Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Reduce washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

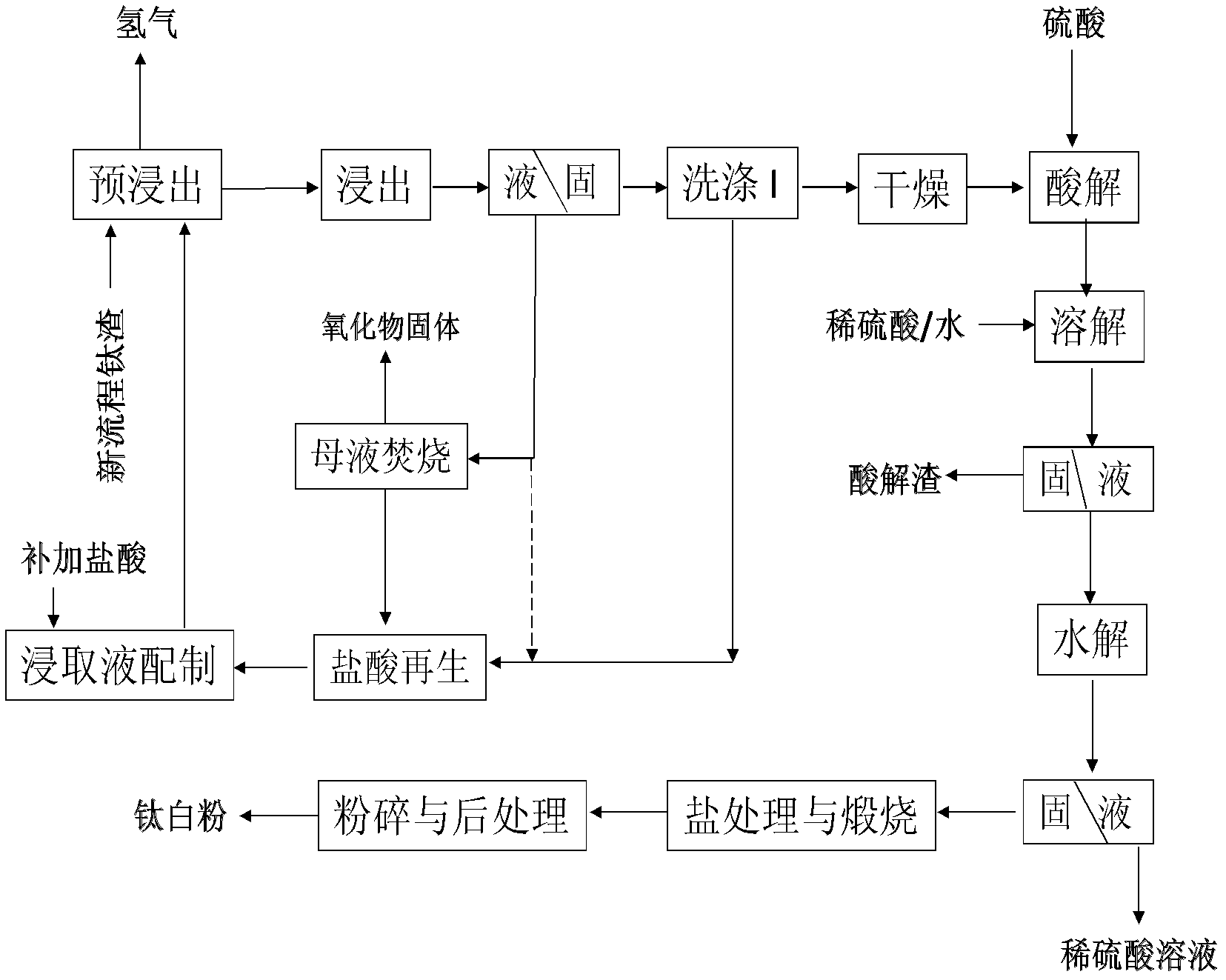

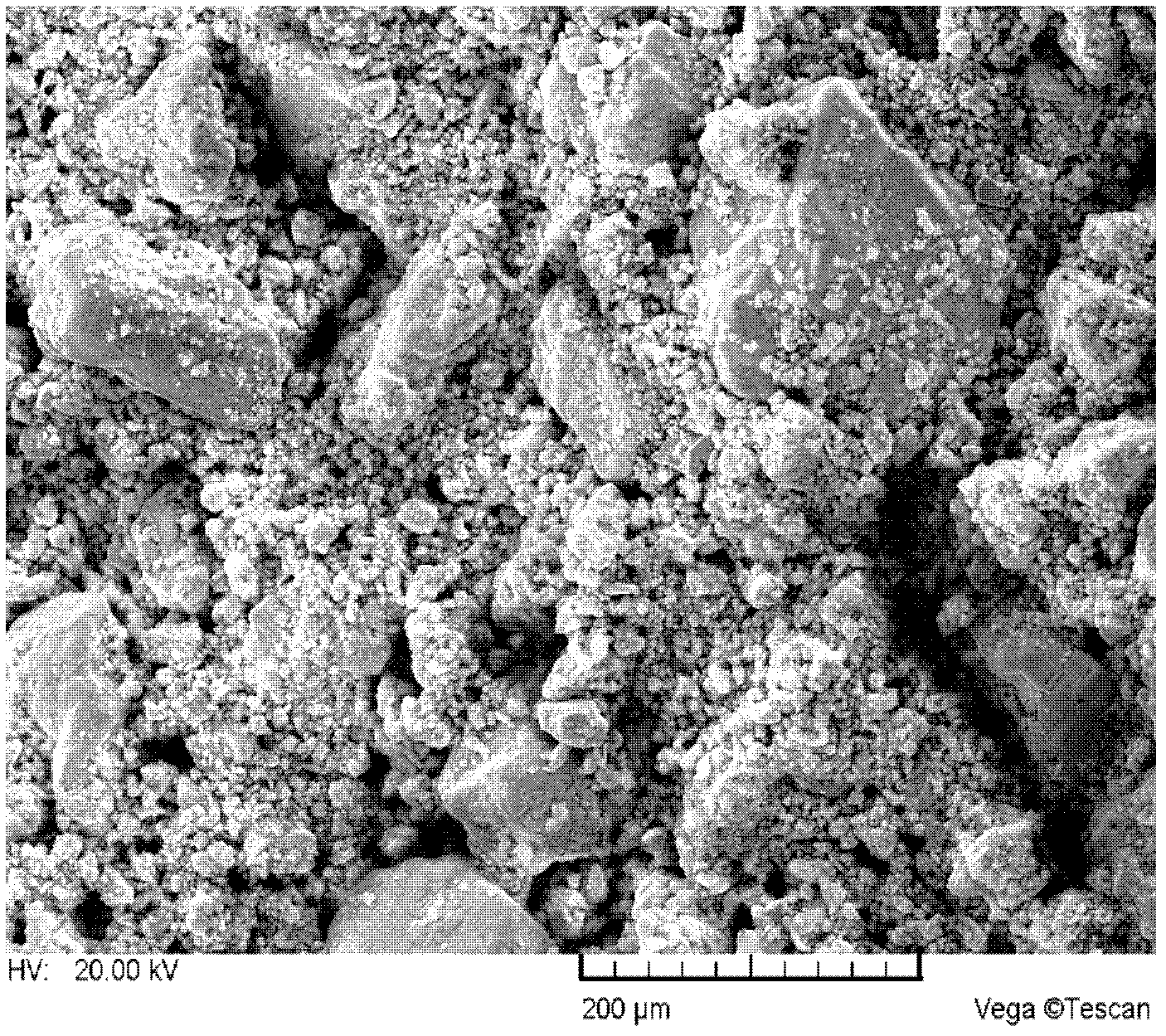

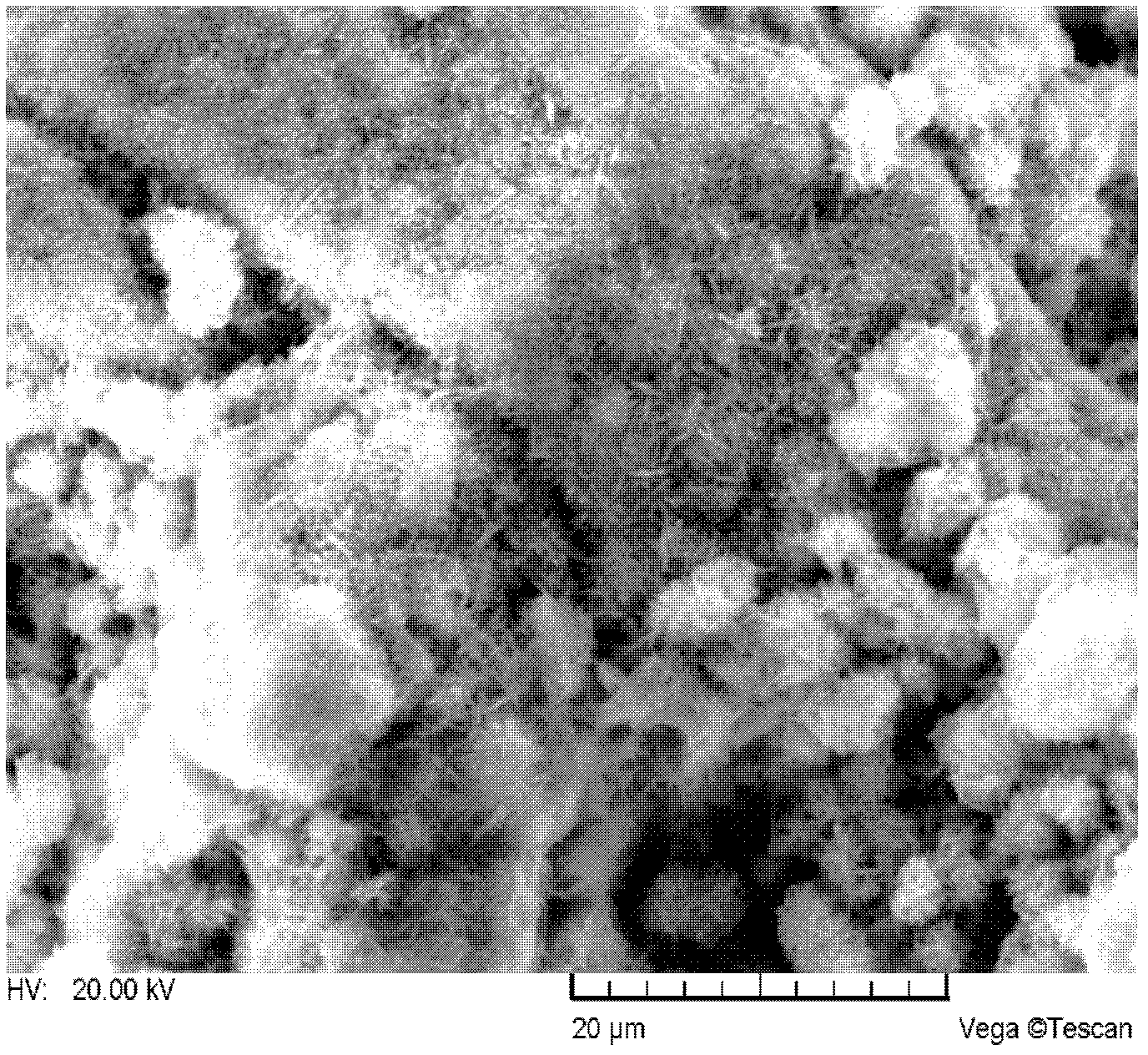

Method for preparing titanium pigment by using titanium residues obtained by directly reducing titanium-iron oxide

InactiveCN102627321AEfficient removalLow impurity contentTitanium dioxideProcess efficiency improvementBrown iron oxideScrap

The invention provides a method for preparing a titanium pigment by adopting a novel direct reduction flow. A novel raw material is provided for the production of a titanium pigment with a sulfuric acid process, and a process flow is provided for downstream utilization of a direct reduction product of vanadium titano-magnetite simultaneously. A novel hydrochloric acid pretreatment process with a novel direct reduction flow for titanium residues is adopted, so that dyeing elements such as aluminum, calcium, magnesium, iron, chromium, vanadium and the like in the titanium residues in the novel process are removed effectively, pretreated titanium-rich hydrochloric acid leaching residues are directly applied to production of a titanium pigment with a sulfuric acid process, the conventional refrigeration iron removing and concentration purifying processes are not required, special aluminum, chromium and vanadium processes are not required, ferrous sulfate is not produced, and ammonia alum waste as well as chromium, vanadium and ferrous sulfide residues which are difficult to treat are not produced. Moreover, the used hydrochloric acid and sulfuric acid are completely recycled in an enclosed loop, and a diluted waste acid liquid is not produced.

Owner:沙立林 +1

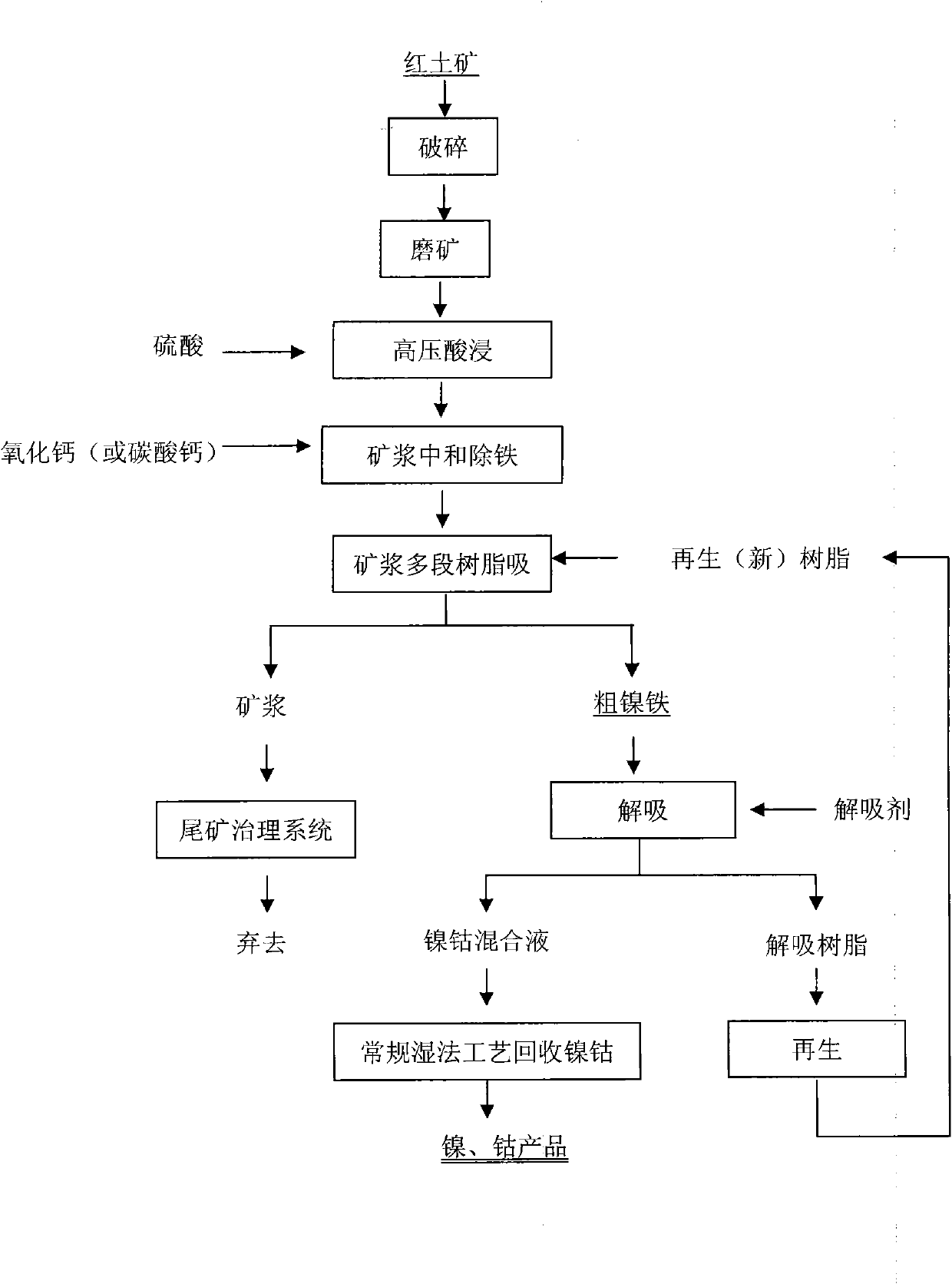

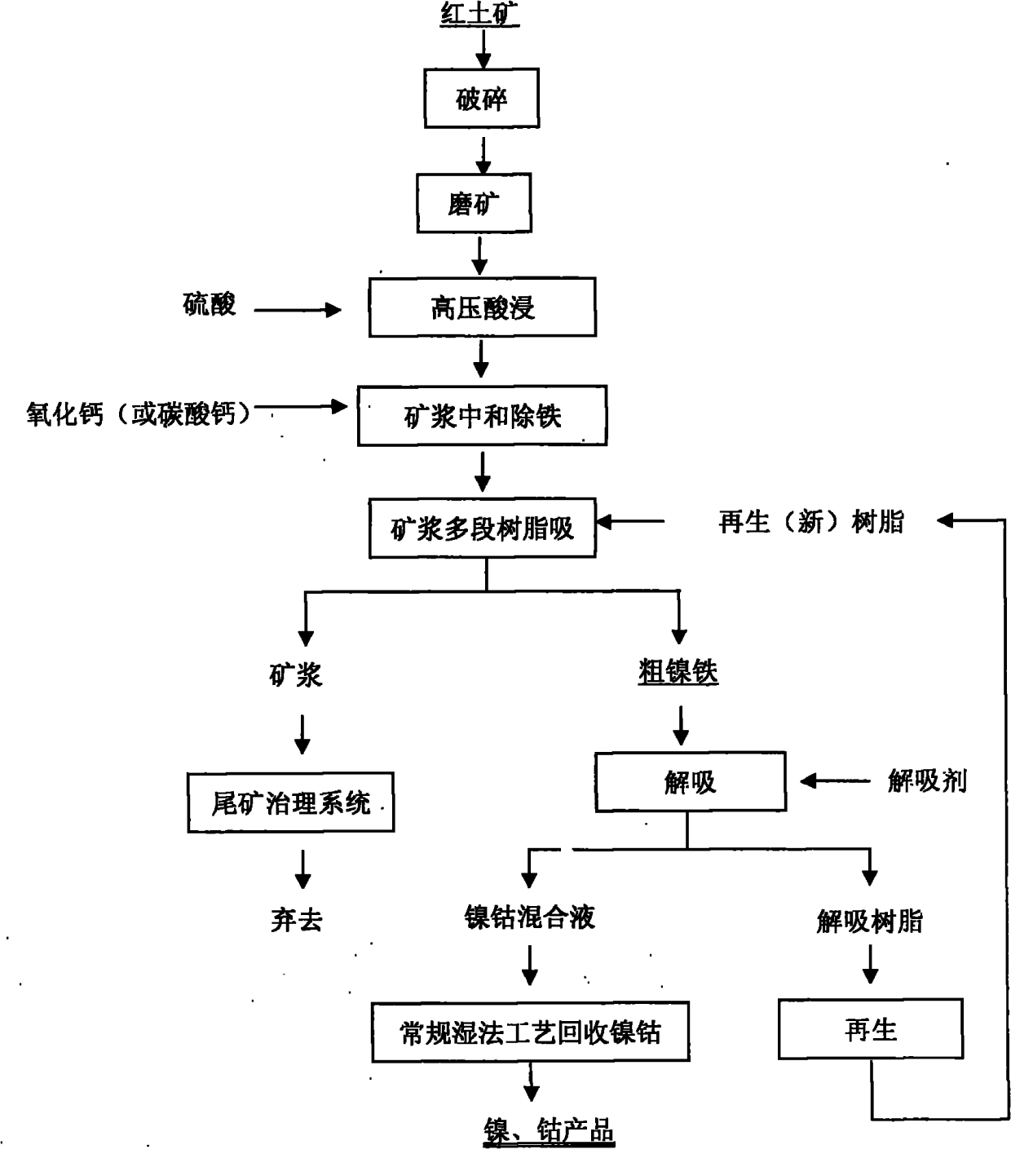

Process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology

ActiveCN101974685AReduce governance costsReduce the burden of separationProcess efficiency improvementDesorptionLaterite

