Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5032 results about "Liquid gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquefied gas (sometimes referred to as liquid gas) is a gas that has been turned into a liquid by cooling or compressing it. Examples of liquefied gases include liquid air, liquefied natural gas, and liquefied petroleum gas.

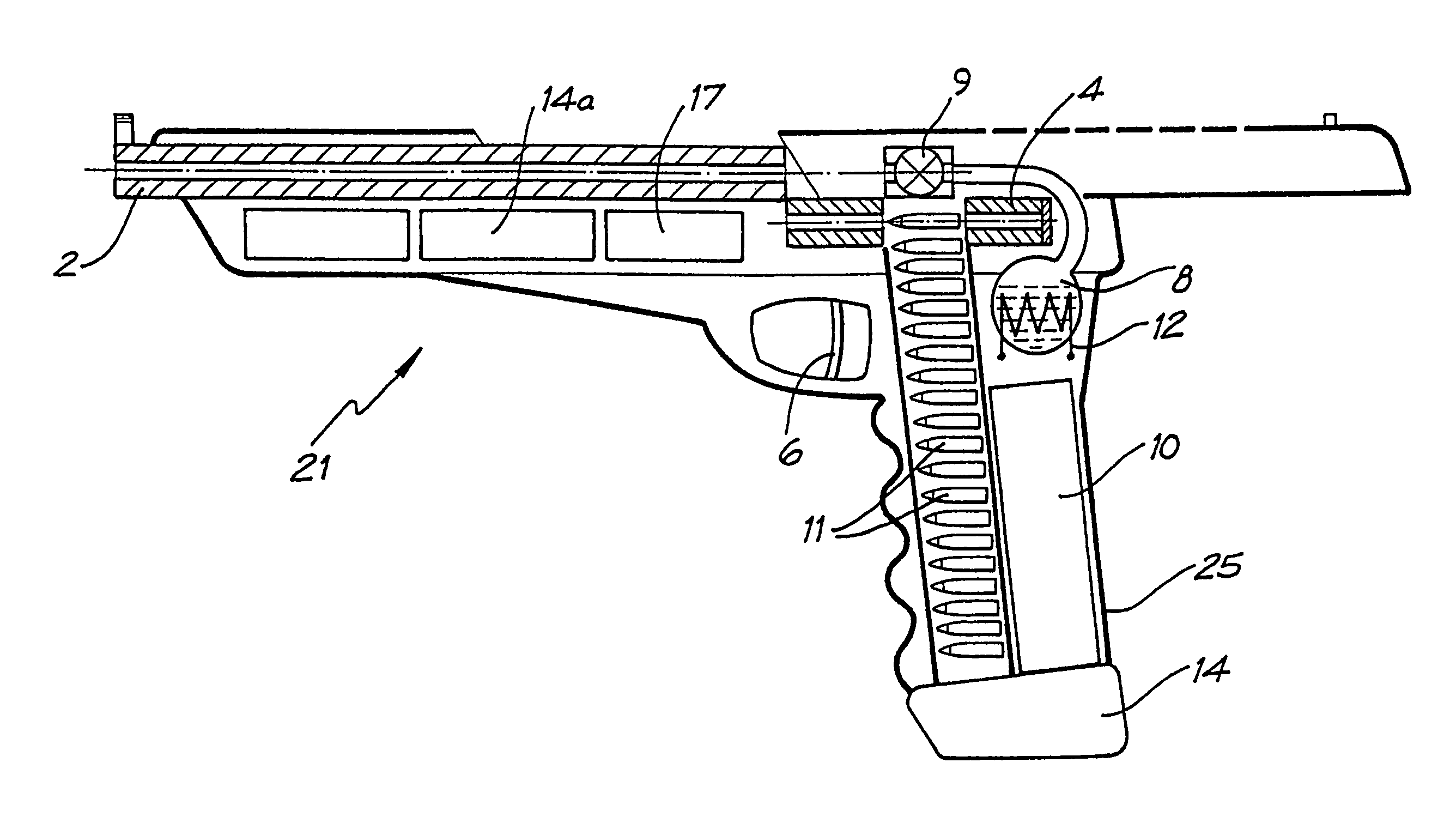

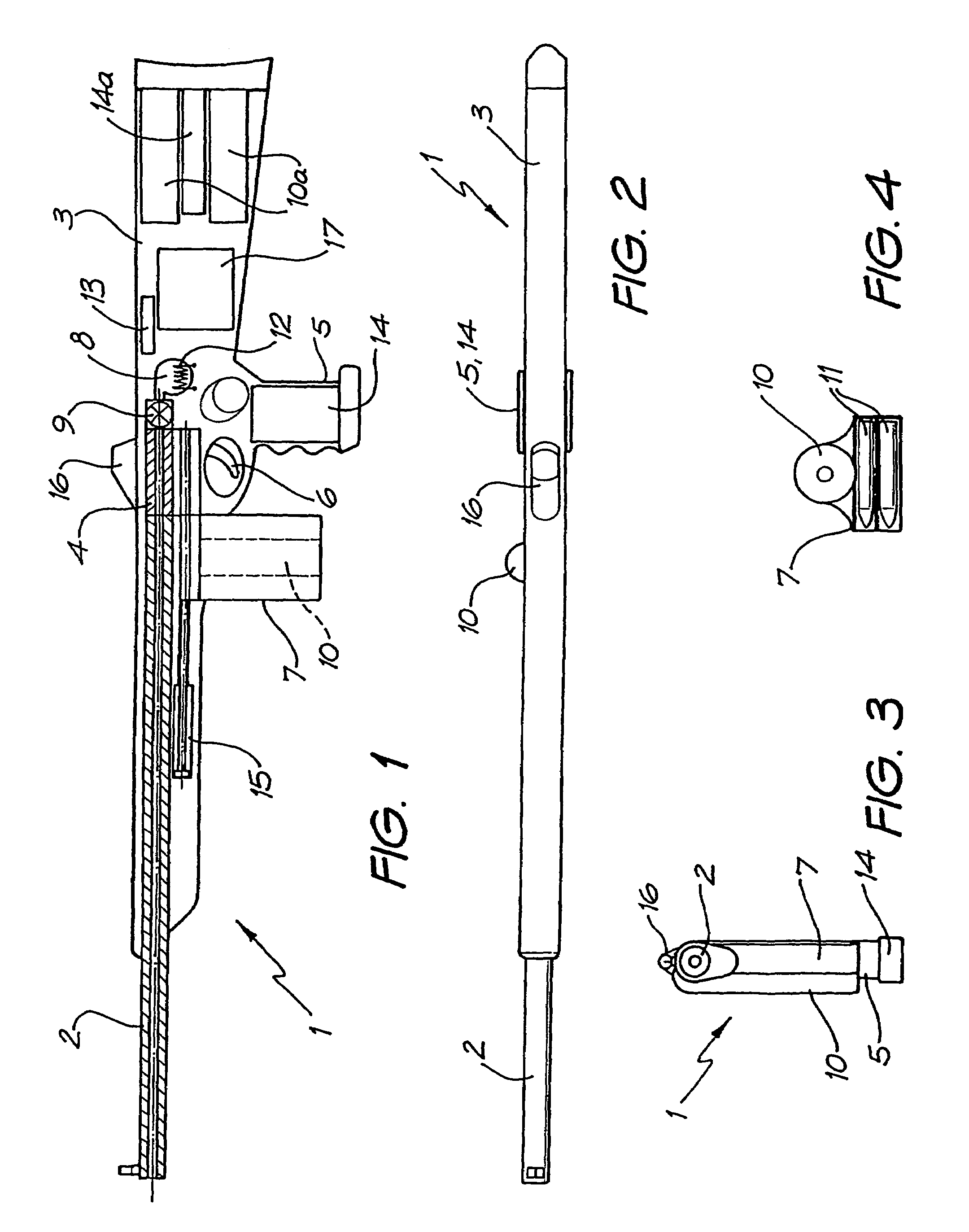

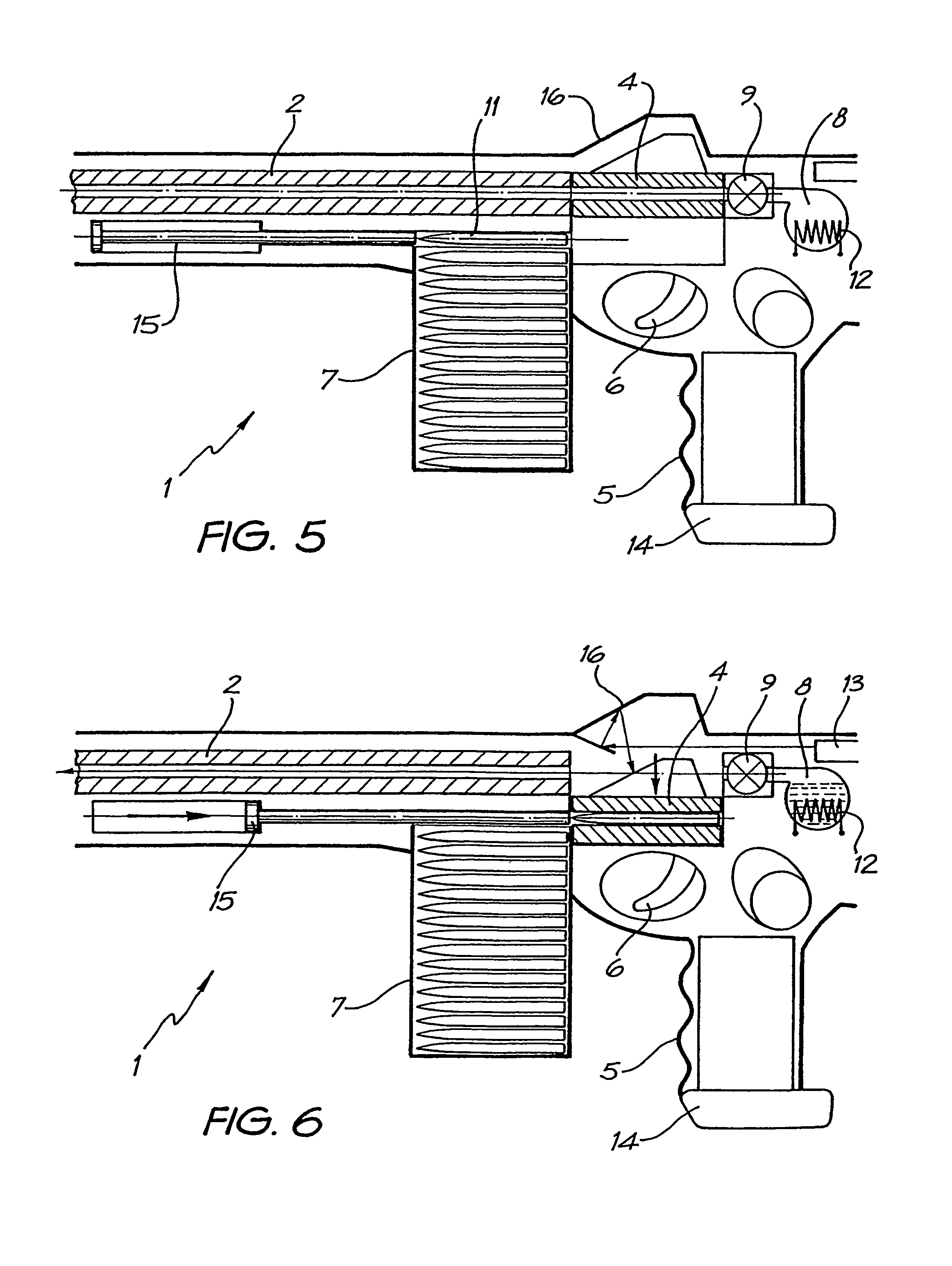

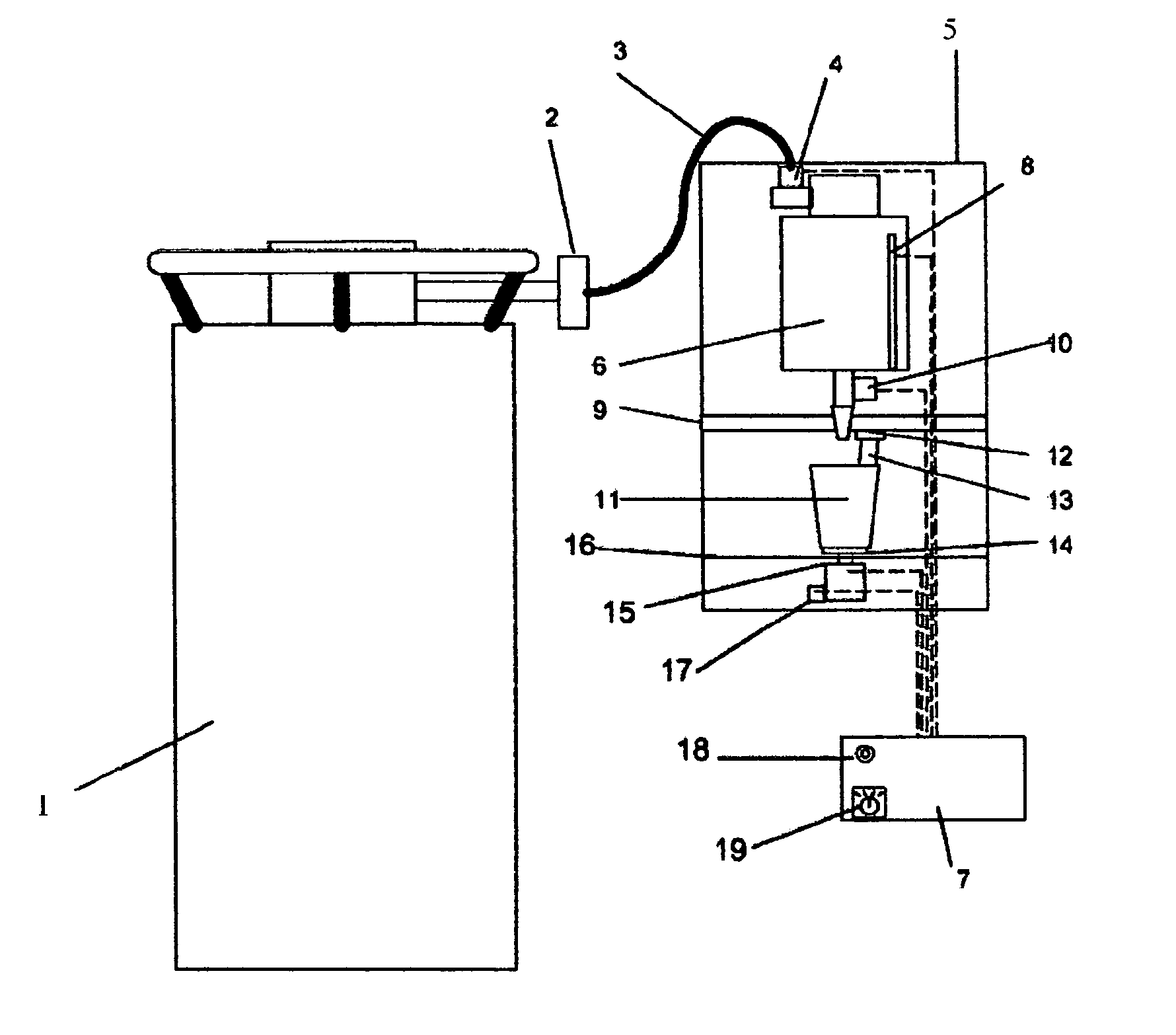

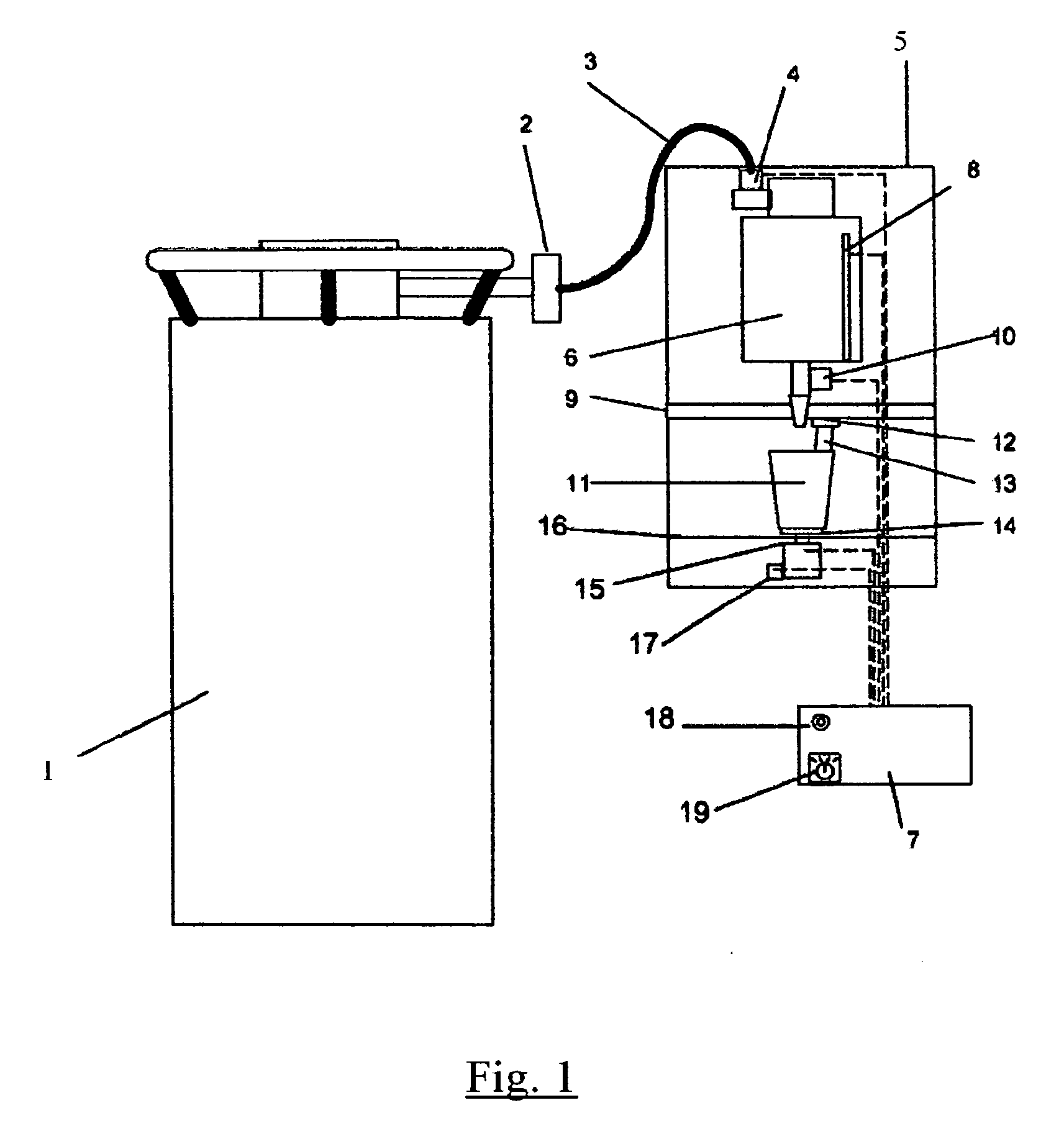

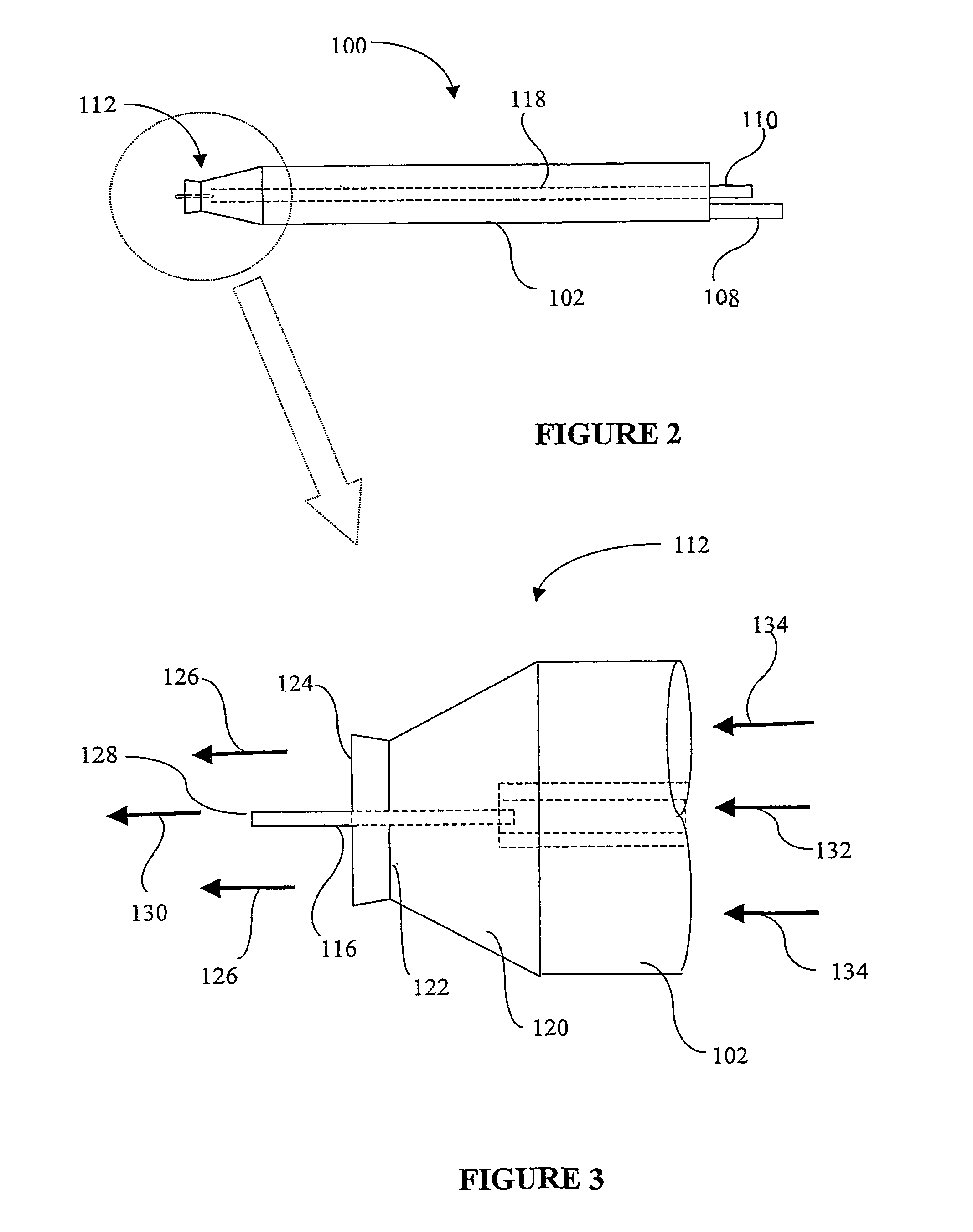

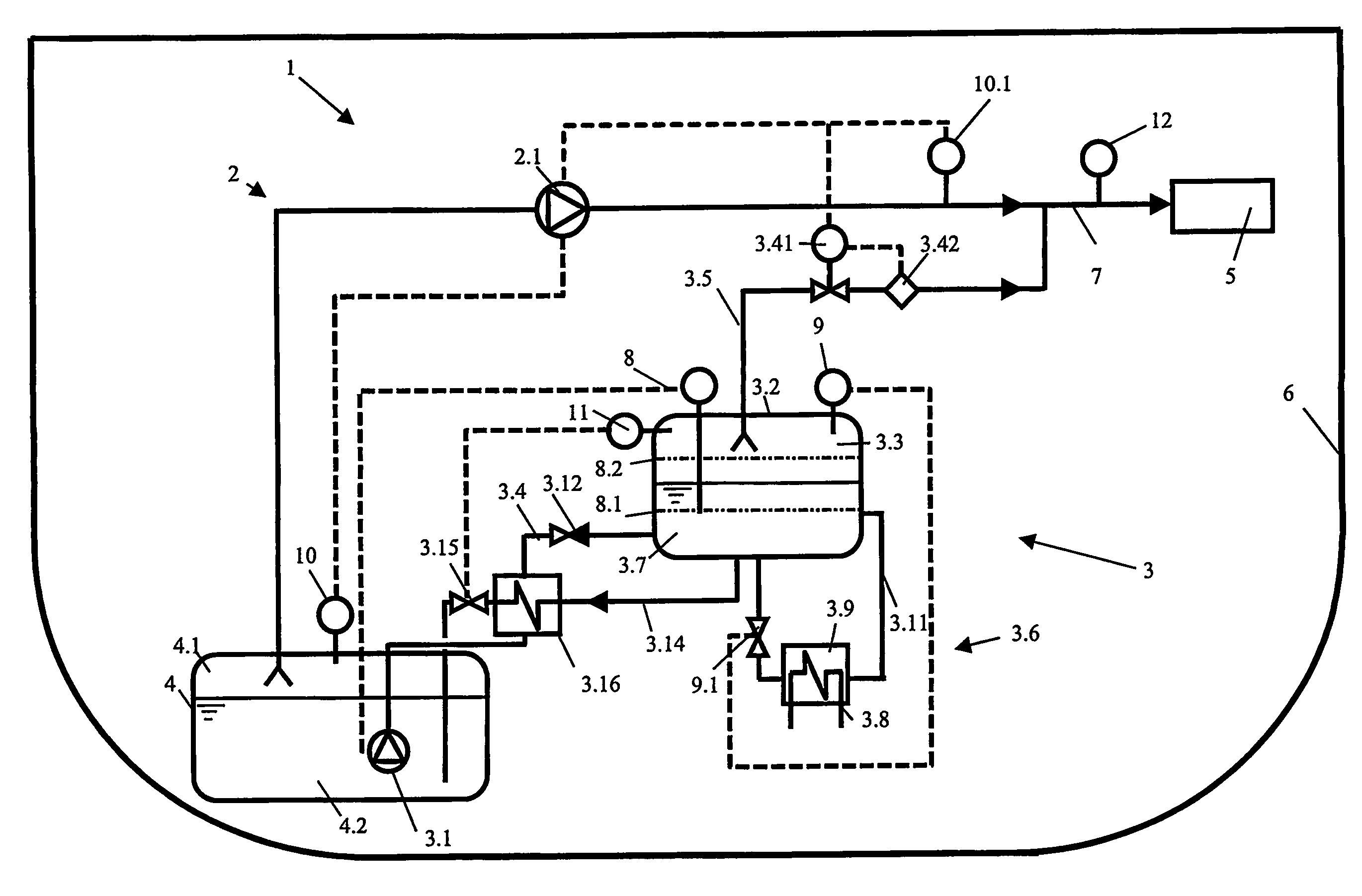

Projectile firing device using liquified gas propellant

Rifle (1) comprises barrel (2) and loading means (15) for introducing a projectile from magazine (7) into breech (4). The projectile is propelled by a compressed gas propellant initially stored as a liquid in canister (10). The liquid is heated to a super critical state in chamber (8) by heating element (12) to induce a phase change such that the liquid becomes a highly dense gas. The phase change from liquid to gas provides the energy required to expel the projectile at high velocity from rifle (1), regardless of the ambient temperature. The propellant is preferably CO2 which is heated to 31.06° C. Rifle (1) produces minimal noise and no heat signature, making it suitable for military and stealth purposes. A pistol and launchers for grenades or mortar bombs are also disclosed. Another version can launch low earth orbit satellites or payloads.

