Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76546 results about "Environmental chemistry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental chemistry is the scientific study of the chemical and biochemical phenomena that occur in natural places. It should not be confused with green chemistry, which seeks to reduce potential pollution at its source. It can be defined as the study of the sources, reactions, transport, effects, and fates of chemical species in the air, soil, and water environments; and the effect of human activity and biological activity on these. Environmental chemistry is an interdisciplinary science that includes atmospheric, aquatic and soil chemistry, as well as heavily relying on analytical chemistry and being related to environmental and other areas of science.

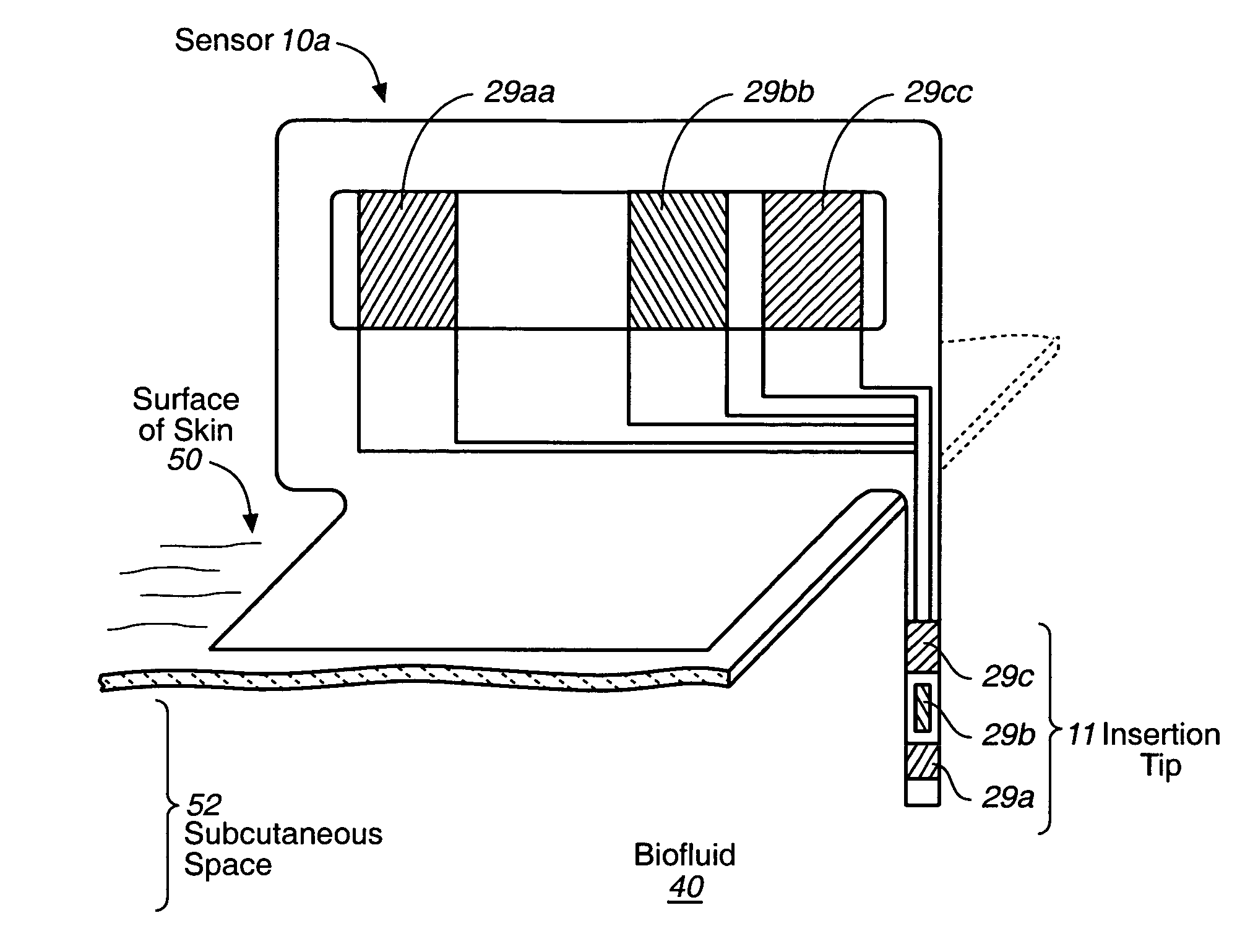

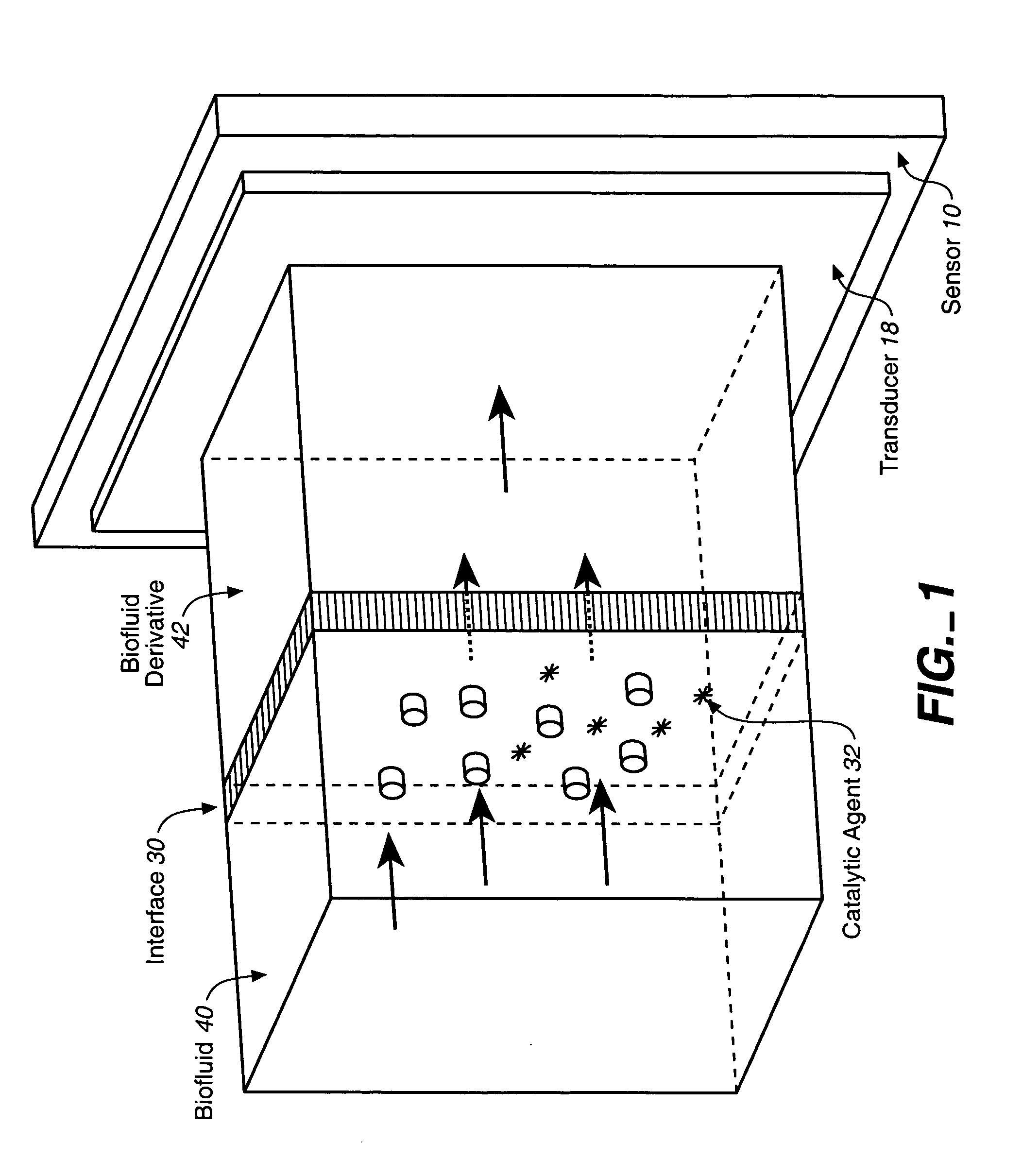

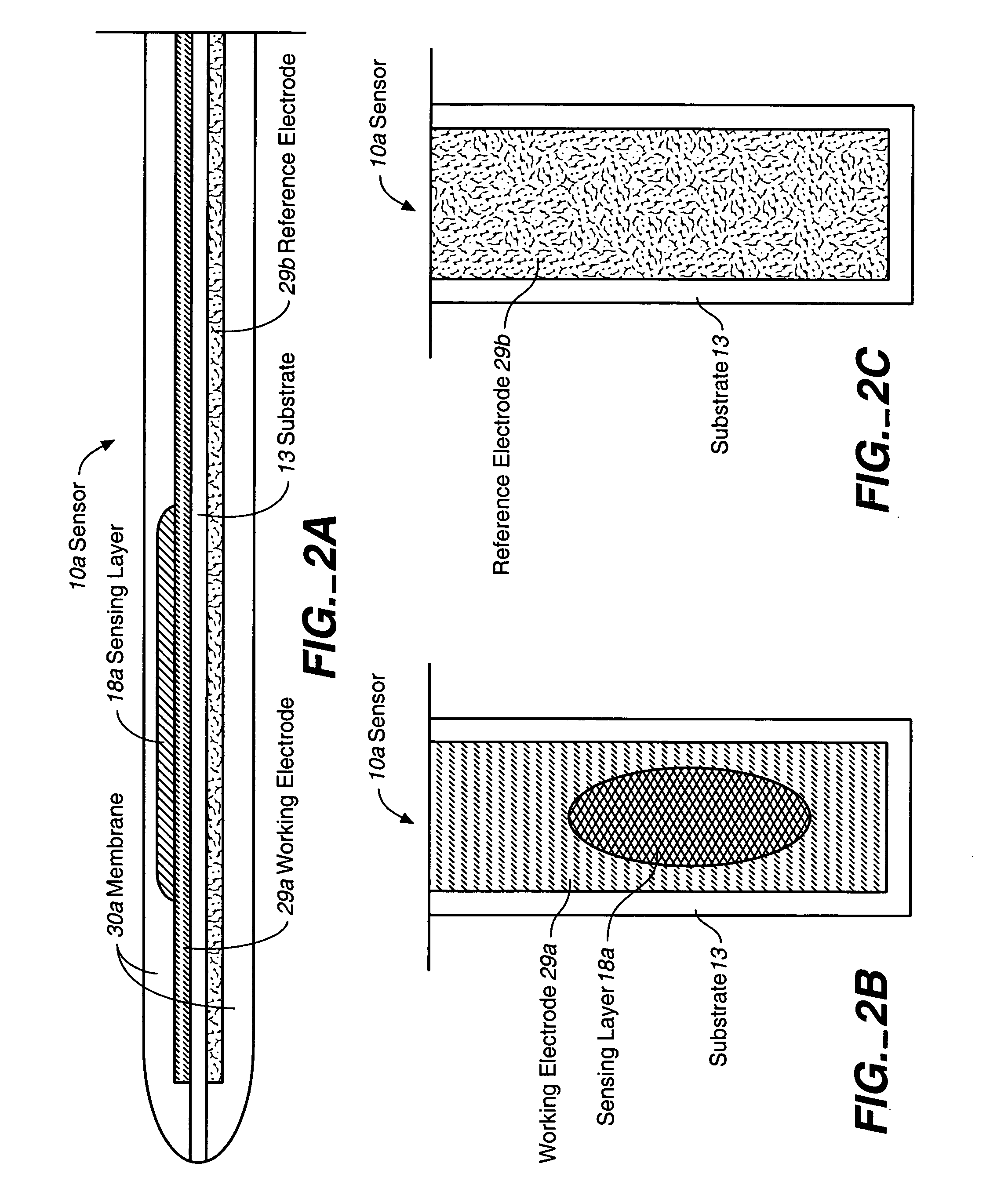

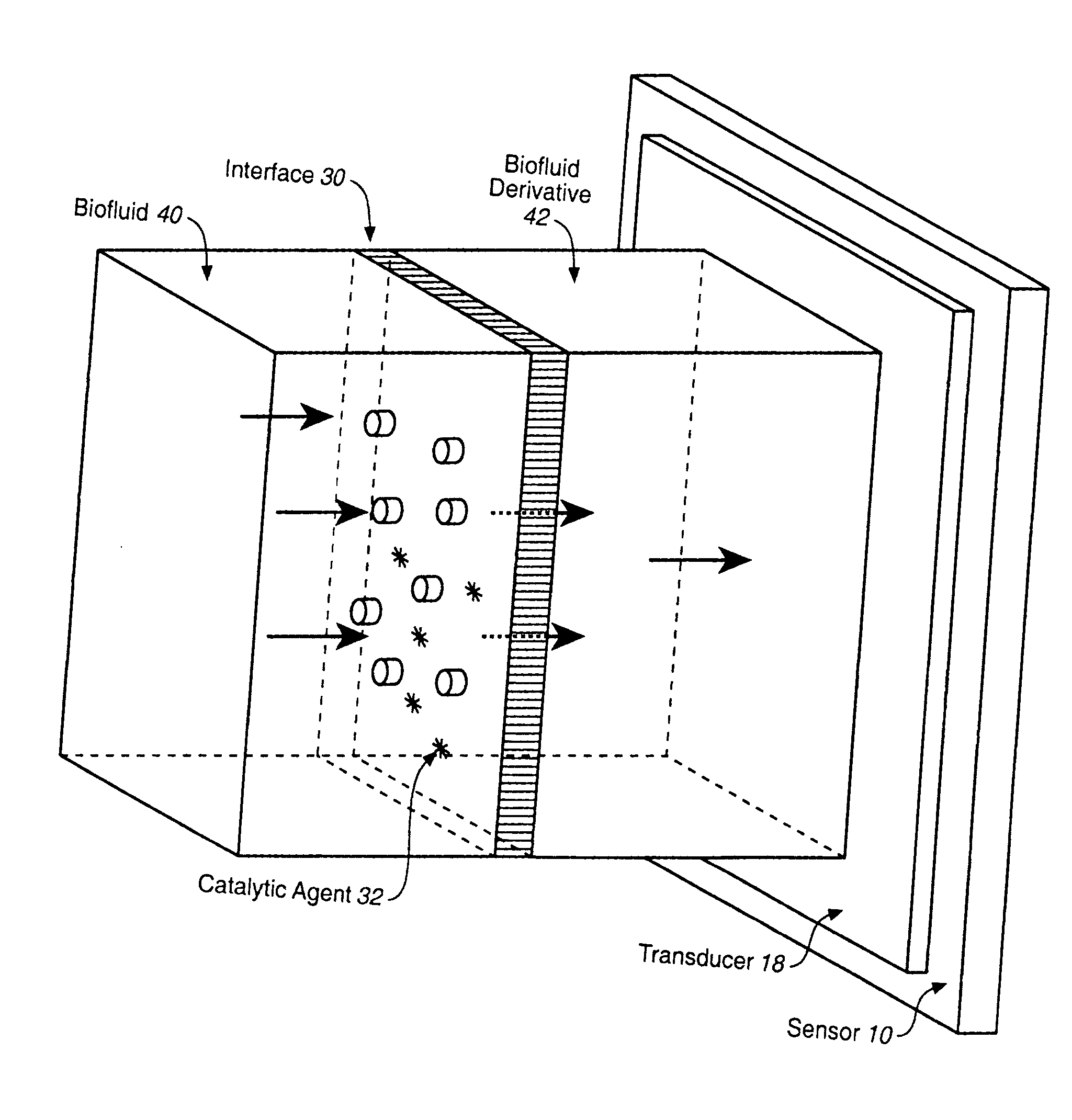

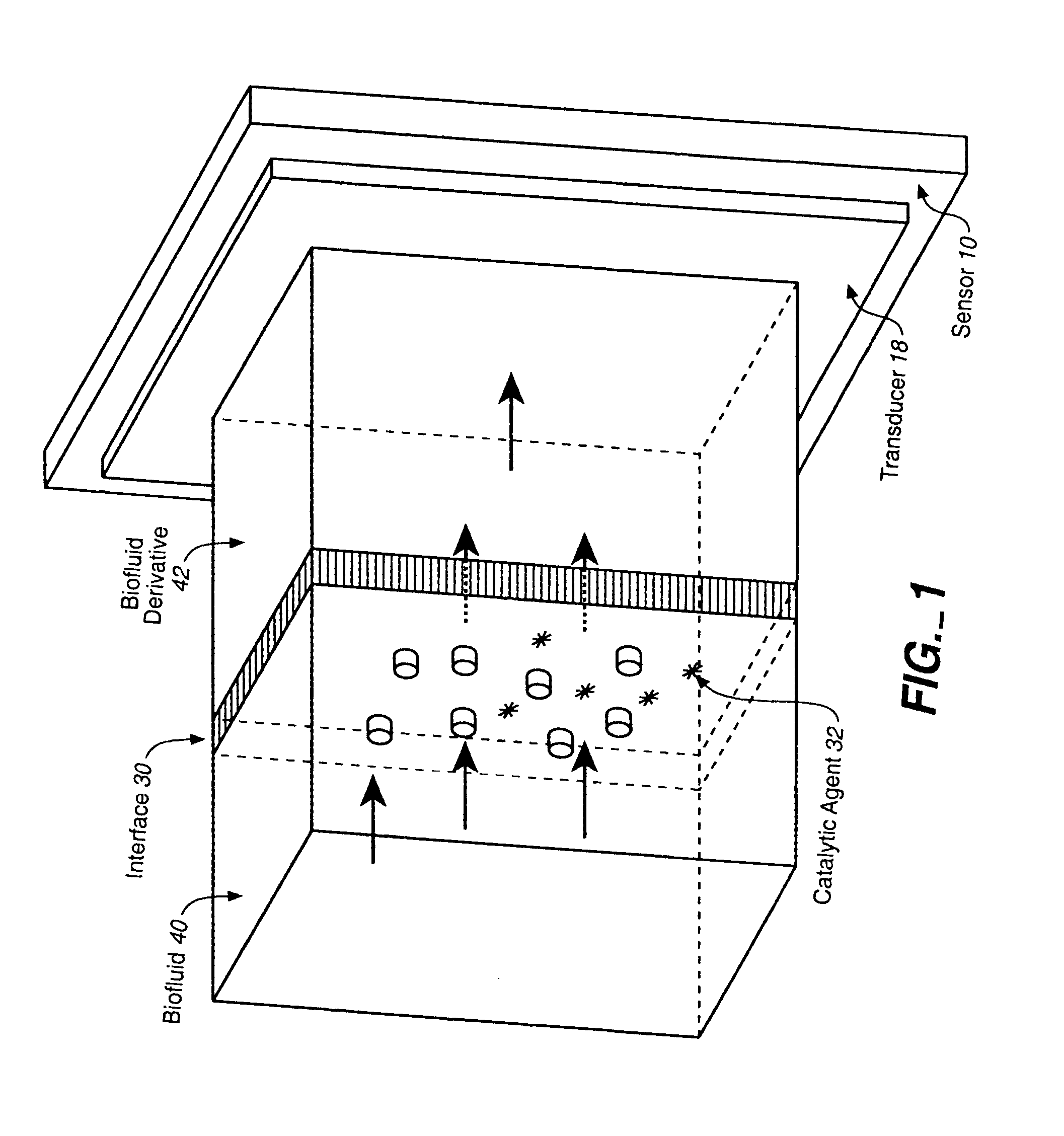

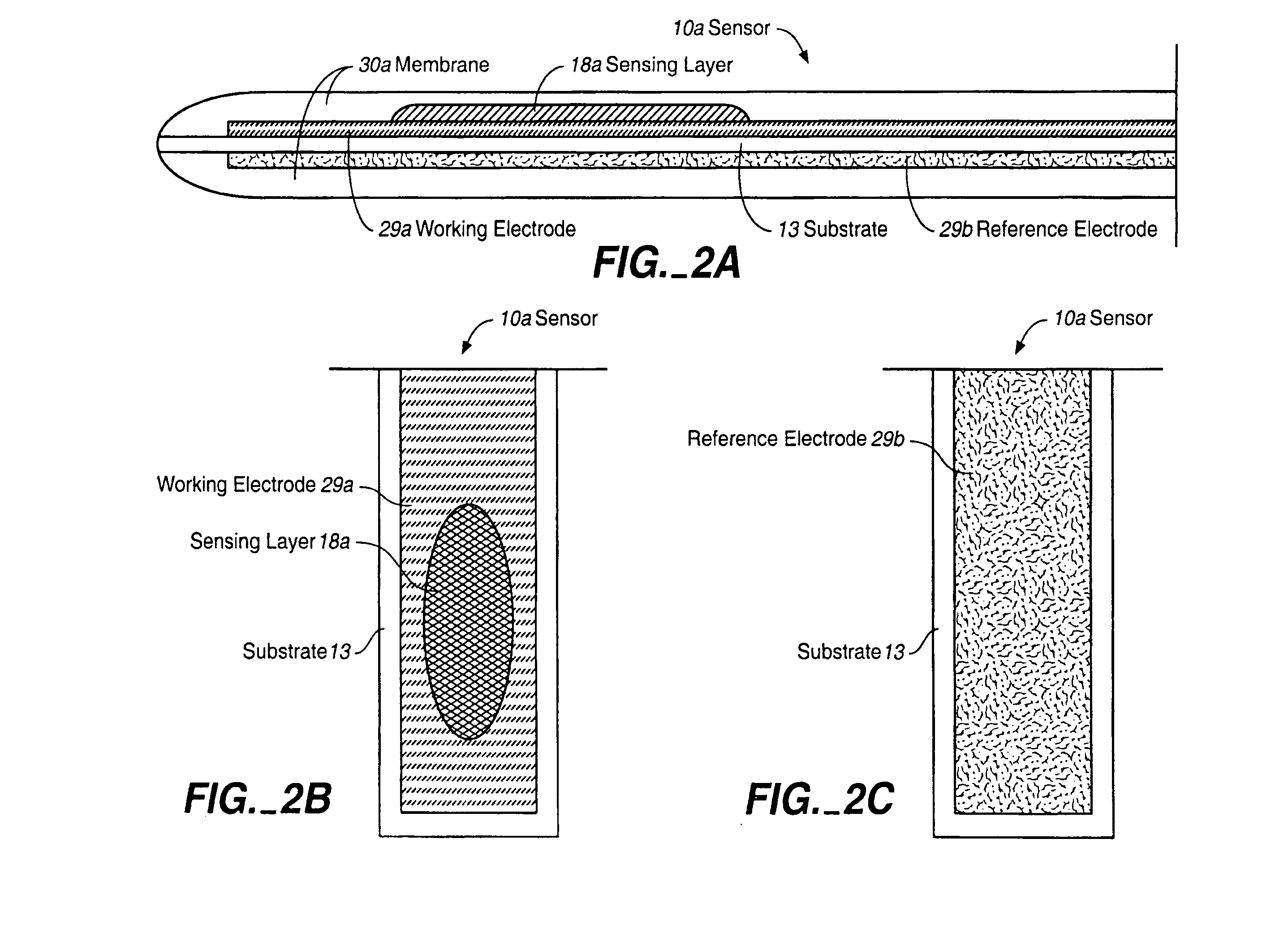

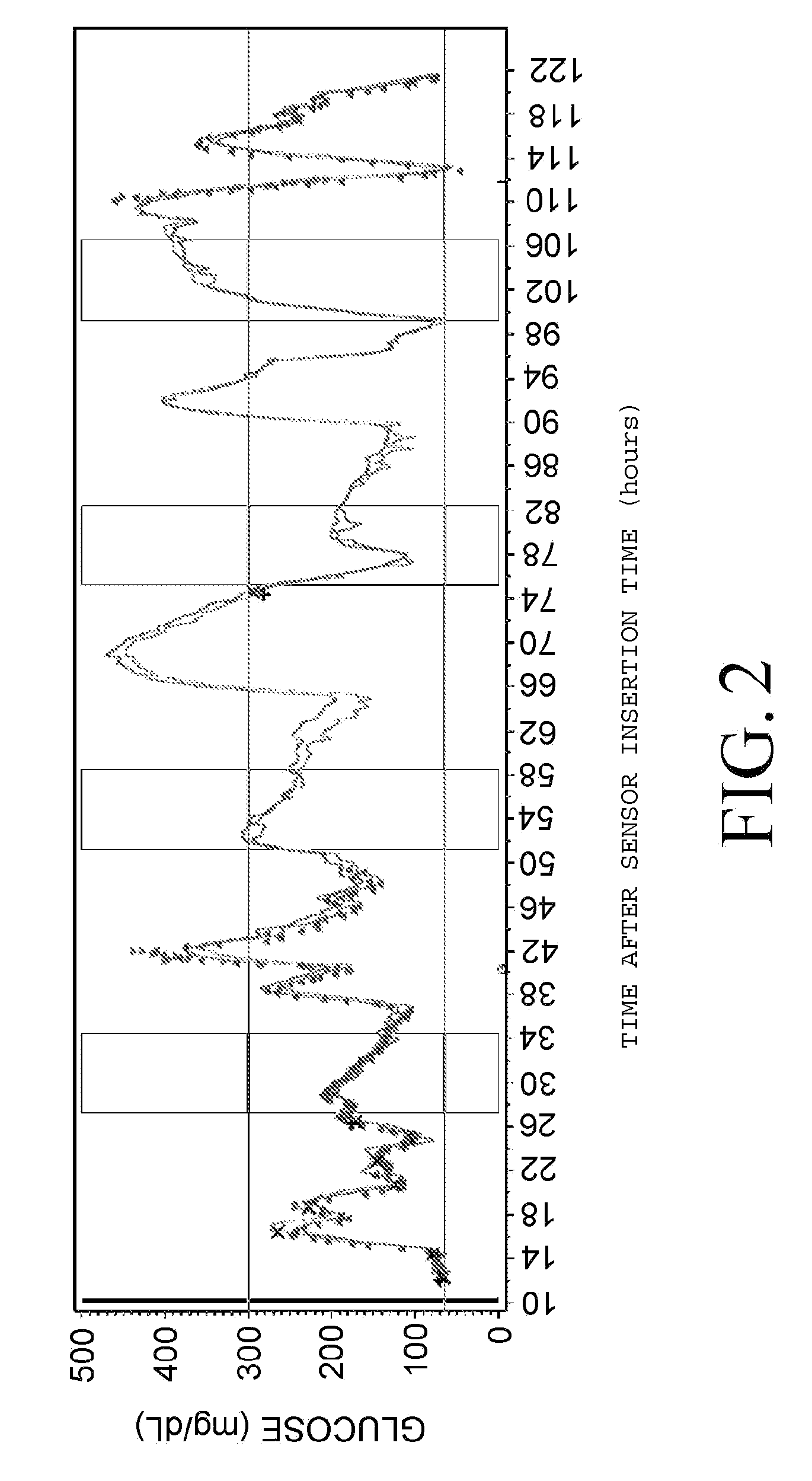

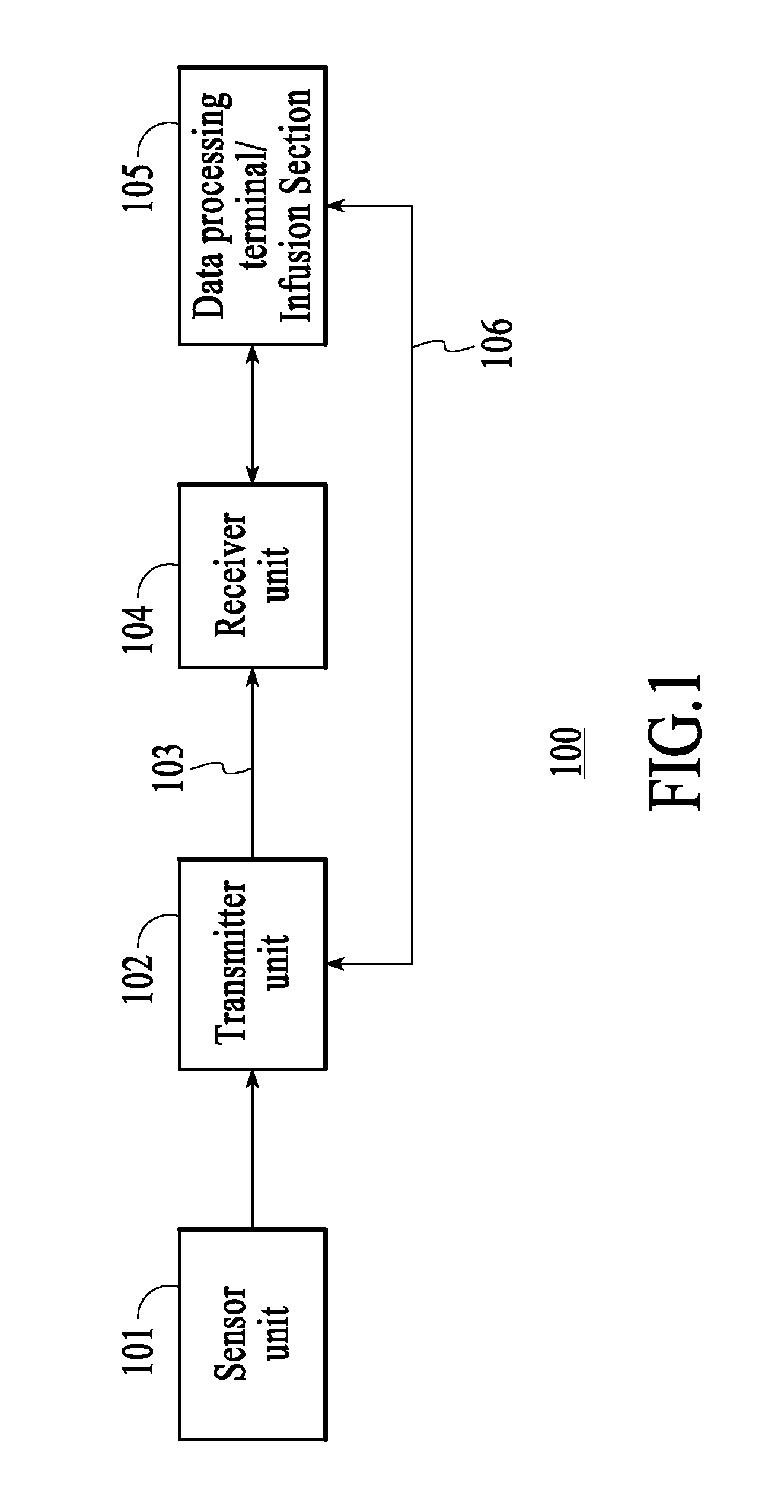

Analyte sensor, and associated system and method employing a catalytic agent

ActiveUS20050215871A1Good biocompatibilityExtend effective lifeImmobilised enzymesBioreactor/fermenter combinationsAnalyteTransducer

An analyte sensor for use in connection with a biofluid is described. The analyte sensor may comprise any suitable interface between the biofluid and a derivative of the biofluid and any suitable transducer of information concerning an analyte. At least one catalytic agent is provided in a locale or vicinity of the interface. The catalytic agent, such as a proteinaceous agent or a non-proteinaceous, organic-metal agent, is sufficient to catalyze the degradation of reactive oxygen and / or nitrogen species that may be present in the vicinity of the interface. An analyte-sensing kit and a method of sensing an analyte are also described.

Owner:ABBOTT DIABETES CARE INC

Analyte Sensor, and Associated System and Method Employing a Catalytic Agent

InactiveUS20070191701A1Good biocompatibilityExtend effective lifeImmobilised enzymesBioreactor/fermenter combinationsAnalyteTransducer

An analyte sensor for use in connection with a biofluid is described. The analyte sensor may comprise any suitable interface between the biofluid and a derivative of the biofluid and any suitable transducer of information concerning an analyte. At least one catalytic agent is provided in a locale or vicinity of the interface. The catalytic agent, such as a proteinaceous agent or a non-proteinaceous, organic-metal agent, is sufficient to catalyze the degradation of reactive oxygen and / or nitrogen species that may be present in the vicinity of the interface. An analyte-sensing kit and a method of sensing an analyte are also described.

