Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Process innovation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of long carbon chain dibasic acid

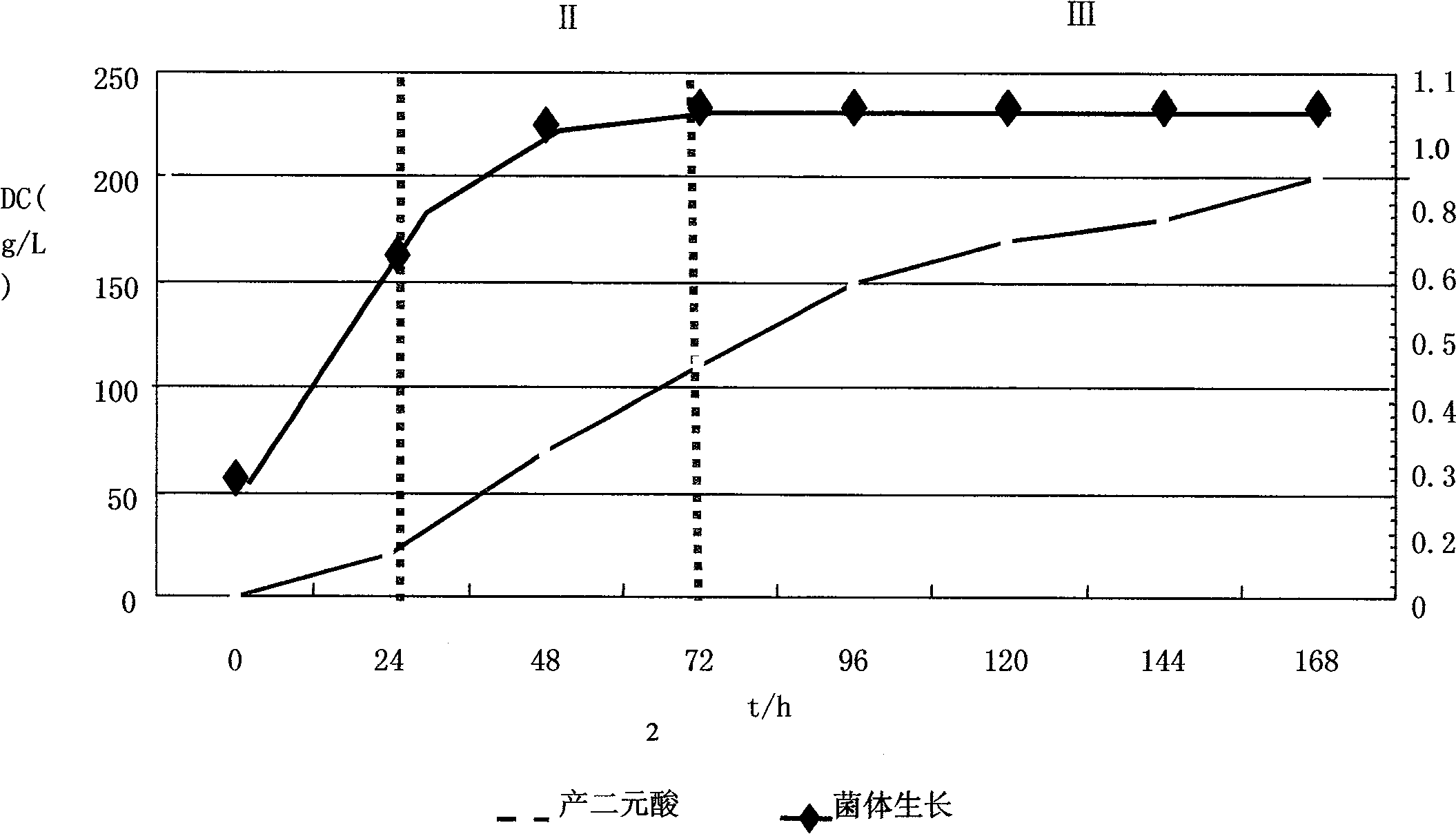

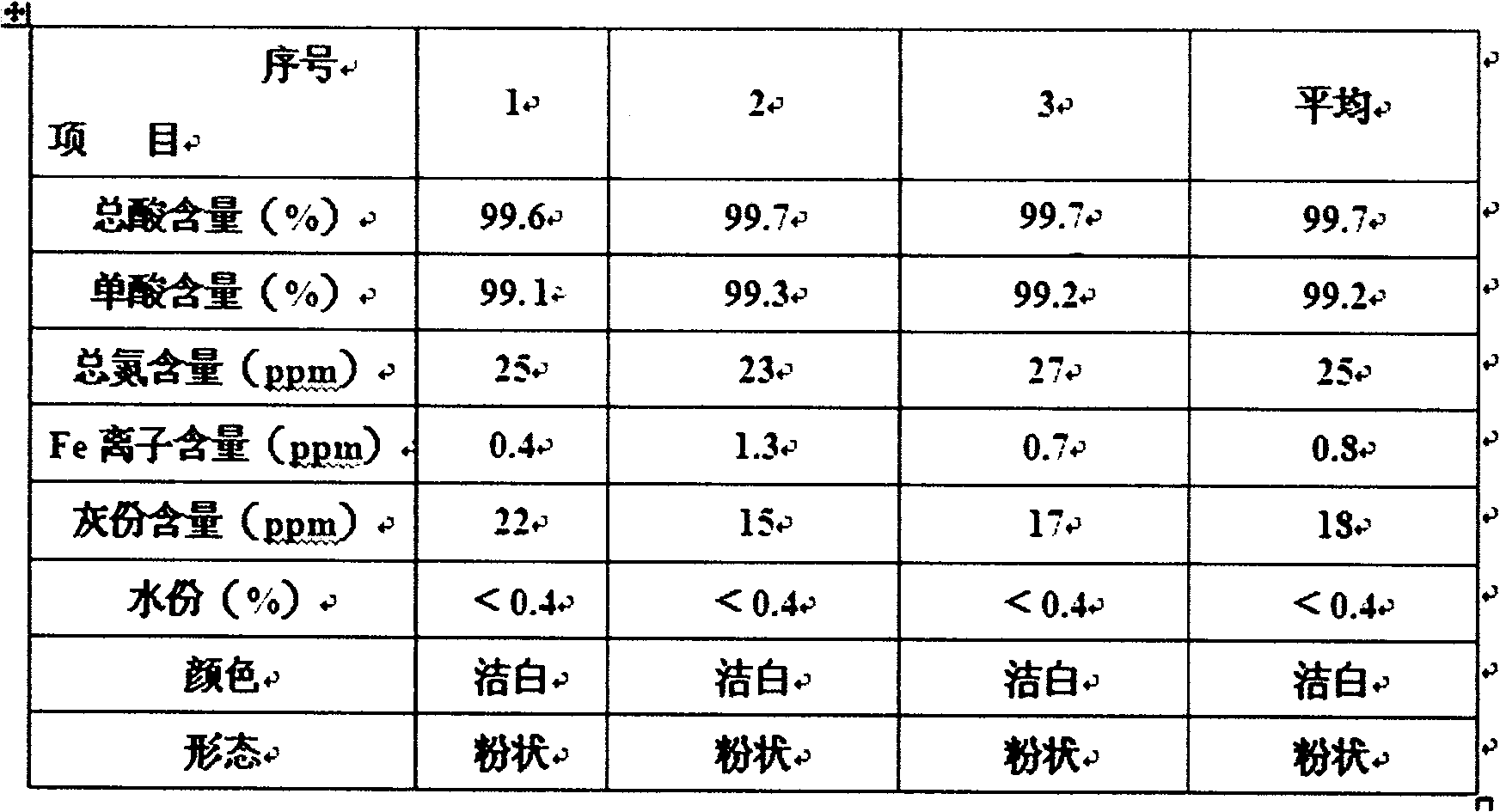

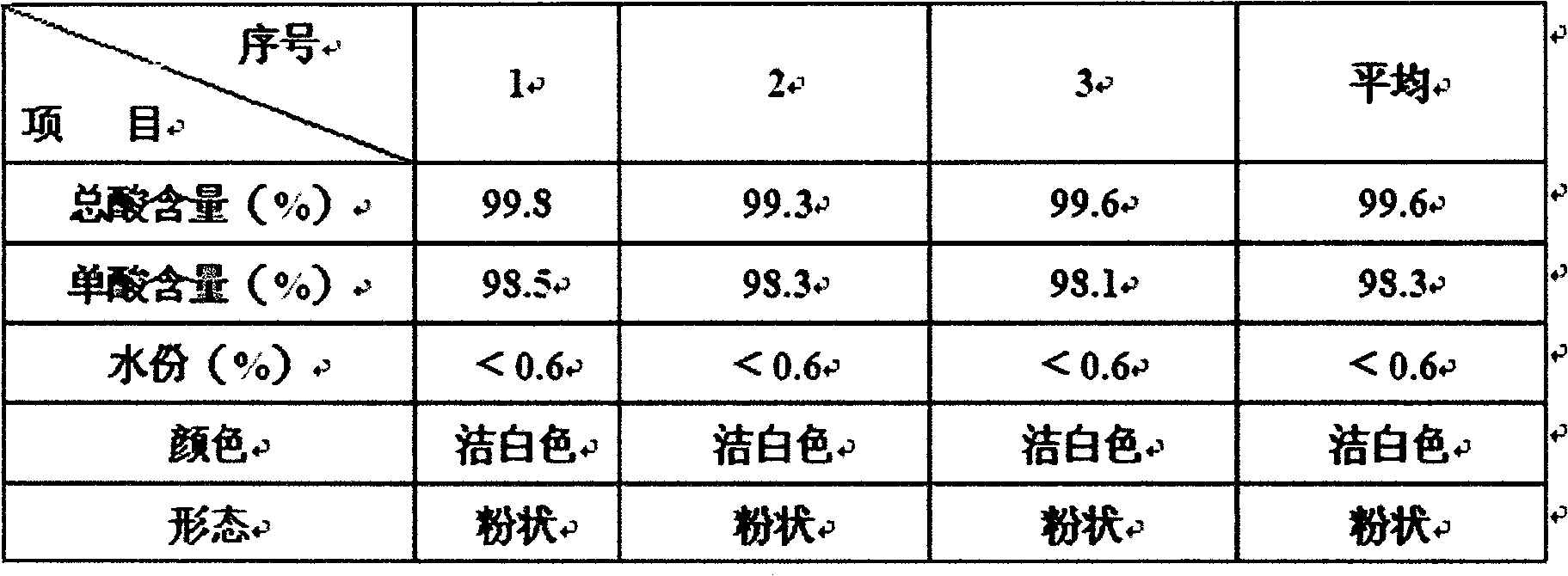

The invention relates to a preparation method of a long carbon chain dibasic acid. C11 and upper alkane is used as a substrate to produce a corresponding long carbon chain dibasic acid product through the conversion of the substrate into the long carbon chain dibasic acid by using a microbial fermentation method as well as the extraction and the separation of fermentation liquid and the refining processes of a crude product of dibasic acid. Through technological innovation and process innovation, the invention researches a new preparation method of the long carbon chain dibasic acid, greatly decreases the production cost of the long carbon chain dibasic acid, improves the yield and the product quality of the long carbon chain dibasic acid, can produce C11 and upper long carbon chain dibasic acid, finally solve the bottleneck problem restricting the rapid development of the long carbon chain dibasic acid, and form the industrialized scale and the technological predominance. The long carbon chain dibasic acid produced by using the bioanalysis provided by the invention has the advantages of high acid generation level, low production cost, good product quality, complete variety, and the like, the prepared long carbon chain dibasic acid product has high single acid content, good light transmission and high thermal stability, can meet the requirements of different clients, and can be used for producing high-grade spices, high-performance engineering plastics, high-temperature dielectric medium, high-grade hot-melt adhesive, coldness-resistant plasticizer, high-grade lubricating oil, high-grade paint, coating, and the like. The invention greatly widens the development space of the downstream products of the long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD +2

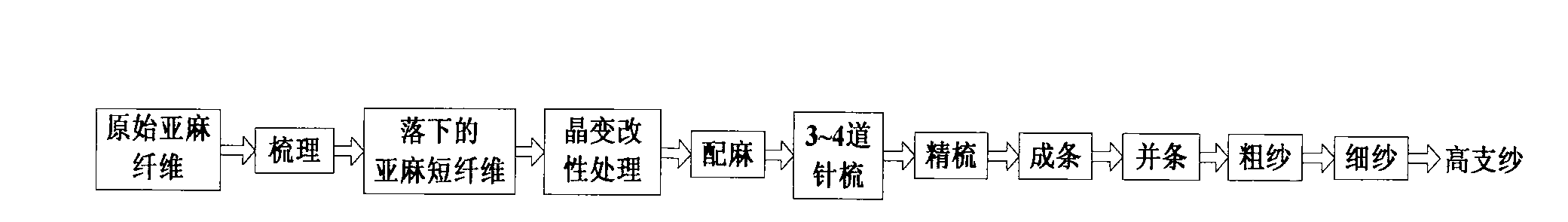

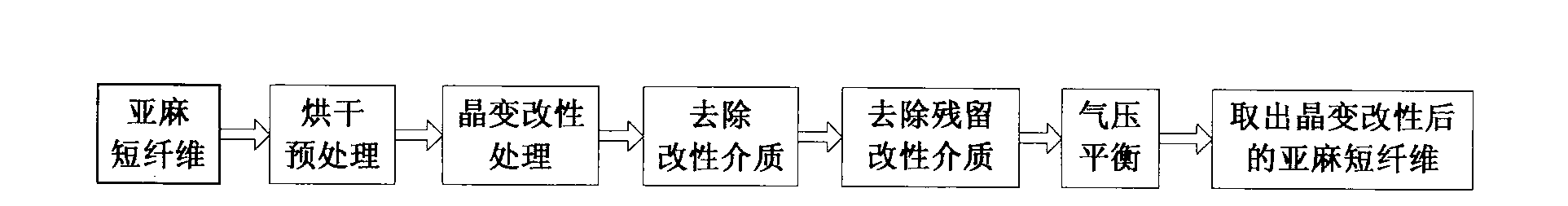

Dry spinning method for spinning flax short fiber into high count yarn

InactiveCN102839456AAvoid pollutionQuality improvementLiquid/gas/vapor treatment of definite length materialsYarnYarnPulp and paper industry

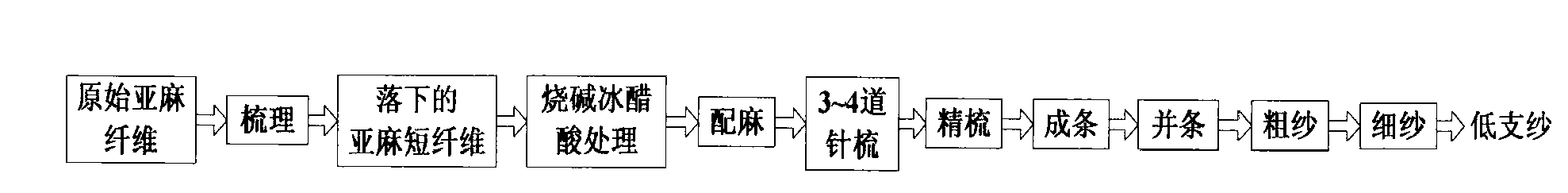

The invention provides a dry spinning method for spinning flax short fiber into high count yarn, comprising the following steps: step 1, original flax fiber is combed to enable flax short fiber to fall down, and then the flax short fiber is used as the raw material for dry spinning; step 3, crystallized and modified flax short fiber obtained in the step 1 is subjected to flax assorting, and the crystallized and modified flax short fiber is spun into flax rough yarn through 3-4 times of gilling, combing, slivering, drawing and roving procedures; step 4, the flax rough yarn is dry-spun into high quality and high count flax fine yarn by a dry spinning frame; the drying spinning method is characterized in that a step 2 is carried out between the first step and the third step; and step 2, the flax short fiber is subjected to crystallization and modification treatment. The dry spinning method has the advantages that the dry spinning method can be used for spinning flax short fiber into 50 metric count according to the fiber proportion which is adopted by the traditional dry spinning method used for spinning flax short fiber into 36 metric count flax yarn, and the technological and process innovation that low-quality flax short fiber can be spun into high quality and high count flax yarn is realized; and the caustic soda and glacial acetic acid treatment adopted in the traditional dry spinning method is replaced by the crystallization and modification treatment, so that no exhaust gas and liquid waste are generated in the whole technological process.

Owner:DONGHUA UNIV +1

Middle-high voltage electrode foil five-section formation two-stage liquid feed production method

ActiveCN103160902AHigh speed productionIncrease productivitySurface reaction electrolytic coatingPressure riseThree stage

The invention discloses a middle-high voltage electrode foil five-section formation two-stage liquid feed production method which sequentially comprises the following steps of hydration processing, one-stage formation processing, two-stage formation processing, one-stage feed, three-stage formation processing, four-stage formation processing, two-stage feed, five-stage formation one-section processing, first roasting, five-stage formation second-section processing, phosphating, five-stage formation three-section processing, second roasting, five-stage formation four-section processing, and post-processing. According to the production method, through improvement on a production procedure, process innovation is matched, the speed of production of products in the same specification is promoted by 30-50%, and performance indexes of pressure rising time, leakage currents, withstand voltage after boiling, the specific volume and the like are effectively improved.

