Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1496 results about "Backwashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In terms of water treatment, including water purification and sewage treatment, backwashing refers to pumping water backwards through the filters media, sometimes including intermittent use of compressed air during the process. Backwashing is a form of preventive maintenance so that the filter media can be reused. In water treatment plants, backwashing can be an automated process that is run by local programmable logic controllers (PLCs). The backwash cycle is triggered after a set time interval, when the filter effluent turbidity is greater than a treatment guideline or when the differential pressure (head loss) across the filter exceeds a set value.

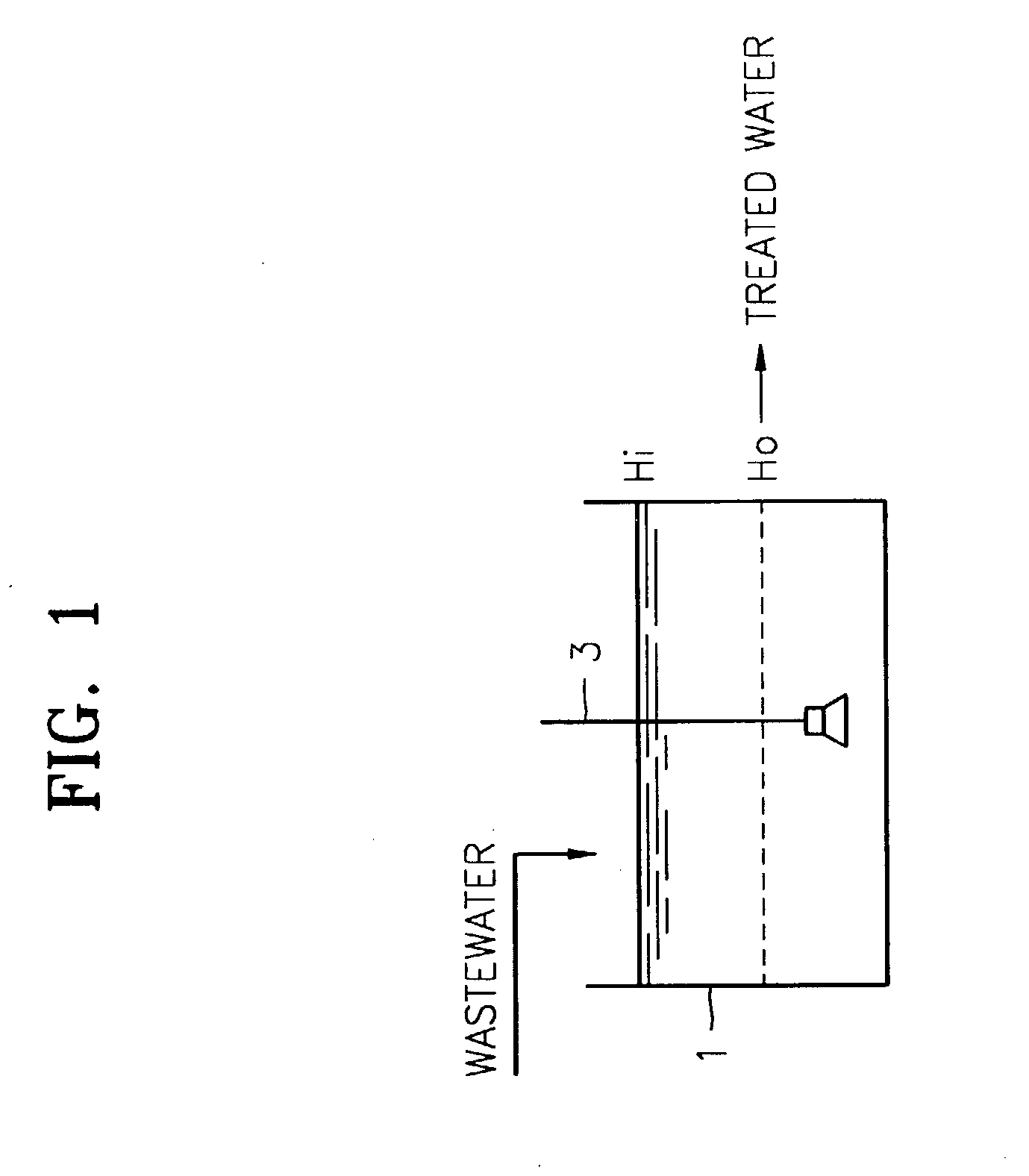

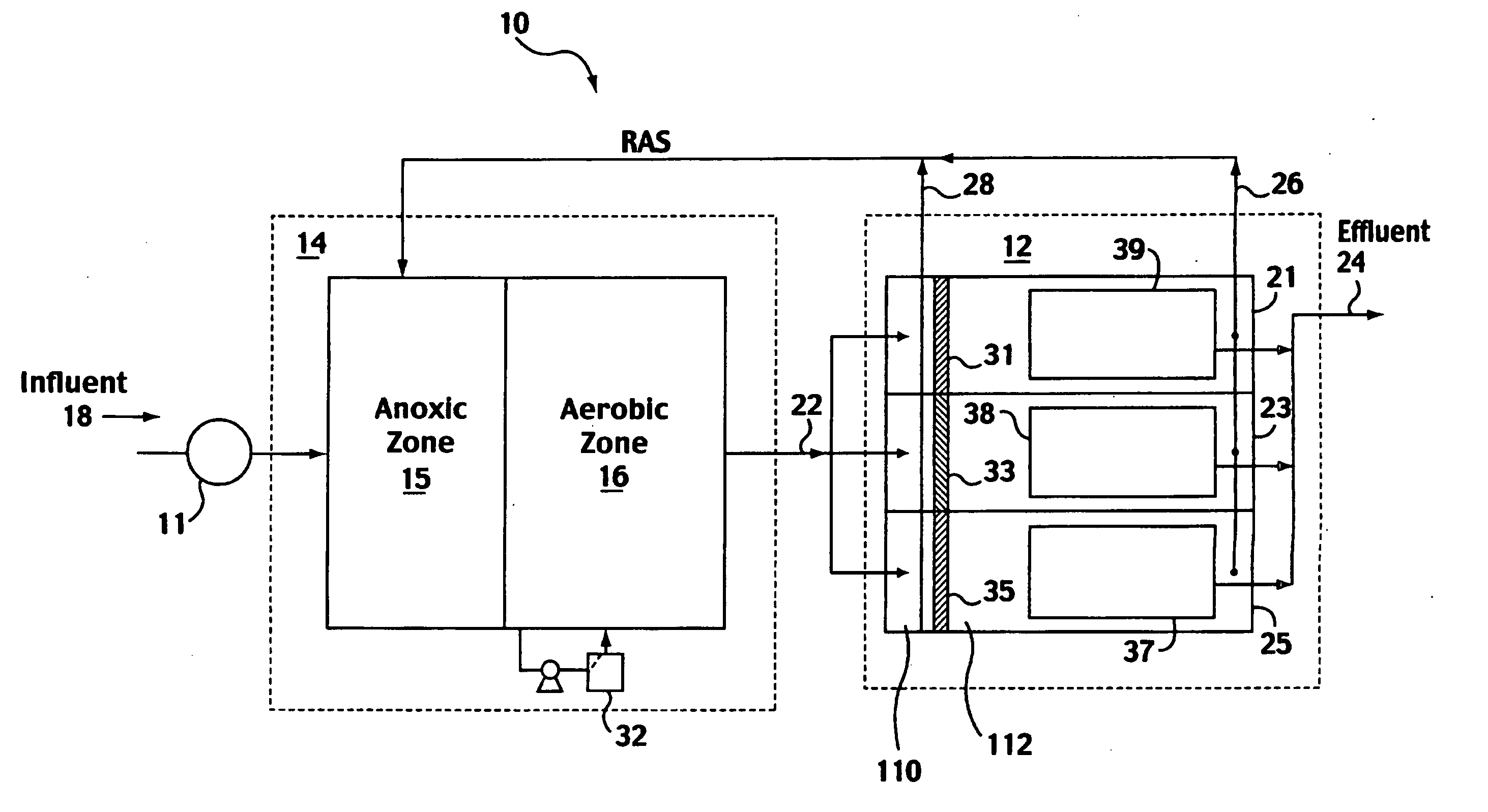

Water filtration using immersed membranes

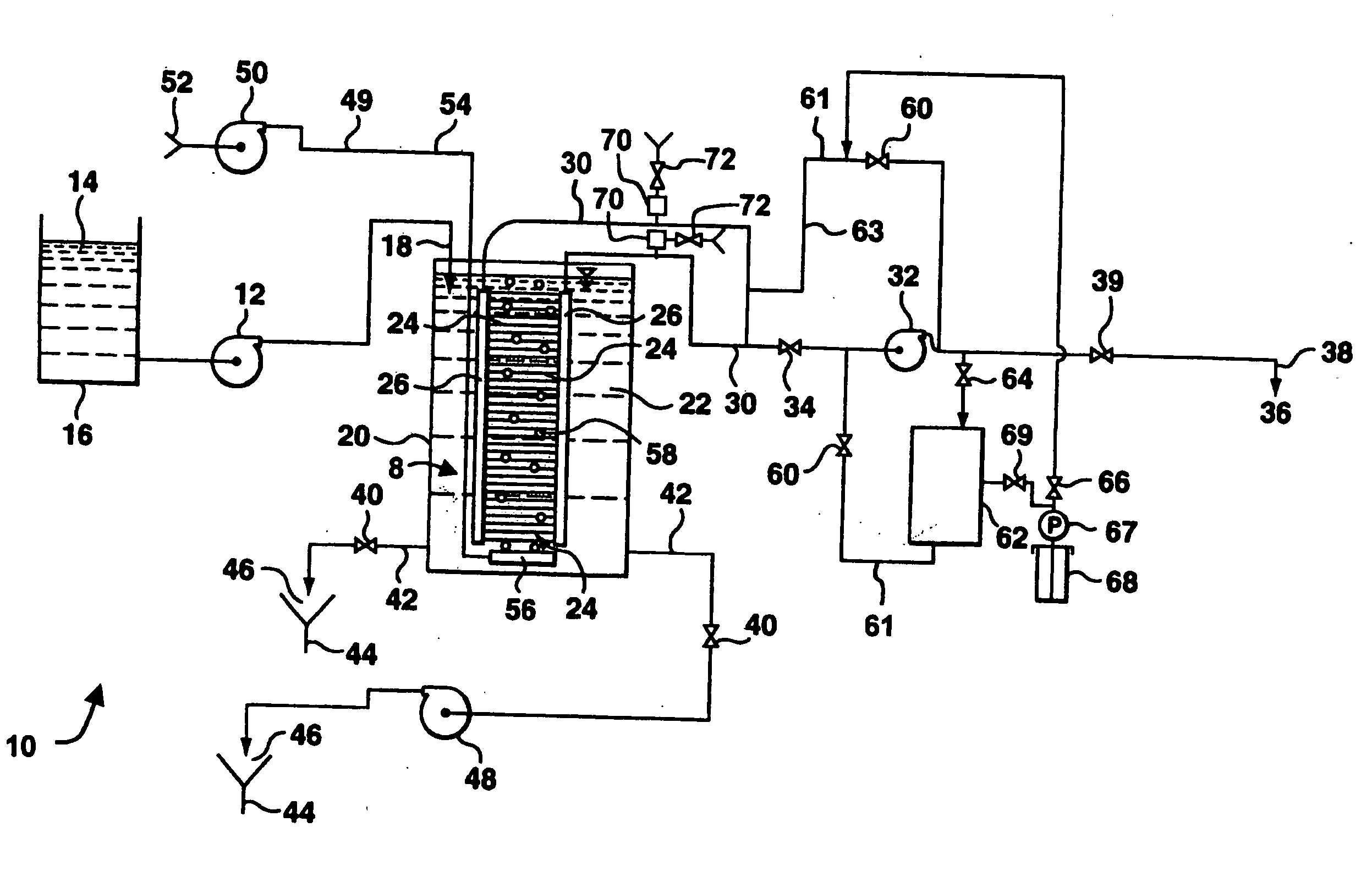

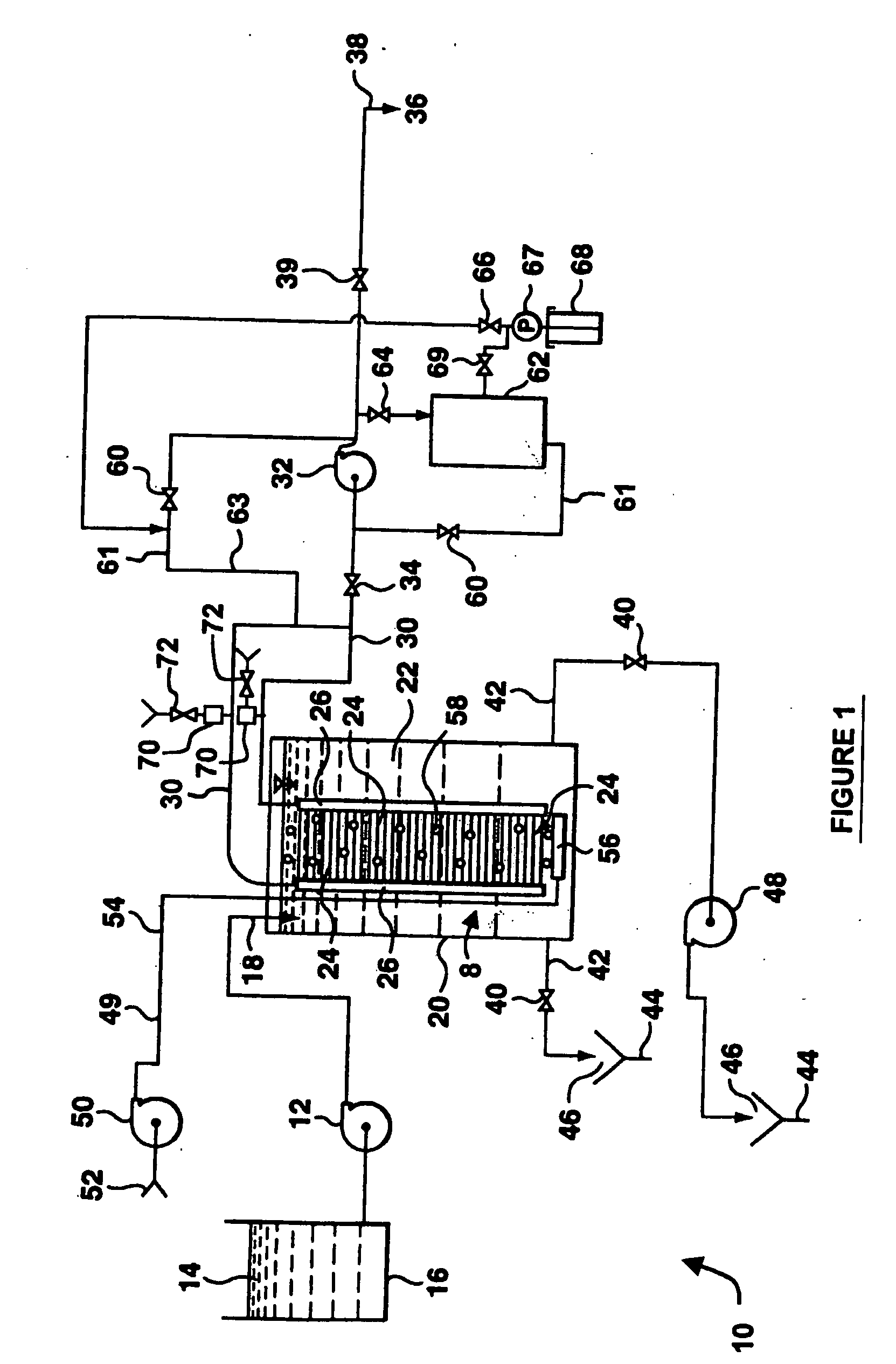

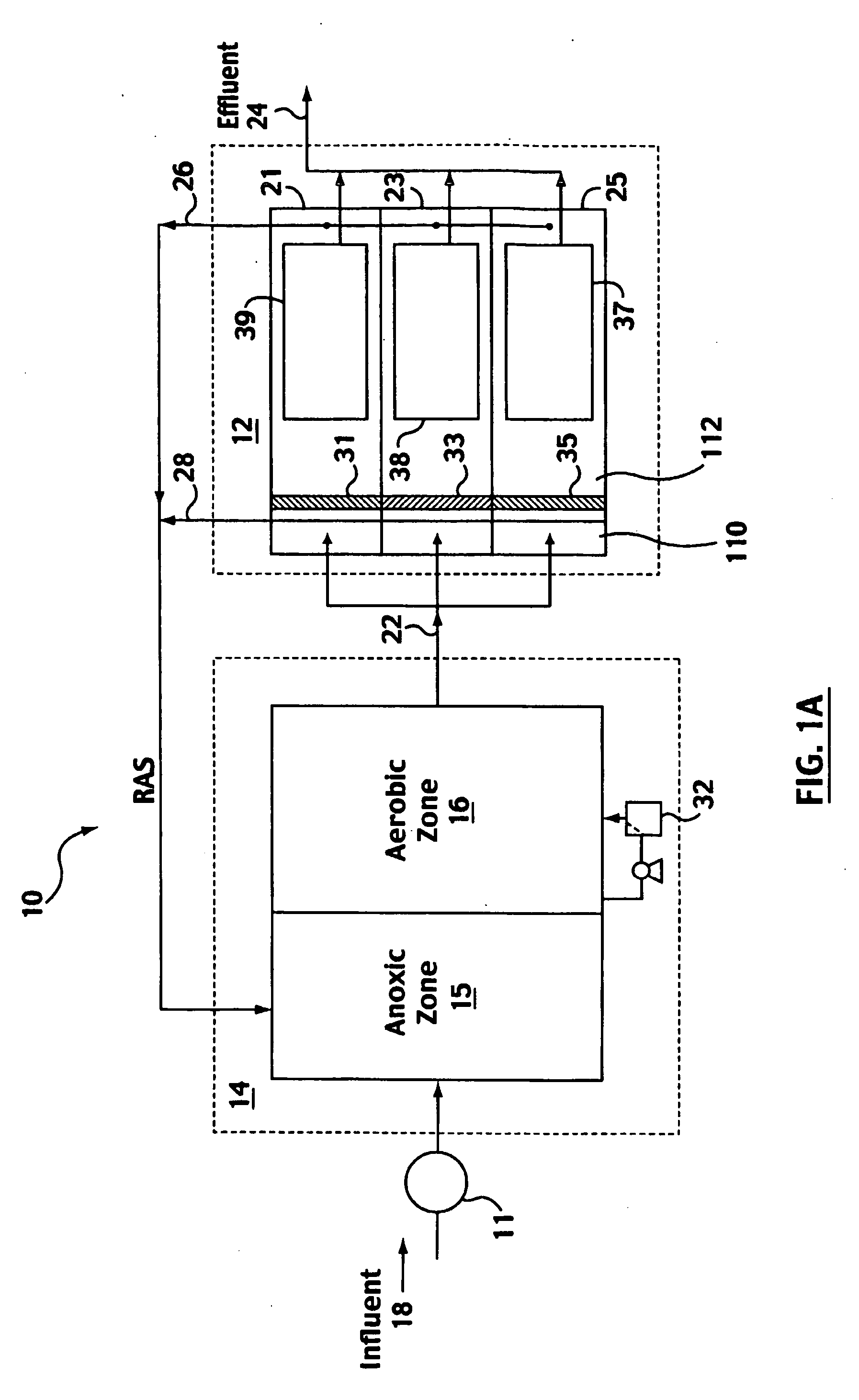

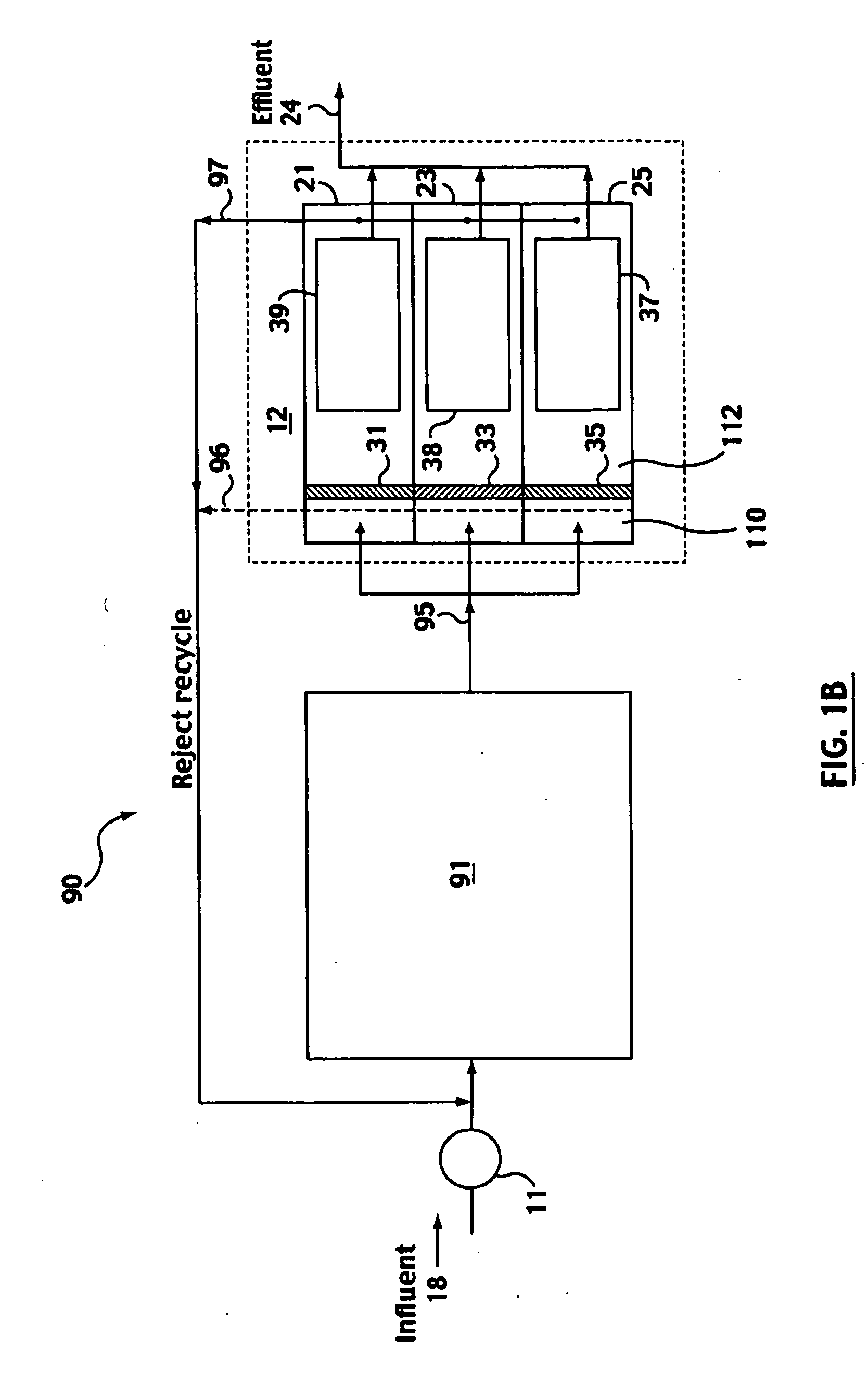

A process and apparatus is described for filtering water with immersed membranes. In a batch process, permeate is withdrawn while the flow of feed is reduced or stopped at the end of a permeation cycle. The water level is reduced to a level where a portion of the membranes are exposed to air before draining the tank. In this or another process, the level of liquid is reduced to correspond with an area of the membrane fibers having an accumulation of solids. Aeration is provided for a period of time with the liquid at this level to dislodge at least a portion of the solids from the membranes. In these or other processes, the tank is partially drained between cycles to deconcentrate the tank, aeration is provided during backwashing and intermittently while permeating, and / or retentate is withdrawn from the tank during a portion of a permeation step.

Owner:ZENON TECH PARTNERSHIP

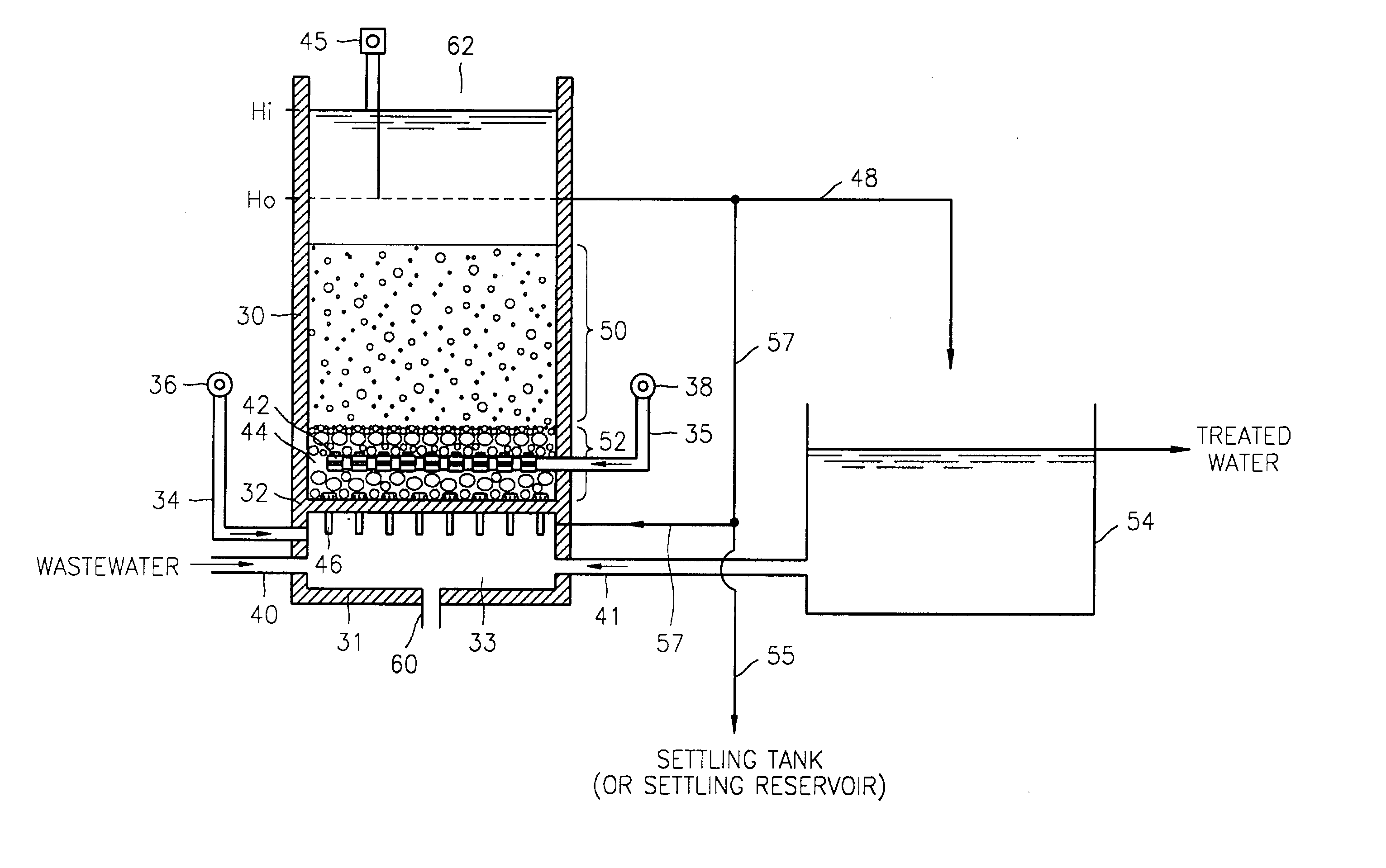

Batch style wastewater treatment apparatus using biological filtering process and wastewater treatment method using the same

InactiveUS20030111412A1Simple configurationEasy to operateTreatment using aerobic processesSpecific water treatment objectivesBio filtrationSludge

Provided is a wastewater treatment apparatus including a bottom portion and a plate formed above and spaced apart from the bottom portion to form a lower chamber with the bottom portion, an outlet installed on the bottom portion for drawing off water and sludge in the lower chamber before backwashing, a filter medium layer supported to the upper portion of the plate by the plate, the upper layer of which forms a bottom portion of an upper chamber, a wastewater introducing means connected to the lower chamber, for introducing wastewater to be treated into the lower chamber, a process air introducing means for supplying process air to the filter medium layer formed over the plate, a plurality of aerators formed over and spaced apart a predetermined distance from the plate, and mounted in a plurality of air flow pipes led to the process air introducing means, a backwash air introducing means for supplying backwash air to the lower chamber during backwashing, a backwash water introducing means for supplying backwash water to the lower chamber during backwashing, a plurality of nozzles extending from the lower chamber to the filter medium layer through the plate, a treated water discharging means for discharging the treated water having passed through the filter medium layer, and a returned water introducing means for returning the treated water having passed through the filter medium layer to the lower chamber. By means of batch style wastewater treatment apparatus utilizing biological filtering process, the organic matter, suspended solid matter, nitrogen and phosphorus can be efficiently removed.

