Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Reduce vanadium content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

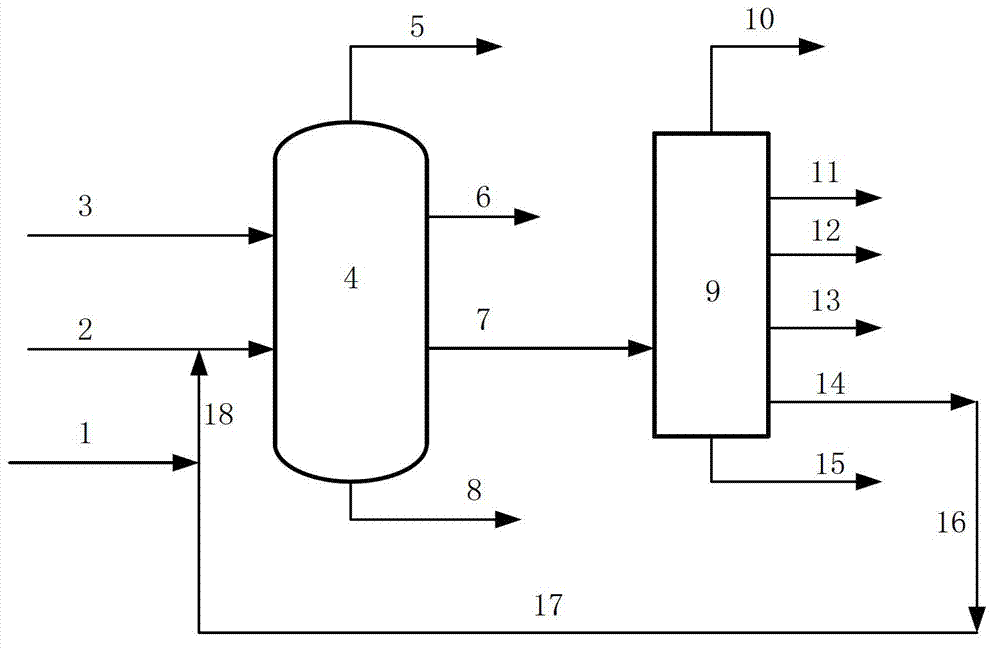

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ferrovanadium by rollover furnace through electro-aluminothermic process

The invention belongs to the field of metallurgy and particularly relates to a method for preparing ferrovanadium by a rollover furnace through the electro-aluminothermic process. The method for preparing the ferrovanadium by the rollover furnace through the electro-aluminothermic process comprises the steps that raw materials of vanadium oxide, aluminum, iron and lime which meet the production requirement are evenly mixed and then added into the rollover type electric-arc furnace, the method combining multi-phase smelting and stepping aluminum distribution is adopted, most slag is removed after the content of vanadium in the slag is reduced to a certain level, the repeated operation of multiple phases of feeding and slag discharging is conducted, the slag and iron are discharged together when the last phase of smelting is conducted and poured into an ingot mould, and ferrovanadium alloy can be obtained after cooling is conducted. The method for preparing the ferrovanadium by the rollover furnace through the electro-aluminothermic process is convenient to operate, capable of lowering aluminum consumption and obvious in economic benefit; meanwhile, the smelting yield of the ferrovanadium is increased, and the obtained ferrovanadium product is low in content of aluminum.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

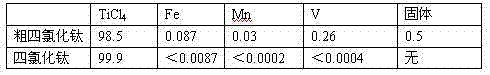

Organic reagent for removing vanadium and method for removing vanadium from titanium tetrachloride

InactiveCN105271383AFast vanadium removalLess residueTitanium halidesUnsaturated fatty acidTitanium tetrachloride

The invention relates to the field of titanium tetrachloride refining and discloses an organic reagent for removing vanadium and a method for removing vanadium from titanium tetrachloride. The organic reagent for removing vanadium comprises saturated fatty acid and unsaturated fatty acid. With the total volume of the organic reagent as the reference, the content of saturated fatty acid is larger than 0 and smaller than or equal to 60% by volume, the content of unsaturated fatty acid is larger than or equal to 40% by volume and smaller than 100% by volume, the chain length of saturated fatty acid ranges from C5 to C9, and the chain length of unsaturated fatty acid ranges from C10 to C30. The organic reagent for removing vanadium is high in vanadium removing speed, good in effect and small in quantity of generated residues.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Load typed varadium catalyst and its preparing method and application

InactiveCN1431045AReduce vanadium contentReduce airspeedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen atmosphere

A carried vanadium catalyst is prepared from activated carbon or gamma-Al2O3, vanadium and assistant through pulverizing activated carbon or gamma Al2O3 by 20-80 meshes, preparing the solutions of V precursor and assistant precursor, immersing for 18-36 hr, drying at 110-120 deg.c for 4-6 hrs, calcining at 450-650 deg.c for 4-5 hrs in nitrogen atmosphere and putting in drier. Its advantages are high transform rate of ethylbenzene (more than 60%) and high selectivity to styrene (more than 96%).

