Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

921 results about "Simulated moving bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

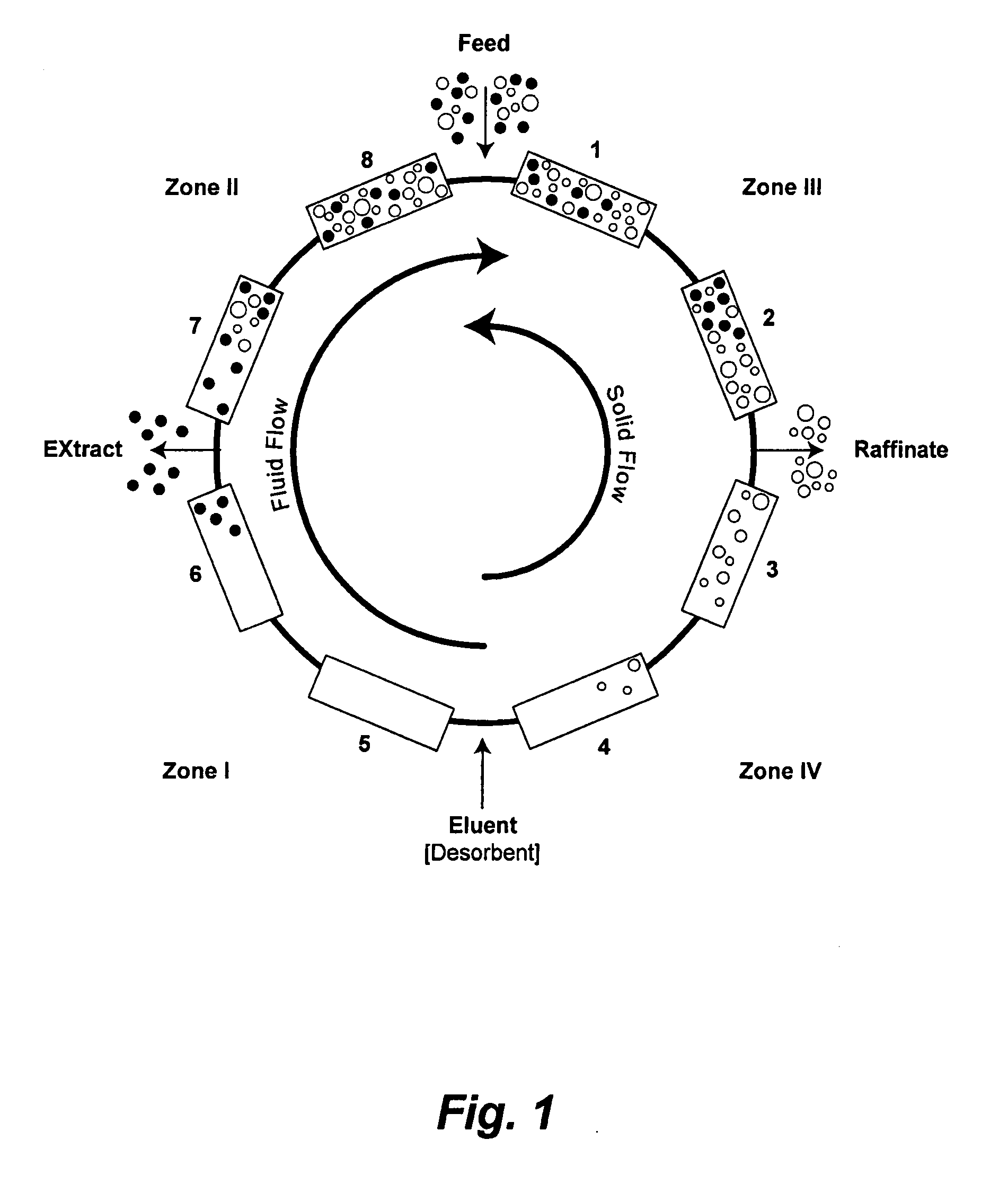

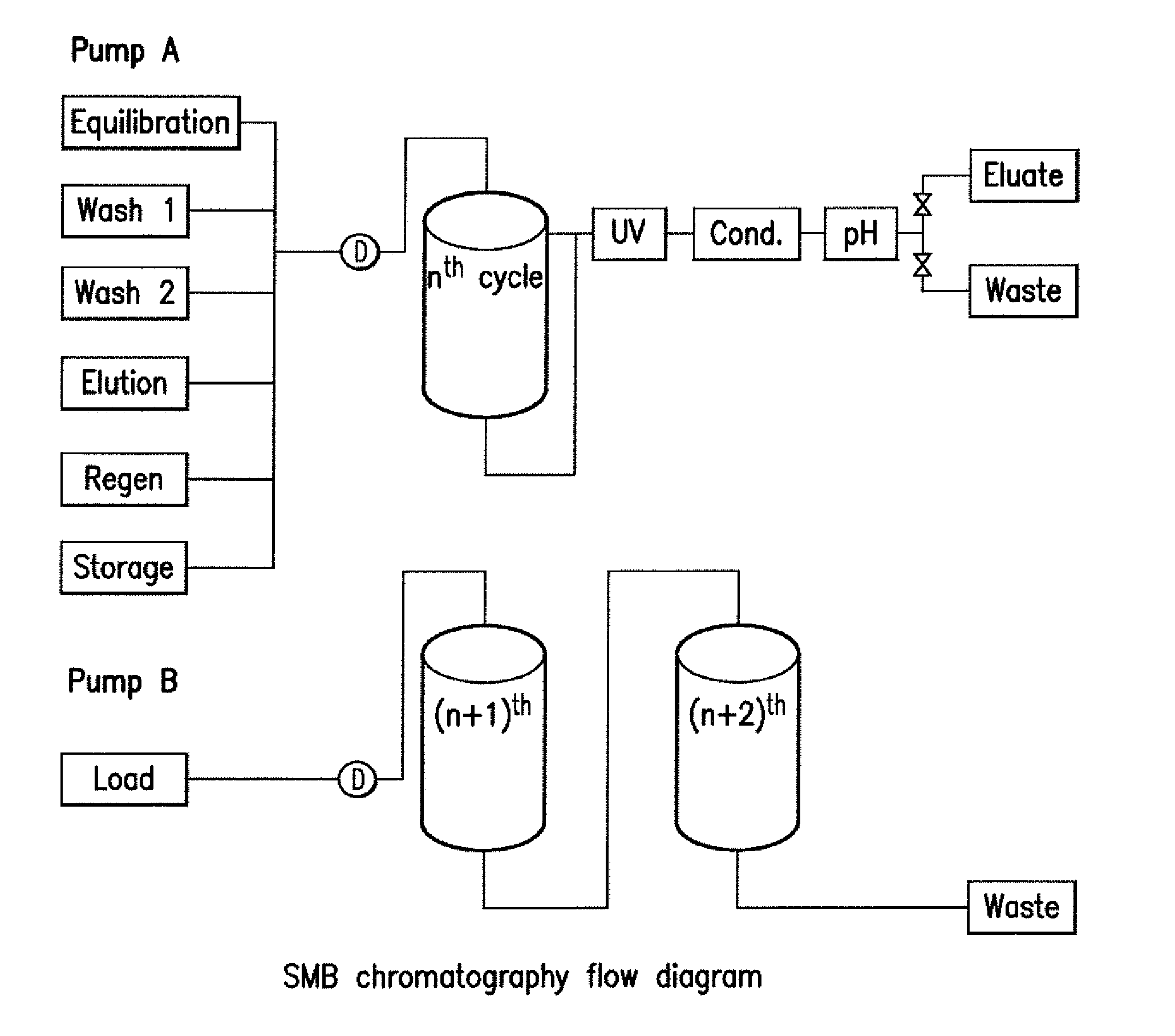

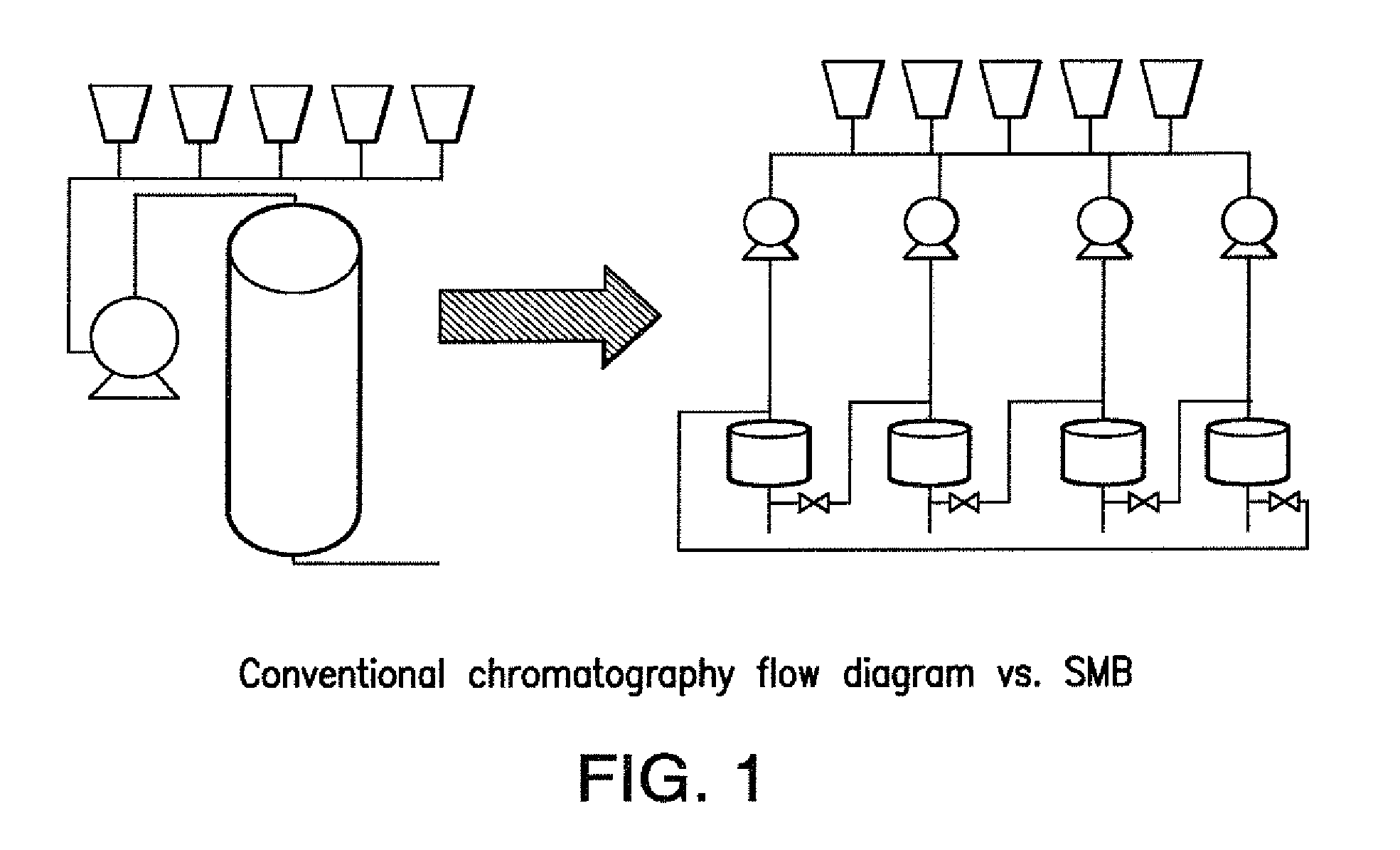

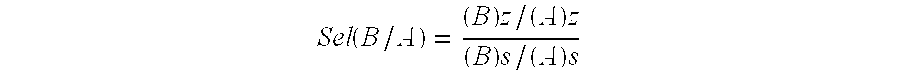

Inventor

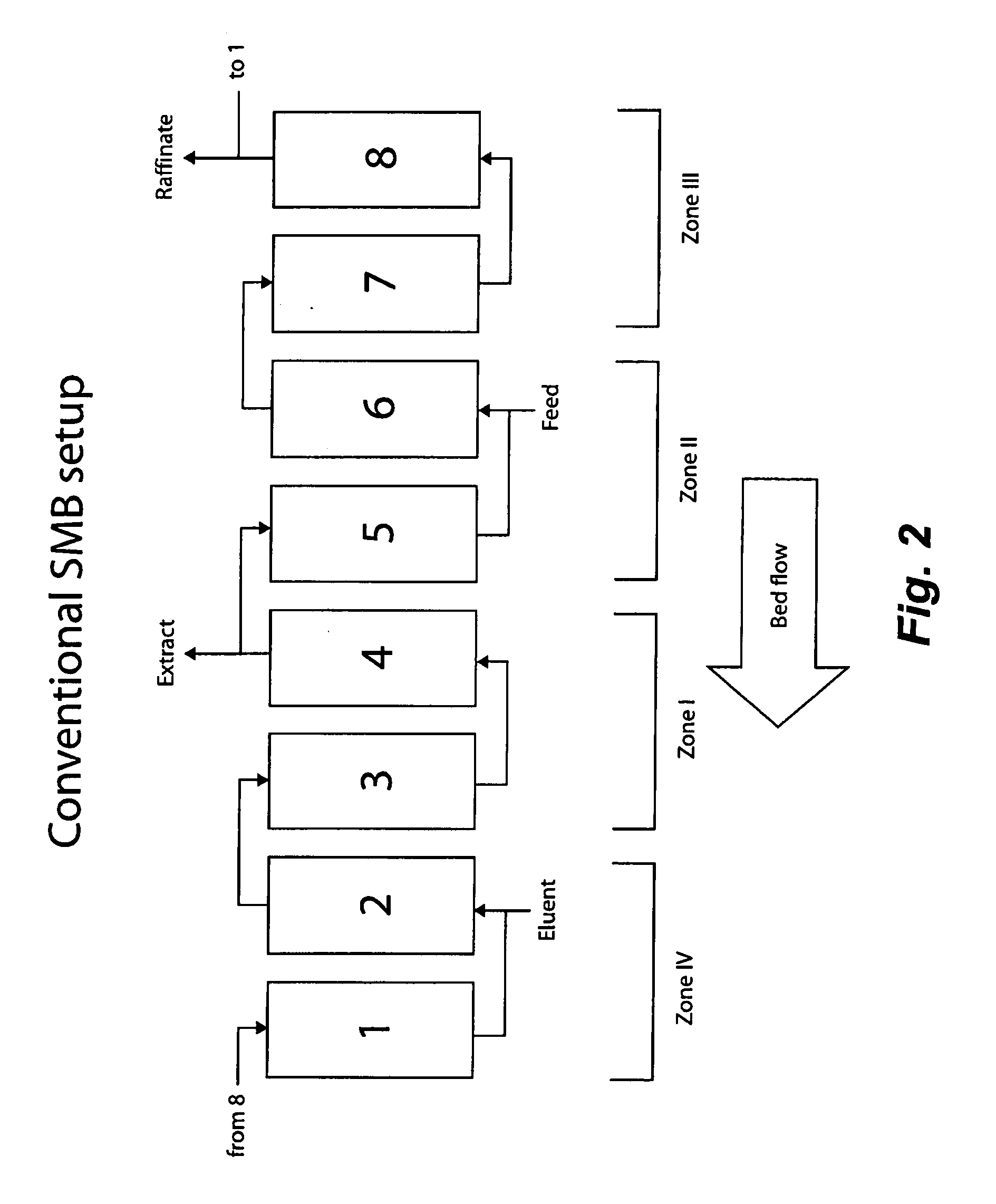

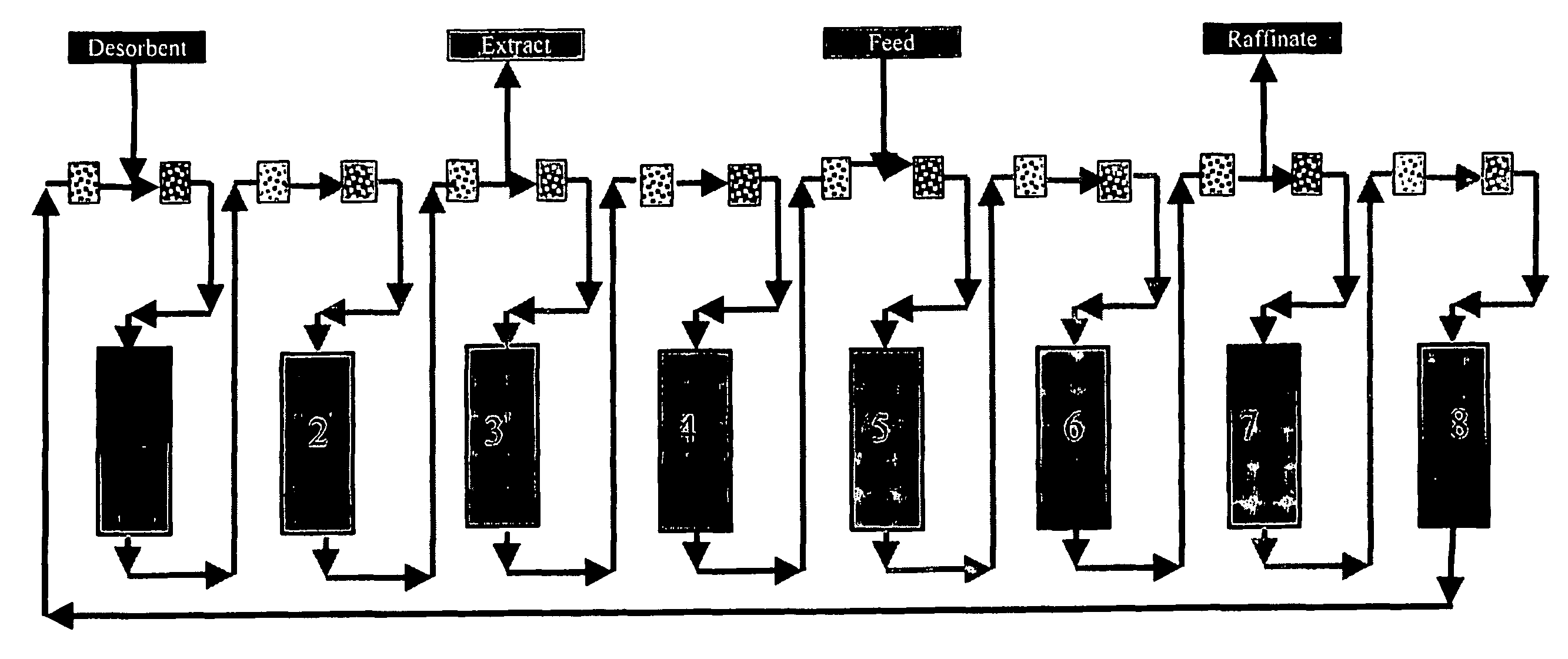

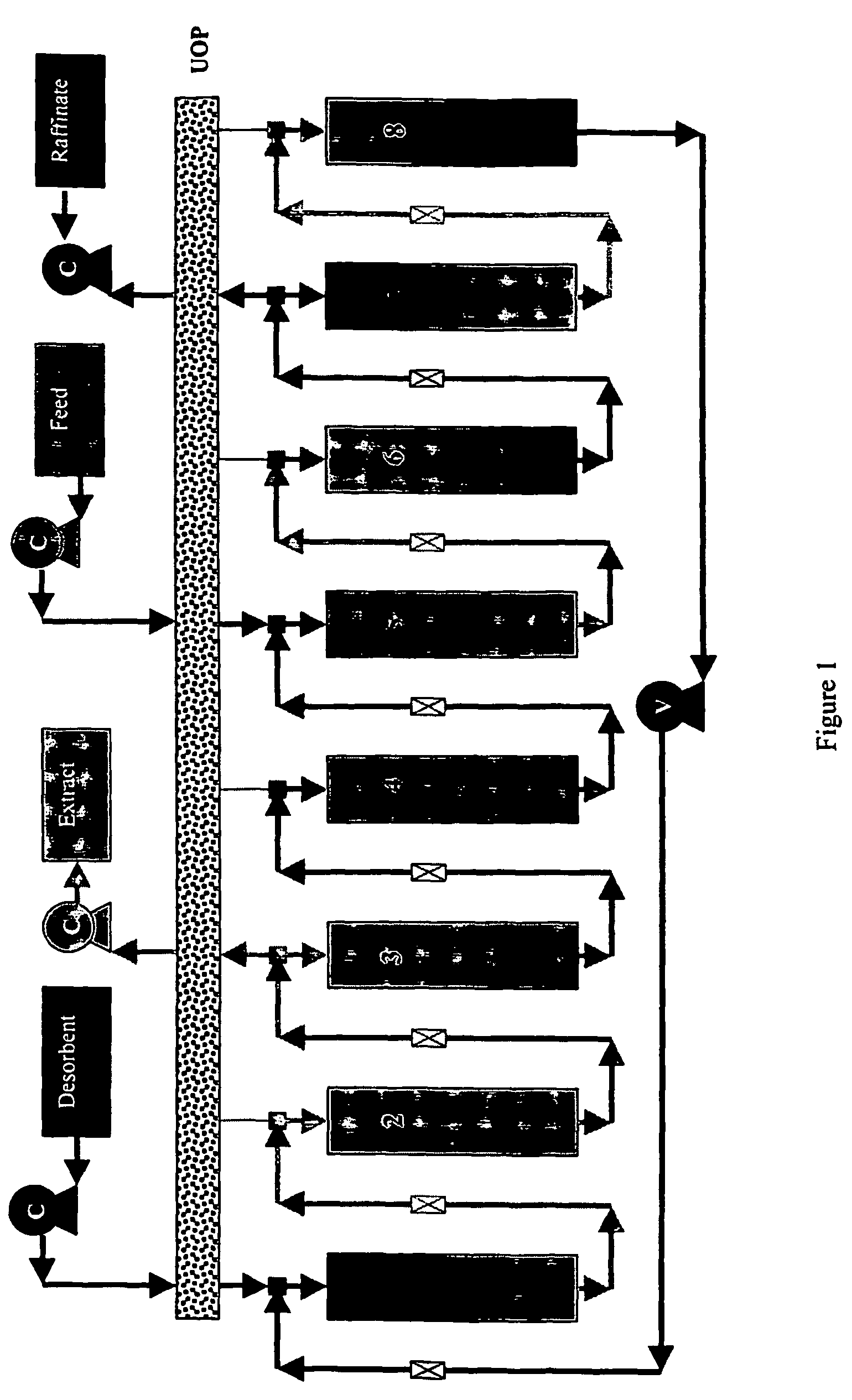

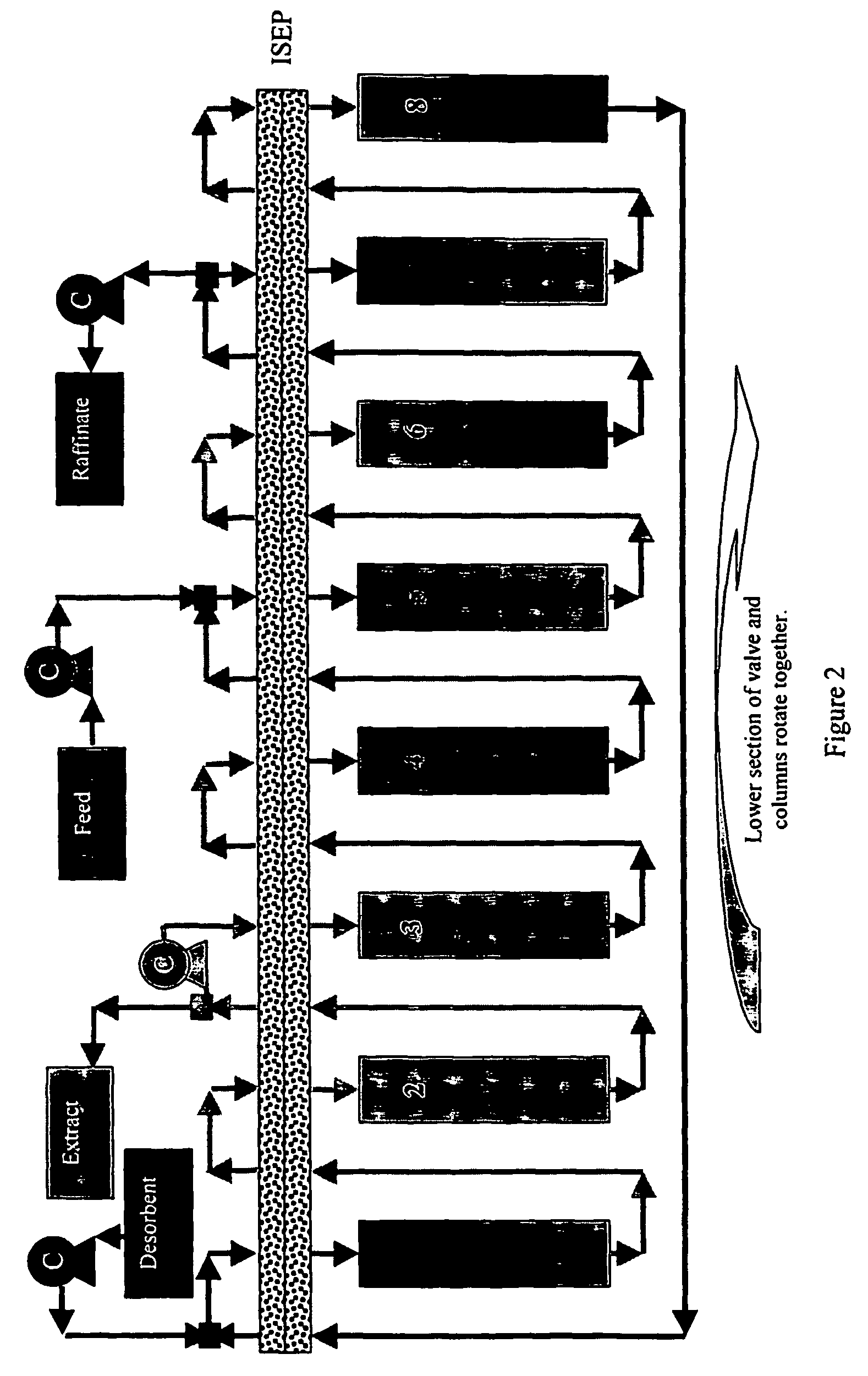

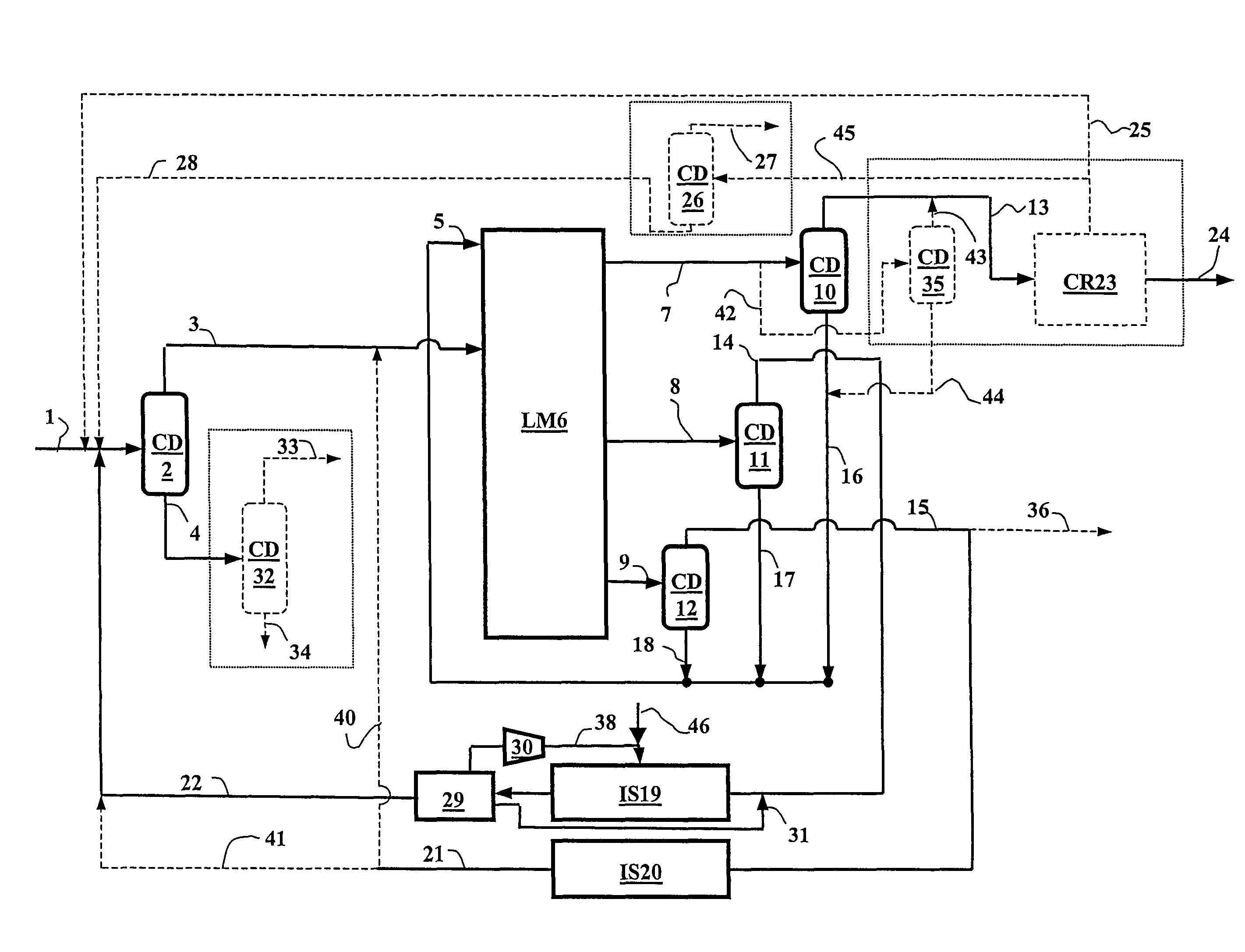

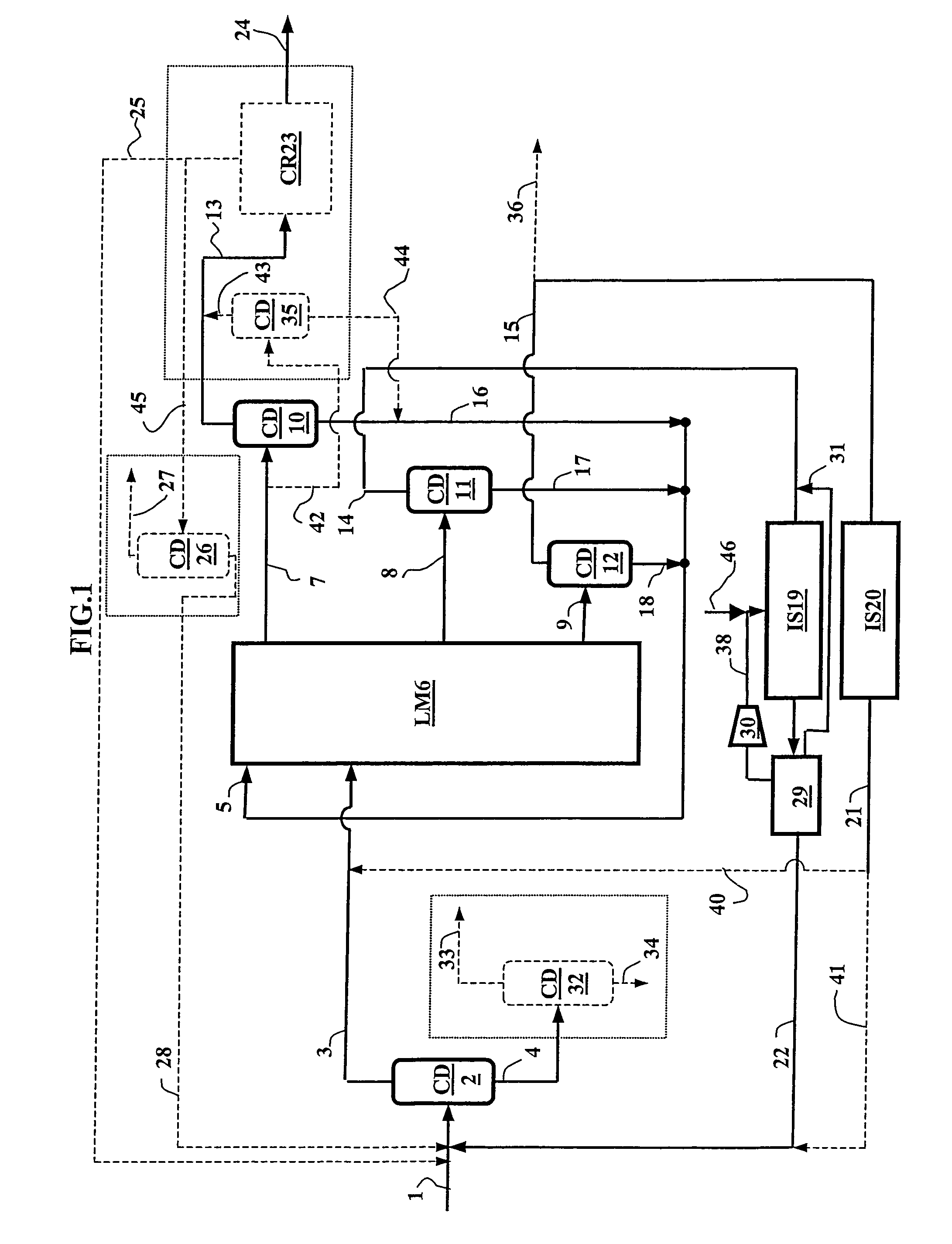

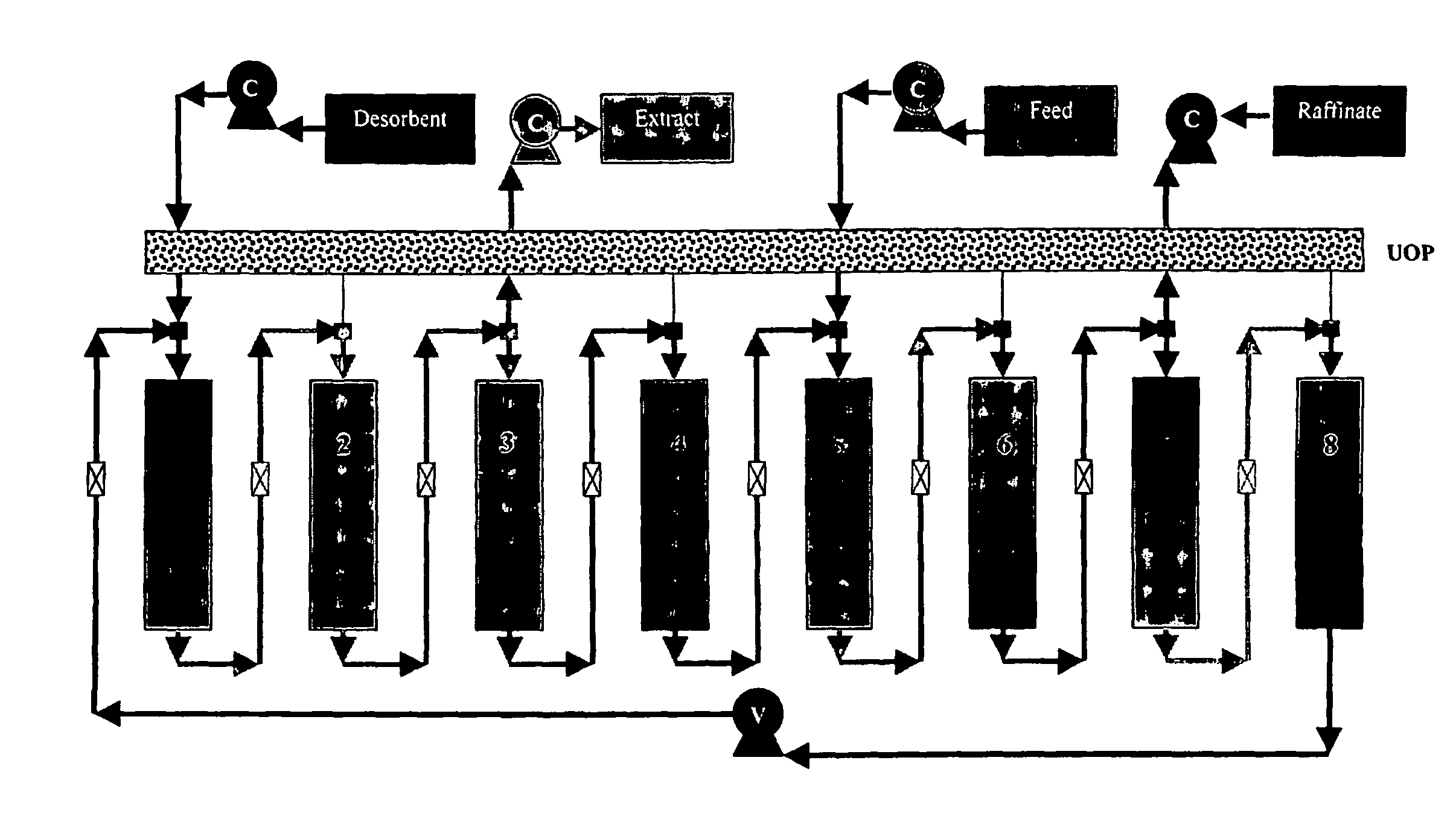

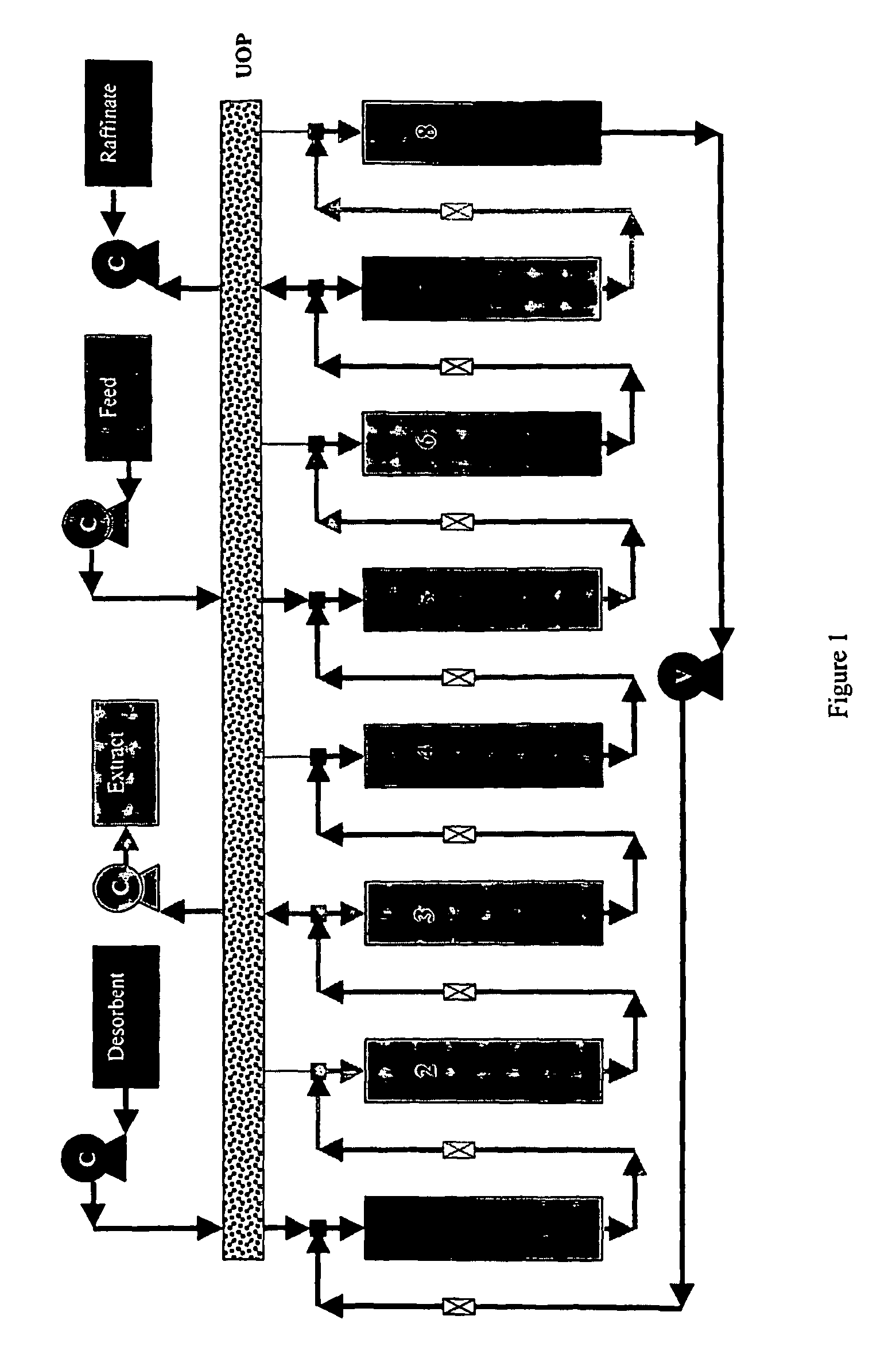

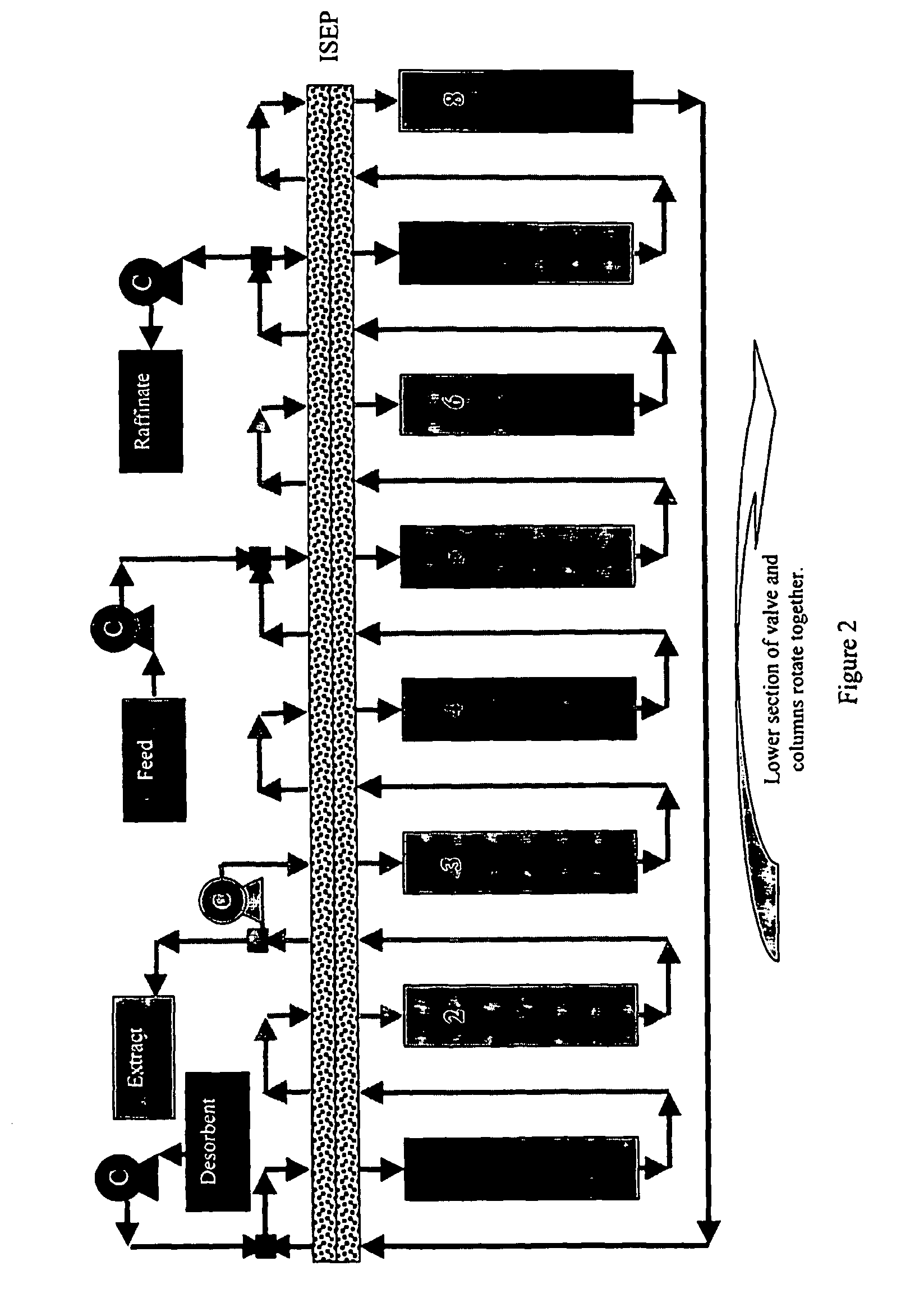

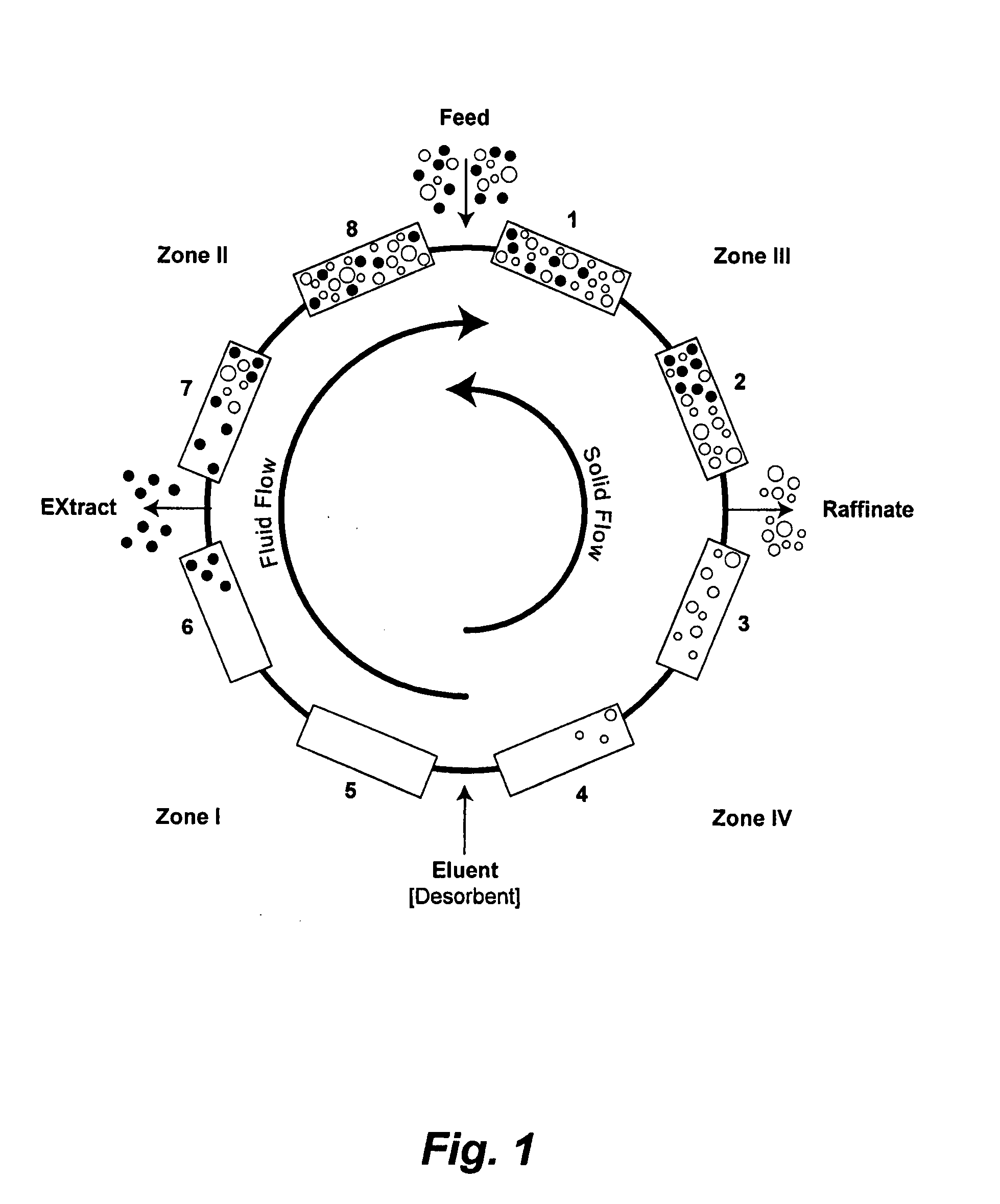

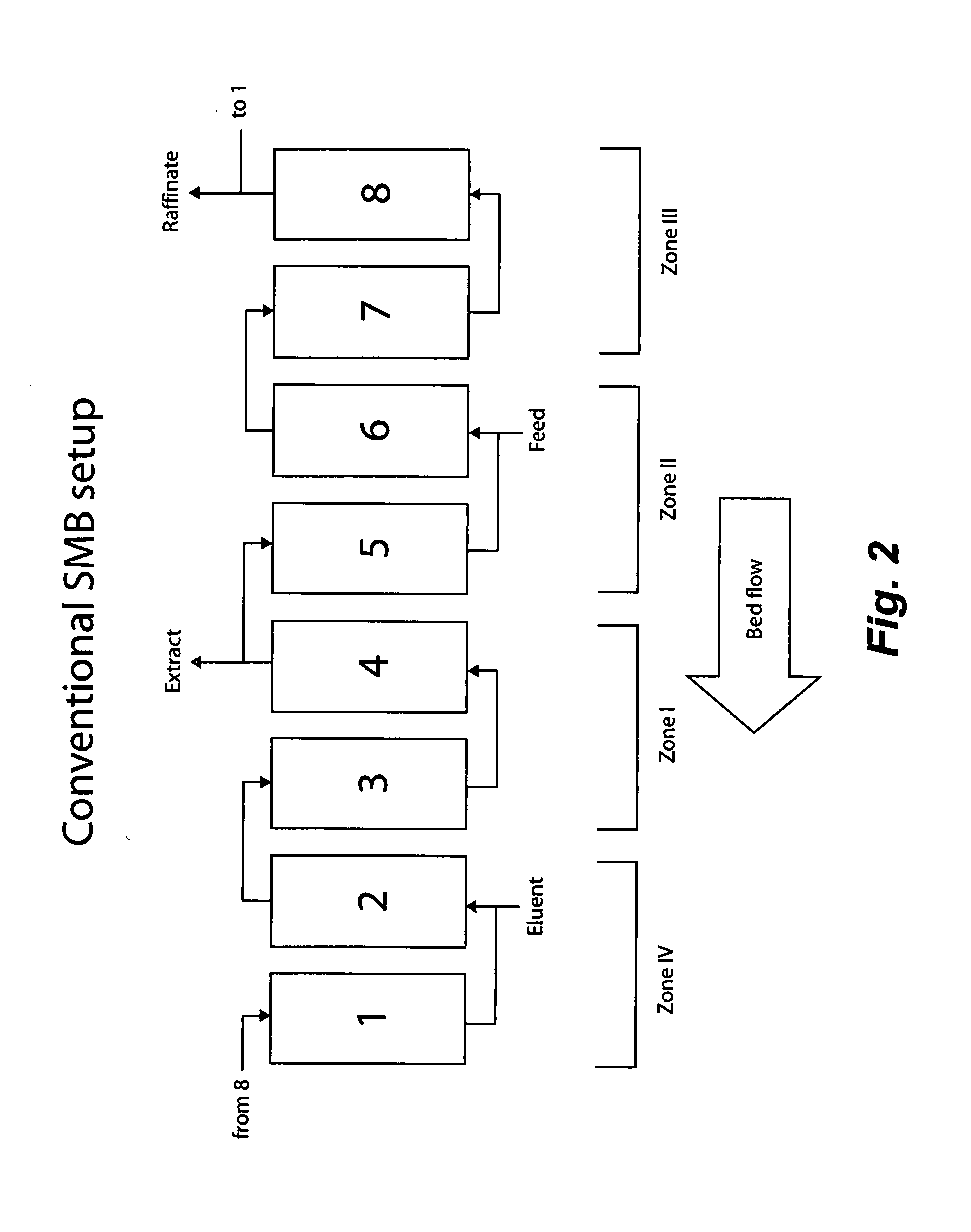

In manufacturing, the simulated moving bed (SMB) process is a highly engineered process for implementing chromatographic separation. It is used to separate one chemical compound or one class of chemical compounds from one or more other chemical compounds to provide significant quantities of the purified or enriched material at a lower cost than could be obtained using simple (batch) chromatography. It cannot provide any separation or purification that cannot be done by a simple column purification. The process is rather complicated. The single advantage which it brings to a chromatographic purification is that it allows the production of large quantities of highly purified material at a dramatically reduced cost. The cost reductions come about as a result of: the use of a smaller amount of chromatographic separation media stationary phase, a continuous and high rate of production, and decreased solvent and energy requirements. This improved economic performance is brought about by a valve-and-column arrangement that is used to lengthen the stationary phase indefinitely and allow very high solute loadings to the process.

Binderless adsorbents comprising nano-size zeolite x and their use in the adsorptive separation of para-xylene

InactiveUS20090326308A1High adsorbent capacity/mass transfer propertyIncreased para-xylene productivityMaterial nanotechnologyOther chemical processesSimulated moving bedSorbent

