Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2092 results about "Coiled tubing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the oil and gas industries, coiled tubing refers to a very long metal pipe, normally 1 to 3.25 in (25 to 83 mm) in diameter which is supplied spooled on a large reel. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Coiled tubing is often used to carry out operations similar to wirelining. The main benefits over wireline are the ability to pump chemicals through the coil and the ability to push it into the hole rather than relying on gravity. Pumping can be fairly self-contained, almost a closed system, since the tube is continuous instead of jointed pipe. For offshore operations, the 'footprint' for a coiled tubing operation is generally larger than a wireline spread, which can limit the number of installations where coiled tubing can be performed and make the operation more costly. A coiled tubing operation is normally performed through the drilling derrick on the oil platform, which is used to support the surface equipment, although on platforms with no drilling facilities a self-supporting tower can be used instead. For coiled tubing operations on sub-sea wells a mobile offshore drilling unit (MODU) e.g. semi-submersible, drillship etc. has to be utilized to support all the surface equipment and personnel, whereas wireline can be carried out from a smaller and cheaper intervention vessel. Onshore, they can be run using smaller service rigs, and for light operations a mobile self-contained coiled tubing rig can be used.

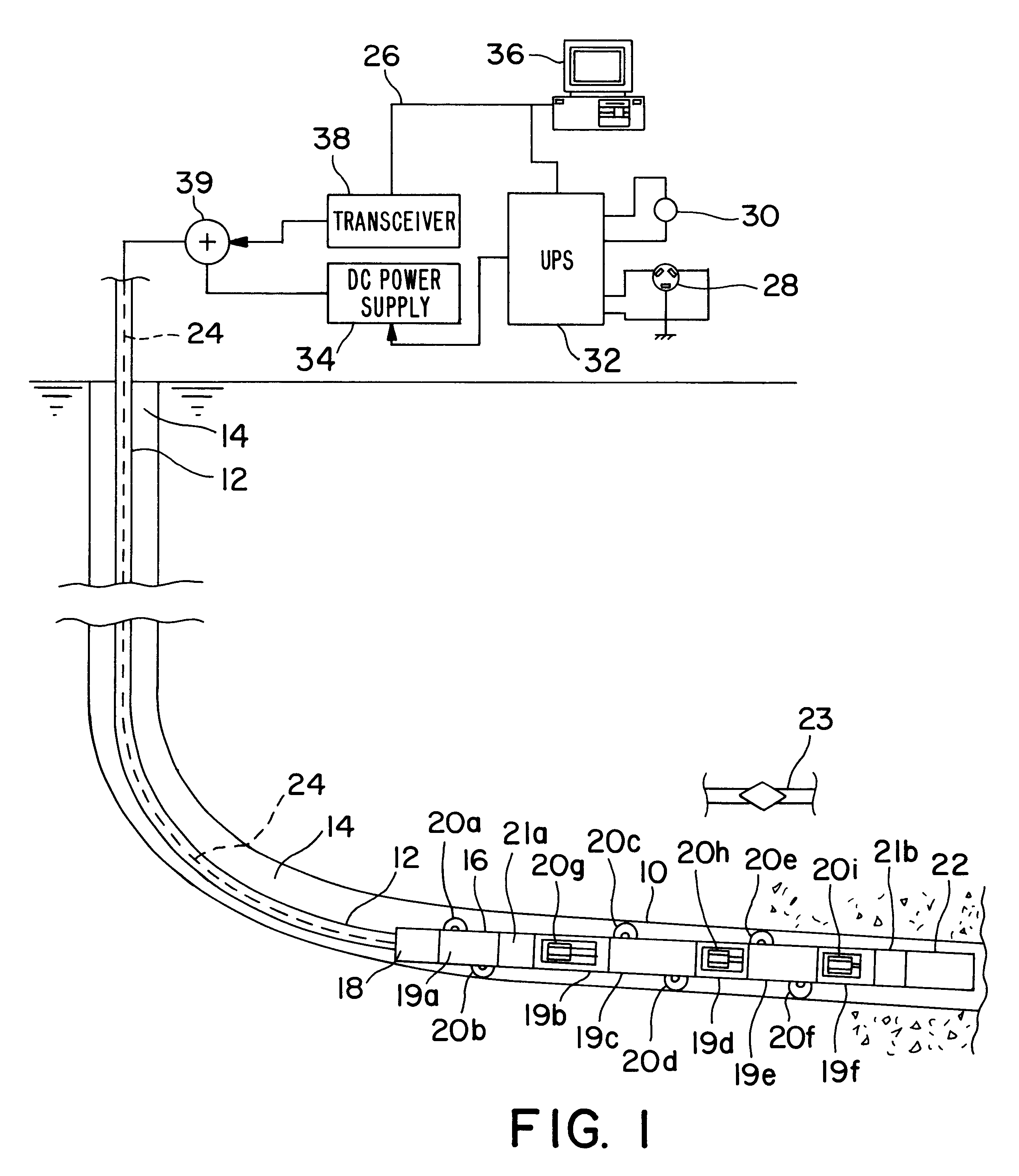

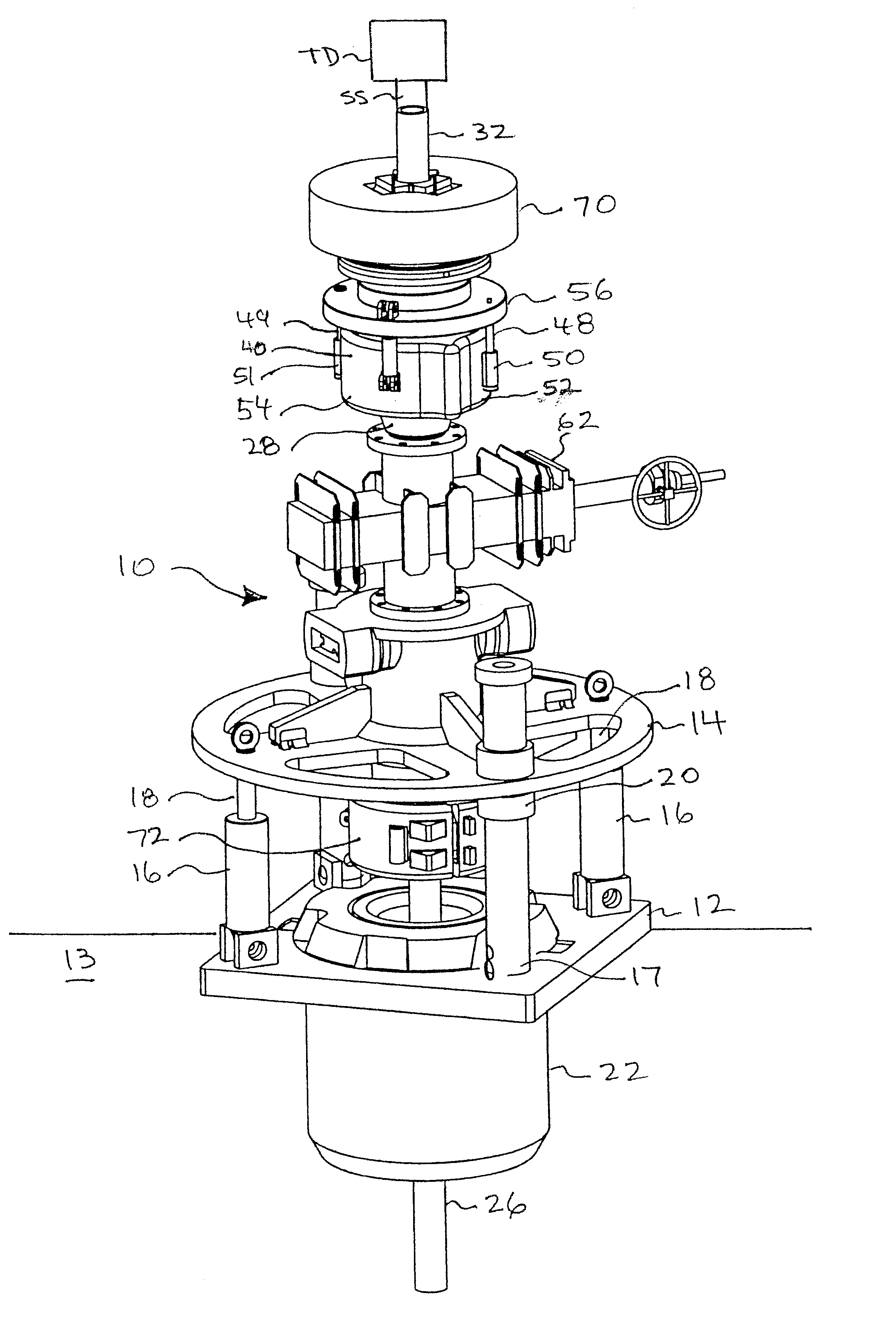

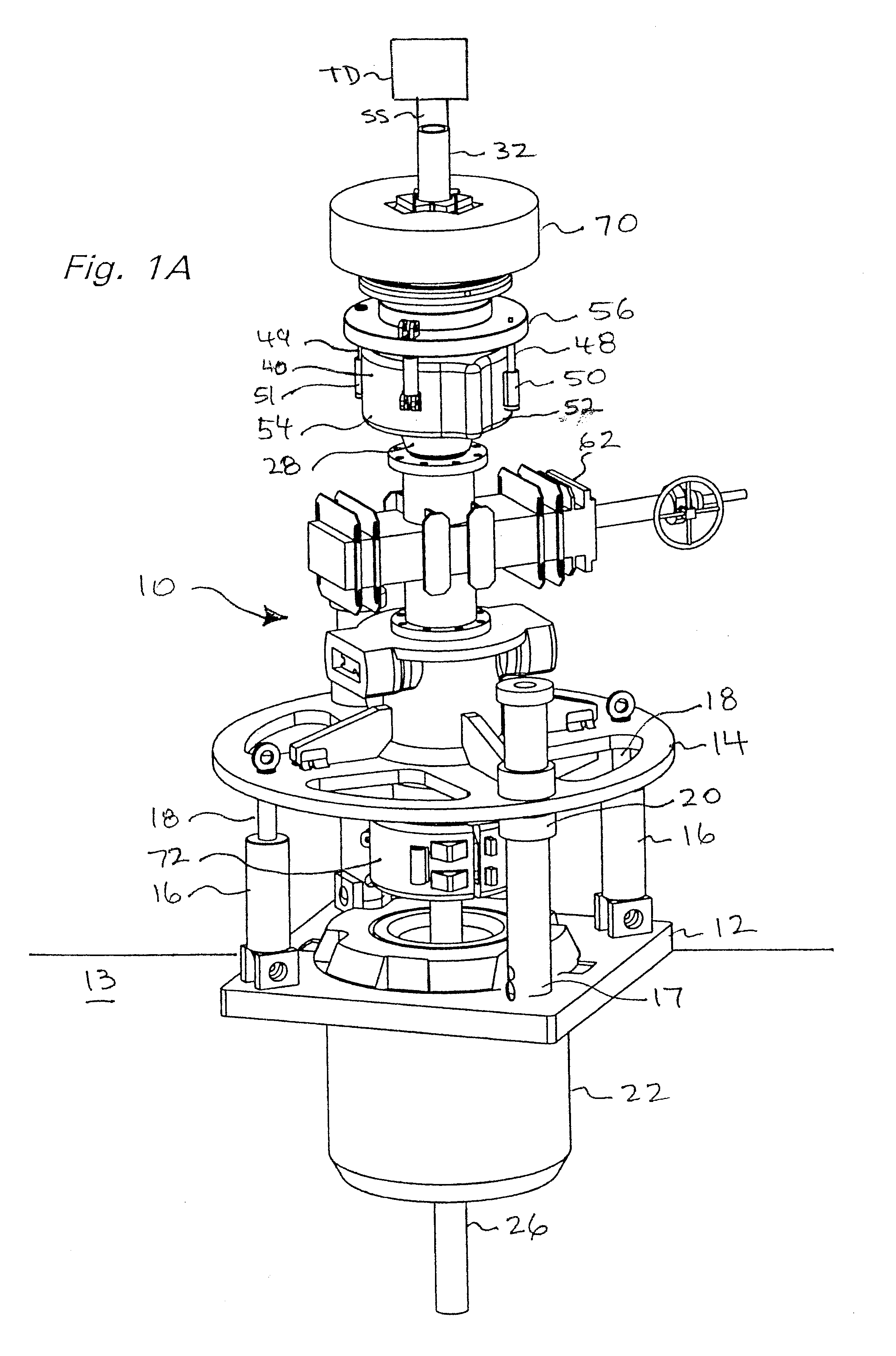

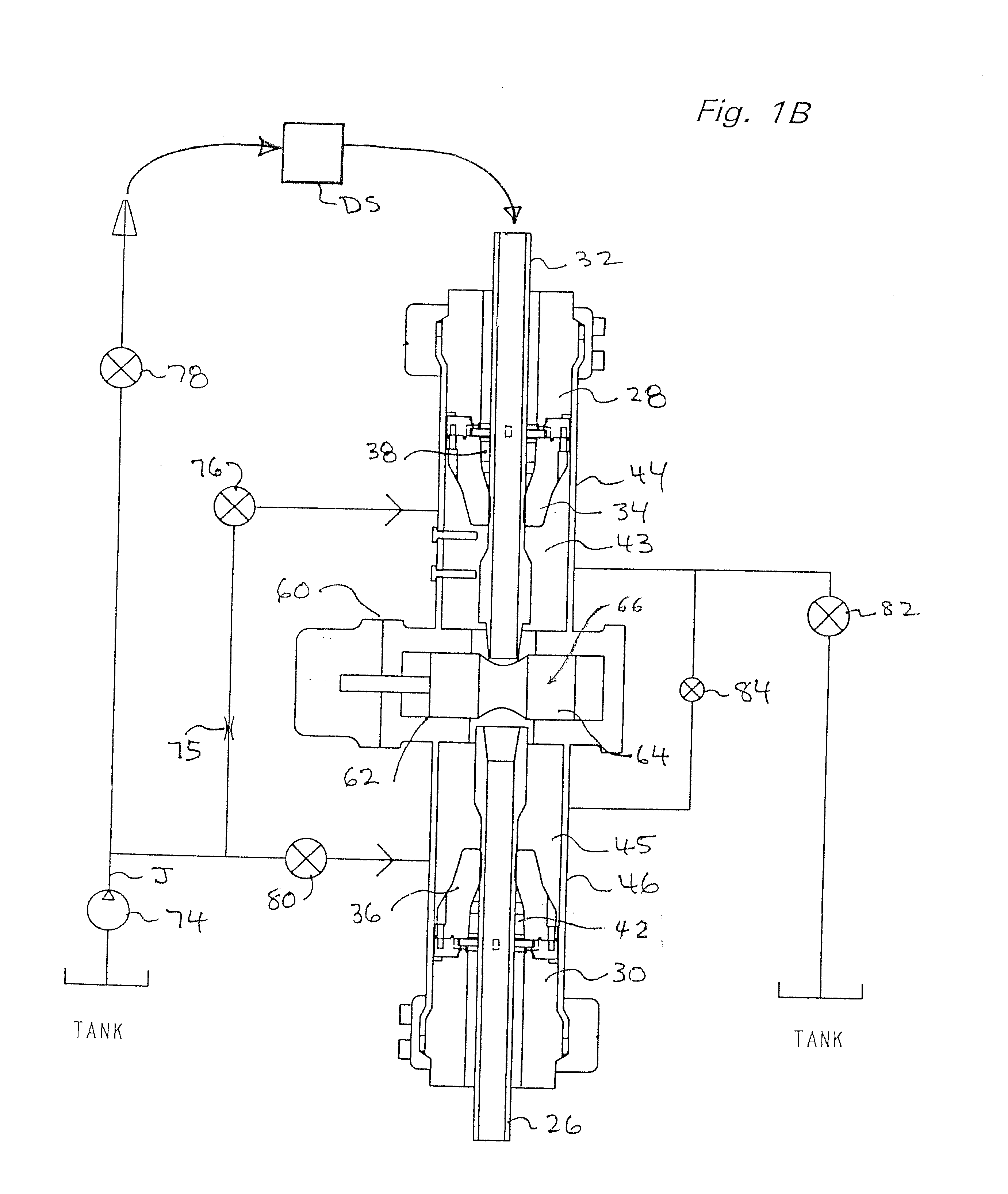

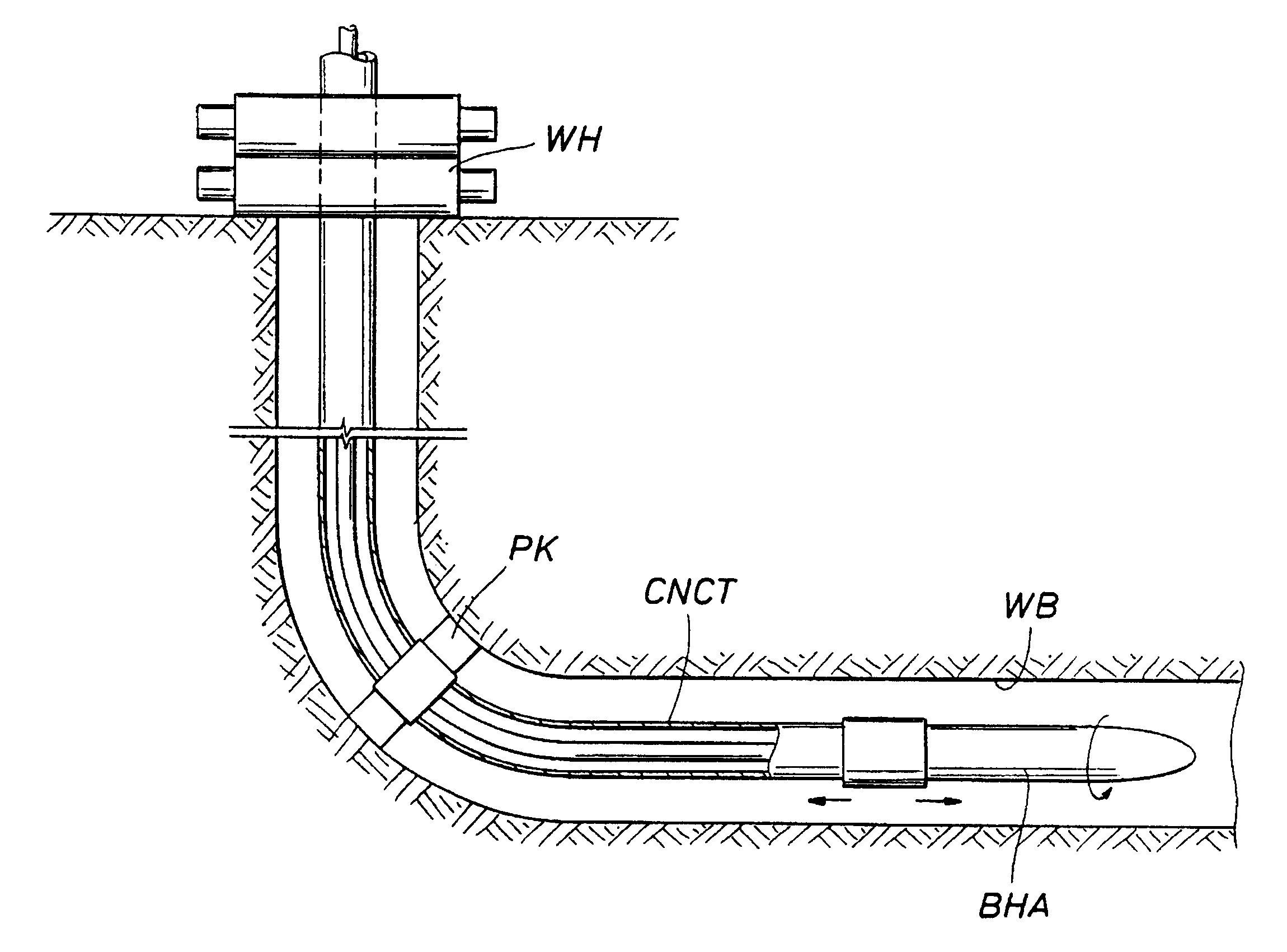

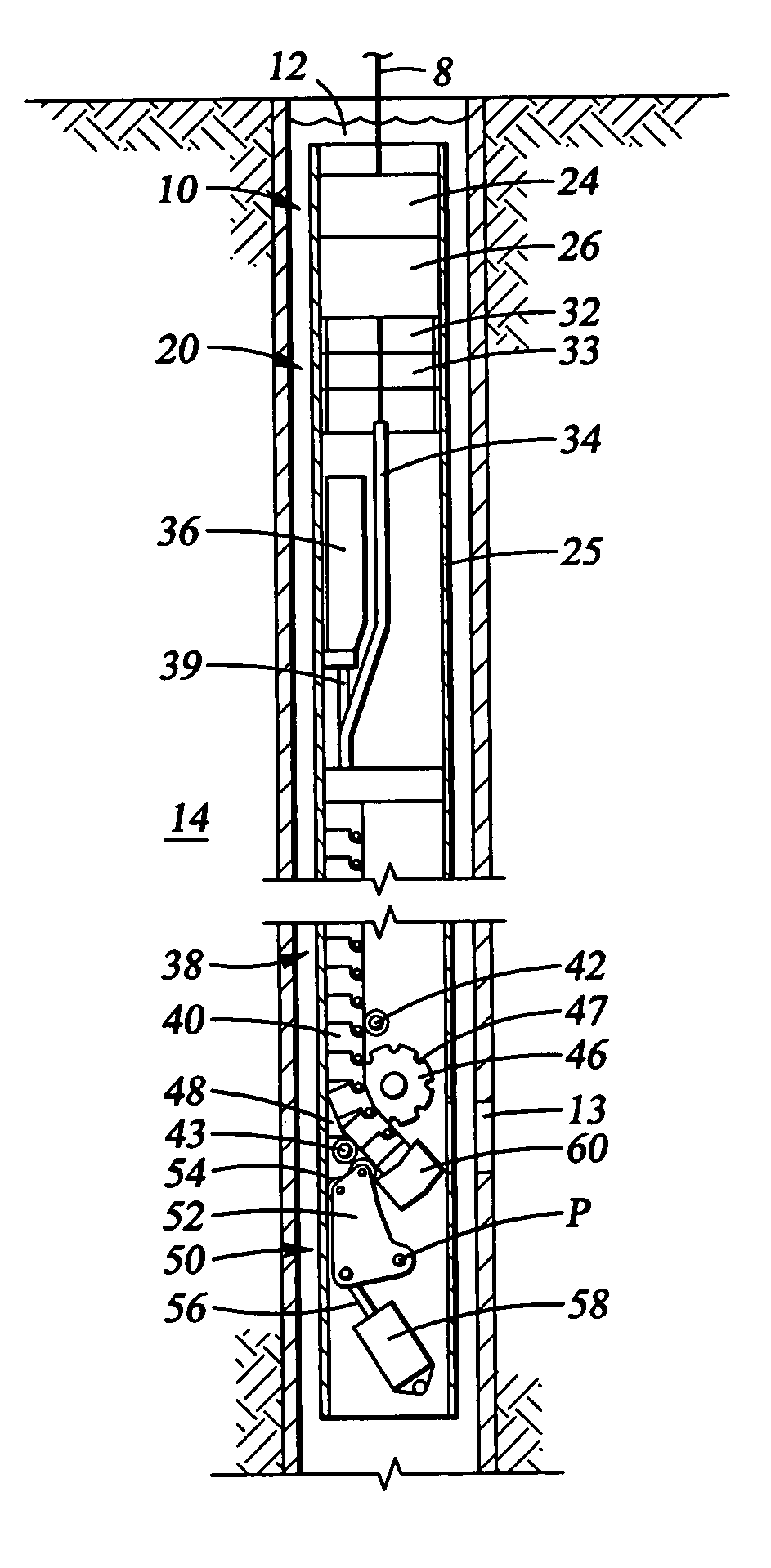

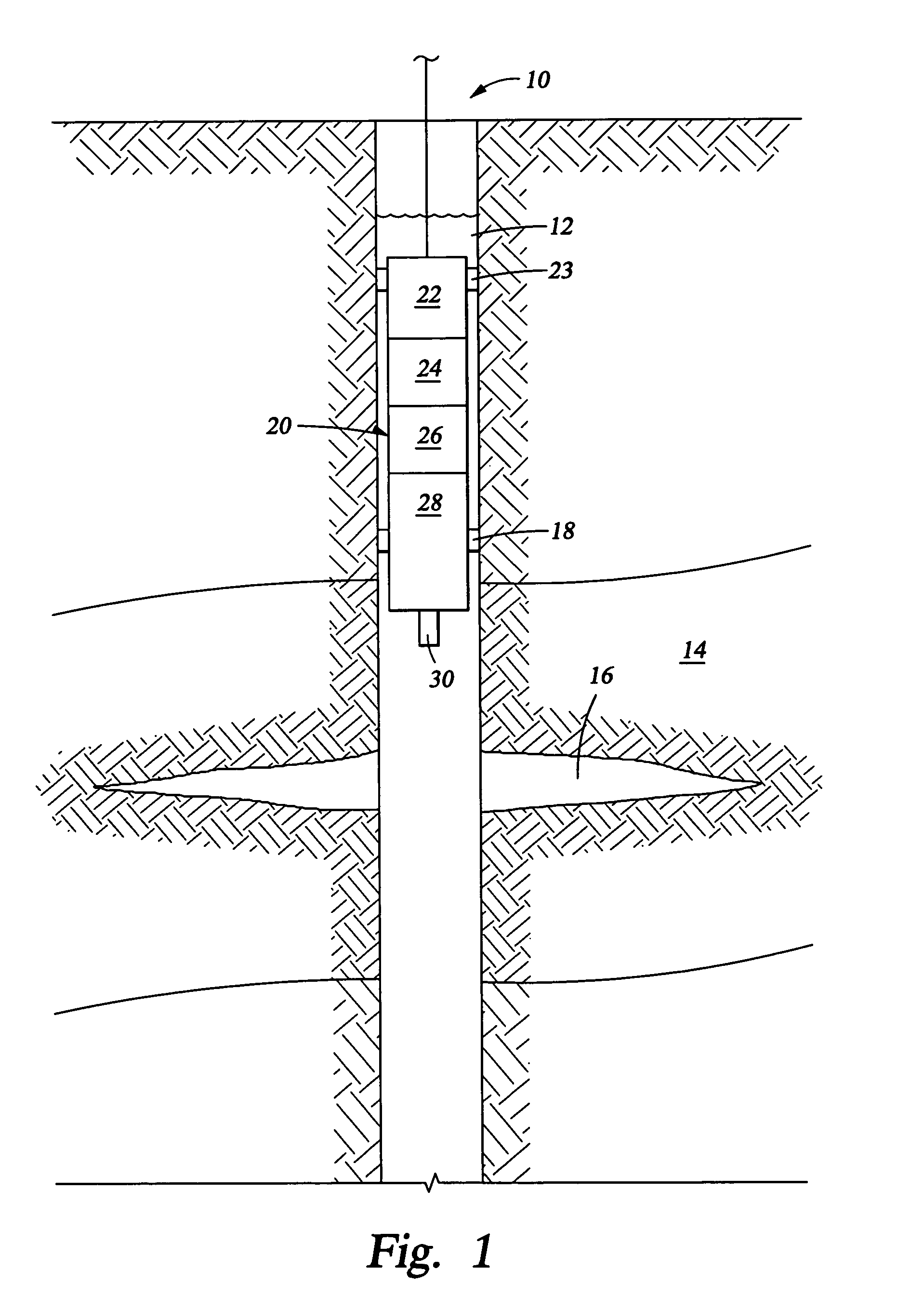

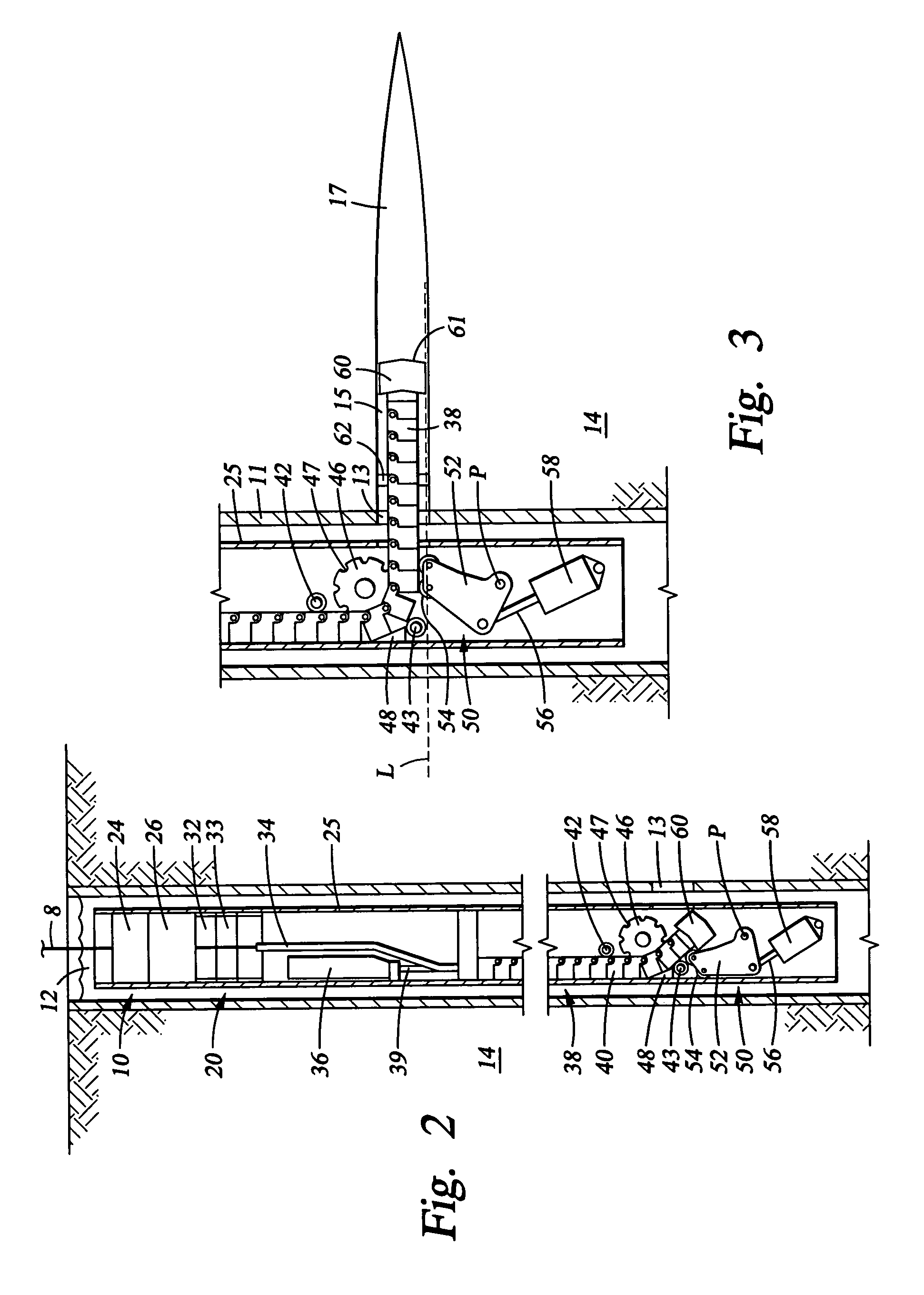

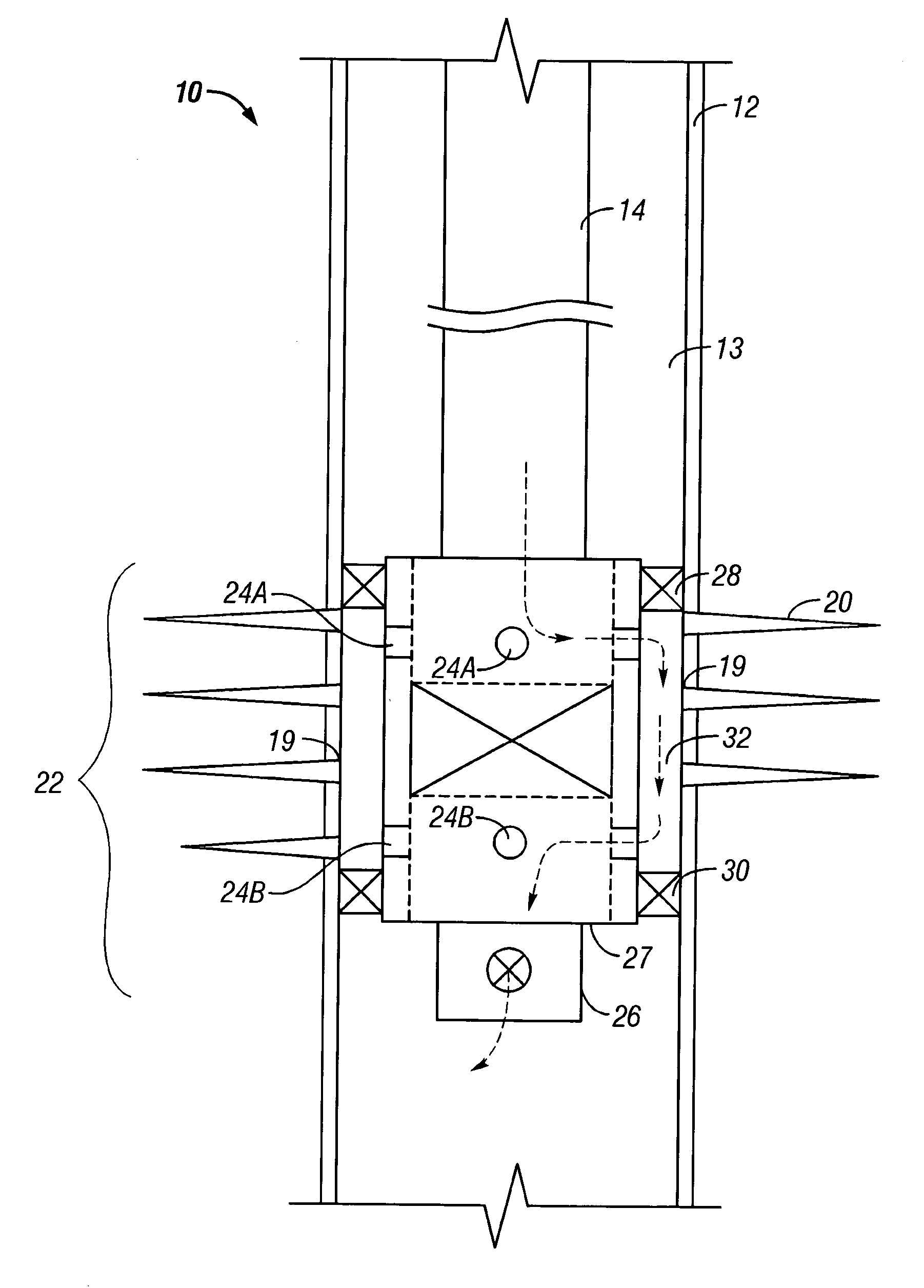

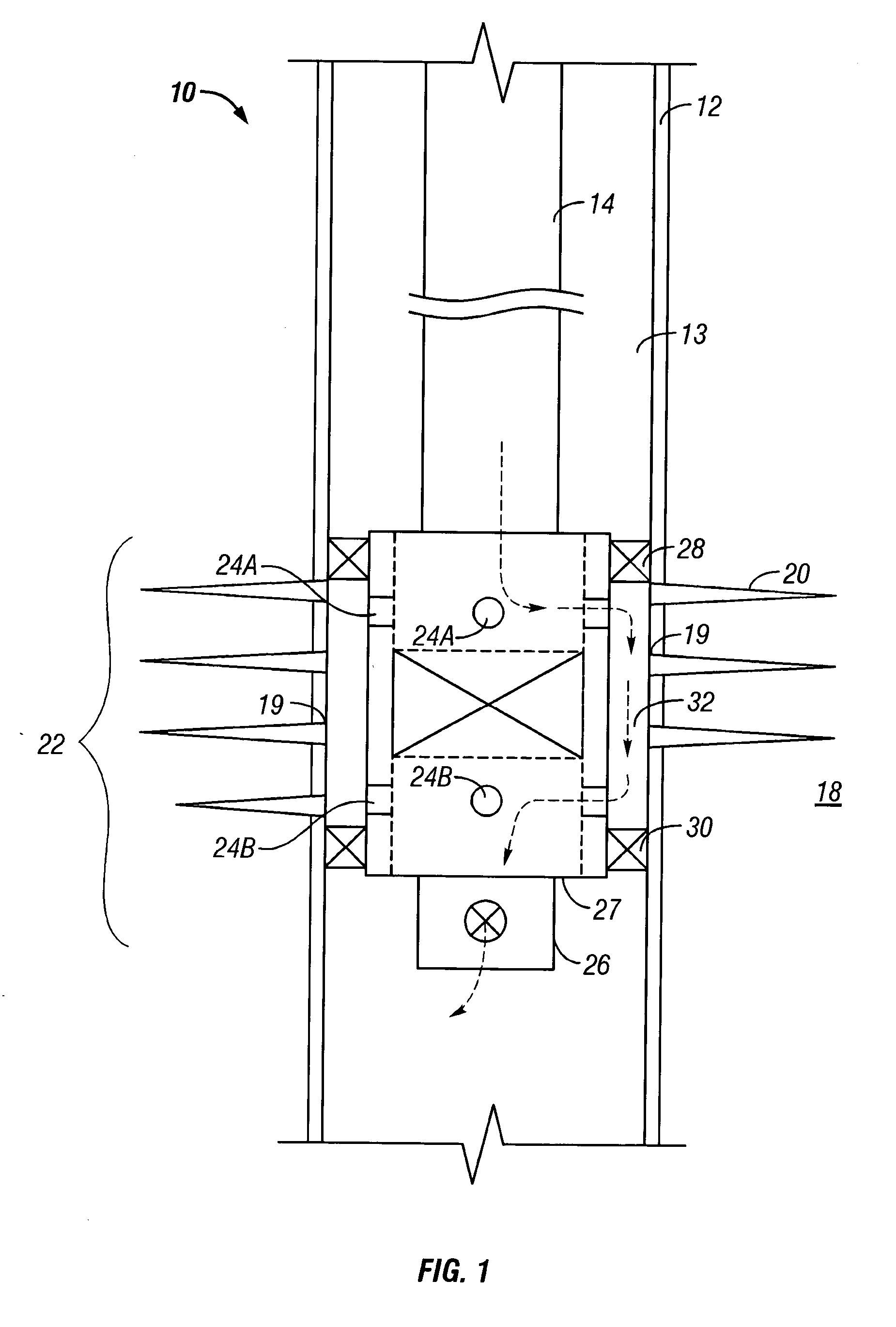

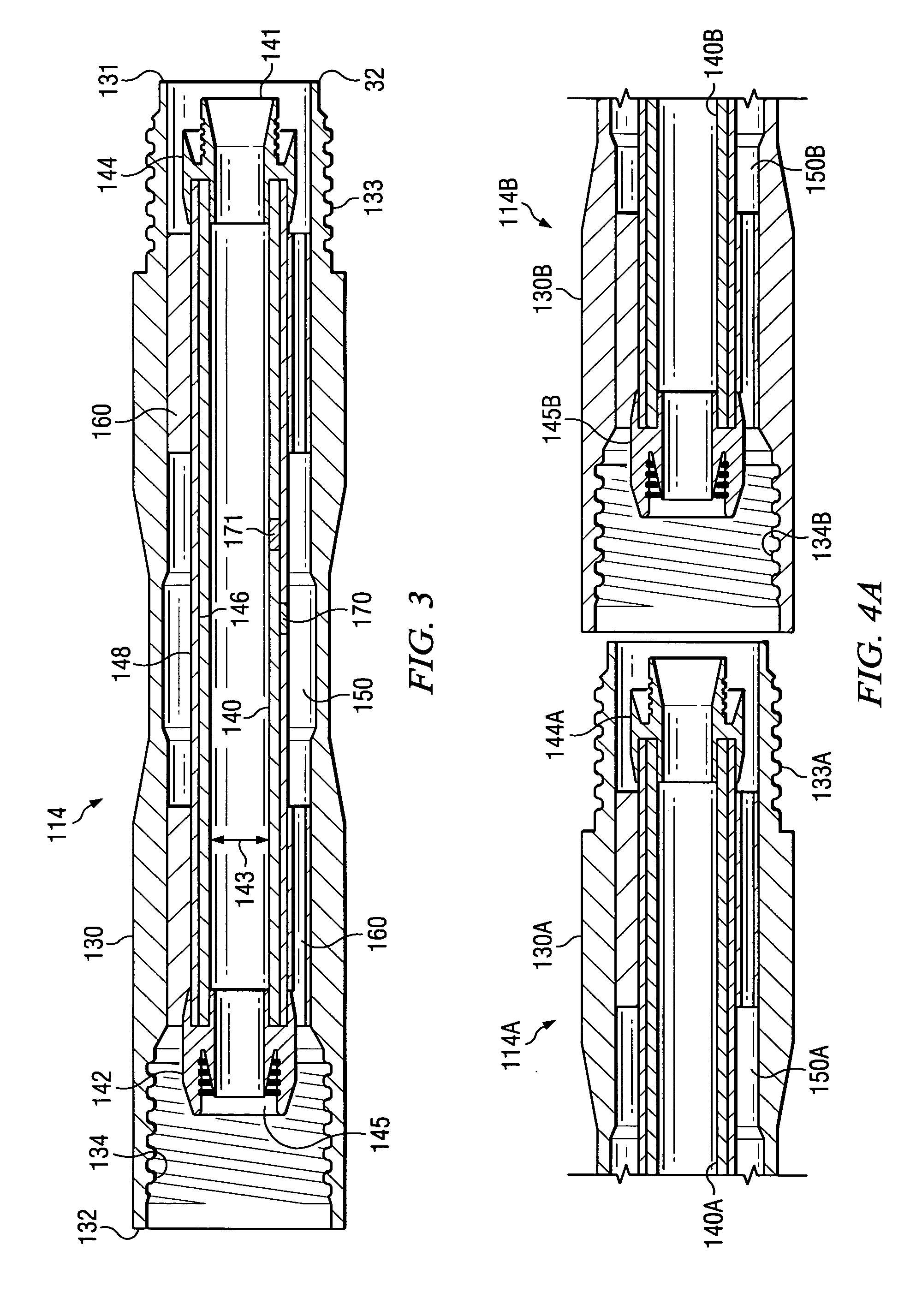

Downhole tractor

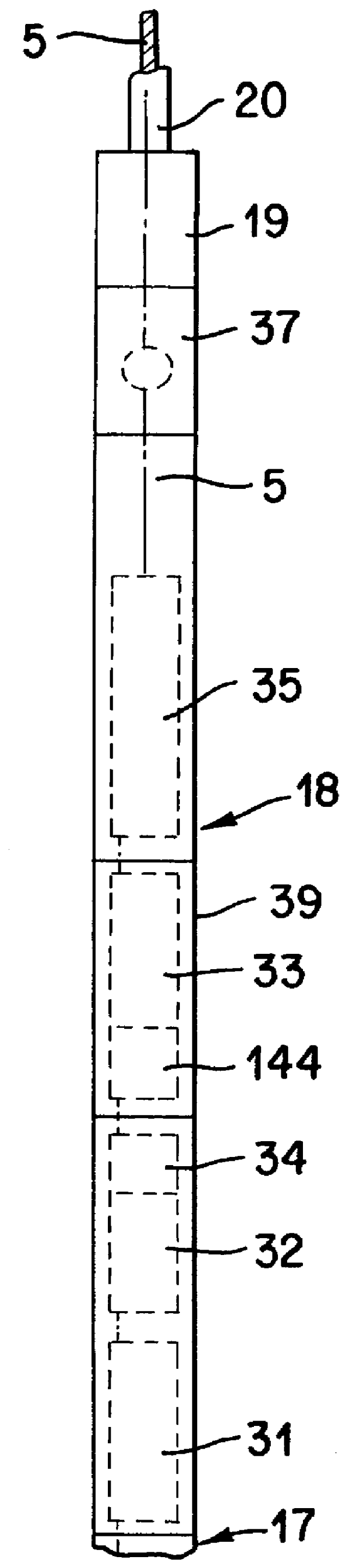

