Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2106 results about "Ethylbenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylbenzene is an organic compound with the formula C₆H₅CH₂CH₃. It is a highly flammable, colorless liquid with an odor similar to that of gasoline. This monocyclic aromatic hydrocarbon is important in the petrochemical industry as an intermediate in the production of styrene, the precursor to polystyrene, a common plastic material. In 2012, more than 99% of ethylbenzene produced was consumed in the production of styrene.

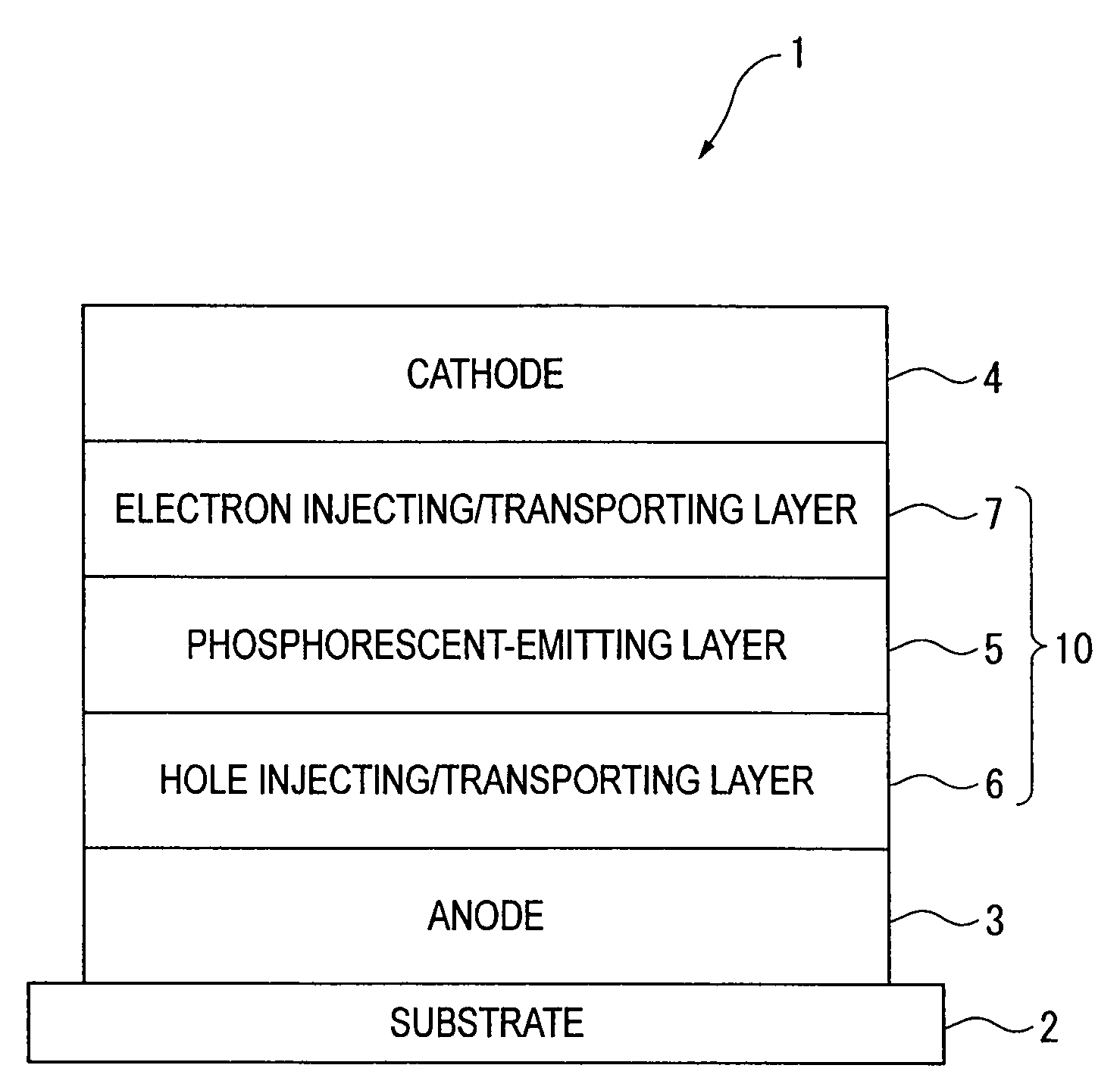

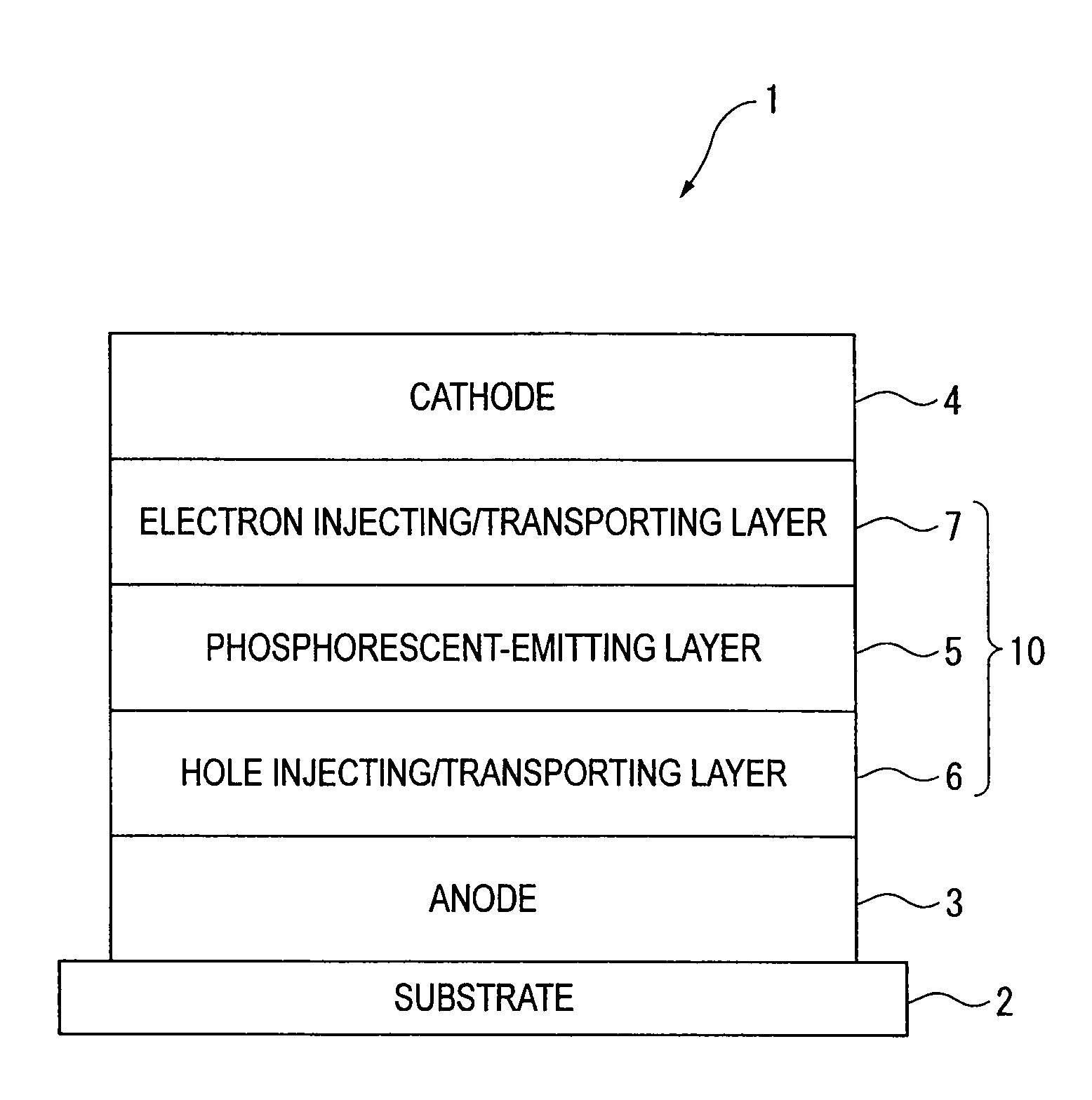

Organic electroluminescence device and material for organic electroluminescence device

InactiveUS20090045731A1Improve efficiencyLong life-timeDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmFluoranthene

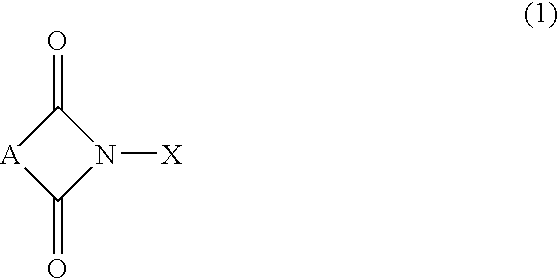

An organic electroluminescence device includes: a cathode; an anode; and a single-layered or multilayered organic thin-film layer provided between the cathode and the anode. The organic thin-film layer includes at least one emitting layer. The at least one emitting layer contains at least one phosphorescent material and a host material represented by the following formula (1).In the formula, Ar1, Ar2, Ar3, B1, B2, B3 and B4 each represent a substituted or unsubstituted benzene ring or a substituted or unsubstituted condensed aromatic hydrocarbon ring selected from a naphthalene ring, a chrysene ring, a fluoranthene ring, a phenanthrene ring, a benzophenanthrene ring, a dibenzophenanthrene ring, a triphenylene ring, a benzo[a]triphenylene ring, a benzochrysene ring, a benzo[b]fluoranthene ring and a picene ring. p is 0 or 1.

Owner:IDEMITSU KOSAN CO LTD

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

Liquid phase process for C8 alkylaromatic isomerization

InactiveUS6872866B1Saving considerable capitalImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAcid washing

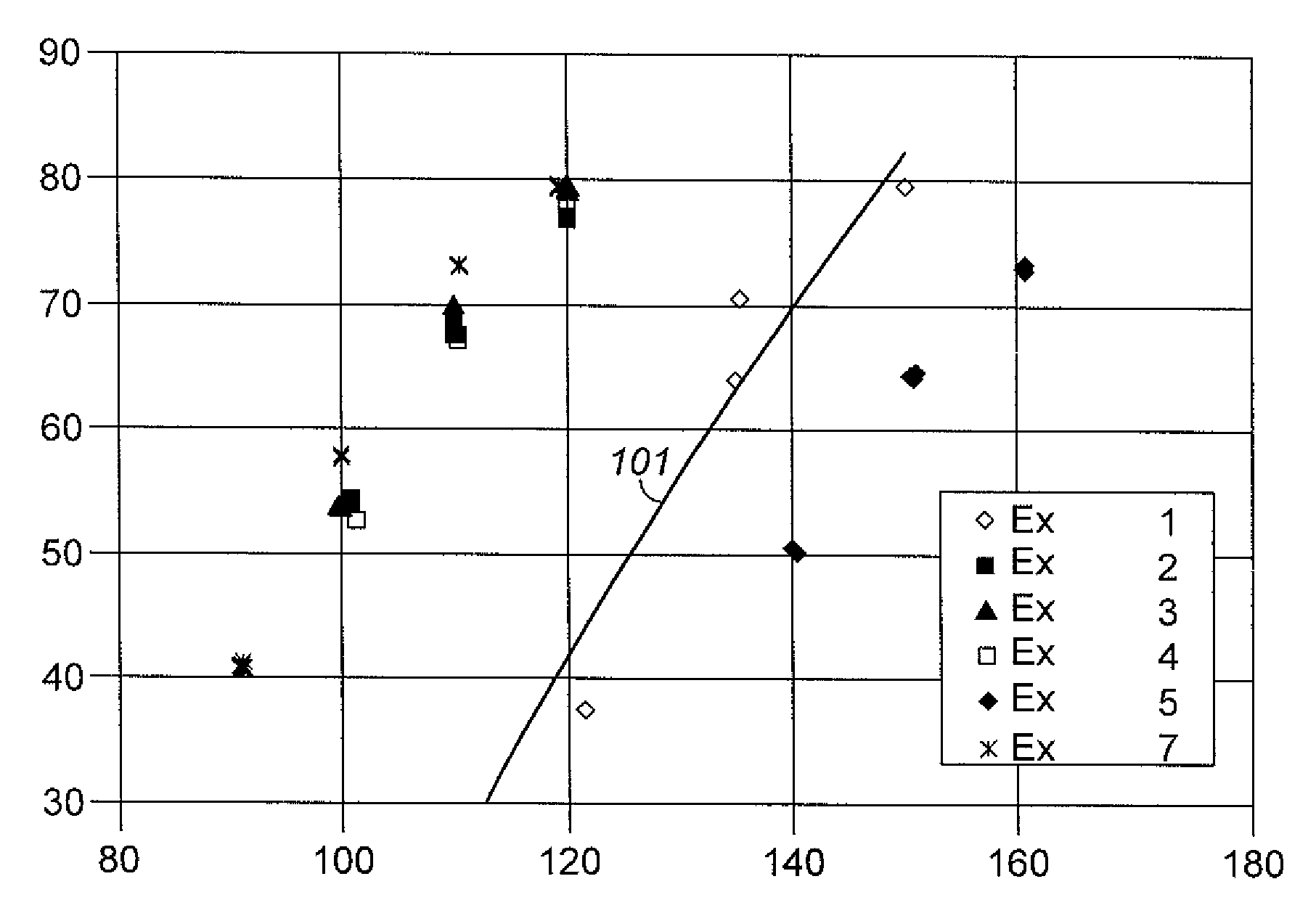

A liquid or partially liquid phase process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene uses a zeolitic catalyst system preferably based on zeolite beta and on pentasil-type zeolite. The invention obtains an improved yield of para-xylene from the mixture relative to prior art processes in a more economical manner. A preferred beta zeolite is a surface-modified zeolite beta resulting from acid washing of a templated native zeolite at conditions insufficient to effect bulk dealumination. A preferred pentasil zeolite is a MTW-type with a silica-to-alumnina ratio between 20 and 45.

Owner:UOP LLC

Selective xylenes isomerization and ethylbenzene conversion

This invention is drawn to a process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene using an oil-dropped catalyst comprising a zeolite, a platinum-group metal and an aluminophosphate binder, resulting in a greater yield of para-xylene at favorable conditions compared to processes of the known art.

