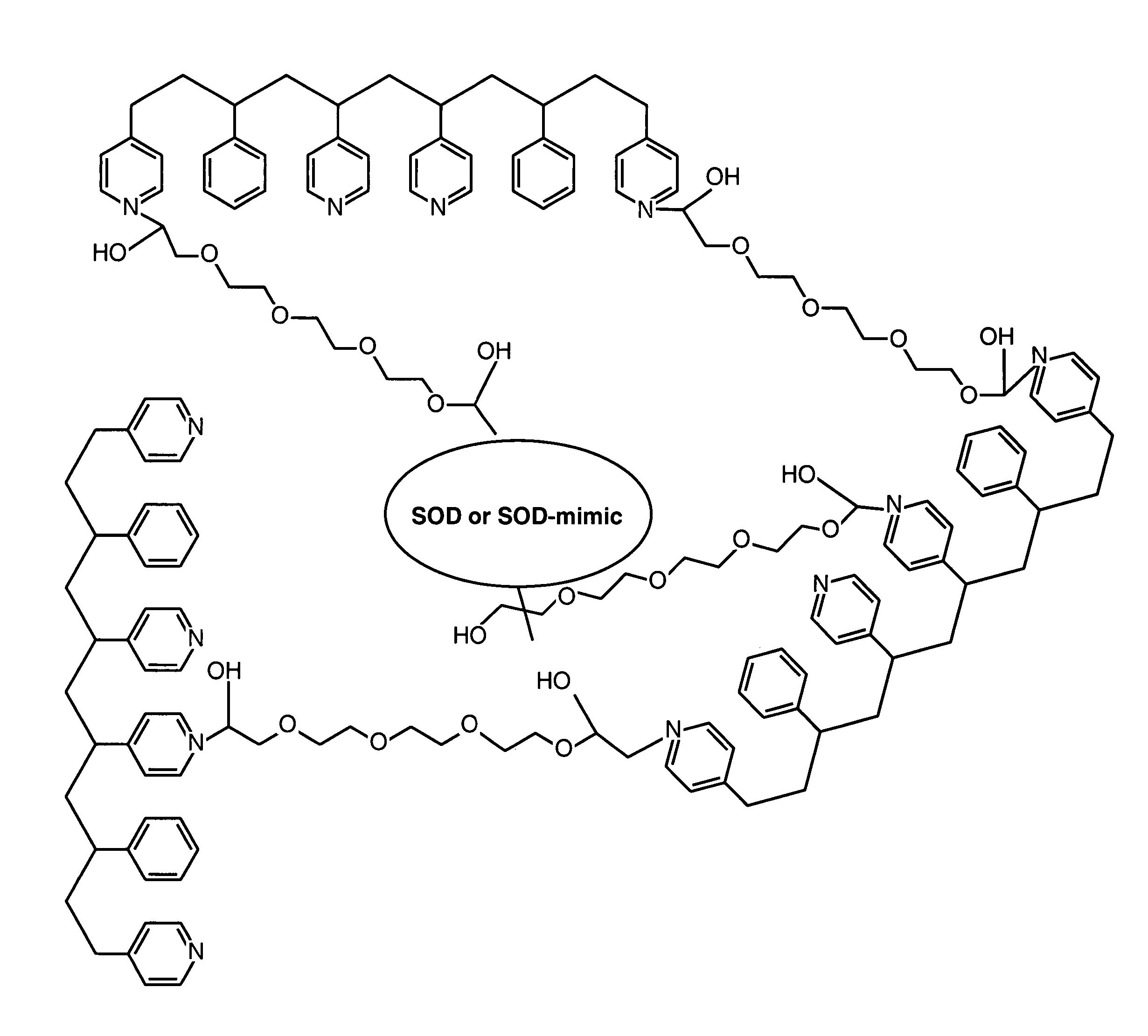

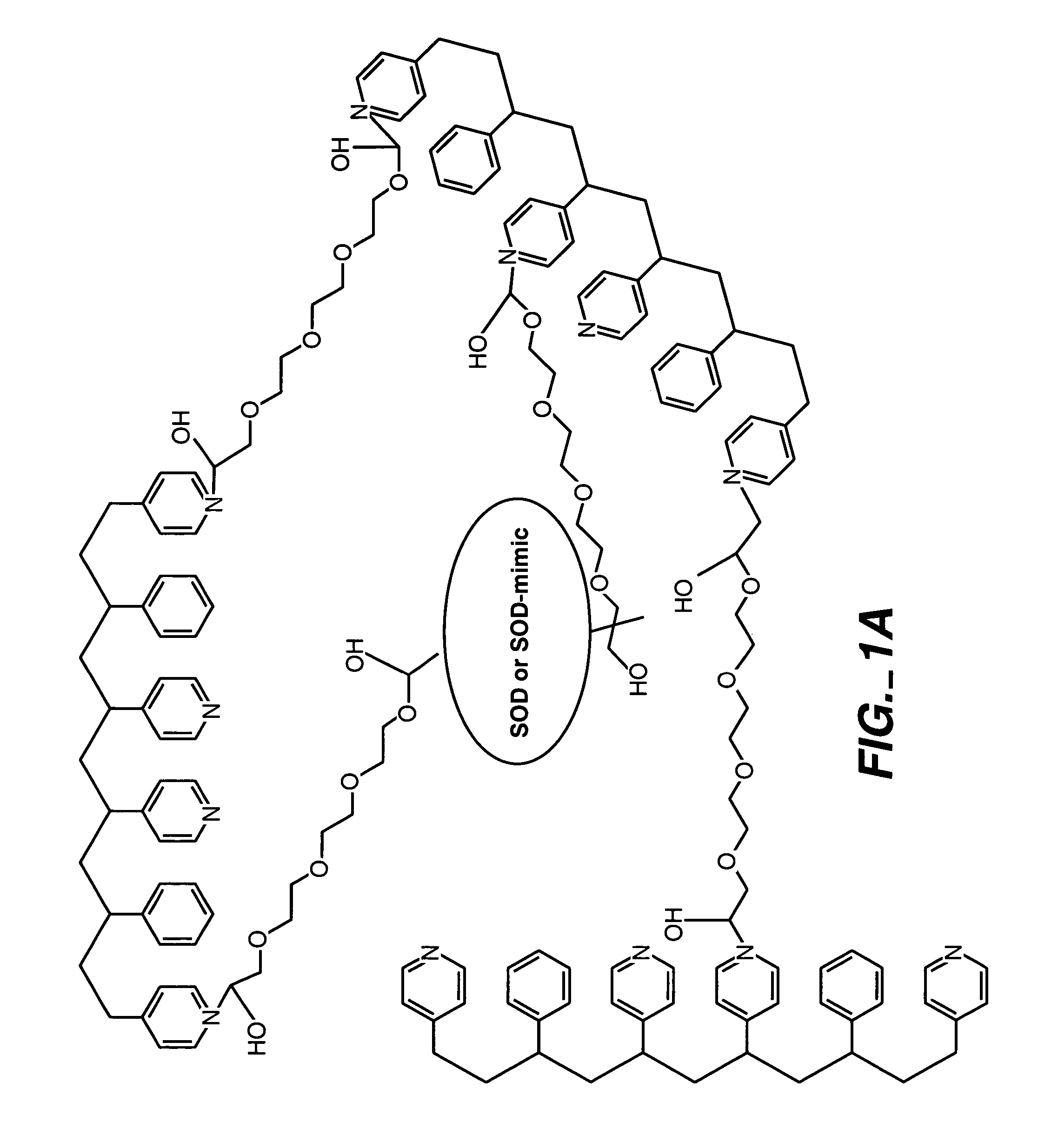

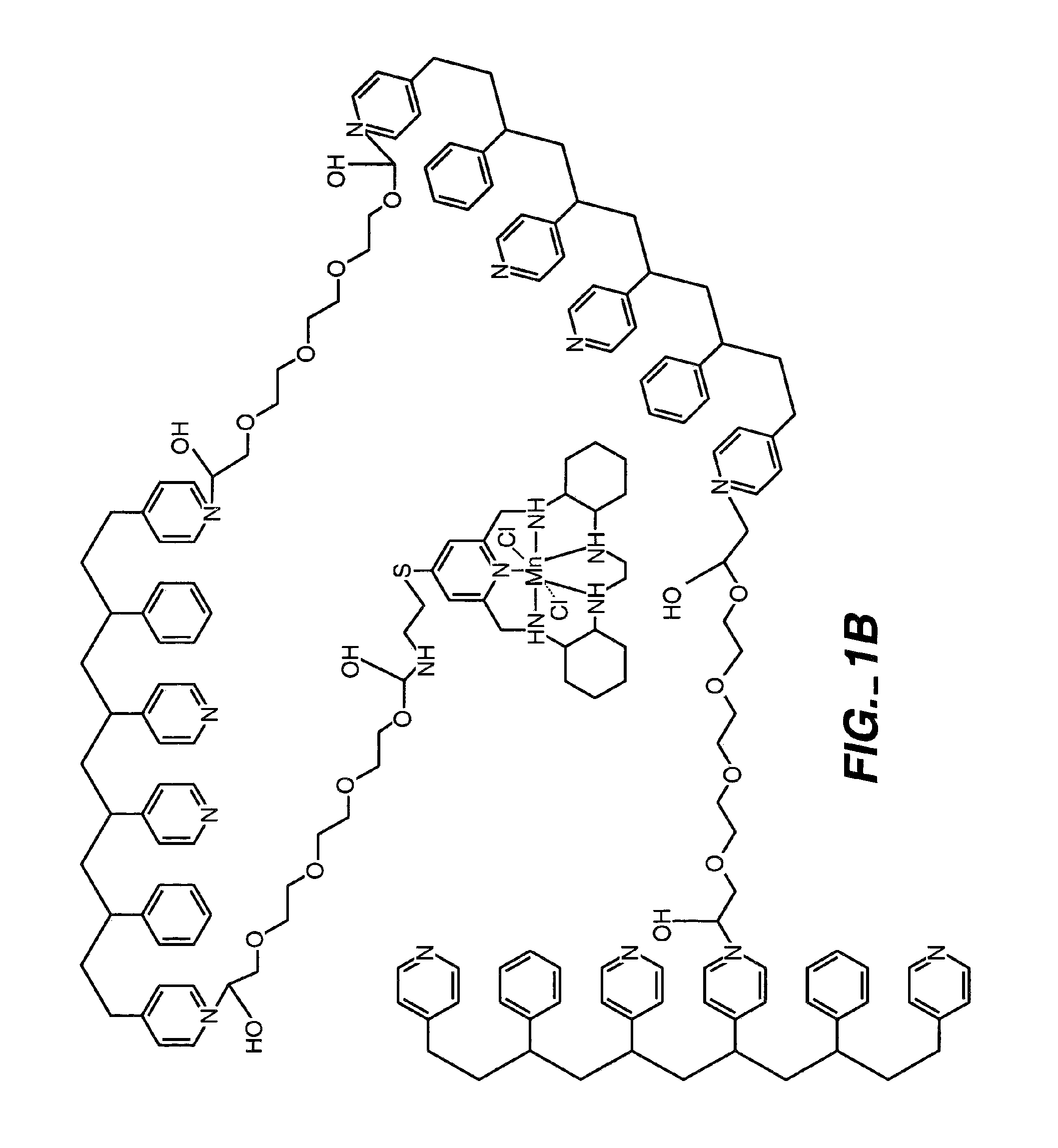

A multifunctional membrane is provided. The multifunctional membrane is suitable for use in an analyte sensor. In a particular application, the multifunctional membrane may be used in connection with an amperometric biosensor, such as a transcutaneous amperometric biosensor. Some functions of the membrane are associated with properties of membrane itself, which is comprised of crosslinked polymers containing heterocyclic nitrogen groups. For example, the membrane, by virtue of its polymeric composition, may regulate the flux of an analyte to a sensor. Such regulation generally improves the kinetic performance of the sensor over a broad range of analyte concentration. Other functions of the membrane are associated with functional components, such as a superoxide-dismutating / catalase catalyst, either in the form of an enzyme or an enzyme mimic, that can be bound to the scaffold provided by the membrane. The effect of any such enzyme or enzyme mimic is to lower the concentration of a metabolite, such as superoxide and / or hydrogen peroxide, in the immediate vicinity of the sensing layer of the biosensor. Lowering the concentrations of such metabolites, which are generally deleterious to the function of the sensor, generally protects or enhances biosensor integrity and performance. The membrane is thus an important tool for use in connection with analyte sensors, amperometric sensors, biosensors, and particularly, transcutaneous biosensors. A membrane-covered sensor and a method for making same are also provided.

