Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

344 results about "Glufosinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

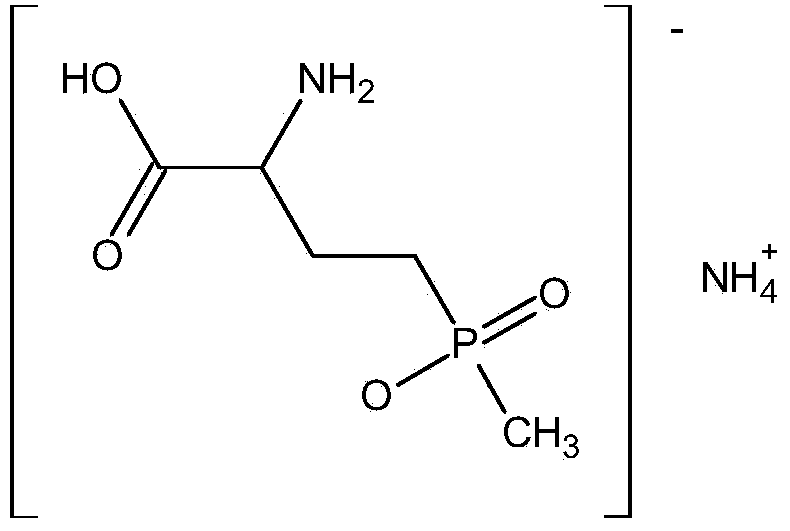

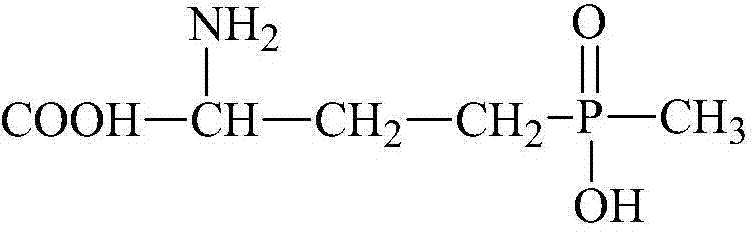

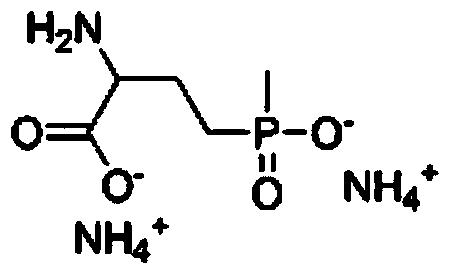

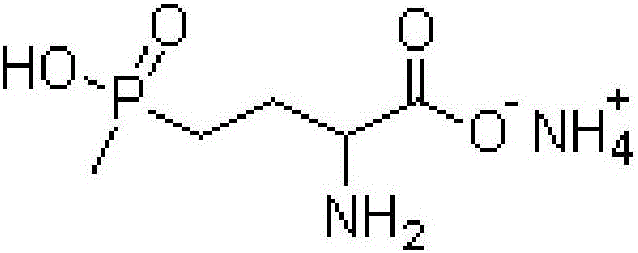

Glufosinate (also known as phosphinothricin and often sold as an ammonium salt) is a naturally occurring broad-spectrum herbicide produced by several species of Streptomyces soil bacteria. It's a non-selective, contact herbicide, with some systemic action. Plants may also metabolize bialaphos, another naturally occurring herbicide, directly into glufosinate. The compound irreversibly inhibits glutamine synthetase, an enzyme necessary for the production of glutamine and for ammonia detoxification, giving it antibacterial, antifungal and herbicidal properties. Application of glufosinate to plants leads to reduced glutamine and elevated ammonia levels in tissues, halting photosynthesis, resulting in plant death.

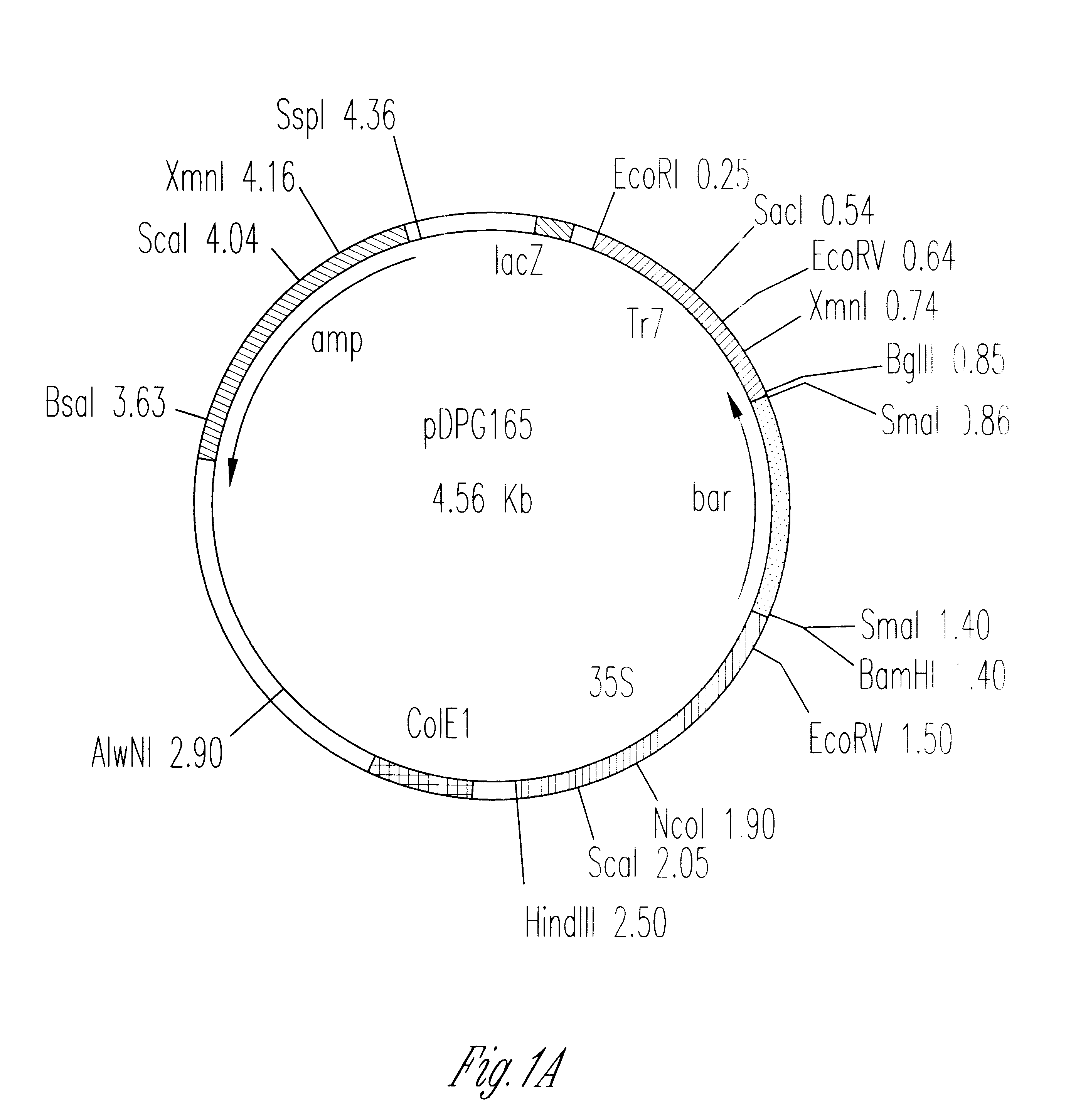

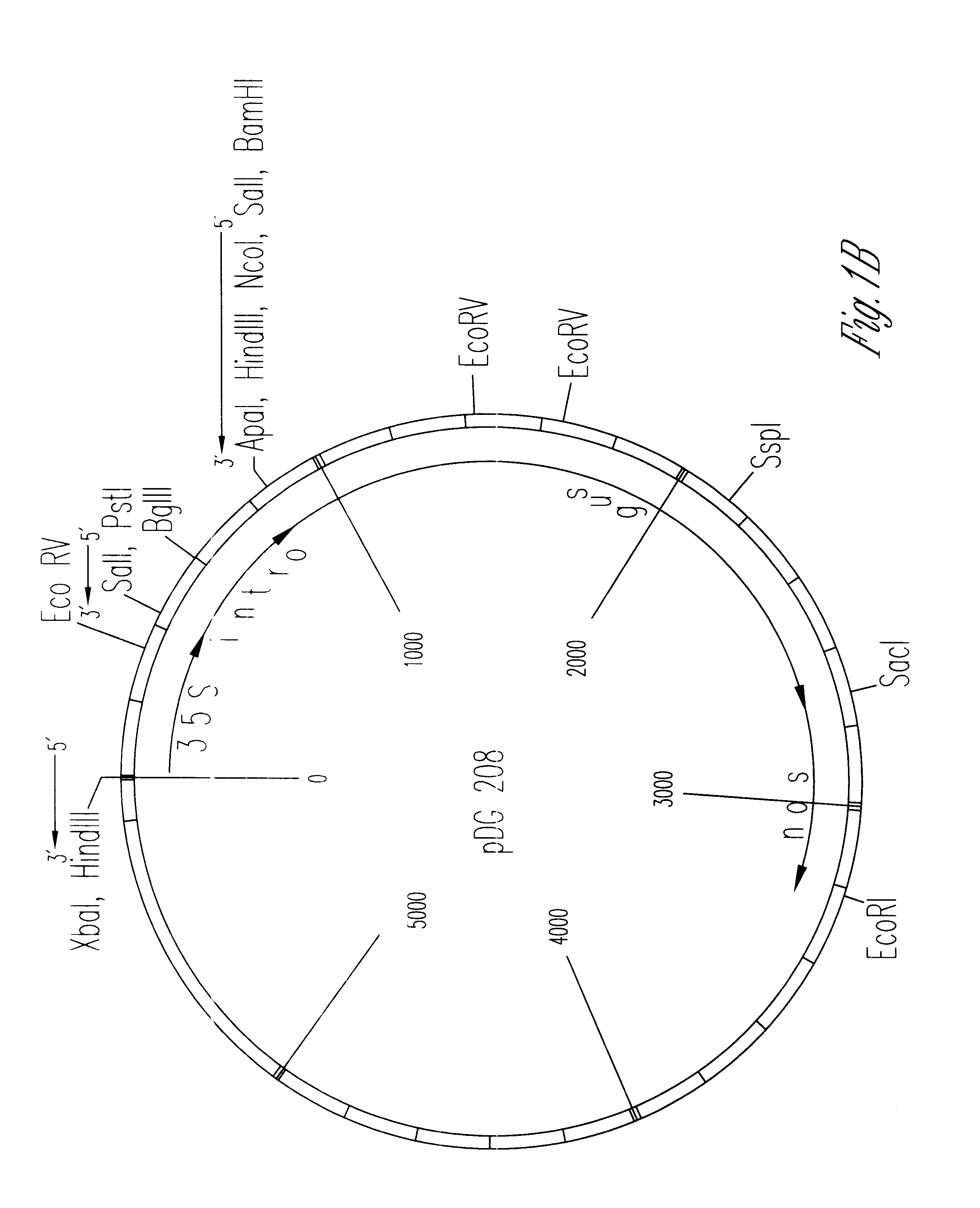

Fertile transgenic maize plants containing a gene encoding the pat protein

InactiveUS6395966B1Other foreign material introduction processesFermentationPhosphinothricin acetyltransferaseBotany

The present invention provides methods for increasing yield in plants by introducing a gene encoding phosphinothricin acetyltransferase. The invention further involves a method of transferring said increased yield phenotype to other lines of plants by crossing. A maize transformant is identified in which the phosphinothricin acetyltransferase gene integration event is correlated with increased yield.