Owner:ABBOTT DIABETES CARE INC

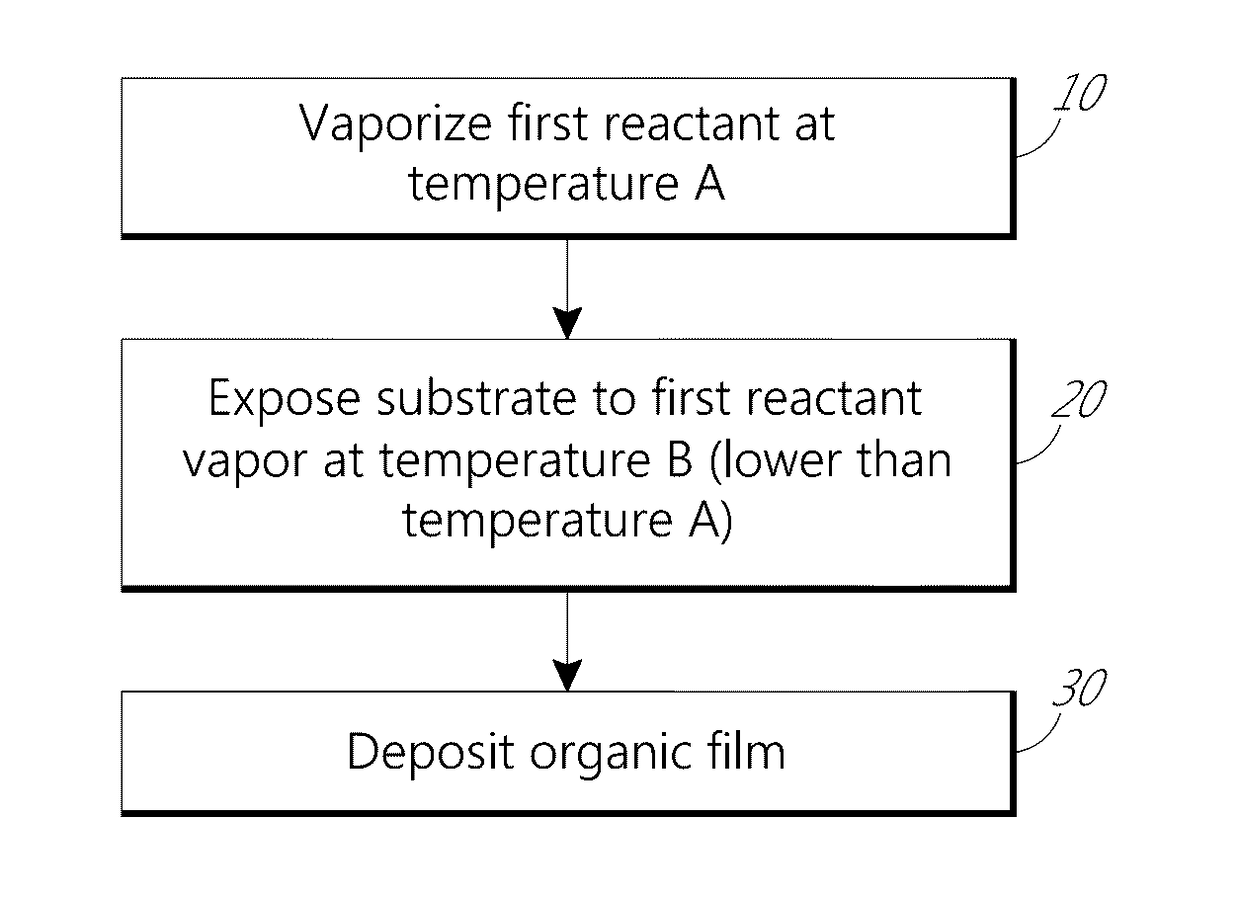

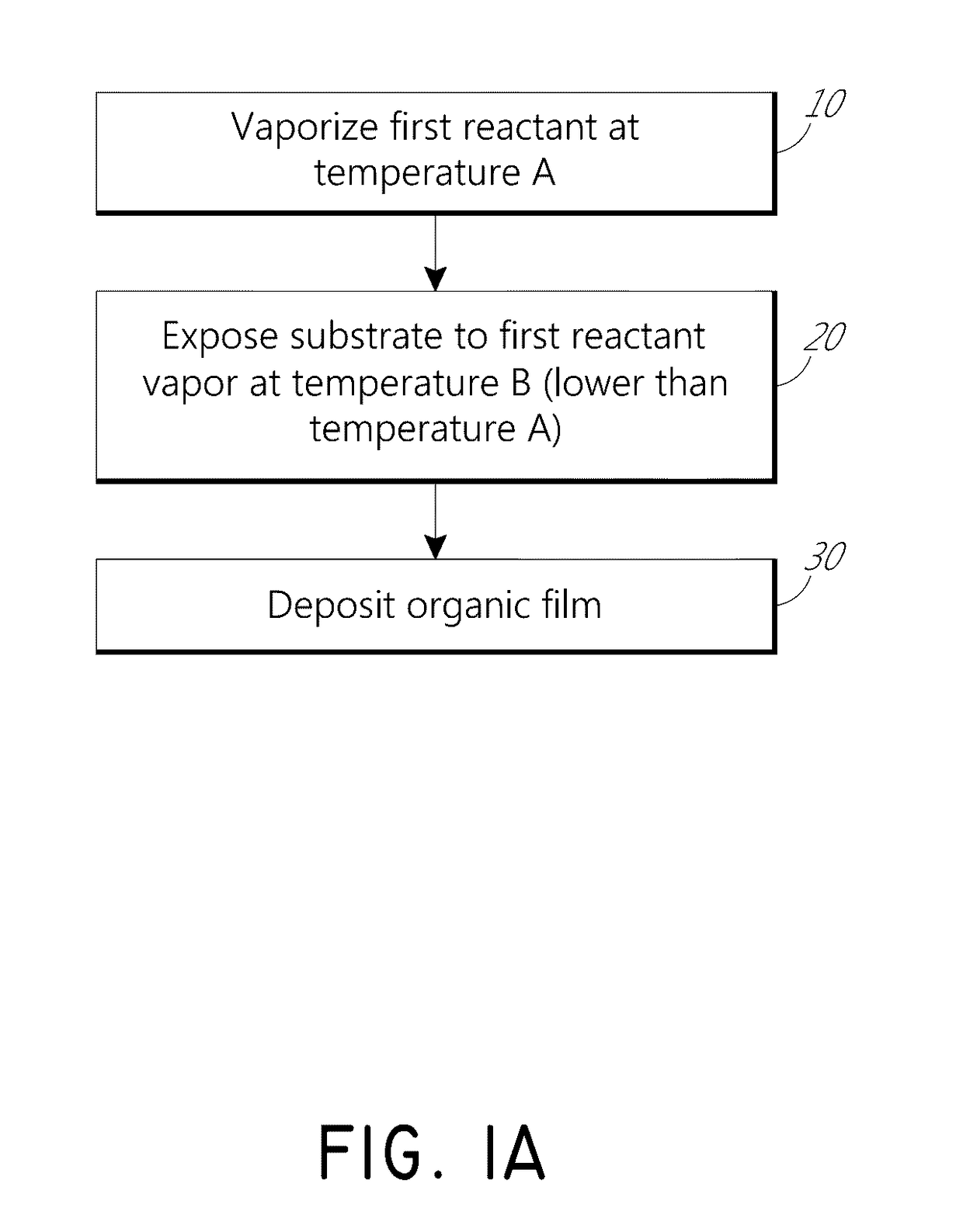

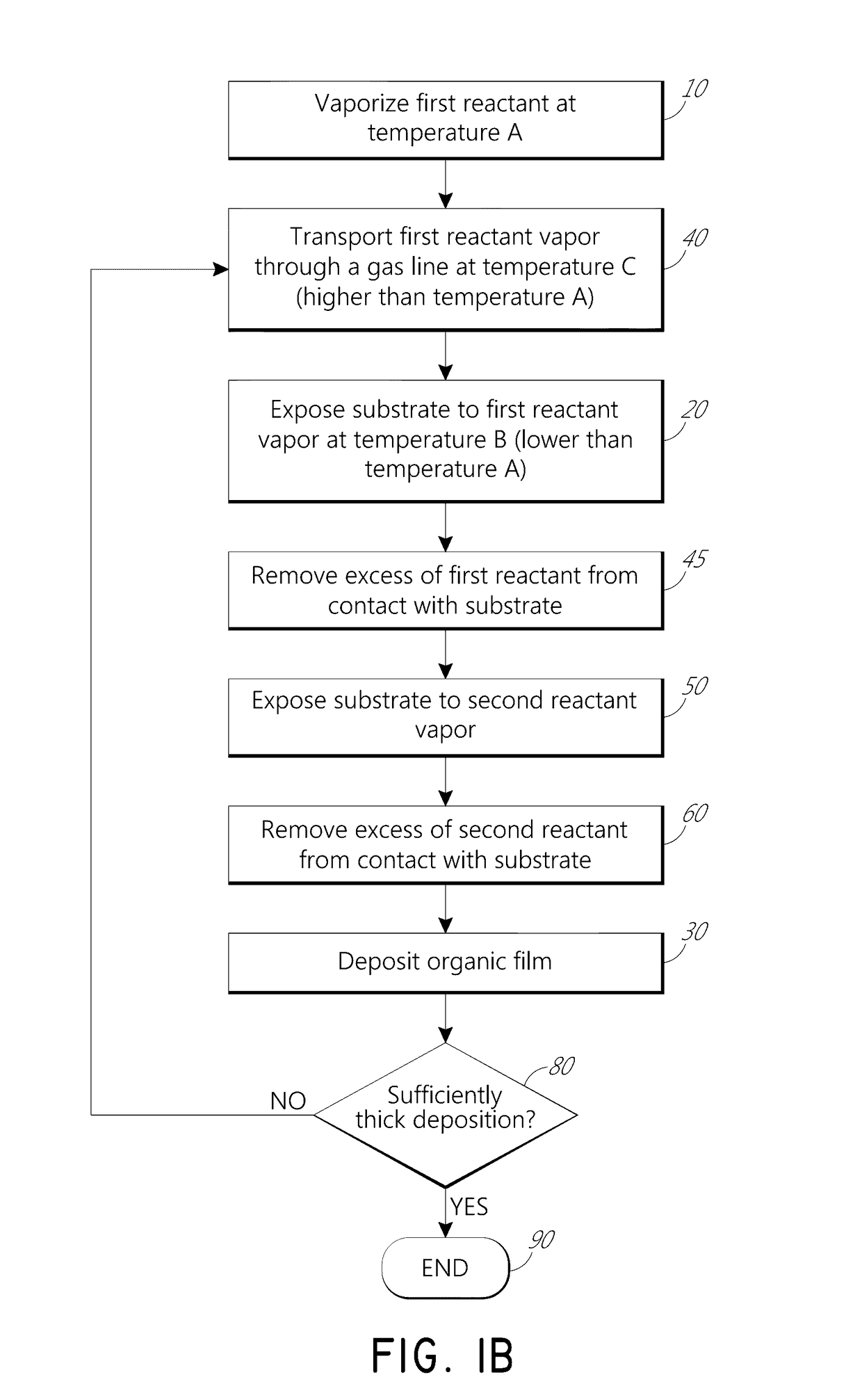

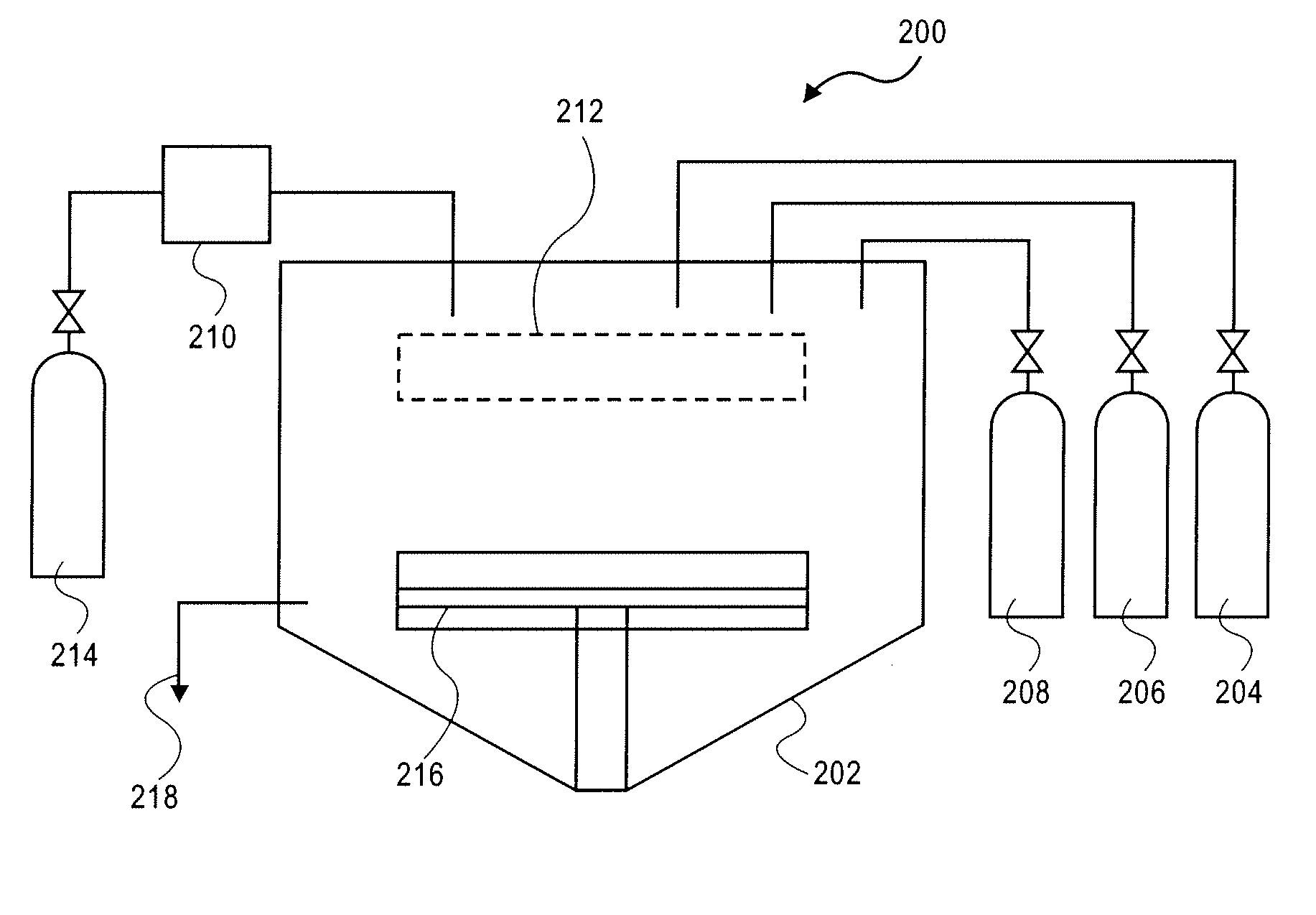

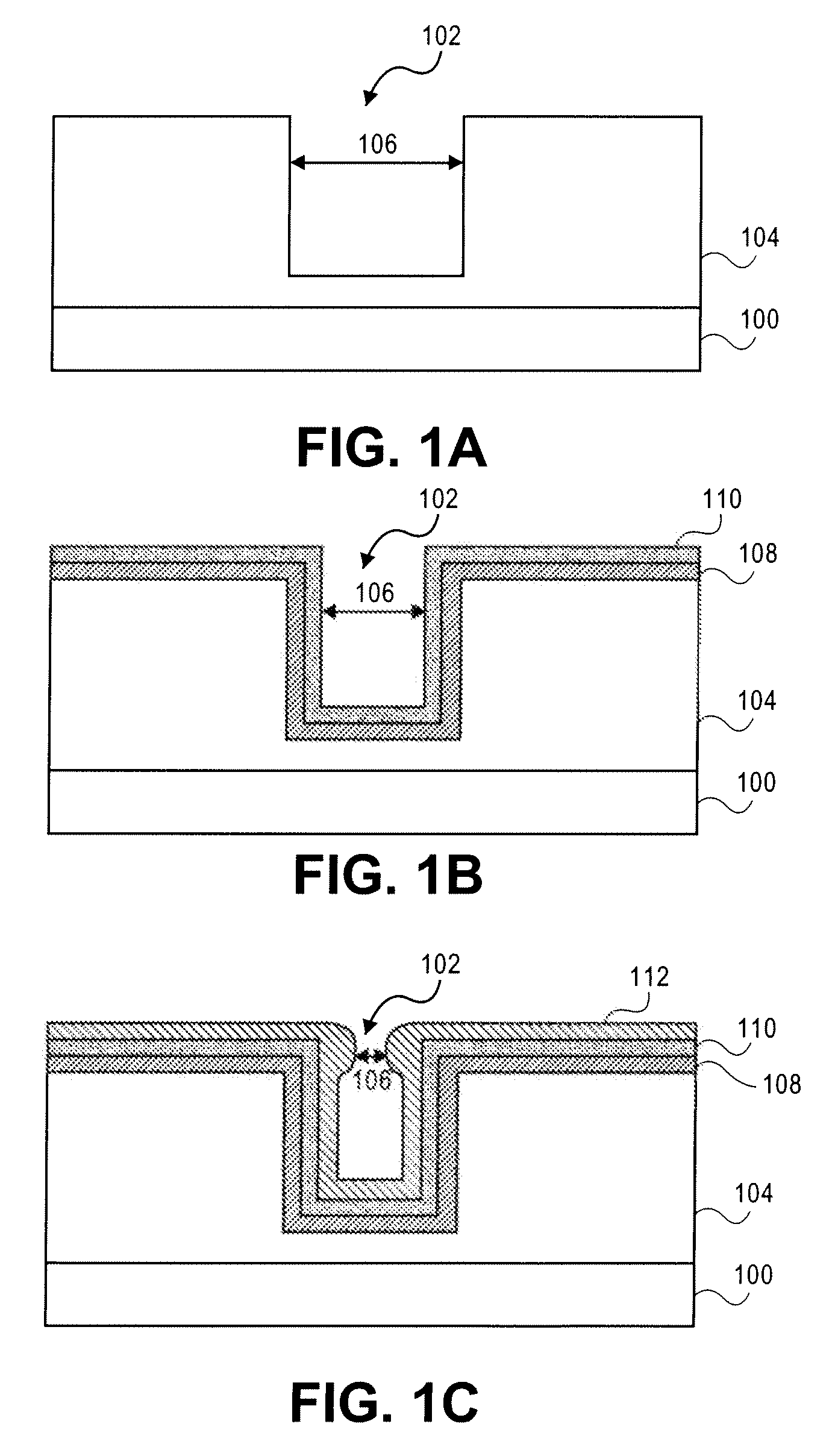

Vapor phase deposition of organic films

ActiveUS20170100742A1Reduce aspect ratioLiquid surface applicatorsChemical vapor deposition coatingOrganic filmGas phase

Methods and apparatus for vapor deposition of an organic film are configured to vaporize an organic reactant at a first temperature, transport the vapor to a reaction chamber housing a substrate, and maintain the substrate at a lower temperature than the vaporization temperature. Alternating contact of the substrate with the organic reactant and a second reactant in a sequential deposition sequence can result in bottom-up filling of voids and trenches with organic film in a manner otherwise difficult to achieve.

Owner:ASM IP HLDG BV

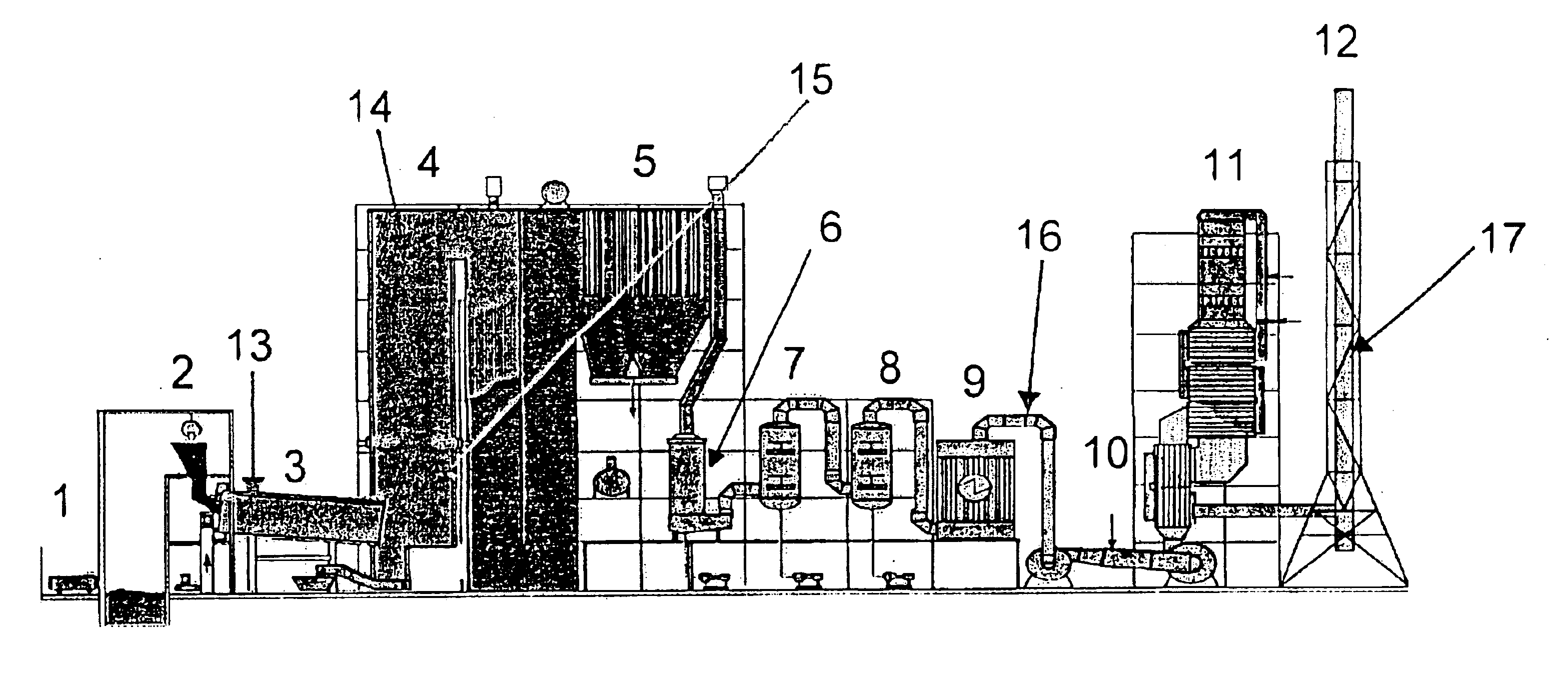

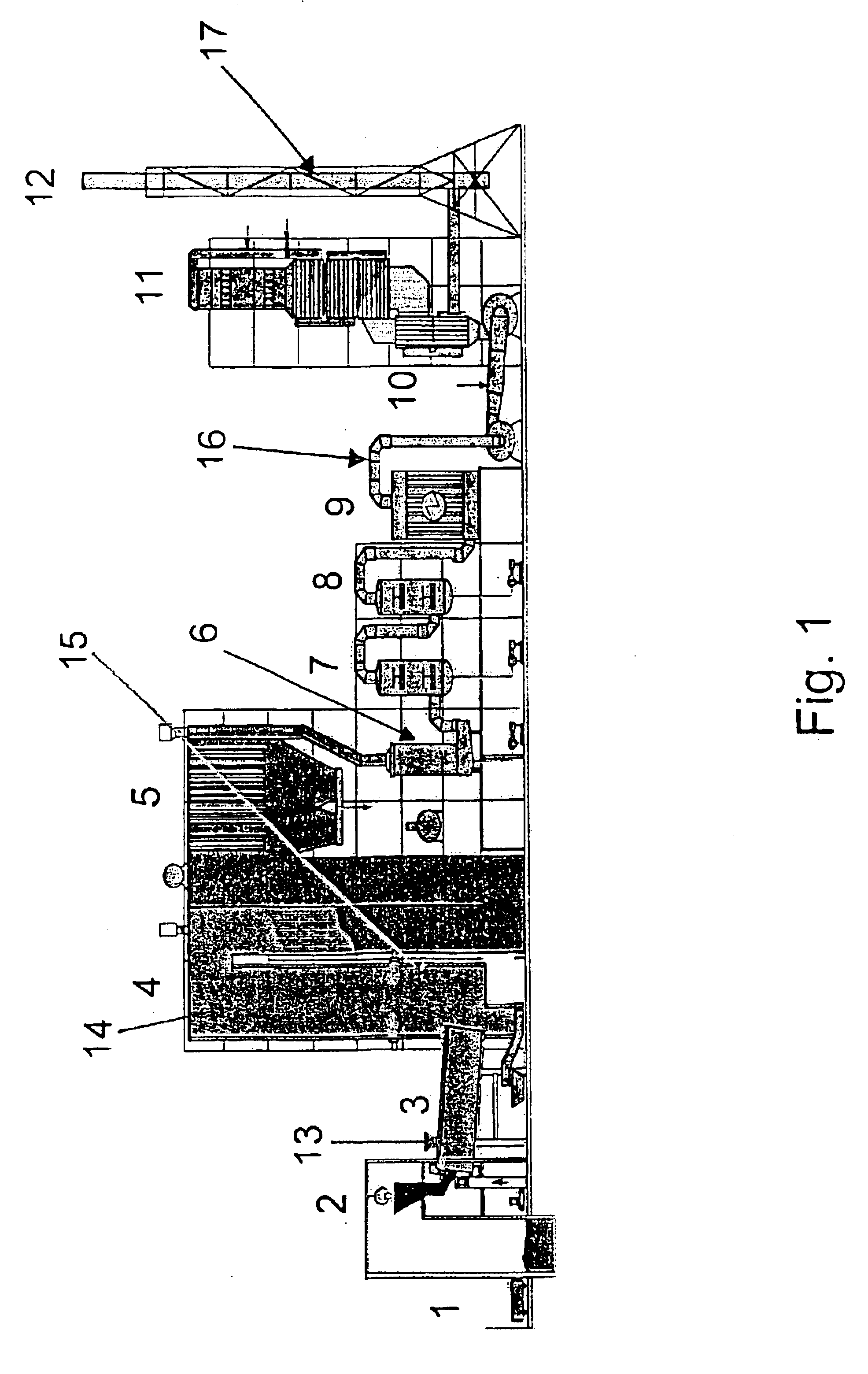

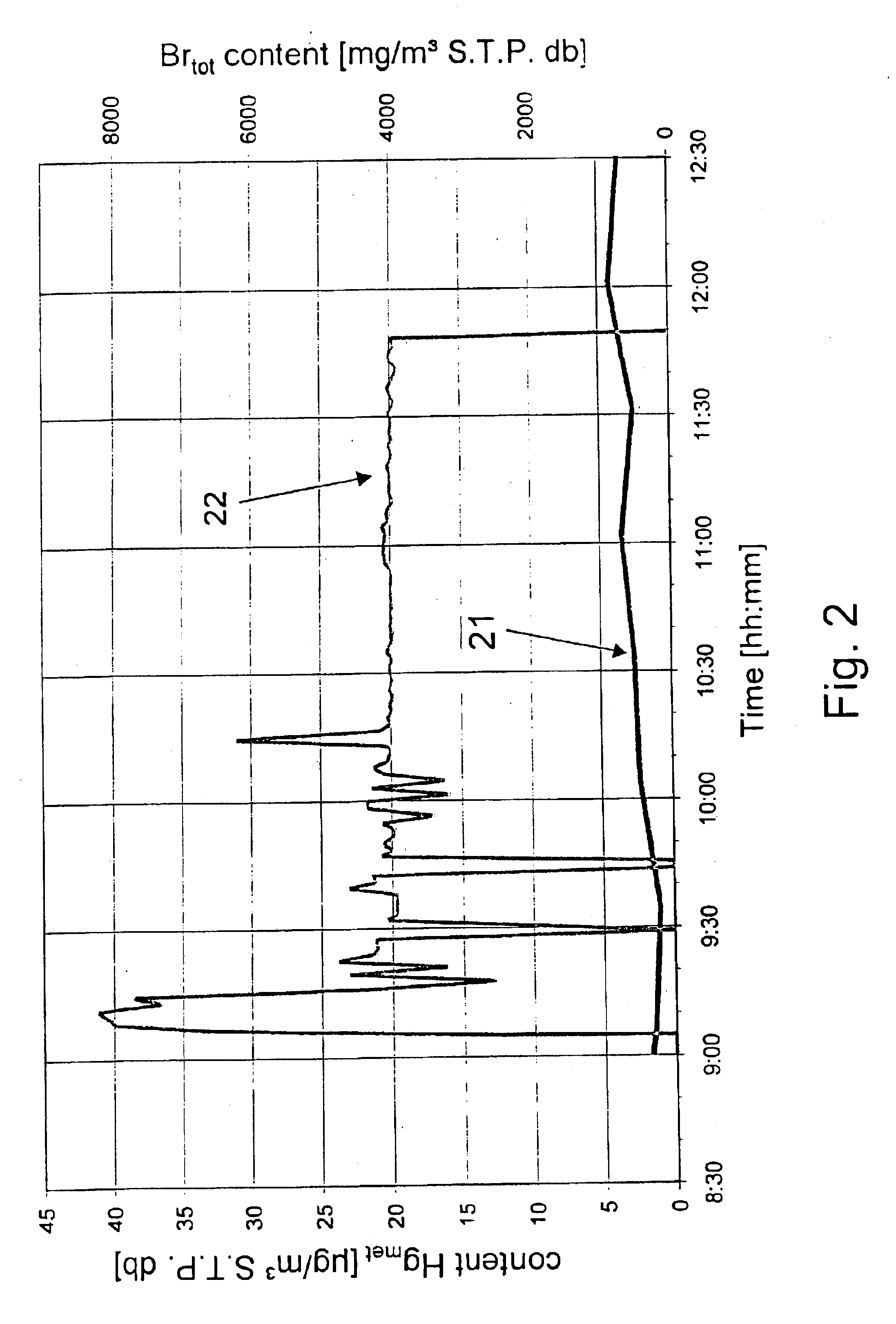

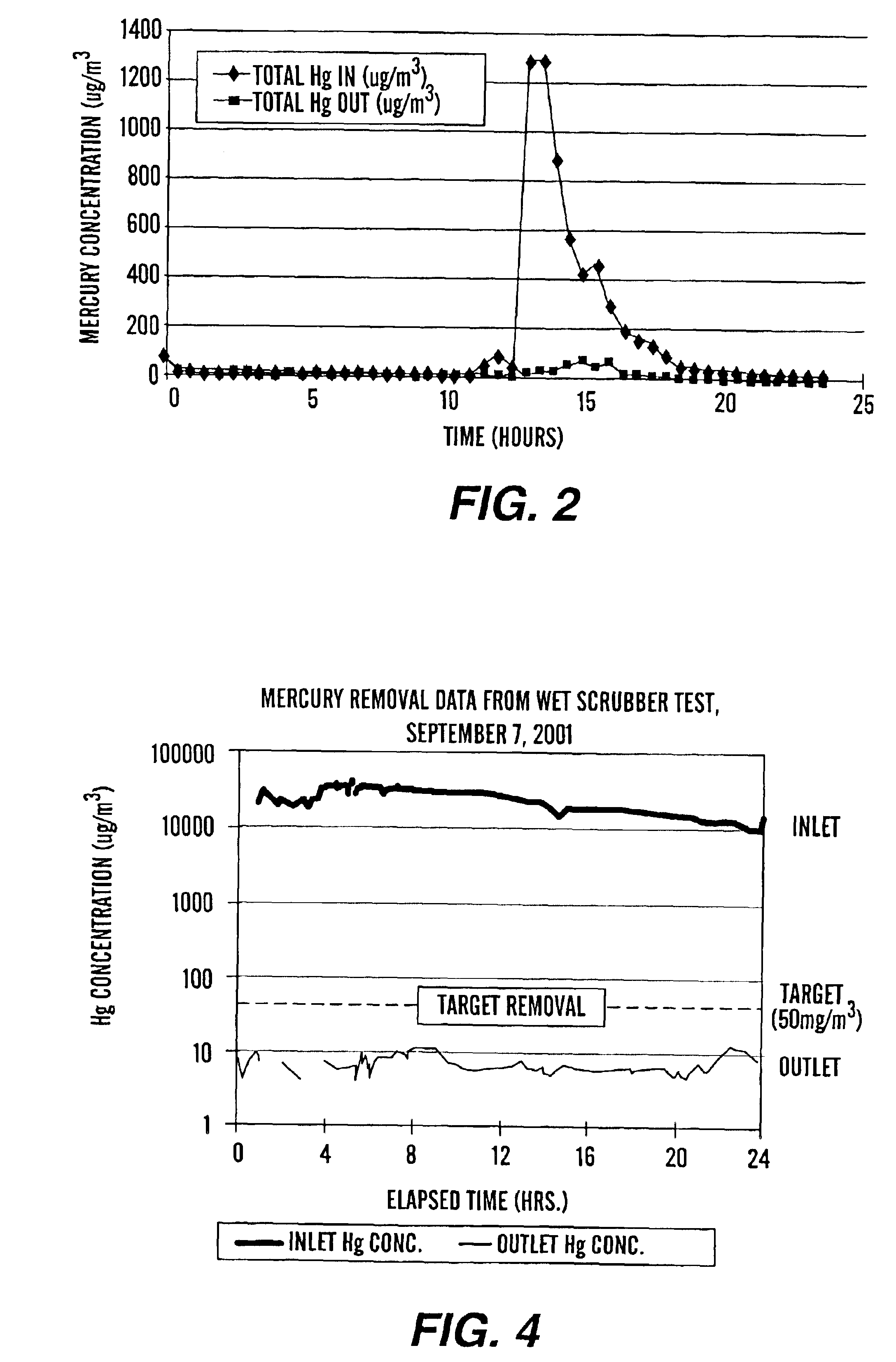

Process for removing mercury from flue gases

InactiveUS6878358B2Reduce operating costsSmall amountUsing liquid separation agentChemical/physical processesPower stationCombustion

Process for removing mercury from flue gases of high-temperature plants, in particular power stations and waste incineration plants in which a bromine compound is fed to the multistage furnace and / or the flue gas in a plant section downstream of the furnace, the temperature during contact of the bromine compound with the flue gas being at least 500° C., preferably at least 800° C. The combustion is carried out in the presence of a sulphur compound, in particular sulphur dioxide. Subsequently to the furnace, the flue gas is subjected to an optional multistage cleanup for removing mercury from the flue gas, which cleanup comprises a wet scrubber and / or a dry cleanup.