Owner:ABBOTT DIABETES CARE INC

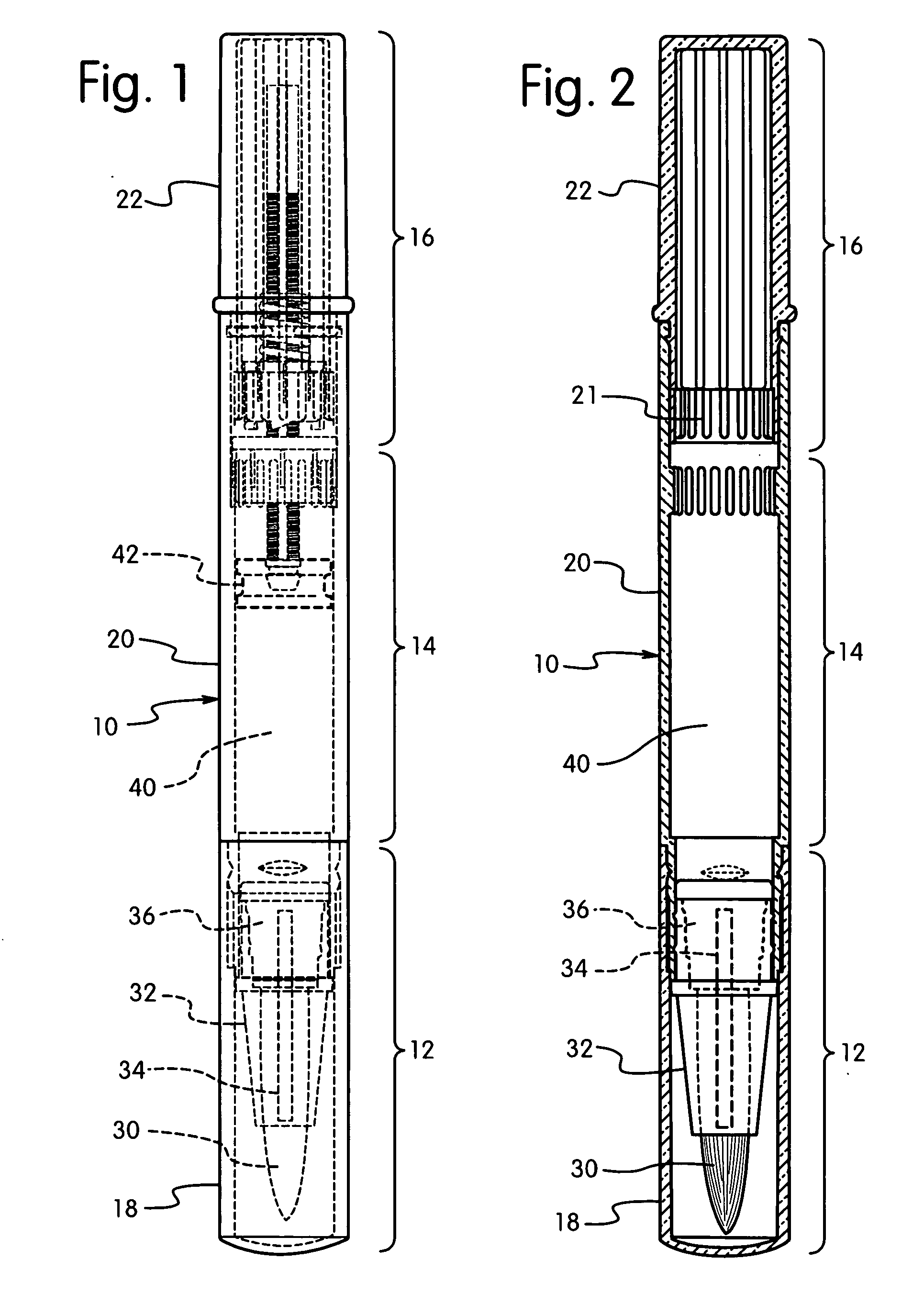

Applicator and method for applying a tooth whitening composition

The method of the present invention is directed to the storage and dispensing of a peroxide containing tooth whitening composition. During storage and subsequent use the composition in the storage chamber must be maintained segregated from the applicator surface. This is accomplished by delivering the peroxide containing tooth whitening composition from the storage chamber through a delivery channel having a length and a cross-sectional diameter sufficient to preclude the migration of moisture and the enzyme catalase from the application surface to the storage chamber. The composition is applied to teeth by means of bristles, a sponge surface or fibrillated surface. This applicator can be used with both aqueous and non-aqueous peroxide containing tooth whitening compositions.

Owner:COLGATE PALMOLIVE CO

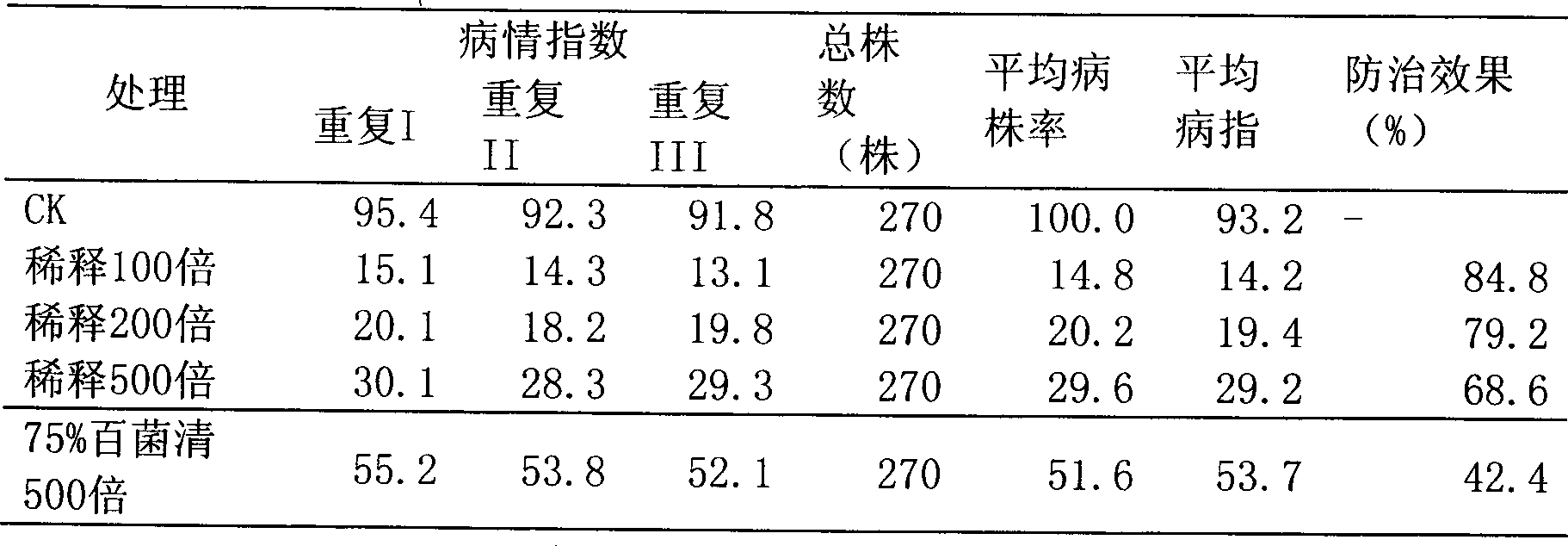

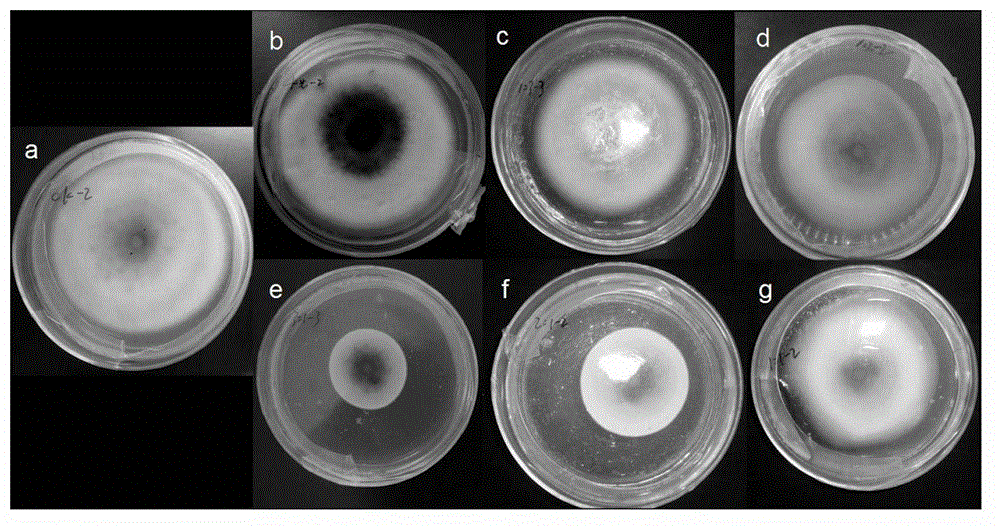

Biological preparation capable of preventing and treating cruciferae club root and use thereof

InactiveCN101416641AGood control effectSolve prevention and control problemsBiocideBacteriaSucroseRussulaceae

The invention relates to a biological agent against crucifer club root and application thereof, belonging to the technical field of bio-pesticide. The strain for production is Bacillus subtilis XF-1, whose preserving number is CGMCC NO.2357. The stain has the characteristics as follows: (1) the primary colony on the LB culture substrate is white and round having a wet surface; the later colony is light yellow having uneven edge with dry and crimple surface; observed from the microscope, the strain is short-bar shaped and movable with spore, peritricha and dimension of 0.7 - 0.8 * 2.0-2.4 mum; (2) the strain is Gram-positive and aerobic and makes use of glycogen, sugar, citrate, gelatin hydrolysate, starch and casein, but does not make use of cellulose, tyrosine and catalase positive; (3) the stain has the function of sterilization, disease prevention, and yield improvement. The embodiment of the invention is as follows: using the test tube of Bacillus subtilis XF-1 stain, shake cultivation, and culture solution for fermentation to prepare biological agent, then applying the biological agent to the rhizosphere soil of crucifer crops, thereby having good effect in preventing and treating, and simple production.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Application of bio-enzyme catalysis in residual sludge treatment

A bio-enzyme consists of pectinase, protease, lipase, cellulose, catalase and amylase; the application of bio-enzyme catalysis in residual sludge treatment is that: the residual sludge is treated by utilizing the high-efficiency biocatalysis of the bio-enzyme, odor molecules in the sludge are decomposed and deodorized through enzyme technology, pathogenic bacteria, ova and larvae are killed by utilizing an acid environment formed by inorganic acid generated by the sludge and a high temperature environment in the fermentation process, heavy metal ions in the sludge are stabilized by utilizing the chelation of the bio-enzyme, and the sludge is catalyzed by the enzyme, so that the sludge and water are quickly separated, a large amount of supernate is discharged, the sludge volume is reduced, and the sludge in inland river is reduced and is subjected to innocent treatment; meanwhile, through the bio-enzyme catalysis, long-chain molecules in the sludge are converted into short-chain molecules, polysaccharide and cellulose are converted into protein and amino acid, nutritional components of organic fertilizers are remained, the fertilizer efficiency is improved and the fermentation period can be shortened.