Owner:POLY SYST PTY LTD

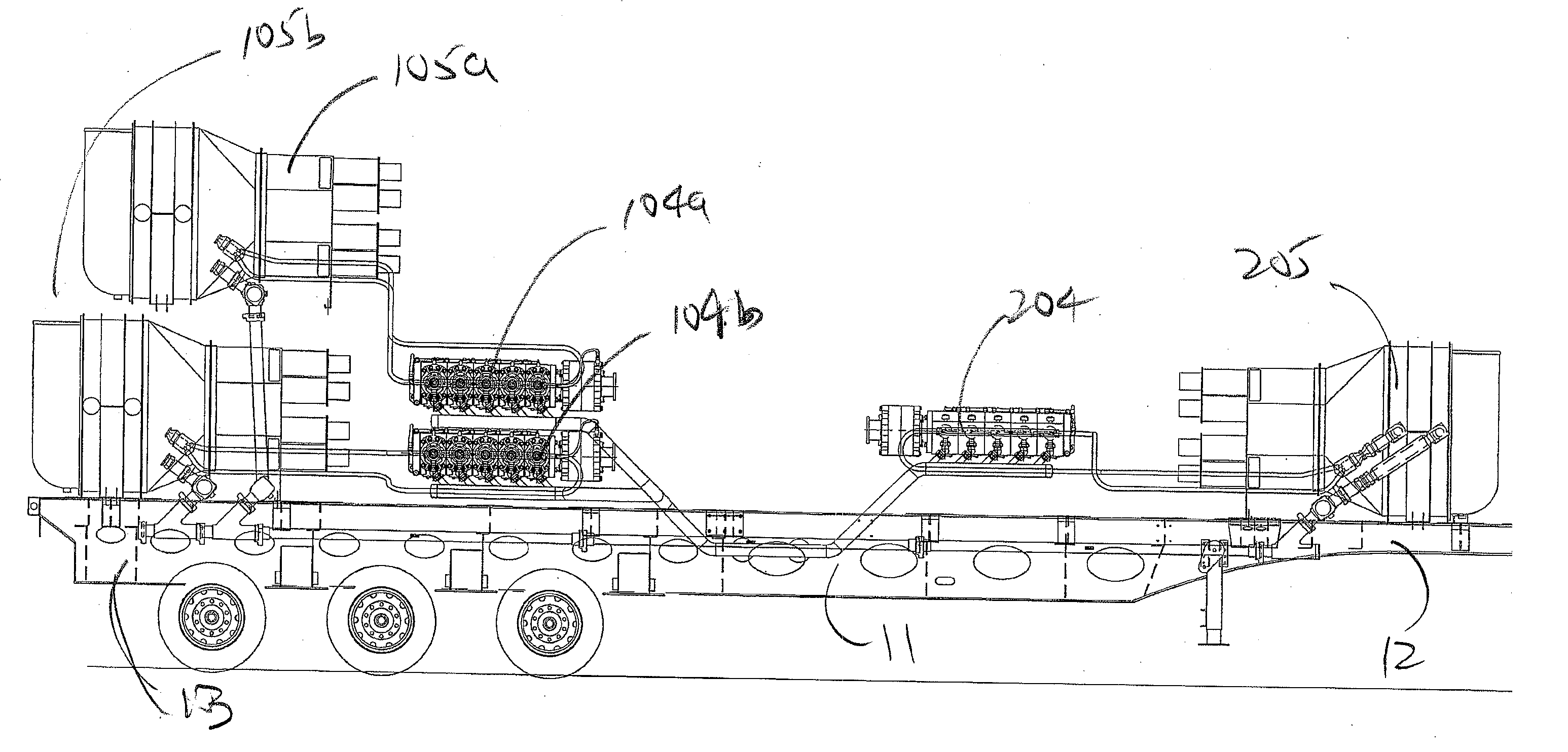

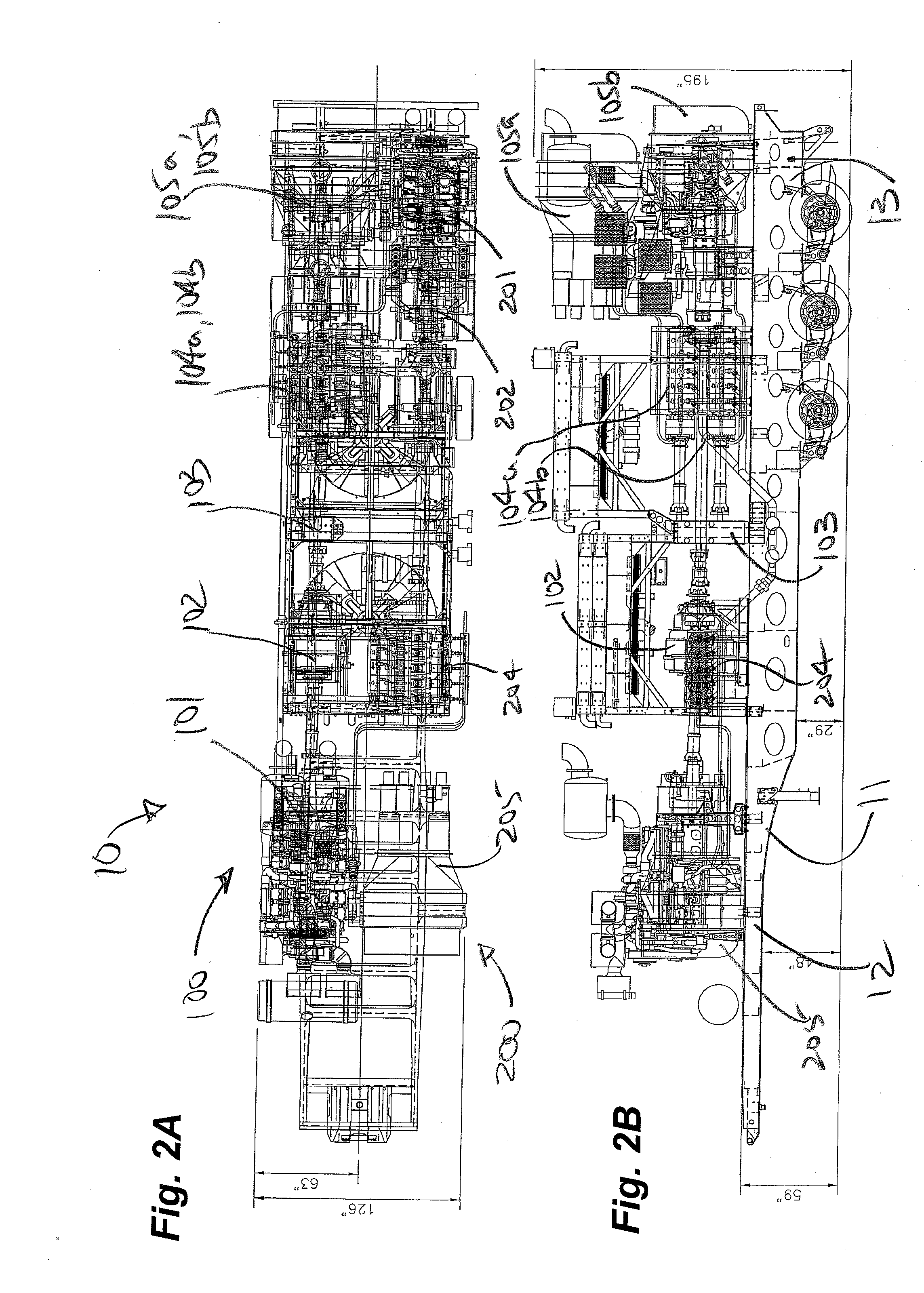

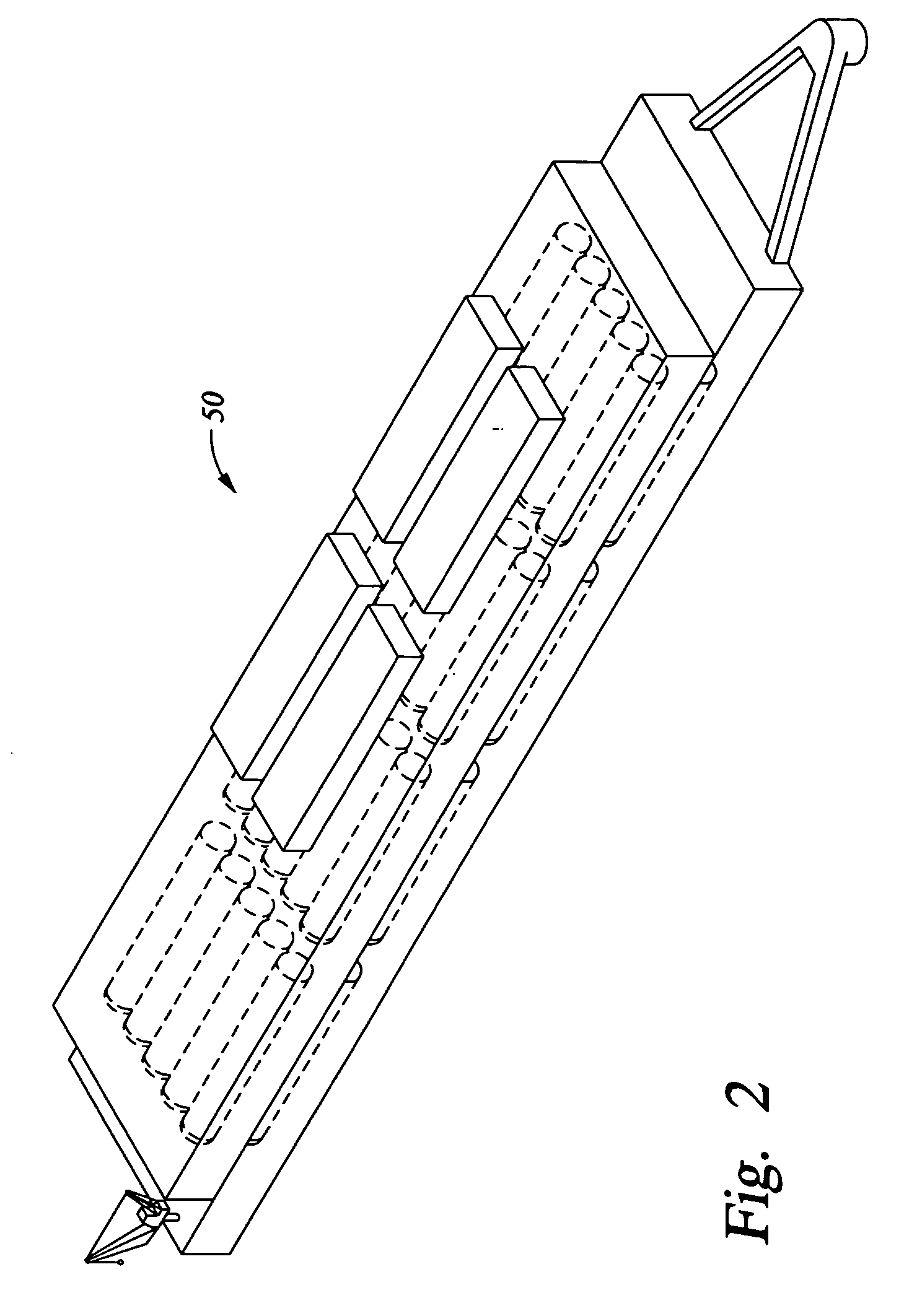

Transportable pumping unit and method of fracturing formations

InactiveUS20060260331A1Increase chanceReduced operating requirementsNon-pressured vesselsPumpsCombustorControl system

A high capacity pumper for liquefied gas incorporates multiple pumping systems distributed in a parallel arrangement and in opposing orientation on a transportable platform such as a trailer. Vaporizers incorporate a burner control system utilizing a primary set of burners operating a baseline and a secondary set of burners providing fine regulating control. A system for fracturing formations is now possible using a minimum number of components including the high capacity pumper, a coiled tubing rig and a source of liquefied gas. An improved manifold for a cryogenic plunger pump includes unions and angled connectors between a supply conduit and each of a plurality of pump heads.

Owner:CENTURY OILFIELD SERVICES

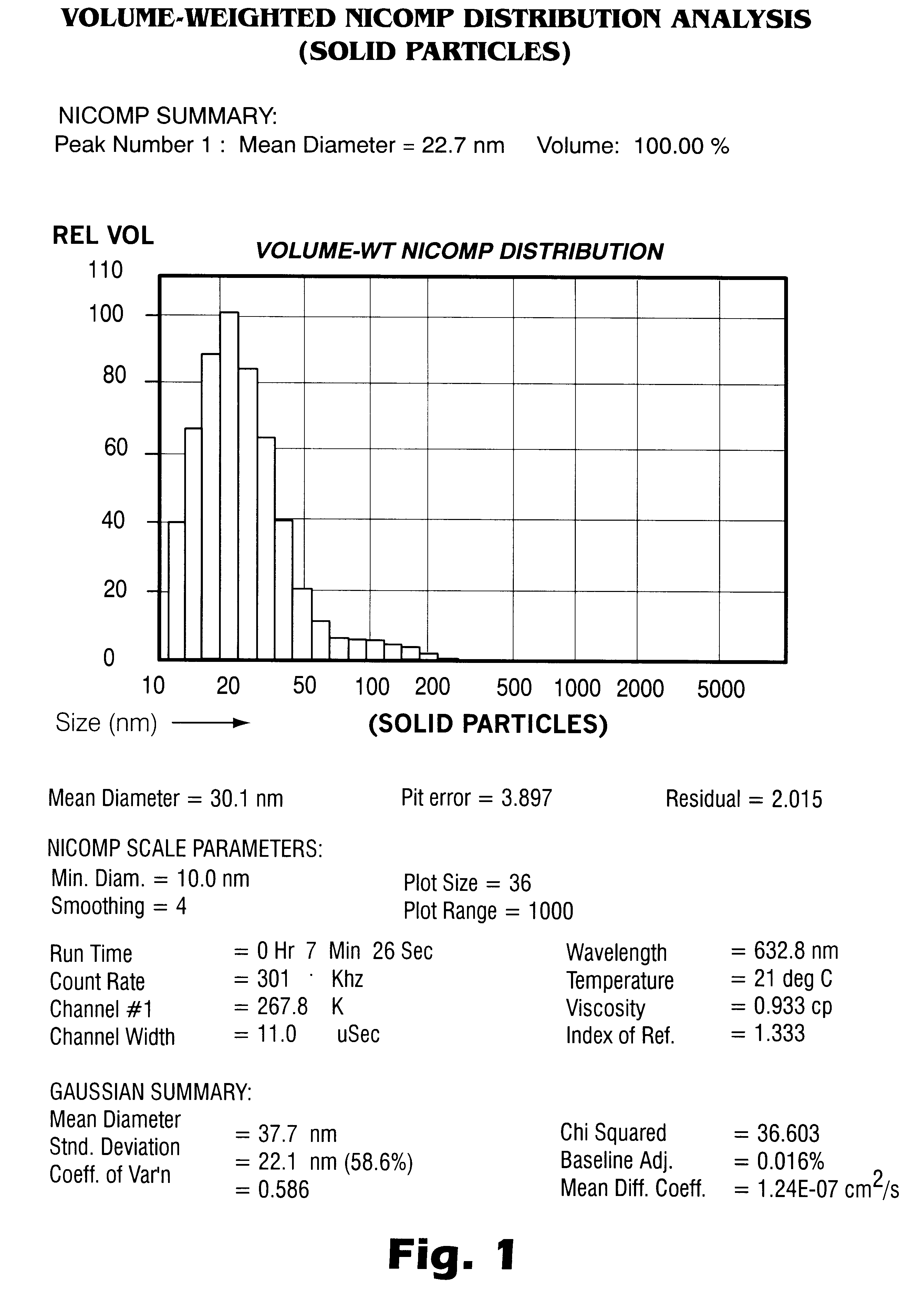

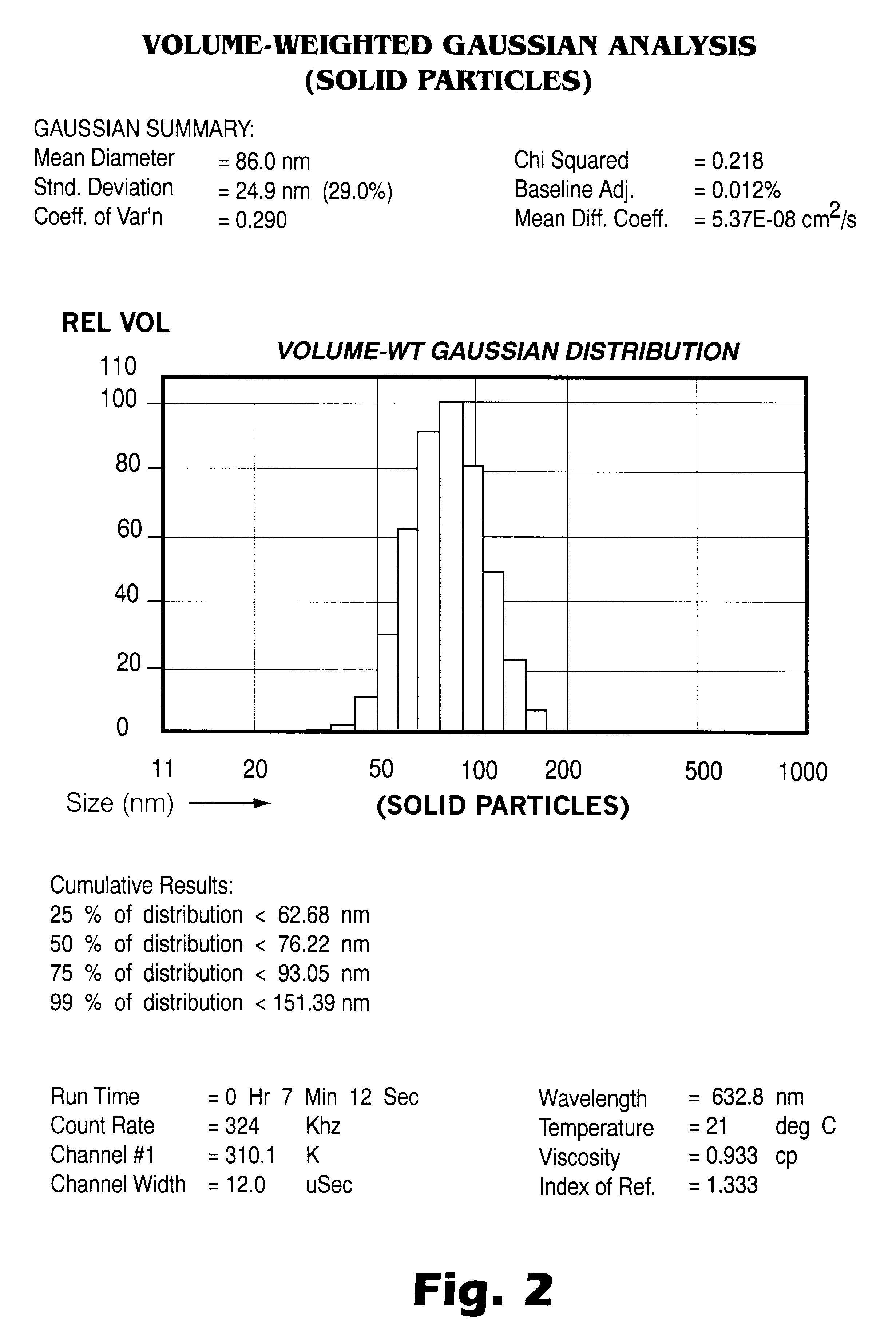

Processes to generate submicron particles of water-insoluble compounds

InactiveUS6177103B1Rapid of surface stabilizedRapid attainmentOrganic active ingredientsPowder deliveryWater insolubleChemical compound

Submicron particles of water-insoluble compounds, particularly drugs, are prepared by simultaneously stabilizing microparticulate suspensions of same with surface modifier molecules by rapid expansion into an aqueous medium from a compressed solution of the compound and surface modifiers in a liquefied gas and optionally homogenizing the aqueous suspension thus formed with a high pressure homogenizer.

