Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

603 results about "Biological oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

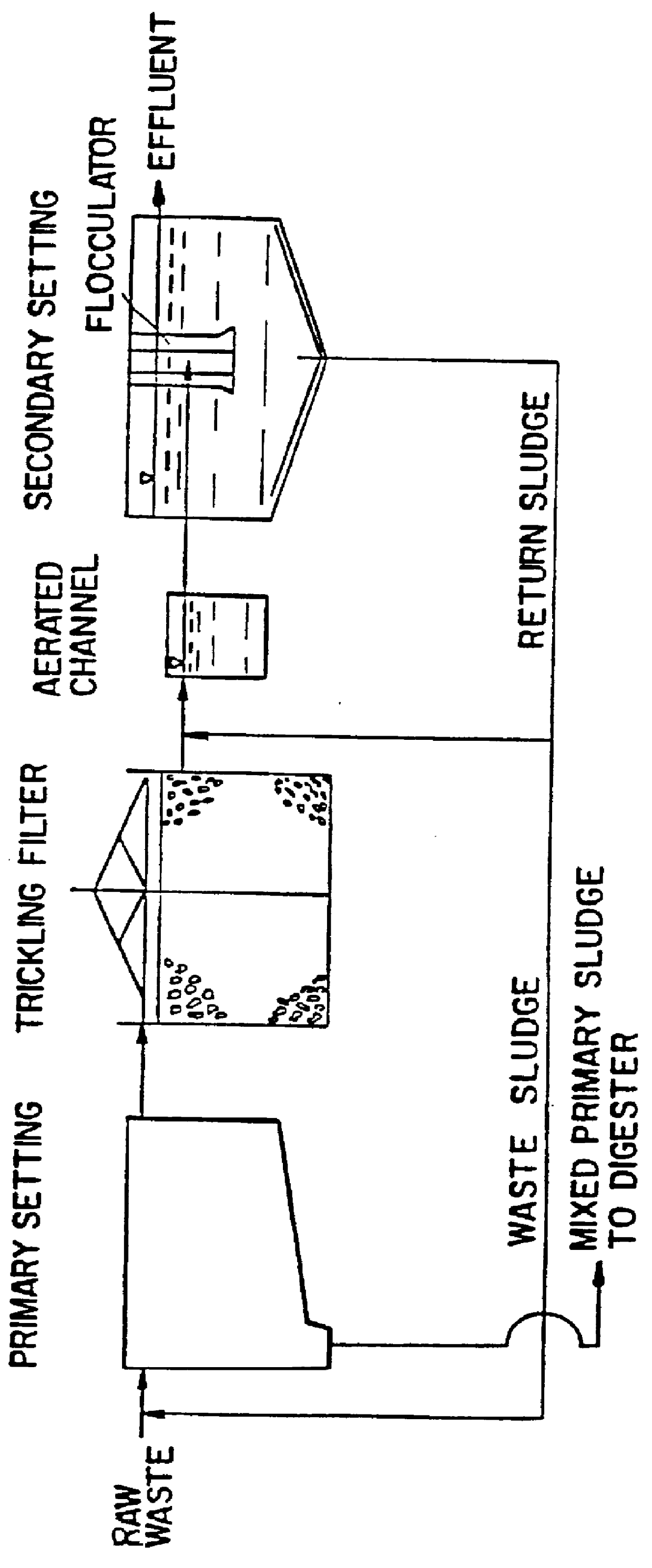

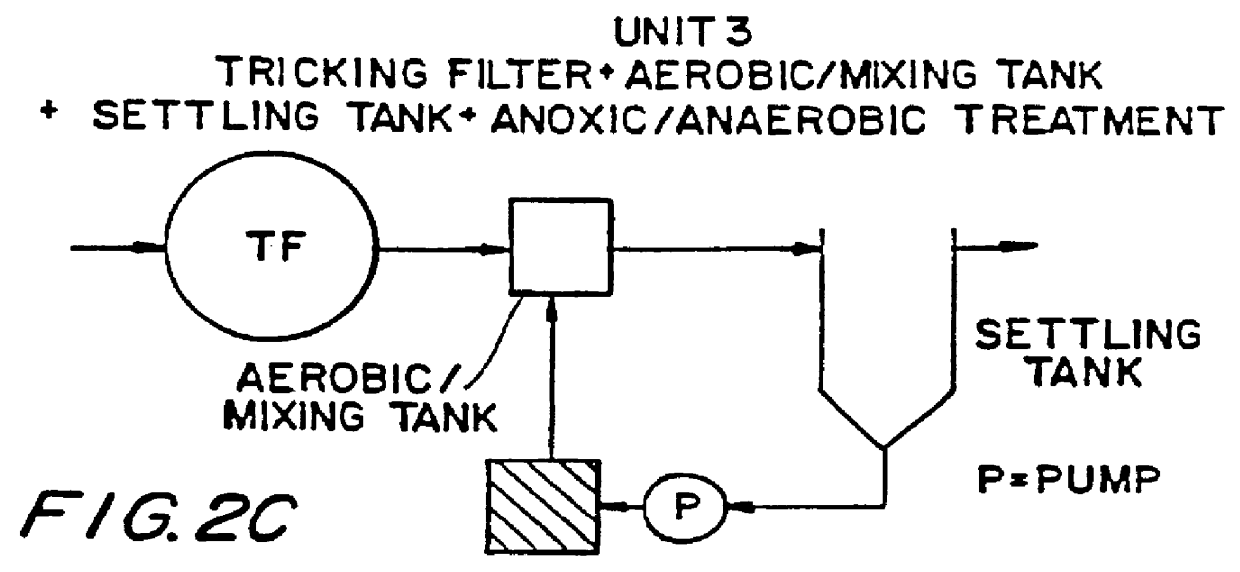

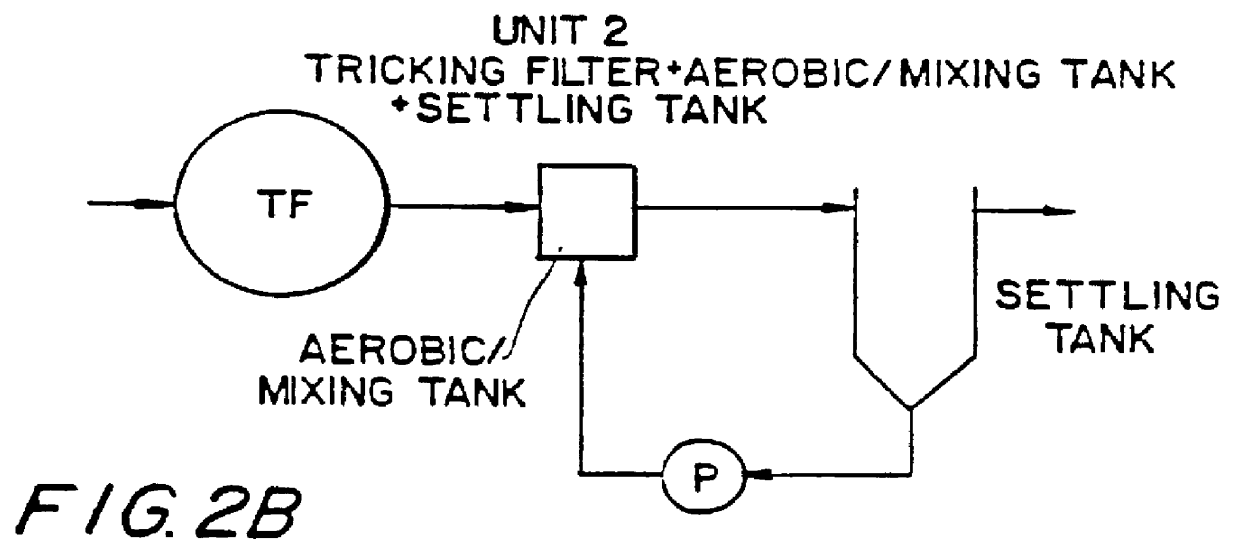

Wastewater treatment process

InactiveUS6113788AImprove efficiencyFacilitated releaseTreatment using aerobic processesSeparation devicesSludgePhosphate

A wastewater treatment process having improved solids separation characteristics and reduced biochemical oxygen demand (BOD) in the purified wastewater comprising the steps of: passing wastewater through a main aerobic biological oxidation zone and therein oxidizing a portion of the BOD a portion of the ammonia nitrogen content (NH3-N); passing the effluent from said aerobic biological oxidation zone to an aerobic / mixing zone and therein mixing said effluent with effluent from the anoxic / anaerobic zone; passing the effluent from said aerobic / mixing zone to a settling zone and therein separating purified wastewater having reduced BOD and suspended solids, and sludge containing suspended solids; passing a portion of the sludge formed in the settling zone and volatile acids to an anoxic / anaerobic zone and therein increasing the extracellular polymer content of said sludge, the release of phosphorus into solution and the reduction of nitrate nitrogen to molecular nitrogen gas; and recycling an effective amount of the effluent from said anoxic / anaerobic zone to said aerobic / mixing zone. In an alternative embodiment, a volatile acid is added to a zone to which no additional oxygen has been added that is in the flow path from the main aerobic biological oxidation zone or, alternatively, it may be added to the anoxic / anaerobic zone and the thus-treated effluent is passed to the aerobic / mixing zone wherein phosphate is removed from the effluent.

Owner:POLYTECHNIC INST OF NEW YORK

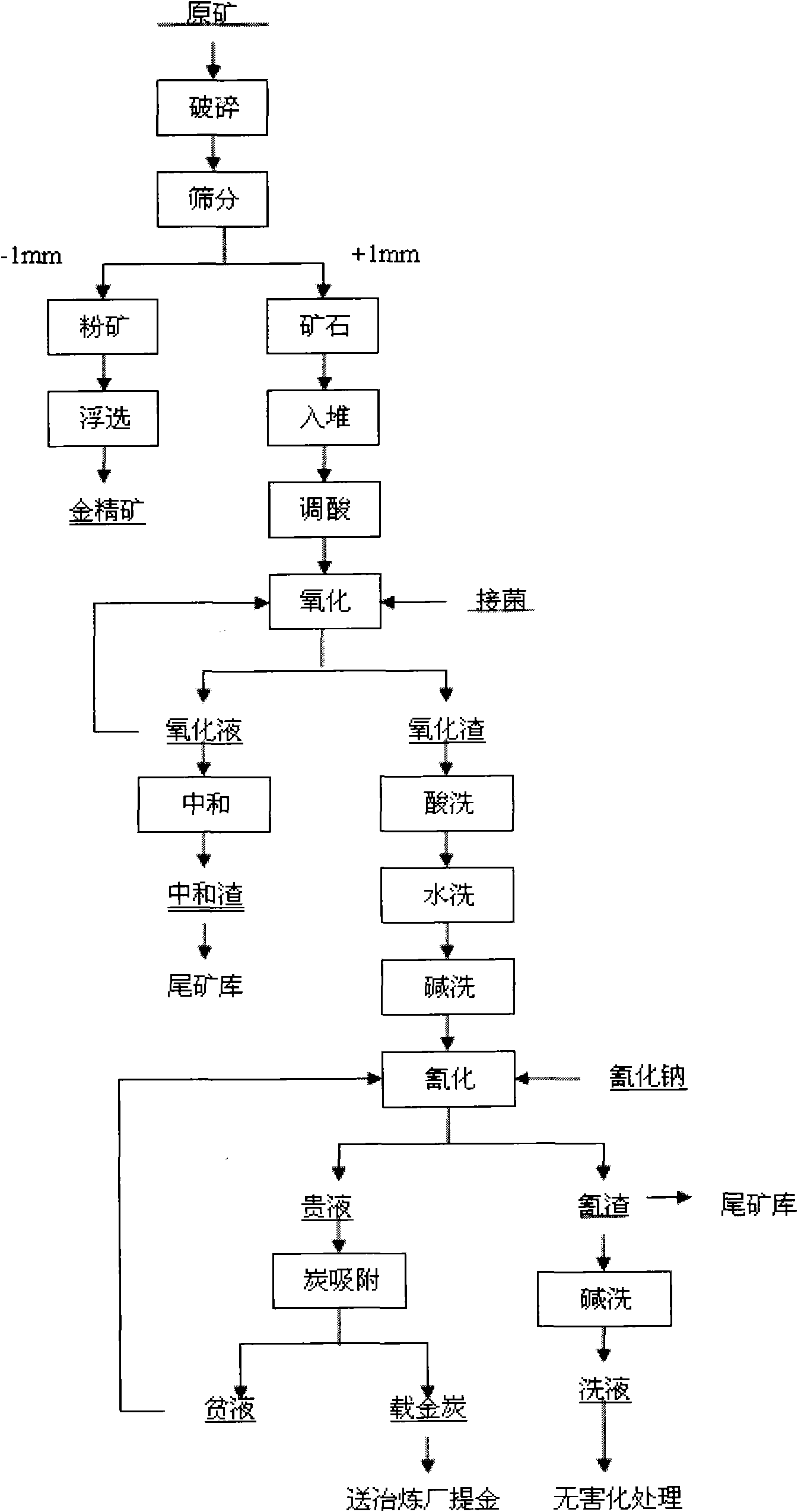

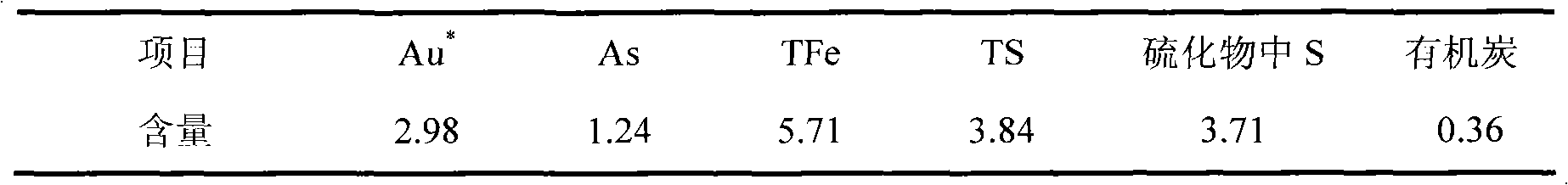

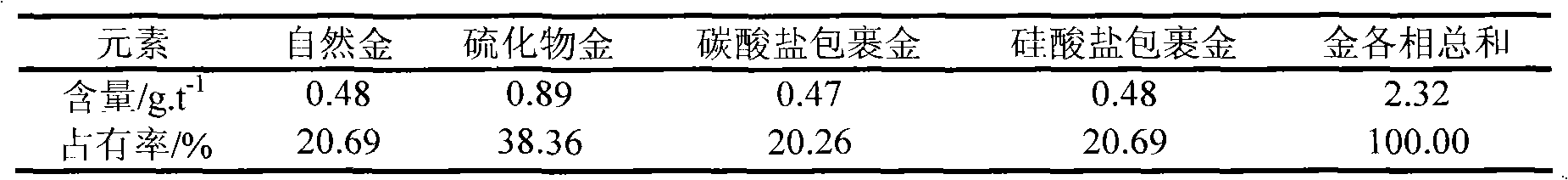

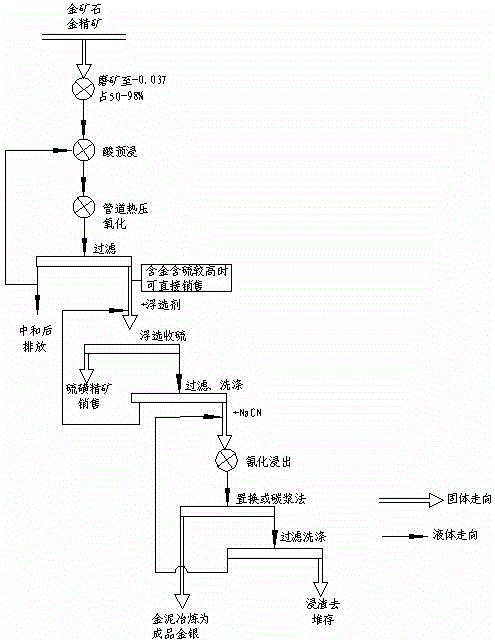

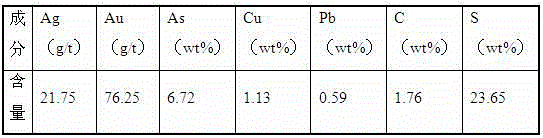

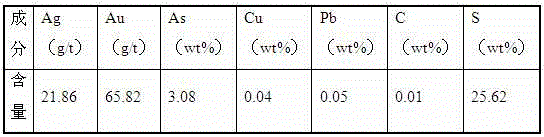

Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

The invention relates to a process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon. The process is characterized in that: the gold ore has the characteristics of high clay mineral content, large fine ore amount after grinding, and the like. The process comprises the following steps of: grinding raw ore to 10 to -30 millimeters; sieving ore through a sample sieve of 1 to -2 millimeters or washing the ore with water so as to separate fine ore from the ore; floating gold concentrate by using the obtained fine ore; performing direct heap leaching on ore of +2 millimeter and performing biological oxidation; performing medium transformation such as acid washing, water washing, alkali washing and the like on the biologically-oxidized ore and cyaniding directly so as to extract gold, wherein gold is extracted from the floated gold concentrate by biological oxidation-cyaniding and carbon soaking-pressure oxidation-cyaniding and gold extraction or baking, oxidation and cyaniding. Due to the adoption of the process, the problem of permeability of gold ore is solved and the gold extracting rate is effectively increased from 2 to 5 percent during direct heap leaching and cyaniding to 55 to 65 percent. The process has the advantages of simple process, high gold extracting rate, low pollution, high benefit and the like.

Owner:ZIJIN MINING GROUP

New method for deeply dewatering sludge through bio-leaching process rapid conditioning

ActiveCN103936246ASimple processLow running costSludge treatment by de-watering/drying/thickeningSludge processingSludge cakeResource utilization

The invention discloses a new method for deeply dewatering sludge through bio-leaching process rapid conditioning. The method comprises the steps of firstly performing bio-leaching conditioning on sludge, namely, directly pumping concentrated liquid sludge of a sewage treatment plant into a bio-leaching reactor which contains special composite microbial community, performing treatment for 1.5-2 days, changing bound water in the sludge into free water which can be removed relatively easily by virtue of the microbial substitution effect, biological oxidation effect and biological acidification effect, dissolving out heavy metals from the sludge at the same time, entering an aqueous phase, killing pathogens in the sludge, then collecting the sludge subjected to bio-leaching in a homogeneous pool, directly transporting to a common-pressure diaphragm chamber type filter press by virtue of a pump, and dewatering, wherein the moisture content of dewatered sludge cake is less than 60%, and no flocculant like PAM (polyacrylamide) is added during the preparation process. The method disclosed by the invention is performed under normal temperature and pressure, and has low cost; the dewatered sludge cake is low in moisture content, odorless, and yellowish-brown in color; and the organic matters, calorific values and nutrients of the dewatered sludge can not be reduced, thus facilitating the subsequent resource utilization.

