Method for carrying out inflating and flushing on filter

A technology of backwashing and filtering devices, applied in gravity filters, chemical instruments and methods, loose filter material filters, etc., can solve problems such as difficulty in implementation, high air pressure, occupation, etc., and achieve the effect of increasing the flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] What the present invention provides is a filter material cleaning technology principle and method. According to the technical method of the present invention, various implementations can be designed. The implementations given here are schematic preferred solutions, which are intended to facilitate understanding of the present invention. , are not all embodiments of the present invention, and cannot be used to limit the scope of the present invention.

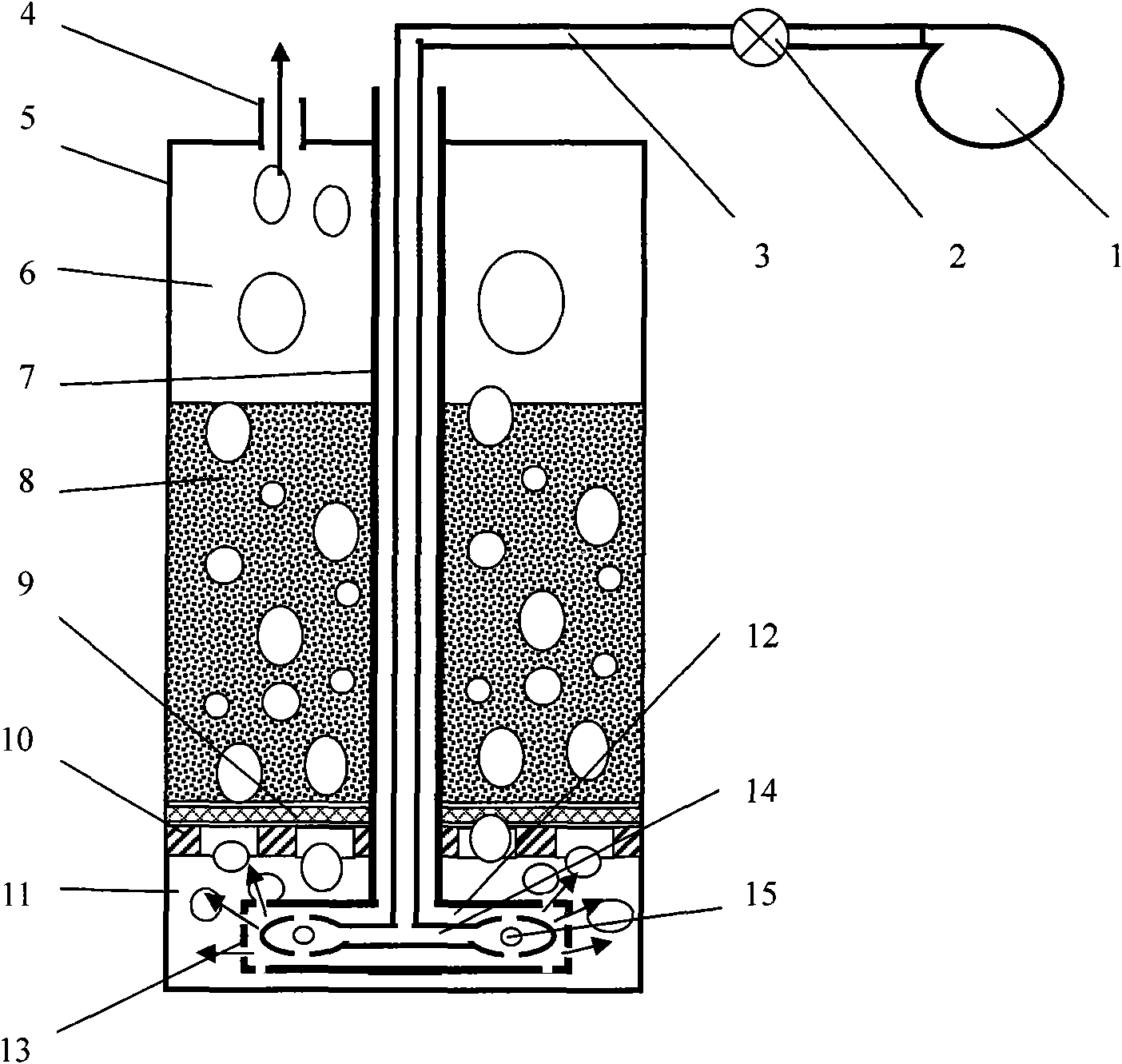

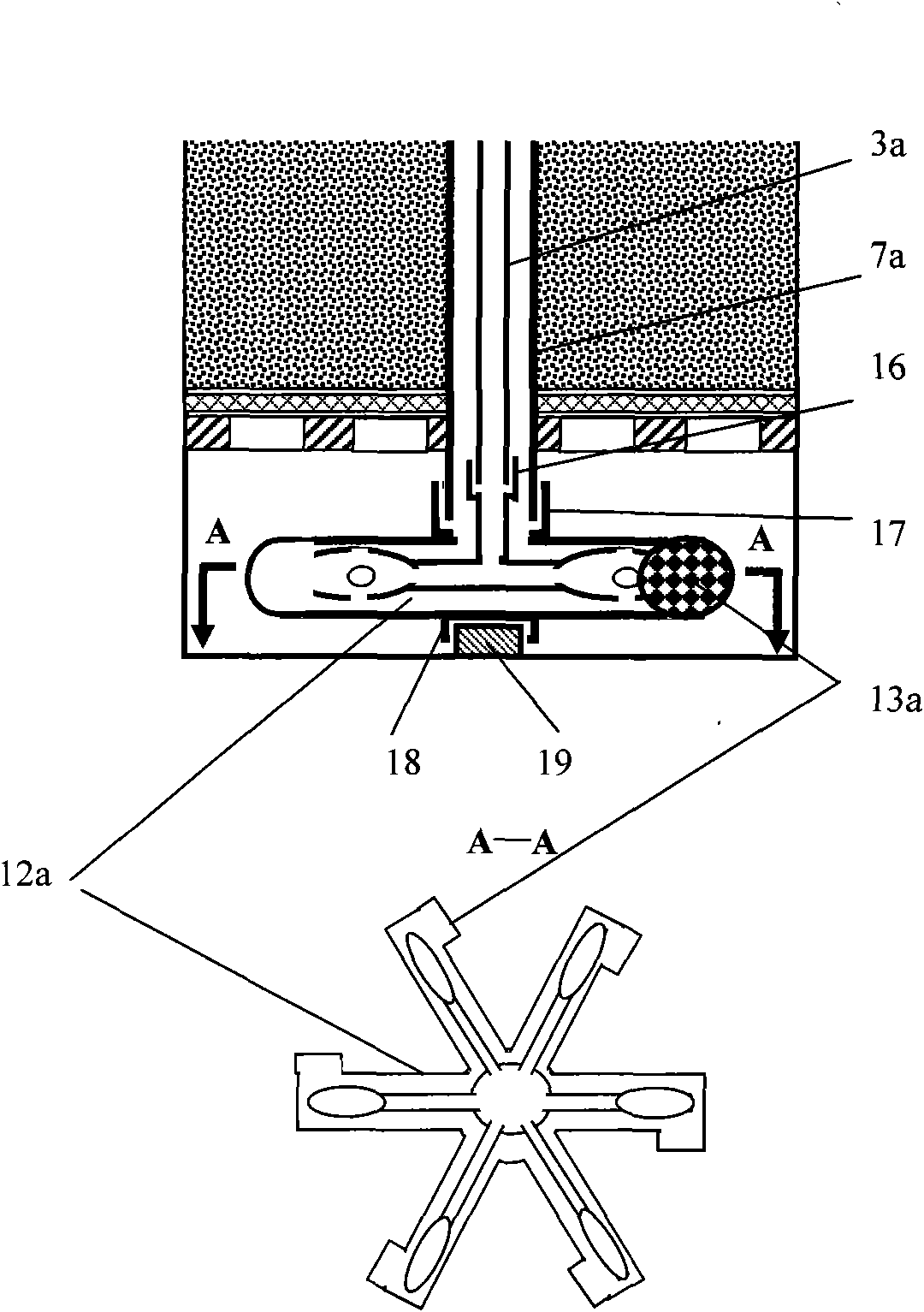

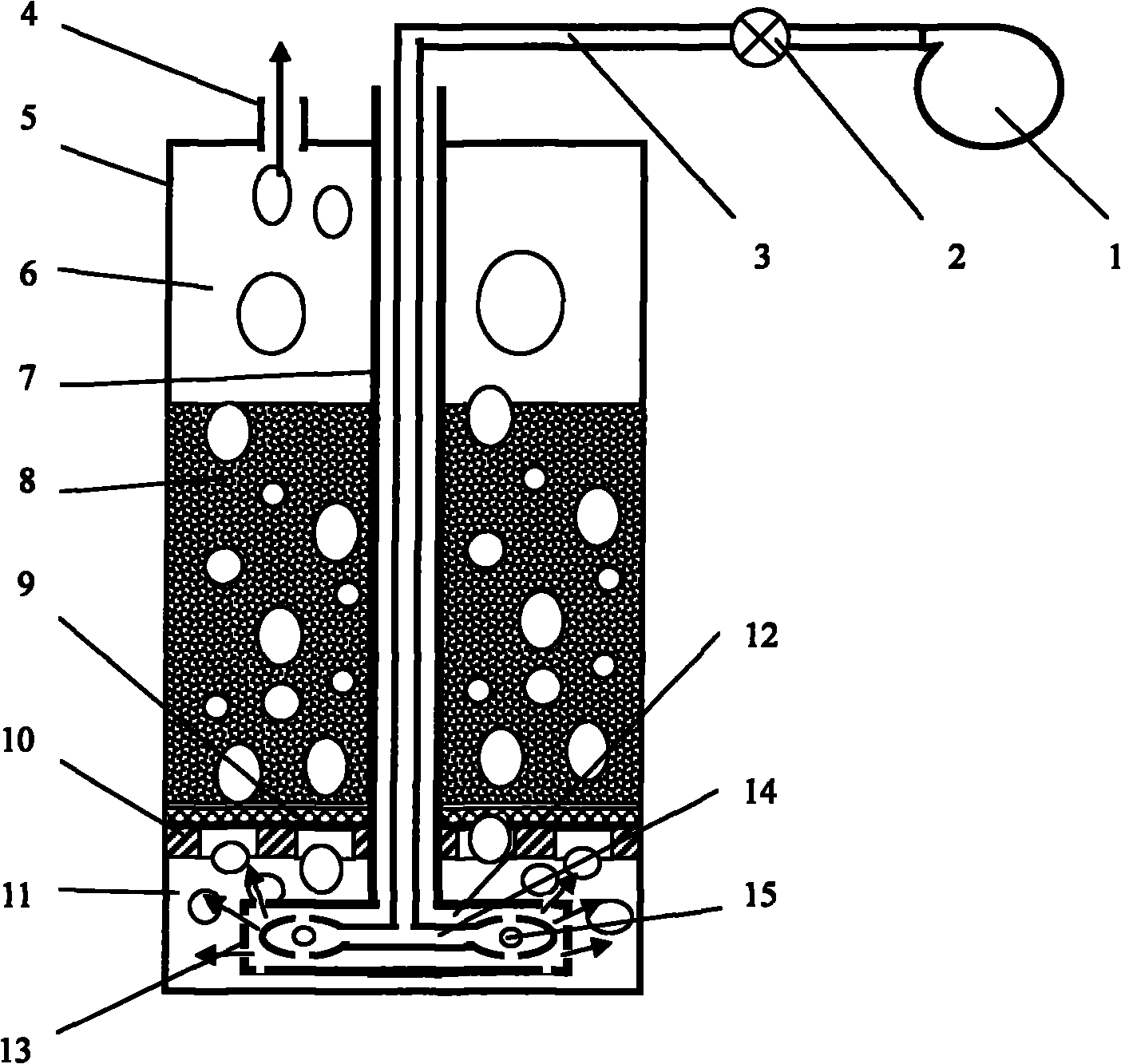

[0036] figure 1 The schematic diagram of the water processor implementing the patented cleaning technology of downstream filtration and reverse gas-entrainment flushing is provided, 5 is a container tank body, and the tank body is divided into a lower water collection chamber 11, a middle filter bed (filter material chamber) 8, The upper raw water chamber 6, in which the water collection chamber integrates the functions of water collection in the working state, water distribution and air distribution in the backwash state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com