Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4278results about How to "Stable production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chip and multi-chip semiconductor device using thereof and method for manufacturing same

InactiveUS7122912B2Improve alignment accuracyReduce the overall diameterSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:RENESAS ELECTRONICS CORP

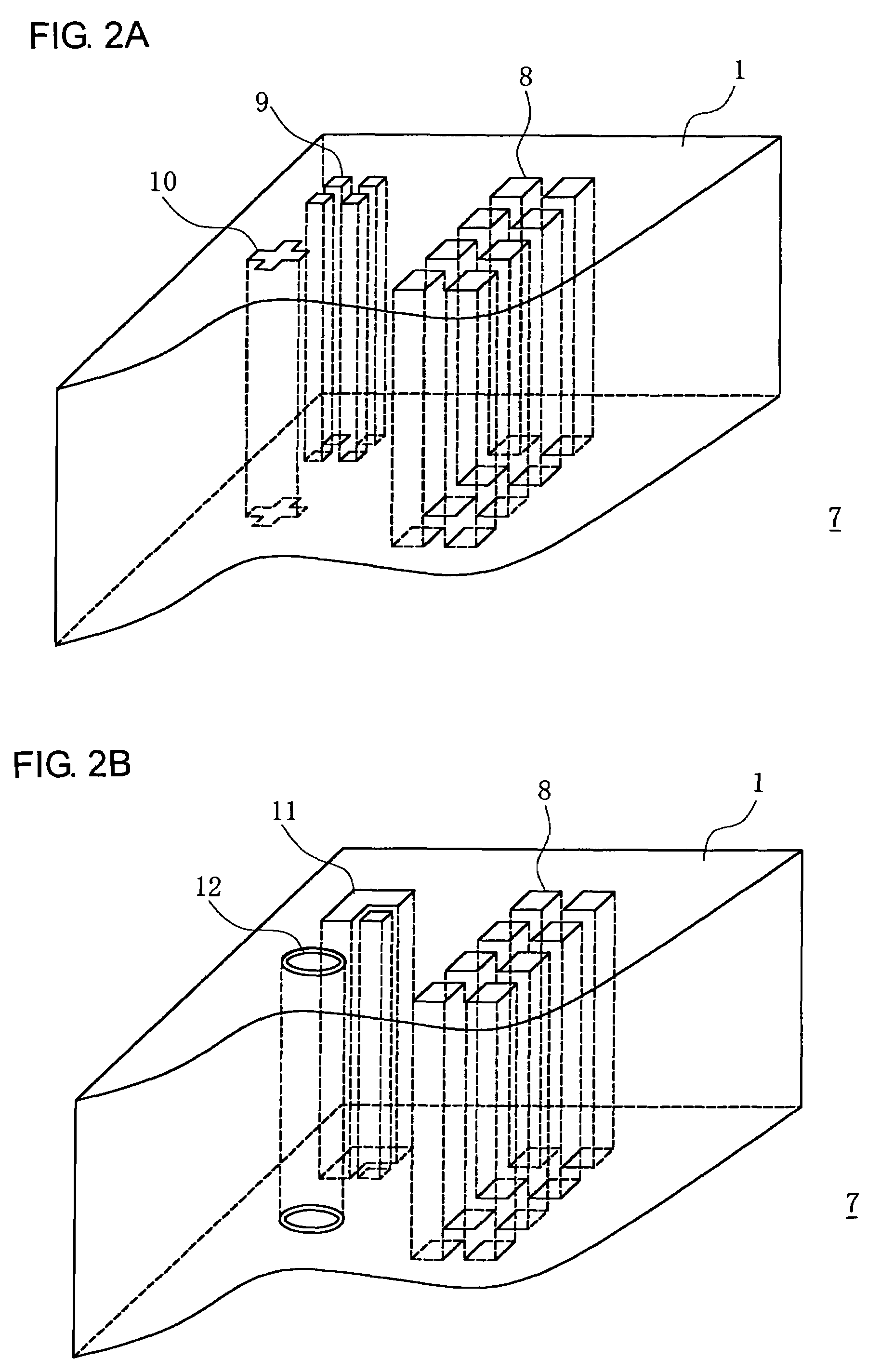

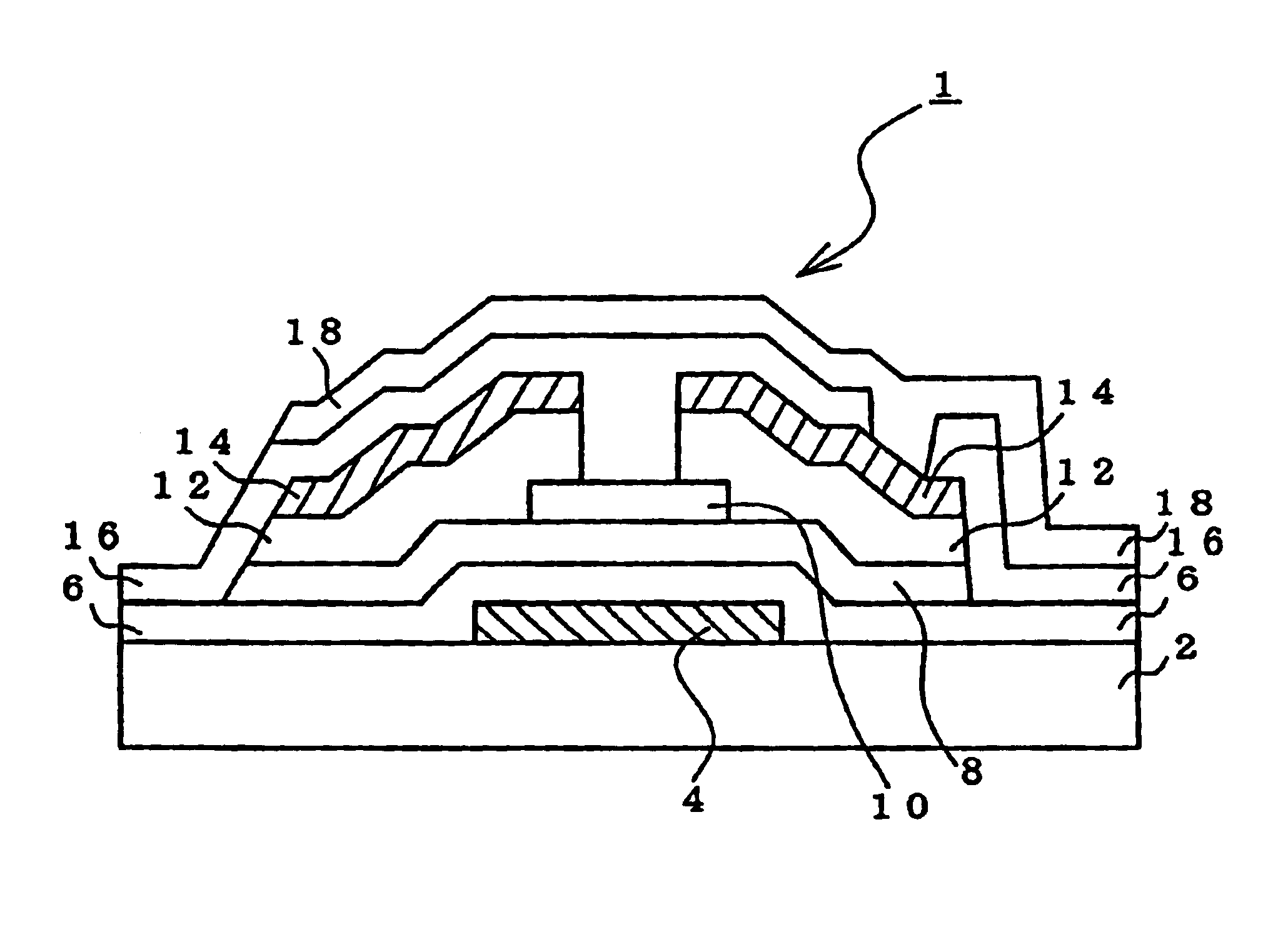

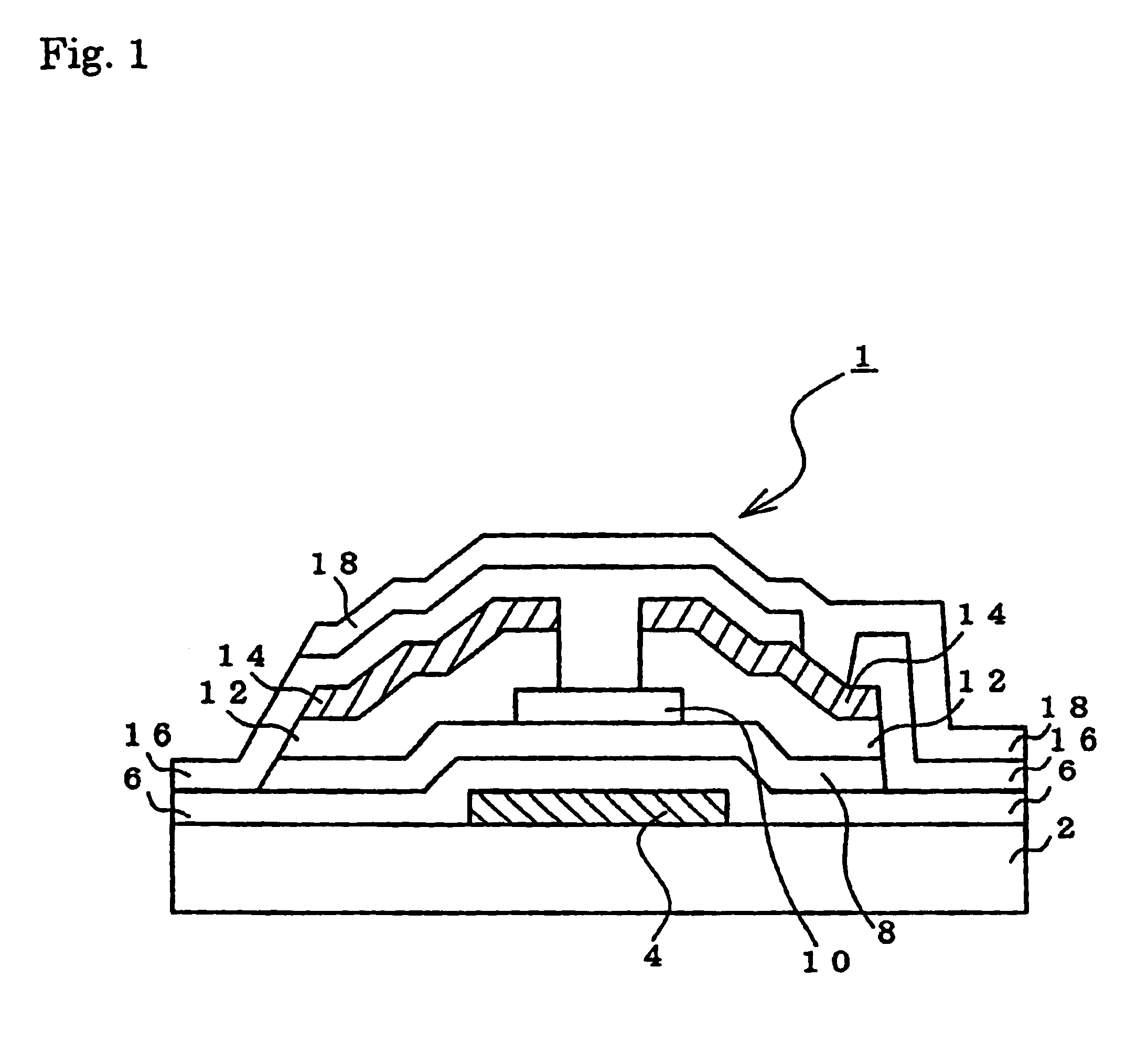

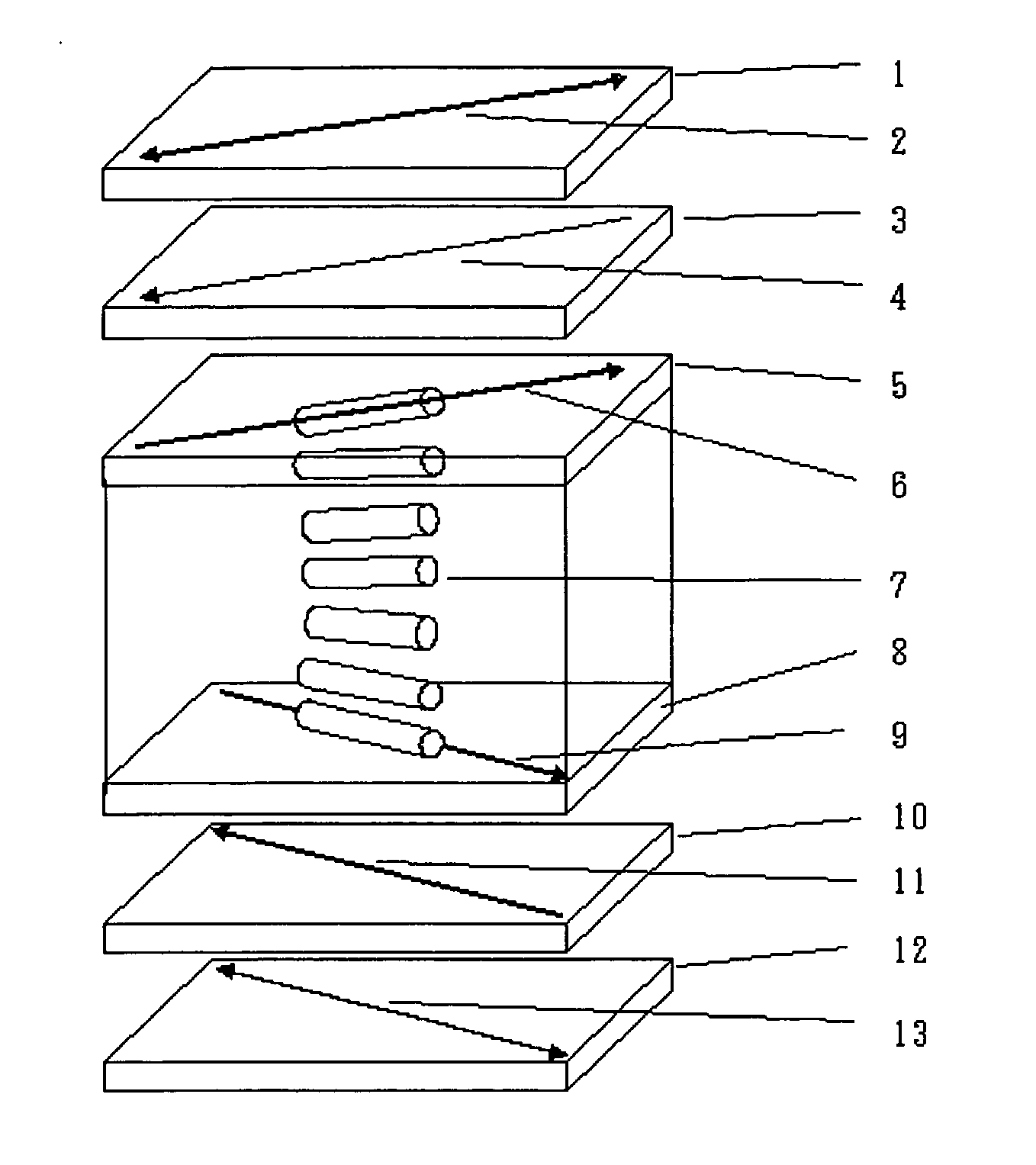

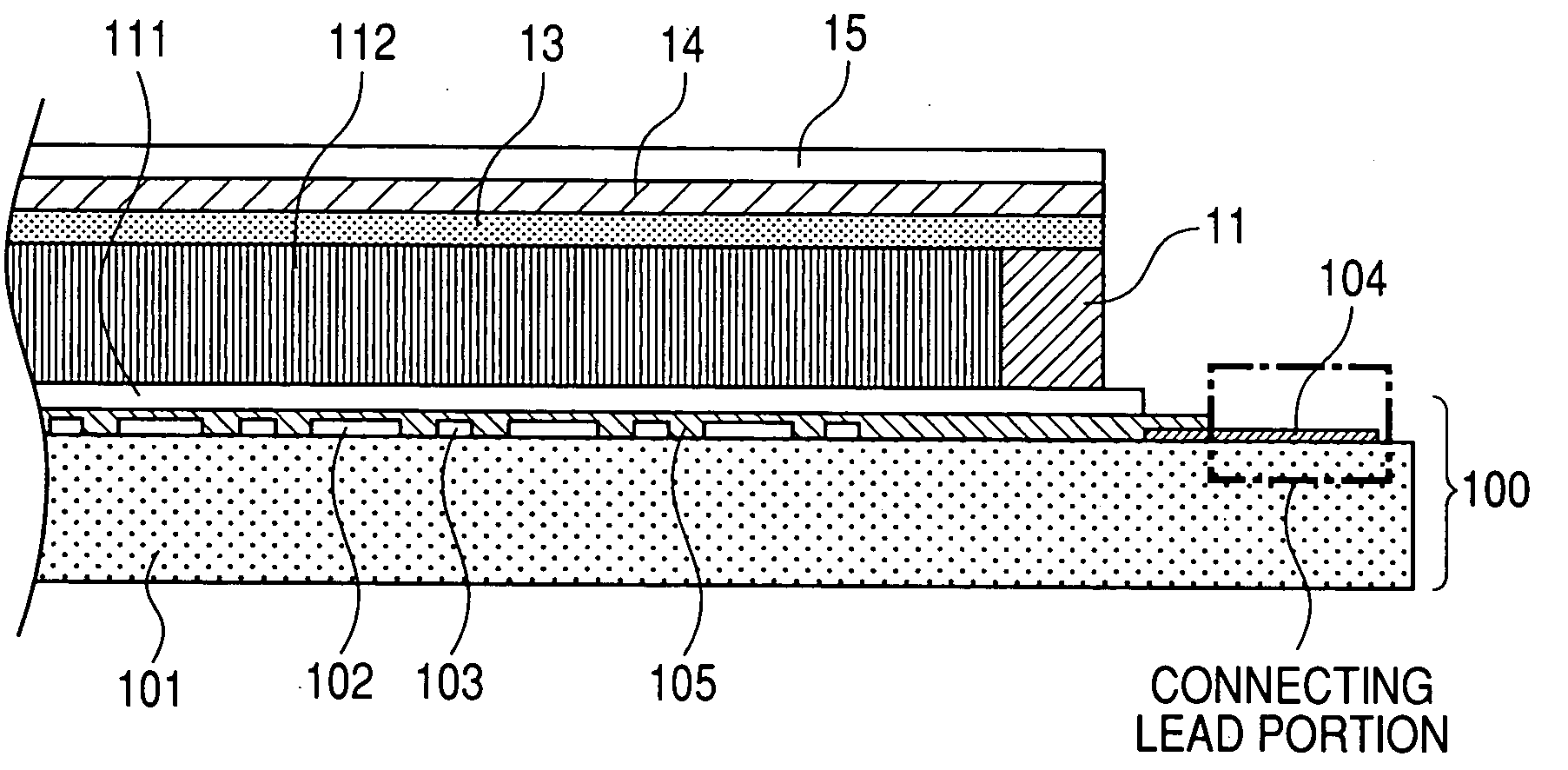

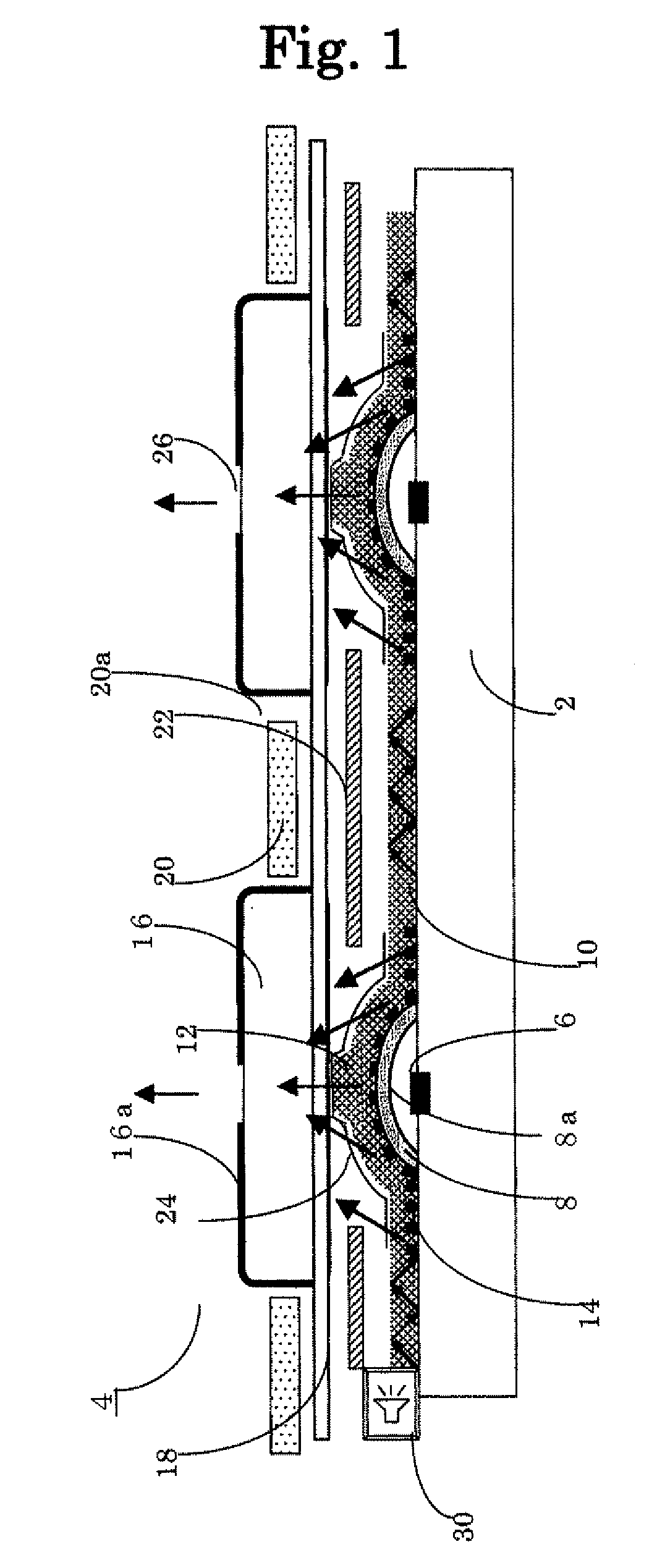

Semiconductor device and method for manufacturing the same

ActiveUS20060001174A1Stable productionSimple processSemiconductor/solid-state device detailsSolid-state devicesSecondary layerEngineering

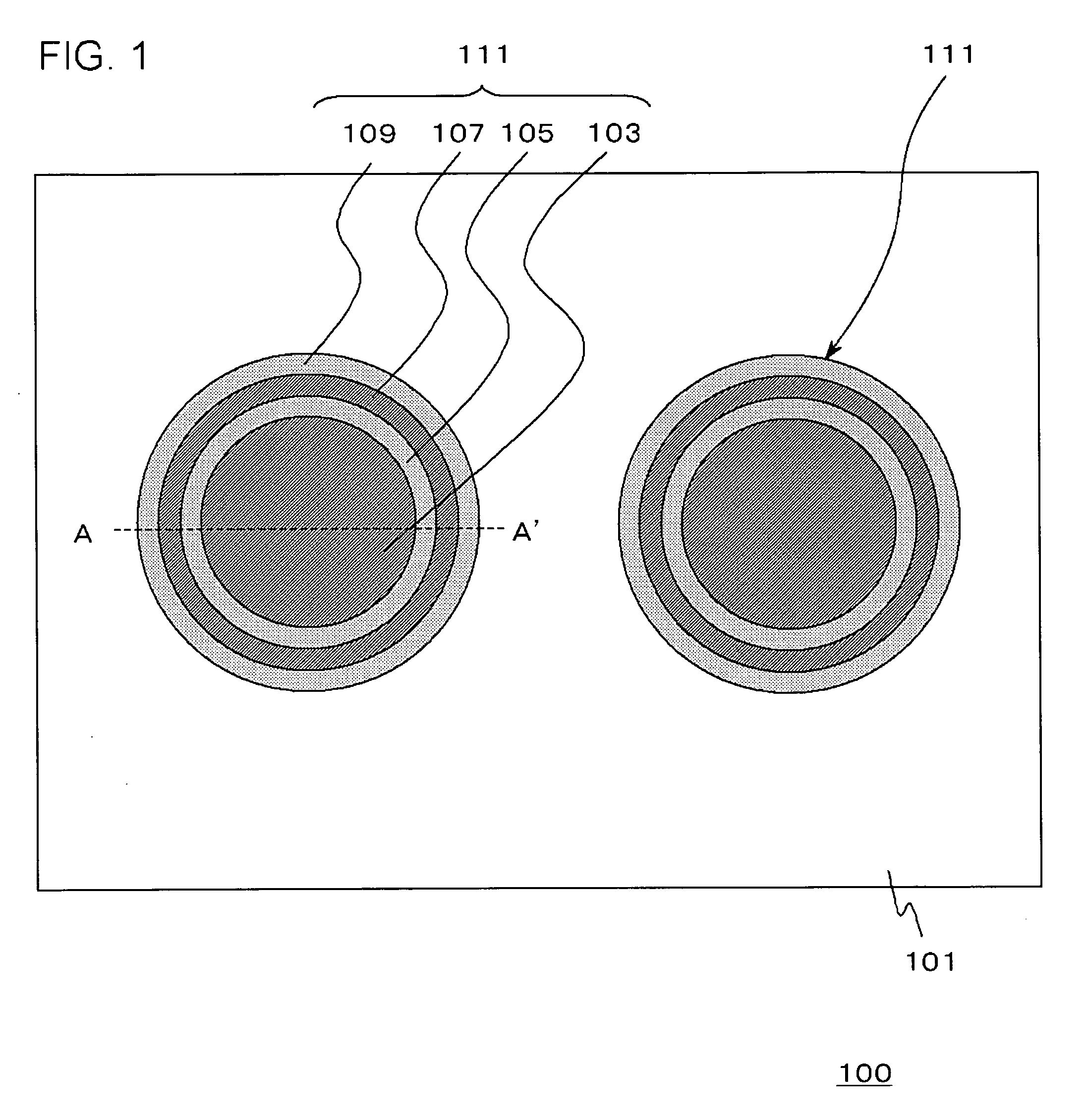

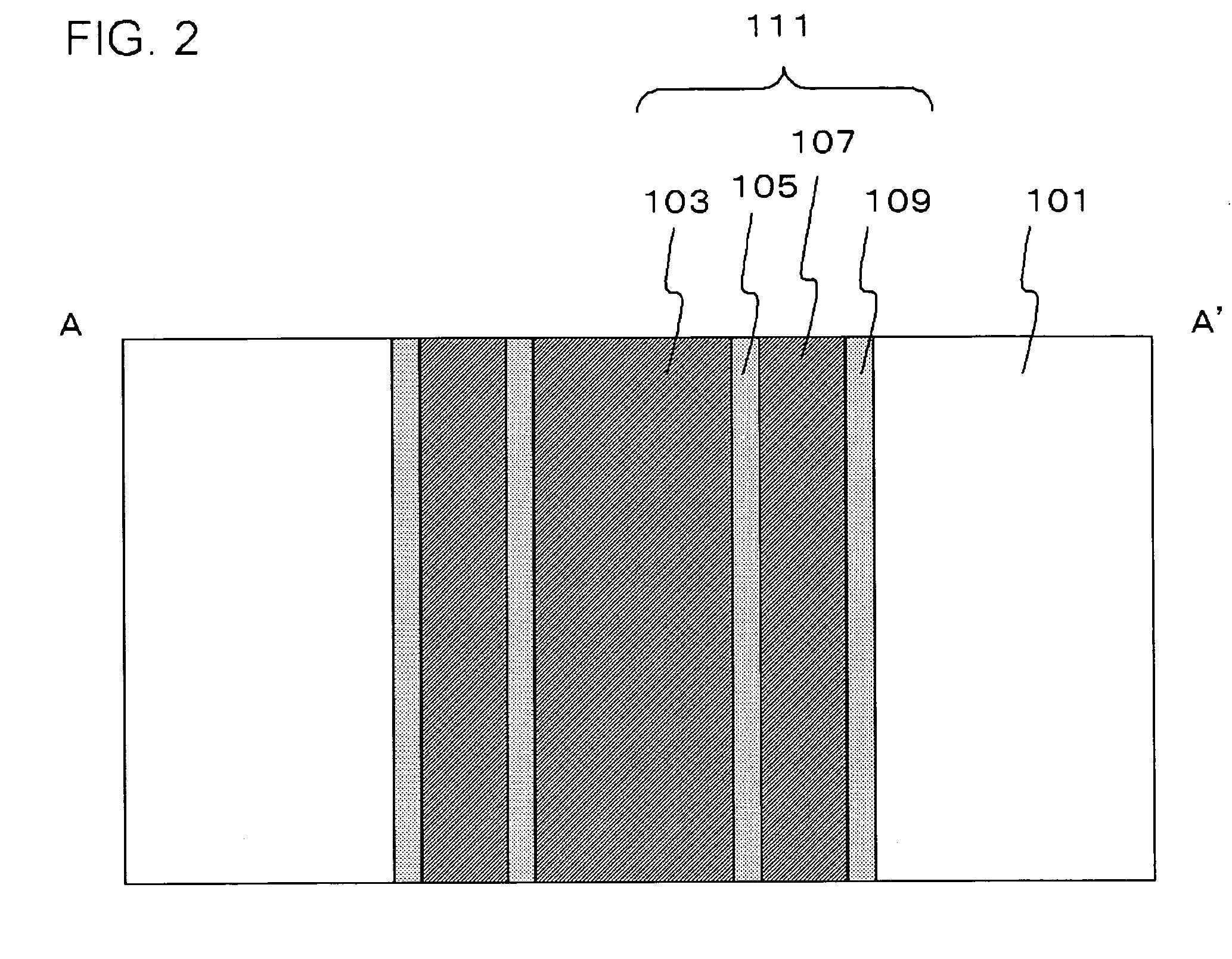

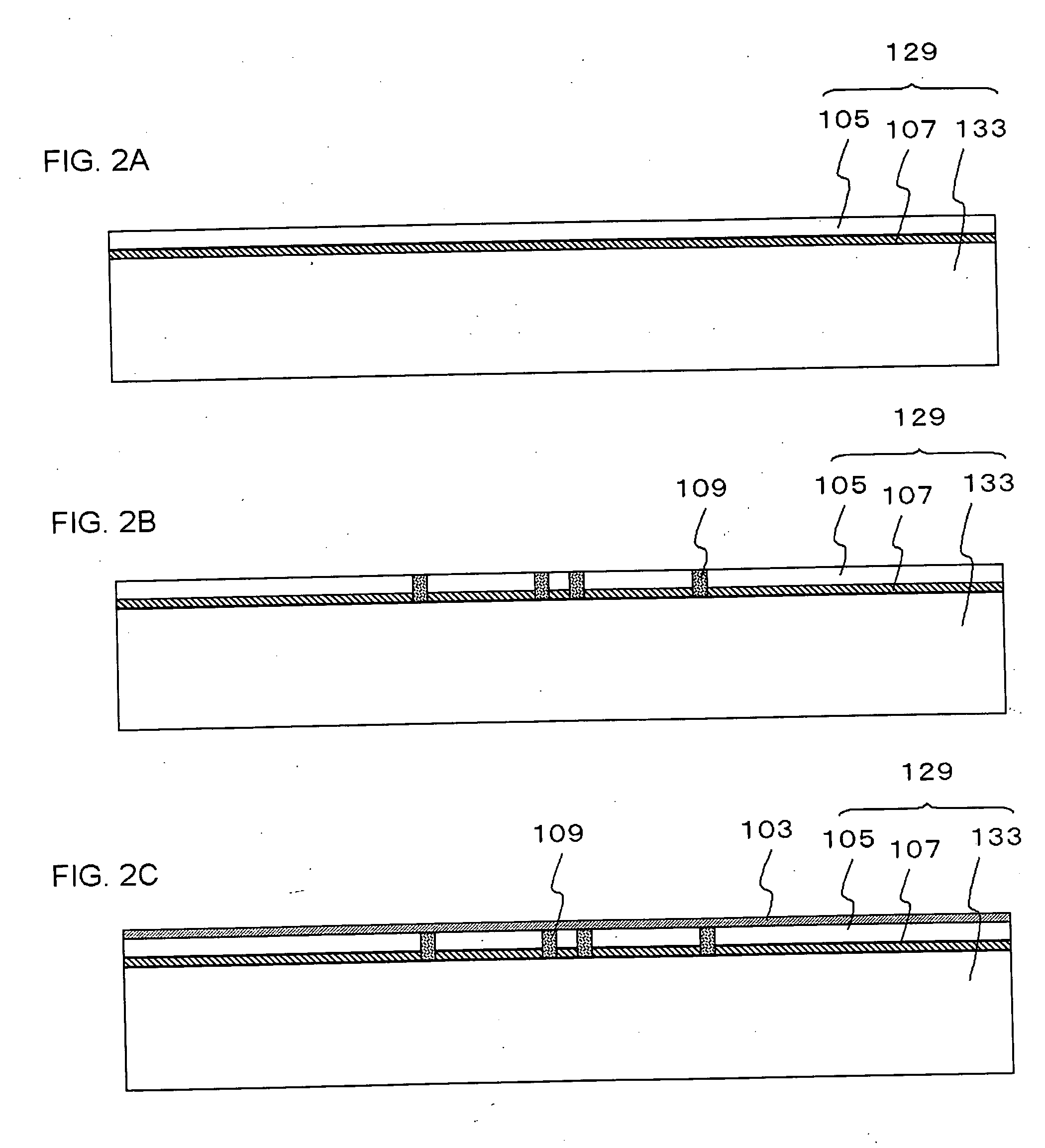

A semiconductor device 100 is provided with a multiplex through plug 111 that fills an opening extending through the silicon substrate 101. The multiplex through plugs 111 comprises a column-shaped and solid first through electrode 103, a first insulating film 105 that covers the cylindrical face of the first through electrode 103, a second through electrode 107 that covers the cylindrical face of the first insulating film 105 and a second insulating film 109 that covers the cylindrical face of the second through electrode 107, and these have a common central axis. The upper cross sections of the first insulating film 105, the second through electrode 107 and the second insulating film 109 are annular-shaped.