Owner:MONSANTO TECH LLC

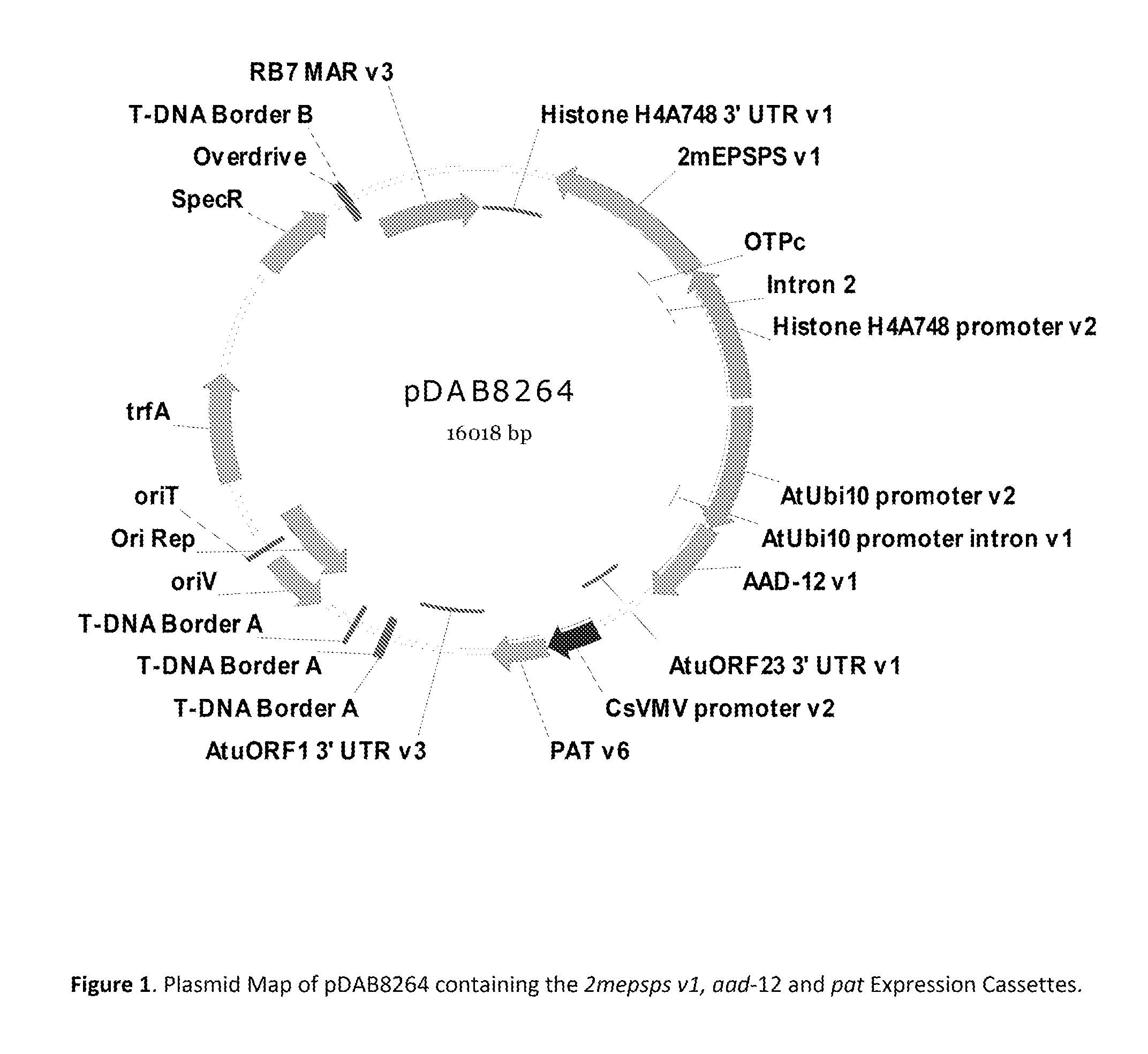

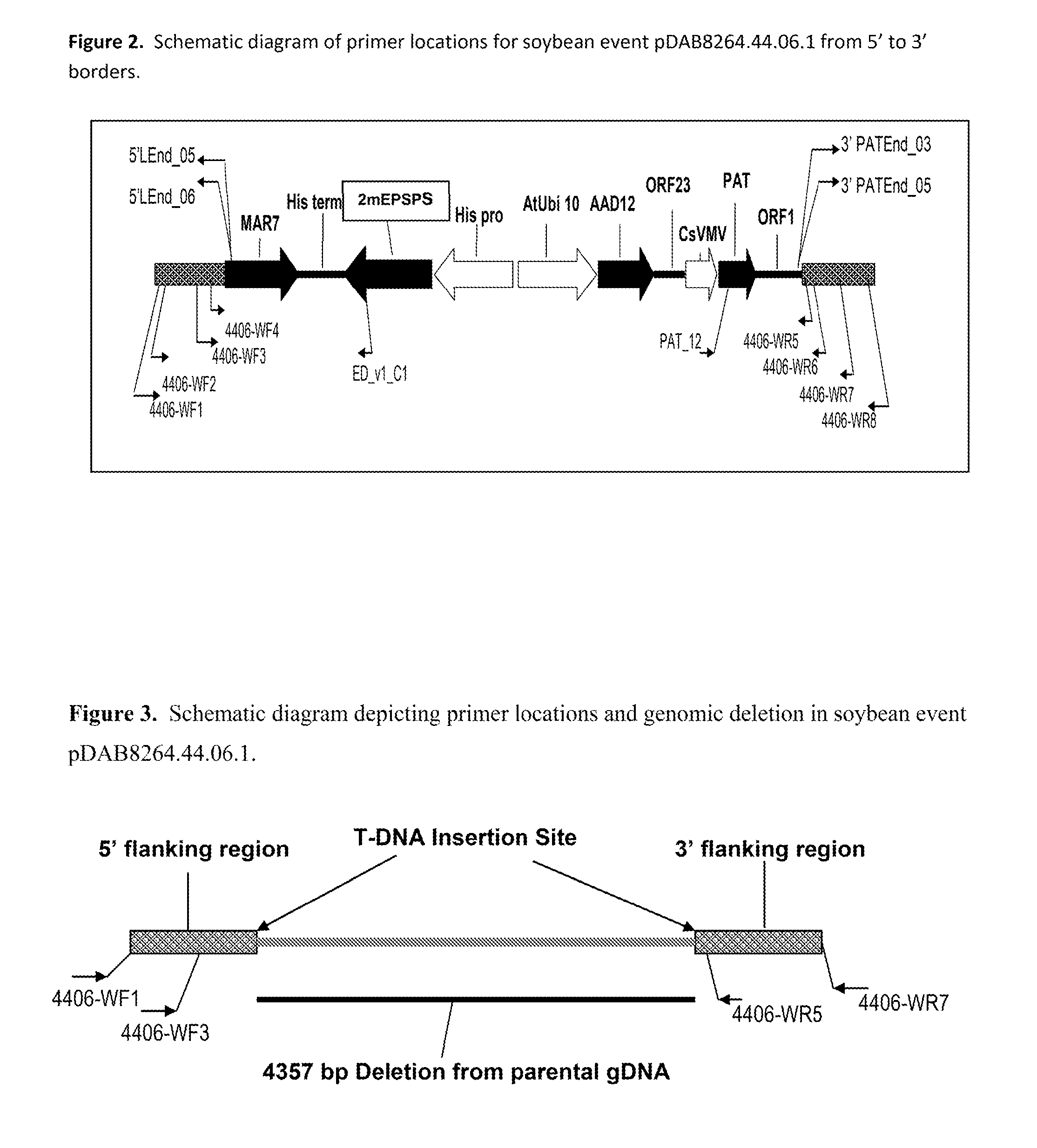

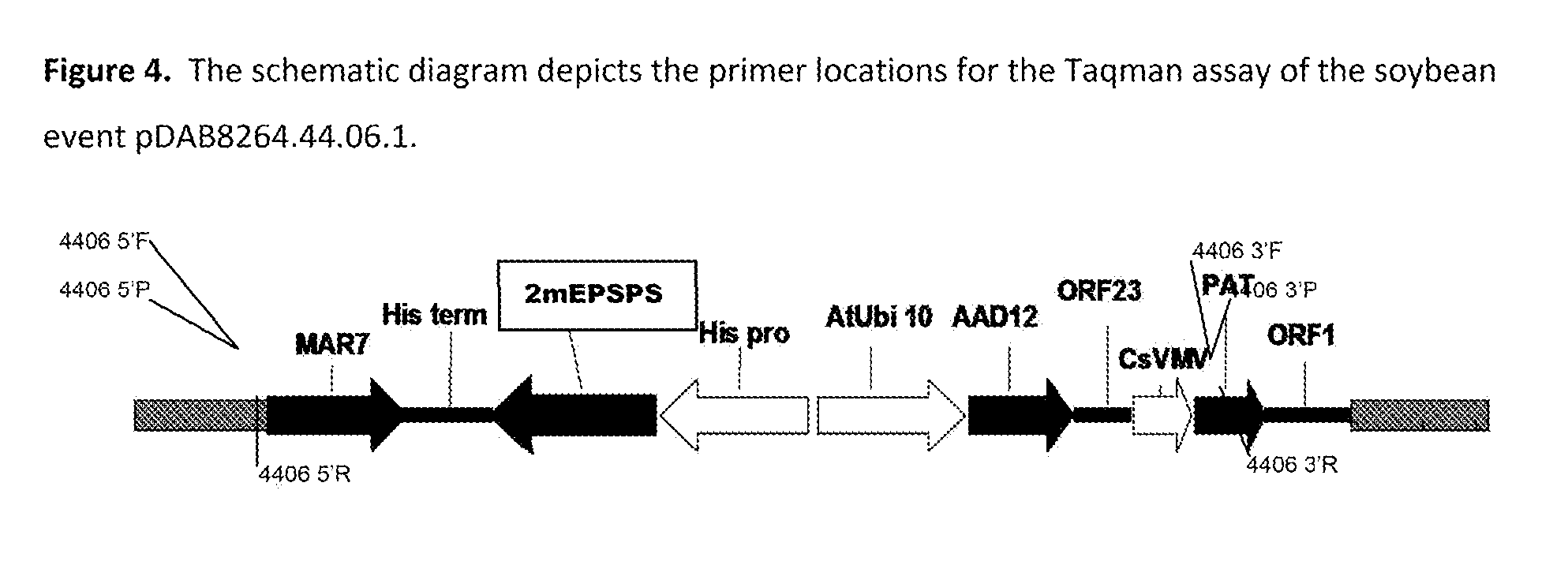

Stacked herbicide tolerance event 8264.44.06.1, related transgenic soybean lines, and detection thereof

ActiveUS9540655B2Preserve usefulnessIncrease flexibilityBiocideMicrobiological testing/measurementPcr assayMultiple traits

Owner:M S TECH +1

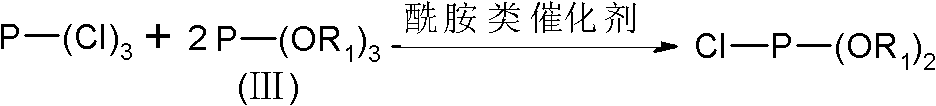

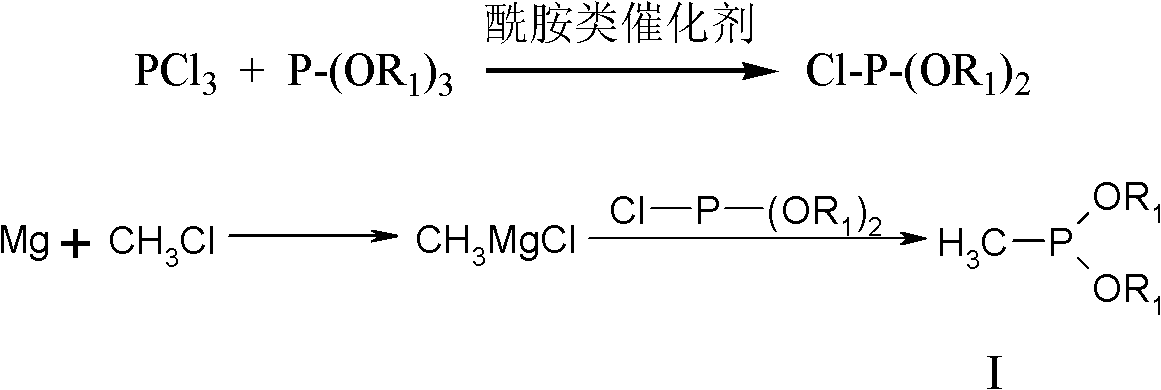

Improved synthesis method for glufosinate and analogue thereof

InactiveCN102399240AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateHydrogen halide

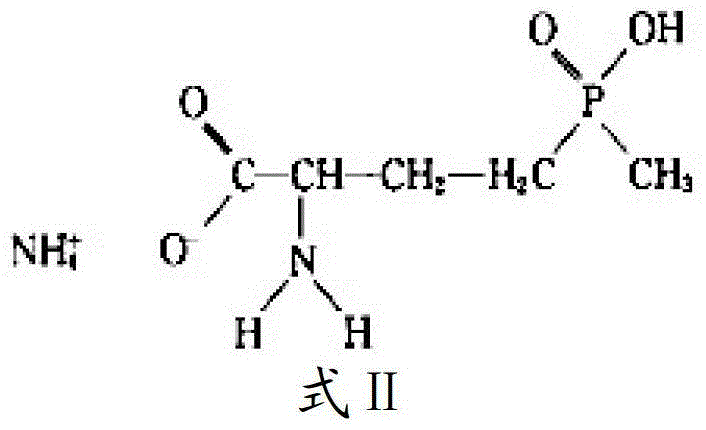

The invention discloses a comprehensive method for synthesizing glufosinate and analogue thereof by using phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials. The method comprises the following steps of: performing Grignard, disproportionation and coupling; introducing a proper amount of hydrogen halide; and synthesizing to obtain two intermediates, namely methyl diethyl phosphate (intermediate I) and methyl phosphinate (intermediate II), wherein the two intermediates can synthesize the glufosinate and the analogue thereof. By the method, the glufosinate and the analogue thereof are synthesized by completely utilizing the methyl diethyl phosphate and the methyl phosphinate synthesized by a Grignard route; yield is increased; production cost is reduced; and three wastes are reduced.

Owner:JIANGSU YOUTH CHEM +1

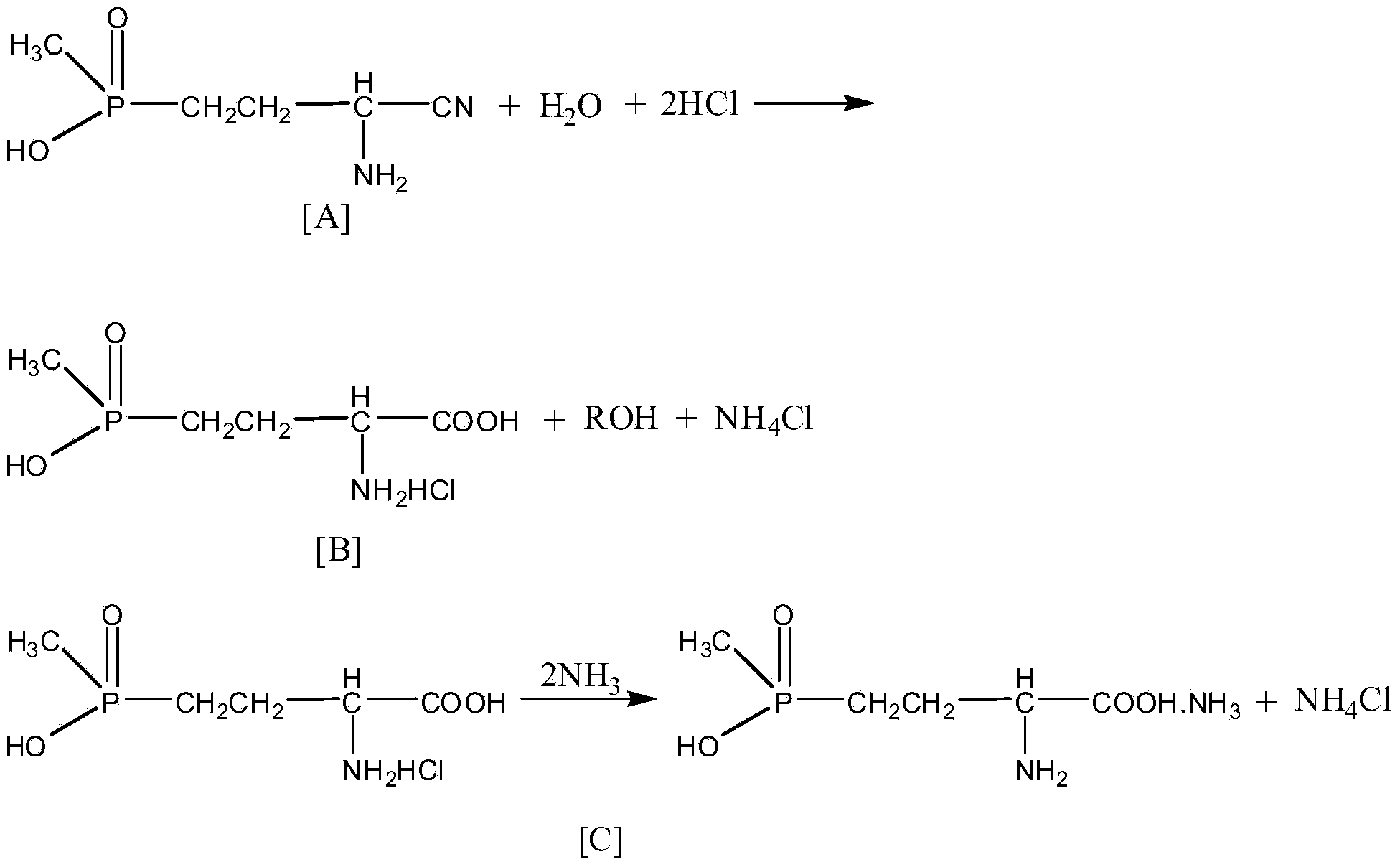

A kind of purification process of glufosinate-ammonium

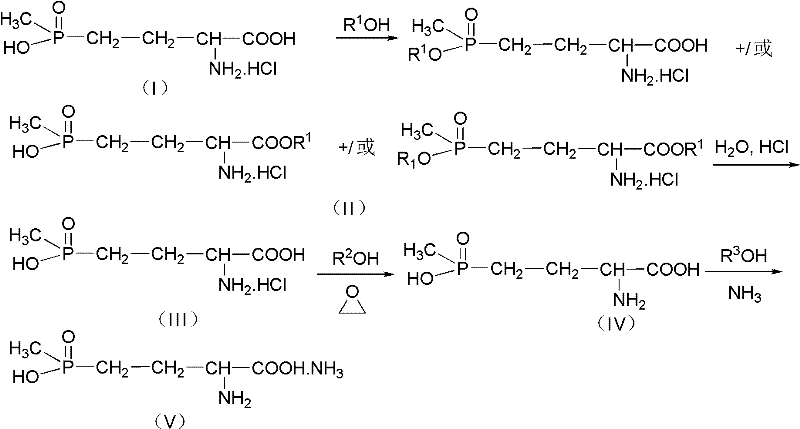

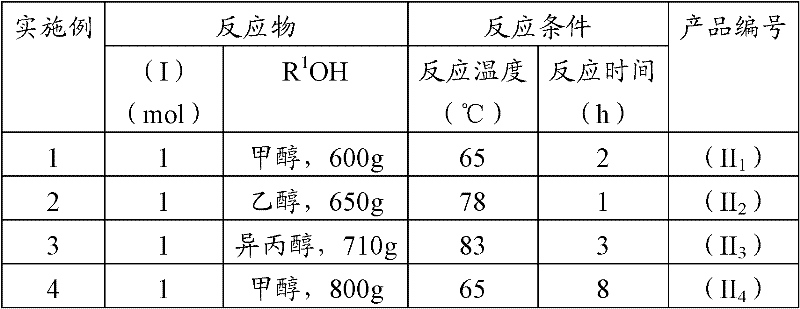

ActiveCN102268037AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsEpoxySolvent

The invention discloses a process for purifying glufosinate-ammonium, which comprises: (1) adding glufosinate-ammonium hydrochloride into an alcohol R1OH to perform an esterification reaction, and after the reaction is accomplished, cooling, filtering, removing solvent from filtrate and obtaining ester product of glufosinate-ammonium; (2) adding the ester product of glufosinate-ammonium, which isobtained by step (1), into water solution of hydrochloric acid to perform a hydrolysis reaction, and obtaining glufosinate-ammonium hydrochloride by post treatment; (3) adding the glufosinate-ammonium hydrochloride obtained by the step (2) into an alcohol R2OH, introducing epoxy ethane and obtaining glufosinate-ammonium acid; and (4) adding the glufosinate-ammonium acid obtained by the step (3) into an alcohol R3OH, introducing ammonia gas, and obtaining glufosinate-ammonium after the reaction is finished. In the invention, the process for purifying glufosinate-ammonium comprises simple steps, the inorganic salt content in the obtained glufosinate-ammonium is low, and the purity of the obtained glufosinate-ammonium is high; the process for separating glufosinate-ammonium hydrochloride from HCl by epoxy ethane is more economic than the conventional process which adopts epoxypropane and epoxy chloropropane; and the method is very safe and has a very bright industrialization prospect.

