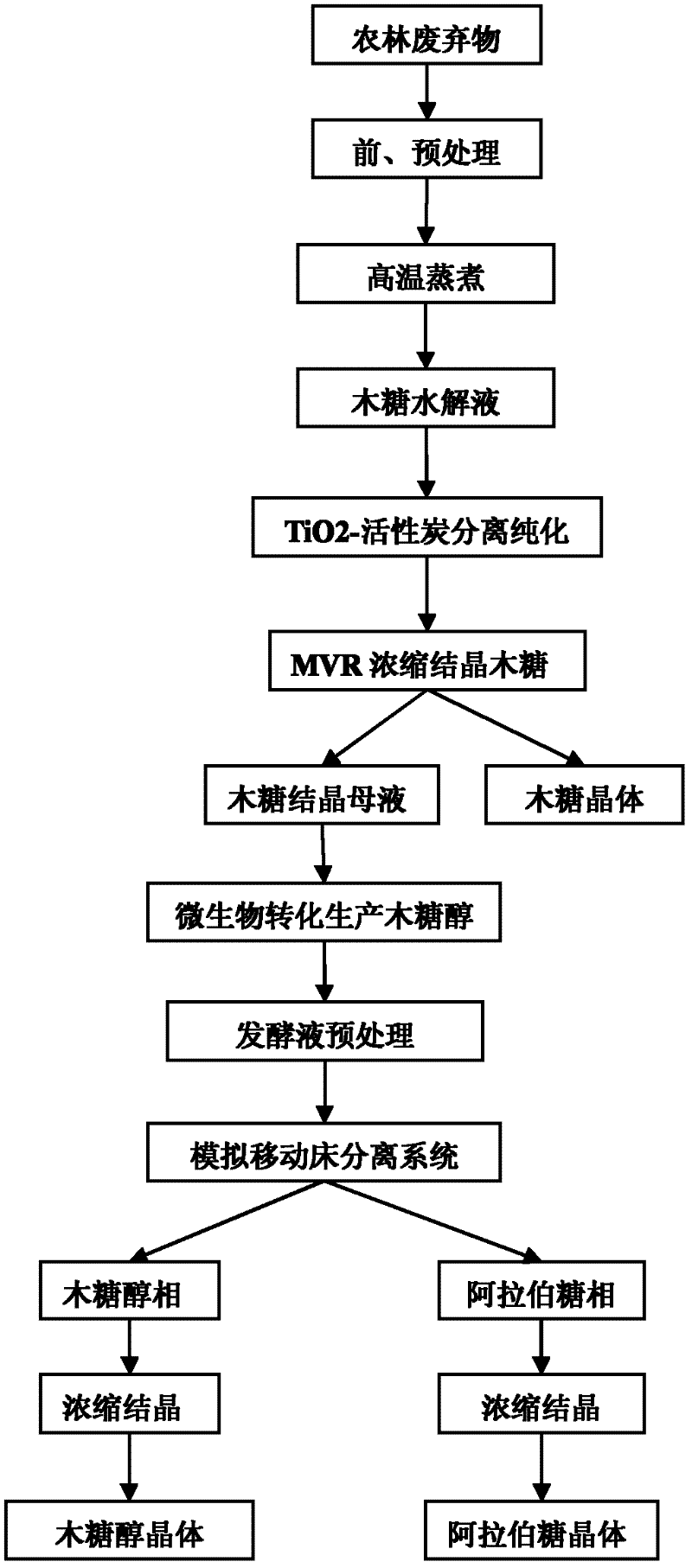

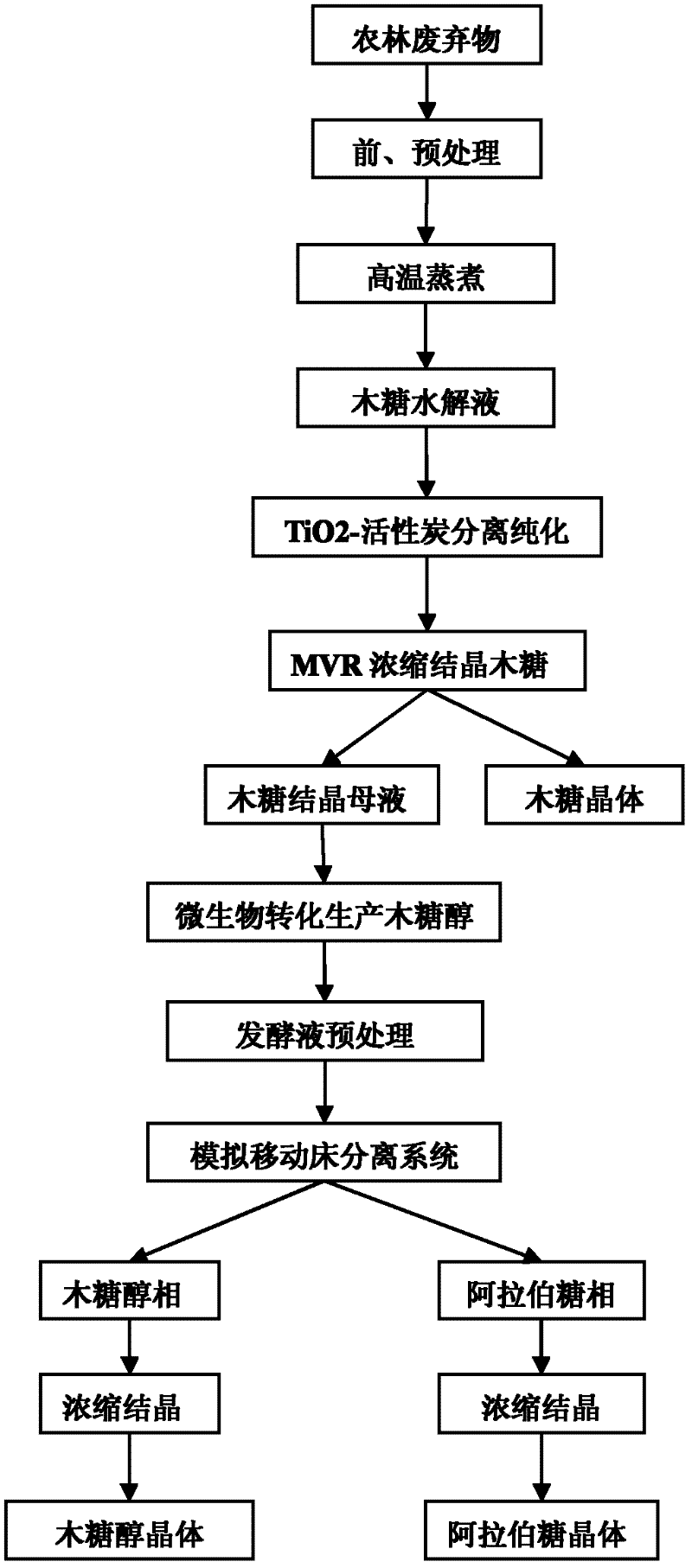

Co-production of xylose, xylitol and arabinose from agricultural and forestry wastes

A technology of agricultural and forestry waste and arabinose, applied in the direction of biochemical equipment and methods, microorganisms, sugar production, etc., can solve the problems of waste of xylose mother liquor, waste of resources, environment, pollution, etc., to reduce salt content and increase production capacity Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0071] (1) Preparation process of high-temperature cooking liquid:

[0072] Choose agricultural and forestry waste corn cobs as raw materials. The corncobs are crushed to 10 meshes, dust-removed, and washed with water. The pretreated corncobs are then pretreated. The pretreatment process selects the dilute oxalic acid soaking method that is easy to operate and simple in process. The soaking solution used in the pretreatment is 0.2% dilute oxalic acid, the mass fraction ratio of the used soaking solution to raw materials is 4:1, and the soaking temperature is 30°C, soaking time is 24h. After soaking, through plate and frame filtration, the soaking system is separated from solid to liquid to obtain pretreated raw materials and soaking liquid, and the soaking liquid is reused, and the separated pretreated raw materials are washed to adjust the pH value of the raw materials themselves to nearly neutral.

[0073] 5Kg (dry weight) of granular corn cobs after pretreatment and pre...

example 2

[0090] (1) Preparation process of high-temperature cooking liquid:

[0091] Choose agricultural and forestry waste corn cobs as raw materials. The corn cobs are crushed to 20 meshes, dust removal treatment, and washed with water in three pre-treatment procedures. The pretreated corncobs are then pretreated. The pretreatment process selects the dilute oxalic acid soaking method that is easy to operate and simple in process. The soaking solution used in the pretreatment is 0.5% dilute oxalic acid, the mass fraction ratio of the soaking solution and raw materials used is 8:1, and the soaking temperature is 60°C, soaking time is 12h. After soaking, through plate and frame filtration, the soaking system is separated from solid to liquid to obtain pretreated raw materials and soaking liquid, and the soaking liquid is reused, and the separated pretreated raw materials are washed to adjust the pH value of the raw materials themselves to nearly neutral.

[0092] Put 8Kg (dry weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com