Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

532 results about "Microbial oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbial oil is a triglyceride (lipid) produced by a microbe, and is similar to vegetable oil, another biologically produced oil. Some species of yeast are able to convert food into triglycerides and accumulate the produced lipids when fed carbohydrates. Production of microbial oil has been researched for production of biodiesel, because impure carbohydrates such as agricultural residues, e.g. waste molasses can be used as a feedstock for production of oil.

Soaps Produced from Oil-Bearing Microbial Biomass and Oils

ActiveUS20090305942A1Improve efficiencyLow costSoap detergents with organic compounding agentsBiofuelsMicroorganismMicrobial oil

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

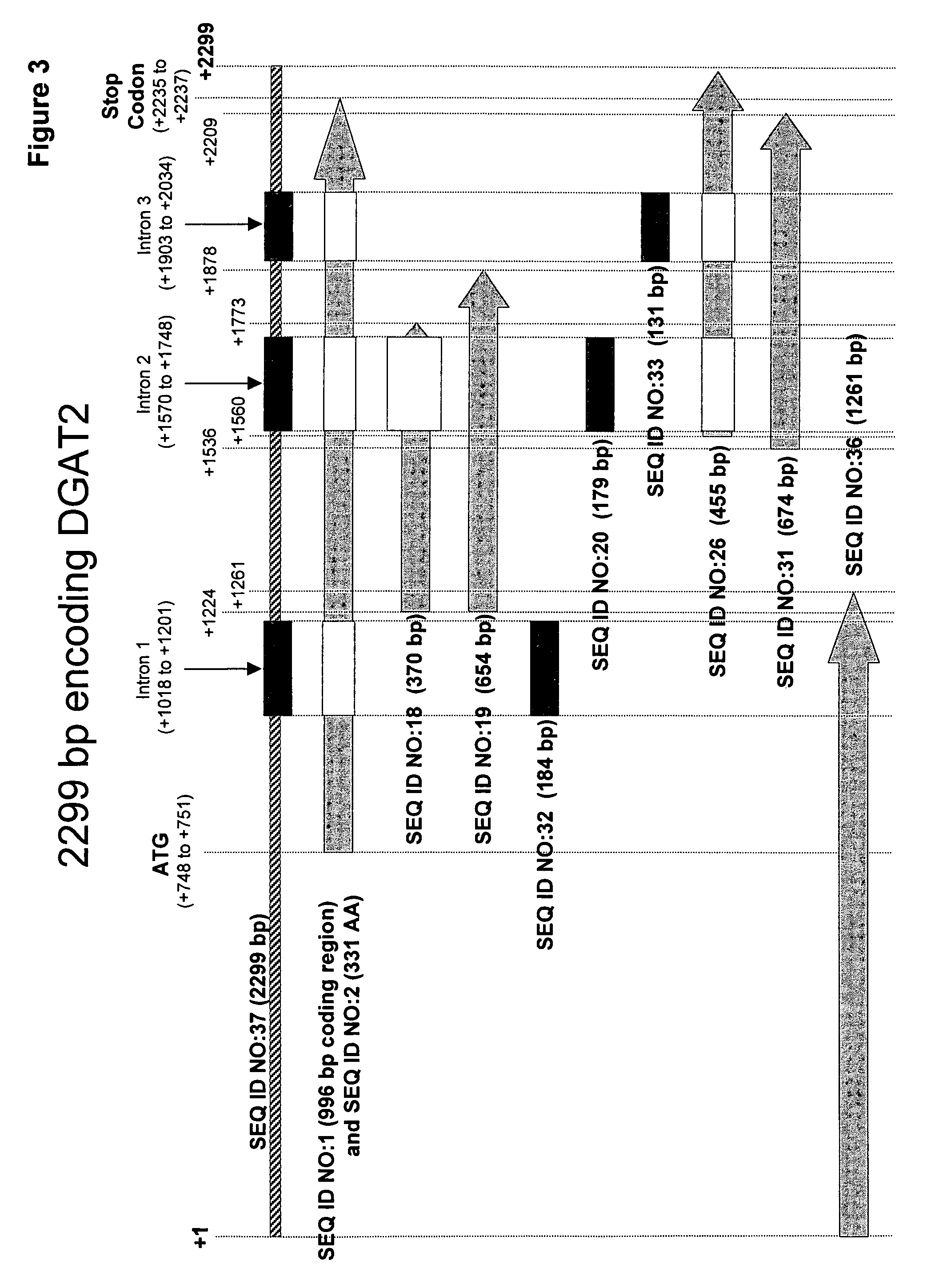

Mortierella alpina diacylglycerol acyltransferase for alteration of polyunsaturated fatty acids and oil content in oleaginous organisms

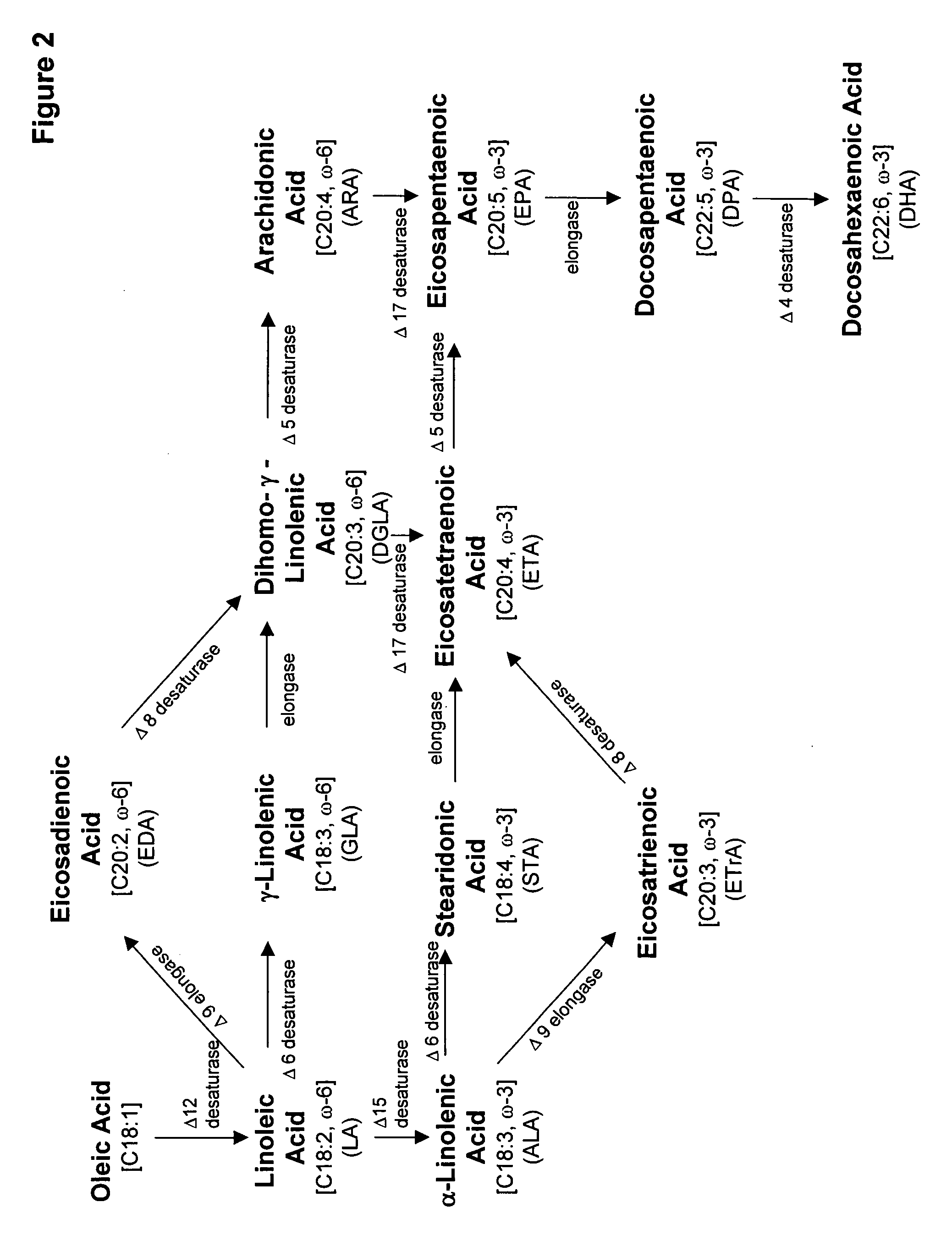

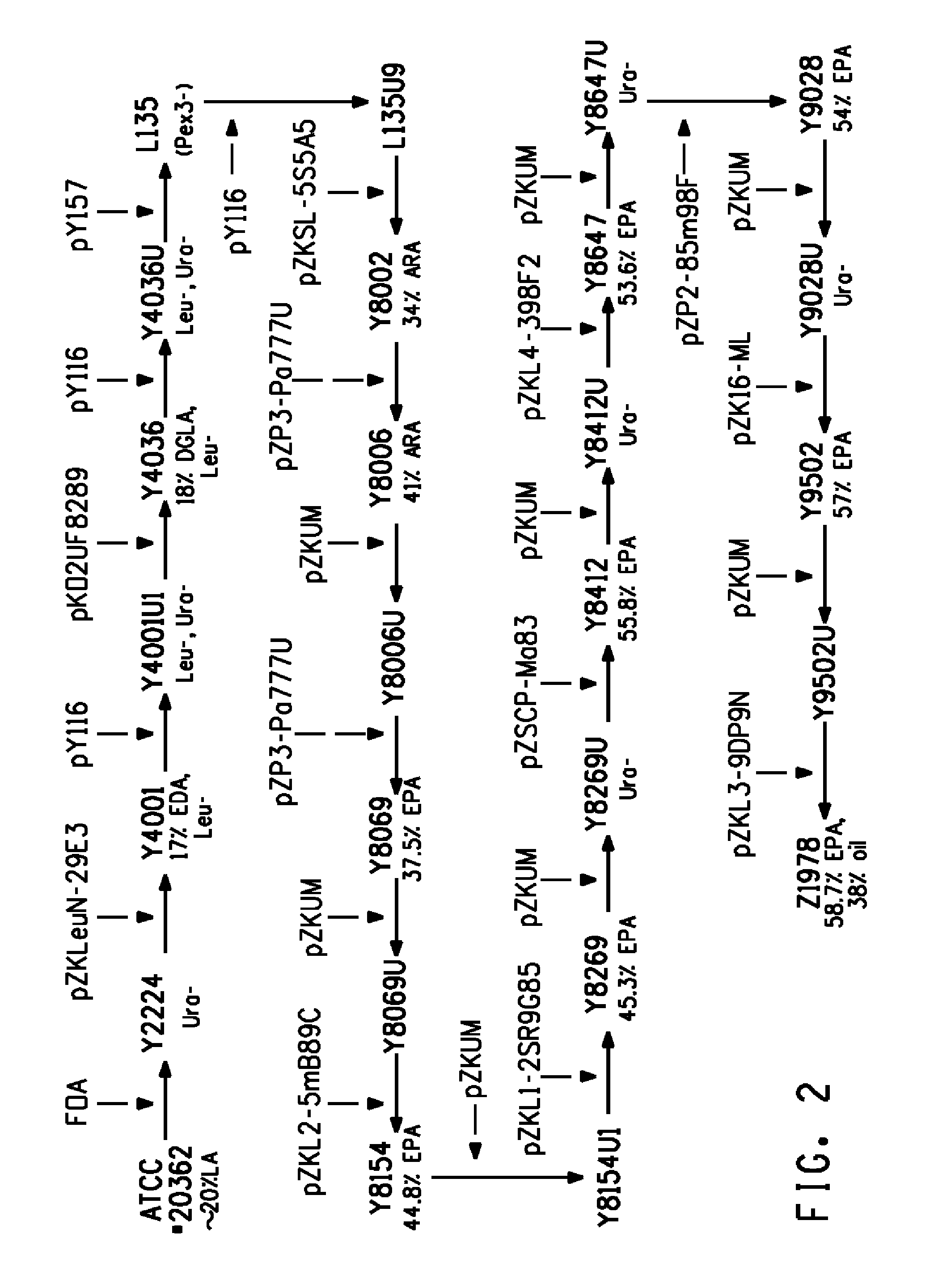

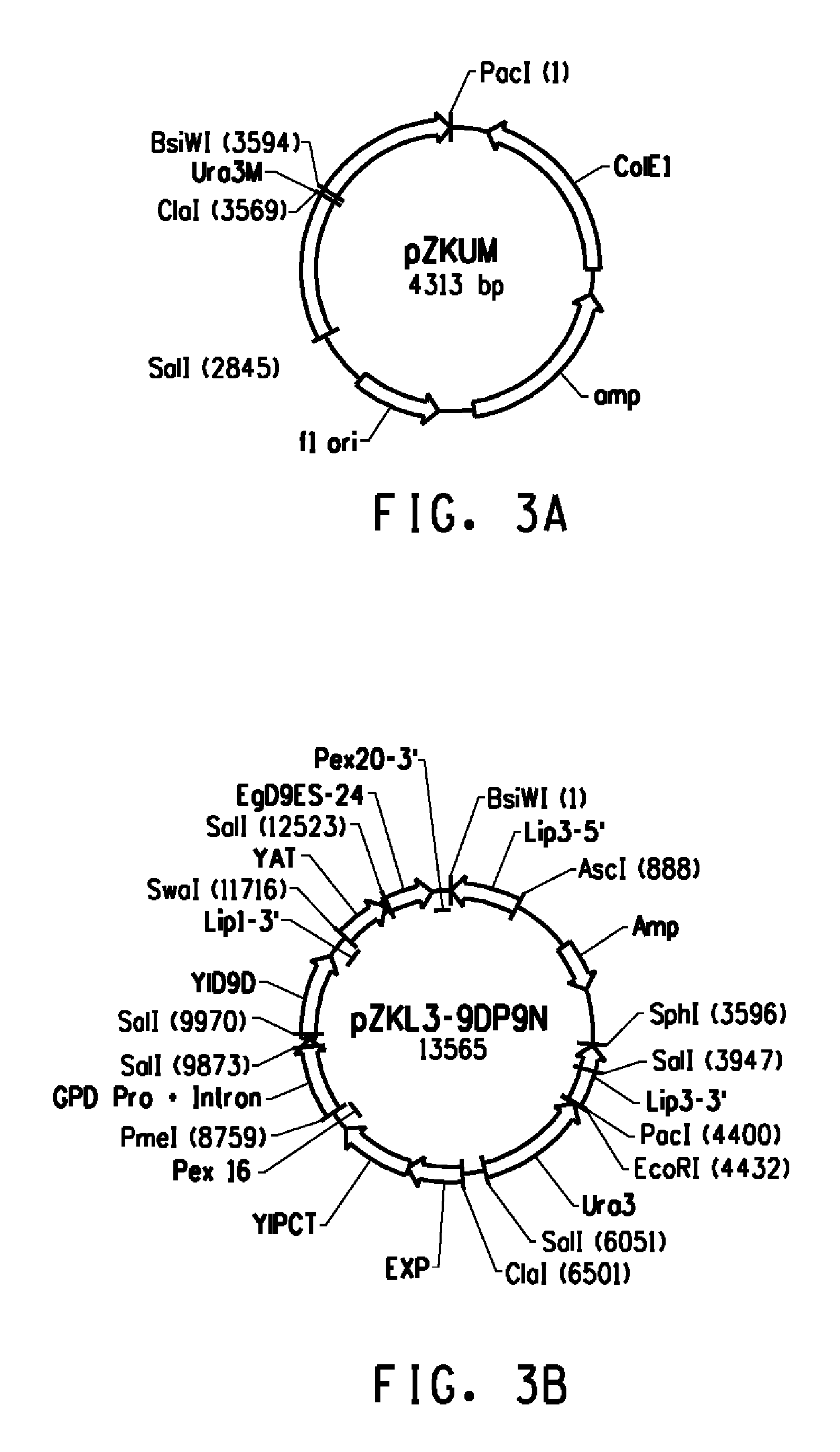

An acyltransferase is provided, suitable for use in the manufacture of microbial oils enriched in omega fatty acids in oleaginous organisms. Specifically, the gene encoding diacylglycerol acyltransferase (DGAT2) has been isolated from Mortierella alpina. This gene encodes an enzyme that participates in the terminal step in oil biosynthesis in fungi and yeast and is expected to play a key role in altering the quantity of long-chain polyunsaturated fatty acids produced in oils of oleaginous organisms. Most desirably, the substrate specificity of the instant DGAT2 will be particularly useful to enable accumulation of long-chain PUFAs having chain lengths equal to or greater than C20 in oleaginous yeast, such as Yarrowia lipolytica.

Owner:DUPONT US HLDG LLC

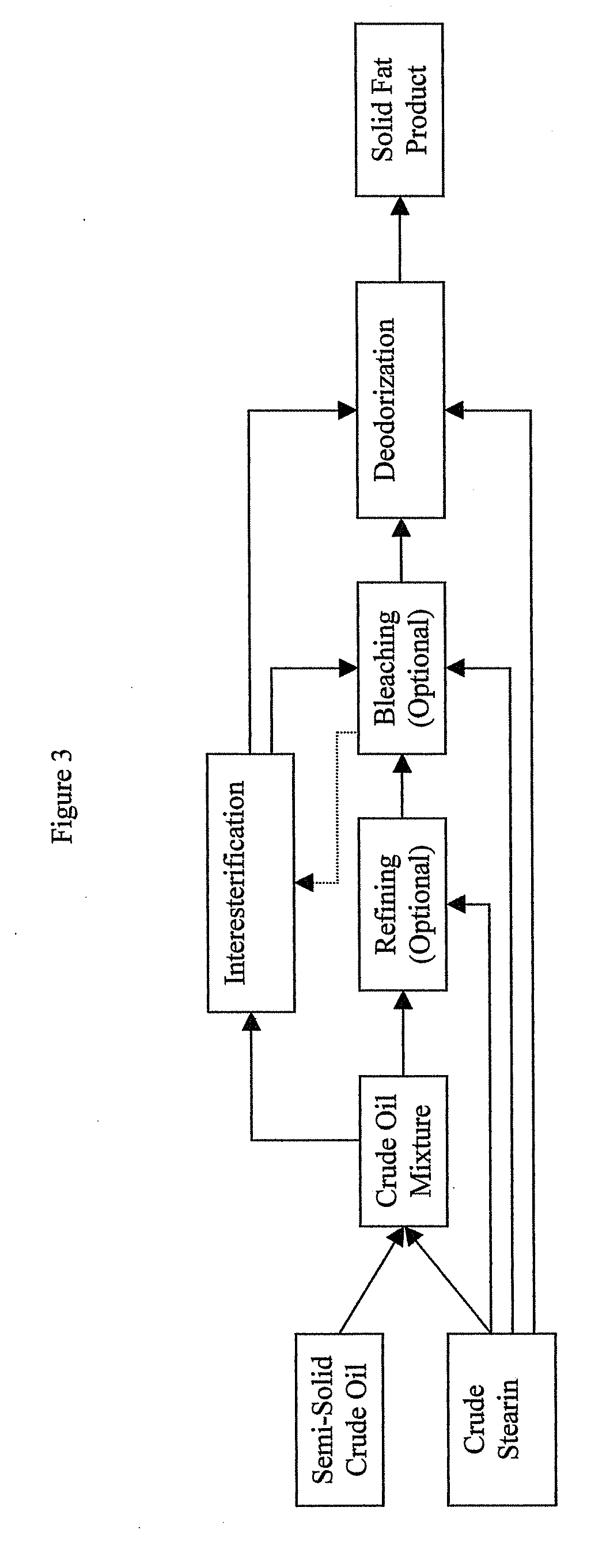

Polyunsaturated Fatty Acid-Containing Solid Fat Compositions and Uses and Production Thereof

InactiveUS20090099260A1Low costMinimum of process stepEdible oils/fats ingredientsBiocideMicrobial oilUnsaturated Oils

The present invention provides a solid fat composition that includes an oil having saturated fat and an oil having at least one long chain polyunsaturated fatty acid. In particular, the solid fat composition can have high levels of long chain polyunsaturated fatty acid and low to no presence of emulsifiers. In preferred embodiments, the polyunsaturated oil is an unwinterized microbial oil. The invention also relates to methods for making such compositions and food, nutritional, and pharmaceutical products comprising said compositions.

