Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1918 results about "Acid hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In organic chemistry, acid hydrolysis is a process in which a protic acid is used to catalyze the cleavage of a chemical bond via a nucleophilic substitution reaction, with the addition of the elements of water (H₂O). For example, in the conversion of cellulose or starch to glucose. For the case of esters and amides, it can be defined as an acid catalyzed nucleophilic acyl substitution reaction.

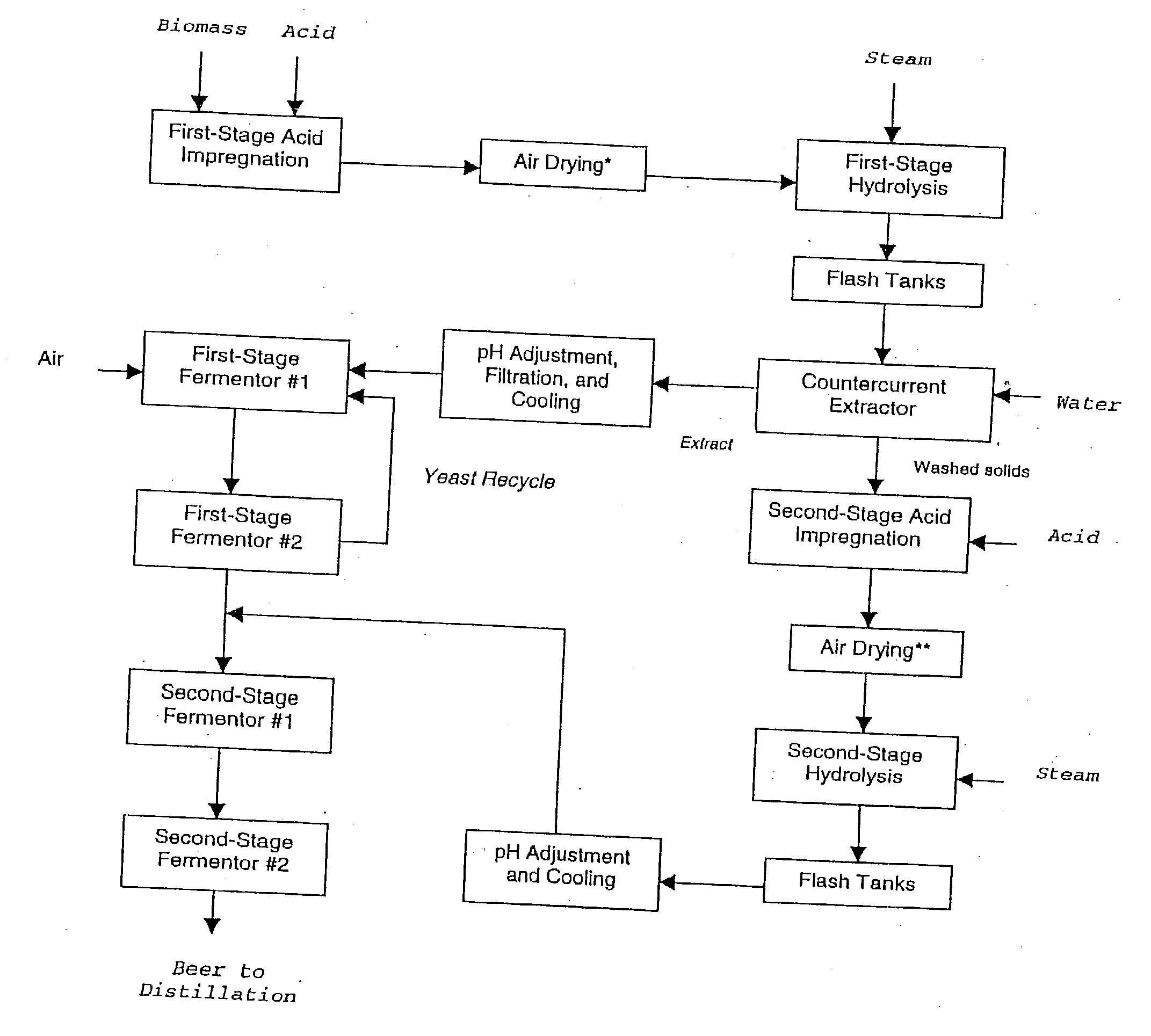

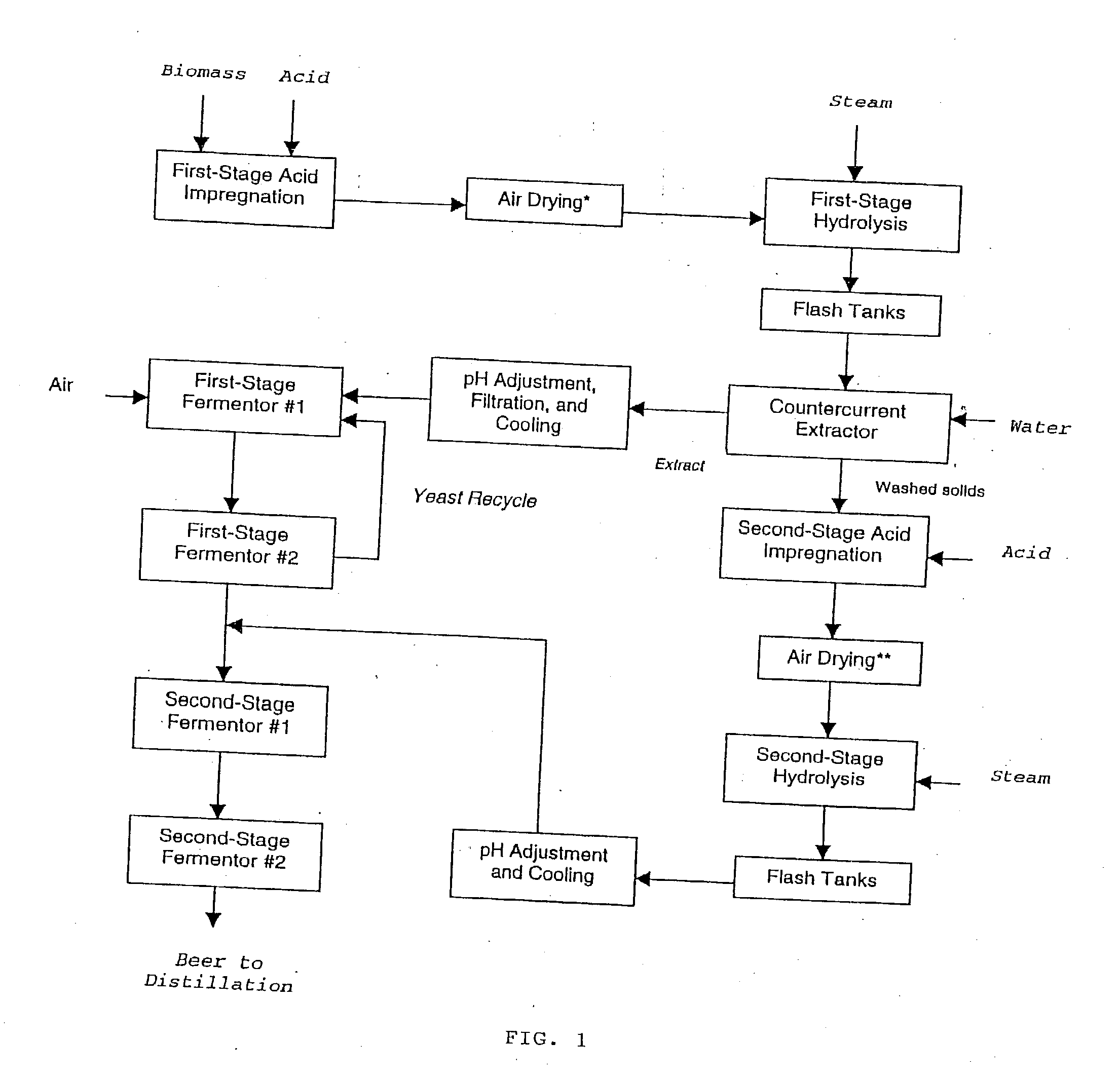

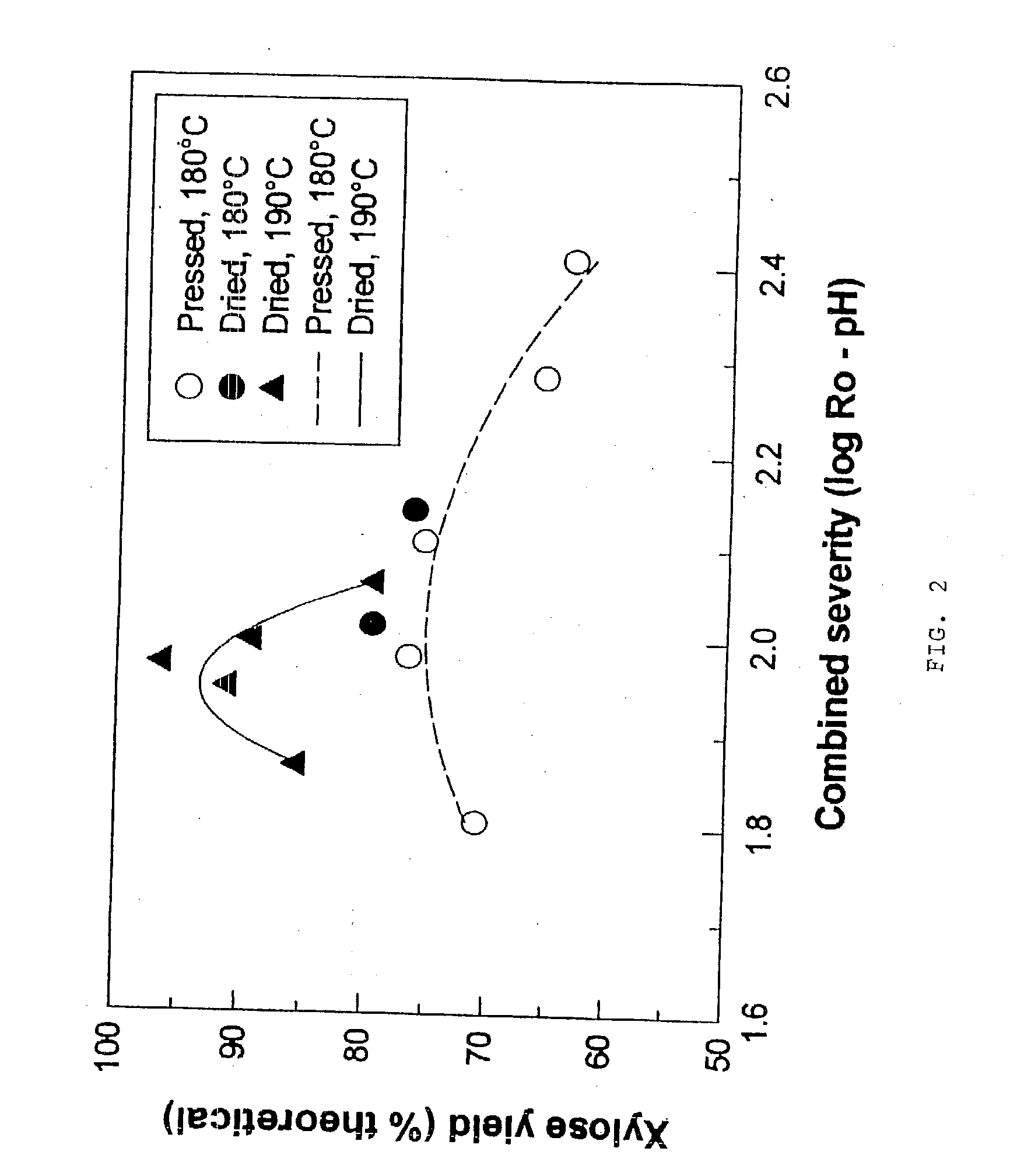

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Biomass refining by selective chemical reactions

InactiveUS20110071306A1High substrate loadingShort reaction timeSugar derivativesSugar derivatives preparationChemical reactionPropanoic acid

A method is disclosed for the acid hydrolysis of carbohydrates in or from biomass, using a solvent system including an aqueous ether, where the ether form a majority of the system, which affords high yields to the platform chemicals such as 2-furfural and 5-hydroxymethylfurfural (5-HMF). The later can also undergo a domino reaction to chemicals including levulinic acid, particularly with oxygenated anions and greater water content. A total dissolution and reaction of biomass occurs under a range of relatively mild conditions (combined Severity range ˜2.2-2.6). Lignin and lignin derived products can be easily separated by precipitation.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

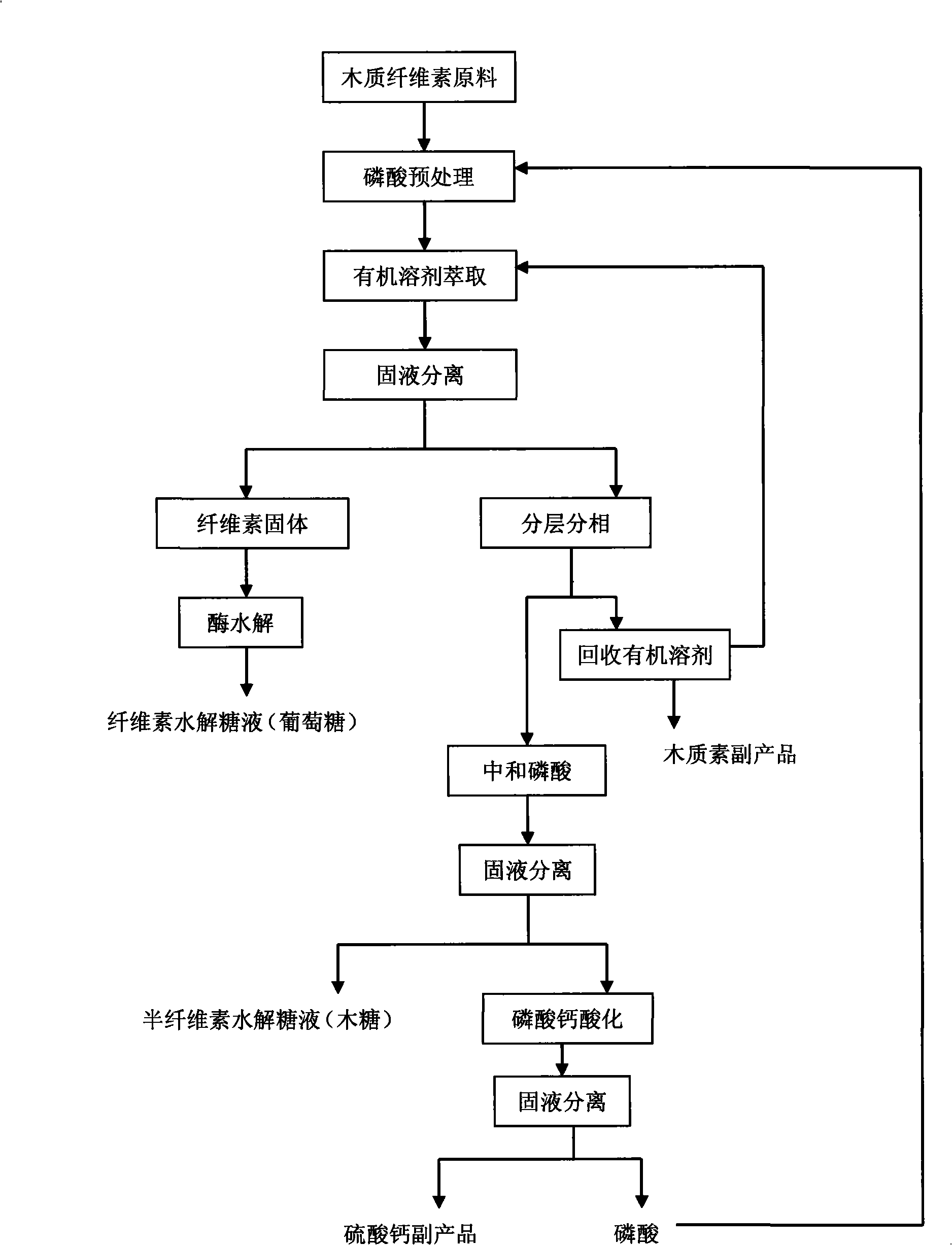

Process for preparing multicomponent liquid glucose and lignose while effectively hydrolyzing lignocellulosic biomass

InactiveCN101285106ASimple recycling processNot volatileSulfate preparationLignin derivativesLiquid glucoseFiltration

The invention discloses a method for efficiently hydrolyzing lignocellulosic biomass and synchronously preparing multi-component liquid glucose and lignin. The method comprises the steps that: the lignocellulosic biomass through physical crushing is added with phosphoric acid to perform acid hydrolysis; then organic solvent is added to extract the lignin, the layering and the phase separation are performed, then the lignin is extracted out while the organic solvent is reclaimed under the condition of pressure reduction and distillation; phosphoric acid can be reclaimed through steps such as neutralization, filtration, acidification and so on, hemicellulose hydrolyzed liquid glucose is obtained at the same time; and the remained cellulose undergoes the zymohydrolysis to prepare cellulosic hydrolyzed liquid glucose. The method can separate lignin, hemicellulose and cellulose, remarkably decreases the degree of crystallinity of the cellulose hydrolyzed by phosphoric acid, and remarkably improves the zymohydrolysis efficiency; and the prepared hydrolyzed liquid glucose does not contain fermentation inhibitors. The method has mild treatment conditions, simple process and less side reactions; the phosphoric acid and the organic solvent can both be reclaimed and circularly used; and the method is environment-friendly, and has broad social and economic benefits.