Owner:孙祥章

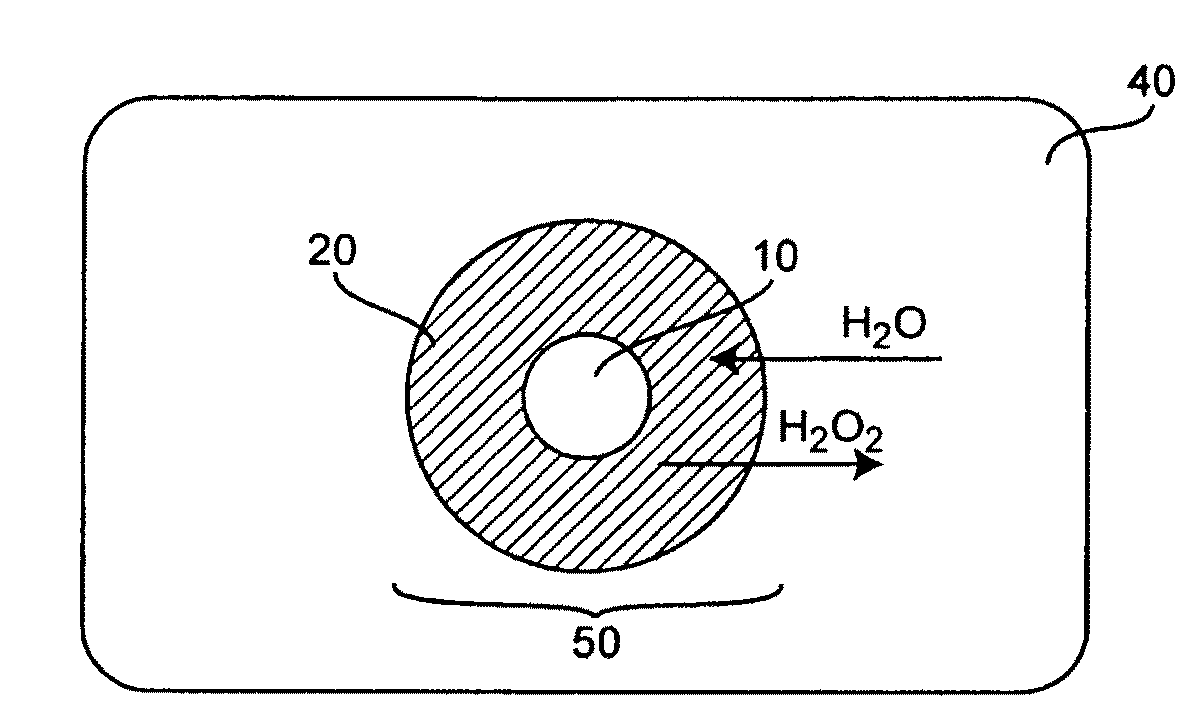

Methods and Compositions for Controlled and Sustained Production and Delivery of Peroxides and/or Oxygen for Biological and Industrial Applications

InactiveUS20090169630A1Reduce chanceProtects against oxidative damageCosmetic preparationsBiocideOxygenAdduct

Methods and compositions for the controlled and sustained release of peroxides or oxygen to aqueous environments (e.g. a patient's body or circulatory system, or for other applications) or non-aqueous environments, include a material coating or encapsulating hydrogen peroxide, inorganic peroxides or peroxide adducts. In the case of peroxide adducts, and particularly in one type of embodiment, the peroxide adducts should be able to permeate the material, but water, hydrogen peroxide and inorganic peroxides should be able to permeate the material. The methods and compositions that allow the release of oxygen, H2O2 or inorganic peroxides from peroxide adducts with movement of these moieties across a selectively permeable barrier into, preferably, an aqueous environment. In the case of hydrogen peroxide, it can be acted upon by catalase or other enzymes, or be simply degraded, or are otherwise acted upon by enzymes or catalysts embedded in the selectively permeable barrier to produce, for example, O2. Alternatively, hydrogen peroxide or inorganic peroxides can be delivered selectively to a site of action of cleaning, disinfecting or other applications.

Owner:VIRGINIA COMMONWEALTH UNIV

Enzymatic reactions in the presence of keto acids

ActiveUS7445911B2Efficient and high yieldImprove bioavailabilityCarbon-nitrogen lyasesOxidoreductasesLyaseKeto acid

Conversion in vitro of X-Gly to X-alpha-hydroxy-Gly or X—NH2 (X being a peptide or any other compound having a carbonyl group capable of forming a covalent bond with glycine) is accomplished enzymatically in the presence of keto acids, or salts or esters thereof, to provide a good yield without the necessity of catalase or similar enzymatic reaction enhancers. Peptidylglycine α-amidating monooxygenase (PAM) is a preferred enzyme for catalyzing the conversion. Alternatively, peptidylglycine α-hydroxylating monooxygenase (PHM) is utilized to convert X-Gly to X-alpha-hydroxy-Gly which may be recovered, or optionally may be simultaneously or sequentially converted to an amide by either a Lewis base or action of the enzyme peptidyl α-hydroxyglycine α-amidating lyase (PAL). Both PHM and PAL are functional domains of PAM.

Owner:ENTERIS BIOPHARMA

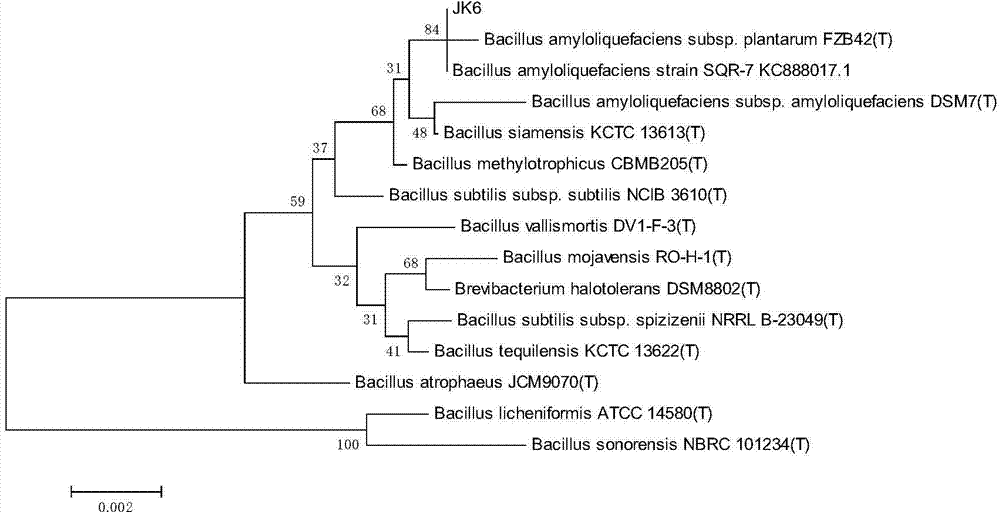

Bacillus amyloliquefaciens JK6 and biological fertilizer and application

The invention discloses bacillus amyloliquefaciens JK6 and biological fertilizer and application. The serial number of strain preservation is CGMCC No. 10658 and is stored in the China general microbiological culture collection center on March 23, 2015. The bacillus amyloliquefaciens JK6 is mainly used for biological prevention and control of pseudomonas solanacearum and is provided with an iron-production carrier, a biological membrane, protease, catalase, cellulose and IAA characteristics, multiple fungal pathogens of banana wilt pathogen, litchi anthrax germs, litchi frost phytophthora pathogens, rice blast fungus, cucumber wilt pathogen and the like, and growth of lettuce plants is obviously promoted; the K6 strain can be successfully planted, and disease preventing functional genes of yndj, srfAB, fend and ituC are expressed in soil; the strain is high in reproduction speed, simple in production technology, high in adverse resistance, easy to store and favorable for industrialized production, the biological fertilizer is prepared with the strain, soil-born diseases can be prevented and controlled, growth of the plants can be promoted, and application prospect is broad.

Owner:SOUTH CHINA AGRI UNIV

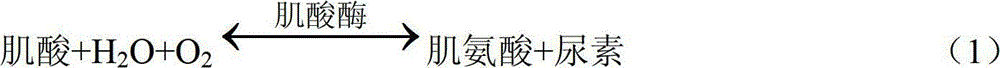

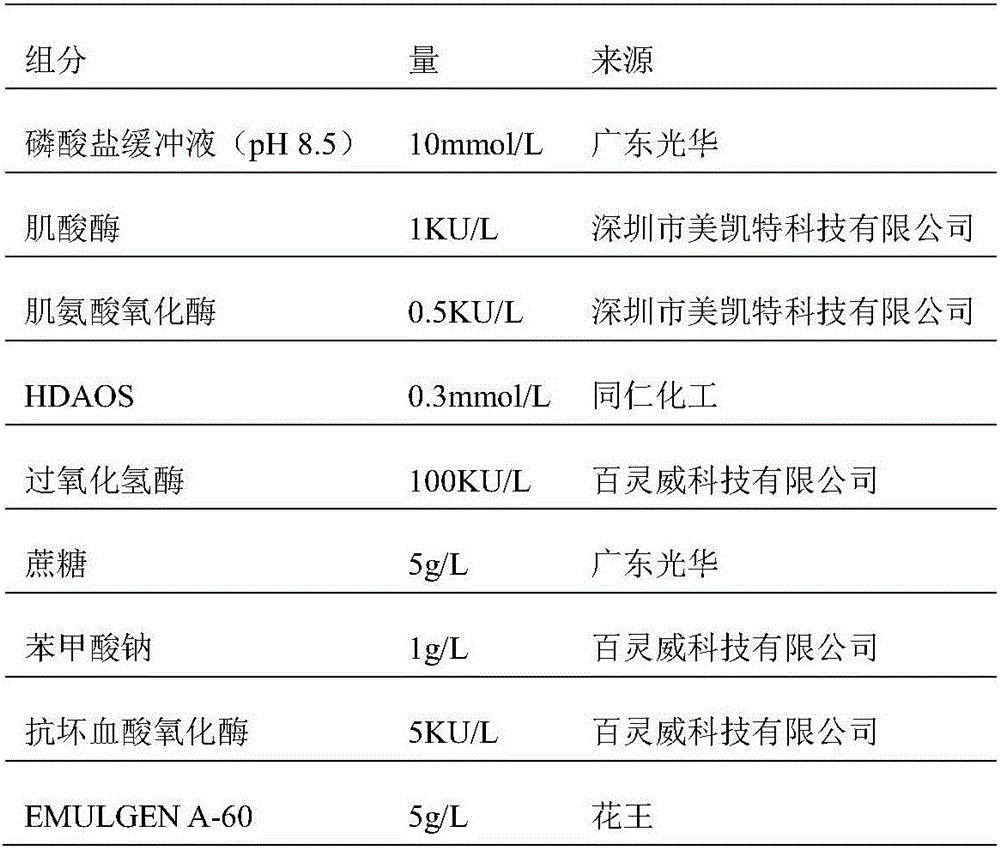

Two-step enzyme measuring method and measuring reagent for creatinine in blood serum

ActiveCN102721684AAvoid accuracyDensity avoidanceMaterial analysis by observing effect on chemical indicatorCreatinine risePeroxidase

The invention discloses a two-step enzyme measuring method and measuring reagents for creatinine in blood serum. The hydrogen peroxide generated by endogenous creatine is eliminated by utilizing catalase in a reagent 1 of the creatinine measuring reagents, and the catalase in the reagent 1 is suppressed by utilizing the catalase in a reagent 2 of the creatinine measuring reagents, so that the creatinine content in a sample is measured. The invention has the advantages that the phenomenon that the cost is increased because of oxidizing hydrogen peroxide by the catalase, so that the detection result is low in accuracy and precision is avoided.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