Owner:SAMSUNG ENGINEERING CO LTD

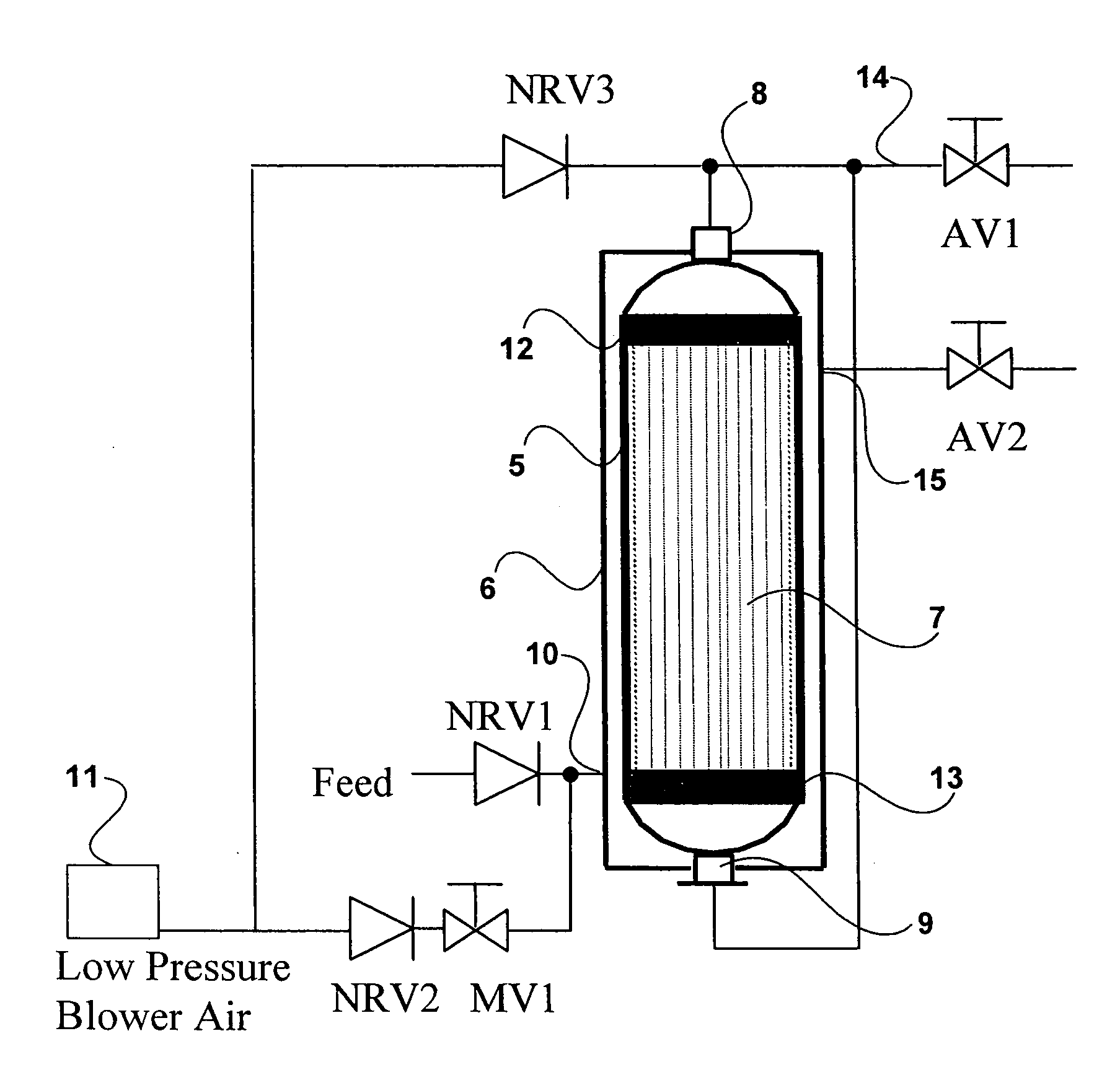

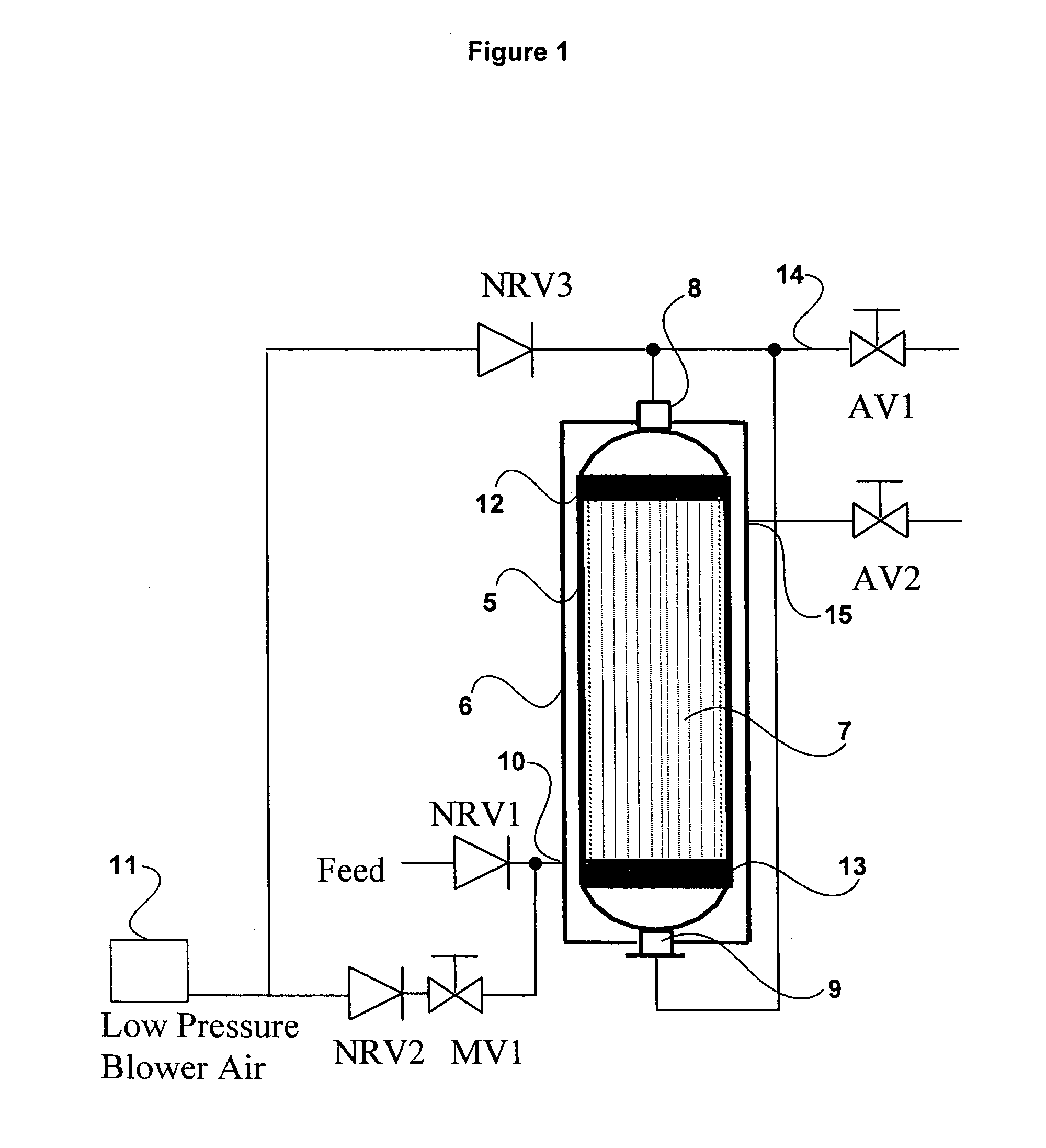

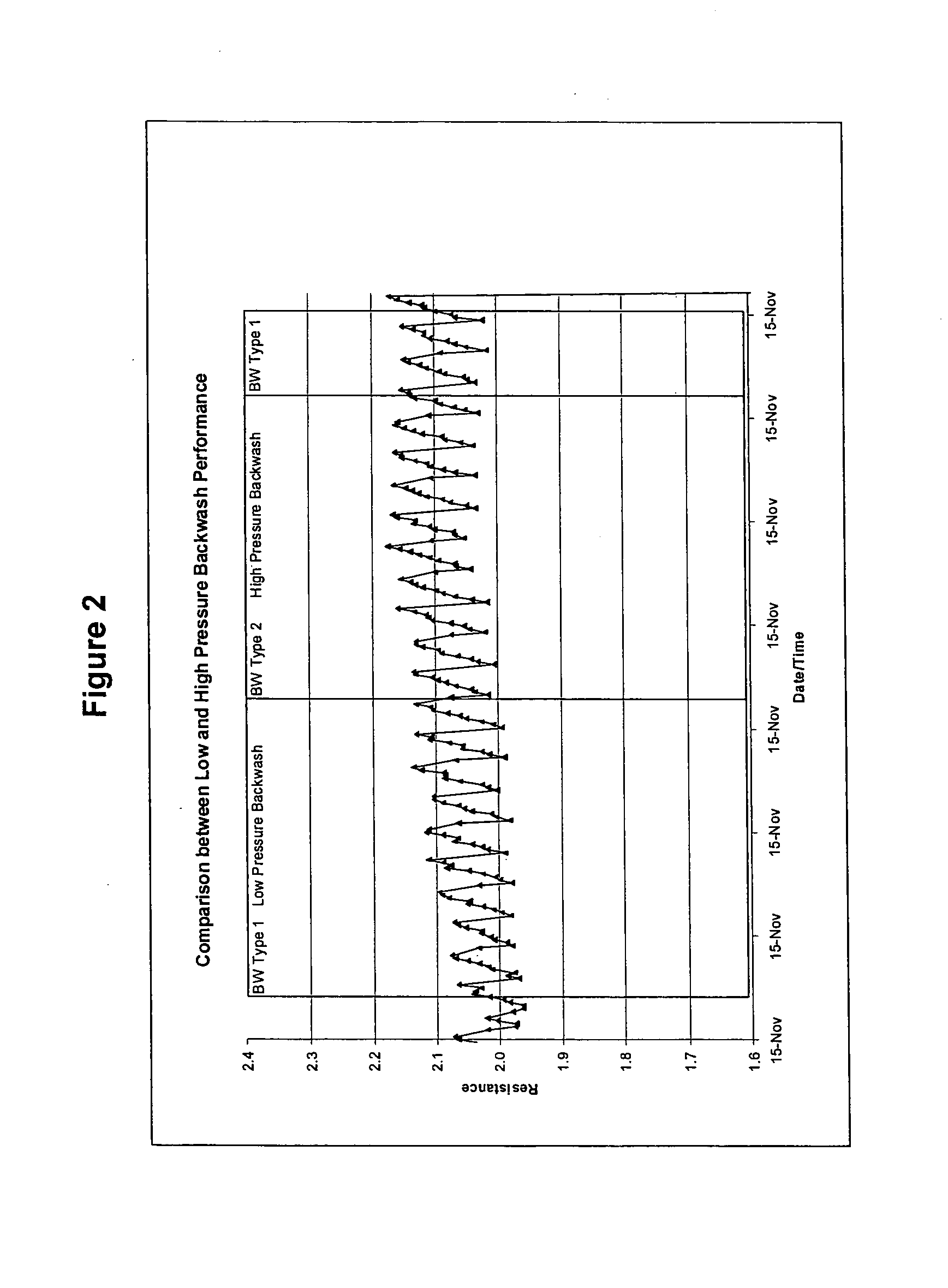

Low pressure backwash

InactiveUS20090255873A1Provide usageMembranesSemi-permeable membranesChemistryMembrane configuration

A method of backwashing a membrane filtration system comprising at least one permeable hollow membrane, the method comprising the step of applying a low-pressure gas to the permeate remaining present in the system when the filtration process is stopped or suspended to provide liquid for backwashing the pores of the membrane during a backwashing process.

Owner:EVOQUA WATER TECH LLC

Efficient photocatalysis water treatment method and device

ActiveCN103086469AReduce COD valueIncreased efficiency in the rearWater/sewage treatment by irradiationWater/sewage treatment by oxidationHigh pressure waterEngineering

The invention provides an efficient photocatalysis water treatment device. The efficient photocatalysis water treatment device comprises a tank body, a quartz tube, a backflow port, an extra-ultraviolet tube, a three-dimensional ceramic honeycomb net photochemical reaction chamber, a sewage distributor, a sewage port, an aeration port, an aeration assembly, a sewage draining port, a medicine distributing assembly, a medicine port, a coarse filtering net, a high-pressure backwashing device, a high-pressure water port, a tail gas recovering port and a reciprocating motion device; three ports are formed at the lower part of the tank body, namely, an organic sewage port, the aeration port and the medicine port; the three-dimensional ceramic honeycomb net photochemical reaction chamber for loading the extra-ultraviolet lamp and a nanometer TiO2 photocatalyst are formed at the upper part of the tank body; and the tail gas recovery port is formed at the upper part of the tank body.

Owner:JIANGSU DDBS ENVIRONMENT REMEDIATION

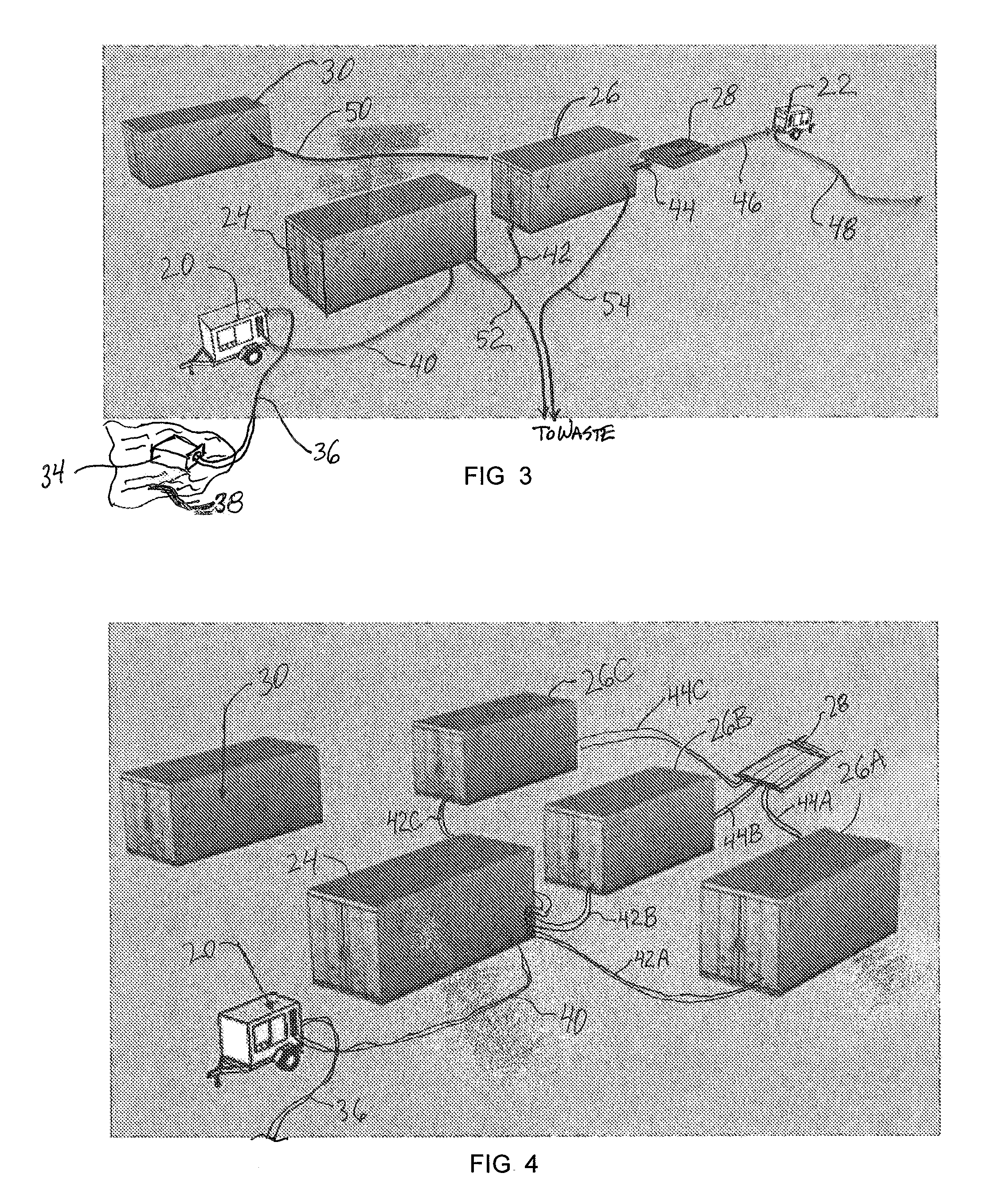

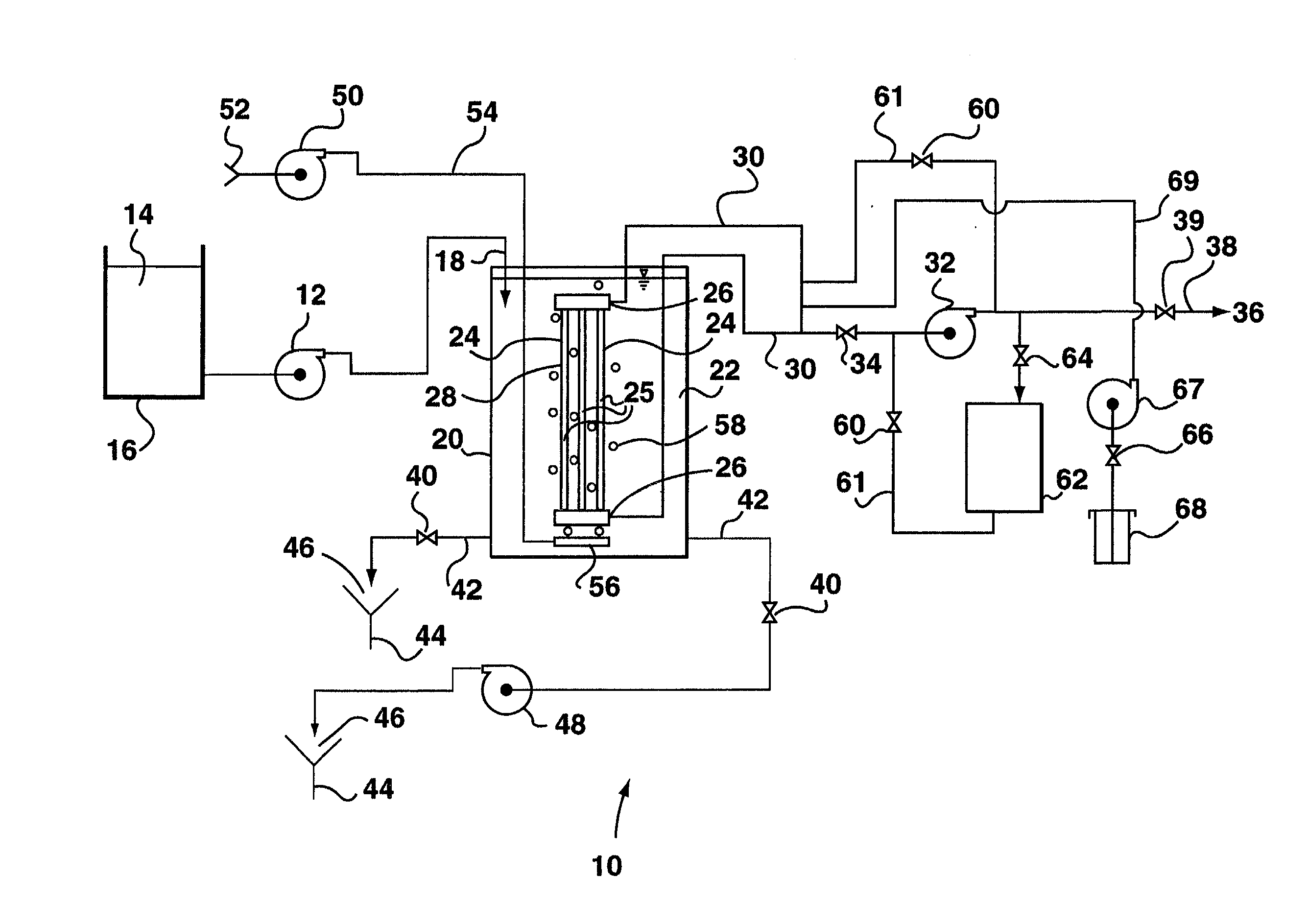

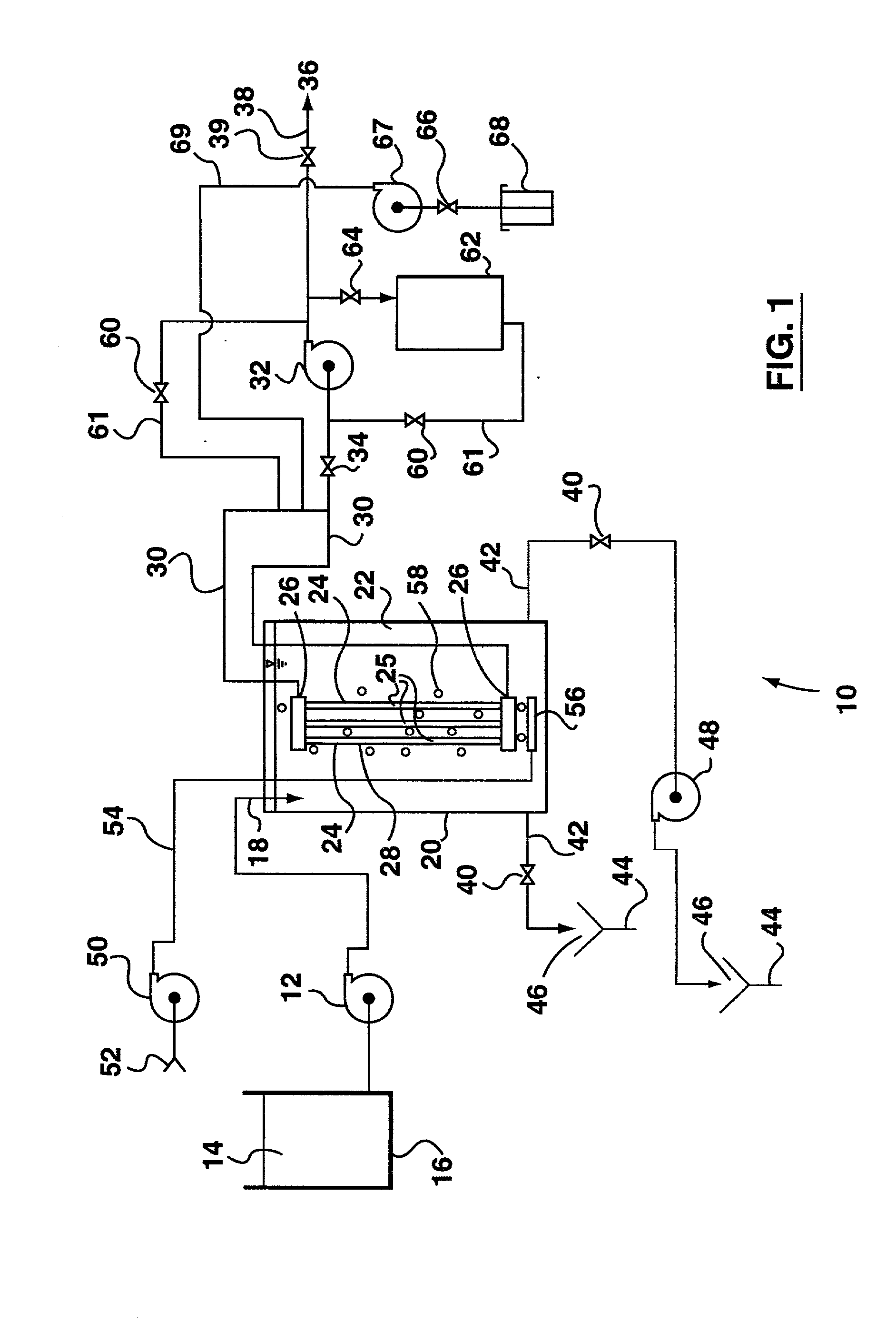

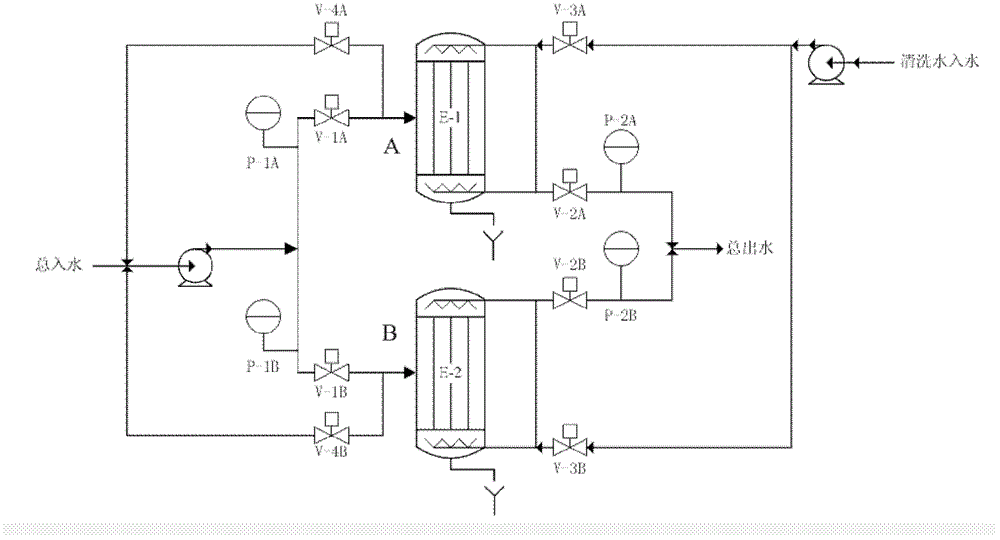

Mobile water purification system and method

InactiveUS20150166385A1Reduce risk of damageIrreparably damagedUltrafiltrationTreatment involving filtrationFiltrationUltrafiltration

A mobile water purification system is configured as modules to be air-lifted to a site requiring potable water. Raw water is pumped to a pre-treatment module that separates suspended solids and preferably oxidizes organic contaminants. At least one, and preferably two or more filtration modules coupled in parallel, then remove contaminants using ultrafiltration and / or reverse osmosis, and pass treated water to a storage tank. A control system operates valves to stagger backwashing of filtration modules, allowing one such module to be backwashed while allowing others to continue filtering water. The control system can selectively bypass a reverse osmosis unit, and disable related booster pumps, depending upon raw water quality. During backwash cycles, sodium bisulfite is added to fill water directed into ultrafiltration units to neutralize free chlorine present in backwash fluid.