Owner:NANJING AGRICULTURAL UNIVERSITY

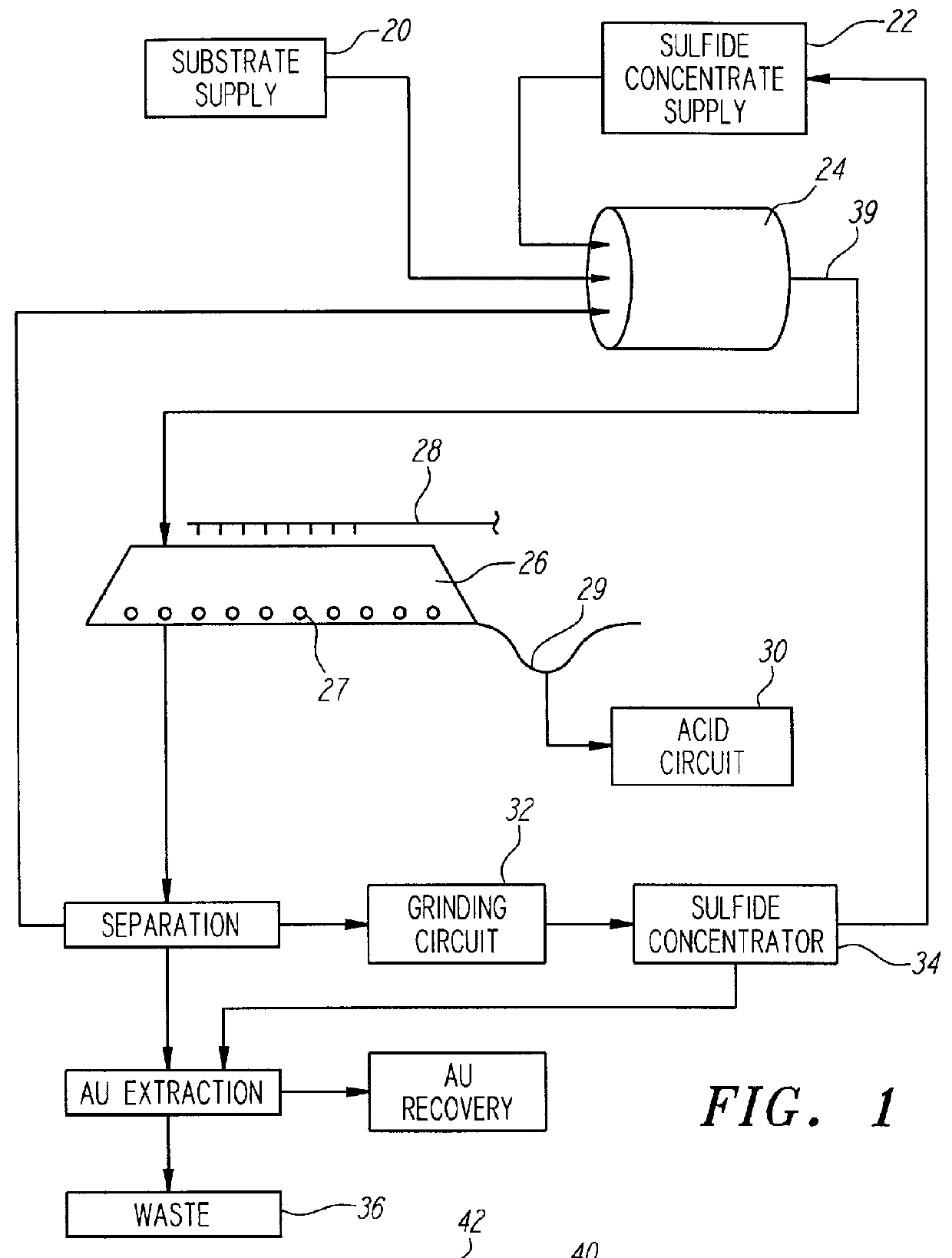

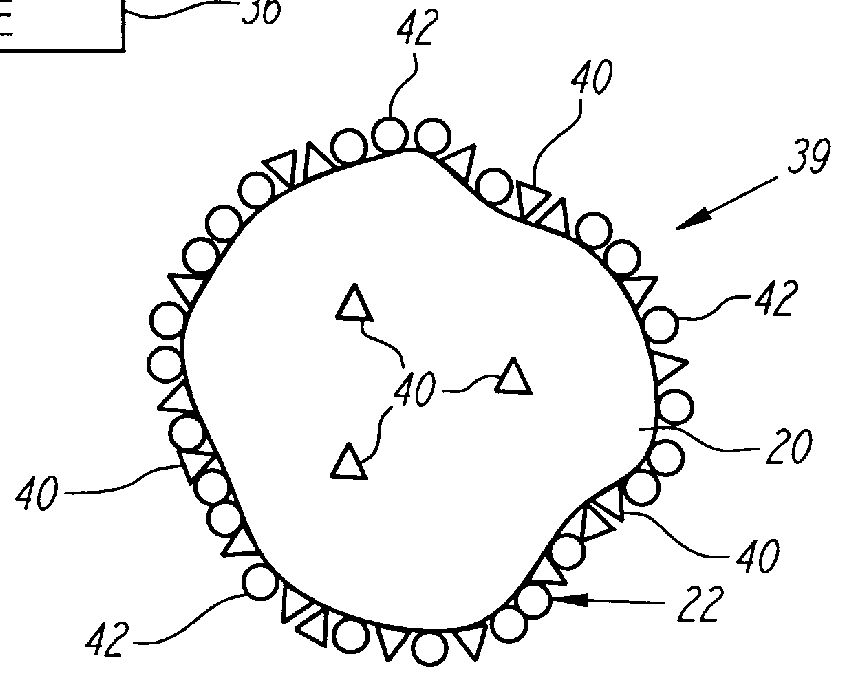

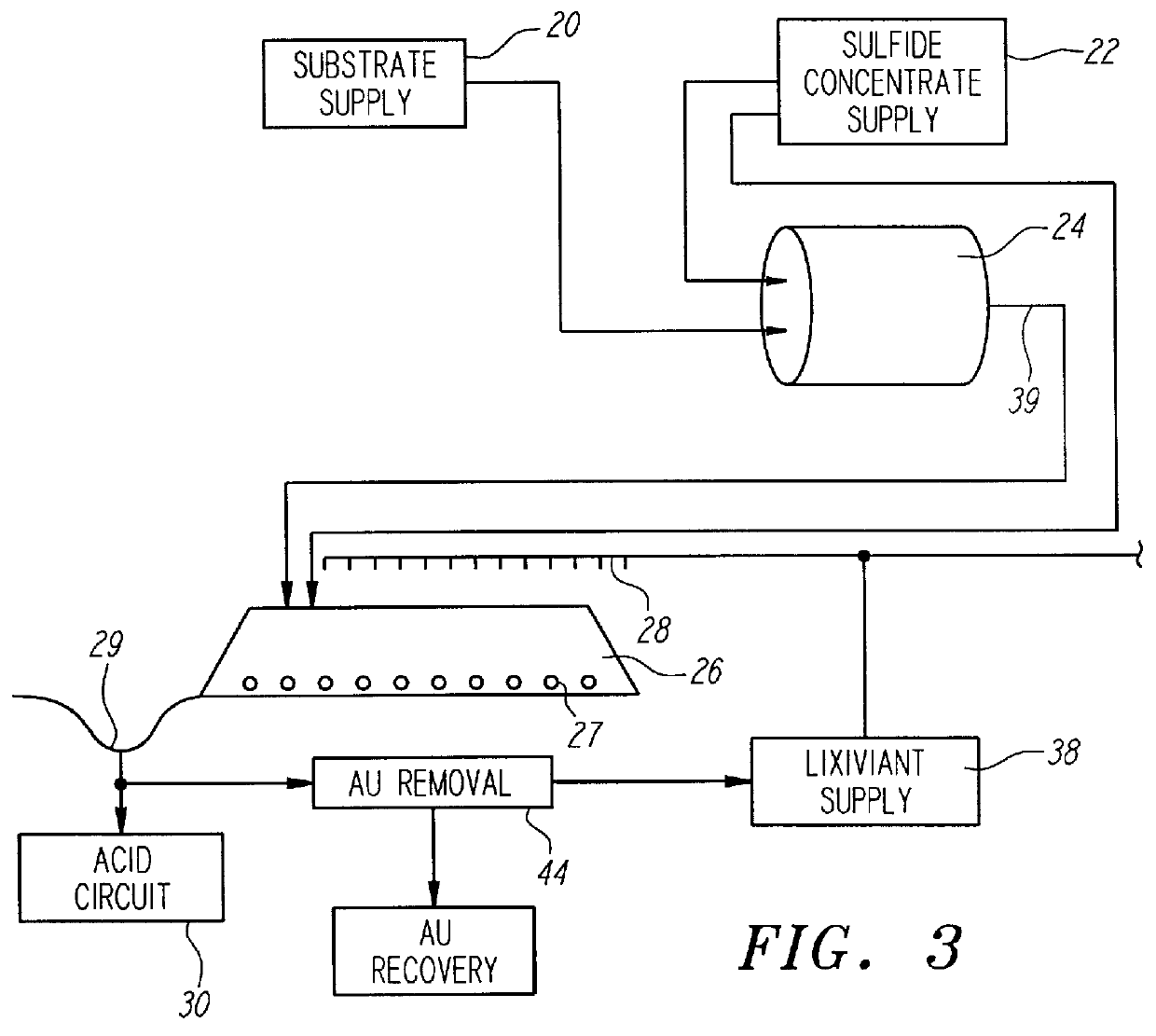

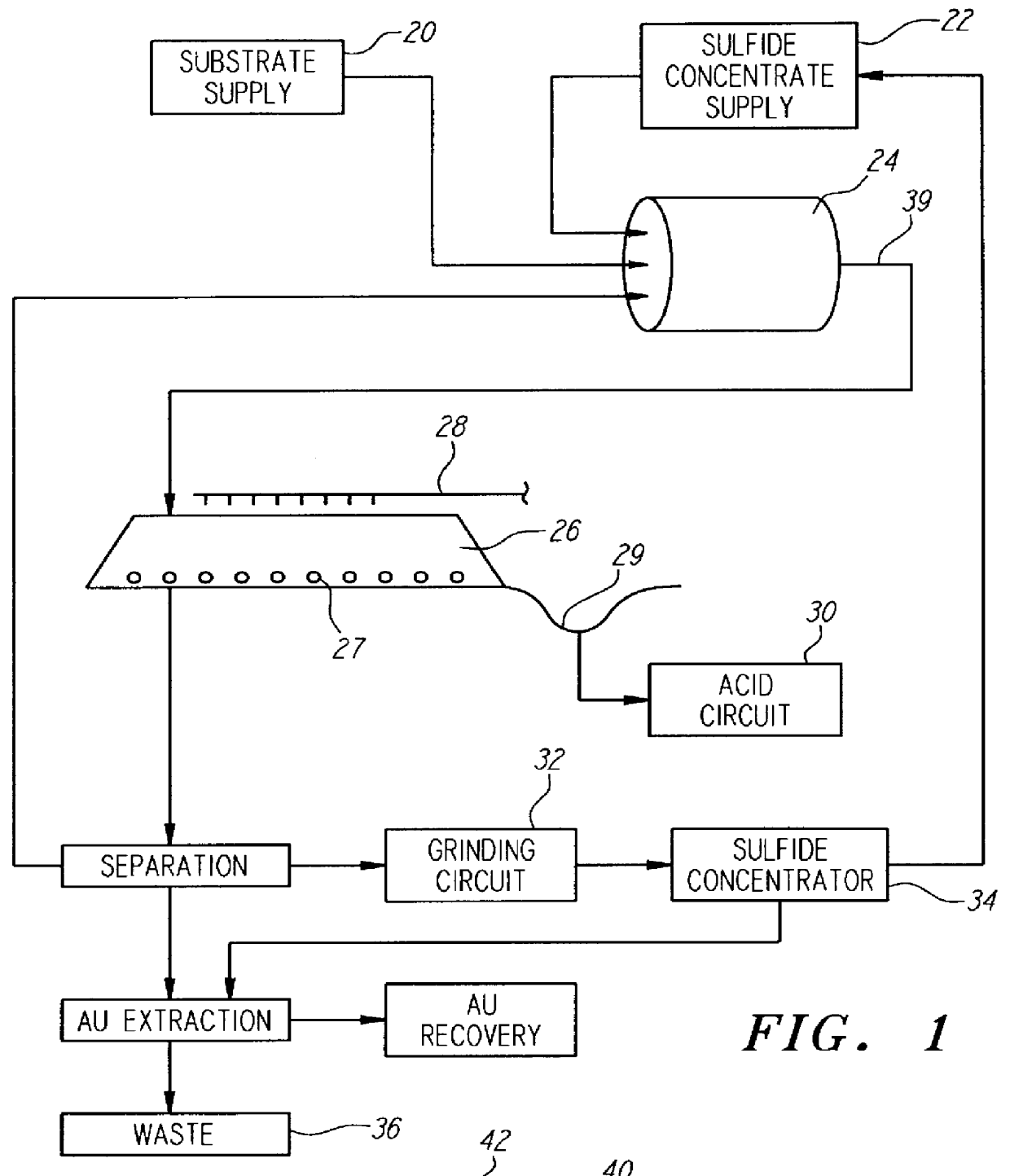

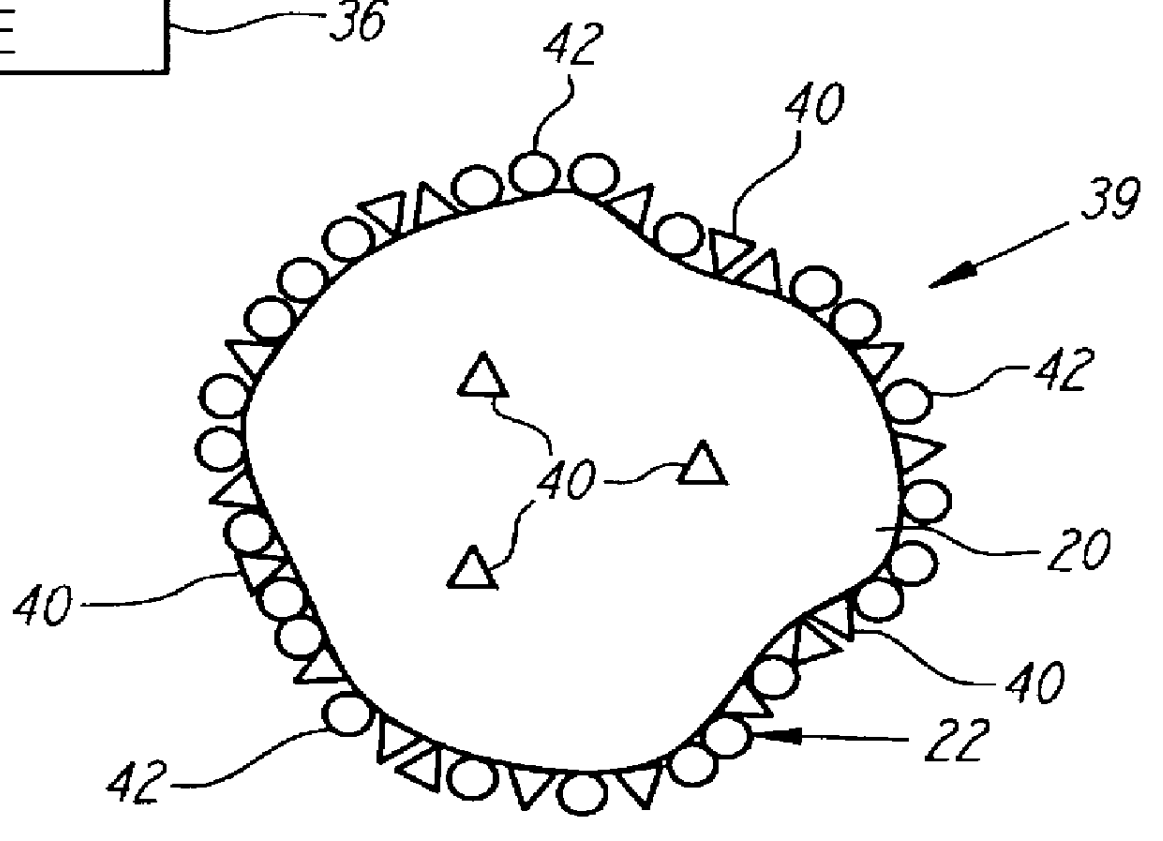

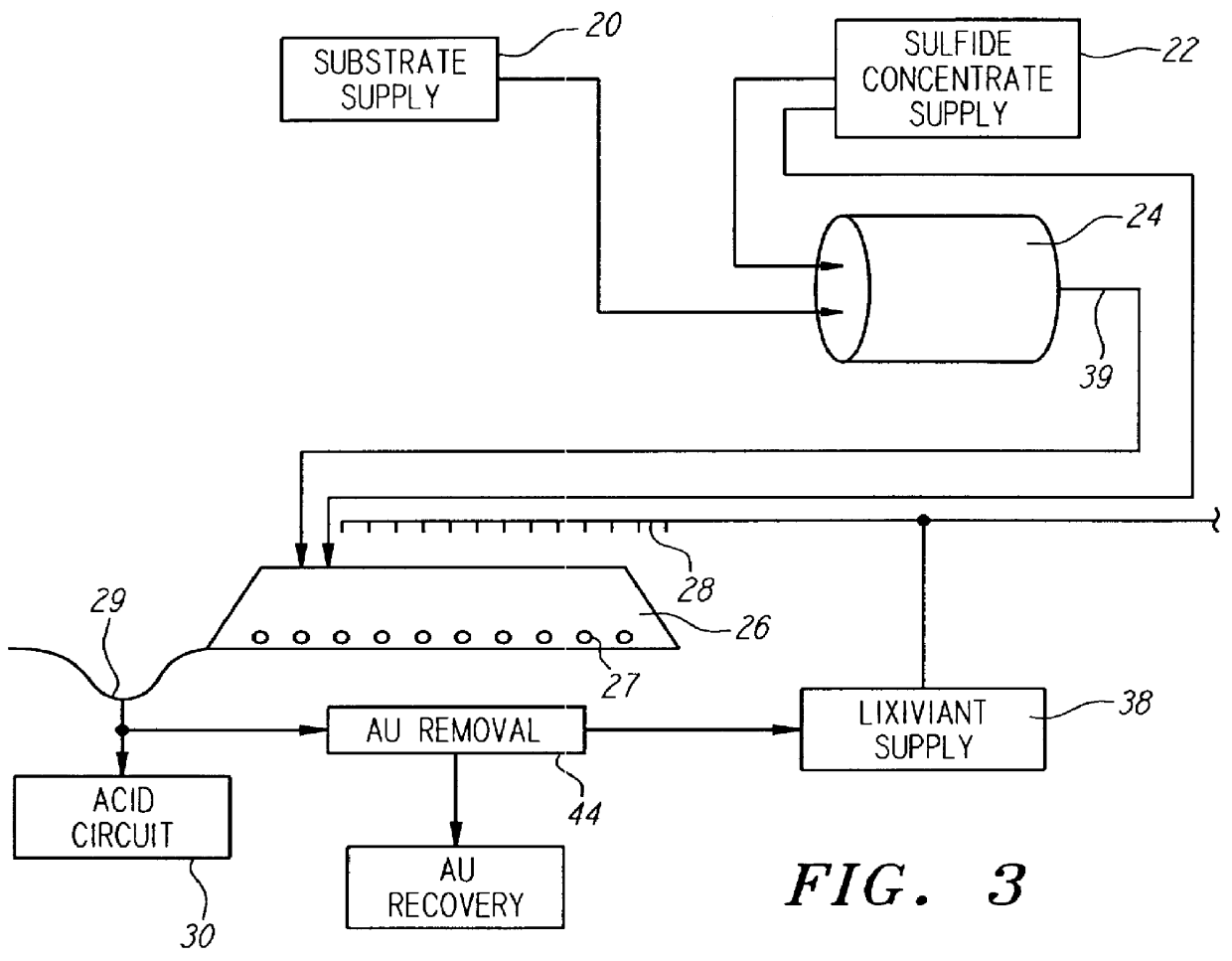

Nonstirred bioreactor for processing refractory sulfide concentrates and method for operating same

InactiveUS6083730AReduced pHIncrease equipment costSolvent extractionContaminated soil reclamationSulfide mineralsMetallic sulfide

A method of biooxidizing sulfide minerals in a nonstirred bioreactor is provided. According to the disclosed method, a concentrate of sulfide minerals is coated onto a substrate, such as coarse ore particles, lava rock, gravel or rock containing mineral carbonate as a source of CO2 for the biooxidizing bacteria. After the sulfide minerals are coated onto the substrate, a heap is formed with the coated substrates or the coated substrates are placed within a tank. The sulfide minerals are then biooxidized to liberate the metal value of interest. Depending on the particular ore deposit being mined, the sulfide mineral concentrates used in the process may comprise sulfide concentrates from precious metal bearing refractory sulfide ores or they may comprise sulfide concentrates from metal sulfide type ores, such as chalcopyrite, millerite or sphalorite. The distinction being that in the former, the metal of interest is a precious metal occluded within the sulfide minerals, whereas in the latter, the metal to be recovered is copper, nickel or zinc and is present as a metal sulfide in the sulfide concentrate.