Owner:DSM IP ASSETS BV

Soaps produced from oil-bearing microbial biomass and oils

ActiveUS8119583B2Low costImprove efficiencySoap detergents with organic compounding agentsCosmetic preparationsMicrobial oilGlycerol

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

Thraustochytrids, Fatty Acid Compositions, and Methods of Making and Uses Thereof

Owner:DSM IP ASSETS BV

Methods of treating senile dementia and Alzheimer's diseases using docosahexaenoic acid and arachidonic acid compositions

InactiveUS20050027004A1Lower triglyceride levelsCorrecting lipid imbalanceBiocideNervous disorderMicrobial oilMedicine

A method of treating a neurological disorder comprises administering to a person affected from such a disorder a microbial oil comprising DHA, a microbial oil comprising ARA or a combination of DHA and ARA oils in an amount sufficient to elevate the levels of circulating DHA and / or ARA in the person's blood to at least normal levels.

Owner:MARTEK BIOSCIENCES CORP

Methods of microbial oil extraction and separation

ActiveUS20120130099A1Increase productionFatty oils/acids recovery from wasteFatty acid esterificationMicrobial oilMoisture

Lipids can be extracted from a microbial biomass that constitutes at least 20% lipids by weight and has a moisture content of less than 4% by weight by applying pressure to the biomass so as to release lipids therefrom, thereby leaving a biomass of reduced lipid content; and collecting the lipids.