Owner:NANJING UNIV OF TECH

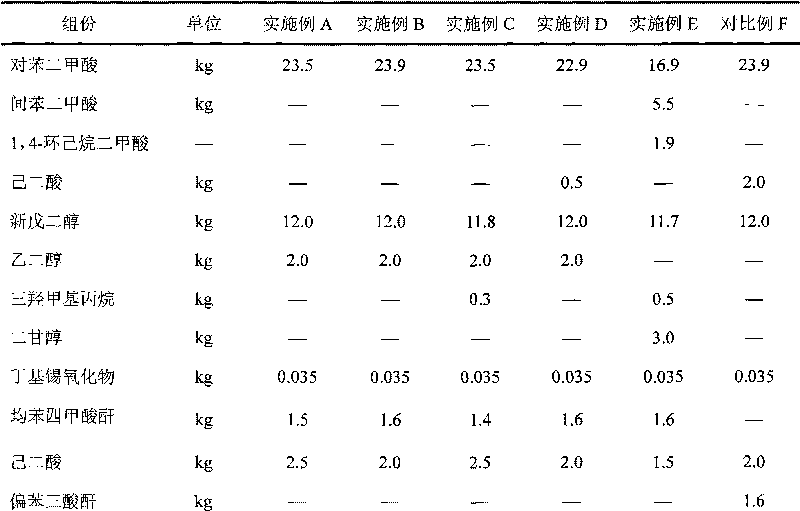

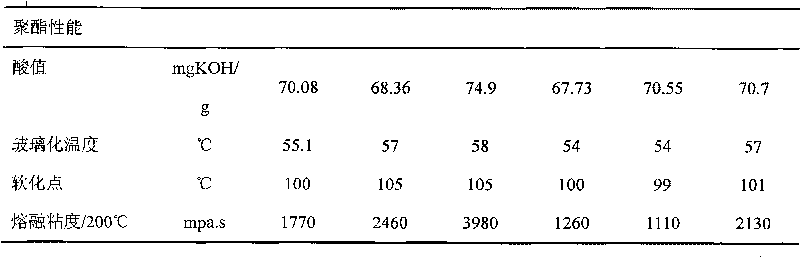

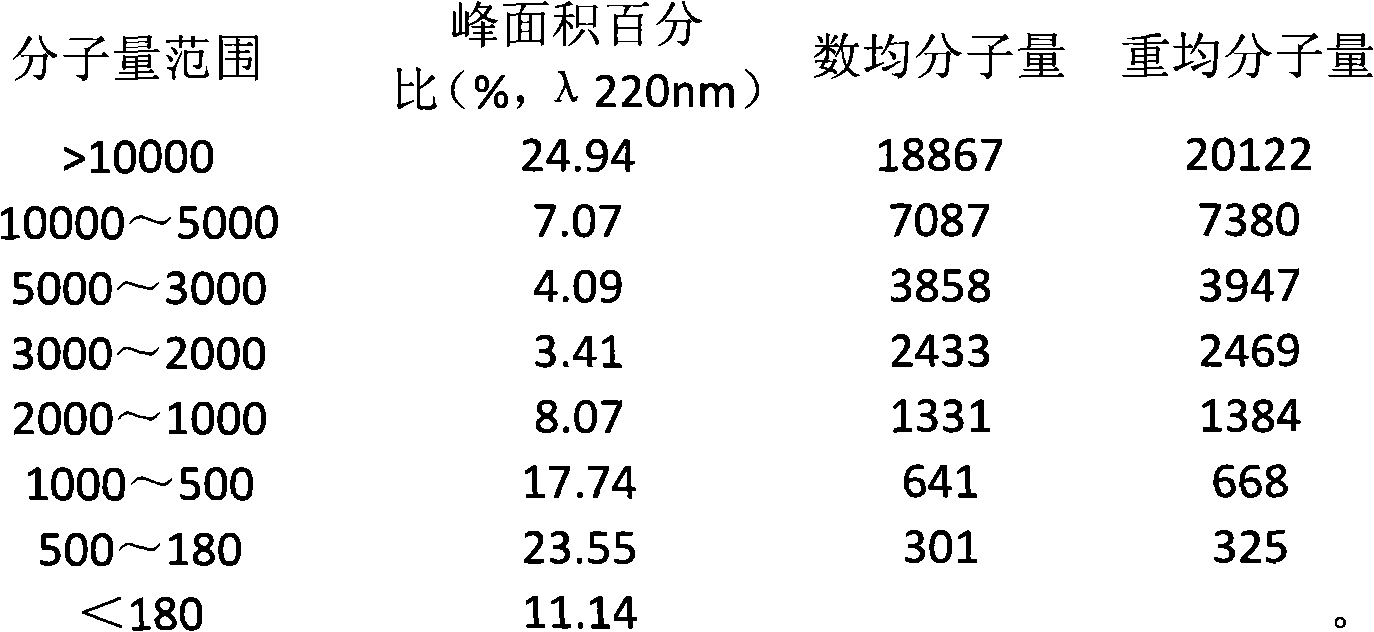

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

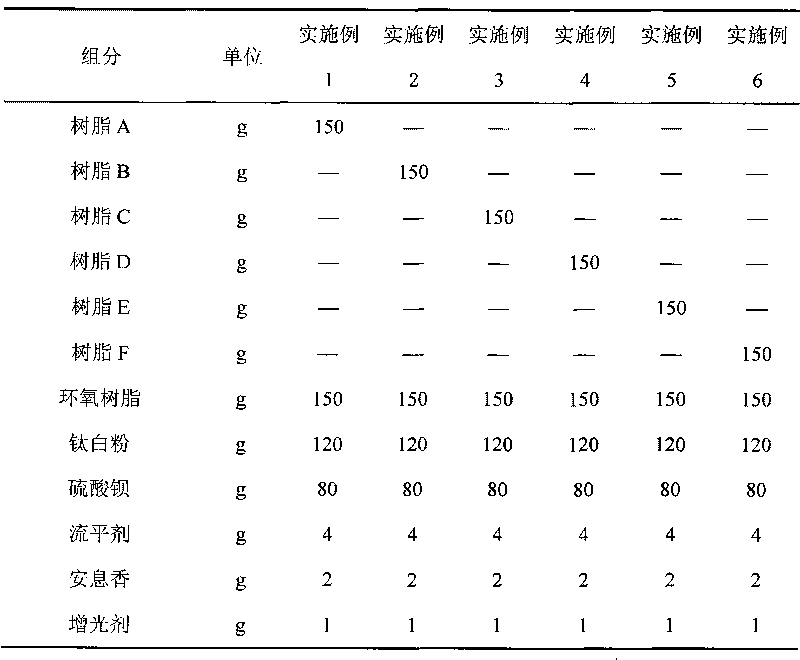

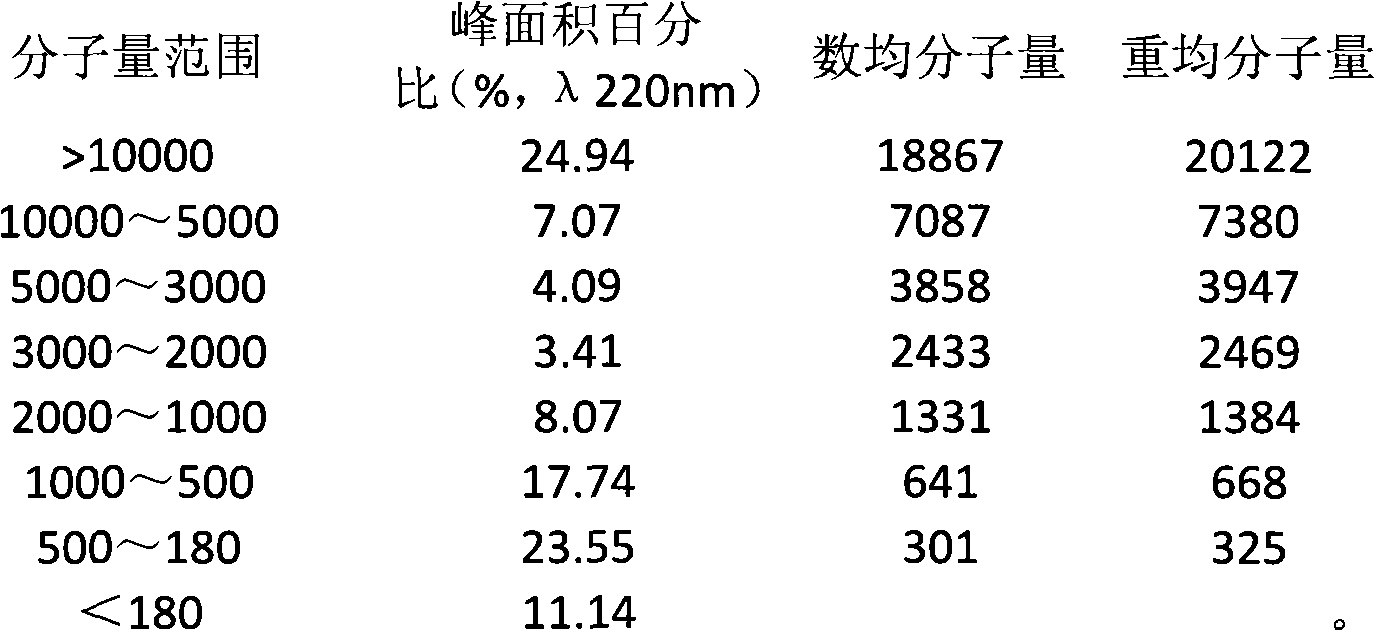

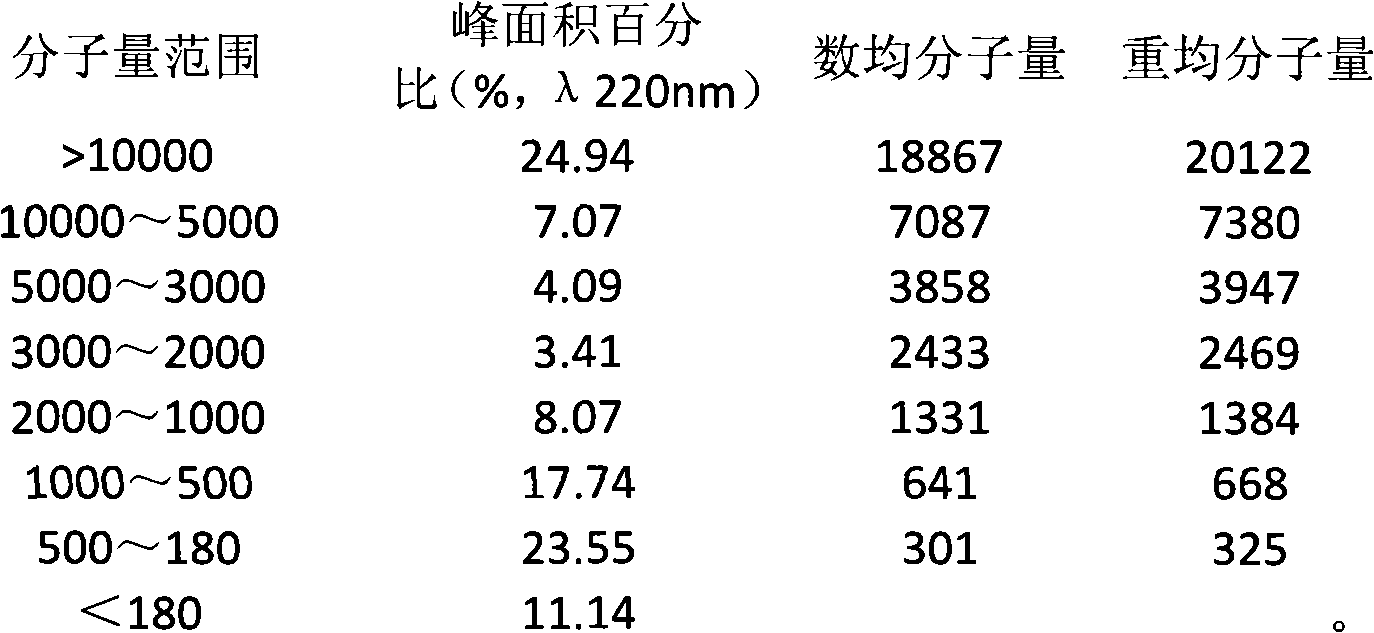

Bird's nest oligopeptide composition and preparation method and use thereof

ActiveCN102102119AImprove immunityUnique biological functionCosmetic preparationsPeptide/protein ingredientsBULK ACTIVE INGREDIENTOligopeptide

The invention provides a method for extracting small molecule oligopeptides from bird's nests by hydrolysis, which is to obtain a small molecular nano oligopeptide containing composition by hydrolyzing the bird's nests through the combination of enzymolysis and acid hydrolysis. The bird's nest oligopeptide composition is characterized in that: the molecular weight of the nano oligopeptides mainlyranges from 180 to 1,000D; preferably, the percentage of Gaussian distribution peak area of the nano oligopeptides with a molecular weight ranging from 180 to 1,000D in the composition is over 40 percent. The Cordyceps militarisoligopeptide extract provided by the invention retain other active ingredients such as polysaccharide, bird's nest sialic acid, micro elements and the like. The invention also relates to the use of the nano oligopeptide containing composition extracted from bird's nests in the preparation of medicines, health-care products and cosmetics.

Owner:BEIJING INST OF OLIGO PEPTIDE BIOLOGY

Method for removing cadmium in rice protein

InactiveCN103340414AEfficient removalDoes not affect appearanceVegetable proteins working-upFood preparationAcid hydrolysisSlurry

The invention relates to a method for removing cadmium in rice protein, belonging to the technical field of further processing for rice. The method comprises the following steps of: taking rice protein powder, adding hot water for size mixing, uniformly mixing, and obtaining size with the concentration being 12-13 percent; and conducting an acid hydrolysis reaction, removing impurities, sterilizing, dewatering, drying, and obtaining a rice protein powder finished-product. The method has the beneficial effects that the content of cadmium in the rice protein can be effectively reduced, the appearance of the rice protein cannot be influenced, and the nutritional ingredients in the rice protein cannon be reduced.