Owner:HENNESY MECHANICAL SALES

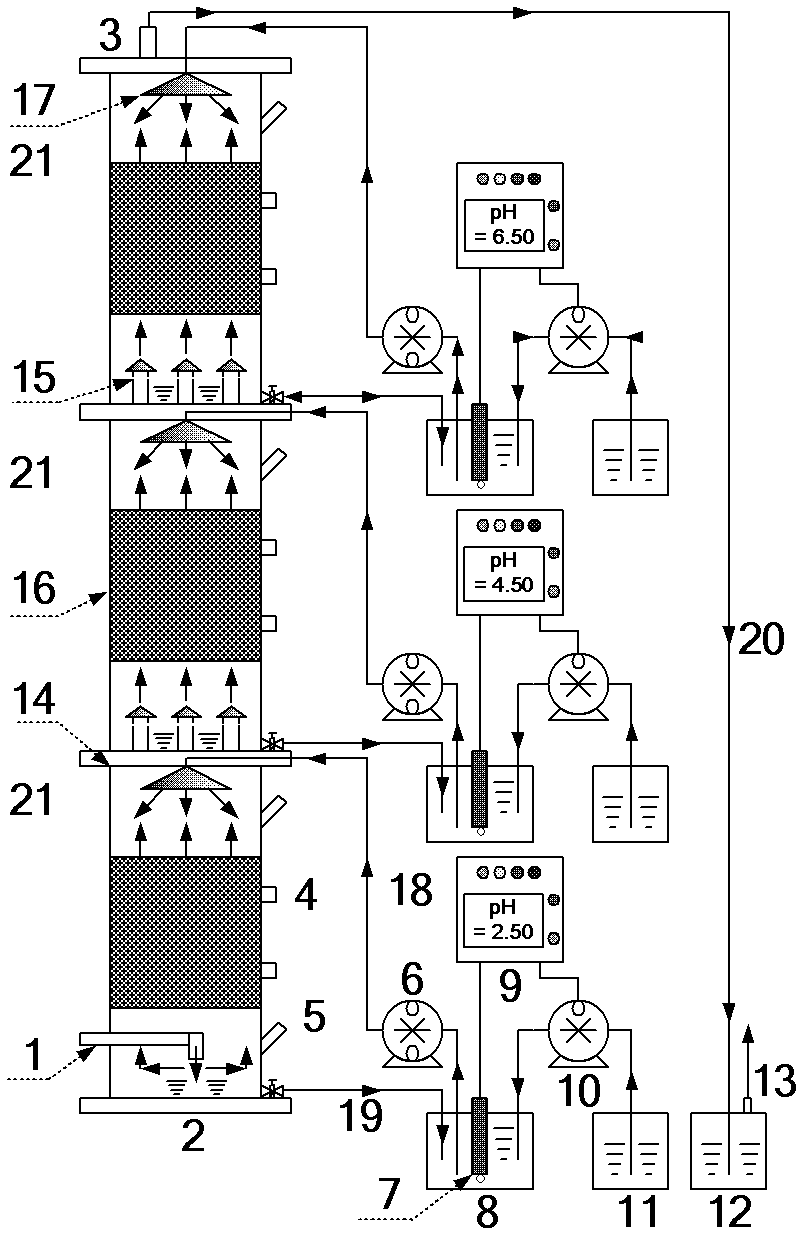

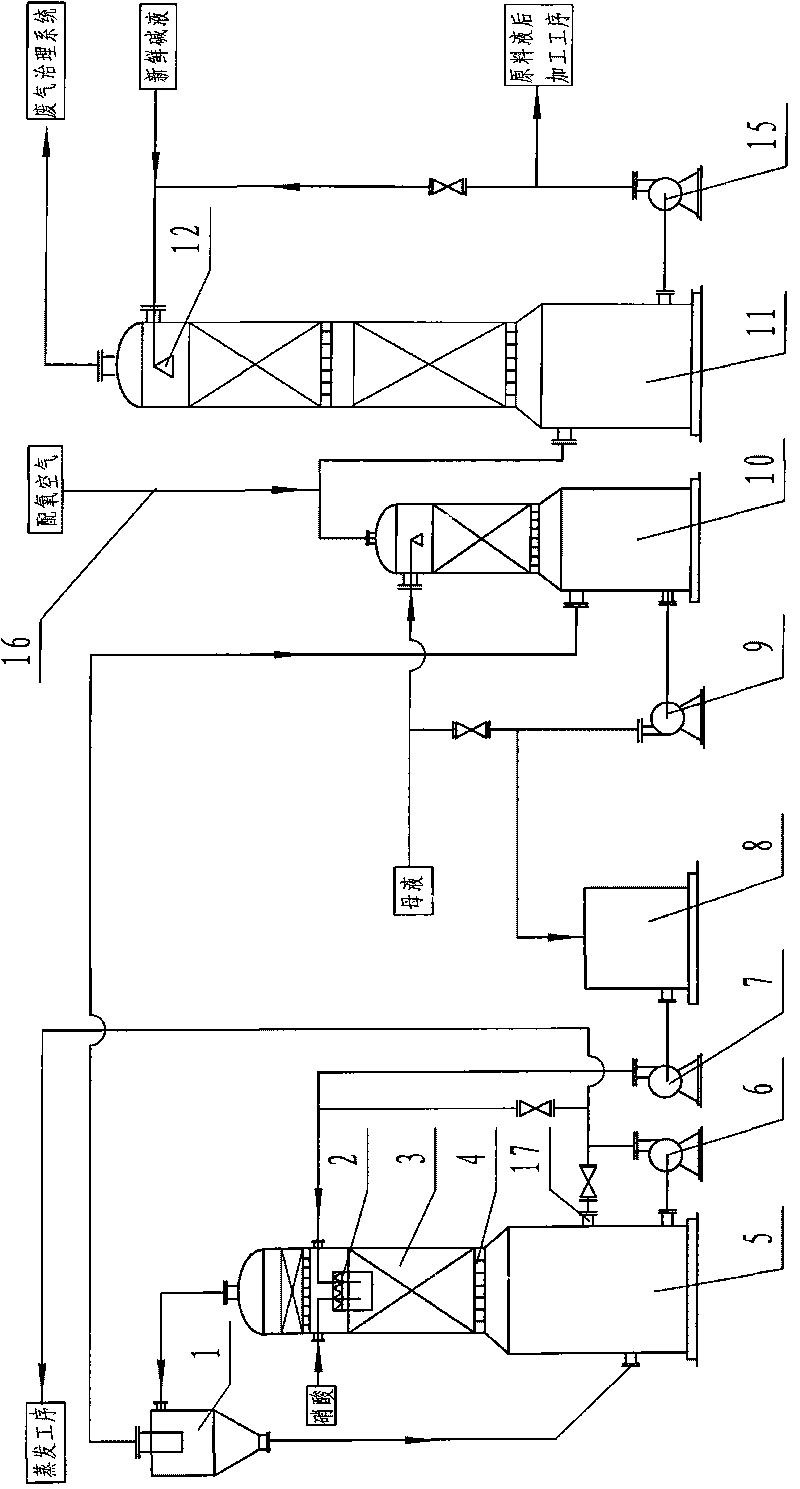

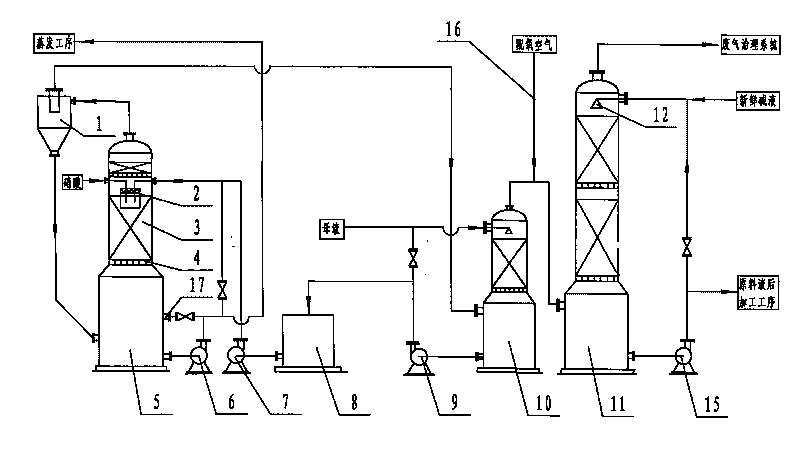

A method for treating waste gas with a biological trickling filter tower and its special device

InactiveCN102284245AImprove blockageEven contactDispersed particle separationAir quality improvementTemperature controlTrickling filter

The invention discloses a method for treating waste gas with a biological trickling filter tower: the waste gas is passed through the bottom of the biological trickling filter tower, treated by the biological trickling filter tower, and the treated waste gas is discharged from the top, and the biological trickling filter tower is composed of The bottom of the tower with exhaust gas inlet, the tower body, and the top of the tower equipped with exhaust gas outlet are composed. The tower body is composed of several biological treatment units stacked from bottom to top, and the biological treatment units on adjacent layers are arranged There is a liquid interlayer, and the air vents for the adjacent layers are arranged on the liquid interlayer, and each layer of biological treatment units is independently equipped with a nutrient solution spray system and a temperature control device from top to bottom. Biological packing layer and nutrient solution receiving pool; the invention increases the processing load of the unit packing; improves the plugging problem of the packing layer, avoids the occurrence of channeling phenomenon, and has uniform and sufficient gas-liquid contact; packing replacement and backwashing are more convenient; the process Economical, suitable for the purification treatment of complex volatile organic mixed pollutants.

Owner:ZHEJIANG UNIV OF TECH

Self-cleaning sewage purification treatment device

InactiveCN110812922AContinuous cleaningEasy to cleanHollow article cleaningMembrane filtersSewageFan blade

The embodiment of the invention discloses a self-cleaning sewage purification treatment device. The self-cleaning sewage purification treatment device comprises a mounting cover with a downward opening; a filter barrel is connected into an opening in the bottom end of the mounting cover through a thread; a partition cylinder with a downward opening is arranged in the middle of the interior of themounting cover; a water inlet and a water outlet which communicates with the partition cylinder are respectively formed in the outer side of the mounting cover; a backflushing opening extending to theouter side of the mounting cover is formed in one side of the partition cylinder; one end of the backflushing opening is obliquely cut on the outer side of the partition cylinder, so that clear waterflowing into the partition cylinder through the backflushing opening flows around the inner wall of the partition cylinder, continuous thrust is generated on fan blades in the process again, a rotaryframe is driven to rotate around the outer side of a screen cylinder, and the interior of the device is continuously cleaned through the rotary frame; a push rod mechanism can drive the rotating rotary frame to do reciprocating up-down sliding action, and when the device is used for backwashing, the effect of cleaning the outer side of the screen cylinder and the inner side of the filter barrel is better.

Owner:韶关市诚湃新能源科技有限公司

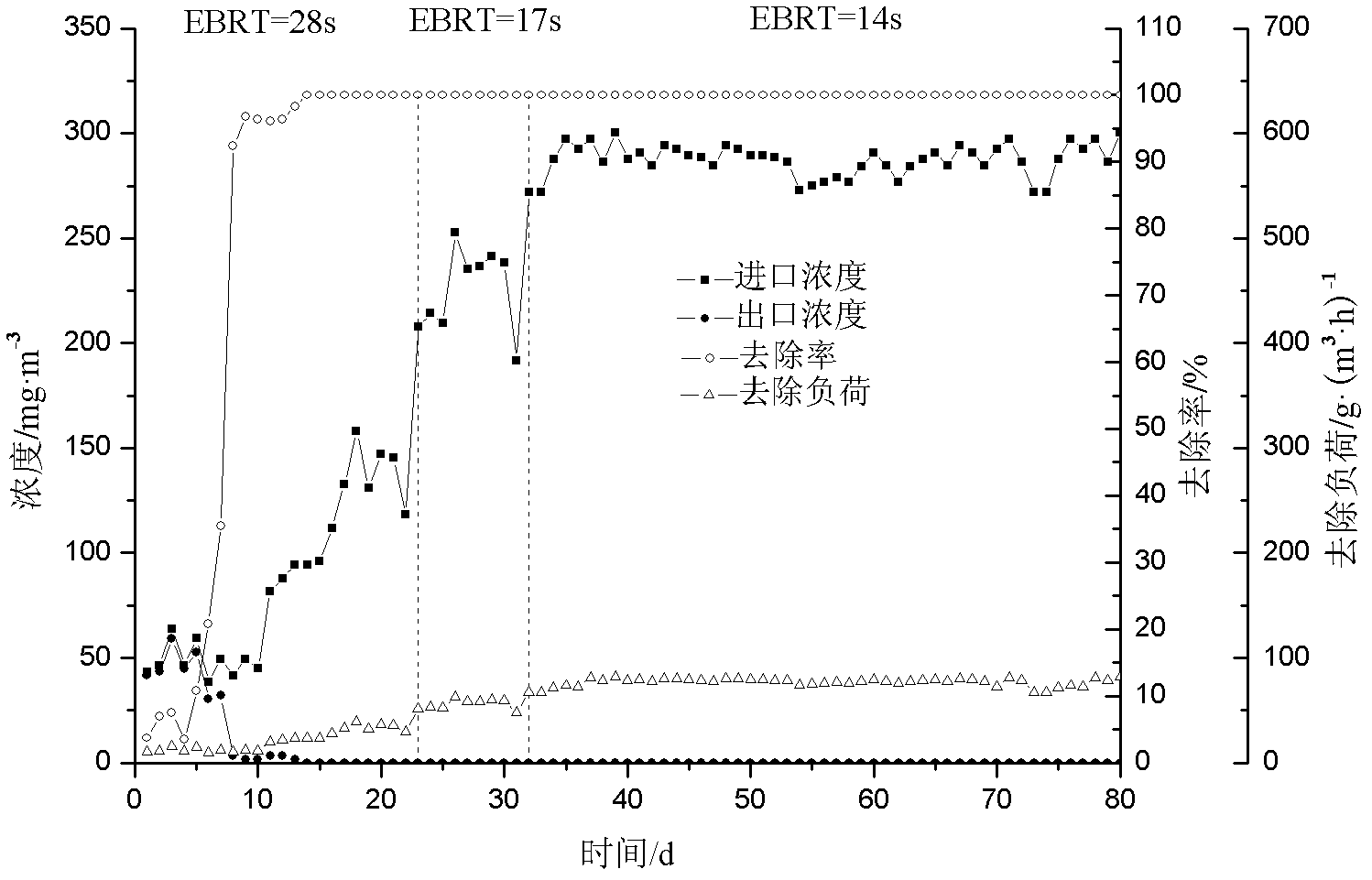

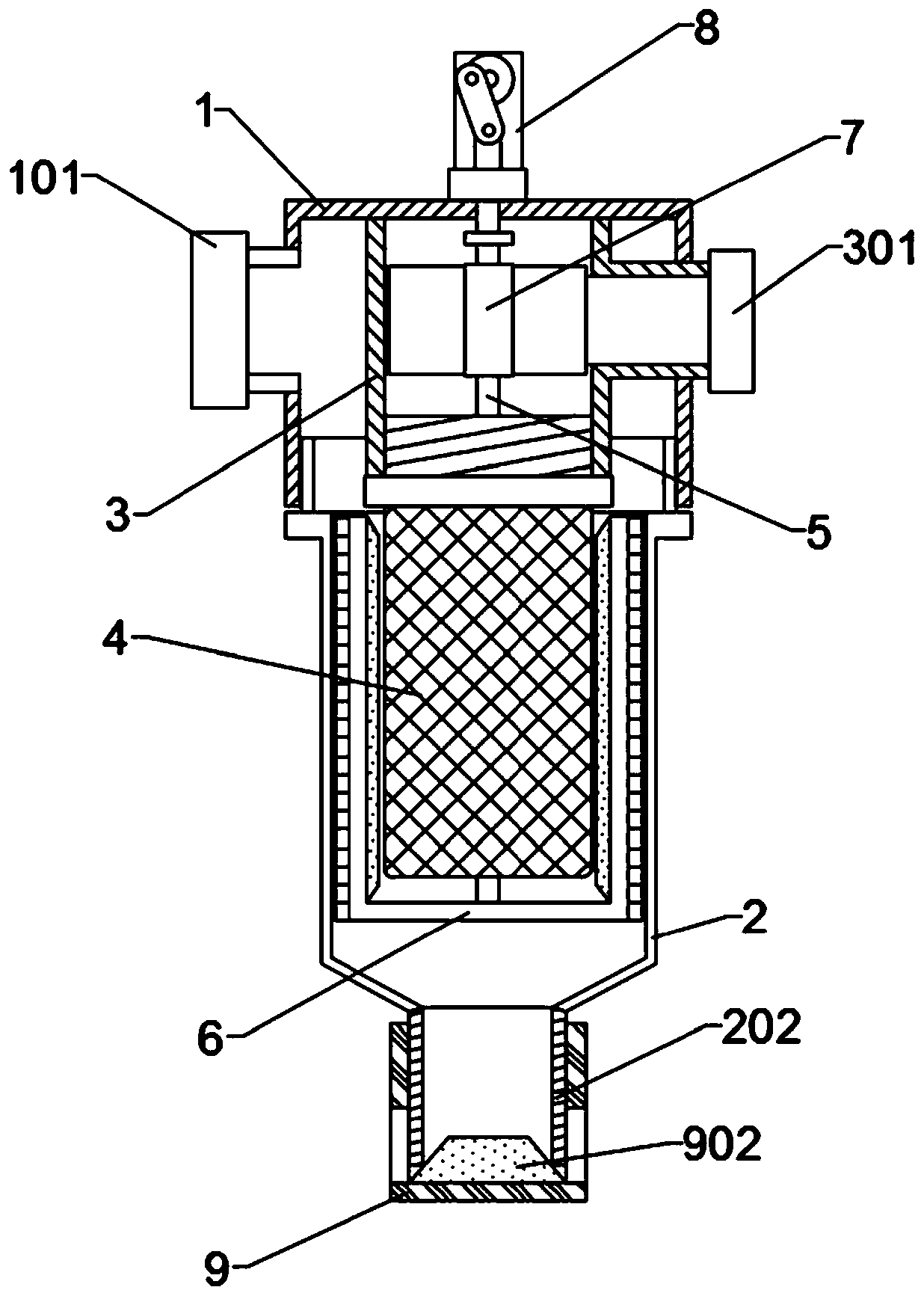

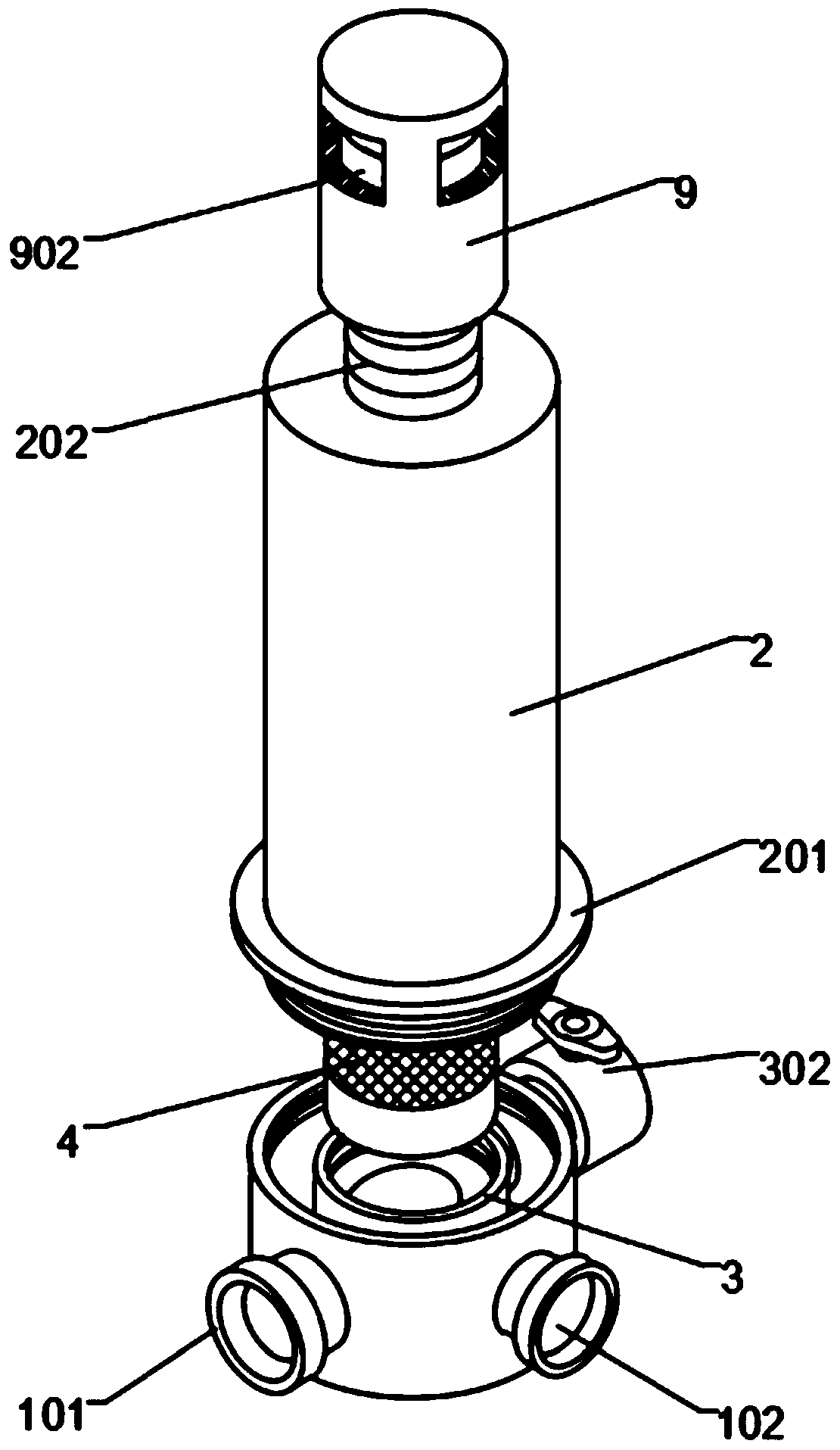

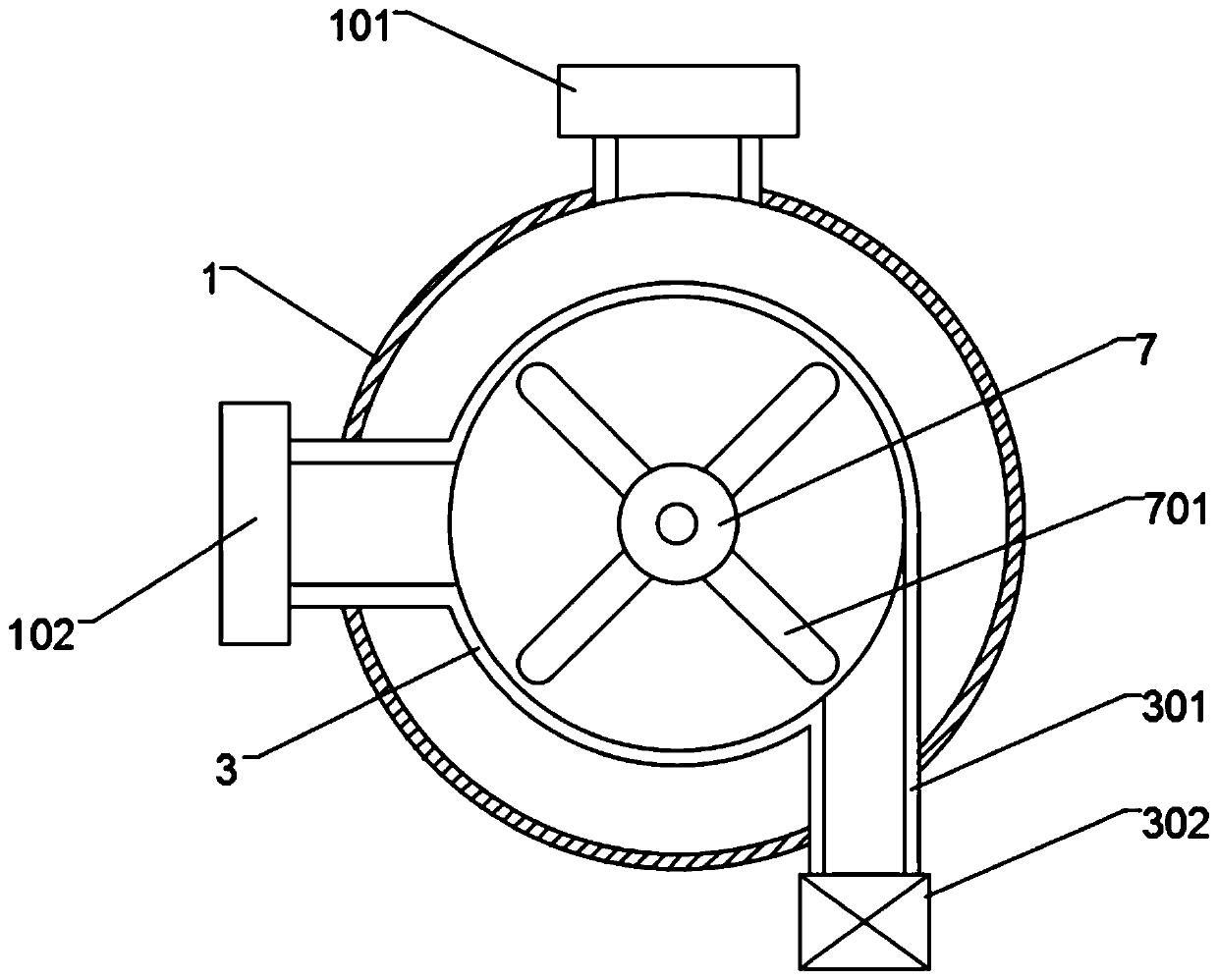

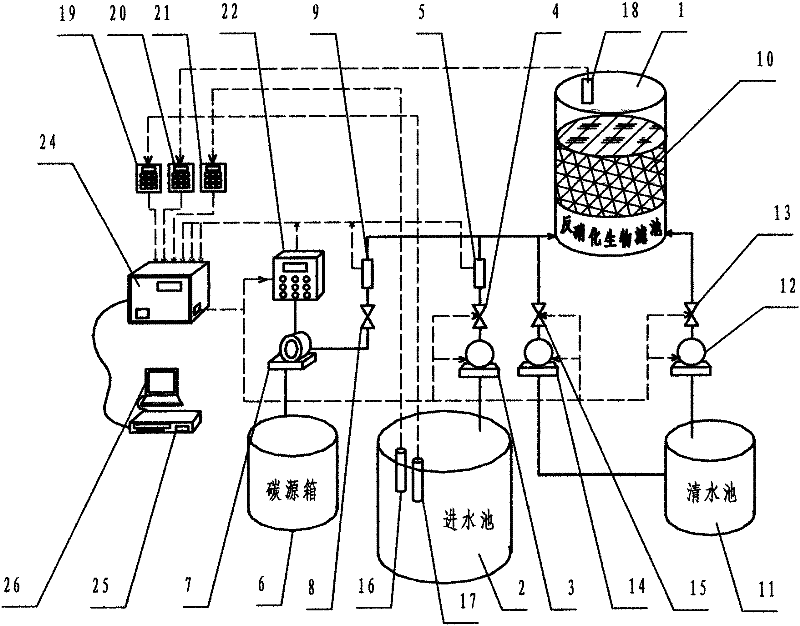

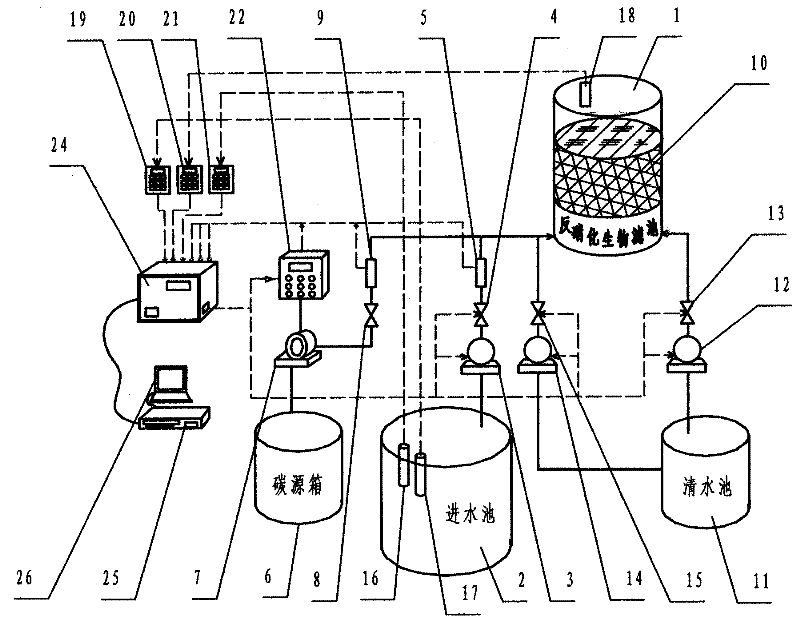

Device and method for optimized control over carbon source feeding in denitrification biofilter process

ActiveCN102328996AFlexible controlImprove denitrification effectTreatment with anaerobic digestion processesInlet valveStreamflow

The invention relates to a device for optimized control over carbon source feeding in a denitrification biofilter process. The device is provided with a denitrification biofilter, a carbon source box, a frequency-conversion carbon source pump, a carbon source flowmeter, a backwashing air pump and a backwashing air inlet valve; the denitrification biofilter is internally provided with an online-water-inlet nitrate sensor, an online-water-inlet dissolved oxygen sensor, an online-water-outlet nitrate sensor, a nitrate determinator, a dissolved oxygen determinator, a process controller, and an industrial personal computer; and a water inlet pipeline is provided with a water inlet pump, a water inlet valve and an online-water inlet flowmeter. A method for optimized control cover the carbon source feeding is characterized by comprising the following steps of: (1) introducing water; (2) processing and judging parameters; (3) processing frequency ft by a frequency converter; (4) preventing excessive feeding of a carbon source; (5) stably running; (6) diagnosing faults; and (7) performing backwashing. The device and the method disclosed by the invention can be widely applied to sewage advanced treatment and nitrogenous industrial wastewater treatment, is particularly suitable for producing high-quality recycled water, have the advantages of complete structure, precision for control, good effect and high efficiency.