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

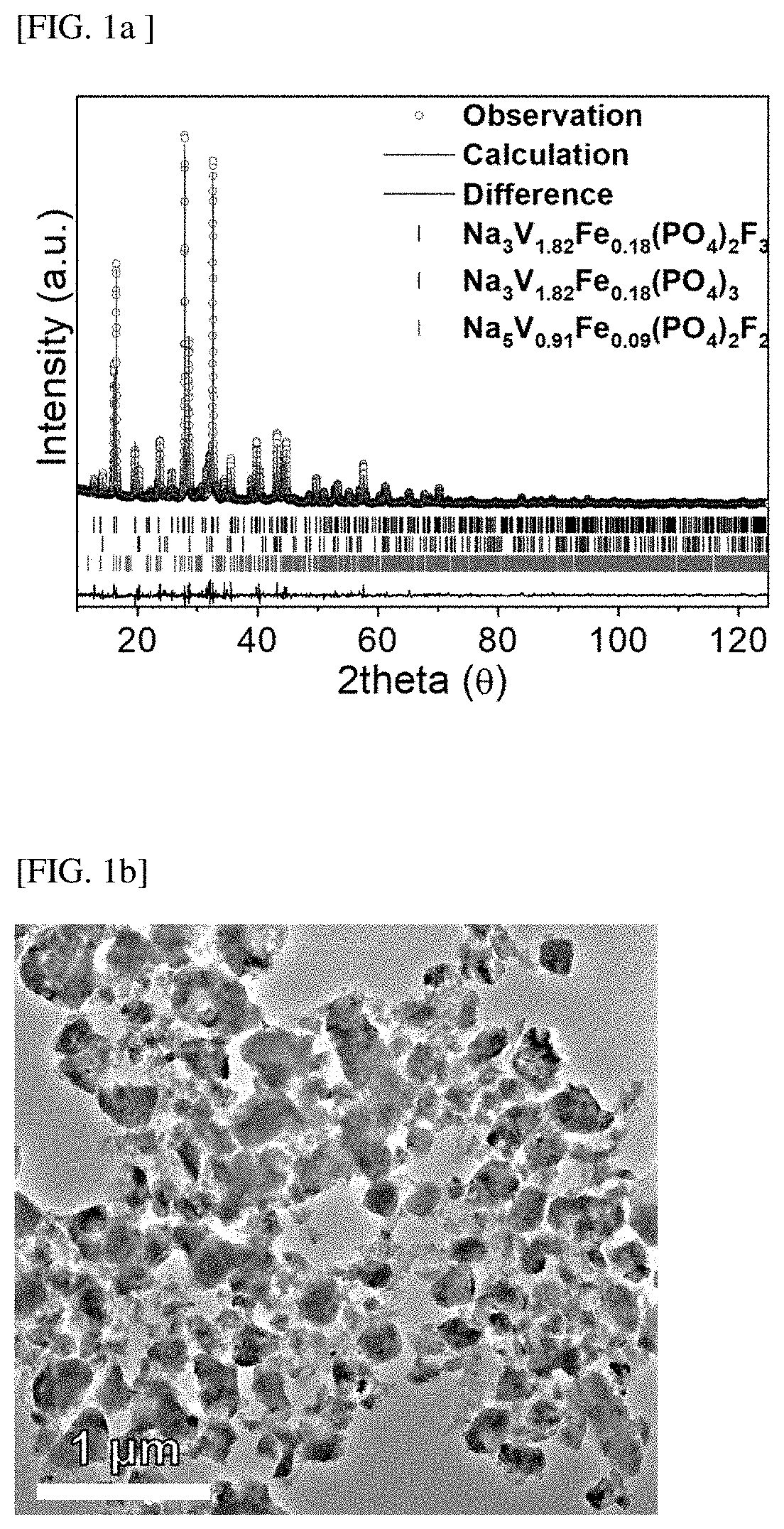

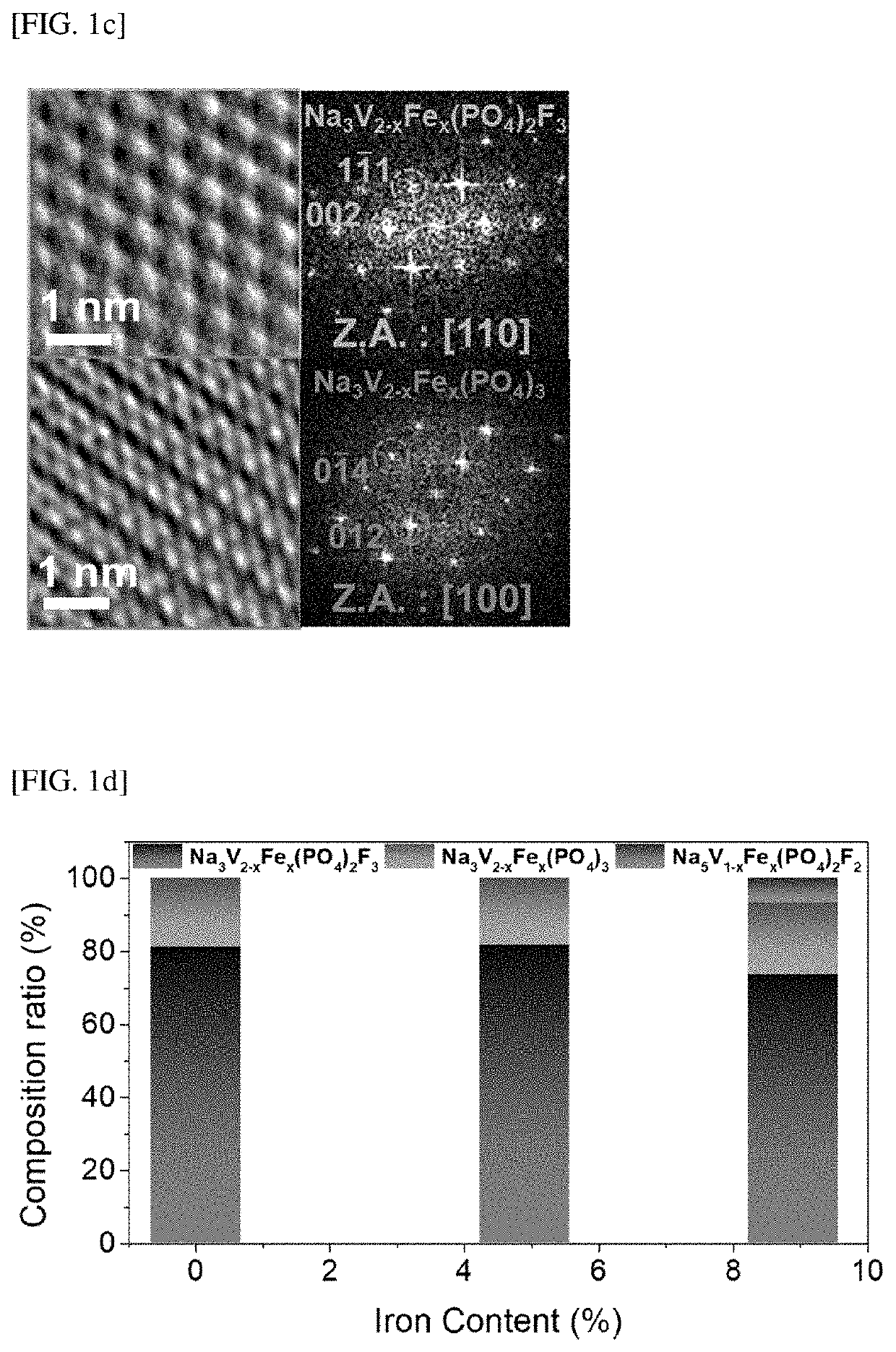

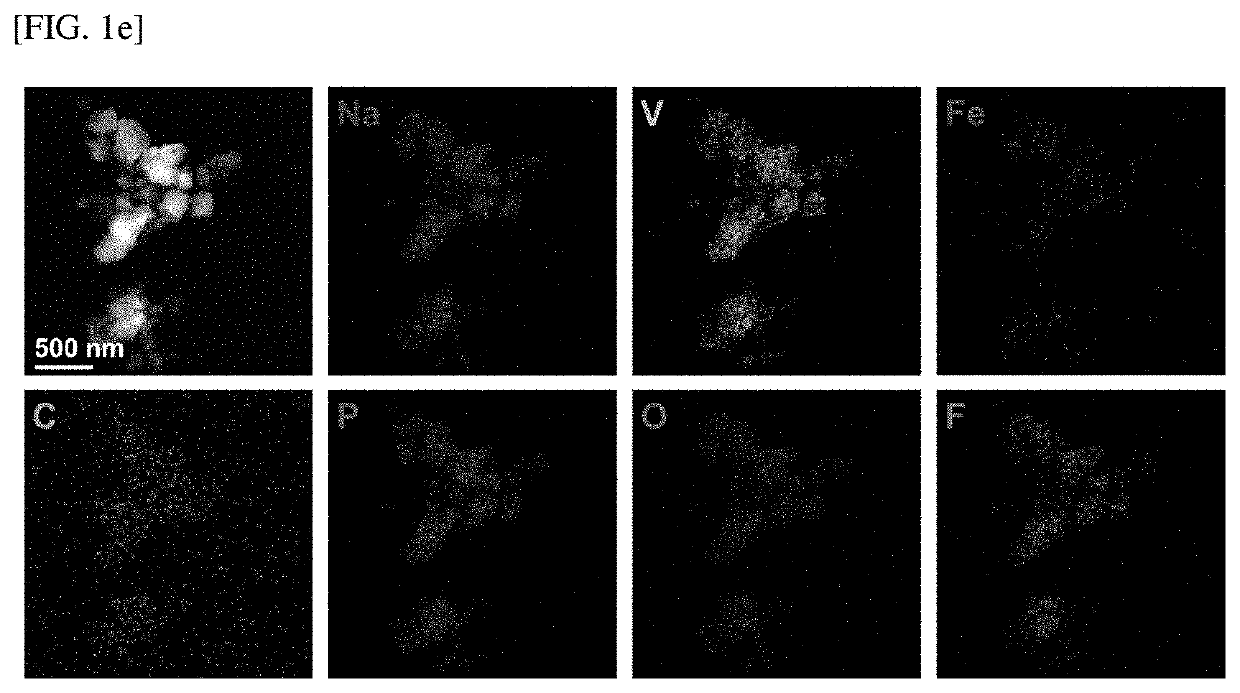

Metal-Doped Sodium Vanadium Fluorophosphate/Sodium Vanadium Phosphate (Na3V2(PO4)2F3/Na3V2(PO4)3) Composite for Sodium-Ion Storage Material

PendingUS20210242451A1Improve featuresReduce vanadium contentCell electrodesSecondary cellsPhosphoric acidSodium-ion battery

The present disclosure relates to a sodium-ion storage material including a doped compound, and an electrode material for a sodium-ion battery, an electrode for a sodium-ion battery, and a sodium-ion battery, which include the sodium-ion storage material. Specifically, the sodium-ion storage material may include a compound consisting of an Na3V2-xMx(PO4)2F3 / Na3V2-yMy(PO4)3 composite (M=Fe, Mn, Cr, Cu, Zn or Ti, 0<x,y≤2). When the sodium-ion storage material according to the present disclosure is used, it may maintain high discharge capacity while reducing the vanadium content, and when the sodium-ion storage material is applied to a sodium-ion secondary battery or a sodium-magnesium hybrid-ion battery, the battery may exhibit excellent charge / discharge cycle characteristics.

Owner:KOREA ADVANCED INST OF SCI & TECH

Vanadium catalysis system for combined polymerization of ethylene, propylene, and diolefin, and application

This invention relates to a vanadium catalyst system for preparing rubber elastomers. This invention introduces an activation promoter into the traditional vanadium catalyst system to form a new active catalyst system, which is composed of vanadium compound, cocatalyst and activation promoter. The vanadium catalyst system can be used in ternary polymerization of ethylene, propylene and diene, and has such advantages as high catalytic activity, low consumption and easy removal of vanadium during post treatment.

Owner:PETROCHINA CO LTD

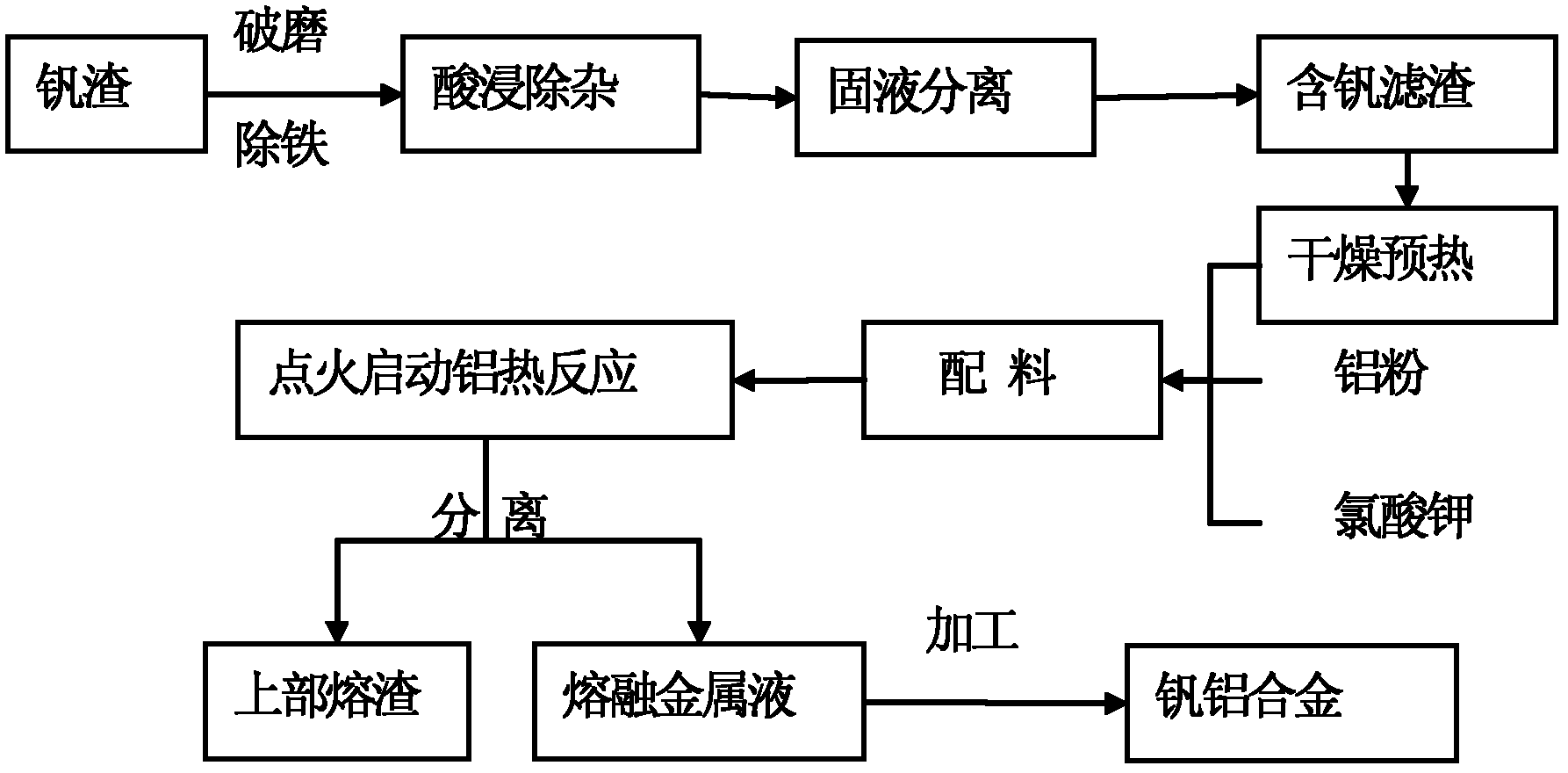

Production method of vanadium-aluminum alloy

ActiveCN102534271AHigh recovery rateReduce manufacturing costProcess efficiency improvementSlagAlloy

The invention discloses a production method of a vanadium-aluminum alloy. The method comprises the following concrete steps of: (1) acid leaching: adding dilute sulphuric acid into vanadium slag with particle size of 100+ / -10 meshes, and performing acid leaching to obtain an acidolysis liquid; (2) impurity removal: adding a solvent for adjusting pH value into the acidolysis liquid so that the pH is 4+ / -0.5 to obtain the precipitation of calcium vanadate; filtering to obtain vanadium-containing filter residue; and drying and crushing and grinding the vanadium-containing filter residue; and (3)aluminothermic reduction: matching the processed vanadium-containing filter residue and aluminum powder at a ratio of (2.0-2.4):1.0, adding a heat assisting agent, mixing uniformly and smelting to obtain a vanadium-aluminum alloy. In the invention, the vanadium slag is used as a raw material, and the production cost of smelting a vanadium-aluminum alloy is reduced. The vanadium slag is used as the smelting raw material, the environmental problem caused by a great quantity of wastewater containing ammonia nitrogen in the production process of vanadium pentoxide can be avoided from raw materials; and therefore, the technology adopted by the invention is more environment-friendly.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

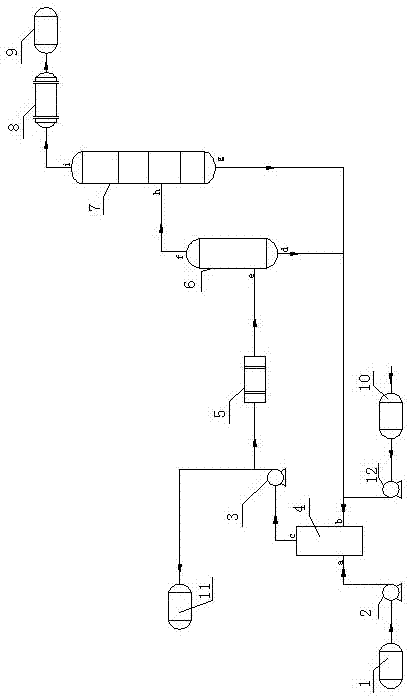

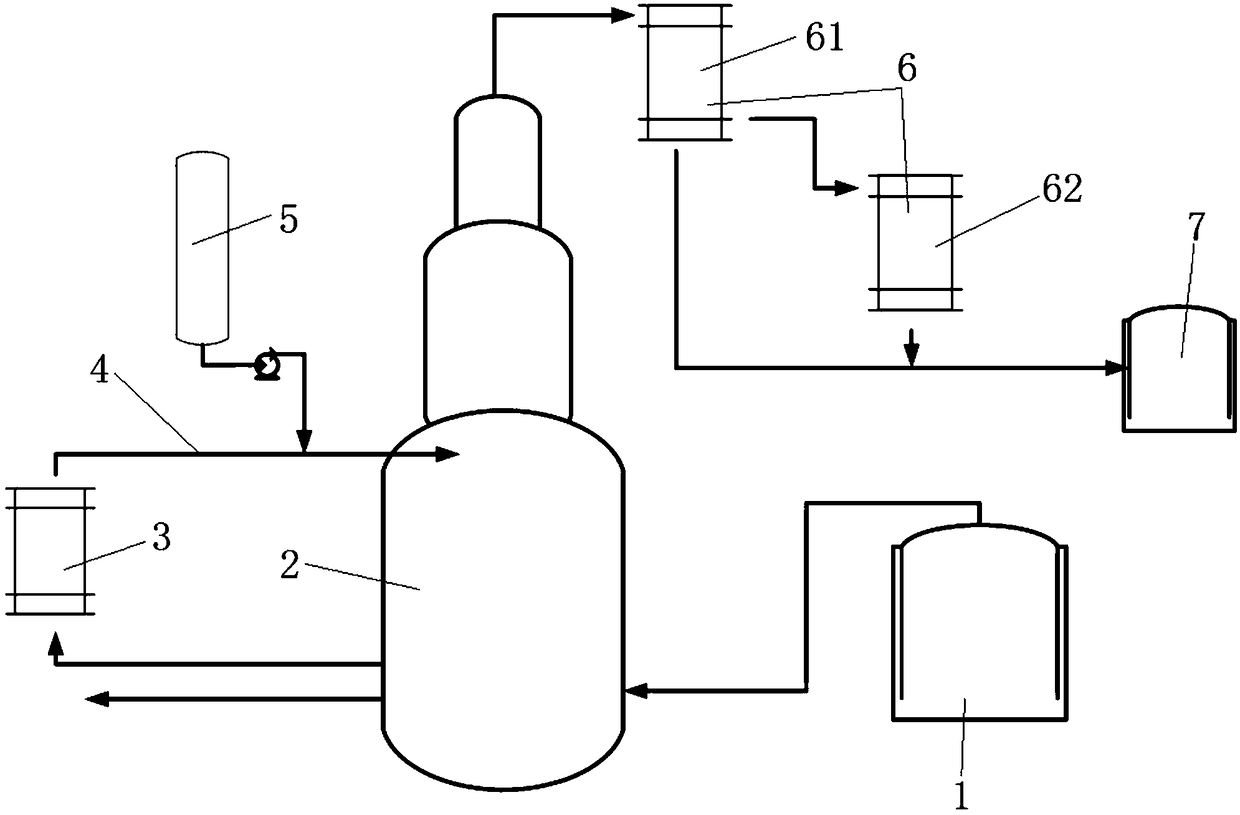

Method and system for removing vanadium impurities in titanium tetrachloride

ActiveCN103613126AFast decompositionHigh activityTitanium halidesTitanium tetrachlorideTitanium chloride

