Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A technology of layered fracturing and construction methods, which is applied in the direction of fluid production, earthwork drilling, wellbore/well components, etc., and can solve problems such as increased workload, difficulty in opening and closing sliding sleeves, and inability to guarantee the full diameter of the wellbore. , to achieve the effect of shortening the construction period and improving operation efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

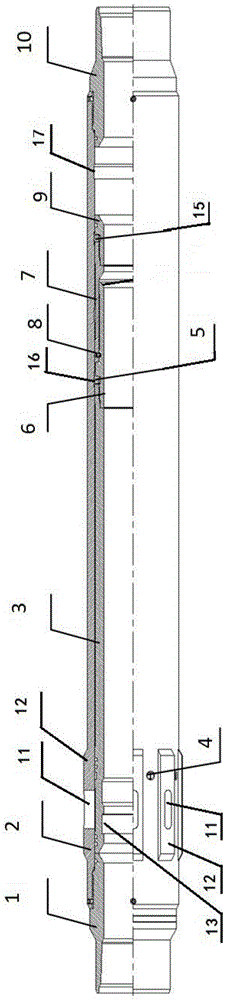

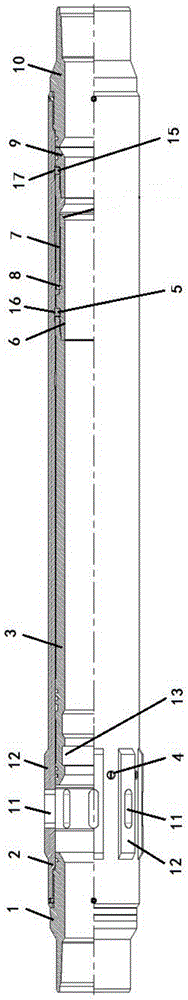

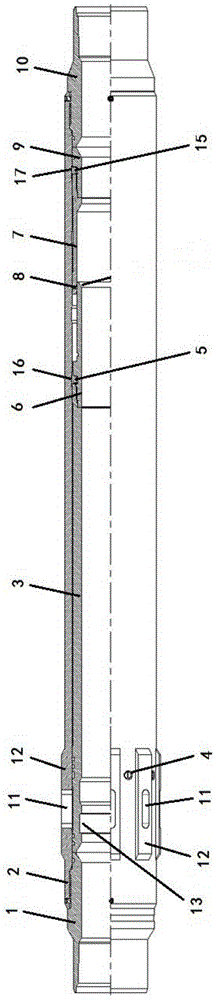

[0048] The switchable layered fracturing cementing sliding sleeve of the present invention, such as Figures 1 to 3 As shown, an outer cylinder 2 is included, and an upper joint 1 and a lower joint 10 are installed on the upper end and the lower end of the outer cylinder 2 respectively.

[0049] There are fracturing openings 11 on the upper side wall of the outer cylinder 2, and protrusions 12 are arranged on the upper outer wall of the outer cylinder 2. There are a plurality of protrusions 12 along the outer wall of the outer cylinder 2, and the fracturing openings 11 are located on the corresponding protrusions. 12, the fracturing port 11 is full of sealing grease to prevent cement from entering and blocking the fracturing port 11.

[0050] An upper central tube 3 , an upper connecting sleeve 6 , a lower central tube 7 and a lower connecting sleeve 9 are installed in the outer cylinder 2 .

[0051] The upper end of the upper central tube 3 is in contact with the upper joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com