Owner:JAGOTEC AG +1

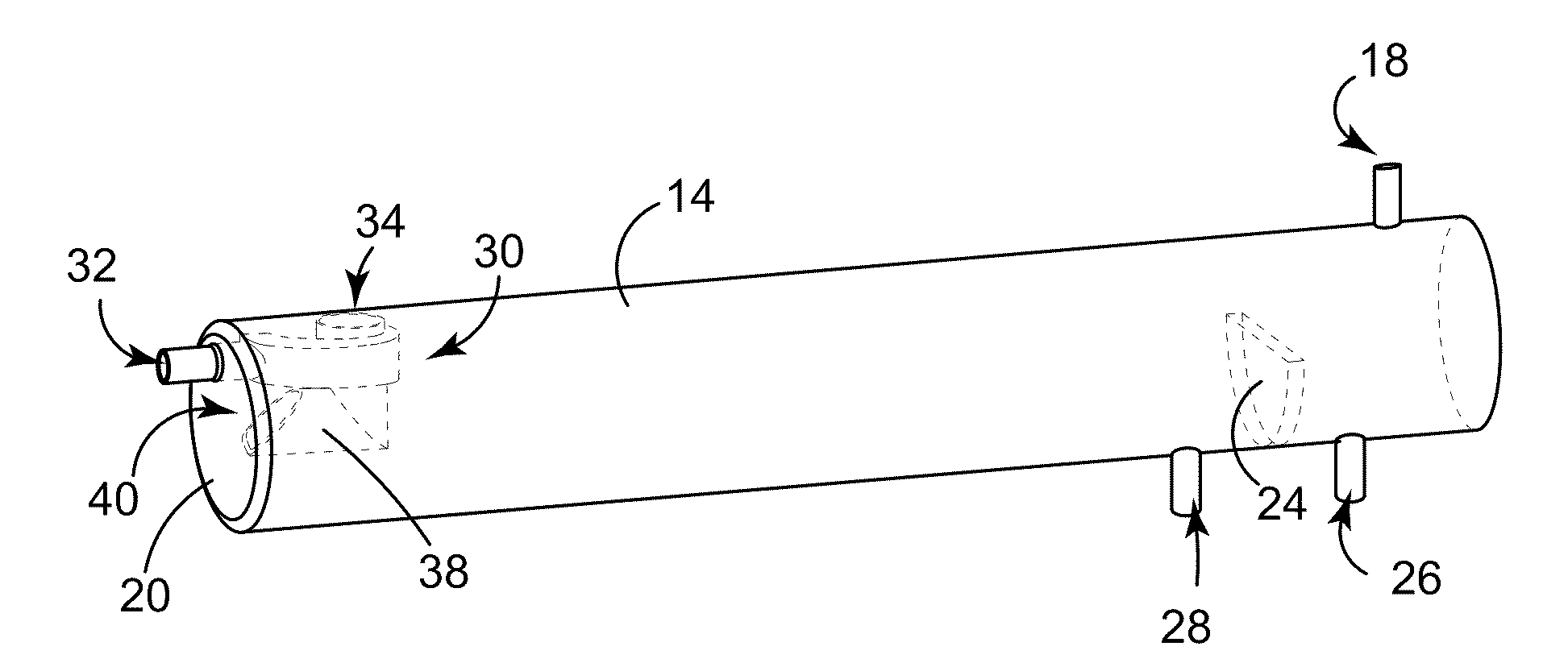

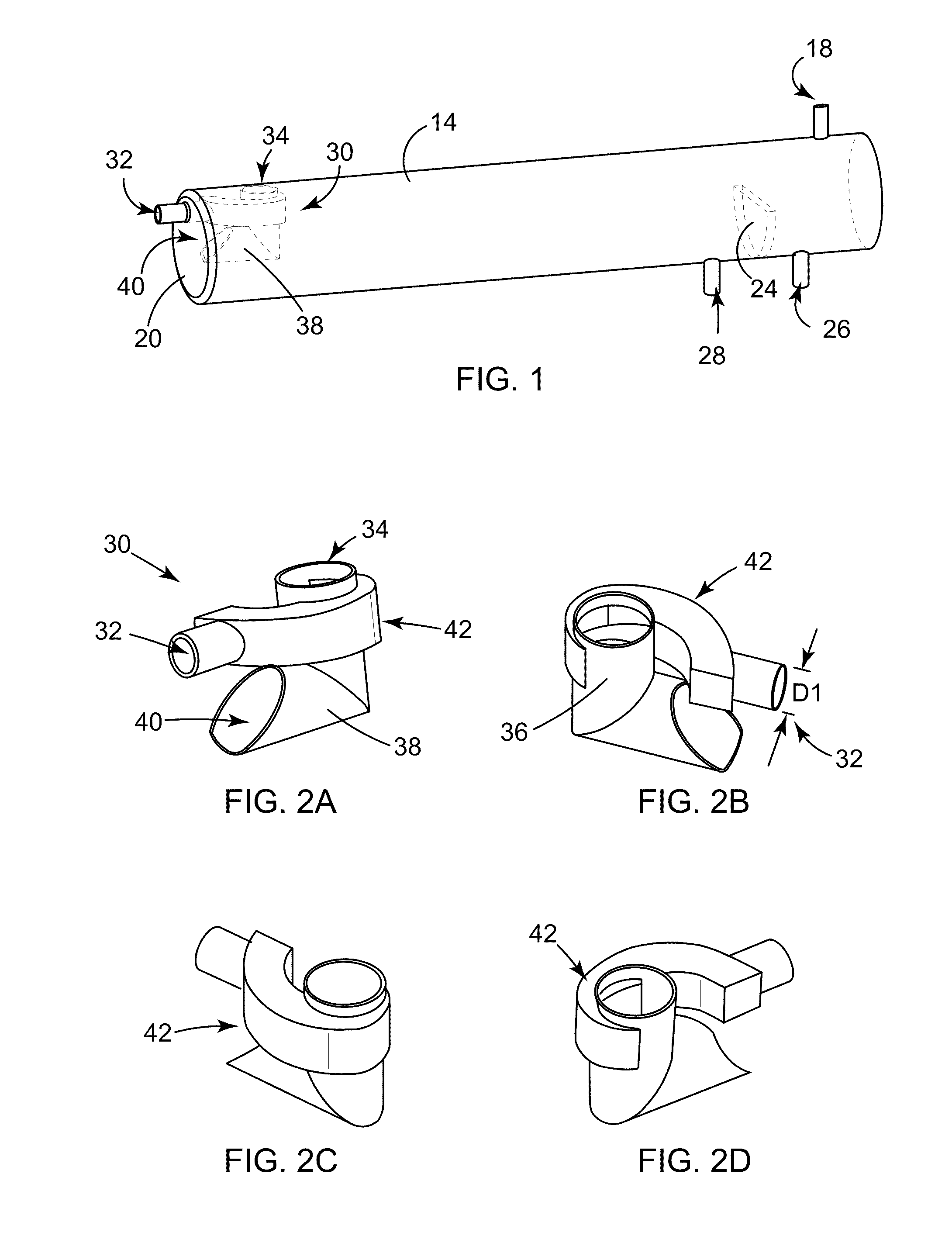

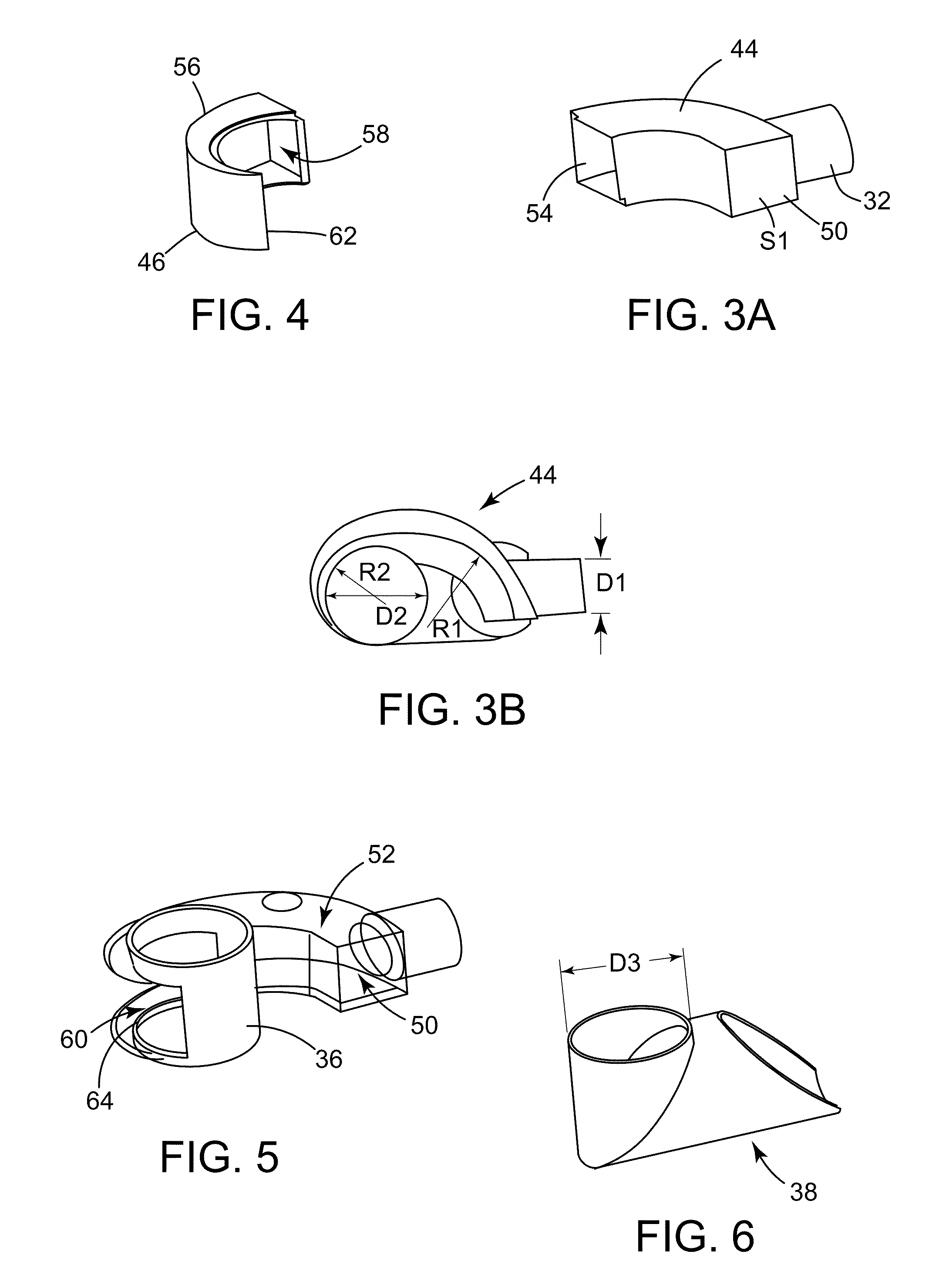

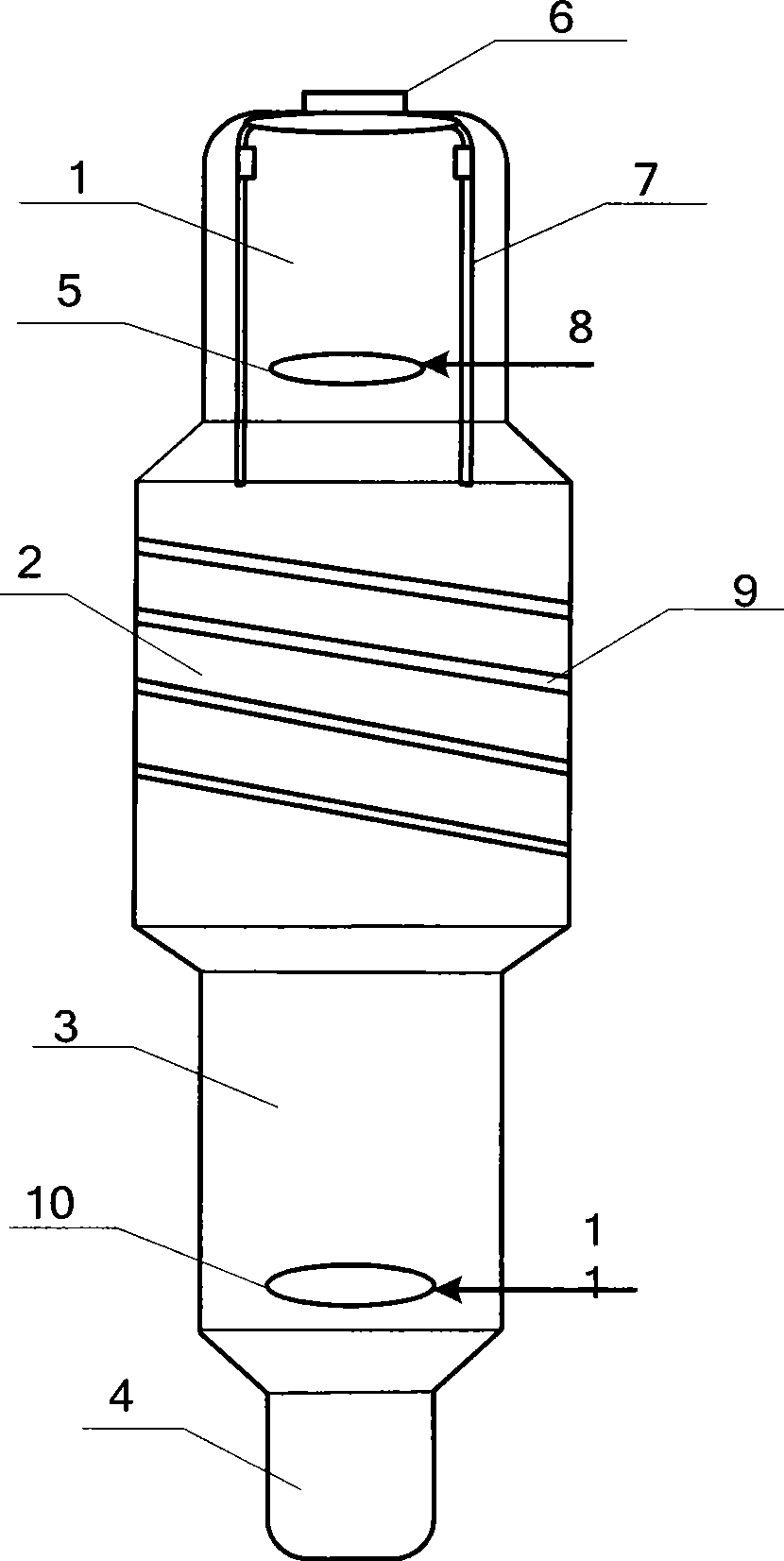

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

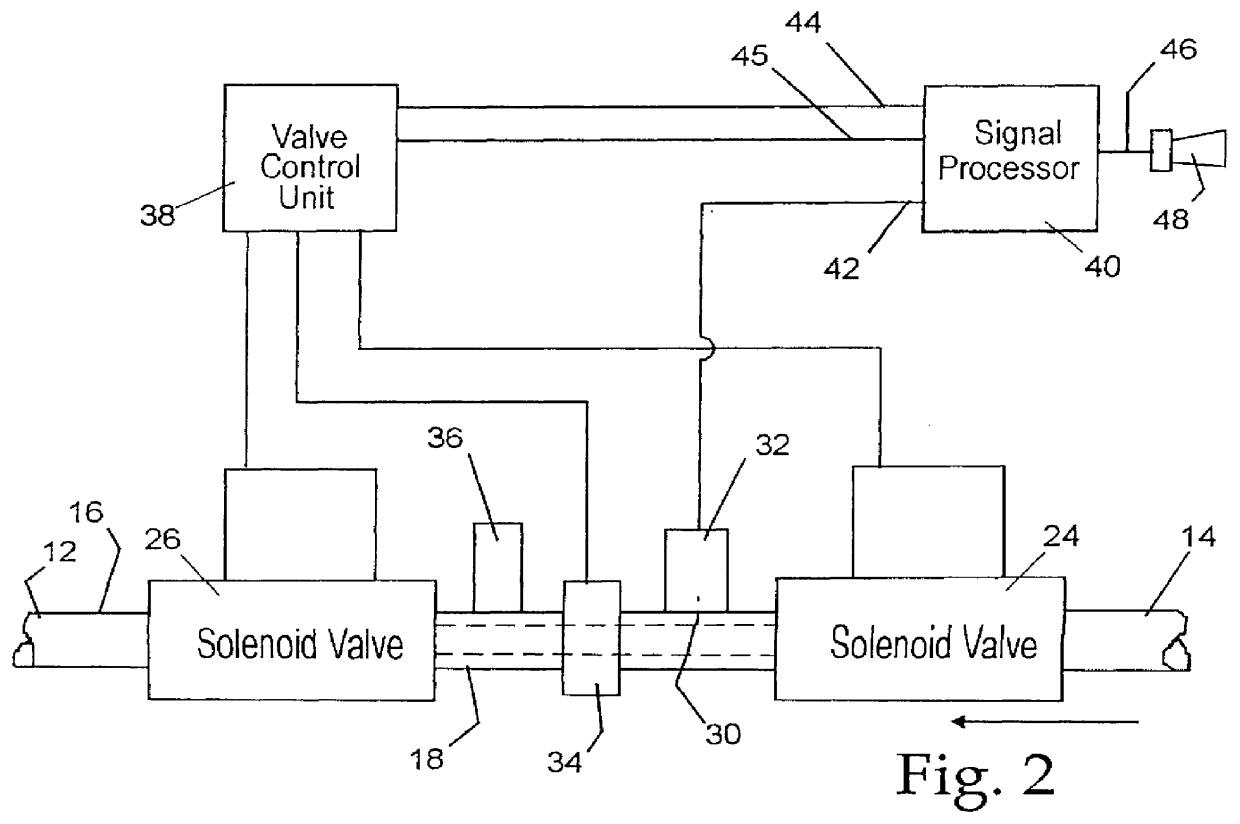

Fluid delivery apparatus

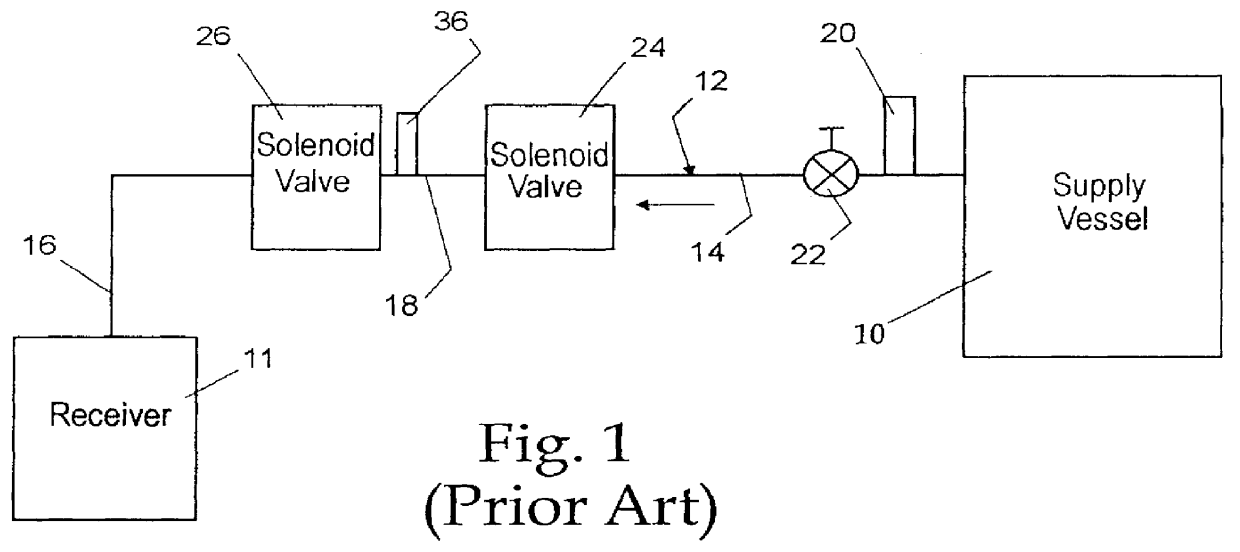

A line, especially for delivery of liquefied gas at ambient temperature, has two solenoid valves connected in series with an intermediate section of the line between them. In normal operation when both valves are closed, the isolated intermediate section contains liquid which absorbs heat from the atmosphere and / or from a heater, and the resulting increase in pressure is detected by a pressure sensor. If either valve fails to close fully to shut off flow, the intermediate section is not then isolated, so the absence of a signal from the sensor (the valves being set to close fully) indicates that at least one of them has not properly closed, and an alarm is given.

Owner:PLANER PROD LTD

Fire extinguishing agent and preparation method thereof

ActiveCN103007478AImprove fire extinguishing efficiencyReduce dispersion speedFire extinguisherSURFACTANT BLENDLiquid gas

The invention provides a fire extinguishing agent. The fire extinguishing agent is prepared by evenly mixing 1-25 parts of hydrophilic solid powder and 100 parts of water or water solution, and then adding 0.001-2 parts of surfactant for evenly mixing; and then adding 2-100 parts of hydrophobic solid particles. The invention provides a preparation method of the fire extinguishing agent. Compared with the existing fire extinguishing agent, the fire extinguishing agent can simultaneously play stifling, cooling and chemical inhibition roles, and the fire extinguishing efficiency is high; according to the fire extinguishing agent, due to addition of the surfactant in the water phase, the dispersion of rotating speed in preparation process can be lowered, the dispersion time can be shortened, and the preparation efficiency can be improved; and with the fire extinguishing agent, the adhesion property of solid gas interface and liquid gas interface can be greatly improved, the usage amount for extinguishing fire can be greatly reduced, and the fire extinguishing property can be obviously improved.

Owner:广州神州安防科技有限公司

Two-component on-site foam system and its use for foaming openings for the purpose of fire protection

InactiveUS6706774B2Increased fire resistance enduranceHigh yieldOther chemical processesGroup 5/15 element organic compoundsPolyesterPolymer science

A two-component on-site foam system for producing an intumescing fire protection foam is described with a density of less than 200 kg / m<3 >and an increased fire resistance endurance, with a polyol component (A), which contains at least one polyol, one catalyst for the reaction between the polyol and the polyisocyanate, water or a blowing agent based on a compressed or liquefied gas as foam-forming agent and at least one intumescing material based on an acid-forming agent, a carbon-supplying compound and a gas-forming agent, and a polyisocyanate component (B), which contains at least one polyisocyanate, wherein the polyol component (A) contains at least one polyester polyol, at least one aminopolyol, at least one halogen-containing polyol, at least one acid-forming agent, expanding graphite and at least one ash crust stabilizer, the quantitative ratios of the polyols to the polyisocyanate or polyisocyanates being matched so that, when the polyol component (A) is mixed with the polyisocyanate component (B) as specified, the molar ratio of isocyanate groups of the polyisocyanate to the hydroxyl groups of the polyol (NCO:OH ratio) is larger than 1:1, as well as to the use of this system for filling openings, cable and pipe leadthroughs in walls, floors and / or ceilings of buildings with foam for the purpose of fire protection.