The invention discloses a method and a system for removing vanadium impurities in titanium tetrachloride. The system is composed of a crude titanium tetrachloride feeding tank, a feeding pump I, a forced circulating pump, a forced circulating pump groove, a heating heat exchanger, a flask tank, a purifying tower, a condensation heat exchanger, a titanium tetrachloride storage tank, a fatty acid feeding tank, a slurry tank and a feeding pump II. The method comprises the steps: adding crude titanium tetrachloride and fatty acid into the forced circulating pump groove; then, adding the crude titanium tetrachloride and the fatty acid into the heating heat exchanger to carry out reduction reaction to obtain titanium tetrachloride slurry, wherein the titanium tetrachloride slurry contains suspended dichlorooxovanadium solids; enabling the titanium tetrachloride slurry to enter the flask tank, and carrying out flask separation; discharging dichlorooxovanadium solid contained slurry into the forced circulating pump groove, and enabling gaseous titanium tetrachloride to enter the purifying tower; and discharging the dichlorooxovanadium solid contained slurry in the purifying tower into the forced circulating pump groove, and enabling the gaseous titanium tetrachloride to enter the condensation heat exchanger to obtain the vanadium removed titanium tetrachloride. The method and system disclosed by the invention have the advantages that the equipment scaling and pipeline blocking phenomena are reduced, the productivity is improved, the energy consumption is reduced, the vanadium removal efficiency is high, and the quality of a product is stable.

Owner:中信钛业股份有限公司

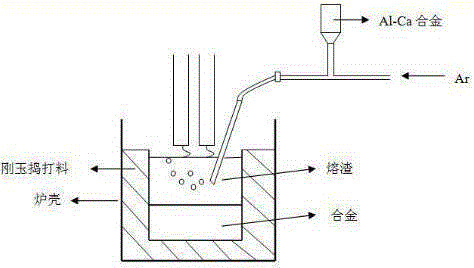

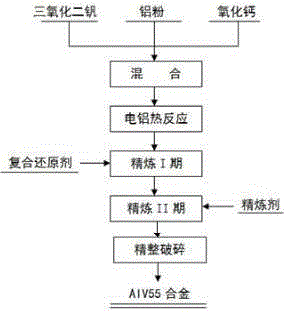

Preparation method of high-quality AlV55 alloy

The invention belongs to the field of metallurgy, and particularly relates to a preparation method of high-quality vanadium-aluminum alloy. The preparation method comprises the following steps: by an electrothermal reduction-two-step refining method, using V2O3 with the purity of 99.9%, Al with the purity of 99.70% and CaO with the purity of 97.0% as raw materials, uniformly mixing, taking a part of the raw materials, and mixing with a heating agent as a base material; igniting the base material to form a molten pool, starting an open arc for smelting, and adding the remaining raw materials in batches; in the later reacting stage, performing blowing refining on the alloy and molten slag; after completion of smelting, deslagging, and casting to obtain the vanadium-aluminum alloy. According to the preparation method, high-purity V2O3 is used as a vanadium source, so that compared with use of V2O5, the using amount of a reducing agent can be significantly reduced and introduction of impurities into the raw materials is reduced; an external heat source can prolong the heat-preserving time so as to promote separation of the slag and the alloy; the open arc is started for smelting by virtue of the molten slag, so that the carbon content of the alloy can be reduced; in the later smelting stage, the recycling rate is increased and the impurity content is reduced by refining the slag and the alloy. The final impurity content meets a standard of the AlV50 vanadium-aluminum alloy of the German GfE company.

Owner:NORTHEASTERN UNIV

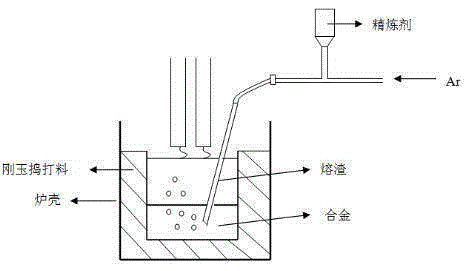

Spray blowing method in smelting of iron-vanadium alloy

The invention belongs to the field of metallurgy, and relates to a spray blowing method in smelting of iron-vanadium alloy. A technical scheme for solving the technical problem is as follows: a, adding the batch mixed smelting raw materials containing V2O5 and V2O3 into a smelting furnace in batches, powering on the smelting furnace, and smelting; b, spray blowing after the smelting is ended, wherein a spray blowing material is a mixture of aluminum powder and vanadium-iron fine powder; and c, continuously electrifying and refining after the spray blowing is ended. By adopting the method, the spray blowing efficiency is improved, the content of vanadium in the vanadium-iron smelting slag is reduced, and the yield of smelting vanadium is increased.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for smelting ferrovanadium through tilting furnace

The invention belongs to the field of metallurgy, and particularly relates to a method for smelting ferrovanadium through a tilting furnace. The technical aim of providing the method for smelting ferrovanadium through the large tilting furnace is achieved. The method comprises the following operation steps that raw materials including vanadium oxide, aluminum, iron and lime meeting the production requirement are added into the tilting type electric-arc furnace after being mixed evenly, and a method combining multi-phase smelting, ladder type aluminum matching and parabola type iron matching is adopted; and when the content of vanadium in slag is reduced to a certain level, most of the slag is removed, the repeated operation of staging feeding and deslagging is carried out, and the slag and iron are output at the same time during smelting of the last stage. Compared with a traditional method, by means of the method, the content of vanadium in the lean slag can be further reduced, and the smelting yield of ferrovanadium can be improved; and meanwhile aluminum consumption is equal to that of a common method combining multi-phase smelting and ladder type aluminum matching.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

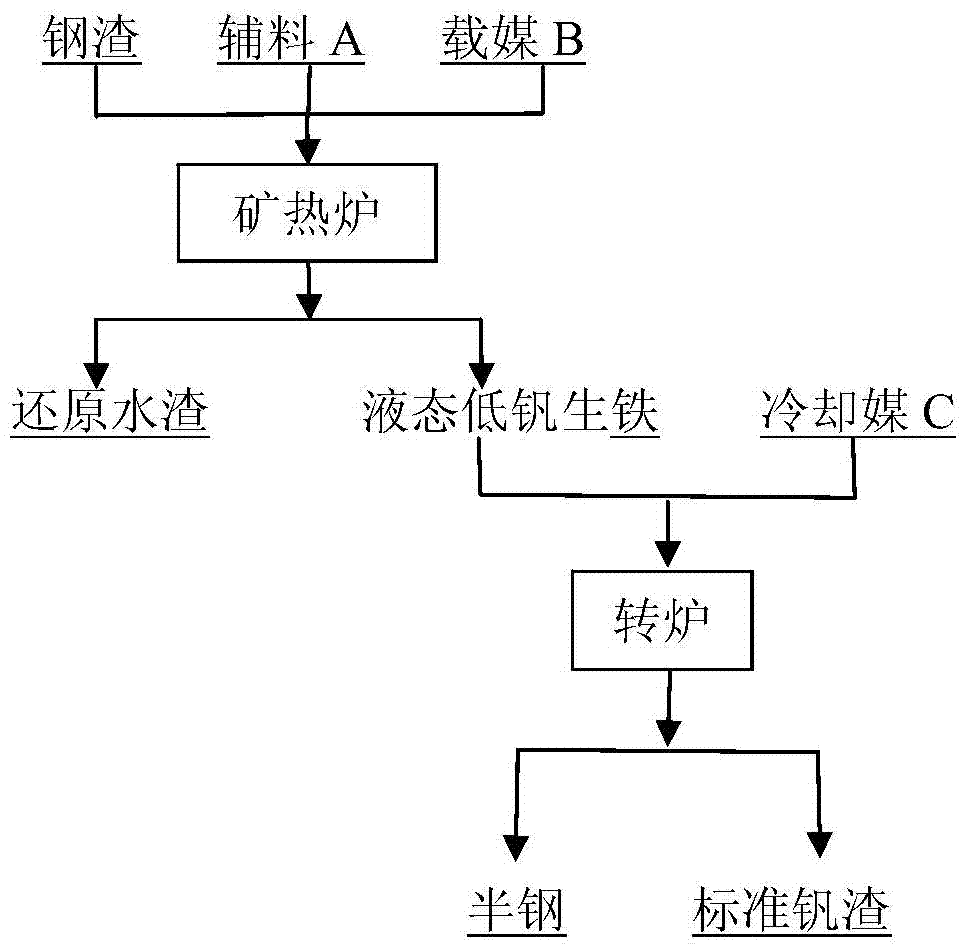

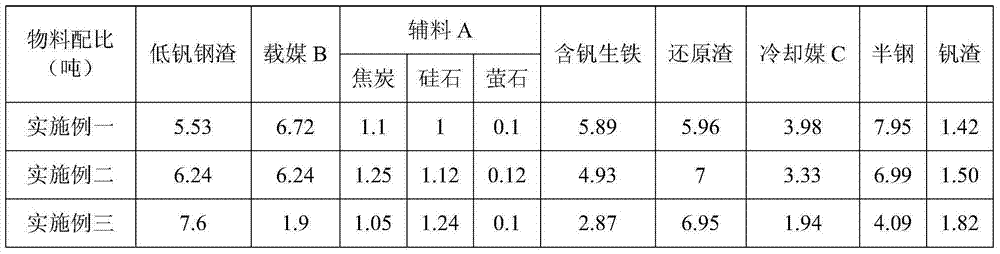

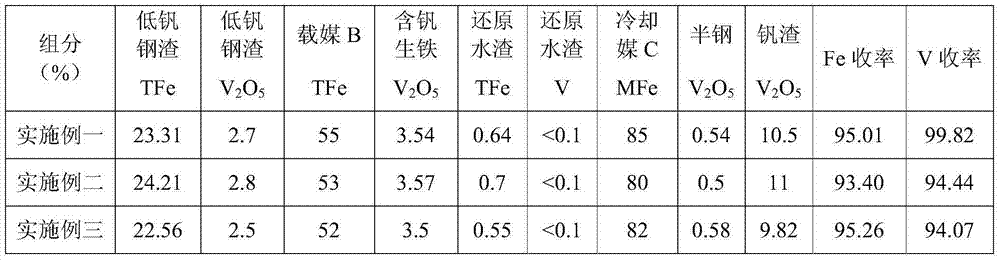

Steel slag tailings vanadium extracting process

ActiveCN103614565AReduce vanadium contentStable vanadium extraction modeRecycling and recovery technologiesProcess efficiency improvementSemi-steelWaste material

The invention belongs to the fields of metallurgy and solid waste comprehensive utilization, and in particular relates to a method for extracting vanadium in vanadium-containing steel slag tailings. The invention aims at providing a high-yield and stable process for recovering vanadium and iron in steel slag for comprehensive utilization, value improvement and vanadium resource recovery of low-vanadium steel slag, wherein recovery rates of both vanadium and iron are above 90%. The process comprises steps of A, preparing materials: combing raw material low-vanadium steel slag tailings with an auxiliary material A and a load vector B, wherein the low-vanadium steel slag tailings account for 40-65%, the auxiliary material A accounts for 14-20% and the load vector B accounts for 15-46%; B, reducing and melting various materials in a submerged arc furnace to obtain low-vanadium pig iron and reduced water slag; and C, hot-charging the low-vanadium pig iron obtained from the step B under a liquid status to a converter, adding a coolant C, and implementing oxygen blowing vanadium extraction to obtain vanadium slag and semi-steel. The vanadium extracting process adopts many waste materials in whole using process, and is short in flow, short in time, high in vanadium recovery rate, free from newly generated solid waste, free from discharge of tailings, and energy-saving, and the environment is protected.