Owner:普洱永吉生物技术有限责任公司

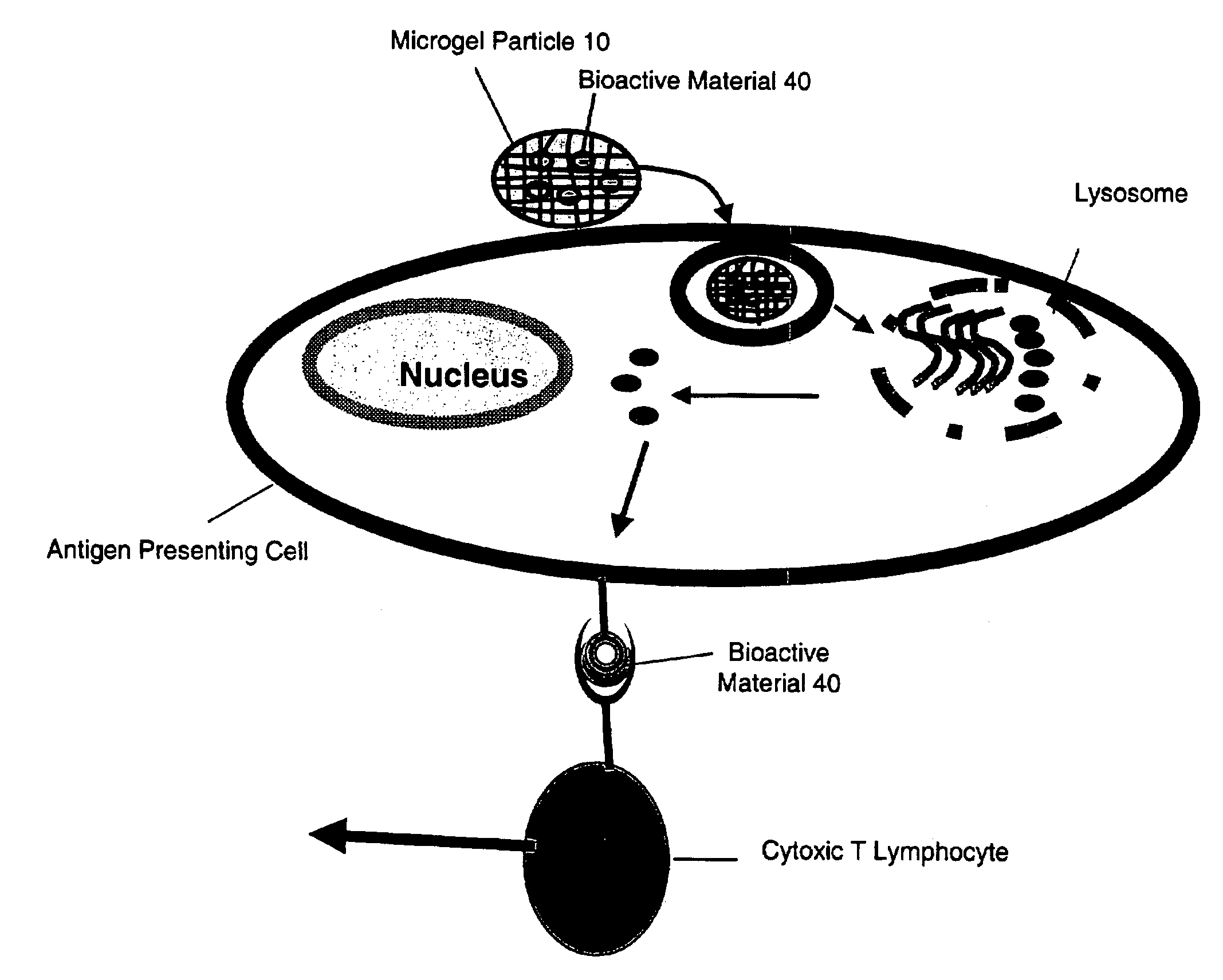

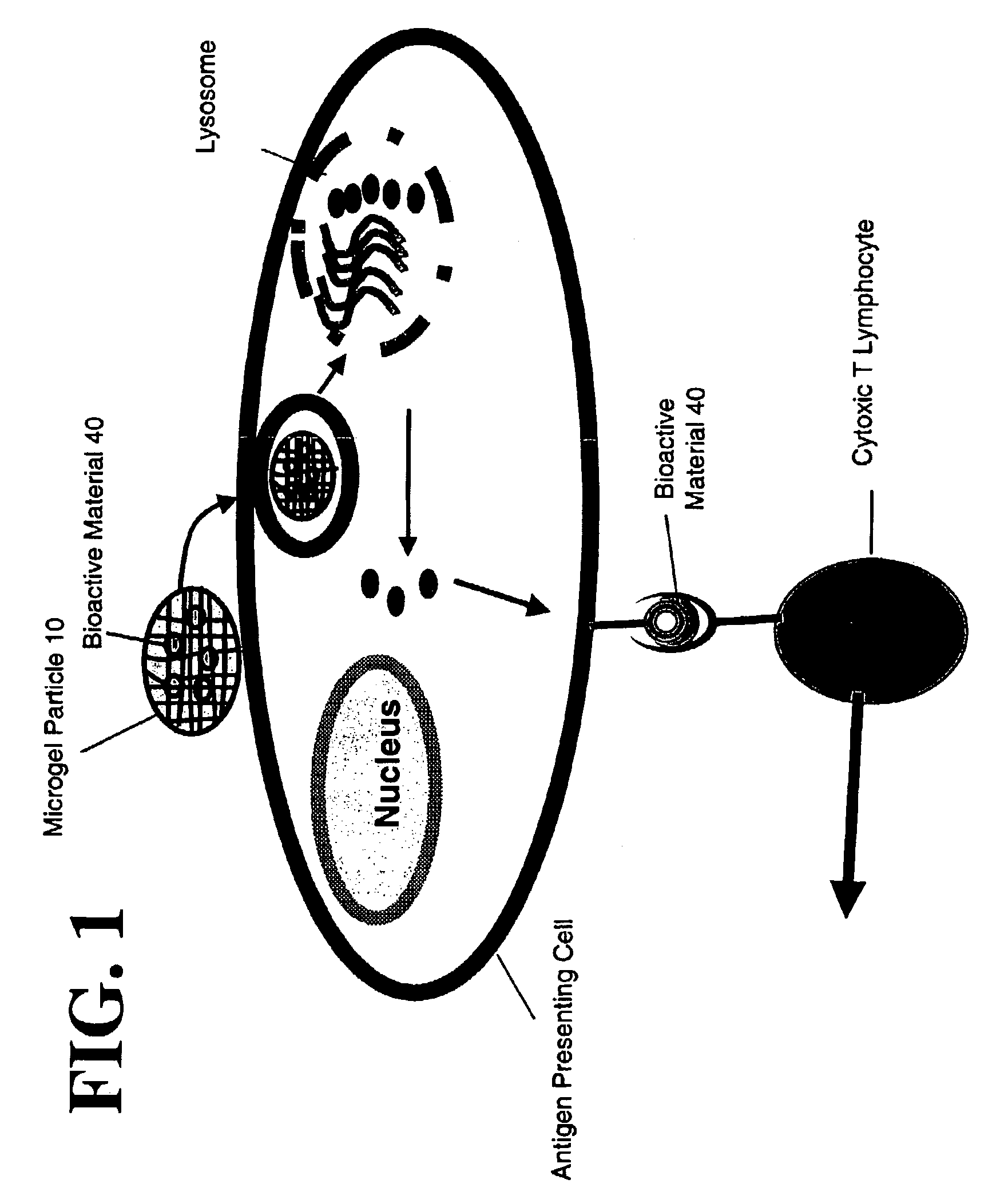

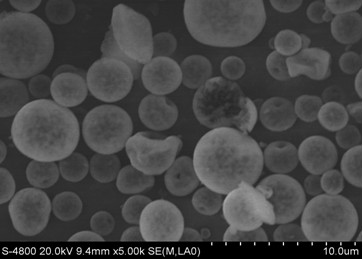

Microgel particles for the delivery of bioactive materials

Novel microgels, microparticles and related polymeric materials capable of delivering bioactive materials to cells for use as vaccines or therapeutic agents. The materials are made using a crosslinker molecule that contains a linkage cleavable under mild acidic conditions. The crosslinker molecule is exemplified by a bisacryloyl acetal crosslinker. The new materials have the common characteristic of being able to degrade by acid hydrolysis under conditions commonly found within the endosomal or lysosomal compartments of cells thereby releasing their payload within the cell. The materials can also be used for the delivery of therapeutics to the acidic regions of tumors and sites of inflammation.

Owner:RGT UNIV OF CALIFORNIA

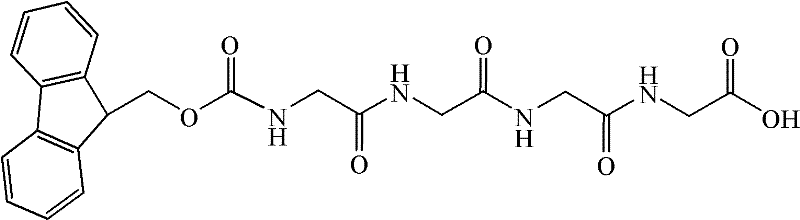

Preparation method for bivalirudin

ActiveCN102286076AEasy to operateReaction temperaturePeptide preparation methodsLeech-based protease inhibitorsSynthesis methodsAcid hydrolysis

The invention belongs to the technical field of polypeptide medicament preparation methods, and in particular relates to a preparation method for bivalirudin. The preparation method for the bivalirudin comprises solid phase polypeptide synthesis for preparing bivalirudin resin, acid hydrolysis of the bivalirudin resin to obtain a crude bivalirudin product, and purification of the crude bivalirudin product to obtain a purified bivalirudin product, wherein the solid phase polypeptide synthesis for preparing the bivalirudin resin comprises the following steps of: sequentially connecting corresponding Fmoc- protected amino acids in the following sequences to Fmoc-Leu-carrier resin by a solid phase coupling synthesis method: R1-D-Phe-Pro-Arg(Pbf)-Pro-X-Asn(R2)-Gly-Asp(OtBu)-, Phe-Glu(OtBu)-Glu(OtBu)-Ile-Pro-Glu(OtBu)-Glu(OtBu)- and Tyr(tBu)-Leu-resin, and thus obtaining the bivalirudin resin; and when the X fragment is connected, only one times of solid phase coupling synthesis reaction is used, and the corresponding Fmoc- protected amino acid is Fmoc-Gly-Gly-Gly-Gly-OH. The purity of the bivalirudin is more than 99.5 percent, and the single impurity is less than 0.2 percent.

Owner:CHENGDU SHENGNUO BIOTEC CO LTD

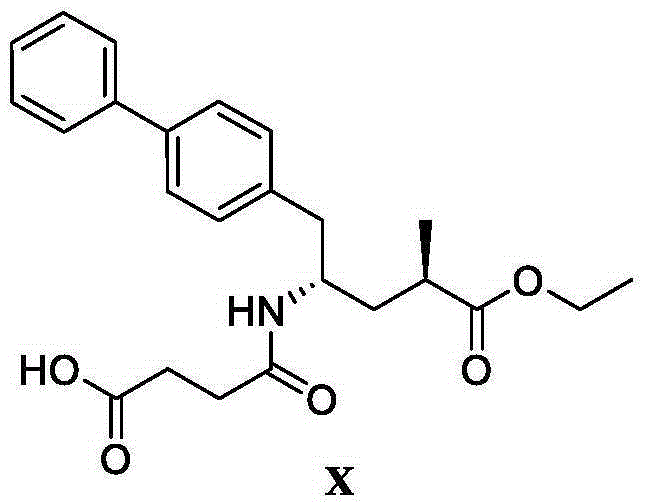

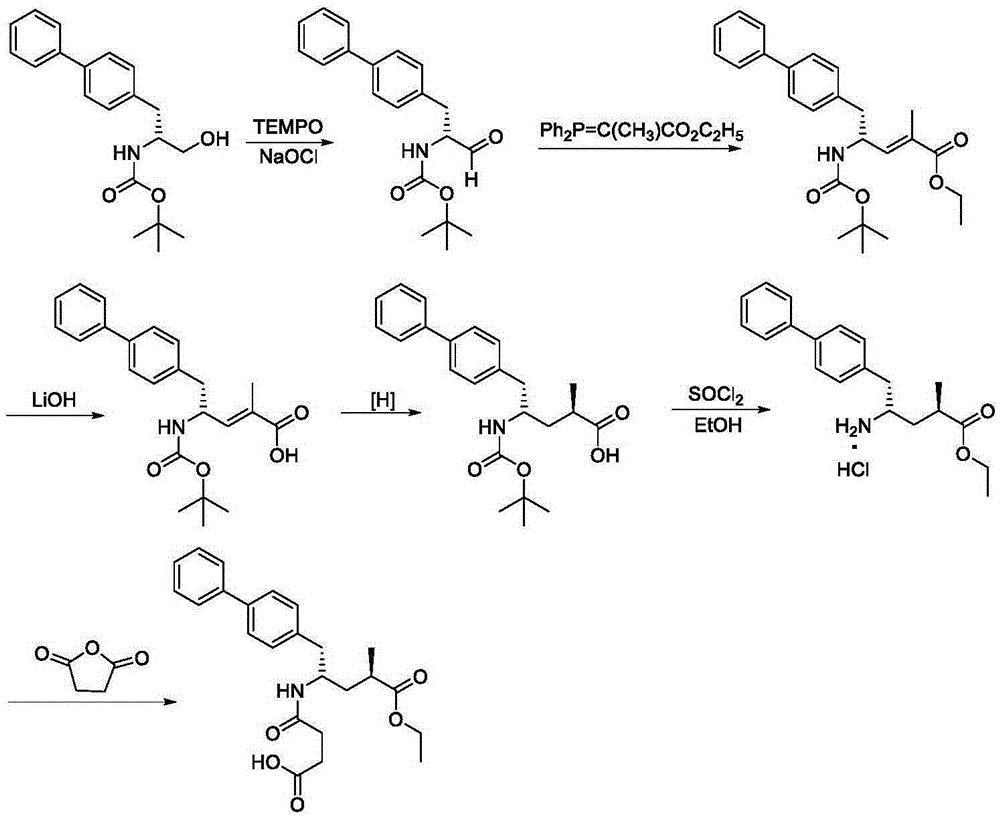

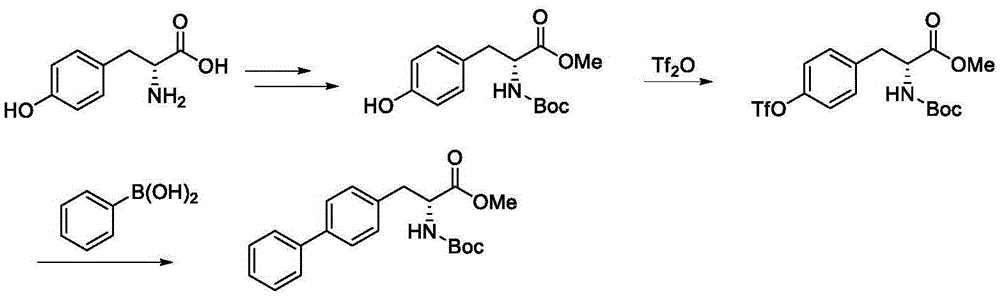

Preparation method of (R)-2-(N-tertbutyloxycarbonylamino)biphenylpropanol

InactiveCN105330569AMild reaction conditionsImprove conversion rateCarbamic acid derivatives preparationOrganic compound preparationAlcoholTert-Butyloxycarbonyl protecting group

The invention discloses a preparation method of (R)-2-(N-tertbutyloxycarbonylamino)biphenylpropanol represented by formula (I). The method comprises the following steps: carrying out an Erlenmeyer-Plochl cyclization reaction on biphenylcarboxaldehyde and N-acylglycine, hydrolyzing or alcoholyzing, and carrying out asymmetric hydrogenation to obtain (R)-N-acylbiphenylalanine or an ester thereof; and carrying out acid hydrolysis, reduction and amino protection on the (R)-N-acylbiphenylalanine or the ester thereof, or carrying out reduction, acid hydrolysis and amino protection on the (R)-N-acylbiphenylalanine or the ester thereof, or directly reducing the (R)-N-acylbiphenylalanine or the ester thereof in order to obtain the product (R)-2-(N-tertbutyloxycarbonylamino)biphenylpropanol. The product is a key intermediate of Sacubitril (AHU-377) which is one of a novel blood pressure reducing medicine LCZ696. The method has the advantages of easily available raw materials, and suitableness for industrial production.