Owner:BEIJING DRAINAGE GRP CO LTD +1

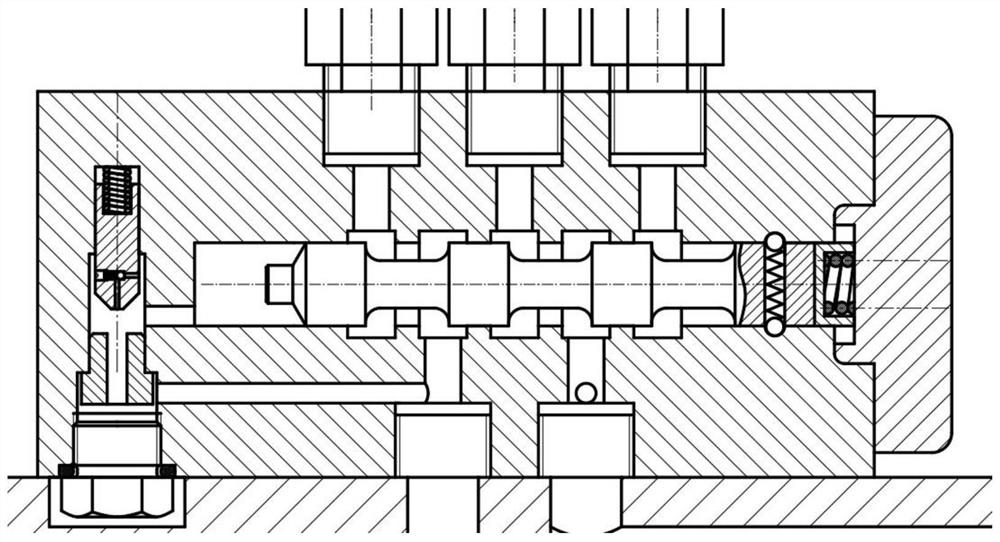

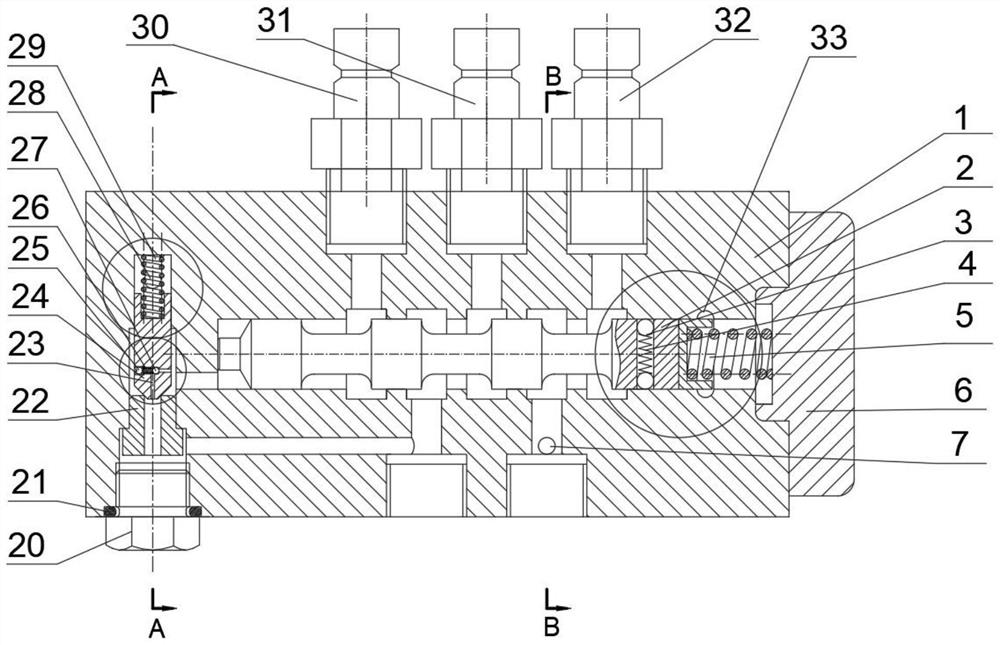

Differential pressure adjustable automatic backwashing filter

InactiveCN101785939AStatus real-time feedbackAchieving Quantitative ControlFluid-pressure actuator componentsStationary filtering element filtersControl engineeringElectrical control

Owner:四川航天神坤科技有限公司

Dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment

ActiveCN102616986ACompact structureReduce energy consumptionMultistage water/sewage treatmentActivated sludgeWater flow

The invention provides a dynamic membrane automatic water flow-out solid-liquid separation method applicable to domestic sewage treatment. The method includes: adding powder particles with fine water permeable performance into activated sludge to form biological intensified powder mixed liquid to structurally improve the activated sludge; combining with the dynamic membrane separation technique to greatly improve the filtering capacity and water permeability of dynamic membrane filter cakes; performing solid-liquid separation of discharged water by allowing a dynamic membrane component to be driven by a water head having lower fixed gravity action and formed by liquid level waterhead between the upper liquid level of the immersed dynamic membrane component in a reaction device and a wateroutlet, stably controlling the unit area membrane filter flux of the dynamic membrane component to be more than 20-60L / m2h and the continuous operating time to be longer than 120h without action of external power; and allowing the dynamic membrane to completely shed with the air backwashing time being 1min-2min and the air inlet pressure being 9.8-49kPa. The dynamic membrane component does not need to be chemically cleaned regularly, and control and operation of the method can be automatically controlled in the whole process. The dynamic membrane solid-liquid separation technique can realize automatic water flowing out under differential pressure of low-liquid-level waterhead, energy consumption is greatly reduced, operation process is simplified, and discharged water is high in quality.

Owner:TONGJI UNIV

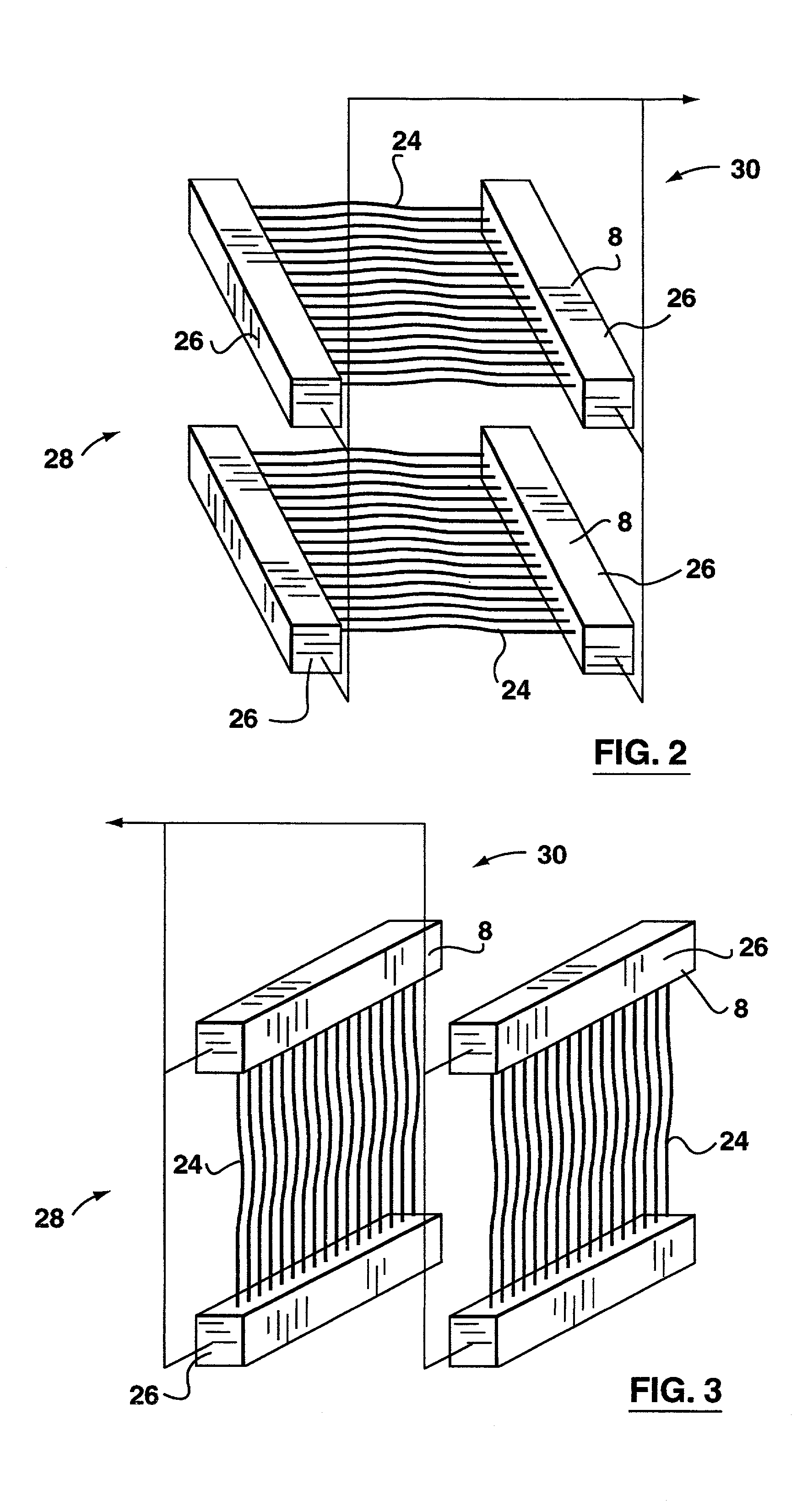

Screening apparatus for water treatment with membranes

InactiveUS20070163959A1Liquid separation auxillary apparatusUltrafiltrationWater treatment systemMechanical engineering

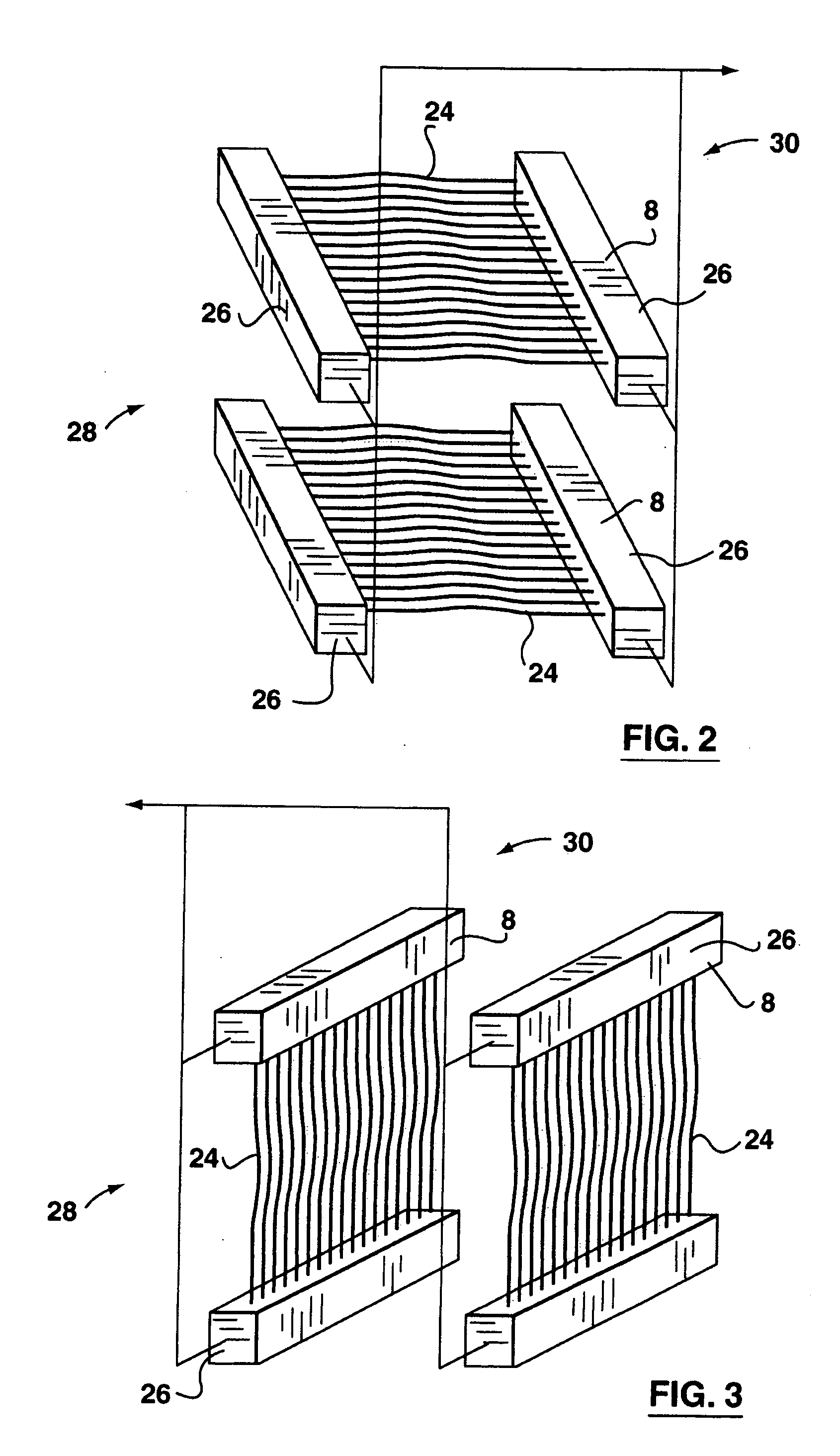

A static screen used upstream of a membrane assembly within a water treatment system has a screening surface with a number of openings distributed over its area. Liquid flows through the screening surface to reach the membrane assembly. Various shapes of screening surfaces are described including undulating panels and geometric shapes. Methods for cleaning the screen are described including aeration and backwashing. Various treatment systems or process designs incorporating the screen are described.

Owner:COTE PIERRE LUCIEN +5

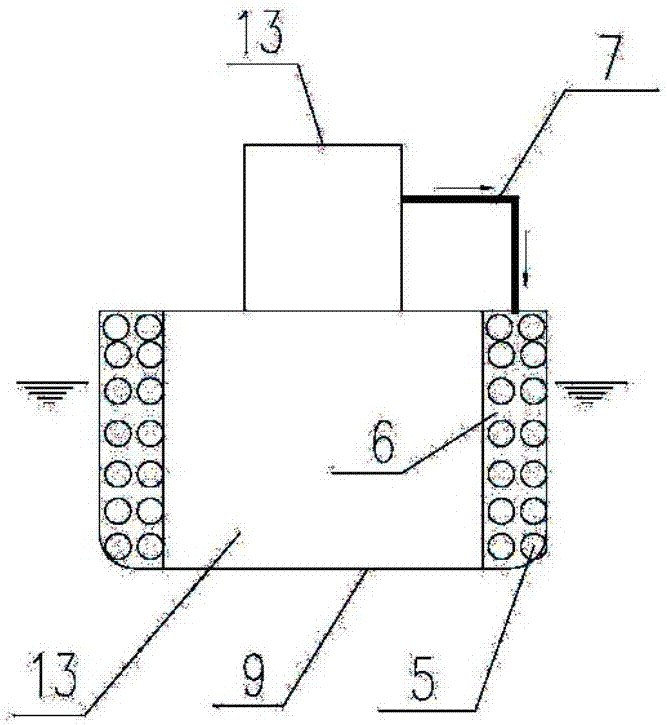

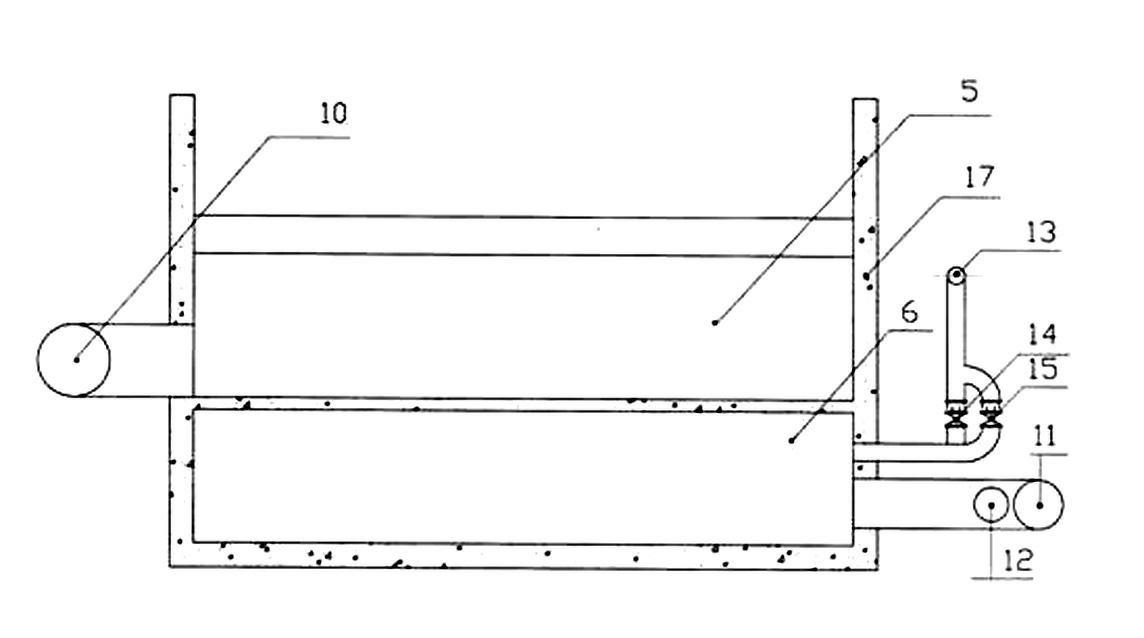

Drainage combined with sludge-cleaning vehicle sludge-water separating system

InactiveCN101333059AAchieving PayloadSludge treatment by de-watering/drying/thickeningDomestic plumbingSludgeSlurry

A sludge-water separation system for a combined sewer sludge-cleaning vehicle comprises a rotary filter cylinder (8), a bracket (5), a buoy (10), a sewage pump, a hydraulic motor (13), a high-pressure backwashing water pipe (6), a sludge discharge valve (12), as well as connecting pipes and valves; wherein, the rotary filter cylinder and the sewage pump adopt hydraulic drive. During operation, the slurry sucked into a sludge tank is filtered through the sieve of the rotary filter cylinder, then pumped out of the tank body through the sewage pump, and finally discharged into the sewer. Therefore, the sludge tank can continue suck sludge and sewage. The hydraulic motor drives the rotary filter cylinder to endlessly rotate to prevent the sieve of the filter cylinder being jammed by the dirt in the sludge tank. The high-pressure backwashing water pipe effectively ensures the smooth screening of the sieve and can thoroughly wash the rotary filter cylinder after the completion of the sludge-cleaning operation so as to reduce the corrosion of the system caused by the slurry and make sure the operation can go on smoothly. The remaining viscous sludge in the tank body is discharged out of the vehicle through a sludge discharge valve, then collected or naturally dried and finally carried to refuse sites.

Owner:WUHAN UNIV OF TECH +1

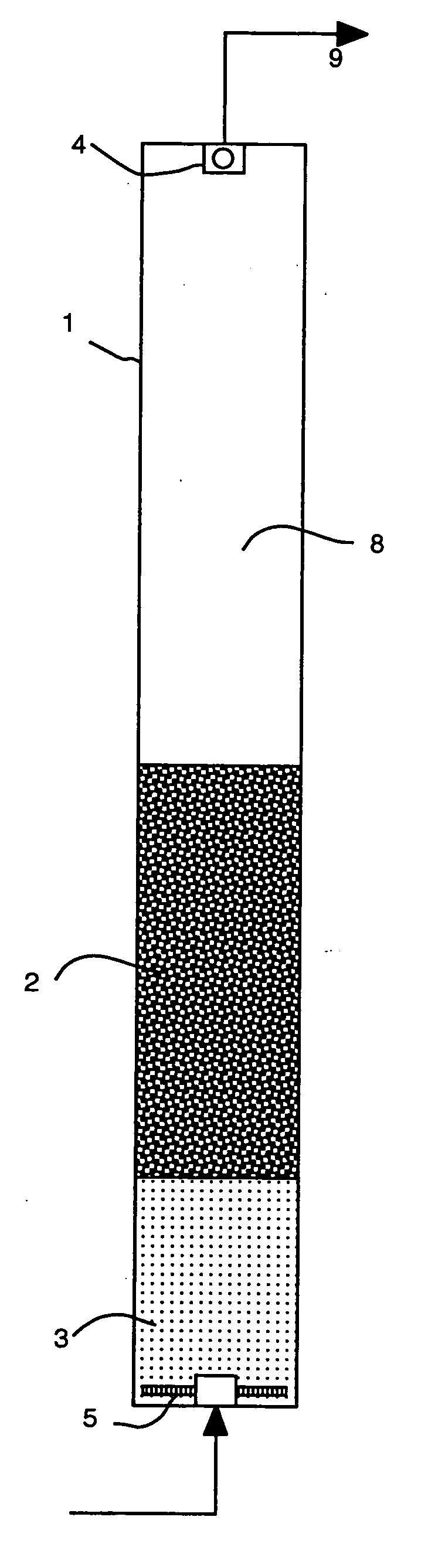

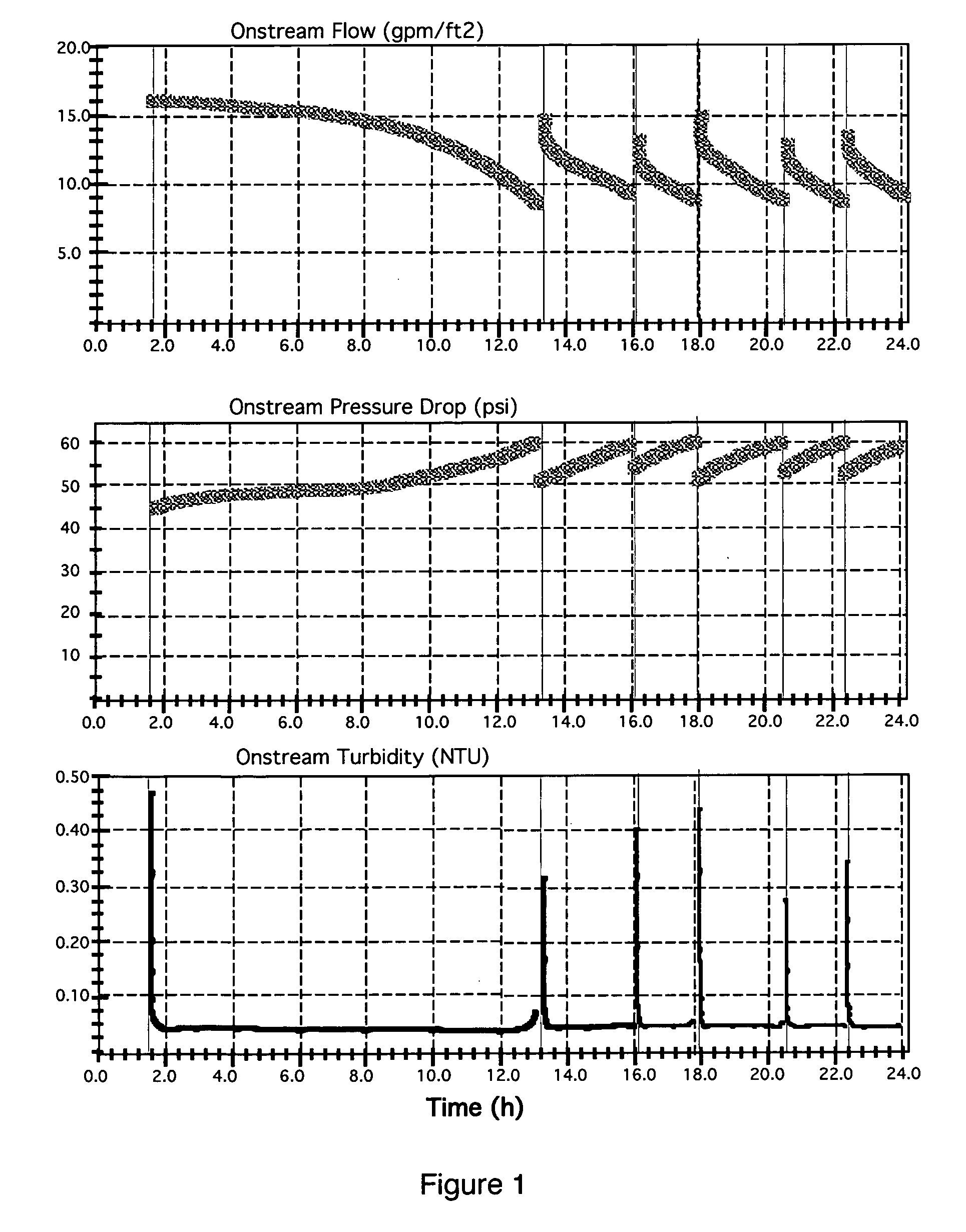

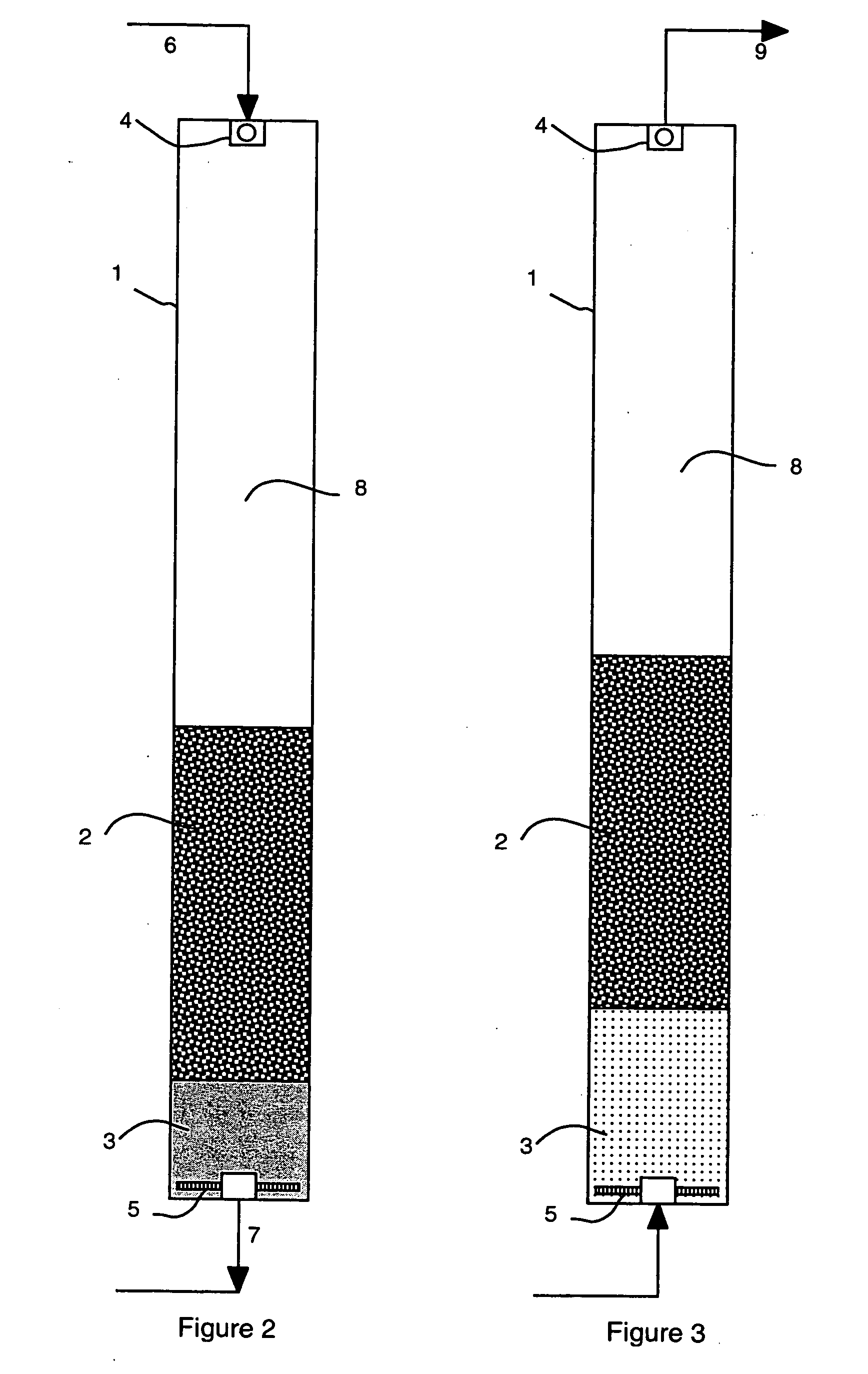

Method and apparatus for increasing filter contaminant loading capacity

ActiveUS20060027511A1Shorten the length of timeReduce penetrationWater/sewage treatmentLoose filtering material filtersEnvironmental engineeringMedia filter

The filter contaminant loading capacity of a depth granular. media filter is increased by imposing a so-called “back-slip” on the filter bed. At intervals between normal backwashing, a volume of liquid is passed upwardly through the media bed under flow conditions selected to displace at least some of the contaminants upwardly in the bed while essentially removing none of the contaminants from the filter vessel. Preferably, the filter bed comprises at least two media types of different but uniform particle sizes and densities, the media types each forming a distinct layer in which the effective particle size of the media in each successive layer decreases in a downward direction in the vessel.

Owner:ECO TEC INC

Automatic backwashing filter and working method

InactiveCN112933697ARealize automatic switchingHigh degree of automationStationary filtering element filtersSewage outfallMechanical engineering

The invention discloses an automatic backwashing filter and a working method, which are suitable for filtering impurities in sewage. The filter comprises a runner switching main valve, a valve plate and a barrel, the valve plate is arranged on an upper opening of the barrel, and the main valve is arranged on the valve plate and communicated with the interior of the barrel through a runner; two flow channels are arranged on the valve plate, one flow channel is a filtering flow channel communicated with the inner space of the filter screen, and the other flow channel is a backwashing flow channel communicated with the space between the filter screen and the cylinder body; the flow channel switching main valve comprises a valve body, a sewage draining exit, a water inlet and a water outlet are sequentially formed in the valve body from left to right, and a filtering outlet connected with the filtering flow channel and a backwashing outlet connected with the backwashing flow channel are sequentially formed in the lower portion of the valve body from left to right; wherein a two-position five-way reversing valve group capable of automatically switching a normal working mode or a backwashing mode according to the blockage condition of the filter screen is arranged among the drain outlet, the water inlet, the water outlet, the filter outlet and the backwashing outlet. The filter is simple in structure, does not consume energy, and automatically switches backwashing.

