Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Reduce the difficulty of washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

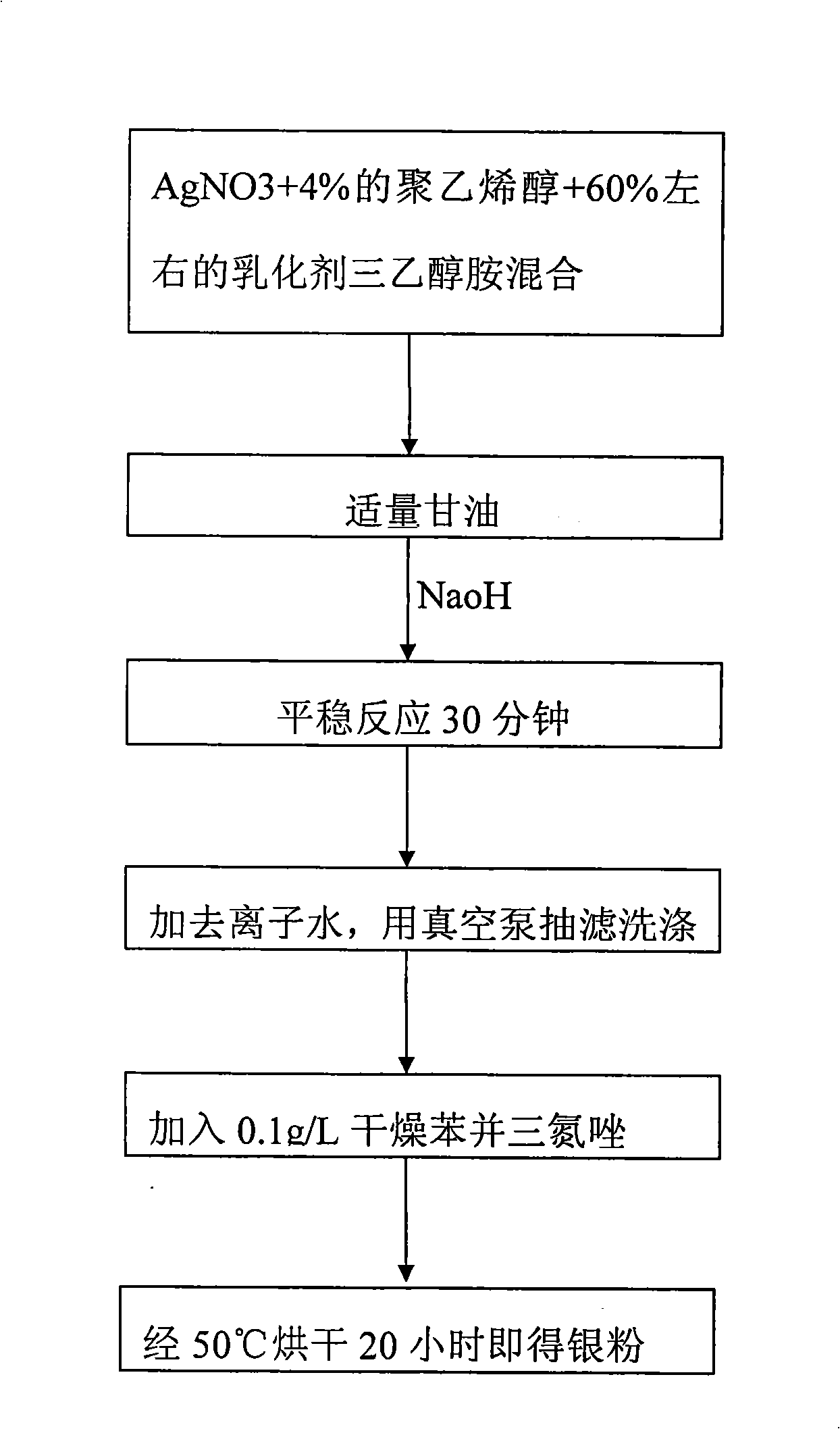

Method for preparing nano silver powder

The invention discloses a method for preparing nanometer silver powders. The method comprises the following steps: a. mixing AgNO+, 4 percent of polyvinyl alcohol and about 60 percent of emulsifier triethanolamine; b. adding proper amount of glycerol into the mixture; c. smoothly reacting the mixture for 30 minutes; d. adding deionized water into the mixture, and performing pumping filtration washing on the mixture through a vacuum pump; e. dehydrating the mixture by using anhydrous alcohol; f. adding 20 to 50 milliliters of 0.1 gram per liter dried protective agent benzotriazole after the dehydration; and g. drying the mixture for 18 to 24 hours at a temperature of 50 DEG C to obtain the nanometer silver powders of which the particle diameter is between 50 and 100 nanometers. The method for preparing the nanometer silver powders has the advantages of simple production process, low production cost, low investment of equipment, easy process control, and high yield.

Owner:桐柏鑫泓银制品有限责任公司 +1

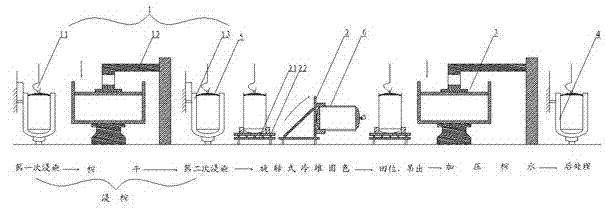

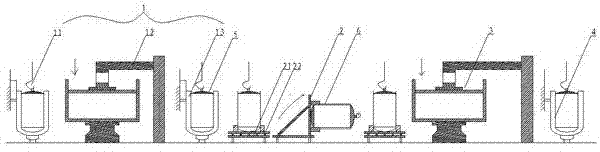

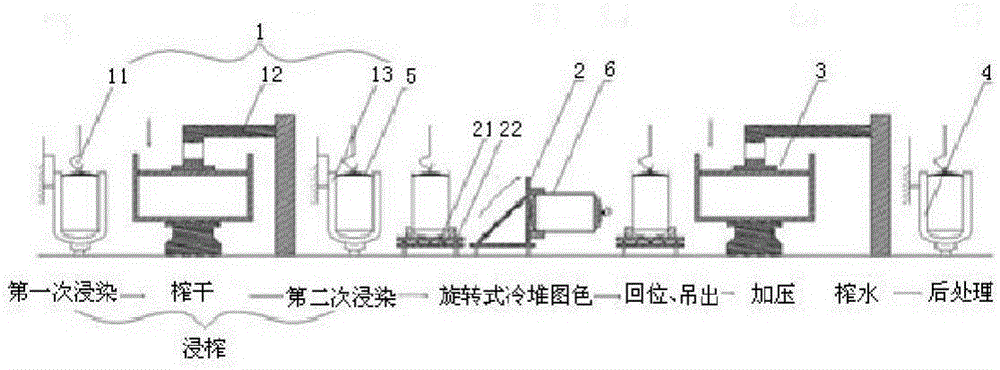

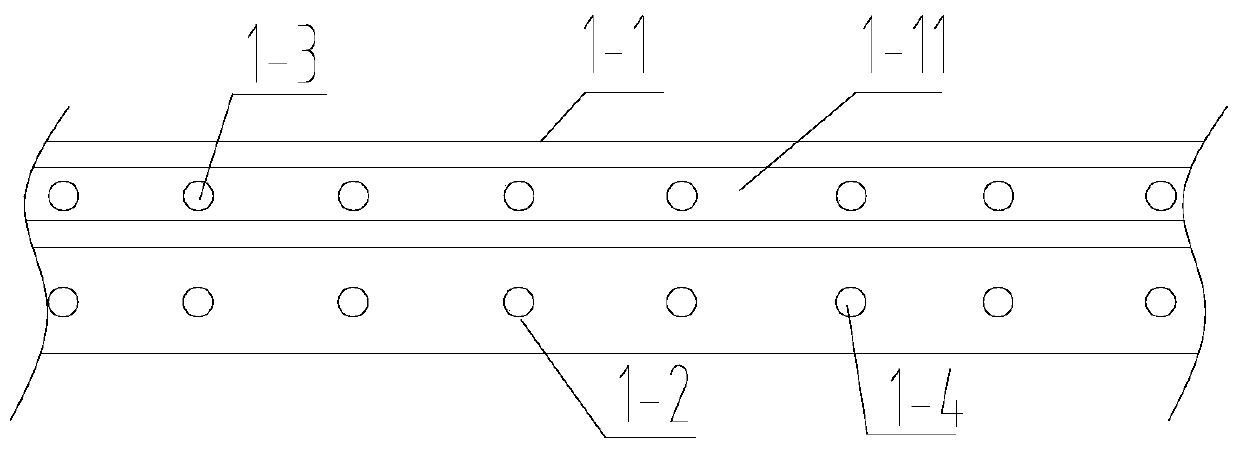

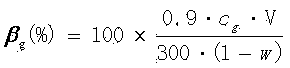

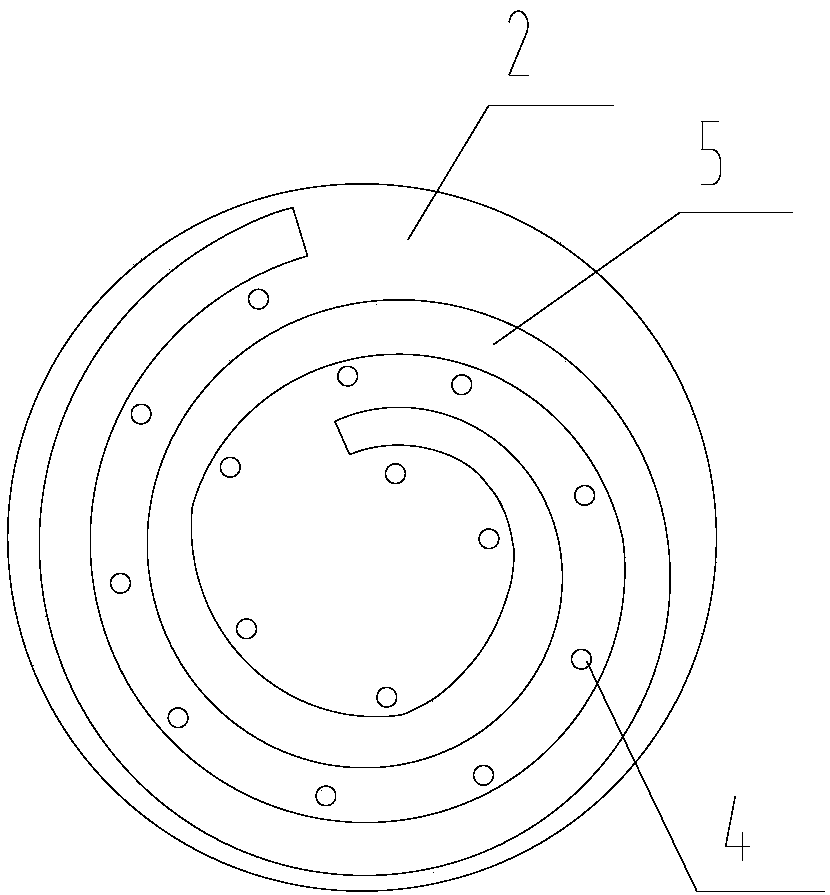

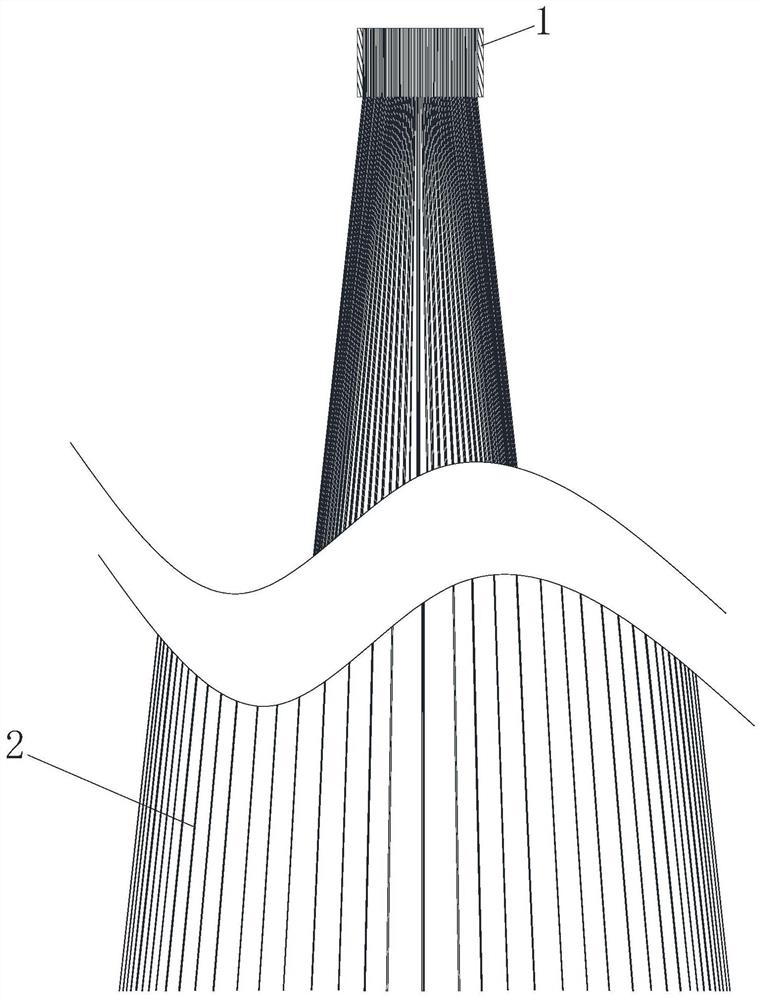

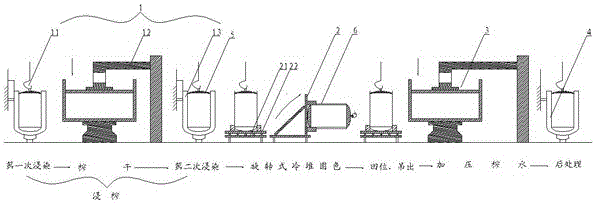

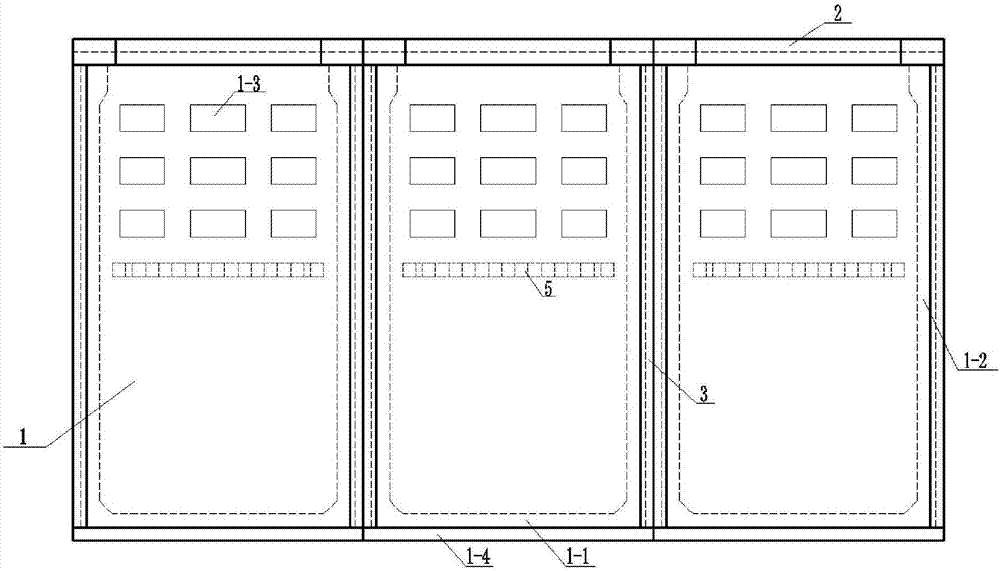

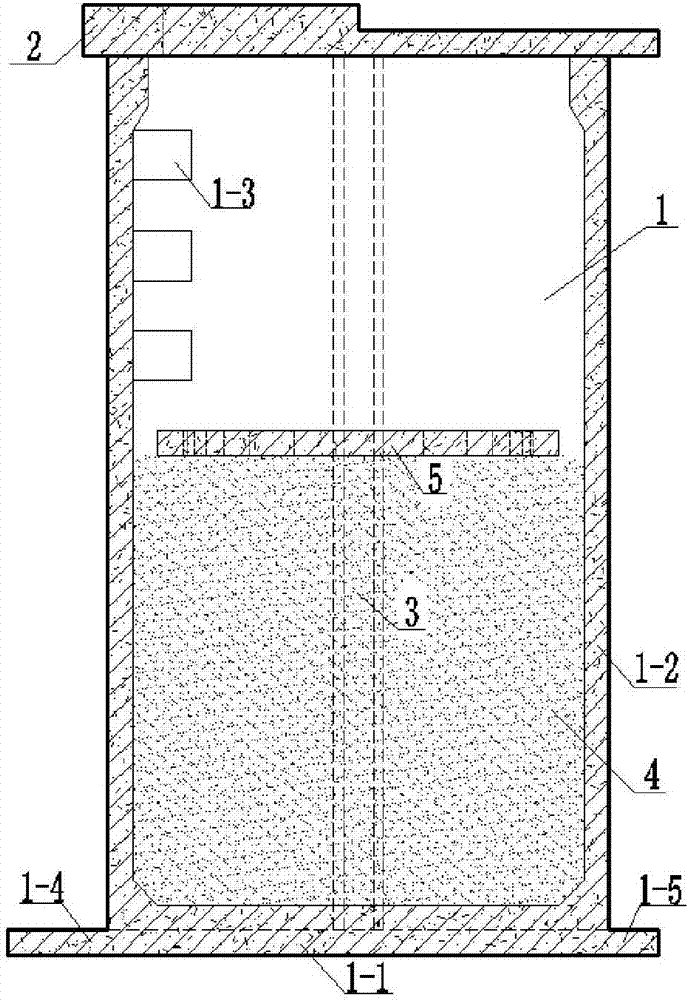

Cold-pad batch dyeing process for loose fibers

ActiveCN103774363AEvenly distributedPromote absorptionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberPolymer science