Owner:天台宜生生化科技有限公司

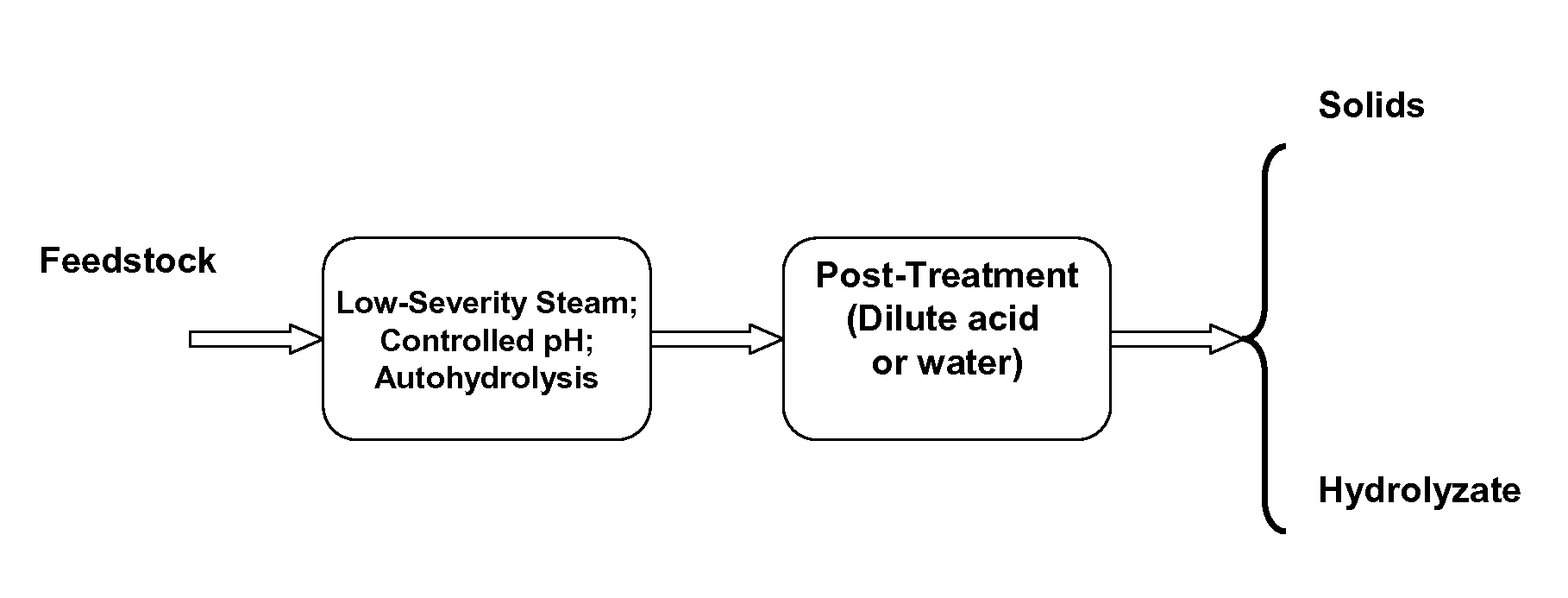

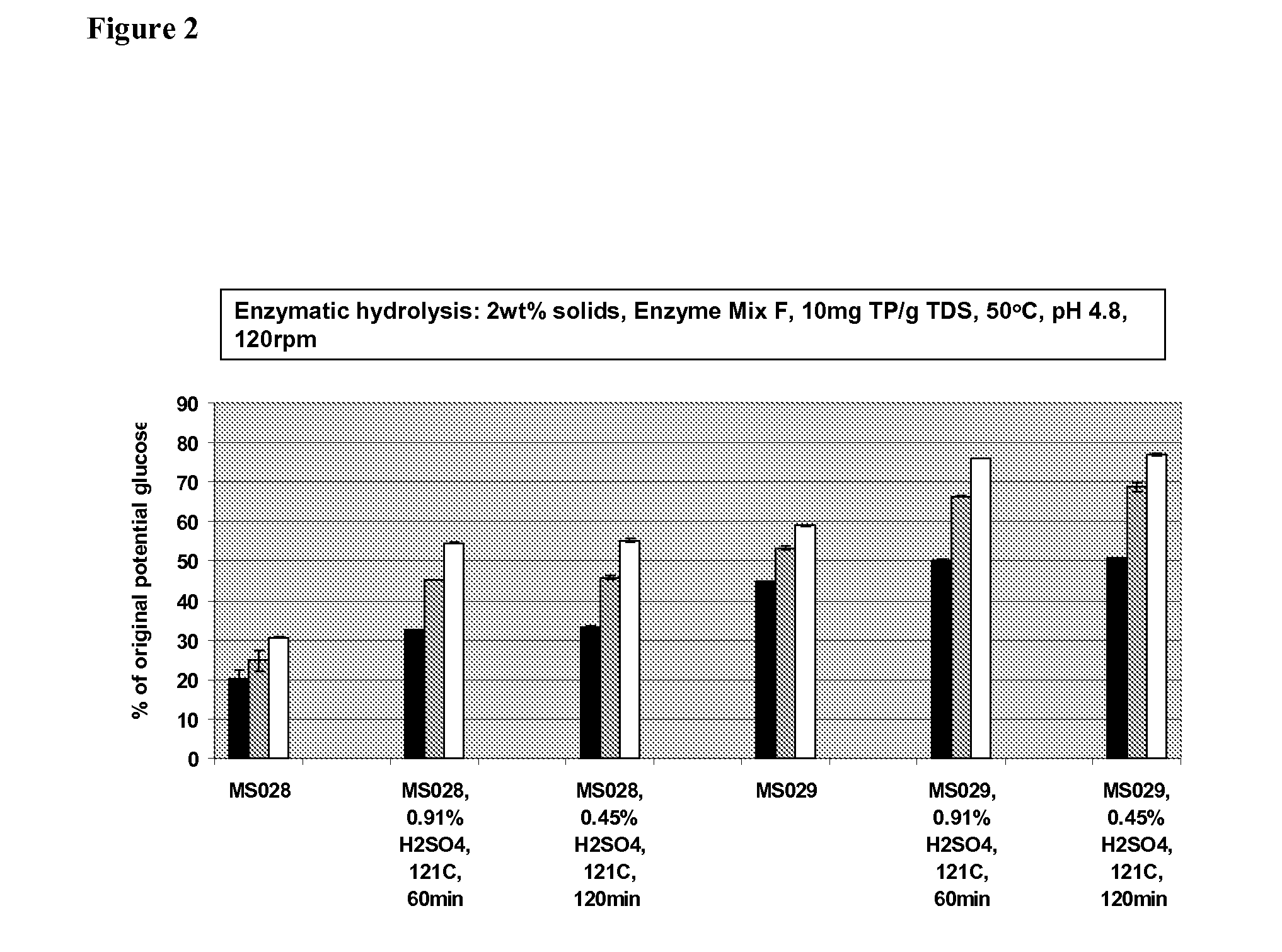

Two-Stage Process for Biomass Pretreatment

InactiveUS20110300586A1Increase rangeImprove digestibilityBiofuelsPulping with acid salts/anhydridesAcid hydrolysisLignocellulosic biomass

Described herein are improved methods of pretreating lignocellulosic biomass. One aspect of the invention relates to a two-stage pretreatment process comprising a relatively low severity steam treatment, a controlled pH pretreatment, or autohydrolysis, followed by hydrolysis with dilute acid or hot water at a relatively low temperature. In certain embodiments, the methods increase hemicellulose sugar yields, substrate digestibility, and suitability for fermentation as compared to steam explosion or acid hydrolysis alone. The two-stage pretreatment processes also employ few chemicals, minimizing the costs associated with pretreatment of lignocellulosic biomass. Moreover, the two-stage pretreatment process may expand the range of suitable feedstocks for bioethanol production.

Owner:MASCOMA CORPORATION

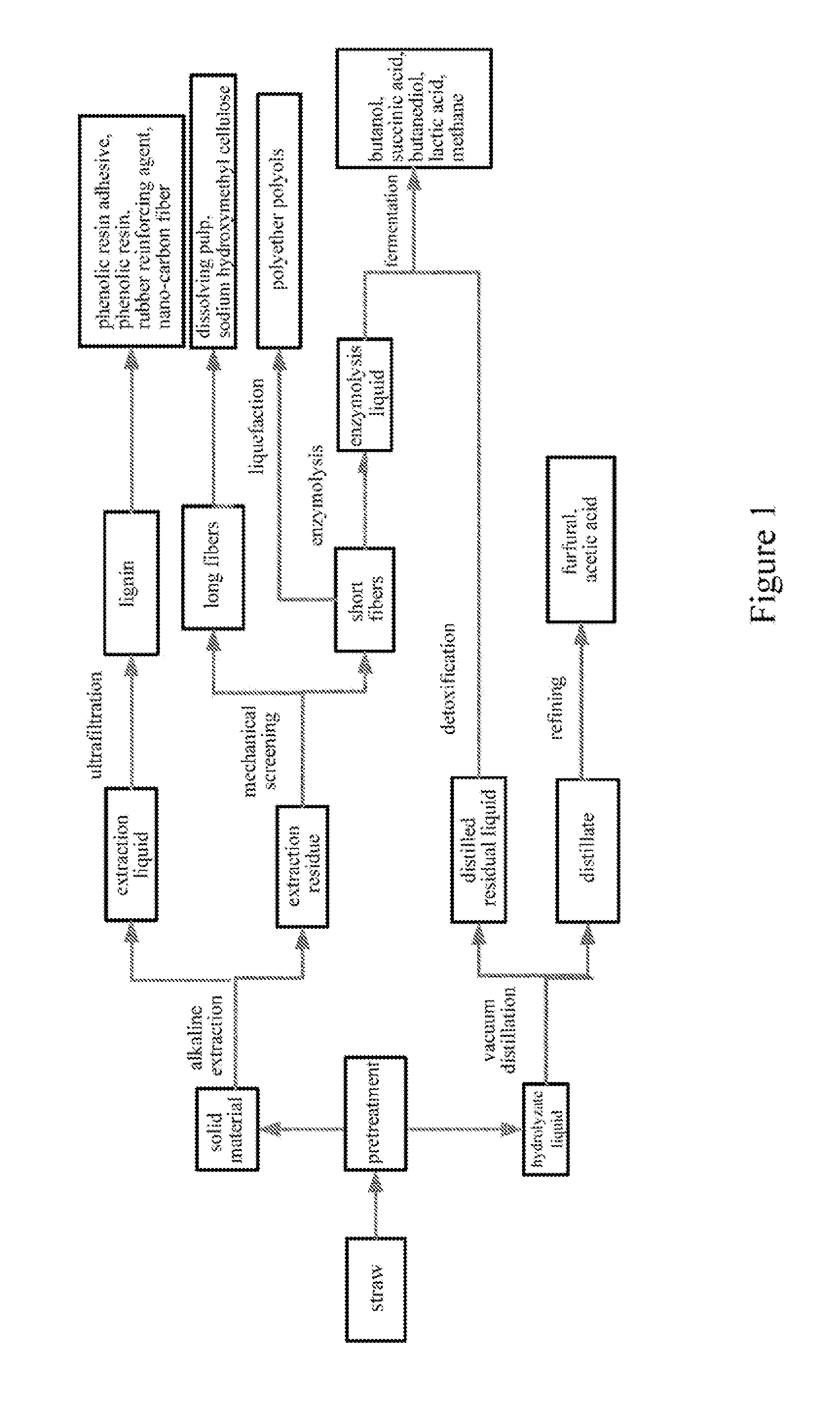

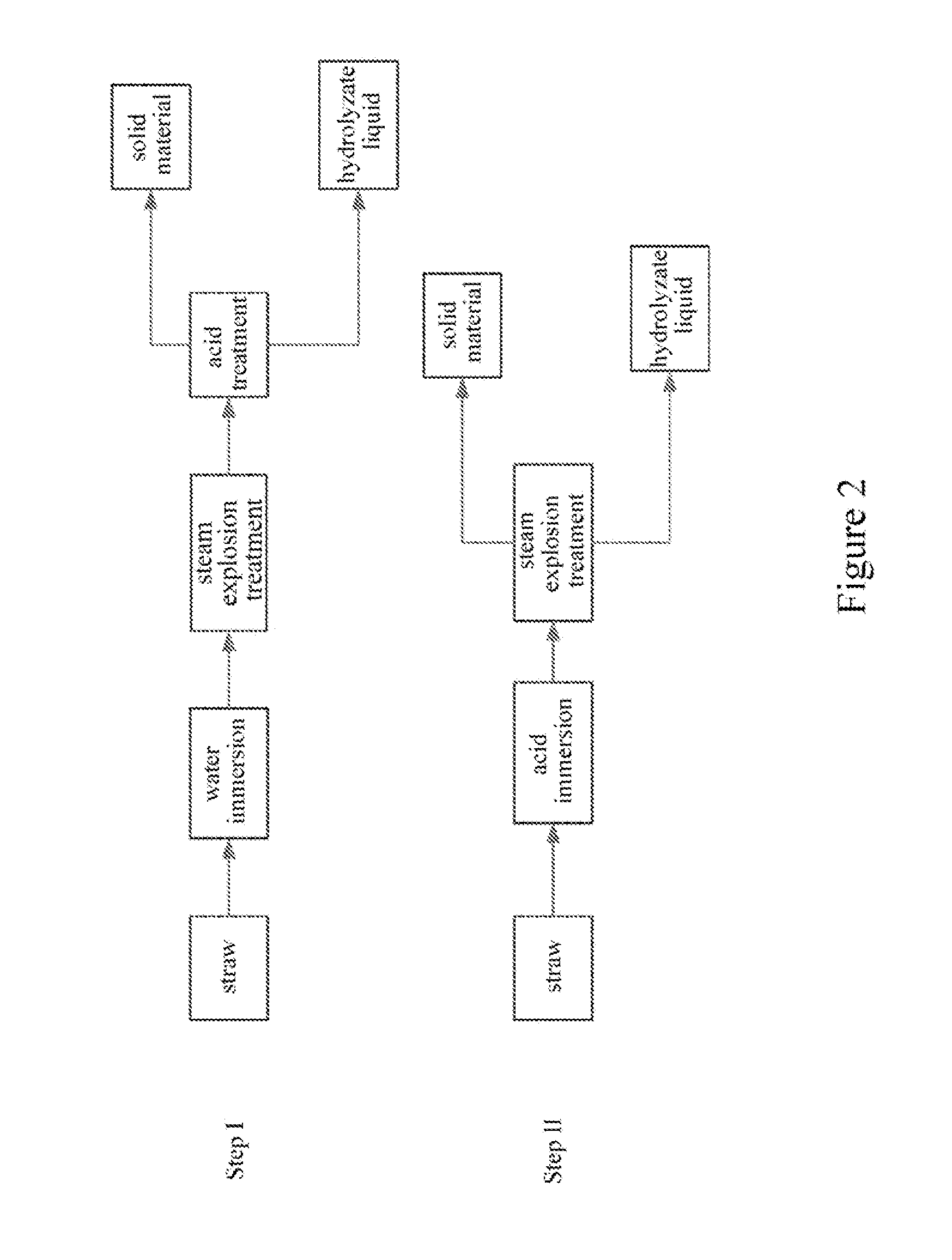

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

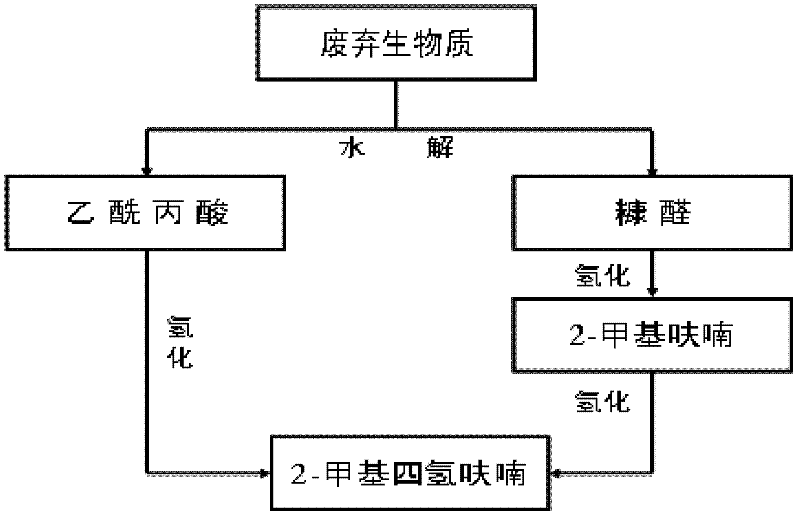

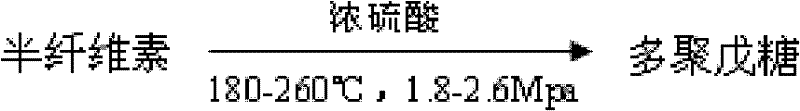

Method for preparing 2-methyltetrahydrofuran from waste biomass

ActiveCN102558106AReduce pollutionReduce manufacturing costOrganic chemistryLevulinic acidPropanoic acid

The invention discloses a method for preparing 2-methyltetrahydrofuran from waste biomass, which comprises the following steps: carrying out acid hydrolysis reaction on the waste biomass to obtain furfural and levulinic acid; sequentially carrying out first hydrogenation reaction and second hydrogenation reaction on the furfural to obtain the 2-methyltetrahydrofuran; and carrying out hydrogenation reaction on the levulinic acid to obtain the 2-methyltetrahydrofuran. The method provided by the invention more sufficiently utilizes the waste biomass, and adopts non-noble metal catalysts, thereby lowering the production cost.

Owner:北京雷恩新材料科技有限公司

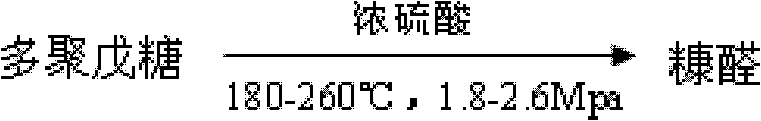

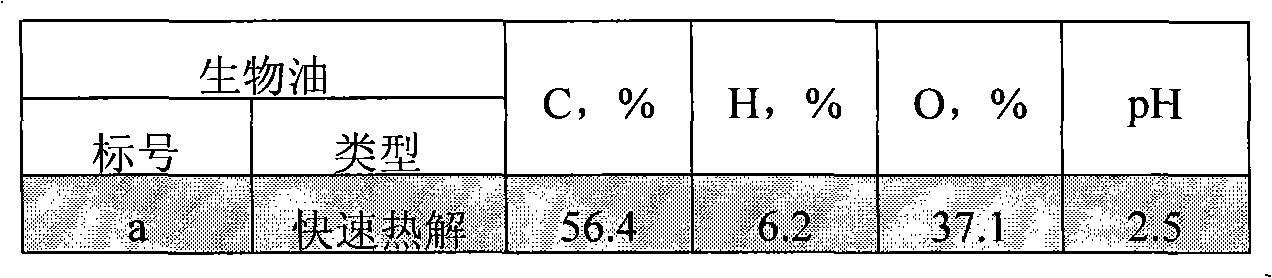

Method for preparing liquid alkane fuel by upgrading bio-oil in aqueous phase catalytic mode

ActiveCN101870881AHigh recovery rateReduce latent heat loss of vaporizationLiquid hydrocarbon mixture productionBio-feedstockAlkaneDesorption

The invention provides a method for preparing liquid alkane fuel by upgrading bio-oil in an aqueous phase catalytic mode. The method comprises the following steps of: 1) pretreating the bio-oil to obtain a water-soluble component and a water-insoluble component; 2) performing a pressurized acid hydrolysis process on a furan compound of the water-insoluble component to prepare the furan compound; 3) performing a reforming and hydrogen production reaction on the water-soluble component; 4) mixing the furan compound with a liquid-phase product separated from the step 3) to perform an aldol condensation reaction to increase carbon chains; and 5) performing a hydrogenation and dehydration reaction on an aldol condensation product to obtain liquid linear alkane. The method has the advantages that: an upgrading process, which is performed in a double-phase system, can effectively contribute to the desorption of an intermediate product from the surface of a catalyst and the mass transfer of an upgraded product, and can reduce the risk of carbon deposition on the surface of the catalyst; the quality of oil obtained by the method is high; the energy density and the energy grade of the bio-oil are improved greatly; and the liquid alkane fuel can be obtained from all kinds of bio-oil so as to partially substitute for the conventional widely-used fossil gasoline and diesel oil fuel.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