The invention relates to a process for extracting nickel-cobalt from laterite by using resin-in-pulp adsorption technology. The process comprises the following steps of: milling the laterite, and adding sulfuric acid into the milled laterite to perform high-pressure leaching; pouring the ore pulp after the leaching into a reaction kettle for neutral impurity removal; directly pouring the ore pulpafter the impurity removal into an adsorption tank to perform resin adsorption; adopting multilevel counter current absorption to perform desorption on the loaded resin so as to obtain pure nickel and cobalt mixed solution; and performing extraction separation to obtain a nickel-cobalt product. The resin can be used repeatedly after regeneration, the damaged resin is less, the service life of theresin is long, the desorption of the loaded resin and the regeneration of a poor resin are performed at normal temperature and normal pressure and are simple and easy to operate without a pressure vessel and heat regeneration device, thereby saving energy resources and reducing equipment investment. The ore pulp after adsorption is uniformly neutralized to reduce the tailings treating cost. The process shortens the technological process, reduces the liquid-solid separation burden, and reduces a great number of washing and filtering process steps, thereby reducing the production energy consumption and reducing the production cost. The process is simple, and the recovery rate of nickel and cobalt is over 90 percent.

Owner:JILIN JIEN NICKEL IND +1

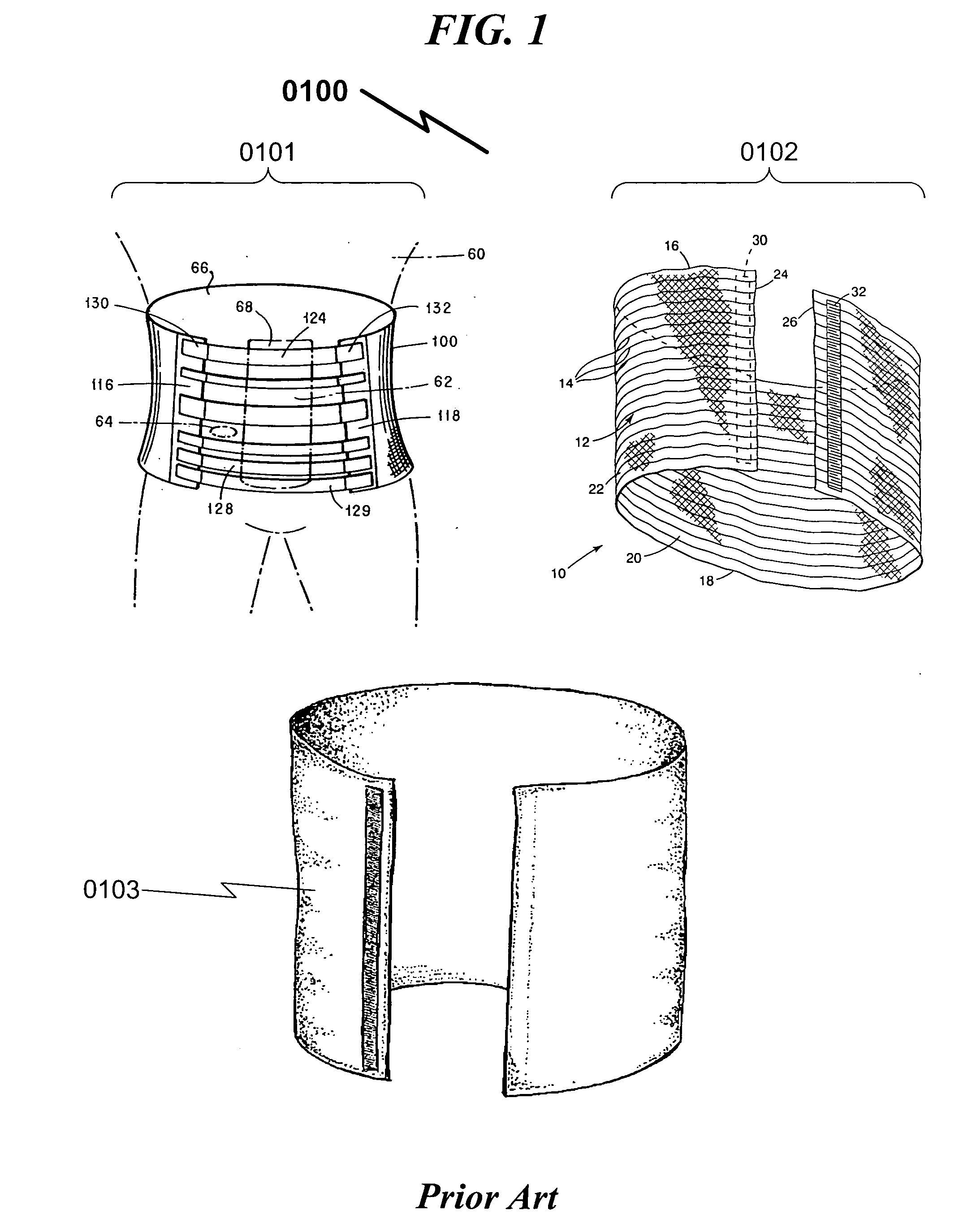

Surgical binder undergarment system and method

InactiveUS20070118062A1Reduce frictionReduce skin/binder frictionAbsorbent padsAbdomen bandagesPolyesterIrritation

A surgical binder undergarment system and method are disclosed which are designed to prevent skin chafing / irritation on patients recovering from abdominal / thoracic / back surgery and who must wear a surgical binder to prevent post-surgical injury to patient muscle and skin tissue because of incisions necessitated by the surgical procedure. The present invention is generally constructed of a seamless tubular fabric optimally comprising a fabric weave of 50% cotton and 50% polyester that is latex free and stretches over the abdomen / thorax of the patient to form a flexible protective low friction interface between the patient's skin and the surrounding surgical binder. Use of the present invention permits the surgical binder to remain clean with a corresponding reduction in incision infections and increase in overall patient comfort during post-operative recovery.

Owner:FLECK JANET FELICIA

Process and systems for peptide synthesis

ActiveUS7439222B2Reduce in quantityReduce the amount requiredBiocidePeptide/protein ingredientsCouplingCombinatorial chemistry

Owner:ROCHE PALO ALTO LLC

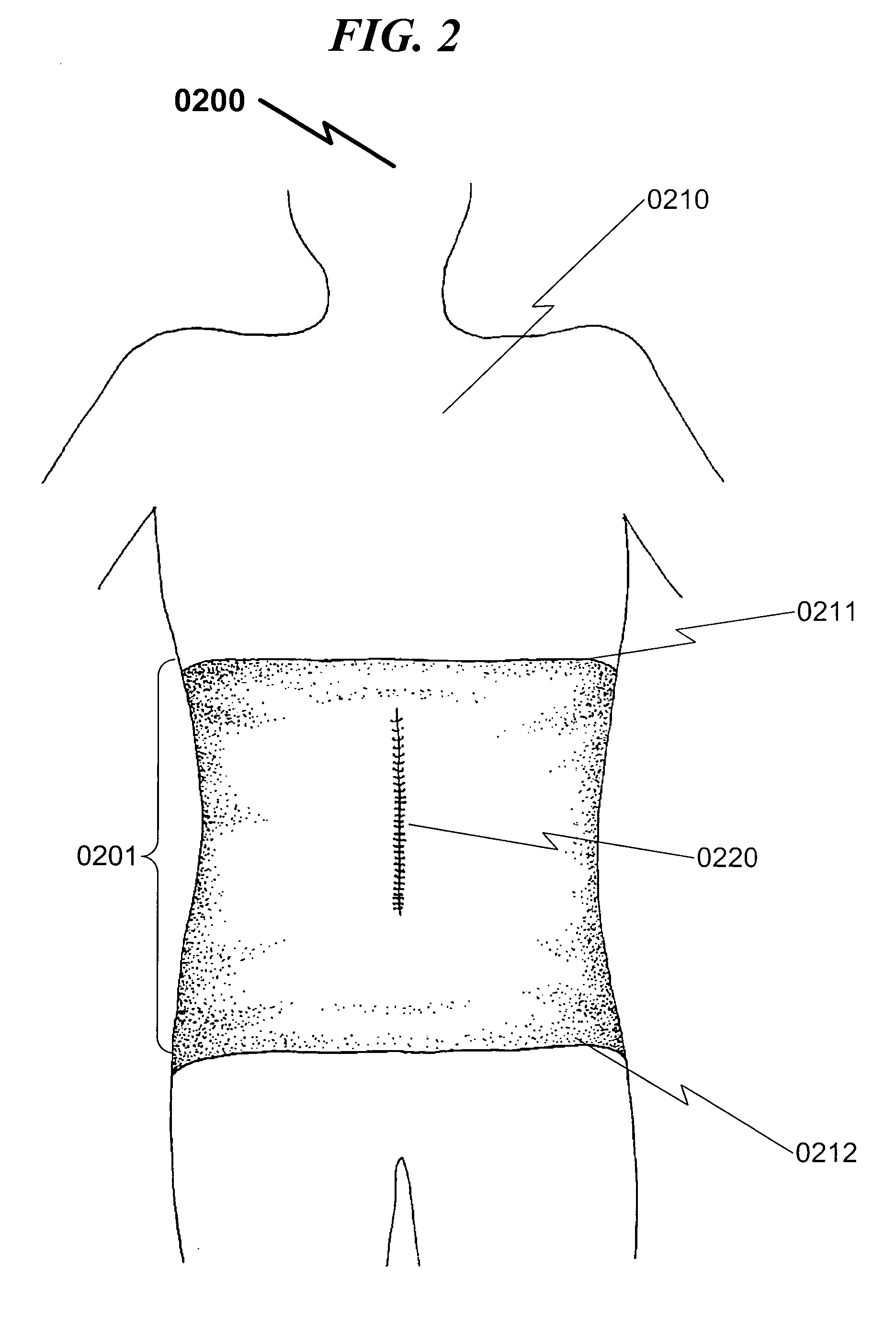

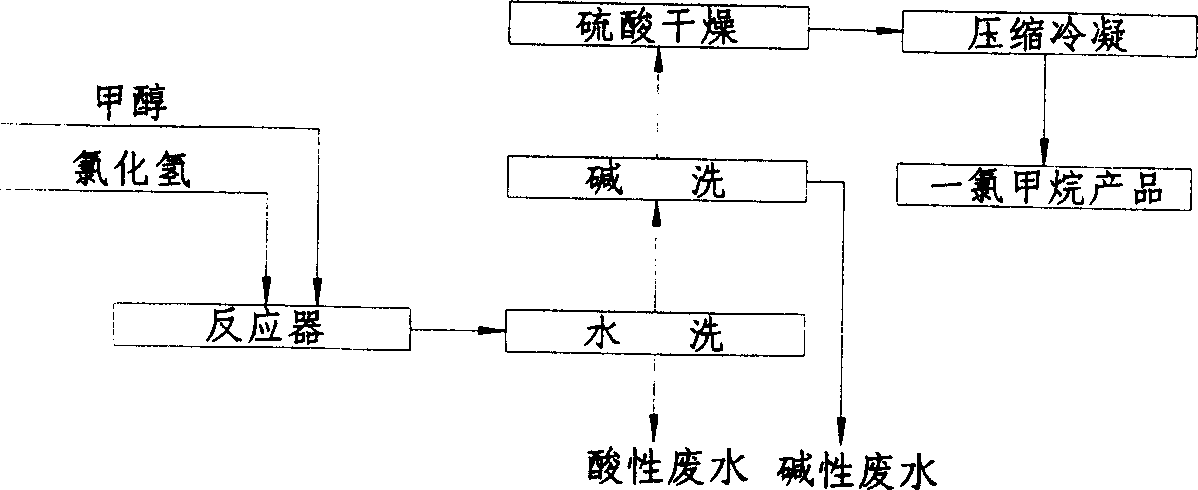

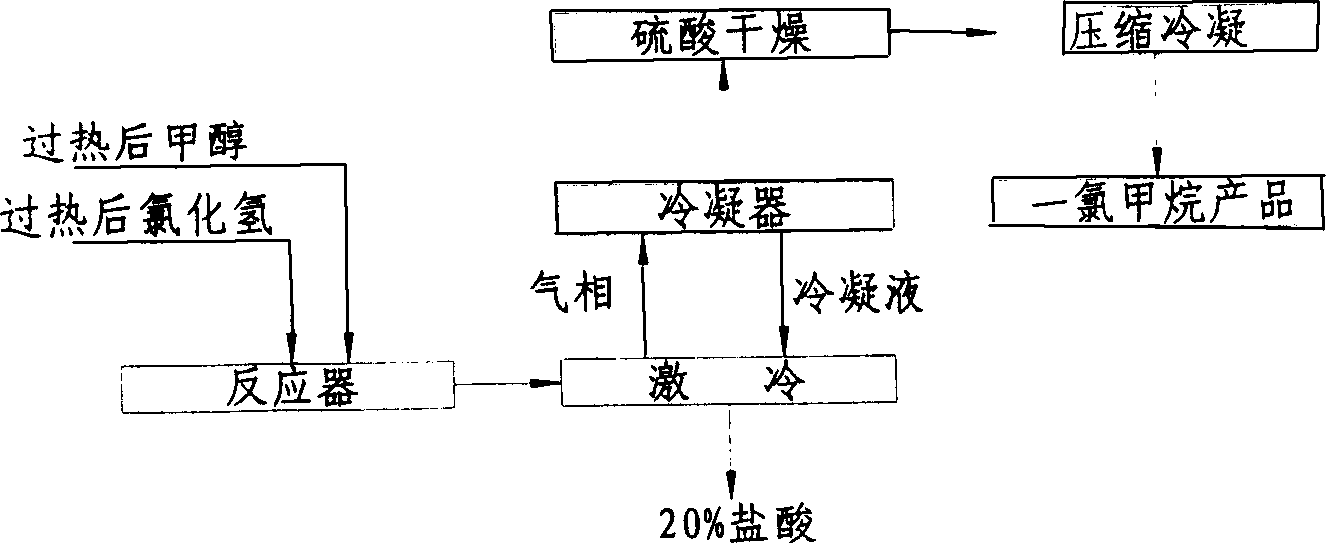

Method fo rproducing high pure methane chloride

InactiveCN1686983AReduce washingSimple processHalogenated hydrocarbon preparationChemistryHydrogen chloride

The present invention discloses a method for producing high-purity methane chloride. It uses methyl alcohol and hydrogen chloride as raw material, in the pressure of active catalyst, under the conditiojn of 280-320 deg.C and 0.2-0.6 MPa it utilizes gas-phase reaction to obtain methane chloride and water, after the high-temperature reaction gas discharged from reactor is chilled by dilute hydrochloric acid, the separated humid gas is condensed by condenser, then dried by sulfuric acid, compressed and condeased to obtain methane chloride crude product, then said method makes said crude product pass through first rectification tower to remove light component from said methane chloride crude material, then makes it pass through secondary rectification tower to remove heavy component so as to raise methane chloride content, its purity can be greater than 99.96%.