Owner:CHINA UNIV OF MINING & TECH

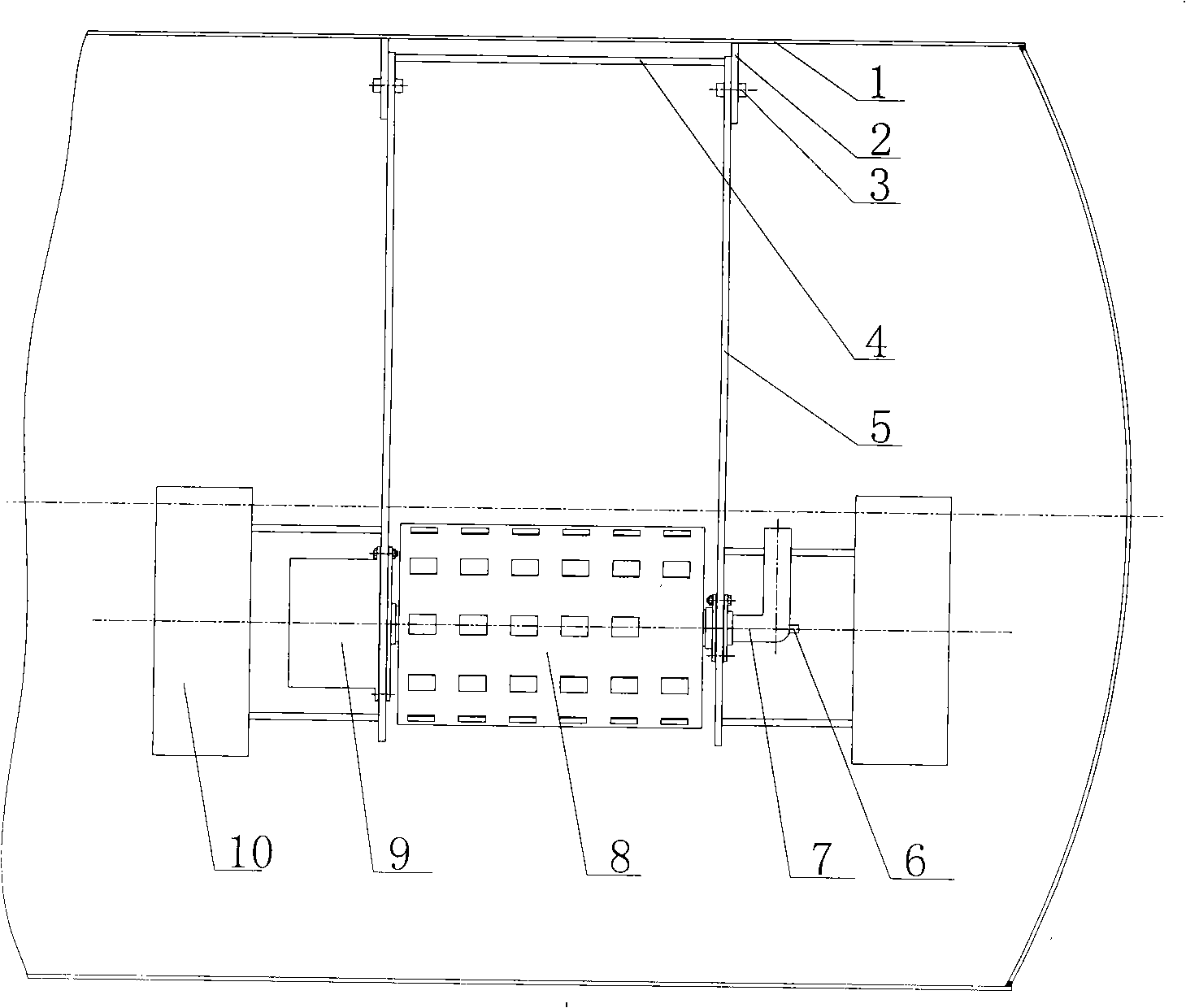

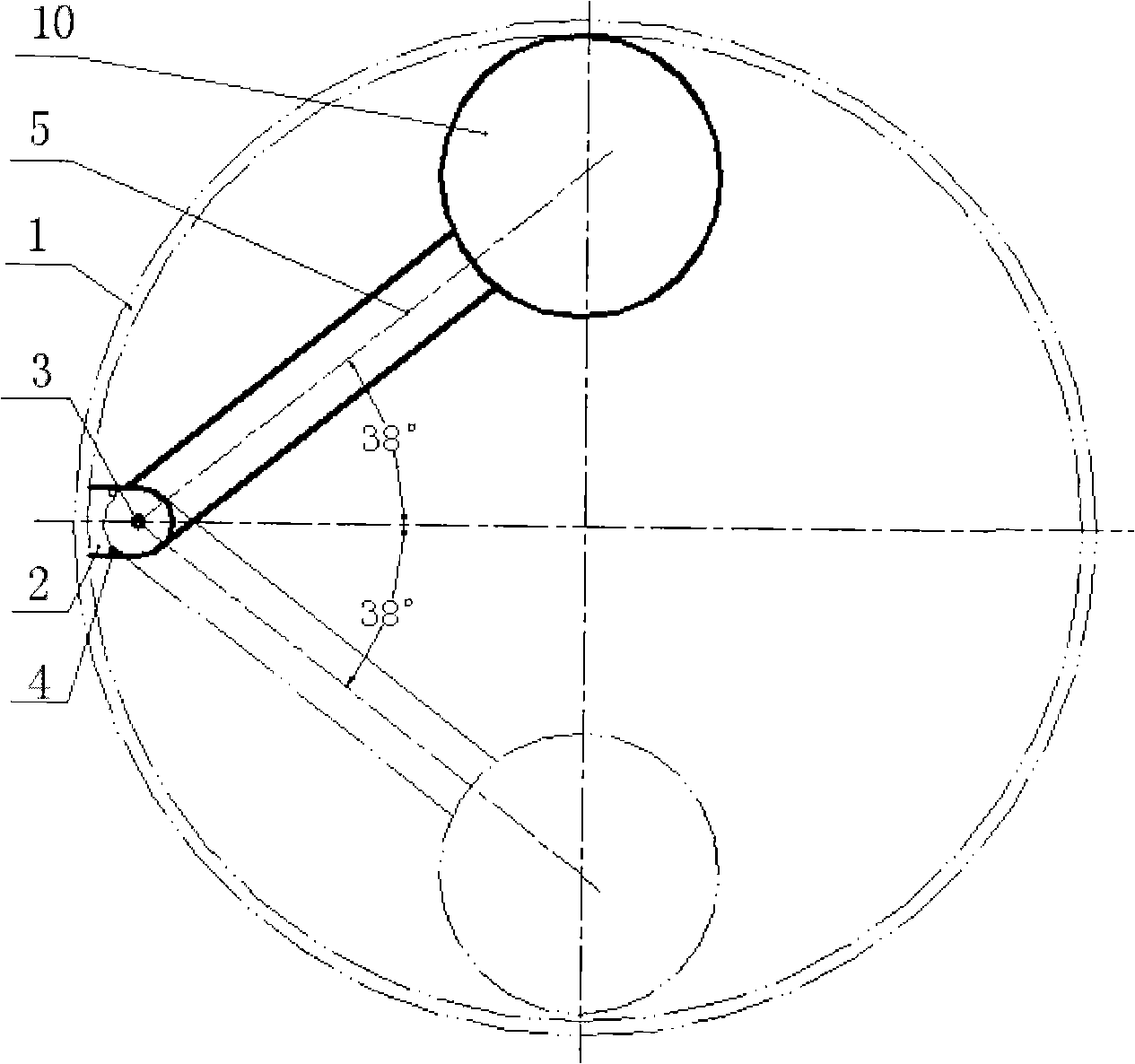

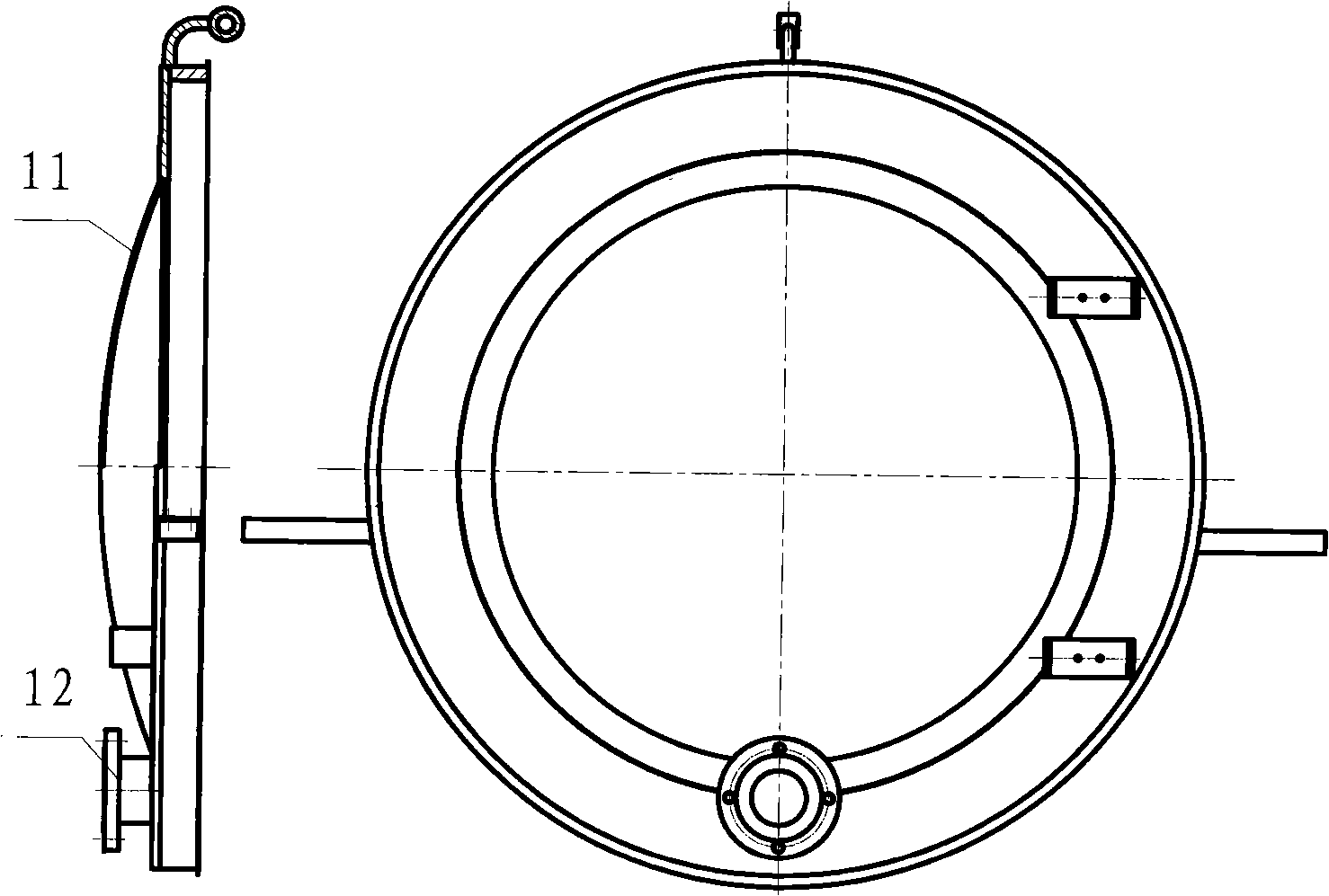

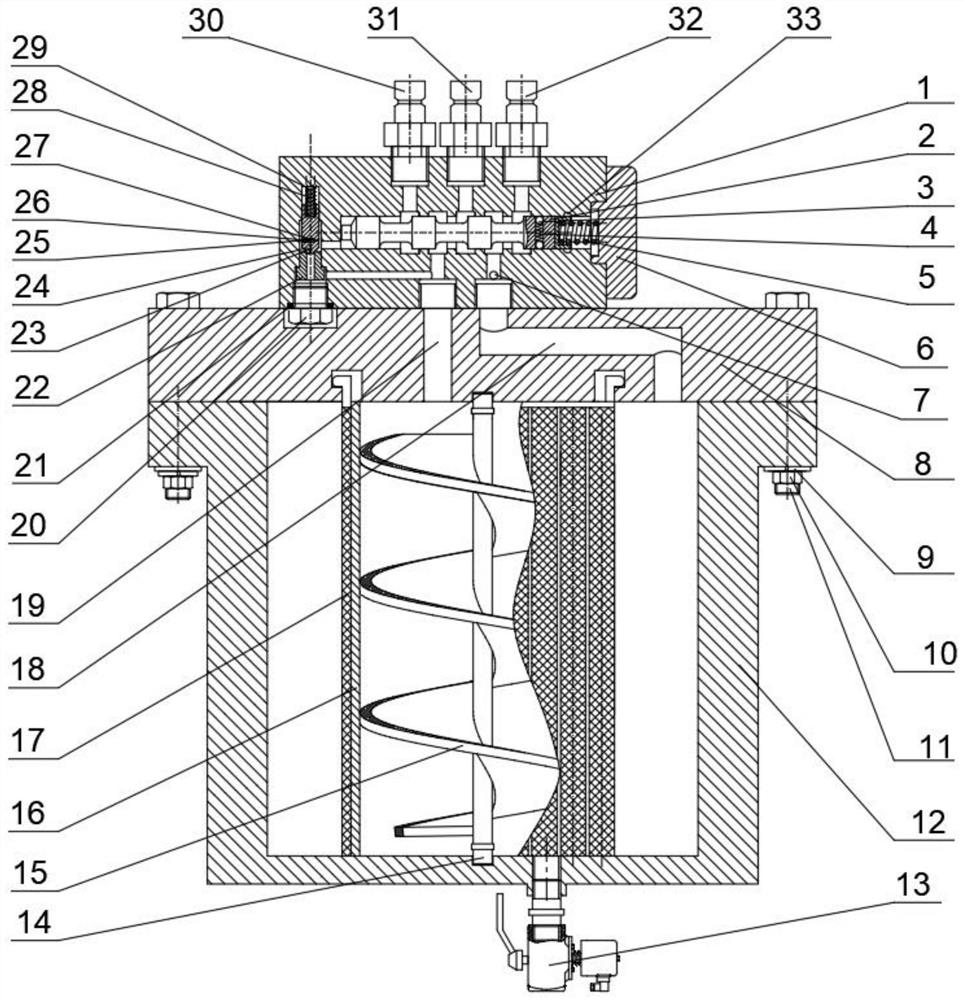

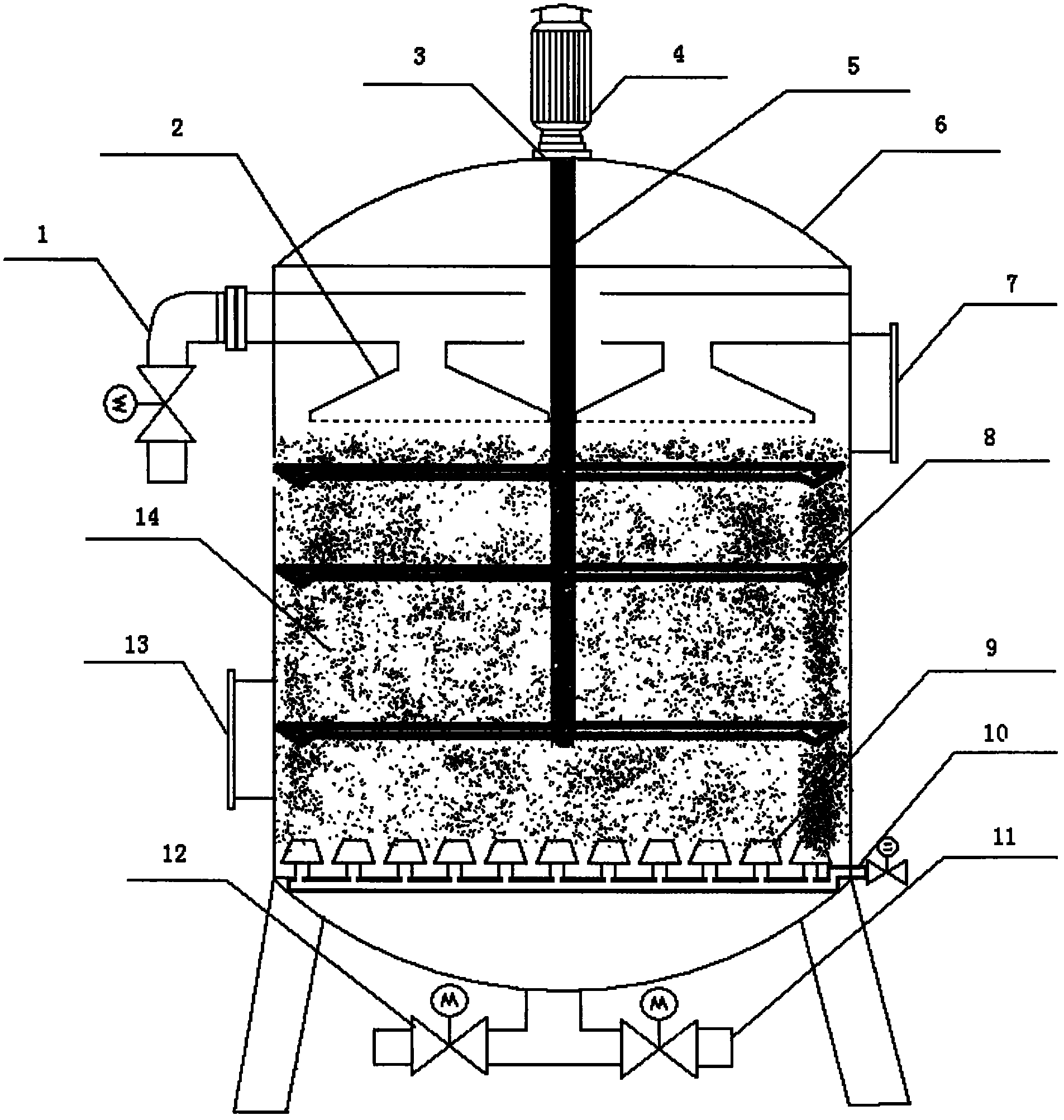

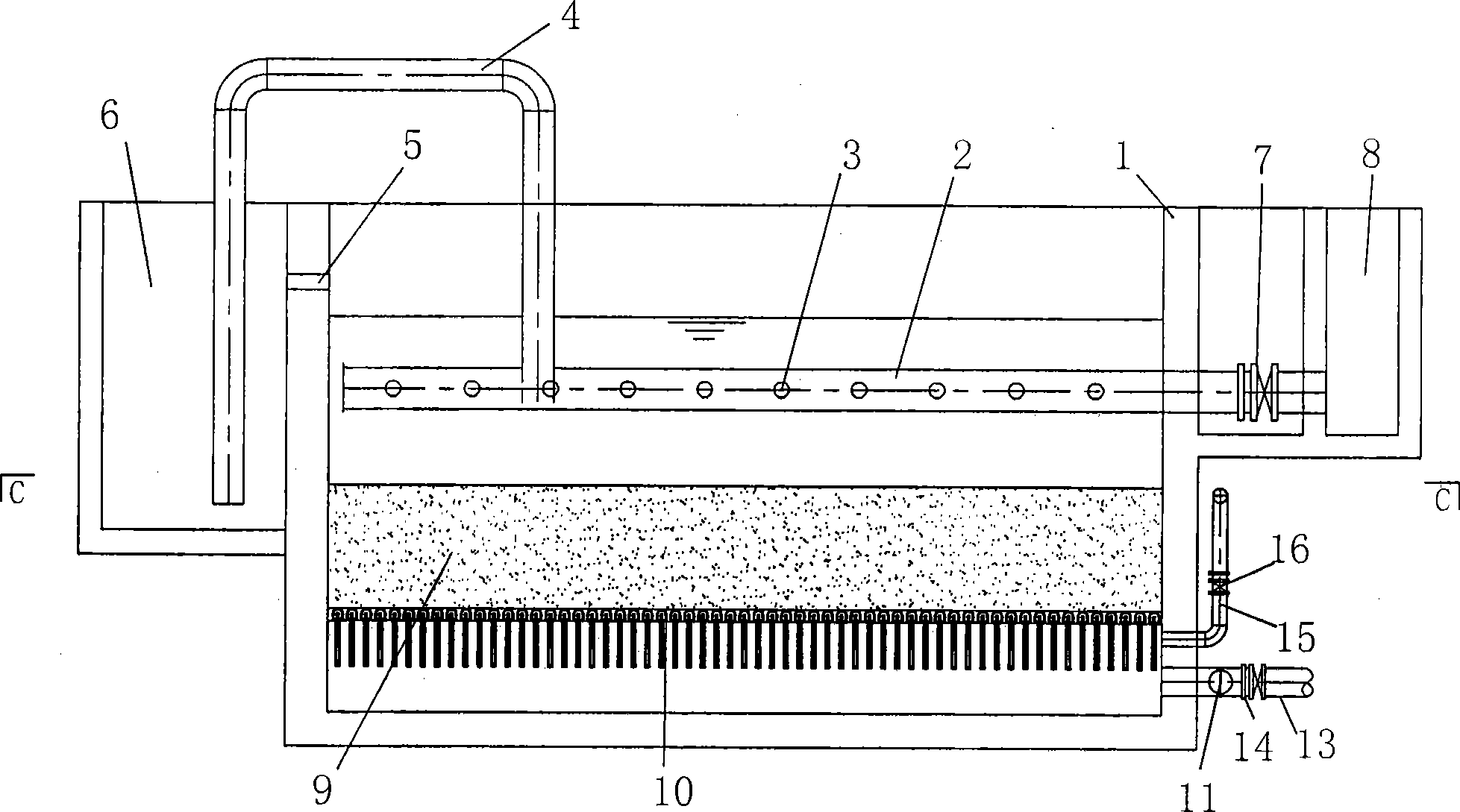

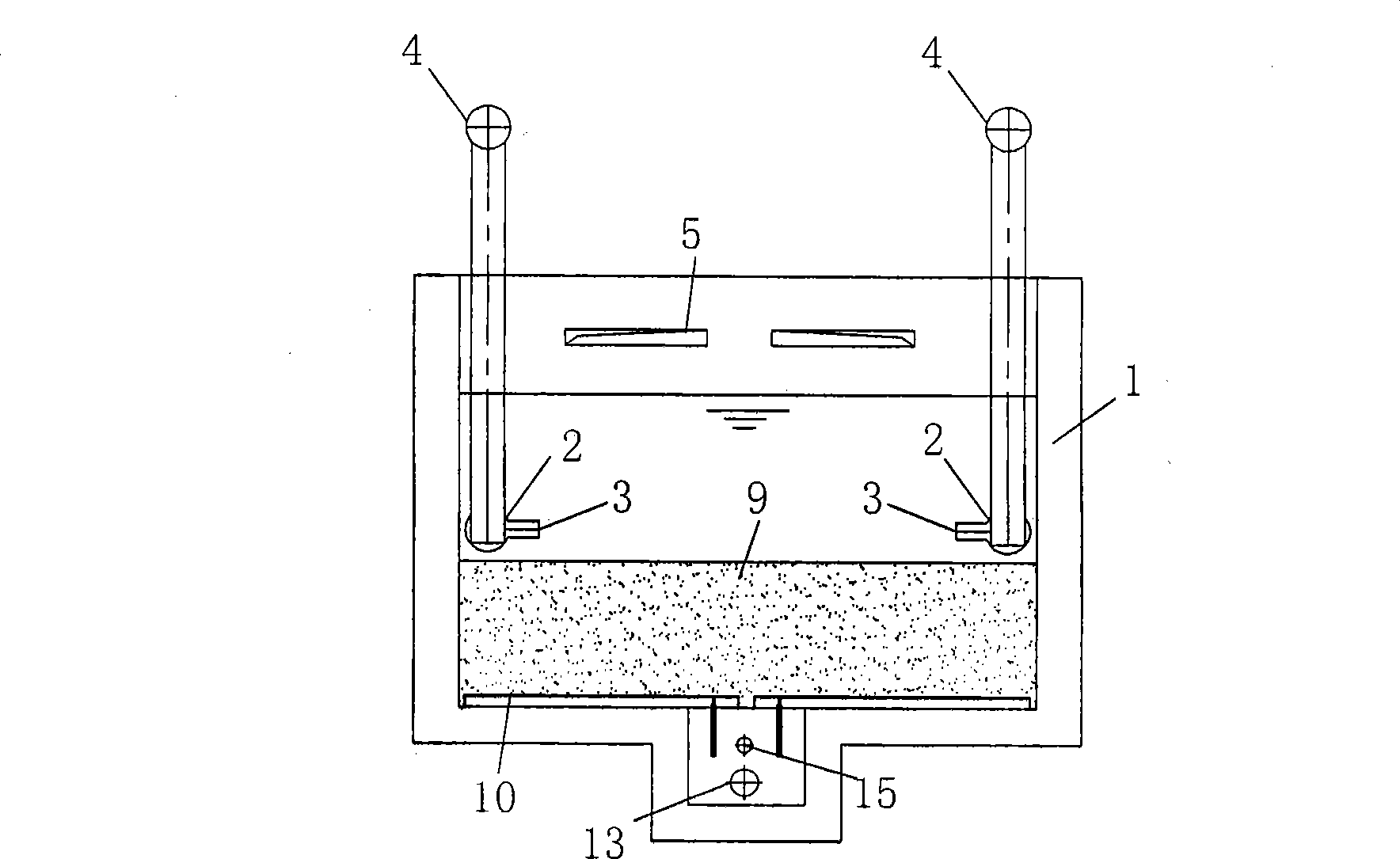

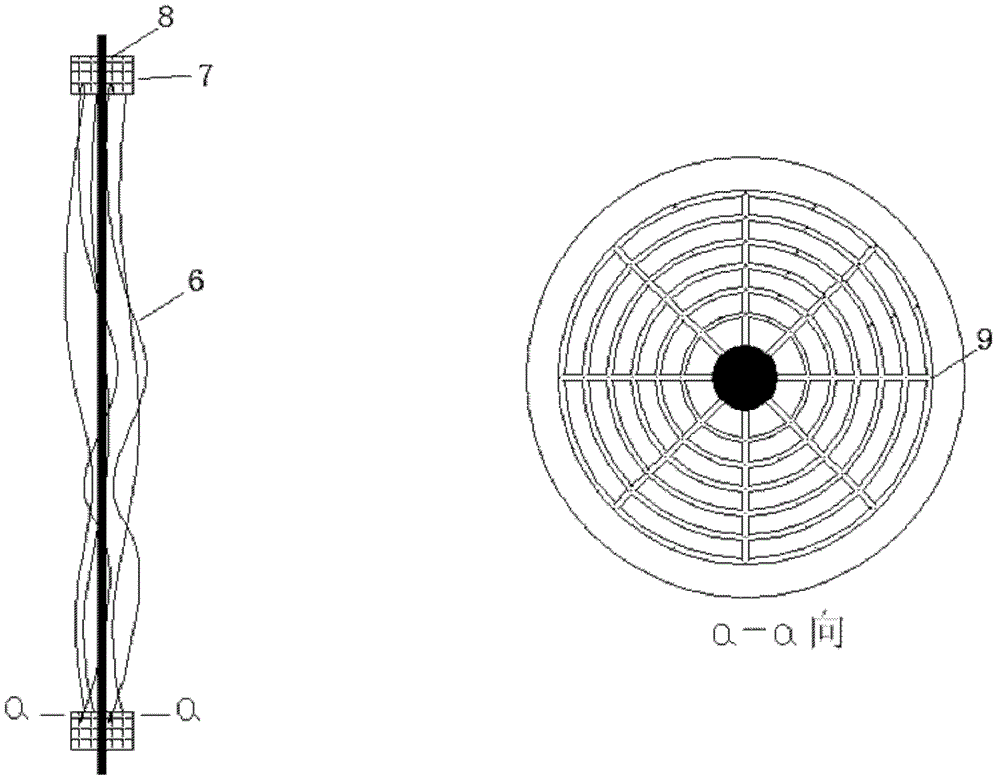

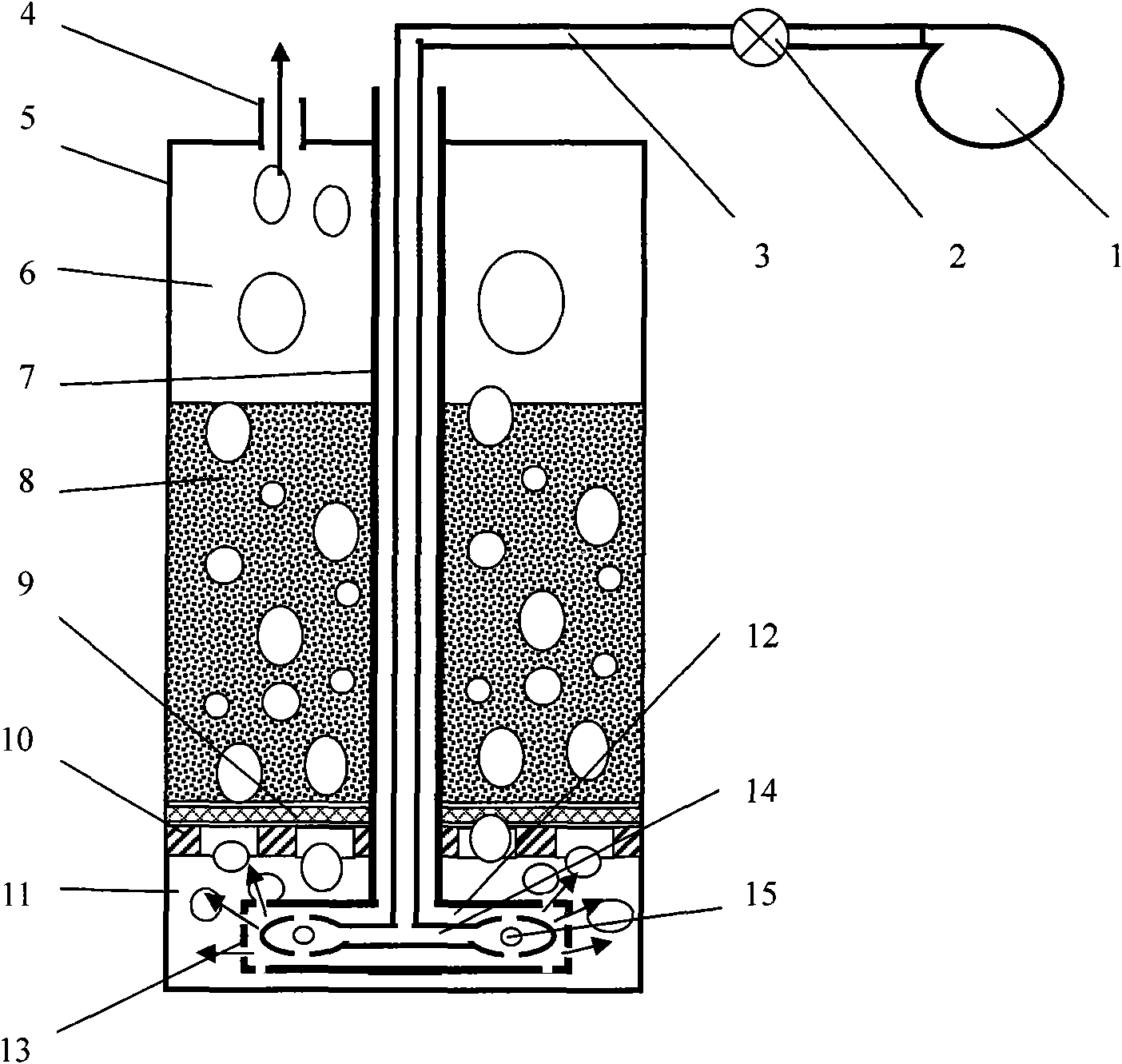

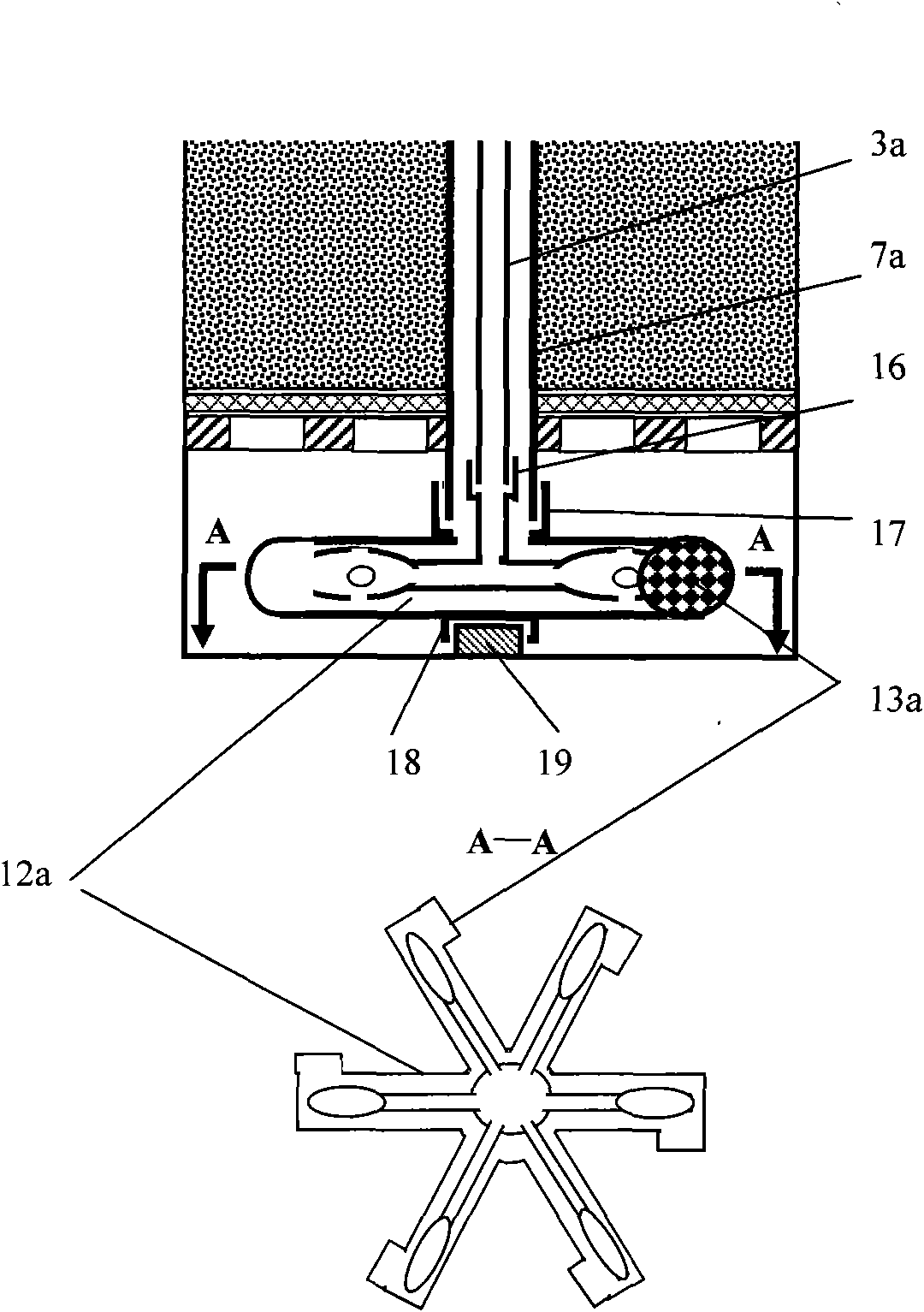

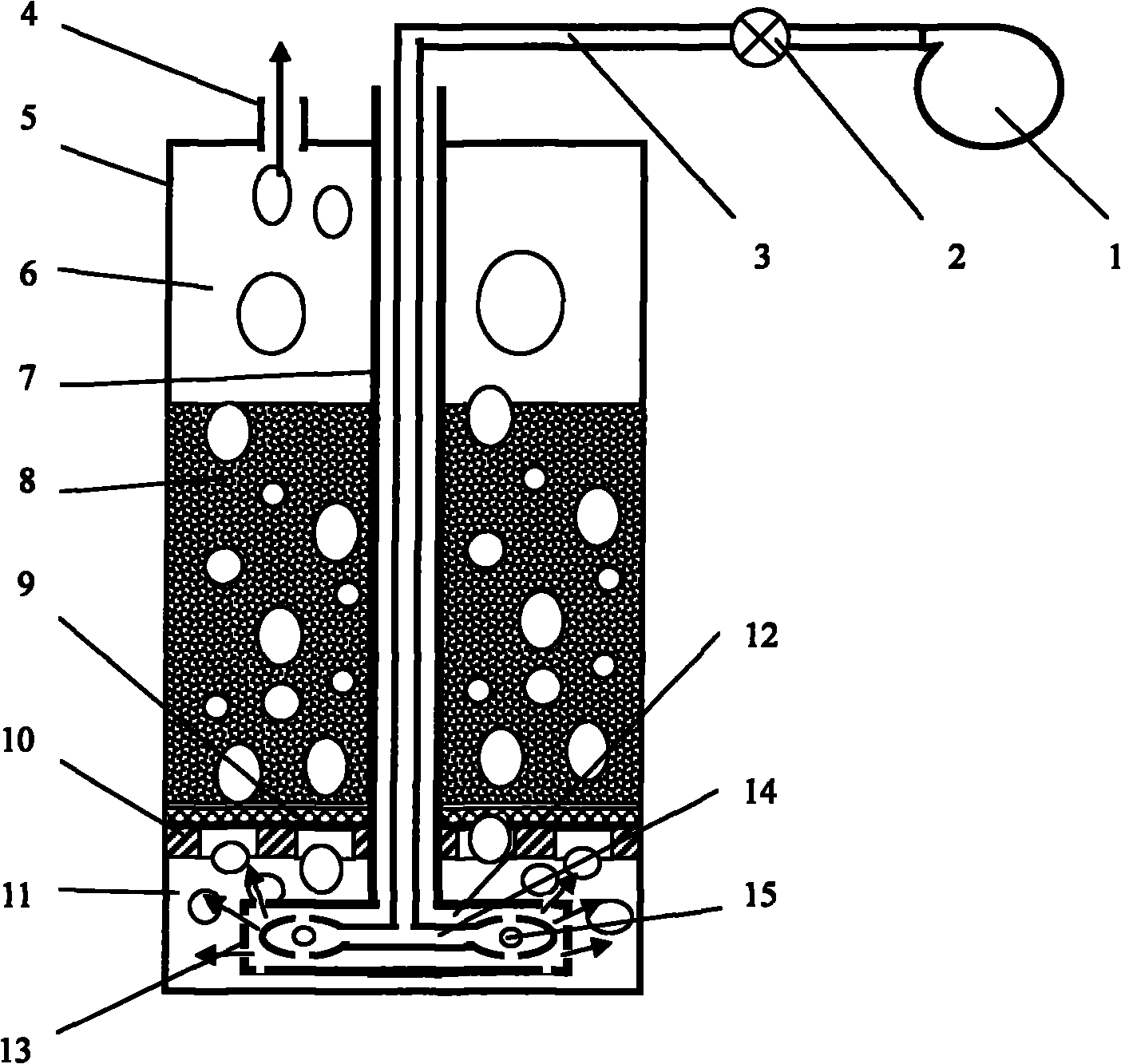

Novel multimedium filter for water treatment

InactiveCN102626564AImprove water qualityHigh water quality standardLoose filtering material filtersGravity filtersAeration systemFilter material

The patent of the invention brings forward a novel multimedium filter for water treatment. The filter comprises a tank, a baffle plate, a water-locator, a filter material layer, an aeration system, a clear water sump and a novel specific backwashing stirring device. The device can be structured in a round, square or other vertical shape. In the meanwhile, a stirring system of the built-in novel specific backwashing stirring device can be used for deep stirring of a filter layer during routine backwashing process of the equipment. Under the action of continuous fiction and repeated stirring by stirring vanes, pollutants on the filter material layer peel off from a filter material. Simultaneously, dropped and separated pollutants are washed away from the inside of the tank by the utilization of a lot of clear water and appropriate compressed air. The unique stirring technology of the device has changed a backward technology of a traditional filter which has defects of unsatisfactory flushing effect, large power consumption and a filter layer which easily undergoes pollution, soil hardening and huddling. The invention is especially applicable to various water purification and sewage treatment fields.

Owner:高全财

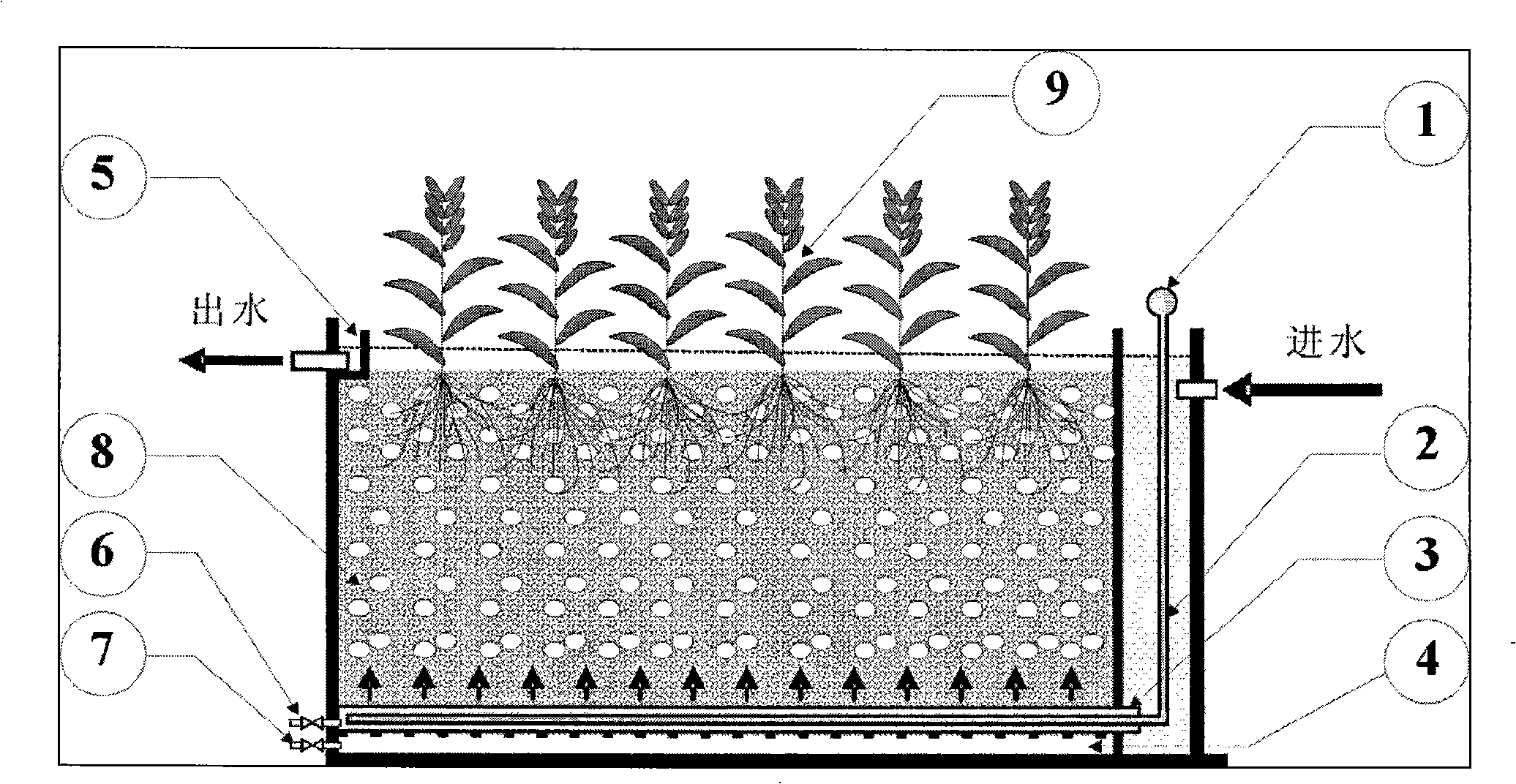

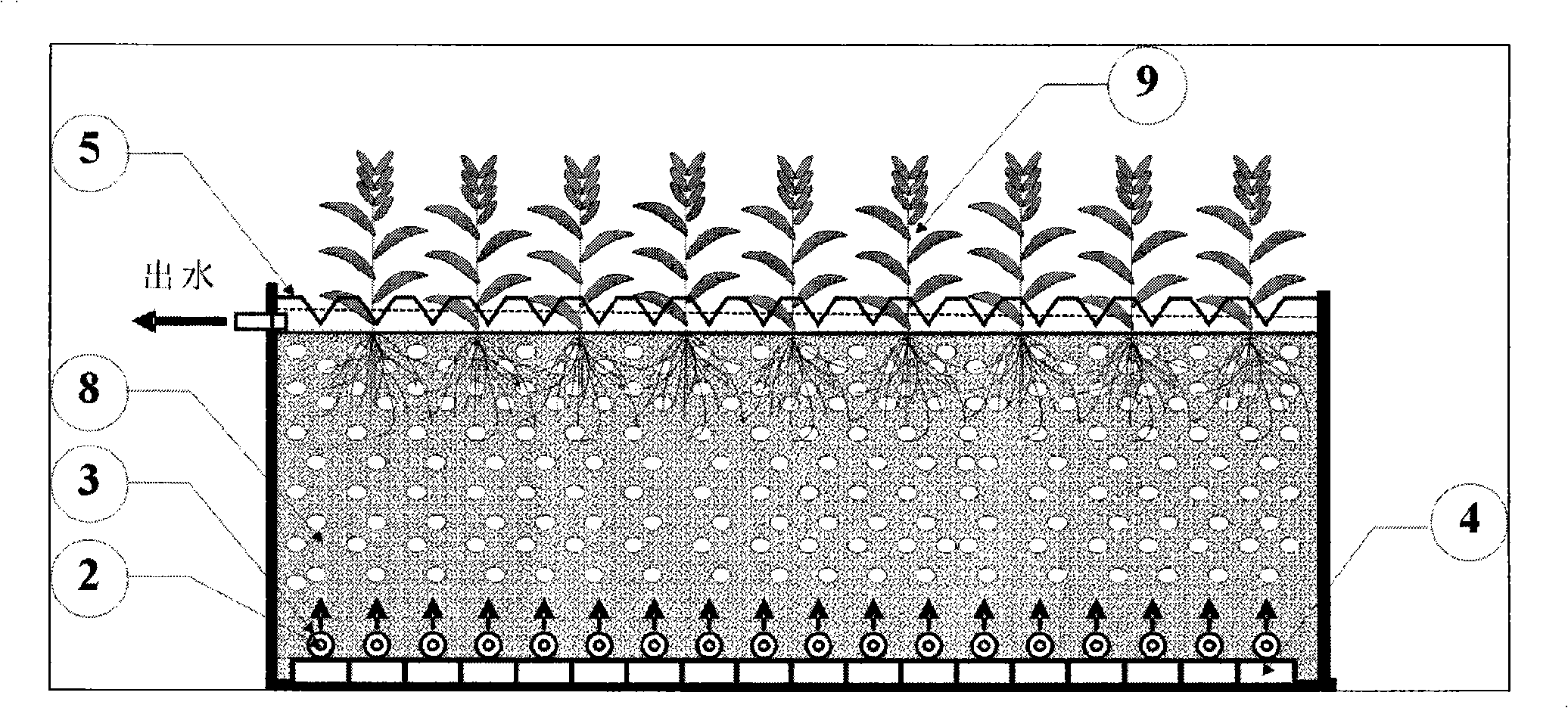

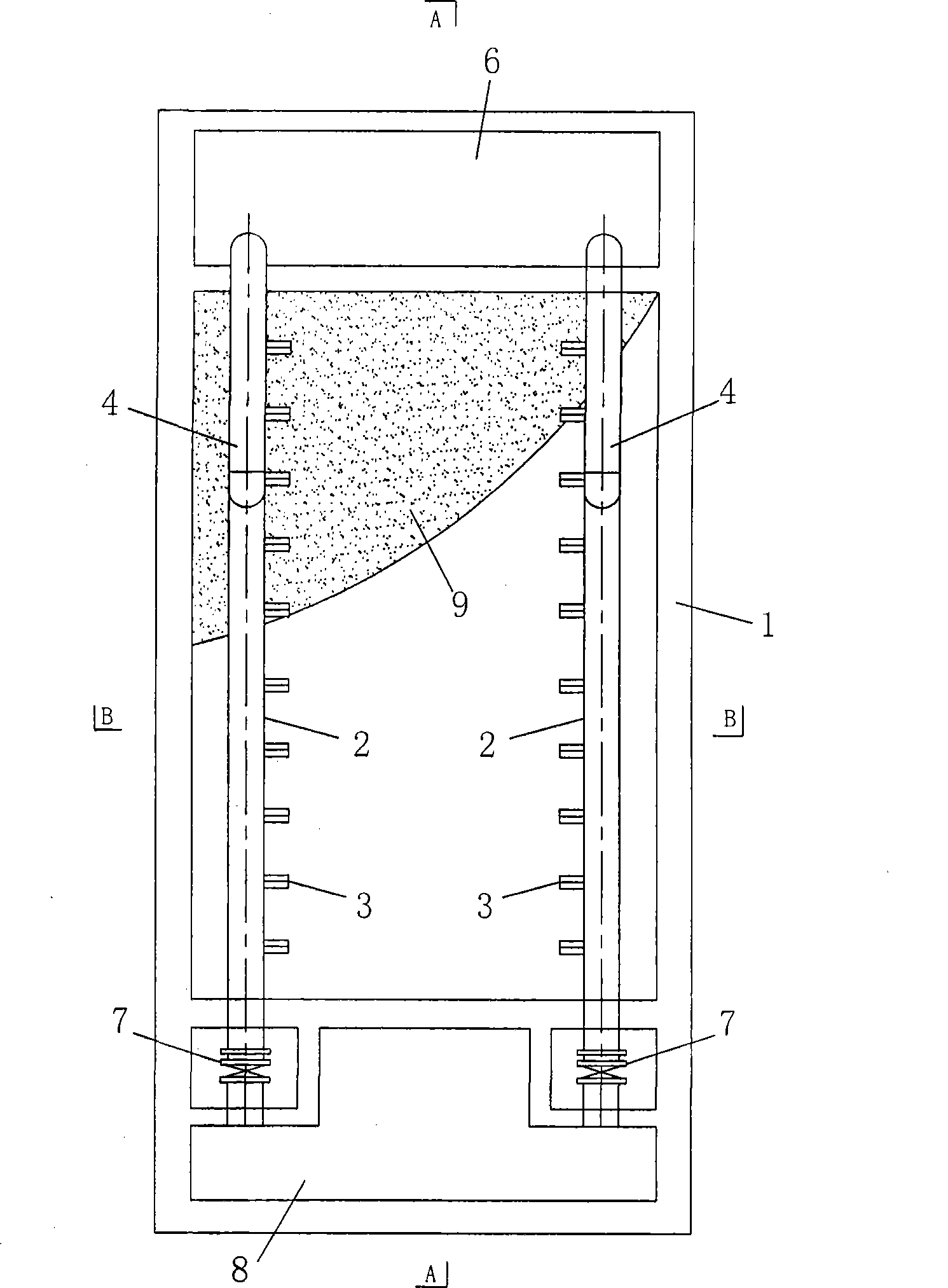

Micro-aeration vertical flow wetland sewage purification technology

InactiveCN101284699AExtended service lifeEasy to handleTreatment using aerobic processesSustainable biological treatmentAeration systemWastewater

The invention relates to a technology for purifying wastewater in micro-aeration vertical flow wetlands, and belongs to the water pollution control field. The technology adds a manual micro-aeration system in the conventional upwelling vertical downward flow wetlands, and adds channels for washing pipelines and outputting sediments at the bottom part of the wetland system, thereby improving the treatment capacity of the wetland system, having the functions of backwashing and sediment outputting, and prolonging the service life of the wetland. The technology can be independently utilized, and can also be combined with other wetlands by serving as an aerobic unit. The technology can be applied to the domestic sewage processing of villages, small towns and scenic spots, the wastewater treatment of a municipal sewage mixed stream entering a lake and the deep purification of tail water of a sewage treatment plant.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

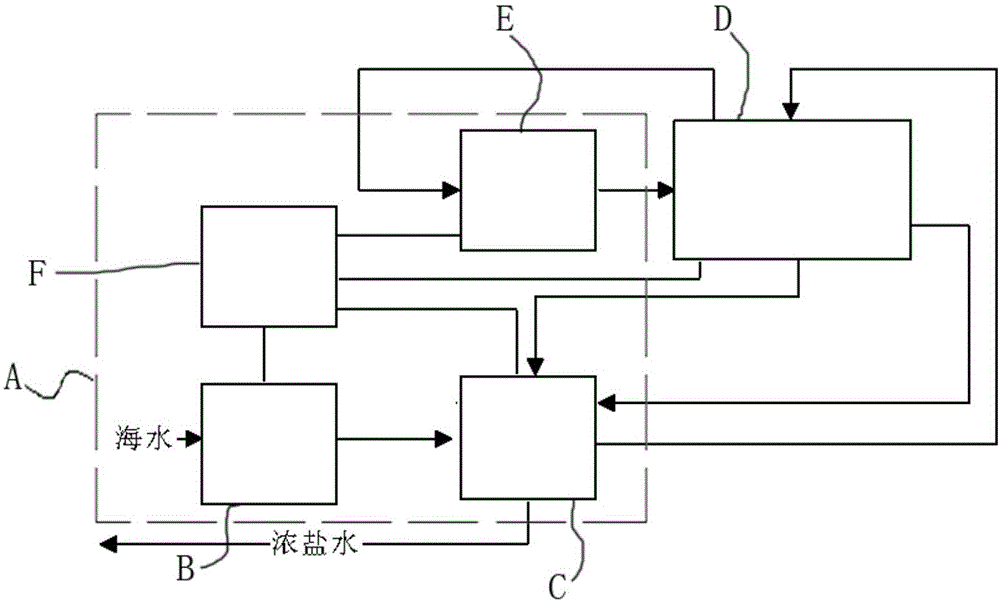

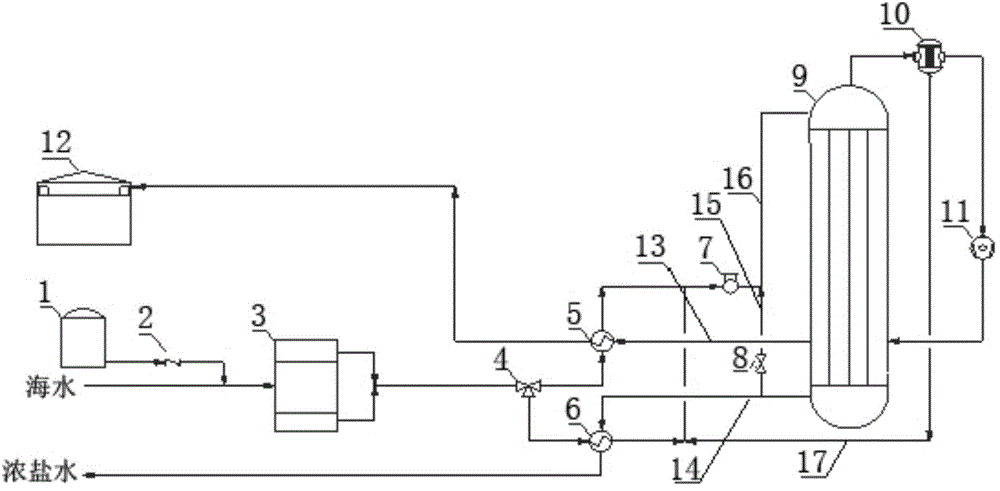

Water processing method and device thereof of seawater desalination system

ActiveCN103601310ANot easy to scaleReduce the burden onGeneral water supply conservationSeawater treatmentEnergy recoverySodium bisulfite