Owner:TESSERA ADVANCED TECH

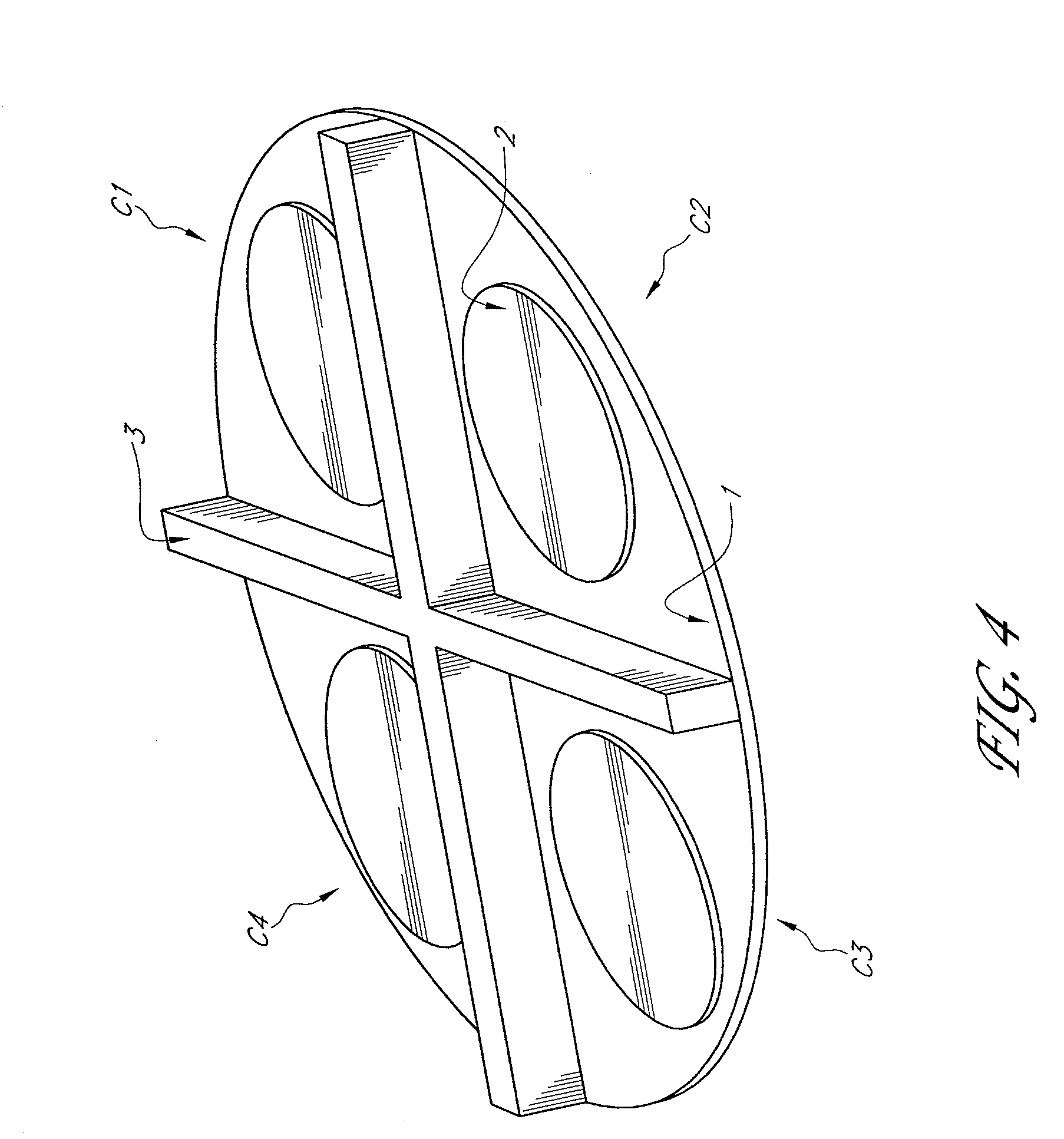

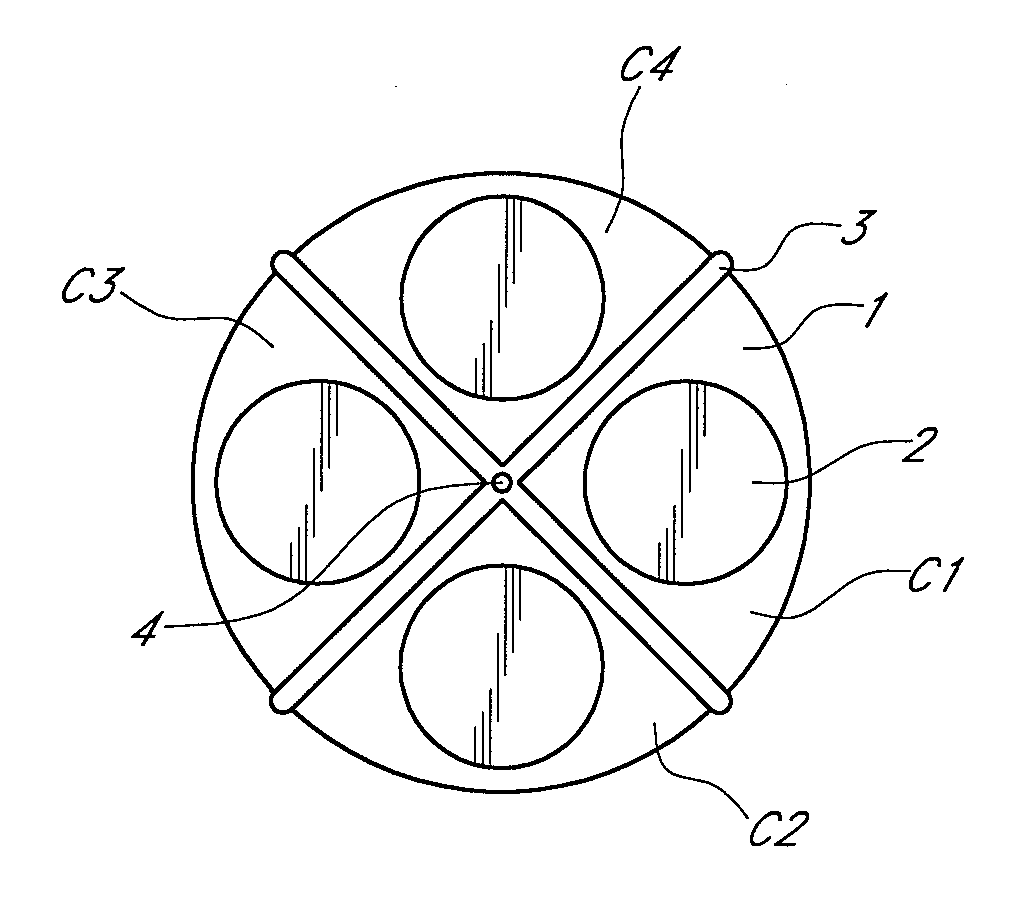

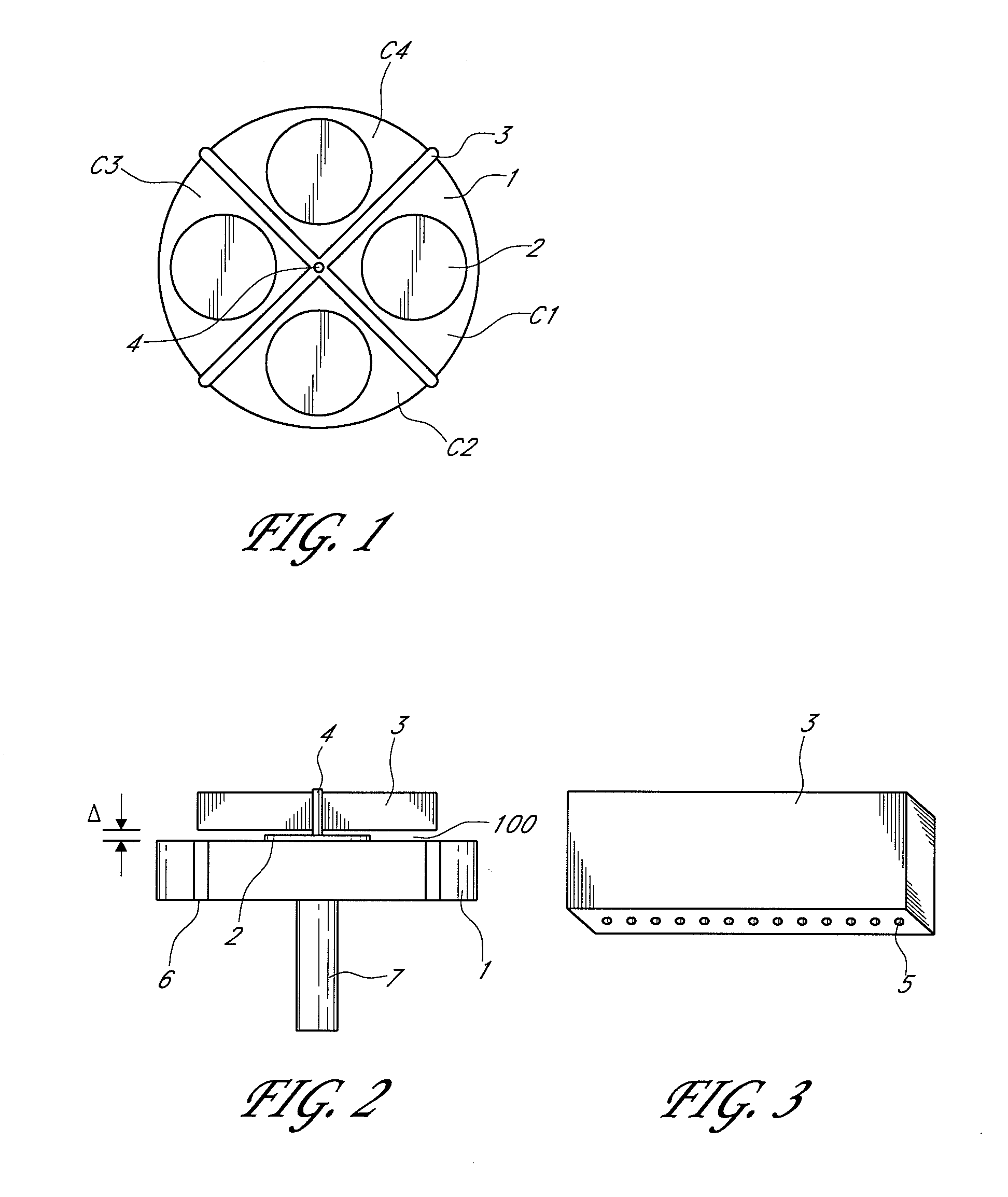

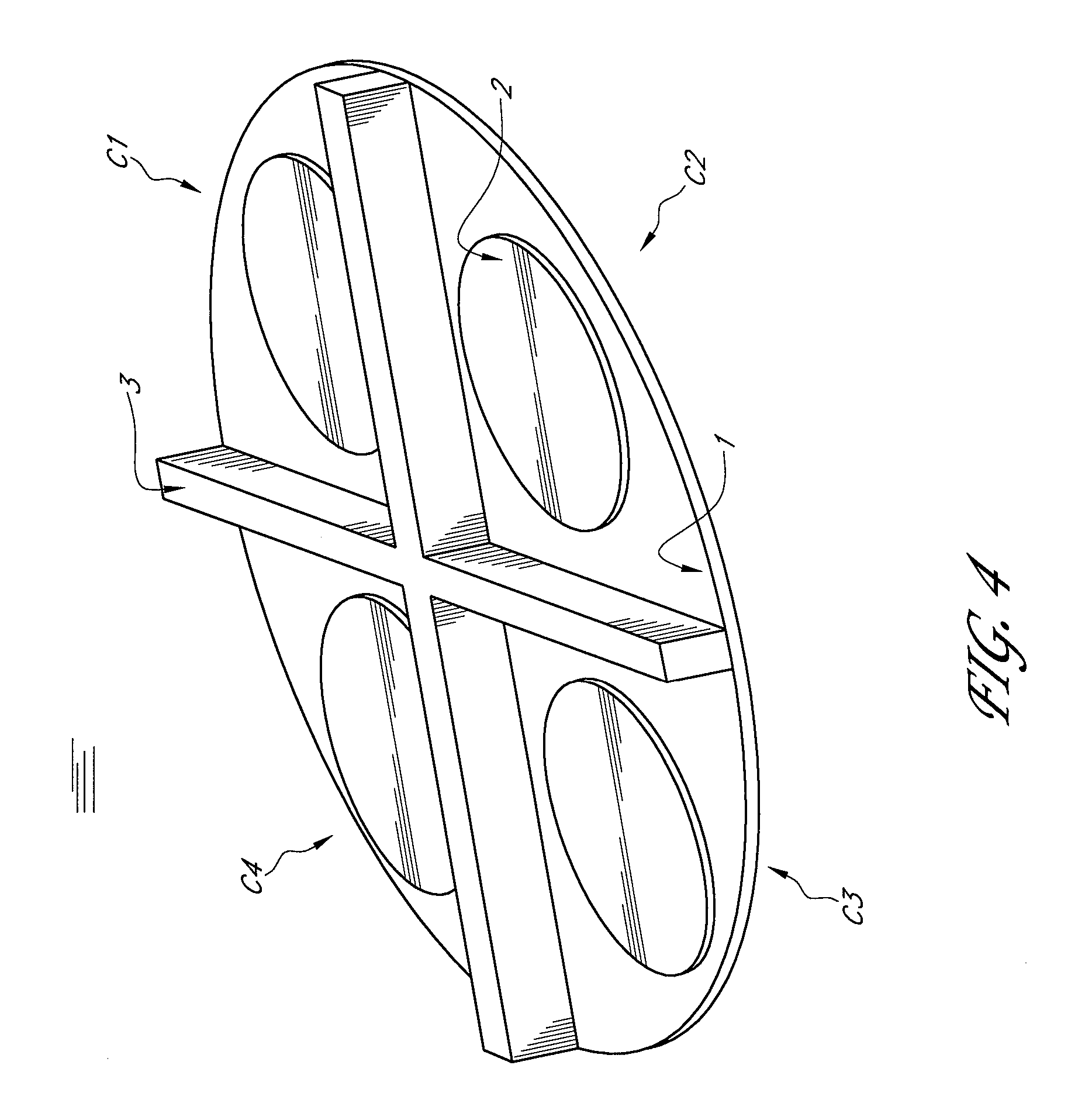

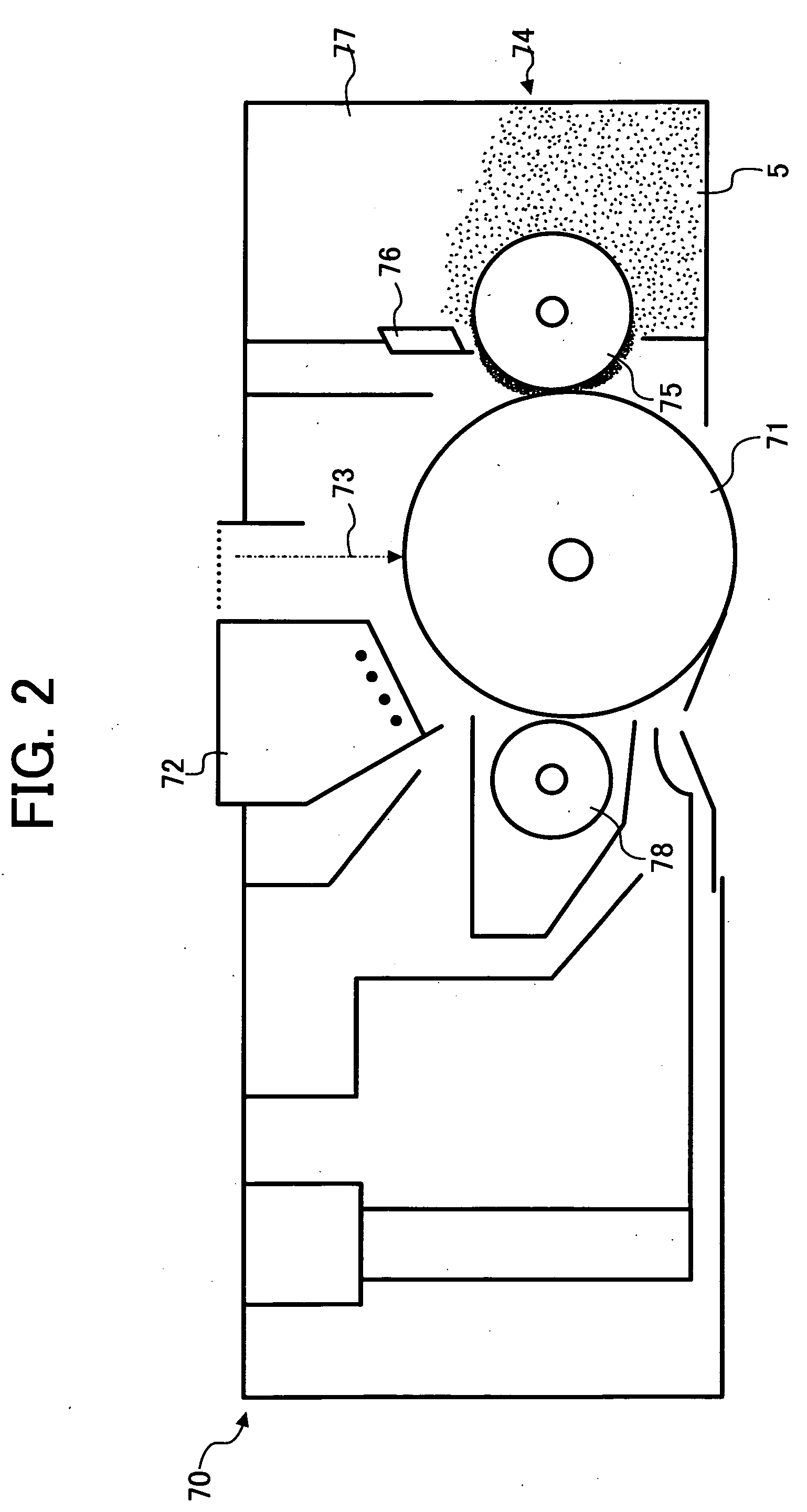

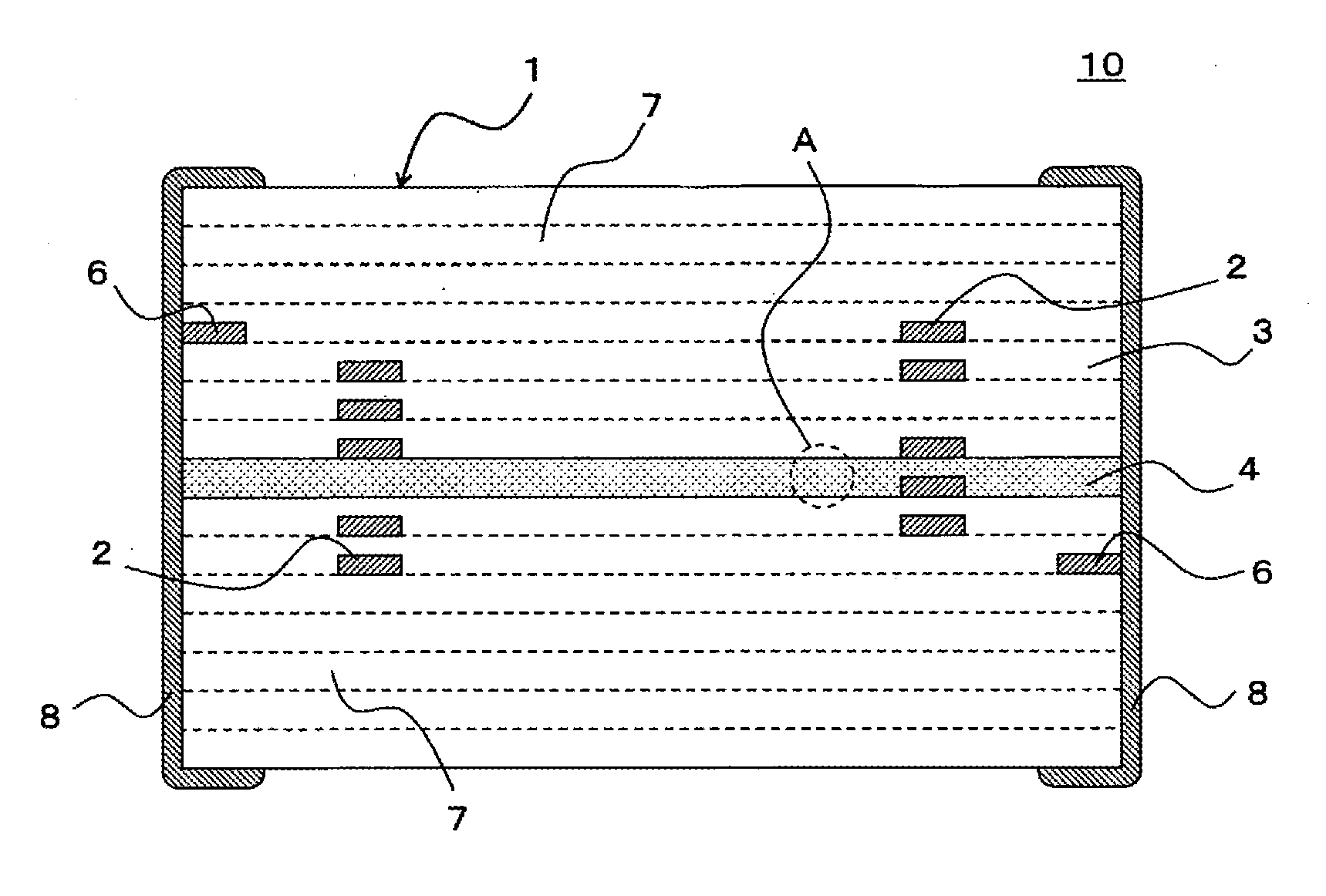

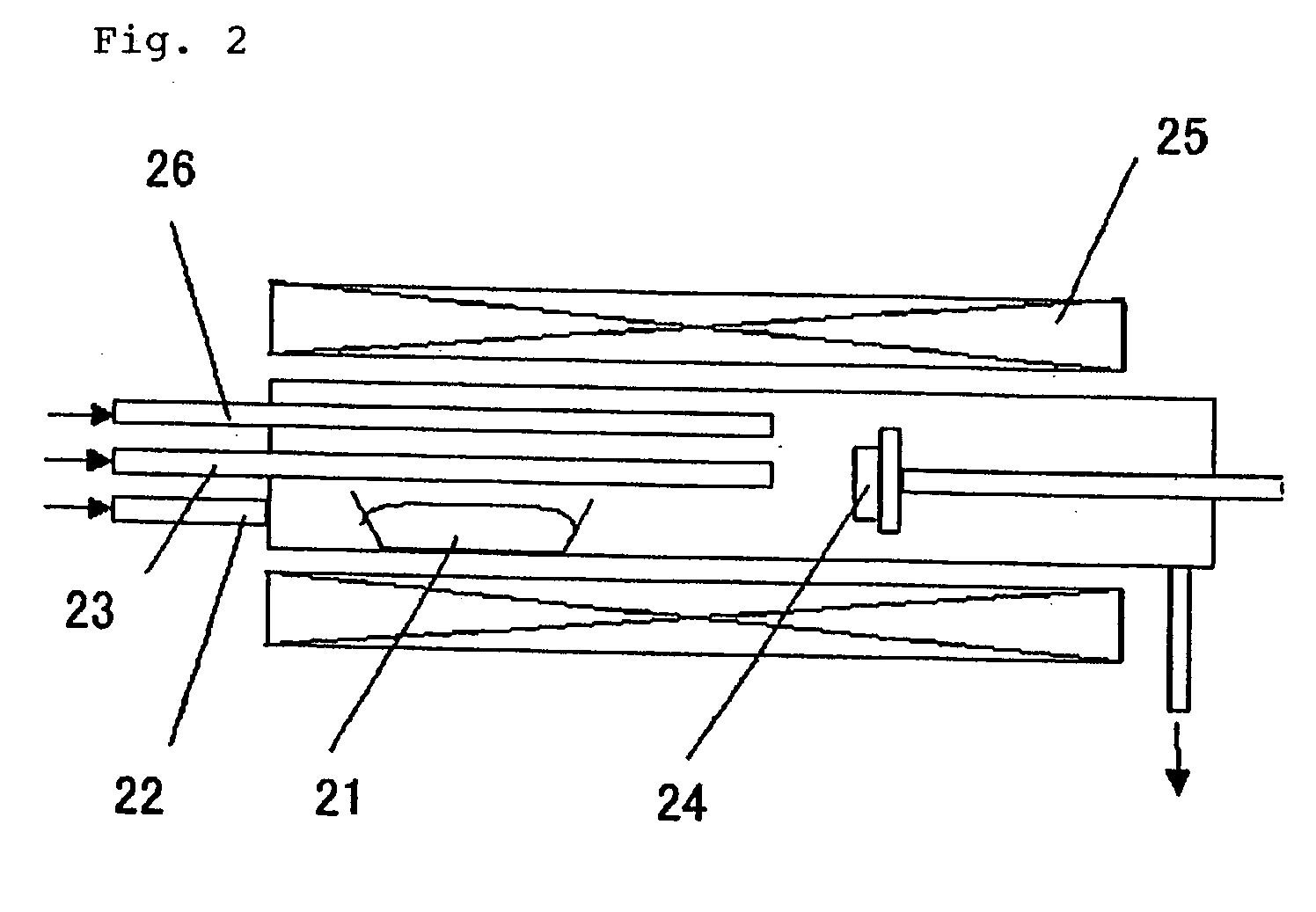

Semiconductor-processing apparatus with rotating susceptor

InactiveUS20070218702A1Establishing separateStable controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

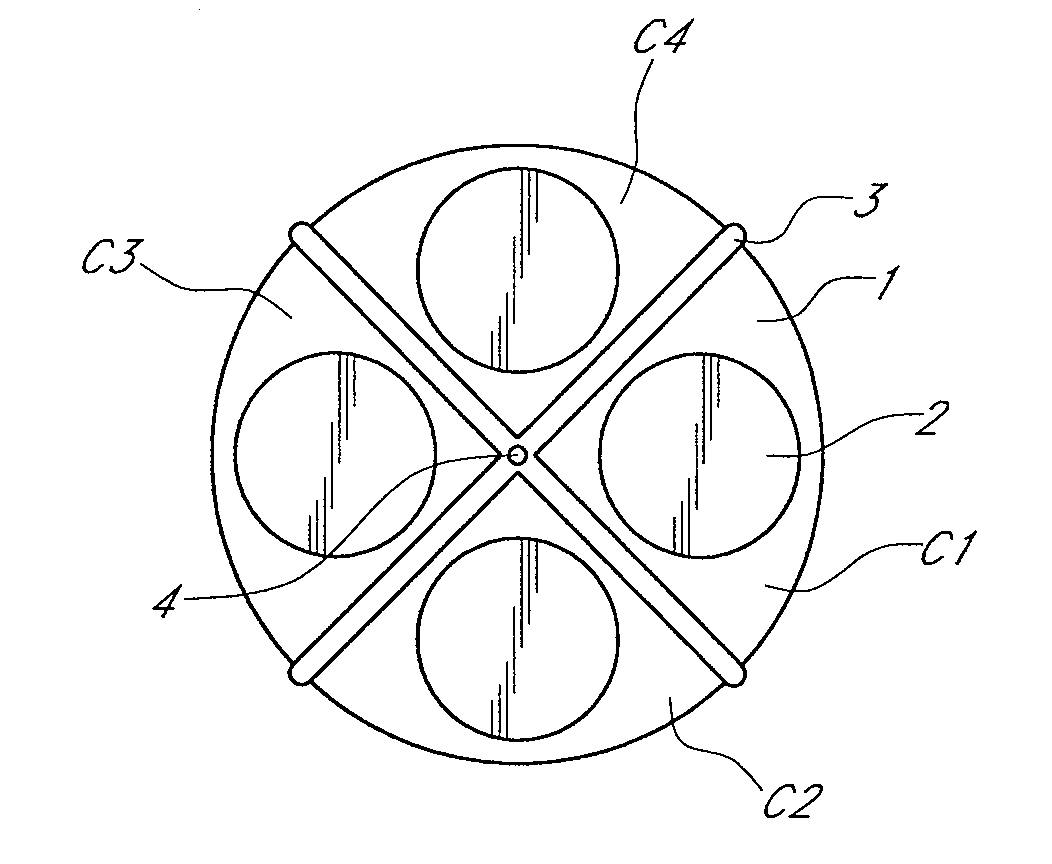

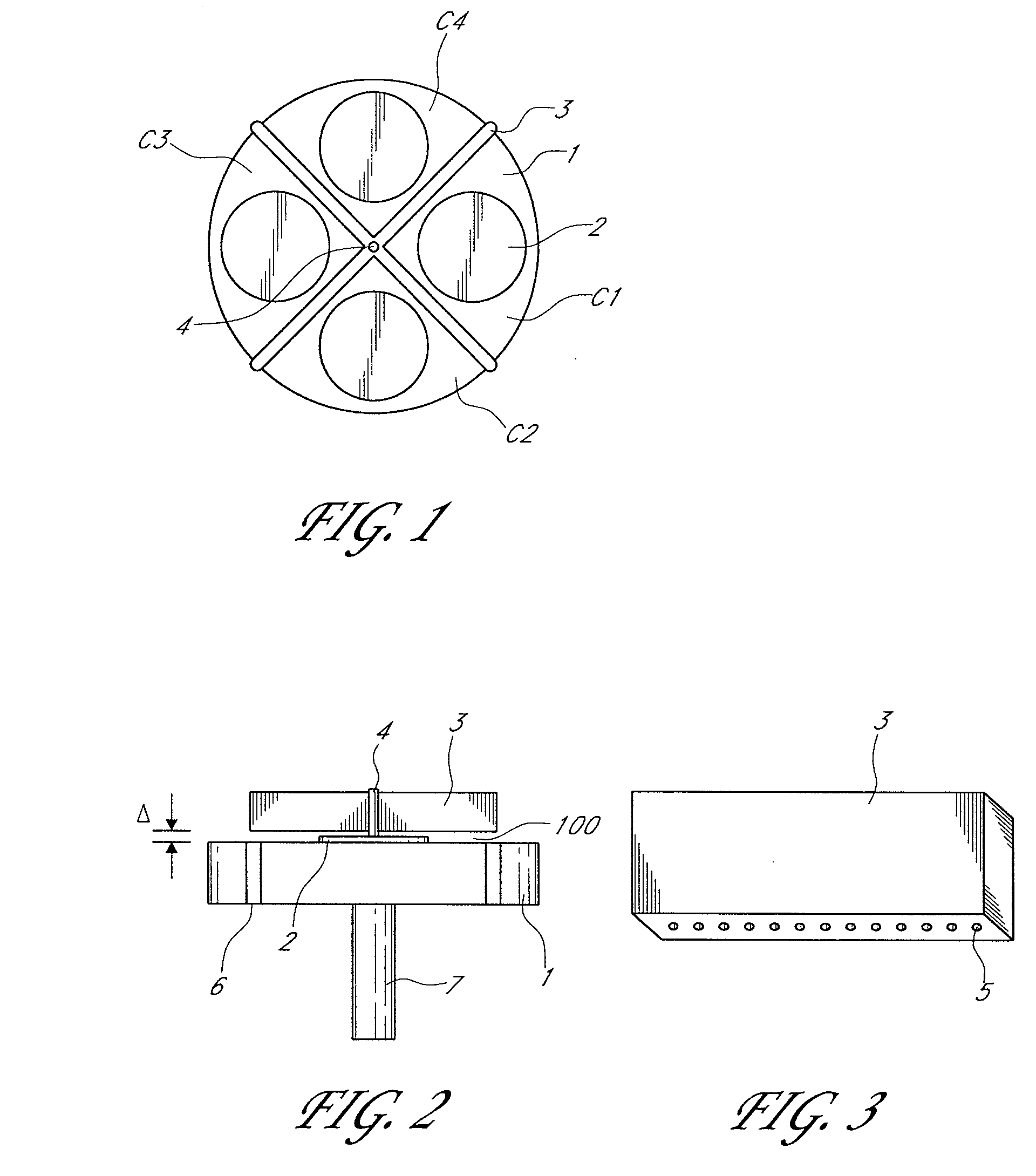

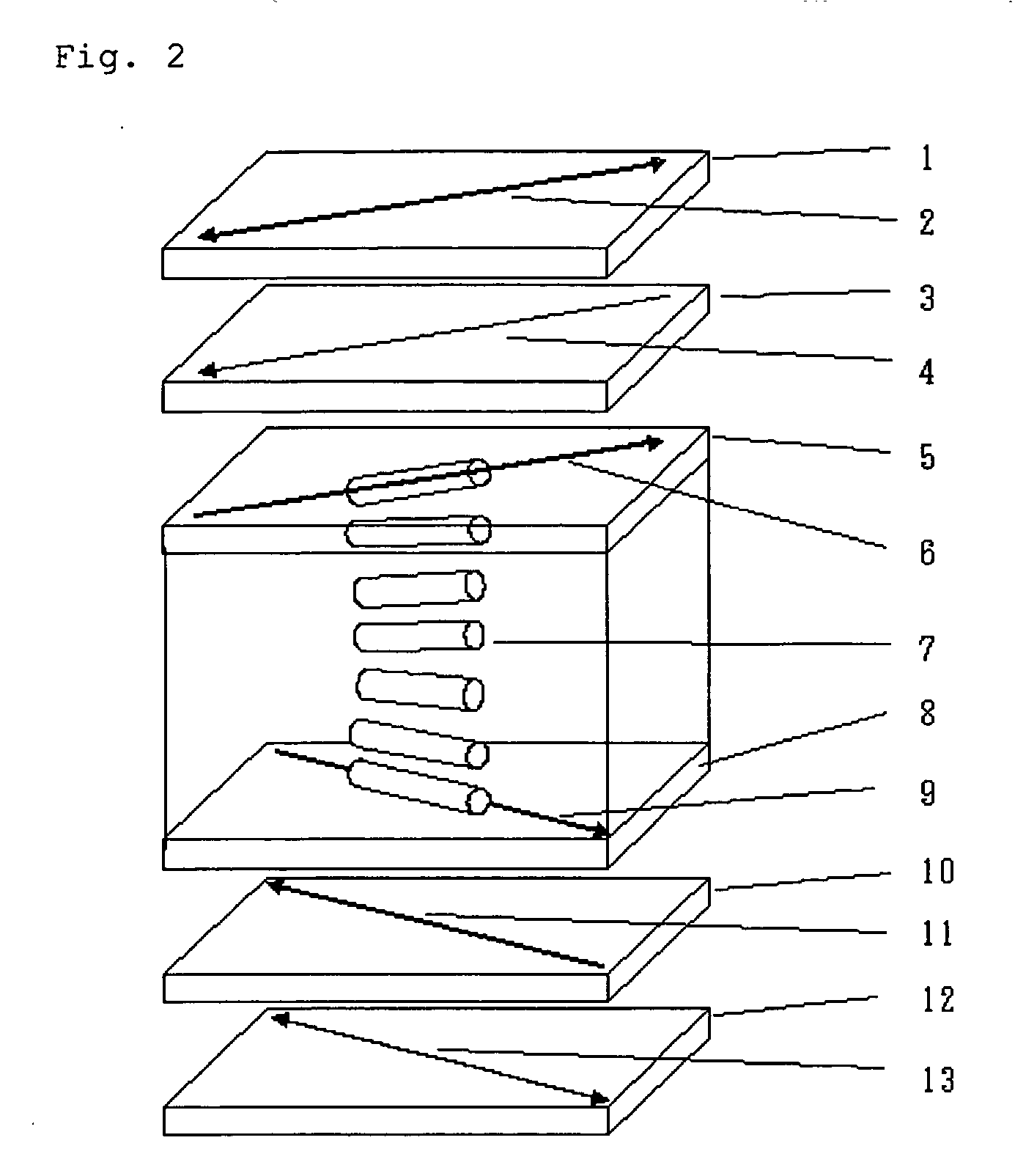

An apparatus for depositing thin film on a processing target includes: a reaction space; a susceptor movable up and down and rotatable around its center axis; and isolation walls that divide the reaction space into multiple compartments including source gas compartments and purge gas compartments, wherein when the susceptor is raised for film deposition, a small gap is created between the susceptor and the isolation walls, thereby establishing gaseous separation between the respective compartments, wherein each source gas compartment and each purge gas compartment are provided alternately in a susceptor-rotating direction of the susceptor.

