Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250 results about "Butterfat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butterfat or milkfat is the fatty portion of milk. Milk and cream are often sold according to the amount of butterfat they contain.

Blackthorn pear products and its production

InactiveCN101073370AImprove stabilityReduce the loss of nutritional valueConfectionerySweetmeatsPEARVitamin C

The invention is concerned with a kind of Rosa roxburghii Tratt candy produce. It produces the syrup of pure Rosa roxburghii Tratt or compound Rosa roxburghii Tratt into horniness candy, horniness candy with filling, soft candy, milk lipid candy, polishing candy, glue-based candy, charging candy, chocolate candy or jelly, and so on. It increases the stability of vitamin C, vitamin P and superoxide dismutase and affords a kind of high quality candy food with double functions of nutritional health care and relaxing. The produce method relates to prepare clarified Rosa roxburghii Tratt concentrated syrup with good stability, add assistant stuff as the amount of 1 to 50 percent of whole amount into the said syrup, prepare Rosa roxburghii Tratt grain or Rosa roxburghii Tratt fast-dissolving powder and follow the routine technology to produce horniness candy, horniness candy with filling, gel candy, glue-based candy, charging candy, chocolate candy or jelly, and so on.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method and application of biological feed additive with nutrition and immunocompetence

The invention discloses a preparation method of a biological feed additive with nutrition and immunocompetence. The biological feed additive with nutrition and immunocompetence comprises the following components: 0.05 to 0.1% of aerobic bacteria, 0.05 to 0.1% of anaerobic bacteria, 0.3 to 0.5% of fermenting promoter, 5 to 15% of soybean meal, 5 to 10% of molasses, 15 to 25% of DDGS (Distillers Dried Grains with Soluble), 10 to 30% of cassava residue, 20 to 50% of bran meal, 5 to 15% of bran, 5 to 15% of maize cob powder, and 20 to 40% of maize slurry protein. The preparation method comprises the processes of activating bacteria, crushing raw materials, aerobically fermenting for 1 to 2 days, and then anaerobically fermenting for 3 to 7 days. The prepared biological feed additive brings piglet, medium and large pigs and sheep with high nutrition value, is high in palatability, and has effects of accelerating growth, improving intestinal health, controlling diarrhea, controlling constipation of sow, increasing birth weight and weaning weight of the piglet, improving the quality of eggshell and egg yolk, controlling feed-containing faeces, raising the lactation level of dairy cattle, as well as increasing butterfat and protein content.

Owner:田子罡 +1

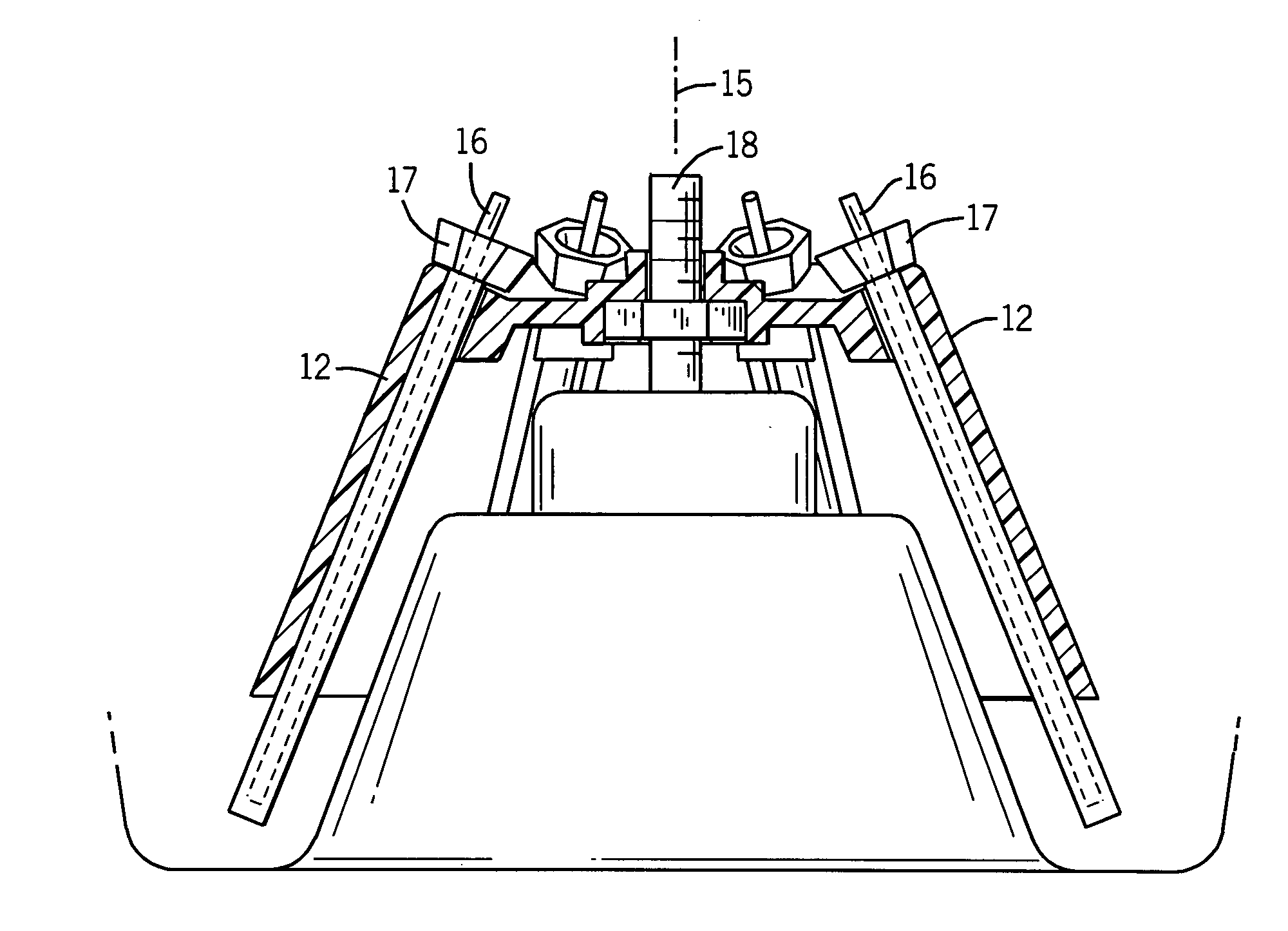

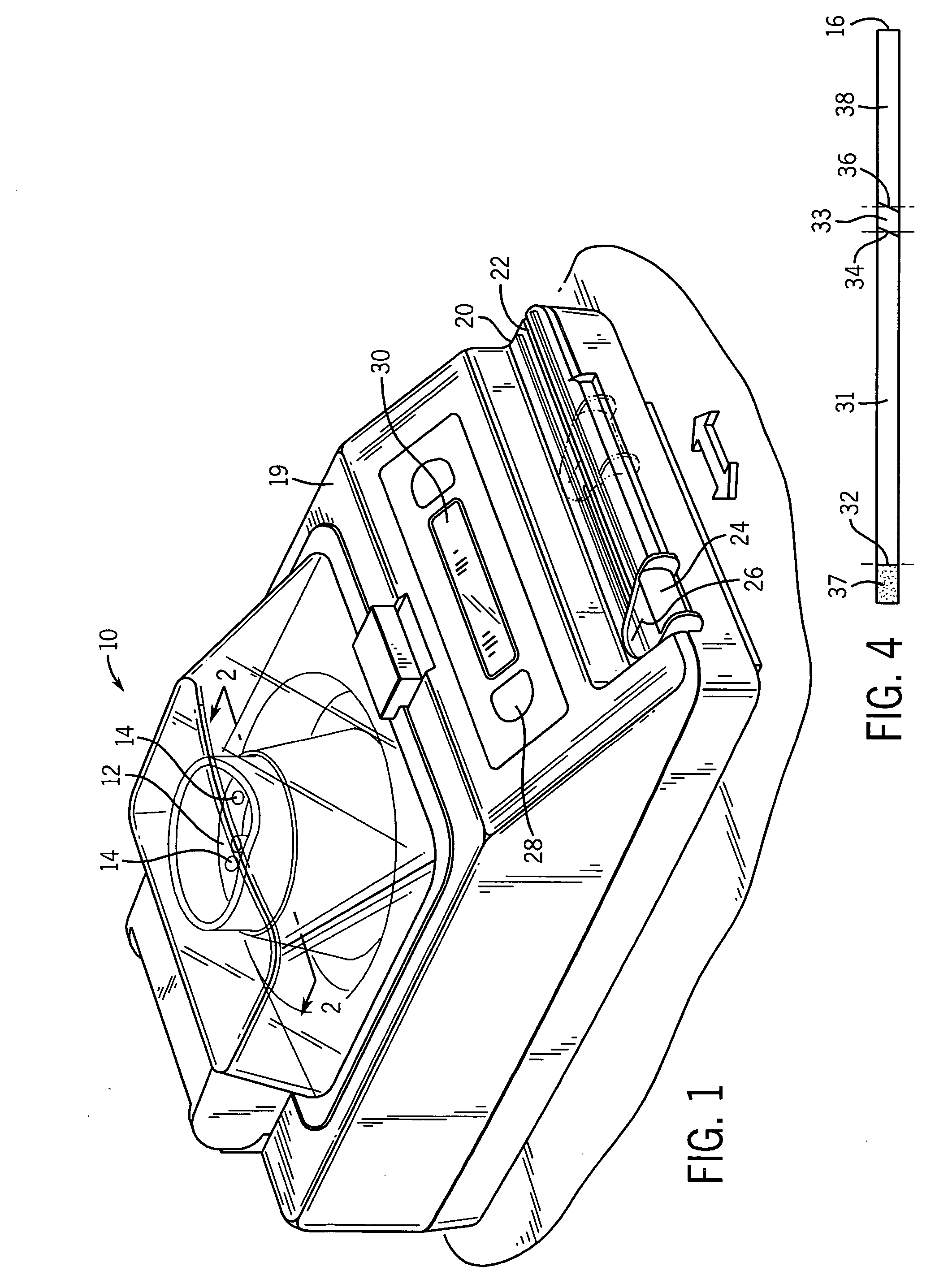

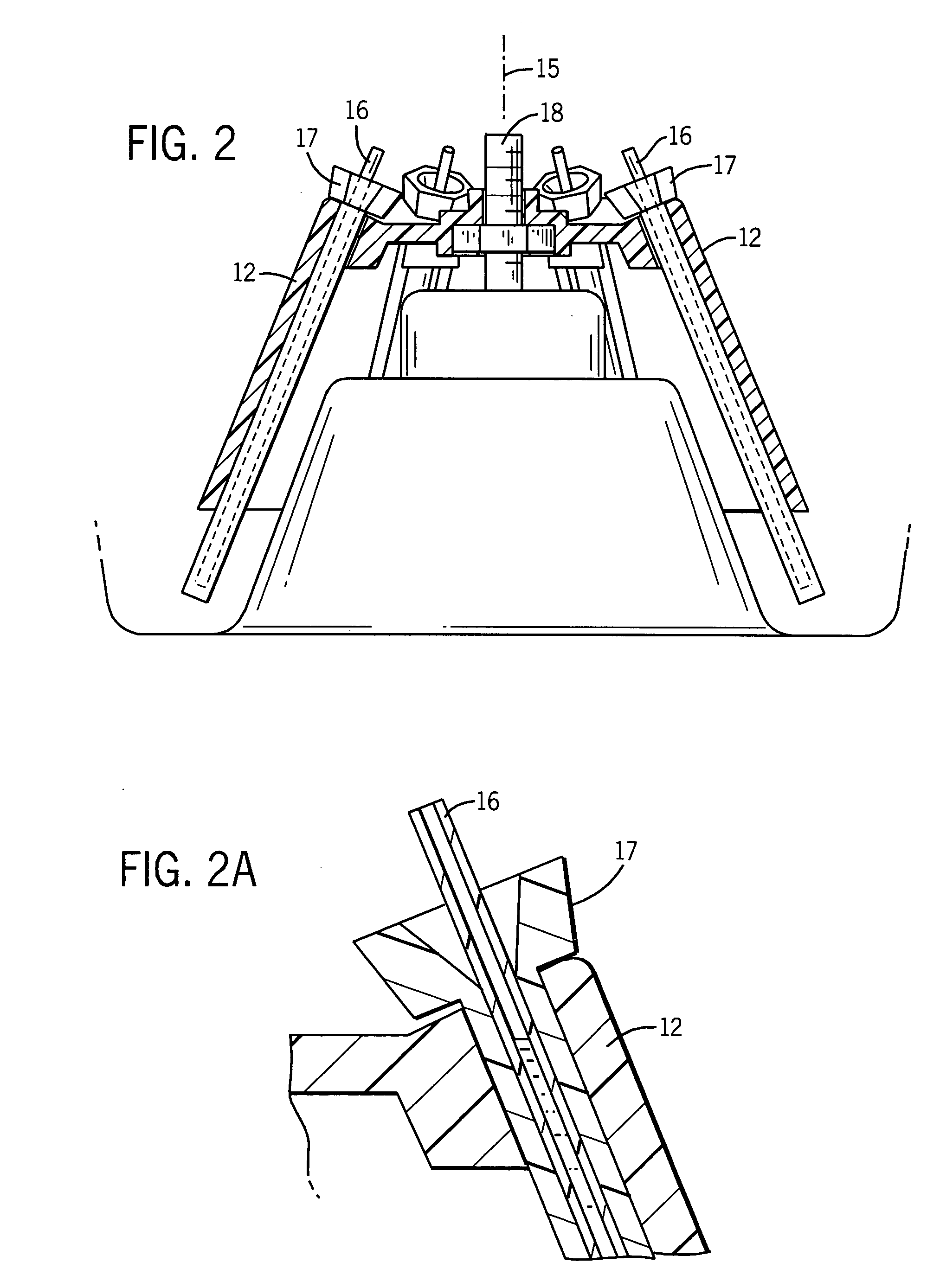

Apparatus and method for obtaining rapid creamatocrit and caloric content values of milk

InactiveUS20060013733A1Quick calculationFast contentSpecific gravity using centrifugal effectsTesting dairy productsFat contentLow volume

The invention relates to a centrifuge apparatus with a built-in sample tube reader and methods for rapidly obtaining measurements of creamatocrit, fat content and / or energy (caloric) content from low-volume fresh and frozen milk specimens.

Owner:SEPARATIONS TECH

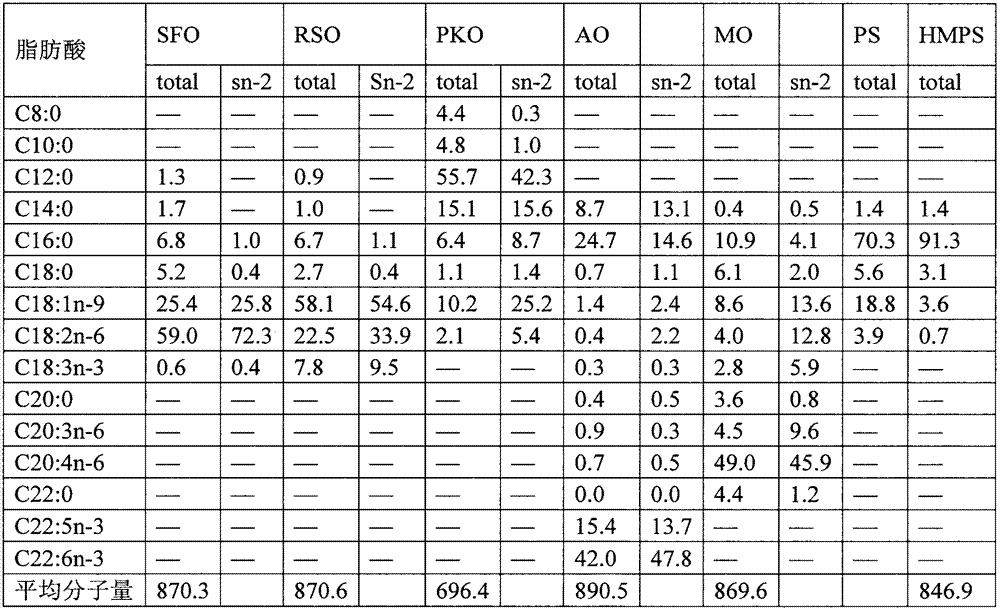

Preparation method of human milk fat substitute

ActiveCN102845537AIncrease contentReduced total palmitic acid contentEdible oils/fatsFood preparationMicrobial oilButterfat

The invention relates to a preparation method of a human milk fat substitute. The method comprises the steps of: step 1) conducting an acid hydrolysis reaction on a raw material of high melting palm stearin subjected to chemical interesterification and alcohol leaching, and an acyl donor of rapeseed oil fatty acid by using Lipozyme RM IM as a catalyst, so as to reduce the total palmitic acid content and increase the relative content of site-two palmitic acid of the raw material; and step 2) deacidifying an intermediate product; and at the same time, calculating the amount of sunflower seed oil, rapeseed oil, palm kernel oil, algae oil and microbial oil added to the intermediate product according to the composition and distribution of fatty acids in human milk fat, by a grease adding model, so as to ensure composition and distribution of fatty acids in a final product meeting requirements of a human milk fat substitute, as well as realize a maximum addition amount. The invention adopts two steps to produce the human milk fat substitute, in order to reduce usage amount of free fatty acids in the acid hydrolysis reaction; meanwhile, two times of oil additions increase yield. Therefore, the invention greatly reduces the cost, and achieves a more than doubled yield compared with a similar products with a similar cost.