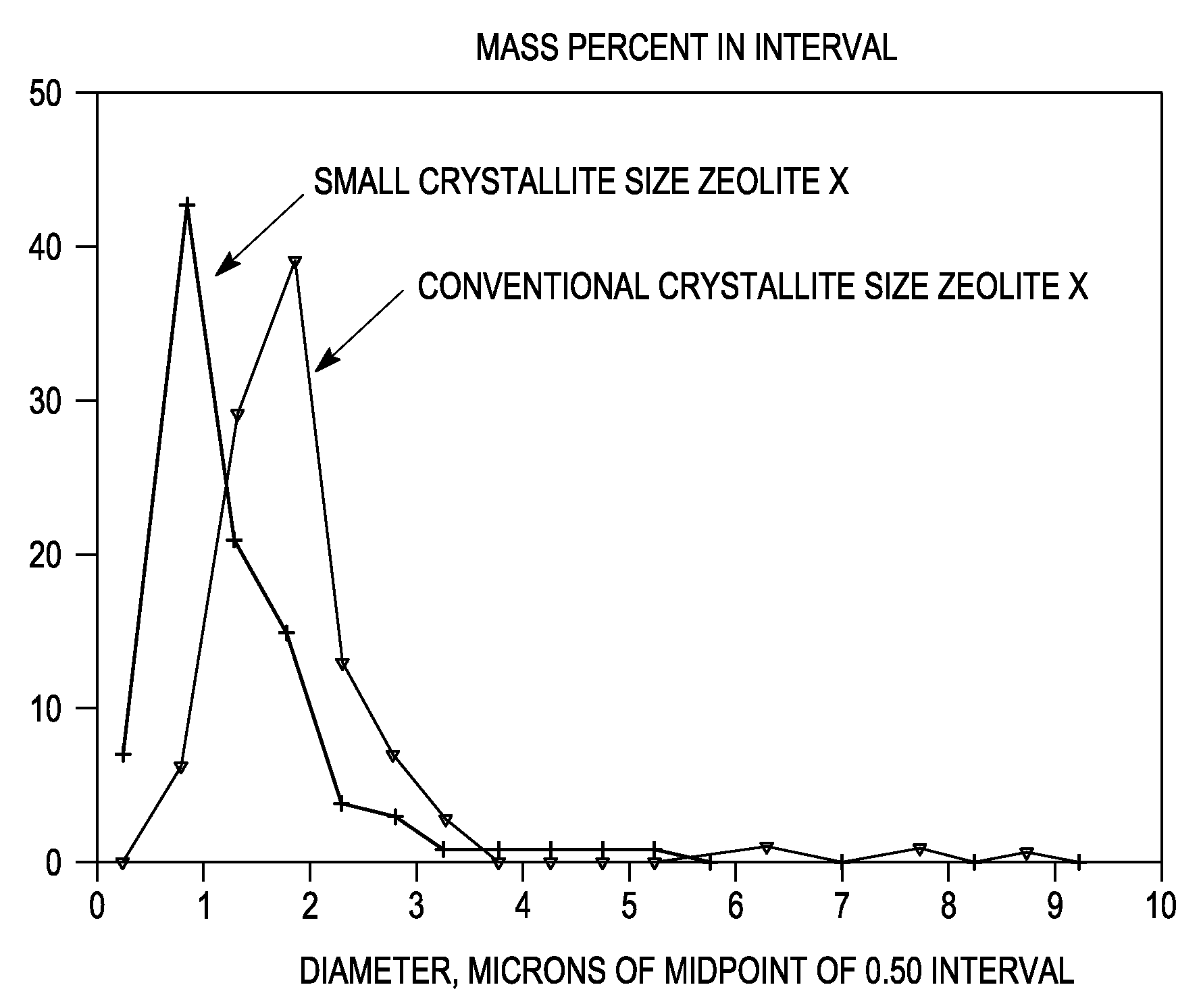

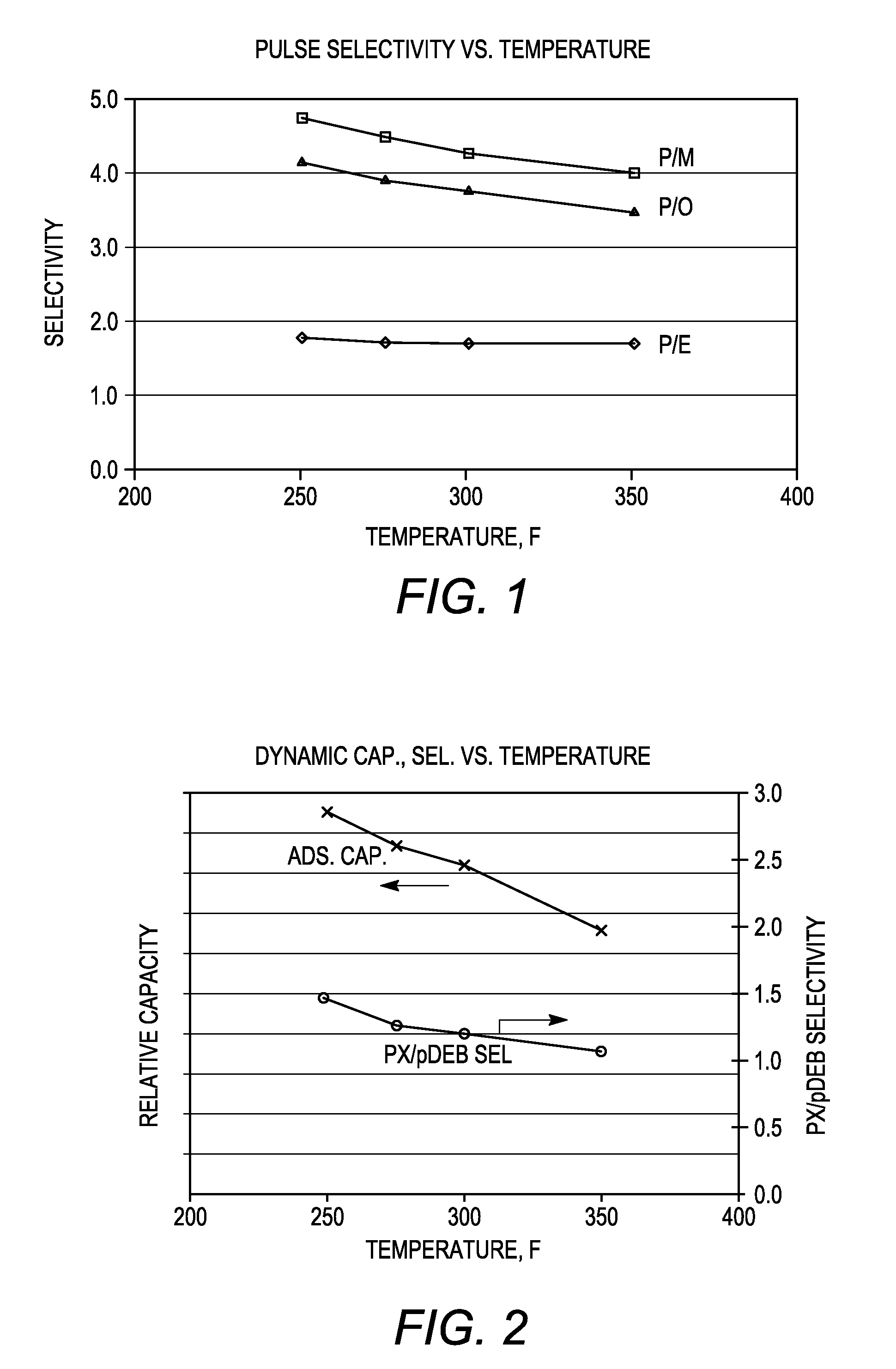

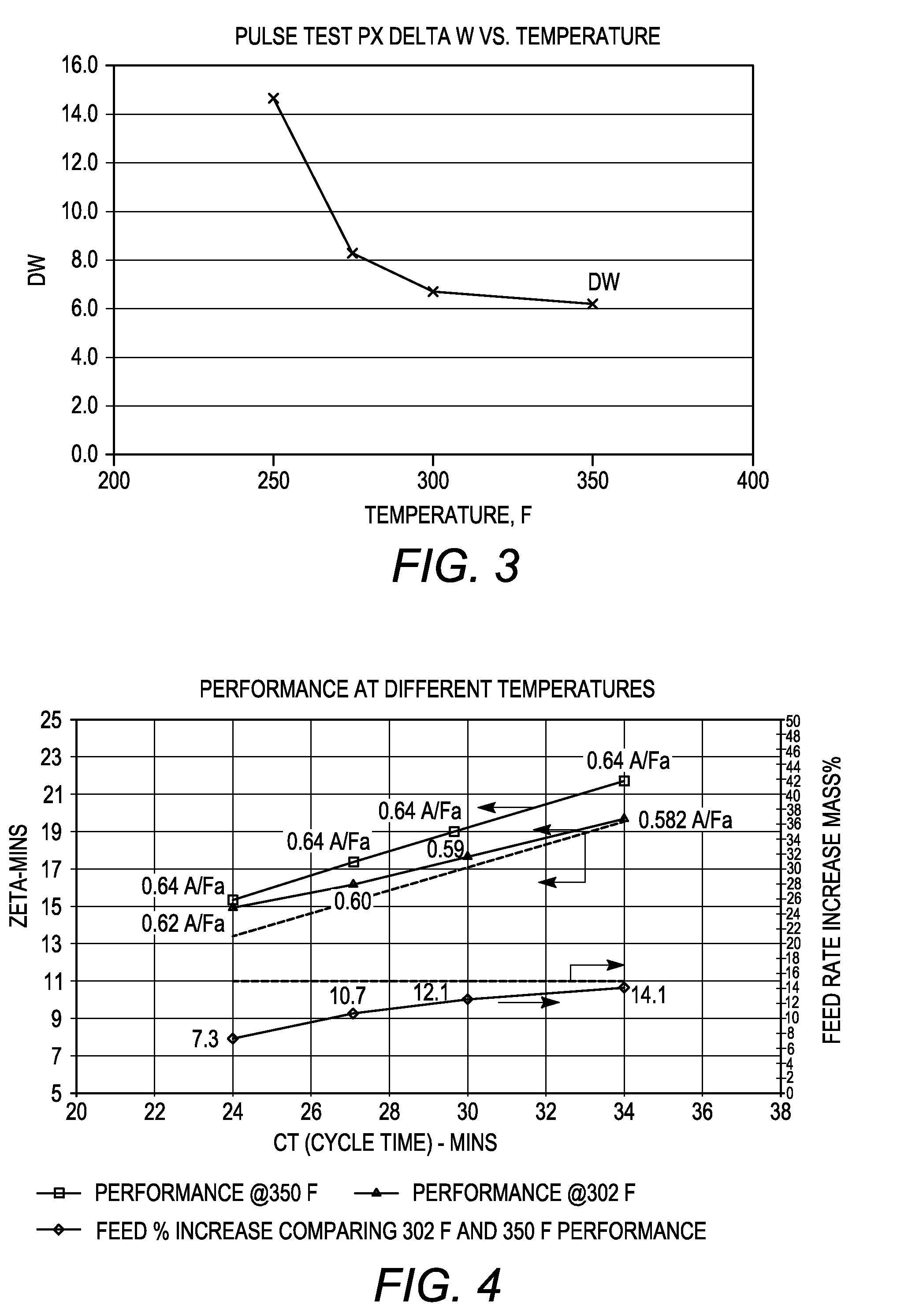

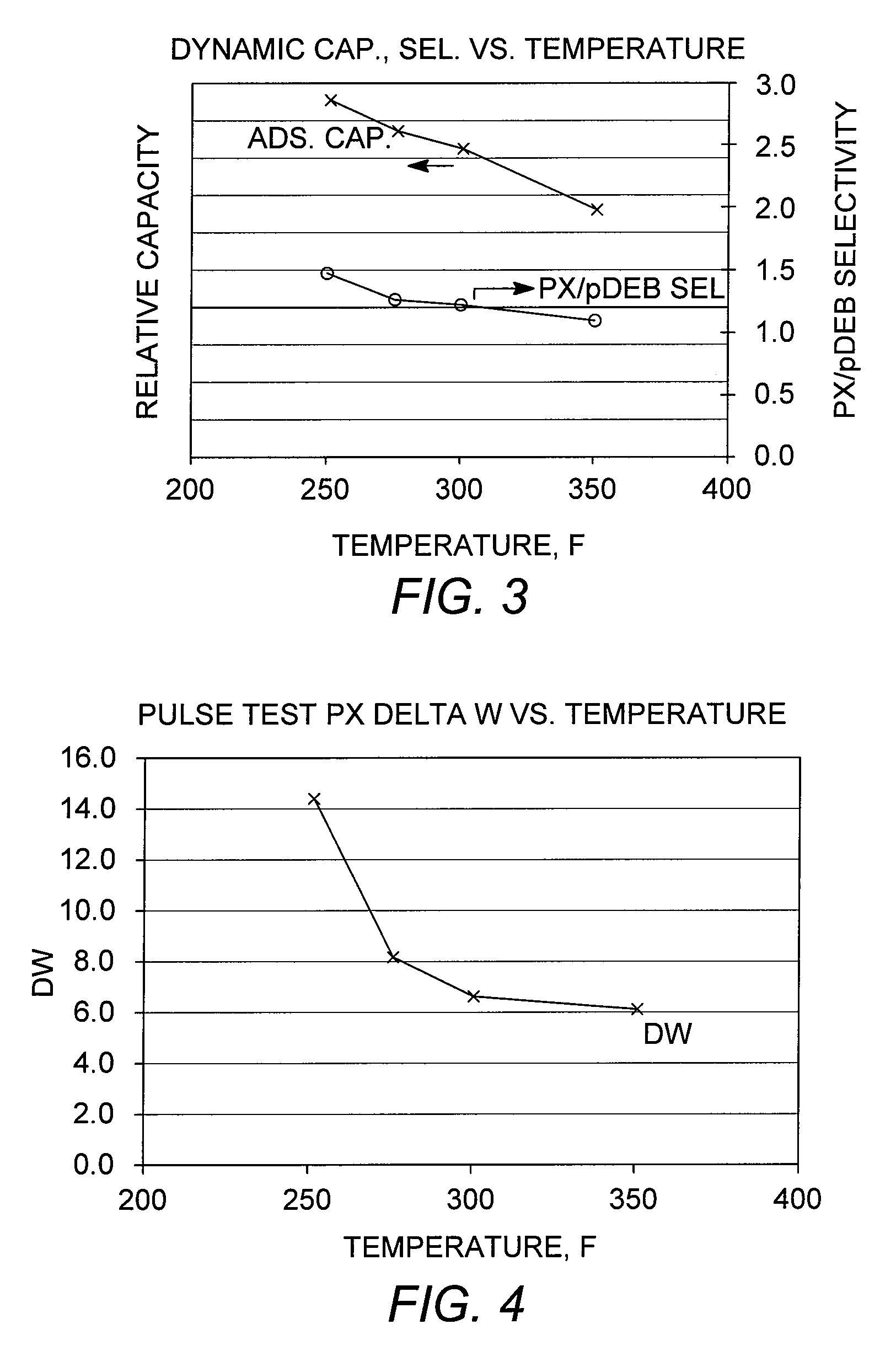

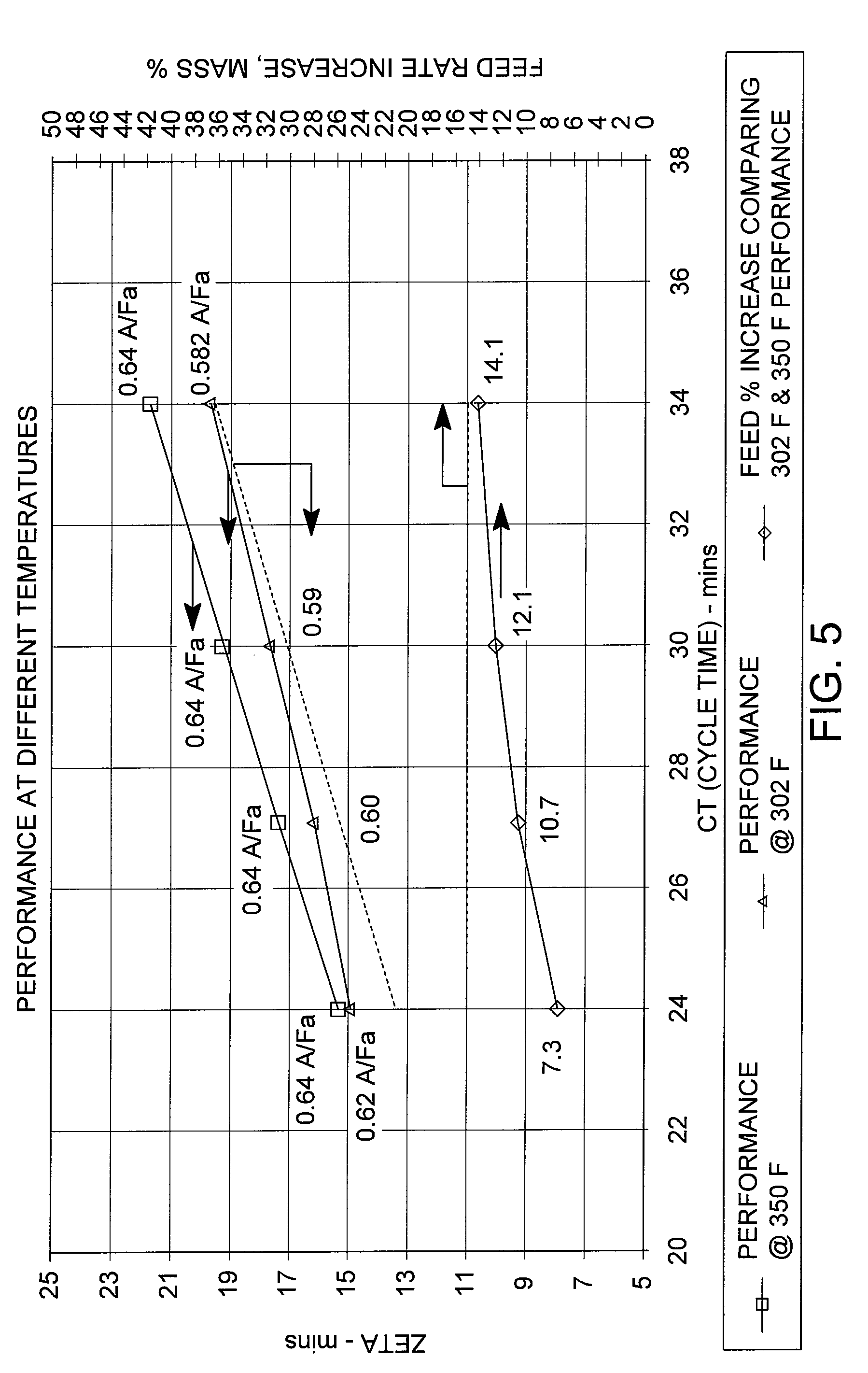

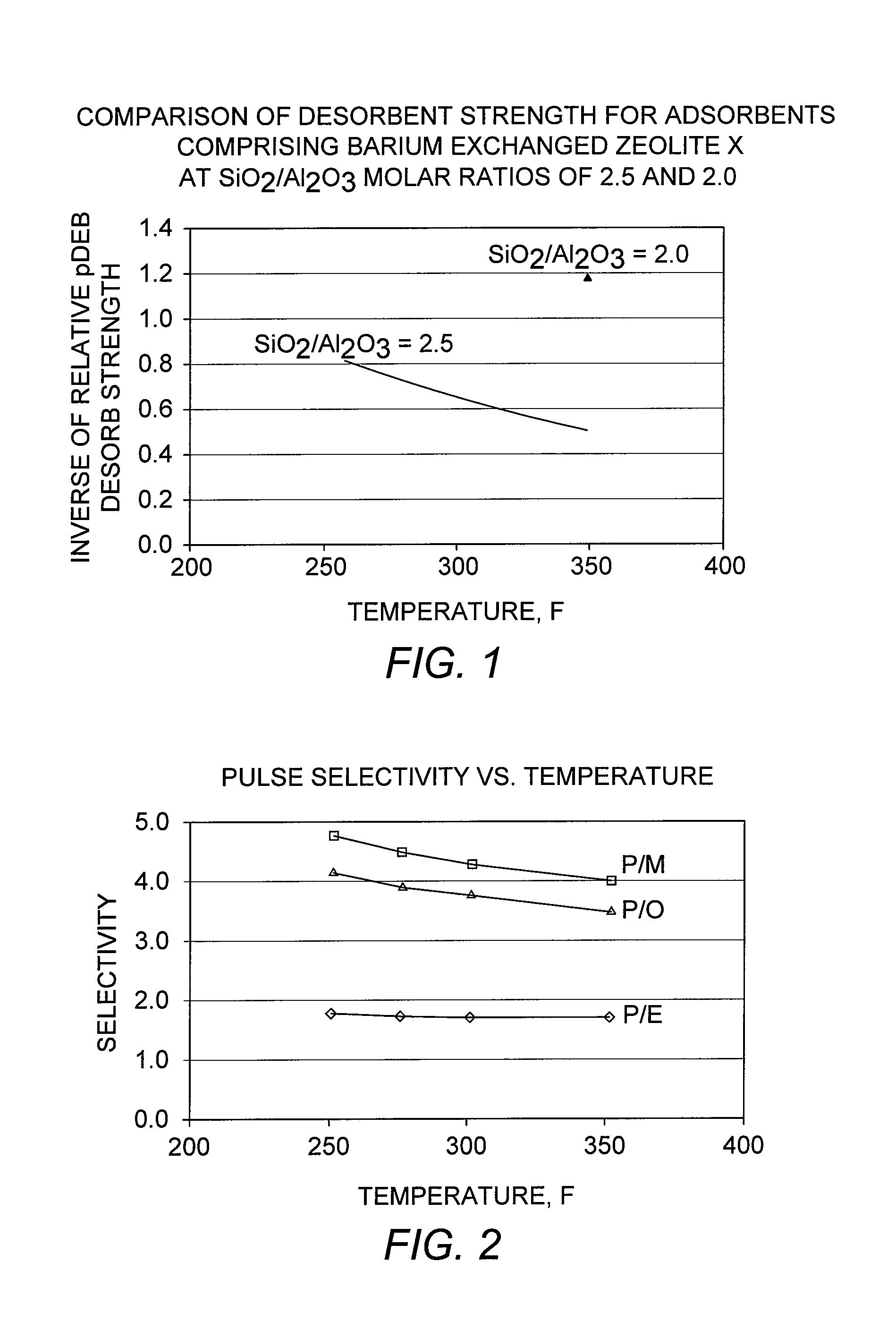

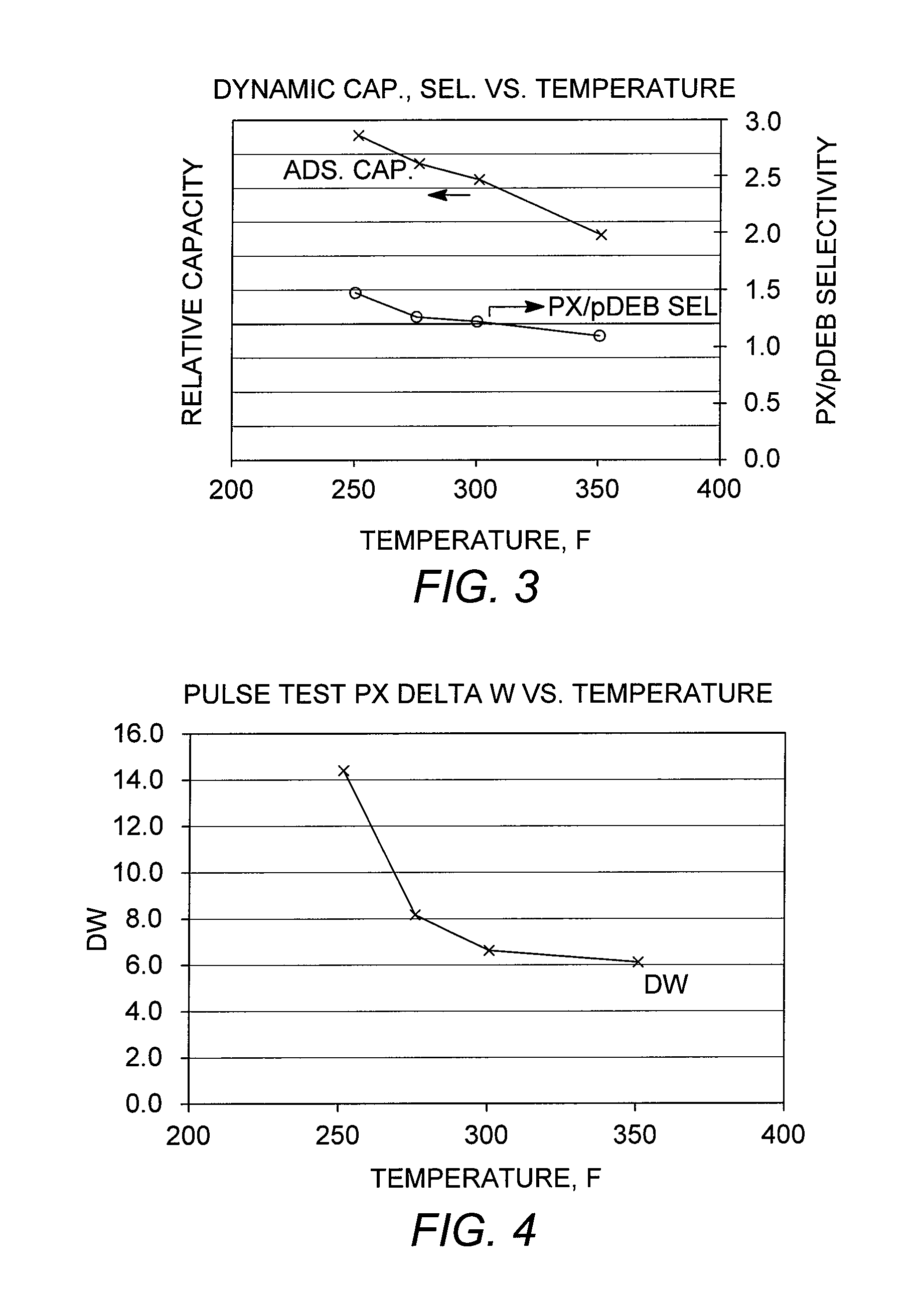

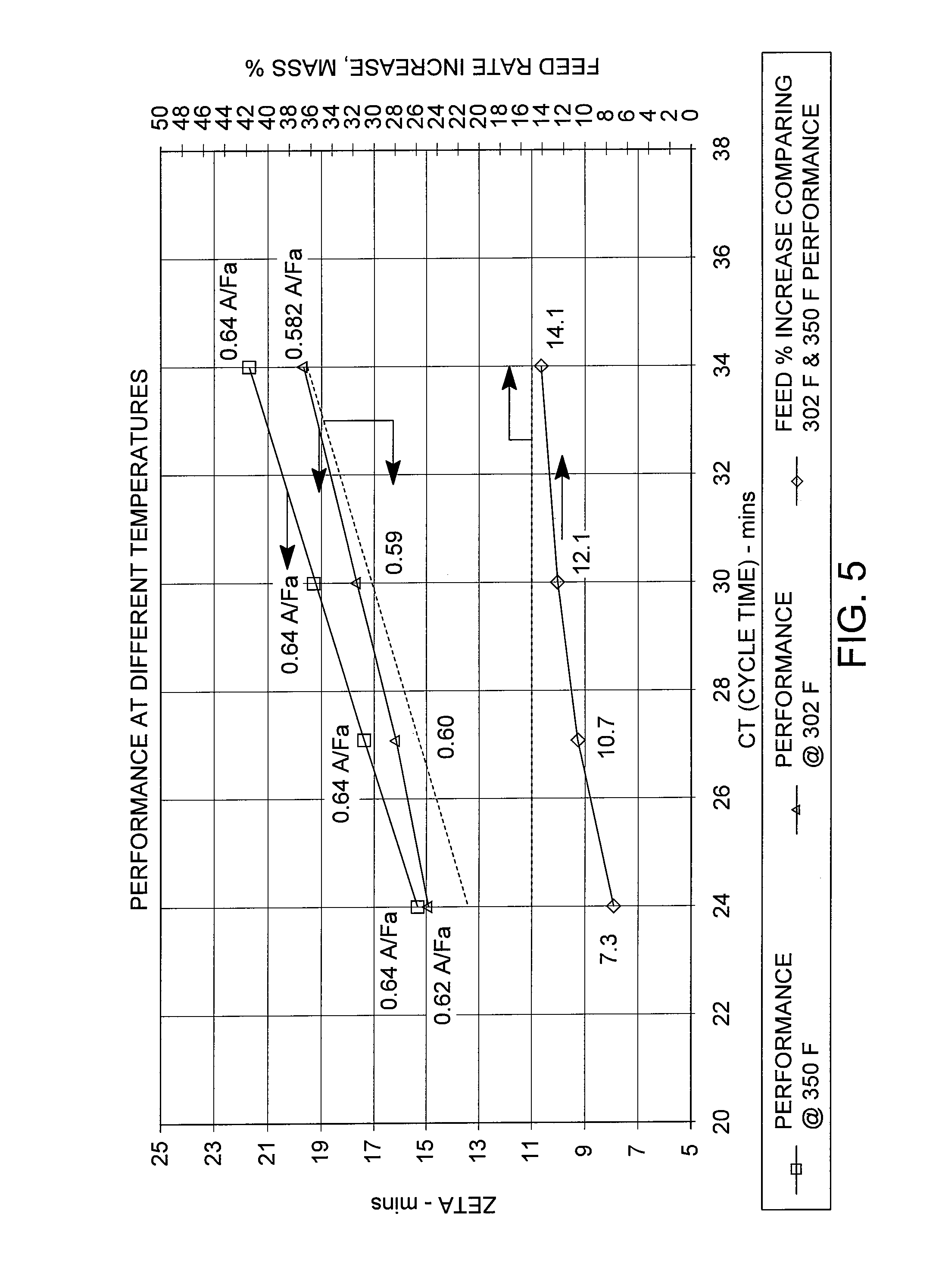

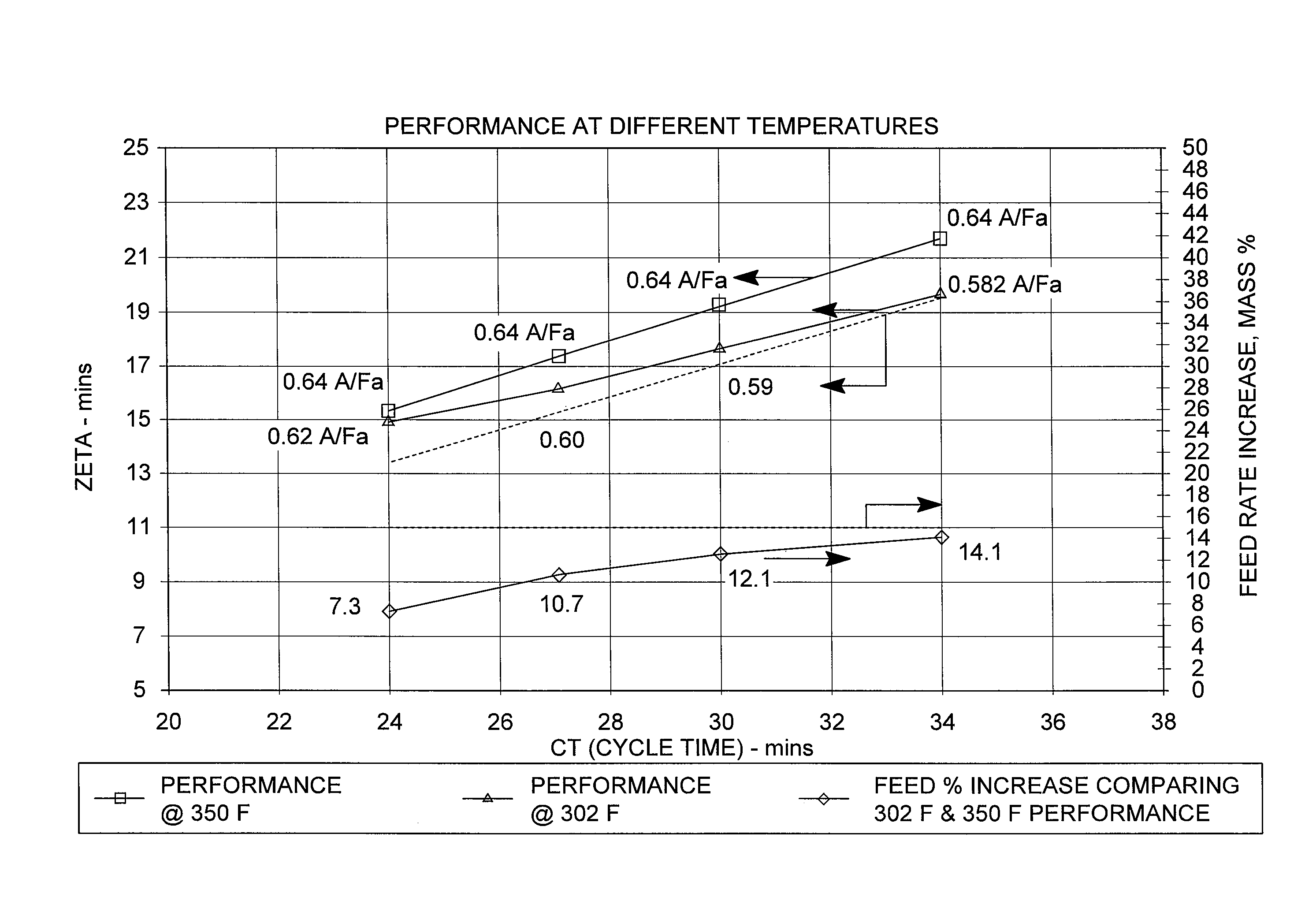

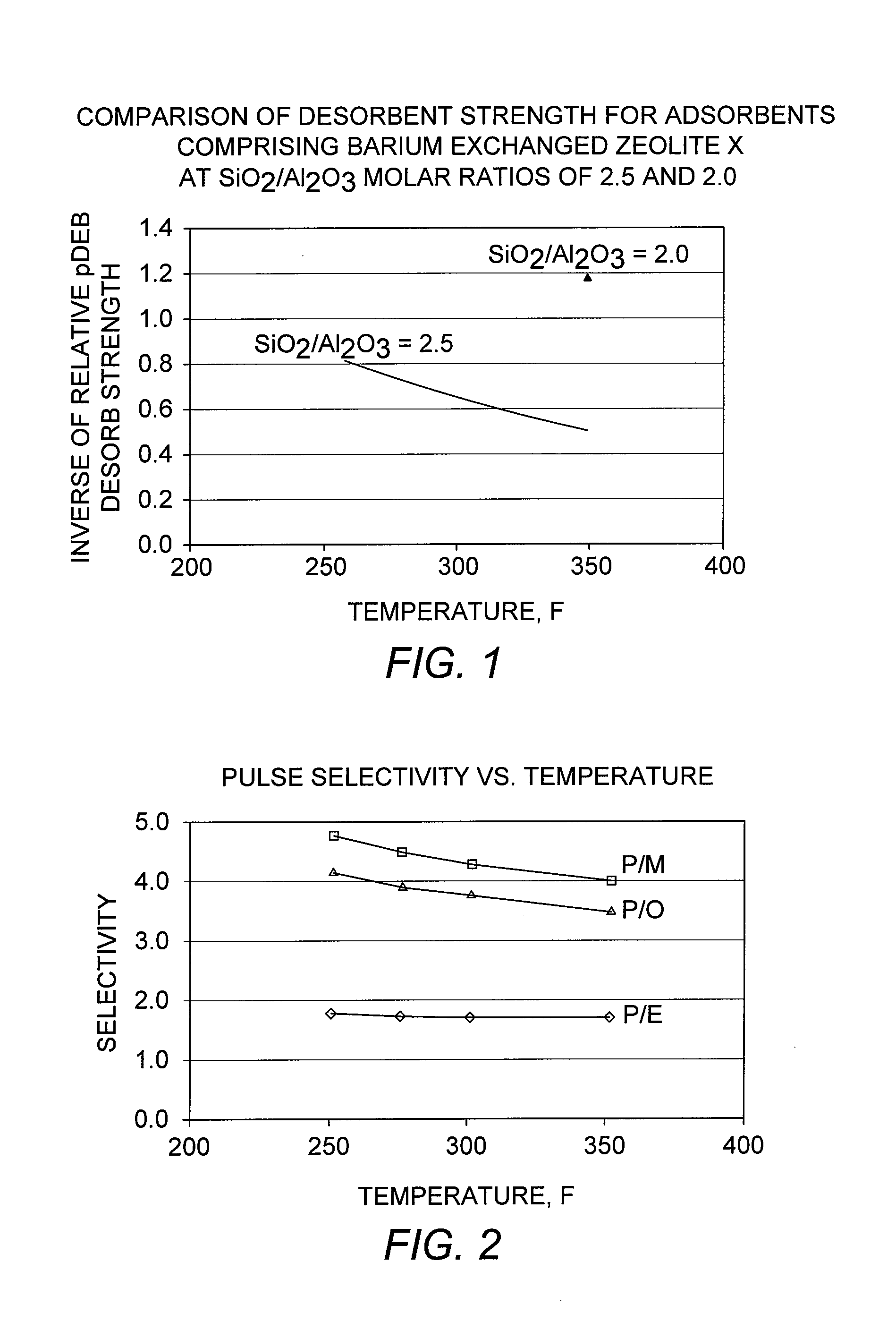

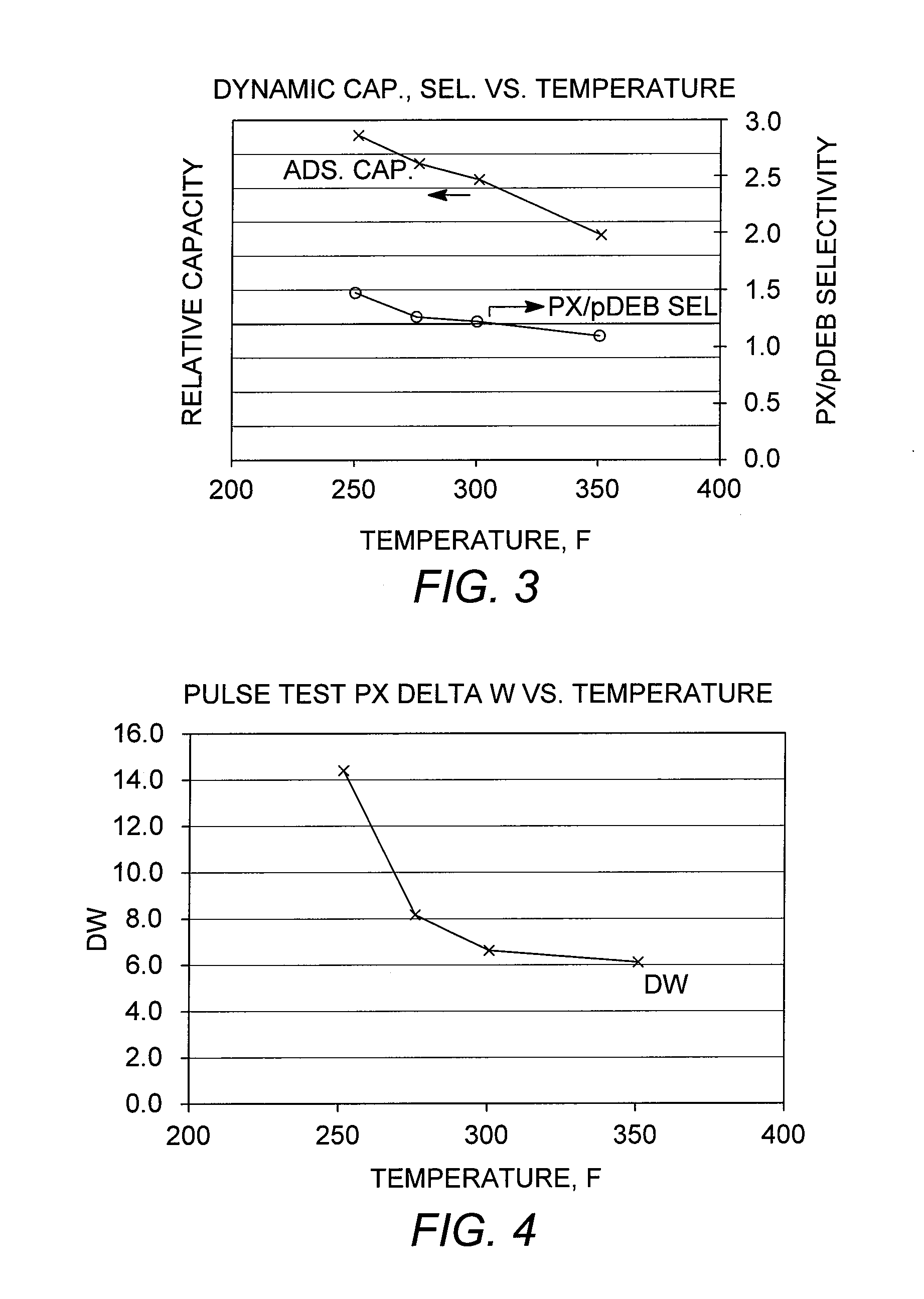

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable adsorbents comprise nano-size zeolite X having an average crystallite size of less than about 500 nanometers. The adsorbents provide both improved capacity and mass transfer, which is especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel

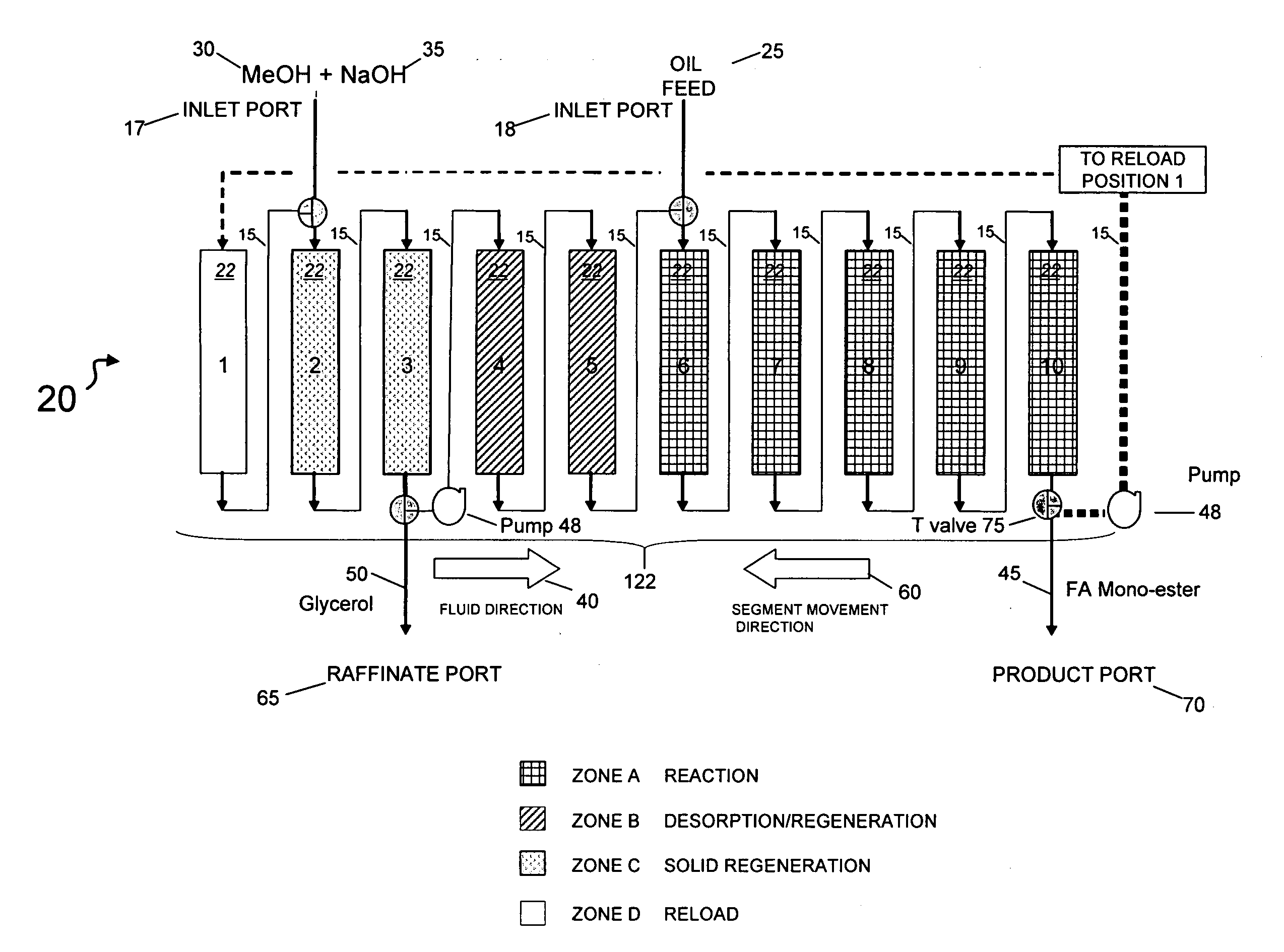

ActiveUS20070158270A1Reduce contentLow costFatty oils/acids recovery from wasteFatty acid esterificationBiodieselAlcohol

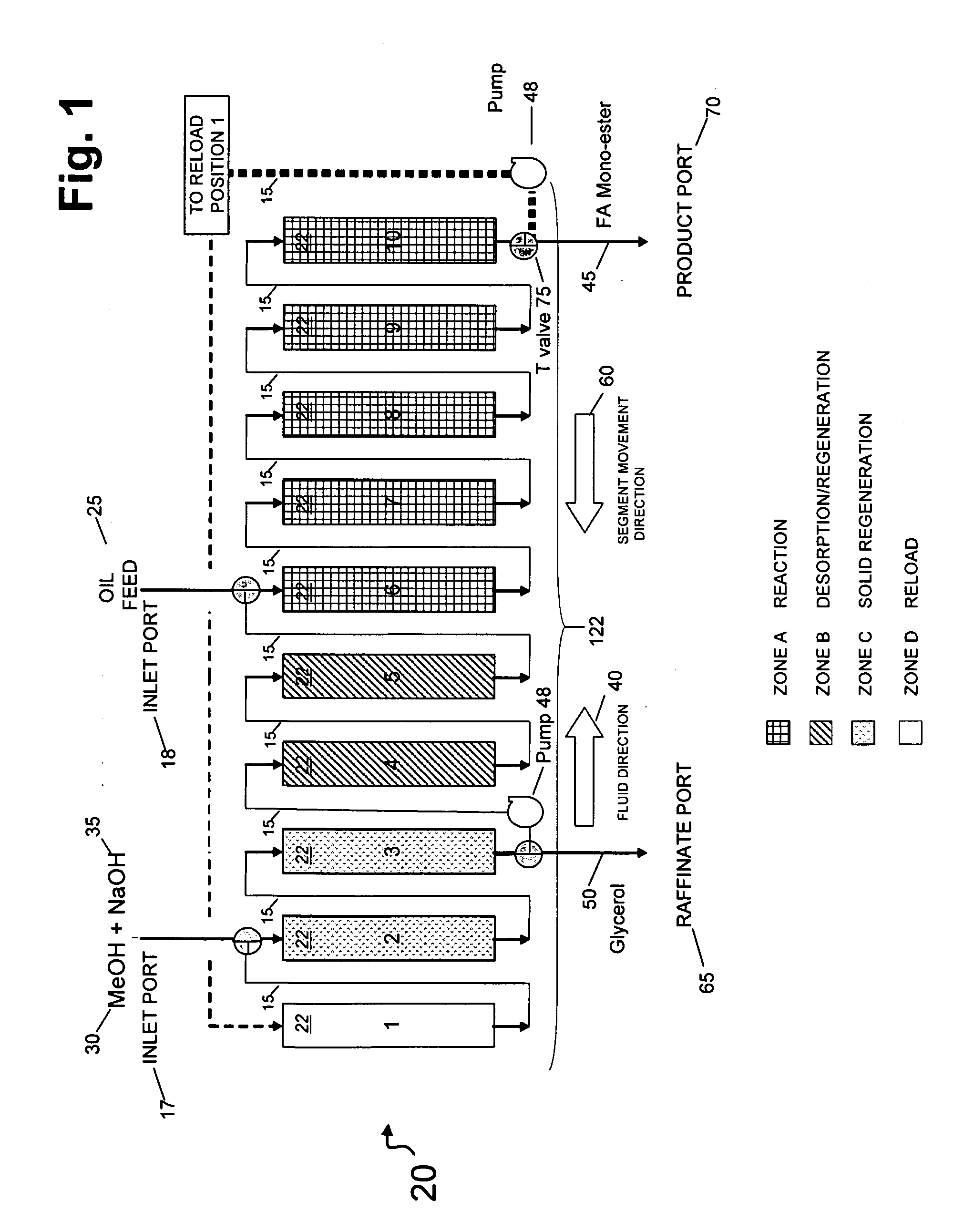

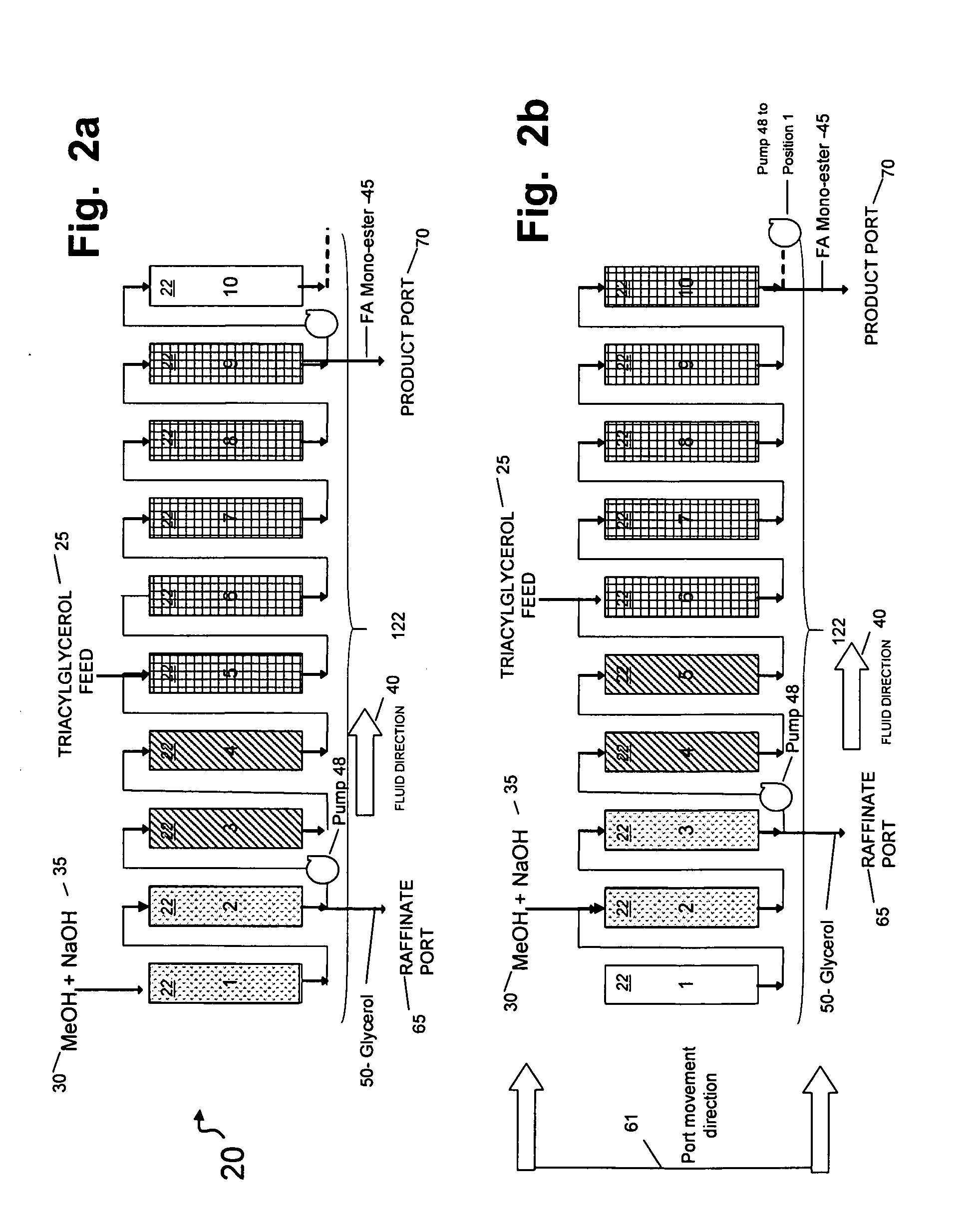

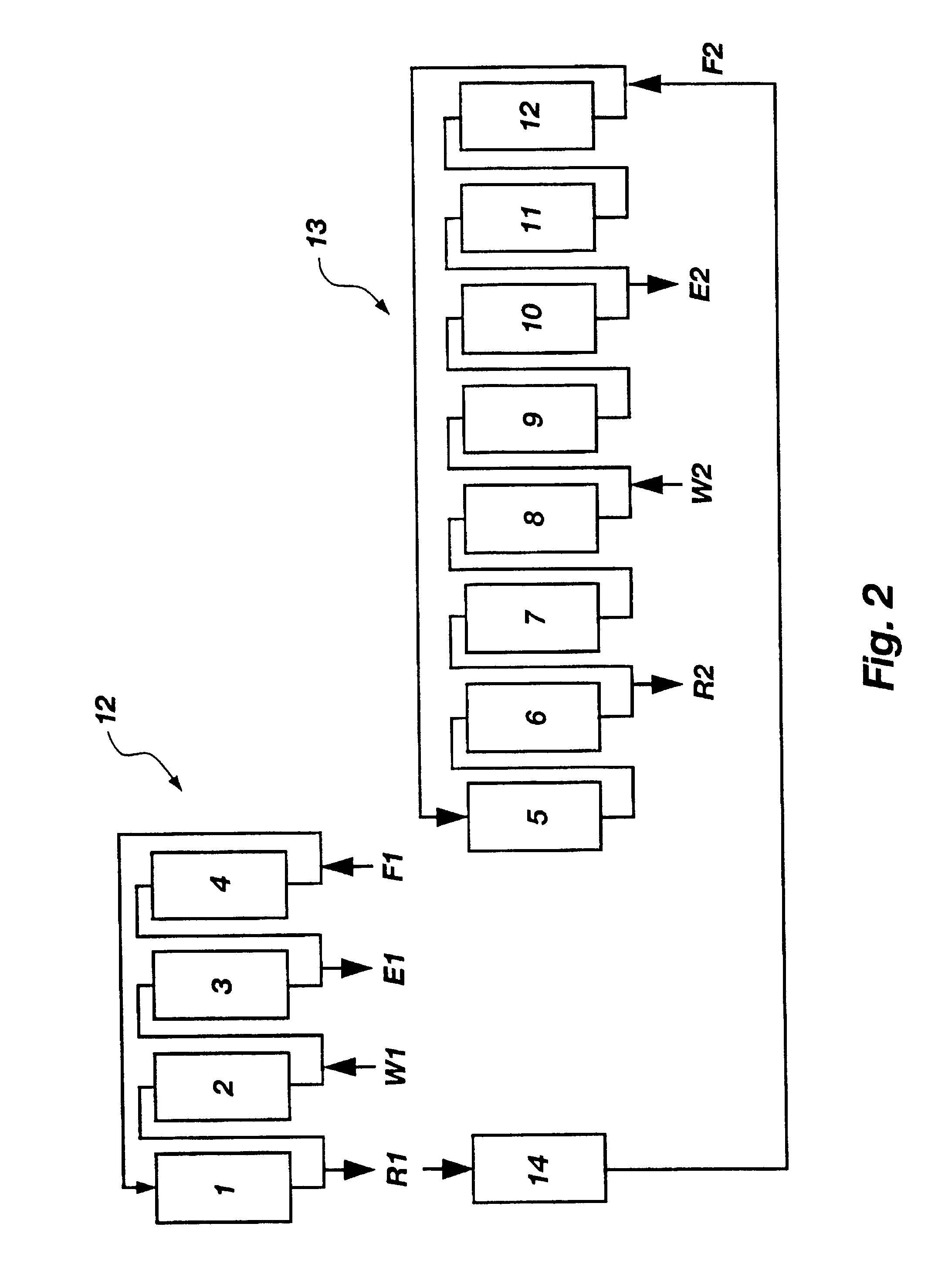

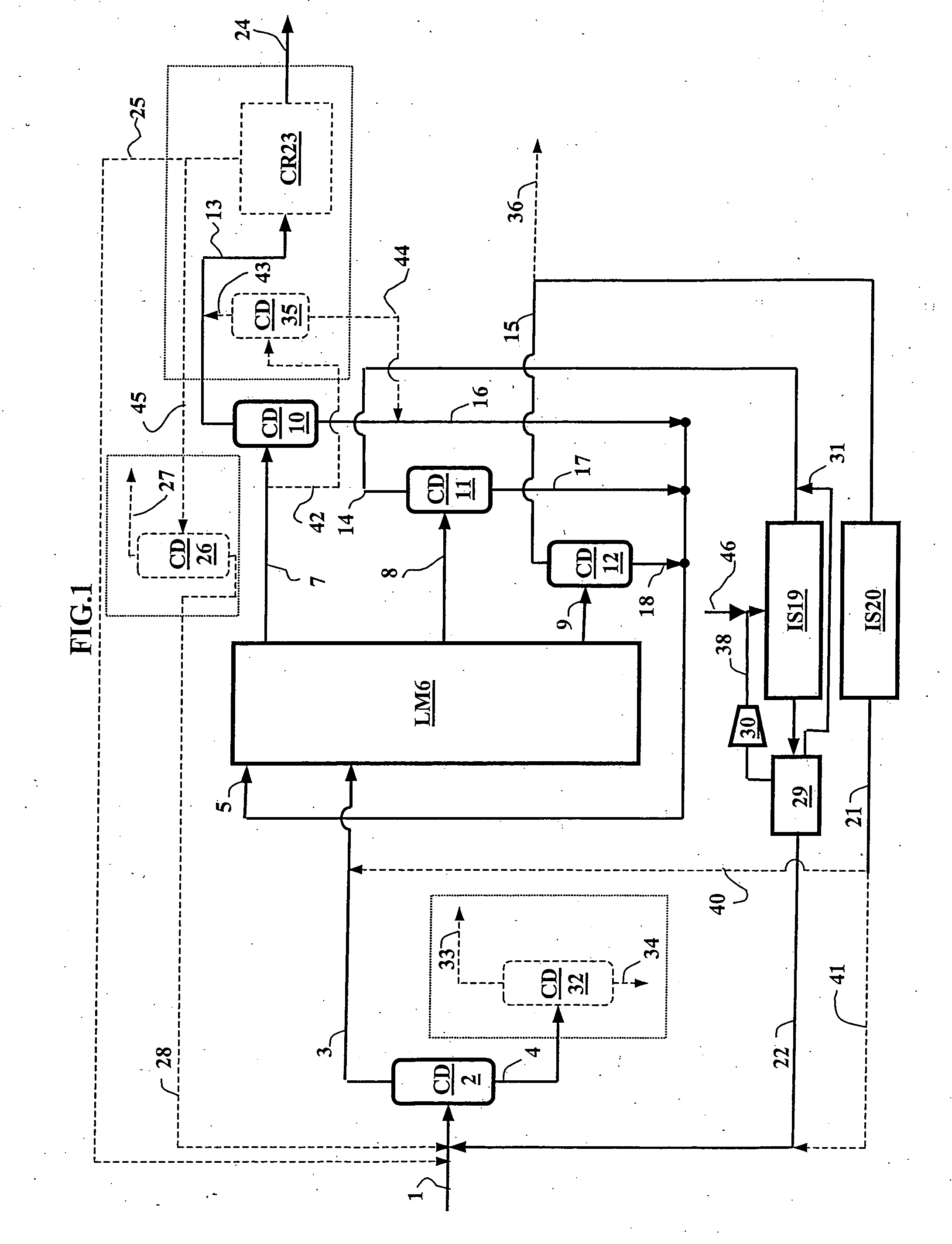