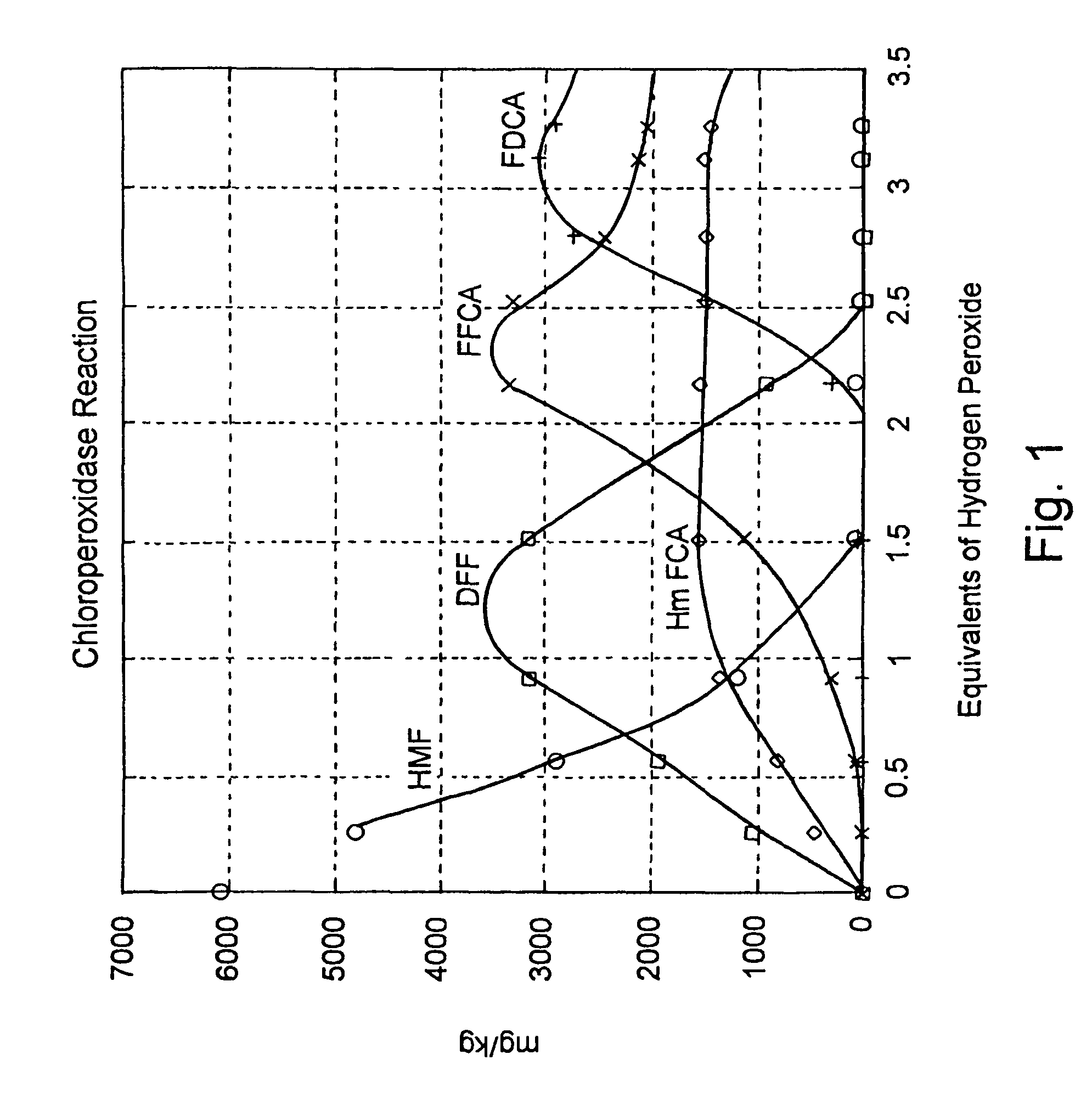

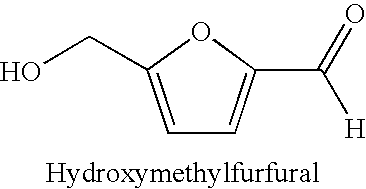

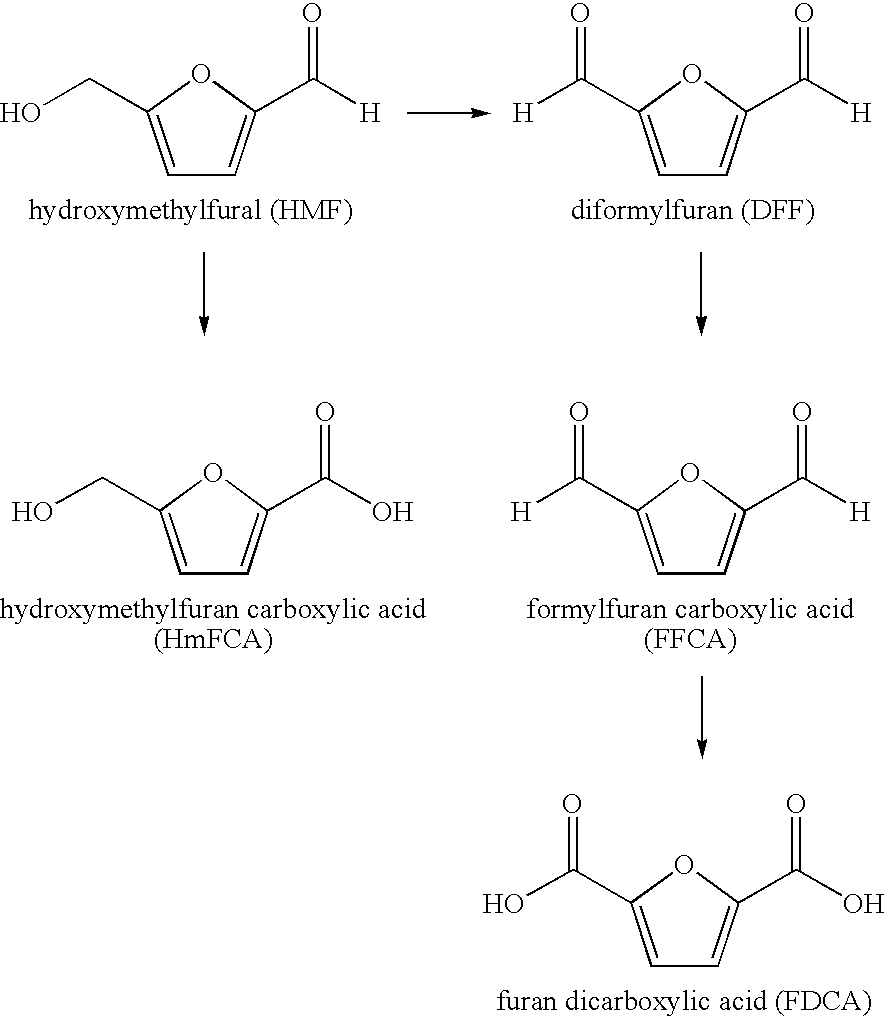

Enzymatic oxidation of hydroxymethylfurfural

A method of converting hydroxymethylfurfural and is derivative species into hydroxymethylfurfural oxidation products is disclosed. The method includes contacting the hydroxymethylfurfural species in a mixture with an enzyme that oxidizes the hydroxymethylfurfural species while controlling hydrogen peroxide in the mixture. In one exemplary embodiment the enzyme is chloroperoxidase and the hydrogen peroxide is metered into the mixture to predominantly and selectively make at least one of formylfuran carboxylic acid or furan dicarboxylic acid. In another embodiment the enzyme is aryl alcohol oxidase and catalase is included in the mixture to remove unwanted hydrogen peroxide by product and the reaction predominantly makes at least one of dimethylfuran or formylfuran carboxylic acid. When the predominant product is a carboxylic acid or furan dicarboxylic acid, it can be recovered in substantially pure form by acid precipitation.

Owner:ARCHER DANIELS MIDLAND CO

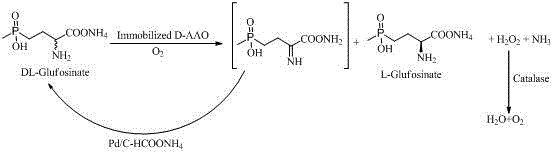

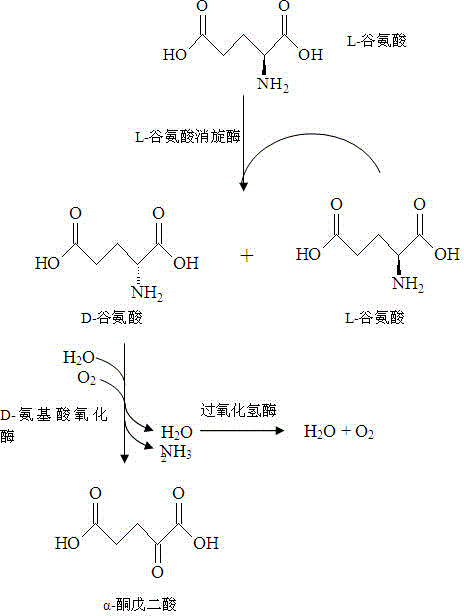

Enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium

The invention discloses an enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium. According to the method, a one-pot reaction manner is adopted, under the molecular oxygen, immobilization D-amino acid oxidase catalyzes D-enantiomer in an enantioselectivity mode into 2-imino-4-(hydroxy methyl phosphonyl) butyric acid in a dehydrogenation mode, and palladium-ammonium formate catalyzes 2-imino -4-(hydroxy methyl phosphonyl) butyric acid into DL-glufosinate-ammonium in an in-situ reduction mode. Hydrogen peroxide produced in the process is efficiently decomposed into water and oxygen through catalase. Complete reacemization removing of DL-glufosinate-ammonium and efficient preparing of L-glufosinate-ammonium are achieved through biological oxidation-chemical reduction circulation. The method has the advantages that the process is simple, cost is low, environmental friendliness is achieved, and energy is saved. High-concentration DL-glufosinate-ammonium can be converted into L-glufosinate-ammonium. The yield is 90%, the optical purity of the product is 99%, and the method is suitable for industrial production of L-glufosinate-ammonium.