Owner:江苏梅兰化工有限公司

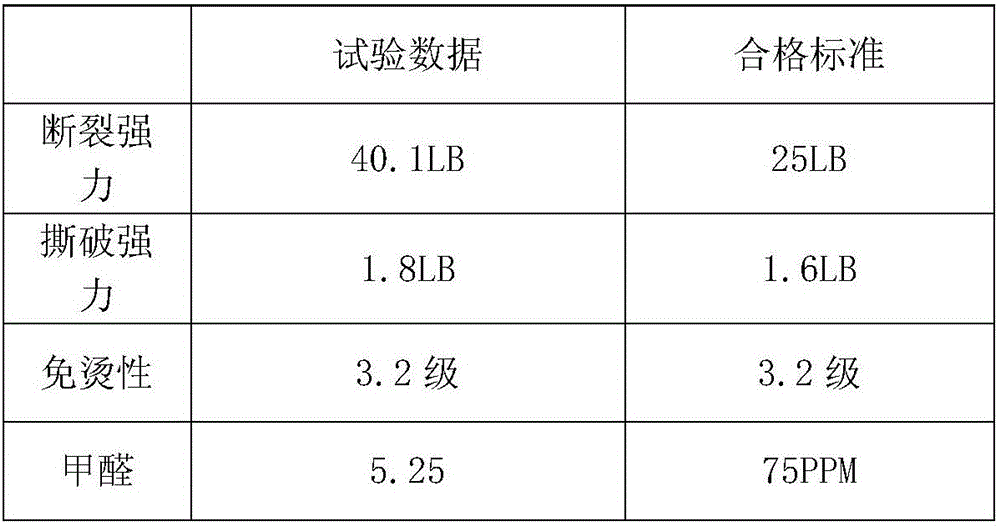

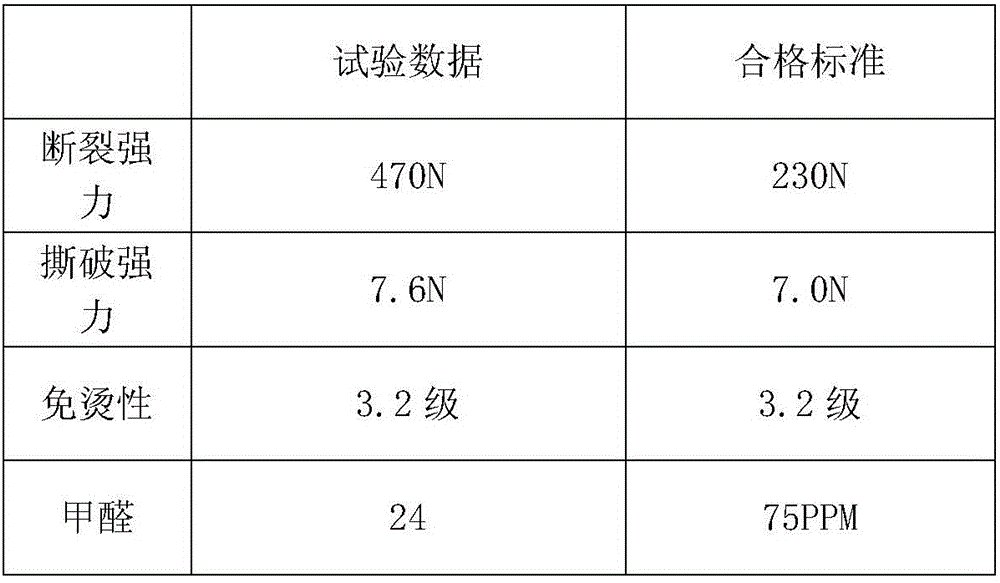

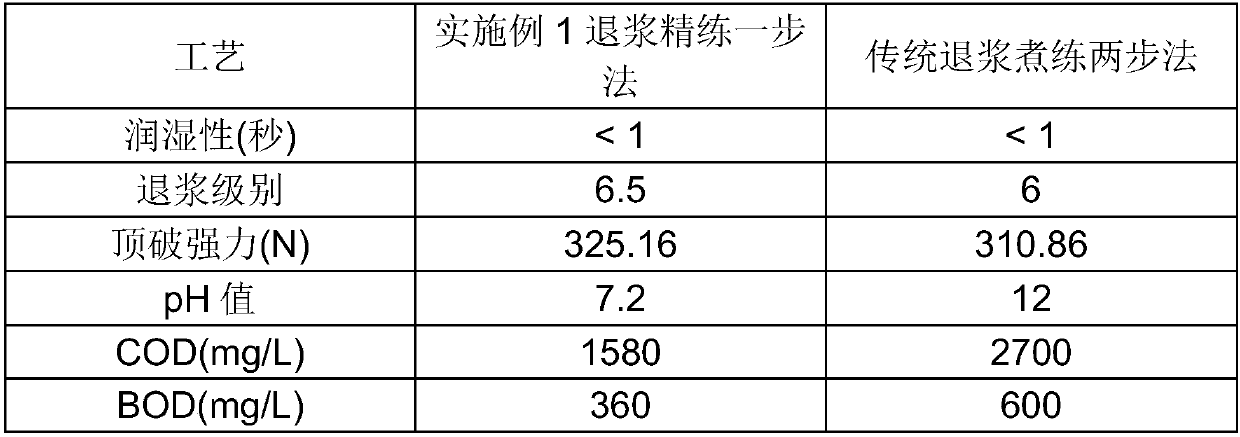

Non-iron finishing method for piece-dyed pure cotton fabric

InactiveCN105714559AGuaranteed responsePrevent strong damageSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention provides a non-iron finishing method for piece-dyed pure cotton fabric. The non-iron finishing method is characterized by comprising technological processes in sequence as follows: cloth turning, singeing, desizing and scouring, bleaching, mercerizing, liquid ammonia finishing, non-ironing, baking, washing, tentering, pre-shrinking as well as checking and packaging, wherein an intelligent non-iron technology is adopted for the fabric, resin and fibers are subjected to a crosslinking reaction sufficiently, formaldehyde and strength loss caused by resin residues are avoided, strength repair is avoided in a dyeing and finishing process, the content of formaldehyde of a cloth cover can be reduced, and the increase of formaldehyde can be prevented; with the adoption of non-iron finishing, the appearance of the fabric washed 5 times with an AATCC 124 method can reach level 3.2 or higher, and the content of formaldehyde is 60 PPM or lower through testing with a JIS L1041:2011 / 8.1.4B method. The processed fabric is soft and comfortable to wear, is environment-friendly and has an excellent non-iron effect.

Owner:鲁丰织染有限公司

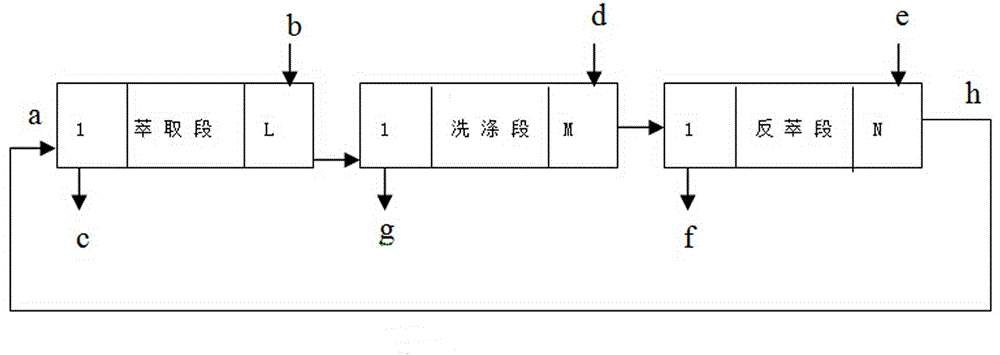

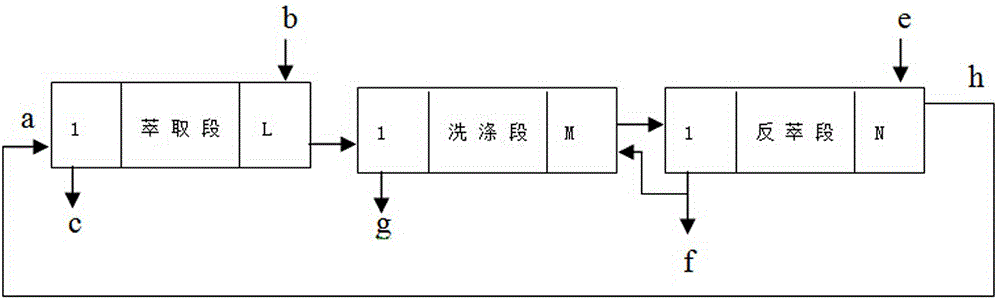

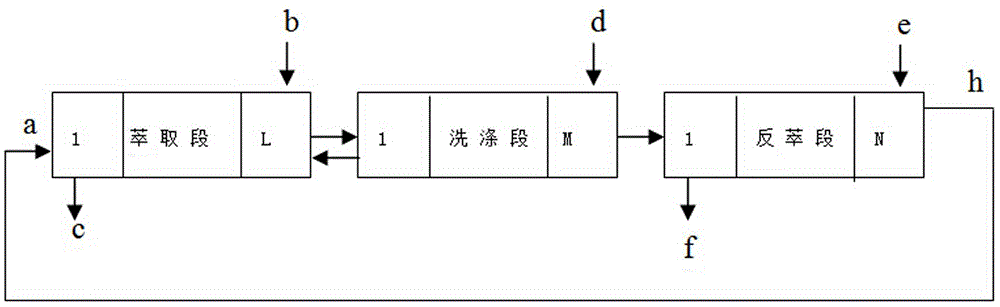

Non-saponification extracting and separating method for light rare earth element

ActiveCN104532021AReduce acidityAvoid consumptionProcess efficiency improvementHigh concentrationRare-earth element

The invention discloses a non-saponification extracting and separating of method for light rare earth element. According to the method, by virtue of a non-saponification extraction agent (organic phase) comprising an acid extraction agent, an alkaline extraction agent and kerosene, chlorinated light rare earth feed liquid is extracted and separated. Water instead of diluted hydrochloric acid or a high-concentration hydrochloric acid is used as a washing agent and a reverse-extraction agent, the stage retention times of the washing section and the reverse-extraction section are controlled so that the blank organic phase after reverse-extraction can be recycled without eluting the acid entrained in the blank organic phase with water, acidities of effluent liquid in the reverse-extraction section and raffinate in the extraction section are low and the subsequent extraction and separation can be performed without neutralizing. According to the method for separating the light rare earth element, the saponification step is not needed and acidic-basic materials are not consumed, the eluting and acid remove steps of the reverse-extraction organic phase are also omitted and thus the production cost is greatly decreased.