Owner:UOP LLC

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

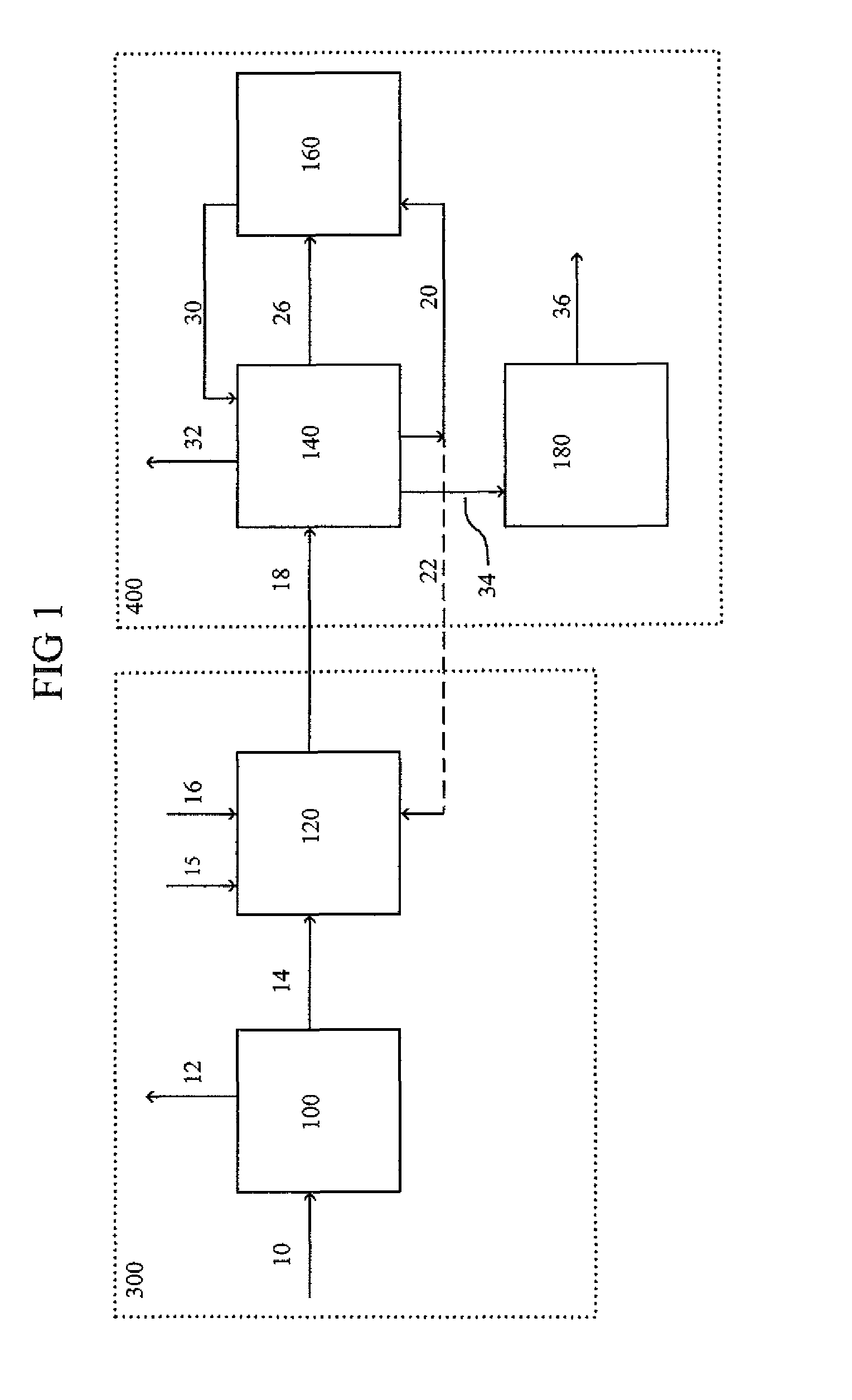

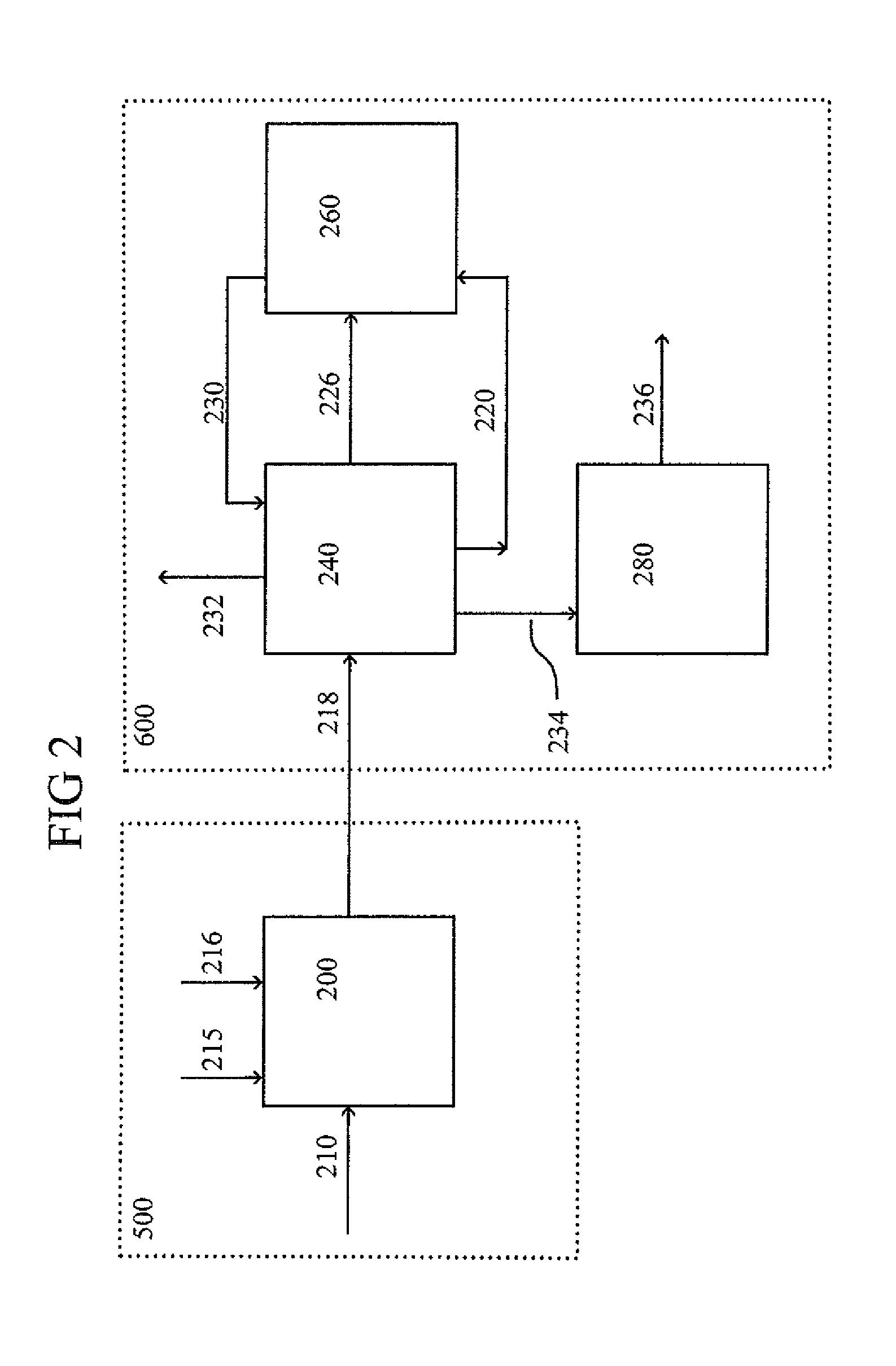

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

Method for producing ethylbenzene

InactiveUS6252126B1Chemical industryFractional condensation purification/separationBenzeneVapor phase

An ethylbenzene production system comprises a reactor vessel, a vapor phase ethylene feed stream, a benzene feed stream entering the reactor vessel, and a product stream containing ethylbenzene exiting the reactor vessel. The reactor vessel has an ethylation section and a benzene stripping section, whereby fluid communication via integrated vapor and liquid traffic is maintained between the ethylation section and stripping section. The vapor phase ethylene feed stream contains 3 to 50 mol % ethylene and at least 20 mol % methane entering the reactor vessel.

Owner:NETZER DAVID

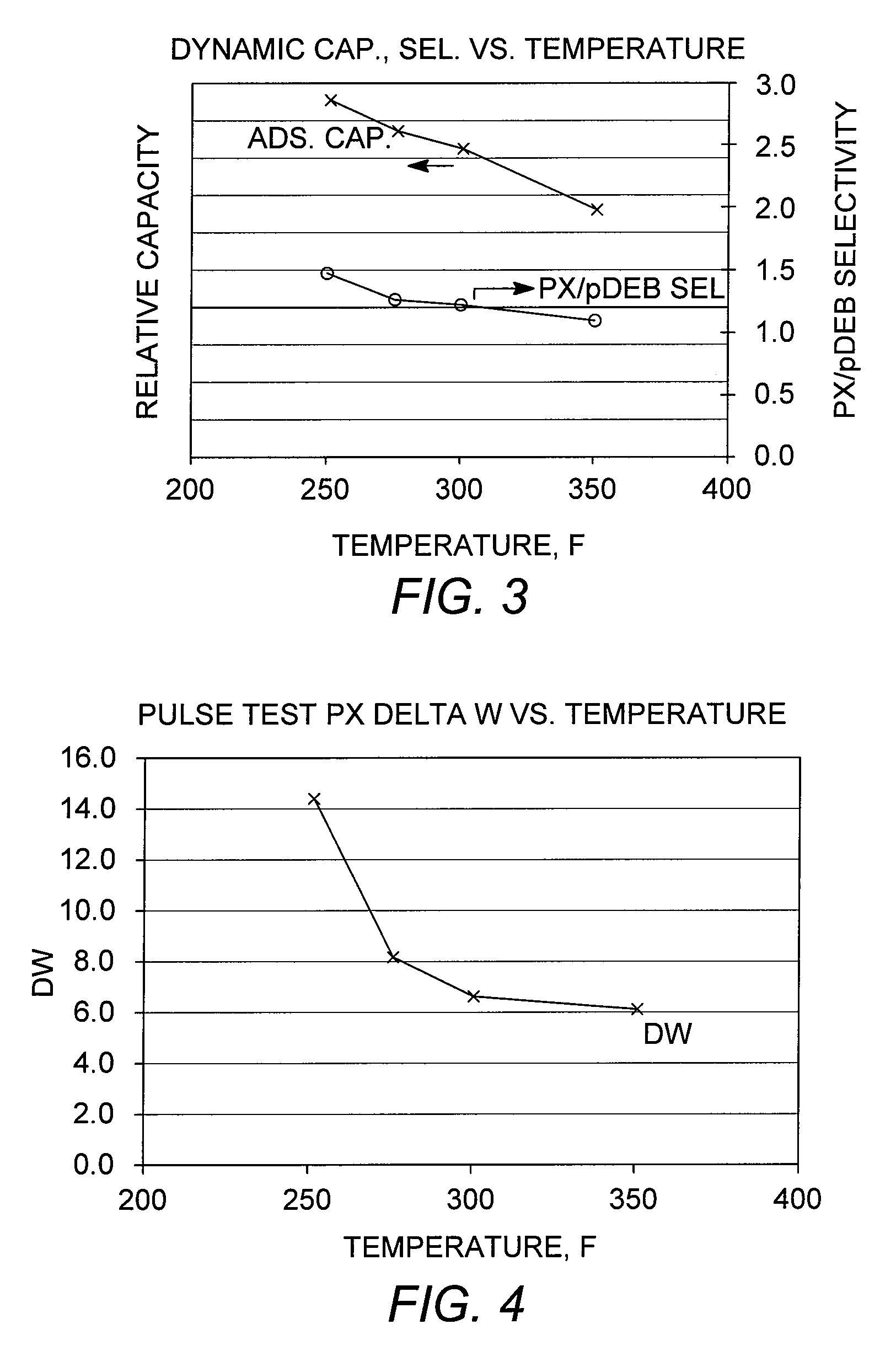

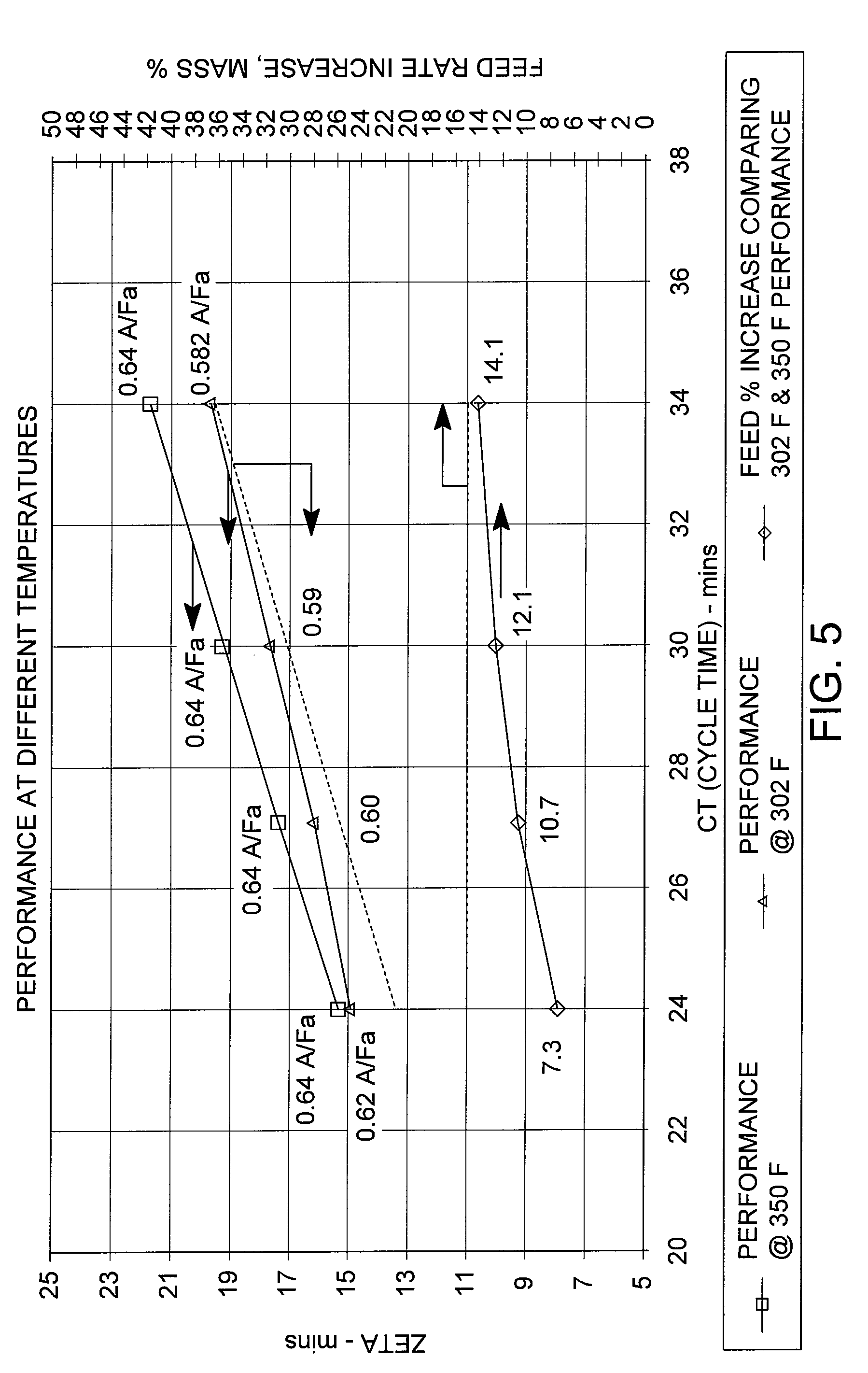

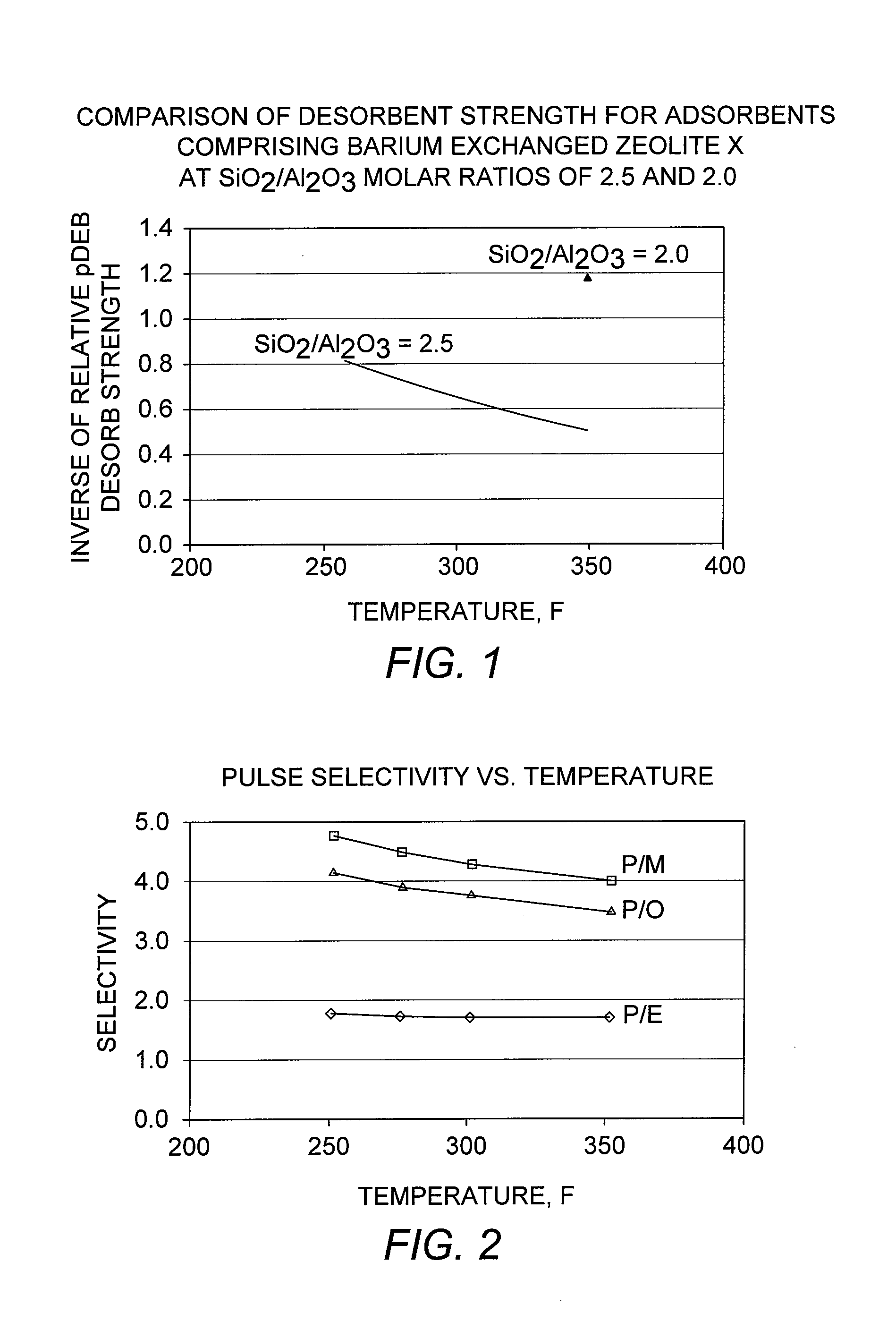

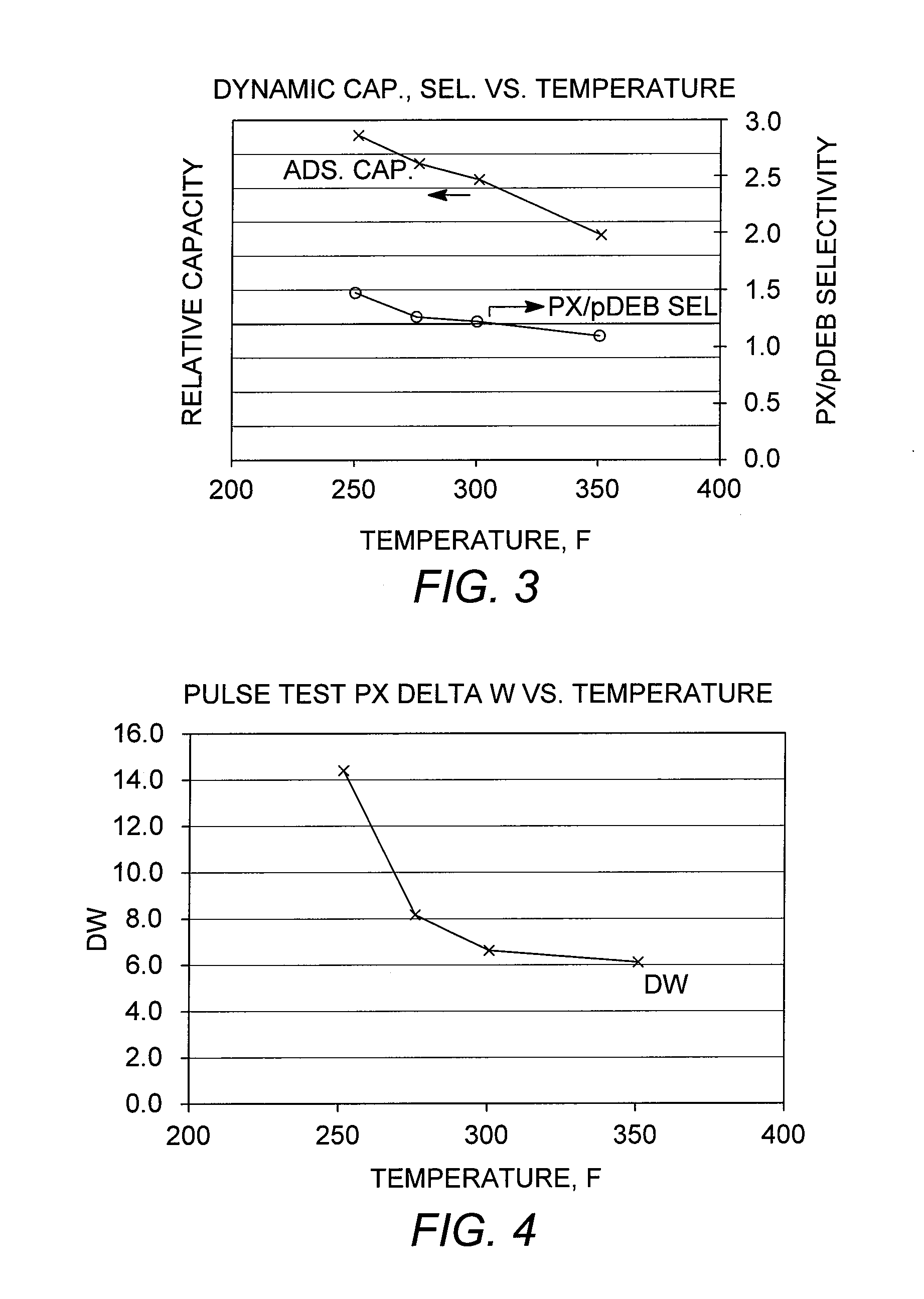

Binderless adsorbents with improved mass transfer properties and their use in the adsorptive separation of para-xylene

ActiveUS7812208B2Improve performanceImprove mass transfer effectOther chemical processesMolecular-sieve and base-exchange compoundsProduction rateSorbent