Owner:ASM JAPAN

Semiconductor-processing apparatus with rotating susceptor

InactiveUS20070218701A1Stable controlUnnecessary film deposition is preventedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

An apparatus for depositing thin film on a processing target includes: a reaction space; a susceptor movable up and down and rotatable around its center axis; and isolation walls that divide the reaction space into multiple compartments including source gas compartments and purge gas compartments, wherein when the susceptor is raised for film deposition, a small gap is created between the susceptor and the isolation walls, thereby establishing gaseous separation between the respective compartments, wherein each source gas compartment and each purge gas compartment are provided alternately in a susceptor-rotating direction of the susceptor.

Owner:ASM JAPAN

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

ActiveUS7342070B2Reduce fuel consumptionImprove performanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

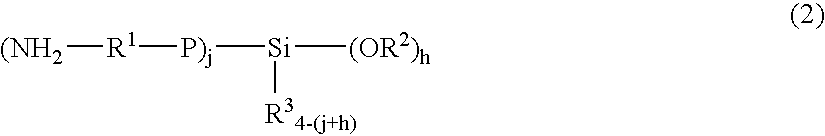

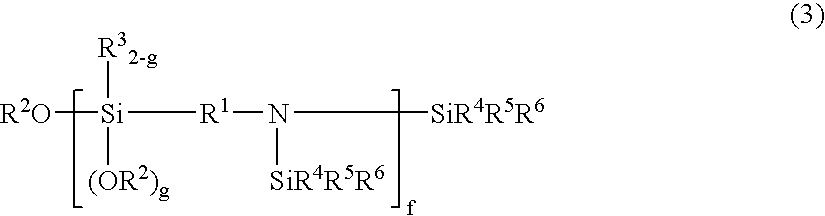

Disclosed are a conjugated diolefin (co) polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co) polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:ENEOS MATERIALS CORP

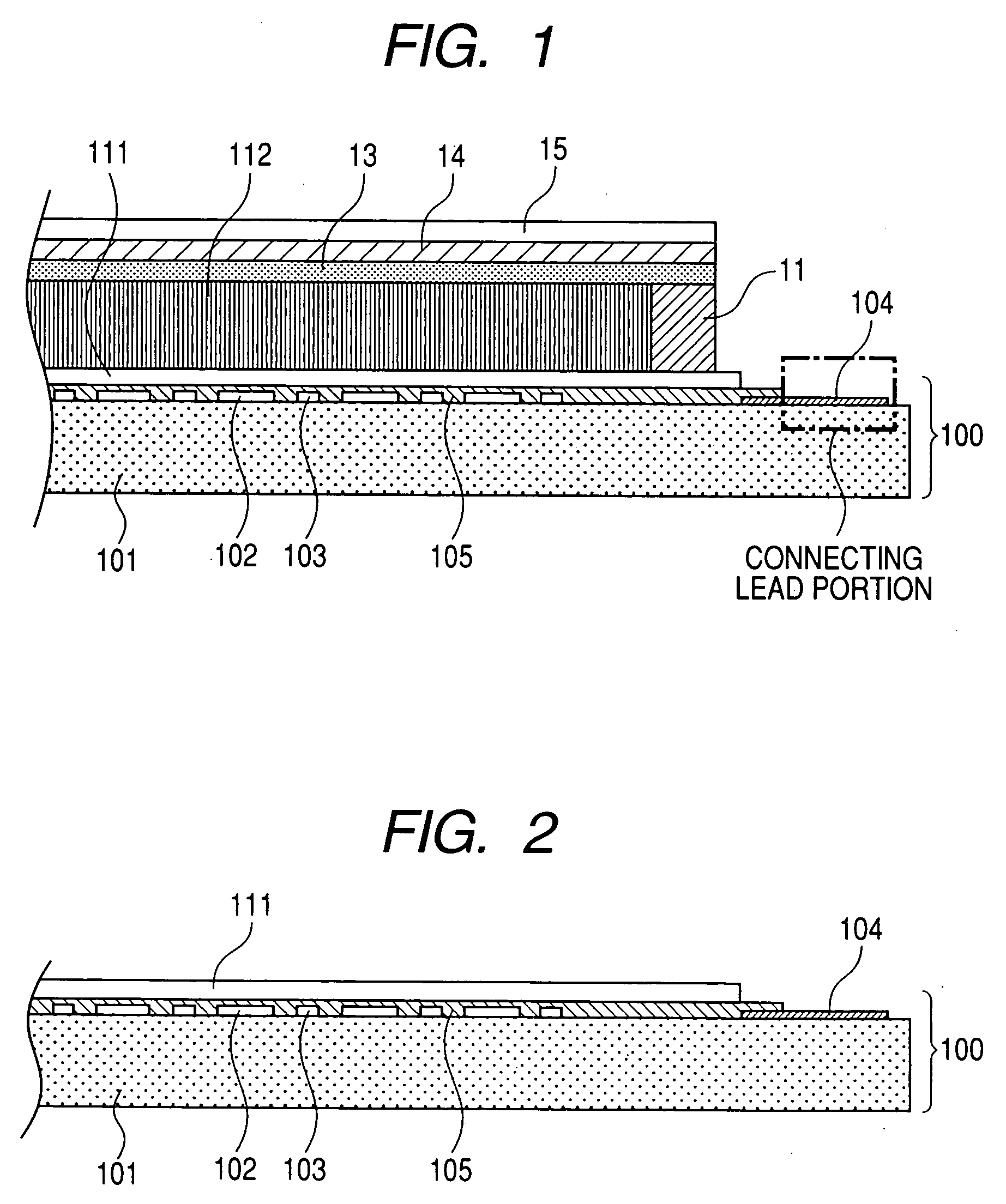

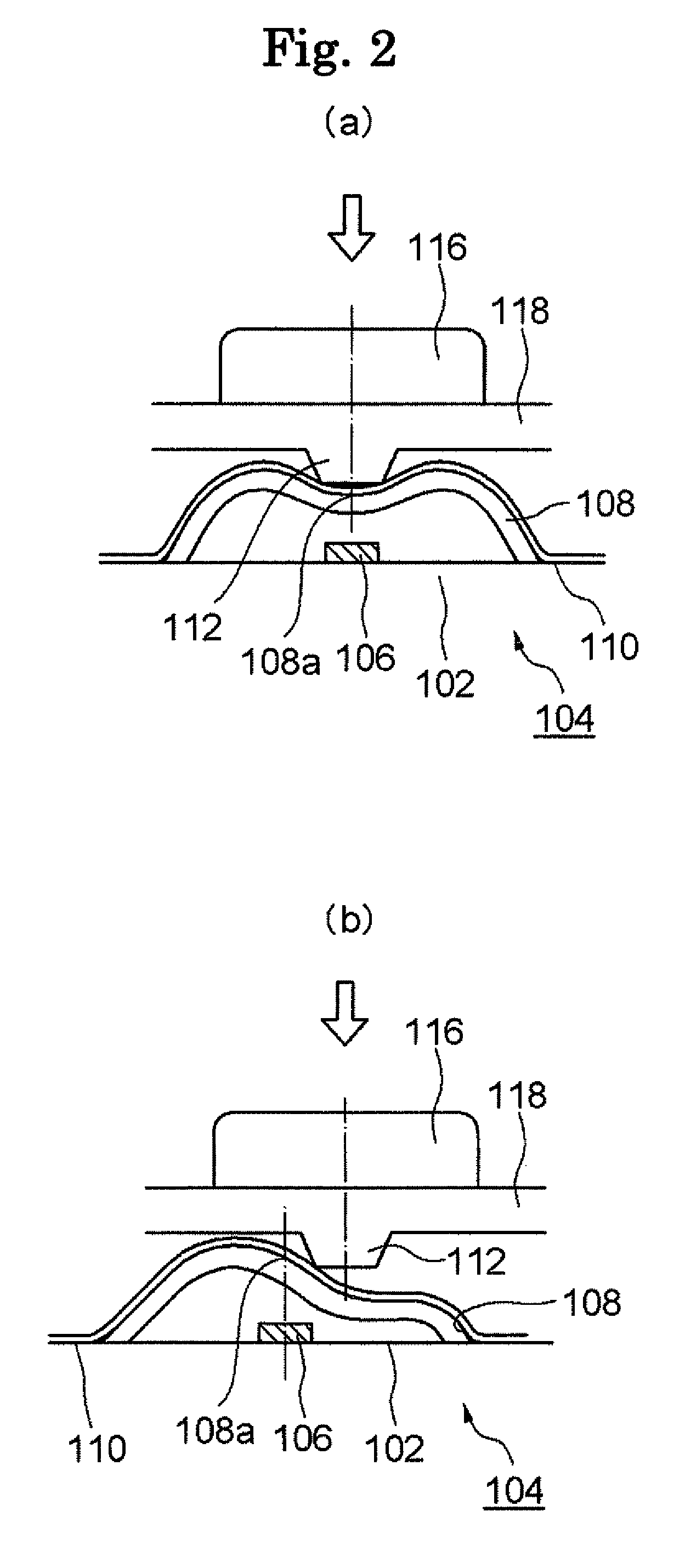

Semiconductor device and method for manufacturing the same

ActiveUS20060063312A1Excellent manufacturing stabilityWarpage suppressionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSilicon

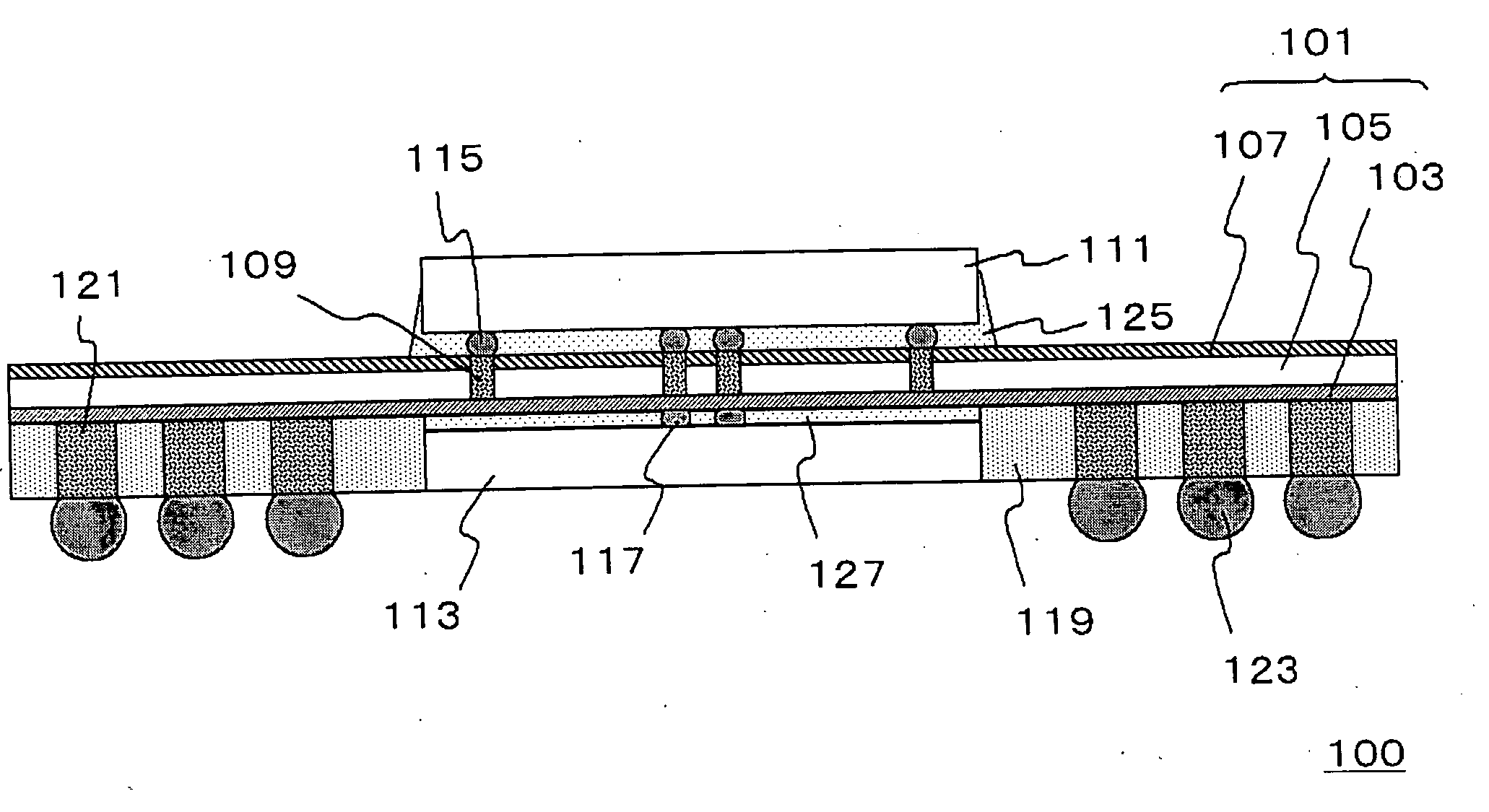

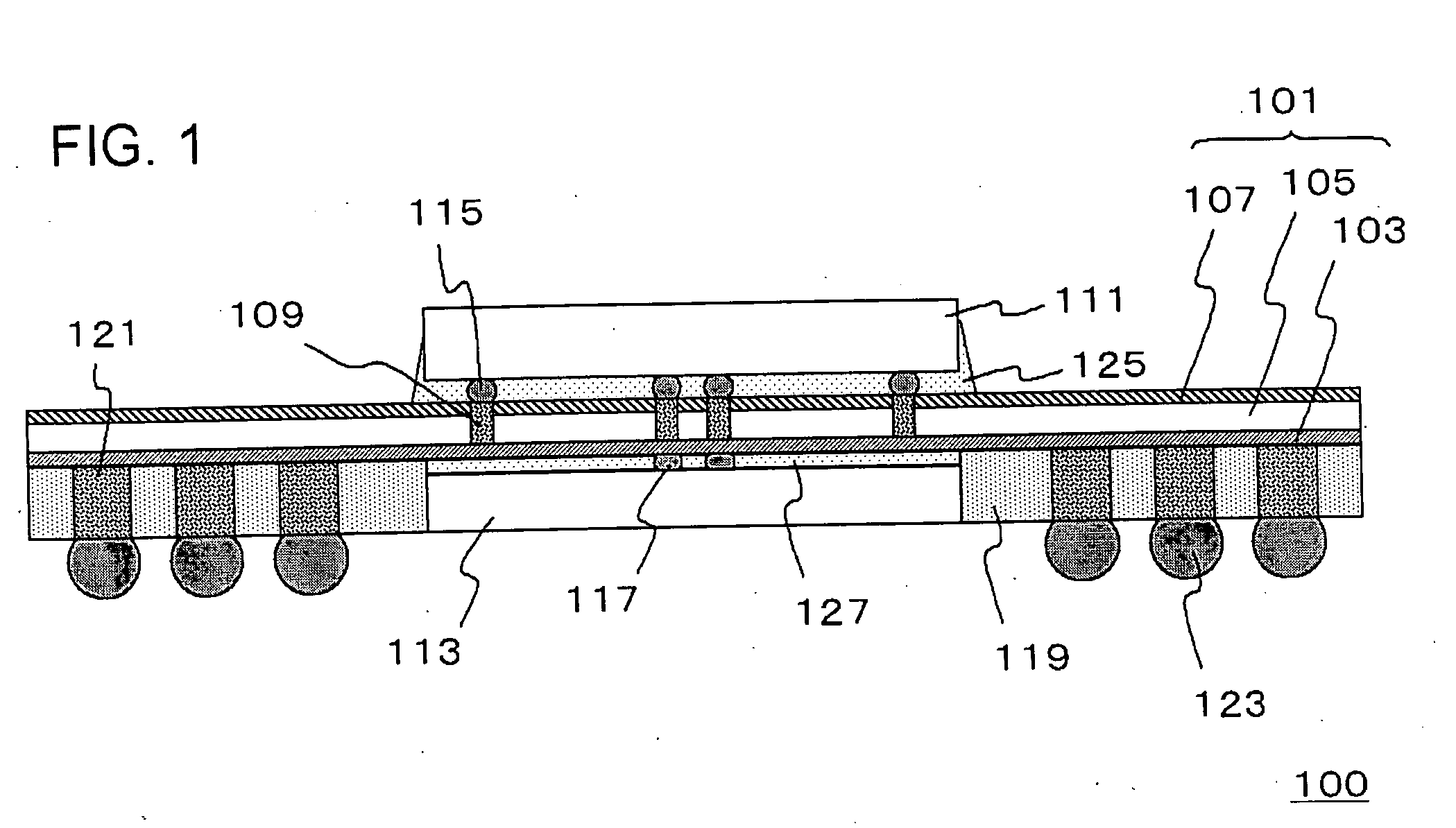

The semiconductor device 100 comprises a first semiconductor element 113 provided on a face on one side of a flat plate shaped interconnect component 101, an insulating resin 119 covering a face of a side where the first semiconductor element 113 of the interconnect component 101 is provided and a side face of the first semiconductor element 113, and a second semiconductor element 111 provided on a face on the other side of the interconnect component 101. The interconnect component 101 has a constitution where an interconnect layer 103, a silicon layer 105 and an insulating film 107 are sequentially formed. The interconnect layer 103 has a constitution where the interconnect layer 103 has a flat plate shaped insulating component and a conductive component extending through the insulating component. The first semiconductor element 113 is electrically connected with the second semiconductor element 111 through the conductive component.

Owner:RENESAS ELECTRONICS CORP

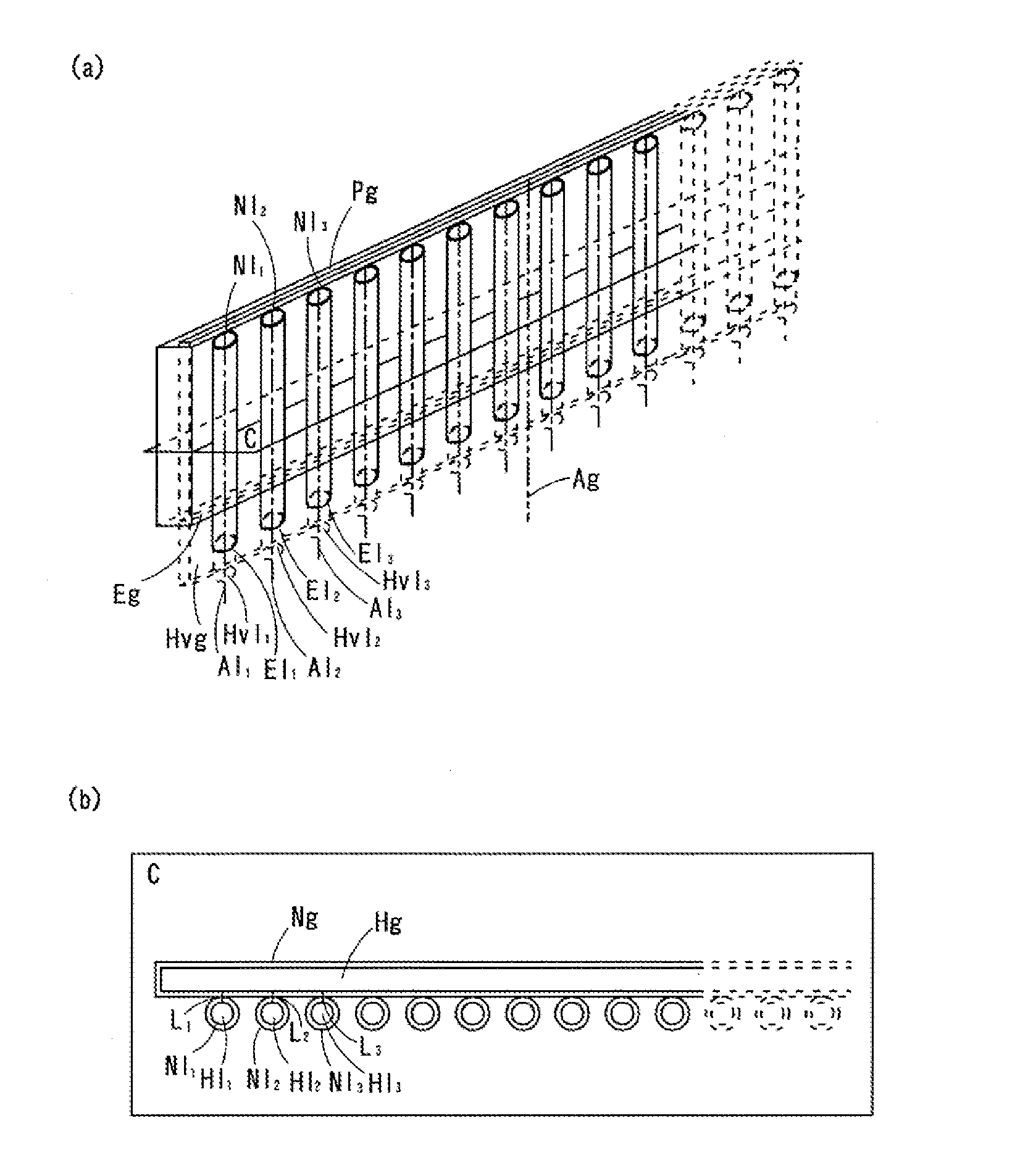

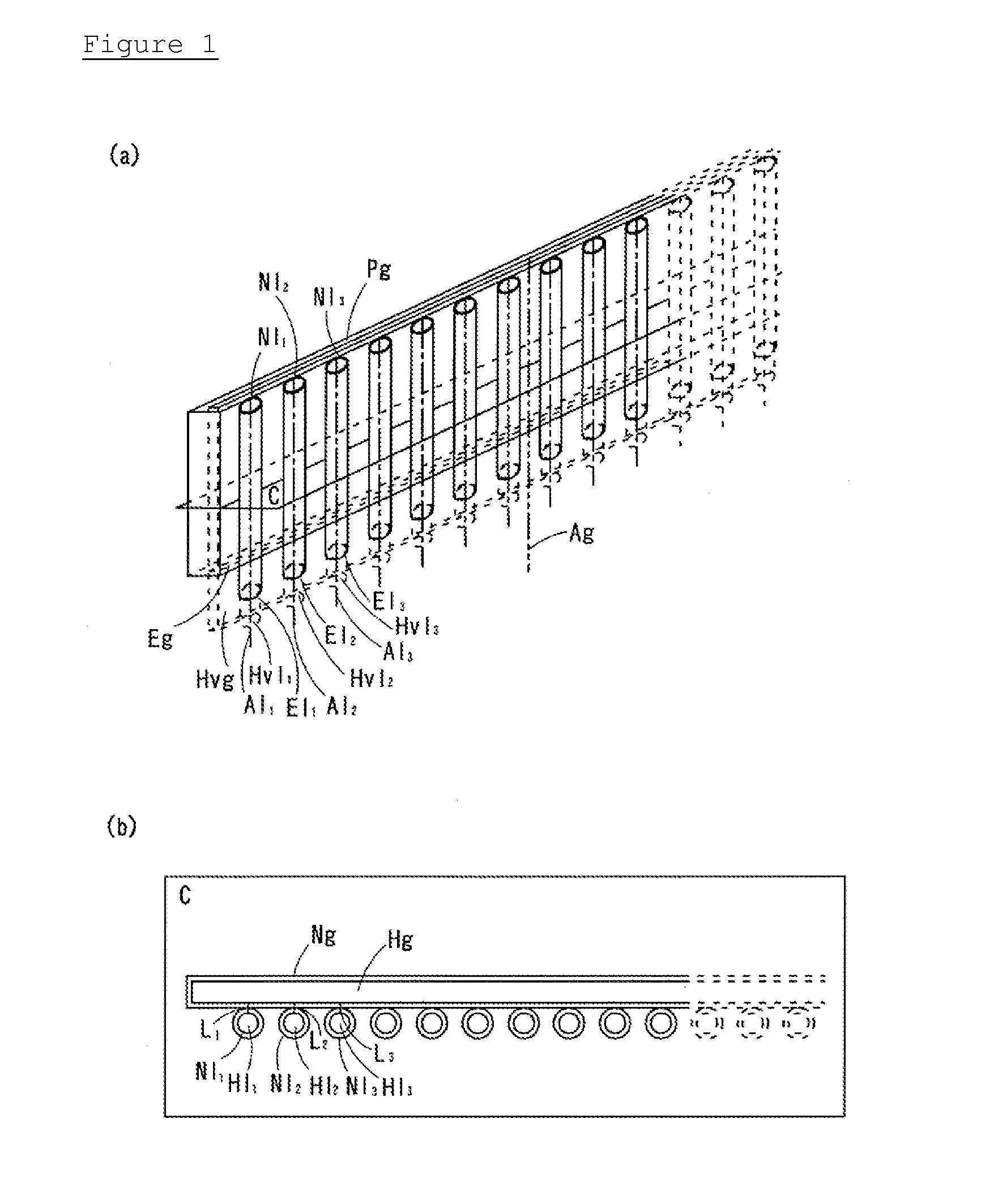

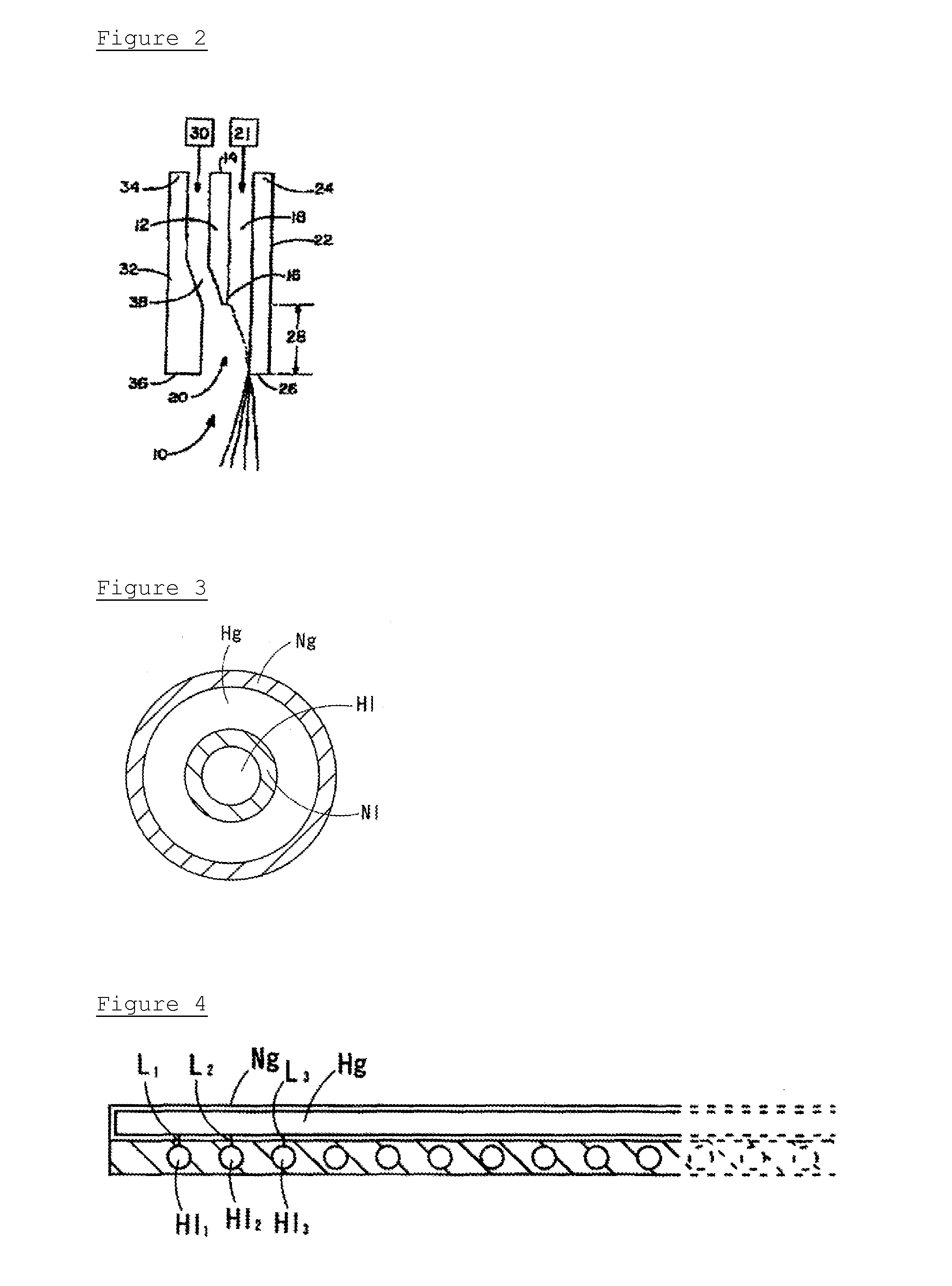

Air ionizer and method

InactiveUS6850403B1Easy to installStable and balanced ion productionElectrographic process apparatusCorona dischargeEngineeringVoltage

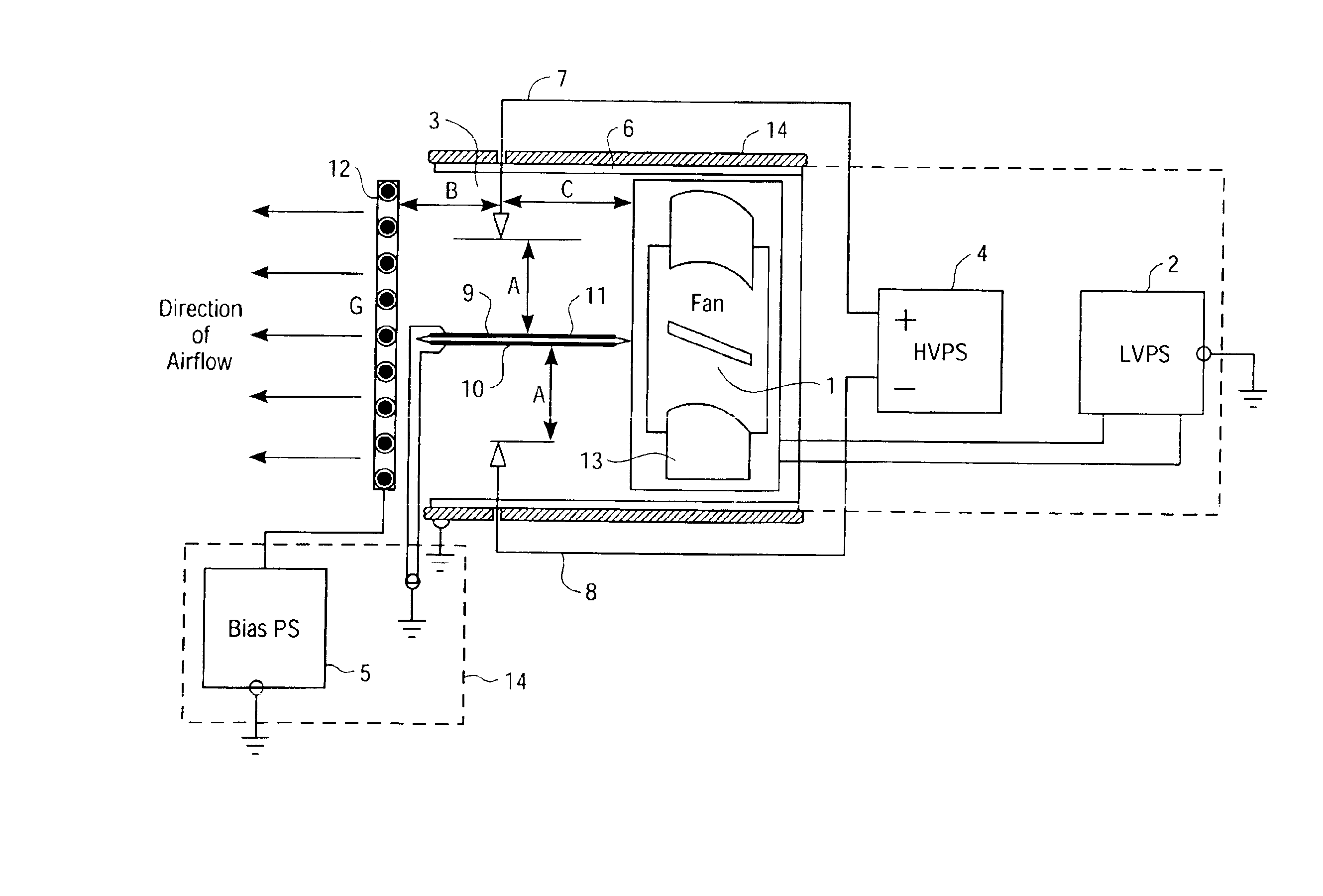

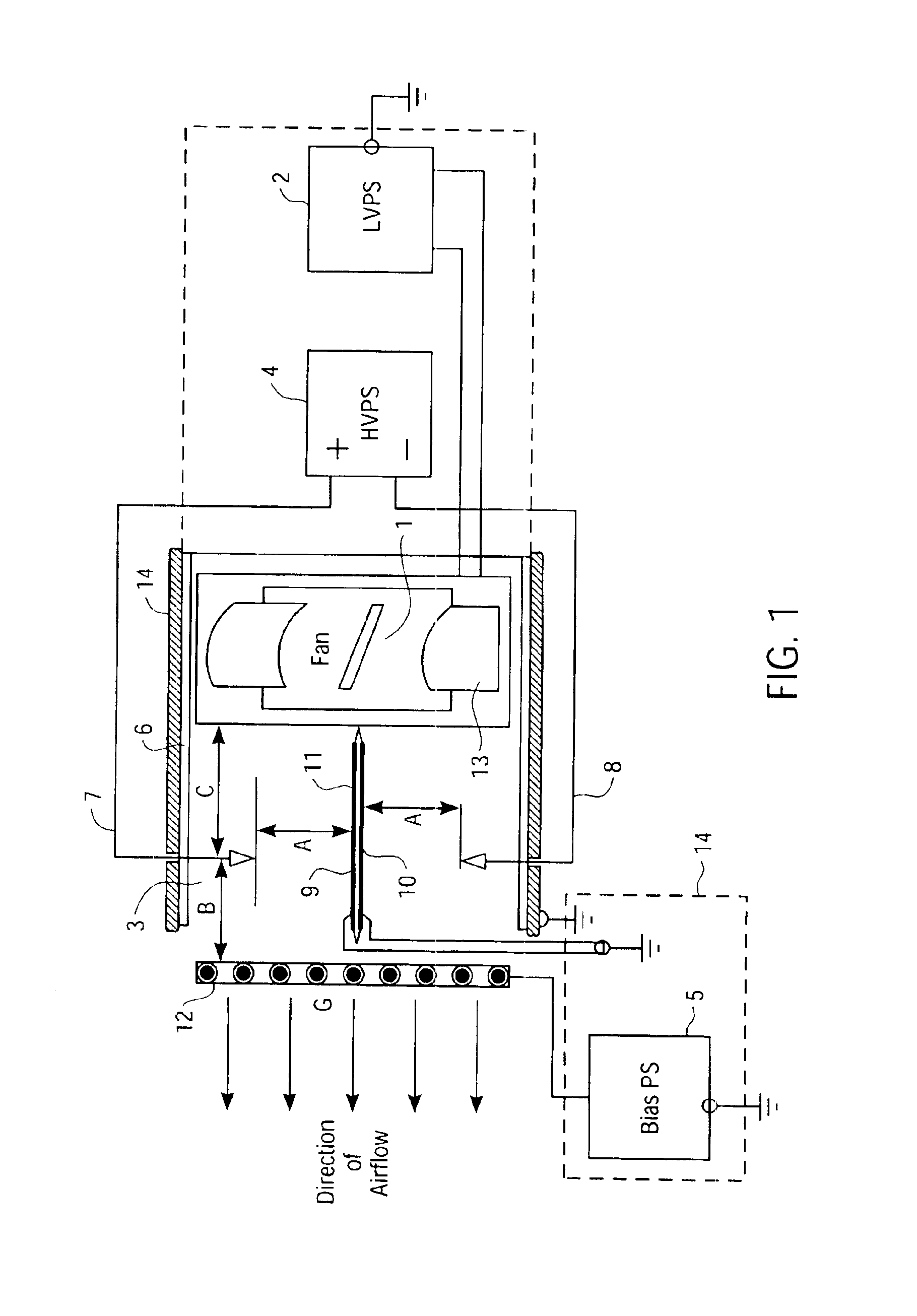

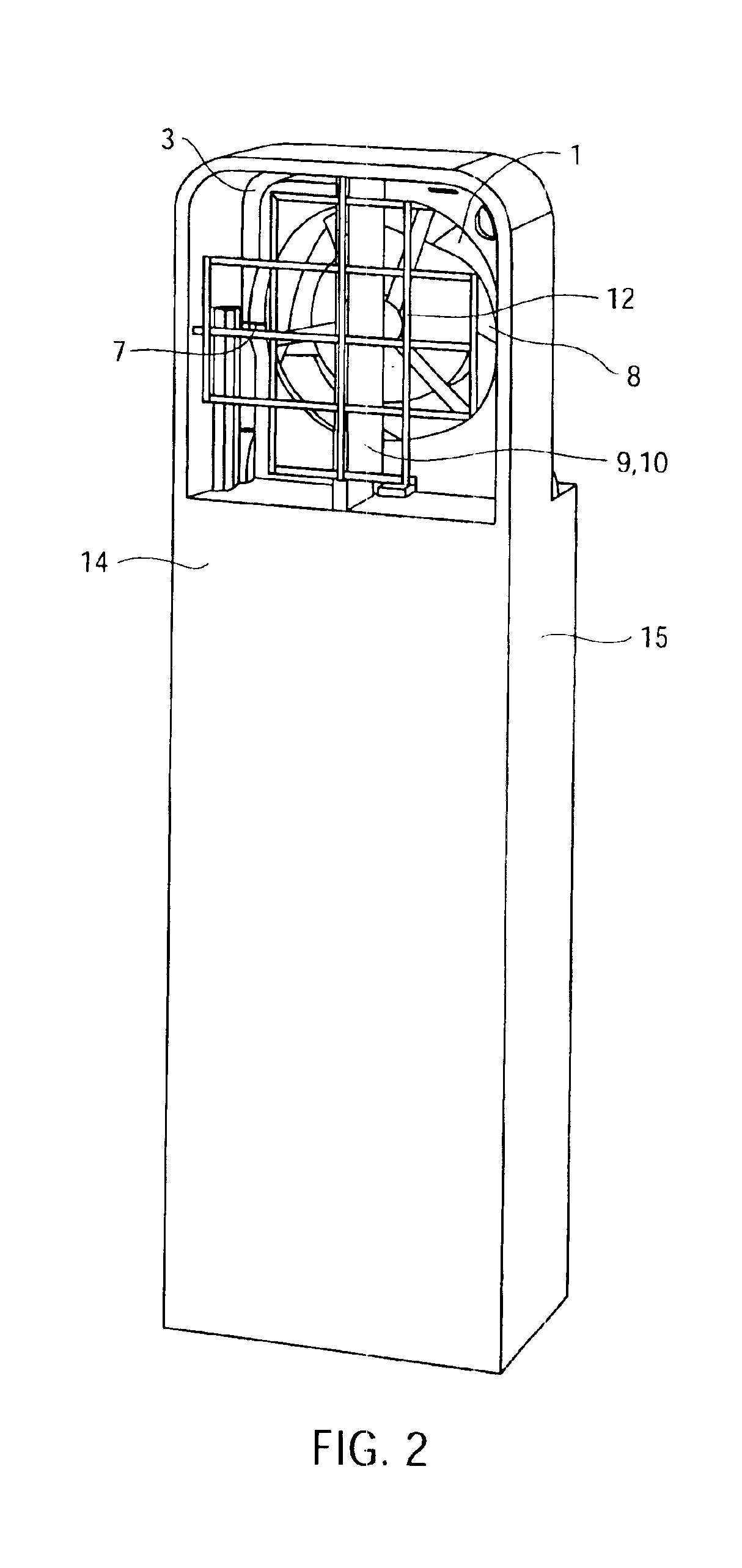

Apparatus and method for generating and controlling flows of positive and negative air ions includes interposing isolated sets of electrodes in a flowing air stream to separately produce positive and negative ions. The rates of separated production of positive and negative ions are sensed to control ionizing voltages applied to electrodes that produce the ions. Variations from a balance condition of substantially equal amounts of positive and negative ions flowing in the air stream are also sensed to alter bias voltage applied to a grid electrode through which the air stream and ions flow.