The invention belongs to the technical field of loose fiber dyeing and relates to cold-pad batch dyeing process for loose fibers. The cold-pad batch dyeing process for loose fibers comprises the steps of soaking and squeezing, rotating type cold-patch treatment, pressing and water squeezing and post-treatment. The loose fibers are soaked and squeezed in a twice soaking and once squeezing mode, the rotating type cold-patch treatment is then conducted, the loose fibers are pressed and water is squeezed out after the rotating type cold-patch treatment is conducted, and after the water and dye in a loose fiber cake or loose fibers are squeezed out, the loose fiber cake or loose fibers are sent for post-treatments of drying and the like. The cold-pad batch dyeing process for loose fibers is applied to cold-pad batch dyeing of the loose fibers and has the advantages of being uniform in dyeing, small in water consumption and the like. In addition, procedures are simple.

Owner:绍兴国周针织科技有限公司

Polyphenylene sulfide resin synthesis process

ActiveCN109535426AReduce the content of metal ionsImproved performance characteristicsSynthesis methodsSodium hydrosulfide

The invention discloses a polyphenylene sulfide resin synthesis process, which aims to obtain a resin synthesis method with good particle formation, high product yield, high solvent recovery rate, andreduced corrosion degree of a polymerization reaction device. The method adopts sodium sulfhydrate containing sodium crystallization, sodium hydroxide, and p-dichlorobenzene as raw materials, and takes N-methylpyrrolidone as a solvent, and a condensation polymerization reaction is carried out in a synthesis system, after the low temperature and high temperature polycondensation is completed, acetate, NMP and an aqueous solution are added by a high-pressure pump, then the materials are insulated at a high temperature, cooled, and filtered, and a filter cake is purified by a NMP solvent, repeatedly washed with deionized water and filtered, and the filter cake is dried to obtain the polyphenylene sulfide resin. The polyphenylene sulfide resin synthesized by the invention is widely used in the fields of aerospace, electronic machinery, petrochemical, food, light industry, thermal power generation, cement industry, steel manufacturing, environmental protection, textile industry and the like.