Owner:JIANGNAN UNIV

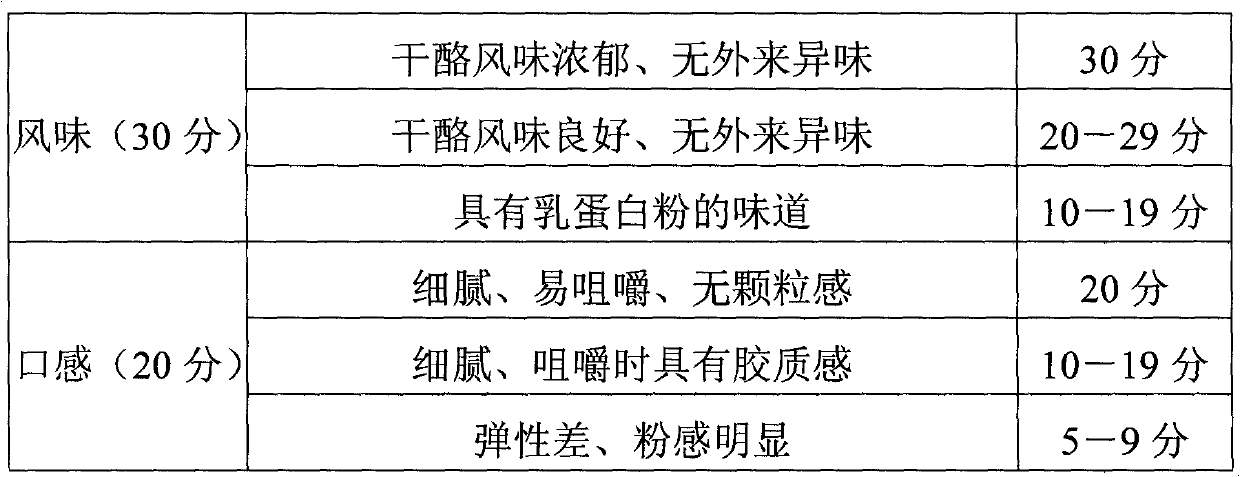

Processing method of remaking soybean cheese combinations

InactiveCN101156632AHigh nutritional valueImprove featuresCheese manufactureFood preparationSporeButterfat

The invention provides a process method for remade soybean cheese products, belongs to the food processing filed, and relates to improved remade cheese made by soybean and the producing method thereof. Firstly, lactobacillus leaven is inoculated in the bean milk, and through ferment, the clabber is made into; clabber grains are obtained through compression; mucor spore liquid is inoculated, proper metal ion is added, after cultivation, sodium chloride is added in the clabber grains, and through compression, the soybean cheese is formed; the soybean cheese is positioned with 4-8 DEG C for maturing; butterine, butterfat, stabilizing salt, or flavoring are added in the soybean cheese, through thaw, concentration, compression, and figuration, the remade soybean cheese is produced. The product has high nutrition value with low salt content, is easy to be stored, can satisfy the taste of the Chinese, and is cheap.

Owner:YANGZHOU UNIV

Process for frozen dairy product

A process for producing a soft frozen fruit flavored dairy product is disclosed. The process requires two freezing steps wherein a flavored concentrate mix is frozen before milk fat is added to the mix. The flavored concentrate mix together with the contained milk fat is then frozen again without mixing or stirring to allow ice crystals to form, preferably of small size, to develop a mouthfeel with components of the fruit flavor.

Owner:BAKER ROBERT S

Process for crystallizing amorphous lactose in milk powder

The present process is directed to a method of crystallizing the lactose in milkfat which comprises (a) mixing the milk powder with water in an amount sufficient to initiate crystallization when subjected to shearing and heating, and (b) subjecting the product of (a) to shearing and heating under conditions effective to crystallize the lactose, said heating being conducted at a temperature greater than the glass transition temperature of the lactose and below the temperature at which the product will have a burnt flavor.

Owner:THE HERSHEY COMPANY

Non-dairy cream of mixed milk fat and preparation method thereof

The invention designs non-dairy cream of mixed milk fat. The non-dairy cream is characterized by comprising the components in percentage by weight: 8-18% of vegetable fat, 0.05-0.5% of anhydrosorbitan monostearate, 0.02-0.5% of lecithin, 0.02-1% of lactic monoglycerate, 0.02-0.5% of sodium stearyl lactate, 0.05-1% of monoglycerin fatty acid ester and diglycerin fatty acid ester, 0.05-0.8% of sucrose fatty acid ester, 0.02-0.5% of polyglycerol ester, 0.01-1.5% of carrageenan, 0.05-0.8% of microcrystalline cellulose, 0.05-1% of modified cellulose, 0.1-1.5% of sodium caseinate, 0.02-0.2% of potassium dihydrogen phosphate, 2-6% of sugar, 2-12% of corn syrup, 8-18% of milk fat dairy products and 20-60% of water. The non-dairy cream provided by the invention has the advantages that the non-dairy cream is convenient to operate without cream and non-dairy cream which are mixed and whipped topped; the non-dairy cream is more convenient to condition and is not affected by original flavor of the non-dairy cream; the whipped topping rate of the product reaches over 3.6 which is greater than that of existing similar products. The non-dairy cream is more economic and applicable for client.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

Infant formula milk powder containing alpha-whey protein powder and beta-casein and preparation method thereof

ActiveCN101766225AThe composition is uniform and stableAvoid difficultiesMilk preparationFood preparationVegetable oilButterfat

The invention provides infant formula milk powder containing alpha-whey protein powder and beta-casein. The milk powder comprises the following components by weight part: 1,400 to 2,500 parts of milk, 150 to 220 parts of demineralized whey powder, 50 to 100 parts of whey protein powder, 200 to 300 parts of lactose, 75 to 200 parts of vegetable oil, 10 to 30 parts of alpha-whey protein powder, 10 to 30 parts of beta-casein, 75 to 200 parts of milk fat, 1 to 3 parts of compound vitamin and 1 to 3 parts of compound trace elements. By adding alpha-whey protein powder and beta-casein to the milk powder, the invention solves the technical problem that the infant formula milk powder is closer to breast milk, so the product of the invention has the advantages of normal flavor and taste and stable quality.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