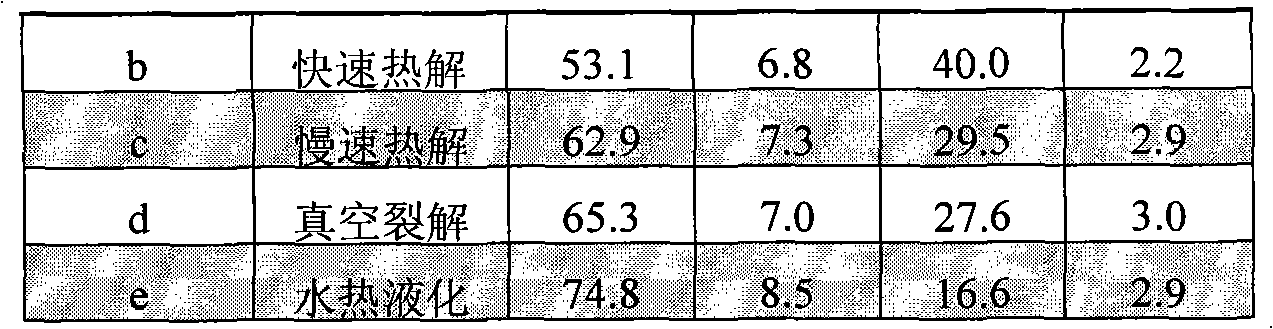

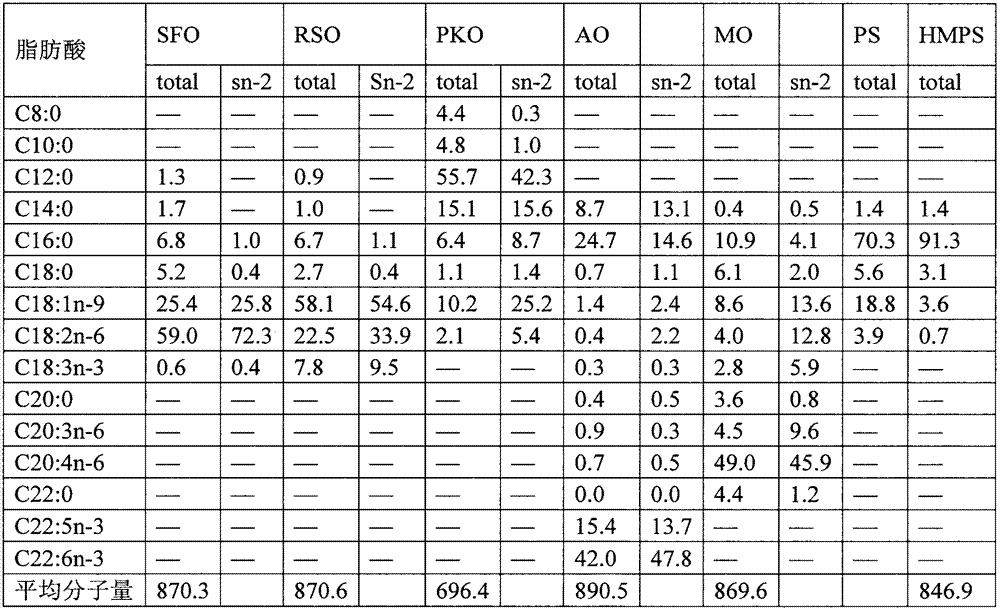

Preparation method of human milk fat substitute

ActiveCN102845537AIncrease contentReduced total palmitic acid contentEdible oils/fatsFood preparationMicrobial oilButterfat

The invention relates to a preparation method of a human milk fat substitute. The method comprises the steps of: step 1) conducting an acid hydrolysis reaction on a raw material of high melting palm stearin subjected to chemical interesterification and alcohol leaching, and an acyl donor of rapeseed oil fatty acid by using Lipozyme RM IM as a catalyst, so as to reduce the total palmitic acid content and increase the relative content of site-two palmitic acid of the raw material; and step 2) deacidifying an intermediate product; and at the same time, calculating the amount of sunflower seed oil, rapeseed oil, palm kernel oil, algae oil and microbial oil added to the intermediate product according to the composition and distribution of fatty acids in human milk fat, by a grease adding model, so as to ensure composition and distribution of fatty acids in a final product meeting requirements of a human milk fat substitute, as well as realize a maximum addition amount. The invention adopts two steps to produce the human milk fat substitute, in order to reduce usage amount of free fatty acids in the acid hydrolysis reaction; meanwhile, two times of oil additions increase yield. Therefore, the invention greatly reduces the cost, and achieves a more than doubled yield compared with a similar products with a similar cost.

Owner:JIANGNAN UNIV

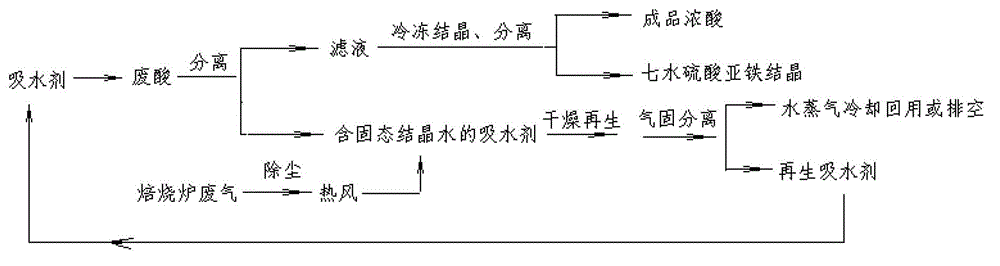

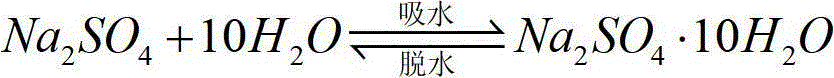

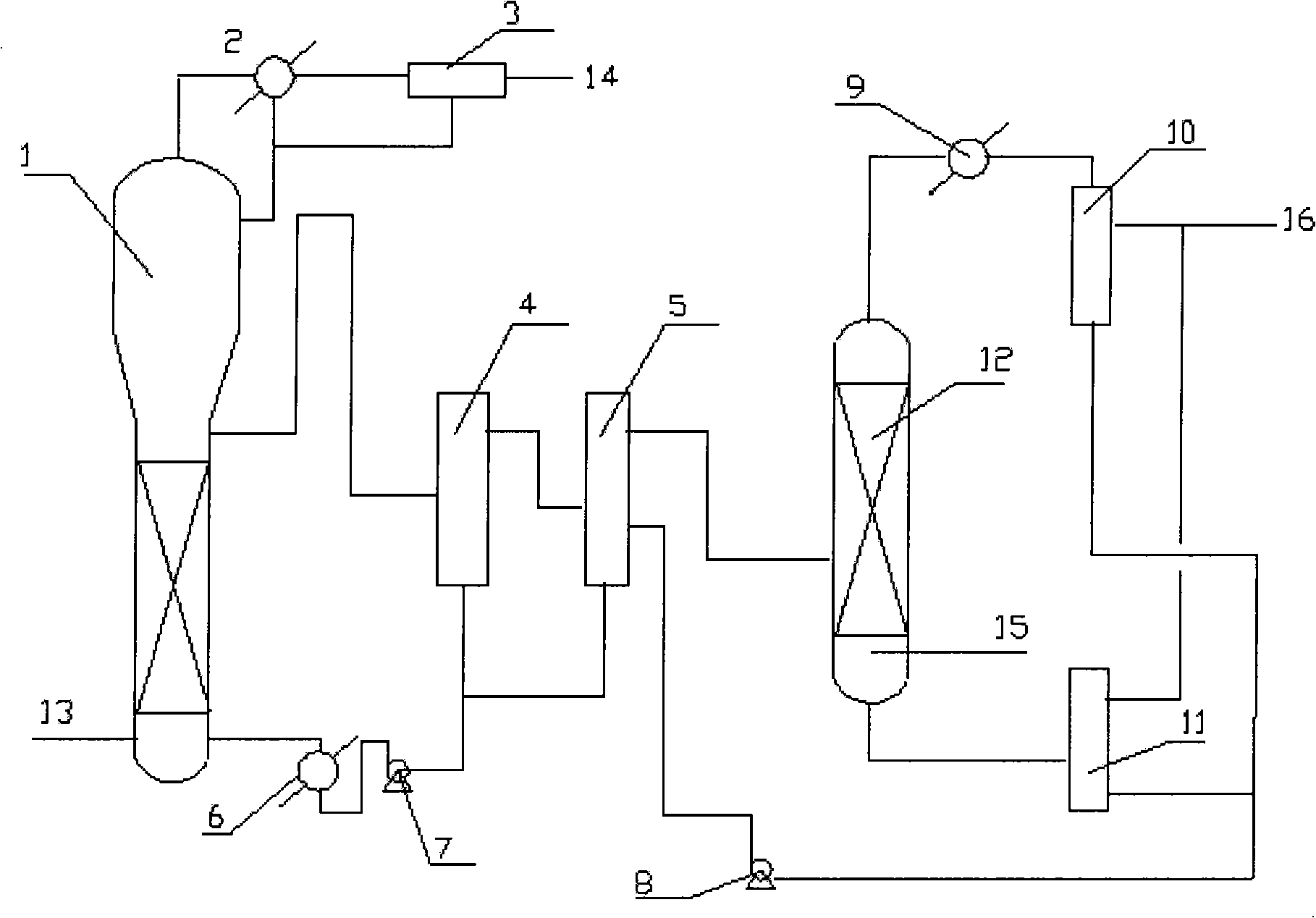

Method for concentrating waste sulfuric acid by utilizing waste heat of titanium dioxide calcinator

InactiveCN102910594ASolve manySolve process problemsSulfur compoundsEnergy inputLiquid waterOperability

The invention discloses a method for concentrating waste sulfuric acid by utilizing waste heat of a titanium dioxide calcinator, comprising the following steps: at normal temperature and pressure, proper amount of water absorbent is added to titanium dioxide waste acid, liquid water is dissolved out in the form of solid crystal water through the water absorbent, filtrate after solid-liquid separation is cooled, iron vitriol in the solution is crystallized and dissolved out, and the acid liquid is further concentrated; the two steps are repeatedly carried out until the concentration of sulfuric acid in the final filtrate reaches more than 60%, and then the final filtrate is utilized in the acid hydrolysis procedure; and the water absorbent is dehydrated and dried to be regenerated by taking dustproof tail gas of the calcinator, and the steam generated in the drying and regeneration is cooled and flows back to technological process as washing water in titanic acid rinsing or is drained. The method provided by the invention solves the problems of more equipment, long flow and easy blockage in the existing technology, and the equipment investment and operating cost are reduced; and the water absorbent is recycled after being regenerated, so that the energy is saved, the consumption is reduced, and the efficiency is obvious; no wastewater, waste gases and residues are generated in the whole technology, the operability is strong, the productivity of equipment is high, the flow is simple, the investment is less, the cost is low, energy is saved, emission is reduced, and the benefit is obvious.

Owner:黄正源

Method for continuous production hydrolysate by methylchlorosilane concentrated acid hydrolyzing

ActiveCN101323666AThe new hydrolysis process is excellentReduce or completely avoid entrainmentChlorine/hydrogen-chlorideDecompositionHydrolysate

The invention relates to a method for hydrolyzing methyl chlorosilane with concentrated acids to obtain hydrolysate, wherein, the methyl chlorosilane and the acidic oil-contained aqueous solution separated from the primary phase separator and the secondary phase separator from the hydrolysate are mixed, pass through a preheater, enter a concentrated-acid hydrolysis reaction system and undergo a circular reaction operation; the hydrogen chloride generated in the hydrolysis reaction is released from the top of a tower, goes through a defroster and a condensator and then becomes qualified HCI gas to be used in the production of methyl chloride. Qualified hydrolysate used for decomposition process is obtained after the hydrolysate of methyl chlorosilane goes through four phase separators and a steam tower.

Owner:BEIJING PETROCHEM ENG +1

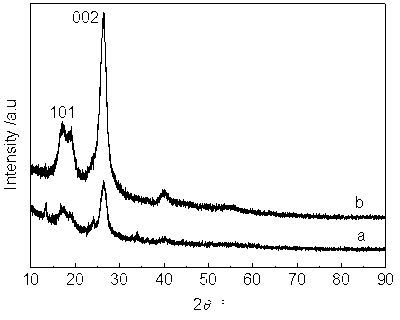

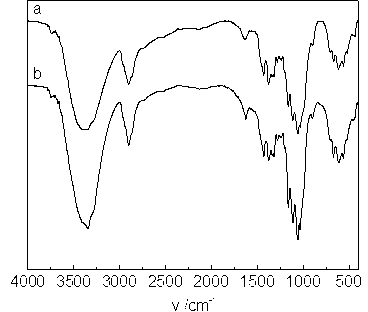

Preparation method and product of nanocellulose crystal/polyaniline composite material

InactiveCN102295786AReduce manufacturing costIncrease productivityLiquid crystal compositionsIn situ polymerizationSynthesis methods

The invention discloses a method for preparing nano-cellulose crystal / polyaniline composite material and a product thereof. In the method, firstly, the cellulose is hydrolyzed by acid to obtain nano-cellulose crystals, and the suspension of the nano-cellulose crystals spontaneously forms lyotropic cholesteric liquid crystals at a certain concentration. Then, the nanocellulose crystal / polyaniline composite material product with reversible redox properties is prepared by in-situ polymerization reaction of the polyaniline conductive monomer in the nanocellulose crystal cholesteric liquid crystal. The invention has the advantages of low cost, simple synthesis method, high production efficiency and the like.

Owner:QINGDAO UNIV OF SCI & TECH

Novel method of acid hydrolysis of biomass and the recovery of sugars thereof by solvent extraction

InactiveUS20120301948A1Minimize formationSugar derivativesOther chemical processesOrganic acidAcid hydrolysis

The present invention provides for a method of hydrolyzing a cellulose, hemicellulose, or ligno-cellulose comprising: (a) contacting (i) an ionic liquid (IL) or ionic liquid-aqueous (ILA) phase comprising cellulose, hemicellulose, or ligno-cellulose, or a mixture thereof, and (ii) an acid, such that the cellulose, hemicellulose, or ligno-cellulose is hydrolyzed into sugar, and (b) optionally adding water to the IL or ILA phase wherein the proportion of water in the IL or ILA phase does not exceed about 60% by weight. The present invention also provides for a method of recovering a sugar comprising contacting an IL or ILA phase and an organic phase comprising an organic acid.