Owner:CORBION BIOTECH INC

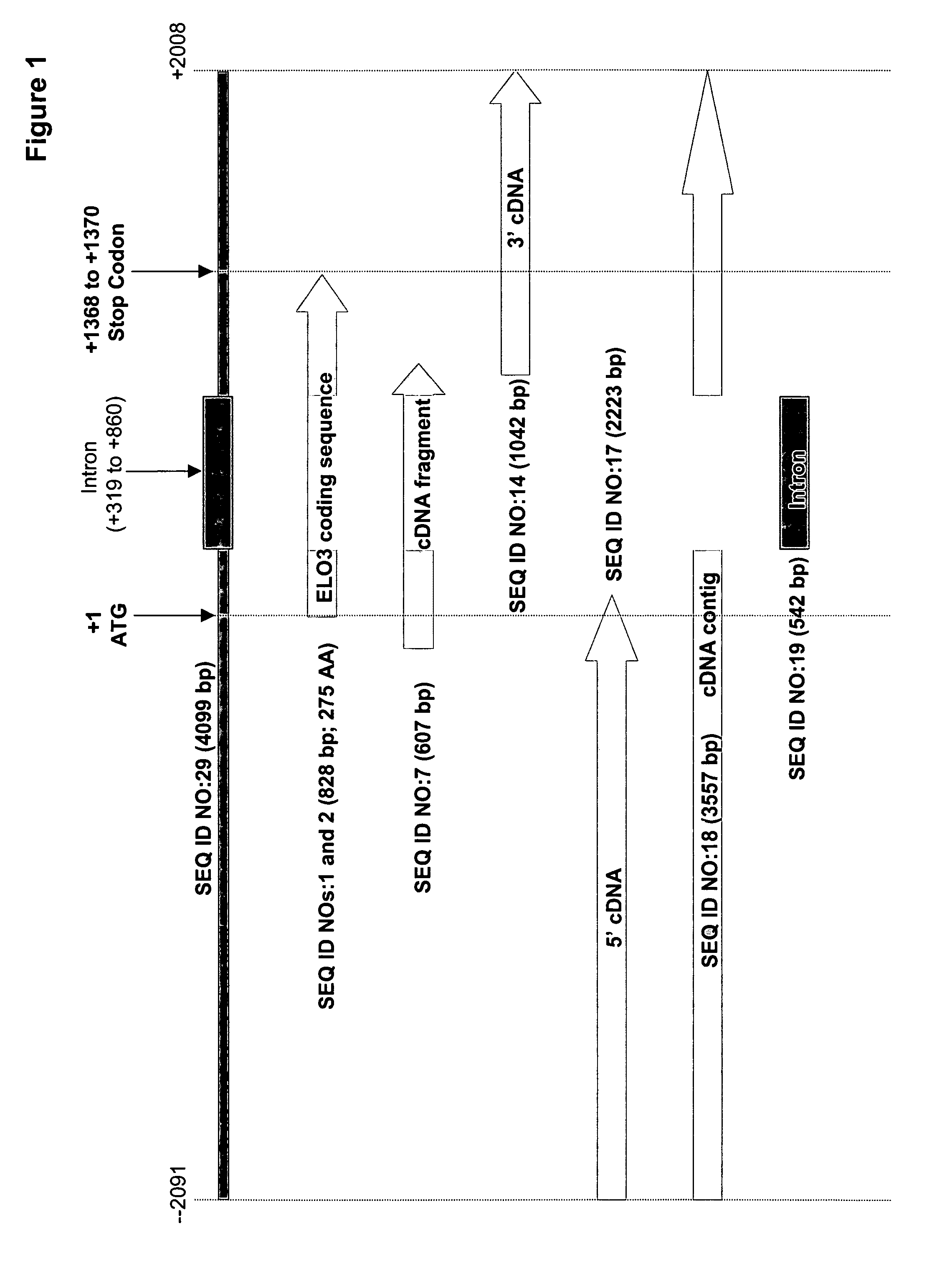

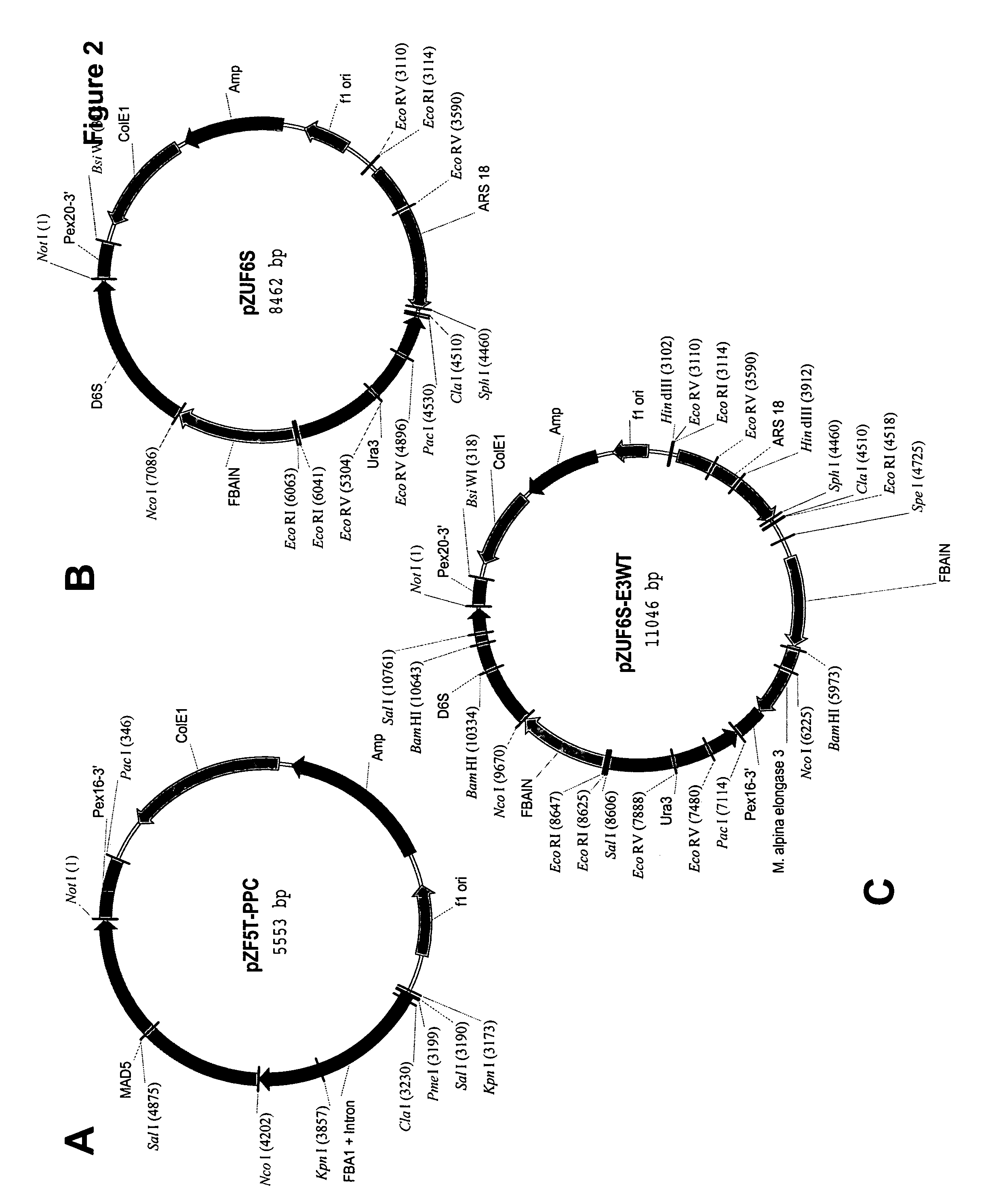

Mortierella alpina C16/18 fatty acid elongase

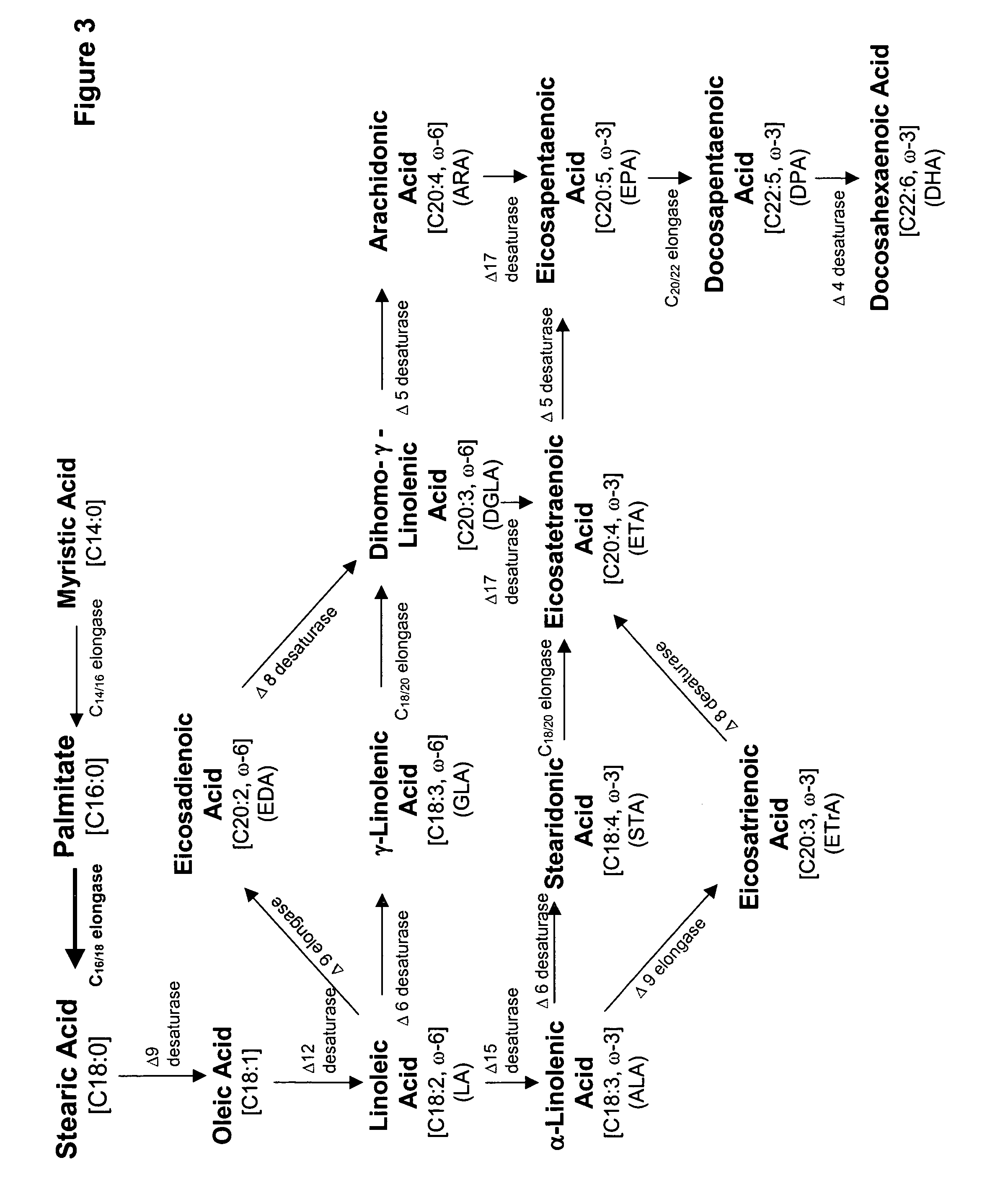

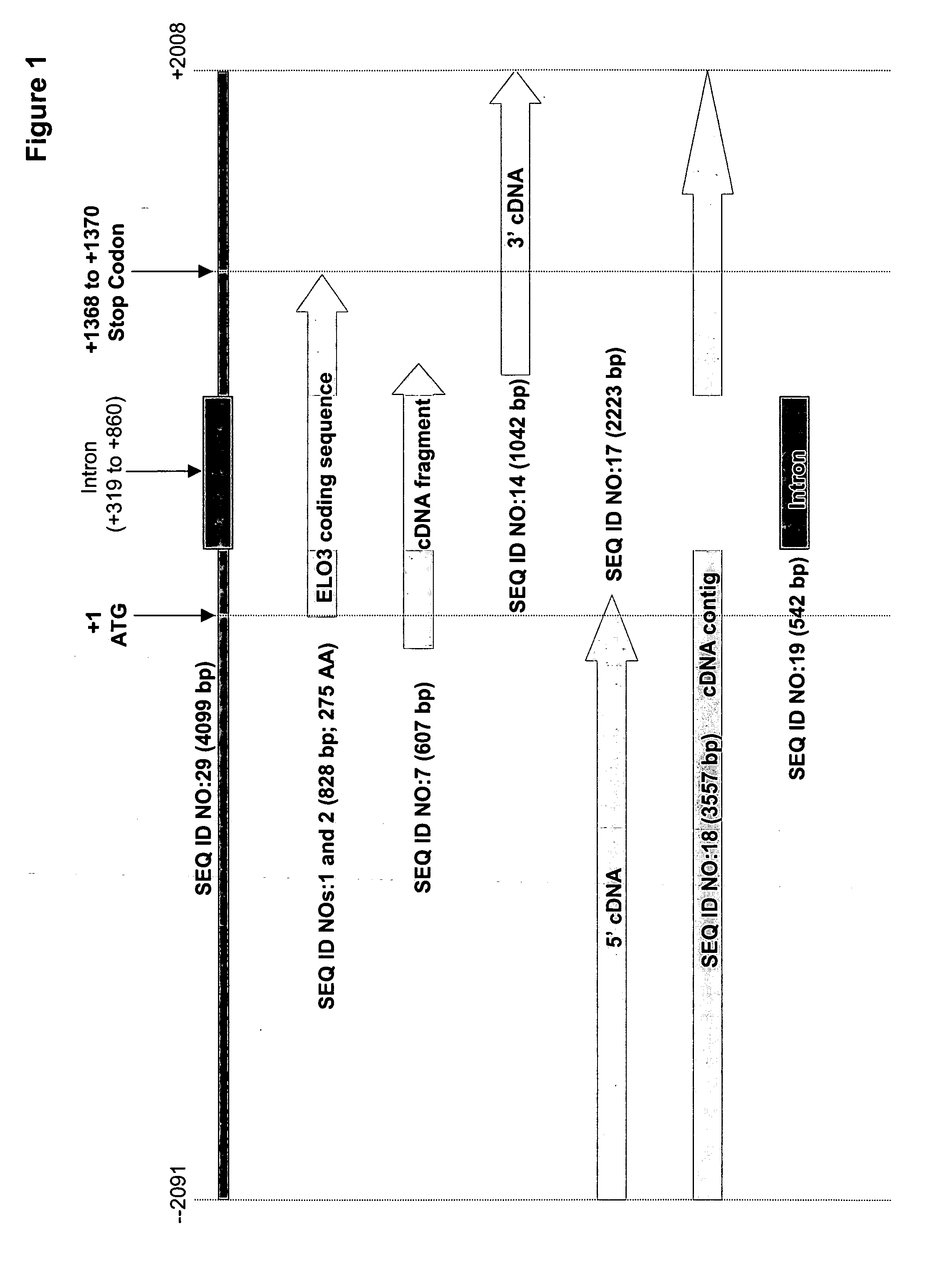

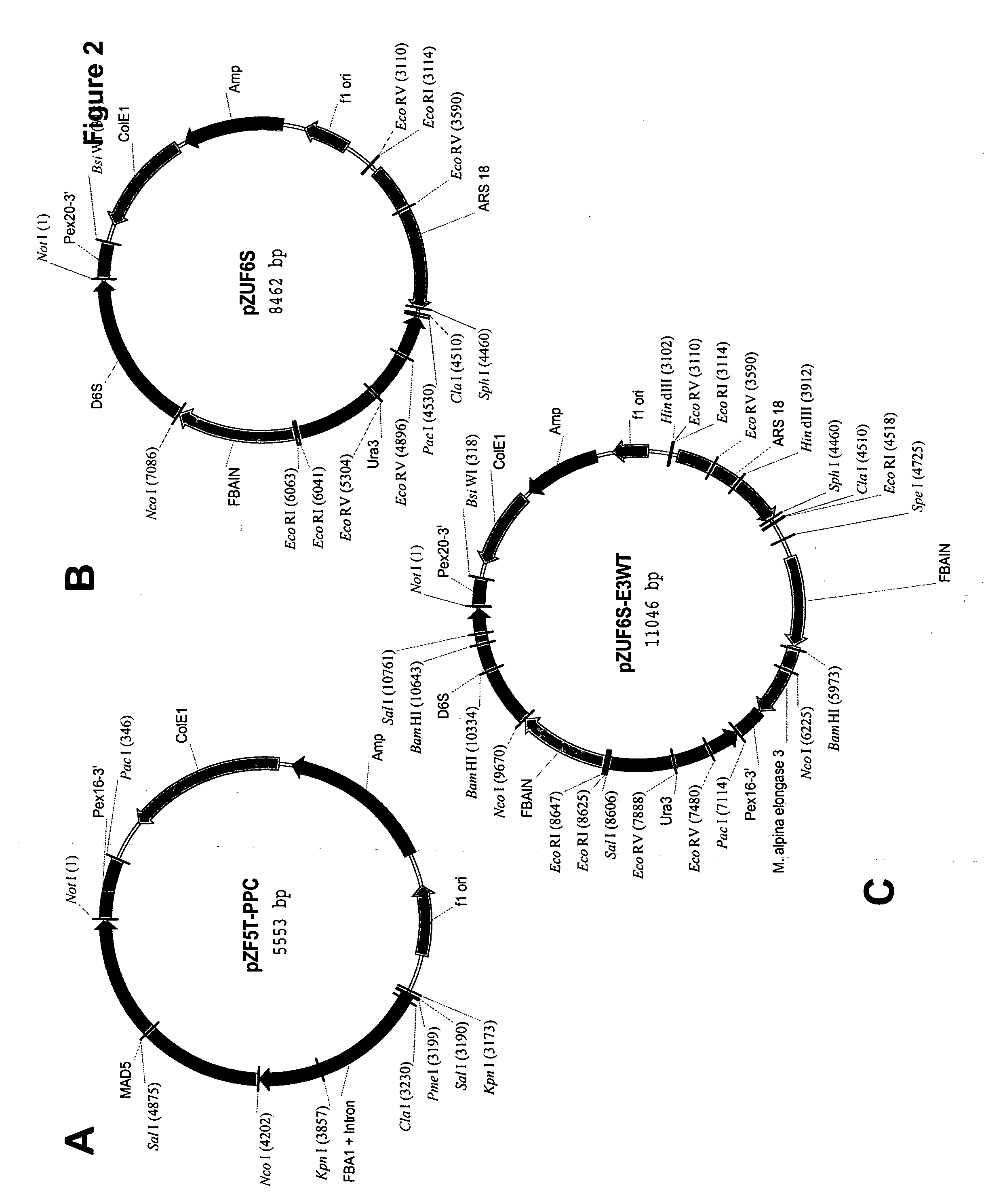

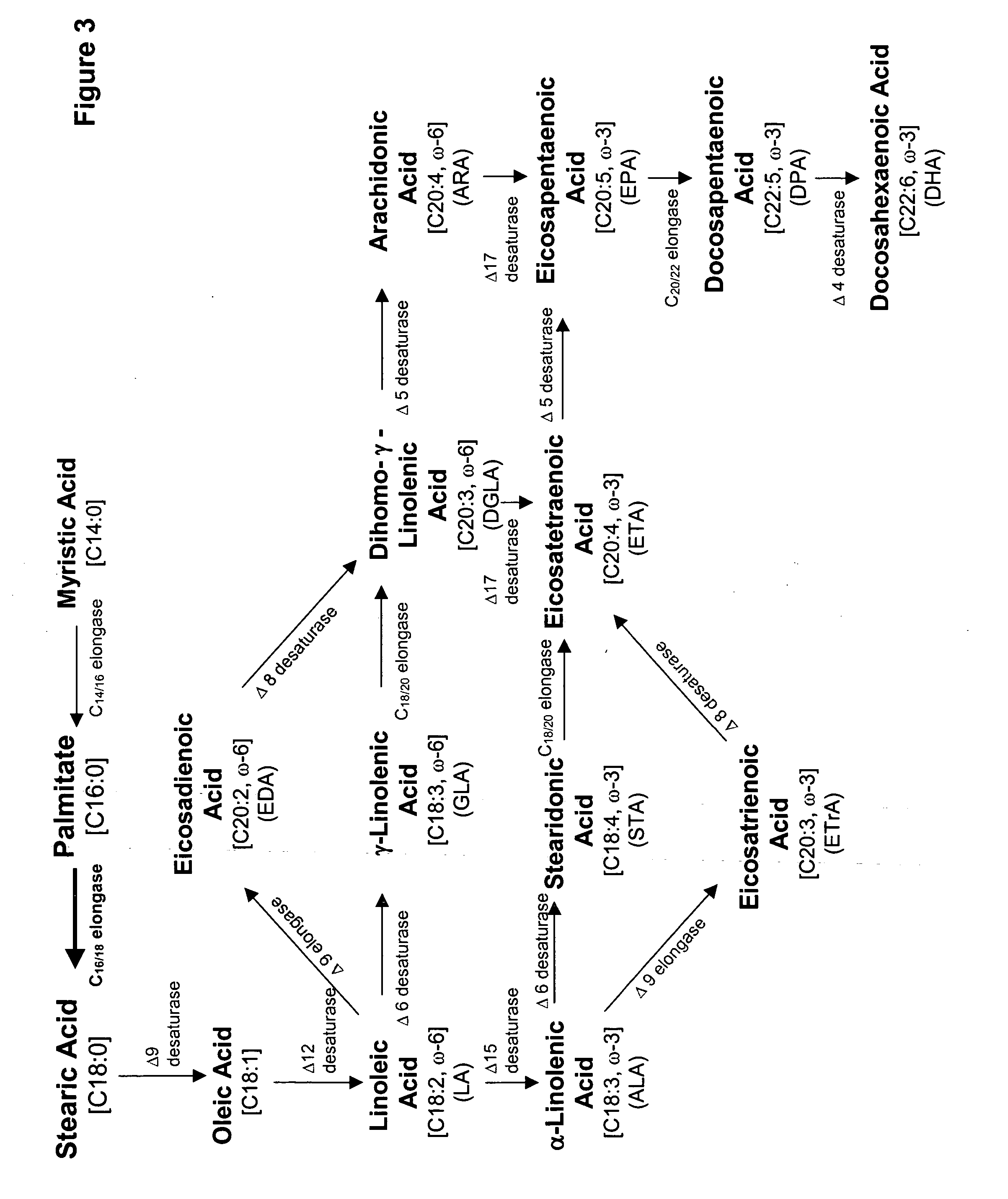

The present invention relates to a fungal C16 / 18 fatty acid elongase that is able to catalyze the conversion of palmitate (16:0) to stearic acid (18:0). Specifically, the nucleotide sequence of a Mortierella alpina C16 / 18 fatty acid elongase is provided (designated as “ELO3”). Methods of increasing microbial oil production, increasing carbon flux into the polyunsaturated fatty acid biosynthetic pathway and increasing the content of polyunsaturated fatty acids by over-expression of the C16 / 18 fatty acid elongase are described herein. Most desirably, the substrate specificity of the instant ELO3 will be particularly useful to enable accumulation of long-chain polyunsaturated fatty acids in oleaginous yeast, such as Yarrowia lipolytica.

Owner:DUPONT US HLDG LLC

Mortierella alpina C16/18 fatty acid elongase

ActiveUS20070087420A1Speed up the conversion processIncreased PUFA contentSugar derivativesBacteriaMicrobial oilNucleotide

The present invention relates to a fungal C16 / 18 fatty acid elongase that is able to catalyze the conversion of palmitate (16:0) to stearic acid (18:0). Specifically, the nucleotide sequence of a Mortierella alpina C16 / 18 fatty acid elongase is provided (designated as “ELO3”). Methods of increasing microbial oil production, increasing carbon flux into the polyunsaturated fatty acid biosynthetic pathway and increasing the content of polyunsaturated fatty acids by over-expression of the C16 / 18 fatty acid elongase are described herein. Most desirably, the substrate specificity of the instant ELO3 will be particularly useful to enable accumulation of long-chain polyunsaturated fatty acids in oleaginous yeast, such as Yarrowia lipolytica.

Owner:DUPONT US HLDG LLC

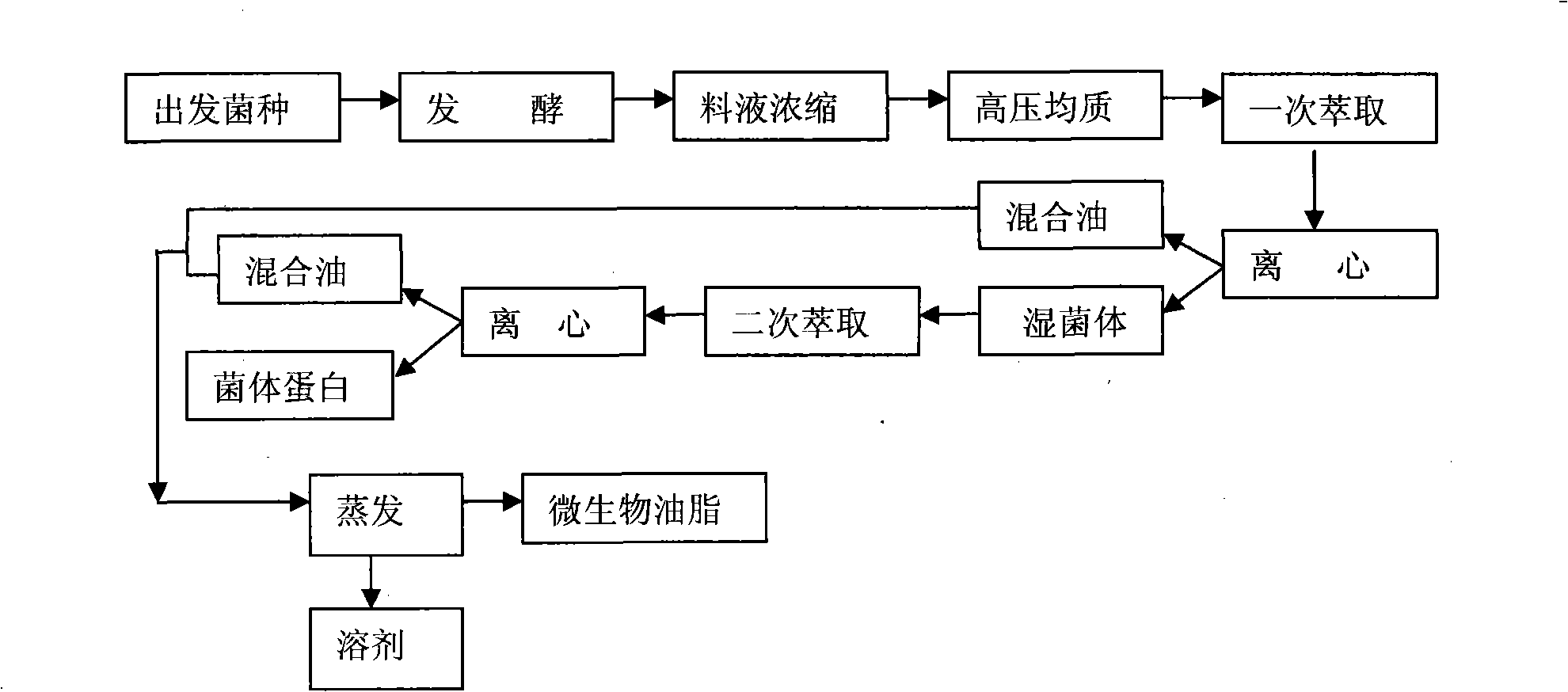

Separation and extraction method of microbial oil

InactiveCN101323865AHigh yieldSimple and fast operationMicroorganism based processesFermentationMicrobial oilOrganic solvent

A method for separating and extracting microbial oil comprises the following steps: (1) microbial strains are inoculated for fermentation; (2) the obtained fermentation liquor is concentrated to remove 45 percent to 55 percent of water in the fermentation liquor so as to obtain the concentrated fermentaton liquor; (3) the concentrated fermentation liquor is fed into a high pressure homogenizer with the pressure of 70 to 130MPa to carry out cell-crushing; (4) an extractive solvent is added, and after two times of extraction, the upper layer organic solution phase is separated and collected to obtain mixed oil; and (5) at last, the solvent in the mixed oil is vaporized and recycled to obtain the microbial oil. The method combines the fermented solution concentration with the high pressure homogenization technology to carry out cell crushing, and then adopts the two-time extraction to collect the contained oil and obtain bacterial protein accordingly. The process improves the original method which needs the steps, such as the separation of strains, drying, grinding and granulation, etc., thus greatly simplifying the technology, improving efficiency and reducing production cost. The method homogenizes the fermented solution under high pressure after concentration, which promotes the utilization rate of facilities, and reduces energy consumption.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