Owner:重庆惠健生物科技有限公司

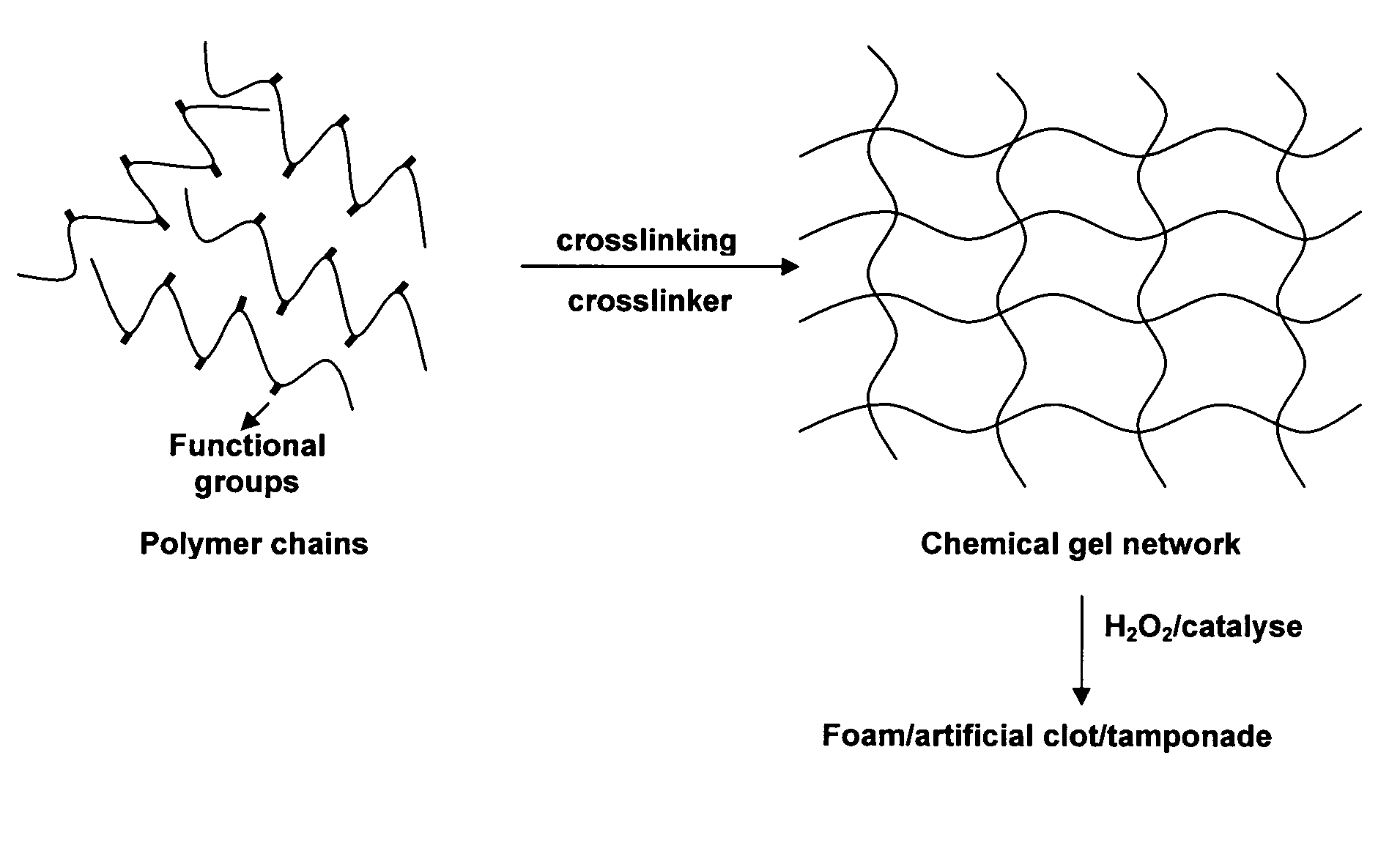

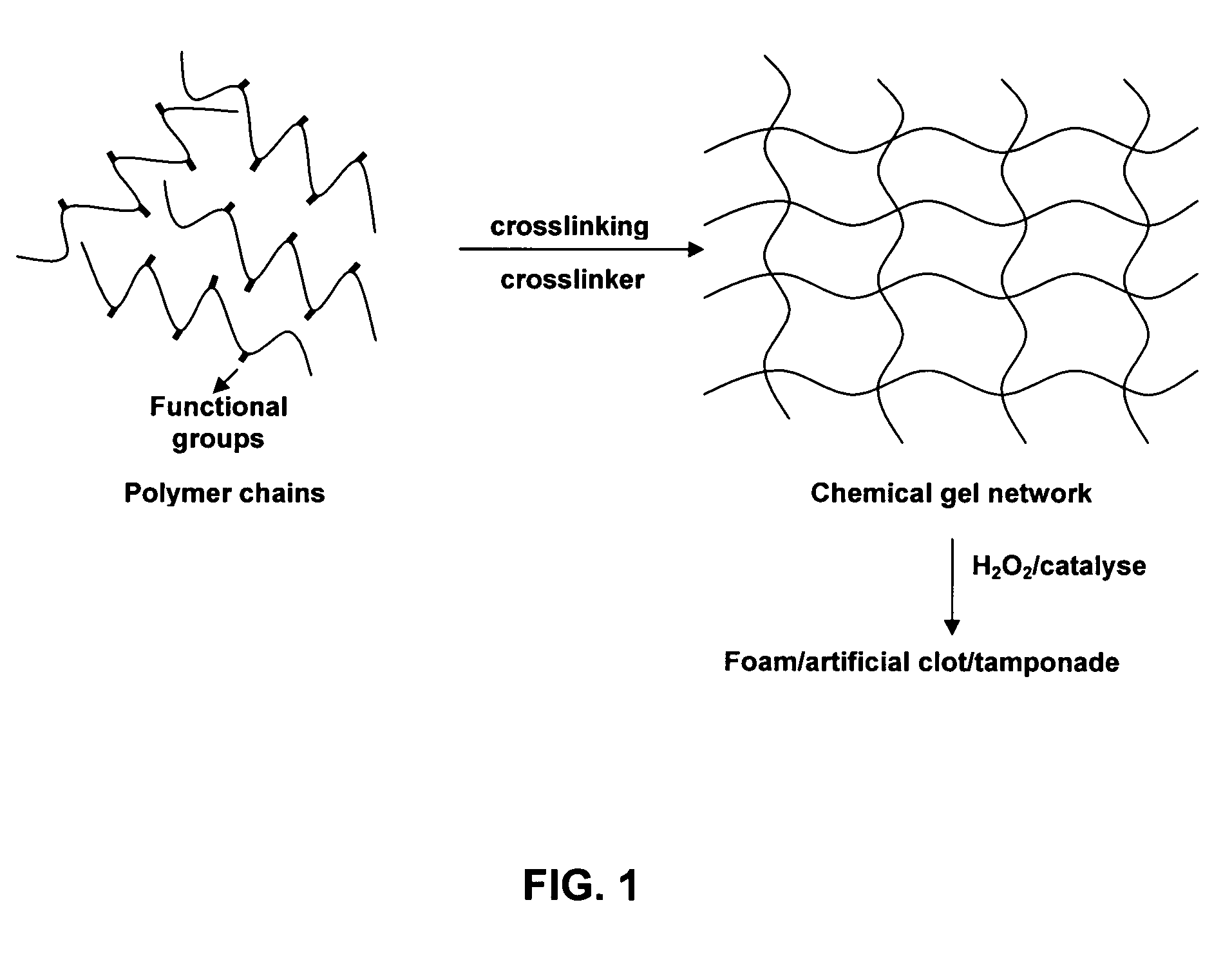

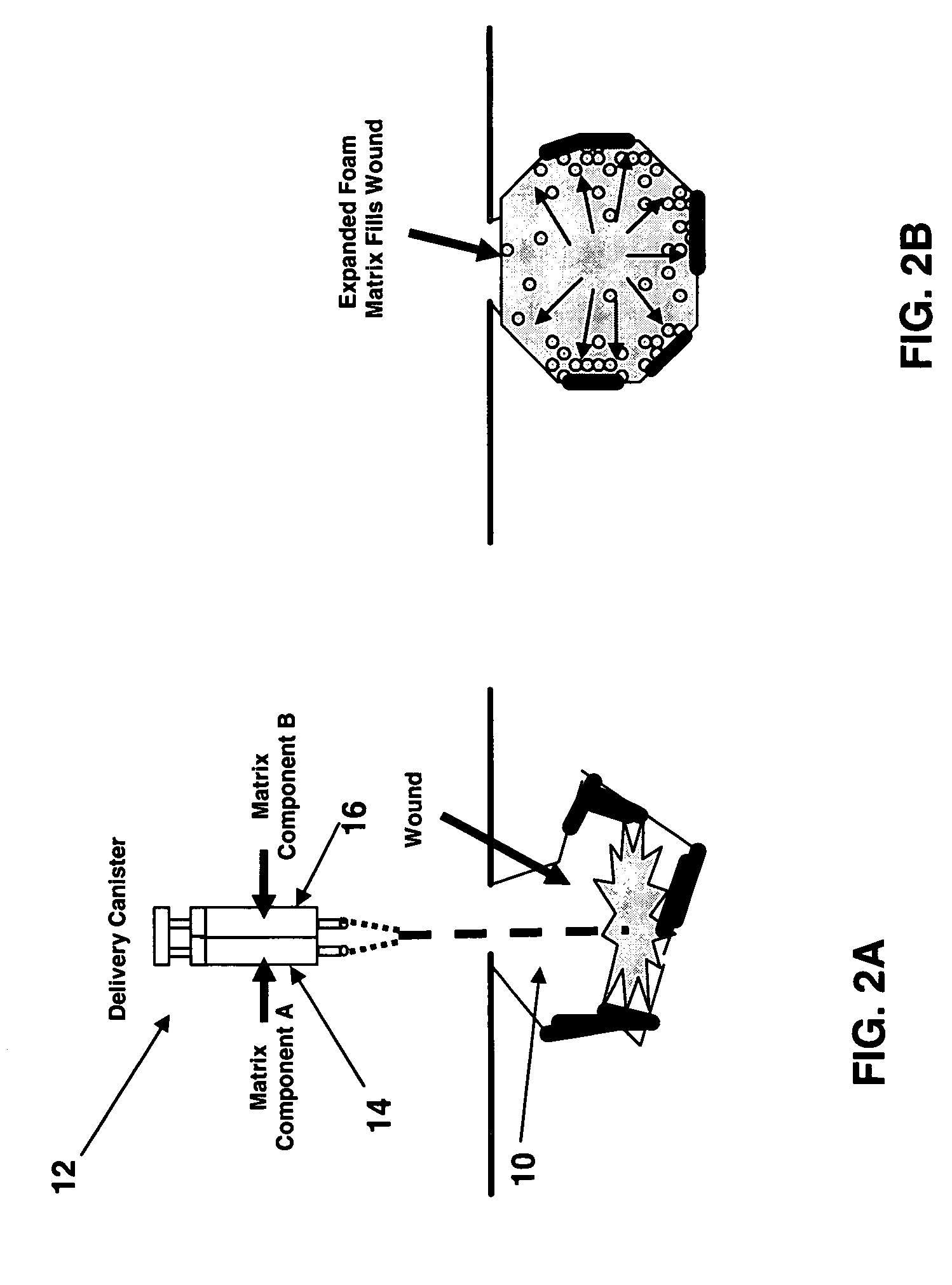

Method and composition for in situ formation of an artificial blockage to control bleeding

ActiveUS20090232876A1Improve delivery efficiencyRestrict blood flow and lossBiocideInorganic boron active ingredientsHydrogen peroxide breakdownMedicine

A composition for in situ formation of an artificial blockage to control bleeding includes a suitable amount of a polymer-forming component, a suitable amount of a crosslinking agent, hydrogen peroxide, and a decomposing agent for hydrogen peroxide. The decomposing agent includes exogenous or endogenous catalase, or both.

Owner:MATERIALS MODIFICATION INC

Preparation method for high purity fructo-oligosaccharide

ActiveCN101368195AImprove performanceSuitable for useOn/in organic carrierFermentationSucrosePeroxidase

The invention relates to a preparation method of high purified fructo-oligosaccharide, in particular to a method for preparing the high purified fructo-oligosaccharide by using immobilized enzyme. The preparation method of the invention prepares immobilized fructosyltransferase, immobilized glucose oxidase and immobilized mimic hydrogen peroxidase; then prepared enzymes are used to prepare the high purified fructo-oligosaccharide through an interrupted or continuous production method. In the preparation method, cheap metalporphyrin compounds are used as the mimic hydrogen peroxidase to replace expansive catalase; the fructosyltransferase, the glucose oxidase and the mimic hydrogen peroxidase are all immobilized and all can be recycled and reused; the stability and the operating factor of the enzymes are improved; the production cost for preparing the high purified fructo-oligosaccharide is greatly reduced. The preparation method can use one step method to directly produce the high purified fructo-oligosaccharide from cane sugar.

Owner:量子高科(广东)生物有限公司

Method for raising stability for preserving catalase prepared by microbiological method

InactiveCN1563373AImprove stabilityLow priceEnzyme stabilisationOxidoreductasesMicroorganismHydrogen

A method for increasing hydrogen peroxidase stability relates to a biological zyme used in clean production in textile industry. This invention takes the thermoascus aurantiacus IFO9862 as the initial strain to be prepared to get the hydrogen peroxidase after liquid deep fermentation to be ultrafitered, concentrated and added by certain stabilizers, NaCl, or glue or glycerol kept for 60days under 40deg.C its alive reservation is over 90%.

Owner:JIANGNAN UNIV

Method and composition for in situ formation and/or expansion of a polymer-based hemostatic agent to control bleeding

ActiveUS20090232877A1Reducing and restricting and arrestingEfficient deliveryPeroxide active ingredientsAbsorbent padsCatalasePolymer

A composition for in situ formation and / or expansion of a polymer-based hemostatic agent to control bleeding includes a suitable amount of a polymer or polymer-forming component, hydrogen peroxide or chemical(s) capable of forming hydrogen peroxide, or a combination of both, and a decomposing agent for hydrogen peroxide. The decomposing agent includes an endogenously or exogenously supplied catalyst (other than catalase), or both, and / or the polymer or polymer-forming component.

Owner:MATERIALS MODIFICATION INC

Preparation method of D-pantoic acid inner ester

The invention relates to the technical field of biosynthesis, and concretely discloses a preparation method of D-pantoic acid inner ester. The preparation method at least comprises the following stepsthat 1, valine is subjected to enzymatic conversion under the effects of catalase and alpha-ketoisovaleric acid reductase to obtain alpha-ketoisovaleric acid; 2, the alpha-ketoisovaleric acid and tetrahydrofolic acid react under the effects of hydroxylmethyl transferase and magnesium chloride to prepare ketopantoic acid; 3, ketopantoic acid is subjected to enzymatic conversion under the effects of alpha-ketoisovaleric acid reductase to obtain pantoic acid; 4, pantoic acid is prepared into the pantoic acid inner ester. The operation process is simple; the conversion condition is mild; the production efficiency is high; the product quality is high; the enzyme used in the process can be cyclically used; the preparation method belongs to an energy-saving, environment-friendly, green and efficient production technology; the industrial production is convenient.