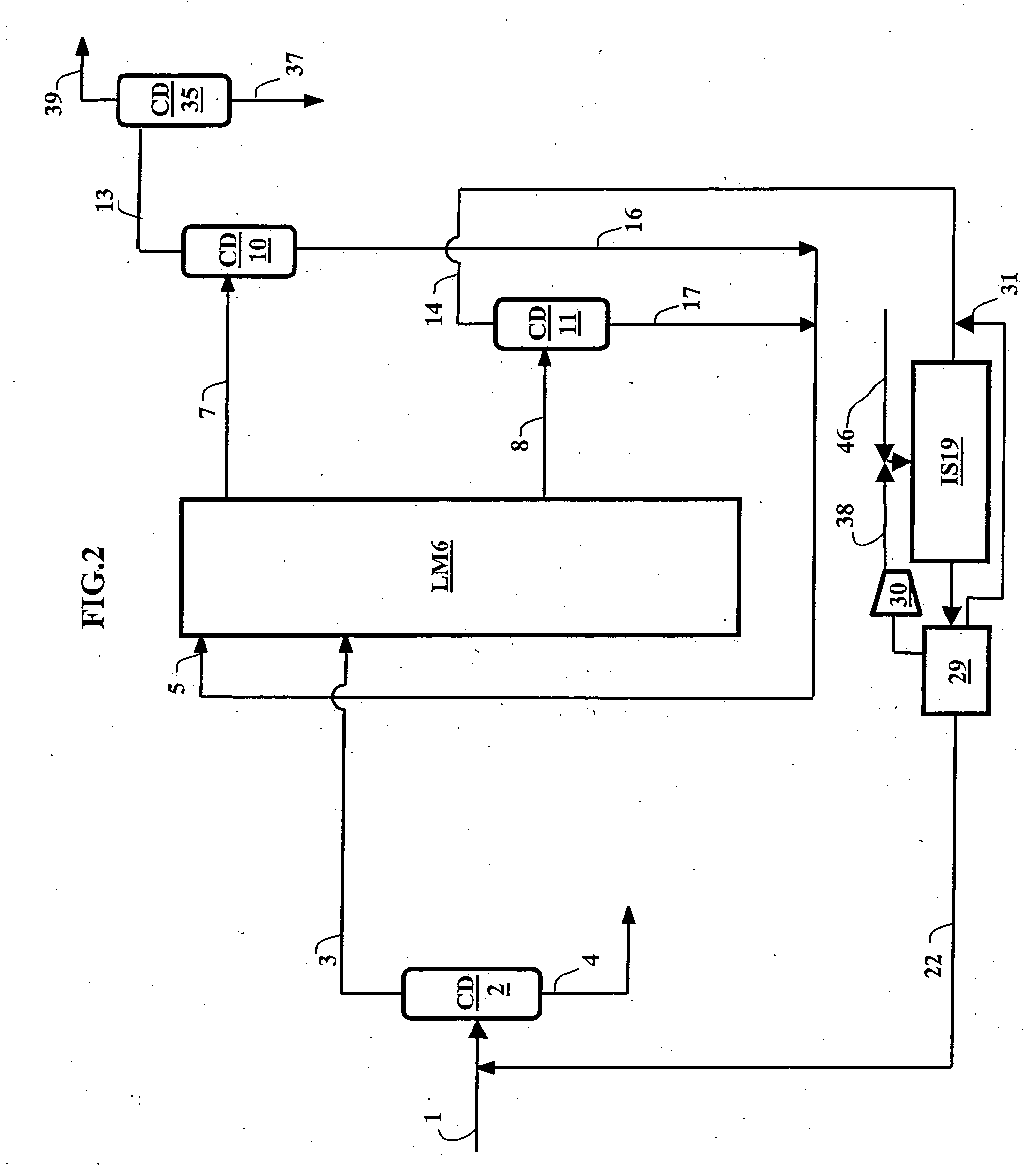

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel from a triacylglycerol feedstock is described. In an exemplary method, the triacylglycerol feedstock is continuously contacted with a catalytic chromatographic bed comprising a first (solid phase) basic catalyst through a first port of a simulated moving bed chromatographic apparatus. A monohydric alcohol and optional second (mobile phase) basic catalyst is continuously contacted with the catalytic chromatographic bed through a second port and pumped in a first direction toward the triacylglycerol feedstock to contact the triacylglycerol in a reaction zone of the catalytic chromatographic bed where the fatty acid monoester and glycerol coproduct are formed. The fatty acid monoester is removed from the reaction zone through a product port of the simulated moving bed apparatus. Segments of the catalytic chromatographic bed are incrementally moved in a second direction, opposite the first direction, and the glycerol is removed from a raffinate port located opposite the product port of the apparatus.