Owner:宝兴县剑锋制箔电子有限公司

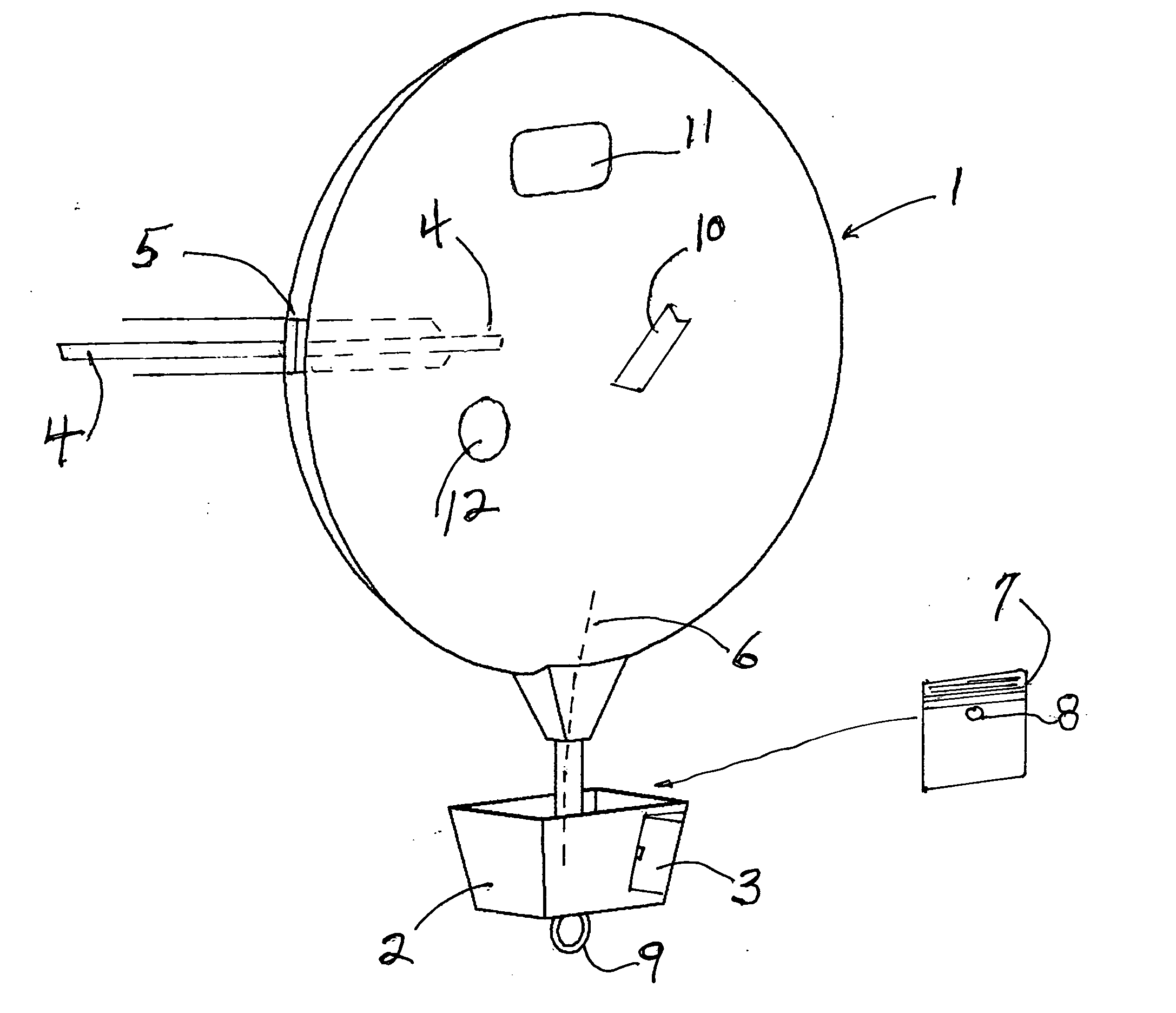

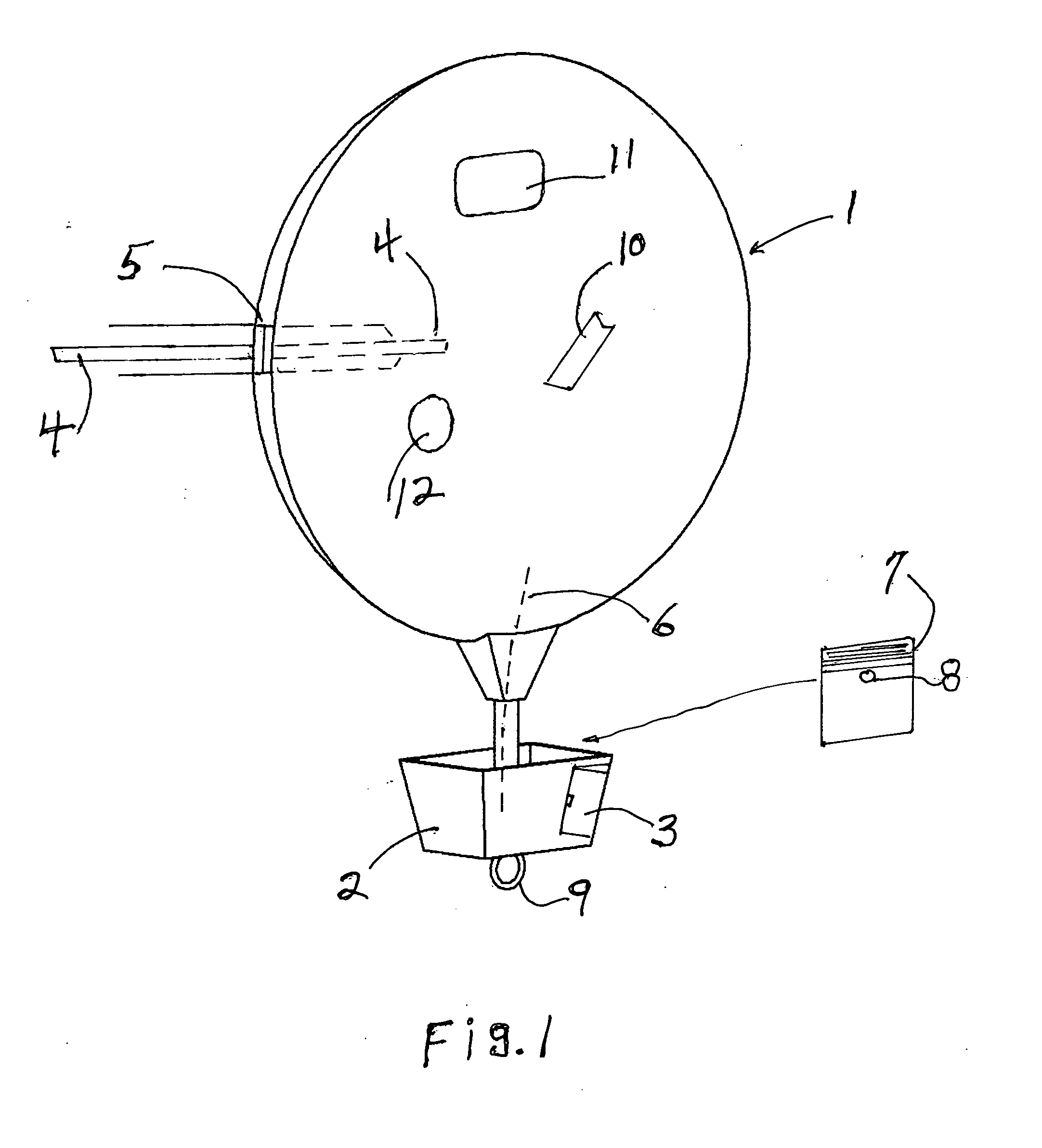

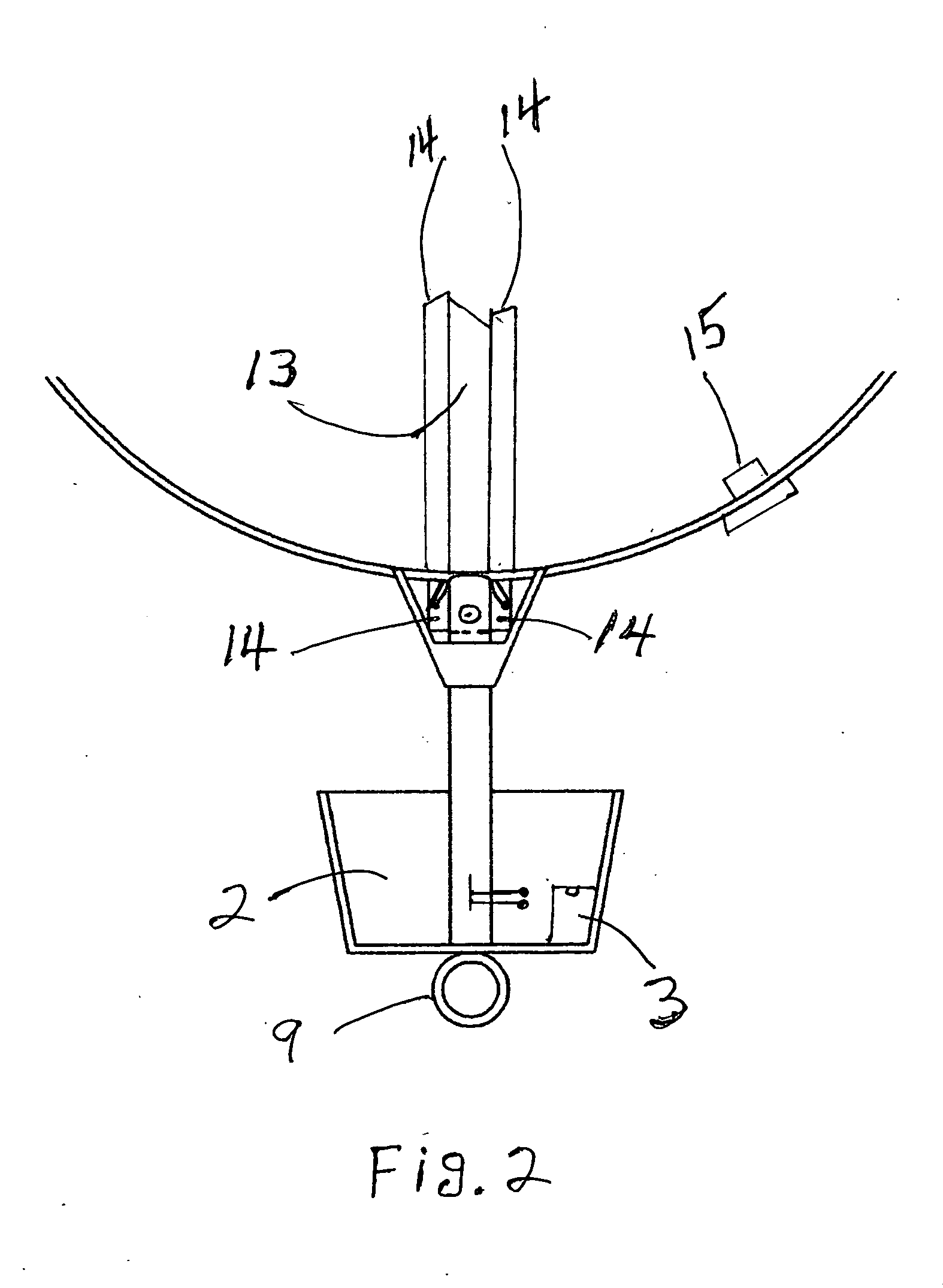

Power transferred by electrical conductors for gas lighter than air inflatable balloons and apparatus with neutral buoyancy maintained by weight adjustable printed material that protects customers and profitably for businesses with software process innovations

InactiveUS20150106138A1Easy to controlNon-electrical signal transmission systemsInsulated cablesElectrical conductorEngineering

Power transferred by electrical conductors for gas lighter than air inflatable balloons and apparatus with neutral buoyancy maintained by weight adjustable printed material that protects customers and profitably for businesses with software process innovations.

Owner:HUB OF WEBMOBILE

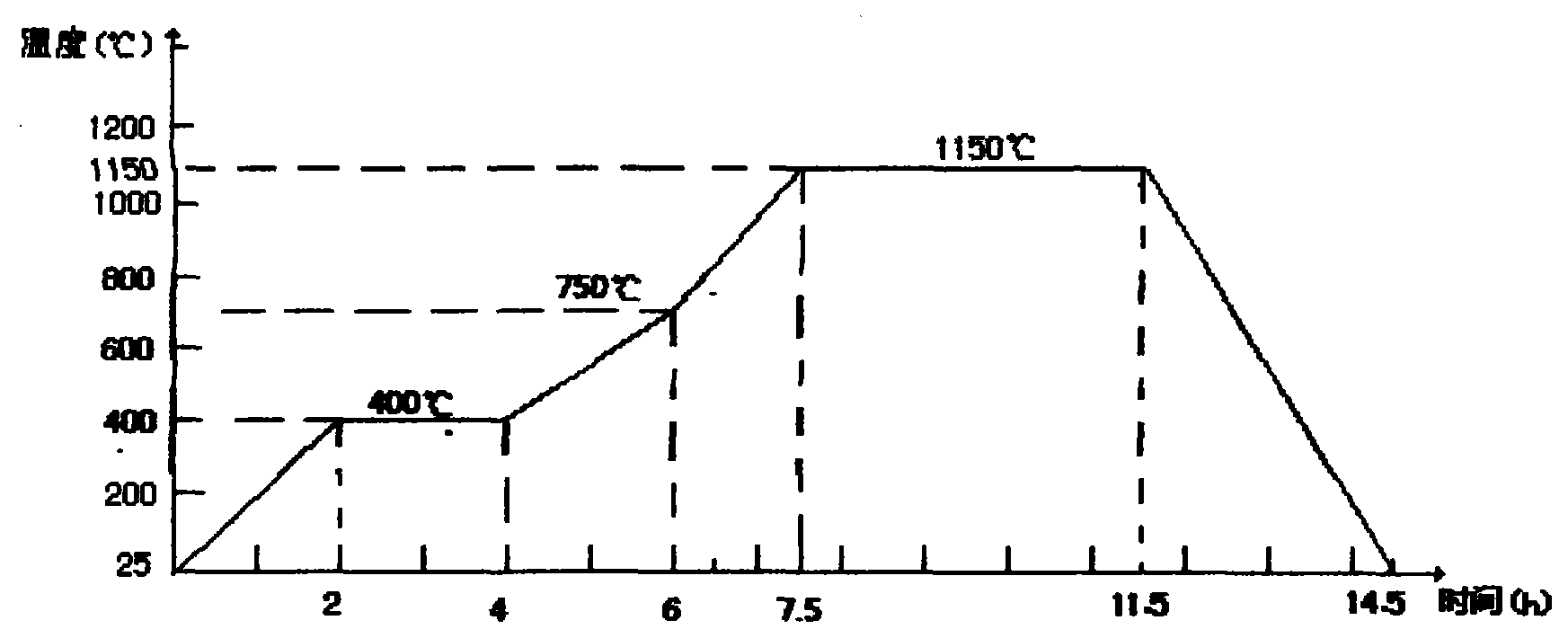

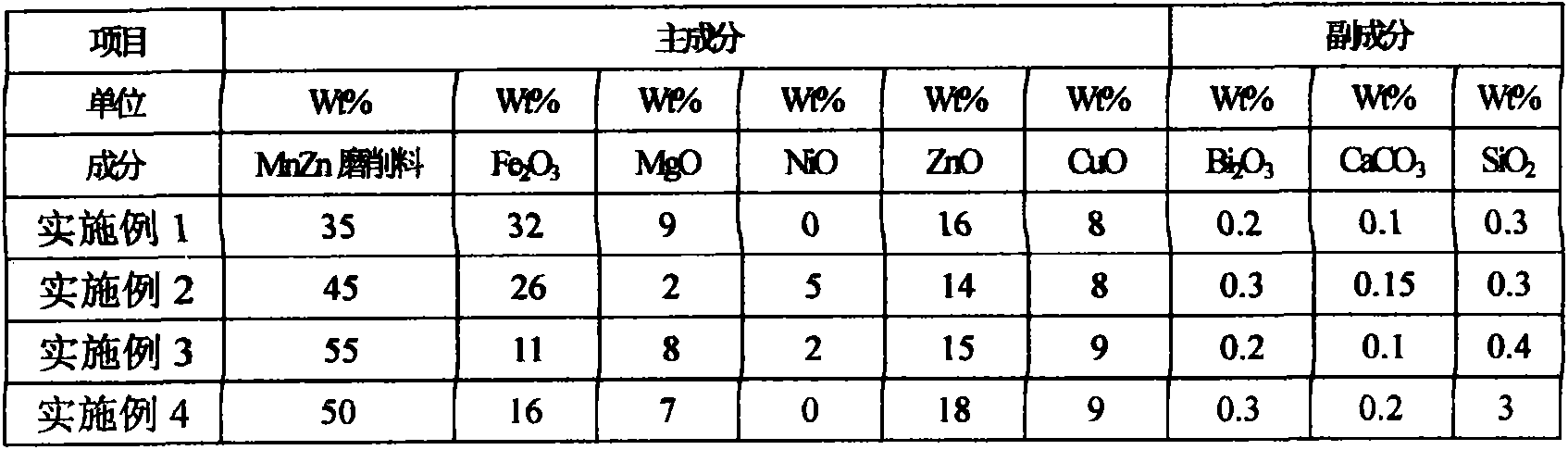

Recycling method of solid waste

ActiveCN104045332AHigh value resourcesProcess innovationSolid waste disposalElectromagnetic interferenceInductance

A recycling method of solid wastes is as below: conducting simple sieving treatment on a MnZn grinding material, adding MgO, CuO, NiO, ZnO, Fe2O3, Bi2O3, CaCO3 and SiO2, producing MgMnZn, NiMnZn or other high performance composite ferrite body materials by a ferrite process, wherein the MgMnZn, NiMnZn or other high performance composite ferrite body materials can be used for the production of anti-electromagnetic interference magnetic element and inductance filter element. The recycling method of solid wastes provided by the invention uses MnZn waste as the raw material, achieves a closed cycle from raw materials to products to wastes to raw material through formula design and process innovation, and realizes high value resource of MnZn ferrite wastes.