The invention relates to a water processing method and a device thereof, and especially relates to a water processing method and a device thereof of a seawater desalination system. The method comprises the following steps: adding an alkaline agent into seawater to carry out a preset coagulating and clarifying treatment, then pumping the seawater into a cleaning and washing device through a raw water pump; carrying out a pretreatment for the produced water by adopting an external pressure type ultrafiltration membrane component; adding sodium hypochlorite during the ultrafiltration process and / or the backwashing process; pumping the produced water, which has been subjected to the ultrafiltration process, to orderly go through a safeguard filter, a primary high-pressure pump, a scale inhibitor feeding device, and a primary reverse osmosis device, wherein a scale inhibitor is added into the water in the primary reverse osmosis device to carry out a primary reverse osmosis treatment, and acid and sodium bisulfite are added at the same time in order to protect the reverse osmosis membrane; adjusting the pH value of the primary reverse osmosis produced water, making the produced water orderly go through a secondary safeguard filter, a secondary high-pressure pump, and a secondary reverse osmosis device to carry out a secondary reverse osmosis treatment, subjecting the reverse osmosis condensed water to an energy recovery treatment; and finally subjecting the secondary reverse osmosis produced water to subsequent treatments. The reverse osmosis membrane provided by the invention has the advantages of difficulty in scaling and high seawater desalination recovery rate.

Owner:ZHEJIANG THINK ENERGY TECH

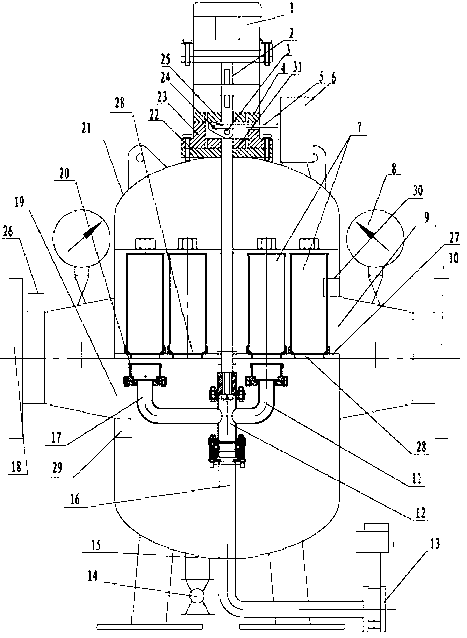

Multi-filter cylinder automatic backwashing filter apparatus

InactiveCN102794044AReduce backwash frequencyMaximum backwash frequencyStationary filtering element filtersElectric machineControl system

The invention discloses a multi-filter cylinder automatic backwashing filter apparatus. A housing is divided into an upper chamber and a lower chamber by a separation plate. The separation plate is provided with filter cylinders in the manner of one, two, or multiple concentric circles. The sidewall of the housing under the separation plate is provided with a sewage inlet, and the sidewall of the housing above the separation plate is provided with a pure water outlet. A motor of a backwashing mechanism drives a main shaft to rotate. A lifting mechanism drives the main shaft to go up and down. A multi-way connection seat connects the main shaft, rotating arms and a waste pipe together. The main shaft drives the rotating arms to lift and rotate. The waste pipe is fixed. Suction nozzles fixed on the upper end port of the rotating arms can be in sealed connection with water inlets on the separation plate. The end part of the waste pipe is connected with an electric drain valve or a pneumatic drain valve. A control system controls the actions of the motor, the lifting mechanism and the electric drain valve or the pneumatic drain valve. The filter apparatus has the advantages of small size, large amount of water filtration, high production efficiency, good filtration effect of filtered water, good backwashing effect, low frequency of backwashing, long-life apparatus, low maintenance rate, and saving backwash water.