Owner:RGT UNIV OF CALIFORNIA +1

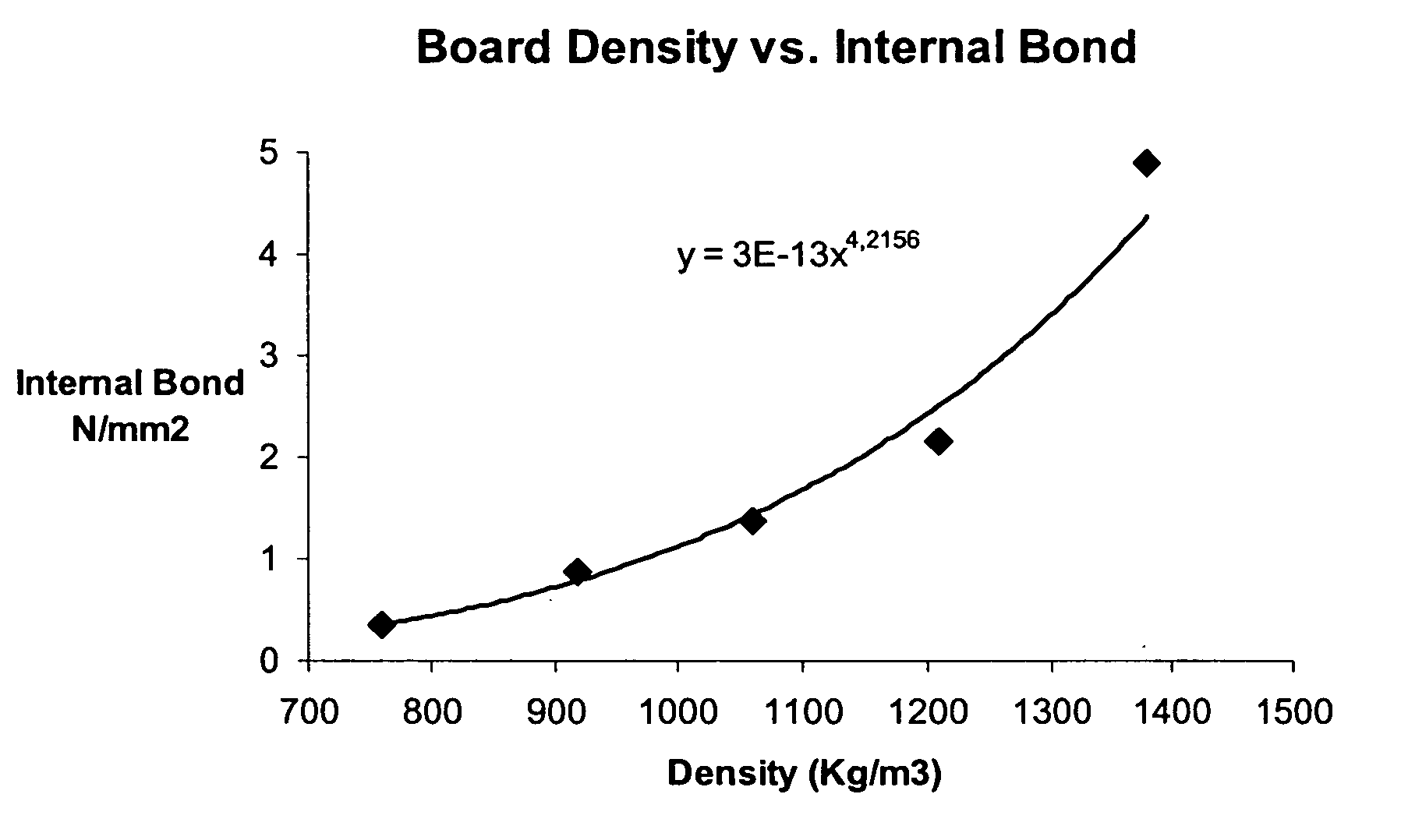

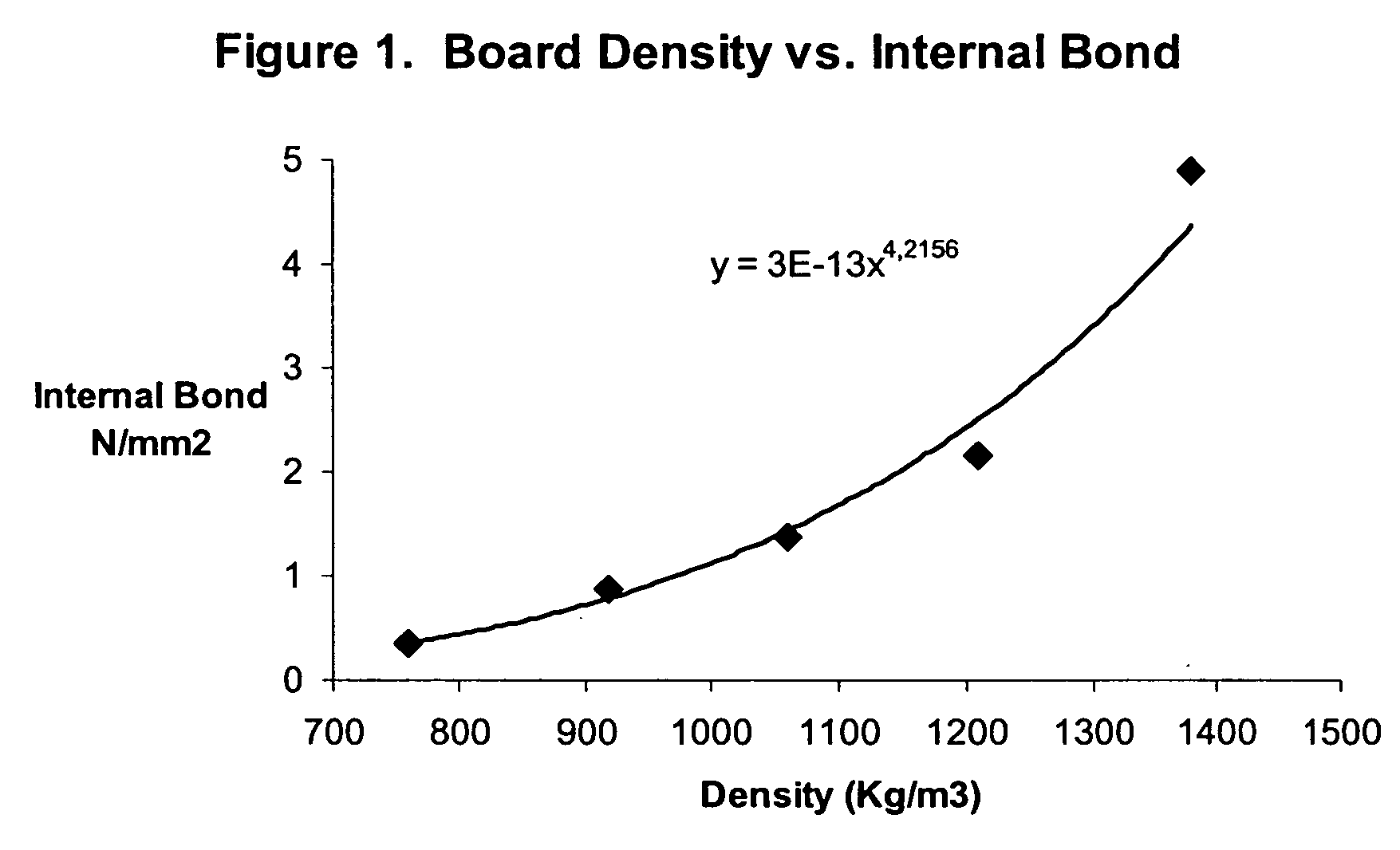

Method for making dimensionally stable composite products from lignocelluloses

InactiveUS20060091577A1Good physical propertiesImprove water resistanceCeramic shaping apparatusCork mechanical workingHigh densityDecomposition

This invention relates to a process for making dimensionally stable reconstituted composite products from lignocellulosic material. By treating lignocellulose with high pressure steam to decompose and hydrolyse the hemicellulose, cellulose and lignin fractions of the lignocellulose and using those decomposition products as both a bonding and bulking agent, it converts, under heat and pressure in a moulding operation, the treated lignocellulose into moulded composite products such as panel boards and moulded articles. The composite products thus produced possess good physical and mechanical properties. Specifically, the dimensional stability in terms of the thickness swelling and linear expansion of panel boards such as fibreboards and particleboard, can be minimized to very low levels when the panel boards are made in high density. The adhesive bond developed from thermosetting of the decomposition products of hemicellulose, cellulose and lignin is strong and stable, and resistant to boiling water and acid hydrolysis, and is free of formaldehyde emissions. Thus, the reconstituted panel boards and moulded products are suitable for exterior and particularly for indoor applications. The absence of free formaldehyde emissions makes the product very suitable for interior applications. The manufacturing cost for the reconstituted products is significantly lower in comparison to the conventional process because expensive synthetic resin is not used.

Owner:SHEN KUO C +1

Fertilizer special for hybrid rice

ActiveCN102815999AIncrease the chelating structureReduce invalid releaseClimate change adaptationAgriculture gas emission reductionVegetable oilCrop

The invention discloses fertilizer special for hybrid rice, which is prepared by barnyard manure, humic acid, bamboo charcoal, medical stone, biological bacterium, ammonium bicarbonate, calcium superphosphate, potassium chloride, bean pulp, cellulose glycolate, 35% sulfuric acid, lime, zinc sulfate, ferrous sulfate, sodium borate, nano iron ore milltailings powder, eucalypt saw dust, nano river sand powder and vegetable oil according to a certain weight proportion, wherein amino acid is generated by acid hydrolysis feather; secondary elements are chelated with microelements; a chelation structure is added to the cellulose glycolate, which is benefit to effectively use the secondary elements and the microelements; unavailable release of the secondary elements and the microelements is reduced; according to a formula of the invention, inorganic slow release component medical stone and soil improvement component bamboo charcoal are increased, thus, soil can be improved; the fertilizer is released effectively and is absorbed by crops completely; biological pesticide component can effectively reduce soil pest and disease damage according to the eucalypt saw dust and is safe and pollution-free and has no pollution to environment and the crops; according to the invention, the fertilizer is characterized by reasonable formula, more comprehensive and balanced nutrition, good use effect and can increase fertilizer utilization rate obviously; thus, output and quality of the hybrid rice are improved greatly so as to increase economic benefit of the hybrid rice.

Owner:MAANSHAN KEBANG ECO FERTILIZER

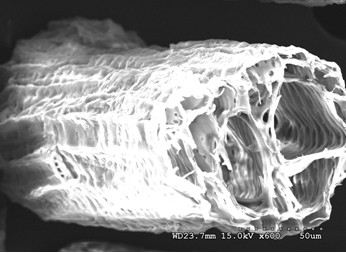

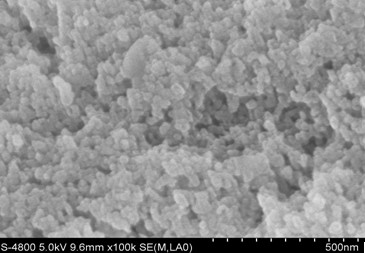

Method for preparing nano cellulose by simultaneous assistance of ultrasonic waves and microwaves

The invention discloses a method for preparing nano cellulose by simultaneous assistance of ultrasonic waves and microwaves, belonging to the field of biomass nano materials. According to the nano material, liquid acid is taken as a catalyst, and the high-efficiency hydrolysis at the amorphous area of cellulose is promoted due to the simultaneous assistance of the ultrasonic waves and microwaves, so that the nano cellulose is rapidly prepared by plant fiber raw materials. The preparation method comprises the steps of acid hydrolysis of plant cellulose, centrifugal recovery of liquid acid and centrifugal separation of nano cellulose. According to the method, the mechanical dispersion action and ultrasonic cavitation effect of the ultrasonic waves, microwave uniform heating effect, catalytic action of the liquid acid and the synergistic effect of the ultrasonic waves and microwaves are utilized sufficiently, and the hydrolytic process of cellulose is enhanced, so that the high-efficiency and rapid preparation of the nano cellulose can be realized. The prepared nano cellulose material can be used for food additives, drug excipients, engineering material additives, specialty paper additives and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

Short fiber food waste residue-based nano cellulose and preparation method thereof

InactiveCN102182089AFine granularityThe compactness of the crystal region is weakPretreatment with water/steamWashing/displacing pulp-treating liquorsFood additiveFiber

The invention relates to the field of processing of agricultural products, in particular to short fiber food waste residue-based nano cellulose and a preparation method thereof. The preparation method comprises three parts of pretreatment of short fiber food waste residues, acid hydrolysis of food residue fibers and homogenization. The nano cellulose prepared by the method has the granularity of 50-300nm, is short bar-shaped or microsphere-shaped and can be widely used for preparing a food additive or medicament excipient, and the like. In the method, acid hydrolysis is combined with high-pressure homogenization, thus the acid consumption and hydrolysis time are reduced, the granularity uniformity of the nano cellulose is improved; and the invention is suitable for mass production.

Owner:SOUTHWEST UNIV

Preparation method of lignin-nanocelluose reinforced polylactic acid composite film

The invention provides a preparation method of a lignin-nanocelluose reinforced polylactic acid composite film. The preparation method comprises the following steps: 1) preparation of lignin-nanocelluose by adopting an acid hydrolysis-high-pressure homogeneity method, namely hydrolyzing raw materials with sulfuric acid, and then performing high-pressure homogeneity to obtain lignin-nanocelluose; and 2) preparation of the lignin-nanocelluose reinforced polylactic acid composite film by adopting a solution casting-solvent evaporation method, namely taking 8-10 parts by weight of polylactic acid and 0.08-0.5 part by weight of lignin-nanocelluose, mixing with an organic solvent to obtain a film casting stock solution, performing vacuum defoamation treatment on the film casting stock solution, and preparing the thin film from the film casting stock solution. According to the preparation method, the lignin-containing nanocelluose and the polylactic acid are compounded for the first time, the polylactic acid is reinforced with nanomaterials, the problem that the compatibility of the nanocelluose and the polylactic acid matrix is bad to cause low mechanical performance can be solved by virtue of the adopted lignin, and the adhesion action of a phase interface can be improved.

Owner:BEIJING FORESTRY UNIVERSITY

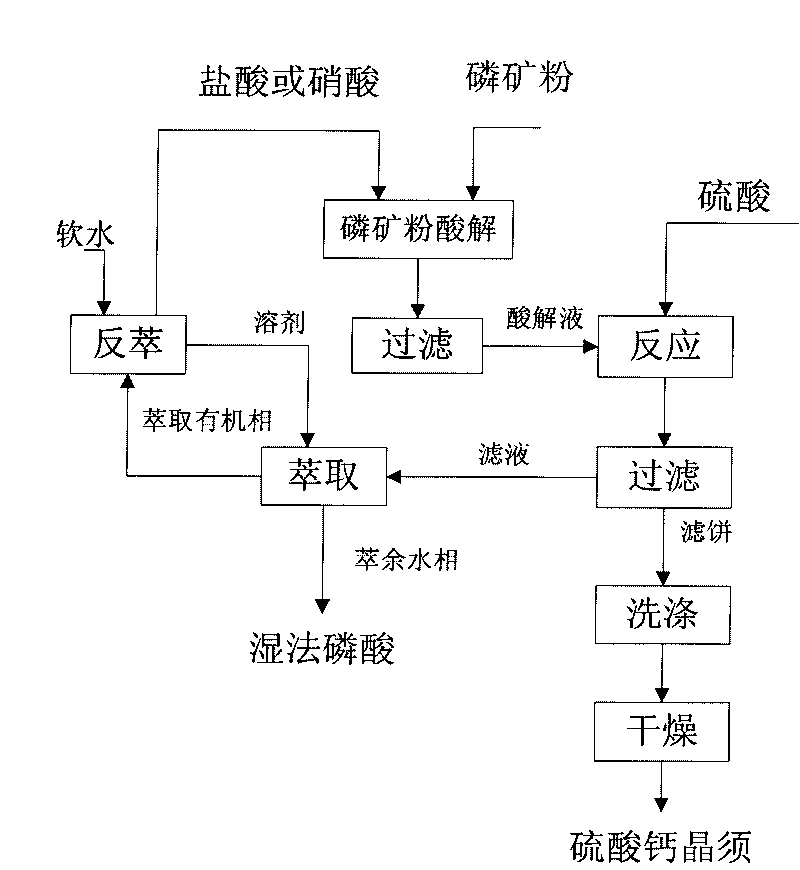

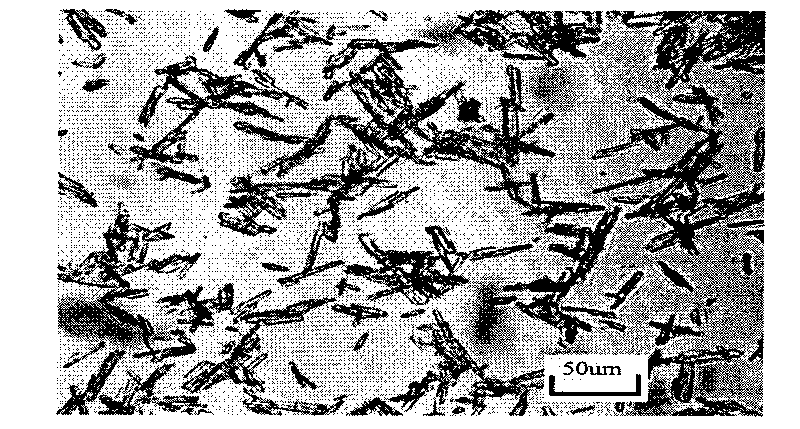

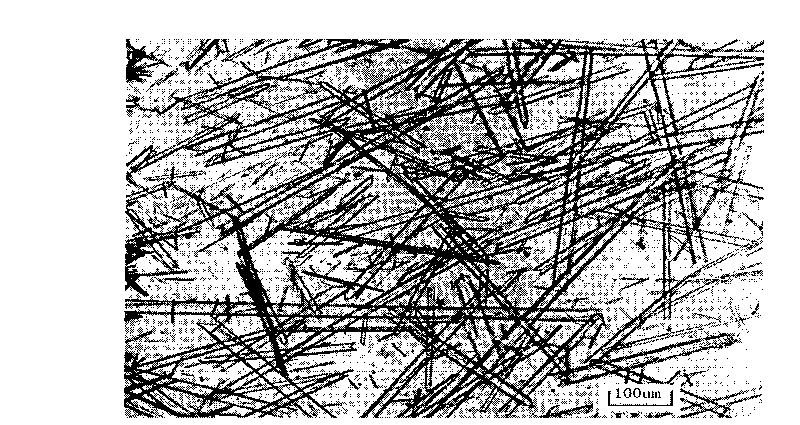

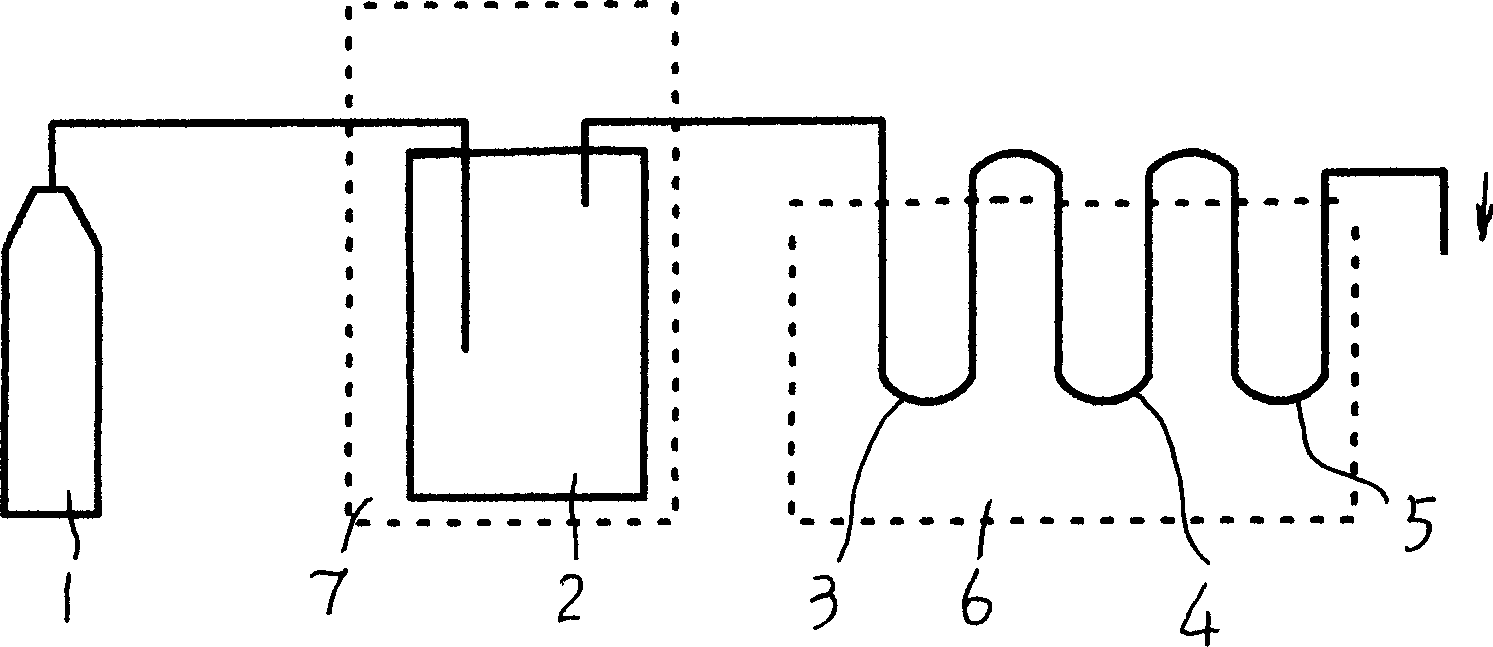

Co-production method of calcium sulfate whisker and phosphoric acid

ActiveCN101736404AIncrease contentSave energyPolycrystalline material growthSingle crystal growth detailsPhosphatePhosphoric acid

The invention relates to a co-production method of calcium sulfate whisker and phosphoric acid. The method comprises the following technical steps of: (1) acid-hydrolyzing phosphate rock powder by hydrochloric acid with the mass concentration of 15 to 26% or nitric acid with the mass concentration of 20 to 90%, filtering the acid-hydrolyzed slurry into the acid hydrolysis solution containing Ca2<+>; (2) using the acid hydrolysis solution containing Ca2<+> and the sulfuric acid with the mass concentration of 20 to 90% as the raw materials, wherein the use level of the sulfuric acid is 100% of the needed theoretical amount of the sulfuric acid when the Ca2<+> in the acid hydrolysis solution and the sulfuric acid react completely, adding the sulfuric acid to the acid hydrolysis solution containing Ca<2+> under the stirring condition, reacting the sulfuric acid with the acid hydrolysis solution containing Ca2<+> at the normal pressure and at 50 to 90 DEG, filtering and separating the calcium sulfate whisker after the reaction is finished, and then washing and drying the calcium sulfate whisker; and (3) carrying out the counter-current extraction on the filtrate obtained in the step (2), wherein the extracted water phase is the phosphoric acid, and acid-hydrolyzing the phosphate rock powder by using the hydrochloric acid obtained by the counter-extraction of the soft water to the extracted organic phase which is separated in the counter-current extraction.