Owner:UOP LLC

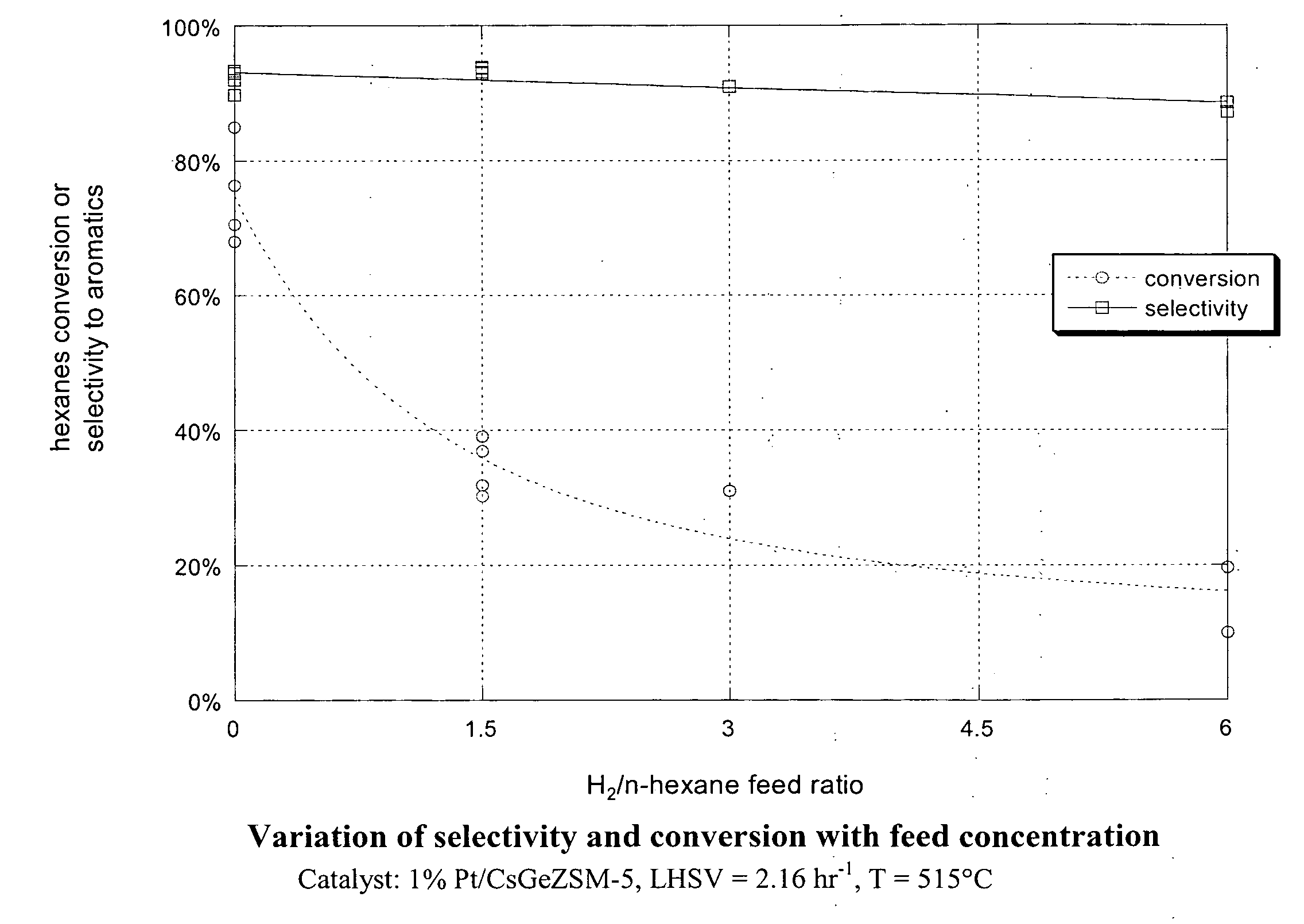

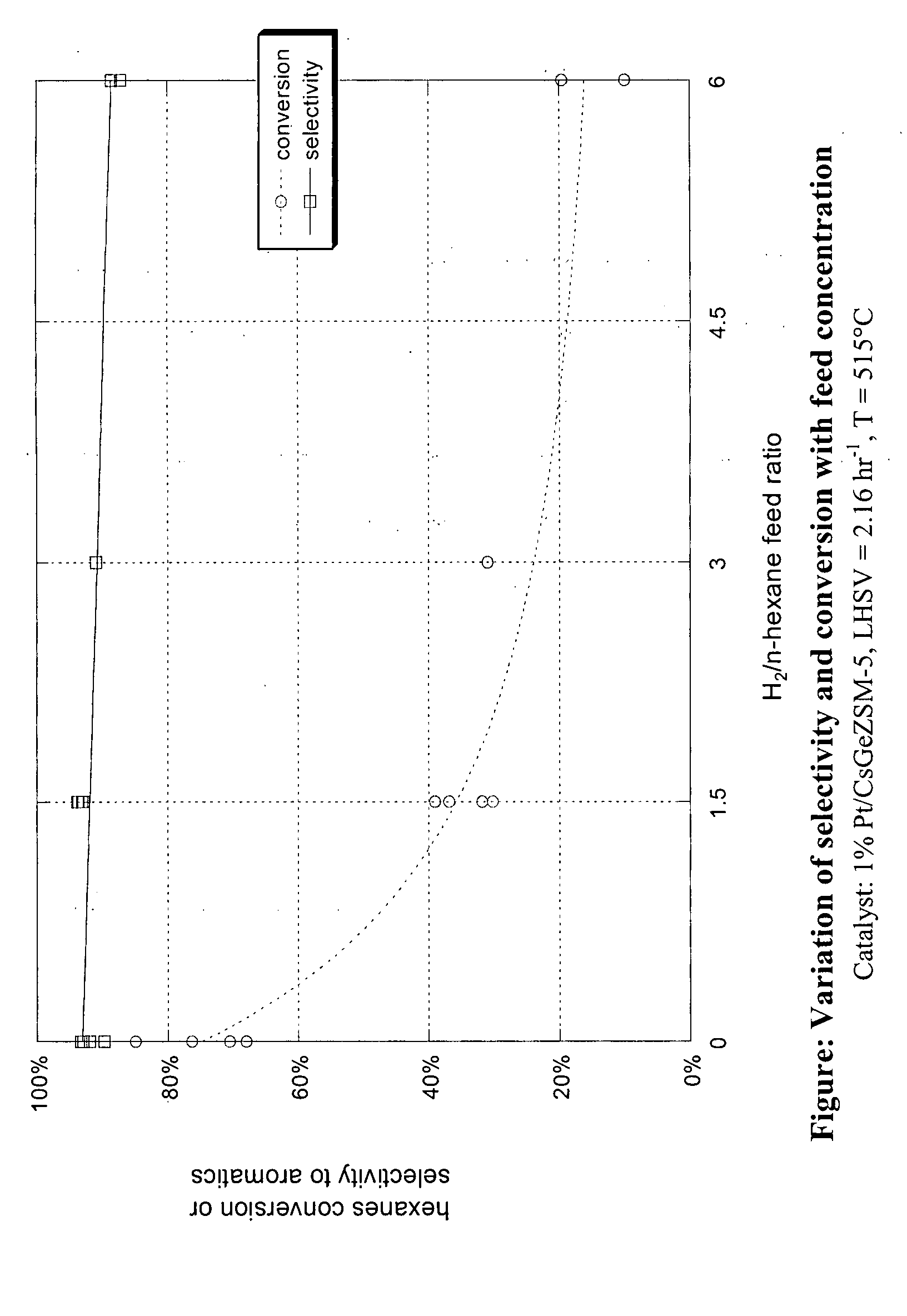

Aromatization of alkanes using a germanium-zeolite catalyst

ActiveUS20080255398A1Molecular sieve catalystsRefining to change hydrocarbon structural skeletonAlkaneAlkaline earth metal

This invention relates to a process for the aromatization of C6 to C12 alkanes, such as hexane, heptane and octane, to aromatics, such as benzene, ethyl benzene, toluene and xylenes, with a germanium-containing zeolite catalyst. The catalyst is a non-acidic aluminum-silicon-germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant and may be pretreated with a sulfur compound, i.e., sulfided. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly paraffinic and / or low in naphthenes. Lowering the hydrogen to hydrocarbon ratio increases conversion and aromatics selectivity.

Owner:SAUDI BASIC IND CORP SA

Process for toluene and methane coupling in a microreactor

InactiveUS8071836B2Hydrocarbon by hydrogenationChemical/physical/physico-chemical microreactorsMicroreactorMethane

A process for making ethylbenzene and / or styrene by reacting toluene with methane in one or more microreactors is disclosed. In one embodiment a method of revamping an existing styrene production facility by adding one or more microreactors capable of reacting toluene with methane to produce a product stream comprising ethylbenzene and / or styrene is disclosed.

Owner:FINA TECH

Modified Y-85 and LZ-210 Zeolites

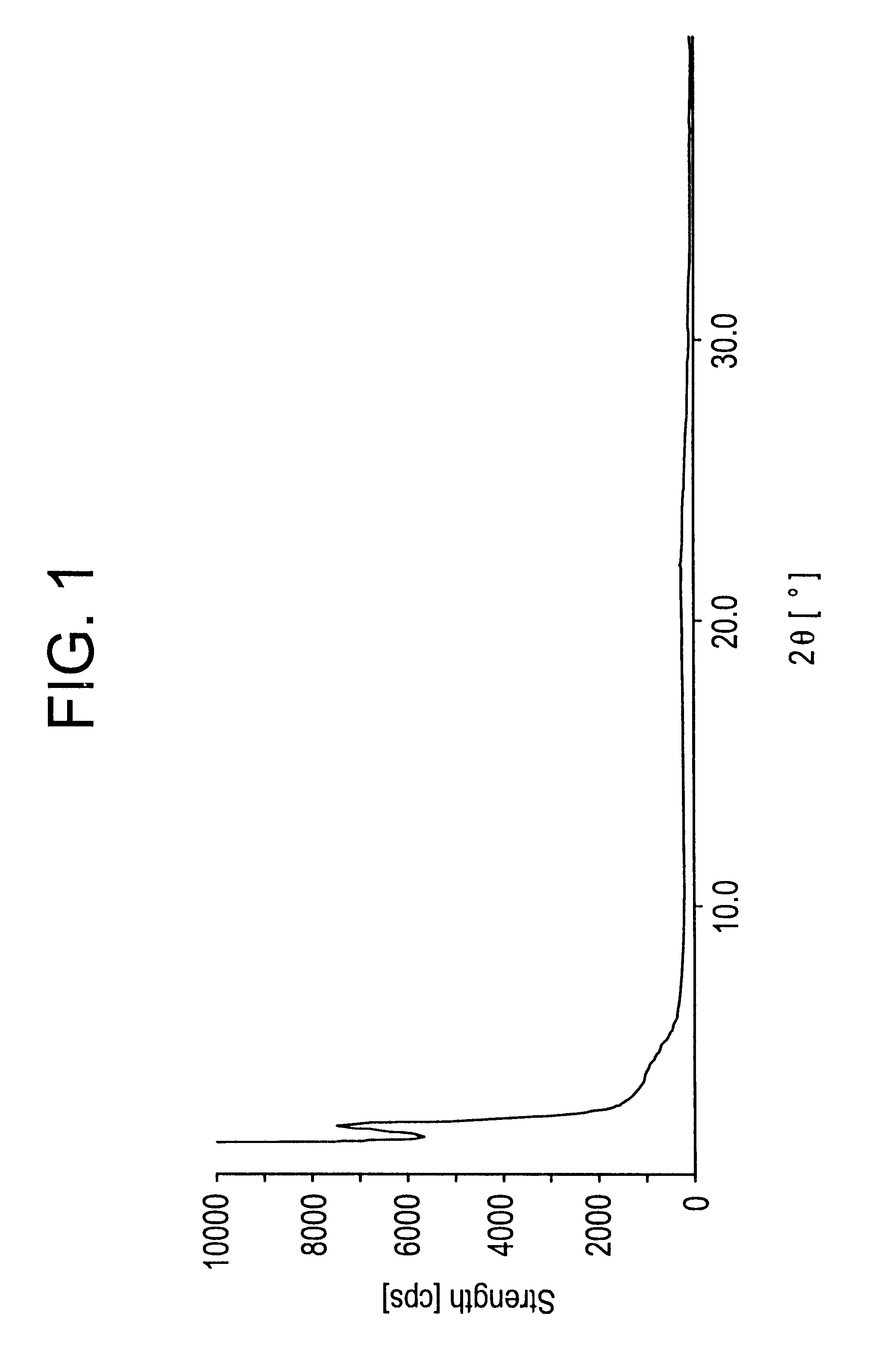

InactiveUS20080171649A1Improved Diffusion PropertiesHigh catalytic activityMolecular sieve catalystsCatalyst activation/preparationX-rayCumene

Catalysts for converting polyalkylaiomatics to monoalkylaromatics, particularly cumene and ethyl benzene are disclosed which comprise modified Y-85 or LZ-210 zeolites. For cumene and ethylbenzene production, a disclosed catalyst, made of 80 wt % zeolite and 20 wt % alumina binder on a volatile-flee basis, has one or more of the following physical characteristics: (1) an absolute intensity of the modified Y zeolite as measured by X-ray diffraction (XRD) of preferably at least 50 and (2) a framework aluminum of the modified Y zeolite of preferably at least 50% of the aluminum of the modified Y zeolite.

Owner:UOP LLC

Gas phase alkylation method and catalyst

InactiveUS6090991AEnhanced ethylbenzene contentReduced polyalkylated aromatic component contentMolecular sieve catalystsMolecular sieve catalystAlkyl transferGram