Owner:ILLINOIS TOOL WORKS INC

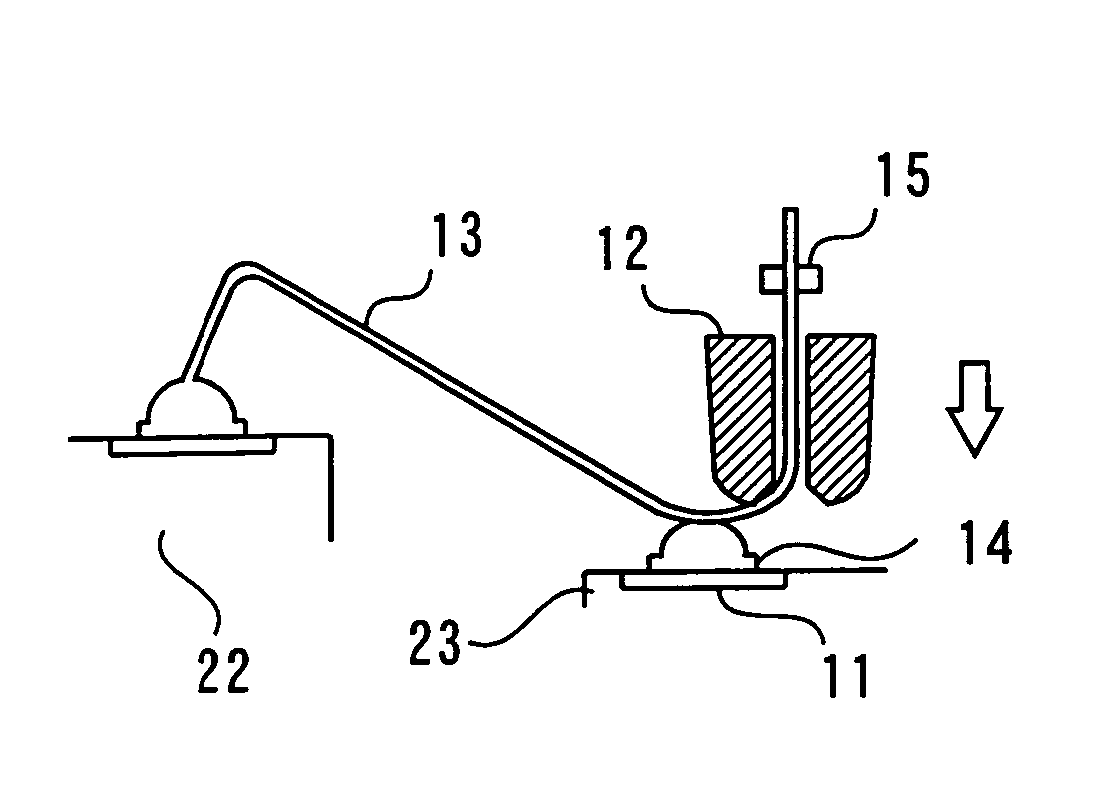

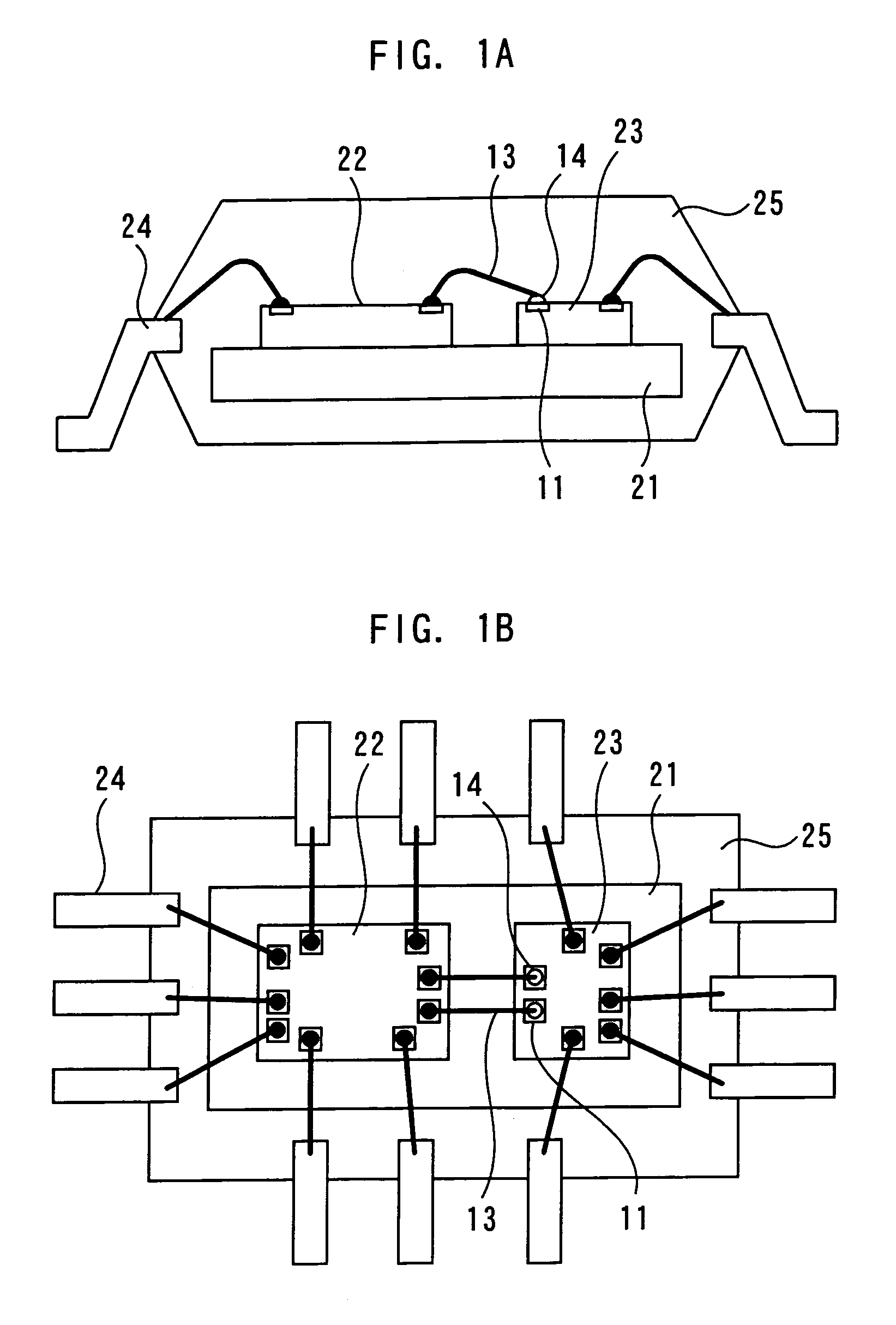

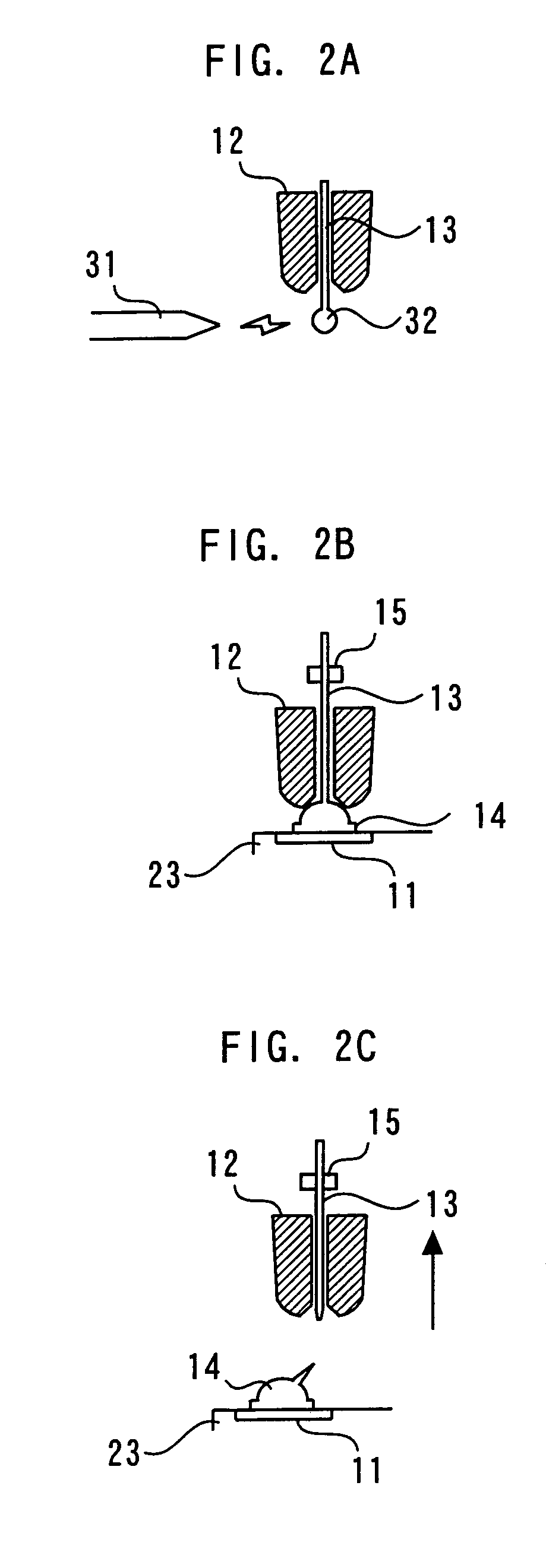

Semiconductor device and method of manufacturing the same

InactiveUS7456091B2Speed up preparationReduce loadSemiconductor/solid-state device detailsSolid-state devicesBreaking strengthUltimate tensile strength

A semiconductor device of the present invention includes a chip which has a pad; a bump electrode formed on the pad; and a wire whose stitch bonding is made on the bump electrode. The wire satisfies a condition: (modulus-of-elasticity / breaking strength per unit area) ≧400.

Owner:RENESAS ELECTRONICS CORP

Stabilized controlled release substrate having a coating derived from an aqueous dispersion of hydrophobic polymer

InactiveUS6316031B1Reduce reunionStable productionLiquid surface applicatorsGranular deliveryHydrophobic polymerDissolution

A stabilized solid controlled release dosage form having a coating derived from an aqueous dispersion of ethylcellulose is obtained by overcoating a substrate including a therapeutically active with an aqueous dispersion of ethylcellulose and then curing the coated substrate at a temperature and relative humidity elevated to a suitable level above ambient conditions until the coated dosage form attains a stabilized dissolution profile substantially unaffected by exposure to storage conditions of elevated temperature and / or elevated relative humidity.

Owner:PURDUE PHARMA LP

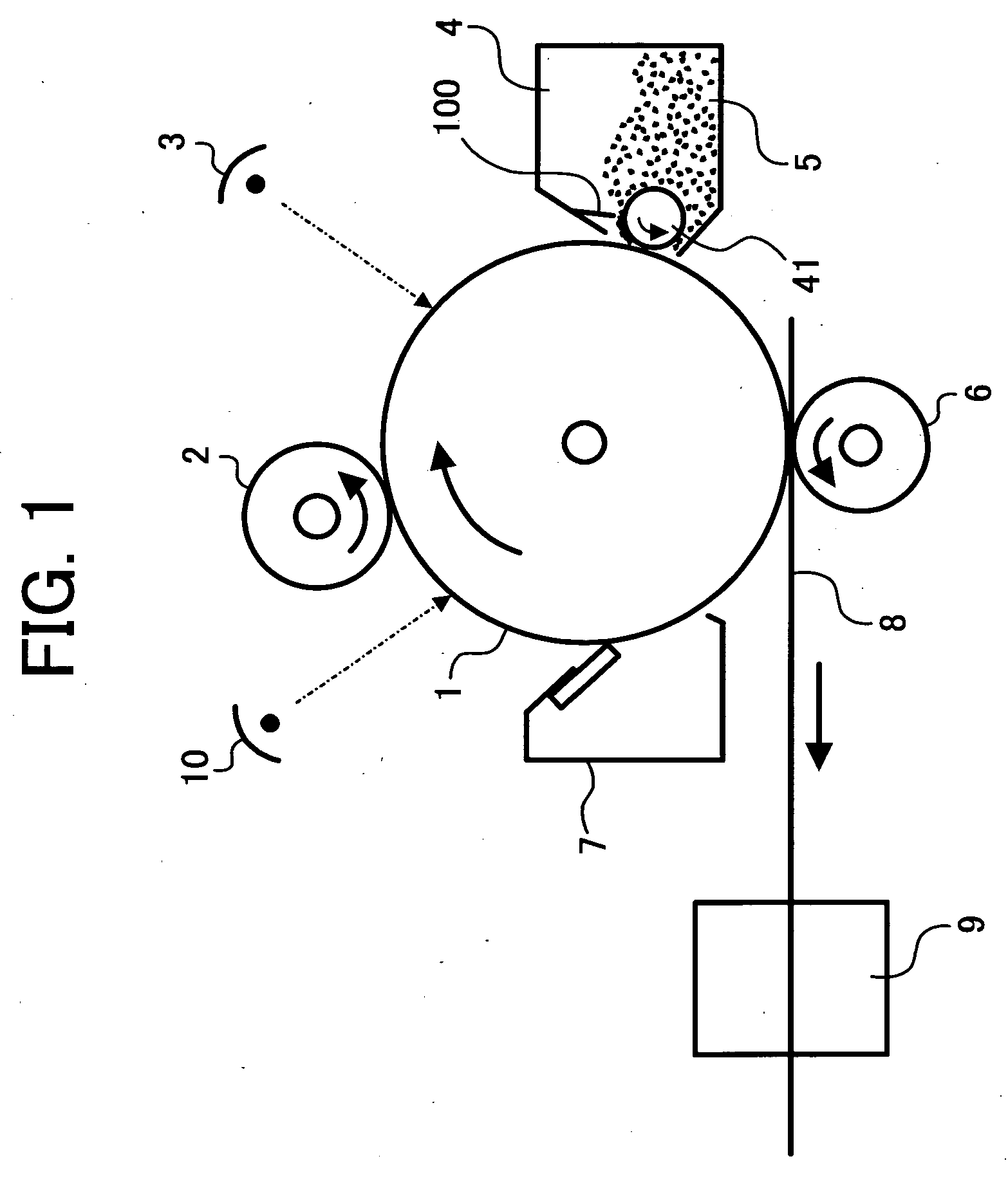

Toner for forming image, developer including the toner, method for preparing the toner, and image forming method and apparatus and process cartridge using the toner

InactiveUS20050164112A1Good combination of resolutionStable productionDevelopersEmulsionOrganic solvent

A toner including a binder resin including a polyester resin in an amount of from 50 to 100% by weight based on total weight of the binder resin; a colorant; and a resin dispersant selected from the group consisting of modified polyurethane dispersants and combinations of a basic copolymer dispersant with a pigment derivative. A developer including the toner and a carrier. A method for preparing the toner including dissolving or dispersing a toner composition including a modified polyester resin, a colorant, and a resin dispersant in an organic solvent; dispersing the toner composition liquid in an aqueous medium to prepare an emulsion while reacting the modified polyester resin with a compound having an active hydrogen atom; removing the solvent from the emulsion to prepare a toner particle dispersion; and washing and drying the toner particles. An image forming method and apparatus using the toner are also provided.

Owner:RICOH KK

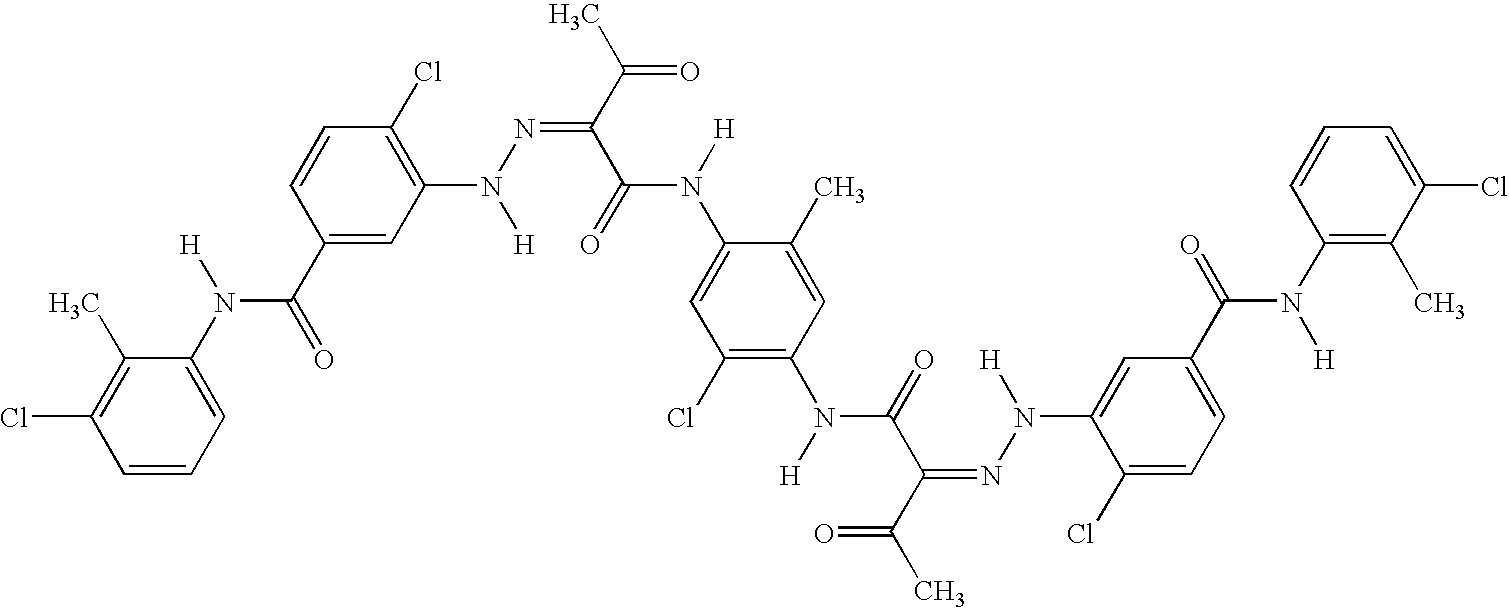

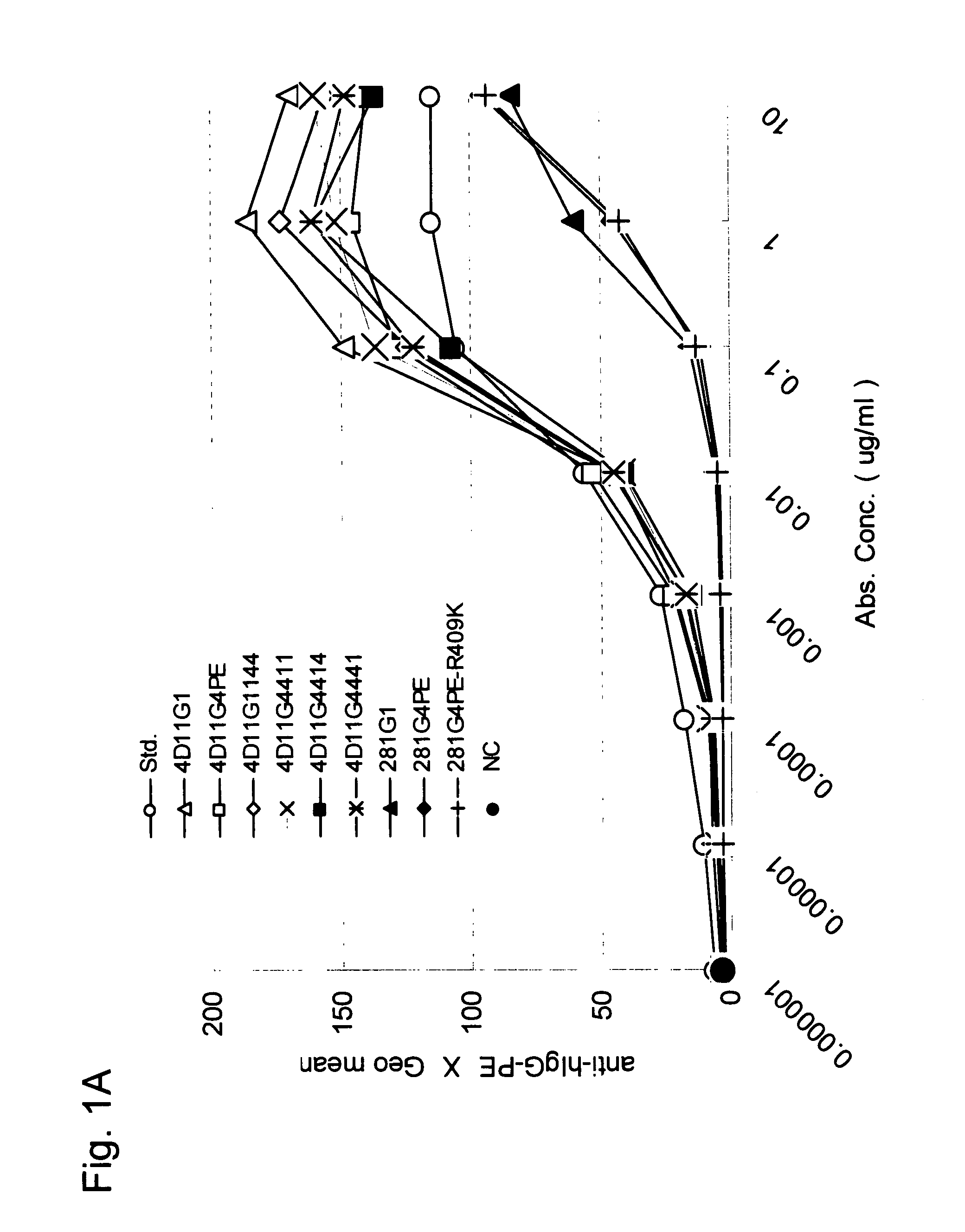

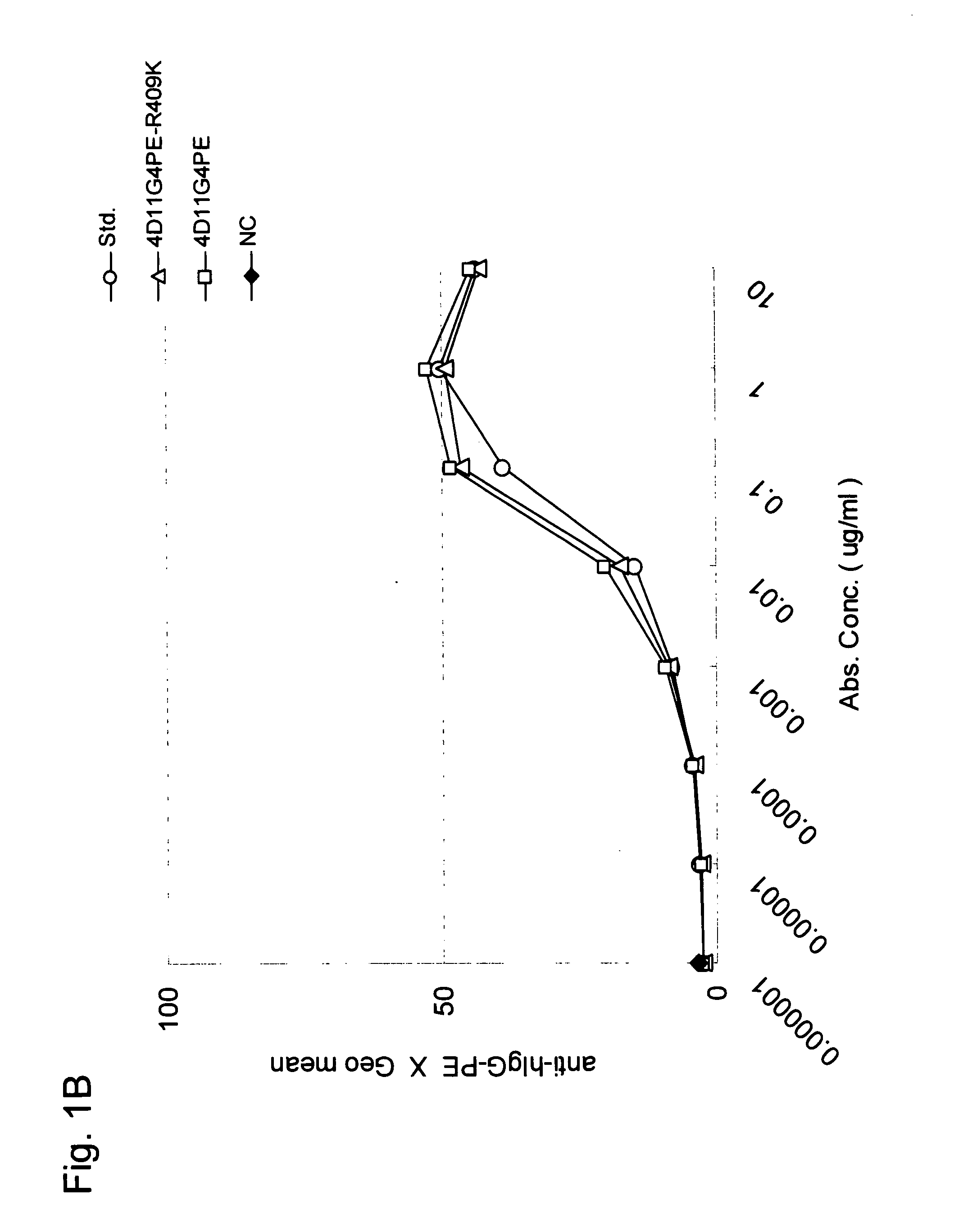

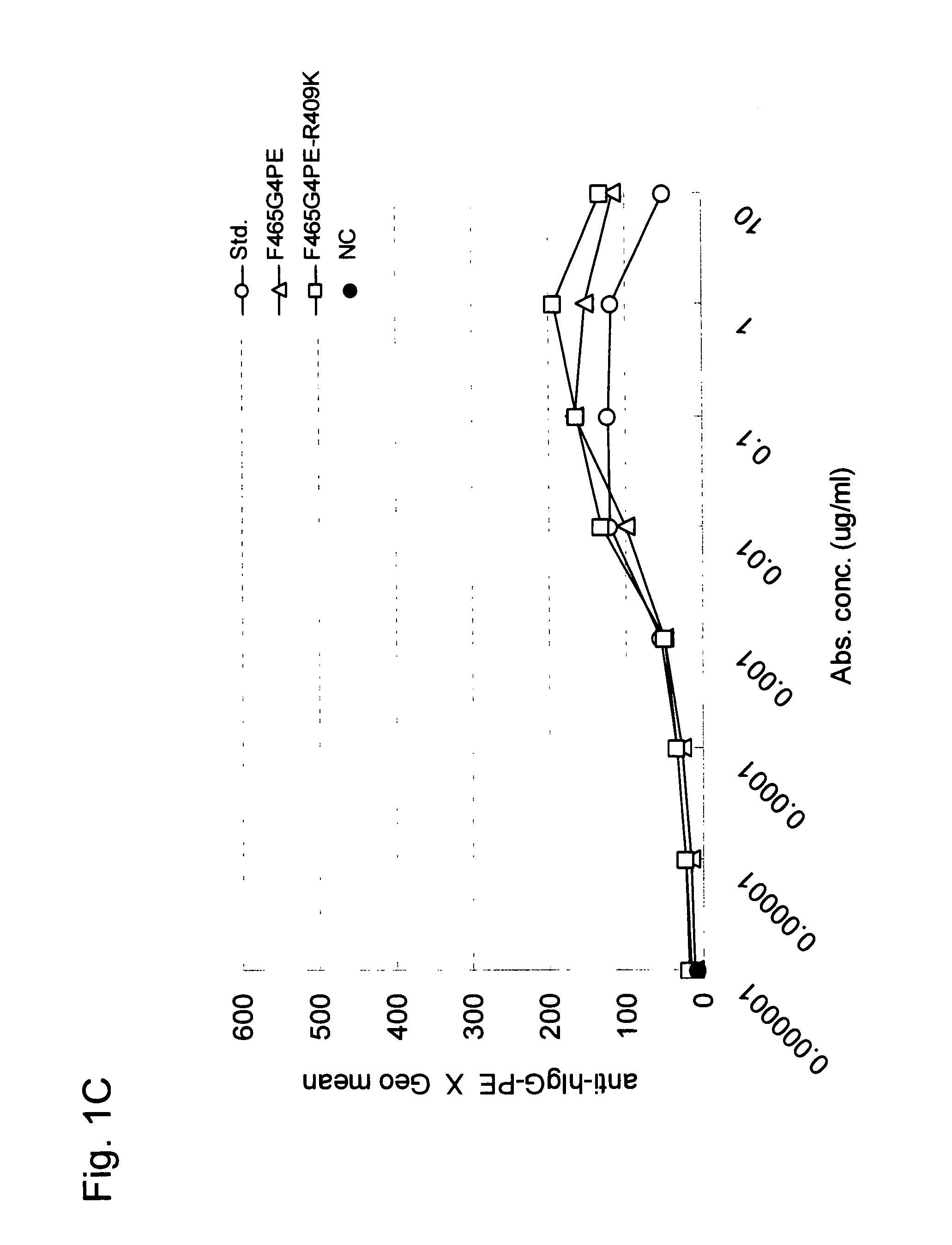

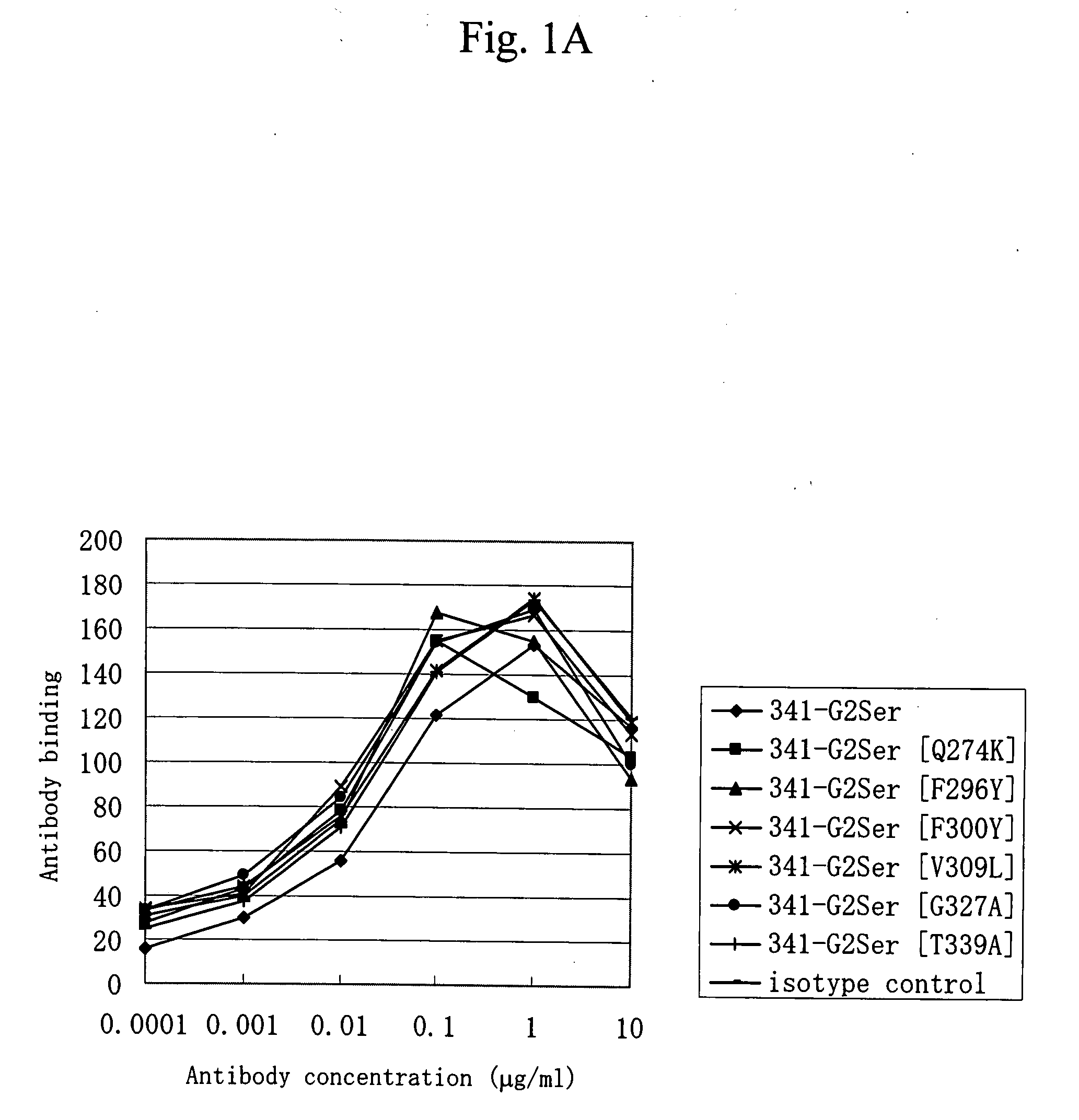

Stabilized human Igg4 antibodies

A highly stable mutant of human IgG4 antibody is provided. Such antibody is an antibody in which the CH3 domain of human IgG4 is substituted with the CH3 domain of human IgG1 and which exhibits inhibited aggregate formation, an antibody in which the CH3 and CH2 domains of human IgG4 are substituted with the CH3 and CH2 domains of human IgG1, respectively, or an antibody in which arginine at position 409 indicated in the EU index proposed by Kabat et al. of human IgG4 is substituted with lysine and which exhibits inhibited aggregate formation.