Owner:德阳科吉高新材料有限责任公司

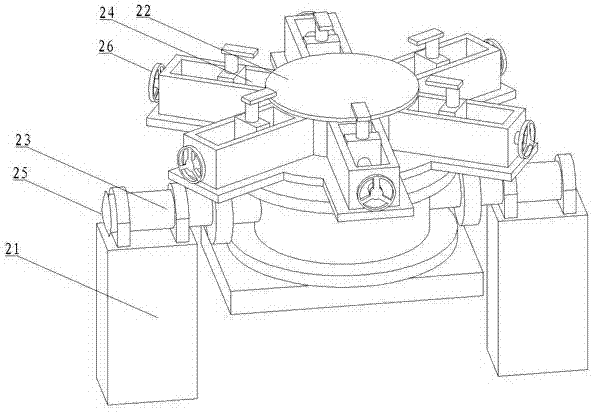

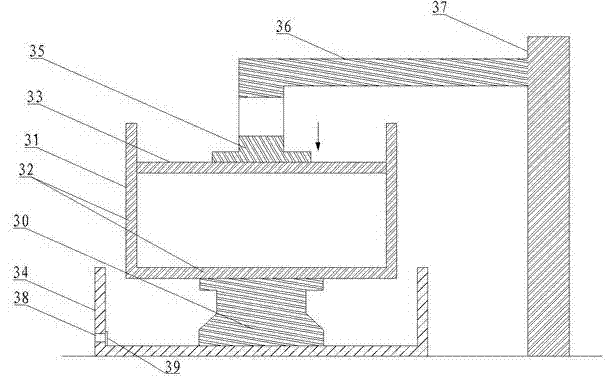

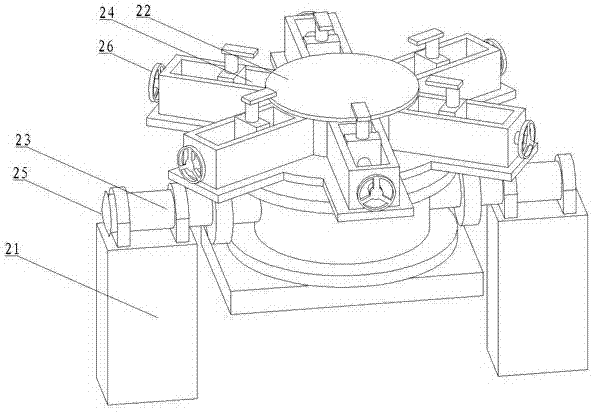

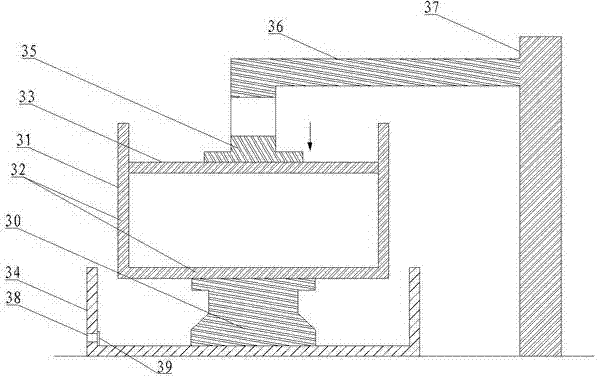

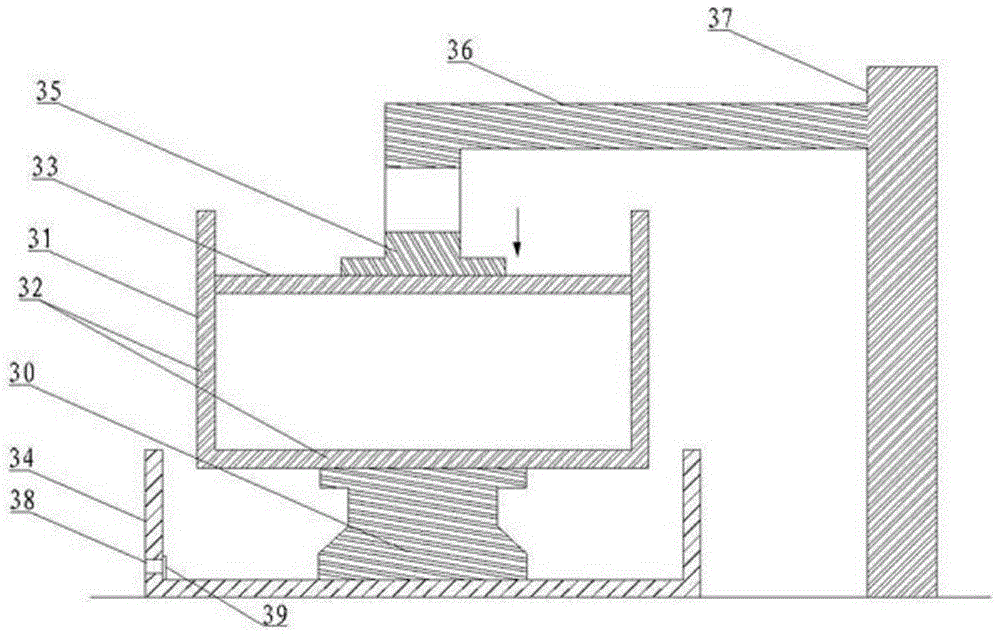

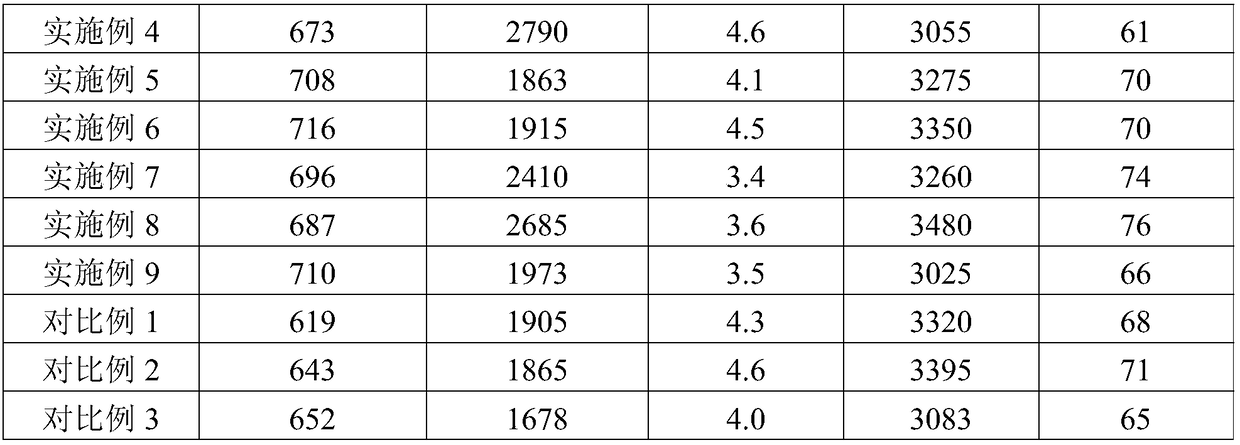

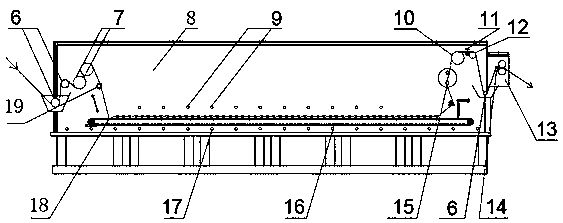

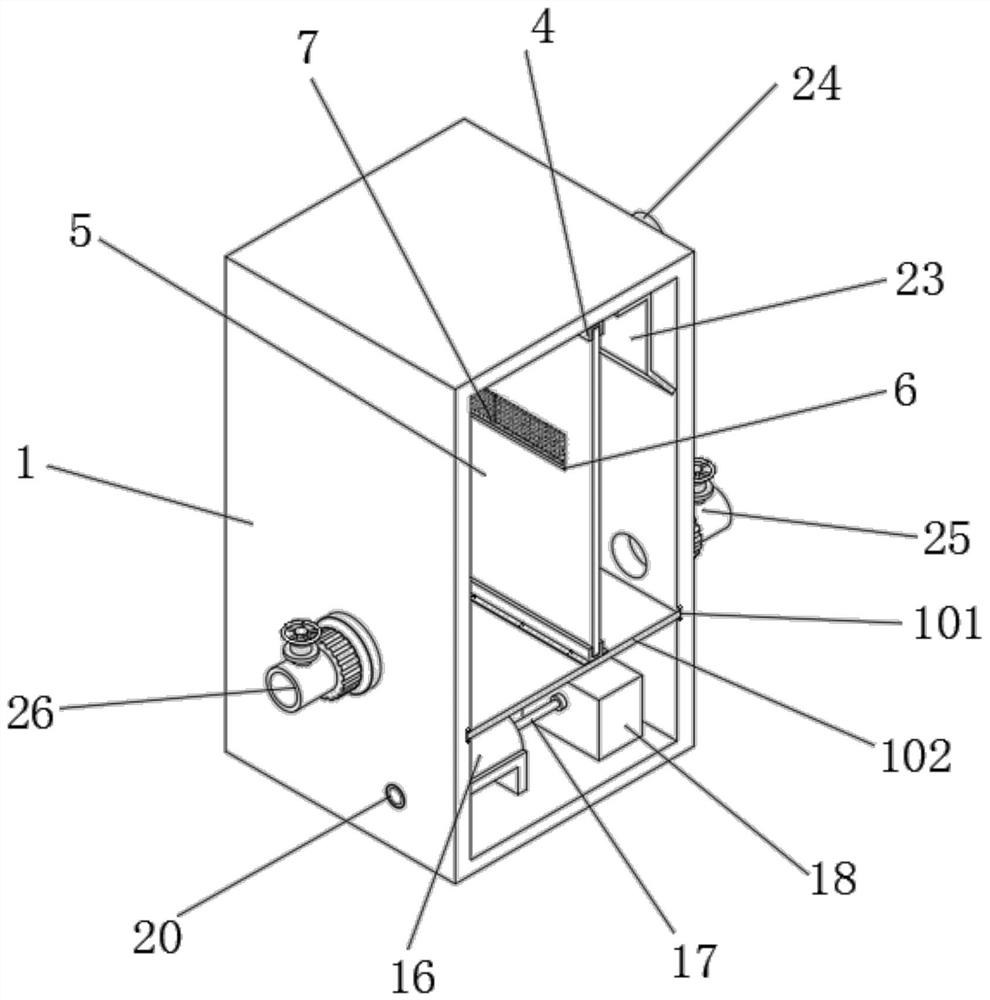

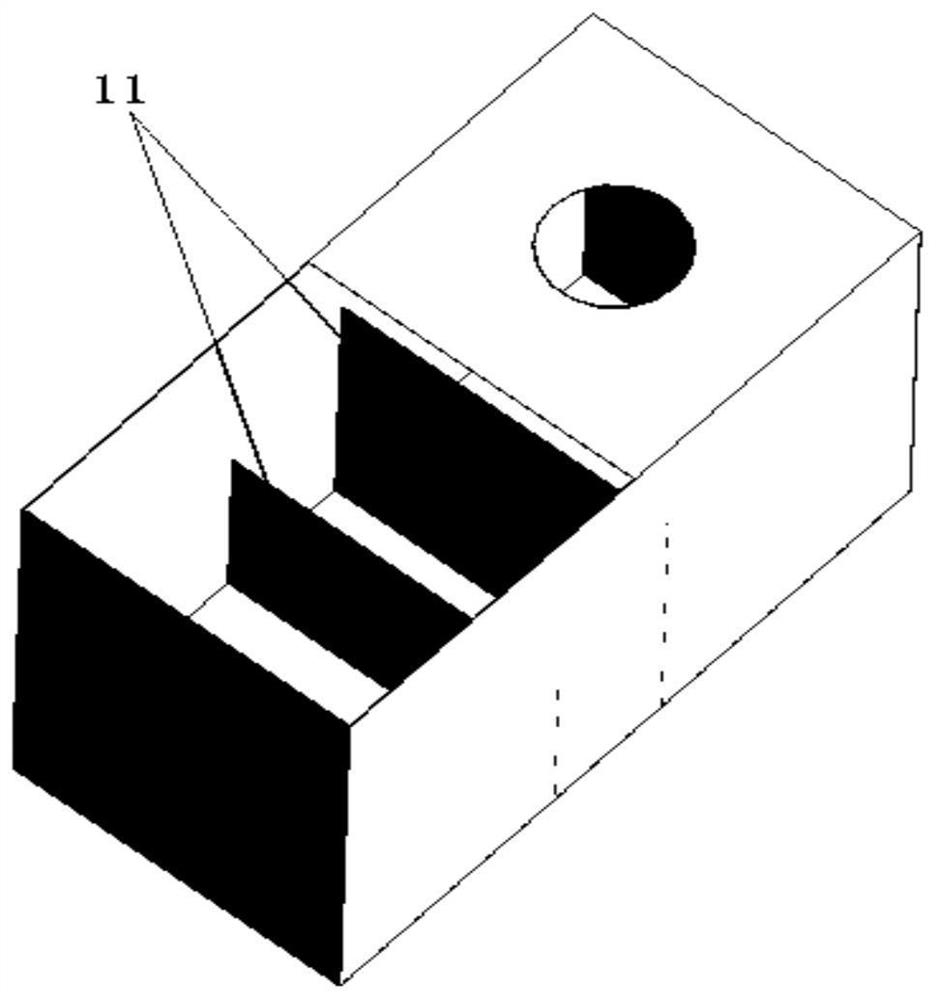

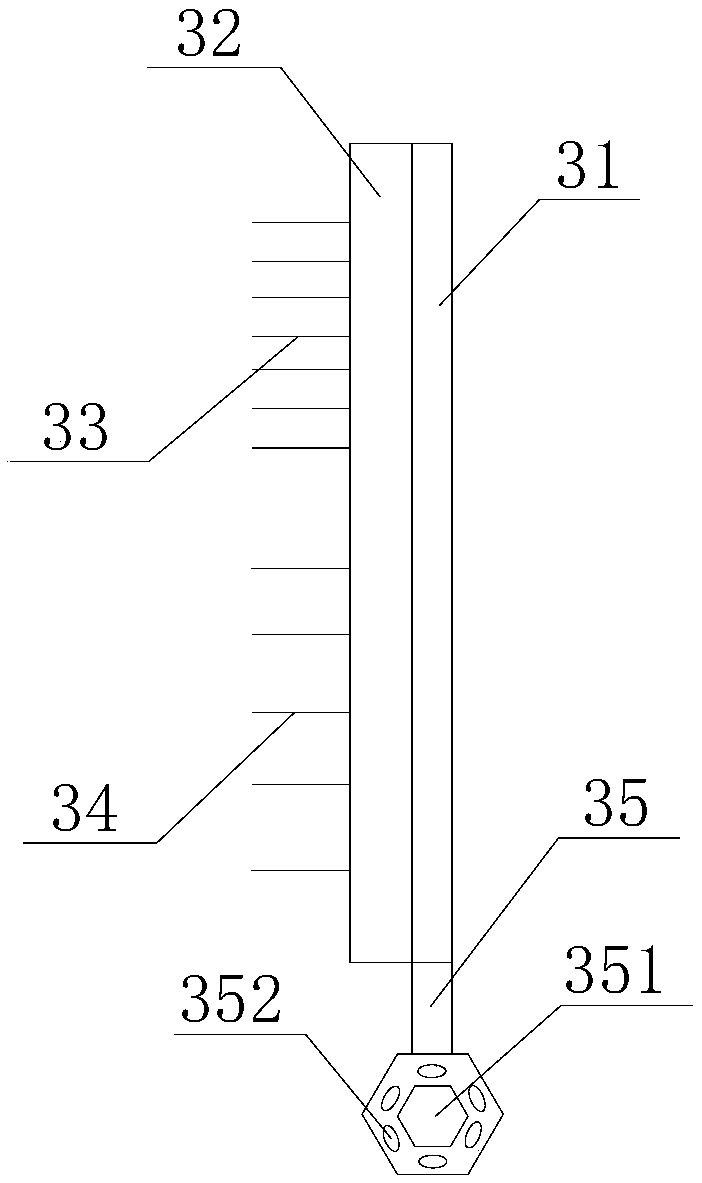

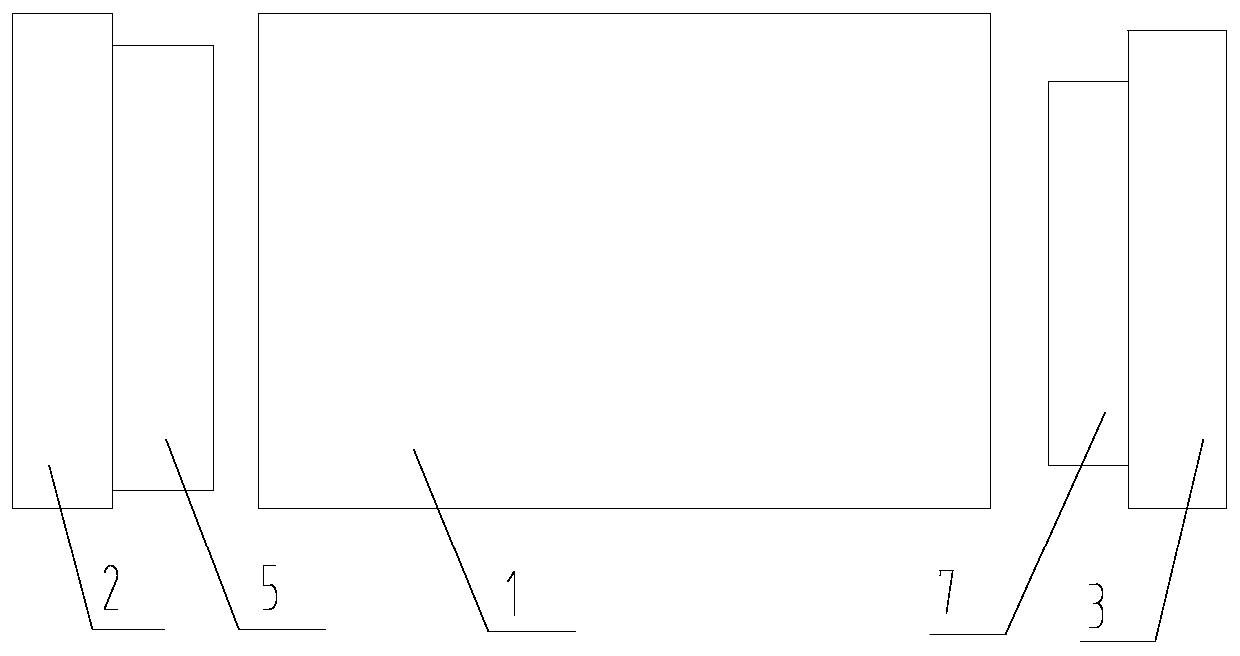

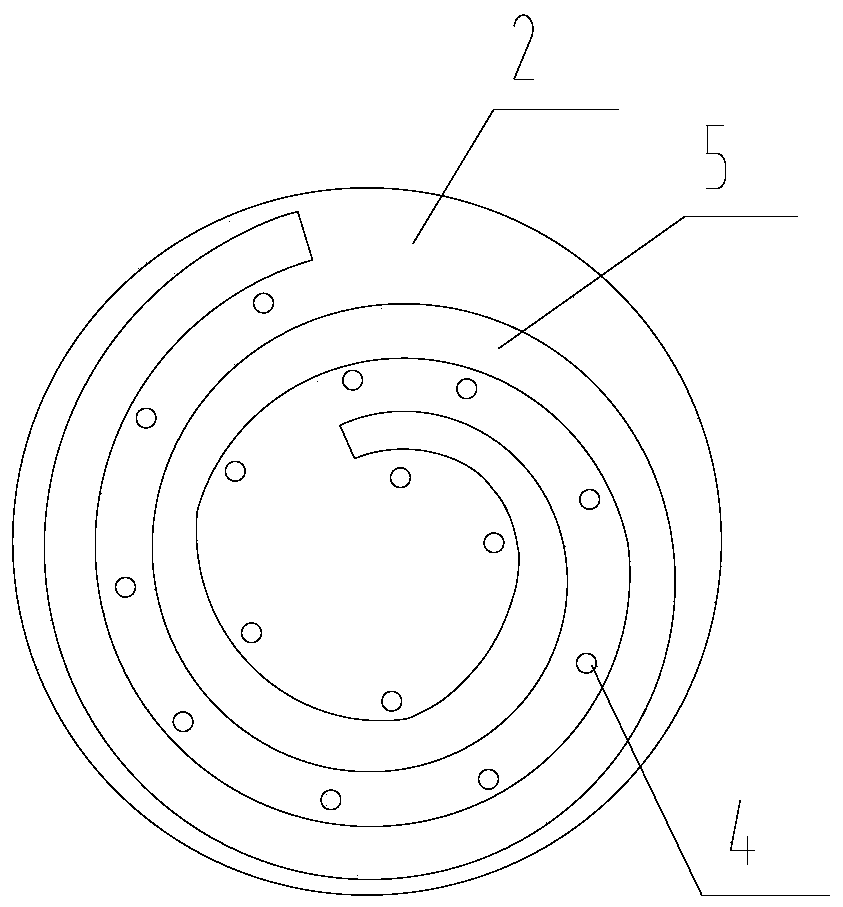

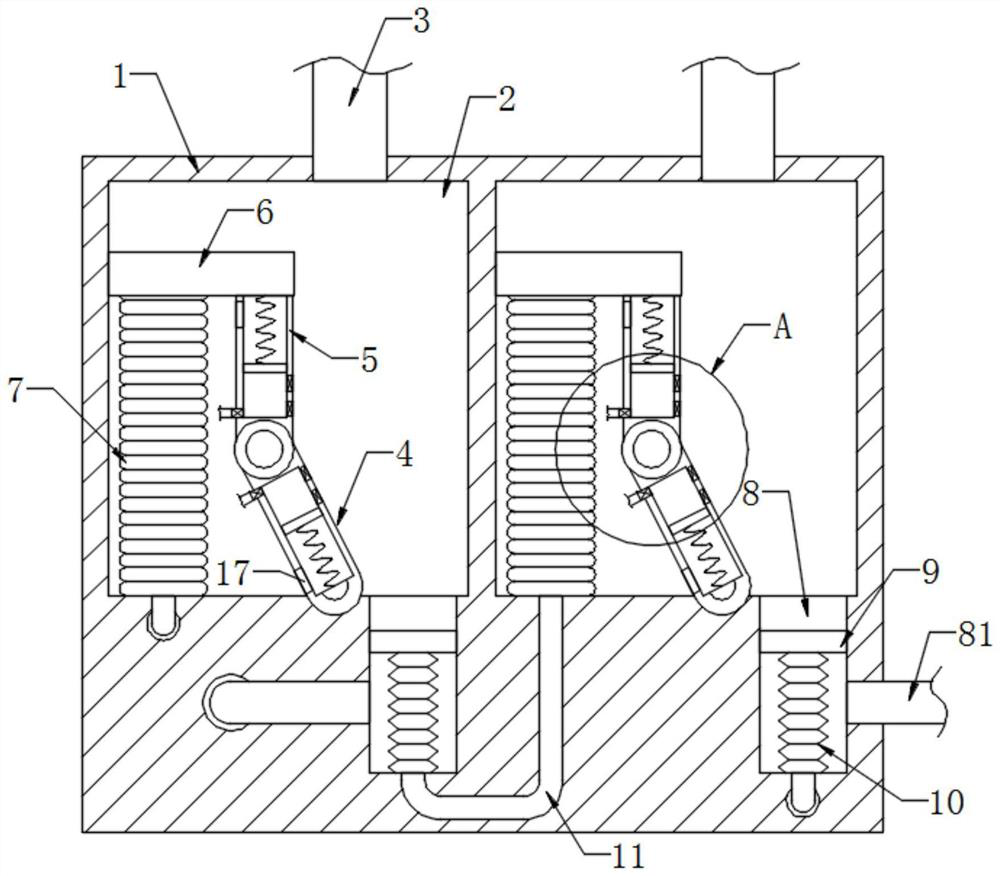

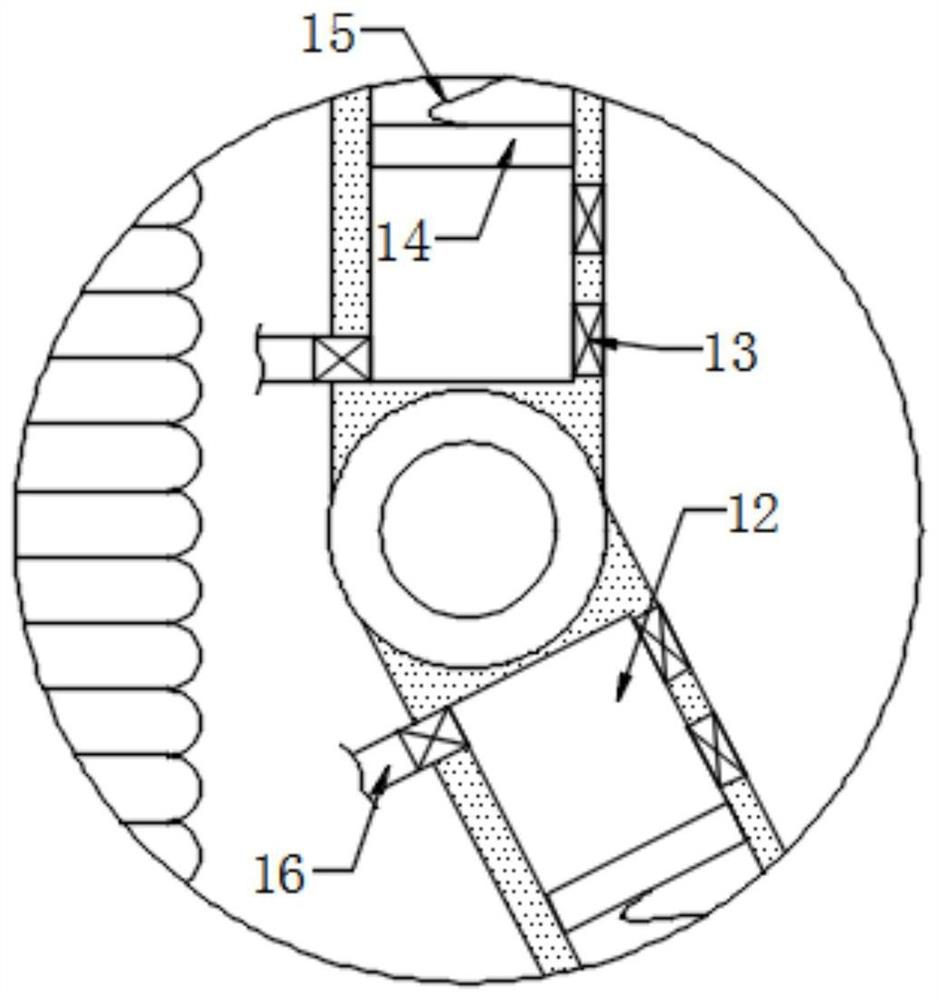

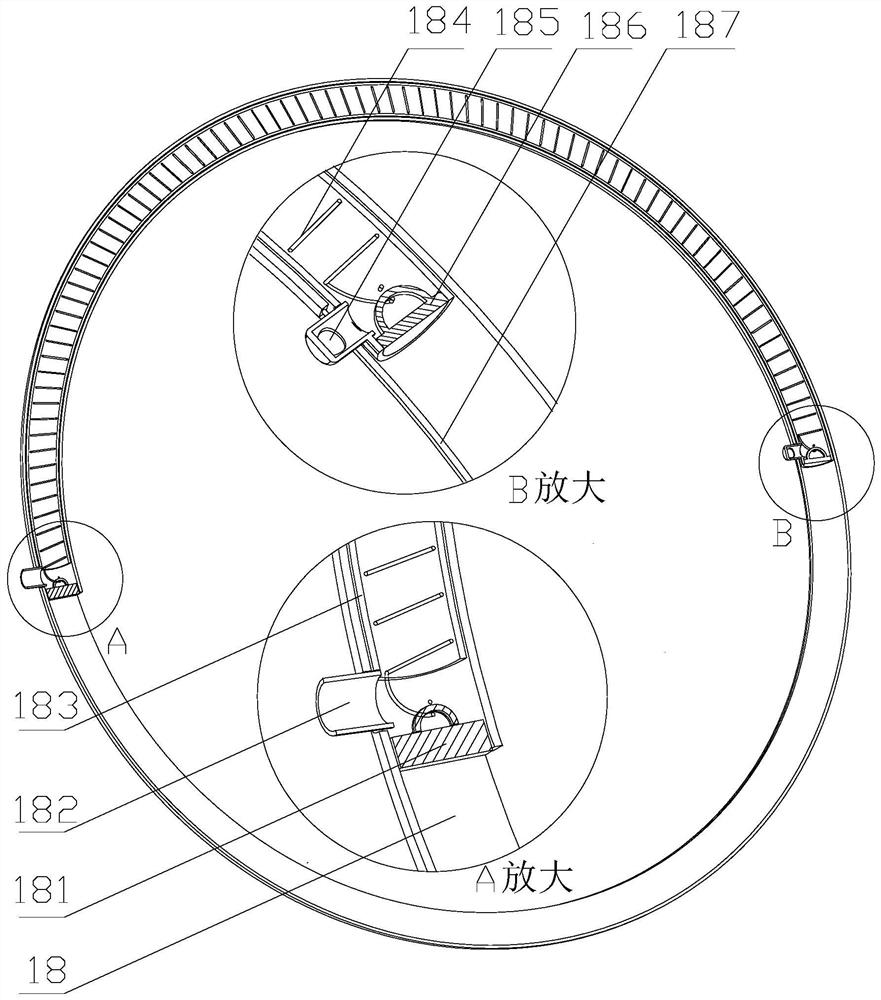

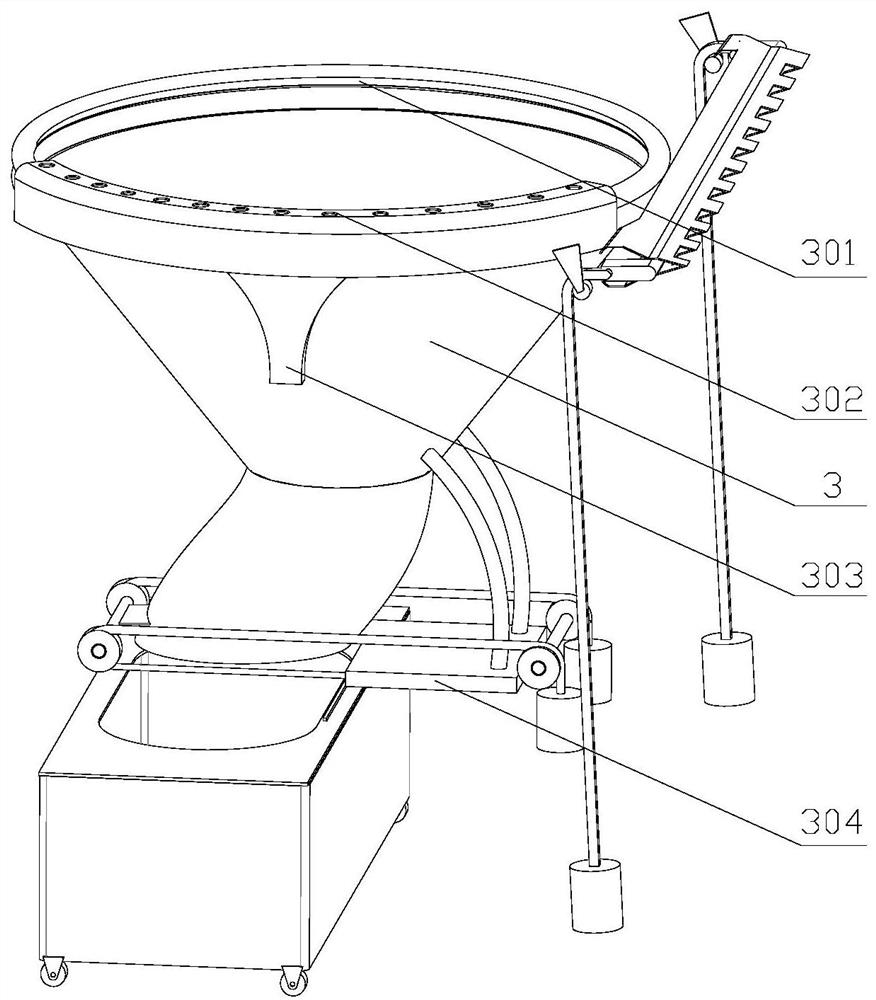

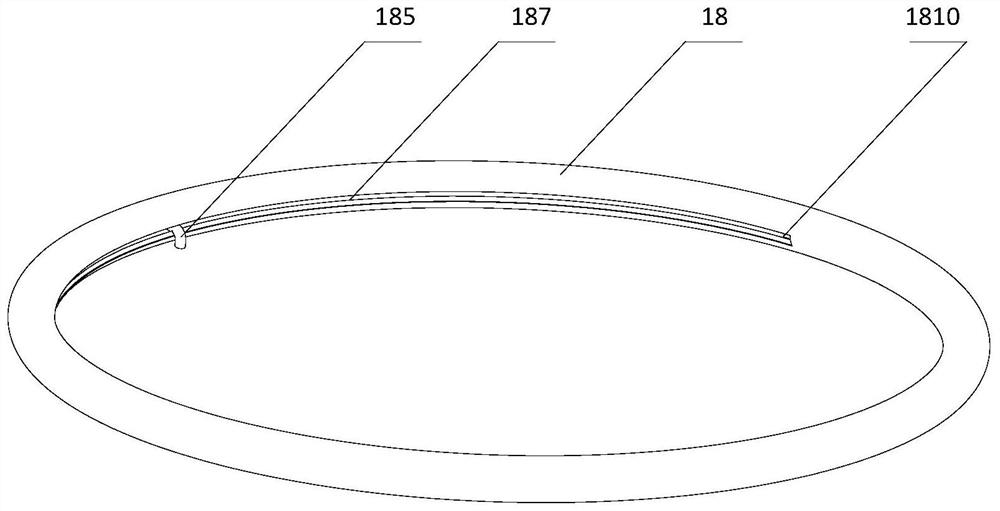

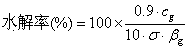

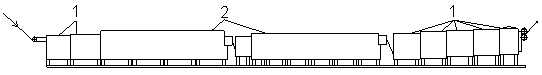

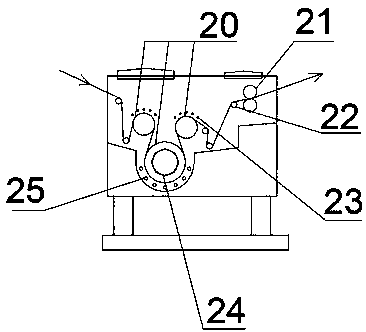

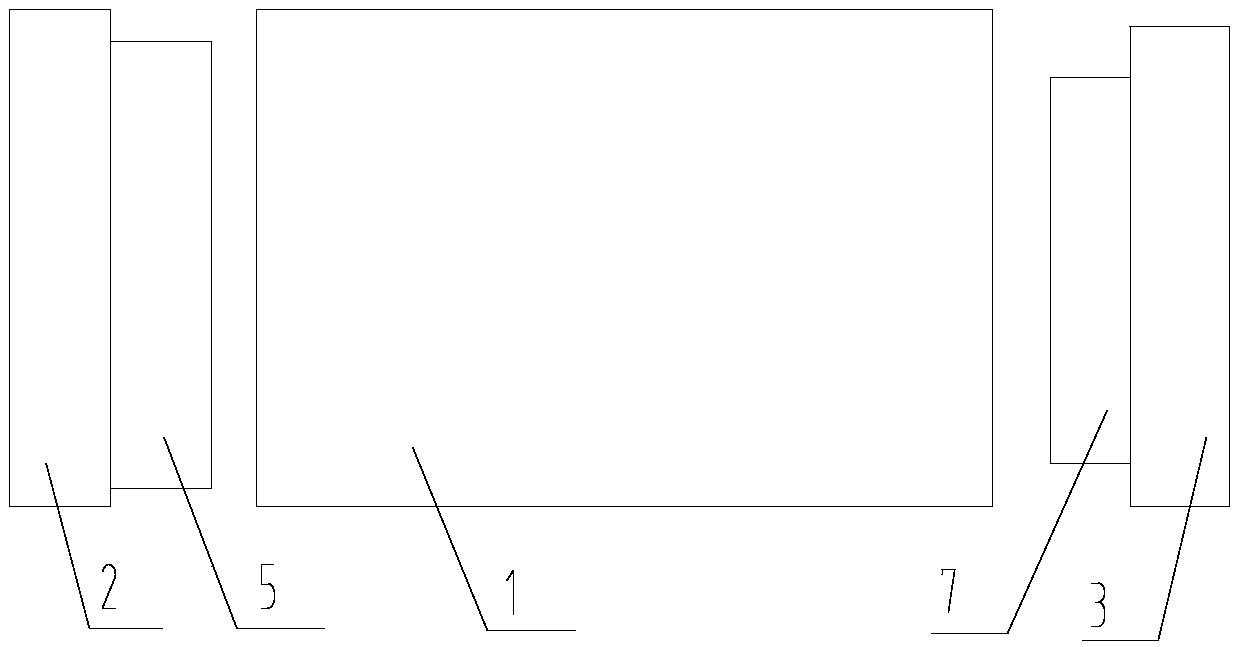

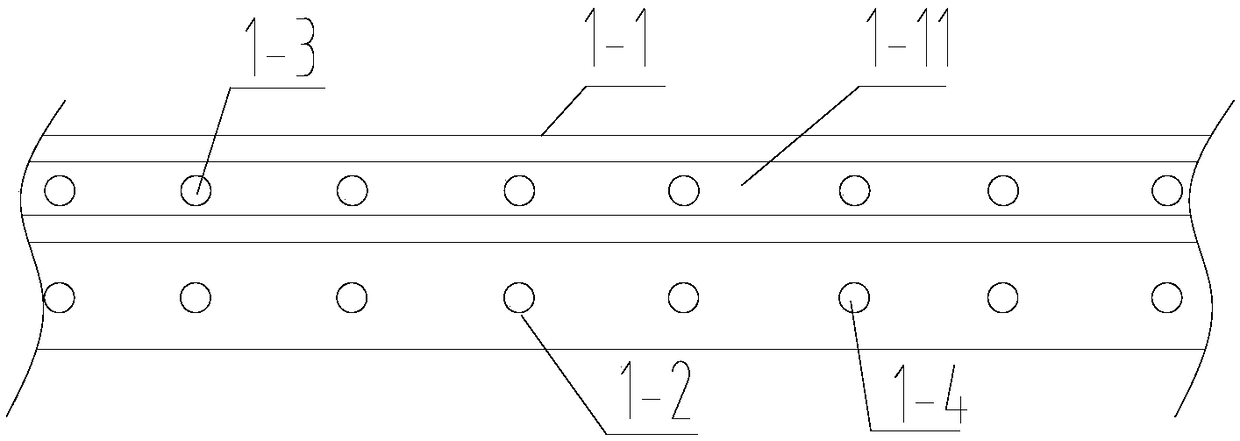

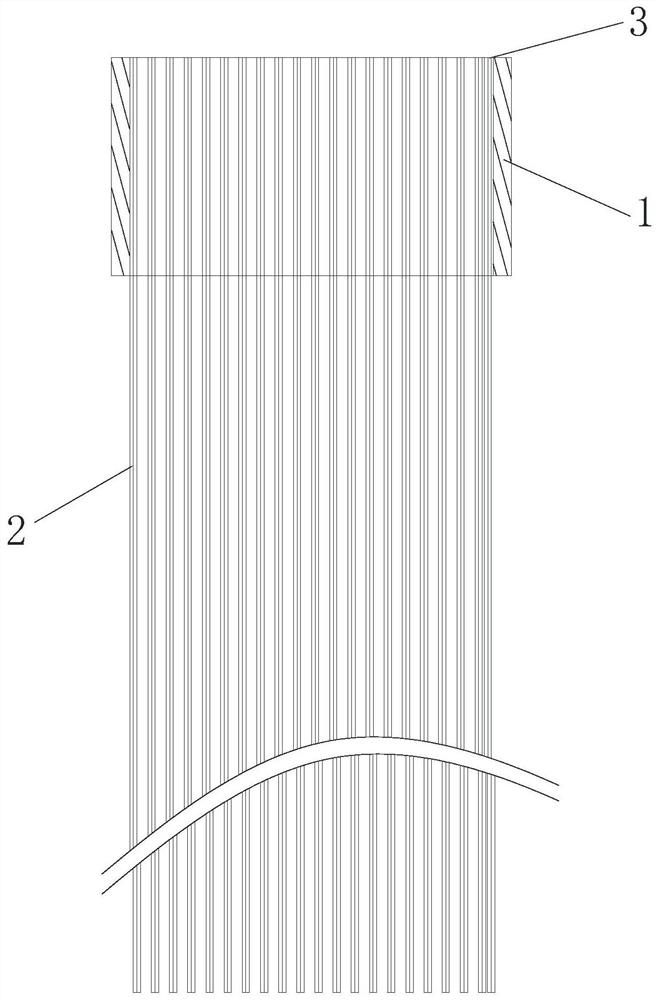

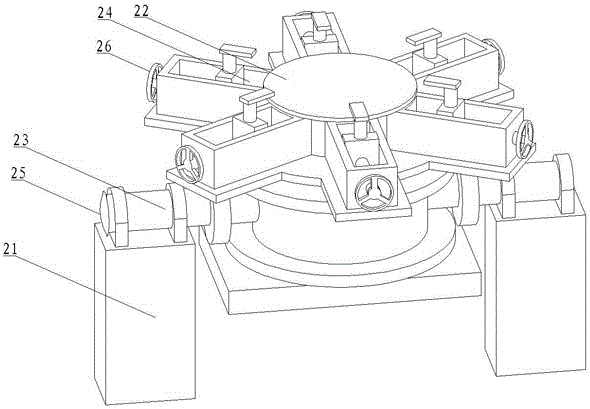

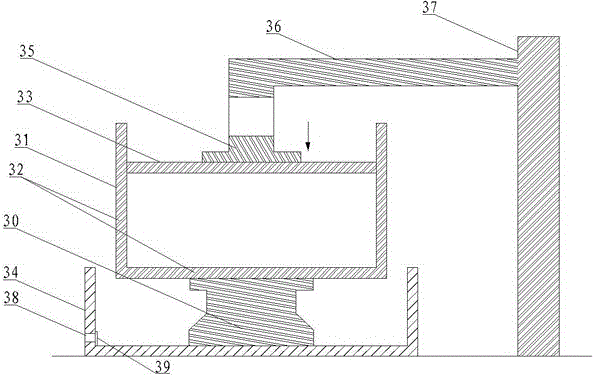