Owner:HILTI AG

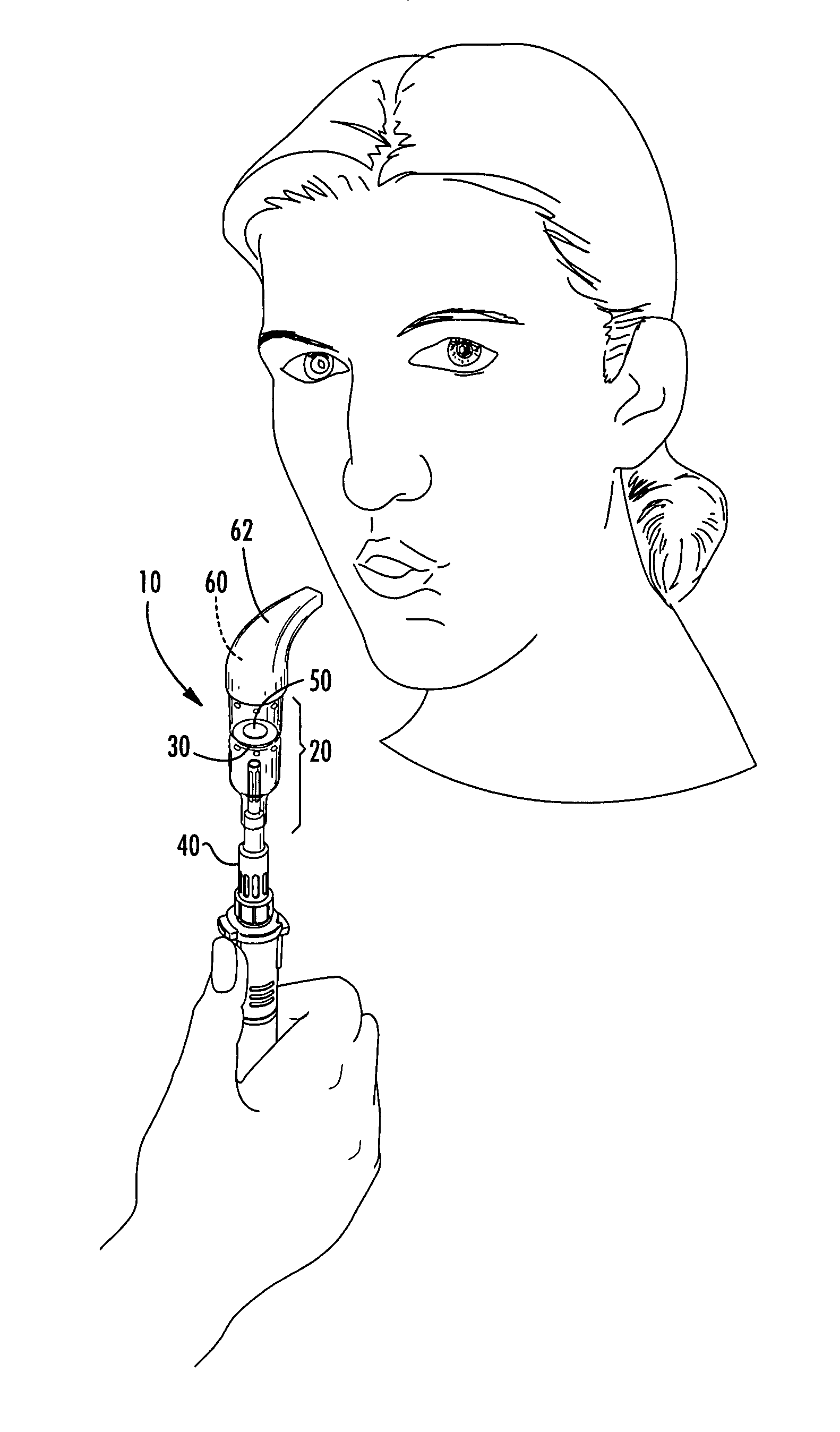

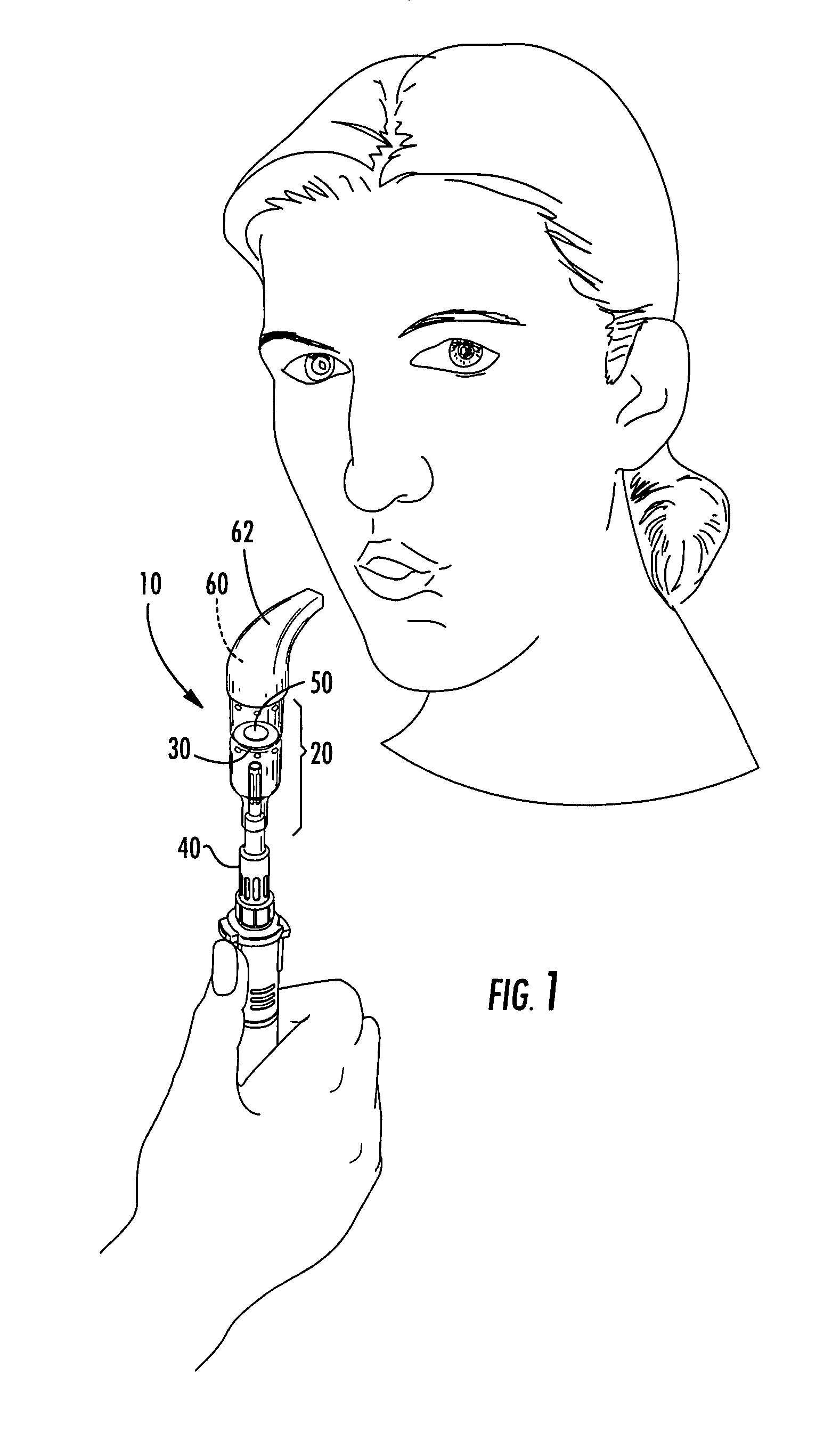

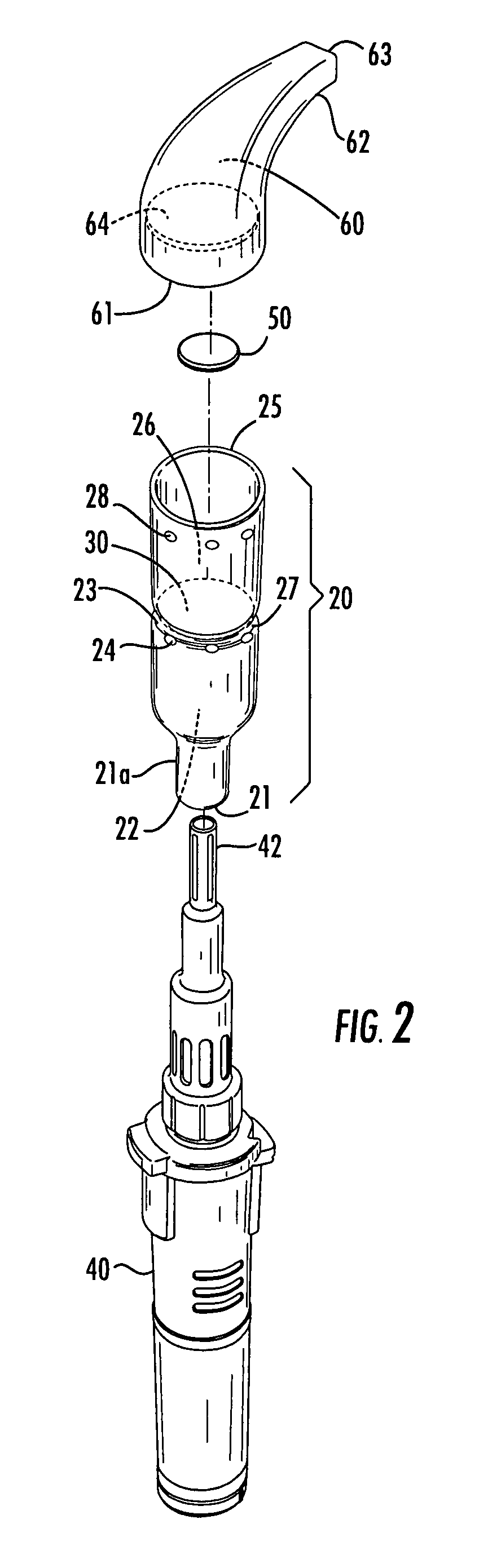

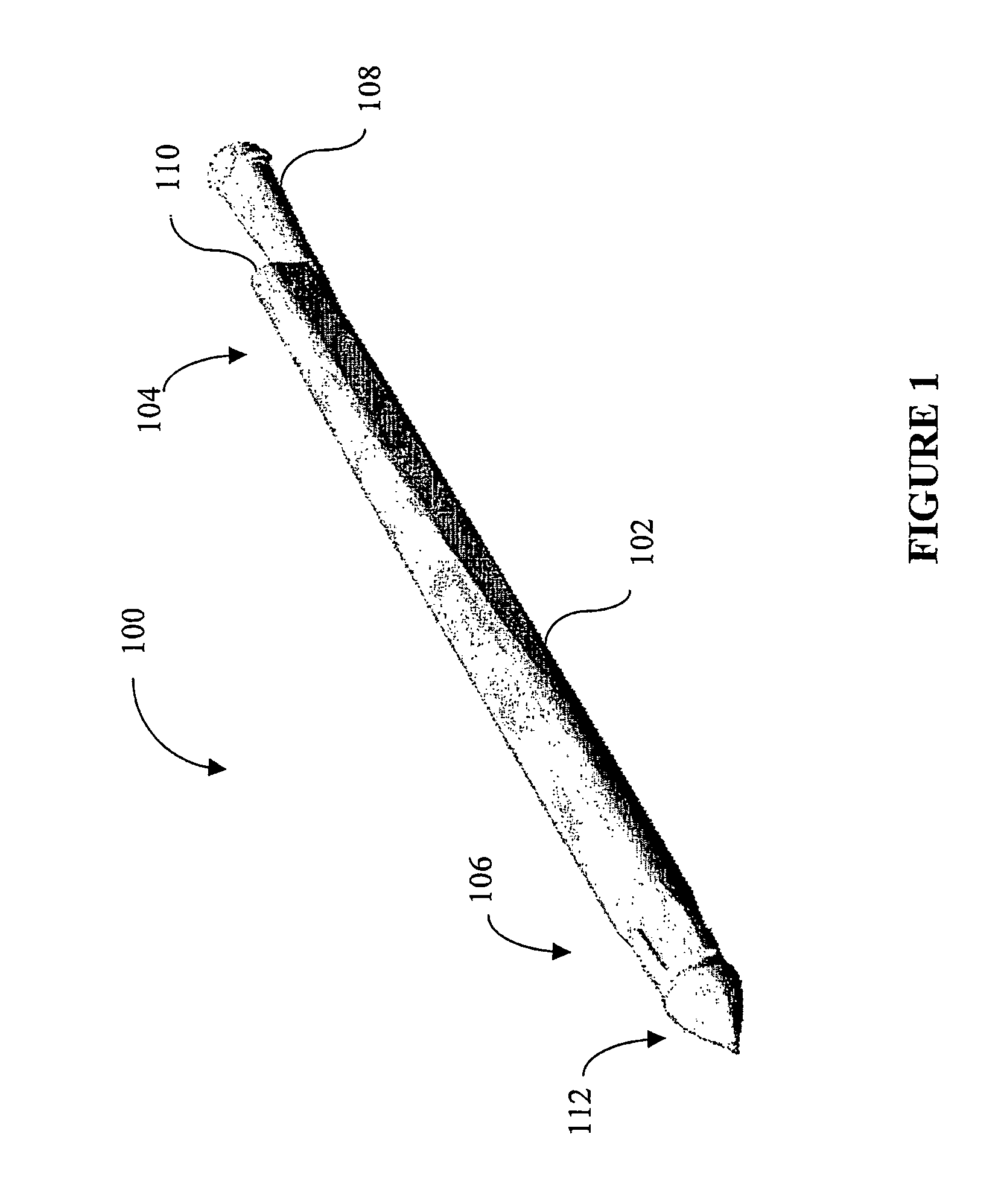

Device and method for delivering an aerosol drug

Owner:PATHFINDER INNOVATIONS LLC +1

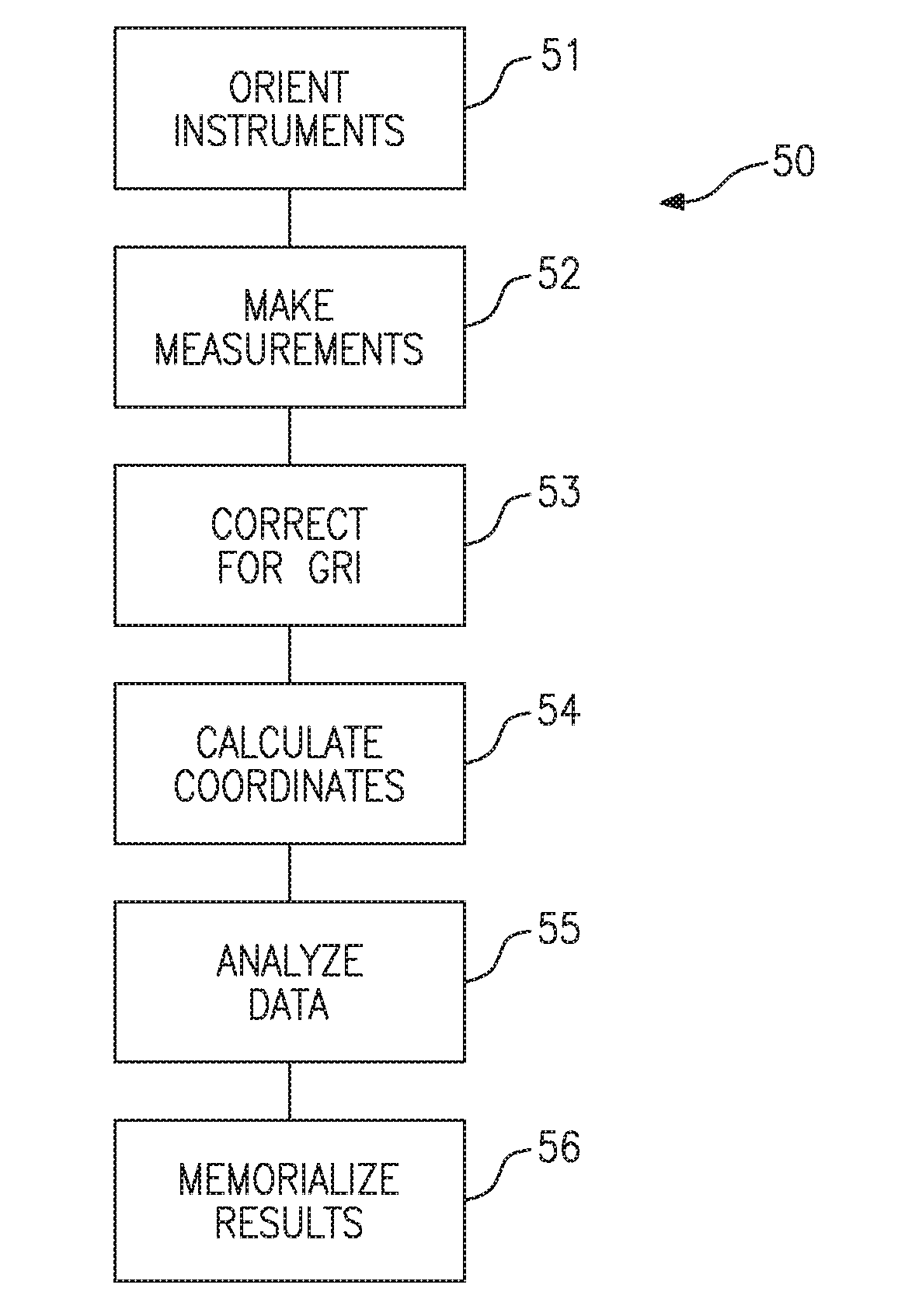

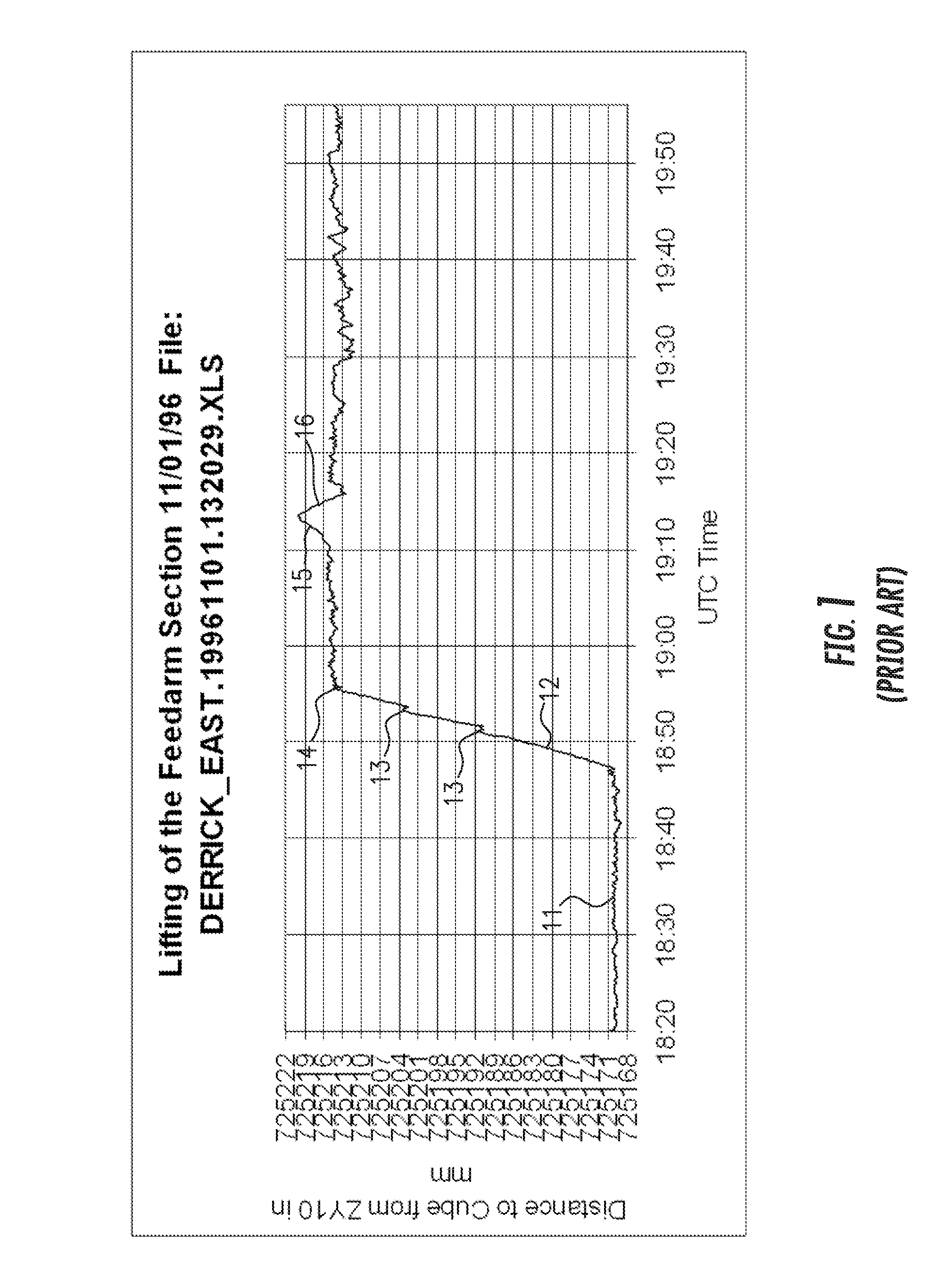

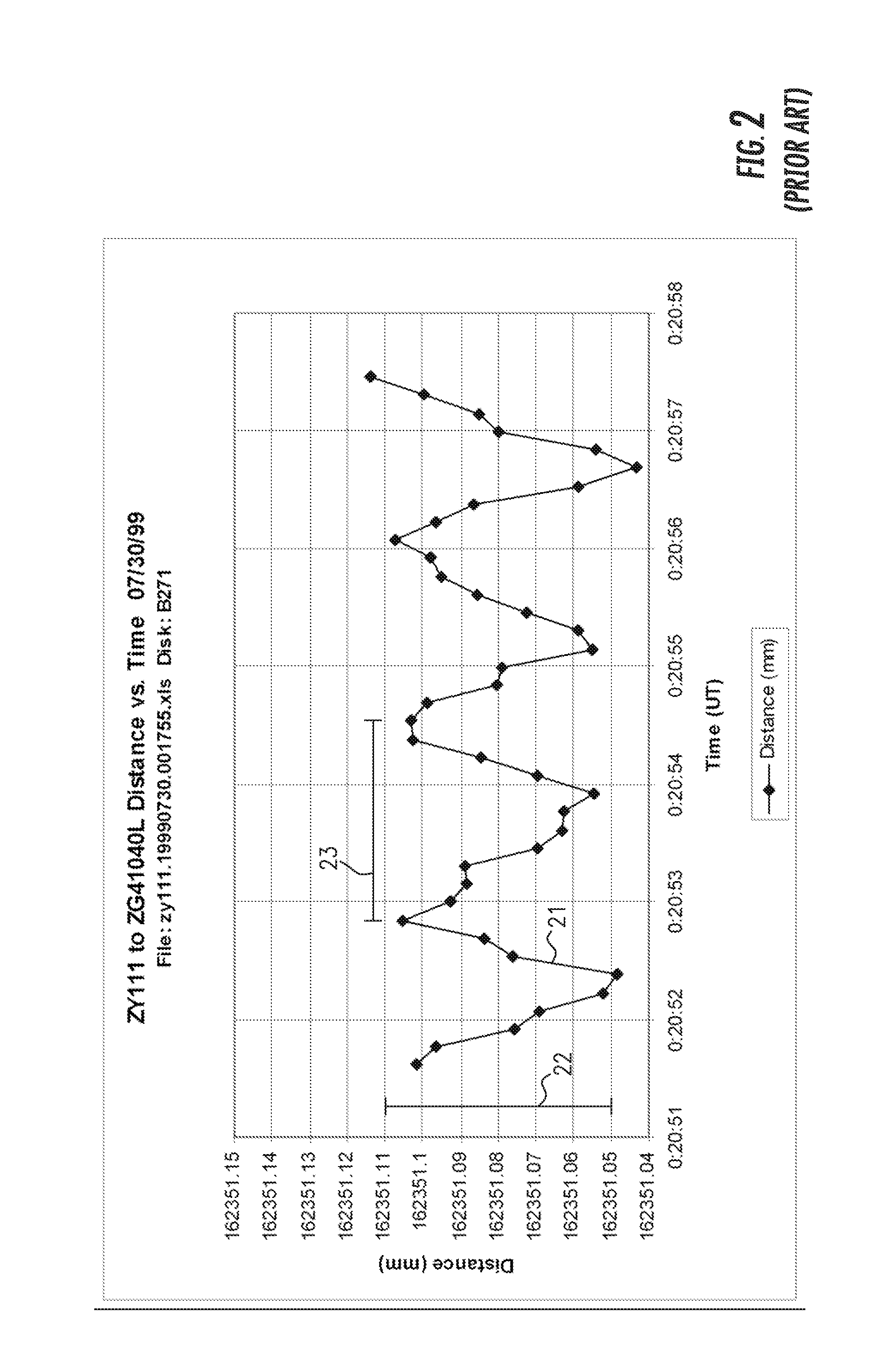

Methods for measuring and modeling the process of prestressing concrete during tensioning/detensioning based on electronic distance measurements

Methods are disclosed for nondestructive testing and measuring the structural health of prestressed concrete structures, such as slabs, columns, girders, bridges, towers, elevated storage tanks, silos, cooling towers, wind power generation towers, liquefied gas storage tanks, nuclear power containment buildings, and the like. Measurements are made as the structure undergoes tensioning and detensioning operations. By measuring actual movements of cardinal points on the structure, in an absolute three-dimensional coordinate system, and comparing the measurements to a model—as tension on a tendon is changed—a margin of safety is assured. High accuracy measurements are made by electronic distance measurement (EDM) instruments over hundreds of meters, which yield coordinates of cardinal points with an uncertainty of the order of one part per million. The methods are proposed as possible alternatives to prior failures of post-tensioned concrete, including the Las Lomas Bridge, the Kapiolani Interchange On-Ramp, Turkey Point Unit 3 Nuclear Power Plant, and Crystal River Unit 3 Nuclear Power Plant. An extensive review of the most closely related prior arts is included.

Owner:SOPHIE LIN TRUSTEE OF THE JOHN MICHAEL PAYNE FAMILY TRUST +1

Apparatus for and method of making a frozen confectionery product

ActiveUS20060110515A1Short timeAvoid cross contaminationMilk preservationWort preparationEvaporationRelative motion

Apparatus for producing a serving of frozen confectionery product is characterized by a supply of liquid gas, a support for removably carrying a disposable container that holds a volume of unfrozen confectionery mix, and a holder for releasably holding a disposable agitator, such that the agitator extends into confectionery mix in the container. A valve controllably dispenses liquid gas into the confectionery mix in the container while relative motion is imparted to the container and agitator to agitate and admix the confectionery mix and liquid gas while the liquid gas mix evaporates to cool and freeze the confectionery mix, through a transfer of heat from the confectionery mix to the liquid gas and through the latent heat of evaporation of the liquid gas, to produce the frozen confectionery product.

Owner:SMITTEN VENTURES

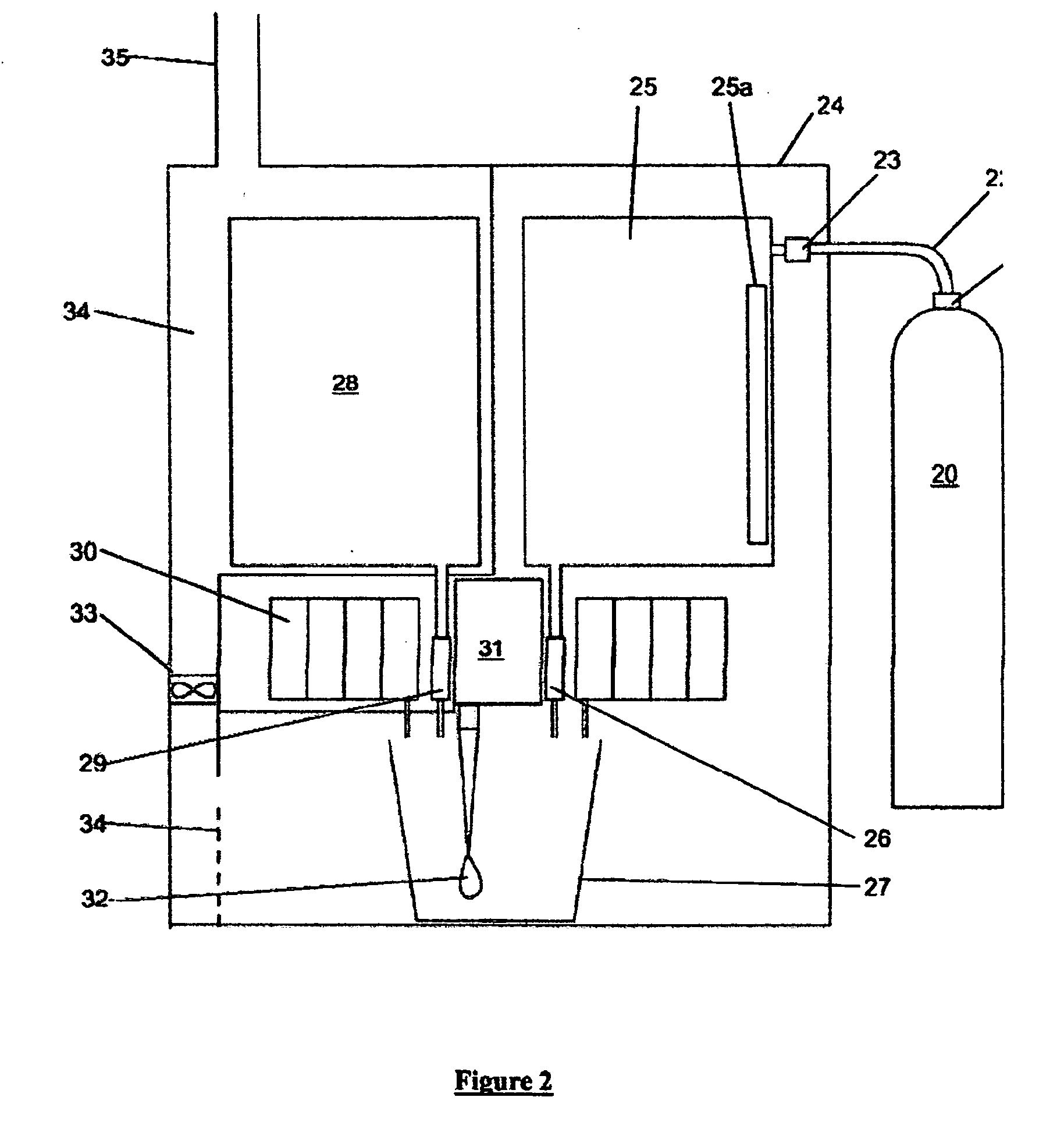

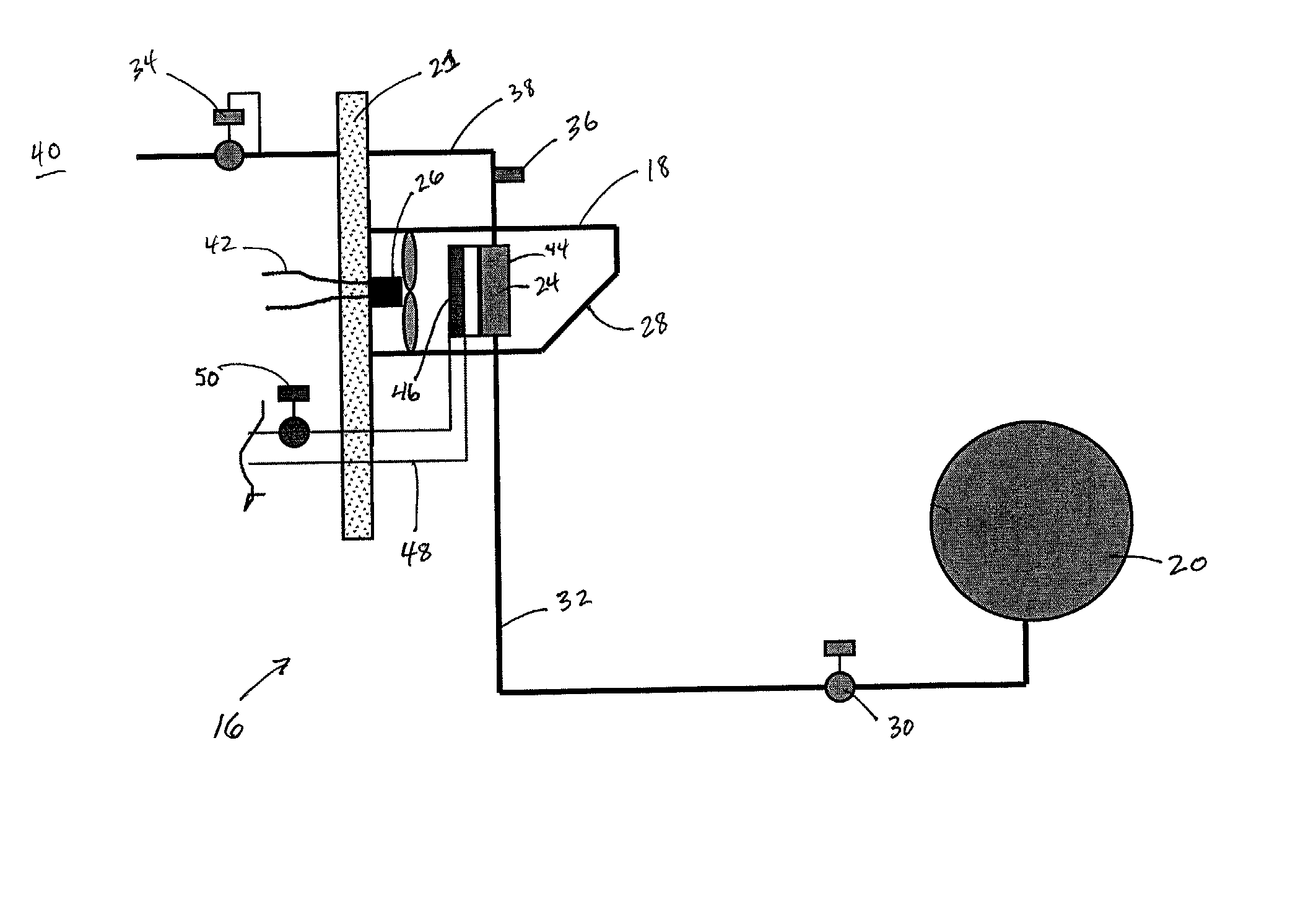

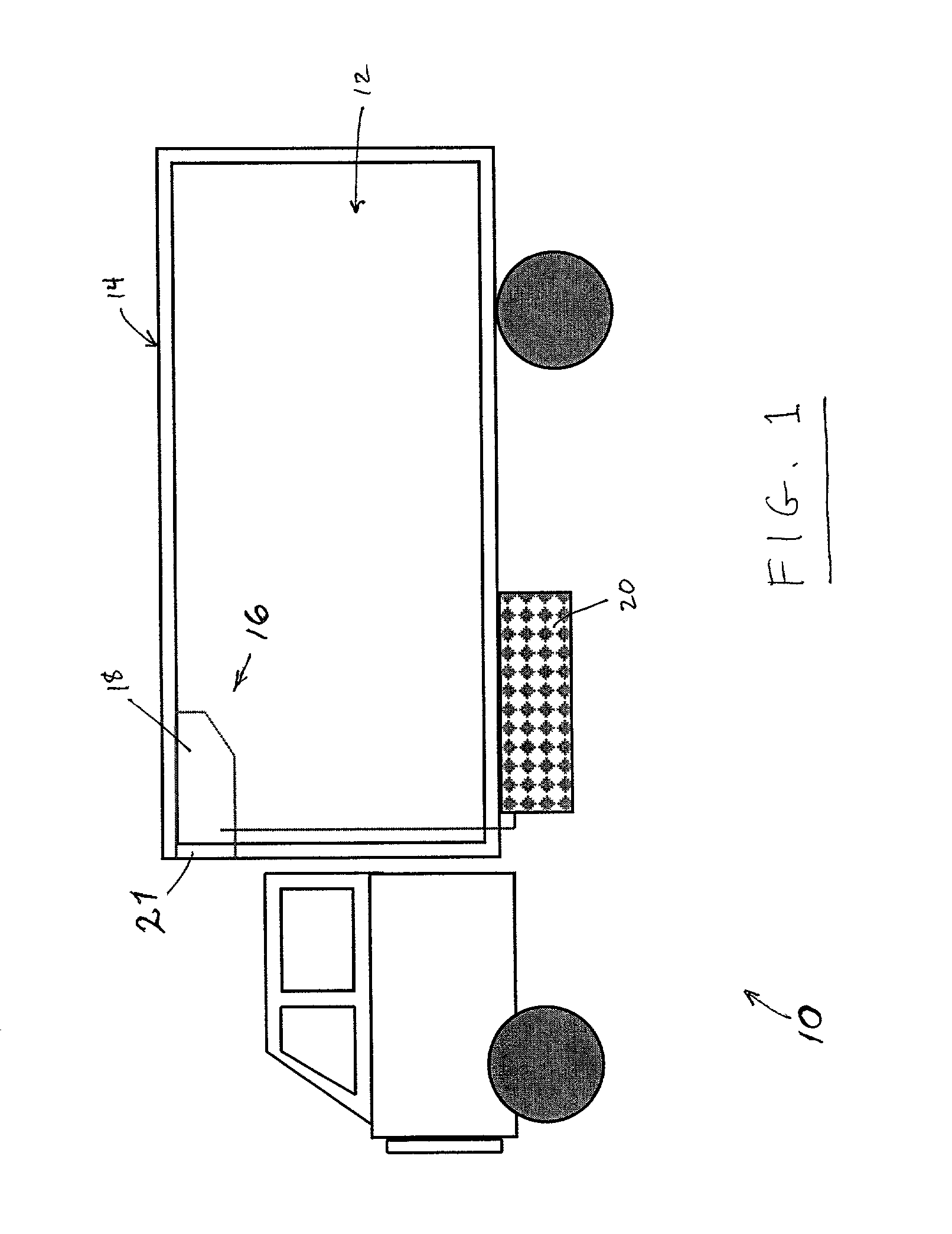

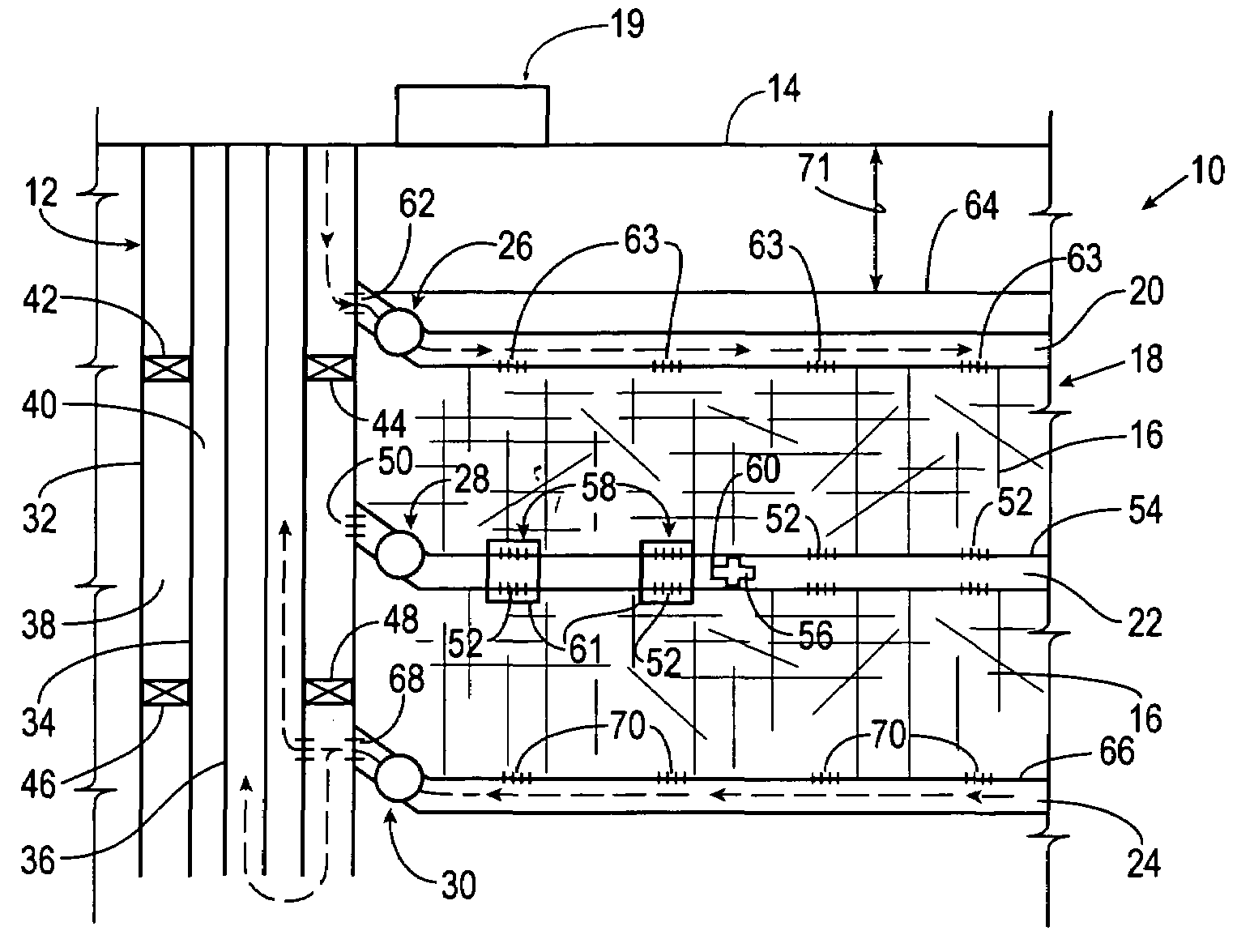

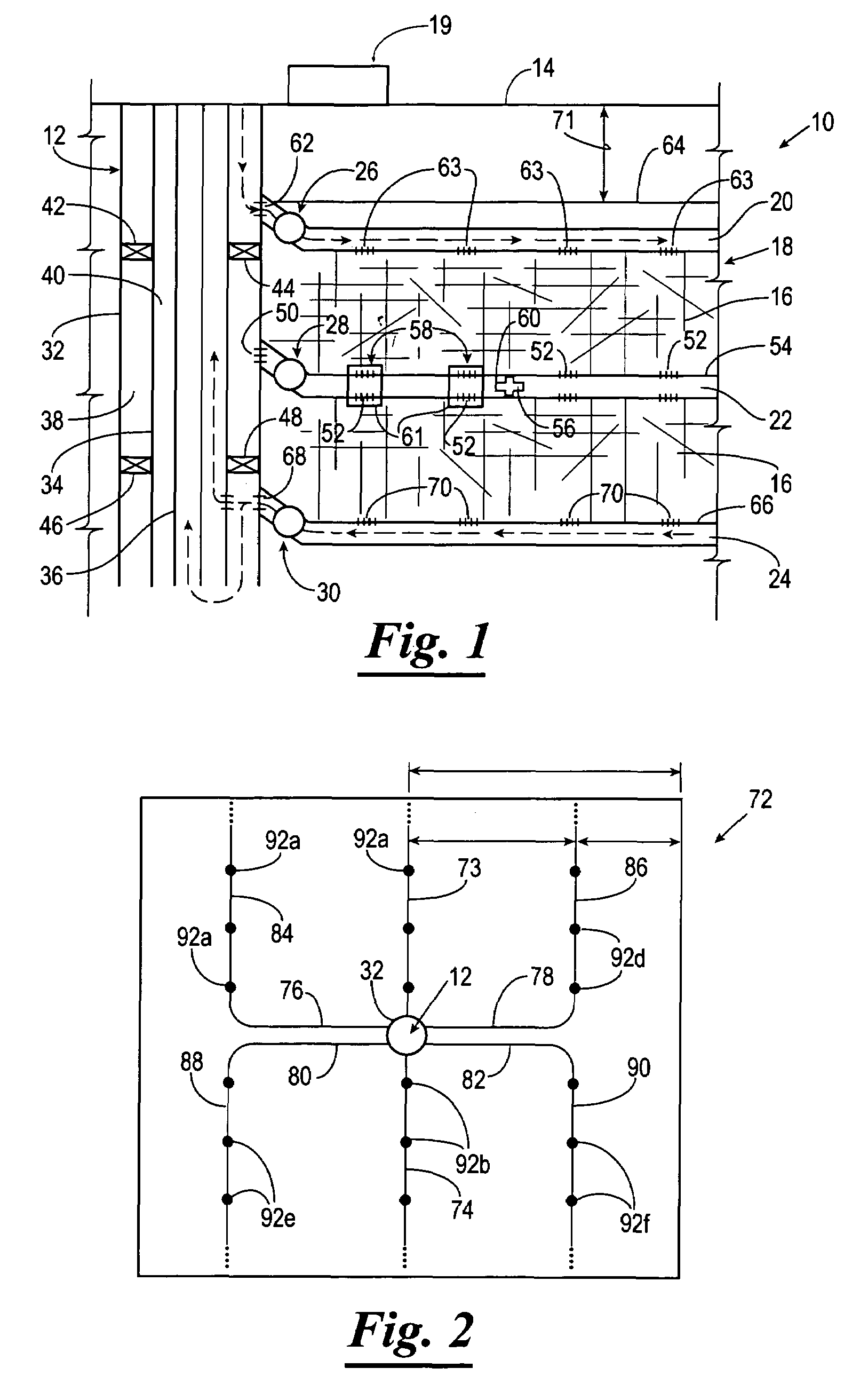

Cryogenic refrigeration unit suited for delivery vehicles

InactiveUS20020129613A1Reduce the temperatureNot contaminate atmosphereAir-treating devicesRefrigerated goods vehicleAir cycleDelivery vehicle

An apparatus to refrigerate the cargo space of delivery vehicles. It provides an environmentally friendly alternative to conventional mechanical a / c and refrigeration units. Cooling is provided by controlled evaporation of a liquefied gas such as CO.sub.2 or nitrogen. Defrost and heating requirements, if needed, are provided by hot engine coolant or by electric heaters powered from the vehicle electrical system. Airflow for the evaporator and for circulation in the temperature controlled space is provided by a blower which is mechanically or electrically driven from vehicle power. This invention can also be applied to multi-temperature control applications. The apparatus is compact and is particularly suited for small inner city delivery vehicles. FIG. 1: The sketch shows an inner city delivery truck for which this invention is most suitable. Refrigerated goods are placed in roller cages that are designed to maximize cargo hauled by use of roller cages that extend to within 2 inches of the ceiling. The evaporator section of this invention is mounted at or near the front wall of the truck and is separated from the cargo by a vertical bulkhead. The conditioned air is delivered at the bottom of the truck to avoid top freeze of perishable cargo that is in close proximity to the ceiling. FIG. 2: This shows the piping schematic and is similar to the invention described in U.S. Application Serial No. 60 / 238,929 (the '929 application) incorporated herein by reference. FIG. 2 shows the engine coolant coil located ahead of the CO.sub.2 coil in the direction of airflow. This prevents the coldest air from coming in contact with the engine coolant--in the cooling mode the air leaving the CO.sub.2 coil can be as low as -50.degree. F. for frozen load applications and this may cause the engine coolant to start freezing. Arrangements must be made to circulate air between the two coils in defrost mode. One means to accomplish this is to place a damper at the outlet of the evaporator section and run the fans. The damper would be closed during defrost. Another method is to place the engine coolant coil on the discharge side of the CO.sub.2 coil and use a cut-out switch if the engine coolant temperature drops below a predetermined value. In this arrangement there is no need for the damper arrangement as the heat will rise to melt any frost on the CO.sub.2 coil. If electric heat is used for defrost and heating freezing of the engine coolant is not a concern and the heaters can be fastened to the discharge side of the CO.sub.2 coil. An electric stand-by mode can be provided to power the system for cooling, heating and defrost when the vehicle is parked with the engine off. A plug-in electrical cable can provide the power needed for the controls, the fans and for heating and defrost. The figure shows the electric heaters attached on the discharge side of the CO.sub.2 coil. Operation: Detailed description is in the '929 application except for the following: The evaporator section is designed for vertical installation to maximize cargo space. Air is discharged at the bottom but may be a conventional top discharge if needed for specific applications. Conventional methods can be used to provide defrost and heating. If engine coolant is used for a heat source, it is preferable to thermally isolate the CO.sub.2 coil from the engine coolant coil to avoid freezing the coolant. The evaporator blower may be located on the inlet side of the coils rather than as shown in the figures. Unique Features: 1. Absence of a conventional condensing section on the exterior of the vehicle makes this an ideal refrigeration unit for small inner city delivery vehicles. Many of the truck cabs are now almost full height (same as the truck body) and there is limited space for the condensing section. 2. Cold plates can be used and still maximize cargo cube. However, this invention has 30-40% less weight than comparable "cold plate" systems. 3. Other features are described in the '929 application.]