Owner:ZHAOQING CHAMPION FERRITE TECH

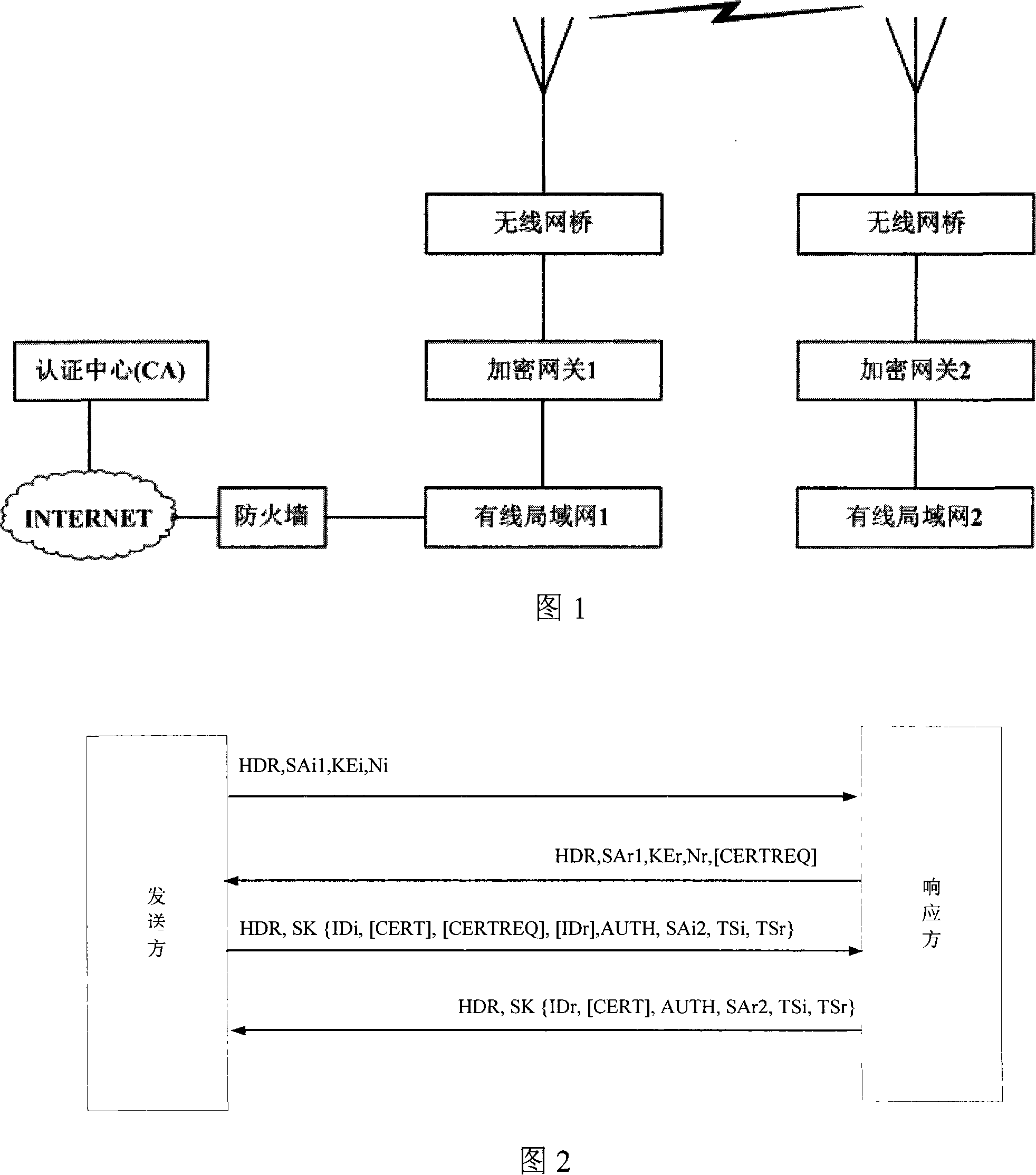

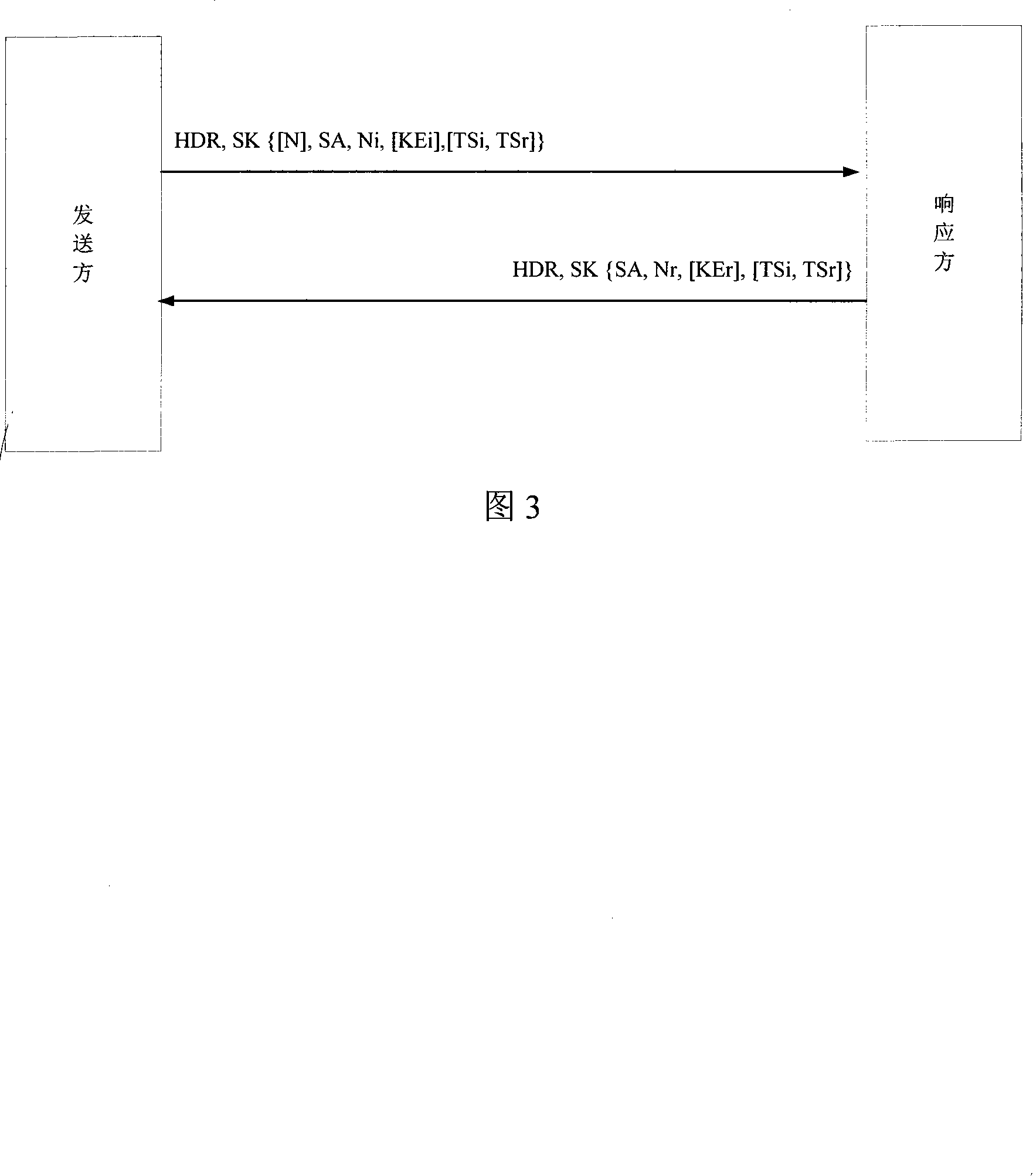

Method for implementing wireless network safety communication

InactiveCN101119368AReduce overheadLow costUser identity/authority verificationNetworks interconnectionData integritySecure transmission

The invention belongs to the safety technical field of computer networks and discloses an achieving method of the safe communication of a wireless network. The achievement on the method bases on the identification of identity and the processed innovation of IKEV2 protocol. The invention adds an encrypted gateway between a wireless bridge and a wire local area network. The communicating physical body in the method has two encrypted keys (a common key and a private key). Each physical body has an incommon private key. The senders of the message adopt the private key to sign and the receivers carry out inspection with the identity of the senders (namely the common key). The communicating physical body does not need the signature of the identifying center (CA) to the certificates, and thus saves the computing capacity of the communicating physical bodies. The method included in the invention ensures the transmitting safety of the information for the wireless network communication solves the problems such as data encryption, identity identification, maintenance on the integrity of the data and management on the encryption, with the safe transmission of the business data.

Owner:BEIJING JIAXUN FEIHONG ELECTRIC CO LTD

Method for manufacturing environment-friendly medium density fiberboard using plant straws instead of partial wood fibers

ActiveCN106272868AReduce usageReduce formaldehyde emissionPretreatment with water/steamDigestersAdhesiveFiberboard

The invention discloses a method for manufacturing an environment-friendly medium density fiberboard using plant straws instead of partial wood fibers. The fiberboard is composed of the following components in parts by weight: 60-70 parts of wood materials, 20-25 parts of plant straws, 15-20 parts of urea resin, 4-6 parts of methylenediphenyl diisocyanate adhesive, 0.8-1.2 parts of paraffin, 0.2-0.3 part of caustic soda flakes, 0.2-0.3 part of formic acid, 0.25-0.3 part of ammonia chloride, and 0.15-0.2 part of melamine. The method for manufacturing an environment-friendly medium density fiberboard using plant straws instead of partial wood fibers has the following advantages: the usage amount of wood is reduced; moreover, as the methylenediphenyl diisocyanate (MDI) is a non-formaldehyde adhesive, the addition thereof results in great reduction of formaldehyde emission of the density fiberboard, improvement in the environmental protection property of the density fiberboard, and promotion of the production level and the product quality, and also promotion of technical innovation, process innovation and product innovation with respect to artificial board products.

Owner:辽宁蓝亿实业有限公司

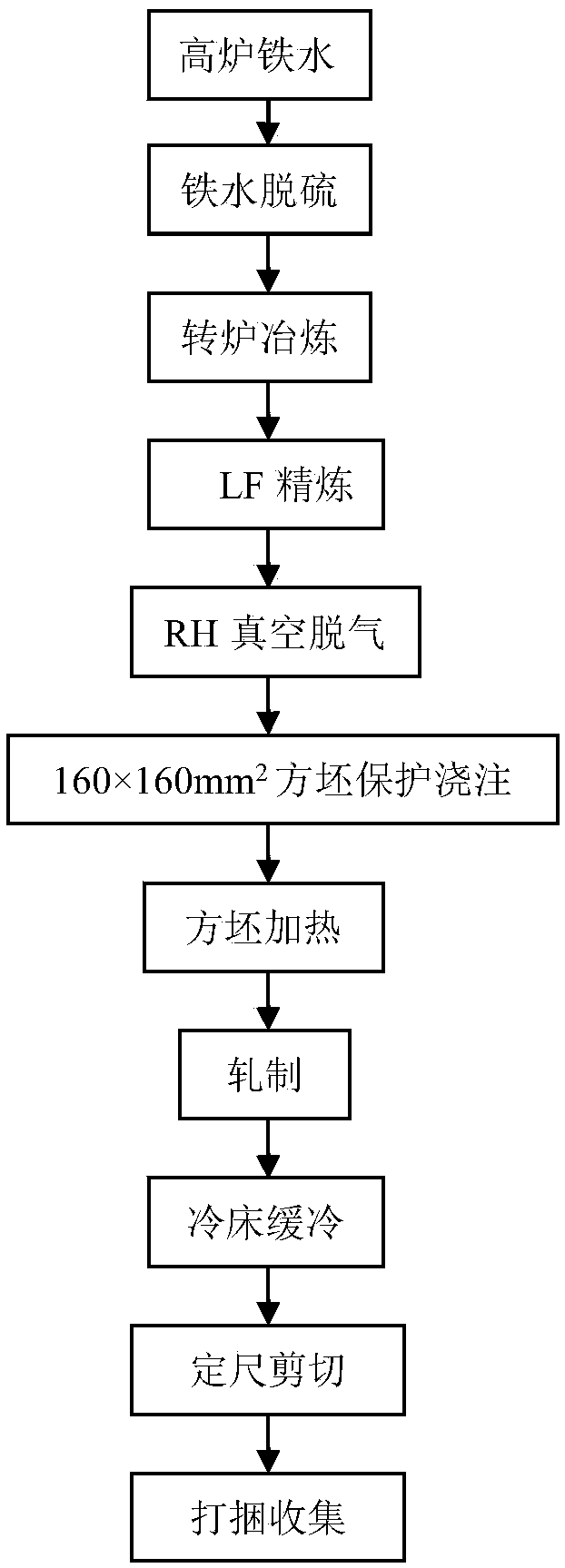

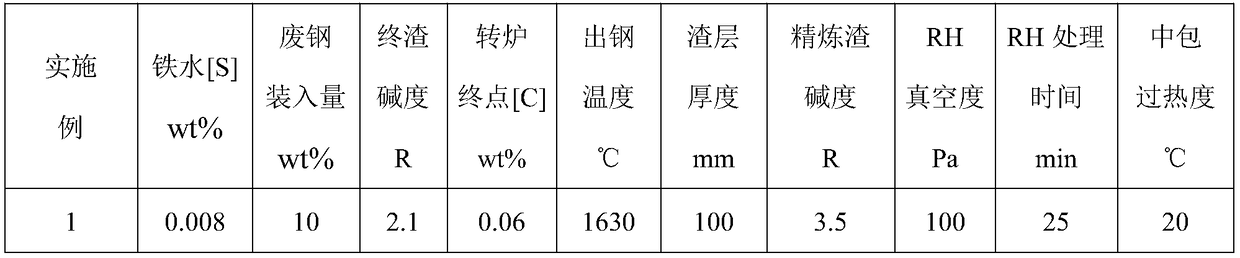

1550MPa-level spring flat steel and production method thereof

ActiveCN109161803AHigh strengthImprove toughnessManufacturing convertersProcess efficiency improvementSpring steelImpurity

The invention discloses 1550MPa-level spring flat steel. The 1550MPa-level spring flat steel comprises the following components in percentage by mass: 0.48 to 0.61 percent of C, 0.4 to 0.9 percent ofSi, 0.60 to 1.20 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.75 to 1.25 percent of Cr, 0.01 to 0.05 percent of Nb, 0.001 to 0.004 percent of B,0.010 to 0.025 percent of Al, 0.005 to 0.009 percent of N and the balance of Fe and unavoidable impurities. The steel for a spring, which has an excellent use property and an optimal tissue structure, is developed by combining composition and process innovation; furthermore, the preparation method is simple and low in cost, and has an important popularization and application value.