Owner:LIANGSHAN RUIJING ENVIRONMENTAL PROTECTION RESOURCE DEV

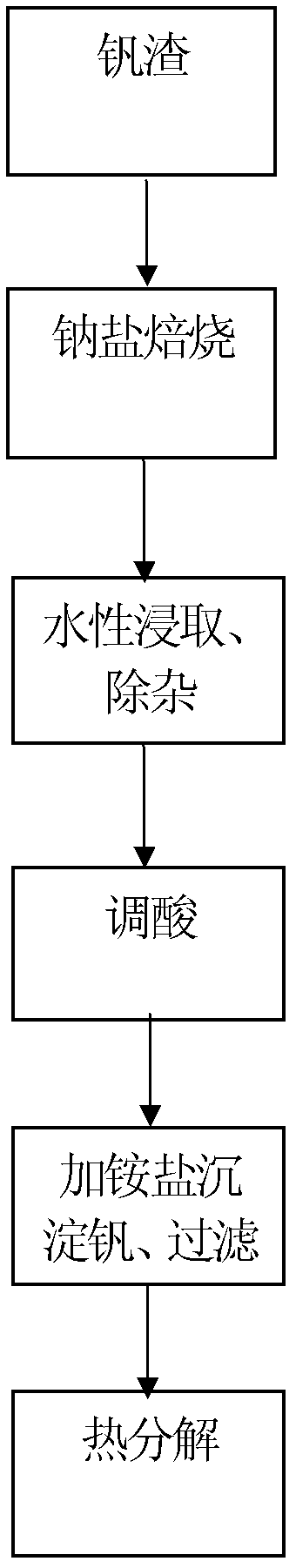

Vanadium extracting method

InactiveCN102534267AEfficient recyclingReduce vanadium contentProcess efficiency improvementSlagVanadate

The invention discloses a vanadium extracting method, which comprises the following steps that: vanadium slag is adopted as a raw material, and the vanadium slag is subjected to sodium-salt-added roasting, water leaching and impurity removing so as to obtain a sodium metavanadate solution; the obtained sodium metavanadate solution is subjected to adjusting acid, adding ammonium salt to precipitate vanadium and filtering so as to obtain poly ammonium vanadate; and the obtained poly ammonium vanadate is prepared into V2O5 powder through thermal decomposition. According to the vanadium extracting method disclosed by the invention, a vanadium resource in the vanadium slag can be effectively recycled.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

Method of smelting low-aluminum medium ferrovanadium by means of tilting furnace

The invention discloses a method of smelting low-aluminum medium ferrovanadium by means of a tilting furnace. The vanadium content in slag can be reduced effectively, the yield of ferrovanadium can beincreased, and the aluminum content of an obtained medium ferrovanadium is relatively low. The method disclosed by the invention comprises the following steps: uniformly mixing raw materials: vanadium oxide, aluminum, ferrum and lime and adding the mixture into a tilting electric-arc furnace; and adopting a multi-phase smelting method, that is, after the vanadium content in slag in each stage isreduced, removing most of slag, then carrying out a repeated operation of charging and slagging in the next stage, adding a dealumination material in the last stage for dealuminating smelting, and then discharging slag and iron to obtain a final product. Parameters and proportions in the process are adjusted well, so that the vanadium content in the slag is reduced, the economical benefit is improved, and the dealumination material is added to dealuminate, so that the aluminum content of the obtained medium ferrovanadium is relatively low. The method disclosed by the invention is particularlysuitable for smelting production of low-aluminum medium ferrovanadium.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Titanium-contained composite alloy reinforcing core-spun yarn and application to HRB400E thread steel

ActiveCN109355460AHigh yieldAchieving reinforcementProcess efficiency improvementYarnSmelting process

The invention discloses a titanium-contained composite alloy reinforcing core-spun yarn and application to HRB400E thread steel. The titanium-contained composite alloy reinforcing core-spun yarn is prepared by coating core powder on an aluminum strip; the core powder comprises the following components in percentage by mass: 30-35% of Ti, 22-28% of N, 15-20% of Si, 3-8% of Cu, 8-12% of Mn, 1-3% ofFe, and 5-8% of Zr; and the sum of the components is 100%. The titanium-contained composite alloy reinforcing core-spun yarn is applied to the HRB400E thread steel; in the smelting process of molten steel, after the preparation of white slag is finished from a molten steel tank to an LF station, the titanium-contained composite alloy reinforcing core-spun yarn is fed in the molten steel tank; theyarn feeding speed is 5-6 m / min; the feeding quantity is 3 m / t steel; after yarn feeding, a soft blowing mode is switched to; the bottom blowing argon flow is 150-180 L / min; and the soft blowing timeis 3-5 min. The titanium-contained composite alloy reinforcing core-spun yarn achieves a reinforcing effect of stabilizing titanium in the HRB400E thread steel, replaces a reinforcing effect of part of vanadium, greatly reduces the production cost of the thread steel, and achieves the popularization and application prospect in production of other vanadium-contained steel types.

Owner:董新安

Crude titanium tetrachloride refining vanadium-removing method

The invention discloses a crude titanium tetrachloride refining vanadium-removing method, relates to the technical field of production of titanium tetrachloride, and provides the crude titanium tetrachloride refining vanadium-removing method which is high in vanadium-removing speed, good in effect and relatively low in cost. The crude titanium tetrachloride refining vanadium-removing method comprises the following steps: A, enabling crude TiCl4 liquid in a TiCl4 storage tank to enter a refining circulating tower; B, pumping the crude TiCl4 liquid in the refining circulating tower into a heat exchanger through a circulating pump in the tower, and enabling the crude TiCl4 liquid to pass through the heat exchanger to form high-temperature and pressurized crude TiCl4 liquid; enabling the high-temperature and pressurized crude TiCl4 liquid to enter a mixing tube; C, pumping fatty acid in a fatty acid storage tank into the mixing tube, mixing with the high-temperature and pressurized crude TiCl4 liquid, and reacting with impurities in the high-temperature and pressurized crude TiCl4 liquid to obtain a vanadium-removed slurry; D, after a reaction, spraying a mixture from the mixing tube into the refining circulating tower, and performing flash evaporation to vaporize a part of the TiCl4 liquid into TiCl4 vapor; enabling the TiCl4 vapor to enter a condensing system through a tower topsieve plate of the refining circulating tower, condensing and then enabling the TiCl4 vapor to enter a refined TiCl4 storage tank; and returning unvaporized TiCl4 liquid to the lower part of the refining circulating tower, and pumping into the heat exchanger again.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

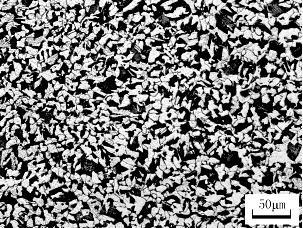

Preparation method of high-quality aluminum-titanium-boron alloy rods

The invention provides a preparation method of high-quality aluminum-titanium-boron alloy rods and belongs to preparation of refiners. The method is characterized by producing aluminum-titanium-boronalloys through cooperation of a frequency-variable induction electric furnace and a medium-frequency induction electric furnace, refining aluminum liquid before charging, adding a mixture of villiaumite and a diffusion agent, taking the mixture as a nucleating agent of TiAl3 and TiB2 mass points in the alloying process, wherein the TiAl3 and TiB2 mass points formed after completing alloying are fine and are more uniformly distributed; the formation of rod shape of the TiAl3 mass points and the aggregation of the TiB2 mass points are eliminated; the diffusion agent is added into the villiaumitemixture, so that the aggregation of the TiAl3 and TiB2 mass points is effectively controlled; the alloying process is equipped with mechanical stirring, so that the enlargement of the TiAl3 and TiB2mass points is effectively prevented; the separation and purification effect of villiaumite slag and alloys can be improved; through check analysis, the TiAl3 and TiB2 mass points in the produced products are fine, are uniform and dispersive in distribution and are extremely low in slag content; the problems that the TiAl3 mass points in the continuously cast and rolled aluminum-titanium-boron alloy rods in the current market are thick and big, the TiB2 mass points are aggregated, the content of the slag in the alloys is high, and the aluminum-titanium-boron alloy rods are poor in refining capacity in the aluminum alloys are effectively solved.

Owner:河北晶宝新金属有限公司

Rectangular ingot for anti-corrosion mold and process method of rectangular ingot

The invention discloses a rectangular ingot for an anti-corrosion mold and a process method of the rectangular ingot, and belongs to the technical field of metallurgy production processes. The rectangular ingot for the anti-corrosion mold is high in strength, and the corrosion resistance, abrasion resistance, creep resistance and fatigue resistance are obviously improved. The process method for producing the rectangular ingot for the anti-corrosion mold is further provided. The rectangular ingot is prepared from, by weight part, 0.25%-0.65% of C, 0.4%-0.8% of Si, 0.4%-0.9% of Mn, 12%-18% of Cr, 0.05%-0.3% of Ni, 0.1%-0.3% of Mo, 0.06%-0.30% of N, not larger than 0.02% of Al, not larger than 0.020% of P, not larger than 0.005% of S and the balance Fe and inevitable impurity elements. The process method comprises the steps of smelting of molten steel with the nitrogen content smaller than or equal to 45 ppm, nitrogen-rich manganese-rich molten steel refining and die casting molding, wherein nitrogen-rich manganese-rich molten steel refining comprises large-slag-amount refining carried out in a refining furnace and secondary refining carried out in a vacuum refining furnace.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Self-stirring Process for Ferro-Vanadium Smelting

The invention discloses a self-stirring process for smelting of ferrovanadium and belongs to the field of iron and steel smelting technology. The provided self-stirring process is simple to operate, ensures a long service life of a furnace lining and is high in alloy yield. The process is characterized in that a spherical self-stirring agent is added into a molten pool after an aluminothermic reduction spontaneous reaction, sufficient stirring of the molten pool is achieved by such means as heat release of the self-stirring agent, characteristic improvement of molten slag and gas generation topromote deep reduction of a material, molten slag gold is poured into a casting sand mold after finish of primary self-stirring for mixed melting of the slag gold, and secondary self-stirring is realized. The content of vanadium in the slag can be remarkably reduced through the self-stirring operation during smelting of ferrovanadium, so that the service life of an electric furnace is greatly prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