A downhole tractor is provided that includes a housing and a first wheel assembly coupled to the housing that is operable to translate away from the housing in a first direction. The first wheel assembly has a first electric motor, a first wheel, and a first reduction gear assembly coupled between the first electric motor and the first wheel. A second wheel assembly is coupled to the housing and is operable to translate away from the housing in a second direction that is opposite to the first direction. The second wheel assembly has a second electric motor, a second wheel, and a second reduction gear assembly coupled between the second electric motor and the second wheel. A fluid ram is coupled to the first and second wheel assemblies for selectively translating the first and second wheel assemblies toward and away from the housing. A first controller is provided for controlling the flow of current to the first and second electric motors. On-board and surface control systems may be incorporated to permit selective active of the wheels assemblies. In addition, couplings and connectors employing shape-memory materials may be included to secure the tractor to coiled tubing or a wireline.

Owner:HALLIBURTON ENERGY SERVICES INC

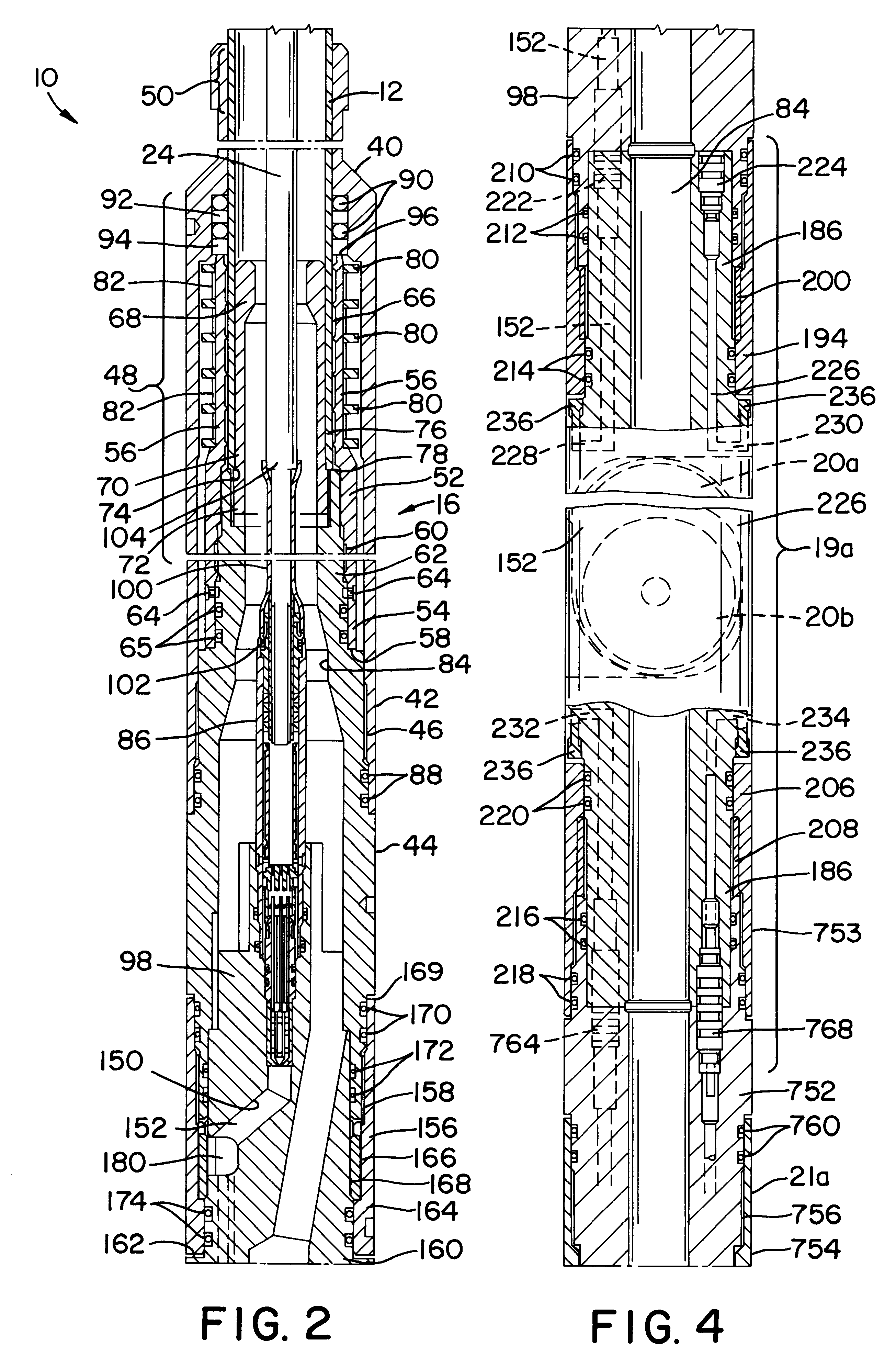

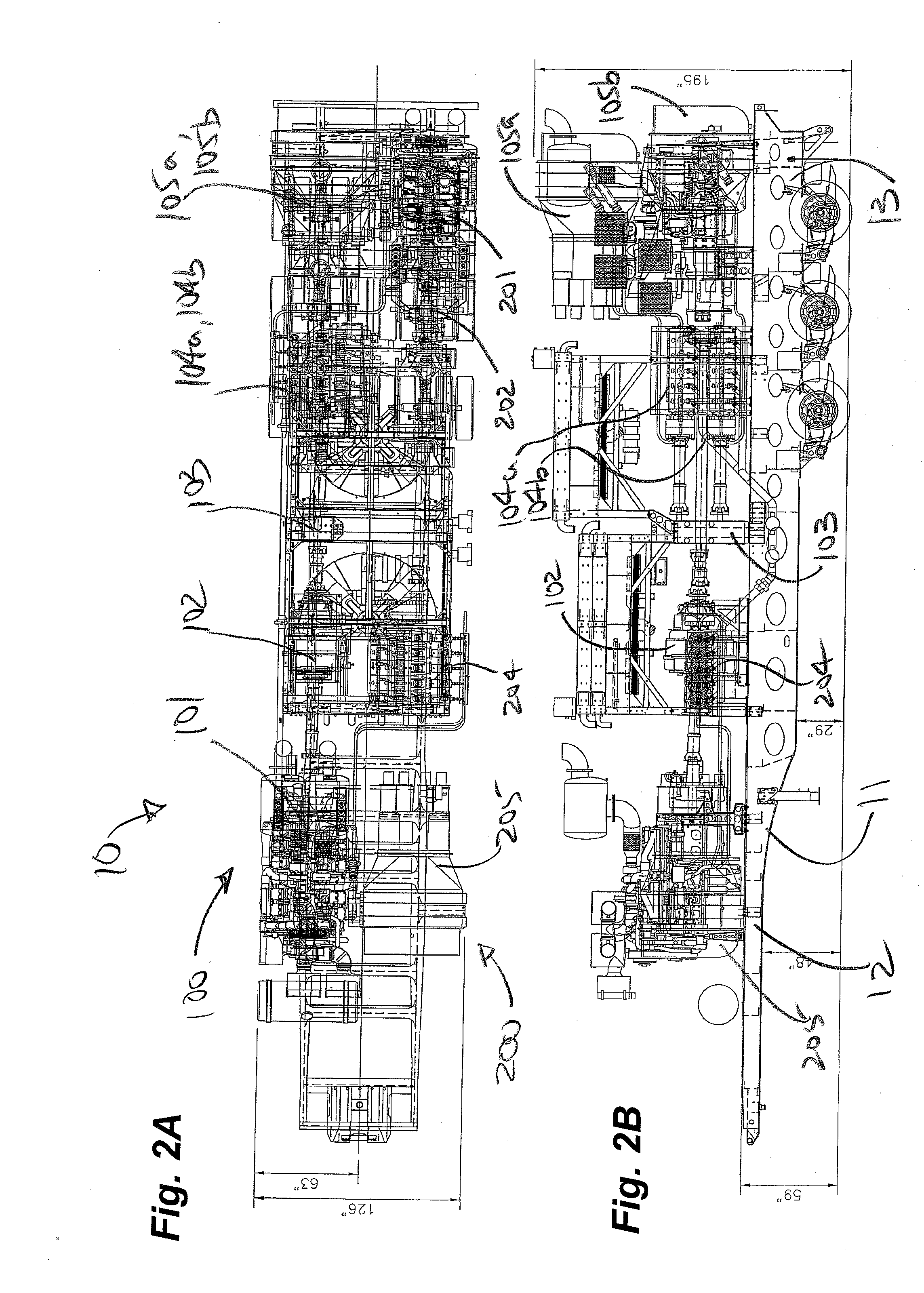

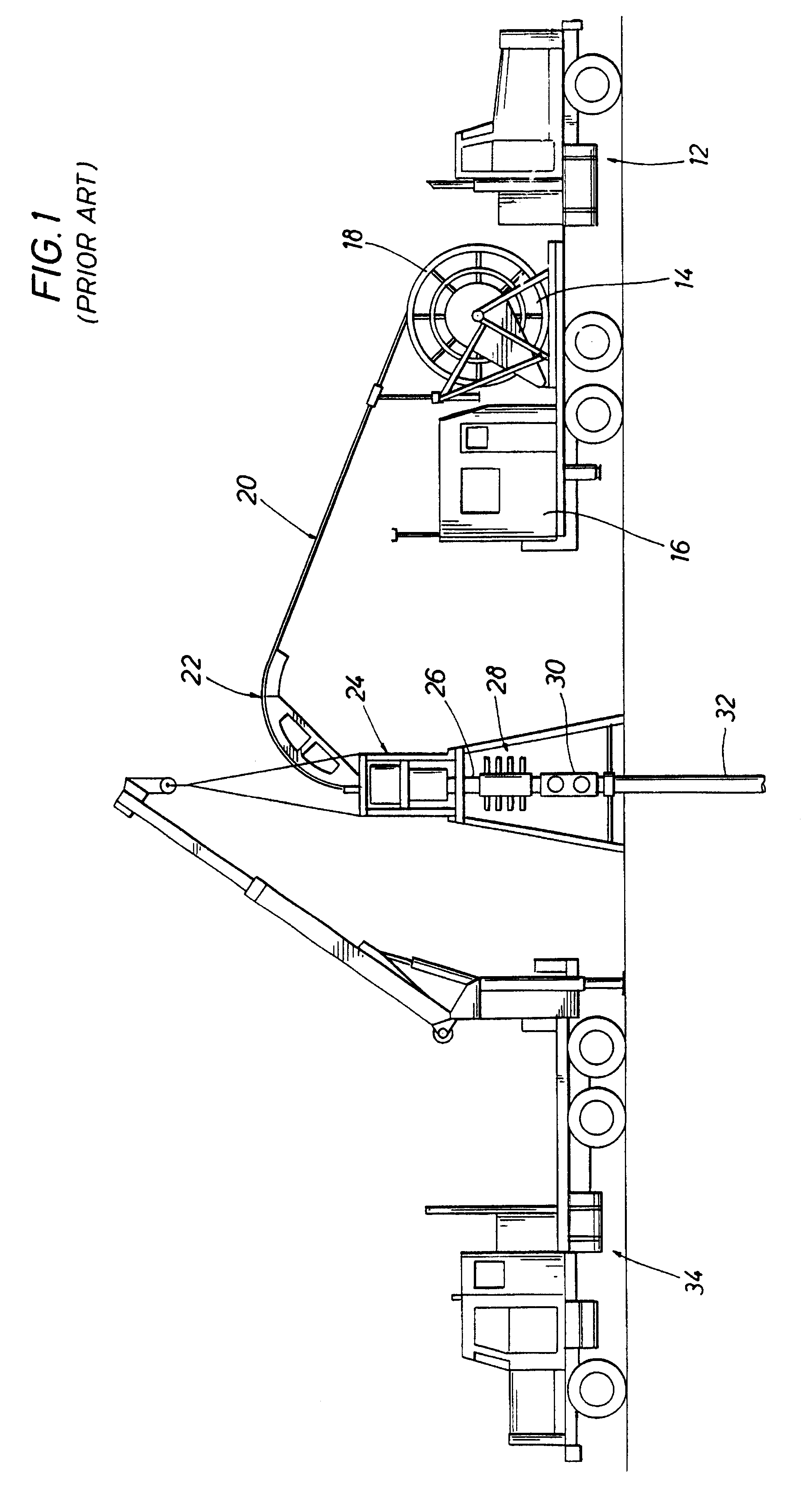

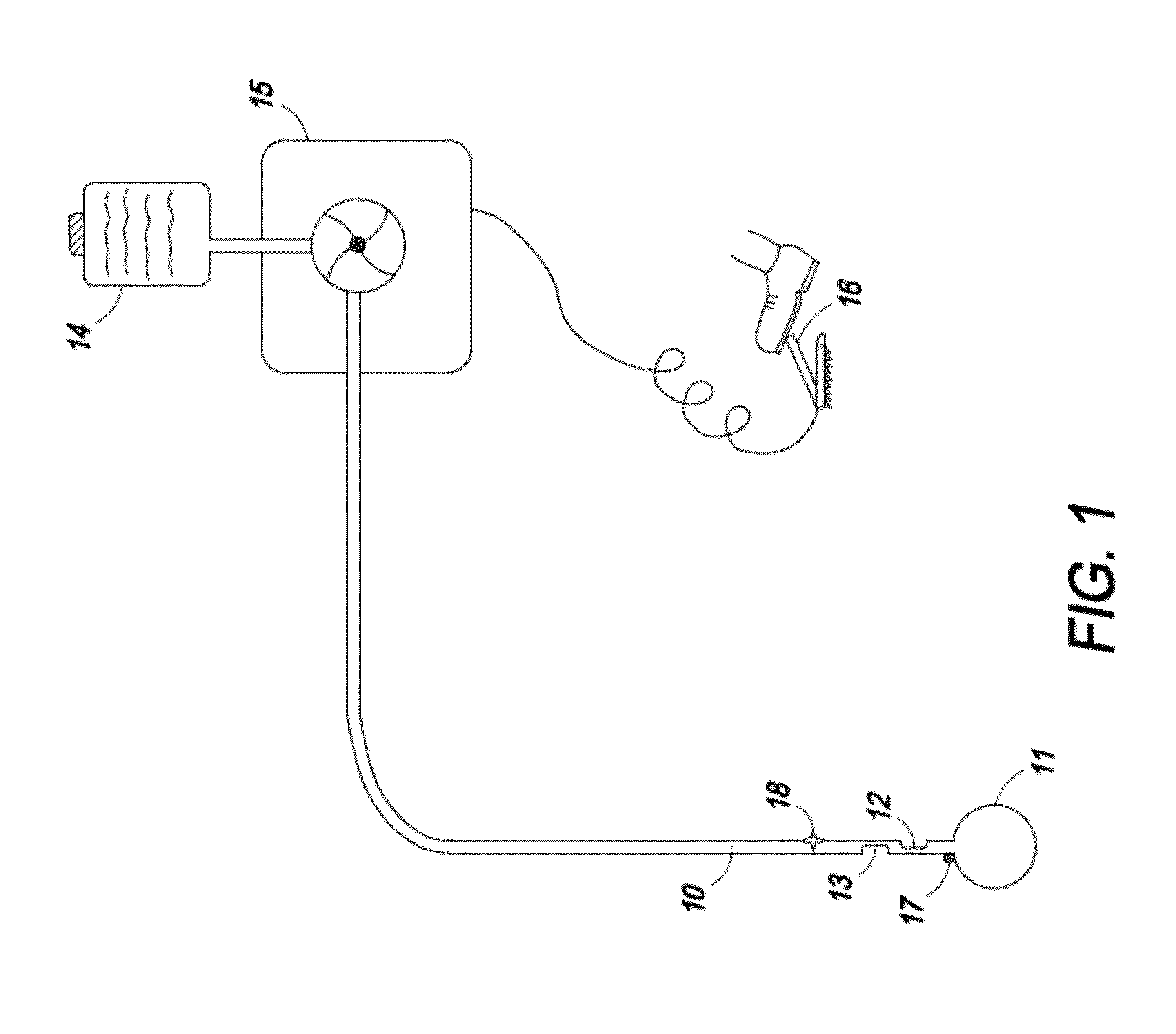

Transportable pumping unit and method of fracturing formations

InactiveUS20060260331A1Increase chanceReduced operating requirementsNon-pressured vesselsPumpsCombustorControl system

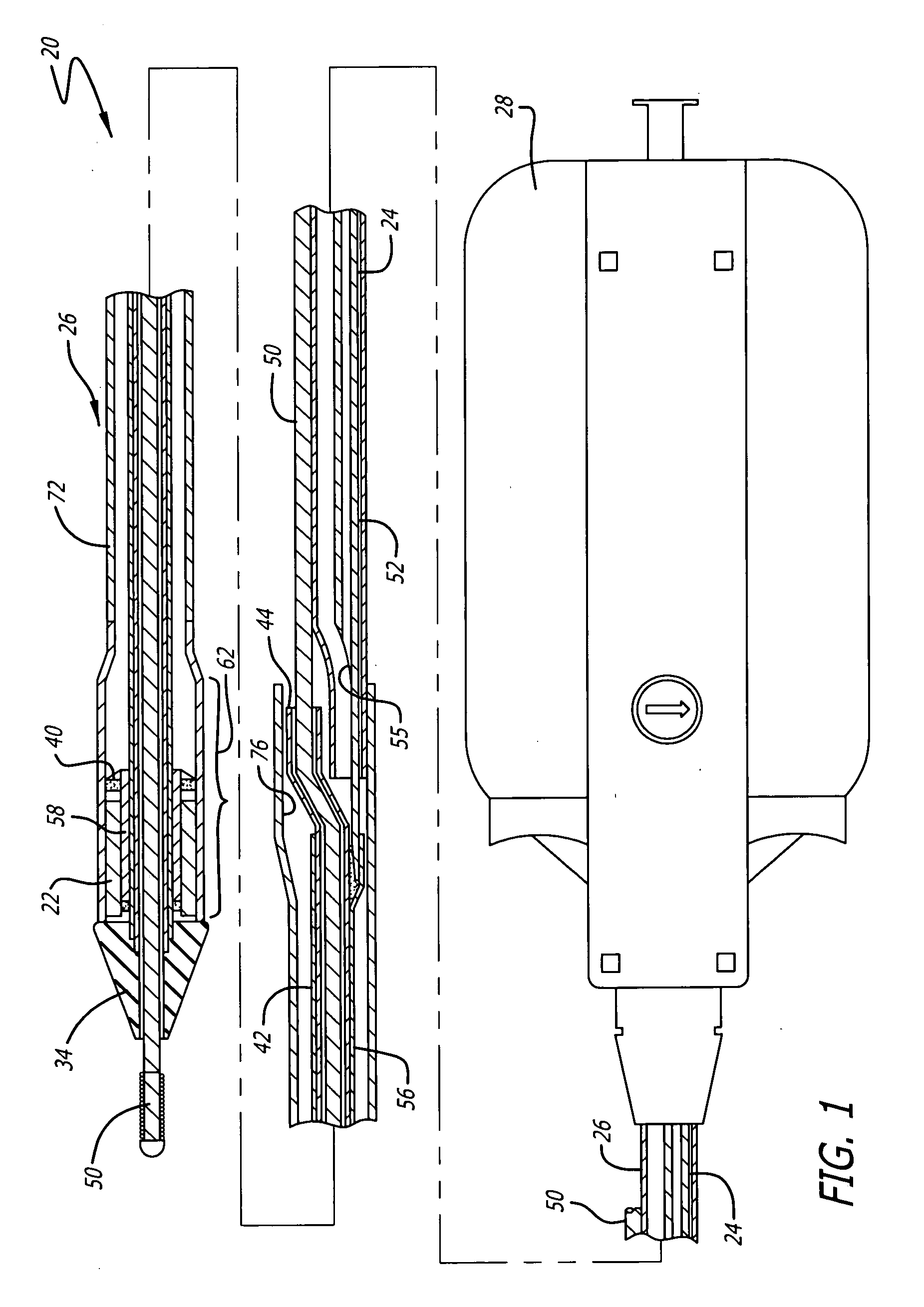

A high capacity pumper for liquefied gas incorporates multiple pumping systems distributed in a parallel arrangement and in opposing orientation on a transportable platform such as a trailer. Vaporizers incorporate a burner control system utilizing a primary set of burners operating a baseline and a secondary set of burners providing fine regulating control. A system for fracturing formations is now possible using a minimum number of components including the high capacity pumper, a coiled tubing rig and a source of liquefied gas. An improved manifold for a cryogenic plunger pump includes unions and angled connectors between a supply conduit and each of a plurality of pump heads.