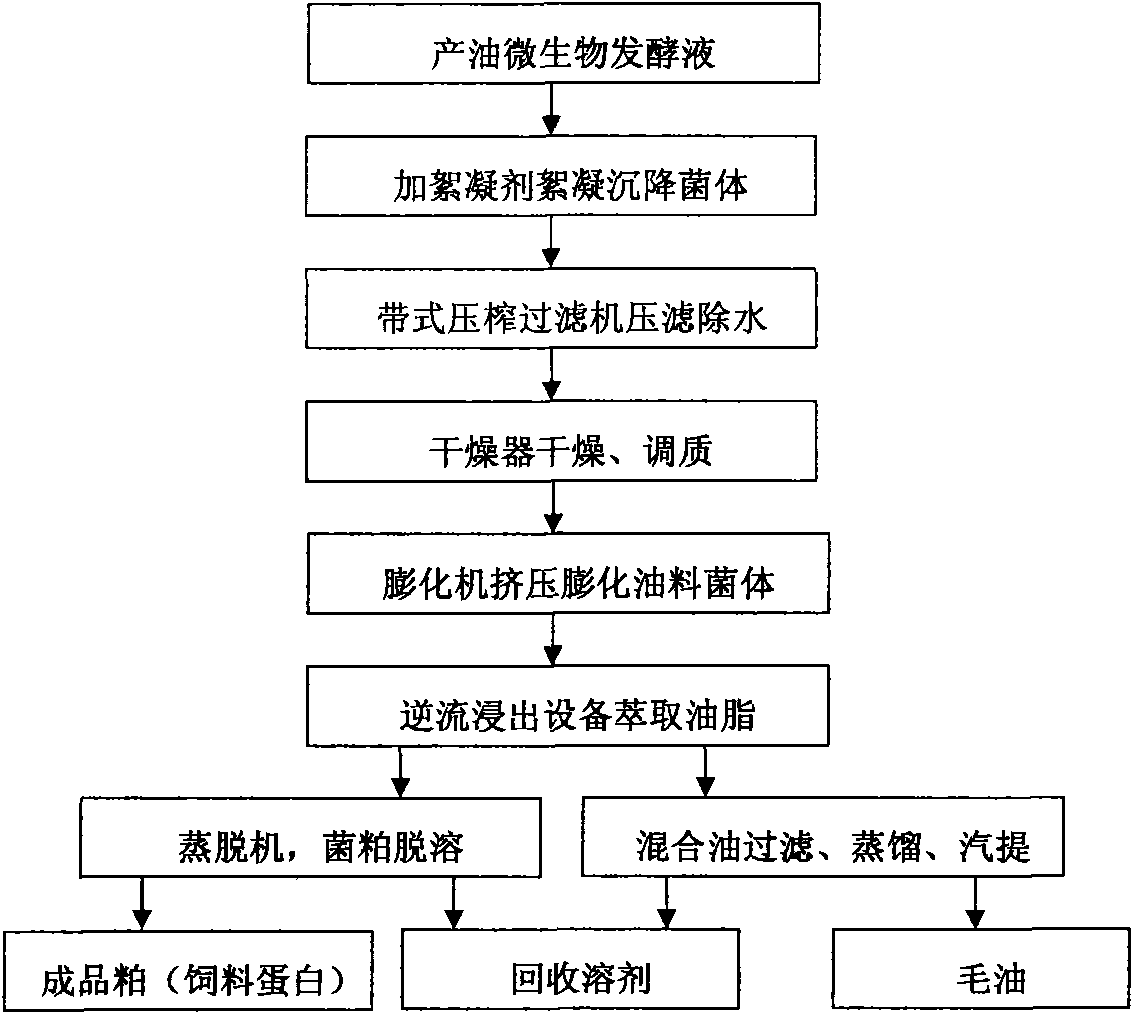

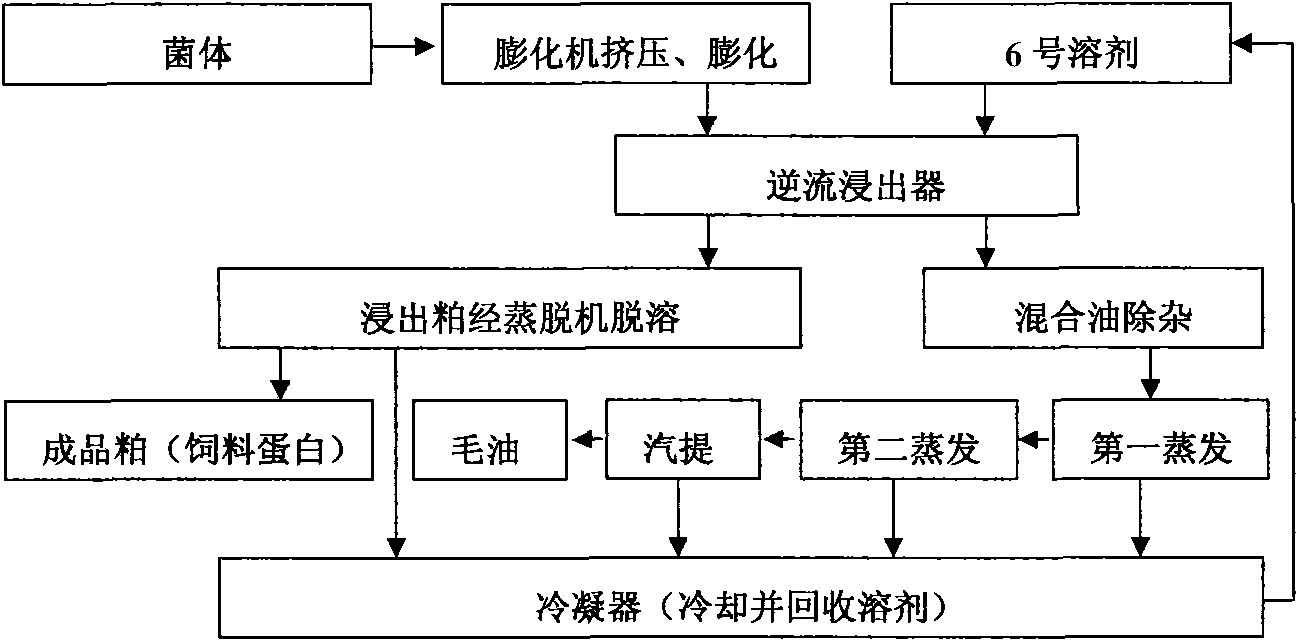

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

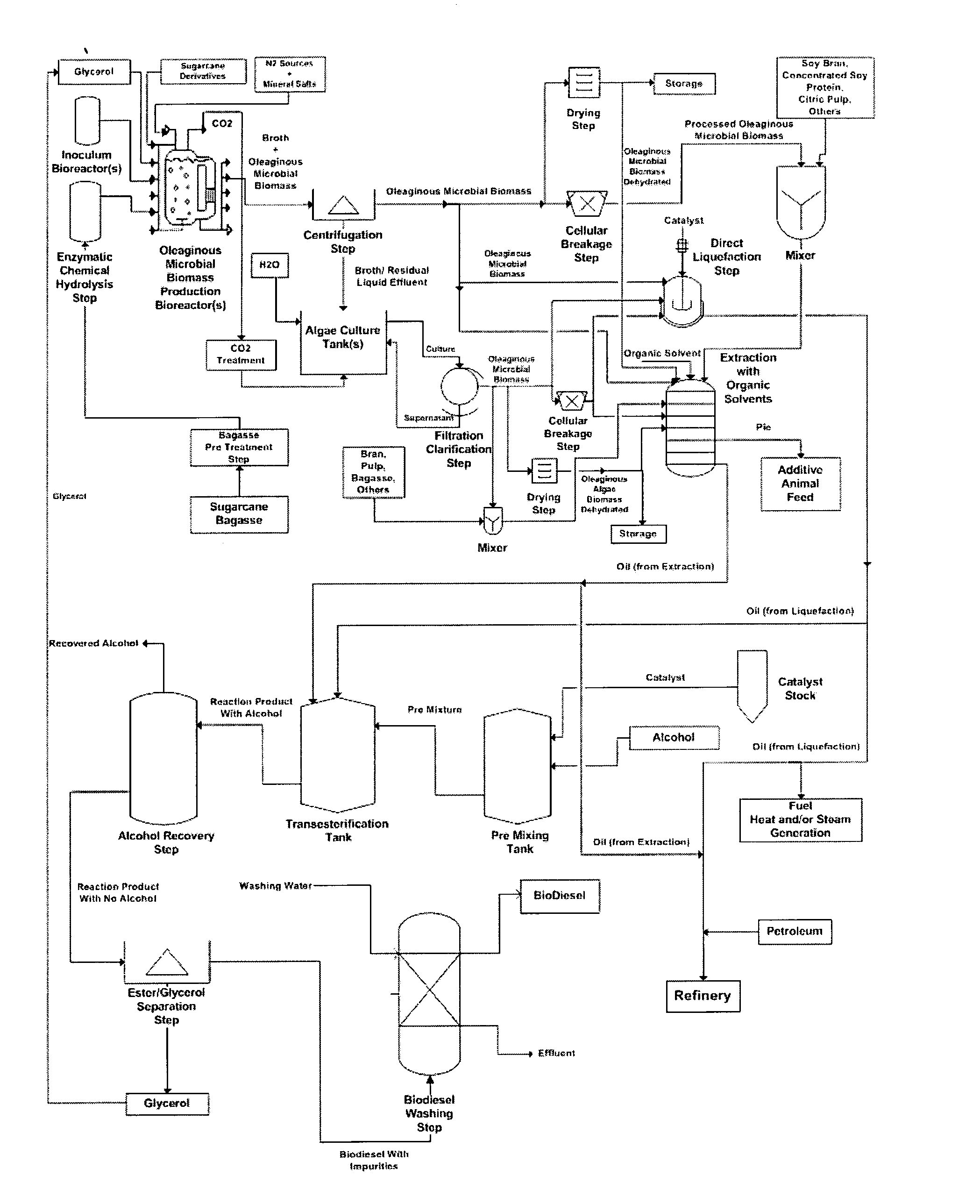

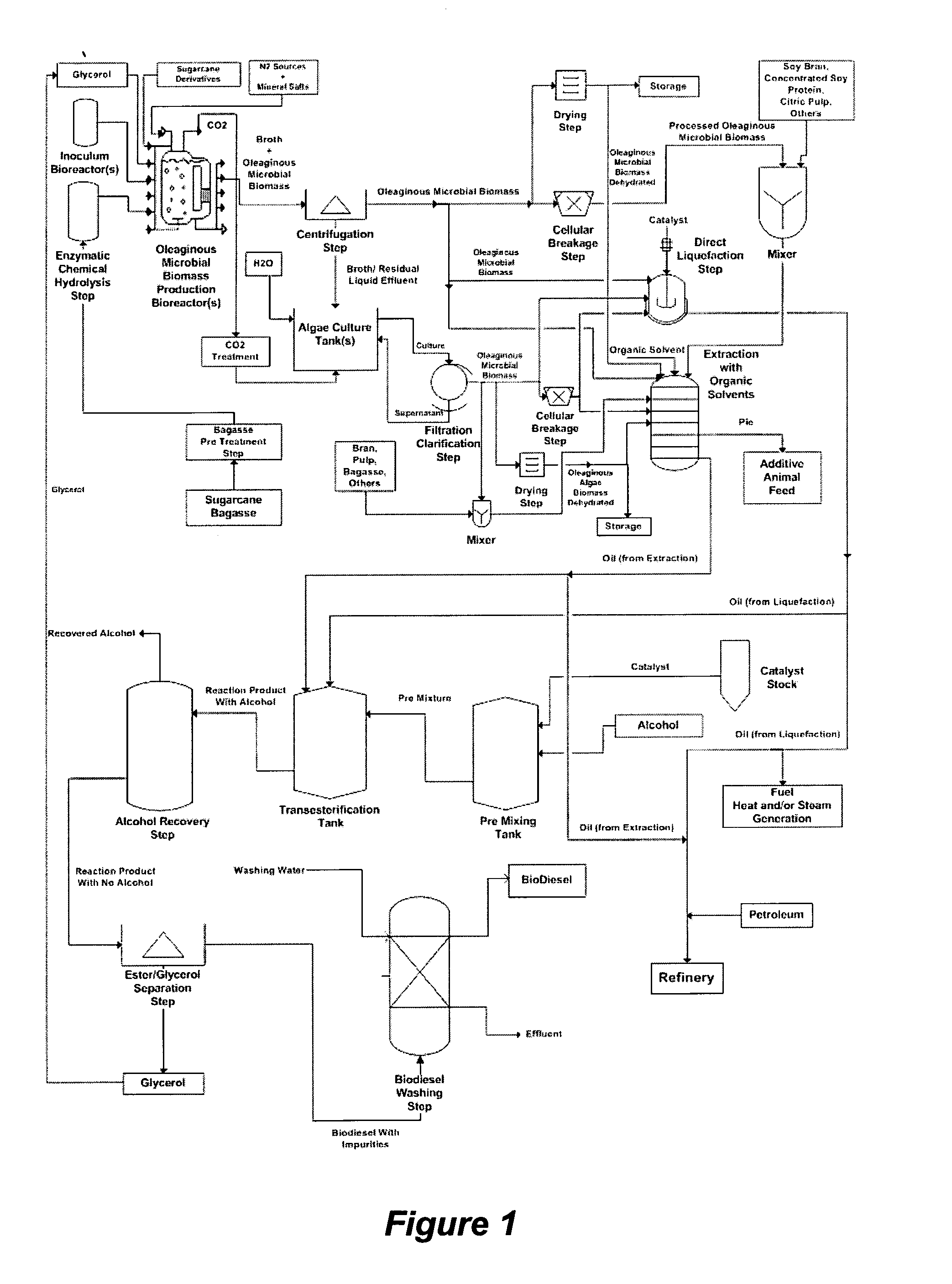

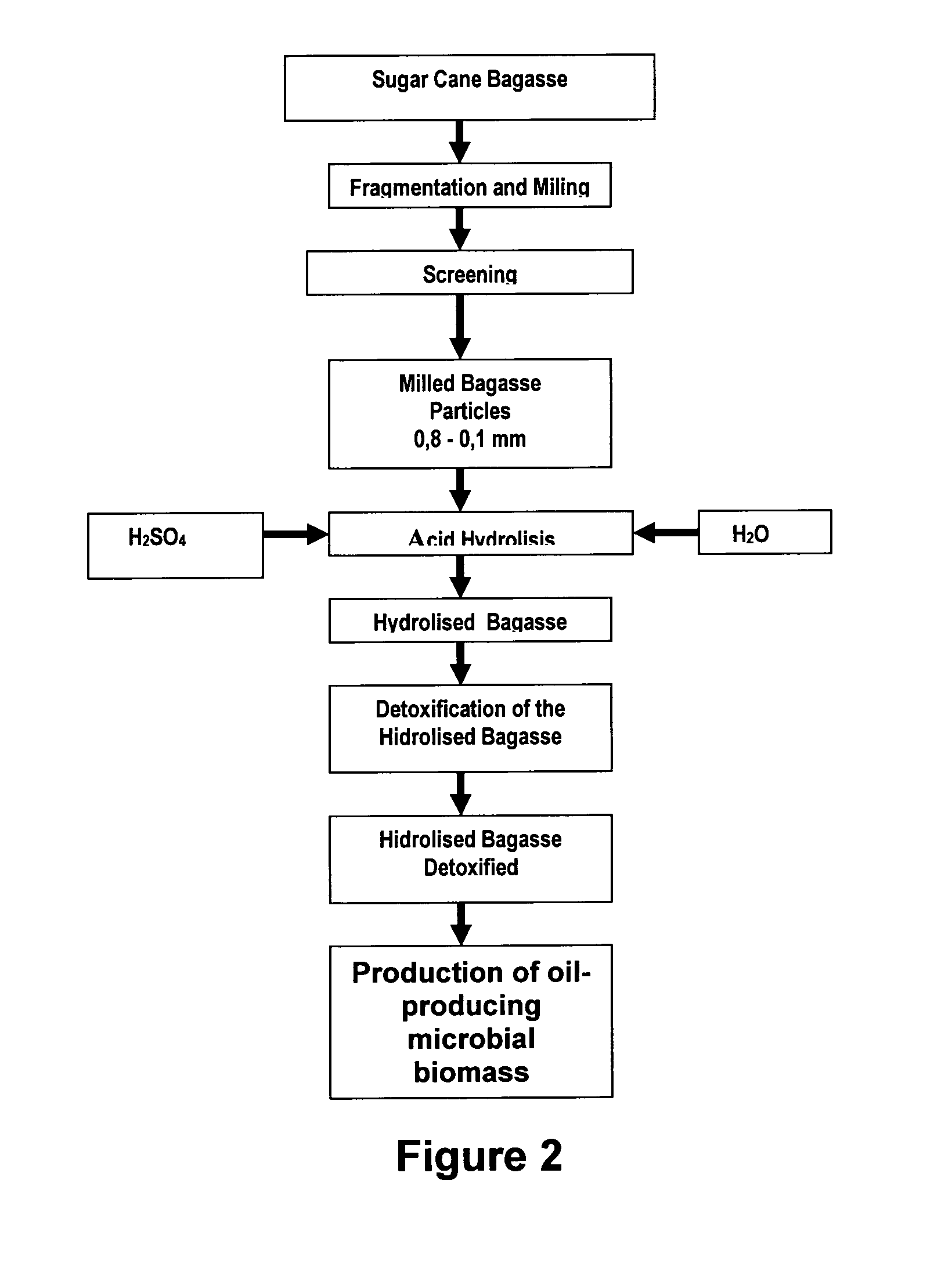

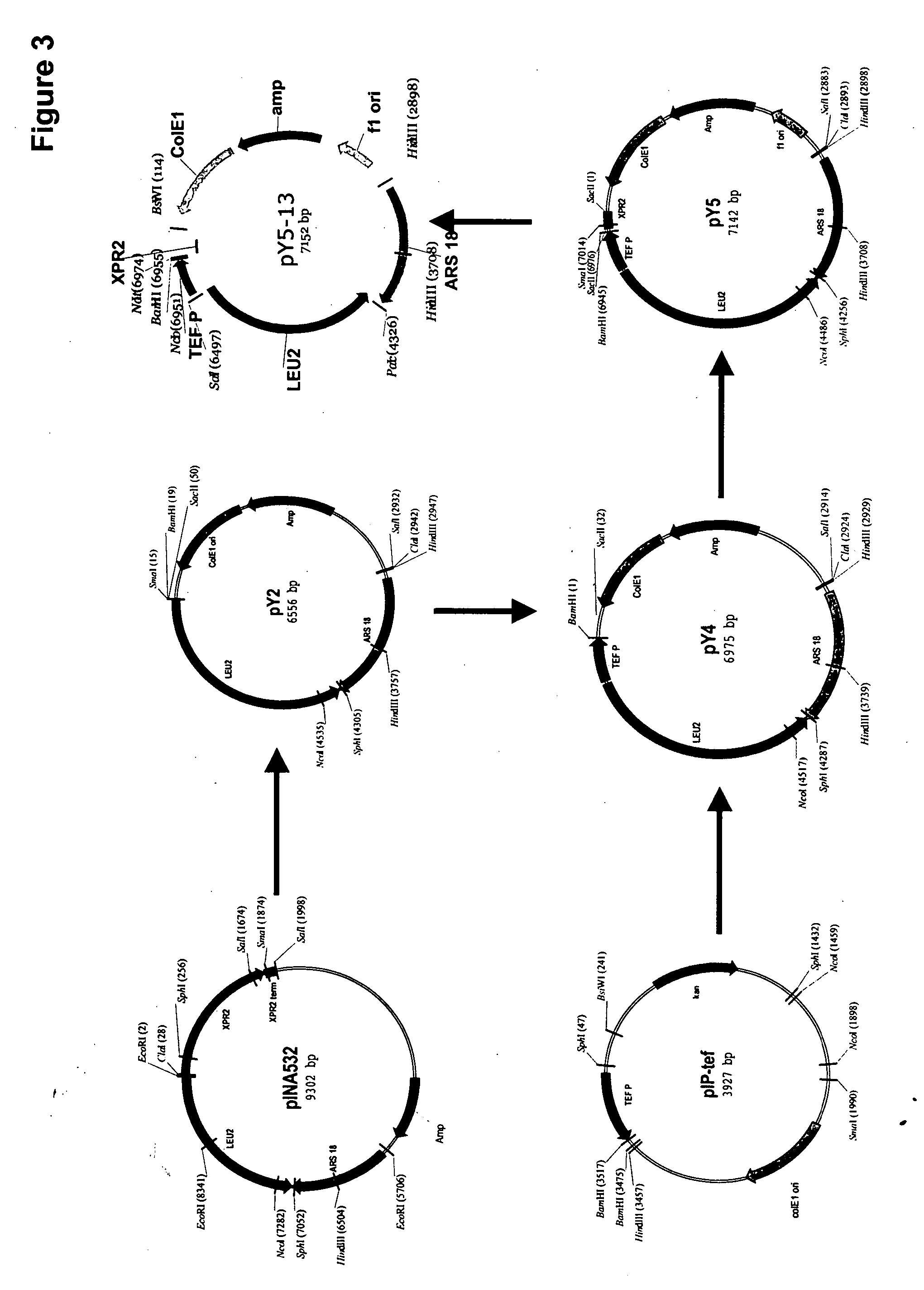

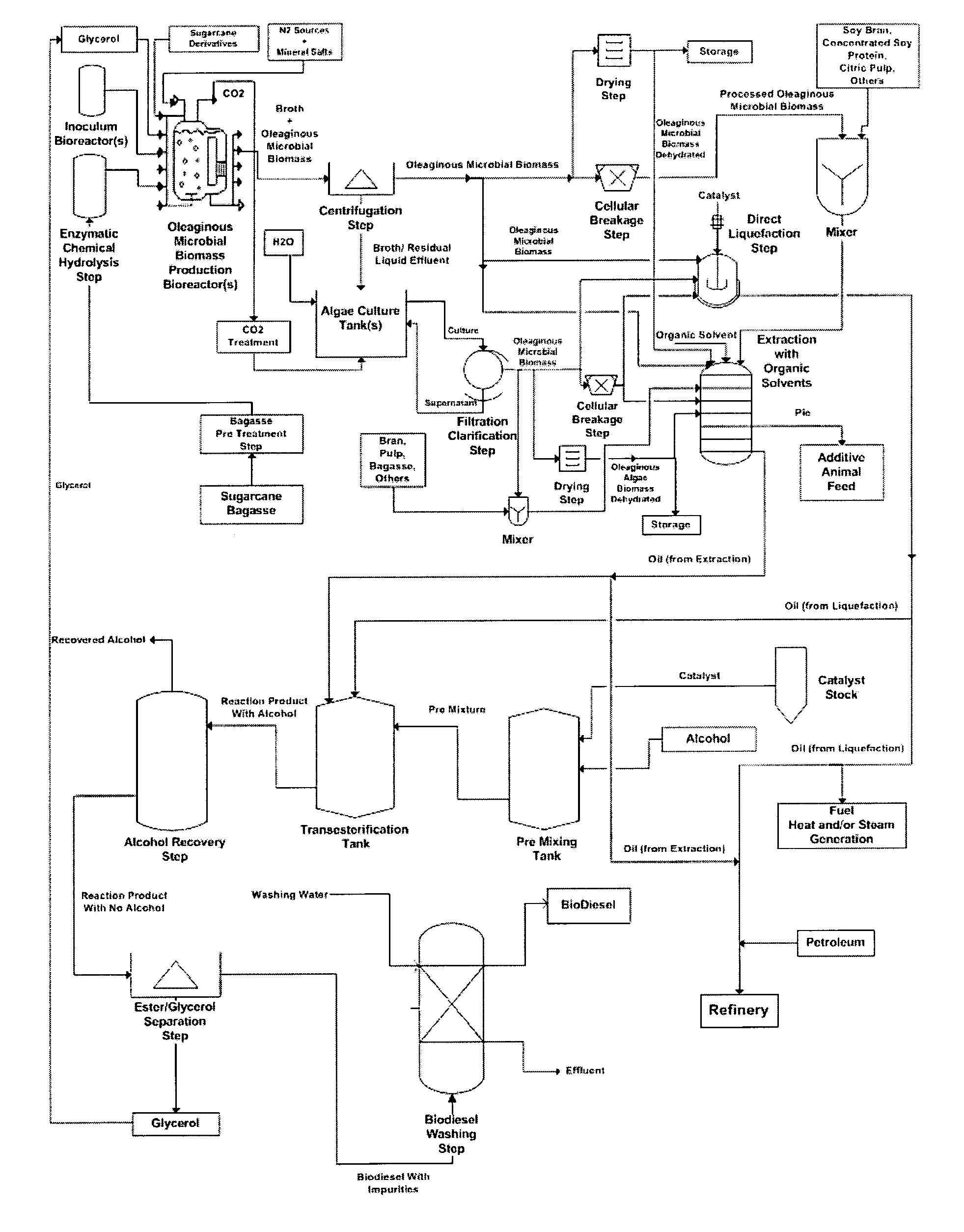

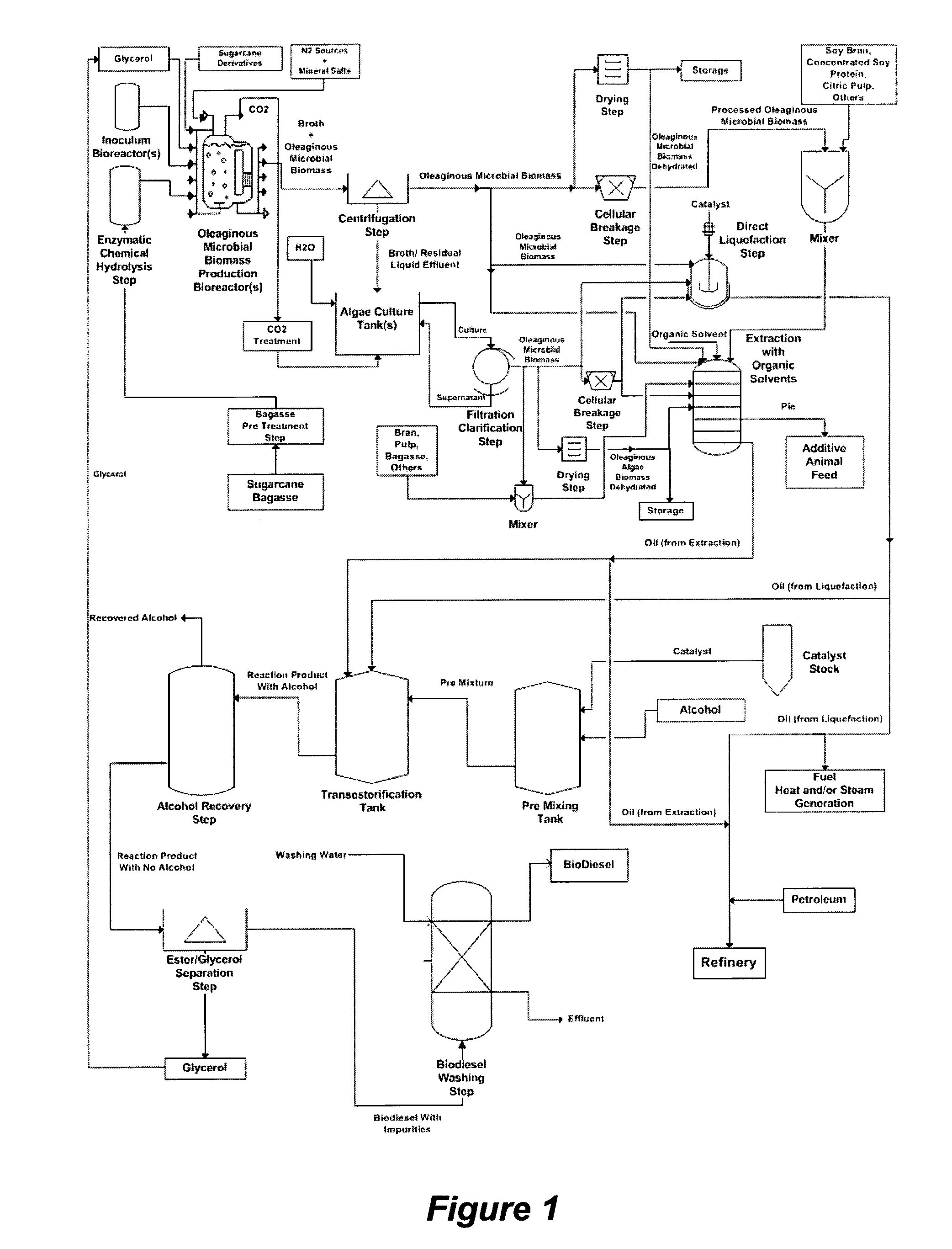

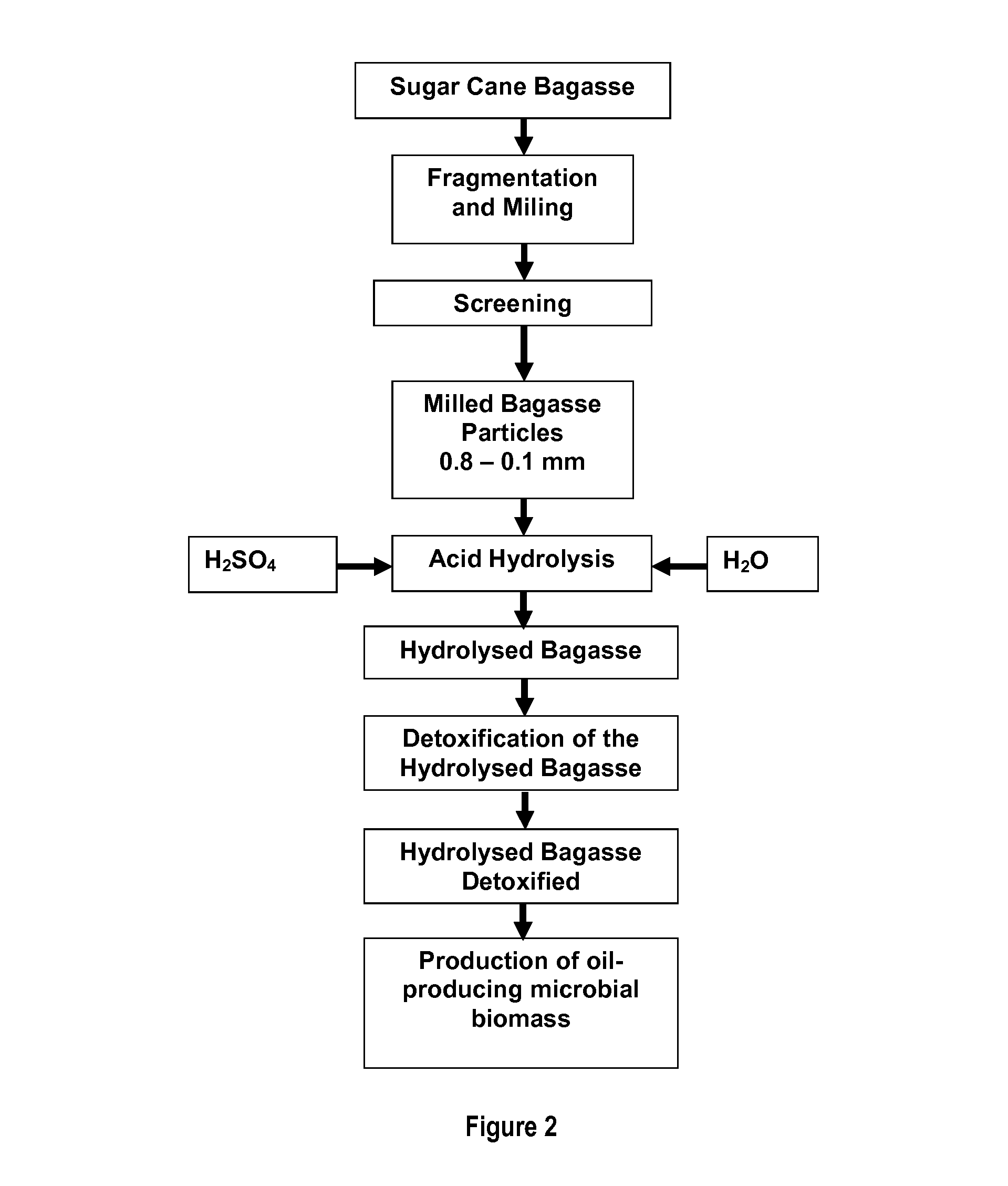

Process to produce biodiesel and/or fuel oil

The present invention refers to a process to produce biodiesel and / or fuel oil from microbial oilseed and / or algal biomass and / or from sugar cane residues and derivatives. The products according to the present invention are appropriate for direct use in motors and to generate energy or steam. The integrated process of the present invention comprises the use, as raw materials, of microbial oil-producing biomass obtained from sugar cane residues and derivatives, which is integrated with algal biomass and / or glycerol and are processed by steps of production of oil-producing microbial biomass from filamentous fungi and / or yeasts, steps of simultaneous production of algal biomass by fully using residues, CO2 and residual broth of said production of microbial biomass, as well as steps of extraction and transesterification of lipids contained in the biomass, with reuse of the residual glycerol thus produced. The process as disclosed deals with innovative and ecologically sustainable technology, not generating any kind of residue, also providing for the advantage of releasing considerable volumes of oxygen into the atmosphere.

Owner:OURO FINO SAUDE ANIMAL PARTICIPACOES SA

Acyltransferases for alteration of polyunsaturated fatty acids and oil content in oleaginous yeasts

Two acyltransferases are provided, suitable for use in the manufacture of microbial oils enriched in omega fatty acids in oleaginous yeast (e.g., Yarrowia lipolytica). Specifically, the genes encoding phophatidylcholine-diacylglycerol acyltransferase (PDAT) and diacylglycerol acyltransferase (DGAT2) have been isolated from Y. lipolytica. These genes encode enzymes that participate in the terminal step in oil biosynthesis in yeast. Each is expected to play a key role in altering the quantity of polyunsaturated fatty acids produced in oils of oleaginous yeasts.

Owner:EI DU PONT DE NEMOURS & CO

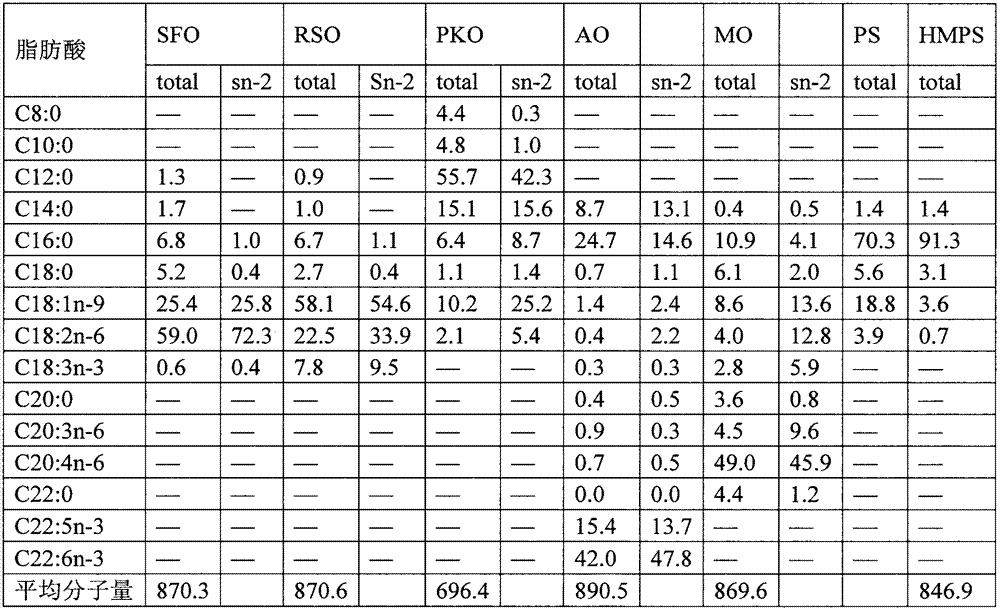

Preparation method of human milk fat substitute

ActiveCN102845537AIncrease contentReduced total palmitic acid contentEdible oils/fatsFood preparationMicrobial oilButterfat

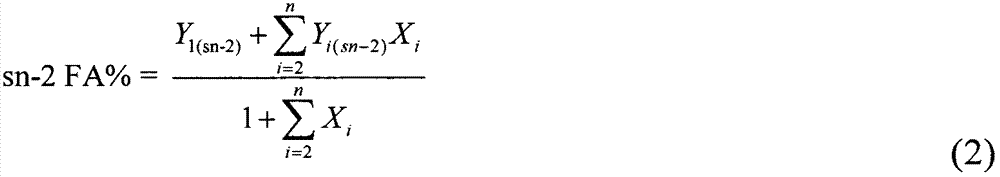

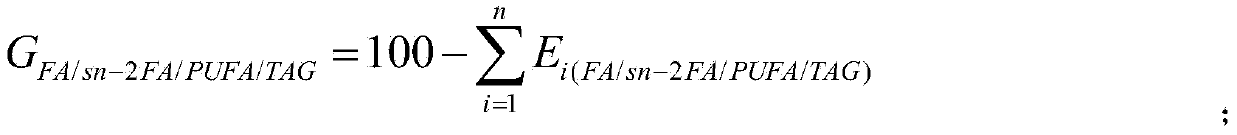

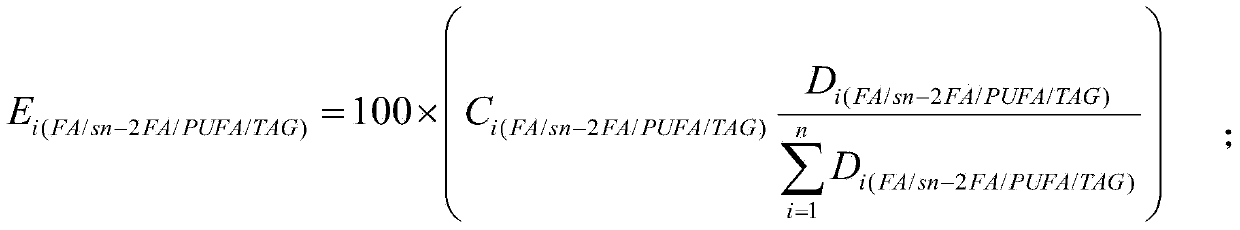

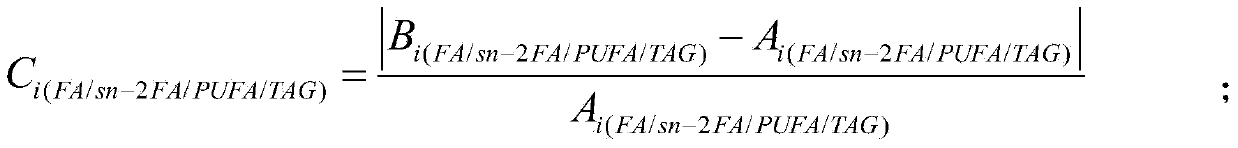