Owner:武汉钢铁有限公司

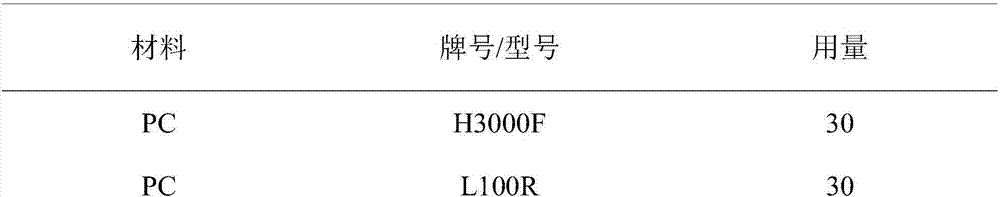

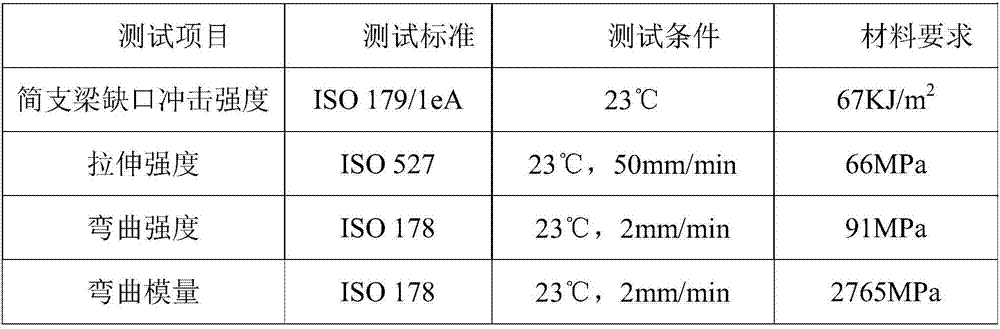

Low-odor spray-coating-free PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

The invention discloses a low-odor spray-coating-free PC / ABS (polycarbonate / acrylonitrile butadiene styrene) material and a preparation method thereof. The material is prepared from the following ingredients including 40 to 80phr of PC, 20 to 60phr of ABS, 5 to 10phr of AS, 0 to 1phr of lubricating agents, 1 to 1.5phr of deodorants, 0.5 to 1phr of heat stabilizers, 0.5 to 1phr of color masterbatch, 0 to 10phr of compatibilizers, 0 to 5phr of processing auxiliary agents, 0.1 to 0.5phr of antioxidants and 0 to 5phr of ultraviolet light absorbers. The material has the low odor and spray-coating-free appearance requirements; the odor grade is lower than or equal to 3.0; the appearance luster is good; the blackness is high; the thermal stability is high; the defects of flowing marks, melting and connecting wires, silver silks and the like cannot be easily generated; the spraying work procedure is omitted; the good spray-coating-free effect is achieved; through the creative selection on raw materials and auxiliary agents and the process innovation, a low-odor spray-coating-free PC / ABS material is produced, and is obviously superior to similar products in the market.

Owner:太仓市华鼎塑料有限公司

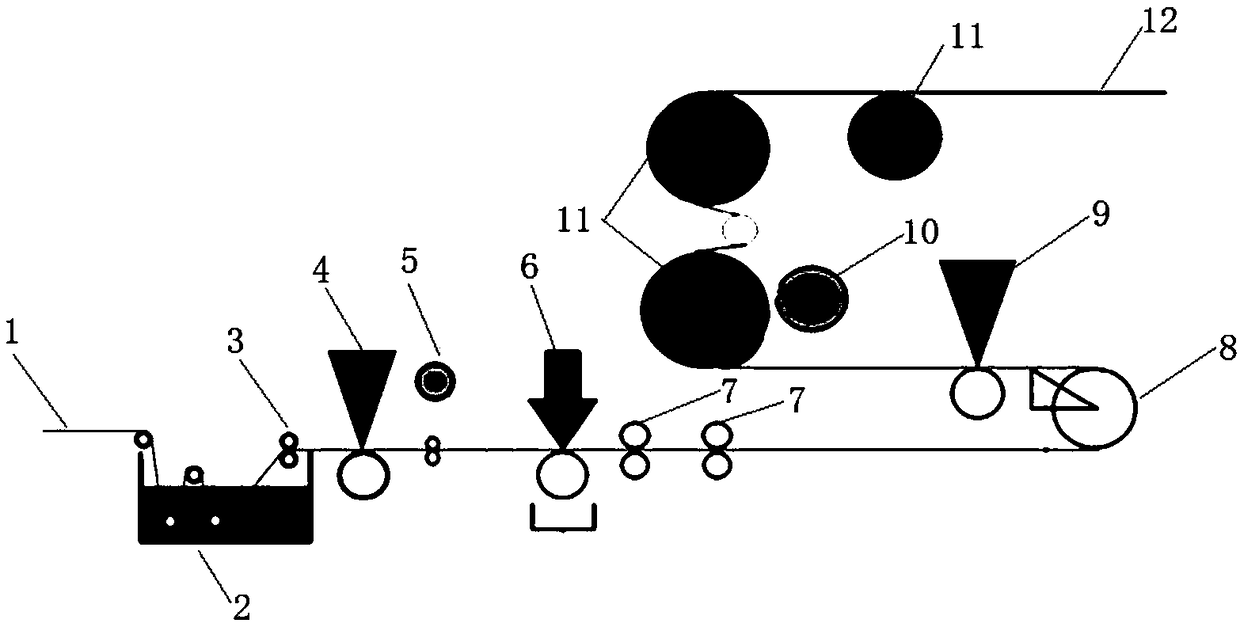

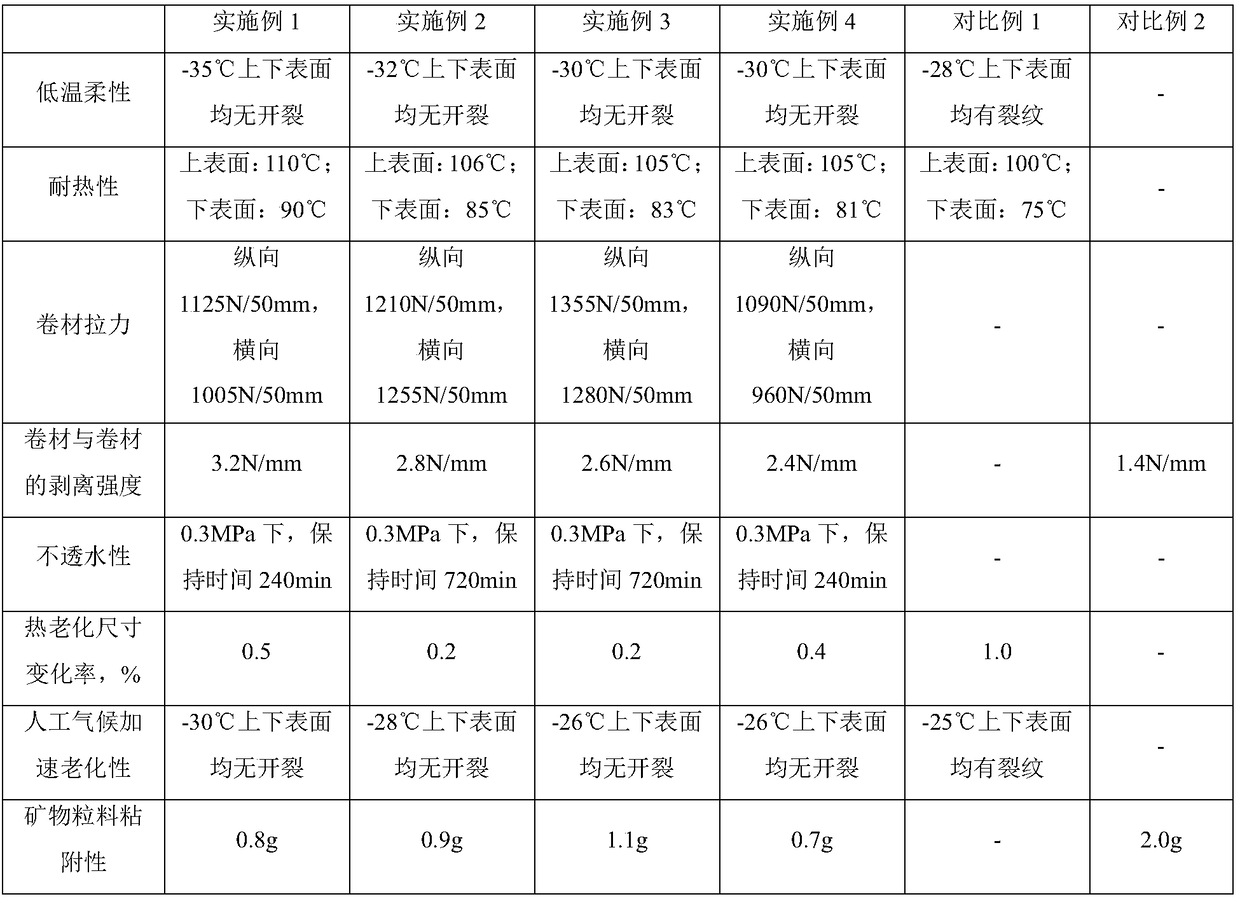

Composite self-adhesive shale surface modified asphalt waterproof roll and preparation method thereof

ActiveCN109130440AReduce energy consumptionGood exposed usabilitySynthetic resin layered productsLaminationProduction linePolyester

The invention discloses a composite self-adhesive shale surface modified asphalt waterproof roll and a preparation method thereof. The preparation method comprises the steps that a polyester base is sequentially subjected to preimpregnation and squeezing, the upper surface of the polyester base is coated with a modified asphalt masking material by a first scraping-coating box, side membranes are applied, sand application is performed, rolling compaction is performed, a turning roller turns, the lower surface of the polyester base is coated with a self-adhered modified asphalt masking materialby a second scraping-coating box, an isolating membrane is applied, roller cooling is performed for formation, and the composite self-adhesive shale surface modified asphalt waterproof roll is obtained. The polyester base modified asphalt waterproof roll is produced by adopting a scraping-coating process through process innovation, and modified asphalt waterproof rolls with upper and lower surfaces made of different asphalt masking materials can be produced. In addition, the links such as discharging from an oil bath, roller heating and water cooling are omitted, and the energy consumption ofa production line is effectively reduced by 20% or above.

Owner:苏州东方雨虹建筑材料有限公司

Preparation method of black pottery art

InactiveCN108790562ABreak through technical barriersMeet the requirements of the status quoDecorative surface effectsOrnamental structuresHorizonFiltration

The invention discloses a preparation method of black pottery art. A raw material is taken from red clay under land cultivated horizon of riversides of Wuyuan River at the foot of Chengziya cliff, Longshan. The black pottery art is prepared through more than ten steps, such as filtration and fermentation, vacuum mud refining, throwing molding, polishing and engraving, glazing and drying in shade,ancient firing, drawing and dedusting, and hard carving. The method breaks through the technical barriers in the firing process of the black pottery art and solves the technical problems of water seepage, fear of water and color difference of Longshan black pottery. The method focuses on innovation in inheritance, realizes modeling innovation and process innovation, is embedded with elements of the times, and brings ancient black pottery art into a novel world, thereby presenting the theme of the times and meeting the requirements for the present situations of the black pottery art.

Owner:刘德功

Method for making canned barley alcohol

InactiveCN101921684AInnovativeAdvancedAlcoholic beverage preparationMicroorganism based processesAlcoholCholesterol

The invention relates to a method for making canned barley alcohol. The method comprises the following process steps of: raw material screening, impurity removing, processing, soaking, cleaning, boiling, water spraying, cylinder feeding, nest building, saccharifying, draining, fermenting, alcohol extracting, pressing, clarifying, filtering, burdening, sterilizing and canning. The conventional barley from Tibet is taken as a raw material, the conventional manual individual workshop mode is changed and process innovation is combined with technological innovation, so that the quality guarantee period of the barley alcohol is prolonged from the conventional multiple days to a year, convenience is brought to the market expanding of a product and a large-scale project becomes possible. The product obtained by the method plays a remarkable role in degrading cholesterol, preventing colon cancer, treating diabetes and the like.