Owner:CENTURY OILFIELD SERVICES

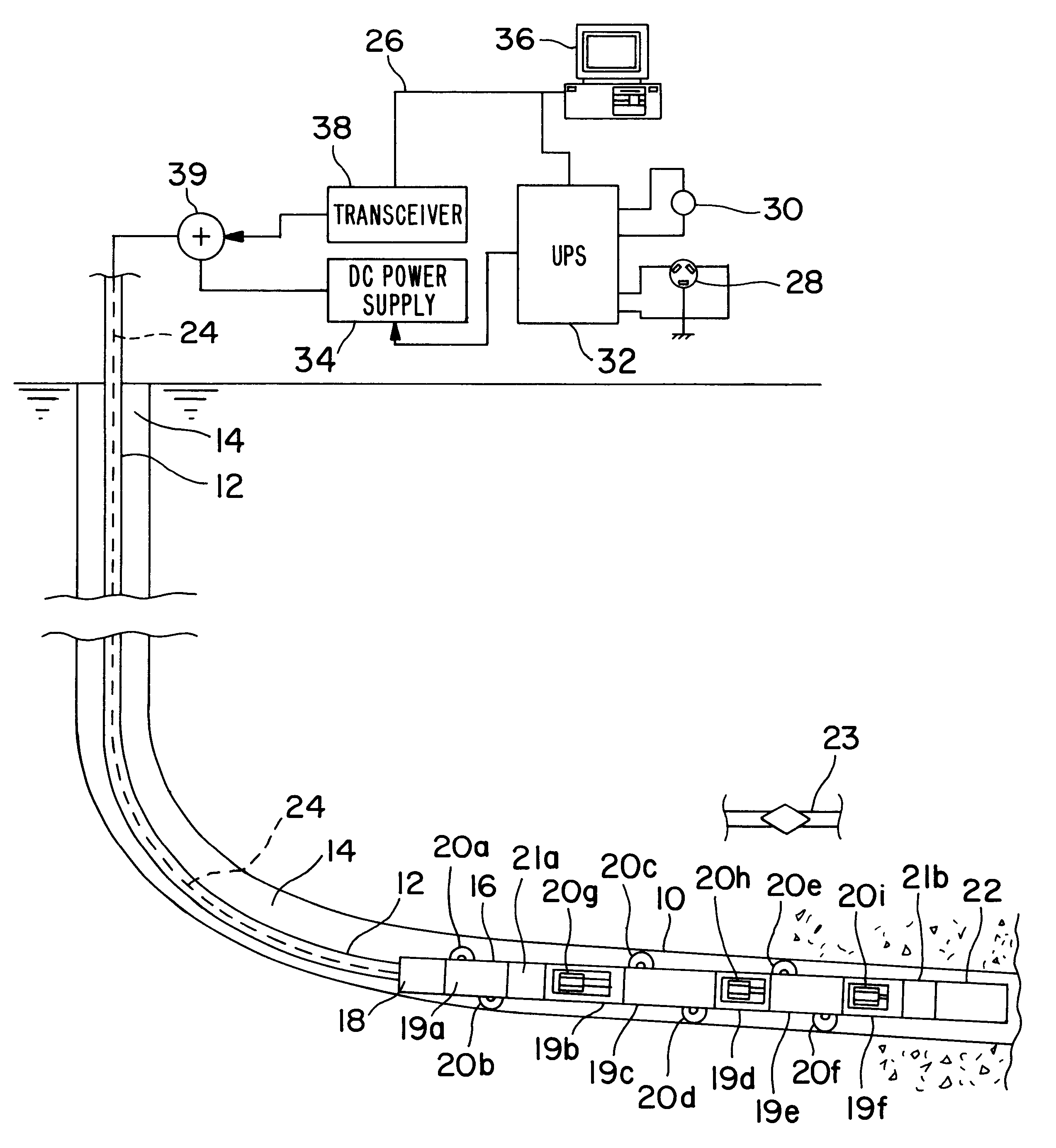

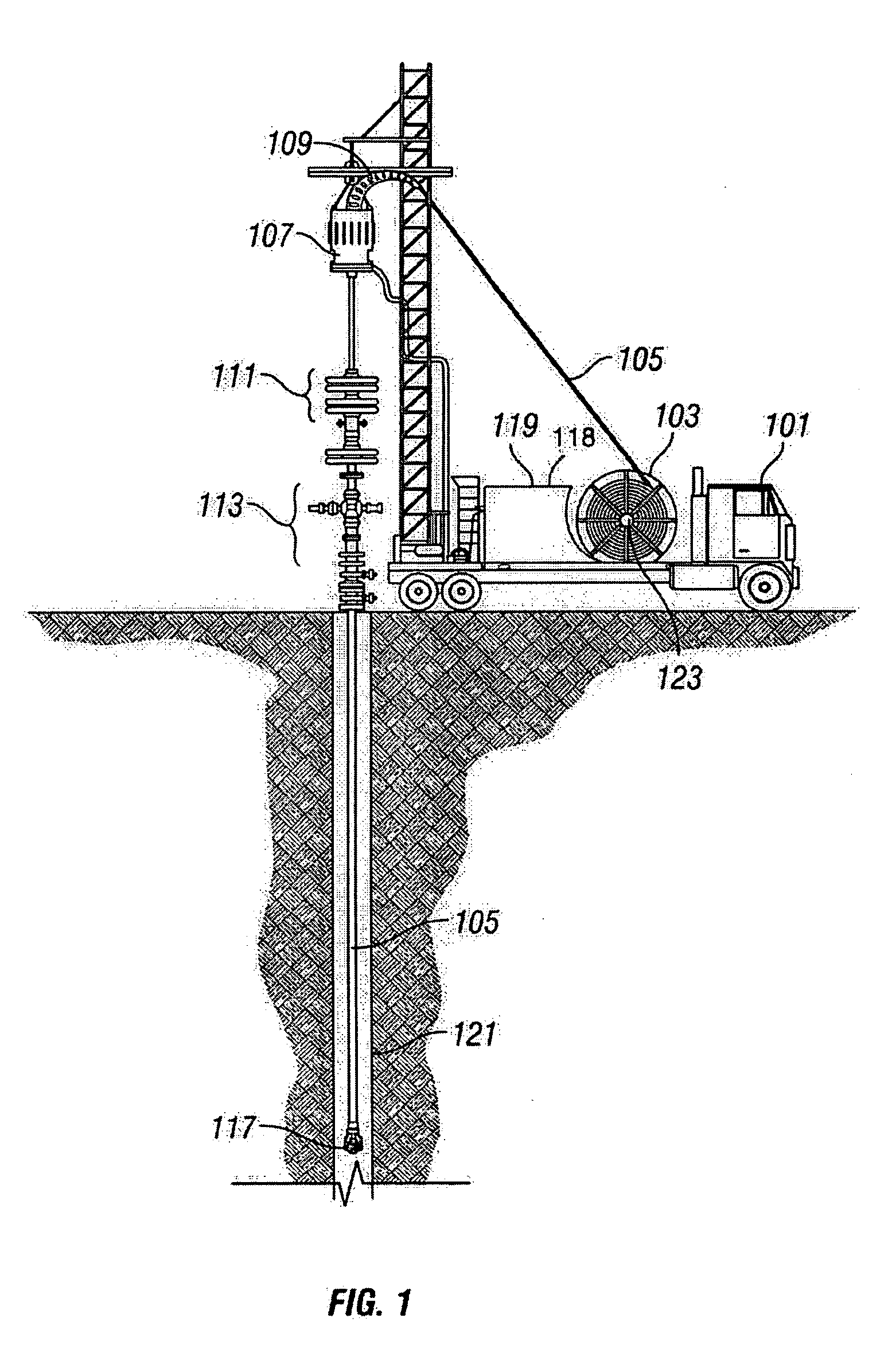

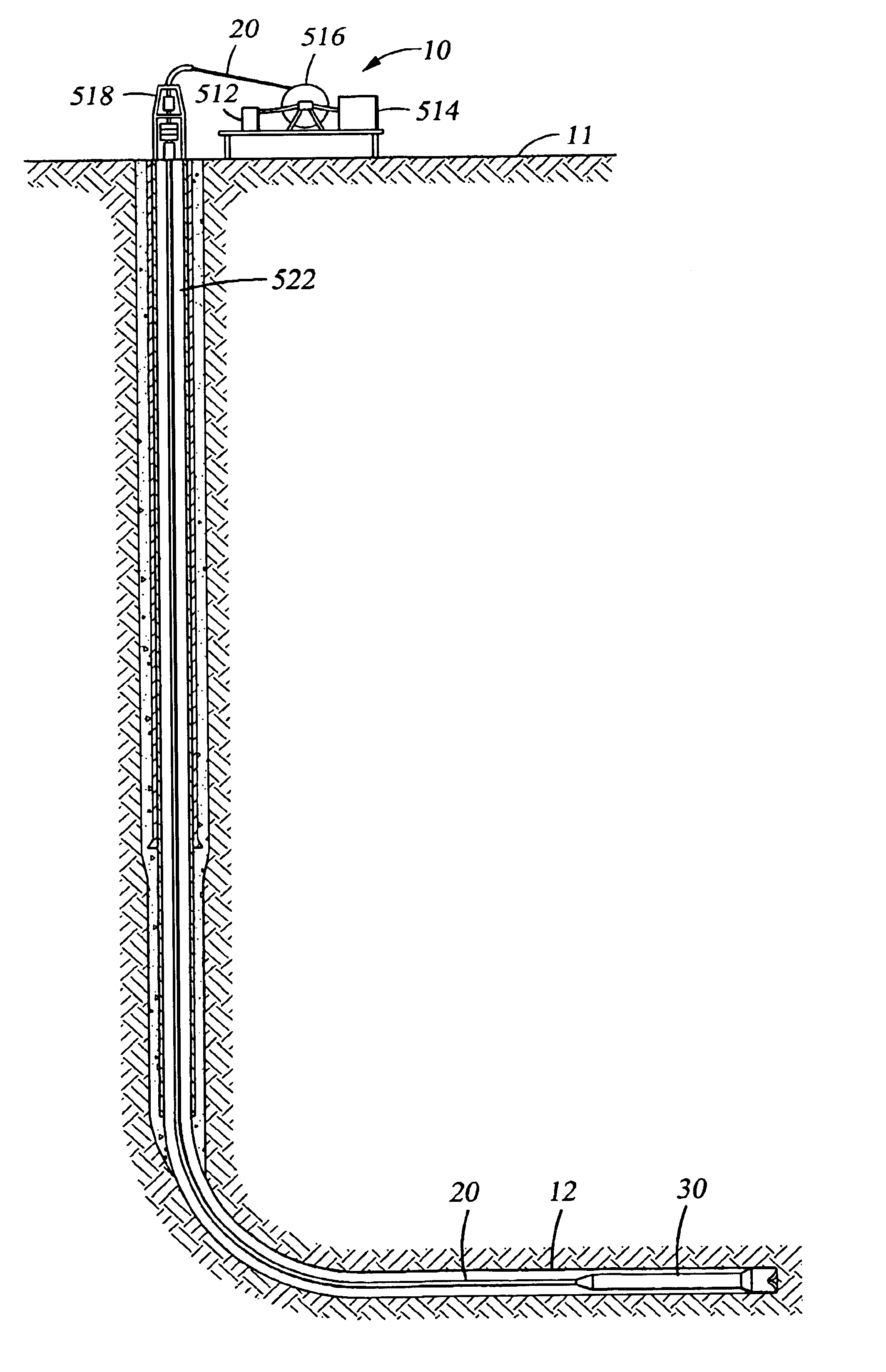

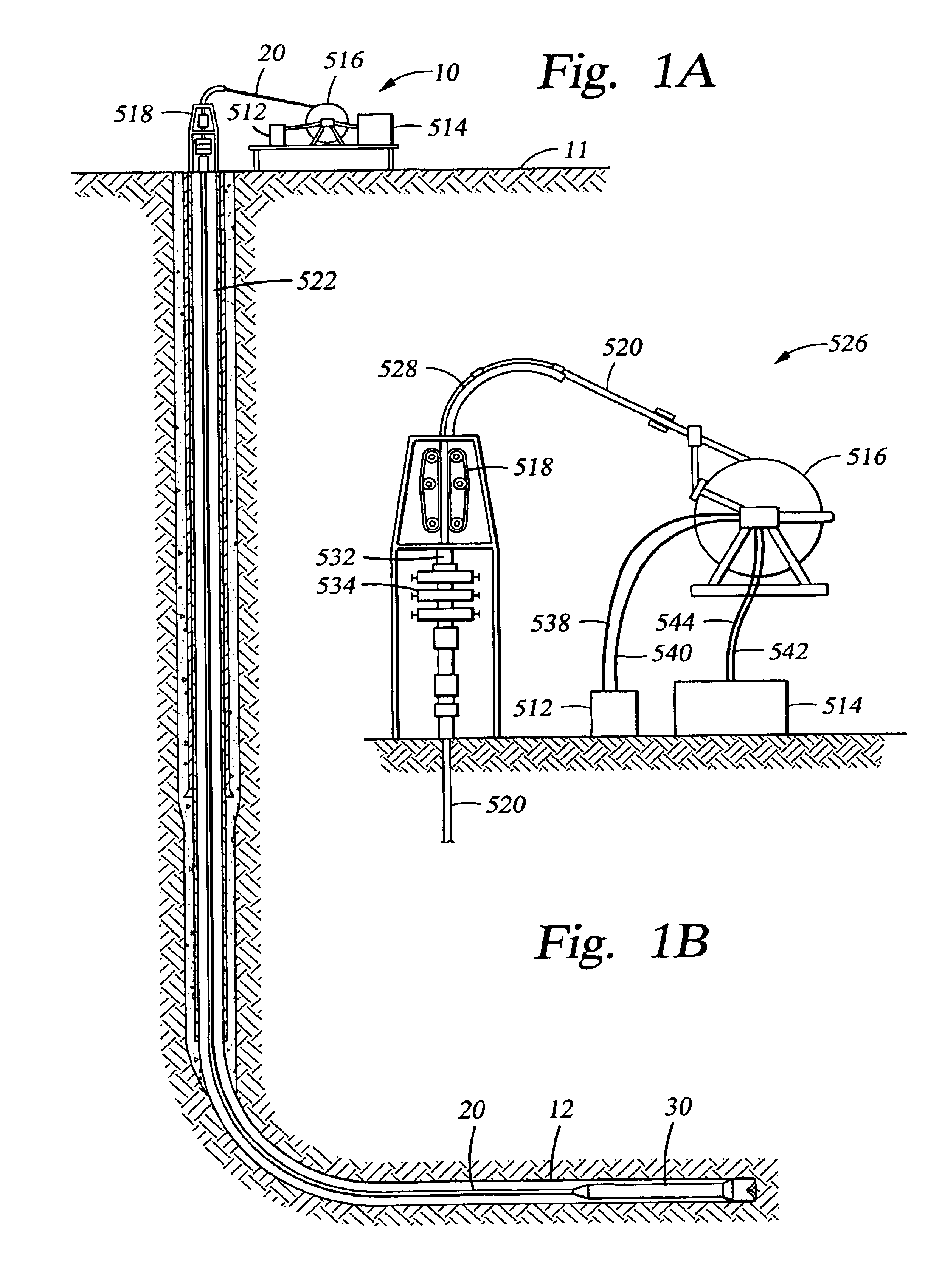

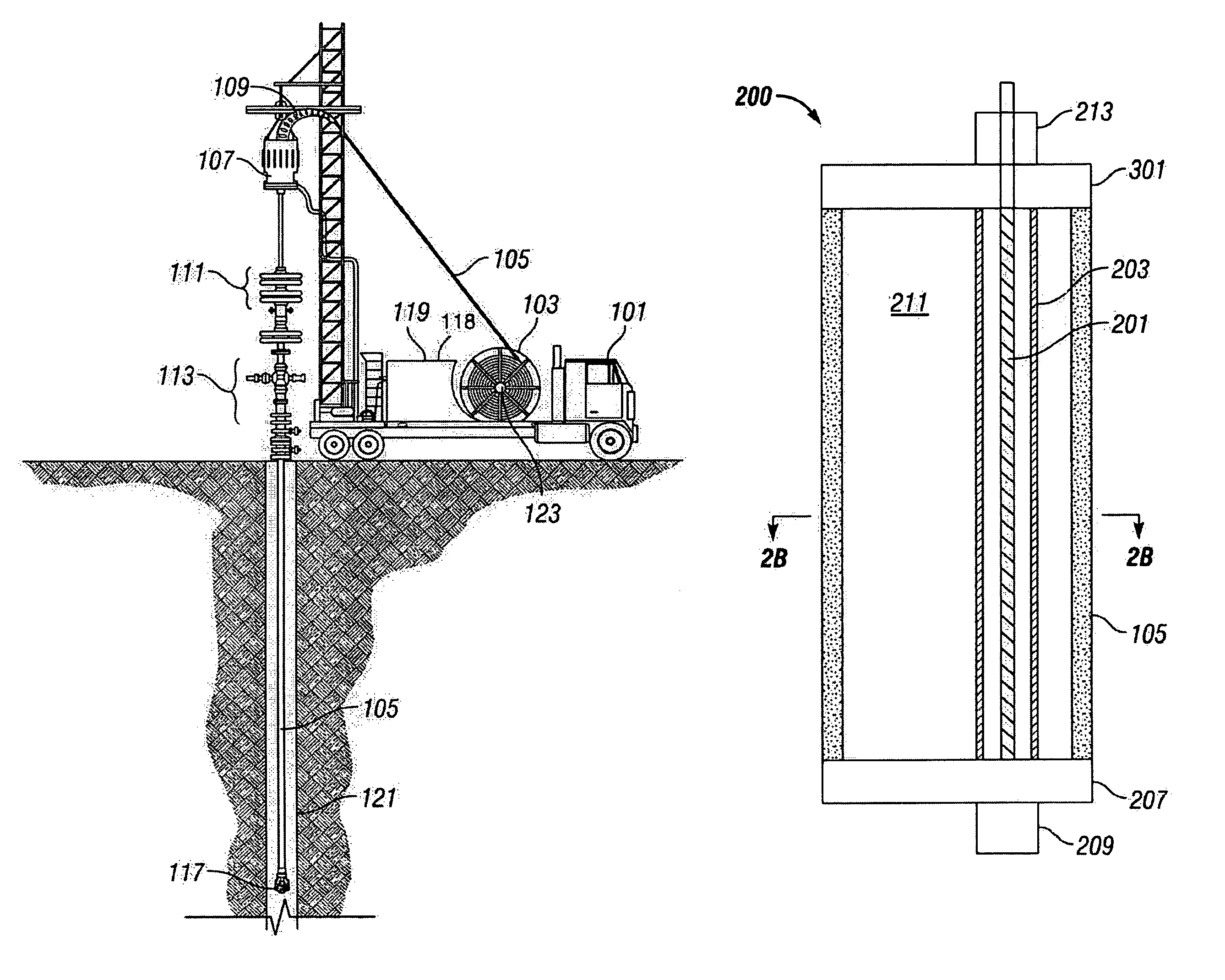

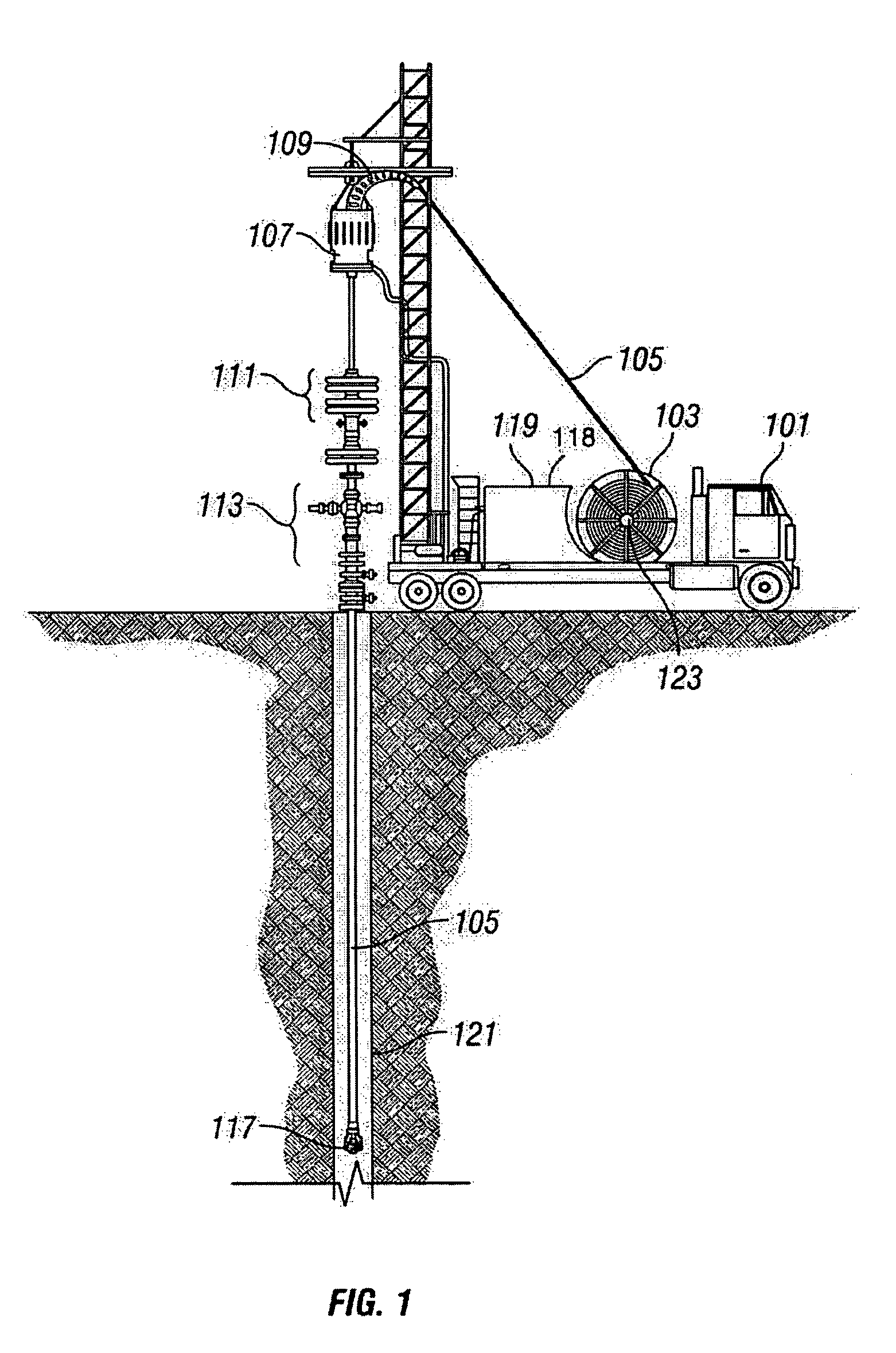

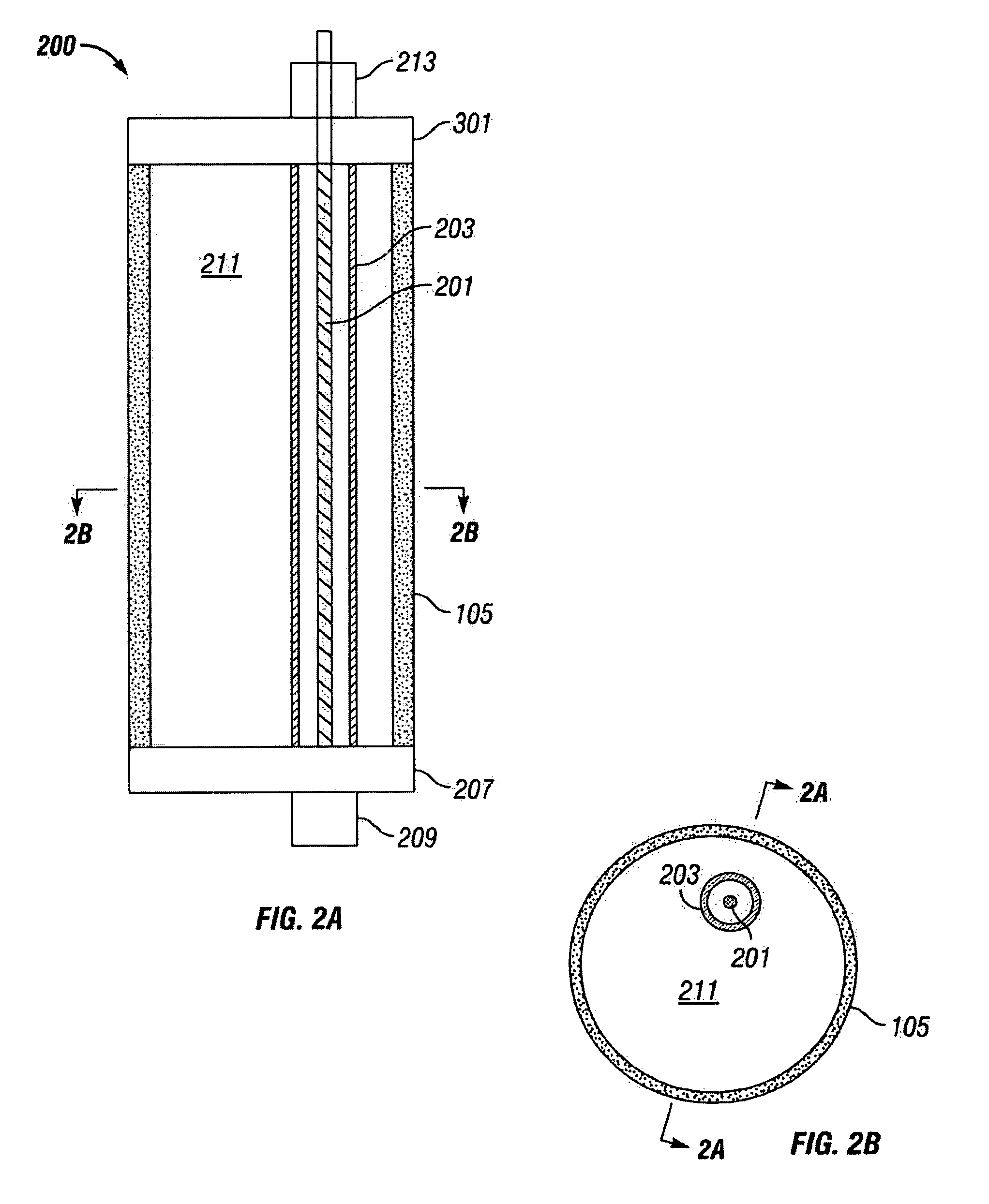

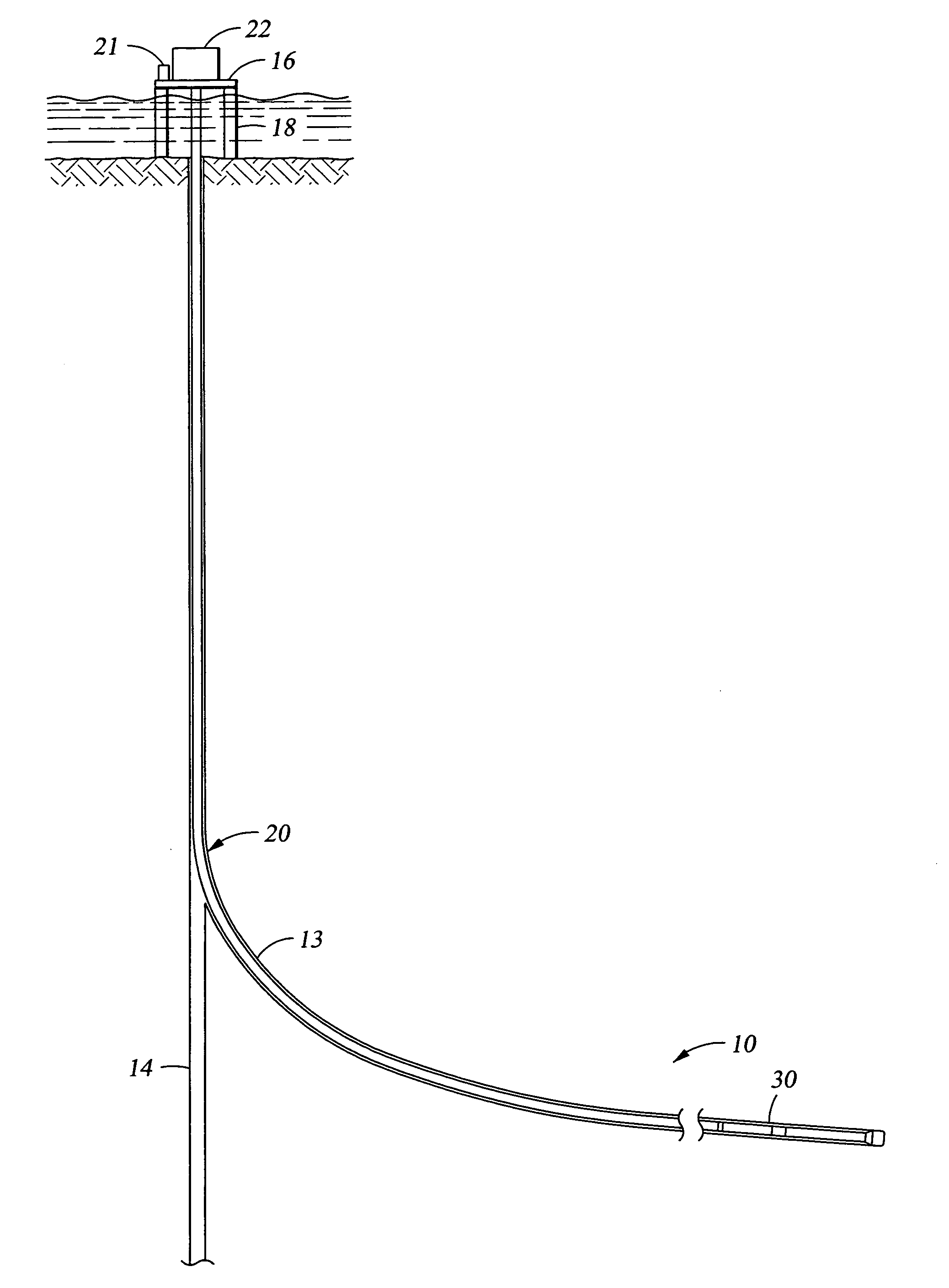

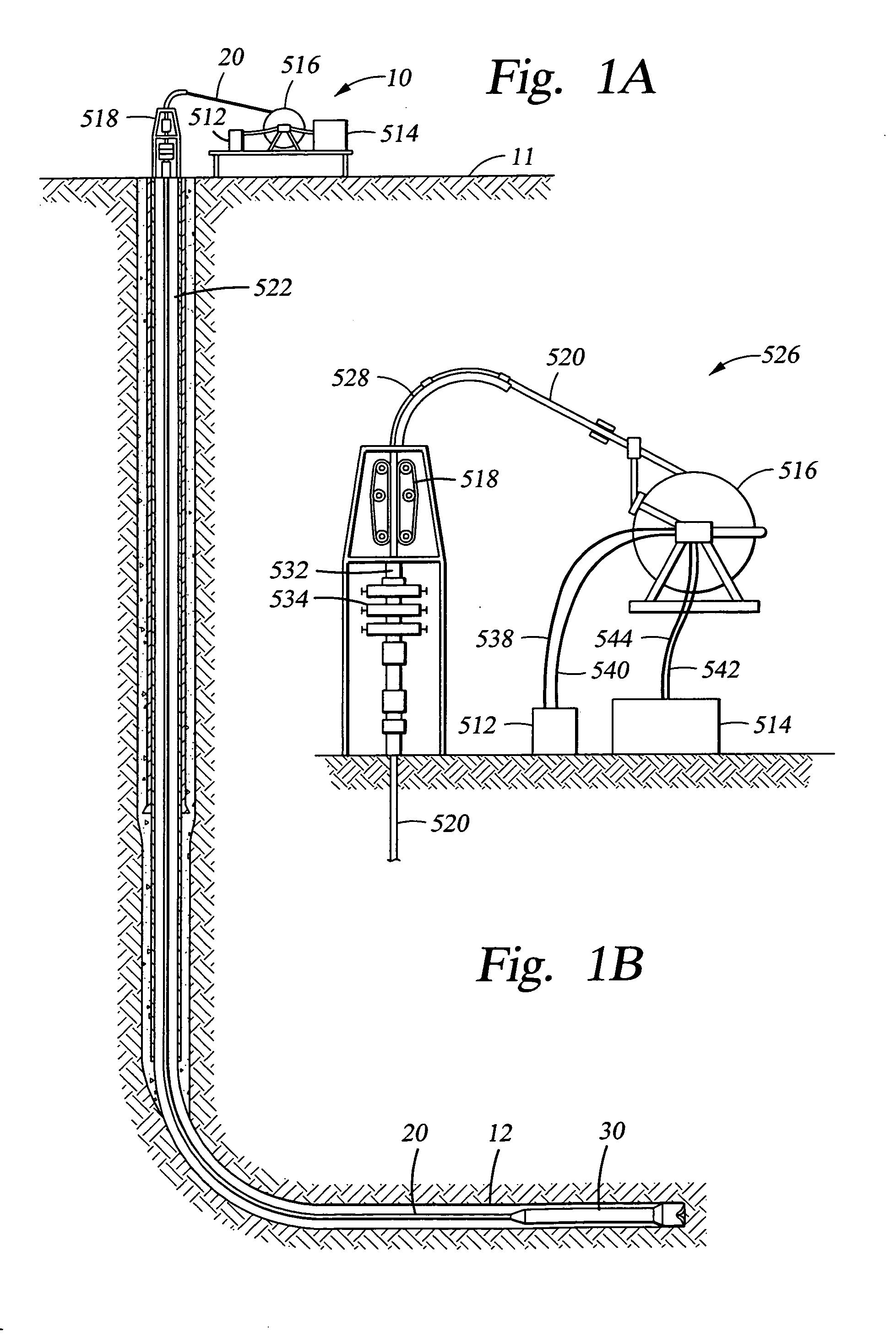

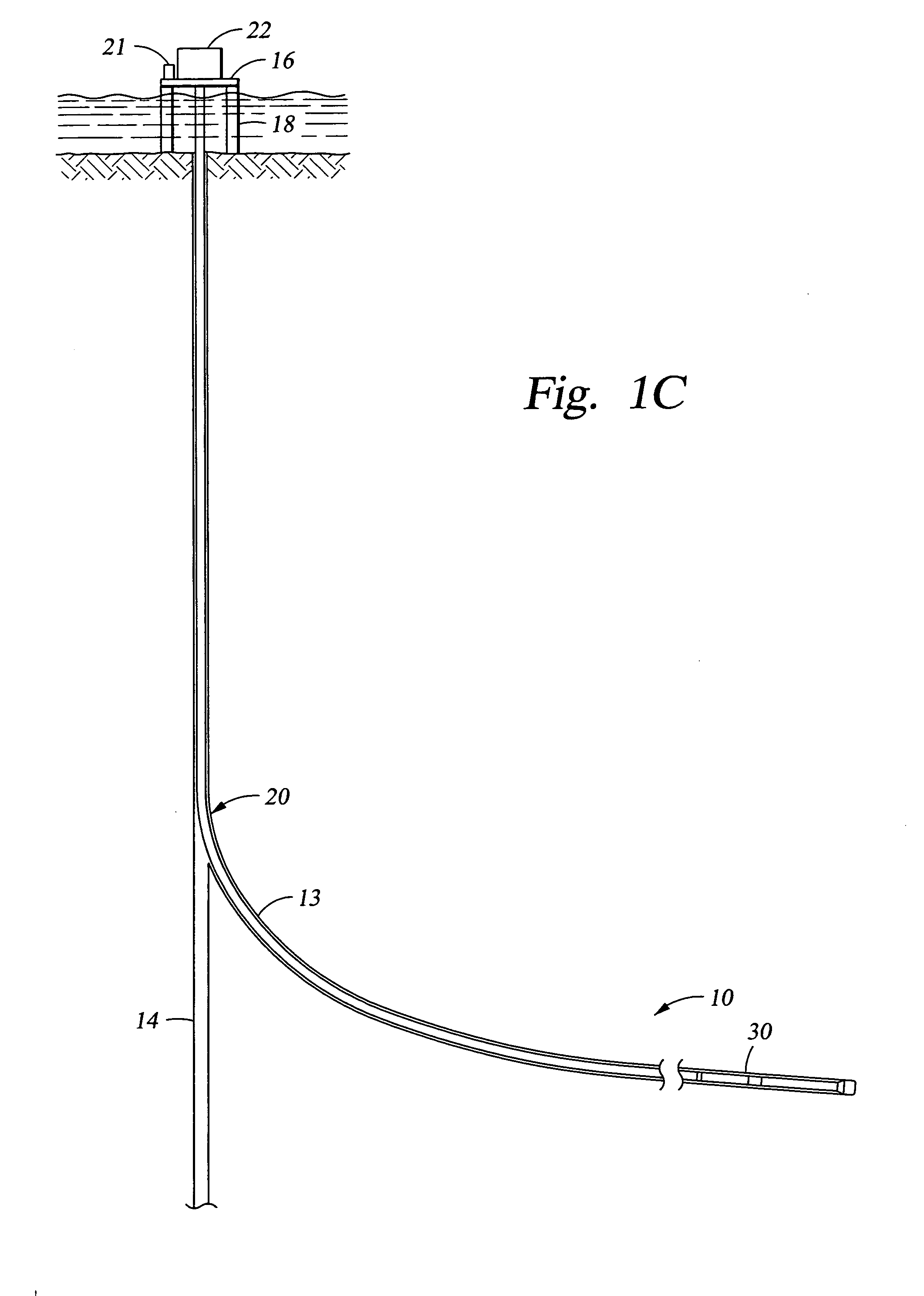

System and methods using fiber optics in coiled tubing

Apparatus having a fiber optic tether disposed in coiled tubing for communicating information between downhole tools and sensors and surface equipment and methods of operating such equipment. Wellbore operations performed using the fiber optic enabled coiled tubing apparatus includes transmitting control signals from the surface equipment to the downhole equipment over the fiber optic tether, transmitting information gathered from at least one downhole sensor to the surface equipment over the fiber optic tether, or collecting information by measuring an optical property observed on the fiber optic tether. The downhole tools or sensors connected to the fiber optic tether may either include devices that manipulate or respond to optical signal directly or tools or sensors that operate according to conventional principles.