The invention relates to a preparation method of a human milk fat substitute. The method comprises the steps of: step 1) conducting an acid hydrolysis reaction on a raw material of high melting palm stearin subjected to chemical interesterification and alcohol leaching, and an acyl donor of rapeseed oil fatty acid by using Lipozyme RM IM as a catalyst, so as to reduce the total palmitic acid content and increase the relative content of site-two palmitic acid of the raw material; and step 2) deacidifying an intermediate product; and at the same time, calculating the amount of sunflower seed oil, rapeseed oil, palm kernel oil, algae oil and microbial oil added to the intermediate product according to the composition and distribution of fatty acids in human milk fat, by a grease adding model, so as to ensure composition and distribution of fatty acids in a final product meeting requirements of a human milk fat substitute, as well as realize a maximum addition amount. The invention adopts two steps to produce the human milk fat substitute, in order to reduce usage amount of free fatty acids in the acid hydrolysis reaction; meanwhile, two times of oil additions increase yield. Therefore, the invention greatly reduces the cost, and achieves a more than doubled yield compared with a similar products with a similar cost.

Owner:JIANGNAN UNIV

Preparation method of human milk substitute fat based on triglyceride composition and evaluating method of human milk substitute fat

The invention discloses a preparation method of a human milk substitute fat based on a triglyceride composition and an evaluating method of the human milk substitute fat. The preparation method comprises the following steps: with lard oil as a base raw material, adding sunflower seed oil, canola oil, palm kernel oil, palm oil, microbial oil and algae oil in the lard oil according to a certain proportion in accordance with composition and distribution of fatty acid of human milk fat to obtain mixed oil similar to the human milk fat on the composition and distribution of the fatty acid; and by adopting specific lipase at 1 and 3 sites as catalysts, and similarities between of mixed oil and human milk fat in aspects of composition and distribution of the fatty acid, composition of polyunsaturated fatty acids and triglyceride as indexes, adjusting the composition of the triglyceride of the mixed fat by using a manner of lactone exchanging to obtain a product with relatively high similarity to the human milk fat on the composition of the triglyceride. The human milk substitute fat is obtained by adopting physical mixing and enzyme catalysis ester exchange manners, the production cost can be greatly reduced, and the relatively high similarity is achieved for the product and the human milk fat.