Owner:YONGNONG BIOSCI

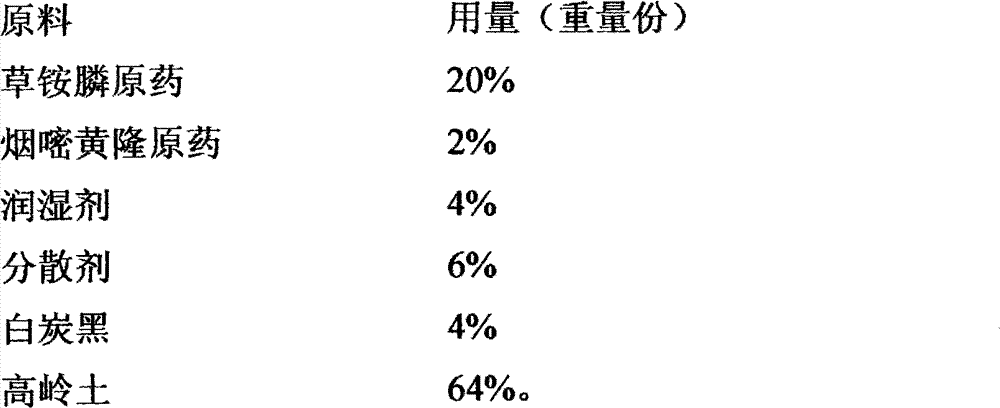

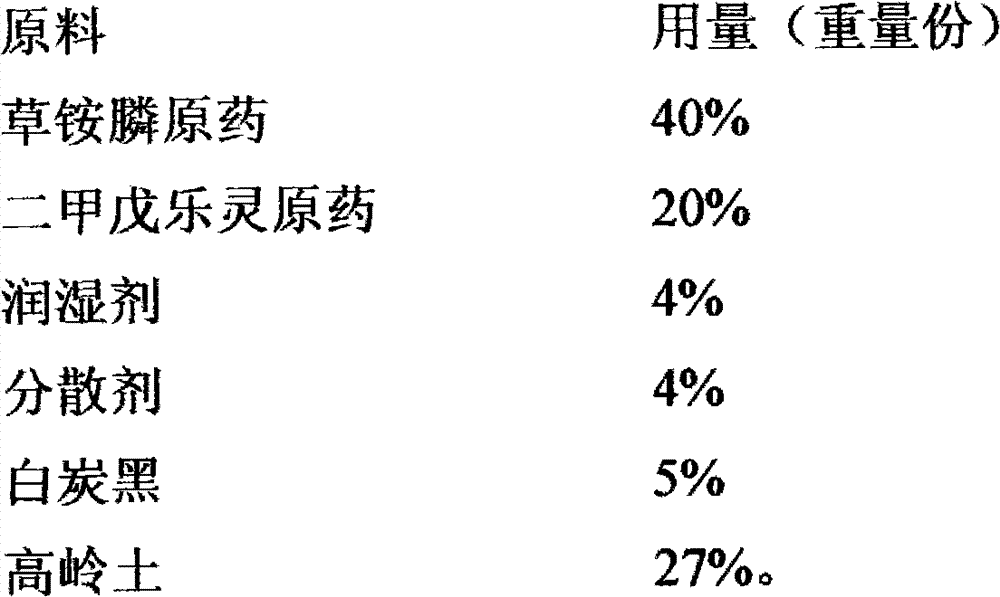

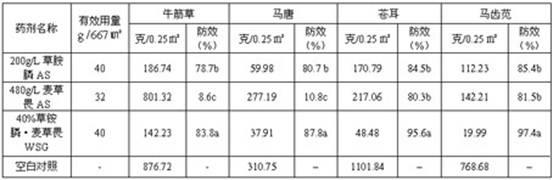

Herbicide containing glufosinate

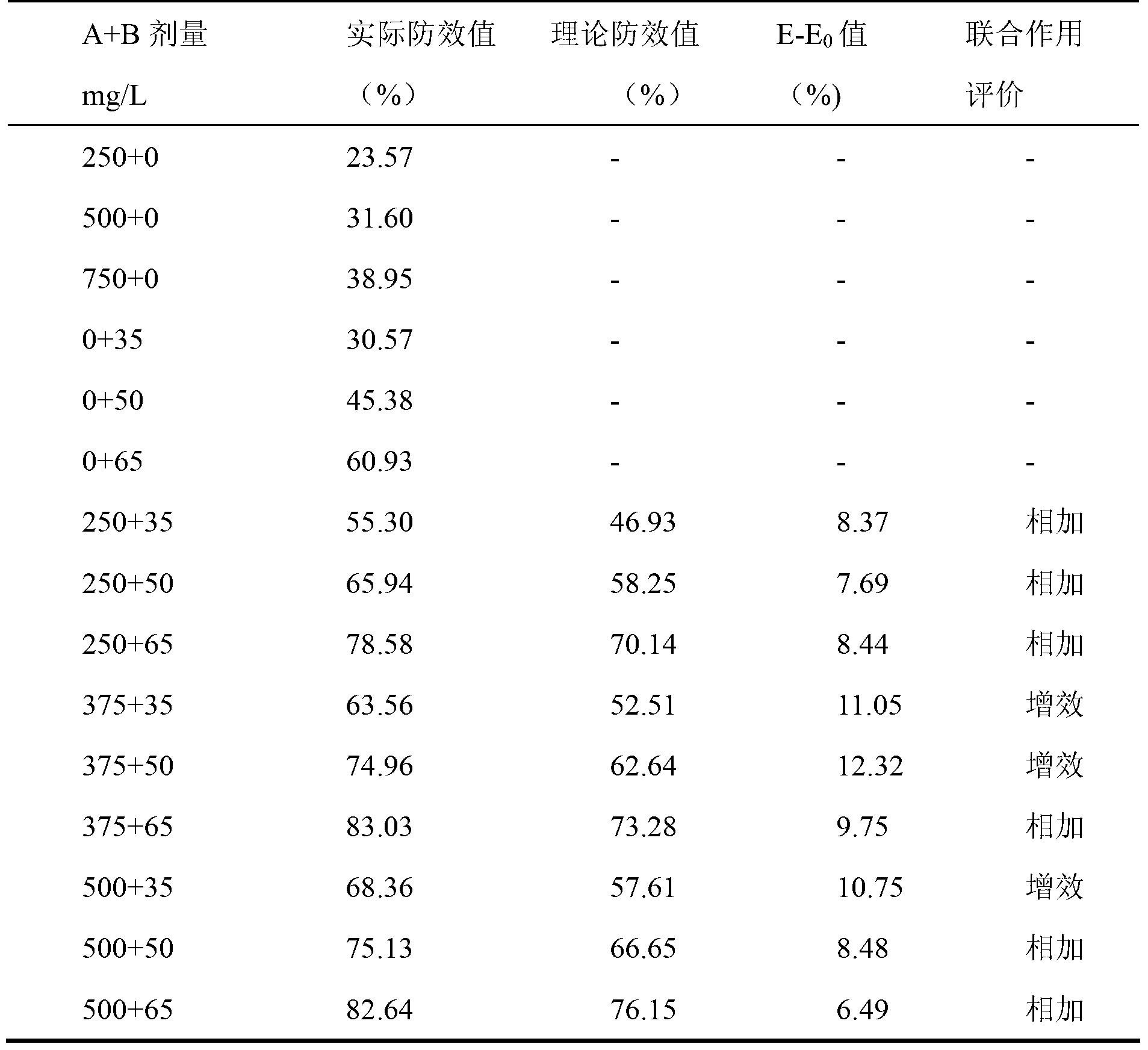

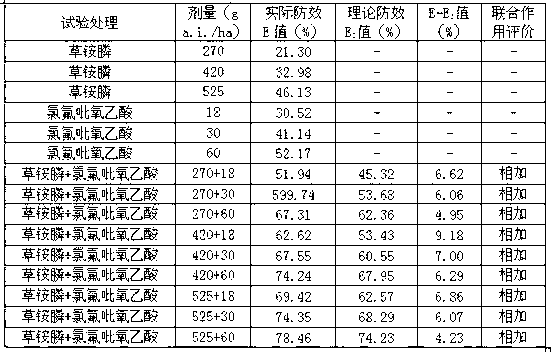

InactiveCN102763676AAnti-explosion safetySignificant synergistic effect on controlBiocideAnimal repellantsPendimethalinDiclofop-methyl

The invention discloses herbicide containing glufosinate. The herbicide containing glufosinate is characterized by comprising technical material composed of glufosinate and herbicide B according to a proportion of 1-80:1-80. The herbicide B is one of fenoxaprop-ethyl, fenoxaprop-P-ethyl, isoproturon, diclofop-methyl, chlortoluron, methabenzthiazuron, imazamethabenz, tralkoxydim, difenzoquat, flampro, flamprop-M, pendimethalin, nicosulfuron, primisulfuron and the like. The herbicide containing glufosinate is composed of herbicide A and the herbicide B and has the advantages that the herbicide is capable of killing ground weeds and grass seeds which are about to germinate and is long in effect duration; herbicide controlling spectrum is wide, and the herbicide is widely applicable to controlling weeds in dry lands; the herbicide is low in toxicity, weak in sensitization and low in poisoness to crops and human, can control weeds safely without harming the crops, and is evident in weed control synergy.

Owner:王学权

Production method of L-glufosinate

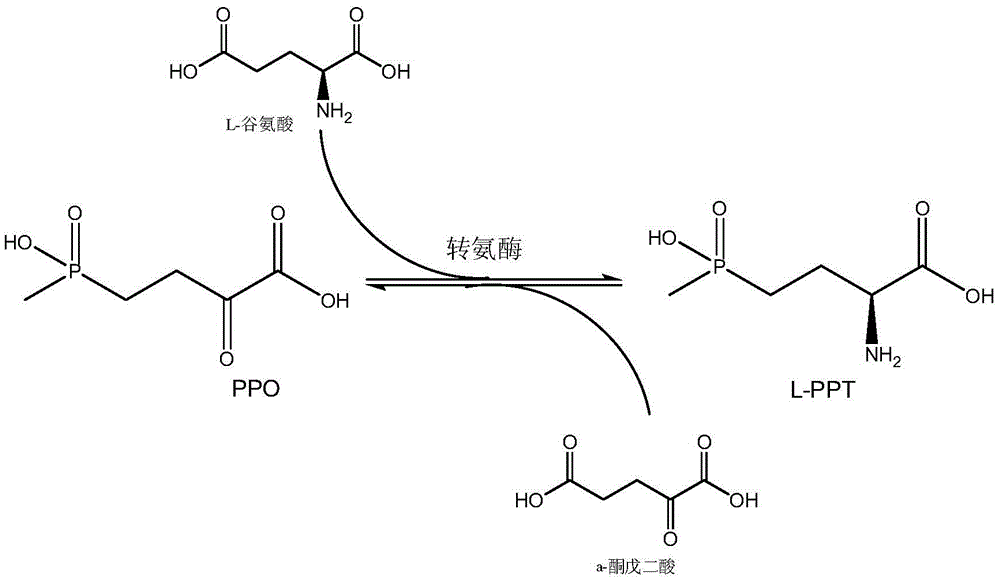

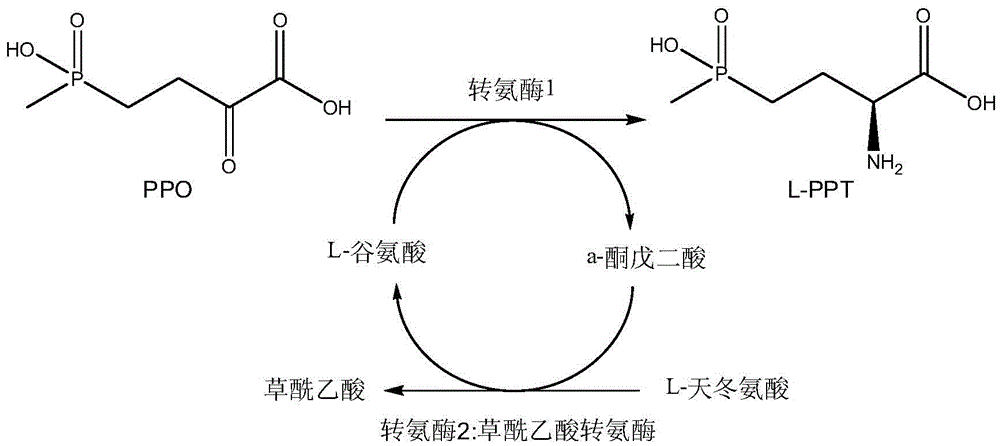

ActiveCN105603015AImprove conversion rateSimple separation processTransferasesMicroorganism based processesButyric acidHydroxy compound

The invention discloses a production method of L-glufosinate. The method includes the steps that with 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid and salt thereof being a substrate, isolated transaminase or a cell catalysis substrate of in-vitro expression transaminase reacts with an amino donor under the condition that the amino donor exists, so that L-glufosinate is obtained, wherein the amino donor is alanine, and the amino acid sequence of transaminase is shown in SEQ ID NO.1-3. With 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid and salt thereof being the substrate and alanine being the amino donor, the transamination reaction occurs through the specific transaminase catalysis substrate, the substrate can be completely converted into L-glufosinate, and the conversion rate of raw materials is high and can reach 100%.