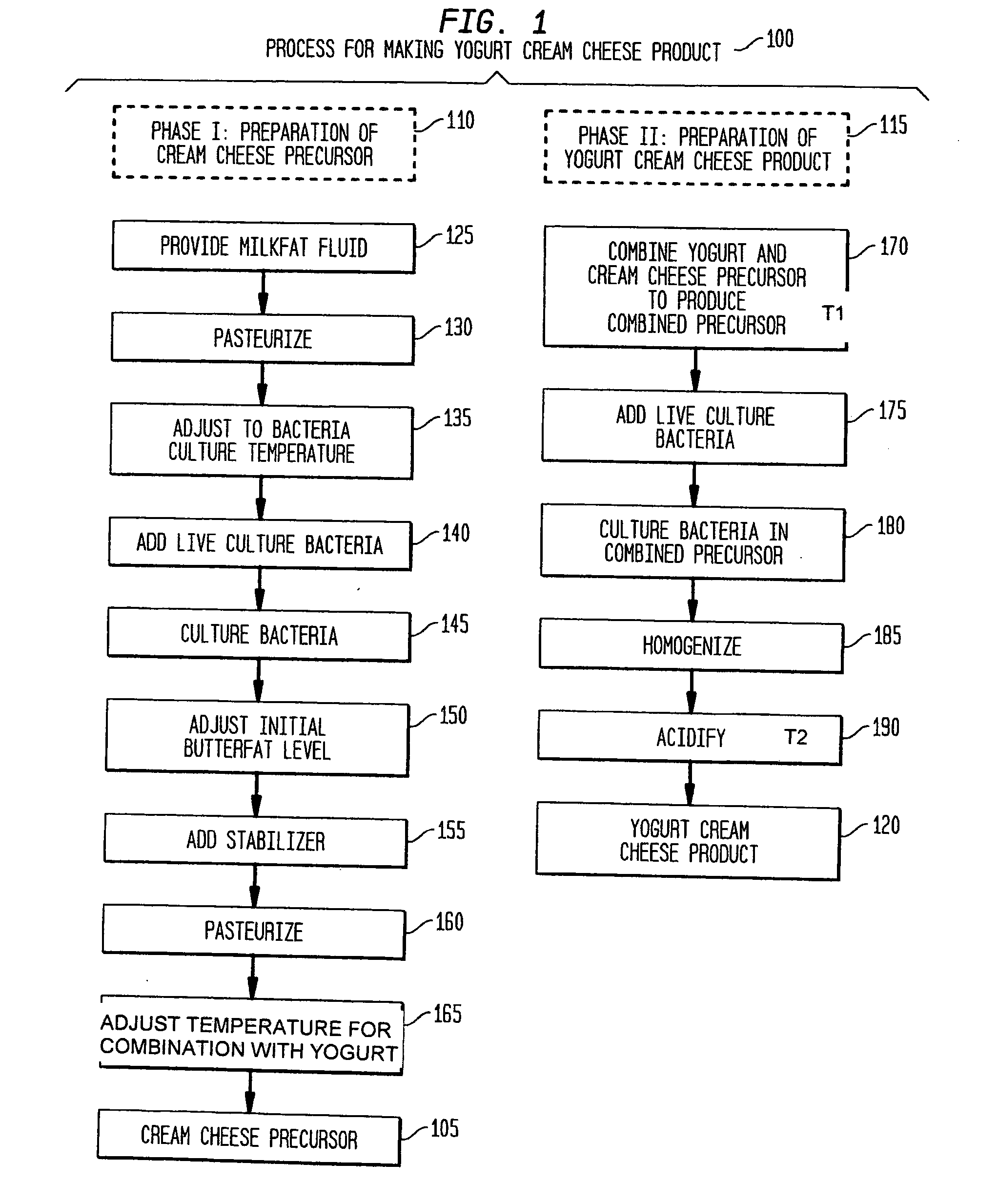

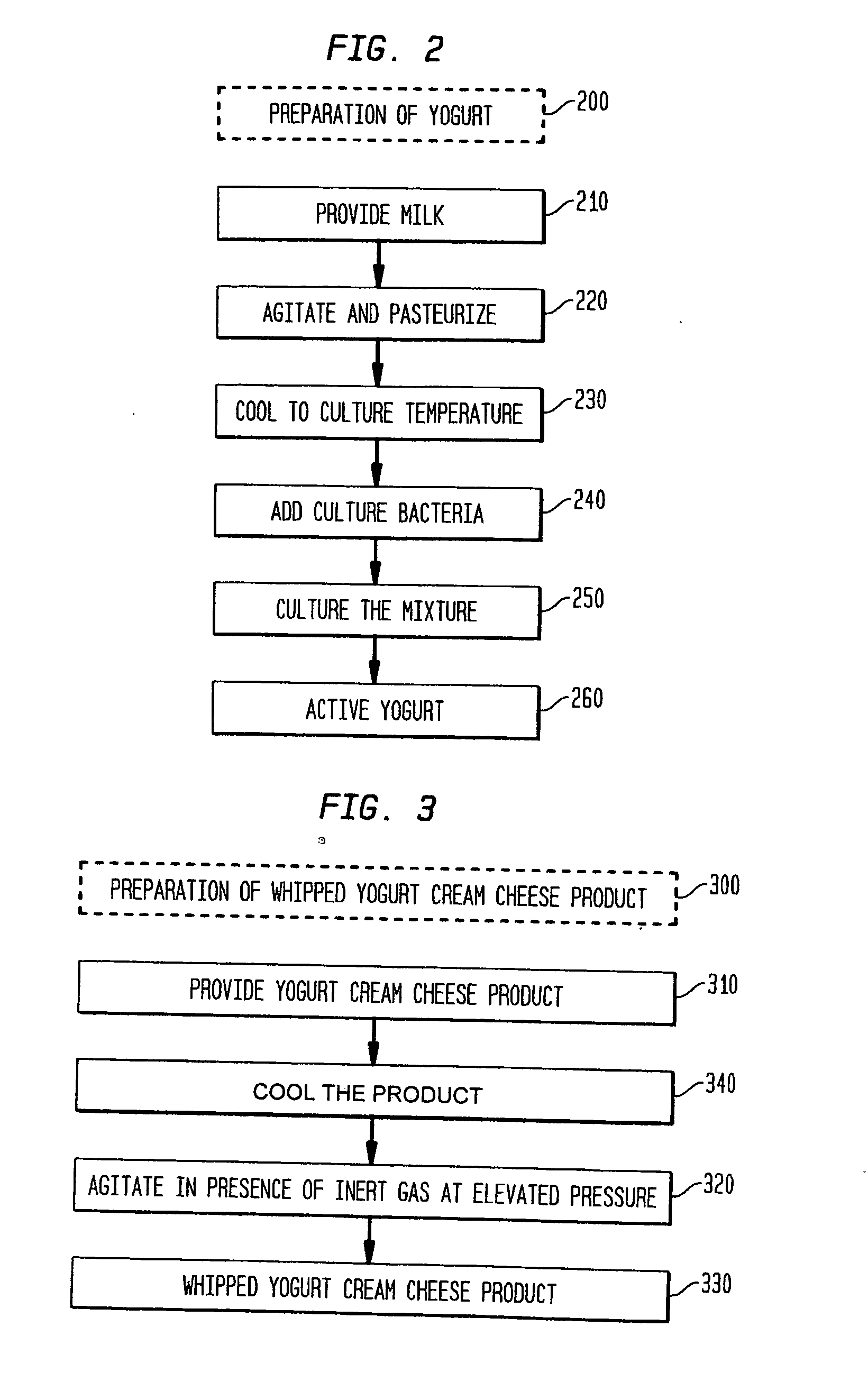

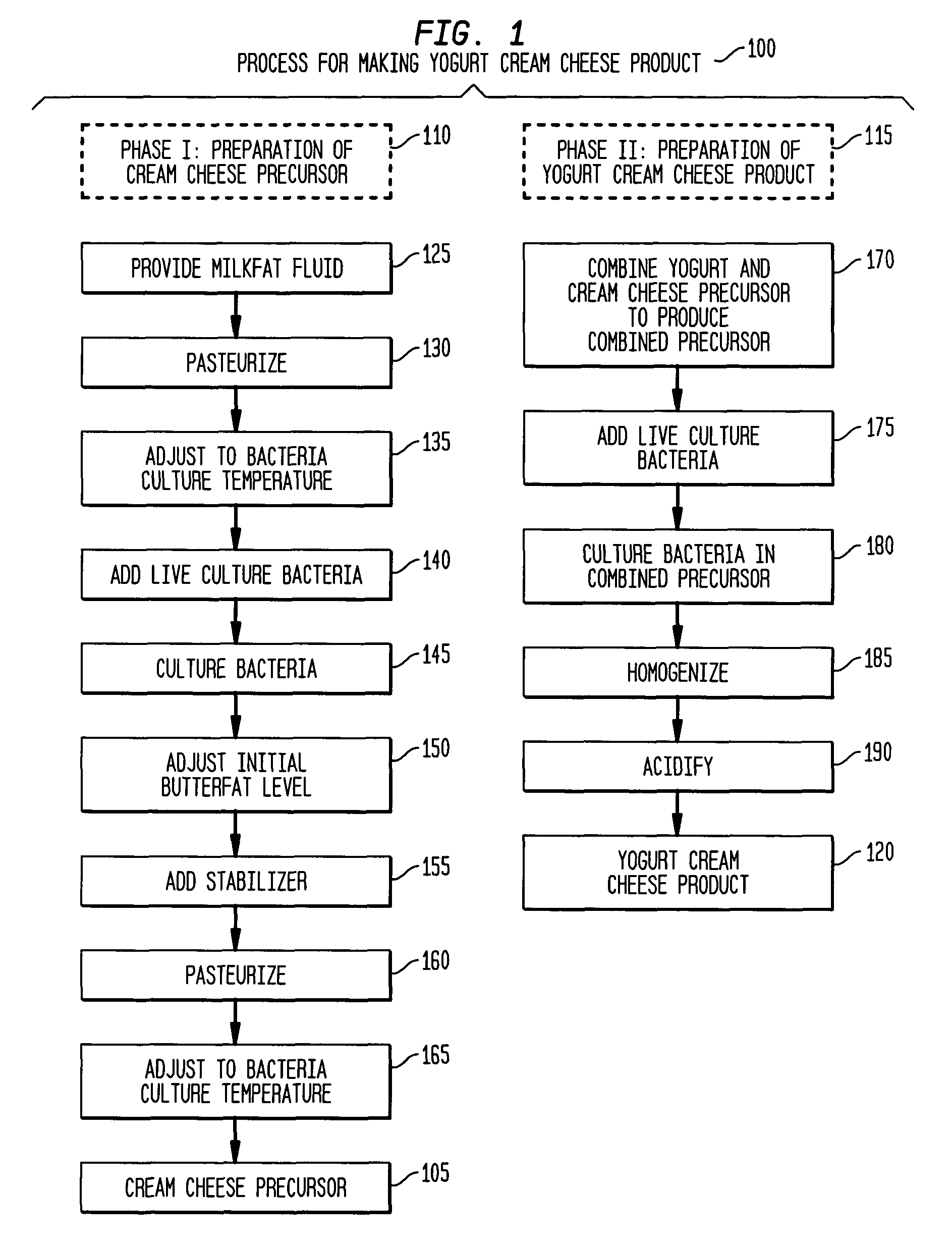

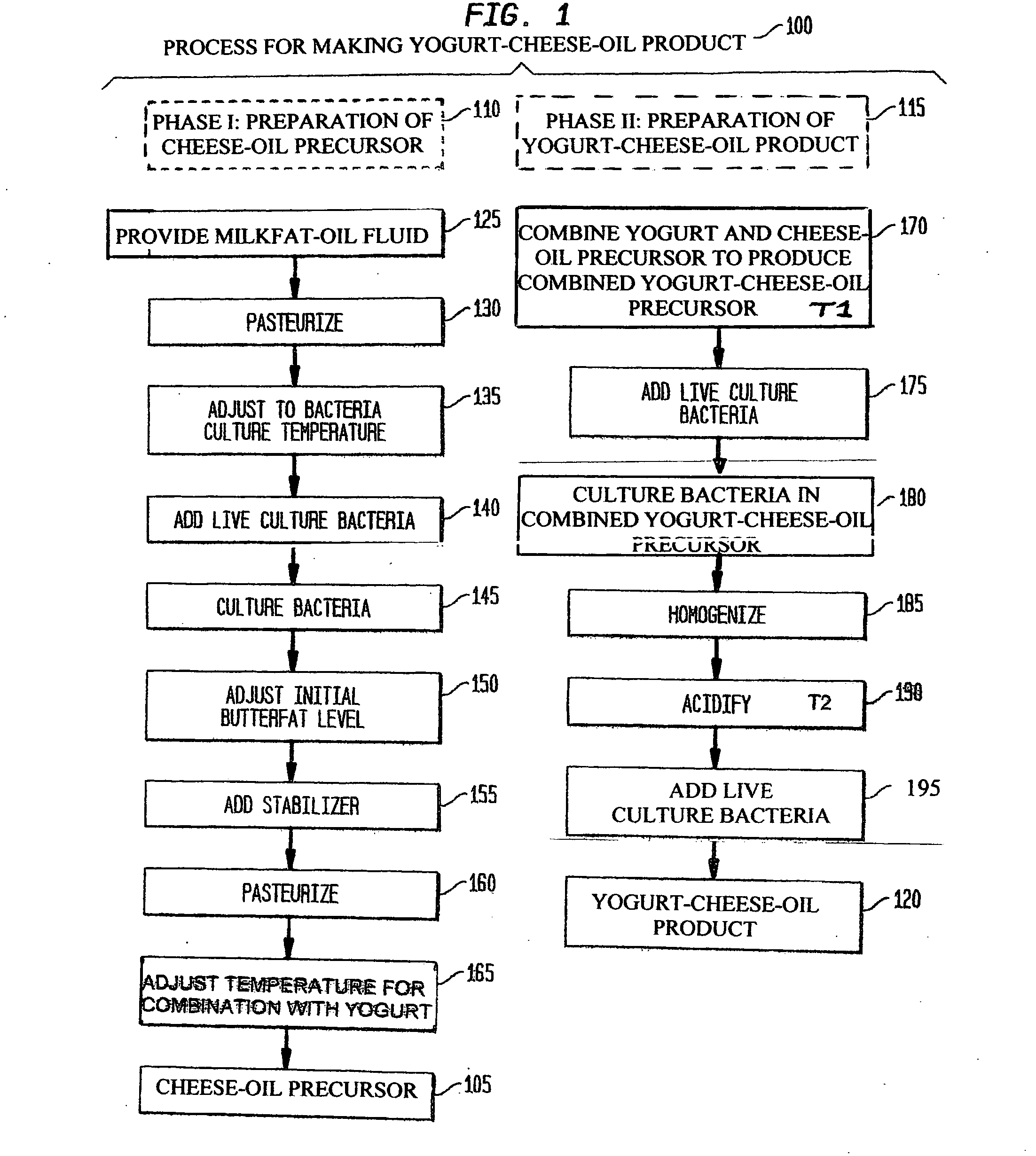

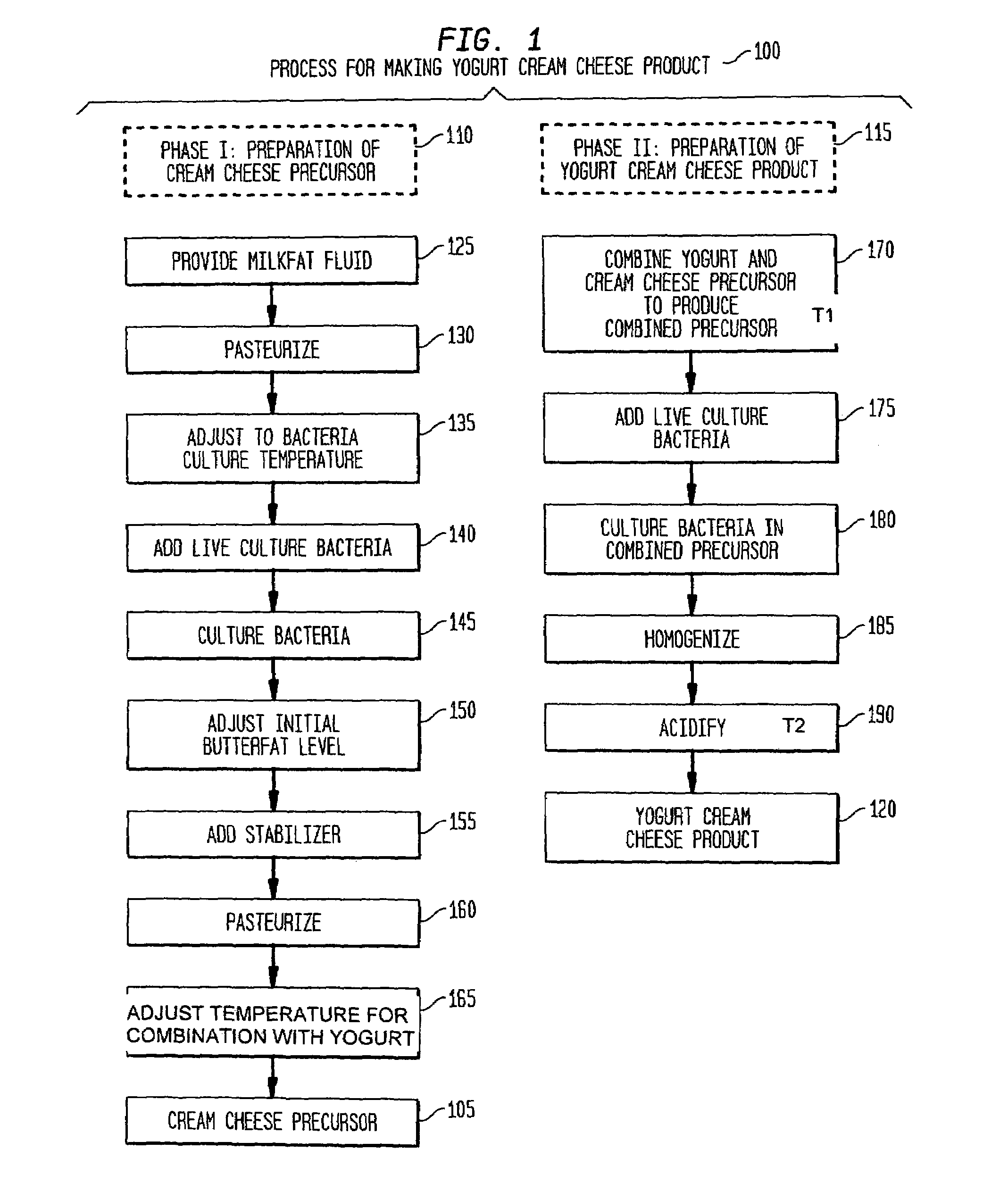

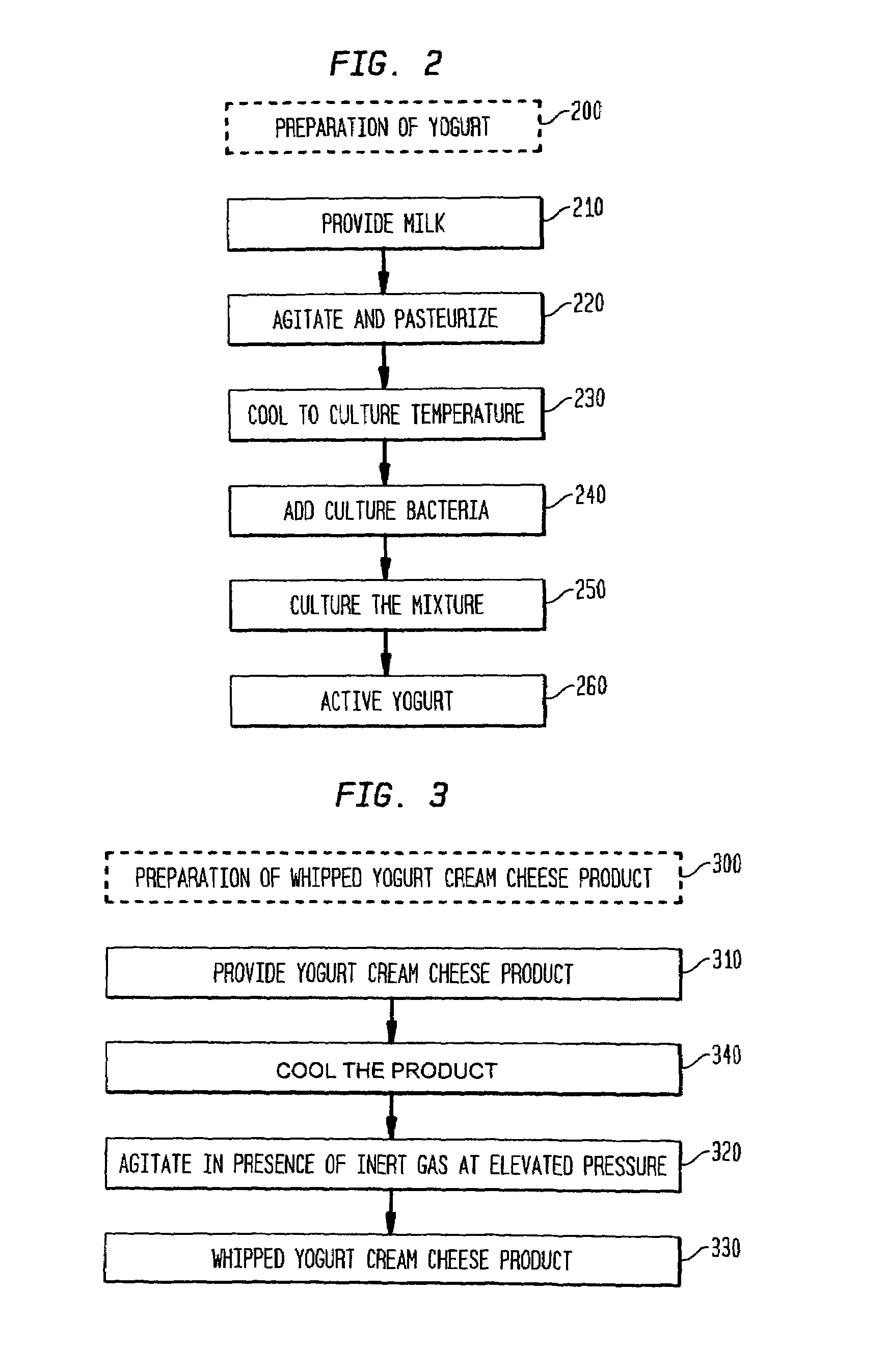

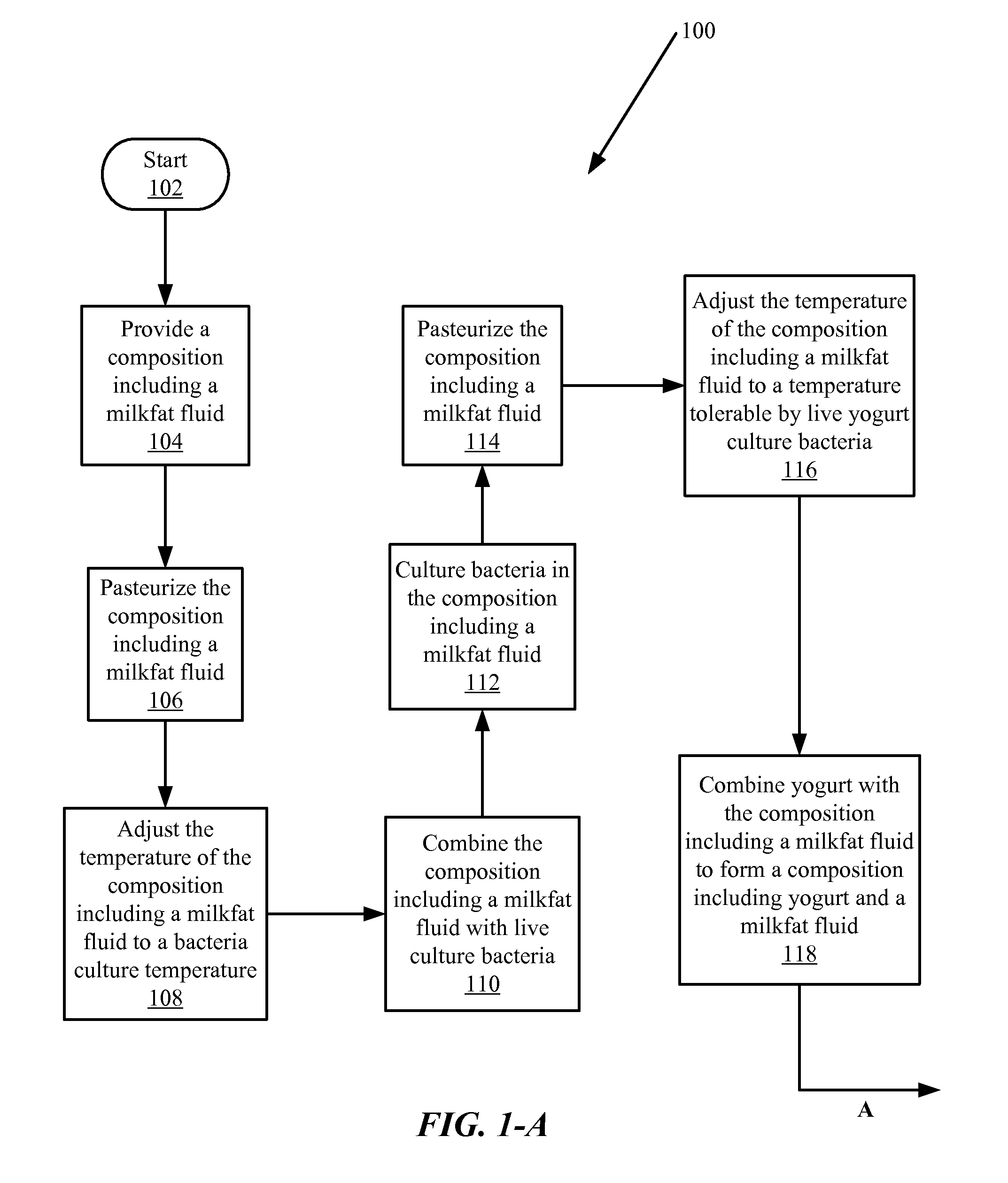

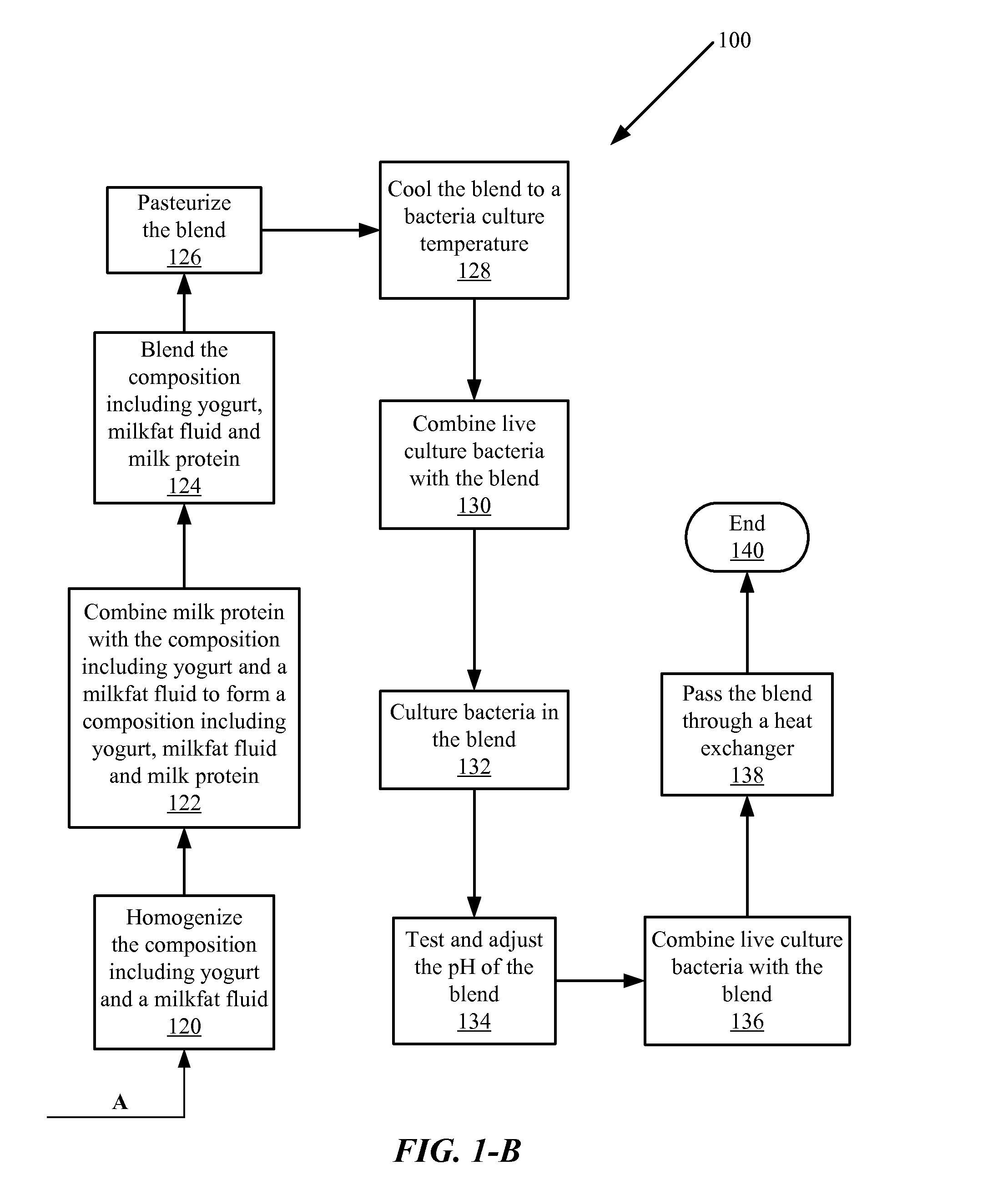

Process for making yogurt cream cheese, and the resulting products

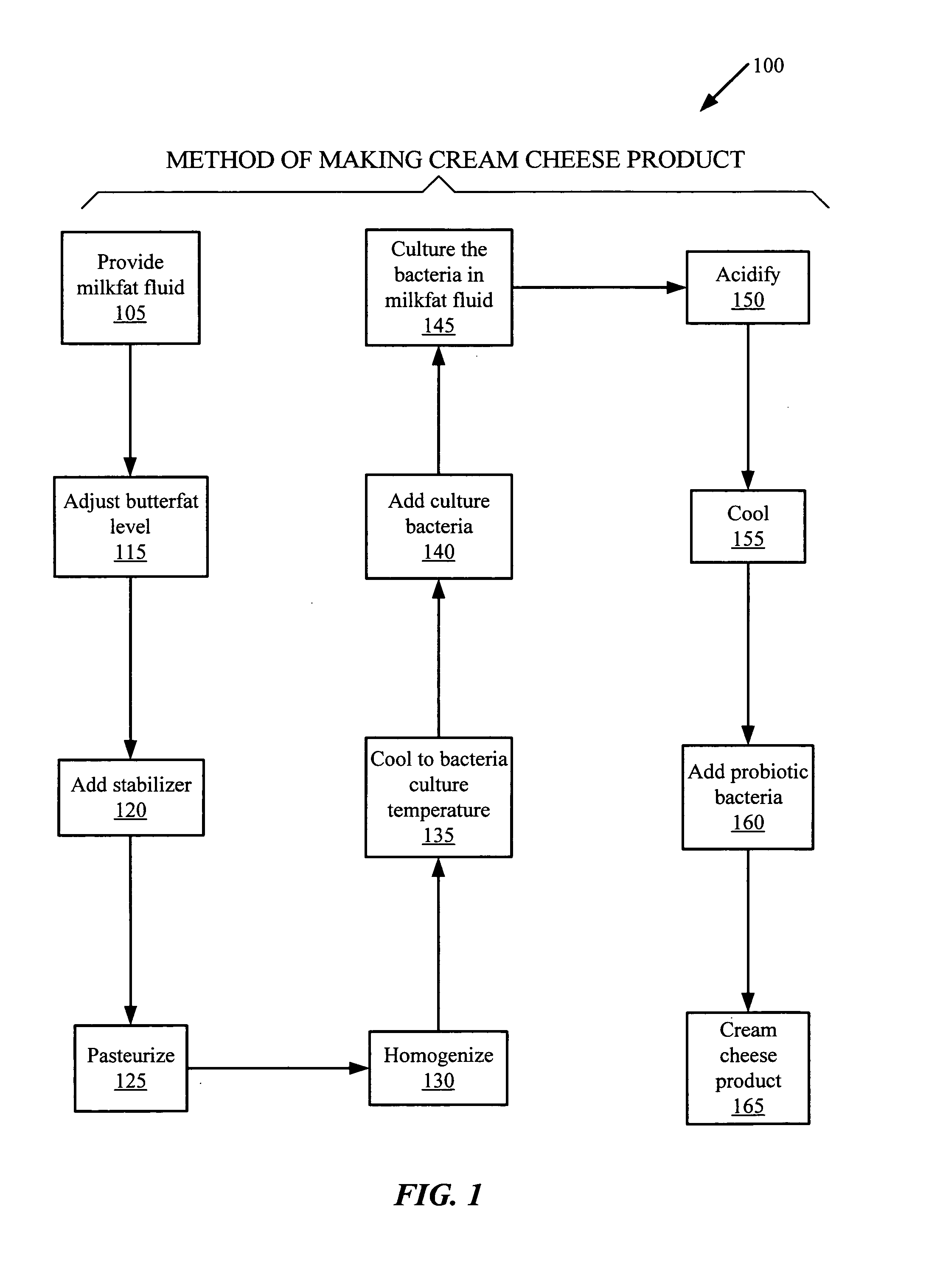

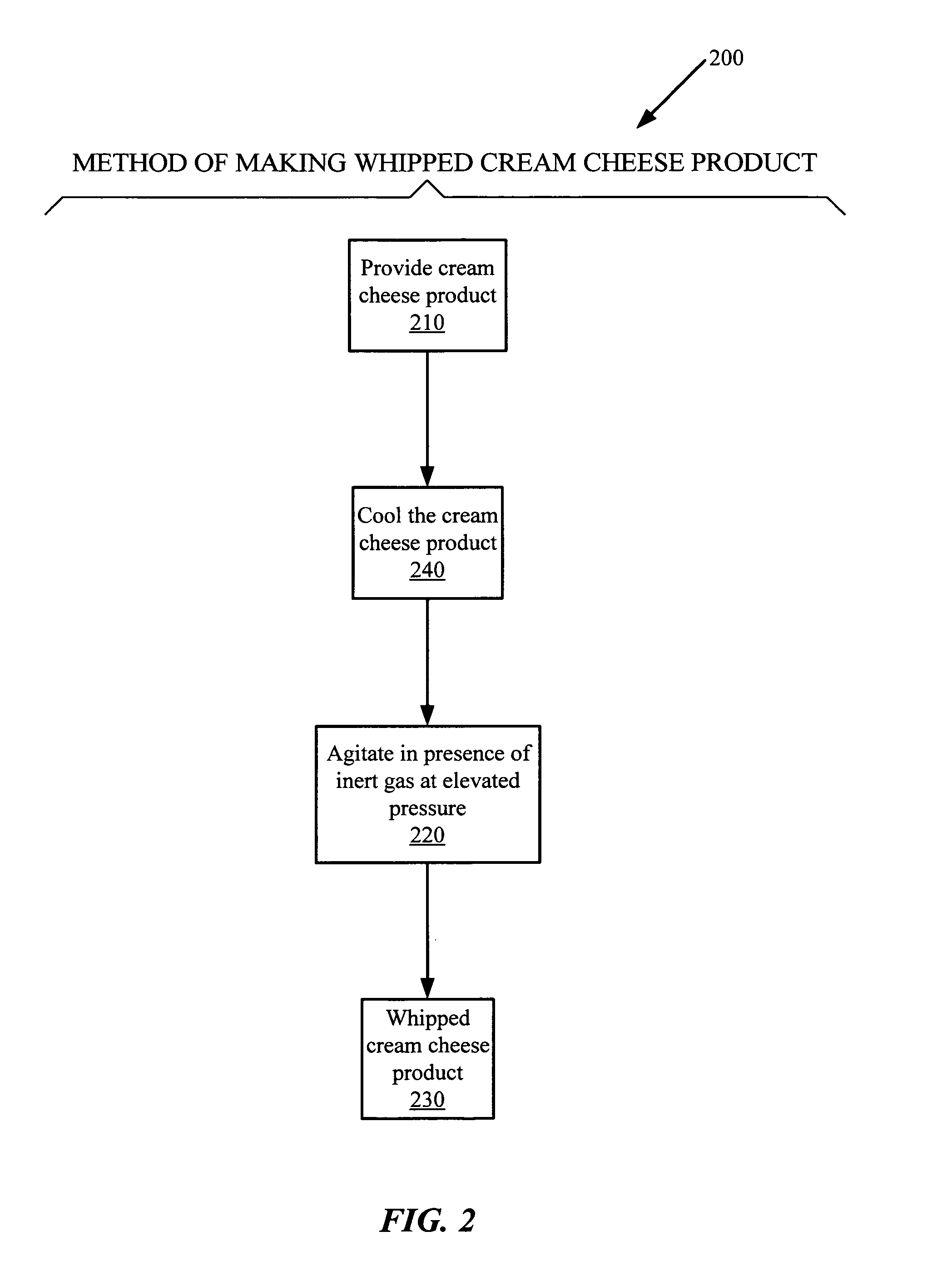

Techniques for making a yogurt cream cheese product comprising steps of providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid to produce a cream cheese precursor; providing a yogurt, and combining the yogurt with the cream cheese precursor to produce a combined precursor; and homogenizing and acidifying the combined precursor; wherein the acidification is completed within about three hours following production of the combined precursor; producing a yogurt cream cheese product. Techniques wherein the combined precursor is cooled to retard bacteria activity prior to the acidifying. Techniques for making a whipped yogurt cream cheese product. Yogurt cream cheese products produced by the processes.

Owner:FRLIN FOODS HLDG

Process for making yogurt cream cheese, and the resulting products

A process for making a yogurt cream cheese product comprising steps of: providing a milkfat fluid having an initial butterfat content level; pasteurizing the milkfat fluid to yield a cream cheese precursor; providing a yogurt, and combining the yogurt with the cream cheese precursor to yield a combined precursor; and homogenizing and acidifying the combined precursor; yielding a yogurt cream cheese product. A yogurt cream cheese product comprising between about 8% by weight and about 35% by weight of total butterfat; the yogurt cream cheese product comprising between about 10% by weight and about 40% by weight of yogurt, having a viscosity between about 1,000,000 centipoises and about 3,000,000 centipoises at a temperature of about 74° F.; and yielding less than about 1% syneresis by weight after 15 hours at about 74° F. to about 75° F.

