Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2055results about How to "Stable combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

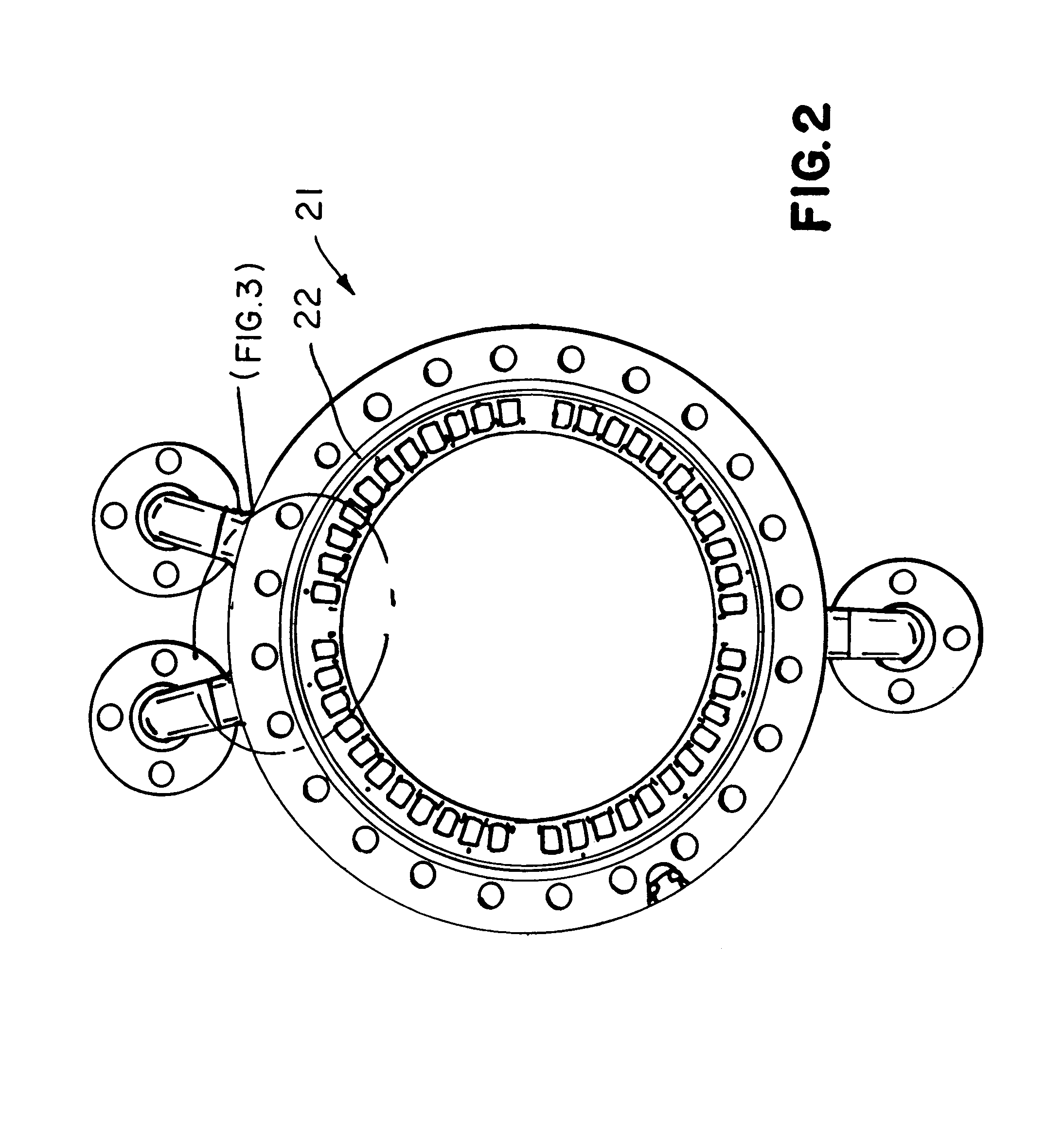

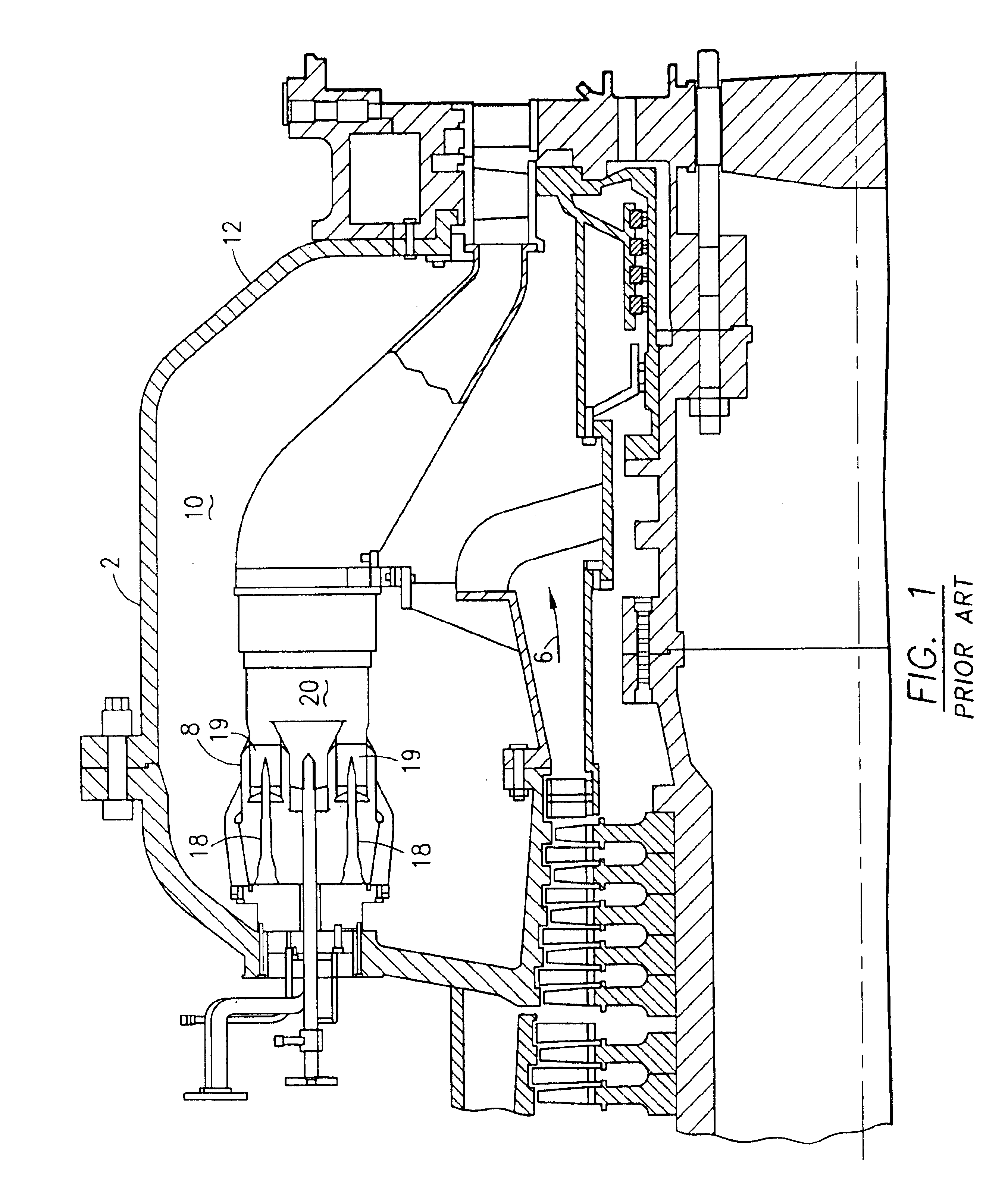

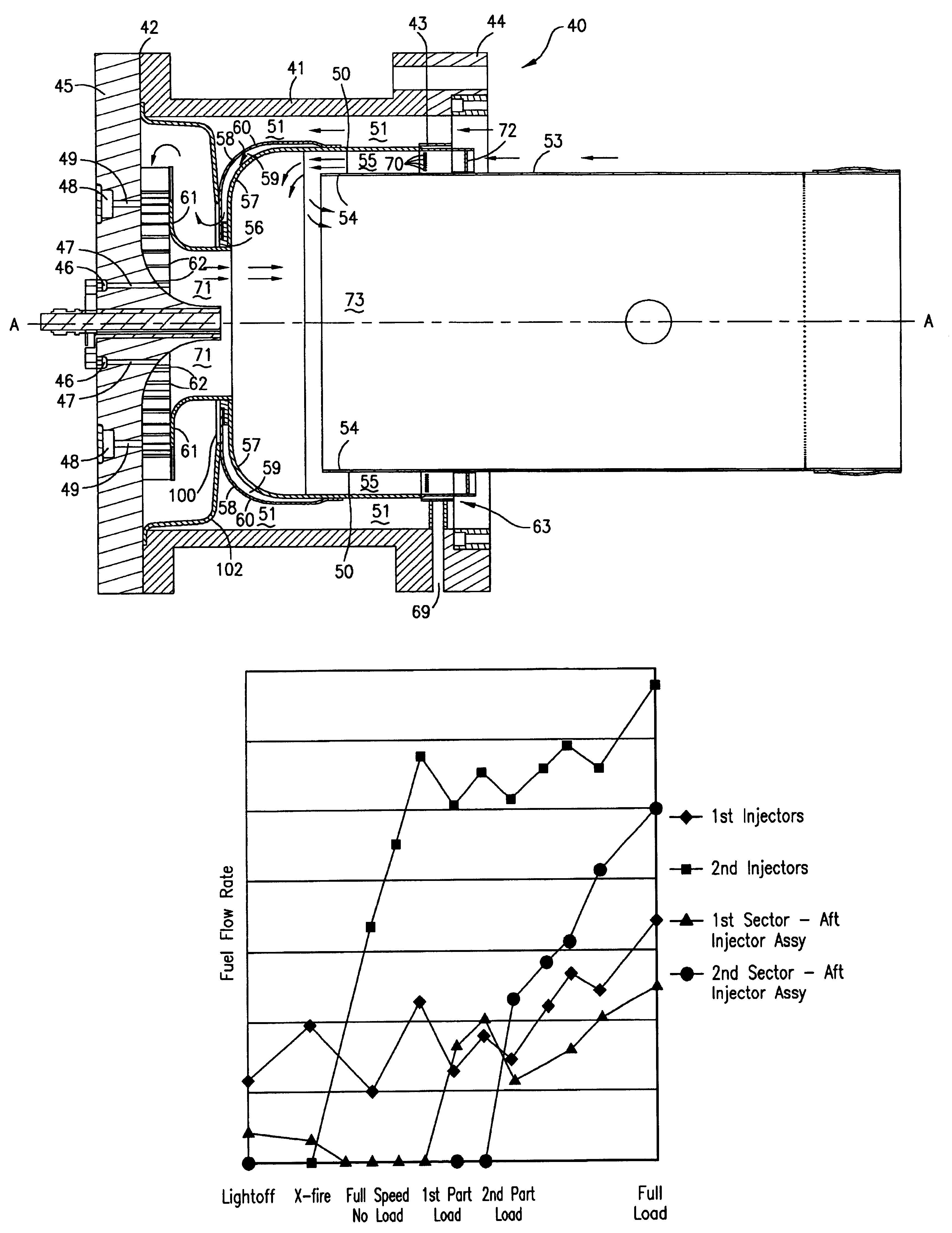

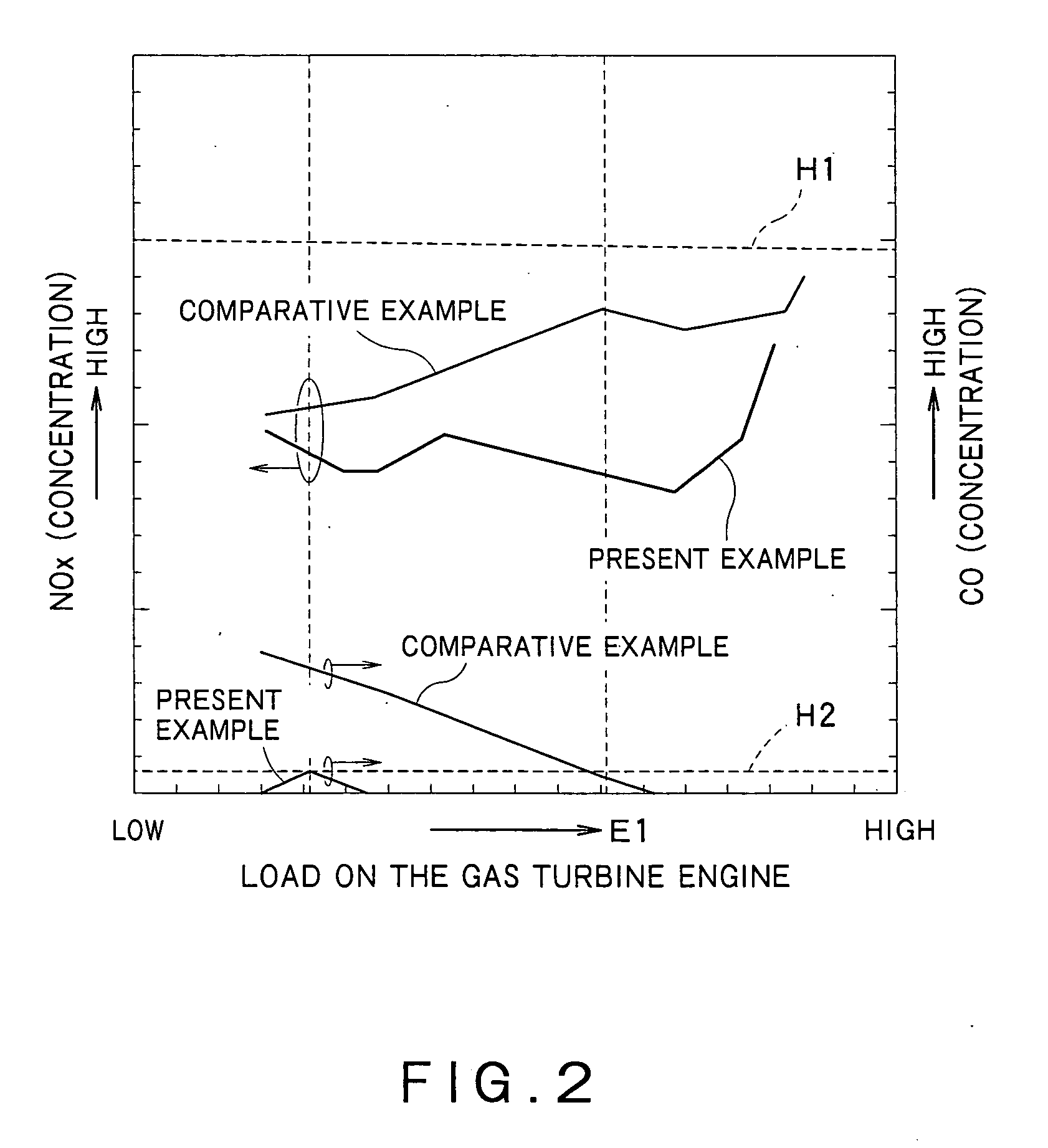

Method of operating a combustion system for increased turndown capability

ActiveUS7137256B1Emission reductionStable combustionContinuous combustion chamberGas turbine plantsCombustion systemLow load

A method of operating a gas turbine engine combustion system at lower load conditions while maintaining required emissions levels is disclosed. The present invention includes multiple embodiments of axial, radial, and circumferential fuel staging within a can-type combustor having alternate ignition techniques of spark ignition or torch ignition.