Owner:无锡益语科技发展有限公司

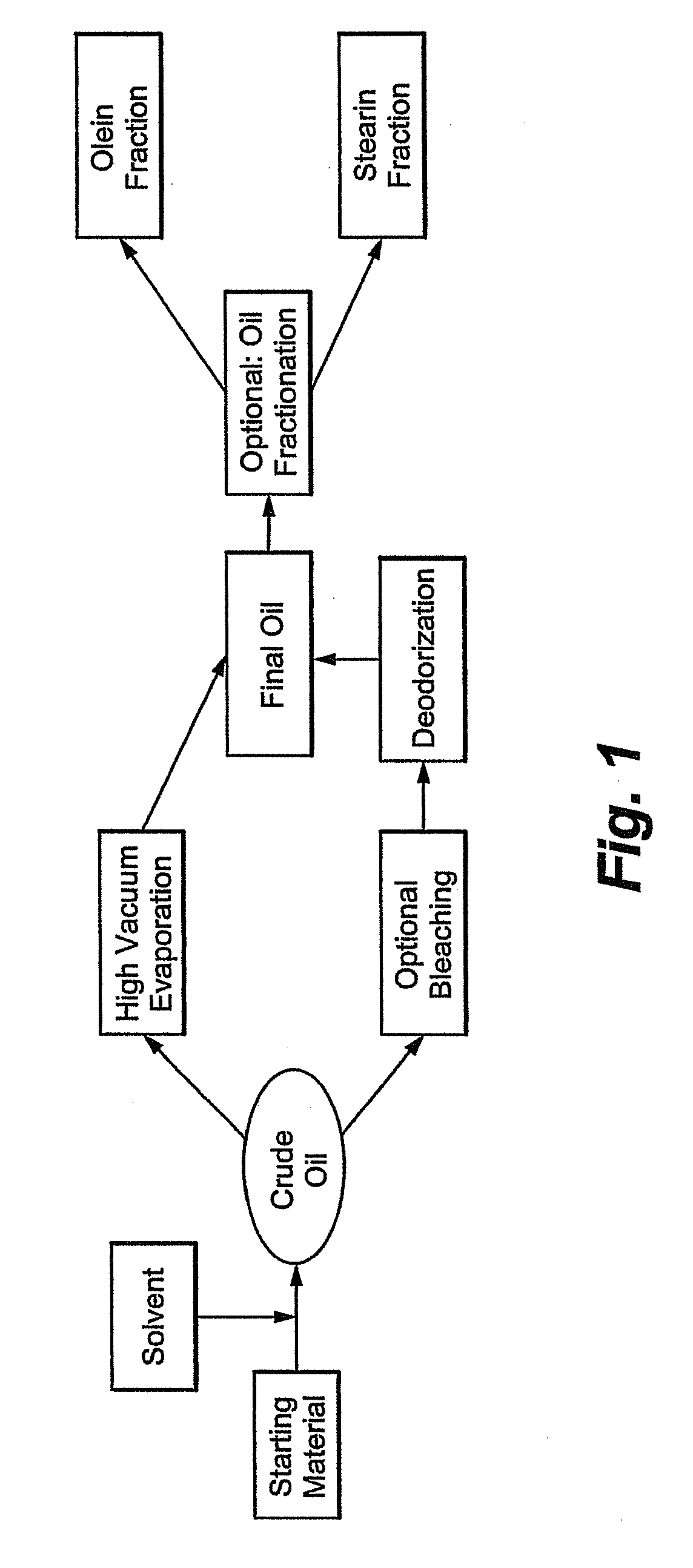

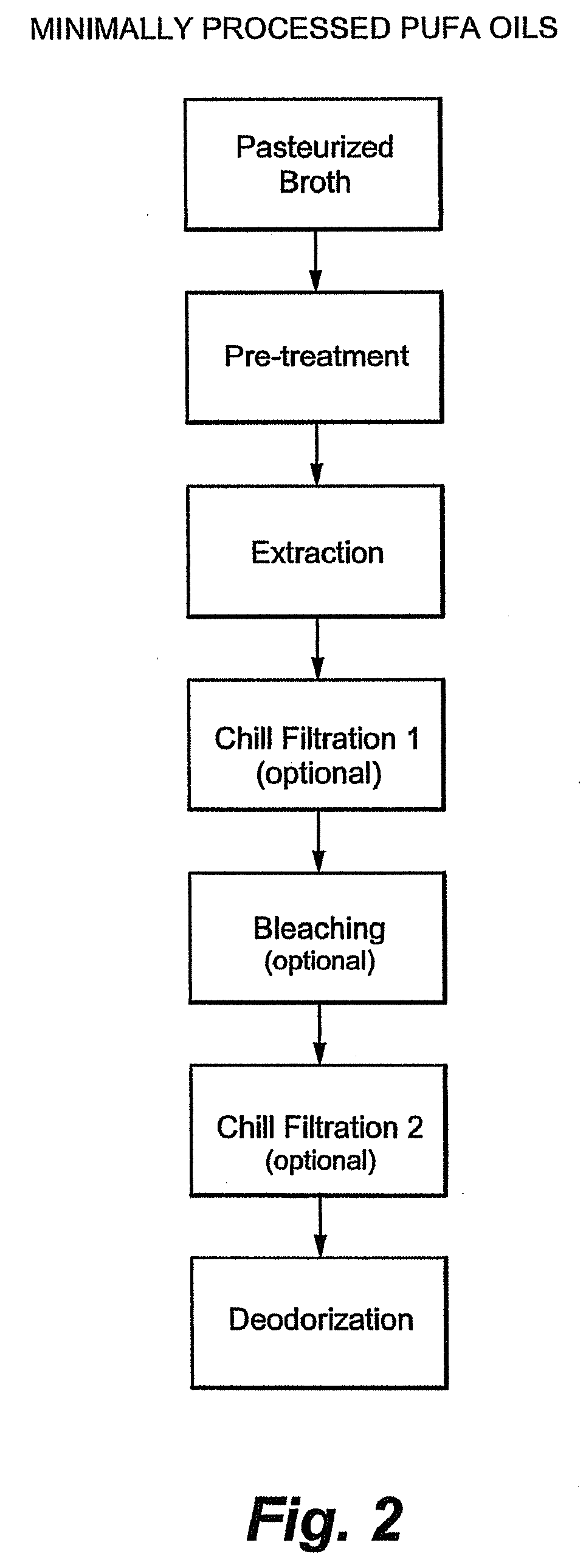

Polyunsaturated Fatty Acid-Containing Oil Product and Uses and Production Thereof

InactiveUS20080026103A1Function increaseNervous disorderFatty-oils/fats/waxes solidificationMicrobial oilFiltration

Owner:DSM IP ASSETS BV

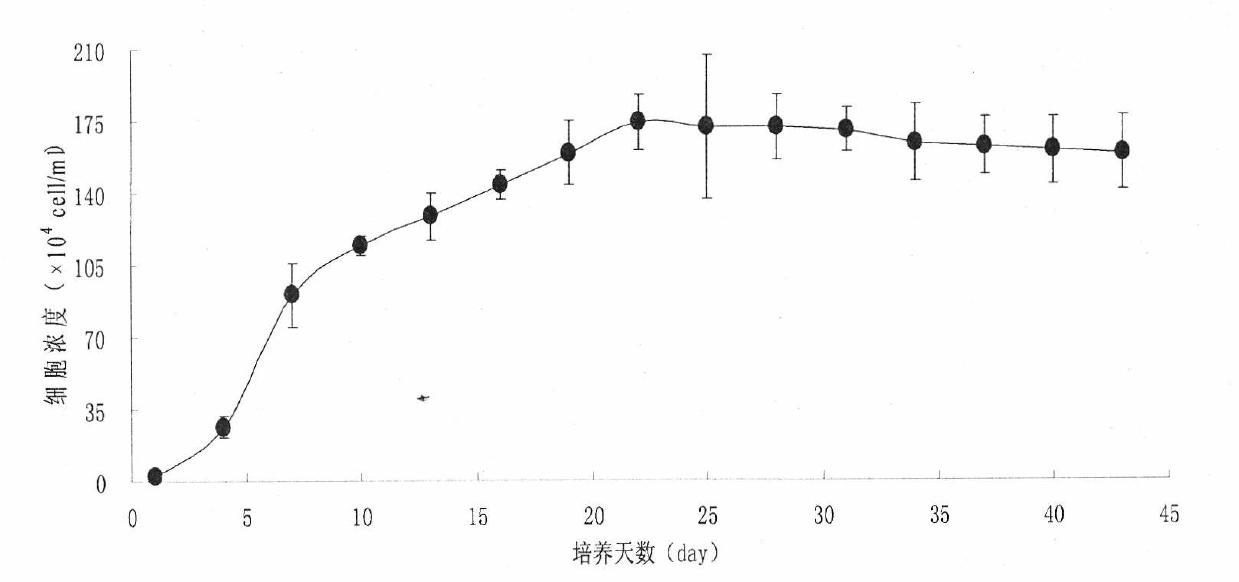

Method for producing oil by mixed culture of yeast and alga

InactiveCN102080119AIncrease productionLow costMicroorganism based processesFermentationOil and greaseHigh concentration

The invention discloses a method for producing oil by mixed culture of yeast and alga. In the method, industrial waste water is used as a culture medium for the mixed culture of yeast and alga, so as to produce microbial oil. The method is characterized in that compared with the single culture of two microorganisms, by the mixed culture of yeast and alga, the chemical oxygen demand (COD) of the waste water can be more effectively degraded and the yeast and alga are also promoted to reliably utilize the nutrient components in the industrial waste water, thereby being beneficial to the synthesis of the oil. The method for producing the microbial oil has the advantages of low cost and high practicable value, is simple to operate, namely, the pollution of high-concentration industrial waste water on environment can be reduced, and waste materials are changed into valuable things so as to produce shortage product oil, thereby achieving the purpose of recycling the waste materials.

Owner:BEIJING UNIV OF CHEM TECH

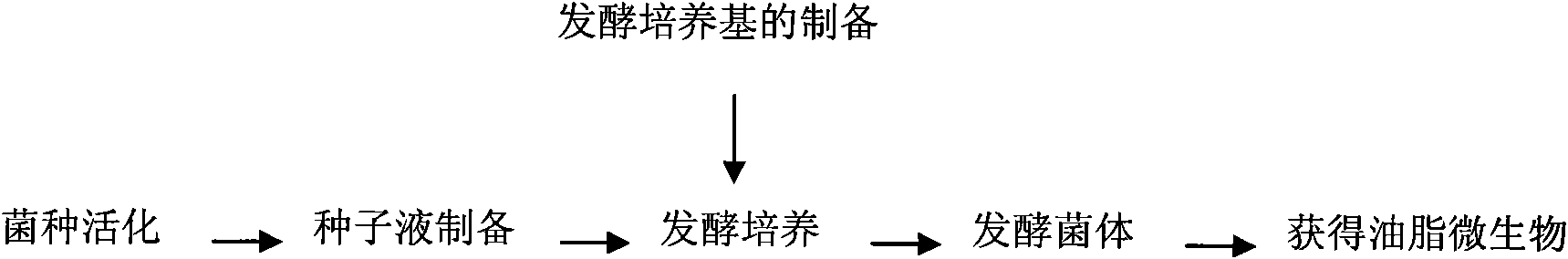

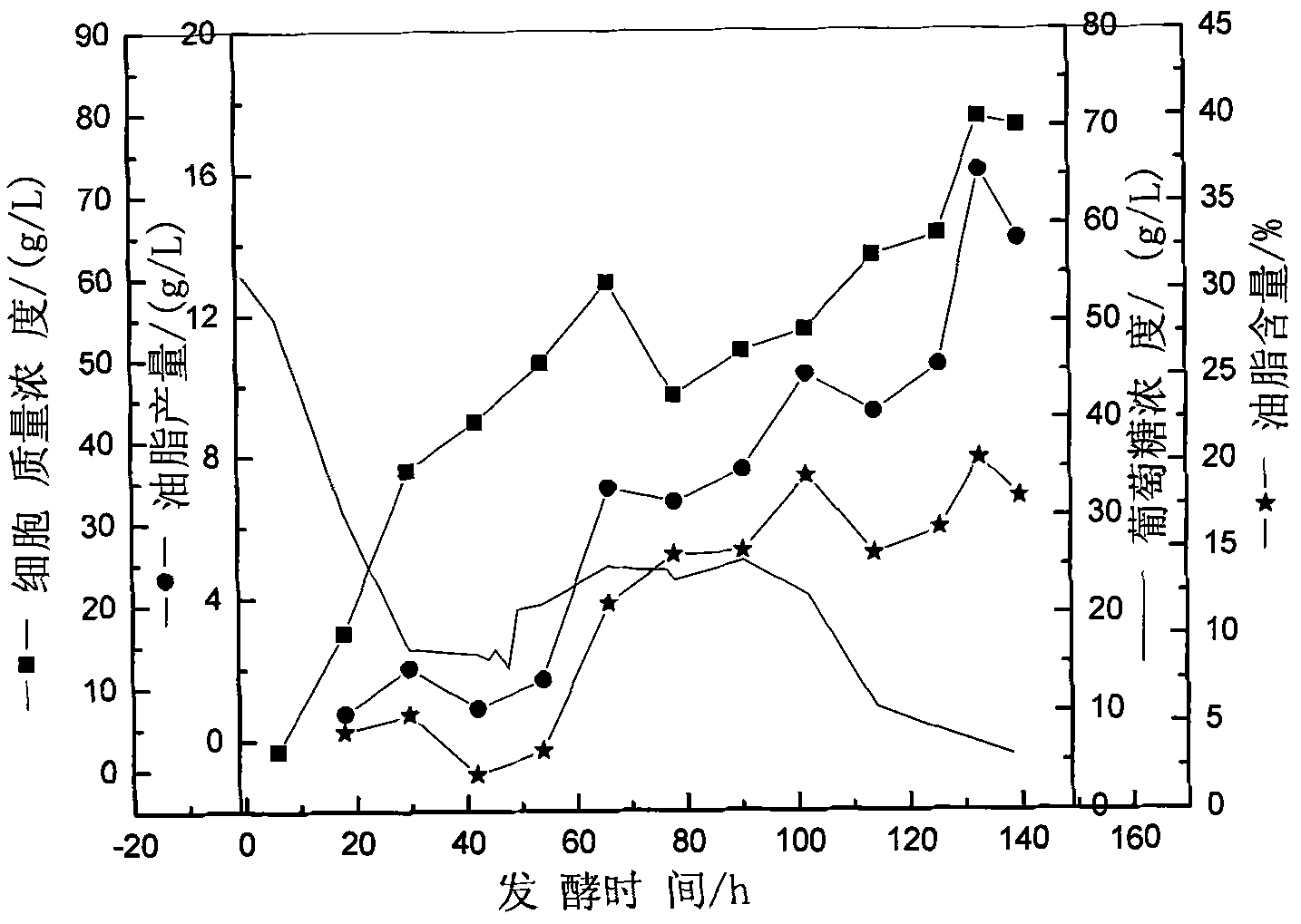

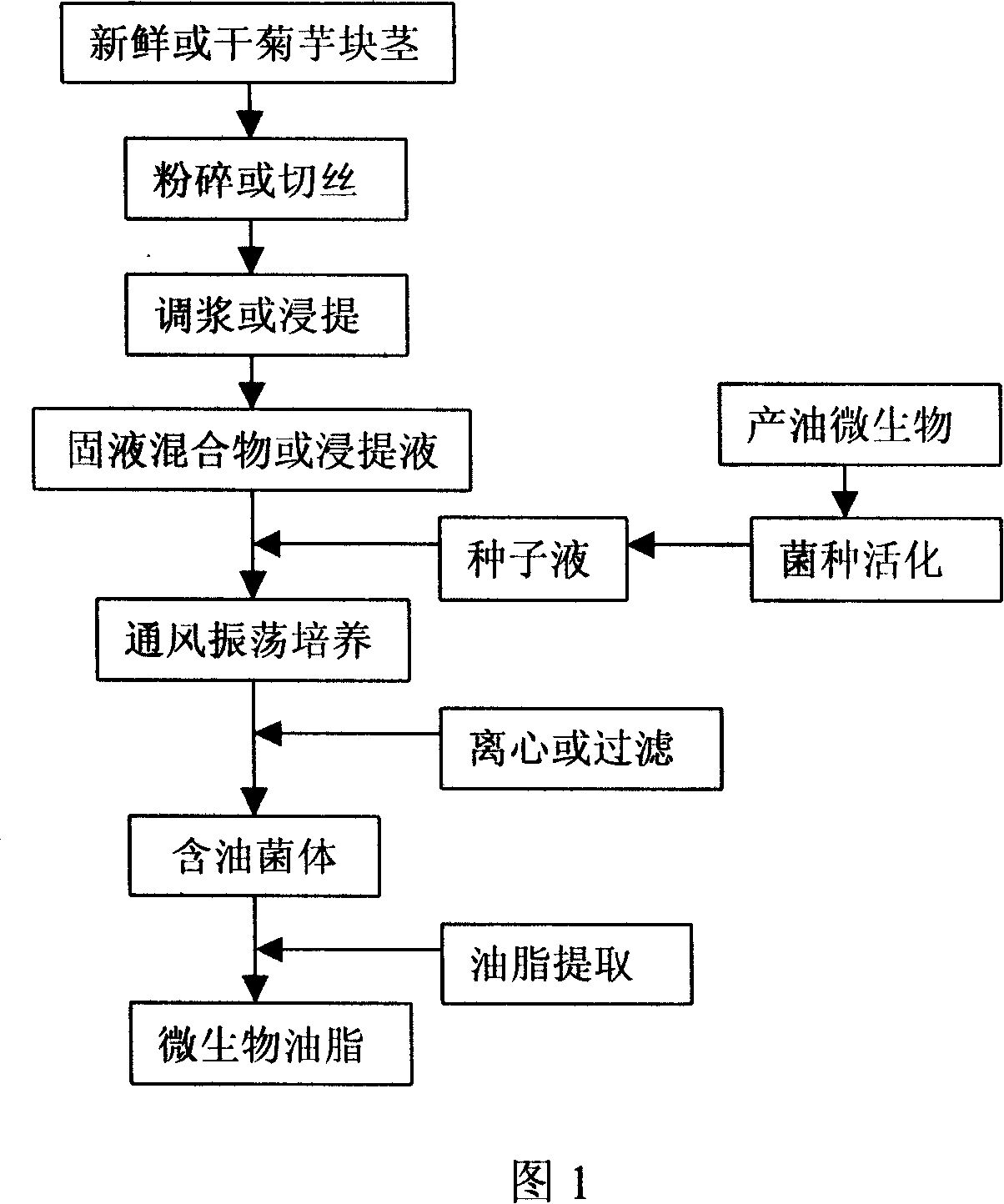

Process for preparing microbe oil

InactiveCN101108997AIncrease productionSimple processFatty acid hydrogenationFatty acid esterificationMicrobial oilOil and grease

The invention relates to a microbial oil preparation method, in particular to a microbial oil preparation method taking jerusalem artichoke tubers as the raw material. After wash, crush or slicing, pulp conditioning or water extraction, the same liquid mixture or extracted fluid is gained; an oil-producing microorganism live bacteria solution is inoculated to a sterilizated solid-liquid mixture or the extracted fluid, is cultivated by ventilation shake, and is fermented until the concentration of total reducing sugar in fermenting mash decreases below 1 per cent; the oil-containing thallus is collected, and the microbial oil is extracted by a regular organic solvent extraction method. The invention can decreases the microbial oil raw material cost, features the simple technique and high oil yield and 5.0 to 10.0g dry fungus and 2.5 to 5.0g microbial oil can be gained from per 100g fresh jerusalem artichoke tubers (with 70 per cent to 80 per cent water content).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for extracting microbial oil

ActiveCN101985637AEfficient extractionHigh extraction rateMicroorganism based processesFatty-oils/fats productionOil and greaseMicrobial oil

The invention provides a method for extracting microbial oil, which comprises the following steps: (1) allowing an oil-producing microbial strain to ferment and obtaining fermentation liquor; (2) regulating the pH value of the fermentation liquor obtained by the step (1) to 3.5 to 4.5, and allowing microbes to autolyze; (3) extracting by adding an extracting solvent into the fermentation liquor obtained by the step (2), and collecting upper mixed oil; (4) extracting again by adding the extracting solvent into the lower solution obtained by the extraction and separation in the step (3), and collecting upper mixed oil; and (5) mixing the upper mixed oil obtained by the step (3) and the upper mixed oil obtained by the step (4), distilling, recovering the extracting solvent and obtaining the microbial oil product. The method can extract the oil in the cells of microbes effectively, has high oil extraction rate and high oil extraction efficiency, makes process simple and is favorable for large-scale production.