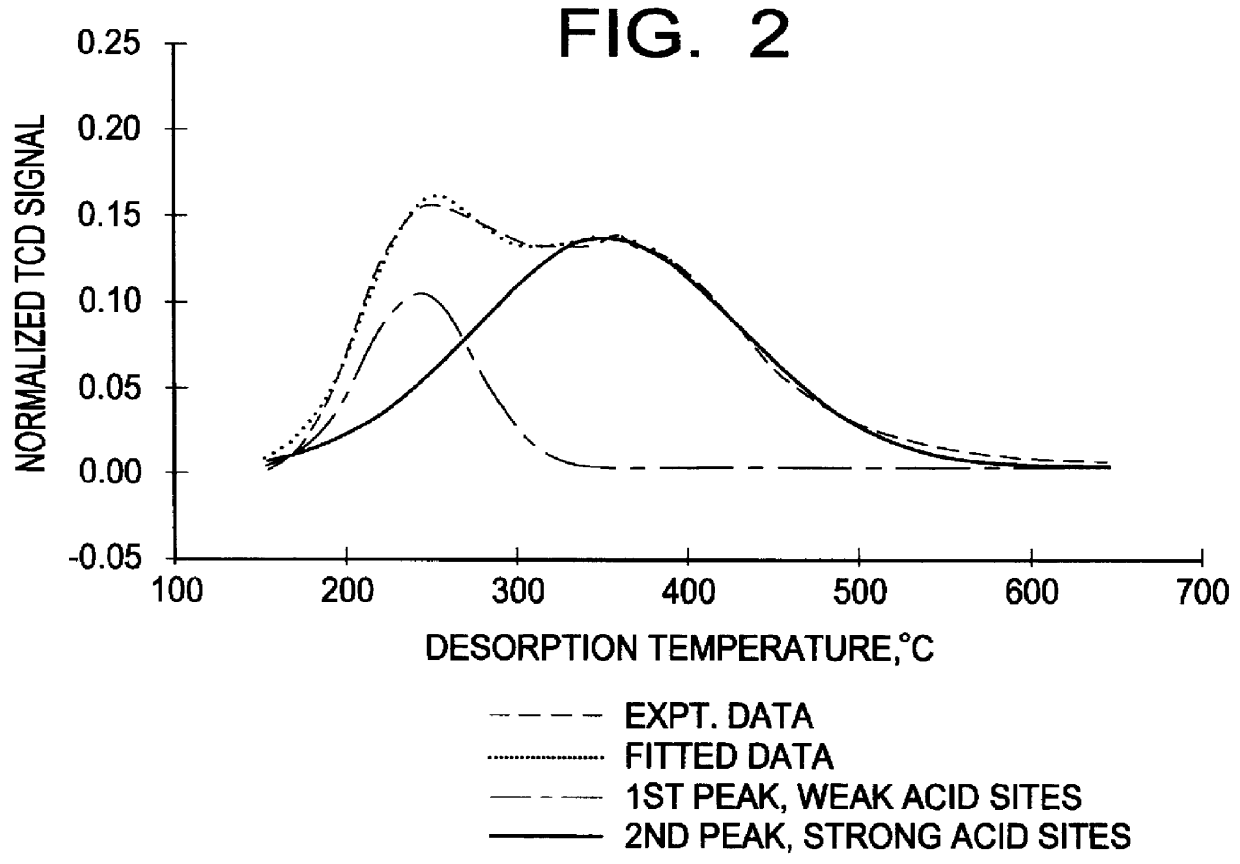

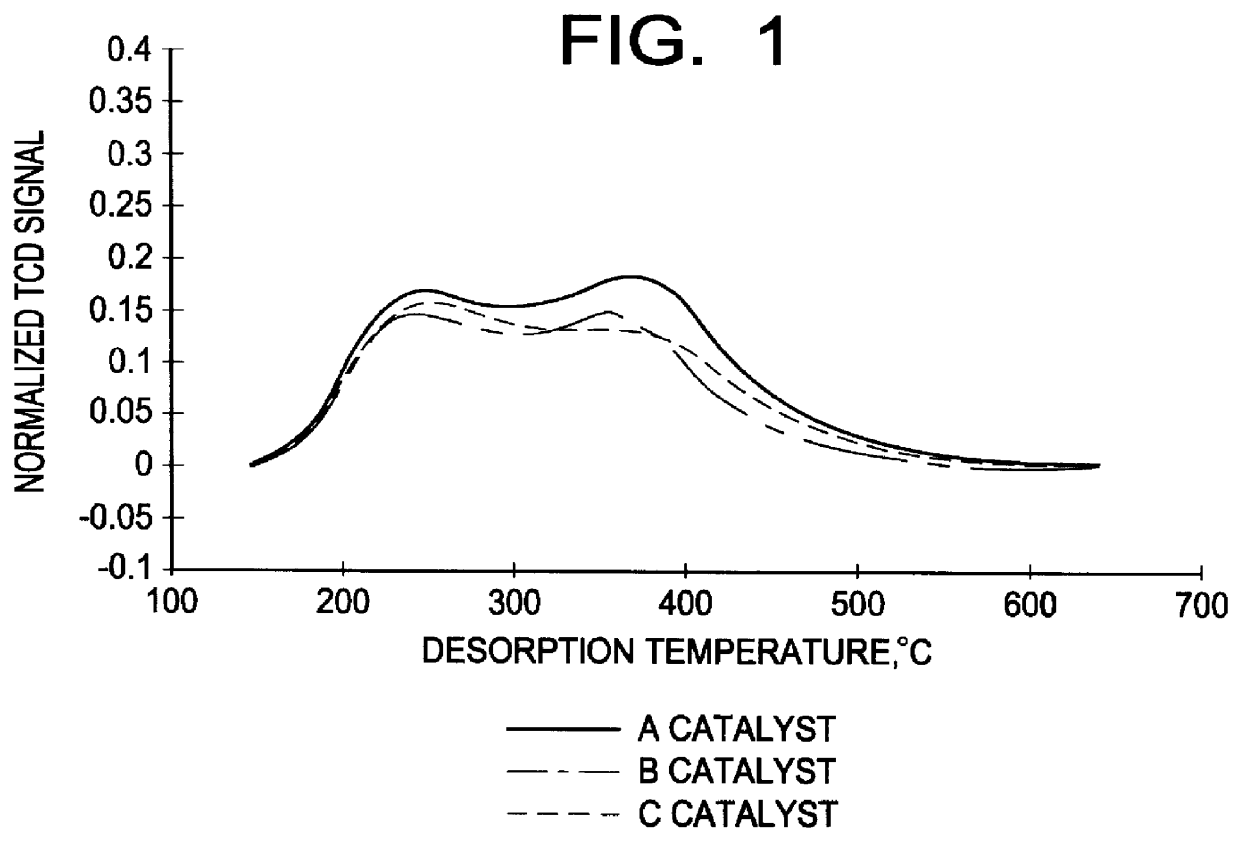

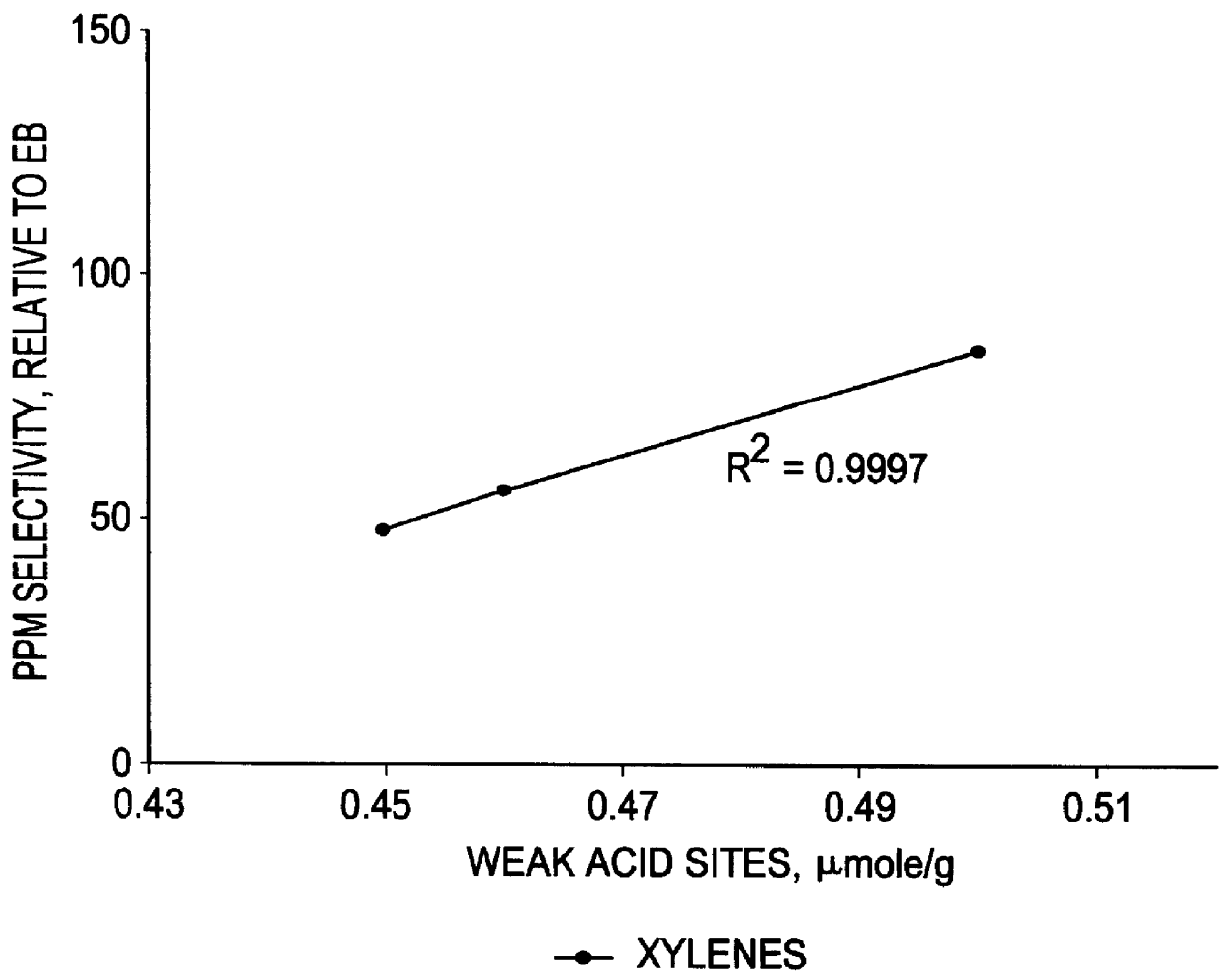

Ethylbenzene is produced by alkylation over monoclinic silicalite catalysts having a weak acid site concentration of less than 50 micromoles per gram. A feedstock containing benzene and ethylene is applied to an alkylation reaction zone having at least one catalyst bed containing a monoclinic silicalite catalyst having a weak acid site concentration of less than 50 micromoles per gram. The alkylation reaction zone is operated at temperature and pressure conditions in which the benzene is in a gaseous phase to cause gas-phase alkylation of the aromatic substrate in the presence of the silicalite catalysts to produce an alkylation product. The alkylation product is then withdrawn from the reaction zone for separation and recovery.

Owner:FINA TECH

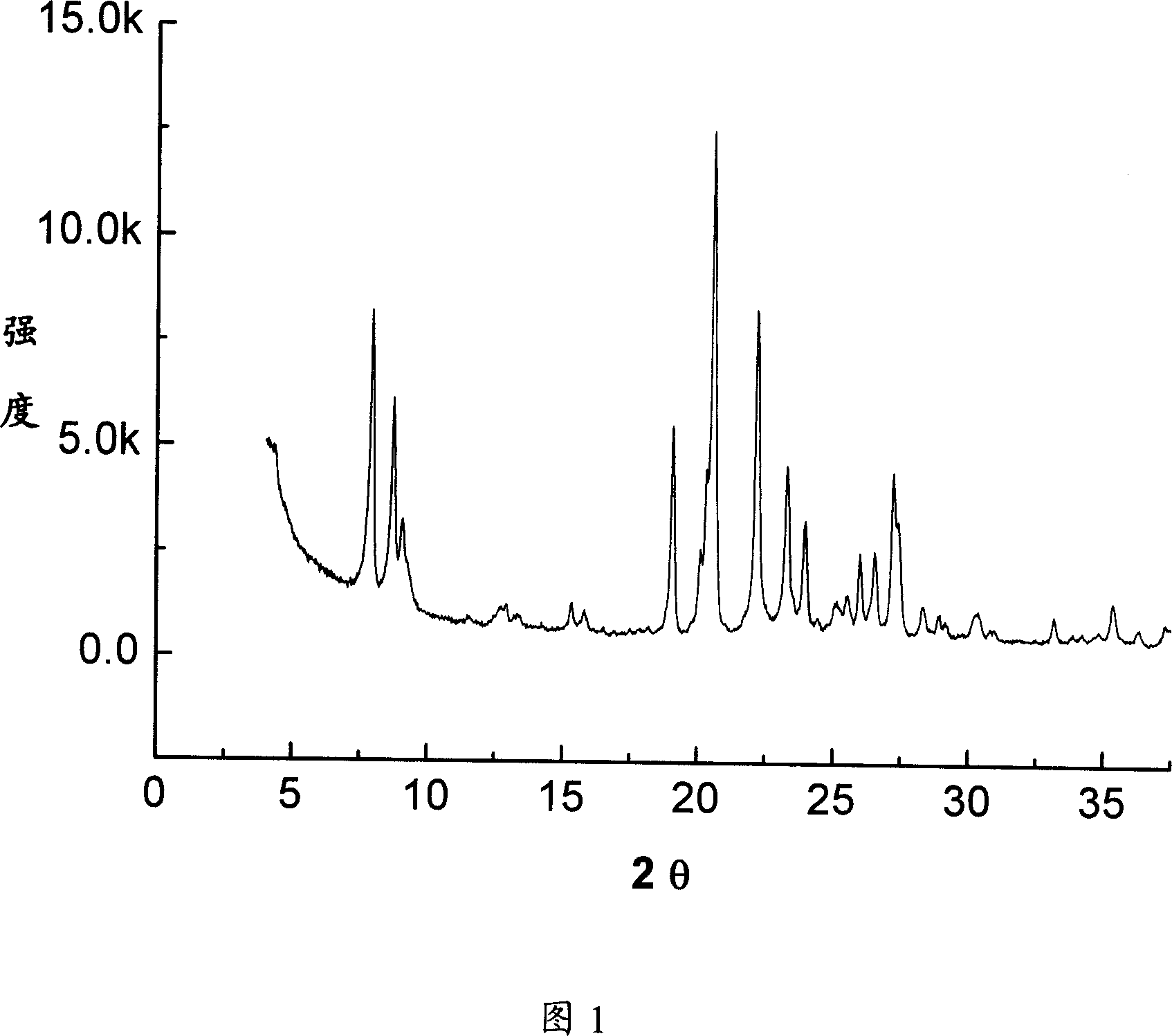

Titanium-containing silicon oxide catalyst

A titanium-containing silicon oxide catalyst satisfying all of the following conditions (1) to (4):(1): an average pore size of 10 Å or more,(2): a pore size of 90% or more of the total pore volume of 5 to 200 Å,(3): a specific pore volume of 0.2 cm3 / g or more, and(4): a quarternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by solvent extraction operation;wherein, R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms, a method for producing said catalyst, and a method for producing propylene oxide by reacting propylene with a hydroperoxide, except for ethylbenzene hydroperoxide, in the presence of said catalyst.

Owner:SUMITOMO CHEM CO LTD

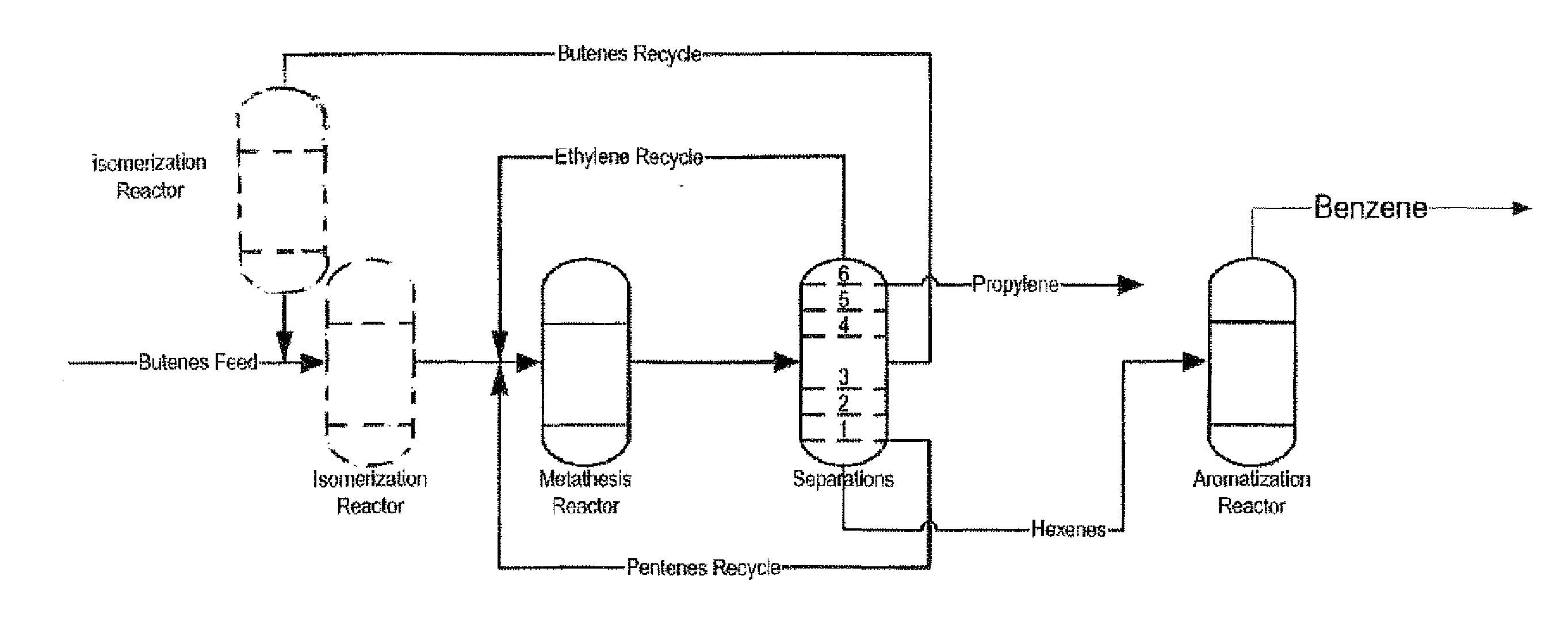

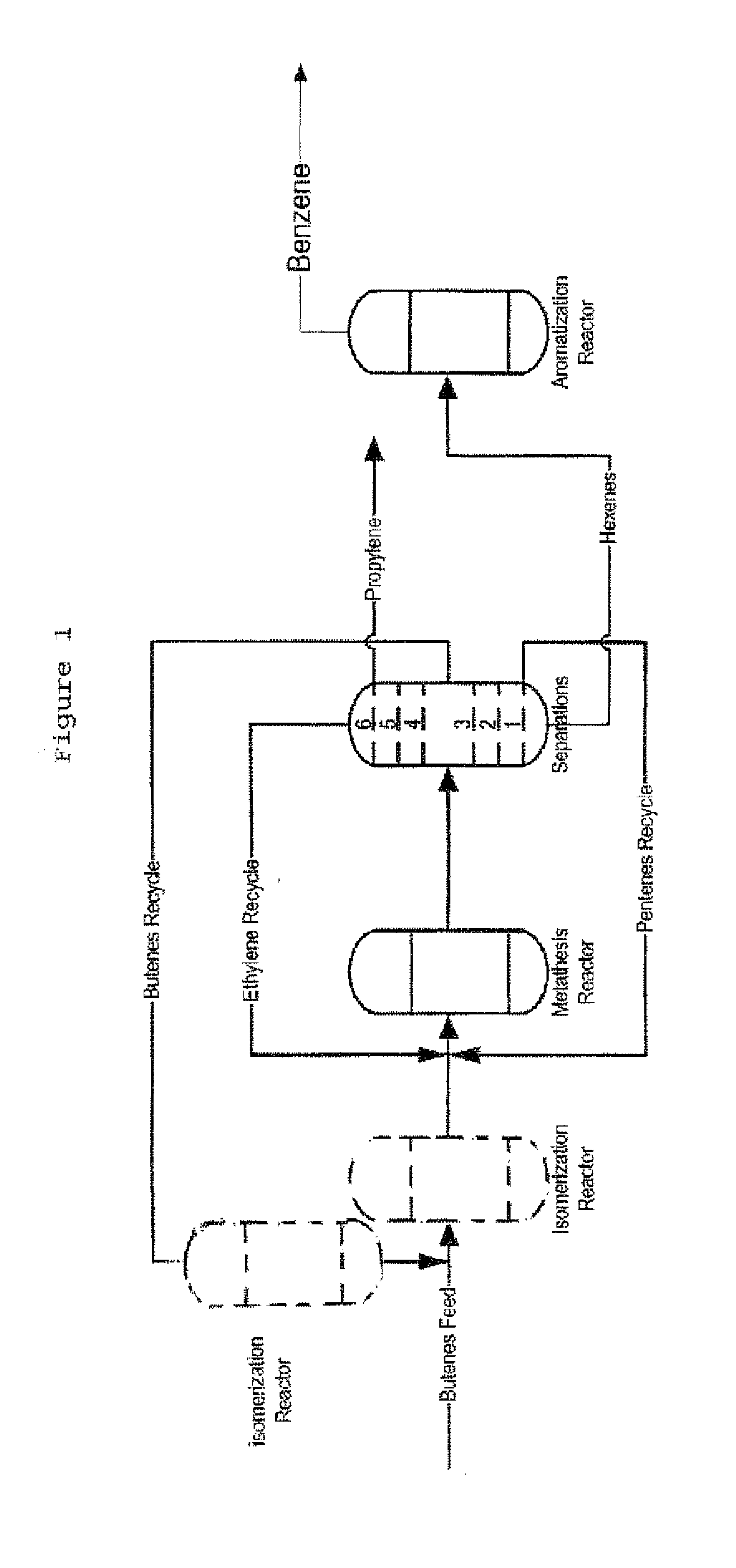

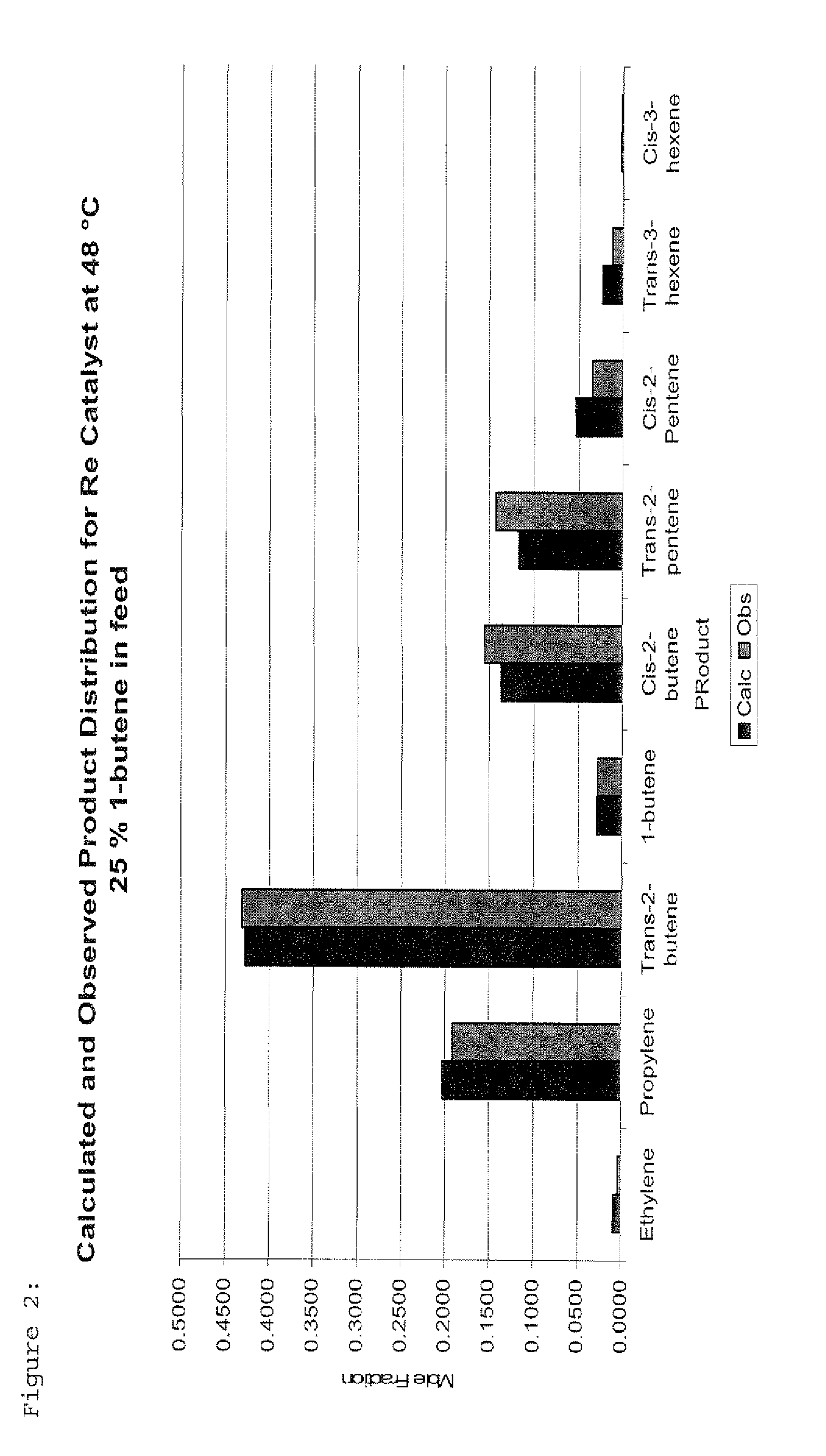

Process for Producing Propylene and Aromatics from Butenes by Metathesis and Aromatization