Owner:SCHLUMBERGER TECH CORP

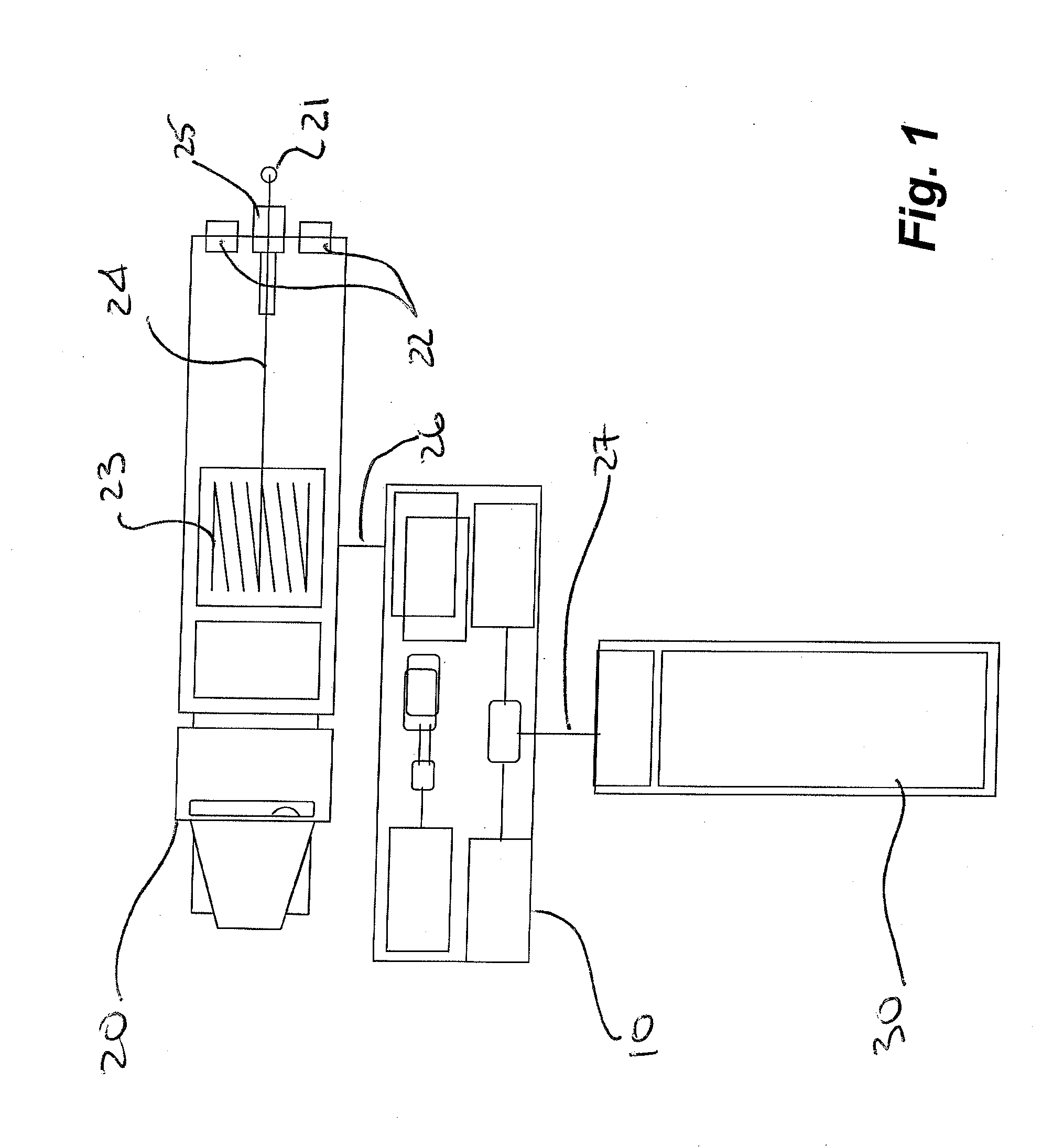

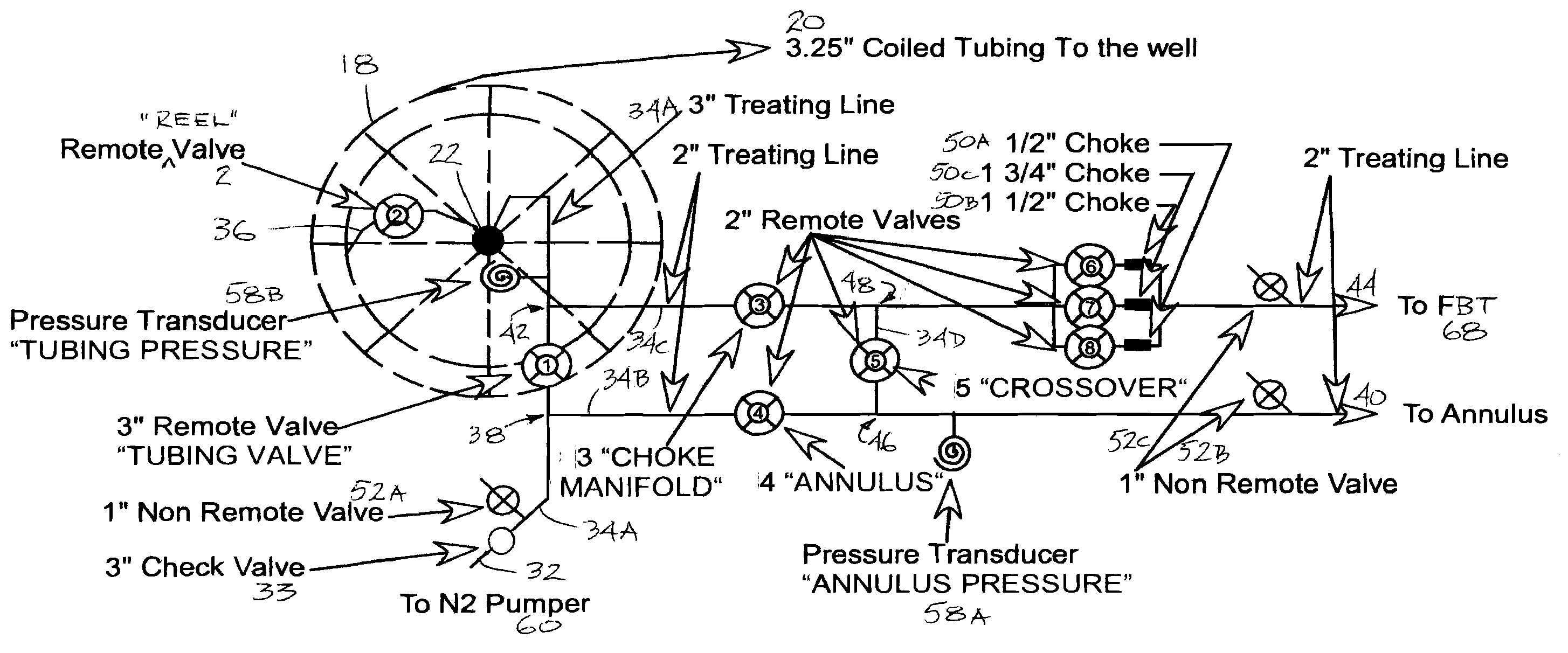

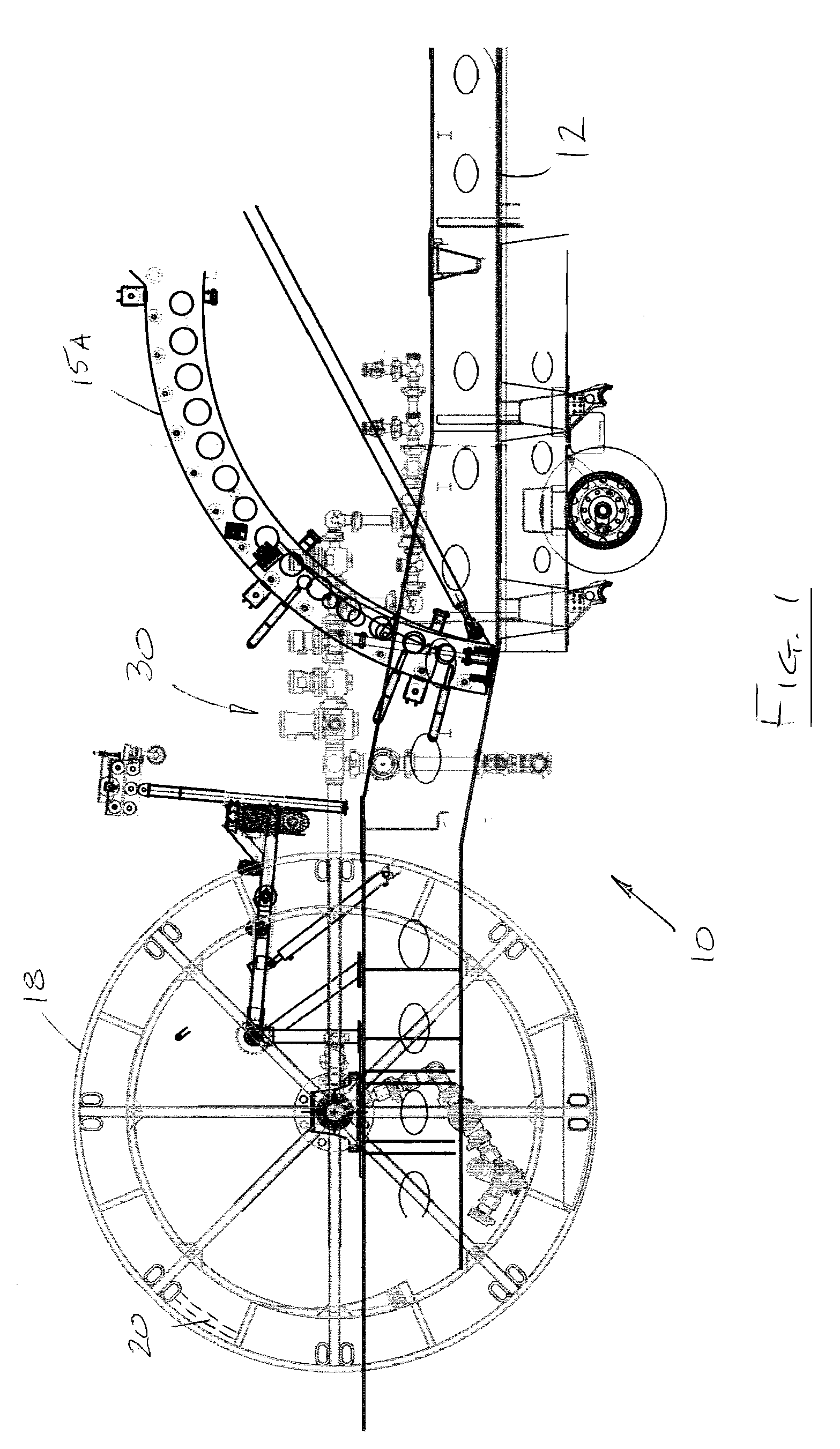

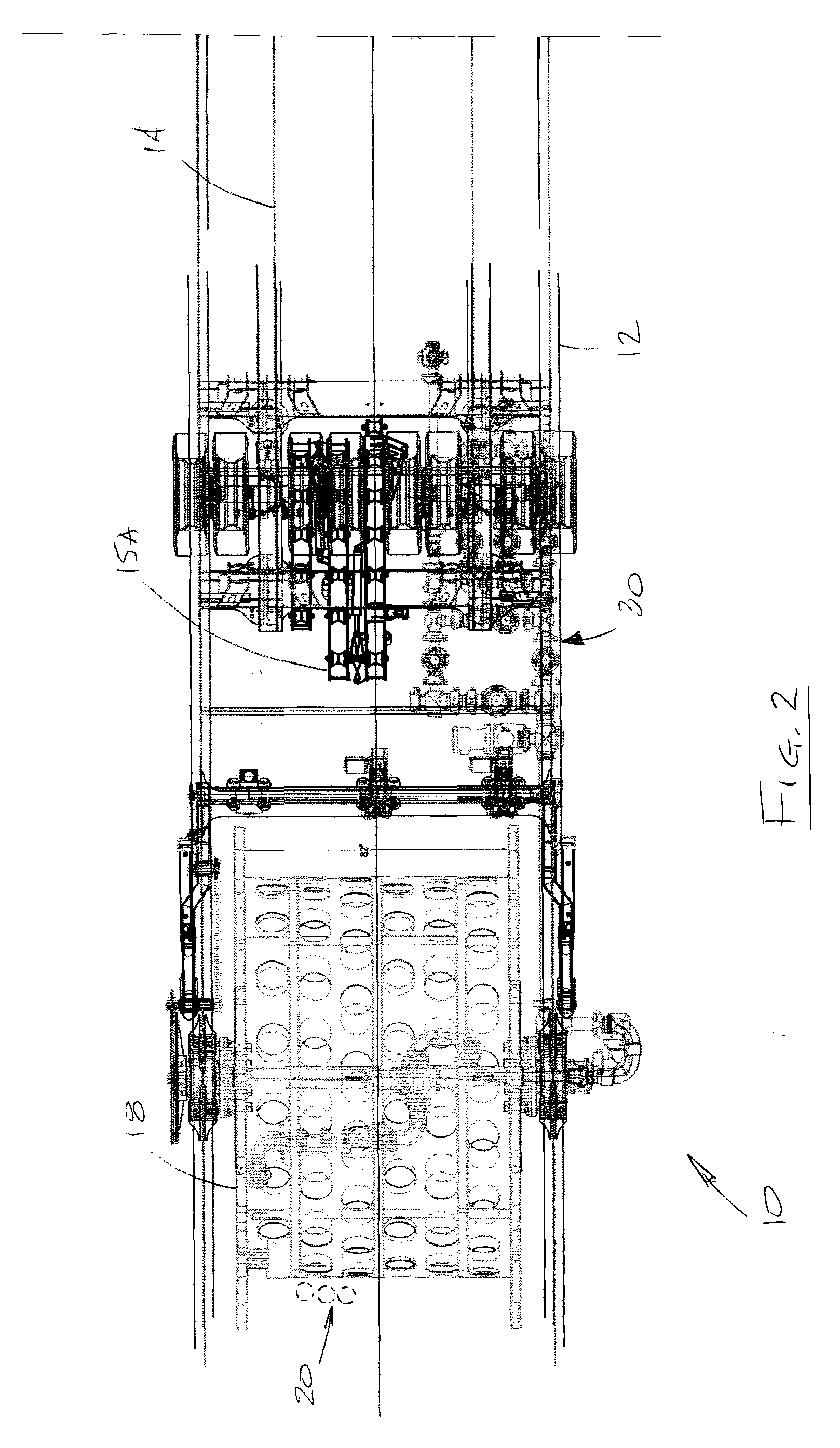

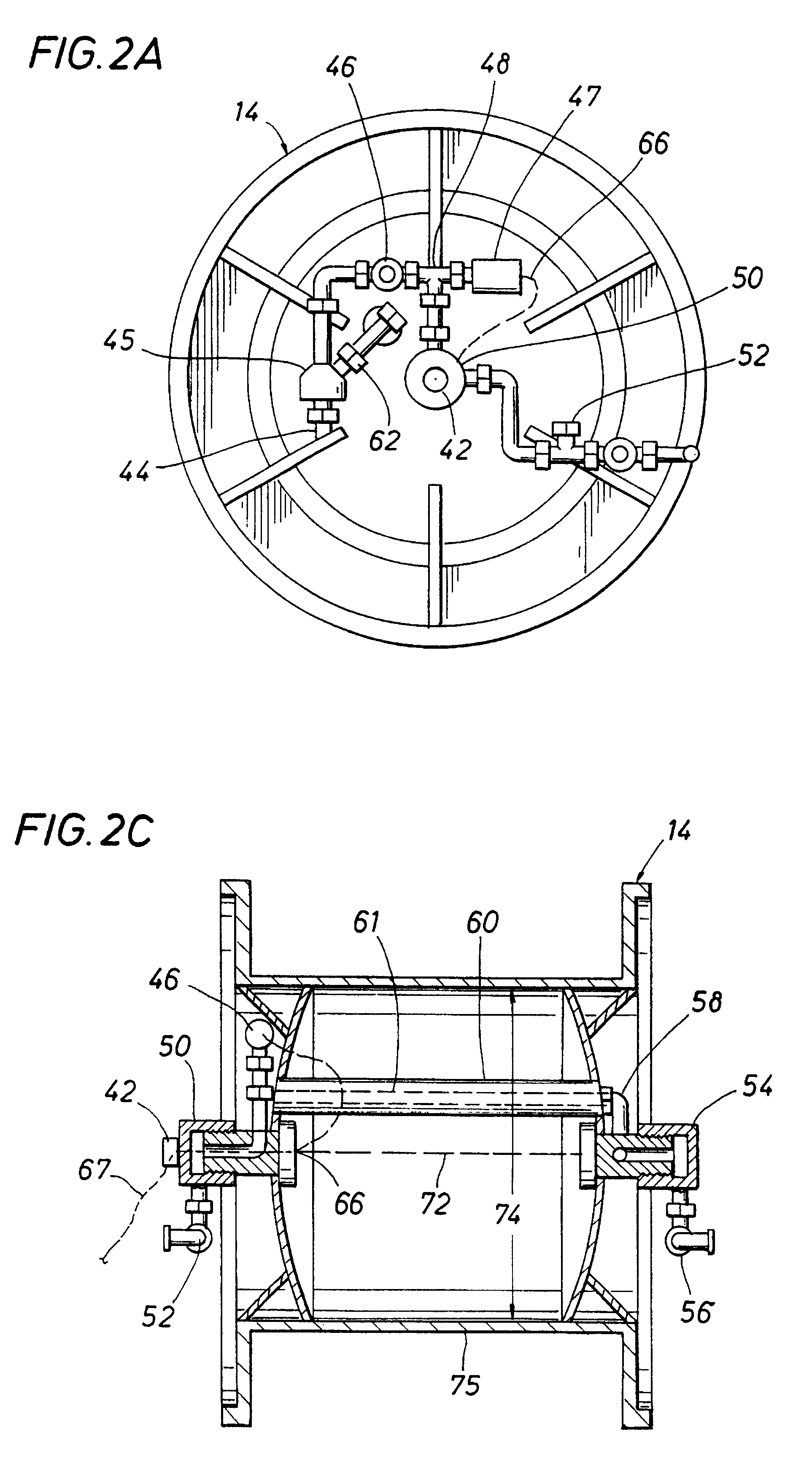

Well Servicing Rig and Manifold Assembly

A well servicing rig for communicating with a fluid source and an effluent reservoir (such as a flow back tank) has an apparatus for holding and dispensing coiled tubing. A manifold assembly is advantageously located on the rig for routing the pressurized fluid (such as nitrogen gas mixed with proppant) from the fluid source between the coiled tubing apparatus, the well and the effluent reservoir. The manifold assembly controls the flow of the fluid to perform fracturing operations, for reverse fluid circulation, for a common coiled tubing operation, for pressure testing, and the like. The assembly includes remotely controlled valves and pressure transducers for controlling the fluid flow, and chokes for diffusing fluid energy prior to entering the effluent reservoir. The rig, fluid source, effluent reservoir and a fluid pumper provide a novel method of servicing an underground formation (such as a coal bed) for natural gas.

Owner:FRAC SOURCE

Wellbore circulation system

InactiveUS6412554B1Fast connection timeNot to damageDrilling rodsConstructionsLine tubingCoiled tubing

A system for continuously circulating fluid to and through a tubular string either of coiled tubing or made up of a plurality of tubulars connected end-to-end while an upper tubular is added to or removed from a top tubular of the plurality of tubulars, all tubulars having a top-to-bottom fluid flow channel therethrough, the system having an upper chamber with a bottom opening, a top opening, and an upper sealing apparatus for sealingly encompassing a portion of the upper tubular, a lower chamber with a bottom opening, a top opening and a lower sealing apparatus for sealingly encompassing a portion of the top tubular, one of the upper chamber and the lower chamber sized for accommodating connection and disconnection therein of the upper tubular and the top tubular, and gate apparatus between and in fluid communication with the upper chamber and the lower chamber. Such a system may have apparatus for isolating a tubular therein from an axial load imposed by fluid pressure in a chamber; at least one of the lower chamber and the upper chamber with inner bushing apparatus with a portion thereof movably disposable within the chamber's sealing apparatus for facilitating movement of a tubular with respect to the chamber's sealing apparatus, and the system connectible to and rotatable by a rotating system for rotating the tubular string; and / or heave compensation interconnections for interconnecting the system to an offshore rig's heave compensation system. The system in certain aspects including fluid flow lines to each of the top and bottom chambers, a supply of fluid for circulating through the tubular string and through the upper and lower chambers, apparatus for continuously moving circulating fluid from the supply through the system into the tubular string.

Owner:WEATHERFORD TECH HLDG LLC

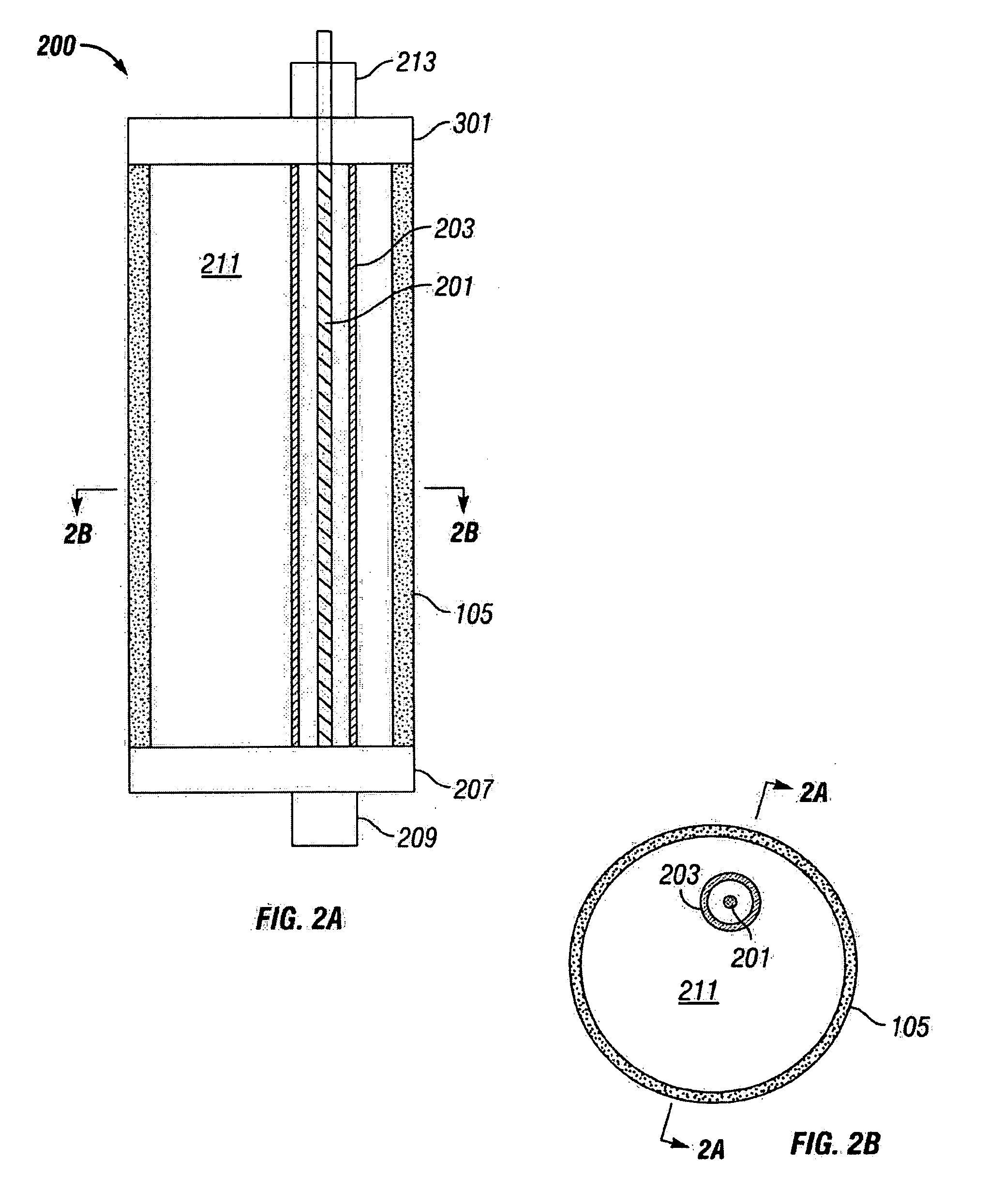

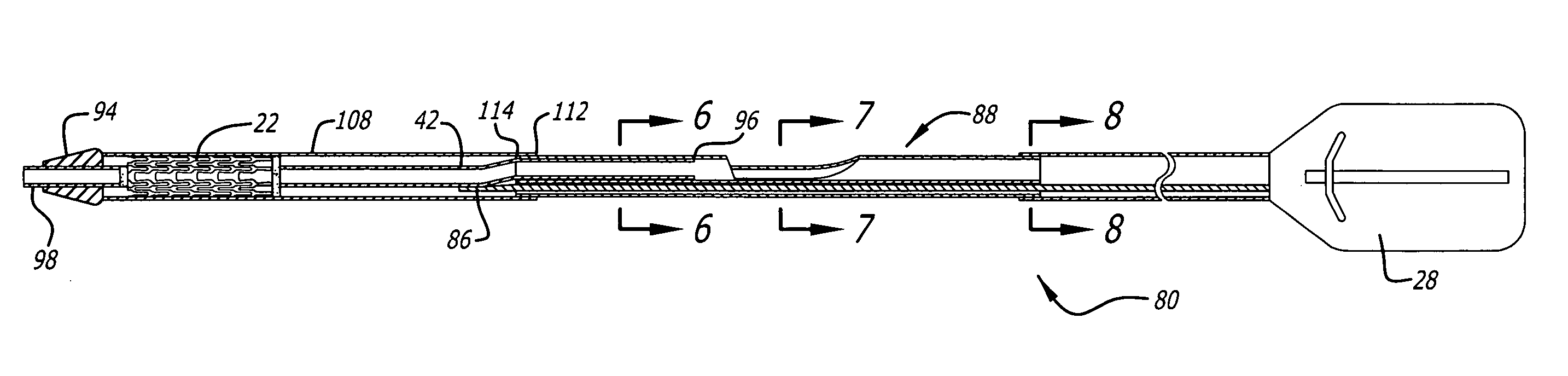

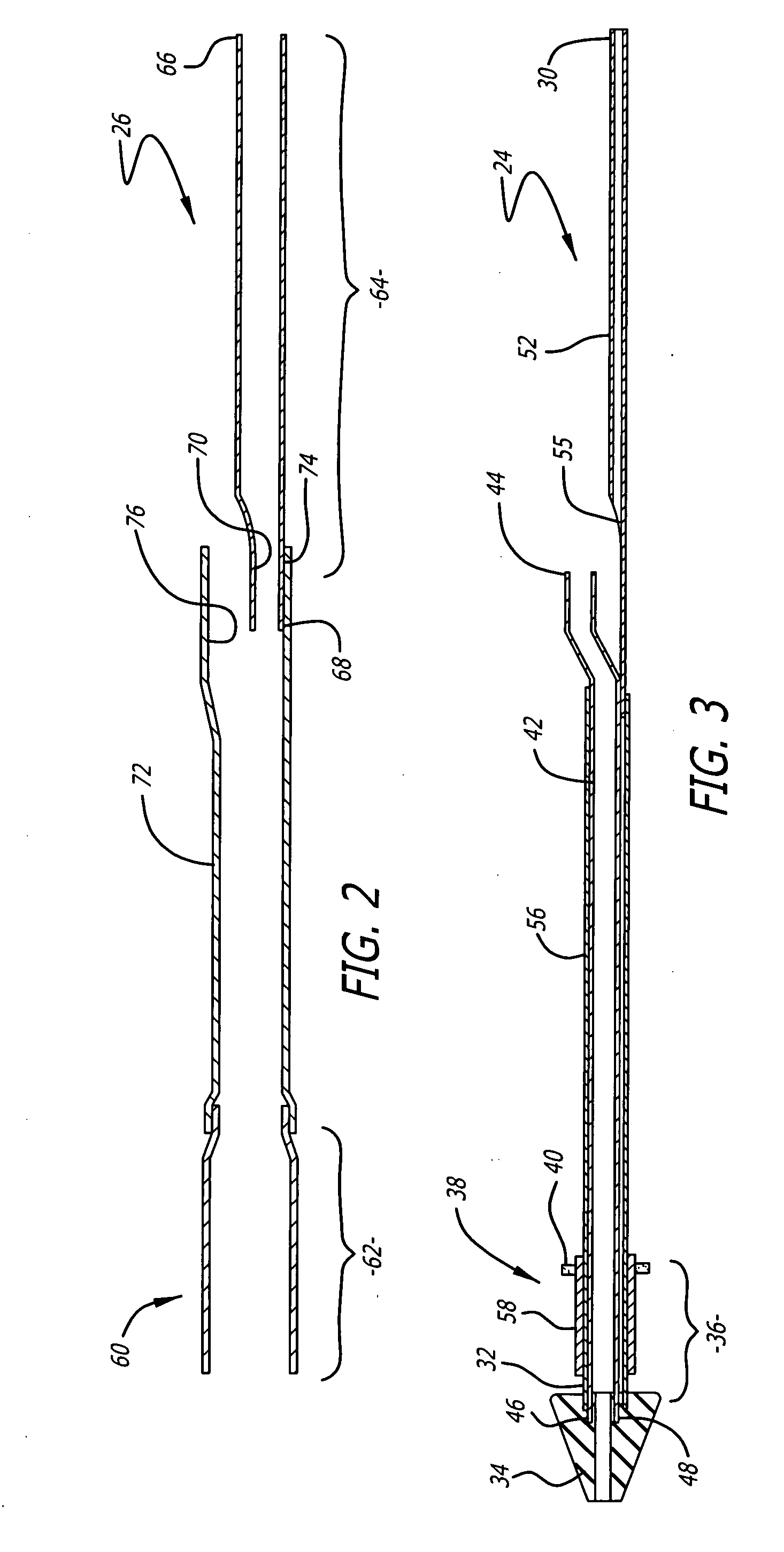

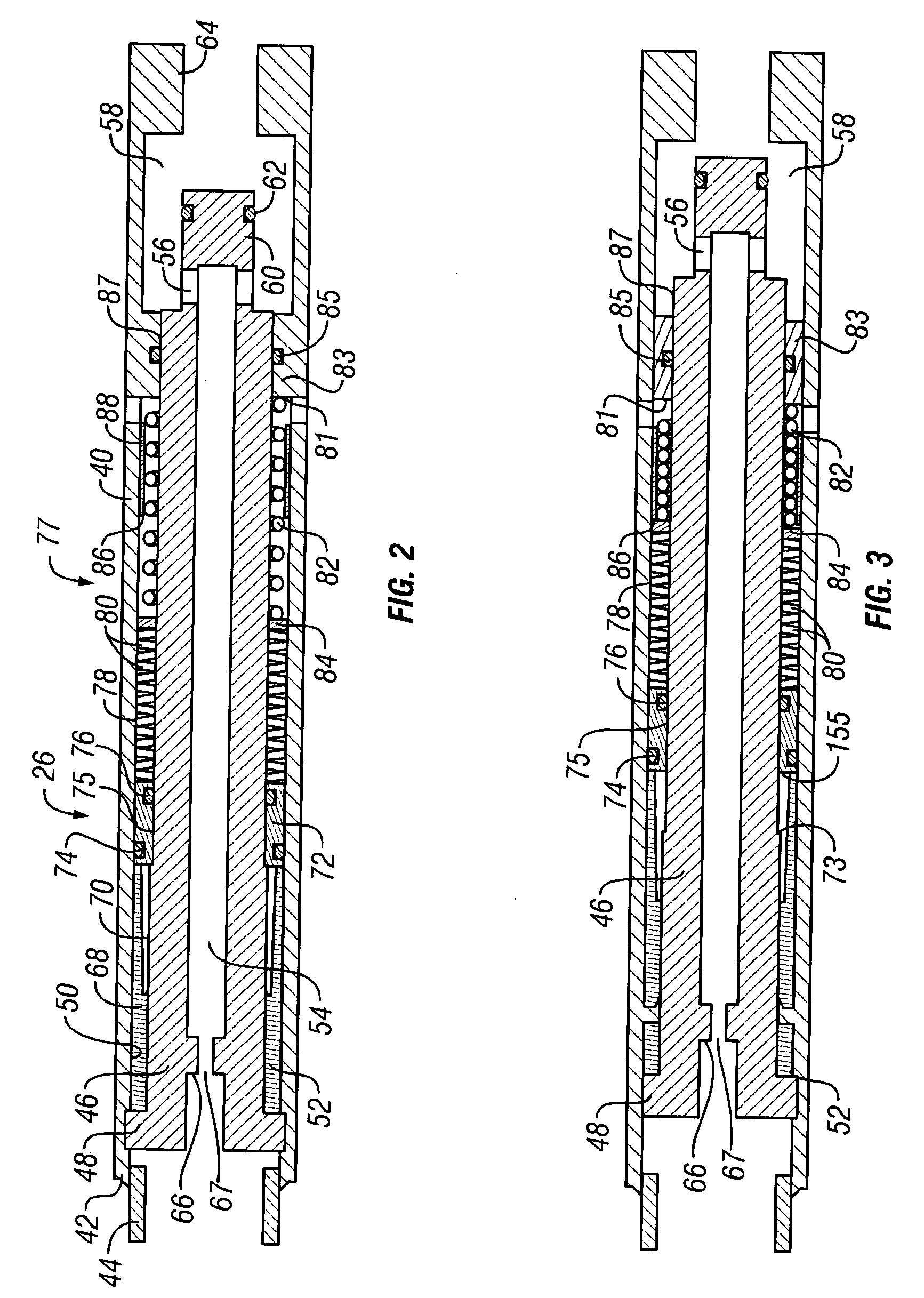

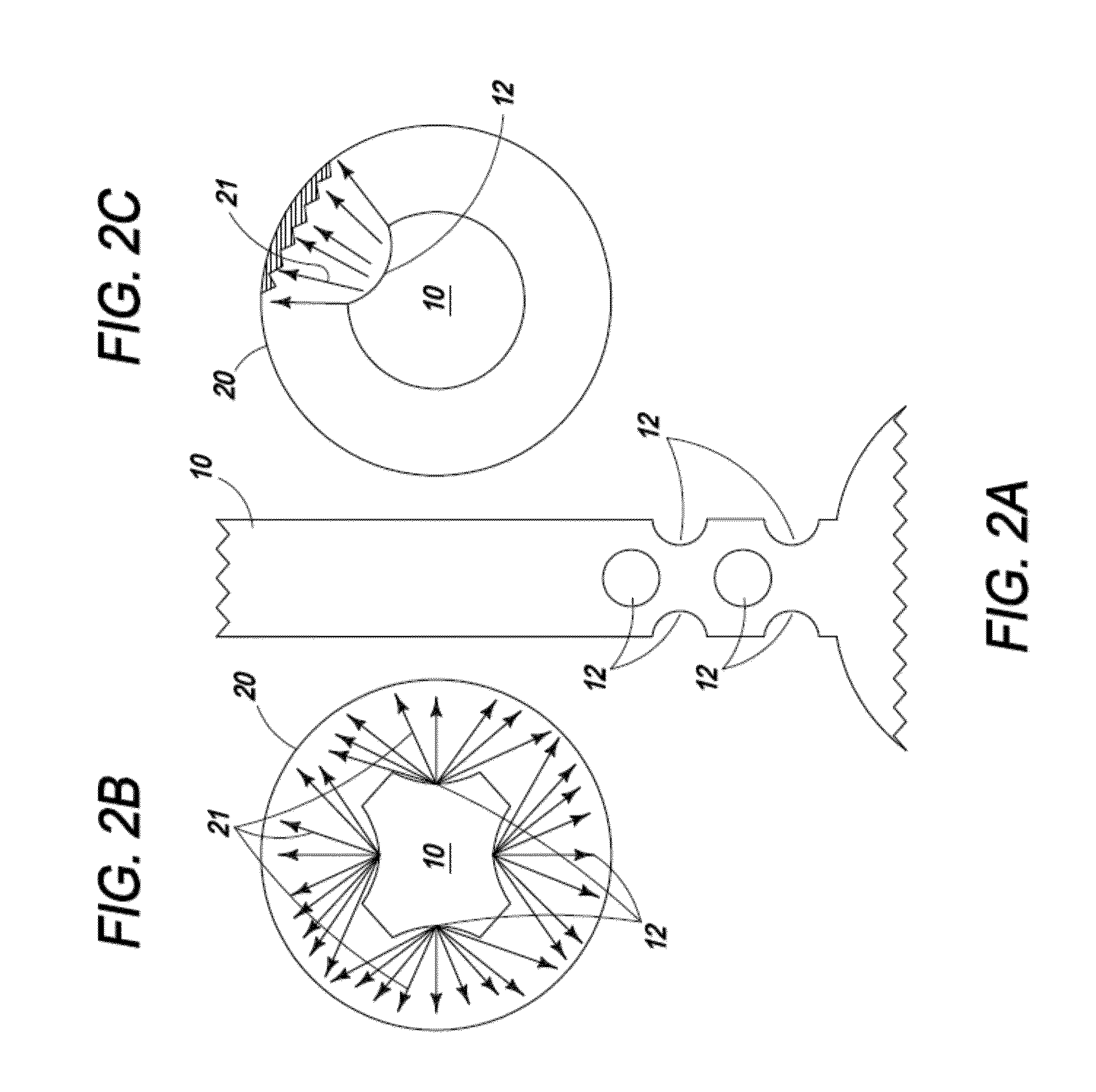

Method and apparatus using coiled-in-coiled tubing

Method and apparatus for performing well operations, such as measuring or forming or testing or treating or the like, and combinations of the above operations, including the use of coiled-in-coiled tubing (CCT) connected to a bottomhole assembly package (BHA), such that the assembly is in communication with both fluid conduits (80 and 82) defined by the coiled-in-coiled tubing.

Owner:BJ SERVICES CO

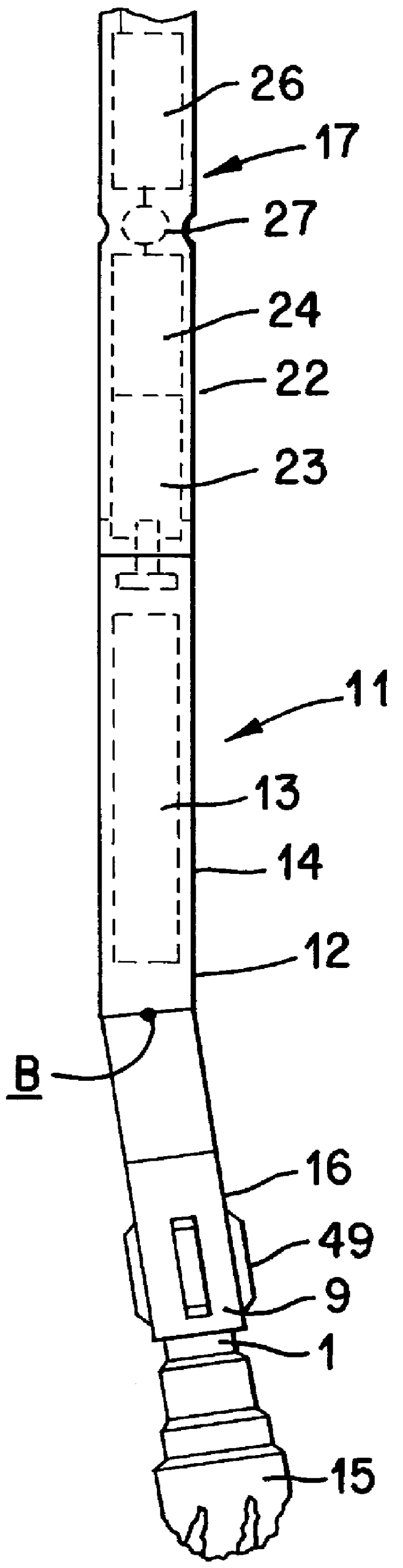

Well system

InactiveUS6923273B2Excessive vibrationLess expensiveElectric/magnetic detection for well-loggingDrilling rodsElectrical conductorEngineering

The drilling system includes a work string supporting a bottom hole assembly. The work string including lengths of pipe having a non-metallic portion. The work string preferably includes a composite coiled tubing having a fluid impermeable liner, multiple load carrying layers, and a wear layer. Multiple electrical conductors and data transmission conductors may be embedded in the load carrying layers for carrying current or transmitting data between the bottom hole assembly and the surface. The bottom hole assembly includes a bit, a gamma ray and inclinometer instrument package, a steerable assembly, an electronics section, a transmission, and a power section for rotating the bit. It may or may not include a propulsion system. The drilling system may be a gravity based drilling system that does include a propulsion system. Various motive means may be provided such as gravity, to apply weight on the bit.

Owner:HALLIBURTON ENERGY SERVICES INC

Localized fracturing system and method

A method and apparatus useful for fracturing subterranean formations with ultra high fluid pressure. The apparatus is capable of producing isolated pressure in a formation surrounding a primary wellbore, sufficient pressure is included within the formation for creating a fracture at the edge of the perforation. The apparatus is comprised of a motor, pump, and nozzle, where the entire apparatus can be disposed within the borehole. The apparatus can be conveyed within the borehole via wireline, coil tubing, slickline, or other tubing. Alternatively, a drill bit can be included for creating the perforation just prior to the fracturing procedure.

