Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11422 results about "Lignin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of vascular plants and some algae. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity and do not rot easily. Chemically, lignins are cross-linked phenolic polymers.

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

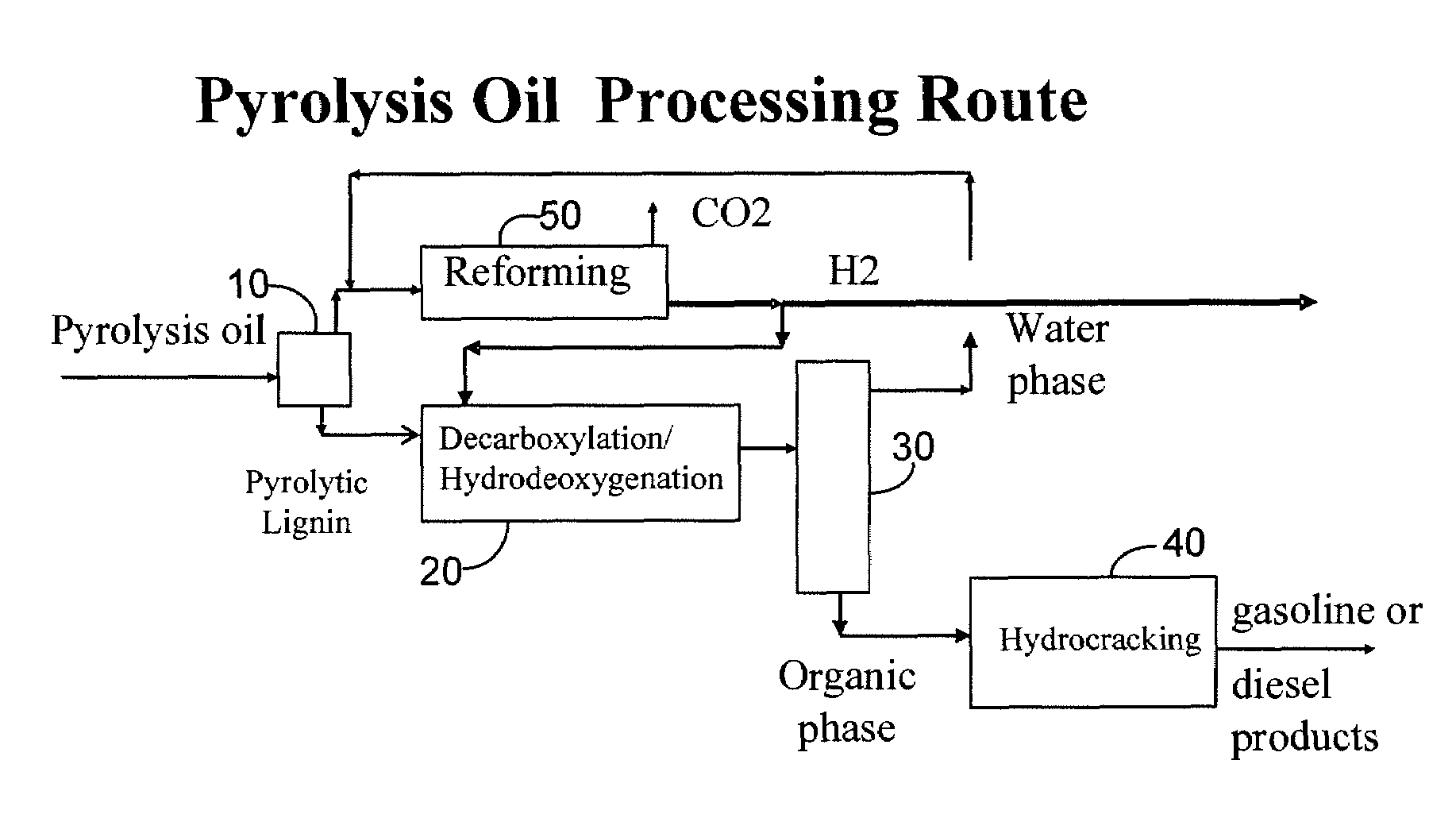

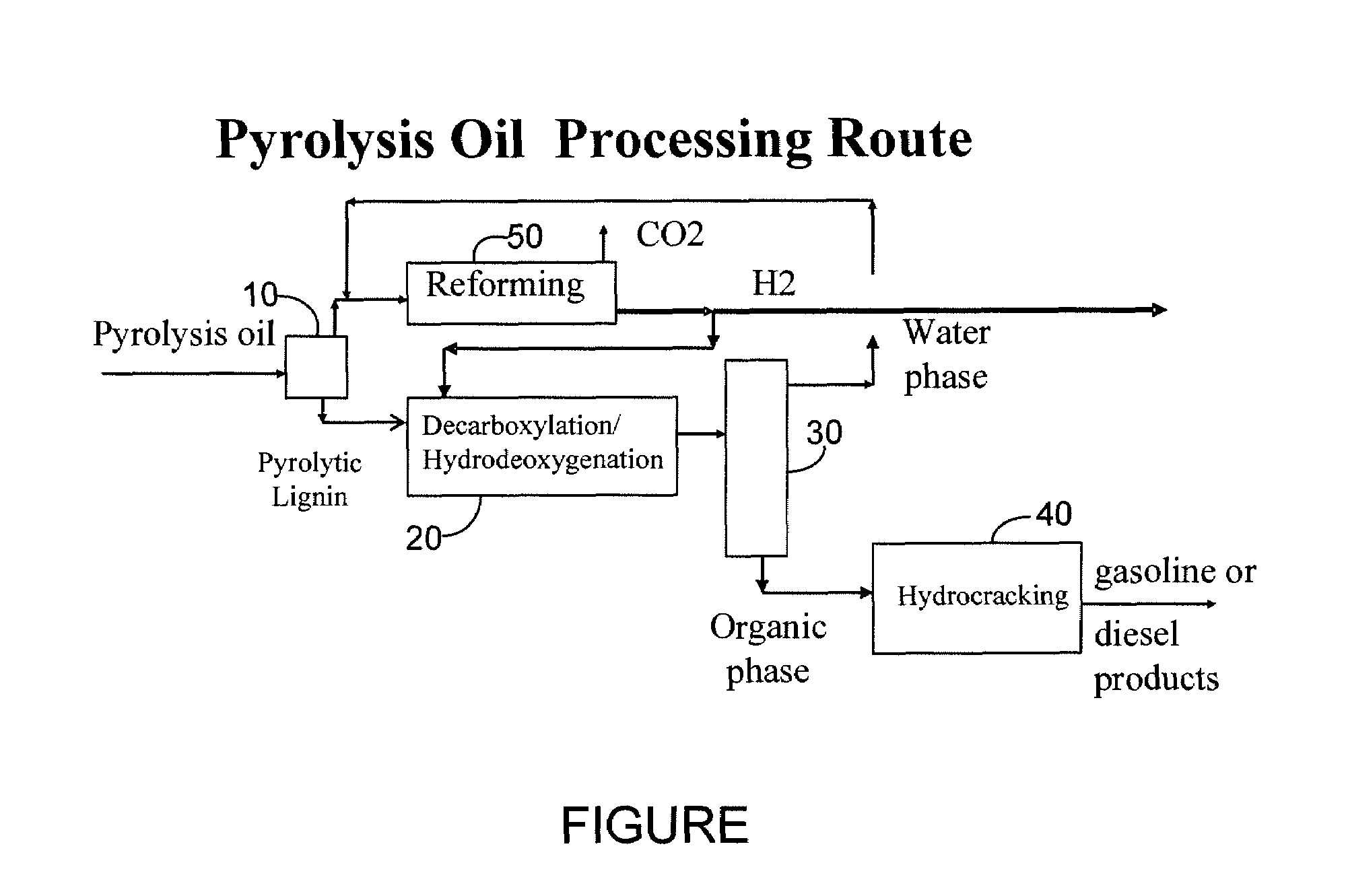

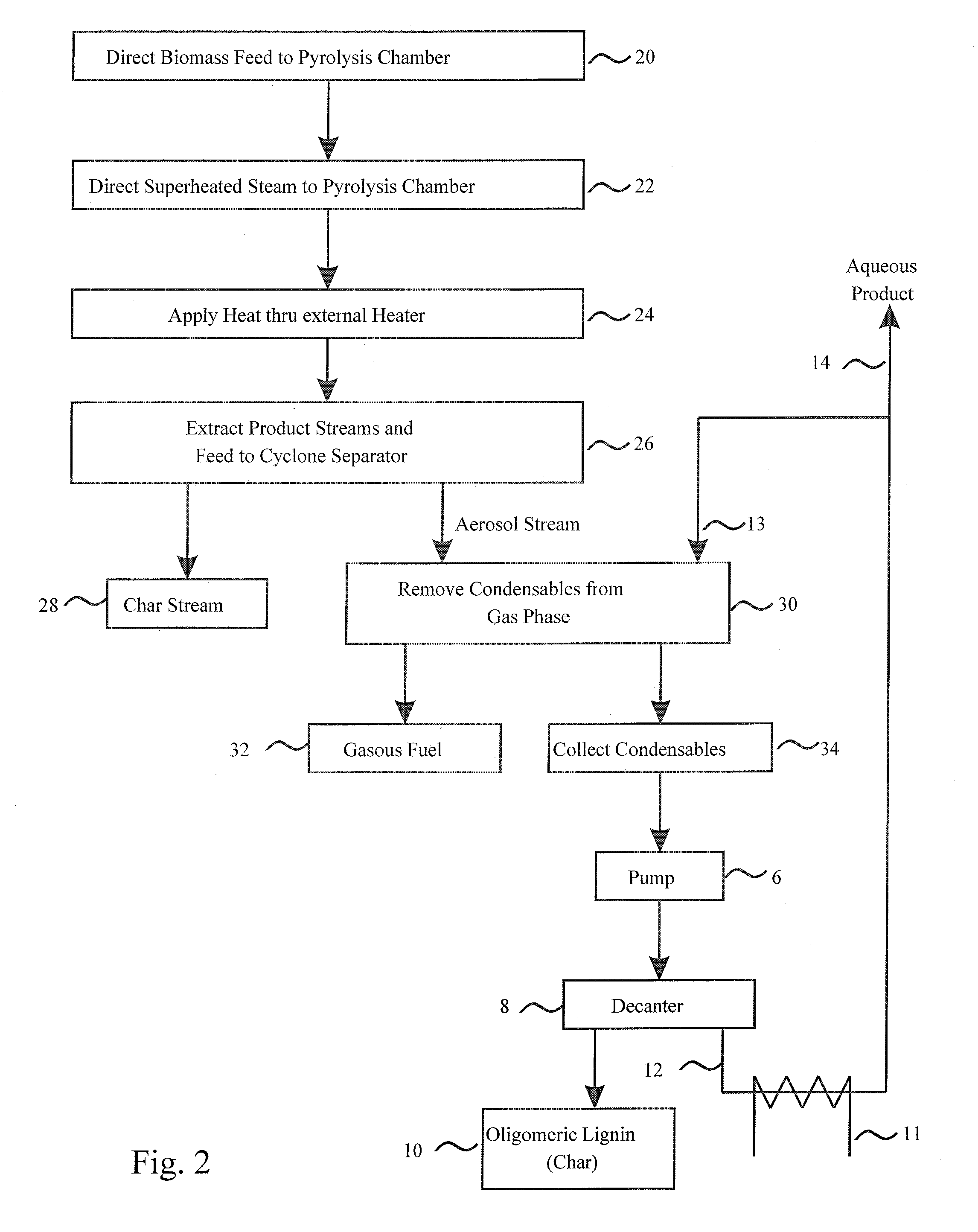

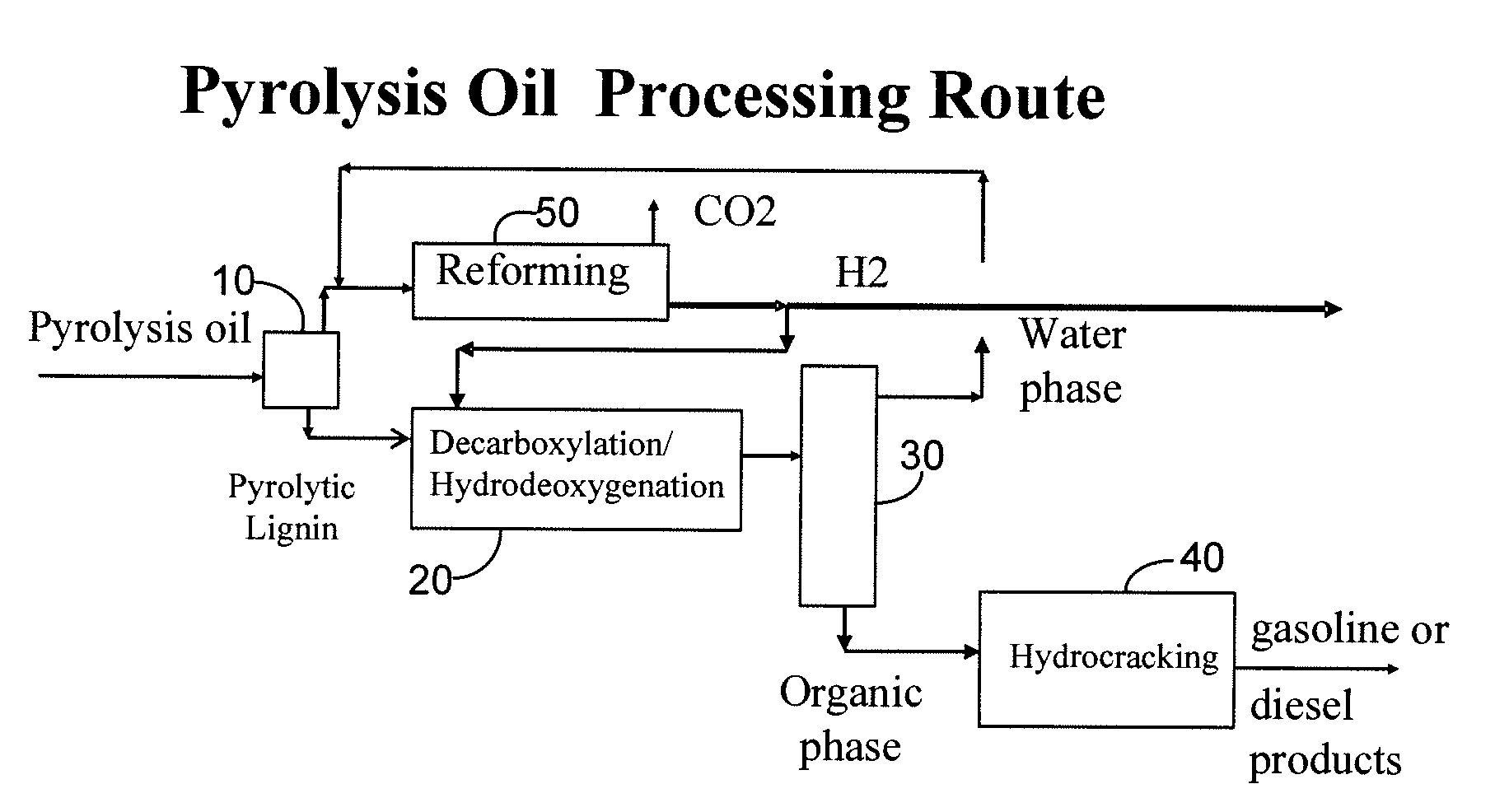

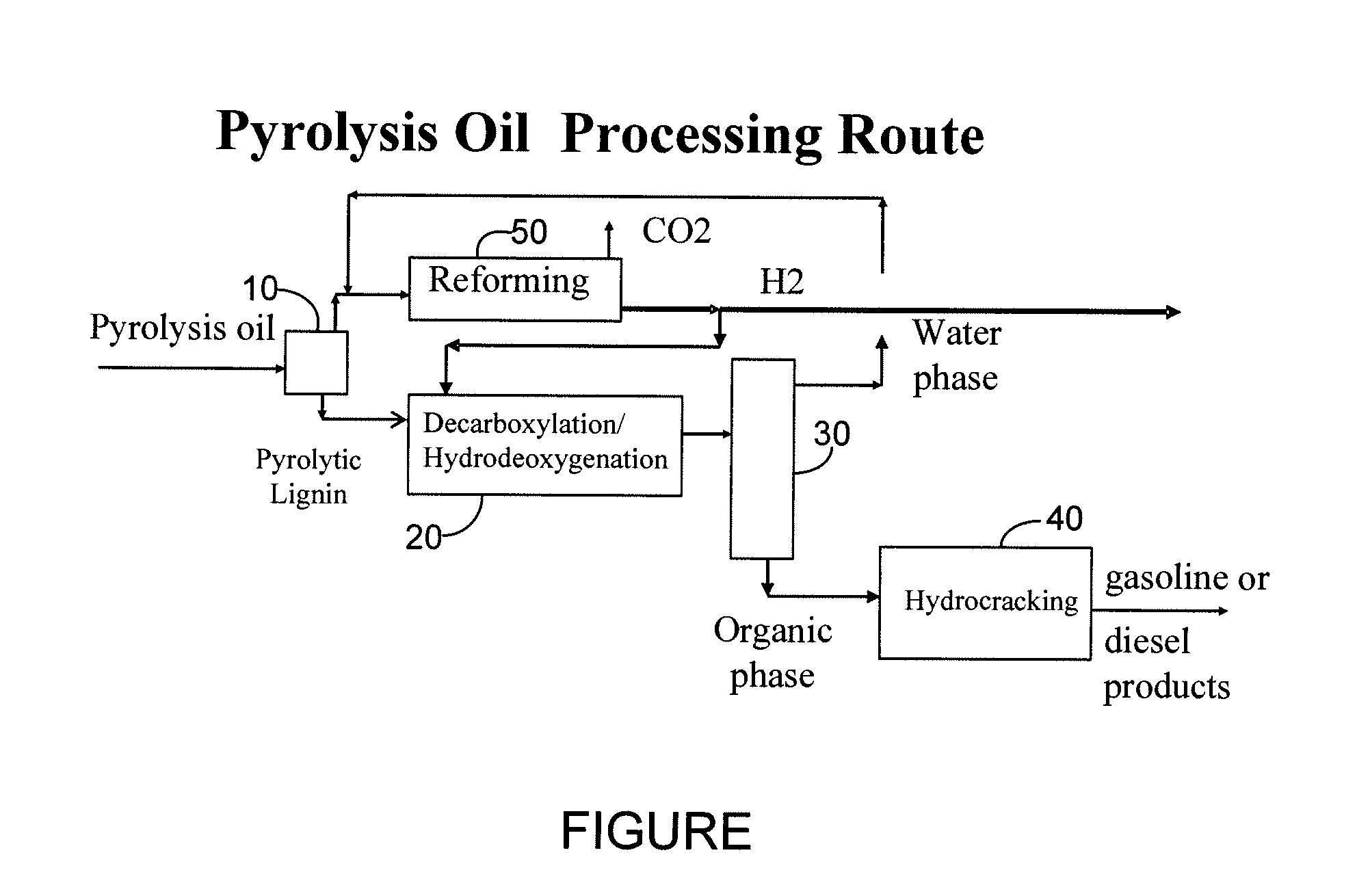

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

High Softness, High Durability Bath Tissue Incorporating High Lignin Eucalyptus Fiber

ActiveUS20130029106A1Less-wet lintOffsetting costsCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