Owner:THERMO KING CORP

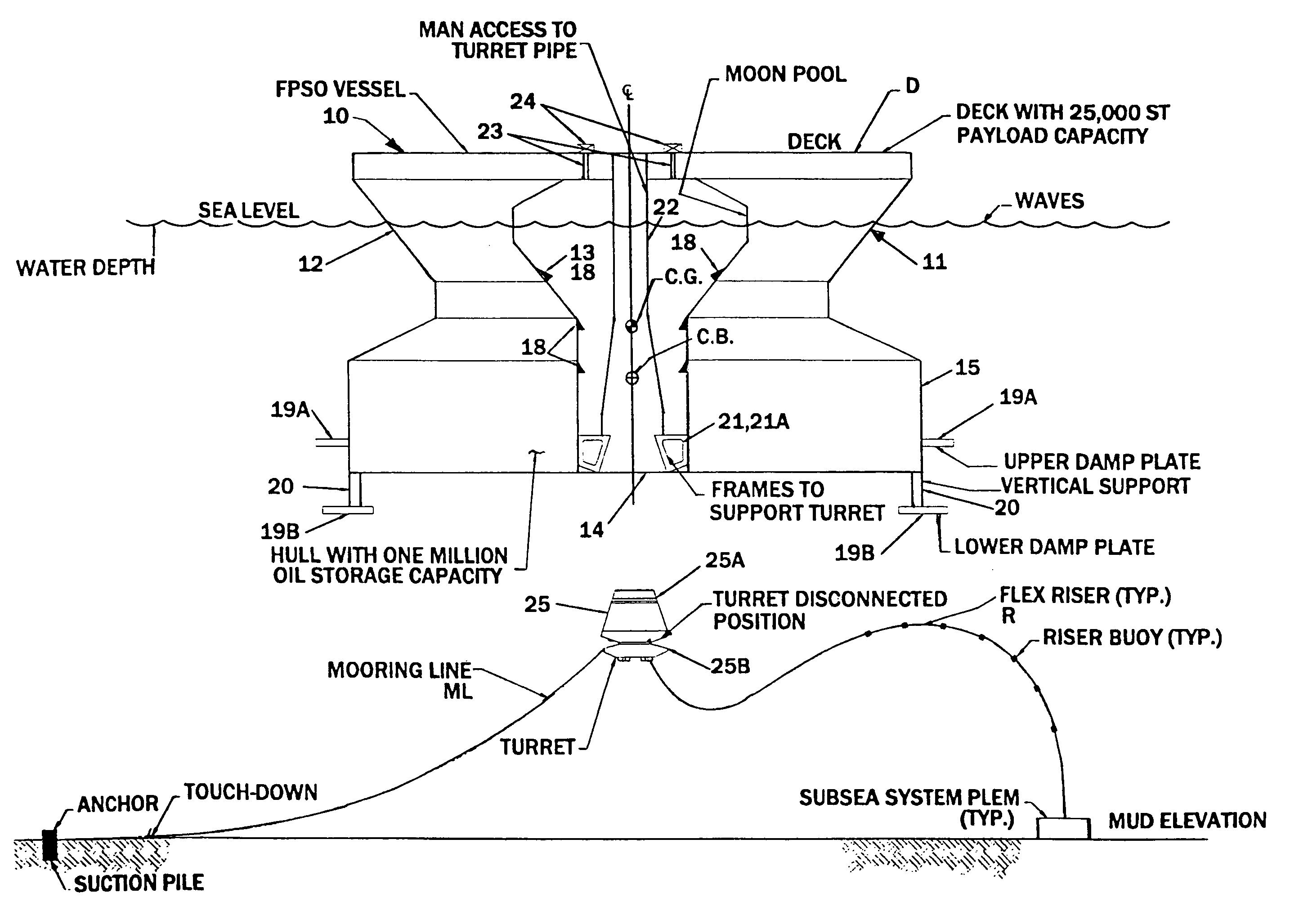

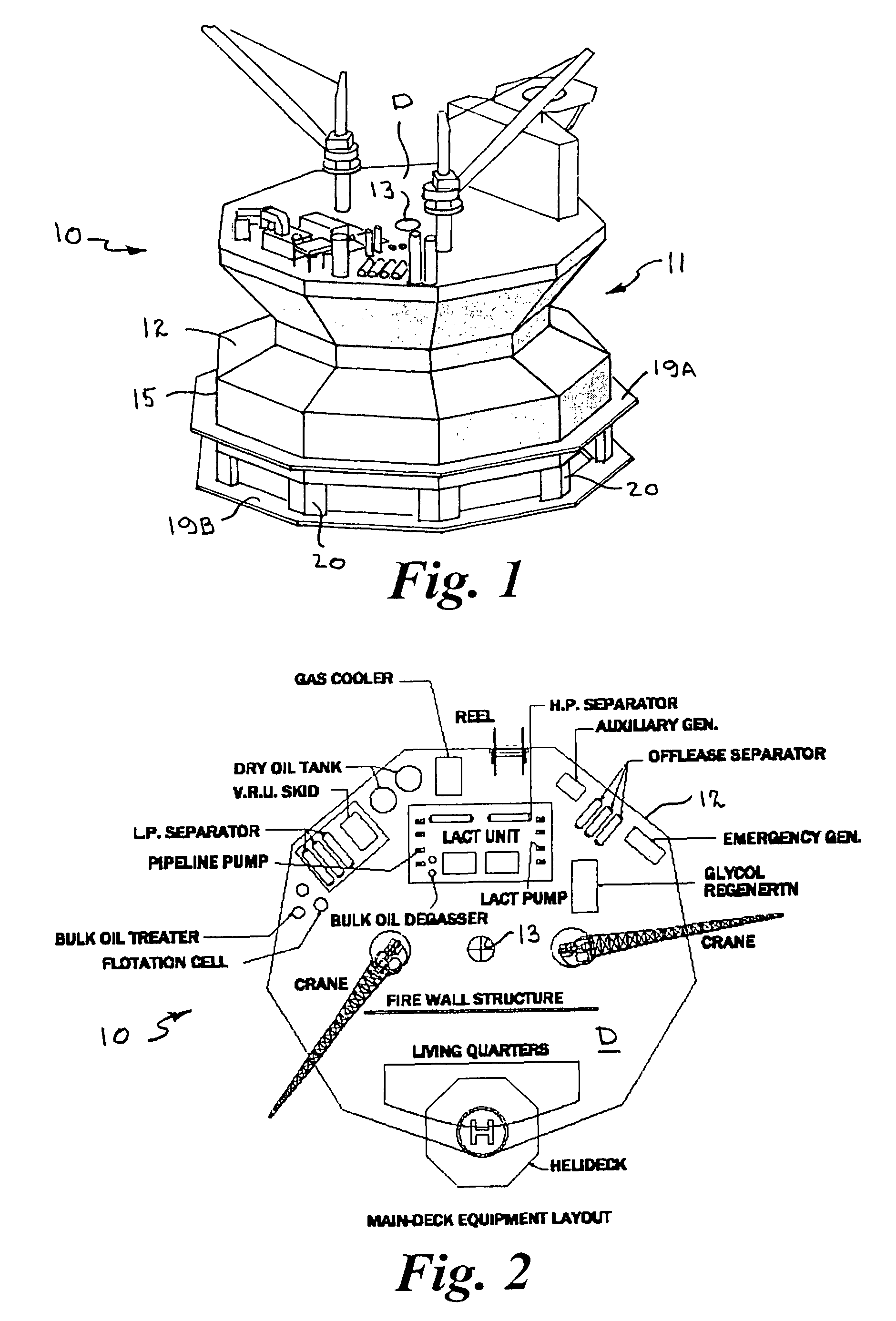

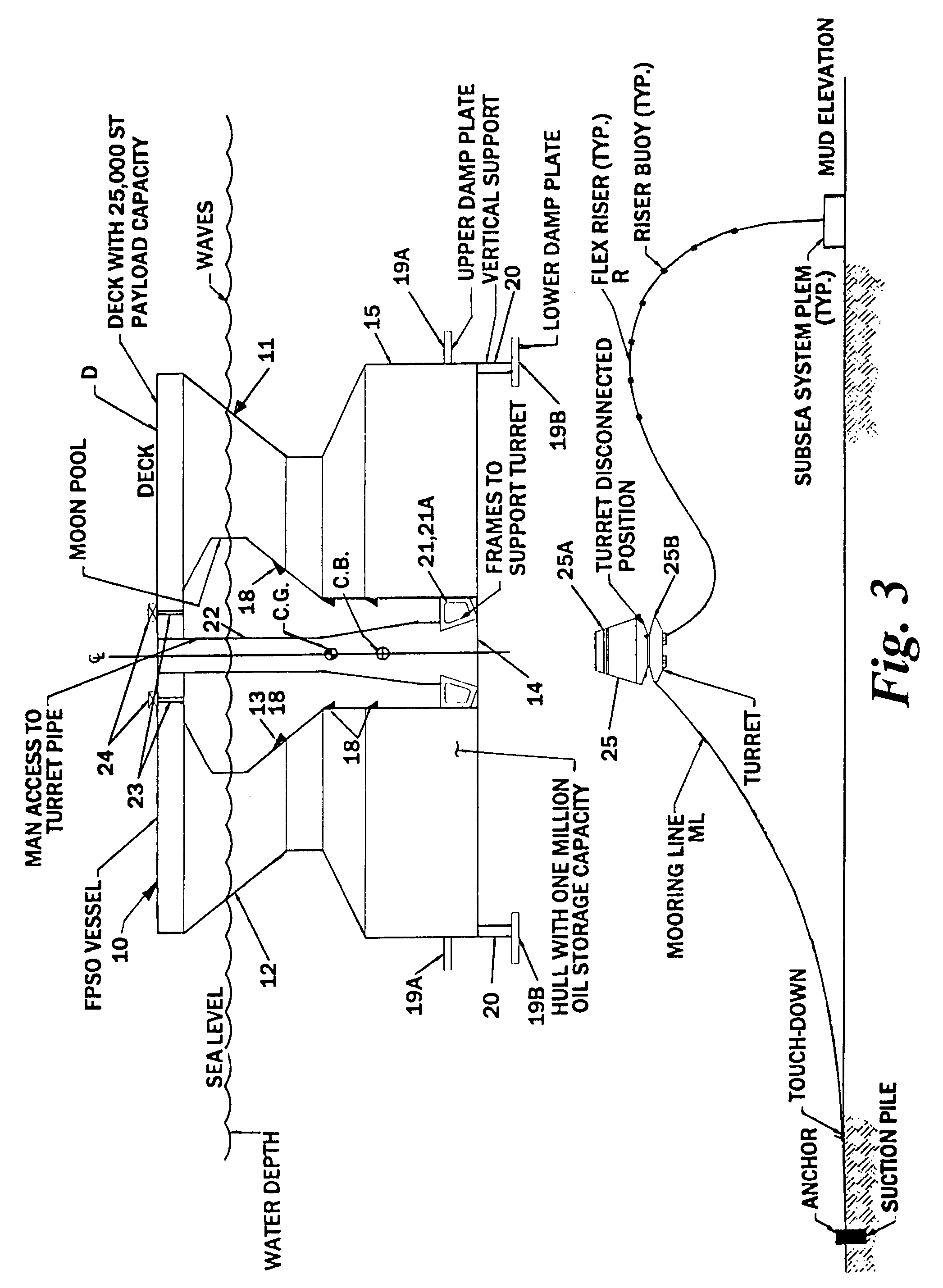

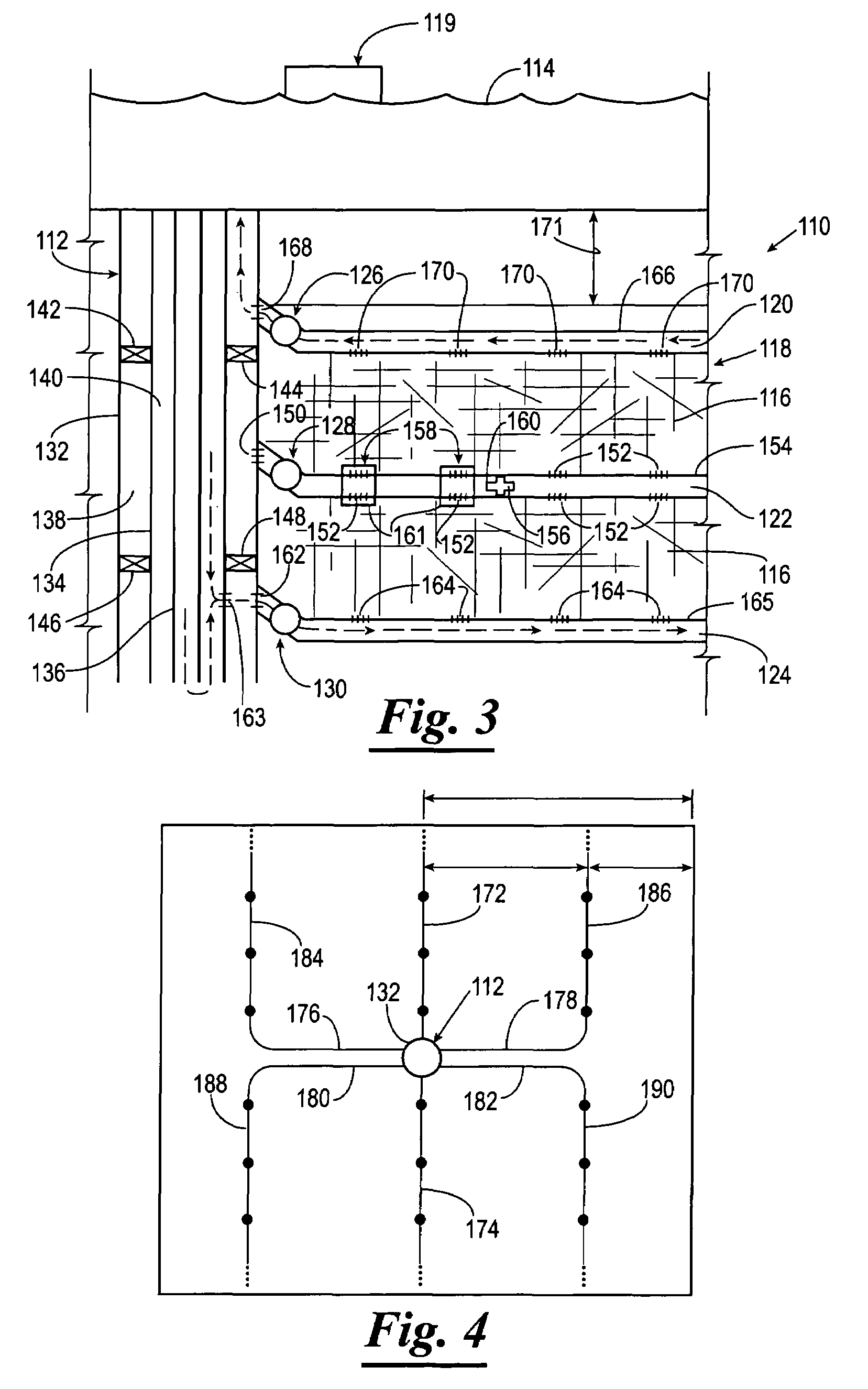

Offshore floating production, storage, and off-loading vessel for use in ice-covered and clear water applications

InactiveUS7958835B2High strengthProtective foundationMovement controllersClassical mechanicsPressure ridge

An offshore floating production, storage, and off-loading vessel has a hull of generally cylindrical or polygonal configuration surrounding a central double tapered conical moon pool and contains water ballast and oil and / or liquefied gas storage compartments. The exterior side walls of the polygonal hull have flat surfaces and sharp corners to cut ice sheets, resist and break ice, and move ice pressure ridges away from the structure. An adjustable water ballast system induces heave, roll, pitch and surge motions of the vessel to dynamically position and maneuver the vessel to accomplish ice cutting, breaking and moving operations. The moon pool shape and other devices on the vessel provide added virtual mass for increasing the natural period of the roll and heave modes, reducing dynamic amplification and resonance due to waves and vessel motion, and facilitate maneuvering the vessel. A disconnectable turret buoy at the bottom of the moon pool connects risers and mooring lines.

Owner:SRINIVASAN NAGAN

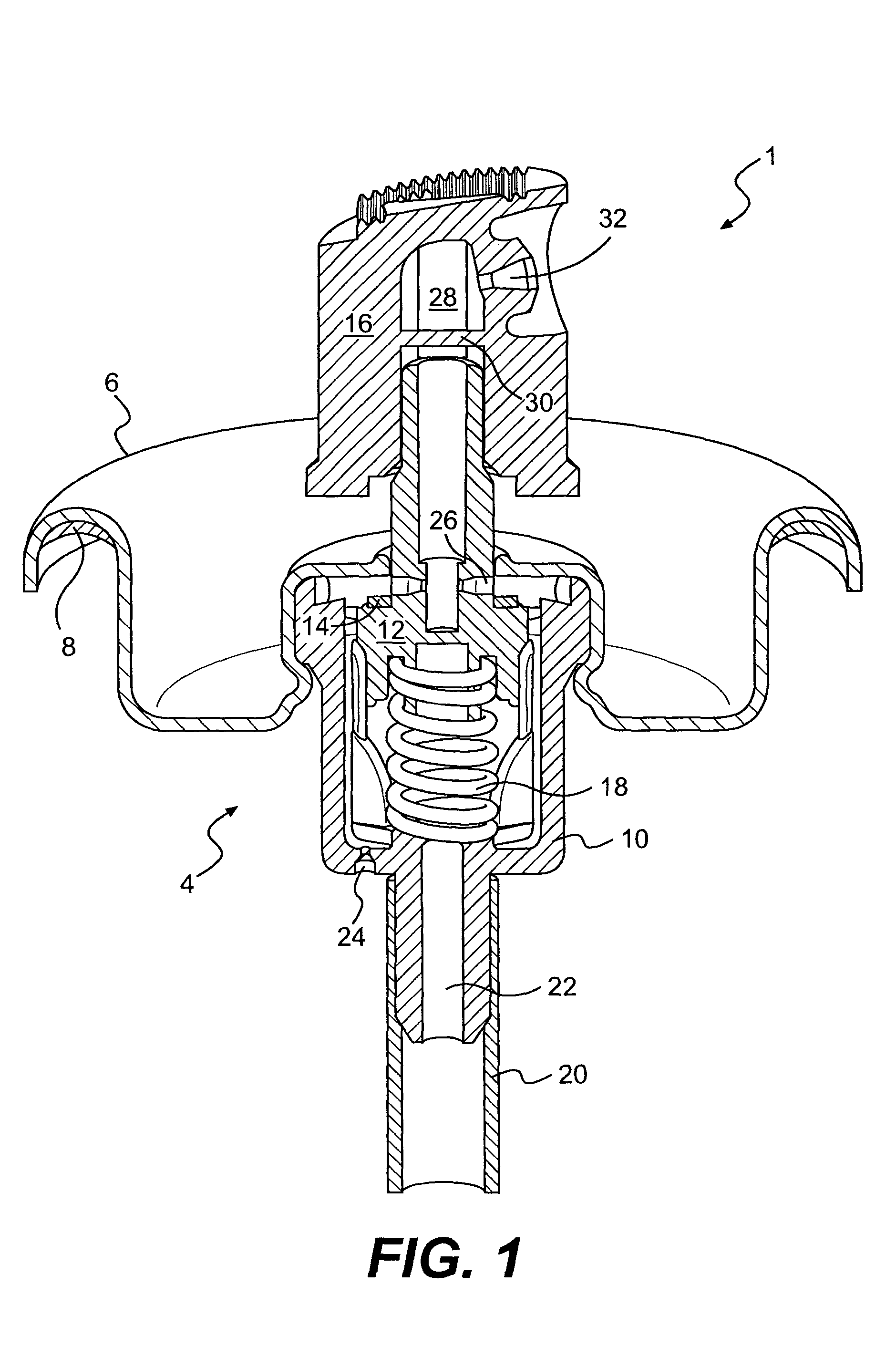

Aerosol dispenser assembly having low volatile organic compound (VOC) content

InactiveUS7014127B2Satisfactory particle sizeSatisfactory spray rateLiquid spraying apparatusLiquid dispensingLiquid productMechanical engineering

An aerosol dispenser assembly (1) has a container (2) holding a liquid product and a liquefied gas propellant for propelling the liquid product from the container, the propellant being present in a quantity of at most about 25% by weight of the contents of the container (2). A valve (4) is attached to the container (2) for selectively dispensing the liquid product from the container (2) as a mist. The assembly (1) is configured such that the mist has a small particle size, is dispensed at an expeditious rate, and very little product is retained in the container (2) when the propellant is depleted.

Owner:SC JOHNSON & SON INC

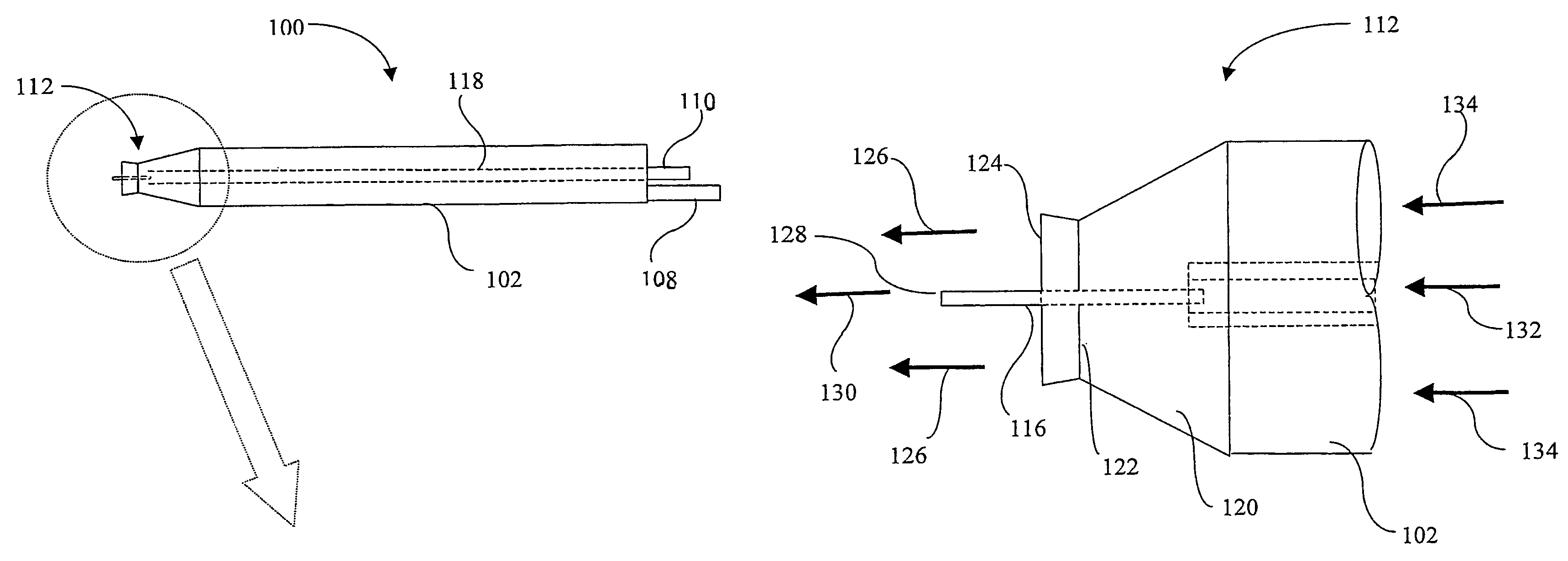

High velocity liquid-gas mist tissue abrasion device

ActiveUS7901373B2Reduce flow rateMaximize the effectMedical devicesSurgical instrument detailsSpray nozzleEngineering

The present invention relates to a device for abrading or cleansing tissue. The device includes a gas inlet port connected to a pressurized gas source, and a liquid inlet port connected to a pressurized liquid source. There is, additionally, a mist jet delivery nozzle arrangement, which includes one or more gas discharge nozzles arranged to receive a flow of pressurized gas from the gas inlet port and configured to accelerate the flow of gas so as to discharge it at an elevated velocity. Further, there are one or more liquid discharge nozzles arranged to receive a flow of liquid from the liquid inlet port and operative to discharge the flow of liquid into the elevated velocity flow of gas, thereby to similarly accelerate the velocity of the discharged liquid as a mist of accelerated droplets.