InactiveUS20110263917A1Molecular sieve catalystDistillation purification/separationIsomerizationOctene

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

Process for preparation of hydroperoxides

Owner:REPSOL QUIMICA

Olefin upgrading process with guard bed regeneration

InactiveUS20080029437A1Continuity of operation is assuredCatalytic crackingMolecular sieve catalystsPetrochemicalAlkylation

A process for the regeneration of materials used in the guard beds preceding the reactors used in an olefin conversion process which converts olefinic refinery streams to higher boiling hydrocarbon products by polymerization (oligomerization) or alkylation of aromatics including benzene. Products of the process may include olefin oligomers and alkylaromatics in the gasoline boiling range as well as alkylaromatic petrochemicals such as cumene and ethylbenzene. The process is integrated with the olefin conversion process to ensure continuous operation of the olefin conversion without sending the feedstock containing the contaminant(s) to the reactor. The process uses reaction products from the olefin conversion process to regenerate the guard bed material and so is economically attractive since it does not require the use of separate purge, regeneration feed and separation systems. A plurality of guard beds is used, each containing a material which removes catalyst poisons. The guard beds are operated on a swing system in which one or more beds is kept on stream to remove the contaminant(s) while one or more of the remaining beds is being purged or regenerated. In this way, continuity of operation is assured. The regeneration medium is a product stream from the olefin conversion process.

Owner:EXXON RES & ENG CO

Binderless adsorbents and their use in the adsorptive separation of para-xylene

ActiveUS7820869B2Improve performanceIncrease mass transfer rateMaterial nanotechnologyMolecular sieve catalystsProduction rateSorbent

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

Production of high purity ethylbenzene from non-extracted feed and non-extracted reformate useful therein

ActiveUS20080194896A1Reduce the presence of impuritiesHigh purityHydrocarbonsHydrocarbon from saturated and unsaturated hydrocarbon additionMolecular sieveAromatic hydrocarbon

A process for producing an ethylbenzene product having a purity of at least 99.50 percent based on the weight of ethylbenzene present in the product by the ethylation of the benzene present in non-extracted feed, e.g., non-extracted hydrocarbon composition. The non-extracted feed is substantially free of both C4− hydrocarbons and the C7+ aromatic hydrocarbons and contains benzene and benzene coboilers. The process is carried out in the liquid phase, in the presence of an acid-active catalyst containing MCM-22 family molecular sieve, and under specified conditions.

Owner:EXXONMOBIL CHEM PAT INC

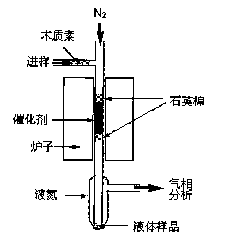

Catalytic thermal cracking method for lignin

InactiveCN101824330AAchieve reuseImprove catalytic performanceBiofuelsLiquid hydrocarbon mixture productionLiquid productMolecular sieve

The invention discloses a catalytic thermal cracking method for lignin. The method comprises the following steps: preheating a molecular sieve catalyst to 200-300 DEG C, gradually adding lignin into the molecular sieve catalyst to carry out catalytic cracking reaction under the temperature of 500-800 DEG C and in the protective atmosphere of inert gas, separating the catalytic thermal cracking product of lignin after the reaction to obtain liquid, gas and solid products. By GC / MS analysis, the main components of the liquid product comprise benzene, toluene, ethylbenzene, naphthalene and other aromatic compounds, which account for 70%-80% of the total mass of the liquid products. The gas product is measured by GC, in which the volume of methane and carbon monoxide accounts for over 90% of that of the total gas. The main component of the solid product is carbon the mass fraction of which is between 75% and 85%. The products can be used for preparing fuel or aromatic chemicals.

Owner:UNIV OF SCI & TECH OF CHINA

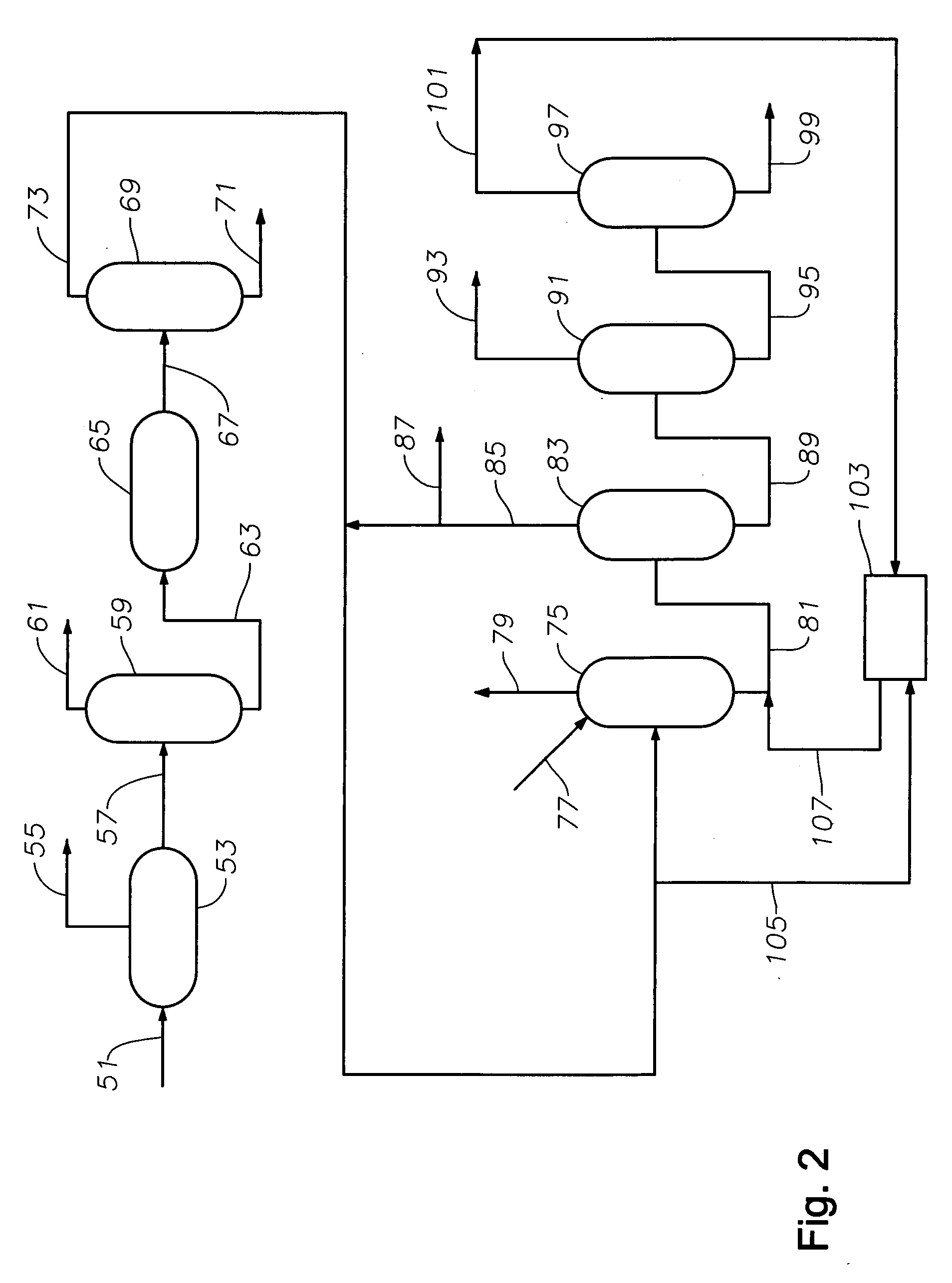

Method for producing paraxylene comprising an adsortion step and two isomerization steps

ActiveUS7915471B2Overcome disadvantagesHydrocarbon by isomerisationSolid sorbent liquid separationIsomerizationSimulated moving bed

A process for producing para-xylene from a hydrocarbon feed is described in which an adsorption column operating as a simulated moving bed with at least five zones delivers an extract, a 2-raffinate and an intermediate raffinate.The extract is distilled and the distillate is optionally re-crystallized to recover para-xylene with a purity of at least 99.7%. The 2-raffinate is distilled then isomerized in a reactor preferably operating in the liquid phase and at a low temperature. The intermediate raffinate with an enriched ethylbenzene content is distilled then isomerized in the vapour phase.

Owner:INST FR DU PETROLE

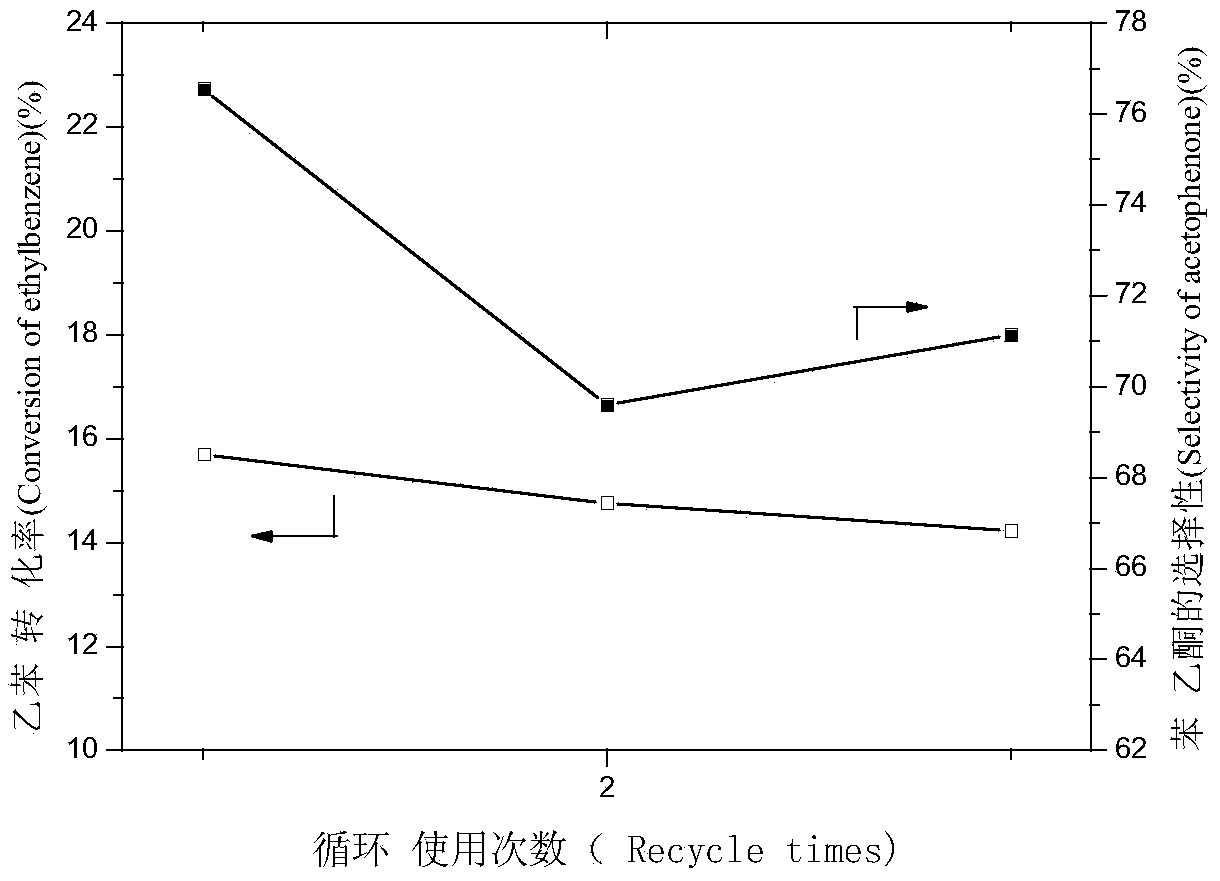

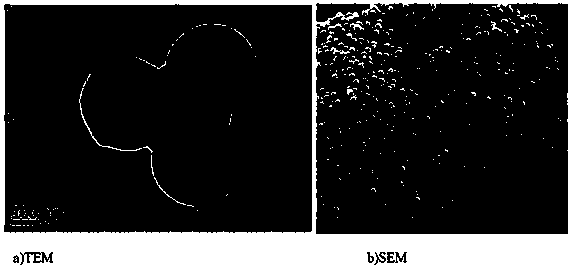

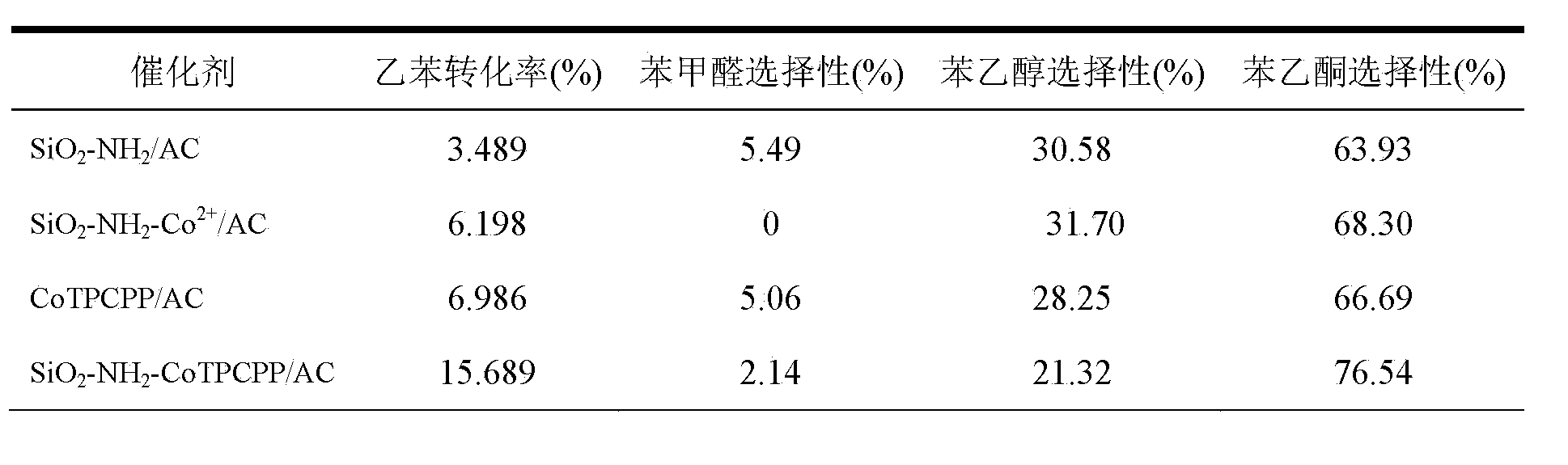

Preparation method of monatomic dispersion catalyst with high catalytic performance

InactiveCN103566935AImprove catalytic performanceImprove stabilityPreparation by oxidation reactionsOrganic compound preparationAlkaneMicrosphere

The invention belongs to the technical field of catalysis and relates to a method for preparing a monatomic cobalt catalyst by roasting silicon dioxide pellets and immobilizing metalloporphyrin. The method is realized by adopting the following technical scheme: namely stirring and dispersing nano silicon dioxide particles, dropwise adding 3-aminopropyl triethoxy silane, so as to obtain amino modified SiO2 pellets, then linking monocarboxyl metalloporphyrin (CoTPCPP) onto an amino modified SiO2 carrier through organic complexing, carbonizing porphyrin through high-temperature calcination in an inert atmosphere, and loading highly dispersed cobalt atoms onto the amino modified SiO2 pellets, thus an amino modified silicon dioxide pellet loaded monatomic cobalt catalyst is obtained. The monatomic dispersion catalyst has high catalytic activity and stability on a molecular oxygen selective ethylbenzene catalytic oxidation reaction in absence of solvent; meanwhile, a preparation method is simple, and product quality can be easily controlled, so that the monatomic dispersion catalyst is applicable to the fields of alkane selective oxidation reactions and synthesis of medical intermediates.