Owner:SICHUAN UNIV

Process of preparing rich furol biological oil by biomass microwave catalytic pyrolysis

InactiveCN100999677AHighly selective generationImprove use valueLiquid hydrocarbon mixture productionLiquid productCatalytic pyrolysis

The microwave catalytic biomass cracking process for preparing biological oil with rich furfural features using ferric sulfate as catalyst, silicon carbide as microwave absorbing medium, microwave source as heat source for cracking biomass, and ice water mixture for cooling volatile component to obtain biological oil with rich furfural. The present invention can obtain liquid product with furfural content of 35-55 % and raise the utilization value of furfural greatly. The present invention uses solid ferric sulfate catalyst and is superior to acid hydrolysis process with corrosion and pollution problems.

Owner:ANHUI UNIV OF SCI & TECH

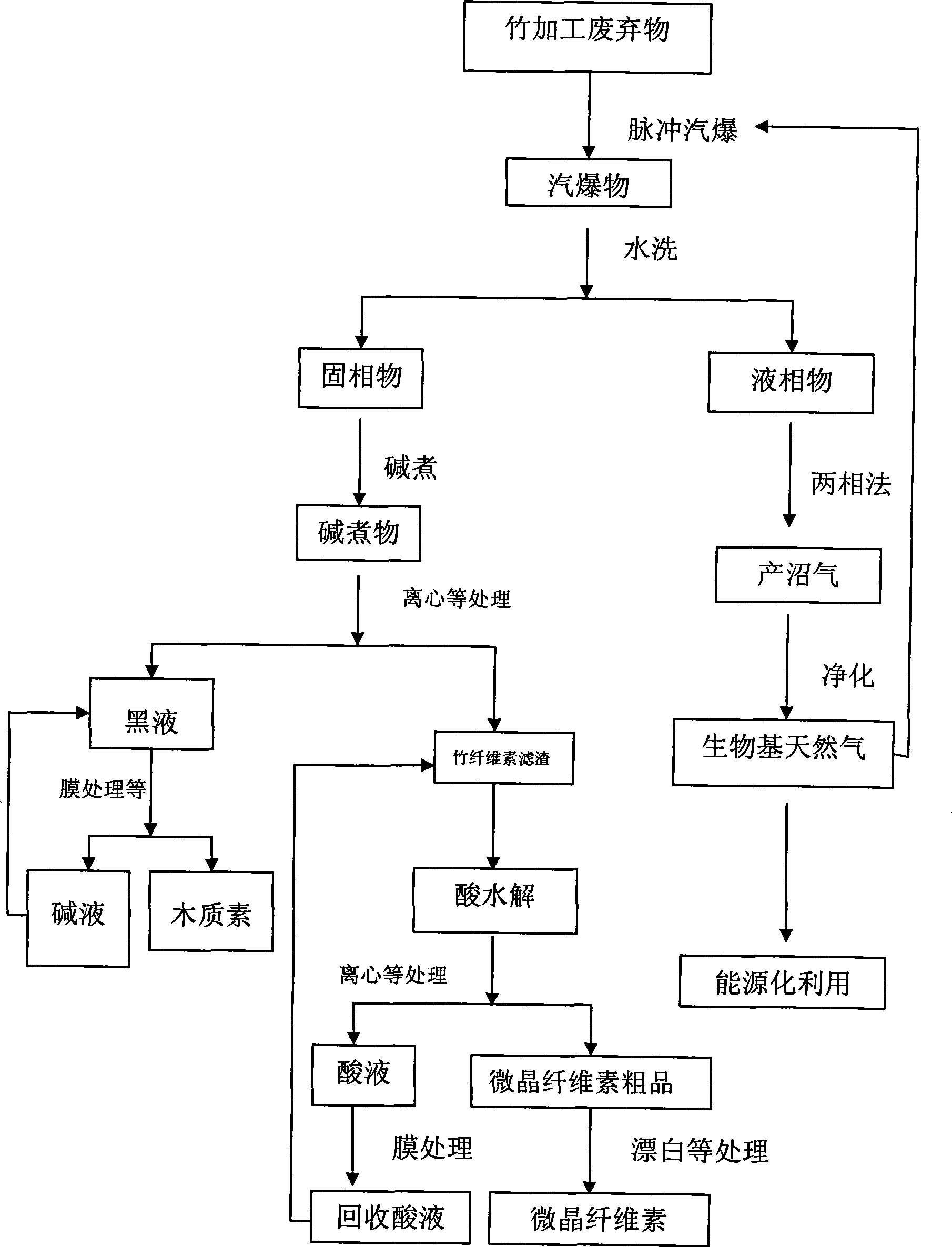

Production process for producing biobase natural gas with coproduction of lignose and microcrystalline cellulose from bamboo processing wastes

ActiveCN101497833ARealize the purpose of anaerobic fermentation to produce biogasGood preprocessing effectGaseous fuelsWaste based fuelFermentationHeat energy

The invention relates to a production process for producing biomass based natural gas, lignose and microcrystalline cellulose by utilizing bamboo-curing waste, which solves the problem that the bamboo-curing waste is utilized economically and effectively. The production process comprises the following steps: performing steam exploded pretreatment to the bamboo-curing waste, lixiviating and separating the steam exploded materials by water, producing marsh by the anaerobic fermentation of liquid phase materials, obtaining bamboo cellulose filter residue and black liquid by the alkali treatment of solid phase materials, separating the black liquid from the lignose, and obtaining the microcrystalline cellulose by the acid hydrolysis of the bamboo cellulose filter residue. The production process has high transition heat energy and can realize energy regeneration of the marsh; the joint lignose and microcrystalline cellulose realizes the energy regeneration utilization of the waste. The production process belongs to a closed circulating system which has high economic benefit and environment-protection without pollution.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

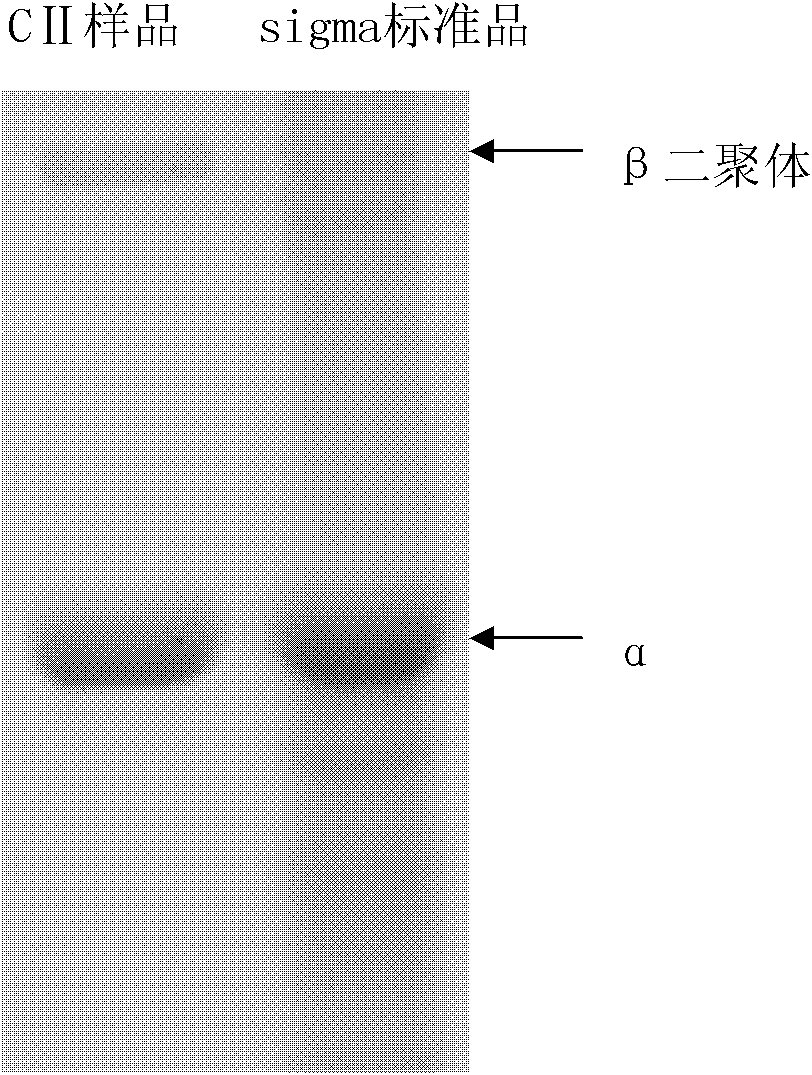

II-type collagen joint cartilage fluid and preparation method thereof

ActiveCN101810855APromotes self-healingImprove lubrication functionPeptide/protein ingredientsSkeletal disorderHazardous substanceHybrid protein

The invention provides II-type collagen joint cartilage fluid and a preparation method thereof. Bacteria, viruses and other hazardous substances of the joint cartilage are removed through degreasing-> serum removing-> surfactant treatment-> oxidant treatment-> disinfection and other links. Hybrid protein and other denatured protein of the cartilage are removed through acid hydrolysis, salt precipitation, dialysis and other processes, and high-purity and high-activity II-type collagen solution is prepared. Non-toxin and non-heat raw materials and auxiliary materials and isotonic solution are mixed in an appropriate ratio, and filled in a sterile non-heat disposable injector, to prepare II-type collagen joint cartilage fluid for disposable injection. Other components of the II-type collagen joint cartilage fluid comprise the auxiliary materials and the isotonic solution. The II-type collagen joint cartilage fluid can play the roles of lubrication, pain relieving and joint activity degree improving to the injured joints, fundamentally realizes the internal repair to the cartilage tissue, and is applicable to a patient with various joint cartilage injuries and all types of arthritis.