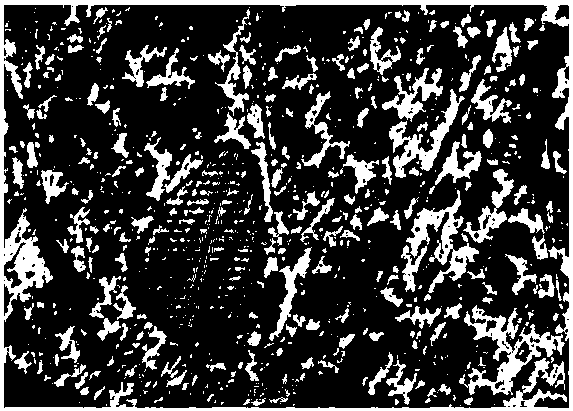

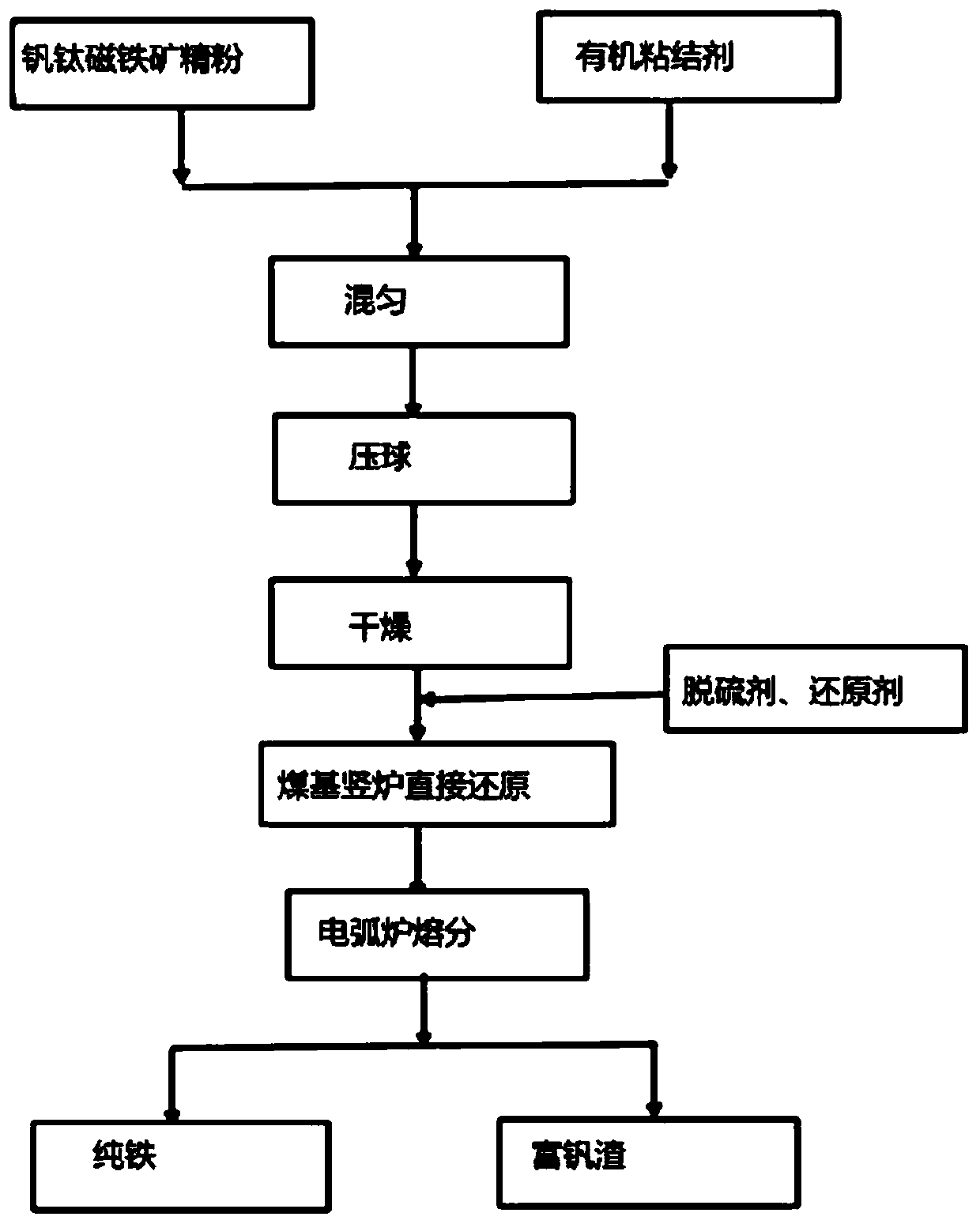

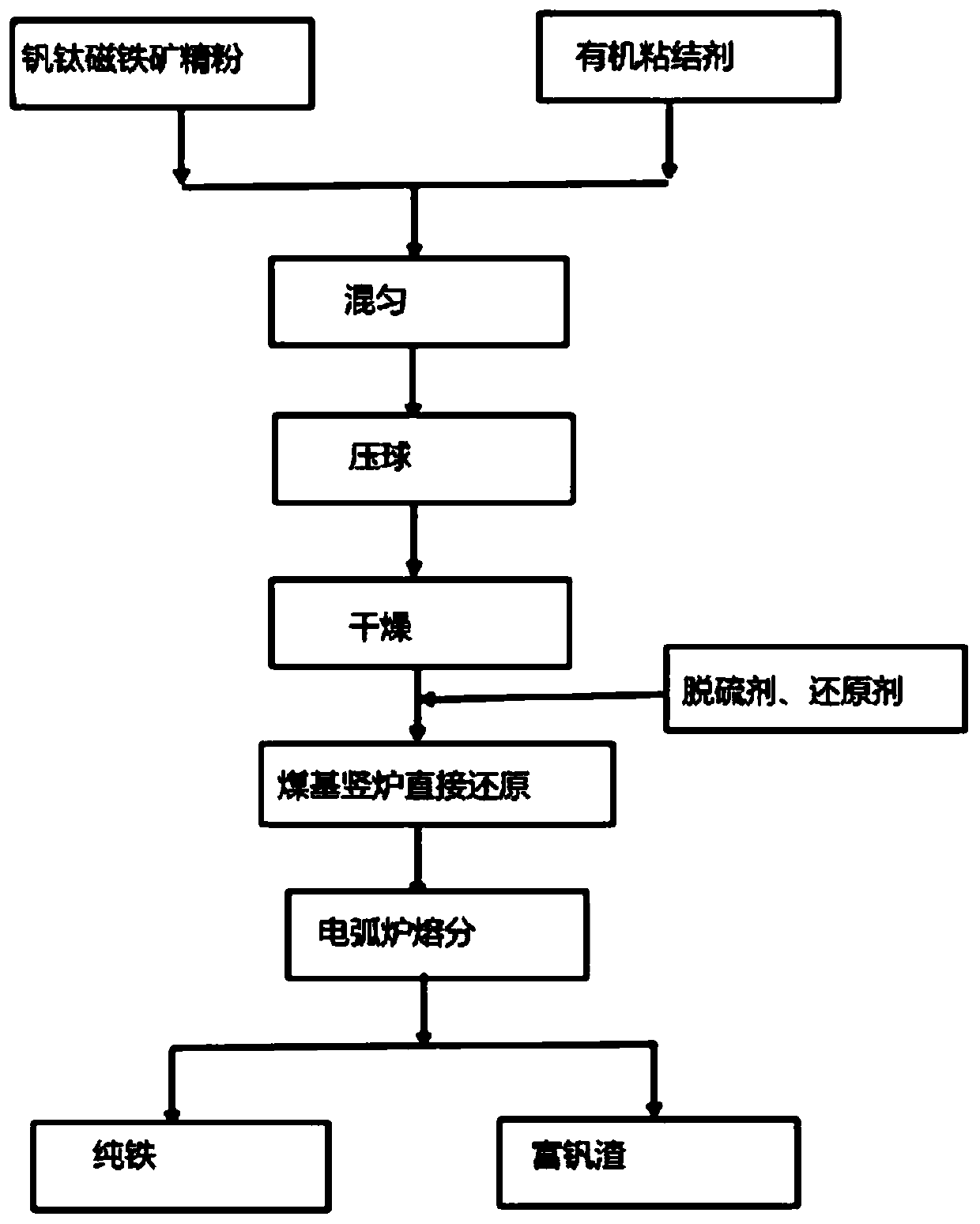

Method for separating and enriching vanadium from iron concentrate and producing pure iron

InactiveCN110564906AHigh recovery rate of vanadiumHigh recovery rateProcess efficiency improvementShaft furnaceIron contentElectric arc furnace

The invention discloses a method for separating and enriching vanadium from iron concentrate and producing pure iron. The method comprises the following steps that after vanadium-titanium magnetite ore is pressed into balls and dried, vanadium-titanium magnetite ore pellets are obtained, the vanadium-titanium magnetite ore pellets are directly reduced through a coal based shaft furnace, metallizedpellets are obtained, and the metallized pellets are subjected to melting, separating and enriching in an electric-arc furnace. According to the method, the vanadium recovery rate reaches 93% or above, the vanadium slag grade is about 6-8%, meanwhile, the purity of molten steel obtained through melting and separating is high, the iron content reaches 99.7% of above, in addition, the contents of phosphorus, sulphur, silicon, manganese and titanium in the molten steel are low, and electromagnetic pure iron and military pure iron can be produced through simple refining.