Owner:GEOSYNFUELS LLC (US)

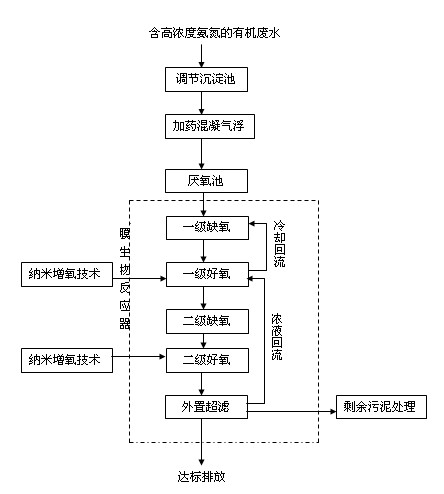

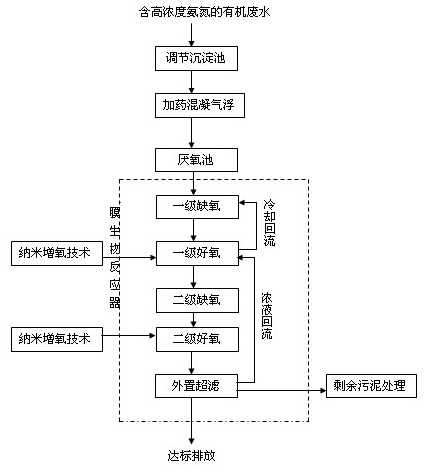

Method for treating organic wastewater containing high-concentration ammonia nitrogen

InactiveCN102101742AEfficient removalTurn up impact resistanceMultistage water/sewage treatmentHigh concentrationOxygen

The invention belongs to the technical field of environment protection and particularly relates to a treatment process of organic wastewater containing high-concentration ammonia nitrogen, which is characterized by comprising the following steps: 1, carrying out pretreatment; 2, carrying out anaerobic treatment, and leading effluent from a coagulation / air floatation pool to an upflow anaerobic sludge blanket (UASB) reactor, wherein the hydraulic power stays for 40 to 120 hours; and 3, treating in a membrane bioreactor system. Through microanaerobic / aerobic environments on a surface layer, as well as the absorption by a microporous structure and biological oxidation action, various pollutants such as organic matters, nitrogen and phosphorus in the wastewater can be removed from wastewater of an ecological base flow, and when the ecological base flow is introduced to a membrane biological reactor (MBR) system, the impact resistance and treatment efficiency of the biological treatment unit can be improved.

Owner:中建中环新能源有限公司

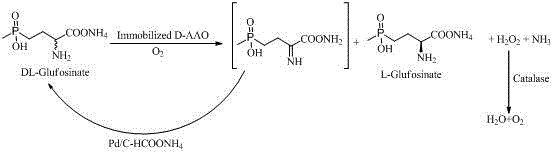

Enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium

The invention discloses an enzyme-chemocatalysis racemization removing preparation method for L-glufosinate-ammonium. According to the method, a one-pot reaction manner is adopted, under the molecular oxygen, immobilization D-amino acid oxidase catalyzes D-enantiomer in an enantioselectivity mode into 2-imino-4-(hydroxy methyl phosphonyl) butyric acid in a dehydrogenation mode, and palladium-ammonium formate catalyzes 2-imino -4-(hydroxy methyl phosphonyl) butyric acid into DL-glufosinate-ammonium in an in-situ reduction mode. Hydrogen peroxide produced in the process is efficiently decomposed into water and oxygen through catalase. Complete reacemization removing of DL-glufosinate-ammonium and efficient preparing of L-glufosinate-ammonium are achieved through biological oxidation-chemical reduction circulation. The method has the advantages that the process is simple, cost is low, environmental friendliness is achieved, and energy is saved. High-concentration DL-glufosinate-ammonium can be converted into L-glufosinate-ammonium. The yield is 90%, the optical purity of the product is 99%, and the method is suitable for industrial production of L-glufosinate-ammonium.

Owner:重庆惠健生物科技有限公司

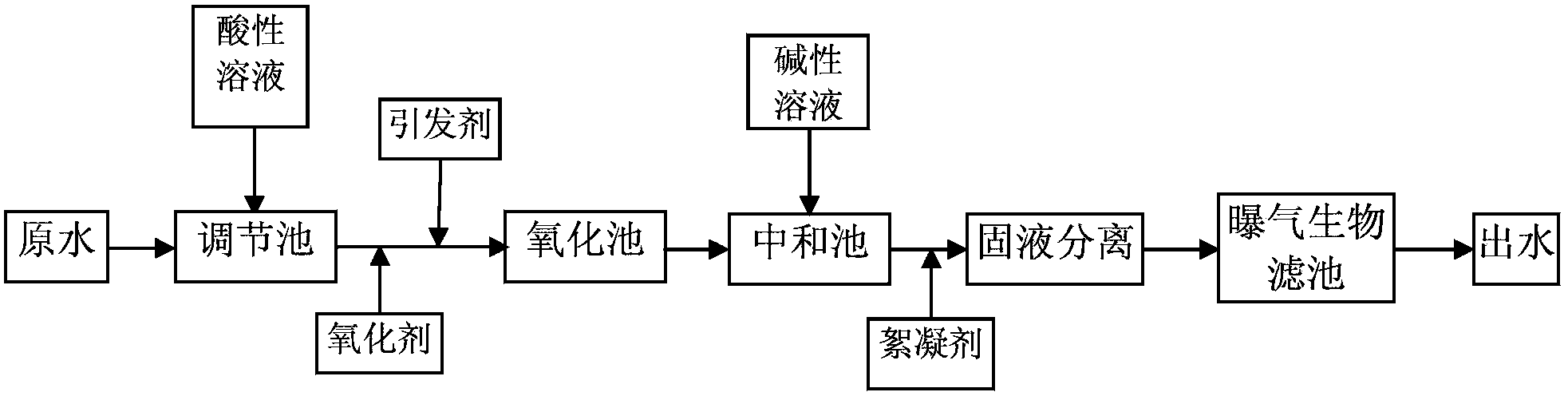

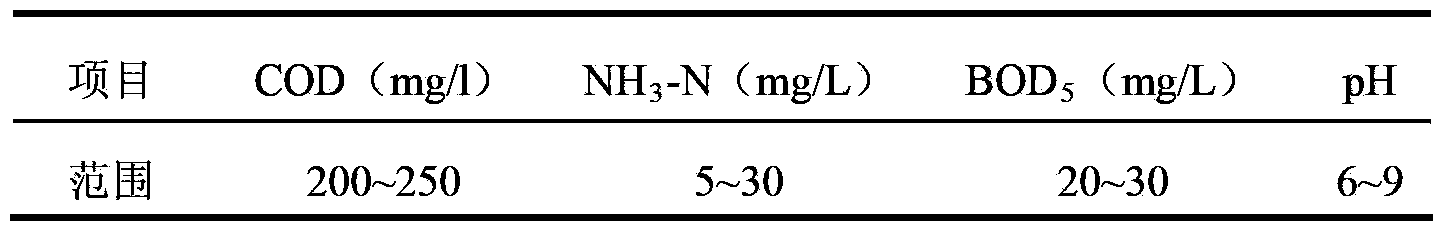

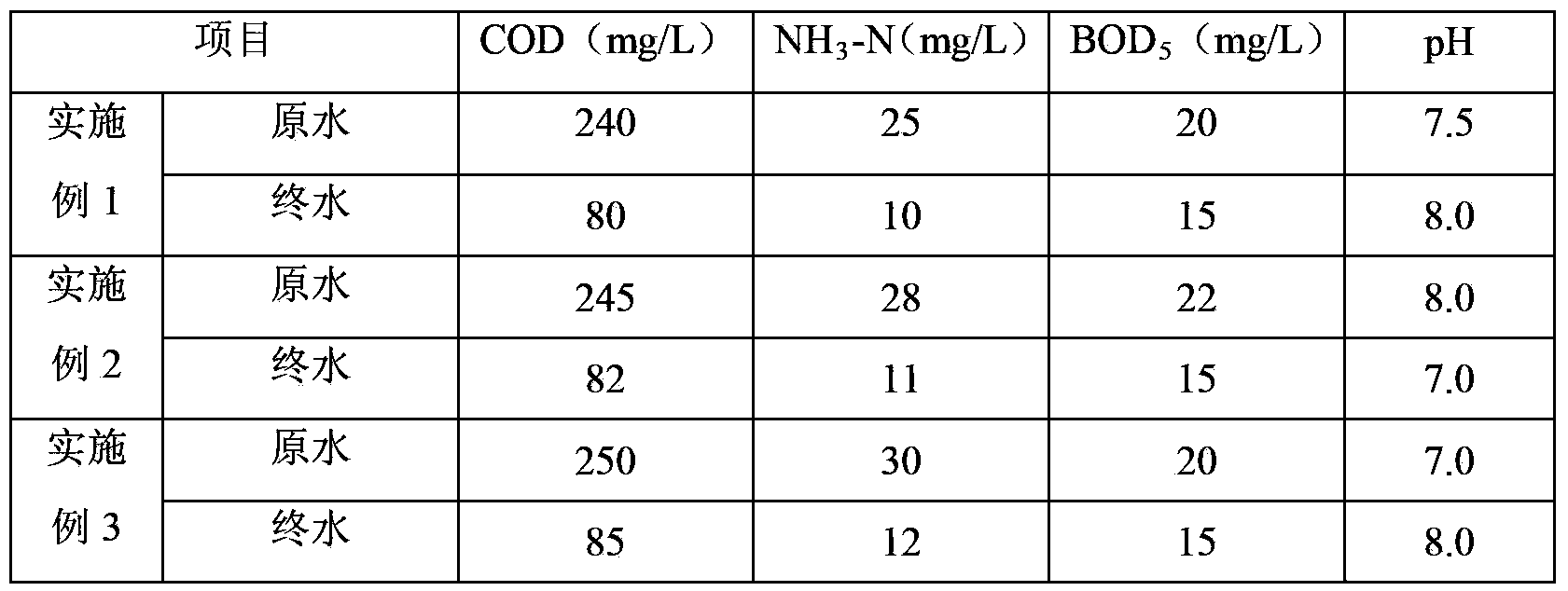

Processing method of wastewater in coal chemistry industry

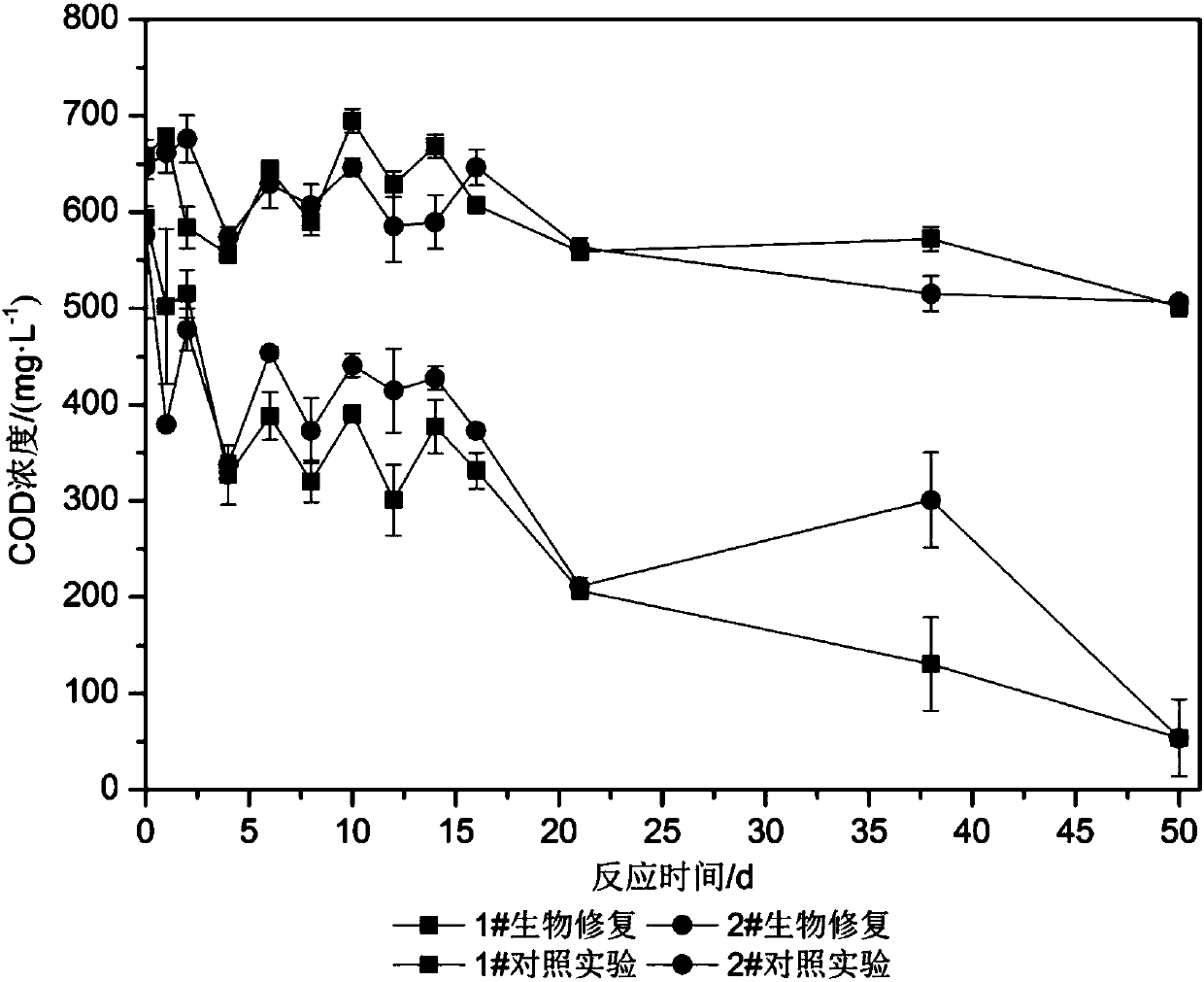

ActiveCN104163539AReduce COD valueReduce CODMultistage water/sewage treatmentBiological oxidationCoal chemistry

The invention relates to a deep processing method of wastewater in the coal chemistry industry. The method comprises the following steps in sequence: subjecting the effluent, which has been processed by a secondary biochemical treatment for wastewater in coal chemistry industry, to a chemical oxidation treatment and a biological oxidation treatment in sequence. The processing method adopts a technology integrating the chemical oxidation and biochemical oxidation, thus overcomes the shortage of high operation cost of the chemical oxidation technology and the shortage of low COD elimination rate of the biochemical oxidation technology, and achieves the degradation of partial organic pollutants in wastewater. The processed wastewater reaches the discharge or recycle standard, and the pollution to the environment is reduced. The processing method has the advantages of high processing efficiency, low operation cost, and strong adaptability for wastewater in coal chemistry industry, the processed wastewater reaches the national environmental requirements, and thus the processing method can achieve good economic and social profits.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

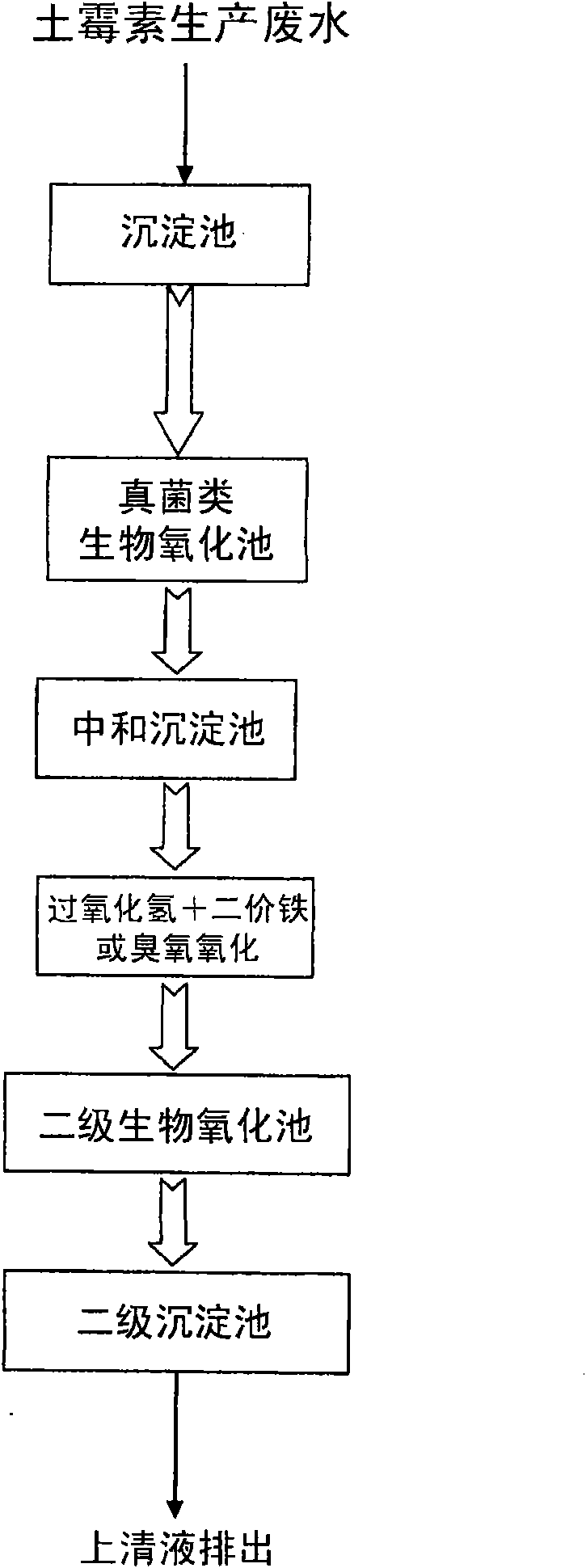

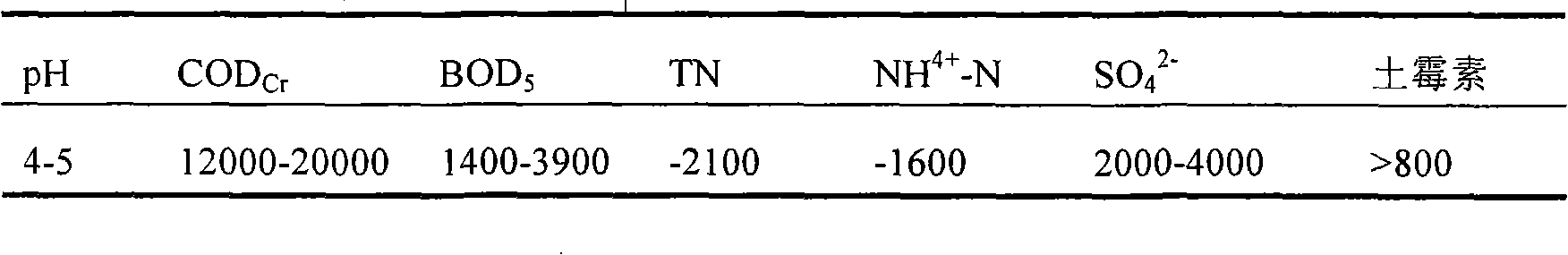

Process for treating antibiotic pharmaceutical wastewater

ActiveCN101570378AEliminate antibiotic-resistant bacteriaEliminate drug resistance genesWater/sewage treatment by irradiationMultistage water/sewage treatmentYeastBiological oxidation