Owner:ARCHER DANIELS MIDLAND CO

Method of displacement chromatography

InactiveUS6379554B1Efficient separationLower requirementIon-exchange process apparatusComponent separationChromatographic separationBetaine

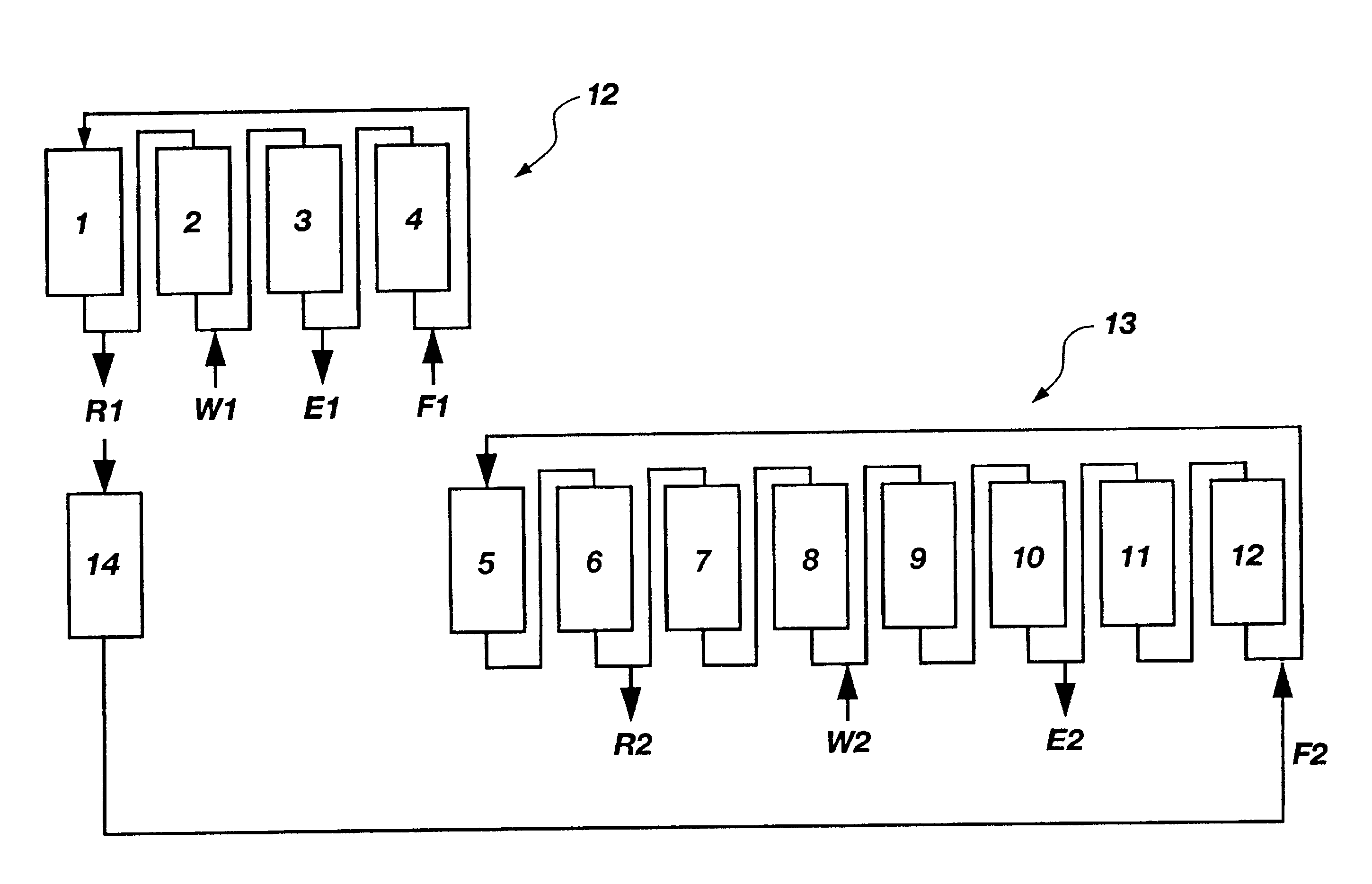

A plurality of chromatographic separation operations, including a first simulated moving bed operation, are coupled into a process which functions, preferably through the application of continuous displacement chromatography, to recover a fraction rich in small organic molecules, notably betaine and / or invert from sucrose solutions, enabling the subsequent production of a high purity sucrose product.

Owner:AMALGAMATED RES

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

Binderless adsorbents with improved mass transfer properties and their use in the adsorptive separation of para-xylene

ActiveUS7812208B2Improve performanceImprove mass transfer effectOther chemical processesMolecular-sieve and base-exchange compoundsProduction rateSorbent

Owner:UOP LLC

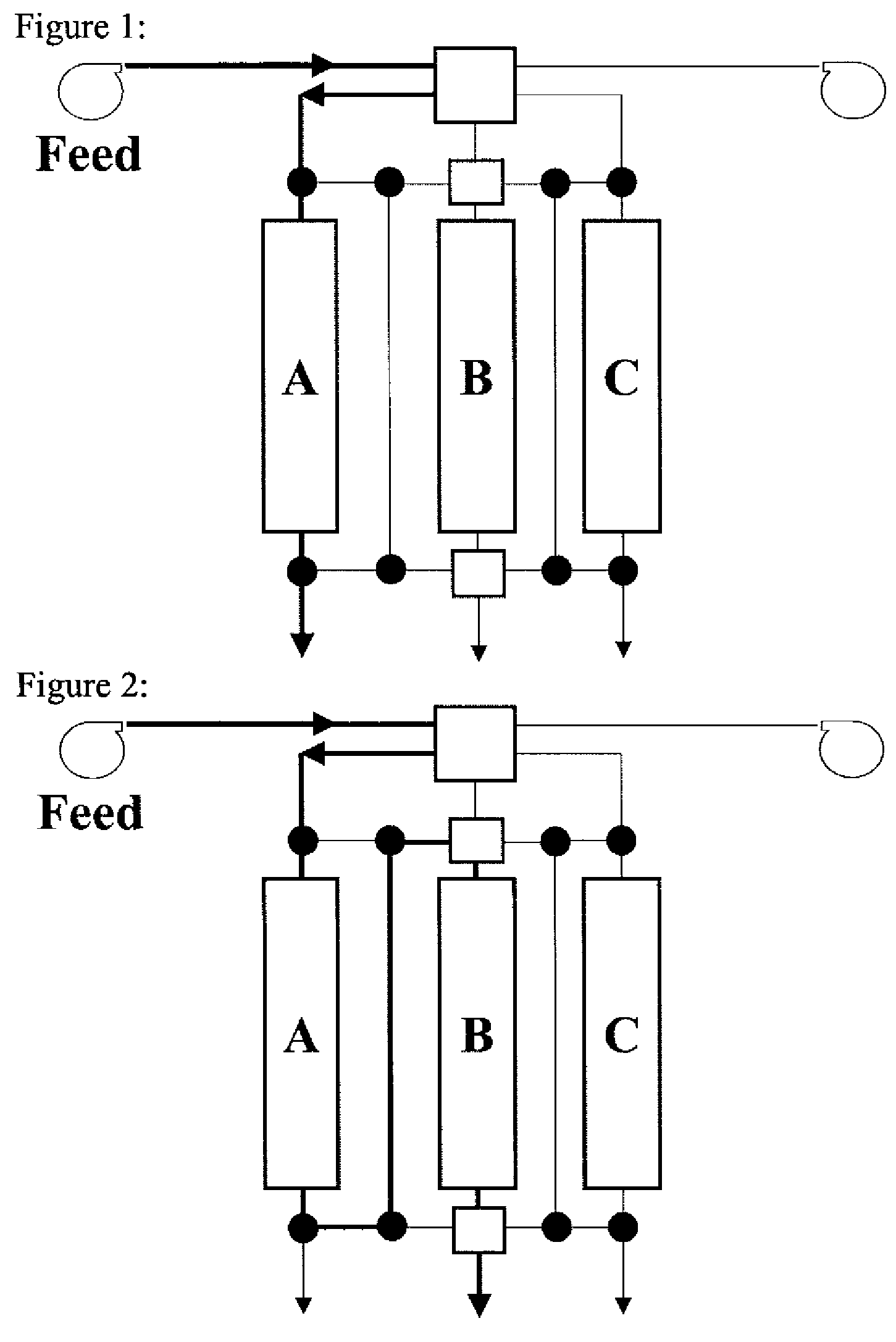

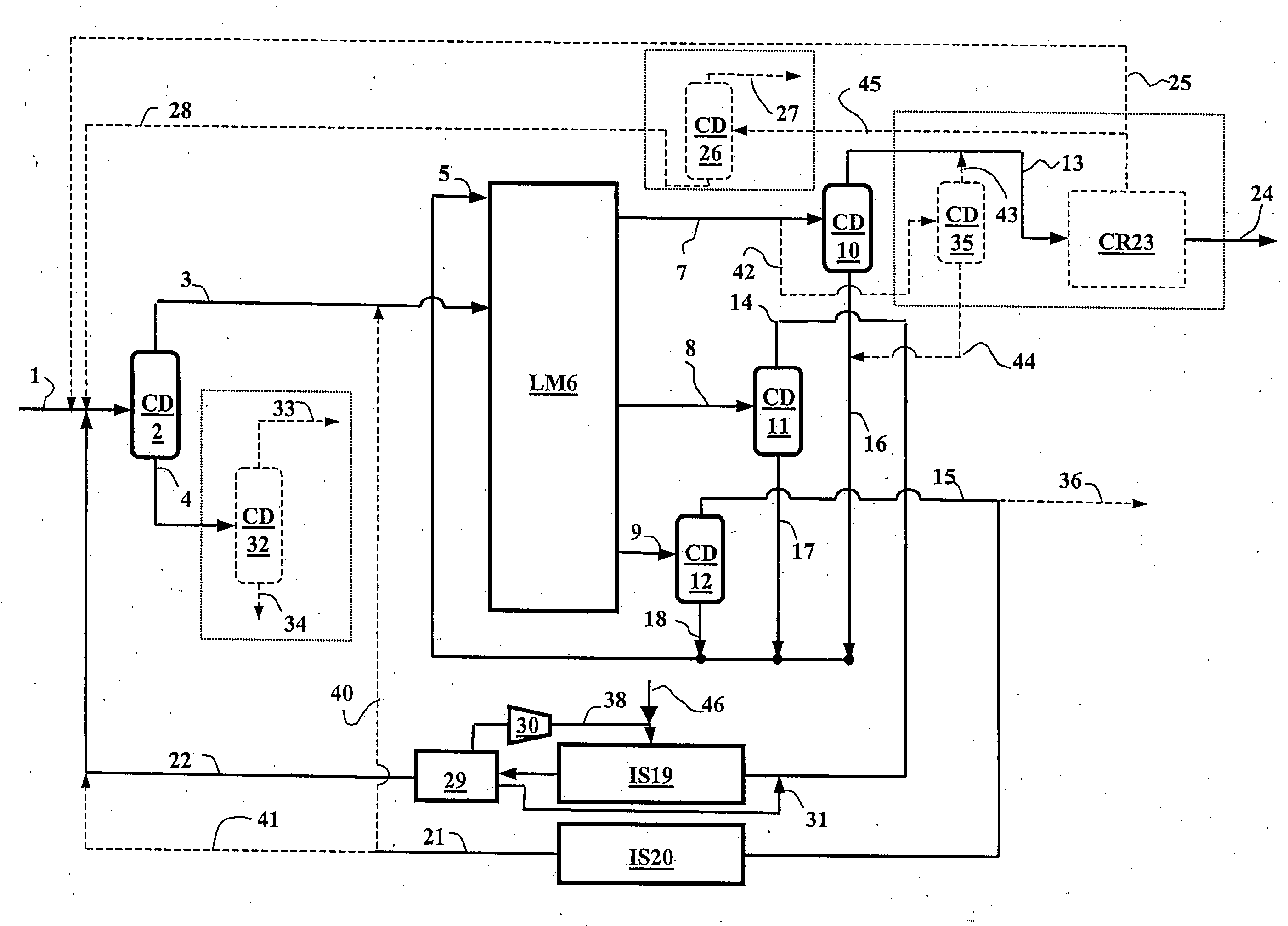

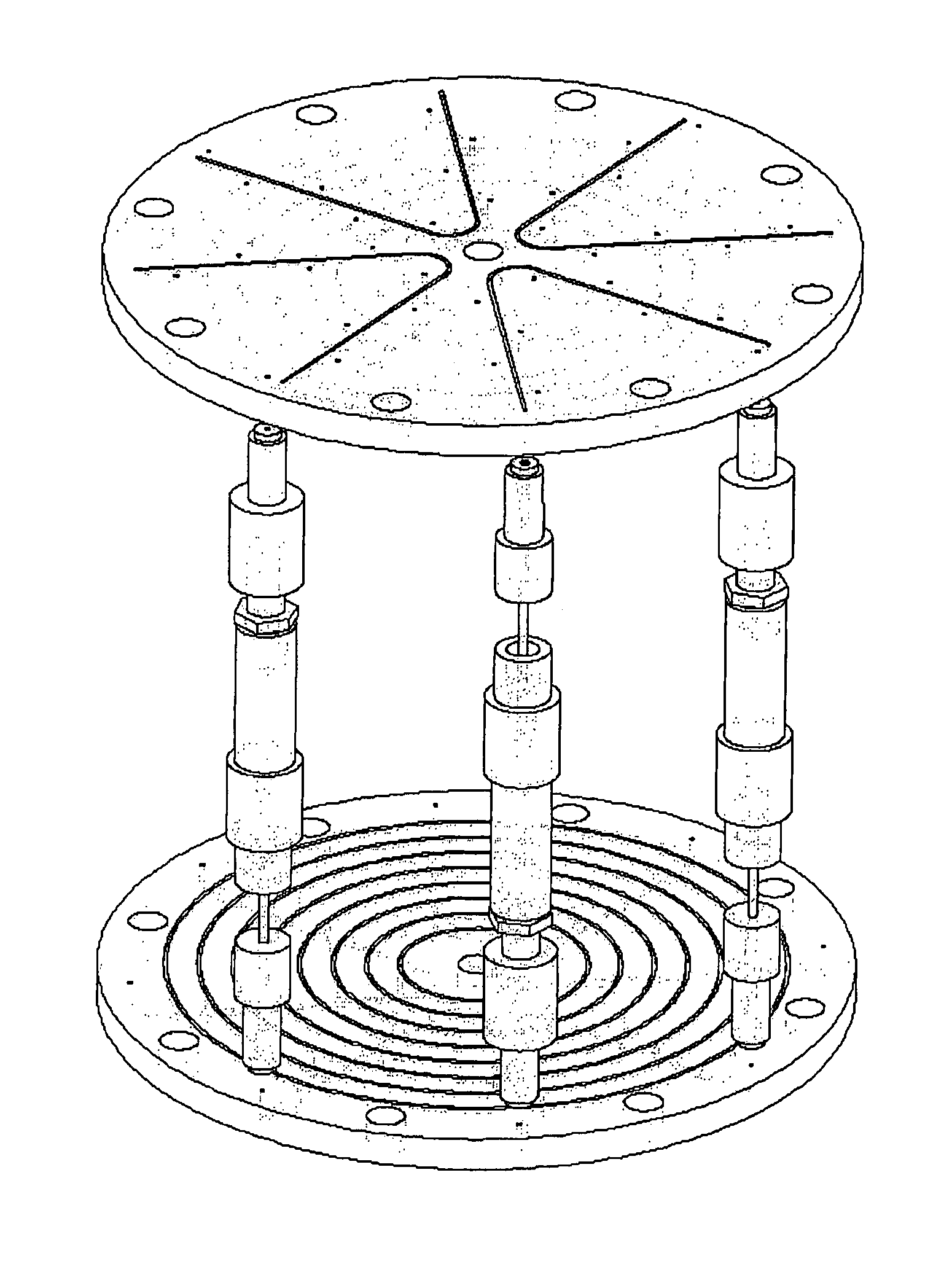

Valve Module And Methods For Simulated Moving Bed Chromatography

ActiveUS20080053543A1Simple and easily programmable controlPromote repairComponent separationSolid sorbent liquid separationSimulated moving bedMoving bed

The present invention provides devices and methods for micro-scale simulated moving bed chromatography (SMB) for continuous preparation of analytic quantities of highly pure fractions of target molecules. The present apparatus and method of the invention is adapted in a preferred embodiment to separations by affinity chromatography involving three discontinuous liquid flow loops. An alternative embodiment of affinity chromatography utilizes standard SMB operating under isocratic conditions.

Owner:TOSOH BIOSCIENCE LLC

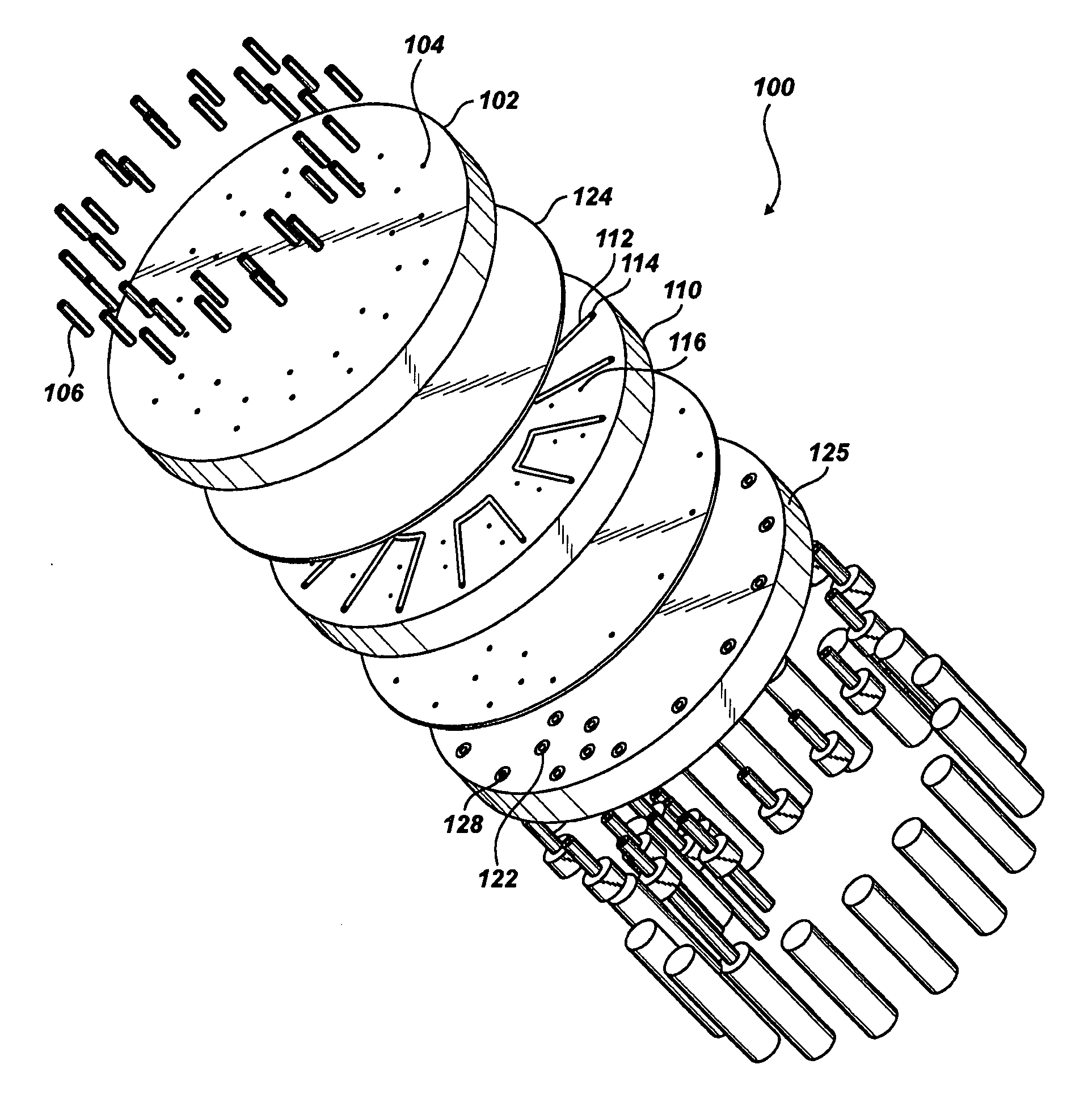

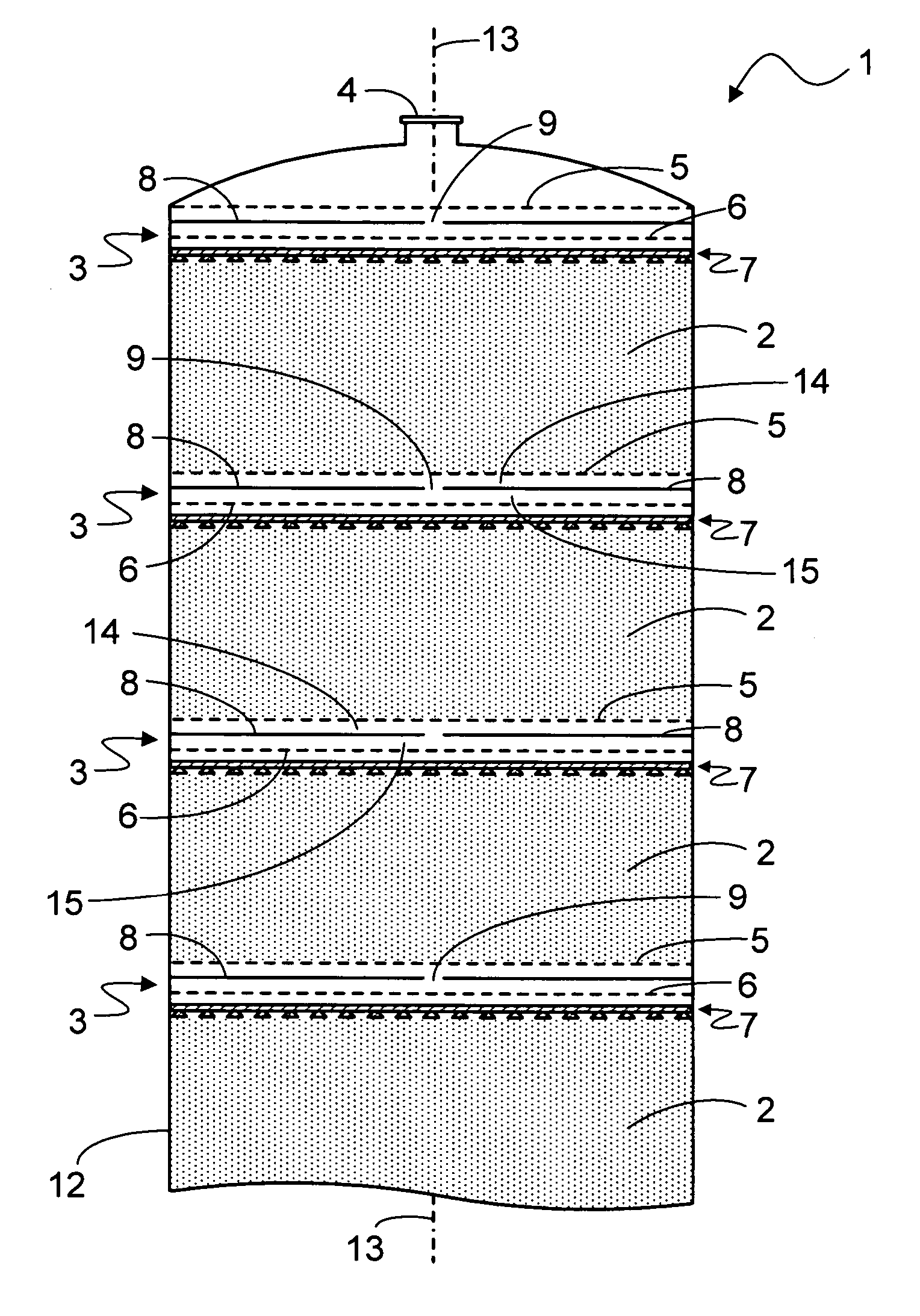

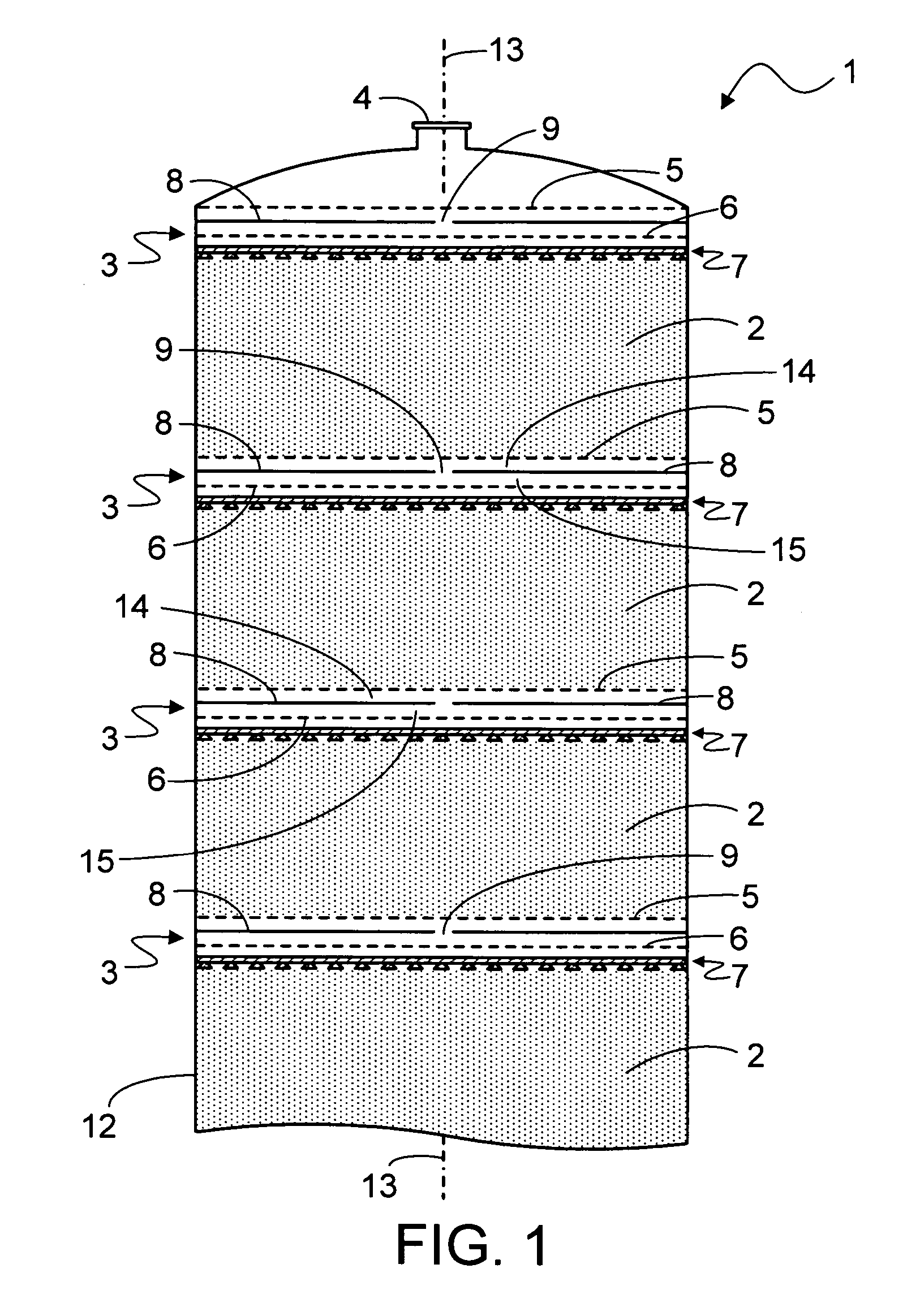

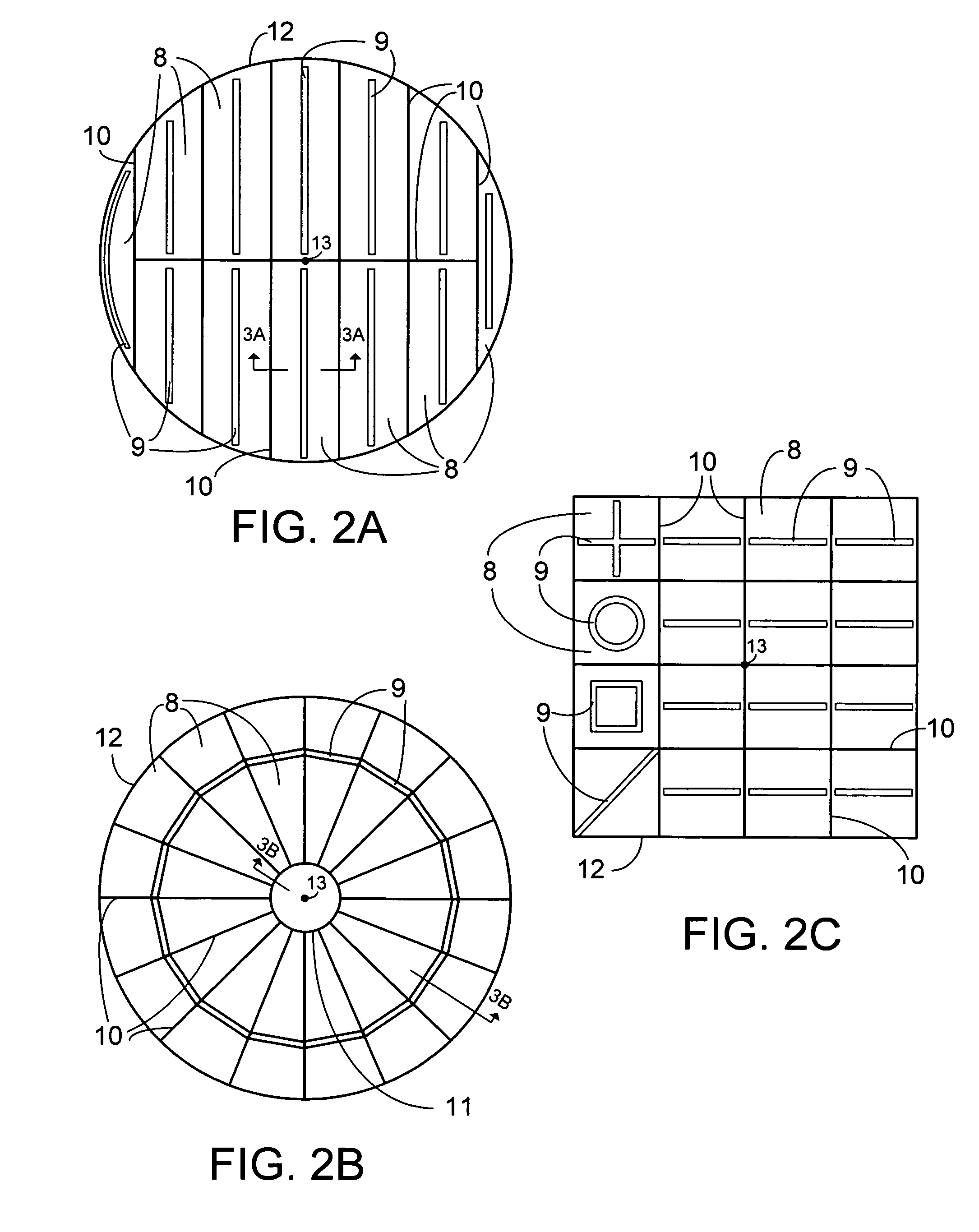

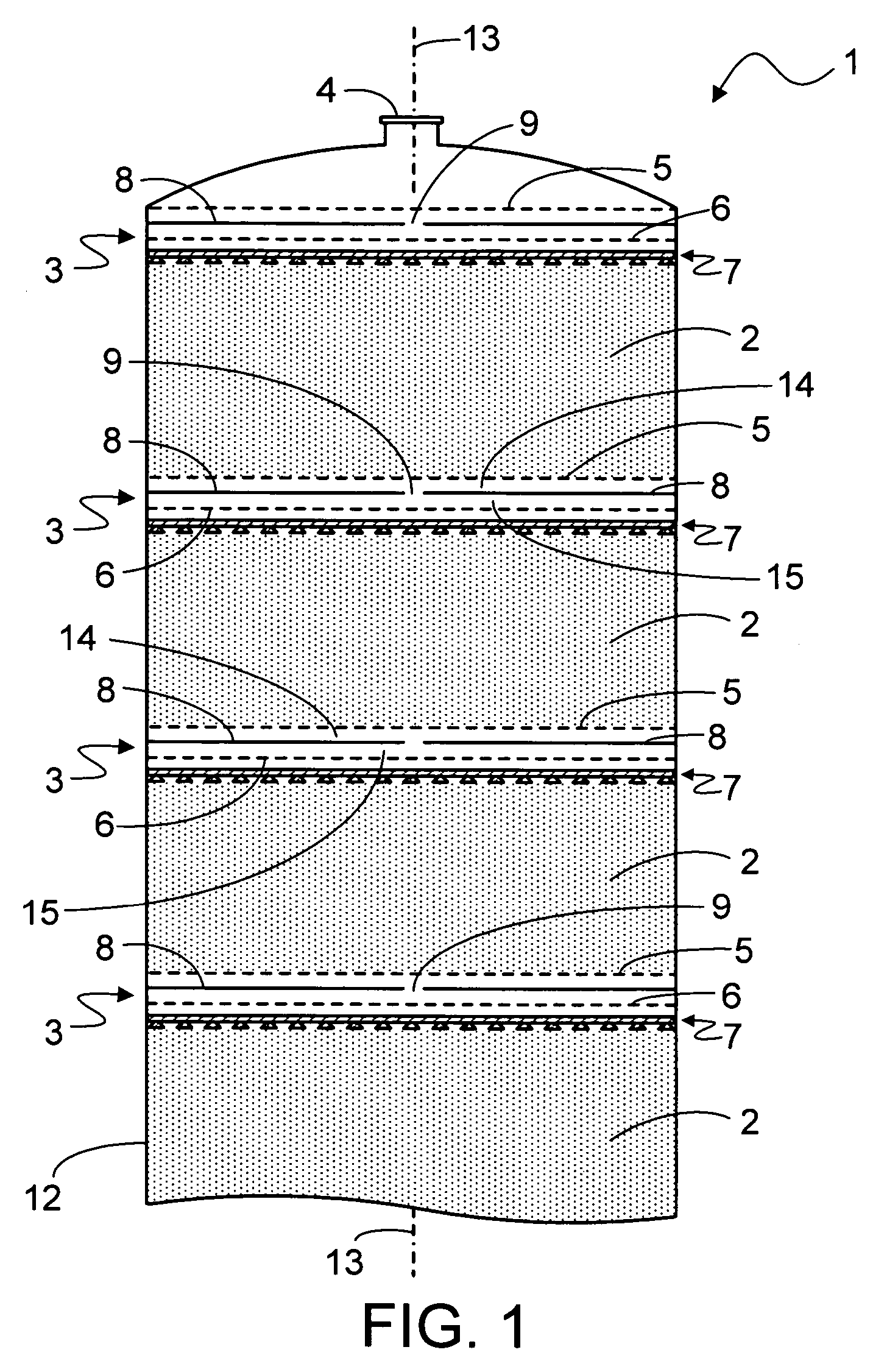

Flow distribution apparatus

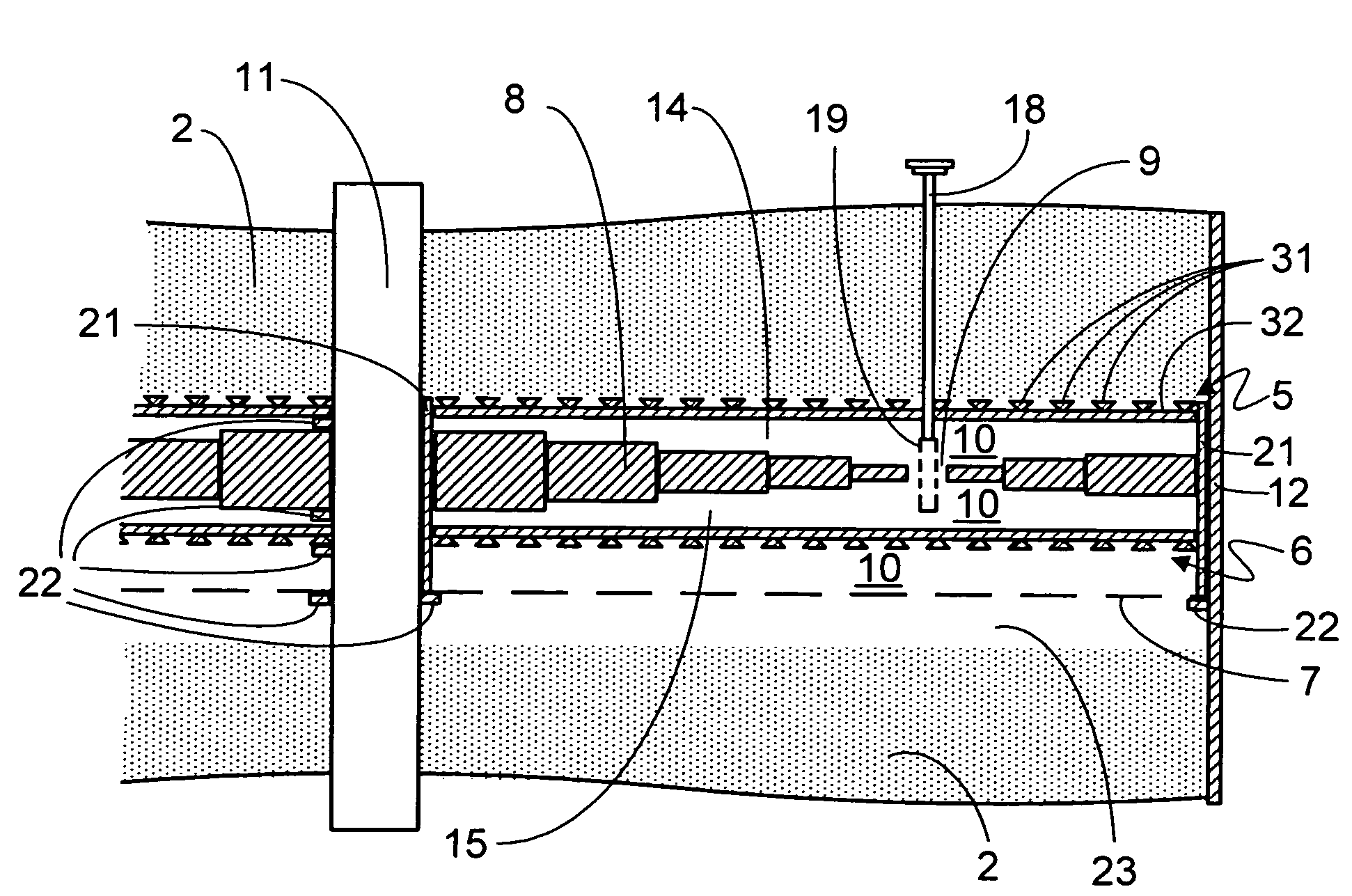

ActiveUS20060108274A1Minimizes eliminatesIon-exchange process apparatusIon-exchanger regenerationStream flowHoneycomb