Owner:KYOWA HAKKO KIRIN CO LTD

Conductive thin film for semiconductor device, semiconductor device, and method of manufacturing the same

InactiveUS6900461B2Performance of semiconductor device does not deteriorateInhibited DiffusionTransistorSemiconductor/solid-state device detailsDevice materialThin membrane

Owner:IDEMITSU KOSAN CO LTD

Rare earth magnet and method therefor

InactiveUS20050133117A1Increase resistanceReduced characteristicsMagnetic circuit rotating partsInorganic material magnetismEddy currentRare-earth magnet

A rare earth magnet includes rare earth magnet particles; and amorphous and / or crystalline terbium oxide present at the boundary of the rare earth magnet particles and represented by the formula: TbOn, wherein 1.5<n≦2. The rare earth magnet prevents decrease eddy current effectively.

Owner:NISSAN MOTOR CO LTD

Electrophotographic photoreceptor, and image forming method, image forming apparatus and process cartridge therefor using the photoreceptor

InactiveUS6861188B2Increased durabilityInhibit deteriorationElectrographic process apparatusCorona dischargePhotochemistryAminal

Owner:RICOH KK

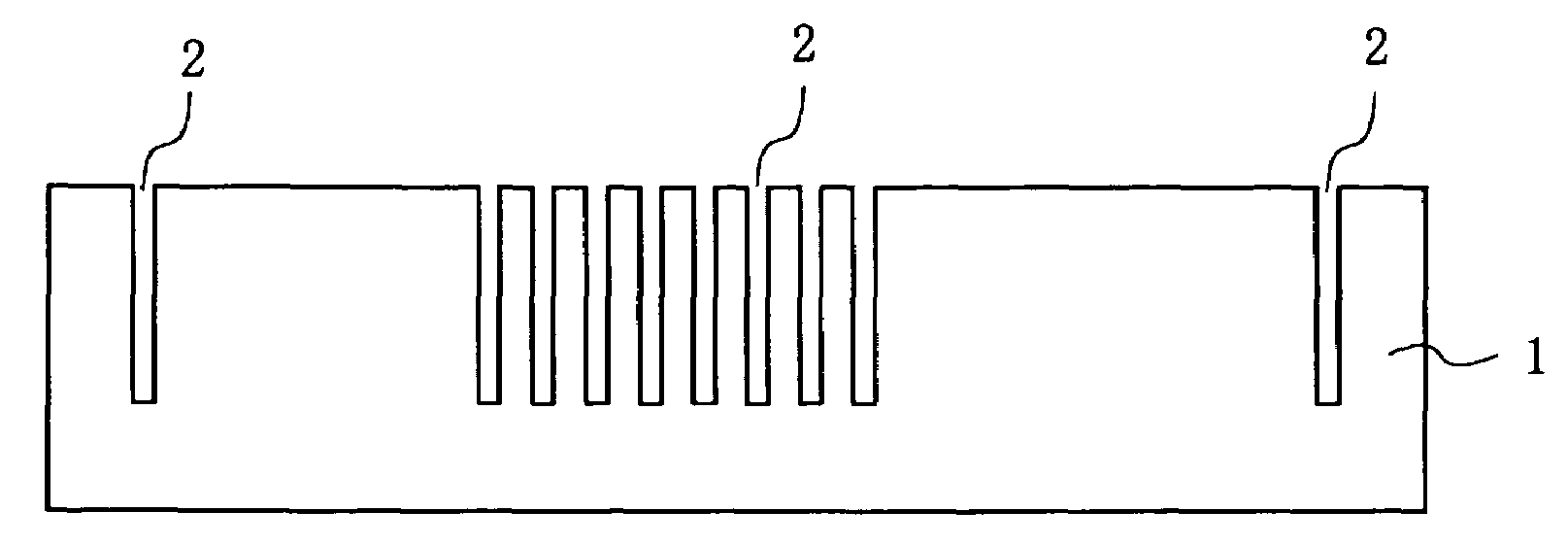

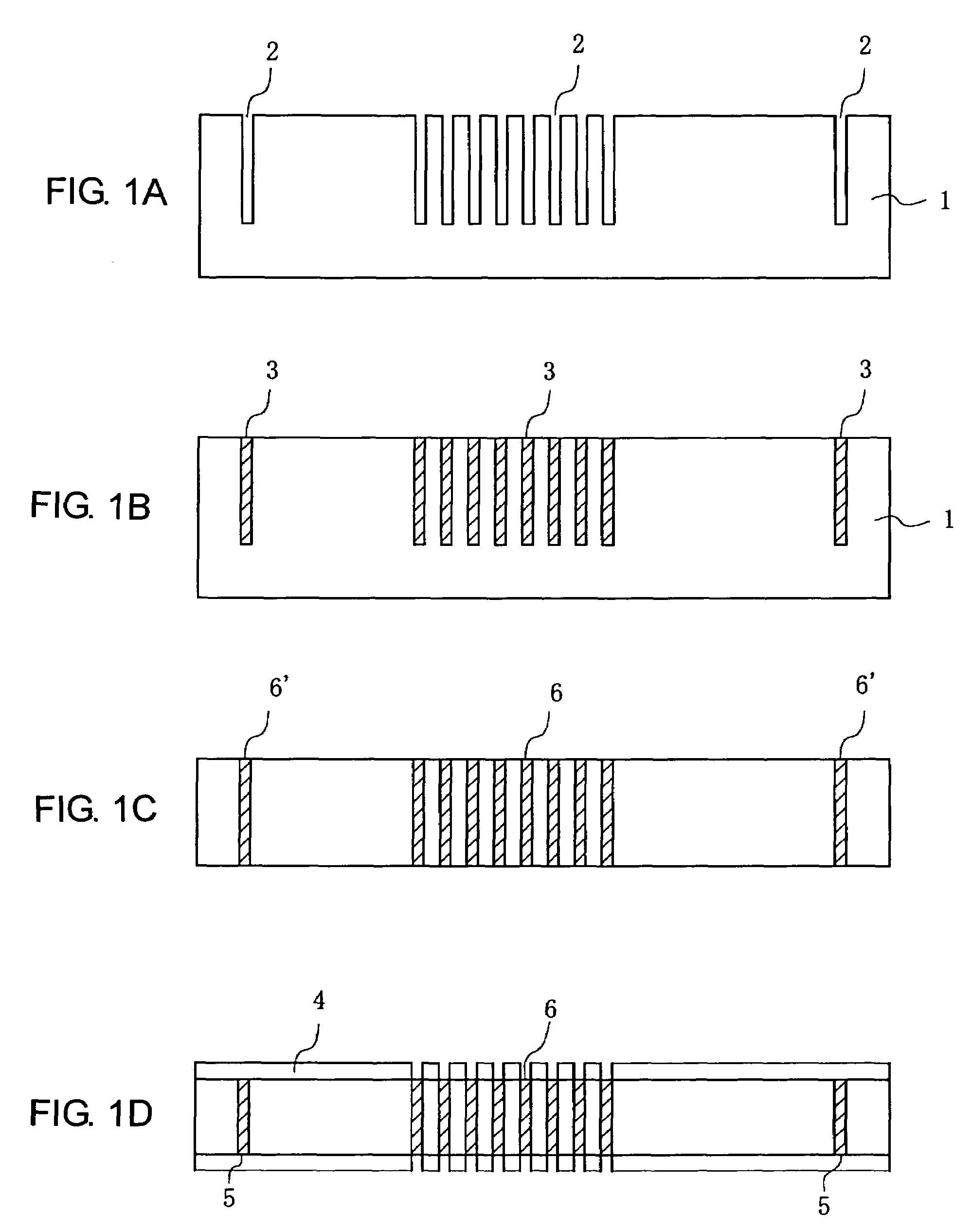

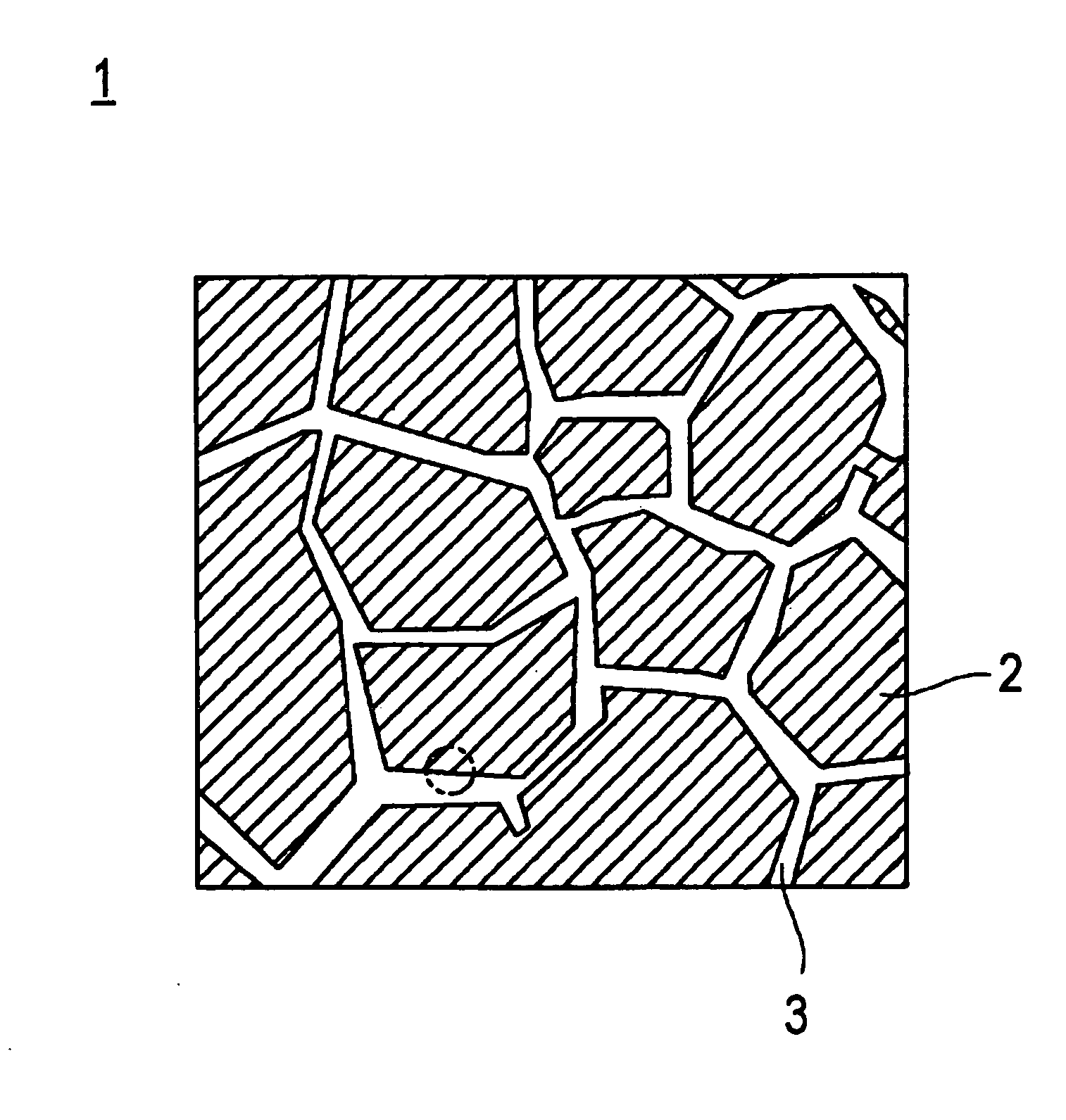

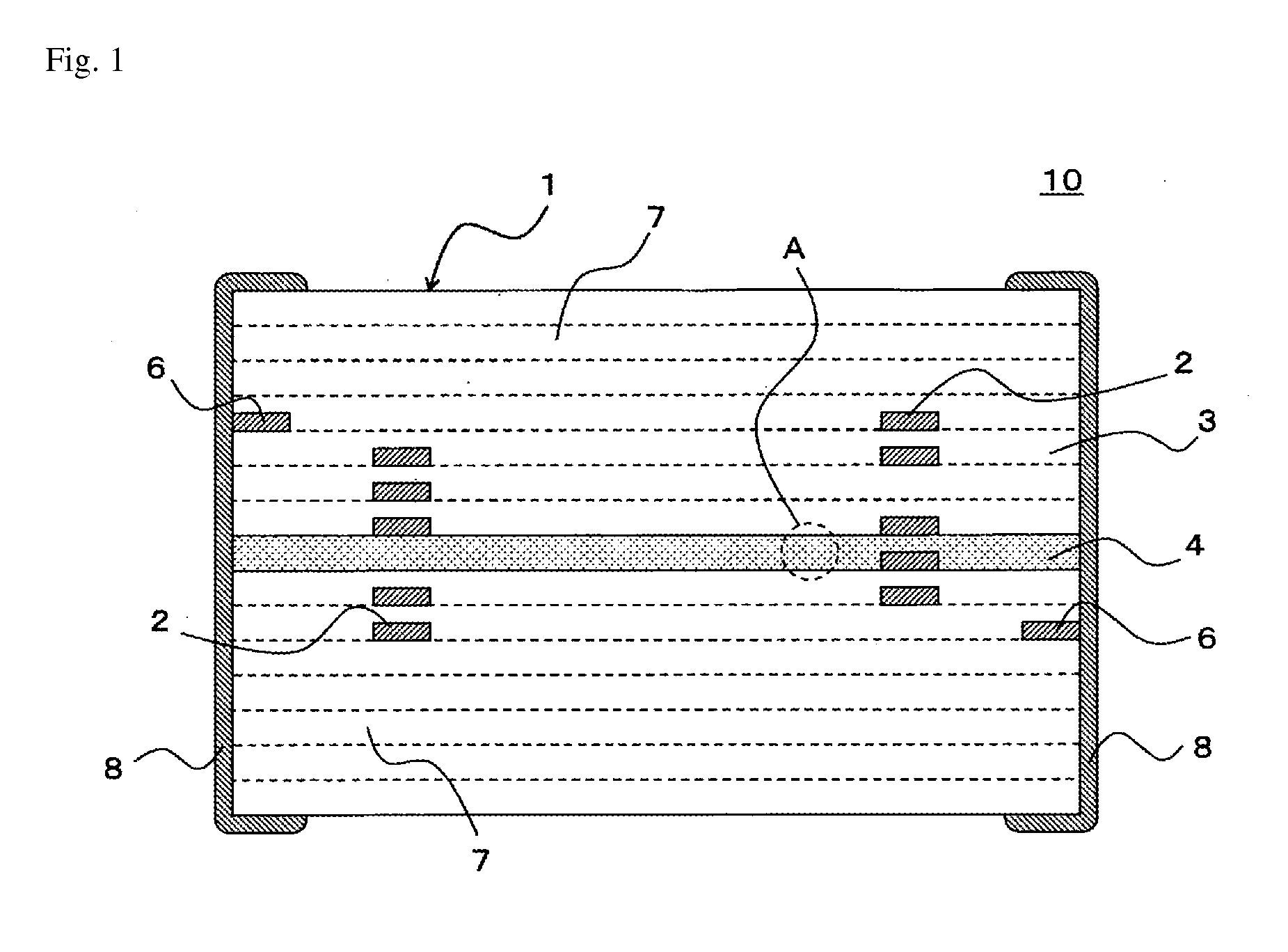

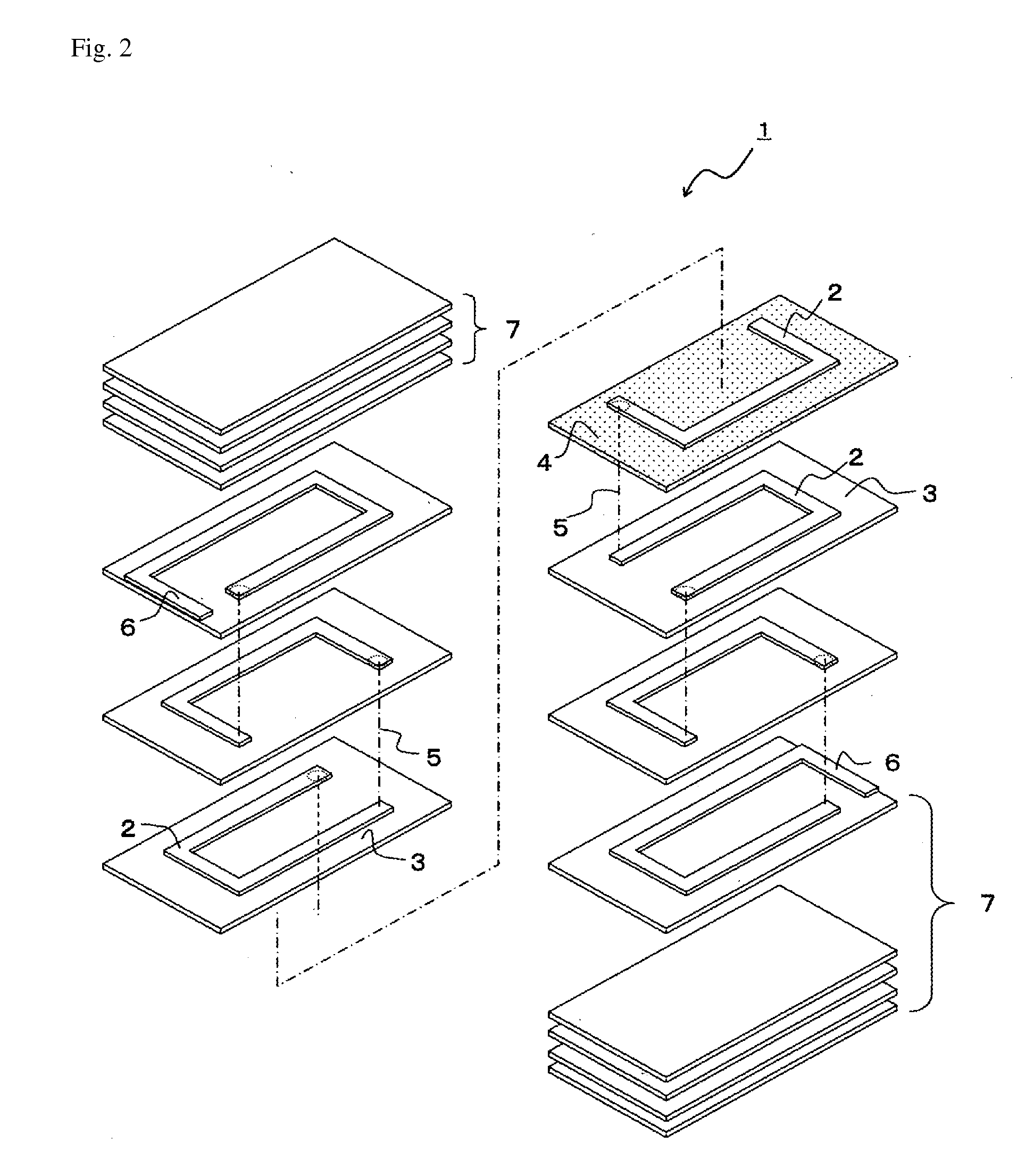

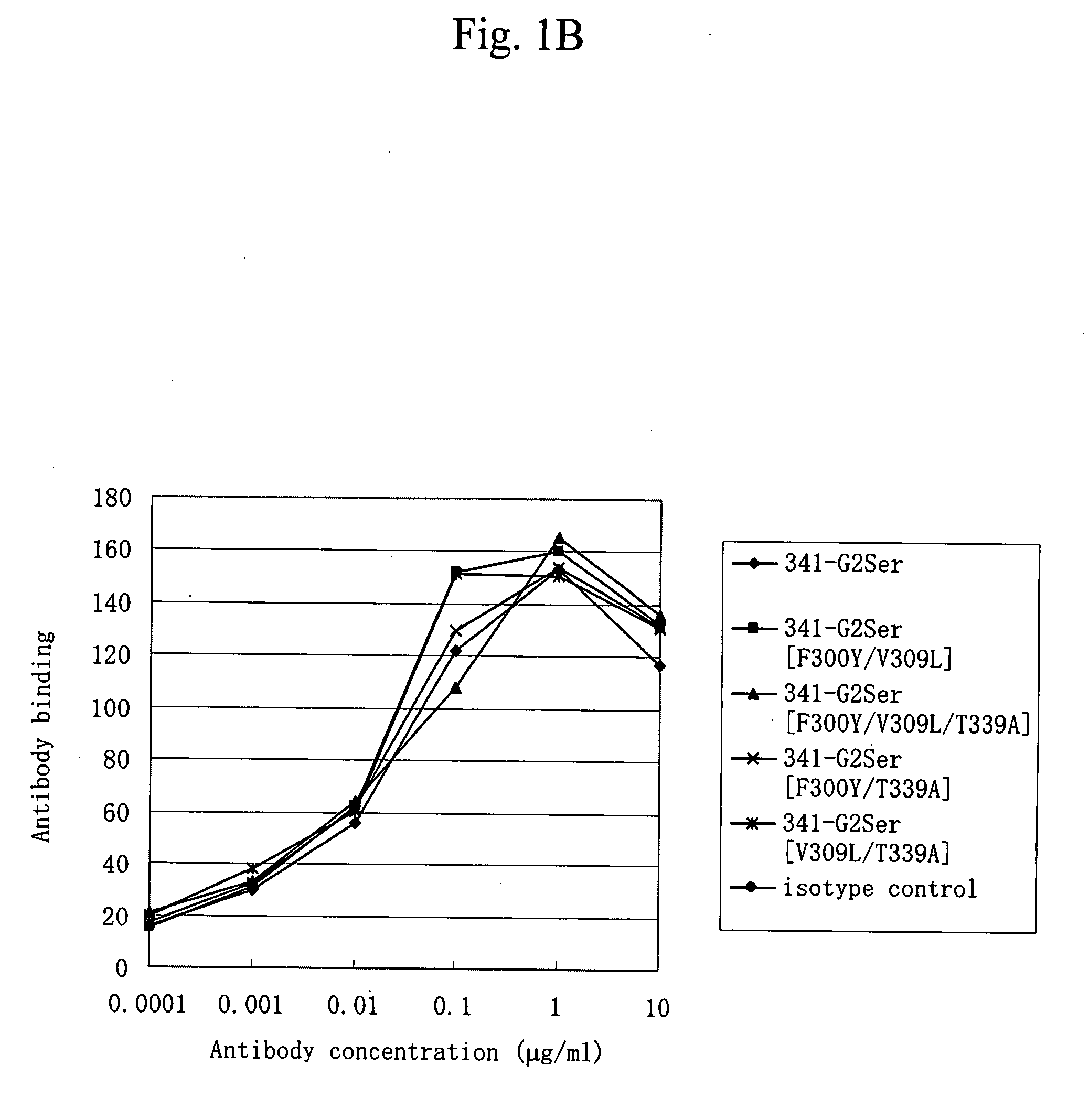

Laminated inductor, method for manufacturing the laminated inductor, and laminated choke coil

ActiveUS20110133881A1Improve DC Superposition CharacteristicsInhibitionTransformers/inductances coils/windings/connectionsCoatingsDielectricSuperimposition

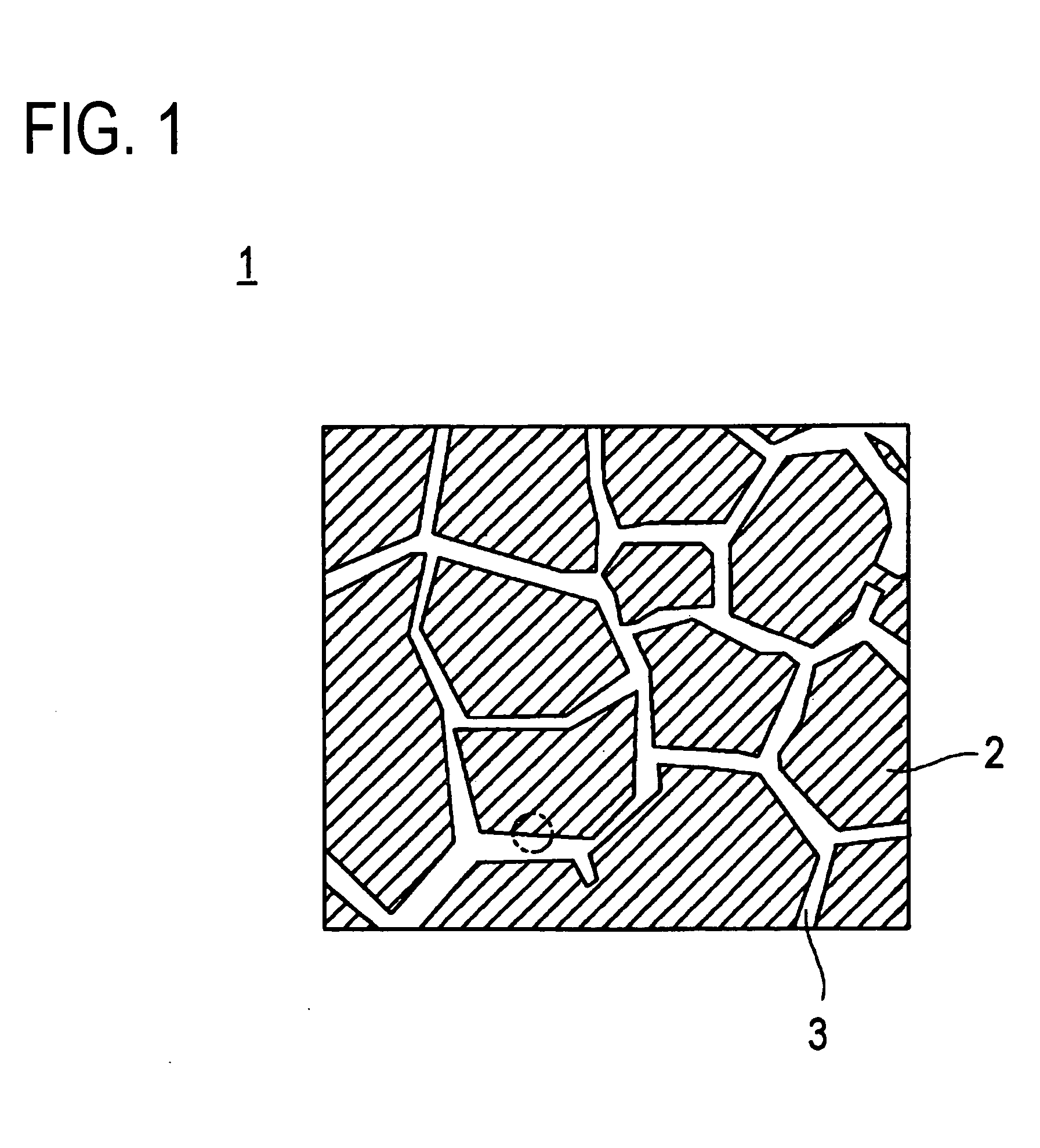

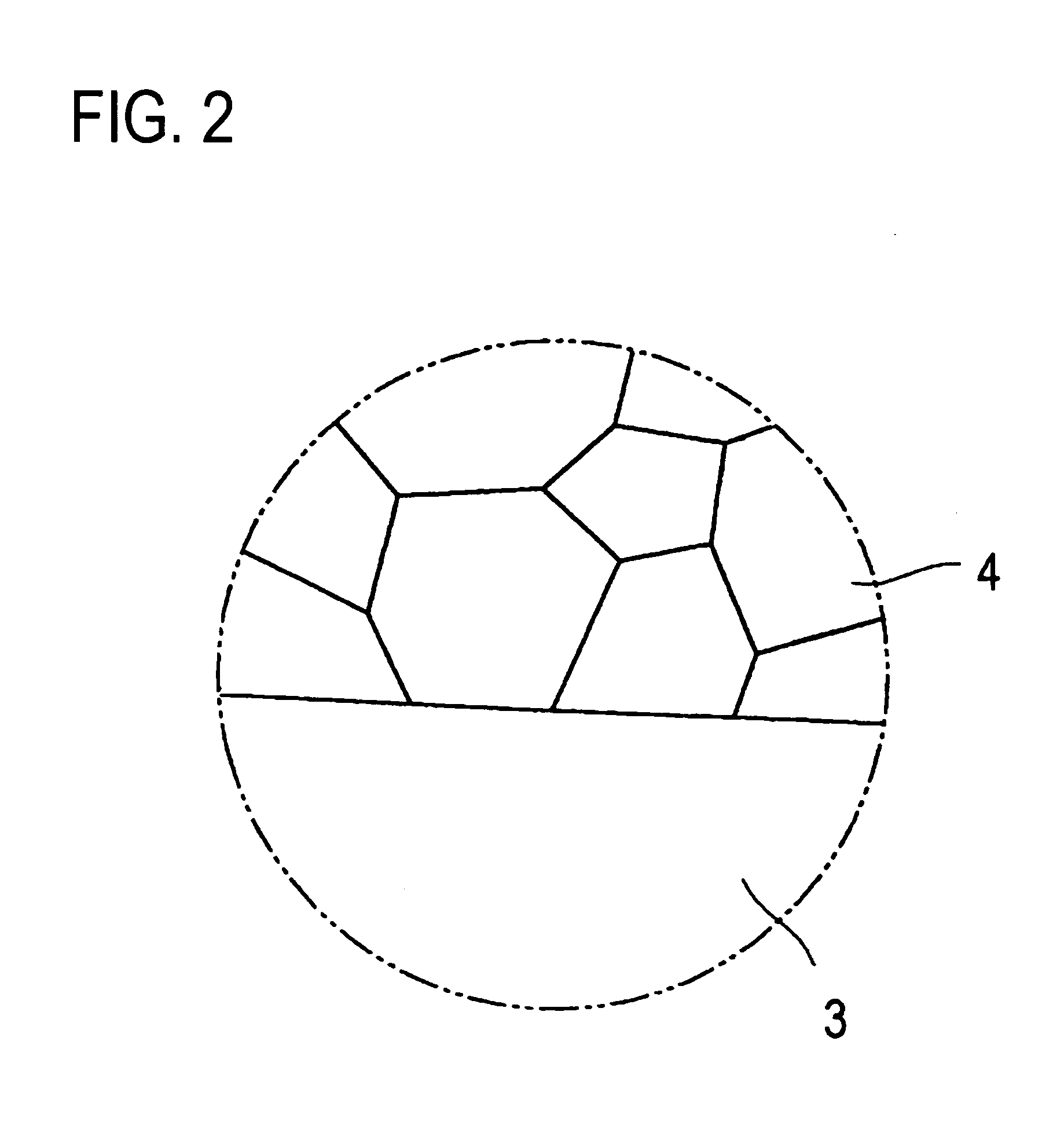

Disclosed is a laminated inductor that has good direct current superimposition characteristics, does not cause a variation in temperature characteristics, suppresses the occurrence of delamination, and can be stably manufactured. Also disclosed are a method for manufacturing the laminated inductor and a laminated choke coil. A laminated inductor (10) for use as a choke coil in a power supply circuit includes a rectangular parallelepiped-shaped laminated chip (1) and at least one pair of external electrodes (8) that are provided at the end of the laminated chip (1) and are conductively connected to the end of a coil. The laminated chip (1) includes a plurality of magnetic material layers (3) formed of an Ni—Zn—Cu ferrite, a plurality of conductive layers (2), which are laminated through the magnetic material layers (3) to constitute a coil, and at least one nonmagnetic layer (4) formed of a Ti—Ni—Cu—Mn—Zr—Ag-base dielectric material and formed in contact with a plurality of the magnetic material layers (3).