The invention provides a process for treating antibiotic pharmaceutical wastewater. The process comprises the following steps that: A, pharmaceutical wastewater is subjected to precipitation separation, enters a primary biological oxidation pond, is added with yeast or mould for biochemical treatment, stays in water for 6 to 72 hours, is taken out from the water, and then is subjected to solid-liquid separation; B, the wastewater treated in a step A is oxidized, wherein oxidation conditions are as follows: the pH of the wastewater is regulated to be between 3 and 4.5; hydrogen peroxide and divalent iron reagent are added for oxidation; oxidation time is 1 to 10 hours; the molar ratio of the hydrogen peroxide H2O2 to divalent iron Fe is 1 to 50; and the hydrogen peroxide is 1 to 10 times the concentration of antibiotics in the wastewater; or the oxidation conditions are as follows: the pH of the wastewater is regulated to be between 7 and 11; ozone is supplied for oxidation; the dosage of the ozone is 30 to 120 mg / L; and the oxidation time is 1 to 10 hours; C, the wastewater treated in a step B is subjected to solid-liquid separation, enters a secondary biological oxidation pond, and then is oxidized to remove substances easy to biodegrade; and D, the wastewater treated in a step C is precipitated, and then supernatant is discharged.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

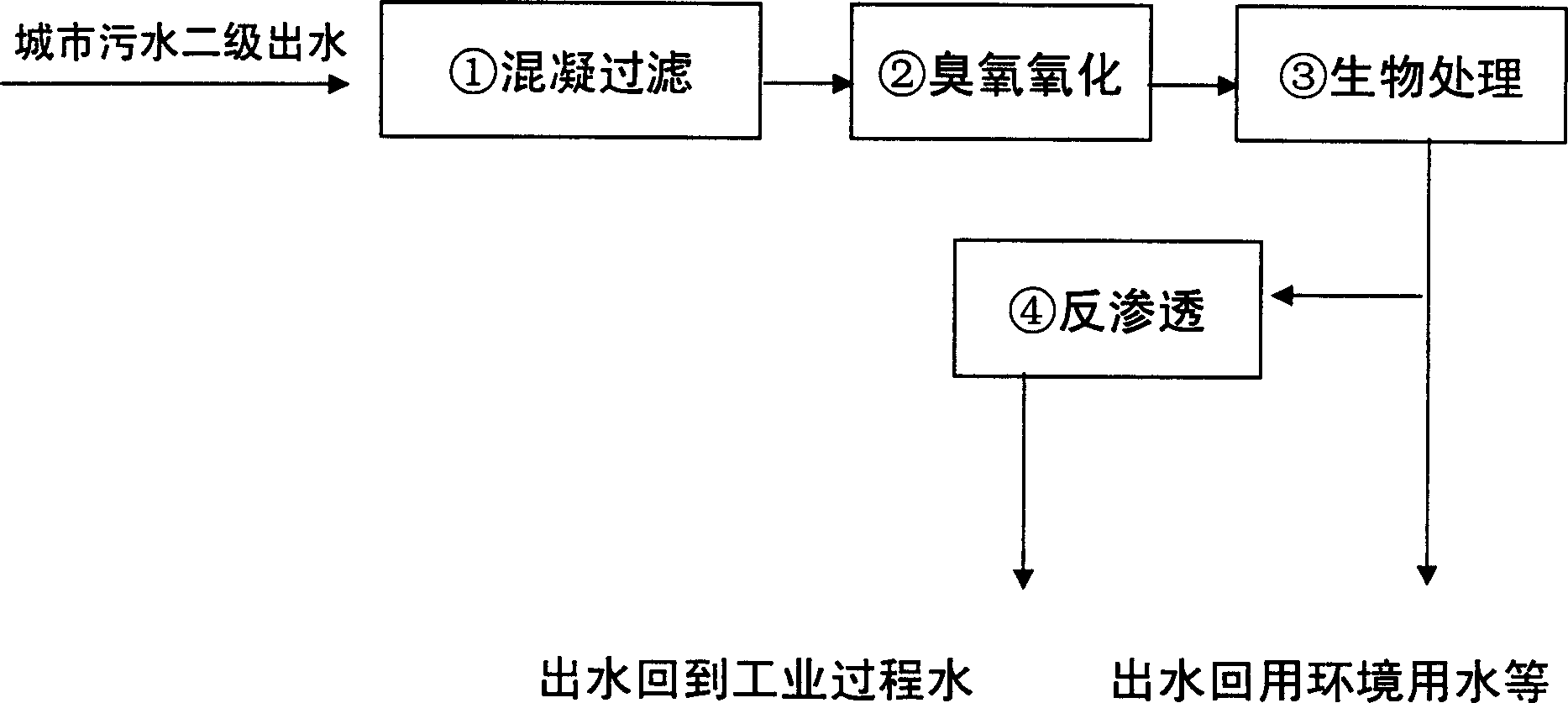

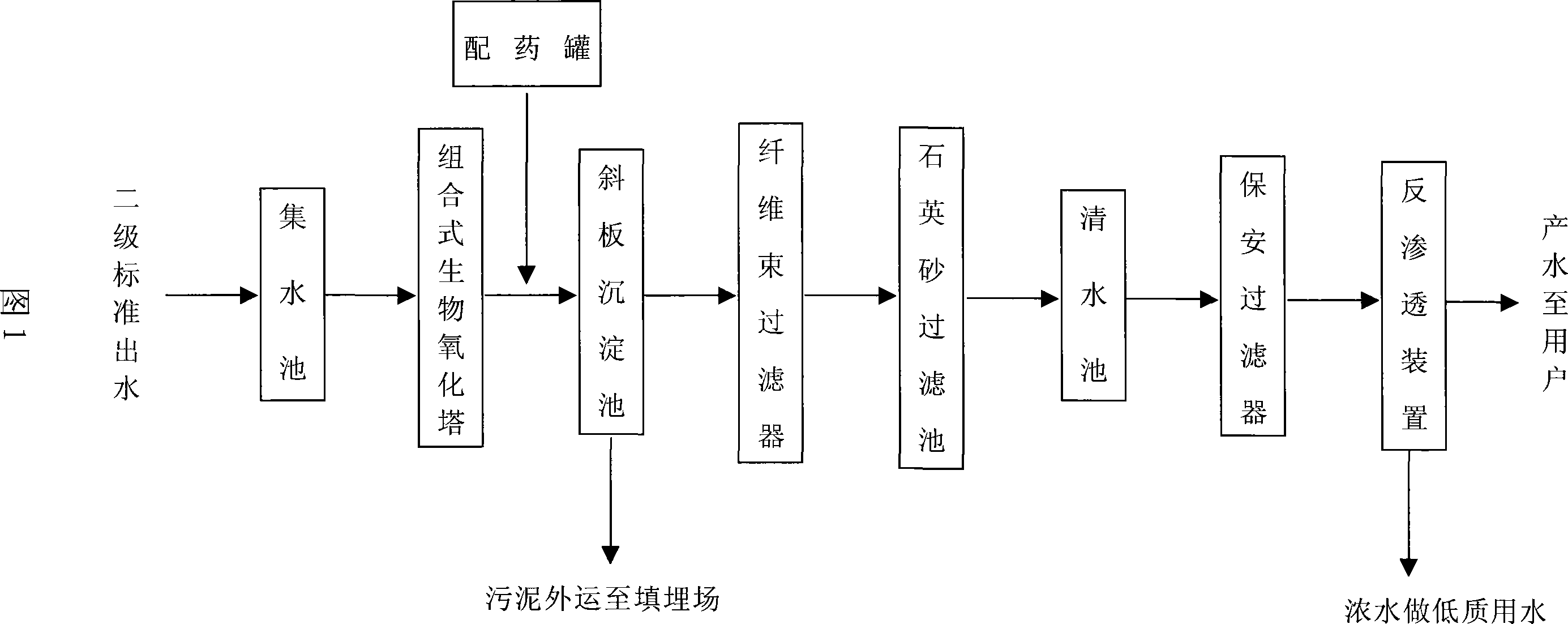

Method for processing urban sewage deeply

ActiveCN1796314AChange sizeChange structureTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationReverse osmosis

This invention is related to a process of disposing urban sewage, which comprise the steps of coagulate filtration, ozone oxidation, biological oxidation to dispose urban sewage, so that the residual undegradable organic substances, bacteria and virus in the second-class urban sewage can be removed and the water can be recycled. According to different usages of the recycled water, the process also comprises reverse osmosis or nanoscale filtration treatment to further remove the residual organic and inorganic substances in the water. The process is a combination of coagulate filtration, ozone oxidation, biological oxidation and reverse osmosis, designed to resolve such problems as urban sewage disposal and water recovery. The process can obtain high-quality recycled water with a low cost, showing high cost performance, which is important to resolving urban water depletion, raising the utilization rate of water resources, reducing environmental pollution and promoting sustainable development of the society.

Owner:北京国中科创环境科技有限责任公司

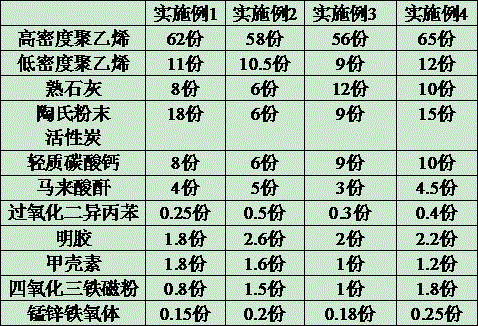

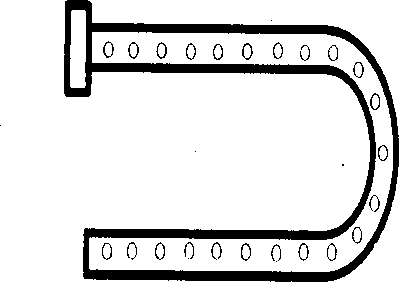

Hydrophilic carrier for microbial biofilm formation

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

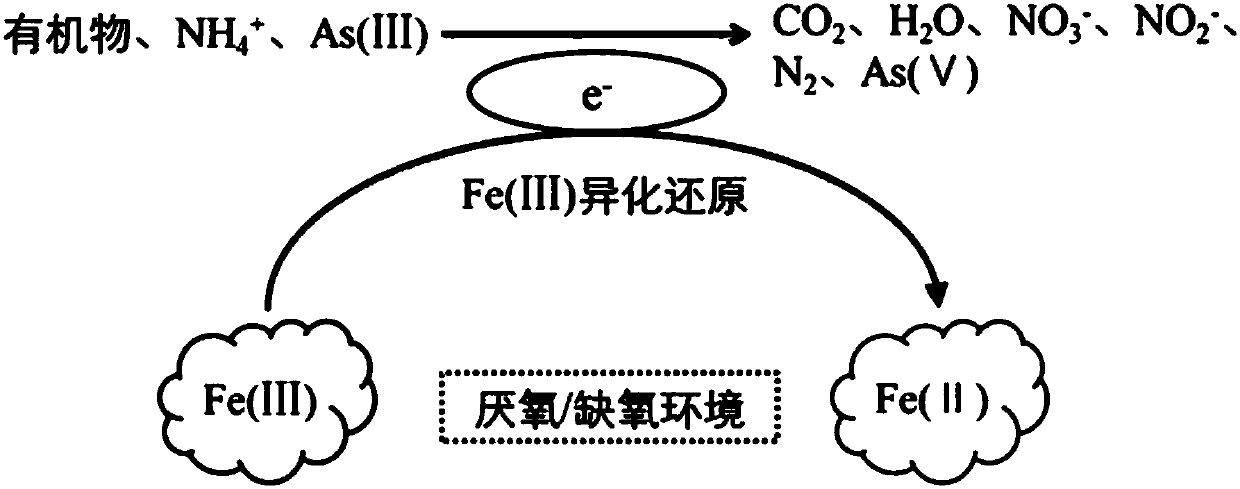

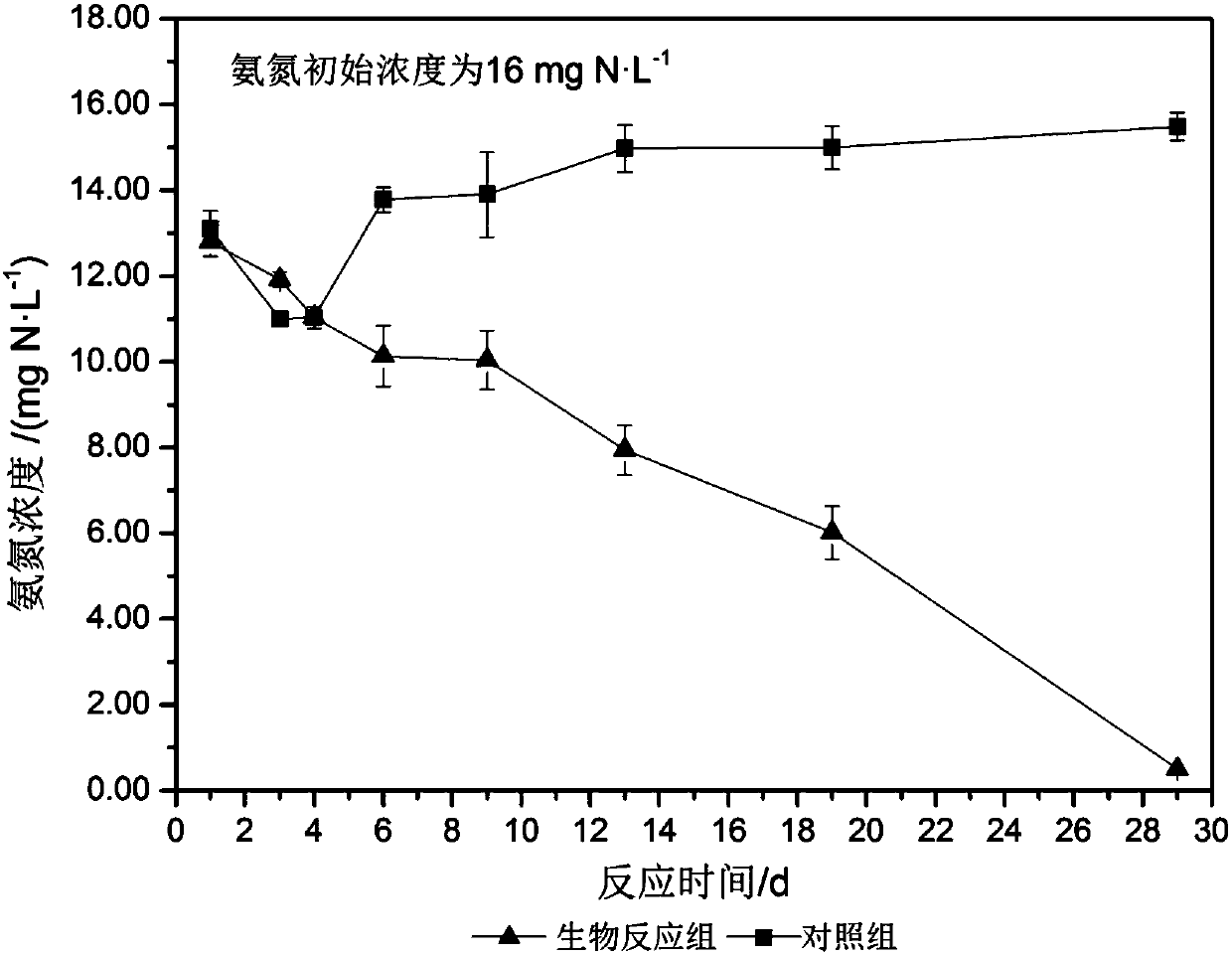

Anaerobic biological oxidation water pollution remediation method with Fe3+ in hematite as electron acceptor

InactiveCN105948280AImprove removal efficiencyLow costWater treatment compoundsTreatment with anaerobic digestion processesMicroorganismBiological oxidation

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

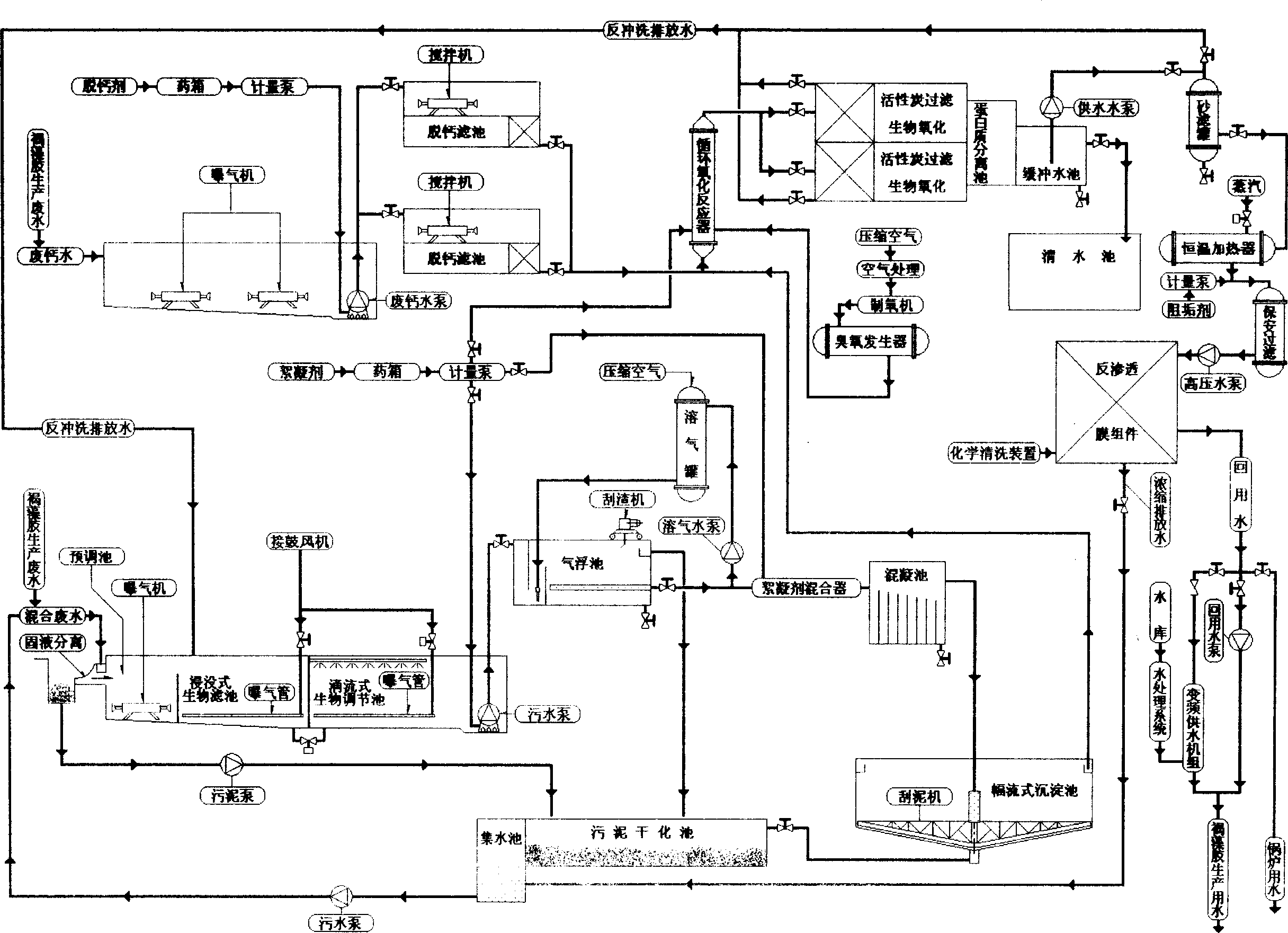

Process for treating, circulation recovering and reutilizing zero-discharge of algin production waste water

InactiveCN101074140AImprove product qualityImprove protectionSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesWater sourceWater quality

A multi-stage treatment for effluent or sewage is carried out by pre-oxidation treating for waste calcium water in production of sodium alginate, decalcifying treating, solid-liquid separating for mixed effluent, oxidation pre-treating, biological filtering, oxidation treating, air-floating treating, flocculating, depositing, efficient ozone circulation and oxidation treating for mixed comprehensive water, de-coloring, filtering, biological oxidation treating and reverse osmosis treating. It's safe, reliable, rational, standard, cheap and efficient, it has better quality and zero-effluent discharge, and saves water sources.