Owner:ZHEJIANG UNIV

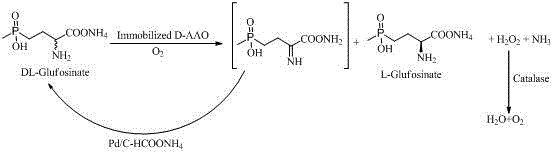

Enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium

The invention discloses an enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium. According to the method, a one-pot reaction manner is adopted, under the molecular oxygen, immobilization D-amino acid oxidase catalyzes D-enantiomer in an enantioselectivity mode into 2-imino-4-(hydroxy methyl phosphonyl) butyric acid in a dehydrogenation mode, and palladium-ammonium formate catalyzes 2-imino -4-(hydroxy methyl phosphonyl) butyric acid into DL-glufosinate-ammonium in an in-situ reduction mode. Hydrogen peroxide produced in the process is efficiently decomposed into water and oxygen through catalase. Complete reacemization removing of DL-glufosinate-ammonium and efficient preparing of L-glufosinate-ammonium are achieved through biological oxidation-chemical reduction circulation. The method has the advantages that the process is simple, cost is low, environmental friendliness is achieved, and energy is saved. High-concentration DL-glufosinate-ammonium can be converted into L-glufosinate-ammonium. The yield is 90%, the optical purity of the product is 99%, and the method is suitable for industrial production of L-glufosinate-ammonium.

Owner:重庆惠健生物科技有限公司

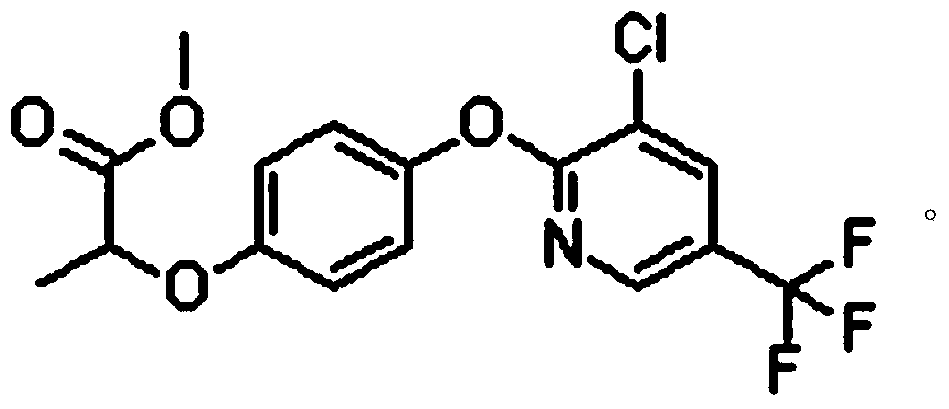

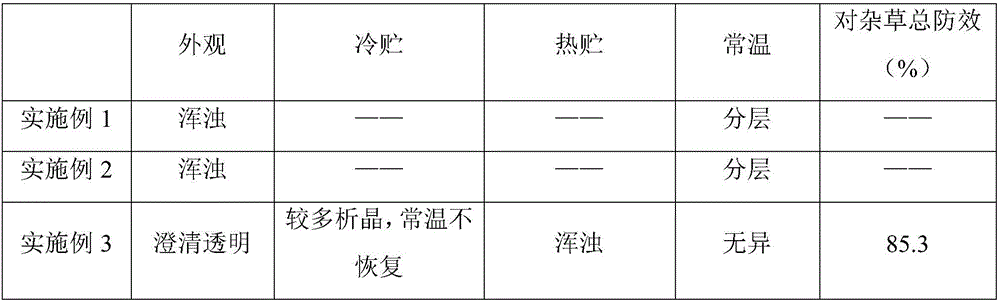

Glufosinate-aryloxyphenoxypropionic acid herbicide weeding composition

InactiveCN103053610AImprove the effect of prevention and controlLower doseBiocideAnimal repellantsOrganic chemistryOrchard

The invention discloses a glufosinate-aryloxyphenoxypropionic acid herbicide weeding composition. The glufosinate-aryloxyphenoxypropionic acid herbicide weeding composition comprises glufosinate and an aryloxyphenoxypropionic acid herbicide as active ingredients, and the balance pesticide assistants. A weight ratio of glufosinate to the aryloxyphenoxypropionic acid herbicide in the glufosinate-aryloxyphenoxypropionic acid herbicide weeding composition is in a range of (50: 1) to (1: 1). The glufosinate-aryloxyphenoxypropionic acid herbicide weeding composition comprises 10 to 80wt% of glufosinate and the aryloxyphenoxypropionic acid herbicide. The glufosinate-aryloxyphenoxypropionic acid herbicide weeding composition can be used for preventing and removing weeds in bare places, orchards and field ridges, has effects superior to effects of a single aryloxyphenoxypropionic acid herbicide or glufosinate, reduces a use amount of a pesticide, reduces the adverse influence produced by a pesticide on the ecological environment, and effectively solves the problem of weed resistance to pesticides.

Owner:GUANGDONG ZHONGXUN AGRI TECH

Glyphosate applications in aquaculture

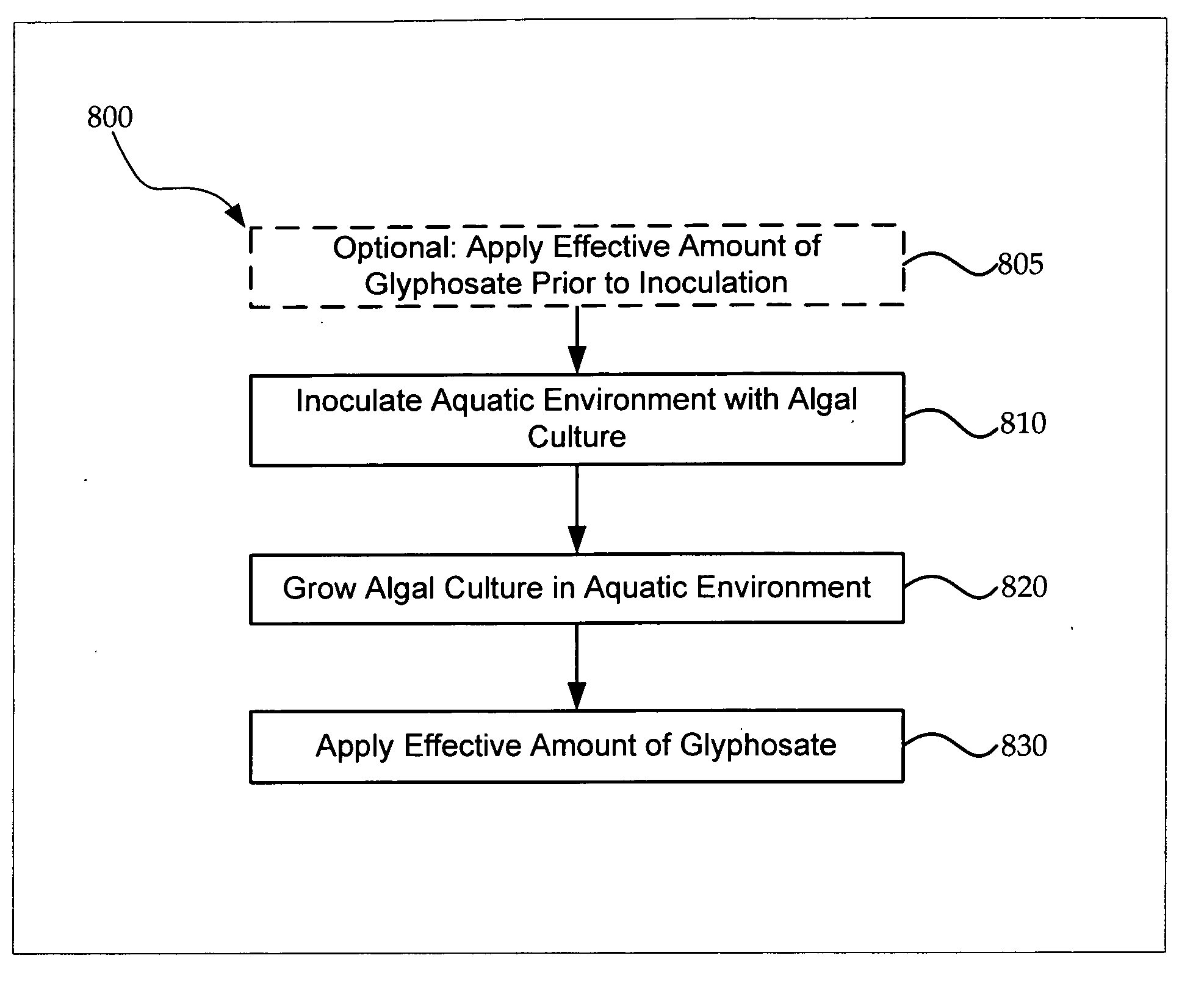

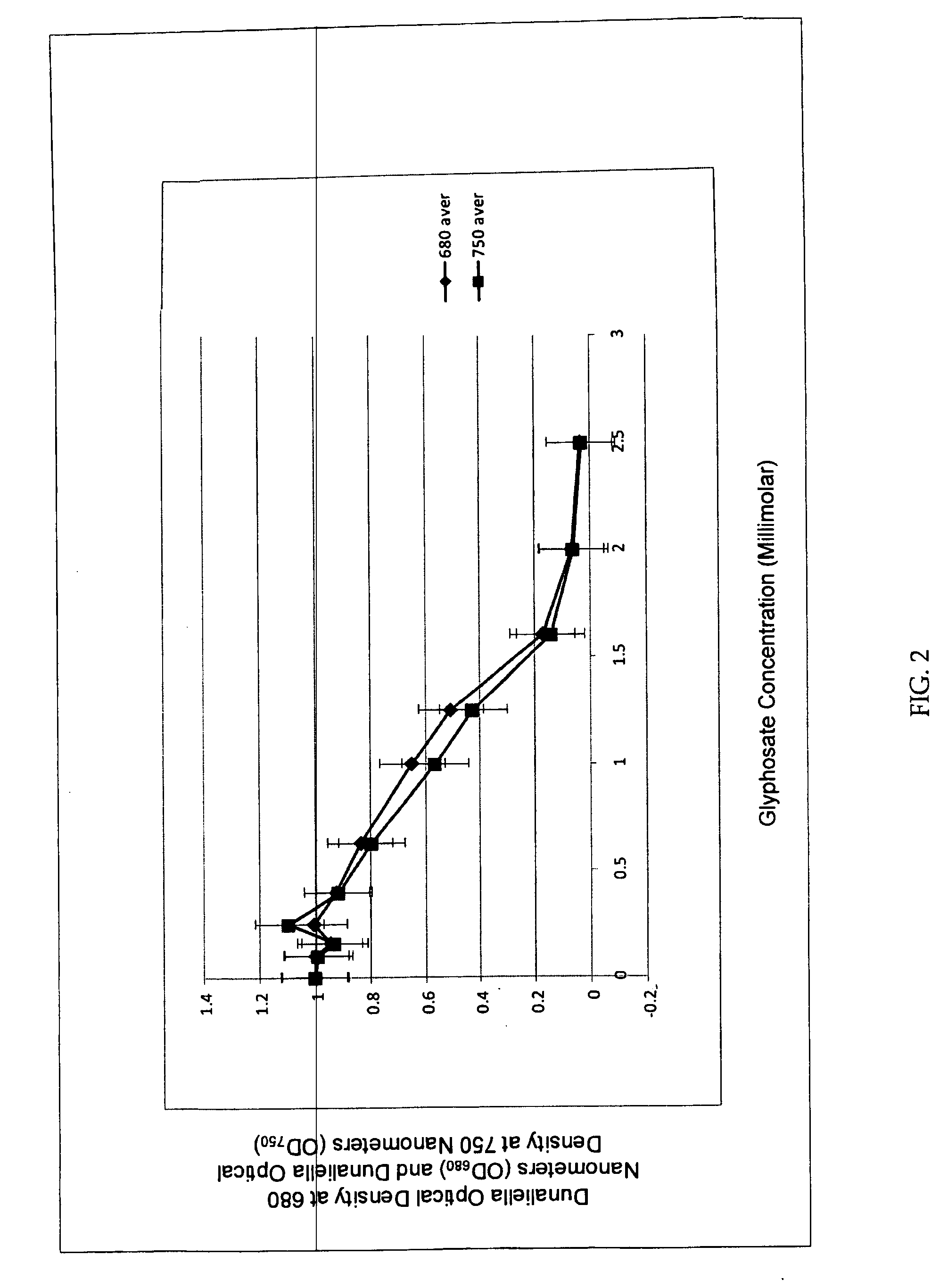

Methods for controlling a density of algae growing in an aquatic environment are provided. Exemplary methods include applying an effective amount of glyphosate to a density of algae growing in an aquatic environment. The algae may include genus Nannochloropsis and / or Dunaliella. The algae may also include a glyphosate resistant strain of genus Nannochloropsis. The effective amount may result in an approximate concentration of between 0.1 millimolar to 0.3 millimolar glyphosate in the aquatic environment. Additionally, the aquatic environment may include seawater. The glyphosate may be applied to the aquatic environment before and / or after the aquatic environment is inoculated with algae. Alternative methods include applying an effective amount of glufosinate to a density of algae growing in an aquatic environment.

Owner:AURORA ALGAE

Weeding composition and preparation thereof

The invention relates to the field of pesticide preparations and discloses a weeding composition. The orchard weeding composition disclosed by the invention consists of indaziflam and glufosinate; the weight ratio of the indaziflam to the glufosinate is 1: (0.2 to 10); the weeding composition has an obvious synergistic effect, not only has good fast-acting property, but also has good persistence, can be used for simultaneously preventing and removing most of weeds in an orchard and has a better preventing and removing effect on resistance weeds in the orchard. A weed killer disclosed by the invention is prepared by the weeding composition and a conventional auxiliary as well as a carrier / solvent. The weed killer disclosed by the invention can be used for effectively preventing and removing weeds in the orchard and particularly preventing and removing gramineous weeds and broad leaf weeds.