Owner:HEBEI AGRICULTURAL UNIV. +1

Stirring-free method and device for producing sodium nitrate through continuous conversion

InactiveCN101696024AReduce entryReduce acid mistAlkali metal nitrate preparationOxygenEnergy expenditure

The invention provides a stirring-free method and a stirring-free device for producing sodium nitrate through continuous conversion. The device mainly comprises an ammoxidation-prepared oxynitride system, a soda ash solution preparing system and a sodium nitrite mother solution conversion system, wherein the sodium nitrite mother solution conversion system mainly comprises a converter tower, a pre-converter tower, an absorption tower, a motor solution storage tank and matched pumps and pipelines. Nitric acid and the mother solution undergo conversion reaction in the converter tower; conversion solution reflows and back washes the bottom of the converter tower; gas of the converter tower is separated by a gas-liquid separator and enters the pre-converter tower; and converted gas and oxygen-mixed air are mixed quantitatively and then the mixture enters the absorption tower for absorption to prepare feed solution. The method and the device have the advantages that: the production of the sodium nitrate can be continuously performed; the reflowing and backwashing of the conversion solution replaces air stirring; in the converted gas absorbing process, the converted gas is added with the oxygen-mixed air in a ratio, the process operation is optimized, and loads of the adsorption tower and subsequent processing procedure are lightened; the production capacity is improved; energy consumption is reduced; NOx emission is decreased; and the method and the device are favorable for environmental protection.

Owner:SHIJIAZHUANG FENGSHAN CHEM

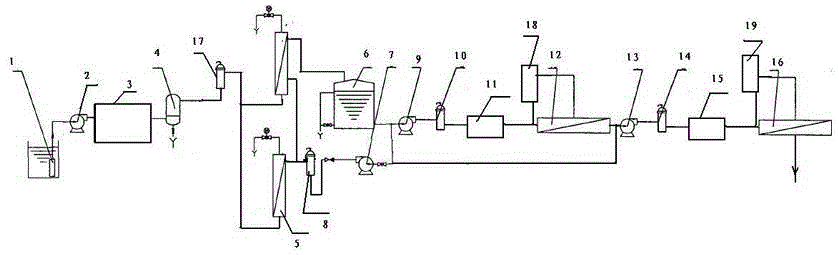

Efficient blue algae salvaging ship

InactiveCN107879403AGuaranteed collectionReduce processingSludge treatment by de-watering/drying/thickeningWater cleaningEutrophicationWater discharge

The invention provides an efficient blue algae salvaging ship for improving salvaging and treatment efficiency of the blue algae salvaging ship. The efficient blue algae salvaging ship mainly comprises a ship body, a water decanter, a water pump, a filtration pipeline, a chemical feeding tank, an algae-mud dehydrating machine, a rear drainage pipe and a side drainage pipe. Algae-laden water on thesurface layer in a nose direction is collected into an algae water bin by the water decanter, is pressurized by virtue of the water pump, the pressurized algae-laden water enters the filtration pipeline to be dehydrated and then is conveyed into the chemical feeding tank and the algae-mud dehydrating machine, produced algae cake is loaded into an algae cake bin, tail water discharged by the filtration pipeline and the algae-mud dehydrating machine is discharged out from the stern direction by virtue of the rear drainage pipe and the side drainage pipe. The filtration pipeline is regularly back-washed by lifting the water decanter, switching a valve and utilizing the tail water of the algae-mud dehydrating machine. After blue algae salvaging is finished, water in the algae water bin, a pipeline bin and the chemical feeding tank is discharged outside the ship body by virtue of the water pump and a backwashing pipe, and the algae cake is transported to a shore to be treated. By implementing the efficient blue algae salvaging ship provided by the invention, a significant role is played for controlling blue algal bloom, water bloom and red tide, improving lake water quality, removing phosphorus and nitrogen in water and alleviating water eutrophication.

Owner:邱学尧

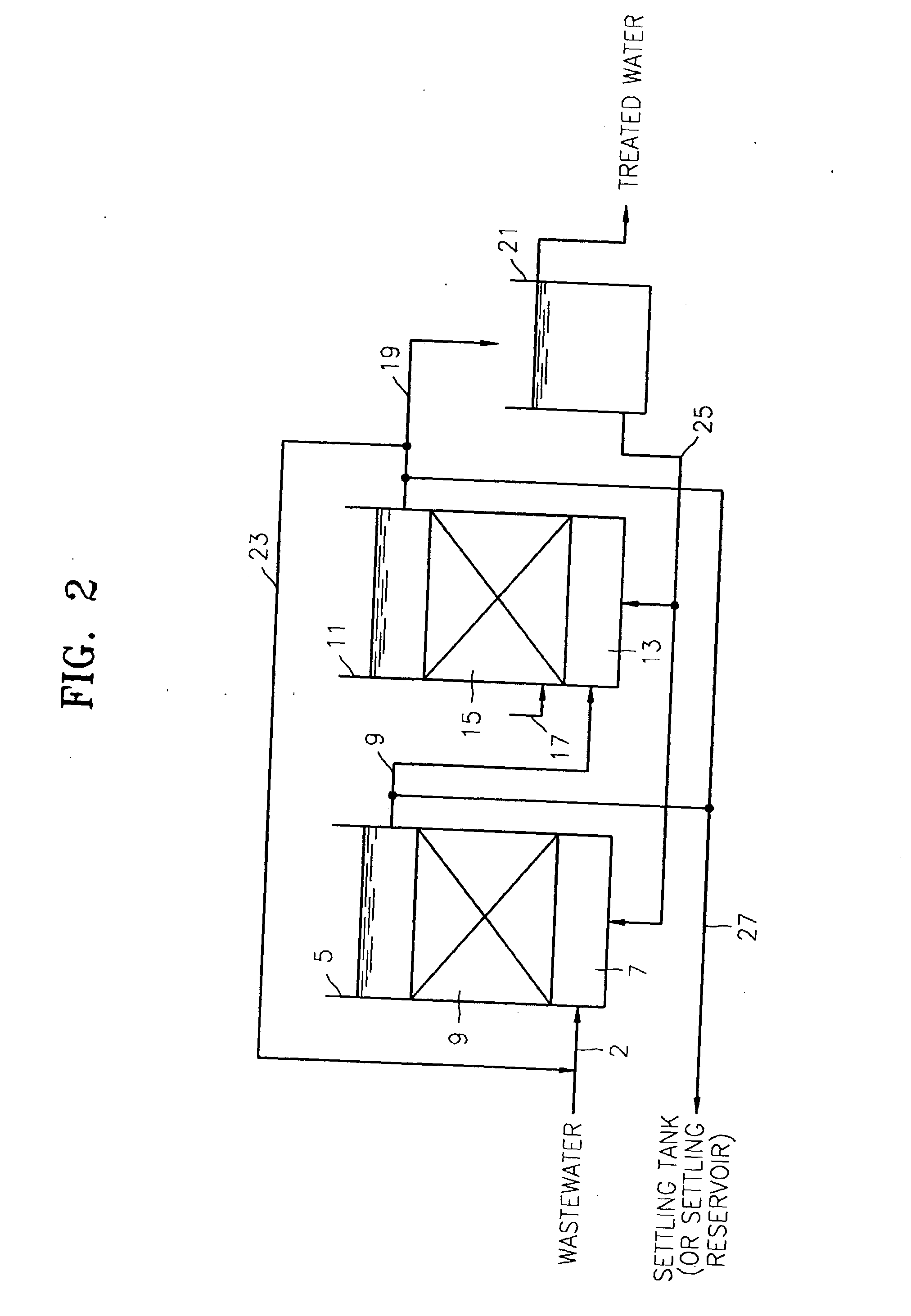

Water filtration using immersed membranes

A process for operating filtering membranes submerged in a tank involves, in one aspect, periodically deconcentrating the tank by at least partially emptying and refilling the tank with fresh water while permeation continues. In another aspect, long trains of membranes modules are placed in series along a flow path in the tank. In one embodiment, constant aeration is provided to prevent tank water from by-passing the membrane modules while proving controlled mixing such that the average concentration of solids in the tank is lower than the concentration of solids in the tank near an outlet for removing retentate from the tank. In another embodiment, the membrane modules are arranged in a series of filtration zones between a feed water inlet and a retentate outlet of a tank. Permeate is withdrawn from the filtration zones by separate means associated with each filtration zone. Tank water containing rejected solids flows in a tank flow through the filtration zones, increasing in concentration from one zone to the next. A preferred membrane module has membranes transverse to the tank flow and fills a substantial portion of each filtration zone. With either embodiment, aeration, backwashing or packing density of membranes varies between filtration zones and the flow pattern in the tank may be periodically reversed.

Owner:ZENON TECH PARTNERSHIP

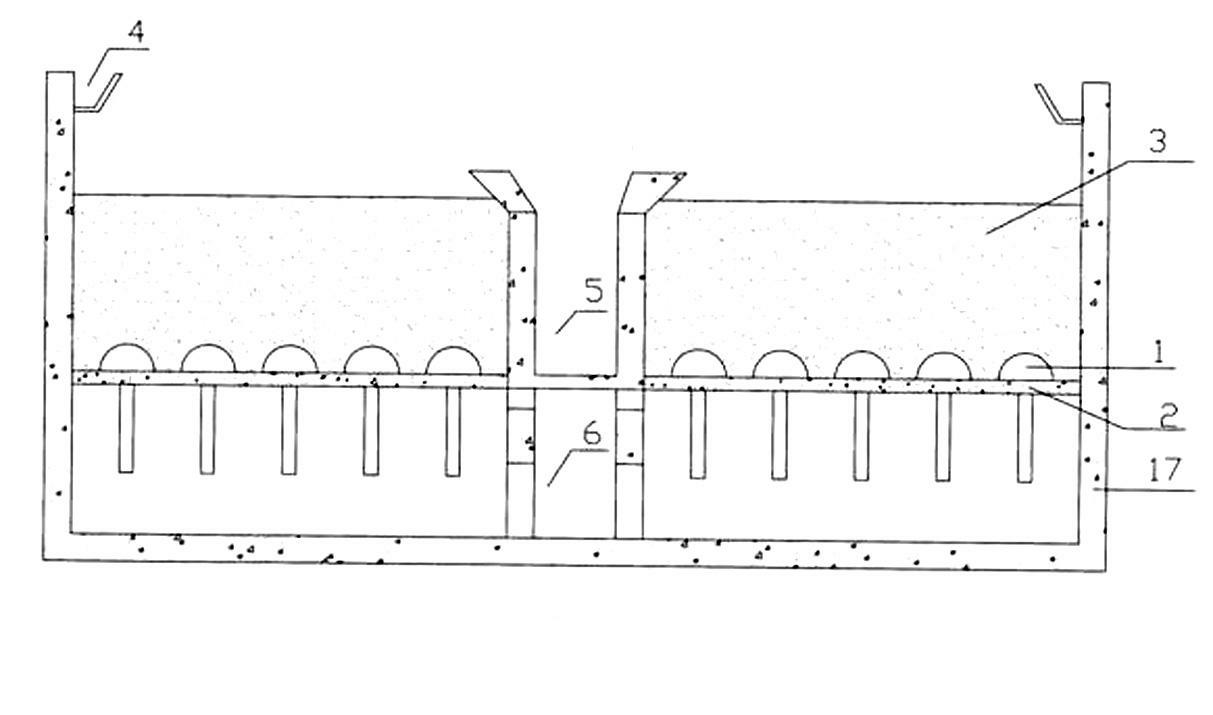

Backwashing method of upward flow filter and backwashing water distribution structure

InactiveCN101423284AEasy dischargeSave flushing water consumptionTreatment using aerobic processesSustainable biological treatmentDistribution systemWater pipe

The invention relates to a backwashing method of an upflow filter chamber and a backwashing water distribution structure. The method orderly comprises: single water washing, combined washing of air and water, and single water rinsing. The water distribution structure is composed of an air intake pipe arranged on the near bottom of the filter chamber and connected with an air distribution and water distribution system at the lower part of a filter material layer in the filter chamber, an original water intake pipe and a washing and water discharging pipe, wherein, an air valve on the air intake pipe, a water intake valve on the original water pipe, and a first water discharging valve on the washing and water discharging pipe are provided with water distribution devices for washing on the upper part of the filter material layer in the filter chamber; each water distribution device consists of a plurality of horizontal main pipes which are communicated with a clean water channel at one side of the filter chamber by a connection pipe through the upper part of the side wall of the filter chamber; each main pipe is evenly provided with a plurality of water distribution nozzles; one end of each main pipe is closed, and the other end penetrates through the chamber wall of the filter chamber and is connected to a second water discharging channel to the water discharging channel. The cleaning capability of the filter materials of the upflow filter chamber is largely improved. In addition, the water quality of water discharging is better. The invention solves the problems of discharging water polluted by backwashing discharging water filtered by the existing upflow filter chamber, and the problem of first filter water discharging.

Owner:深圳市清泉水业股份有限公司

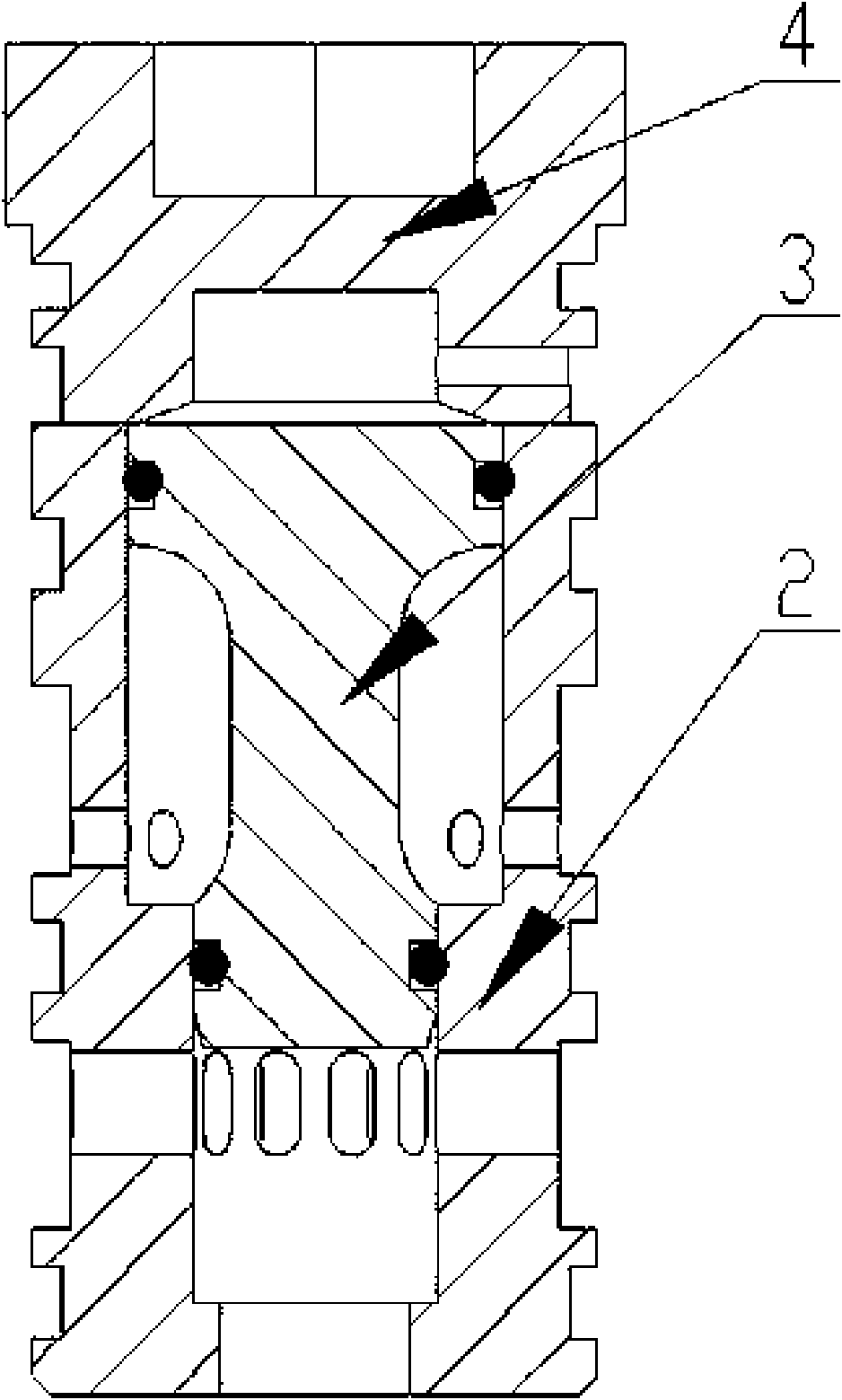

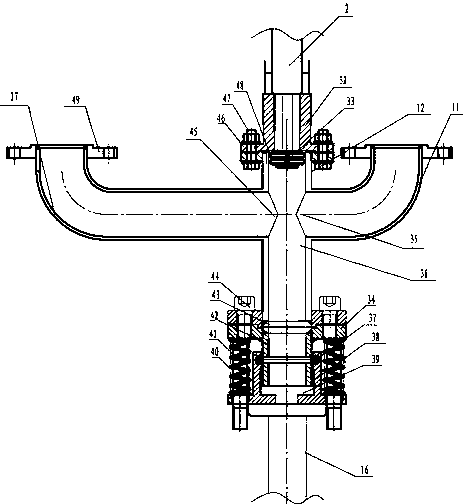

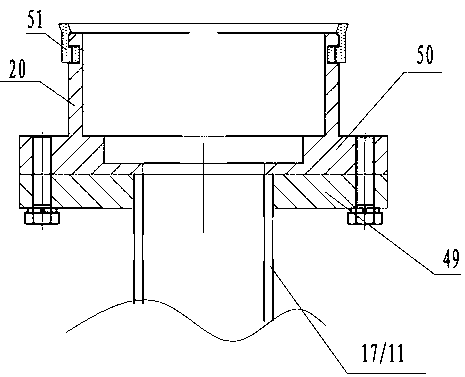

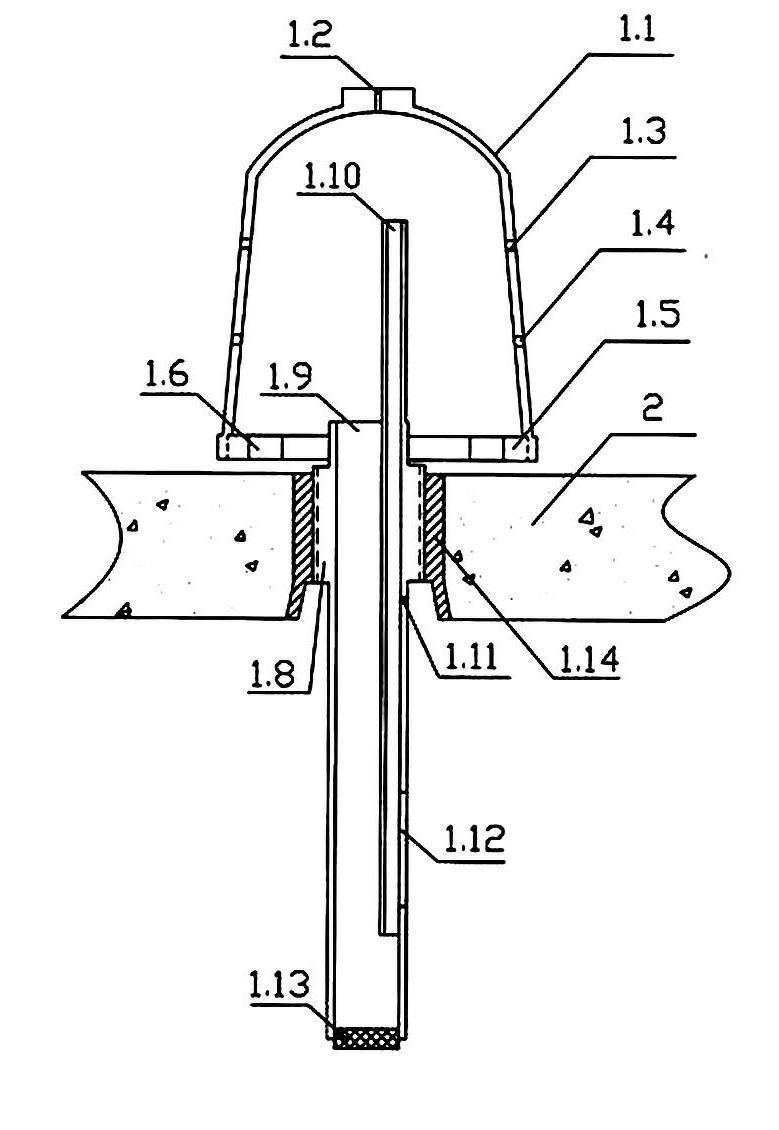

Independent filter head for stable-pressure water distribution and gas distribution of air cushion layer and application method thereof

InactiveCN102372359AUniform aerationSolve the defect that the air pressure is not stable enoughTreatment using aerobic processesSustainable biological treatmentBiological filterSewage

The invention discloses an independent filter head for stable-pressure water distribution and gas distribution of an air cushion layer and an application method thereof. The filter head comprises a filter head cap, a filter head cap bottom plate, a filter head rod, a filter screen and a pre-embedded pipe sleeve, wherein the filter head cap is of a circular arch; the top of the filter head cap is provided with a residual gas releasing hole, the waist is provided with an upper gas distribution hole and a lower gas distribution hole, and the bottom plate is provided with a water distribution hole; the upper part of the filter head rod is provided with filter head rod installation screw thread, a filter head rod water distribution pipe is arranged in the filter head rod, a filter head rod gas distribution pipe is adhered on the inner pipe wall at one side of the filter head rod water distribution pipe, the length of the lower part of the filter head rod water distribution pipe is larger than that of the gas distribution pipe, the middle part of the filter head rod gas distribution pipe is provided with a filter head rod residual gas releasing hole, and the pipe wall at the outer side of the lower part of the filter head rod gas distribution pipe is provided with a vertical gas inlet seam; and the filter screen of the filter head can be assembled at the bottom of the water distribution pipe, the filter head pre-embedded pipe sleeve is of a pipe clamp shape, and the lower part of the filter head pre-embedded pipe sleeve is of a bell mouth shape. The filter head disclosed by the invention integrates aeration, water filtration and back washing functions, thereby simplifying the structure of a filter pool, ensuring work quality and improving efficiency. The filter head disclosed by the invention can be widely applied to a sewage biological filter pool treatment system and gas-water backwashing filter pools in water supply and other industries.

Owner:惠州市铭博实业发展有限公司 +1

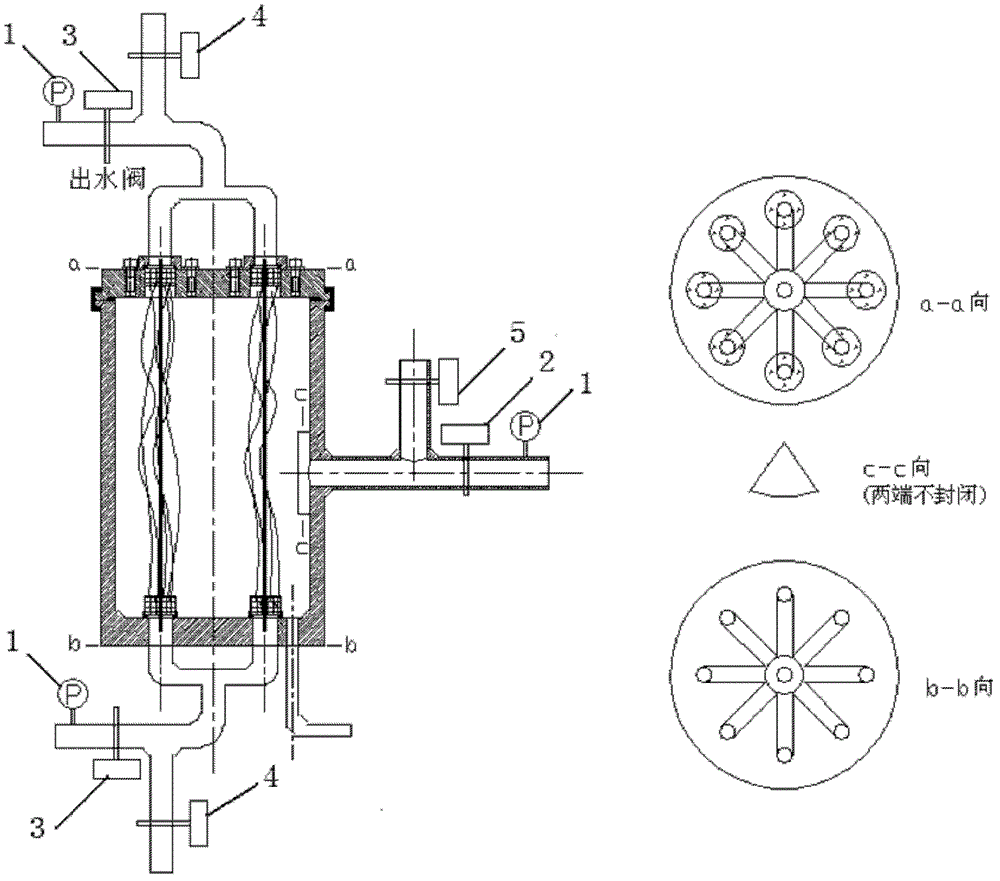

Cleanable security filter and its application

ActiveCN103055701ARestore fluxReduce differential pressureUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater useParticulates

The invention relates to a security filter that can realize online automatic backwashing and its application. The invention solves the technical problems that currently used filter elements in industry have low filter precision, are easy to cause deep pollution, and cannot achieve long-term use through automatic cleaning. The security filter provided in the invention can mainly be used for a double-membrane system in the field of wastewater treatment by a membrane method, such as the security filtering measures in ultrafiltration and reverse osmosis systems, and also can be applied to circulating water replenishing and other water treatment processes with high requirements for filter precision and effluent water quality. The security filter can be used as an effective pretreatment filter means to reduce the influence of particles in water or water quality change caused by inflow water impact on stable running of follow-up processes, so that the effluent water quality can be improved to meet following water use requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