Owner:TAIYO YUDEN KK

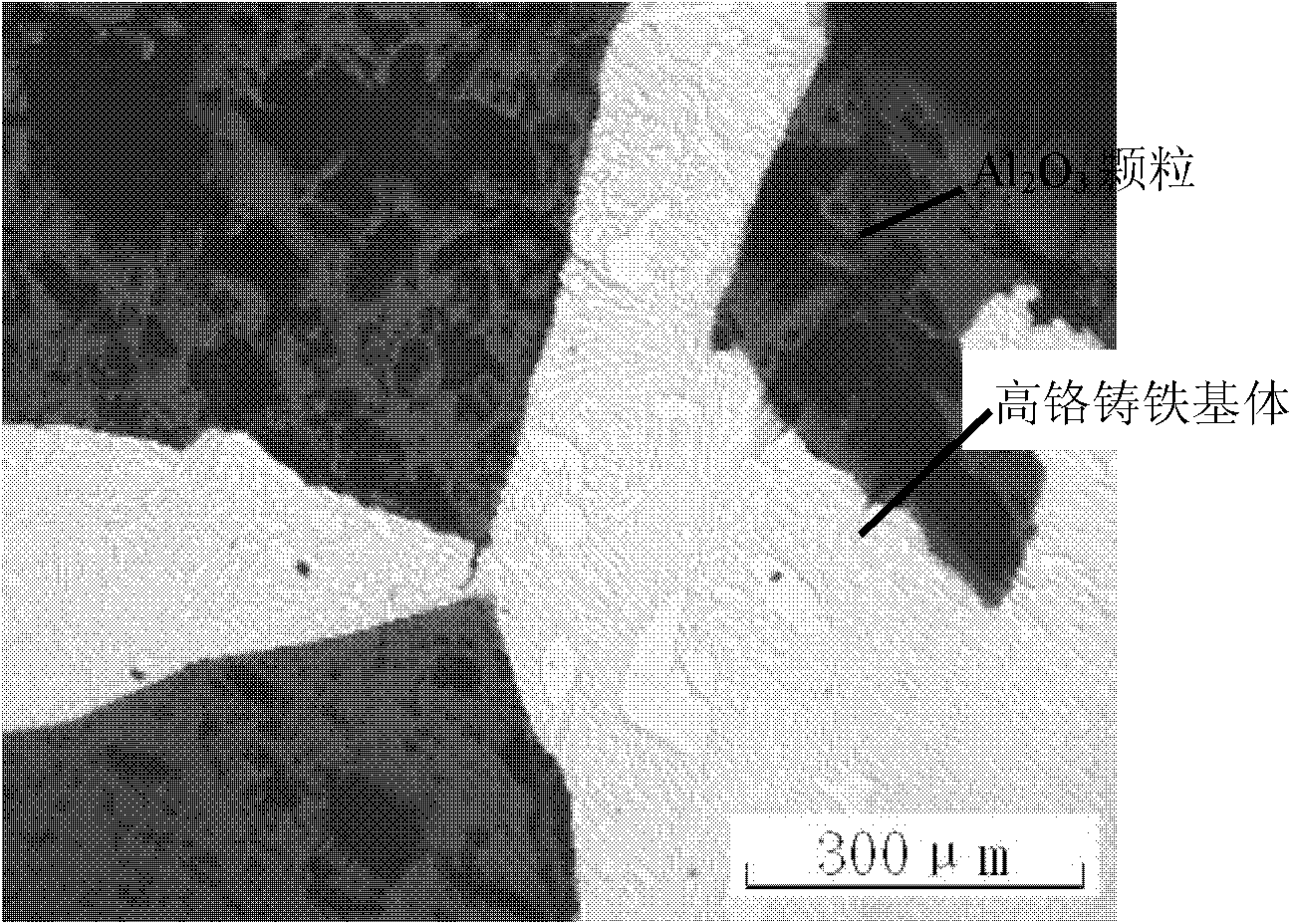

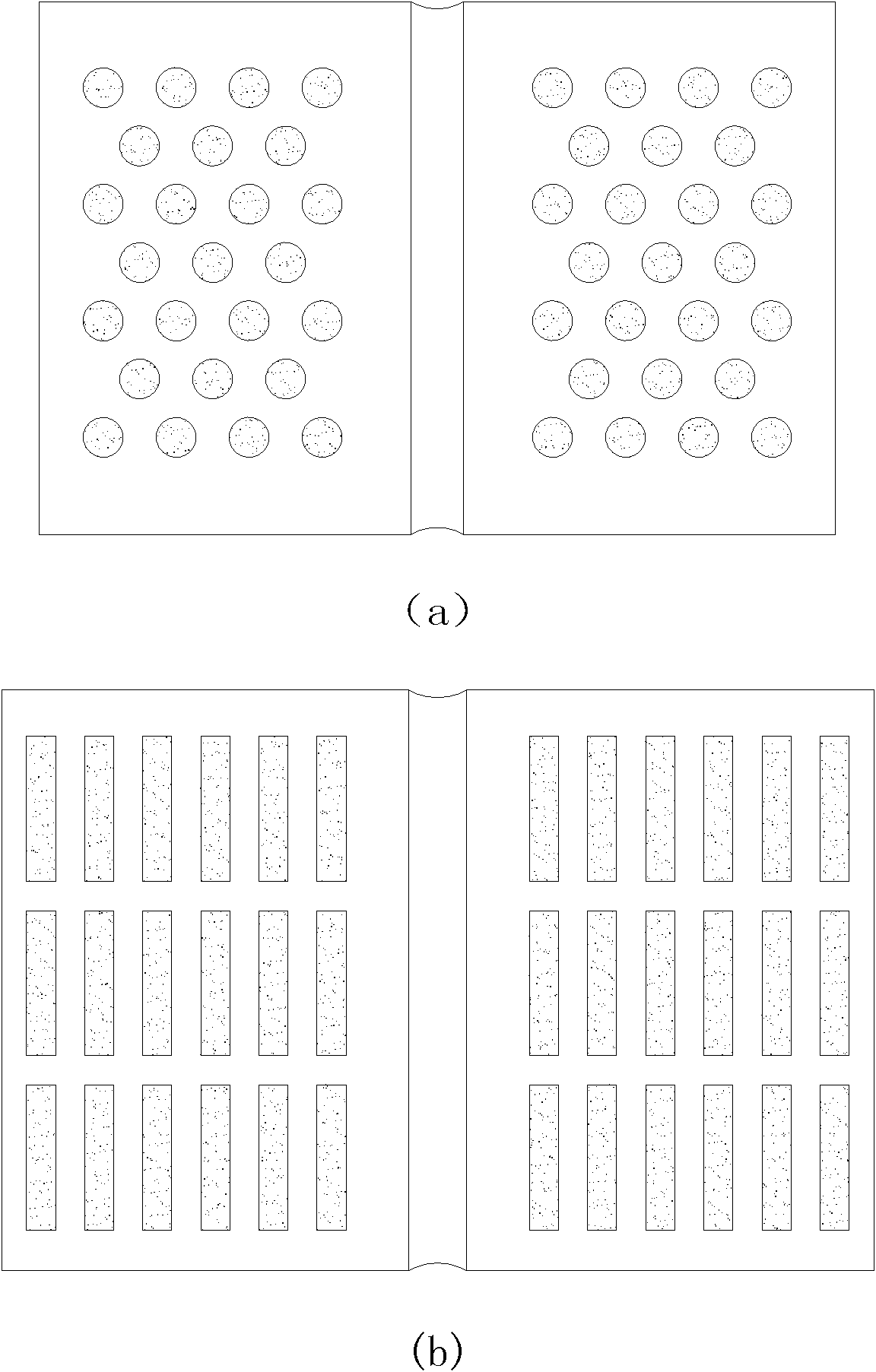

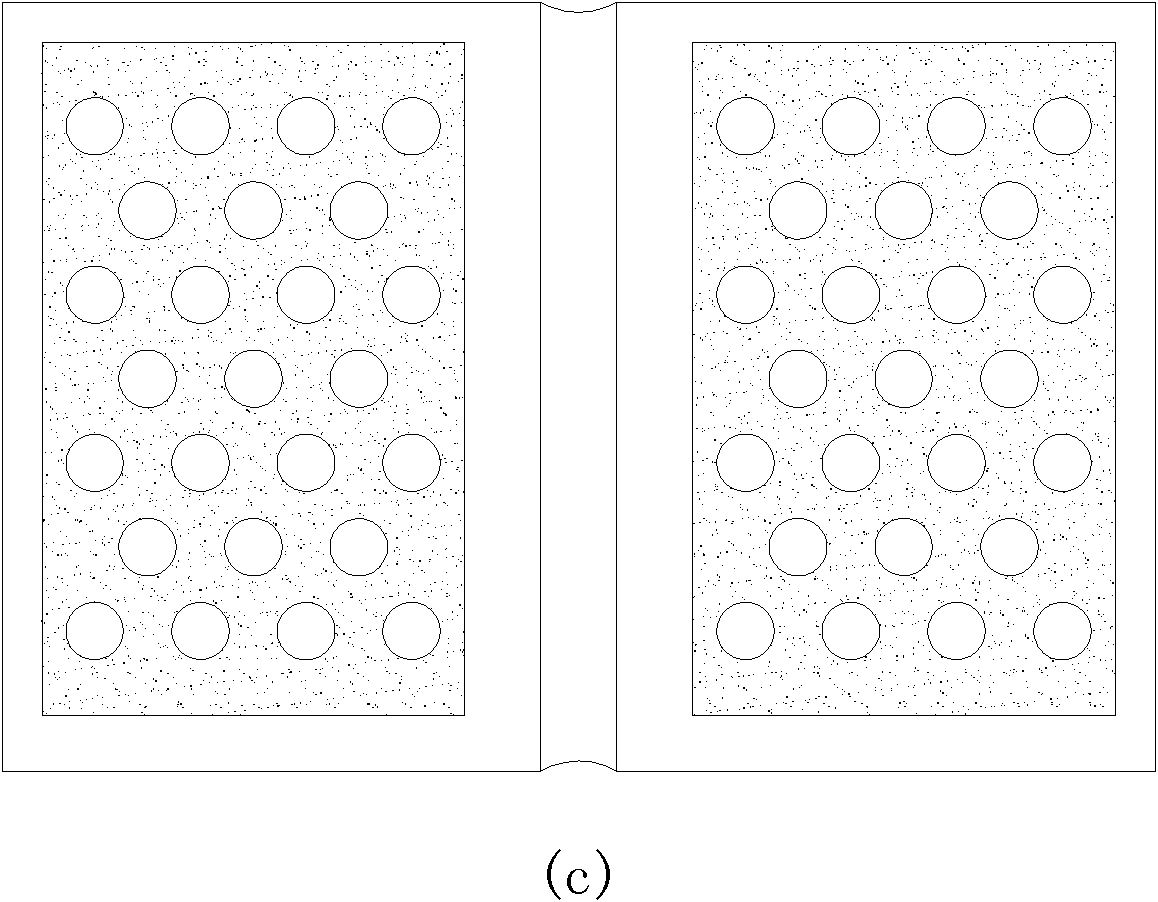

Ceramic particle reinforced composite wear-resistant part and preparation method thereof

InactiveCN101898238ASolve the problem of difficult penetrationImprove wear resistanceCeramic particleWear resistant

The invention relates to a ceramic particle reinforced composite wear-resistant part and a preparation method thereof. The method comprises the following steps: ceramic particles and metal powder are mixed evenly to fill in a special mould; then the mixture along with the mould is placed in a vacuum sintering furnace to sinter, wherein metal powder and ceramic particles are bound together to form a perform; after cooled, the mould is opened to take the perform out and place the perform on the side of the end face of a casting mold cavity; parent metal material is smelted by a medium-frequency induction furnace to form molten metal; during the casting, the molten metal is poured, metal powder in the perform is molten to form a cast-penetration path under the heat of molten metal, thus the molten metal can easily penetrate ceramic particles to form particle reinforced composite material in situ; and the surface layer of the obtained wear-resistant part consists of parent metal and composite material. The wear resistance of the composite material prepared by the method of the invention is ensured and the composite material has high impact resistance.

Owner:XI AN JIAOTONG UNIV +1

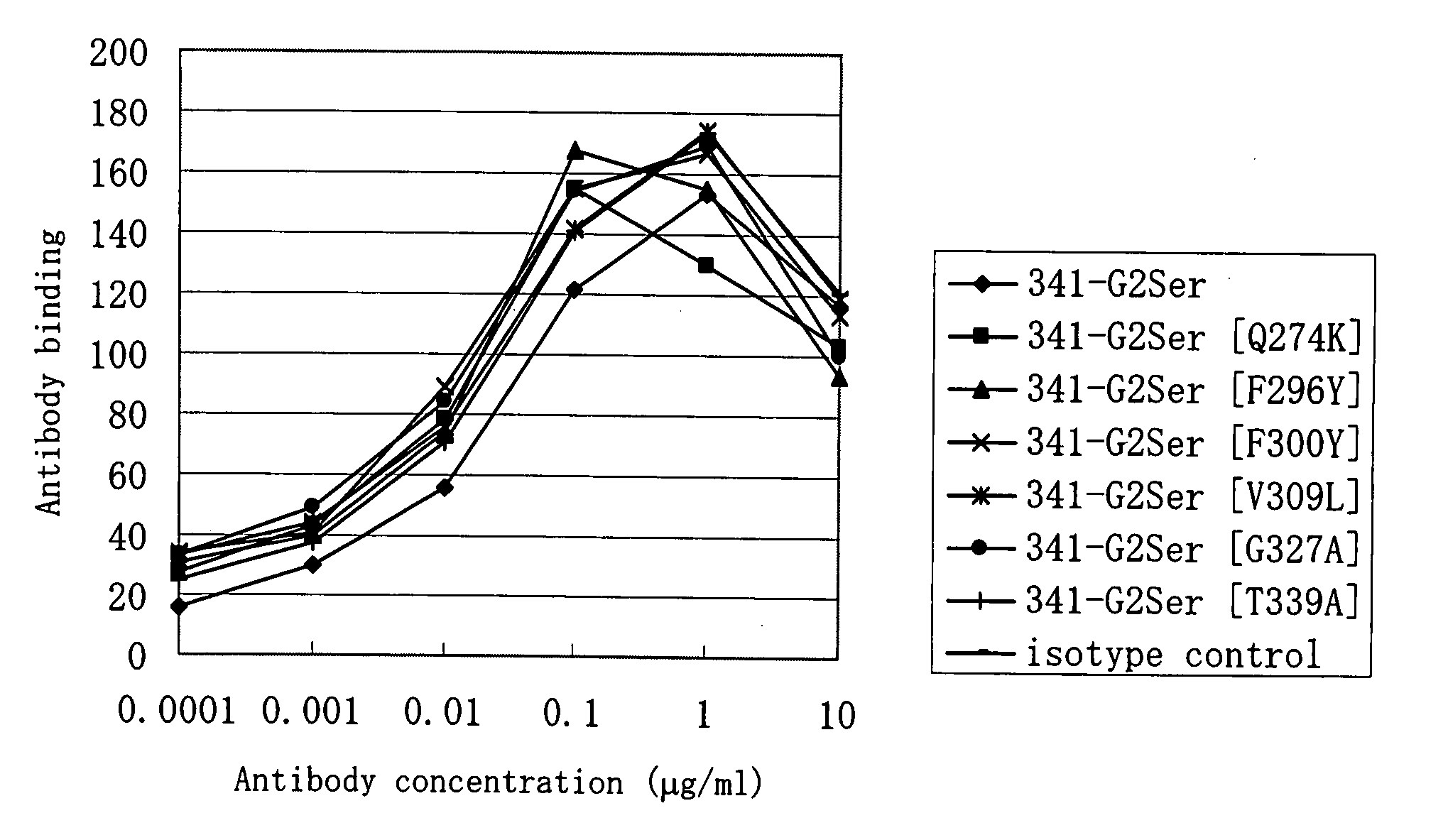

Stabilized Human IgG2 And IgG3 Antibodies

ActiveUS20080138335A1Improve stabilityReduced aggregate formationAntibacterial agentsAntimycoticsIgG.heavy chainMonoclonal antibody

It is intended to provide highly stable variants of human antibody IgG2 and IgG3 subclasses. The present invention provides an IgG heavy chain comprising the constant region of a human IgG2 heavy chain having at least a substitution of Y for F at the 300th position, L for V at the 309th position, or A for T at the 339th position designated by the EU index of Kabat et al. and an IgG heavy chain comprising the constant region of a human IgG3 heavy chain having at least a substitution of K for N at the 392nd position or V for M at the 397th position designated by the EU index of Kabat et al. The present invention also provides monoclonal antibodies comprising these heavy chains.

Owner:KYOWA HAKKO KIRIN CO LTD

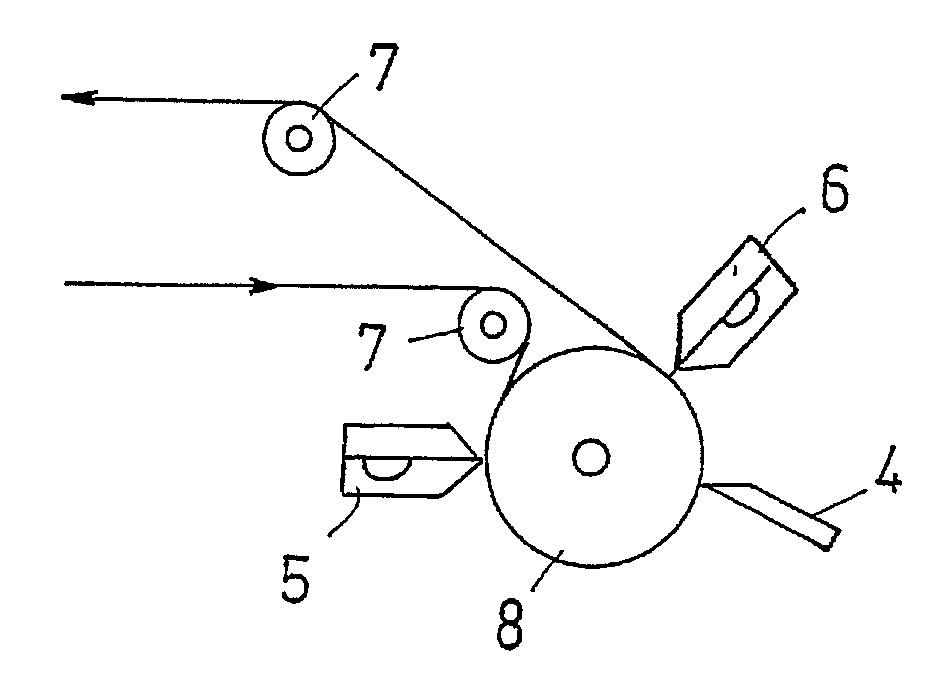

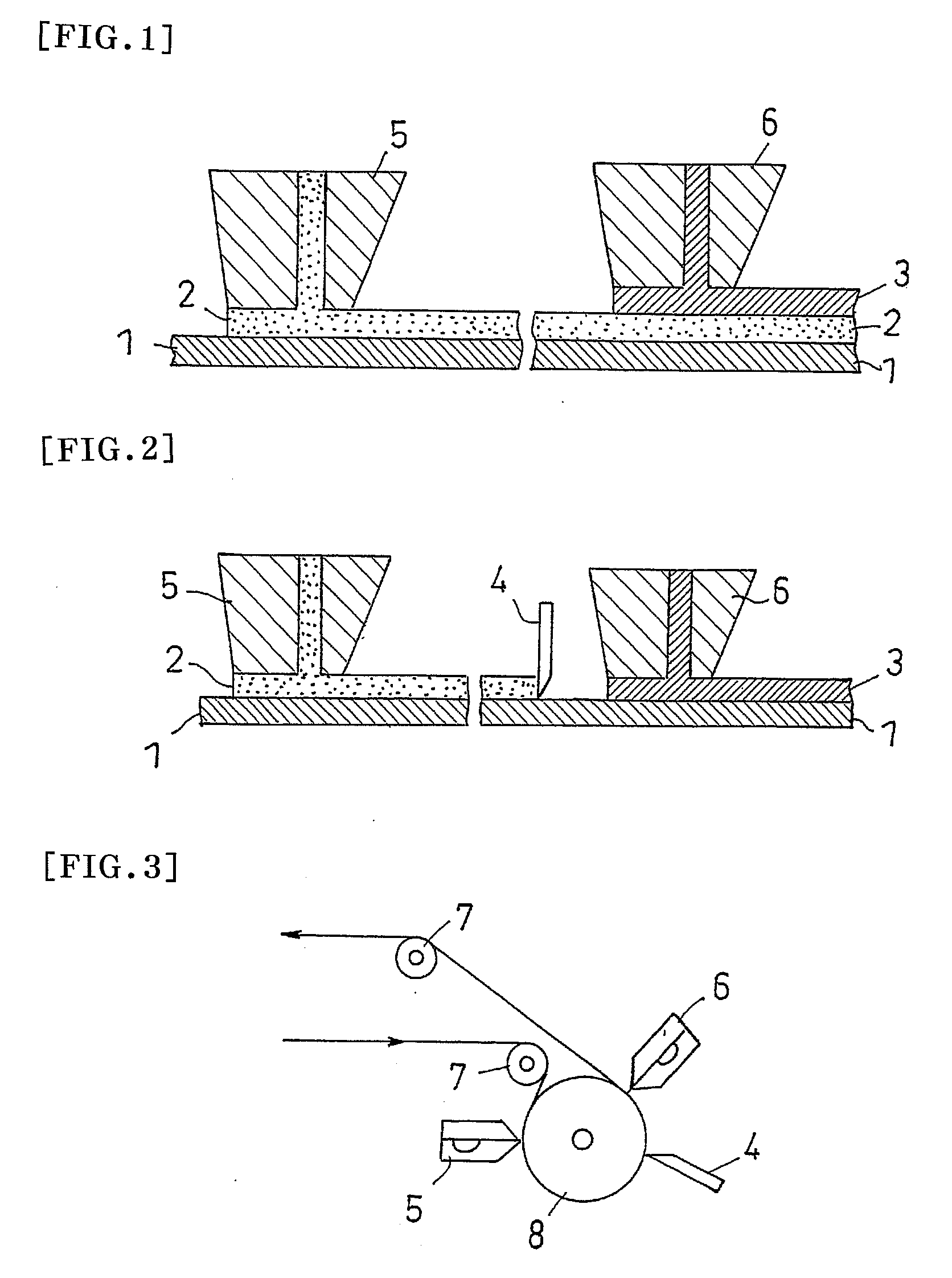

Polarizing plate and production process of the same

InactiveUS20050243245A1Improve adhesionStable productionNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentTectorial membranePolyvinyl alcohol

A novel polarizing plate is disclosed. The polarizing plate comprises a polyvinyl alcohol based polarizer, a protective film comprising a saturated alicyclic structure-containing thermoplastic polymer, and an adhesive layer comprising a water-soluble polymer between the protective film and the polarizer wherein the surface of the protective film contacting with the adhesive layer is subjected to a surface treatment.

Owner:FUJIFILM CORP

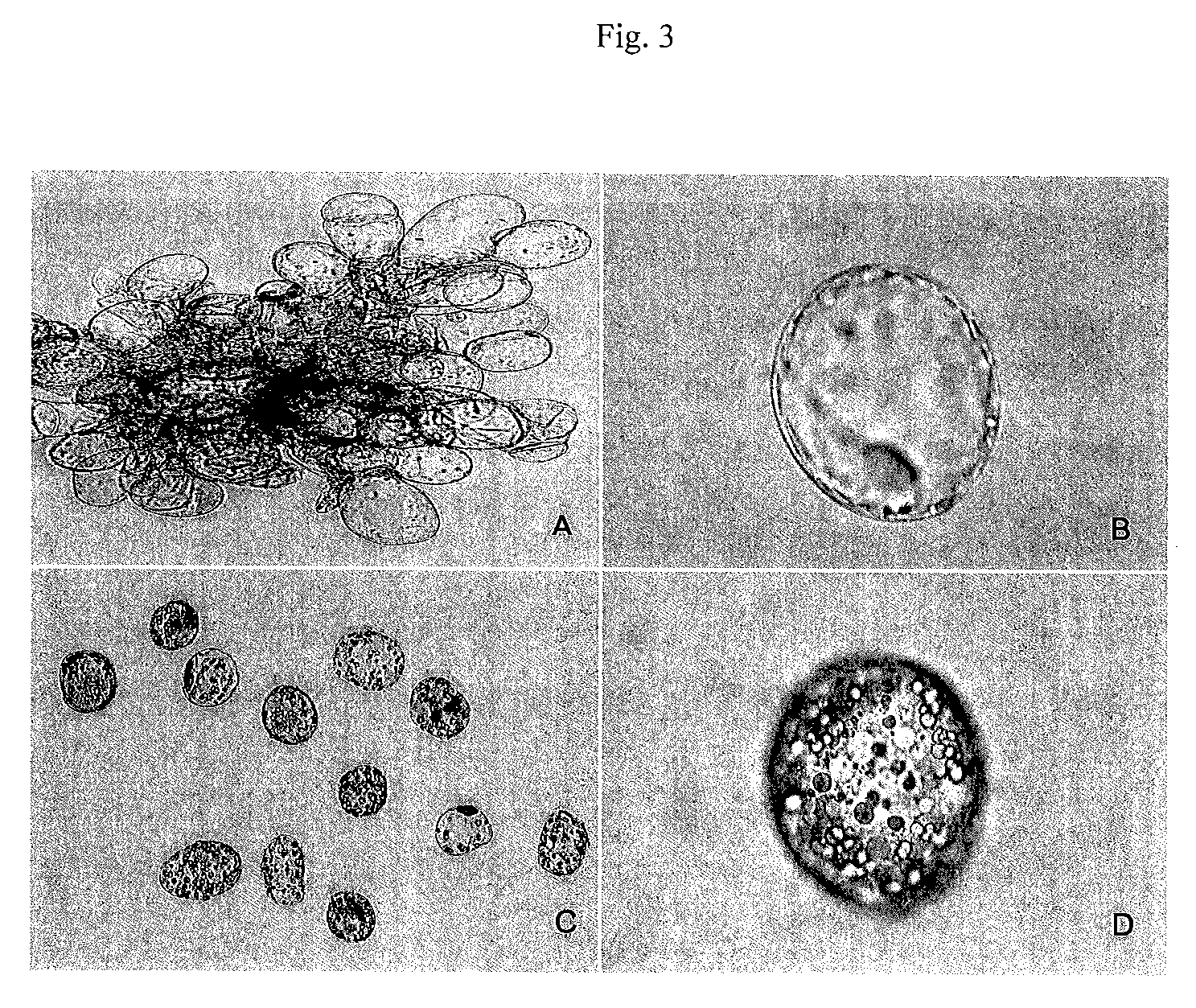

Isolated population of plant single cells and method of preparing the same

ActiveUS8053238B2Stable productionAvoid excessive changesFermentationPlant cellsPlant SourcesCell growth

This invention is a method of minimizing the variation of cell growth and production through homogeneous cell line development. To be more specific, it is the method of isolating and proliferating single cell clone from the procambium to promote the stability of the plant-derived biologically active substances production by solving the problems of decrease in cell growth and the productivity during the long term culture.

Owner:WELLKEY HLDG LTD

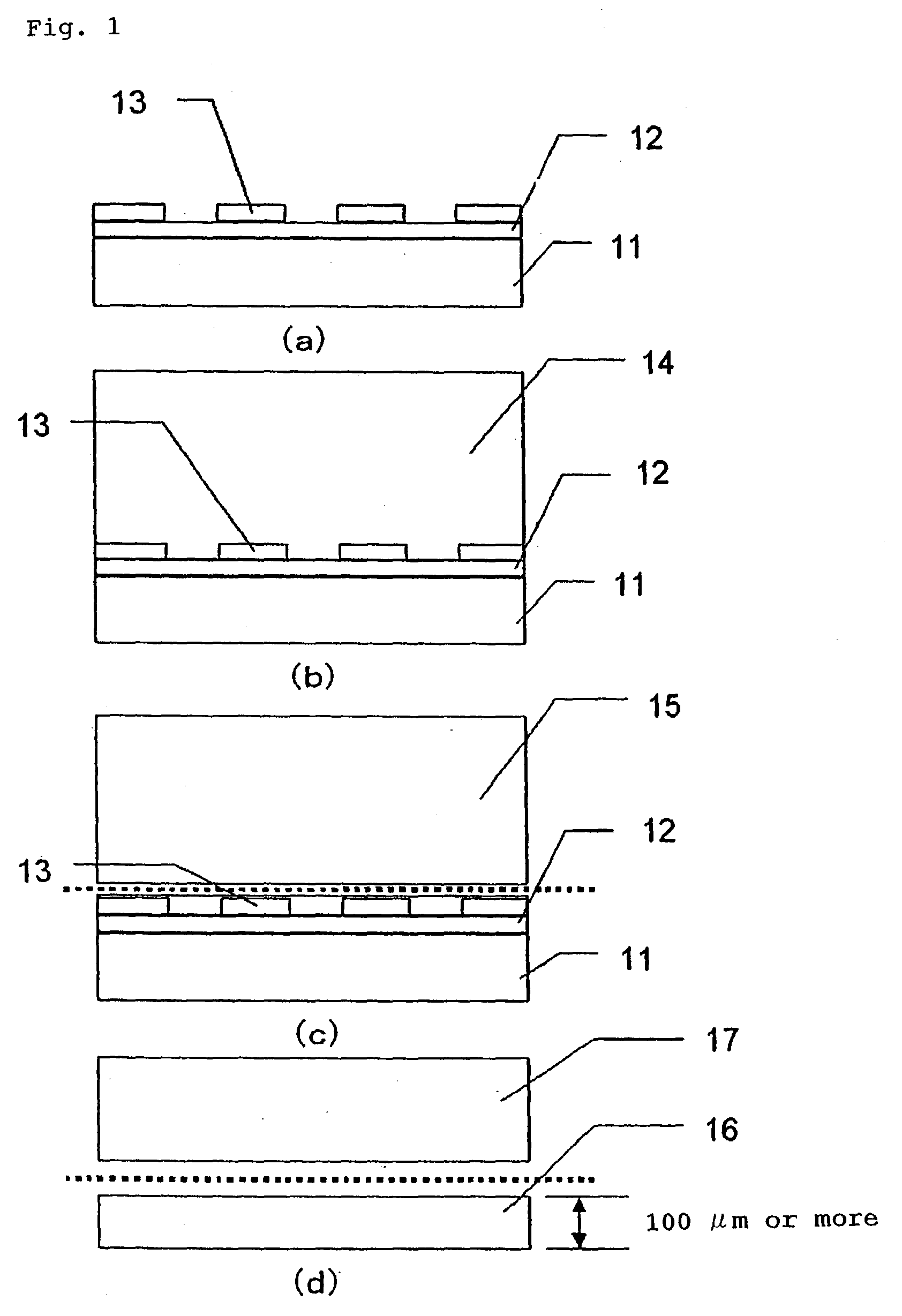

Radiation detecting apparatus, producing method therefor and radiation image pickup system

InactiveUS20060033031A1Stable productionHigh product yieldElectroluminescent light sourcesMaterial analysis by optical meansFluorescenceOpto electronic

A radiation detection apparatus including a sensor panel, having a photoreceiving unit constituted of plural photoelectric converting elements two-dimensionally arranged on a substrate and electrical connecting portions provided in an external portion of the photoreceiving unit and electrically connected to the photoelectric converting elements of respective rows or columns of the photoreceiving unit, a phosphor layer provided at least on the photoreceiving unit for converting a radiation into a light detectable by the photoelectric converting element, and a phosphor protective member covering the phosphor layer and in contact with the sensor panel, characterized in that the phosphor protective member includes a frame member provided between the phosphor layer and the electric connecting portion on the sensor panel, and a phosphor protective layer covering an upper surface of the phosphor layer and provided in close contact with an upper surface of the frame member. This configuration allows to prevent a discharge of an electrostatic charge accumulated on the sensor panel, thereby providing a stable radiation detection apparatus with a high production yield.