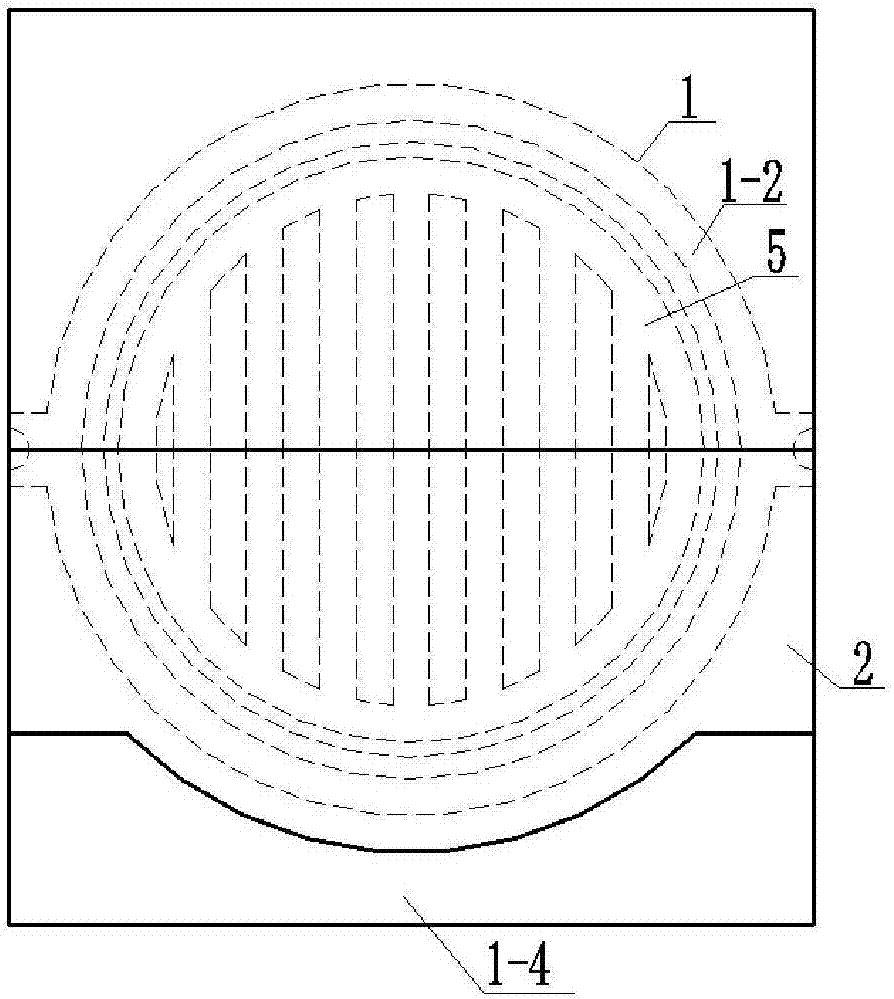

Wringer suitable for loose fiber or loose fiber cake dehydration

InactiveCN103774367AReduce the difficulty of washingReduce water consumptionLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentPistonPower component

The invention relates to a wringer suitable for loose fiber or loose fiber cake dehydration and belongs to the technical field of loose fiber dyeing. The wringer comprises a base, a cylindrical cylinder body and a top plate. The cylindrical cylinder body is arranged on the base. A leakage hole is formed in the cylindrical cylinder body. The top plate is movably connected with the cylindrical cylinder body. The upper portion of the top plate is connected with a pressure component. A power component drives the top plate to carry out piston motion in the cylindrical cylinder body, so that moisture in loose fibers in the cylindrical cylinder body is squeezed out. The wringer is used for loose fiber cold rolling stack dyeing and has the advantages that dyeing is even, the amount of used water is small, and procedures are simple.