Owner:ANSALDO ENERGIA SWITZERLAND AG

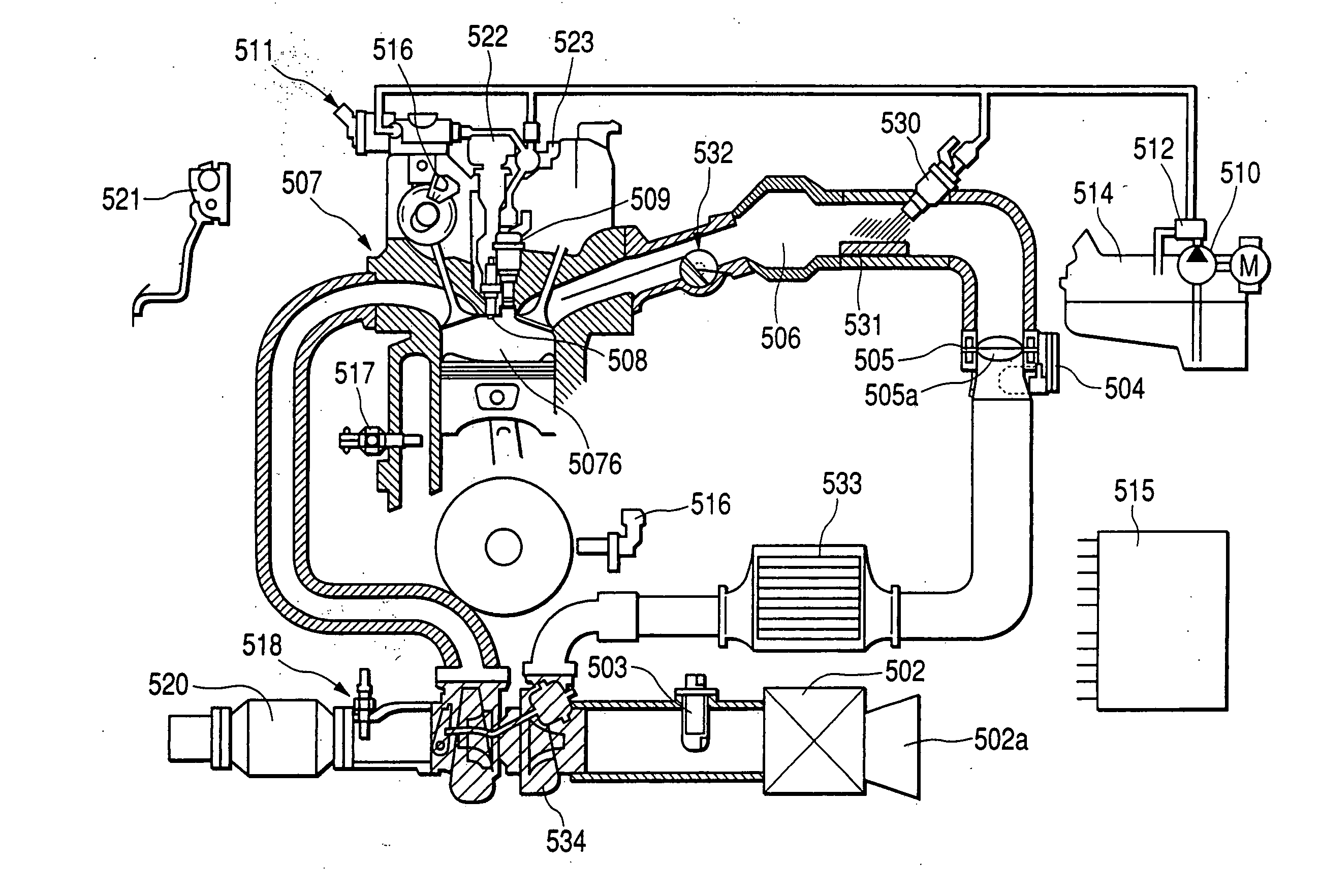

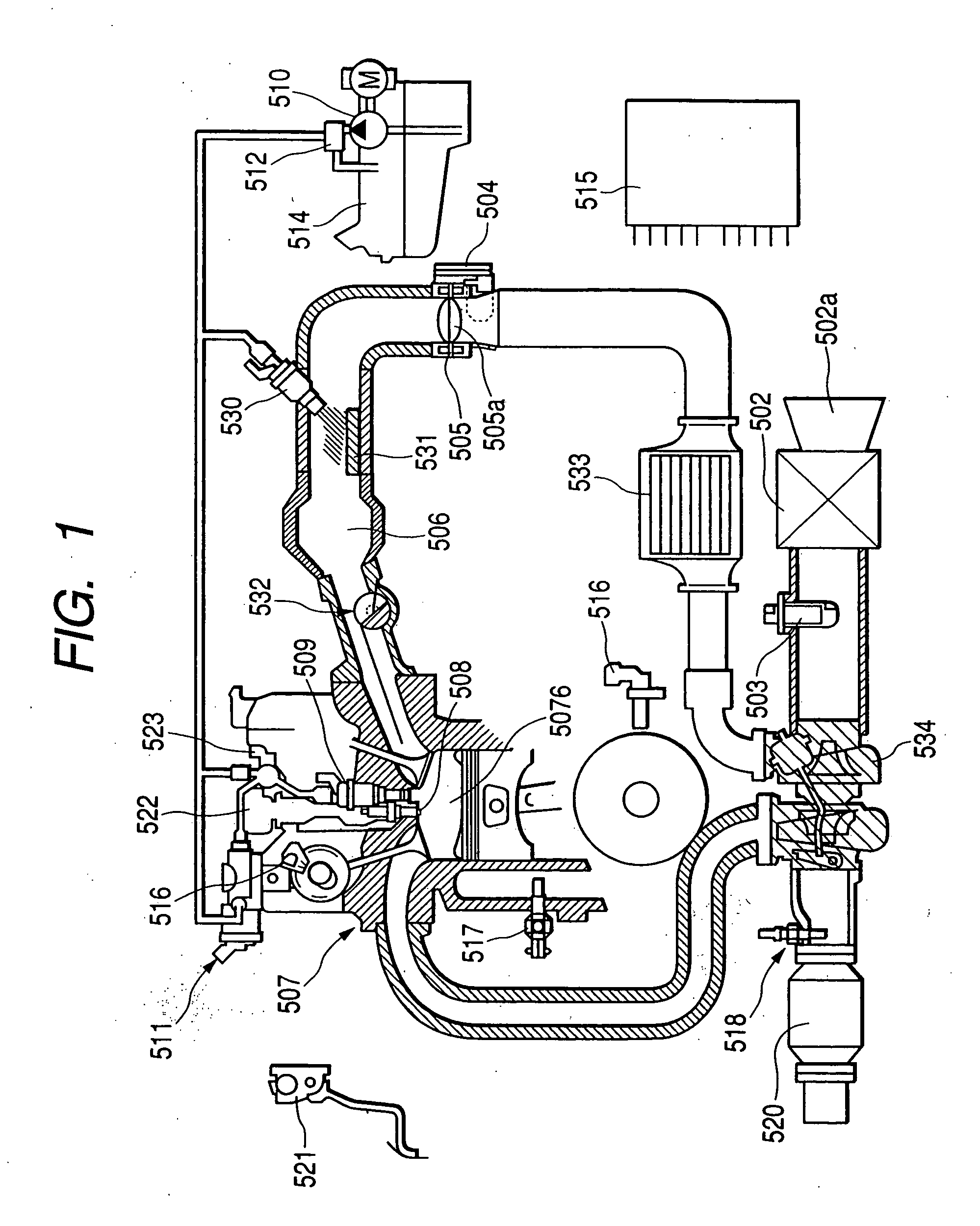

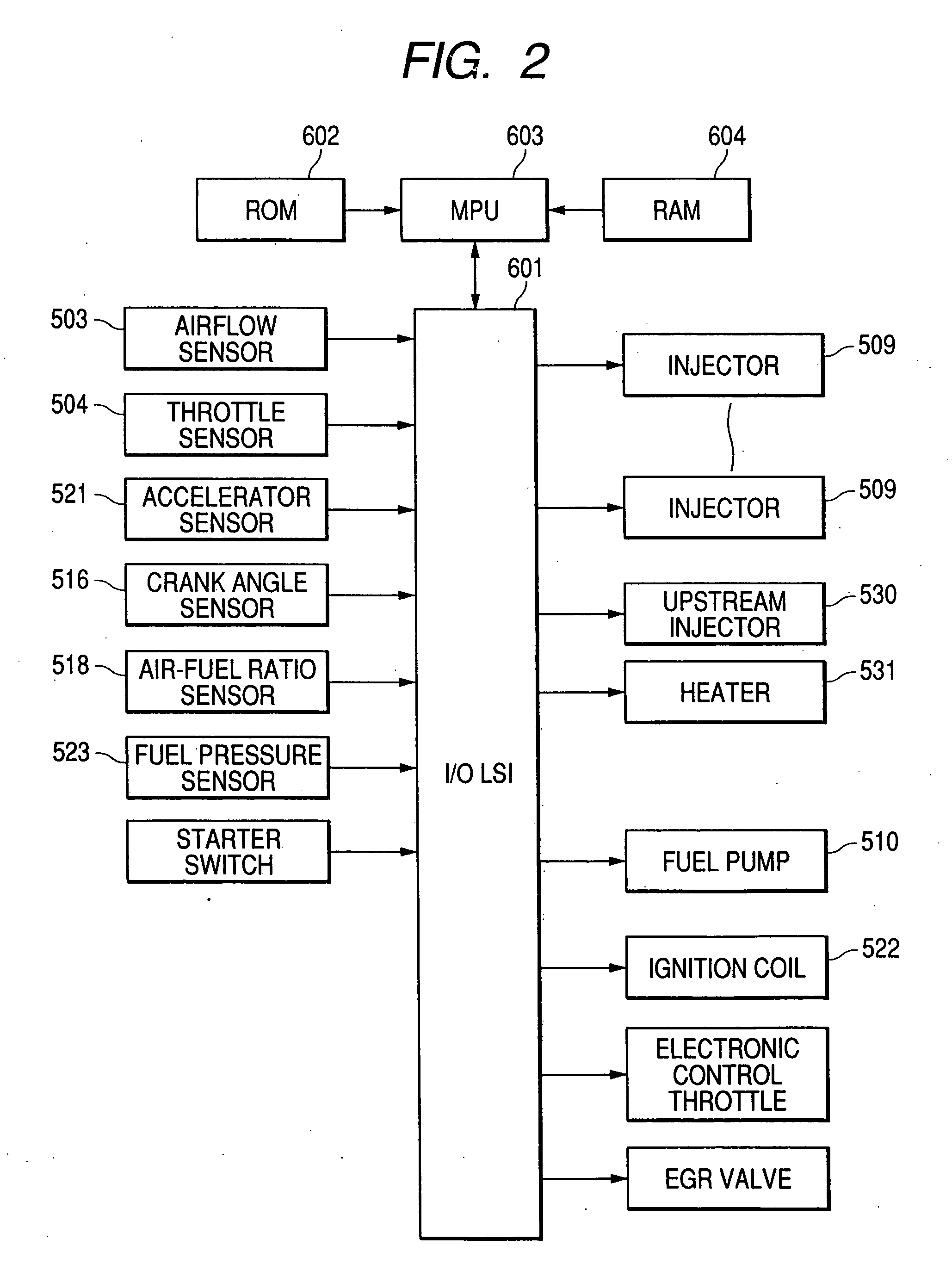

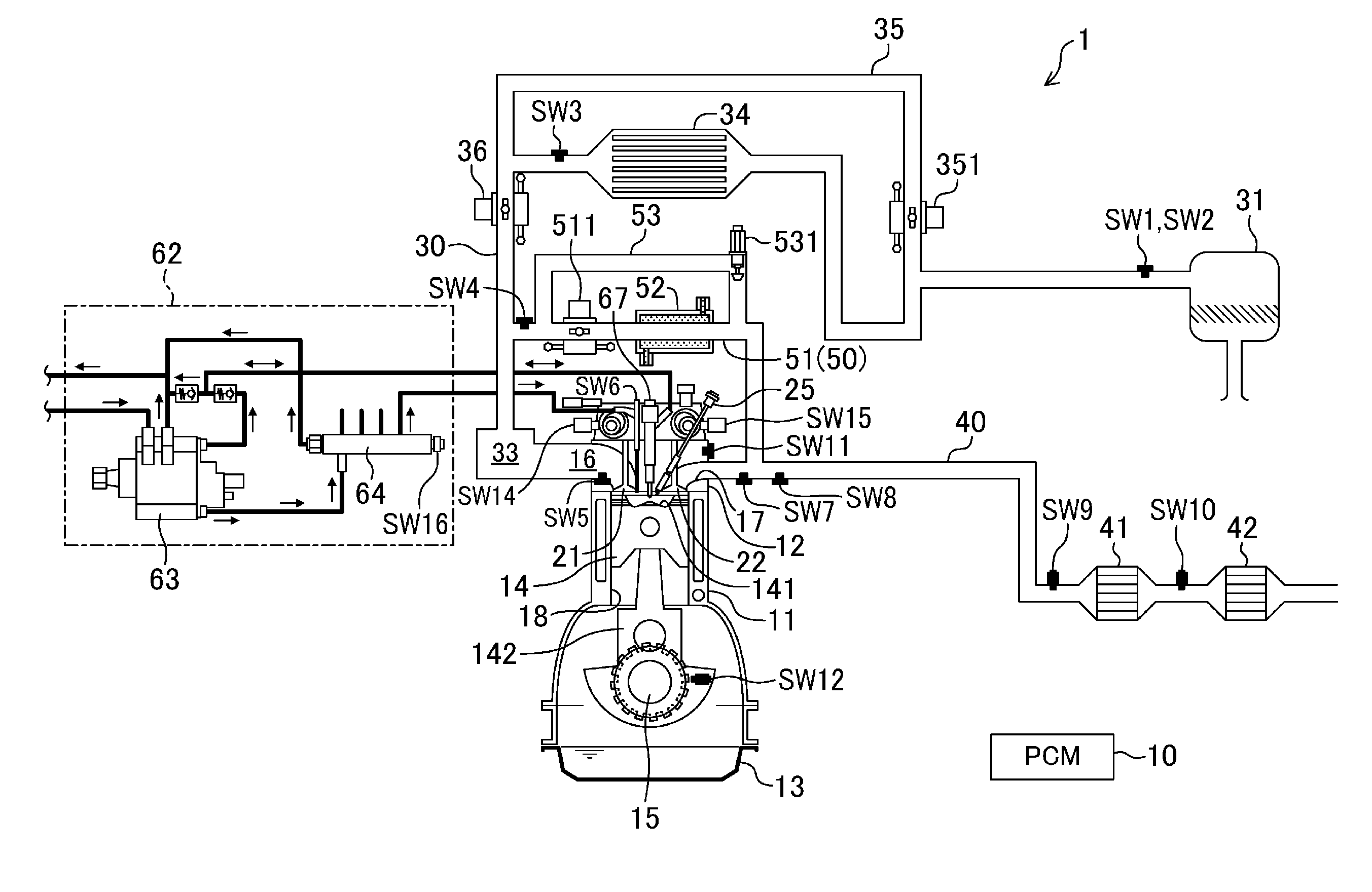

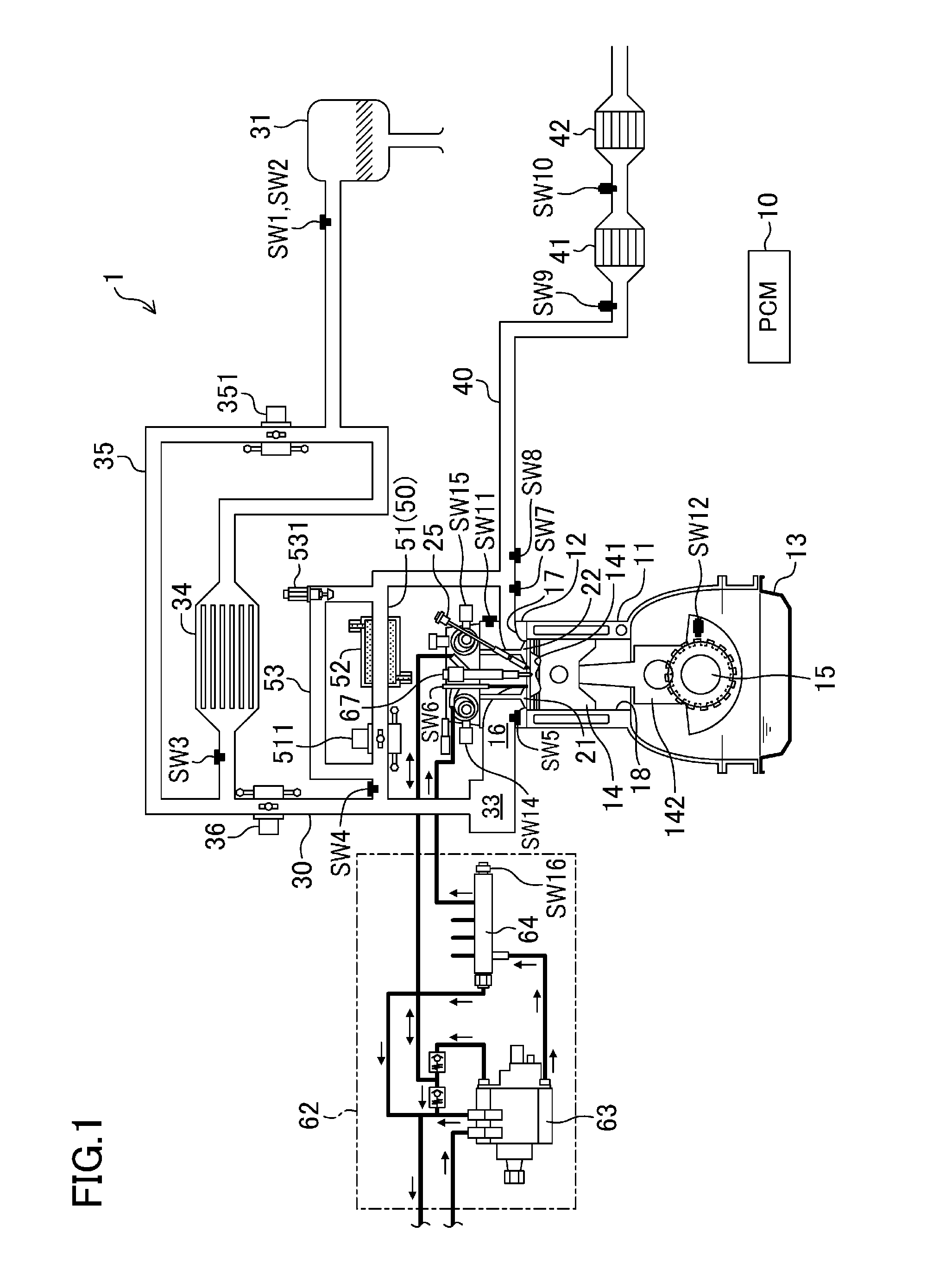

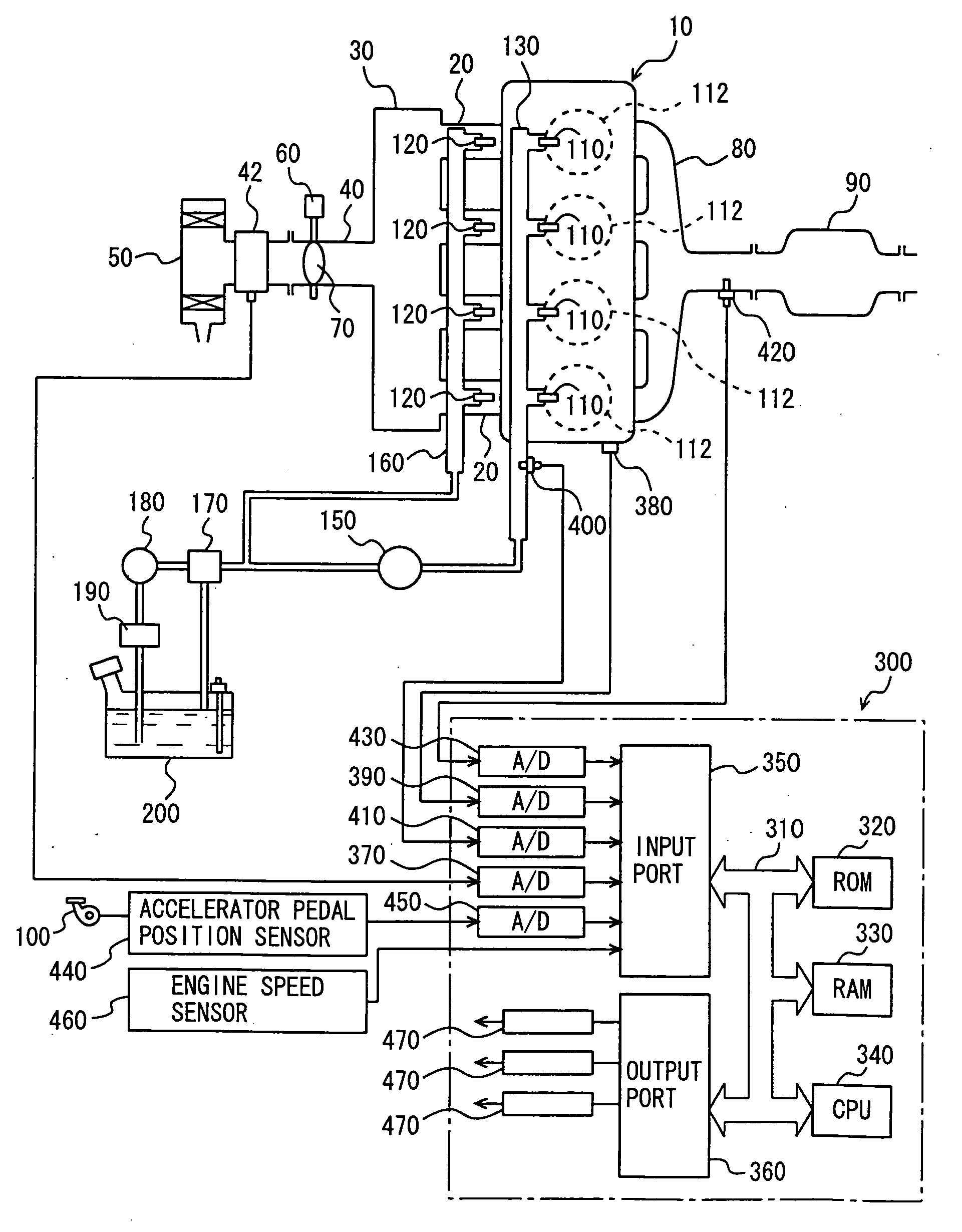

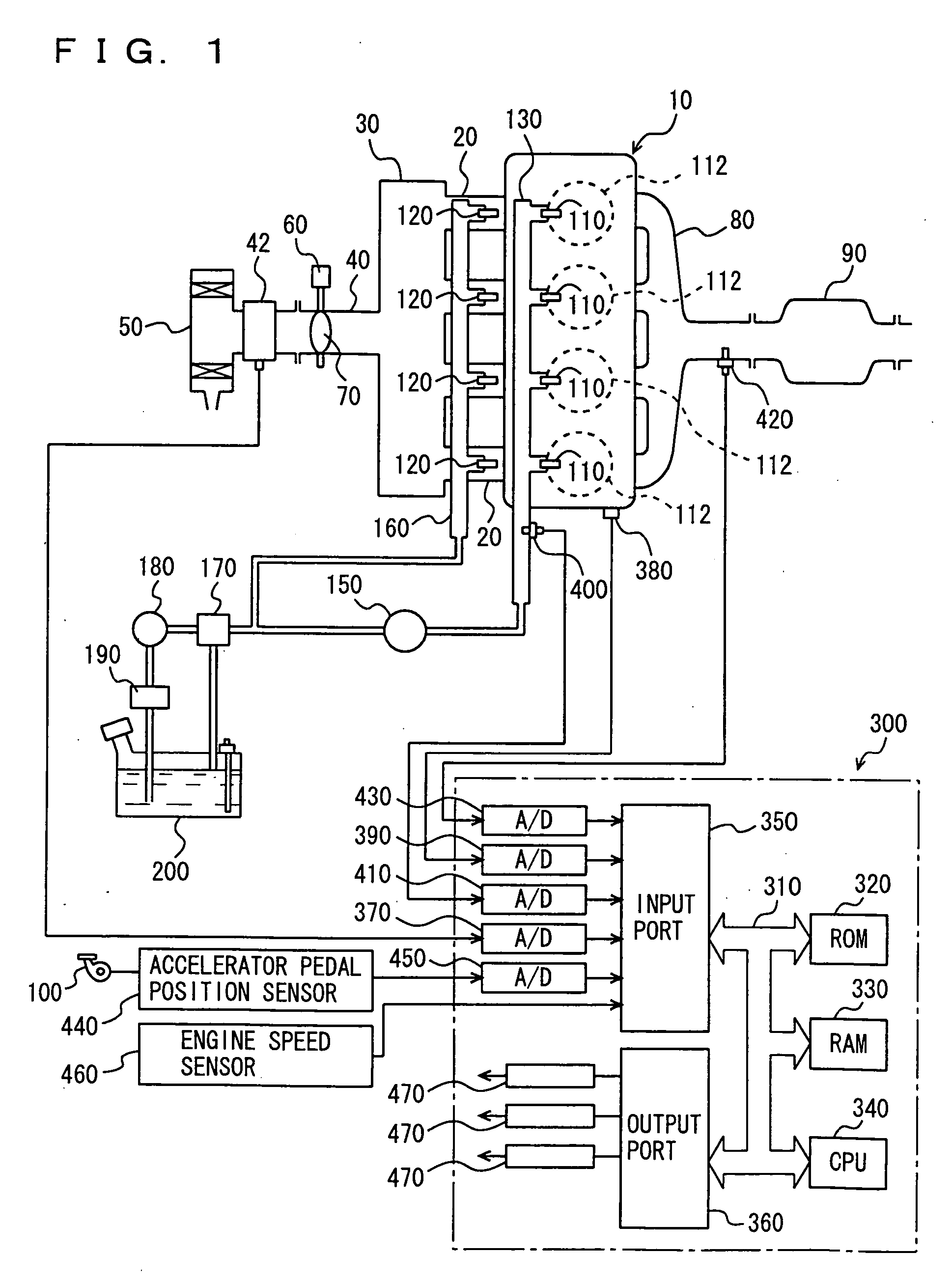

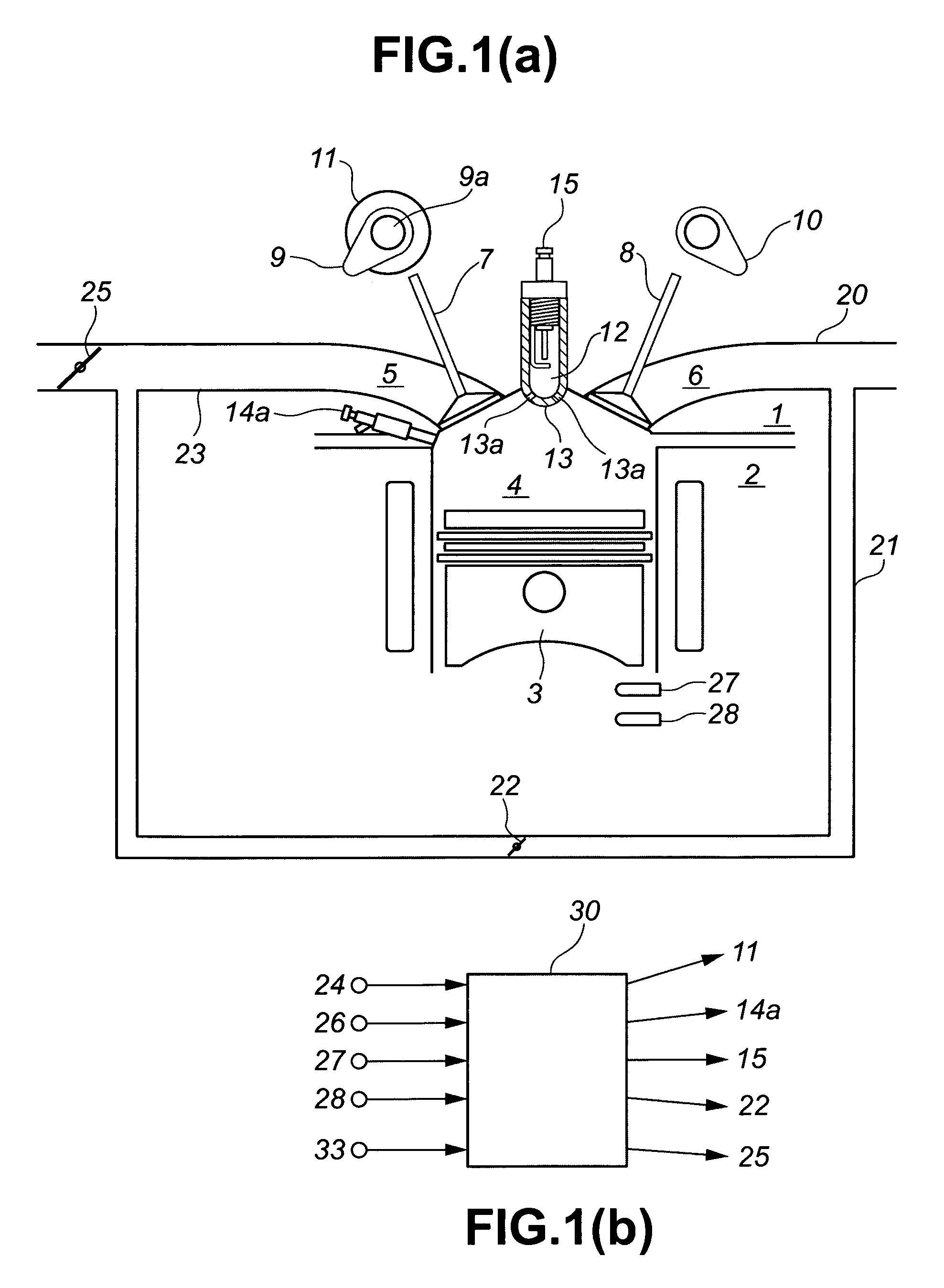

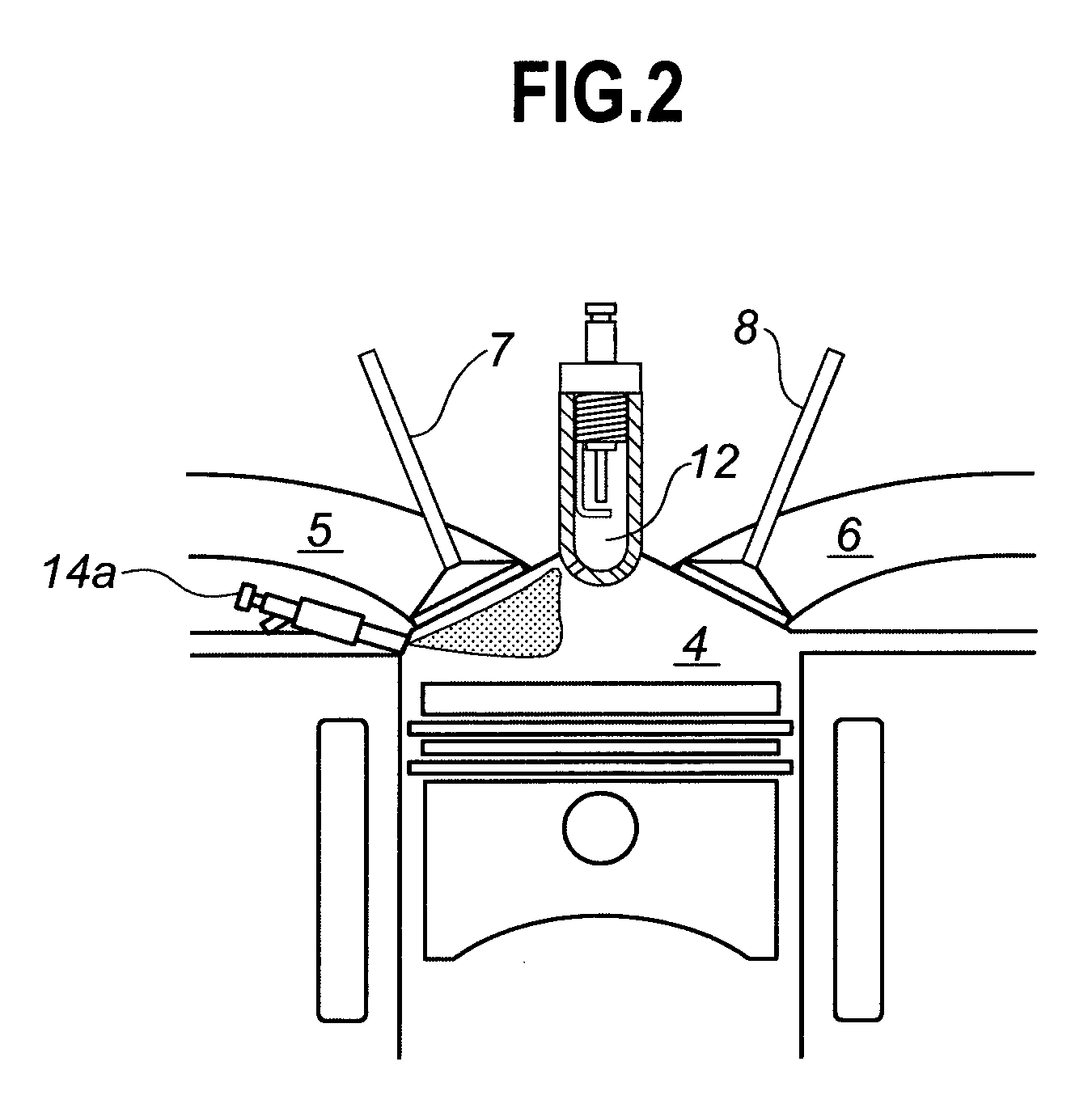

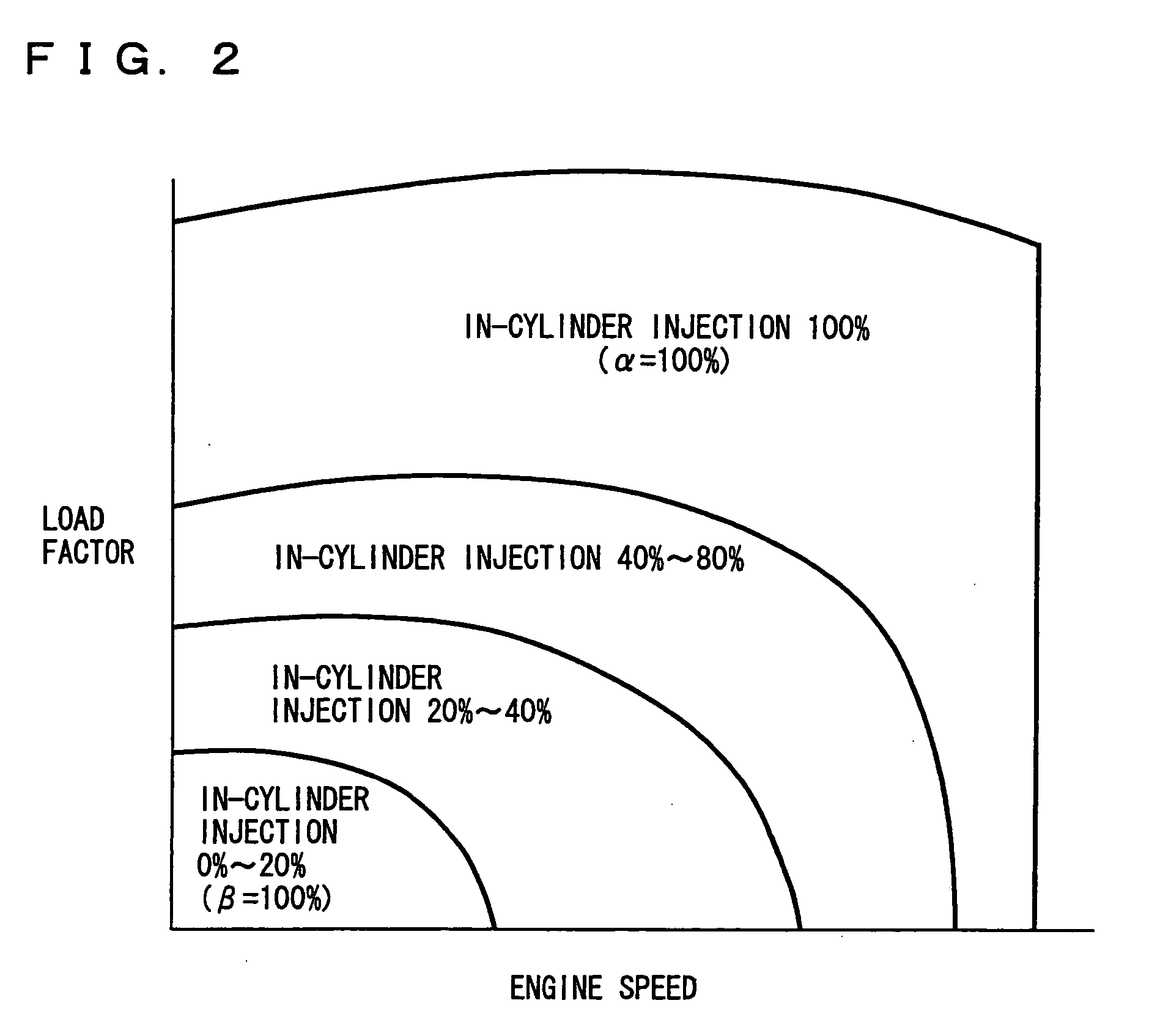

Fuel supply system and fuel supply method for in-cylinder direct fuel injection engine

InactiveUS20050066939A1Increase productionHigh outputElectrical controlInternal combustion piston enginesFuel supplyFuel injection

To offer a fuel supply system and fuel supply method for direct injection engine that realizes higher output. In a fuel supply system for direct injection engine of the present invention, equipped with a primary fuel injector that injects fuel directly into the cylinder of the direct injection engine and supercharger that increase the intake air quantity of the engine, a secondary fuel injector is installed in addition to the primary fuel injector. In a specified engine load area, fuel is supplied using the primary fuel injector and secondary fuel injector. Even though the fuel quantity injected from the primary fuel injector into the cylinder is limited, the fuel supply system for direct injection engine constructed as above can increase the engine output because the fuel insufficiency can be supplied by the secondary fuel injector.