Owner:BROMERC

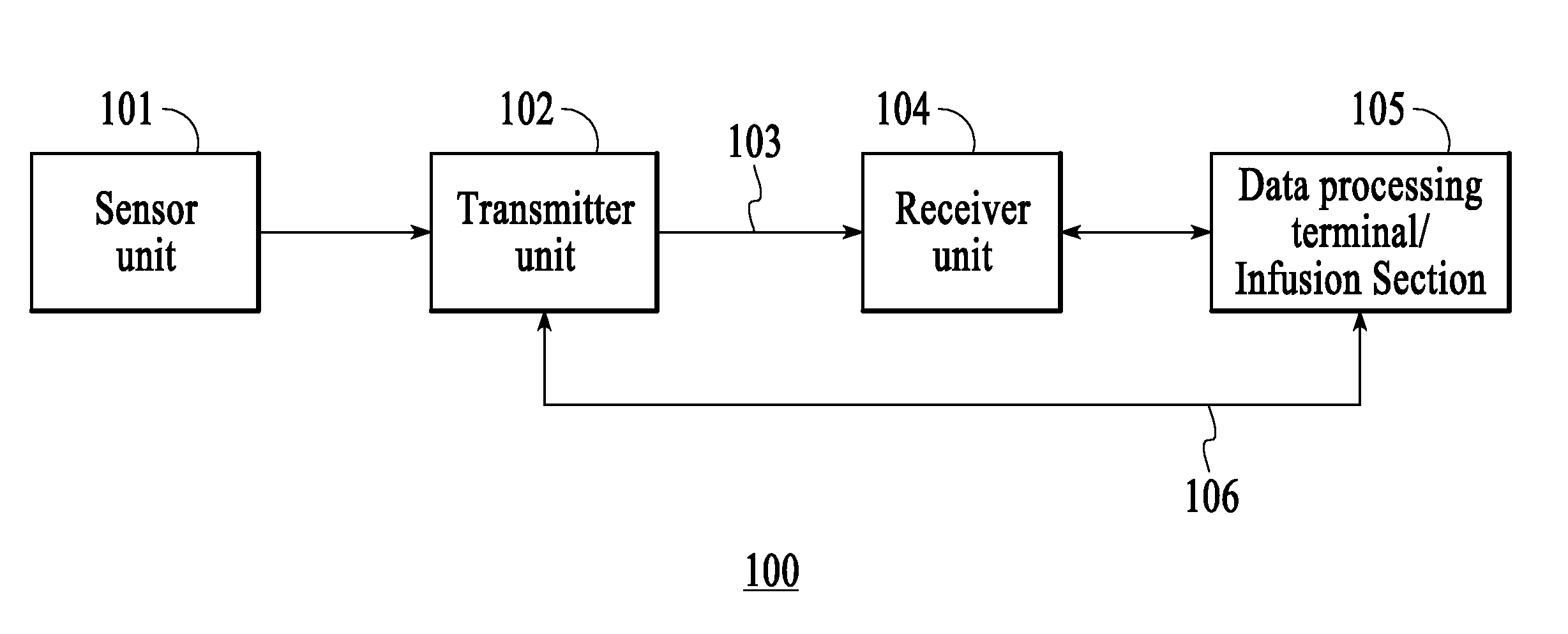

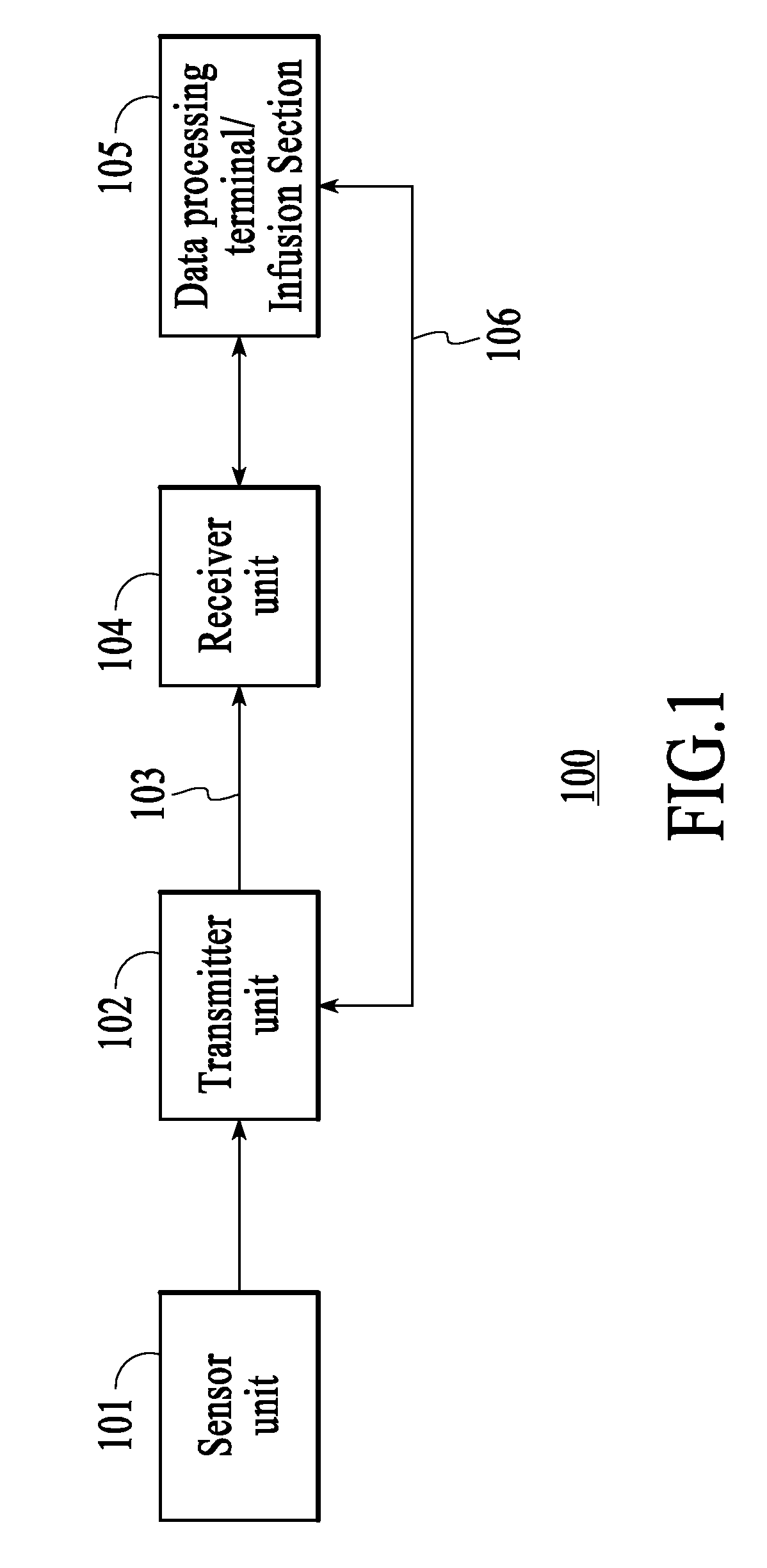

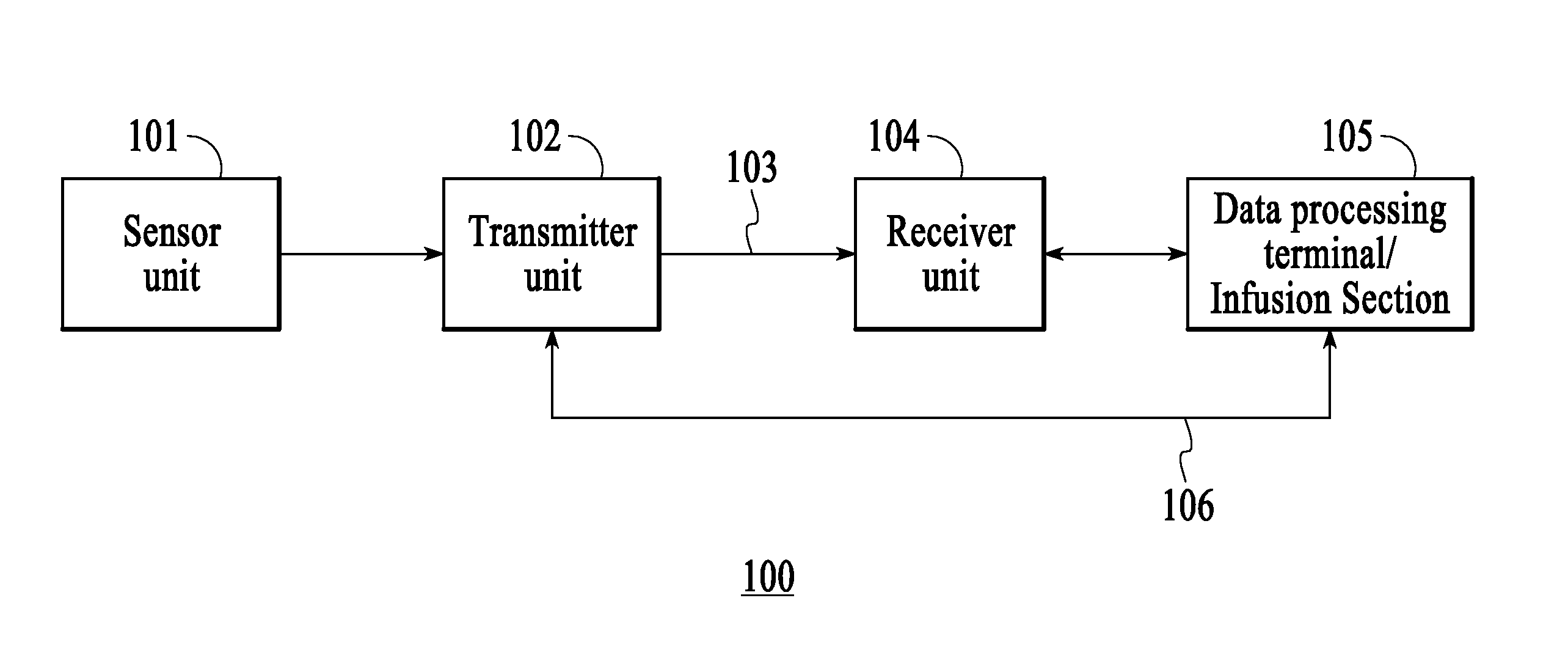

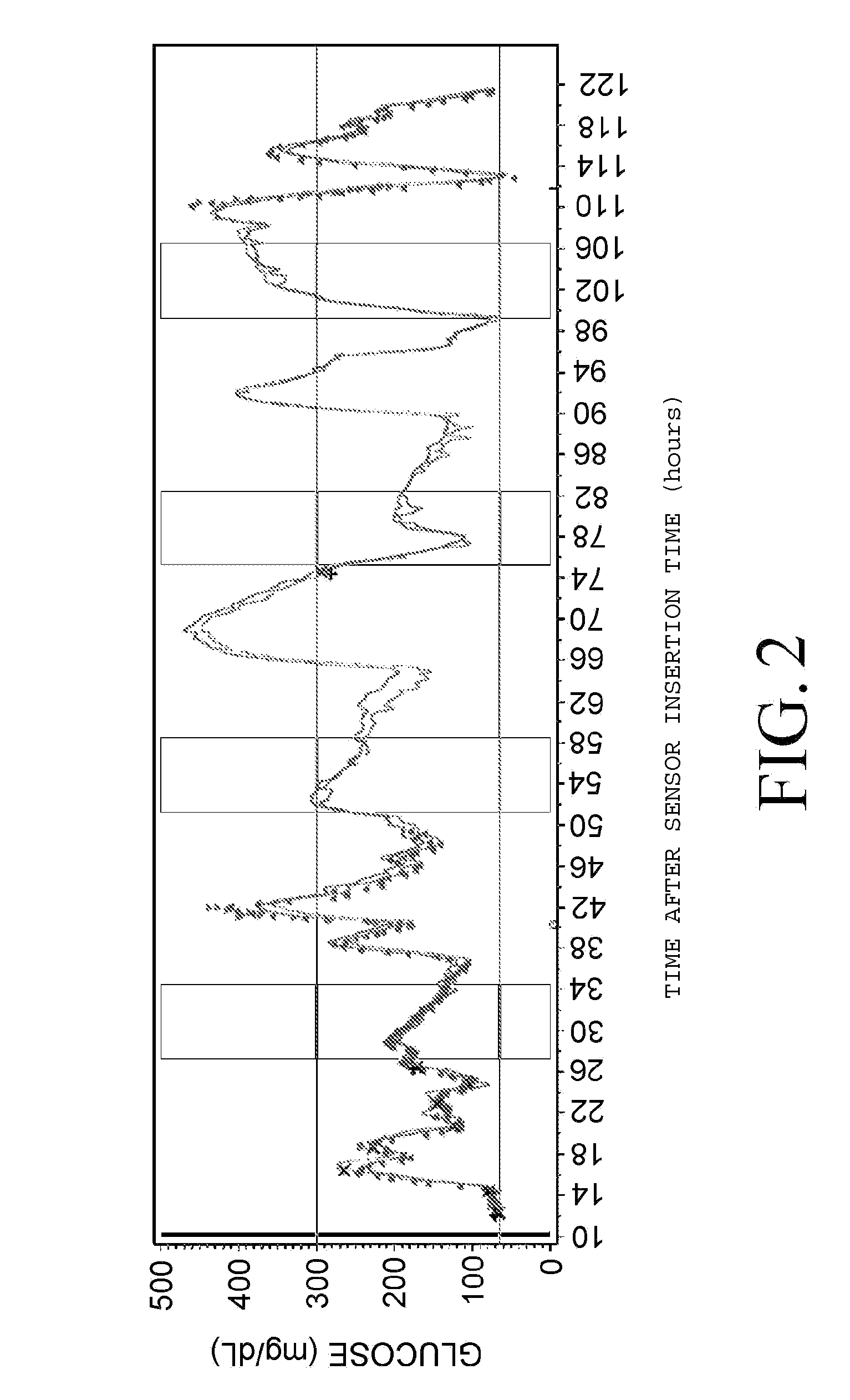

Analyte monitoring system and method

ActiveUS20080058625A1Improve accuracyMicrobiological testing/measurementEndoradiosondesAnalyteMonitoring system