Owner:BAKER HUGHES HLDG LLC

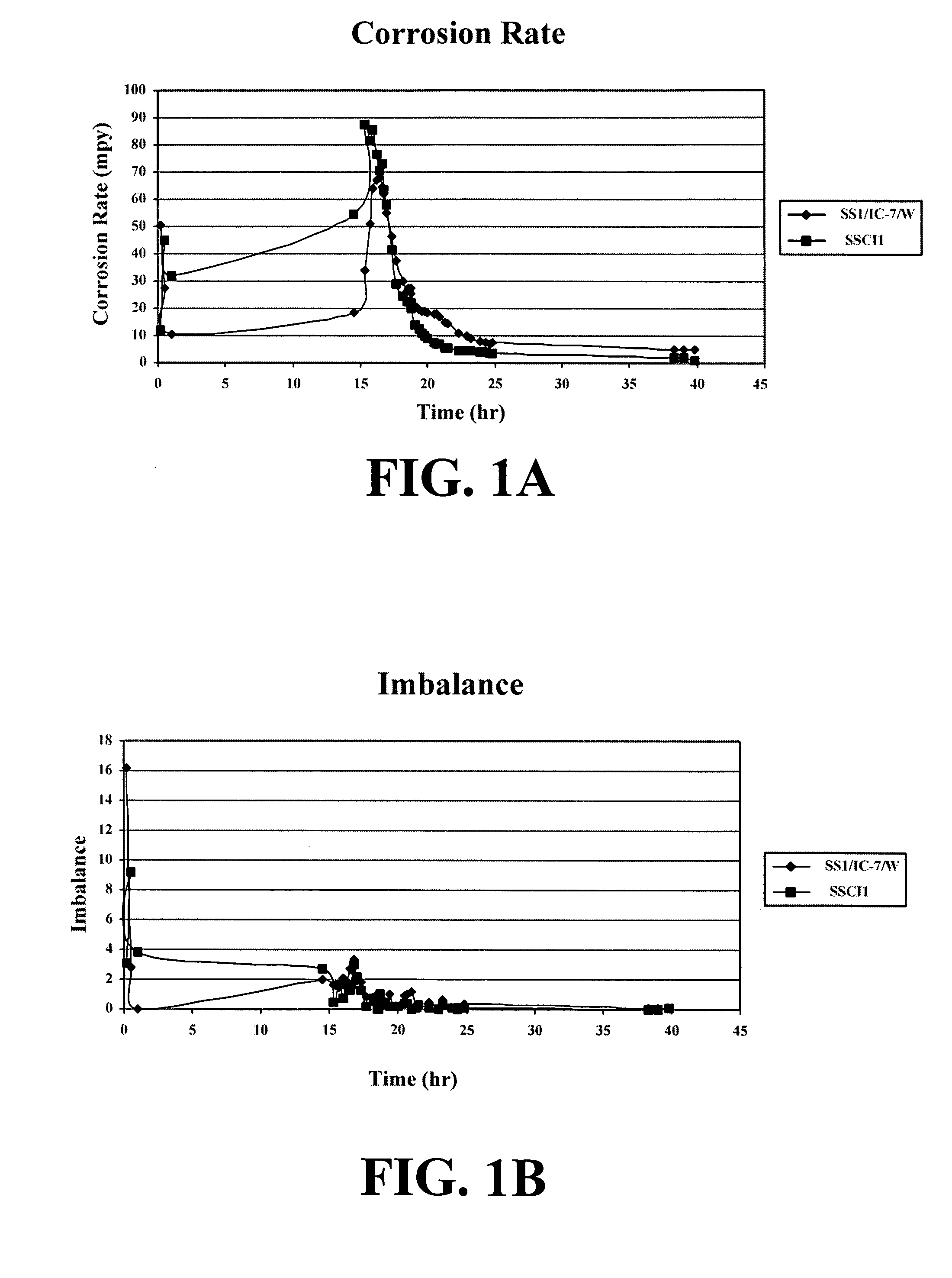

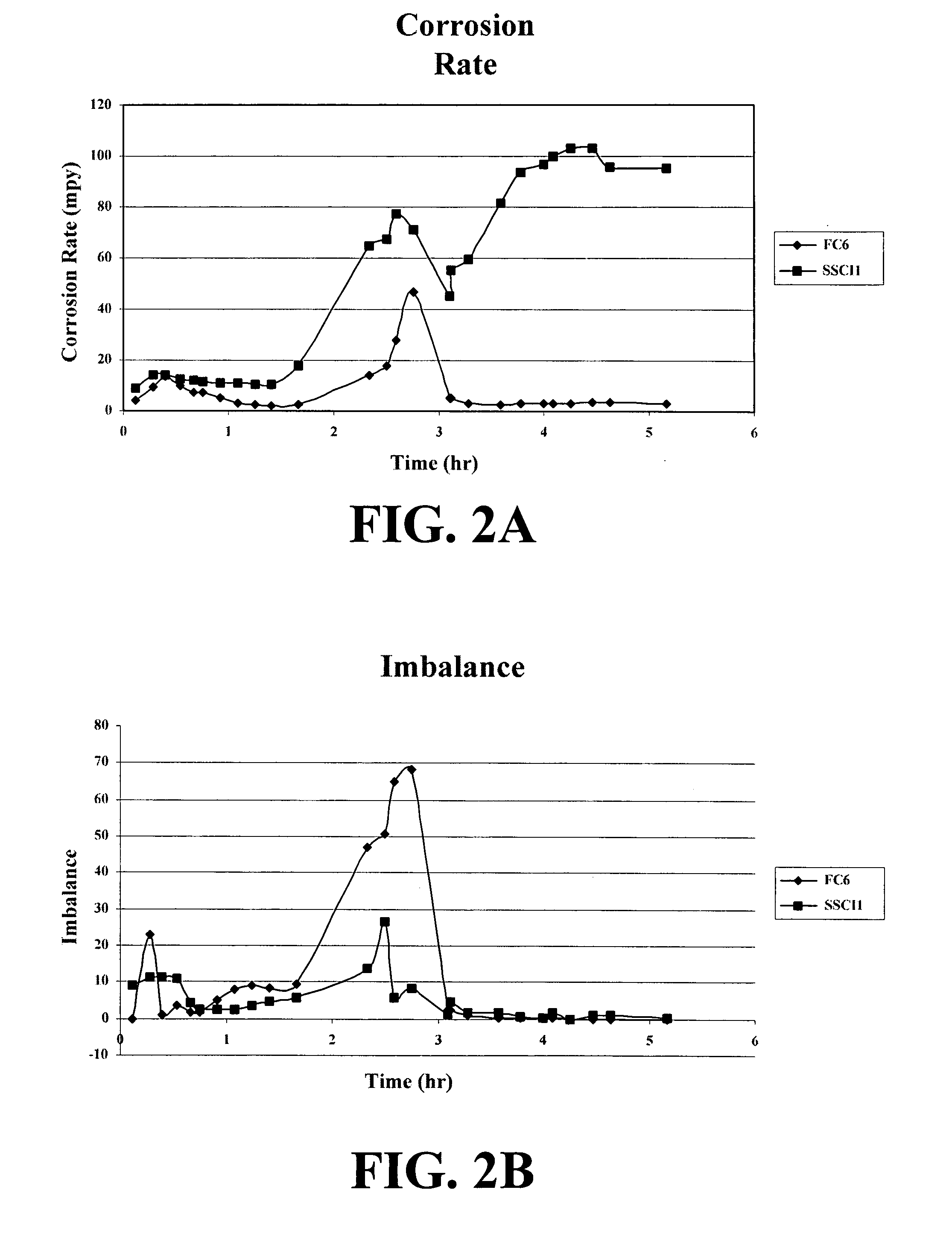

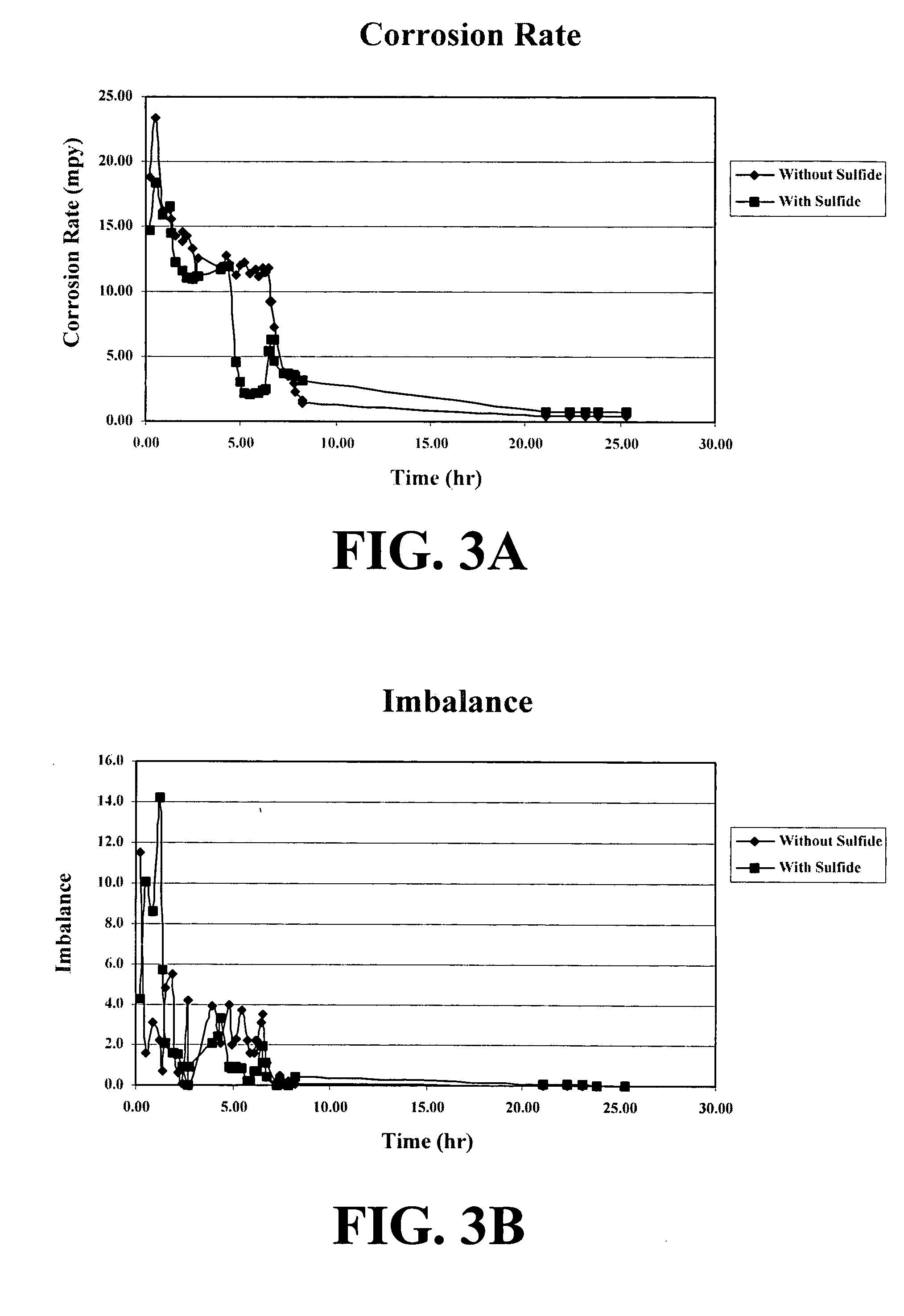

Foamer/sulfur scavenger composition and methods for making and using same

InactiveUS20050250666A1High activityImprove featuresOrganic chemistryConstructionsFoaming agentDisposal waste

A new multi-purpose foaming composition having applications in oil field application, industrial applications, waste management applications, or other applications that can be benefitted by a foam, is disclosed, where the composition includes a surfactant, a sulfur scavenger and optionally an additive, where the sulfur scavenger and / or additive improve foam characteristics and / or the foam improves an activity of the sulfur scavenger and / or the additives. Method for using and making the foaming compositions are also disclosed, especially, coiled and capillary coiled tubing downhole applications.

Owner:LUBRIZOL OILFIELD SOLUTIONS

Rapid-exchange delivery systems for self-expanding stents

A catheter assembly is provided having an inner member and an outer member extending along a longitudinal axis, the inner member and the outer member having a coaxial configuration and dimensioned for relative axial movement. The outer member may include an anti rotation member adapted to engage with a longitudinal slot formed on the inner member so as to maintain rotational alignment between inner member and outer member. The inner member can be made with a proximal portion made from a tubing such as hypotubing or a coil tubing. The inner member also may be made with a proximal portion made with a support mandrel. A coil tubing can be utilized to form the guide wire receiving member which is attached to the inner member.

Owner:ABBOTT CARDIOVASCULAR

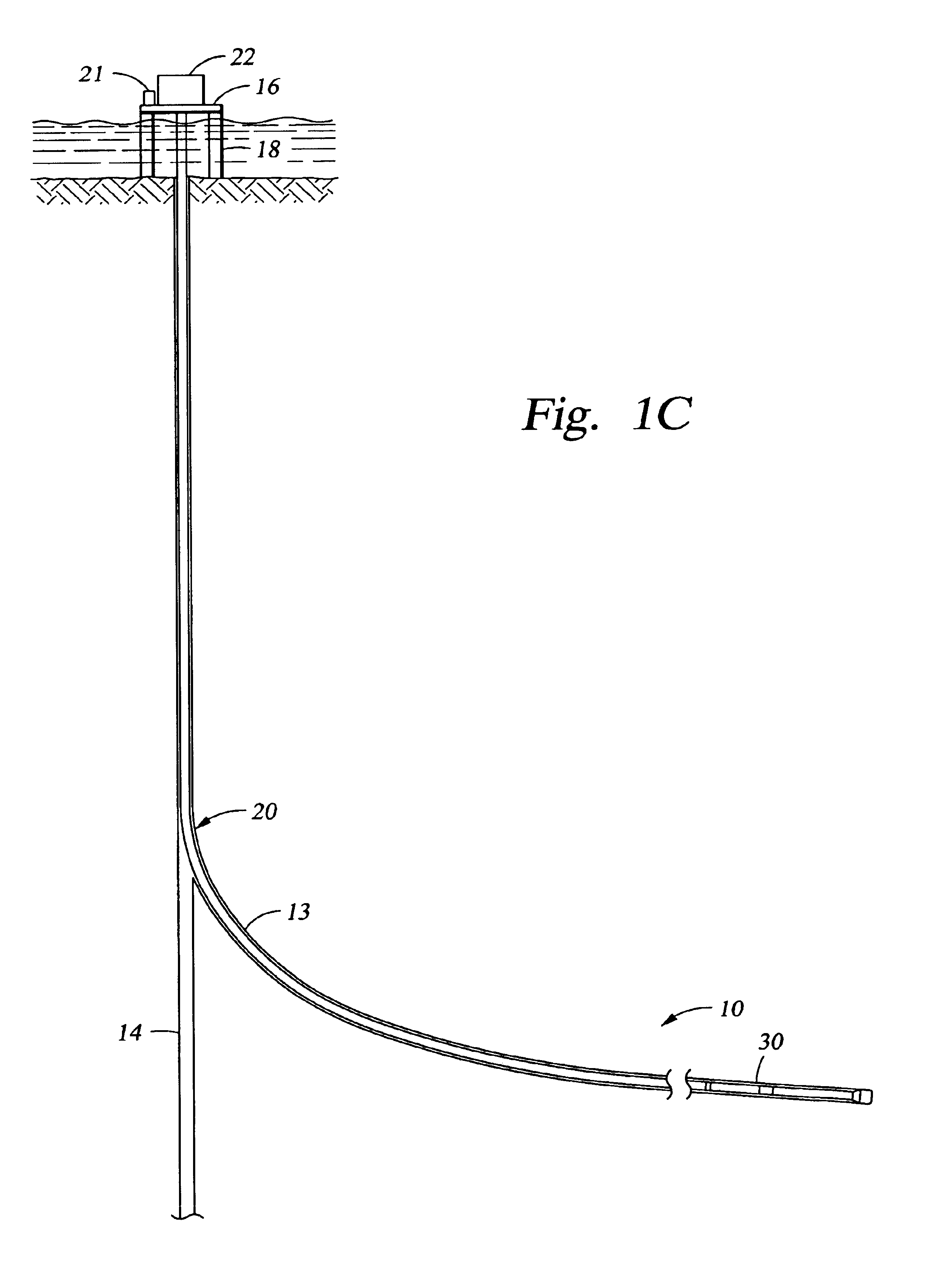

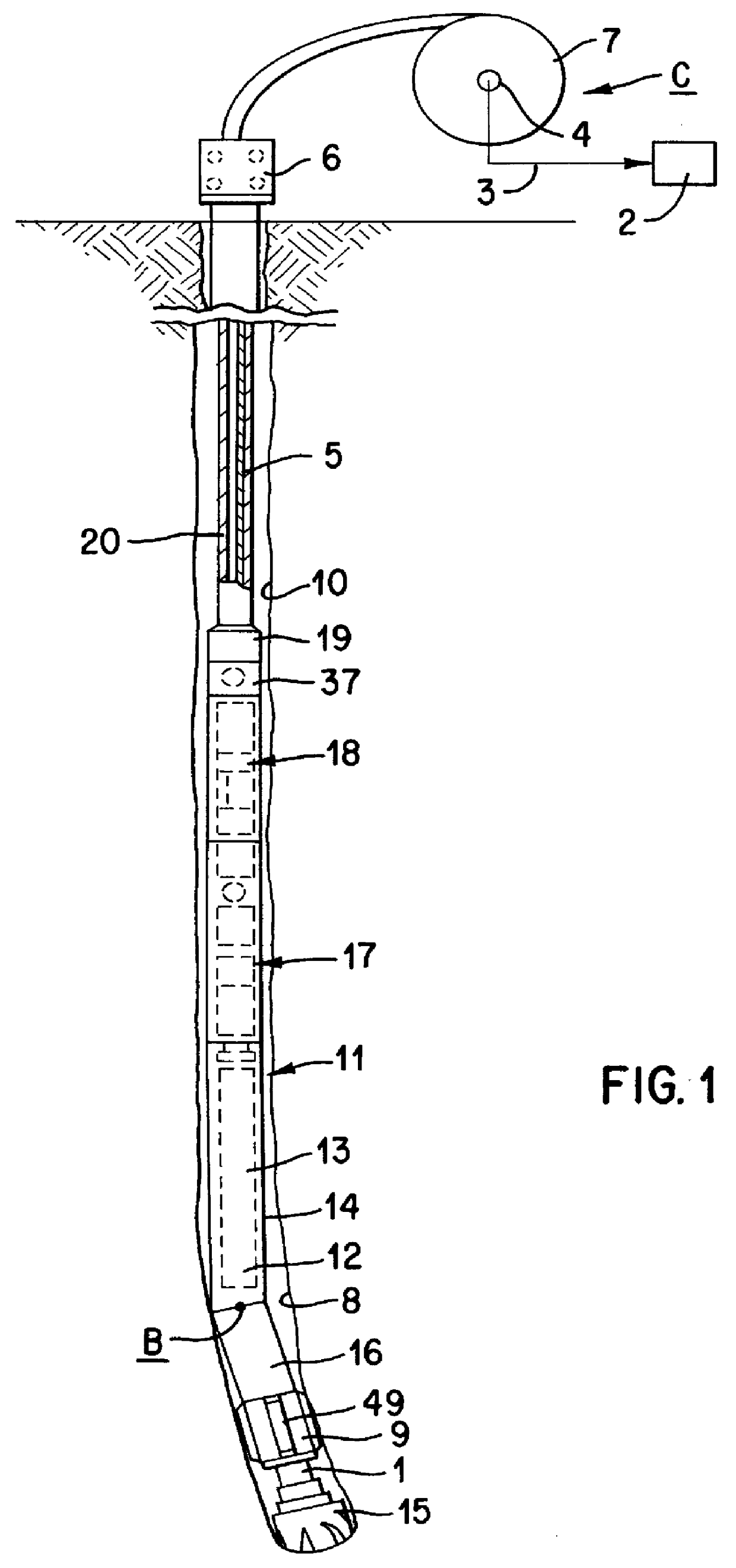

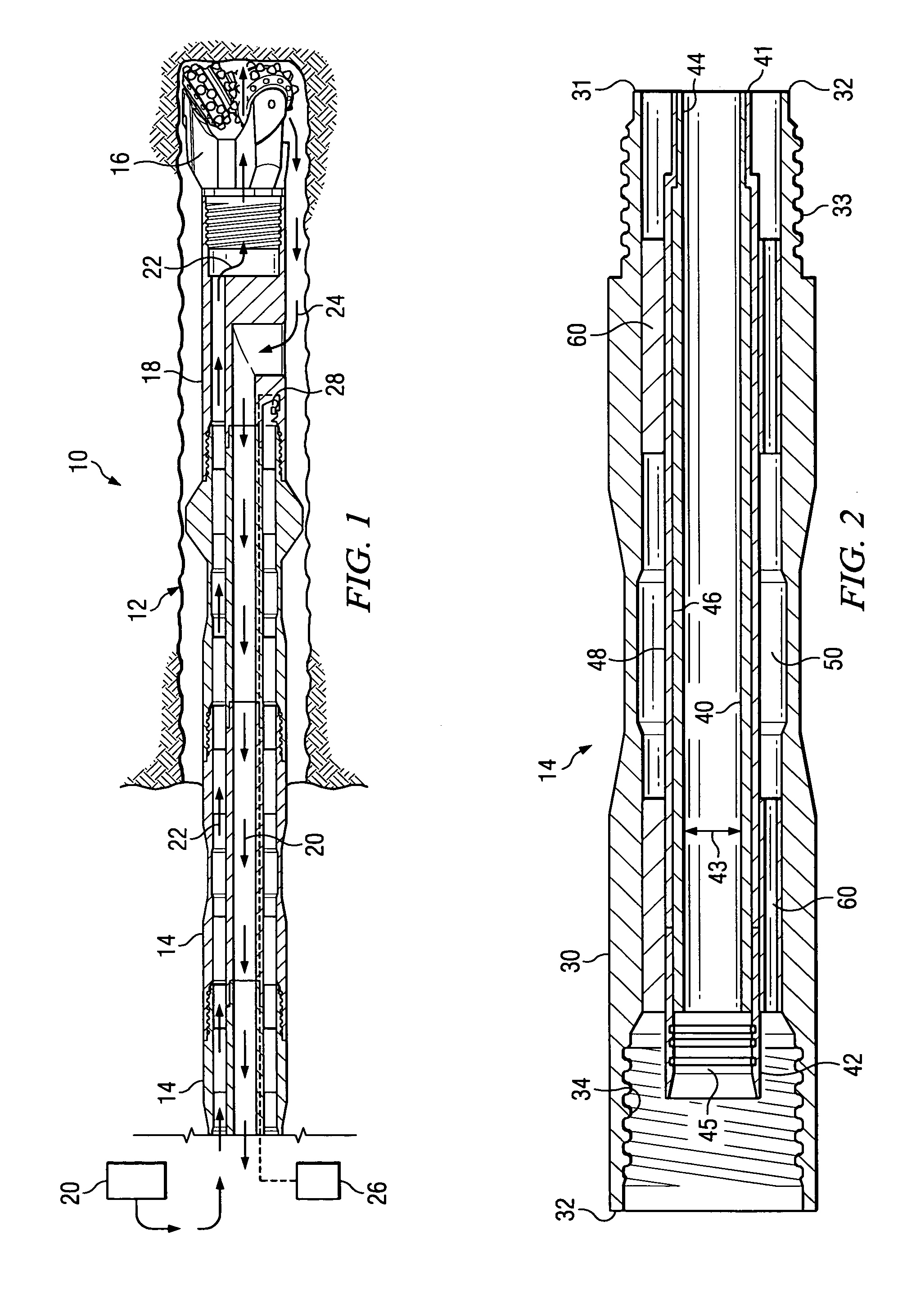

Apparatus and method for directional drilling using coiled tubing

A steerable directional drilling tool assembly includes a bent housing defining a bend angle and having a mud motor in its upper section and a drill bit below its lower section, an orienting tool rotatably coupled to such upper section and suspended on coiled tubing that extends upward to the surface, an electric motor in the orienting tool operable to rotate the bent housing in either hand direction to change or adjust the tool face angle of the bit, or continuously rotate the bent housing so that the bit drills straight-ahead, and an electric cable extending throughout the coiled tubing to furnish power from the surface to the electric motor and transmit electric signals to and from the surface. A logging tool can be included in the assembly for measuring characteristics of the formation, the borehole, and the tool assembly.

Owner:HEWLETT PACKARD CO +1

System and methods using fiber optics in coiled tubing

Apparatus having a fiber optic tether disposed in coiled tubing for communicating information between downhole tools and sensors and surface equipment and methods of operating such equipment. Wellbore operations performed using the fiber optic enabled coiled tubing apparatus includes transmitting control signals from the surface equipment to the downhole equipment over the fiber optic tether, transmitting information gathered from at least one downhole sensor to the surface equipment over the fiber optic tether, or collecting information by measuring an optical property observed on the fiber optic tether. The downhole tools or sensors connected to the fiber optic tether may either include devices that manipulate or respond to optical signal directly or tools or sensors that operate according to conventional principles.

Owner:SCHLUMBERGER TECH CORP

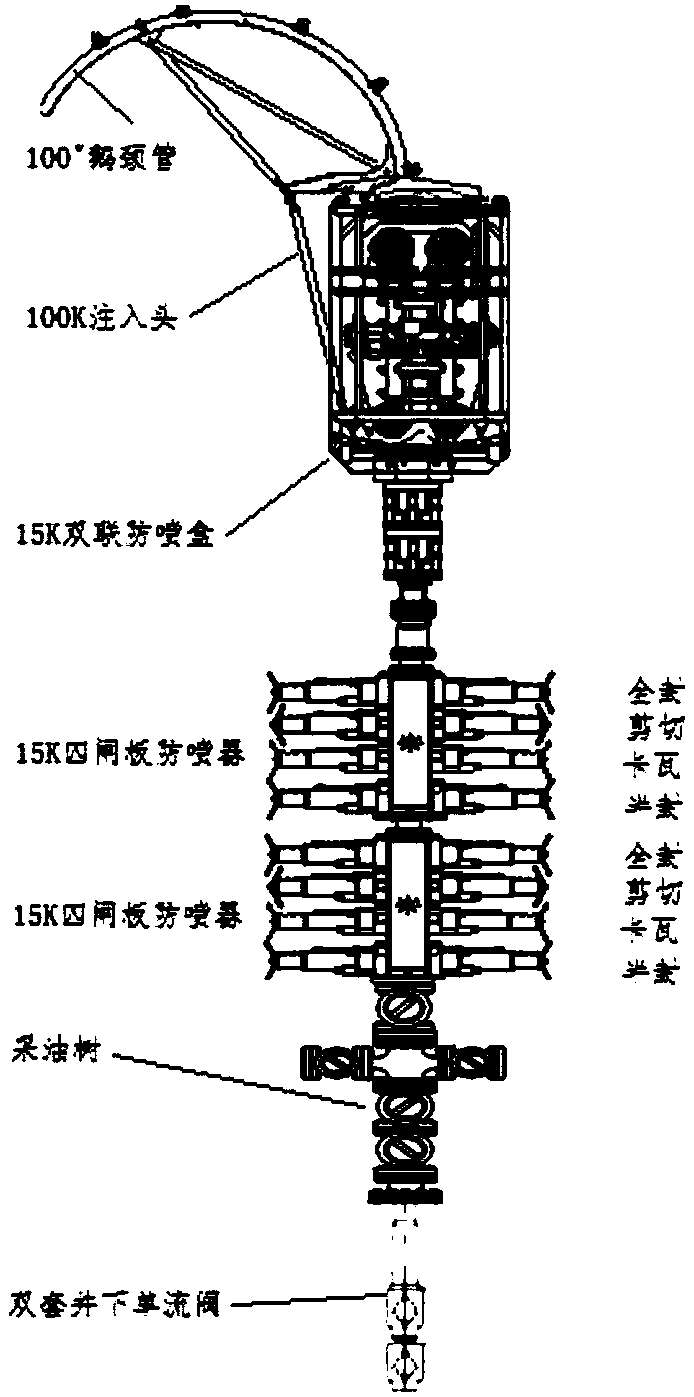

Oil and gas field coiled tubing paraffin removal and contaminant release process and tool thereof

PendingCN106761561AWill not artificially cause blockageImprove cleanlinessCleaning apparatusWaxCoiled tubing

The invention relates to an oil and gas field coiled tubing paraffin removal and contaminant release process and a tool thereof. Paraffin removal is performed by using coiled tubing, and removed paraffin can be recycled to the ground, and therefore a wellbore cannot be blocked due to human factors. A flushing port is designed at the upper end of a flushing tool, and then paraffin remaining on mechanical scraping portions can be cleared. The coiled tubing is connected with the paraffin removal and contaminant release tool for paraffin removal and contaminant release. The flushing tool at the front end of a pipe string can first perform 360 degree hydraulic cleaning on the wellbore, and then along with descending of the pipe string, a paraffin remover in the pipe string performs mechanical cleaning on the wellbore, and therefore dual cleaning mode combining the hydraulic cleaning with mechanical scraping is achieved, removal effects are greatly improved, cost is saved, and work efficiency is improved.

Owner:JEREH ENERGY SERVICES

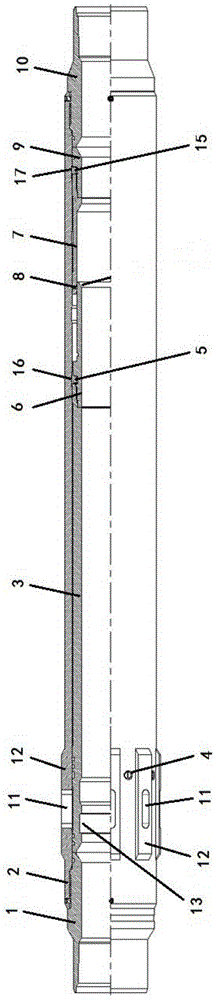

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

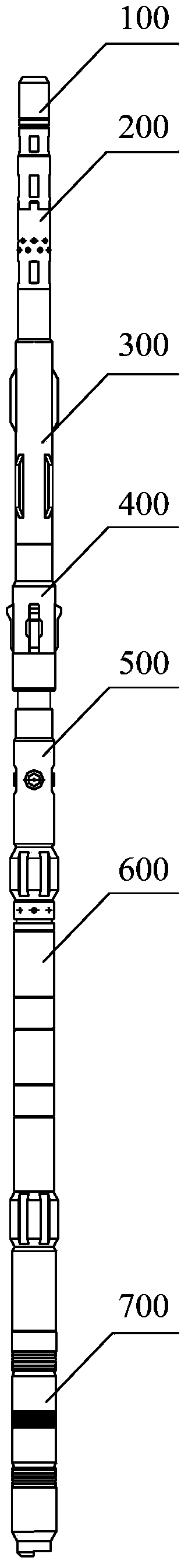

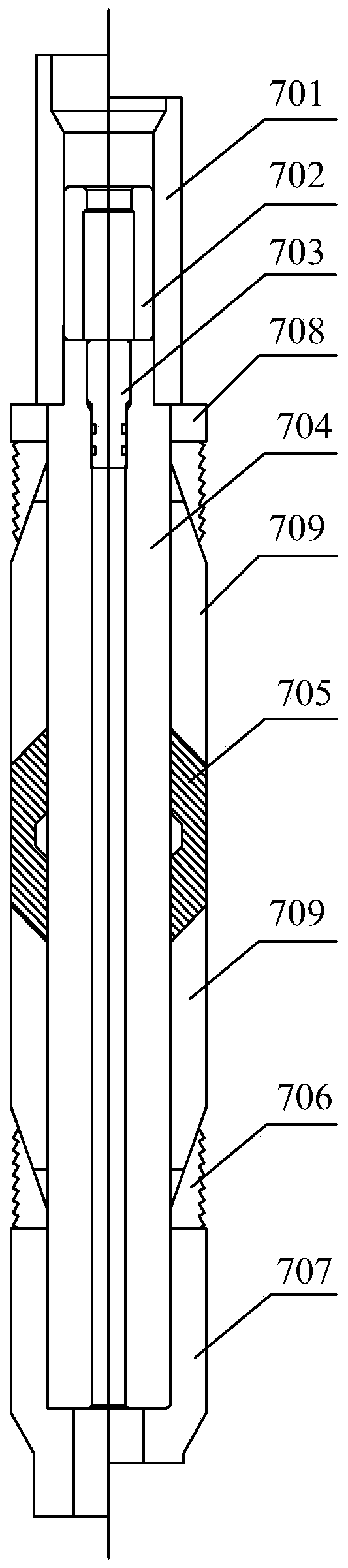

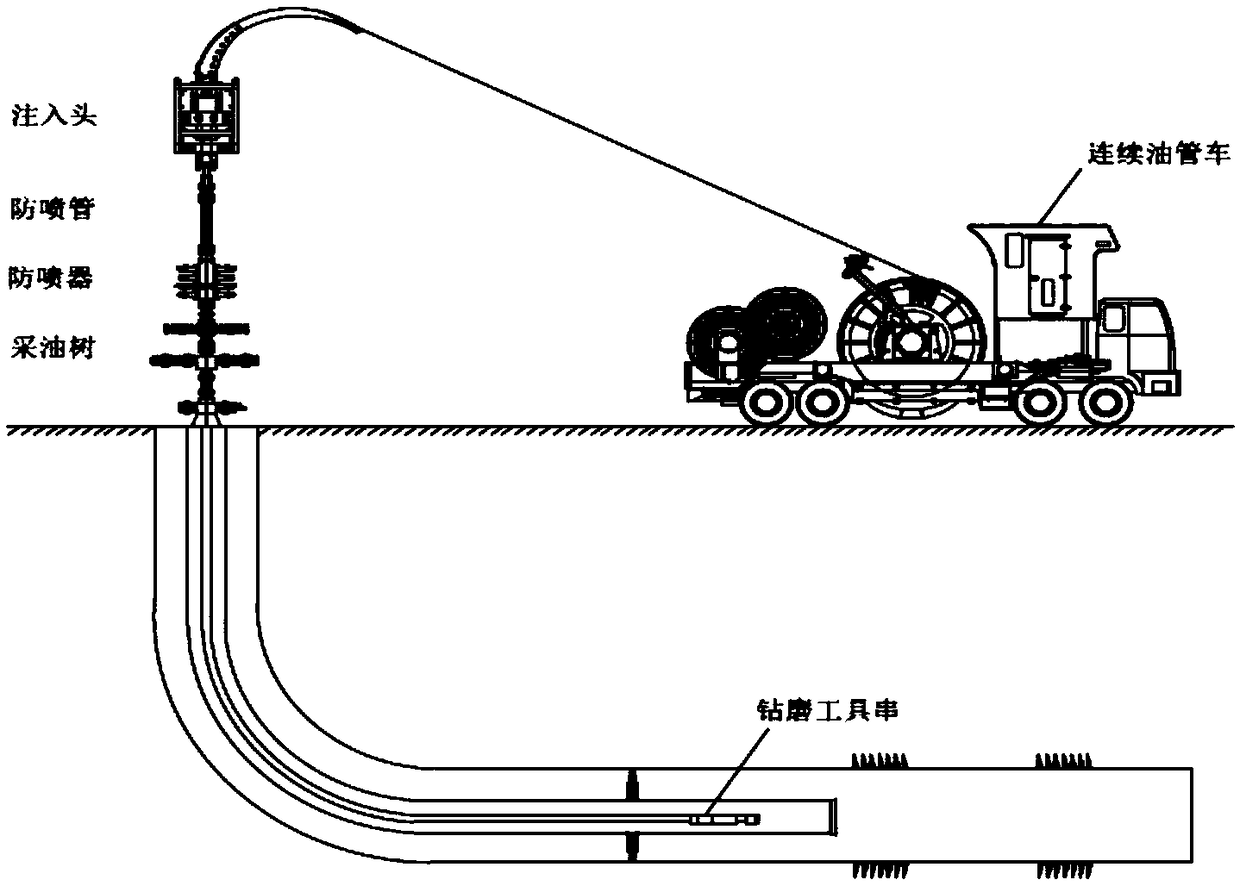

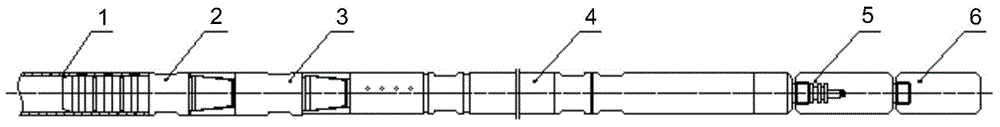

Tubular column string and bridge plug setting and sand blasting perforation combining method

The embodiment of the invention discloses a tubular column string. The tubular column string at least comprises a coiled tubing connector, a mechanical releasing tool, a centering device, a collar locator, a sand blasting perforation sliding sleeve, a hydraulic setting tool and a bridge plug. The sand blasting perforation sliding sleeve, the hydraulic setting tool and the bridge plug are sequentially connected in series in the direction from one end to the other end of the coiled tubing connector of the tubular column string, and the coiled tubing connector is used for being connected with coiled tubing. The whole operation of bridge plug tripping and setting can be completed through coiled tubing equipment, so that less equipment is used in construction, working procedures are few, and manual work is less; pyrotechnics equipment can be avoided, safety performance is high, the coiled tubing equipment is high in adaptability to well conditions, and large-discharge-capacity staged fracturing of a casing horizontal well can be achieved due to the full bore after the bridge plug is removed through drilling. The invention further discloses a bridge plug setting and sand blasting perforation combining method.

Owner:JEREH ENERGY SERVICES

Multi-cycle dump valve

InactiveUS20040084190A1Less timePrevent siphonFluid removalWell/borehole valve arrangementsControl flowFree falling

A flow responsive dump valve mechanism for a straddle packer tool and has a valve controlled flow passage from which underflushed fluid, typically well treatment slurry, in a conveyance and fluid supplying tubing string can be dumped into a well casing. The dump valve mechanism incorporates a ratcheting power piston, an indexing mechanism and high and low load energy storage systems to accomplish open, closed and intermediate dump valve positions. The intermediate position increases the functionality of the tool by preventing accidental closure either due to the free fall of fluid through the coiled tubing or during flushing of the tool and permits the flow rate to be increased for thorough cleaning of the straddle tool and coiled tubing. For energy storage, a light compression spring provides power to cycle the indexing mechanism. Heavier load disc springs (Bellville Washers) are used to provide power for the ratcheting power piston to open the valve.

Owner:SCHLUMBERGER TECH CORP

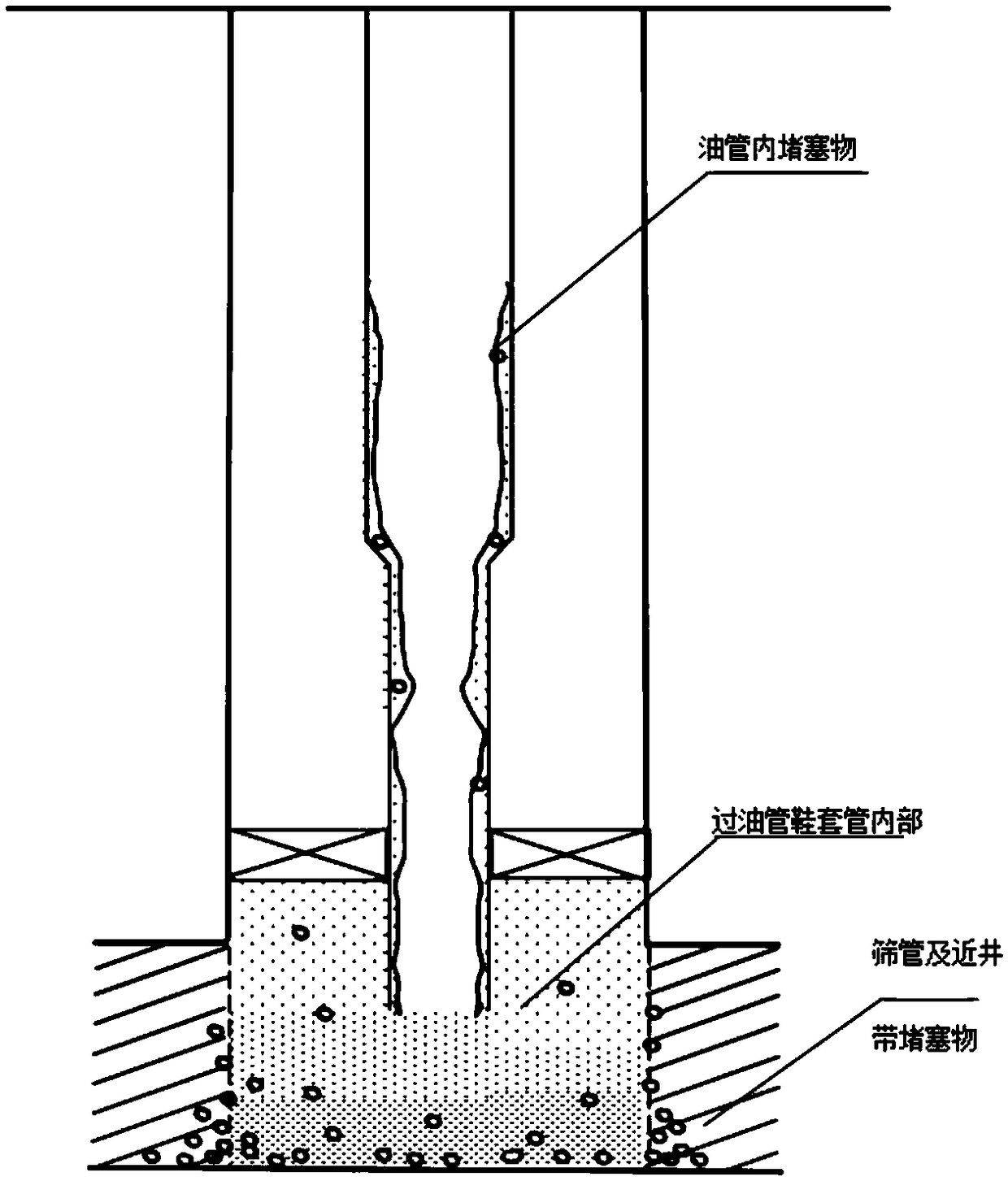

Method for three-layer unblocking for immovable string

InactiveCN108979569AEasy constructionLow costCleaning apparatusFluid removalCoiled tubingEngineering

The invention relates to the technical field of unblocking of oilfield gas wells, in particular to a method for three-layer unblocking for an immovable string. The three-layer unblocking includes oiltube internal unblocking, through-tubing casing internal unblocking and unblocking of immediate vicinity of a wellbore. The method comprises the following specific steps: arranging coiled tubing wellcontrol equipment at the position of an inlet of a high-pressure gas well; arranging a circulating working liquid sand removal system on the ground; and carrying downhole tools and delivering unblocking liquid by coiled tubing to realize three-layer unblocking. The method is proposed for a blocked gas well of an oilfield, the coiled tubing is used as a carrier of unblocking tools, and used as a deliverer for unlocking liquid. The method is simple to construct, the cost is saved, well control is safe, reservoir protection is implemented, occupied area is small, the method runs safely and reliably, and the requirements for unblocking operation of a high-pressure gas well of an oilfield can be met completely.