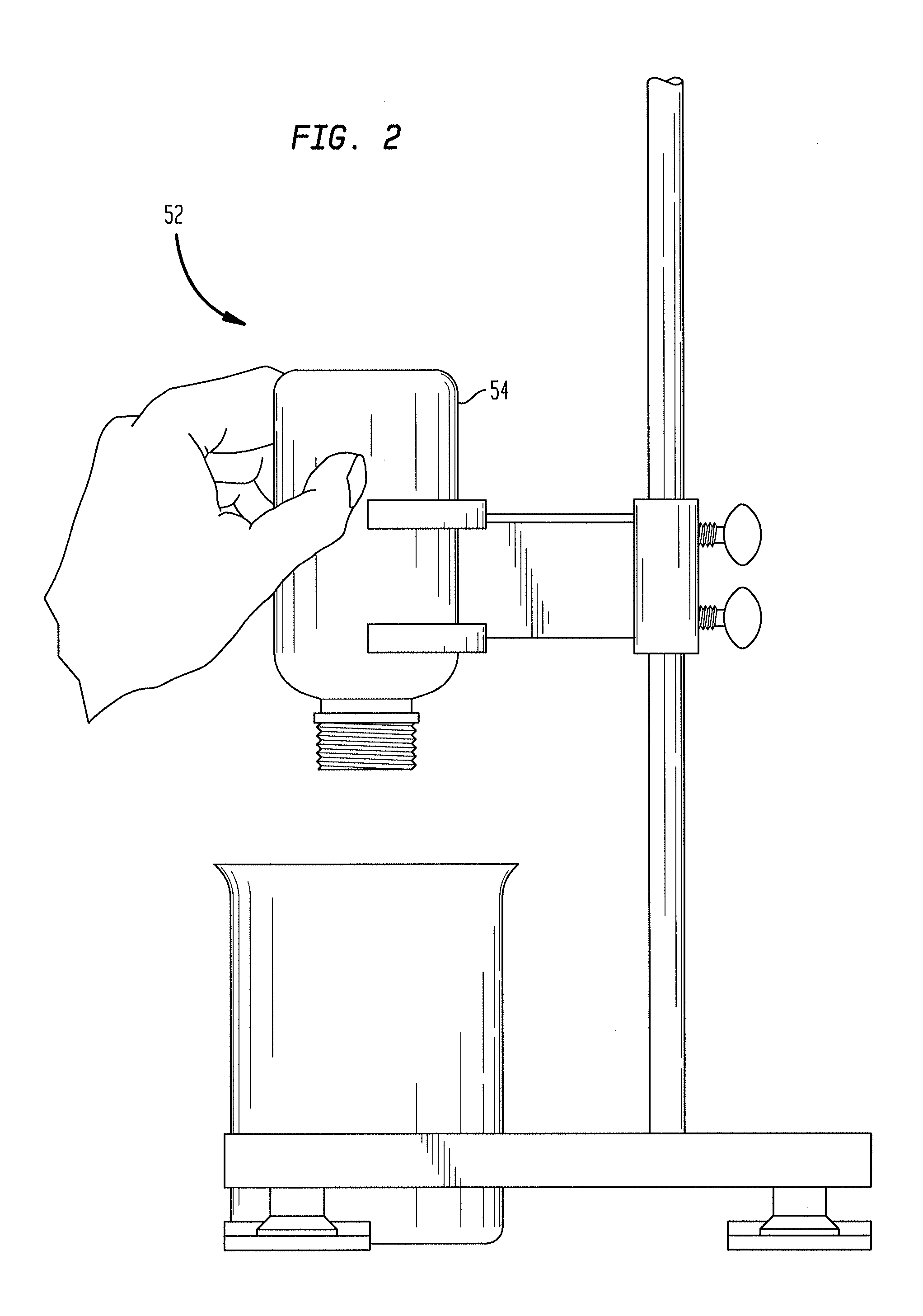

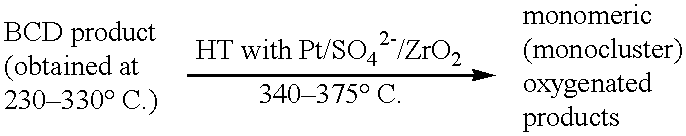

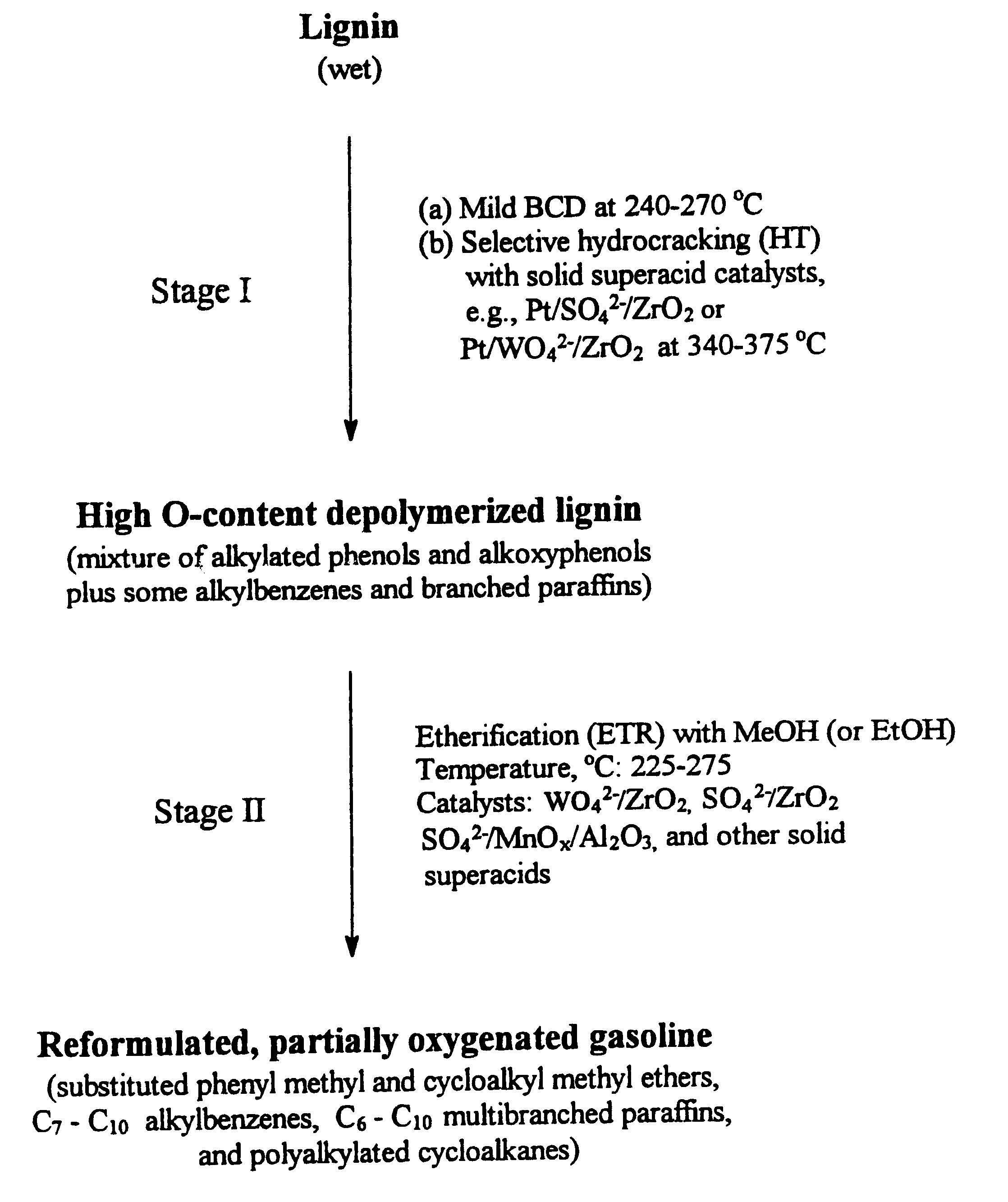

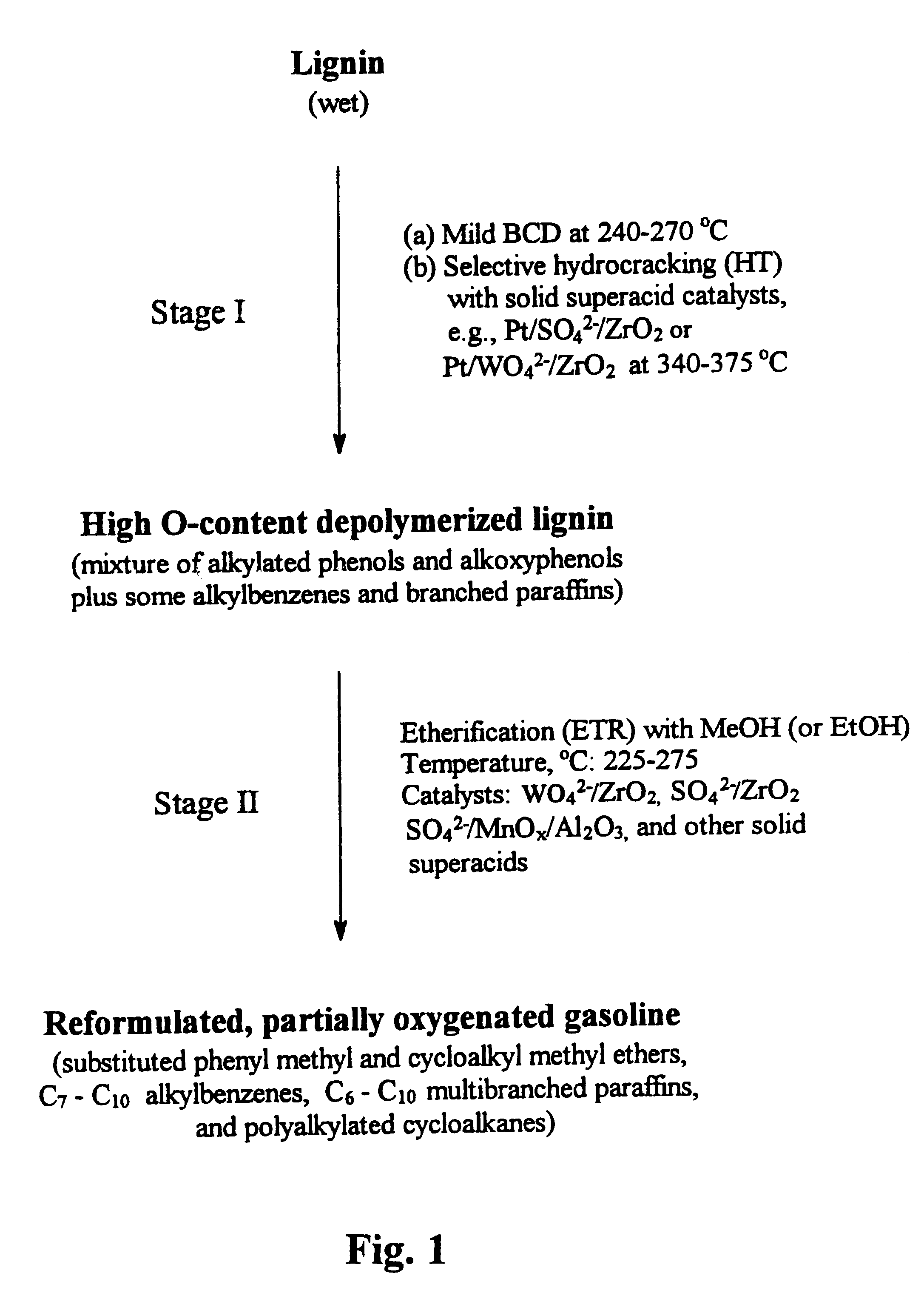

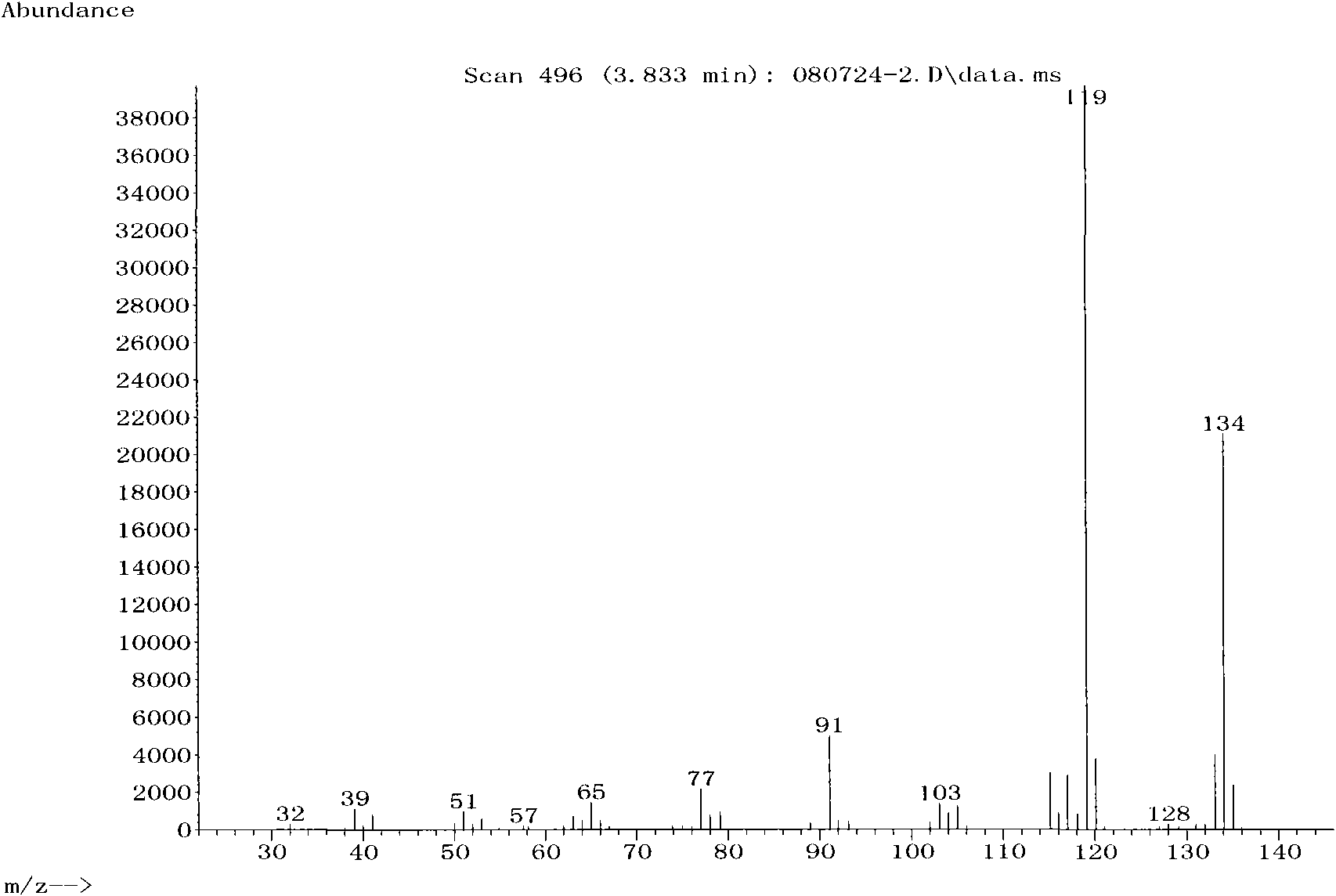

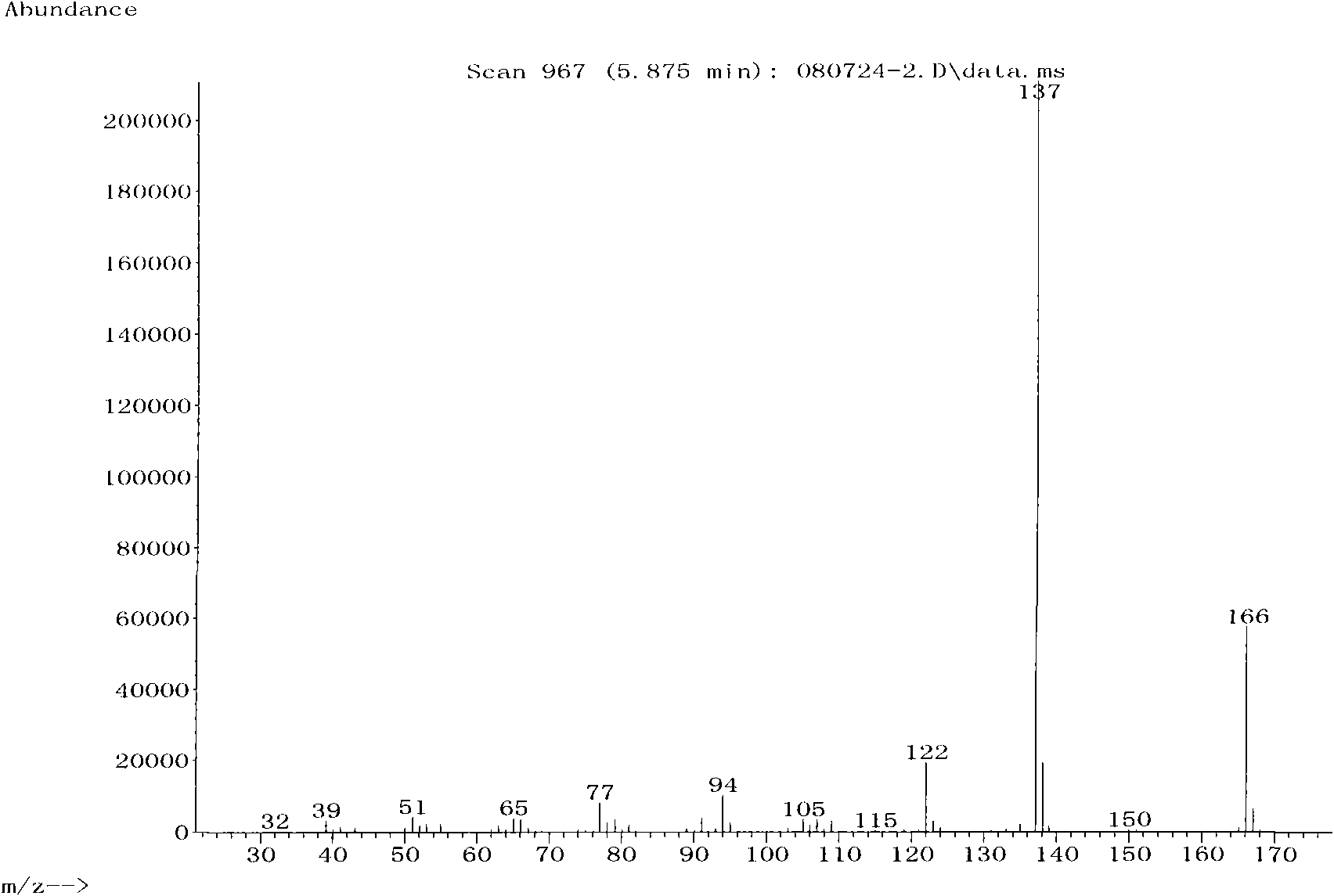

Process for conversion of lignin to reformulated, partially oxygenated gasoline

InactiveUS6172272B1Short reaction timeMaintain good propertiesOrganic compound preparationHydrocarbon from oxygen organic compoundsDepolymerizationMethyl group

A high-yield process for converting lignin into reformulated, partially oxygenated gasoline compositions of high quality is provided. The process is a two-stage catalytic reaction process that produces a reformulated, partially oxygenated gasoline product with a controlled amount of aromatics. In the first stage of the process, a lignin feed material is subjected to a base-catalyzed depolymerization reaction, followed by a selective hydrocracking reaction which utilizes a superacid catalyst to produce a high oxygen-content depolymerized lignin product mainly composed of alkylated phenols, alkylated alkoxyphenols, and alkylbenzenes. In the second stage of the process, the depolymerized lignin product is subjected to an exhaustive etherification reaction, optionally followed by a partial ring hydrogenation reaction, to produce a reformulated, partially oxygenated / etherified gasoline product, which includes a mixture of substituted phenyl / methyl ethers, cycloalkyl methyl ethers, C7-C10 alkylbenzenes, C6-C10 branched and multibranched paraffins, and alkylated and polyalkylated cycloalkanes.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

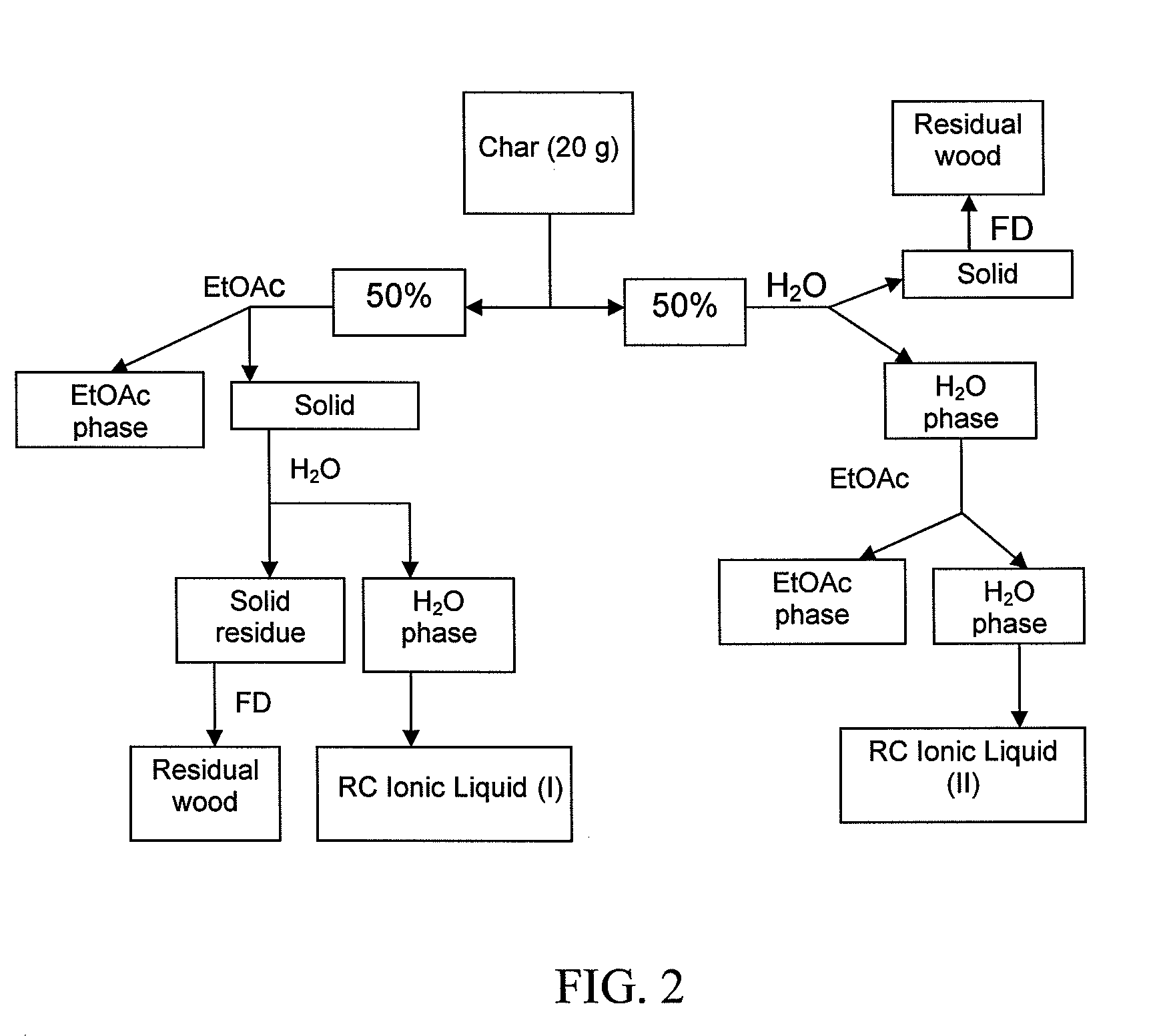

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS20080185112A1Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

The present invention provides methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose. In specific embodiments, the methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to pyrolytic conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