Owner:陕西有色冶金矿业集团有限公司

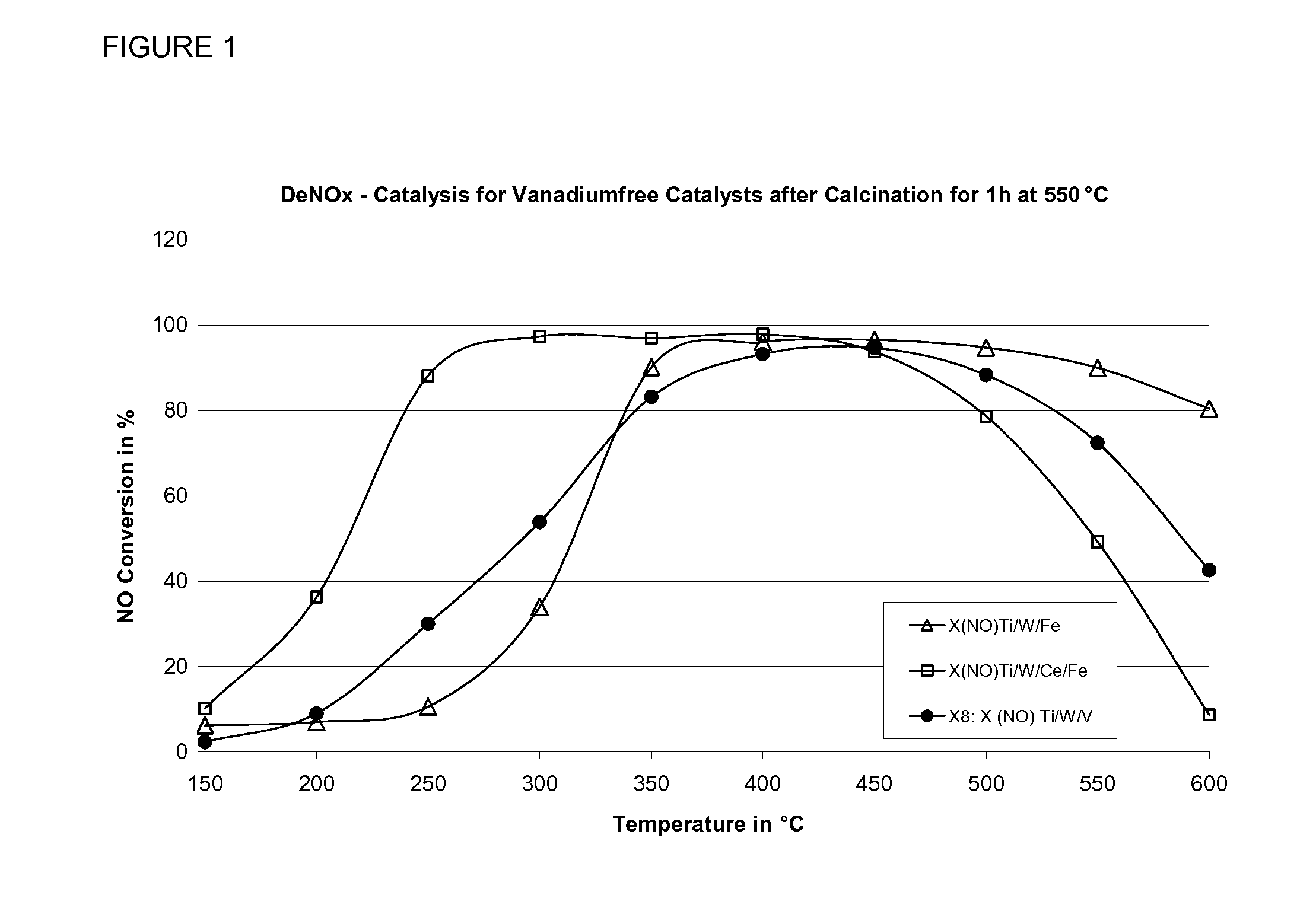

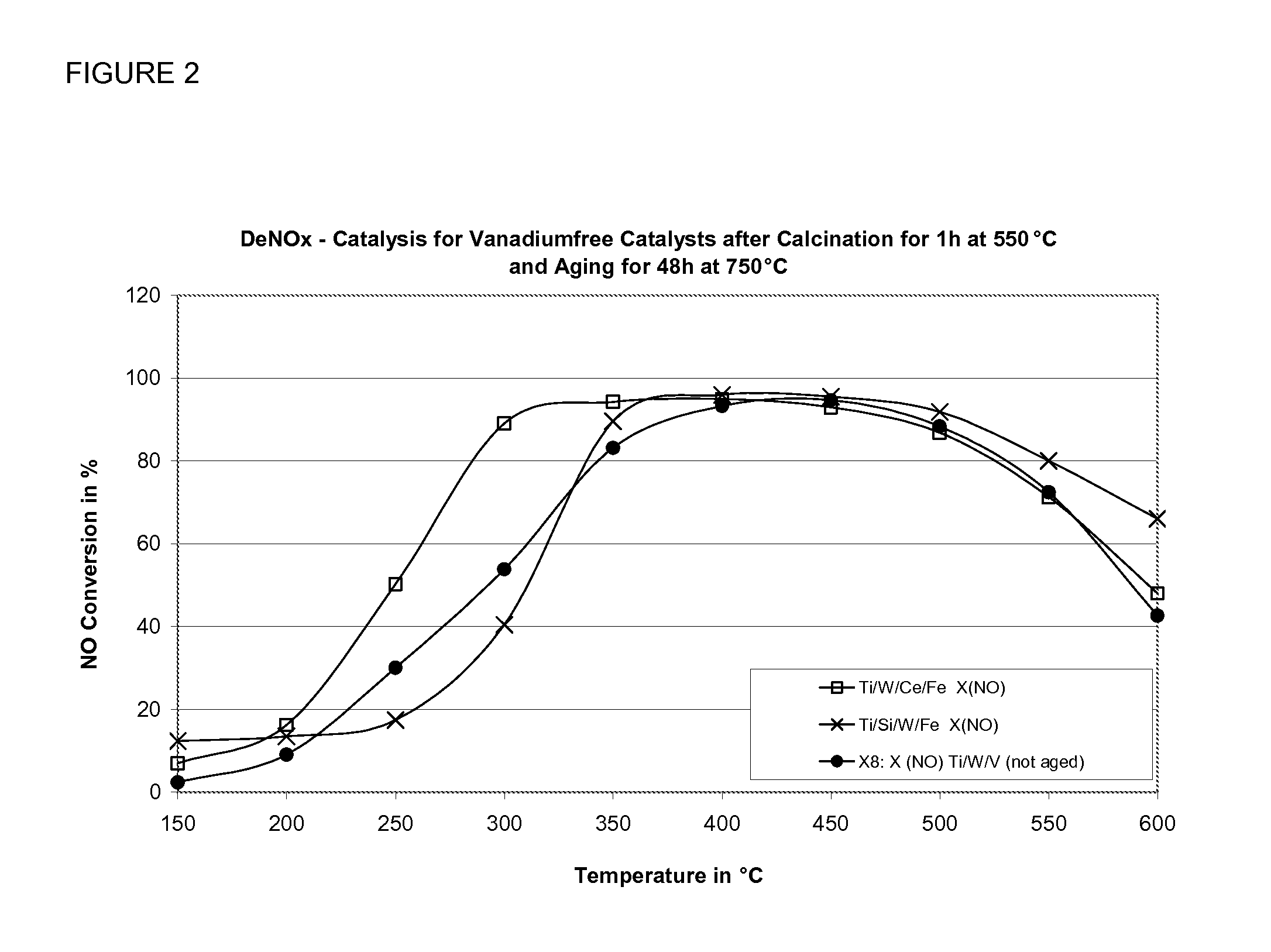

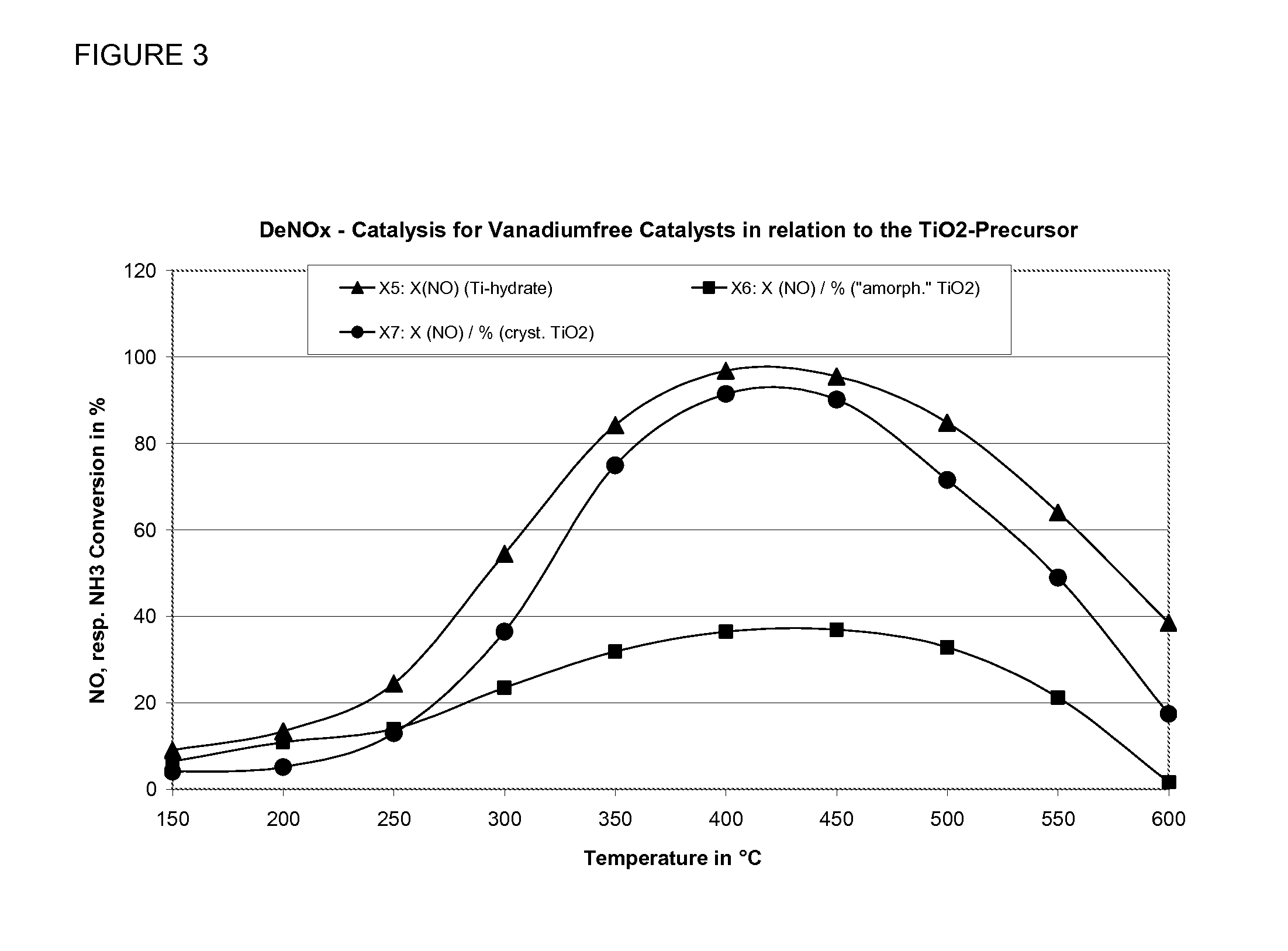

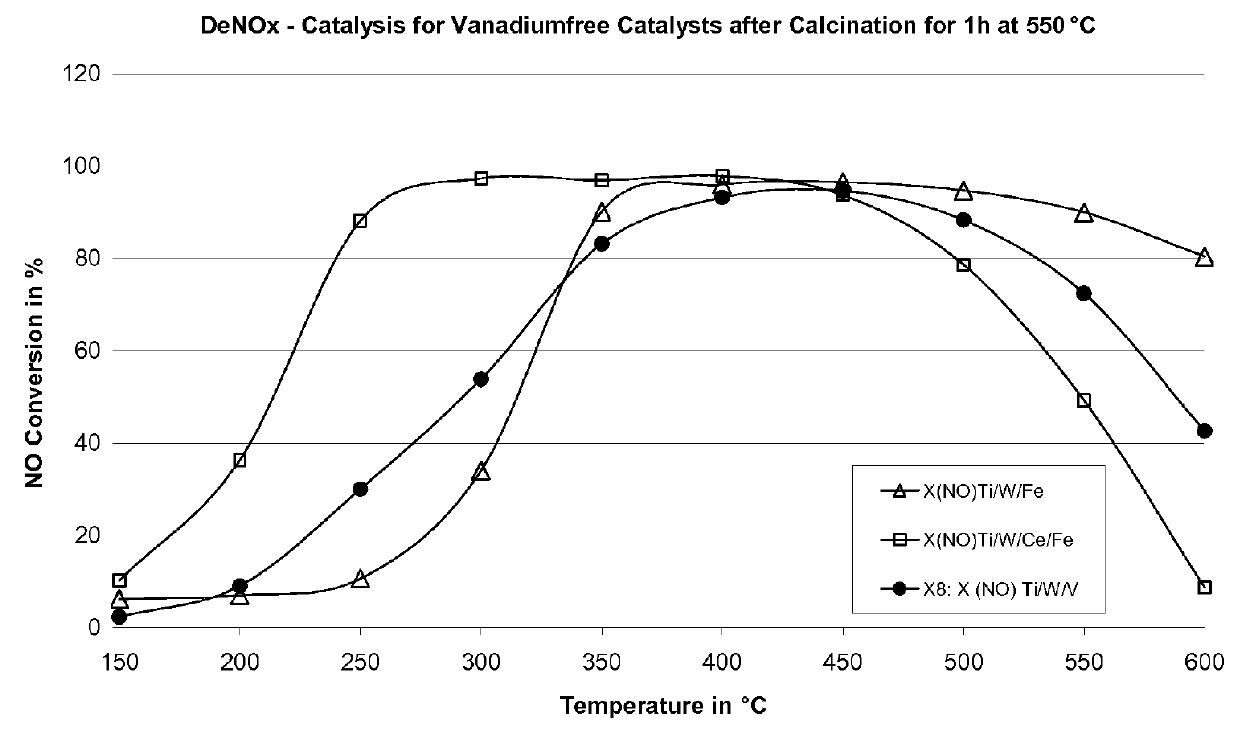

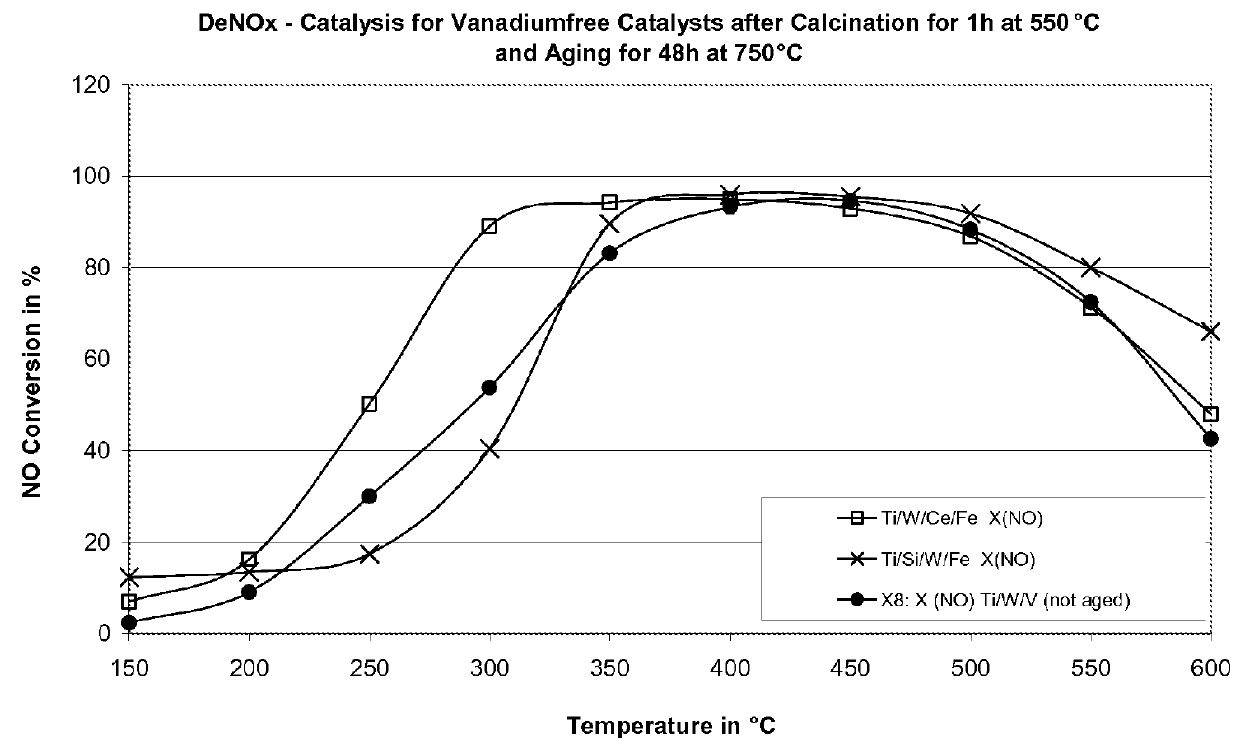

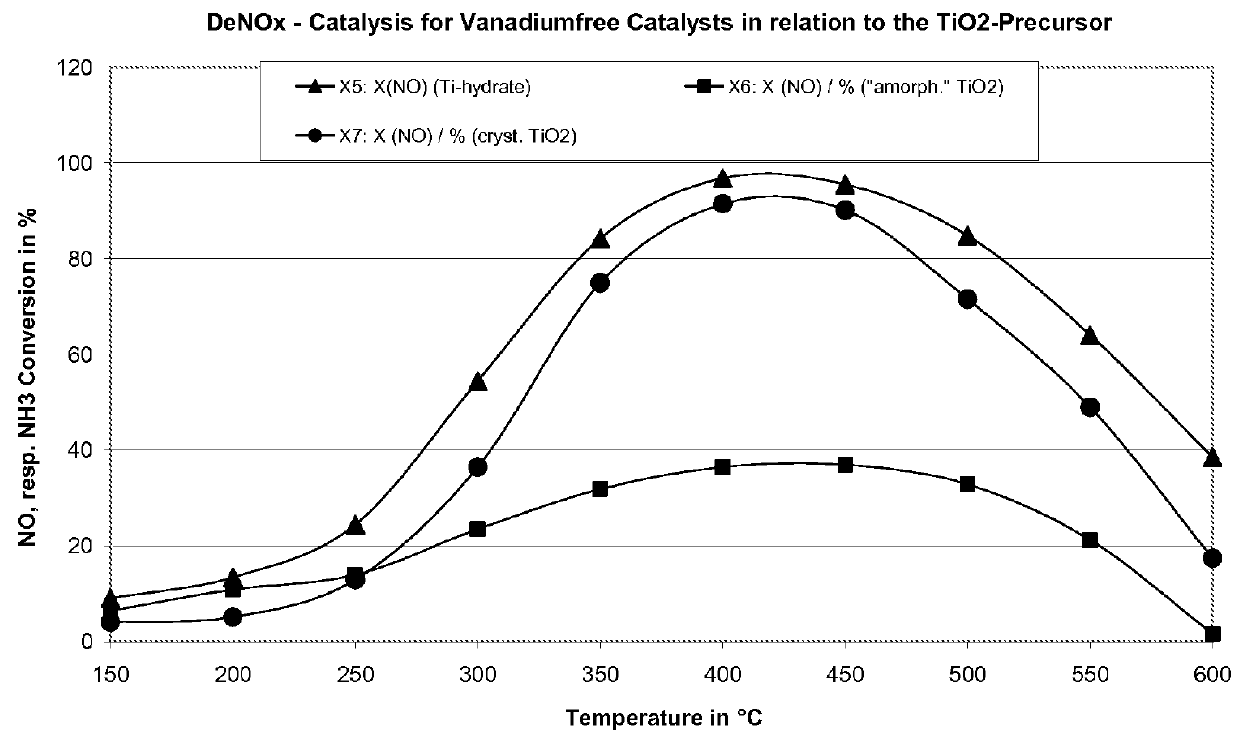

Raw Materials for Vanadium-Free or Vanadium-Reduced Denox Catalysts, and Method for Producing Same