Disclosed is a mixer-distributor-collector apparatus for use between beds of solid particles in a fluid-solid contacting vessel. The apparatus includes a solids retaining screen, fluid deflector, passageway, fluid distributor, and flow manipulator. The flow manipulator is a device such as a honeycomb, porous solid, perforated plate, screen, or grid having an open area greater than the open area of the fluid distributor and is located below and spaced apart from the fluid distributor. The apparatus improves the fluid flow characteristics by minimizing or eliminating fluid velocity jets and / or other turbulence which can disturb the downstream particle bed. In an exemplary application, the invention finds use in simulated moving bed (SMB) adsorptive separation processes.

Owner:UOP LLC

Agglomerated zeolitic adsorbents, method for obtaining same uses thereof

InactiveUS6884918B1Amino compound purification/separationOrganic compound preparationSorbentSimulated moving bed

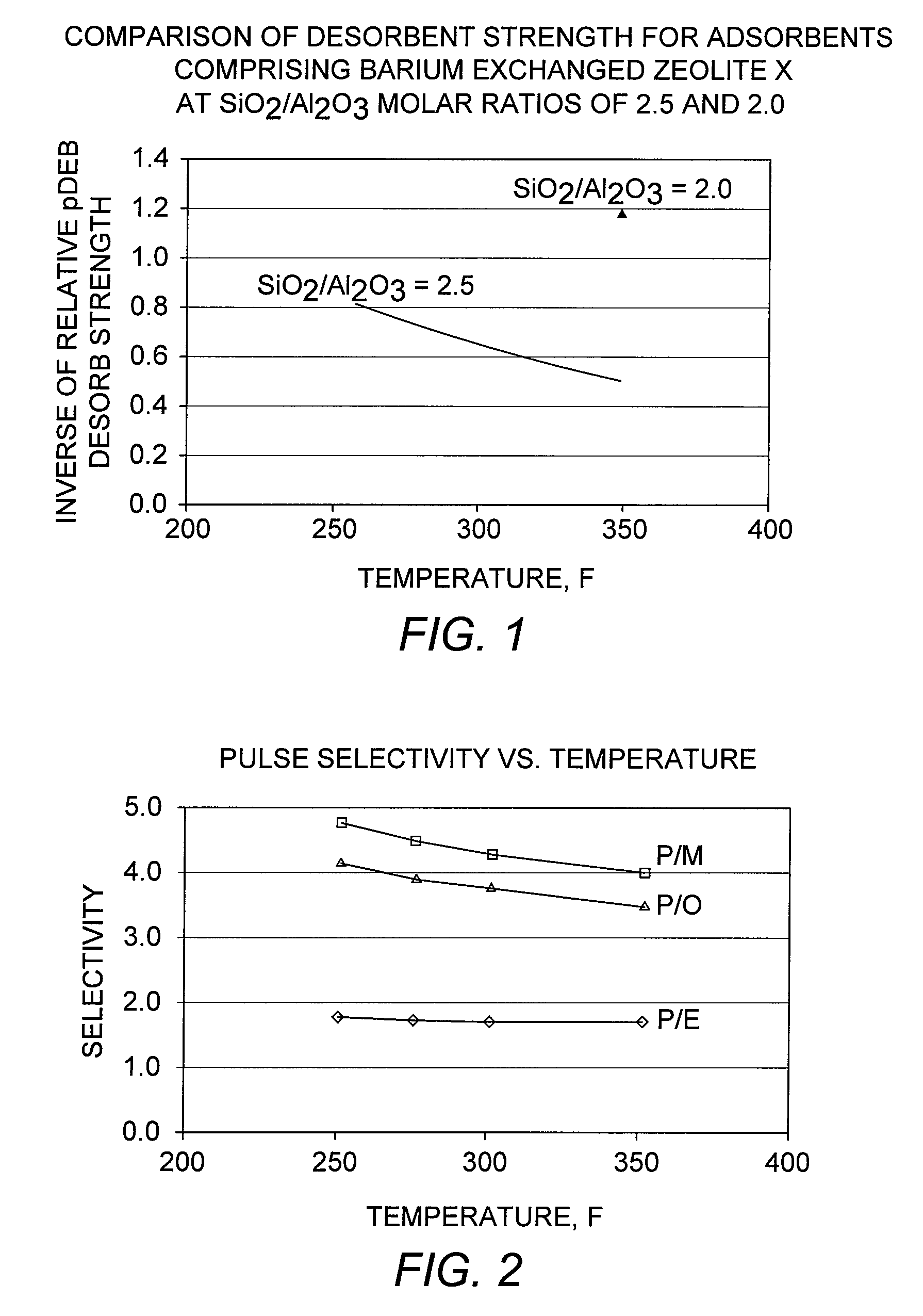

The present invention relates to agglomerated zeolitic adsorbents based on zeolite X with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g.They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged.These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

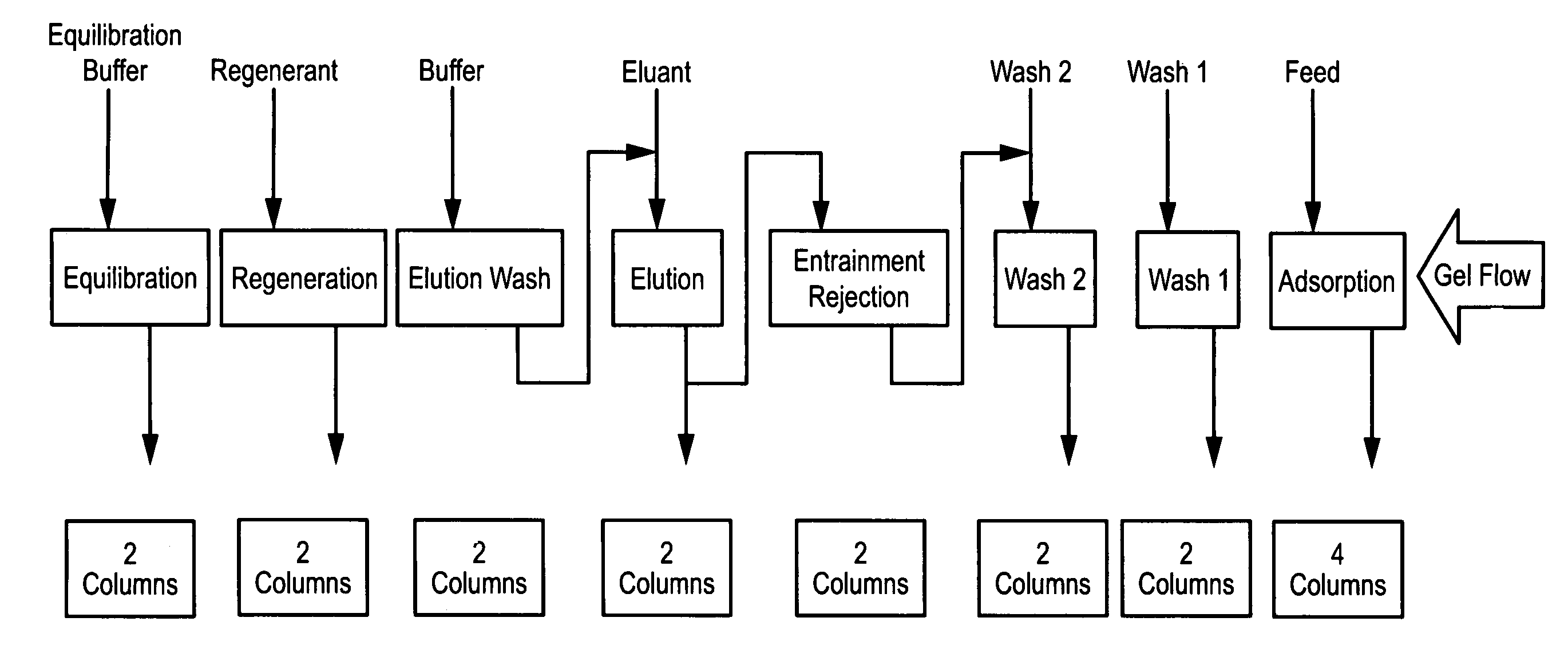

Method of purifying polypeptides by simulated moving bed chromatography

Provided are methods of separating an immunoreactive compound from at least one immaterial component, using a simulated moving bed (“SMB”) system and a SMB apparatus for use in these methods. Also provided are purified immunoreactive compounds prepared using the SMB methods and apparatus and methods of treatment with the purified immunoreactive compounds.

Owner:BIOGEN INC

Versatile simulated moving bed systems

InactiveUS7141172B2Increase flexibilityImprove performanceIon-exchange process apparatusGas treatmentSimulated moving bedEngineering

Owner:PURDUE RES FOUND INC

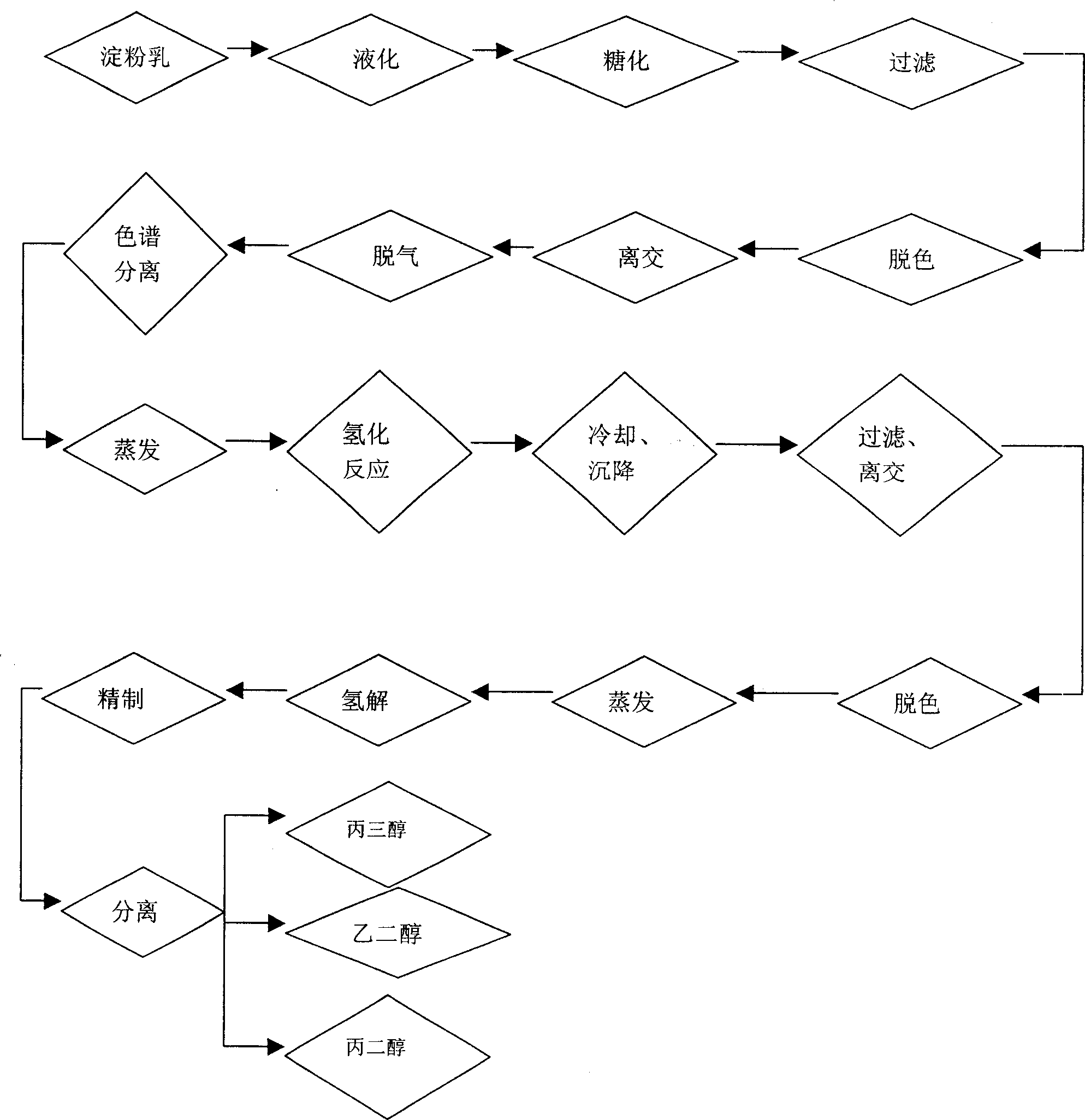

Novel technique for preparing ethylene glycol

InactiveCN1919814AReduce utilizationIncrease productivityOrganic compound preparationHydroxy compound preparationSimulated moving bedSlurry

The invention discloses a new technology to manufacture ethandiol, which is characterized by the following: liquefying starch emulsion; saccharifying; filtering; decolouring; separating through simulated mobile chromatogramic separating system; obtaining DX 99-99.7% glucose slurry; evaporating DX value glucose slurry to 50% as dried material; adopting ruthenium or nickel as catalyst; proceeding hydrogenation reaction to obtain the sorbitol solution; hydrogenolyzing for certain time under one catalyst of Ru, Ni / Ru and Co / Re to produce compound with ethandiol, glycerin and propanediol; cooling multi-alcohol; sedimenting; filtering; separating; decolouring; separating ethandiol, glycerin and propanediol.

Owner:SHANDONG XIWANG SUGAR

Binderless adsorbents and their use in the adsorptive separation of para-xylene

ActiveUS7820869B2Improve performanceIncrease mass transfer rateMaterial nanotechnologyMolecular sieve catalystsProduction rateSorbent

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

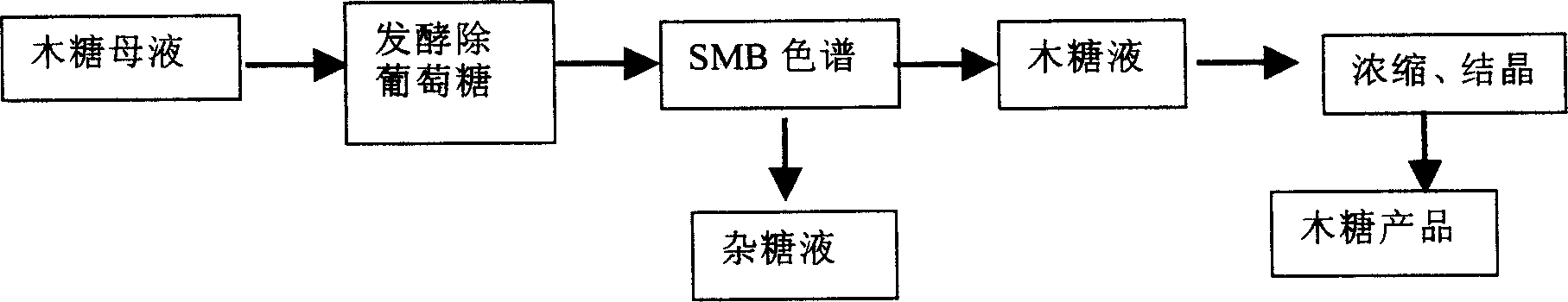

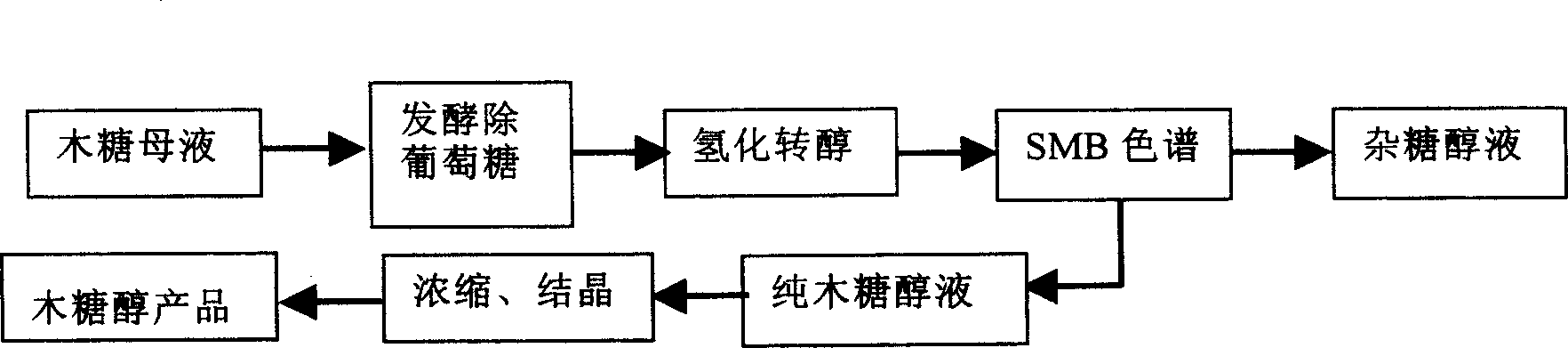

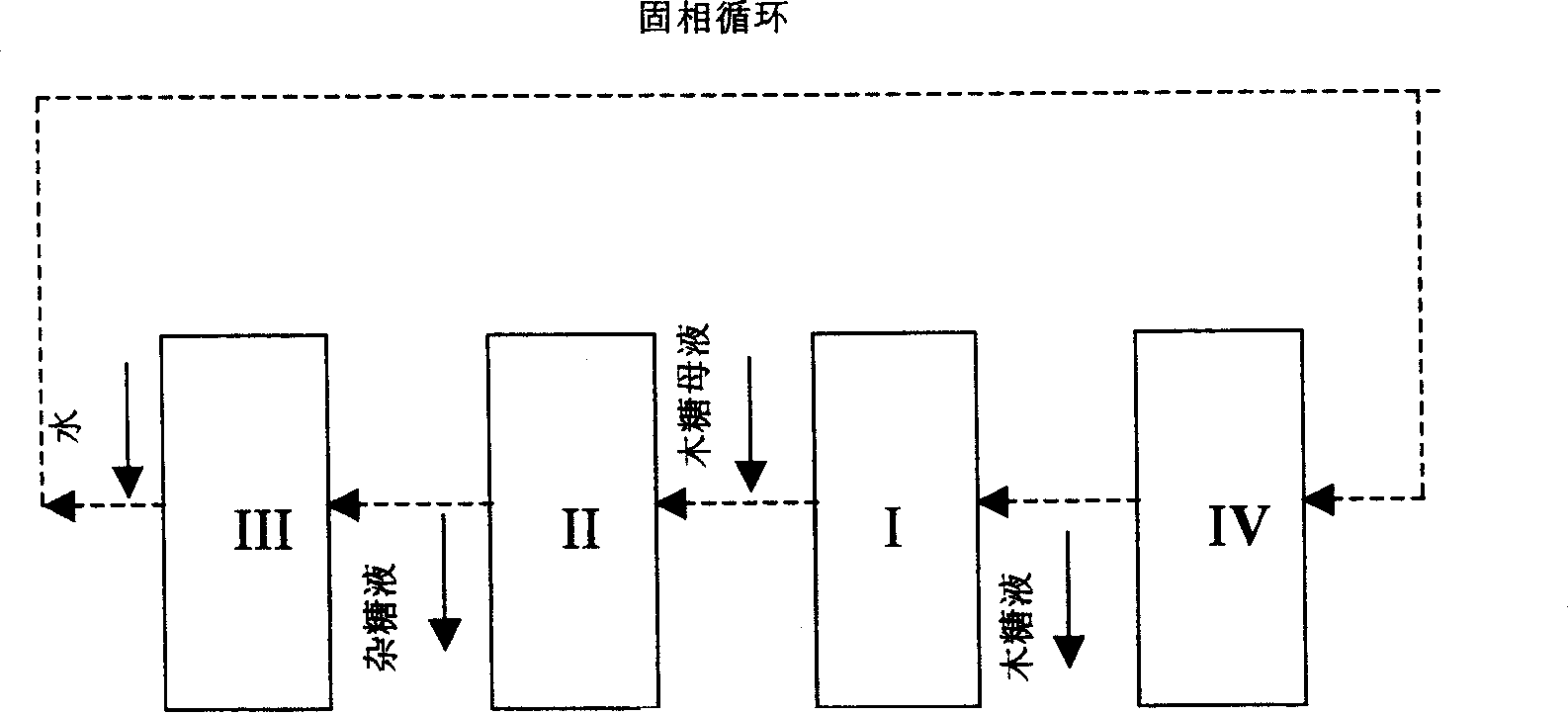

Process for extracting xylose and xylitol from a xylose mother liquor or a xylose digest

InactiveCN1699587AImprove physical stabilityImprove adsorption capacitySugar derivativesFermentationForeign matterHydrolysate

Owner:JIANGNAN UNIV

Method for producing paraxylene comprising an adsortion step and two isomerization steps

ActiveUS7915471B2Overcome disadvantagesHydrocarbon by isomerisationSolid sorbent liquid separationIsomerizationSimulated moving bed

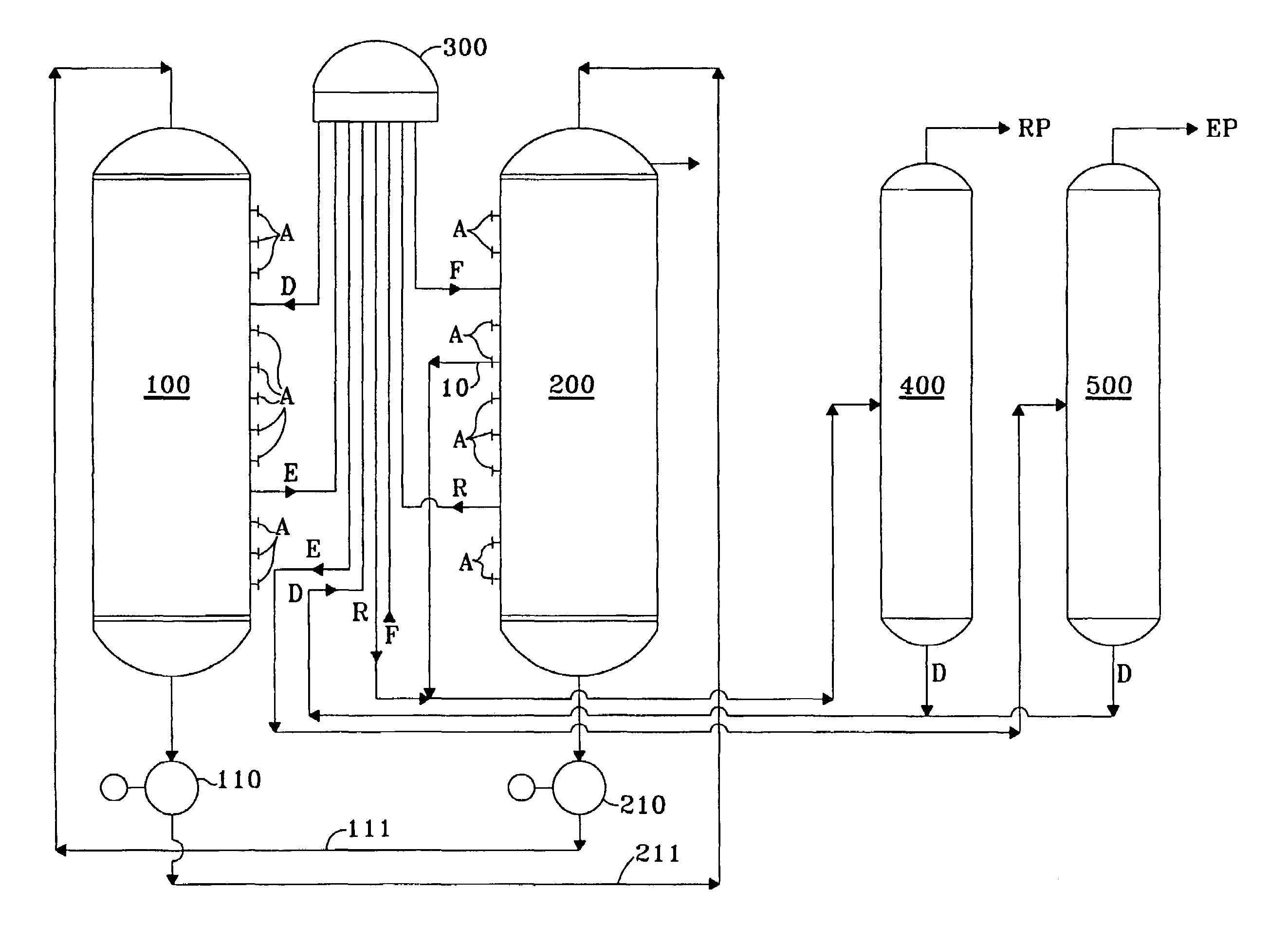

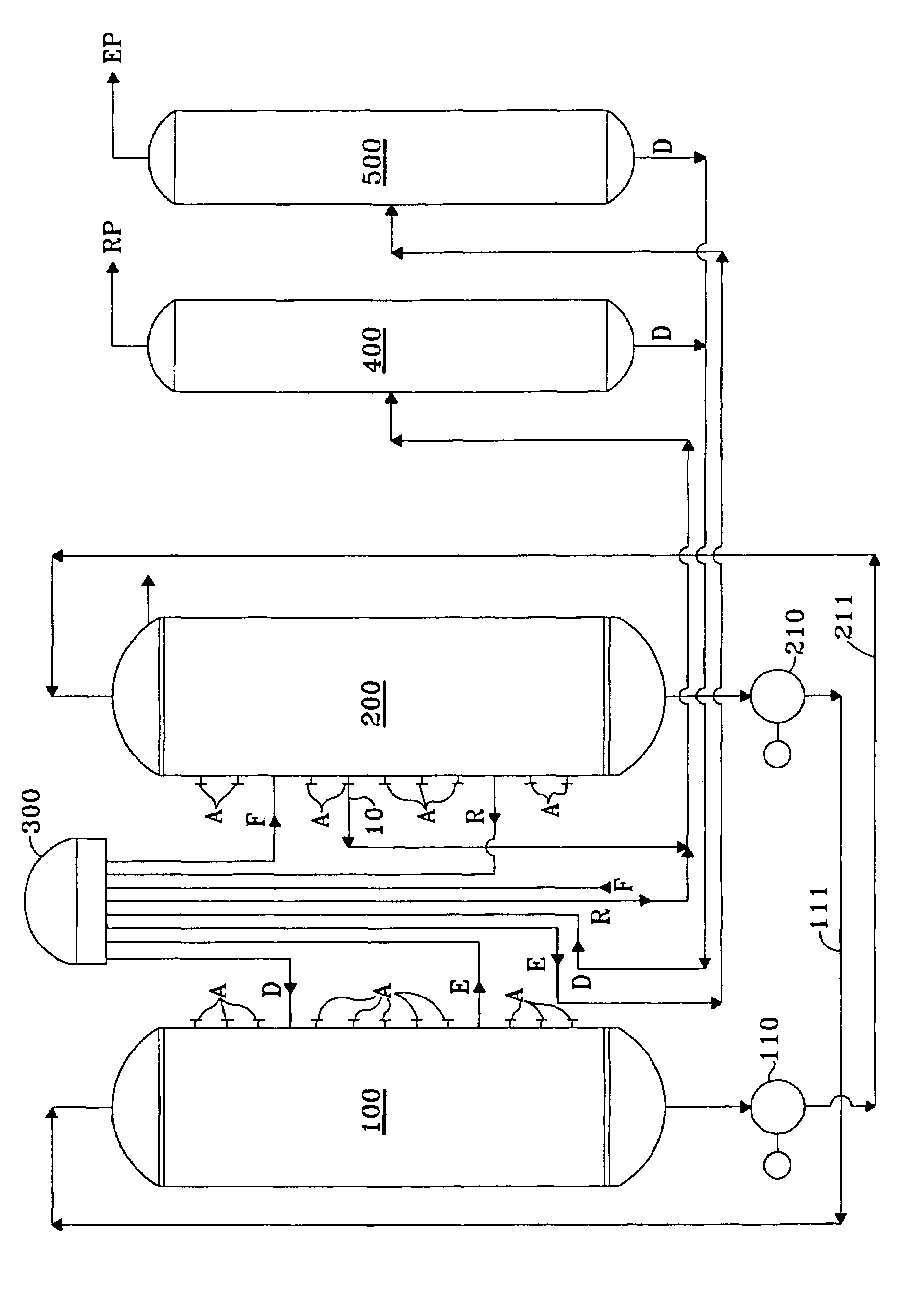

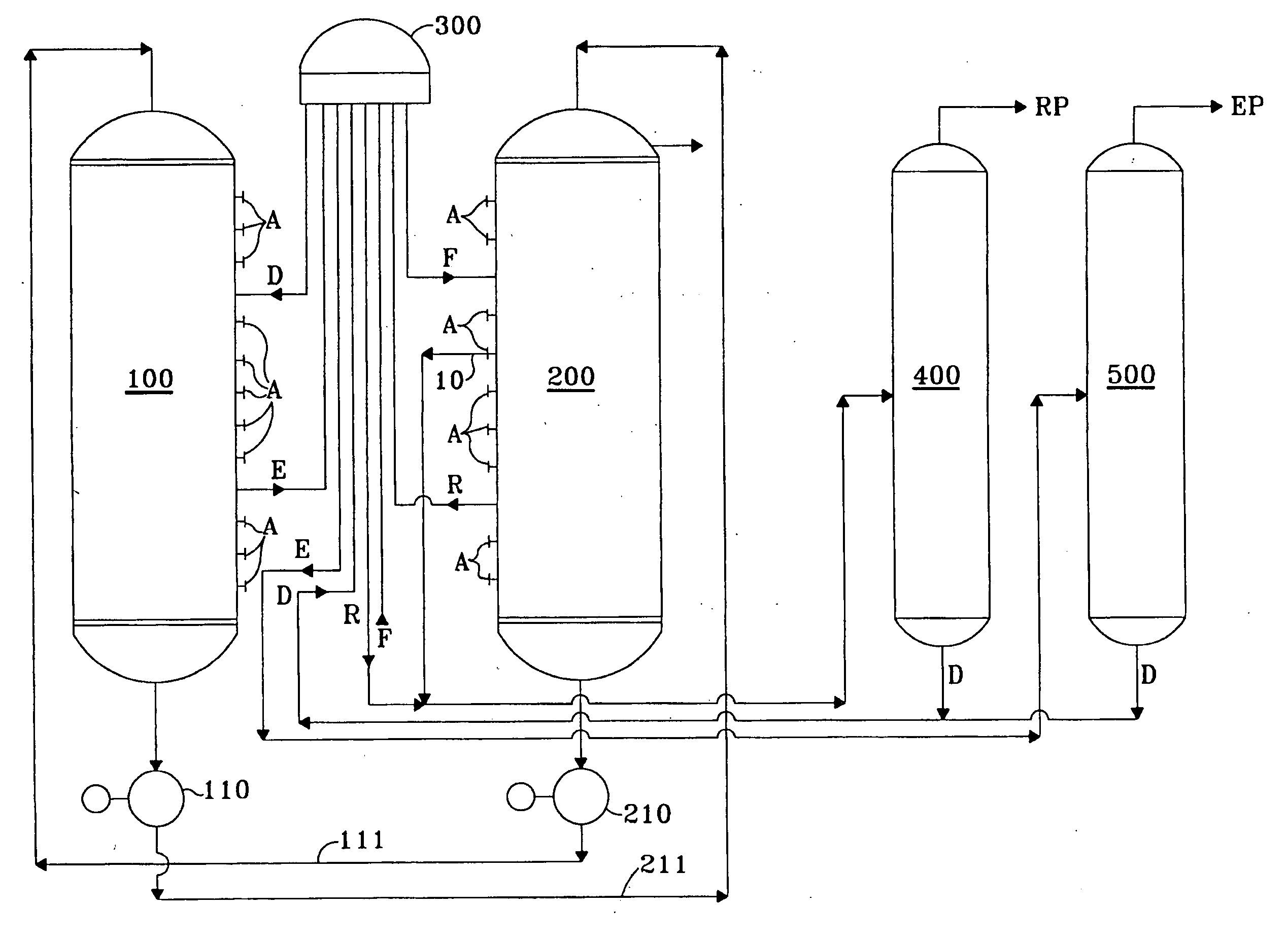

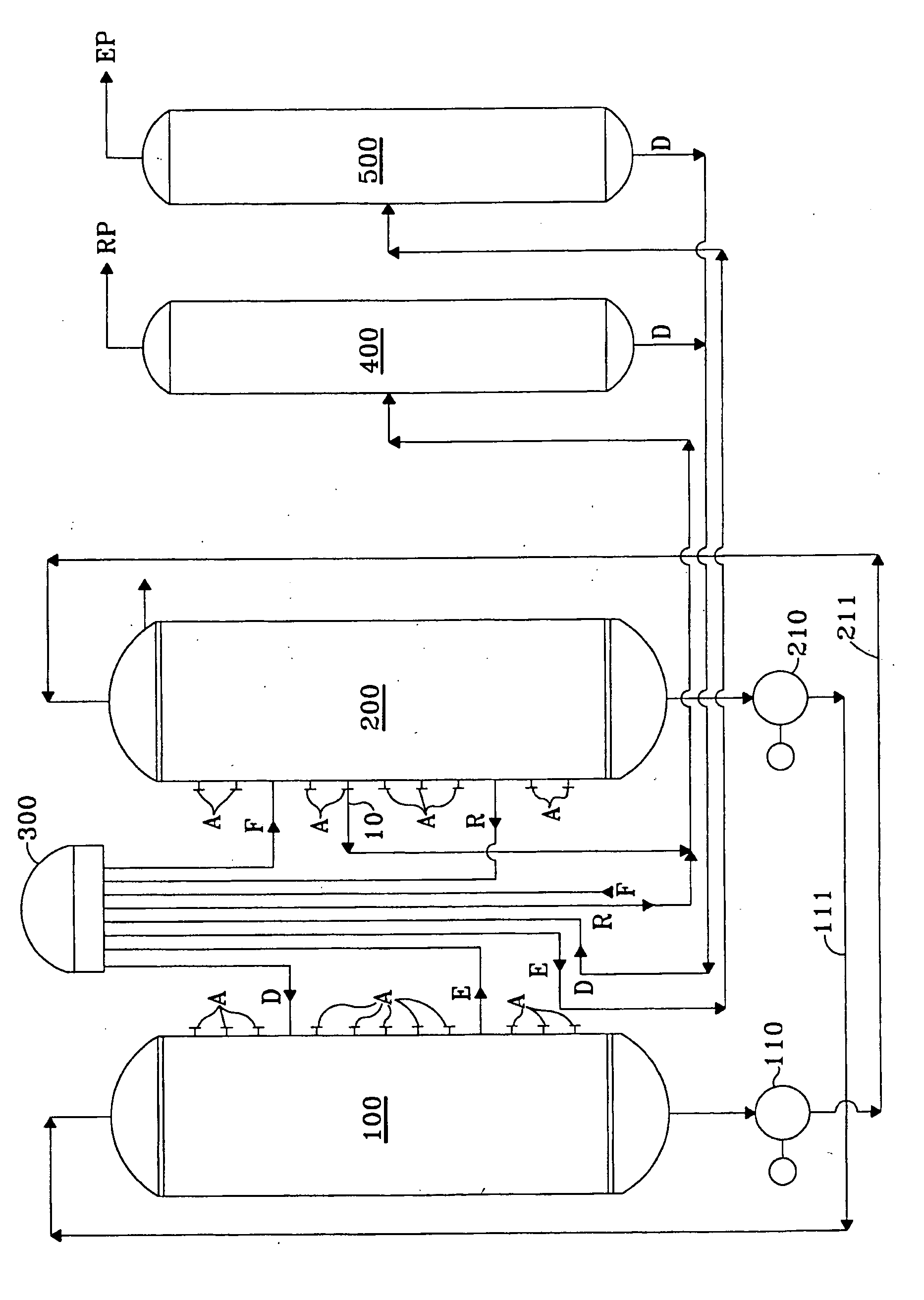

A process for producing para-xylene from a hydrocarbon feed is described in which an adsorption column operating as a simulated moving bed with at least five zones delivers an extract, a 2-raffinate and an intermediate raffinate.The extract is distilled and the distillate is optionally re-crystallized to recover para-xylene with a purity of at least 99.7%. The 2-raffinate is distilled then isomerized in a reactor preferably operating in the liquid phase and at a low temperature. The intermediate raffinate with an enriched ethylbenzene content is distilled then isomerized in the vapour phase.