Owner:CANON KK

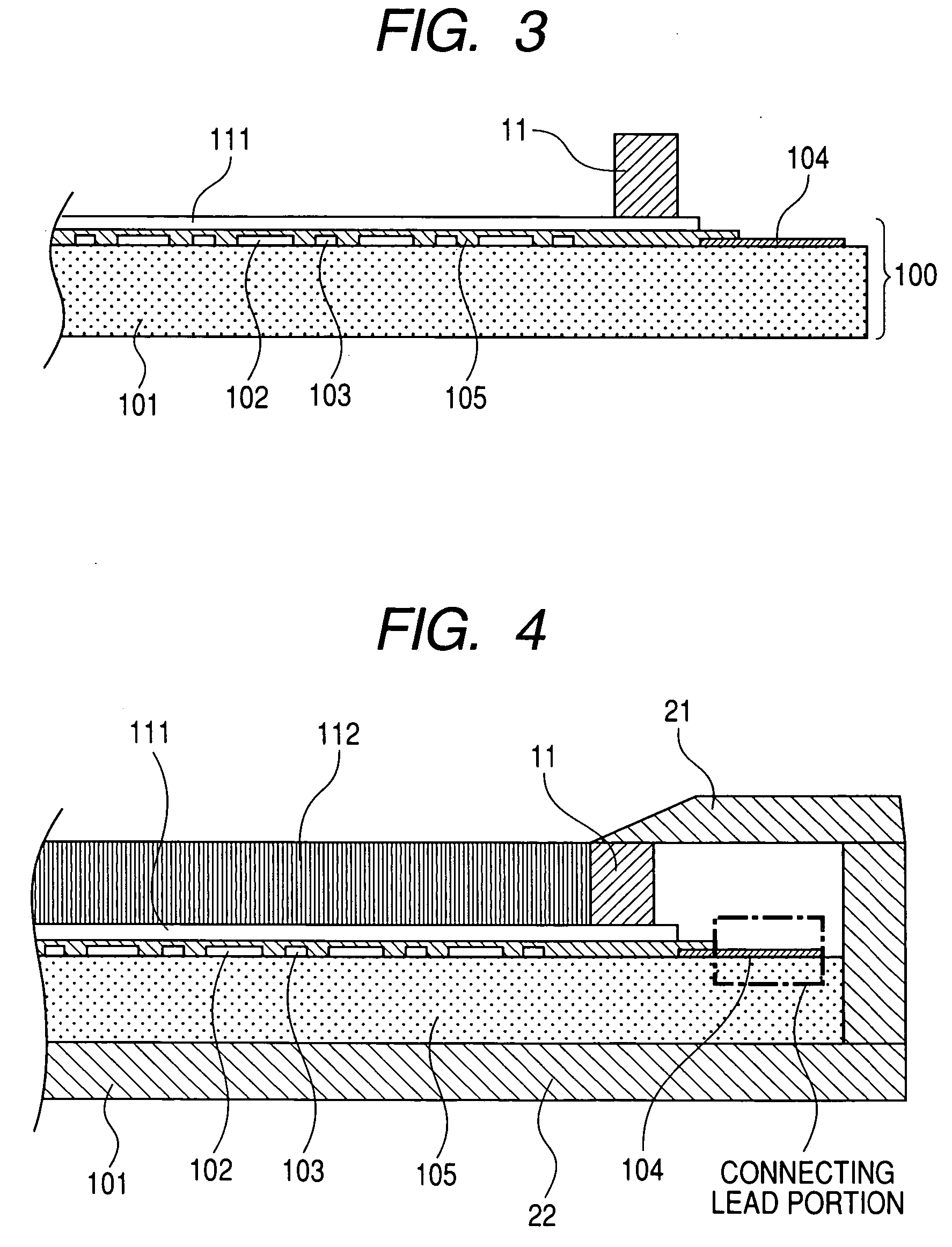

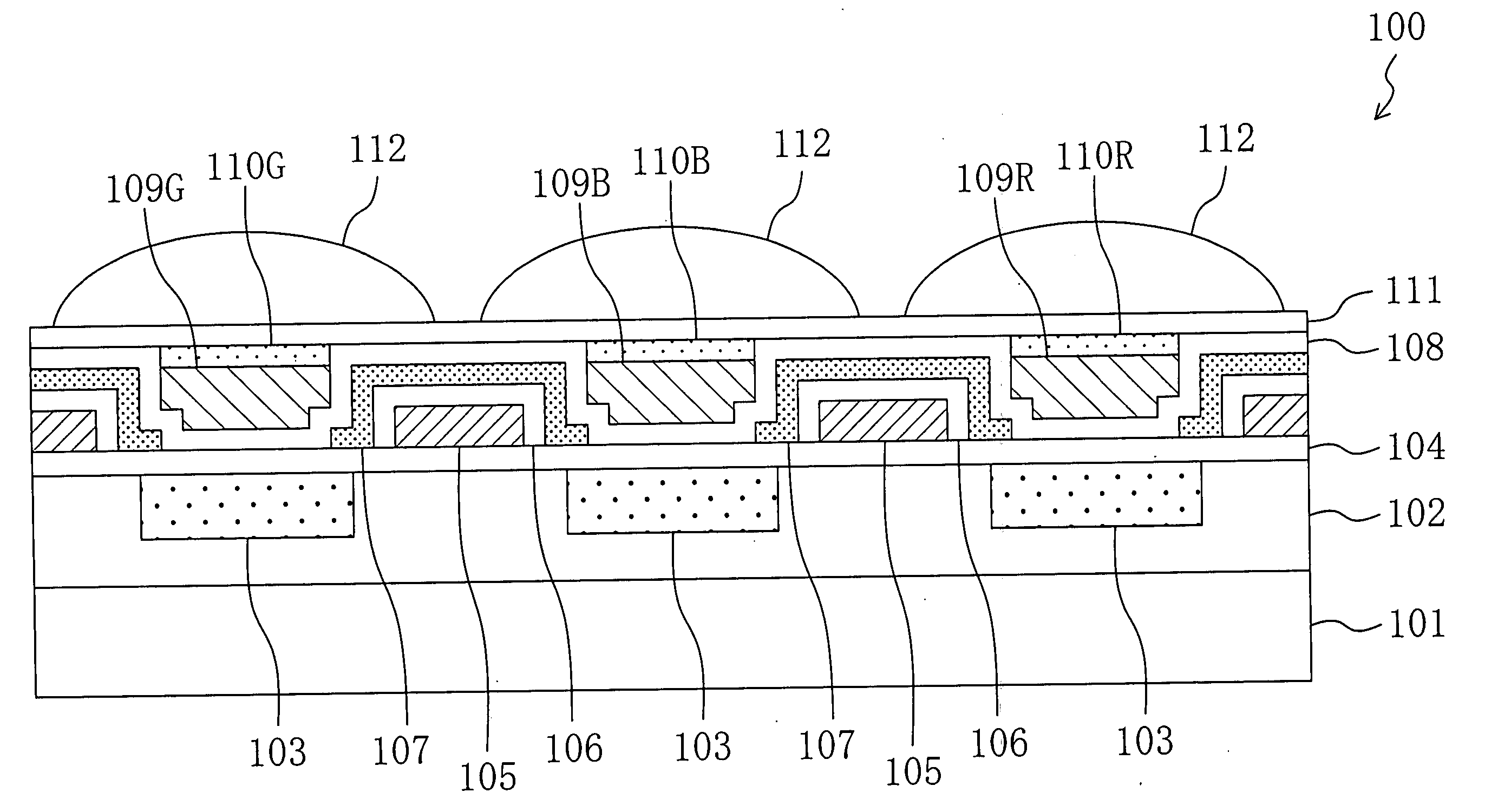

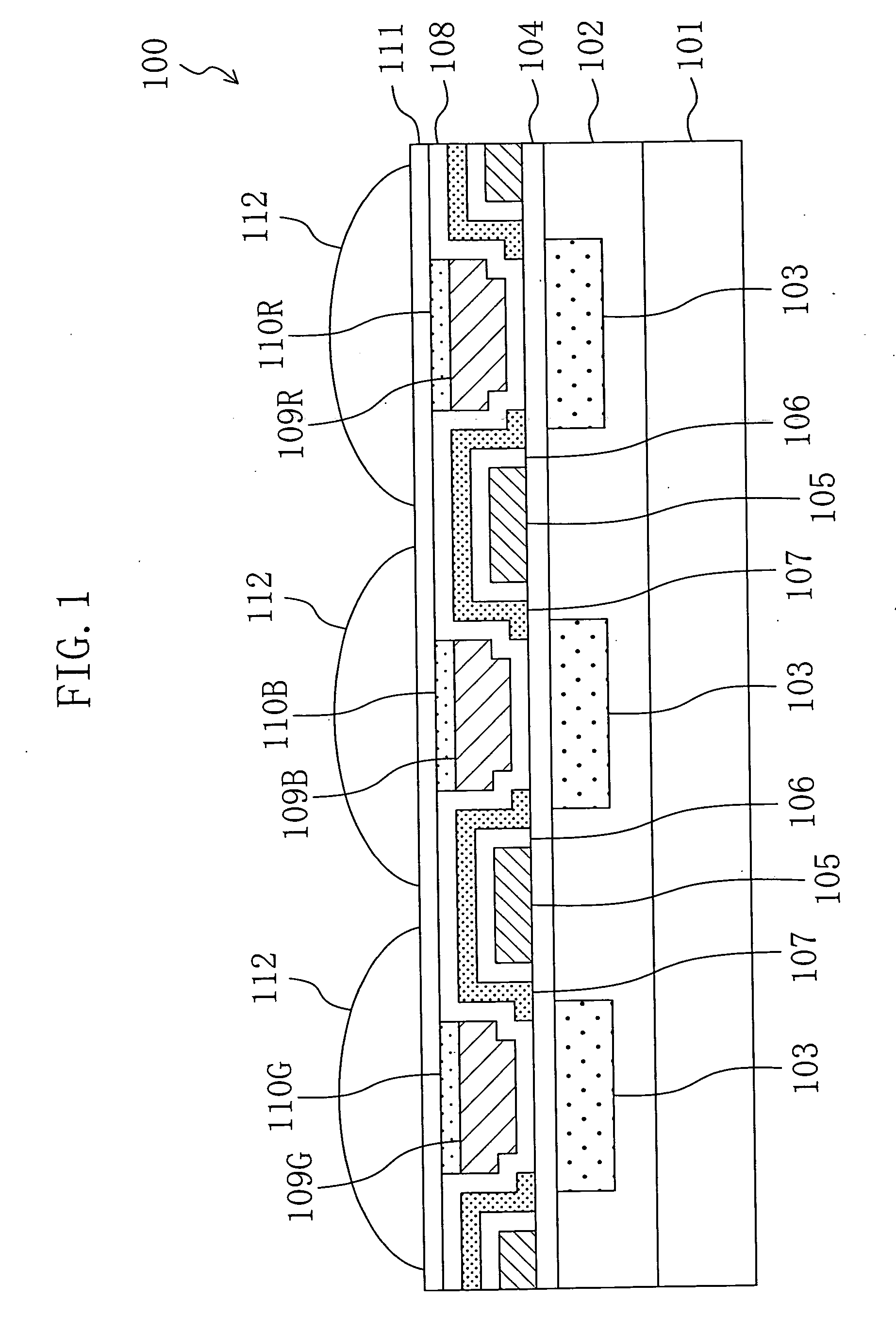

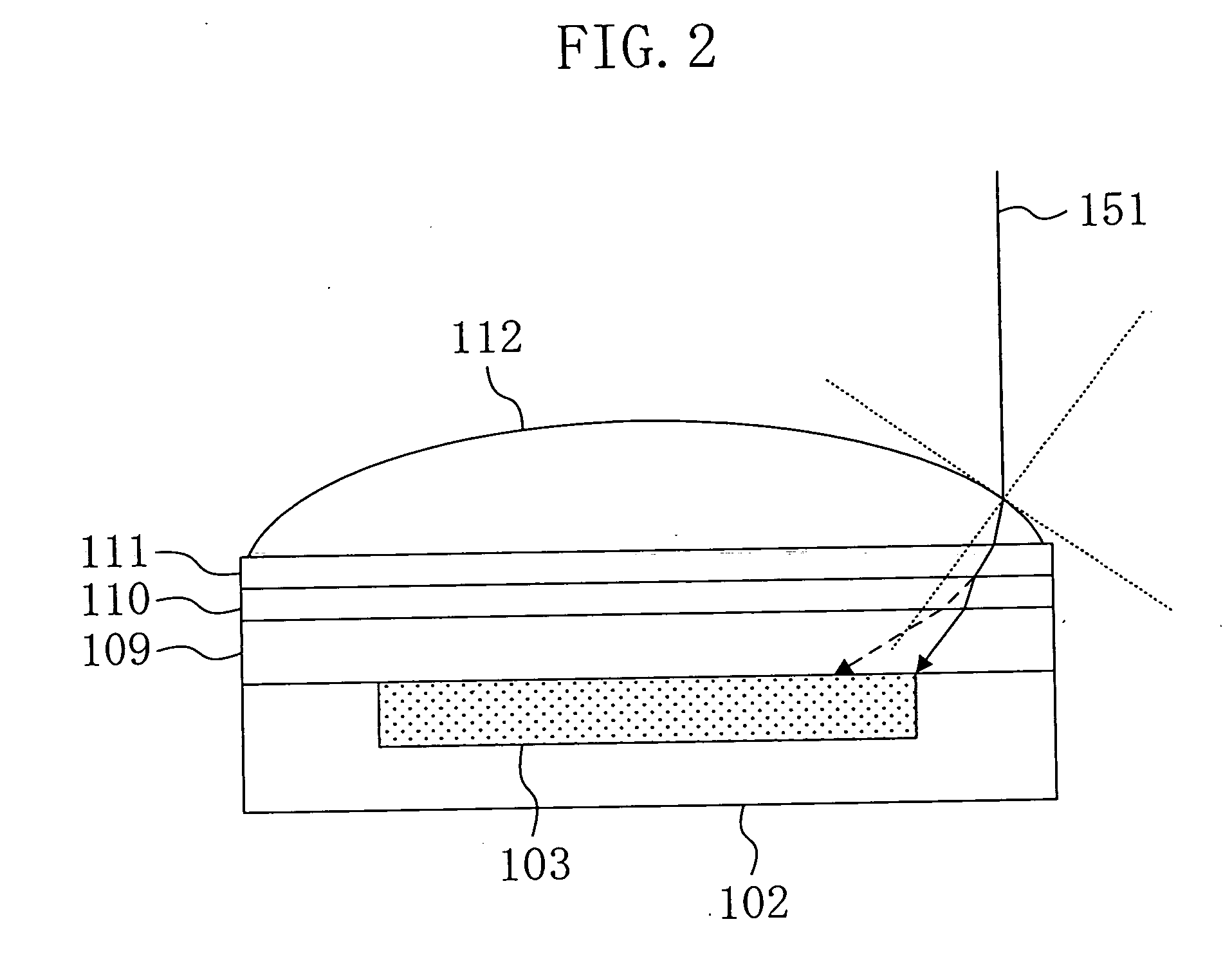

Solid State imaging device and method for producing the same

InactiveUS20060187381A1Excellent spectral characteristic and durabilityStable productionTelevision system detailsTelevision system scanning detailsColor gelHue

A solid state imaging device comprises a plurality of pixels arranged in a matrix, each of the pixels including: a substrate; a photoelectric conversion element for converting light to electric charges; and a color filter formed on the photoelectric conversion element for color separation. The color filter is a layered color filter including a dye-contained color filter layer and a pigment-dispersed color filter layer formed on the dye-contained color filter layer, the dye-contained color filter layer and the pigment-dispersed color filter layer having the same hue.

Owner:PANASONIC CORP

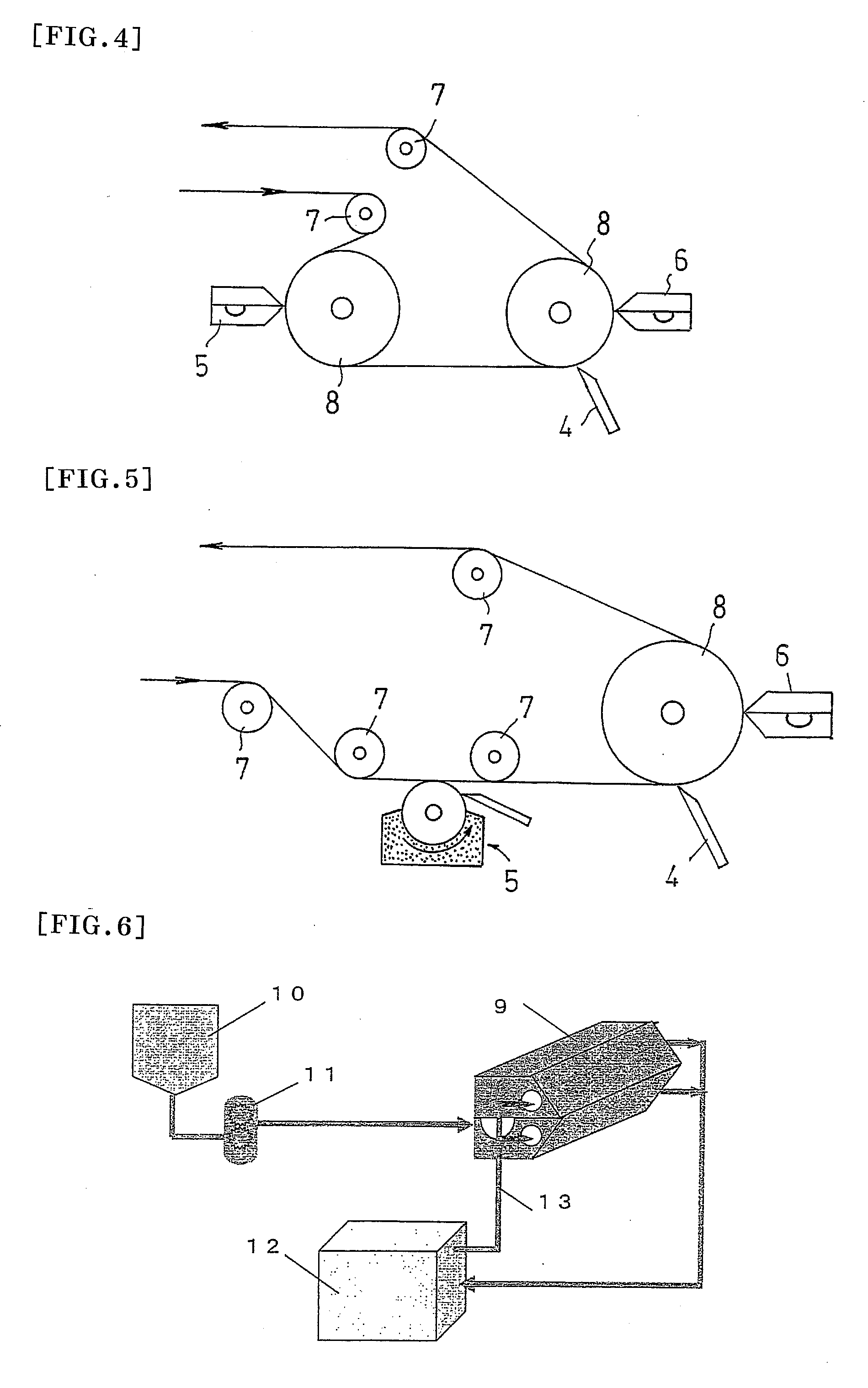

Process for producing composite reverse osmosis membrane

InactiveUS20090050558A1Reduce the amount of solutionEasy to operateMembranesPretreated surfacesReverse osmosisPolyamide

Provided is a process for continuously producing a composite reverse osmosis membrane comprising a polyamide skin layer and a porous support for supporting the polyamide skin layer, the method comprising: A) applying an aqueous solution α containing a compound having two or more reactive amino groups to form a covering layer of an aqueous solution on the porous support while moving the porous support; B) permeating the aqueous solution α in micro pores of the porous support by holding the covering layer on the porous support for 0.2 to 15 seconds; C) removing the covering layer while holding the aqueous solution α within the micro pores of the porous support; and D) forming the polyamide skin layer by applying an organic solution β containing a polyfunctional acid halide onto the surface of the porous support to make the aqueous solution α contact the organic solution β for interfacial polymerization.

Owner:NITTO DENKO CORP

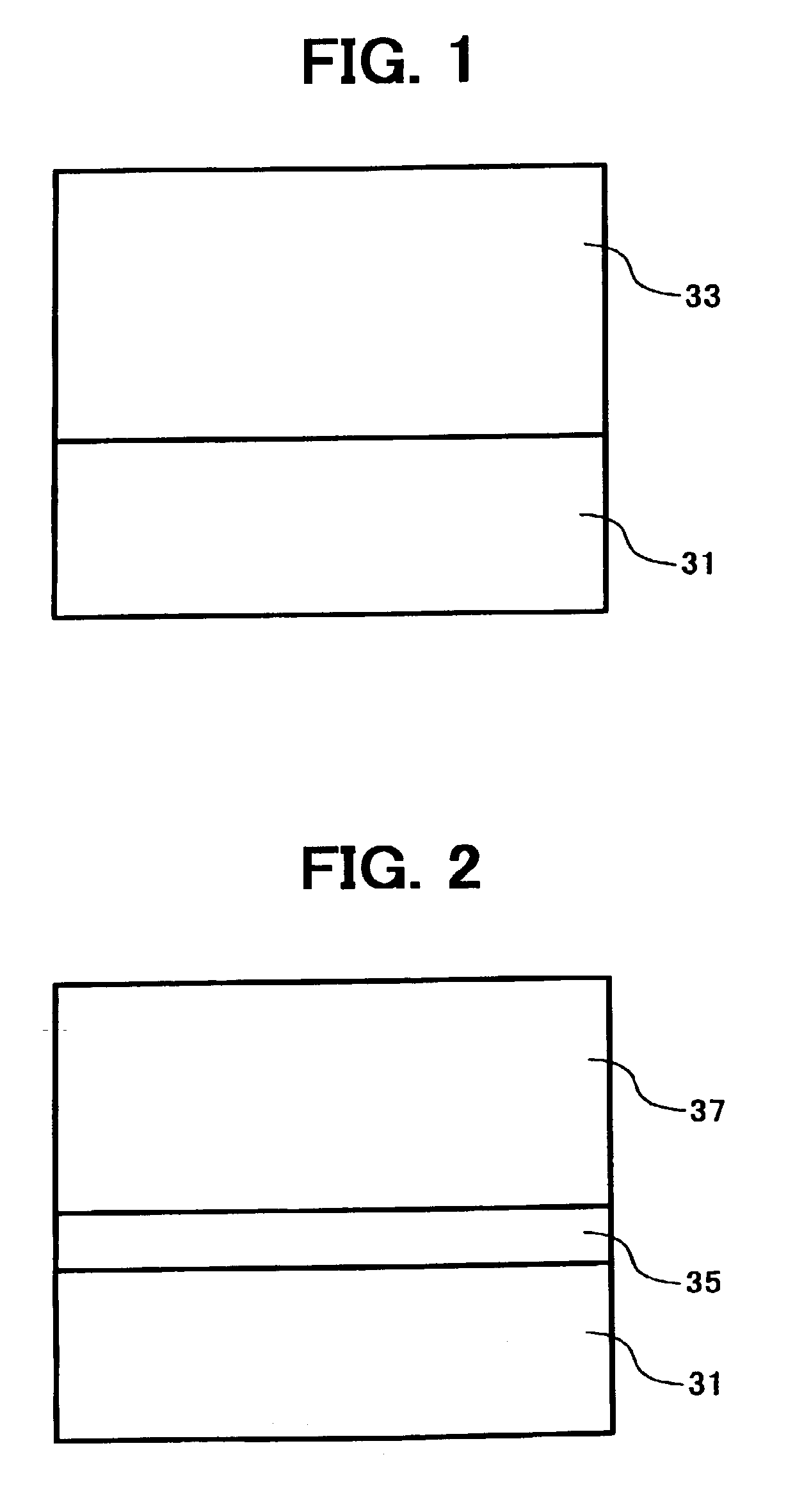

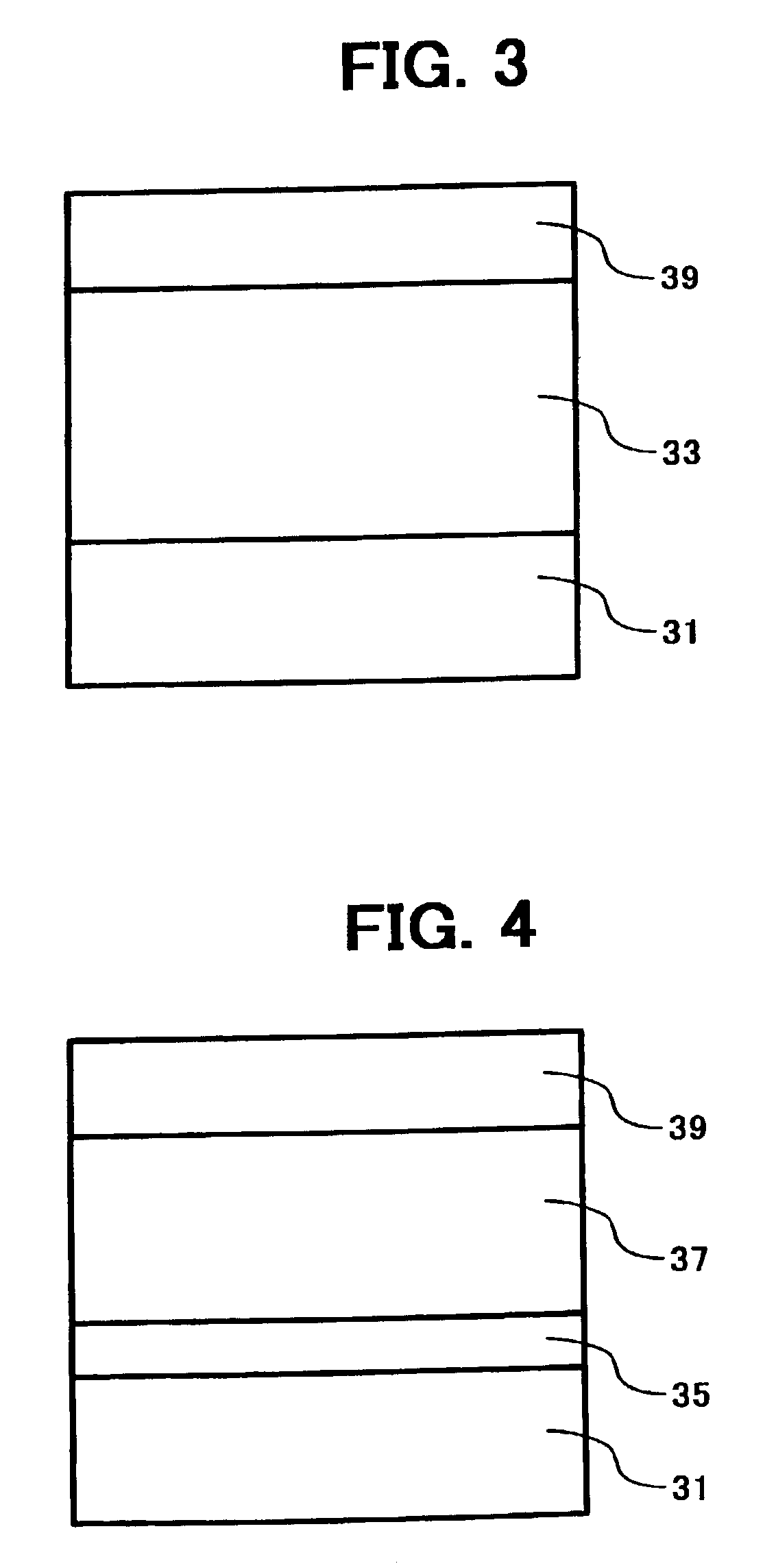

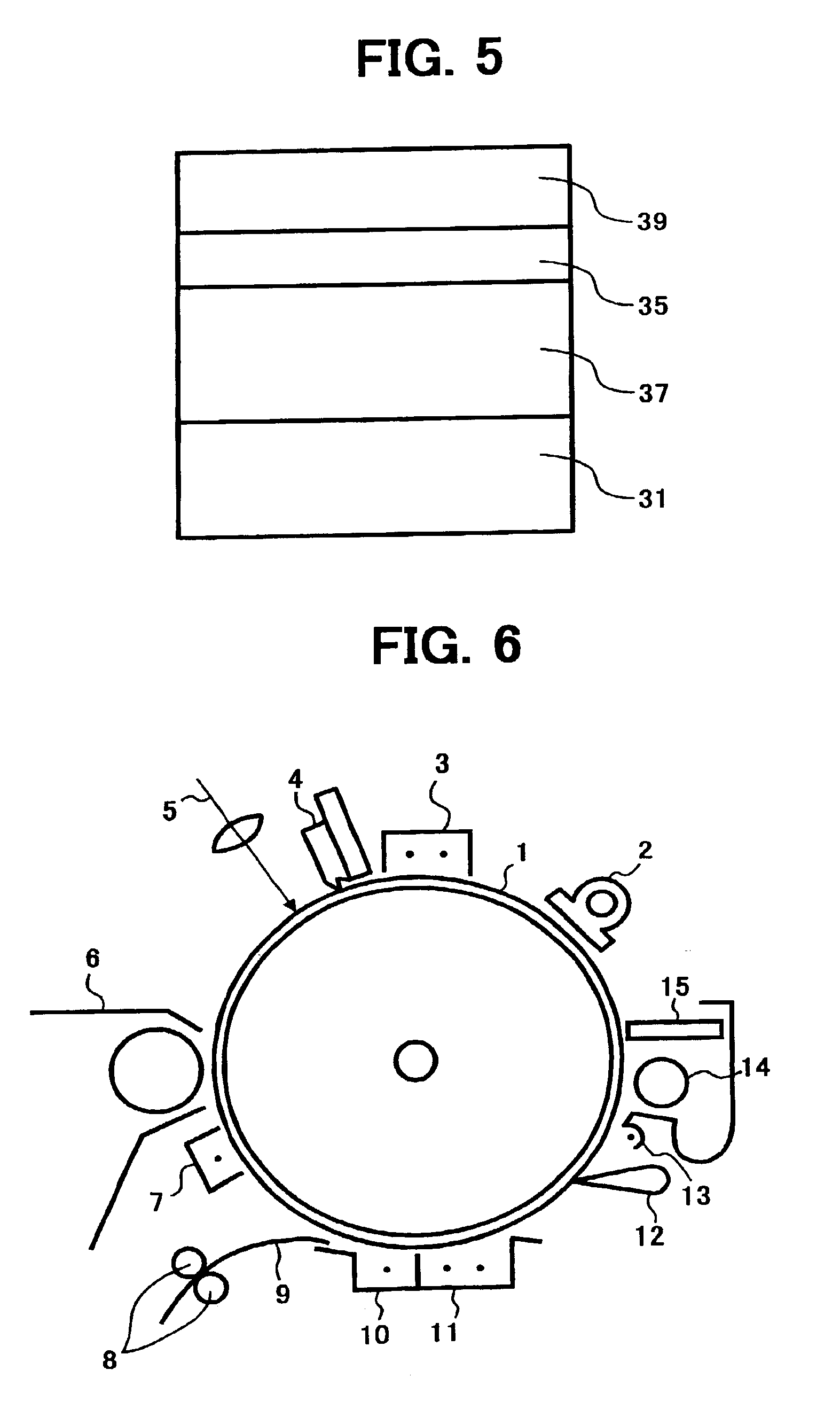

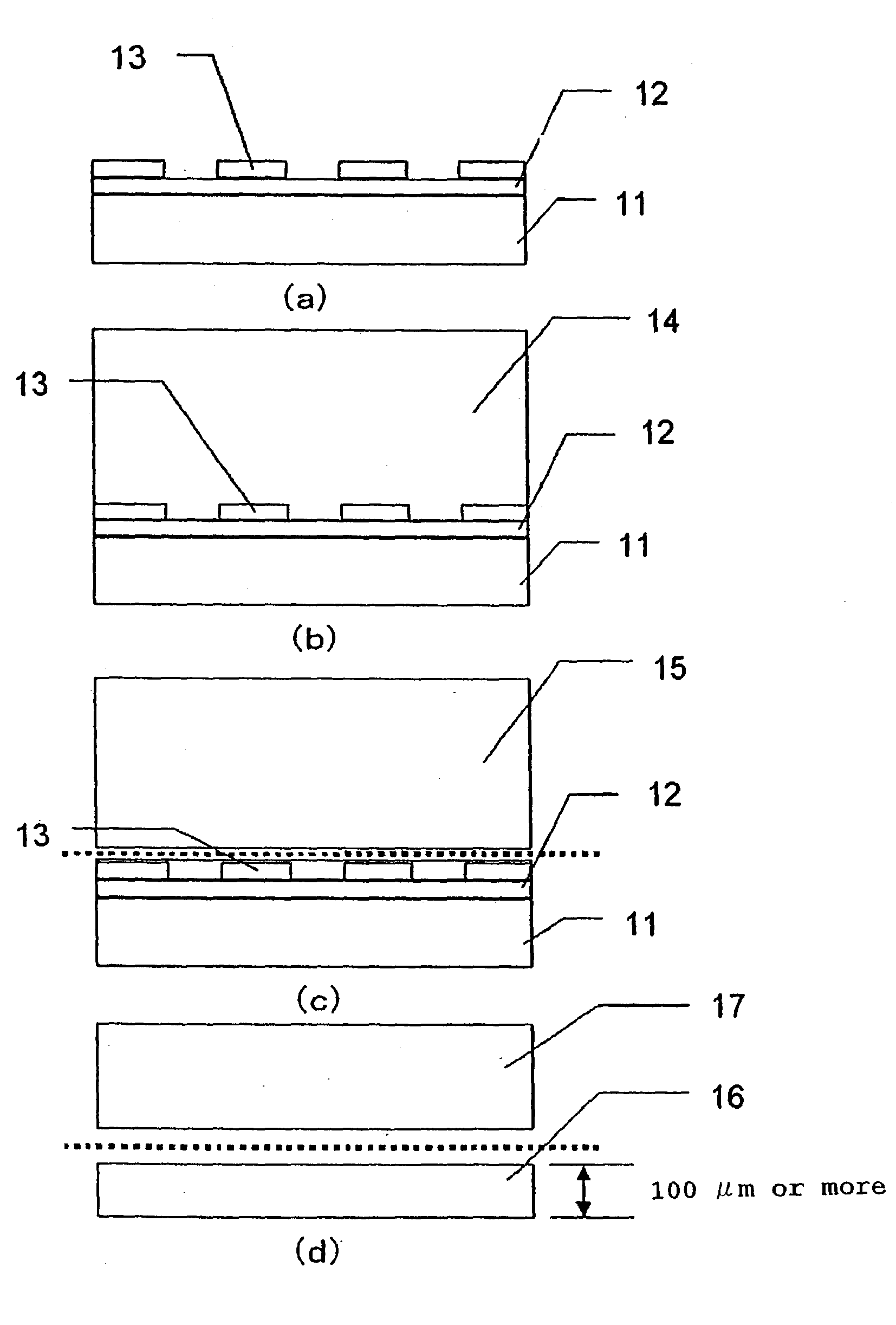

Group III nitride based semiconductor substrate and process for manufacture thereof

InactiveUS20030183157A1Quality improvementStable productionLaser detailsFrom solid stateDislocationNitride

To provide a semiconductor substrate of a group III nitride with a little warp, this invention provides a process comprising such steps of: epitaxial-growing a GaN layer 33 with a GaN low temperature grown buffer layer 32 upon a sapphire substrate 31; removing the sapphire substrate 31, the GaN buffer layer 32 and a small portion of the GaN layer 33 from the substrate taken out of a growth reactor to obtain a self-supporting GaN substrate 35; and after that, heat-treating the GaN substrate 35 by putting it into an electric furnace under the NH3 atmosphere at 1200° C. for 24 hours; which leads to a marked reduction of the warp of the self-supporting GaN substrate 35 such that dislocation densities of its obverse and reverse surface are 4x10<7 >cm<-2 >and 8x10<5 >cm<-2>, and thereby such a low ratio of dislocation densities of 50 is well-controlled.

Owner:SUMITOMO CHEM CO LTD

Spinning apparatus, apparatus and process for manufacturing nonwoven fabric, and nonwoven fabric

InactiveUS20110130063A1Smooth rotationImprove productivitySpinnerette packsCeramic shaping apparatusProduction rateManufactured apparatus

Provided are a spinning apparatus capable of stably spinning fibers having a small fiber diameter with a high productivity, an apparatus comprising the same for manufacturing a nonwoven fabric, a process for manufacturing a nonwoven fabric using the nonwoven fabric manufacturing apparatus, and a nonwoven fabric produced by the process.The spinning apparatus of the present invention comprises one or more exits for extruding liquid, which are capable of extruding a spinning liquid, and one or more exits for ejecting gas, which extend linearly and are located upstream of each of the exits for extruding liquid and which are capable of ejecting a gas, wherein a shearing force by the gas and its accompanying airstream can be single-linearly exerted on the spinning liquid extruded. The apparatus of the present invention for manufacturing a nonwoven fabric comprises a fibers collection means as well as the spinning apparatus. The process of the present invention for manufacturing a nonwoven fabric is a process using the apparatus for manufacturing a nonwoven fabric. The nonwoven fabric of the present invention is a nonwoven fabric produced by the process.

Owner:NIPPON BAIRIIN

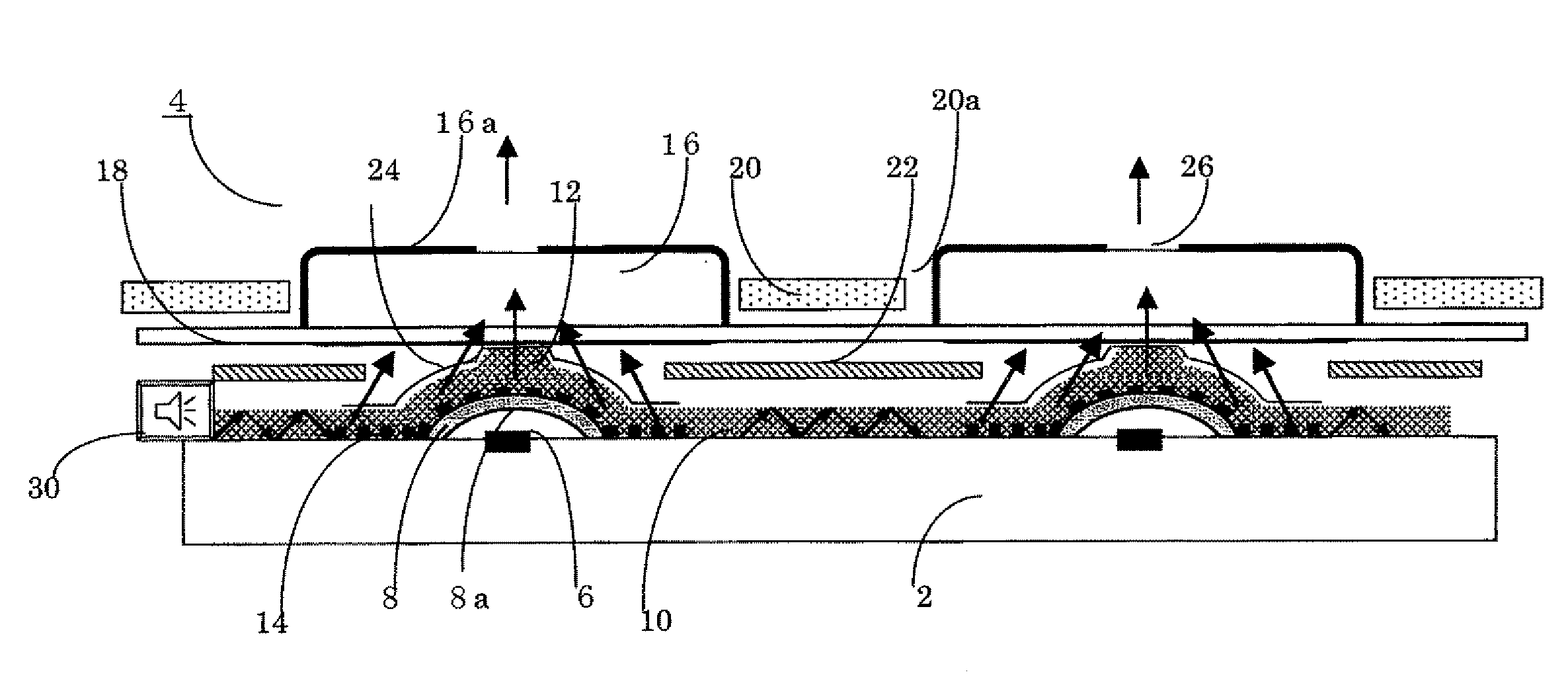

Metal dome sheet having pressing projection, push button switch, and method of producing the push button switch

InactiveUS20100108486A1Feel goodReduce in quantityEmergency actuatorsOperation facilitationEngineeringPush switch

To provide a metal dome sheet 10 to which a metal dome 8 is attached. The metal dome 8 elastically deforms with a pressing operation of a key top 16, thereby to have electrical conduction with a contact 6 provided on a substrate 2, and restores from a deformed state when the pressing operation is released, thereby to release the conduction with the contact. The metal dome sheet 10 has an elastic pressing projection 12 which transmits pressing force applied from the key top 16 side to a top 8a of the metal dome 8.