Owner:TAVTECH

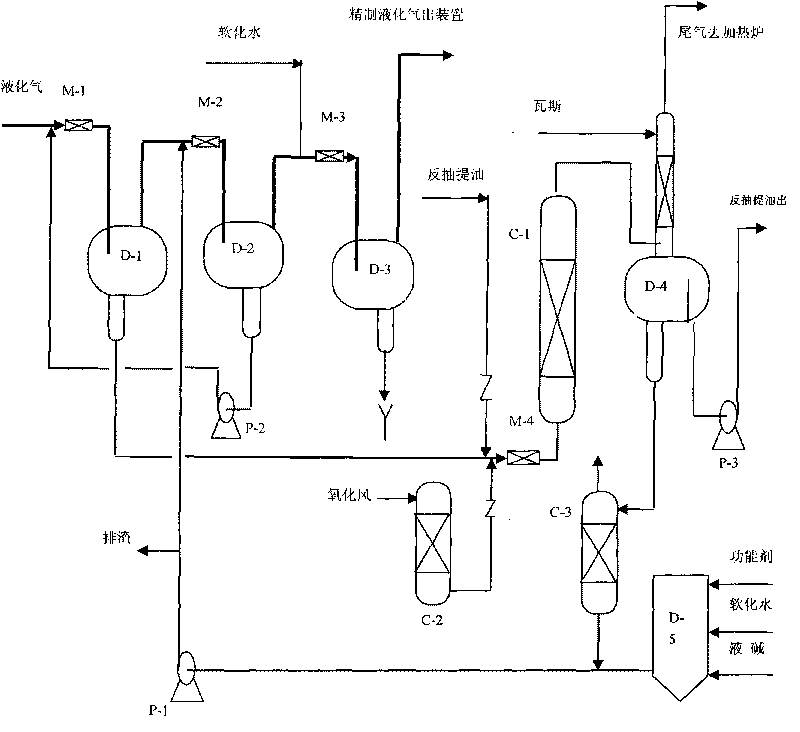

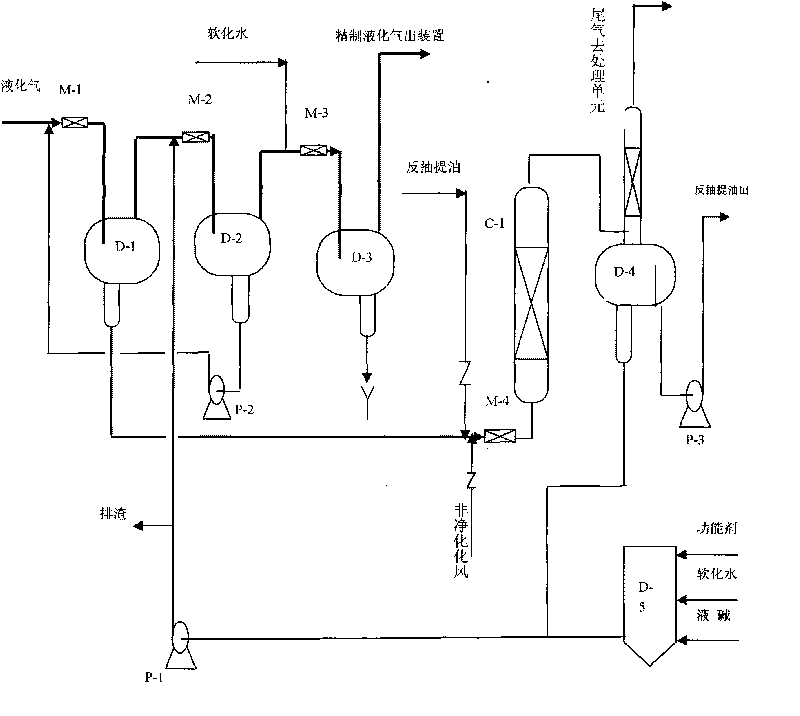

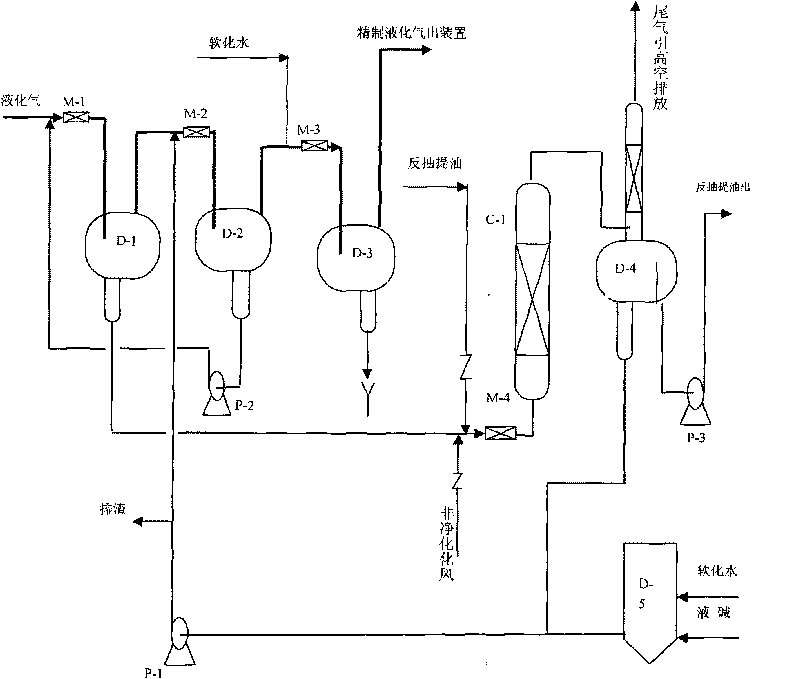

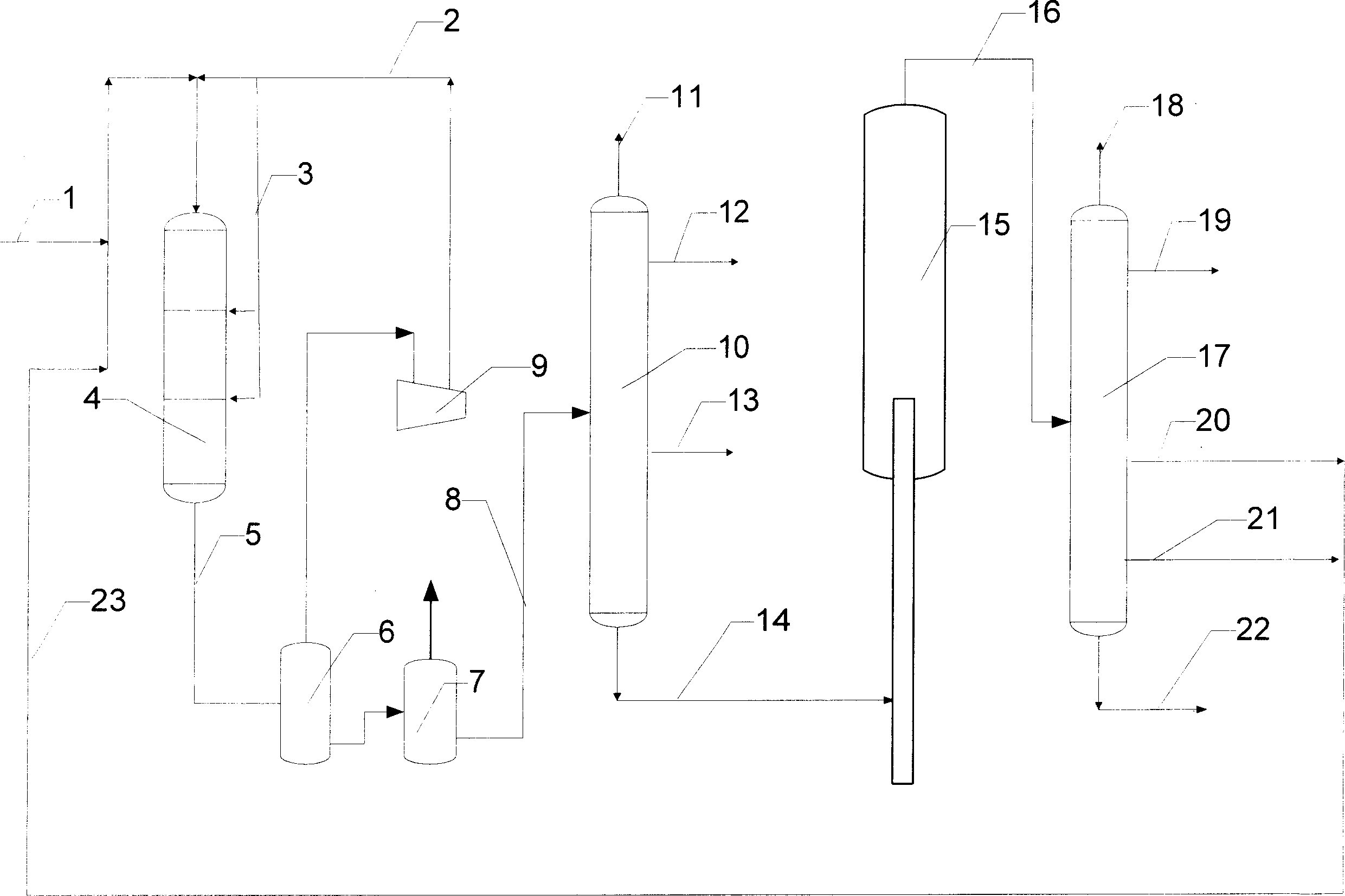

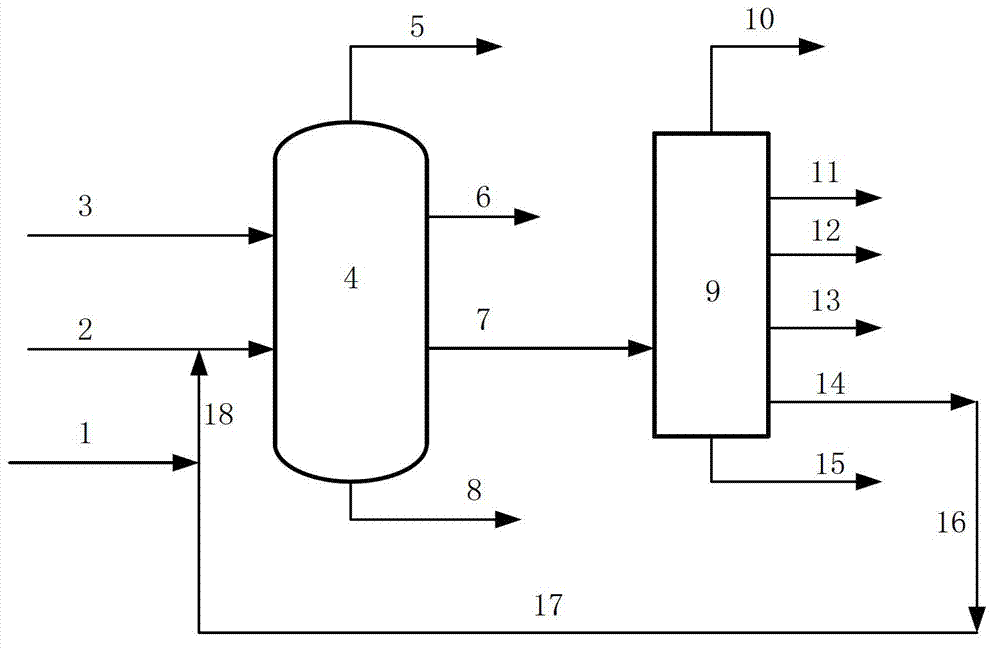

Liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur

ActiveCN101705108AImprove abilitiesHigh activityGaseous fuelsRefining with aqueous alkaline solutionsSlagCarbonyl sulfide

The invention relates to a liquid hydrocarbon mercaptan removal technique capable of deeply removing total sulfur, in particular to a sweetening technique for liquefied gas in an oil refinery. The oil refining liquid hydrocarbon refers to components of liquefied gas and light gasoline, wherein the liquefied gas is a raw material for producing MTBE, and the light gasoline is a component for producing high-cleanness gasoline. In order to solve the problem of high total sulfur in the oil refining MTBE and the light gasoline, according to the shape and the distribution rule of sulfocompounds in the liquid hydrocarbon, processes such as functional reinforcement of a recycle solvent, three-phase mixed reinforced regeneration, regenerated catalyst and extractant separation and recycle solvent deoxidization and the like are adopted in the conventional process of liquid hydrocarbon extraction, oxidization and mercaptan removal, so the technical effects of reinforcing the mercaptan removal depth, improving carbonyl sulfide removal rate, and avoiding forming disulphide in the extracting, saving energy and reducing emission and the like are achieved. Thus, the liquid hydrocarbon can be deeply desulfurated, the problem of high total sulfur in the oil refining MTBE and the light gasoline is solved and the slag discharging quantity in the conventional process is greatly reduced.

Owner:HEBEI REFINING TECH CO LTD

Method for reliving FCC dead catalyst

ActiveCN101219396AIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

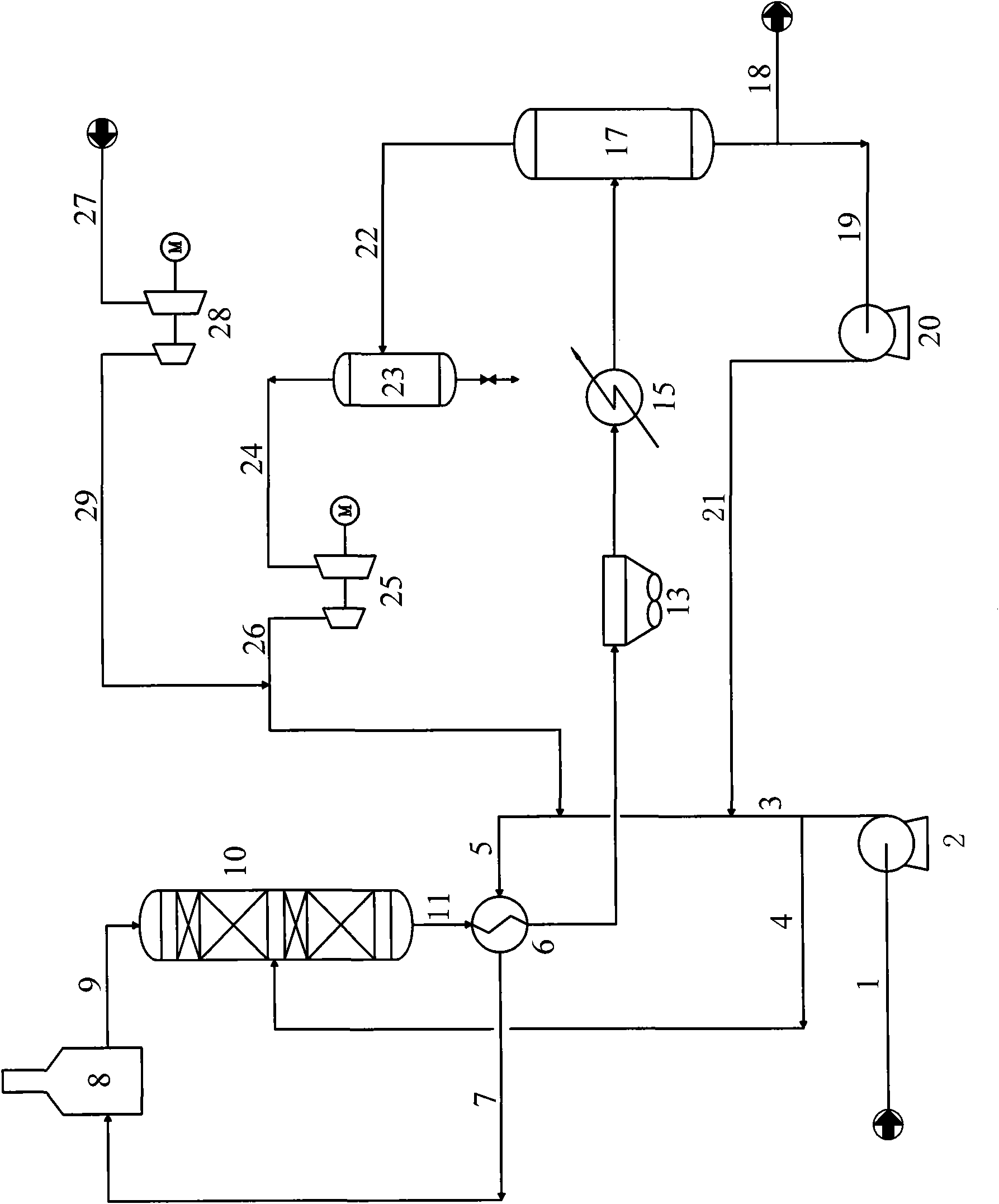

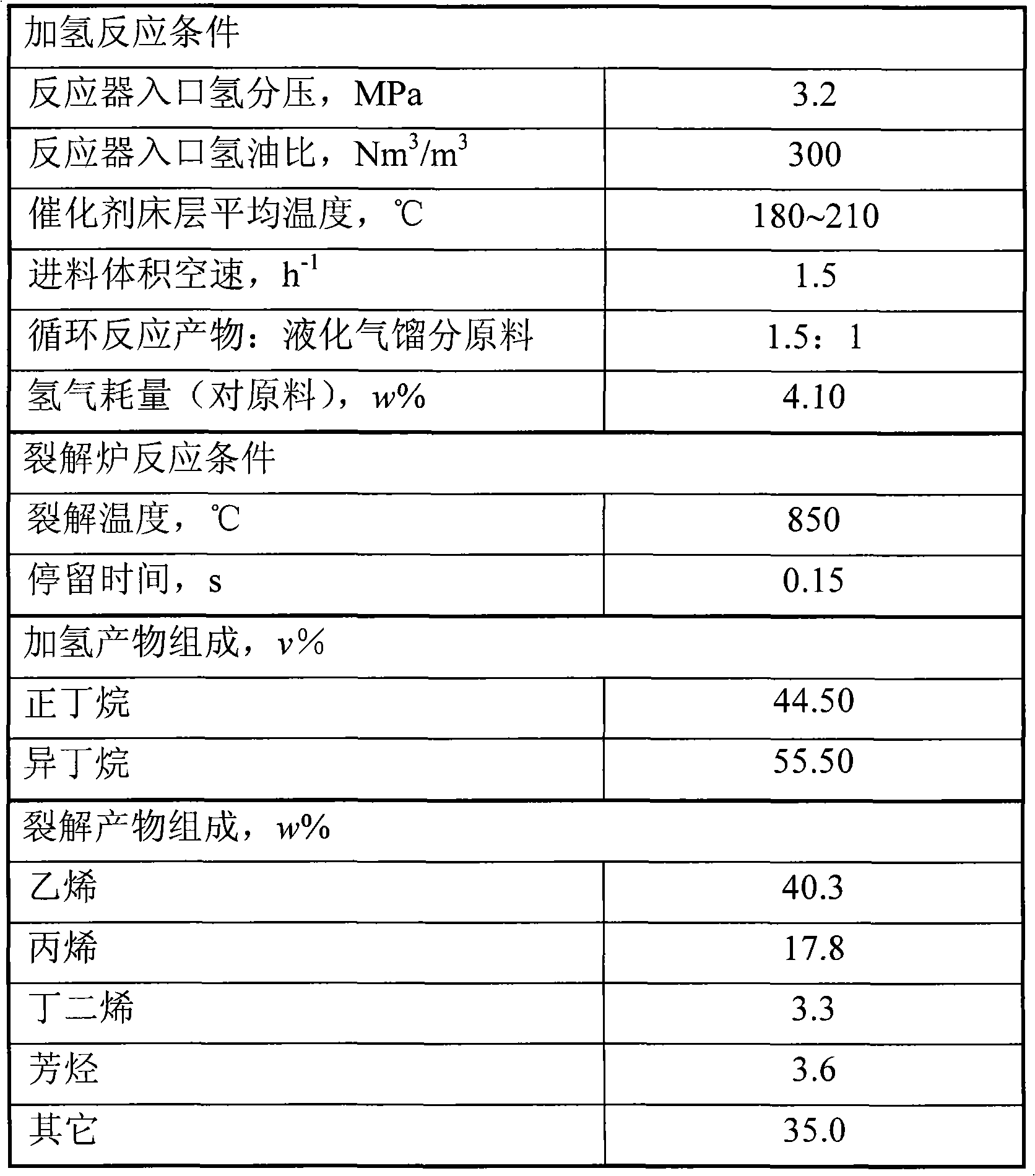

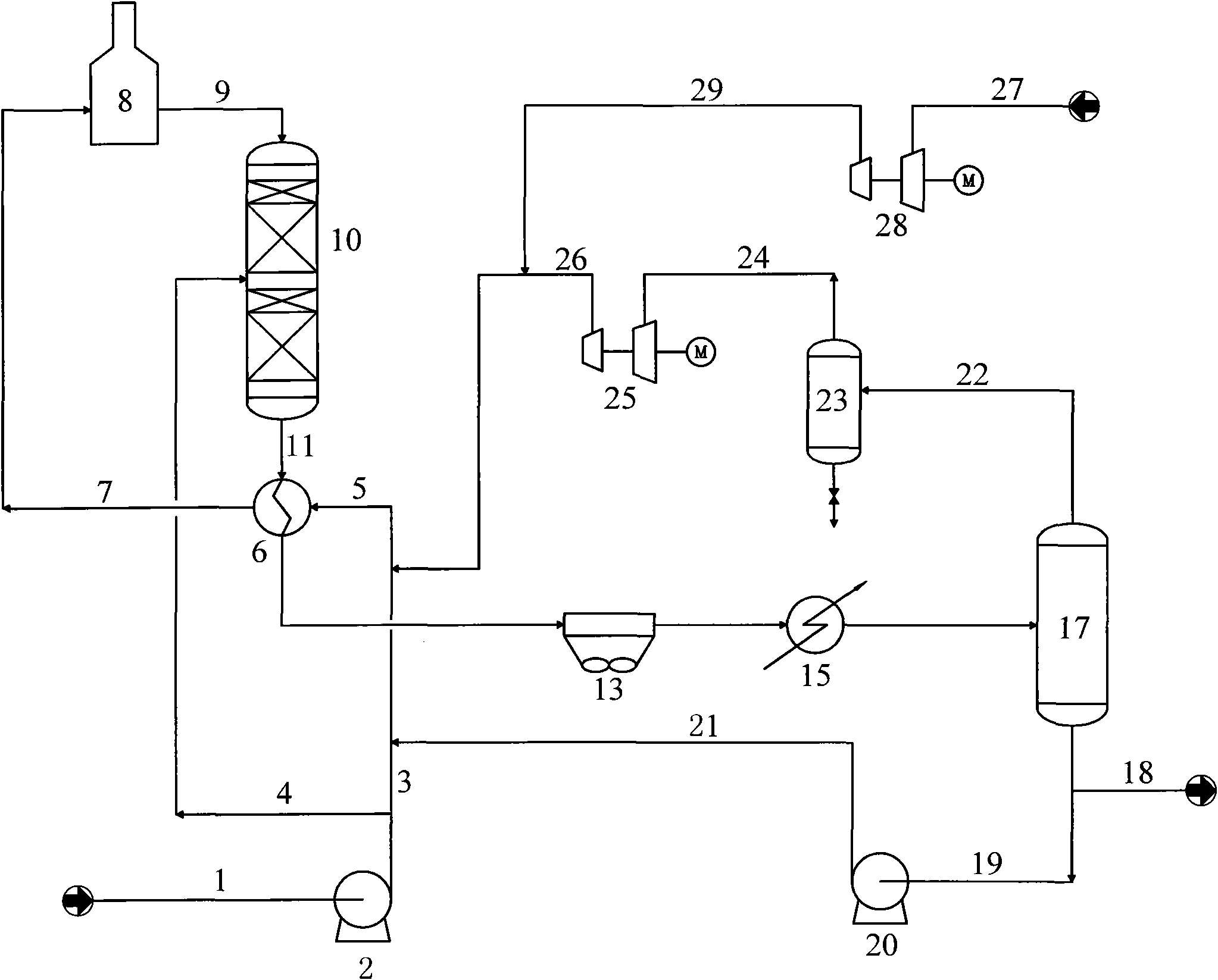

Hydrogenation method for liquefied gas fraction

InactiveCN101880549AExpand application channelsExpand sourceHydrocarbon by hydrogenationTreatment with hydrotreatment processesAlkaneGas phase

The invention discloses a hydrogenation method for liquefied gas fraction, which is characterized by comprising the following steps of: filling at least one section of catalyst bed layer into a reactor, introducing a liquefied gas fraction raw material and hydrogen into the reactor from one or more sections of catalyst bed layers to contact a catalyst and perform hydrogenation saturation reaction, and reacting olefin in the liquefied gas fraction and the hydrogen to generate alkane and release a large amount of heat; after heat exchange, feeding the reaction product into a gas-liquid separator and separating the reaction product into a gas phase and a liquid phase, and introducing the separated gas phase flow into the reactor to perform repeated use; and introducing a part of separated liquid phase flow serving as a cyclic reaction product back to the reactor, and introducing the other part of the separated liquid phase flow serving as a liquefied gas fraction hydrogenation product out of the reactor to perform reuse. The hydrogenation product obtained by the method is saturated light hydrocarbon fraction which can be directly used as a raw material for an ethylene cracking device and also can be fractionated and cut into propane, n-butane and iso-butane and the like serving as high value-added chemical base raw materials so as to increase the economic benefit of an oil refining enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