Owner:HUNAN UNIV

Binderless adsprbents and their use in the adsorptive separation of para-xylene

ActiveUS20090326309A1High adsorbent capacity/mass transfer propertyIncreased para-xylene productivityMaterial nanotechnologyMolecular sieve catalystsSorbentSimulated moving bed

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

Method of producing C8 arene isomerization catalyst

ActiveCN101134171AExpand sourceReduce lossesHydrocarbon by isomerisationMolecular sieve catalystsAlkaneMolecular sieve

The process of preparing catalyst for C8 arene isomerization includes forming the mixture of EUO type molecular sieve and adhesive to obtain carrier, introducing VIII metal, drying, roasting and reducing with reductant gas. The catalyst contains EUO type molecular sieve in 5-90 wt%, adhesive 10-90 wt%, and VIII metal 0.1-5.0 wt%. The EUO type molecular sieve is prepared through mixing compound containing element X, compound containing element T, alkali metal compound and water, hydrothermal crystallization reaction in the presence of template agent precursor compounded with coarse dibromoalkane and monamine, collecting the solid and drying, where X is Si and Ge, T is Al, Fe, Ga or B, and the coarse dibromoalkane is mixture of dibromoalkane in the content of 80-95 wt%, Monobromoalkane and paraffin hydrocarbon diol. The catalyst has high ethyl benzene converting rate and low arene losing rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-water ratio ethylbenzene dehydrogenation catalyst

ActiveCN1981929AIncrease alkalinityHigh activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationRare earth

A catalyst for dehydrogenating ethylbenzene in the condition of low water ratio is prepared through adding at least two compounds of light RE elements other than Ce, and at least one oxide of metal chosen from Ca, Mg, Ba, B, Sn, Pb, Cu, Zn, Ti, Zr, V and Mo to the Fe-K-Ce-W system. It has high stability and activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