Owner:ABBOTT DIABETES CARE INC

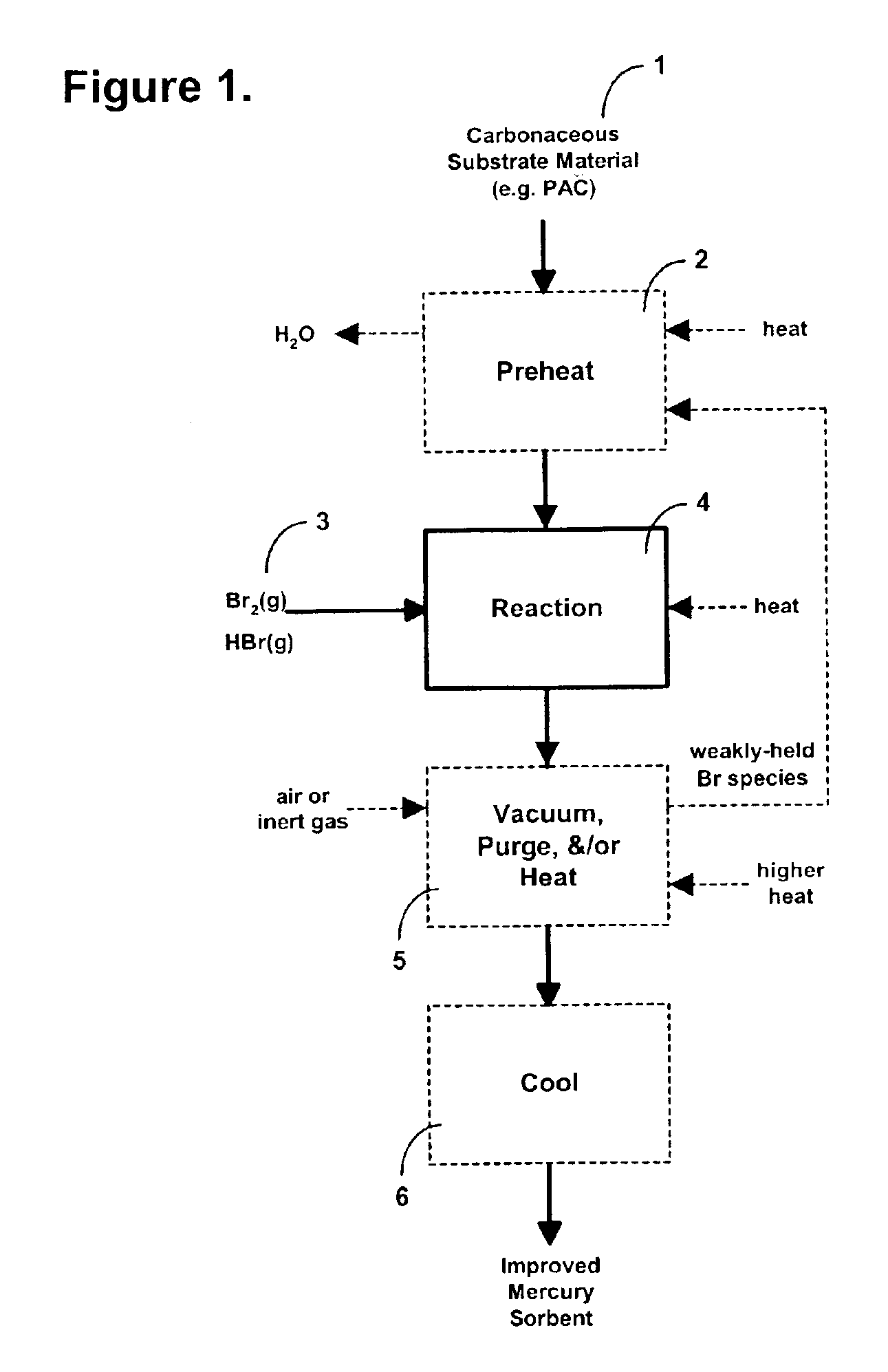

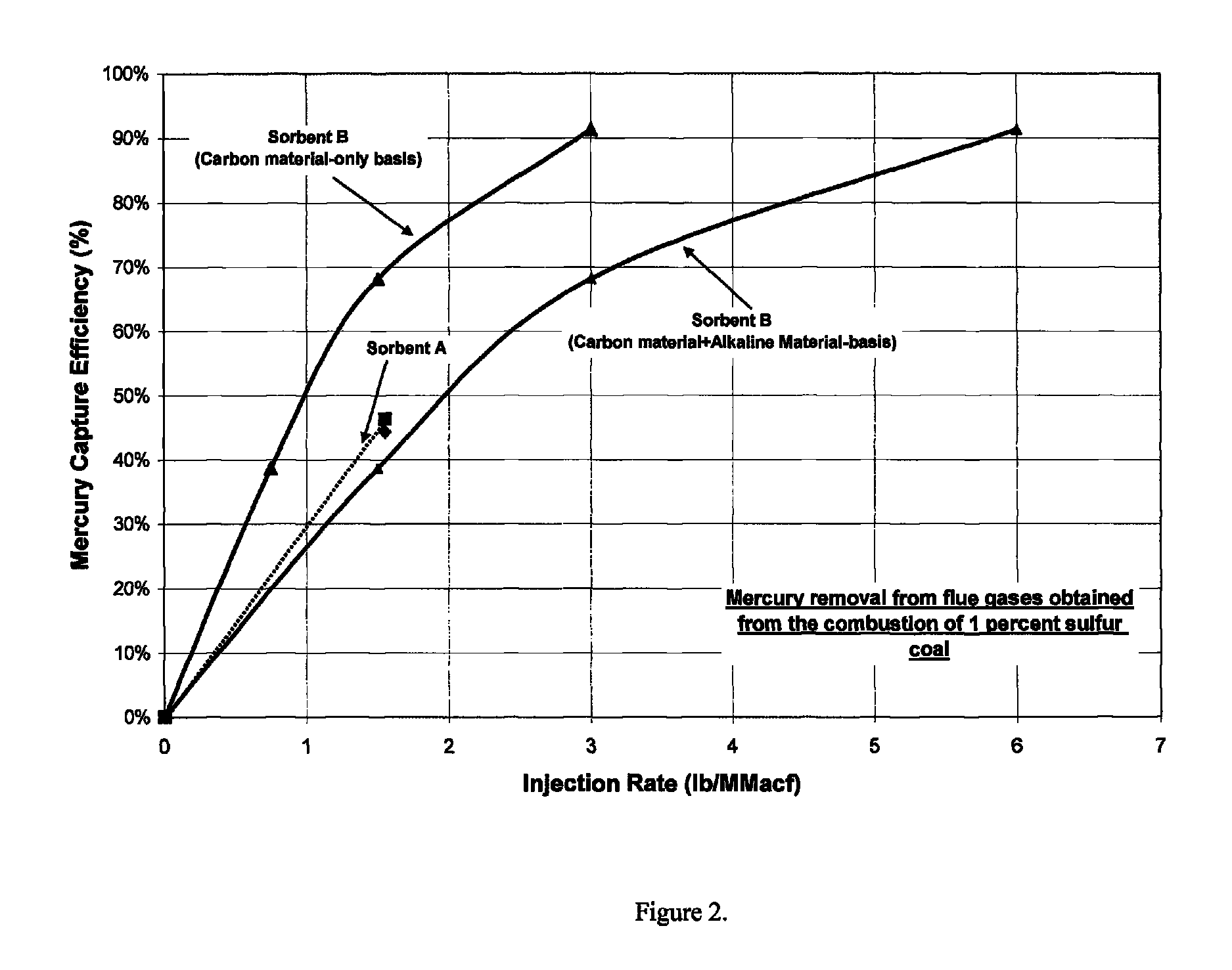

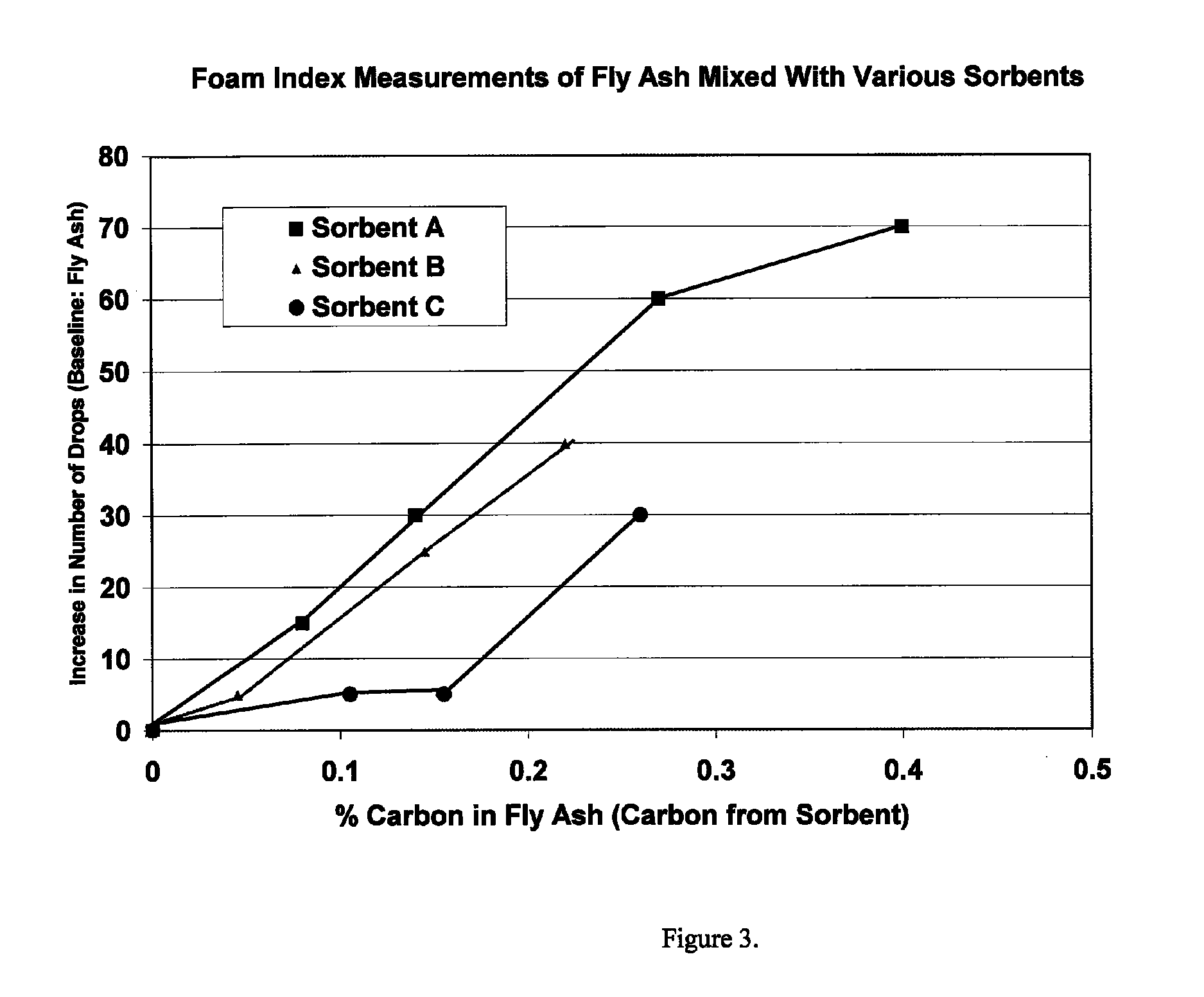

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

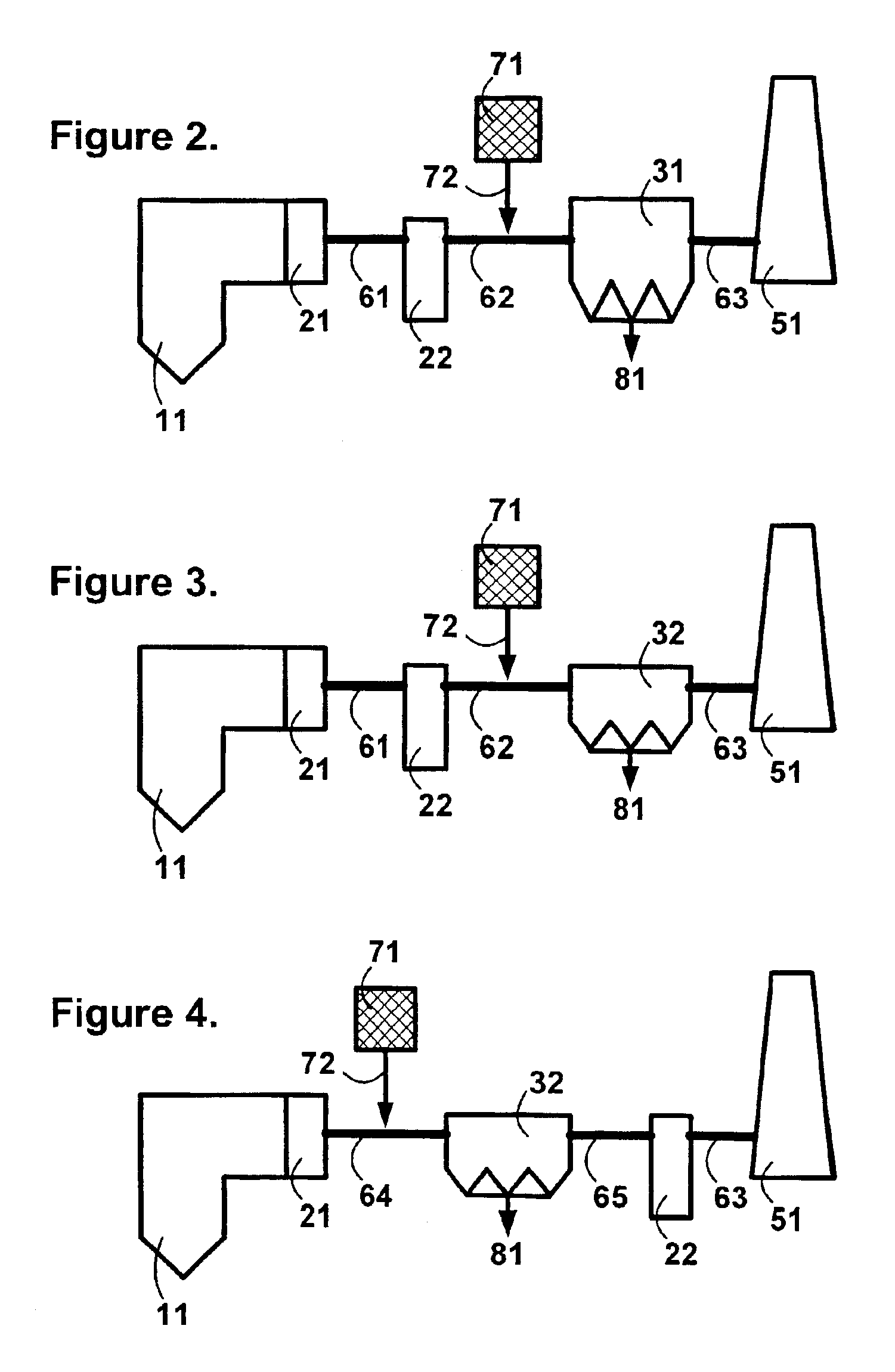

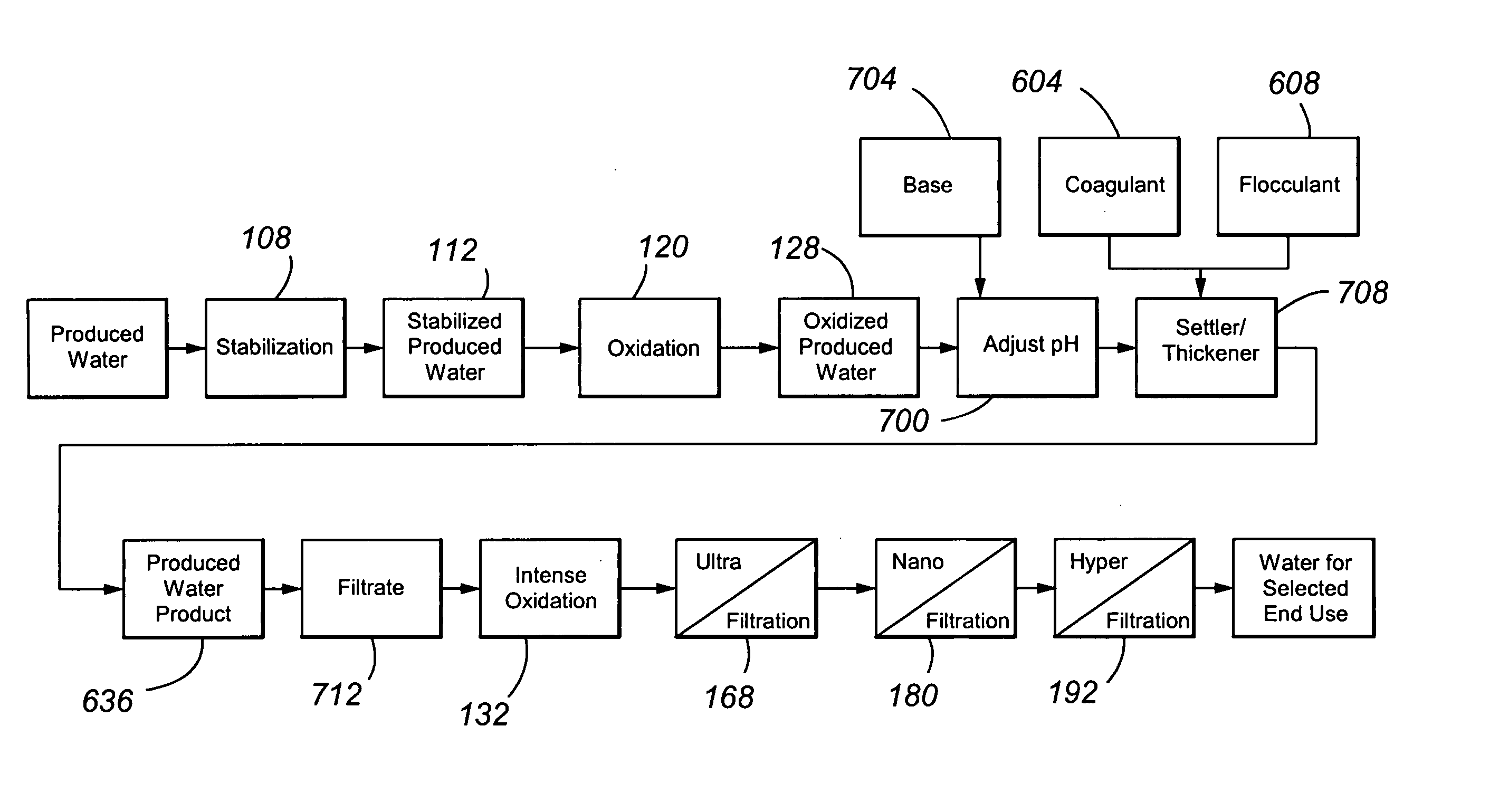

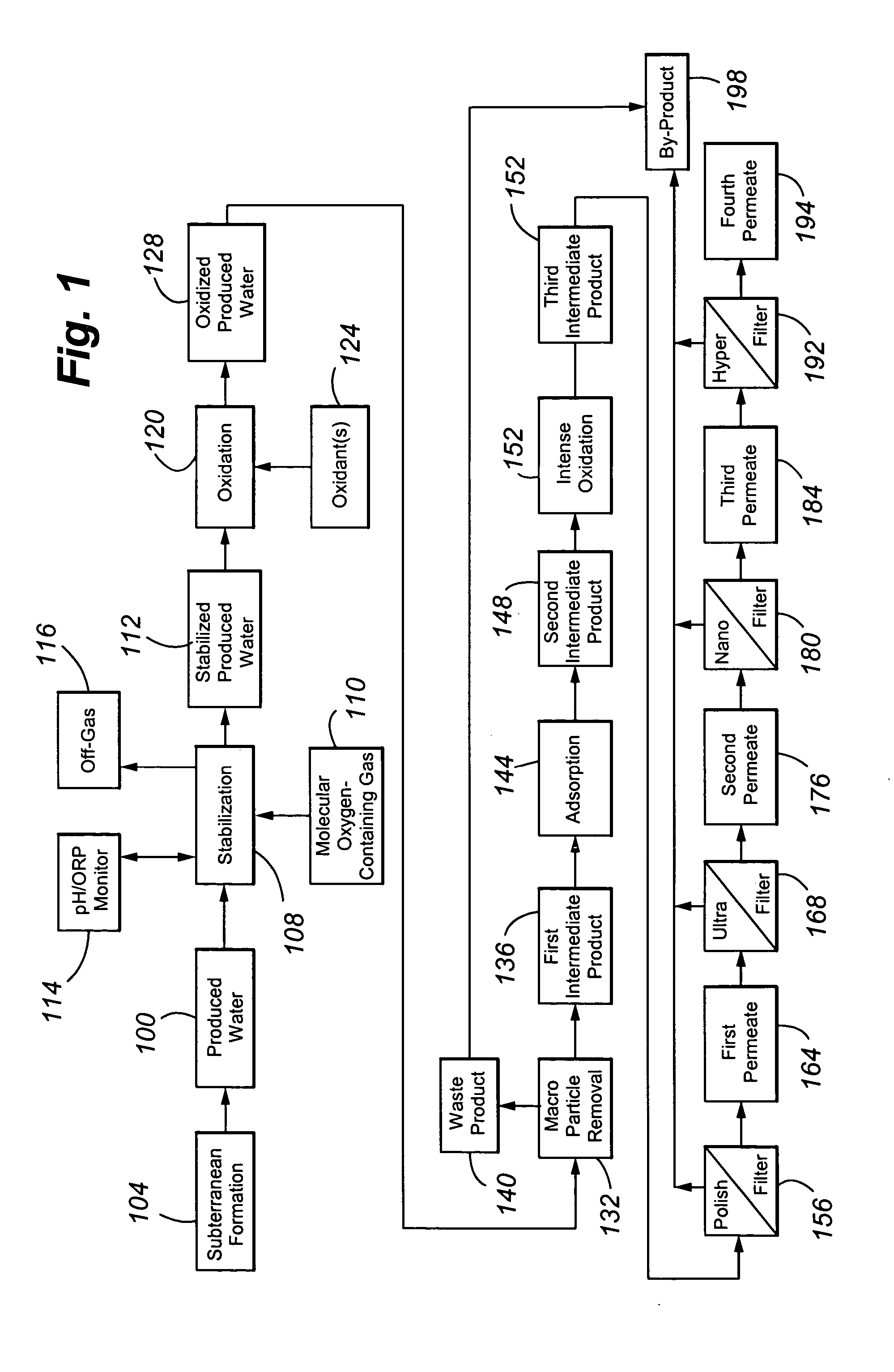

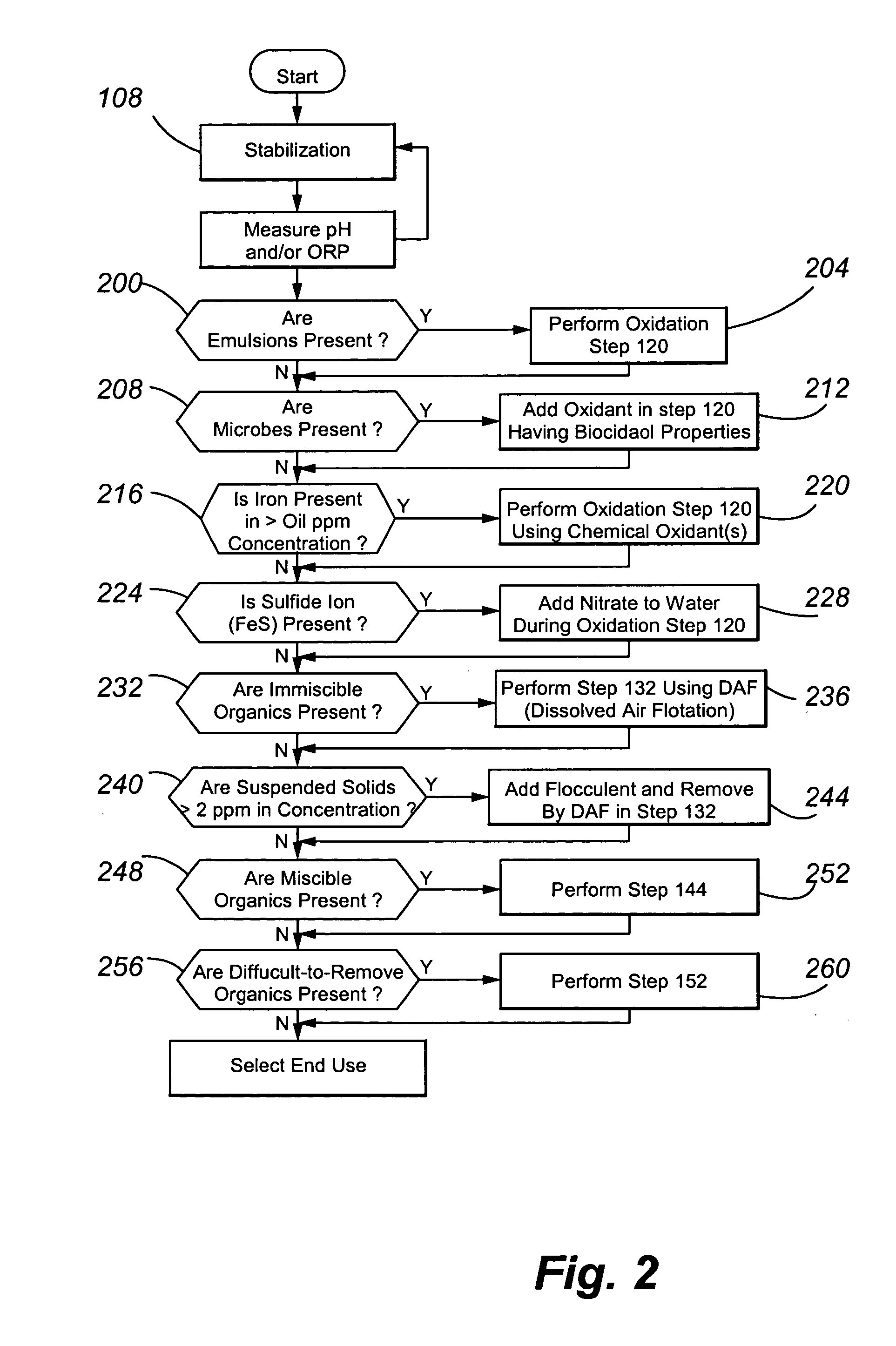

Treating produced waters

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

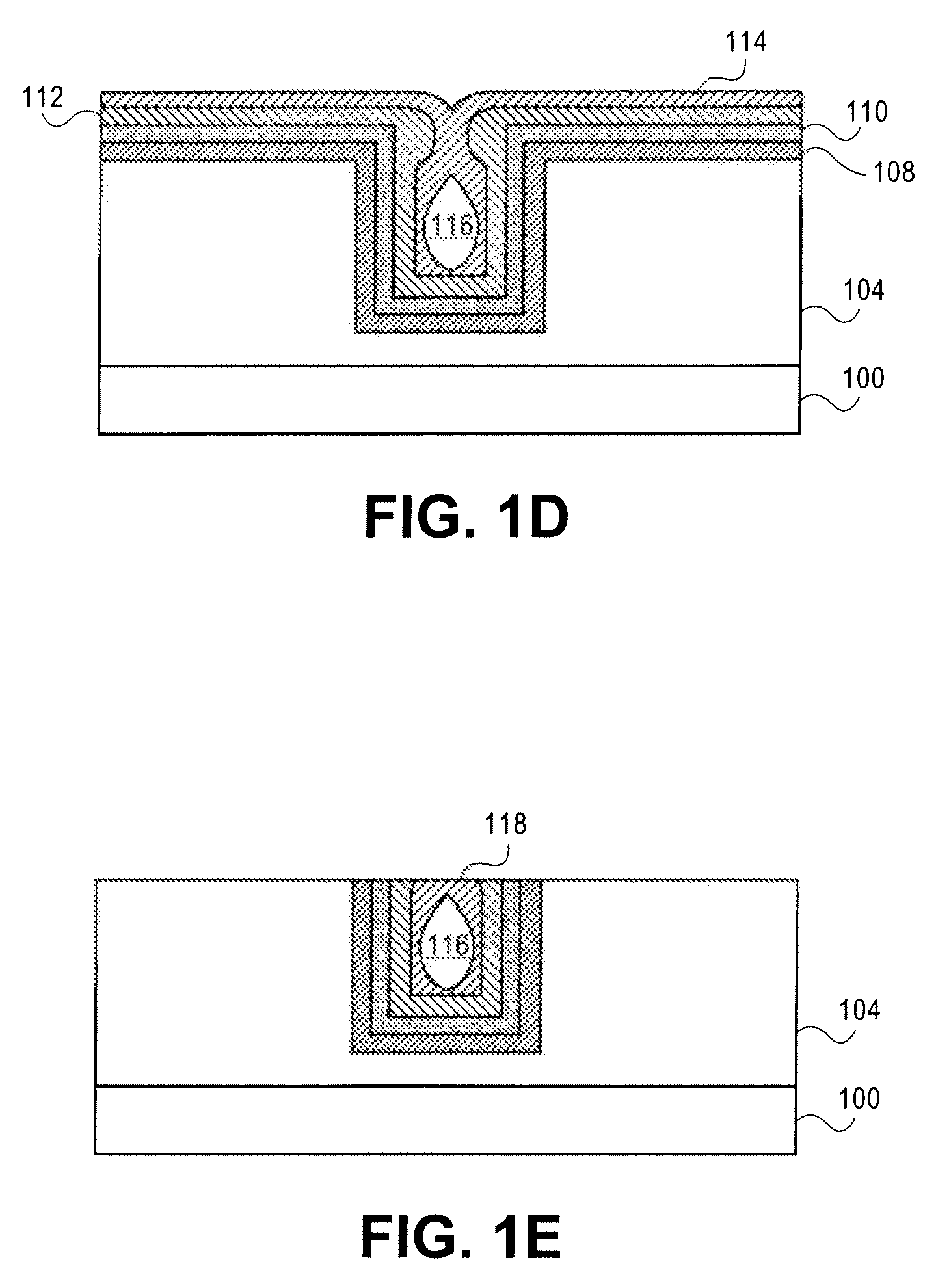

Organometallic precursors for seed/barrier processes and methods thereof

InactiveUS20080194105A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseRuthenium

Organometallic precursors and methods for deposition on a substrate in seed / barrier applications are herein disclosed. In some embodiments, the organometallic precursor is a ruthenium-containing, tantalum-containing precursor or combination thereof and may be deposited by atomic layer deposition, chemical vapor deposition and / or physical vapor deposition.

Owner:INTEL CORP

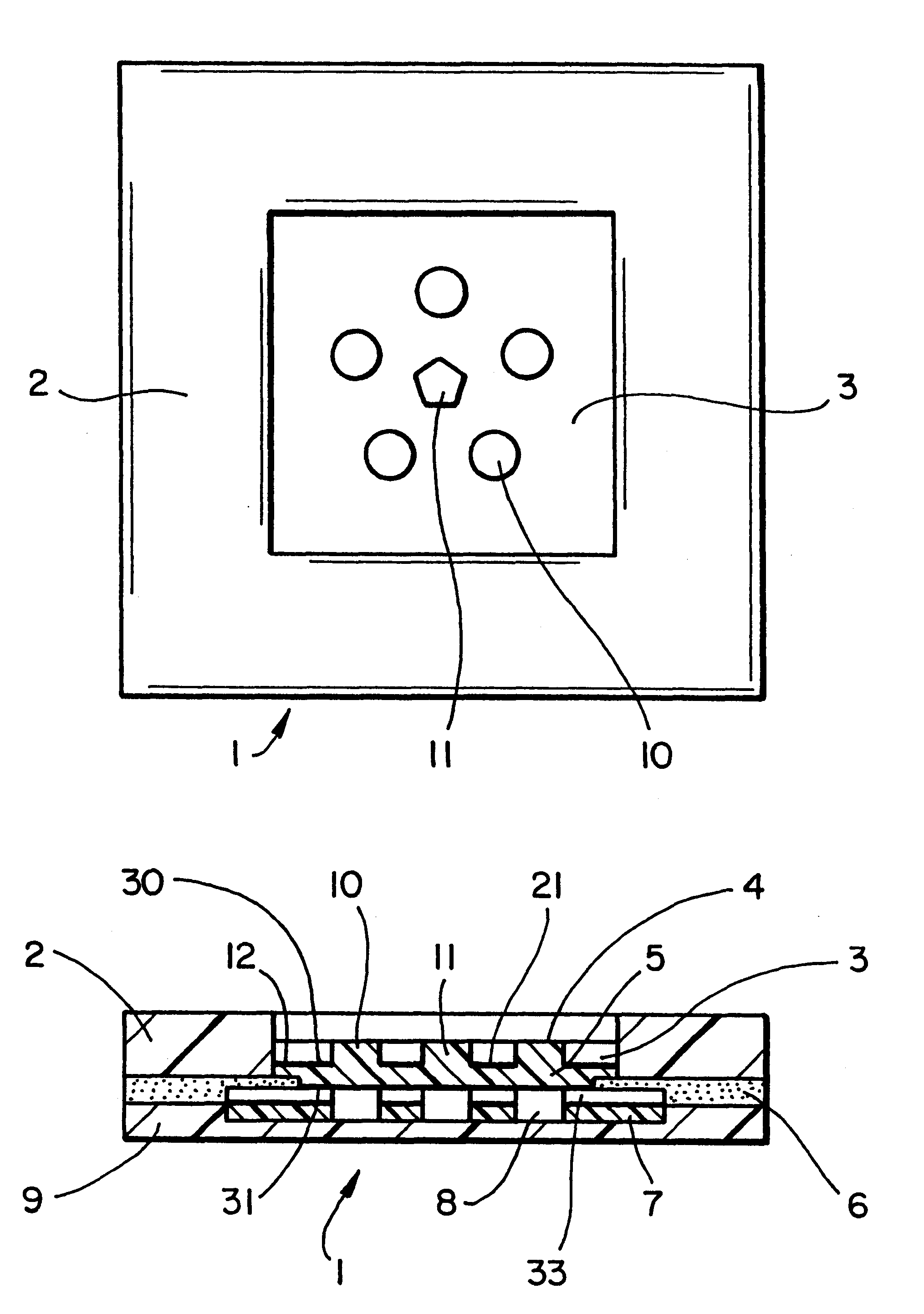

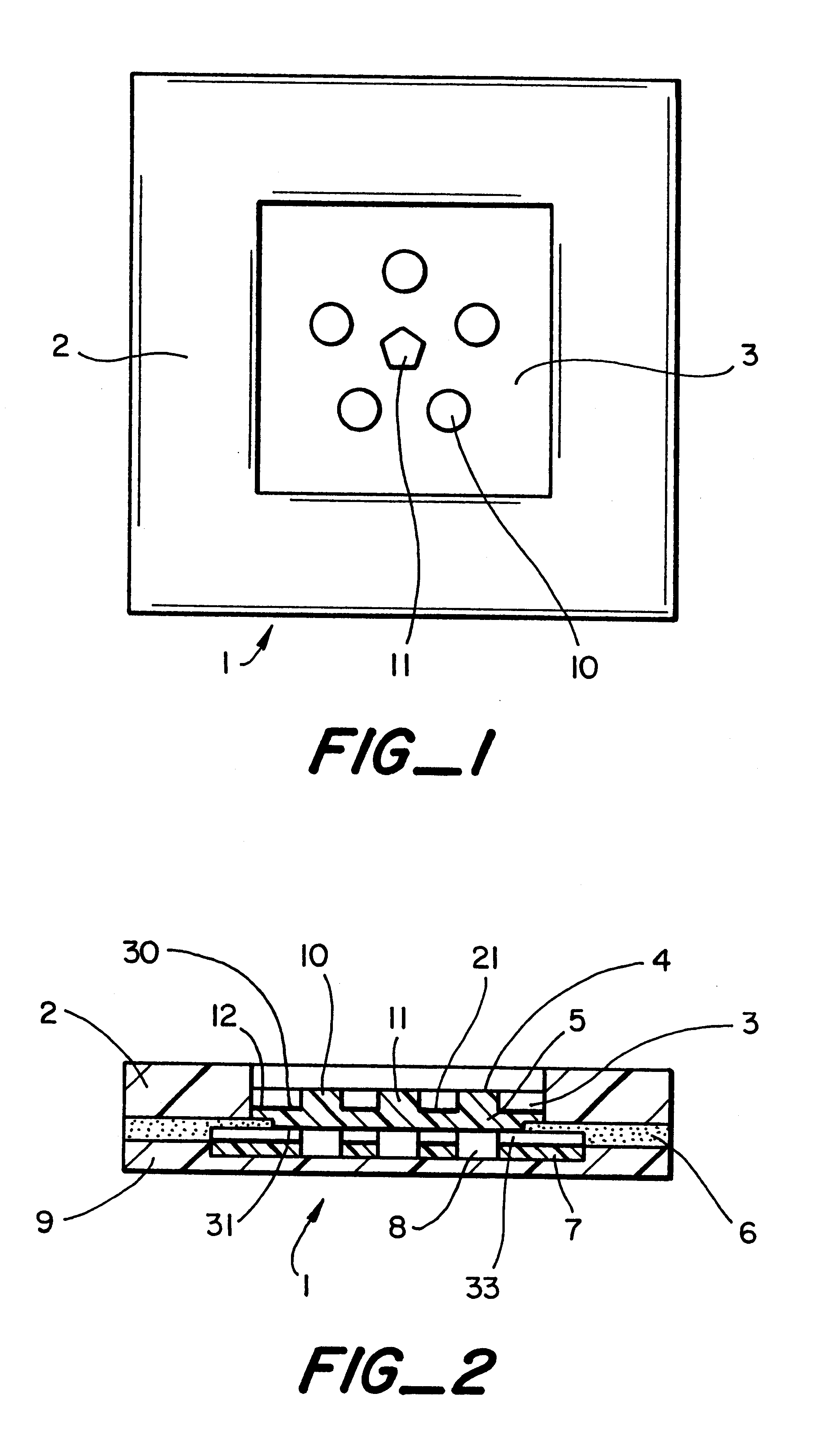

Interstitial fluid methods and devices for determination of an analyte in the body

InactiveUS6251083B1Simpler to useFacilitate increased patient complianceDiagnostic recording/measuringSensorsAnalytePorous membrane

Devices and methods for utilizing dry chemistry dye indicator systems for body fluid analysis, such as glucose level provided by incorporating a porous membrane in a disposable patch. The devices also provide for microtitration of fluid samples in fixed volumetric openings containing indicator reagent. The devices provided are low cost due to efficient manufacturing methods provided.

Owner:ROCHE DIABETES CARE INC

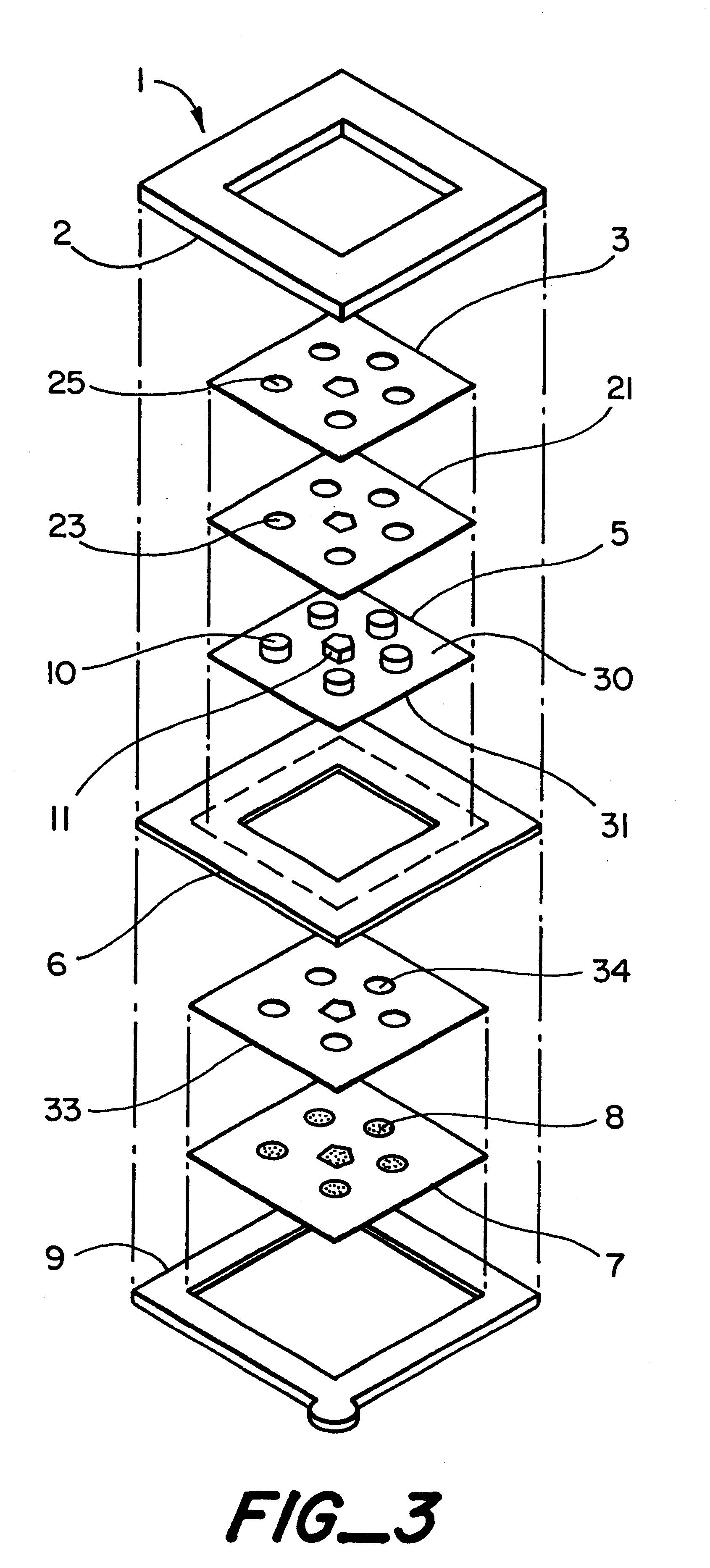

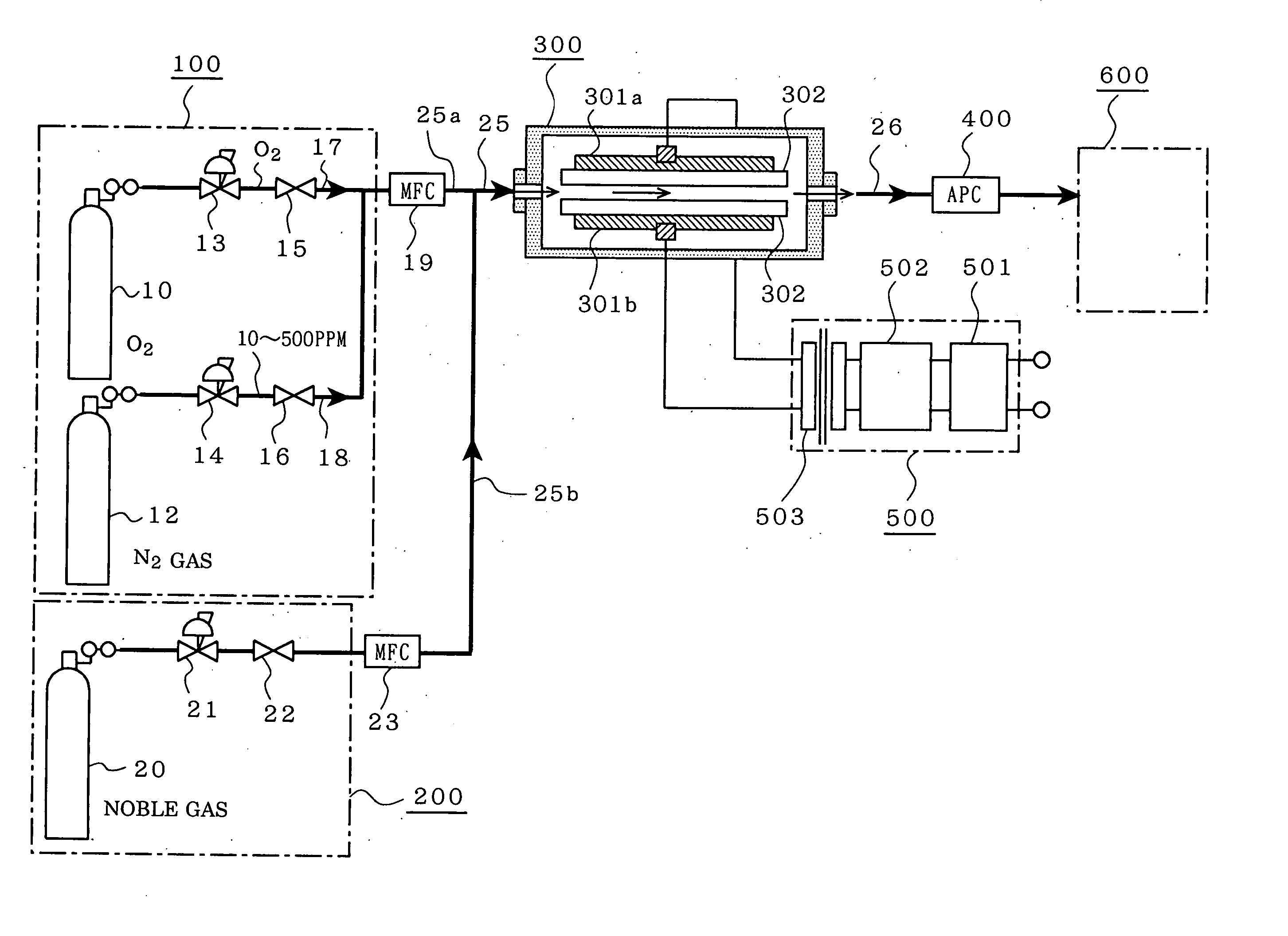

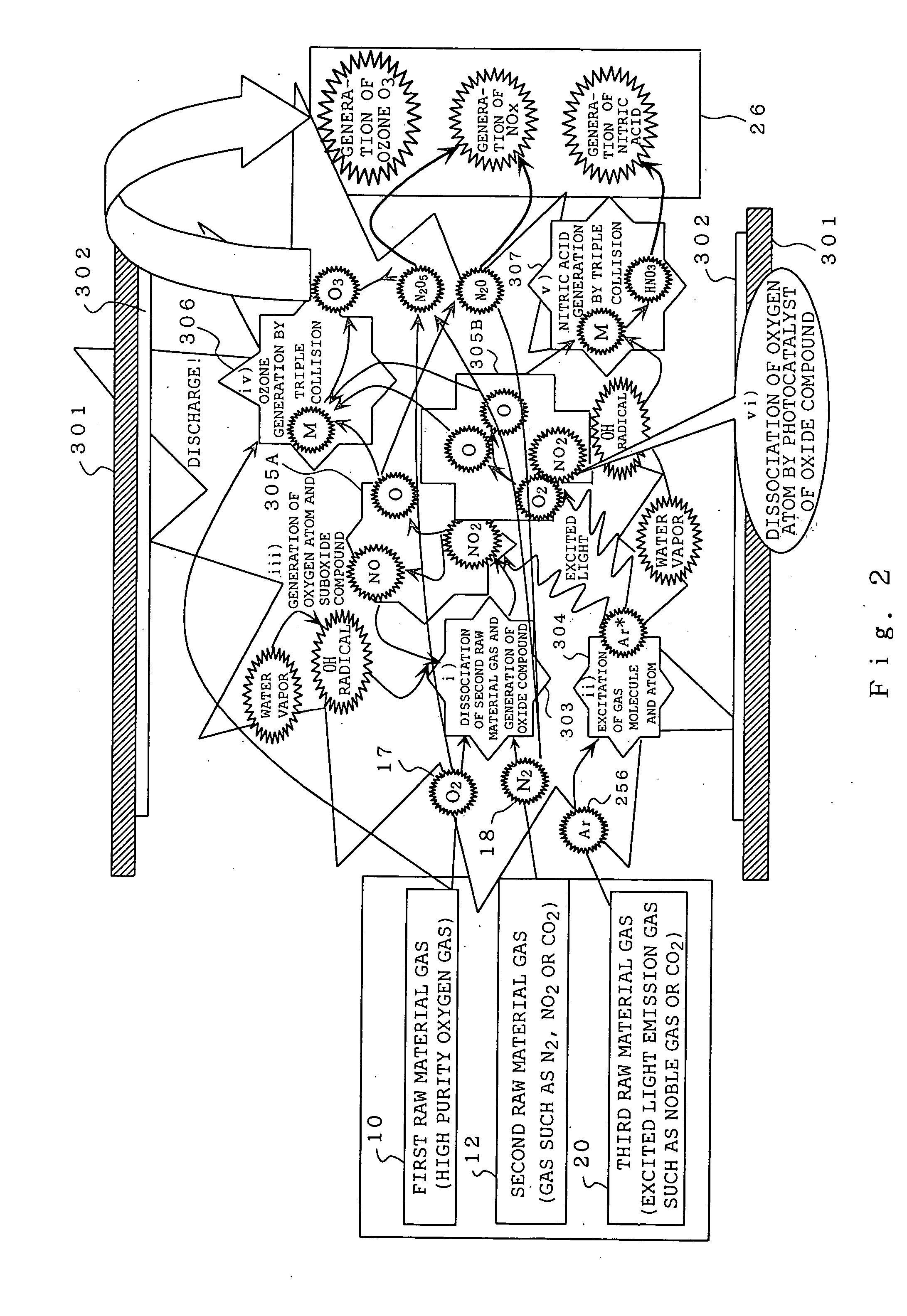

Ozone generator

ActiveUS20040223893A1Physical/chemical process catalystsElectrical discharge ozone preparationAtmospheric sciencesGas supply

An ozone generator for generating ozone by applying a specified process to oxygen by discharge includes a first raw material gas supply unit for supplying the oxygen as a first raw material gas, and a second raw material gas supply unit for supplying an oxide compound gas as a second raw material gas, in which, by excited light, excited and generated by a discharge in the oxygen and the oxide compound gas, the oxide compound gas is dissociated, or the oxide compound gas is excited accelerating dissociation of the oxygen, and ozone is generated. In this way, ozone generation efficiency is raised.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

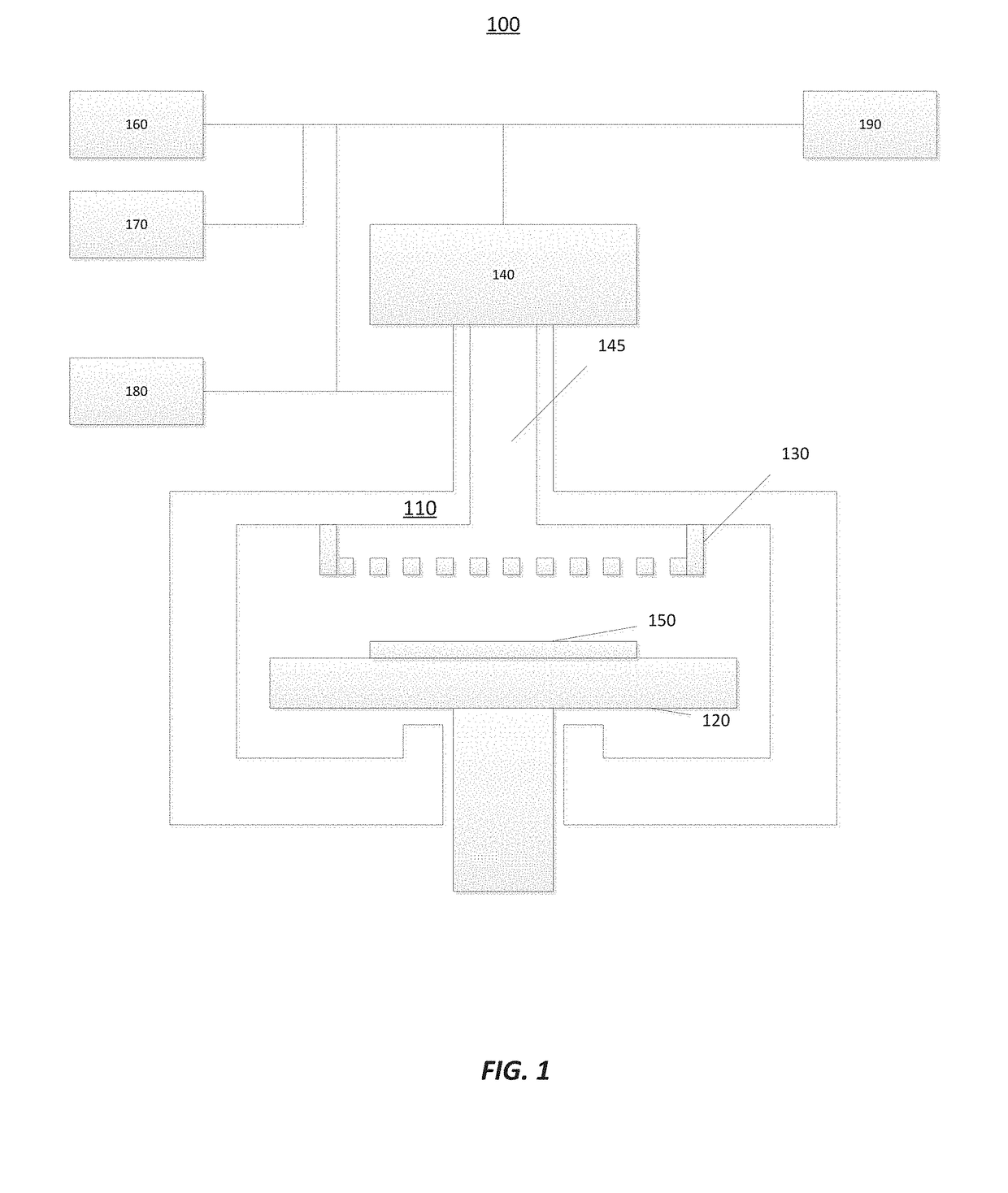

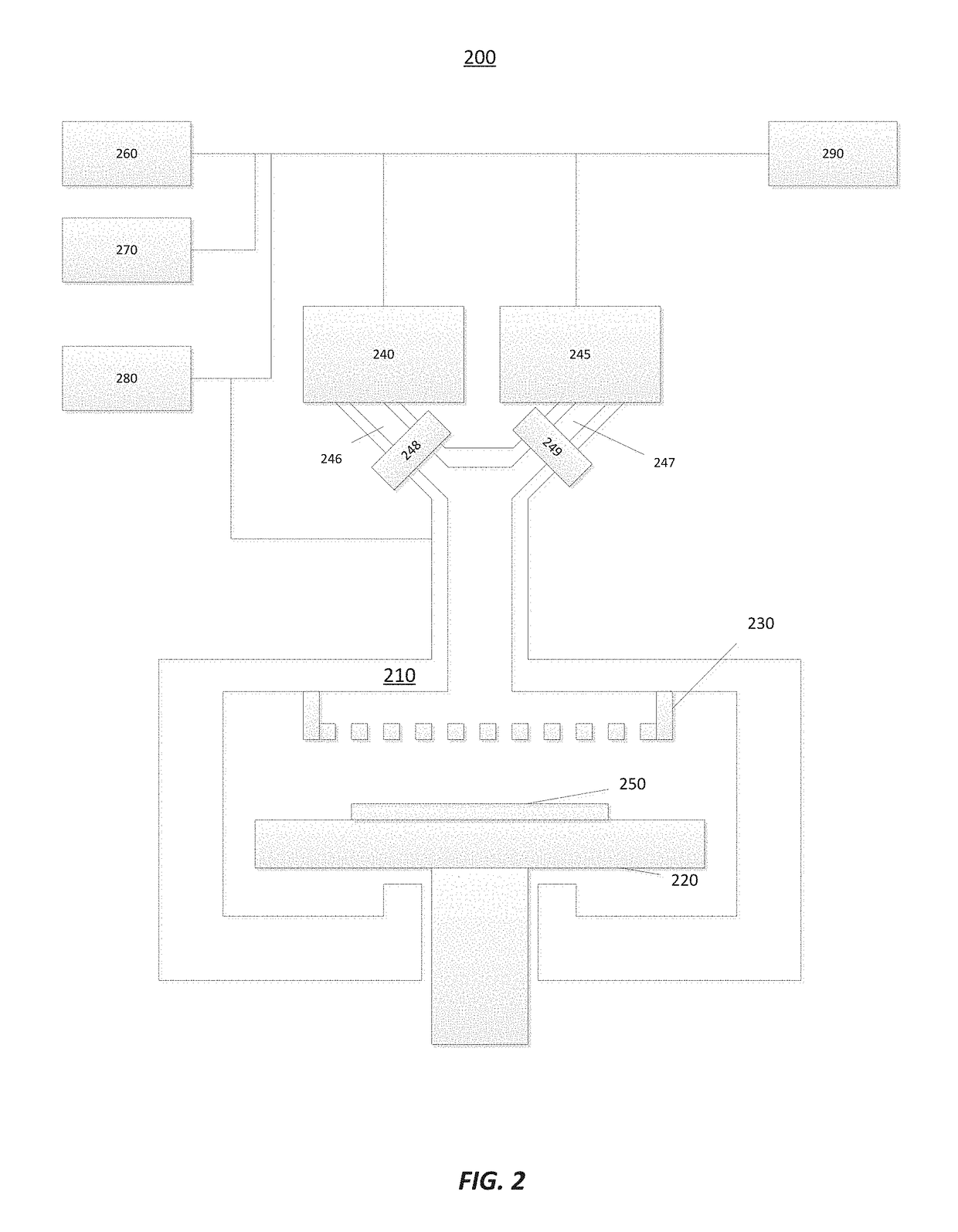

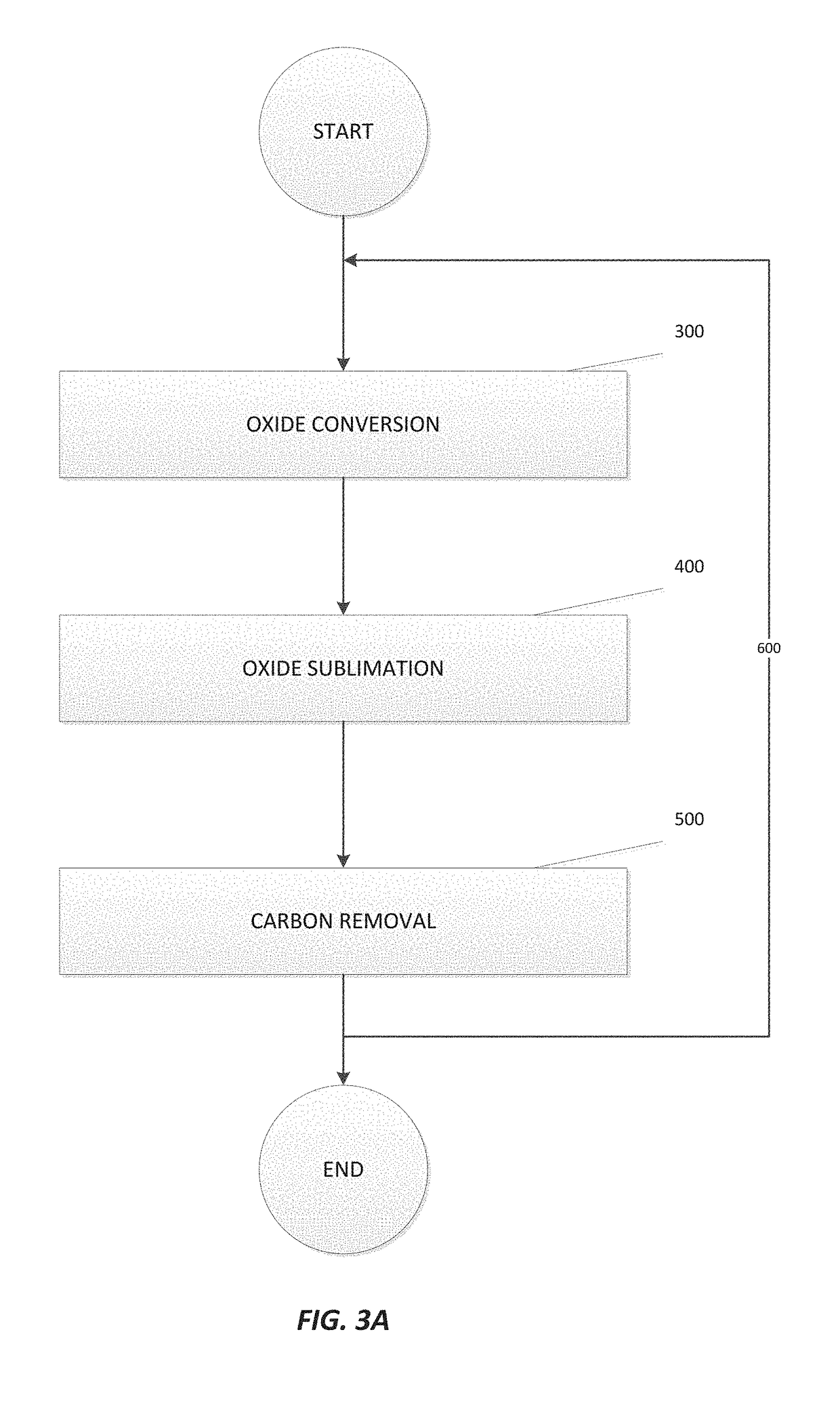

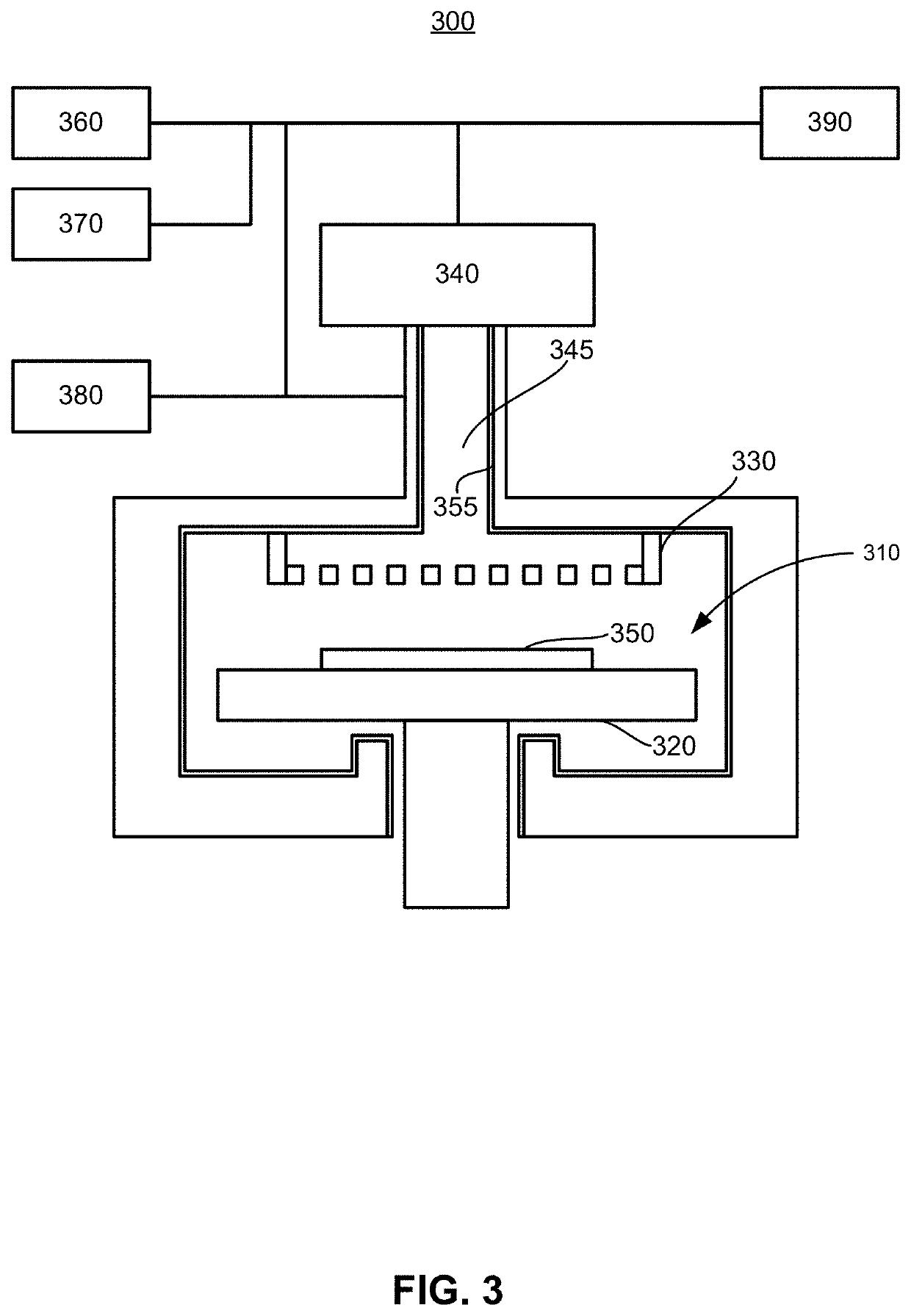

Apparatus and method for removal of oxide and carbon from semiconductor films in a single processing chamber