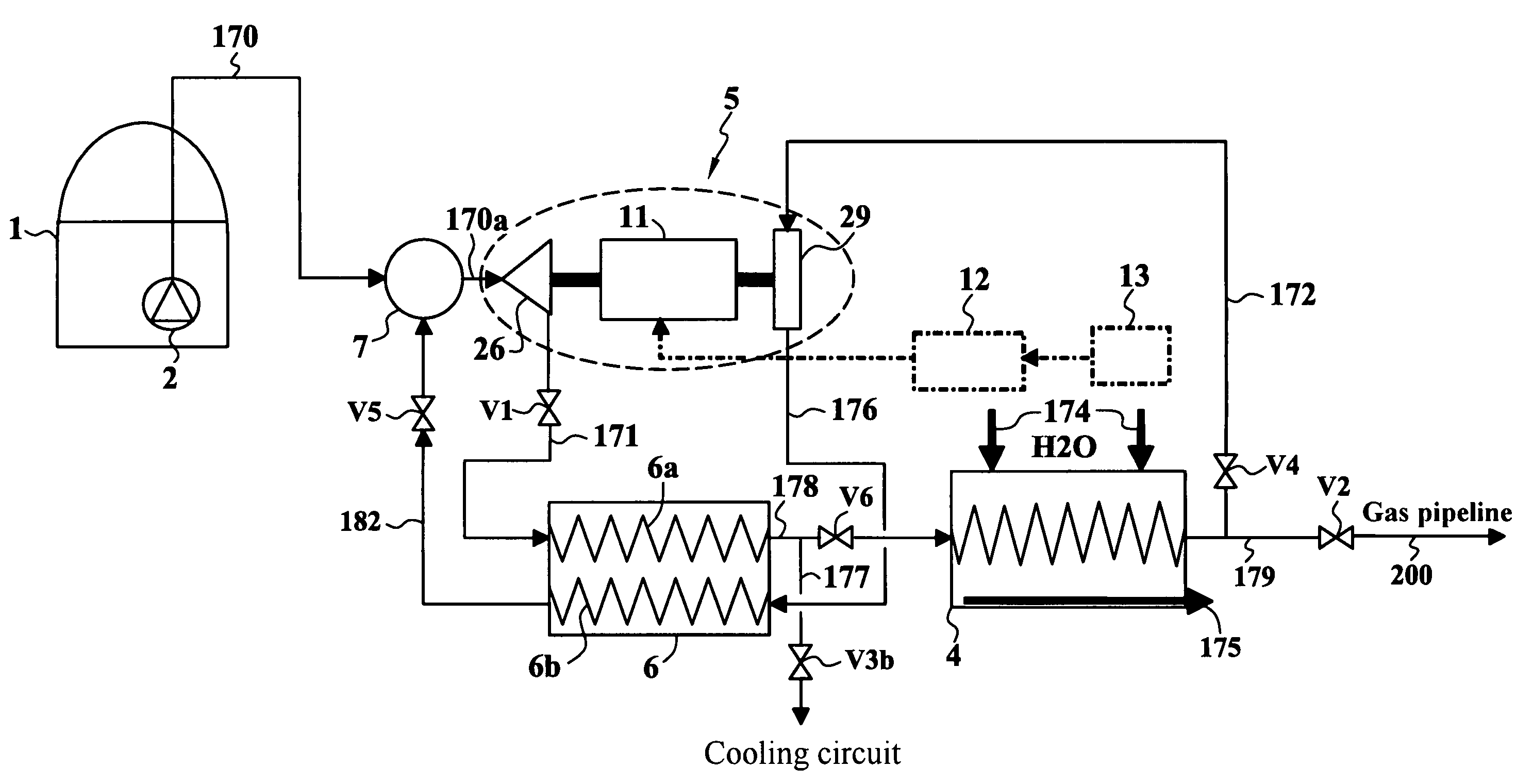

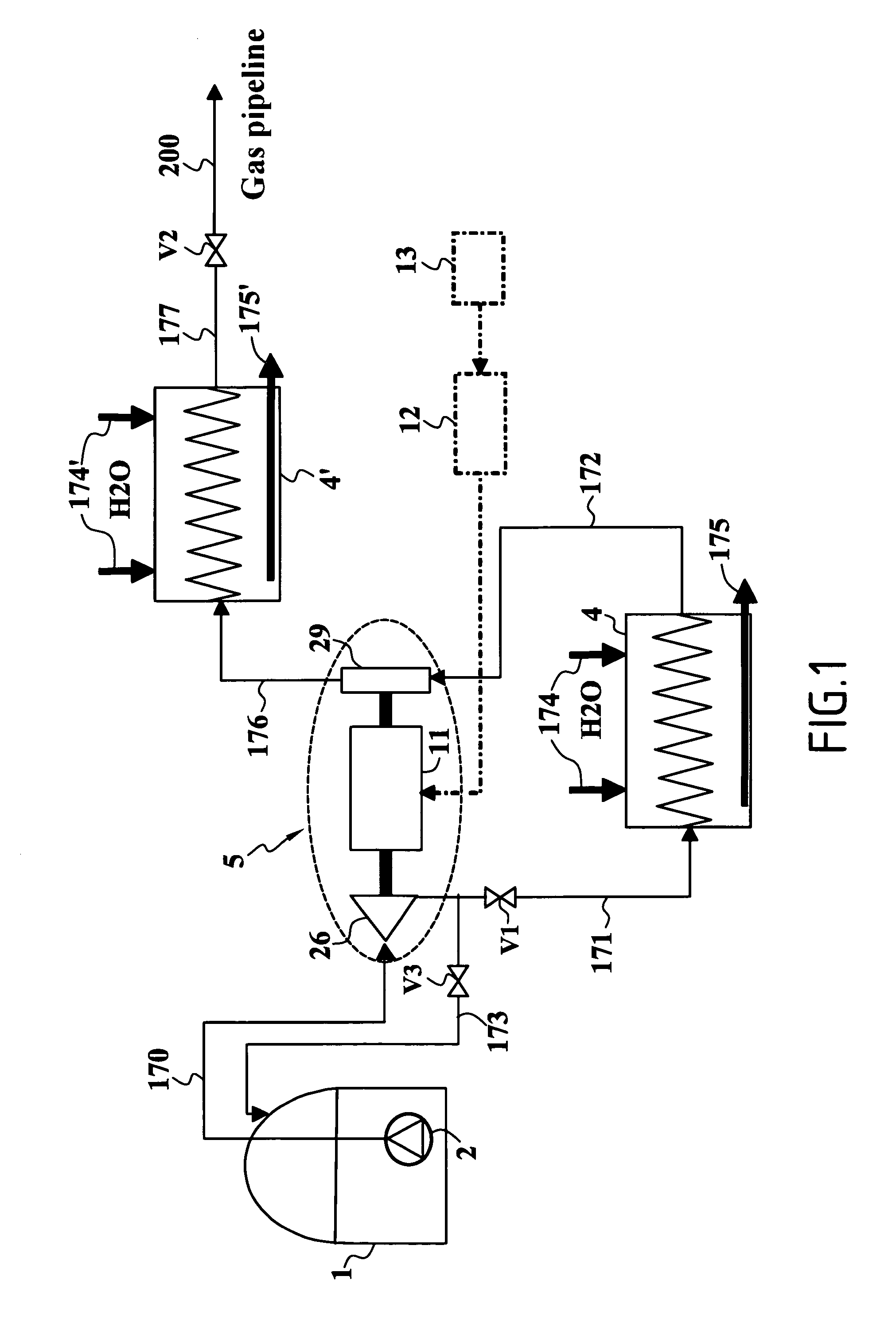

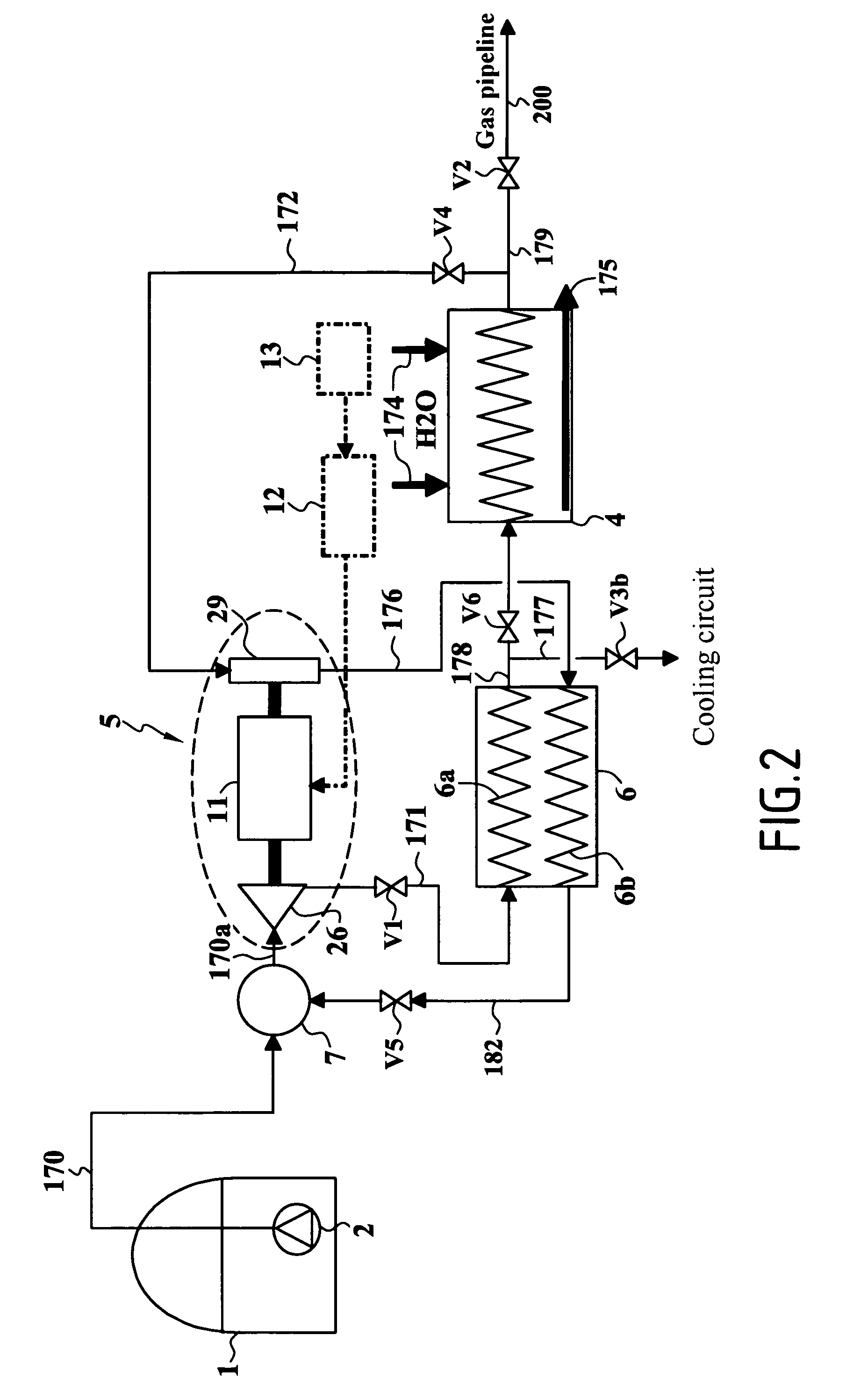

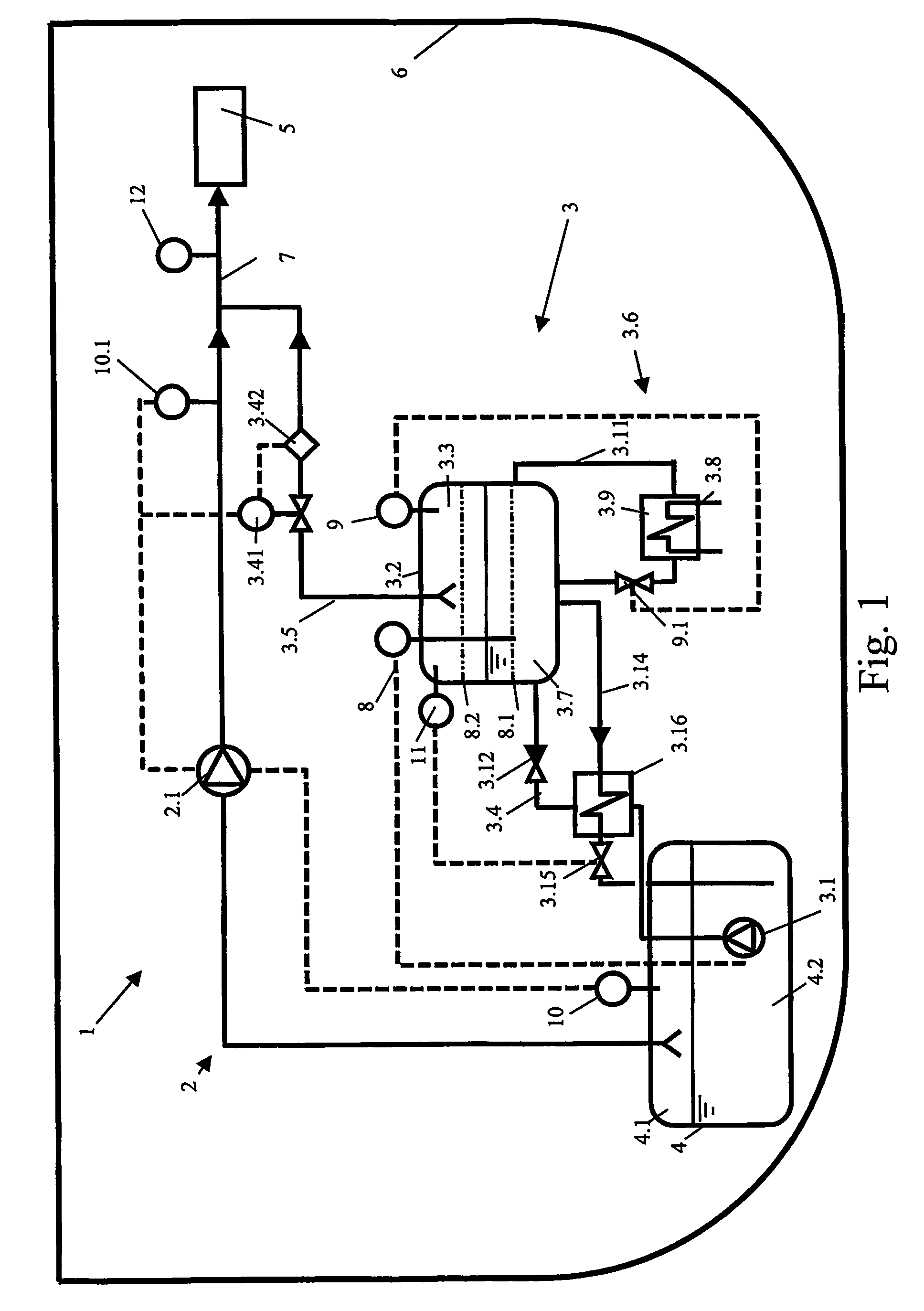

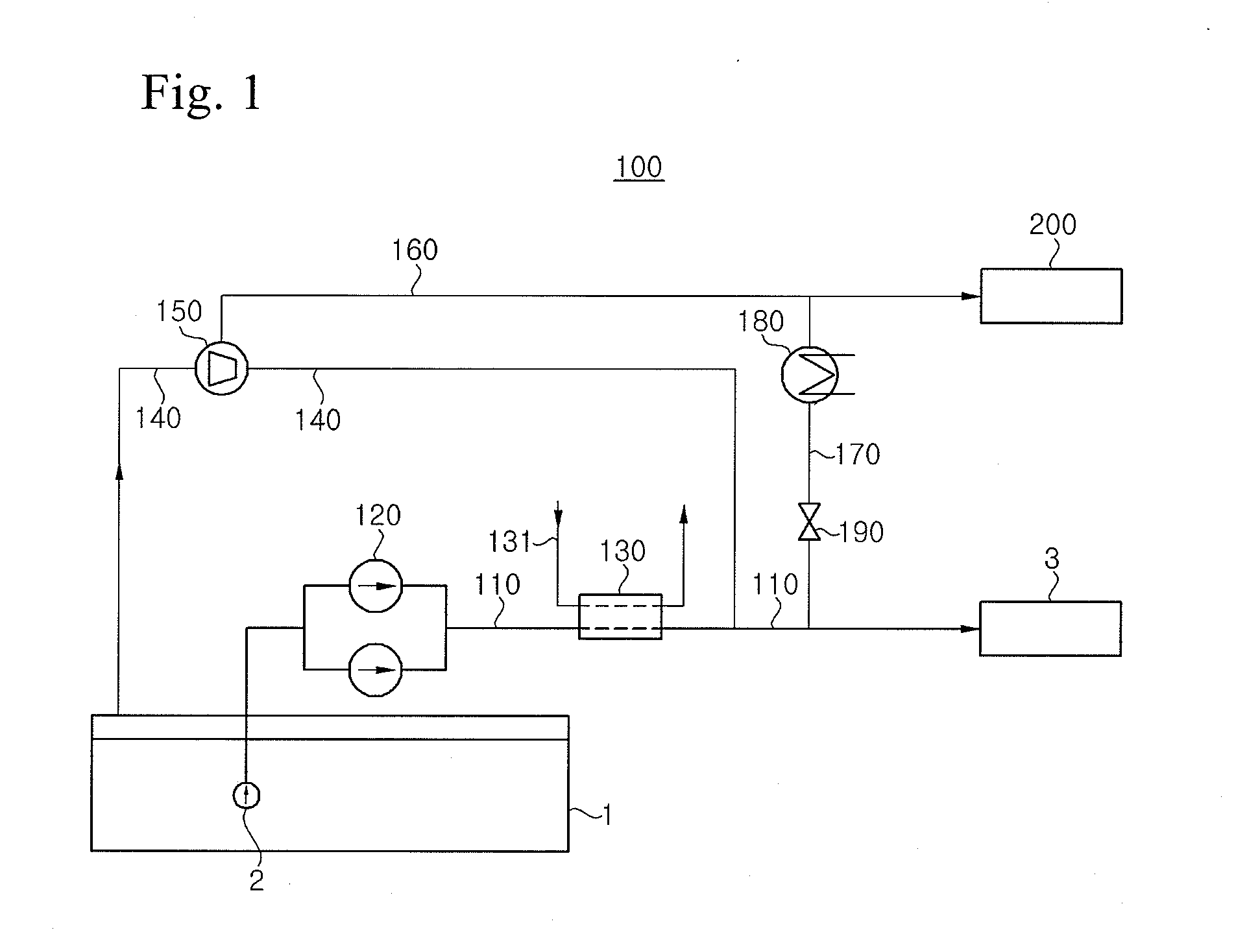

Compression-evaporation system for liquefied gas

InactiveUS7406830B2Reduce and even eliminate consumptionGas handling applicationsGas handling/storage effectsEvaporationEngineering

The compressor-evaporator system for liquefied gas contained in a tank comprises, in addition to a deice for evaporation by heat exchange with a liquid and devices for conditioning and transferring gas to a pipeline, a motor-driven turbopump comprising a rotary assembly of high bending stiffness on a common shaft line, with at least one high pressure pump, a turbine, and a central electrical machine capable of being used in motor mode or in generator mode. The rotary assembly of the motor-driven turbopump is adapted to present a high speed of rotation, greater than 12,000 rpm, while remaining outside ranges for exciting critical speeds in rotation. All of the internal portions of the motor-driven turbopump are immersed in a cryogenic fluid that is the same as the liquefied gas contained in the tank. The internal cavities of the motor-driven turbopump that are under different thermodynamic conditions are separated by contactless dynamic seals. Electronic power circuits connected to an electricity network control the central electrical machine in motor mode or generator mode.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Two-component on-site foam system and its use for foaming openings for the purpose of fire protection

InactiveUS20020020827A1High foaming rateIncreased fire resistance enduranceOther chemical processesGroup 5/15 element organic compoundsPolyesterVolumetric Mass Density

A two-component on-site foam system for producing an intumescing fire protection foam is described with a density of less than 200 kg / m3 and an increased fire resistance endurance, with a polyol component (A), which contains at least one polyol, one catalyst for the reaction between the polyol and the polyisocyanate, water or a blowing agent based on a compressed or liquefied gas as foam-forming agent and at least one intumescing material based on an acid-forming agent, a carbon-supplying compound and a gas-forming agent, and a polyisocyanate component (B), which contains at least one polyisocyanate, wherein the polyol component (A) contains at least one polyester polyol, at least one aminopolyol, at least one halogen-containing polyol, at least one acidforming agent, expanding graphite and at least one ash crust stabilizer, the quantitative ratios of the polyols to the polyisocyanate or polyisocyanates being matched so that, when the polyol component (A) is mixed with the polyisocyanate component (B) as specified, the molar ratio of isocyanate groups of the polyisocyanate to the hydroxyl groups of the polyol (NCO: OH ratio) is larger than 1: 1, as well as to the use of this system for filling openings, cable and pipe leadthroughs in walls, floors and / or ceilings of buildings with foam for the purpose of fire protection.

Owner:HILTI AG

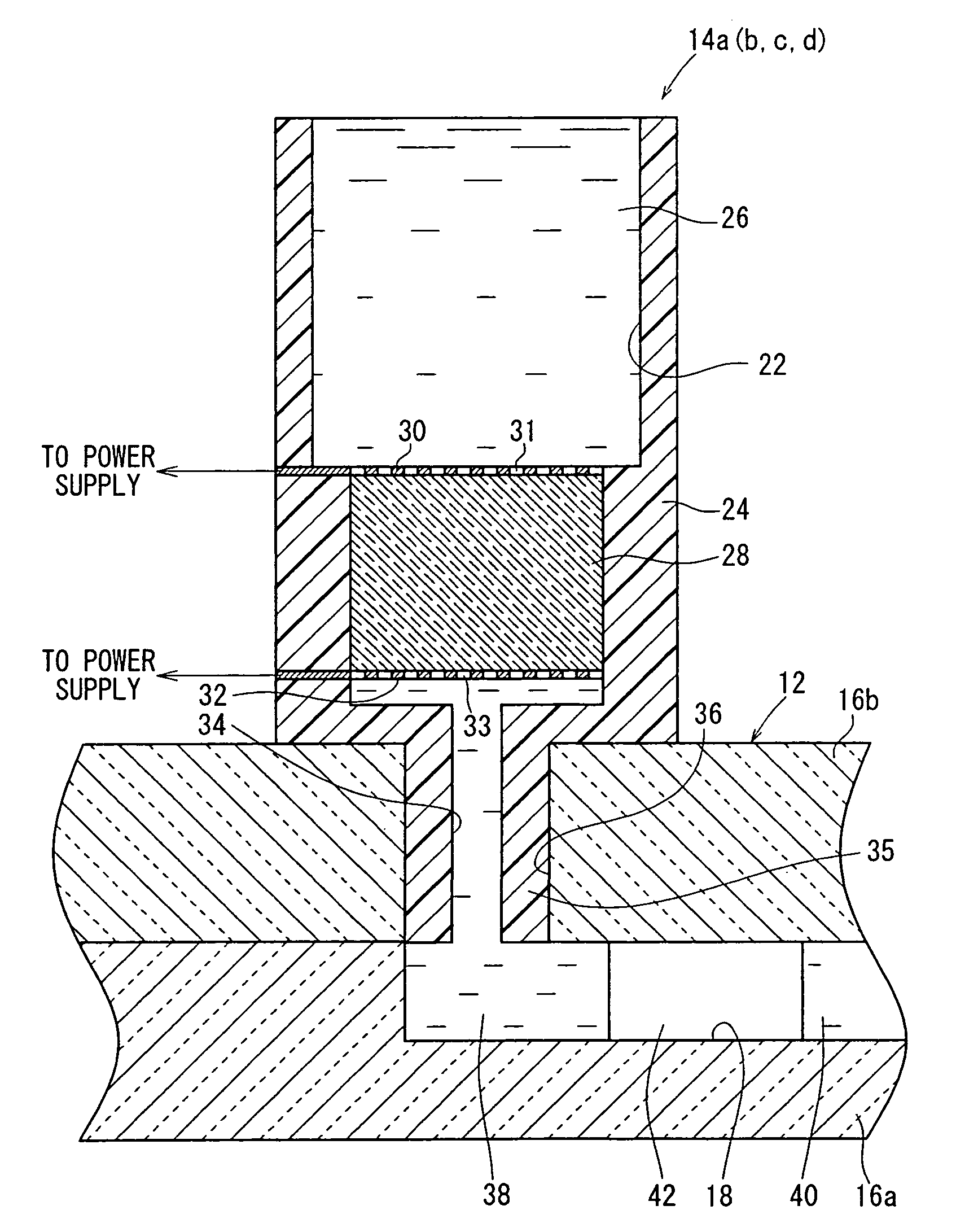

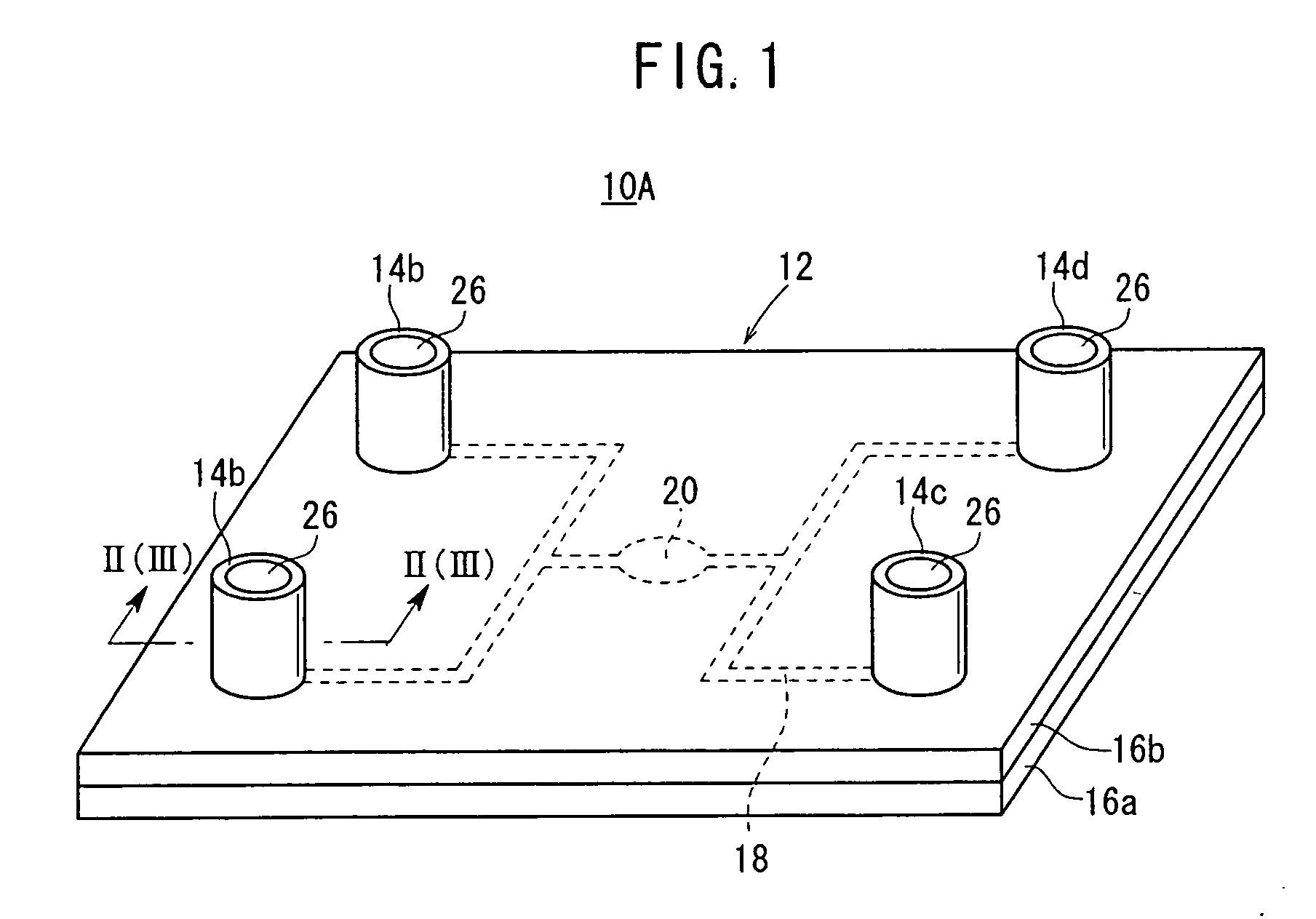

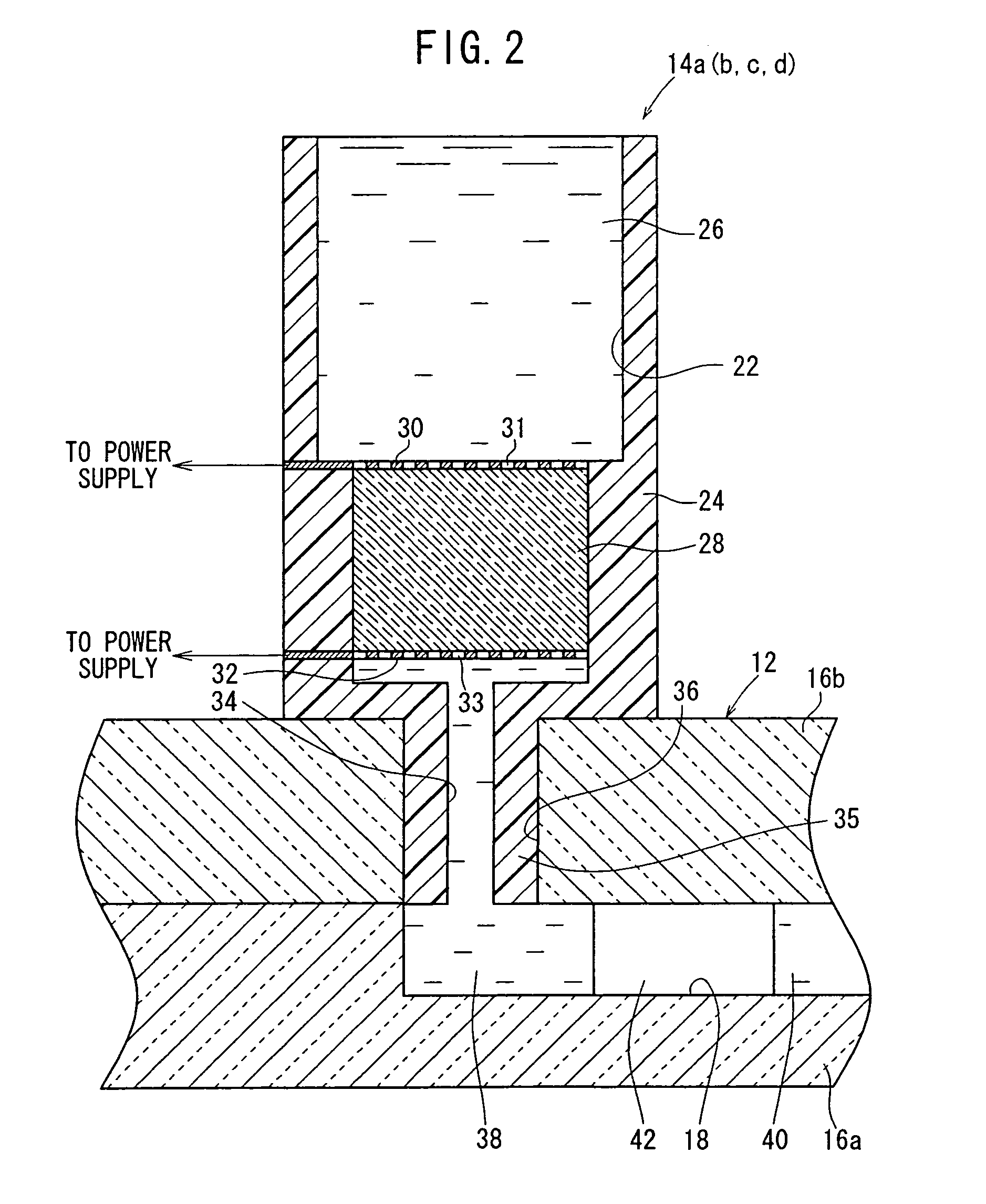

Electroosmotic Pump System and Electroosmotic Pump

InactiveUS20080260542A1Improve mobilityEfficient evaporationPump componentsFixed microstructural devicesEngineeringLiquid gas

A projection is formed on a pump body of an electroosmotic flow pump so as to face a communication hole of a micro fluid chip. When the projection and the communication hole are fitted together, a first flow path of the pump and a second flow path of the micro fluid chip are communicated and the pump is fixed to the micro fluid chip. At the same time, the connection between the first flow path and the second flow path is sealed to prevent leakage of liquid gas, etc. to the outside.