Owner:HITACHI LTD

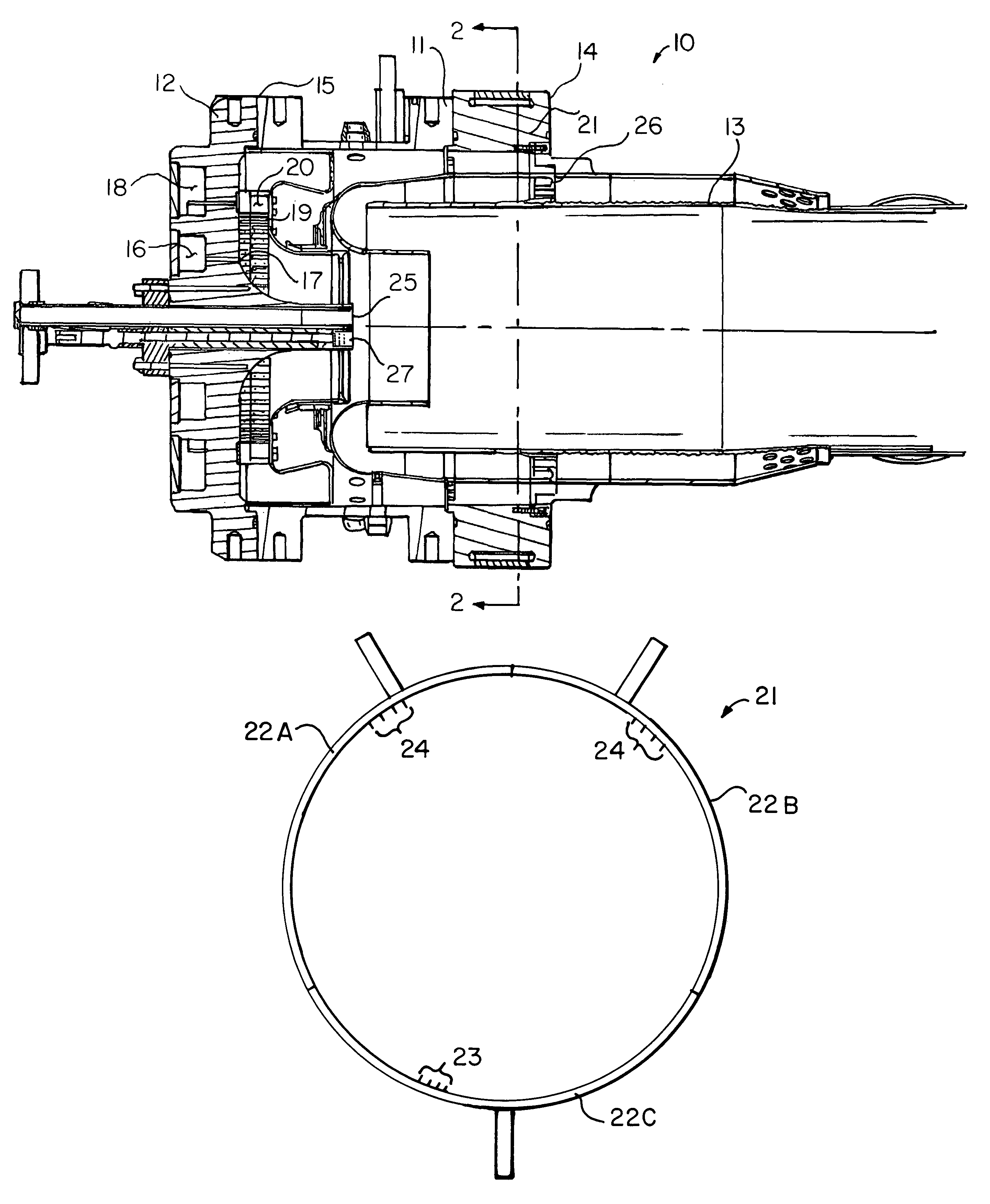

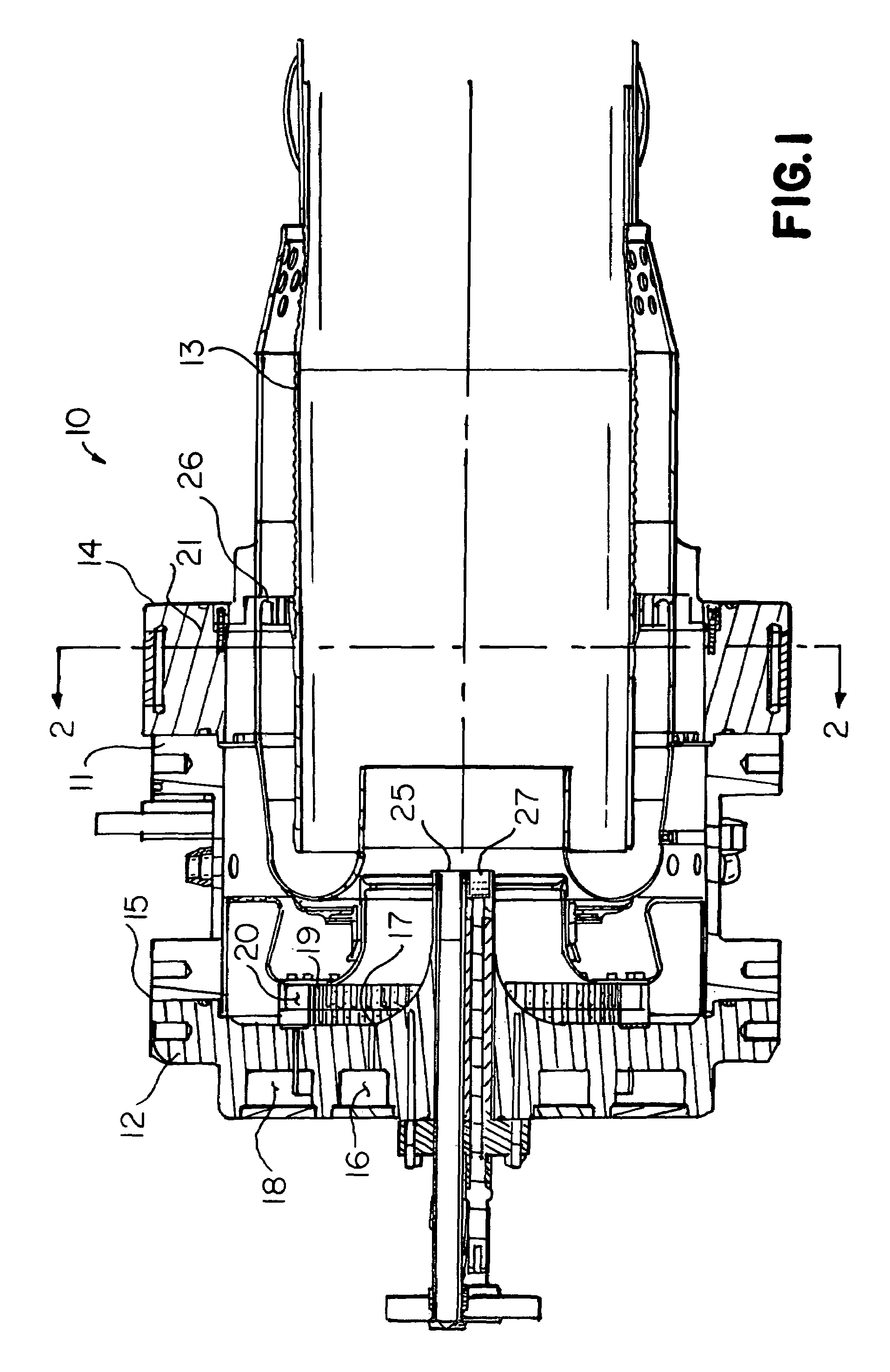

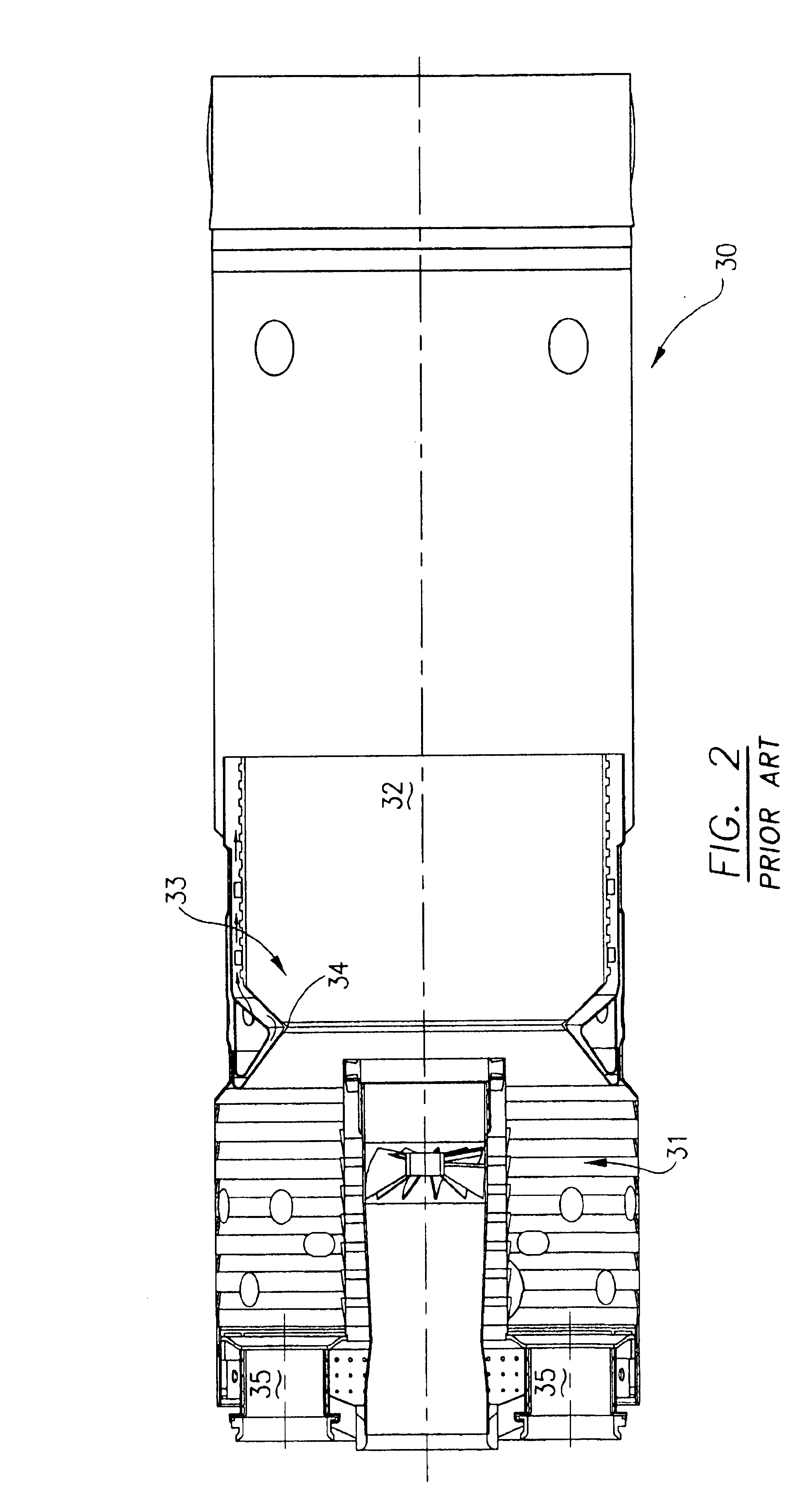

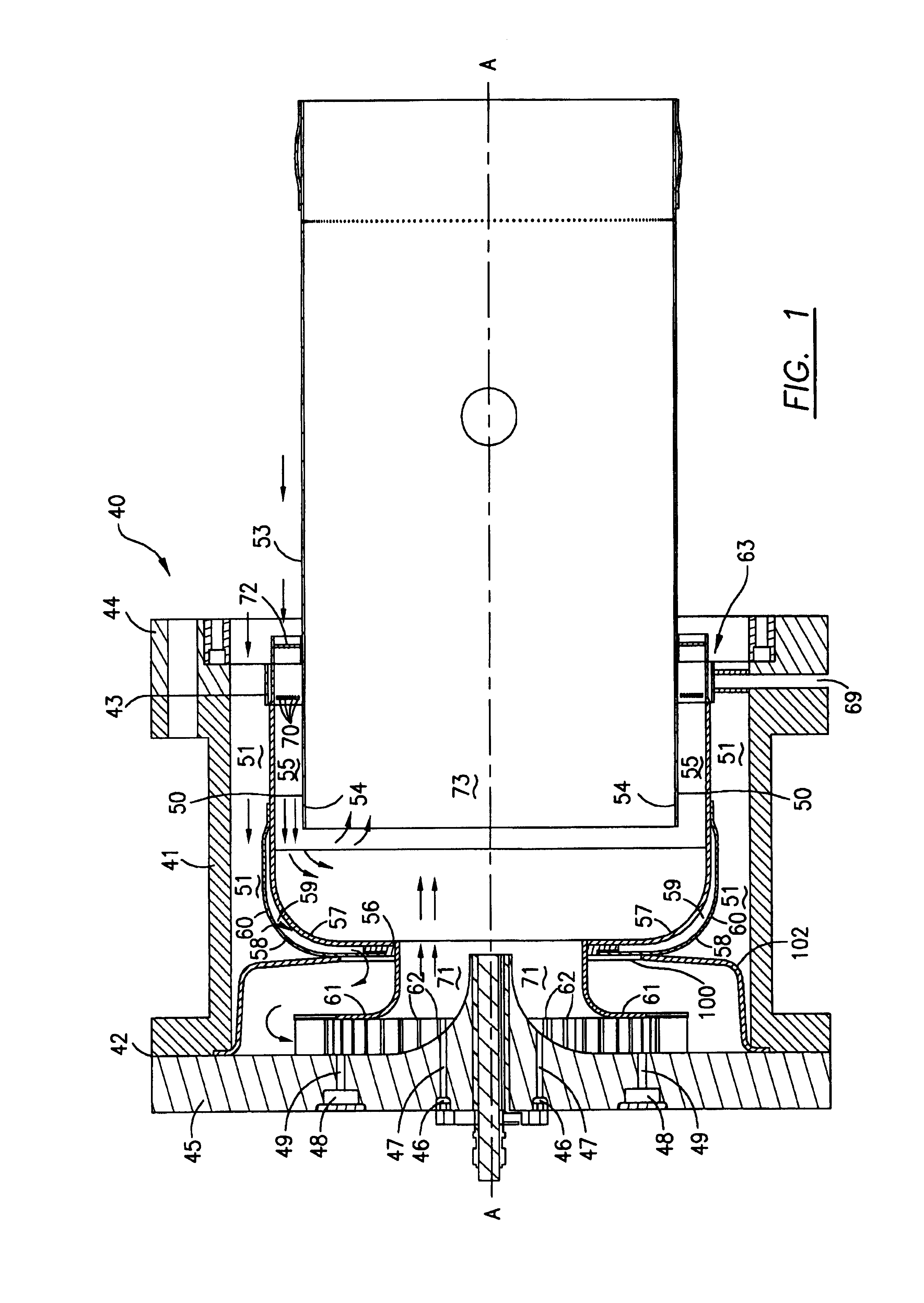

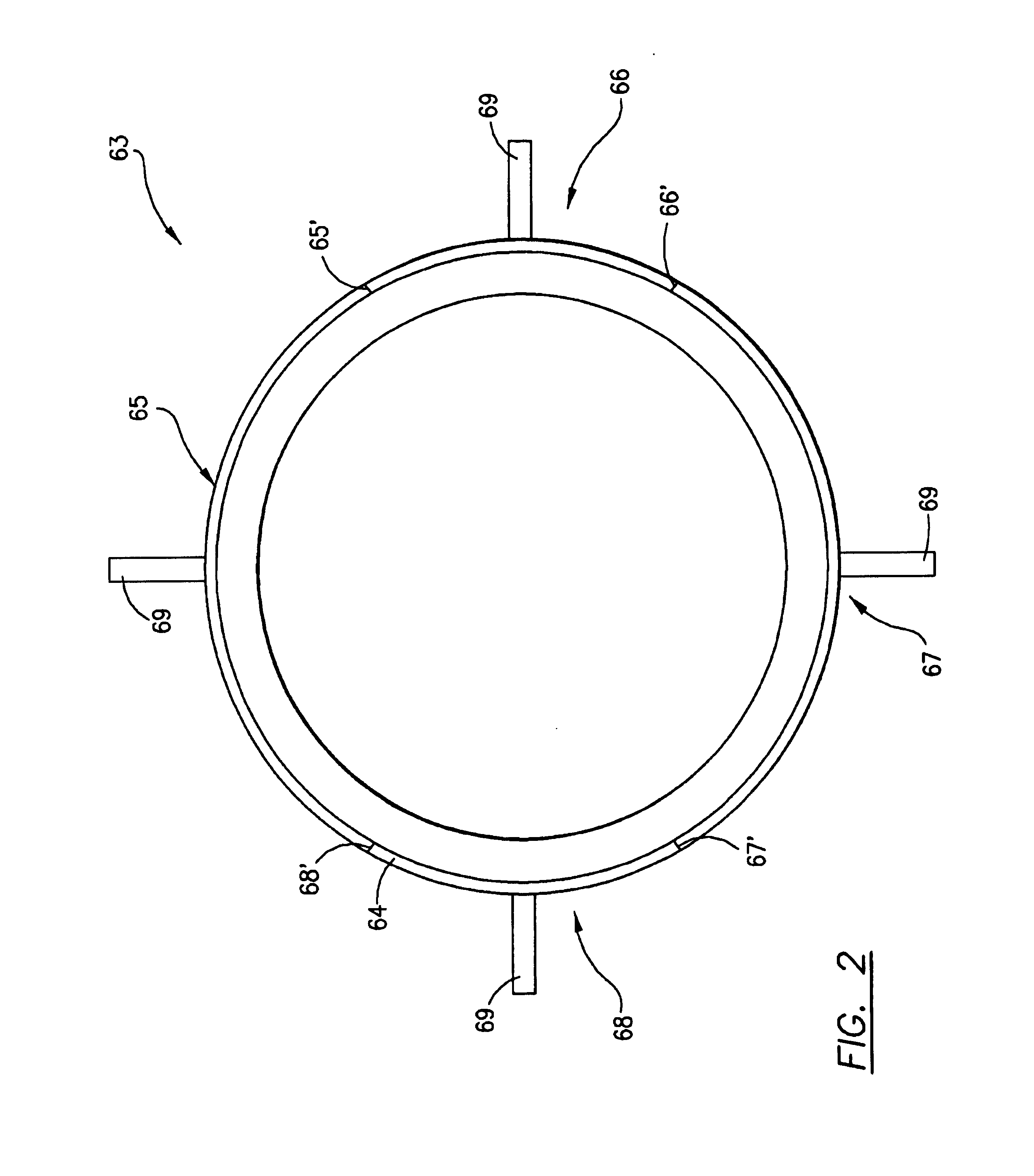

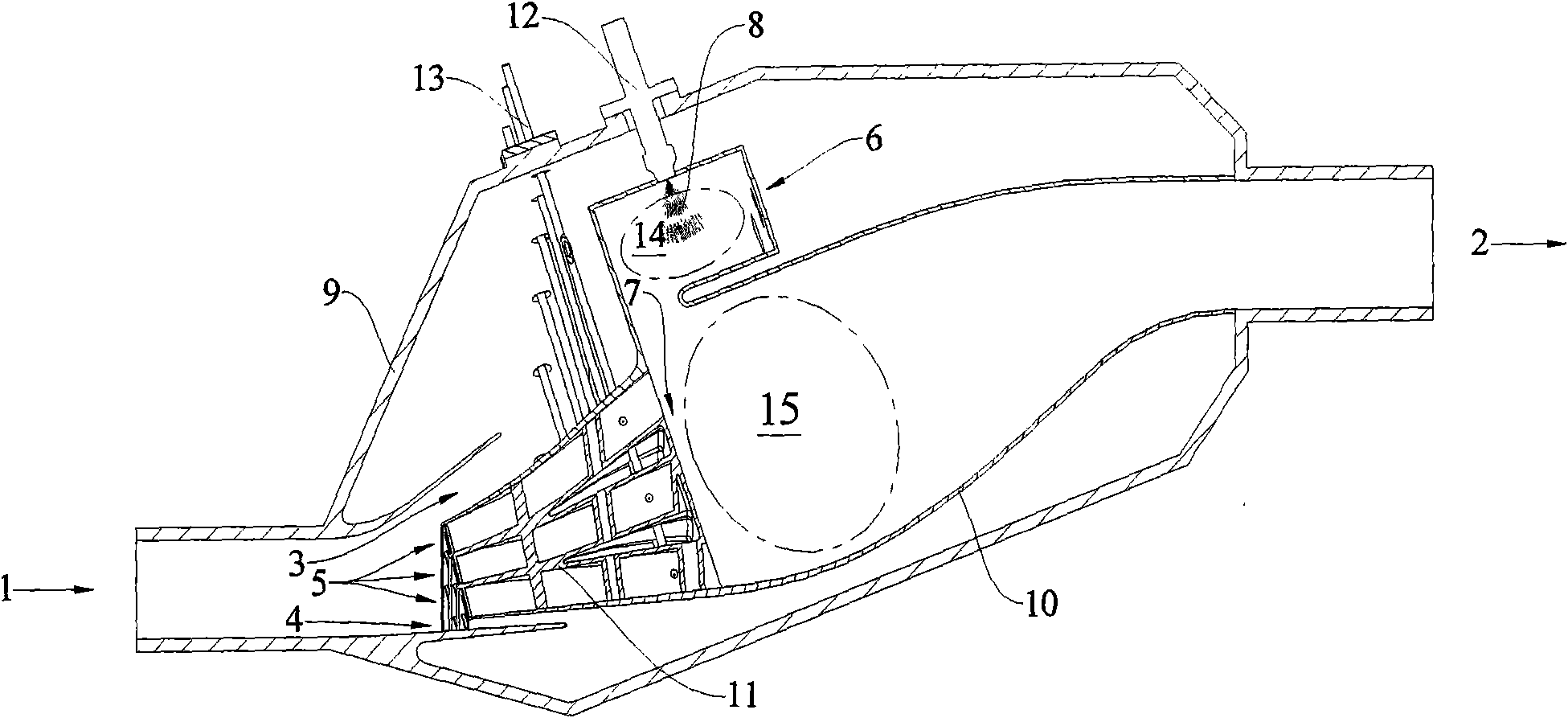

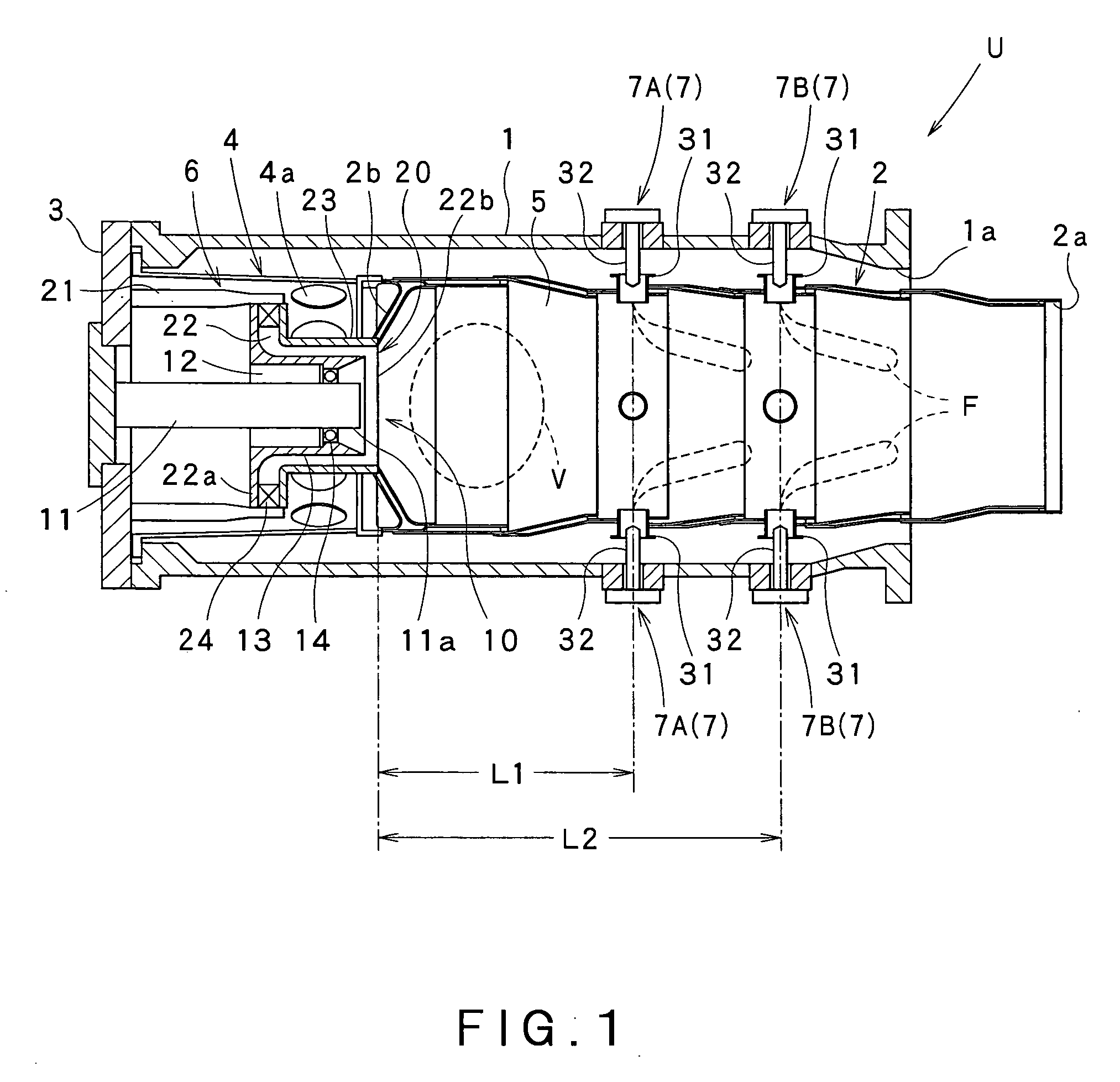

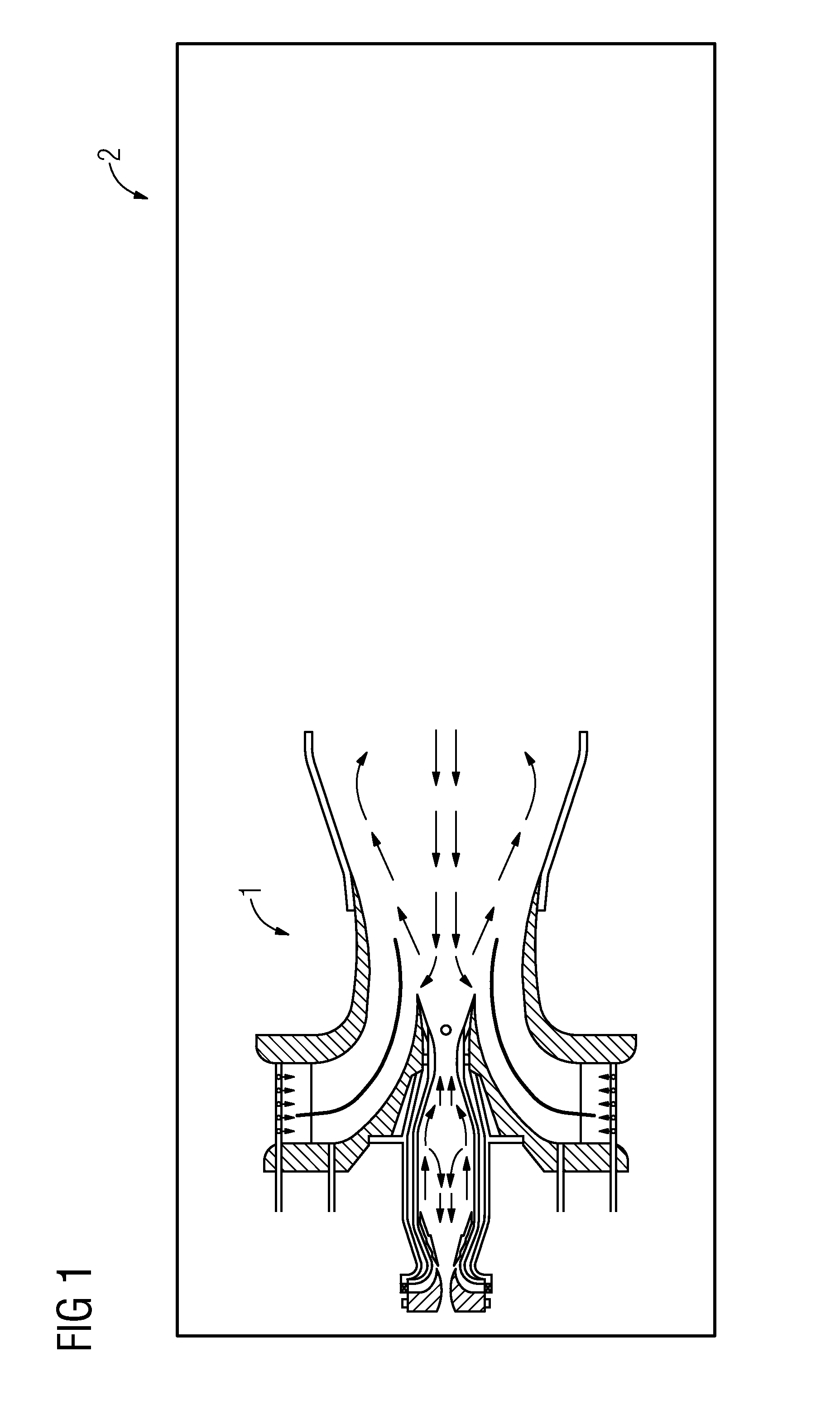

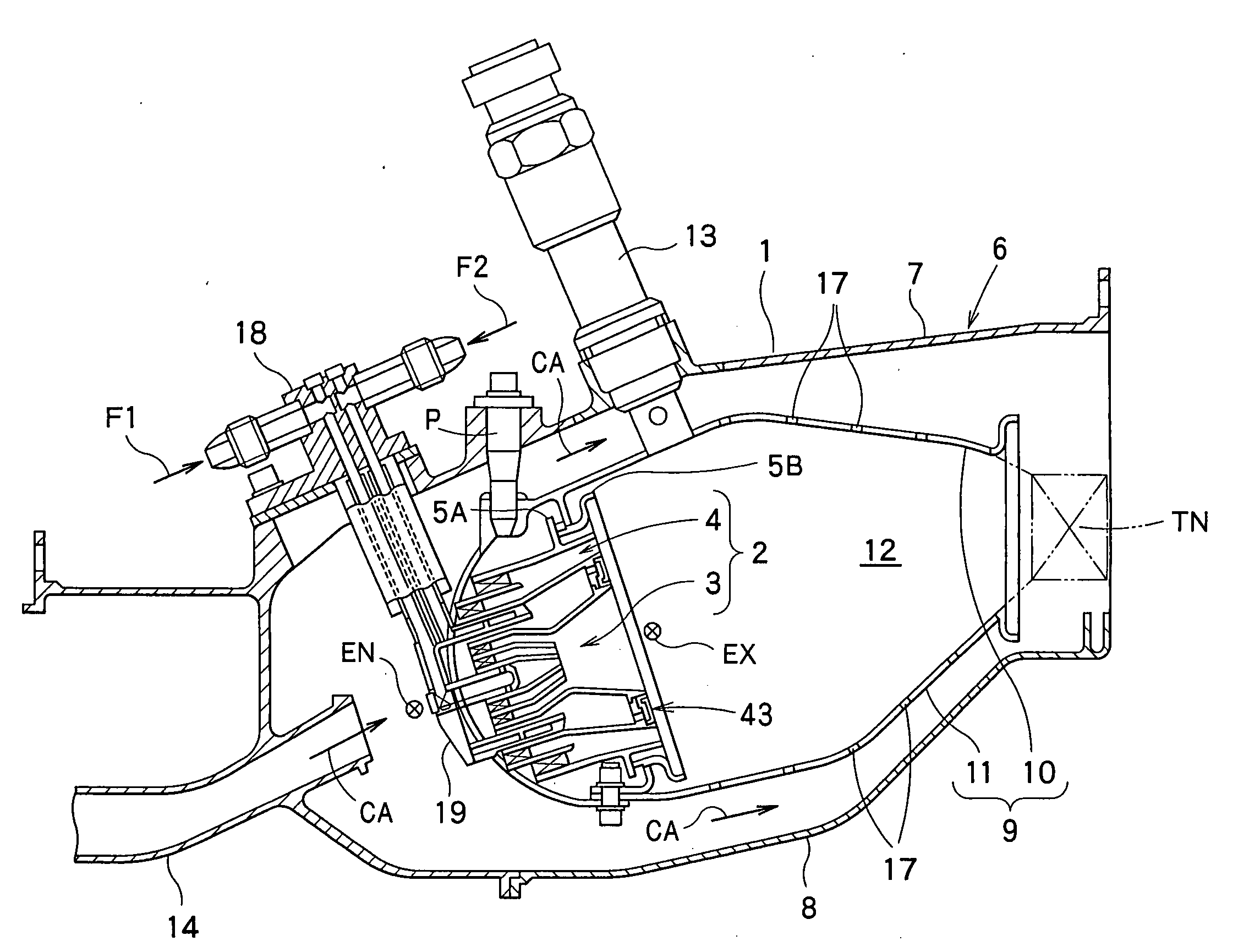

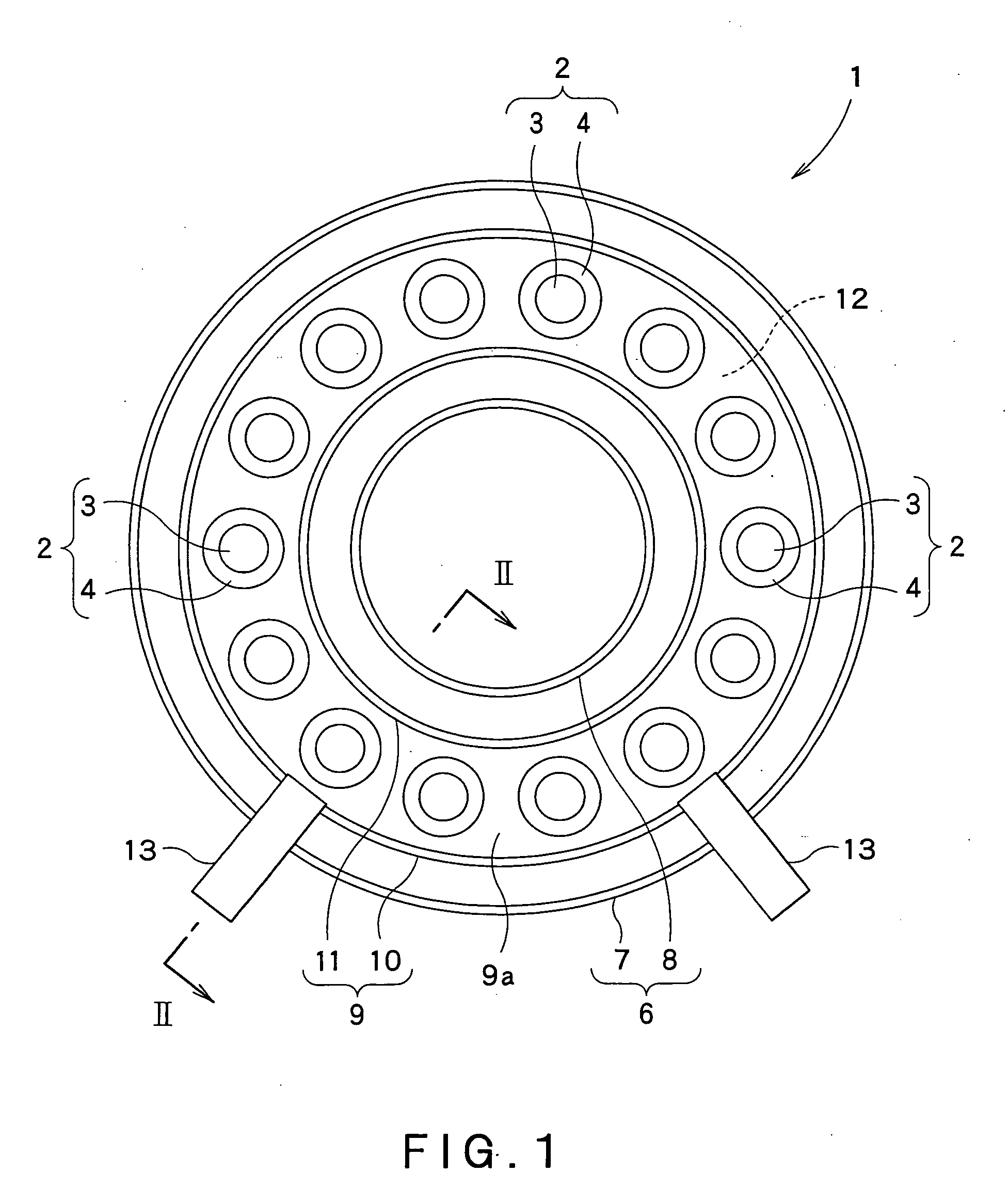

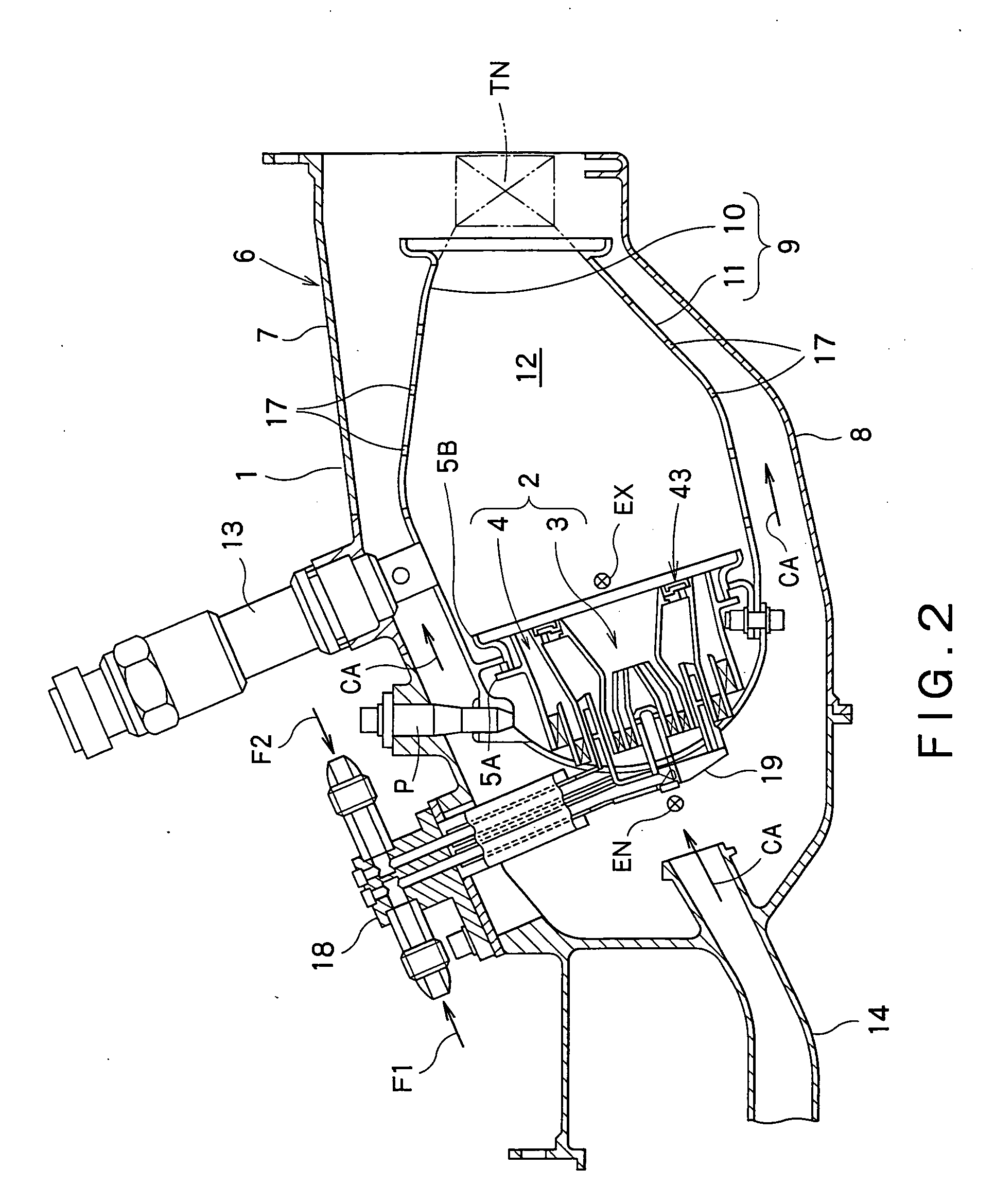

Flamesheet combustor

InactiveUS6935116B2Well mixedEmission reductionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemCombustion chamber

A gas turbine combustion system having reduced emissions and improved flame stability at multiple load conditions is disclosed. The improved combustion system accomplishes this through complete premixing, a plurality of fuel injector locations, combustor geometry, and precise three dimensional staging between fuel injectors. Axial, radial, and circumferential fuel staging is utilized including fuel injection proximate air swirlers. Furthermore, strong recirculation zones are established proximate the introduction of fuel and air premixture from different stages to the combustion zone. The combination of the strong recirculation zones, efficient premixing, and staged fuel flow thereby provide the opportunity to produce low emissions combustion at various load conditions.