Owner:INST FR DU PETROLE

Method of displacement chromatography

InactiveUS6602420B2Efficient separationLower requirementIon-exchange process apparatusComponent separationChromatographic separationBetaine

A plurality of chromatographic separation operations, including a first simulated moving bed operation, are coupled into a process which functions, preferably through the application of continuous displacement chromatography, to recover a fraction rich in small organic molecules, notably betaine and / or invert from sucrose solutions, enabling the subsequent production of a high purity sucrose product.

Owner:AMALGAMATED RES

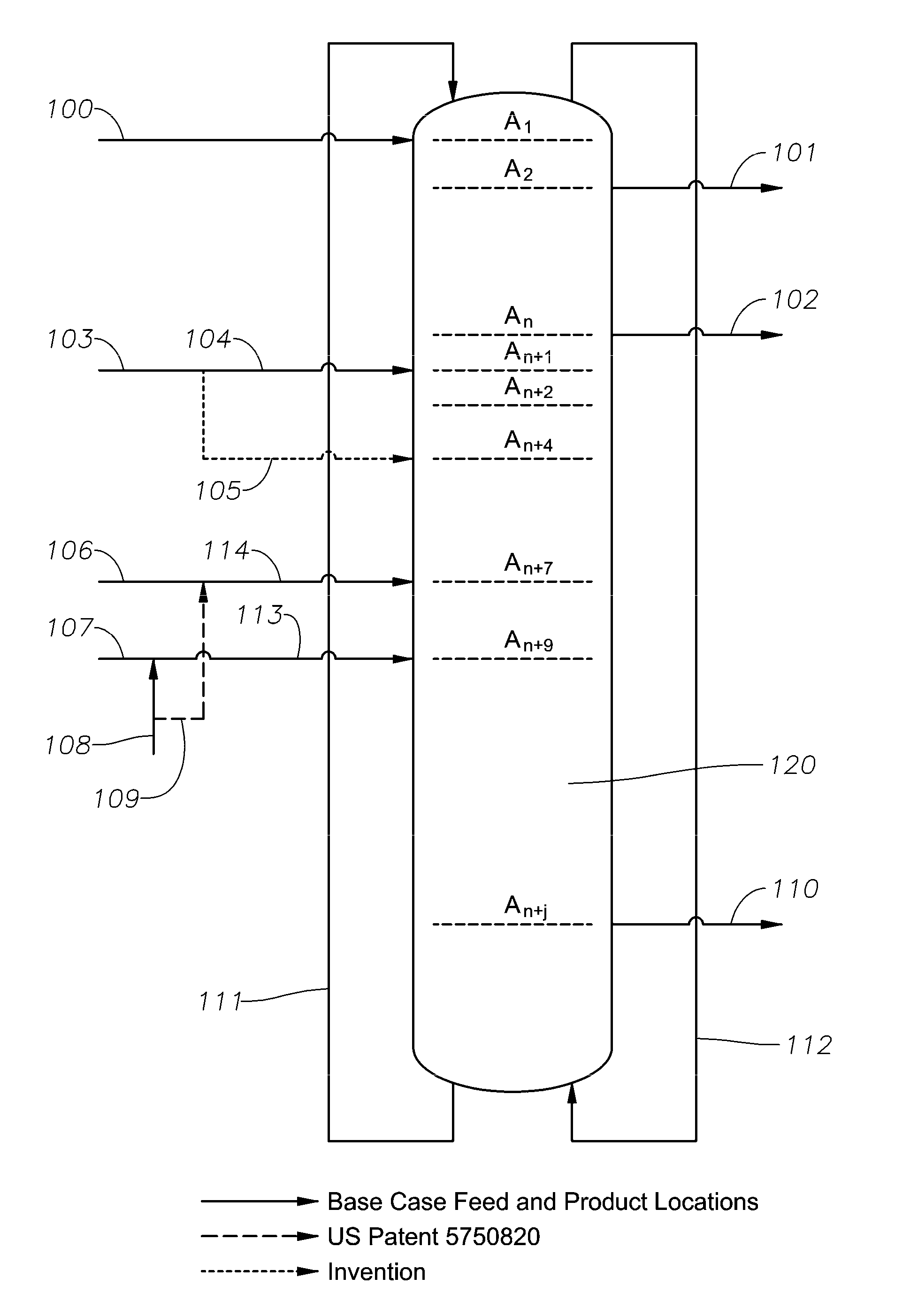

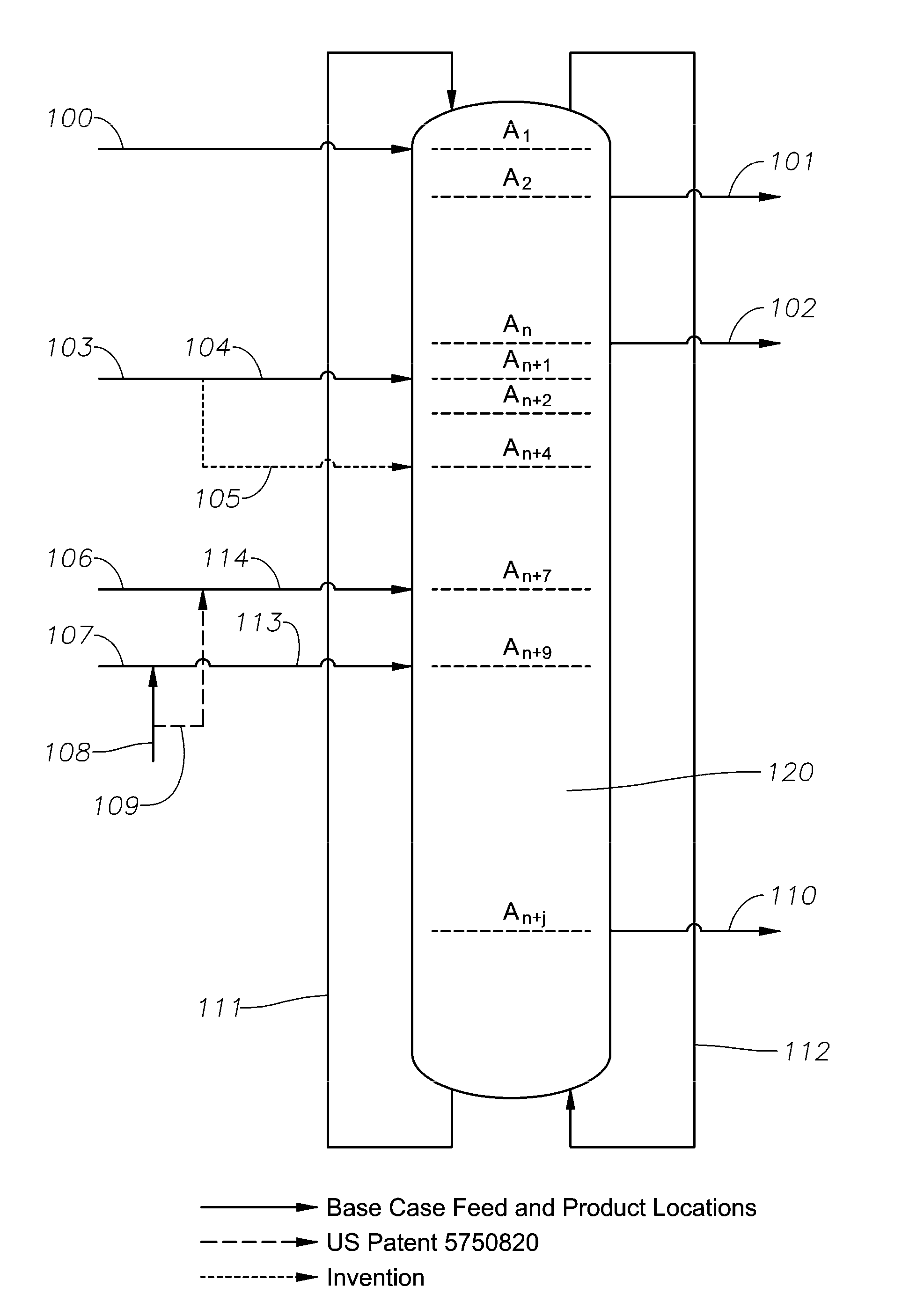

Parex unit feed

ActiveUS8529757B2More of of capacityMore of efficiencyIon-exchange process apparatusIon-exchanger regenerationArylSimulated moving bed

A process for separating a product from a multicomponent feedstream to an adsorption apparatus or system. The apparatus or system may comprise a moving-bed or a simulated moving-bed adsorption means. The product comprises at least one organic compound, such as an aryl compound with alkyl substitutes. In embodiments the conduits used to supply the feedstream to the apparatus or system are flushed with media of multiple grades. In embodiments the process achieves improvements in one or more of efficiency of adsorption separation, capacity of adsorption apparatus systems, and purity of product attainable by adsorption process.

Owner:EXXONMOBIL CHEM PAT INC

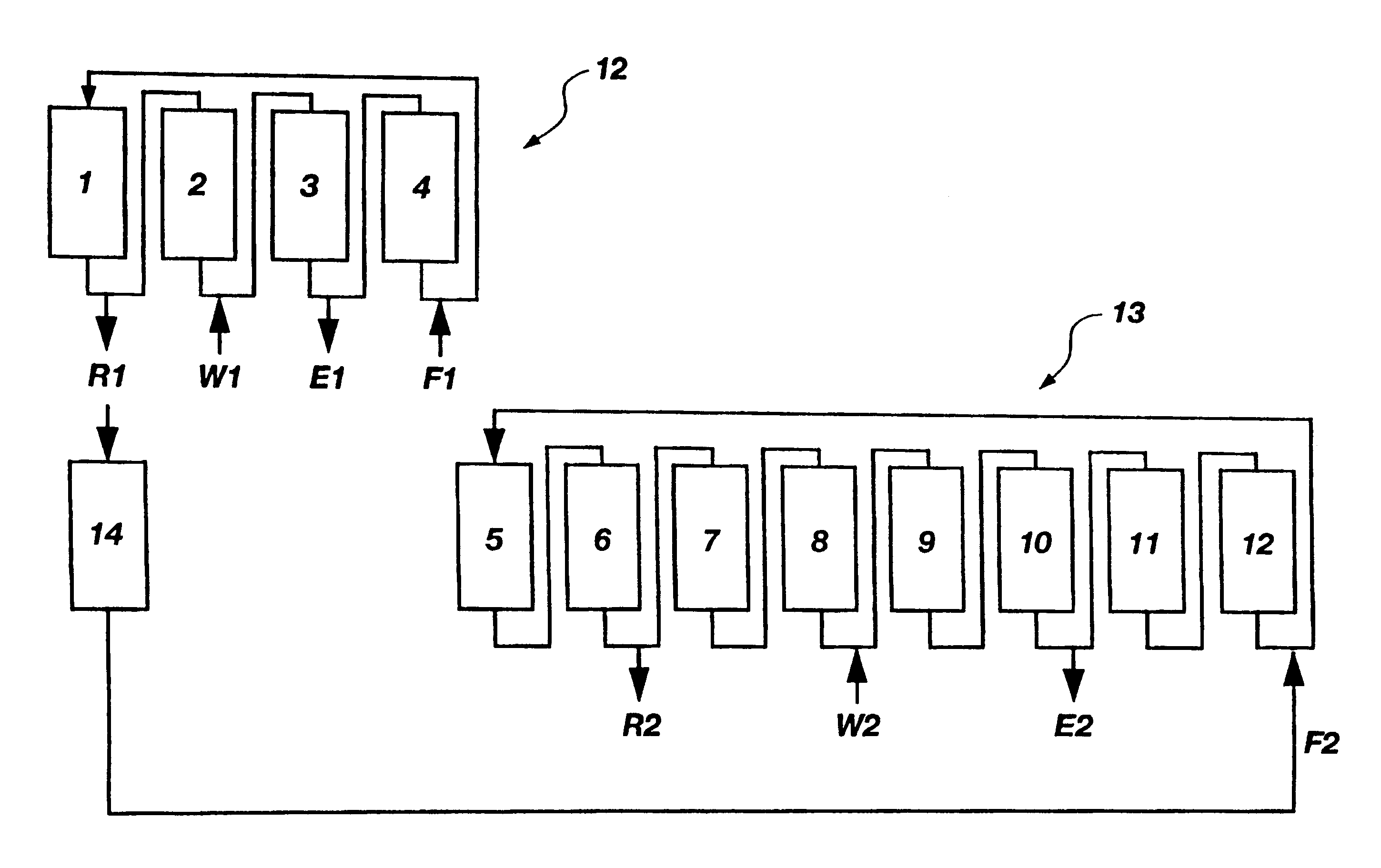

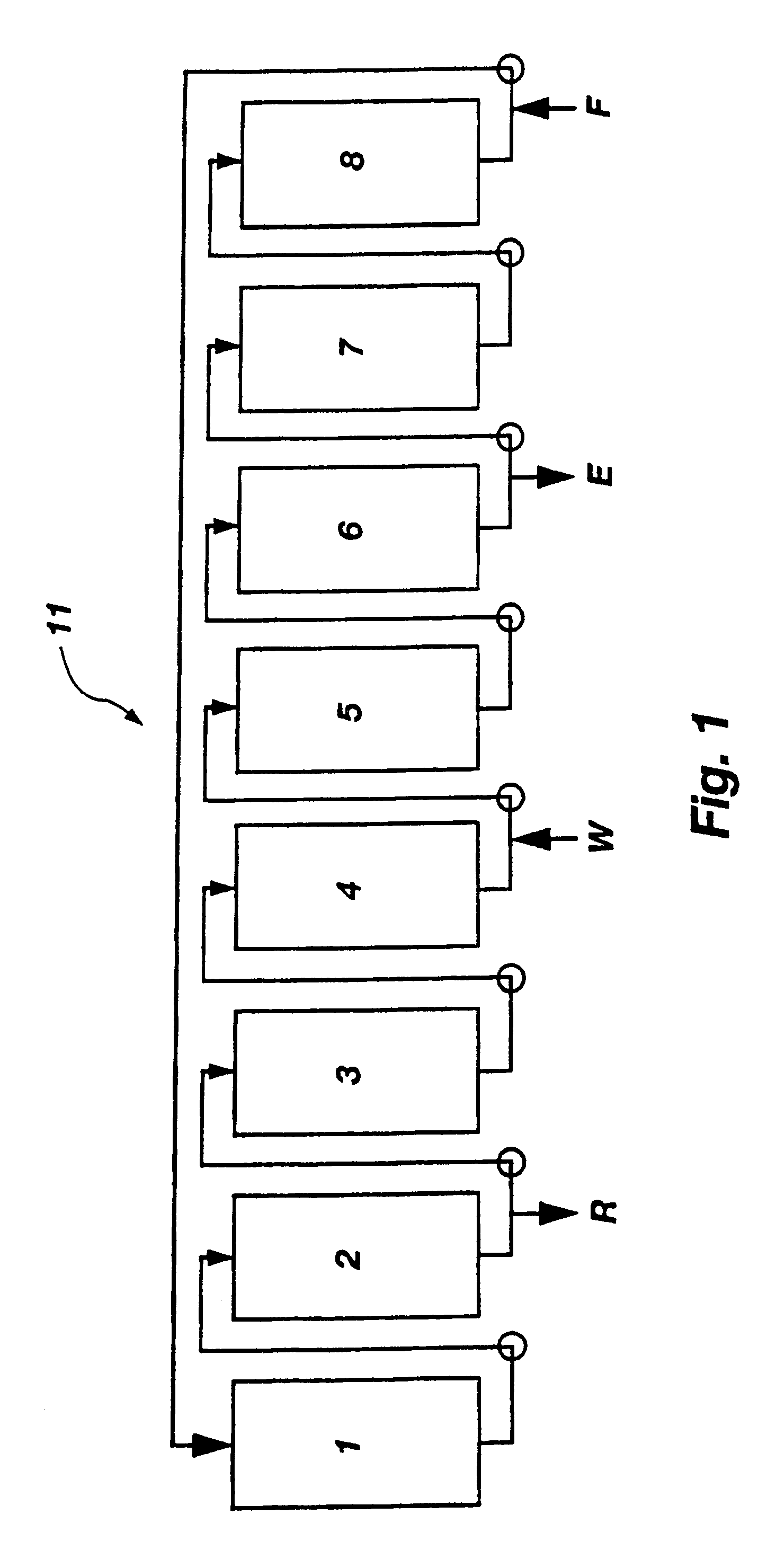

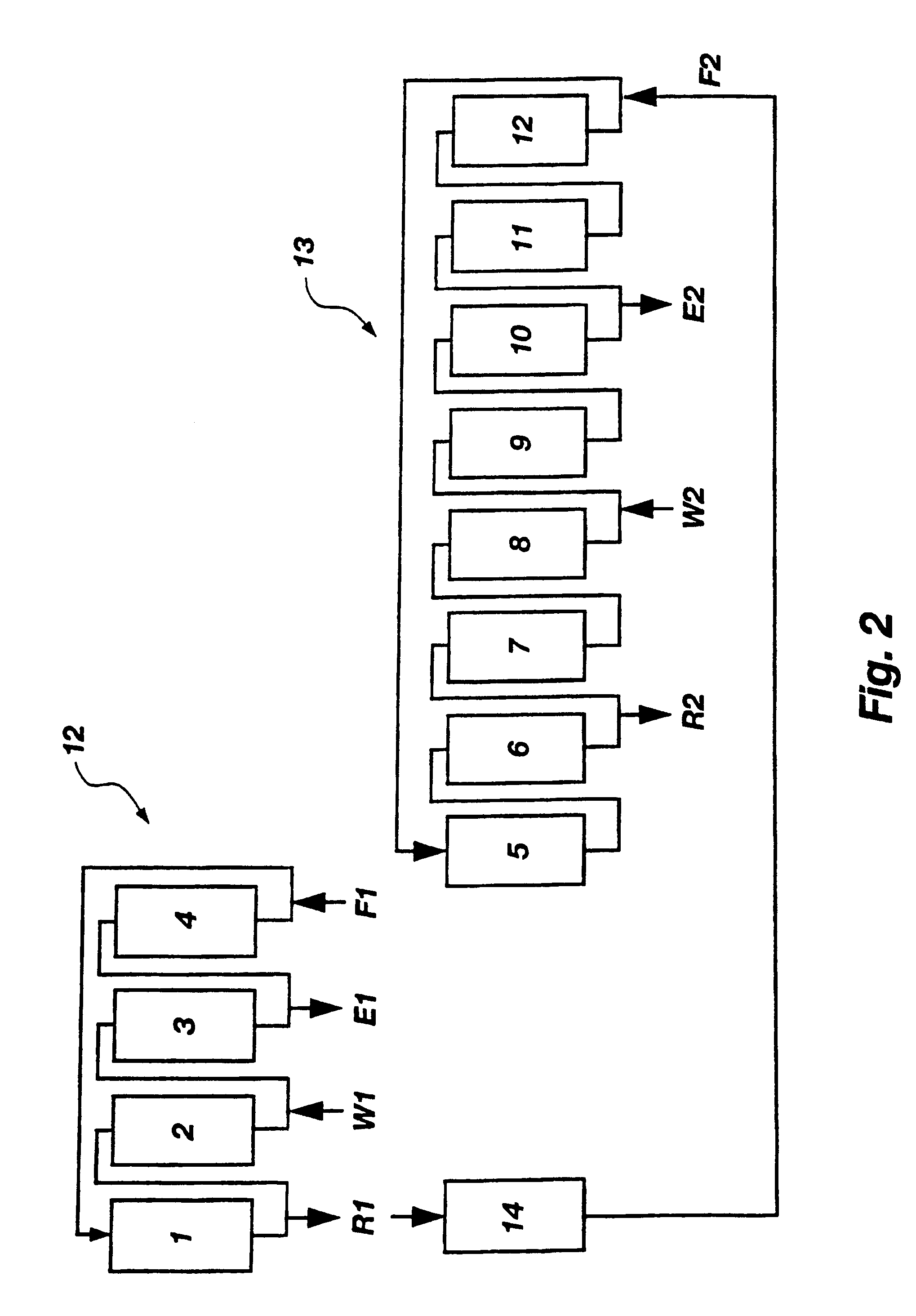

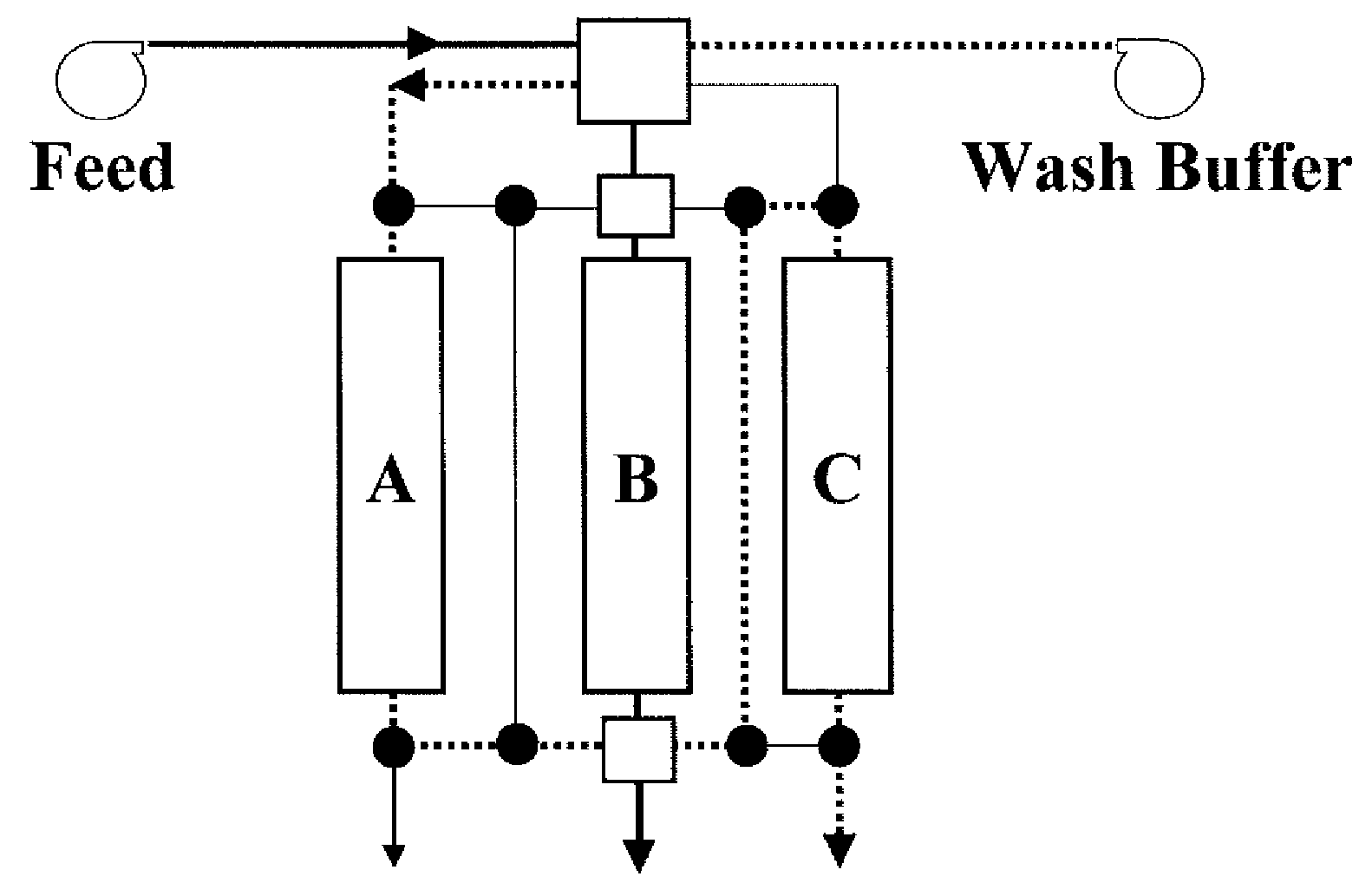

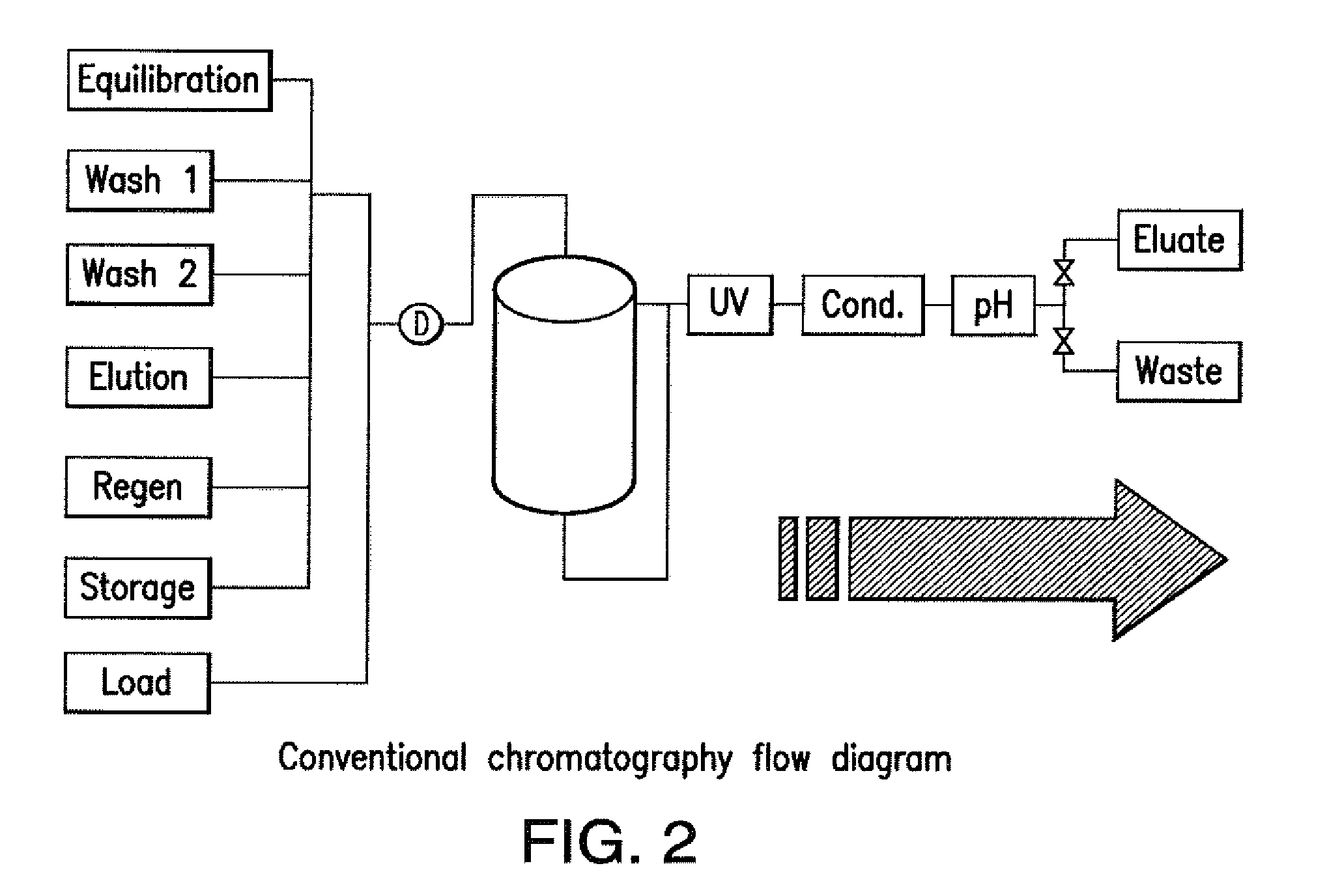

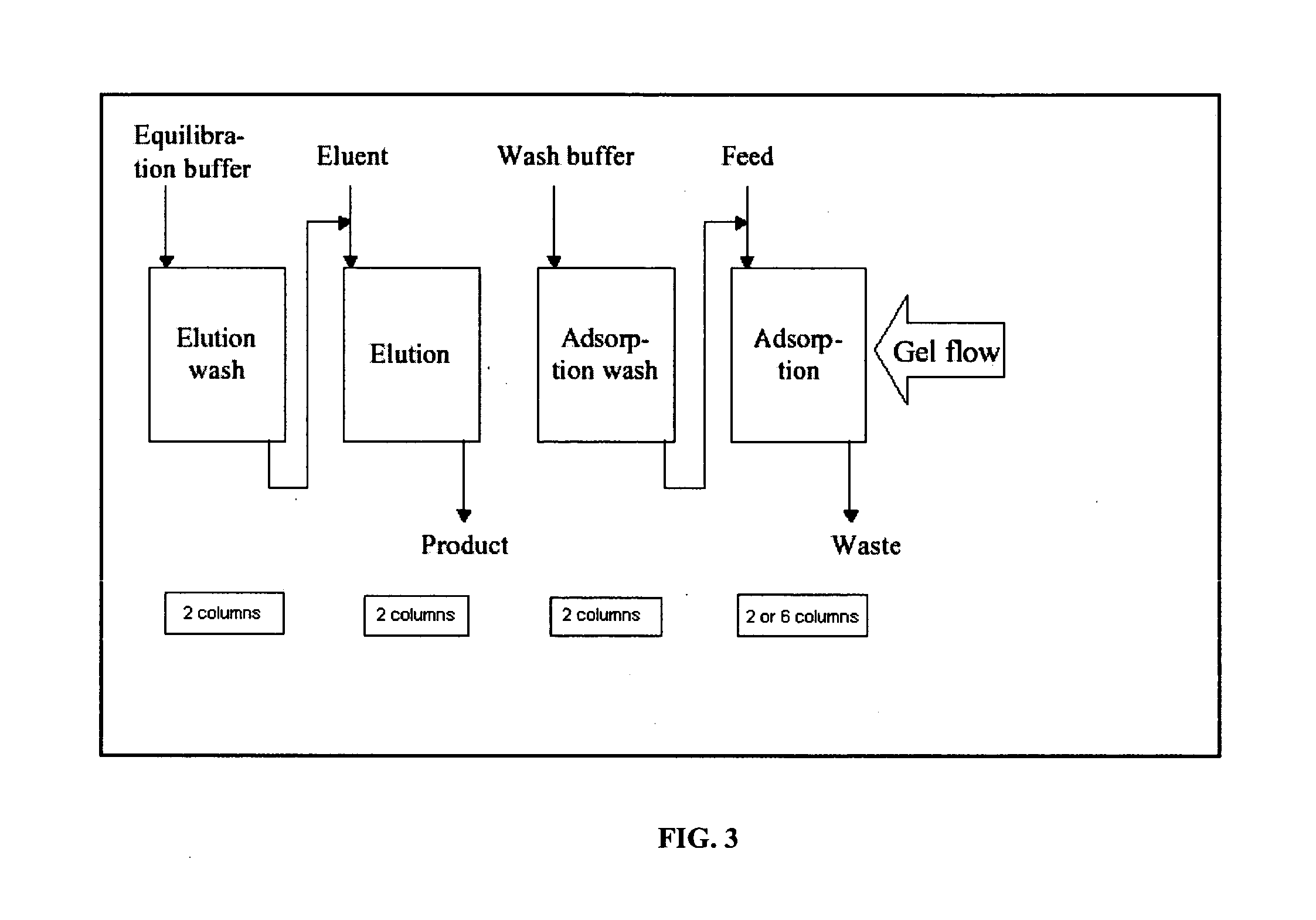

Chromatography method

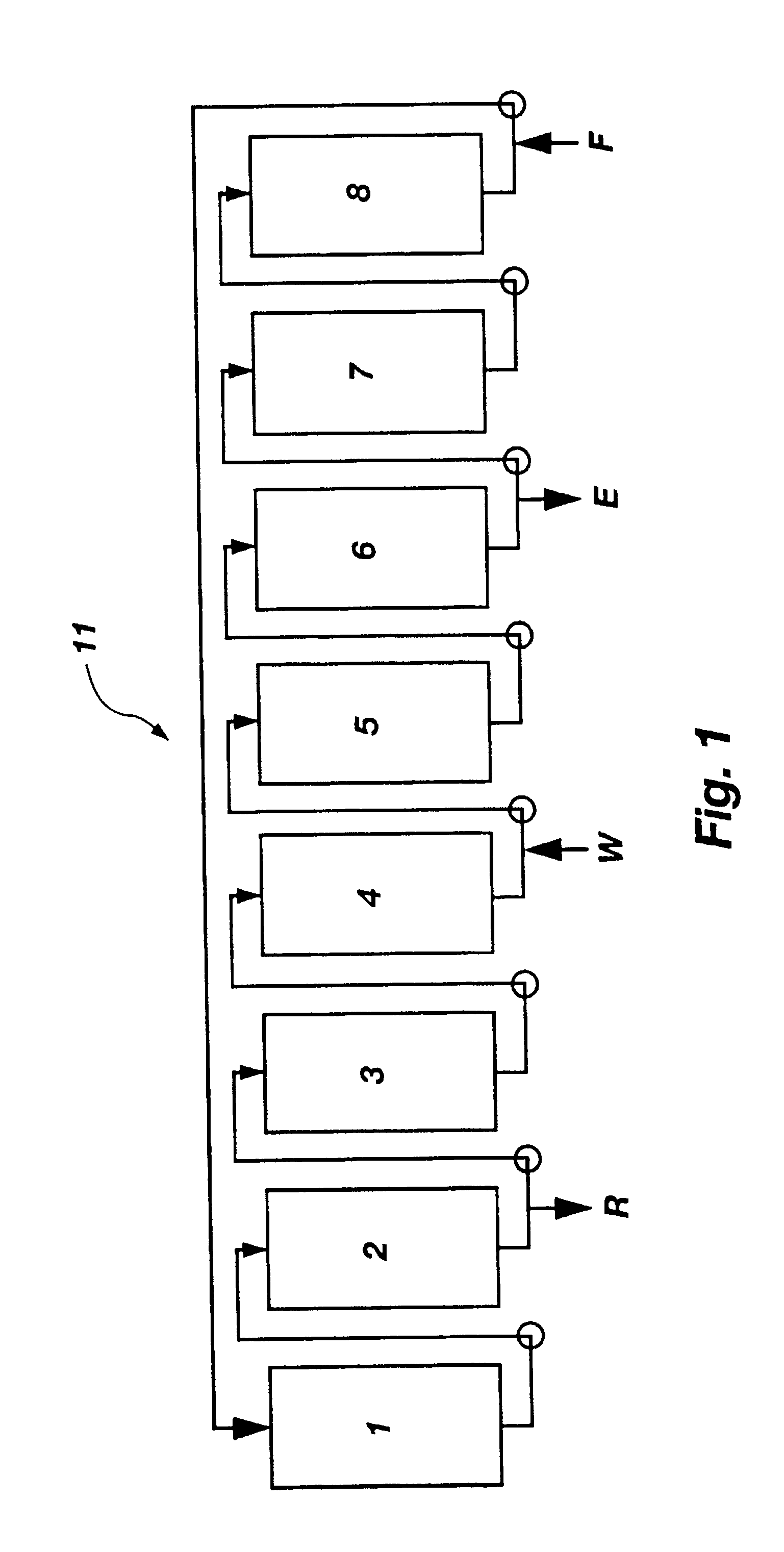

ActiveUS7901581B2Improve throughputImprove performanceIon-exchange process apparatusComponent separationSorbentSimulated moving bed

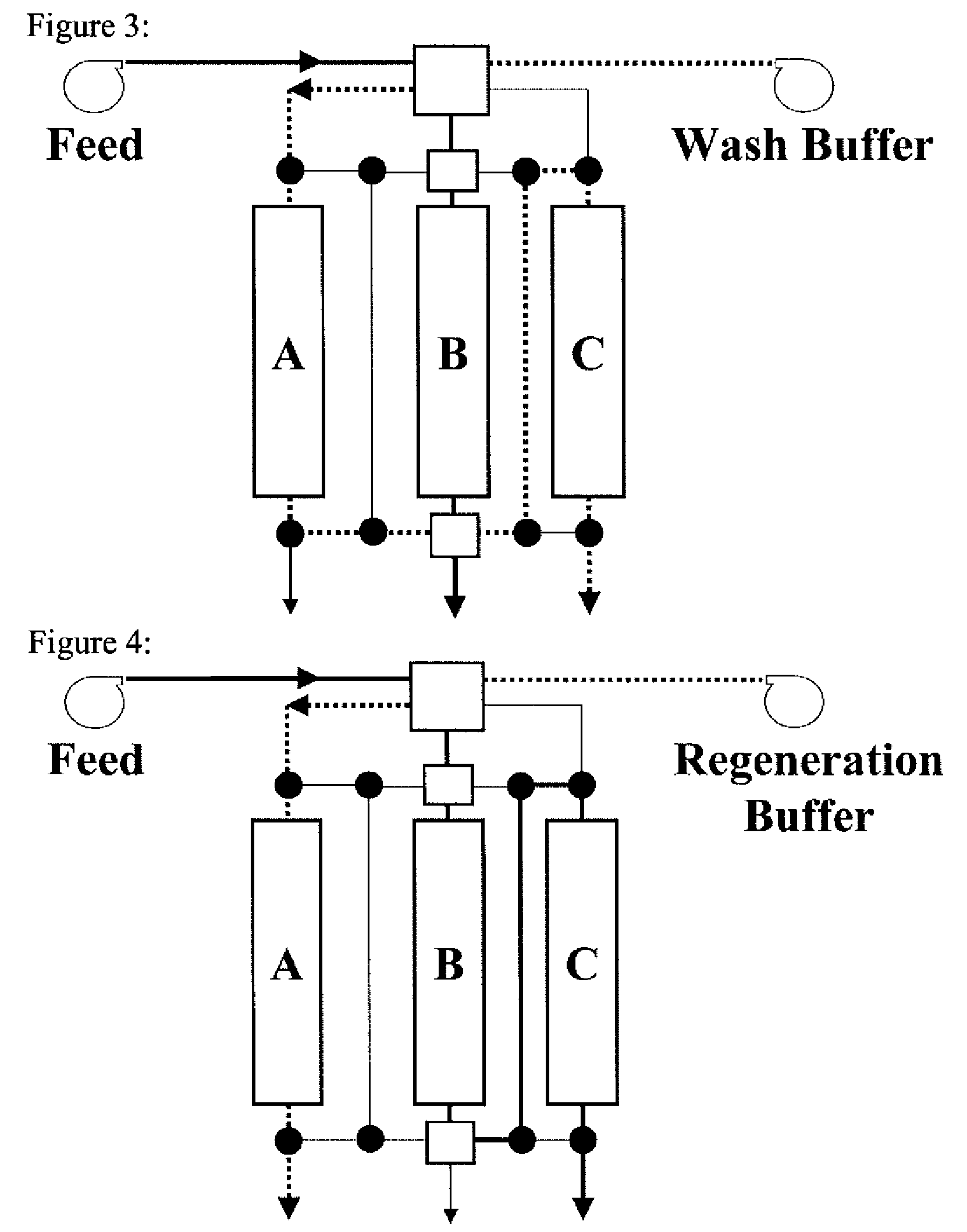

The present invention relates to a simulated moving bed process, wherein at least one adsorbent is washed after binding of target compound and wherein the outlet of wash liquid from the adsorbent is subsequently passed onto another adsorbent for binding of target compound removed by the washing. In one embodiment, the method comprises binding of at least one target compound using three or more adsorbents connected in series and elution of target compound from said three adsorbents. After the binding to an adsorbent, wash liquid is passed across the adsorbent to recover desorbed and / or unbound target compound, and the outlet of such wash liquid is directed to the adsorbent after the next in the series, to which no feed has yet been added. The target compound is recovered by eluting target compound from the washed adsorbents.