Owner:FRLIN FOODS HLDG

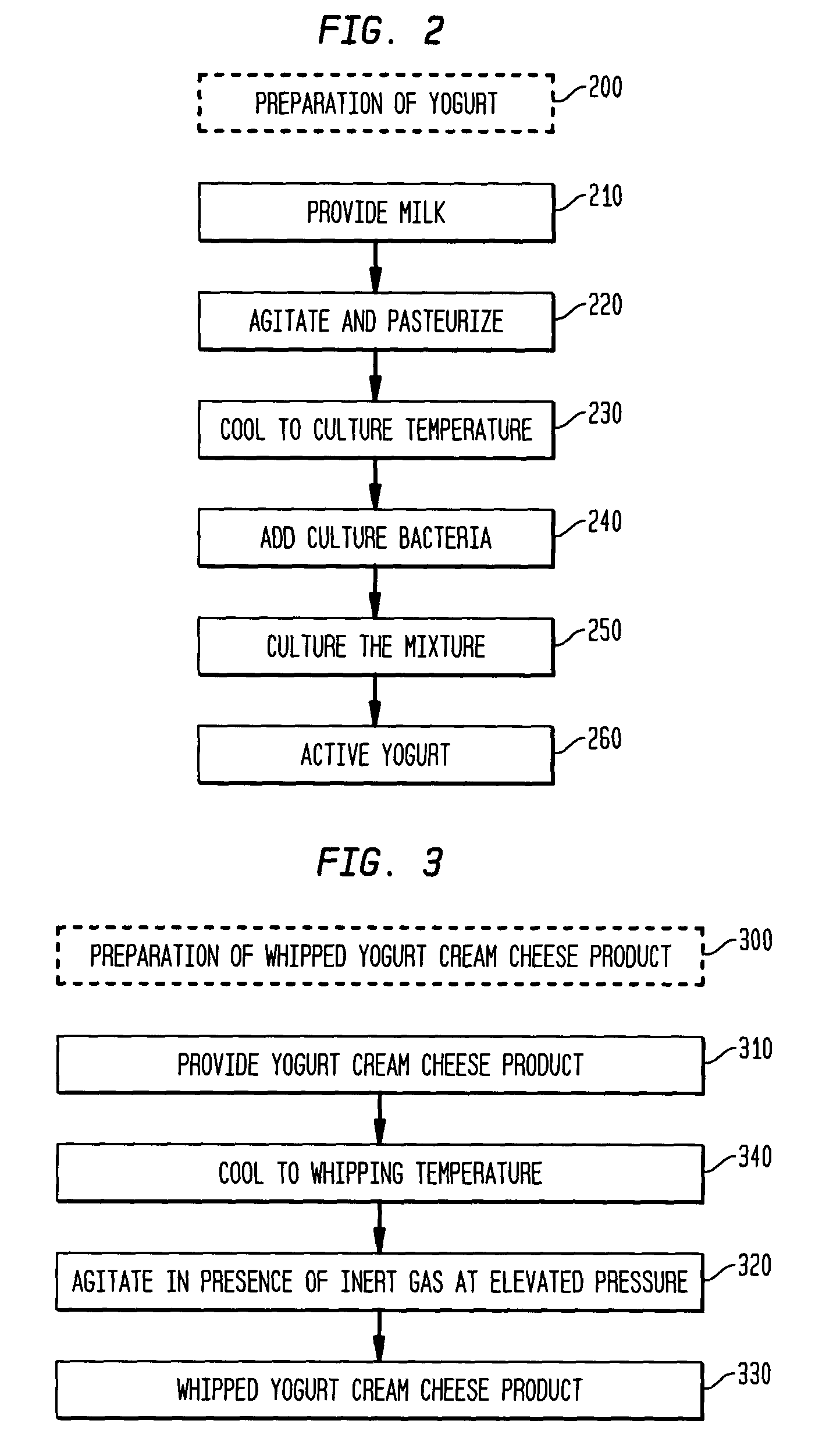

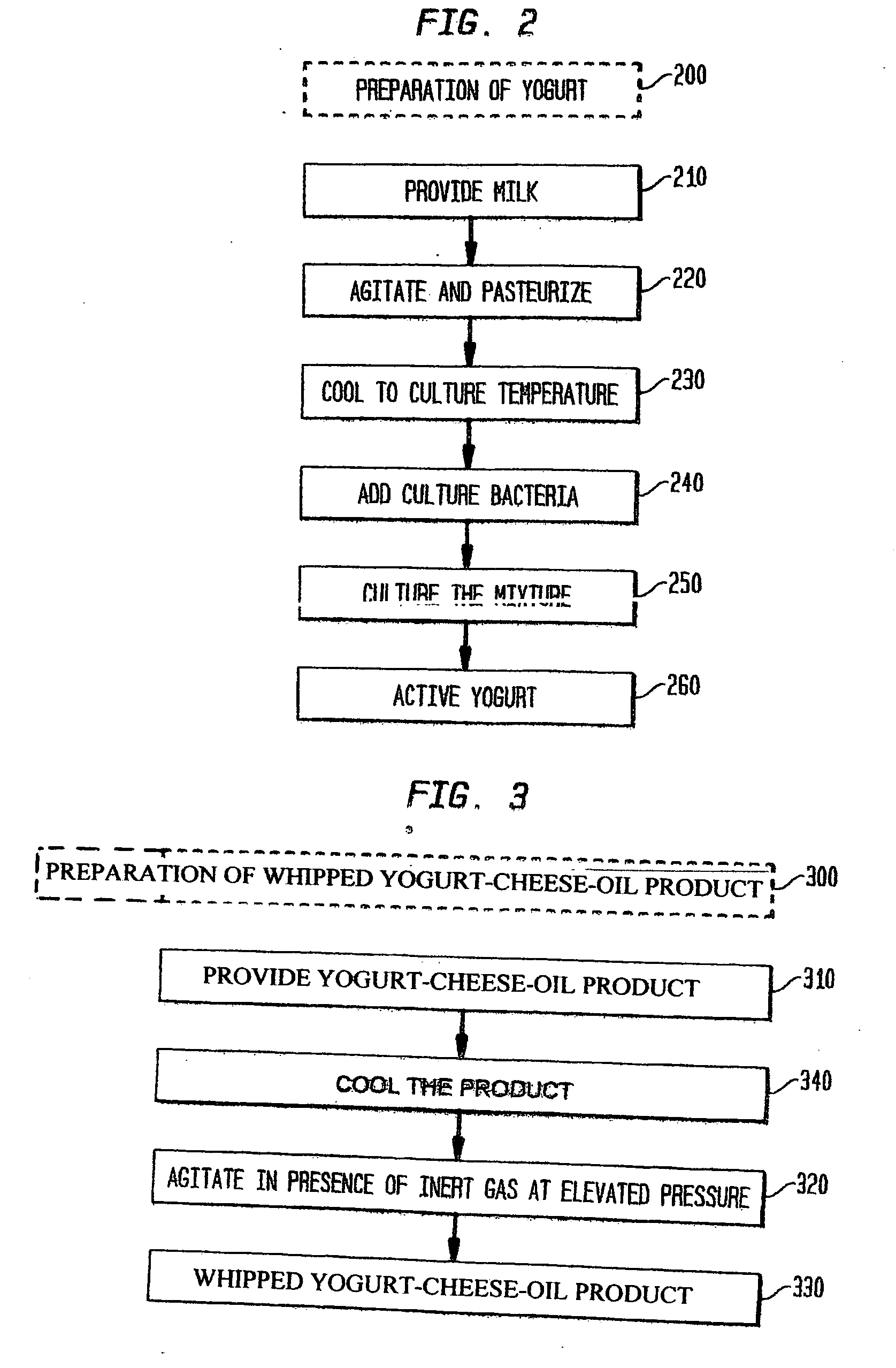

Yogurt-cheese products, and methods of making the same

Techniques for making a yogurt-cheese-oil product, comprising steps of: providing a milkfat-oil fluid comprising butterfat and an oil; pasteurizing the milkfat-oil fluid to produce a cheese-oil precursor; combining yogurt with the cheese-oil precursor to produce a combined yogurt-cheese-oil precursor; and homogenizing and acidifying the combined yogurt-cheese-oil precursor; producing a yogurt-cheese-oil product. Yogurt-cheese-oil products: comprising between about 10% by weight and about 80% by weight of total butterfat; comprising between about 2% by weight and about 52.5% by weight of an oil; comprising between about 10% by weight and about 50% by weight of yogurt; and yielding less than about 1% syneresis by weight after 15 hours at about 74° F. to about 75° F.

Owner:FRLIN FOODS HLDG

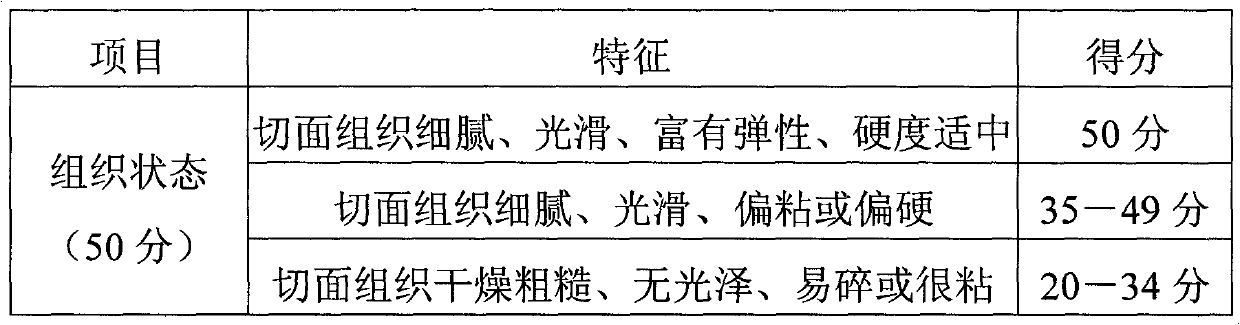

Low energy and low fat processed cheese slice/block, and preparation method thereof

The invention provides a low energy and low fat processed cheese slice / block. The energy content of the cheese slice / block is 604kJ / 100g to 837kJ / 100g. The cheese slice / block contains, by mass: 10.72% to 18.64% of protein, 5.01% to 13.10% of fat, 2.4% to 11.9% of carbohydrate, 57.71% to 64.27% of water, and 1% to 4% of emulsifying salts. The cheese slice / block is prepared by shear-mixing the ingredients of, by mass: 10% to 60% of cheese, 2% to 15% of milk protein products, 3% to 15% of butterfat, 1% to 4% of emulsifying salts, 0.1% to 0.5% of colloid, and 19% to 57% of water. The processed cheese provided by the present invention has a suitable viscosity, a suitable quality and an ideal flavor. With the processed cheese provided by the present invention, a consumer requirement of processed cheese with low energy and low fat is satisfied.