Owner:LIANBAO CROP TECH

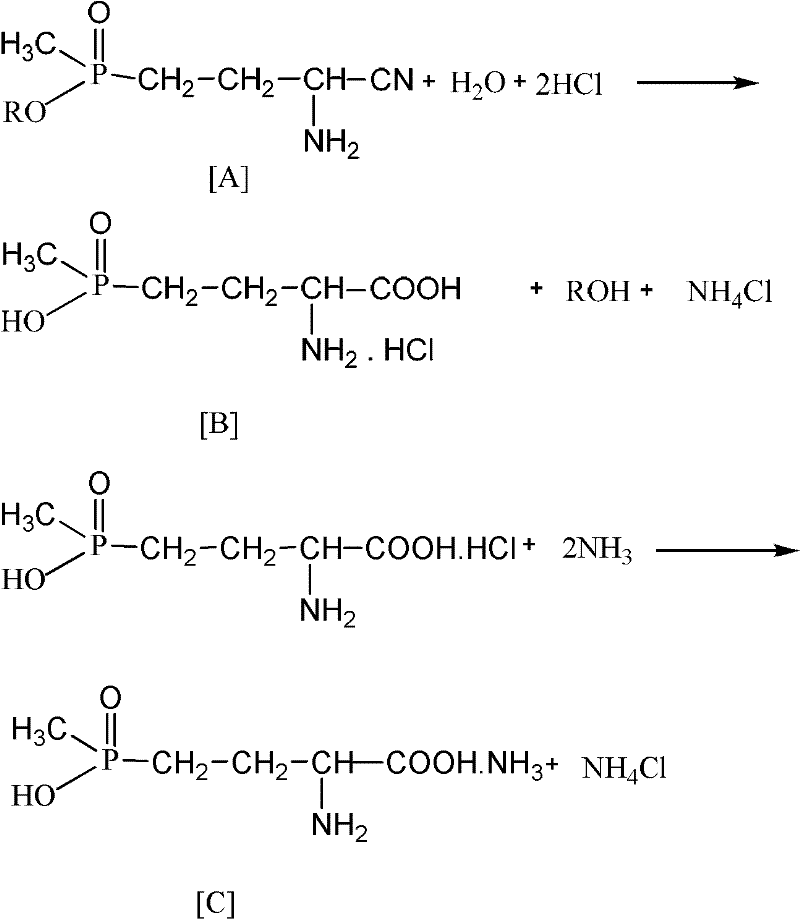

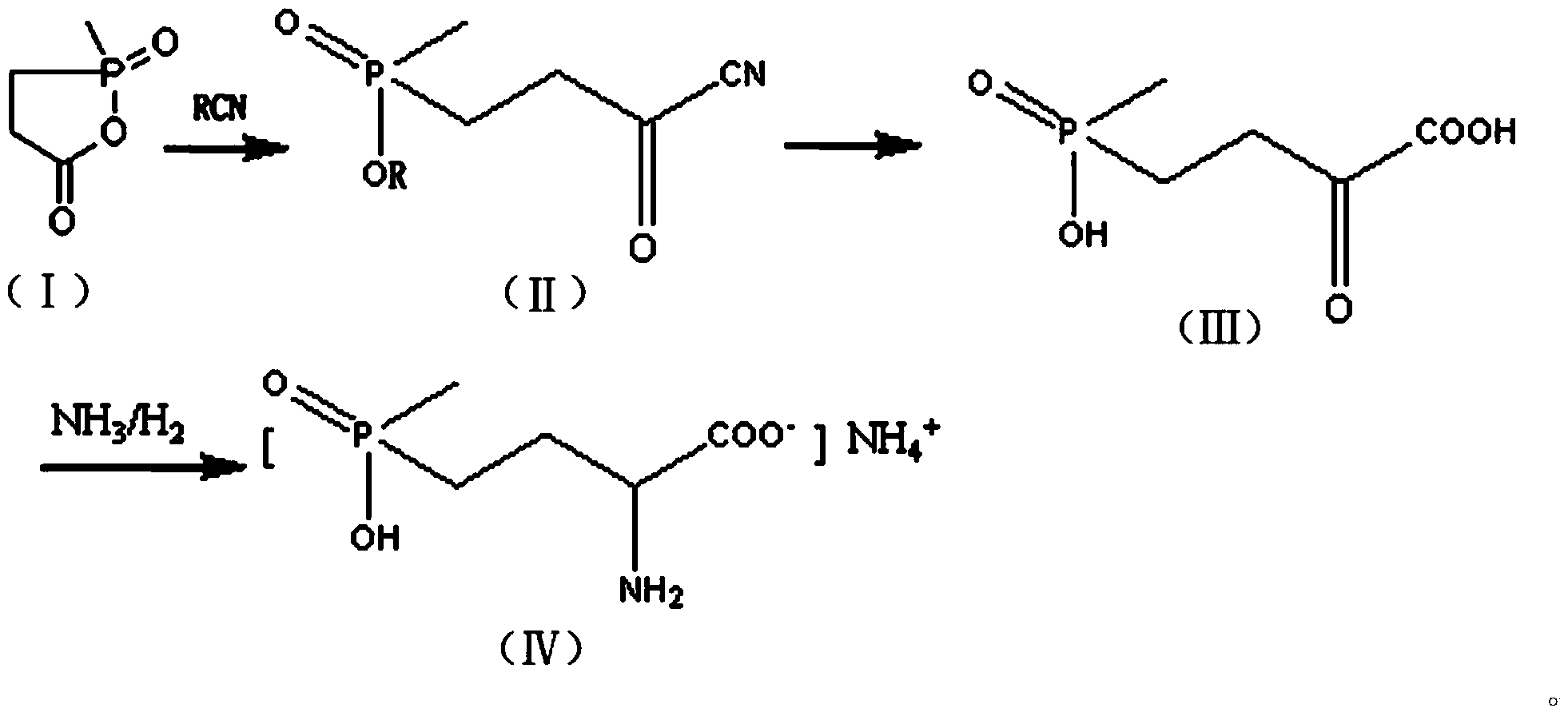

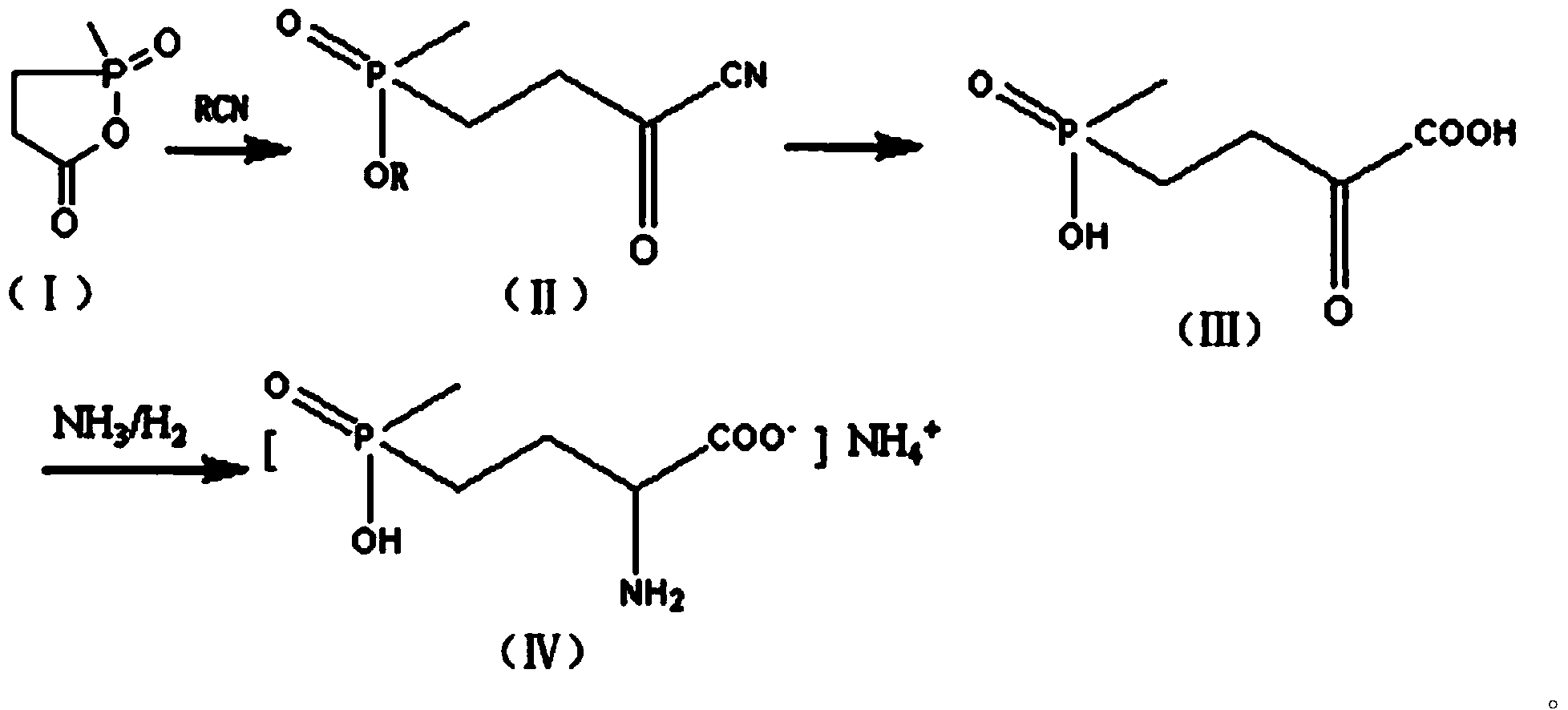

Preparation method of glufosinate and analogue of glufosinate

InactiveCN104892670AHigh yieldHigh purityGroup 5/15 element organic compoundsPhosphite esterHydrolysis

The invention discloses a method used for synthesizing glufosinate and an analogue of glufosinate by taking methylphosphoric dichloride and 2-hydroxy butane-3-nitrile as initial raw materials. According to the method, esterification is carried out so as to obtain methyl phosphite ester (I) and 2-acetyloxy-3-butenenitrile (II), intermediate (3-acetyloxy-3-cyano-propyl)-methylphosphonate (III) is obtained via Michael free radical addition, and glufosinate and the analogue (IV) are obtained via ammoniation and hydrolysis. Synthetic route of the method is short; yield is high; by-product is less; product purity is high; and the method is suitable for industrialized production.

Owner:ANHUI COSTAR BIOCHEM CO LTD

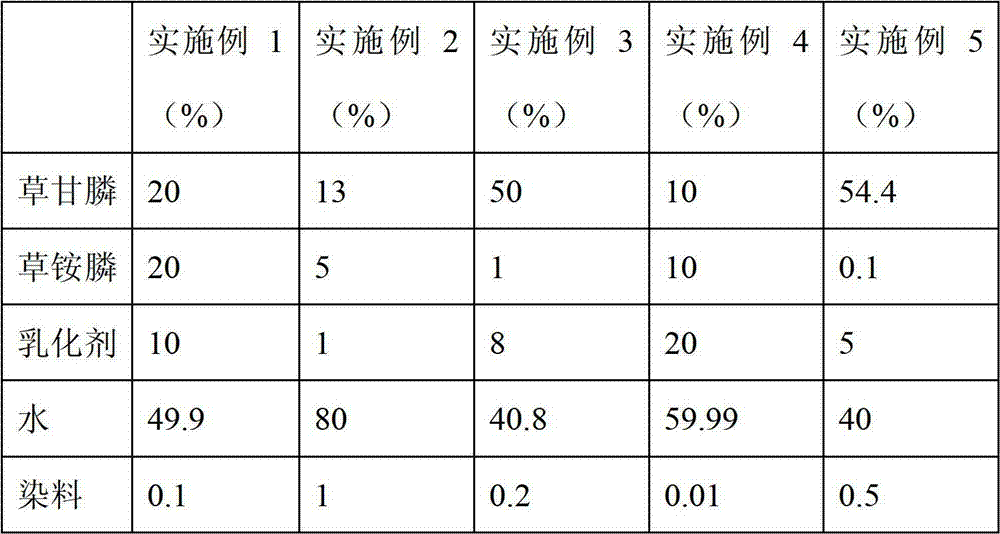

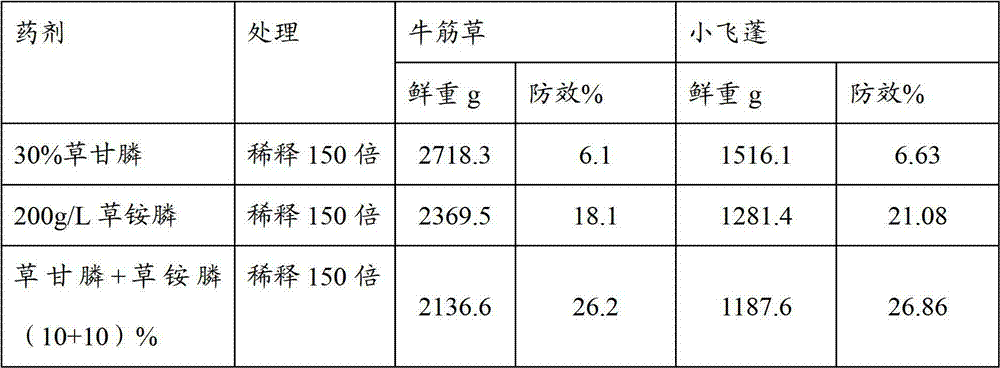

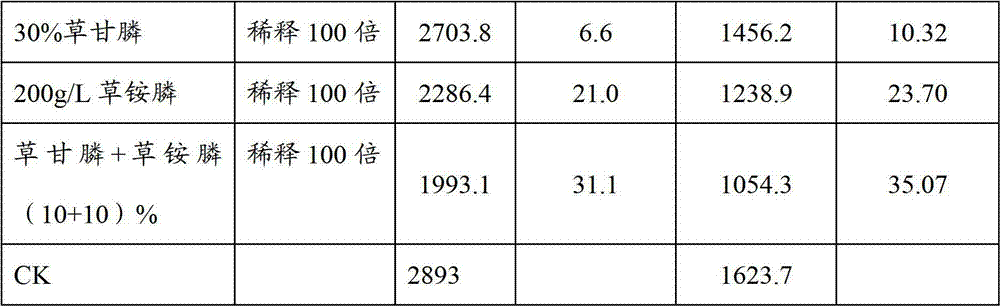

Compounded weed killer of glyphosate and glufosinate

InactiveCN101773143AImprove the effect of prevention and controlGood effectBiocideAnimal repellantsOrchardWeed

The invention relates to a pesticide composition, in particular to a compounded weed killer of glyphosate and glufosinate, which can be used for preventing and controlling weeds in farmlands, orchards, tea gardens, vegetable fields, uncultivated areas and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

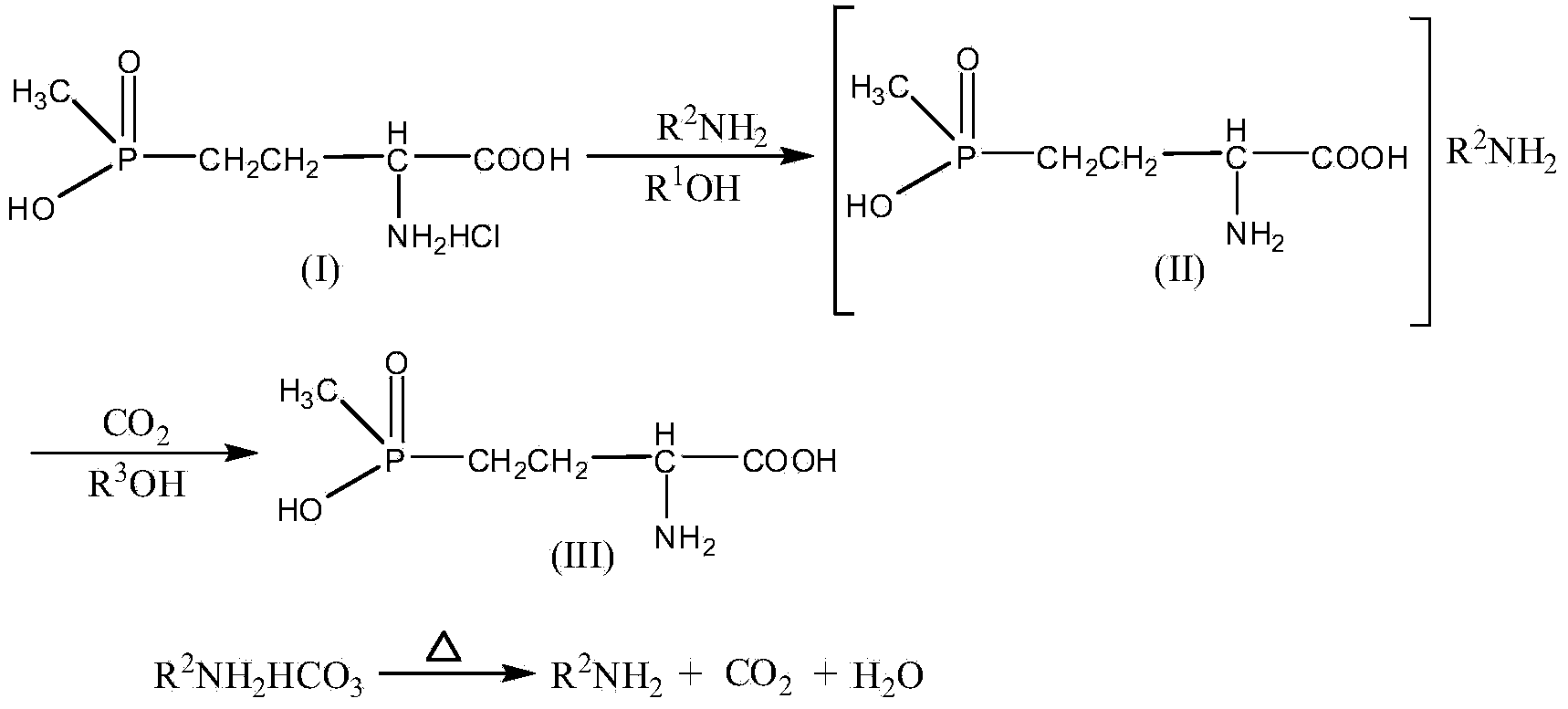

Glufosinate purifying technology

ActiveCN103819503AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsDecompositionSolvent

The invention provides a glufosinate purifying technology including the following steps: (1) adding glufosinate hydrochloride to alcohol R1OH, adding R2NH2 for ammoniation, adjusting the pH to 7.0-14.0, cooling and filtering, removing a solvent from a filtrate to obtain glufosinate ammonium salt and a small amount of organic impurities; (2) dissolving the glufosinate ammonium salt obtained by the steps (1) in an appropriate amount of water, leading in CO2 for neutralizing to the pH of 2.0-5.0, adding a proper amount of alcohol R3OH for precipitation of glufosinate acid, centrifugally filtrating to obtain the glufosinate acid which contains a small amount of ammonium hydrogen carbonate or organic amine carbonates; (3) heating for drying a glufosinate acid filtering cake obtained by the step (2) for decomposition and volatilization of the ammonium hydrogen carbonate or organic amine carbonates to obtain high purity glufosinate acid. The glufosinate purifying technology is simple in steps, the obtained glufosinate is low in inorganic salt content and high in purity, and compared with a traditional technology using epoxy ethane and epoxy propane, the purifying technology using carbon dioxide for separation of glufosinate hydrochloride and HCl is more economical, and high in safety, and has a higher industrialization prospect.

Owner:SHANDONG BINNONG TECH

Preparation method of fine glufosinate

InactiveCN108516991AHigh yieldEasy to synthesizeGroup 5/15 element organic compoundsSimple Organic CompoundsHalogen

The invention belongs to the technical field of organic compound synthesis and relates to a preparation method of fine glufosinate, in particular to a preparation method of fine glufosinate with L-homoserine as a raw material. According to the preparation method of fine glufosinate, L-homoserine prepared through a biological fermentation method serves as an initial raw material, L-3,6-di(2-halogenethyl)-2,5-diketopiperazine is prepared through the steps such as azeotropic dehydration and halogenation, a Serhiy Arbuzov reaction is conducted between L-3,6-di(2-halogen ethyl)-2,5-diketopiperazine and methyl phosphonic acid dibutyl, and fine glufosinate is prepared through a hydrolysis reaction. Compared with an existing preparation technology, the preparation method of fine glufosinate has the advantages that the total yield of fine glufosinate is greatly increased, the technological process is simple, and fine glufosinate is suitable for industrial production.

Owner:SHANDONG ACADEMY OF PESTICIDE SCI

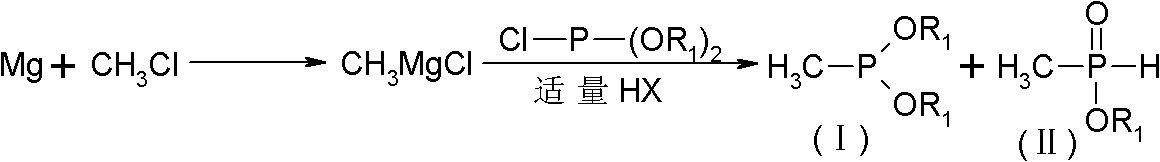

Method for synthesizing glufosinate

The invention relates to a synthesizing method for pesticide glufosinate, i.e., ((D,L)-2-amino-4-(hydroxyl(methyl)phosphinyl)butyrate) and a salt of an acid or an alkali thereof. In the synthesizing method, the pesticide glufosinate is prepared by undergoing a strecker reaction, and an intermediate compound, i.e., (3-nitrile-3-hydroxy)propyl methyl phosphonic acid directly reacts with carbon dioxide and ammonia gas in an aqueous solution to synthesize the pesticide glufosinate and a salt of an acid or an alkali thereof. The method comprises the following specific steps of: adding the intermediate compound, i.e., (3-nitrile-3-hydroxy) propyl methyl phosphonic acid into a high-pressure kettle; adding carbon dioxide, ammonia gas and water, wherein ammonium bicarbonate or ammonium carbonate and the like can be used for replacing carbon dioxide carbon and ammonium, the molar ratio of the intermediate to the carbon dioxide is between 1 and 12, and the ratio of the ammonia gas to the carbon dioxide is between 0.5 and 5; adding 15-75 times of water; heating to 120-180 DEG C; reacting for about 4-20 hours; and after the reaction, cooling, taking the reaction liquid out, and concentrating to directly obtain an ammonium salt of glufosinate. The yield is over 80 percent.

Owner:HEBEI VEYONG BIO CHEM

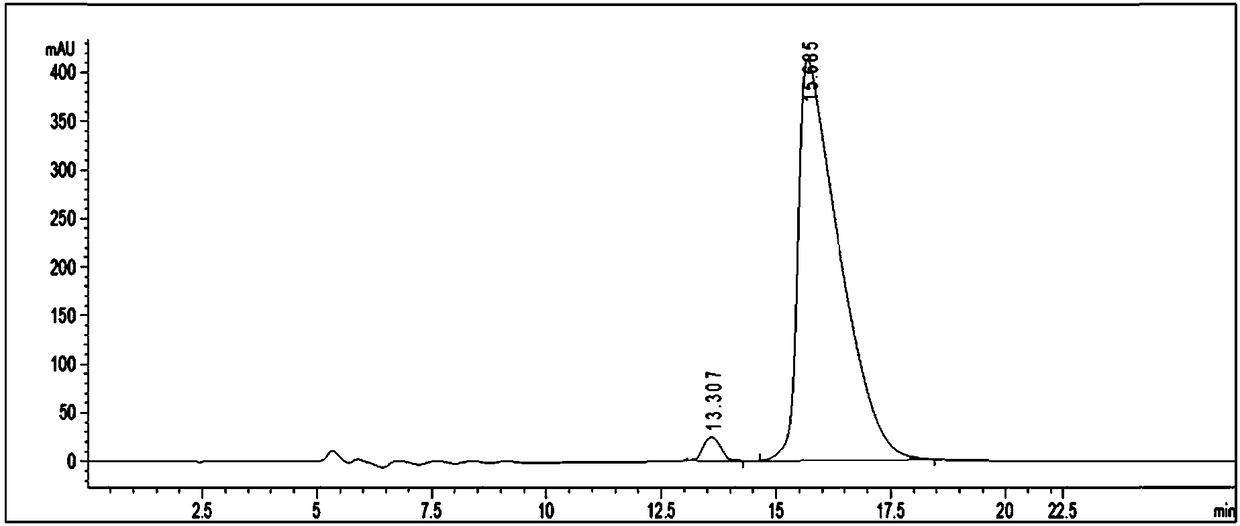

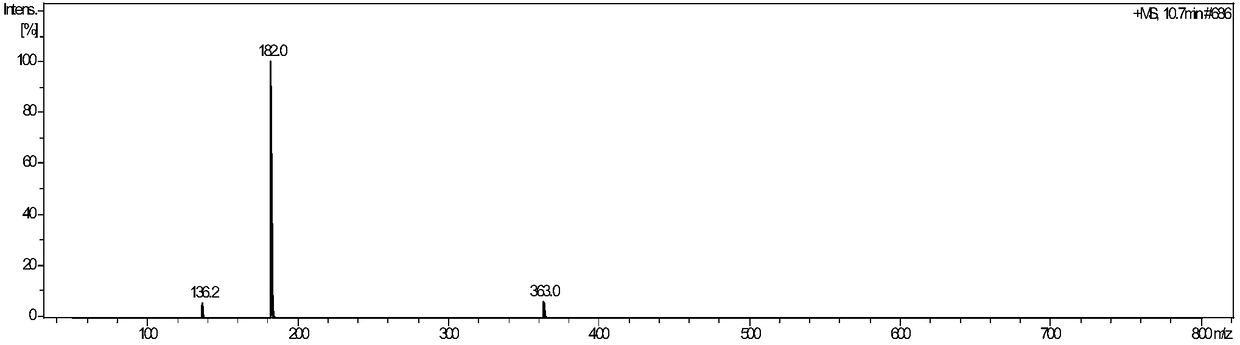

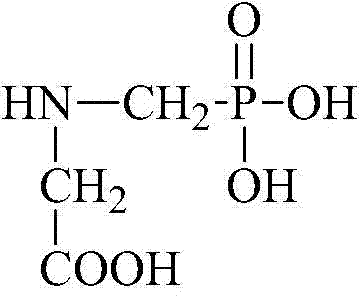

Determination method of residual amount of glufosinate, glyphosate and aminomethyl phosphoric acid in food

InactiveCN103822995AReduce matrix interferenceSimple and fast operationComponent separationRelative standard deviationPhosphoric acid

The invention discloses a determination method of residual amount of glufosinate, glyphosate and aminomethyl phosphoric acid in food. The determination method of residual amount of glufosinate, glyphosate and aminomethyl phosphoric acid in food comprises the following steps: in the sample pretreatment, firstly, extracting glufosinate, glyphosate and aminomethyl phosphoric acid in a food sample by a methanol water solution in sample pretreatment; then purifying an extracting solution by selecting a C18 dispersive solid-phase extraction agent; and finally, filtering, deriving, and determining three compounds qualitatively and quantitatively synchronously by combining with high performance liquid chromatography-tandem mass spectrum. According to the method provided by the invention, the operation is simple and convenient, and the reproducibility is good, and impurities in a sample extraction solution can be removed effectively; the pretreatment is the supplement and improvement of the existing QuEChERS method; the recycling rate can reach 70.5%-91.2%; the relative standard deviation is 4.5%-7.83%; the limit of quantification is 50micro-g / kg; the determination method can completely meet the technical requirement on safety detection of China, European Union, America and Japan, and can provide powerful technical support for food safety and export trade healthy development for people of China.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