Owner:CYTIVA SWEDEN AB

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

Binderless adsprbents and their use in the adsorptive separation of para-xylene

ActiveUS20090326309A1High adsorbent capacity/mass transfer propertyIncreased para-xylene productivityMaterial nanotechnologyMolecular sieve catalystsSorbentSimulated moving bed

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

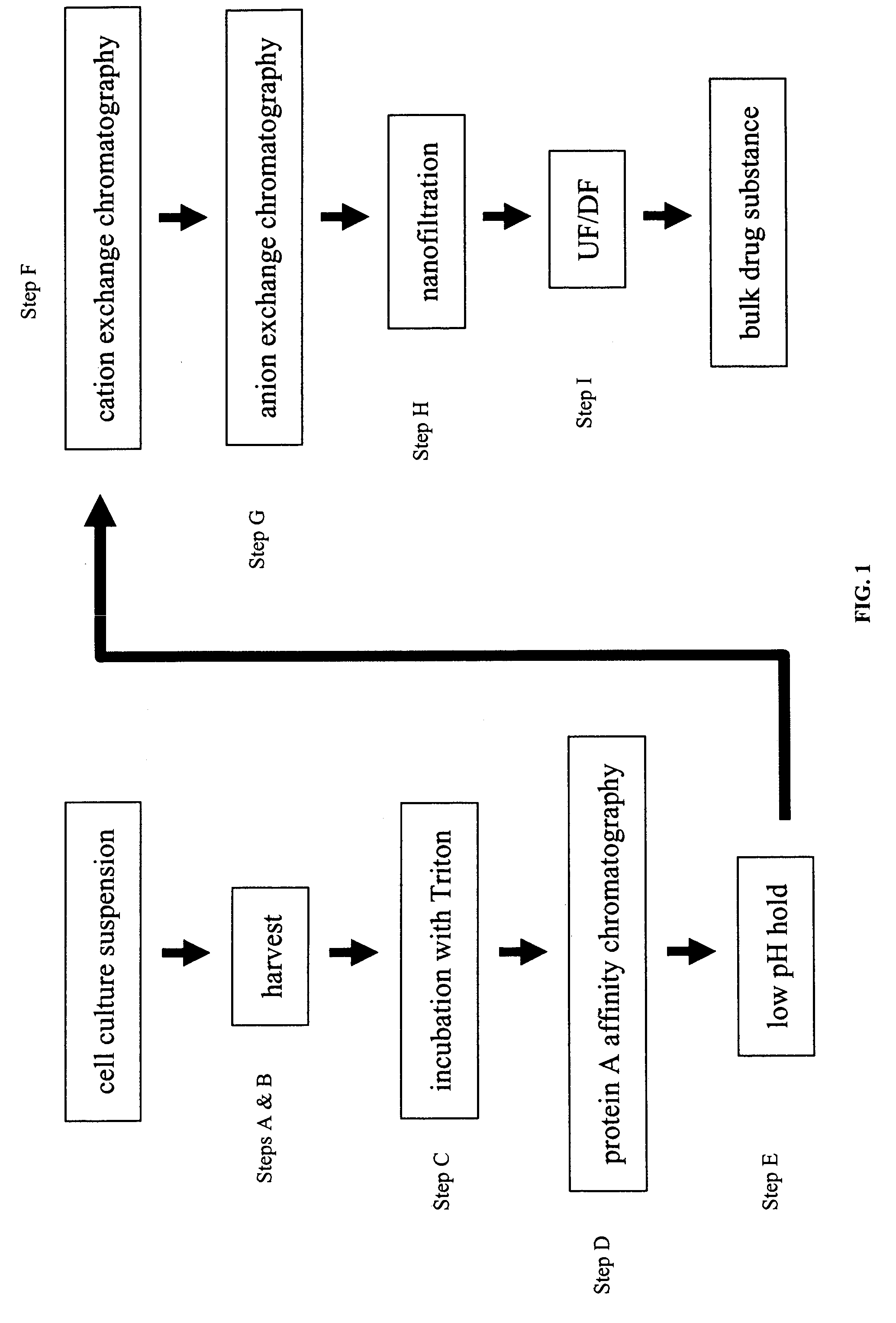

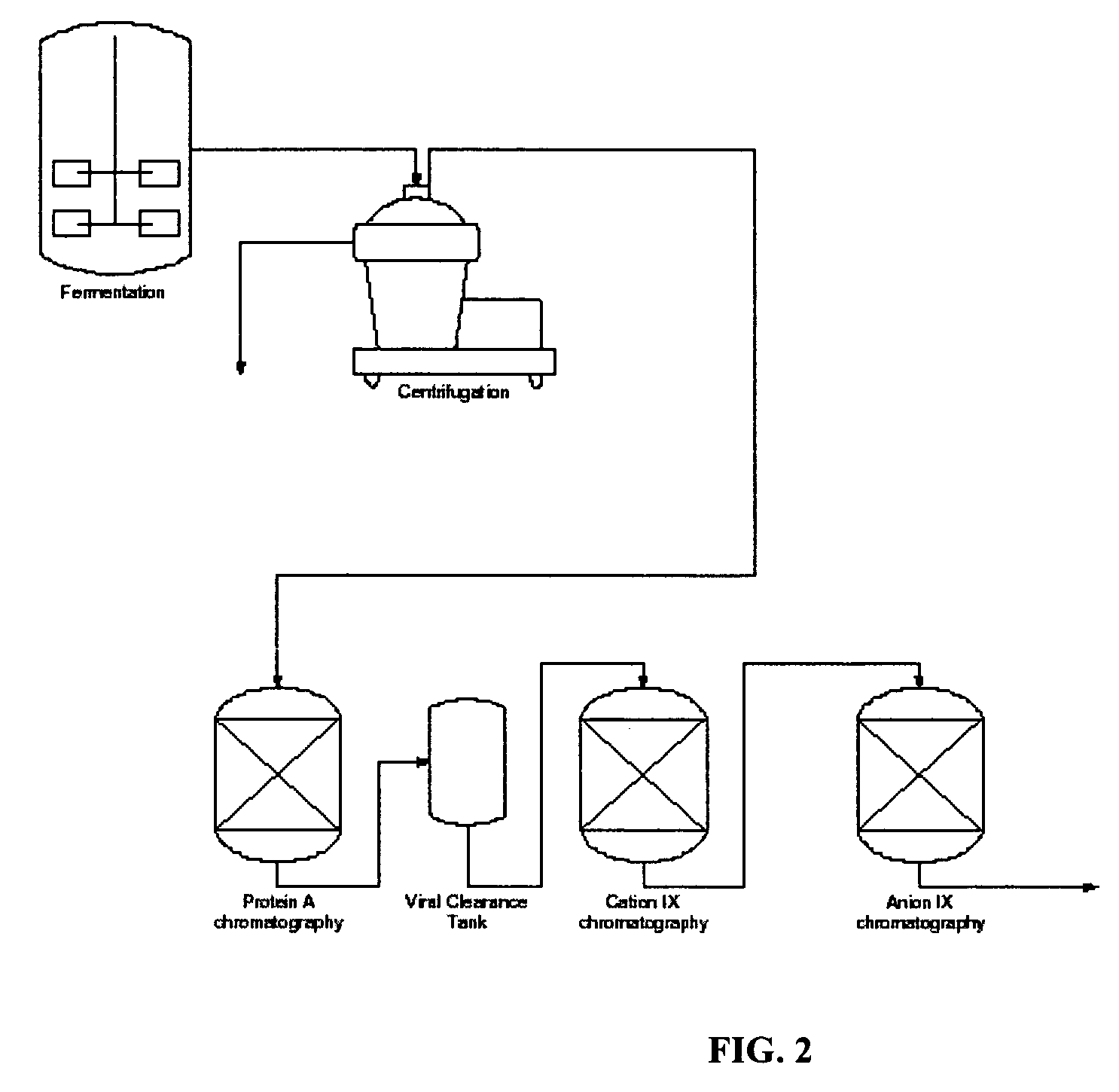

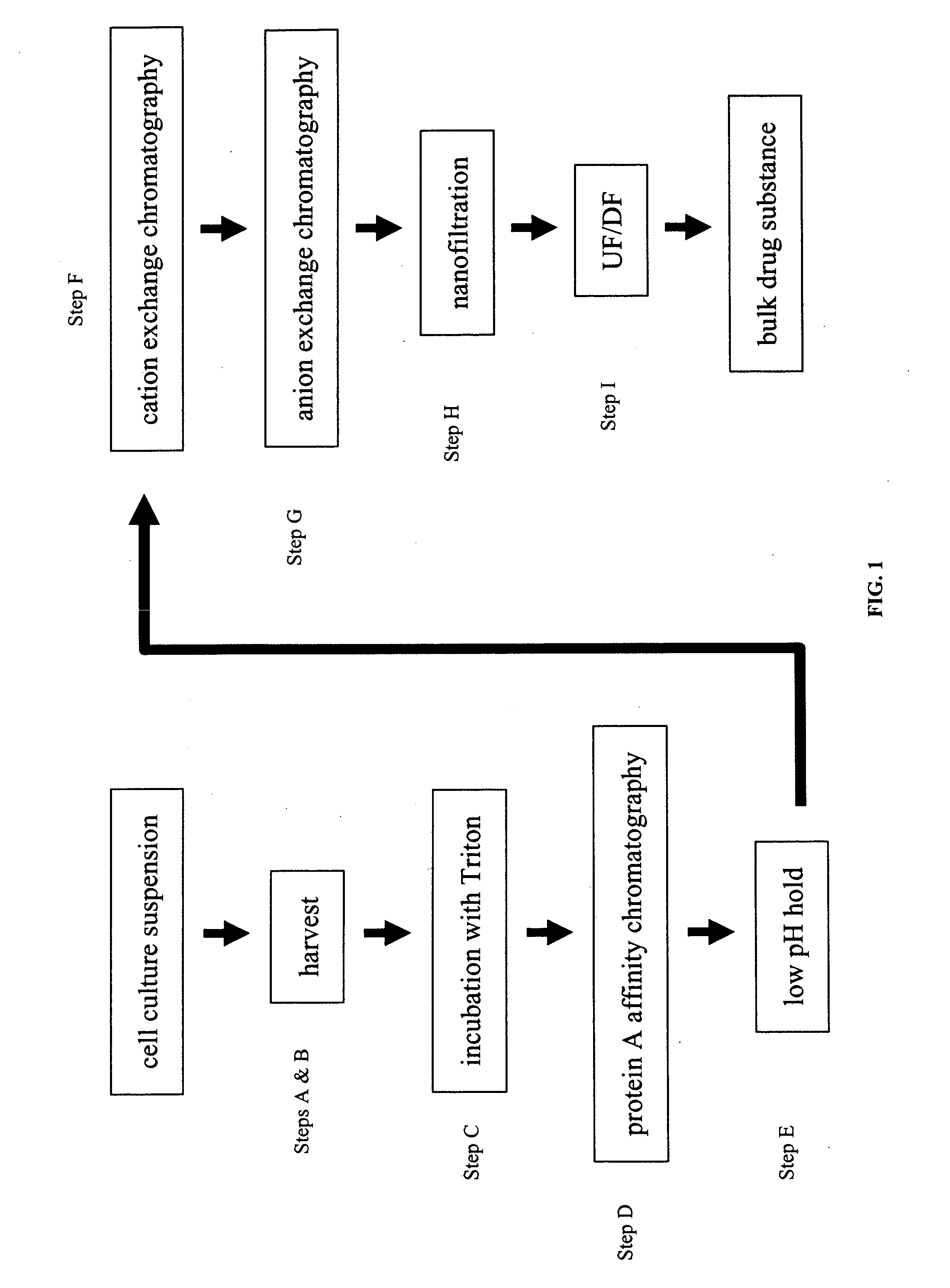

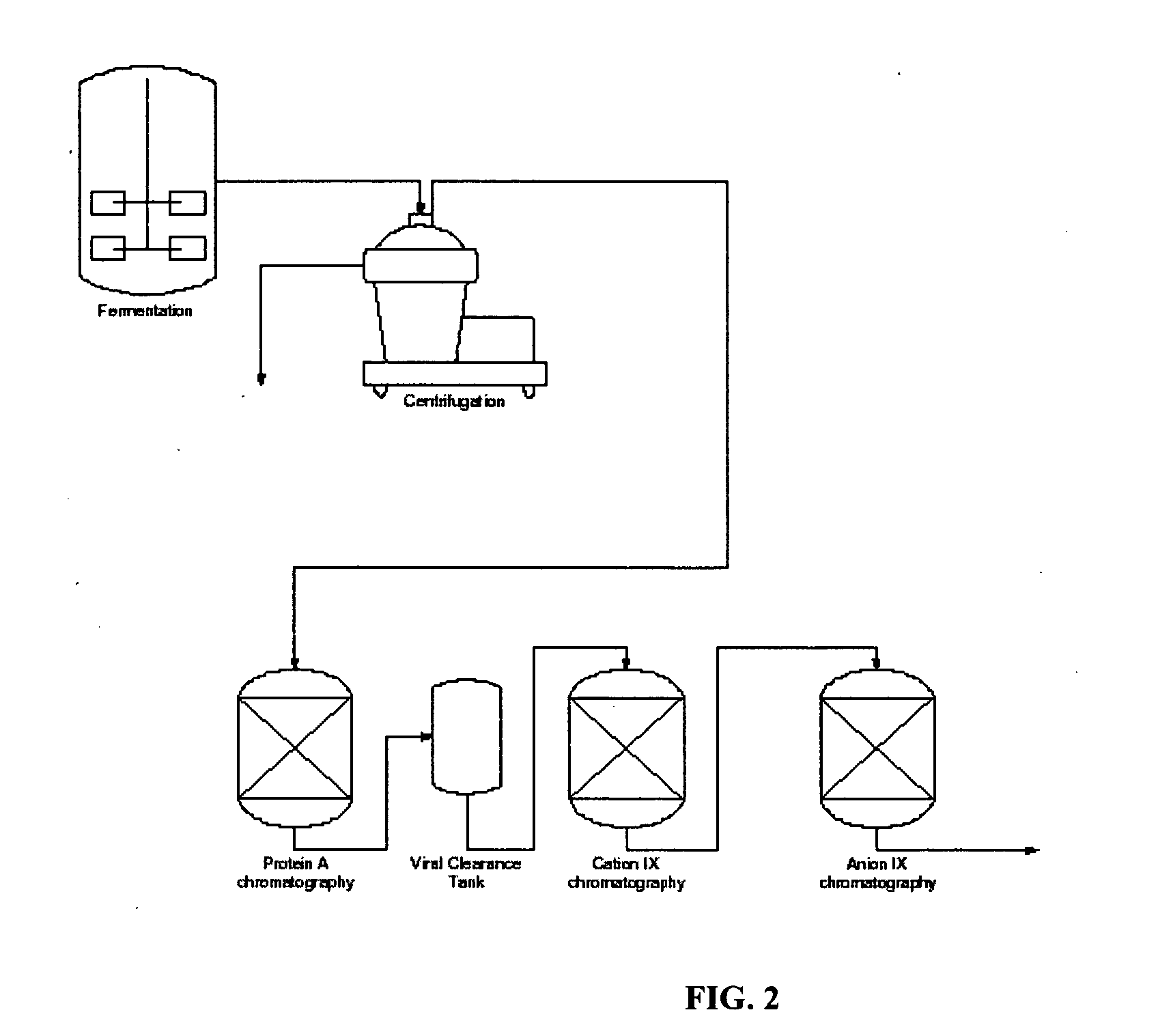

Purification of antibodies using simulated moving bed chromatography

InactiveUS20120122076A1Hormone peptidesPeptide/protein ingredientsSimulated moving bedMonoclonal antibody

The present invention relates to compositions and methods for the chromatographic purification of antibodies, such as monoclonal antibodies, employing improved simulated moving bed separation strategies and, in certain embodiments, Raman spectroscopy.

Owner:ABBVIE INC

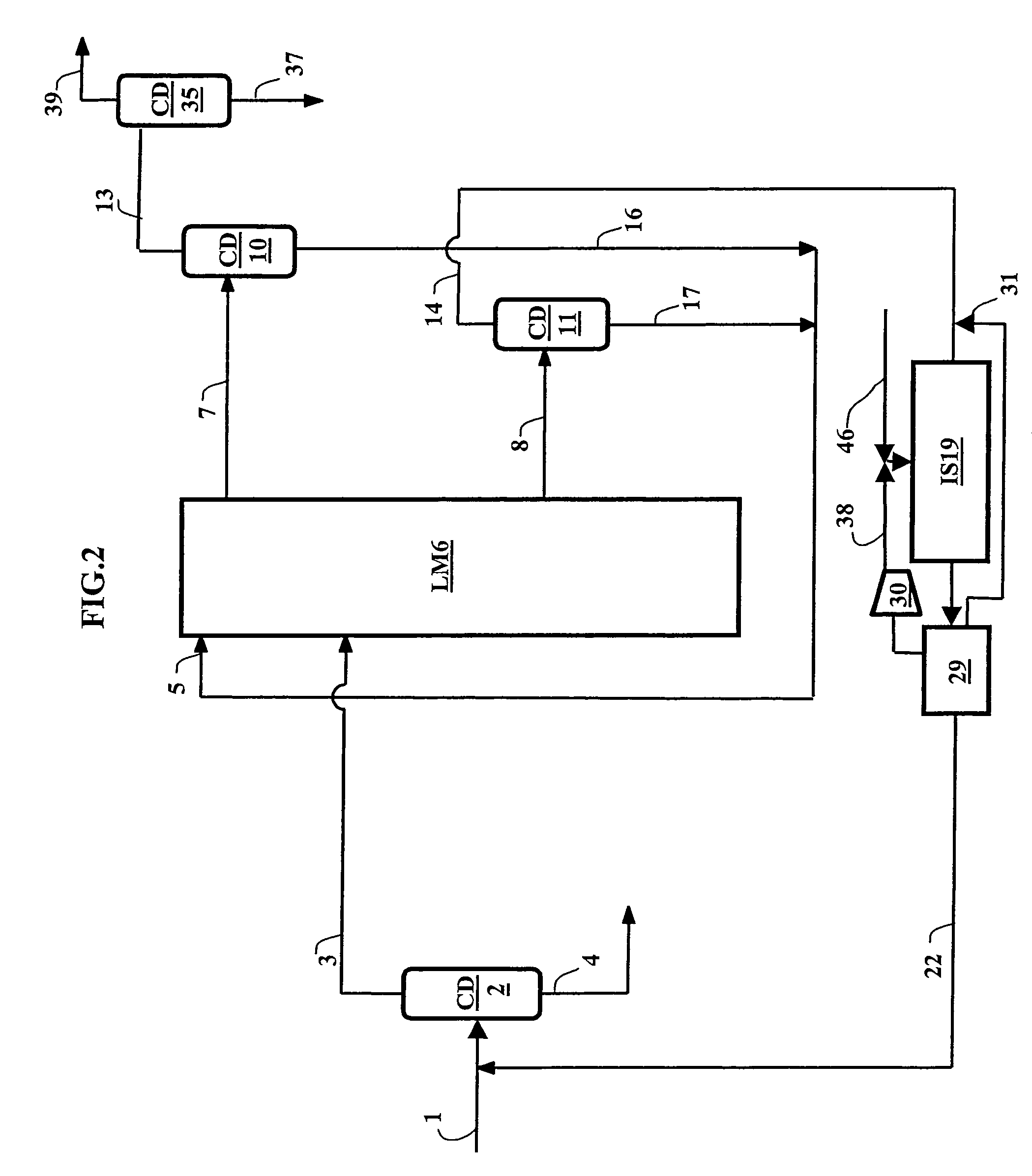

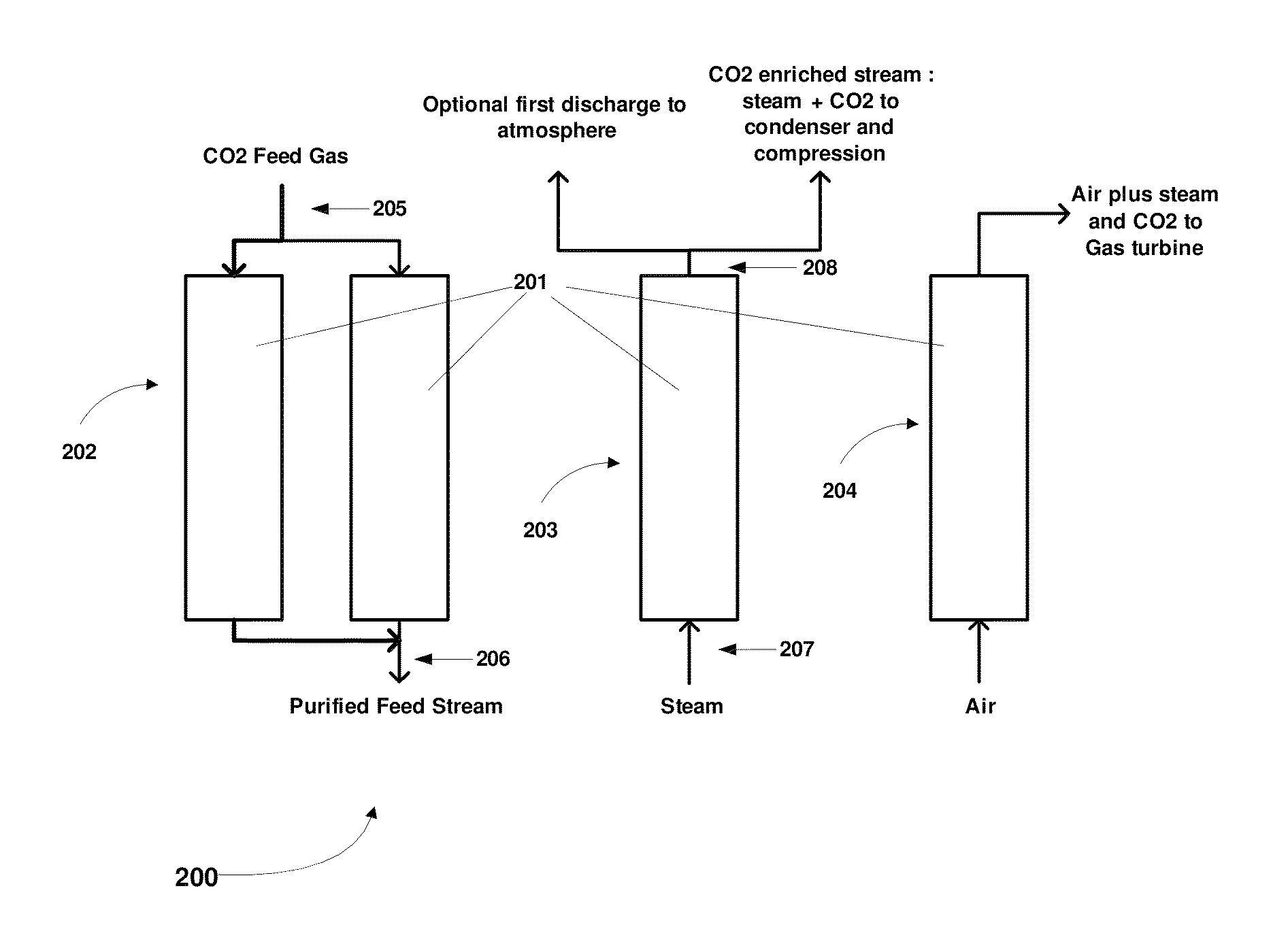

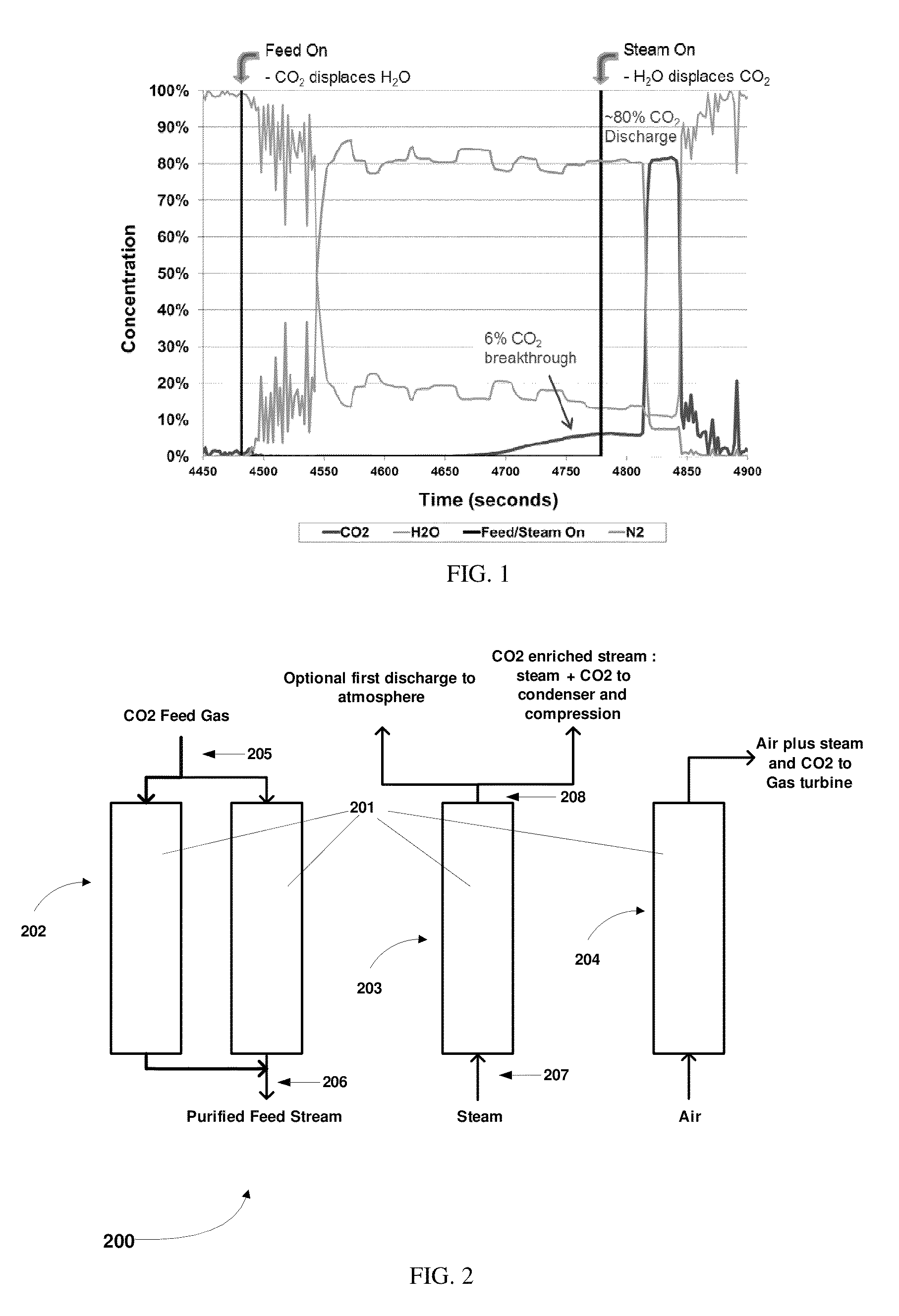

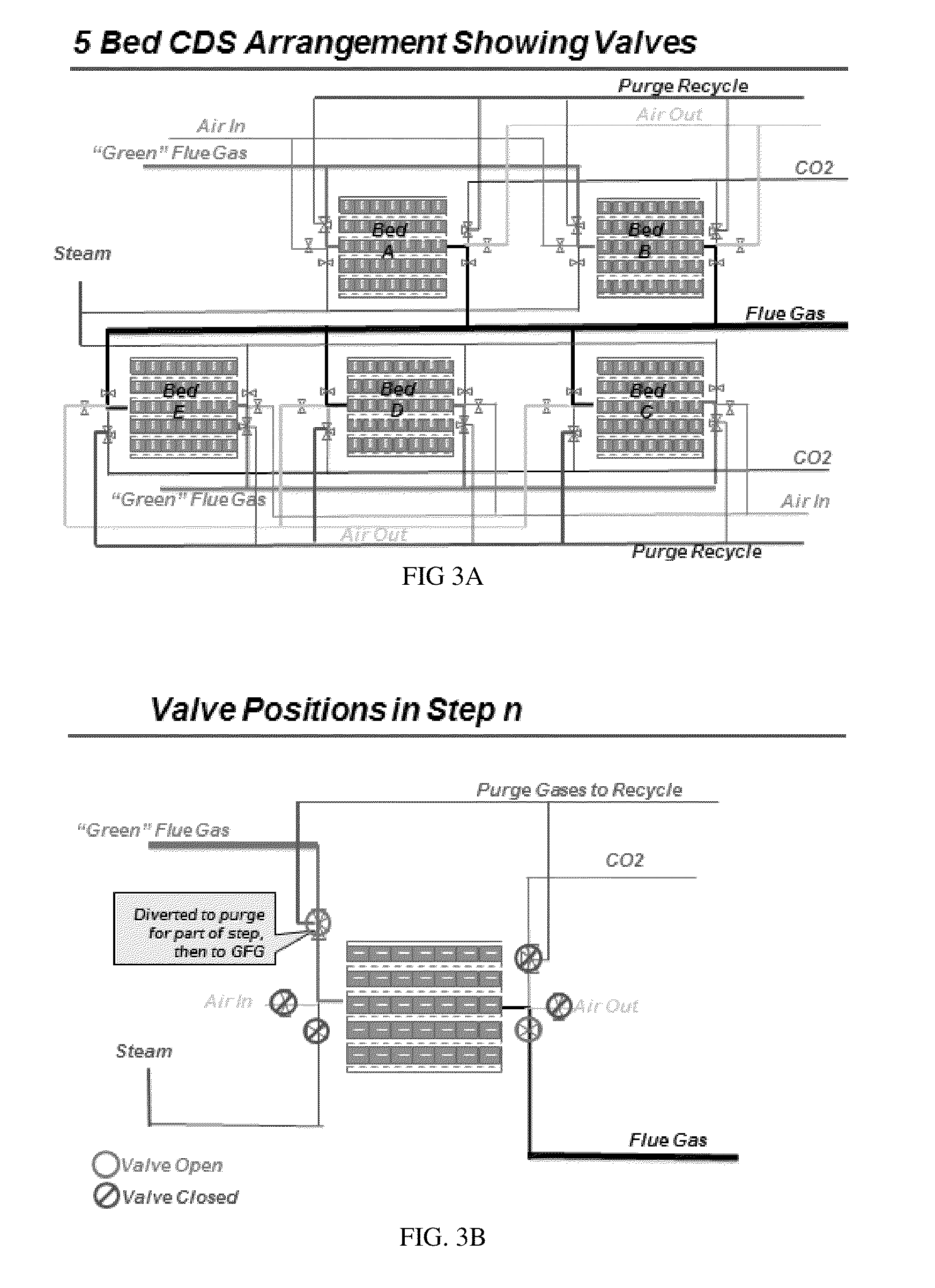

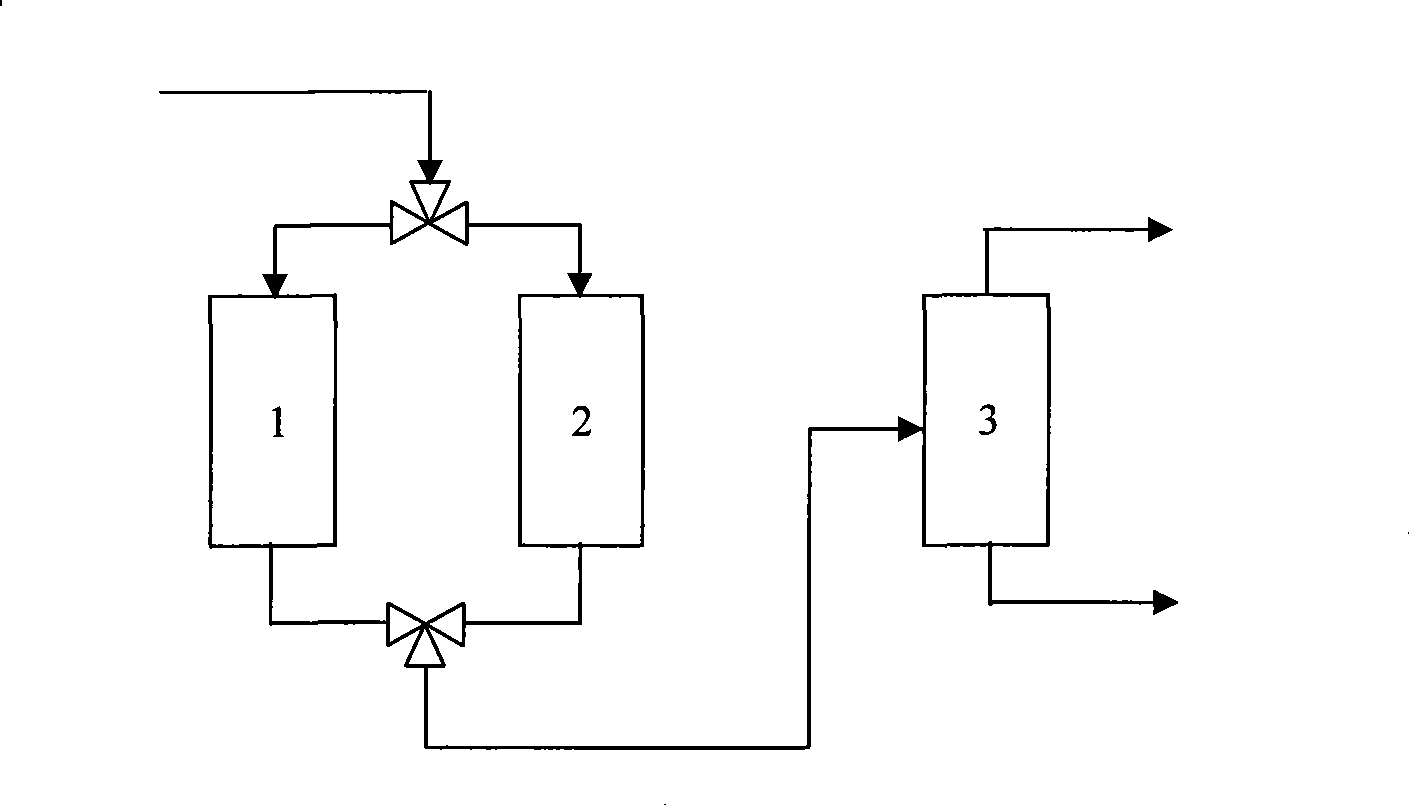

Simulated moving bed system for CO2 separation, and method of same

A system and method for separating and / or purification of CO2 gas from a CO2 feed stream is described. The system and method include a plurality of fixed sorbent beds, adsorption zones and desorption zones, where the sorbent beds are connected via valve and lines to create a simulated moving bed system, where the sorbent beds move from one adsorption position to another adsorption position, and then into one regeneration position to another regeneration position, and optionally back to an adsorption position. The system and method operate by concentration swing adsorption / desorption and by adsorptive / desorptive displacement.