Owner:JEREH ENERGY SERVICES

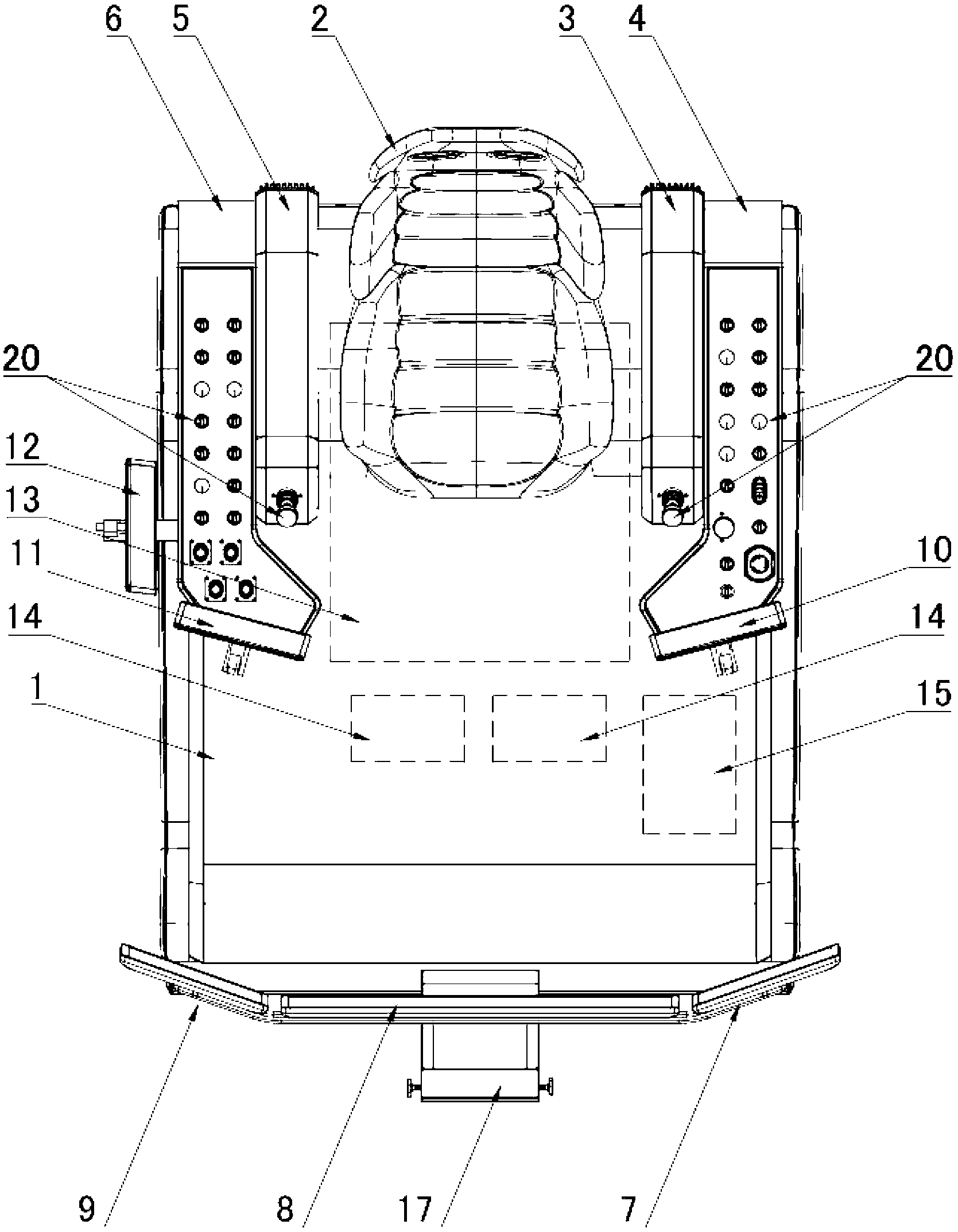

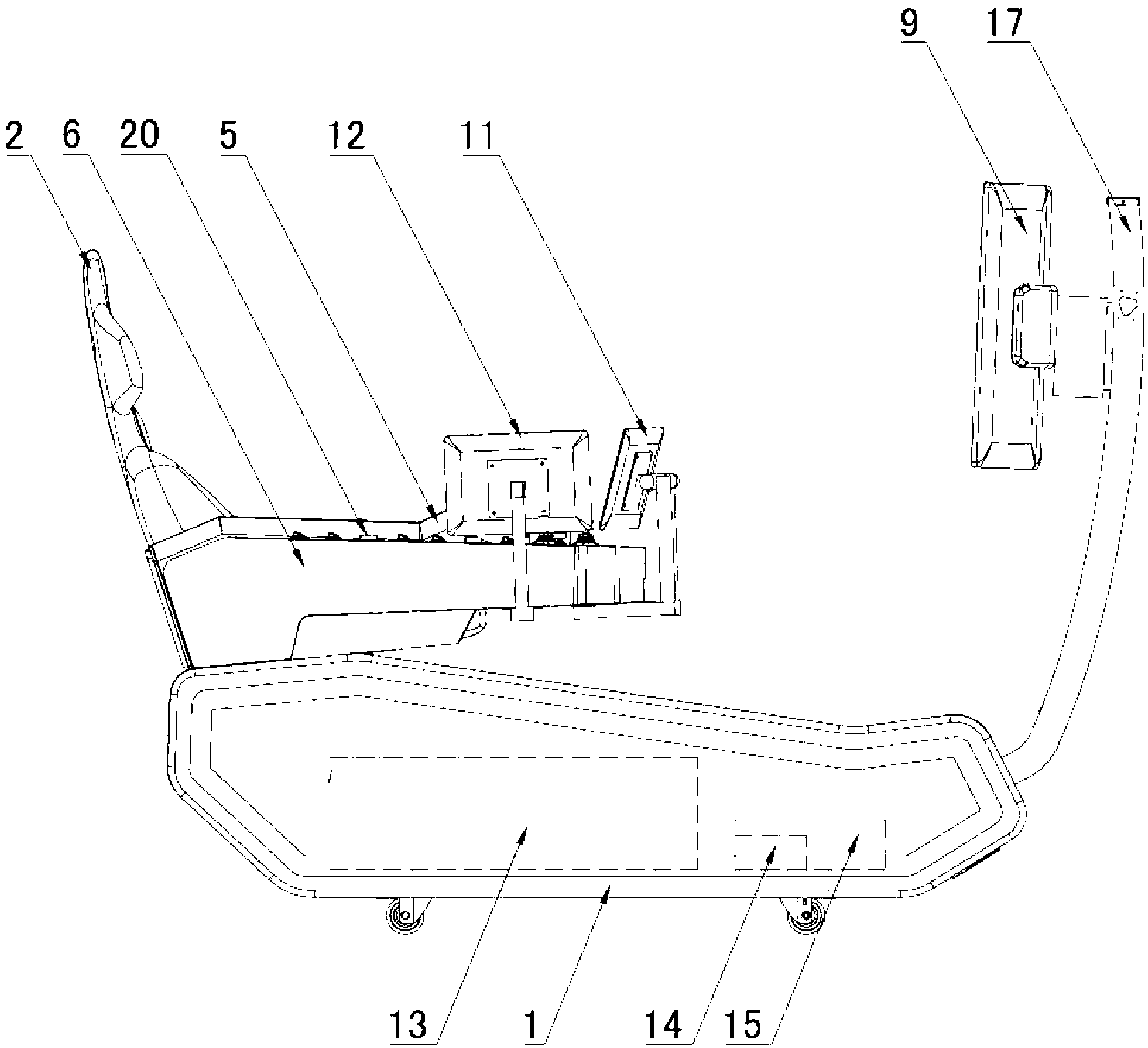

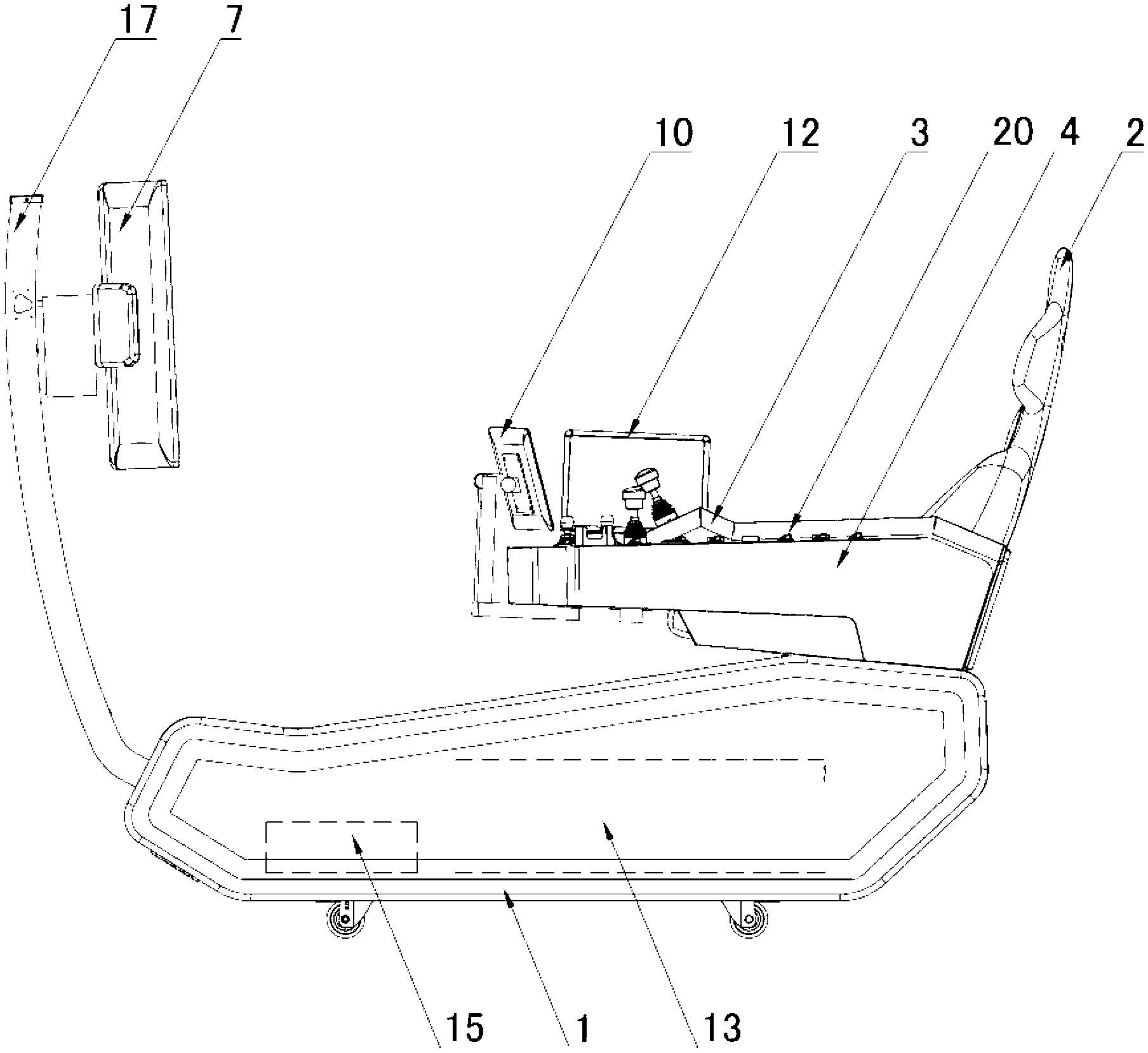

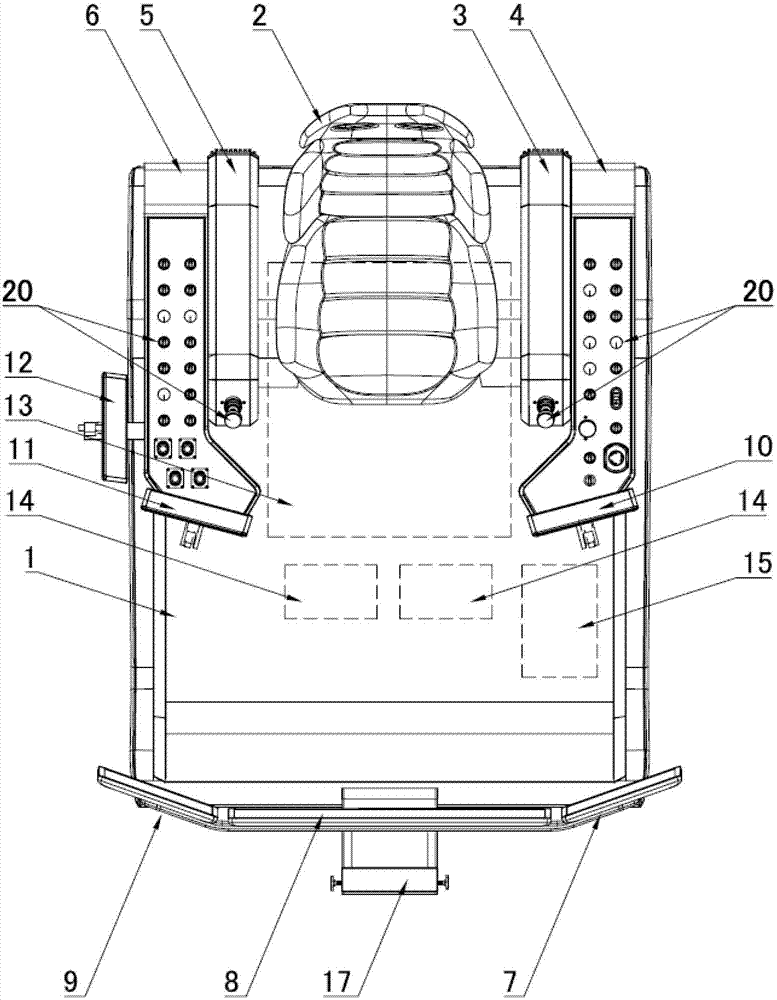

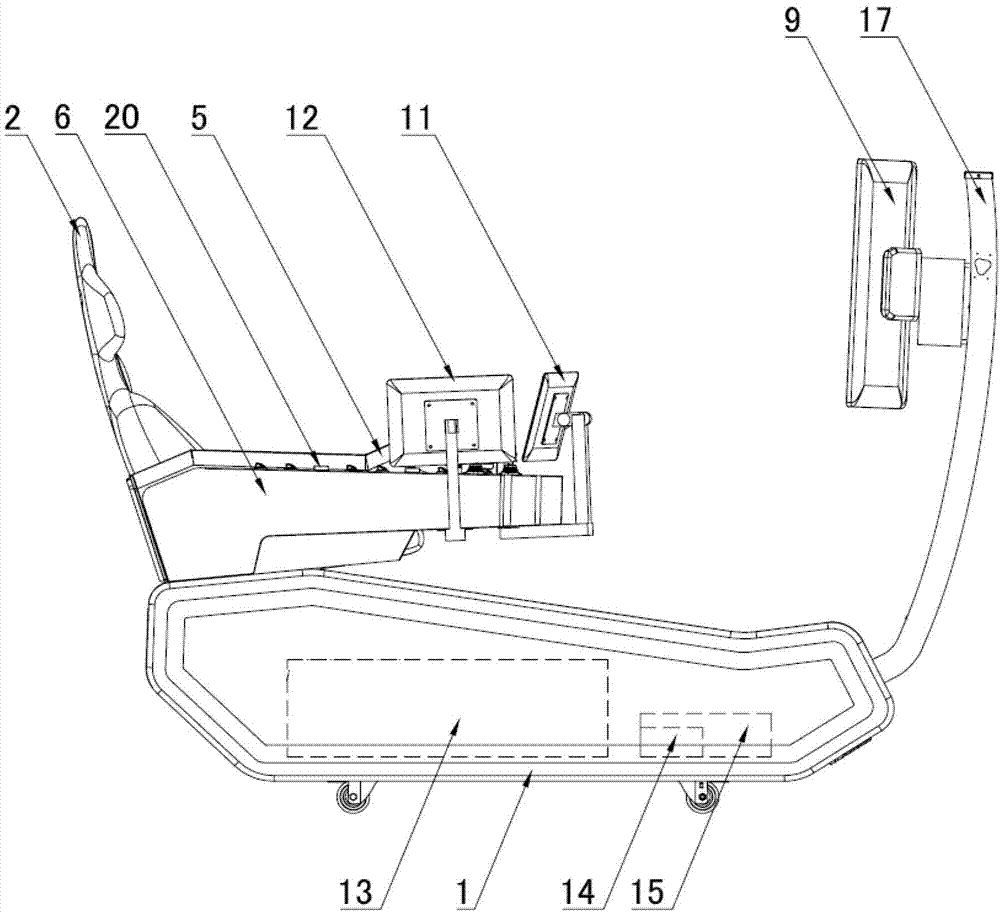

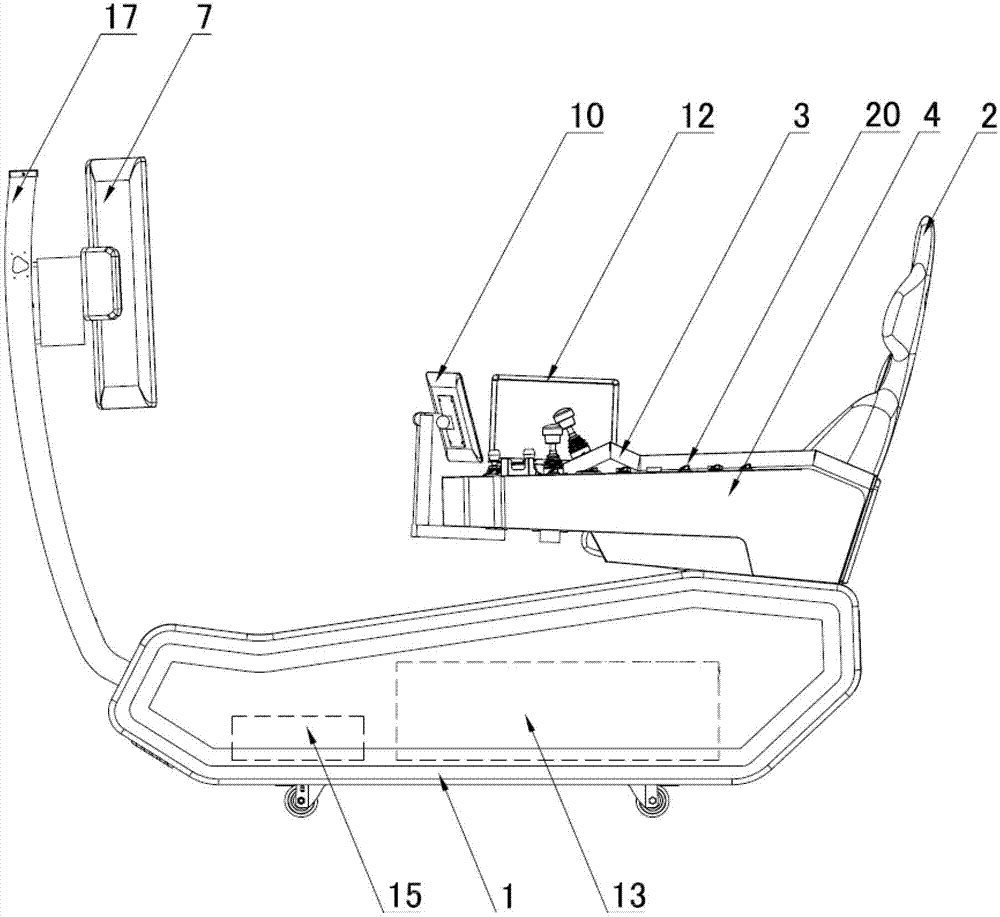

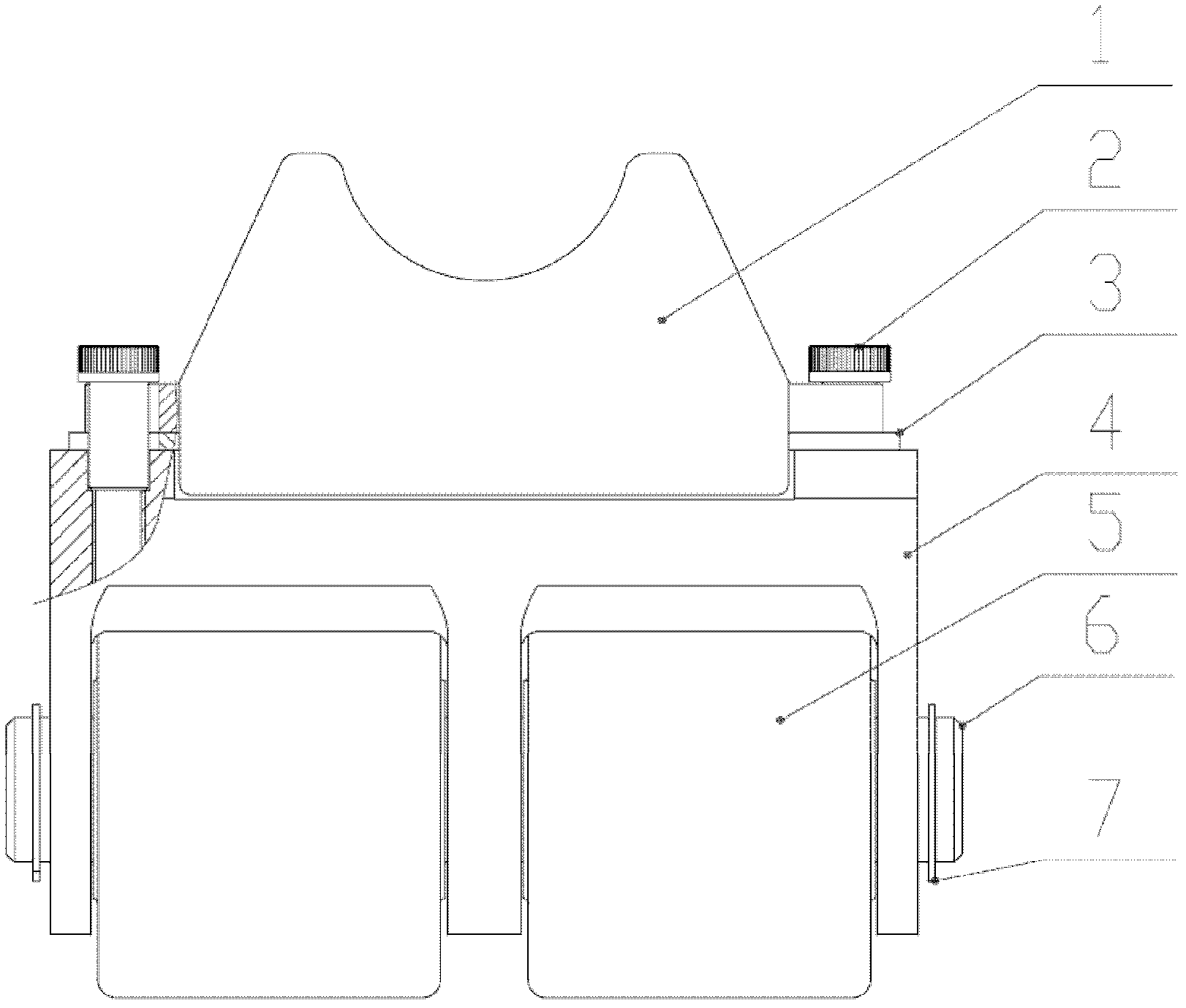

Coiled tubing operation equipment simulator

The invention discloses a coiled tubing operation equipment simulator, which comprises a base, a seat which is arranged at the middle part of the rear end of the base, simulation control parts which are arranged on the two sides of the seat, a data acquisition module which is used for receiving control signals of the simulation control parts, a main scene display which is arranged at the front of the seat, an injection head scene display and a downhole scene display which are arranged on the two sides of the main scene display, a computer system which is connected with the displays and the data acquisition module and can display simulated scenes in the displays, a simulation instrument display which is connected with the computer system, and an input device which is used for man-machine interaction. The coiled tubing operation equipment simulator can simulate various operation scenes in the actual working process of coiled tubing operation equipment, realize various simulation operations on the coiled tubing operation equipment and reproduce the actual operation and working process of the real coiled tubing operation equipment.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD +1

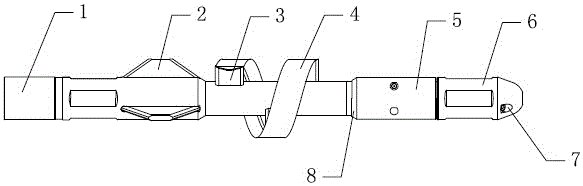

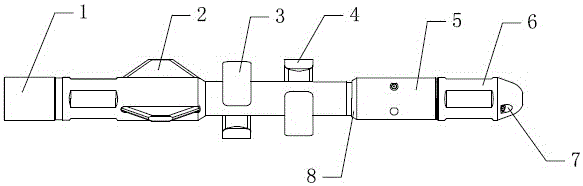

Coiled tubing tool set with cable perforations and technology

InactiveCN104533392AHigh strengthImprove toughnessSurveyFluid removalHorizontal wellsEconomic benefits

The invention discloses a coiled tubing tool set with cable perforations. The coiled tubing tool set comprises coiled tubing, a coiled tubing joint and a logging tool string or a perforation tool set. A cable is arranged in the coiled tubing. According to the coiled tubing tool set with the cable perforations, the structure of combining the coiled tubing and the logging tool string or the perforation tool set is adopted, and on the one hand, due to the characteristic that the coiled tubing is high in strength, toughness and loading capacity to work under pressure, the perforation requirements for highly-deviated wells and horizontal wells can be met, and the application range is wider; on the other hand, the coiled tubing can continuously work, work time is short, and efficiency is high. Meanwhile, due to production under pressure, a press does not need to be introduced, and the overall equipment occupied area is small. Therefore, through the coiled tubing, the cost of a work well is lowered, and economic benefits are improved. The invention further discloses a coiled tubing technology with cable perforations adopting the coiled tubing tool set with the cable perforations.

