Method for preparing microbial oil and fat

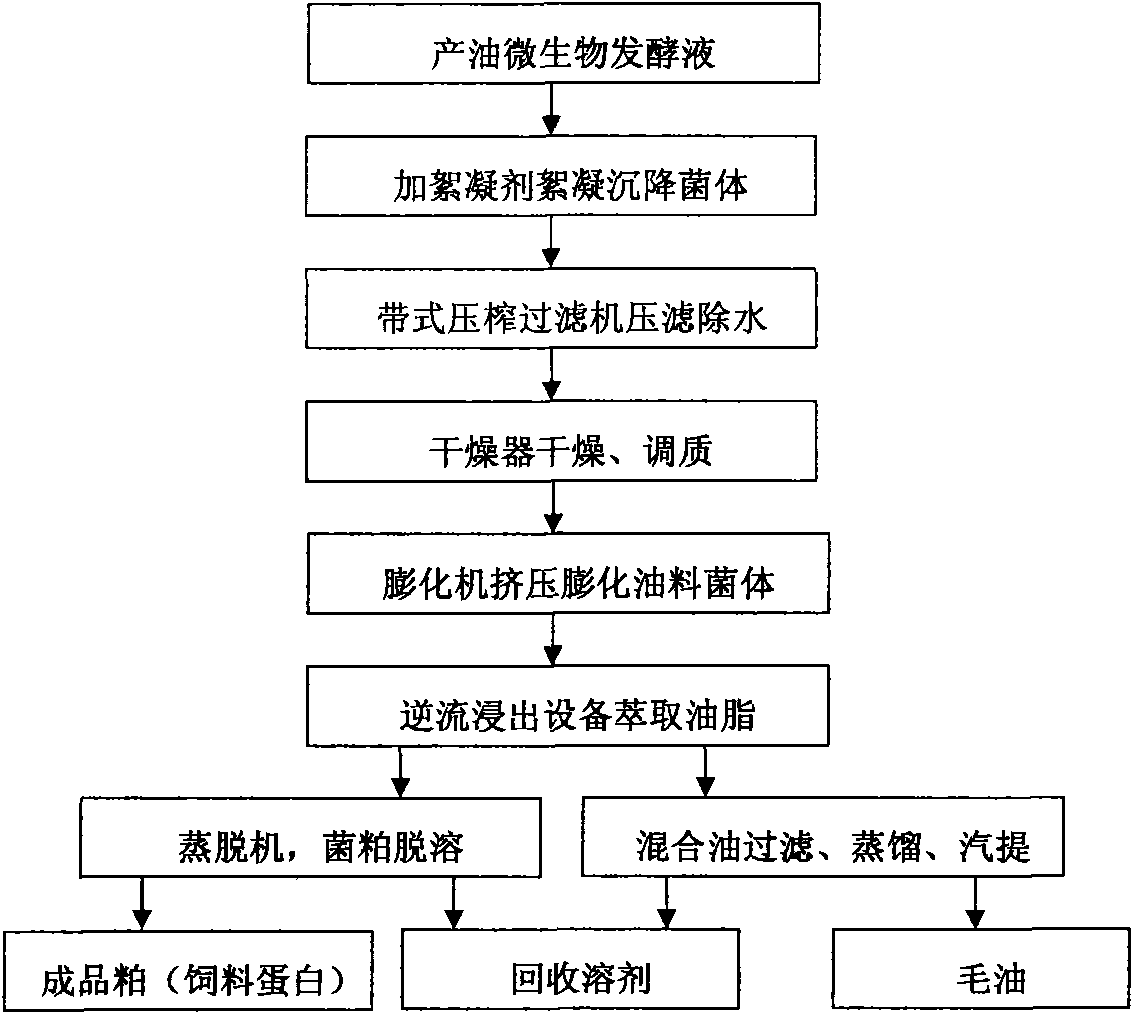

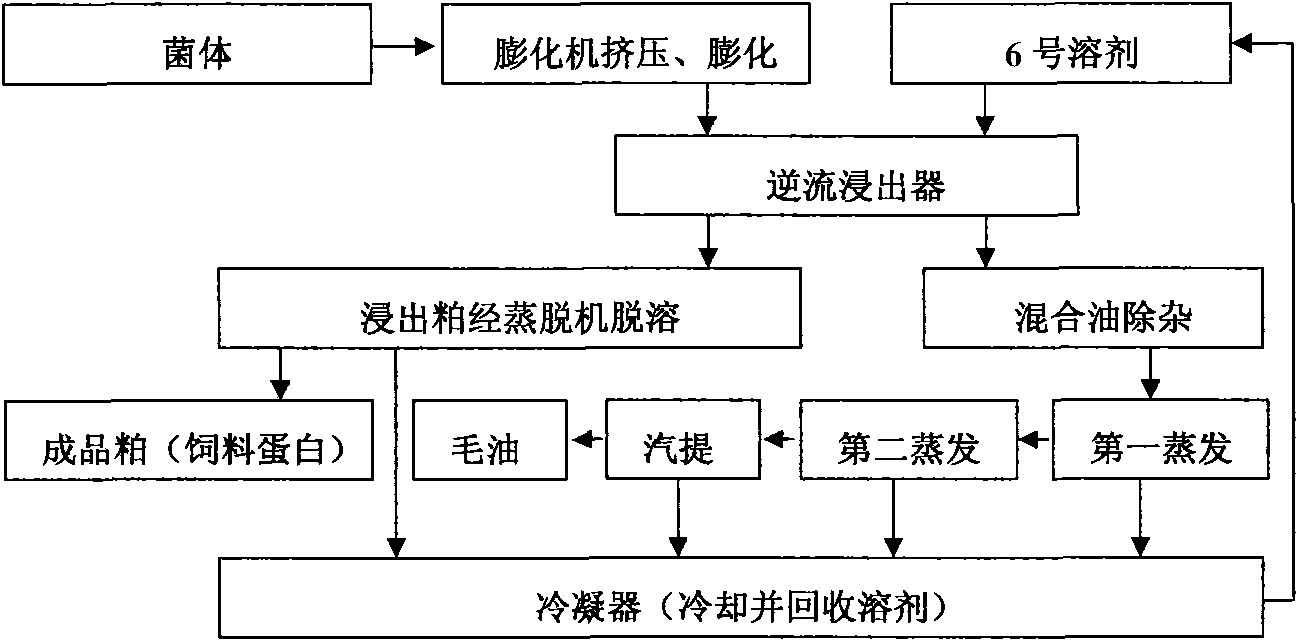

A technology of microbial oil and microbial bacteria, which is applied in the production of fat, fat oil/fat production, fermentation, etc., can solve the problems of small batch processing volume, small processing volume and high residual oil rate, so as to reduce labor consumption and power consumption, reduce Effects of steam and power consumption, and increased oil mixture concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 5m after fermentation of oleaginous red yeast 3 The fermentation broth is processed according to the method of the present invention, and the sequential steps are as follows:

[0050] (1) Flocculation, add a pre-prepared 0.2wt‰ polyacrylamide aqueous solution to the fermentation broth at the amount of 40ppm, the flocculation reaction time is 10min, the precipitation time is 30min, the water removal rate reaches 67%, and the dry cell content is 3wt % Increased to 9wt%.

[0051] (2) Filter press, send the flocculated bacteria to the belt press filter, under 2.5 atmospheres, go through gravity concentration dehydration, wedge pre-pressing dehydration and roller pressing dehydration for 20 minutes to obtain the moisture content of the filter cake (in dry cells The weight is 73% by weight on a dry basis. The dry cell content is 27wt%.

[0052] (3) Conditioning: In the chain plate dryer, steam at 120°C is used for drying and conditioning until the water content is reduced to 10% ...

Embodiment 2

[0060] 10m after fermentation of oleaginous red yeast 3 The fermentation broth is processed according to the method of the present invention, and the sequential steps are as follows:

[0061] (1) Flocculation, add a pre-prepared 0.5wt‰ polyacrylamide aqueous solution to the fermentation broth at an amount of 120ppm. The flocculation reaction time is 20min, the precipitation time is 1h, the water removal rate reaches 70%, and the dry cell content is 3wt. % Increased to 10wt%.

[0062] (2) Filter press, send the flocculated bacteria to the belt press filter, under 2 atmospheres, through gravity concentration dehydration, wedge pre-pressing dehydration and roller squeezing dehydration for 30 minutes to obtain the moisture content of the filter cake (in terms of dry bacteria The weight is 70% by weight on a dry basis, and the dry cell content is 30% by weight.

[0063] (3) Conditioning: In the chain plate dryer, steam at 125°C is used for drying and conditioning, the water content is ...

Embodiment 3

[0070] 5m after culturing Chlorella oleifera 3 The fermentation broth is processed according to the method of the present invention, and the sequential steps are as follows:

[0071] (1) Flocculation, add the pre-prepared 0.3wt‰ chitosan aqueous solution to the fermentation broth at a dosage of 20ppm, stir at low speed, the flocculation reaction time is 30min, the precipitation time is 1.5h, the air flotation method collects chlorella and removes The water content reached 96%, and the dry cell content of the algae was increased from 0.3wt% to 7.5wt%.

[0072] (2) Filter press, send the flocculated bacteria to the belt press filter, under 3 atmospheres, through gravity concentration dehydration, wedge pre-pressing dehydration and roller squeezing dehydration for 30 minutes, the water content of the filter cake is obtained (in the dry cell The weight is 65wt% on a dry basis, and the dry cell content is 35wt%.

[0073] (3) Conditioning: In the chain plate dryer, steam at 125°C is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com