Owner:H2 IP UK LTD

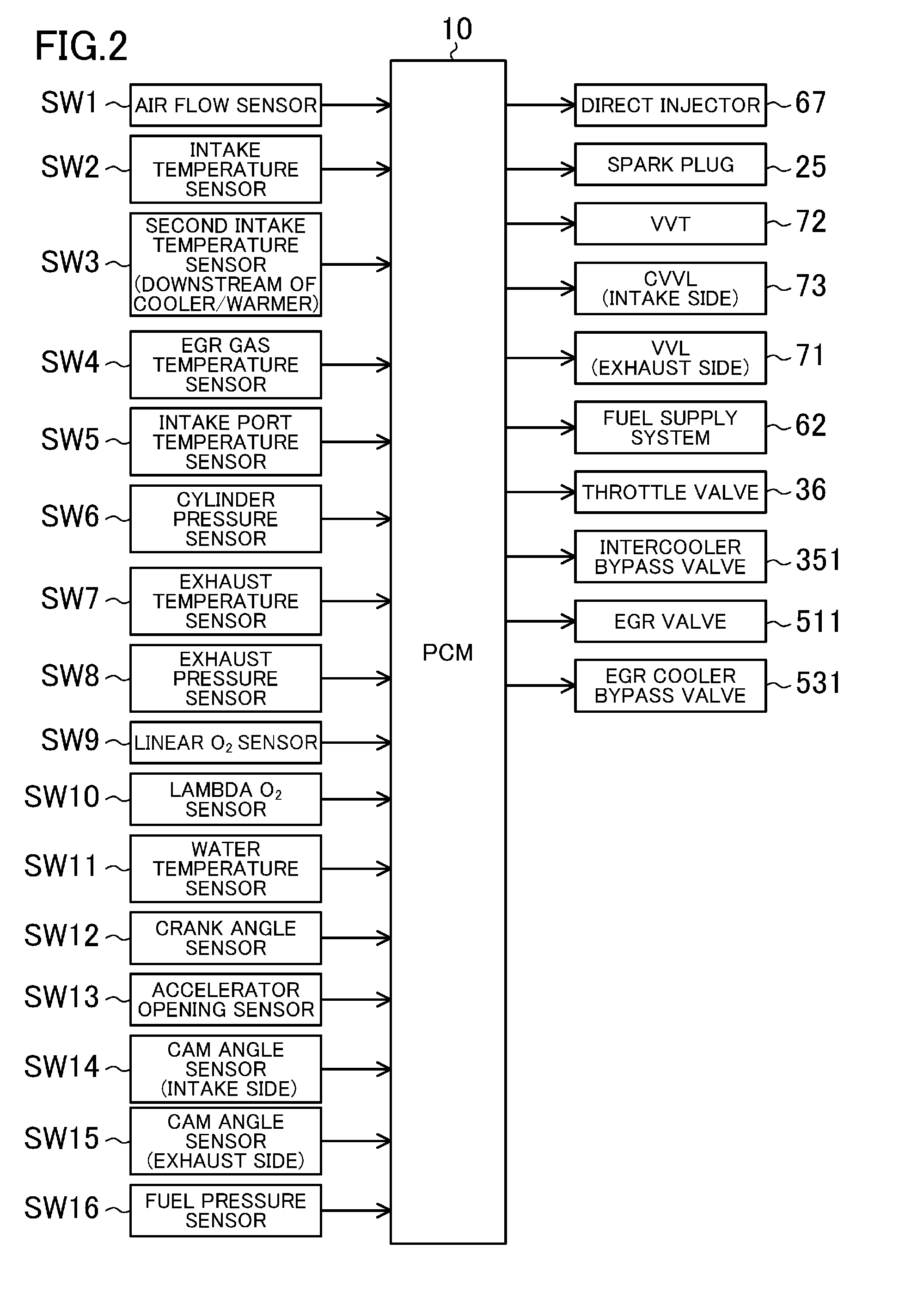

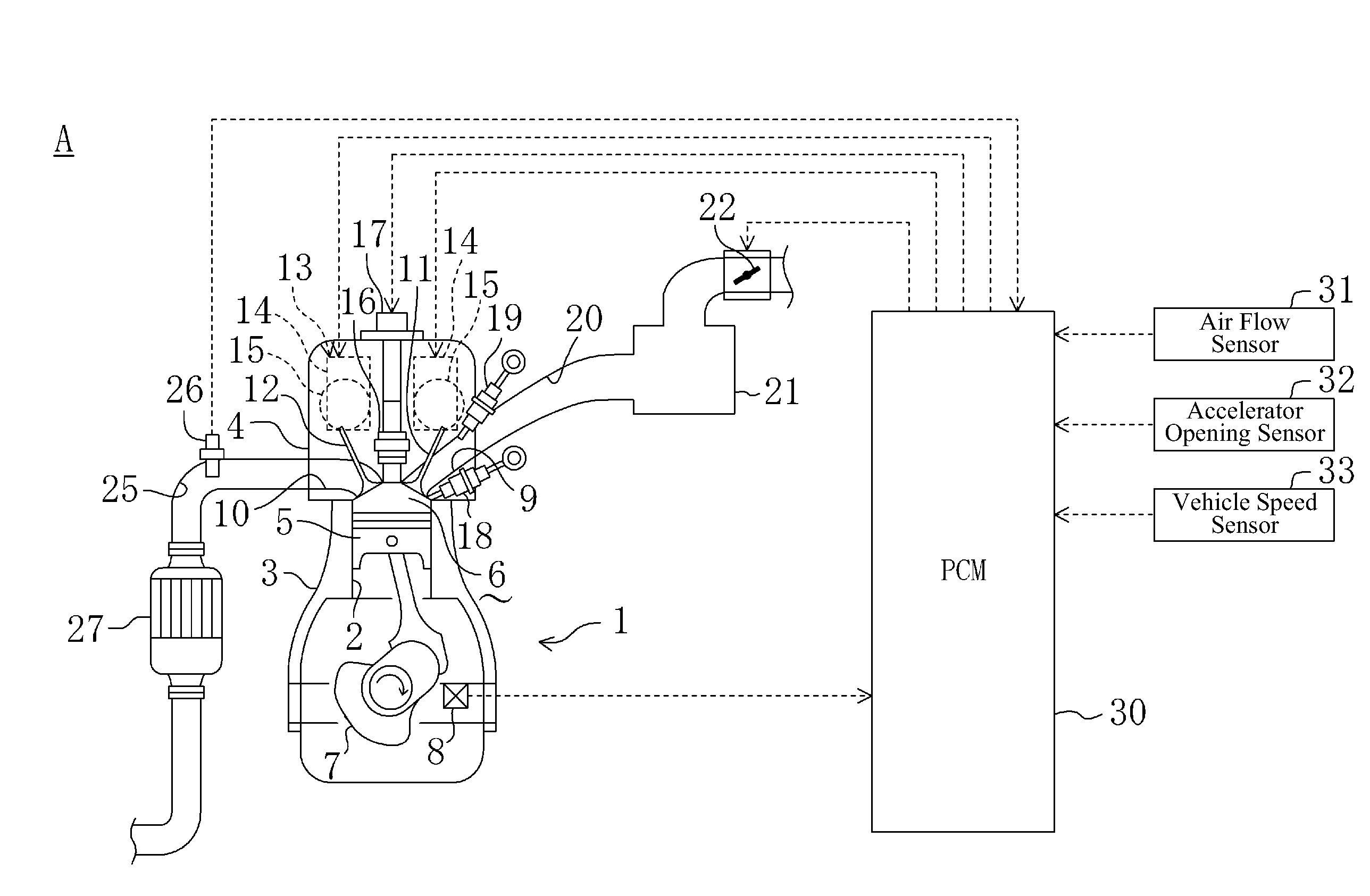

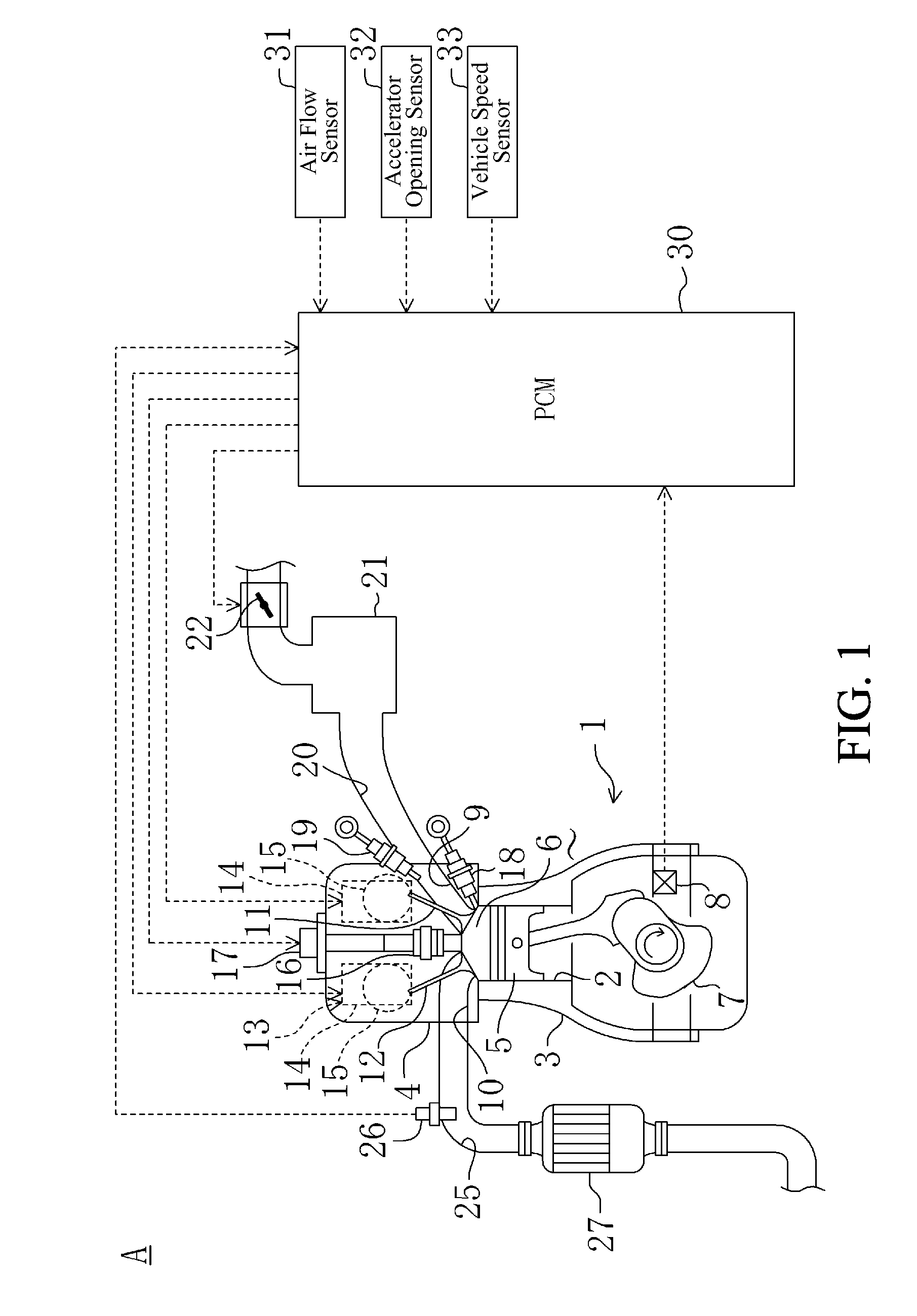

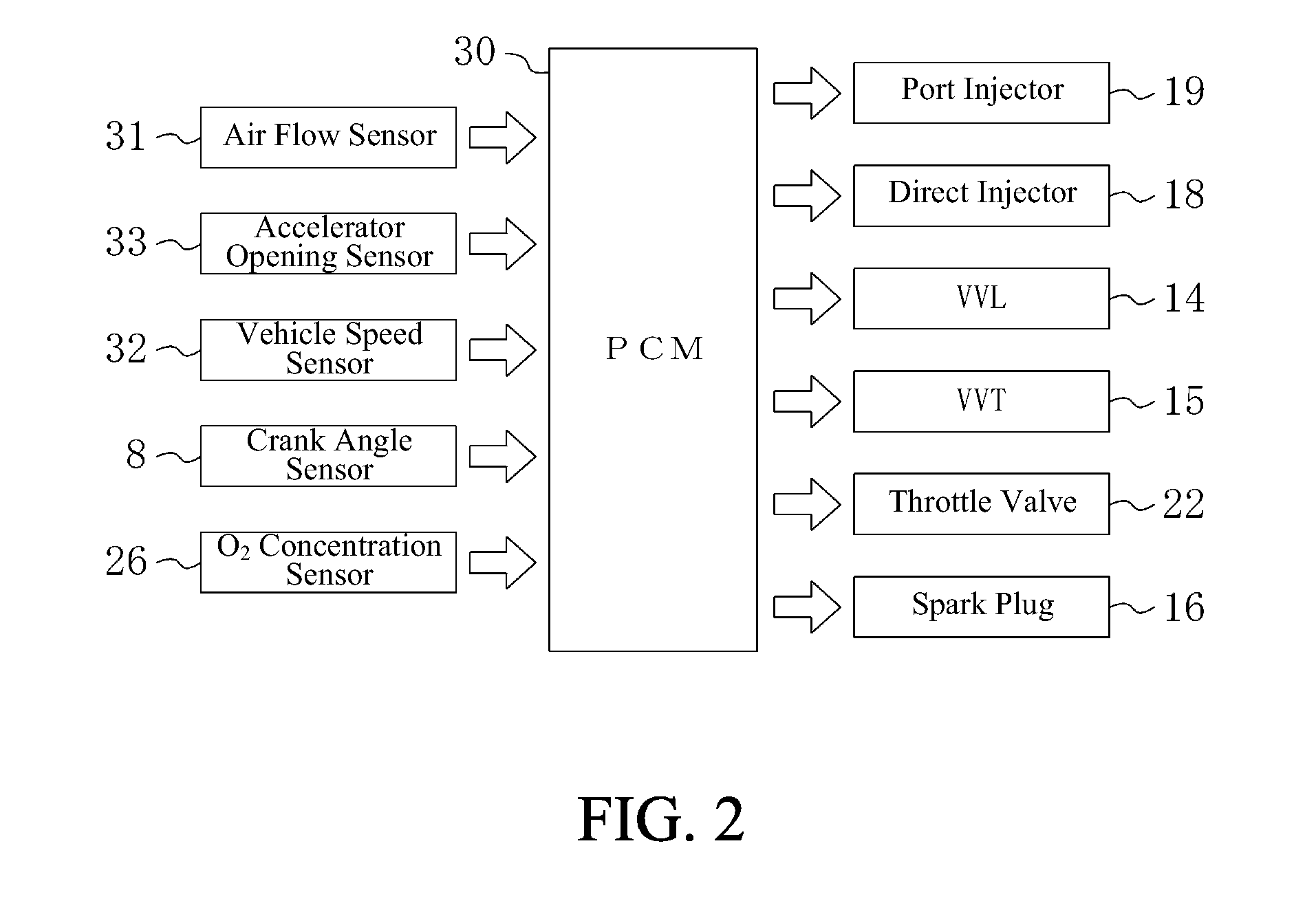

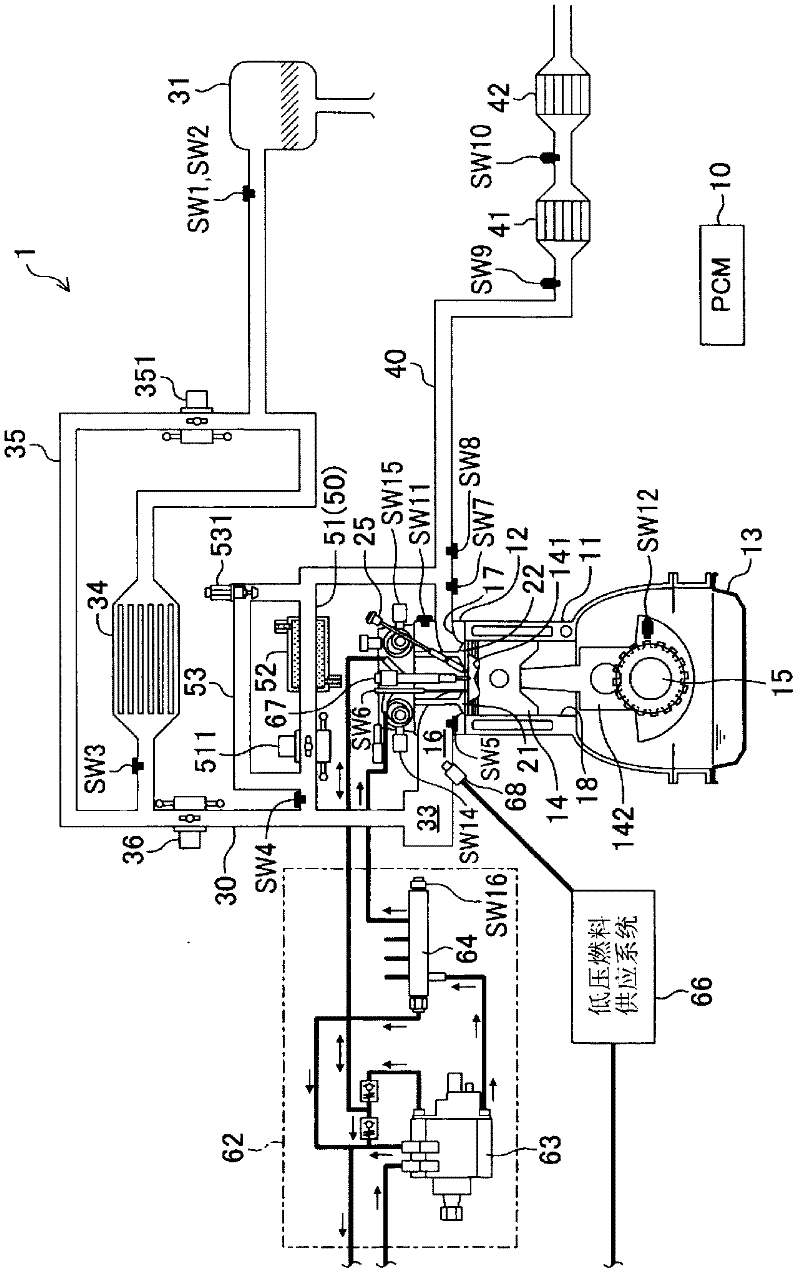

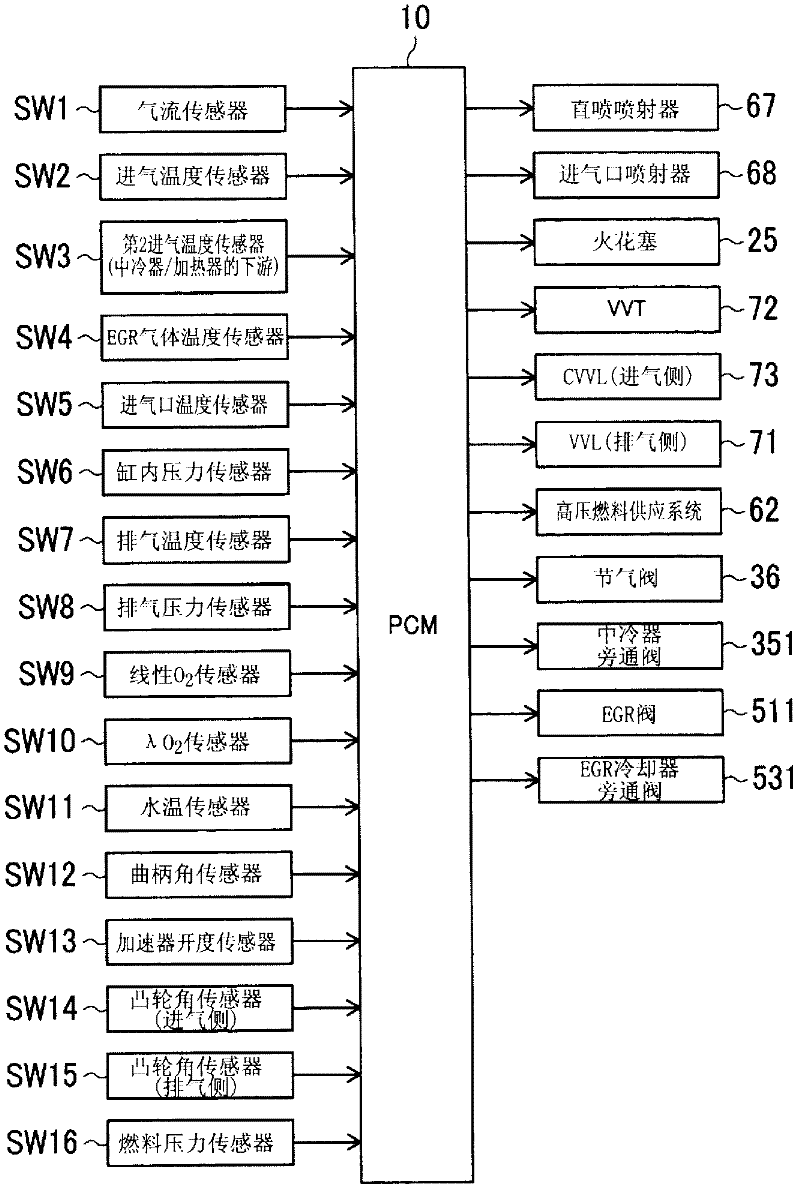

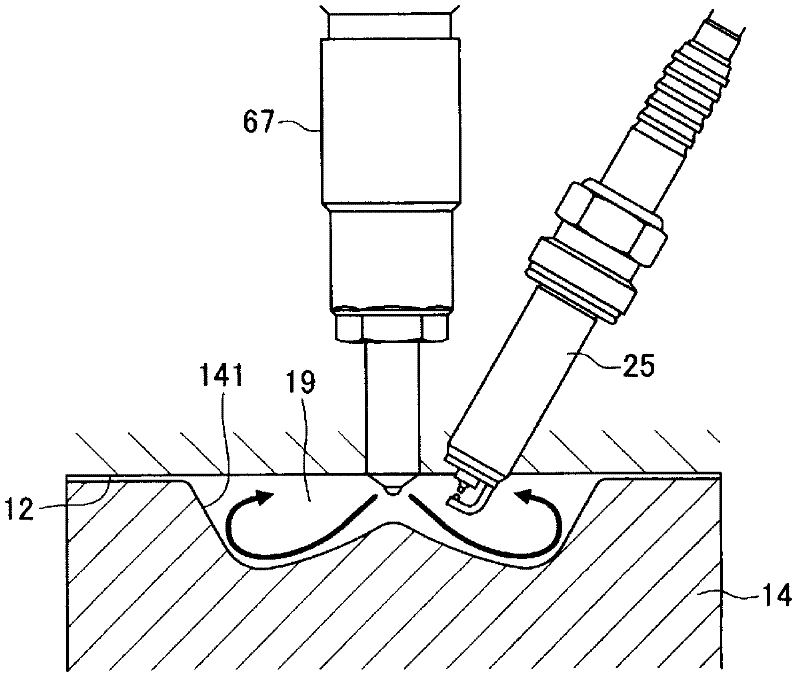

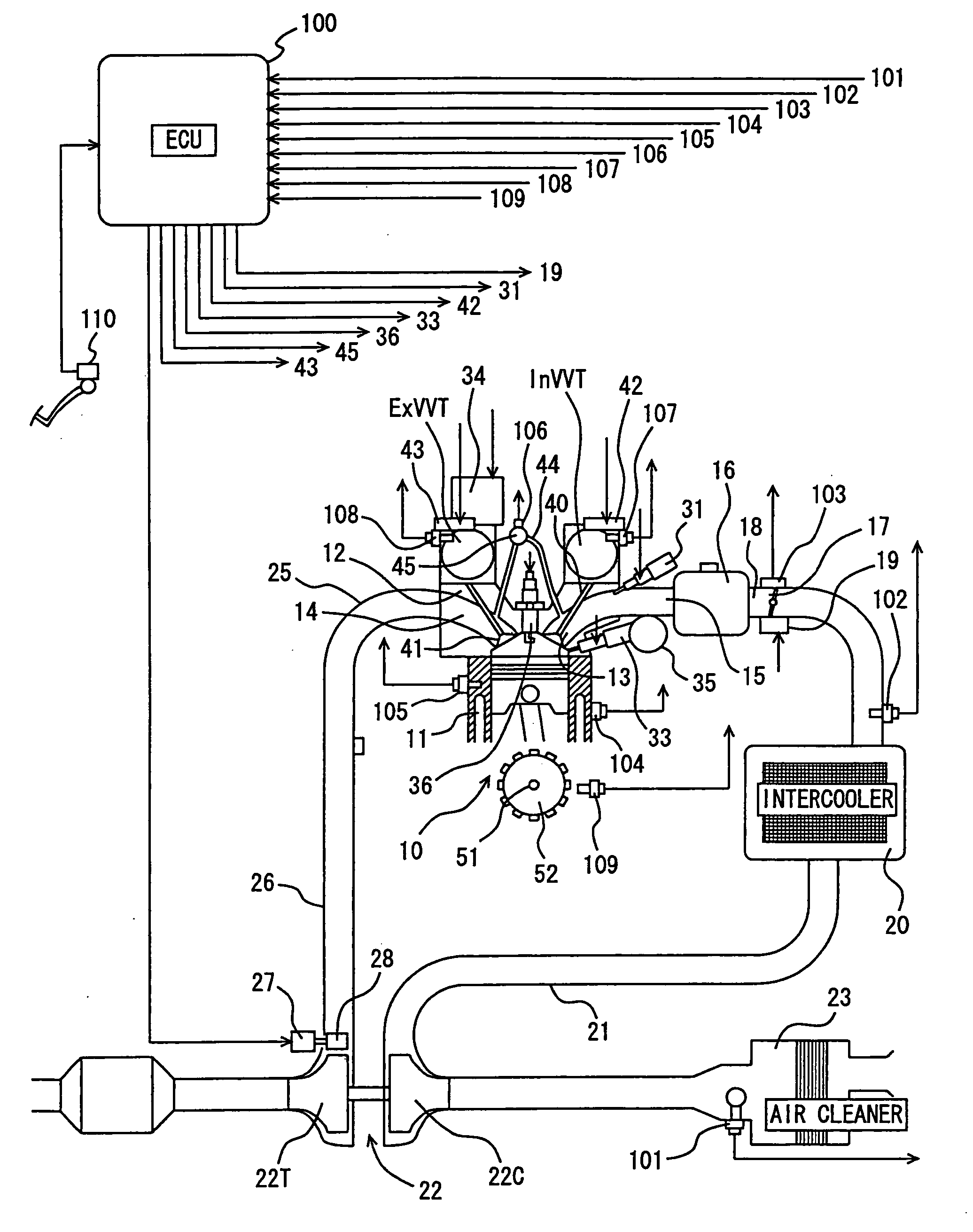

Spark-ignition direct-injection engine

ActiveUS20150114342A1Promote atomizationShorten the overall cycleElectrical controlInternal combustion piston enginesLow loadHigh load

A controller injects fuel into a cylinder at a high fuel pressure of 30 MPa or higher, at least in a period between a terminal stage of a compression stroke and an initial stage of an expansion stroke when an operating mode of an engine body is at least in a first specified sub-range of a low load range, and at least in a second specified sub-range of a high load range. The controller sets an EGR ratio in the first specified sub-range to be higher than an EGR ratio in the second specified sub-range, and advances start of fuel injection in the first specified sub-range to start of fuel injection in the second specified sub-range.

Owner:MAZDA MOTOR CORP

Method of operating a flamesheet combustor

InactiveUS6986254B2Emission reductionStable combustionContinuous combustion chamberTurbine/propulsion engine ignitionCombustion systemEngineering

A method of operating a gas turbine combustion system having reduced emissions and improved flame stability at multiple load conditions is disclosed. The improved combustion system accomplishes this through complete premixing, a plurality of fuel injector locations, combustor geometry, and precise three dimensional staging between fuel injectors. Axial, radial, and circumferential fuel staging is utilized including fuel injection proximate air swirlers. Furthermore, strong recirculation zones are established proximate the introduction of fuel and air premixture from different stages to the combustion zone. Fuel injection staging sequences are disclosed that create the conditions necessary to provide stable combustion and reduced emissions at multiple load conditions.

