Hydrophilic carrier for microbial biofilm formation

A microbial and hydrophilic technology, which is applied in the treatment of granular microbial carriers, biological water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of the film hanging speed, film hanging amount and the tightness between the film and the filler. , poor hydrophilic performance and bioaffinity, inconvenient filler installation and replacement, etc., to achieve the effect of short time required for film hanging, strong hydrophilicity and bioaffinity, and fast film hanging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0030] Embodiment 1~4: A kind of hydrophilic carrier for microbial film-hanging, described hydrophilic carrier comprises hollow short tube, the first concentric ring that is concentrically arranged on the outside of hollow short tube successively, the second concentric ring, described The hollow short pipe, the first concentric ring and the second concentric ring are connected by connecting ribs, and the surface of the second concentric ring located on the outermost side is serrated;

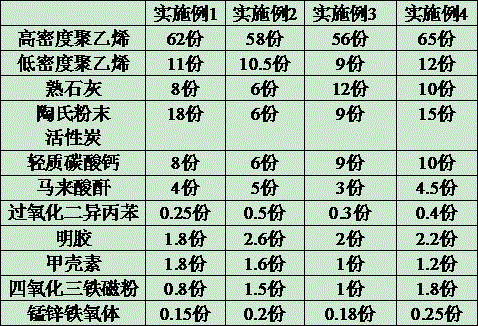

[0031] The hydrophilic carrier is composed of the following components by weight, as shown in Table 1:

[0032] Table 1

[0033]

[0034] The density of the above-mentioned suspended filler for rapid film-hanging of microorganisms is 0.96-0.98g / cm 3 .

[0035] The above-mentioned slaked lime is mixed with Dow powdered activated carbon and light calcium carbonate according to the ratio of 1:1.2:0.9 by weight.

[0036] The above-mentioned ferroferric oxide magnetic powder, manganese zinc fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com