Owner:BRIGHT DAIRY & FOOD

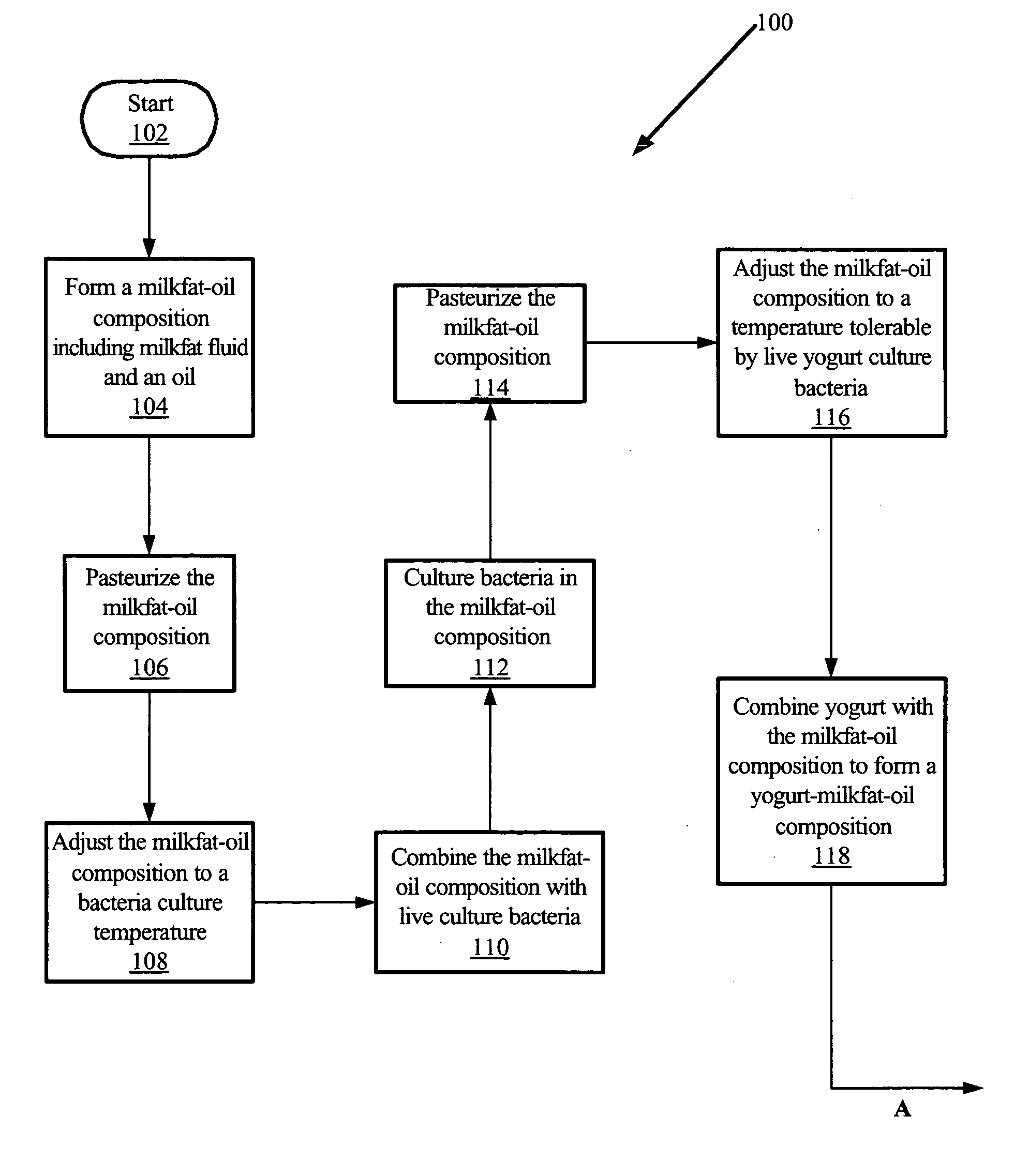

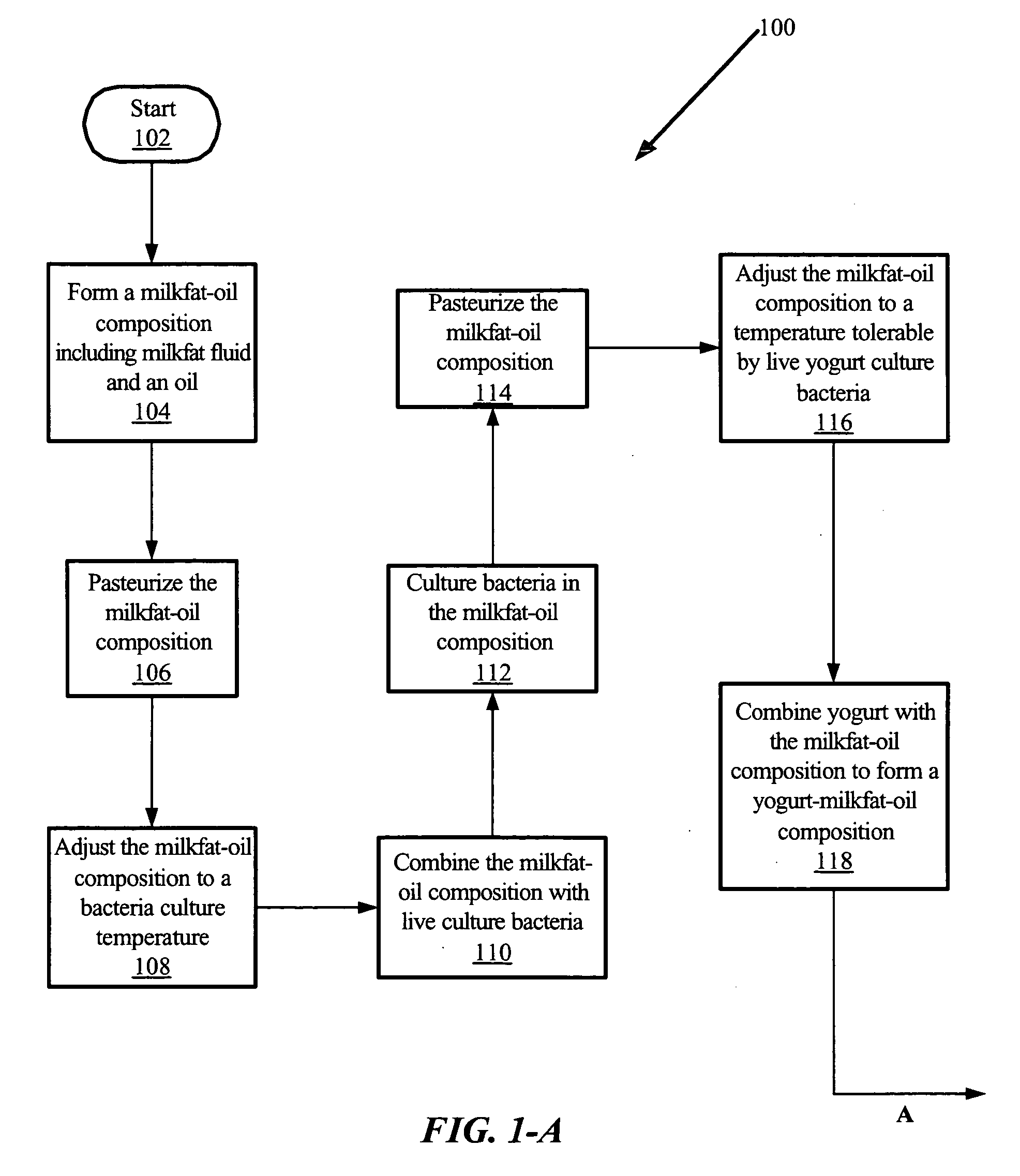

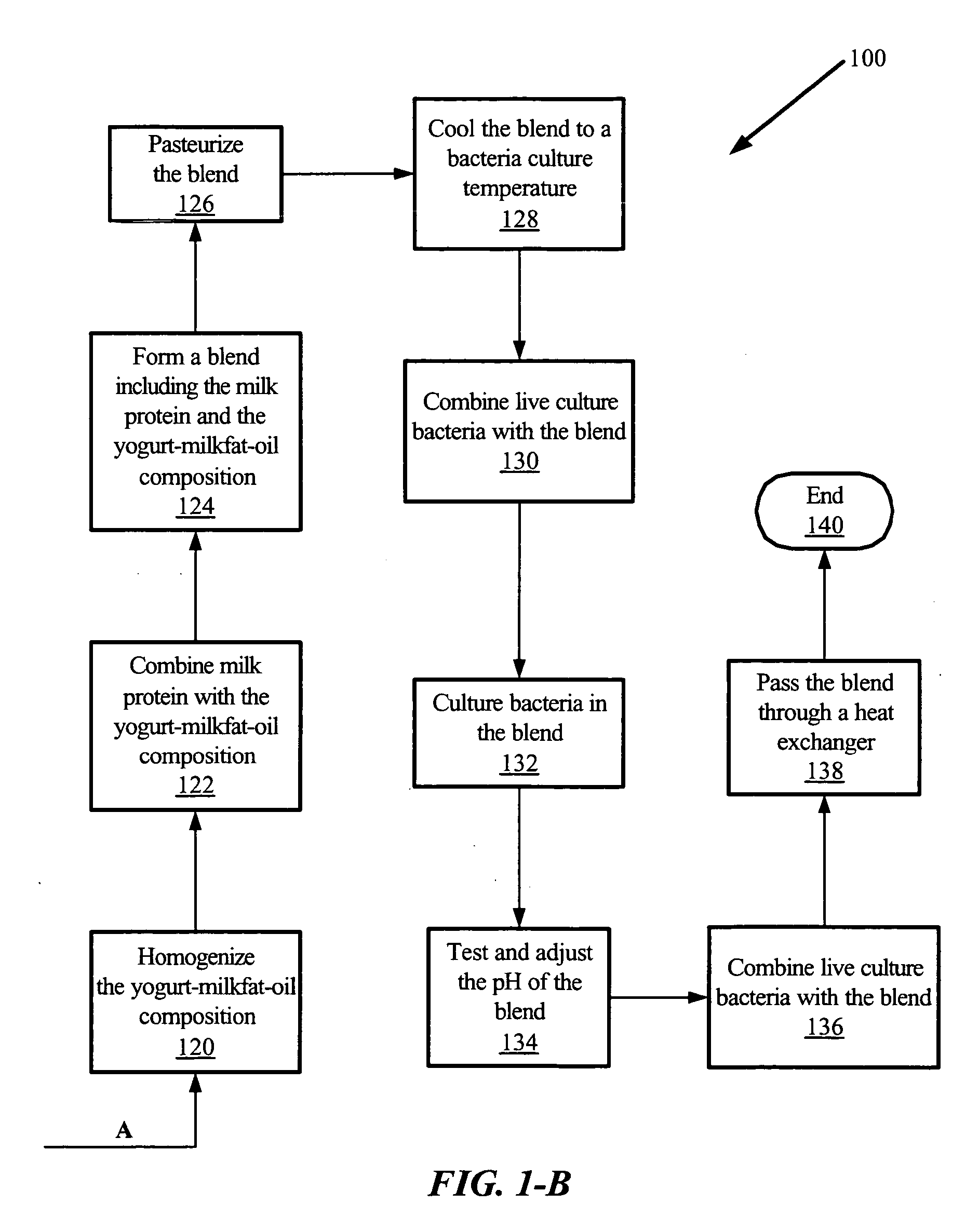

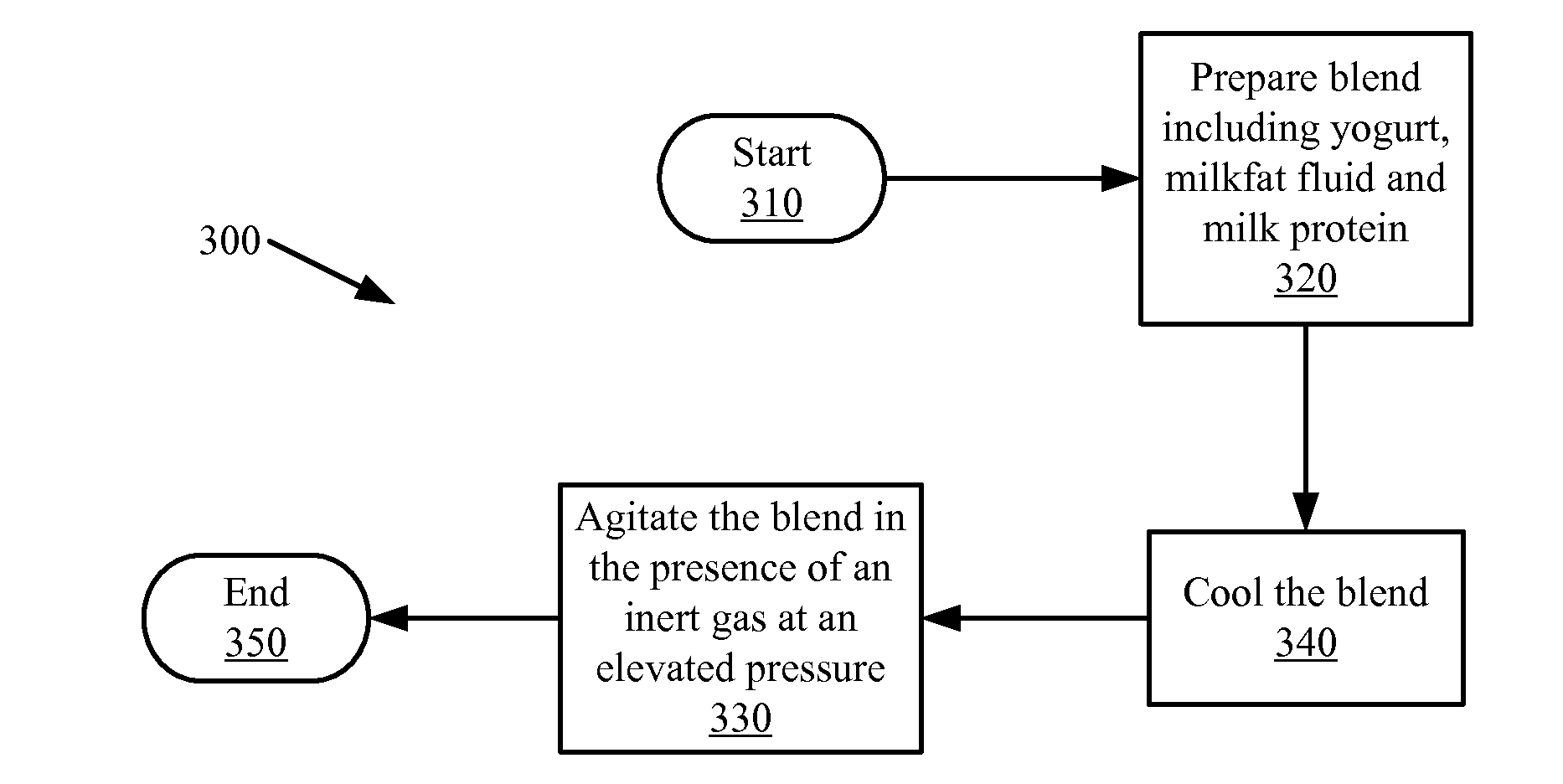

Yogurt-cheese compositions

Technique for making a Low-Fat Yogurt-Cheese-Oil Composition, including: forming a milkfat-oil composition including a milkfat fluid and an oil; combining yogurt with the milkfat-oil composition to form a yogurt-milkfat-oil composition; combining milk protein with the yogurt-milkfat-oil composition; and forming a blend including the milk protein and the yogurt-milkfat-oil composition. Low-Fat Yogurt-Cheese-Oil Compositions.

Owner:FRLIN FOODS HLDG

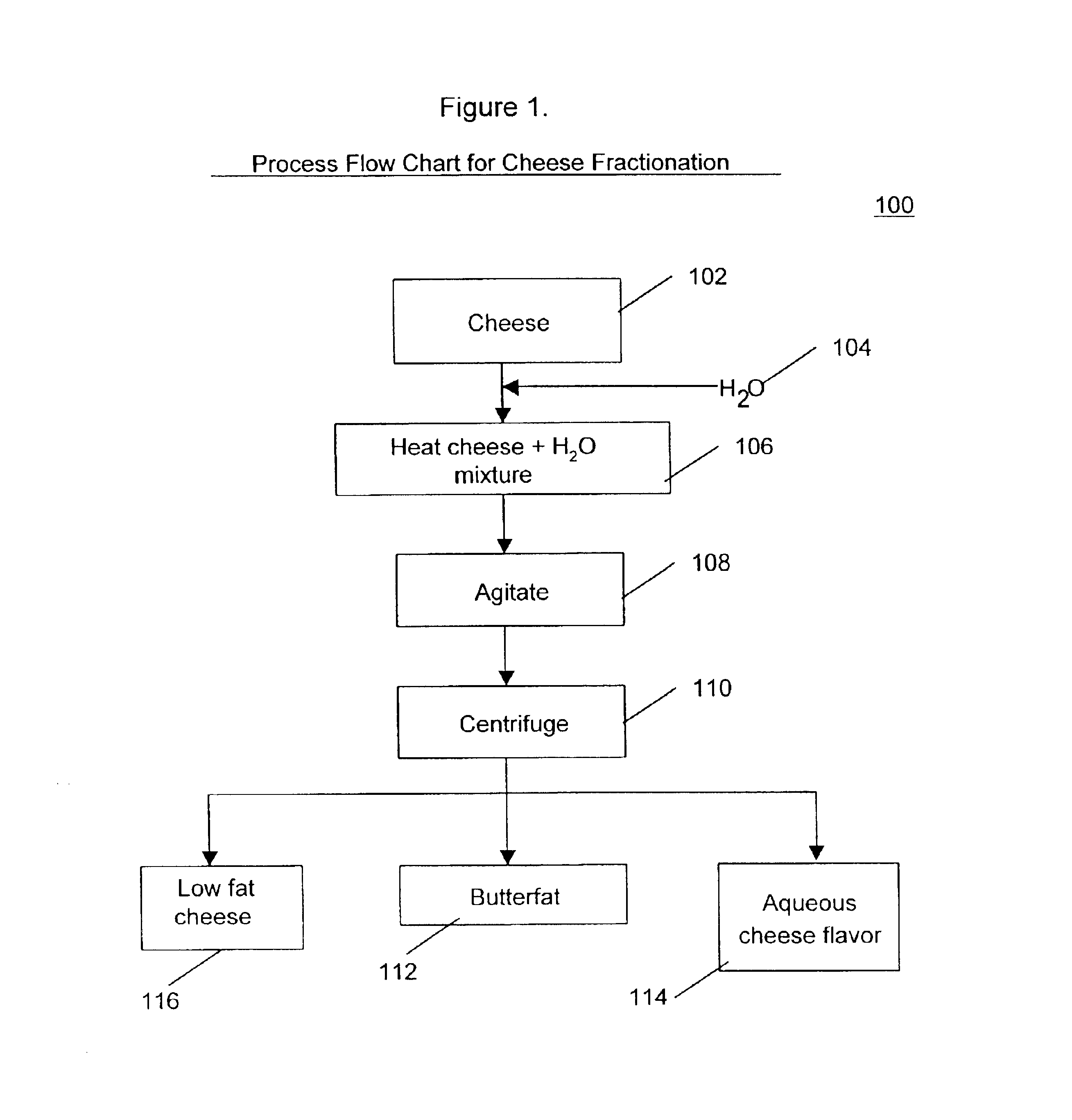

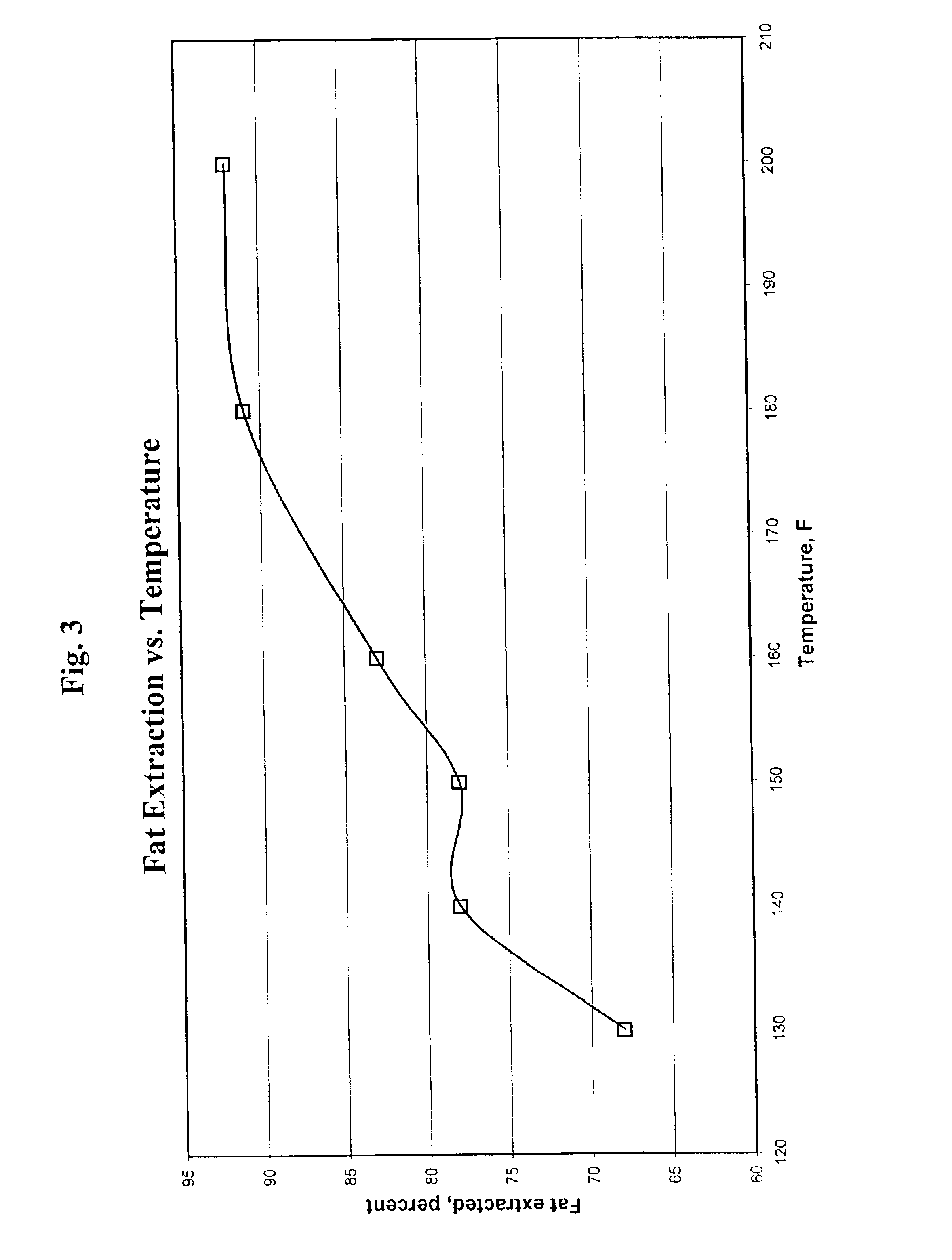

Cheese fractionating process

A method for fractionating or separating a cheese uses heat and mixing of the cheese to separate the cheese into three phases. The three phases include a butterfat phase, an aqueous phase, and a cheese product from which some fat and flavor have been removed. The process may be hastened by adding water, and may be further hastened by using enhanced gravitational forces to effect separation of the portions. The process may also be used to remove undesirable flavor components from the cheese or to make a dairy spread.

Owner:SCHREIBER FOODS

Method for preparing egg and milk essence substrate

ActiveCN102232534AImprove securityAdd flavorAnimal feeding stuffWorking-up animal fodderMonoglycerideButterfat

The invention relates to the technology in the field of food and beverage processing, in particular to preparation of an egg and milk essence substrate by using a dual enzymatic method in cooperation with the mailard reaction; and the prepared egg and milk essence substrate can be widely applied to various food industries. The method comprises the following steps of: hydrolyzing natural cream by using lipase and subjecting dried egg yolk to enzymolysis by using protease; mixing a hydrolysis product and an enzymolysis product based on a certain ratio, homogenizing by a homogenizer, and obtain a homogenous emulsification system by using the monoglyceride and lecithin in a mixture per se as emulsifiers; then adding reducing sugar-xylose and amino acid-methionine for producing the egg characteristic flavor, mixing to reach a uniform state, directly heating to 105-110 DEG C, reacting for 1-3 hours; and performing the mailard reaction and enzyme deactivation at the same time. A final product has the flavor mixture of free fatty acid, lactone, methyl ketone, alcohol, aldehyde, black-like essence with antioxidant activity and the like, wherein the free fatty acid is obtained through hydrolyzing the fat, the lactone, methyl ketone, alcohol and aldehyde are obtained through heating the fat, and the black-like essence is generated by the mailard reaction; and thus, the product has an intense egg and milk flavor.

Owner:GUANGZHOU FLOWER FLAVOURS & FRAGRANCES

Process for making yogurt cream cheese, and the resulting products

Techniques for making a yogurt cream cheese product comprising steps of providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid to produce a cream cheese precursor; providing a yogurt, and combining the yogurt with the cream cheese precursor to produce a combined precursor; and homogenizing and acidifying the combined precursor; wherein the acidification is completed within about three hours following production of the combined precursor; producing a yogurt cream cheese product. Techniques wherein the combined precursor is cooled to retard bacteria activity prior to the acidifying. Techniques for making a whipped yogurt cream cheese product. Yogurt cream cheese products produced by the processes.

Owner:FRLIN FOODS HLDG

Sheep milk fat and its production method and application

InactiveCN101077193AGood cosmetic effectImprove functionalityCosmetic preparationsPeptide/protein ingredientsSheep milkSide effect

The present invention discloses sheep milk fat and its production process, belongs to the field of fat product technology, and aims at sheep milk fat containing epidermal growth factor. The production process includes the steps of eliminating mutton smell from sheep milk or first sheep milk, high speed separation to obtain sheep milk fat, extruding to dewater and final cooling to form paste. The sheep milk fat product is nutritious, white health food without additive and side effect. It may be also used as the cosmetic material.

Owner:DALIAN JIUYANG DAIRY

Health characteristic Caramel Flavored Confection, Chews, Hard Candy, and Caramel Flavored Milk

The present invention provides for caramel flavored confections, chews, hard candies or caramel flavored milk that has an improved, healthier fat structure, unique antioxidant taste profile, fiber component, and a 0% or greater supplement component that can add additional dietary benefits. Cholesterol reduction and cardiovascular health and removal of cholesterol from the bloodstream can be accomplished within certain compositions of this invention. Specific ratios of ingredients create a taste, texture, to mouthfeel, and rich flavor similar to a high milk fat or butter fat based caramel without the negative health ramifications of high milk fat based type caramels. Additionally, the method for preparing a caramel flavored confection, chews, and milk with these improved health characteristics, taste profile, and dietary benefits are covered.