Owner:GUANGXI NORMAL UNIV

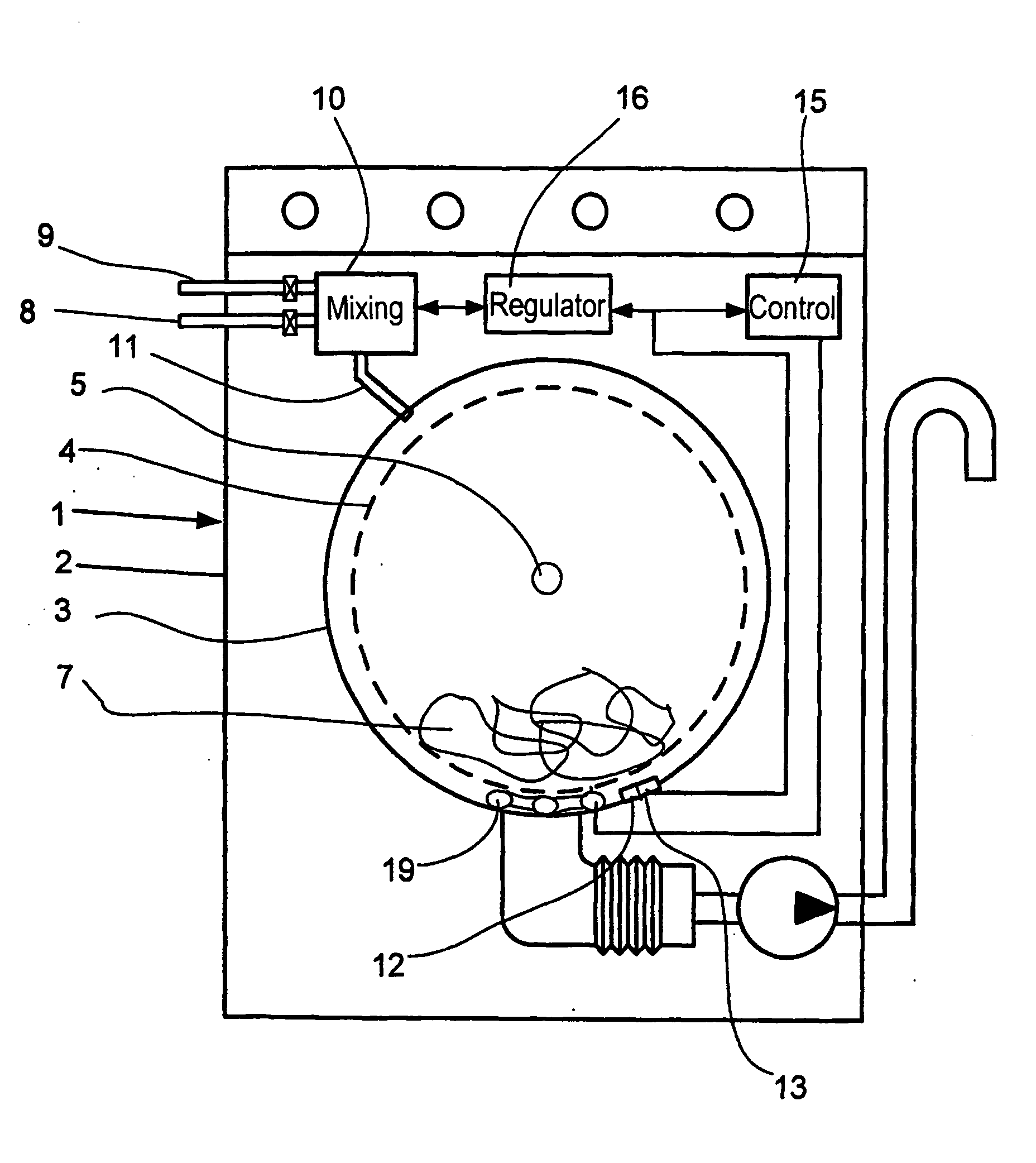

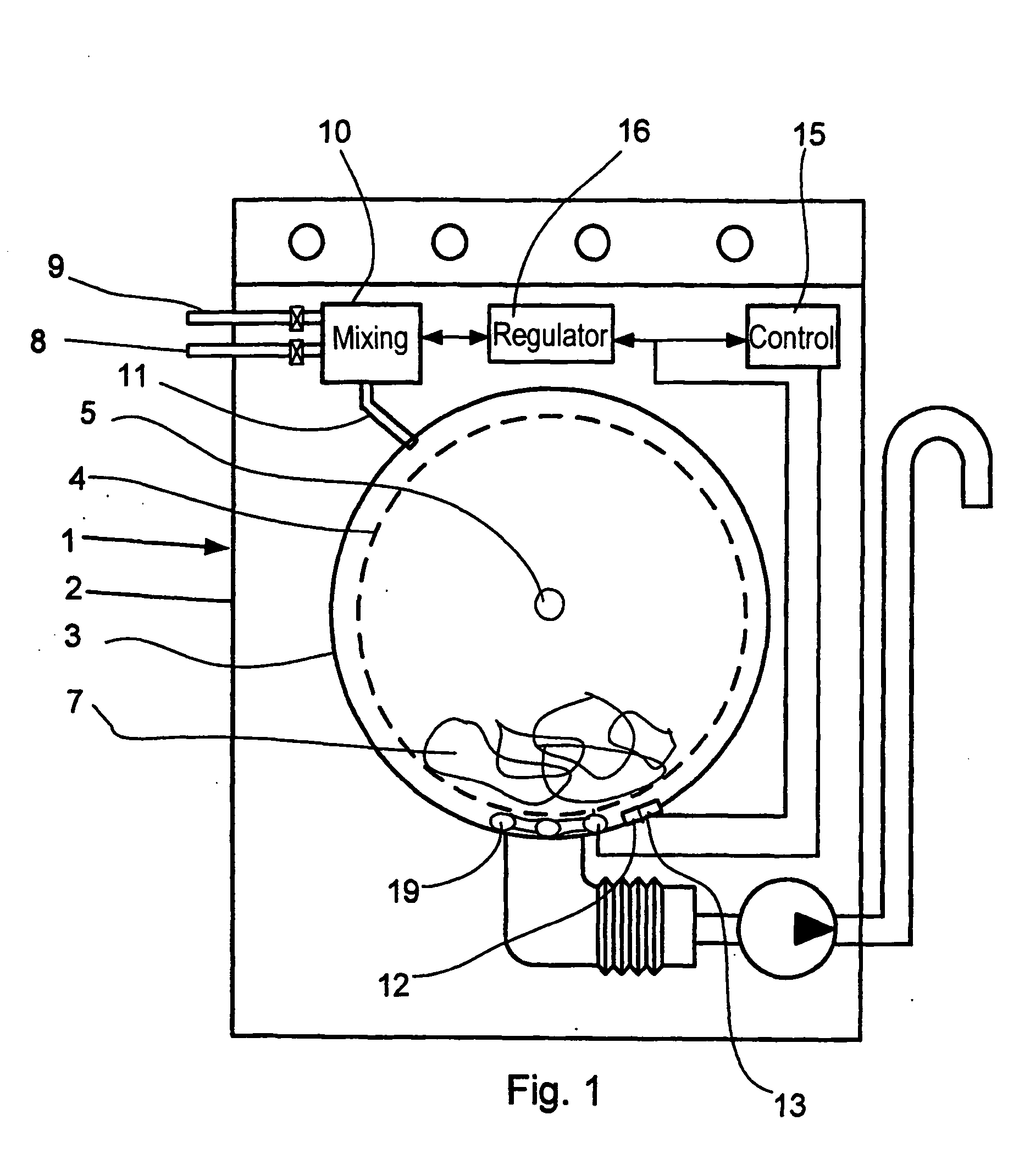

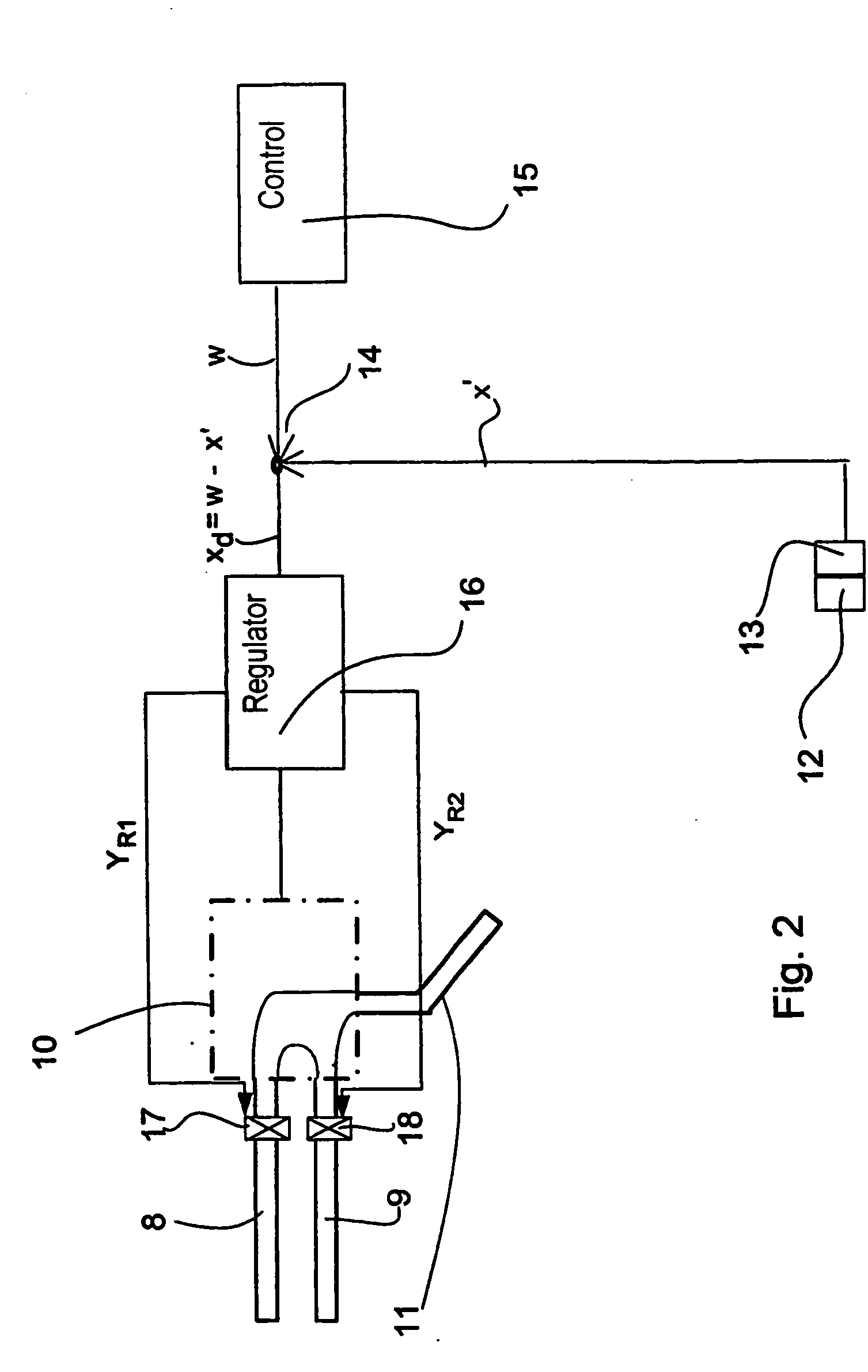

Water-bearing household appliance, in particular, washing machine

InactiveUS20050127194A1TimelyPermit useTemperature control without auxillary powerOther washing machinesWater flowHome appliance

A water-guiding household appliance, in particular, a washing machine, connected to a first water supply line for cold water and to a second water supply line for hot water has the water supply lines connected to a mixer tap enabling water to flow into a suds container through a supply line. The mixer tap is integrated into a regulating device used to regulate the temperature of the water flowing into the suds container.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