Owner:管新飞

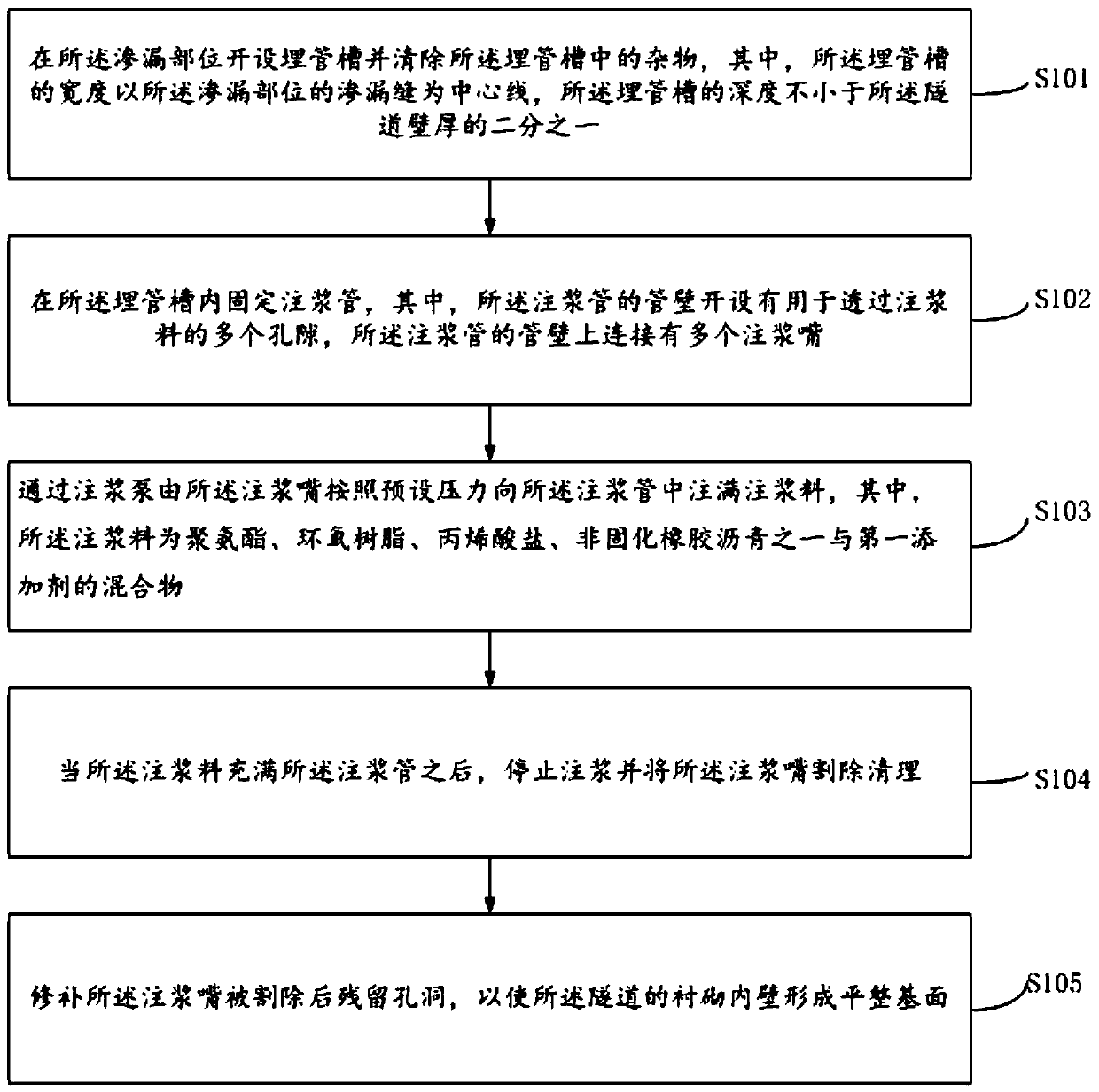

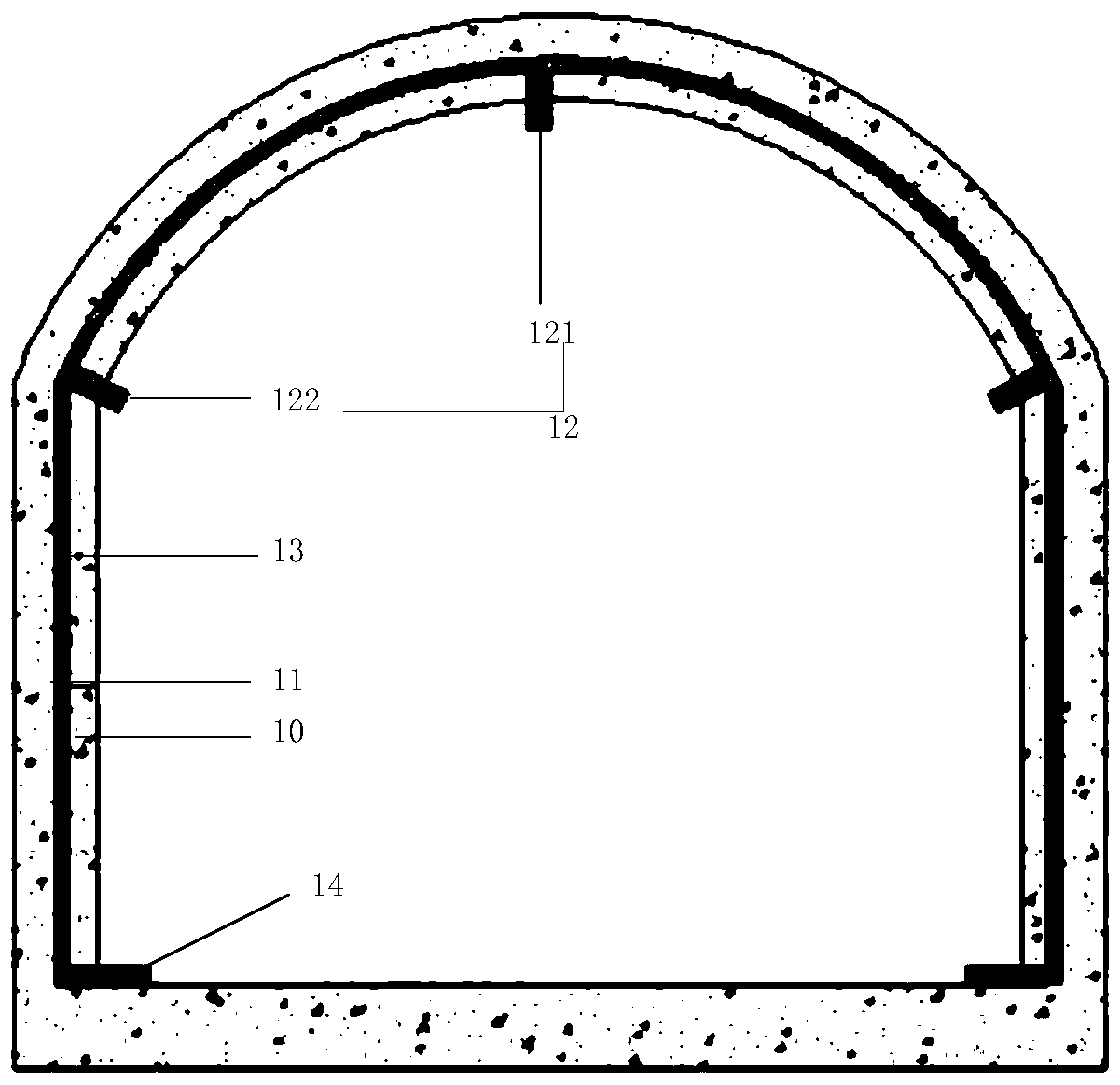

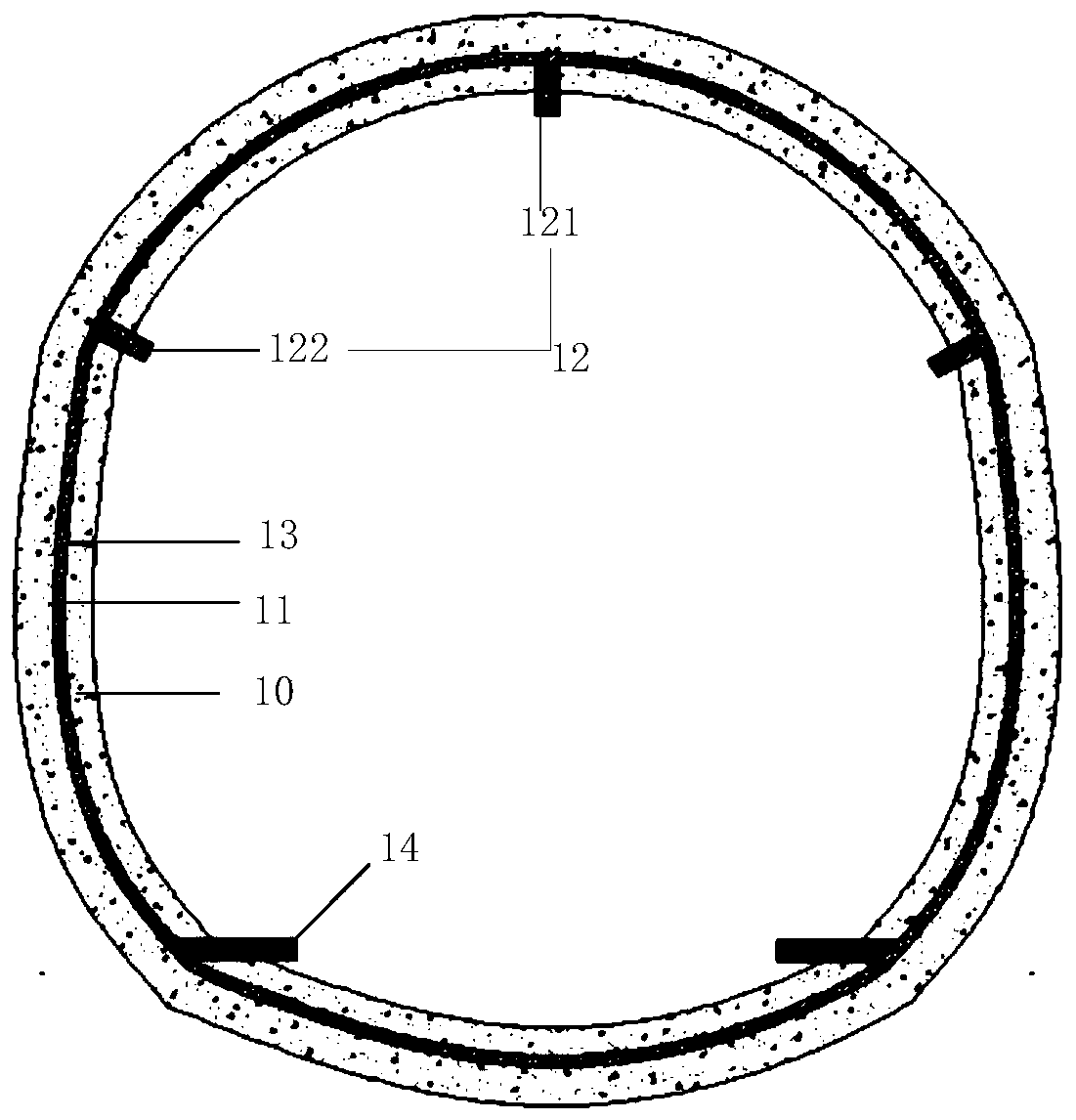

Waterproof construction method for engineering joint of tunnel

InactiveCN110410112AGuaranteed fillingImprove waterproof reliabilityUnderground chambersTunnel liningArchitectural engineeringProcess innovation

The embodiment of the invention provides a waterproof construction method for an engineering joint of a tunnel. The waterproof construction method is applied to a leakage part of a circumferential construction joint or a deformation joint of the tunnel. The waterproof construction method comprises the following steps: forming a pipe laying groove in the leakage part and eliminating sundries in thepipe laying groove; fixing a grouting pipe in the pipe laying groove; filling the grouting pipe full with a grouting material by a grouting nozzle by a grouting pump according to a preset pressure; when the grouting pipe is filled with the grouting material, stopping grouting and cutting and cleaning the grouting nozzle; and repairing residual holes after the grouting nozzle is cut so as to forma smooth basal plane on the lining inner wall of the tunnel. According to the waterproof construction method for the engineering joint of the tunnel, by means of process innovation, for example, groove removing, pipe laying, grouting and etc, in the leakage part of the engineering joint, the grouting material in the gap is full, and the waterproof reliability of the circumferential construction joint and the deformation joint of the tunnel is improved.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Pouring molding process for thermoplastic elastomer foam particles

The invention relates to a pouring molding process for thermoplastic elastomer foam particles. Thermoplastic elastomer foam particles with closed pore structures in composition with open pore structures extending to the epidermis are taken as a raw material; then the thermoplastic elastomer foam particle raw material is loaded into a molding mold, reactive polyurethane adhesive is injected, hot pressing, cooling molding are carried out, and a molding product is obtained. Compared with the prior art, according to the pouring molding process for the thermoplastic elastomer foam particles, through production process innovation of the bead-shaped thermoplastic elastomer foam particles, appropriate foam hole structures are designed, at the same time, functional groups or polar groups are contained, in addition, further through the unique foam particle surface treatment process, the particles obtained by foaming of various thermoplastic elastomers can be directly poured and bonded with polyurethane elastomers or can be directly poured and bonded with foamed polyurethane elastomers to form sole materials with the unique physical property and the unique appearance and other foaming products.

Owner:NANTONG DE NEW MATERIAL CO LTD

One-step leaven washing method

InactiveCN101696546ASimplify the washing processShorten washing timeDry-cleaning apparatus for textilesGramEngineering

The invention relates to a washing process for worn-out finishing of denims, in particular to a one-step leaven washing method. In the one-step leaven washing method, when the bath ratio of 1 weight part of cloth to water is smaller than 1:15, the adding dosage of a washing leaven is 1.0 to 1.8 percent (o.w.f); or, when the bath ratio of 1 weight part of the cloth to the water is between 1:20 and 1:30, the adding dosage of the washing leaven is above 2.5 percent (o.w.f); or, when the bath ratio of 1 weight part of the cloth to the water is between 1:15 and 1:20, the adding dosage of the washing leaven is 1.8 to 2.5 percent (o.w.f); and after finishing the material adding, the method comprises the steps of raising the temperature to between 40 and 60 DEG C, performing constant temperature washing for 40 to 90 minutes, draining, adding clear water, adding an auxiliary agent in a ratio of 1-2 grams per liter, performing washing for 10 to 15 minutes, and performing dewatering and drying. The one-step leaven washing method effectively overcomes various difficulties in the production by a two-step method, can perform desizing and washing in one step, namely finish the desizing and the washing through one step, achieves process innovation, can change the present status of the prior production process, and is favorable for saving energy and water, improving the working efficiency and reducing the cost; besides, the product selling price can be matched with the price of the conventional washing leaven in the prior market, so the method has a good application and popularization prospect.

Owner:南京川平科技开发有限公司

A process for treating uranium-containing waste liquid in a uranium enrichment process

ActiveCN107182281BInnovative processLess expansionMultistage water/sewage treatmentRadioactive decontaminationWater treatment systemProcess equipment

The invention provides a new process for treating uranium-containing waste liquid that does not require large-scale expansion of the original system and greatly improves the processing capacity. On the basis of some low-level uranium-containing waste liquid treatment systems, use the original process equipment and innovate the process flow to realize the expansion of the uranium-containing waste water treatment system on the premise of no increase in ion exchange columns, no expansion or less expansion of the existing system , and at the same time achieve the purpose of reducing the discharge of uranium-containing waste liquid.

Owner:CHINA NAT NUCLEAR URANIUM ENRICHMENT

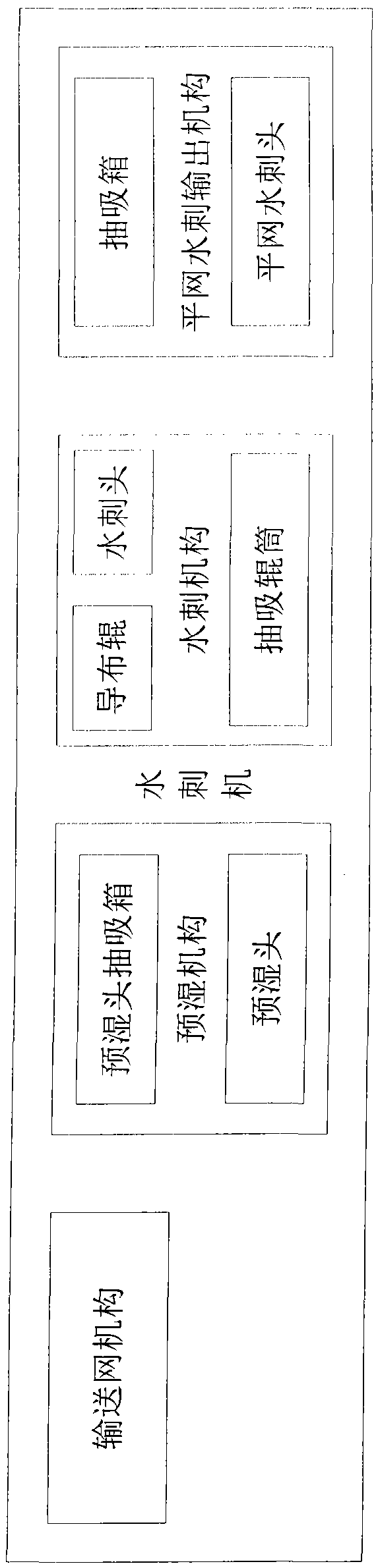

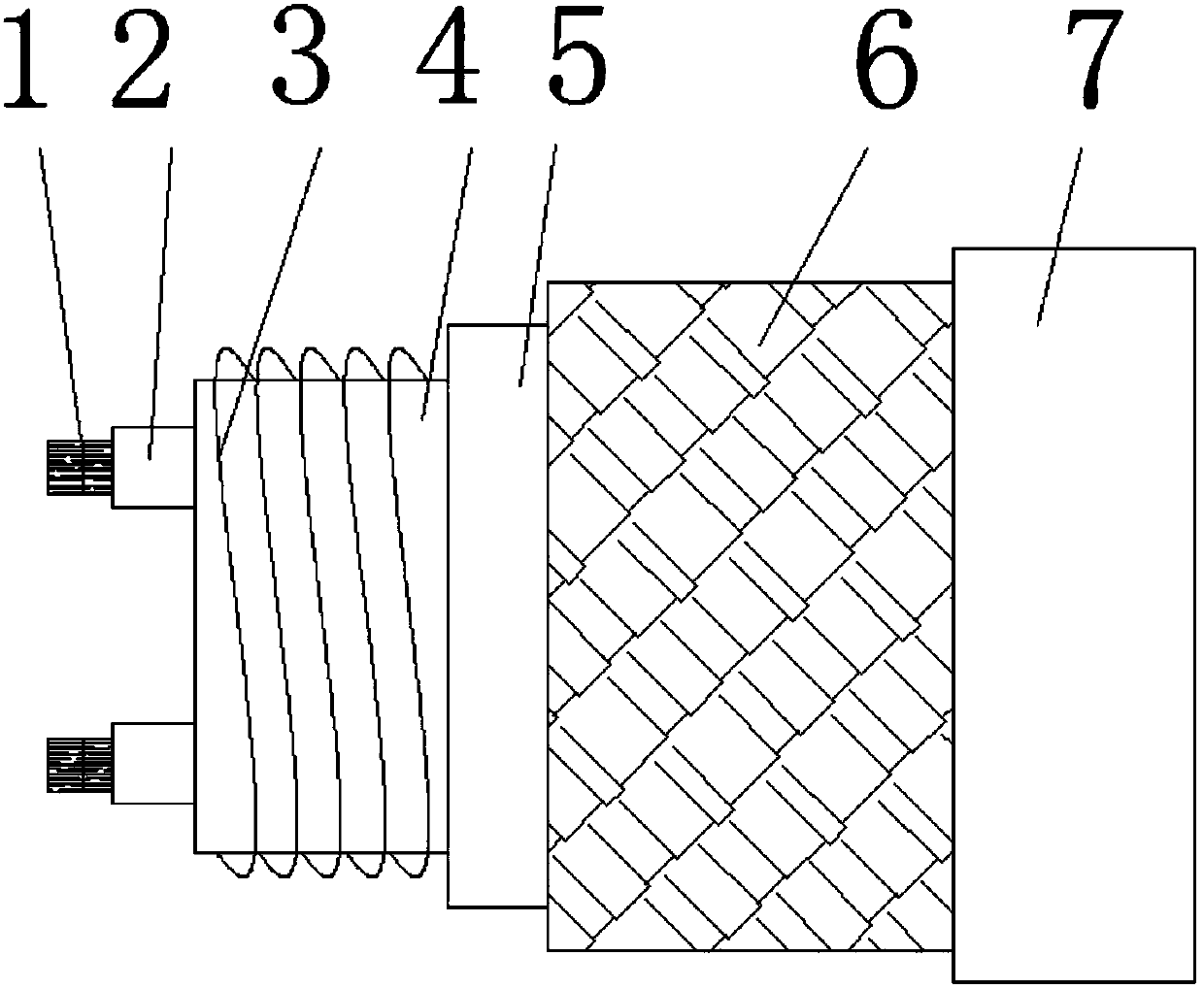

Spunlacing machine allowing rotation direction of suction roller to be adjusted

InactiveCN103789931AAdjustable direction of rotationEasy to operateNeedling machinesMechanical engineeringProcess innovation

The invention discloses a spunlacing machine allowing the rotation direction of a suction roller to be adjusted. The spunlacing machine is composed of a conveying screen mechanism, a prewetting mechanism, a spunlacing mechanism and a flat screen spunlacing output mechanism, wherein the prewetting mechanism is composed of a prewetting head suction box and a prewetting head; the spunlacing mechanism is composed of a cloth guide roller, a suction roller and spunlacing heads distributed along the suction roller and provided with water needle holes inside; the flat screen spunlacing output mechanism is composed of a suction box and a flat screen spunlacing head provided with a water needle hole inside. The spunlacing machine is characterized in that equipment adjustment and process innovation are carried out on the basis of an existing spunlacing machine, and has the advantages of being simple to operate, low in cost and high in production speed. The spunlacing machine obtained in the method allows the rotation direction of the suction roller to be adjusted, two sides of spunlacing non-woven cloth can be strengthened, the single side of the spunlacing non-woven cloth can be strengthened repeatedly, and manufacturing of spunlacing non-woven cloth of various styles is facilitated.