Owner:绍兴国周针织科技有限公司

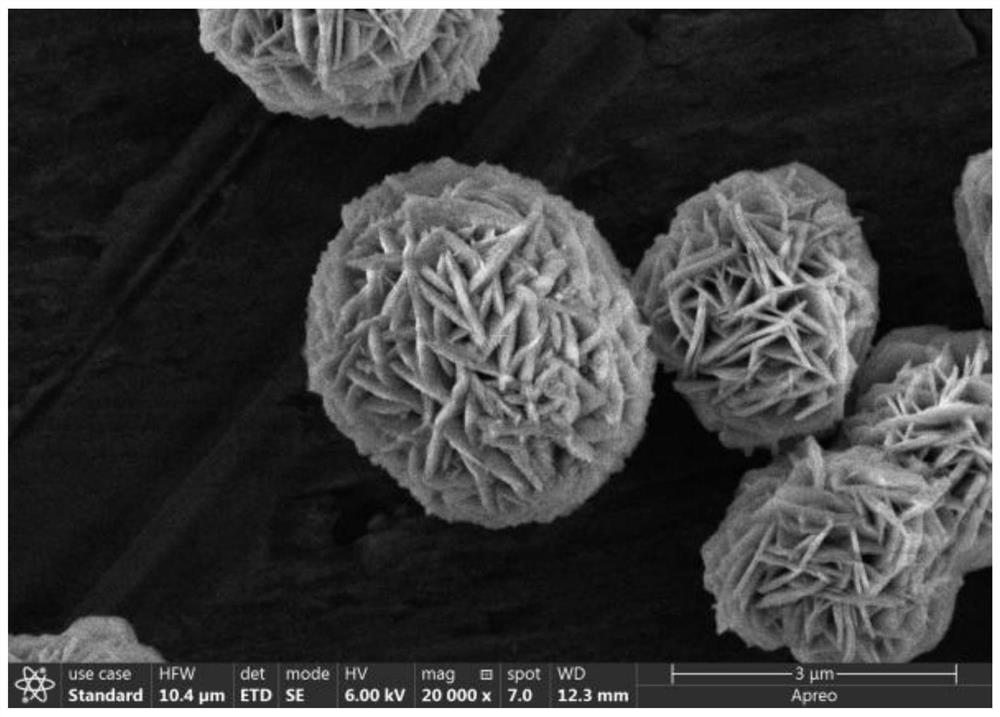

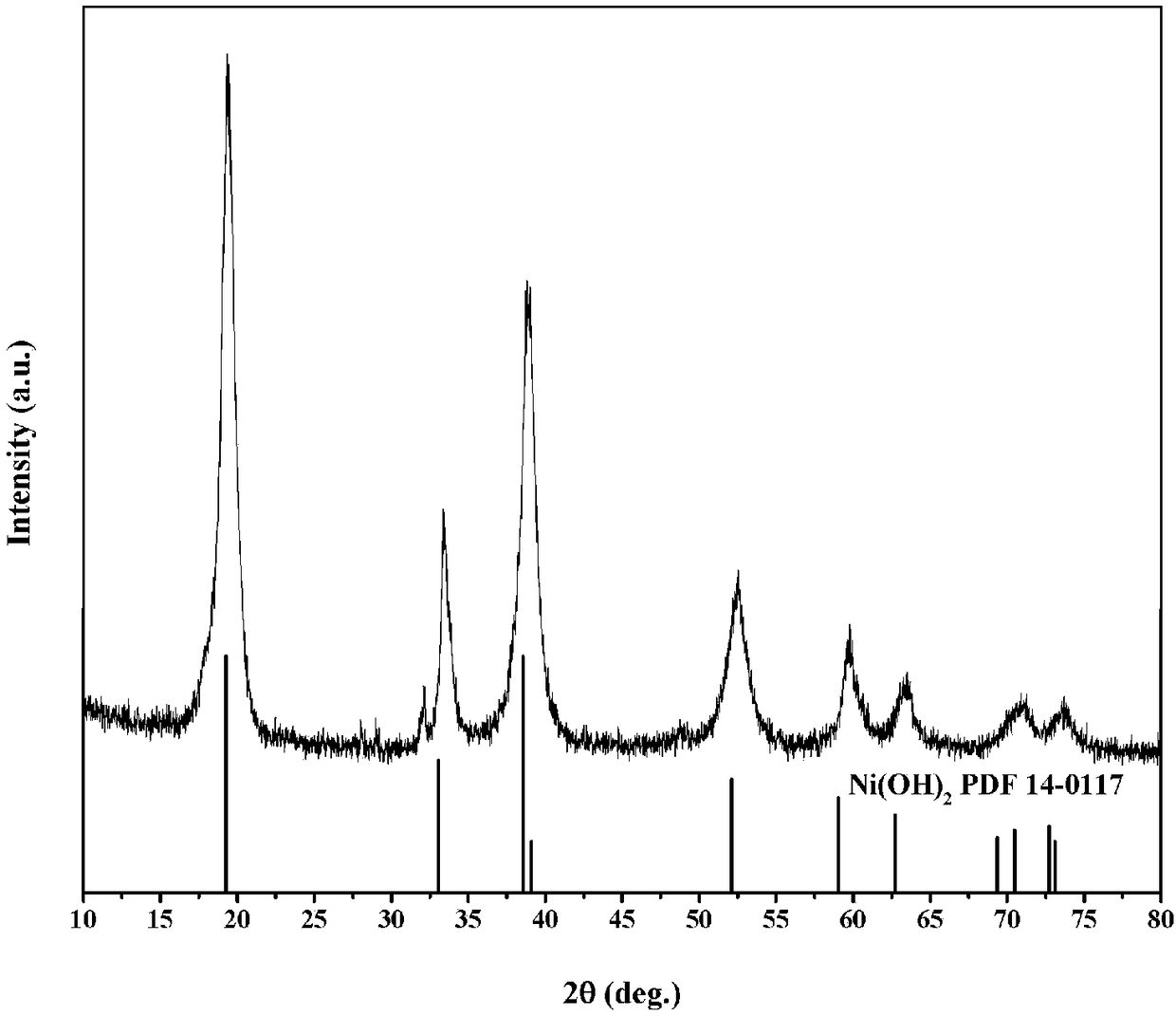

Preparation method of ternary precursor with controllable structure

InactiveCN111943282AControllable tightnessImprove lithium ion diffusion efficiencyMaterial nanotechnologySecondary cellsLithium-ion batteryBattery cell

The invention provides a preparation method of a ternary precursor with a controllable structure, belonging to the technical field of positive electrode materials of lithium ion batteries. Accordign to the invention, on the basis of preparing a ternary precursor by using a coprecipitation method, a structure control agent is introduced in a reaction stage; the structure control agent is decomposedat a high temperature to generate gas, so the stacking density degree of the ternary precursor is changed under the condition that the primary particle morphology of the ternary precursor is not changed; and since the gas generated by decomposition of the structure control agent is released from the interior of the ternary precursor to the exterior of the ternary precursor, metal salt which doesnot react completely inside can be brought out of a stacked structure, so the washing difficulty of sodium and sulfur in post-treatment is reduced and the ternary precursor with a low sodium and sulfur level is obtained.

Owner:ZHUJI PAWA NEW ENERGY

Preparation device and method for ternary material precursor

The invention belongs to the technical field of positive electrode materials of lithium ion batteries, and particularly relates to a preparation device for a ternary material precursor. The device comprises a jetting type tubular reactor, an ultrasonic ageing tank, a first bulging membrane type plate-and-frame filter press, a pre-drying device, a wet stirring ball milling machine, a second bulgingmembrane type plate-and-frame filter press, a pulping machine, a material conveying pump and a spraying drying tower which are sequentially connected through pipelines, wherein the jetting tubular reactor is connected to a mixed salt solution storing tank and a co-precipitation agent storing tank. Compared with the prior art, the device has the advantages that the controllability of the co-precipitation reaction can be improved; the preparation period can be reduced; massive continuous preparation is achieved; and the actual application in industrial preparation of the ternary material is ensured; in addition, the scale parameters of nickel, cobalt and manganese are adjusted to obtain the ternary precursors with different types so as to meet different application demands. The invention also discloses a method for preparing the ternary material precursor through the abovementioned device.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Cellulose fiber fabric printing process

ActiveCN111411538AHigh color fixing rateAvoid stainsDyeing processVegetal fibresTextile printerCellulose fiber

The invention discloses a cellulose fiber fabric printing process. The cellulose fiber fabric printing process comprises the following steps that 1, cationic modification of cellulose fiber fabric iscarried out; 2, bleaching, acid neutralization and drying are carried out; 3, reactive dye printing is carried out; 4, aging, washing, soaping and finished product shaping are carried out; cationic modification is cold reactor modification or impregnation modification; the amount of a cationic modifier in cold reactor modification is 20-50g / L, and the amount of a cationic modifier in impregnationmodification is 10-30g / L; and in reactive dye printing, catalysts such as triethylene diamine, niacin, trimethylamine, and pyridine need to be added. According to the cellulose fiber fabric printing process, moderate cationic modification is carried out on the cellulose fiber fabric, and meanwhile, the catalysts are assed during printing, so that in the process of ageing and color-fixing, cation adsorption and catalysis and color-fixing are performed simultaneously, a synergistic effect is achieved, the high color-fixing rate of the reactive dye is ensured, the difficulty of washing after printing is reduced, the problem of white background staining is effectively solved, and the amount of water used for printing washing is reduced.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

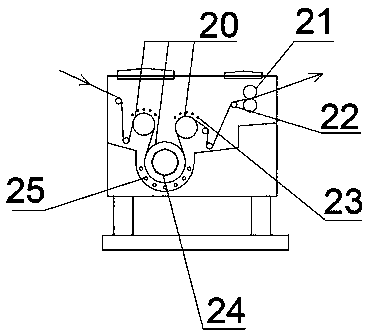

Cold-pad batch dyeing process of loose fibers

InactiveCN105671833ASmall particlesImprove dye uptakeTextile storage in superimposed formLiquid/gas/vapor removalFiberCavitation

The invention provides cold-pad batch dyeing process of loose fibers. The process comprises following steps: supersonic wave dyeing through pressing extraction, rotary cold-batch, water extraction through pressurization and aftertreatment. In the ultrasonic treatment, dyes are placed into an ultrasonic dyeing machine for increasing temperature. After supersonic waves are started, carboxylic carbon nanospheres and levelling agents are added and stirred for dyeing by putting loose fibers.Due to effect of acoustic cavitation of supersonic waves, loose fibers maintain their smaller particle with dispersibility not affected by temperature control. The manufacturing process is simple and helps save water and cost. Meanwhile, carboxylic carbon nanospheres and physical absorption and hydrogen bond combination performance of dyes as well as chemical effect of active groups of carboxylic carbon nanospheres, combination degree of dyes and loose fibers is increased and therefore dye rate is improved and up to more than 95%.

Owner:朱忠良

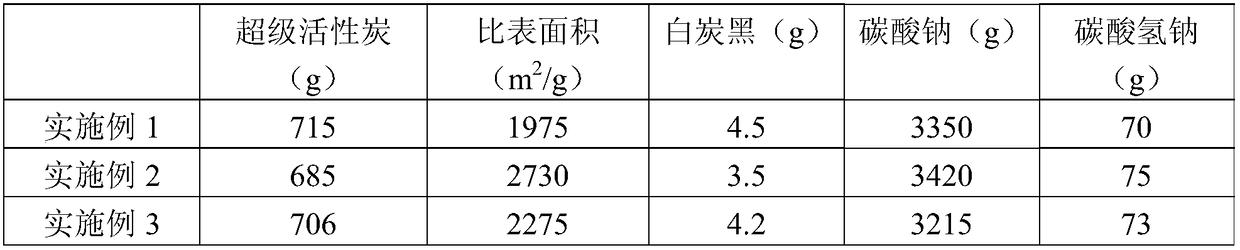

Preparation method for super activated carbon and method for recycling produced waste liquid and by-producing carbonate

ActiveCN108117074AImprove the activation effectEffective immersionSilicaCarbon compoundsActivated carbonEconomic benefits

The invention relates to the fields of biological material processing, energy materials and environmental protection, and discloses a preparation method for super activated carbon and a method for recycling a produced waste liquid and by-producing a carbonate. The preparation method for the super activated carbon comprises the following steps: contacting a carbonaceous material with an oxidizing agent and a hydrated alkaline activator under vacuum conditions, and immersing the oxidizing agent and the hydrated alkaline activator into the carbonaceous material; performing first heat treatment onthe carbonaceous material in which the oxidizing agent and the hydrated alkaline activator are immersed to activate the carbonaceous material and obtain a carbon dioxide gas; and performing cooling on the obtained activated carbonaceous material, performing washing, and performing drying to obtain the super activated carbon and the carbon dioxide gas. The invention also discloses that the waste liquid produced by the above process is treated at different pH values to realize recovery of by-products and recycling of the waste liquid. According to the method provided by the invention, through the above method, the product yield can be effectively improved, the waste liquid can be recycled and the by-products can be recycled; and the method saves energy, protects the environment, and has significant social, environmental and economic benefits.