Owner:SUNARROW CO LTD

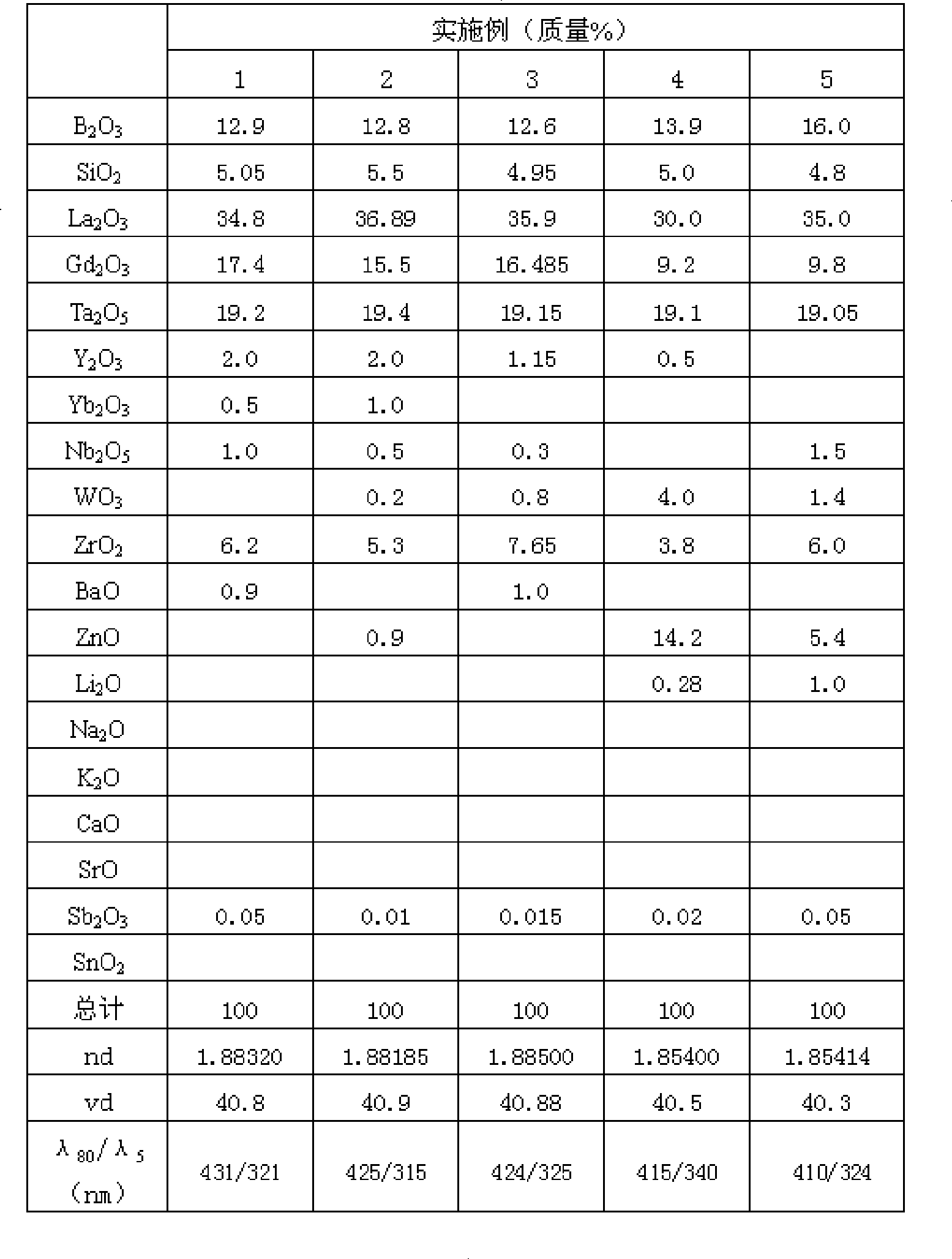

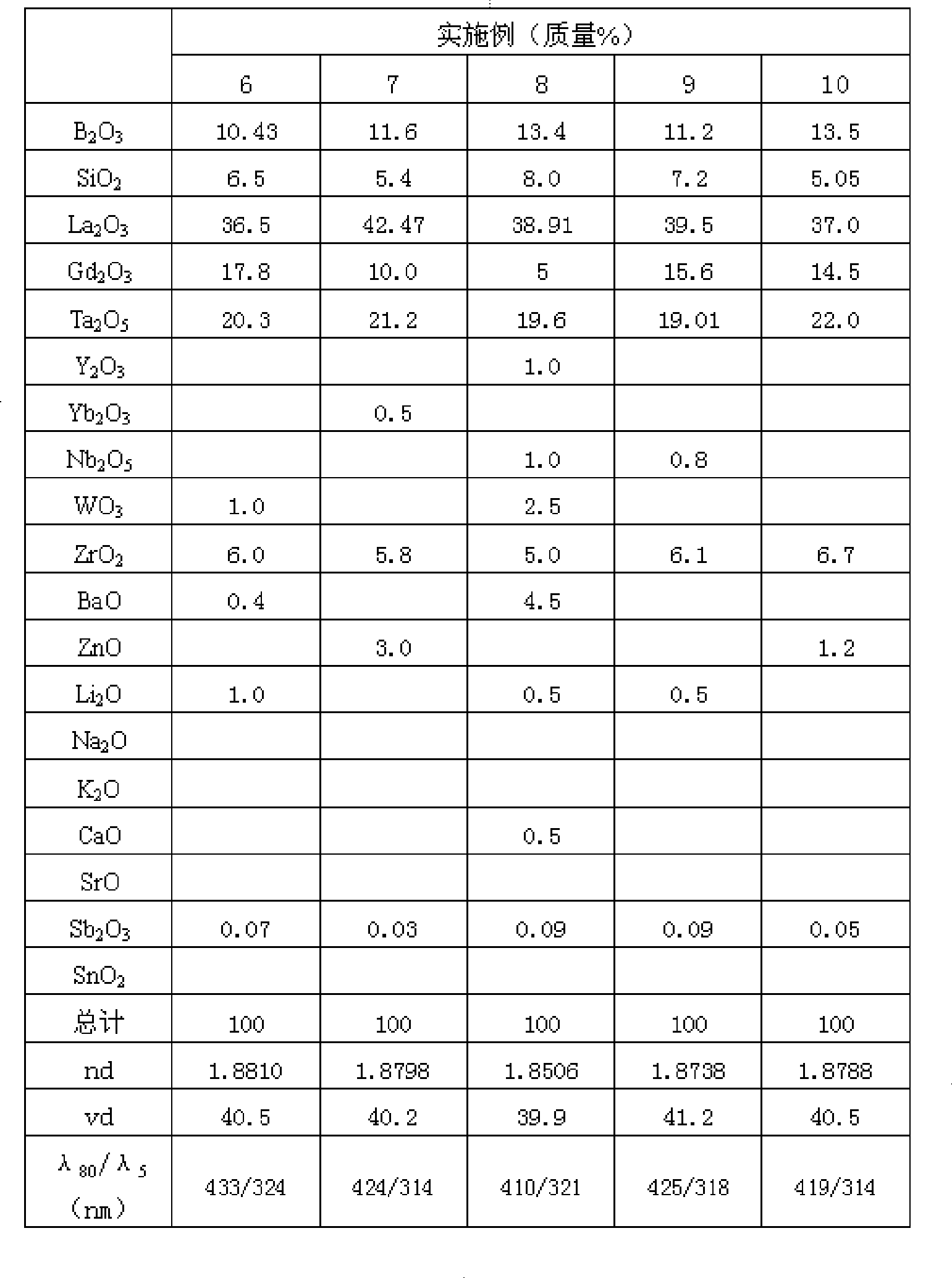

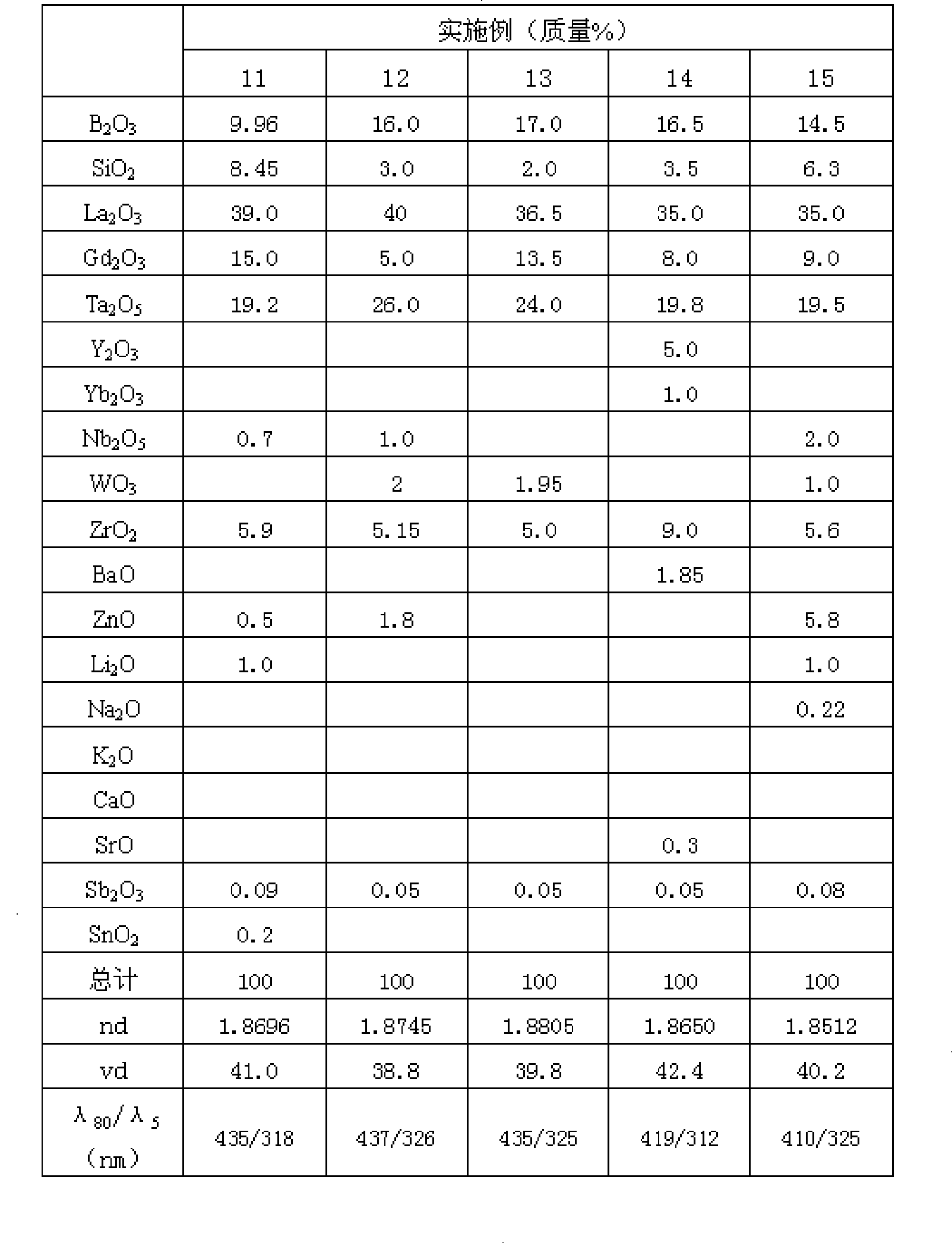

High refraction and low dispersion optical glass

The invention provides an environment-friendly optical glass with high refractive index, low dispersion and high light transmittance, which has components according to weight percentage: B2O3: 6 percent to 17 percent, SiO2: 2 percent to 10 percent, La2O3: more than 25 percent but less than 45 percent, Gd2O3: 5 percent to 25 percent, Nb2O5: 0 to 3 percent, Ta2O5: more than 19 percent but less than 27 percent, ZnO: 0 percent to 16 percent, BaO: 0 percent to 5 percent, CaO: 0 percent to 5 percent, SrO: 0 percent to 5 percent, ZrO2: 0 percent to 9 percent, Y2O3: 0 percent to 8 percent, Yb2O3: 0 percent to 8 percent, WO3: 0 percent to 5 percent, Li2O, Na2O and K2O: the total content of 0 percent to 2 percent, Sb2O: equal to 0.01 percent or less than 0.1 percent, SnO2: 0 percent to 1 percent. GeO2 is not included in the components of the environment-friendly optical glass and the refractive index is 1.85 to 1.90, while the Abbe number is 35 to 45. Meanwhile, the corresponding wavelength is below 440nm when the transmittance thereof is up to 80 percent, and the environment-friendly optical glass has high light transmittance.

Owner:CDGM OPTICAL GLASS

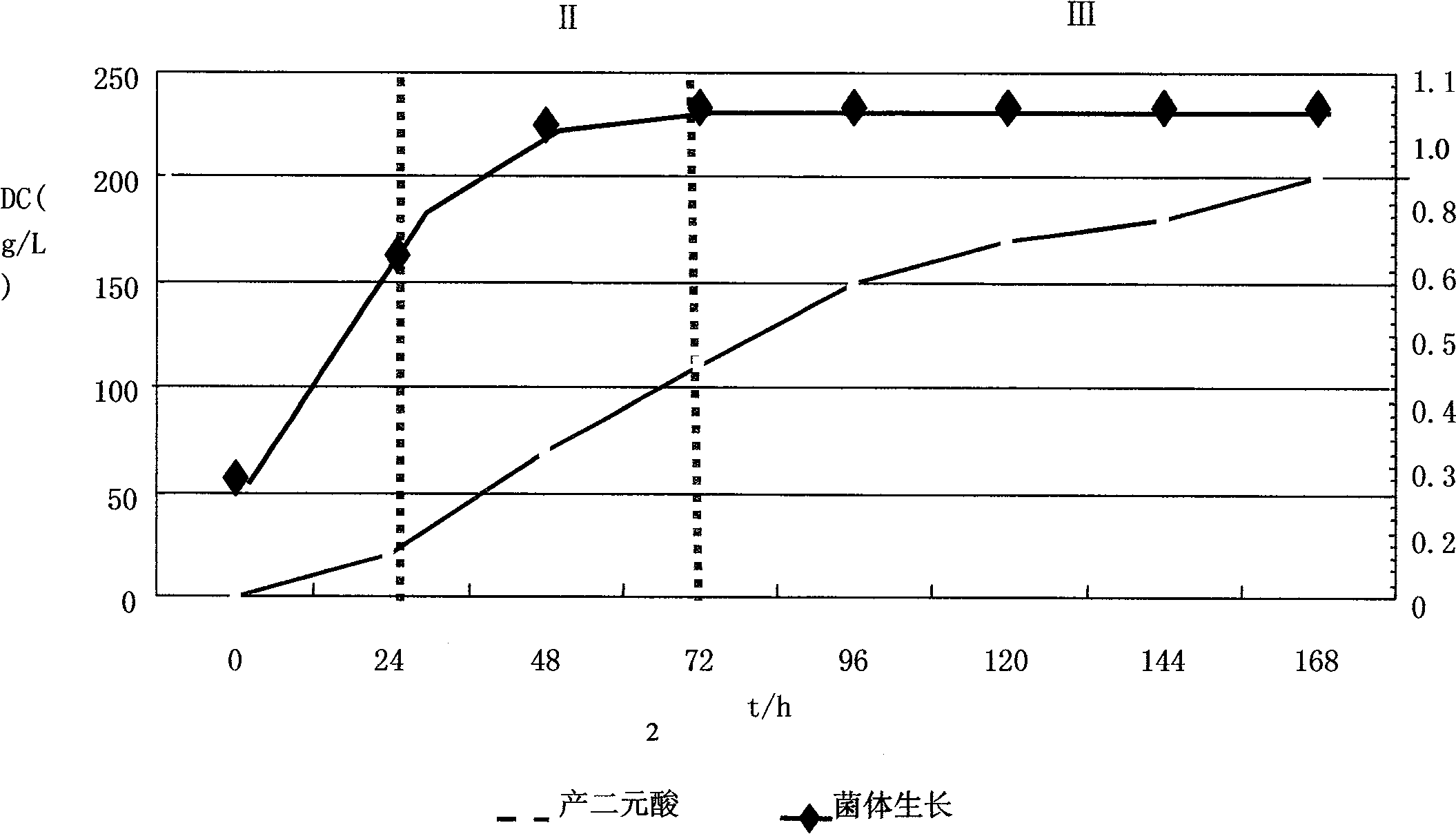

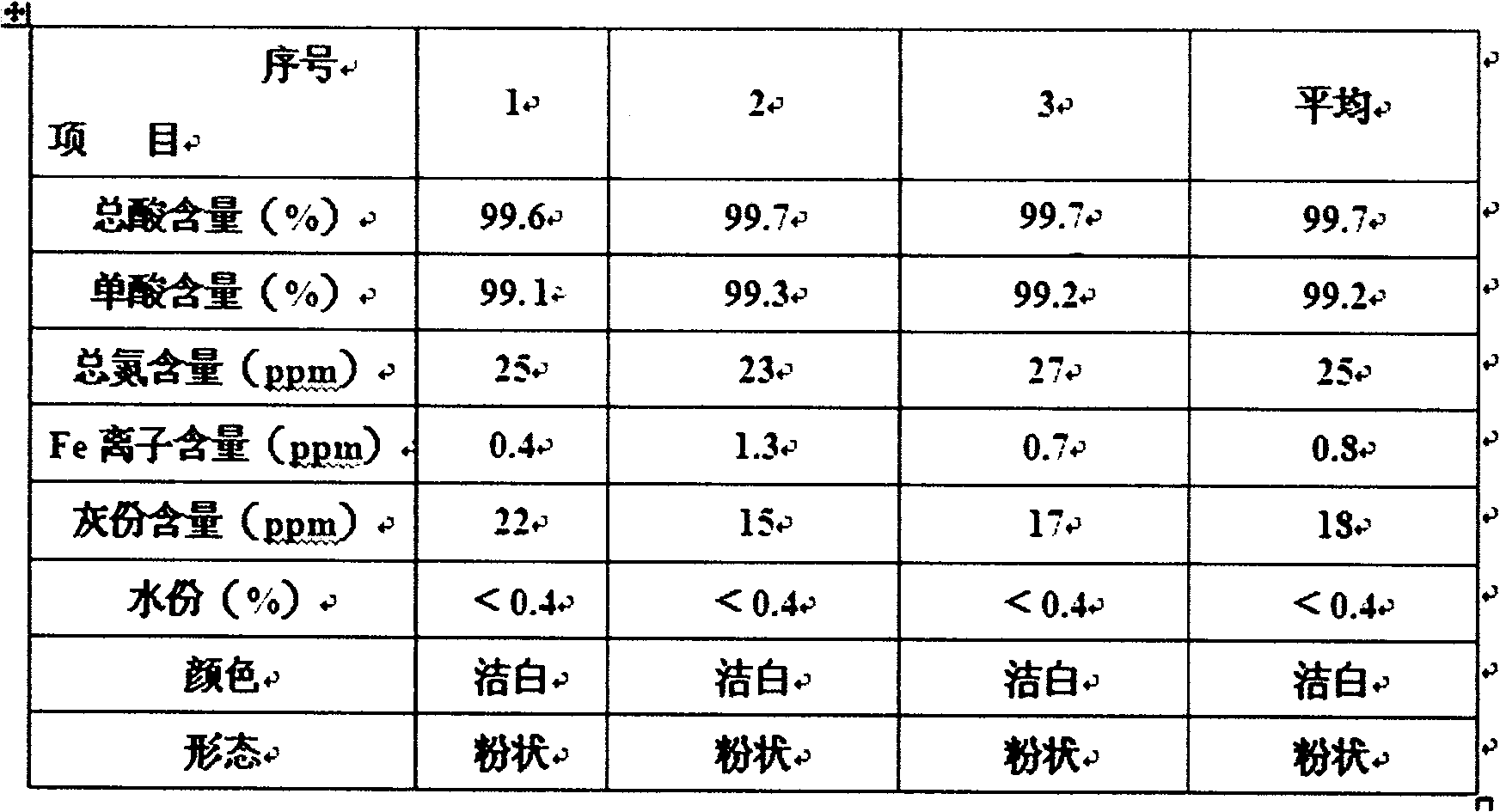

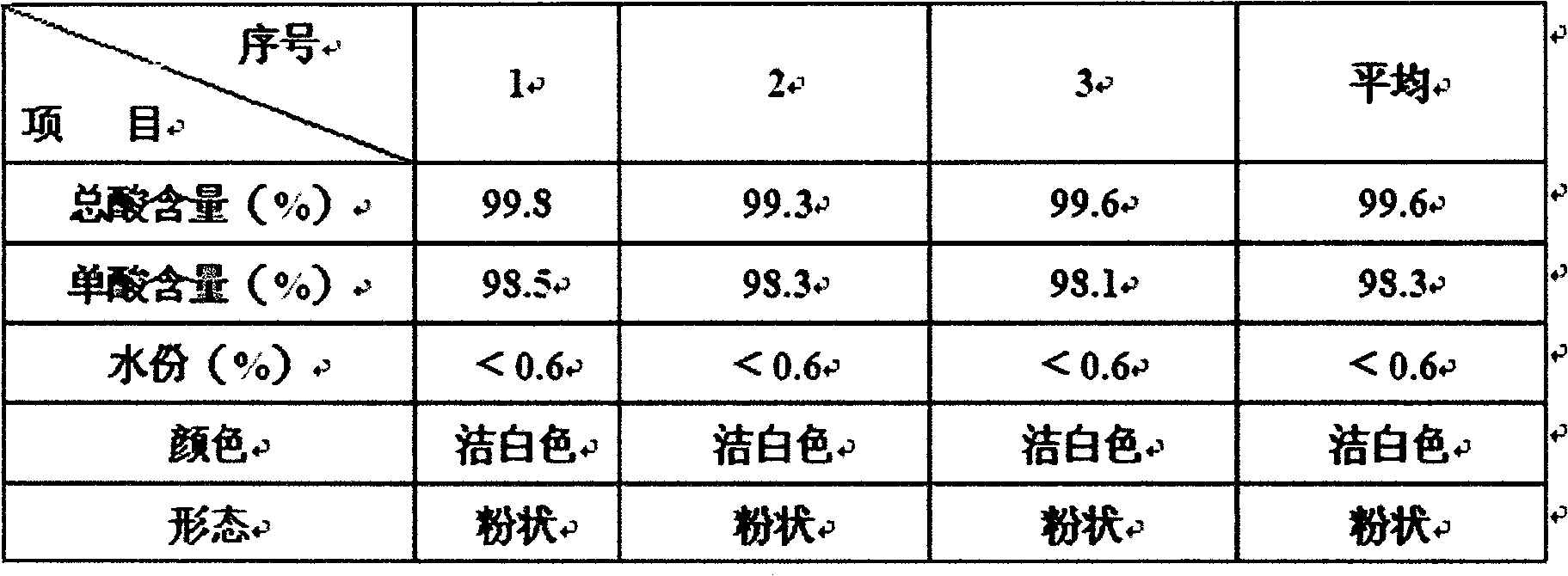

Preparation method of long carbon chain dibasic acid

The invention relates to a preparation method of a long carbon chain dibasic acid. C11 and upper alkane is used as a substrate to produce a corresponding long carbon chain dibasic acid product through the conversion of the substrate into the long carbon chain dibasic acid by using a microbial fermentation method as well as the extraction and the separation of fermentation liquid and the refining processes of a crude product of dibasic acid. Through technological innovation and process innovation, the invention researches a new preparation method of the long carbon chain dibasic acid, greatly decreases the production cost of the long carbon chain dibasic acid, improves the yield and the product quality of the long carbon chain dibasic acid, can produce C11 and upper long carbon chain dibasic acid, finally solve the bottleneck problem restricting the rapid development of the long carbon chain dibasic acid, and form the industrialized scale and the technological predominance. The long carbon chain dibasic acid produced by using the bioanalysis provided by the invention has the advantages of high acid generation level, low production cost, good product quality, complete variety, and the like, the prepared long carbon chain dibasic acid product has high single acid content, good light transmission and high thermal stability, can meet the requirements of different clients, and can be used for producing high-grade spices, high-performance engineering plastics, high-temperature dielectric medium, high-grade hot-melt adhesive, coldness-resistant plasticizer, high-grade lubricating oil, high-grade paint, coating, and the like. The invention greatly widens the development space of the downstream products of the long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD +2

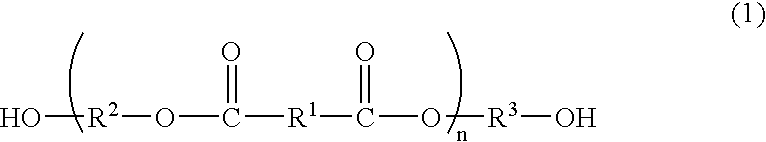

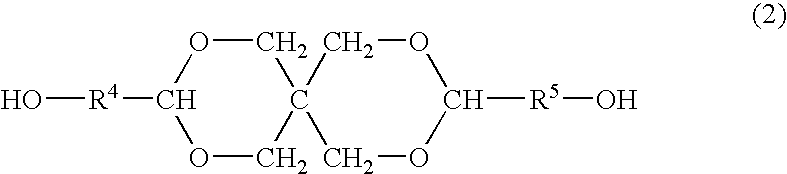

Process for producing polyester resins

In the invention, a polyester resin having dicarboxylic acid constitutional units and diol constitutional units wherein 5 to 60 mol % of the diol constitutional units has a cyclic acetal skeleton is produced by a process including an oligomerization step and a polymerization step. In the oligomerization step, an ester having a limited acid value is transesterified with a diol having a cyclic acetal skeleton in the presence of a titanium compound to obtain an oligomer. The oligomer is then polymerized in the subsequent polymerization step to increase the molecular weight.

Owner:MITSUBISHI GAS CHEM CO INC

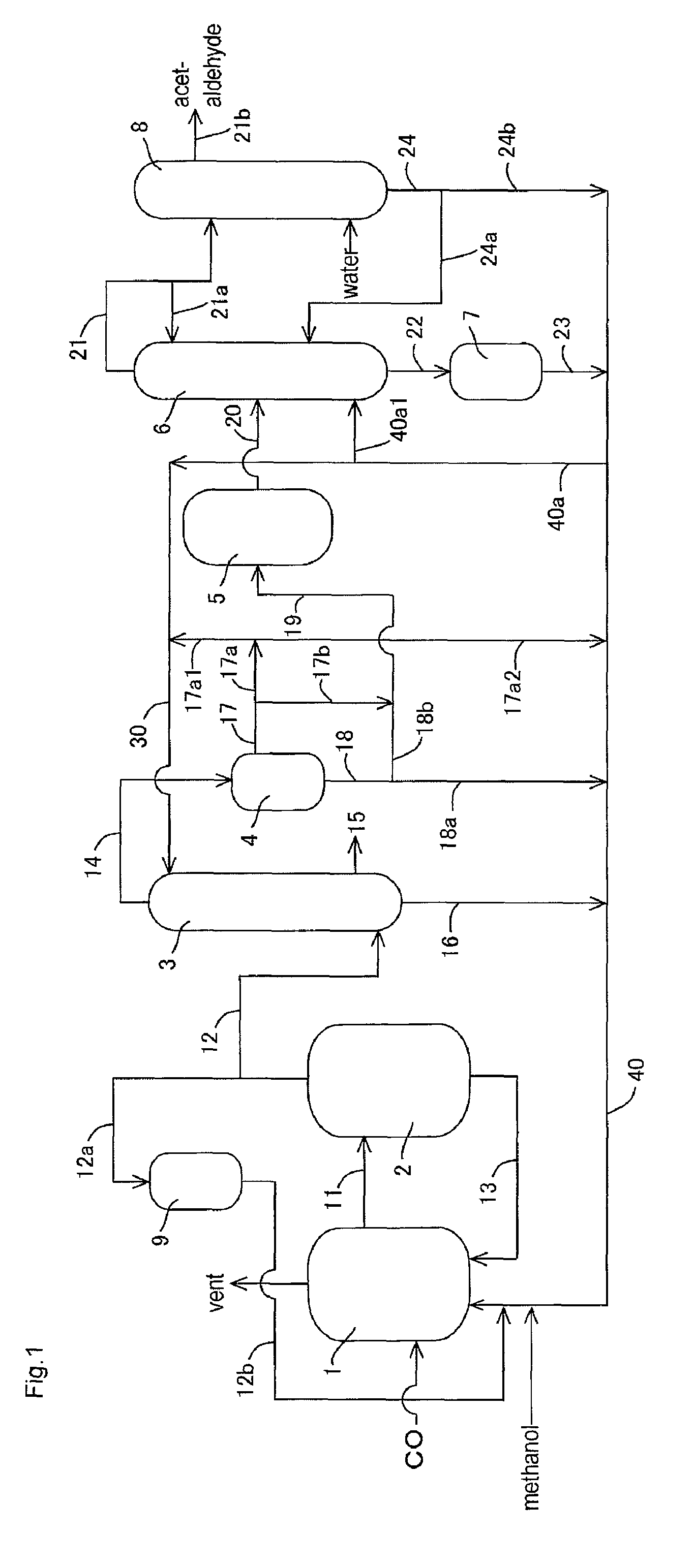

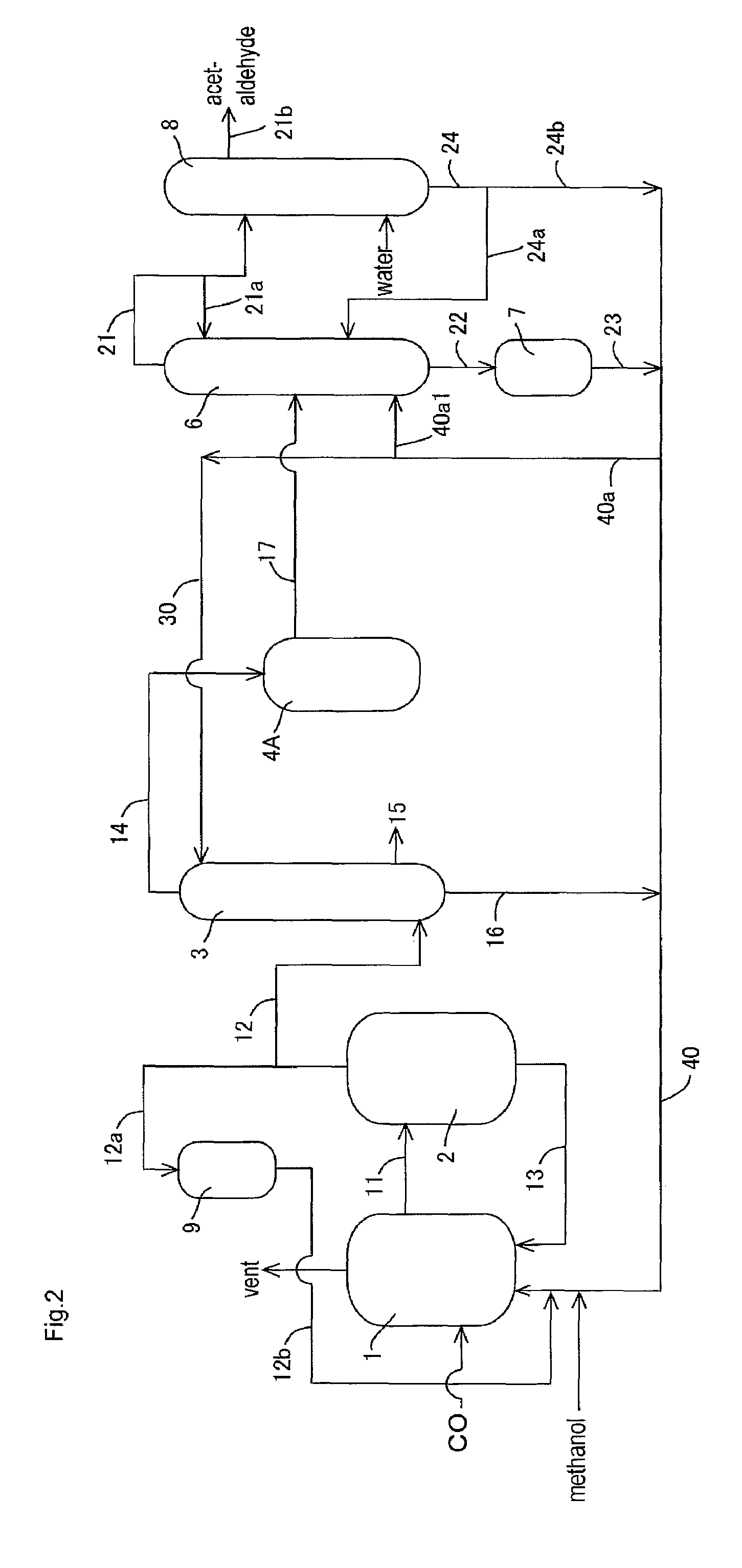

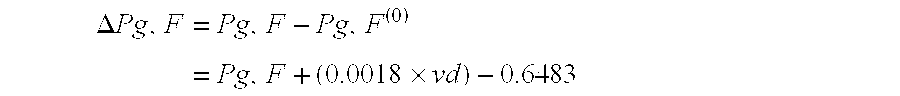

Process for producing acetic acid

ActiveUS8940932B2Stable productionEfficient removalOrganic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidBoiling point

A process for stably producing high purity acetic acid comprising a condensation step for condensing and temporarily holding the lower boiling component in a decanter and discharging from the decanter; and a step for separating the lower boiling component discharged from the decanter into acetaldehyde and a liquid residue and recycling the liquid residue to the reaction system. In the condensation step, the amount of the lower boiling component to be held is controlled based on the fluctuating flow rate of the lower boiling component to be fed to the decanter.

Owner:DAICEL CHEM IND LTD

Optical glass, preform for precision press molding, optical element, and method for manufacturing optical element

ActiveUS20110257001A1Stable productionLittle tendencyGlass reforming apparatusGlass severing apparatusEngineeringRefractive index

The present invention relates to an optical glass having a refractive index nd of 1.86 or higher and an Abbé number v(nu)d of 28 to 36; a preform for precision press molding and an optical element that are comprised of this glass; and a method for manufacturing the optical element.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com