Owner:JEREH ENERGY SERVICES

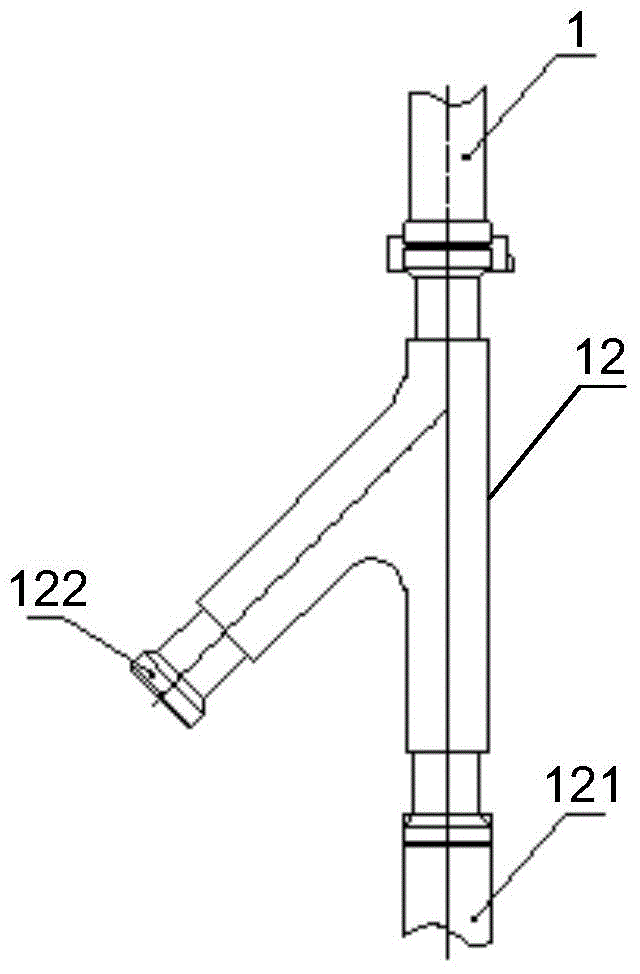

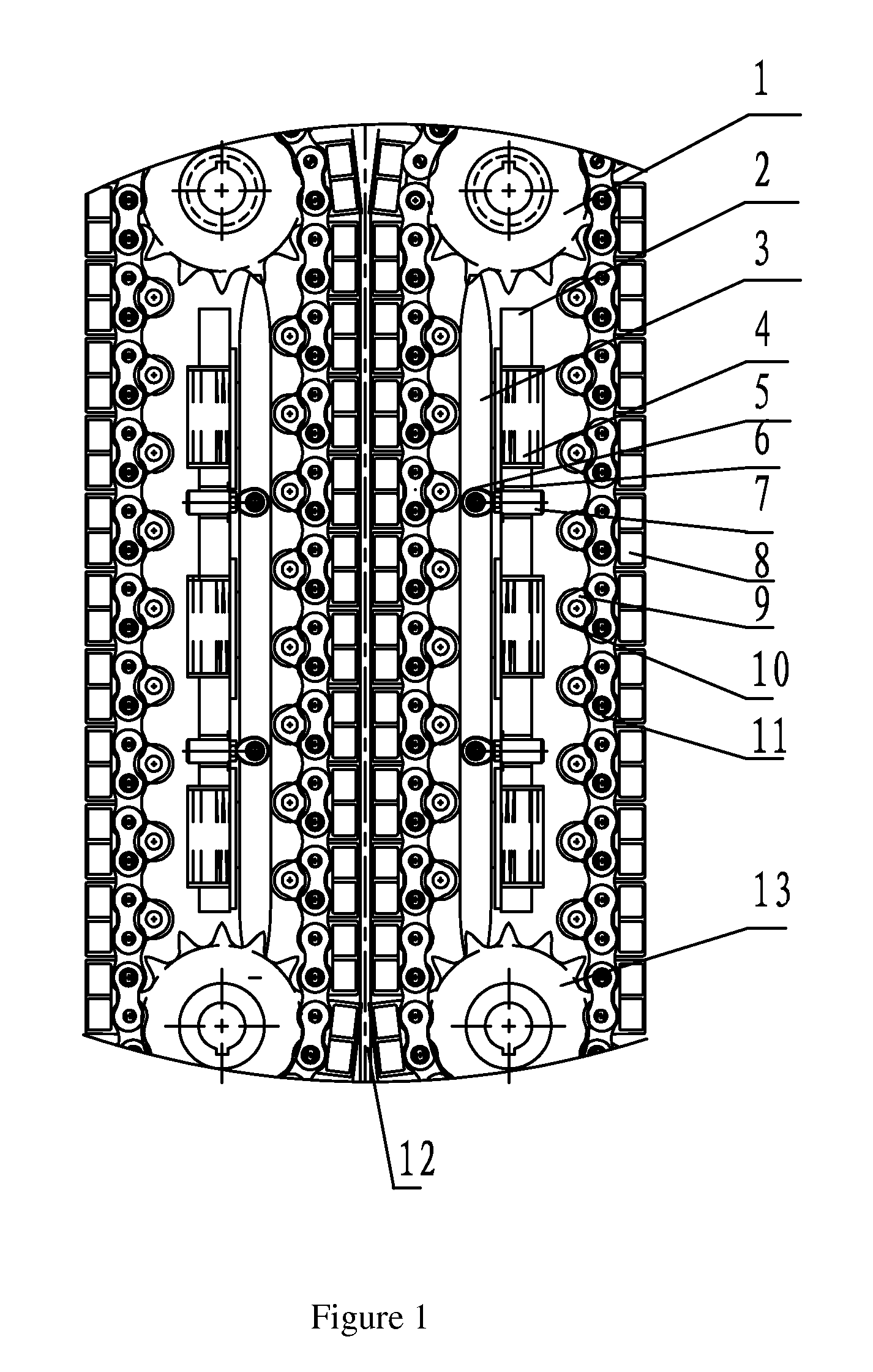

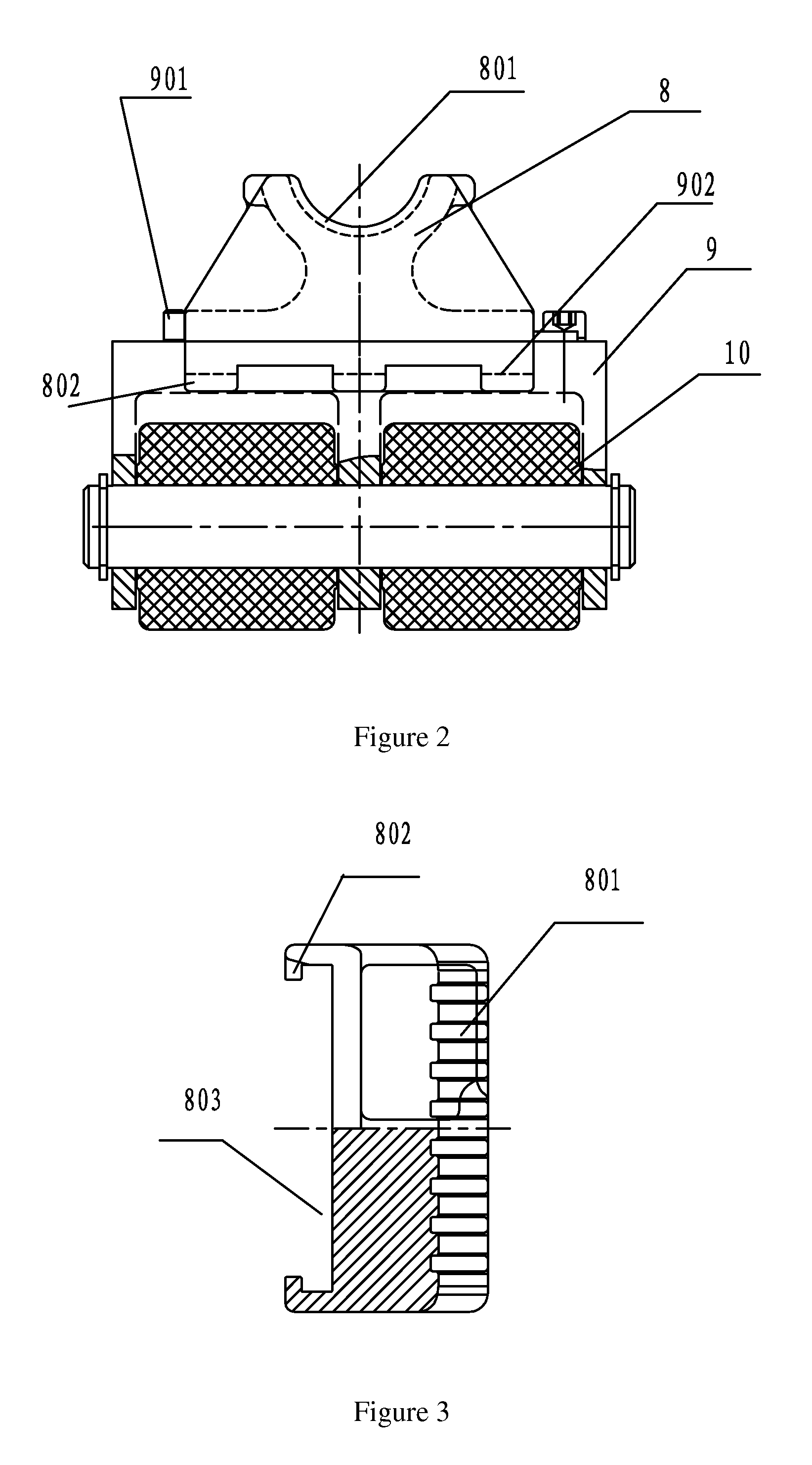

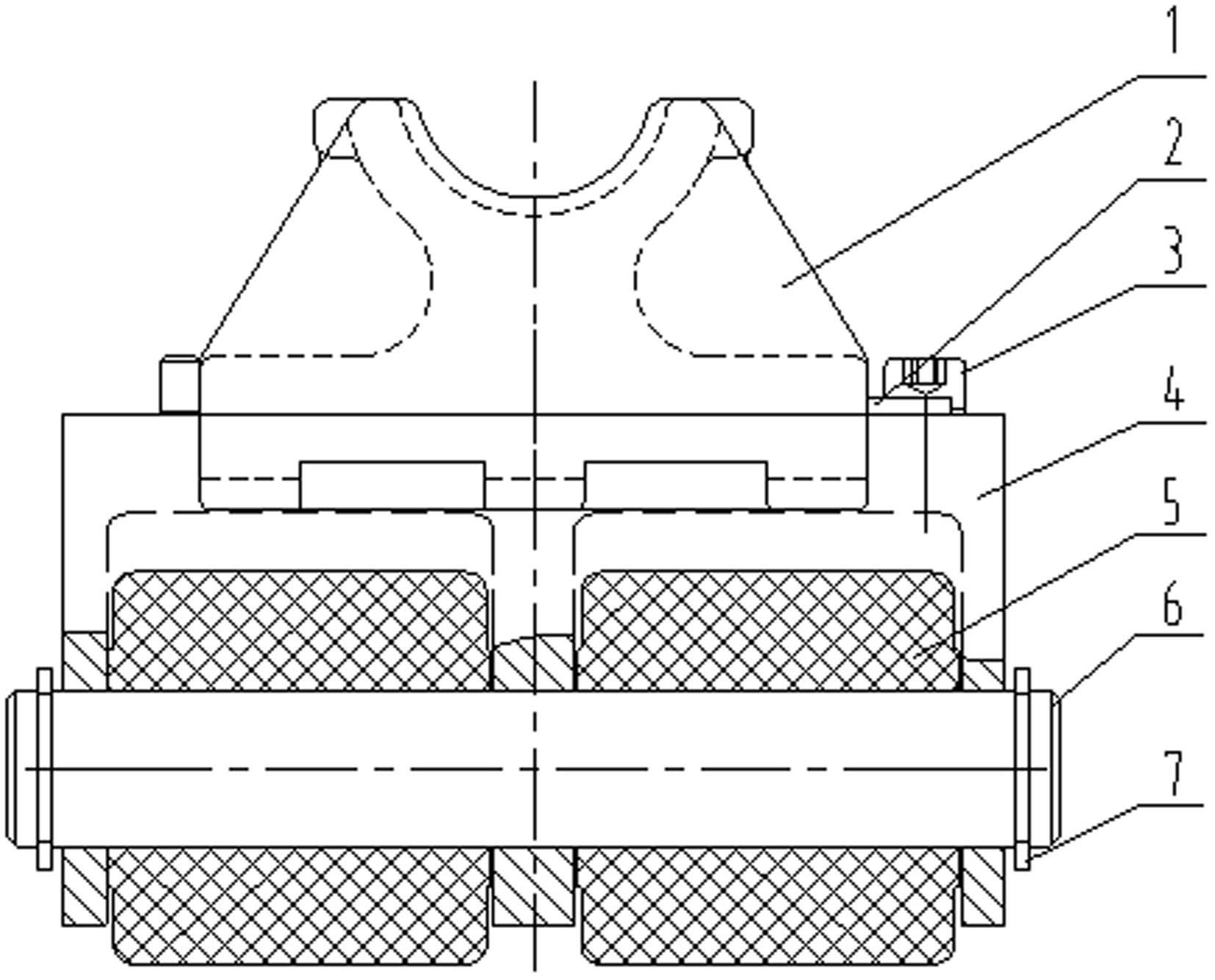

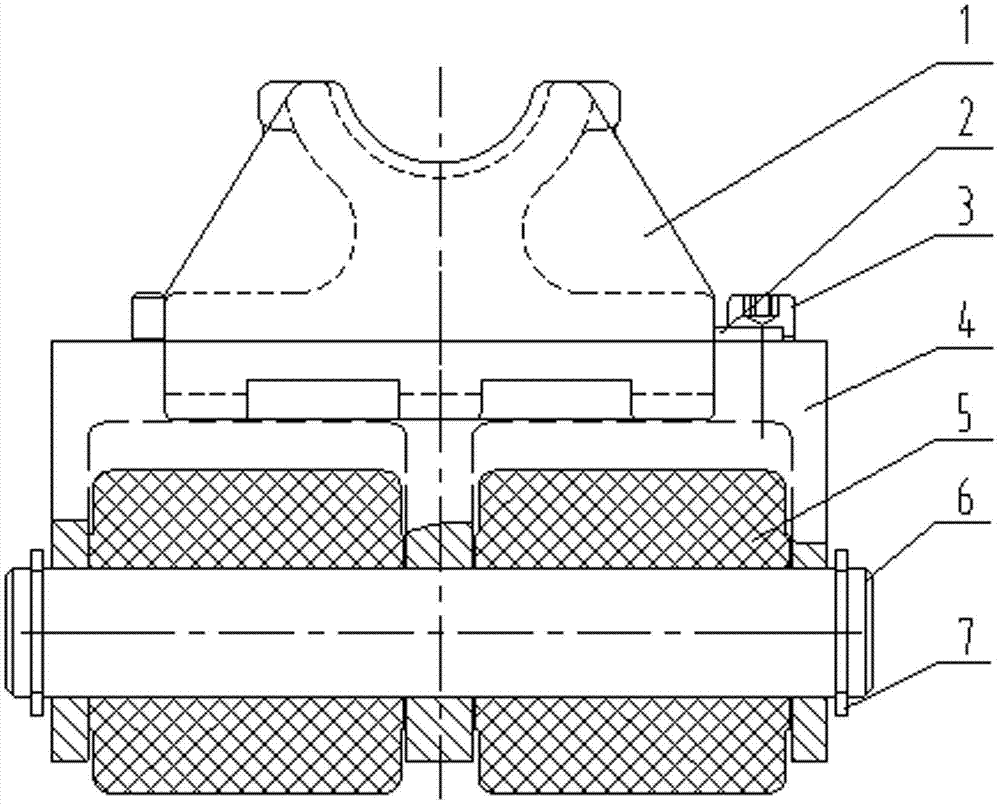

Floating clamping device for injection head of continuous oil pipe

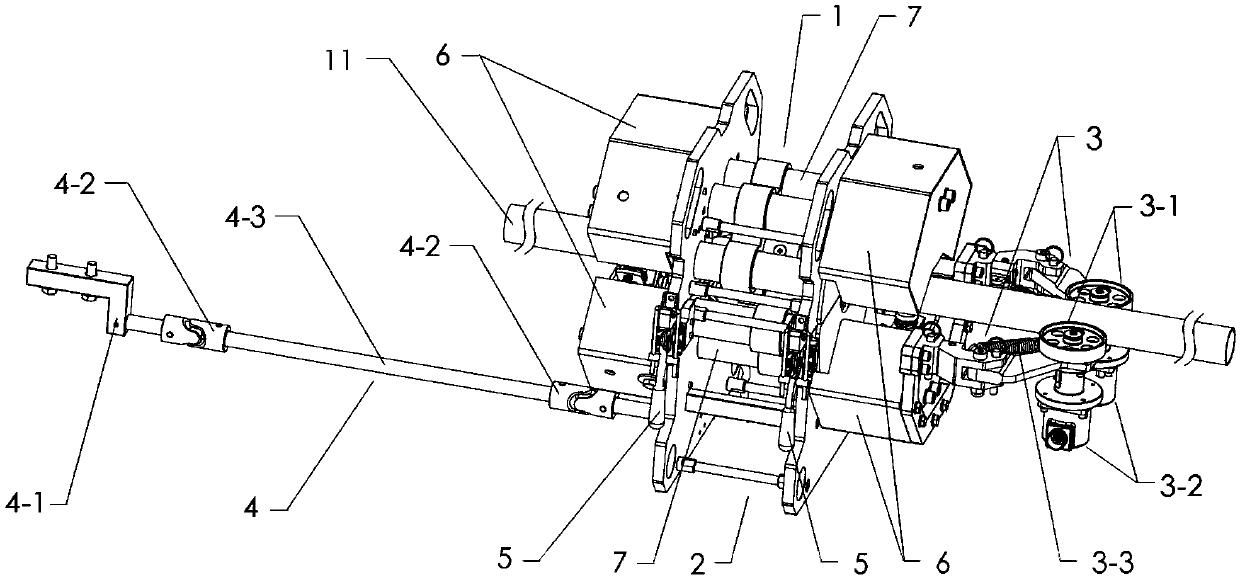

ActiveUS9493997B2Easy to serviceEasy to operateDrilling rodsDrilling casingsCoiled tubingEngineering

A floating clamping device for an injection head of a continuous oil pipe, including a drive sprocket, a transmission chain, a supporting plate, a pushing plate, clamping oil cylinders and a clamping assembly. At least two clamping oil cylinders are installed on the supporting plate fixedly. The pushing plate is fixed on the supporting plate through a pin shaft. The clamping assembly includes a saddle-shaped clamping block, a clamping block seat and rollers which are mounted on the clamping block seat. The clamping assembly is mounted on the transmission chain. A piston rod of the clamping oil cylinder is pressed on one face of the pushing plate, while the other face of the pushing plate is pressed on the rollers. The pushing plate has a simple structure and is convenient for maintenance; the clamping device has a compact structure and a reduced volume.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

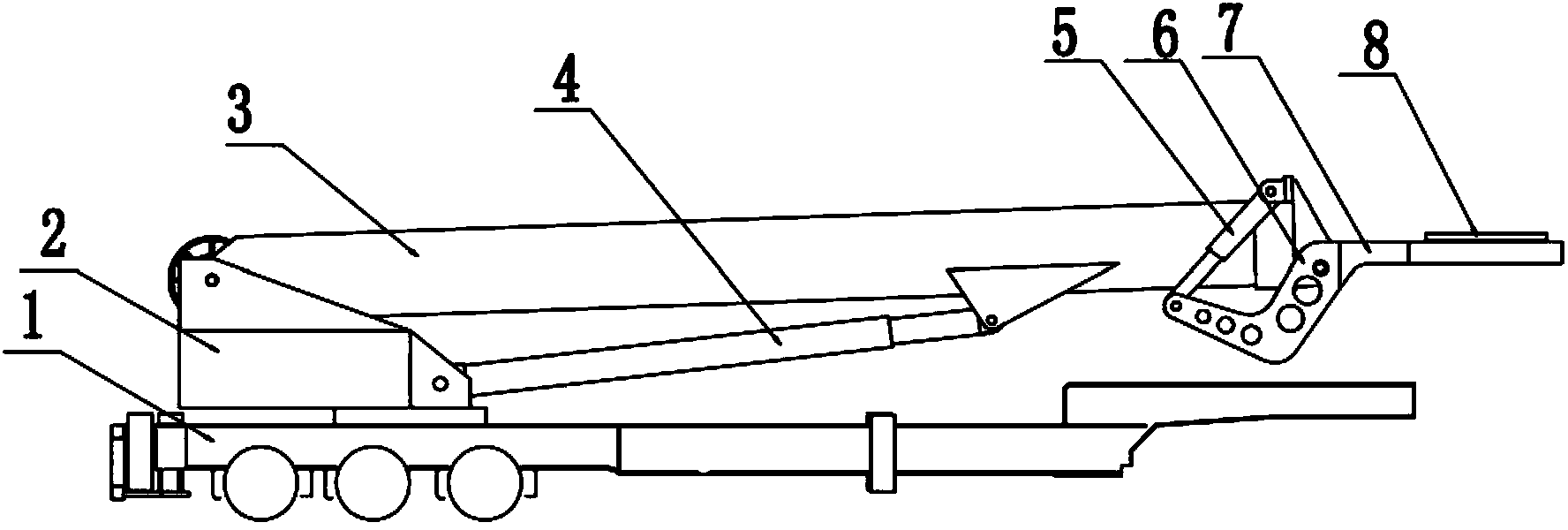

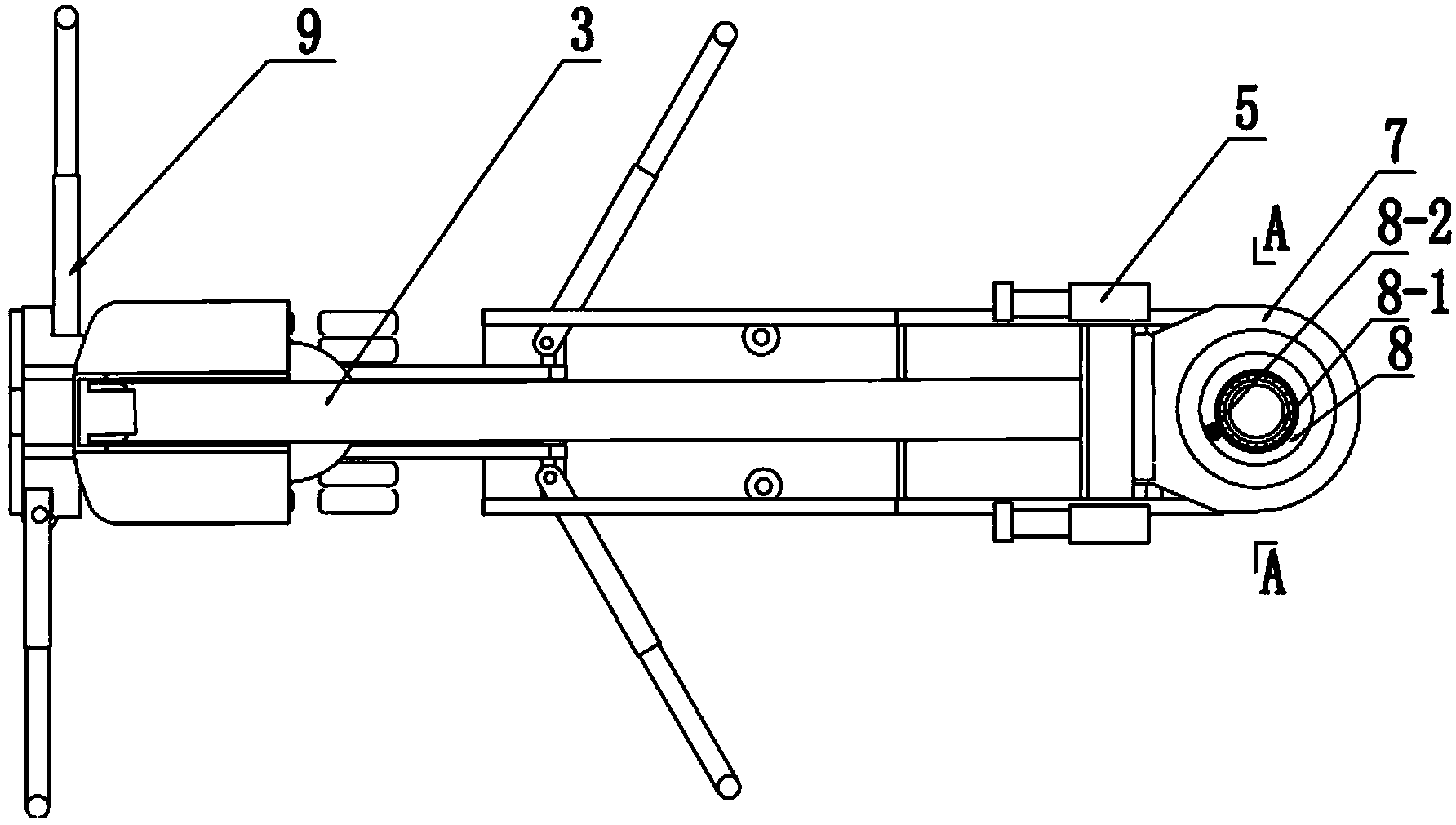

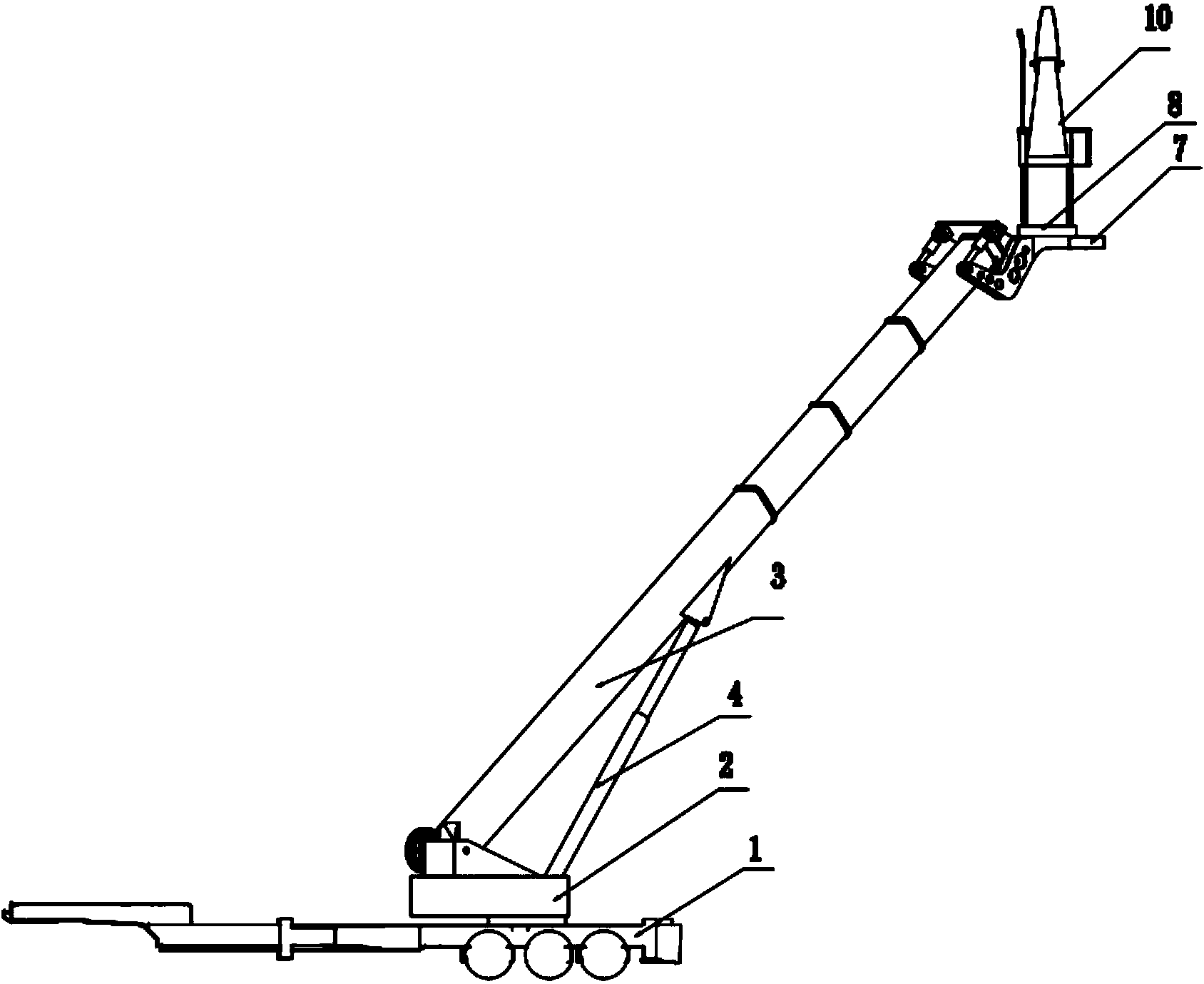

Hoisting derrick specially for coiled tubing equipment

The invention relates to a hoisting derrick specially for coiled tubing equipment. The hoisting derrick comprises a derrick transportation supporting platform, a derrick swinging base, a derrick telescopic boom, a first telescoping cylinder and second telescoping cylinders, which are connected with one another through rotation and articulation; the hoisting derrick is characterized by also comprising an injection head mounting platform, wherein lever arms are arranged on the injection head mounting platform, one ends of the level arms are fixedly connected with the injection head mounting platform, the other ends of the level arms are articulated with the plunger piston ends of the second telescoping cylinders, the cylinder body ends of the second telescoping cylinders are articulated with the derrick telescopic boom, and the level arms and the second telescoping cylinders are arranged in pairs and are arranged on two sides of the derrick telescopic boom respectively. The hoisting derrick has the beneficial effects that the injection head and an oil well can be centered rapidly, the labor intensity of workers is reduced and the mounting cost is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

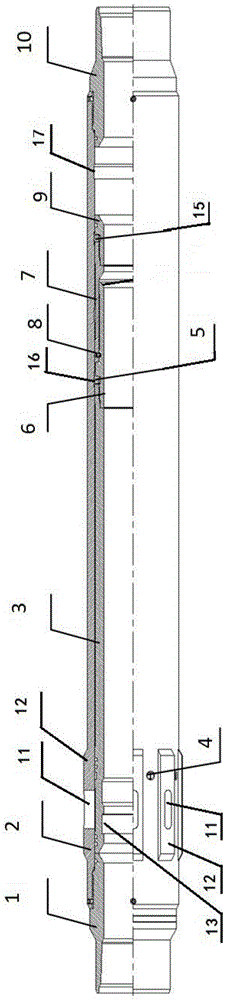

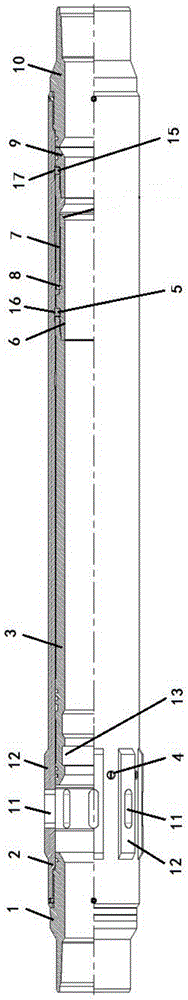

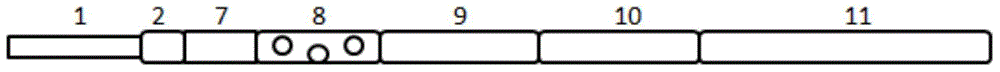

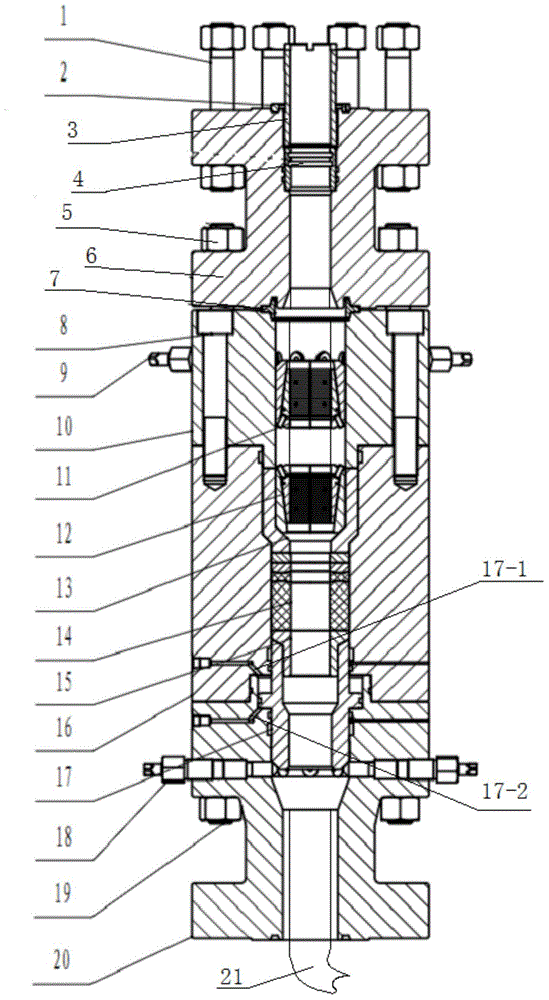

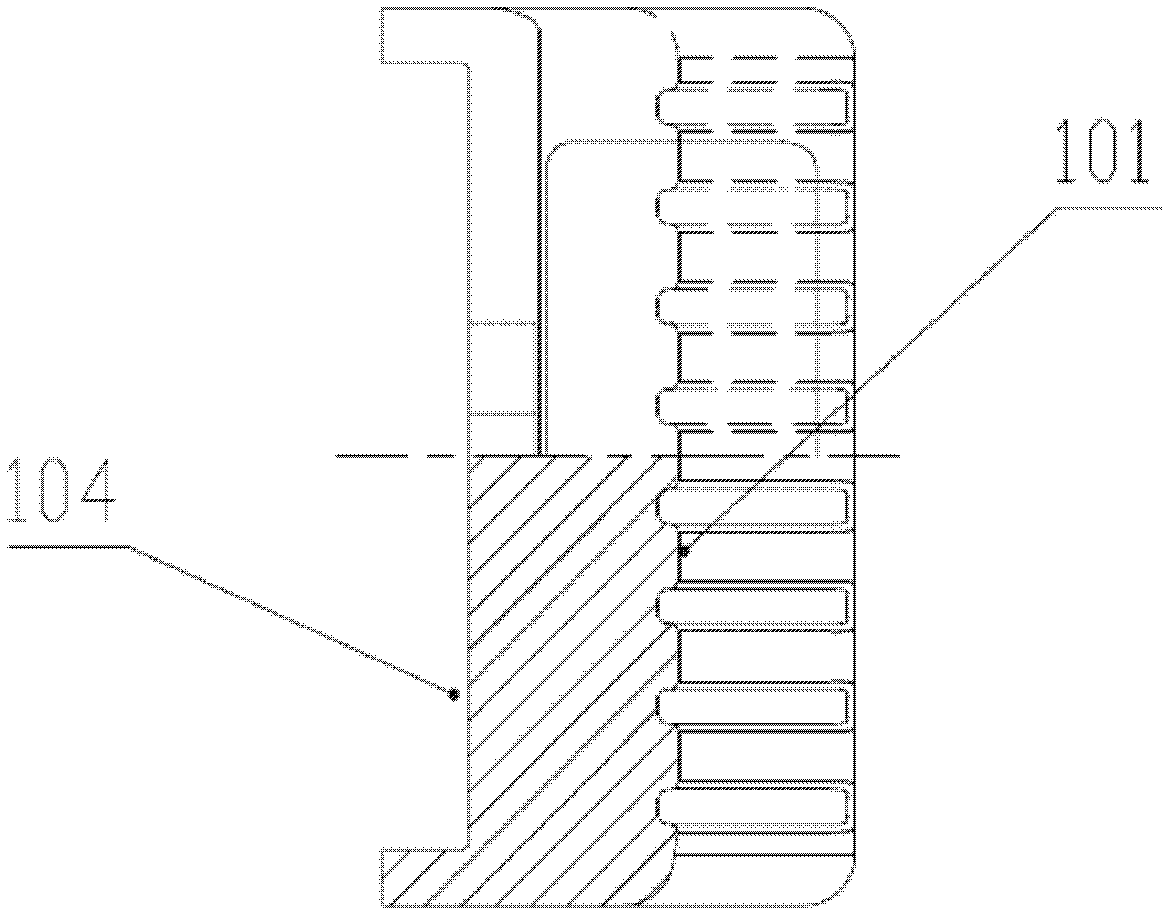

Continuous oil pipe hanger for velocity tubular column

ActiveCN104358536AGuaranteed sealing performanceFix the leakBorehole/well accessoriesCoiled tubingEngineering

The invention relates to a continuous oil pipe hanger for a velocity tubular column. The continuous oil pipe hanger comprises a continuous oil pipe, an I-shaped flange, an upper slip assembly, a lower slip assembly, an upper shell, a middle shell and a lower shell, wherein vertically penetrating central holes are formed in the upper shell, the middle shell and the lower shell; the I-shaped flange is fixedly arranged at the top of the upper shell; the continuous oil pipe passes through the I-shaped flange and the central holes of the upper shell, the middle shell and the lower shell in turn; the upper slip assembly is clamped on an inner wall of the central hole of the upper shell; the lower slip assembly is located in the central hole of the middle shell; a connecting pipe sealing set is fixedly arranged on an inner wall of the central hole of the middle shell and the lower side of a hanging supporting sleeve; at least one pair of driving pistons is arranged on the inner walls of the central holes of the middle shell and the lower shell and under the connecting pipe sealing set; an upper oil port and a lower oil port respectively communicated with the driving pistons are arranged on the side walls of the middle shell and the lower shell. The continuous oil pipe hanger has the beneficial effect of capability of hanging the continuous oil pipe.

Owner:JEREH ENERGY SERVICES

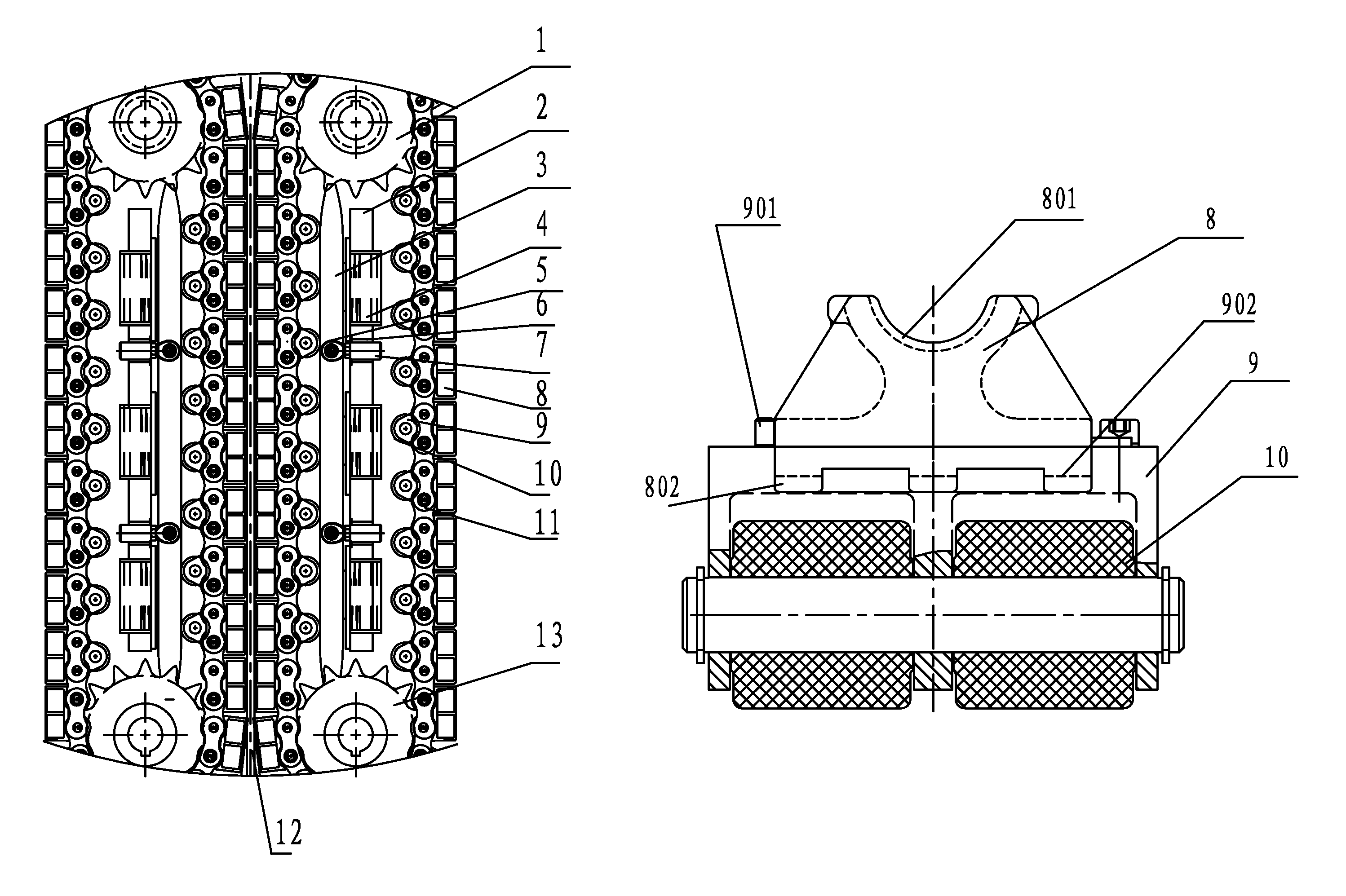

Integrated coiled tubing defect detection device

PendingCN109682881AAccurate defect detectionAccurate detection of wall thicknessElectric/magnetic contours/curvatures measurementsUsing electrical meansCoiled tubingEngineering

The invention provides an integrated coiled tubing defect detection device. The coiled tubing defect detection device comprises an upper half detection unit and a lower half detection unit, and a passage for coiled tubing to pass through is formed between the two detection units after the two detection units are matched and assembled with each other, and internally provided with a magnetism generating device, a magnetism leakage detection probe, an ellipticity detection probe and a guide device which are arranged on the two detection units; a measuring arm assembly kit for guiding the two detection units in moving along the coiled tubing is connected to the outsides of the detection units. The device can achieve real-time and precise detection of the wall thickness, outer diameter, ovalityand various physical defects such as corrosion, cracks, mechanical damage and pitting corrosion of coiled tubing columns.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

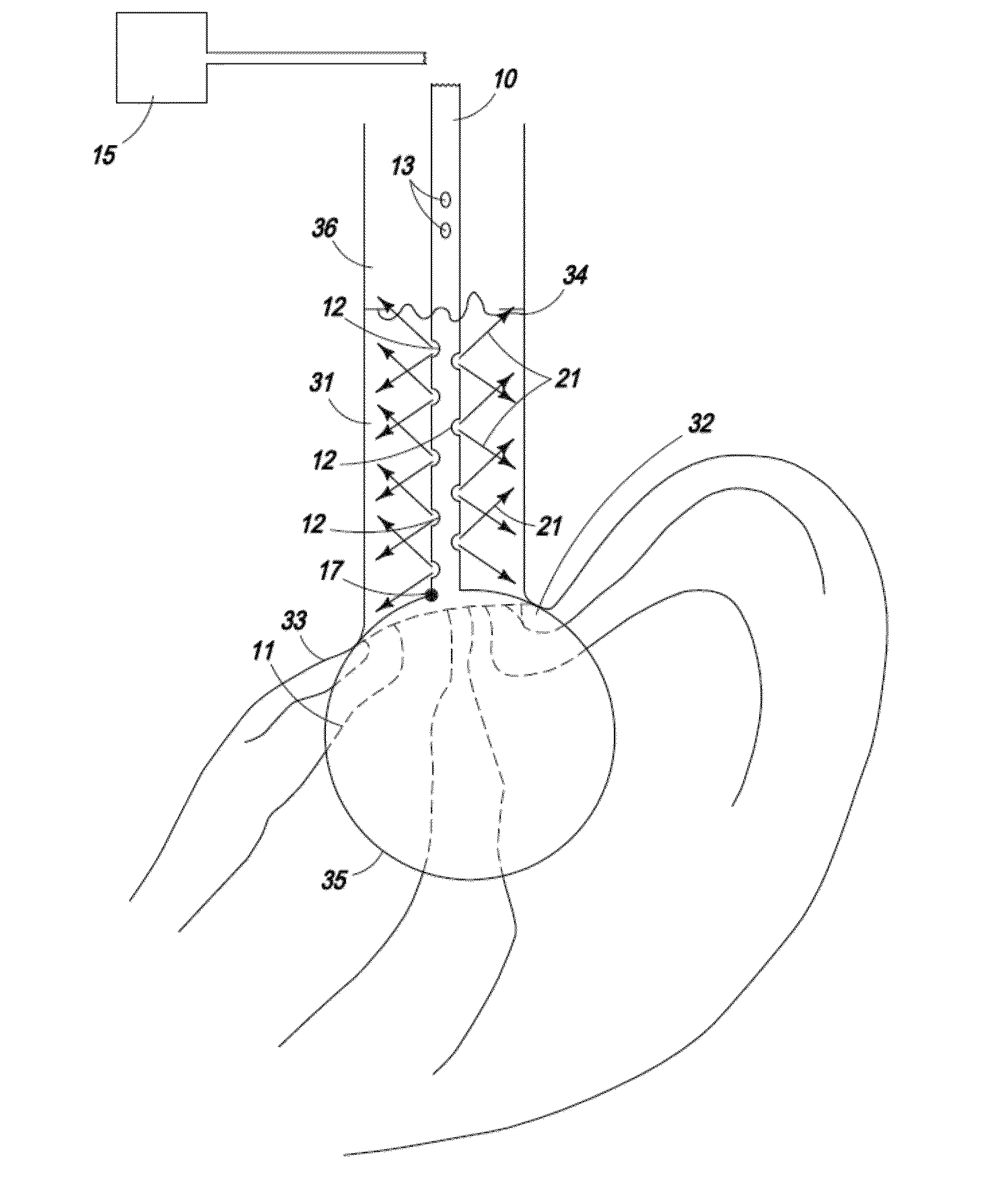

Method and Apparatus for Tissue Ablation

ActiveUS20130006231A1Avoid condensationAvoid heat damageDiagnosticsMedical devicesCoiled tubingCatheter

The present application discloses devices that ablate human tissue. The device comprises a catheter with a shaft through which an ablative agent can travel, a liquid reservoir and a heating component, which may comprise a length of coiled tubing contained within a heating element, wherein activation of said heating element causes said coiled tubing to increase from a first temperature to a second temperature and wherein the increase causes a conversion of liquid within the coiled tubing to vapor, a reusable cord connecting the outlet of the reservoir to the inlet of the heating component, and a single use cord connecting a pressure-resistant inlet port of a vapor based ablation device to the outlet of the heating component.