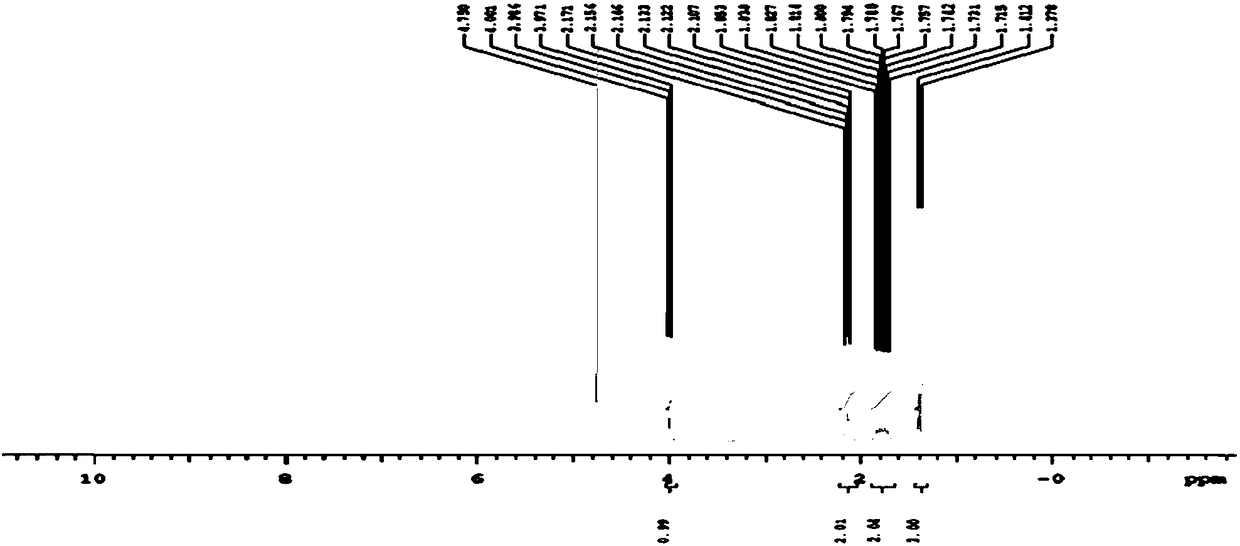

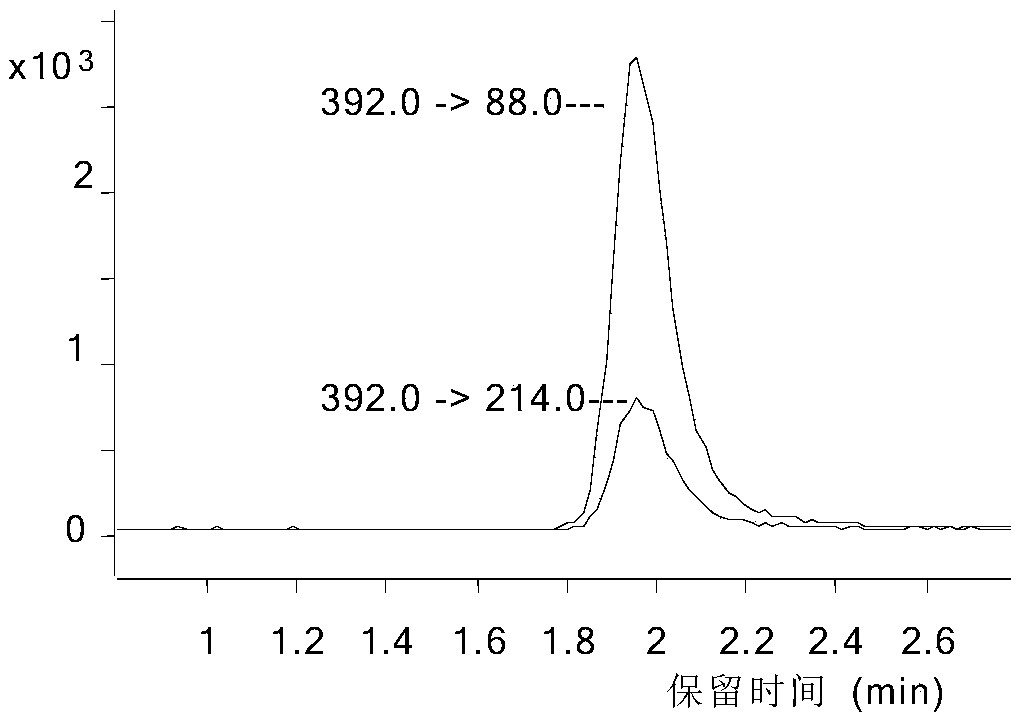

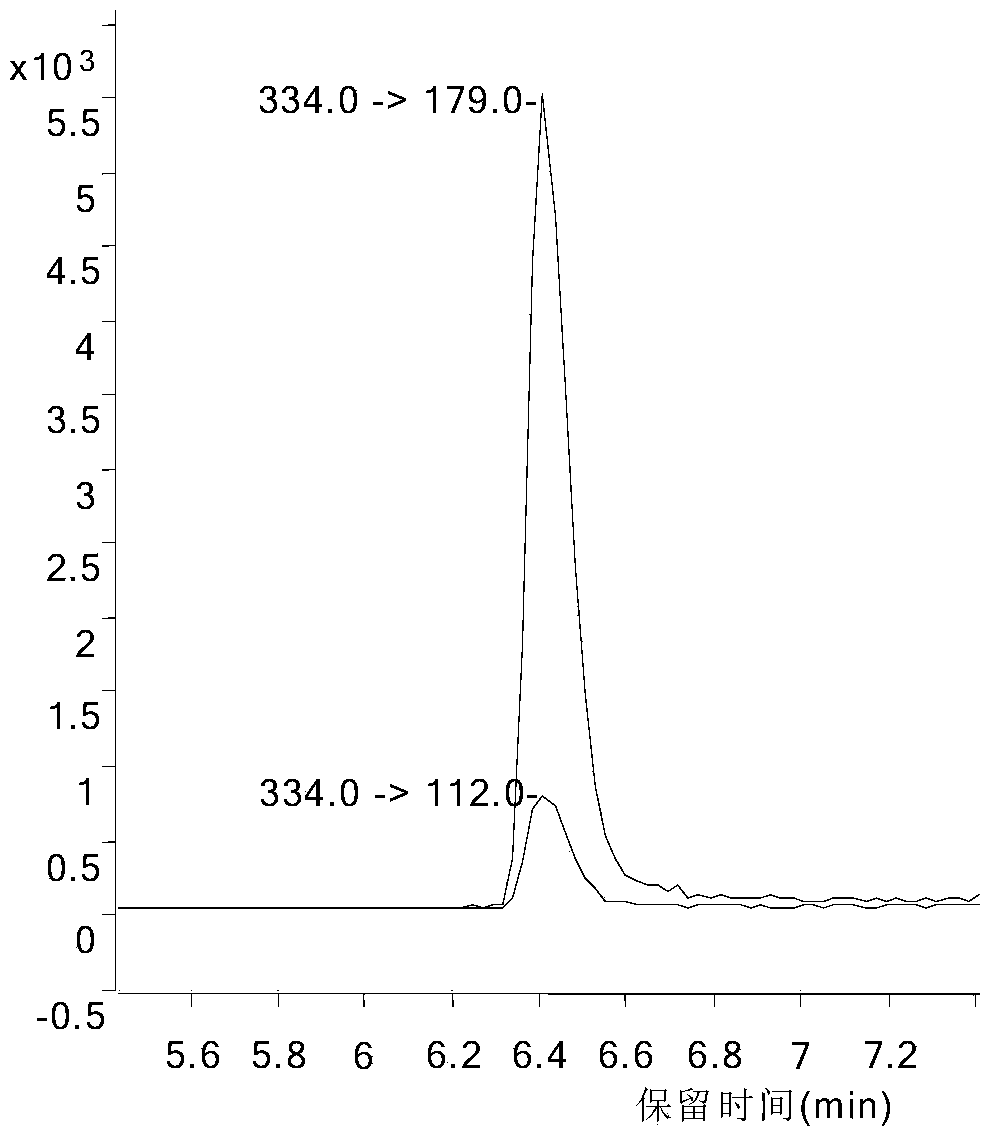

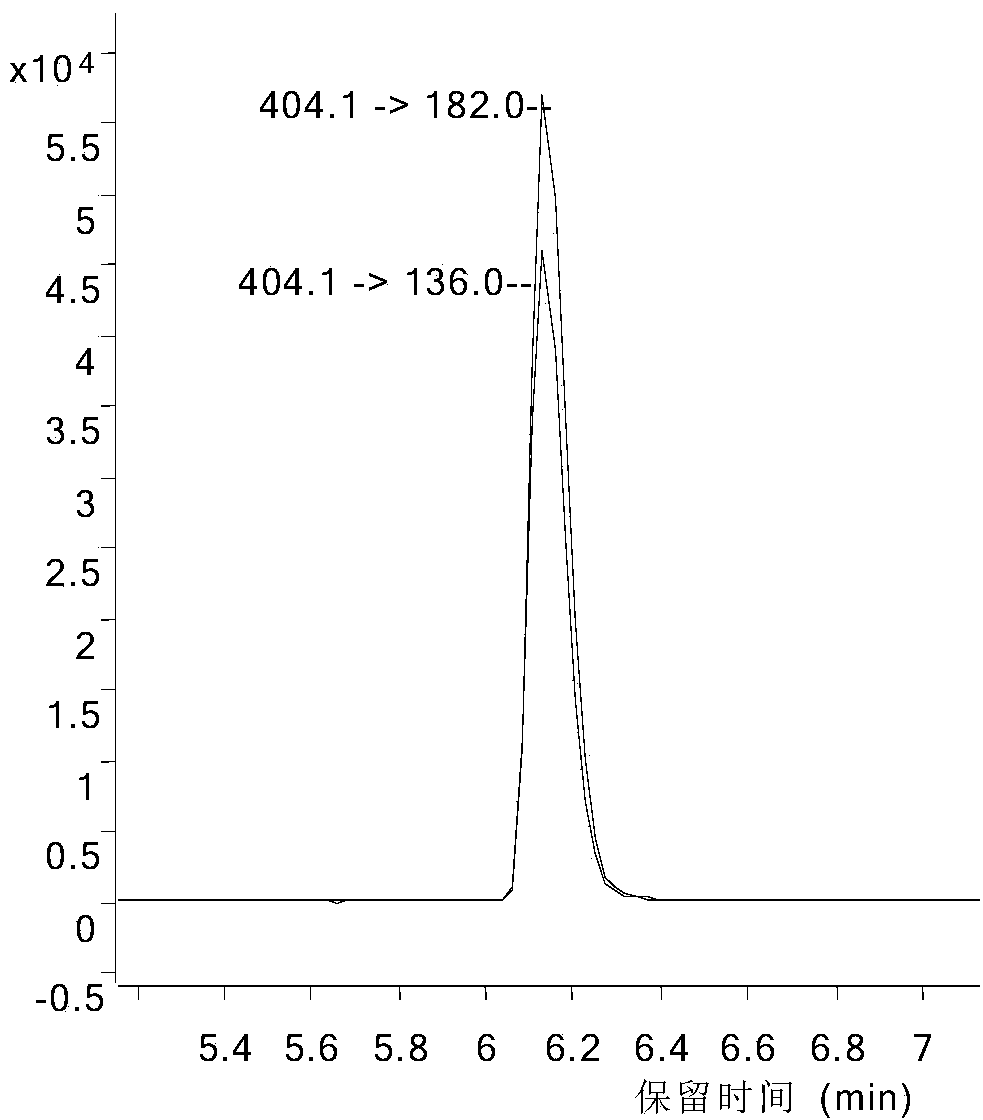

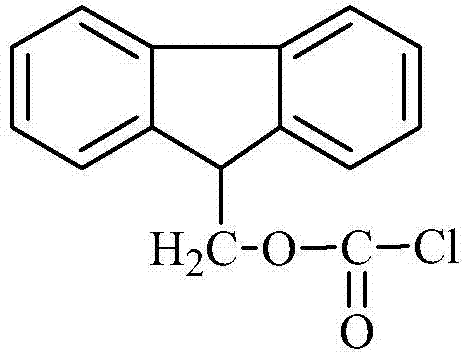

Precolumn derivatization-UPLC(ultra performance liquid chromatography)-ESI(electronic spray ion)+-MS/MS (mass spectrometry) detection method of glyphosate and glufosinate-ammonium pesticide residue in tea

The invention discloses a precolumn derivatization-UPLC(ultra performance liquid chromatography)-ESI(electronic spray ion)+-MS / MS (mass spectrometry) detection method of glyphosate and glufosinate-ammonium pesticide residue in tea, sodium borate is used as a buffer salt, a relatively pure target derived product can be obtained by derivatization of glyphosate and glufosinate-ammonium and FMOC-Cl and then ultra performance liquid chromatography (UPLC) washing out and separation, and response signals can be detected by tandem mass spectrometry (MS-MS). According to the method, competition between the two pesticide residue derivatization can be eliminated, the detection effect caused by matrix effect can be effectively weakened, and the derivatization time is shortened. By experimental verification, the detection method of glyphosate and glufosinate-ammonium pesticide (herbicide) residue in tea has the characteristics of being efficient, fast and accurate, good in sensitivity and the like, is applicable in detection of the glyphosate and glufosinate-ammonium pesticide residue in tea samples of sundried green crude tea, fermented tea and substitutional tea (green food substitutional tea of agricultural industry standards of NY / T2140-2012 of the people's Republic of China) and finished tea (brick tea, Tuo tea, melon-shaped tea, cake tea, scattered tea and bagged tea and the like).

Owner:MENGHAI TEA IND

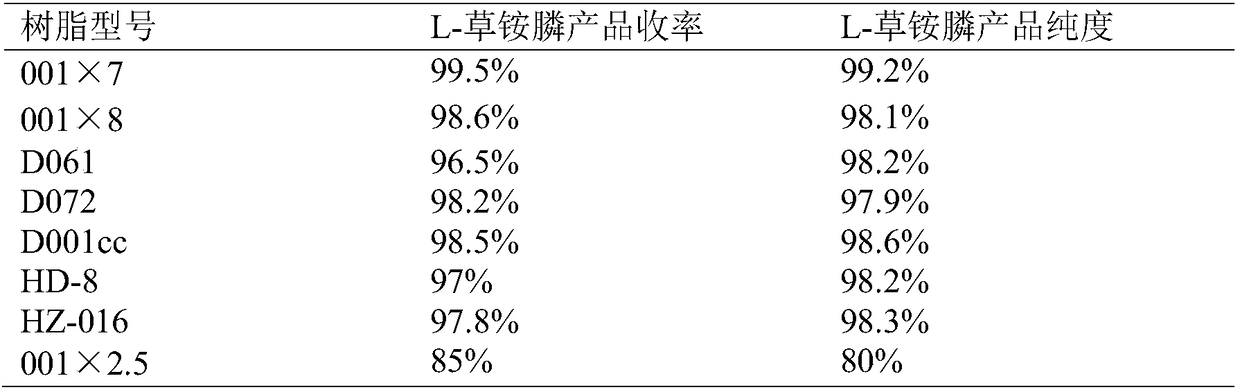

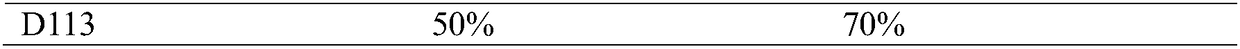

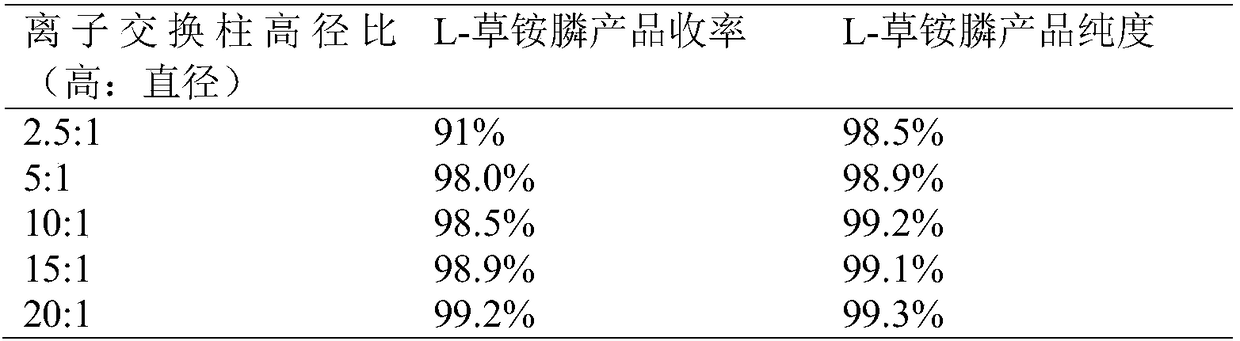

Glufosinate separation and purification method

ActiveCN104860988ASlow flowFast flowGroup 5/15 element organic compoundsPurification methodsCentrifugation

The invention belongs to the field of pesticide production and particularly relates to a glufosinate separation and purification method. According to the method, the separation and purification is started when a glufosinate hydrochloride reaction solution in the steps of distilling the glufosinate hydrochloride reaction solution under reduced pressure to remove dilute hydrochloric acid, adding ammonia water to adjust the pH to maximally produce ammonium chloride, distilling under reduced pressure to remove water, adding a flotation solvent for dispersion, placing the material into a chute at specific temperature and speed, performing flotation separation according to the difference in the proportion of a principal component and subsidiary salt, removing the solvent, dissolving the material in aqueous methanol to remove trace ammonium chloride, filling ammonia gas to adjust the pH value to 8, performing centrifugation and drying to obtain a final product. The glufosinate separation and purification method uses a flotation method for separating the principal component glufosinate and an intermediate of the principal component from the subsidiary salt ammonium chloride and the aqueous methanol for purification and is high in yield, good in purity, simple in process, low in cost and is suitable for industrial production.

Owner:石家庄瑞凯化工有限公司

Weeding composition comprising glufosinate and saflufenacil

InactiveCN103283778AImprove the effect of prevention and controlReduce dosageBiocideAnimal repellantsSaflufenacilAdjuvant

The invention discloses a weeding composition. The weeding composition comprises a glufosinate weed killer and saflufenaci which are taken as effective ingredients and the balance of acceptable adjuvant in pesticide preparation, wherein the sum of the mass percentage of the glufosinate weed killer and the mass percentage of the saflufenaci in the composition is 10-85%, and the mass ratio of the glufosinate weed killer to the saflufenaci is (1:12)-(12:1). The weeding composition disclosed by the invention is more prominent in the control efficiency on weeds which cannot be well controlled by the single glufosinate weed killer, so that weeding spectrum range is expanded; as for lasting period, the weeding composition product disclosed by the invention can reach more than 30 days, even longer, and is more thorough and lasting when compared with a single glufosinate product and a single saflufenacil product; the weeding composition disclosed by the invention presents obvious synergetic effect within a certain proportion range; the control effect of the weeding composition is obviously improved when compared with a single agent; the use amount of the glufosinate is effectively reduced; the composition application times is reduced, however, weeding effect can be achieved; the composition application cost is reduced; environment pollution is reduced.