Owner:CABIO BIOTECH WUHAN CO LTD

Microbial oil extraction method

The invention discloses a microbial oil extraction method, and belongs to the field of bioengineering downstream technology. Oil-producing microorganism fermented liquor is used as a raw material, and is subjected to enzymolysis and extraction by organic solvent to obtain the microbial oil, wherein the extraction rate is up to 100% maximally. The microbial oil extraction method disclosed by the invention does not need concentration of the fermented liquor, recovery of strains, drying of the strains and other pretreatment operations, has mild enzymolysis conditions, short treatment time, low extraction temperature, high extraction rate, low requirements on equipment and low toxicity of the used organic solvent, greatly reduces the power and energy consumptions in the microbial oil extraction process, lowers the process cost and alleviates the environmental pollution and damage to human health. According to the method, a new way is provided for mass production and extraction of the microbial oil.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process to produce biodiesel and/or fuel oil

The present invention refers to a process to produce biodiesel and / or fuel oil from microbial oilseed and / or algal biomass and / or from sugar cane residues and derivatives. The products according to the present invention are appropriate for direct use in motors and to generate energy or steam. The integrated process of the present invention comprises the use, as raw materials, of microbial oil-producing biomass obtained from sugar cane residues and derivatives, which is integrated with algal biomass and / or glycerol and are processed by steps of production of oil-producing microbial biomass from filamentous fungi and / or yeasts, steps of simultaneous production of algal biomass by fully using residues, CO2 and residual broth of said production of microbial biomass, as well as steps of extraction and transesterification of lipids contained in the biomass, with reuse of the residual glycerol thus produced. The process as disclosed deals with innovative and ecologically sustainable technology, not generating any kind of residue, also providing for the advantage of releasing considerable volumes of oxygen into the atmosphere.

Owner:OURO FINO SAUDE ANIMAL PARTICIPACOES SA

Method for strengthening indigenous microbes and improving oil recovery by improving microbial florae in oil deposit

The invention provides a method for strengthening indigenous microbes and improving oil recovery by improving microbial florae in an oil deposit. The method comprises the following steps of: (1) analyzing composition of microbial florae in the oil deposit; and (2) introducing exogenous microbes into the oil deposit according to an analysis result, so that the oil deposit with the introduced exogenous microbes contains the following microbes: hydrocarbon-oxiding bacteria, fermentative bacteria, heterotrophic bacteria, methanogenic bacteria, sulphate-reducing bacteria, and nitrate-reducing bacteria. Due to the adoption of the method provided by the invention, by adding the exogenous microbes into the oil deposit, the structure of the microbial florae in the oil deposit is improved, the function of the microbial florae in the oil deposit is strengthened, as a result, the oil displacement effect is improved, and the application range of microbial oil recovery technology is enlarged.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Hyposmosis oil pool microbial oil recovery method

ActiveCN101699026AImprove recoveryImprove seepage capacityMicroorganism based processesFluid removalMicrobial oilRecovery method

The invention relates to a hyposmosis oil pool microbial oil recovery method, comprising the following steps: (1) fracturing production is carried out to the hyposmosis oil pool; (2) microbes and nutrients are filled in an oil layer from cracks formed by fracturing to carry out microbial oil recovery. Compared with the prior art, the oil pool fracturing and the microbial oil recovery are combined together, so as to increase the action range of the microbes in the hyposmosis oil pool on one hand, on the other hand, the metabolic action of the microbes is helpful to keeping seeping channels to be open at the fracturing position, thereby promoting stable output of oil wells and prolonging steady yield time of oil fields; therefore, the invention is a scientific, economic and effective hyposmosis oil pool microbial oil recovery method.

Owner:DAQING HUALI ENERGY BIOLOGICAL TECH

Method for producing diglyceride

InactiveCN1438308ASolve the problem of excessive viscosityGood compatibilityFatty acid esterificationPreparation by ester-hydroxy reactionMicrobial oilAlcohol

The invention refers to a method of producing diglyceride, mixing lower alcohol and triglyceride to react under fixed lipase, separating reaction product to get the diglyceride, and at the same time getting the by-product, fatty acid lower alcohol ester; the lower alcohol is monobasic alcohol, C number less than 3, the triglyceride is refined animal oil, or vegetable oil, or microbial oil or their mixture, and the fixed liphase is fixed on carrier by physical adsorption, and covalent cross-linking.

Owner:广东润隆再生资源股份有限公司

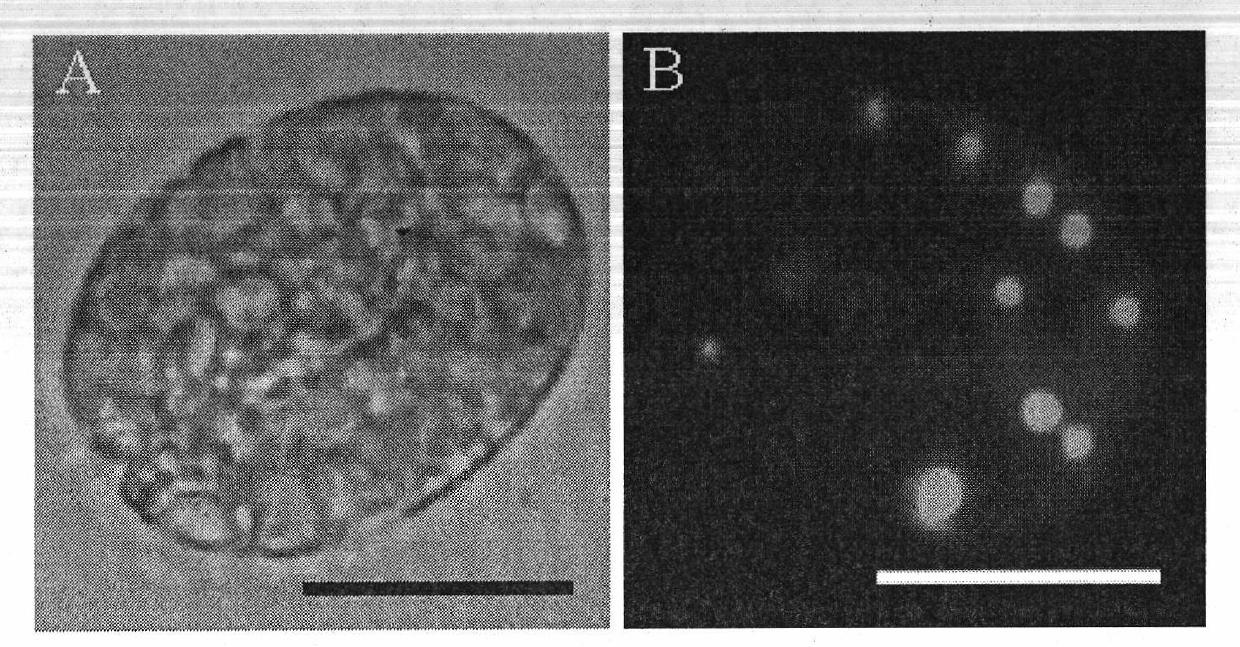

Method for detecting oil content of microalgae

InactiveCN102565012AEasy to detectThe process is simple and convenientUsing optical meansIndividual particle analysisLipid formationMicrobial oil

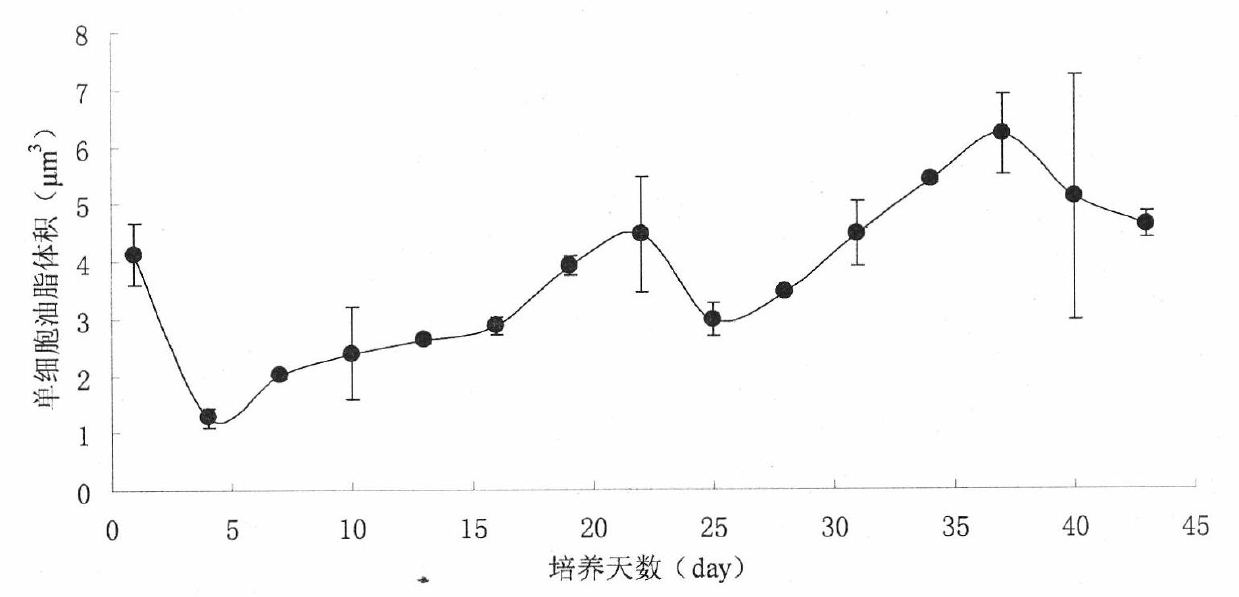

The invention relates to lipid producing microalgae, in particular relates to a method for detecting the oil content of microalgae, comprising the following steps of: 1) taking microalgae-cultivated algae liquid, and computing the quantity concentration C of microalgae cells; 2) observing the lipid of the microalgae: adopting a BODIPY (boron-dipyrromethene) 505 / 515 staining fluorescent recording method; staining for 1-2min by adopting dye use liquid with concentration of 1-2mM, and observing and recording accumulation change conditions of single-celled lipid in a photographing way by using excitation light with wave length of 488nm under a fluorescence microscope; recording the number (n) of single-celled oil drop grains according to a photograph, detecting the diameter (d) of each oil drop, and computing the volume of each oil drop according to a ball volume formula, wherein the content of each cell lipid is the sum of the volume of all the oil drops; and computing the lipid content of the algae liquid in unit volume according to the quantity concentration C of the microalgae and the lipid content of a single cell: Vt=CV, wherein C is the concentration of tetraselmis cells, V is the lipid volume of the single cell, and Vt is the lipid content in the unit volume.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Method for improving oil recovery efficiency through microbial oil displacement

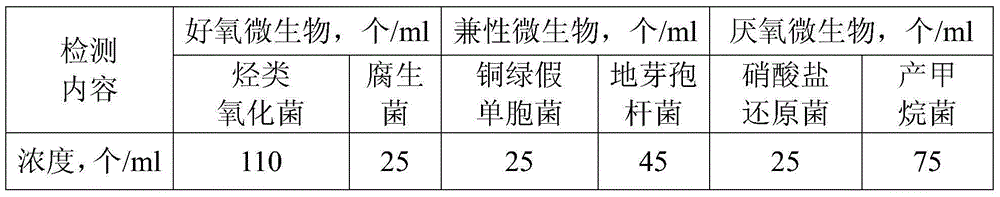

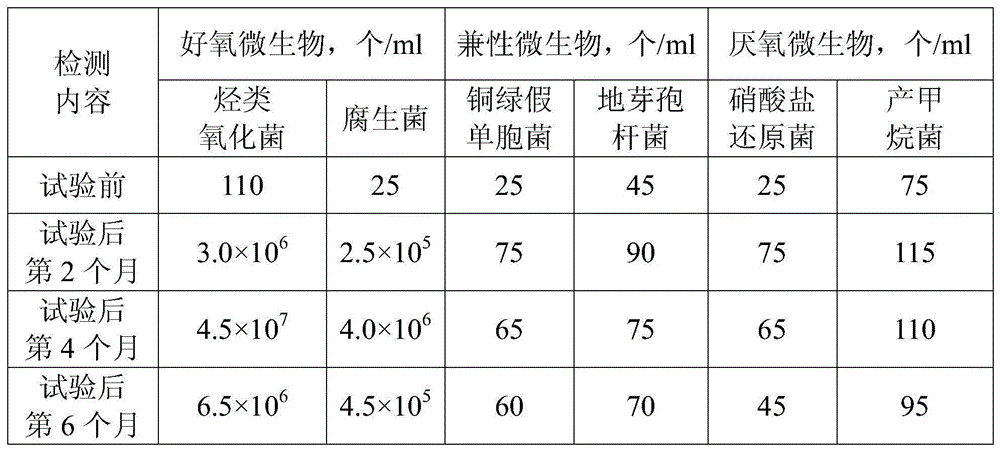

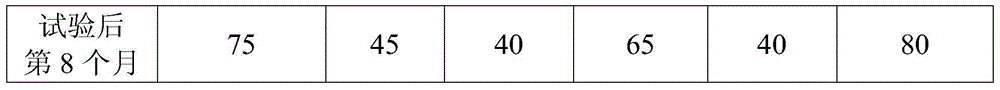

The invention discloses a method for improving oil recovery efficiency through microbial oil replacement and belongs to the technical field of microbial oil recovery. The method specifically comprises the following steps of performing in-situ sampling on a test site and detecting indigenous microorganisms, wherein the detected indigenous microorganisms are composed of aerobic, facultative and anaerobic microorganisms; performing oil displacement on oil reservoir through the aerobic microorganisms, filling the aerobic microorganisms or the activator of the aerobic microorganisms and air into the oil reservoir, and detecting the aerobic microorganisms inside the output liquid of the oil reservoir; performing oil displacement on oil reservoir through the facultative microorganisms, filling the facultative microorganisms or the activator of the facultative microorganisms and air into the oil reservoir, and detecting the facultative microorganisms inside the output liquid of the oil reservoir; performing oil displacement on oil reservoir through the anaerobic microorganisms and filling the anaerobic microorganisms or the activator of the anaerobic microorganisms and air into the oil reservoir. According to the method for improving the oil recovery efficiency through the microbial oil replacement, the activators are abundant in sources, low in price and free from damage to stratums. The method for improving the oil recovery efficiency through the microbial oil replacement is simple in process, high in pertinence and operability and good in in-situ testing effects and improves the recovery efficiency of in-situ tests by larger than 10.0%, thereby being capable of being widely applied to in-situ tests for improving the recovery efficiency through microorganisms.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyunsaturated fatty acid-containing oil product and uses and production thereof