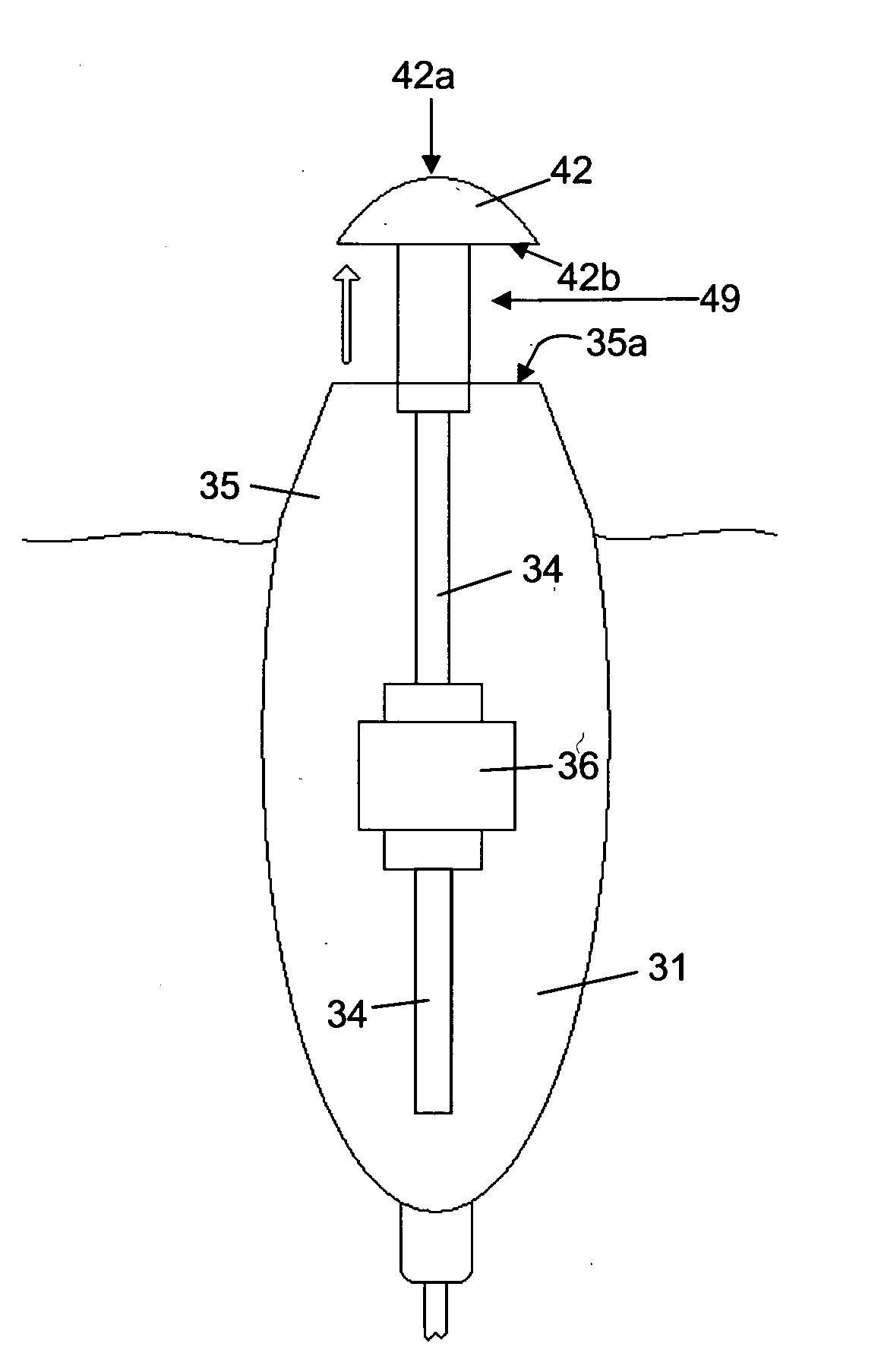

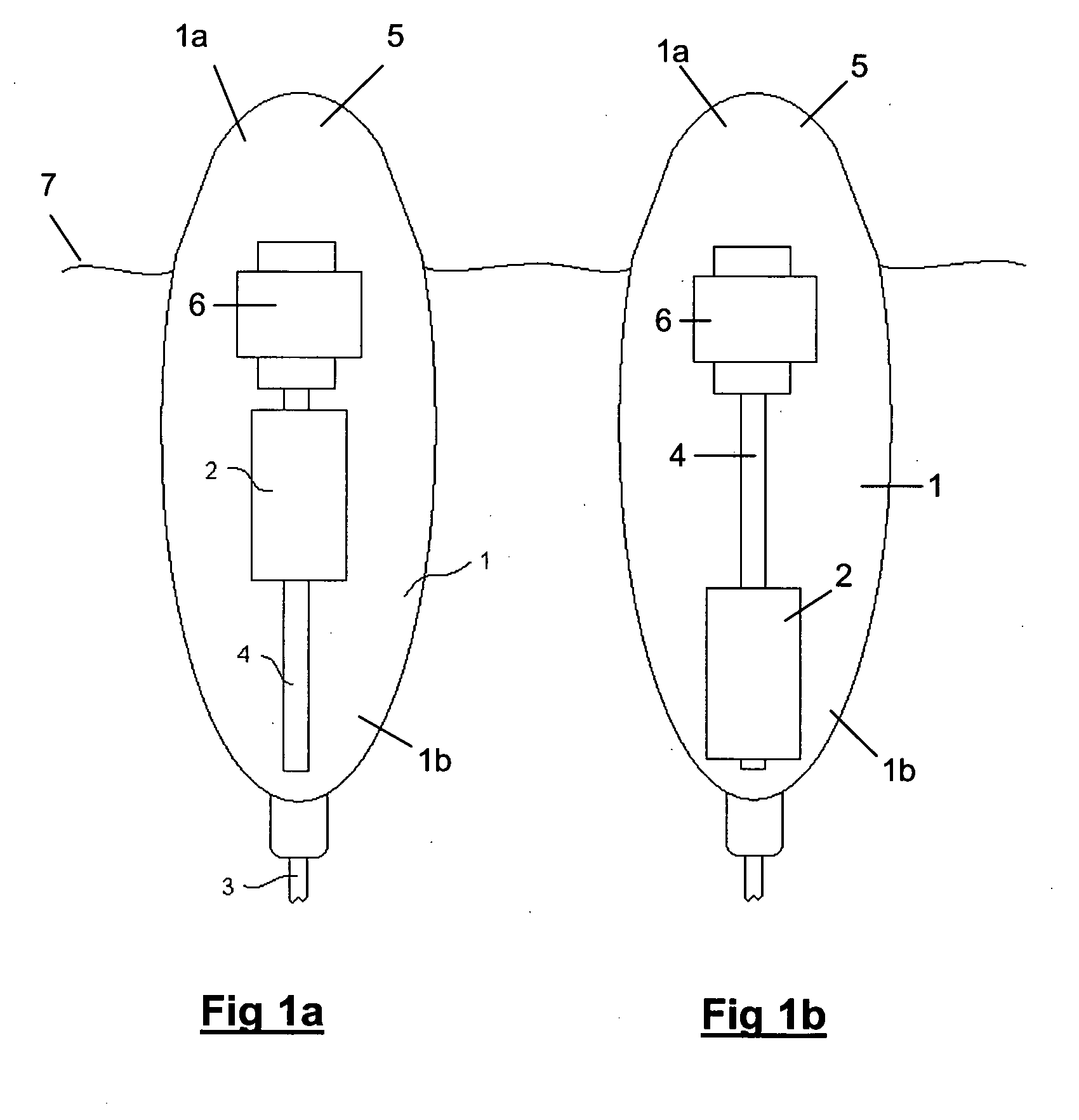

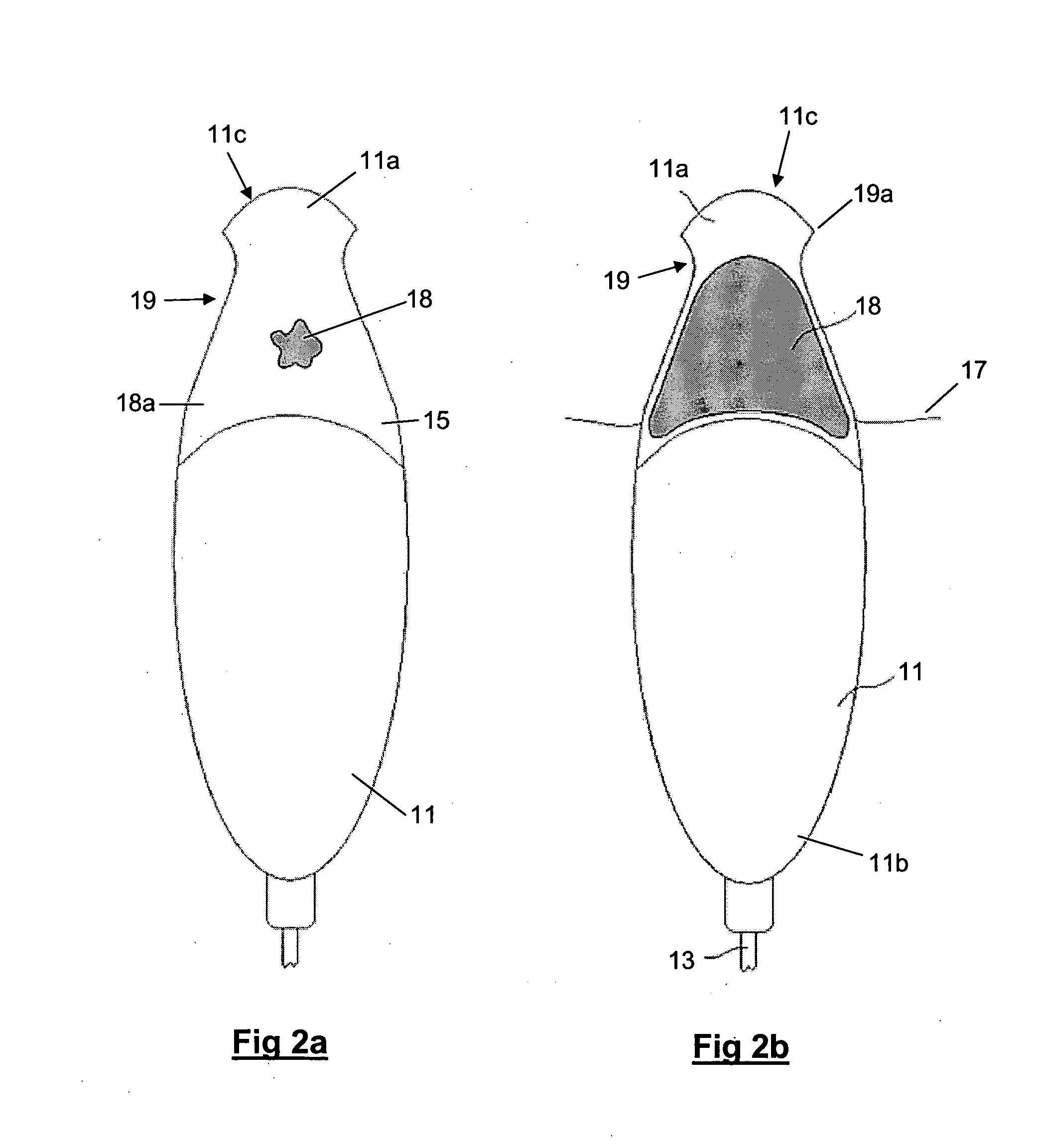

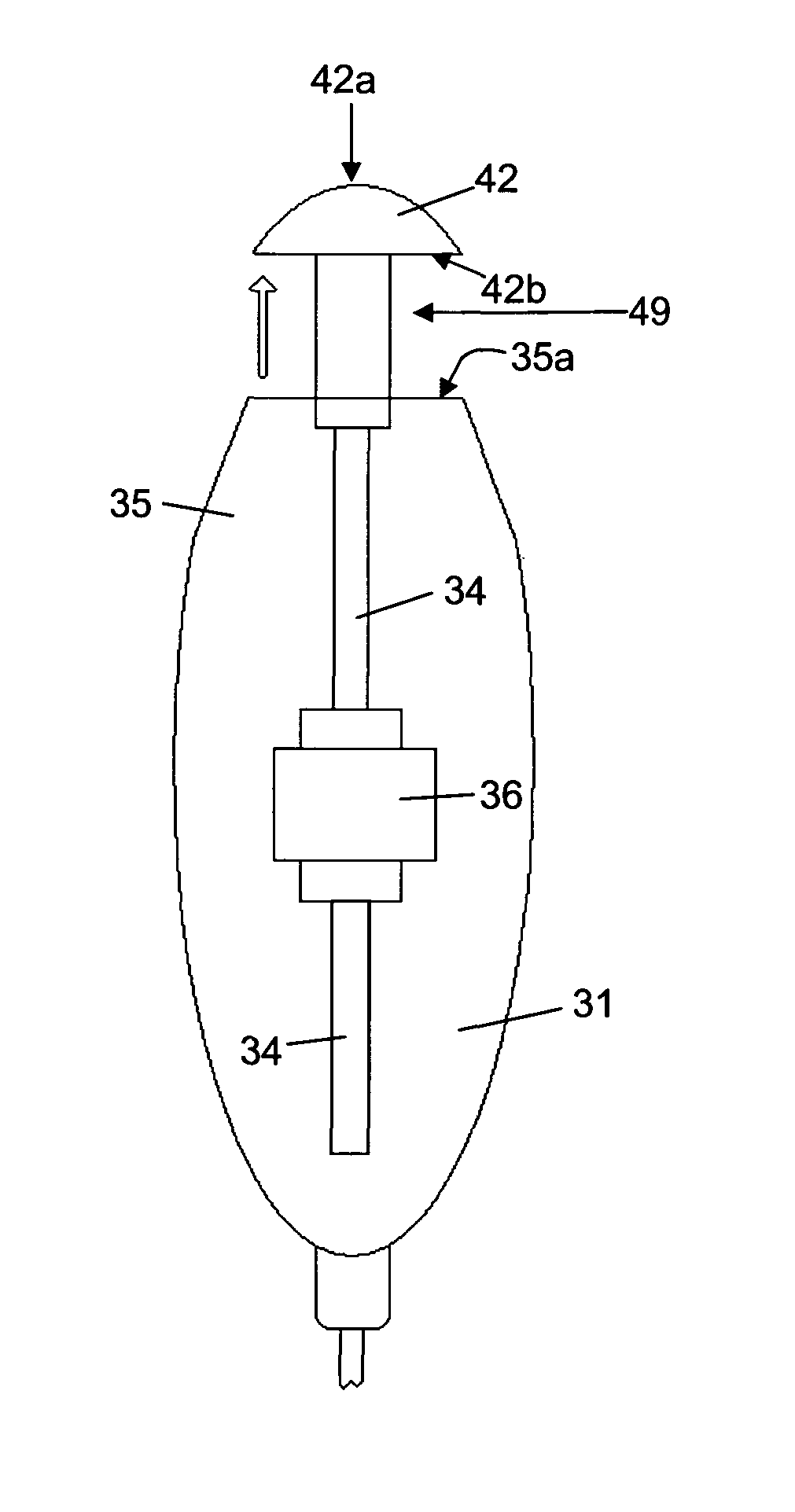

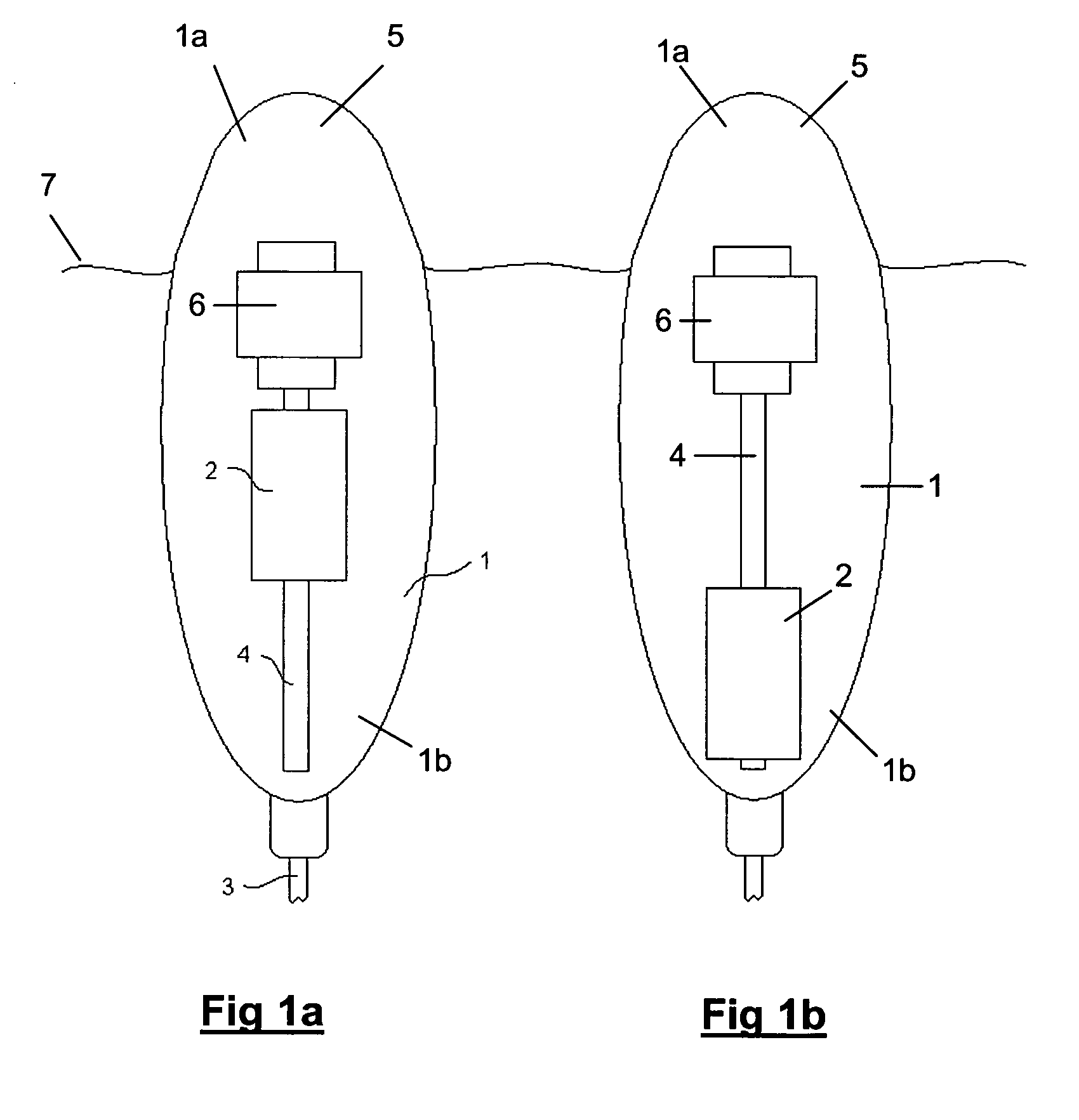

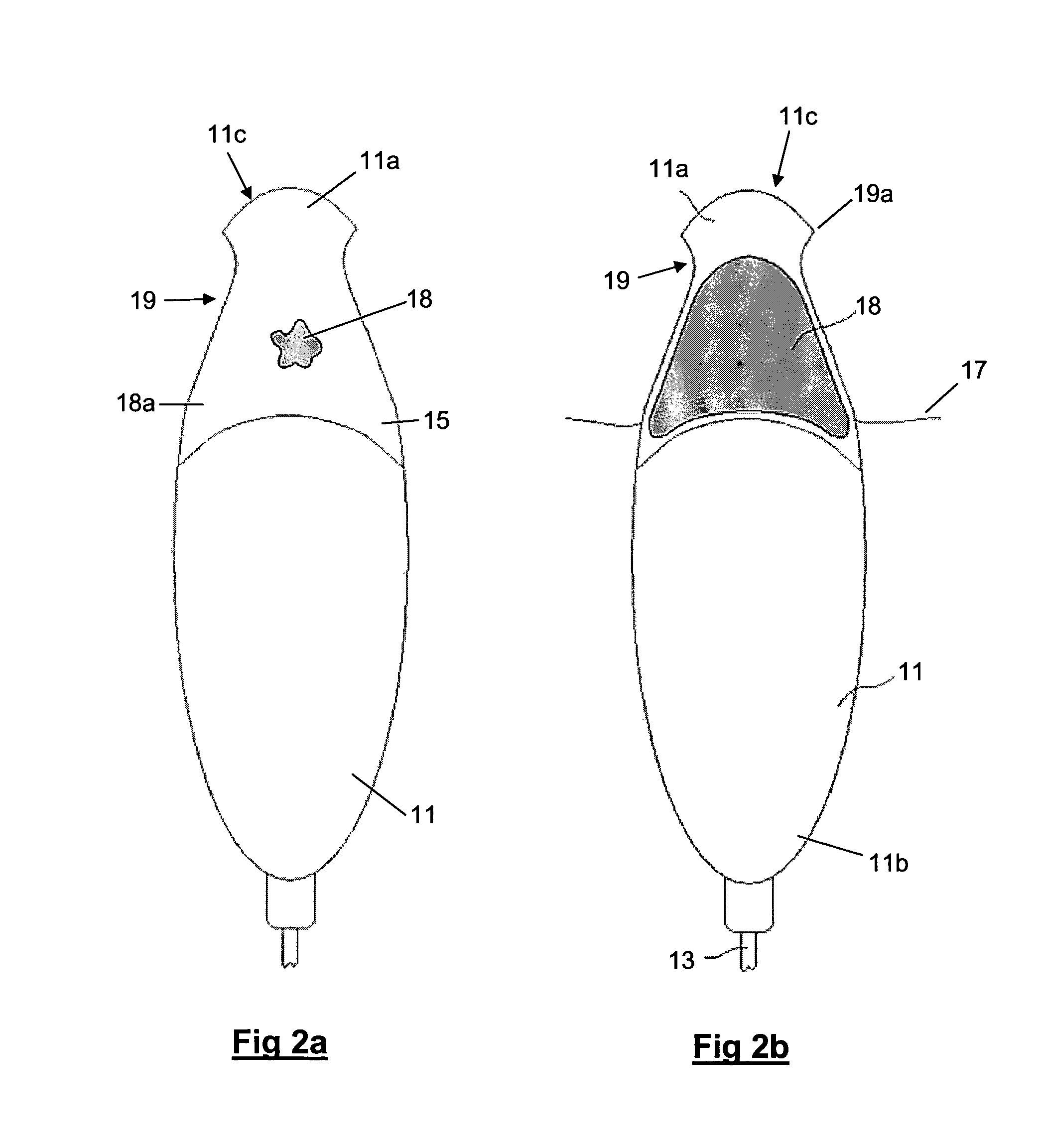

Buoy

ActiveUS20110000417A1Improve protectionImprove water stabilityAntenna adaptation in movable bodiesBuoysUnderwaterLong axis

A buoy (1) has a main body (5), and a moveable mass (2) positioned inside the main body. The buoy (1) may be tethered to a submarine vessel and used as a communications buoy. The buoy (1) may be configured for floating in a generally upright orientation at the water surface (7) in a position ready for communication, when the mass (2) is in a first position (FIG. 1a) in which the centre of mass is offset from the centre of buoyancy to improve stability in the water. The buoy (1) may be configured for being towed underwater at speed, when the mass (2) is in a second position (FIG. 1b), in which the centre of mass is closer to the centre of buoyancy, to improve towing stability in the water, thereby allowing the buoy (1) to be towed with its long axis substantially aligned with the direction of motion, thereby reducing wake / plume in the water.

Owner:BABCOCK IP MANAGEMENT NUMBER ONE LTD

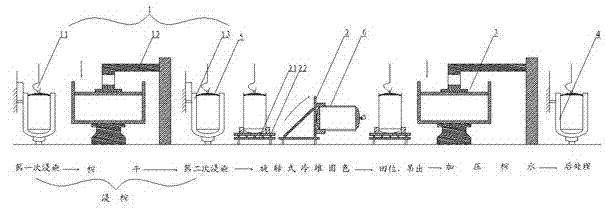

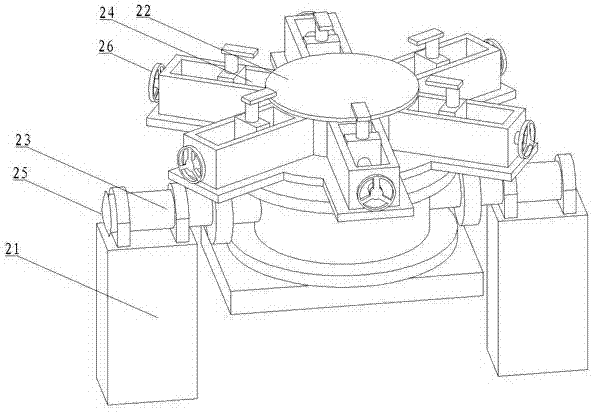

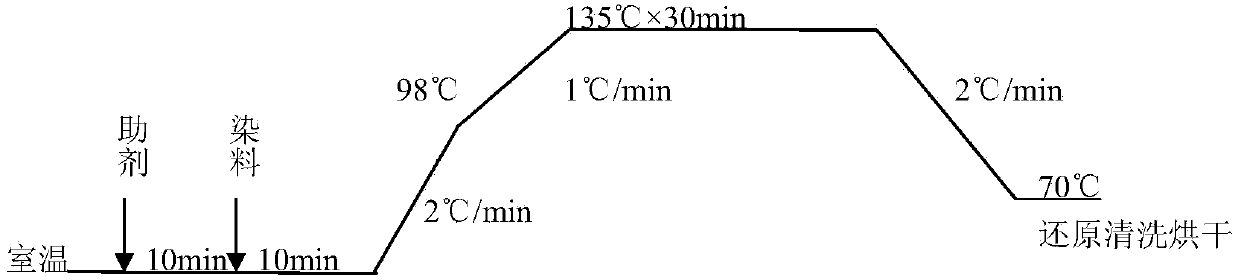

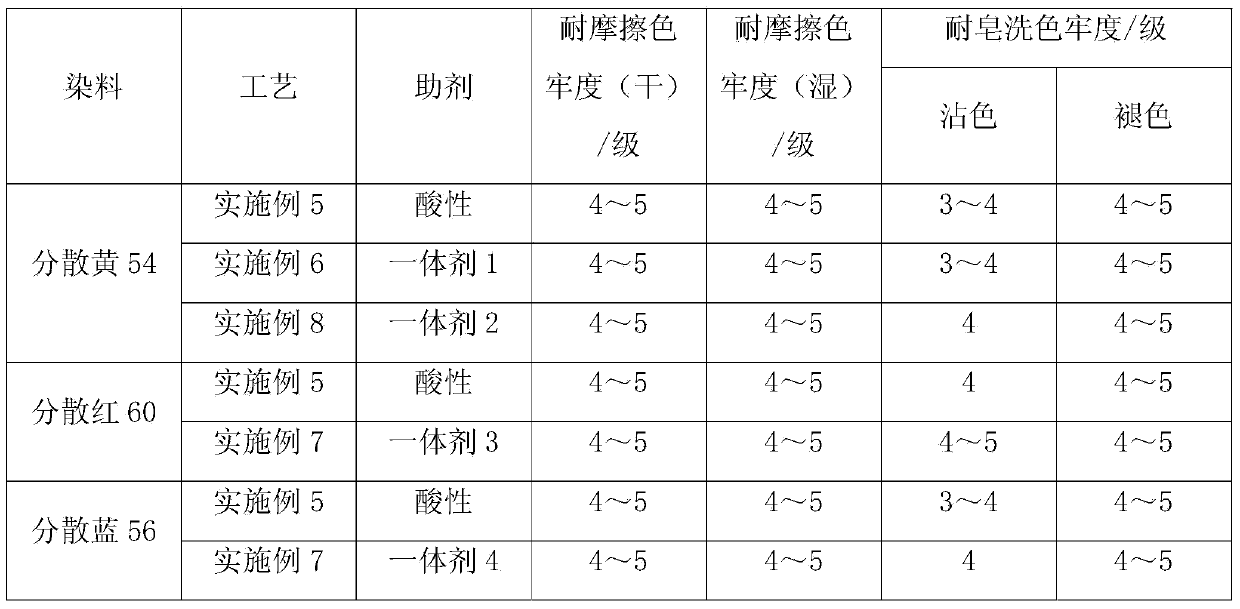

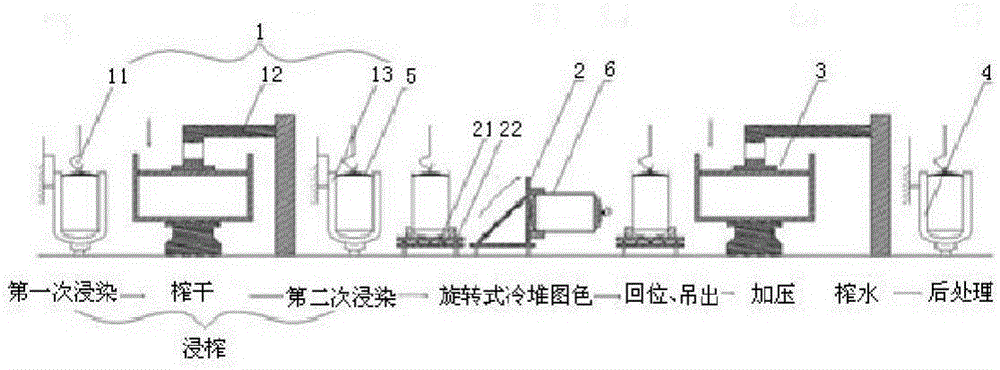

Cold-pad batch dyeing process for loose fibers

ActiveCN103774363AEvenly distributedPromote absorptionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberPolymer science

The invention belongs to the technical field of loose fiber dyeing and relates to cold-pad batch dyeing process for loose fibers. The cold-pad batch dyeing process for loose fibers comprises the steps of soaking and squeezing, rotating type cold-patch treatment, pressing and water squeezing and post-treatment. The loose fibers are soaked and squeezed in a twice soaking and once squeezing mode, the rotating type cold-patch treatment is then conducted, the loose fibers are pressed and water is squeezed out after the rotating type cold-patch treatment is conducted, and after the water and dye in a loose fiber cake or loose fibers are squeezed out, the loose fiber cake or loose fibers are sent for post-treatments of drying and the like. The cold-pad batch dyeing process for loose fibers is applied to cold-pad batch dyeing of the loose fibers and has the advantages of being uniform in dyeing, small in water consumption and the like. In addition, procedures are simple.

Owner:绍兴国周针织科技有限公司

Blended yarn weaving and ecological finishing method for silk-ramie fibers colored by vegetable dyes

InactiveCN104862870AIncrease color spectrumChromatography is completeSucessive textile treatmentsWeft knittingYarnSpinning

The invention relates to a blended yarn weaving and ecological finishing method for silk-ramie fibers colored by vegetable dyes. One or two kinds of ramie fibers colored by vegetable dyes and silk colored by vegetable dyes and one or more kinds of cotton fibers, Tencel fibers and modal fibers are made into blended colored spun yarns by adopting the spinning modes of compact spinning, Siro compact spinning, spinning conducted through air exhaust type revolving cups and air-jet vortex spinning. The yarns are directly woven into gray fabric through knitting equipment without oil and wax application, and the gray fabric is subjected to water scrubbing and low temperature drying shaping at the temperature lower than 140 DEG C and then is subjected to preshrinking processing to become finished product fabric. The blended colored spun yarns are plied to be used as warp yarns, sizing-free weaving is conduced through tatting equipment, and fabric obtained after sizing-free weaving is calendared by a calender under normal temperature or processed by a preshrinking machine to become finished product fabric. High temperature processing is not needed in aftertreatment of the fabric, finished products have soft hand feel and are smooth, softening agents are omitted, and safety and environment friendliness are facilitated. Besides, the bacterium resistance and inhibition performance of the fabric colored by the vegetable dyes is guaranteed effectively.