Owner:ERVIN GARY

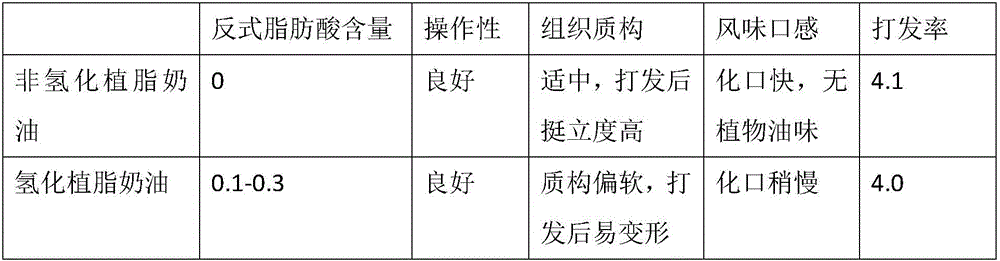

Non-hydrogenation mixed milk fat and plant fat cream and preparation method thereof

PendingCN106387092AMeet quality requirementsEdible oils/fats ingredientsCream substitutesButterfatVegetable oil

The invention discloses non-hydrogenation mixed milk fat and plant fat cream and a preparation method thereof. The non-hydrogenation mixed milk fat and plant fat cream is prepared from the following raw materials in percentage by weight: 8-18% of non-hydrogenation vegetable oil, 0.05-0.5% of dehydrated sorbitan monostearate, 0.02-0.5% of citrate fatty acid glyceride, 0.05-1% of monoglyceride fatty acid ester and diglycerol fatty acid ester, 0.02-1% of lactic acid monoglyceride, 0.02-0.5% of sodium stearoyl lactylate, 0.05-0.5% of sucrose fatty acid ester, 0.02-0.5% of polyglycerol ester, 0.01-0.1% of carrageenin, 0.05-0.8% of microcrystalline cellulose, 0.05-1% of modified cellulose, 0.1-1.5% of sodium caseinate, 0.02-0.2% of potassium dihydrogen phosphate, 2-6% of sugar, 2-12% of glucose syrup, 8-18% of dairy products containing milk fat and 20-60% of water. According to the non-hydrogenation mixed milk fat and plant fat cream and the preparation method thereof, the disadvantages that non-hydrogenation plant oil is soft in texture, not liable to operate and poor in flavor and mouth feel in the process of producing the mixed milk fat and plant fat cream are overcome.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

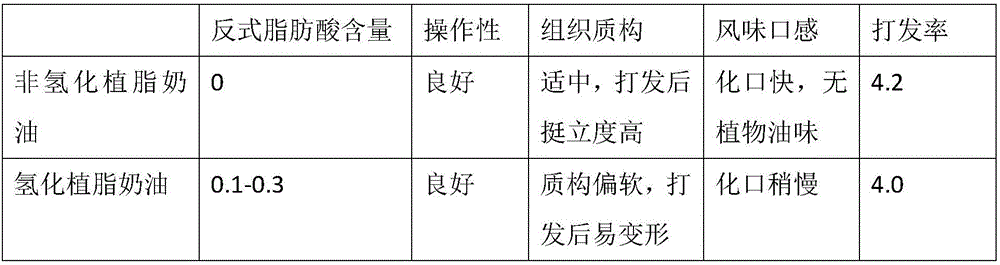

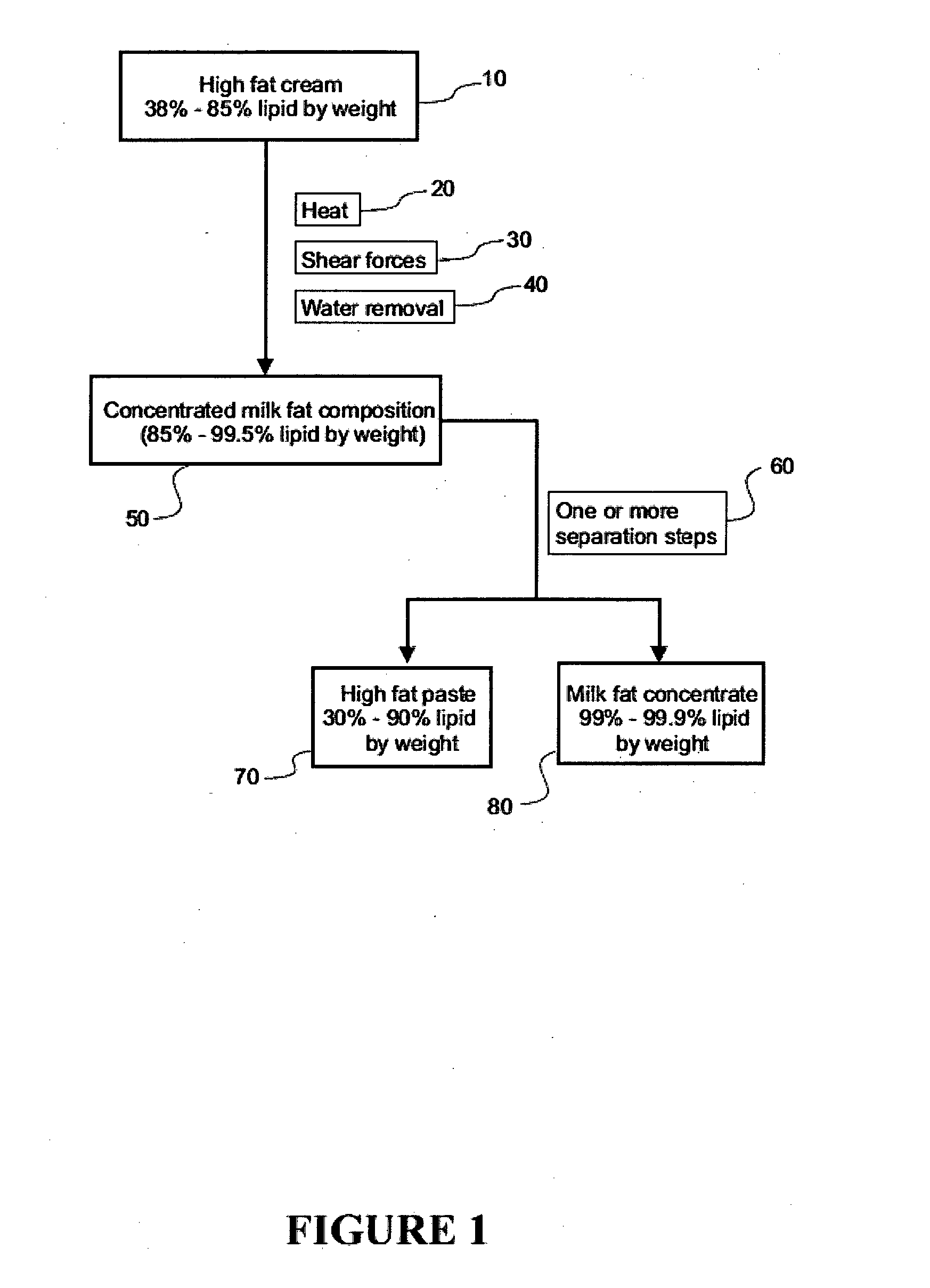

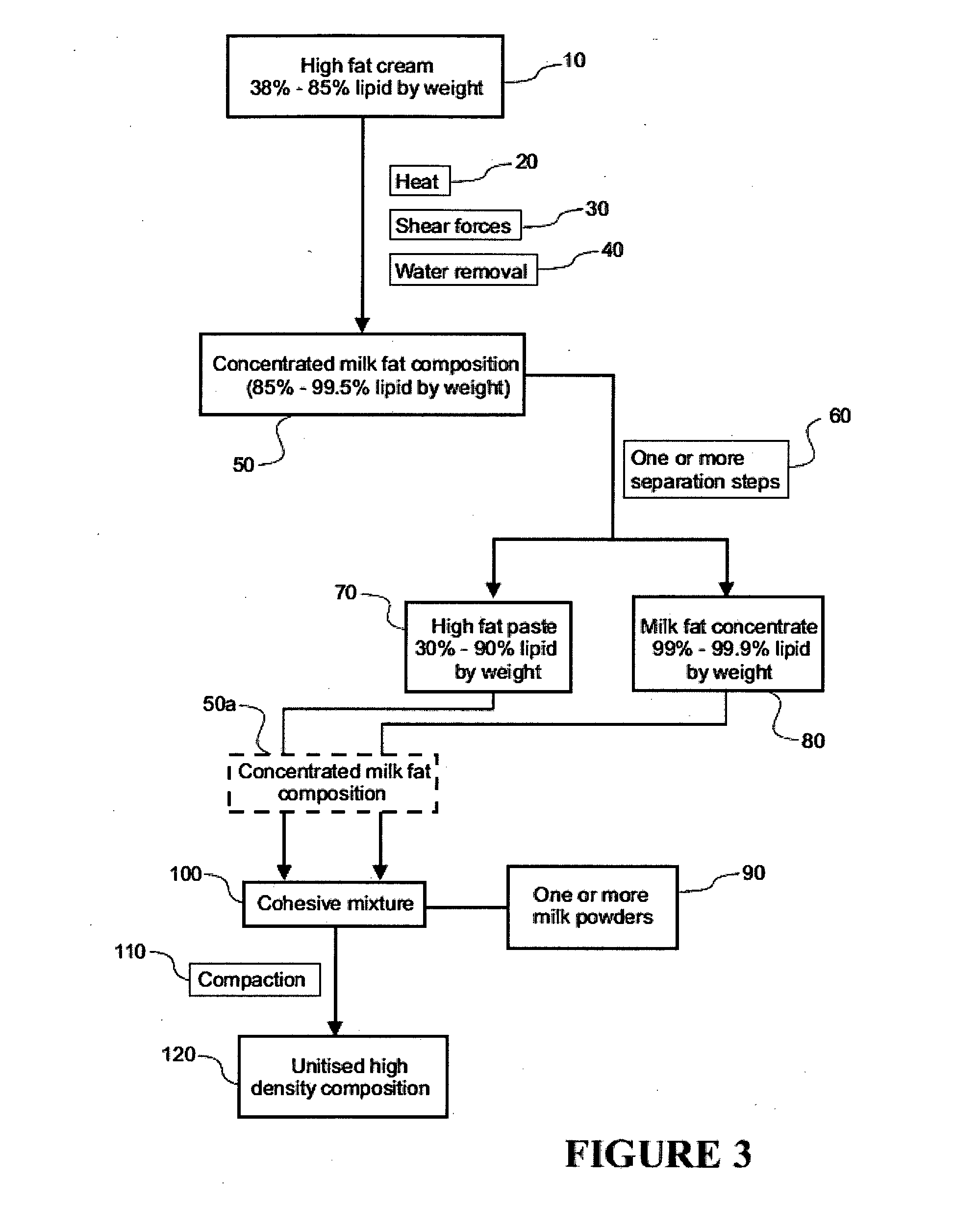

Production of concentrated milk fat compositions and unitised high density compositions

The present application is directed to a method comprising; heating high fat cream, subjecting the high fat cream to shear forces, and removing water to provide a milk fat composition being a water-in-oil emulsion and comprising about 85-99.5% lipid and moisture content of about 0.05-15%. A method comprising the separation of concentrated milk fat to provide a high fat paste comprising about 1 to about 90% by weight lipid, about 0.1 to about 20% by weight moisture, and about 0.5 to about 35% phospholipid, and a milk fat concentrate comprising about 99 to about 99.9% lipid is also disclosed. In addition a method of producing a unitised high density composition comprising; providing a mixture comprising one or more liquid or semi-liquid milk fat compositions, and one or more milk powders, and compacting the mixture to produce a unitised high density composition is disclosed.