Owner:JING JING PHARMA

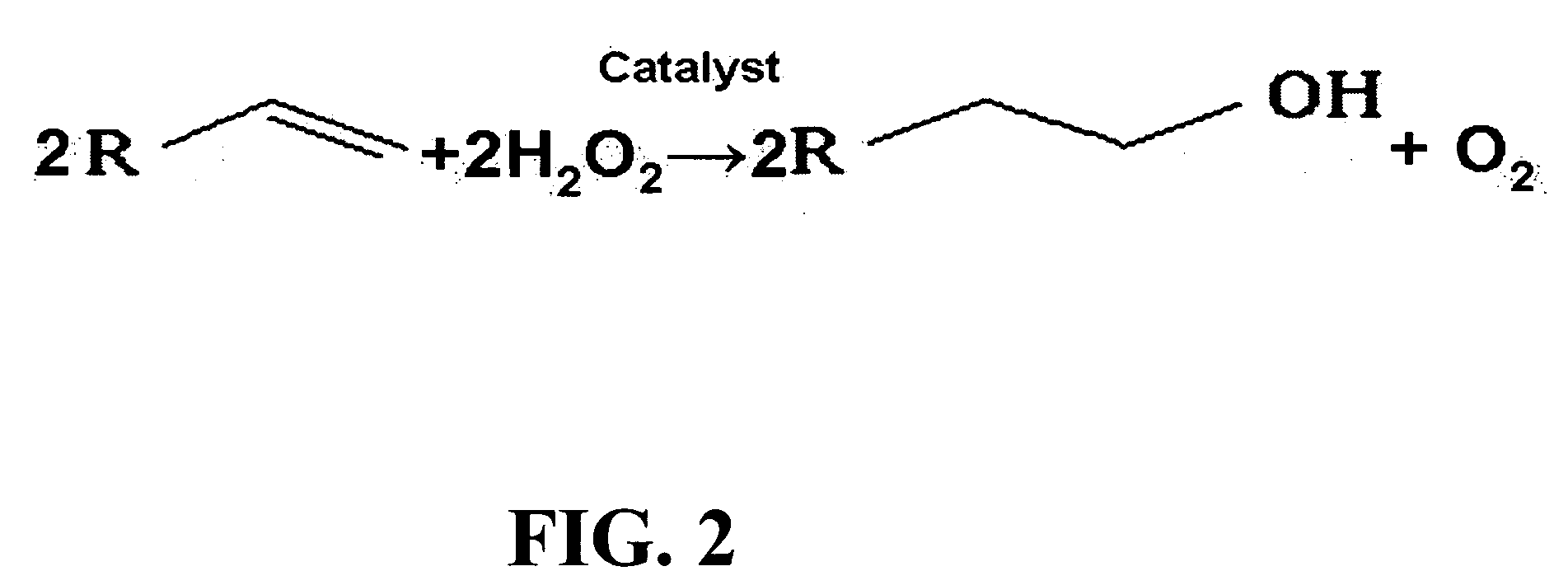

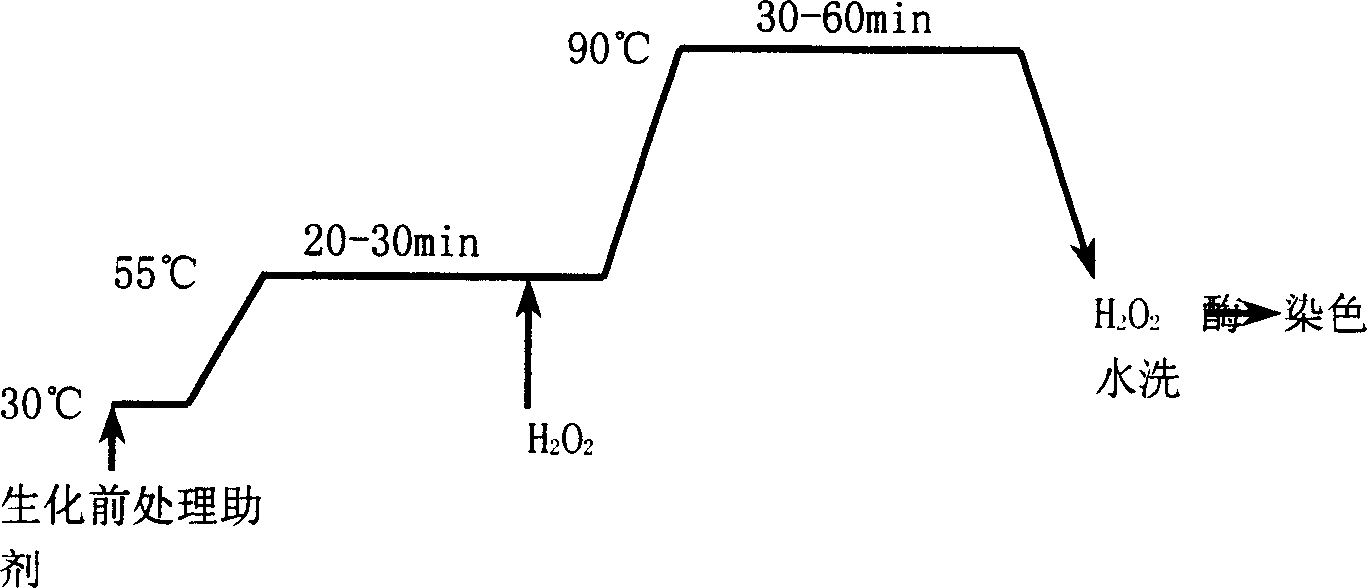

Cellulose fibre, textile assistant for union biochemical pretreatment, perparing method and use

The invention relates to the method to use special biology enzyme (pectic enzyme, fibrin enzyme, lipase, albumen enzyme, lacquer enzyme, xylan enzyme, polysaccharide enzyme, and catalase) and environment-friendly effective surfactant to produce aid fitting the biochemical pretreatment of fibrin fiber, and its fabric, and its processing technology. The aid for short flow of zoology pretreatment made of a host of biology enzyme and environment-friendly surfactant can fit the short flow of zoology pretreatment of fibrin fiber and its fabric. The invention advances the quality of the production. At the same tie, it reduces pollution to the environment, and it achieves the process of pretreatment of fibrin fiber and its fabric with the interreaction with biology enzyme and surfactant. Moreover, thep rocess does little harm to the fiber and it has an effective removement of residue. Additionally, it is friendly to the environment.

Owner:DONGHUA UNIV +1

Method for preparing alkyl glycoside

InactiveCN1775790ALight colorMild reaction conditionsSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperaturePotassium

The invention discloses a new method for preparing alkyl indicant, technically characterized in making ultramicro pulverization processing on anhydrous glucose or crystal water containing glucose, then reacting with C8-C20 high grade alcohol under the existence of organic sulphonic acid catalyst, vacuum dehydrating and obtaining alcohol solution of alkyl indicant, then neutralizing acdic catalyst with organic acid sodium or potassium salt, vacuum distilling to eliminate excessive high grade alcohol, using chelating agent or sodium silicate to screen Fe ions, Mn ions and other ions, using tetraacetyl ethylene diamine as oxydol activating agent, bleaching alkyl indicant solution, and finally using hydrogen peroxide enzyme to eliminate the residual hydrogen peroxide from the products. The advantages of the invention: the reaction temperature is low and the reacting time is short, the process is simple and convenient, the production cost is low, and the prepared alkyl indicant is colorless or approximately colorless, transparent, peculiar smell-free, and stable to store.

Owner:NORTHWEST UNIV(CN)

Mimic enzyme, preparation method, application method and application of mimic enzyme

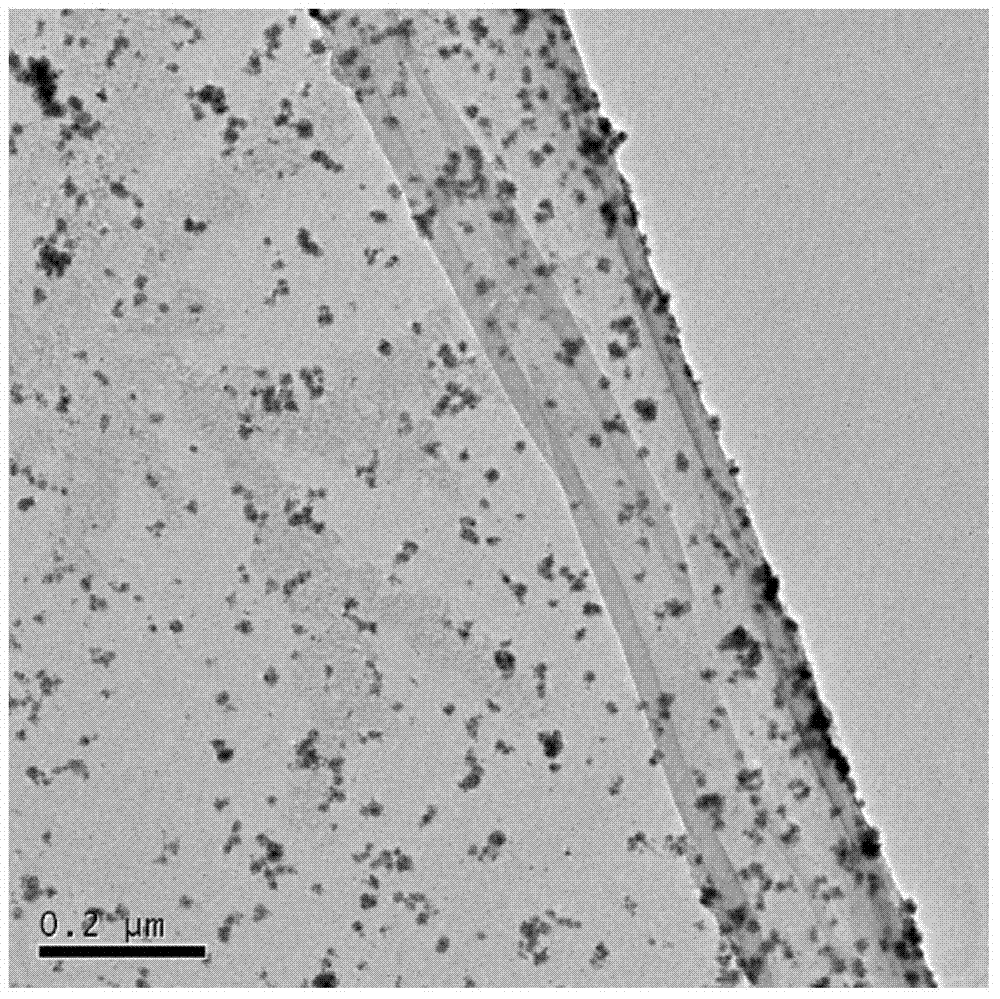

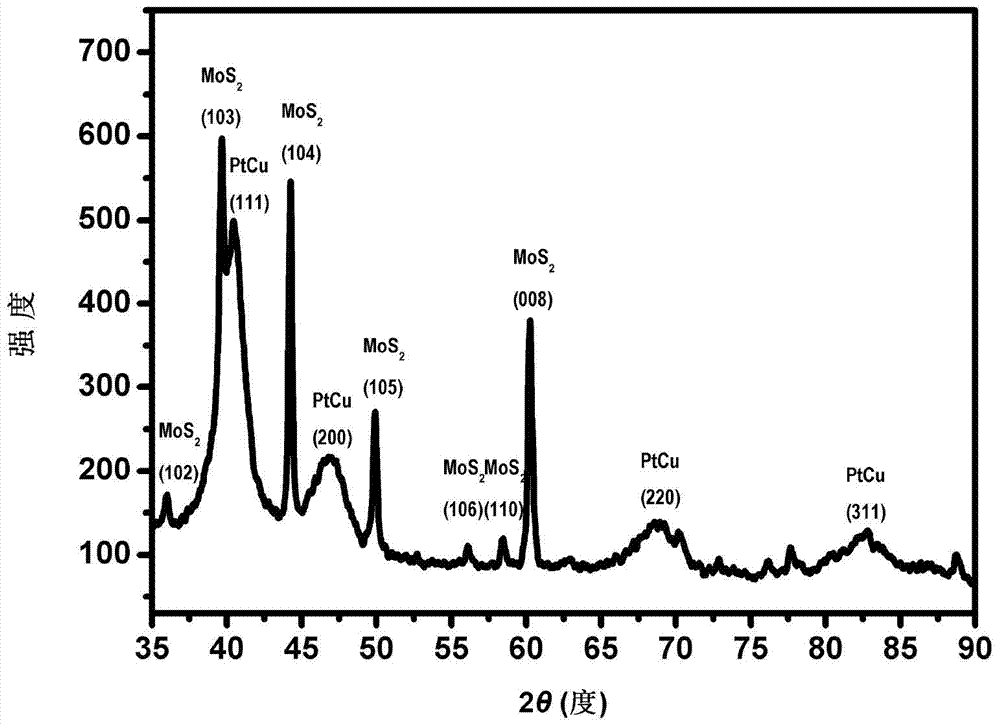

ActiveCN104759633AGood water solubilityGood dispersionPhysical/chemical process catalystsMaterial analysis by observing effect on chemical indicatorPlatinum saltsPeroxidase

The invention relates to mimic enzyme. The mimic enzyme is a molybdenum disulfide sheet layer of which the surface is loaded with platinum-copper alloy nanoparticles. The preparation method comprises the step of performing reduction reaction for a water solution in which the molybdenum disulfide sheet layer, platinum salt and copper salt to obtain the mimic enzyme that is the molybdenum disulfide sheet layer of which the surface is loaded with the platinum-copper alloy nanoparticles. The mimic enzyme has a plurality characteristics of activity of oxidase, peroxidase and catalase; different mimic enzyme activity can be used for creating different methods or applied to the unknown fields; the preparation method is simple and easy to be carried out; the conditions are mild; the one-step method can be carried out to reduce and prepare through a water-phase system.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