Owner:威海长青海洋科技股份有限公司

Method of biotreatment for solid materials in a nonstirred surface bioreactor

InactiveUS6159726AIncrease capacitySpeed up the processSolvent extractionSolid waste disposalMicrobial inoculationSulfide minerals

A method of biotreating a solid material to remove an undesired compound using a nonstirred surface bioreactor is provided. According to the method the surface of a plurality of coarse substrates is coated with a solid material to be biotreated to form a plurality of coated coarse substrates. The coarse substrates have a particle size greater than about 0.3 cm and the solid material to be biotreated has a particle size less than about 250 mu m. A nonstirred surface reactor is then formed by stacking the plurality of coated coarse substrates into a heap or placing the plurality of coated coarse substrates into a tank so that the void volume of the reactor is greater than or equal to about 25%. The reactor is inoculated with a microorganism capable of degrading the undesired compound in the solid material, and the solid material is then biotreated in the surface bioreactor until the undesired compound in the solid material is degraded to a desired concentration. Preferably the thickness of the solid material coating on the plurality of coarse substrates is less than about 1 mm and the void volume of the reactor is greater than or equal to about 35%. The process is useful for many different biotreatment processes, including the bioremediation of contaminated soils, the desulfurization of coal, and the biooxidation of refractory sulfide ores and concentrates. In bioremediation applications, the undesired compound is typically an organic compound. In coal desulfurization and refractory sulfide ore biooxidation applications, the undesired compound is sulfide minerals.

Owner:GEOSYNFUELS LLC (US)

Process and apparatus for treating petrochemical sewage by coupling ozone oxidation in aerating biological filtering pool

InactiveCN1792896AMass transfer speedSmall mass transfer velocityTreatment using aerobic processesMultistage water/sewage treatmentBiological oxidationBiological filter

An apparatus for treating the petrochemical sewage by aerating, bio-filtering and ozone oxidizing is composed of bio-filtering pool and ozone oxidizing unit. Its method includes such steps as primary bio-filtering, biologic oxidizing, aerating for filling oxygen, ozone oxidizing, and bio-filtering to form a treating circulation.

Owner:SOUTH CHINA UNIV OF TECH

Processing method for malodorous gas of chemical area sewage plant

InactiveCN104001413AHigh and stable processing effectEasy to operateDispersed particle separationSorbentBiological filter

The invention discloses a processing method for a malodorous gas of a chemical area sewage plant, and particularly relates to a chemical absorption-biological oxidation-absorption combined processing method. The malodorous gas enters a chemical washing tower, is subjected to absorption, oxidation and humidification in the washing tower, then enters a biological filter tower, contacts with microbe inoculated on filler surfaces, then enters an absorption device after being degraded by the microbe, and is discharged after being further purified by an adsorbent. An empty bed residence time of the gas in the biological tower is 10-120 s; and an empty bed residence time of the gas in the absorption device is 0.5-120 s. A nutrition liquid needed by the microbe in the biological filter tower is effluent of a secondary sedimentation tank of a sewage treatment plant or diluted raw water of a buffer and homogenization tank. The chemical absorption-biological oxidation-absorption combined processing method can remove hydrogen sulfide and volatile organic compounds from the malodorous gas of the chemical area sewage plant efficiently and realizes standard discharge. The method has the advantages of simple process flow, simple operations, low investment and operation cost, high processing efficiency and no secondary pollution.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

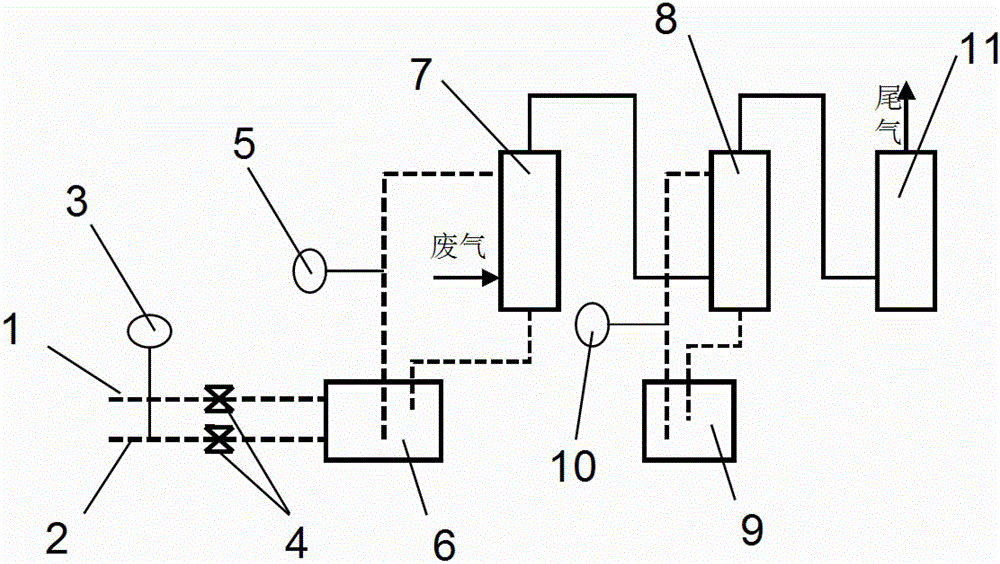

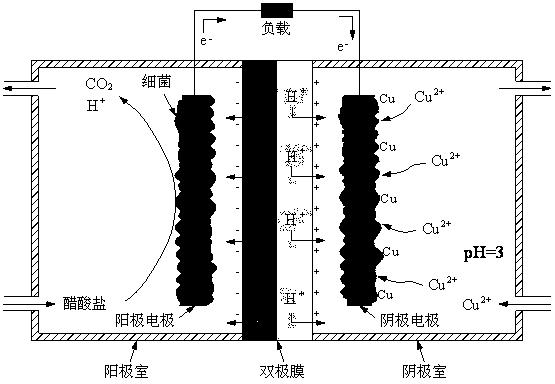

Recovery device and recovery method of metallic copper of waste printed circuit board

InactiveCN103397195ALow Energy RecoveryReduce usagePhotography auxillary processesProcess efficiency improvementMicrobial fuel cellFuel cells

The invention discloses a recovery device and a recovery method of metallic copper of a waste printed circuit board. The device comprises a microbial fuel cell, a reactor for leaching copper of the waste printed circuit board and an Fe<2+> biological oxidation reactor. The recovery method comprises the steps: firstly, iron-oxidizing bacteria in the Fe<2+> biological oxidation reactor oxidizes Fe<2+> into Fe<3+>; then the solution containing Fe<3+> is inputted into the reactor for leaching copper of the waste printed circuit board, the metallic copper is oxidized into Cu<2+> by Fe<3+>, and at the same time, Fe<3+> is reduced into Fe<2+>; and finally, the solution containing Cu<2+> is inputted into a cathode chamber of the microbial fuel cell, Cu<2+> is reduced into the metallic copper in the cathode chamber of the microbial fuel cell, while Fe<2+> in the cathode chamber of the microbial fuel cell is inputted to the Fe<2+> biological oxidation reactor and then is oxidized into Fe<3+>. The recovery device and the recovery method not only reduce the energy consumption, but also can gain electric energy, and simultaneously reduce the use of chemical reagents and the environmental pollution of organic waste.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