InactiveUS20190019670A1Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaSingle process

A system and method for removing both carbon-based contaminants and oxygen-based contaminants from a semiconductor substrate within a single process chamber is disclosed. The invention may comprise utilization of remote plasma units and multiple gas sources to perform the process within the single process chamber.

Owner:ASM IP HLDG BV

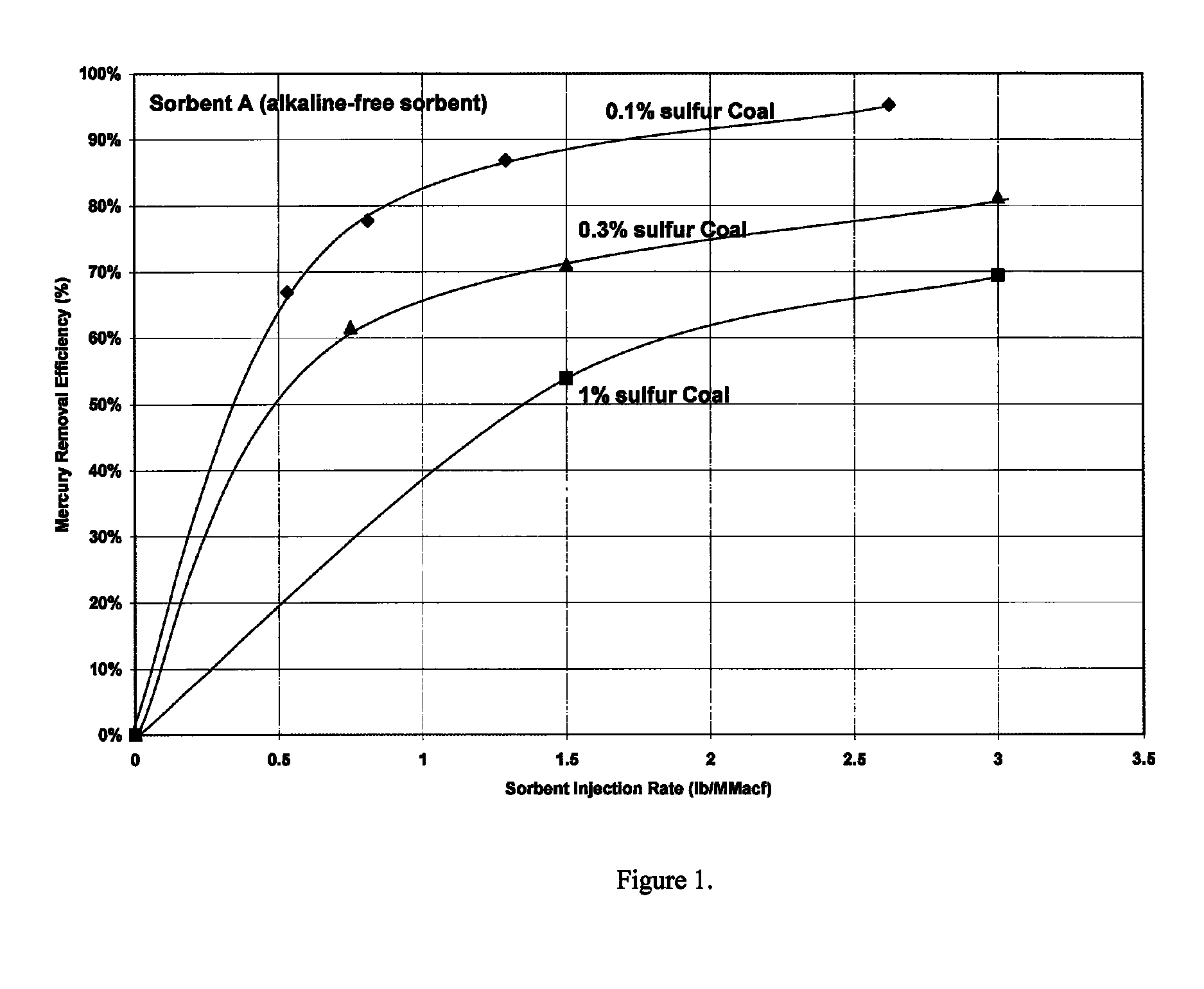

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

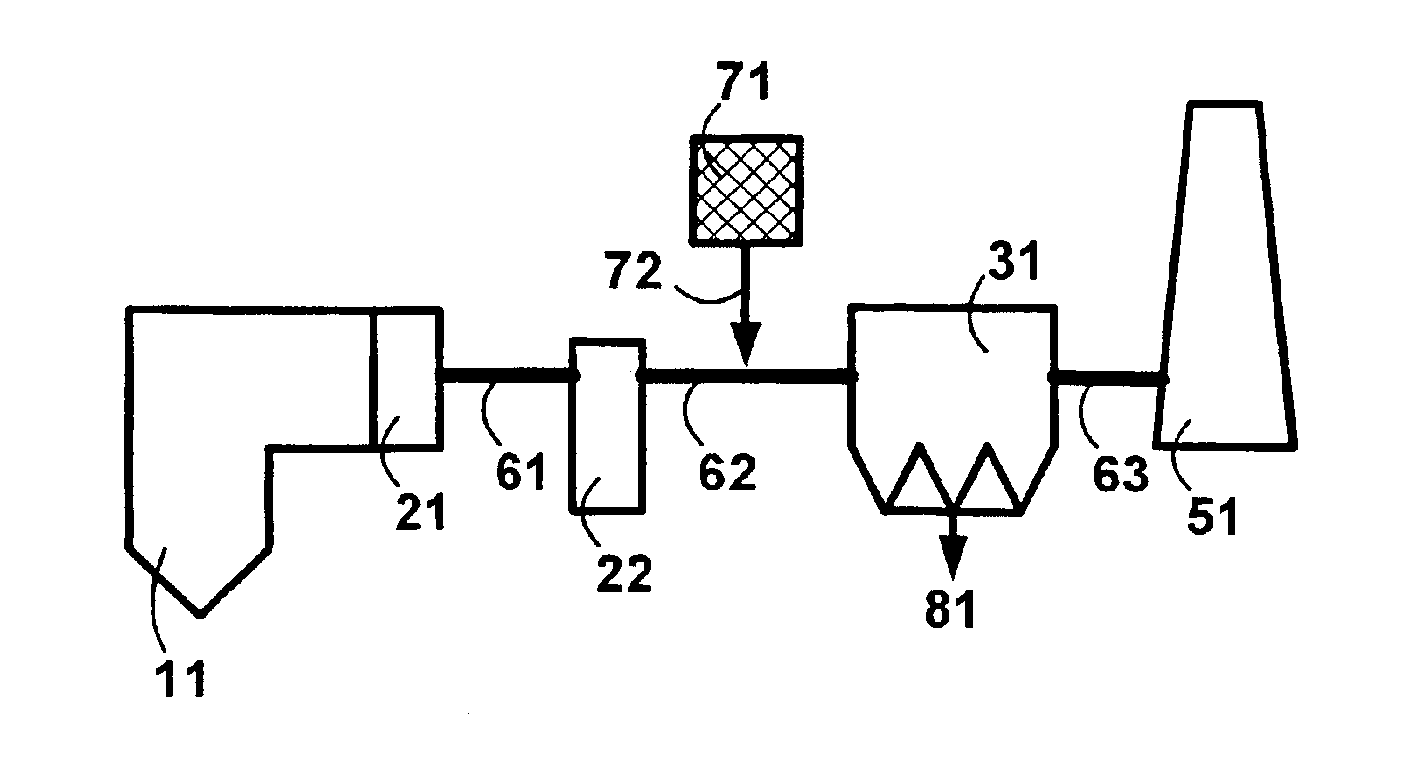

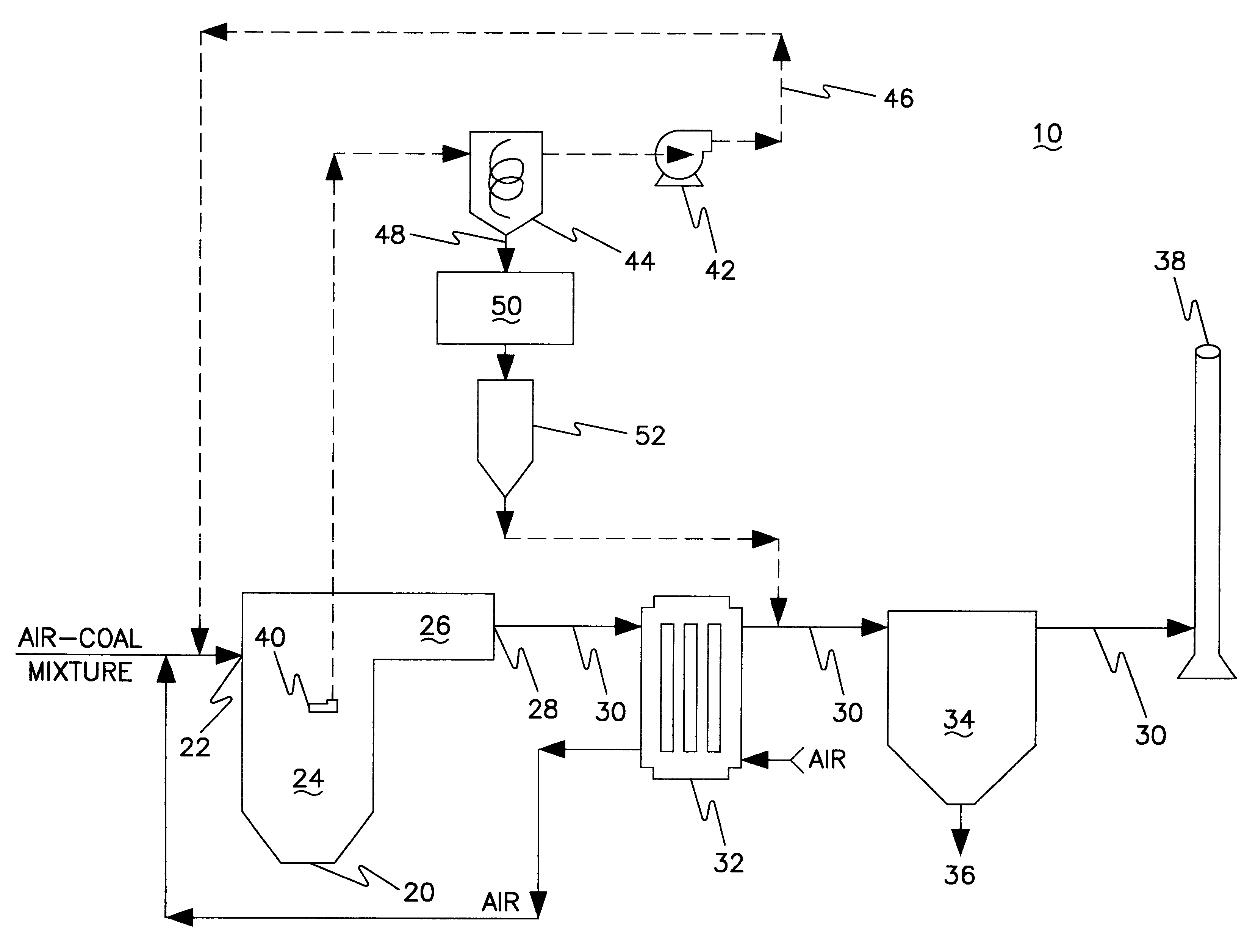

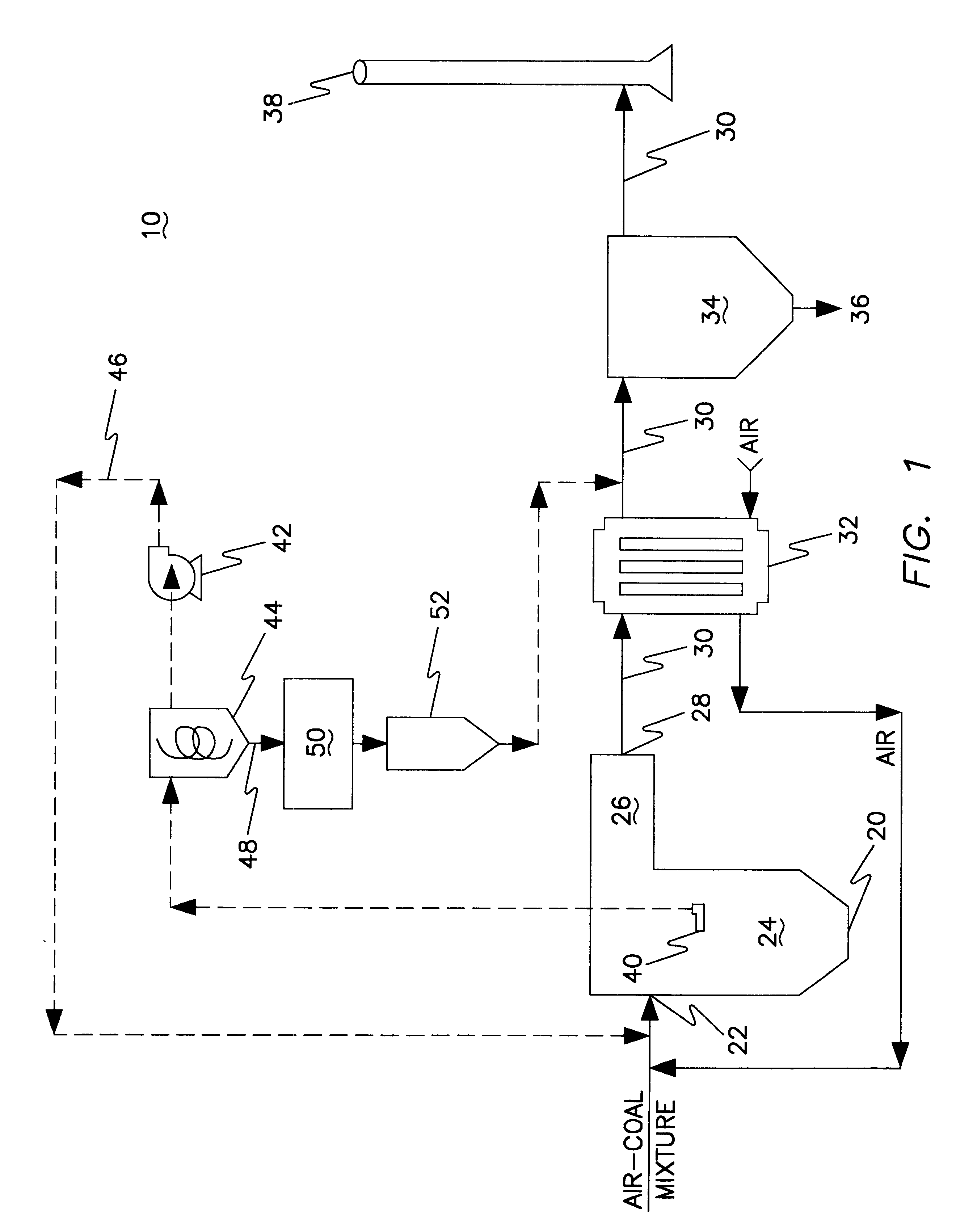

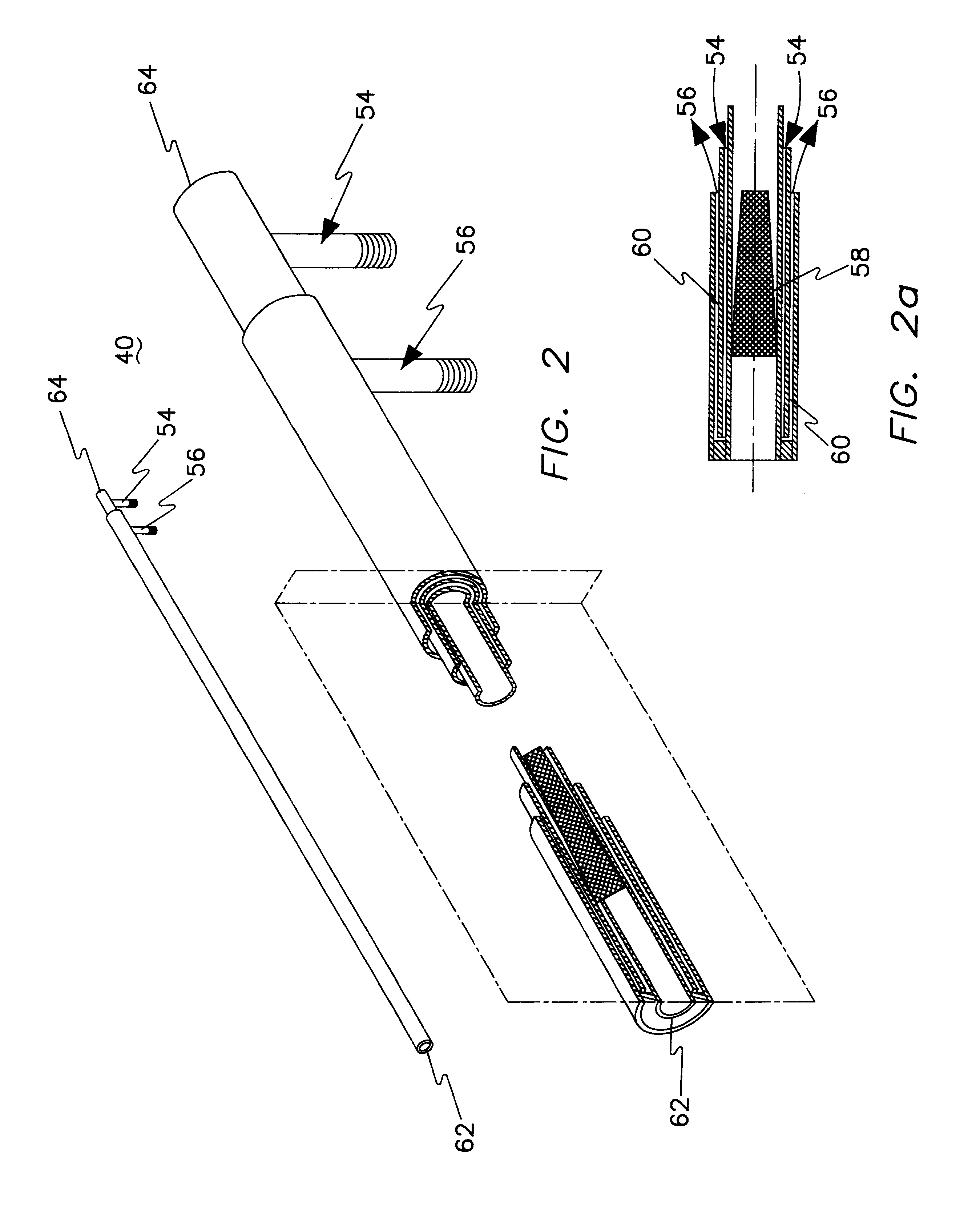

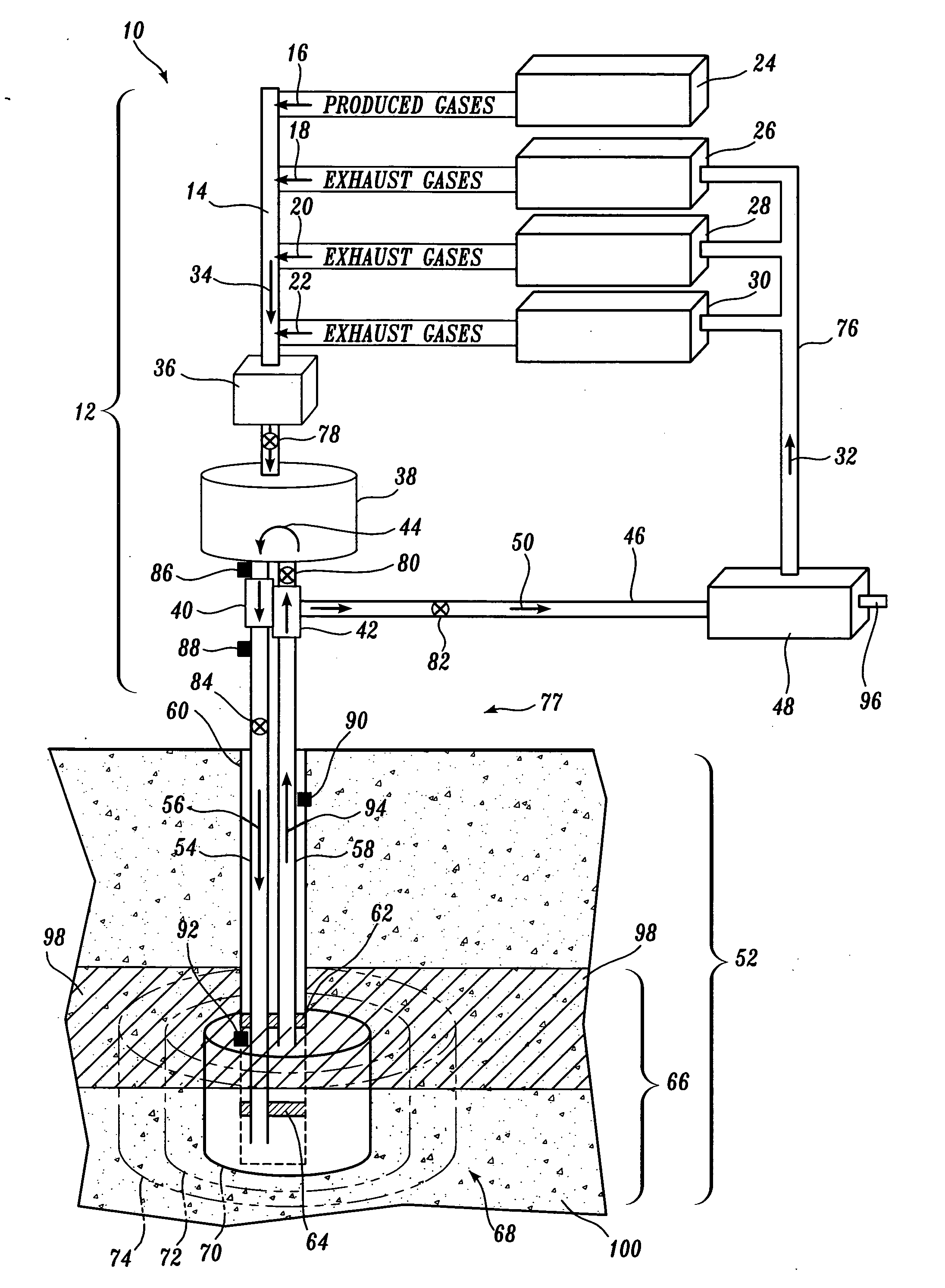

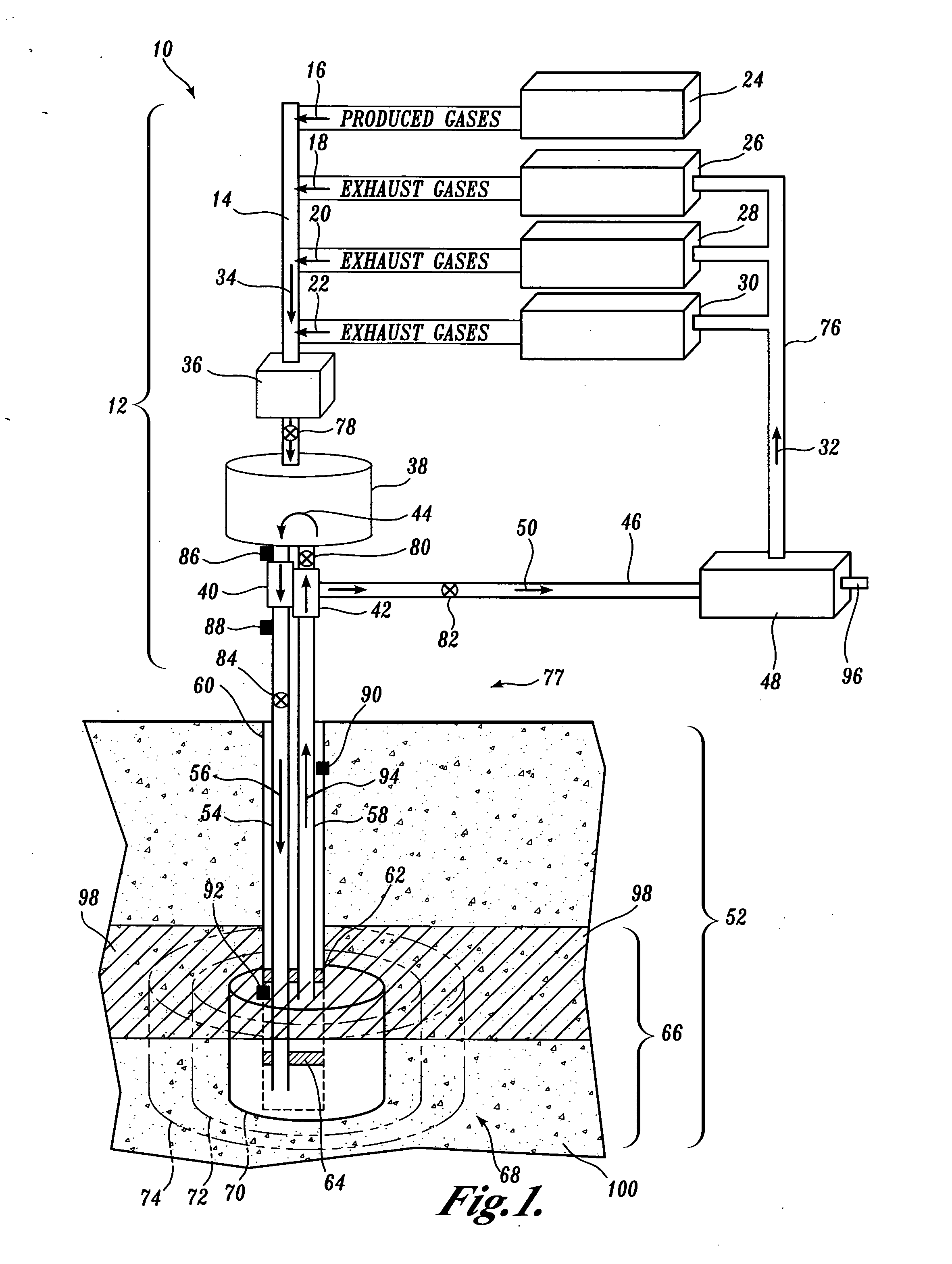

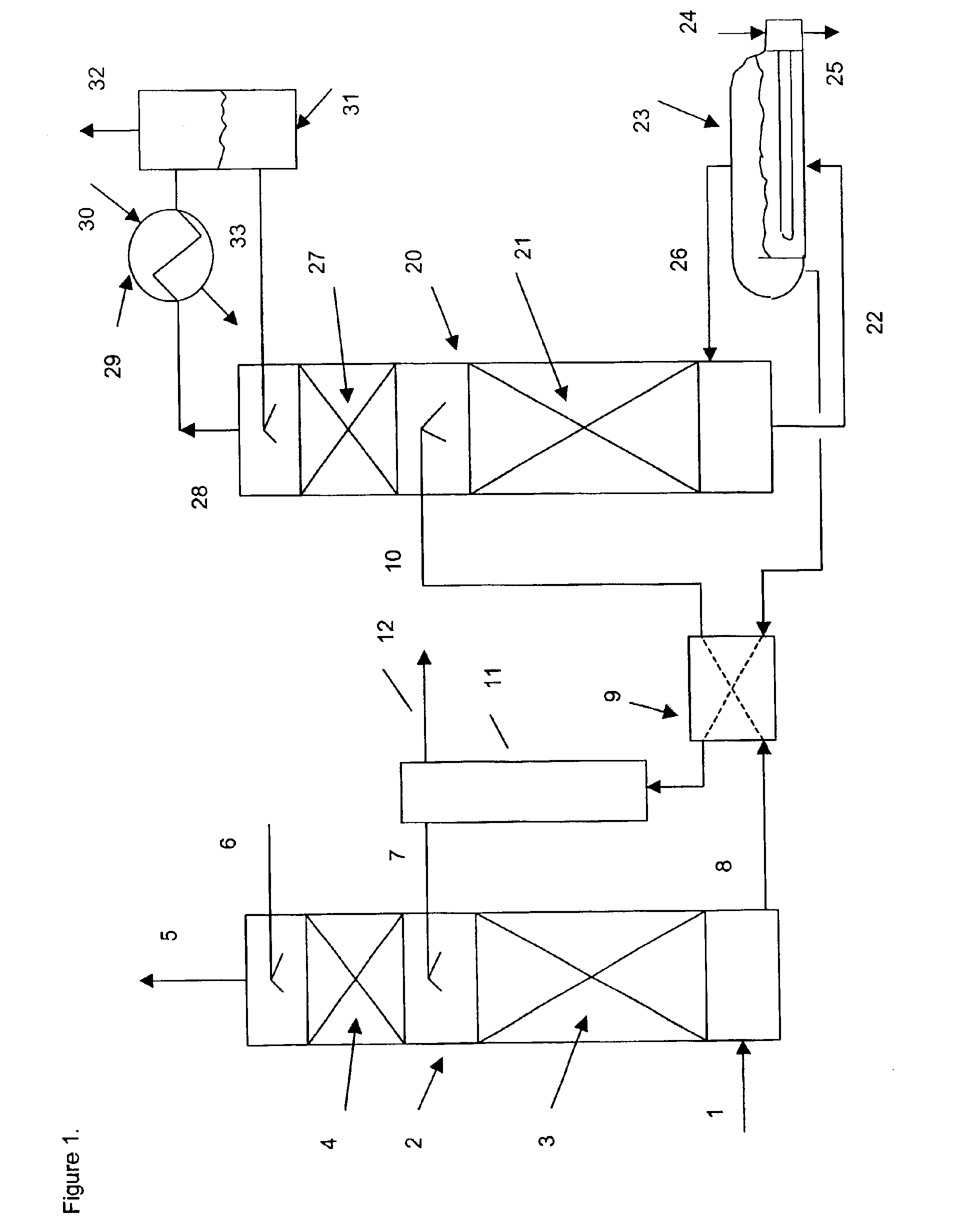

Thief process for the removal of mercury from flue gas

InactiveUS6521021B1Low costQuench oxidationGas treatmentUsing liquid separation agentParticulatesCombustion chamber