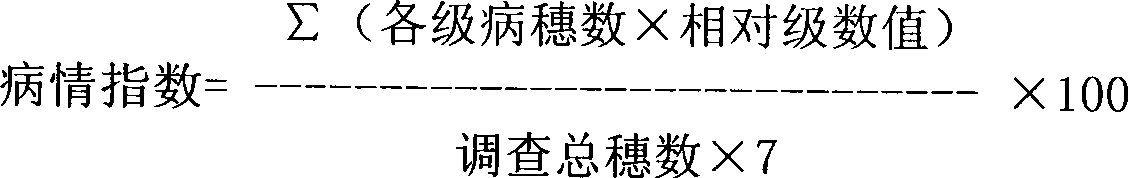

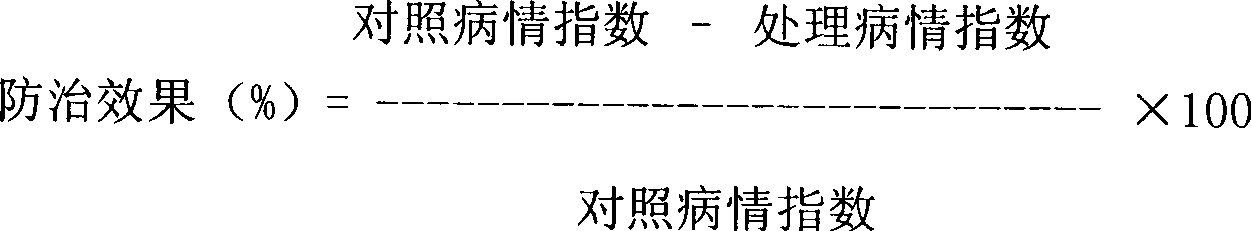

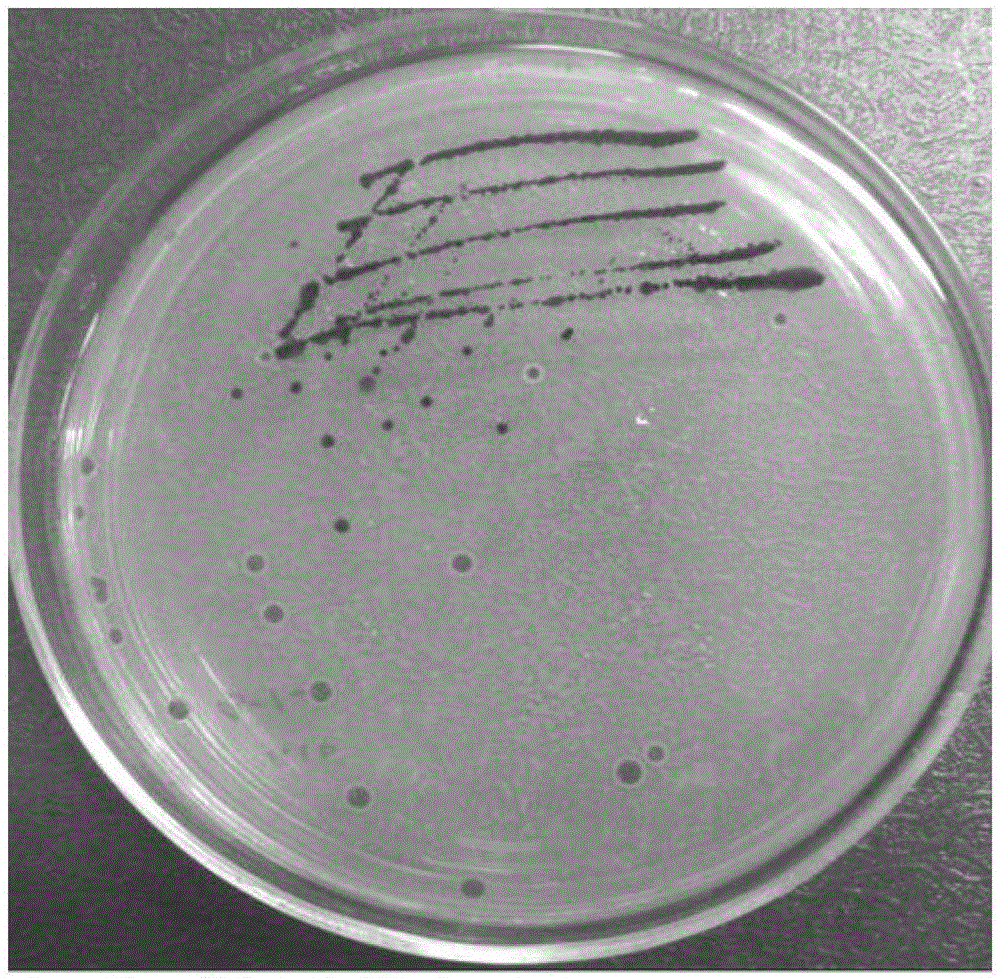

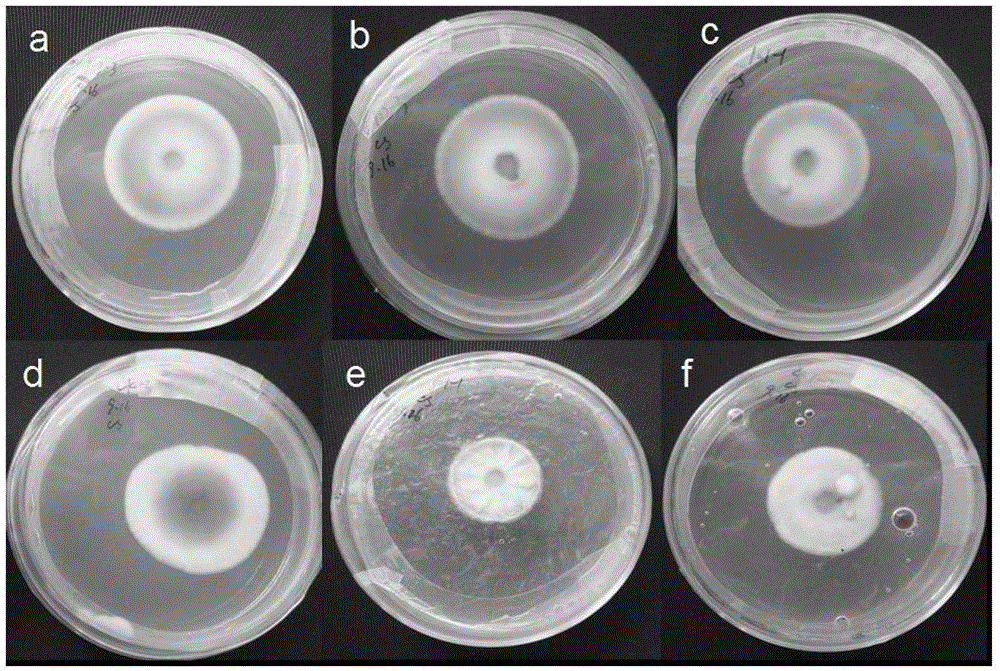

Rhodopseudomonas palustris strains, application of rhodopseudomonas palustris strains, fungicide pesticide as well as preparation method and application of fungicide pesticide

ActiveCN102876615AThe cultivation method is simpleReduce manufacturing costBiocideBacteriaBiological activationFermentation

The invention discloses a rhodopseudomonas palustris CCTCC M 2012224, and application of the rhodopseudomonas palustris CCTCC M 2012224 in prevention and control of rice false smut or improvement of catalase activity in the rice body, and further discloses an antagonistic fungicide obtained by activation, seed culture and production culture of the strains. Fermentation supernate obtained through fermentation and centrifugation of the antagonistic fungicide can be used as an antagonistic pesticide; thallus crushing liquid obtained by fermentation culture and crushing of the antagonistic fungicide can also be used as the antagonistic pesticide. The antagonistic fungicide and the antagonistic pesticides obtained both can be used for preventing and controlling the rice false smut and improving the catalase activity in the rice body. The rhodopseudomonas palustris CCTCC M 2012224, the antagonistic fungicide and the antagonistic pesticides have the advantages of low production cost, nontoxicity, environmental friendliness and the like, is convenient to use, and can be used for preventing and controlling the rice false smut and improving the disease resistance of rice.

Owner:湖南新长山农业发展股份有限公司

Heat-generating composition for topical application to skin

ActiveUS7211249B2Protection from damageHeated withCosmetic preparationsPeptide/protein ingredientsSkin surfaceOxygen

The present invention provides a method of sustaining the rate of heat felt on the skin as a result of an exothermic reaction between a combination of an unencapsulated and an encapsulated catalase, and peroxide. The catalase component provides a sustained heat release and in combination with other non-catalase heat-generating agents, the rate of heat released and felt on the skin can be further controlled. The compositions of the present invention also soften the skin and contribute to the health of the skin by reducing the presence of oxygen free radicals on the skin surface.

Owner:COLOR ACCESS

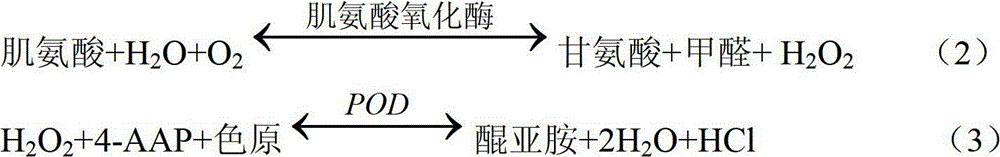

Kit and method for assaying creatinine

ActiveCN106198509AMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementSarcosine oxidaseCreatininase

The invention relates to a kit and a method for assaying creatinine. The kit includes a first reagent group and a second reagent group. The first reagent group includes creatinase, sarcosine oxidase, chromogen and catalase; the second reagent group includes creatininase, 4-amino antipyrine and peroxidase. The chromogen is selected from N-(2-hydroxyl-3-sulfopropyl)-3,5-dimethoxyaniline or a sodium salt thereof, and N-ethyl-N-(2-hydroxyl-3-sulfopropyl)-3,5-dimethoxyaniline. The kit and the method can reduce interference during the detection of the creatinine due to the calcium dobesilate and / or etamsylate that exist in a sample.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI +1

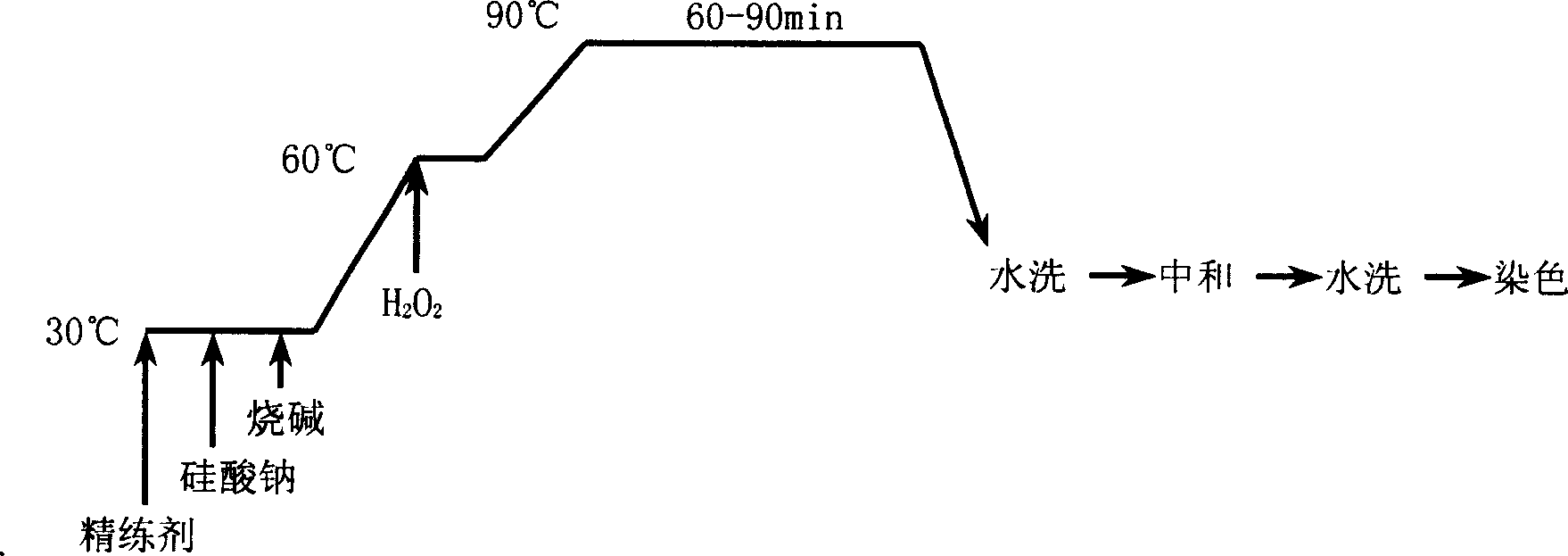

Elastic polyester-cotton fabric dyeing and finishing pretreatment method

InactiveCN103821006AReduce energy consumptionLow processingBiochemical fibre treatmentBleaching apparatusPolyesterTextile printer

The invention relates to an elastic polyester-cotton fabric dyeing and finishing pretreatment method and belongs to the field of a textile printing and dyeing technology. The invention aims to raise whiteness and water absorbability of a product and minimize reduction of mechanical properties of fabric. Firstly, hot-water preshrinking and pre-setting treatment are carried out on fabric so as to raise external dimension stability of the elastic fabric; then, dyeing and finishing pretreatment is carried out with amylase, pectase and the like so as to remove most non-fibrous symbiont; and finally, hydrogen peroxide bleaching and deoxygenation treatment are combined to remove a few pigment and impurities in the elastic fabric so as to finish dyeing and finishing pretreatment of the fabric. The method comprises the following technological steps: preshrinking and pre-setting; bio-enzyme (amylase, pectase, laccase and cellulose) treatment; hydrogen peroxide bleaching; and catalase deoxygenation. In comparison with a traditional alkali pretreatment process, the method provided by the invention has advantages as follows: production energy consumption is reduced, and quality of the elastic polyester-cotton fabric is raised.