Owner:H2 IP UK LTD

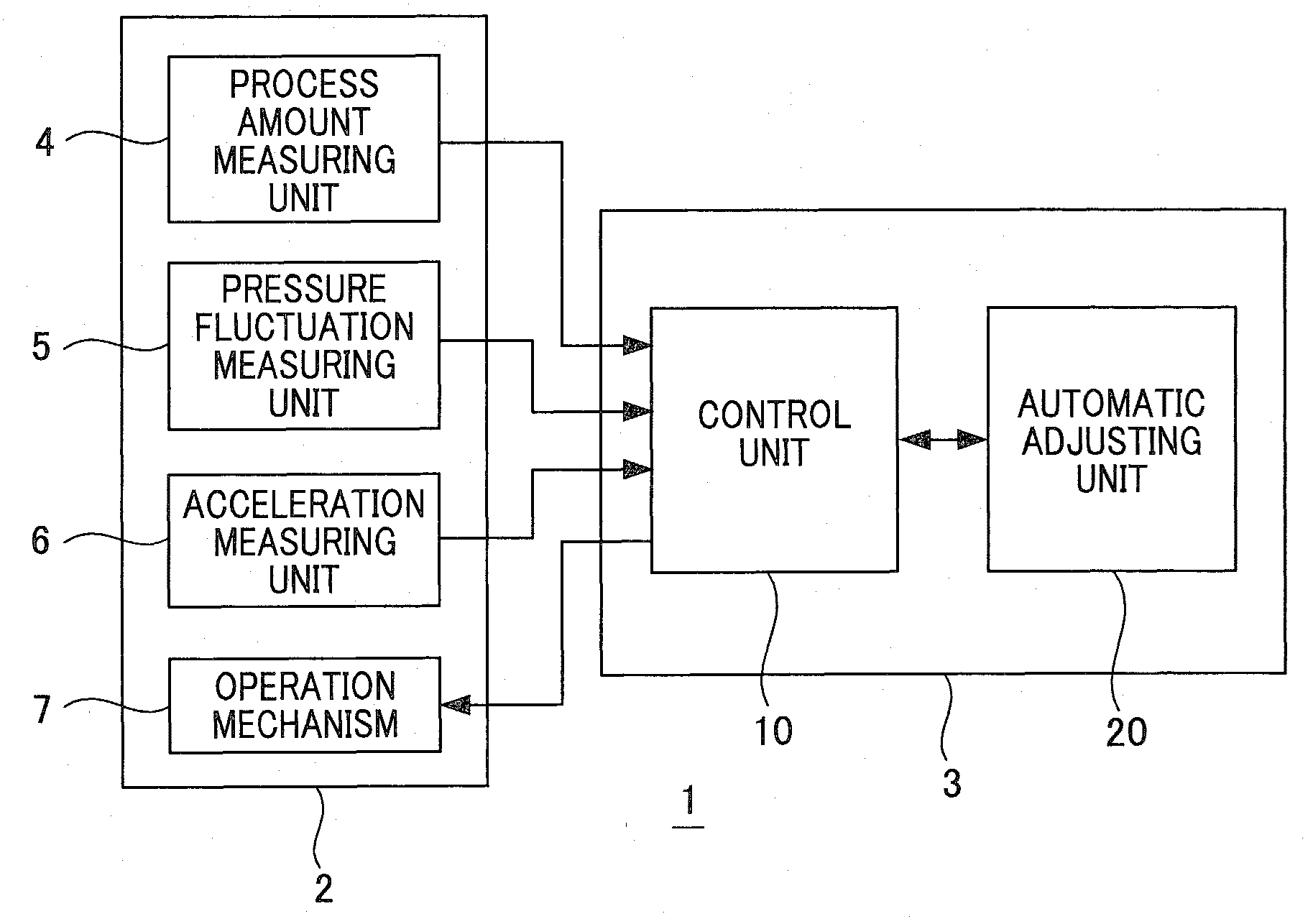

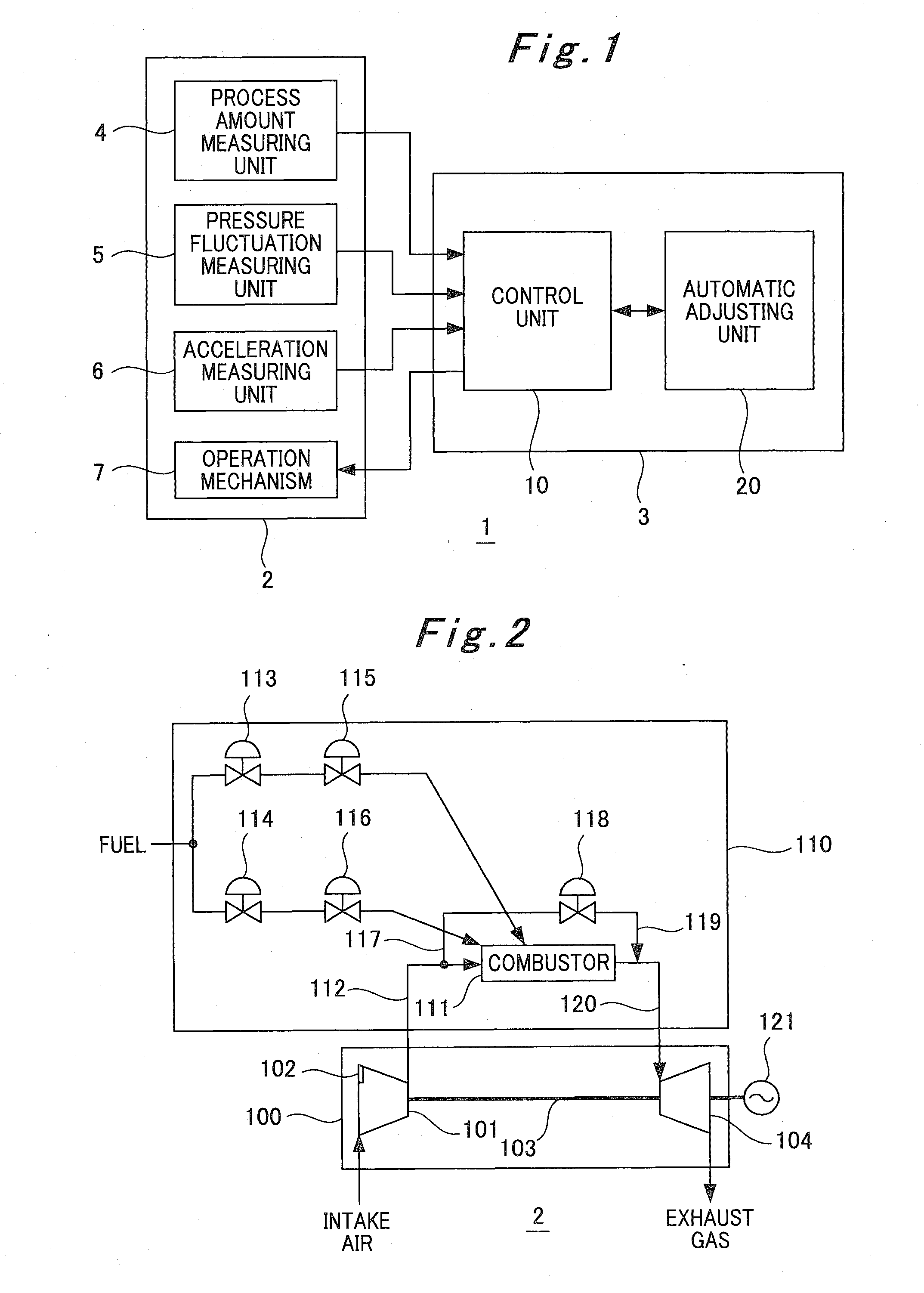

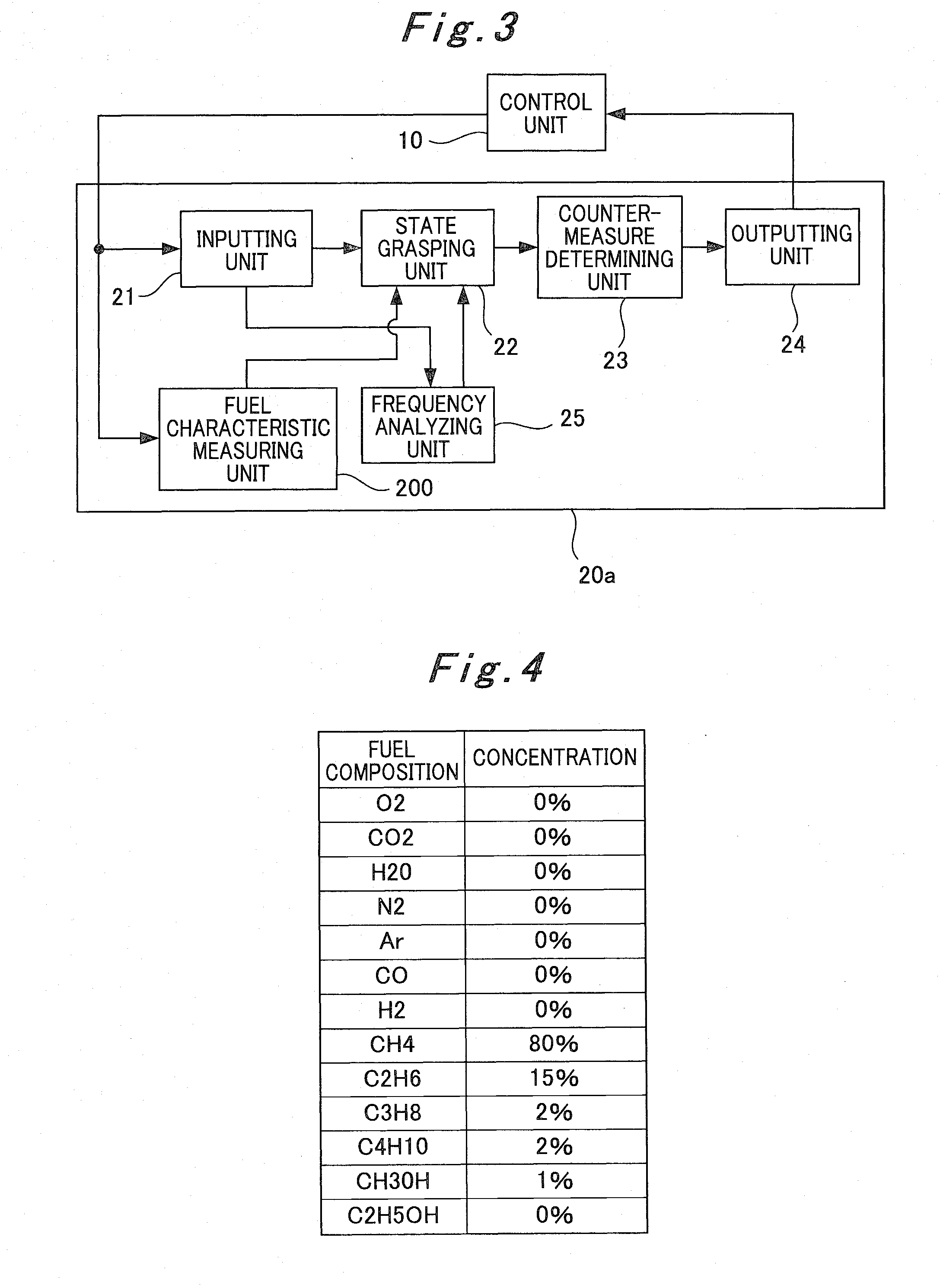

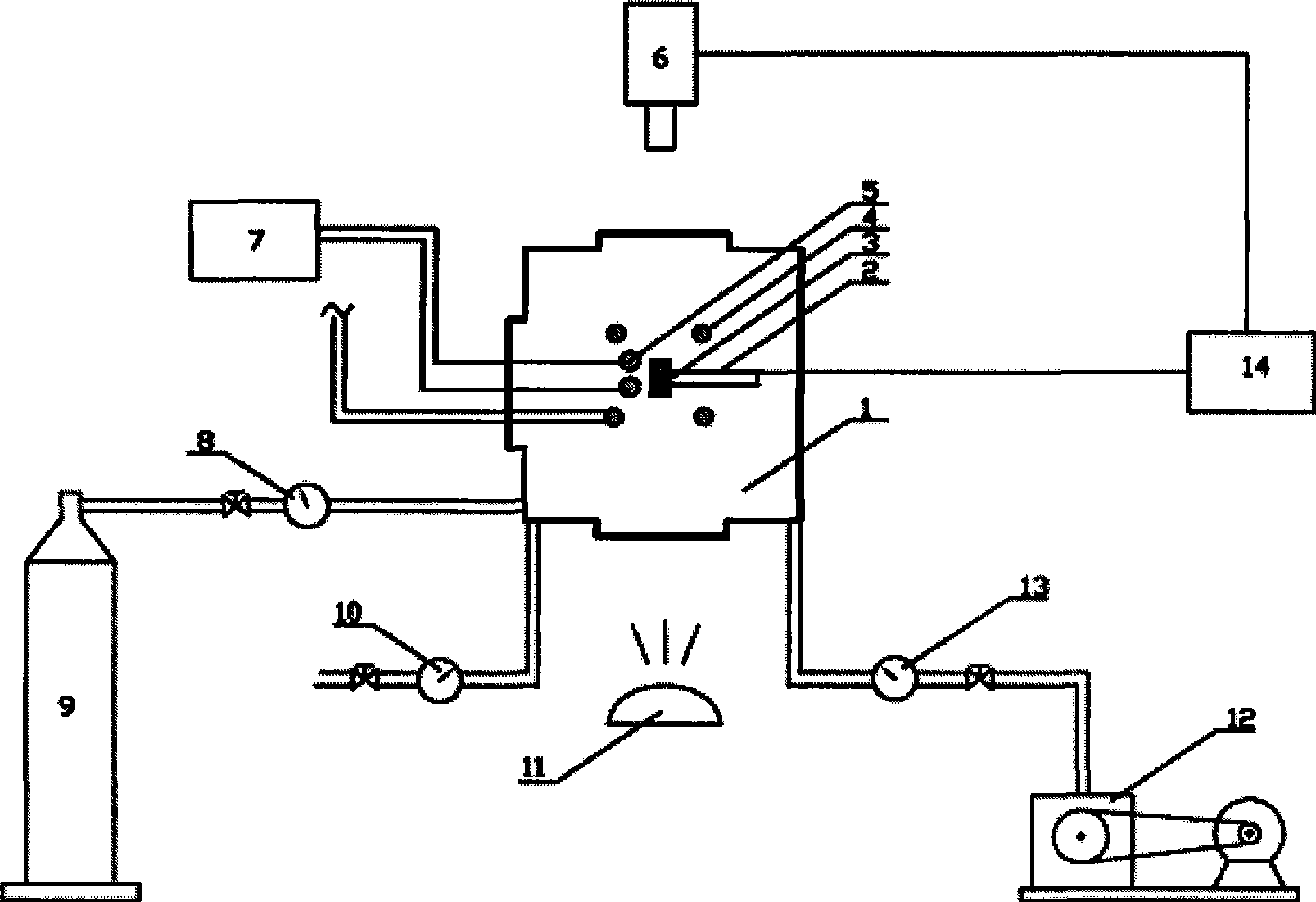

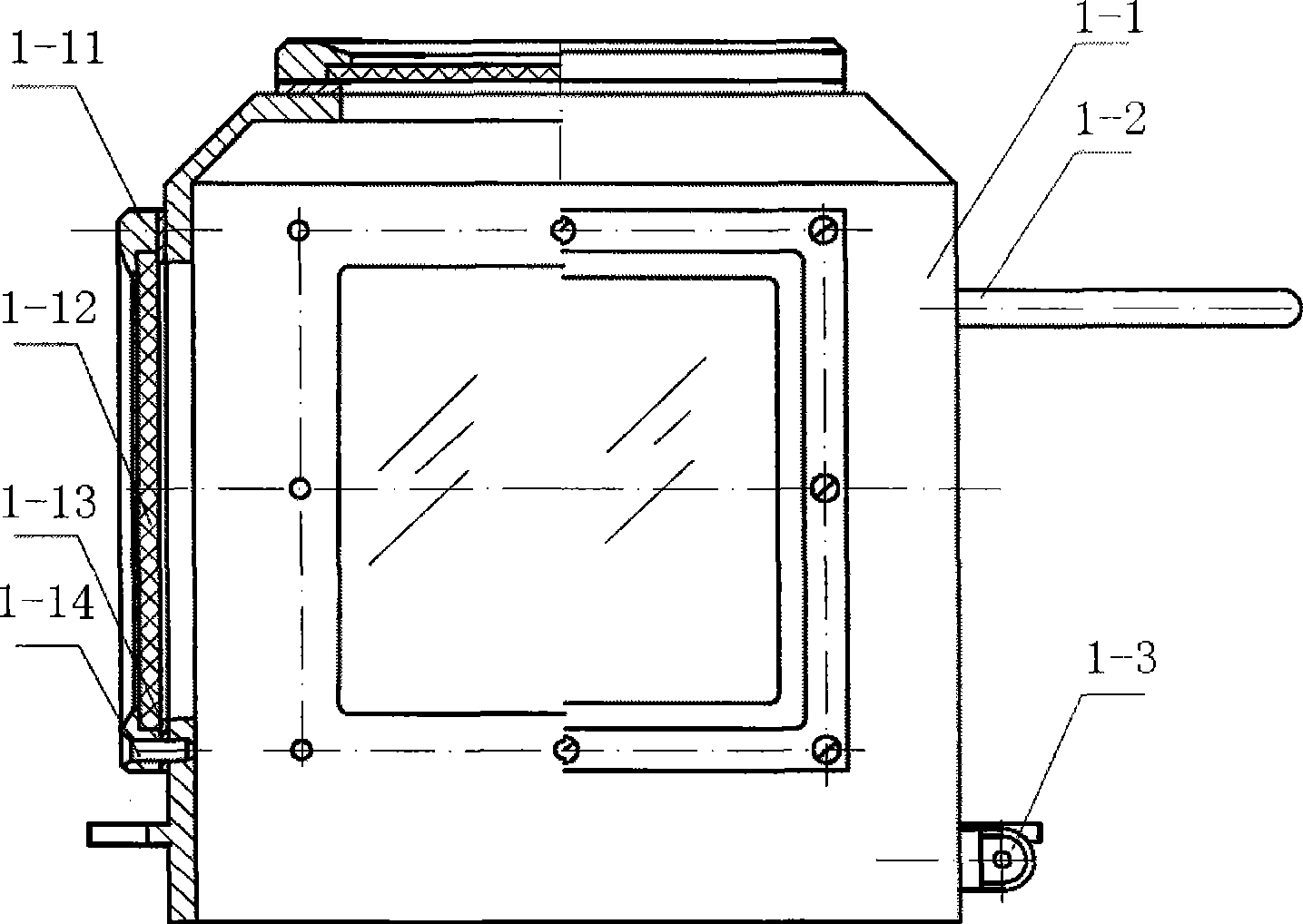

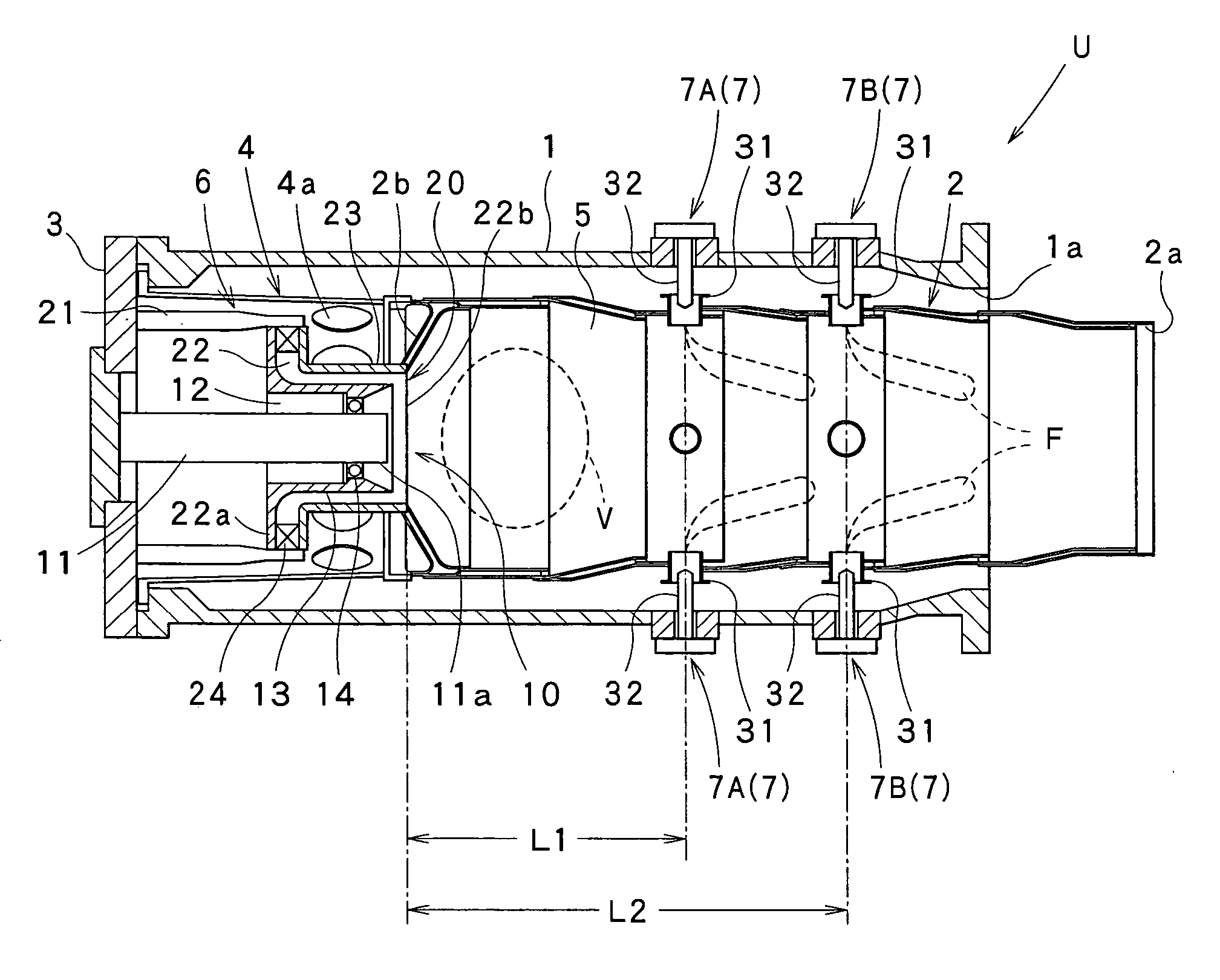

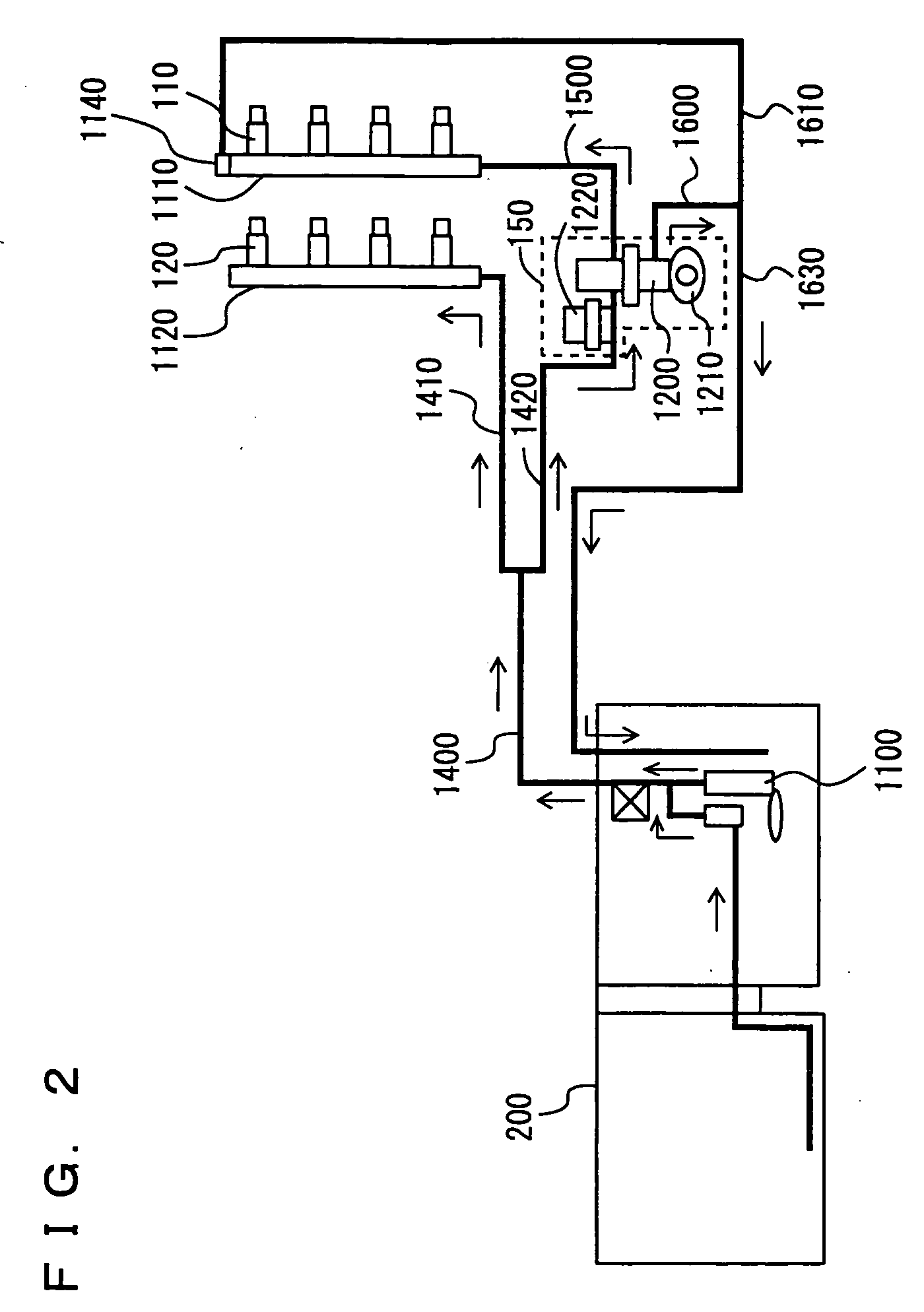

Gas turbine control device and gas turbine system

ActiveUS20090125207A1Oscillation suppressionStable combustionAnalogue computers for vehiclesContinuous combustion chamberCombustorCountermeasure

An object of the present invention is to provide a gas turbine control device which is capable of performing correction on the basis of a fuel composition of fuel gas to be supplied to a gas turbine, and is capable of changing an amount of correction in response to variation with time of the gas turbine. To attain this, a frequency analyzing unit 25 performs a frequency analysis of combustion oscillation of a combustor and splits a result of the analysis into respective frequency bands. Then, a state grasping unit 22 checks an operating state of the gas turbine on the basis of the result of the analysis of the combustion oscillation and process value of the gas turbine, and corrects the checked operating state on the basis of a fuel composition or a heat capacity of fuel gas measured by a fuel characteristic measuring unit 200. A countermeasure determining unit 23 conducts a countermeasure for controlling an operating action of the gas turbine on the basis of the operating state thus checked.

Owner:MITSUBISHI POWER LTD

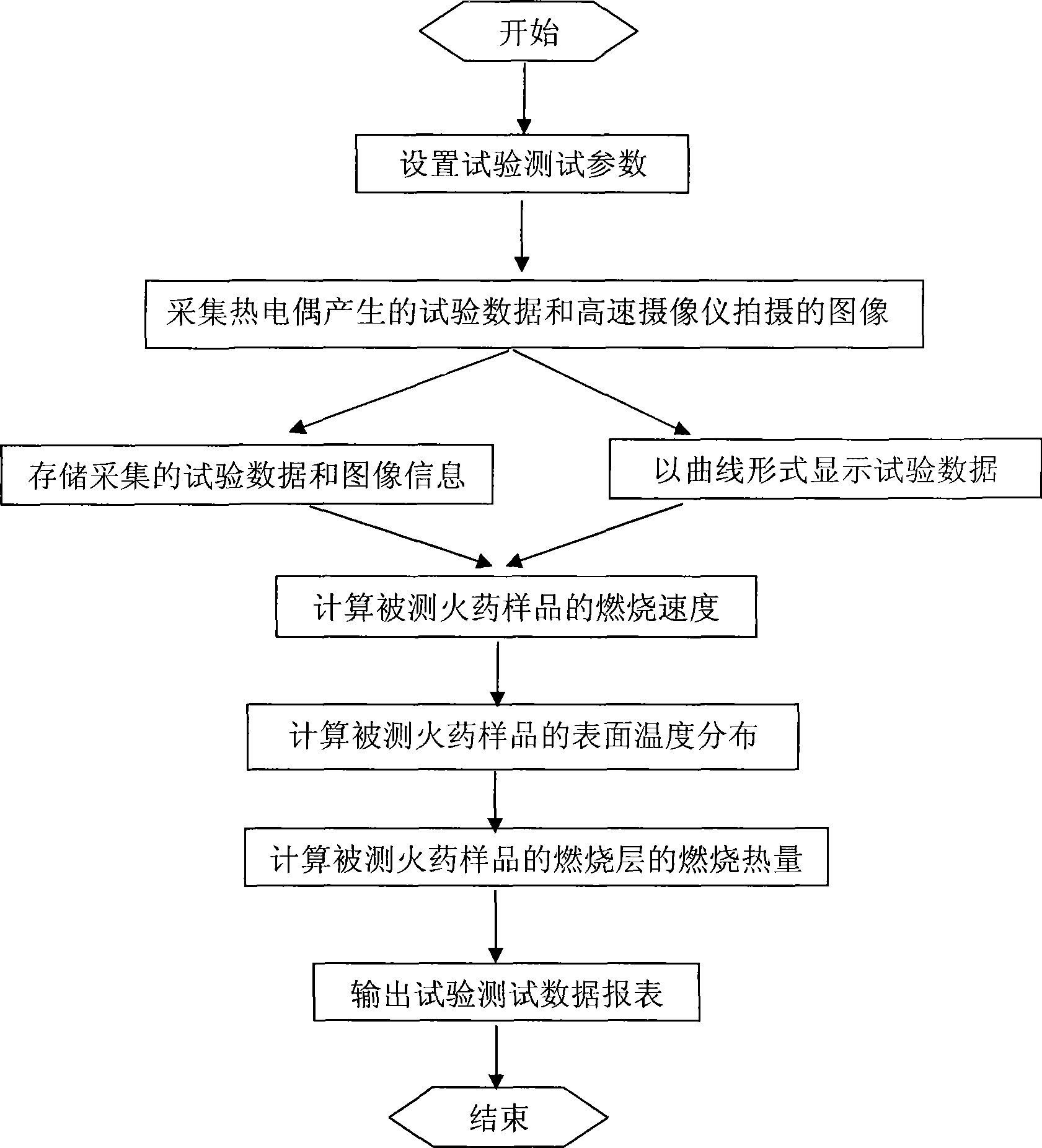

Device for testing powder combustion characteristics in vacuum condition

InactiveCN101382533ARealize measurementEfficient use ofChemical analysis using combustionFuel testingCombustion chamberHeating time

The invention discloses a testing device of gunpowder combustion characteristics in vacuum, which mainly comprises a combustion chamber, a vacuum pump, an electric heater, a thermoelectric couple, a high speed camera and a data acquisition and processing system; wherein, the vacuum pump provides vacuum environment for the combustion chamber; by controlling the heating current and the heating time of the electric heater, different ignition isoperibols can be provided for tested gunpowder samples in the combustion chamber; and the data acquisition and processing system collects the test data generated by the thermoelectric couple and the gunpowder combustion images shot by the high speed camera when the tested gunpowder samples combust, and finally obtains the combustion characteristics of the tested gunpowder samples through corresponding processing and calculation. The invention not only can be used for testing the parameters such as combustion speed, combustion surface temperature and combustion heat and the like of the gunpowder in vacuum, but also can be used for the generation and collection of the combustion products of the gunpowder under different vacuum conditions. The invention has the overriding advantages of high integration level, obtaining various parameters by one testing and low testing expenses.

Owner:XIAN MODERN CHEM RES INST

Method of operating an internal combustion engine

ActiveUS20080178836A1Overcome disadvantagesAccelerate emissionsValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

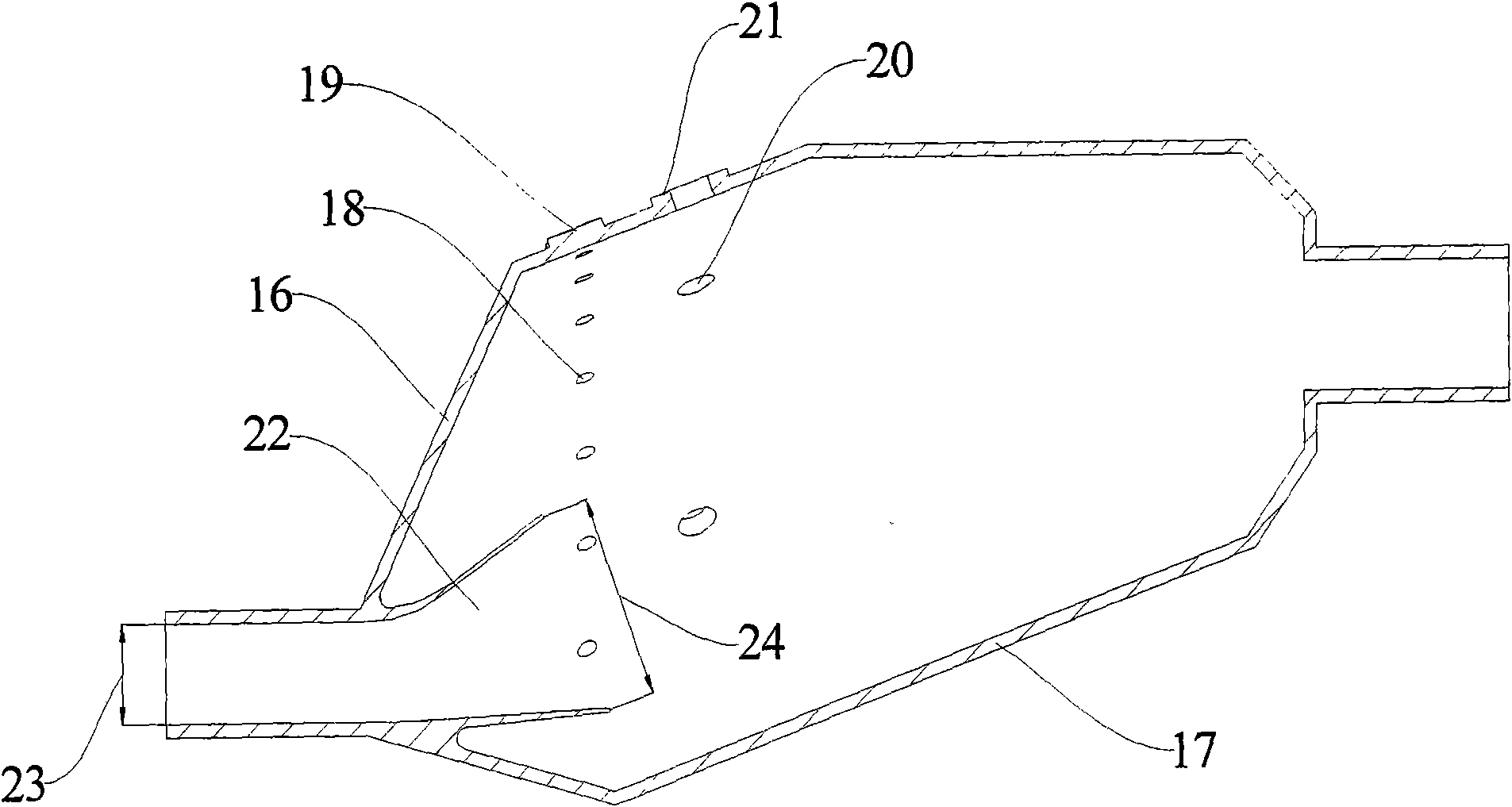

Integrated diffusion oriented combustion chamber

InactiveCN101650038AGuaranteed temperature distributionSimplified matching structureContinuous combustion chamberLow speedCombustion chamber

The invention relates to an integrated diffusion oriented combustion chamber which adopts a full ring combustion chamber structure. The integrated diffusion oriented combustion chamber mainly comprises a crankcase, a combustion liner and an oriented diffuser. The oriented diffuser realizes pneumatic and structural coupling, controls the tangential flow direction and carries out diffusion and speedreduction, and a local return low-speed zone is formed, thereby being good for flame linkage and tangential stable combustion; grading combustion is adopted, and a pre-combustion grade can be selected to work alone and work together with a main pre-combustion grade according to work conditions; the pre-combustion grade utilizes the trapped vortex combustion technology for stable work, goes into amain combustion zone to inflame a main combustion grade through a contraction outlet, and provides a stable ignition source for the main combustion grade; fuel of the main combustion grade is injected to a main combustion grade airflow in the oriented diffuser, atomization evaporation mixing with short distance is realized, and combustible mixture gas with uniform mixing is provided for the maincombustion zone. The invention allows tangential rotational flow of a gas compressor to directly go into the combustion chamber so as to realize tangential highly efficient and stable combustion; in addition, the discharge of pollutants is low, pre-rotation is provided for a turbine, the structure can be simplified, the weight is lightened, and the densification of a gas turbine is realized.