Owner:GUANGDONG ZHENGE BIOLOGICAL TECH CO LTD

Preparation method for glufosinate

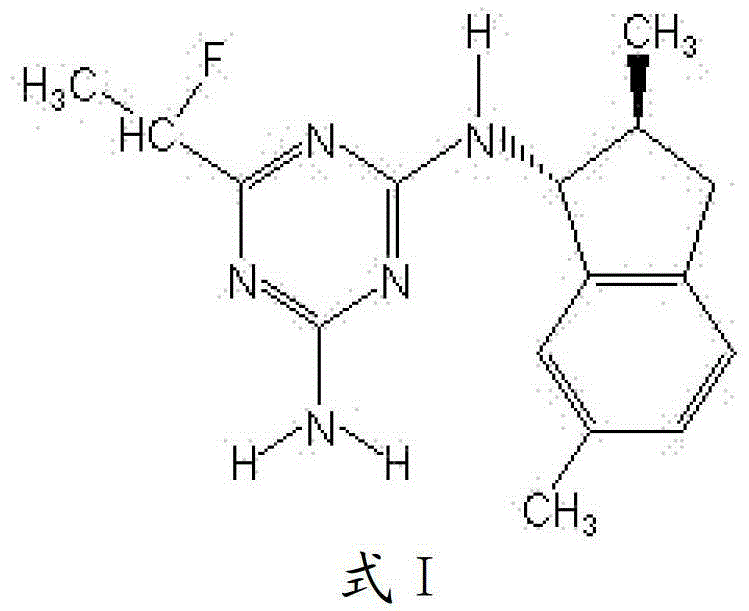

ActiveCN102584893AHigh purityHigh yieldGroup 5/15 element organic compoundsCyanideMethylphosphinic acid

The invention relates to a new preparation method for herbicide glufosinate. The method comprises the following steps of: performing Bucherer-Bergs cyclization reaction on a methylphosphonate derivative type compound (II), ammonium carbonate and cyanide serving as raw materials to obtain a compound shown by a formula (III); and then hydrolyzing to prepare glufosinate compound shown by a formula (I). According to the preparation method, hemiacetal or acetal is used as a raw material, and the Bucherer-Bergs cyclization reaction is performed to obtain a glycolylurea derivative, so that high yield, easiness for detection and mild condition are guaranteed; and after glycolylurea is cyclihydrolyzed, a product has high purity, and ammonium salt can be removed without multiple recrystallization processes.

Owner:ZHEJIANG UNIV OF TECH

Glufosinate-picolinic acid herbicide weeding composition

InactiveCN103053609AImprove the effect of prevention and controlLower doseBiocideAnimal repellantsEcological environmentToxicology

The invention discloses a glufosinate-picolinic acid herbicide weeding composition. The glufosinate-picolinic acid herbicide weeding composition comprises glufosinate and a picolinic acid herbicide as active ingredients, and the balance pesticide assistants. A weight ratio of glufosinate to the picolinic acid herbicide in the glufosinate-picolinic acid herbicide weeding composition is in a range of (20: 1) to (1: 10). The glufosinate-picolinic acid herbicide weeding composition comprises 10 to 80wt% of glufosinate and the picolinic acid herbicide. The glufosinate-picolinic acid herbicide weeding composition can be used for preventing and removing weeds in bare places, orchards and farmlands, has effects superior to effects of a single picolinic acid herbicide or glufosinate, reduces a use amount of a pesticide, reduces the adverse influence produced by a pesticide on the ecological environment, and effectively solves the problem of weed resistance to pesticides.

Owner:苏州曦龙净化设备有限公司

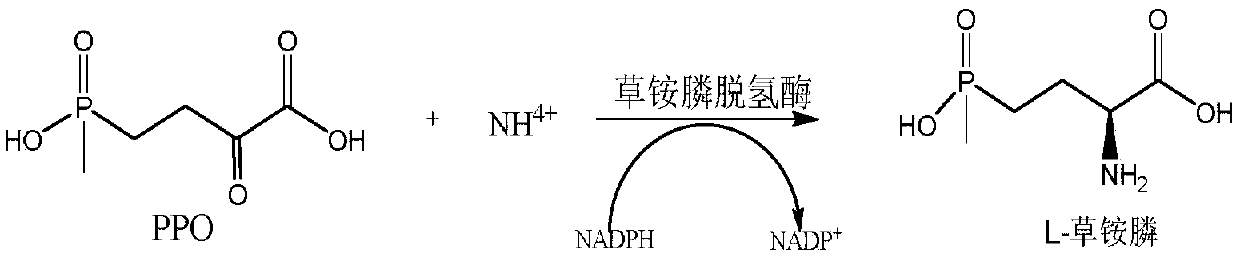

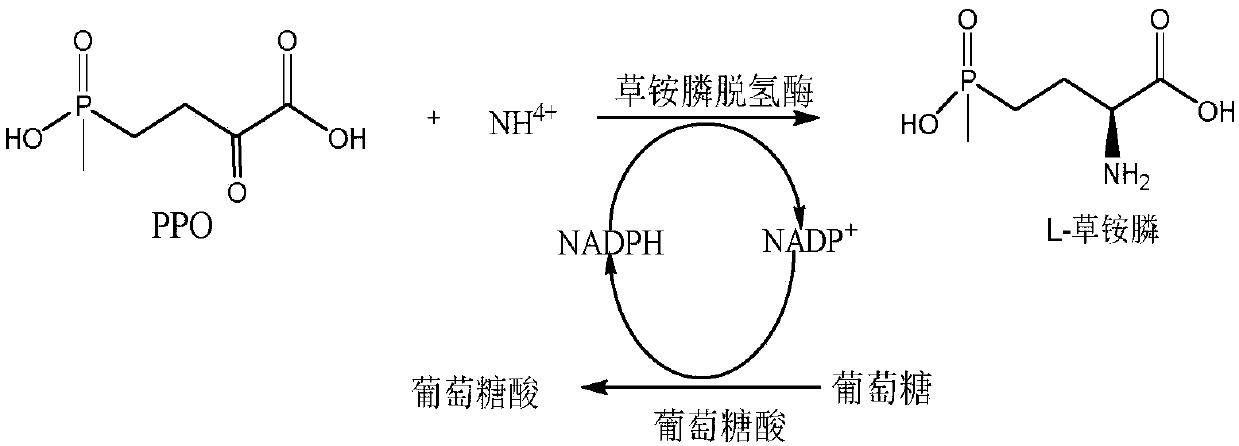

Glufosinate-ammonium dehydrogenase mutant and application thereof to synthetizing L- glufosinate-ammonium

ActiveCN109609475AIncrease concentrationHigh activityBacteriaMicroorganism based processesGlufosinate-ammoniumMutant

Owner:ZHEJIANG UNIV OF TECH

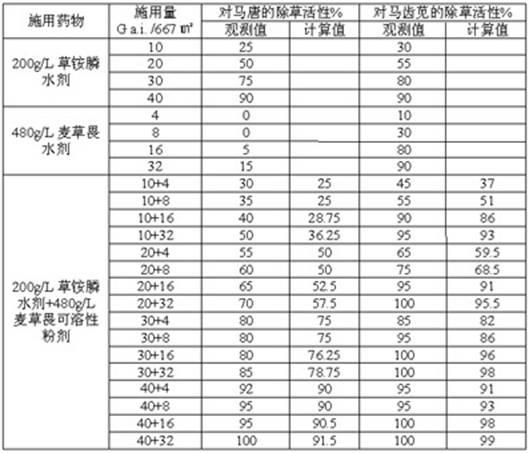

Weeding composition with glufosinate and efficient haloxyfop-methyl, and preparation method of weeding composition

ActiveCN103688994ASimple production processEasy to store and transportBiocideAnimal repellantsMicroemulsionBiology

The invention discloses a weeding composition with glufosinate and efficient haloxyfop methyl, and a preparation method of the weeding composition, and belongs to the agricultural field and aim to solve the problems that glufosinate has a poor prevention effect on perennial resistant plants, limitation of prevention and movement for perennial weeds, low weeding effect and high cost with exclusive use because of long-term massive use. The dosage form of the weeding composition is microemulsion and comprises glufosinate and efficient haloxyfop methyl. The ratio by weight of the glufosinate to efficient haloxyfop methyl is 1:5 to 45:1. The weeding composition prepared by the method has the characteristics of wide weeding range, high weeding effect and low cost. The pesticide effect is obviously better than any one of the glufosinate and the efficient haloxyfop methyl. The preparation method is simple and convenient to operate, and has the advantages of high feasibility, stable product quality and obvious market value. The composition still has good stability after being stored for a long time, thereby having obvious market values and being suitable for extensive generalization and use.

Owner:LIER CROPSCIENCE CO LTD

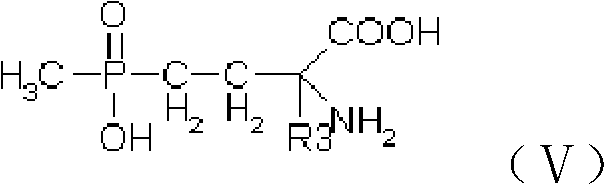

Synthesis method for glufosinate and analogue thereof

InactiveCN102399239AReduce generationReduce processing costsGroup 5/15 element organic compoundsDiethyl phosphateSynthesis methods

The invention provides a synthesis method for glufosinate shown as a formula (V) and an analogue thereof. The method comprises the following steps of: preparing an intermediate such as methyl diethyl phosphate by Grignard, disproportionation and coupling and with phosphorus trichloride, triethyl phosphate and chloromethane as initiative raw materials; condensing the methyl diethyl phosphate, anhydride and acrolein substances; performing Strecker reaction and hydrolysis and thus obtaining the glufosinate and the analogue thereof. In the synthesis method, the reaction condition is mild; safety is high; and yield is obviously increased.

Owner:JIANGSU YOUTH CHEM +1

Preparation method of glufosinate

The invention relates to a preparation method of glufosinate. The preparation method comprises the following steps: with a compound represented by a formula (I) as a starting material, reacting the compound represented by the formula (I) with cyanide RCN to obtain ketone nitrile; then hydrolyzing ketone nitrile in the presence of an acidic substance and water so as to obtain ketoacid; and reacting ketoacid successively with ammonia gas and hydrogen under the action of a catalyst so as to obtain glufosinate; wherein the compound represented by the formula (I) is cyclic phosphonic acid anhydride. The preparation method in the invention has the advantages of simple process, convenient operation, high product purity, high yield, no need for repeated recrystallization, ect.; and the final product of the preparation method is directly glufosinate ammonium, the step of converting glufosinate chloride into glufosinate ammonium is omitted, so the method has great economic benefit and is suitable for industrialization production.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

Method for separating and extracting L-glufosinate from enzymatical reaction liquid

ActiveCN108484665AHigh purityHigh yieldGroup 5/15 element organic compoundsOrganic solventIon exchange

The invention discloses a method for separating and extracting L-glufosinate from enzymatical reaction liquid. When an enzyme catalysis method is adopted for producing the L-glufosinate, enzyme catalysis liquid contains not only the L-glufosinate, but also impurities including enzyme or thalli, byproducts(normally organic matters), unreacted D-type substrates, ammonium salt and the like, and due to the fact that the L-glufosinate has such characteristics as being soluble in water and insoluble in organic solvent, separation and extraction difficulty levels are high; the method for separating and extracting the L-glufosinate mainly includes the following three steps of (1) pre-treatment, (2) an ion exchange method and (3) crystallization; the purity of the product finally obtained reaches 98% or above, and the yield reaches 98% or above. According to the method, the technological process is short, operation is simple, the application range is wide, the cost is low, the yield of the L-glufosinate is high, and the product quality is high.

Owner:ZHEJIANG UNIV OF TECH

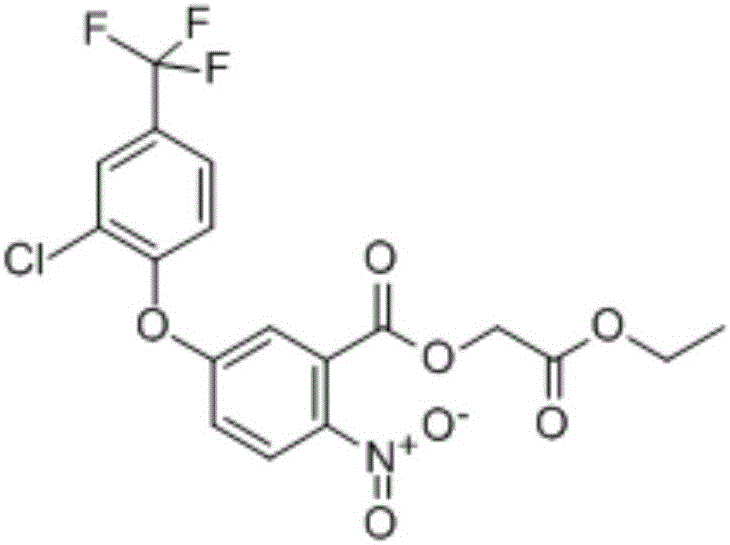

Weeding composition containing glufosinate-ammonium and fluoroglycofen-ethyl, and preparation method of composition

InactiveCN106070305AProtect healthImprove protectionBiocideDead animal preservationGlufosinate-ammoniumEmulsion

The invention provides a weeding composition containing glufosinate-ammonium and fluoroglycofen-ethyl, and a preparation method of the composition, and belongs to the technical field of pesticides. The dosage form of the composition is a micro-emulsion, the composition comprises glufosinate-ammonium, fluoroglycofen-ethyl, a cosolvent, a first surfactant and a second surfactant, the first surfactant is alkyl glycoside, and the second surfactant is polyoxyethylene phosphonate or polyoxyethylene phosphonate salt. The weeding composition prepared in the invention has the characteristics of fast weeding speed, good weeding effect, low production cost and environmental protection, and has an obvious better weeding effect than single doses of glufosinate-ammonium and fluoroglycofen-ethyl. The preparation method has the advantages of simplicity, convenience in operation, and high feasibility; and the above product has stable quality, still has good quality stability after being stored for a long term, has obvious market values, and is suitable for large-scale promotion application.

Owner:济南绿霸农药有限公司

Synergistic herbicidal composition for uncultivated land and orchard

InactiveCN102027992ASynergistic effect is obviousExpand the spectrum of weed controlBiocideAnimal repellantsToxicologyOrchard

The invention discloses a synergistic herbicidal composition for an uncultivated land and an orchard. The synergistic herbicidal composition consists of glufosinate and dicamba serving as active ingredients and acceptable auxiliary components in pesticides, wherein the weight ratio of the glufosinate to the dicamba is 1:3.2-10:1. After the two active ingredients are compounded, the synergistic herbicidal composition has the herbicide effect obviously superior to that of single glufosinate or single dicamba, has obvious synergism, can control perennial vines, undershrub weeds and broadleaf weeds and also can control annual and biennial weeds; and the herbicidal spectrum is enlarged, the use amount of single glufosinate and single dicamba is reduced, the production cost is reduced, and the herbicidal composition has obvious market popularization value.

Owner:LIER CHEM CO LTD

Method for producing glufosinate P free acid

ActiveCN103827127ASimple and cheap to manufactureHigh purityOrganic chemistry methodsGroup 5/15 element organic compoundsAlcoholDissolution

Owner:MMAG CO LTD

Weedicide composition and preparation method thereof

InactiveCN103168798AReduce use costFast weedingBiocideAnimal repellantsGlufosinate-ammoniumToxicology

The invention discloses a weedicide composition and a preparation method thereof, wherein the weedicide composition comprises the following components in percentage by weight: 1-50% of glyphosate and 0.1-50% of glufosinate-ammonium. The weedicide composition disclosed by the invention has the advantages that the glufosinate-ammonium can be compounded with the glyphosate, and the glufosinate-ammonium has no negative effect on the using effect of the glyphosate, so that the resistance problem of the single glufosinate is solved, the using cost of the glufosinate-ammonium is also effectively reduced, meanwhile, the weeding speed of the glufosinate is accelerated, and the using effect of a glufosinate product is also enhanced.

Owner:GUANGDONG ZHENGE BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com