Owner:吴江市桃源海润印染有限公司

Degradation method for agar polysaccharide

A process for degradating the agar polyose to obtain agar oligose includes such steps as dissolving the agar powder or agar strips in the solution of sodium hydrogen phosphate and sodium dihydrogen phosphate, adding H2O2 for degradating under existance of Fe ions, adding VC for triggering reaction, adding hydrogen peroxidase for stopping reaction, high-speed centrifugal treating, depositing in alcohol, taking supernatant, evaporating and freeze drying. The resultant product has the molecular weight of about 3000 and the action and function of alpha-glucosidase inhibitor. Its advantages are high output rate (more than 85%) and low cost.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

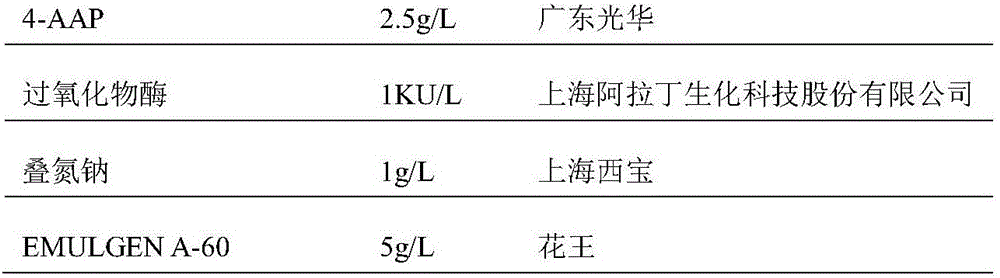

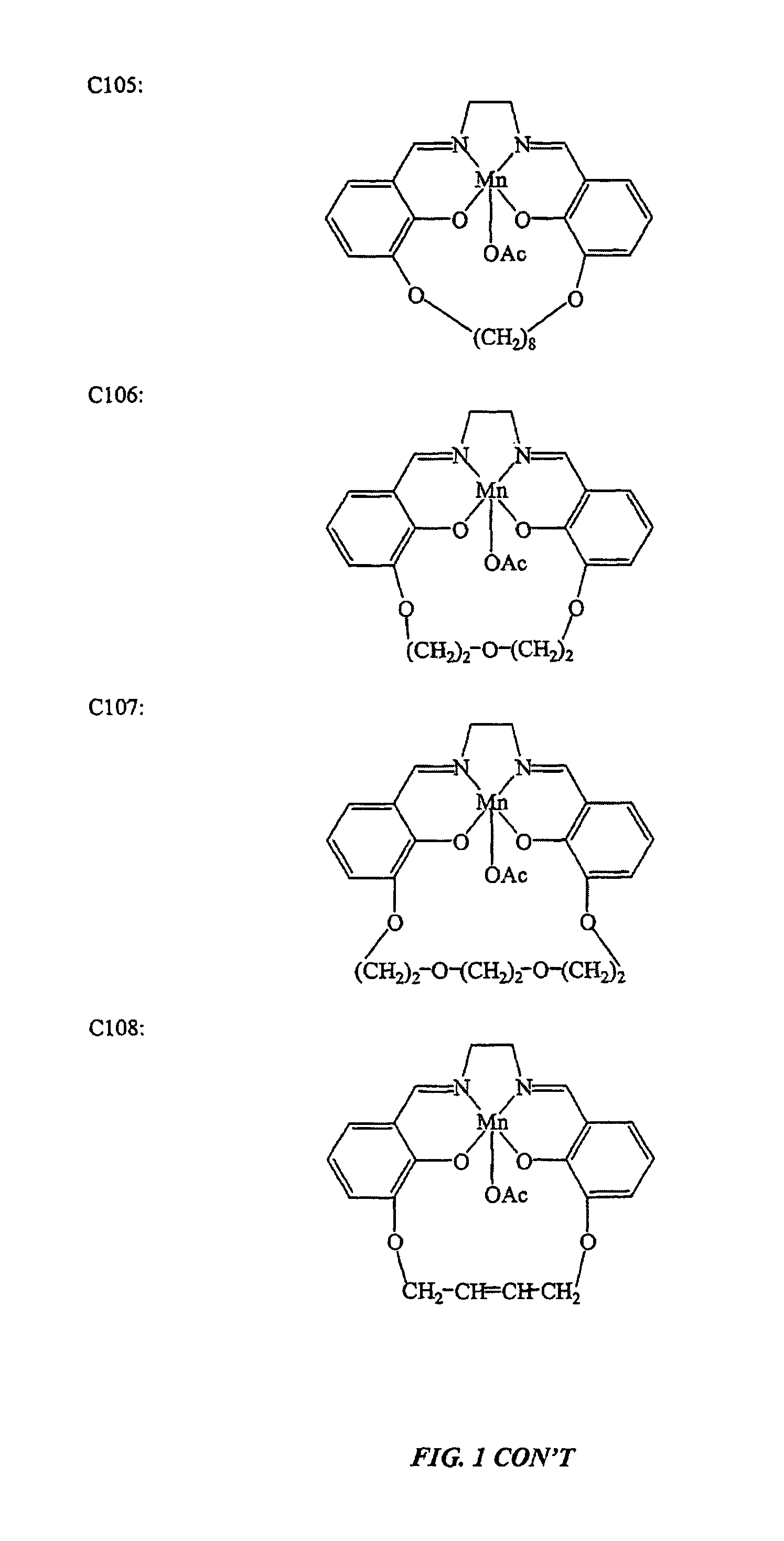

Cyclic salen-metal compounds as scavengers for oxygen radicals and useful as antioxidants in the treatment and prevention of diseases

InactiveUS7122537B2Improve stabilityPotent antioxidant and/or free radical scavenging propertiesBiocideNervous disorderDiseaseScavenger

This invention provides antioxidant cyclic salen-metal compounds, compositions of such antioxidant cyclic salen-metal compounds having superoxide activity, catalase activity and / or peroxidase activity and methods of using such antioxidant cyclic salen-metal compositions to treat or prevent a disease associated with cell or tissue damage produced by free radicals, such as superoxide.

Owner:EUKARION

Mimic enzyme test paper for detecting hydrogen peroxide and application thereof

ActiveCN103674939ASimple structureEasy to detectMaterial analysis by observing effect on chemical indicatorChemical industryCellulose

The invention relates to detection on hydrogen peroxide, and specifically discloses mimic enzyme test paper for detecting hydrogen peroxide, and preparation and application thereof. The mimic enzyme test paper is a surface modified cellulosic material loaded with an iron-based compound and a color developing agent, wherein the load amount of the iron-based compound is 1%-30% of the mass of the surface modified cellulosic material; the load amount of the color developing agent is 0.1%-20% of the mass of the surface modified cellulosic material; the color developing agent is 3, 3', 5, 5'-tetramethyl benzidine (TMB). According to the test paper provided by the invention, the color developing agent and the iron-based compound are loaded on the cellulosic material (such as filter paper, cotton and cotton cloth), the test paper simulates enzymatic decomposition of hydrogen peroxide and detects hydrogen peroxide, the mimic enzyme test paper is used in chemical industry, spinning, environment protection, medical treatment and food processing, and the application belongs to detection on hydrogen peroxide in the range of food safety, medical treatment, public health and environmental technology.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for preparing mixed immobilized glucose oxidase/catalase microspheres

InactiveCN102199592ACo-immobilizationReduce steric hindrance effectOn/in organic carrierMulti-enzyme systemsFreeze-dryingArginine

The invention provides a method for preparing mixed immobilized glucose oxidase (GOD) / catalase (CAT) microspheres and belongs to the technical field of immobilized enzyme. The method comprises the following steps: on the basis of using chitosan-arginine anionic microspheres as carrier, adding a mixed solution of GOD and CAT and glutaraldehyde, performing crosslinking reaction, filtering, washing,and performing freeze drying to prepare mixed immobilized GOD / CAT microspheres. The method has the characteristics of mild reaction conditions, higher recovery rate of enzyme activity, long half-lifeof immobilized enzyme, simplicity in operation, low cost, cleanness, safety, and the like. The product prepared by the method can be widely used in the industries of medicines, food, water treatment,cement and the like. The product can also be used as a glucose-removing reagent, an anti-oxidation reagent, a bactericide, a glucose quantitative analysis reagent and the like.

Owner:CHONGQING UNIV

Straw bio-enzyme degradation aid and degradation pulping process

InactiveCN102230288AThe role of strong biological enzymesHigh activityPulp bleachingAlkylphenolStrong acids

The invention relates to a straw bio-enzyme degradation aid in the technical field of straw degradation, which comprises the following components in percentage by weight: 8 to 10 percent of cellulase, 6 to 11 percent of lipase, 6 to 10 percent of alpha-1,4-glucose hydrolase, 4 to 10 percent of catalase, 6 to 20 percent of urea, 6 to 16 percent of magnesium sulfate, 8 to 15 percent of fatty alcohol-polyoxyethylene ether, 11 to 15 percent of alkylphenol polyoxyethylene ether OP and the balance of excipient. A degradation pulping process for the straw bio-enzyme degradation aid comprises the following steps of: cleaning straw, cutting into segments, putting the segments into a quick pulping machine, adding water and the straw bio-enzyme degradation aid, mixing uniformly, and heating to the temperature of between 50 and 60 DEG C in the quick pulping machine for rubbing to perform reaction for 1 to 1.5 hours; and adding hydrogen peroxide for bleaching, and when the whiteness is more than 70 percent which is required by International standard organization (ISO), stopping the reaction to obtain paper pulp. The degradation pulping process is non-pollution, thermophilic digestion is avoided, strong base and strong acid are not used, the requirement of environment-friendly pulping is met, waste water is not discharged during pulping, a large amount of water for production and energy canbe saved, the production cost is reduced, and the pulping speed is accelerated.

Owner:TAIAN QINENG CHEM TECH

Treatment of skin damage

InactiveUS20100267825A1Keep in touchBiocideBioreactor/fermenter combinationsTreatment optionsStratum corneum

Methods and apparatus are disclosed for diagnosing and treating oxidative skin damage in a subject. The therapeutic method can comprise: (i) diagnosing a level of oxidative skin damage in a sample comprising stratum corneum of the subject; and (ii) recommending a therapeutic regime for treatment of oxidative skin damage in the subject, wherein said recommendation comprises a recommendation to administer a pharmaceutical formulation comprising an amount of one or more specific synthetic SOD / catalase mimetics sufficient to treat the level of oxidative skin damage of the subject as diagnosed. The diagnostic method can further include obtaining a sample from the stratum corneum of a subject; measuring the level of at least one oxidized substance in the sample; and comparing a detected level of the oxidized substance with a standard, whereby an elevated level of the oxidized substance is indicative of skin damage.

Owner:EUKARION

Method for producing alpha-ketoglutaric acid by virtue of enzymic method

InactiveCN104152498AEasy to removeAvoid the defect of slow conversion reactionBacteriaMicroorganism based processesBiotechnologyGlutaric acid

The invention relates to a method for producing alpha-ketoglutaric acid by virtue of an enzymic method. The method comprises the following steps: respectively synthesizing a glr gene and a daao gene and constructing expression vectors pET24a-glr and pET24a-daao; after double digestion of the expression vectors pET24a-glr and pET24a-daao respectively, connecting the expression vectors pET24a-glr and pET24a-daao to construct a double expression vector pET24a-glr-daao and transforming the double expression vector to escherichia coli to prepare a genetically engineered bacterium which simultaneously expresses glutamate racemase and D-amino acid oxidase; adding a wet thallus of the genetically engineered bacterium into water in a fermentation tank, then adding L-glutamic acid and catalase, and finally adjusting the pH by virtue of sodium hydroxide to prepare a reaction system for reaction; separating and purifying alpha-ketoglutaric acid converted in the reaction system after reaction. The method provided by the invention is low in cost, high in conversion rate (over 84%) and product concentration, and suitable for industrial application.

Owner:洛阳华荣生物技术有限公司

Co-immobilization glucose oxidase/catalase microspheres and application thereof in production of gluconic acid or gluconic salt

InactiveCN102943069AFacilitates covalent attachmentExtended service lifeChemical industryOn/in organic carrierMicrosphereCatalytic oxidation

The invention discloses co-immobilization glucose oxidase / catalase microspheres and application thereof in preparation of gluconic acid (salt) for catalytic oxidation of glucose. The co-immobilization glucose oxidase / the catalase microspheres can effectively promote covalent linkage of carriers and enzyme molecules, immobilization efficiency is improved greatly, service life of immobilization glucose oxidase (GOD) / catalase (CAT) is prolonged remarkably, the co-immobilization glucose oxidase / the catalase microspheres can be used repeatedly, are low in production cost, and facilitate sustainable development. Gluconic acid (salt) prepared by the co-immobilization glucose oxidase / the catalase microspheres is high in yield, reaction condition is temperate, a device is simple and easy to obtain, and the production method is environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com