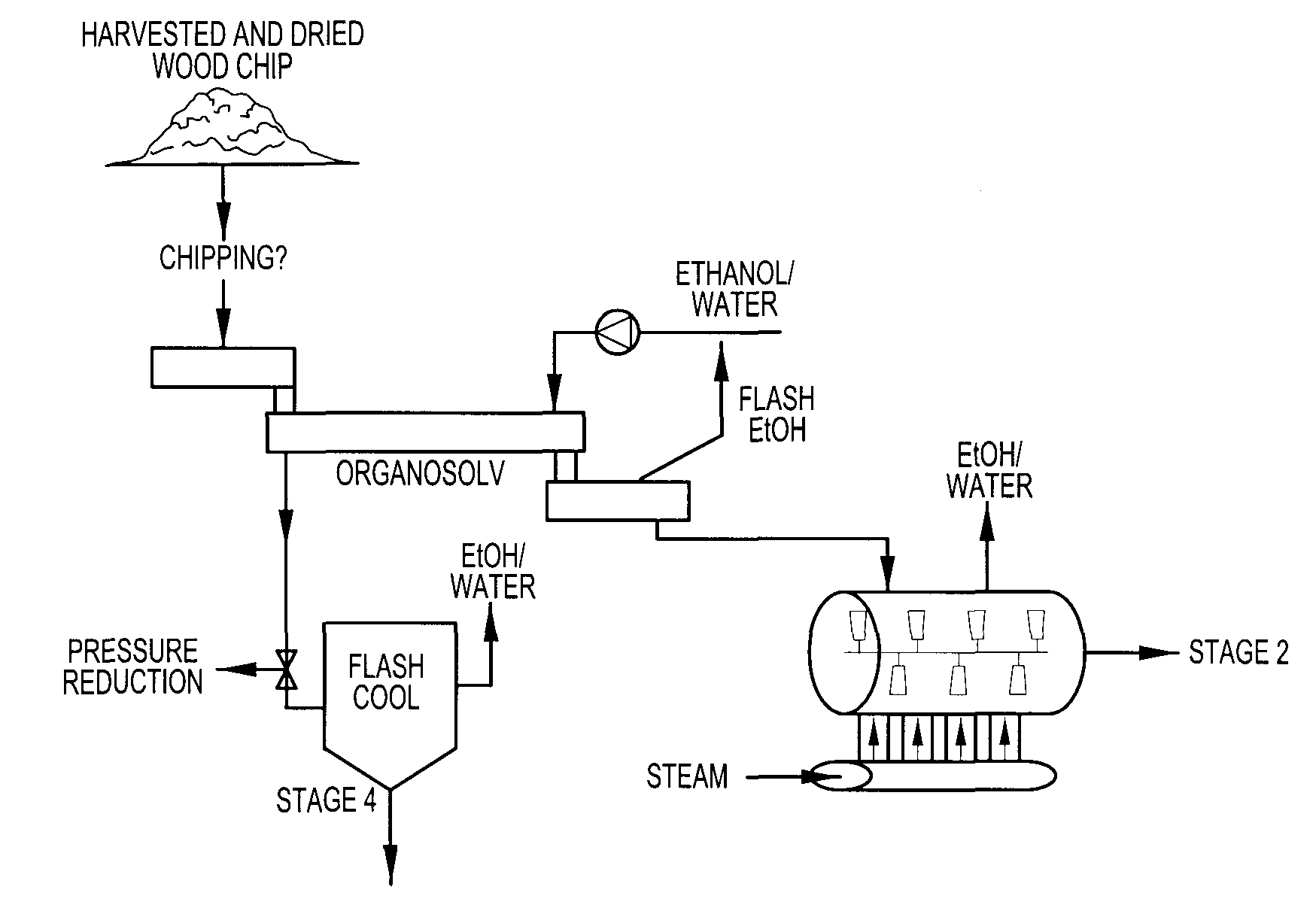

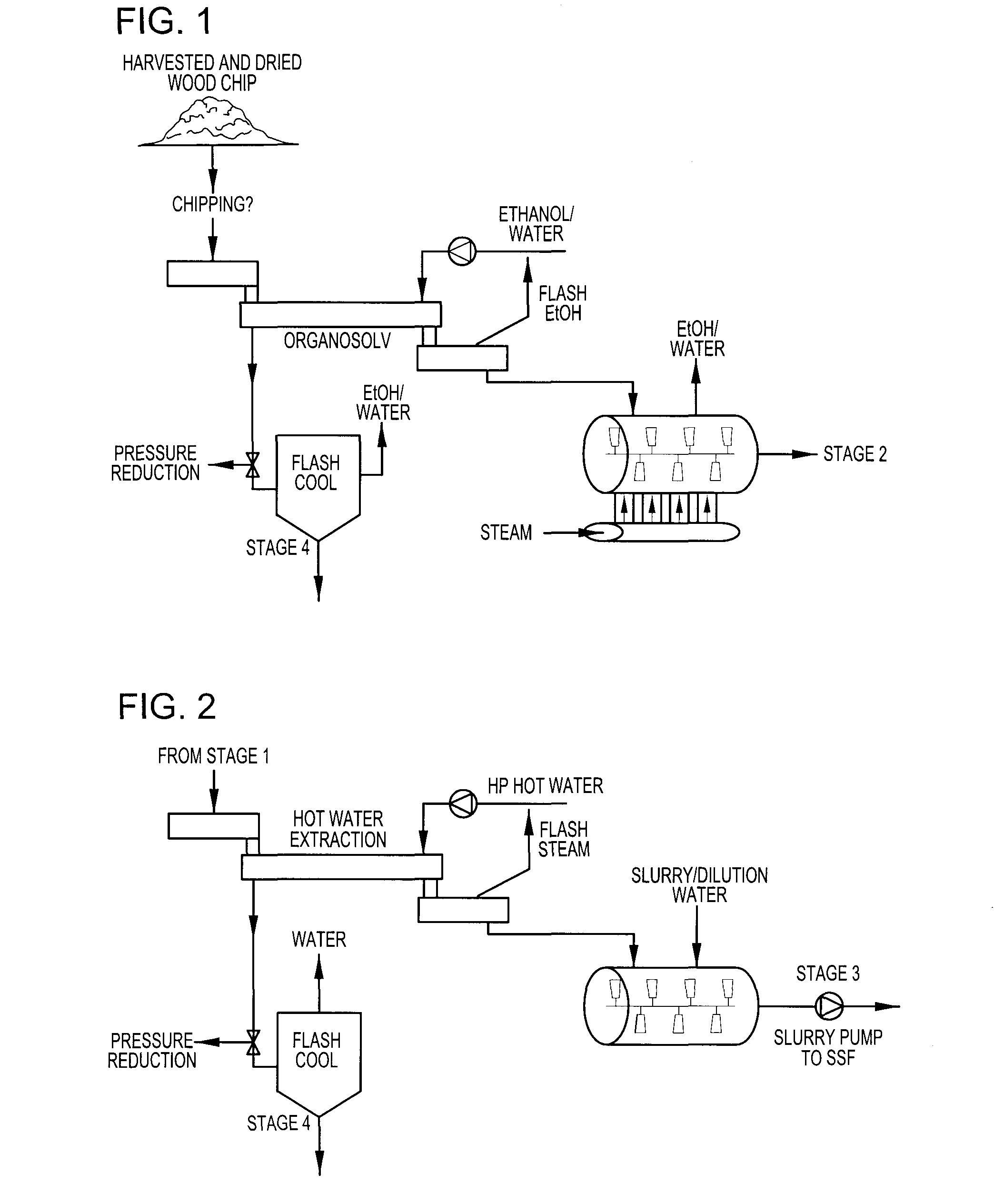

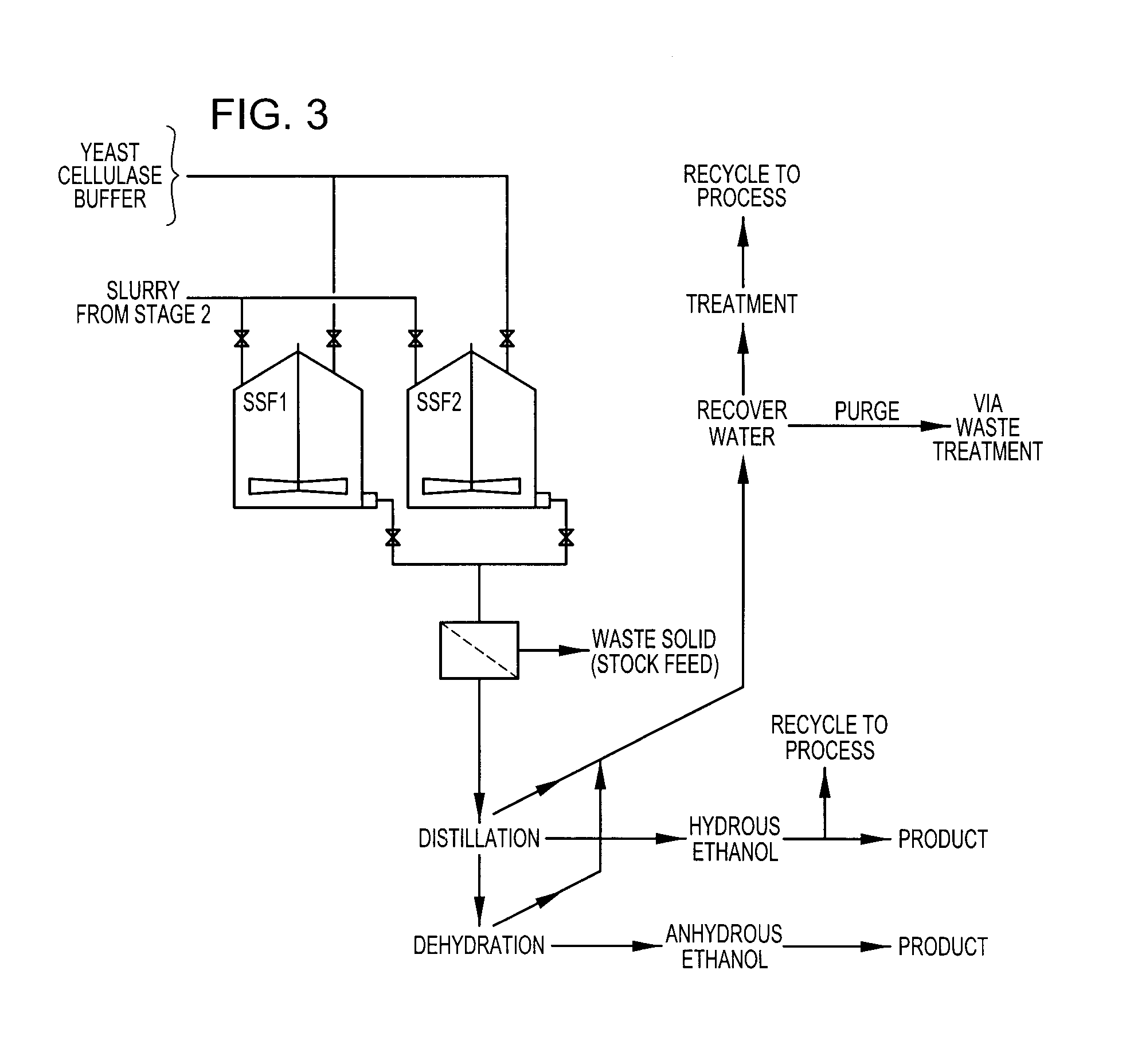

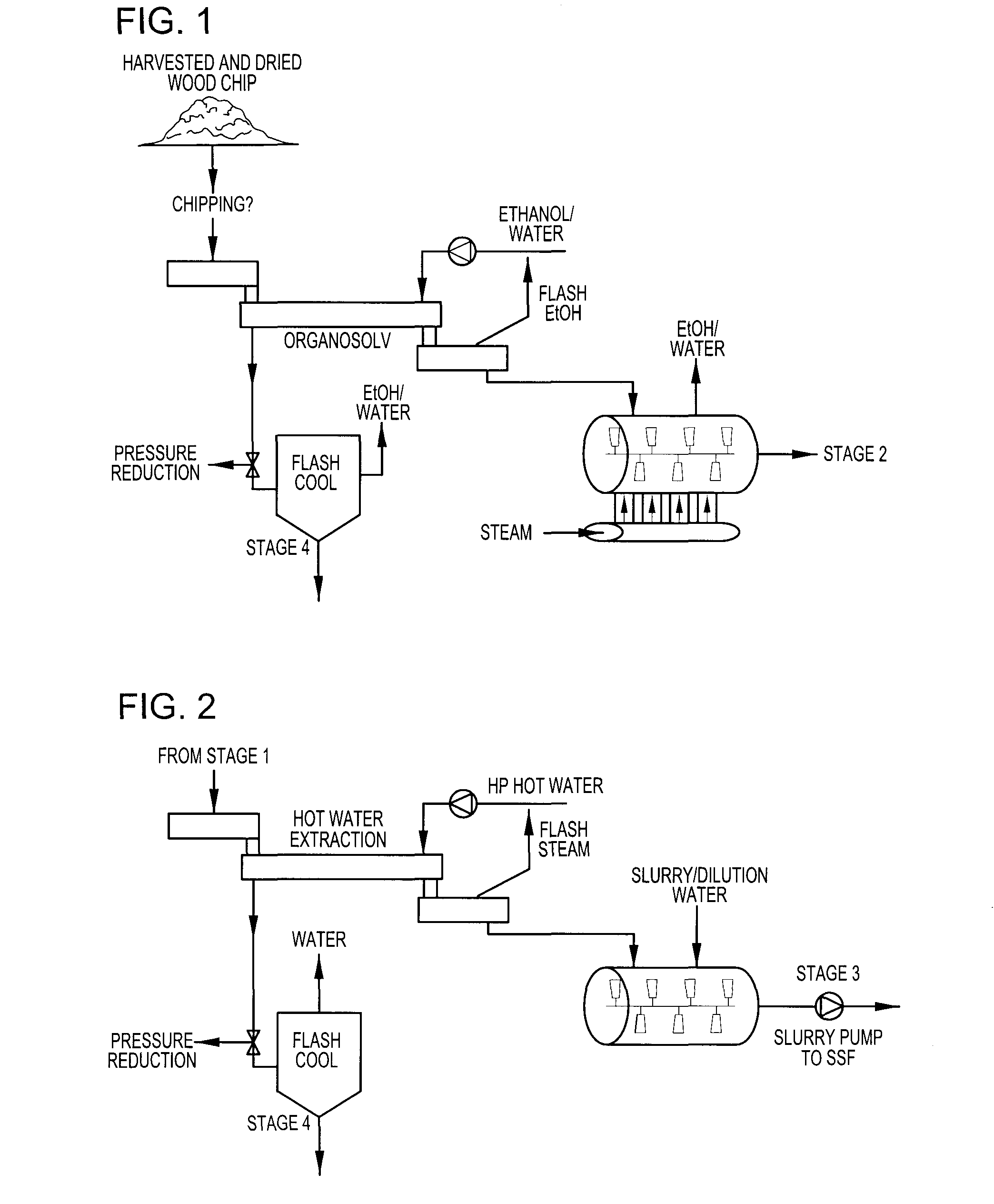

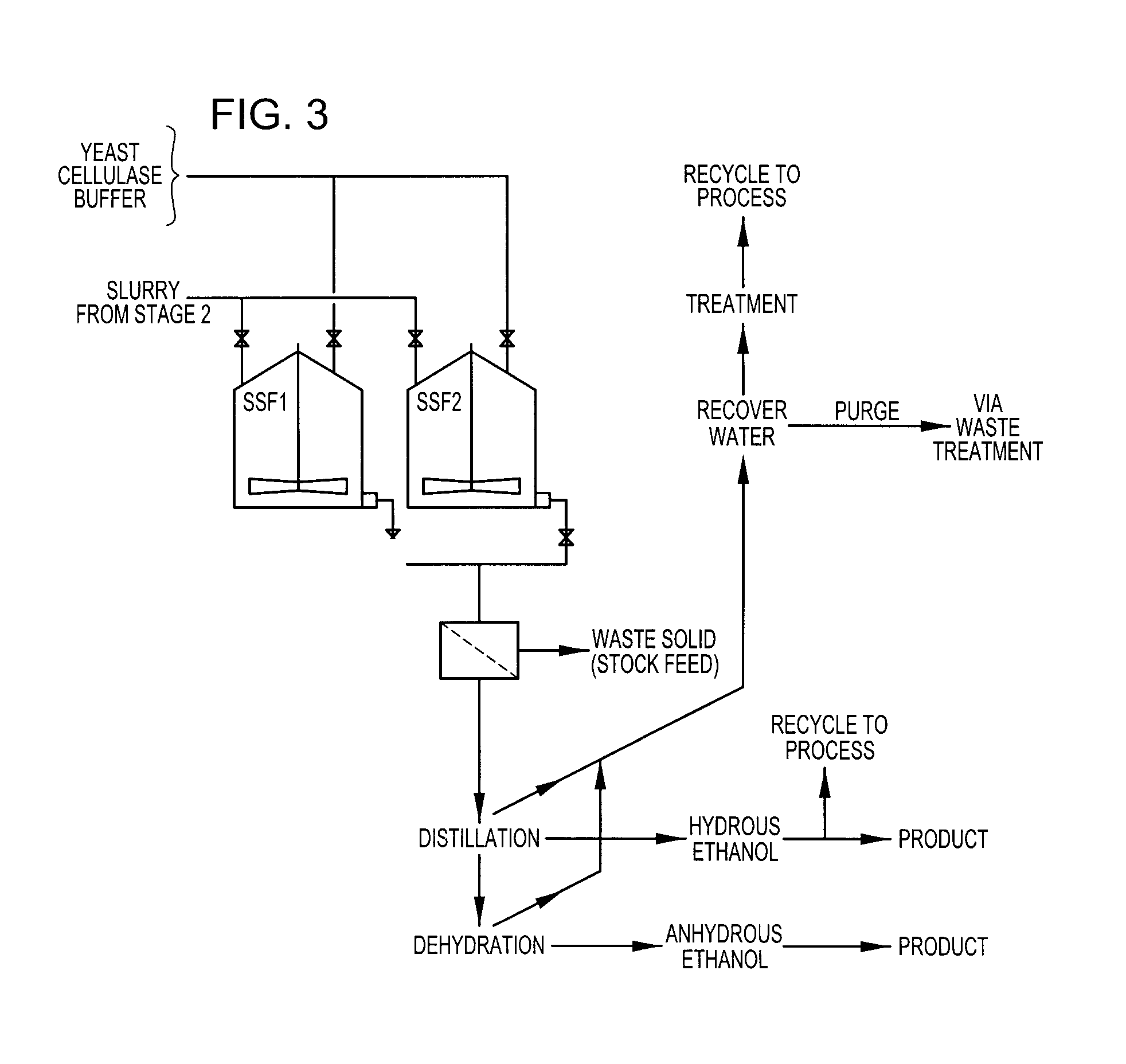

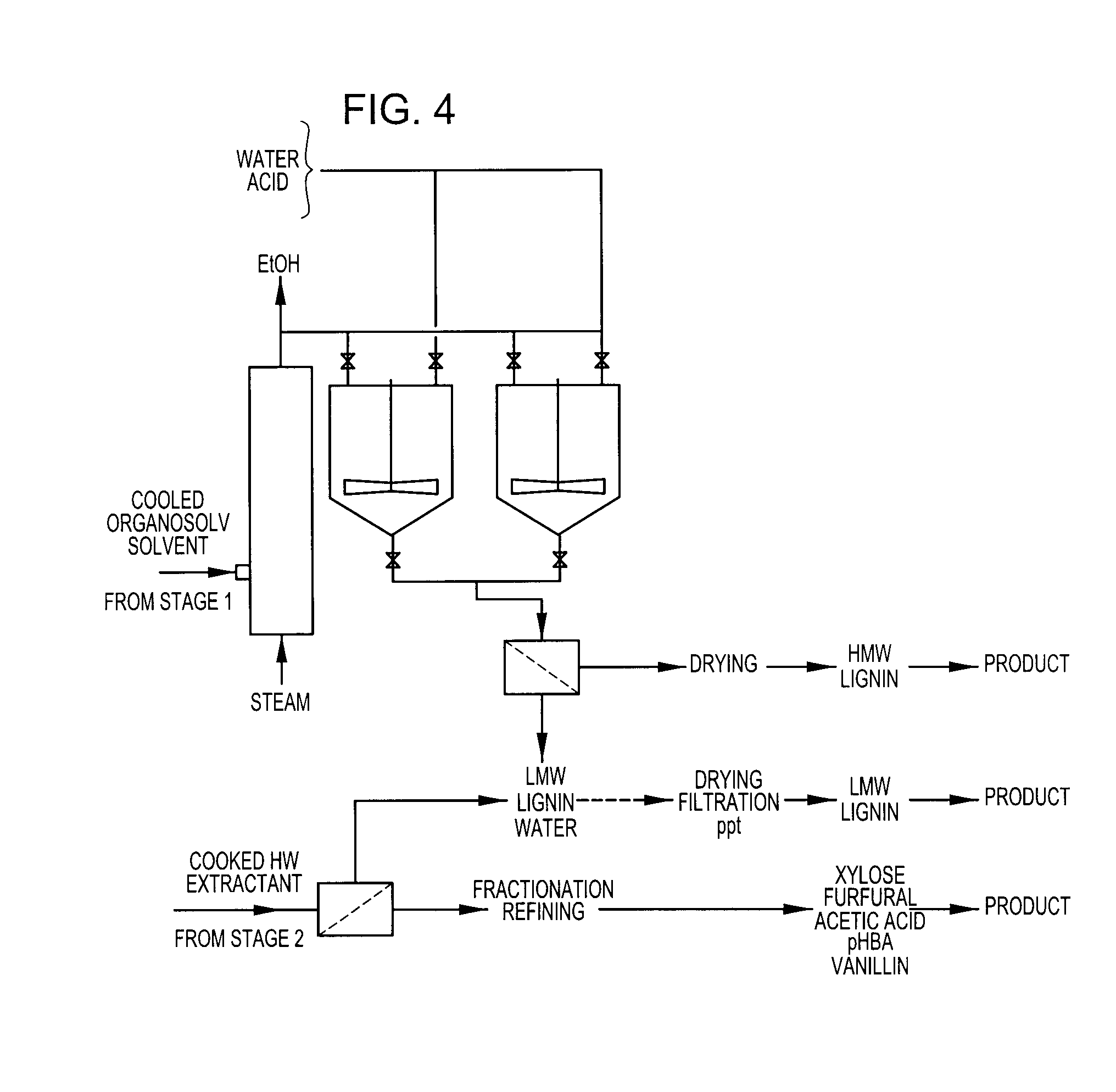

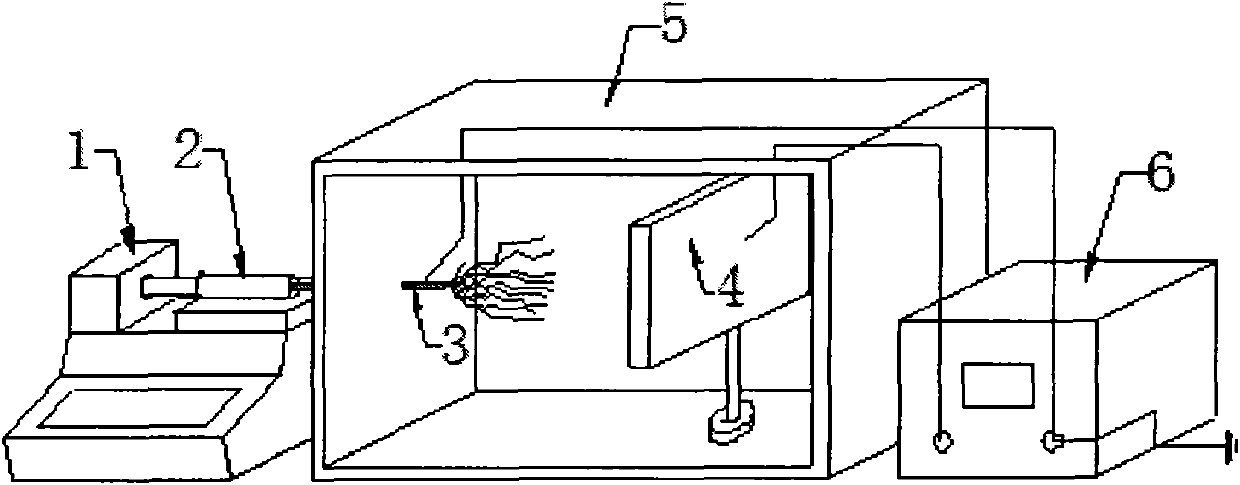

Process for the production of biofuel from plant materials

InactiveUS20070259412A1Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseBiofuel

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

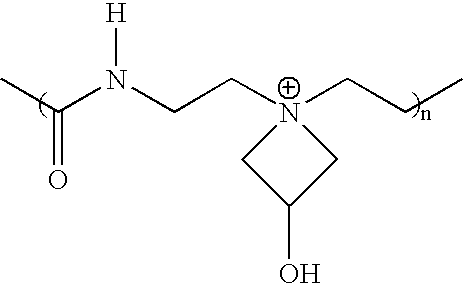

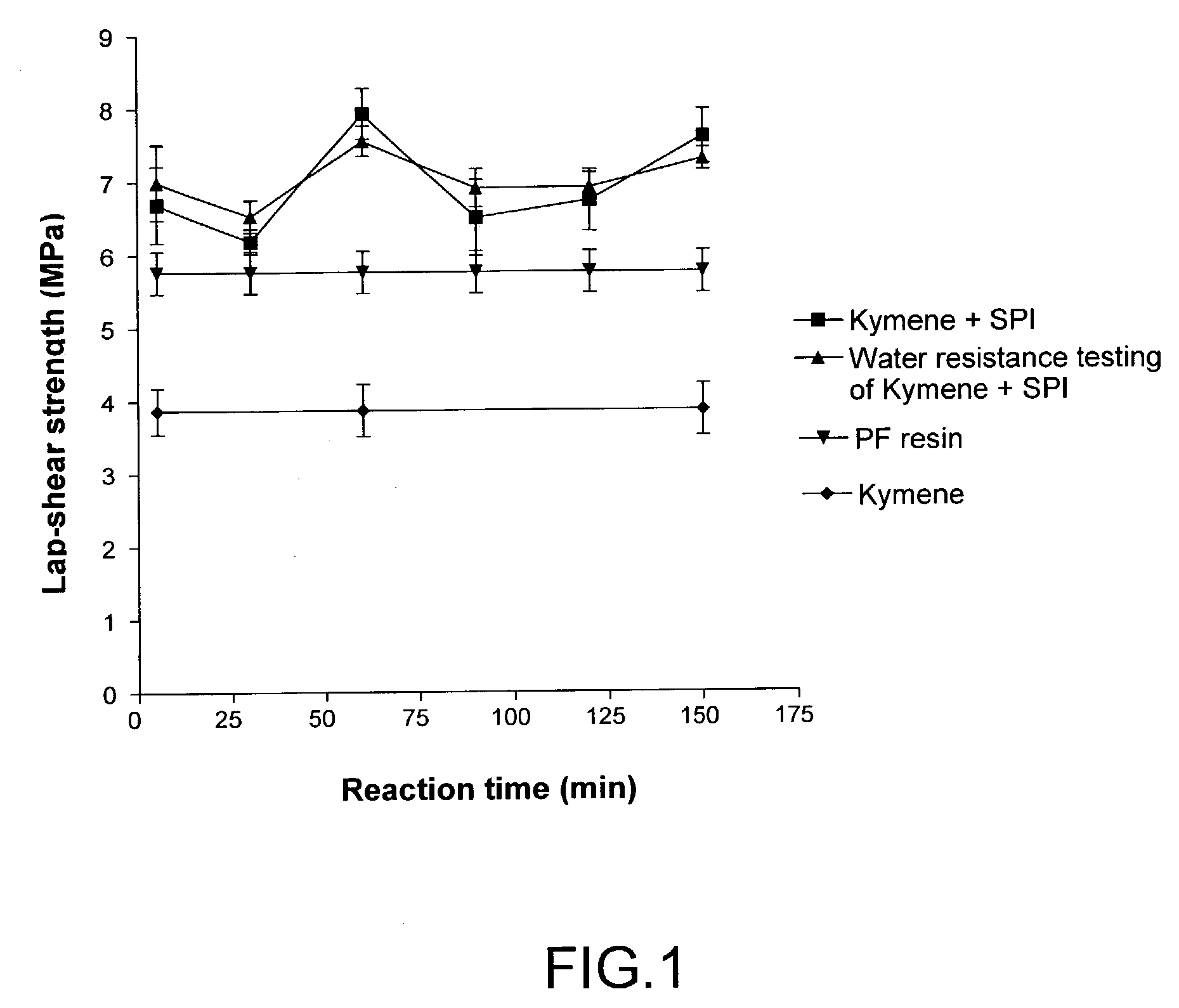

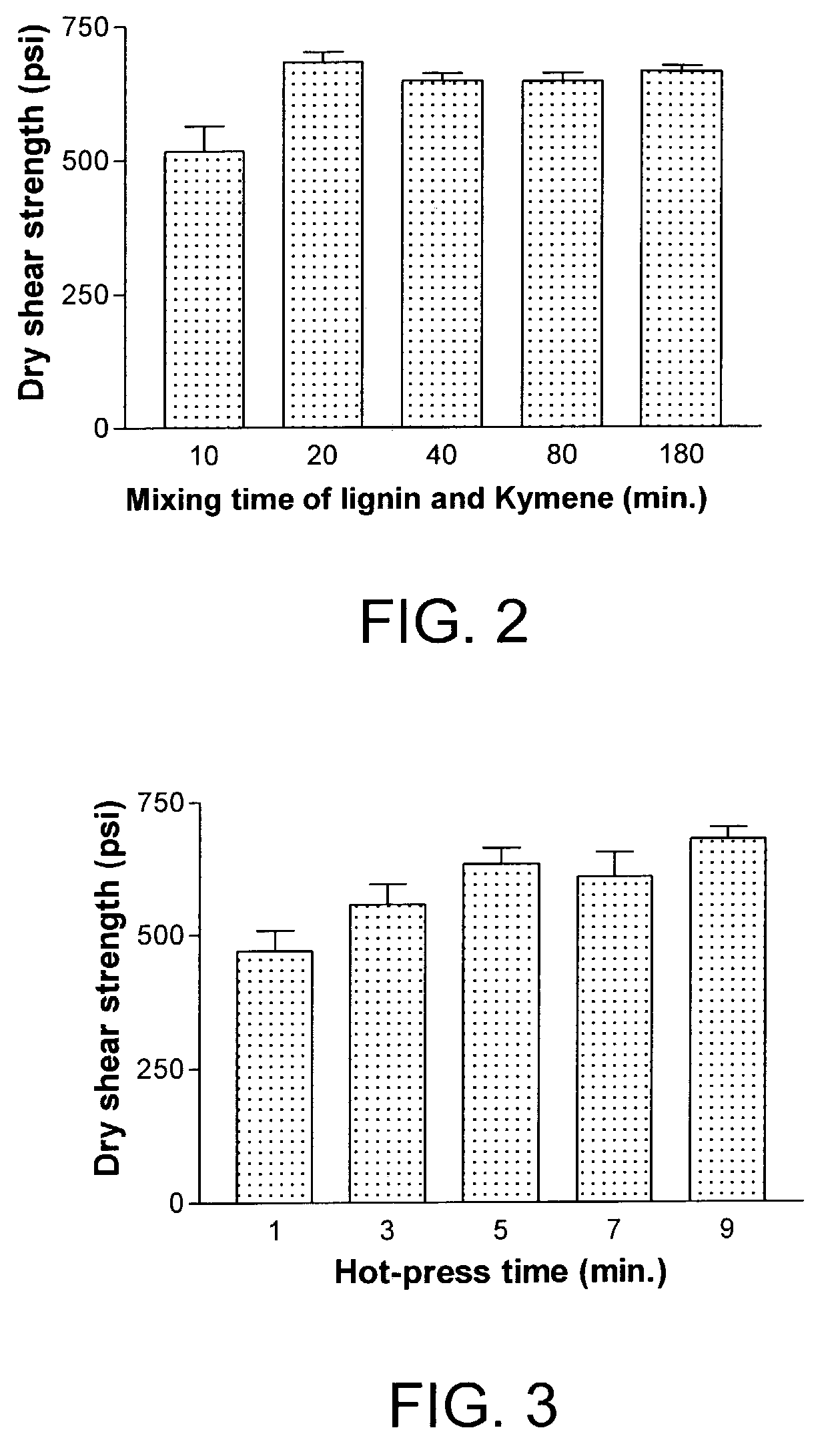

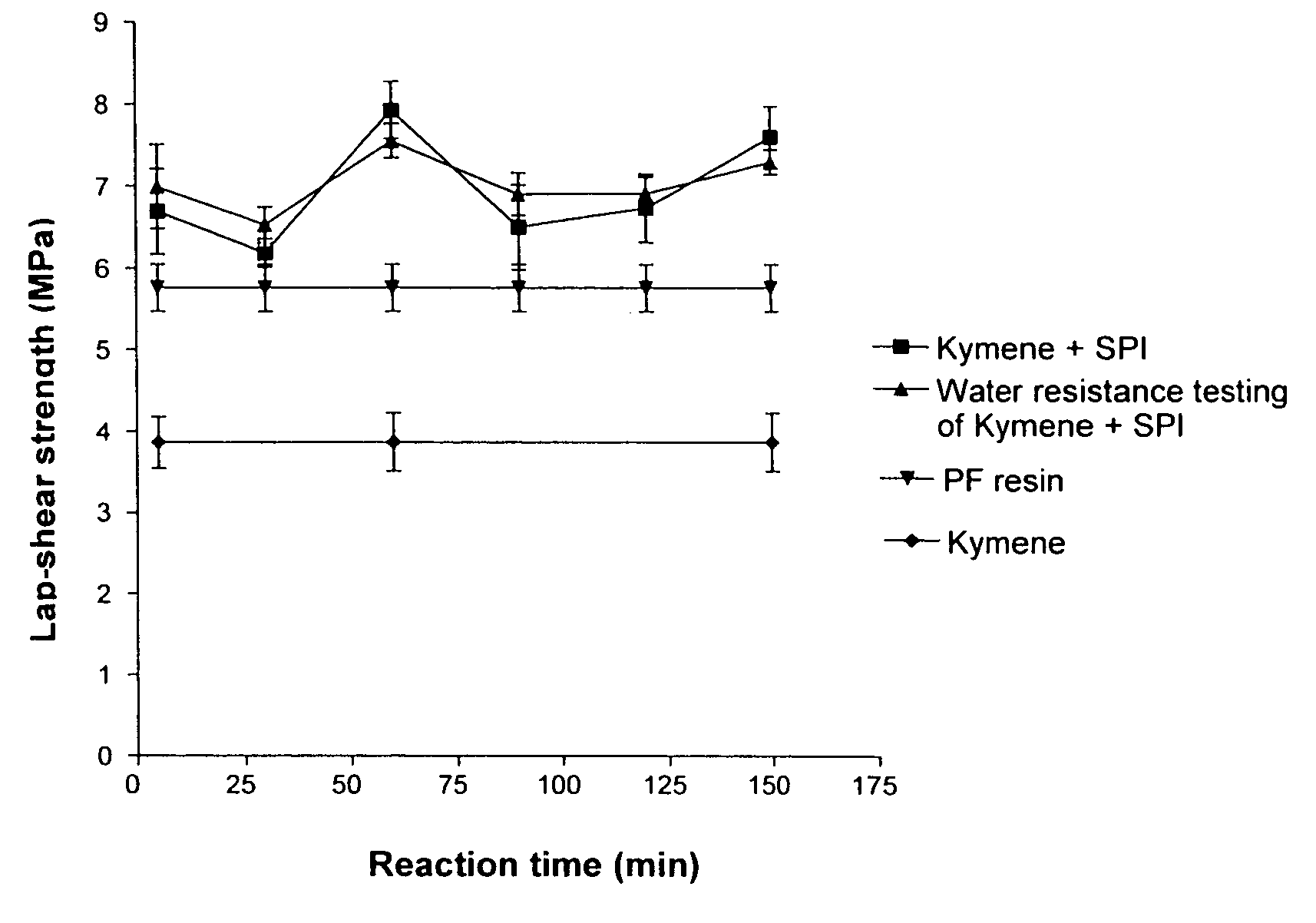

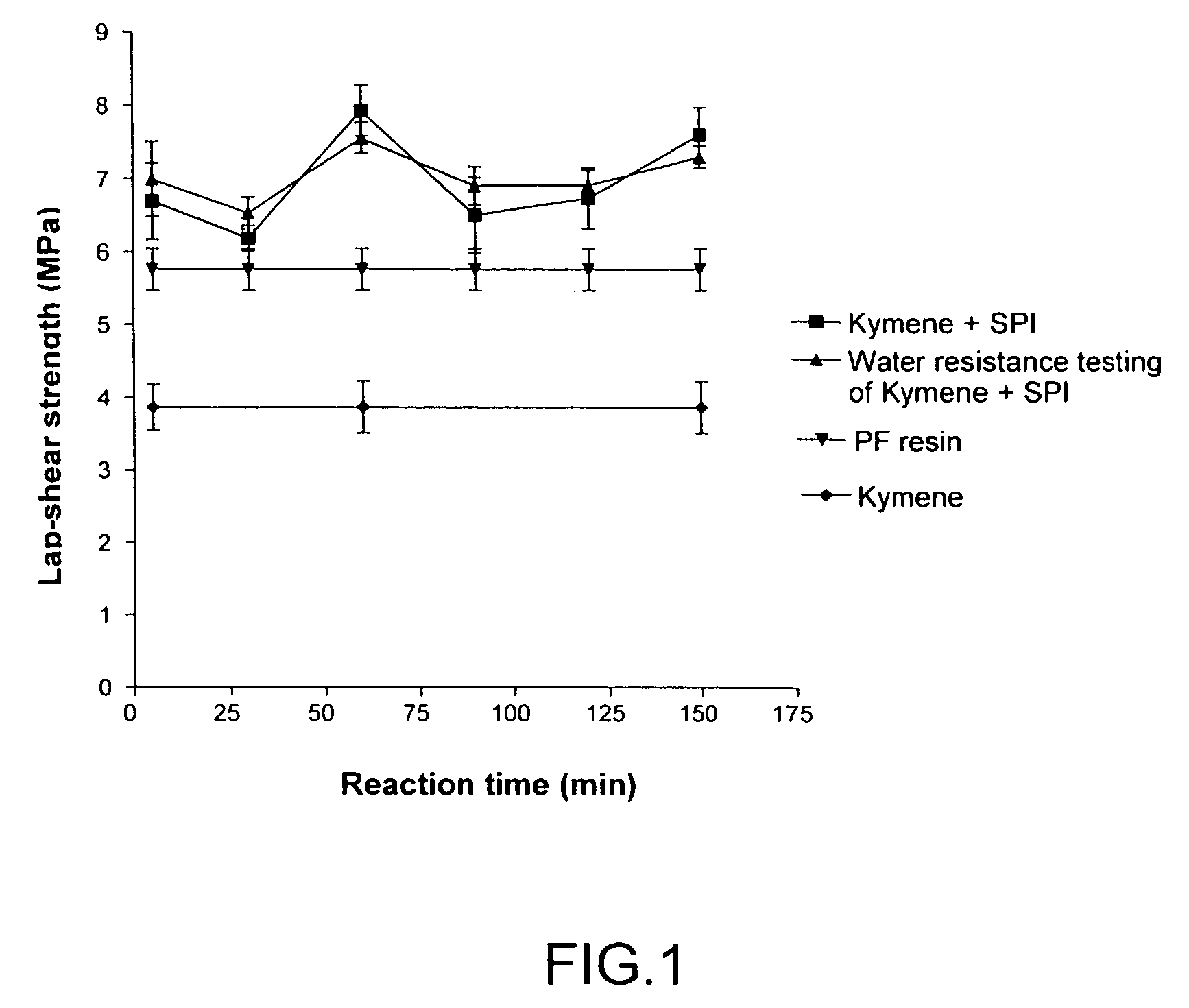

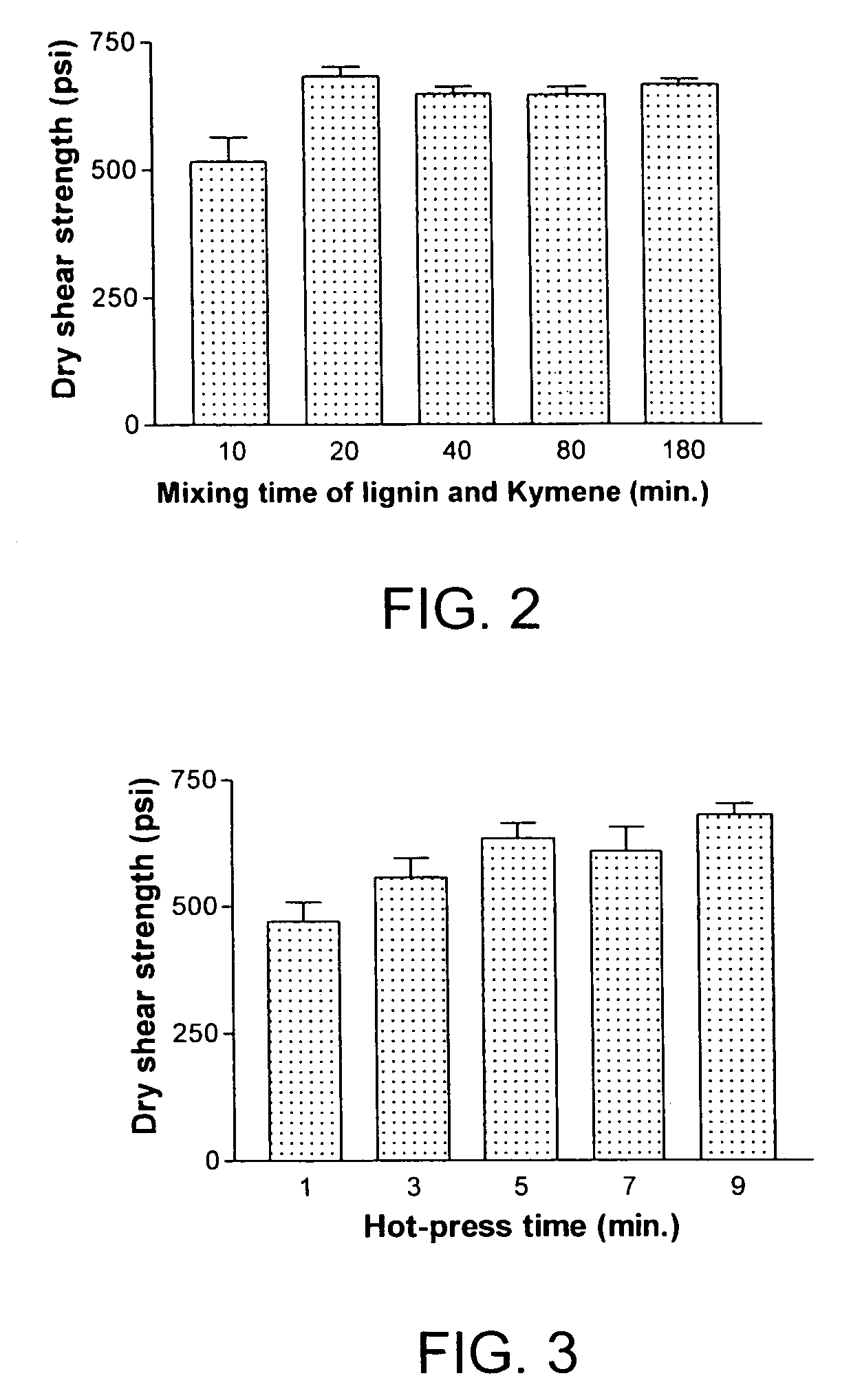

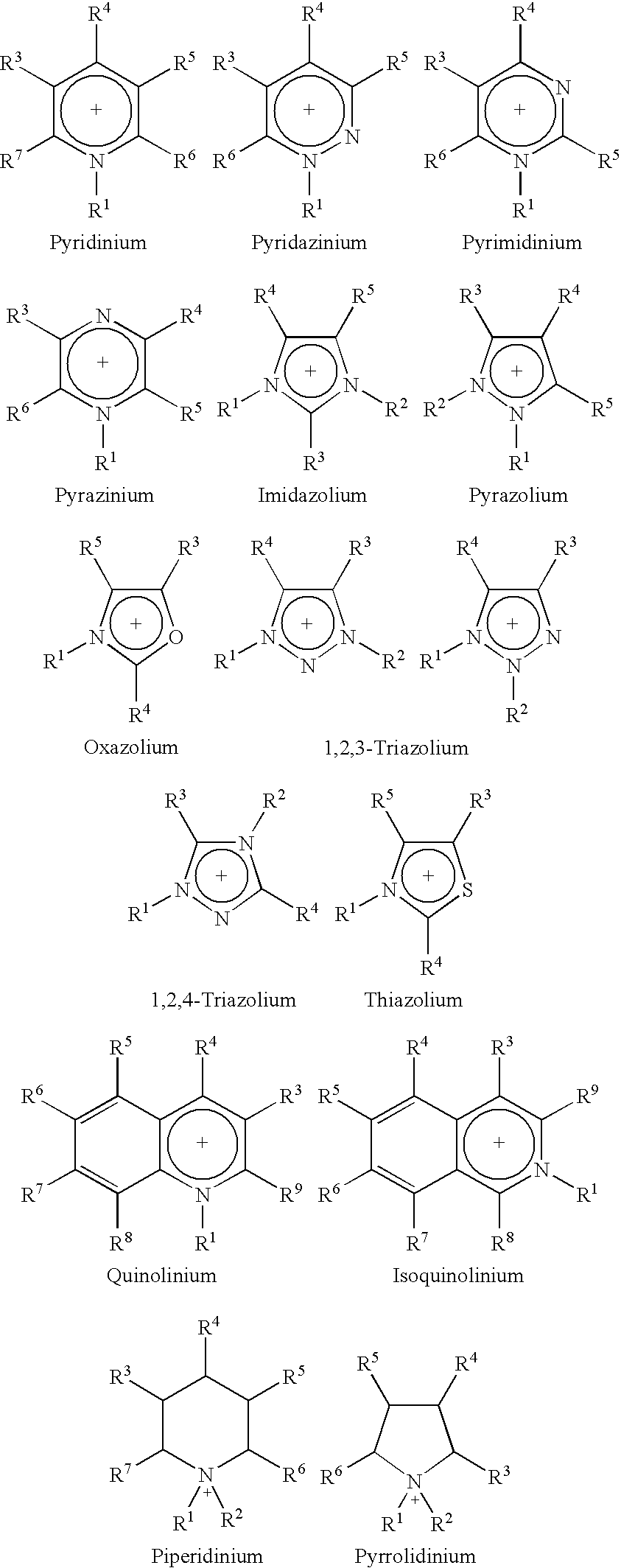

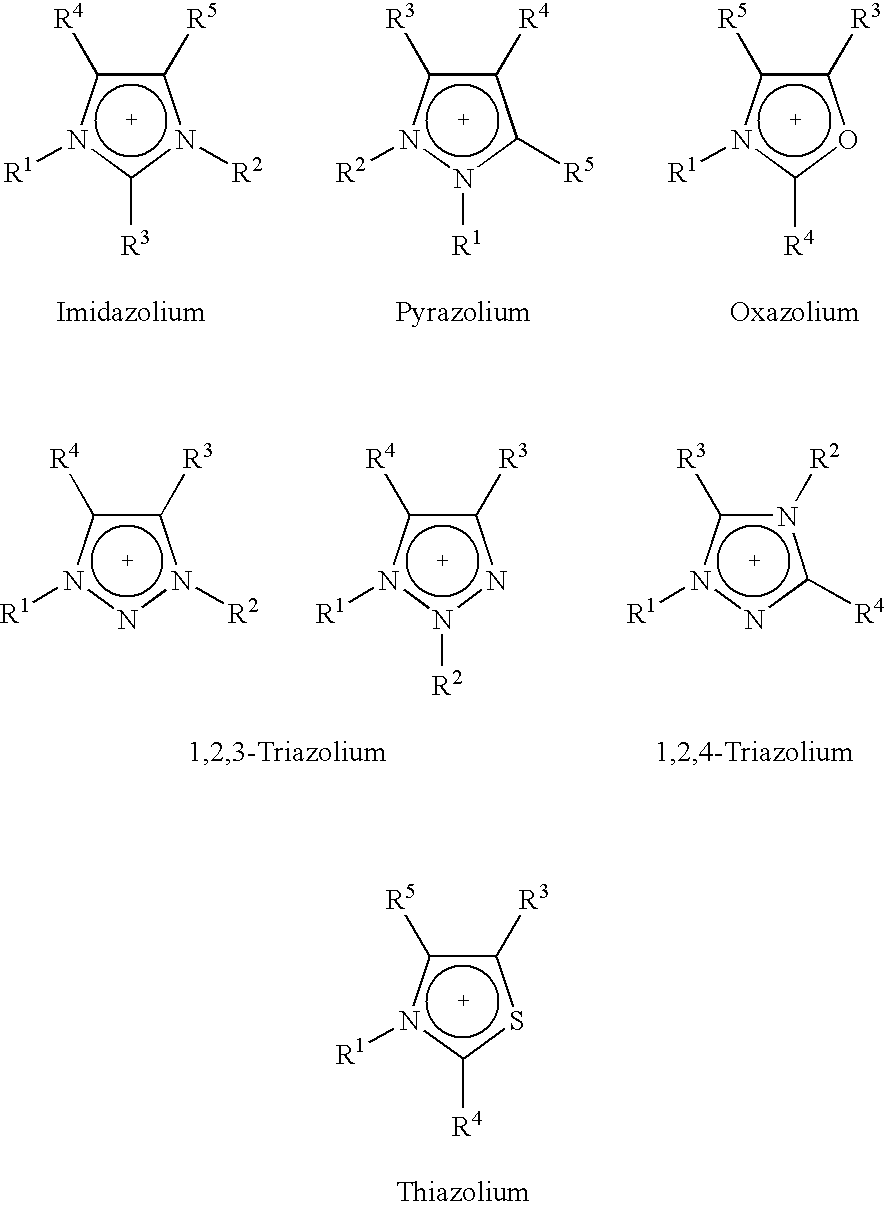

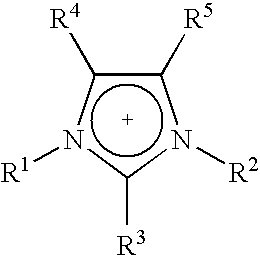

Formaldehyde-free lignocellulosic adhesives and composites made from the adhesives

Method for making lignocellulosic composites by adhering lignocellulosic substrates together. A first variant of the method involves using an adhesive composition that comprises a reaction product of (i) first ingredient selected from a soy protein or lignin and (ii) at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein. A second variant of the method involves using an adhesive composition that comprises a reaction product of (i) a protein or lignin, (ii) a first compound that includes at least one amine, amide, imine, imide or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the protein and (iii) a curing agent.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