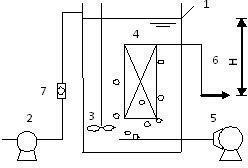

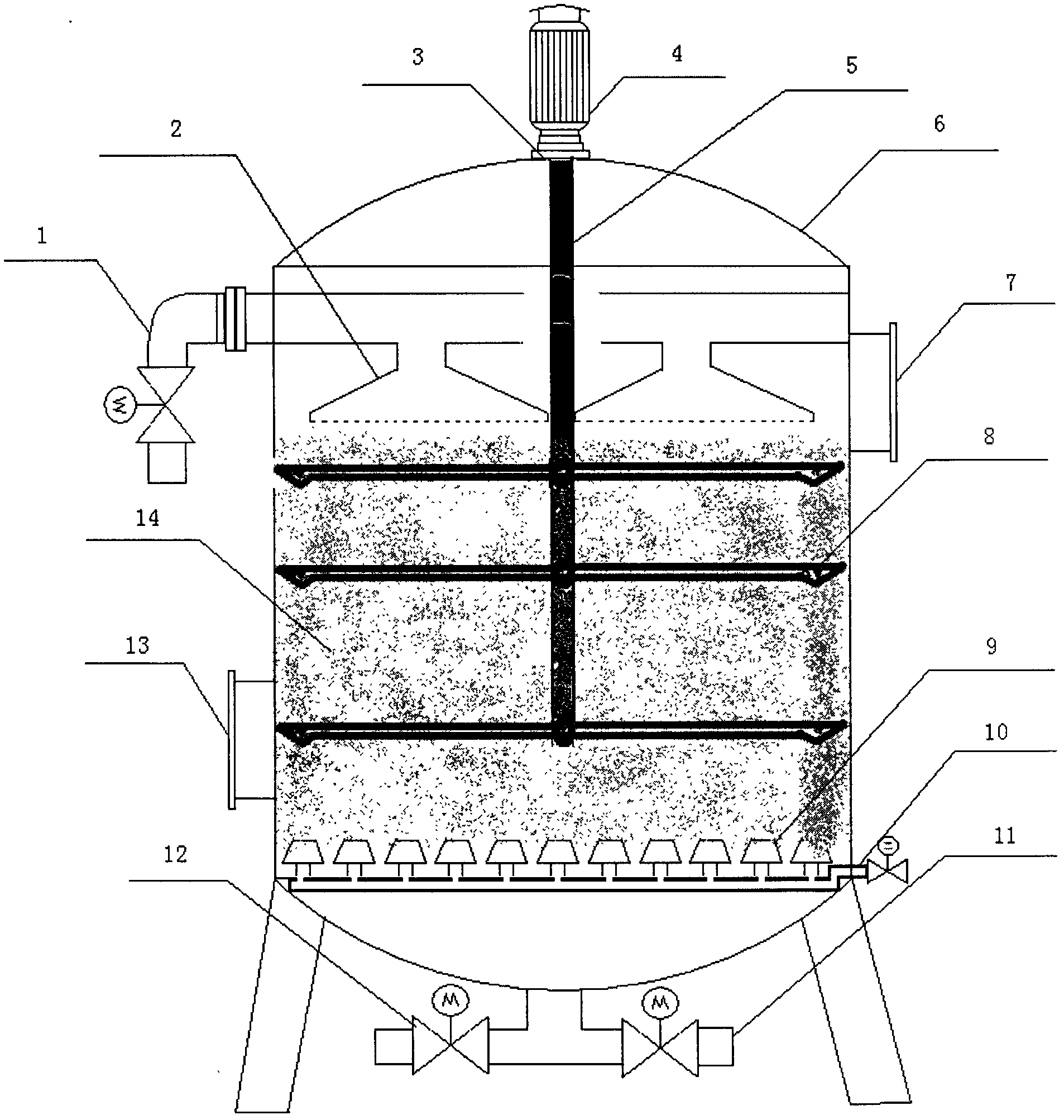

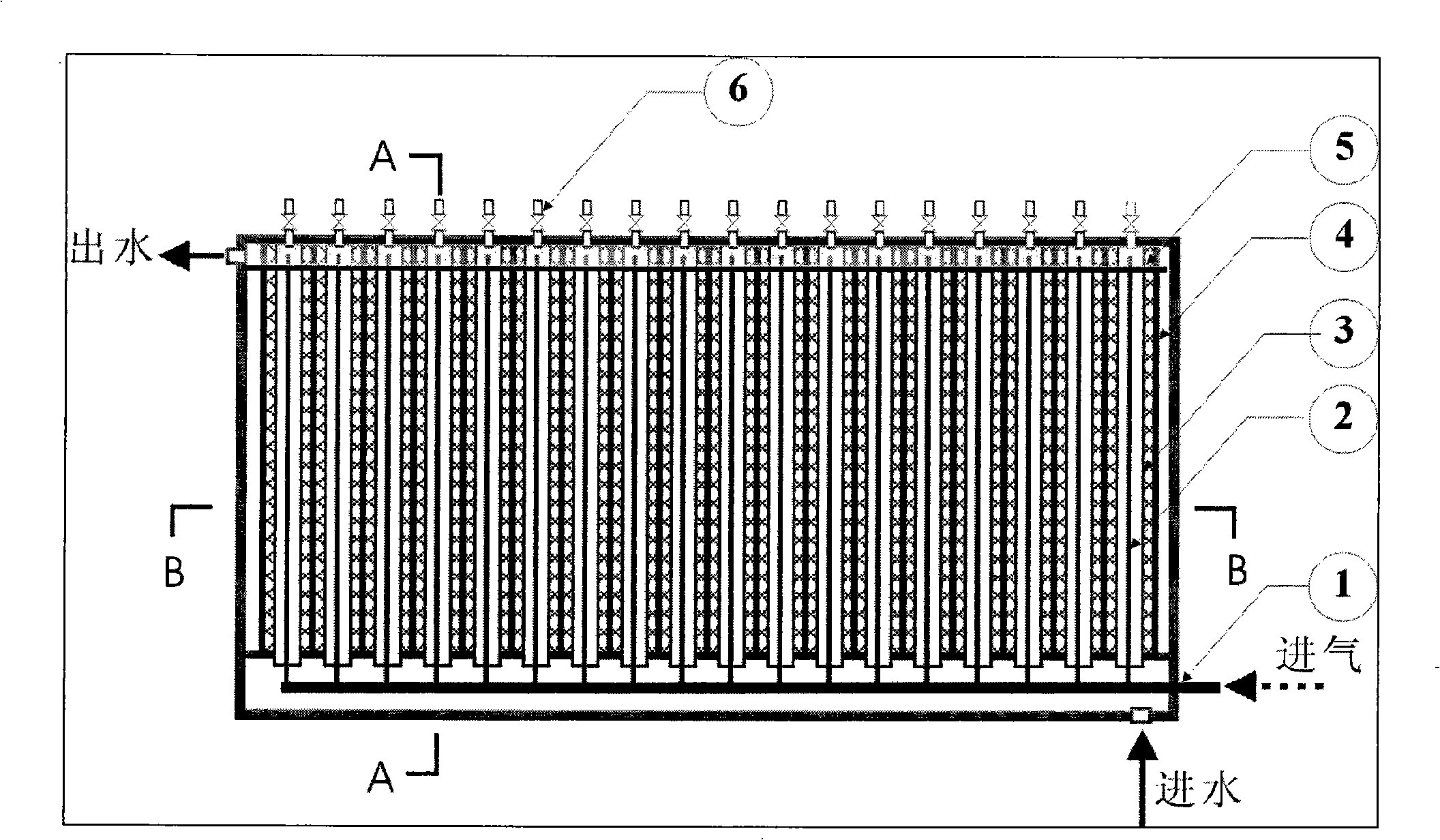

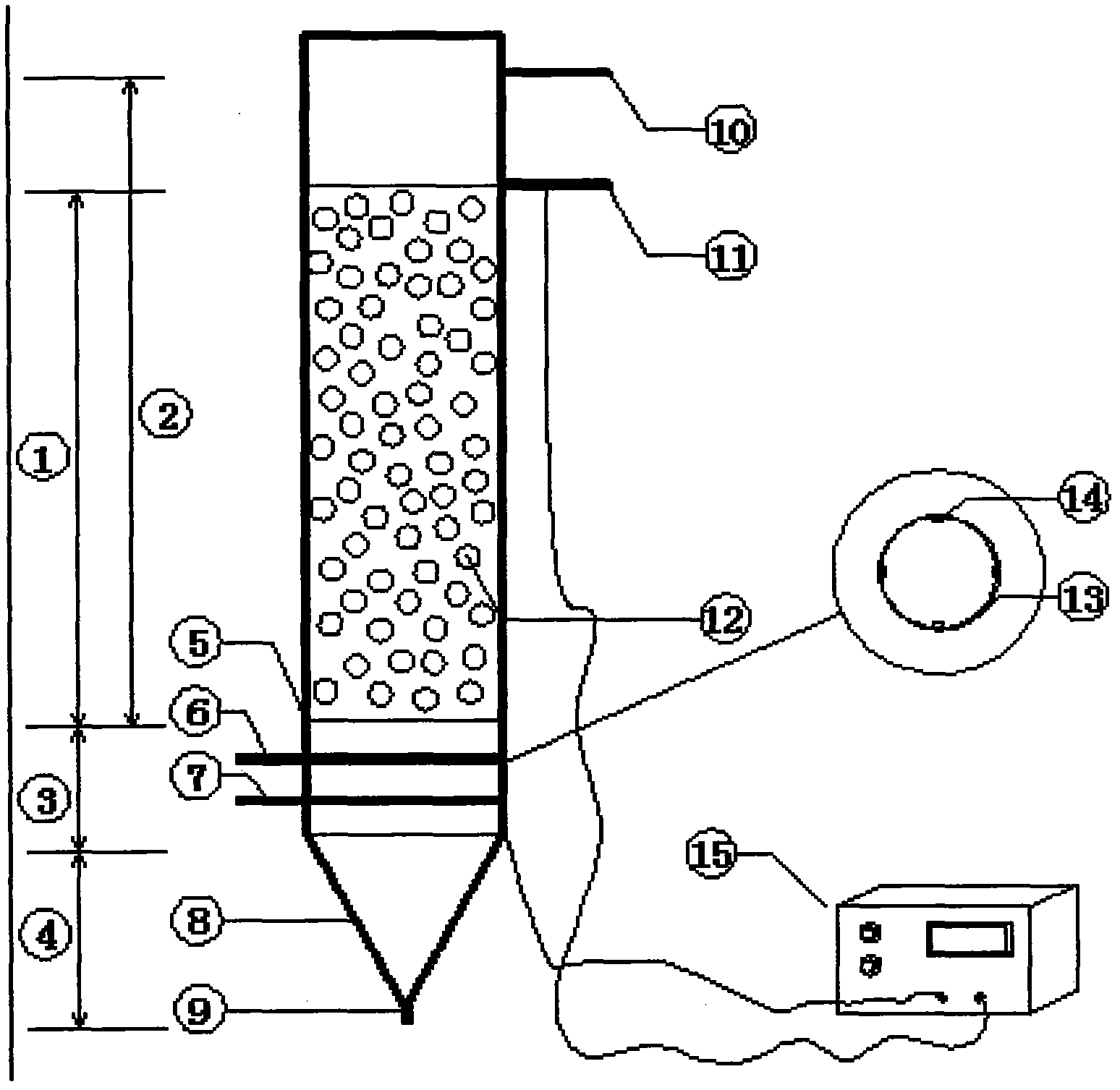

Novel biological aerated filter capable of solving backwashing problem

InactiveCN102351304ARealize continuous water intakeImprove processing efficiencyTreatment using aerobic processesSustainable biological treatmentAutomatic controlEnvironmental resistance

The invention belongs to the field of application of environmental protection technologies, and in particular relates to a novel biological aerated filter which is integrated with a settling tank and changes a filter operation mode by controlling suspension fillers and liquid levels so as to solve the problem of backwashing of a biological filter. In order to overcome the defects of frequent blocking and difficult overhauling of the biological aerated filter, the suspension fillers of which the density is slightly lower than that of water are used as filter media to design the internal structure of the filter, automatic equipment is used for controlling the variation of the liquid levels to ensure than a reactor is changed from the filter to a fluidized bed, and the fillers are changed from static fillers to flowing fillers which overturn along airflow and water flow, so that sludge among filler slits automatically falls; therefore, the novel biological aerated filter is provided in combination with an automatic control principle and a reactor structure optimization principle, so that the problems of difficulty in backwashing and overhauling of the filler are solved. Simultaneously, the aims of continuously injecting water, saving primary settling tanks, integrating two settling tanks and improving sewage treatment efficiency are fulfilled.

Owner:BEIJING FORESTRY UNIVERSITY

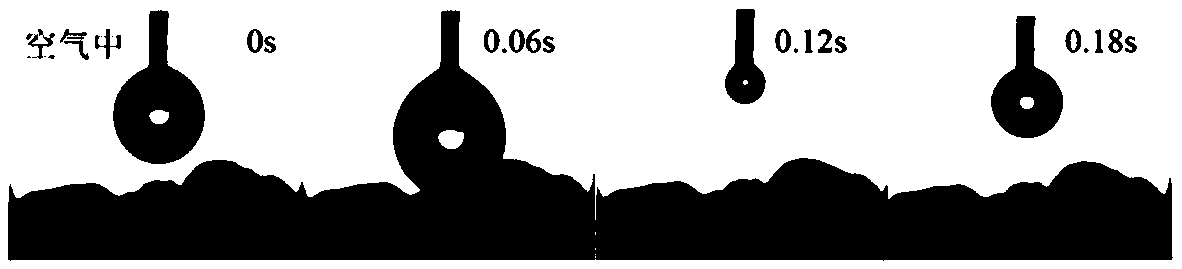

Method for carrying out inflating and flushing on filter

The invention relates to a method for carrying out inflating and flushing on a filter. The invention does not depend on direct impact of an airflow and only needs to uniformly distribute gas on the bottom of the filter. The principle of the invention is that in the backwashing process, when air bubbles and water move upwards, the air bubbles are broken and polymerized continuously after being cut by filter material particles and being torn by the water flow, a water-phase medium and a gas-phase medium surrounding the filter material particles are rapidly converted to form a high-speed turbulent flow, then the bubbles crack to form impact to make the filter material particles collide mutually, and various mechanisms make impurities adsorbed on the surface of a filter material drop off so as to realize carrying out complete flushing on the heavy-duty filter material. The method has low requirement on the inlet pressure and the flow, wherein the gas source pressure is 0.5 to 2 times of the flushing pressure; and the air flow is 0.5 to 2.5 times of the flushing water flow. A microminiature air pump can meet the requirements and can be integrated with a water purifying machine main body. The method for carring out inflating and flushing on the filter has the advantages of low working noise, safe operation and low manufacturing and operating cost, solves the problem of flushing the heavy-duty filter material in the filter under the condition that the working environment is limited and is particularly suitable for civil and domestic water purification systems.

Owner:朱凤翔

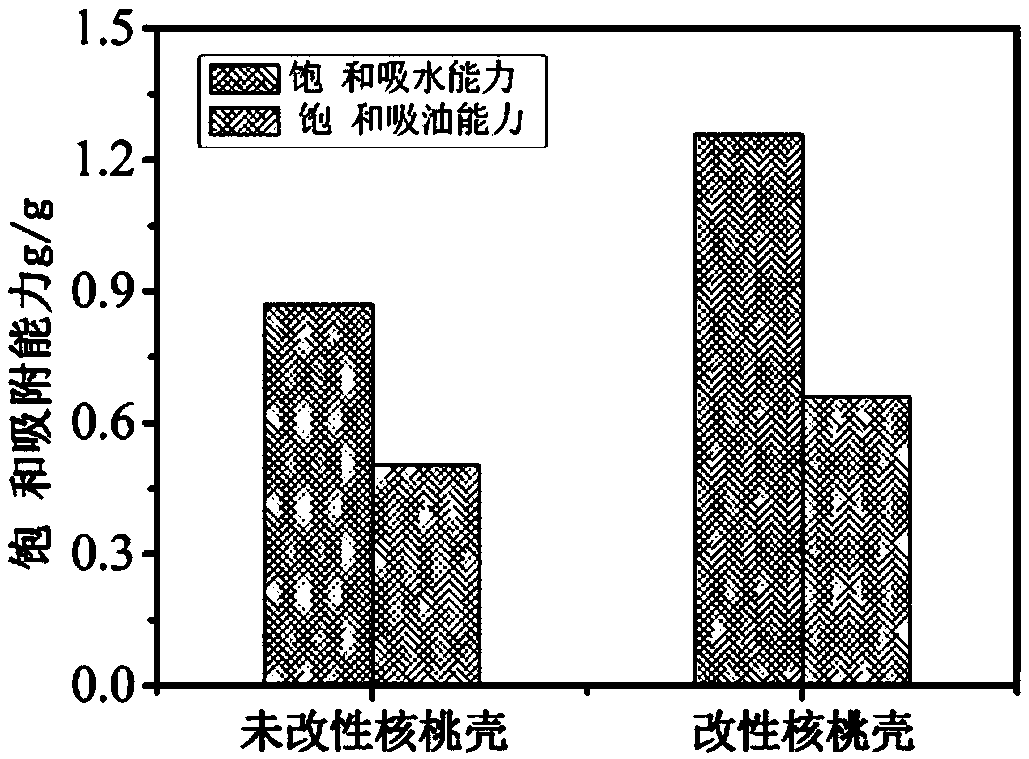

Antifouling modified walnut shell filter material as well as preparation method and application thereof

ActiveCN109603302ASuperhydrophilicSuper lipophilicWaste water treatment from quariesWater contaminantsMicro nanoWater based

An antifouling modified walnut shell filter material as well as preparation method and application thereof are disclosed, and the method is as follows: washing a walnut shell filter material with water, and drying for later use; dispersing hydrophilic micro-nano particles and a silane coupling agent into water, and stirring to obtain a mixed solution; adding water-based resin and an assistant intothe mixed solution, and uniformly stirring and uniformly mixing to obtain a required modifying solution; and adding the cleaned walnut shell filter material into the modifying solution, stirring, filtering, and drying to obtain the antifouling modified walnut shell filter material. According to the invention, the surface modification is adopted, and the contact angle of the walnut shell filter material to water and oil in air is 0 degree, so that the antifouling modified walnut shell filter material has superhydrophilicity and superoleophylic property, has super-oleophobic property at underwater, and has the characteristic of low adhesion to oil drops, so that the anti-fouling property is achieved, the filtering effect is optimized, and the backwashing capability is improved.

Owner:SOUTHEAST UNIV

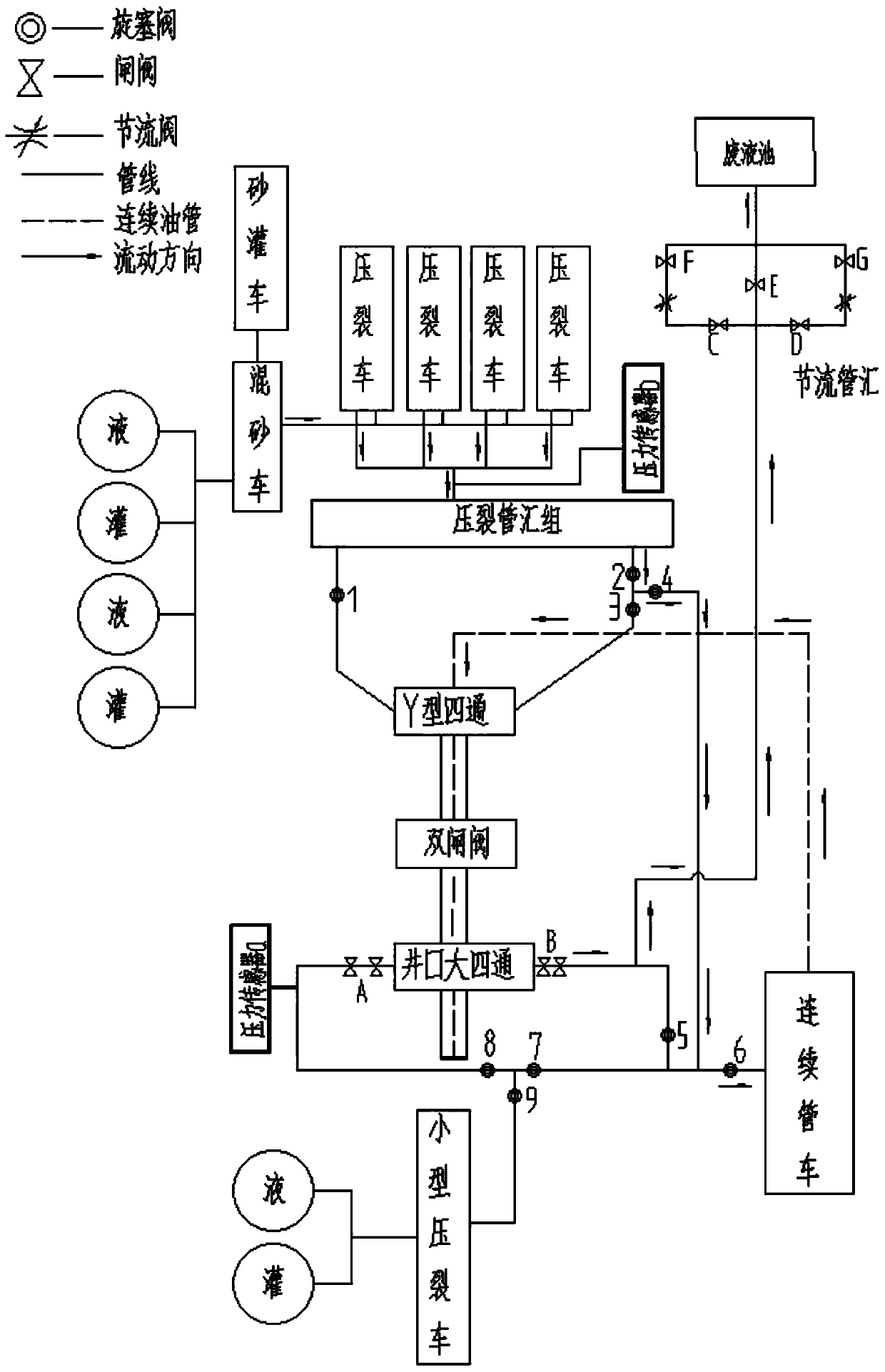

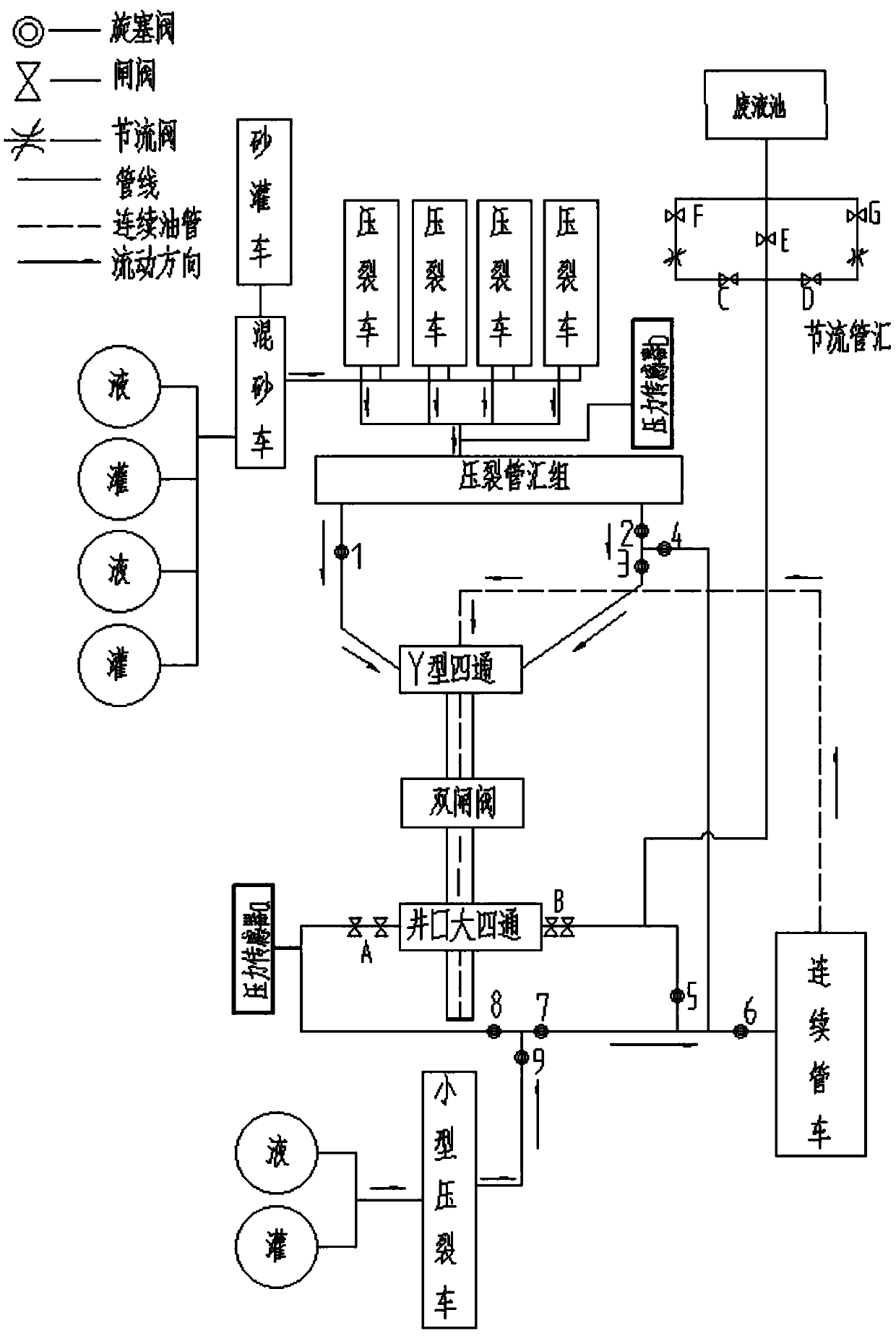

Sandblasting perforating annular fracturing ground control system and method

The invention discloses a sandblasting perforating annular fracturing ground control system and method. The system comprises a fracturing annulus pumping system, a coiled tubing pumping system, a wellhead device, a wellhead pressure control throttle manifold, a coiled tubing vehicle, a coiled tubing, a waste liquid recovery tank and a throttle manifold; the wellhead device comprises a Y-shaped four-way, a double-gate valve and a wellhead large four-way which are connected in sequence, the fracturing annulus pumping system comprises a liquid filling vehicle, a sand filling vehicle, a sand mixing vehicle, fracturing vehicle groups and a fracturing manifold, the liquid filling vehicle and the sand filling vehicle are connected to the sand mixing vehicle separately, and the fracturing vehiclegroups are connected to two passages of the Y-shaped four-way and the coiled tubing vehicle respectively. The sandblasting perforating annular fracturing ground control system and method have the advantages that it can be achieved that the sanding operation of sandblasting perforating operation and a fracturing process by using one sand mixing vehicle through the system, the data collection and display work of the pumping pressure of the two fracturing vehicle groups are achieved during sandblasting perforating pumping pressure, wellhead pressure and fracturing, and washing of a wellbore fromthe coiled tubing or backwashing of the wellbore from oil jacket annulus is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

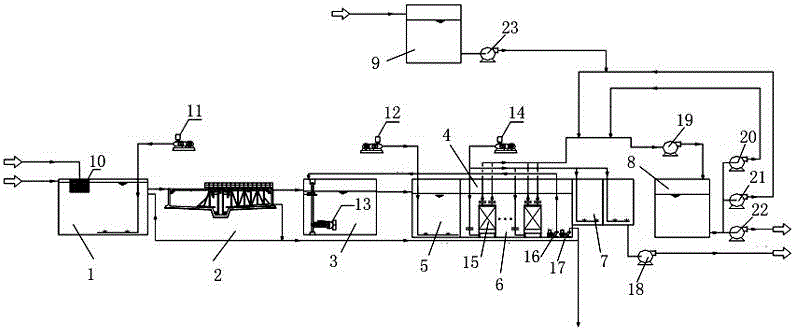

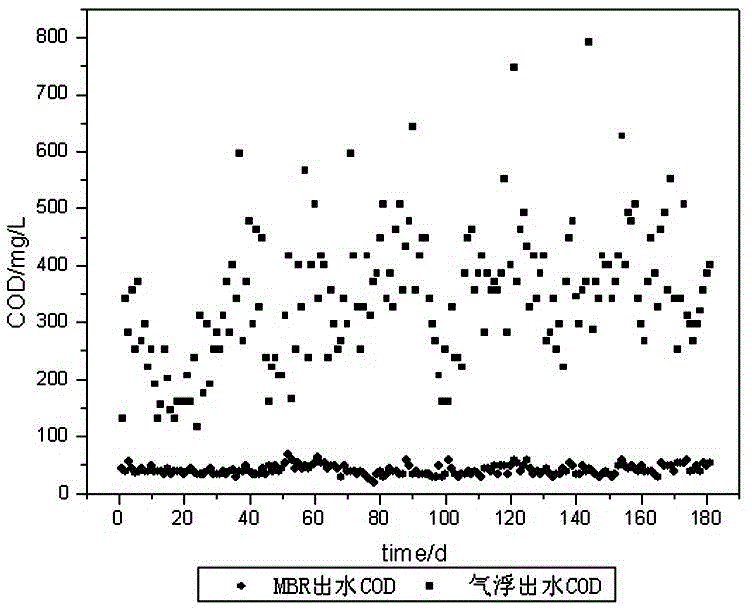

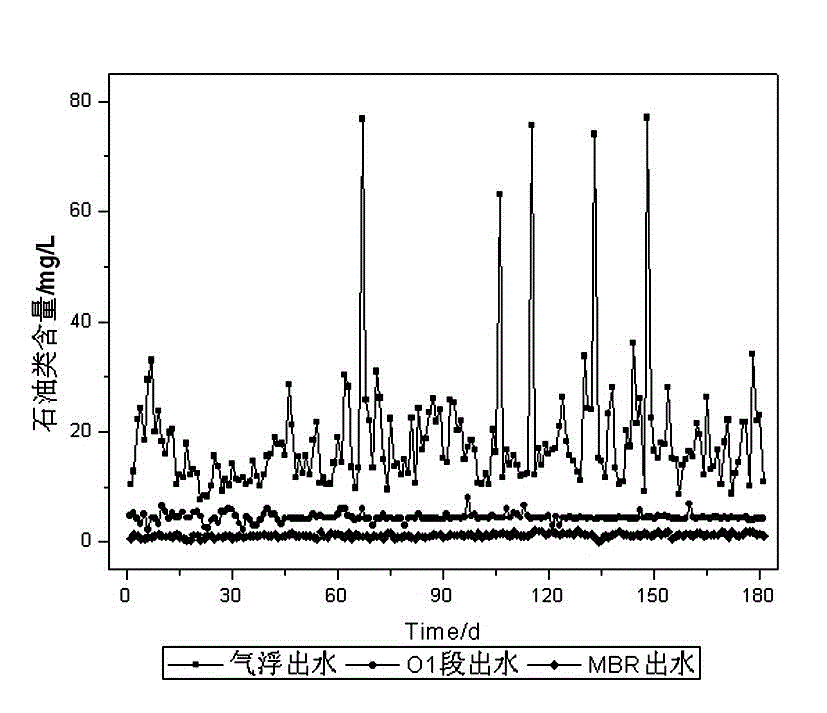

MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and membrane component cleaning method

ActiveCN102718359AImprove adsorption capacitySlow the rate of pollutionSemi-permeable membranesMultistage water/sewage treatmentHigh concentrationMembrane bioreactor

The invention discloses an MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and a membrane component cleaning method. A biochemical treatment system comprises an aerobic aeration tank, a middle sedimentation tank, an anoxic tank and a membrane bioreactor. The aerobic aeration tank allows pretreated oil refining wastewater to enter, and the middle sedimentation tank connected with the aerobic aeration tank is used for separation mud and water in the aerobic aeration tank to enable part of sludge to be discharged and part of precipitated sludge to flow back into the aerobic aeration tank. The anoxic tank is connected with the middle sedimentation tank, supernatant in the middle sedimentation tank enters the anoxic tank for denitrification, and the membrane bioreactor which forms an organic pollutant main removing unit is connected with the anoxic tank. The MBR system membrane component cleaning method includes: air scrubbing, online backwashing, online chemical cleaning and offline cleaning, especially online cleaning adopts high-concentration NaClO solution and low-concentration NaClO solution alternately, and offline cleaning adopts sodium dodecyl sulfate and sodium carbonate solution for cleaning or NaClO solution for cleaning.

Owner:ZHEJIANG SHUANGYI ENVIRONMENTAL PROTECTION TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com