Owner:廊坊中纺新元无纺材料有限公司 +2

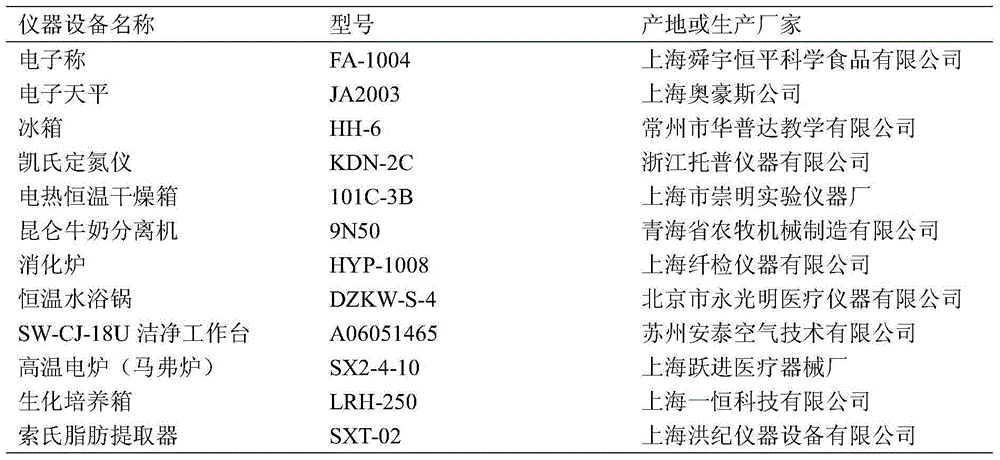

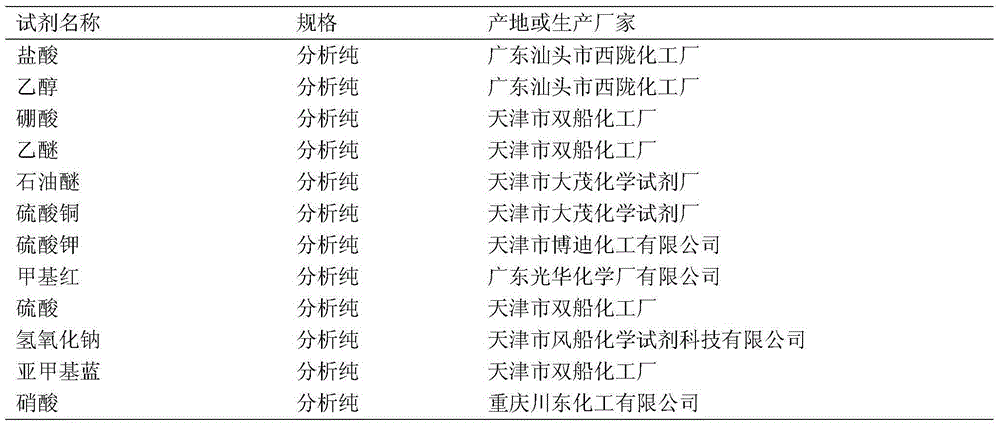

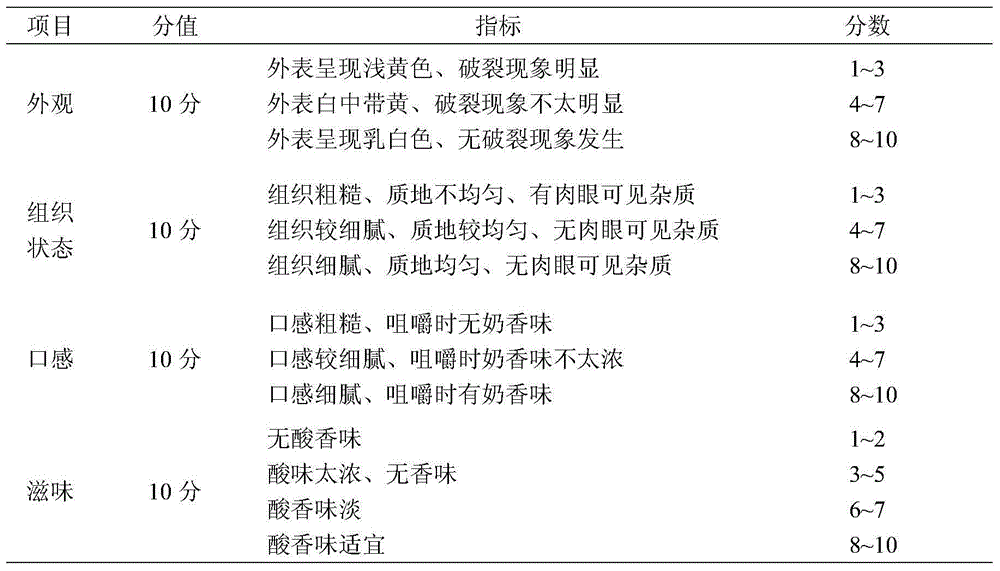

Method for processing milk dregs

InactiveCN104054821ASimple extraction methodHigh extraction rateMilk preparationMaterial resourcesFermentation

The invention discloses a method for processing milk dregs. The method comprises the following steps: (1) sorting; (2) preheating; (4) heating, namely heating raw milk in which impurities are removed to 45-50 DEG C; (5) extracting butter; (6) sterilizing skim milk; (8) carrying out heat preservation and fermentation; (9) discharging whey; (10) squeezing and molding; (11) carrying out quality testing, namely inspecting sensory index, and physicochemical and hygienic indexes; and (12) forming the product. According to the method, the extraction rate of the butter is increased by process innovation, manpower and material resources are greatly reduced, and an efficient, useful and convenient butter separation method is provided for herders.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

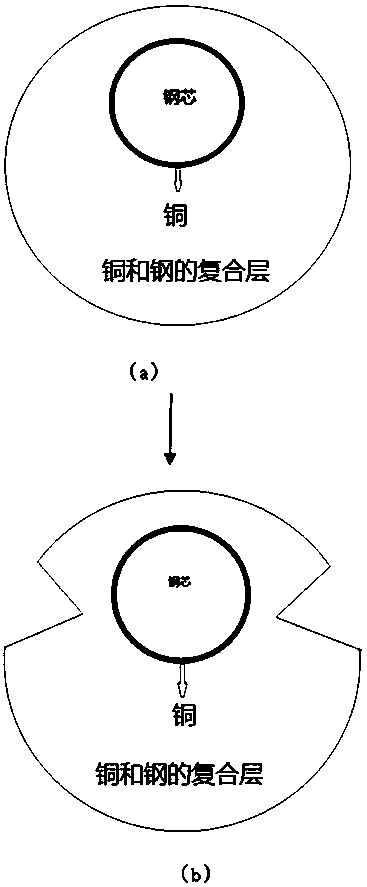

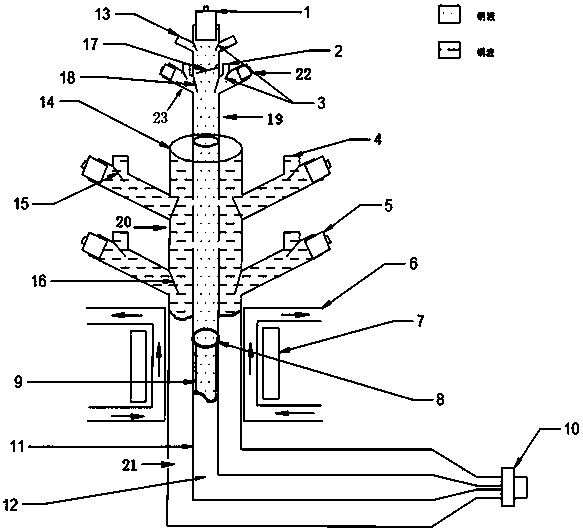

Continuous casting and continuous extrusion device and process of large-plasticity equal channel right-angle copper-steel composite contact wire

PendingCN108015246ARealize process productionRealize independent innovationExpansion factorProcess innovation

The invention provides a continuous casting and continuous extrusion device and process of a large-plasticity equal channel right-angle copper-steel composite contact wire. The device is characterizedin that a steel mold, a copper mold, a right-angle extrusion device, cooling circulating systems and coils are included; and a steel mold pipeline is placed in a copper mold pipeline and located above the circle center of the copper mold pipeline, and the steel mold pipeline and the copper mold pipeline are not on the same circle center. According to the device and process, through cooperative use of a large mold and a small mold, process production of the copper-steel composite contact wire is achieved; the problem that electric conductivity and tensile strength are in mutual contradiction and sacrifice each other are broken through; the problem that a coating layer and a steel core are separated from each other due to the reason that expansion factors are not matched is solved; and production process innovation and tool device self-dependent innovation are achieved.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

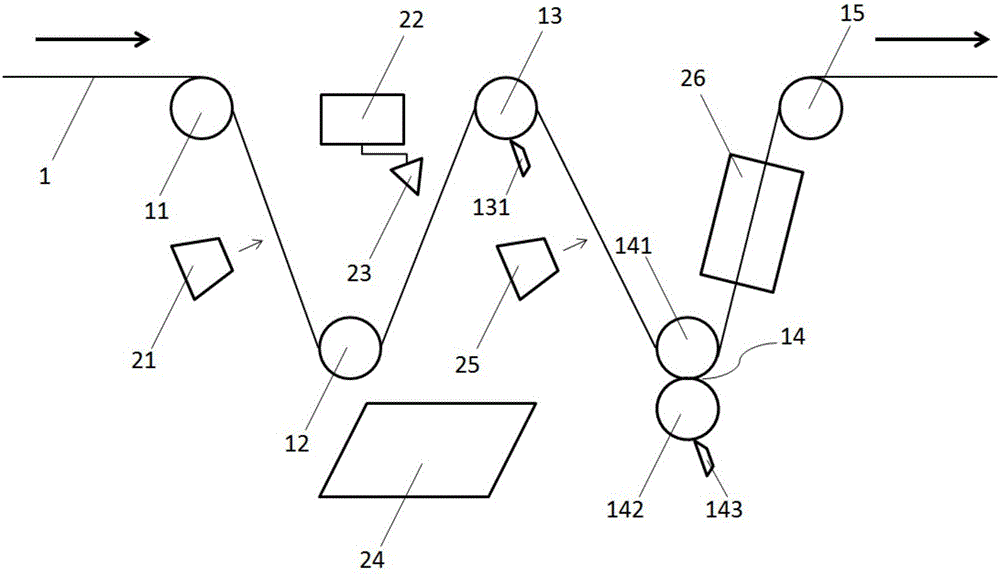

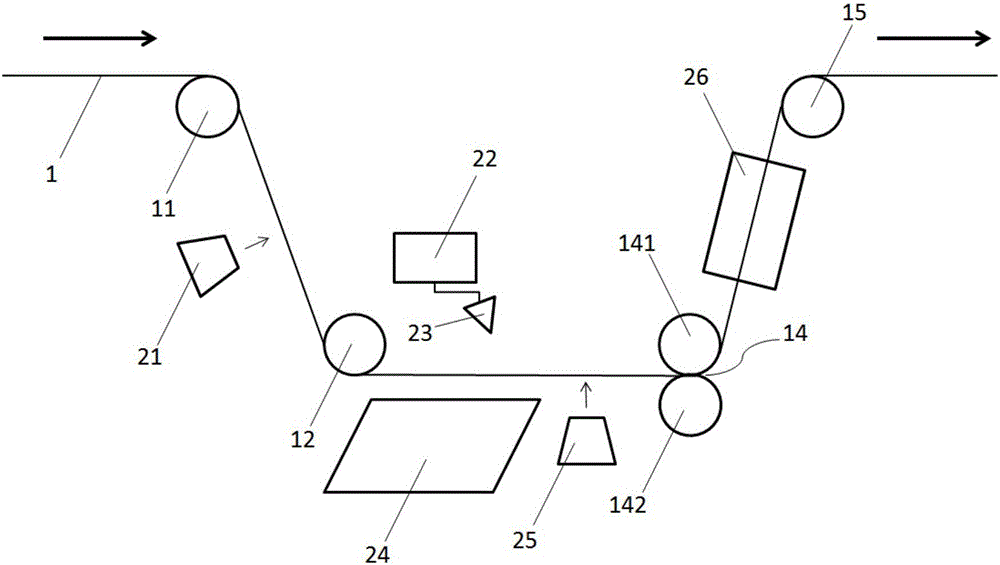

Salient point non-woven fabric production device

PendingCN104988695AEasy to operateLow costPattern makingLiquid/gas/vapor removalSlurry coatingPulp and paper industry

The invention relates to a salient point non-woven fabric production device. The salient point non-woven fabric production device is characterized by comprising a first cloth guide roller, a second cloth guide roller, a third cloth guide roller, a salient point roller group and a fourth cloth guide roller which are arranged in sequence in a W type, a first air heater is arranged between the first cloth guide roller and the second cloth guide roller, a spray device is arranged between the second cloth guide roller and the third cloth guide roller, a dryer is arranged between the salient point roller group and the fourth cloth guide roller, and the salient point roller group comprises a convex roller and a concave roller. According to the salient point non-woven fabric production device, the equipment adjustment and the process innovation are conducted on an original salient point non-woven fabric production device, and salient point non-woven fabric can be made to use a slurry coating; the salient point non-woven fabric production device has the advantages that the operation is simple, the cost is low, and the production speed is fast. The original salient point non-woven fabric production device can produce non-woven fabric with various styles after being simply transformed.

Owner:ANHUI JINCHUN NONWOVEN CO LTD

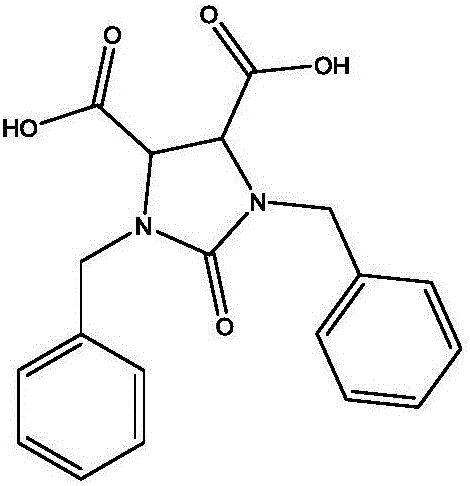

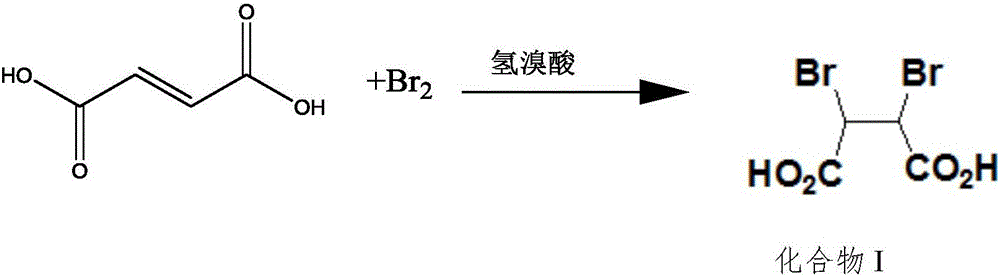

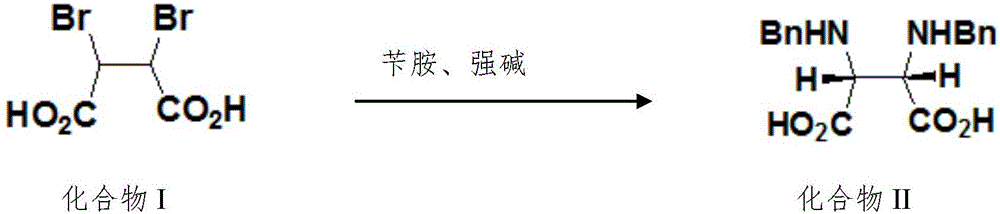

Preparation method of 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid

The invention relates to a preparation method of 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid, comprising the steps of subjecting fumaric acid, bromine and hydrobromic acid to additive reaction to generate meso-2,3-dDibromosuccinic acid, subjecting the meso-2,3-dDibromosuccinic acid, benzylamine and a strong base to aminating reaction to generate dibenzylamino salt, subjecting the dibenzylamino salt and triphosgene to cyclization to generate the 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid. The fumaric acid is subjected to addition, and then substitution and cyclization are performed to obtain the 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid, and detection shows that HPLC (high-performance liquid chromatography) content of the 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid may reach 98-99%. The preparation method has the advantages that hydrobromic acid is added for bromination additive reaction, the concentration and reaction temperature of the hydrobromic acid are optimized, and bromine loss is more reduced; amination mother liquid is used in amination, the cost is saved, and product yield is increased; in ring-closure reaction, pH and reaction product concentration are decreased, the yield of the 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid is increased greatly, and the quality of the 1,3-dibenzyl-2-oxoimidazolidine-4,5-dicarboxylic acid is improved; experiments verify that through process innovation, production cost is reduced greatly, production efficiency is improved, and the process is energy efficient and environmentally friendly.