ActiveUS20140155256A1Reduce vanadium contentEasy to getGas treatmentHeterogenous catalyst chemical elementsCalcinationAnatase

A composition that comprises a titanium compound, an iron compound, and a tungsten compound, wherein the titanium compound has a microcrystalline anatase structure and / or is obtained in the production of TiO2 according to the sulphate process, during hydrolysis of a solution which contains titanyl sulphate, and also in that the composition has a vanadium content, calculated as V, of less than 0.15 wt. % in relation to the solids content of the composition. A catalyst or catalyst raw material containing the claimed composition, as well as to a dimensionally stable and catalytically active solid body can be obtained by mixing the composition defined above with binders, plasticisers and optionally, further additives, molding the obtained composition preferably by extrusion, and subsequently carrying out calcination, or by providing a dimensionally stable and catalytically active solid body that can be obtained by applying the composition, optionally together with binders, plasticisers and further additives, to a substrate, and subsequently carrying out calcination.

Owner:SACHTLEBEN PIGMENT GMBH

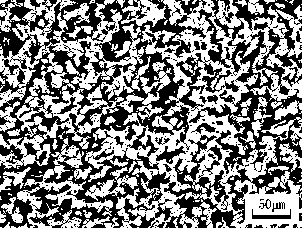

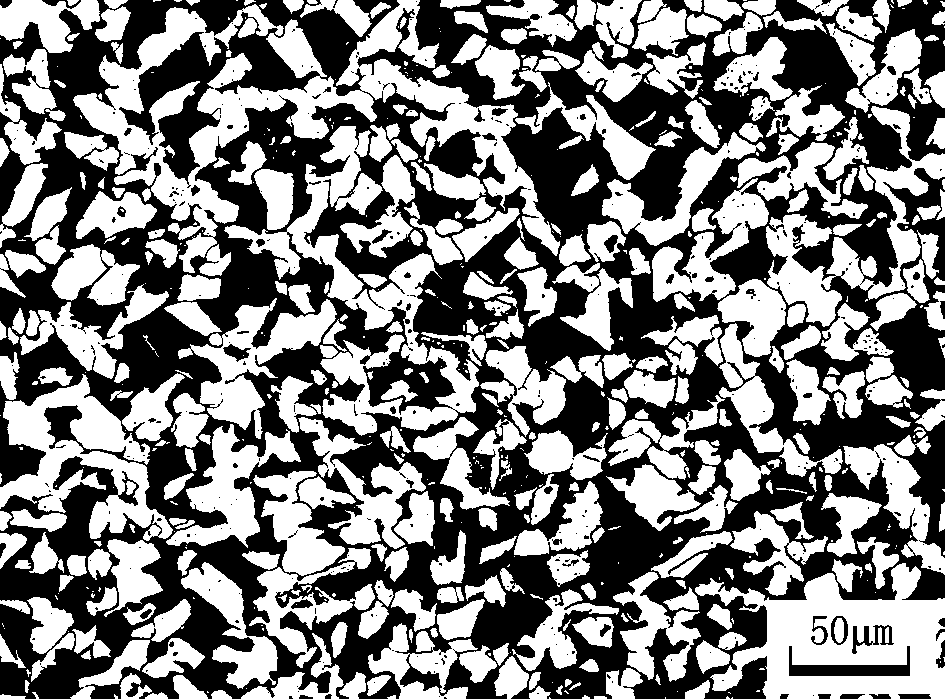

Low-vanadium nitrogenous hot work die steel and manufacturing method thereof

ActiveCN113046641AInhibition of segregationReduce the degree of segregationIncreasing energy efficiencyTemperingHot work

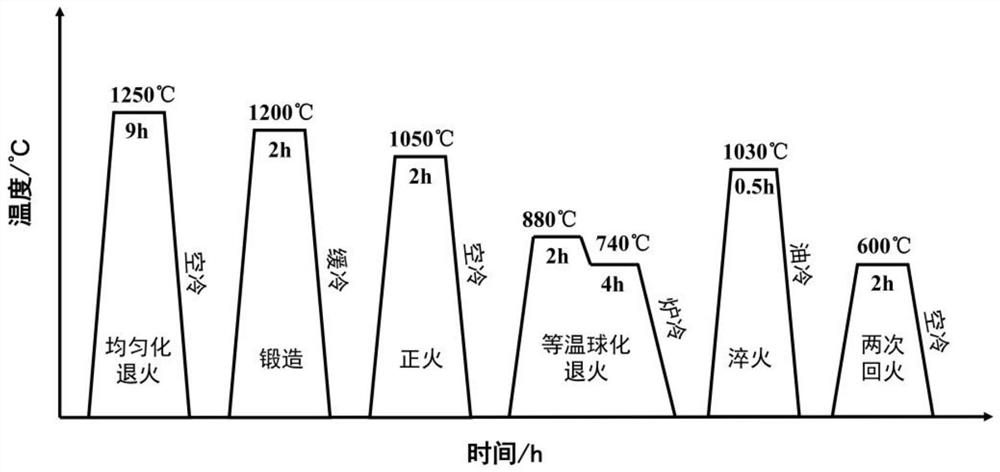

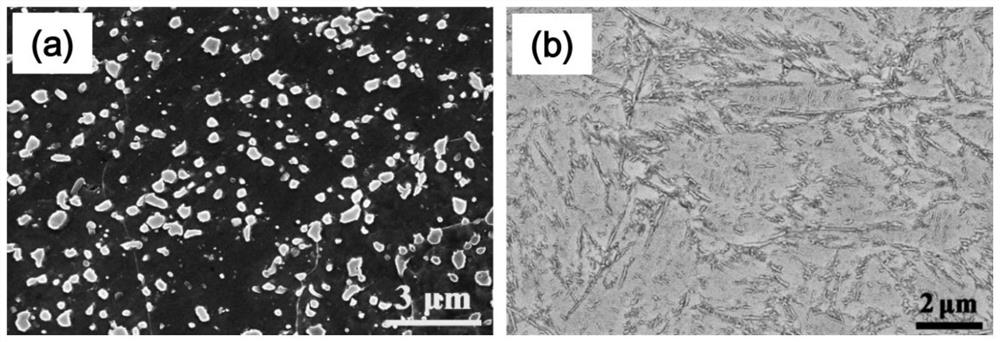

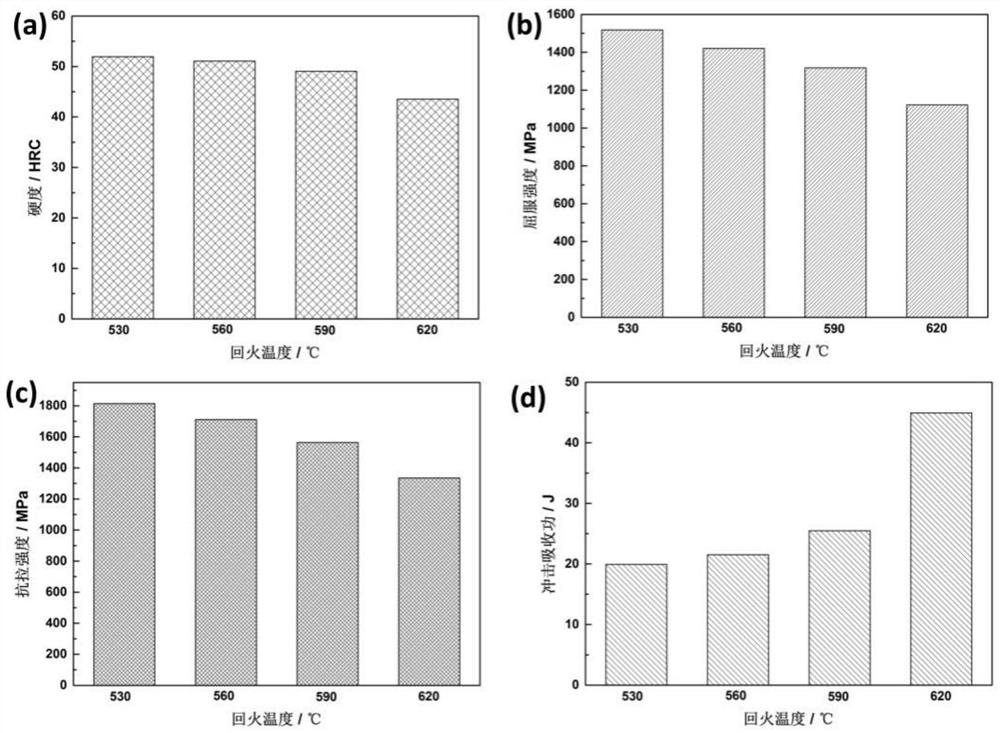

The invention discloses low-vanadium nitrogenous hot work die steel and a manufacturing method of the low-vanadium nitrogenous hot work die steel. The low-vanadium nitrogenous hot work die steel comprises, by mass percentage, 0.3%-0.4% of C, 0.2%-0.6% of Si, 0.2%-0.5% of Mn, 4.5%-5.5% of Cr, 1.1%-1.7% of Mo, 0.4%-0.6% of V, 0.02%-0.07% of N, 0.005%-0.03% of Ce, 0.001%-0.006% of Mg and the balance Fe. The method comprises the following steps of (1) smelting molten steel according to the set components, and carrying out nitrogen increasing by adopting a gas-phase nitriding method, and conducting pouring operation; (2) conducting homogenizing operation at the temperature ranging from 1200 DEG C to 1250 DEG C; (3) conducting forging operation; (4) conducting normalizing operation at the temperature ranging from 1000 DEG C to 1100 DEG C; (5) conducting spheroidizing annealing operation; (6) conducting heat preservation at the temperature ranging from 1000 DEG C to 1050 DEG C, conducting oil cooling and accomplishing quenching; and (7) carrying out heat preservation at the temperature ranging from 530 DEG C to 620 DEG C for 2-6 hours twice, and conducting tempering. According to the components of the low-vanadium nitrogenous hot work die steel, the content of vanadium and the content of silicon are reduced, the proper amount of nitrogen is added, the trace amount of rare earth and the trace amount of magnesium are cooperatively added, the cleanliness of the steel is improved, the carbide distribution effect is improved, and finally the performance of the die steel is improved.