Owner:BEIHANG UNIV

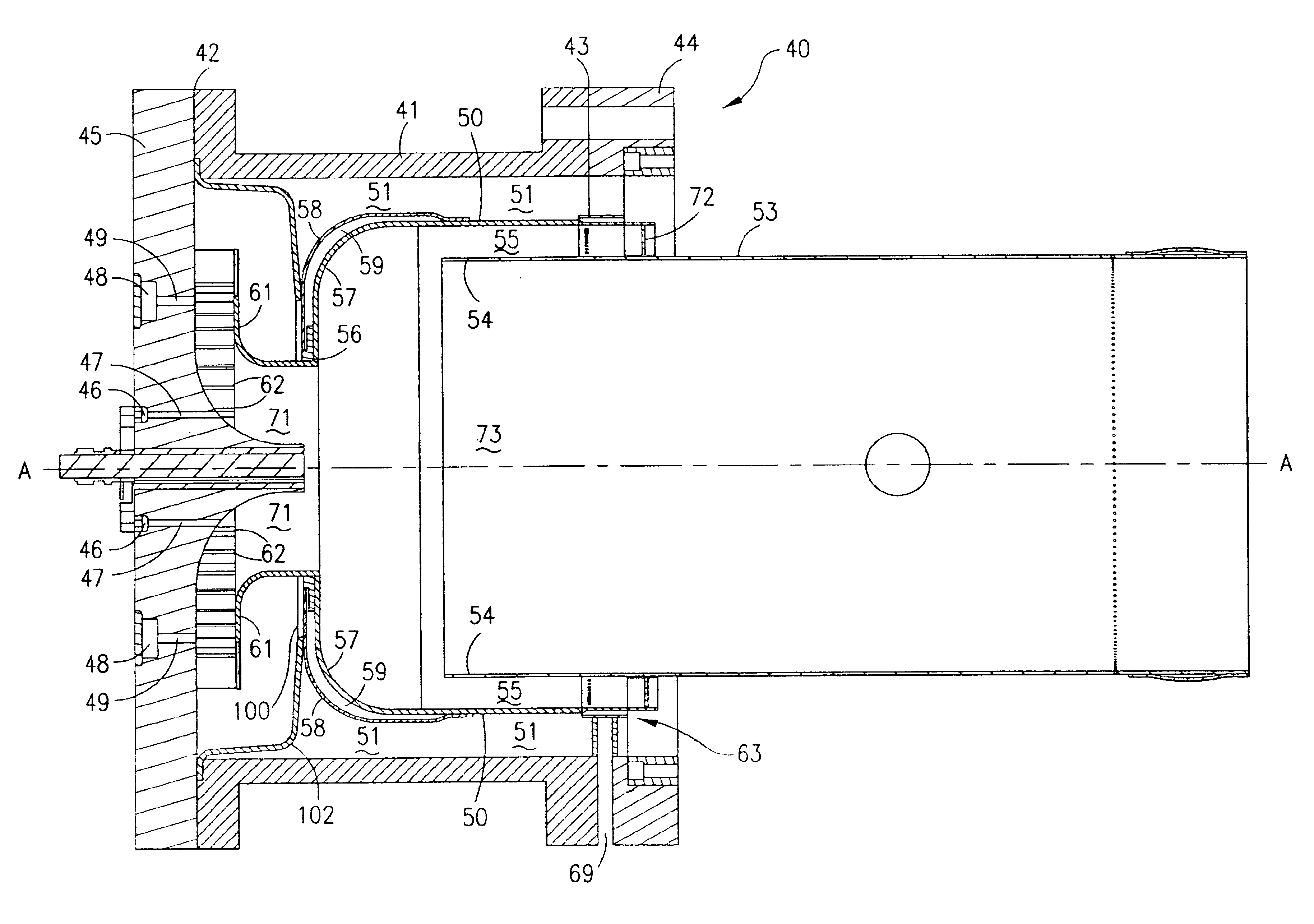

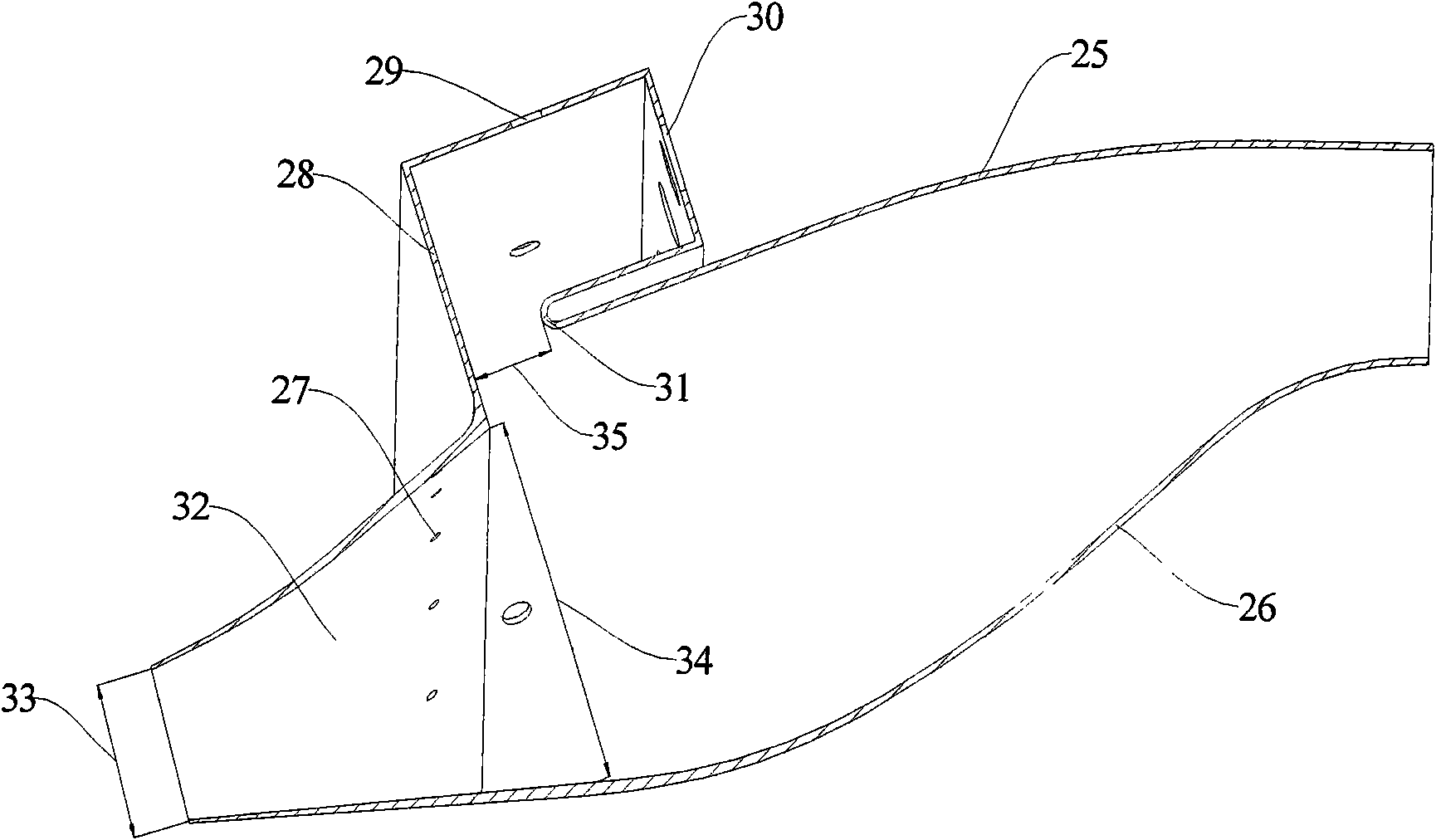

Combustor for gas turbine engine

InactiveUS20070089419A1Reduce the amount requiredStable combustionContinuous combustion chamberGas turbine plantsFuel supplyGas turbines

A combustor for a gas turbine engine of a lean premixed combustion type, includes: a fuel jetting device configured to jet a premixed fuel into a combustion chamber so that the premixed fuel burns in a premixed combustion zone which is formed in the combustion chamber; and an additive fuel supply unit disposed downstream of the premixed combustion zone so as to additionally supply fuel into the combustion chamber. The additive fuel supply unit includes first and second additive fuel supply devices disposed in a two-stage arrangement such that the second additive fuel supply device is positioned downstream of the first additive fuel supply device.

Owner:KAWASAKI HEAVY IND LTD

Control apparatus for internal combustion engine

InactiveUS20070000478A1Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionIdle speed

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

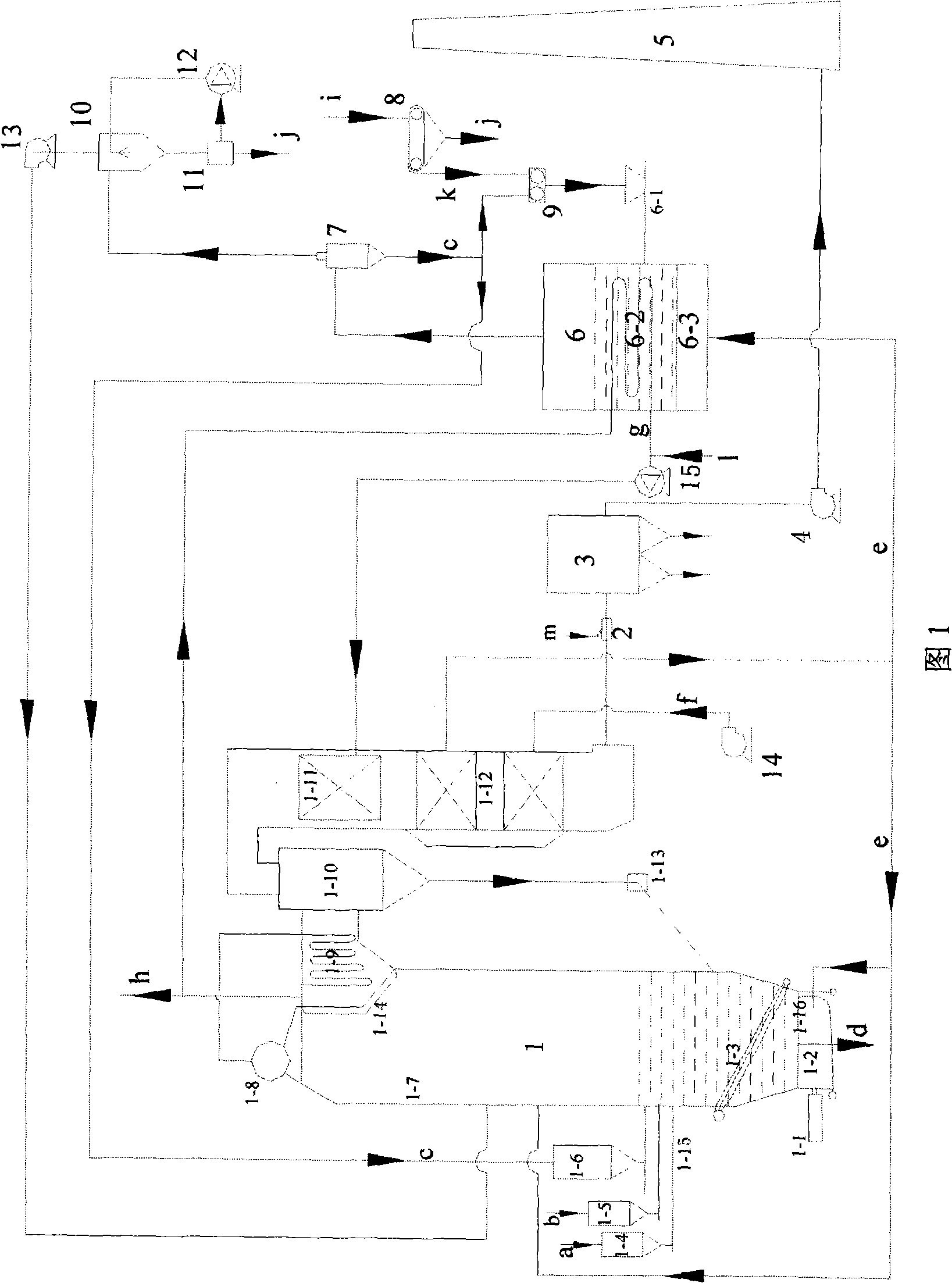

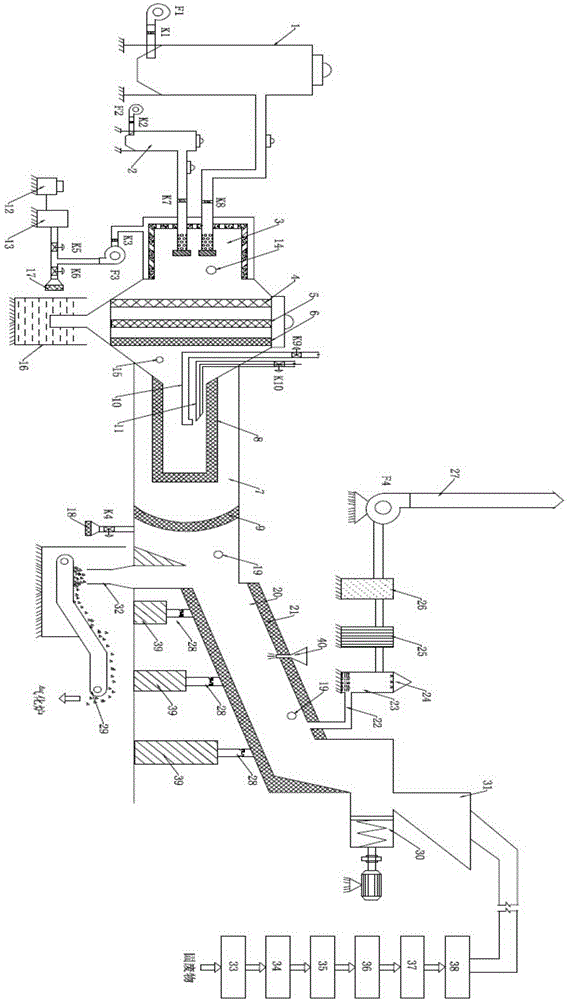

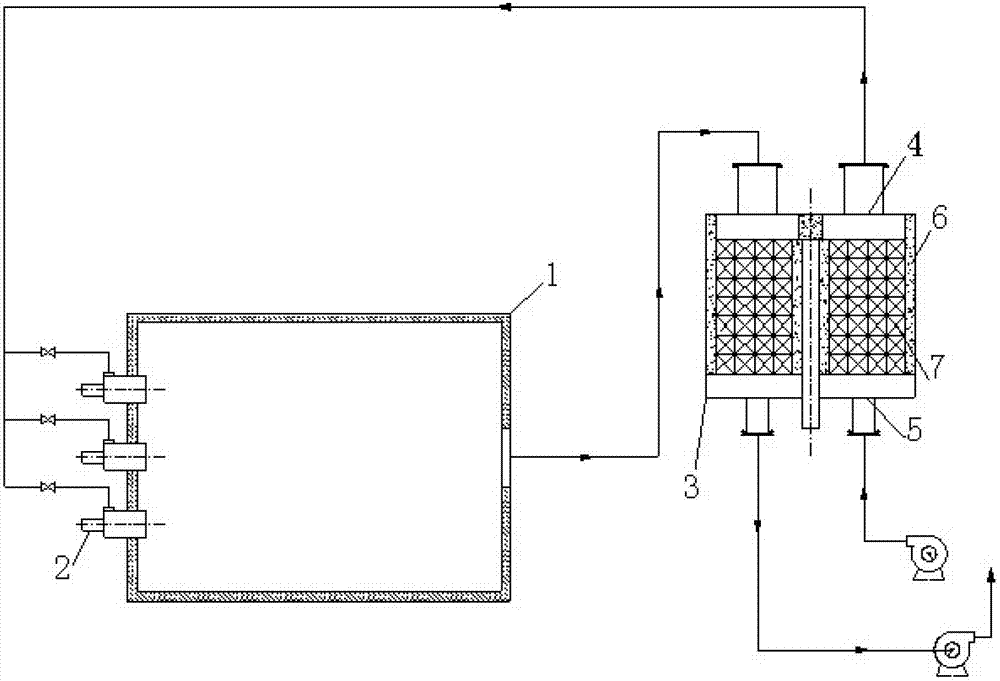

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

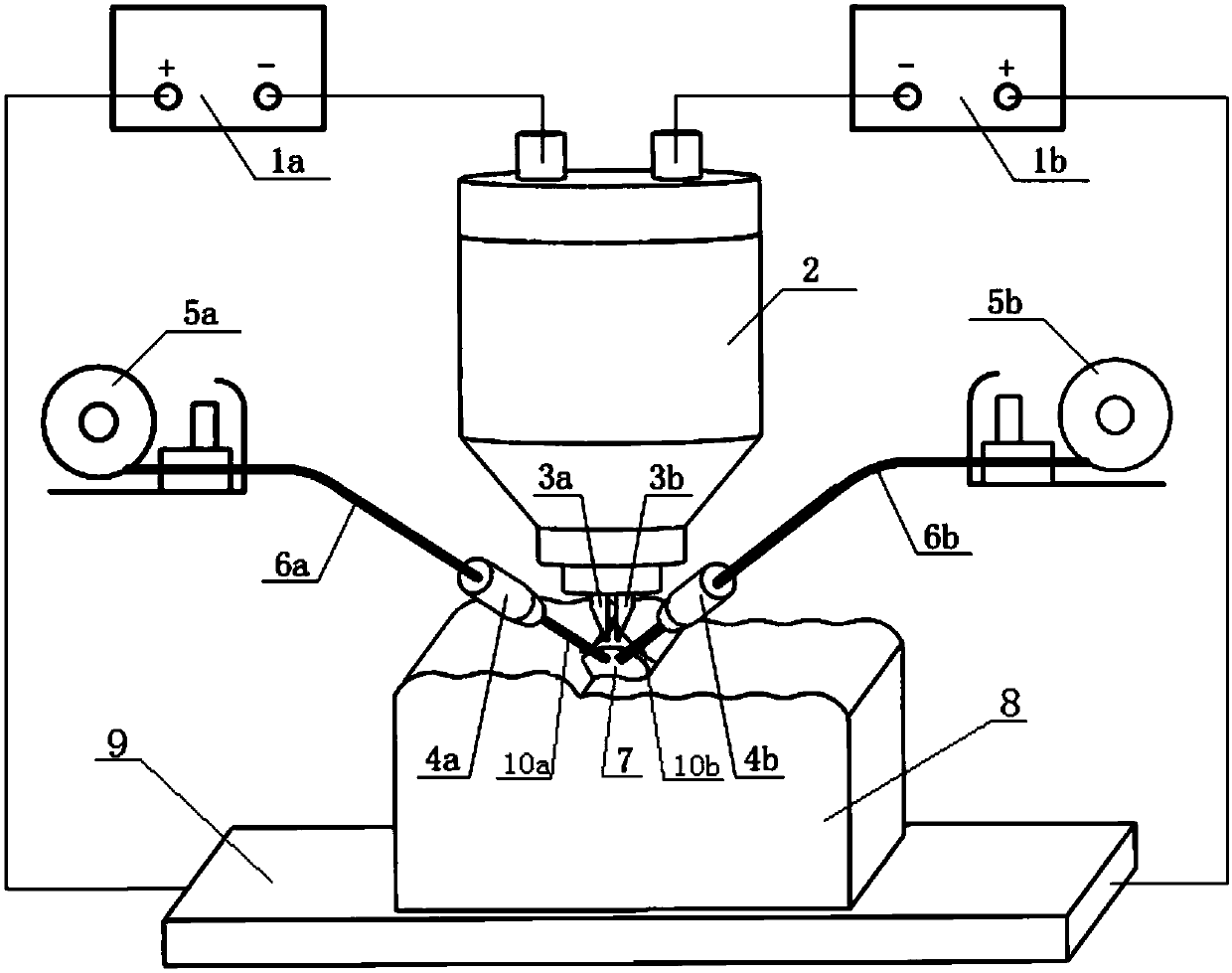

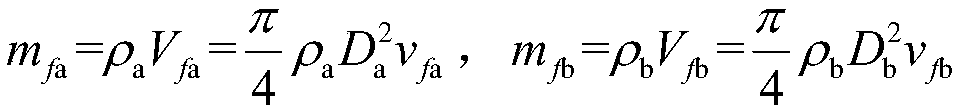

Device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc

InactiveCN108788389ABroaden process specification windowImprove deposition efficiencyAdditive manufacturing apparatusArc welding apparatusMelting tankPower flow

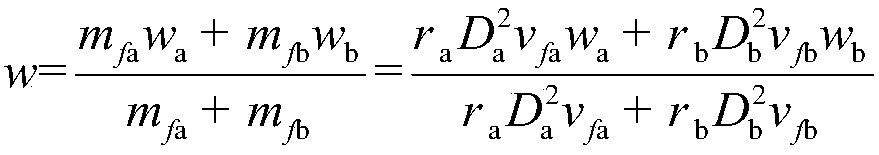

The invention provides a device and method for gradient materials additive manufacturing by using two-wire twin-electrode tungsten inert gas arc. A first partial tungsten electrode and a second partial tungsten electrode are installed below a two-tungsten-electrode argon arc additional material manufacturing gun of the device, and are vertically arranged above a base plate. A first wire guide nozzle and a second wire guide nozzle are arranged in front of the two-tungsten-electrode argon arc additional material manufacturing gun. In the deposition process, two metal wires of dissimilar compositions are conveyed to a melting bath at the same time, the composition and performance of a deposition bead are controlled by adjusting the feeding proportion of the metal wires, and thus manufacturingof the gradient material arc additional material is achieved. It is ensured that excellent forming can still be achieved in the deposition process with large current and high wire feeding speed, thecomposition of the prepared gradient material formed part can be continuously transited from the composition of one metal wire to the composition of the other metal wire without replacement of the welding wires, and the deposition efficiency is up to 330 cm<3> / h; and in addition, the deposition bead is more uniform in composition, and the relative error between the components of the deposition bead and target set compositions is smaller than 10%.

Owner:HARBIN INST OF TECH

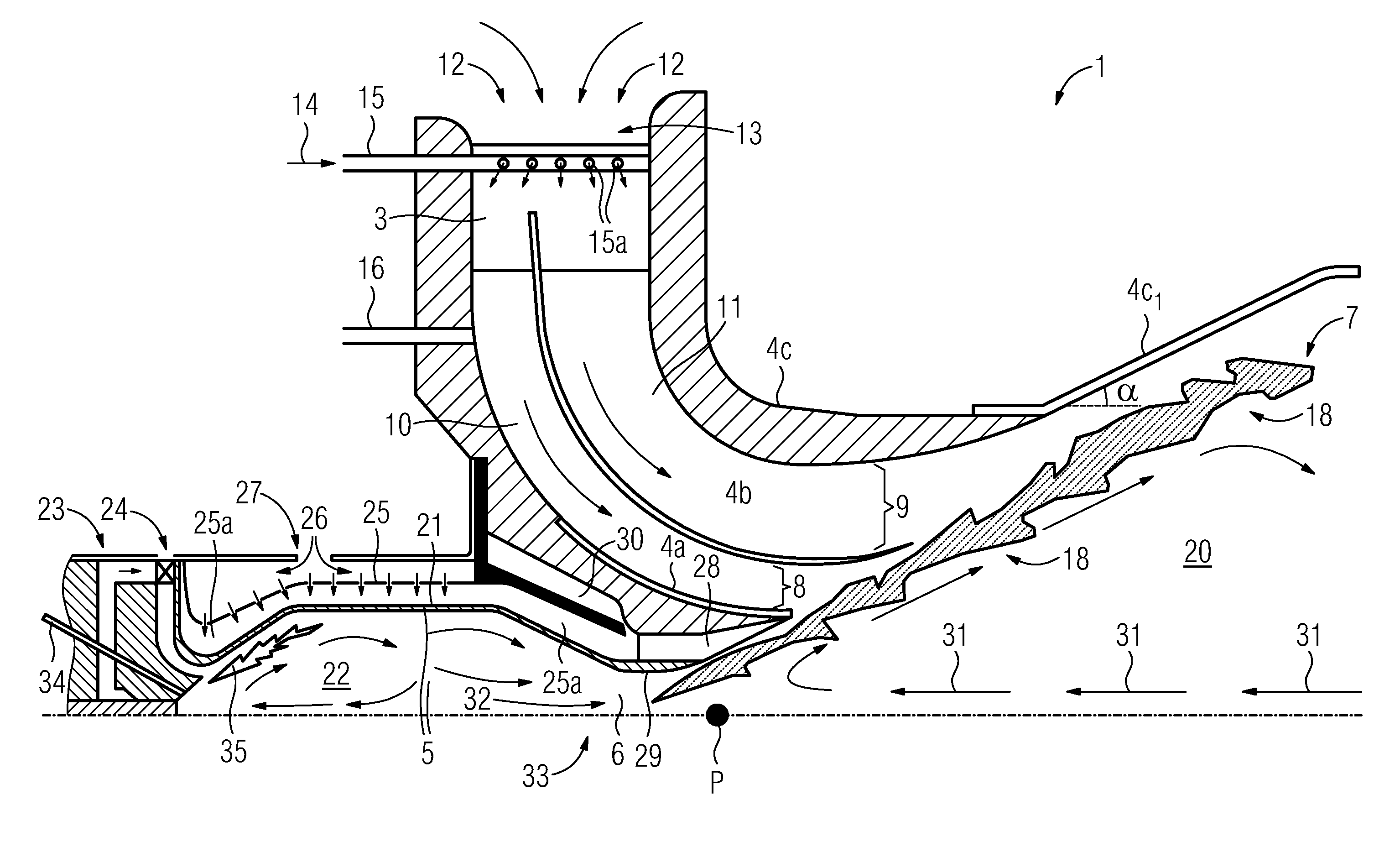

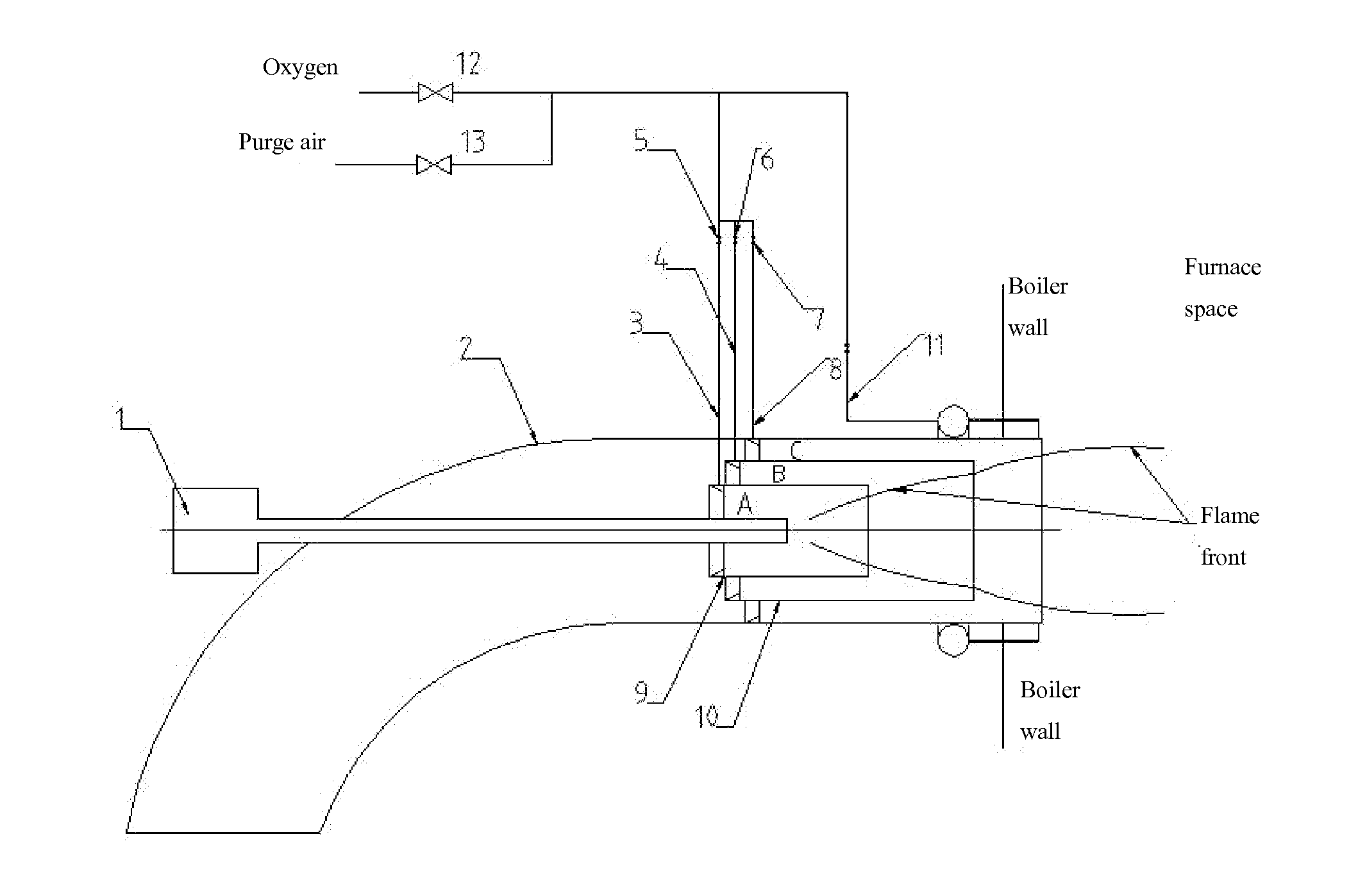

Pilot combustor in a burner

InactiveUS20110113787A1Rapid and stable combustionReduce the temperatureBurnersContinuous combustion chamberCombustorCombustion chamber

A pilot combustor particularly for use in a burner of a gas turbine engine is provided. A method for burning a fuel in a pilot combustor zone of a pilot combustor is also provided. The pilot combustor includes rotationally symmetric walls defining a combustion room with an exit having a rich concentration of fuel in air for burning the fuel for the creation of a flow of an non equilibrium unquenched concentration of radicals elevated to a temperature above 2000 K in the combustion room and directed along a centre line of the pilot combustor through a throat at the exit of the pilot combustor, wherein a quarl is located downstream of the throat of the pilot combustor. According to the method the pilot combustor is arranged upstream of a burner for providing a main lean partially premixed combustion process.