Owner:BEIJING UNIV OF CHEM TECH

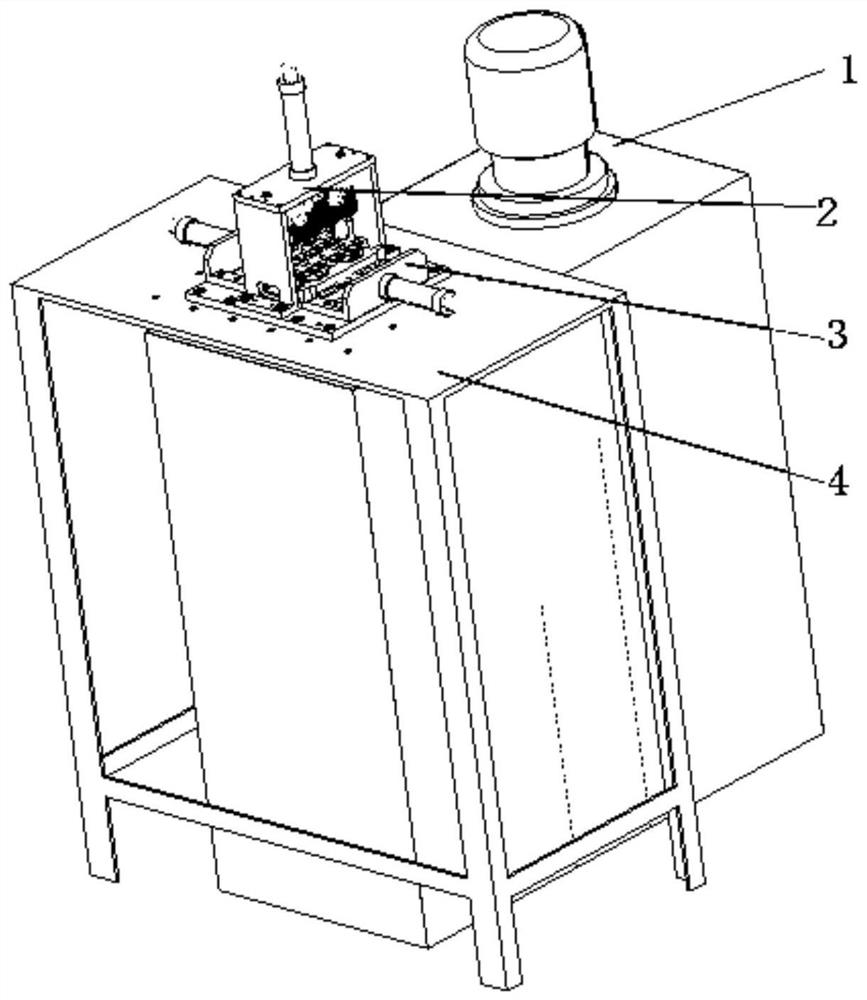

Three-dimension printer with terminal processing

InactiveCN107538746AImprove securityAvoid pollutionAdditive manufacturing apparatusManufacturing recyclingButt jointEngineering

The invention discloses a three-dimension printer with terminal processing. The three-dimension printer with terminal processing is characterized in that the three-dimension printer with terminal processing comprises a powder backlash device, a guarding shell and a powder recovering device; the powder backlash device comprises a first air pump and a but joint head, one end of the butt joint head communicates with the output end of the first air pump, and the other end of the butt joint head is of a structure matched with a painter spray head; the printer spray head can communicate with the first air pump through the butt joint head, and the bottom of the printer spray head is provided with a backlash outlet; and the guarding shell is of an inverted container structure and arranged on the outer periphery of the printer spray head in a sleeving mode. According to the three-dimension printer with terminal processing, by forming the backlash outlet, a nearby outlet is provided for pluggedpowder in the printer spray head, compared with the fact of backlashing the printer spray head through a powder conveying pipe, the washing difficulty is reduced, and the washing efficiency is improved.

Owner:芜湖联动三维科技有限公司

Low-shrinkage treatment method and device and after-treatment method

ActiveCN110016769AAchieve high elasticity and low shrinkageReduce the difficulty of washingTextile storage in superimposed formSucessive textile treatmentsAfter treatmentMedicine

The invention discloses a low-shrinkage treatment method and device and an after-treatment method. The low-shrinkage treatment method comprises the following steps that soaking and complete squeezingare conducted at least one time; wet boiling spraying loose-type piling is conducted at least one time; low-tension spraying vibration washing treatment is conducted at least three times; complete squeezing and drying are conducted. According to the low-shrinkage treatment method for a highly-elastic fabric, the highly-elastic fabric can be produced continuously, the production efficiency is improved, using of manpower, water and equipment is reduced, and production cost of production process links and the like is reduced. After treatment by the low-shrinkage treatment method, the effects of high-elasticity and low-shrinkage rate of the highly-elastic fabric can be achieved, and therefore the difficultly in highly-elastic type garment production and garment washing is reduced.

Owner:GUANGDONG FORWARD DENIM

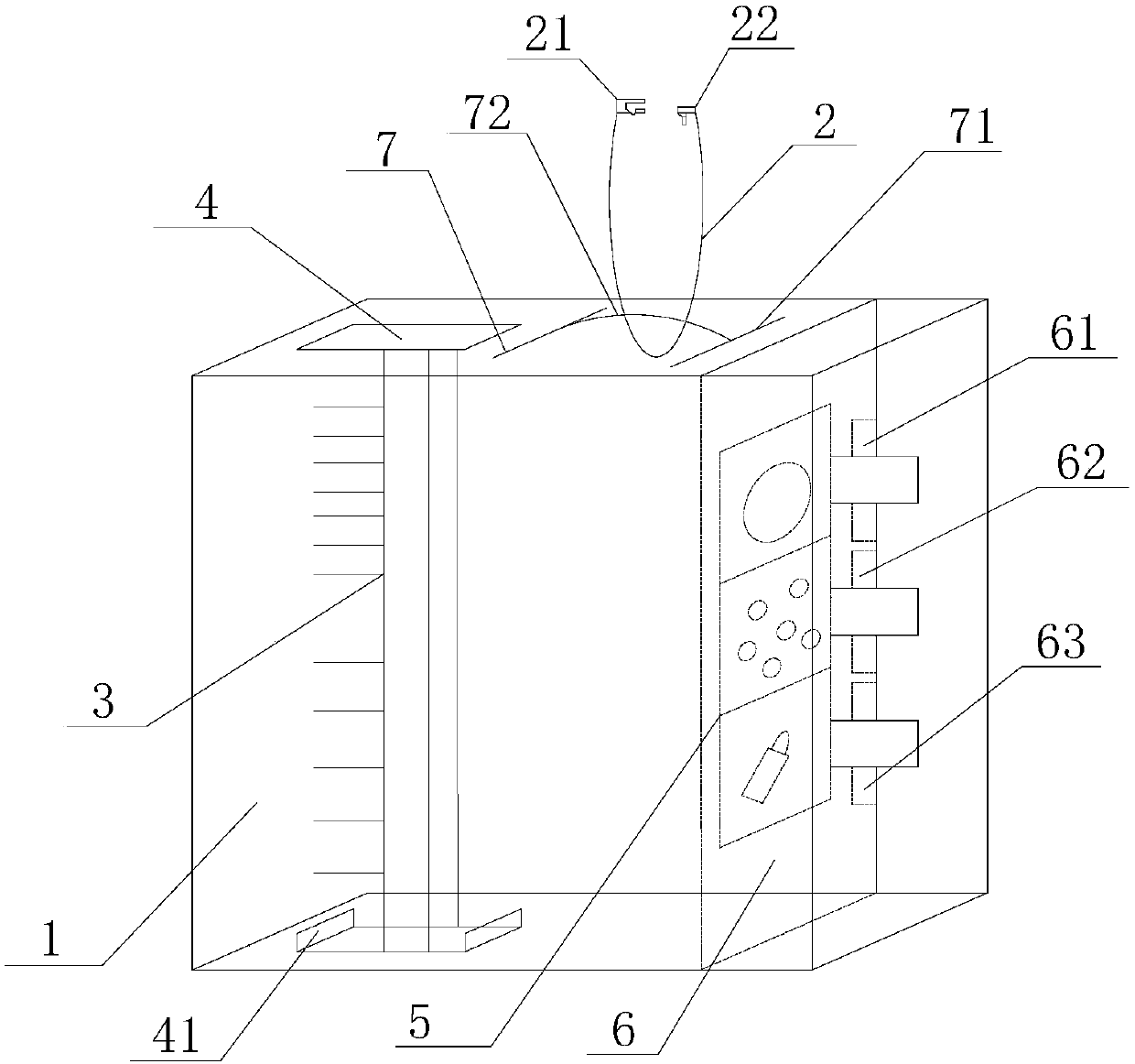

Energy-saving and environment-friendly water tank type secondary water supply device

PendingCN112854356AAutomatic water level controlPrevent backflowWater supply tanksFiltration circuitsAir compressorImpulse generator

The invention discloses an energy-saving and environment-friendly water tank type secondary water supply device. The energy-saving and environment-friendly water tank type secondary water supply device comprises a water tank, wherein a purification chamber is formed in the upper part of an inner cavity of the water tank; a first limiting block is arranged at the bottom of an outer ring of a vertical rod; the top of the vertical rod is fixedly connected with a second limiting block; a floating block sleeves the middle part of the outer ring of the vertical rod; the right side of the floating block is fixedly connected with a supporting rod; one end of the right side of the supporting rod is fixedly connected with a closing block; the top of the closing block is fixedly connected with a clamping block; the vertical rod, the first limiting block, the second limiting block, the floating block, the supporting rod, the closing block and the clamping block are matched to use, so that a water level in the purification chamber can be automatically controlled; the left side of an inner cavity of a washing chamber is fixedly connected with an air compressor; the right side of an air conveying pipe is fixedly connected with a pulse generator; the top of the pulse generator is fixedly connected with a water spraying pipe; and scouring and sand spraying effects can be generated in the purification chamber in all directions, so that dirt attached on an inner wall is crushed and separated and then is discharged from a blow-off pipe.

Owner:重庆昕晟环保科技有限公司

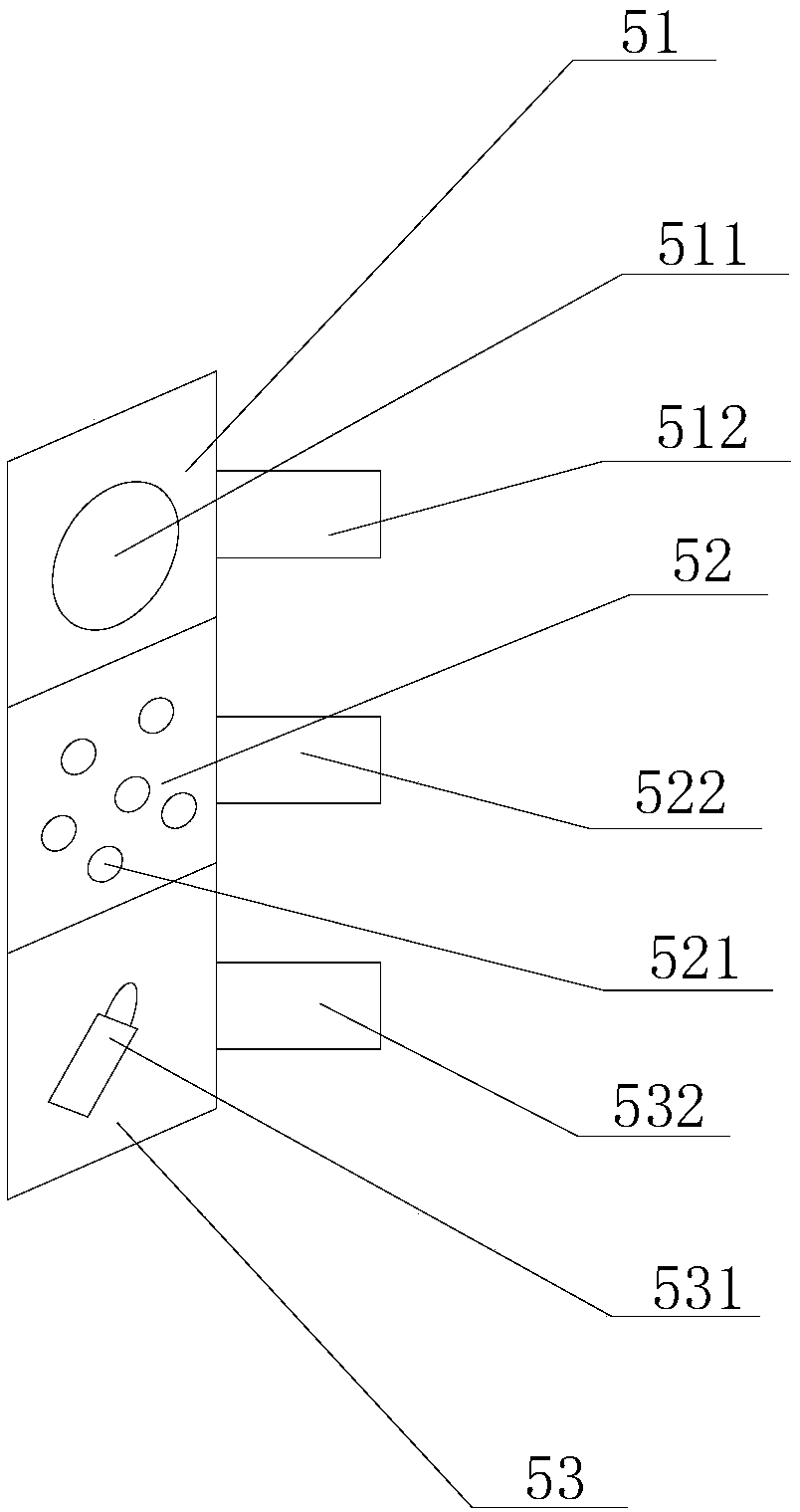

Novel multi-station valve element automatic cleaning device

PendingCN111957645APrecision cleaningReduce the difficulty of washingCleaning using liquidsWater flowRinse water

The invention discloses a novel multi-station valve element automatic cleaning device. The device comprises a flushing water tank, a flushing device, a clamp and a rack; the flushing water tank is arranged below the rack, water in the water tank is pumped into the flushing device through a pump to flush a valve element on the clamp, the flushed water flows back into the water tank through a hole in the rack to be recycled, the clamp is arranged above the rack, the flushing device is arranged above the clamp, three water spraying holes are formed in the spray head and are aligned with three to-be-cleaned holes in the valve element correspondingly, and the clamp adopts a floating clamping mode. Two pressing blocks are installed on one pressing plate, the pressing plate and the pressing blocks are connected through pins, the positioning benchmark of the valve element is machined with a guide rod hole as the benchmark, the water spraying holes are machined with the guide rod hole as the benchmark, it is guaranteed that the water spraying holes are accurately aligned with 24 holes needing to be cleaned, and the device can automatically and efficiently clean the valve element.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Clothes hang tag capable of cleaning

The invention provides a clothes hang tag capable of cleaning. The clothes hang tag comprises a tag body and a hanging rope belt, the tag body is a cuboid, a first cleaning device is arranged at the left side of the tag body, first slide grooves are formed in both the upper end and the lower end of the first cleaning device, a second cleaning device is arranged at the right side of the tag body, asecond slide groove is formed in the lower portion of the second cleaning device, a connecting device is arranged on the upper portion of the tag body, the middle of the hanging rope belt is connected with the connecting device, a parent fastener is arranged at the left end of the hanging rope belt, and a child fastener is arranged at the right end of the hanging rope belt. By means of the clothes hang tag capable of cleaning, the hang tag can be easily untied from clothes, and the clothes can be not damaged either; meanwhile, when the clothes are contaminated by dirt of oil stains, dish stains, soil and the like, the dirt part can be wiped and washed at any time, the washing difficulty of the oil stains is lowered, the influence on later wearing of the clothes is reduced, the value of the hang tag is drastically increased, and the clothes hang tag has a good market prospect.

Owner:嘉兴市凯欣印刷股份有限公司

Digital active wet process transfer printing method of cellulose fabric

ActiveCN107447555AReduce the difficulty of washingReduce sewage dischargeTransfer printing processDyeing processWater contentUrea

The invention discloses a digital active wet process transfer printing method of a cellulose fabric. The digital active wet process transfer printing method of the cellulose fabric is performed by the five steps: manufacturing a special transfer printing medium; jet-printing a pattern; pre-processing a fabric; performing transfer printing; and performing post-finishing of the fabric. According to wet process transfer printing, by spraying a pre-processing liquid, the fabric is dyed and fixed in color in a clinical water content stat when fibers are subjected to maximum swelling without taking urea as a moisture absorbent, and the fabric is not padded and pasted, so that the washing difficulty is reduced, and sewage discharge is reduced. The method disclosed by the invention not only has the advantages of clear and smooth digital inkjet printing pattern and rich layers of picture, but also has the characteristics of efficient production of conventional transfer printing and environmental protection and energy conservation, and further has the characteristics that the active print is bright in color, excellent in hand feel, good in color fastness and healthy and comfortable.