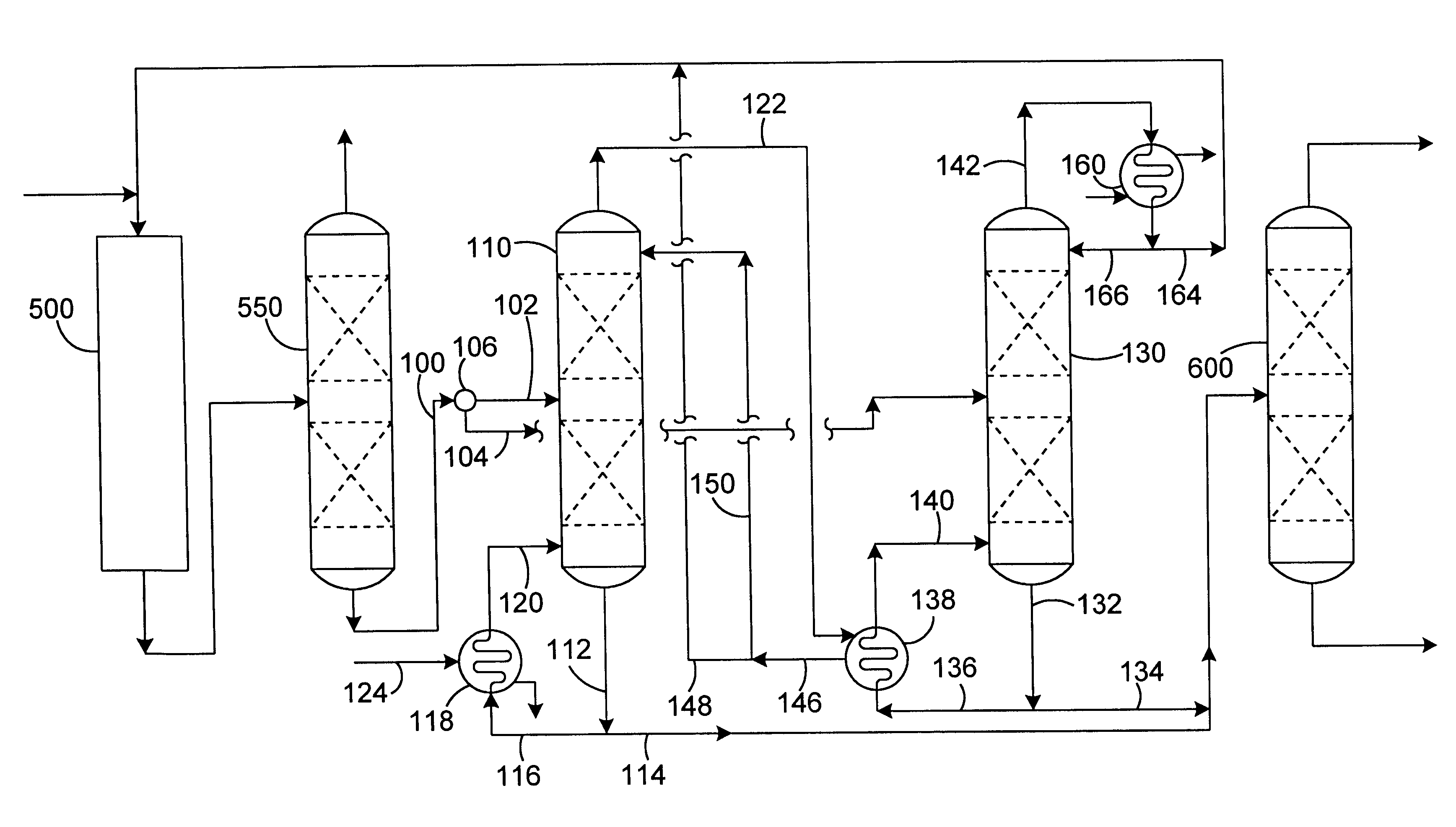

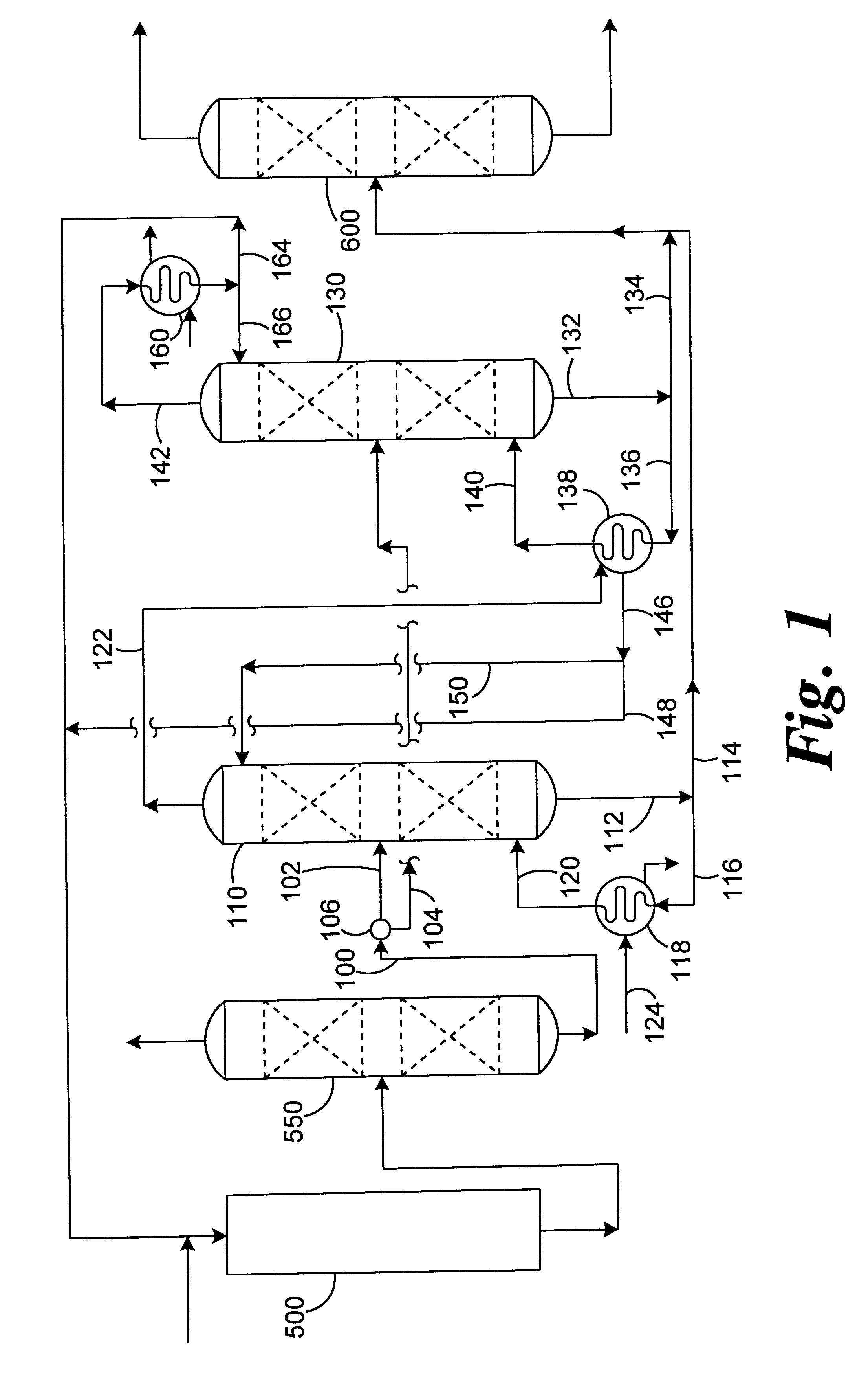

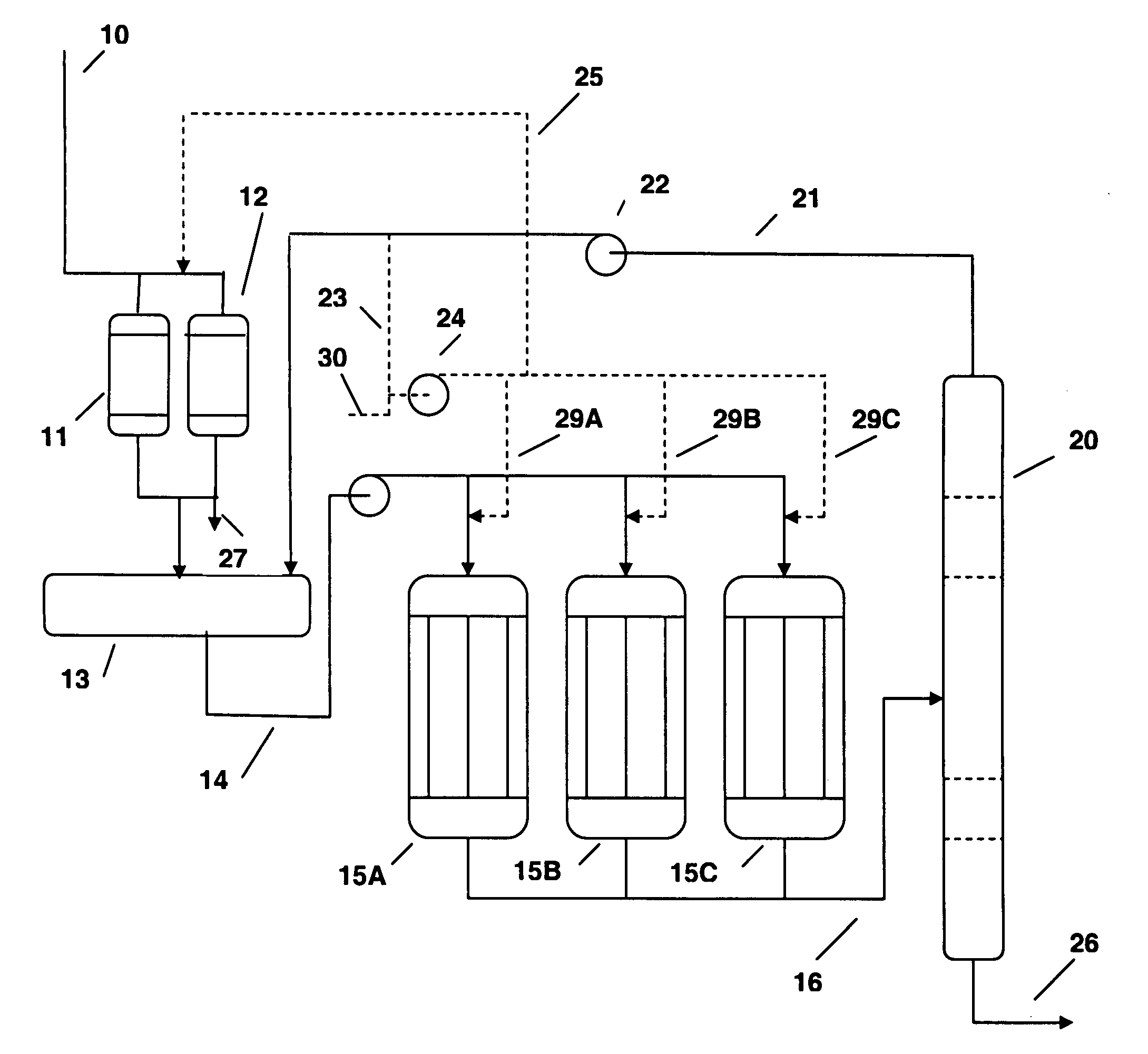

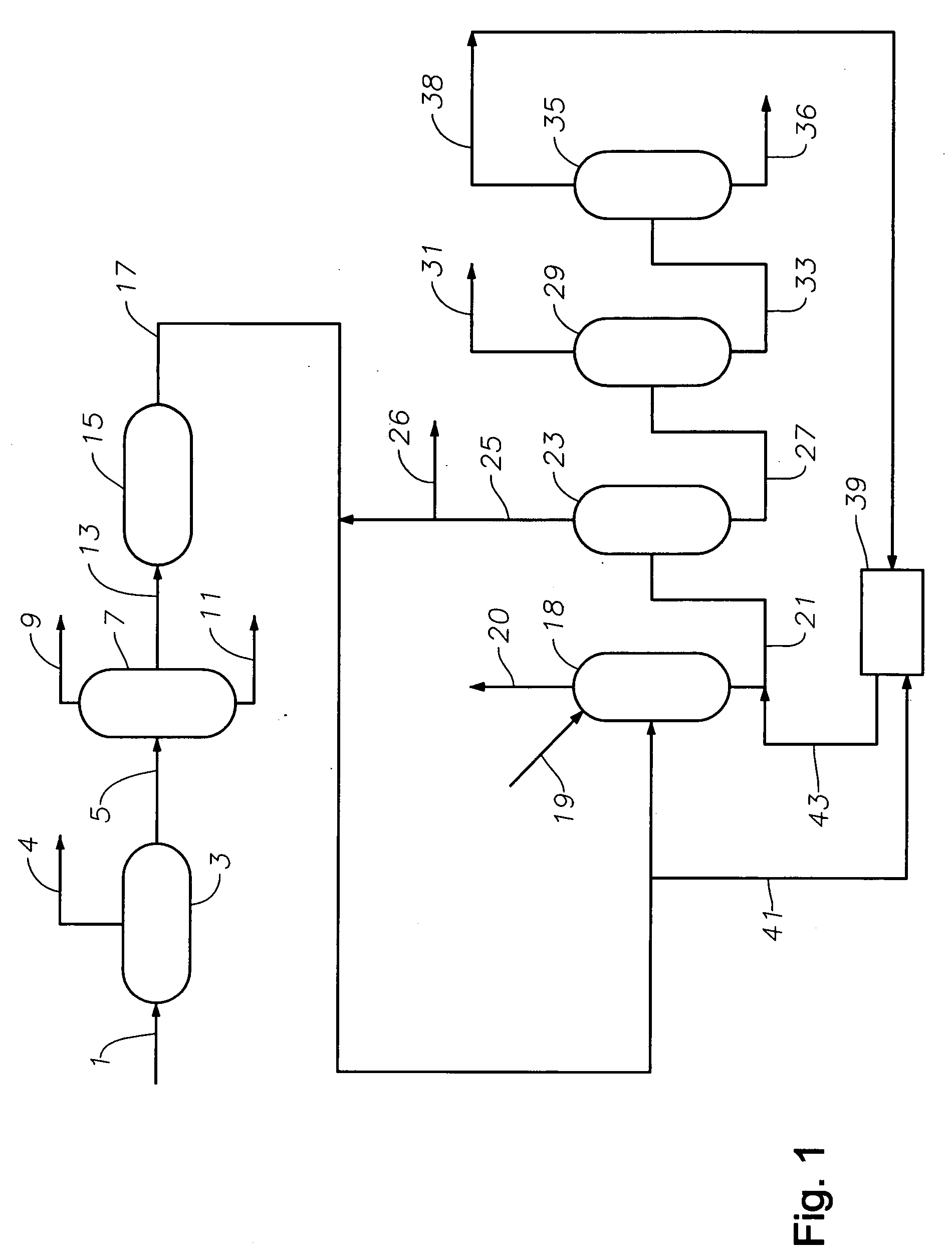

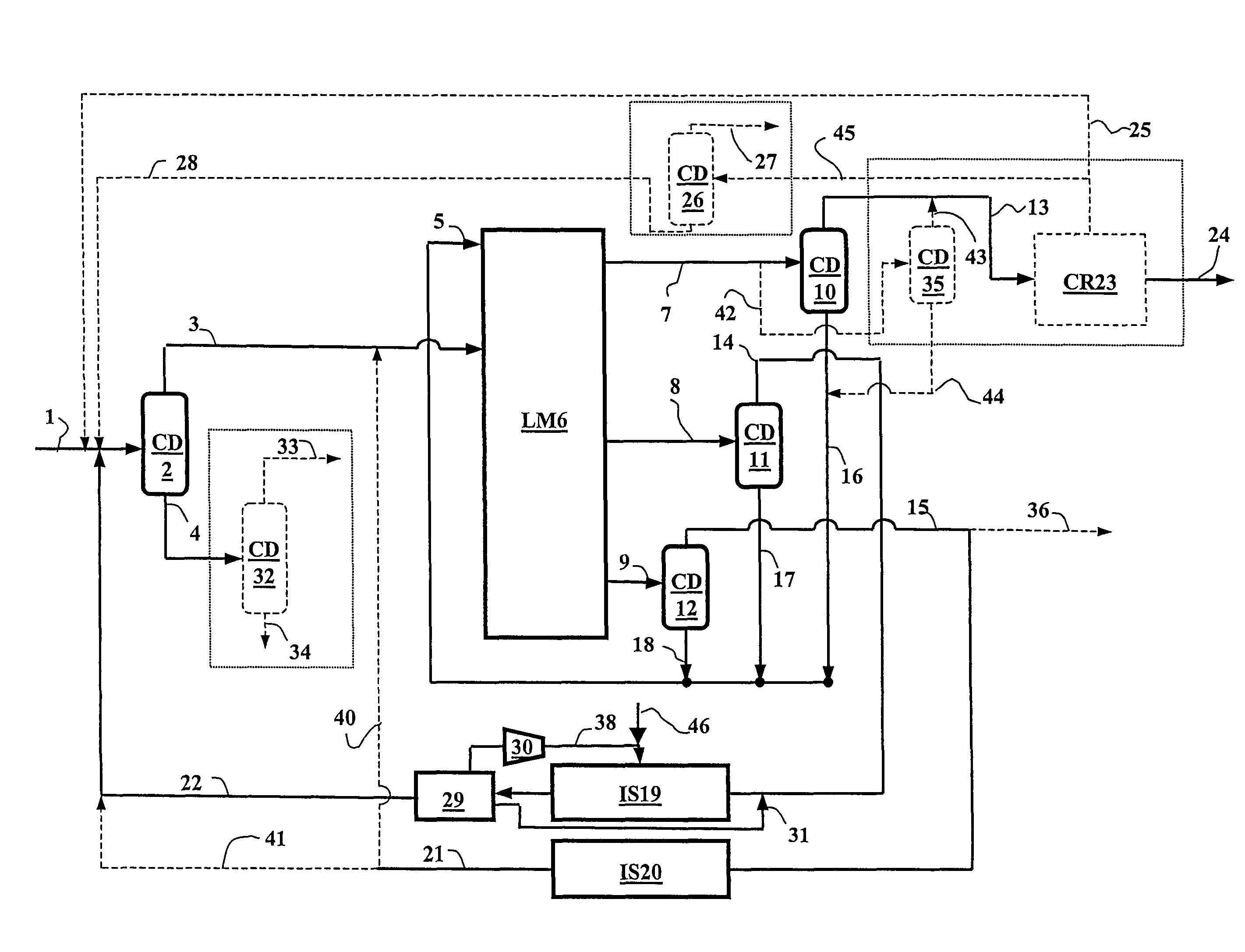

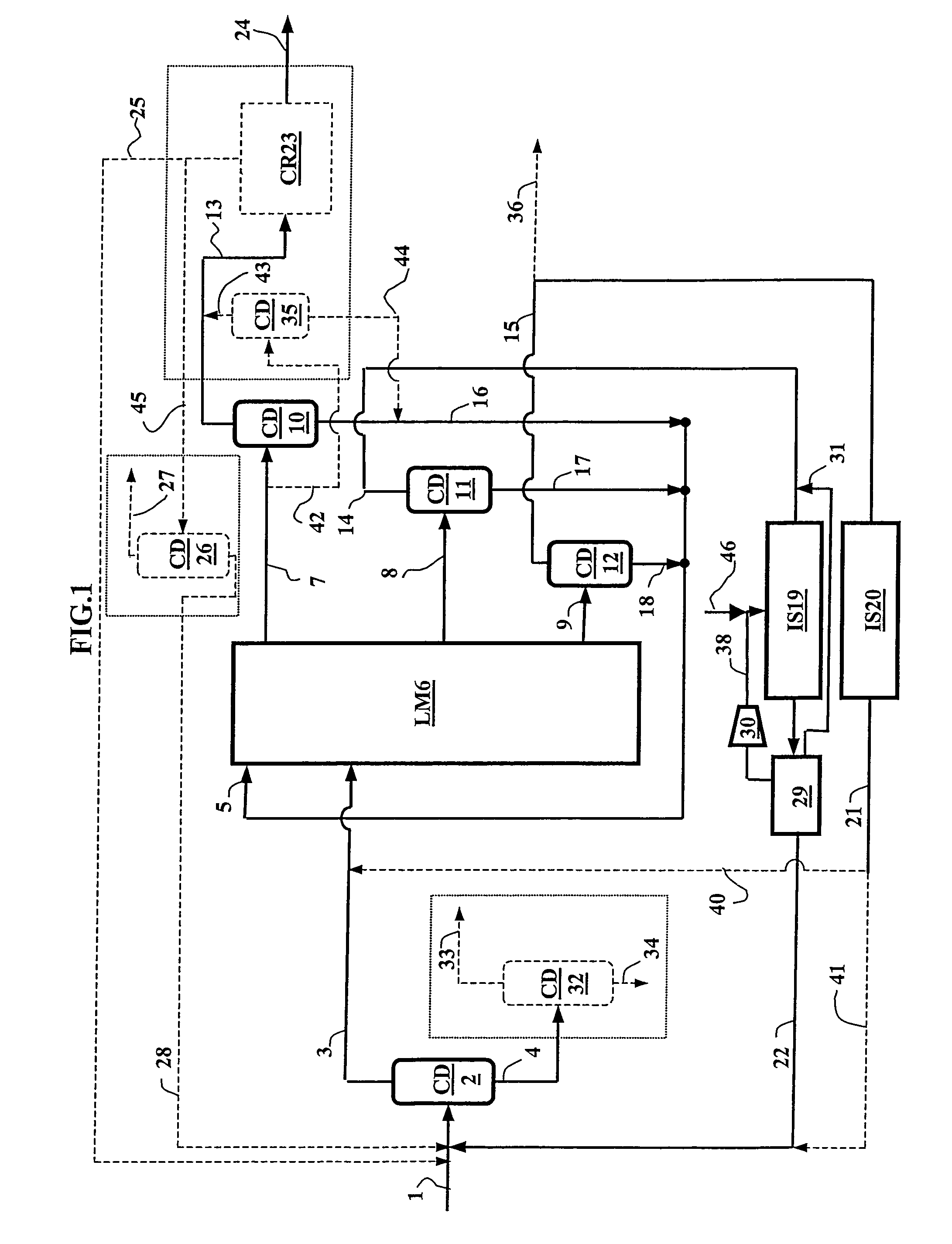

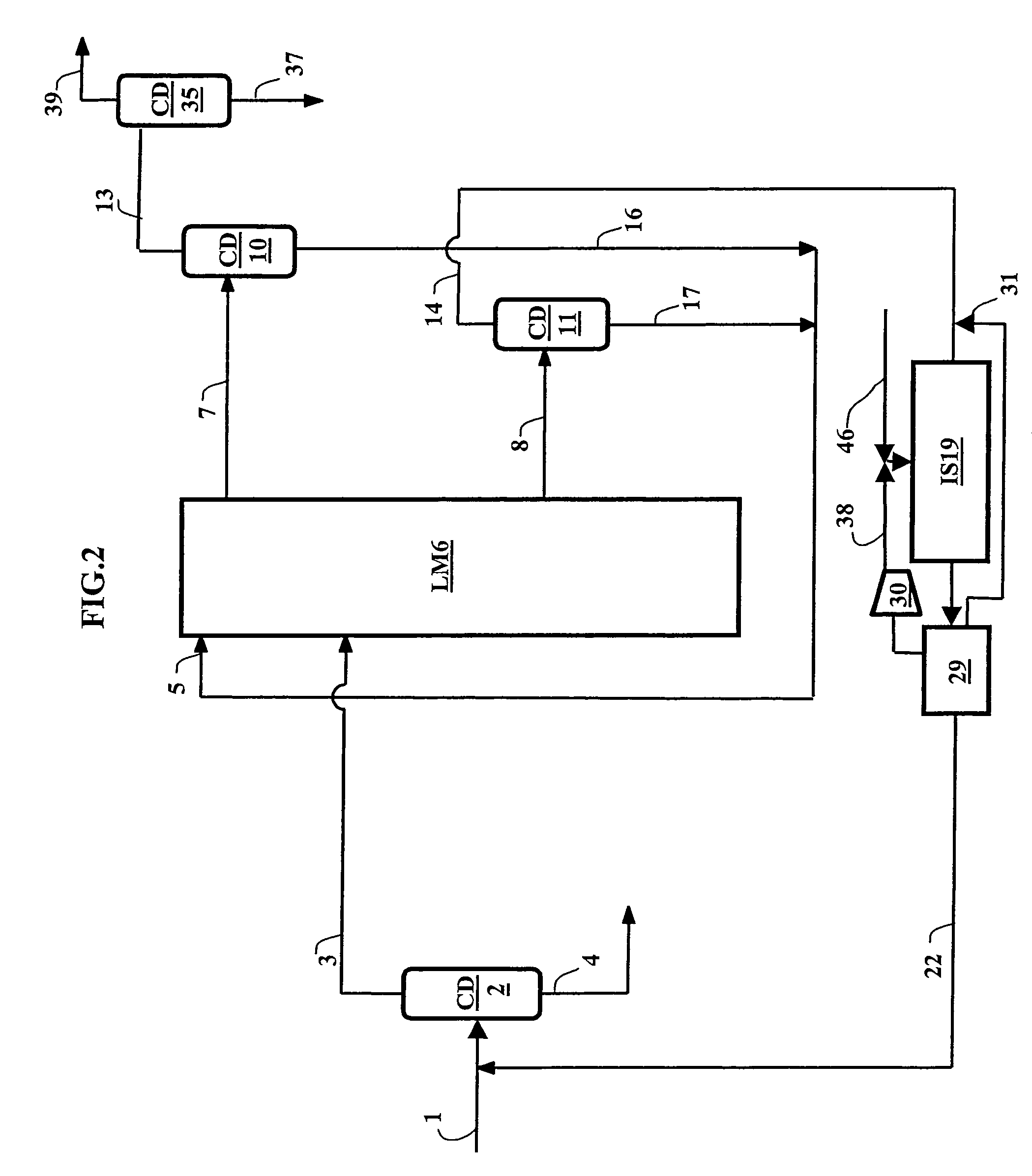

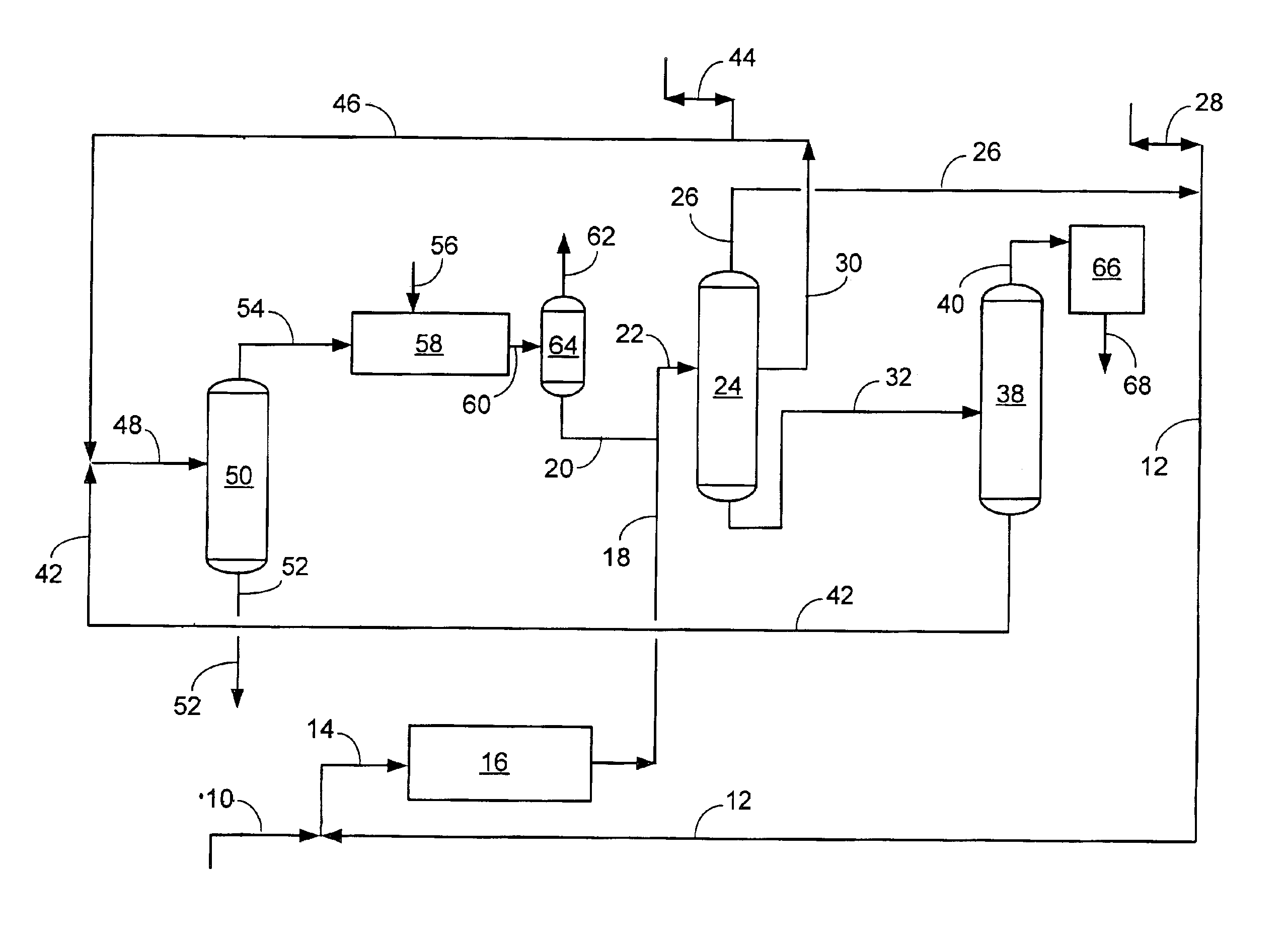

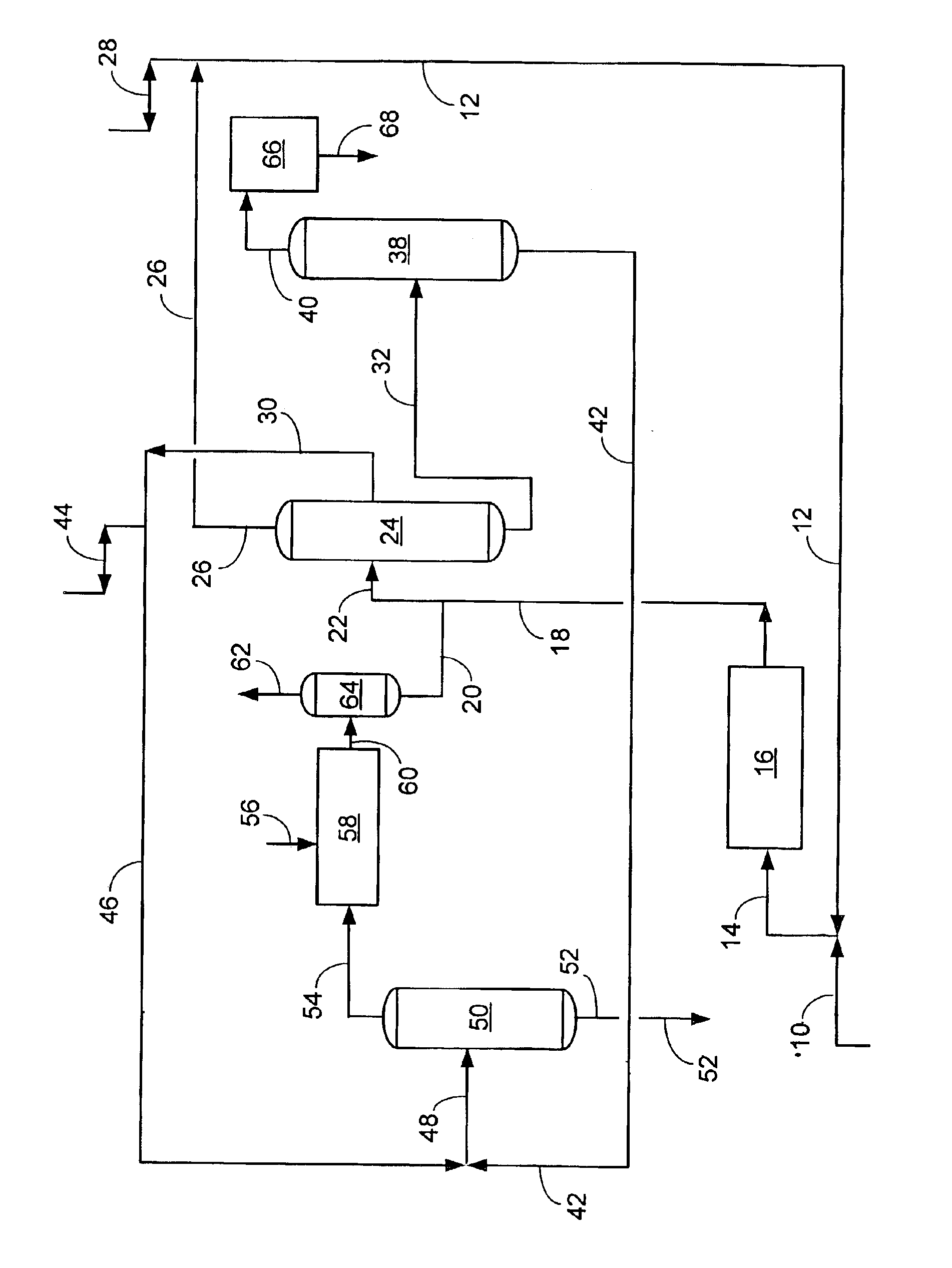

Process and apparatus for ethylbenzene production and transalkylation to xylene

InactiveUS6855854B1High selectivityHigh yieldHydrocarbon by isomerisationMolecular sieve catalystCarbon numberGas phase

The use of two transalkylation catalysts to react aromatic compounds of carbon number nine (and heavier carbon numbers) with benzene to form carbon number eight aromatics is disclosed. The two catalyst system preserves ethyl-group species on the heavier aromatics that would otherwise de-ethylate over most gas-phase transalkylation catalysts to form undesired ethane gas with benzene or toluene. Thus, by using a transalkylation step to save ethylbenzene, a greater yield of para-xylene or other carbon number eight aromatics may be achieved within an integrated complex. An apparatus and process for the two transalkylation catalyst system is disclosed with a liquid-phase unit and a gas-phase unit.

Owner:UOP LLC

Selective aromatics isomerization process

InactiveUS7371913B2Increase productionImprove retentionHydrocarbon by isomerisationHydrocarbon by hydrogenationIsomerizationHydrogen

A process for isomerizing xylenes while retaining ethylbenzene in a C8-aromatics stream in liquid phase uses a gallium-substituted pentasil zeolite in the absence of hydrogen.

Owner:UOP LLC

Method for producing propylene oxide

InactiveUS6211388B1Molecular sieve catalystsOrganic chemistry methodsEthylbenzene hydroperoxideQuaternary ammonium ions

A method for producing propylene oxide by reacting propylene with ethylbenzene hydroperoxide, wherein the reaction is conducted in the presence of a catalyst comprising a titanium-containing silicon oxide and satisfying all of the following conditions (1) to (6):(1) there is at least one peak showing a interplanar spacing (d) larger than 18 Å in X-ray diffraction;(2) an average pore size is 10 Å or more;(3) a pore size of 90% or more of the total pore volume is 5 to 200 Å;(4) a specific pore volume is 0.2 cm3 / g or more;(5) a quaternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by calcination operation:wherein R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms; and(6) The catalyst has been subjected to silylation treatment.