A system and method for removing mercury from the flue gas of a coal-fired power plant is described. Mercury removal is by adsorption onto a thermally activated sorbent produced in-situ at the power plant. To obtain the thermally activated sorbent, a lance (thief) is inserted into a location within the combustion zone of the combustion chamber and extracts a mixture of semi-combusted coal and gas. The semi-combusted coal has adsorptive properties suitable for the removal of elemental and oxidized mercury. The mixture of semi-combusted coal and gas is separated into a stream of gas and semi-combusted coal that has been converted to a stream of thermally activated sorbent. The separated stream of gas is recycled to the combustion chamber. The thermally activated sorbent is injected into the duct work of the power plant at a location downstream from the exit port of the combustion chamber. Mercury within the flue gas contacts and adsorbs onto the thermally activated sorbent. The sorbent-mercury combination is removed from the plant by a particulate collection system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

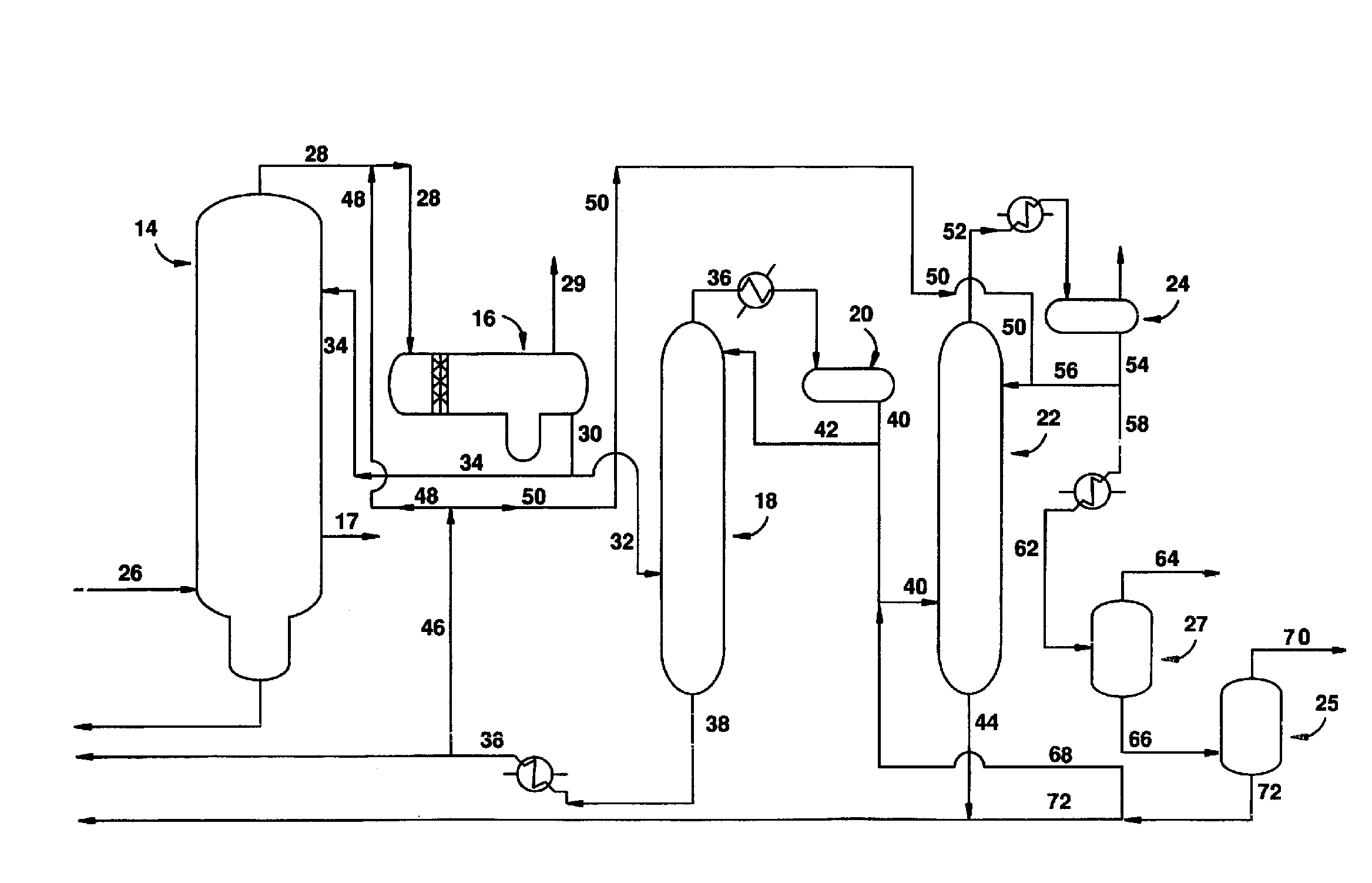

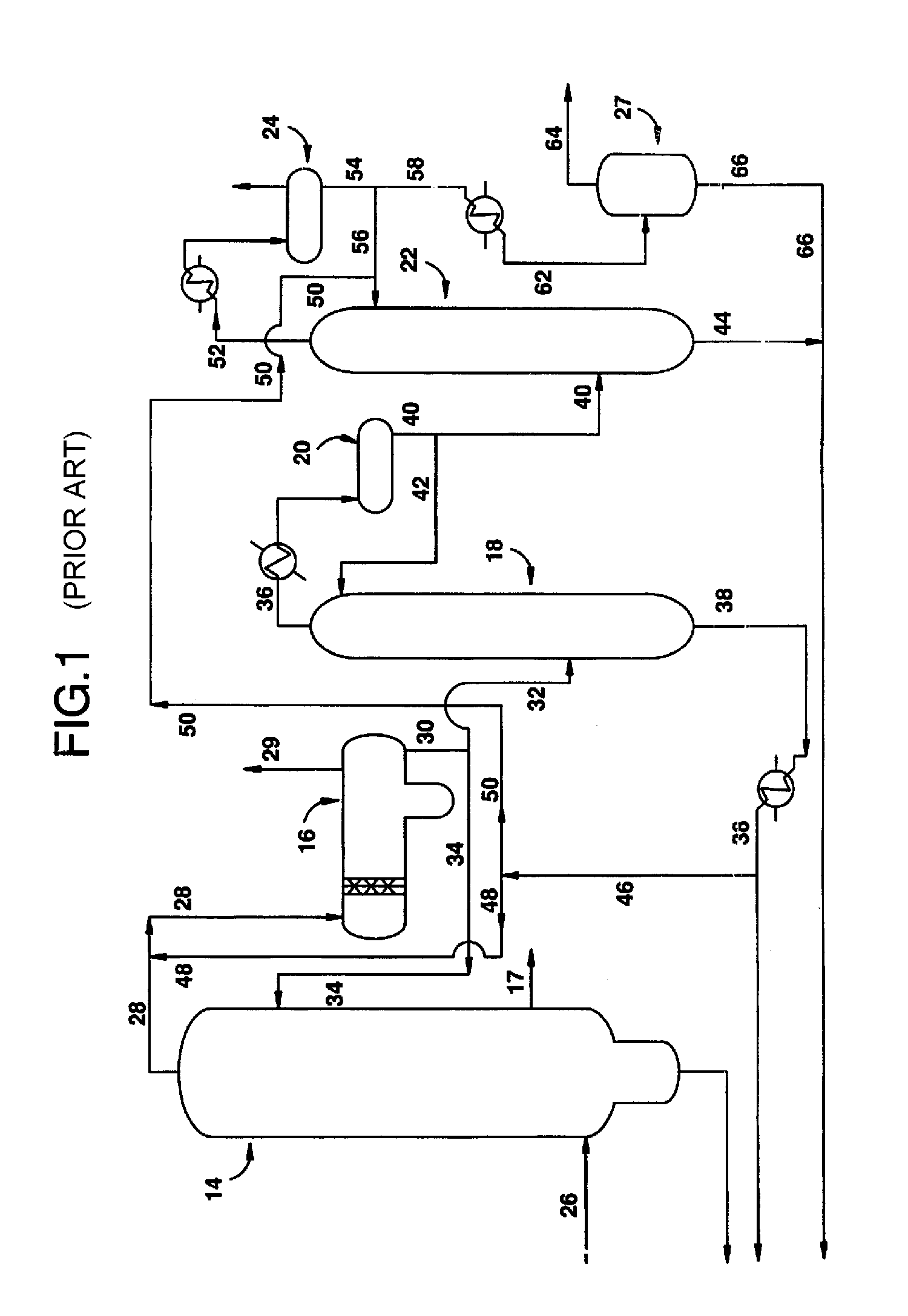

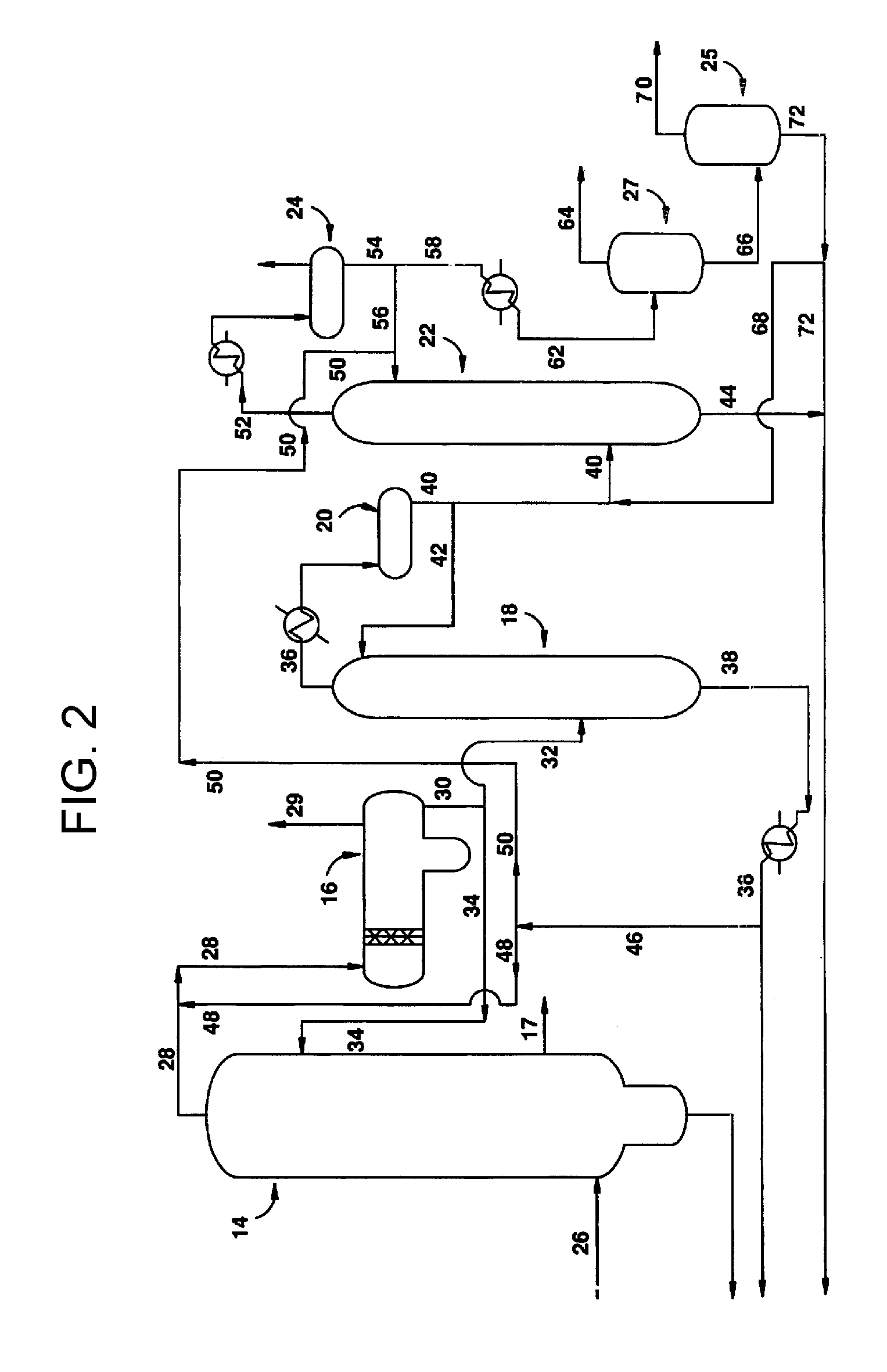

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223886B2Reduce solubilitySimple methodOrganic compound preparationPreparation by carbon monoxide or formate reactionAcetic acidIodide

An improvement of the methanol carbonylation process for manufacturing acetic acid is disclosed. Specifically disclosed is a method for reducing the formation of alkyl iodides and C3-8 carboxylic acids by removing permanganate reducing compounds (“PRC's”) from the light phase of the condensed light ends overhead stream, including (a) distilling the light phase to yield a PRC enriched overhead stream; and (b) extracting the third overhead stream with water in at least two consecutive stages and separating therefrom one or more aqueous streams containing PRC's.

Owner:CELANESE INT CORP

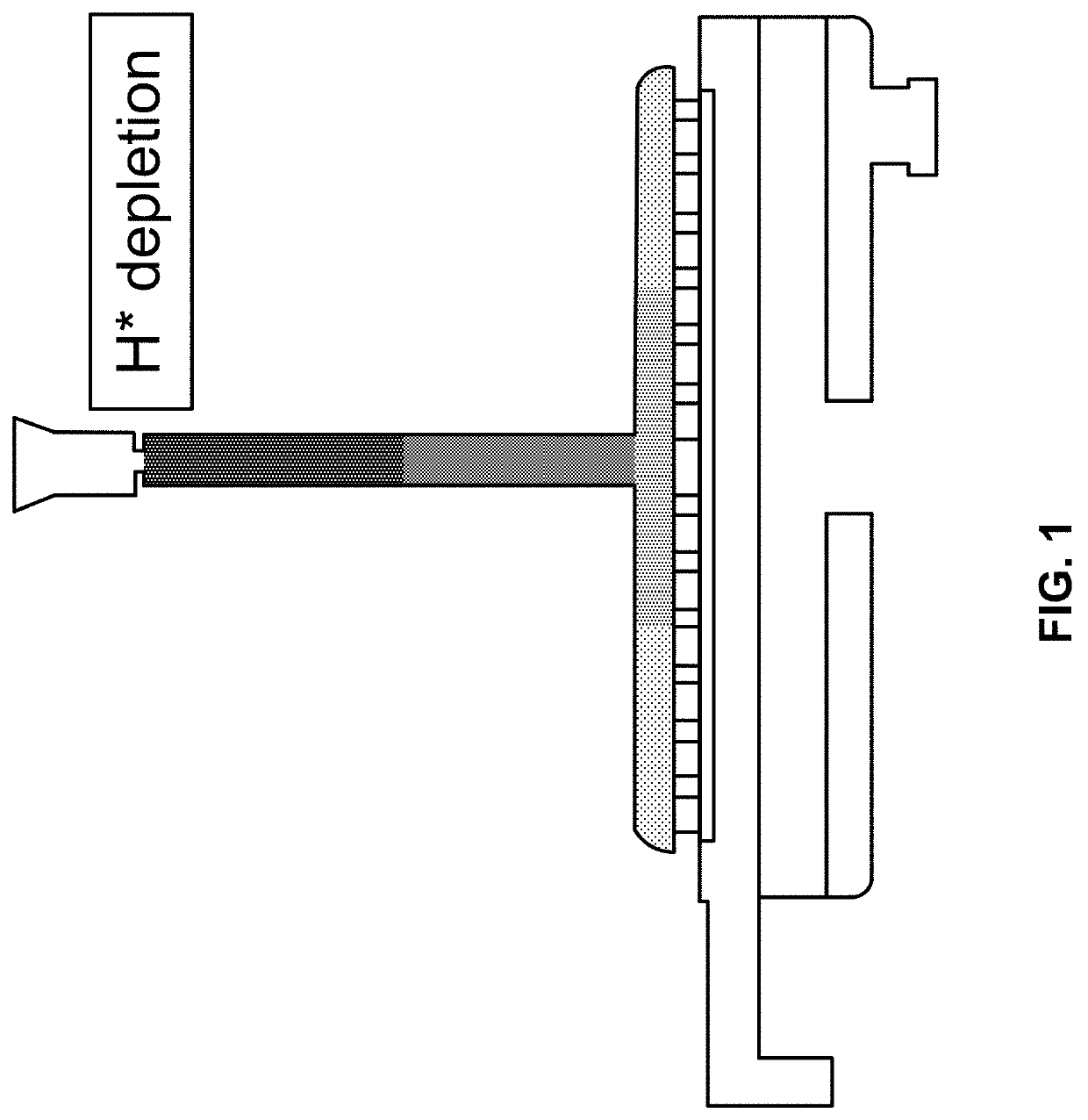

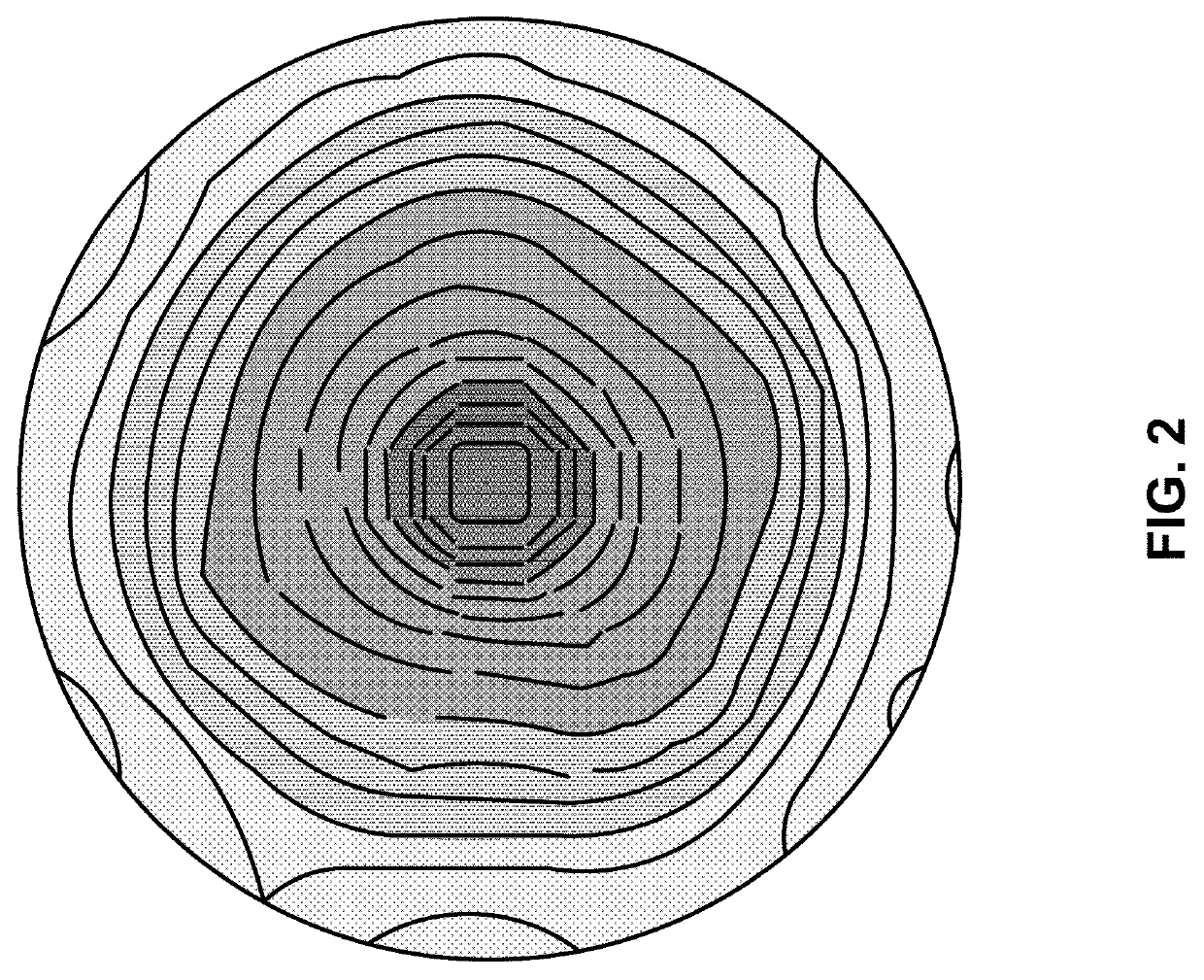

Apparatus for use with hydrogen radicals and method of using same

PendingUS20190348261A1To offer comfortExtend your lifeFouling preventionElectric discharge tubesEnvironmental engineeringChemical engineering

A system and method suitable for removing both carbon-based contaminants and oxygen-based contaminants from a substrate within a single process chamber are disclosed.

Owner:ASM IP HLDG BV

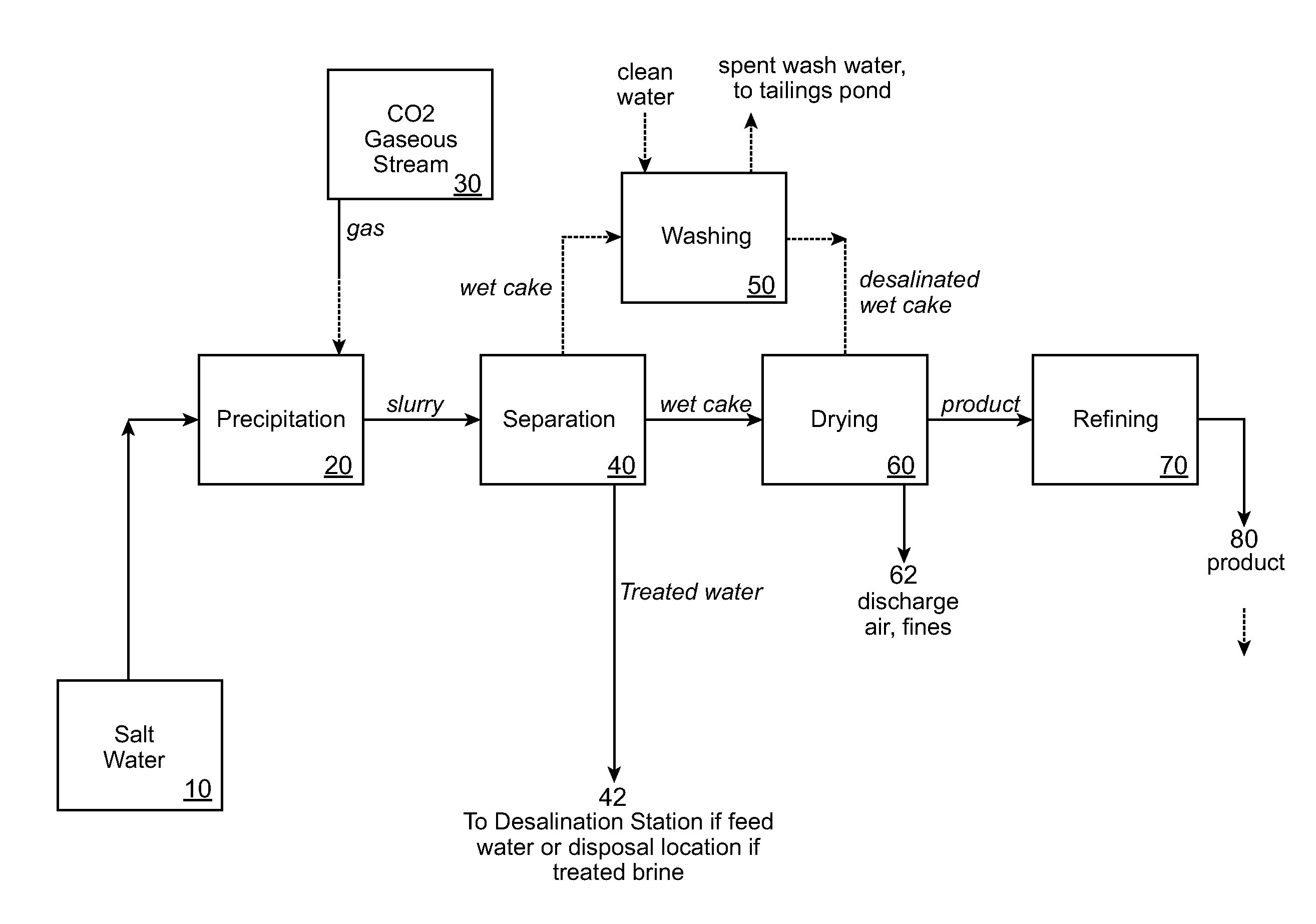

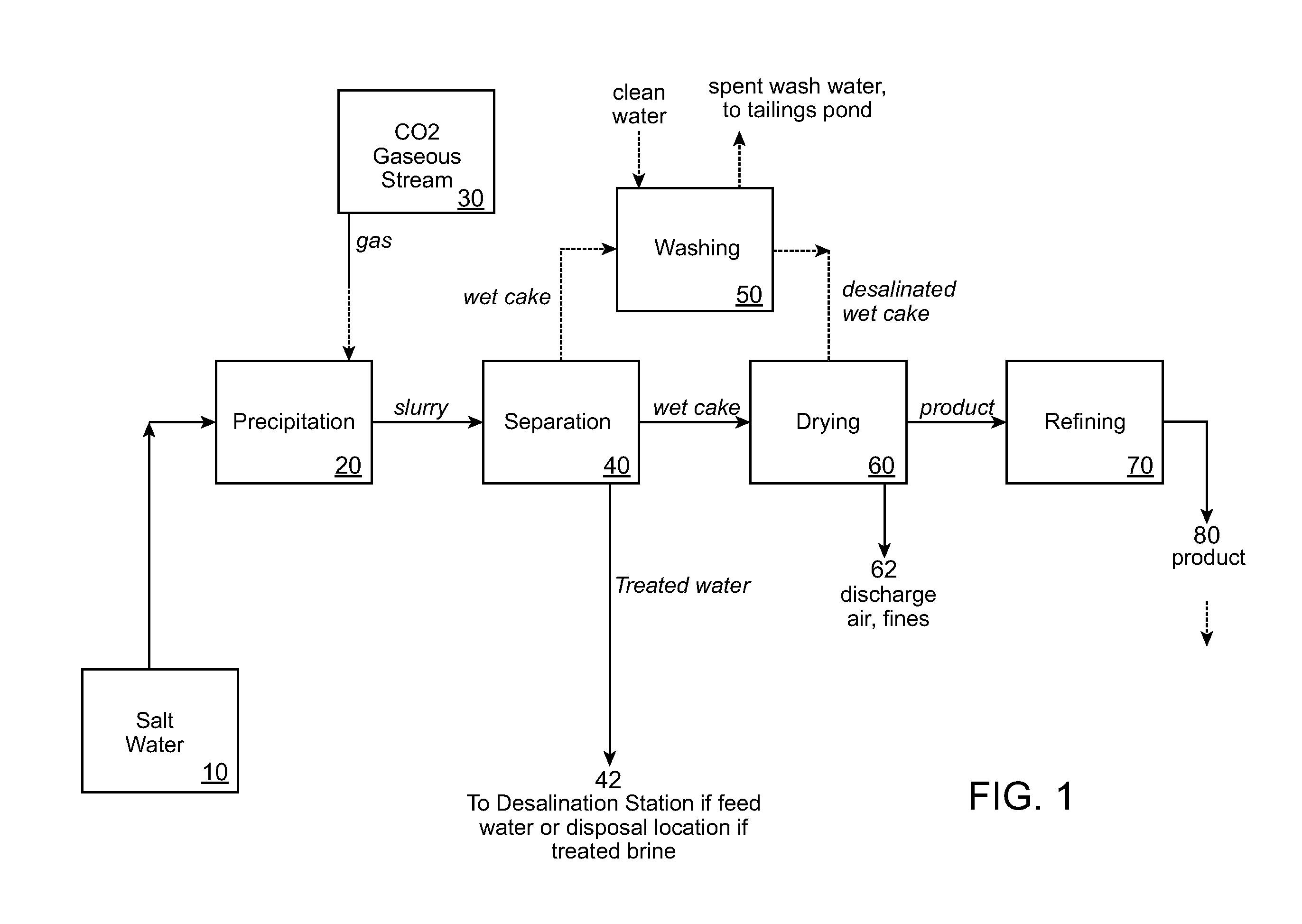

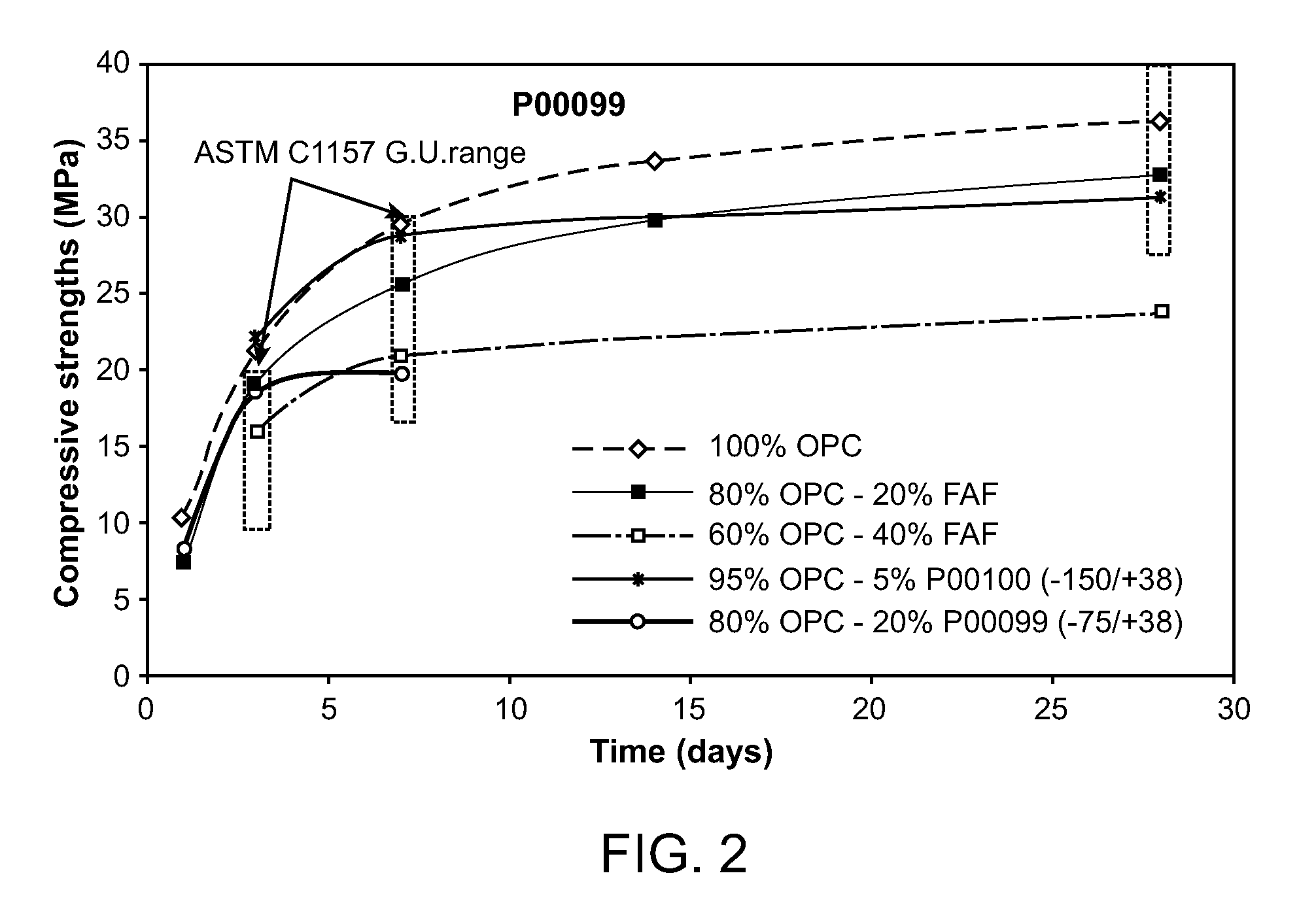

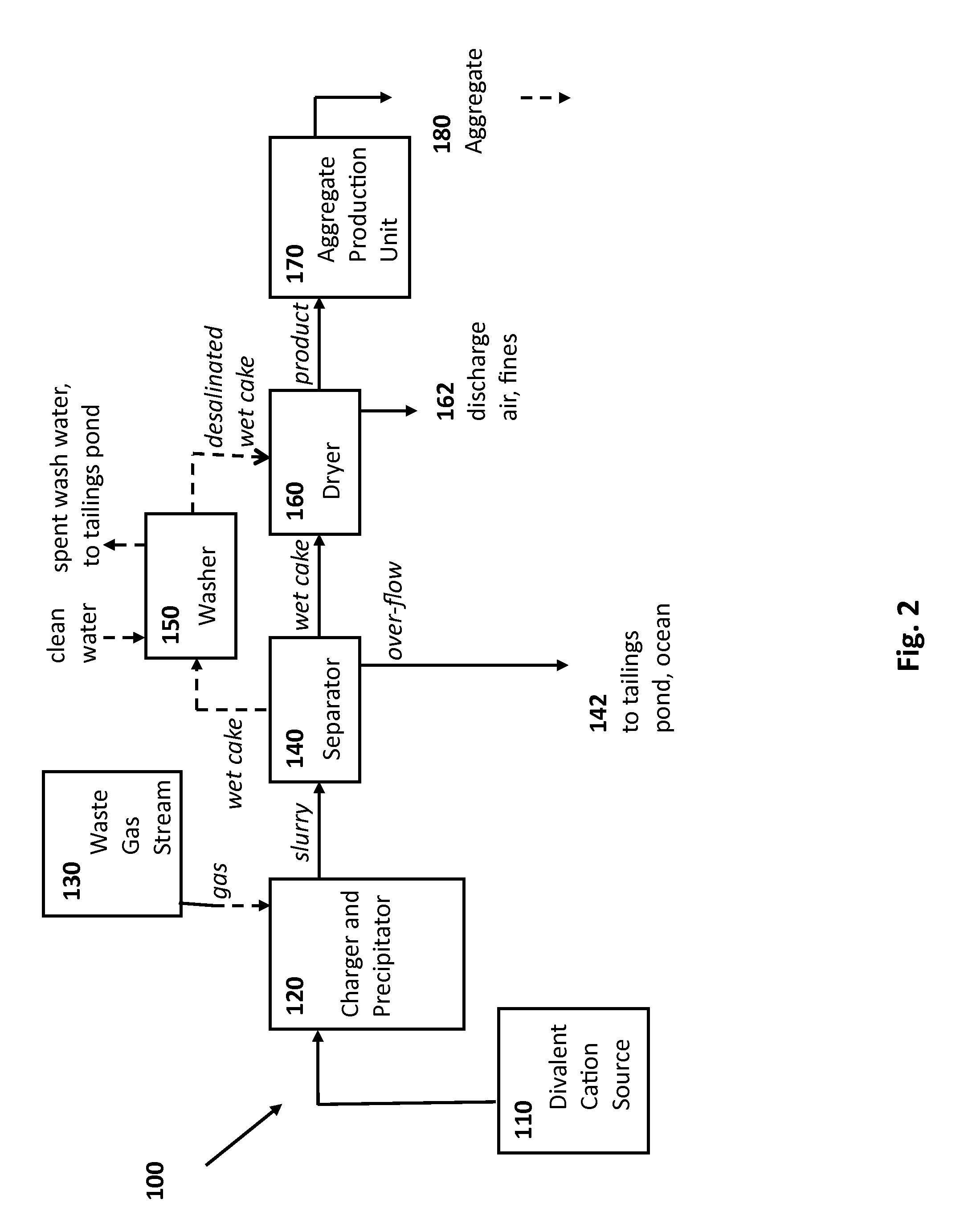

Desalination methods and systems that include carbonate compound precipitation

ActiveUS20090001020A1Easy complianceImprove desalination efficiencyGeneral water supply conservationSeawater treatmentSaline waterDesalination

Desalination methods that include carbonate compound precipitation are provided. In certain embodiments, feed water is subjected to carbonate compound precipitation conditions prior to desalination. In certain embodiments, desalination waste brine is subjected to carbonate compound precipitation conditions. In yet other embodiments, both feed water and waste brine are subjected to carbonate compound precipitation conditions. Aspects of embodiments of the invention include carbone dioxide sequestration. Embodiments of the invention further employ a precipitate product of the carbonate compound precipitation conditions as a building material, e.g., a cement. Also provided are systems configured for use in methods of the invention.