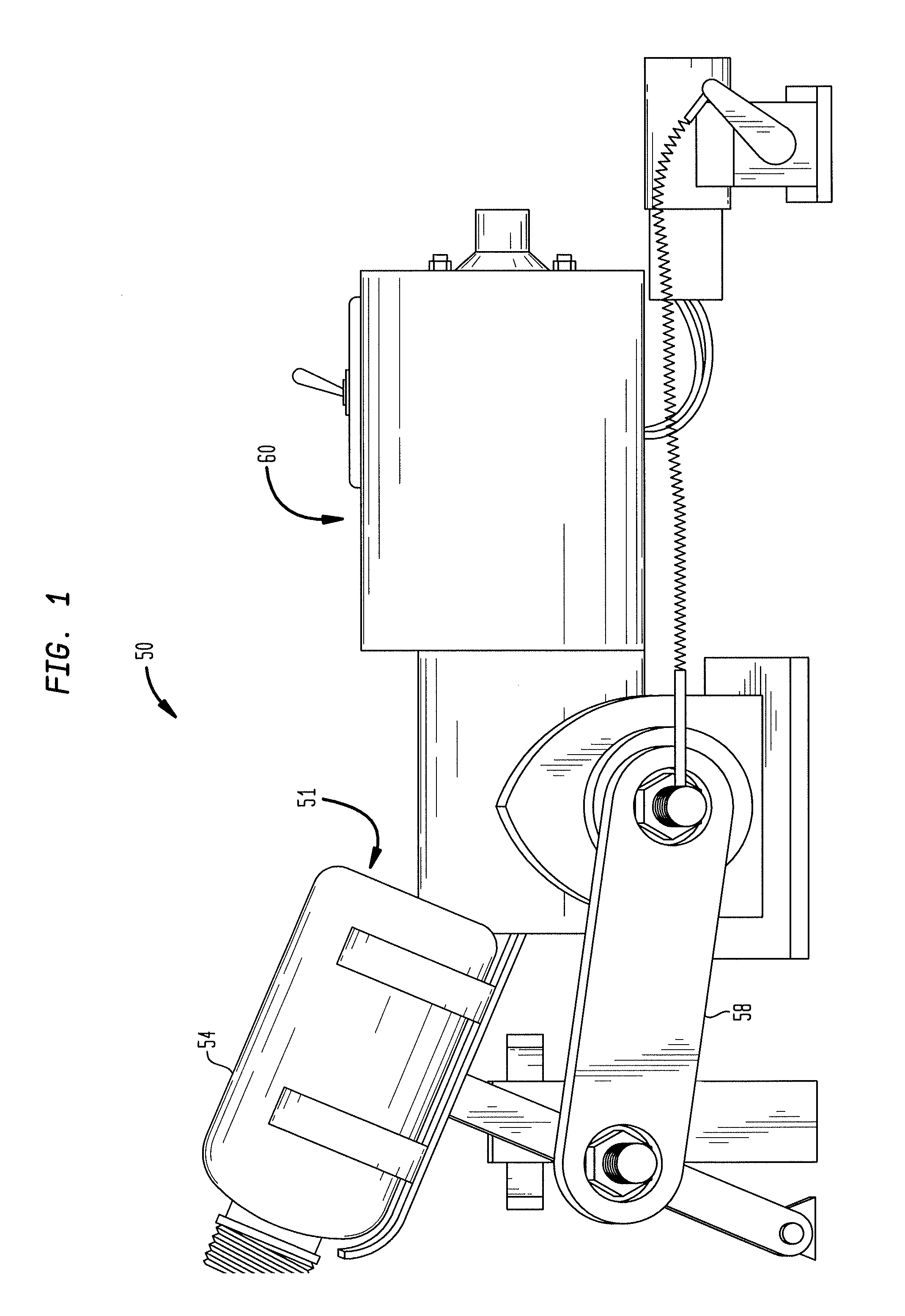

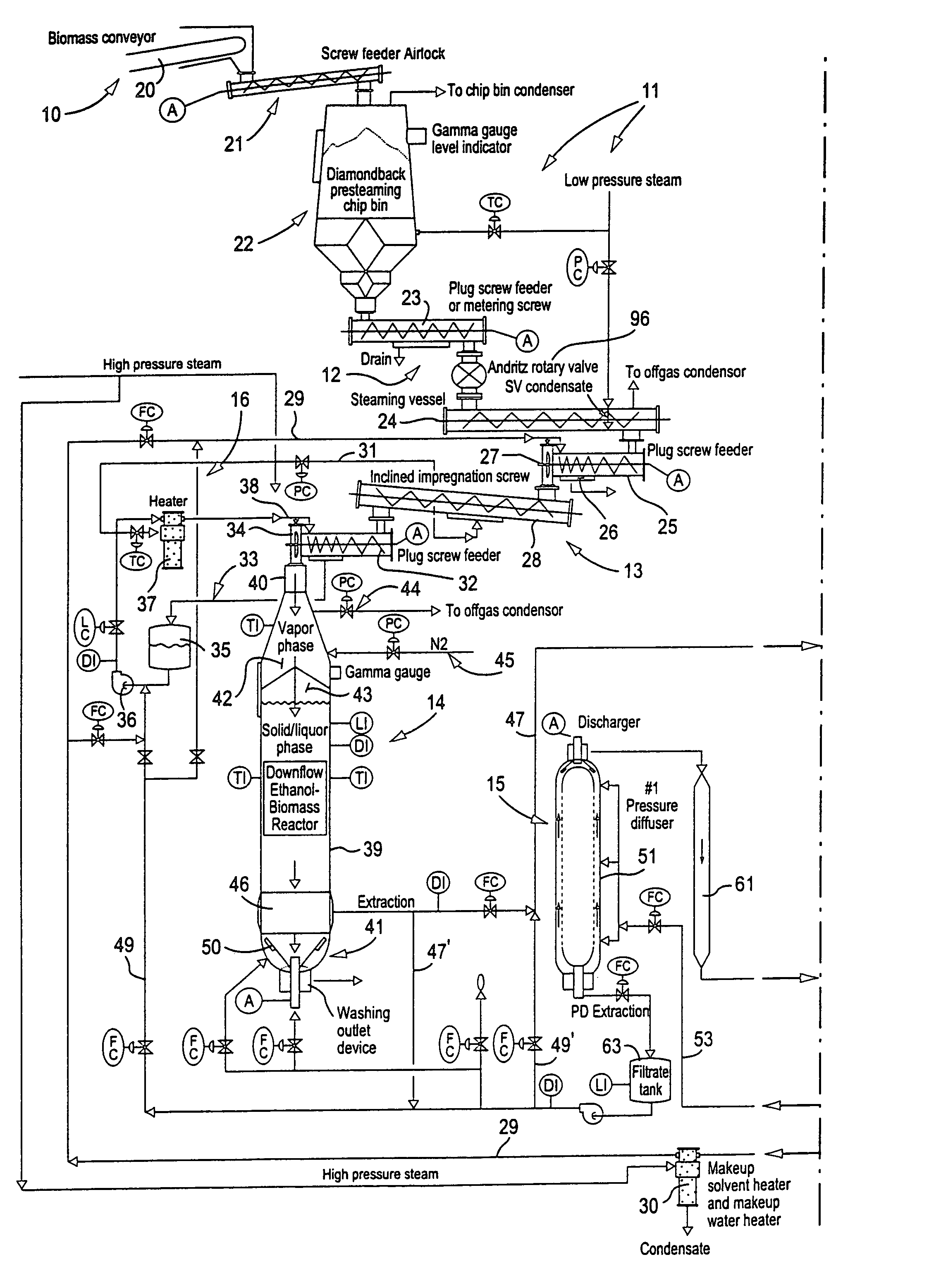

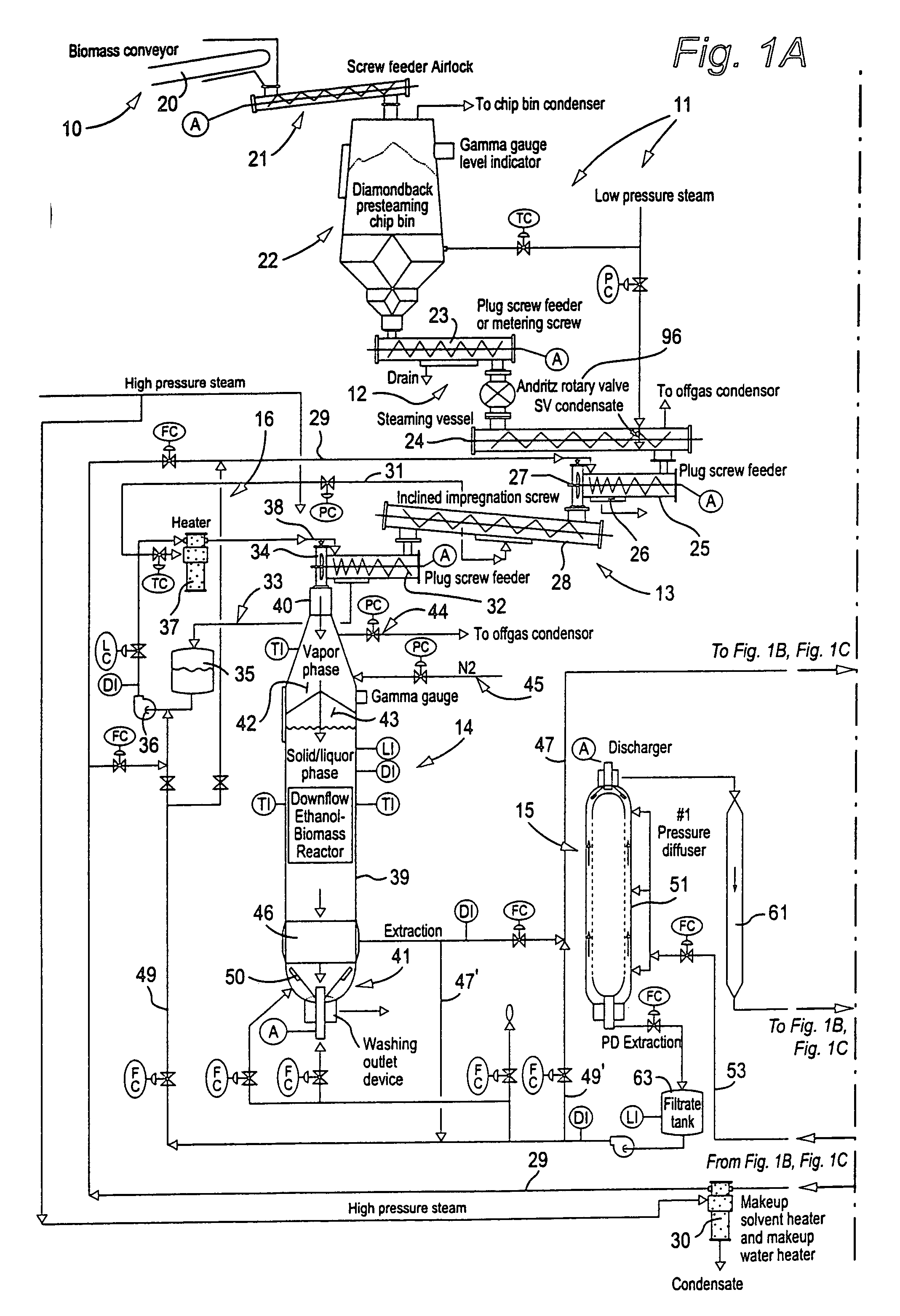

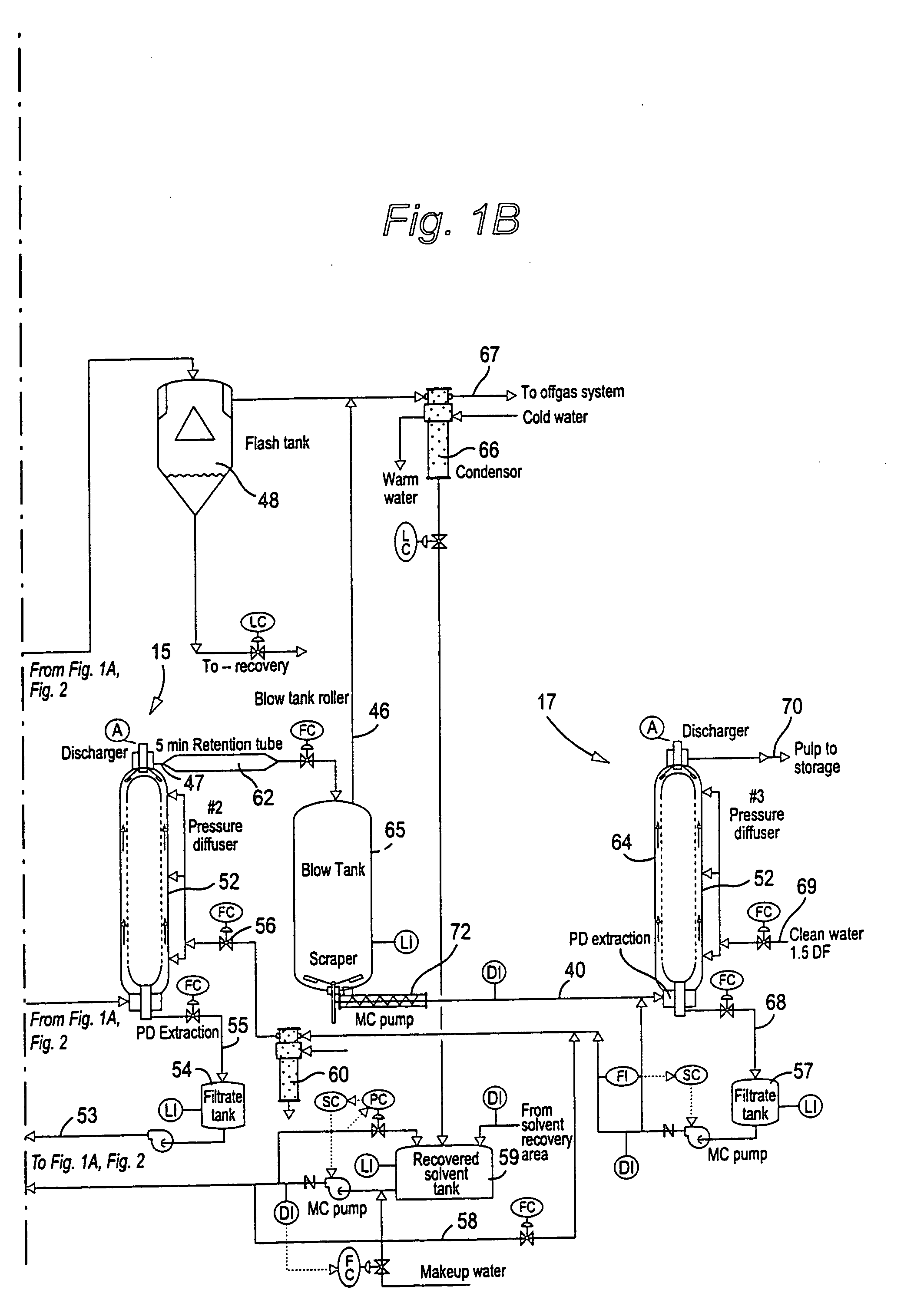

Solvent pulping of biomass

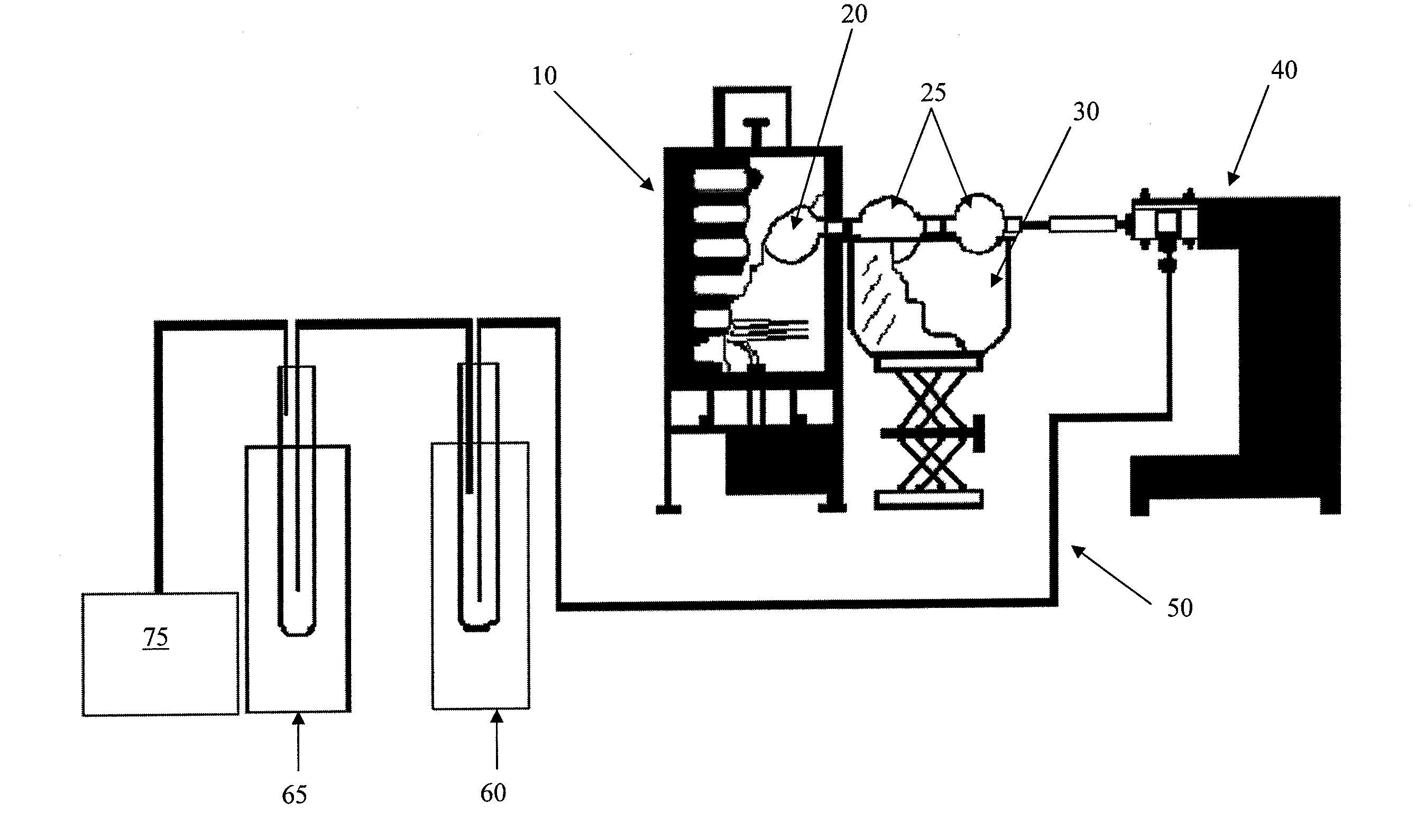

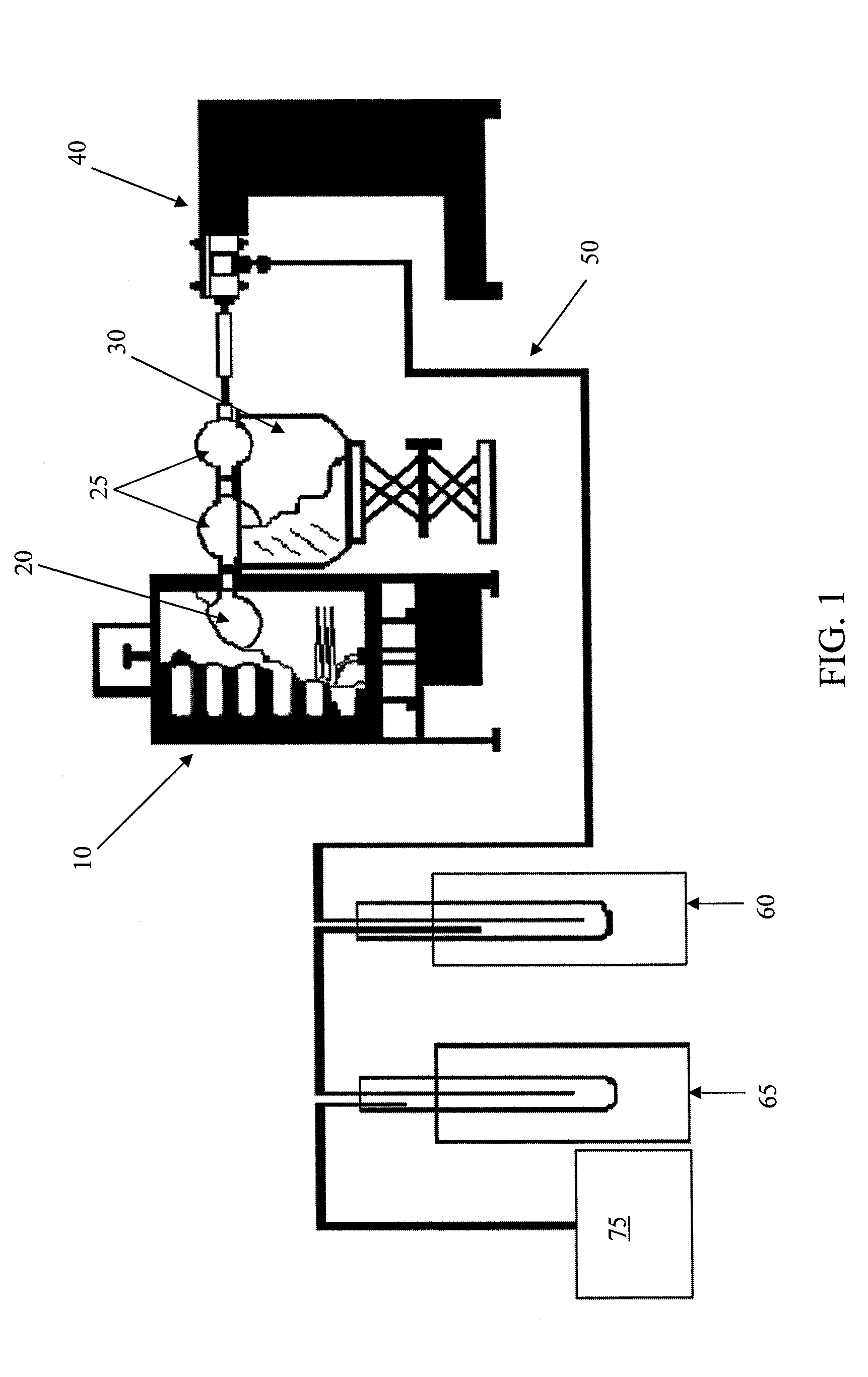

InactiveUS20040060673A1Pretreatment with water/steamWashing/displacing pulp-treating liquorsCellulose fiberChemistry

An apparatus and process for solvent pulping of cellulose-containing biomass utilizes at least one steaming vessel, a plug screw feeder or compression screw device, at least one super-atmospheric impregnation vessel, a solvent delignification reactor capable of operating at a pressure of 350 psig or more, and a solvent containing line for introducing solvent-containing liquor at the plug screw feeder outlet or compression screw device outlet. The process and system can also include at least one series connected pressure diffuser and optionally a retention tube downstream of each pressure diffuser to provide sufficient retention time to substantially preclude re-deposition of lignin on the cellulose fibers of the biomass, a blow tank connected to the last of the pressure diffusers and retention tubes, and vessels for multistage alcohol washing. The method steams the biomass and impregnates it with solvent to produce an aqueous slurry of biomass and solvent, delignifies the particulate biomass in the slurry, removes solvent while continuing delignification of the biomass in the slurry and while substantially precluding re-deposition of lignin on the cellulose of the biomass, reduces the pressure of the slurry; and then washes the slurry.

Owner:ANDRITZ INC

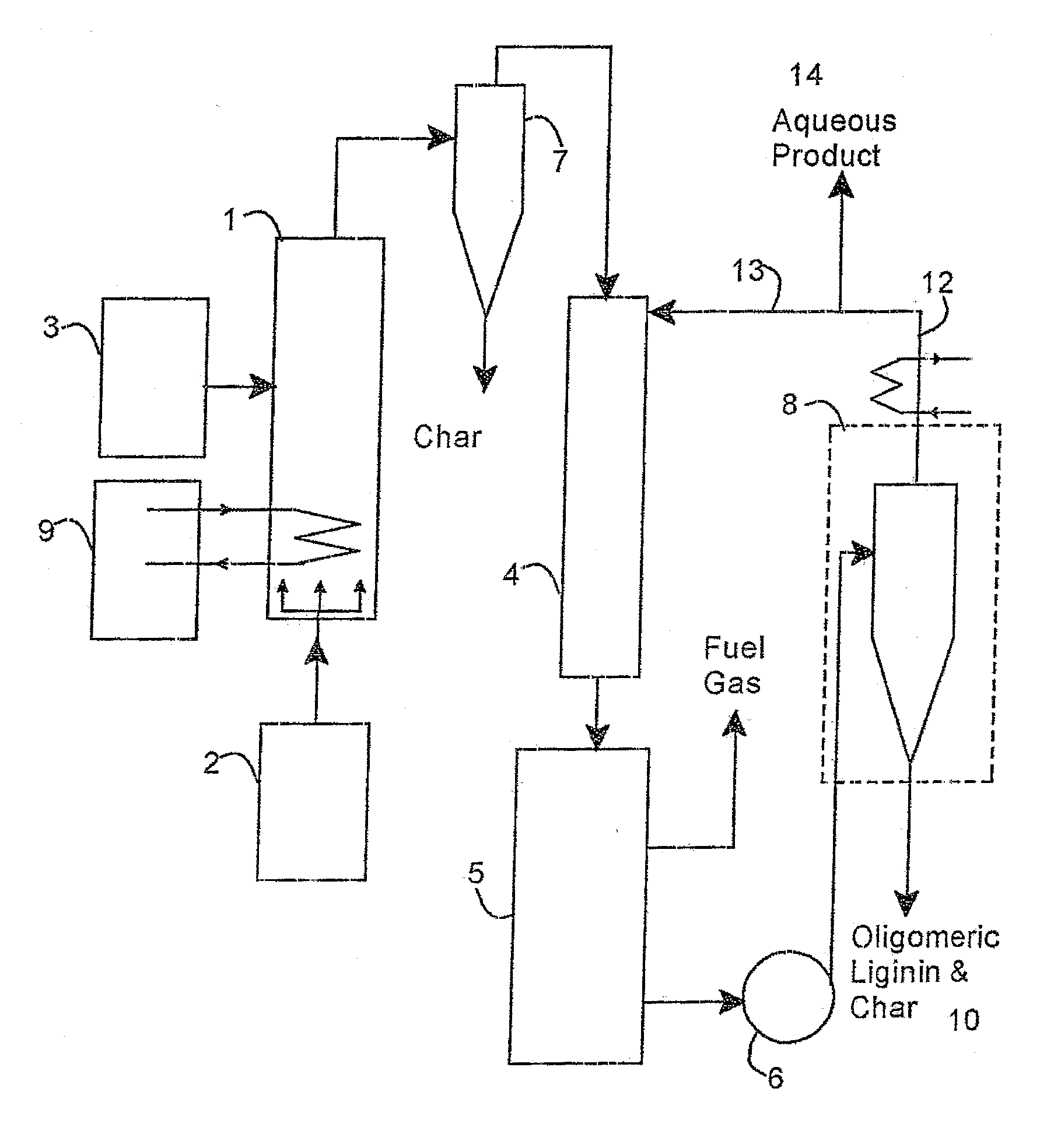

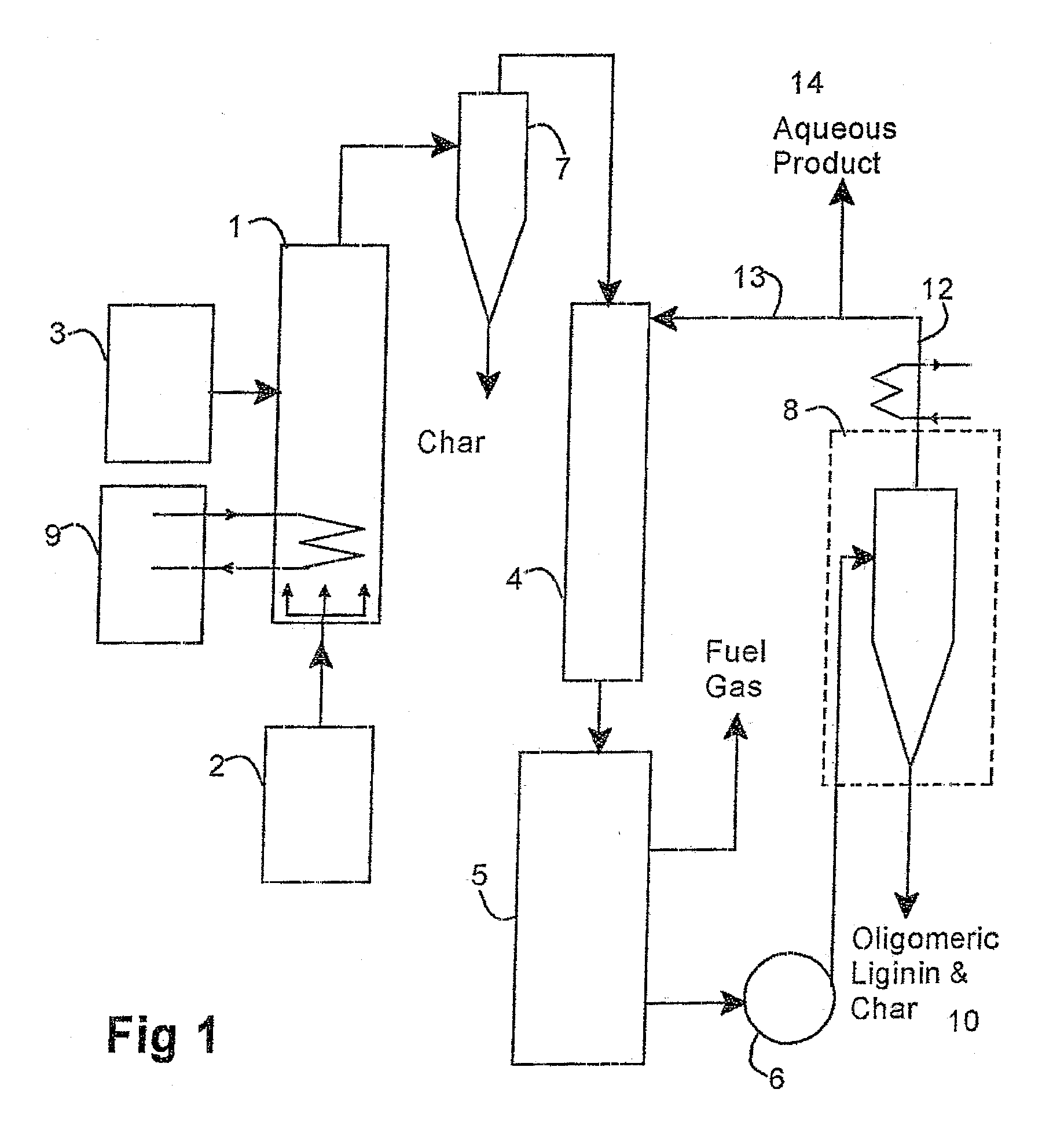

Method of producing hodge carbonyls and oligomeric lignin

ActiveUS20090126433A1Low lignin contentBiofuelsIndirect and direct heating destructive distillationSufficient timeProcess engineering

A method of treating biomass feed by pyrolyzing it in the presence of superheated steam at a selected temperature for a sufficient time to produce at least one product stream.

Owner:KERRY GRP SERVICES INT

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS20080053870A1High yieldTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

Owner:UOP LLC

Formaldehyde-free lignocellulosic adhesives and composites made from the adhesives

Method for making lignocellulosic composites by adhering lignocellulosic substrates together. A first variant of the method involves using an adhesive composition that comprises a reaction product of (i) first ingredient selected from a soy protein or lignin and (ii) at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein. A second variant of the method involves using an adhesive composition that comprises a reaction product of (i) a protein or lignin, (ii) a first compound that includes at least one amine, amide, imine, imide or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the protein and (iii) a curing agent.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