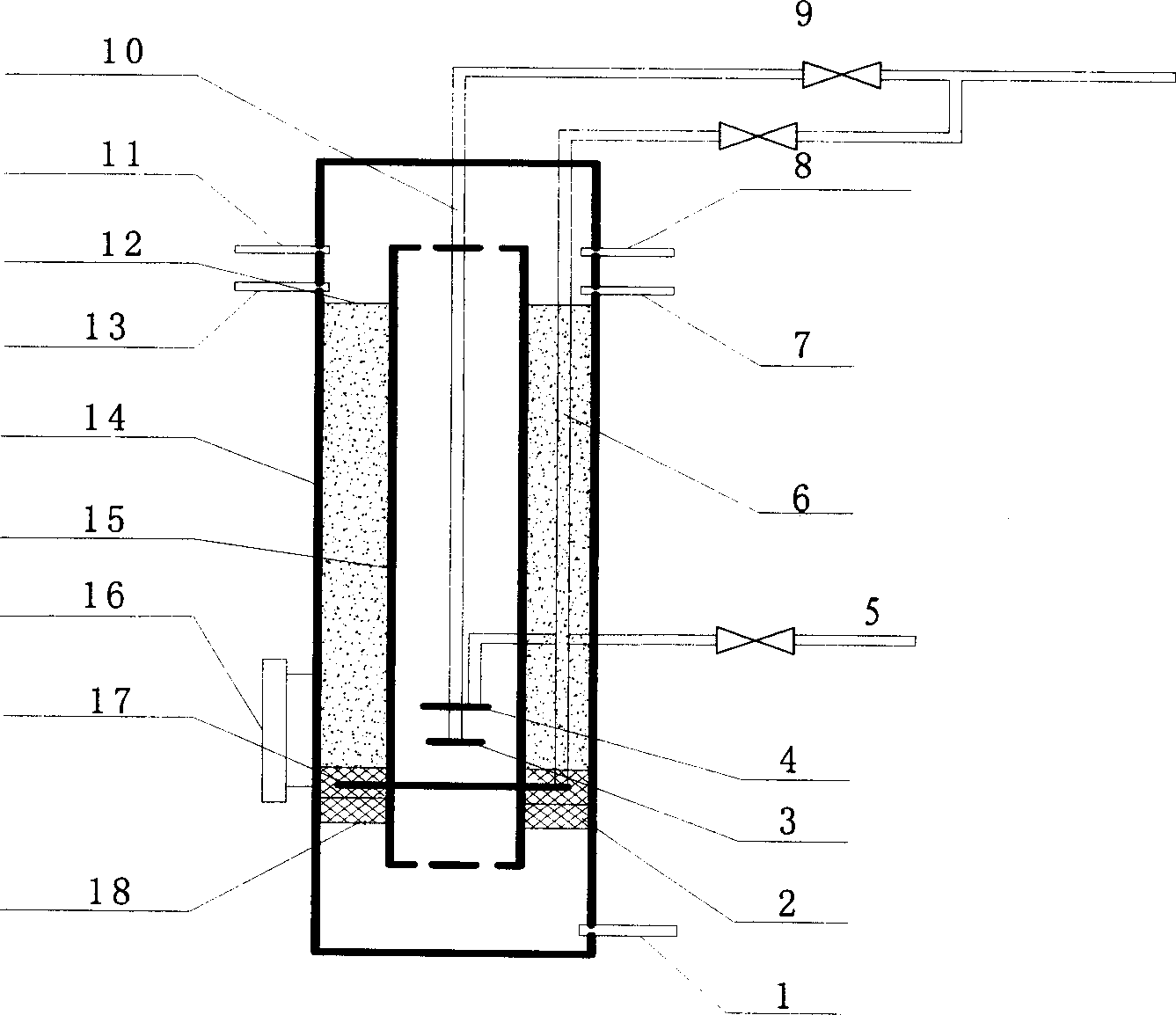

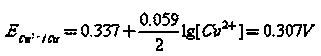

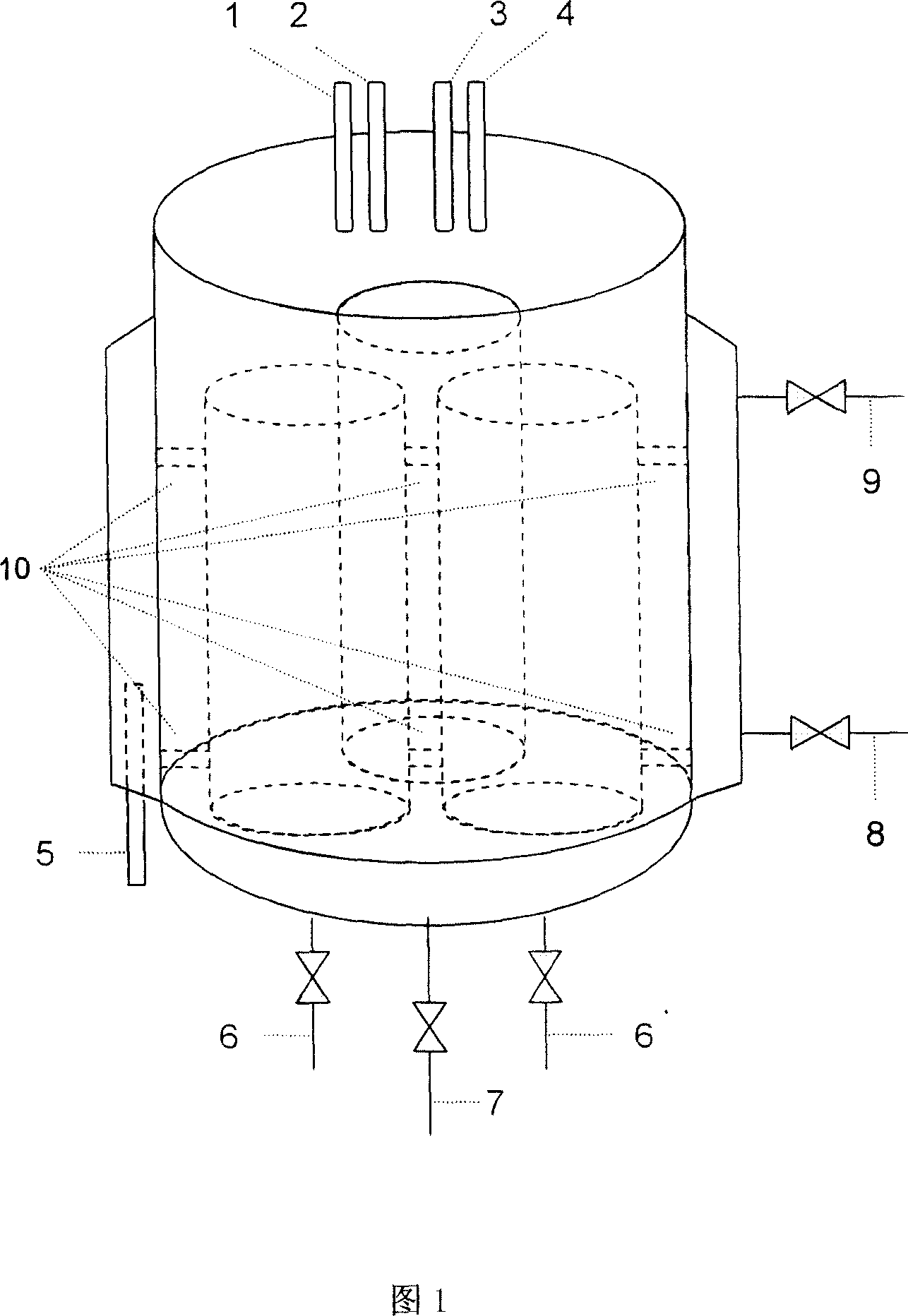

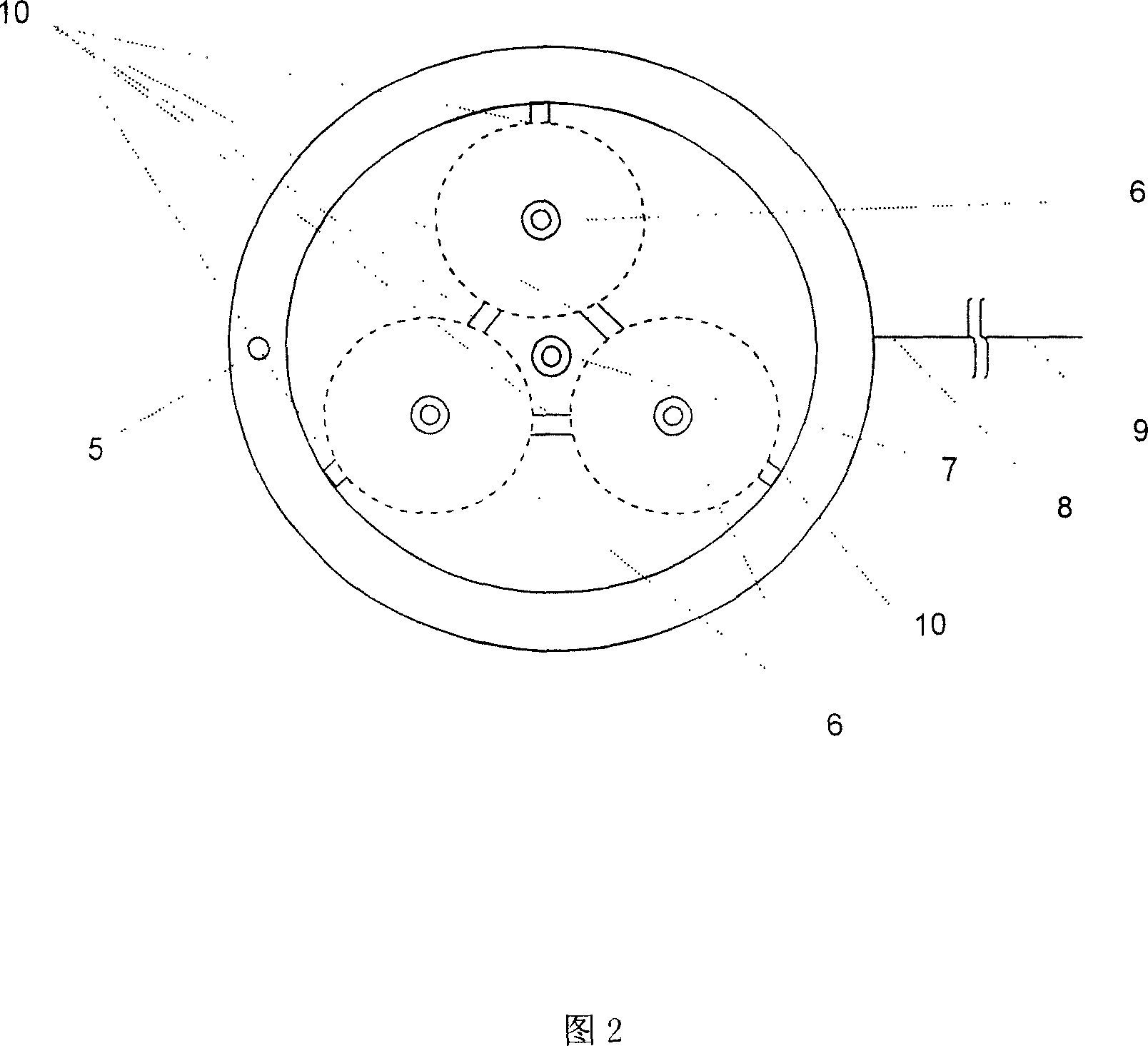

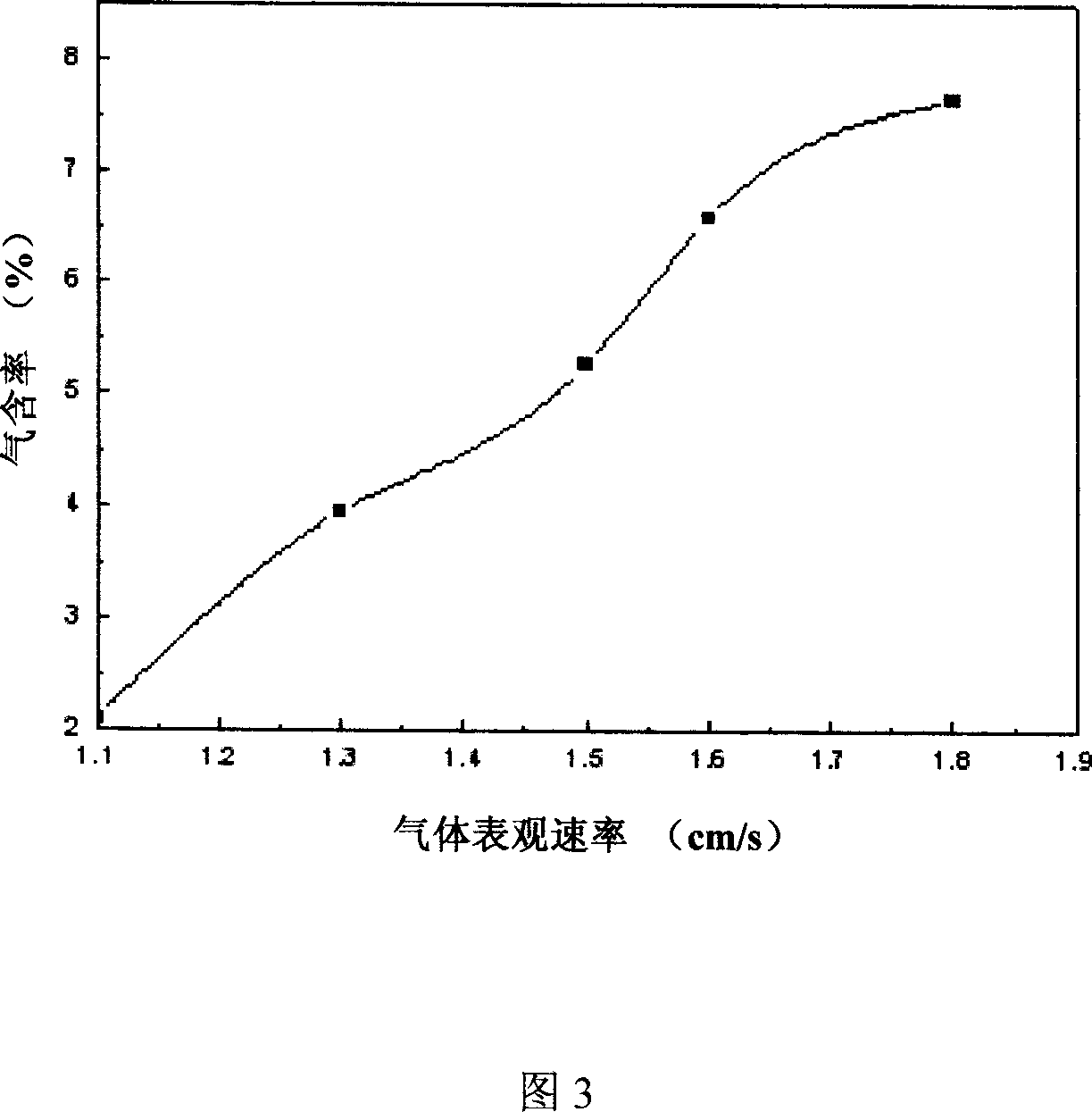

Multiple guide shell gas circulating bioreactor bacteria ore leaching and ore leaching bacteria culture

The invention discloses a new type immersion ore bioreactor to proceed biological oxidation of sulfide mineral in biological metallurgical technical domain, which is characterized by the following: adopting internal ring gas-flow elevating type reactor; using compressed air as liquid hoisting power to accelerate the macrography mixing of material and mass transfer course; and providing oxygen for growth of microbe and biological oxidation of mineral; lightening the attrition and damage of microbiological thallus caused by ore sand greatly; comparing to traditional stirring type immersion ore bioreactor; composing by cylindrical tank and bottom of tank; assembling three built-in type guild shell to decrease the height of reactor; making the high diameter ratio (H / D) reach 1-1.5 range of the reactor. This invention possesses merits of soft stirring, small hurt for cell, good mass transfer effect and simple structure, which compared to traditional method.

Owner:SHANDONG UNIV

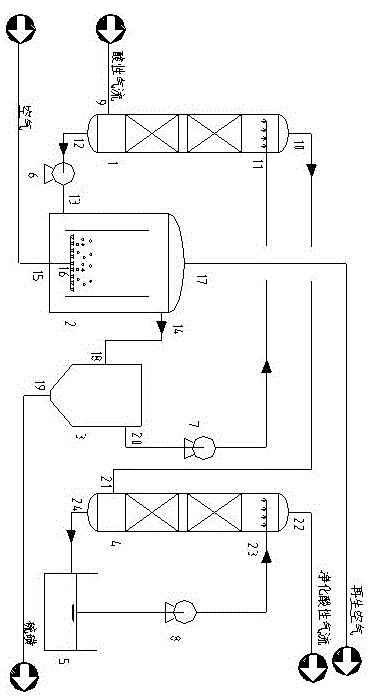

Wastewater purifying system in hospitals

InactiveUS20090166280A1Reduce pollutant loadGood treatment effectTreatment using aerobic processesTreatment by combined electrochemical biological processesSludgeBiological oxidation

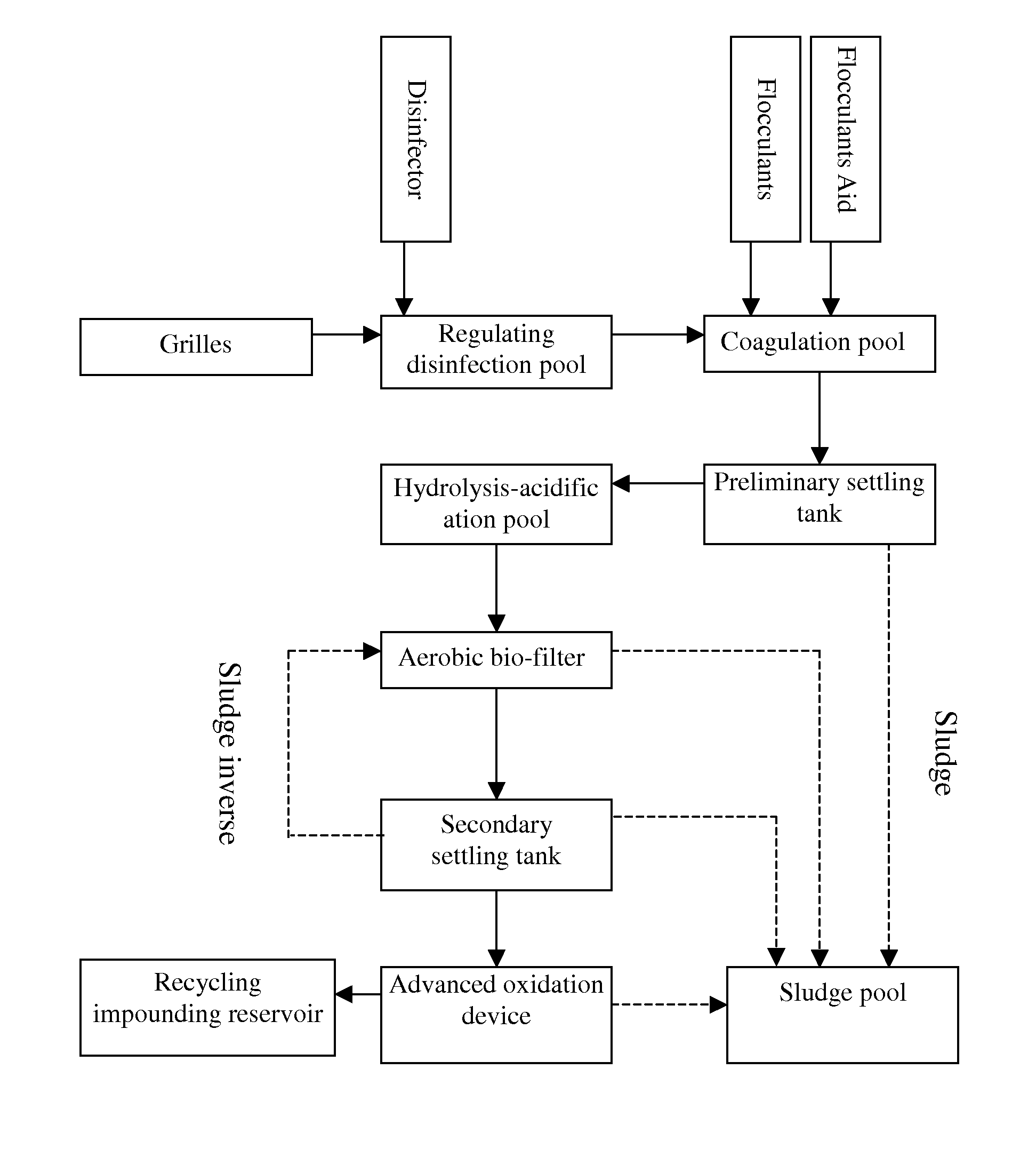

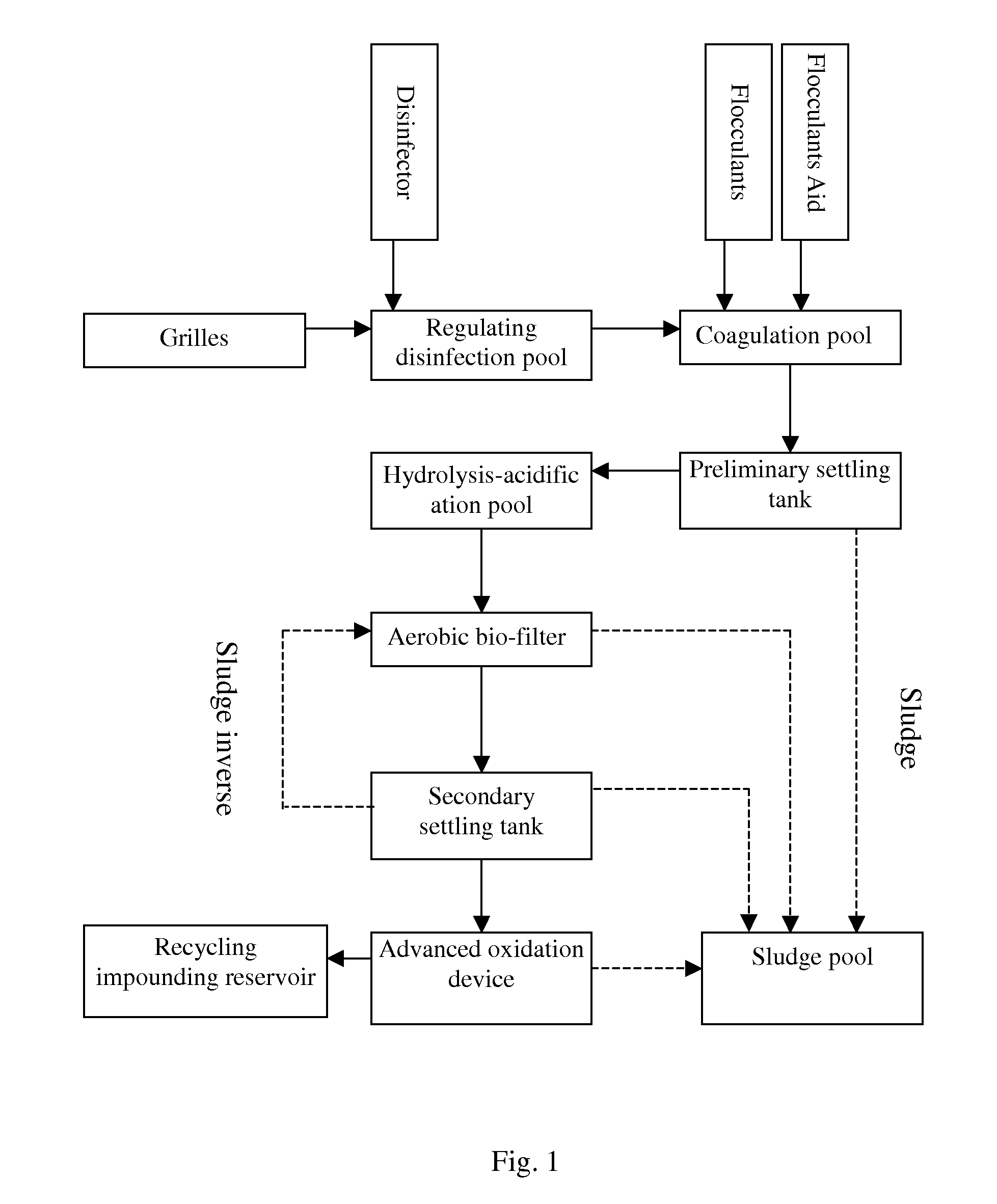

This invention relates a wastewater purifying system in hospitals, comprising interconnected grilles, a regulating disinfection pool, a coagulation pool, a preliminary settling tank, a hydrolysis-acidification pool, an aerobic bio-filter, a secondary settling tank, an advanced oxidation device, a sludge pool and a recycling impounding reservoir. The regulating disinfection pool is used to accumulate original wastewater released from every source and the advanced oxidation device is used to oxidize remained organic matters into inorganic molecules via chemical and biochemical methods or via physical methods and could be an electric biological oxidation treatment device. This system possesses high purifying degree and purified water from this system can be used as reclaimed water.

Owner:BEIJING JINAOHUARONG TECH

Method for reclaiming valuable element from acidic arsenic-containing biological oxidation gold extraction waste liquor

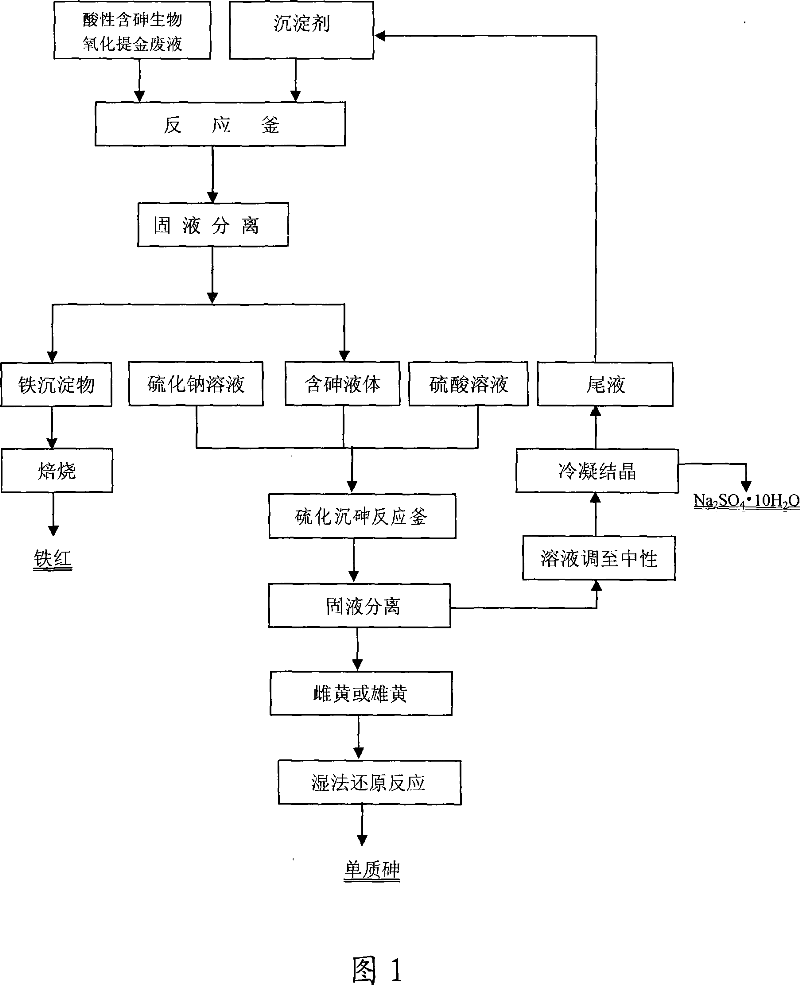

ActiveCN101041498AEfficient separationNo secondary pollutionWaste water treatment from metallurgical processFerric oxidesBiological oxidationGold extraction

The invention discloses a reclaiming method of valency element from acidic rocan biological oxidation extract gold waste liquid, which comprises the following steps: adding acidic rocan biological oxidation extract gold waste liquid and precipitant into autoclave at the same time; depositing selectively; realizing arsenic iron separation; adopting filtering technology; realizing solid and liquid separation; leading solid phase into iron-oxide red preparing process; leading liquid into process of reclaiming rocan; adjusting the solution to neutral with solid-liquid; condensing at 0-4 deg.c; crystallizing to Na2SO4.10H2O; returning the tail liquid to the first process; using to formulating queous alkali. The good effect of this invention can realize effective segregation of rocan and iron of acidic rocan biological oxidation extract gold waste liquid.