Owner:邱平

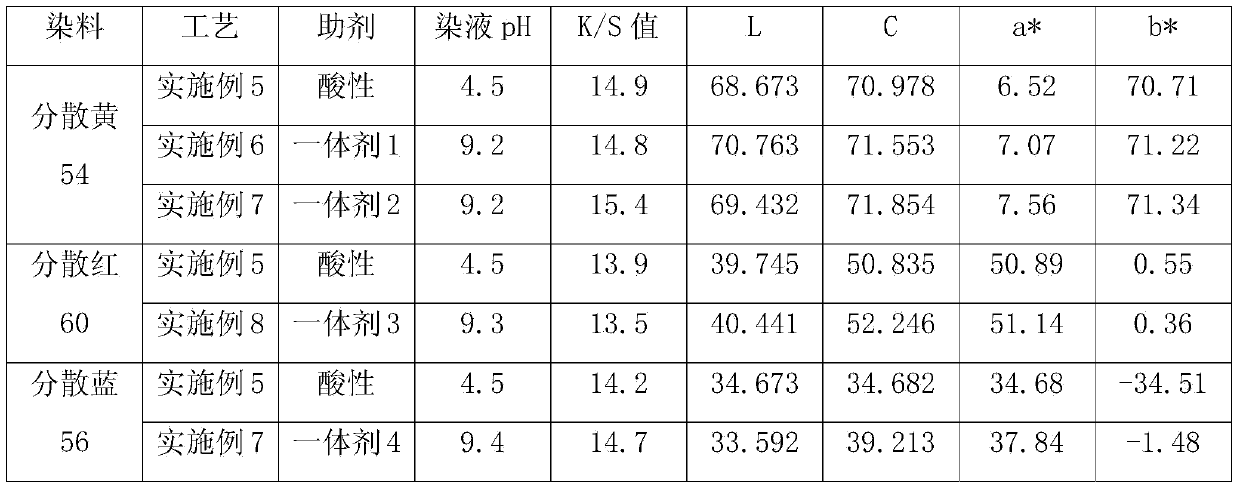

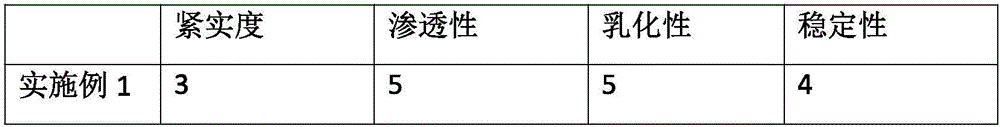

Polyester basic dyeing integrated auxiliary agent and application thereof

The present invention belongs to the field of light chemical engineering, and particularly to a polyester fiber dyeing auxiliary agent. The present invention provides a special auxiliary agent for polyester disperse dye basic dyeing, wherein the special auxiliary agent can be adapted to basic dye bath and dying, can eliminate the reduction cleaning step, and even can be matched with the one-bath process of desizing, refining and dyeing, the final dyeing fabric has characteristics of good level dyeing property and soft hand feeling, and the color fastness reducing due to carrier dyeing is avoided.

Owner:CHANGZHOU UNIV

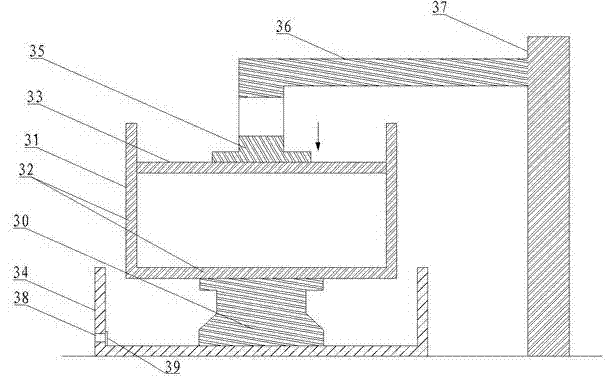

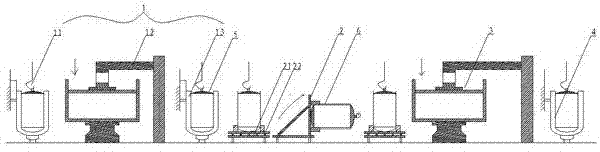

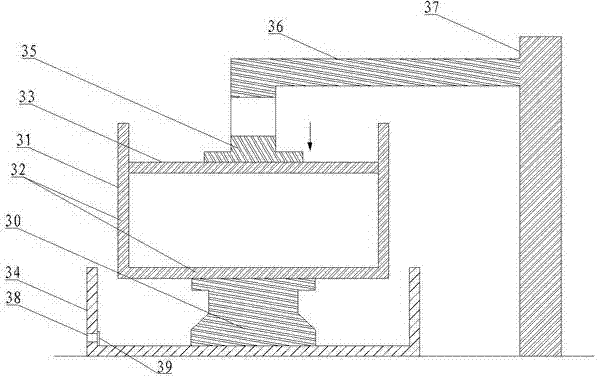

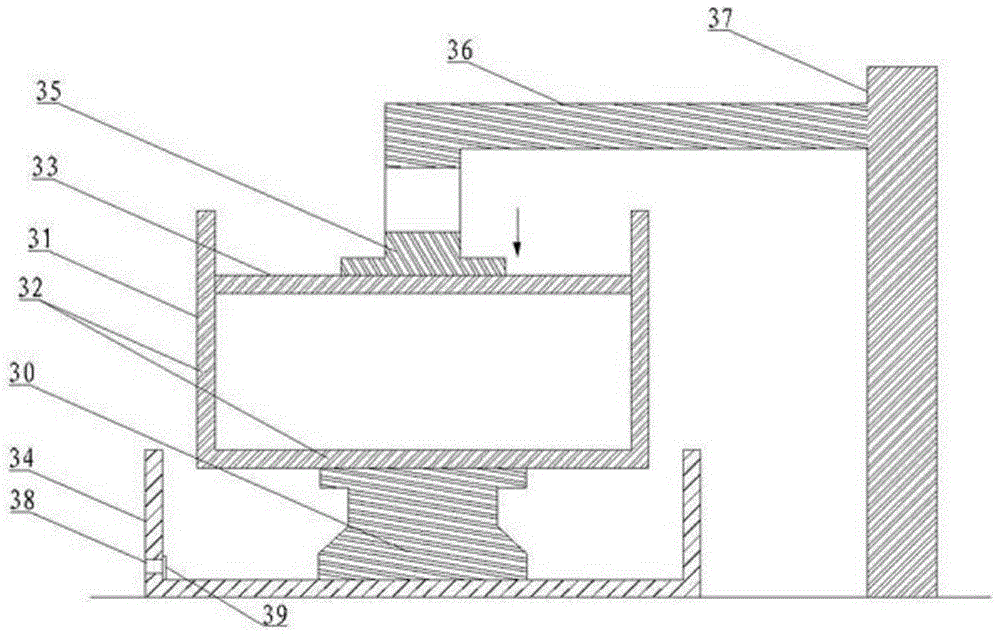

Wringer suitable for loose fiber or loose fiber cake dehydration

InactiveCN103774367AReduce the difficulty of washingReduce water consumptionLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentPistonPower component

The invention relates to a wringer suitable for loose fiber or loose fiber cake dehydration and belongs to the technical field of loose fiber dyeing. The wringer comprises a base, a cylindrical cylinder body and a top plate. The cylindrical cylinder body is arranged on the base. A leakage hole is formed in the cylindrical cylinder body. The top plate is movably connected with the cylindrical cylinder body. The upper portion of the top plate is connected with a pressure component. A power component drives the top plate to carry out piston motion in the cylindrical cylinder body, so that moisture in loose fibers in the cylindrical cylinder body is squeezed out. The wringer is used for loose fiber cold rolling stack dyeing and has the advantages that dyeing is even, the amount of used water is small, and procedures are simple.

Owner:绍兴国周针织科技有限公司

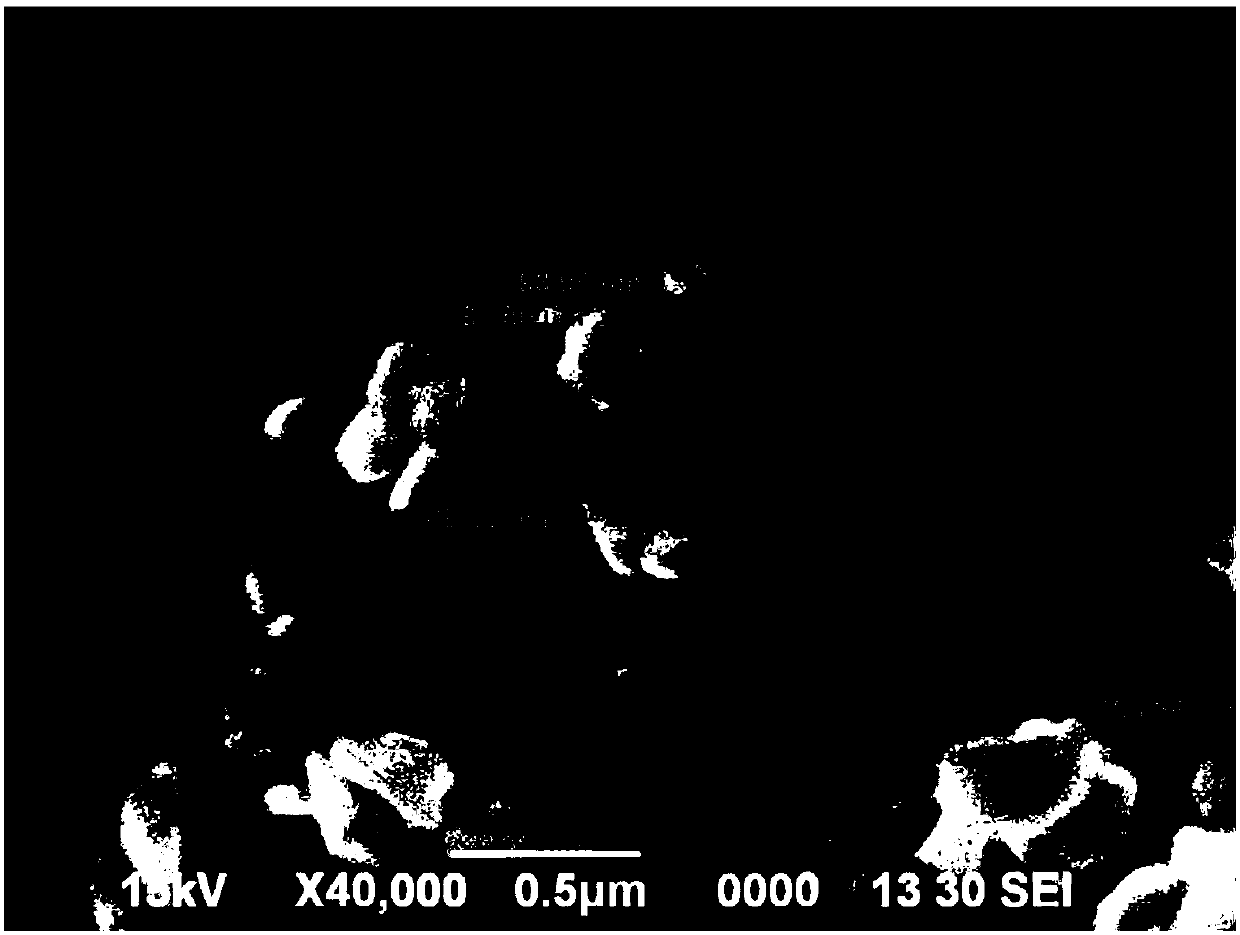

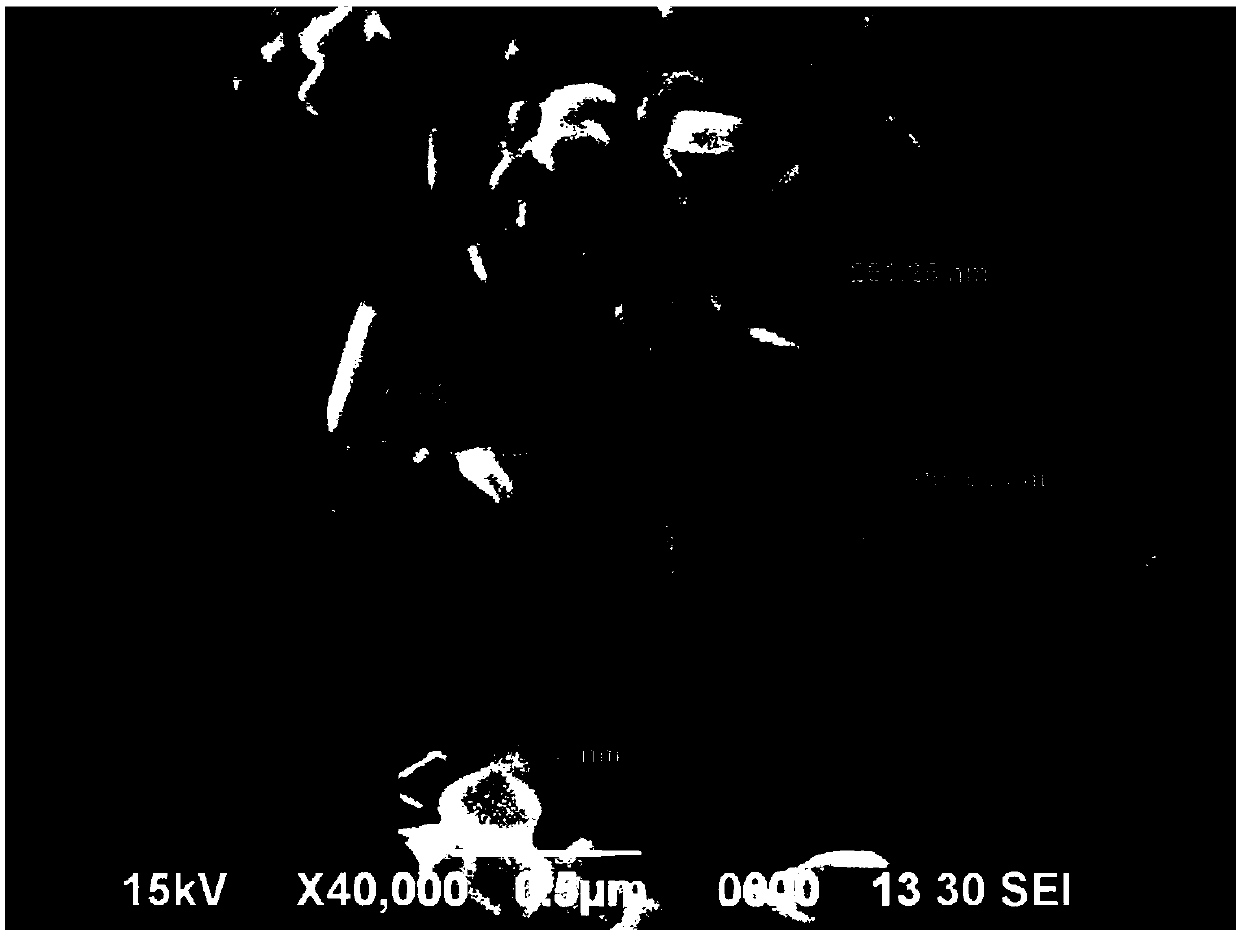

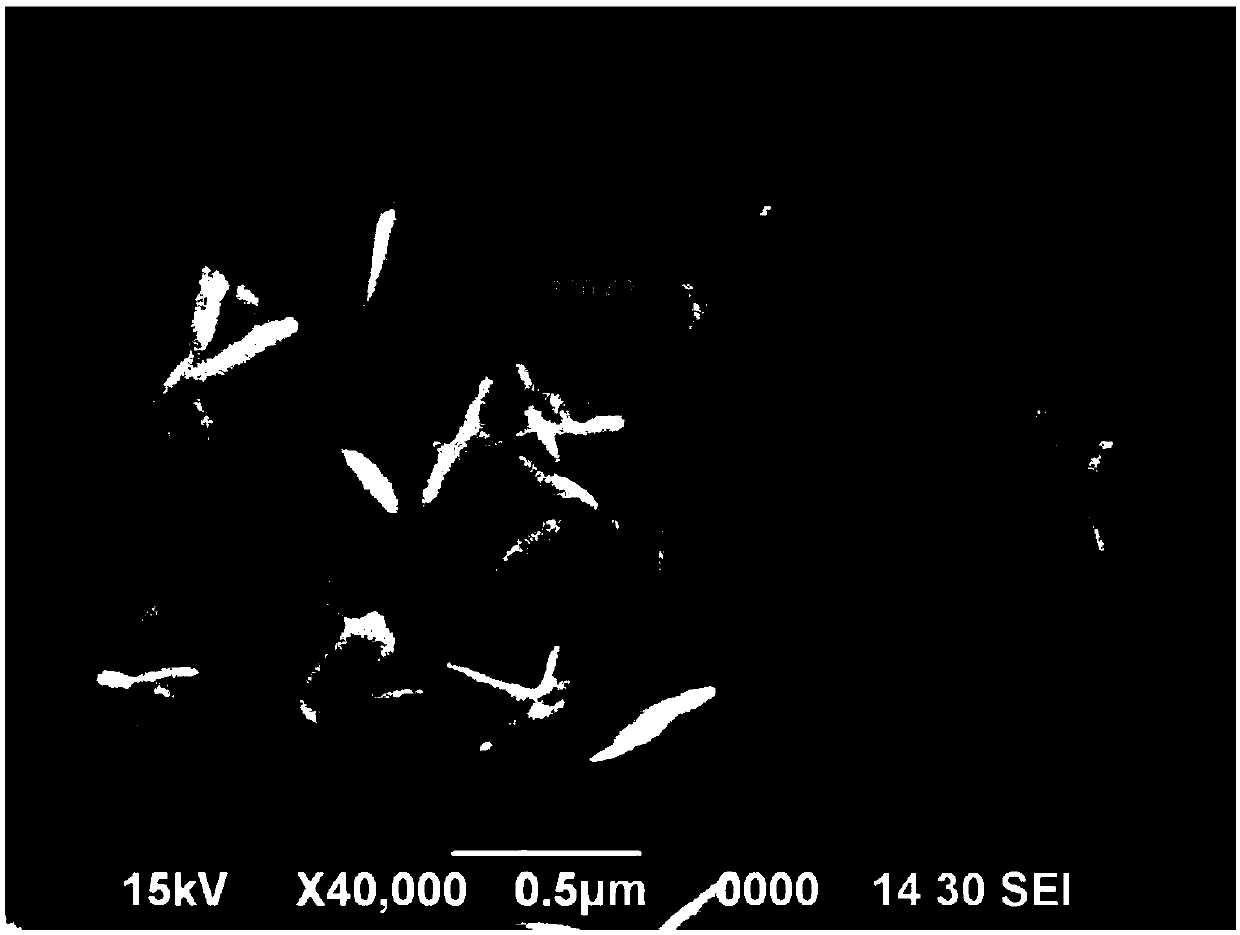

Chemical method for preparing nanoscale flaked silver powder

ActiveCN107716944AUniform sizeGood settlement performanceMaterial nanotechnologyTransportation and packagingMicro nanoSeed crystal

The invention relates a chemical method for preparing nanoscale flaked silver powder, and belongs to the field of preparation of micro-nano silver materials. The chemical method comprises the steps that reaction raw material solutions are prepared, seed crystals are prepared, the solution A and the solution B are added into a container containing the solution C at a constant speed, the solutions are mixed to be uniform and sufficiently reacted, and the product is filtered, washed, dried under vacuum and then stored. According to the chemical method, reaction conditions are mild, reaction is rapid, a reaction system has the high solid content, silver powder collection and washing are facilitated, meanwhile, waste water drained during large-scale production can be reduced, and a feasible path is provided for preparing micro-nano flaked silver powder on a large scale through the chemical method. The prepared flaked silver powder is uniform in size, regular in morphology and good in application prospect.

