Catalysis conversion method for producing aromatic compounds

An aromatic compound, catalytic conversion method technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve problems such as a large amount of coke, and achieve the effect of increasing the space velocity of the raw material, reducing the viscosity of the feed, and improving the reaction rate of impurity removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

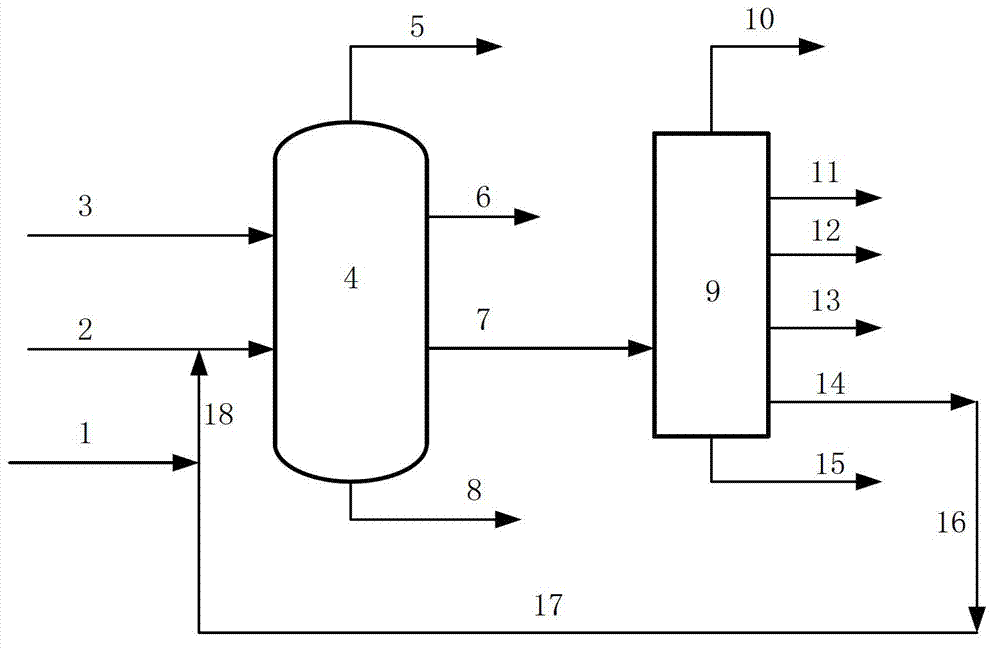

Image

Examples

Embodiment 1

[0048] This example illustrates the product distribution and product properties of raw materials treated by a medium-sized catalytic cracking unit and a medium-sized residual oil hydrotreating unit using the method provided by the present invention.

[0049] The raw oil entering the residual oil hydrogenation unit is a mixture of vacuum residual oil and catalytic cracking heavy cycle oil, and the mass ratio of the two is 90:10. The test conditions for residual oil hydrogenation are: hydrogen partial pressure 14.2MPa, reaction temperature 400℃, hydrogen-oil ratio 1000Nm 3 / m 3 , the airspeed is 0.28h -1 .

[0050] Hydrogenated diesel oil (distillation range 200-380°C) is used as the raw material for catalytic cracking. The test conditions for catalytic cracking are: reaction temperature 590°C, agent-oil ratio 10:1, water-oil ratio 0.2, and reaction time 4.6 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com