Owner:SIEMENS AG

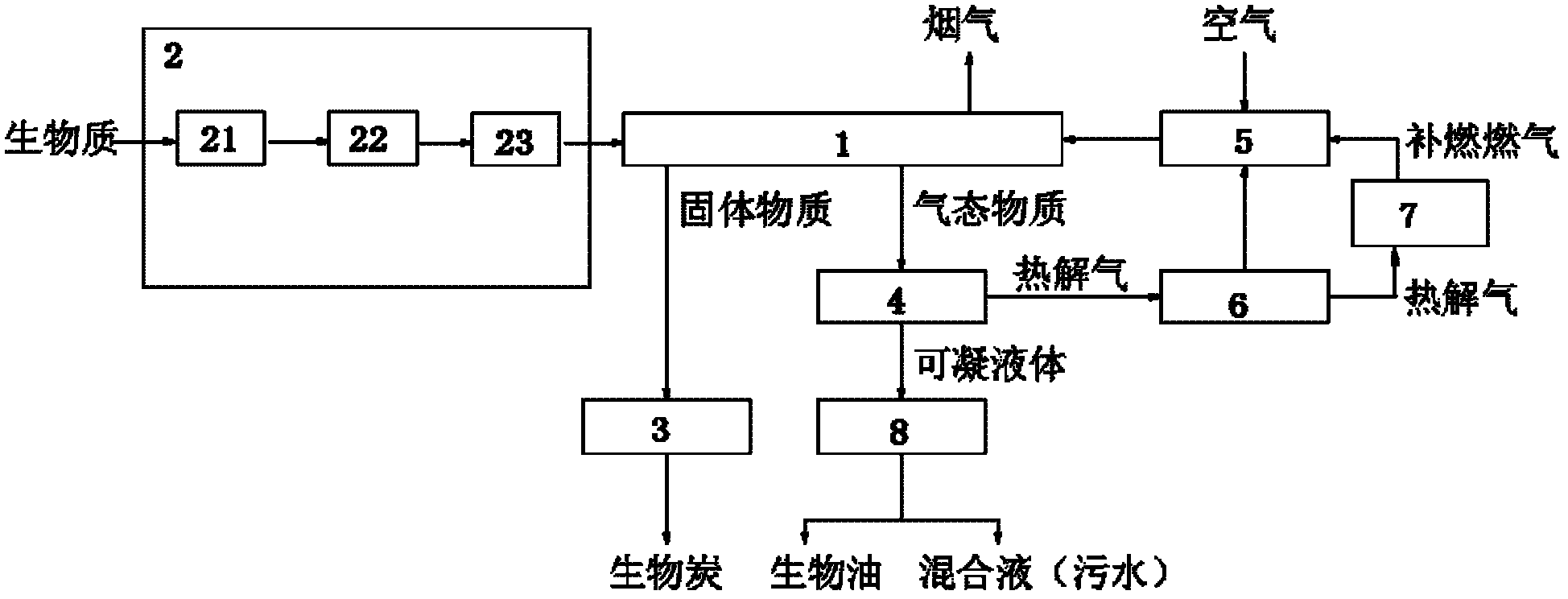

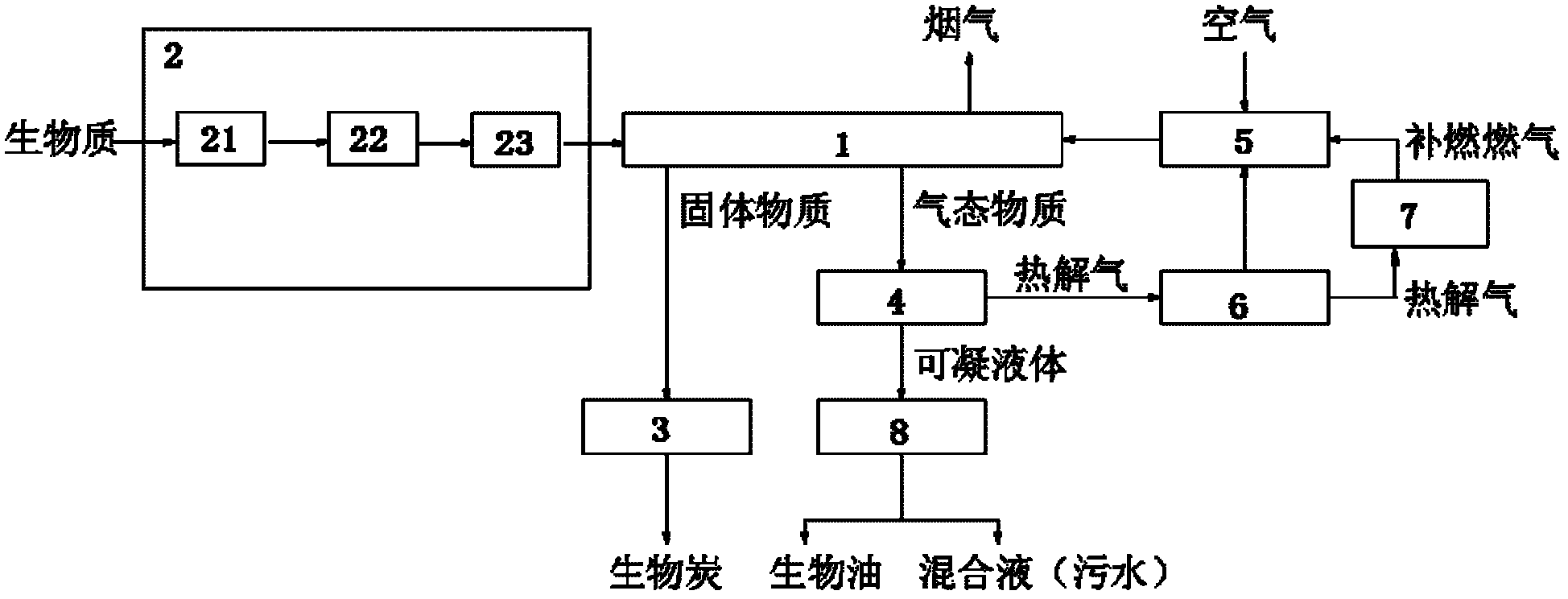

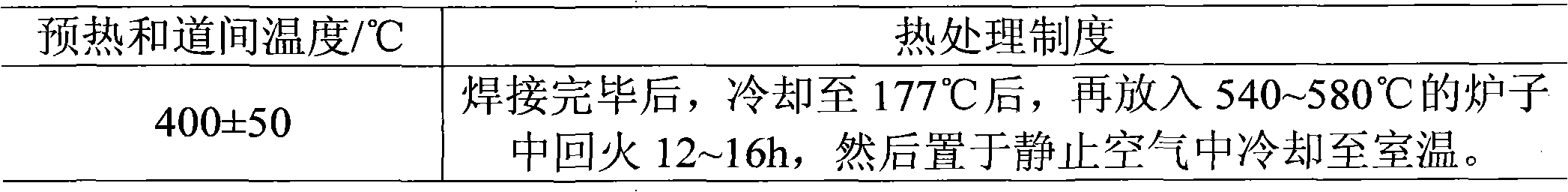

Heat-storage type biomass pyrolysis method and system

InactiveCN102604656AHigh bulk densityEasy to handleDirect heating destructive distillationBiofuelsReaction temperatureProcess engineering

The invention provides a heat-storage type biomass pyrolysis method and system which can realize large-scale production and has low operation cost and low total energy consumption. The heat-storage type biomass pyrolysis method comprises the following steps: (1) pretreating the biomass: pretreating the raw materials of a biomass to obtain the raw materials which can be used for the pyrolysis of the biomass; (2) subjecting the biomass to pyrolysis: spreading the pretreated raw materials of the biomass on the rotating bottom of a heat-storage type gas radiating tube rotating bed uniformly, making the raw materials of the biomass heated gradually in a sealed spaced along with the rotating of the rotating bottom of a heat-storage type gas radiating tube rotating bed, keeping the raw materials of the biomass at the reaction temperature of 200-800 DEG C for 30-120 minutes, subjecting the raw materials of the biomass to reaction to produce the gaseous substance and the solid biological carbon; and (3) collecting and posttreating the products of pyrolysis; collecting the gaseous substance generated in the step (2), condensing, and separating the pyrolysis gas and the condensible liquid. The pyrolysis gas can be totally or partially used as the fuel of a heat-storage type gas radiating tube, and the discharged solid biological carbon is collected after being quenched and cooled.

Owner:SHENWU TECH GRP CO LTD

Biomass solid fuel and processing technique thereof

InactiveCN103374427AAchieve innovative resultsAchieving a circular economy modelBiofuelsSolid fuelsAlternative fuelsToxic material

The invention relates to a biomass solid fuel and a processing technology thereof. The biomass solid fuel is prepared by pressing the following raw materials in percentage by weight: 90% of a biomass raw material and 10% of water, wherein the biomass raw material adopts crop derelicts, bamboo-wood processing residues or residual branches and leaves after timber cutting. The biomass solid fuel can replace coal, oil and other primary energy sources and serves as an alternative fuel; because the biomass solid fuel is a renewable energy source, the short supply of energy sources is alleviated; the biomass solid fuel is an environment-friendly fuel, and the combustion emission data reaches the national environmental protection standard, so that the pollution to the air is reduced, and the living environment is improved; and meanwhile, the biomass solid fuel is simple in processing technique, and the production process does not generate toxic substances and can not cause damages to the environment, so that the biomass fuel has an important significance for promoting the construction of a new socialist countryside.

Owner:佛山市三水环能再生能源有限公司

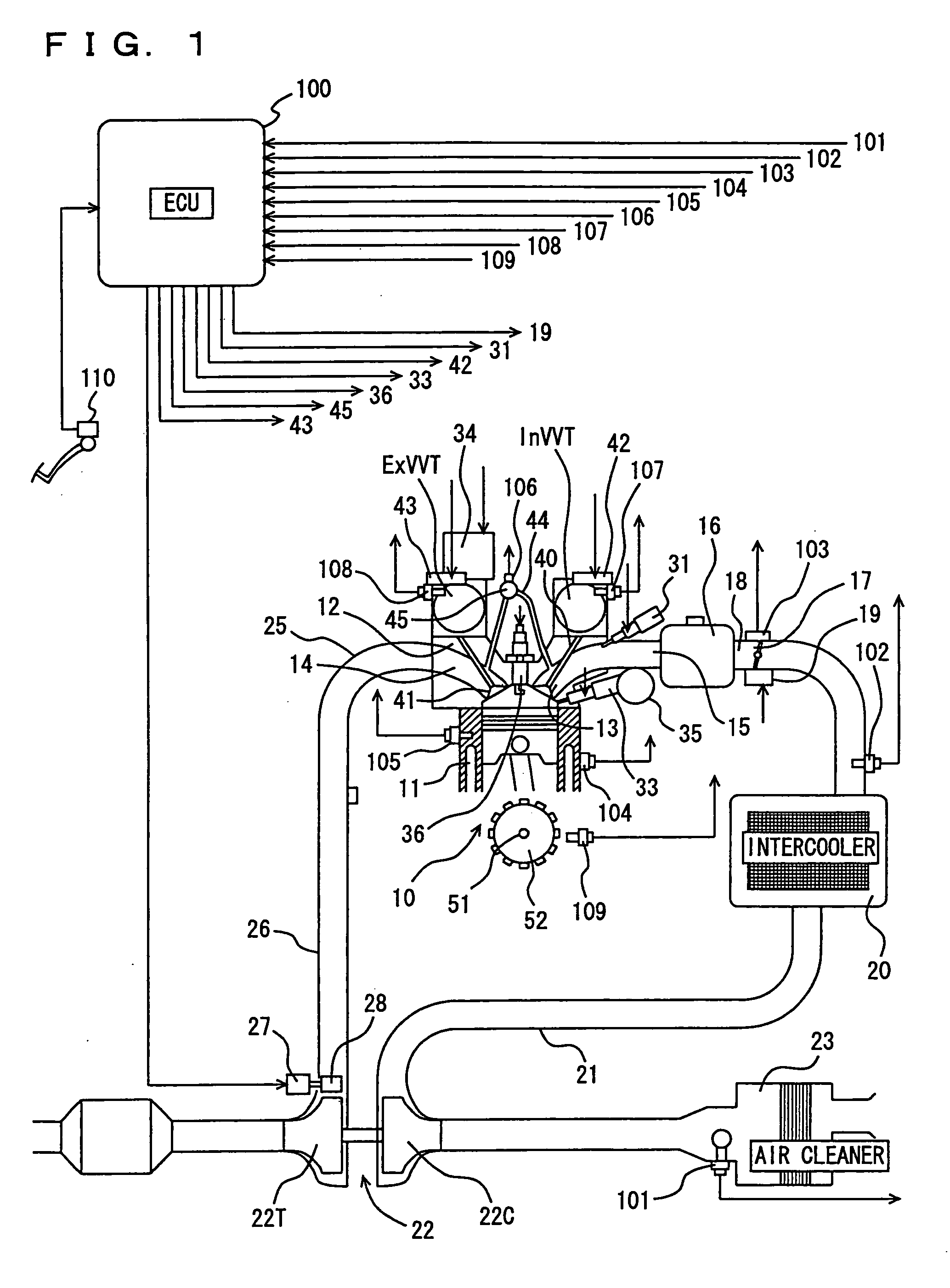

Control device and method of spark-ignition gasoline engine

InactiveCN102650242ABurning period shortenedStable combustionElectrical controlInternal combustion piston enginesLow loadGasoline

A control device and method of a spark-ignition gasoline engine is provided. An engine operates in a compression ignition model in a low load area and in a spark ignition model in a high load area. In the spark ignition model, within a retard period from a late stage of a compression stroke to an early stage of an expansion stroke, an external EGR is executed for control. In a switching area with comparatively lower load in an execution area in the spark ignition model, an EGR rate controlled by the external EGR is set higher than a load of the switching area and filling quantity control for making an intake filling quantity lower than an intake filling quantity of the compression ignition model. Accordingly, combustion stability in the spark ignition model can be raised and the load area for reducing intake filling quantity can be reduced as much as possible.

Owner:MAZDA MOTOR CORP

Combustor of a gas turbine engine

InactiveUS20080289340A1Enhance stabilityWell combustibleBurnersContinuous combustion chamberAutomotive engineeringGas turbines

The present invention provides a combustor of a gas turbine engine, including: a fuel spray portion configured to spray a fuel so as to create a diffusion combustion region in a combustion chamber; a pre-mixture supply portion configured to supply a pre-mixture gas including the fuel and an air so as to create a pre-mixture combustion region in the combustion chamber, the pre-mixture supply portion being positioned concentrically with the fuel spray portion so as to surround the fuel spray portion; and an annular separation portion disposed between a downstream end of the fuel spray portion and a downstream end of the pre-mixture supply portion so as to separate the diffusion combustion region and the pre-mixture combustion region from each other.

Owner:KAWASAKI HEAVY IND LTD

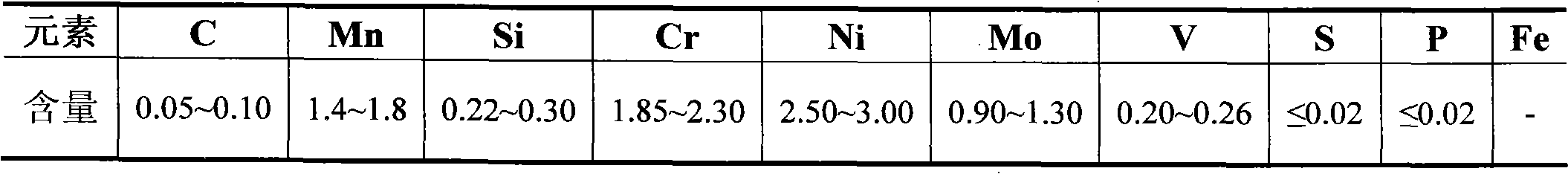

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Solid waste innocent treatment device and method

ActiveCN104588402AExcellent emission indicatorsMeet environmental protection requirementsSolid waste disposalIncinerator apparatusCombustion chamberEmission standard

The invention discloses a solid waste innocent treatment device and a solid waste innocent treatment method. The solid waste innocent treatment device comprises a solid waste pyrolysis gasifier, a fuel gas oxygen replenishment premixing and filtering chamber, a fuel gas combustion chamber, a dechloridation and desulfurization drying device and a solid waste pretreatment device which are sequentially communicated; the solid waste innocent treatment device also comprises a biomass pyrolysis gasifier and a tail gas treatment device, wherein the biomass pyrolysis gasifier is communicated with the fuel gas oxygen replenishment premixing and filtering chamber; the tail gas treatment device is communicated with the top of the dechloridation and desulfurization drying device. When the method and the device are used for treating solid waste, the content of Dioxin in a detected emitted tail gas is lower than 0.023ng / m<3>, and the emission allowances of other gases, such as CO, SO2, HC1 and NOx, are also highly superior to the emission standard (GB18485-2014) issued by the nation in July 1st, 2014, and can completely meet the requirement of environment-friendliness.

Owner:深鹏环保工程有限公司

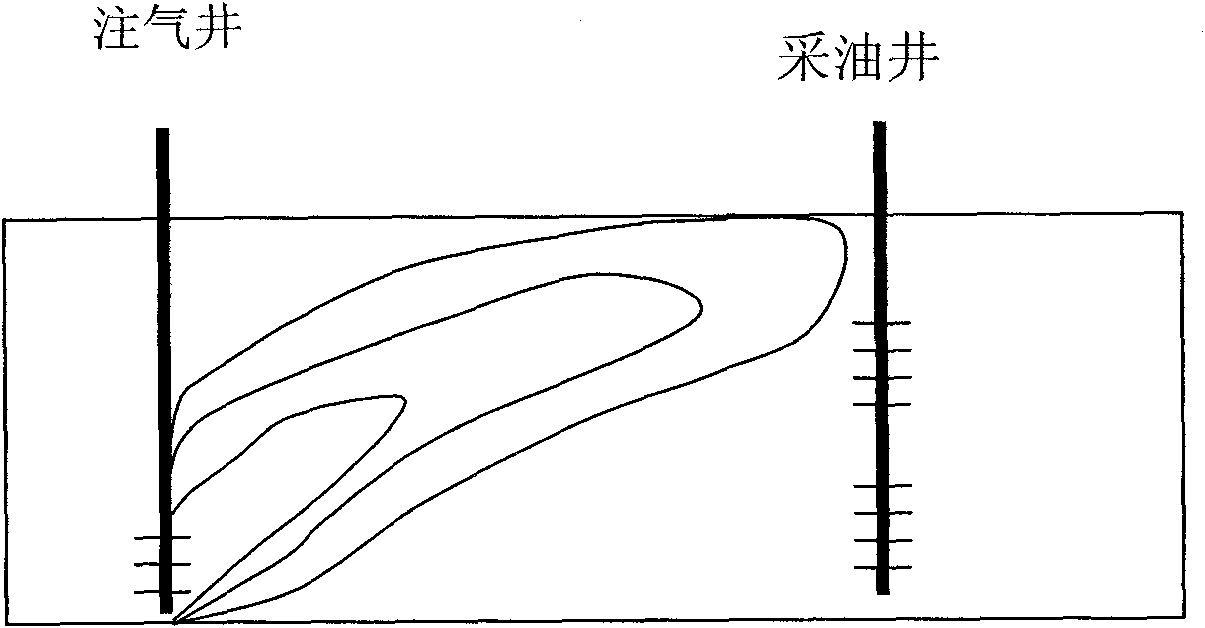

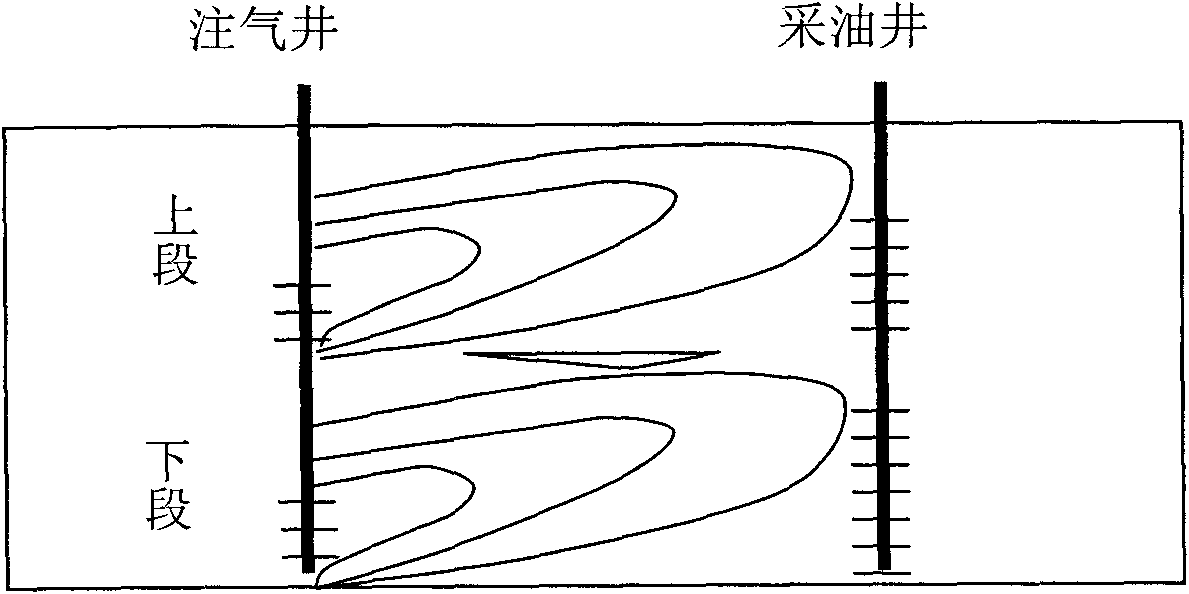

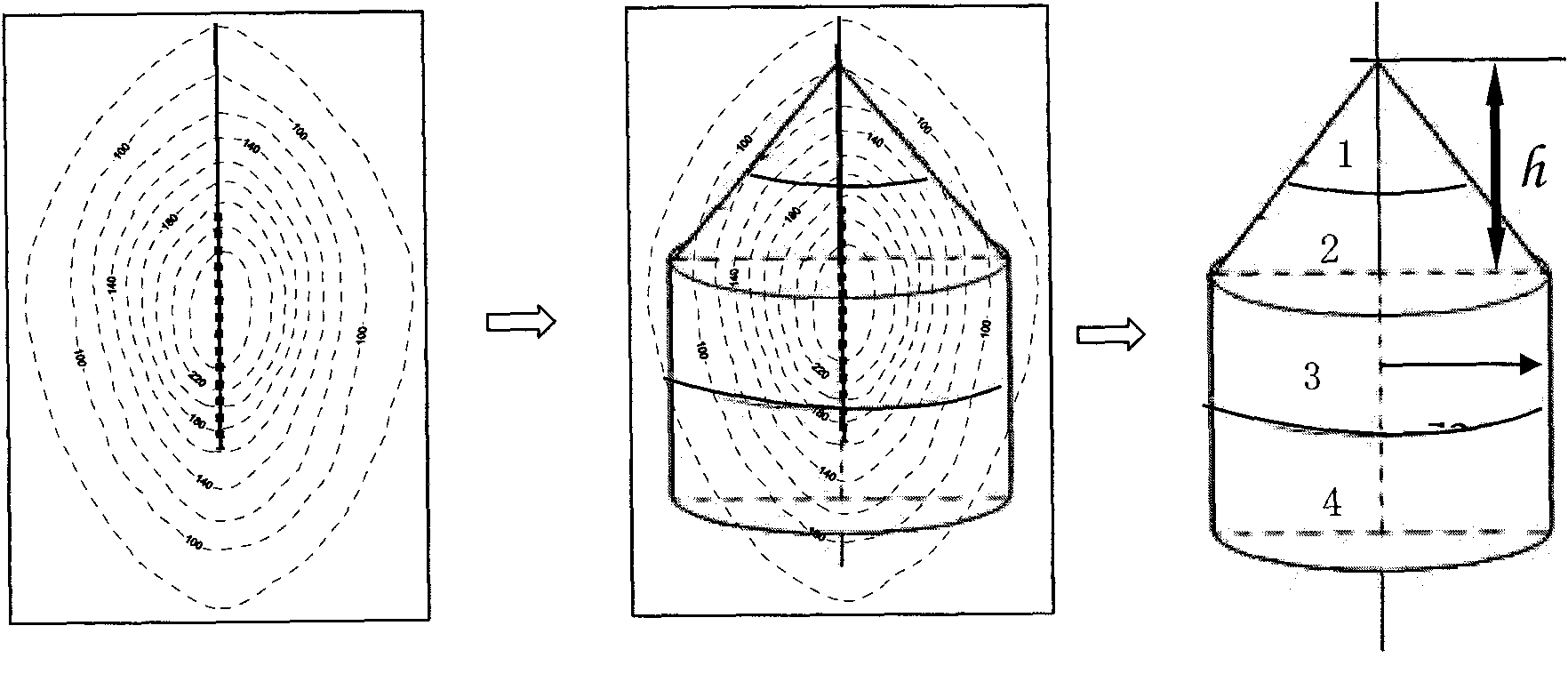

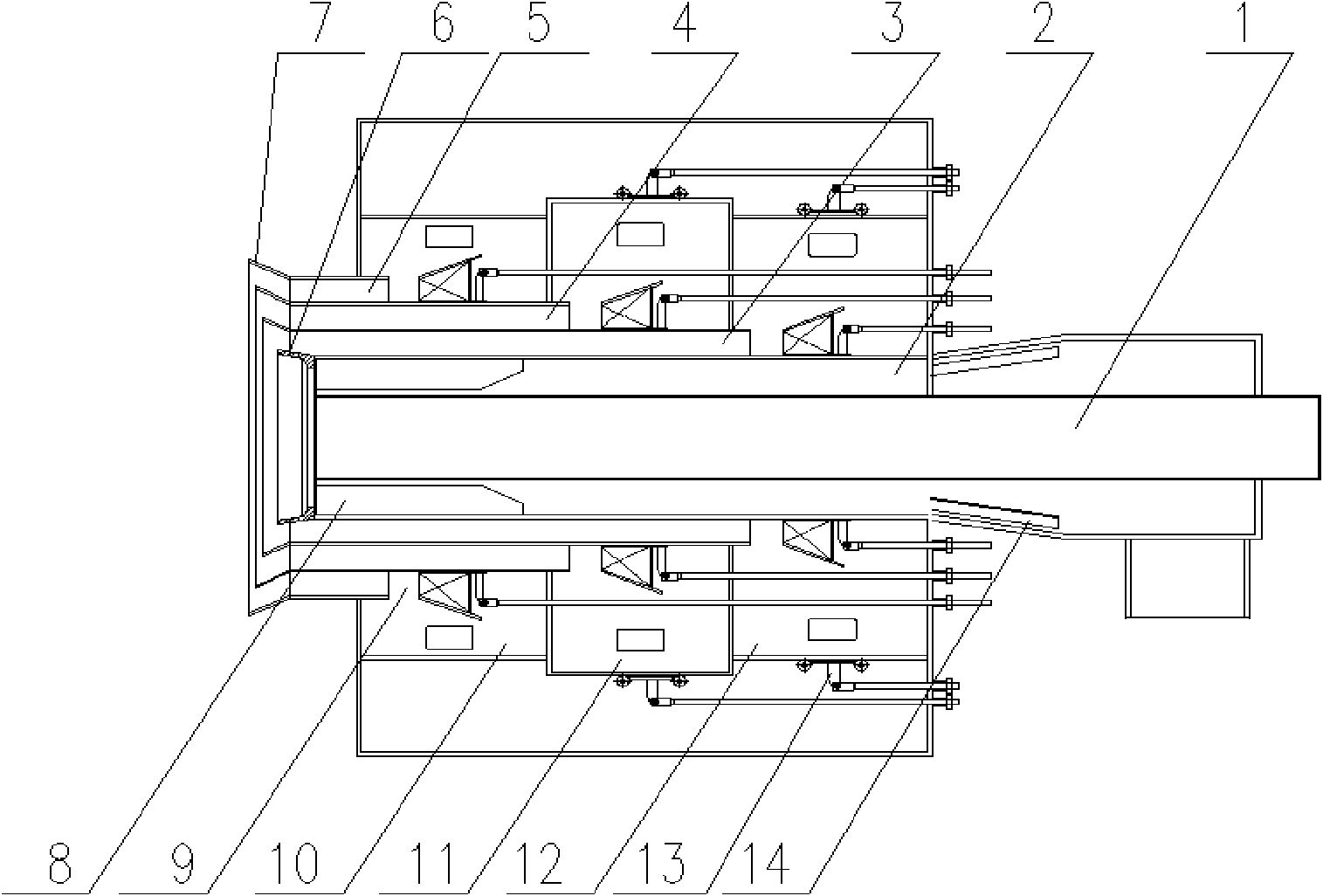

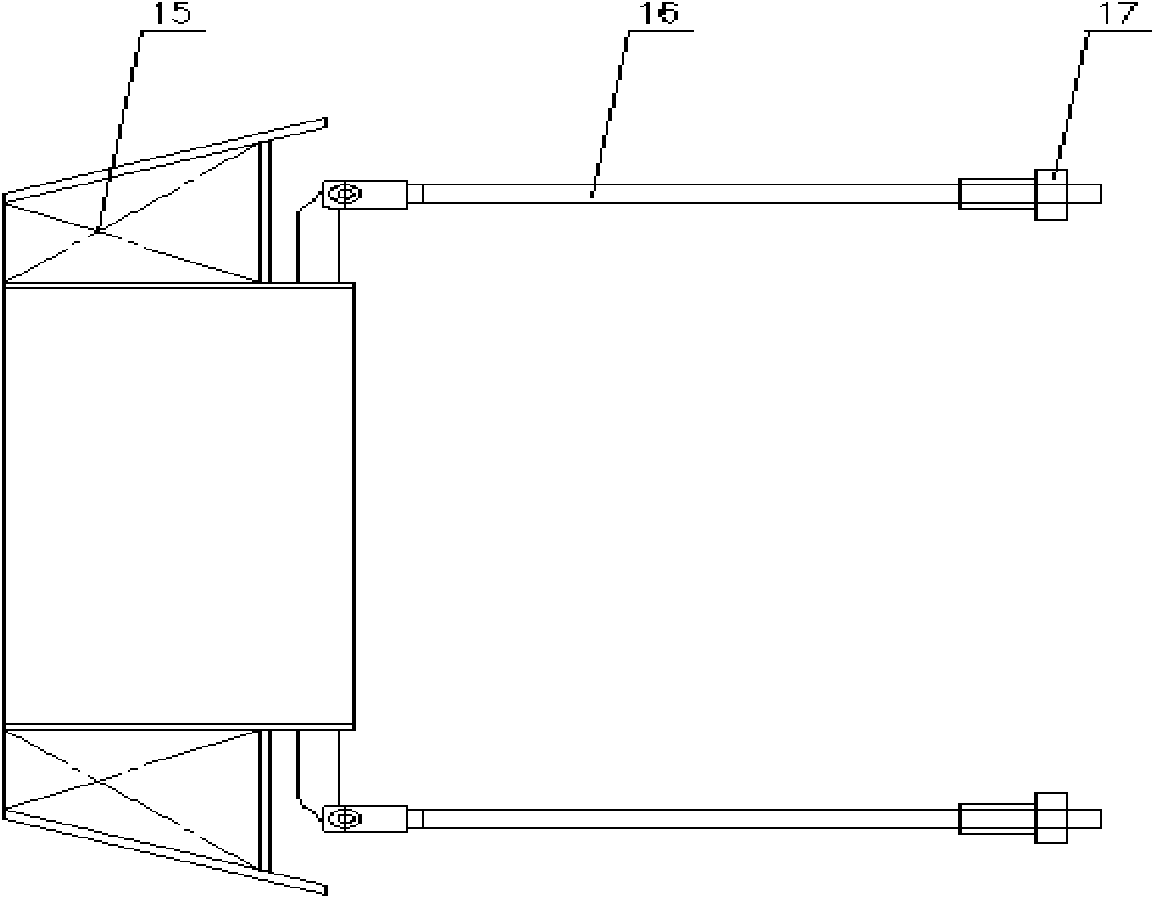

Method for improving recovery ratio of thick-layer massive thickened oil by utilizing subsection fireflooding exploitation

ActiveCN101798915AImprove development performanceHigh yieldFluid removalCombustionMaterial Perforation

The invention relates to a method for improving recovery ratio of massive oil pool with large monolayer thickness by utilizing subsection fireflooding exploitation. The method comprises the following steps: selecting oil pool meeting the following requirements through exploration; taking viscosity-temperature inflection point temperature of which the oil layer temperature exceeds the temperature of underground raw oil as a boundary to judge whether the oil layer is explored or not, using the heating volume occupied by each small layer as a weight factor of output compartment, and carrying outoutput compartment according to a small layer output compartment module; distributing multistage grading perforations on a gas well casing by utilizing space thickness of the oil layer in the length wise direction and referring to the distribution of the interlayer in the oil layer, firing the perforations at the bottom inside each stage; and expanding the ultimate swept volume of the oil layer by making full use of the space of the oil layer in the length wise direction and the lapout characteristic of the combustion of oil in situ. The method of the invention improves the recovery ratio of a thickened oil block.

Owner:PETROCHINA CO LTD

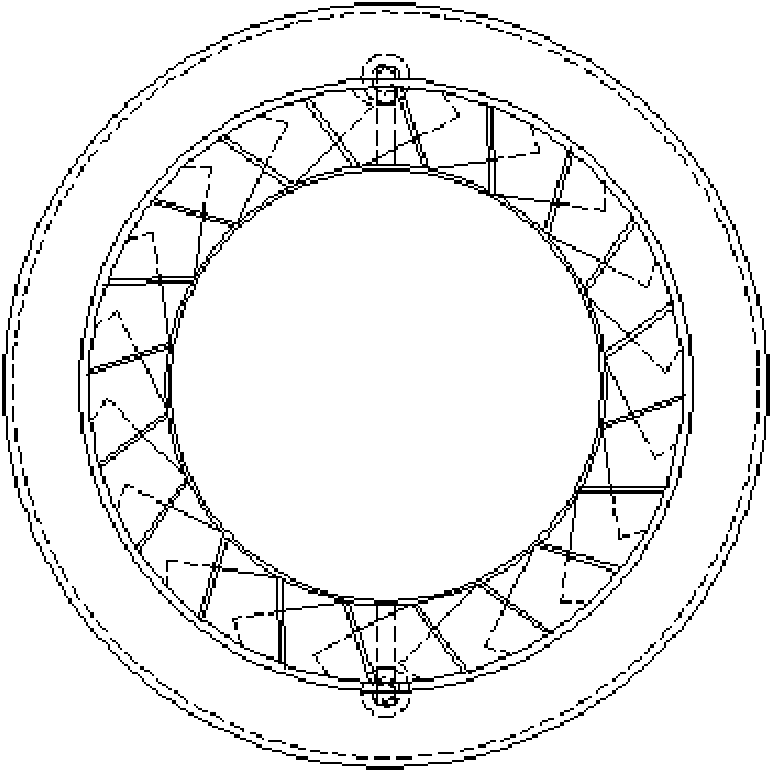

Three-layer secondary air low nitrogen oxide swirling burner

InactiveCN102434878AImprove circumferential unevennessConducive to stable combustionPulverulent fuel combustion burnersAir volumeCombustor

The invention discloses a three-layer secondary air low nitrogen oxide (NOx) swirling burner which comprises a central air pipe as well as a primary air pipe, an inner secondary air pipe, a middle secondary air pipe and an outer secondary air pipe which are concentrically arranged at the periphery of the central air pipe from inside to outside, wherein the air inlets of the inner secondary air pipe, the middle secondary air pipe and the outer secondary air pipe are provided with swirling adjusting mechanisms for generating straightly-flowing secondary air or secondary air with variable swirling intensity by virtue of the respective secondary air pipes; three independent air boxes are sleeved outside each secondary air pipe; and the air volume of each secondary air pipe can be adjusted by air box baffle plate adjusting mechanisms on the air boxes. By adopting the structure of the low NOx swirling burner, the partial grading burning effect of the burner is enhanced and the high temperature smoke reflow is increased, thus finally achieving the aim that the burner burns coals stably and reduces the NOx generated by burning. The three-layer secondary air low NOx swirling burner has a simple structure, is easy to manufacture and install, is high in industrial applicability, is applicable to various coals and guarantees the burning stability and the burning economy of a boiler.