Owner:SANTA ANNA TECH LLC

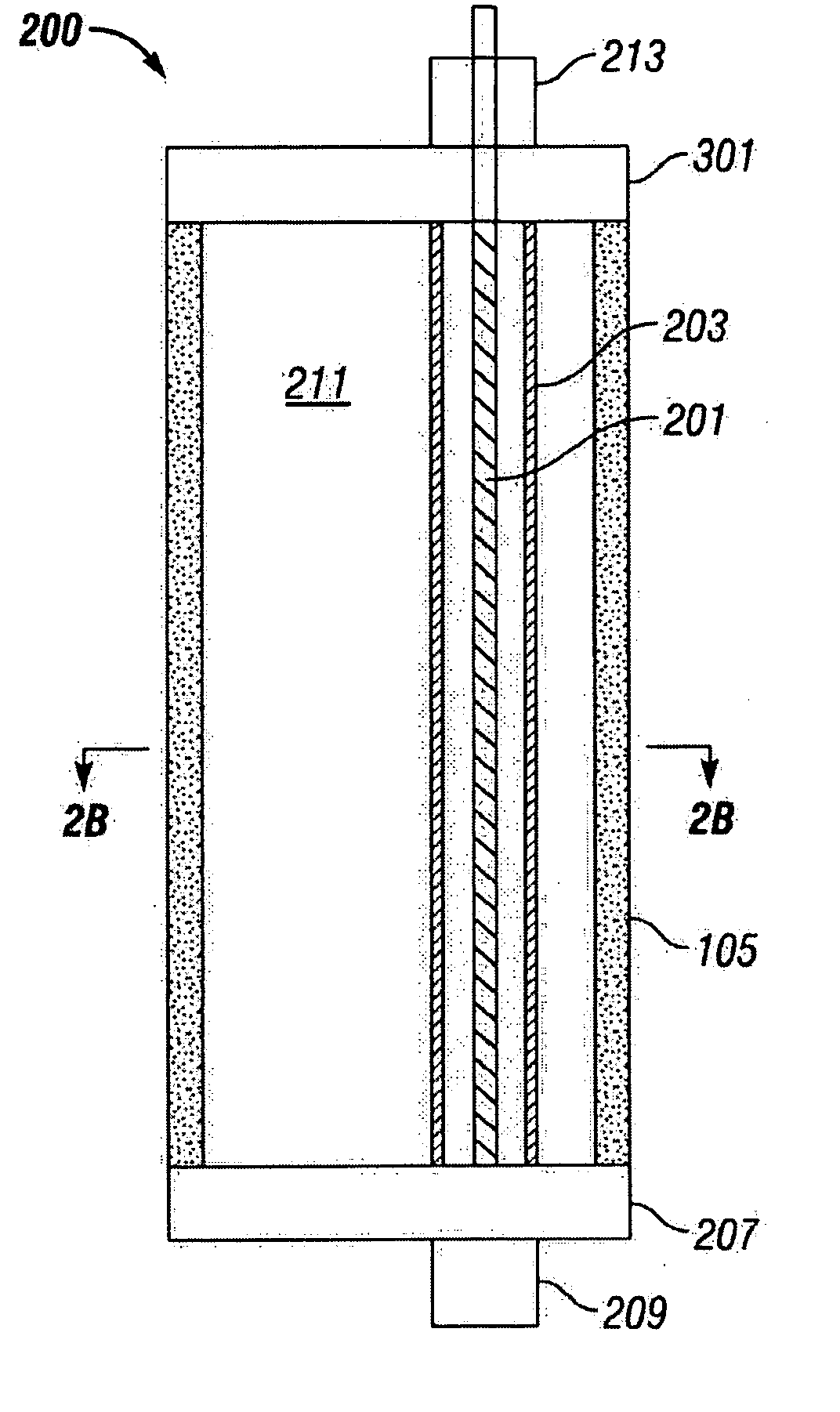

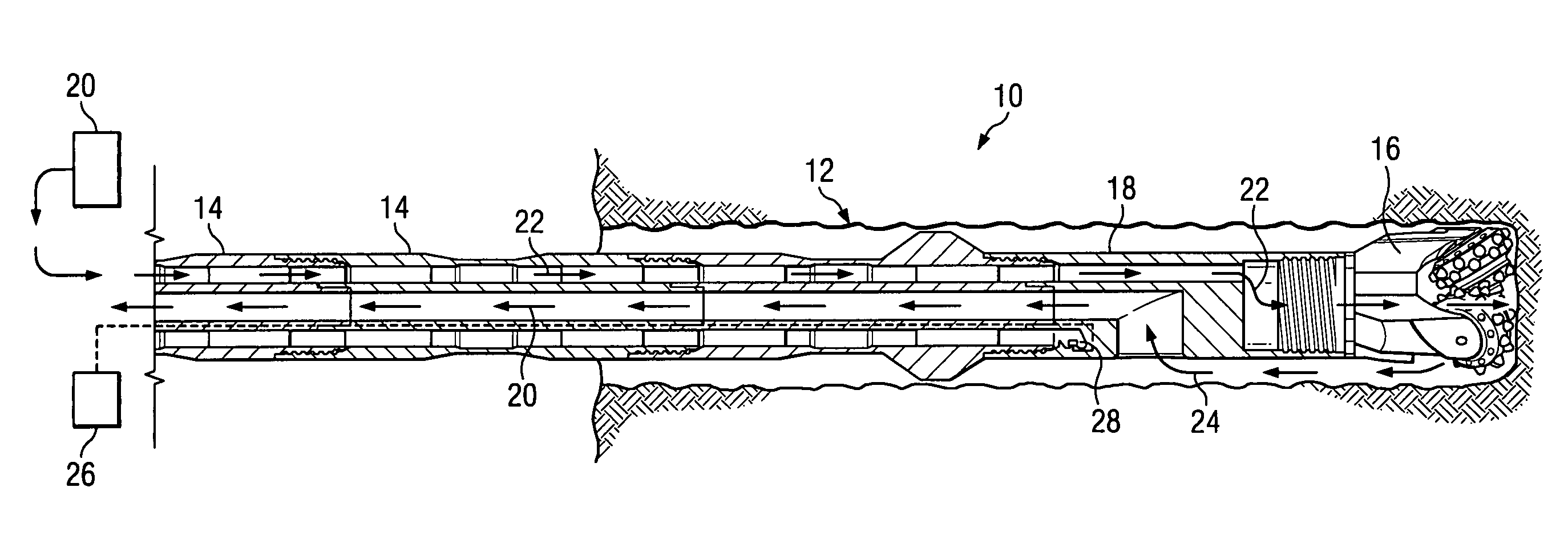

Dual wall drill string assembly

ActiveUS20050103527A1Little and no resistanceIncrease volumeDrilling rodsFlushingCoiled tubingEngineering

A coil tubing or jointed dual wall drill string assembly for subsurface drilling. The drill string assembly includes a metallic outer tube having an outer tube first end and an outer tube second end opposite the outer tube first end. The assembly also includes a flexible, substantially non-metallic inner tube that is substantially enclosed within and generally coaxially aligned with the outer tube. The flexible, substantially non-metallic inner tube has an inner tube first end, an inner tube second end opposite the inner tube first end, and an inner tube inner diameter. The inner tube and the outer tube define an annular channel therebetween. The drill string assembly also includes a means for conveying fluid through the annular channel toward the inner tube first end. The annular channel is adapted to convey drilling fluid under pressure toward the inner tube first end and the inner tube is adapted to convey cuttings toward the inner tube second end.

Owner:AMERICAN AUGERS +1

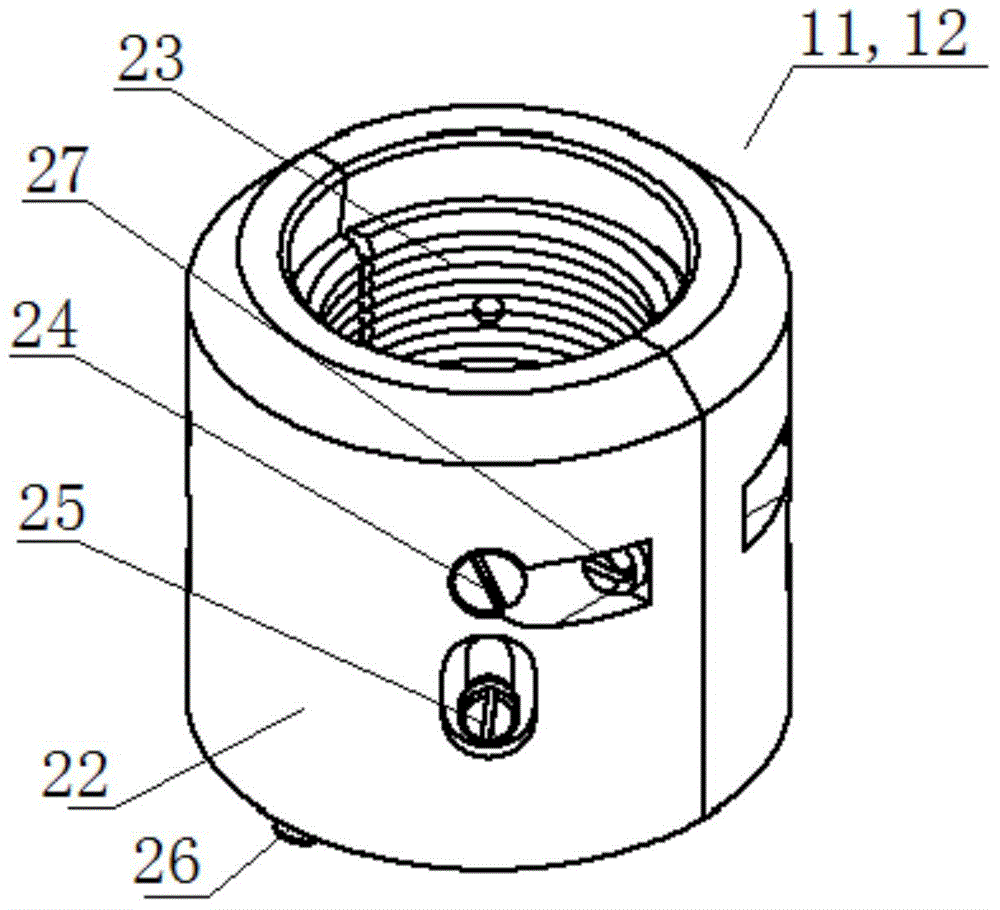

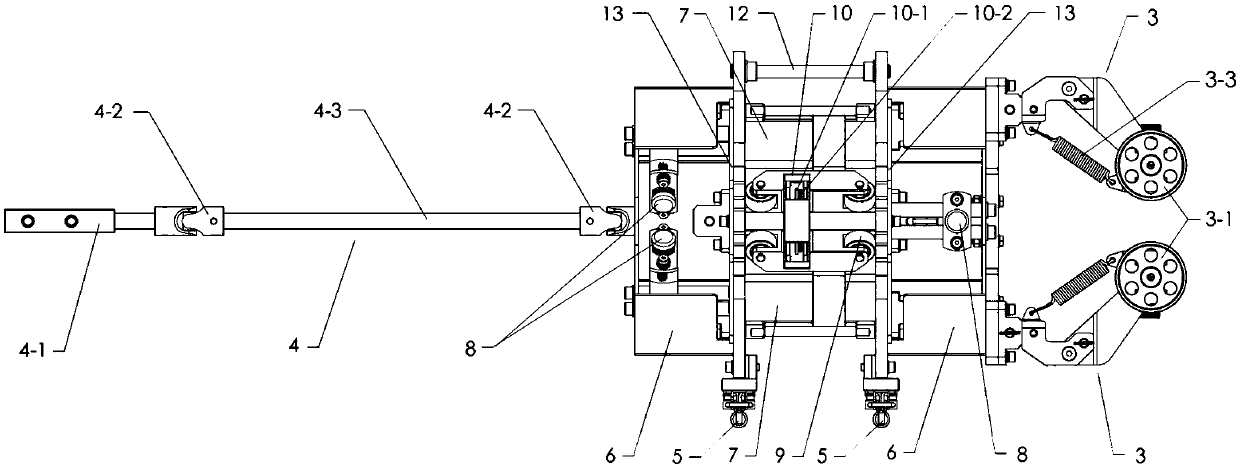

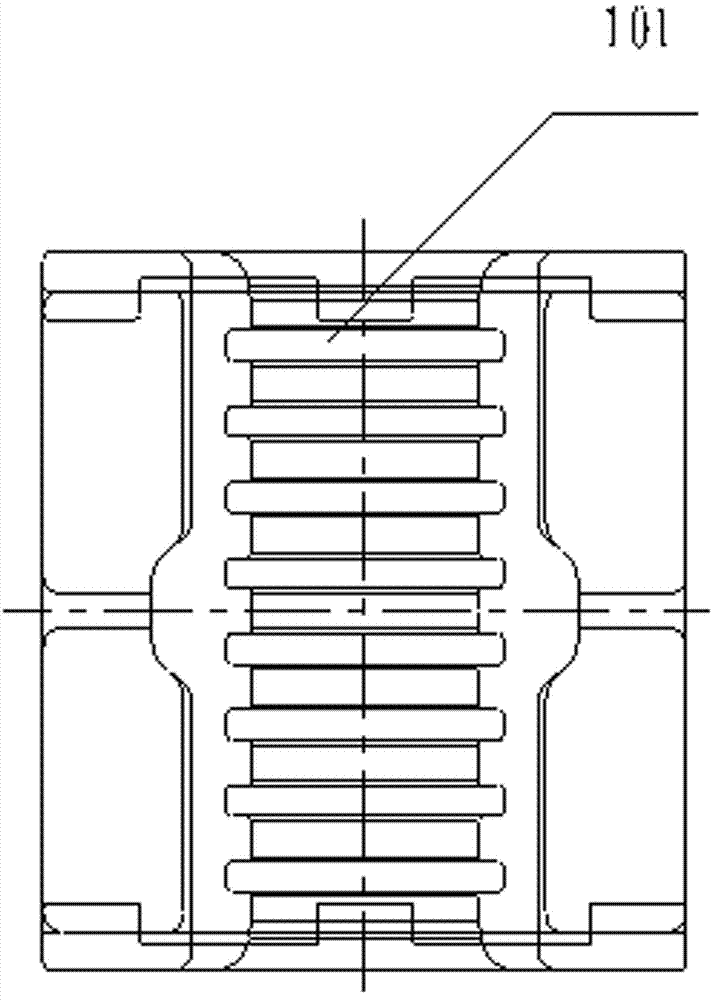

Coiled tubing clamping device and injection head using same

ActiveCN102140898AAvoid hard squeezeNo lubricationDrilling rodsDrilling casingsCoiled tubingOil production

The invention provides a coiled tubing clamping device and an injection head using the clamping device, belonging to the field of oil production and drilling equipment. The clamping device comprises a saddle-type clamping block, a clamping block seat and a gasket, wherein the saddle-type clamping block has a groove on the bottom; at least two pairs of hook blocks are arranged on the sidewall of the groove; the clamping block seat includes a hinge pin and a rolling shaft sleeve sheathed on the hinge pin; a position limiting stage and a bolt hole are arranged on the bottom of the clamping blockseat; bosses corresponding to the hook blocks of the clamping block are arranged on both sides of the bottom of the clamping block seat; and two through holes are formed on the lower part of the clamping block seat along the hinge pin direction. The injection head comprises an oil pipe clamping device and a transmission chain, wherein the oil pipe clamping device is mounted on the transmission chain through two hinge pin holes on the clamping block seat. The injection head is convenient in maintenance and has long service life by using the rolling shaft sleeve to substitute for a bearing. The clamping blocks are convenient in replacement, and have a large floating range so as to reduce the abrasion of the oil pipes during operation.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

Coiled tubing operation equipment simulator

The invention discloses a coiled tubing operation equipment simulator, which comprises a base, a seat which is arranged at the middle part of the rear end of the base, simulation control parts which are arranged on the two sides of the seat, a data acquisition module which is used for receiving control signals of the simulation control parts, a main scene display which is arranged at the front of the seat, an injection head scene display and a downhole scene display which are arranged on the two sides of the main scene display, a computer system which is connected with the displays and the data acquisition module and can display simulated scenes in the displays, a simulation instrument display which is connected with the computer system, and an input device which is used for man-machine interaction. The coiled tubing operation equipment simulator can simulate various operation scenes in the actual working process of coiled tubing operation equipment, realize various simulation operations on the coiled tubing operation equipment and reproduce the actual operation and working process of the real coiled tubing operation equipment.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD +1

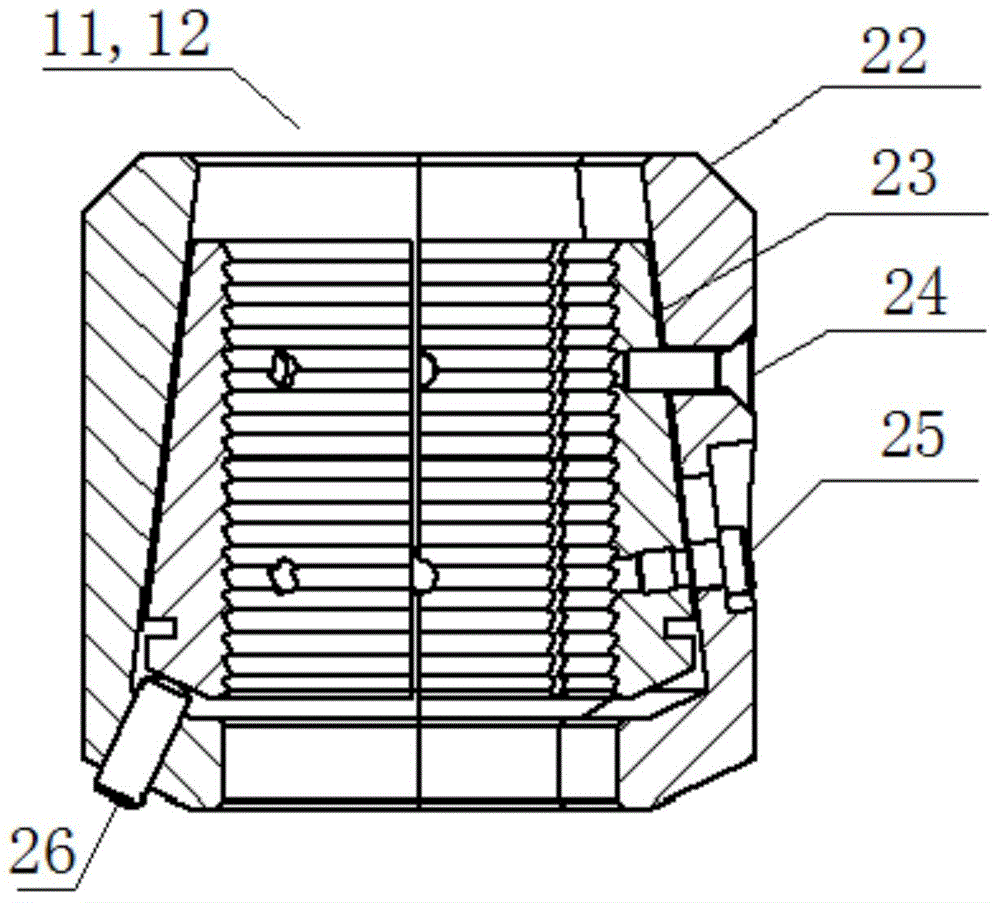

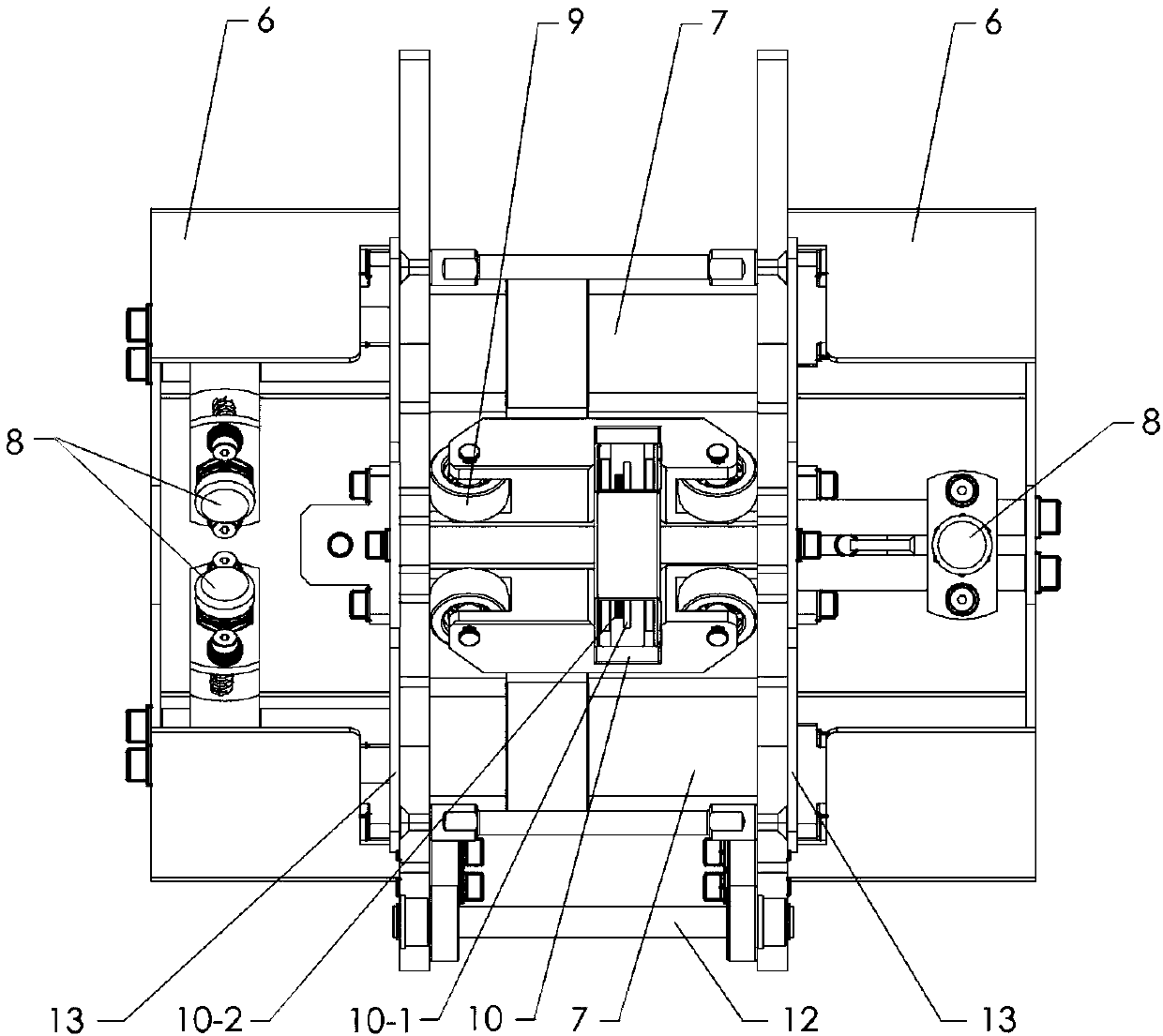

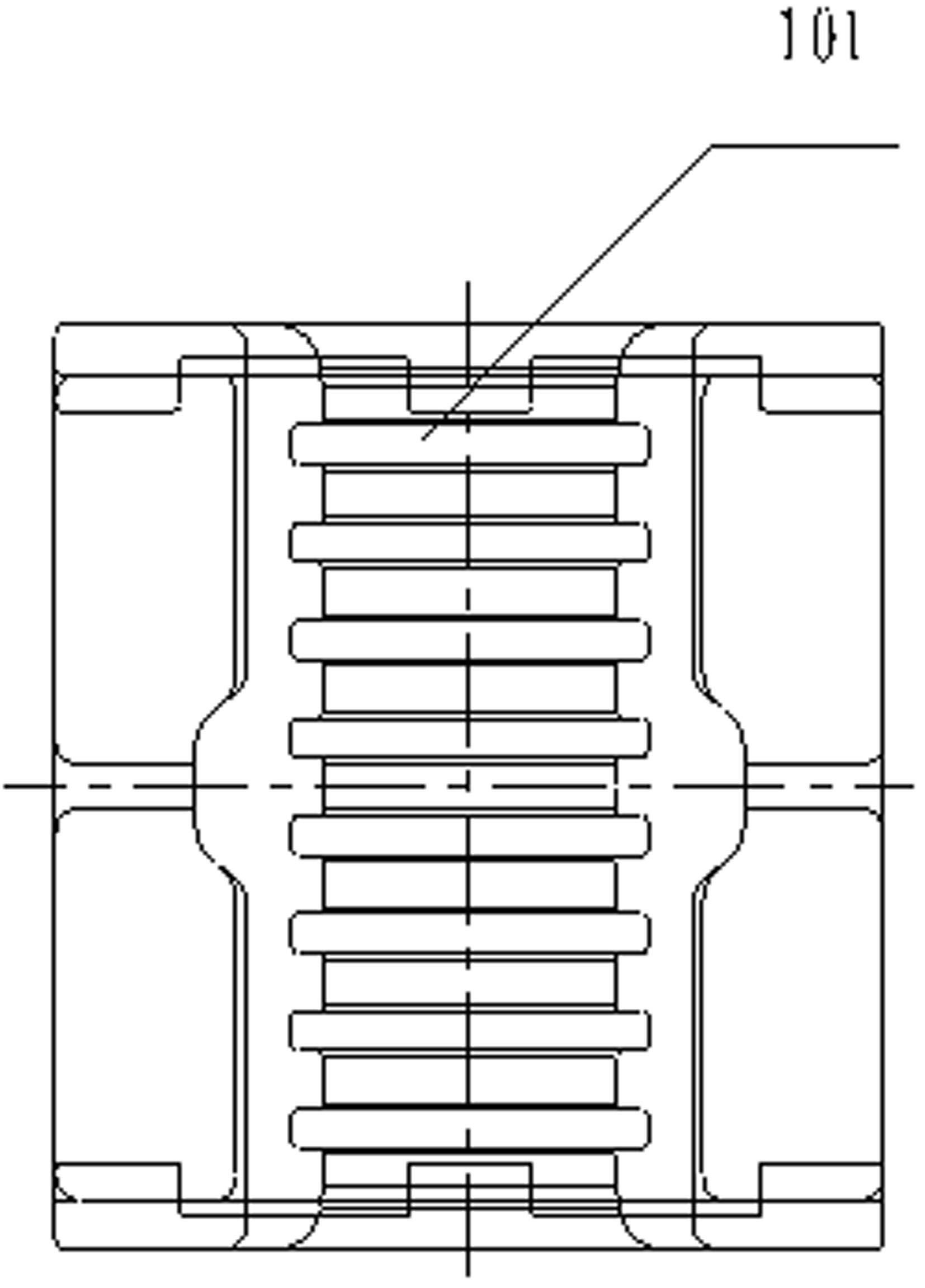

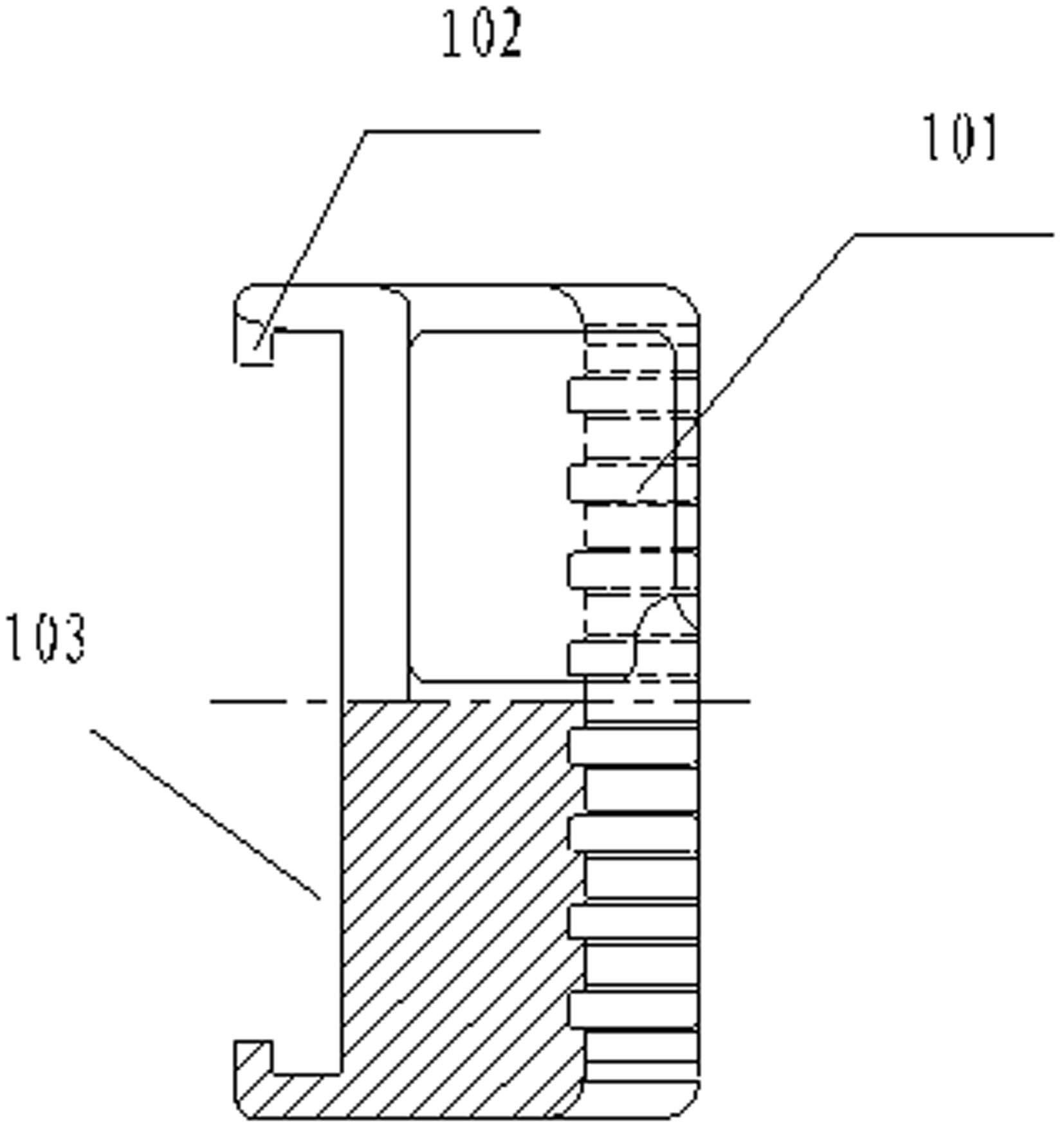

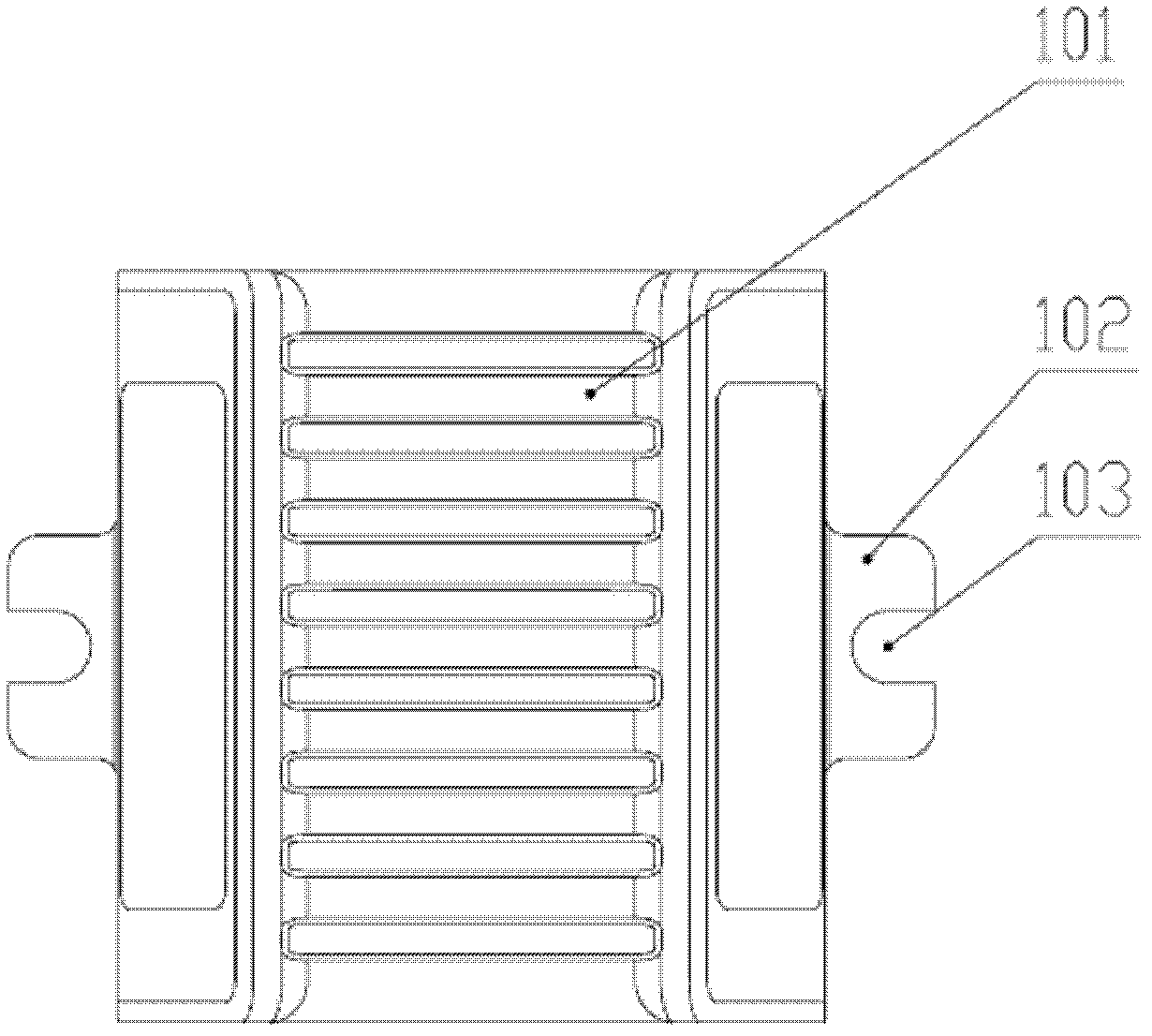

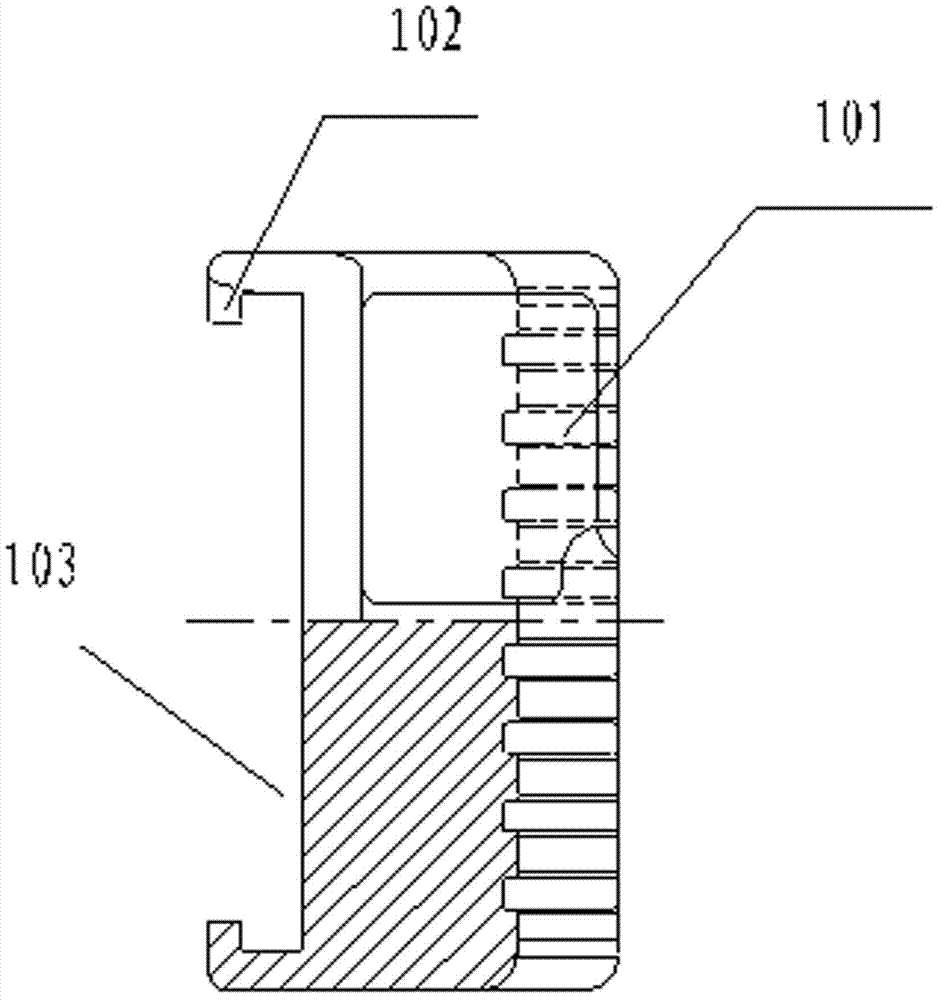

Coiled tubing clamping device and injection head using same

ActiveCN102704870BAvoid wear and tearImprove reliabilityDrilling rodsDrilling casingsCoiled tubingEngineering

A coiled tubing clamping mechanism comprises a saddle-shaped clamping block (1) and a clamping block seat (4). The saddle-shaped clamping block (1) is connected to the clamping block seat (4). Two sides of the saddle-shaped clamping block (1) are provided with a tongue platform (102). The tongue platform (102) is provided with an open hole (103). The back of the saddle-shaped clamping block (1) is provided with a groove (104). Two sides of the clamping block seat (4) are provided with a pair of bosses (406) respectively. The groove (104) of the saddle-shaped clamping block (1) is inserted in a holding slot (405) formed by the bosses (406) of the clamping block seat. A traverse gap is kept between the groove (104) and the holding slot (405). The clamping block seat (4) is provided with a positioning screw (2) for limiting the position of the saddle-shaped clamping block (1). Also disclosed is an injector head using the coiled tubing clamping mechanism, comprising a tubing clamping mechanism (11) and a drive chain (13). The tubing clamping mechanism (11) is mounted on the drive chain (13) through two pin holes (401) in the clamping block seat (4). The present invention can effectively prevent the tubing from being worn, is reliable in use, and makes it convenient to replace the clamping block.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

Coiled tubing clamping device and injection head using same

ActiveCN102140898BEasy to replaceAvoid hard squeezeDrilling rodsDrilling casingsCoiled tubingInjector

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

Well system

InactiveUS20050115741A1Excessive vibrationLow costElectric/magnetic detection for well-loggingDrilling rodsElectrical conductorCoiled tubing

The drilling system includes a work string supporting a bottom hole assembly. The work string including lengths of pipe having a non-metallic portion. The work string preferably includes a composite coiled tubing having a fluid impermeable liner, multiple load carrying layers, and a wear layer. Multiple electrical conductors and data transmission conductors may be embedded in the load carrying layers for carrying current or transmitting data between the bottom hole assembly and the surface. The bottom hole assembly includes a bit, a gamma ray and inclinometer instrument package, a steerable assembly, an electronics section, a transmission, and a power section for rotating the bit. It may or may not include a propulsion system. The drilling system may be a gravity based drilling system that does include a propulsion system. Various motive means may be provided, such as gravity, to apply weight on the bit.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com