Owner:NANO FUSION TECH

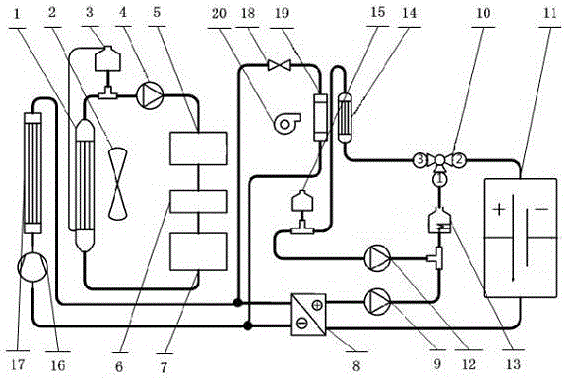

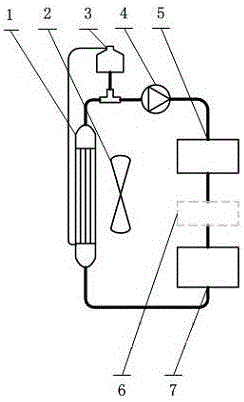

Whole vehicle heat management system of pure electric vehicle

InactiveCN105984304AImprove environmental adaptabilityImprove powerAir-treating devicesVehicle heating/cooling devicesThermal management systemPure electric vehicle

The invention relates to a thermal management system for a pure electric vehicle, which is characterized in that it includes an electric drive system and a charger cooling circuit, a power battery cooling circuit, a power battery charging heating circuit, a passenger compartment heating circuit and a passenger compartment refrigeration circuit; The electric drive system and charger cooling circuit includes radiators, fans, kettles connected by pipelines, the electric drive system and charger cooling water pump installed in the circuit, as well as the motor controller and DCDC, as well as the charger and motor. The radiator realizes liquid-gas heat exchange to cool the heat dissipation components. Improve the environmental adaptability of electric vehicles, the power performance in high-temperature environments, the durability of key components, and the energy utilization efficiency of the entire vehicle.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

In-situ method of producing oil shale and gas (methane) hydrates, on-shore and off-shore

A method is provided for in-situ production of oil shale and gas (methane) hydrates wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Heat is thereafter applied to liquify the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

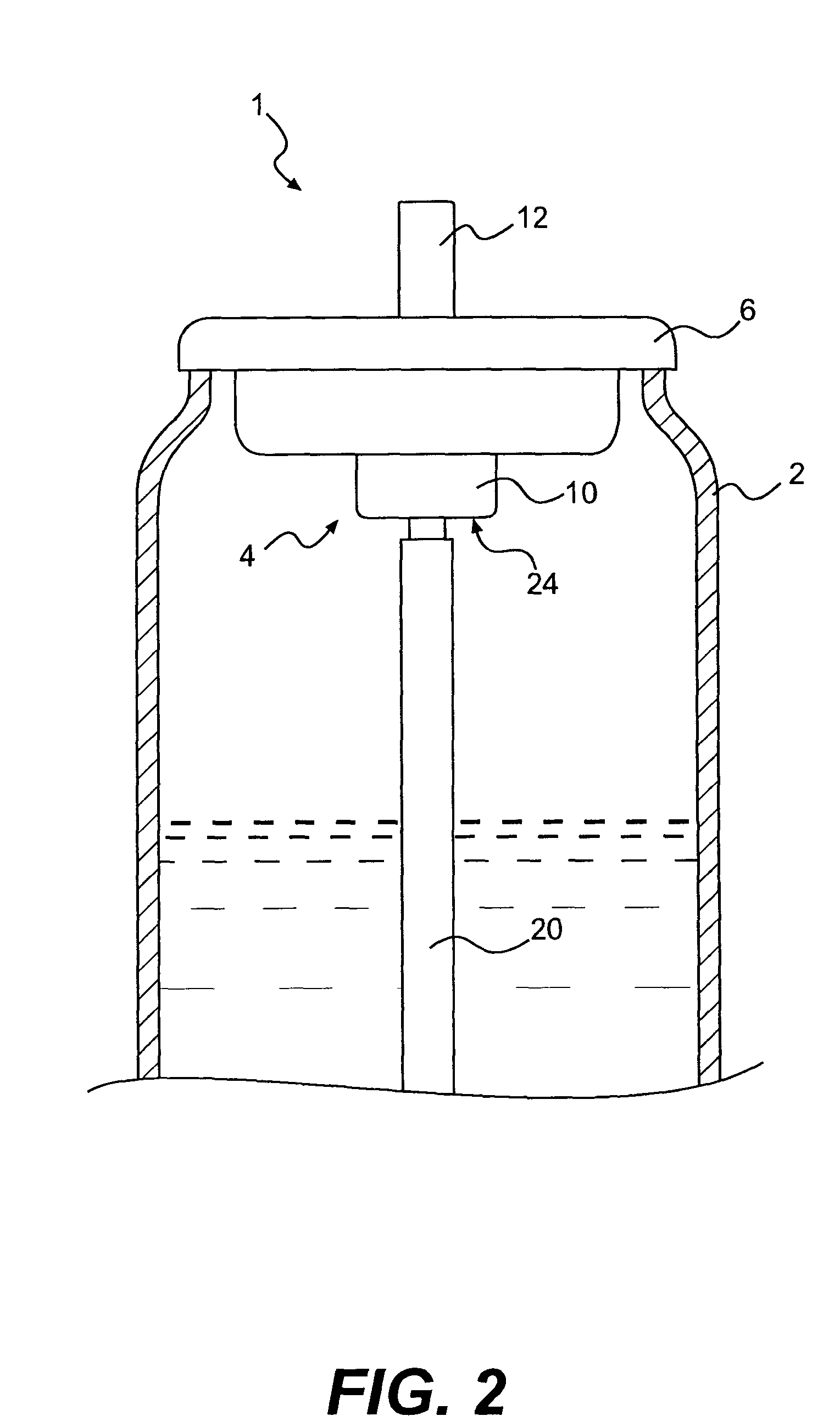

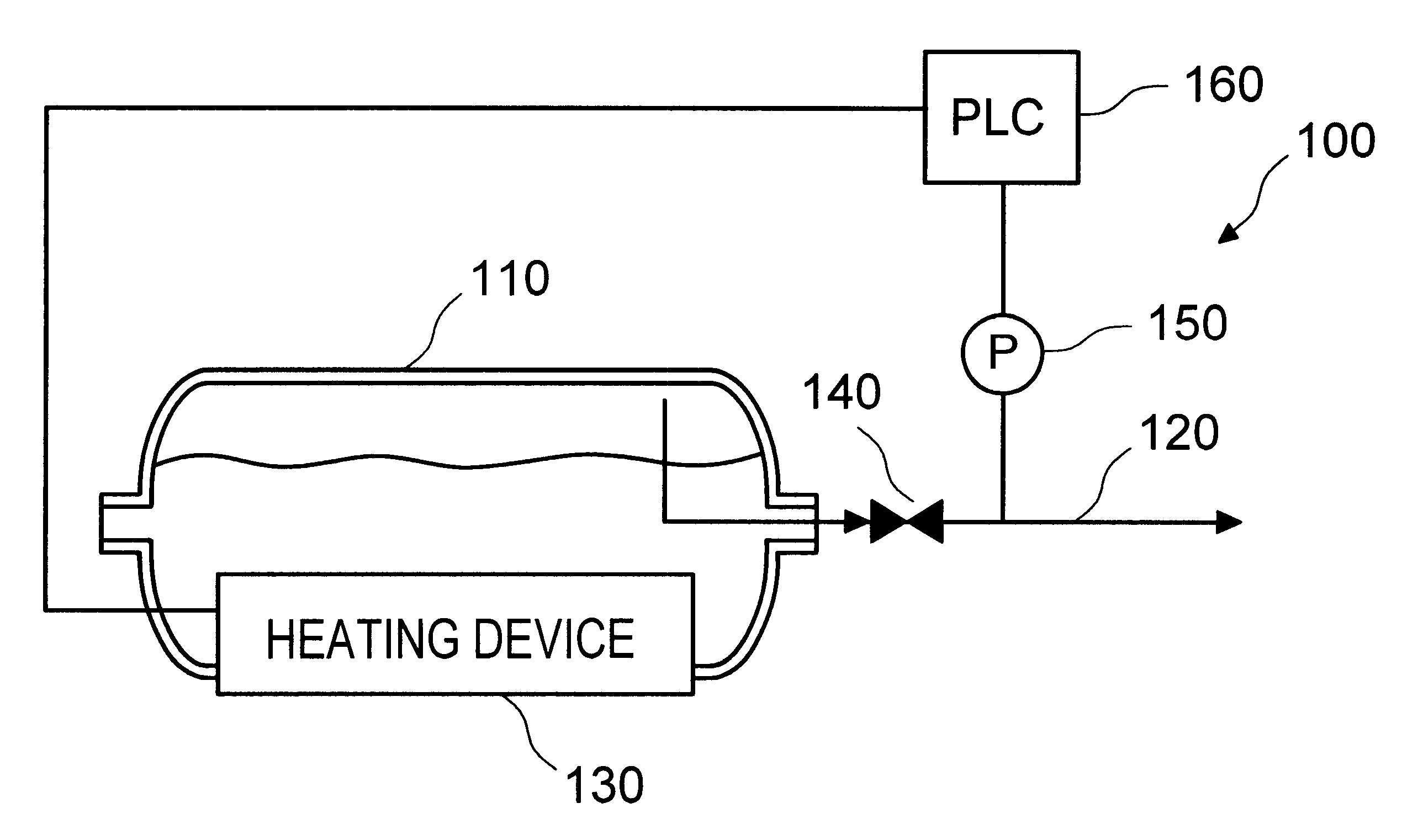

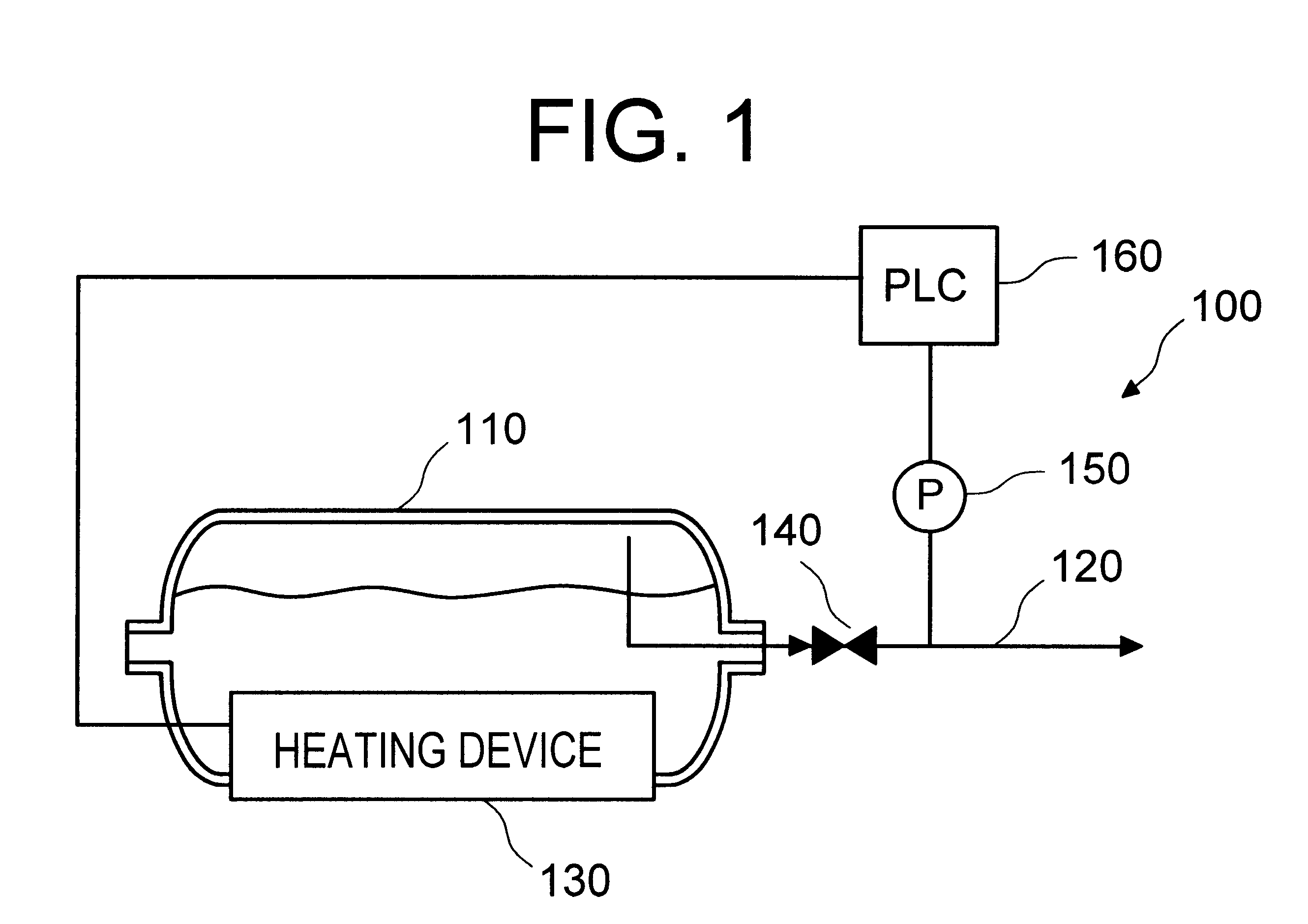

System and method for controlled delivery of liquefied gases from a bulk source

Provided is a novel system and method for delivery of gas from a liquefied state. The system includes (a) a delivery vessel holding a bulk quantity of liquefied gas therein; (b) a heat exchanger disposed on the delivery vessel to provide or remove energy from the liquefied gas only; and (c) a pressure controller for monitoring and adjusting the energy delivered to the vessel. The system and method allow for controlled delivery of liquefied gas from a delivery vessel at a predetermined flow rate. Particular applicability is found in the delivery of gases to semiconductor process tools.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

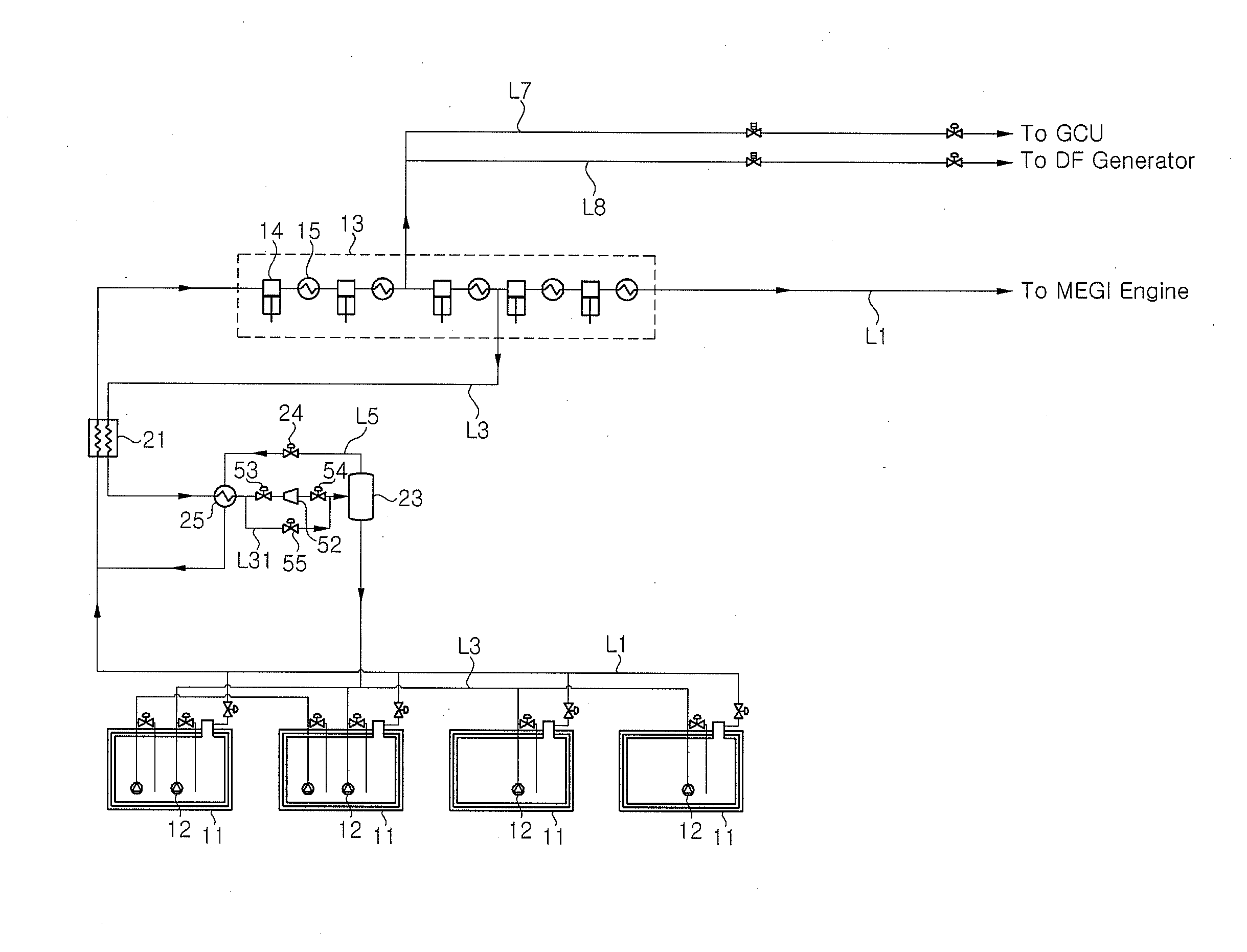

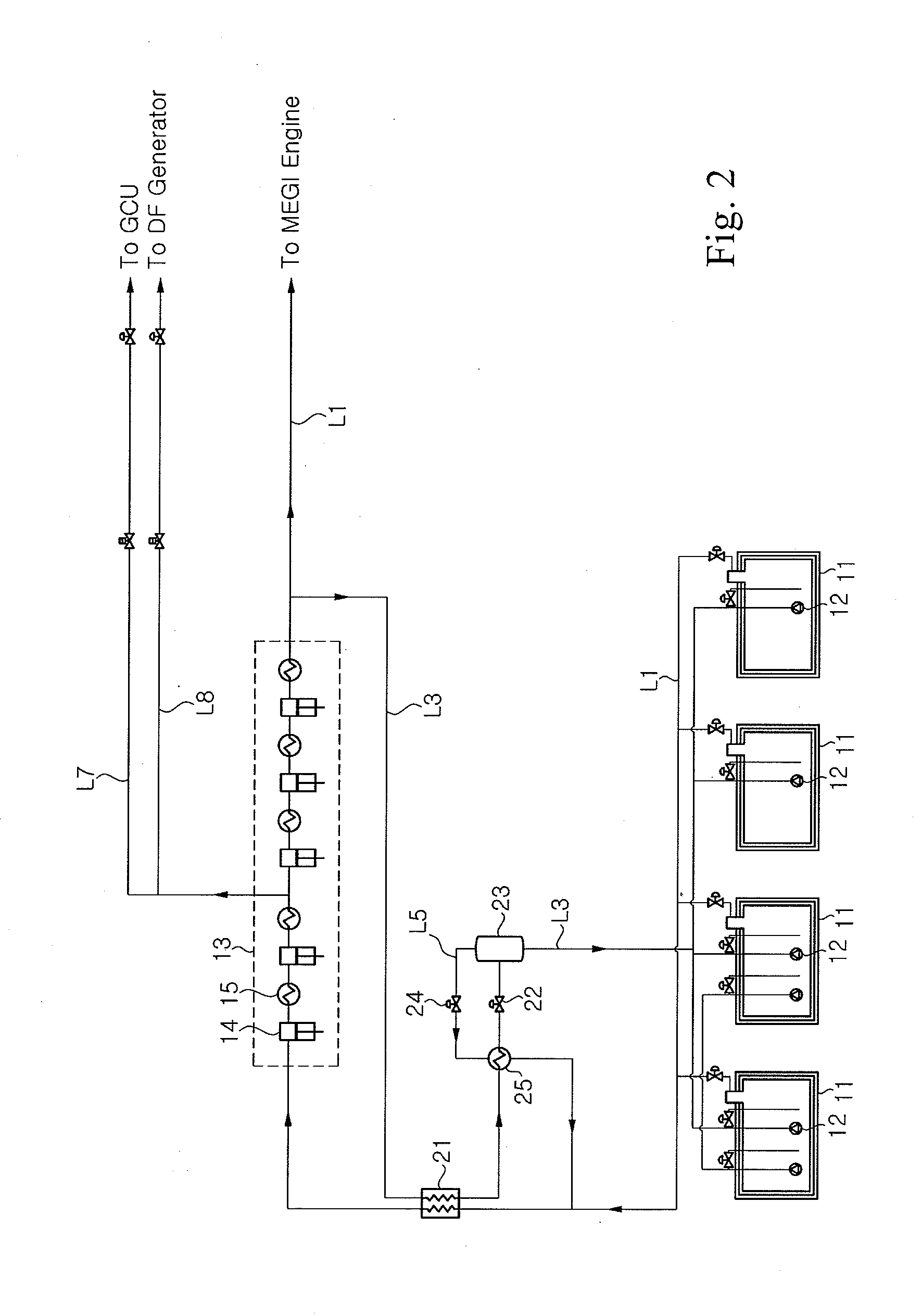

Gas supply arrangement of a marine vessel and method of providing gas in a gas supply arrangement of a marine vessel

InactiveUS7497180B2Easy to maintain temperatureReduce the impactAuxillariesContainer filling methodsEngineeringControl valves

A gas supply arrangement of a marine vessel being adapted to carry liquefied gas in its cargo tank having an ullage space section and a liquid phase section, which arrangement utilizes the gas as fuel to provide power for the vessel, the arrangement comprising a first gas supply line provided for processing the natural boil-off gas formed in the cargo tank, a second gas supply line which connects the cargo tank and the gas main supply line and which is provided with at least a pump for raising the pressure of the liquid gas and for pumping it forward. The second gas supply line is provided with a gas reservoir having an ullage space section and liquid phase section, and that the arrangement is provided with a first duct section of the second gas supply line connecting the liquid phase section of the cargo tank and the liquid phase section of the gas reservoir, and being provided with the pump, and that the arrangement is additionally provided with a return line connecting the liquid phase section of the reservoir and the cargo tank being provided with a control valve for controllable returning liquid gas back into the cargo tank.

Owner:WARTSILA FINLAND OY

Liquefied gas treatment system for vessel

InactiveUS20140290279A1Save energy consumptionLower initial installation costsSolidificationLiquefactionProcess engineeringRefrigerant

A liquefied gas treatment system includes: a first stream of boil-off gas, which is generated from the liquefied natural gas in the cargo tank and is discharged from the cargo tank; a second stream of the boil-off gas, which is supplied as fuel to the engine in the first stream; and a third stream of the boil-off gas, which is not supplied to the engine in the first stream. The first stream is compressed in a compressor and is then branched into the second stream and the third stream. The third stream is liquefied by exchanging heat with the first stream in a heat exchanger, so that the boil-off gas is treated without employing a reliquefaction apparatus using a separate refrigerant.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

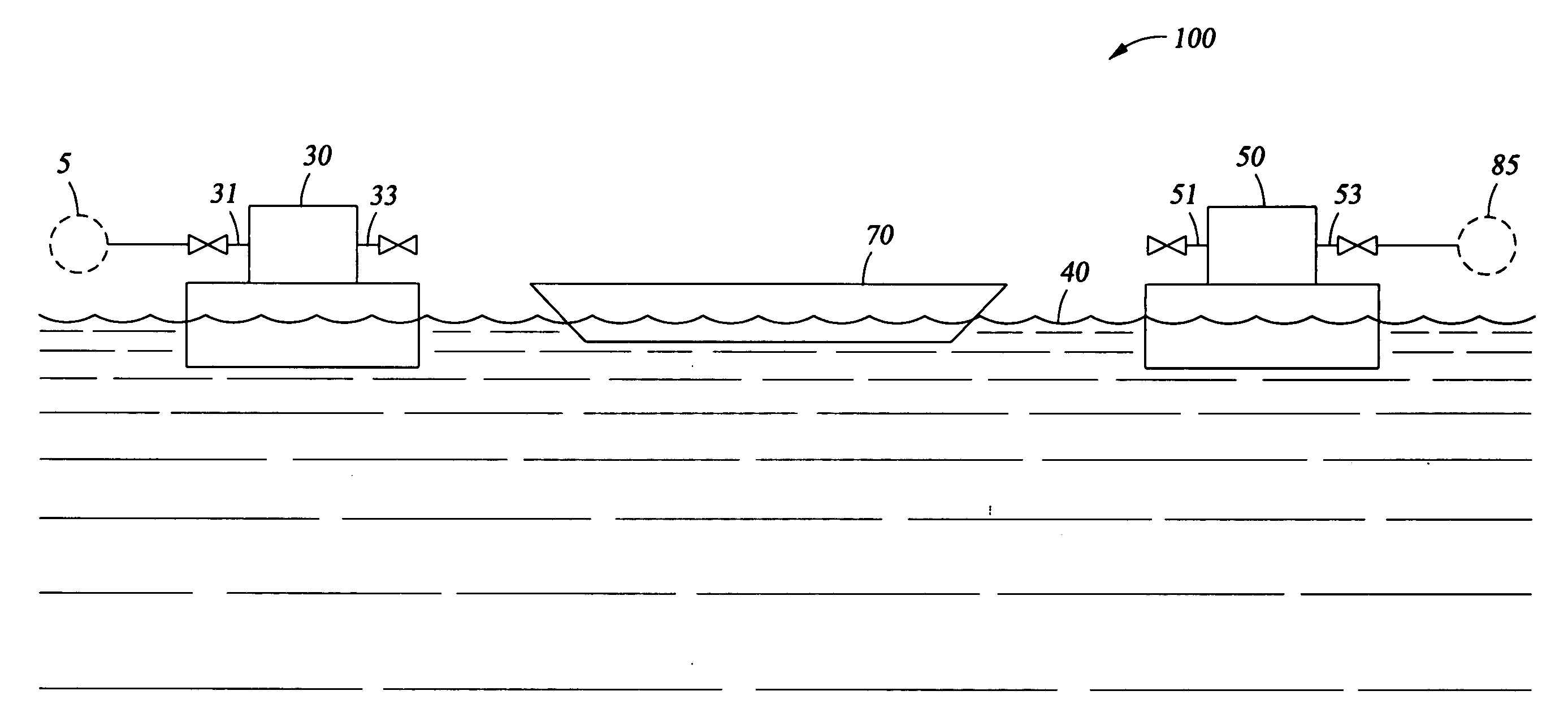

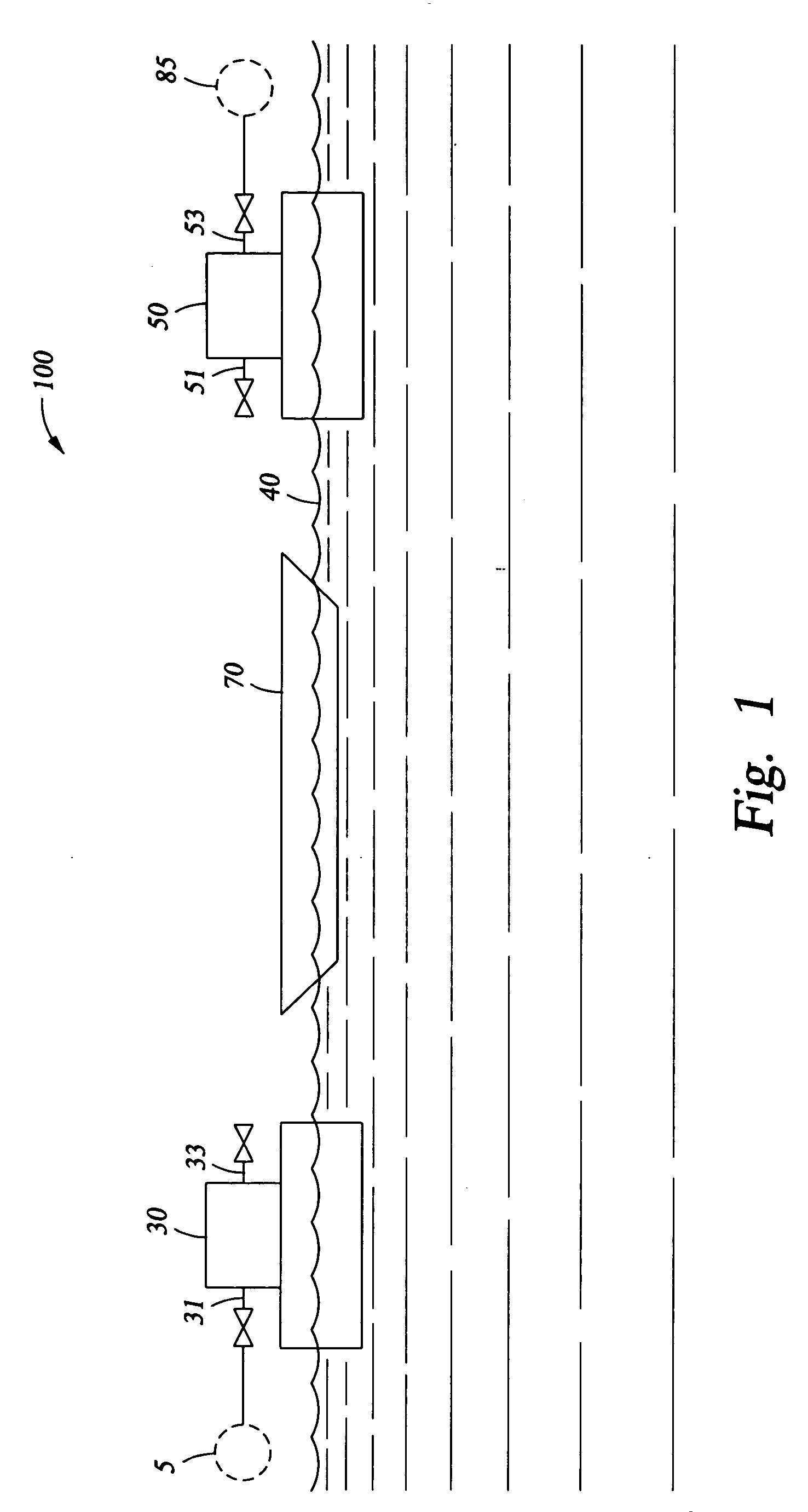

Apparatus for cryogenic fluids having floating liquefaction unit and floating regasification unit connected by shuttle vessel, and cryogenic fluid methods

Methods and systems for transportation of a cryogenic fluid. The system includes a floating liquefaction unit receiving a gas from a source, a shuttle vessel for carrying liquefied gas away from the liquefaction unit, and a floating regasification unit for receiving the liquefied gas from the vessel, regassifying the liquefied gas and providing the gas to a distribution system.

Owner:MUSTANG ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com