Owner:IANGSU COLLEGE OF ENG & TECH

A kind of industrialized production method of extracting inulin in Jerusalem artichoke

The invention discloses an industrial production method for extracting inulin from jerusalem artichokes and belongs to the field of industrial production of natural plant extract. The industrial production method comprises the following steps: obtaining a jerusalem artichoke total extracting solution by adopting a method of crushing and squeezing jerusalem artichoke residues obtained by crushing and squeezing jerusalem artichokes, and further squeezing residual jerusalem artichoke residues of two times of squeezing; then carrying out flocculation, desalting and de-coloring, and concentrating and drying in sequence to obtain the inulin. The industrial production method disclosed by the invention has the advantages of simplicity in operation, high production efficiency, low cost, energy saving and consumption reduction, and is suitable for large-scale continuous industrial production.

Owner:CHENGUANG BIOTECH GRP CO LTD

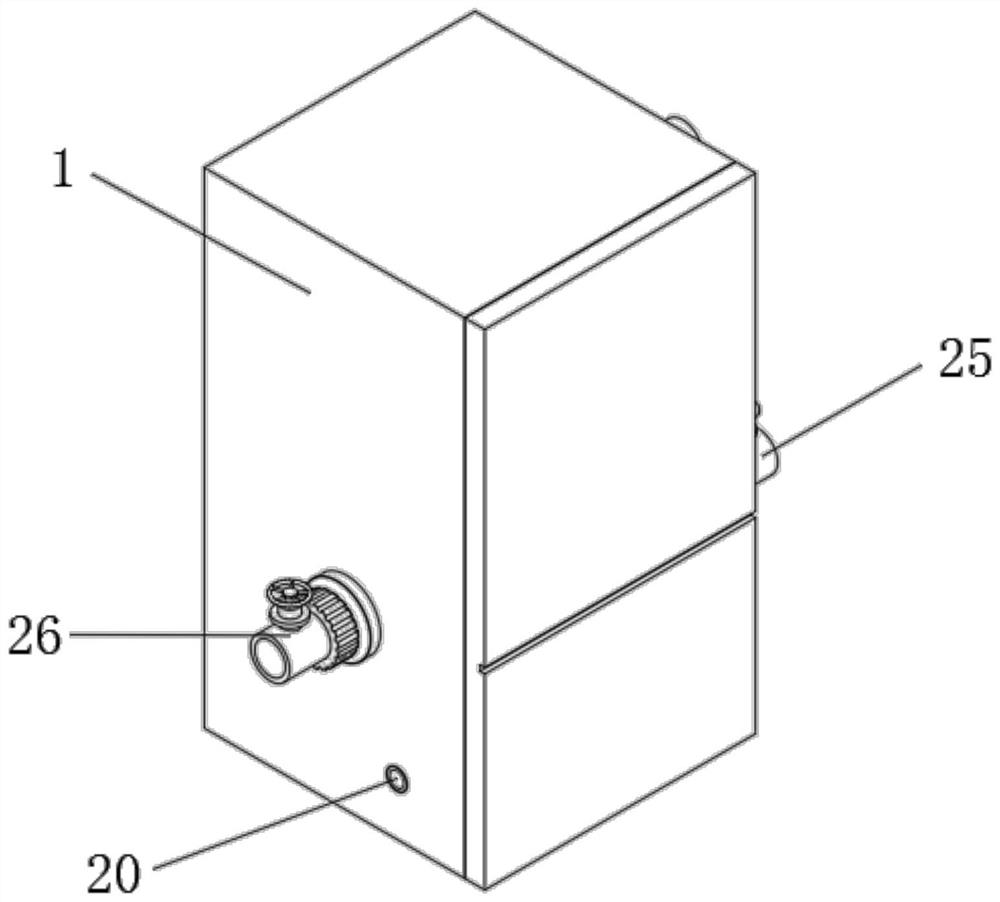

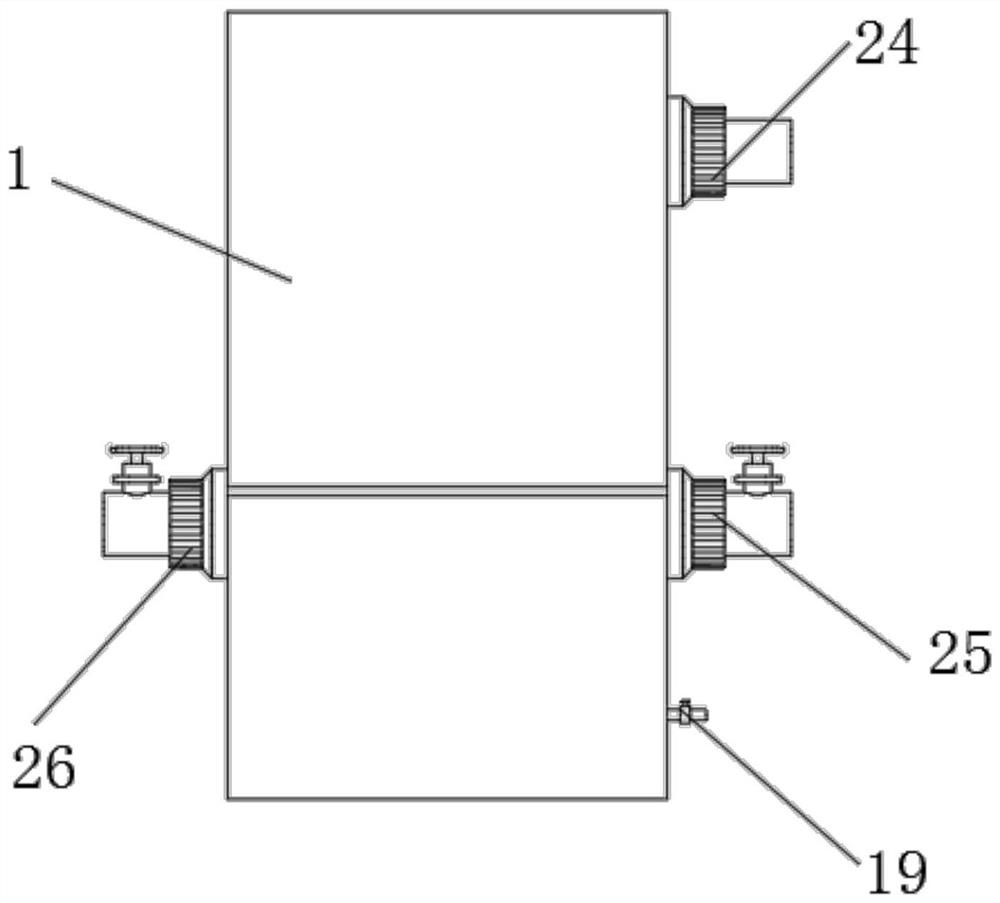

A Cleanable Spiral Heat Exchanger

ActiveCN108955303BReduce the difficulty of washingReduce adverse effects of workHeat exchanger casingsStationary tubular conduit assembliesEngineeringGas supply

The invention provides a cleanable spiral heat exchanger. The cleanable spiral heat exchanger comprises a main body, a first end cover and a second end cover; the main body is wound by a first U-shaped groove plate and a second U-shaped groove plate, which are laminated; the first U-shaped groove plate and the second U-shaped groove plate respectively form a first spiral channel and a second spiral channel; the bottom of the first U-shaped groove plate is positioned at a first end of the main body; and the bottom of the second U-shaped groove plate is positioned at a second end of the main body. In the cleanable spiral heat exchanger, when the first spiral channel is blocked, the second end cover is only disassembled; then, a first cavity is inflated through an air supply mechanism, so that the inside of the first spiral channel can be flushed through a first air valve without disassembling the first end cover and emptying the second spiral channel, and the flushing difficulty is greatly reduced; and similarly, when the second spiral channel is blocked, the first end cover is only disassembled, and the second spiral channel is washed by air through the air supply mechanism and a second connecting head.

Owner:安徽省碧绿春生物科技有限公司

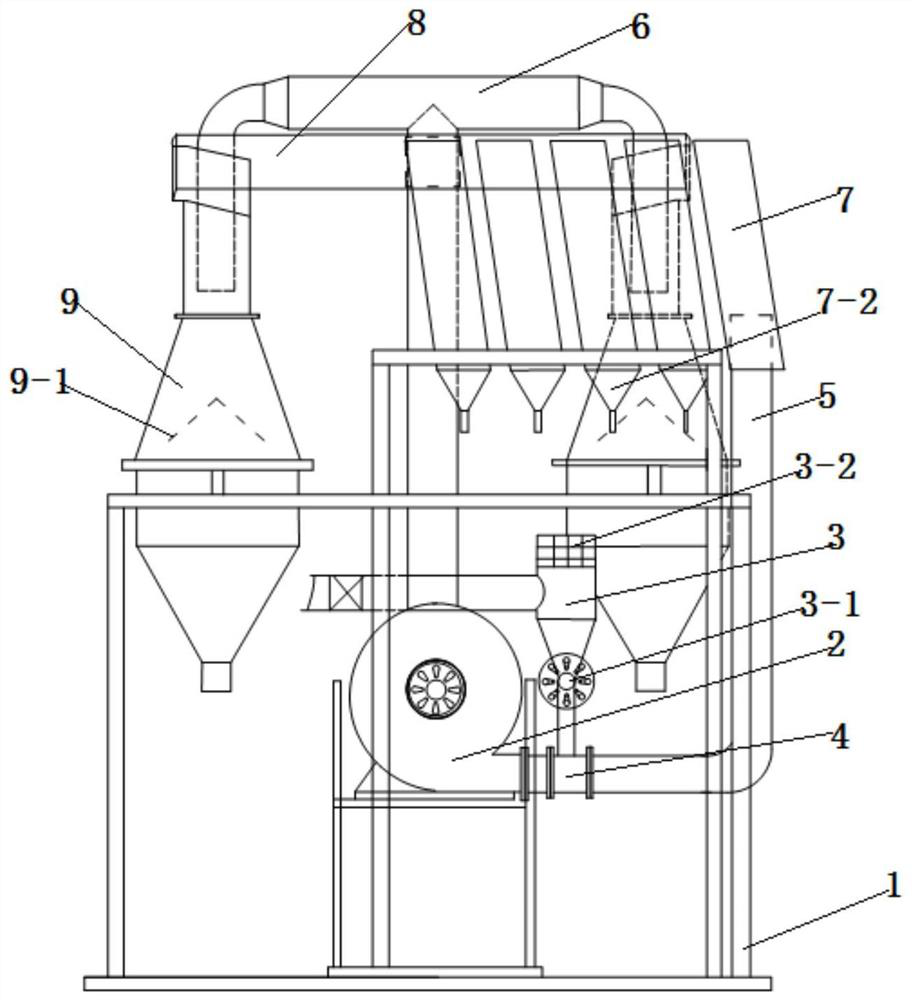

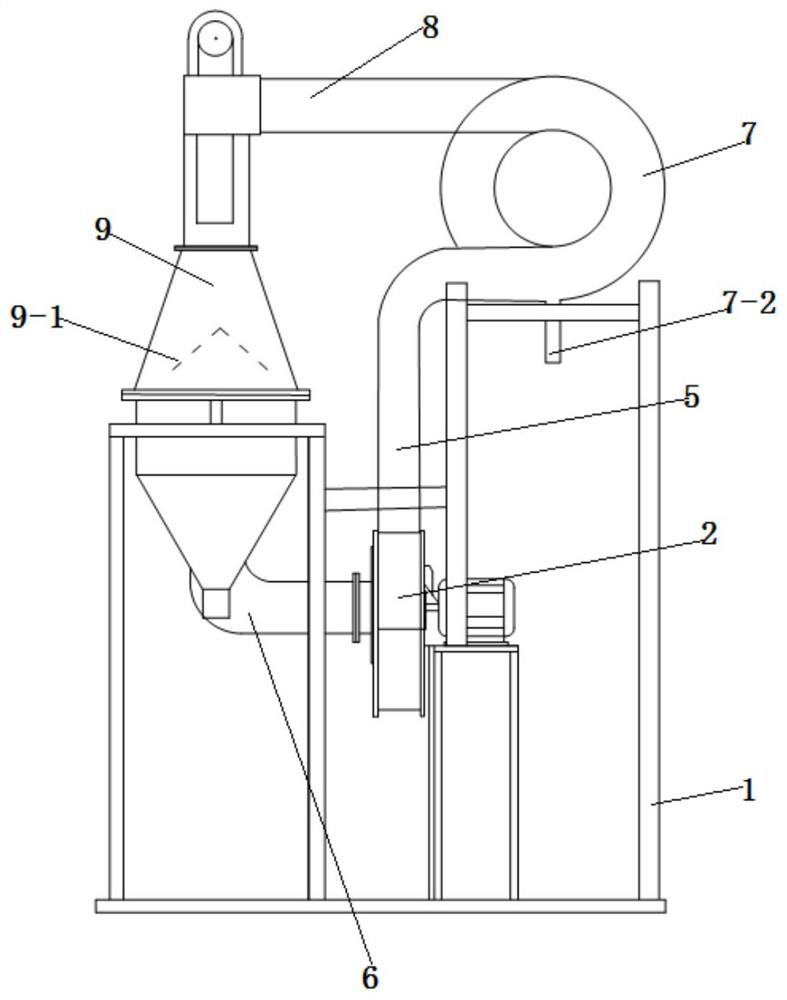

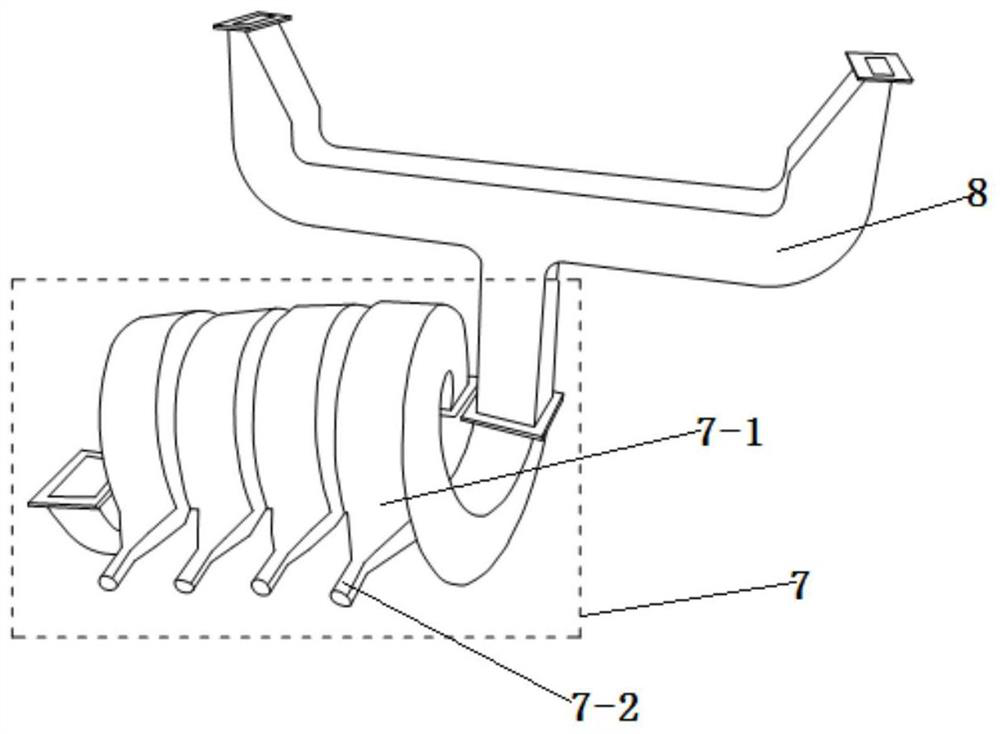

Fly ash winnowing floating bead equipment and winnowing separation method thereof

InactiveCN112108367AReduce the difficulty of washingExtended service lifeGas current separationDispersed particle separationEconomic benefitsEnvironmental engineering

The invention discloses fly ash winnowing floating bead equipment and a winnowing separation method thereof, and belongs to the technical field of separation equipment. The fly ash winnowing floatingbead equipment comprises a support, a fly ash conveying mechanism, a fly ash winnowing mechanism and a fly ash recycling mechanism, the fly ash conveying mechanism comprises a circulating fan, the circulating fan conveys fly ash to the fly ash winnowing mechanism, the fly ash winnowing mechanism comprises an enrichment loop, the circulating fan conveys the fly ash into the enrichment loop, and thefly ash recovery mechanism is used for recovering small ash obtained after winnowing of the fly ash winnowing mechanism. According to the fly ash winnowing floating bead equipment and the winnowing separation method thereof, the fly ash winnowing mechanism is used for carrying out coarse separation on floating beads in the fly ash, so that the content of the floating beads in separated enriched ash is high; and then the enriched ash is washed with water, the small ash can be collected to the maximum extent and fully utilized while the multiple floating beads can be extracted, resource waste is avoided, considerable economic benefits can be created, and the requirement for washing equipment is reduced, and the cost is reduced. The equipment is simple in structure and convenient to use, andprotects the environment.