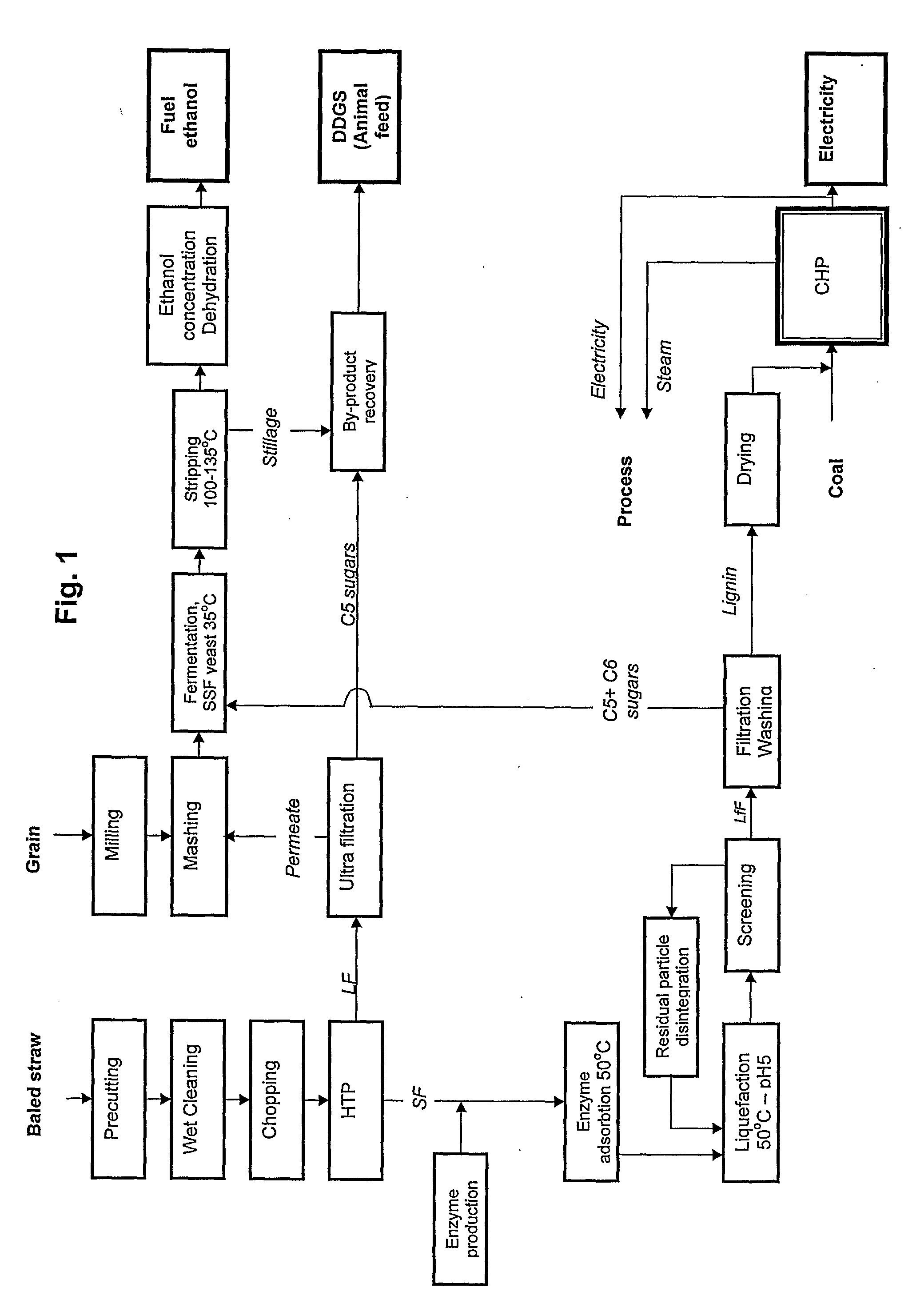

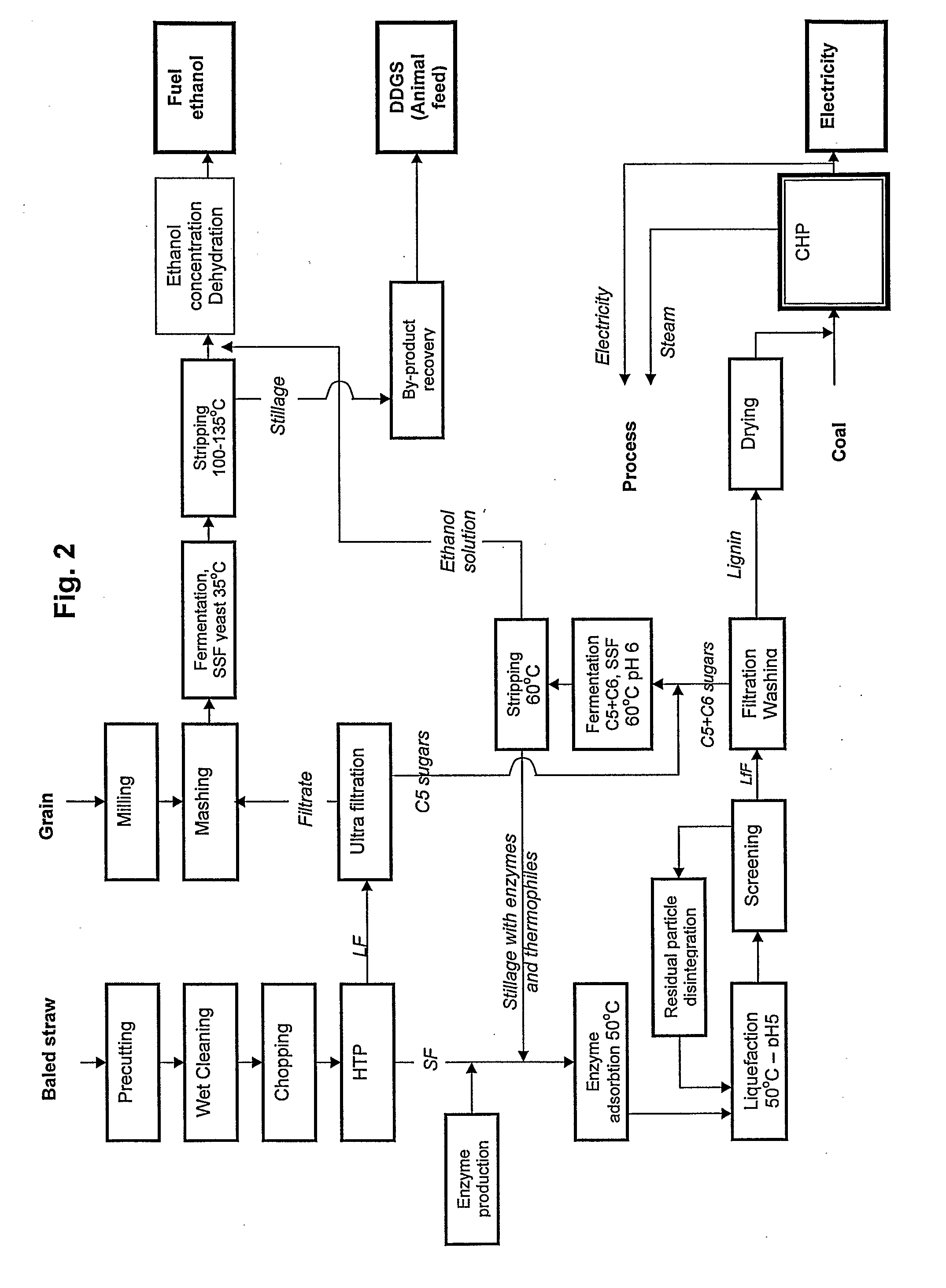

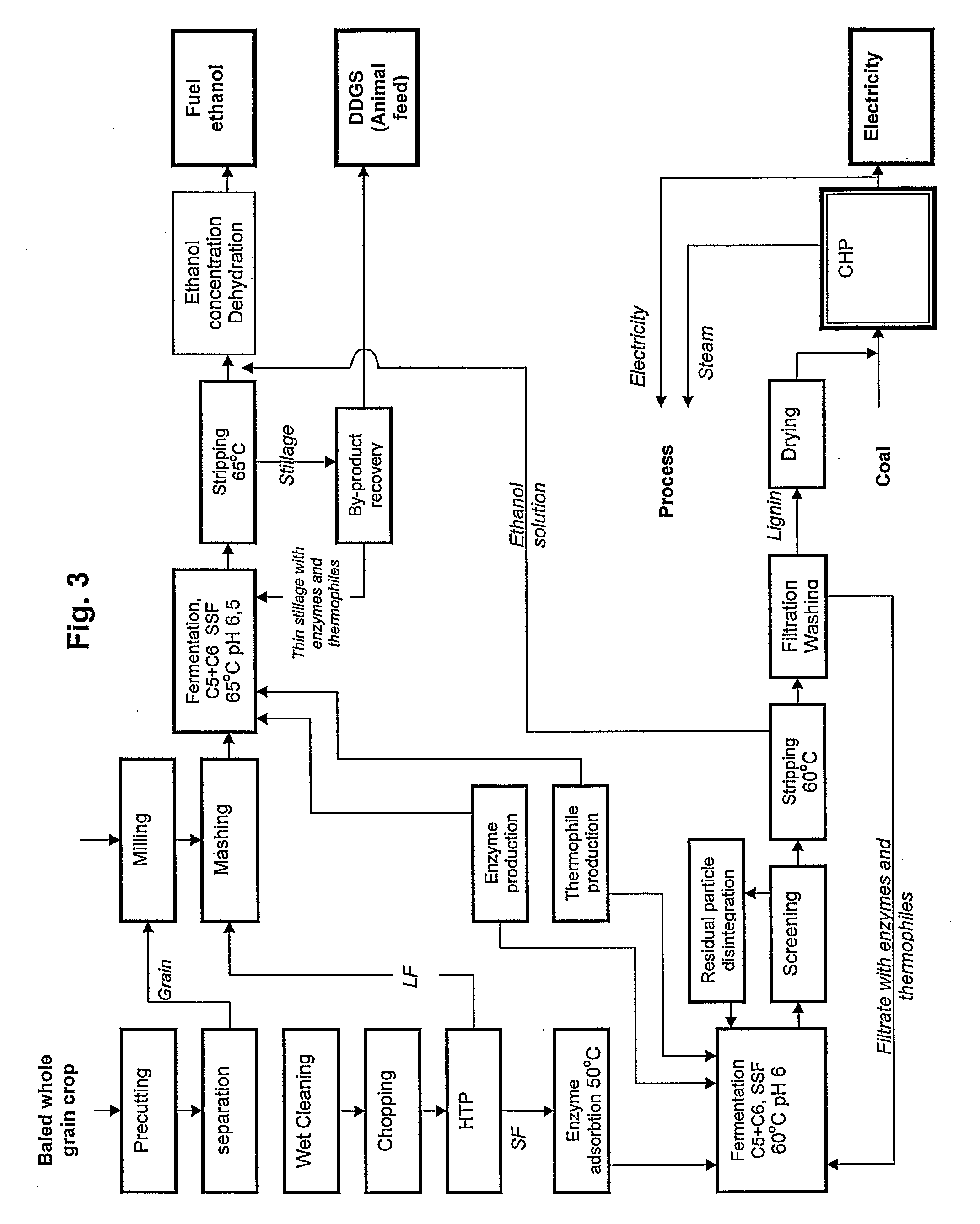

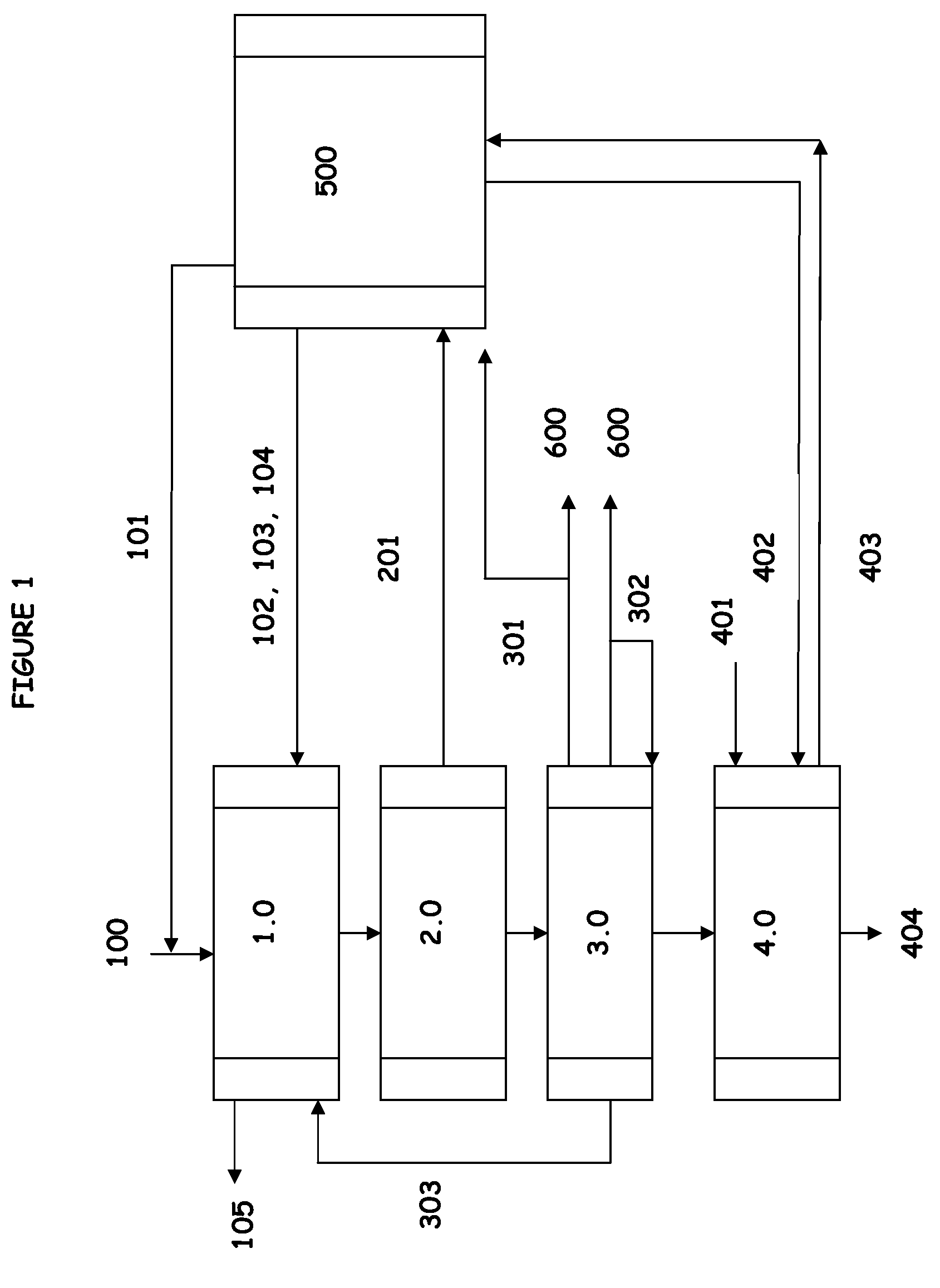

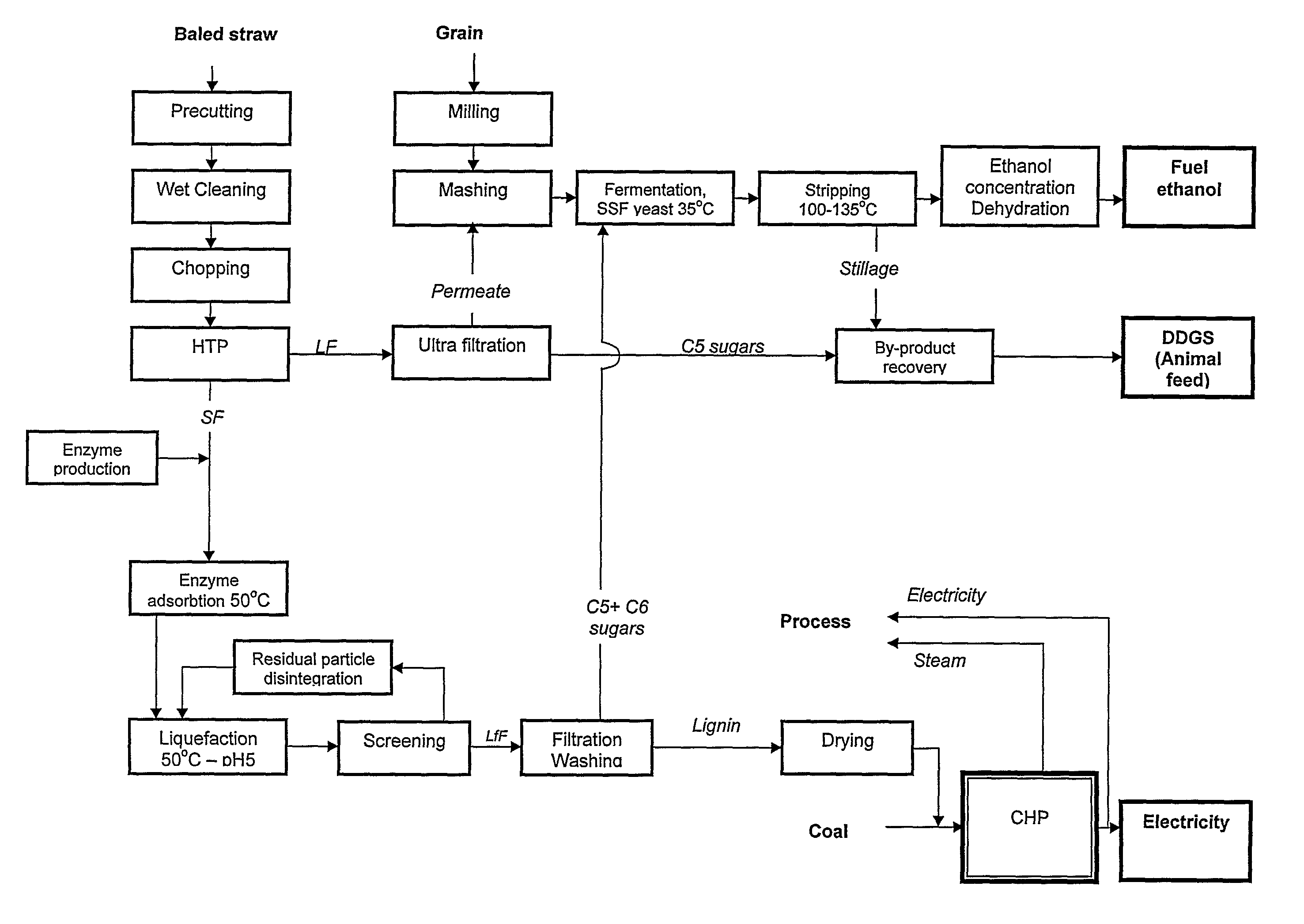

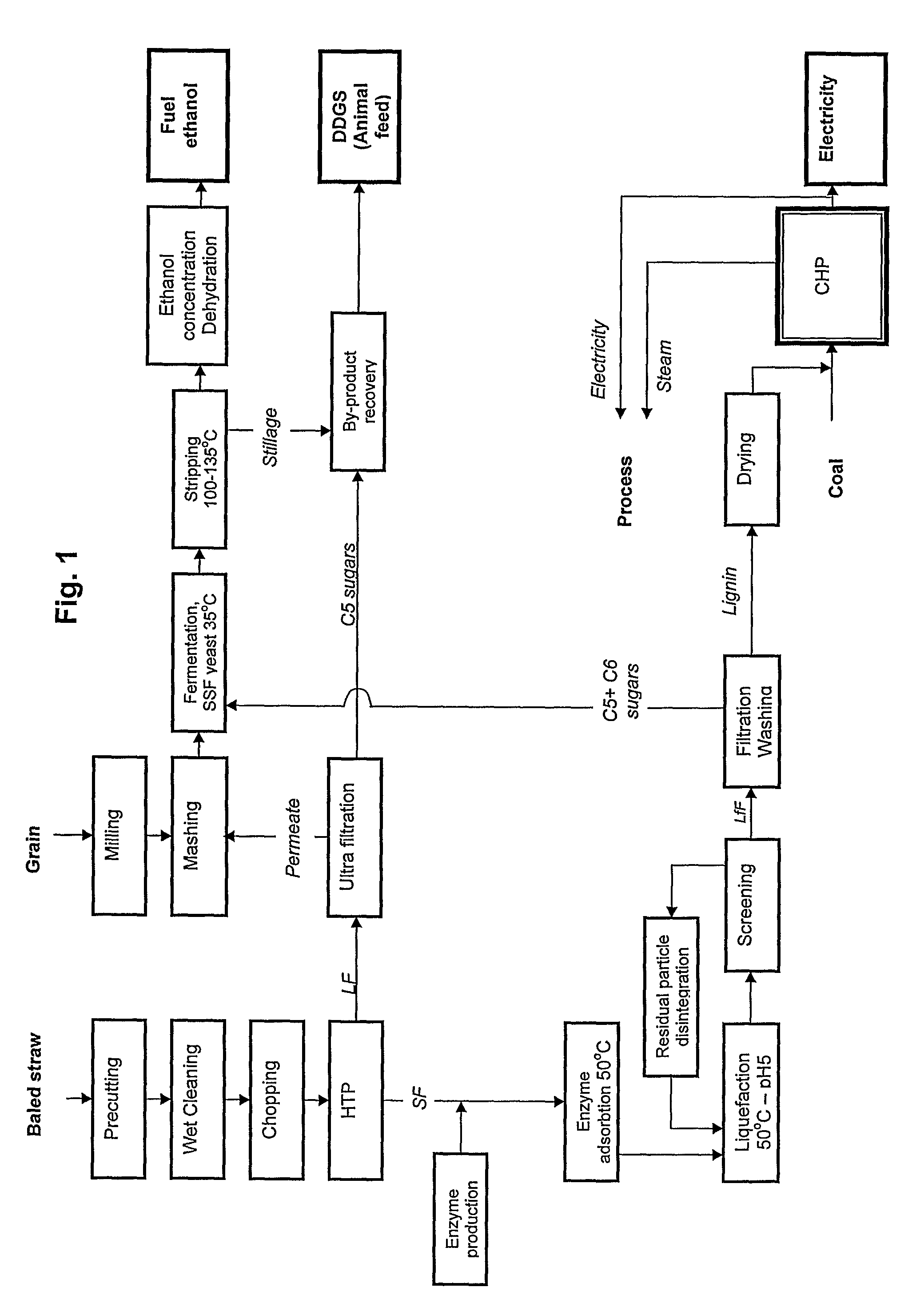

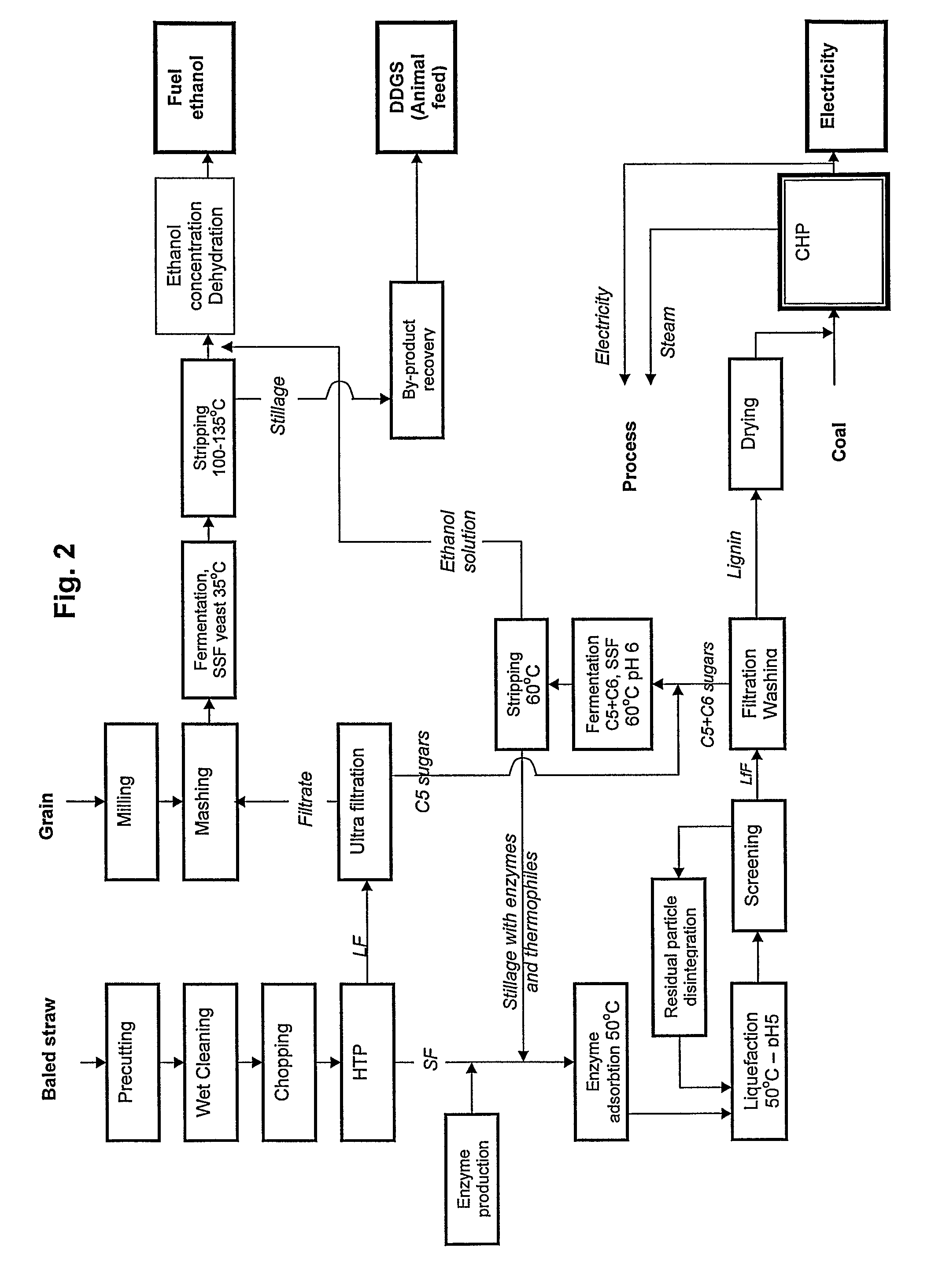

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

Process aid for preparing a flowable slurry

A process for preparing a flowable slurry comprising mixing 25-70 wt. % water; an alkaline material selected from the group consisting of chlorosilicon manufacturing byproducts, direct process residue gels, cement kiln dust, and mixtures thereof; and a process aid selected from the group consisting of sucrose, raffinose, lignin, methylglucopyranoside, lactose, fructose, sodium polyphosphate, trehalose and mixtures thereof to form a flowable slurry. This slurry is especially useful in the manufacture of cement.

Owner:DOW CORNING CORP

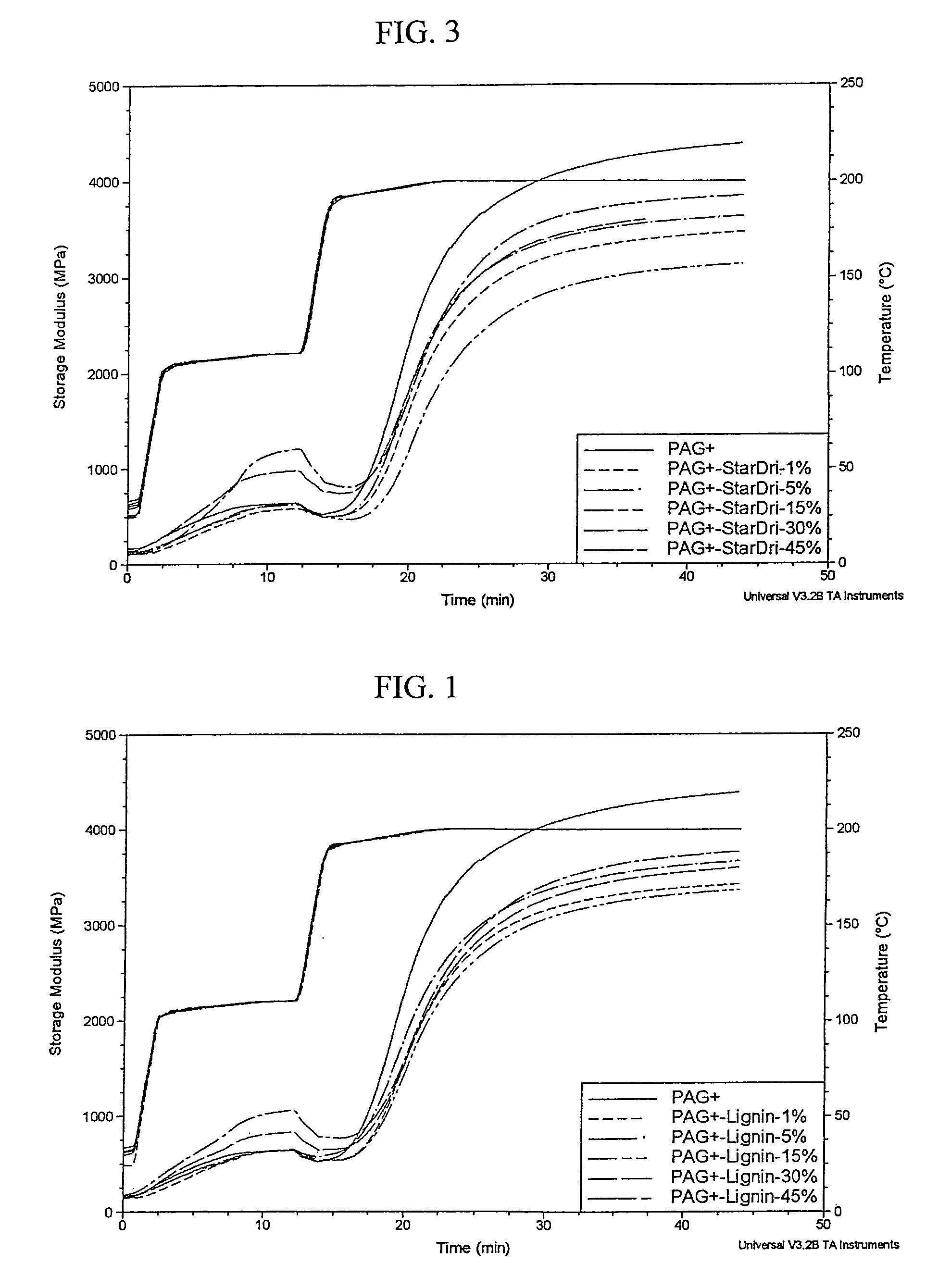

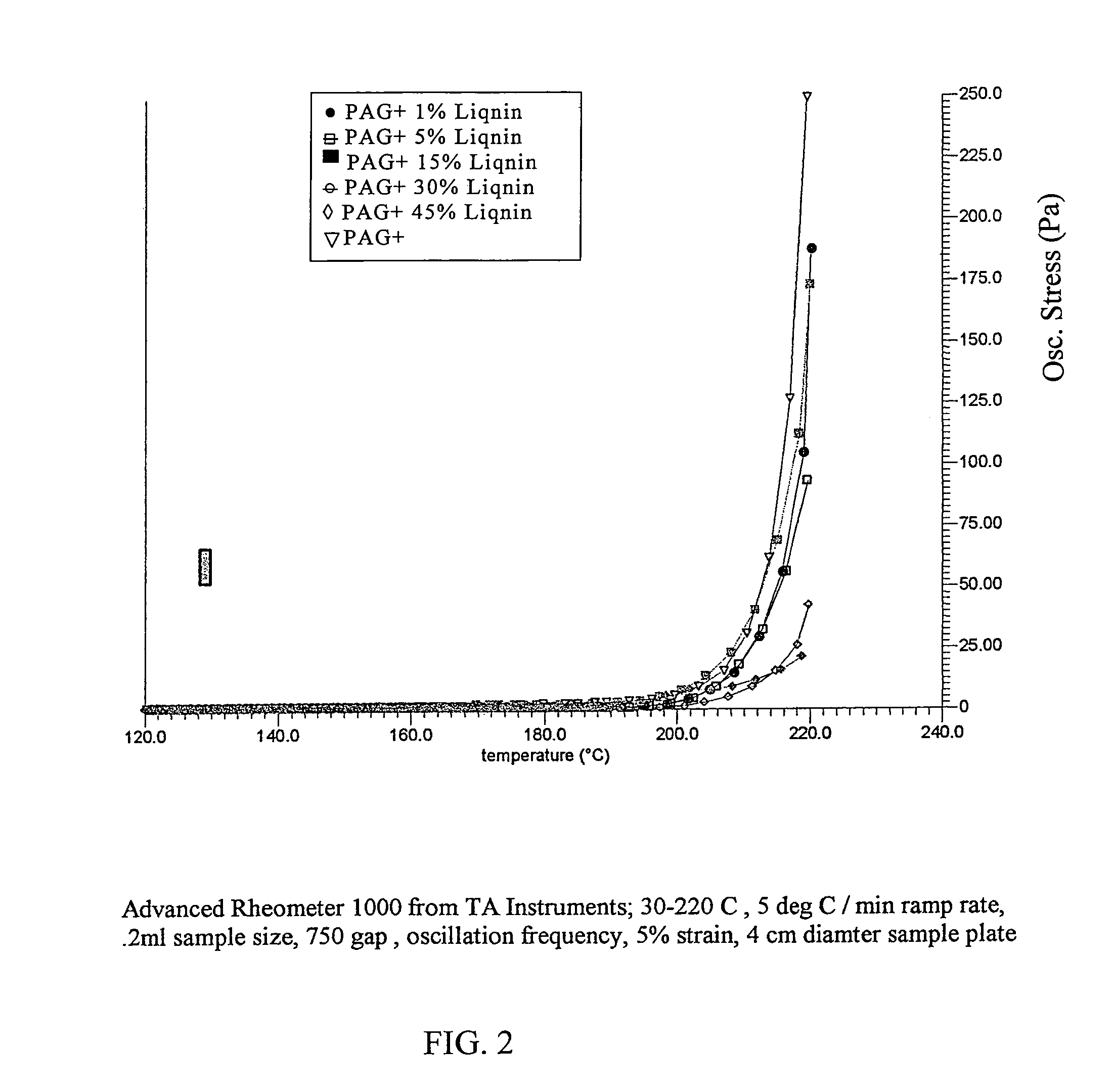

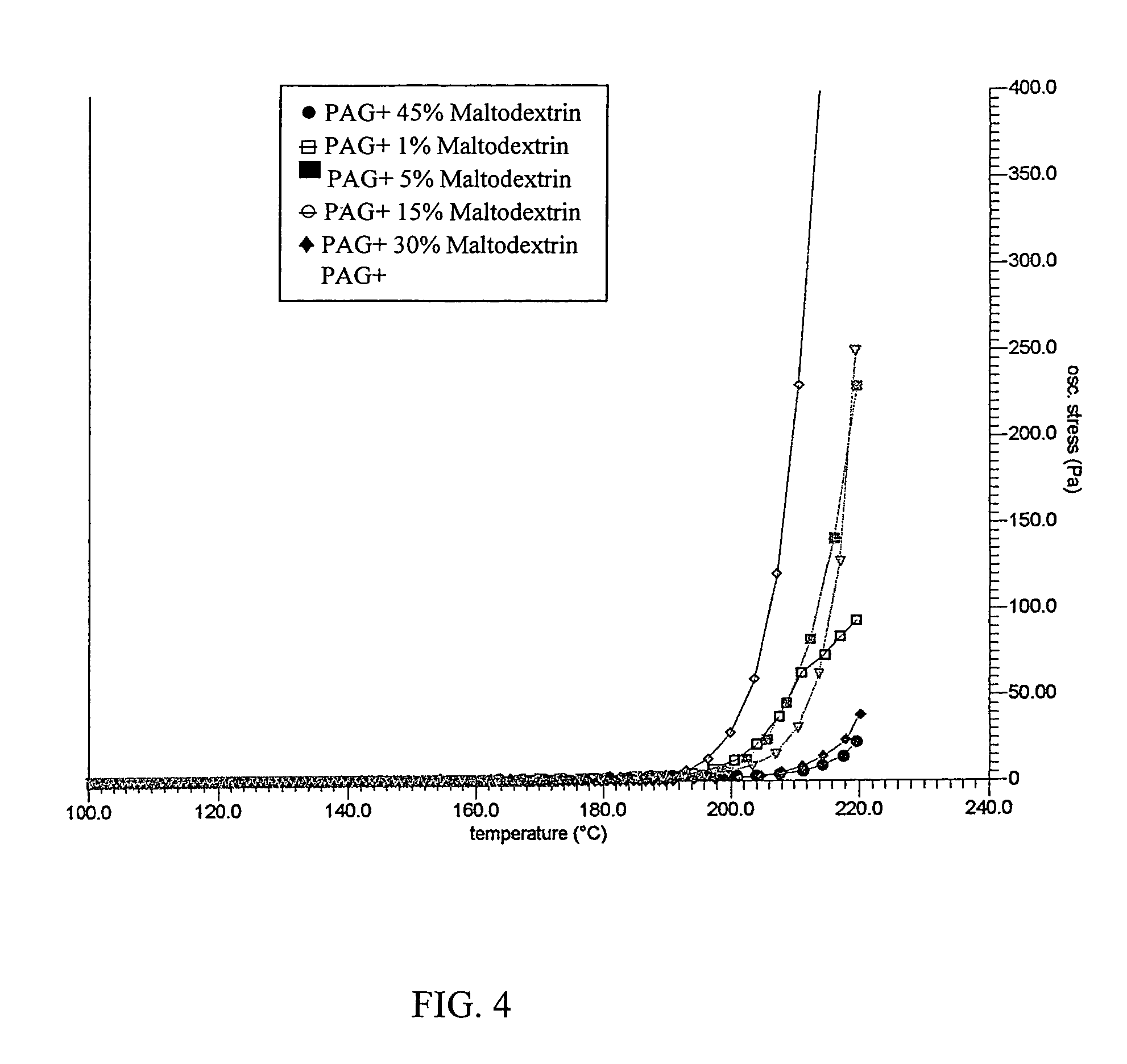

Extended binder compositions

The present invention provides a variety of extended polyacrylic acid based binder compositions comprising a low molecular weight polyacrylic acid (typically hypophosphite or sulfite terminated), a crosslinking agent (such as triethanolamine or glycerol) and one or more water soluble materials, such as lignin, low molecular weight starch and soybean protein. The extended binder composition of the present invention provides a lower cost binder composition without degrading the performance and may be selected to alter one or more characteristics of the basic binder composition such binder wetting, emulsion compatibility, dust suppression and wash water flow properties.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