Owner:CHANGCHUN GOLD RES INST

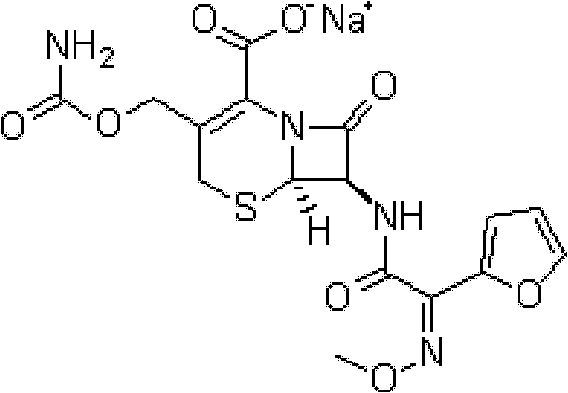

Method utilizing coupling reaction crystallization to prepare cefuroxime sodium

InactiveCN102617604AReduce adsorption filtration processReduce degradationOrganic chemistryActivated carbonFiltration

The invention relates to a method utilizing coupling reaction crystallization to prepare cefuroxime sodium, which comprises dissolving cefuroxime acid in a mixed solvent at 20-30 DEG C to prepare a solution with the concentration to be 0.025g / ML-0.1g / Ml; adding an alkaline sodium salt water solution into the solution; mixing for 10-20min at constant temperature to enable a reaction to be complete, and adding cefuroxime sodium seed crystal; adding an elution agent after 10-20min; cooling the temperature of the solution to 0-5 DEG C, and keeping at the constant temperature for 0.5-2h; filtering, washing and drying the obtained suspension, and obtaining a cefuroxime sodium product. The method reduces the adsorption filtration process of activated carbon and avoids loss of yield. The method achieves coupling of reactions and crystallization, and the methods of elution crystallization and cooling crystallization are combined with each other in the crystallization process, the crystallization process is controlled easily, the particle size of the product is uniform, the liquidity is greatly improved, the purity is higher than 99.5%, and the yield is over 92%.

Owner:TIANJIN UNIV +1

Method of producing corrugated paper with straw

InactiveCN104928958AHarm reductionHigh extraction ratePretreatment with acid reacting compoundsFibrous raw materialsEconomic benefitsProcess engineering

The invention discloses a method of producing corrugated paper with straw. The method includes the steps of preparing of raw materials, pretreatment of the straw, chemical pre-impregnating, primary hot grinding, tertiary hot grinding, screening, pulping, sheet making, and finishing. The short process is used in the production process, thus a washing and concentrating step is shortened and the pumping step is omitted. In the whole pulping process, power consumption is 10% lower than the power consumption for chemical pulps, water consumption is more than 70% higher than that for chemical pumps, boiling time is shorter, fuel consumption is decreased by 10% to 20%, the pulping rate is up to greater than 80%, and the production cost is lowered. On the basis of production of the high-strength corrugated paper, direct production cost of the paper is less than 1000 RMB per ton, and the economic benefit is excellent.

Owner:ZHANGJIAGANG XINFA PACKING

Process for preparing nanometer zirconium dioxide powder by double liquid phase hydrolysis

The present invention discloses double-liquid phase hydrolysis process of preparing nano zirconia powder in the field of chemical material preparation. Hydrolysis of zirconium oxychloride or zirconyl nitrate is completed in double-liquid phase, i. e., via water-oil azeotropic process; the hydrolysis product HCl or HNO3 is eliminated; and through further stoving and roasting treatment, homogeneous and dispersed spherical nano zirconia powder of about 10 nm size is produced. The product is used in information ceramic and structural ceramic and as chemical material. The technological process is simple, easy to operate, high in material utilization and low in power consumption, and may be realized in production line.

Owner:TSINGHUA UNIV

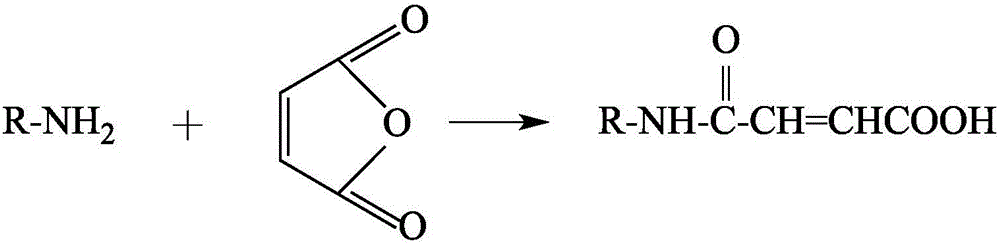

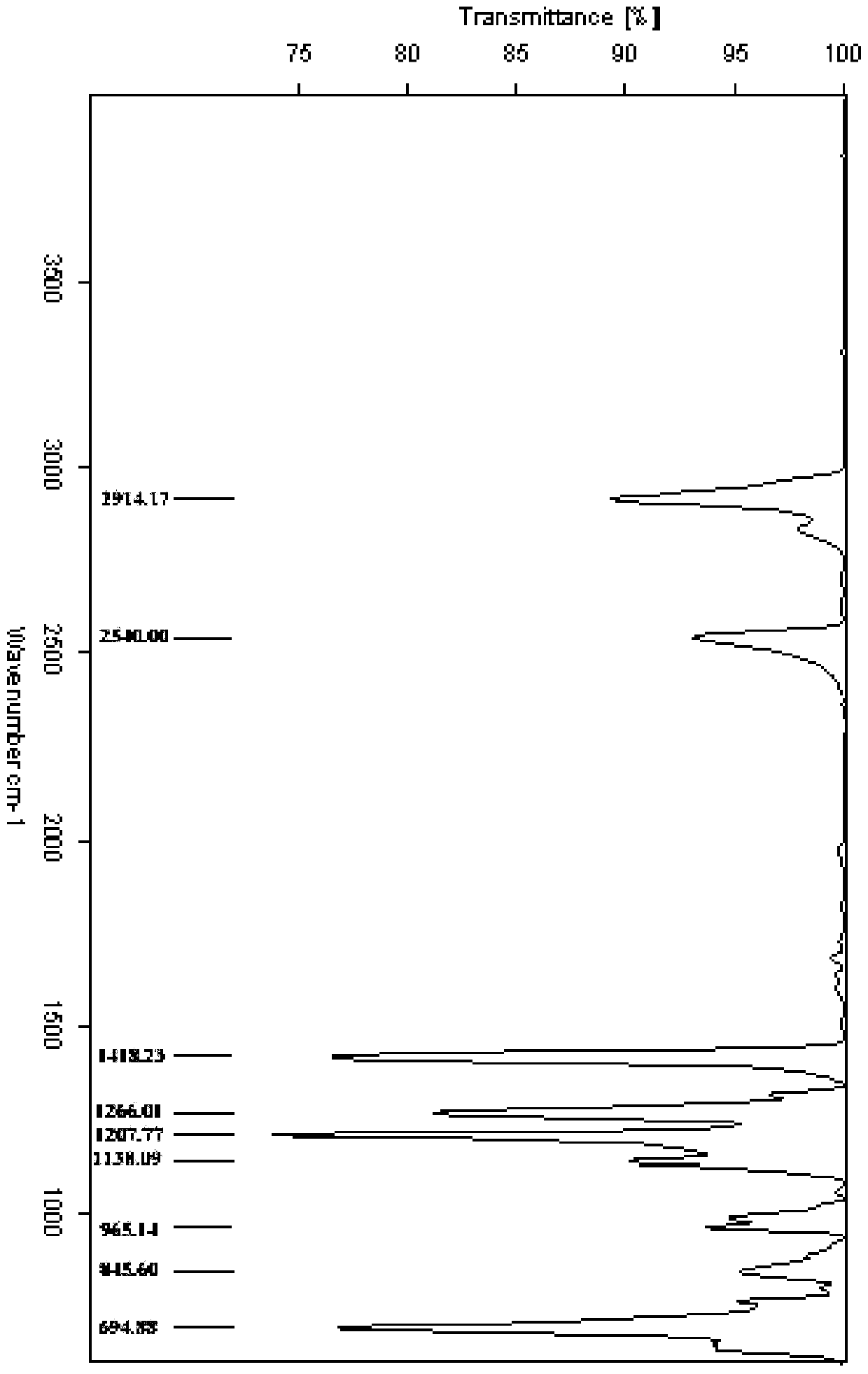

Amphoteric retanning fatting agent and preparation method thereof

ActiveCN106544453AGood for retanning and fillingSolve the simplification of the retanning processTanning treatmentLeather impregnationMaleic anhydridePhosphate

The invention discloses an amphoteric retanning fatting agent and a preparation method thereof. The preparation method of the amphoteric retanning fatting agent comprises the steps that maleic anhydride, maleic anhydride monoamide, acrylic acid and tri-methylamino ethyl methacrylate serve as raw materials, wherein maleic anhydride monoamide is generated through a reaction of amine C12, amine C13, amine C14, amine C15, amine C16, amine C17 and amine C18; terpolymer is synthesized; and then, terpolymer is compounded with vegetable-oil-modified phosphate ester, so that the amphoteric retanning fatting agent is generated. The retanning fatting agent has the double functions of retanning and fatting; technological time can be shortened; and in addition, due to the amphoteric structure of the retanning fatting agent, bleaching cannot occur, and besides, other chemical materials can be assisted in permeation and absorption.

Owner:汤普勒新材料嘉兴有限公司

Device and method for producing biodiesel with illegal cooking oil and waste engine oil

InactiveCN103013554AGood choiceReduce sulfur contentBiofuelsLiquid hydrocarbon mixture productionFixed bedGasoline

The invention provides a device and a method for producing biodiesel with illegal cooking oil and waste engine oil. The device comprises an illegal cooking oil settling tank, a waste engine oil settling tank, a mixer, a heat exchanger, a tower-type fixed bed reactor, a condensing system, a gas storage tank, a diesel tank and a gasoline tank, wherein the mixer is connected with the heat exchanger; the heat exchanger is connected with the lower part of the tower-type fixed bed reactor through a preheater; and the condensing system is connected with the heat exchanger. The method comprises the following steps: pretreating, performing catalytic cracking reaction and collecting a product. The produced biodiesel is light yellow in color, has the condensing point of about minus 5 DEG C, has good low temperature fluidity, has a heat value far higher than that of the conventional biodiesel, and has stable product quality; environment pollution is reduced, and a decoloring step is not required; the tower-type fixed bed reactor is applied to the catalytic cracking reaction, so that the method has the advantages of convenience in heating, small investment, easiness in control of treatment amount and low operating cost; and a catalyst can be recycled, so that the device and the method are suitable to be popularized and applied.

Owner:青岛福瑞斯生物能源科技开发有限公司

High-efficiency environment-friendly acidic soap washing agent, and preparation method thereof

ActiveCN110499218AGood anti-staining effectStrong dispersion abilityCationic surface-active compoundsOrganic detergent compounding agentsAcrylic acidSulfonic acid ester

The invention belongs to the field of fine chemistry, and more specifically relates to a high-efficiency environment-friendly acidic soap washing agent, and a preparation method thereof. The high-efficiency environment-friendly acidic soap washing agent comprises, by mass, 10 to 30 parts of carboxyalkylthiosuccinic acid, 30 to 50 parts of acrylic acid-2-acrylamido-2-methyl propyl sulfonic acid (AA / AMPS) copolymer 20 to 50 parts of sodium gluconate, 5 to 10 parts of hydrolytic polymaleic anhydride, 0.1 to 2 parts of a surfactant, 0.5 to 10 parts of a complexing agent, and 30 to 50 parts of water. When the high-efficiency environment-friendly acidic soap washing agent is used in cotton and cotton blended fabric reactive dye dying, surface dyeing removing effect is better, and fabric color fastness and brightness are ensured; the high-efficiency environment-friendly acidic soap washing agent contains no nitrogen and phosphorus, and is relatively high in acidity, so that the acid neutralizing process before common soaping can be avoided, waste discharge amount is reduced, human labor is saved, electricity cost is reduced, and better market advantages are achieved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

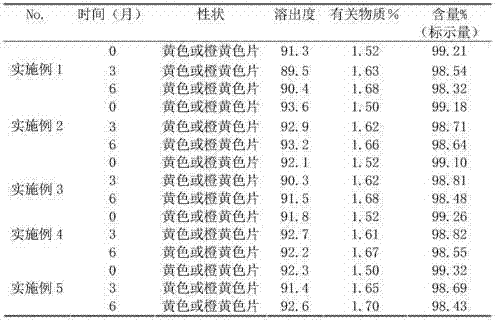

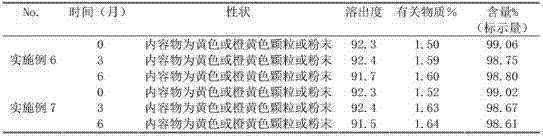

Folic acid pharmaceutical composition for preventing administration

InactiveCN104116743AReduce drying stepsReduced granulation processOrganic active ingredientsNervous disorderMedicineEnergy consumption

The invention relates to a folic acid pharmaceutical composition for preventing administration, and a preparation method thereof. A preparation of the composition adopts a dry granulation process, so that the manufacturing process is simplified, the energy consumption and the total production cost can be reduced, the output per unit time, the product quality and the like are improved, and the stability of the medicine storage period and the clinical safe medication are kept.

Owner:YANTAI ZHONGZHOU PHARMA CO LTD

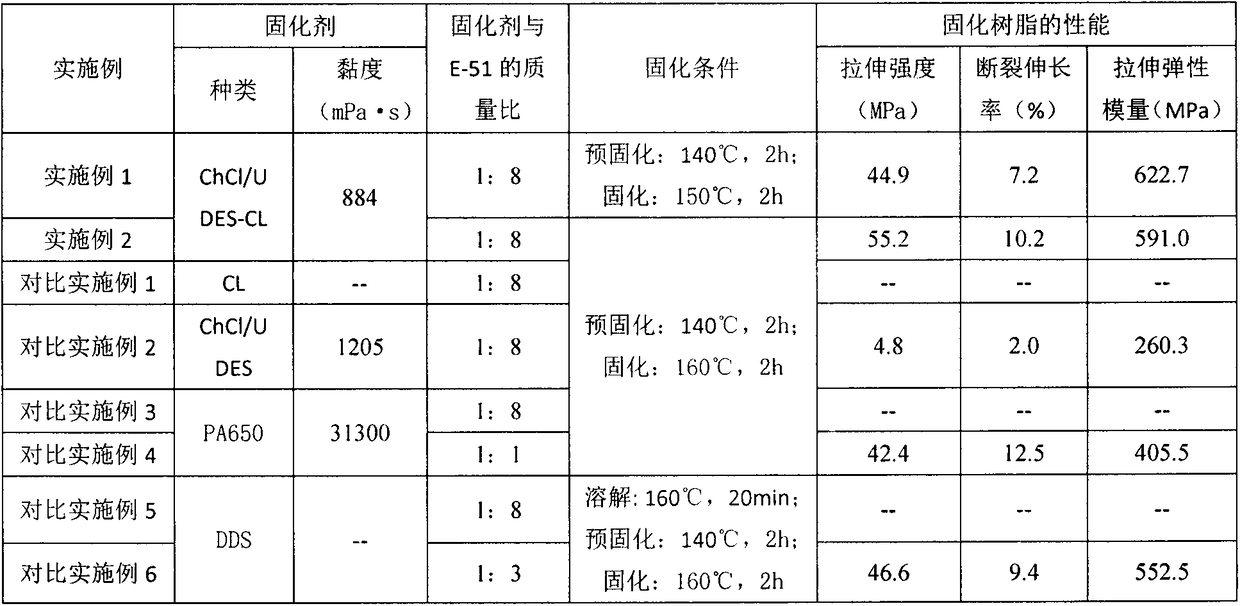

Method of deep eutectic solvent modified lignin for epoxy resin curing agent

The invention relates to a preparation method of deep eutectic solvent modified lignin for an epoxy resin curing agent. The preparation method comprises the following steps: adding choline chloride and another raw material into a sealed container in a certain molar ratio, and stirring at 30-100 DEG C until reaction liquid is transparent, so as to obtain a deep eutectic solvent (DES); processing lignin at 60-140 DEG C for 1-12 hours, so as to obtain a mixture of modified lignin and DES, namely the epoxy resin curing agent. The preparation method is characterized in that after lignin is processed by virtue of multiple synergistic effects of salvation, catalysis, activation and the like of cheap and non-toxic choline chloride series DES, lignin can be directly taken as the epoxy resin curingagent without being separated, so that the separation, washing and regeneration steps after traditional activation treatment of lignin are reduced, and the process is simple and easy to control; and the prepared epoxy resin curing agent has the advantages of no toxin, low viscosity, use amount and price and good operability and usability.

