Low Density Microbubble Workover Fluid

A workover fluid and low-density technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of solid-phase particles blocking downhole tools, poor stability of ordinary foam, inconvenient use on site, etc., and achieve good flowback ability, plugging ability, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of low-density microbubble workover fluid of the present invention comprises the following steps:

[0026] On-site preparation method:

[0027] Taking 200 parts of clear water as an example, 200 parts of clear water can represent 20 tons of clear water in actual production. First, add 200 parts of clean water to a 30-square-meter liquid mixing tank with a stirrer. It is best to adjust the liquid level of the clean water base liquid in the liquid mixing tank to the vicinity of the stirring blade to fully exert the stirring effect of the stirrer, thereby increasing the stirring force , followed by circulating 200 parts of clear water in the liquid mixing tank through the feeding funnel, and slowly adding 3 parts of hydroxypropyl starch ether into the feeding funnel, stirring for 10 minutes; then slowly and uniformly adding 1.2 parts of xanthan gum, and simultaneously adding 0.6 parts of dodecane Sodium sulfate, 0.4 parts of sodium dodecylbenzenesul...

example 1

[0031] Example 1: Take 300 parts of clear water as an example in the laboratory, first in a beaker with a volume of 500 milliliters, measure 300 parts of clear water with a graduated cylinder as base liquid, add 5.43 parts of hydroxypropyl starch ether earlier, and stir at high speed for 10 minutes; Slowly and evenly add (while stirring, add) 1.98 parts of xanthan gum, stir at high speed for 20 minutes; after stirring for 20 minutes, add 2.58 parts of sodium dodecyl sulfate and 2.58 parts of sodium dodecylbenzenesulfonate at the same time, stir at high speed 10-15 minutes; add 1.98 parts of thiourea and stir for 5-10 minutes, add 3 parts of potassium chloride and stir for 5 minutes to prepare the finished product.

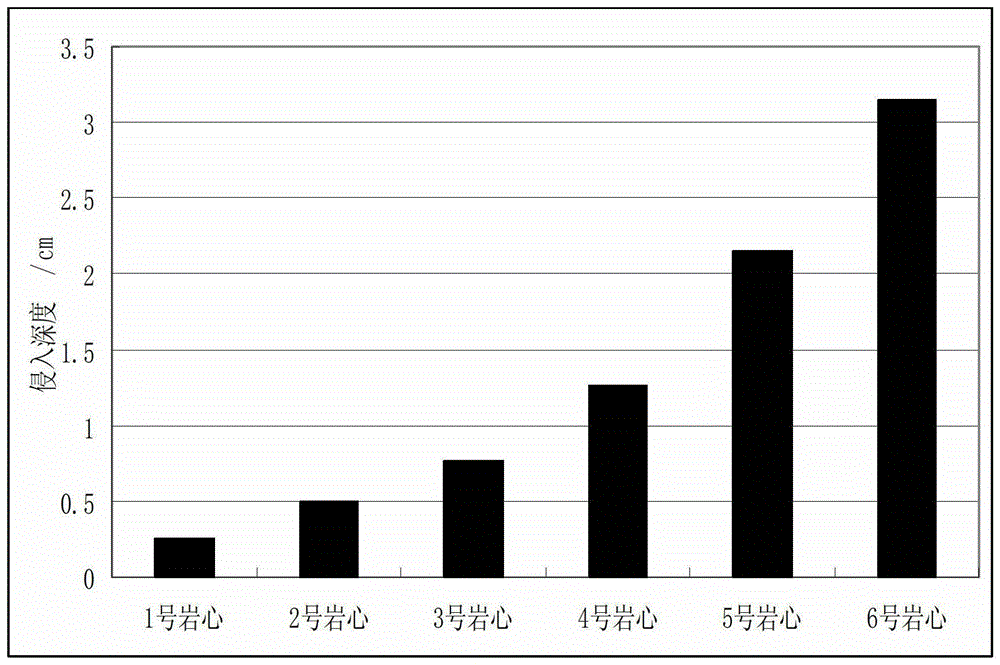

[0032] The low-density micro-bubble workover fluid of the present invention has a temperature resistance of 110 degrees. figure 1 , the density is 0.85, see Table 1, the API filter loss is only 10.3ml / 30min, see Table 1, the high temperature and high pressure filte...

example 2

[0042] Example 2: Take 200 parts of clear water as an example in the laboratory, first in a beaker with a volume of 500 milliliters, measure 200 parts of clear water with a graduated cylinder as base liquid, add 2.32 parts of hydroxypropyl starch ether earlier, and stir at high speed for 10 minutes; Slowly and evenly add (while stirring, adding) 0.9 parts of xanthan gum, stir at high speed for 20 minutes; after stirring for 20 minutes, add 0.5 parts of sodium dodecyl sulfate and 0.5 parts of sodium dodecylbenzenesulfonate at the same time, stir at high speed 10-15 minutes; add 0.62 parts of thiourea and stir for 5-10 minutes, add 4 parts of potassium chloride and stir for 5 minutes to prepare the finished product.

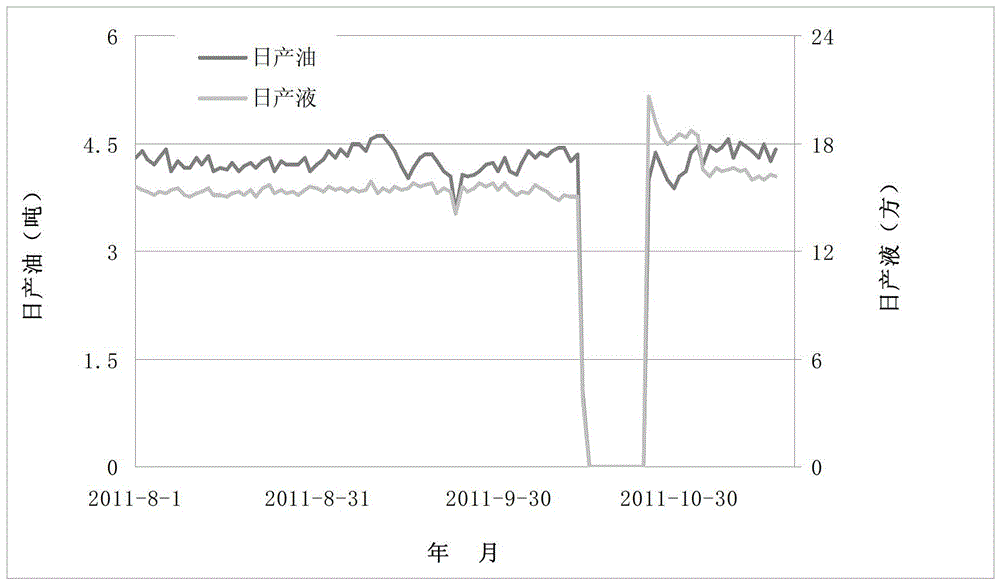

[0043] The core permeability recovery rate of the low-density microbubble workover fluid of the present invention is above 89%, as shown in Table 6, and the oil-water interfacial tension is only 0.1076mN / m, as shown in Table 5, and has excellent oil layer protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com