Owner:TDA RES +1

Method of purifying polypeptides by simulated moving bed chromatography

InactiveUS20040241878A1Reduce linear flow rateSlow velocityIon-exchange process apparatusComponent separationBiotechnologyChemical compound

Provided are methods of separating an immunoreactive compound from at least one immaterial component, using a simulated moving bed ("SMB") system and a SMB apparatus for use in these methods. Also provided are purified immunoreactive compounds prepared using the SMB methods and apparatus and methods of treatment with the purified immunoreactive compounds.

Owner:BIOGEN INC

Method for Producing Paraxylene Comprising an Adsortion Step and Two Isomerization Steps

ActiveUS20080262282A1Overcome disadvantagesHydrocarbon by isomerisationHydrocarbon by hydrogenationXylyleneIsomerization

A process for producing para-xylene from a hydrocarbon feed is described in which an adsorption column operating as a simulated moving bed with at least five zones delivers an extract, a 2-raffinate and an intermediate raffinate.The extract is distilled and the distillate is optionally re-crystallized to recover para-xylene with a purity of at least 99.7%. The 2-raffmate is distilled then isomerized in a reactor preferably operating in the liquid phase and at a low temperature. The intermediate raffinate with an enriched ethylbenzene content is distilled then isomerized in the vapour phase.

Owner:INST FR DU PETROLE

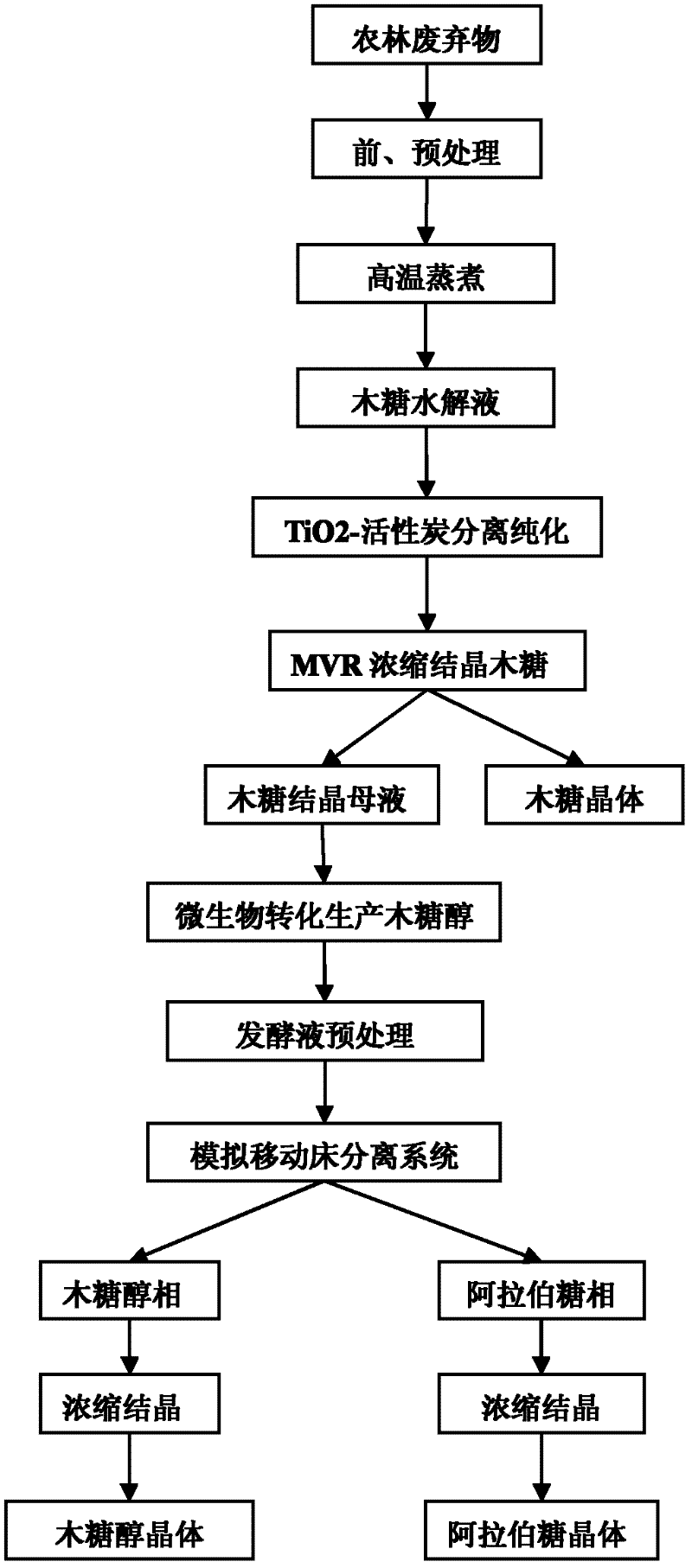

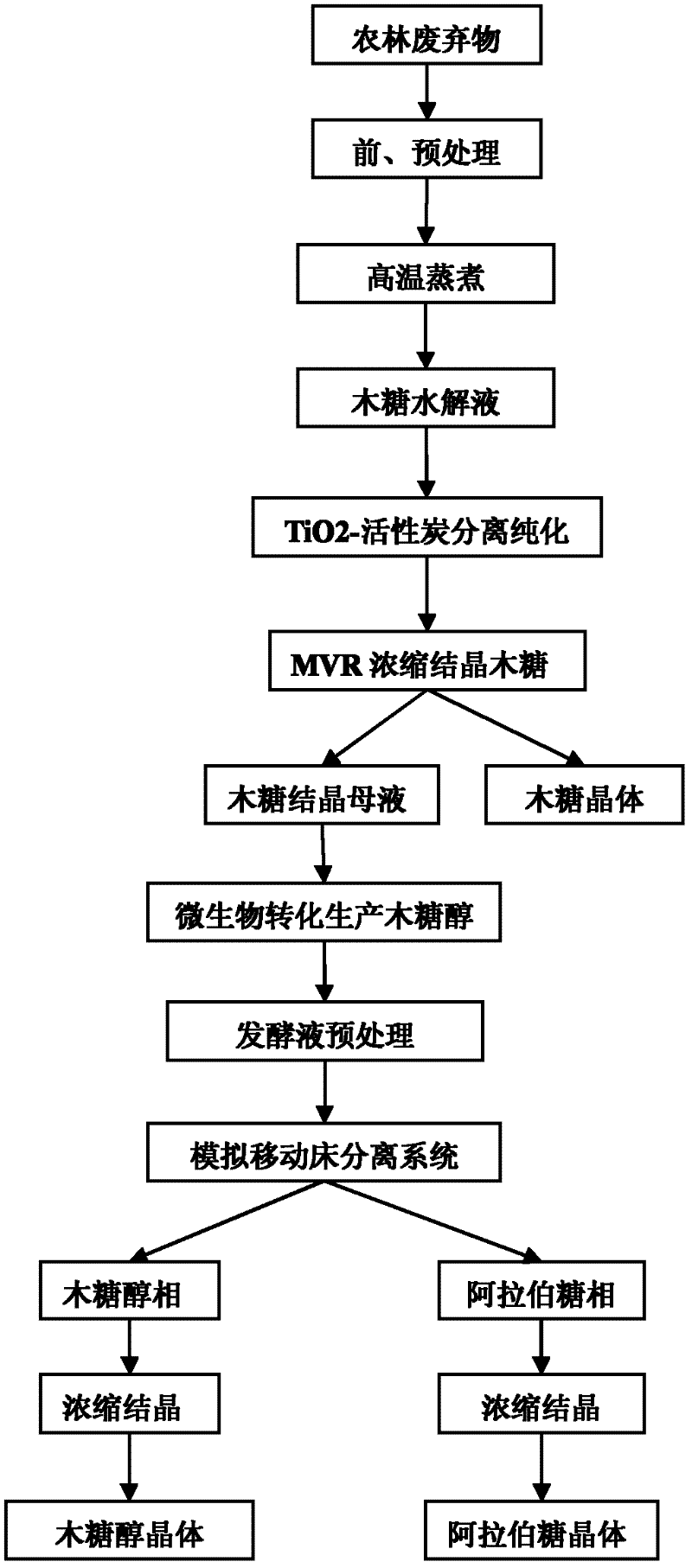

Co-production of xylose, xylitol and arabinose from agricultural and forestry wastes

ActiveCN102268490AEmission reductionReduce salt contentMicroorganism based processesFermentationChromatographic separationHydrolysate

The invention relates to a clean technique for co-producing xylose, xylitol and arabinose from agricultural and forestal waste, belonging to the field of utilization of agricultural and forestal waste. The technique comprises the following steps: pretreating and preprocessing the raw material, and hydrolyzing in a thermophilic digestion mode to prepare a hemicellulose hydrolysate; after centrifugalizing to remove solid residues, carrying out TiO2-loaded activated carbon photocatalysis or ion exchange resin decolorization and detoxification treatment on the hydrolysate; carrying out MVR (mechanical vapor recompression) concentration treatment and gradient-cooling crystallization to obtain a xylose product and a xylose mother solution; fermenting L-arabinose unconverted xylitol fermentationhigh-yield strain xylitol by using the xylose mother solution as the medium to produce the xylitol; centrifugalizing to remove thalli, and carrying out decolorization and desalting treatment by membrane-process or resin adsorption; separating by using a simulated moving bed or chromatographic separation technology to obtain a xylitol phase and an L-arabinose phase; and carrying out MVR or vacuum concentration treatment on the two phases, and crystallizing in a gradient programmed cooling mode to respectively obtaining a xylitol product and an L-arabinose product, wherein the two mother solutions can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

Agglomerated zeolitic adsorbents, their process of preparation and their uses

InactiveUS20050170947A1Amino compound purification/separationMolecular sieve catalystsSorbentSimulated moving bed

The present invention relates to agglomerated zeolitic adsorbents containing zeolite X and an inert binder, the inert binder containing at least 80% by weight of clay which has undergone zeolitization by the action of an alkaline solution, the zeolite X having with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g. They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged. These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

Method for producing high-octane gasoline

ActiveCN101429452AReduce gasoline olefin contentHigh aromatic contentCatalytic naphtha reformingRare-earth elementSimulated moving bed

The invention provides a method for producing high octane gasoline by aromatization reaction of a mixed raw material of catalytic gasoline and C4, and catalyst on an aromatization reactor after the mixed raw material contacts the catalyst. The method is as follows: the catalytic gasoline is mixed with the C4 olefin, and the mixed raw material enters into a fixed bed aromatization reactor or a simulated moving bed aromatization reactor which is filled with the molecular sieve catalyst, contacts the aromatizing catalyst, and undergoes olefin aromatization reaction, wherein the reaction conditions are as follows: the reaction temperature is between 250 and 340 DEG C; the pressure is between 0.5 and 3.0 MPa; the weight space velocity is between 0.5 and 10h<-1>; the mass ratio of the C4 olefin to the catalytic gasoline is between 90 to 10 and 2 to 98; and active ingredients of a molecular sieve carrier of the catalyst are one or more than one among rare earth element, No. 4B element and No. 8 element, and the weight of the active ingredients is 0.01 to 10 percent of that of the carrier. The method can obviously reduce the olefin content of the raw gasoline, effectively improve the octane number, and achieve the aim of production of the clean high-octane gasoline.

Owner:PETROCHINA CO LTD

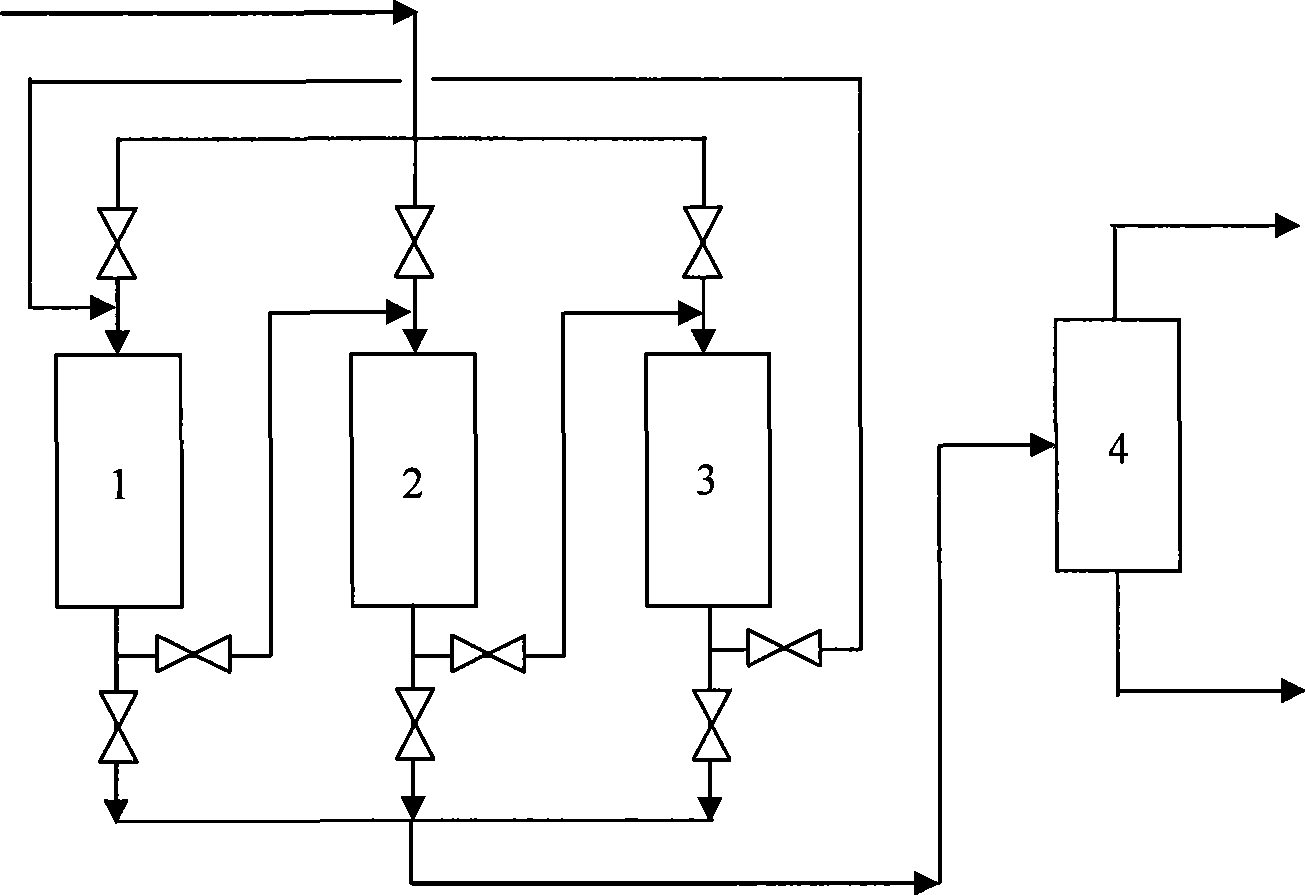

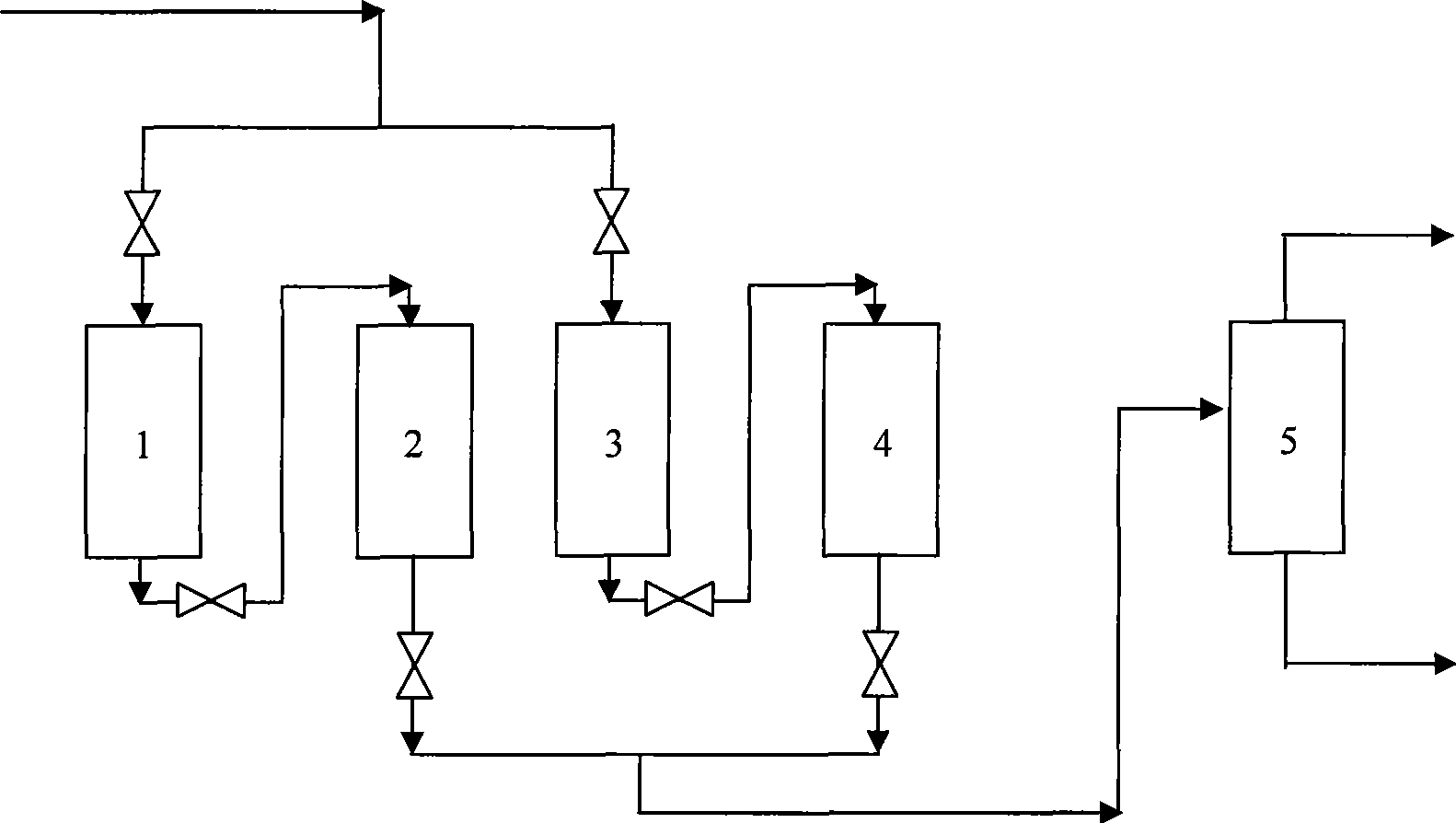

Versatile simulated moving bed systems

InactiveUS20060273013A1Increase flexibilityImprove performanceIon-exchange process apparatusGas treatmentSimulated moving bedEngineering

Distributed valve simulated moving beds are described in which junctions located between successive columns interrupt the flow of process fluid between columns, and either transmit the process fluid through a zone bypass to a succeeding column within the same zone or, if the junction is located between zones, direct the process fluid to an input / output line that is dedicated to the particular zone that immediately follows the junction. At each step of the SMB's operation, the distribution of flows in each junction is modulated to accomplish movement of ports consistent with the SMB's design. The described system can be employed to accomplish moving ports chromatography. Further described are simulated moving beds that contain one or more decoupled on-line regeneration zones. The regeneration zone is decoupled from the separation zones in the sense that it observes a step time (a “regeneration interval”) that is different than the step time observed by the separation zones of the SMB. Because the regeneration zone is “on-line,” the SMB need not be stopped to remove columns for regeneration. Because the regeneration zone is decoupled from the separation zones, the column can stay in the regeneration zone as long as needed to accomplish the regeneration, regardless of the step time observed by the SMB.

Owner:CHIN NIEN HWA LINDA +1

Flow distribution apparatus

ActiveUS7314551B2Minimizes eliminatesIon-exchange process apparatusIon-exchanger regenerationHoneycombSimulated moving bed

Owner:UOP LLC

Control System For Simulated Moving Bed Chromatography

ActiveUS20080053917A1Simple and easily programmable controlPromote repairSolid sorbent liquid separationWater/sewage treatmentControl systemSimulated moving bed

The present invention provides devices and methods for micro-scale simulated moving bed chromatography (SMB) for continuous preparation of analytic quantities of highly pure fractions of target molecules. The present apparatus and method of the invention is adapted in a preferred embodiment to separations by affinity chromatography involving three discontinuous liquid flow loops. An alternative embodiment of affinity chromatography utilizes standard SMB operating under isocratic conditions.

Owner:TOSOH BIOSCIENCE LLC

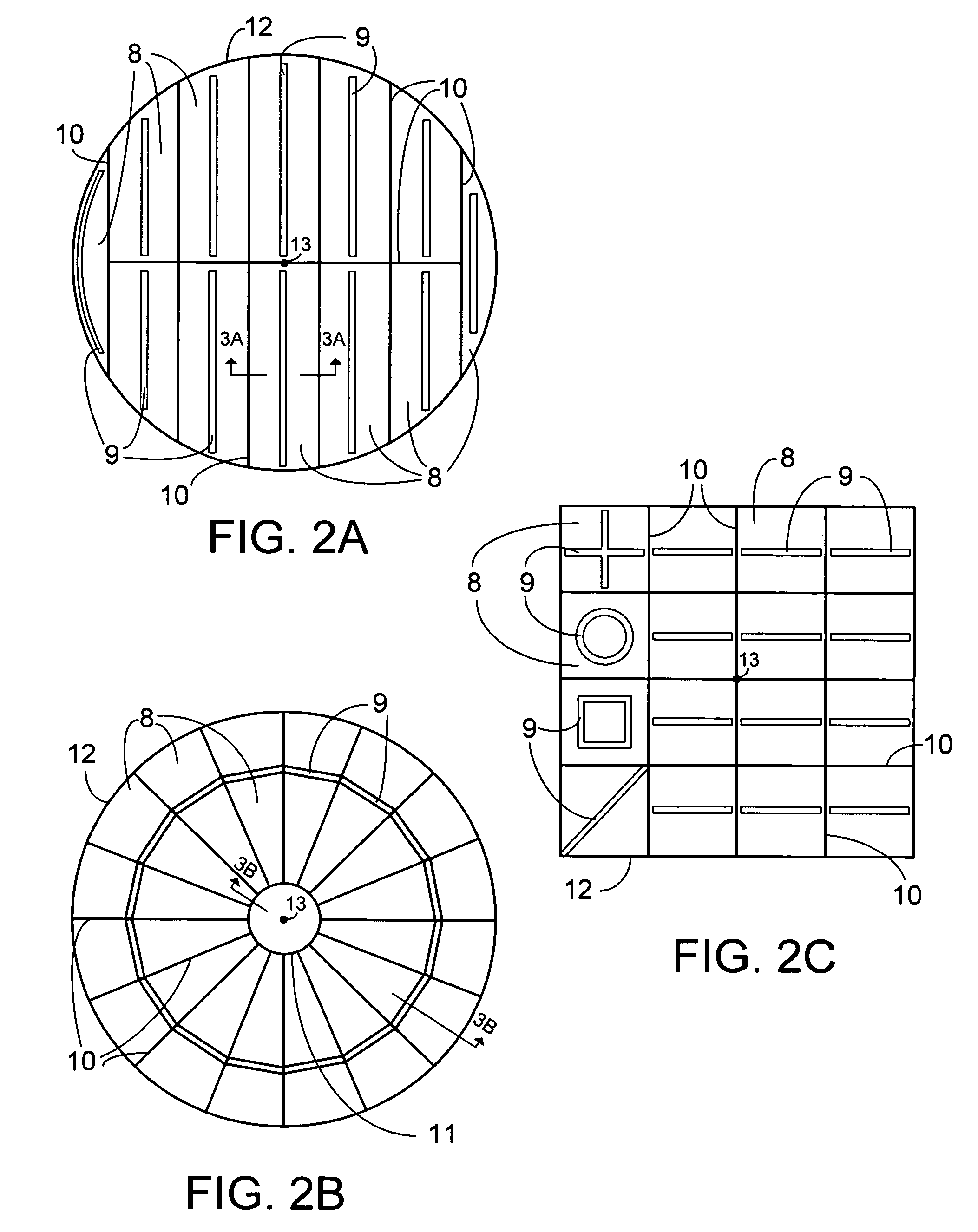

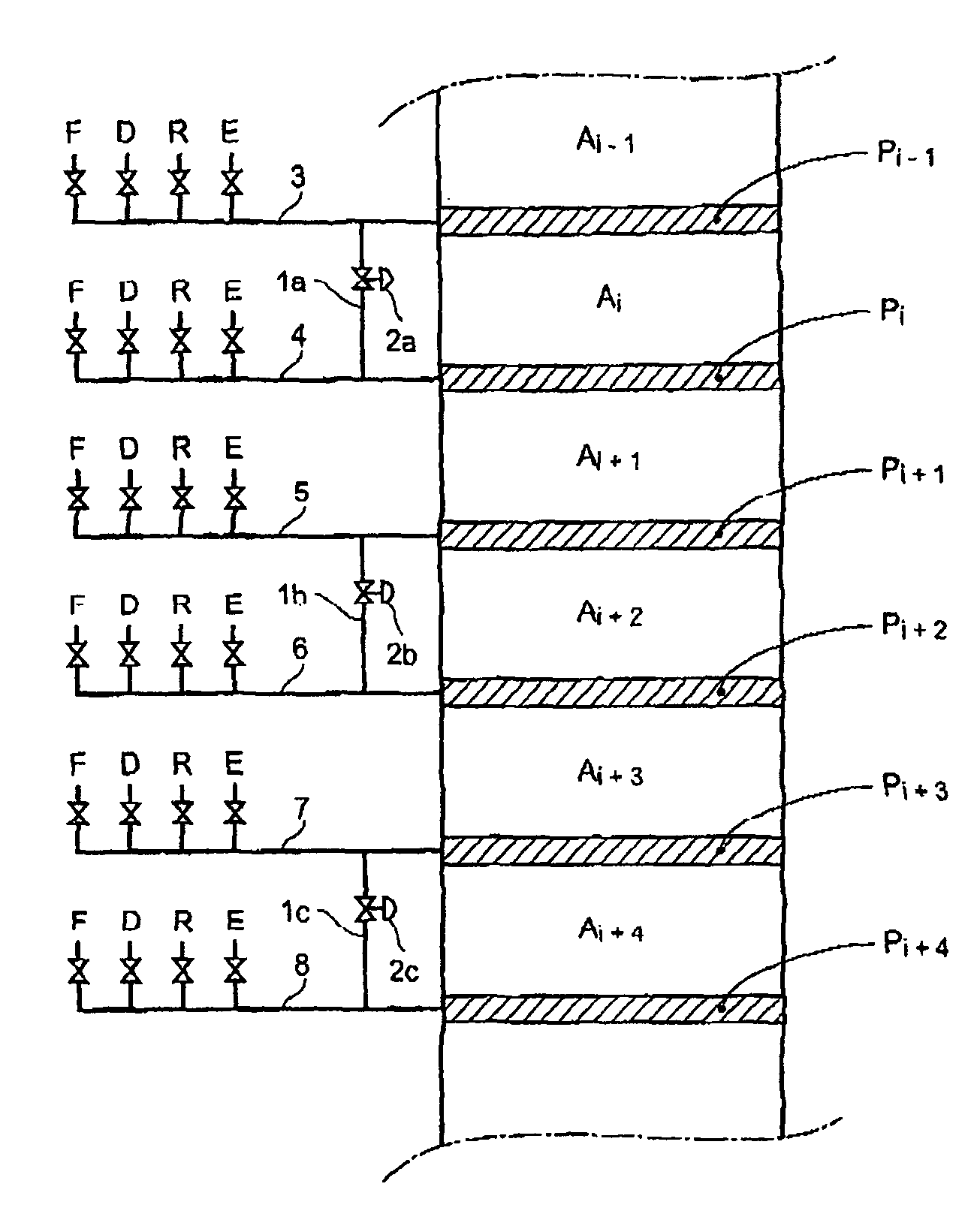

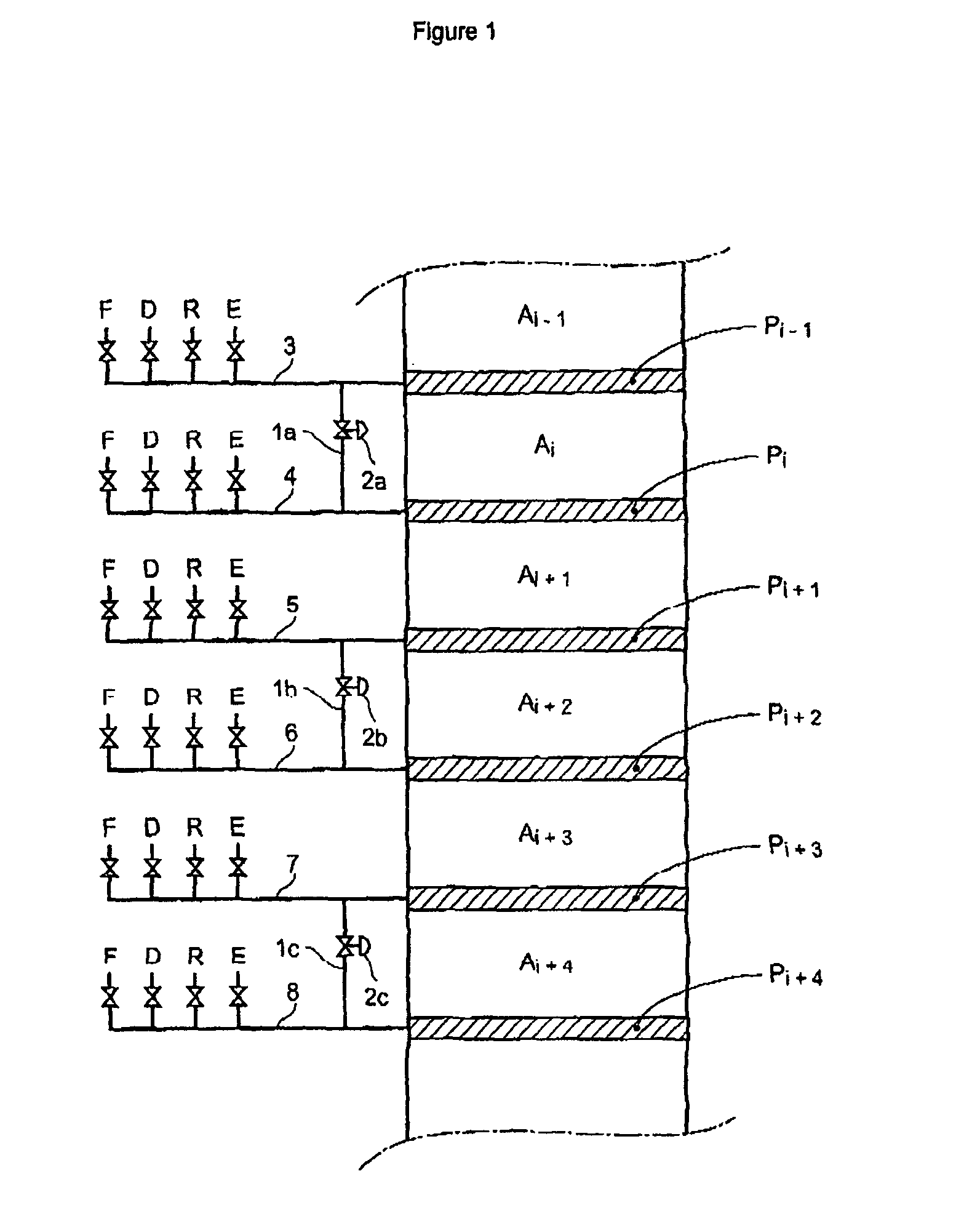

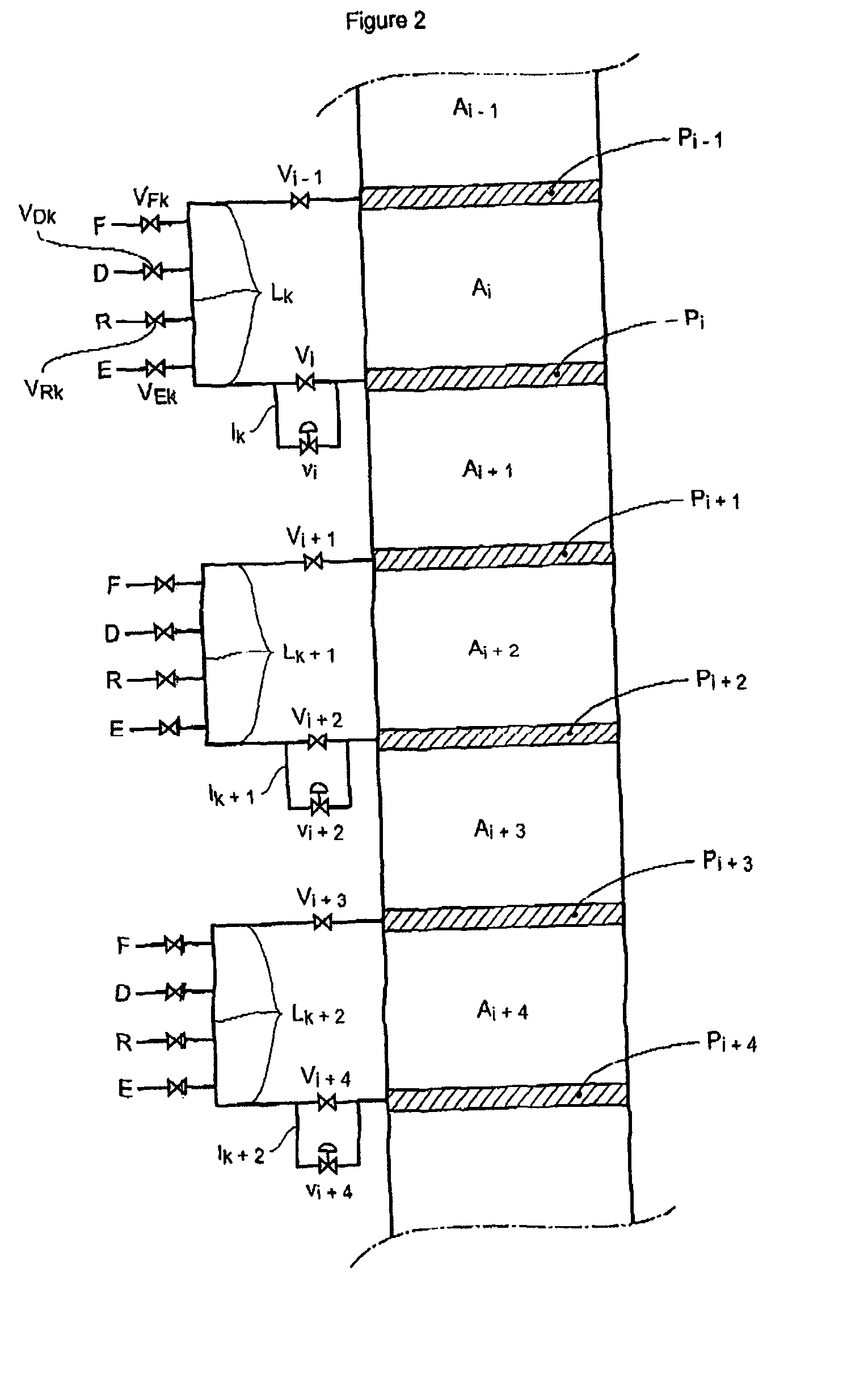

Process and device for simulated moving bed separation with a reduced number of valves and lines

InactiveUS20080237132A1Reduce in quantityReduce disadvantagesComponent separationIon-exchanger regenerationSimulated moving bedMeta-xylene

The invention concerns a simulated moving bed adsorption separation device comprising a limited number of valves. According to the invention, the device comprises a column with a plurality of sectors Sk with 2 superimposed plates Pi with a single distribution network, each sector Sk comprising an external principal bypass line Lk connected to each plate Pi of Sk via a plate valve Vi. Each line Lk comprises a flow limitation means and is connected to each of the fluid networks via a single valve.Further, the connectors of lines Lk onto the column are offset by at most 20° inside Sk to limit the volume of lines Lk, and are offset by a mean angle in the range 70° to 110° between two neighbouring sectors Sk and Sk+1 so as not to weaken the column mechanically. The plates preferably comprise panels DMEi,j with parallel segments the direction of which varies from plate to plate or per group of 2 plates.The invention also concerns a separation process using said device, in particular to separate para-xylene or meta-xylene from an aromatic C8 cut.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com