Owner:SUMITOMO CHEM CO LTD

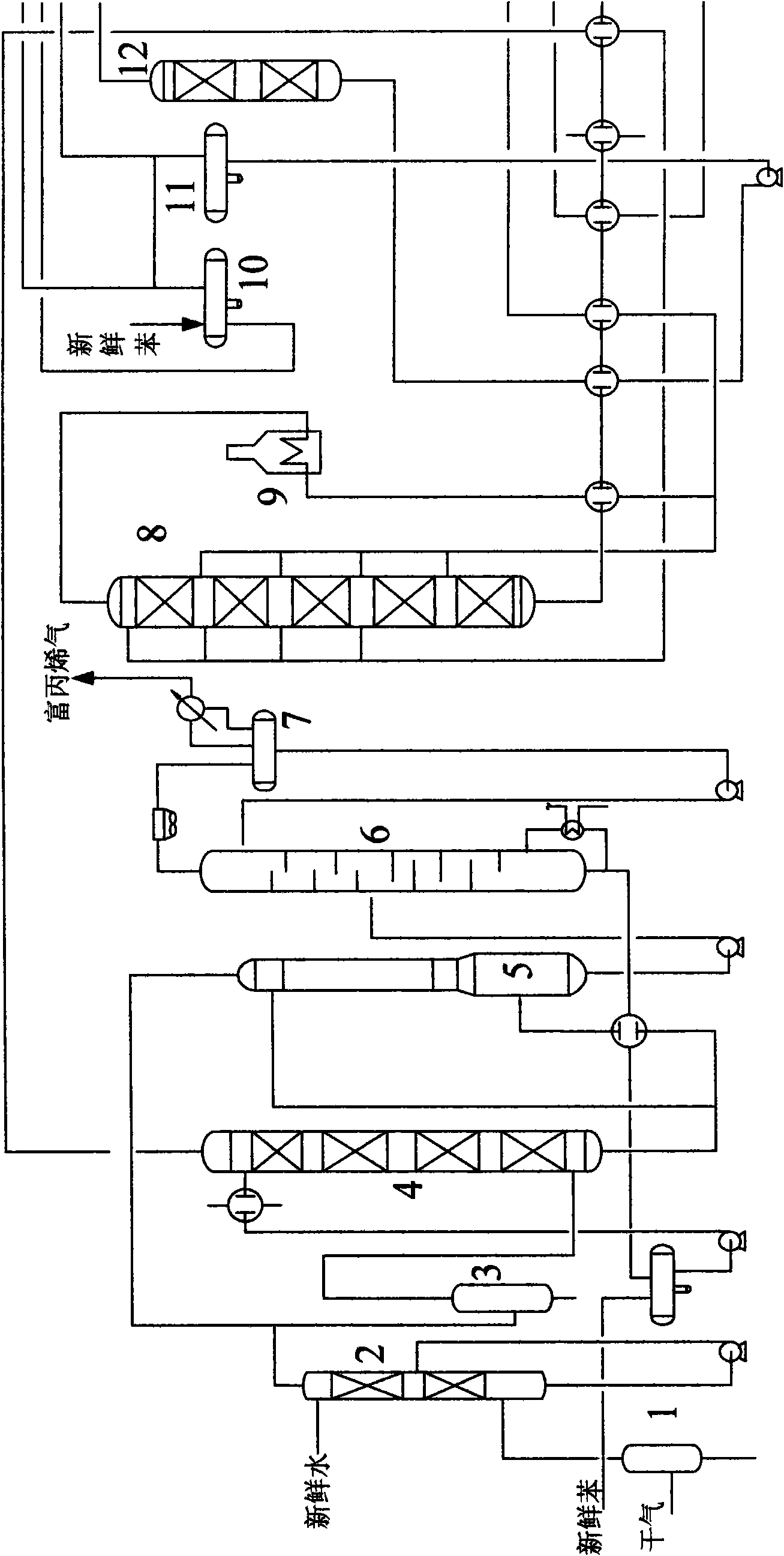

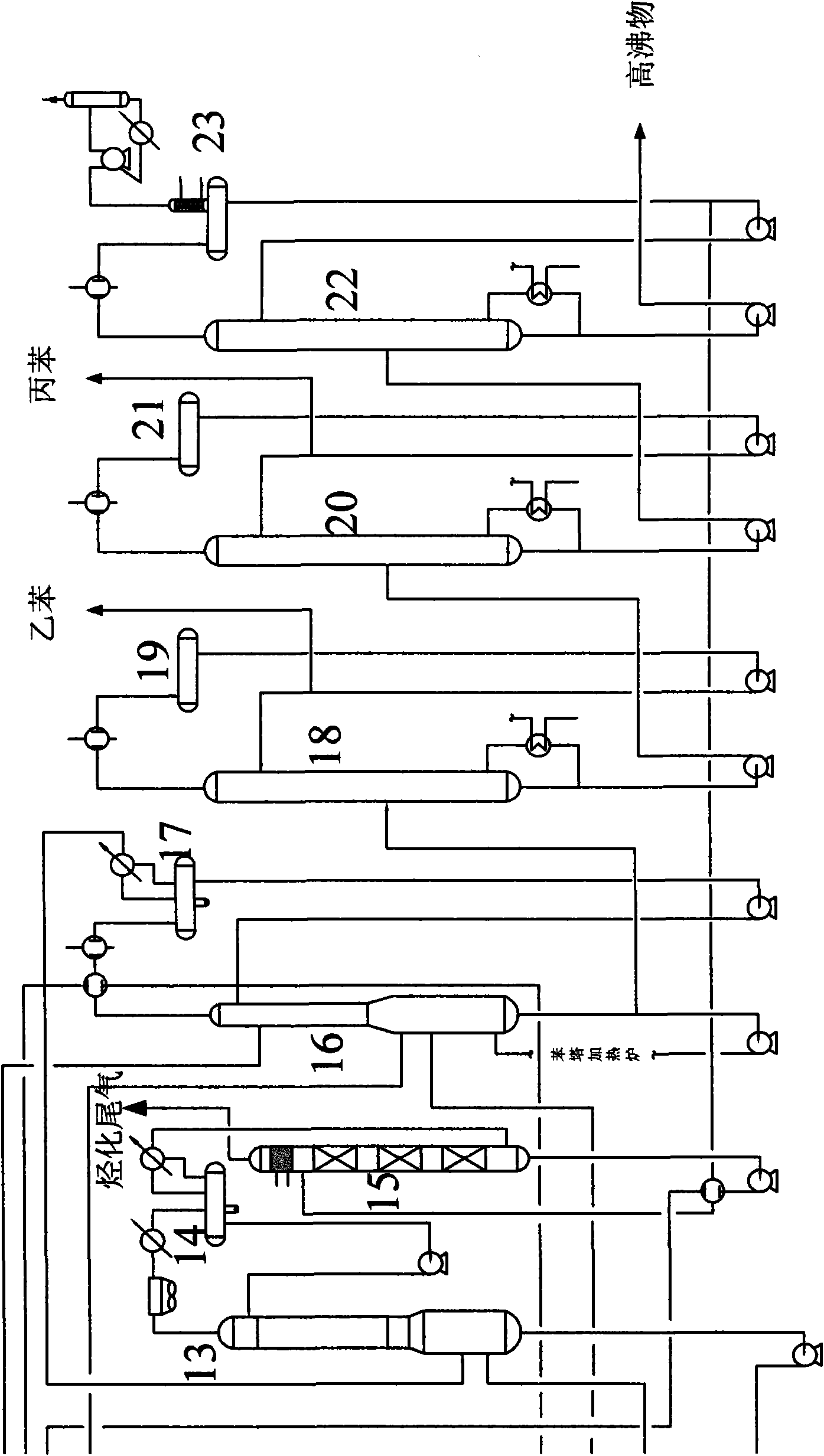

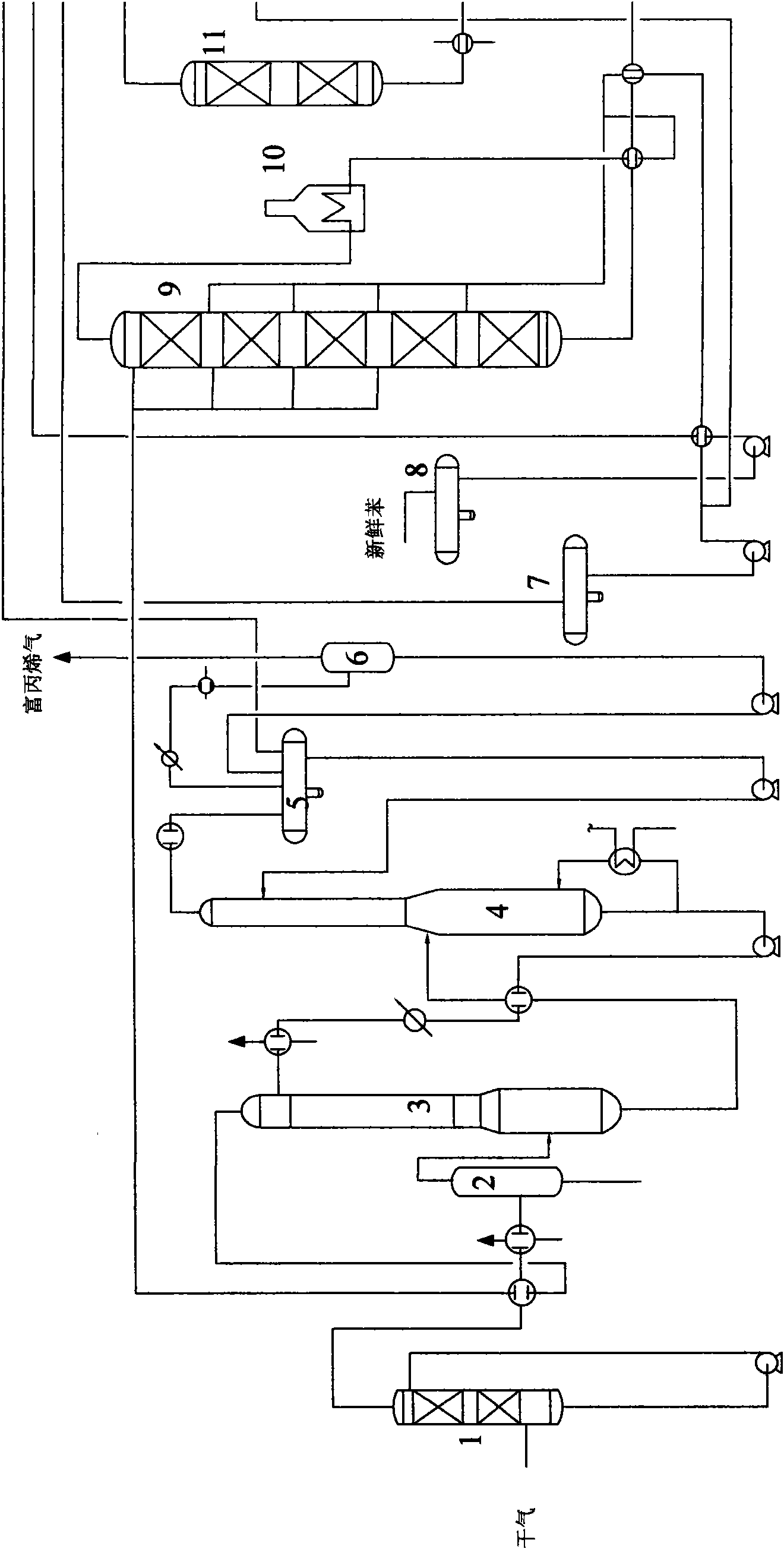

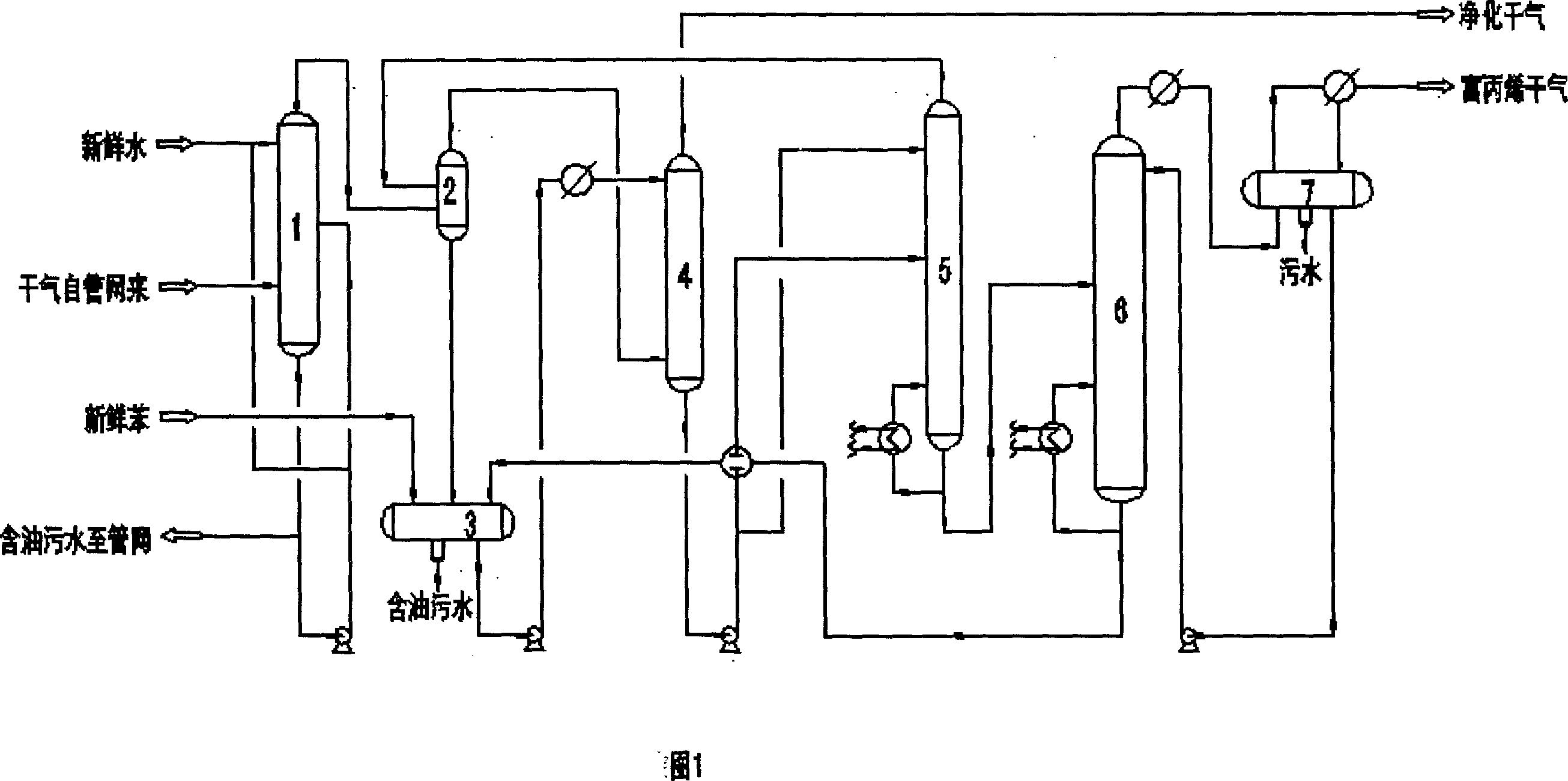

Method for preparing ethylbenzene by reaction of dilute ethylene and benzene

ActiveCN101768043AReduce temperature riseEfficient use ofHydrocarbonsBulk chemical productionVapor liquidLiquid product

The invention discloses a method for preparing ethylbenzene by reaction of dilute ethylene and benzene, which uses the dilute ethylene in dry gas of oil refinery as raw material, water washing and selective removal of propylene are conducted for the dry gas before the dry gas enters an alkylation reactor in sections, alkylation reaction of the dilute ethylene in dry gas and the benzene proceeds under the circumstances that zeolite catalyst exists, the dry gas and / or low-temperature gas-phase benzene are utilized for taking heat during the alkylation reaction, and the reaction temperature rising is reduced; after the vapor-liquid separation of the alkylation reaction product, tail gas is discharged from the device through low-temperature absorption, and cycle benzene, ethylbenzene, propyl benzene, diethylbenzene and heavy component are sequentially separated from the liquid product through a separation system; the diethylbenzene and the benzene are mixed and enter an anti-alkylation reactor and anti-alkylation reaction proceeds on molecular sieve catalyst for further converting to the ethylbenzene. The invention effectively reduces the benzene consumption and the energy consumption during the course of preparing ethylbenzene by dilute ethylene, the ethylene conversion rate is more than or equal to 99%, the total selectivity of generating ethylbenzene is more than or equal to 99%, the recovery rate of benzene carried by the tail gas is more than or equal to 99.5%, and the xylene content in the ethylbenzene is less than 800 ppm.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process flow for raw material pretreatment portion of catalytic dry gas produced phenylethane

The invention discloses a predisposing technological flow path of ethylbenzene through catalyzing dried gas, which comprises the following steps: adsorbing propylene; desorbing ethylene; desorbing propylene; adding raw material to strip propylene; washing most of MEDA; entering standard dried gas in the delivery tank; entering into propylene adsorbing tower; draining purified dried gas from top of propylene adsorbing tower; making one path as cool material in the ethylene stripping tower and one path to exchange heat with base material of propylene stripping tower under 10-300 deg.c in the ethylene stripping tower; desorbing ethylene component; draining ethylene gas; returning in the dried gas delivery tank; circulating between ethylene stripping tower and propylene stripping tower; desorbing propylene component from adsorbant with 150ppm-0.7% dried propylene in the stripped propylene.

Owner:中国寰球工程有限公司辽宁分公司

Method for Producing Paraxylene Comprising an Adsortion Step and Two Isomerization Steps

ActiveUS20080262282A1Overcome disadvantagesHydrocarbon by isomerisationHydrocarbon by hydrogenationXylyleneIsomerization

A process for producing para-xylene from a hydrocarbon feed is described in which an adsorption column operating as a simulated moving bed with at least five zones delivers an extract, a 2-raffinate and an intermediate raffinate.The extract is distilled and the distillate is optionally re-crystallized to recover para-xylene with a purity of at least 99.7%. The 2-raffmate is distilled then isomerized in a reactor preferably operating in the liquid phase and at a low temperature. The intermediate raffinate with an enriched ethylbenzene content is distilled then isomerized in the vapour phase.

Owner:INST FR DU PETROLE

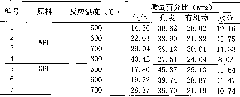

Catalyst for preparing phenylethane from dilute ethylene and benzene alkylation and method for preparing same

ActiveCN101584993AIncrease profitHigh activityMolecular sieve catalystsCatalyst activation/preparationReaction temperatureHigh activity

The invention aims to provide a catalyst for preparing phenylethane from dilute ethylene and benzene alkylation and a method for preparing the same. The catalyst is characterized in that the crystal is formed by a small crystal grain ZSM-5 molecular screen with the crystal grain size of between 0.15 and 0.8 mircometer and a bonding agent of aluminum oxide and silicon dioxide, and then prepared by steps of vapor / ammonia vapor treatment and acid treatment, wherein the relative mass ratio of the ZSM-5 molecular screen to the bonding agent of the aluminum oxide and the silicon dioxide is (5-9):(1-5). When the catalyst is used for preparing the phenylethane from the dilute ethylene and the benzene alkylation in dry gas, because the crystal grain size of the used molecular screen is small, the number of acidic sites and the acidic utilization ratio of the catalyst are high, and simultaneously the pore canal of the molecular screen is short, which is favorable for dispersion of reactants and products, so that the catalyst has the characteristics of high activity, low reaction temperature, high selectivity of target products, low content of xylene impurity in the product and good satiability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com