Owner:MACKERETH ANTONY RAYMOND +2

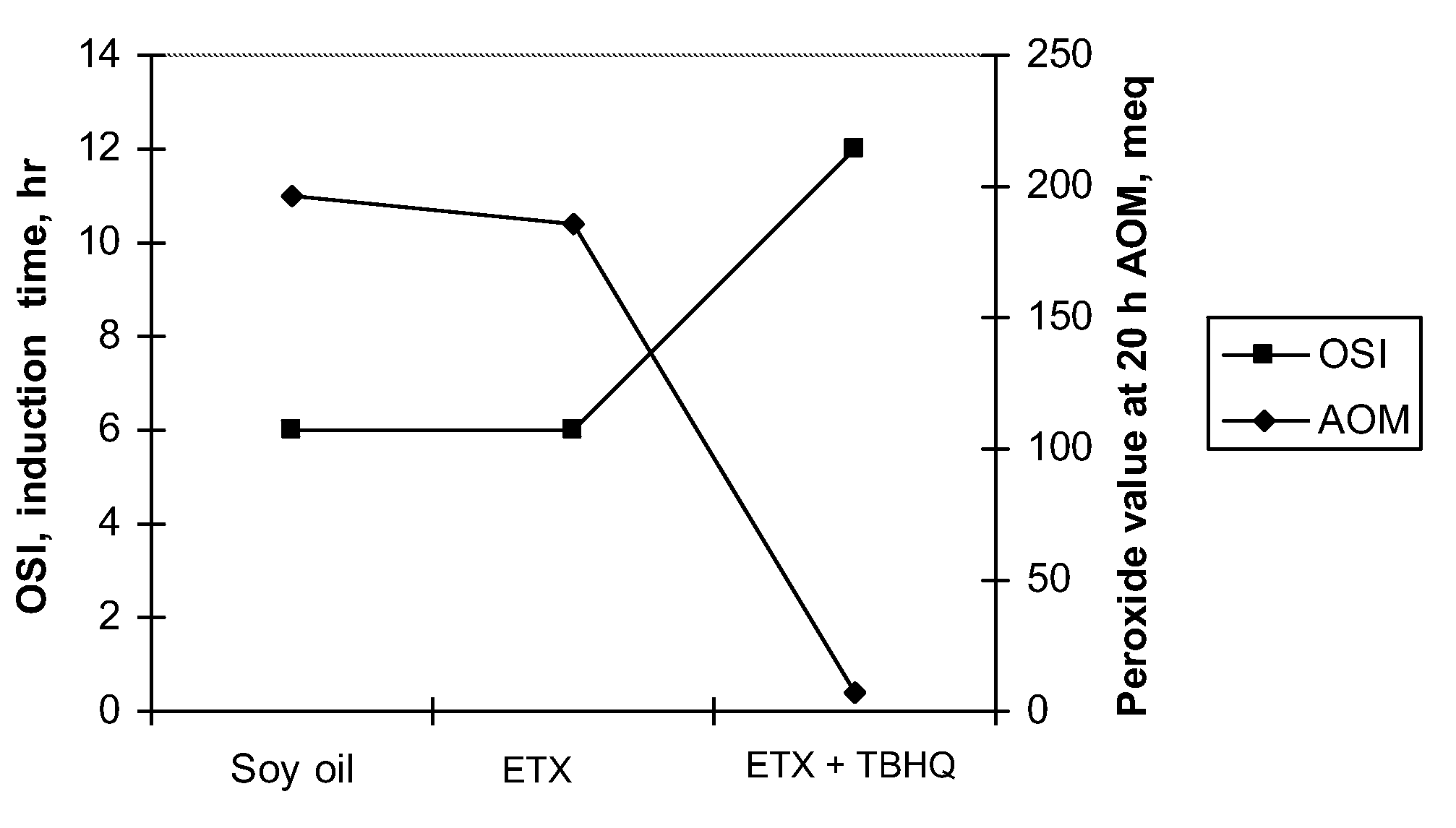

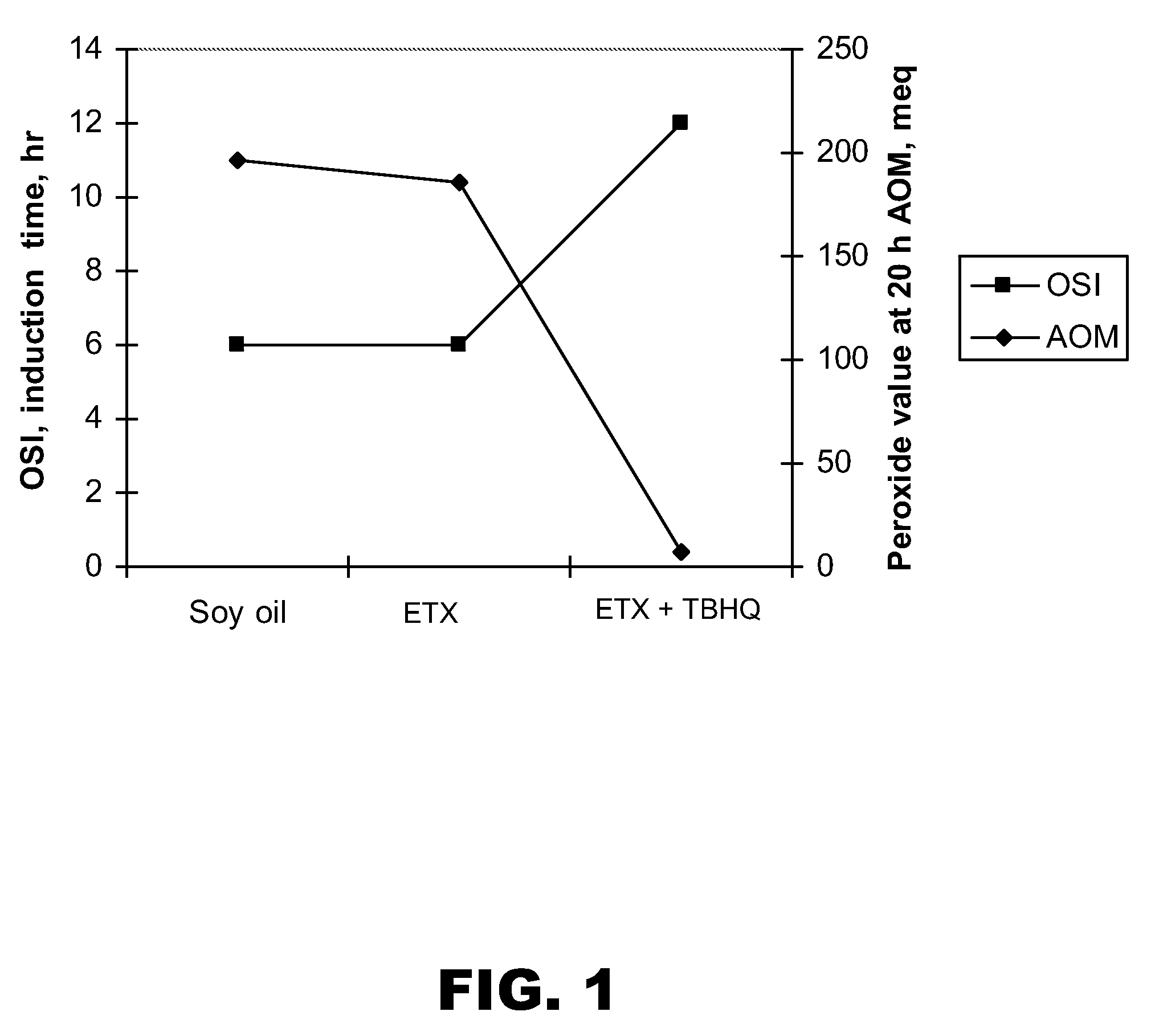

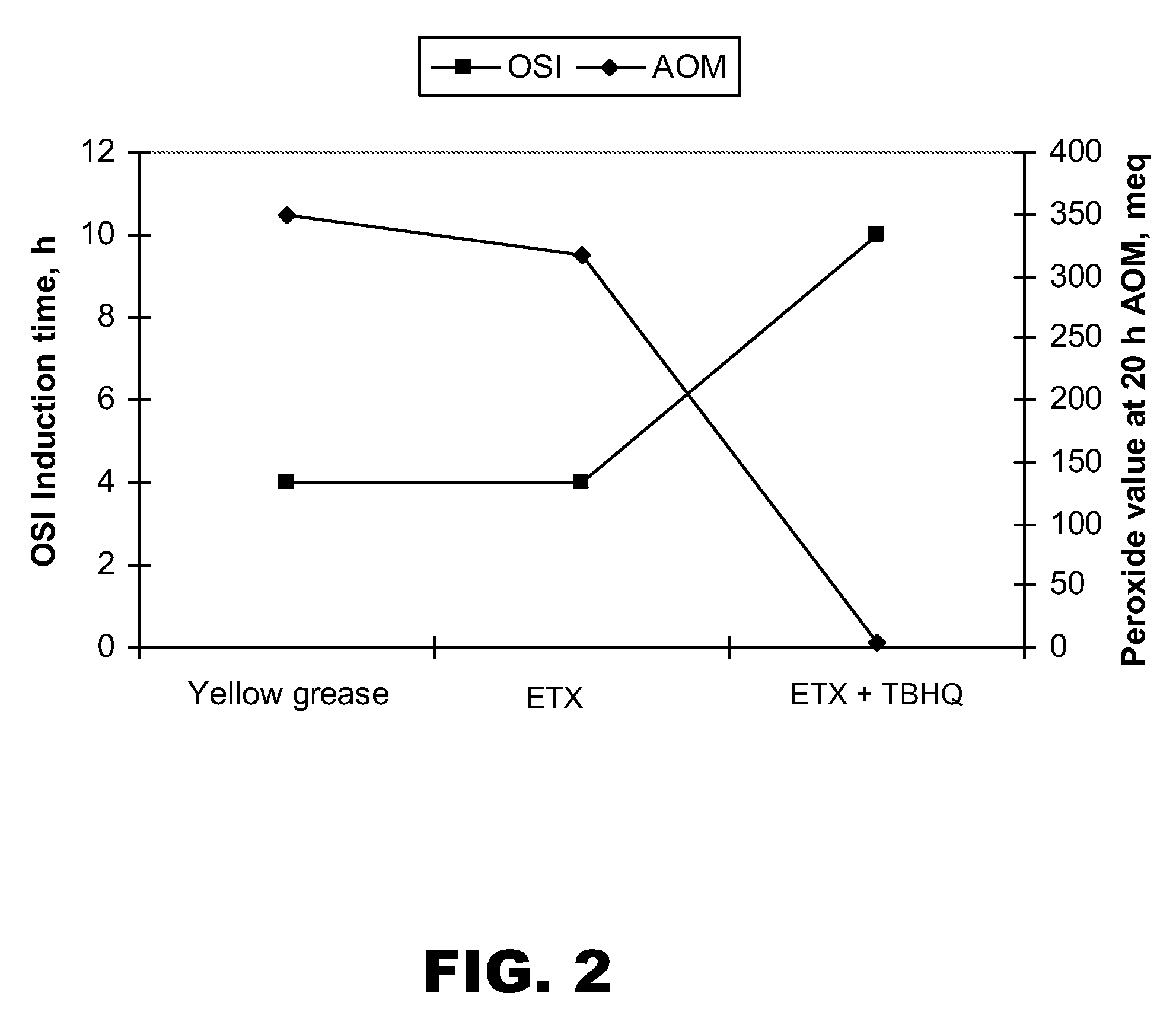

Antioxidant combinations for use in ruminant feed rations having a fat source

The present invention provides a combination of antioxidants that effectively stabilize different types of fats utilized in a ruminant diet. When included in a ruminant feed ration or water source, the antioxidant combination typically increases nutrient digestion, such as fiber and protein, improves rumen fermentation, improves microbial growth, improves microbial efficiency, increases milk production and / or milk fat, improves antioxidant status of the ruminant, and attenuates the negative effects of some fats in the ruminant animal.

Owner:NOVUS INTERNATIONAL INC

Yogurt-cheese compositions

Technique for making a Low-Fat Yogurt-Cheese Composition, including: providing a composition including a milkfat fluid; combining yogurt with the composition including a milkfat fluid to form a composition including yogurt and a milkfat fluid; combining milk protein with the composition including yogurt and a milkfat fluid; and forming a blend including the milk protein and the composition including yogurt and a milkfat fluid. Low-Fat Yogurt-Cheese Composition, including: cream cheese at a concentration within a range of between about 75% by weight and about 15% by weight; yogurt at a concentration within a range of between about 40% by weight and about 10% by weight; and milk protein at a concentration within a range of between about 45% by weight and about 15% by weight.

Owner:FRLIN FOODS HLDG

Chocolate composition

The invention relates to chocolate compositions where the fat phase comprises at least cocoa butter and optionally milk fat and / or a cocoa butter equivalent and the chocolate can be liquefied and re-solidified without bloom and without a pre-crystallization step.

Owner:SOC DES PROD NESTLE SA

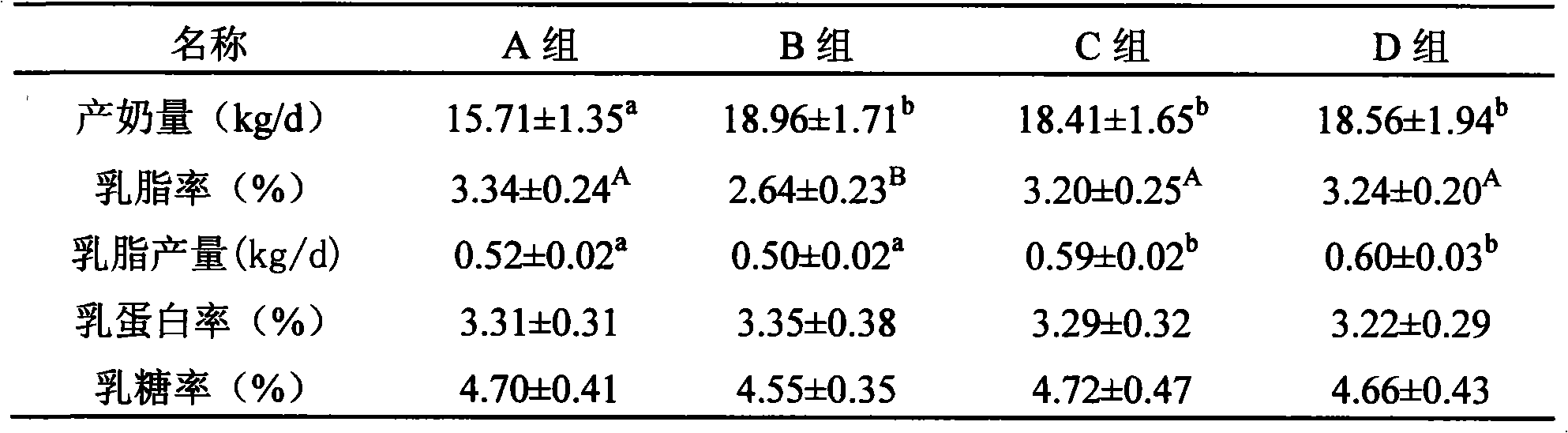

Feed additive for increasing milk cow dairy food quality and milk cow anti-heat stress

InactiveCN101579059AAlleviate heat stressAvoid damageAnimal feeding stuffAccessory food factorsButterfatSide effect

Feed additive for increasing milk cow dairy quality and milk cow anti-heat stress relates to a feed additive. The additive comprises calcium conjugated linoleic acid, selenium and vitamin E, the ratio of the additive is 15-50mg selenium of and 25,000-750,000 IU of vitamin E to each 1 Kg of calcium conjugated linoleic acid. The invention has the advantages that the yield of milk fat of milk cows, the contents of unsaturated fatty acid in milk fat and the selenium and VE in milk are increased, thus improving the dairy quality, the heat stress reaction of milk cows can also be alleviated, thus increasing the milk production , furthermore, the active oxygen in the heat stress milk cows can be reduced to decrease peroxidation reaction, thus reducing the injure of heat stress on milk cows and increasing the anti-oxidation ability of milk cow organism. The invention has the advantages of simple production process, no requirement of special equipment, safe and simple operation and no side effect.

Owner:广州风行乳业股份有限公司 +2

Cream cheese products and methods of making the same

Technique for making a cream cheese product comprising steps of: providing a milkfat fluid comprising butterfat; pasteurizing the milkfat fluid; homogenizing the milkfat fluid; and culturing bacteria in the milkfat fluid; producing a cream cheese product comprising live probiotic bacteria cultures. Cream cheese product comprising: between about 10% by weight and about 55% by weight of total butterfat; and a live probiotic bacteria culture.

Owner:FRLIN FOODS HLDG

Processing method of concentrated milk

The invention provides a processing method of concentrated milk. The method comprises the following steps of degreasing milk, and pumping butterfat to a market cream temporary storage pot; heating milk liquid to 25-70 DEG C through a plate type heat exchanger, wherein the degree of vacuum is 200-1000Pa, performing circulating for 5-15 minutes, infiltrating the circulated milk liquid to the market cream temporary storage pot, and after 5 minutes of turning on a stirrer, detecting indexes; leading in steam for heating a jacket outside the market cream temporary storage pot to 95 DEG C, performing heat insulation for 0.5-1 hour, and performing concentration treatment on protein and fat, so that the weight concentration is increased, and comprehensive flavor of special milk is improved; cooling products obtained after the market cream pot is concentrated in the third step through the plate type heat exchanger to 4-25 DEG C, pumping the cooled market cream to the skim milk pot, and performing standard blending, homogenizing and sterilizing once again. The processing method disclosed by the invention has the beneficial effects of having flavor after a maillaid braun reaction and frying animal oil and fat, and shorter production time compared with the prior art.

Owner:ZHEJIANG INM FOOD

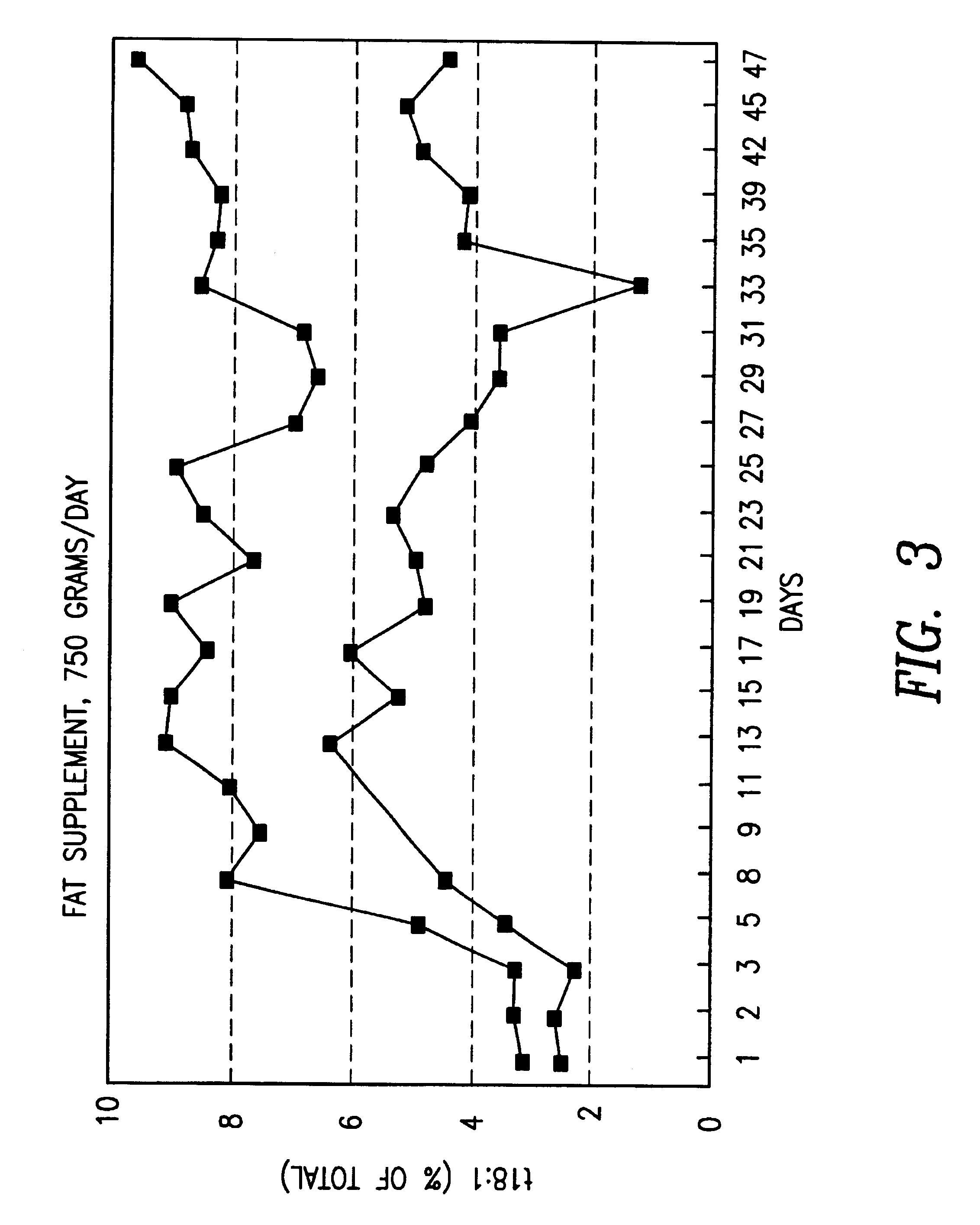

Cow milk with enhanced nutritive and health values

InactiveUS6602537B1Easy to retouchIncrease contentMilk preparationAnimal feeding stuffCow milkingButterfat

A cow milk product with enhanced nutritional and health values for human consumption, obtained from cows fed with a feedstock having a supplement containing at least about 60 weight percent of calcium oleate, which product has milk fat with a profile of fat constituents including about 1-3.5 weight percent of conjugated linoleic acid, about 2-6 weight percent of trans-11 18:1 fatty acid, about 20-30 weight percent of cis-9 18:1 fatty acid, and about 30-38 weight percent of 14:0 and 16:0 fatty acid, per total milk fat, and wherein the 18:1 to 18:0 fatty acid ratio in the milk fat is about 2-3.2:1.

Owner:CHURCH & DWIGHT CO INC

Conditioning cream for egg tart pudding and application of conditioning cream

The invention discloses conditioning cream for egg tart pudding and application of the conditioning cream.The conditioning cream is prepared from, by weight, 80-200 parts of vegetable oil, 0-20 parts of glucose, 1-200 parts of white granulated sugar, 0-200 parts of sugar alcohol, 50-100 parts of butterfat, 50-100 parts of milk powder, 100-250 parts of liquid whole eggs, 0-100 parts of liquid egg yolks, 60-120 parts of emulsifier, 0.1-0.5 part of carrageenan, 0.1-5 parts of phosphate buffer salt, 0.5-2 parts of edible salt, 0-2 parts of flavoring essence and the balance water, and the raw materials are added to 1,000 parts.The conditioning cream can replace traditional manual liquid egg tars and pudding liquid, time and labor are saved, the quality is stable, frost resistance and high temperature resistance are achieved, user using or DIY is convenient, the conditioning cream can also be added to desserts to enhance the flavor, and the baking quality is improved; the conditioning cream is moderate in milk flavor, the egg flavor is rich, high temperature resistant baking is achieved, the unique flavor of animal fat is achieved, and use is convenient; meanwhile, the texture state of a product is improved, the stability is good, baking resistance and collapsing are achieved, and the Portuguese-style egg tart or Hong Kong-style egg tart state can be achieved through baking according to needs.

Owner:ZENGCHENG LEGO FOODS CO LTD

Antioxidant combinations for use in feed rations to increase milk production and milk fat

The present invention provides a combination of antioxidants that effectively stabilize different types of fats utilized in a ruminant diet. When included in a ruminant feed ration or water source, the antioxidant combination typically increases nutrient digestion, such as fiber and protein, improves rumen fermentation, improves microbial growth, improves microbial efficiency, increases milk production and / or milk fat, improves antioxidant status of the ruminant, and attenuates the negative effects of some fats in the ruminant animal.

Owner:EW NUTRITION CAROTENOID TECH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com