Owner:NANJING FORESTRY UNIV

Preparation method for zinc oxide nano particles

InactiveCN102153131AEasy to buyNo pollutionZinc oxides/hydroxidesNanotechnologyAlcoholDistilled water

The invention discloses a preparation method for zinc oxide nano particles, relating to the preparation field of inorganic nonmetal nanometer materials. The preparation method includes the steps as follows; firstly preparing zinc source dispersion solution and oxygen source dispersion solution; adding the oxygen source dispersion solution in the zinc source dispersion solution under the condition of 70-80 DEG C and the dropping time of the oxygen source dispersion solution is 90-120 minutes; reacting to generate white precipitates; later, conducting centrifugal separation on reactant to obtain precipitates; washing, centrifugating and drying the obtained precipitates by distilled water, water-ethanol mixed liquor and absolute ethyl alcohol in sequence; and roasting the obtained precipitates for 3-5 hours at the temperature of 350-470 DEG C to obtain the zinc oxide nano particles. The preparation method has low cost, recyclability, simple equipment, simple and easily-controlled operation conditions, no environment pollution, no toxicity and no harm, and is convenient to large-scale production.

Owner:LUOYANG NORMAL UNIV

Buoy

A buoy (1) has a main body (5) and a moveable mass (2) positioned inside the main body. The buoy may be tethered to a submarine vessel and used as a communications buoy. The buoy may be configured for floating in a generally upright orientation at the water surface (7) in a position ready for communication, when the mass (2) is in a first position (FIG. 1a) in which the center of mass is offset from the center of buoyancy to improve stability in the water. The buoy may be configured for being towed underwater at speed, when the mass is in a second position (FIG. 1b), in which the center of mass is closer to the center of buoyancy, to improve towing stability in the water, thereby allowing the buoy to be towed with its long axis substantially aligned with the direction of motion, thereby reducing wake / plume in the water.

Owner:BABCOCK IP MANAGEMENT NUMBER ONE LTD

Blood platelet magnetizing and immunolabeling analysis method

InactiveCN103323586AAvoid non-specific adsorptionEasy to judgeBiological testingDouble phaseMagnetic bead

The invention discloses a blood platelet magnetizing and immunolabeling analysis method. The method comprises the following steps: uniformly mixing blood platelets and magnetic beads; magnetizing the blood platelets to obtain suspension; uniformly mixing, incubating and washing the magnetized blood platelets and a detected sample; adding a labeled second antibody and incubating to obtain mixed liquid; applying magnetic force to layer the mixed liquid; determining upper reaction liquid or determining after washing the magnetized blood platelets in the lower layer to obtain a result, namely performing double-phase complementary immune analysis. In the mode, the blood platelet magnetizing and immunolabeling analysis method provided by the invention is used for detecting blood platelet related antigen antibody and cross-matching of blood; the magnetic force is applied so that the magnetized blood platelet is washed without centrifuging; the method is easy and convenient to operate; by a labeled antibody adsorption test for directly determining the upper reaction liquid, the non-specific adsorption in an immunolabeling technology is overcome, the processes of closing and washing are reduced, and the time consumption is short. The method can detect a large number of samples and facilitates automation; the two detection results of the double phases can be verified mutually, so that the accuracy of the detection results is improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

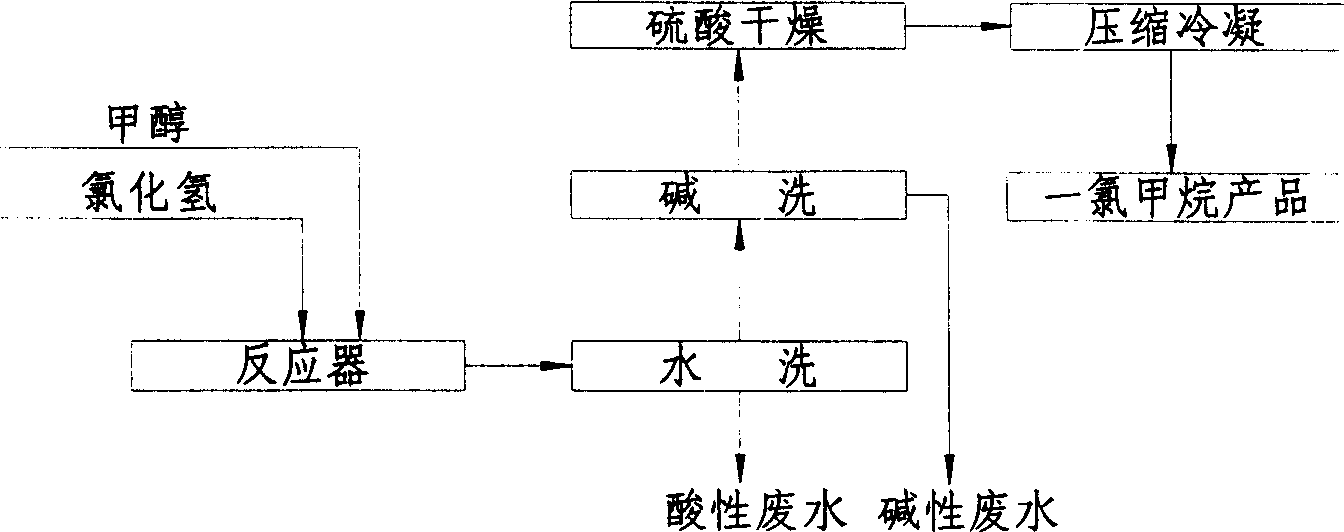

Preparation method of methane chloride

InactiveCN1686981ANo pollution in the processReduce washingHalogenated hydrocarbon preparationAlcoholGas phase

The present invention discloses a preparation method of methane chloride. It uses methyl alcohol and hydrogen chloride as raw material, in the pressure of active catalyst, under the condition of 260-320 deg.C and 0.2-0.6 MpaG it utilizes gas-phase reaction of obtain methane chloride and water, after the high-temperature reaction gas discharged from reactor is chilled by dilute hydrochloric acid, the separated humid gas is condensed by means of condenser, dried by utilizing sulfuric acid, compressed and condensed so as to obtain methane chloride.

Owner:江苏梅兰化工有限公司

Reactive dyeing post-treatment method of viscose fibers without color fixing treatment

ActiveCN101736617AEmission reductionLow costDry-cleaning apparatus for textilesDyeing processEcological environmentHigh energy

The invention discloses a reactive dyeing post-treatment method of viscose fibers without color fixing treatment, which can solve the technical problems of a plurality of washing times, large water consumption and high energy consumption in the reactive dyeing post-treatment of the viscose fibers, thereby achieving the purposes of saving energy, reducing consumption, improving efficiency and improving quality. The method changes the post-treatment procedures of the post-treatment dyeing into the procedures of water washing, soaping, water washing and oiling through the application of a complex soaping agent of XC-W in the reactive dyeing post-treatment of the viscose fibers, thereby leading the post-treatment to eliminate the color fixing treatment by using a color fixing agent, reducing the times of water washing, shortening the process time, effectively eliminating floating color on the surface of the dyed fibers, improving the color fastness to washing of dyed fabric, being conductive to unwinding of the reeled dyed fabric, reducing the burden on printing and dyeing wastewater treatment and being conductive to ecological environment protection.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Preparation method of desizing and scouring compound enzyme

InactiveCN107653686AReduce washingReduce dosageBiochemical treatment with enzymes/microorganismsGrip property fibresFiberWastewater

The invention discloses a preparation method of desizing and scouring compound enzyme. The prepared desizing and scouring compound enzyme effectively removes starch size and pectin on cotton fiber andother impurities on the surface of cotton fiber that influence dyeing property, and endows fabrics with good wetability. The desizing and scouring compound enzyme can simultaneously complete desizingand scouring by one step. Thus, processing procedures of dyeing factories is reduced, production efficiency is raised, and production cost is lowered. Process innovation is realized, and current production process can be changed. In addition, traditional high-temperature soda boiling is avoided, discharge amount of wastewater is reduced, and energy conservation, water conservation and emission reduction are realized, thus meeting the energy conservation and emission reduction requirements for green printing and dyeing. The desizing and scouring compound enzyme can meet requirements of pretreatment of dyeing factories, also can make the process to be energy-saving and environmentally-friendly, and is an ideal choice for pretreatment processing of dyeing factories.

Owner:WUXI JIAJIA NANO TECH

Cold-pad batch dyeing process of loose fibers

InactiveCN105671833ASmall particlesImprove dye uptakeTextile storage in superimposed formLiquid/gas/vapor removalFiberCavitation

The invention provides cold-pad batch dyeing process of loose fibers. The process comprises following steps: supersonic wave dyeing through pressing extraction, rotary cold-batch, water extraction through pressurization and aftertreatment. In the ultrasonic treatment, dyes are placed into an ultrasonic dyeing machine for increasing temperature. After supersonic waves are started, carboxylic carbon nanospheres and levelling agents are added and stirred for dyeing by putting loose fibers.Due to effect of acoustic cavitation of supersonic waves, loose fibers maintain their smaller particle with dispersibility not affected by temperature control. The manufacturing process is simple and helps save water and cost. Meanwhile, carboxylic carbon nanospheres and physical absorption and hydrogen bond combination performance of dyes as well as chemical effect of active groups of carboxylic carbon nanospheres, combination degree of dyes and loose fibers is increased and therefore dye rate is improved and up to more than 95%.

Owner:朱忠良

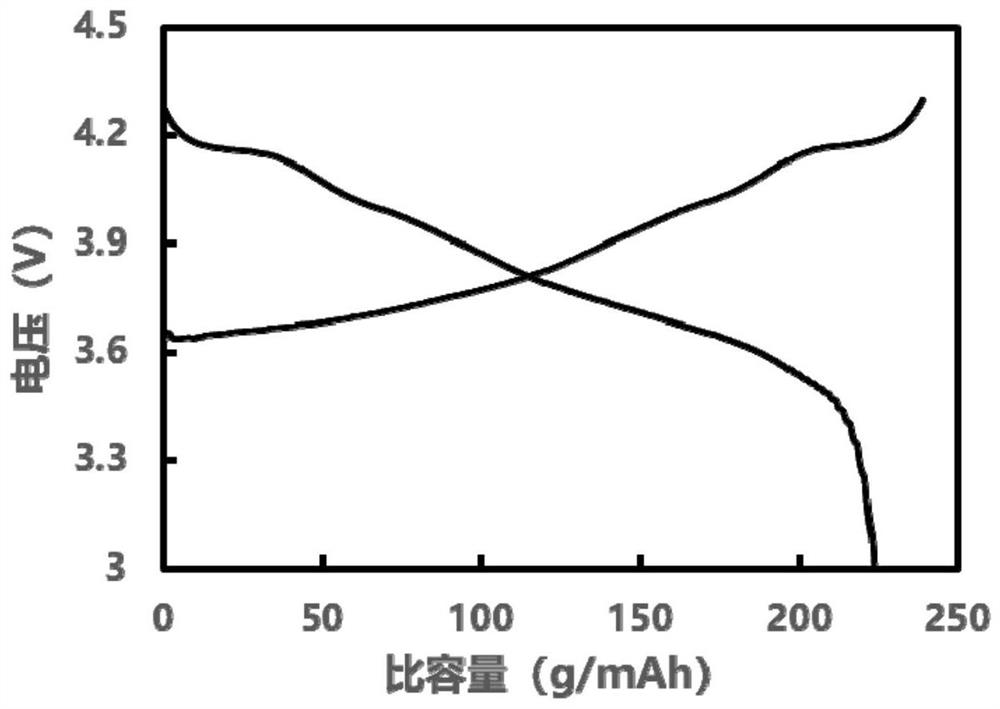

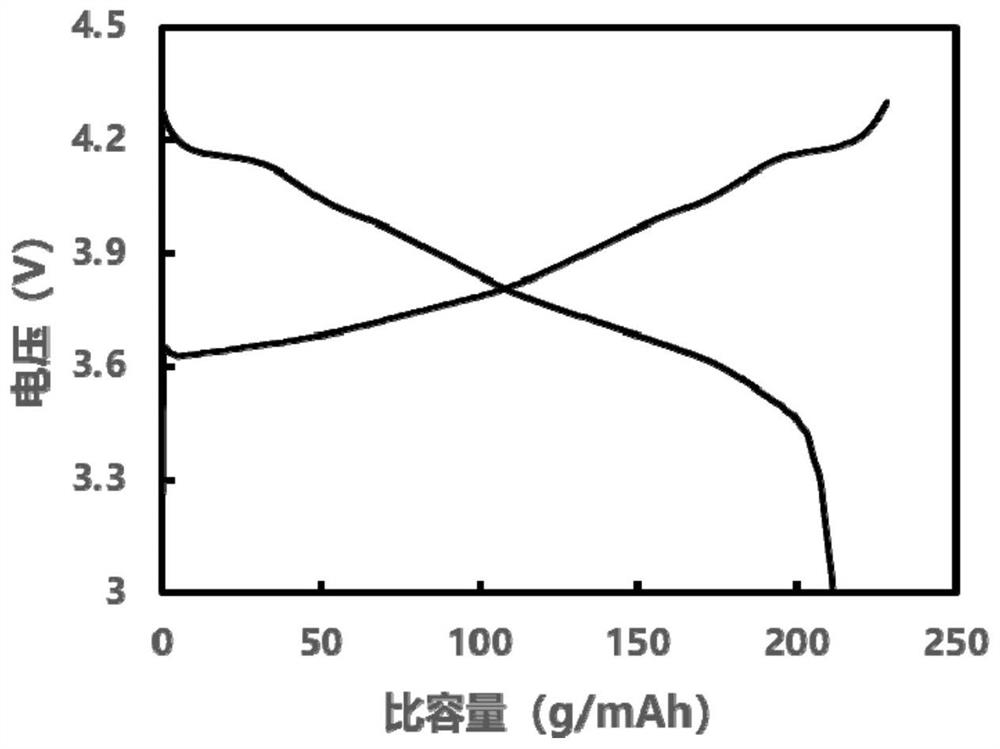

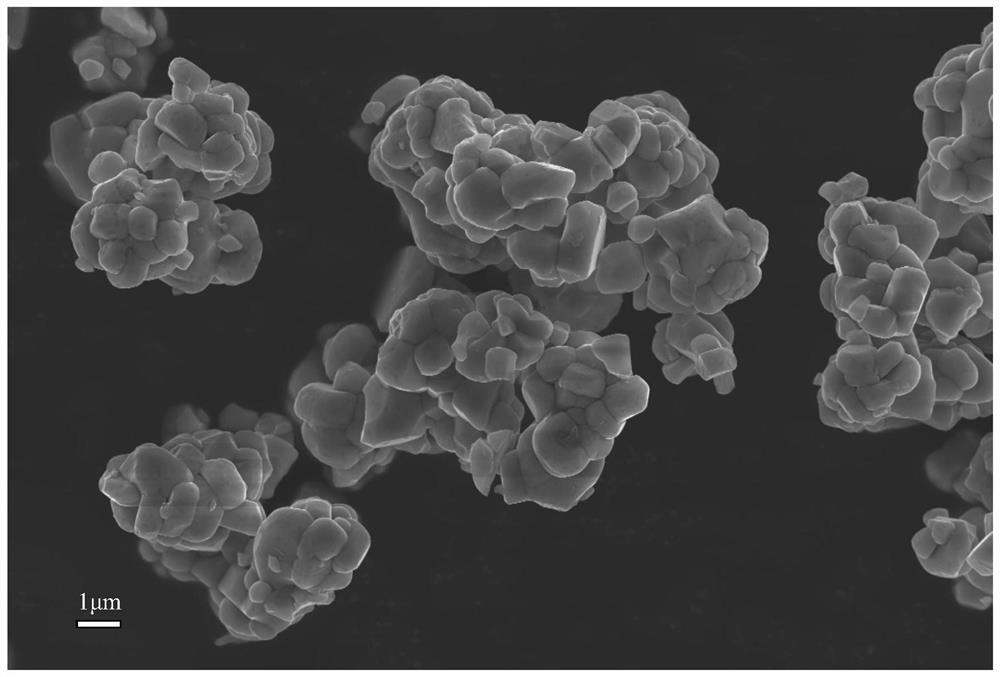

Ultrahigh nickel single-crystal positive electrode material and preparation method thereof

PendingCN113839015AImprove cycle stabilityPromote crystallization co-growthSecondary cellsPositive electrodesManganeseSingle crystal

The invention belongs to the technical field of lithium ion battery positive electrode material preparation, and particularly relates to an ultrahigh nickel single crystal positive electrode material and a preparation method thereof. According to the invention, an ultrahigh nickel positive electrode material precursor (nickel-cobalt-manganese-aluminum hydroxide) is used as a matrix raw material, the precursor is fully crushed by using the acting force of high rotating speed and high pressure, and a lithium source and strontium carbonate are added during the period, so that the lithium source and the precursor are promoted to be mutually dissolved and then crystallized and co-grown at a relatively low temperature, the lithium-nickel mixing is reduced, and finally, calcining is performed to obtain the single-crystal-like material. The monocrystal-like material provided by the invention is uniform in size and high in particle strength, and the cycling stability of the material is enhanced. The technical problems that due to the fact that the nickel content in the ultrahigh nickel material is high, nickel in generated mono-like crystals is severely separated out due to high-temperature calcination, the later battery capacity fades, the residual alkali content is high and the like in the preparation process of the ultrahigh nickel mono-like materials are solved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com