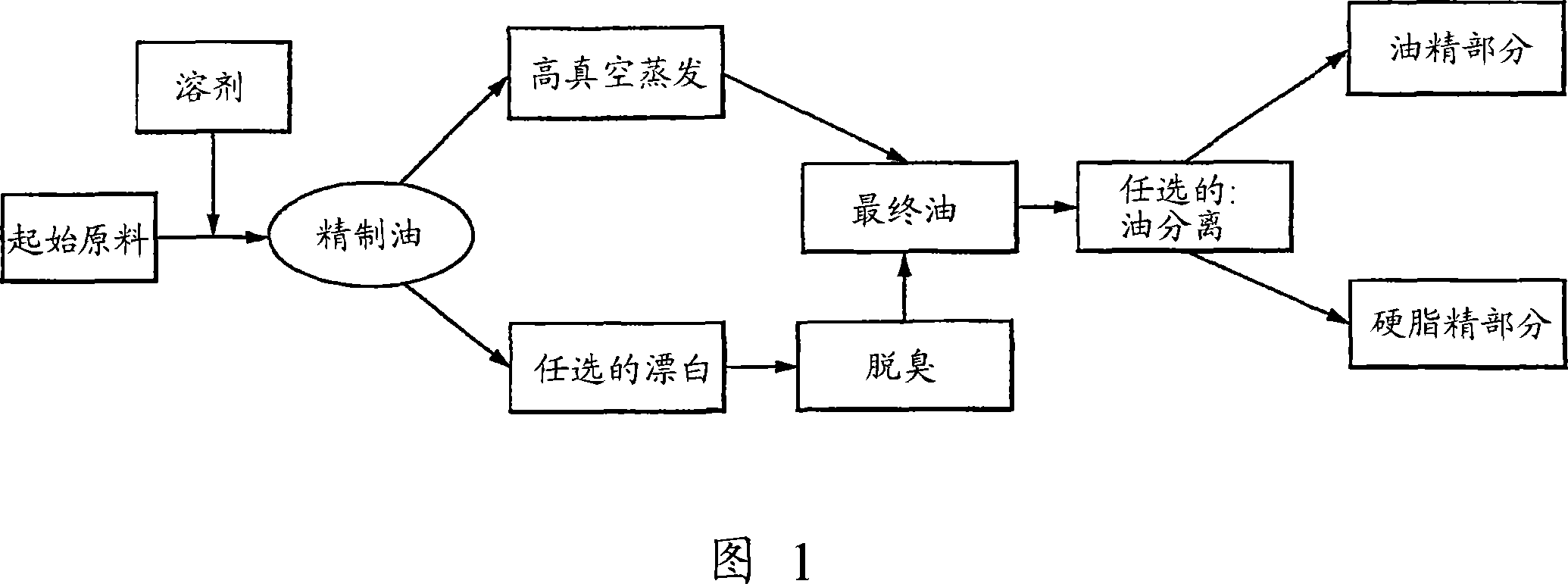

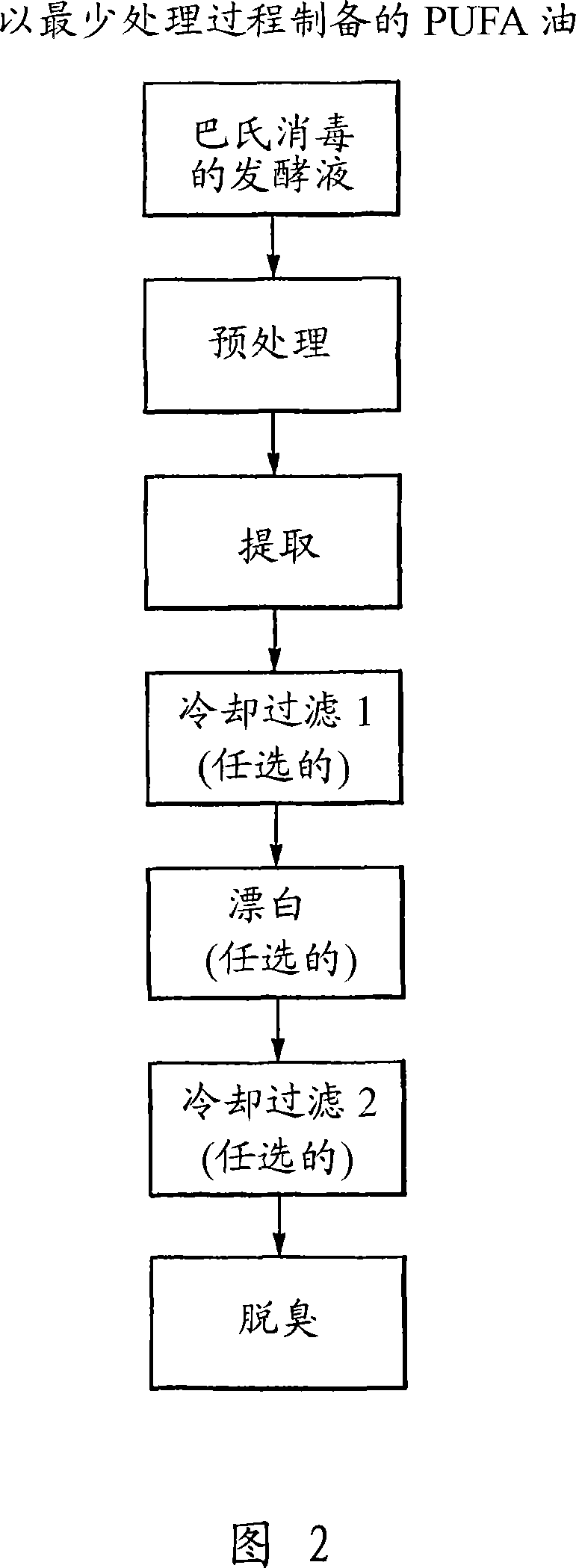

The present invention includes a solid fat composition that includes an oil having saturated fat and a microbial oil having a long chain polyunsaturated fatty acid and an emulsifier. In particular, the solid fat composition can have high levels of long chain polyunsaturated fatty acid and low amounts of emulsifiers. In preferred embodiments, the polyunsaturated oil is an unwinterized microbial oil. The invention also relates to methods for making such compositions and food, nutritional, and pharmaceutical products comprising said compositions. The present invention also includes a microbial oil product prepared by extracting an oil-containing fraction comprising at least one LC-PUFA from a microbial biomass, and treating the fraction by a process of vacuum evaporation, wherein the oil product has not been subject to one or more of a solvent winterization step, a caustic refining process, a chill filtration process, or a bleaching process.

Owner:DSM IP ASSETS BV

Eicosapentaenoic acid concentrate

An omega-3 oil concentrate comprising at least 70 weight percent of eicosapentaenoic acid [“EPA”; cis-5,8,11,14,17-eicosapentaenoic acid; omega-3], measured as a weight percent of oil, and substantially free of docosahexaenoic acid, said concentrate obtained from a microbial oil having 30 to 70 weight percent of eicosapentaenoic acid, measured as a weight percent of total fatty acids, and substantially free of docosahexaenoic acid and wherein said microbial oil is obtained from a microorganism that accumulates in excess of 25% of its dry cell weight as oil. Also disclosed are methods of making such eicosapentaenoic acid concentrates.

Owner:EI DU PONT DE NEMOURS & CO

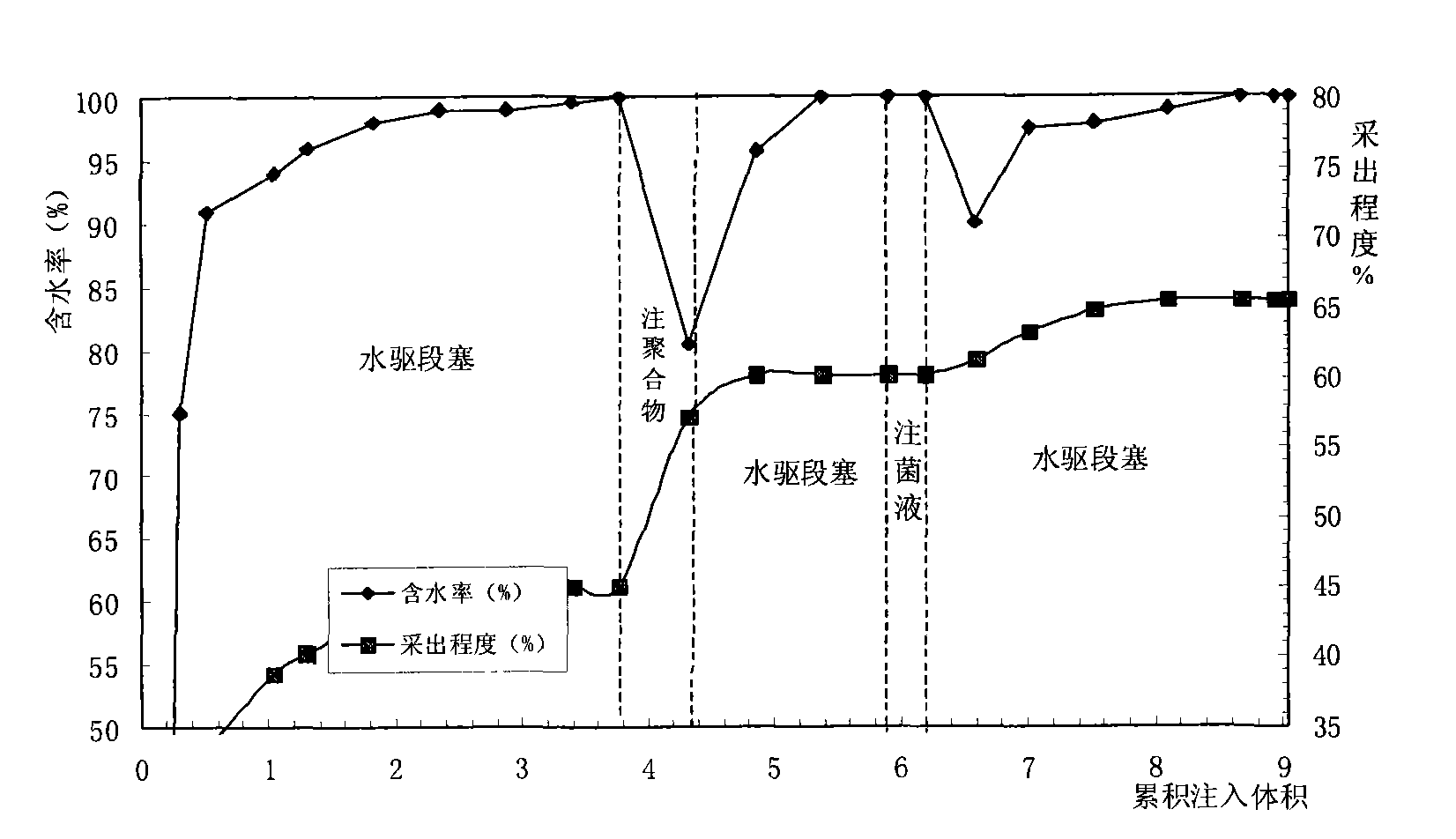

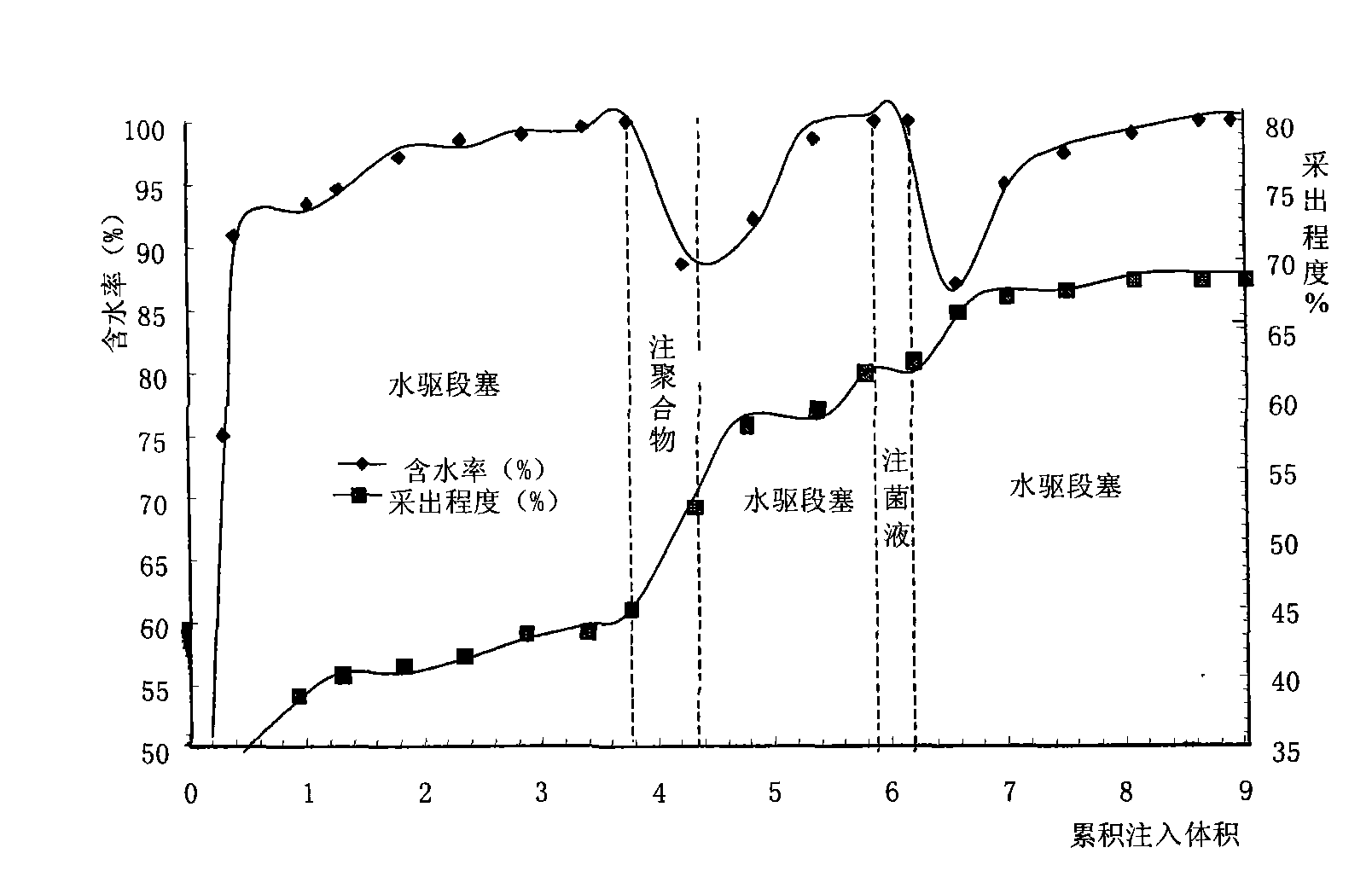

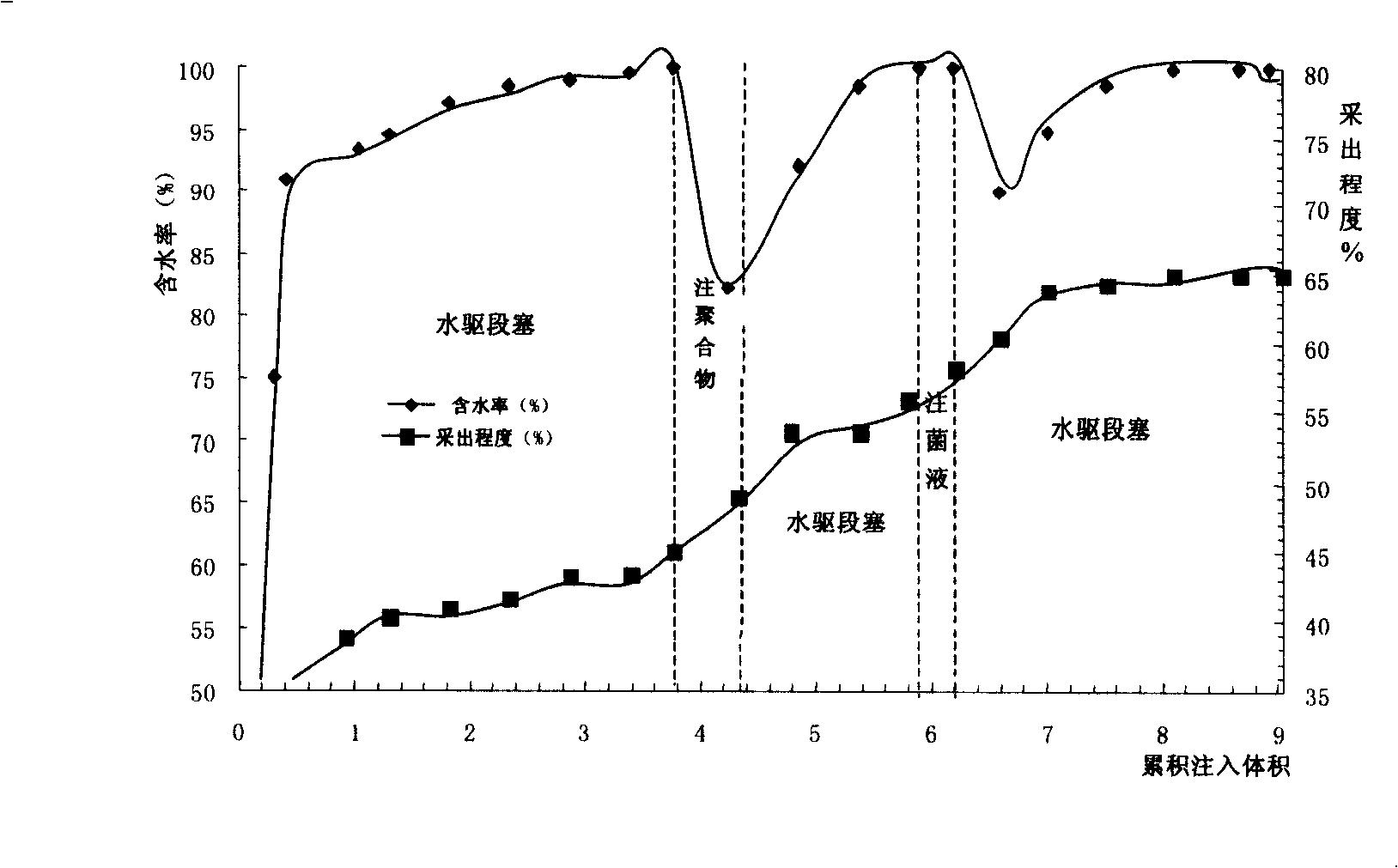

Microbe oil production method after polymer drive

The invention discloses a microbial oil production method, including a process of displacement of reservoir oil by using bacterial liquid after polymer flooding of oil layers; the bacterial liquid is a mixed liquid or zymotic fluid of bacillus fusiformis 6# CGMCC No.2439, Potsdam Bacillus brevis Po CGMCC No.2441 or Bacillus licheniformis U1-3 CGMCC No.2437 singly mixed with a culture medium, or compatible liquid of the three with the culture medium. The experimental results of model displacement of reservoir oil show that the bacterial liquid is used for displacement of reservoir oil after the polymer flooding, so that recovery ratio is increased by 3-5 percent (OOIP), the bacterial liquid, coupled with polymer protection slug flooding, is used for displacement of reservoir oil after the polymer flooding, so that the recovery ratio is increased by about 7-9 percent (OOIP), and a method with the bacterial liquid displacement and chemical displacement combined is used for displacement of reservoir oil after the polymer flooding, so that the recovery ratio can be increased by 13% (OOIP). The experimental results show that the method of the invention can be widely applied to the field of oil production engineering, especially the field of microbial intensified oil production, and is suitable for large-scale popularization and application.

Owner:DAQING OILFIELD CO LTD +1

Method for regulating and controlling microbial enhanced oil recovery

ActiveCN101699025AEasy to extract oilOil displacement effect is goodBacteriaMicroorganism based processesBiotechnologyMicrobial oil

The invention relates to a method for regulating and controlling microbial enhanced oil recovery. The method comprises the following steps: (1) analyzing a microbial community structure in oil deposit produced fluid and / or metabolic products in detection produced fluid by adopting a molecular biological method; (2) regulating a microbe to be injected into the oil deposit and / or a nutritious system corresponding to the microbe; (3) injecting the regulated microbe and / or the nutritious system corresponding to the microbe into the oil deposit by a water injection well; and (4) gathering crude oil by a corresponding beneficial producing well. Compared with the prior art, the method for regulating the microbial community structure in the oil deposit contributes to the direction evolution of oil recovery, can sufficiently play the performance of functional microbes, injects the nutritious system specifically, and avoids blindness in application of the nutritious system, thus the method is a scientific, economic and effective microbial oil recovery method.

Owner:DAQING HUALI ENERGY BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com