Owner:ARELAC INC

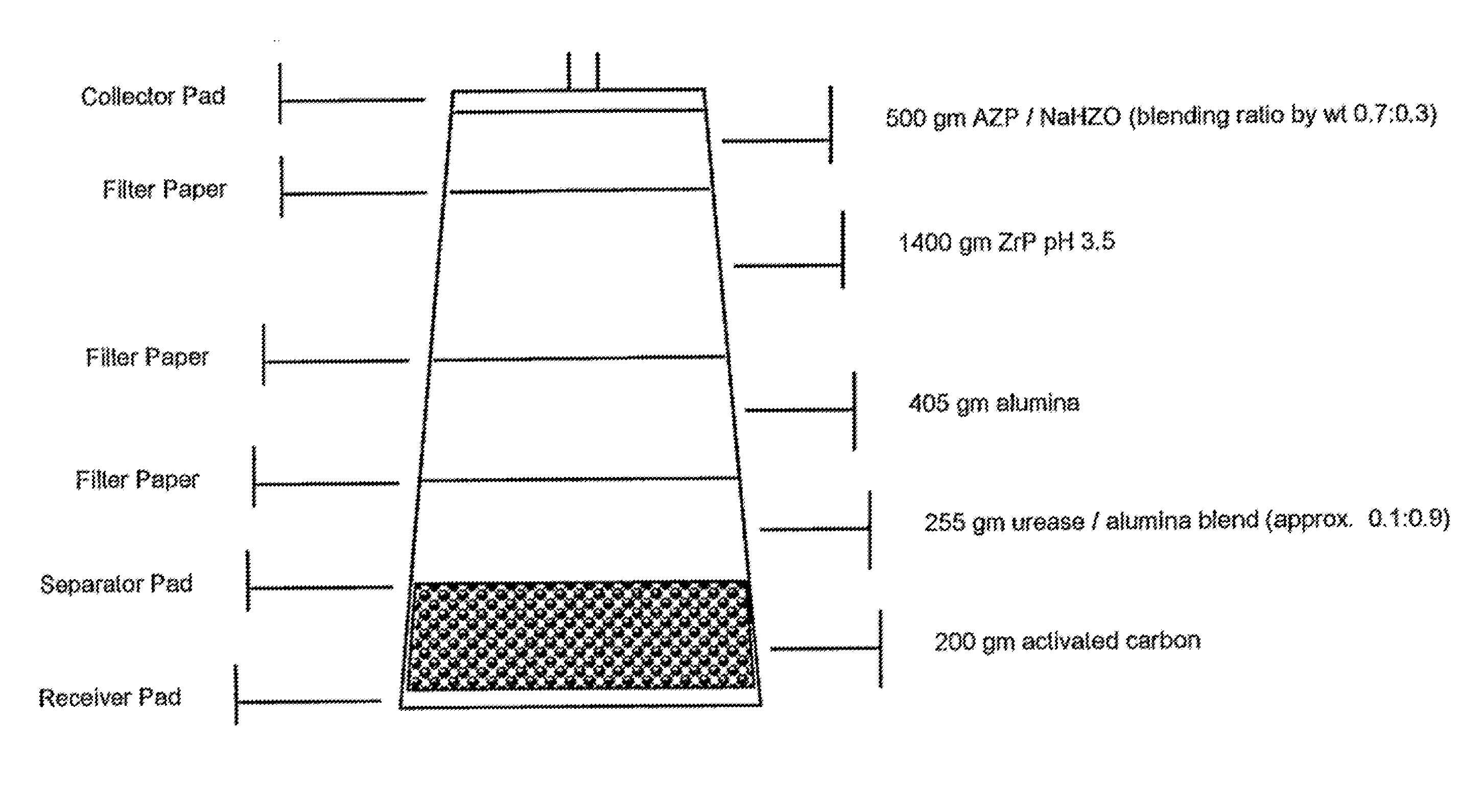

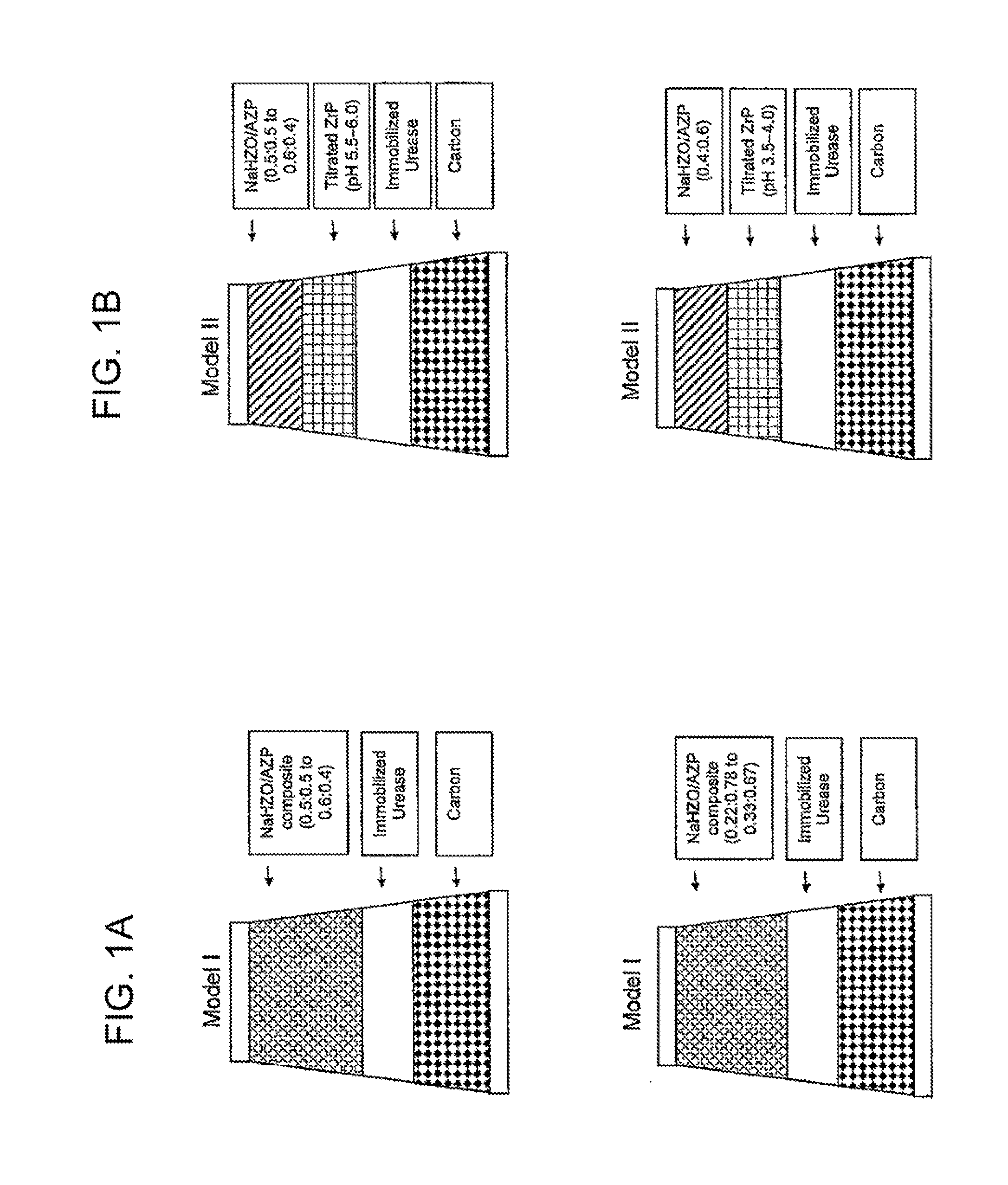

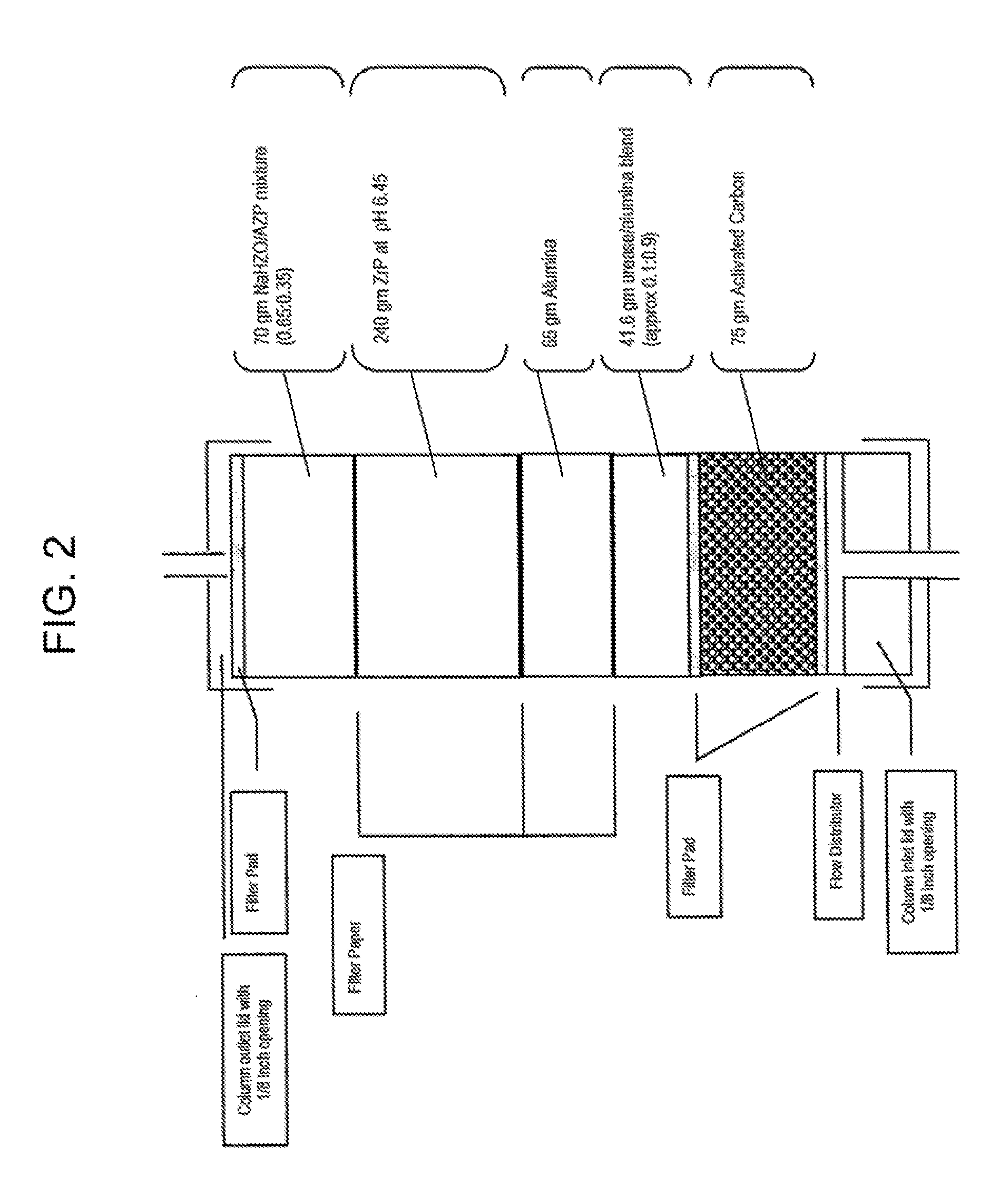

Acid Zirconium Phosphate and Alkaline Hydrous Zirconium Oxide Materials For Sorbent Dialysis

ActiveUS20100078387A1Avoid disadvantagesRestore balanceCation exchanger materialsOrganic anion exchangersIon exchangeDialysis fluid

Owner:FRESENIUS MEDICAL CARE HLDG INC

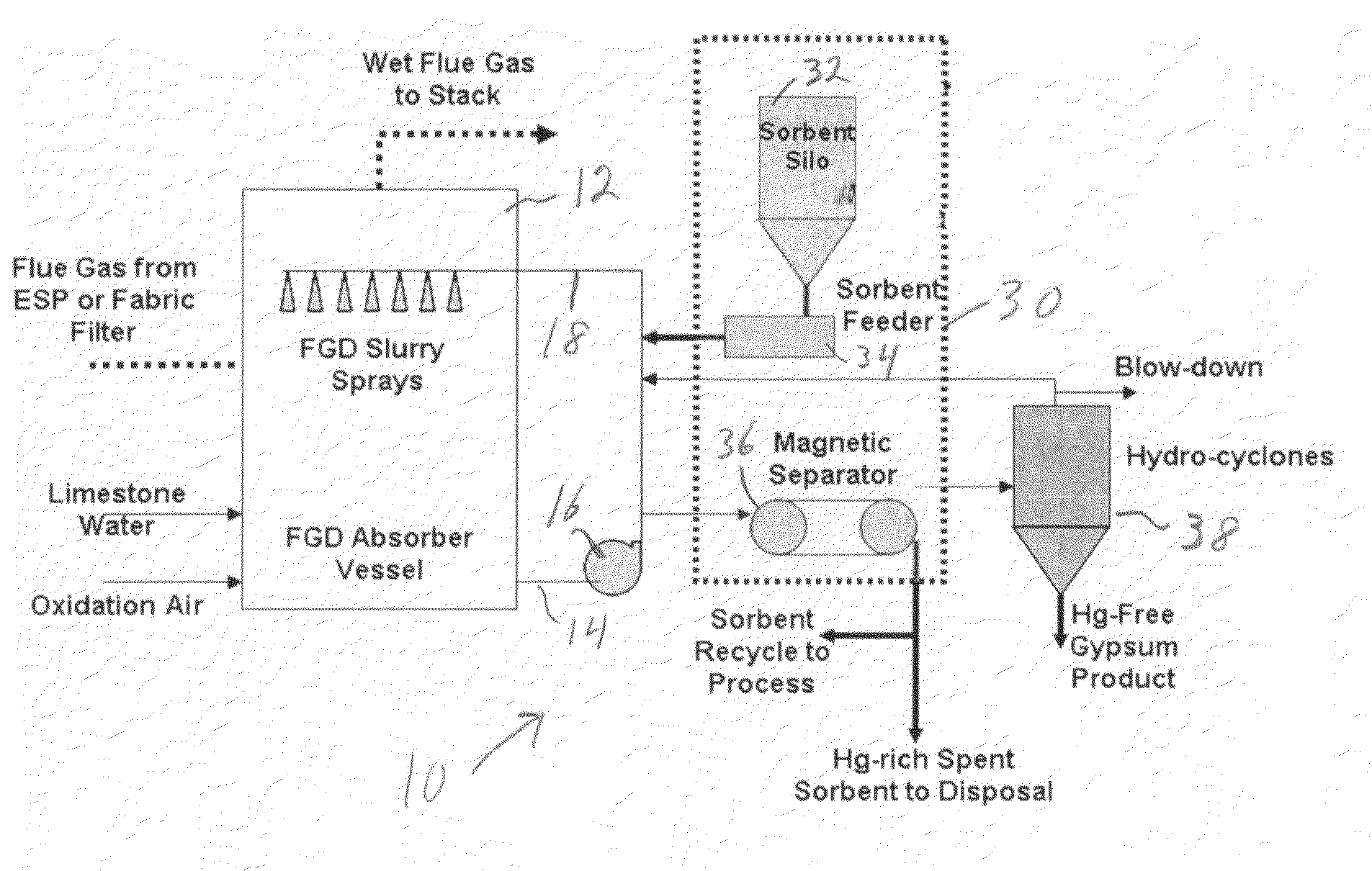

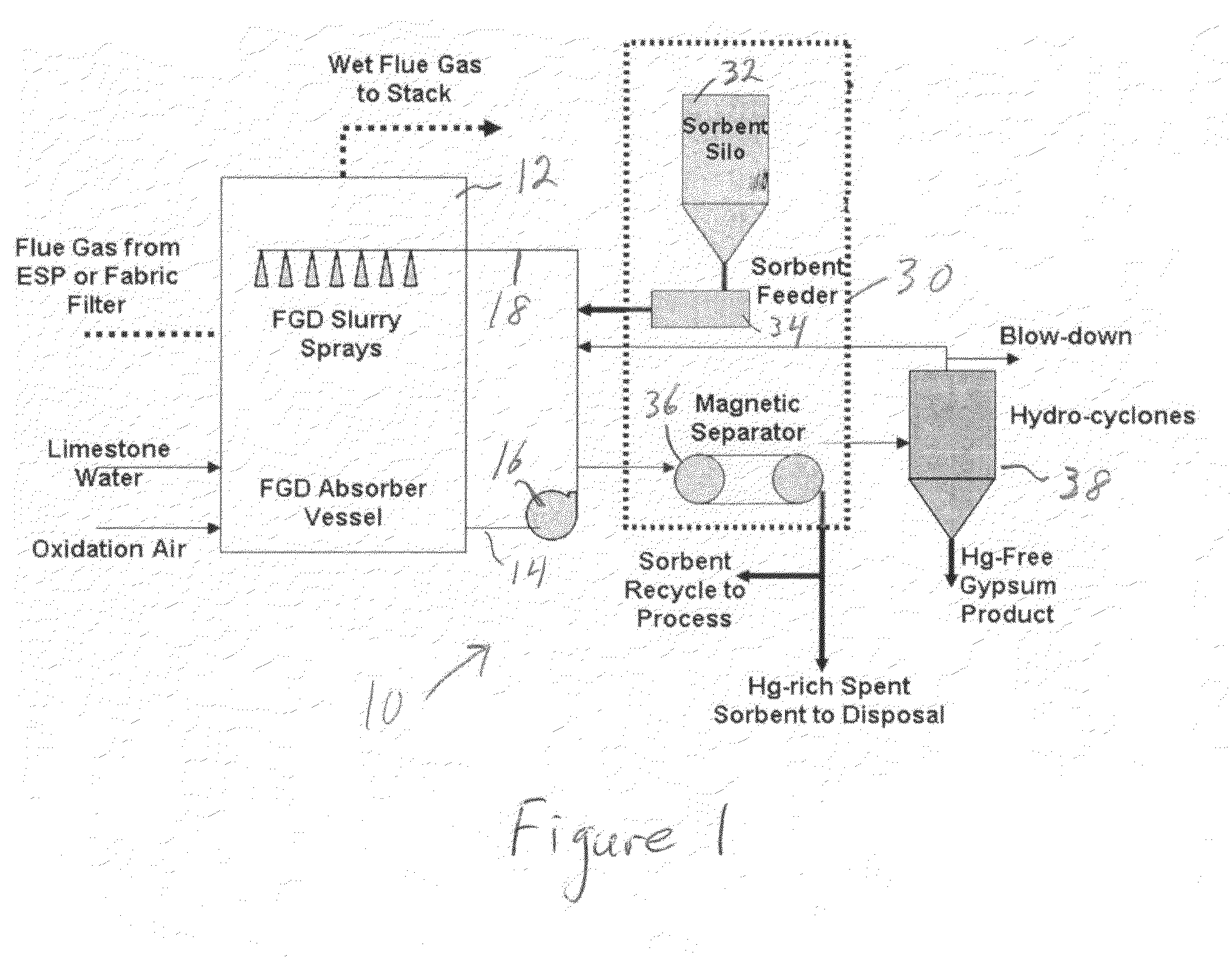

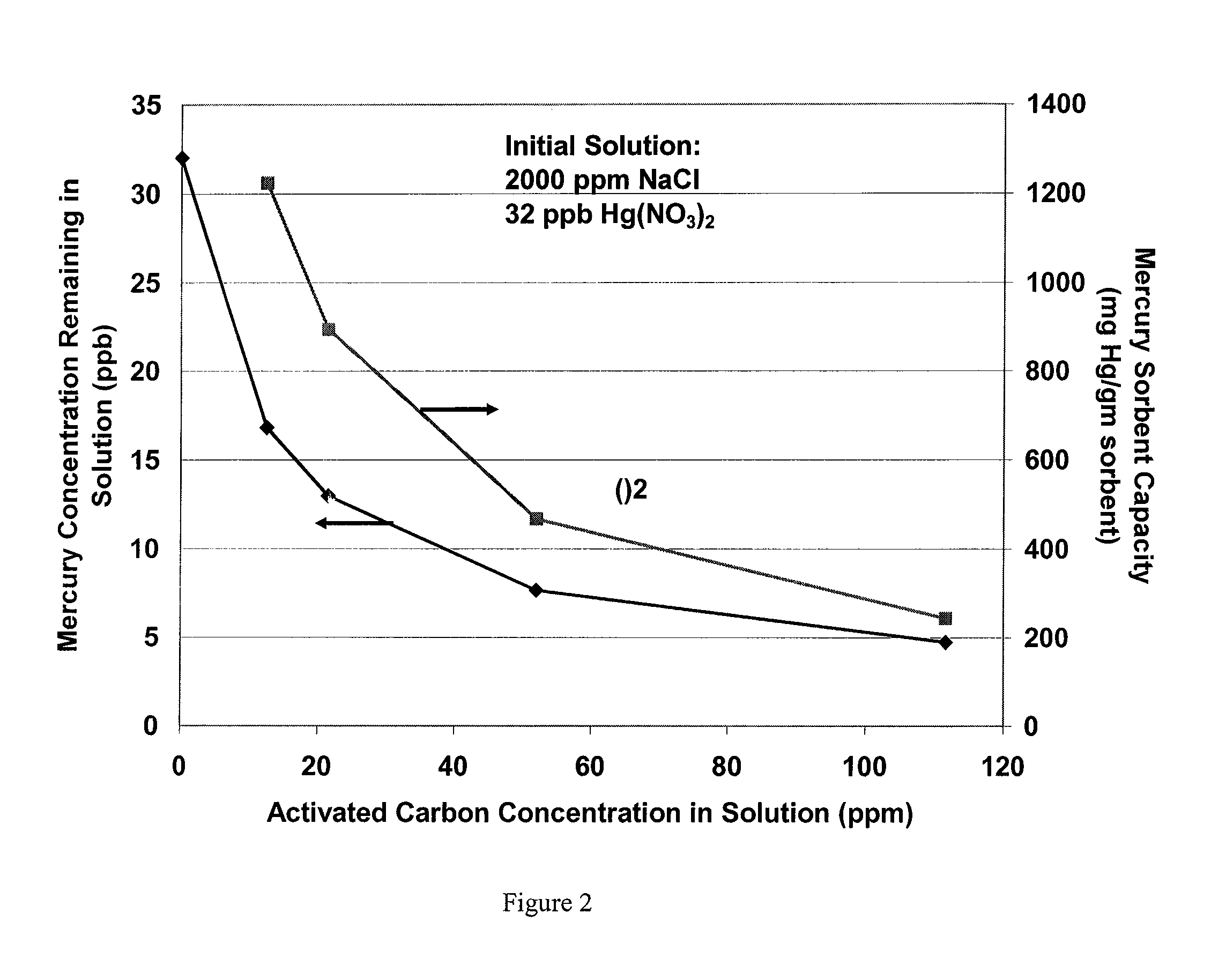

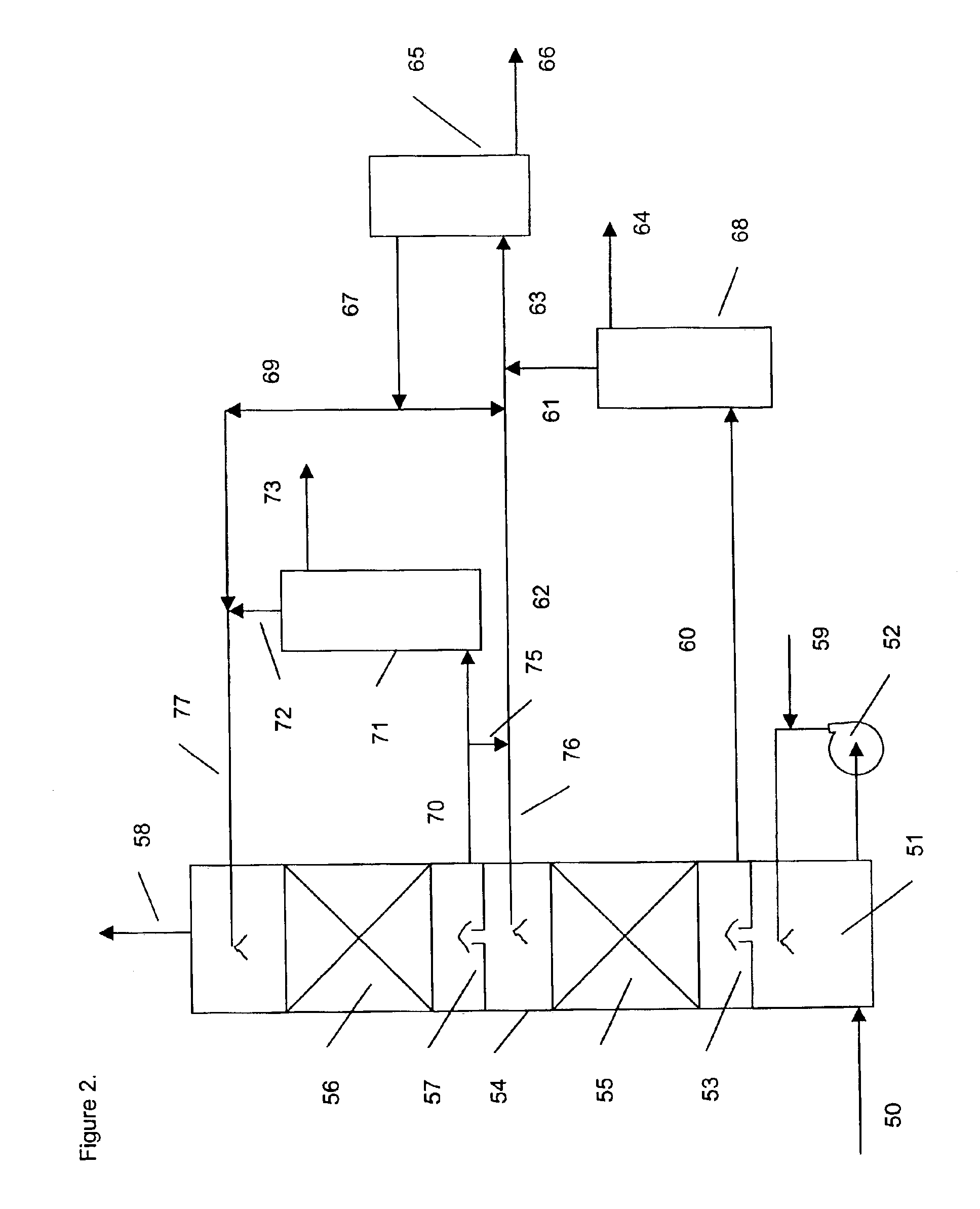

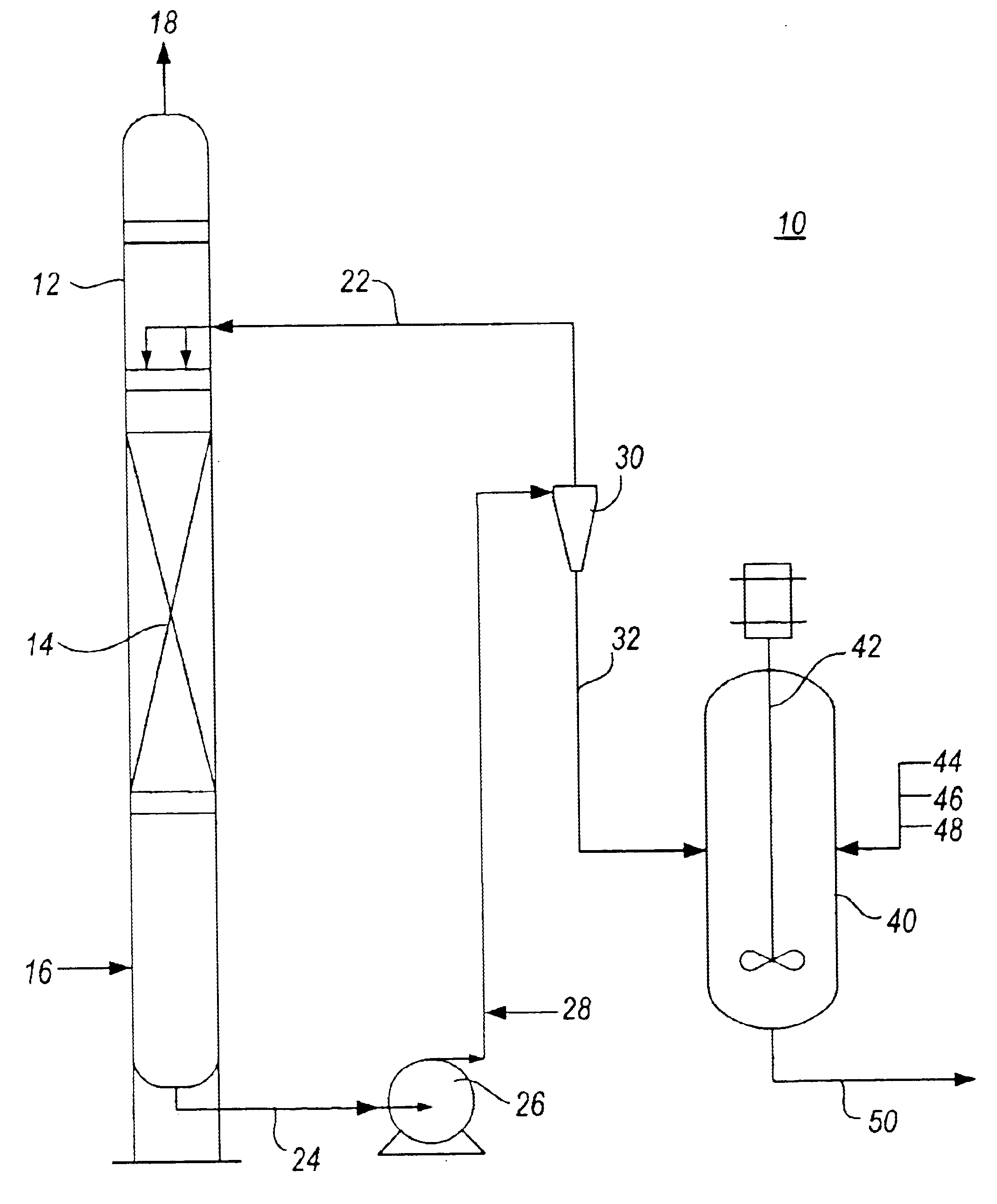

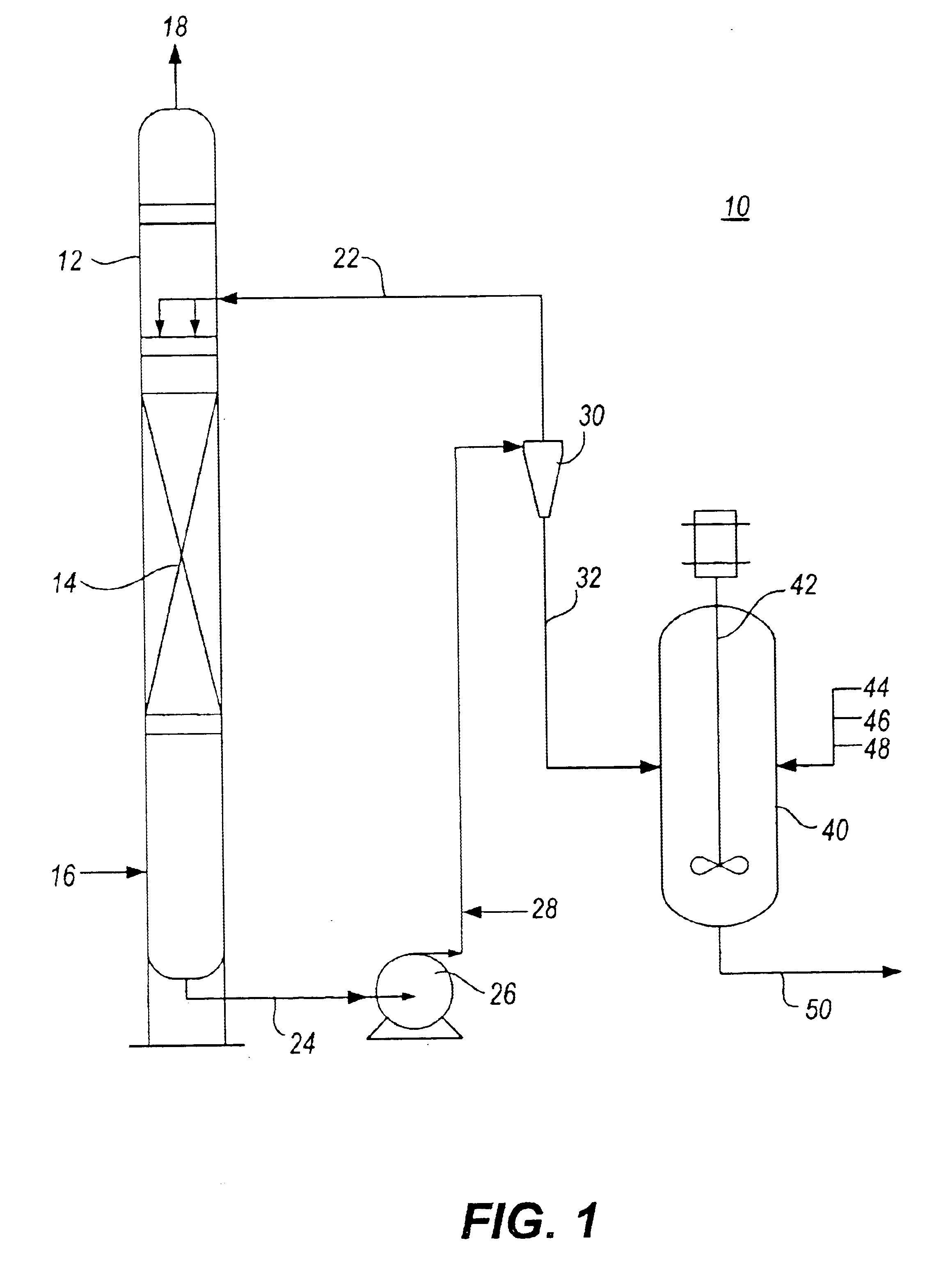

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

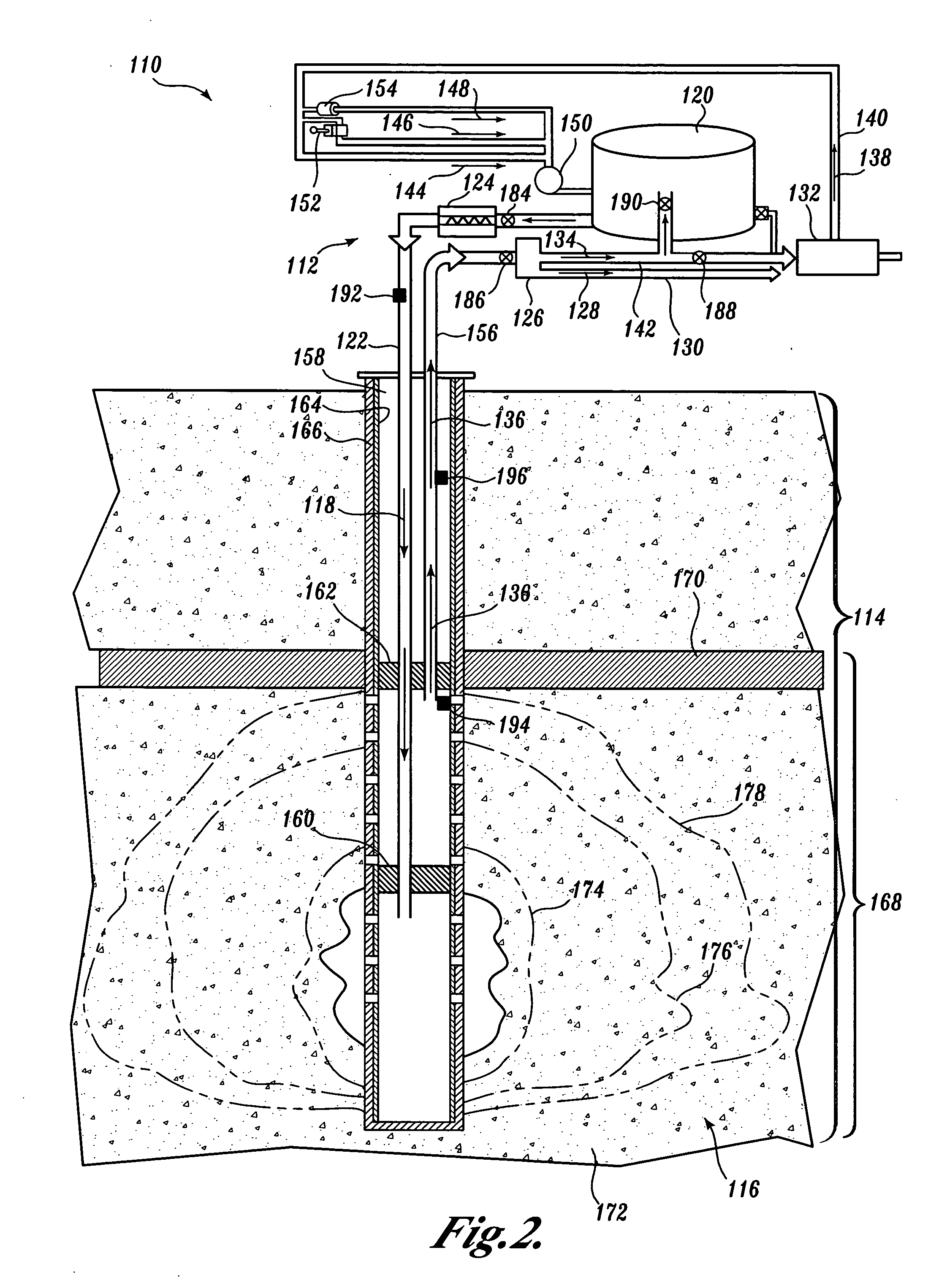

Method of sequestering carbon dioxide while producing natural gas

InactiveUS20040200618A1ConstructionsOther gas emission reduction technologiesEnvironmental engineeringCarbon dioxide

A method of sequestering carbon dioxide and producing natural gas including: (a) injecting an injectant containing at least some amount of carbon dioxide into a zone containing natural gas hydrates; (b) releasing natural gas from the hydrates by allowing thermal transfer and pressure changes from the injectant to the hydrates; and (c) sequestering the carbon dioxide in the zone that previously contained the natural gas hydrates.