Owner:GUANGZHOU TRAUER BIOTECH

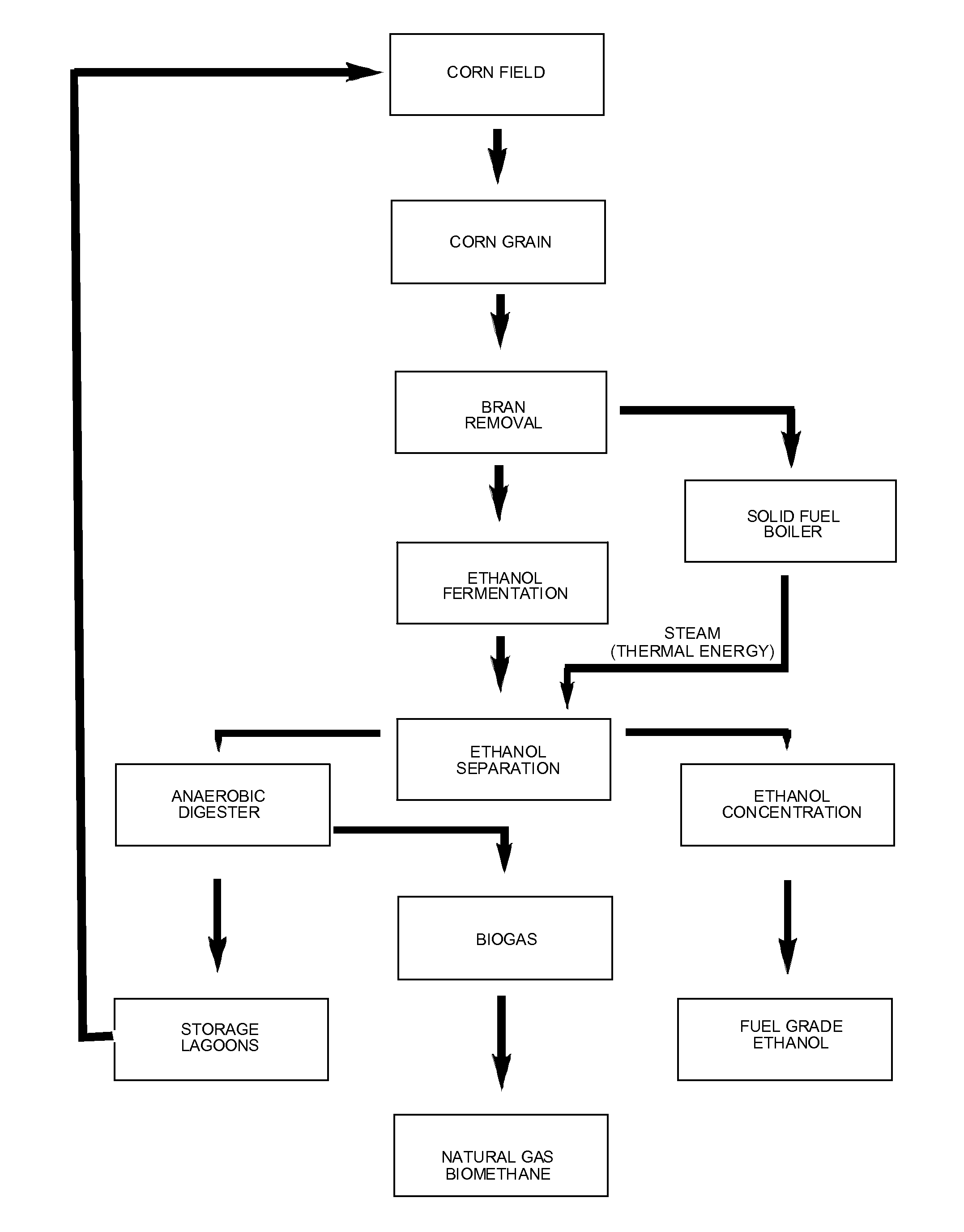

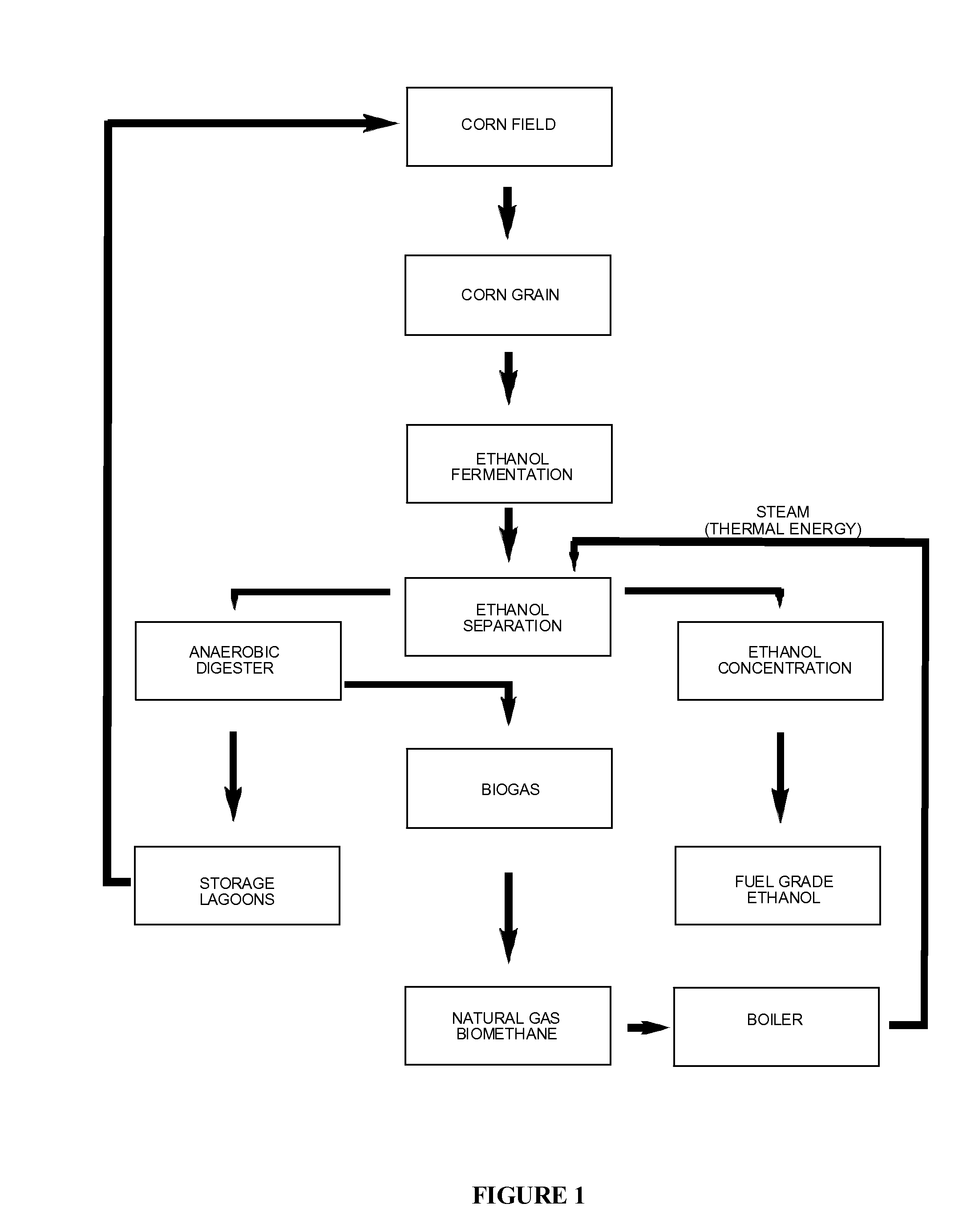

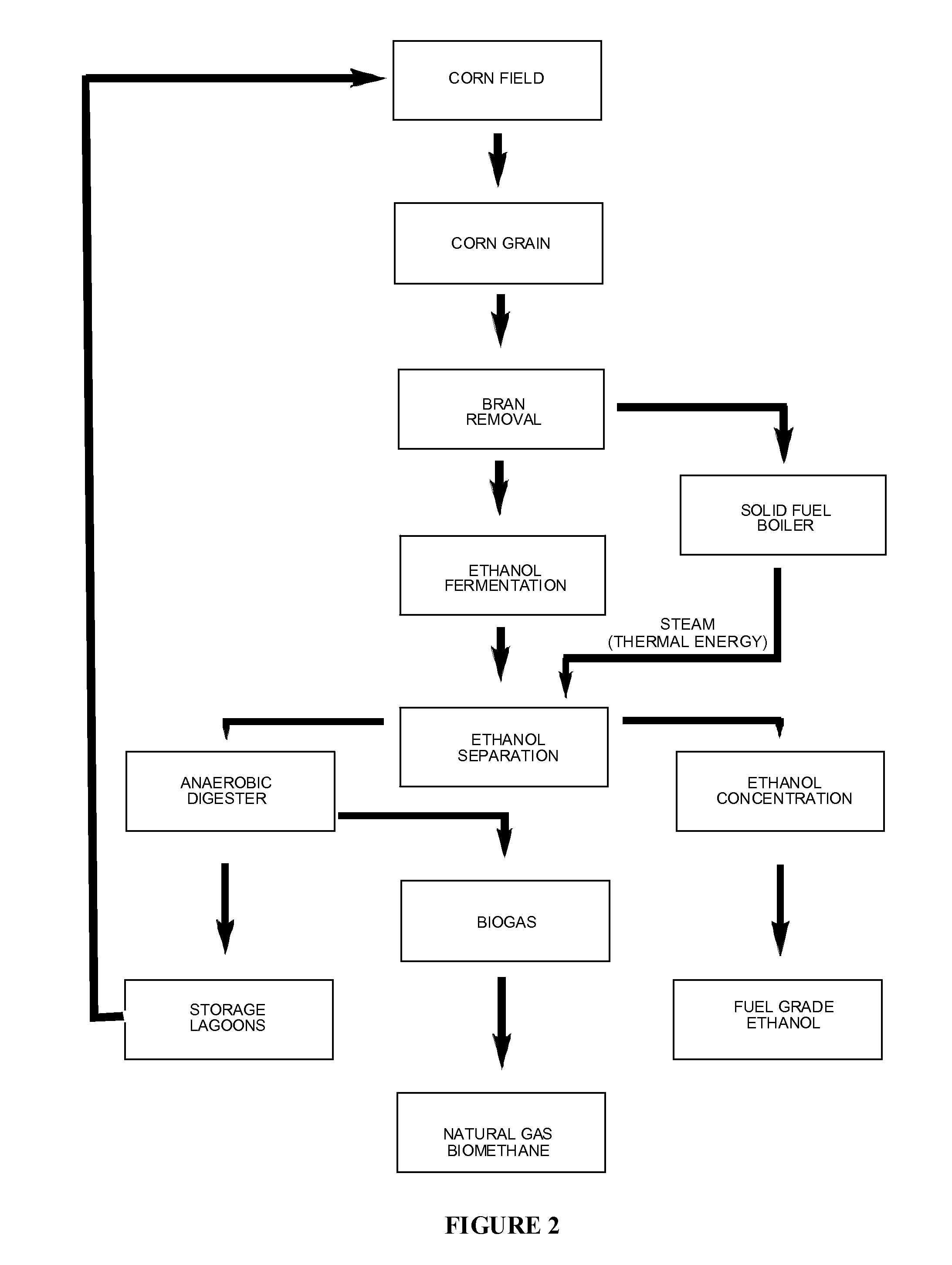

Farm Scale Ethanol Plant

An energy-efficient cycle for the production of ethanol and optionally natural gas from sunlight and biomass comprising first producing or obtaining biomass, for example by planting and harvesting of either an annual or perennial crop or both, and optionally tilling, fertilizing and obtaining wood wastes or paper wastes on-site or from a secondary site, for example, to supplement the on-site production of biomass, or for use as the sole source of biomass. The biomass is then converted to fermentable sugars through enzymatic conversion, acid hydrolysis, thermal cracking, or other processes that reduce cellulosic and hemi-cellulosic compounds to simple sugars. The reduced product is then fermented, producing ethanol in an intermediate beer product followed by recovery of ethanol from the resulting fermentation beer, wherein liquids are concentrated and recovered as fuel grade product. Recovery of ethanol may be by any suitable means including distillation, membrane separation or similar methods, and chromatographic rectification

Owner:6SOLUTIONS

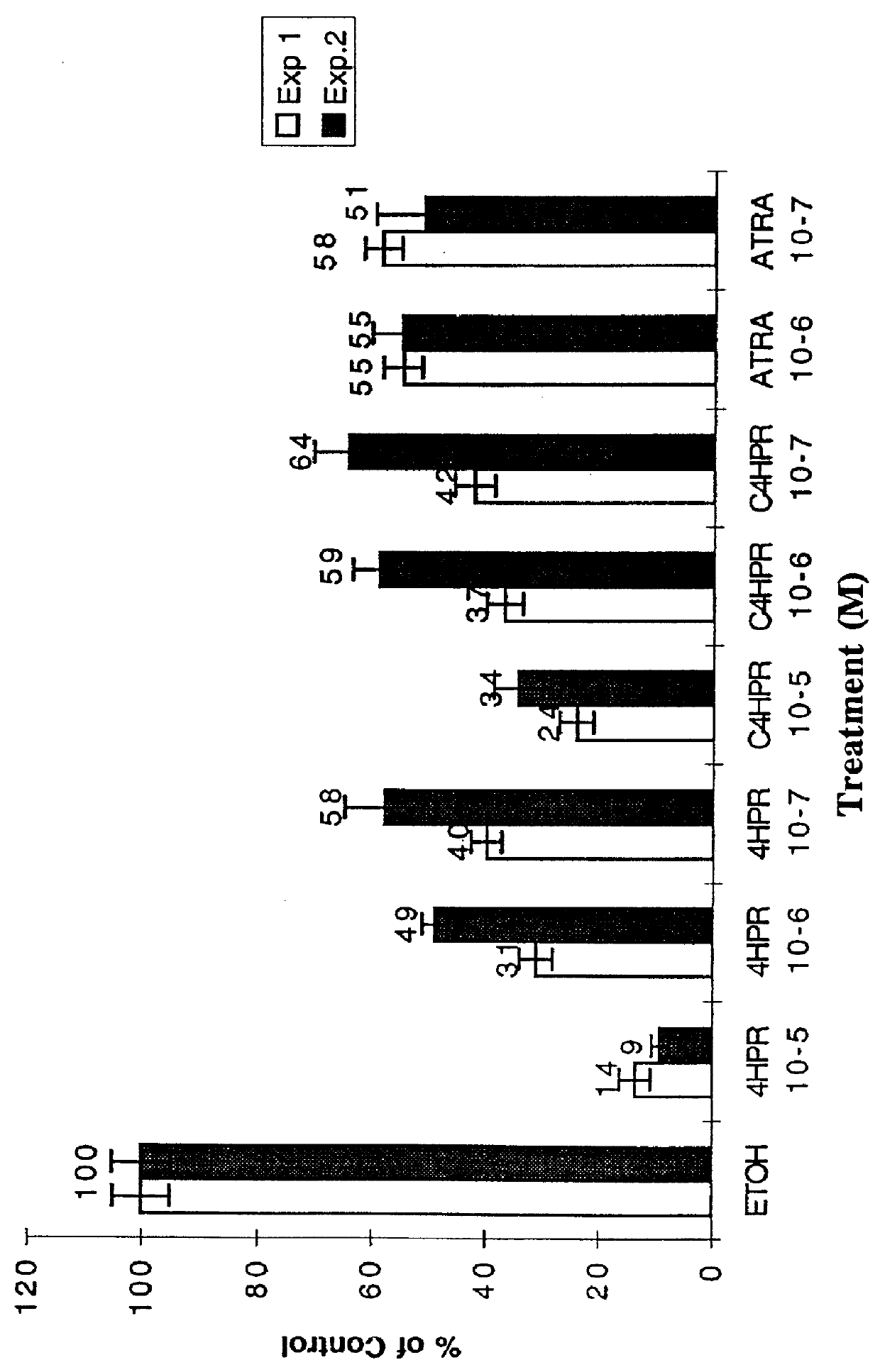

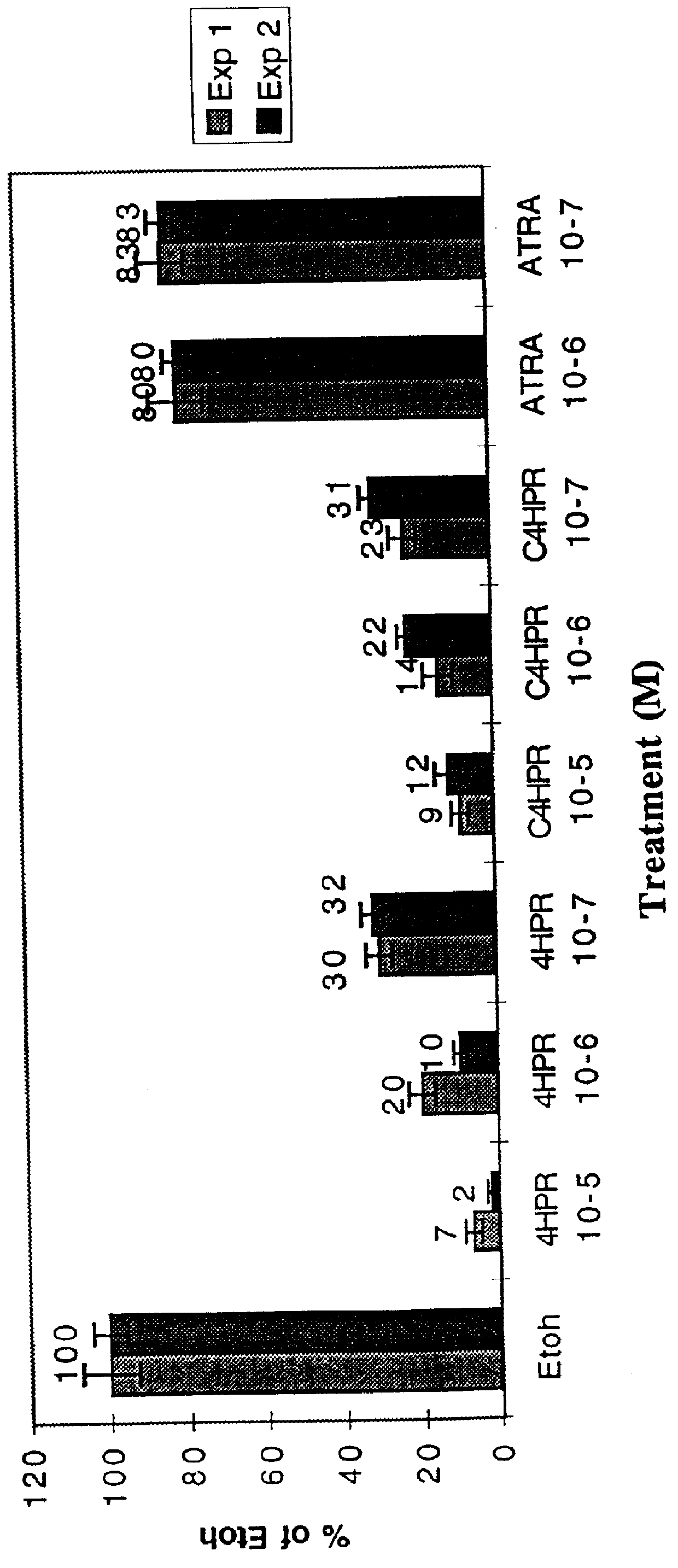

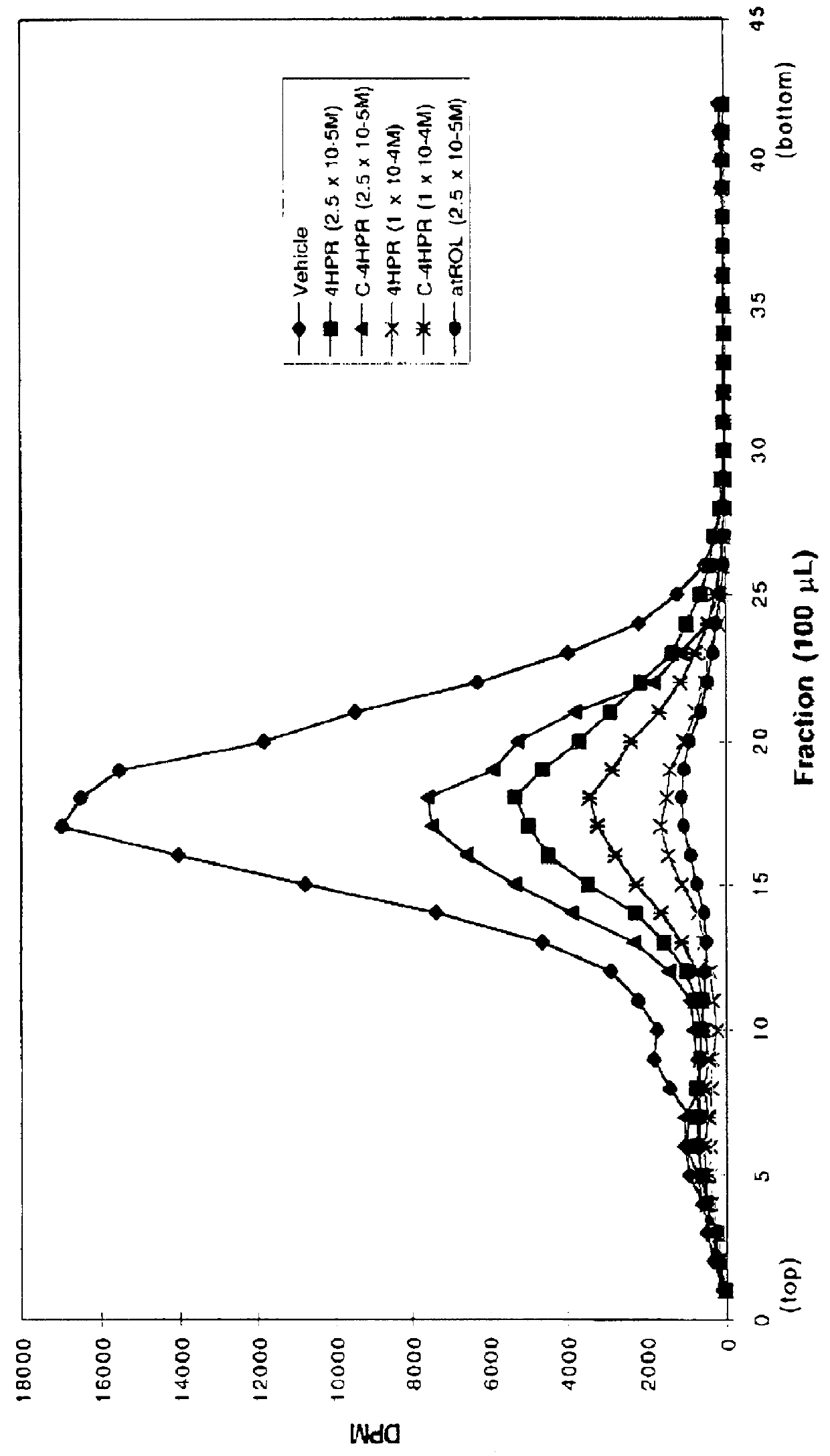

C-linked analogs of N-(4-hydroxyphenyl) retinamide

Disclosed are acid-stable compounds of Formula I: as well as pharmaceutical compositions containing the compounds as active ingredients, and methods to treat cancers in mammal, including humans, by administering one or more of the compounds to a subject in need thereof. The compounds are resistant to acid hydrolysis.

Owner:WISCONSIN ALUMNI RES FOUND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com