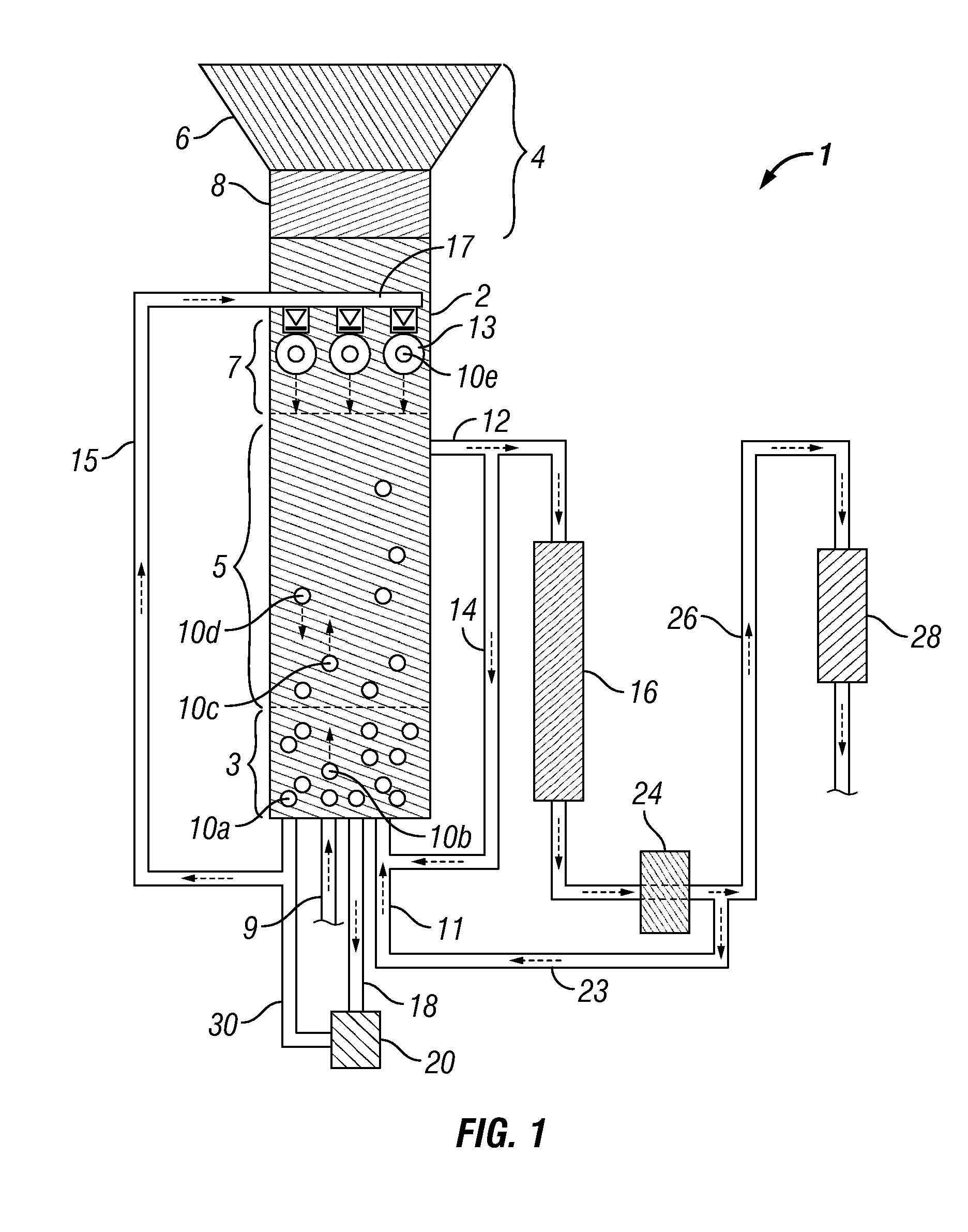

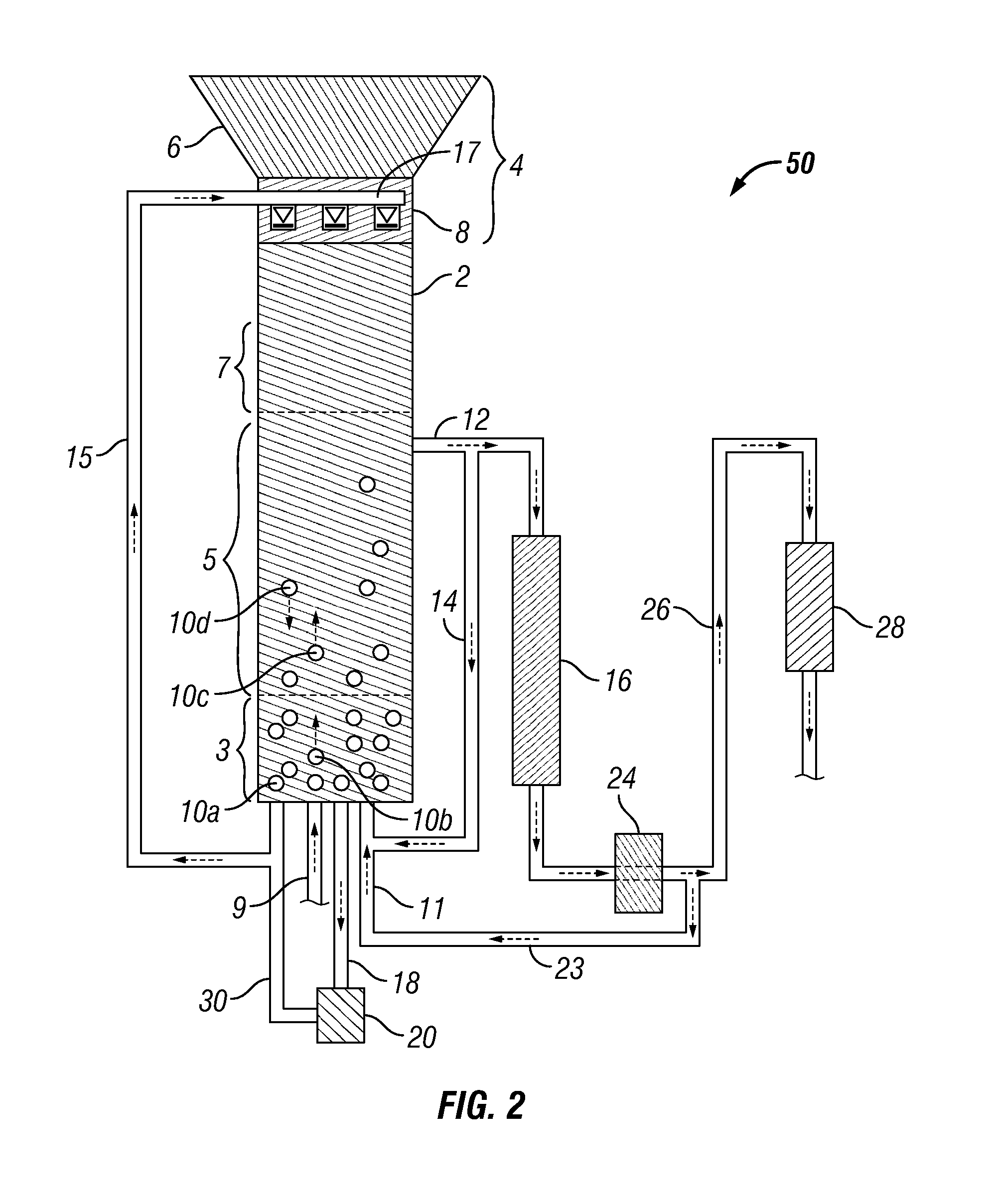

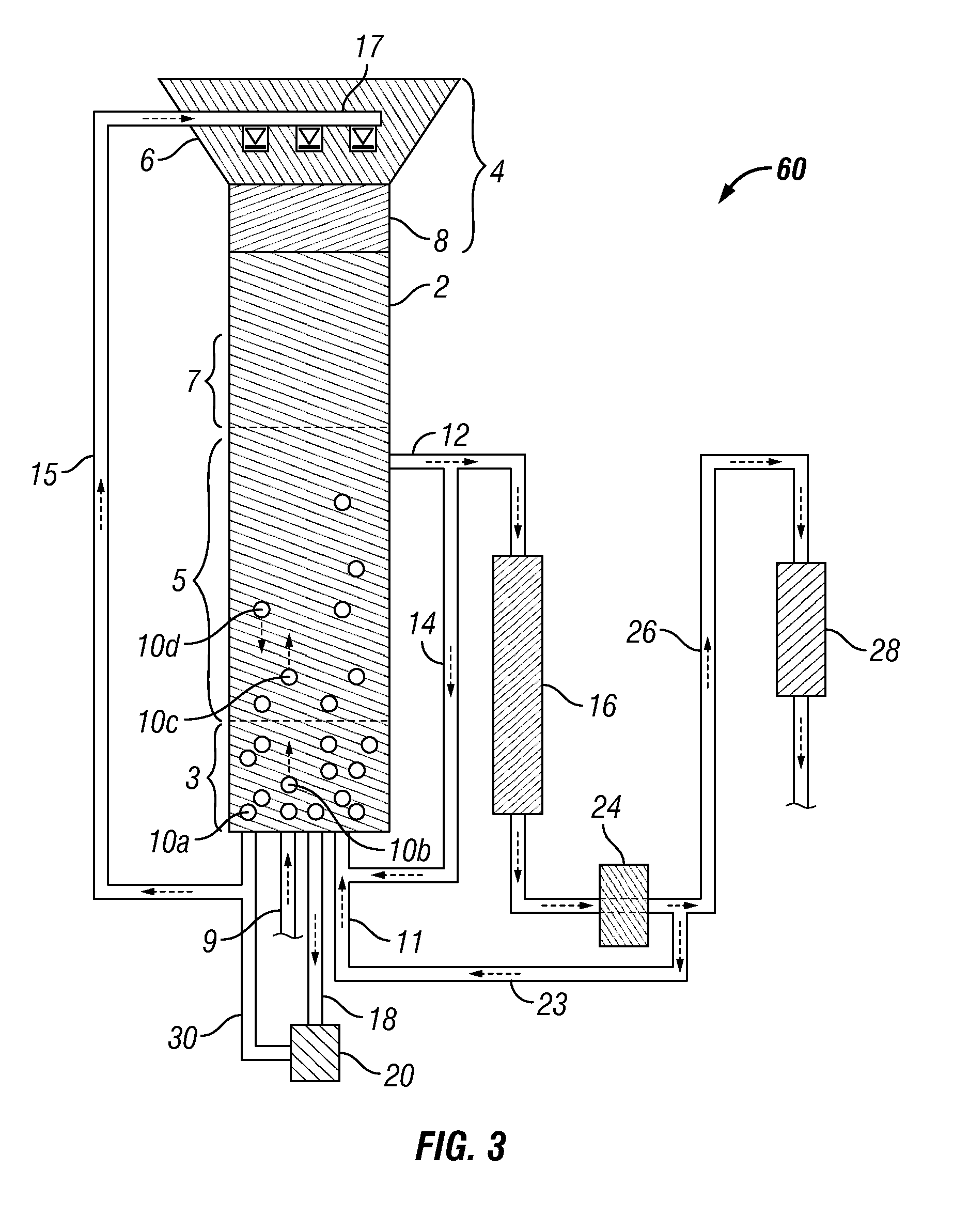

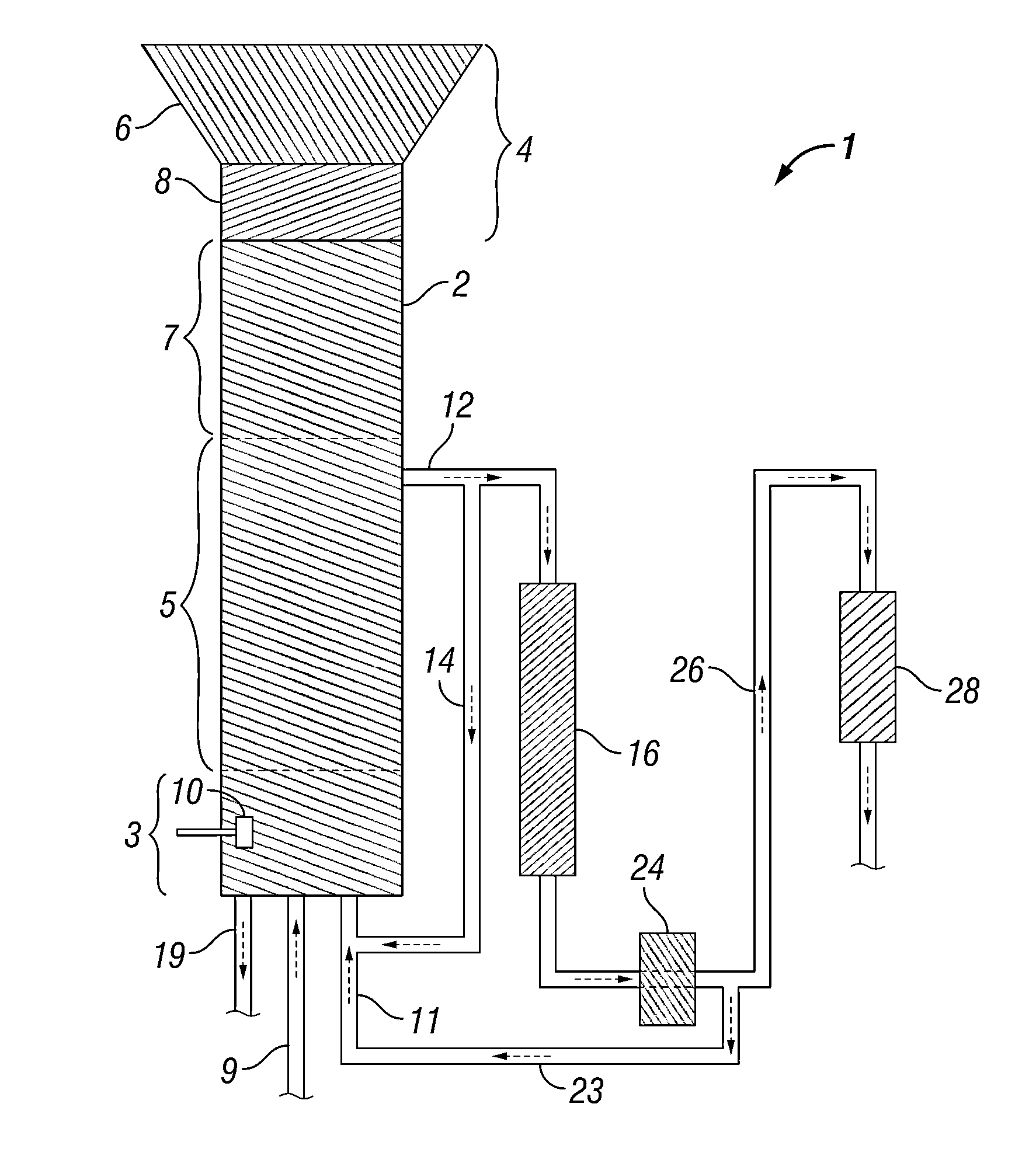

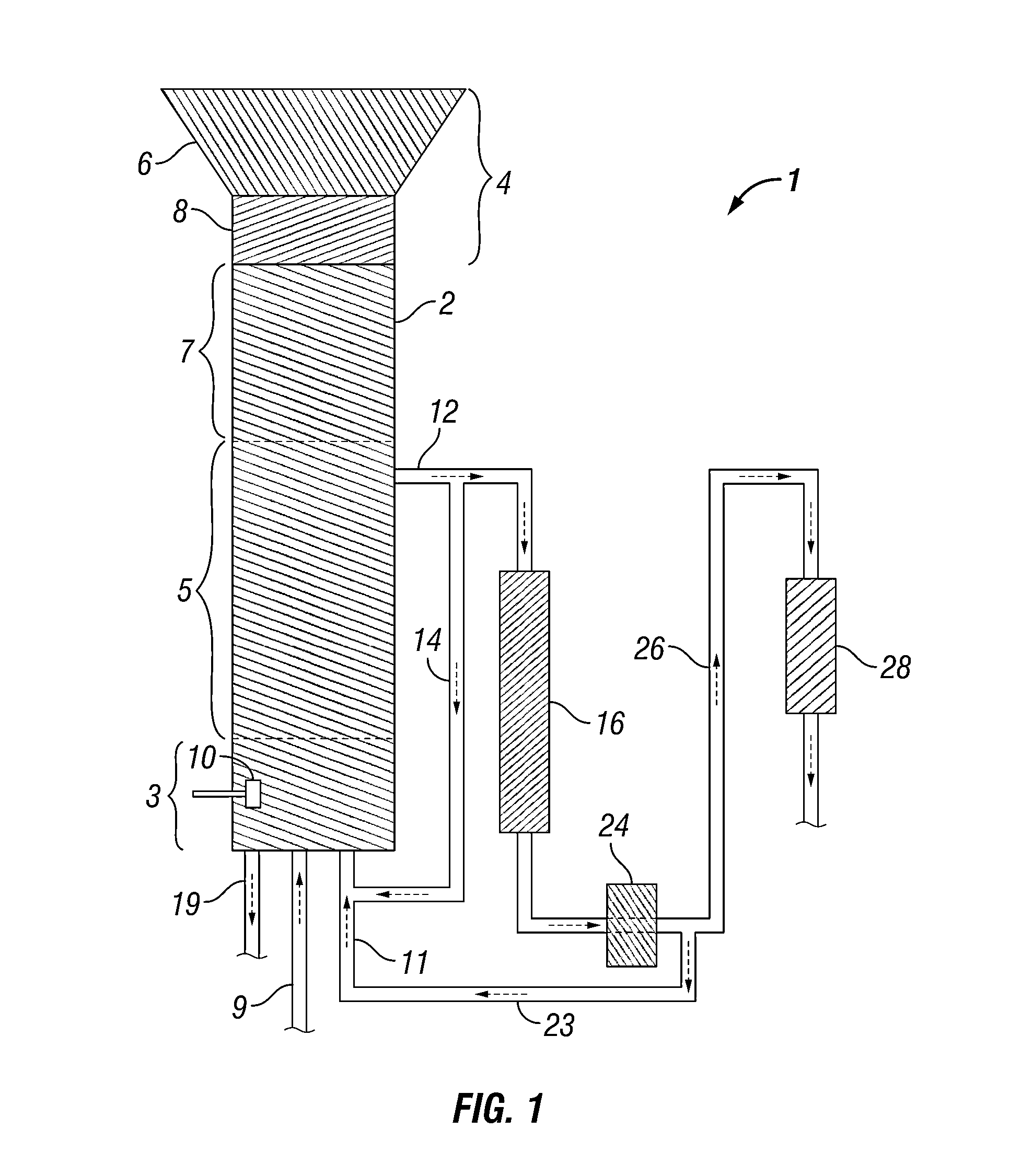

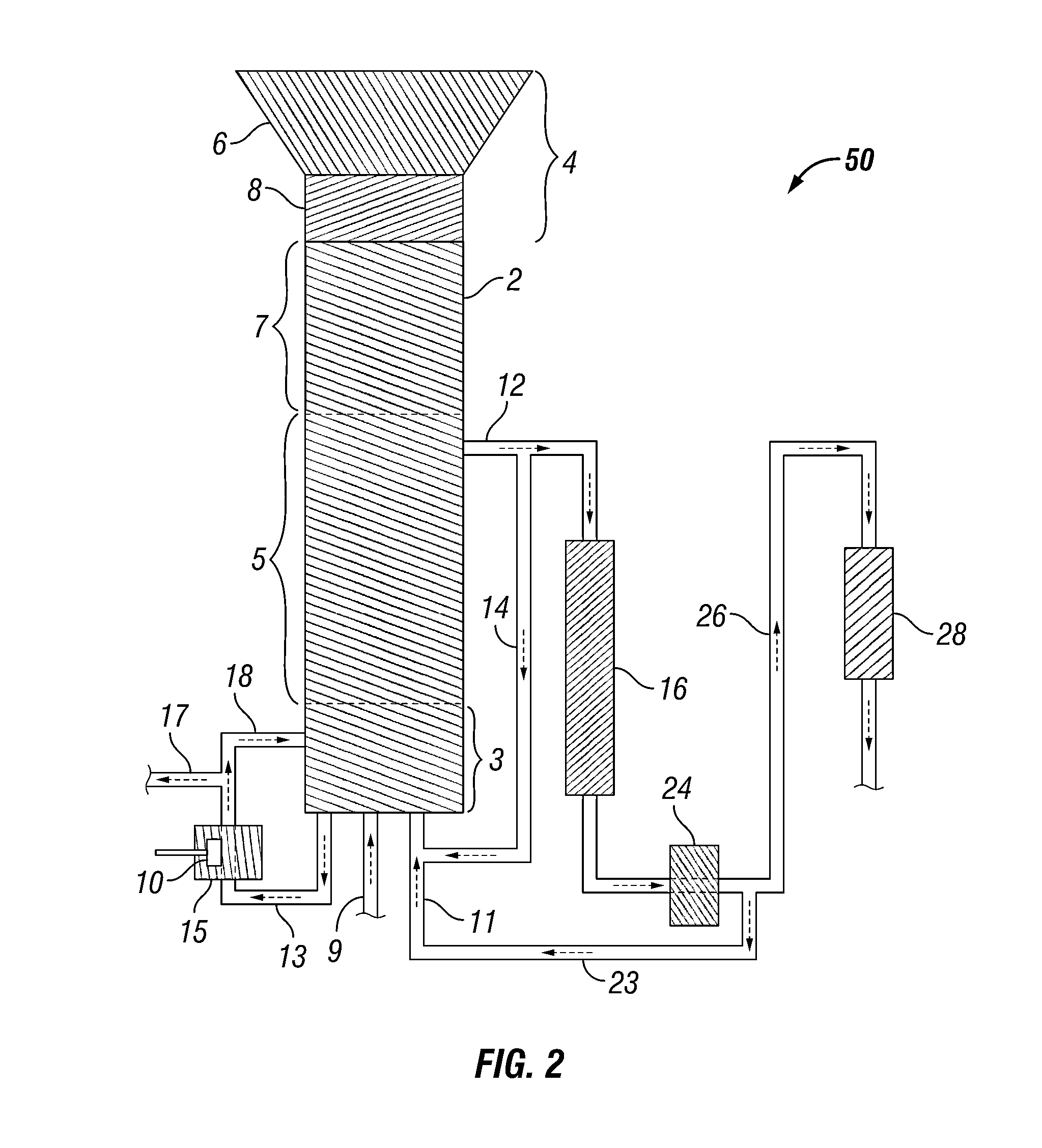

Methods and systems for distributing a slurry catalyst in cellulosic biomass solids

Digestion of cellulosic biomass solids may be complicated by release of lignin therefrom. Methods for digesting cellulosic biomass solids may comprise: heating cellulosic biomass solids and a digestion solvent in the presence of molecular hydrogen and a slurry catalyst capable of activating molecular hydrogen, thereby forming a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase, the slurry catalyst being distributed in the cellulosic biomass solids and at least a portion of the slurry catalyst accumulating in the phenolics liquid phase as it forms; conveying at least a portion of the phenolics liquid phase and the slurry catalyst to a location above at least a portion of the cellulosic biomass solids; and after conveying the phenolics liquid phase and the slurry catalyst, releasing them such that they come in contact with the cellulosic biomass solids.