Owner:安徽泰格维生素实业有限公司

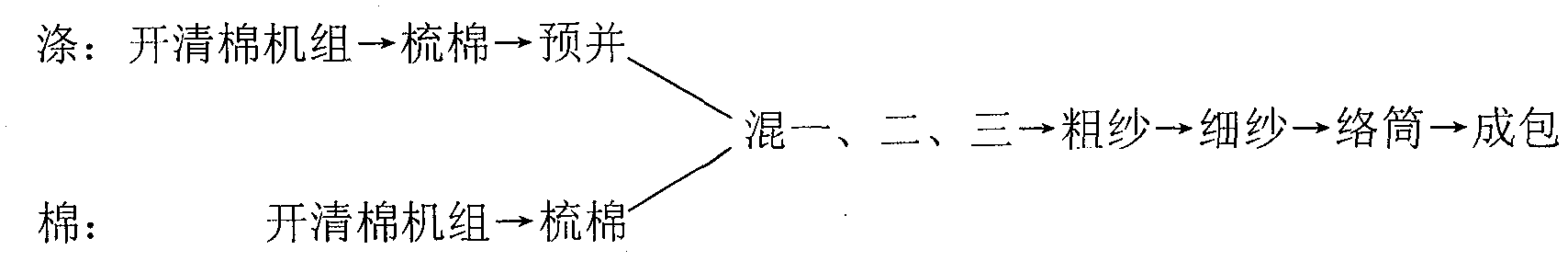

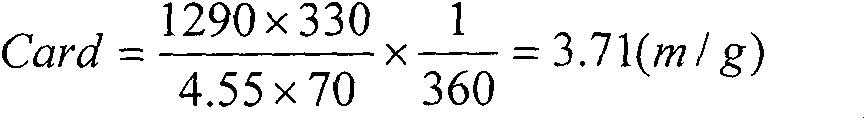

Process for carded polyester and cotton blending differential white and simple staining yarn

The invention relates to the cotton manufacturing industry, in particular to a process for carded polyester cotton blending differential white and simple staining yarn. Process innovation is carried out on an existing polyester and cotton blending process technology, when blending rolls of polyester fibers and cotton fibers enter a carding purified cotton machine table for production, the blending rolls and blending card silvers are quantitative and are mastered in a proper under-weight mode, polyester and cotton are fully carded, and the phenomena of white silks and white spots do not happen easily after simple staining is carried out on cloth or the yarn. The problem of full carding of the polyester is solved, meanwhile, the polyester (including the cotton) is fully carded due to the fact that the blending rolls are not prone to being wound on cylinders in the production process, and product quality is improved.

Owner:DAFENG WANDA TEXTILE

Asphalt resin composite spherical activated carbon with developed apertures and low energy consumption and preparation method thereof

InactiveCN104986763AUniform sizeLarge specific surface areaDibenzoyl PeroxideSODIUM DODECYL BENZENE SULFONATE

The invention discloses asphalt resin composite spherical activated carbon with developed apertures and low energy consumption. The asphalt resin composite spherical activated carbon with the developed apertures and the low energy consumption is characterized by being prepared from the following raw materials including, by weight, 46-50 parts of octadecyl acrylic ester, 39-44 parts of ethylhexanoate, 2-3 parts of benzoyl peroxide, 1-2 parts of N,N'-methylene bisacrylamide, 18-20 parts of butanediol, 10-13 parts of ethyl acetate, 1-2 parts of sodium dodecyl benzene sulfonate, appropriate amount of distilled water, appropriate amount of acetone, 25-28 parts of sulfonated gilsonite powder, 3-4 parts of attapulgite, 2-3 parts of nano-silicon dioxide, 0.8-1 part of a silane coupling agent kh560, 5-6 parts of hydrochloric acid with concentration of 15% and 5-6 parts of a sodium hydroxide solution with concentration of 12%. Through the addition of modified nano-titanium dioxide and the attapulgite, the amount of apertures and the sizes of the apertures of products are increased, reaction time and reaction energy consumption are greatly reduced through process innovation, the industrial production is easy to achieve, the hardness is large, and the recycling can be achieved.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

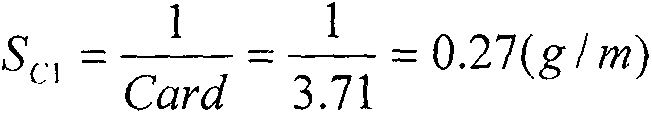

Preparation method of desizing and scouring compound enzyme

InactiveCN107653686AReduce washingReduce dosageBiochemical treatment with enzymes/microorganismsGrip property fibresFiberWastewater

The invention discloses a preparation method of desizing and scouring compound enzyme. The prepared desizing and scouring compound enzyme effectively removes starch size and pectin on cotton fiber andother impurities on the surface of cotton fiber that influence dyeing property, and endows fabrics with good wetability. The desizing and scouring compound enzyme can simultaneously complete desizingand scouring by one step. Thus, processing procedures of dyeing factories is reduced, production efficiency is raised, and production cost is lowered. Process innovation is realized, and current production process can be changed. In addition, traditional high-temperature soda boiling is avoided, discharge amount of wastewater is reduced, and energy conservation, water conservation and emission reduction are realized, thus meeting the energy conservation and emission reduction requirements for green printing and dyeing. The desizing and scouring compound enzyme can meet requirements of pretreatment of dyeing factories, also can make the process to be energy-saving and environmentally-friendly, and is an ideal choice for pretreatment processing of dyeing factories.

Owner:WUXI JIAJIA NANO TECH

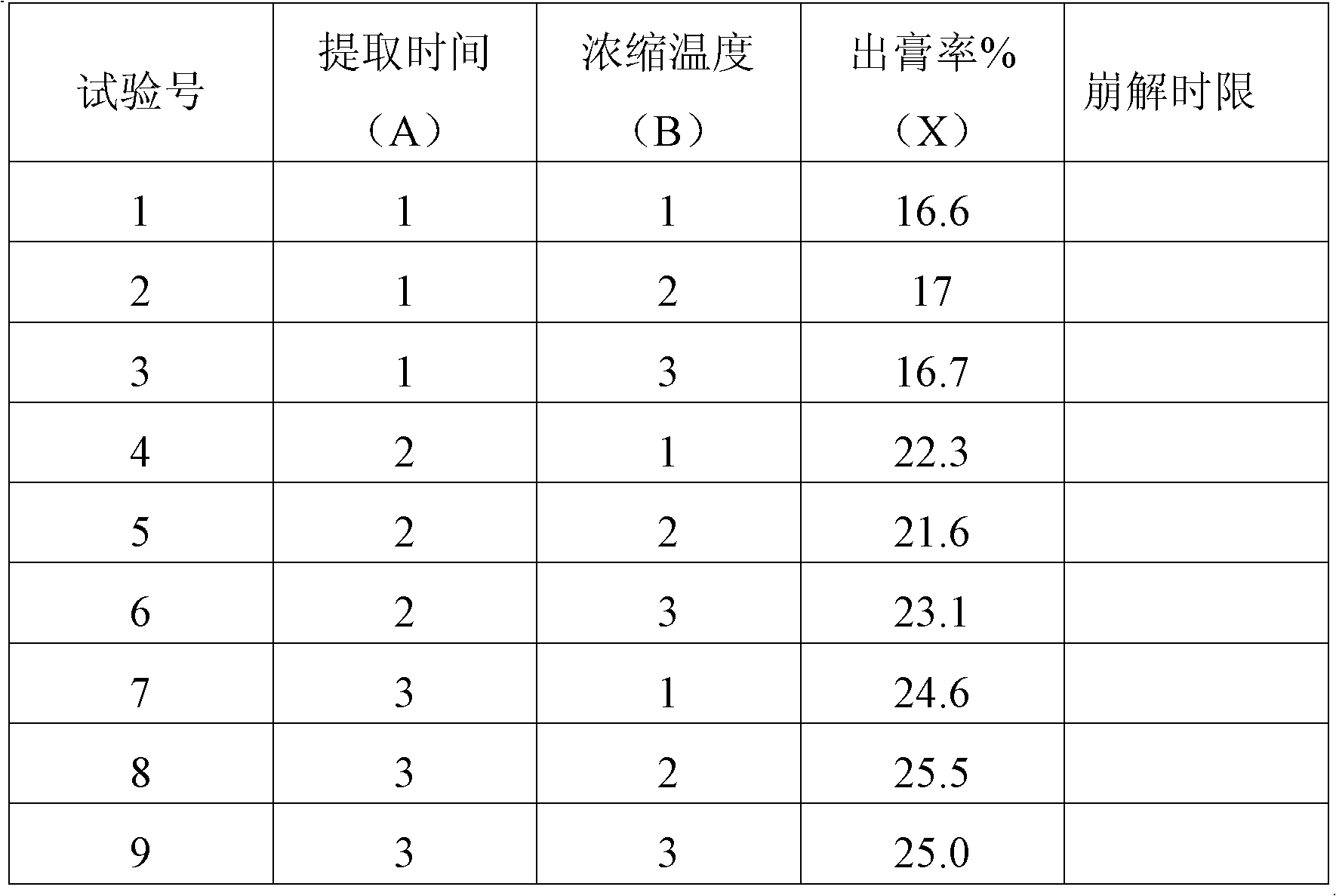

Parallel constant-power heat tracing band and manufacturing method thereof

InactiveCN108024400AImprove interface contact resistanceExtend your lifeHeating element shapesElectrical resistance and conductanceConstant power

The invention discloses a parallel constant-power heat tracing band and a manufacturing method thereof, and relates to the field of a heat tracing band. The manufacturing method comprises the following steps of 1) preparing a metal wire electrode; 2) preparing a bus insulating layer; 3) performing extrusion of the bus insulating layer; 4) performing irradiation cross linking; 5) performing heatingbody extrusion and heating element winding; 6) preparing an insulating inner sheath and a reinforced outer sheath; 7) performing extrusion of the insulating inner sheath; 8) performing secondary irradiation cross linking; 9) weaving a metal woven shielded layer; and 10) performing extrusion of the reinforced outer sheath. By virtue of structural innovation of adding the bus insulating layer on the outer layer of the metal conductive electrode, the interface contact resistance is improved and product service life is prolonged; by virtue of process innovation of adopting a co-extrusion processmethod, expansion difference is lowered; by adopting a manufacturing method of an equal-tension regular structure stranded wire, the requirements of ultra thin appearance and high length extrusion ofthe bus insulating layer can be ensured; by adding the step of one time of irradiation cross linking, product durability is improved; and the parallel constant-power heat tracing band is uniform and stable in heating, suitable for the majority of environments, and resistant to water and oil.

Owner:ANHUI HERTE ELECTRIC CO LTD

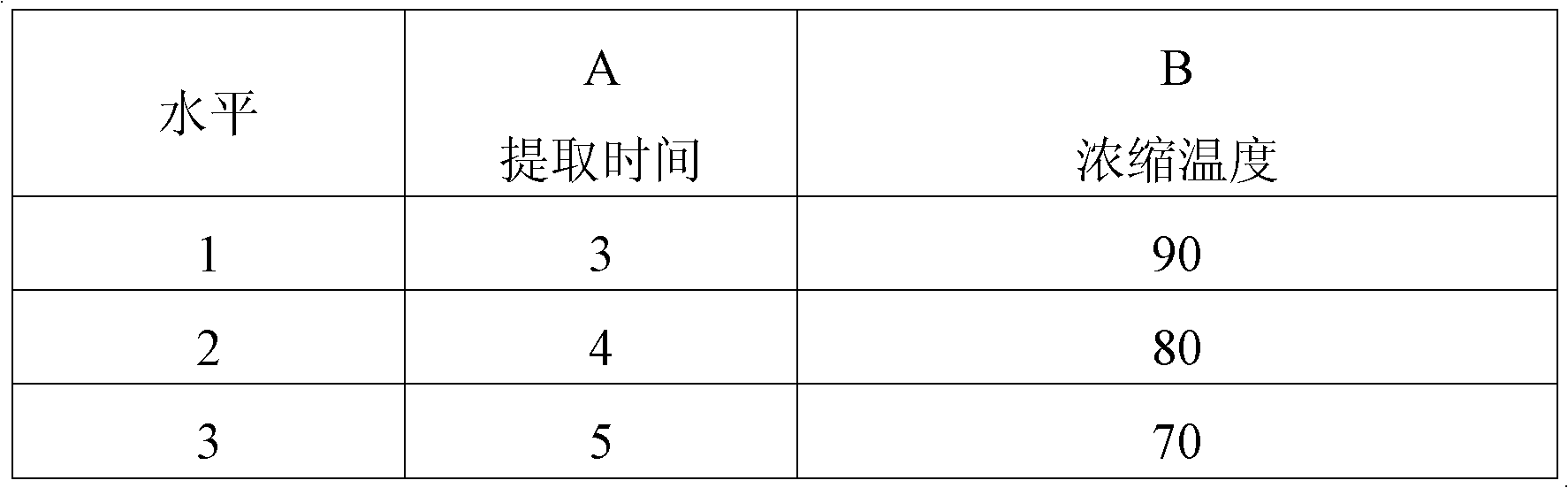

Drug capable of increasing gastric motility and treating chronic gastritis and preparation method thereof

InactiveCN102552795AFast absorptionImprove bioavailabilityDigestive systemPlant ingredientsRefluxAdditive ingredient

The invention relates to a preparation method of traditional Chinese medicine, in particular to a drug capable of increasing gastric motility and treating chronic gastritis and a preparation method thereof. The drug is prepared via mixing drug residues, licorice, poria cocos, fructus evodiae, grifola and rhizoma pinelliae preparata, adding water of five times, soaking for 60 minutes, extracting for 5 hours in heat reflux, filtering to prepare 1000 pieces and then coating icing. The losses of effective ingredients of the drug prepared by the preparation method are reduced. Compared with the traditional process, the yield is increased. Moreover, the drug can be rapidly absorbed in the human body. The effective ingredients are not decomposed during the preparation process, and thus the bioavailability of the drug is improved. Therefore, the preparation method has obvious advantages than the original method. Compared with the product prepared in the original process, the ratio of cream extraction is increased by 3 percent, and the bioavailability can be increased by 13 percent. Therefore, the effects are obvious after process innovation, and the efficacy of the product is improved greatly.

Owner:通化斯威药业股份有限公司

Glass tube cladding extrusion molding process

InactiveCN105729746ARealize automated productionDriven by automated productionCoatingsSemiconductor devices for light sourcesMolding machineEngineering

Owner:DONGGUAN HONG XIN PHOTOELECTRIC TECH CO LTD

Extensible hose with special-shaped lining-ring connector and injection molding method thereof

ActiveCN102313101AManufacturing is practicableMeet supporting needsHose connectionsConvex structureEngineering

The invention relates to an extensible hose with a special-shaped lining-ring connector, and a molding method thereof, belonging to the technical field of rubber and plastic hoses. The hose is provided with a hose body into which spiral steel wires are embedded, the inside of one end of the hose body is inlaid with a hard plastic lining ring, and the outside of the hose body is cladded with a soft plastic connector, thereby forming a connector; the excircle of the hard plastic lining ring is provided with a spiral guiding rib, and an inner hole is provided with a concave-convex structure; and an end head of the hose body is drawn and spirally buckled on the hard plastic lining ring; the soft plastic connector is in the shape of a ring, and tightly hooped on the outside of the end head of the hose body in which the hard plastic lining ring is inlaid, and the soft plastic connector, the hose body and the hard plastic lining ring are formed into a closely bonding whole. The extensible hose with a special-shaped lining-ring connector provided by the invention is provided with a guiding-positioning concave-convex structure, and hard outside and soft inside, therefore, the supporting demands of new products can be satisfied; meanwhile, the hose provided by the invention also breaks the rules, and through process innovation, the manufacturing of the extensible hose with a special-shaped lining-ring connector is feasible and practical.