Owner:NORTHEASTERN UNIV +1

Method for pelletizing and vanadium extracting from vanadium extraction tailings

InactiveCN111575506ASticking phenomenon controlReduce vanadium contentProcess efficiency improvementVanadium atomSodium salt

The invention belongs to the technical field of vanadium metallurgy, and particularly relates to a method for pelletizing and vanadium extracting from vanadium extraction tailings. The technical problem to be solved is to provide the method for pelletizing and vanadium extracting from the vanadium extraction tailings, and the method can reduce the vanadium content in leached residues. The method comprises the following steps of a, uniformly mixing a vanadium-containing material with the vanadium extraction tailings, and drying to obtain a mixture 1; b, mixing the mixture 1 with sodium salt toobtain a mixture 2, preparing a bonding solution by using sodium hydroxide, a binder and water, and mixing the mixture 2 with the bonding solution to obtain wet pellets; and c, drying, roasting and leaching the wet pellets. By the adoption of the method, the vanadium content in the leached residues can be reduced to 0.3% or below.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing high-density ammonium polyvanadate by calcified roasting pickle liquor through heat preservation

ActiveCN111218572AReduce lossesHigh densityVanadium compoundsProcess efficiency improvementMetallurgyPhysical chemistry

The invention belongs to the technical field of hydrometallurgy of vanadium, and particularly relates to a method for preparing high-density ammonium polyvanadate by calcified roasting pickle liquor through heat preservation. The method aims at the problems of low density and the like of ammonium polyvanadate which is a vanadium precipitation product of the calcified roasting pickle liquor of vanadium slags. The method for preparing the high-density ammonium polyvanadate comprises the following steps that a. the calcified roasting pickle liquor of the vanadium slags is taken, the pH value is regulated to 2.2 - 3.8, and the temperature is regulated to be 20 DEG C - 75 DEG C, the concentration of NH4<+> is controlled to be 0.22 - 0.44 time of the concentration of vanadium in the pickle liquor; b, the pH value of the liquor is adjusted to 1.7 - 2.1, the temperature is regulated to be 83 DEG C-91 DEG C, and heat preservation is carried out for 60 min - 90 min under the stirring condition;c, after heat preservation is finished, the temperature is raised till the liquor is boiled, and reaction is carried out; and d, solid-liquid separation, washing and drying are carried out to obtain the high-density ammonium polyvanadate. According to the method for preparing the high-density ammonium polyvanadate by the calcified roasting pickle liquor through heat preservation, the ammonium polyvanadate with the density being 0.5 g / cm<3> or above is prepared from the calcified roasting pickle liquor of the vanadium slags, the density is increased by two times compared with an existing method, and meanwhile, vanadium in the pickle liquor is fully recycled, so that economic benefits are remarkable.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Smelting system for separating and enriching vanadium and producing pure iron from iron ore concentrate

InactiveCN110564956AReduce vanadium contentFacilitate extraction of vanadium into slagShaft furnaceElectric arc furnaceSlag

The invention discloses a smelting system for separating and enriching vanadium and producing pure iron from iron ore concentrate. The smelting system comprises a vanadium titano-magnetite pellet, a coal-based vertical furnace and an electric-arc furnace, wherein the vanadium titano-magnetite pellet is obtained after pelleting and drying a vanadium titano-magnetite ore; the coal-based vertical furnace is used for selectively reducing the vanadium titano-magnetite pellet to obtain a metalized pellet; and the electric-arc furnace is used for smelting separating and enriching of the metalized pellet inside the electric-arc furnace. By adopting the smelting system disclosed by the invention, the recycle rate of vanadium is as high as 93% or higher, and the grade of vanadium slag is 6%-8%. Meanwhile, the purity of molten steel obtained through smelting separating is high, the iron content is as high as 99.7% or higher; moreover the content of phosphorus, sulfur, silicon, manganese and titanium in the molten steel is low; and magnetic pure iron and military pure iron can be produced in a simple smelting way.

Owner:陕西有色冶金矿业集团有限公司

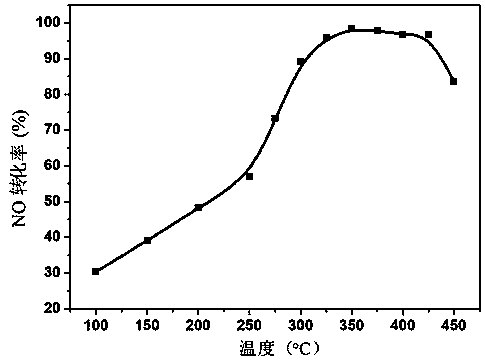

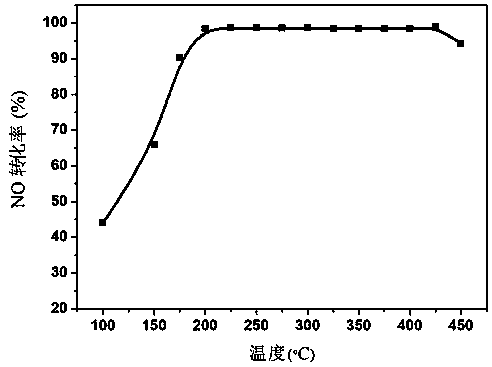

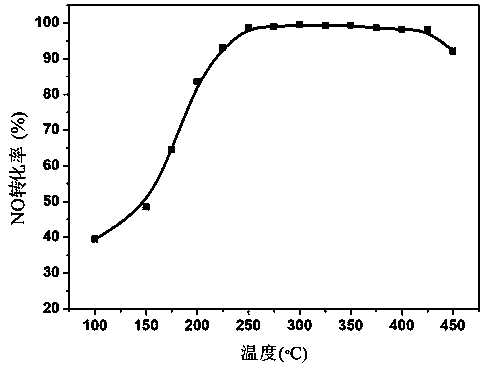

Titanium oxide supported cerium zirconium vanadate denitration catalyst, preparation method and application

ActiveCN105363430BHigh low temperature activityHigh selectivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrogen oxides

The invention discloses a titanium oxide supported cerium zirconium vanadate denitration catalyst, a preparation method and an application. The denitration catalyst is composed of TiO2 as a carrier and cerium zirconium vanadate active components supported on the carrier. The invention also discloses a preparation method and application of a titanium oxide supported cerium zirconium vanadate denitration catalyst. The catalyst is prepared by an impregnation method, and 1-16 wt % of cerium zirconium vanadate is supported on titanium oxide based on the mass of TiO 2 as 100 wt %. The catalyst of the invention has the advantages of good thermal stability, excellent anti-H2O and anti-SO2 poisoning performance, wide operating temperature window, simple preparation process, low cost, etc., and is suitable for the treatment of nitrogen oxides in various exhaust gases, and is suitable for practical applications.

Owner:SHANGHAI UNIV

Method for controlling content of vanadium in chromium sesquioxide

InactiveCN109182753AReduce vanadium contentAchieve removalChromium trioxideProcess efficiency improvementChromium sesquioxideHydrogen

The invention relates to a method for controlling the content of vanadium in chromium sesquioxide, belongs to the technical field of vanadium and chromium metallurgy, and solves the technical problemsof complicated process for preparing low-vanadium-content chromium sesquioxide products and high cost in the prior art. In the method for controlling the content of vanadium in chromium sesquioxide,vanadium and chromium contained solution is reduced, and the pH of the solution is adjusted within 7-9, so that tetravalent vanadium and trivalent chromium are precipitated to obtain vanadium-contained rough hydrogen chromium oxide; finish hydrogen chromium oxide is obtained through pulping, washing and control of the Na2O content within 3.5-6%; and finally, chromium sesquioxide with lower vanadium content is obtained by calcining, crushing, pulping and washing. The method omits special vanadium removing process, reduces the consumption of energy and reagents needed in the vanadium removing process, simplifies the process, and reduces the cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for vanadium aluminum alloy fine powder being used for vanadium iron spray blowing refining

The invention relates to the field of vanadium alloy smelting methods, in particular to a method for vanadium aluminum alloy fine powder being used for vanadium iron spray blowing refining which improves the vanadium iron spray blowing refining efficiency to reduce the vanadium content in slag and improve the vanadium iron smelting vanadium yield. The method comprises the following steps that a, the vanadium aluminum alloy fine powder and aluminium powder are weighed and mixed evenly according to the proportion of the mass ratio of the vanadium aluminum alloy fine powder and the aluminium powder being 0.4-0.6 to fabricate spray blowing material powder, and the mixed spray blowing material powder is firstly added into a spray blowing material tank for later use before the spray blowing refining; b, batching is performed according to the method for preparing vanadium iron alloy by an electro-aluminothermic process, and front segment material adding and powered smelting are performed; c,an inert gas is used as a spray blowing carrier gas, and powered refining is performed after completion; and d, furnace body standing cooling and alloy cake water quenching and crushing are performed,and finally, the vanadium iron alloy is obtained. By means of the method for the vanadium aluminum alloy fine powder being used for the vanadium iron spray blowing refining, the vanadium iron spray blowing refining efficiency can be improved, the vanadium content in the slag is reduced, the vanadium iron smelting vanadium yield is improved, the purpose of efficiently recycling the vanadium aluminum alloy fine powder from vanadium aluminium workshops is achieved, and the method for the vanadium aluminum alloy fine powder being used for the vanadium iron spray blowing refining is especially suitable for vanadium alloy preparation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Raw materials for vanadium-free or vanadium-reduced denox catalysts, and method for producing same

ActiveUS9248433B2Reduce vanadium contentEasy to getGas treatmentHeterogenous catalyst chemical elementsHydrolysisCalcination

A composition that comprises a titanium compound, an iron compound, and a tungsten compound, wherein the titanium compound has a microcrystalline anatase structure and / or is obtained in the production of TiO2 according to the sulphate process, during hydrolysis of a solution which contains titanyl sulphate, and also in that the composition has a vanadium content, calculated as V, of less than 0.15 wt. % in relation to the solids content of the composition. A catalyst or catalyst raw material containing the claimed composition, as well as to a dimensionally stable and catalytically active solid body can be obtained by mixing the composition defined above with binders, plasticisers and optionally, further additives, molding the obtained composition preferably by extrusion, and subsequently carrying out calcination, or by providing a dimensionally stable and catalytically active solid body that can be obtained by applying the composition, optionally together with binders, plasticisers and further additives, to a substrate, and subsequently carrying out calcination.

Owner:SACHTLEBEN PIGMENT GMBH

Method for recovering vanadium from vanadium precipitation waste water

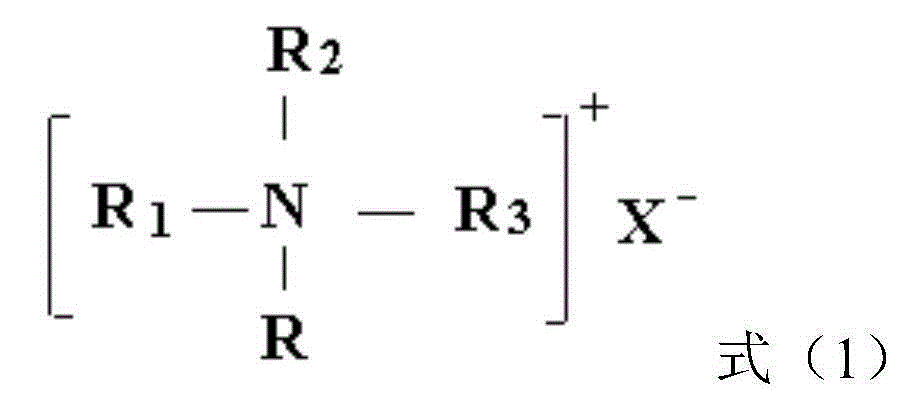

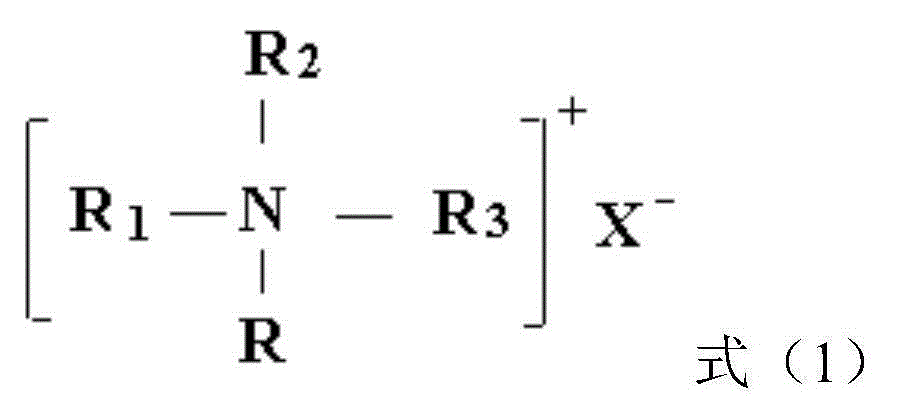

ActiveCN105016520AChange natureReduce vanadium contentMultistage water/sewage treatmentVanadium compoundsMethyl groupCost savings

The invention discloses a method for recovering vanadium from vanadium precipitation waste water, which comprises the following steps: 1)adjusting pH value of vanadium precipitation waste water to be acidic; 2)adding C1-C4 alcohol to vanadium precipitation waste water in the step 1), performing a first contact reaction under stirring condition; and 3)adding a surfactant shown in a step 1) to the vanadium precipitation waste water in the step 2), performing a second contact reaction under stirring condition, then performing solid-liquid separation on the product. The method can be characterized in that the surfactant is added for changing the property of the vanadium precipitation waste water, and sediment can be formed by directly combining with vanadium, total vanadium content in vanadium precipitation waste water is reduced from 0.05-5g / L to 0.001-0.005g / L, vanadium precipitation rate can reach more than 99%, the method can be carried out at low temperature in short time, operation is simple, and the method has the advantages of energy consumption saving and cost saving, and has good social benefit and economic benefit. Wherein, R is C10-C18 long chain alkyl, R1-R3 is methyl or ethyl, and X is Cl, Br or I.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com