Owner:LIAONING TIANLI GOLD +1

Method for removing acidic gases through biological technology

ActiveCN106310890AAchieve co-removalAchieve recyclingDispersed particle separationWaste water treatment from gaseous effluentsCarbonyl sulfidePollution

The invention belongs to the field of environmentally-friendly purification, and relates to a method for removing acidic gases through a biological technology. The method is mainly used to remove acidic gas flow containing carbon dioxide, hydrogen sulfide, carbonyl sulfide, carbon disulfide and mercaptan. A chemical absorption, microbial oxidation regeneration and biotrickling filter three-tower technology is adopted, and the chemical absorption characterized in that an alkaline solution is used to absorb carbon dioxide, hydrogen sulfide and a small amount of organic sulfur which are introduced to the alkaline solution; the microbial oxidation regeneration realizes biological oxidation of sulfides into biological sulfur under aeration conditions and alkaline solution regeneration; and biotrickling filter purification of organic sulfur is used for removing carbonyl sulfide, carbon disulfide, mercaptan and other organic sulfurs. The method adopting carbon dioxide fixation, sulfur resource recovery, absorption liquid recycling and organic sulfur deodorizing purification realizes acidic gas integral treatment, and solves the environmental protection problem of acidic gas pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

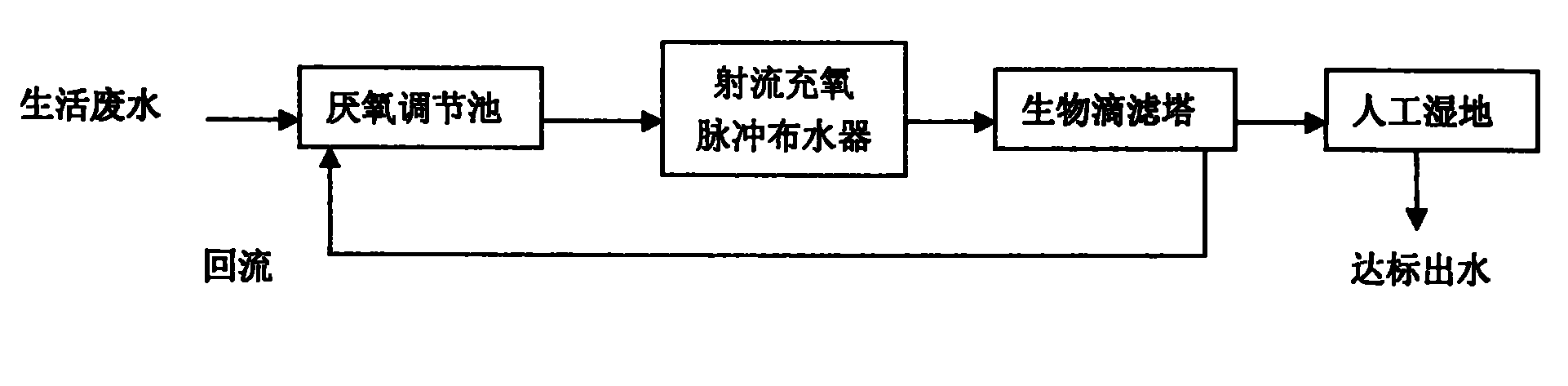

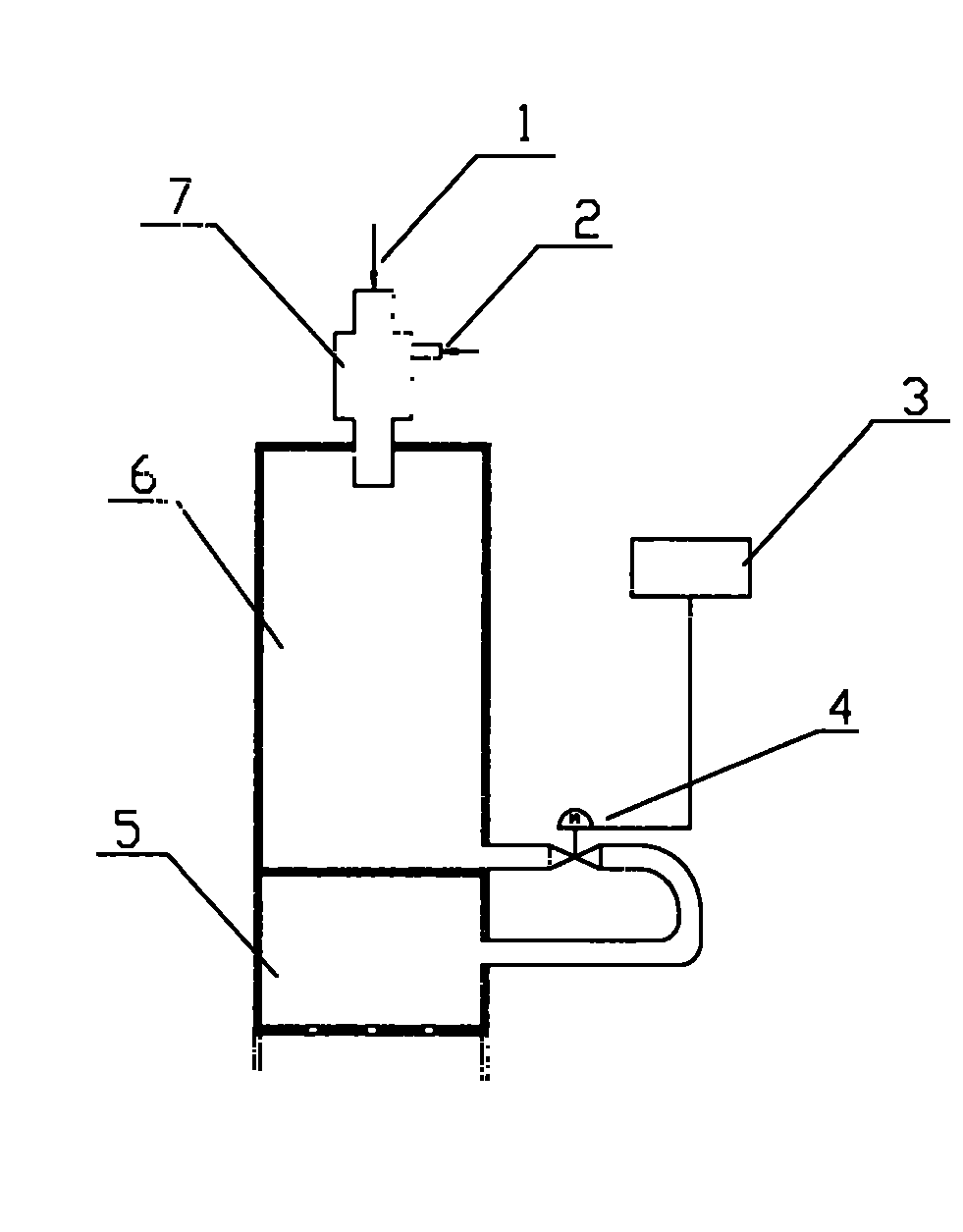

Distributed domestic sewage treatment method

InactiveCN101928095AEffective Phosphorus and Nitrogen RemovalStable waterTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandFiltration

The invention discloses a distributed domestic sewage treatment method. The method combines process units of anaerobic, jet oxygenation, biological oxidation, artificial wetland and the like together to perform anaerobic, aerobic and wetland ecological three-stage treatment on the domestic sewage so as to effectively reduce CODcr and BOD5 of the domestic sewage; and dephosphorization and denitrification are performed, and the effluent is stable and reaches the standards before emitting. A jet oxygenation pulse water distributor is adopted in the jet oxygenation, and the jet oxygenation pulse water distributor oxygenates the anaerobic effluent and provides pre-oxygenation treatment for a subsequent aerobic process; the biological oxidation is performed in a trickling filtration tower which is designed with 2 to 3 layers and provided with vent holes, a ceramic filler is placed in the trickling filtration tower, and the trickling filtration tower distributes water by adopting time control pulse so that the re-oxygenation effect of the trickling filtration tower can be improved and no power is consumed; and the artificial wetland is designed in an undercurrent form, proper fillers such as coal cinder, plaster, gravels and the like are placed in the artificial wetland, and pollutants can be further degraded and removed from the wetland environment. The method is suitable for standard-reaching treatment of rural or urban distributed domestic sewage.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI +2

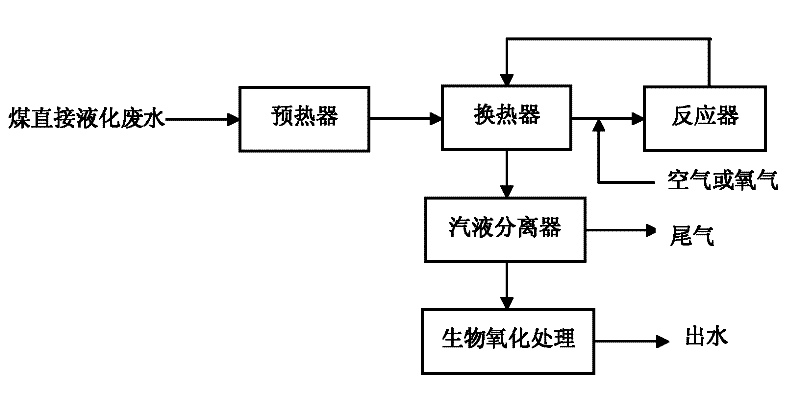

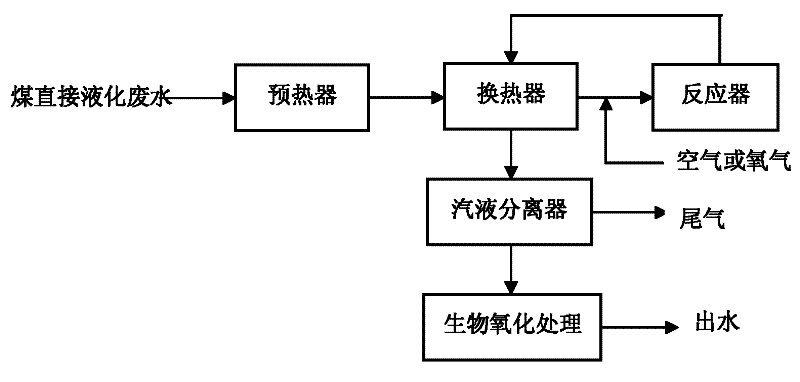

Method for treating wastewater produced in process for directly liquefying coal

ActiveCN102515447ASimple processImprove processing efficiencyMultistage water/sewage treatmentWater/sewage treatment by heatingChemical oxygen demandBiological oxidation

The invention discloses a method for treating wastewater produced in a process for directly liquefying coal. The method for treating the wastewater comprises the following steps of: treating wastewater produced in the process for directly liquefying the coal by a catalytic wet air oxidation method to obtain wastewater subjected to primary treatment; and performing secondary treatment on the wastewater subjected to primary treatment by a biological oxidation method. According to the method for treating the wastewater produced in the process for directly liquefying the coal, the wastewater produced in the process for directly liquefying the coal is treated by the catalytic wet air oxidation method, so the chemical oxygen demand (COD) removal rate of the wastewater can reach over 80 percent, phenol, aldehyde and other substances which have the toxic effects on microorganisms can be oxidized into micromolecule carboxylic acid and other substances which can be decomposed by the microorganisms easily, and wastewater which is further subjected to biological oxidation can be discharged under the condition of meeting the standard. The method is simple, the wastewater produced in the process for directly liquefying the coal can be treated in a centralized and unified way, and independent treatment is not required; and therefore, treatment efficiency is greatly improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Biological-chemical metallurgy method by jointly utilizing oxidized ore and sulfide ore

InactiveCN101608260AHigh recovery rateUniversalProcess efficiency improvementMineral SourcesBiological oxidation

The invention belongs to the field of mineral resource comprehensive utilization, and relates to methods for reduced leaching of oxidized ore and oxidation leaching of sulfide ore through biological and chemical catalysis, in particular to a biological-chemical metallurgy method by jointly utilizing the oxidized ore and the sulfide ore. The reduced leaching of the metal oxidized ore and the oxidation leaching of the metal sulfide ore are realized by utilizing auxoautotrophs, auxohetertrophs or a mixture thereof under mild conditions; and the mixture ratio of the metal oxidized ore to the metal sulfide ore can be adjusted by adding organic biomass. The leachate is purified, concentrated and crystallized into metal sulfates which are then reduced and thermally decomposed into products of sulfur dioxide and metal oxides; and the sulfur dioxide is subjected to biological oxidation to prepare sulphuric acid for recycling.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for highly-efficiently performing hazard-free and biochemical treatment on alkaline residue from oil refinery

InactiveCN101758057AHigh removal rateStrong biological oxidationSolid waste disposalBiological oxidationCatalytic oxidation

The invention relates to a method for highly-efficiently performing hazard-free and biochemical treatment on alkaline residue from oil refinery, which mainly comprises the following steps: diluting and neutralizing the alkaline residue; performing two stages of biological pretreatment on alkaline residue sewage produced by the dilution and neutralization; and filtering the alkaline residue sewage subjected to the two stages of biological oxidation pretreatment, introducing the filtered alkaline residue sewage into an oxidation column, catalyzing and oxidizing the alkaline residue sewage at the normal temperature and under the normal pressure, performing a subsequent third stage of biological oxidation treatment on the alkaline residue sewage which is catalyzed and oxidized with ozone until the alkaline residue sewage reaches a standard, and discharging the alkaline residue sewage. The method has the advantages of low investment, low operating cost and high pollutant removal rate.