Owner:淮南市九方皋科技咨询有限公司

Folded plate type demister for treating flue gas desulfurization waste gas

ActiveCN112933748AReduce consumptionReduce the difficulty of washingGas treatmentDispersed particle separationProcess engineeringMechanical engineering

The invention discloses a folded plate type demister for treating flue gas desulfurization waste gas. The folded plate type demister comprises a protective shell, two demisting cavities are formed in the side wall of the protective shell, air inlet pipes are arranged at the inner tops of the demisting cavities, and first separation plates are rotationally connected to the inner bottoms of the demisting cavities; a second separation plate is rotatably connected to the upper end of the first separation plate, a supporting plate is fixedly connected to the upper end of the second separation plate, a sliding groove is formed in the bottom in the demisting cavity, and a driving device for driving the supporting plate to move up and down is installed in the sliding groove. By alternately blowing entrainment-containing airflow into the two demisting cavities, the two supporting plates can be sequentially driven to move up and down under the action of the driving device, so that the included angle between the first separation plate and the second separation plate is continuously changed, the entrainment gathered at the corner is guided into the interception tank, the washing difficulty can be greatly reduced, and meanwhile, the consumption of water resources for cleaning can be saved.

Owner:SHANDONG HAIHUI ENVIRONMENTAL PROTECTION EQUIP

A scanning type bedpan flushing mechanism

ActiveCN109044683BMeet flushing requirementsReduce contaminationCleaning devicesBedpansBedpanStructural engineering

Provided is a scanning type bedpan flushing mechanism. A pair of flushing main bodies are both of a semi-annular tubular hydraulic water tank structure and both look like a nozzle walking groove whichis as long as a half inner ring, and each half ring also serves as a semi-arc hollow piston running guide pipe of the semi-annular tubular hydraulic water tank. After water is supplied to the semi-annular tubular hydraulic water tanks, the pressure of water counteracts the elasticity of springs, semi-annular tubular pistons are pushed to move along the half guiding rings when water is sprayed bya nozzle at the frontmost end of each semi-annular tubular piston to the wall of a bedpan, and therefore a scanning type semi-arc flushing mode is achieved. After supply of the water is stopped, underthe drawing effect of the tension springs in the semi-annular tubular pistons, the semi-annular tubular pistons retract when water remaining in the hollow pistons is extruded by the nozzles at the frontmost ends of the semi-annular tubular pistons to the wall of the bedpan. The two flushing main bodies which look like walking grooves are symmetrically stacked and installed to form a whole circular scanning type bedpan flushing mechanism body. The scanning type bedpan flushing mechanism moves like a bicycle lock during locking. According to the mechanism, the flushing amount for meeting flushing and cleaning requirements is far more lower than that of a pedestal pan.

Owner:张惠丽

Preparation method of fluorine-containing polymer powder

ActiveCN111349252AReduced and Coagulated DosesImprove coagulation efficiencyPolymer scienceFluorine containing

The invention provides a preparation method of fluorine-containing polymer powder, wherein the preparation method is realized by jointly using a coagulant and a mechanical coagulation mode and settingdifferent mechanical stirring speeds before and after the adding of the coagulant. The preparation method provided by the invention has the advantages of high emulsion coagulation efficiency, short coagulation time and the like.

Owner:中化蓝天氟材料有限公司 +1

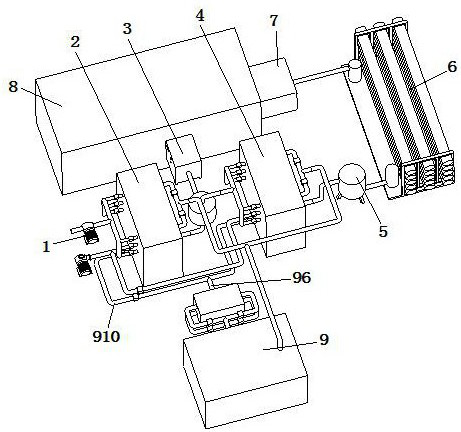

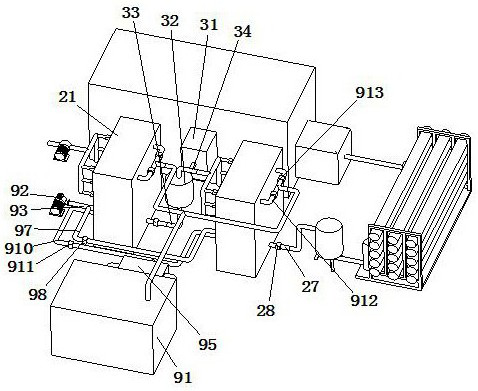

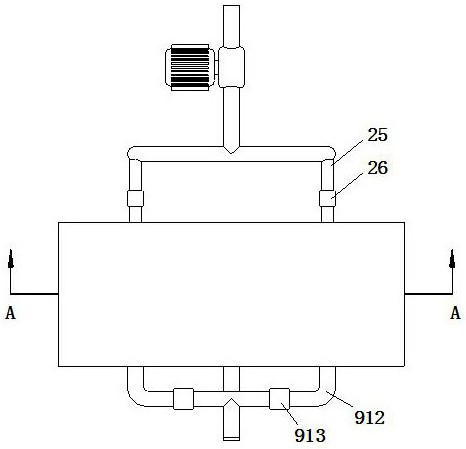

Natural Mineral Water Treatment System

ActiveCN111732251BReduce the overall heightReduce areaWater/sewage treatment by irradiationTreatment involving filtrationActivated carbon filtrationReverse osmosis

The invention discloses a natural mineral water treatment system, and relates to the technical field of mineral water production. The system comprises a water pump, a quartz sand filter, an ozone mixing assembly, an activated carbon filter, a precision filter, a reverse osmosis main machine mechanism, an ultraviolet sterilization box and a water tank, the water pump, the quartz sand filter, the ozone mixing assembly, the activated carbon filter, the precision filter, the reverse osmosis main machine mechanism, the ultraviolet sterilization box and the water tank are sequentially communicated through pipelines, a backwashing circulation mechanism is arranged beside the activated carbon filter, the quartz sand filter and the activated carbon filter are both communicated with the backwashingcirculation mechanism through pipelines, the quartz sand filter and the activated carbon filter are the same in structure and each comprise a shell and two filtering assemblies, and the two filteringassemblies are both arranged in the shell. Through the structural design of the quartz sand filter, the activated carbon filter, the ozone mixing assembly and the backwashing circulating mechanism, the filtering and adsorbing effects can be improved, the washing efficiency is improved, and the operation cost is reduced.

Owner:烟台市百事特消防科技有限公司 +1

A digital active wet transfer printing method for cellulose fabrics

ActiveCN107447555BEmission reductionReduce the difficulty of washingTransfer printing processDyeing processCelluloseFiber

Owner:IANGSU COLLEGE OF ENG & TECH

Pretreatment method for high-efficiency enzyme hydrolysis of wood waste fiber

InactiveCN102703545BReduce volume usageHigh enzymatic hydrolysis effectFermentationFiberBeta-glucosidase

Owner:SOUTH CHINA UNIV OF TECH

A kind of polyphenylene sulfide resin synthesis process

ActiveCN109535426BReduce the content of metal ionsImproved performance characteristicsSodium hydrosulfidePetrochemical

The invention discloses a polyphenylene sulfide resin synthesis process, and the purpose is to obtain a resin synthesis method with good particle shape, high product yield, high solvent recovery rate and reduced corrosion degree of a polymerization reaction device. Sodium hydrosulfide, sodium hydroxide, and p-dichlorobenzene of water are used as raw materials, and N-methylpyrrolidone is used as a solvent, and a condensation polymerization reaction occurs in the synthesis system. After the low-temperature and high-temperature polycondensation is completed, acetate, NMP and aqueous solution are then subjected to high temperature insulation, cooling, and filtration. After the filter cake is purified by NMP solvent, it is repeatedly washed with deionized water, filtered, and the filter cake is dried to obtain polyphenylene sulfide resin. Synthesis of the present invention The polyphenylene sulfide resin is widely used in aerospace, electronic machinery, petrochemical, food, light industry, thermal power generation, cement industry, steel manufacturing, environmental protection, textile industry and other fields.

Owner:德阳科吉高新材料有限责任公司

A low-shrinkage treatment method, finishing method and device

ActiveCN110016769BAchieve high elasticity and low shrinkageReduce the difficulty of washingTextile storage in superimposed formSucessive textile treatmentsAfter treatmentMedicine

The invention discloses a low-shrinkage treatment method and device and an after-treatment method. The low-shrinkage treatment method comprises the following steps that soaking and complete squeezingare conducted at least one time; wet boiling spraying loose-type piling is conducted at least one time; low-tension spraying vibration washing treatment is conducted at least three times; complete squeezing and drying are conducted. According to the low-shrinkage treatment method for a highly-elastic fabric, the highly-elastic fabric can be produced continuously, the production efficiency is improved, using of manpower, water and equipment is reduced, and production cost of production process links and the like is reduced. After treatment by the low-shrinkage treatment method, the effects of high-elasticity and low-shrinkage rate of the highly-elastic fabric can be achieved, and therefore the difficultly in highly-elastic type garment production and garment washing is reduced.

Owner:GUANGDONG FORWARD DENIM

Cleanable spiral heat exchanger

ActiveCN108955303AReduce the difficulty of washingReduce adverse effects of workHeat exchanger casingsStationary tubular conduit assembliesEngineeringSpiral heat exchanger

The invention provides a cleanable spiral heat exchanger. The cleanable spiral heat exchanger comprises a main body, a first end cover and a second end cover; the main body is wound by a first U-shaped groove plate and a second U-shaped groove plate, which are laminated; the first U-shaped groove plate and the second U-shaped groove plate respectively form a first spiral channel and a second spiral channel; the bottom of the first U-shaped groove plate is positioned at a first end of the main body; and the bottom of the second U-shaped groove plate is positioned at a second end of the main body. In the cleanable spiral heat exchanger, when the first spiral channel is blocked, the second end cover is only disassembled; then, a first cavity is inflated through an air supply mechanism, so that the inside of the first spiral channel can be flushed through a first air valve without disassembling the first end cover and emptying the second spiral channel, and the flushing difficulty is greatly reduced; and similarly, when the second spiral channel is blocked, the first end cover is only disassembled, and the second spiral channel is washed by air through the air supply mechanism and a second connecting head.

Owner:安徽省碧绿春生物科技有限公司

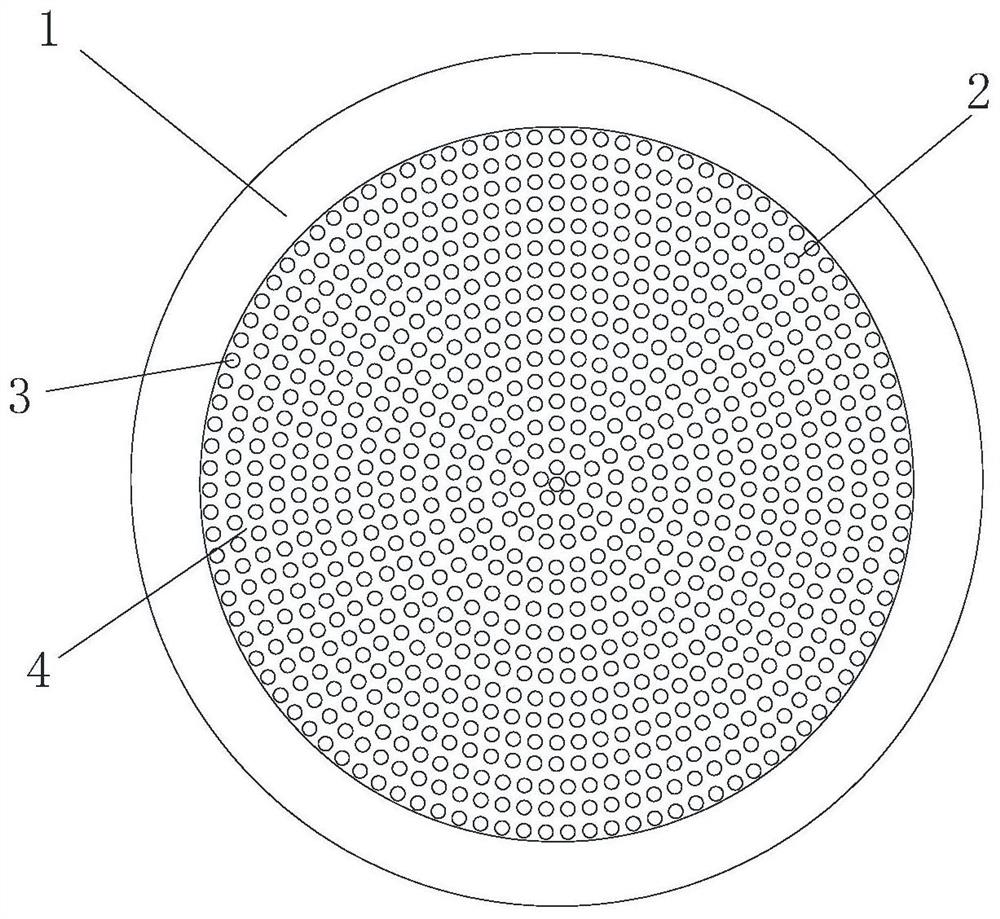

Water purification ultrafiltration membrane assembly

PendingCN112263913AEasy to cleanReduce the difficulty of washingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHollow fibreFiber

The invention discloses a water purification ultrafiltration membrane component which comprises a fixing ring, a plurality of external pressure type hollow fibers which are not communicated with one another are clamped by the fixing ring, the upper ends of the external pressure type hollow fibers are clamped and tightly fixed in the fixing ring, and the lower end of a single external pressure typehollow fiber freely floats. A water outlet is formed in the top of the single external pressure type hollow fiber, the bottom of the single external pressure type hollow fiber is sealed, water permeable micropores are formed in the side wall of the single external pressure type hollow fiber in a penetrating mode, the water purification principle is the same as that in the prior art, but due to the fact that each external pressure type hollow fiber is in a free state in water and moves along with water flow, impurities in water cannot be accumulated among the plurality of external pressure type hollow fibers; during backwashing, purified water flows downwards from the water outlet through the permeable micropores and permeates out to wash impurities attached to the surface of the externalpressure type hollow fiber, so that the external pressure type hollow fiber is convenient to wash, the washing difficulty is greatly reduced compared with the prior art, and the washing cost is saved.

Owner:重庆普瑞泰环保科技有限公司

Cold pad-batch dyeing process of loose fiber

ActiveCN103774363BEvenly distributedPromote absorptionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberPolymer science

Owner:绍兴国周针织科技有限公司

Protection structure for artificial island revetment

InactiveCN107268527AReduce the difficulty of washingIncreased flushing difficultyBreakwatersQuaysEngineeringRevetment

The invention discloses a protection structure for an artificial island revetment. The protection structure comprises multiple parallel prefabricated cylinders and a cover plate for coving all the prefabricated cylinders in a sealed manner. A bottom plate is arranged on each prefabricated cylinder. The cylinder wall and the bottom plate of each prefabricated cylinder are formed through overall pouring. Every two adjacent prefabricated cylinders are connected together through a cast-in-place concrete structure equal to the prefabricated cylinders in height. The lower portion in each prefabricated cylinder is filled with sand. Barrier boards are pressed on the sand. Wave dissipating holes are formed in the side facing waves of the upper portion of each prefabricated cylinder. By the adoption of the protection structure for the artificial island revetment, the wave reflection, wave force and wave run-up of the structure can be reduced, the foundation stress is lowered, the anti-sliding stability of the structure is improved, the washout difficulty of waves to the foundation is increased, and the anti-washout stability of the structure is improved; transportation and construction are easy; and the protection structure is adaptive to coral reef foundations, capable of resisting the bad wave condition and effectively reducing the washout of the waves and suitable for artificial islands or atolls with the bad ocean environment and the complex geological conditions.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com