Owner:JINHUA CHUNGUANG RUBBER & PLASTIC HOSE

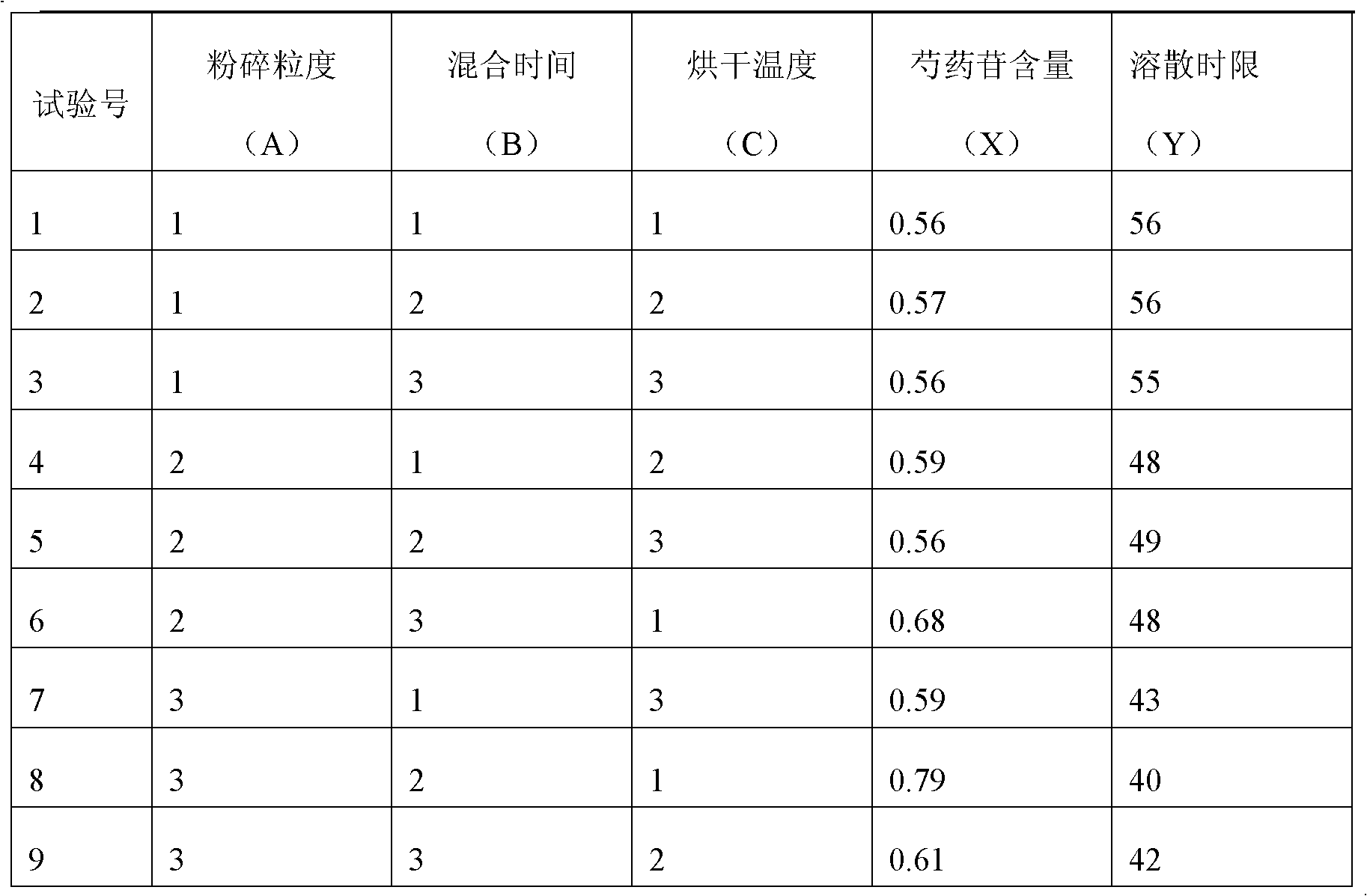

Medicament for treating apoplexy and hemiplegia and preparation method

InactiveCN102614386AHigh content of active ingredientsImprove bioavailabilityNervous disorderPill deliveryMedicineCurative effect

The invention relates to a preparation method of a traditional Chinese medicine, in particular to a medicament for treating apoplexy and hemiplegia and a preparation method. The preparation method comprises the following steps of: pulverizing the rest twenty-one herbs such as black snake apart from muskiness with a super micro pulverizer into fine powder of 200 meshes and mixing for 30 minutes; and grinding the muskiness, mixing and grinding with the fine powder, uniformly mixing, utilizing 20 g of refined honey for every 100 g of powder and adding water, mixing uniformly and then pressing into pills; and drying to obtain the medicament. Compared with an original process product, a process product has the advantages that: the difference in the content of an active ingredient paeoniflorin (C23H28O11) in each pill is 0.3 mg, the difference in dissolution time limit is 15 minutes, the bioavailability can be improved by 60 percent, the effect is obvious after process innovation and optimization, and the curative effect of the product is greatly improved.

Owner:JILIN TIANQIANG PHARMA

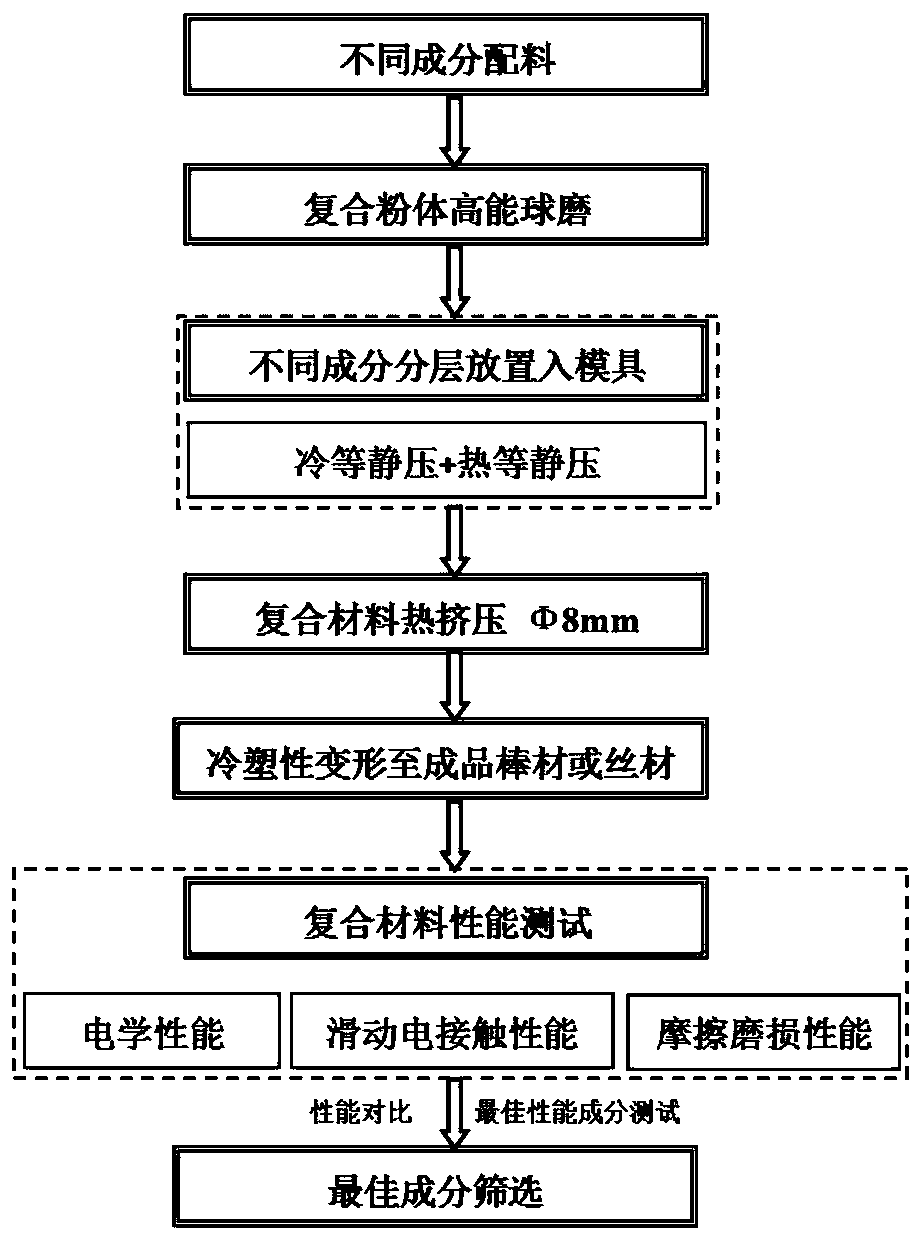

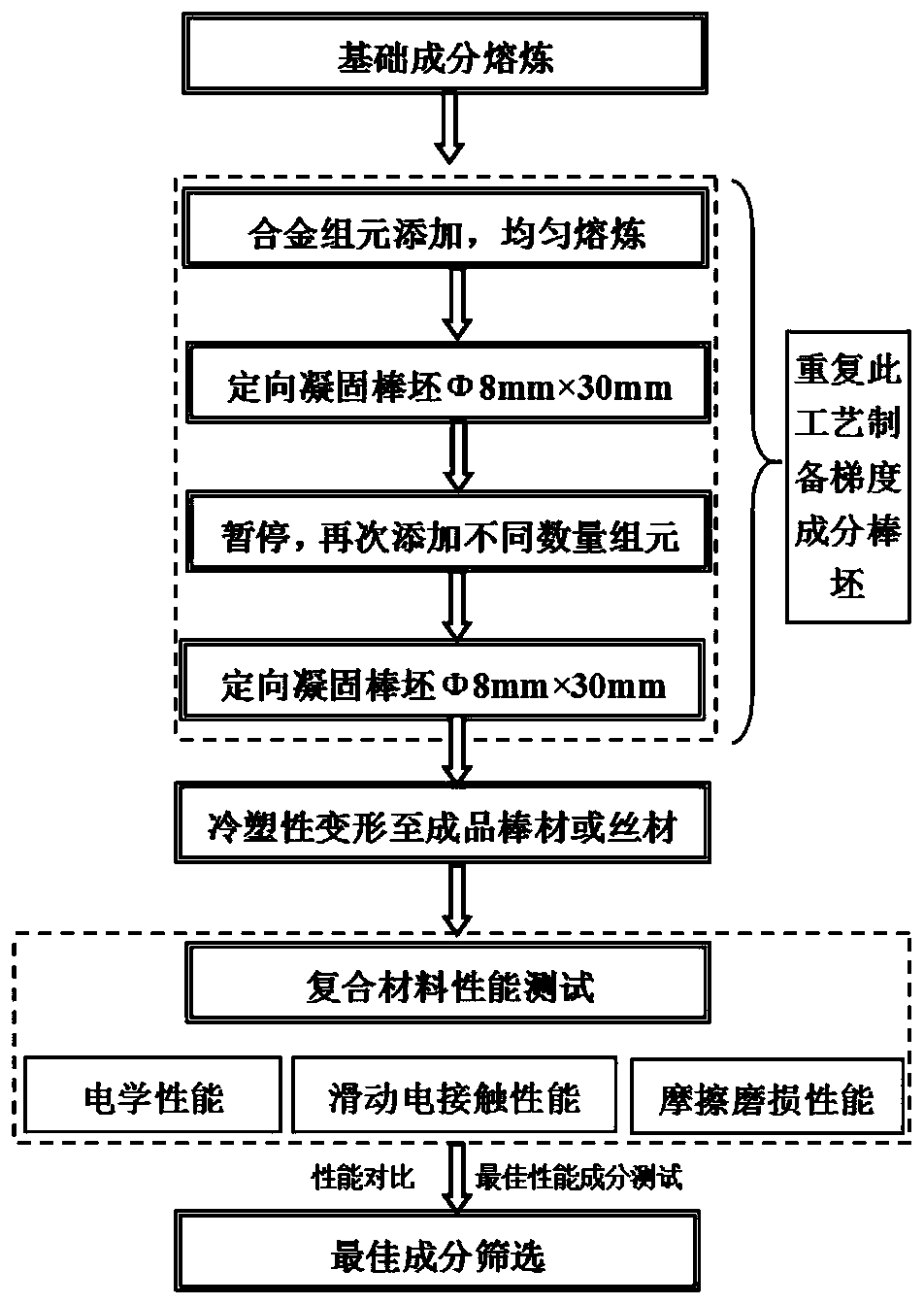

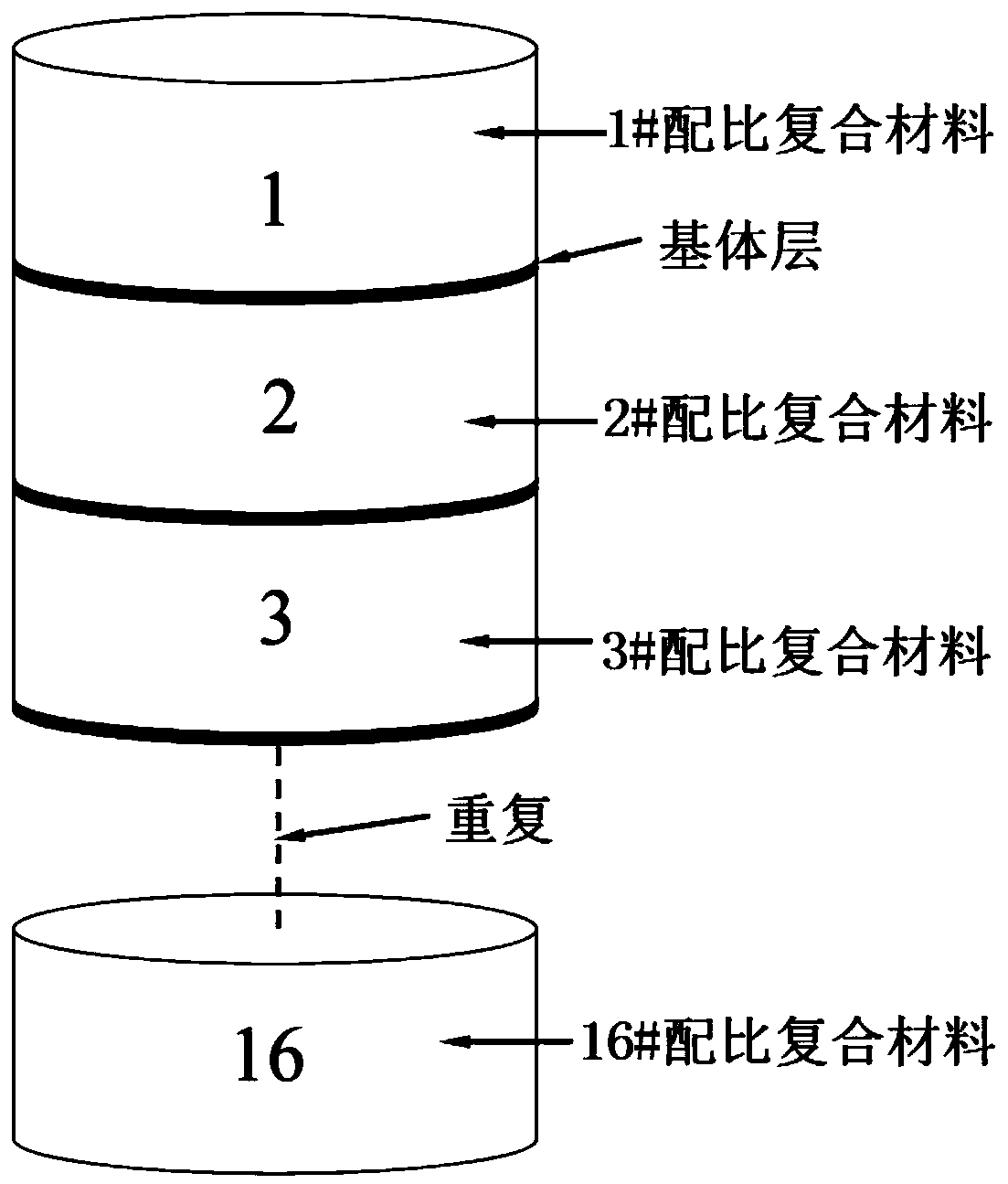

High throughput preparation method of sliding electric contact material composed of ingredients in gradient distribution

The invention discloses a high throughput preparation method of a sliding electric contact material composed of ingredients in gradient distribution. The high throughput preparation method of the sliding electric contact material composed of the ingredients in the gradient distribution includes following steps: (1) preparing a composite composed of ingredients in gradient distribution of 1# proportion / matrix / 2# proportion / matrix / ... / n# proportion by using a powder metallurgic method; (2) performing directional solidification for preparing an alloy material composed of ingredients in gradient distribution of 1#proportion / 2#proportion / 3#proportion / ... / n# proportion; (3) performing steps of isostatic cool pressing, hot isostatic pressing, hot extrusion, rolling, drawing and the like on the composite for preparing a bar material or a wire material; and (4) performing steps of rolling, drawing and the like on the alloy material for preparing a bar material or a wire material. The high throughput preparation method of the sliding electric contact material composed of the ingredients in the gradient distribution can realize the effect of synchronously preparing various or even hundreds oftypes of composite and alloy material test samples once through process innovation of the gradient distribution of the ingredients, can substantially reduce the number of experiment times and shortenexperiment time, rapidly optimizes or screens the alloy ingredients, and greatly improves experiment and research efficiency.

Owner:KUNMING INST OF PRECIOUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com