Owner:广东奥美特集团有限公司

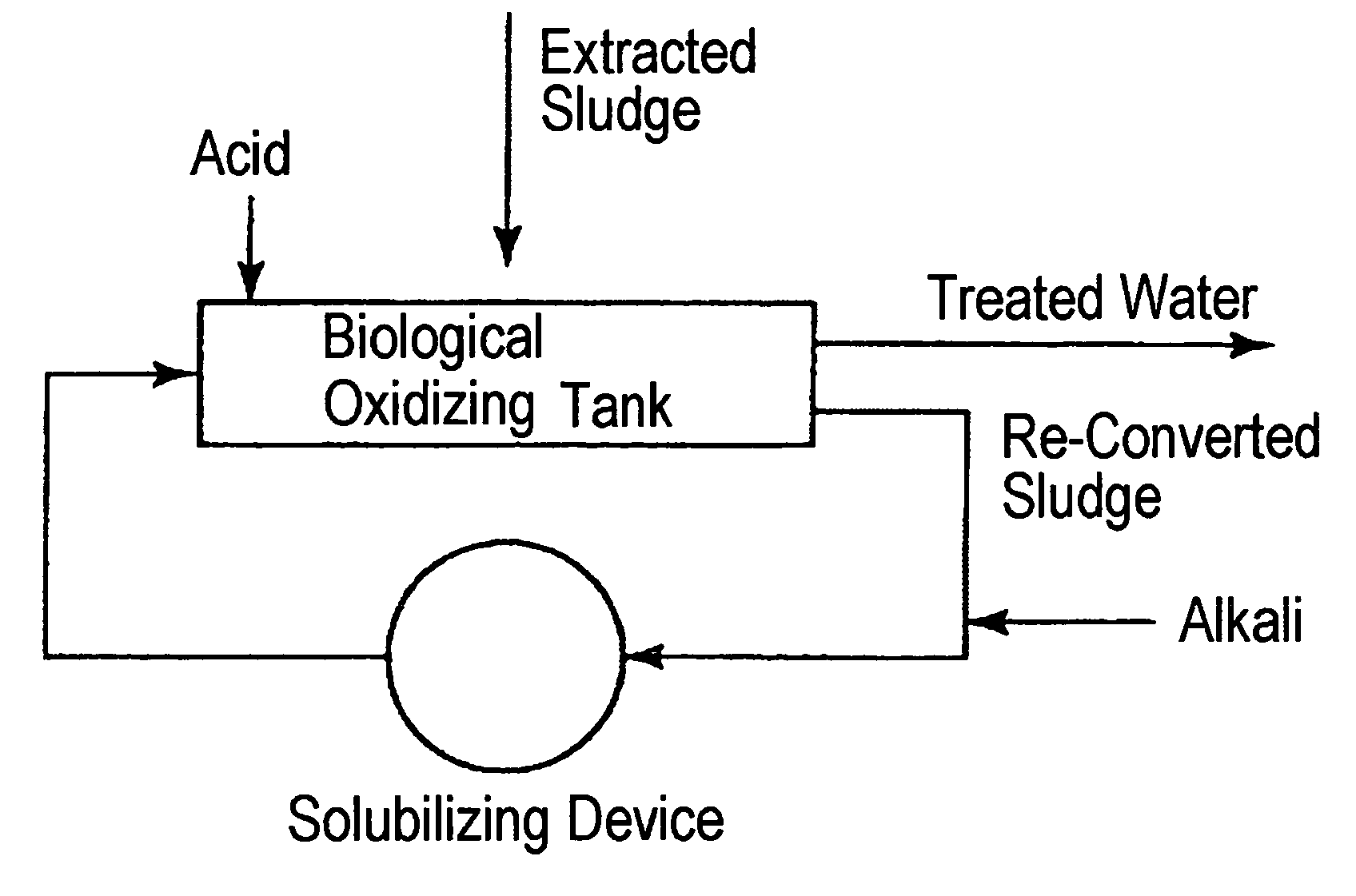

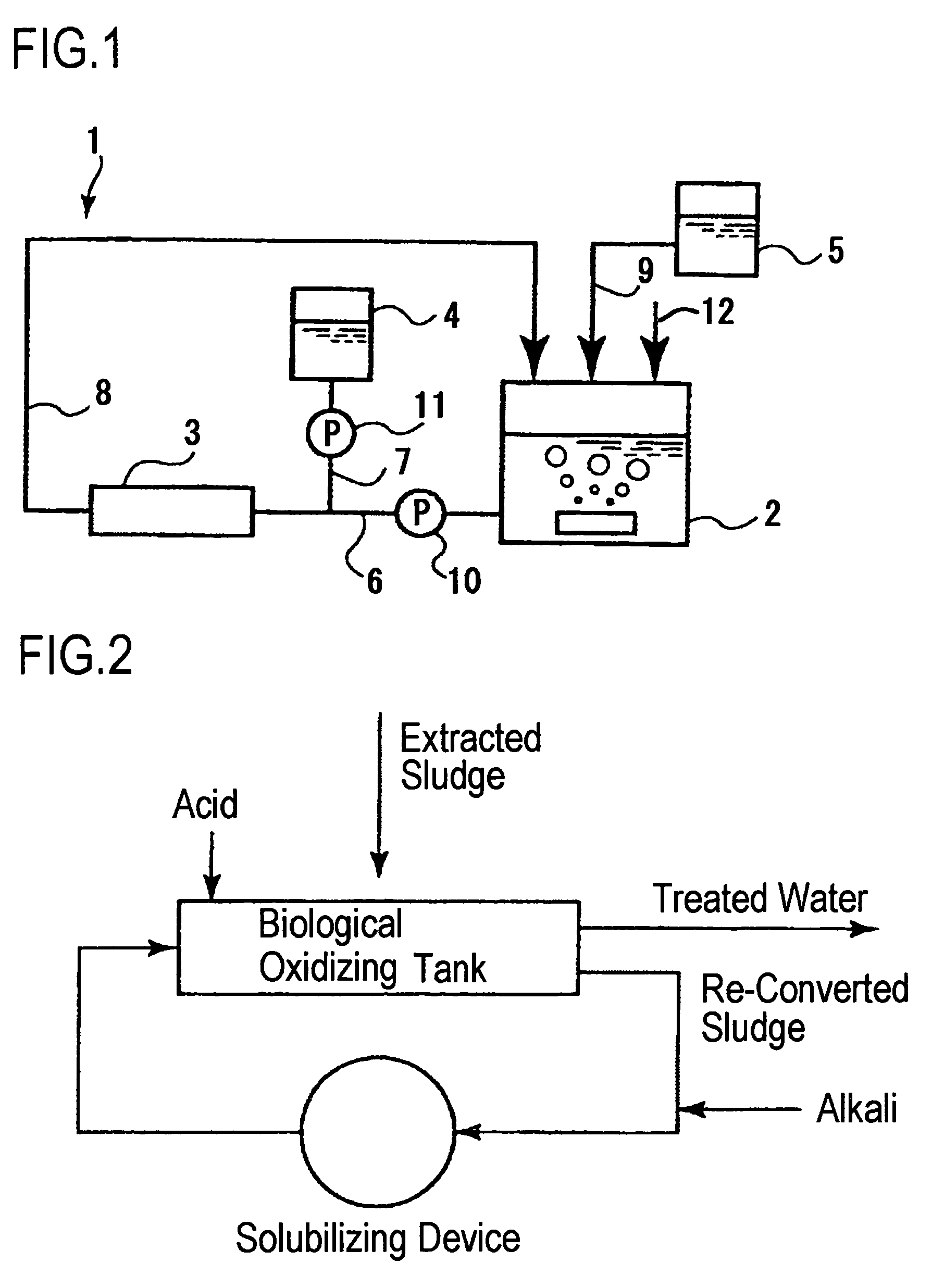

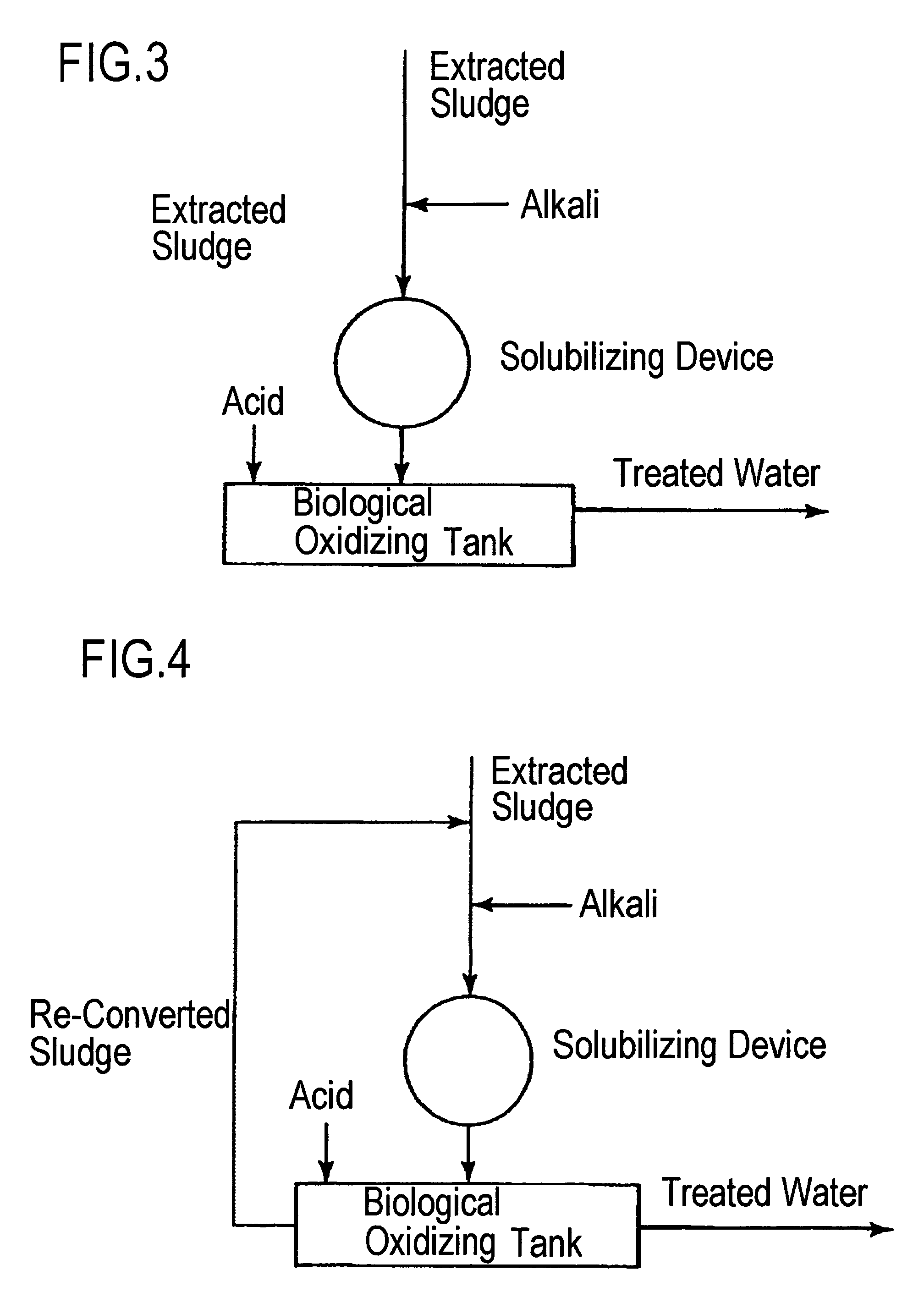

Method of reducing volume of sludge

InactiveUS7258791B2Lower the volumeReduce molecular weightSludge treatment by thermal conditioningTreatment using aerobic processesSteam pressureSludge

The pH value of excess sludge taken out from a biological oxidation tank (2) is adjusted to 8 to 14, and the pH-adjusted sludge is injected into a solubilizing device (3). The sludge taken out from the solubilizing device (3) is heated to 110° C. to 350° C. at a pressure higher than saturated steam pressure to solubilize the sludge to a state readily degradable by microorganisms. The solubilized sludge is returned to a biological oxidizing tank (2), and the pH value of the sludge in the biological oxidizing tank (2) to 5 to 9. The use of the above method of treating excess sludge and an apparatus therefore enables substantially reducing the volume of excess sludge with economic advantage.

Owner:KOGA TAKESHI

Low concentration wastewater treatment system and process

InactiveUS20110006002A1Water/sewage treatment by irradiationOther chemical processesWater treatment systemBiological oxidation

A low concentration wastewater treatment system is provided that includes a high flux adsorbent material treatment system integrated with a low flux adsorbent material biological regeneration reactor. The high flux adsorbent material treatment system includes one or more unit operations for mixing low concentration wastewater with adsorbent material that is fresh, recycled, or a combination of both, and for decanting a liquid effluent having a reduced level of contaminants. The adsorbent material with adsorbed contaminants is regenerated in a low flux adsorbent material biological regeneration reactor in which a biological reaction occurs, such as biological oxidation, wherein organic contaminants in the wastewater are metabolized generally into carbon dioxide and water. Excess biomass is removed from the adsorbent material, and the thus-regenerated adsorbent material is recycled to the high flux adsorbent material treatment system.

Owner:SIEMENS ENERGY INC +1

Method for recovering gold and silver from refractory gold ores

InactiveCN104818380AReduce pollutionAchieve recyclingProcess efficiency improvementBiological oxidationGold ore

The invention discloses a method for recovering gold and silver from refractory gold ores, and belongs to the field of metallurgy. The method includes two steps: firstly, pre-oxidizing and breaking inclusions of the gold and the silver in a hot-pressing manner, oxidizing organic carbon in the ores, and recovering sulfur in the ores; secondly, recovering the gold and the silver in presoaked residues by cyanidation or other non-cyanide leaching. The gold and the silver are recovered from the refractory gold ores by the method, the recovery rate of the gold and the silver is higher than 90% and increased by 40 percentage points as compared with that of a conventional cyanidation method, and the recovery rate of the sulfur is higher than 50%. By the aid of the scheme, production cost is about 400 Yuan / ton. Compared with biological oxidation, two-stage roasting and conventional hot-pressing oxidation processes, investment and the production cost can be reduced, the recovery rate is increased, multi-element comprehensive recovery is realized, environmental pollution is reduced, and economic and social benefits are obvious.

Owner:张伟晓

Method for treating electroplating wastewater

InactiveCN102010102AAdded secondary physical and chemical treatmentImprove water qualityWaste water treatment from metallurgical processMultistage water/sewage treatmentChemical oxygen demandRetention time

The invention discloses a method for treating electroplating wastewater. The method comprises the following steps: (1) primary physical-chemical treatment; (2) secondary physical-chemical treatment: after the discharged water generated in step (1) is subject to homogenizing treatment, adding sodium hypochlorite into the homogenized water, then adding sodium pyrosulfite into the obtained product to remove residual chlorine, and adding aluminum chlorhydroxide into the obtained product; and (3) biochemical system treatment: adding appropriate biochemical sewage into the product obtained in step (2), mixing the biochemical sewage and the product, then feeding the obtained mixture into a biological hydrolysis pool; controlling the mixture under appropriate conditions and within an appropriate retention time; carrying out reduction on the obtained mixture by utilizing facultative anaerobes; and hydrolyzing the obtained discharged water subjected to reduction, feeding the discharged water into an aerobic biological oxidation pond, and then carrying out mass propagation of engineering bacterias under an appropriate condition by using organic pollutants in wastewater. By using the method provided by the invention, the total treatment rates of a system are as follows: the treatment rate of heavy metal is greater than or equal to 99.7 percent, the treatment rate of ammonia nitrogen is greater than or equal to 90 percent, and the treatment rate of chemical oxygen demand (COD) is greater than or equal to 88 percent, therefore, the electroplating wastewater treated by using the method comprehensively meets the requirements of the Discharge Standard for Pollutants from Electroplating Industry (GB21900-2008).

Owner:兰溪市卓越电子有限公司

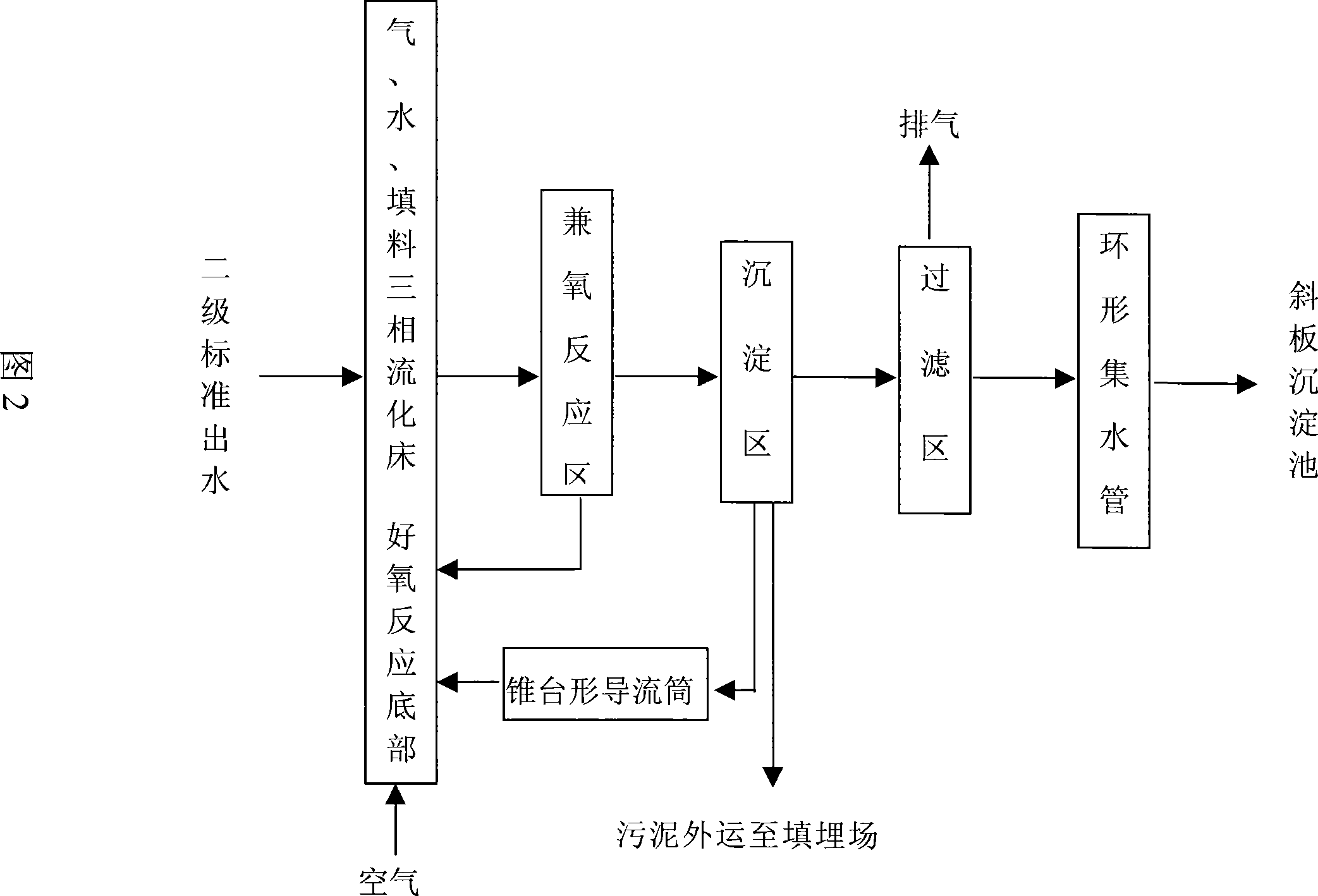

Process for regenerating, recovering and reutilizing low-concentration organic waste water

InactiveCN101074141ASave spaceSmall footprintTreatment using aerobic processesWater contaminantsBiological oxidationSewage

Process for regenerating, recovering and utilizing low-concentration organic effluent is carried out by biological oxidation treating for low-concentration organic effluent, entering it into tilted-plate settling tank, adding flocculating agent into inlet pipe of tilted-plate settling tank, depositing while separating out supernatant fluid, two-stage filtering by fibrous filter and quartz sand filter, filtering by security filter, passing into high-pressure pump, entering into reverse osmose filter and separating. It's cheap, stable and convenient, COD removing rate reaches 96%, ammonia-nitrogen removing rate reaches 99%.

Owner:大连春兴科技股份有限公司

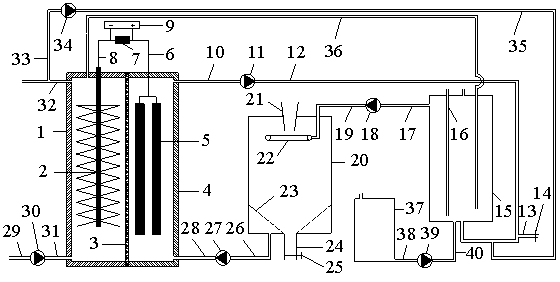

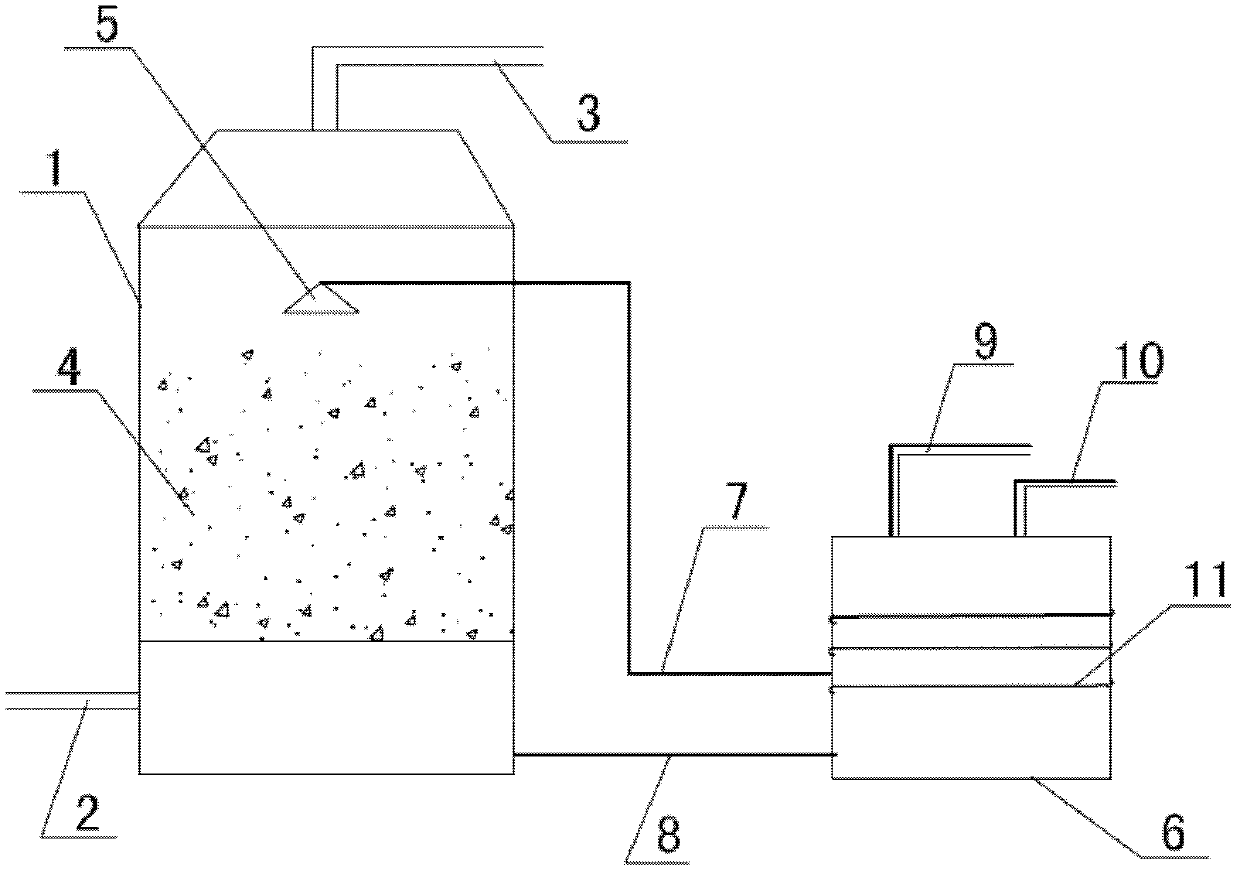

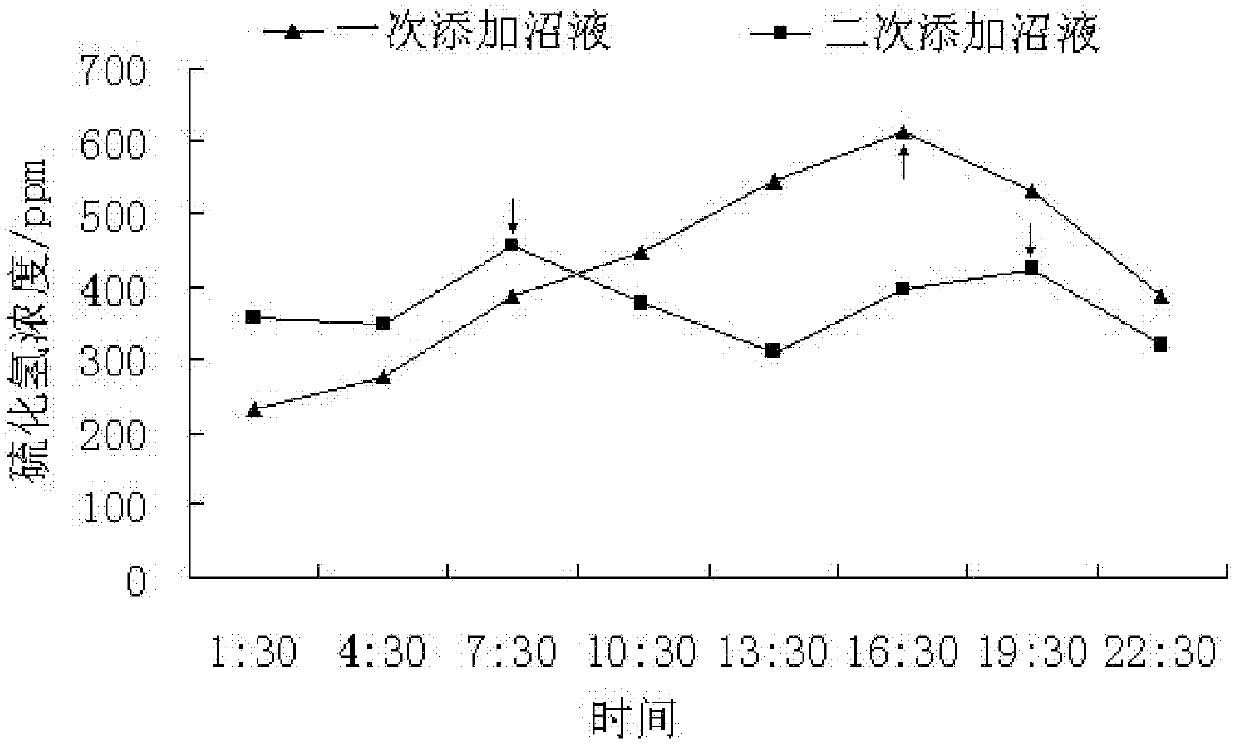

Methane biodesulfurization method

ActiveCN102604701AGood desulfurization effectReduce the impactGaseous fuelsWaste based fuelBiological oxidationTower

The invention belongs to the technical field of methane desulfurization, and particularly relates to a methane biodesulfurization method. The methane biodesulfurization method comprises the following steps that: a circulating liquid containing desulfurizing bacteria is sprayed down by a spraying head at the top part of a desulfurization tower, methane is blown into a gas inlet pipe from the lower part of the desulfurization tower, and is fully contacted with the circulating liquid in the middle filler, the desulfurizing bacteria contained in the circulating liquid oxidizes and removes hydrogen sulfide in the methane by the action of biological oxidation, wherein 2.0-2.5L methane liquid is added into each cubic meter of circulating liquid every day. The methane biodesulfurization method has the characteristics that the control is convenient, the operation is simple, and the desulfurization efficiency is high.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com