Owner:SHELL OIL CO

Lignin polyurethane and preparation method thereof

The invention discloses a method for preparing lignin polyurethane, which comprises the following steps of: using an organic solvent to dissolve the lignin which is extracted and separated from residues after producing ethanol from straws by sodium hydroxide; removing the residues, and depositing the mixture with water; separating the lignin; modifying the lignin with an epoxide; dissolving the lignin into a polylol; and finally compounding the lignin with raw materials of isocyanate and the like to obtain a polyurethane material. The lignin used in the method has high reactivity which can be further enhanced through modification so as to obtain a lignin polyurethane material; the polylol used in the method not only can be used as a solvent but also can take part in a synthetic reaction, has good dissolvability to the lignin, and ensures that undissolved lignin particles cannot appear in a polyurethane foam material; and the link for polyurethane synthesis uses no volatile organic solvents, so the production process causes no pollution to the environment, and simultaneously the cost of a polyurethane product is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Dissolution Method

The invention relates to a method for dissolving wood, straw and other natural lignocellulosic materials in an ionic liquid solvent under microwave irradiation and / or under pressure. The invention also relates to the resulting solution and to methods for separating cellulose and other organic compounds, such as lignin and extractives, from the solution.

Owner:VESA MYLLYMAKI +1

Integrated processing of plant biomass

InactiveUS7649086B2Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseWoody plant

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

Method for making bamboo fiber

InactiveCN1621580ASolve the problem of excessive lignin contentHigh strengthWood working apparatusMechanical fibre separationCardingToughness

The present invention is preparation process of bamboo fiber, including coarse bamboo fiber, refined bamboo fiber and spinnable bamboo fiber. The coarse bamboo fiber is prepared through cutting bamboo, separating bamboo fiber, steaming inside the No. 1 softening liquid and enzyme fermentation; the refined bamboo fiber is prepared through steaming inside the No. 2 softening liquid, enzyme fermentation, rinsing and bleaching, acid treatment, and oil soaking and drying; and the spinnable bamboo fiber is prepared through emulsifying, initial carding, combing and drawing. The bamboo fiber has lignin content lower than 5 %, and has the features of being natural and green, high in strength, high toughness, high brightness and high elasticity.

Owner:临安力源竹纤维技术开发有限公司

Lignin carbon nanofiber and preparation method thereof

ActiveCN101768799AImprove spinnabilityGuaranteed reliabilityFilament/thread formingFibre chemical featuresFiberCarbon fibers

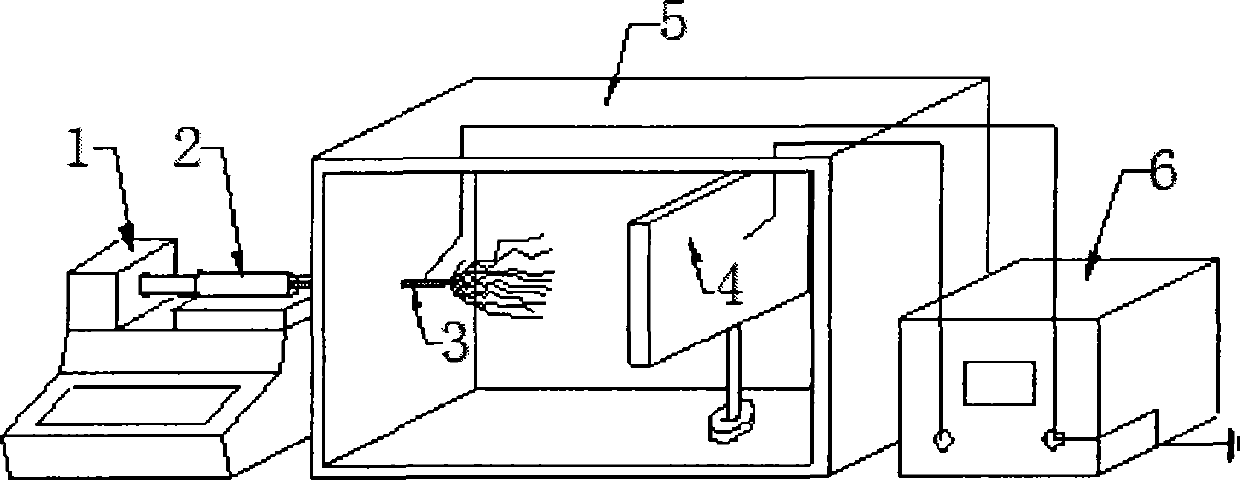

The invention discloses a lignin carbon nanofiber and a preparation method thereof, belonging to the field of materials. The preparation method comprises 5 steps of lignin pretreatment, preparation of spinning solution, electrostatic spinning, pre-oxidation and carbonization. The preparation method is characterized in that the lignin pretreatment means that lignin with the relative molecular mass within 5,000 to 50,000 is selected, and then the treatment of removing carbohydrate and inorganic salt is respectively carried out on alkali lignin and acetic acid lignin (or formic acid lignin). The diameter of the obtained carbon nanofiber is within 50 to 300nm and the length is within 1 to 10mum. As the obtained lignin has good spinnability, the nanofiber can be spun and further processed into the carbon nanofiber without synthetic macromolecules. In addition, the method adopts simple electrospinning equipment for electrospinning, the diameter of a spinning nozzle is large, the blockage cannot easily occur, and the working reliability of the spinning equipment is ensured.

Owner:SOUTH CHINA UNIV OF TECH

Comprehensive utilization process of wood cellulose

The invention discloses a comprehensive utilization process of wood cellulose, which comprises the processes of comprehensive treatment, oligosaccharide preparation, lignin preparation, fiber ethanol preparation and the like. The invention has the advantages of decomposing a biomass macromolecular natural compact structure by using a high-pressure instant steam exploding technology, being beneficial to the separation and the extraction of the lignin, the cellulose and the cellulose, reducing the consumption of the energy sources and the materials, such as acid, alkali, heat, catalyst and the like for preprocessing, reducing the emission of pollutants and lightening the pollution of the environment. Secondly, the cogeneration of oligosaccharide and lignin realizes the comprehensive utilization of the energy sources, especially the application of the steam exploding technology ensures that the quality of the two products of the oligosaccharide and the lignin is greatly improved and the yield is greatly increased; and alcohol and the lignin of production fuels of sugar residues can be extracted irrespective of the order.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

Methods and systems for processing lignin during hydrothermal digestion of cellulosic biomass solids

InactiveUS20140117275A1Low viscosityCellulosic pulp after-treatmentOther chemical processesCelluloseFluid phase

Digestion of cellulosic biomass solids may be complicated by lignin release therefrom, which can produce a highly viscous phenolics liquid phase comprising lignin polymer. Methods for digesting cellulosic biomass solids may comprise: providing cellulosic biomass solids in the presence of a digestion solvent, molecular hydrogen, and a slurry catalyst capable of activating molecular hydrogen; at least partially converting the cellulosic biomass solids into a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase; wherein at least a portion of the slurry catalyst accumulates in the phenolics liquid phase as it forms; and reducing the viscosity of the phenolics liquid phase.

Owner:SHELL OIL CO

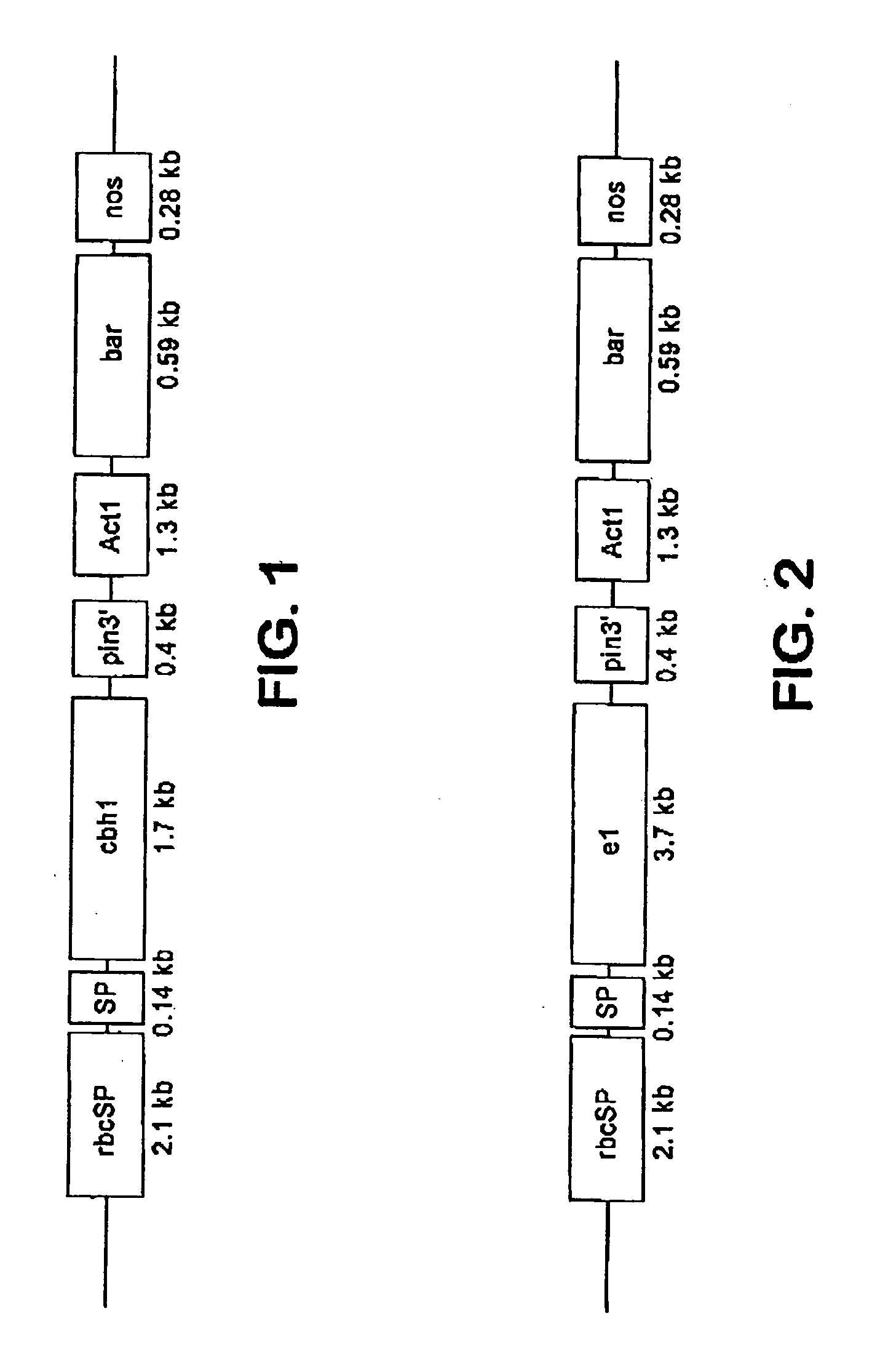

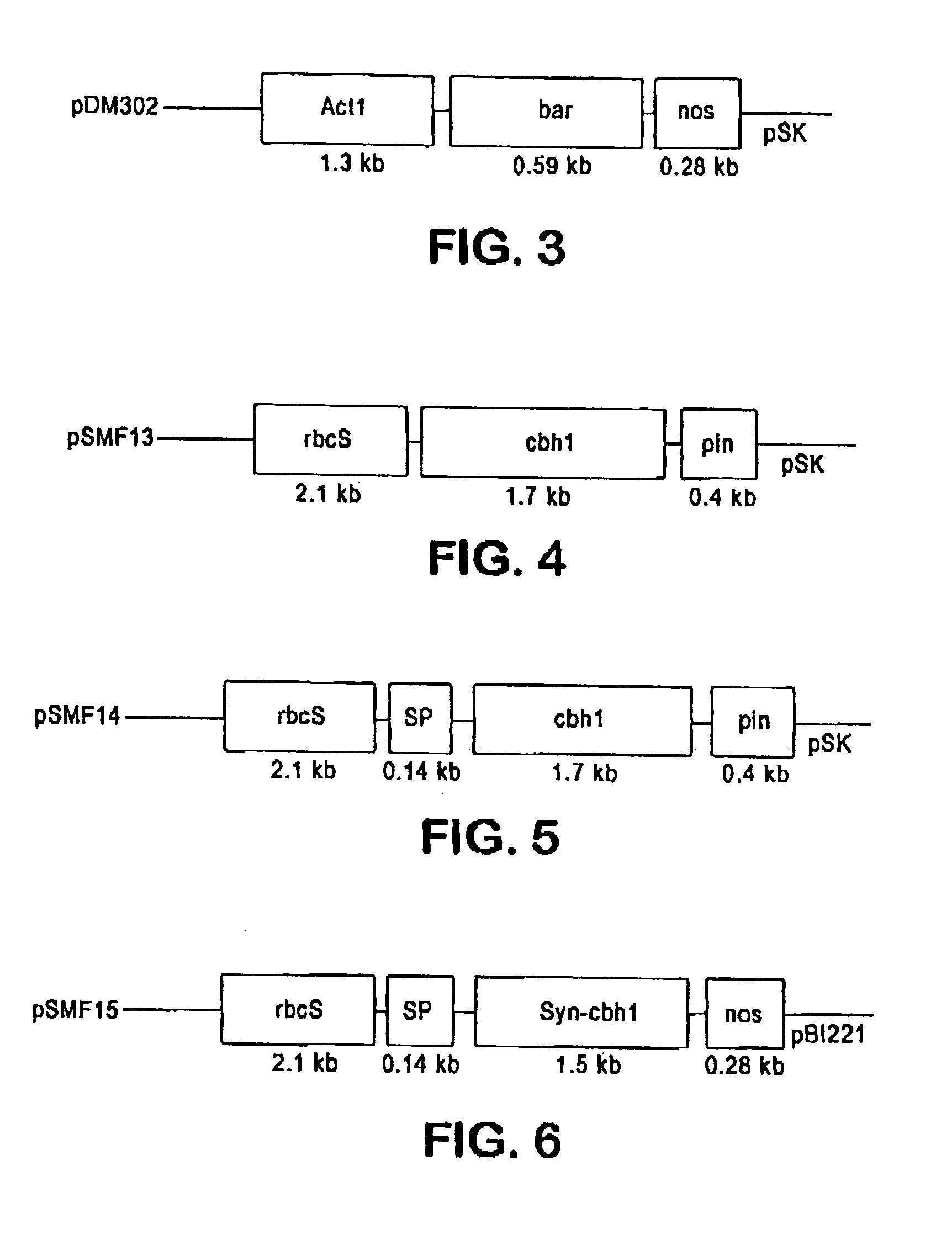

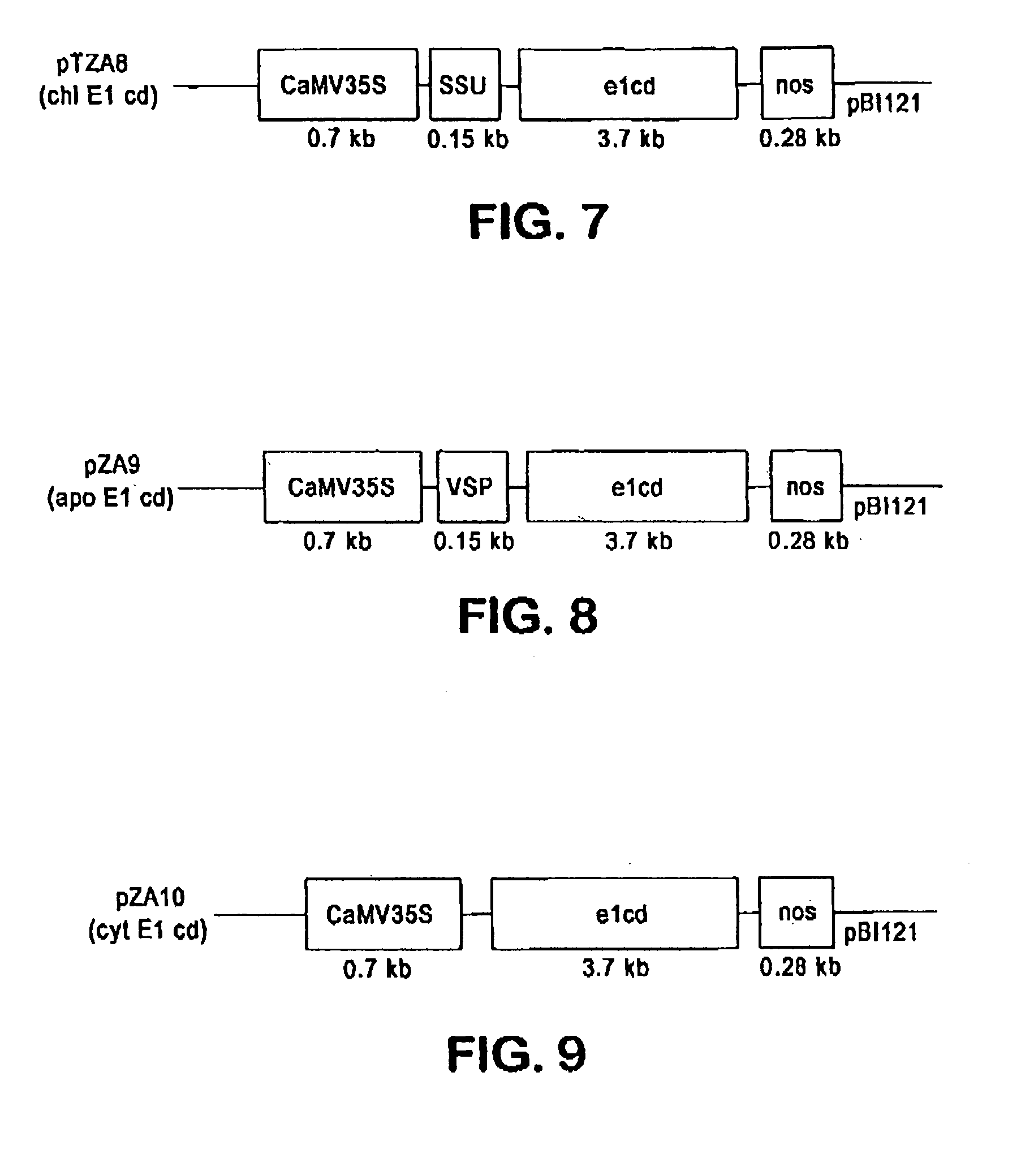

Production of beta-glucosidase, hemicellulase and ligninase in E1 and FLC-cellulase-transgenic plants

InactiveUS20070192900A1Increase biomassReduce the amount of solutionClimate change adaptationOther foreign material introduction processesAlgluceraseBeta-glucosidase

The present invention provides transgenic plants expressing one or more cell wall degrading enzymes that can degrade lignocellulose to fermentable sugars. These fermentable sugars can further be fermented to ethanol or other products. The enzymes are directed to the plastids or the apoplasts or the transgenic plant for storage. When the transgenic plants are harvested, the plants are ground to release the enzymes which then are used to degrade the lignocellulose of plant material to produce the fermentable sugars. The transgenic plants express the flowering locus c gene so that flowering is delayed and the plant biomass is increased.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

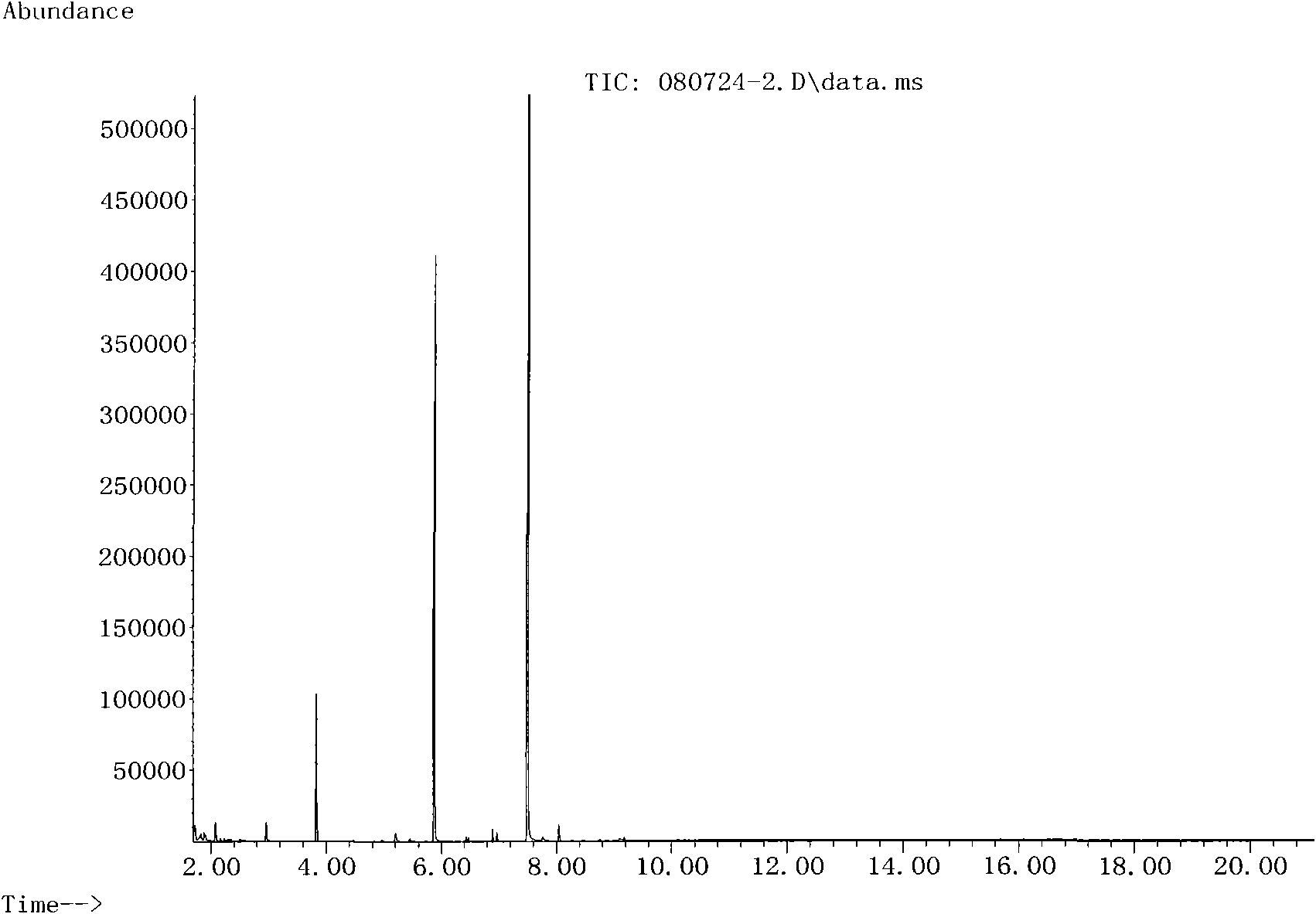

Method for preparing aromatic compound by catalytic hydrocracking of lignin

InactiveCN101768052AReduce tensionReduce pollutionMolecular sieve catalystsOrganic compound preparationSulfonateGuaiacol

The invention relates to a method for preparing an aromatic compound by direct catalytic cracking of lignin. Under the combined action of a catalyst and a solvent, industrial lignins such as natural lignin, sodium lignin sulfonate, alkali lignin and dealkalized lignin are used as raw materials and are selectively cracked into the aromatic compound derived from C6-C9 phenolic group, guaiacol group or syringyl through the catalytic process. The conversion rate of the raw materials reaches over 50%, and the guaiacol group and the syringyl aromatic compound account for over 90% in a cracking product. The method has the characteristics of cheap raw materials, high conversion rate, high yield of the aromatic compound and mild reaction condition.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Production of levulinic acid and levulinate esters from biomass

InactiveUS20100312006A1Improve production yieldHigh purityPreparation by ester-hydroxy reactionOrganic compound preparationPropanoic acidFurfural

A process for producing levulinic acid and its esters from biomass is disclosed comprising: (i) feed preparation module characterized by subjecting biomass to a high-temperature refining treatment; (ii) hydrolysis reaction module that facilitates the hydrolysis of biomass to its respective sugars and their subsequent transformation to levulinic acid, formic acid, furfural, and char as well as facilitates the separation of lignin-based char by-product; (iii) product separation and recovery module utilizing a solvent extraction technique such as using furfural by-product as extracting solvent; and (iv) optionally, conversion of levulinic acid to levulinate ester. When desired, the disclosed process may be integrated into existing pulp mills.

Owner:MEADWESTVACO CORP

Biomass refining by selective chemical reactions

InactiveUS20110071306A1High substrate loadingShort reaction timeSugar derivativesSugar derivatives preparationChemical reactionPropanoic acid

A method is disclosed for the acid hydrolysis of carbohydrates in or from biomass, using a solvent system including an aqueous ether, where the ether form a majority of the system, which affords high yields to the platform chemicals such as 2-furfural and 5-hydroxymethylfurfural (5-HMF). The later can also undergo a domino reaction to chemicals including levulinic acid, particularly with oxygenated anions and greater water content. A total dissolution and reaction of biomass occurs under a range of relatively mild conditions (combined Severity range ˜2.2-2.6). Lignin and lignin derived products can be easily separated by precipitation.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS8123864B2Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fiber fraction are produced. The fiber fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurized reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fiber fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fiber fraction.

Owner:INBICON AS

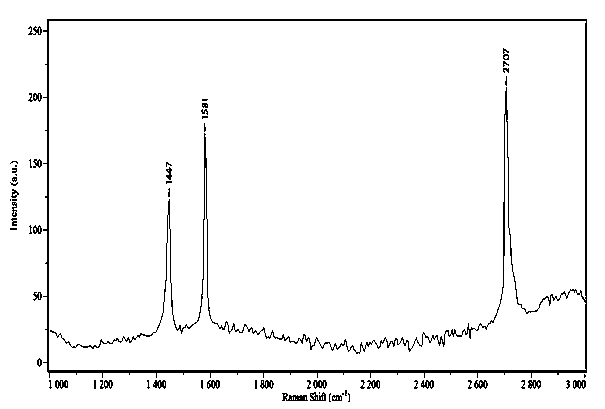

Method for preparing graphene from lignin

The invention discloses a method for preparing graphene from lignin, which comprises the following steps: putting a porcelain sample boat filled with lignin and a catalyst into a hinge pipe furnace, introducing shielding gas at uniform speed while heating the sample in the furnace from room temperature to the target temperature at a constant heating speed, and keeping at the target temperature; and after the sample is cooled to room temperature, taking out the sample, washing with deionized water, carrying out vacuum filtration, and drying at low temperature to obtain the graphene. The preparation technique is simple and convenient; and the obtained graphene has the advantages of high quality and considerable yield.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

Compositions for reduced lignin content in sorghum and improving cell wall digestibility, and methods of making the same

InactiveUS20150291969A1Reduces and silence expressionSuppressing and silencing expressionOther foreign material introduction processesFermentationSorghumCell wall

RNAi vectors comprising a fragment of the SbCSE polynucleotide sequence and transgenic plants, e.g. transgenic sorghum plants, comprising said RNAi vectors are described. Aspects of the technology are further directed to methods of using the RNAi vectors of the present technology to silence SbCSE gene expression or activity in a transgenic plant, such as a transgenic sorghum plant. Silencing the SbCSE gene leads to reduced lignin content in a transgenic plant.

Owner:CHROMATIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com