Owner:PIEKENBROCK EUGENE J

Process for sequestering carbon dioxide and sulfur dioxide

A process for sequestering carbon dioxide, which includes reacting a silicate based material with an acid to form a suspension, and combining the suspension with carbon dioxide to create active carbonation of the silicate-based material, and thereafter producing a metal salt, silica and regenerating the acid in the liquid phase of the suspension.

Owner:PENN STATE RES FOUND

Process to produce biofuels from biomass

Biofuels can be produced by: (i) providing a biomass containing celluloses, hemicelluloses, lignin, nitrogen compounds and sulfur compounds; (ii) contacting the biomass with a digestive solvent to form a pretreated biomass containing carbohydrates; (iii) contacting the pretreated biomass with hydrogen in the presence of a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co and / or Ni incorporated into a suitable support to form a plurality of oxygenated intermediates, and (vi) processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

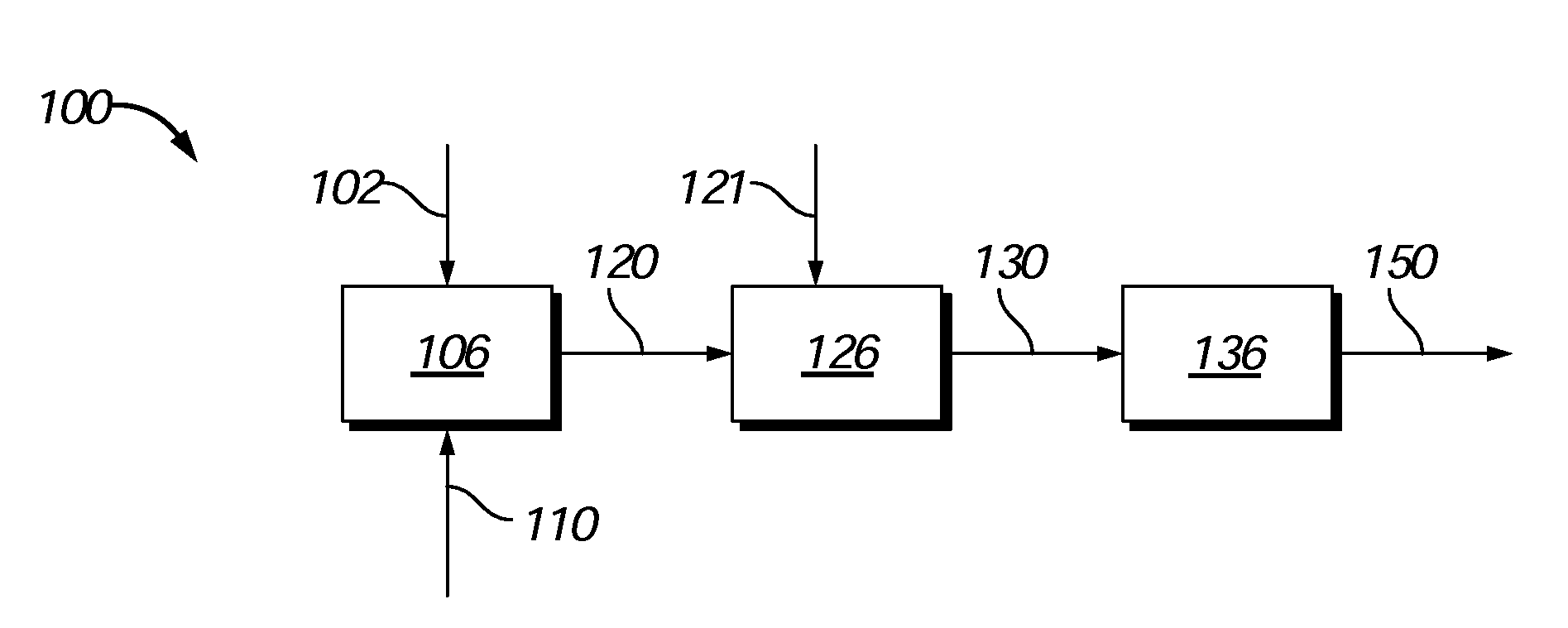

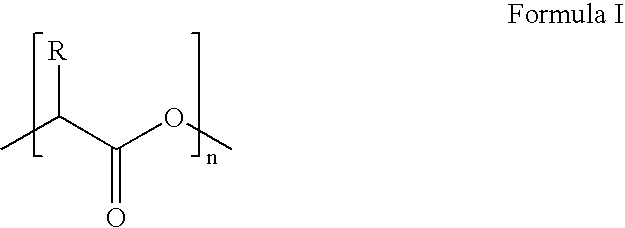

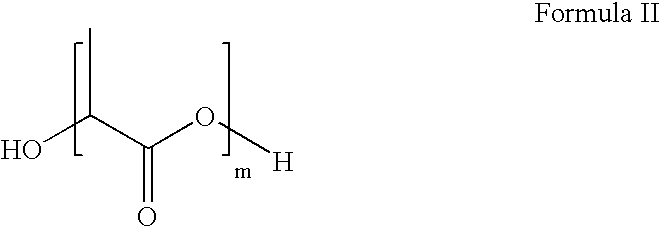

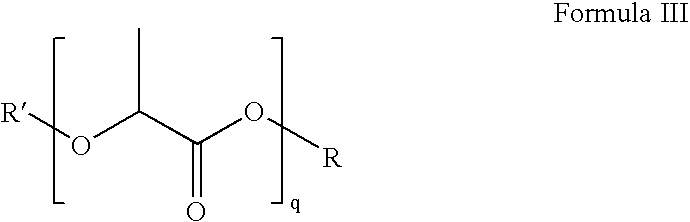

Methods of diverting treating fluids in subterranean zones and degradable diverting materials

ActiveUS7036587B2Readily apparentCleaning apparatusFluid removalParticulatesEnvironmental engineering

Owner:HALLIBURTON ENERGY SERVICES INC

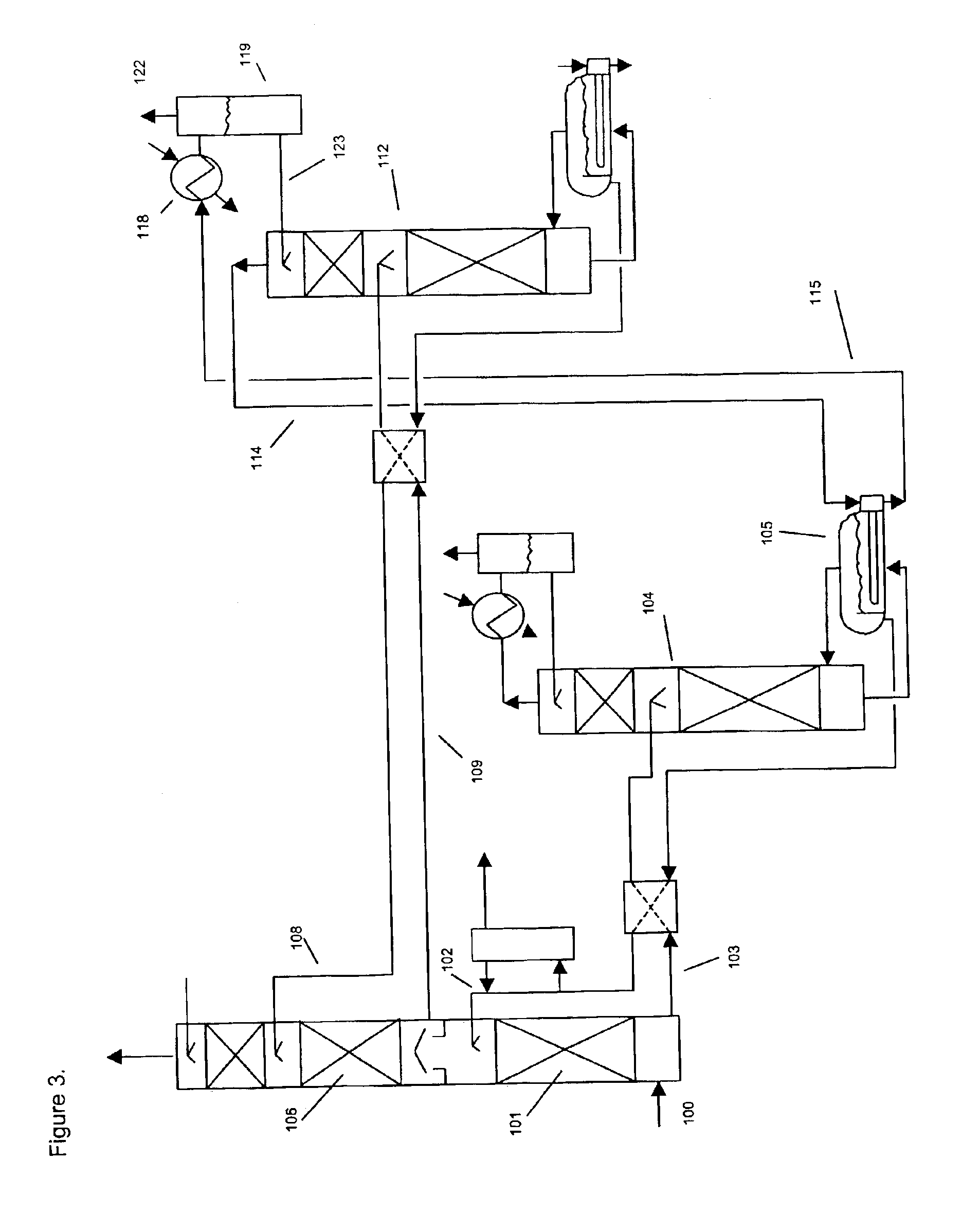

Flue gas mercury control

ActiveUS8080088B1Enhance particulate collectionReducing fly ash resistivityGas treatmentIsotope separationActivated carbonHalogen

An adsorbent composition for removing mercury from a flue gas stream, and a method of its use. The composition is a powdered activated carbon having at least one of a halogen-containing component and an alkaline component dispersed thereon. A flow agent can be composited with the material to maintain flowability in situ.

Owner:SRINIVASACHAR SRIVATS

Method for recovery of CO2 from gas streams

InactiveUS7056482B2Reduce solubilityMinimizing its negative effectCarbon compoundsDispersed particle separationEnvironmental engineeringCarbon dioxide

A process for recovering CO2 from a feed gas stream comprises treating the feed gas stream with a regenerated absorbent comprising at least one tertiary amine absorbent having a pKa for the amino function of from about 6.5 to about 9 in the presence of an oxidation inhibitor to obtain a CO2 rich stream and subsequently treating the CO2 rich stream to obtain the regenerated absorbent and a CO2 rich product stream. The feed gas stream may also include SO2 and / or NOx.

Owner:CANSOLV TECH INC

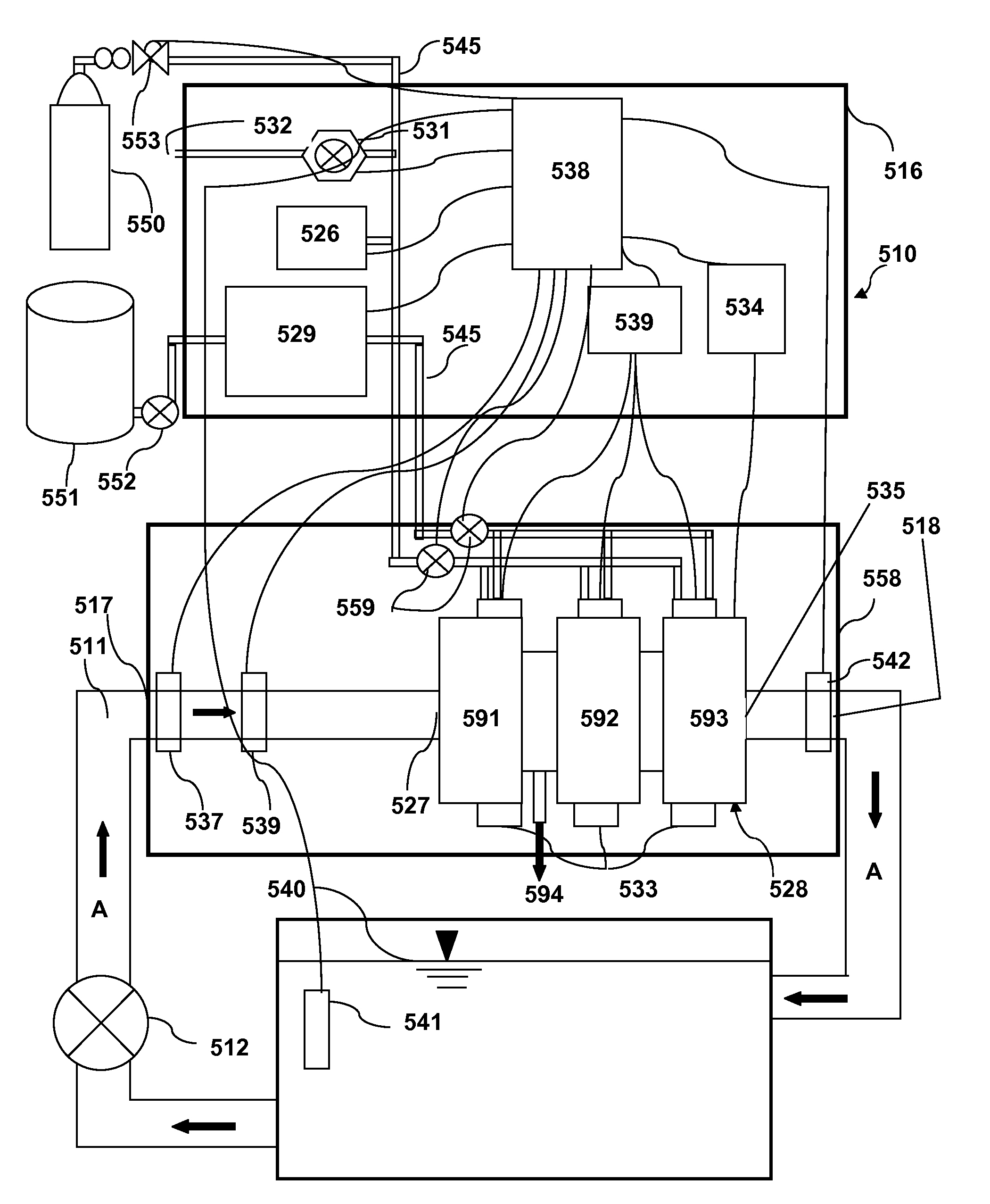

Method for removal and stabilization of mercury in mercury-containing gas streams

InactiveUS6942840B1Improve scalabilityCombination devicesDispersed particle filtrationOxygenVapor phase

The present invention is directed to a process and apparatus for removing and stabilizing mercury from mercury-containing gas streams. A gas stream containing vapor phase elemental and / or speciated mercury is contacted with reagent, such as an oxygen-containing oxidant, in a liquid environment to form a mercury-containing precipitate. The mercury-containing precipitate is kept or placed in solution and reacts with one or more additional reagents to form a solid, stable mercury-containing compound.

Owner:MERCURY CONTROL TECH

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst. The particulate compositions are gasified in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

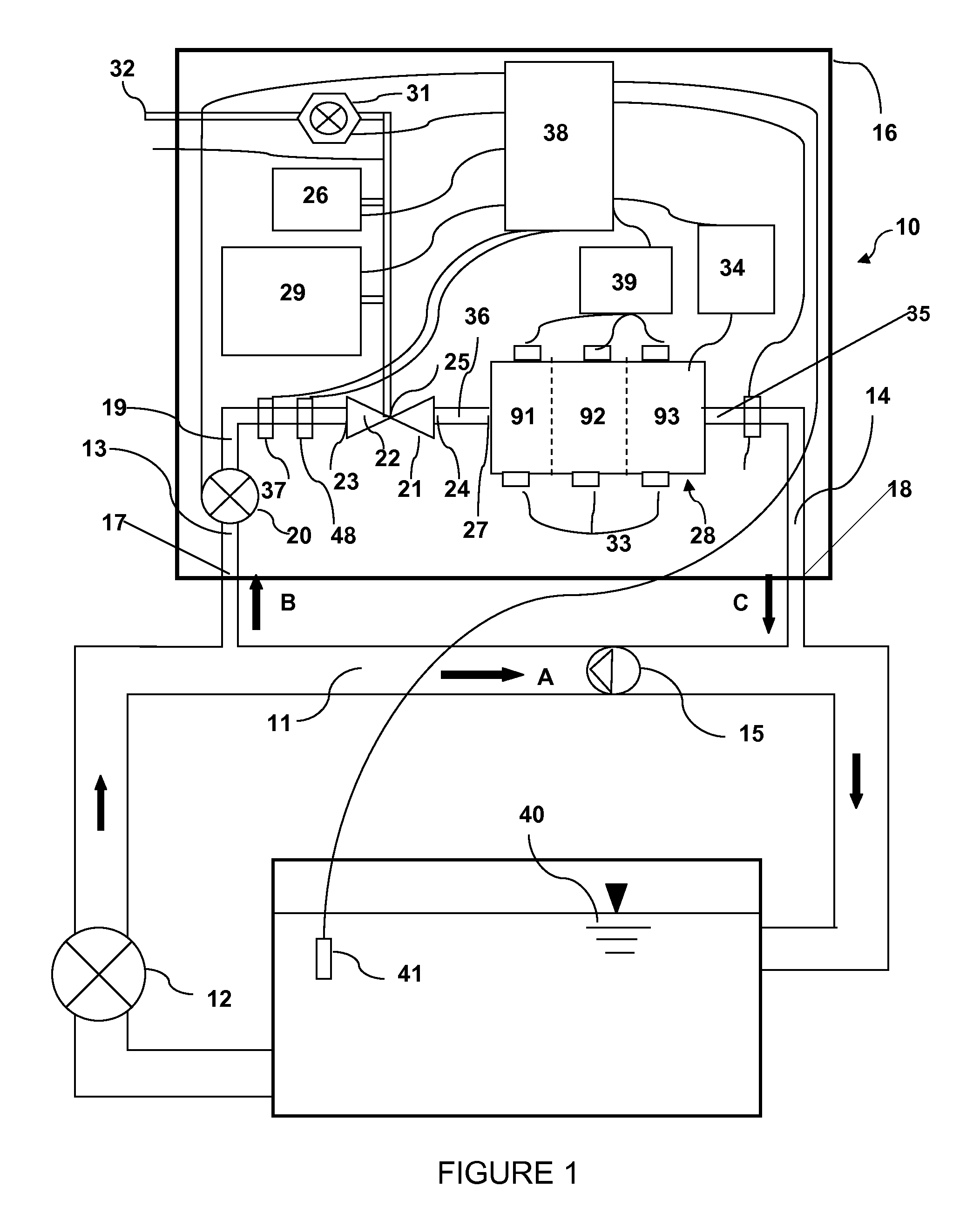

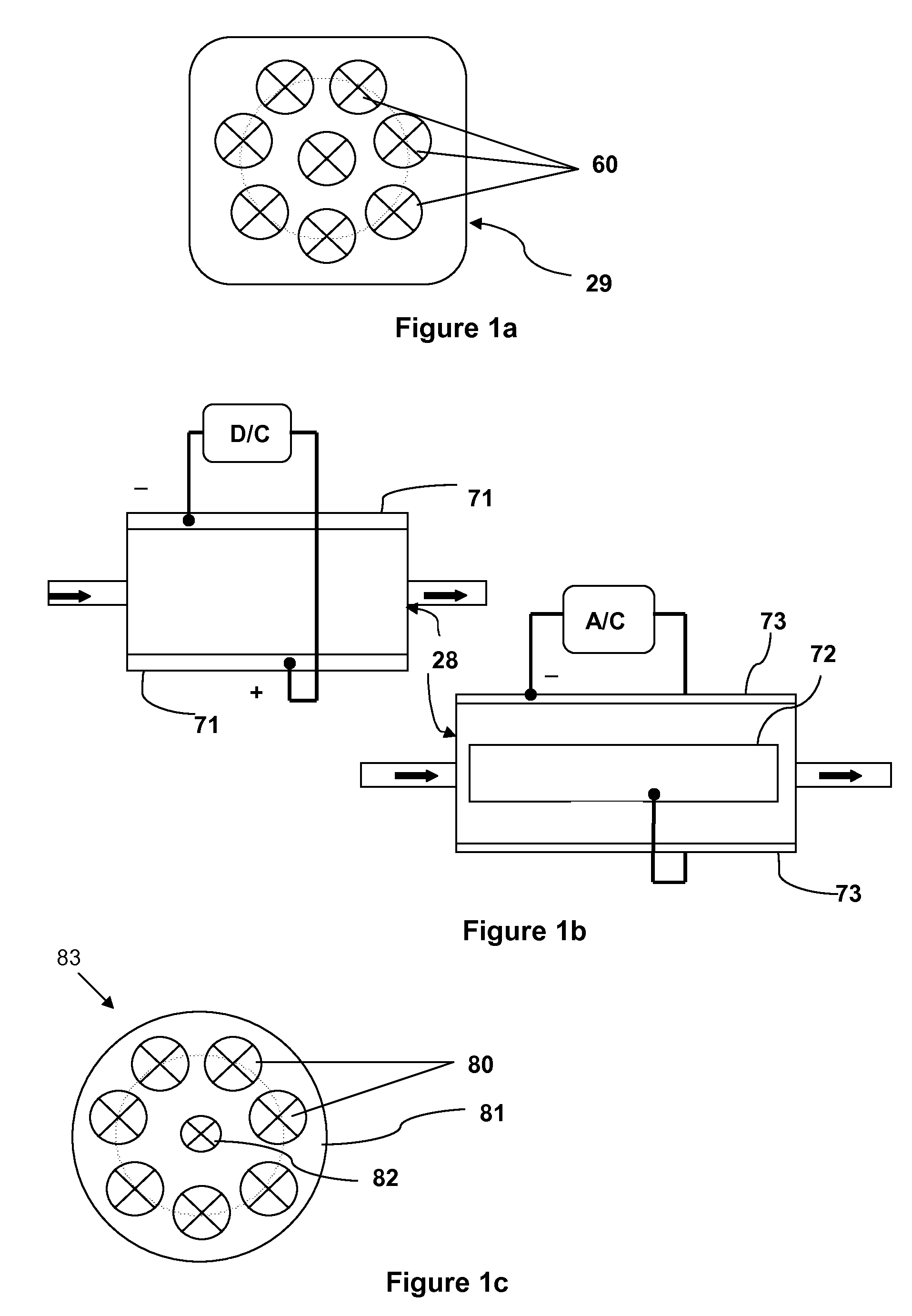

Aqueous treatment apparatus utilizing precursor materials and ultrasonics to generate customized oxidation-reduction-reactant chemistry environments in electrochemical cells and/or similar devices

ActiveUS20110024361A1Prevent precipitationReduce maintenance costsFrom normal temperature solutionsLiquid separation by electricityEnvironmental chemistrySet point

An electrochlorination and electrochemical system for the on-site generation and treatment of municipal water supplies and other reservoirs of water, by using a custom mixed oxidant and mixed reductant generating system for the enhanced destruction of water borne contaminants by creating custom oxidation-reduction-reactant chemistries with real time monitoring. A range of chemical precursors are provided that when acted upon in an electrochemical cell either create an enhanced oxidation, or reduction environment for the destruction or control of contaminants. Chemical agents that can be used to control standard water quality parameters such as total hardness, total alkalinity, pH, total dissolved solids, and the like are introduced via the chemical precursor injection subsystem infrequently or in real time based on sensor inputs and controller set points.

Owner:GLOBAL WATER INVESTMENTS LLC

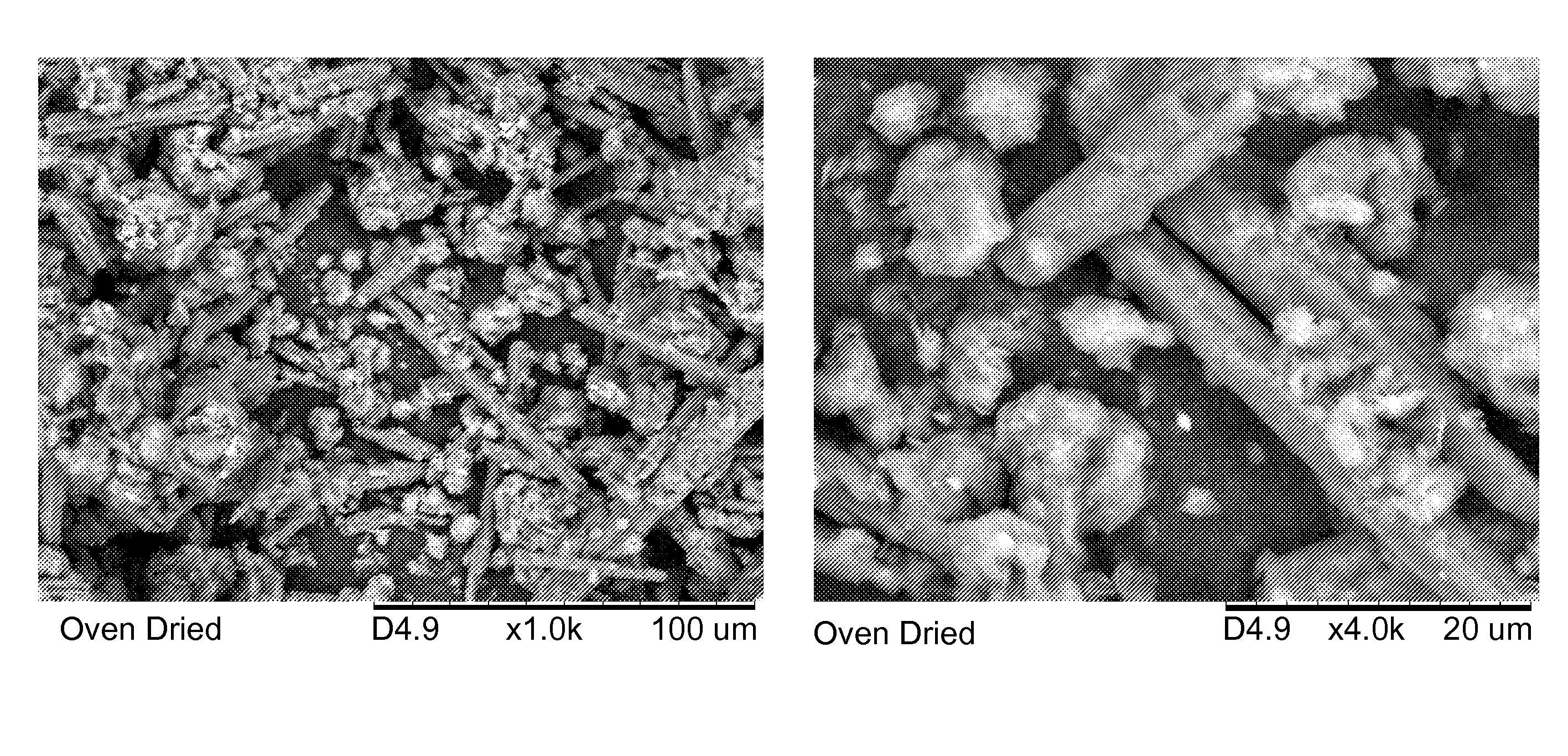

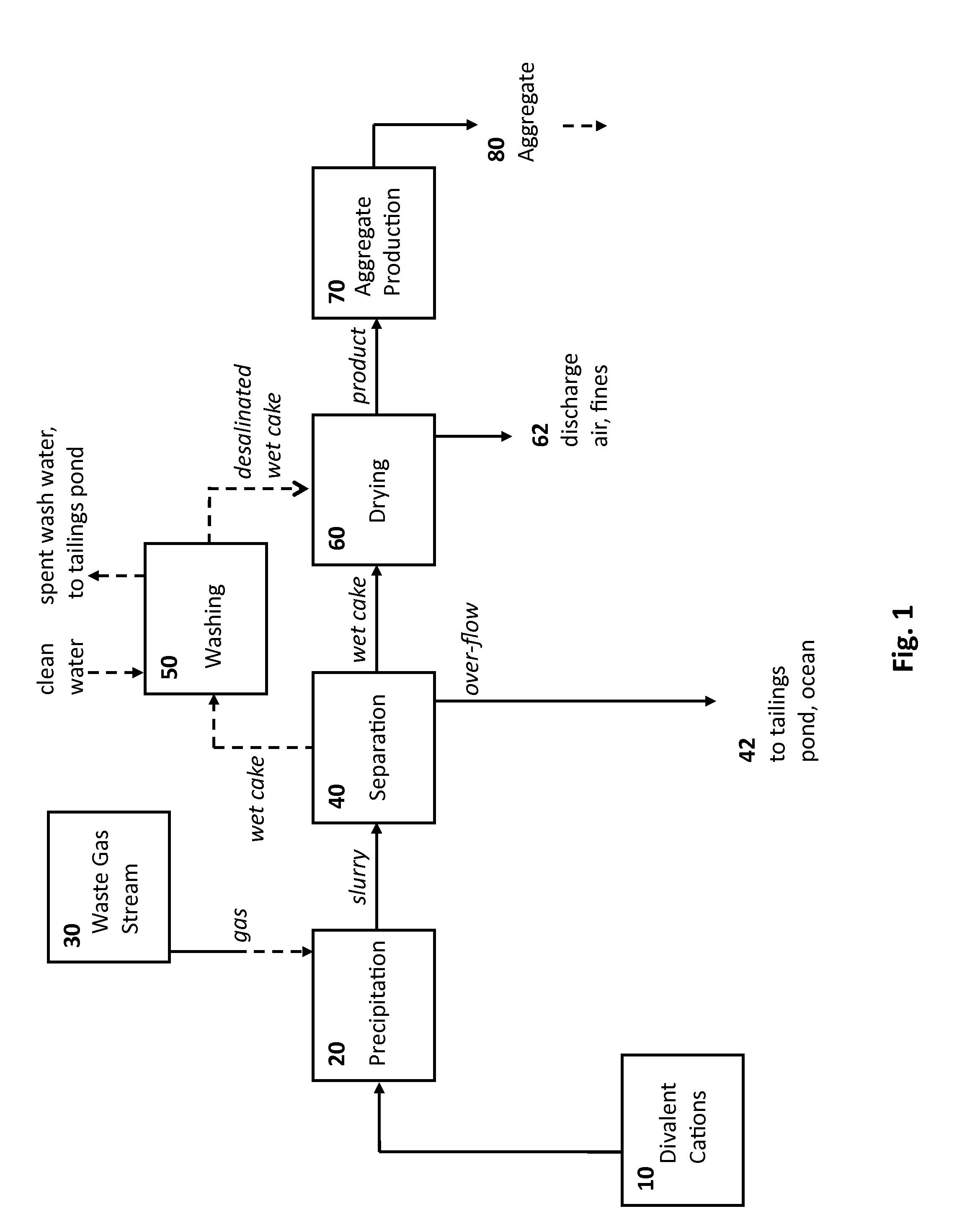

Rocks and aggregate, and methods of making and using the same

ActiveUS20100024686A1Calcium/strontium/barium carbonatesPigmenting treatmentCarbonateToxic industrial waste

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

Sorbent composition, process for producing same and use in desulfurization

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com