Owner:HUAZHONG UNIV OF SCI & TECH

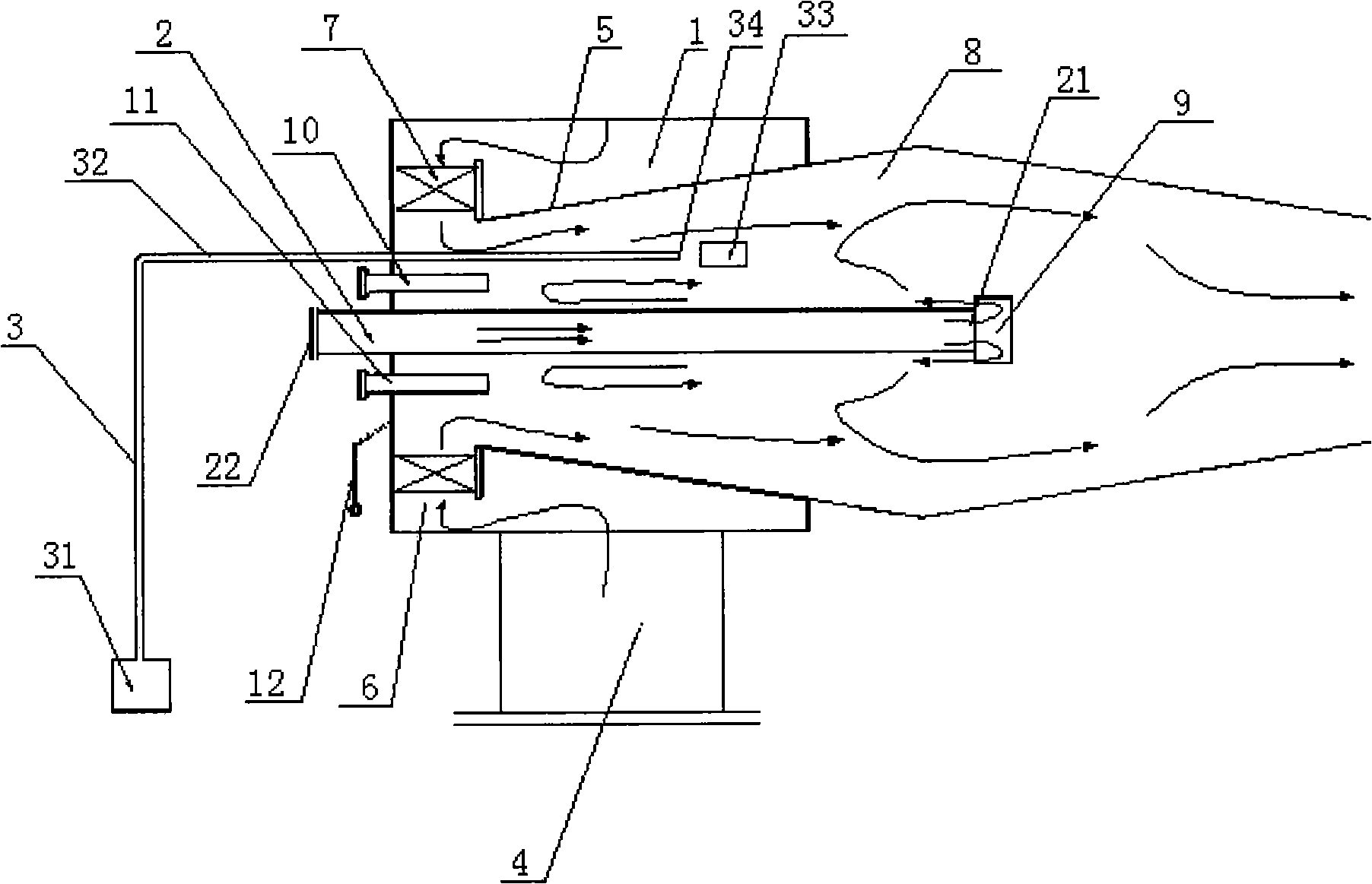

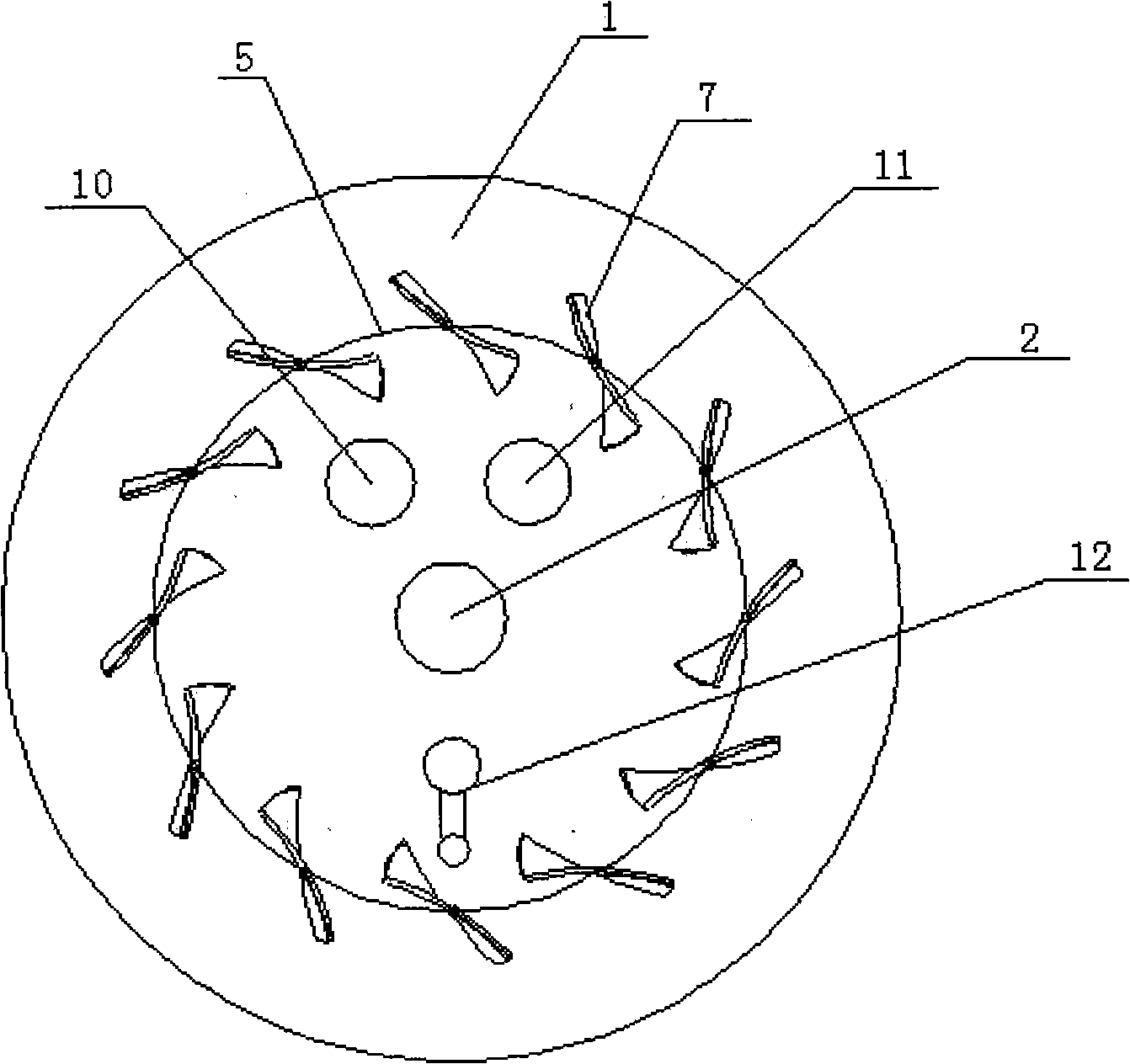

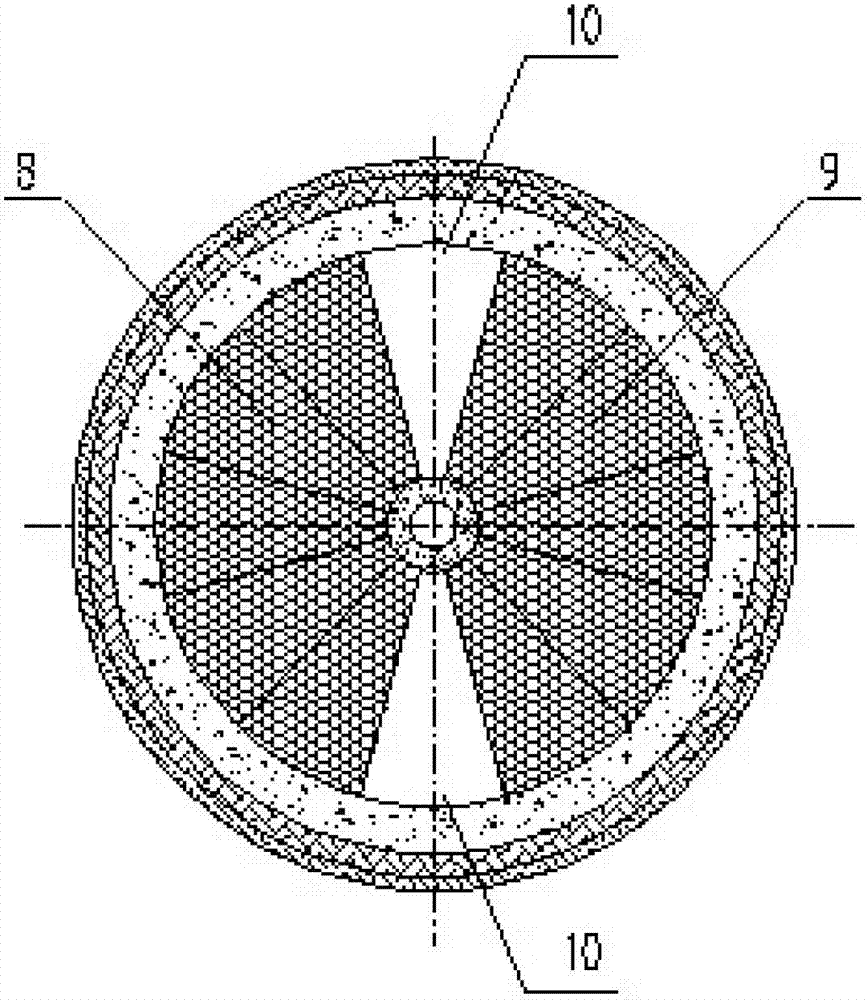

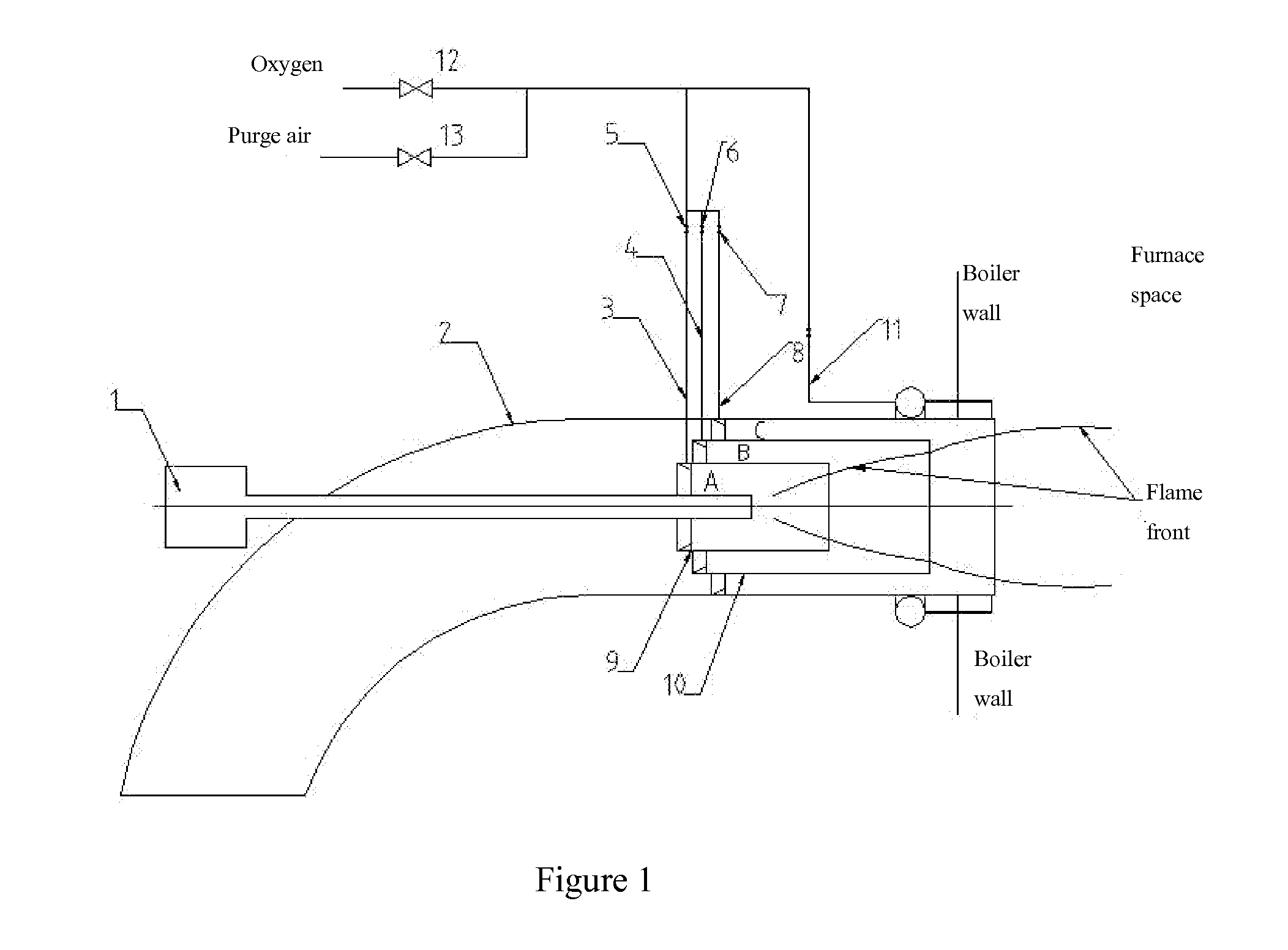

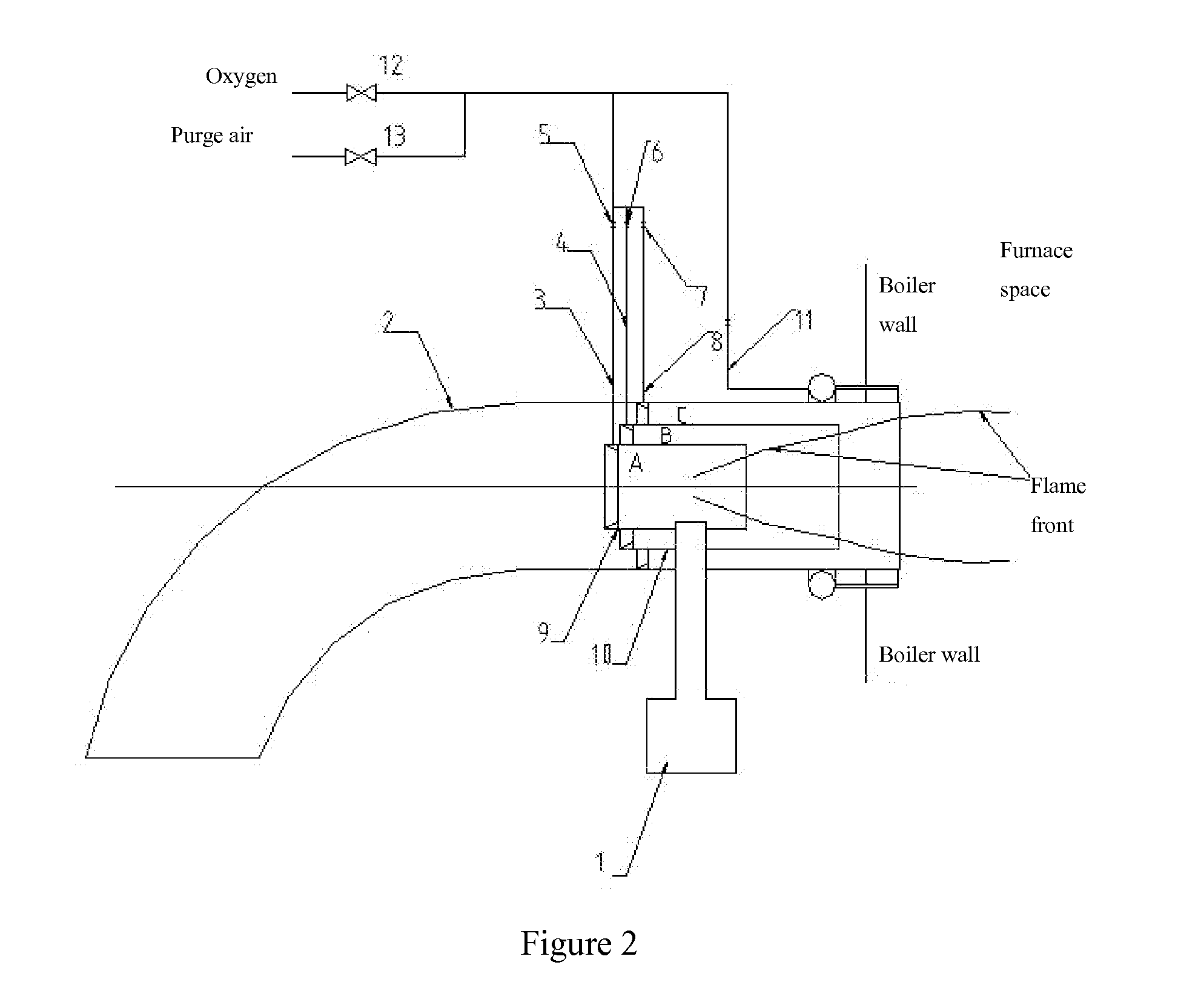

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

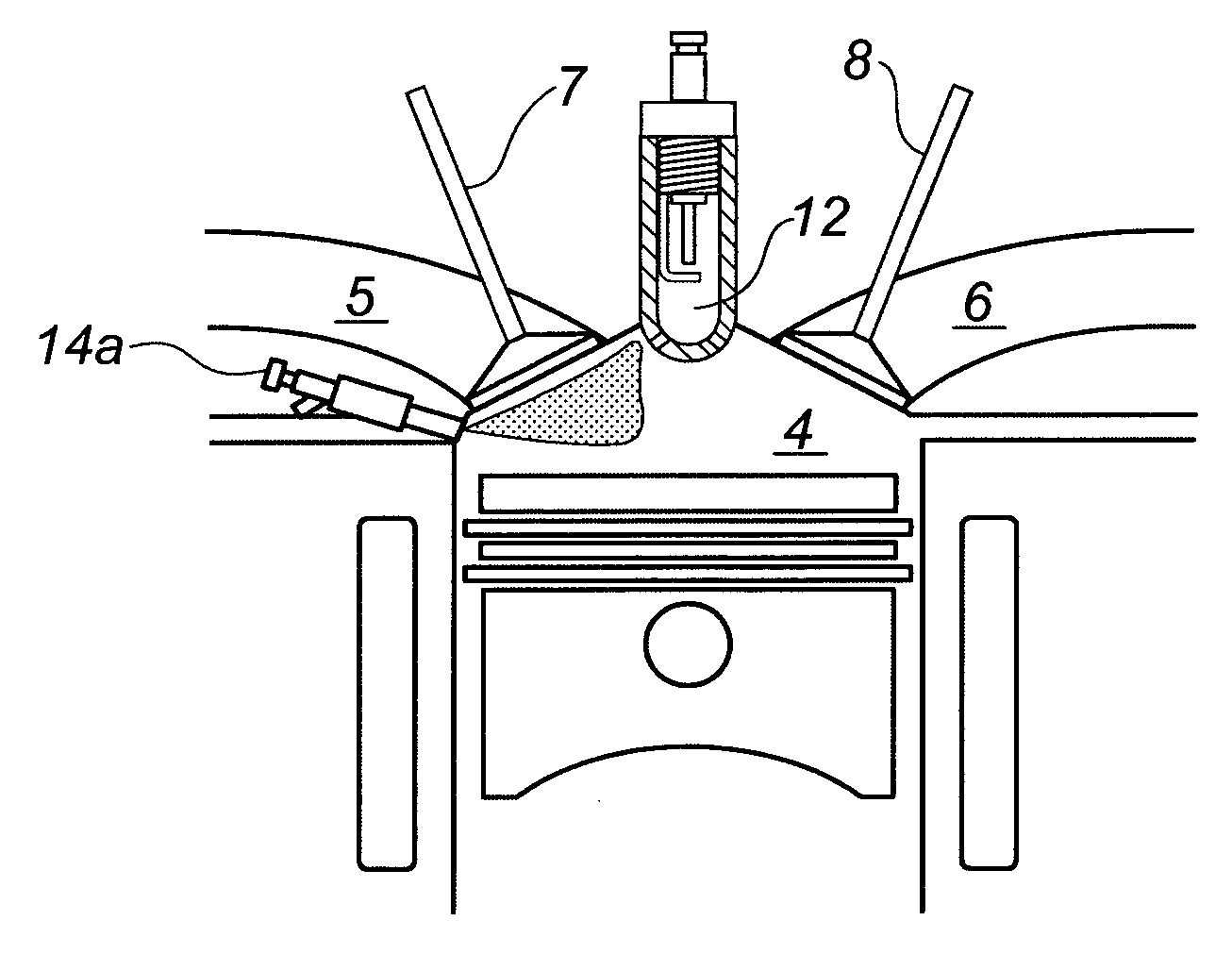

Internal combustion engine with a precombustion chamber

InactiveUS20070151540A1Easy to igniteStable combustionInternal combustion piston enginesOutput powerTop dead centerCombustion chamber

An internal combustion engine includes neighboring main and auxiliary combustion chambers that are separated by a partition wall including a communicating passage. Ignition of an air / fuel mixture in the auxiliary combustion chamber produces a fuel torch that is jetted into an air / fuel mixture in the main combustion chamber. Under a predetermined operation condition, timing for opening an intake valve is retarded relative to both the timing for closing an exhaust valve and the timing for top dead center of a piston on an exhaust stroke. By retarding the timing for opening the intake valve, residual gas in the auxiliary combustion that is left over from a previous cycle can be reduced.

Owner:NISSAN MOTOR CO LTD

Ignition timing control apparatus for internal combustion engine

InactiveUS20060021595A1Stable combustionPrevent degradationElectrical controlInternal combustion piston enginesInjectorExhaust fumes

An ignition timing control apparatus for an internal combustion engine having an in-cylinder injector for injecting a fuel into a cylinder and an intake port injector for injecting a fuel into an intake port is configured to correct a basic ignition timing, having been determined corresponding to an operation state, in accordance with a fluctuation of at least one factor affecting the combustion rate selected from a coolant temperature, an intake air temperature and an EGR (exhaust gas recirculation) amount, to set a final ignition timing. The correction amount of the ignition timing is set greater for the port injection than for the in-cylinder injection.

Owner:TOYOTA JIDOSHA KK

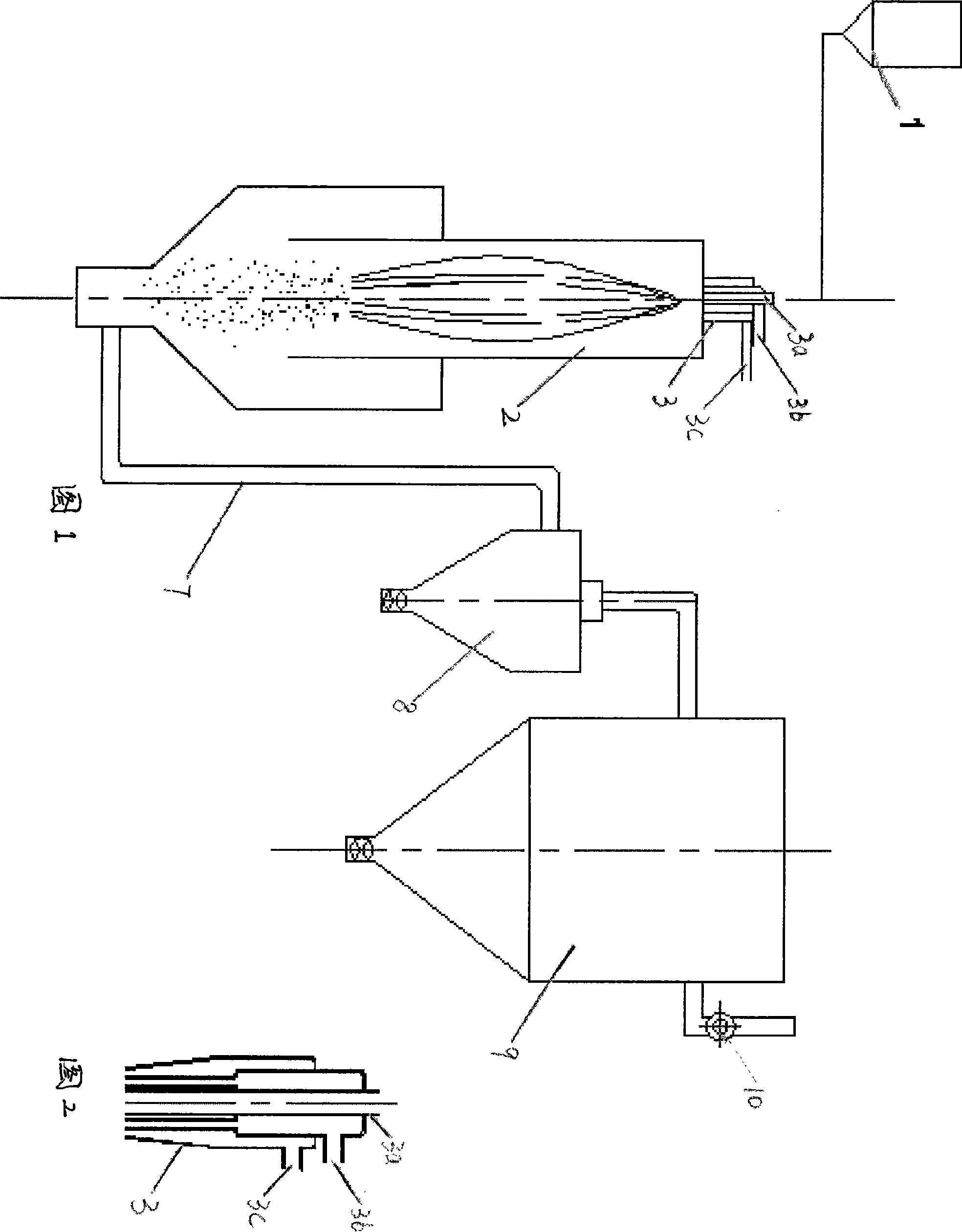

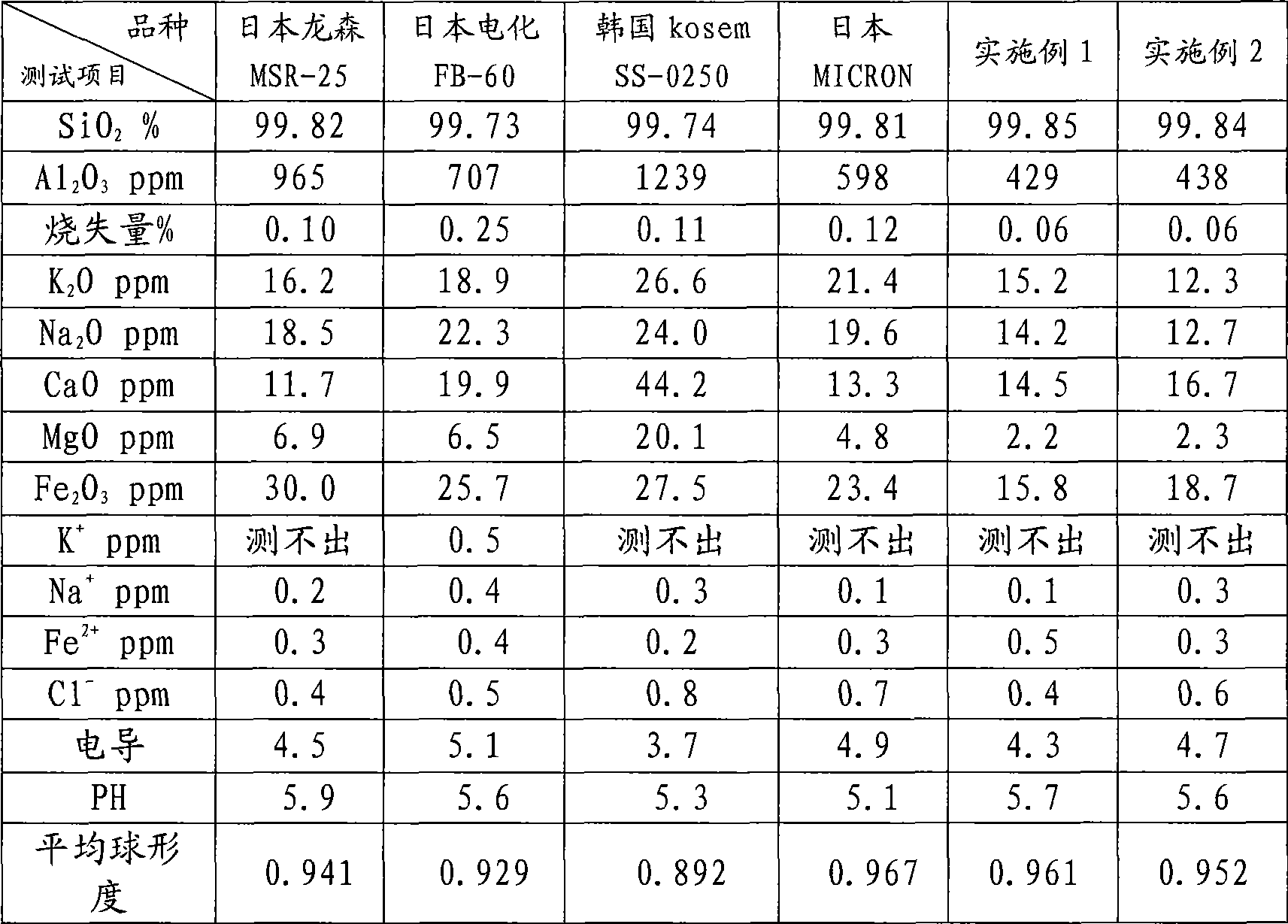

Preparation of spherical silicon dioxide

The invention relates to a method for preparing fine spherical granular silicon dioxide. The method comprises the steps of passing angular silicon dioxide through the combustion flame of natural gas and oxygen, passing the angular silicon dioxide through a cooling region and grading particles. The method adopts pure oxygen and natural gas which are the energy with low price, uses high-temperature flame to melt angular silicon dioxide particles, and spheroidizes the silicon dioxide through surface tension after melting. As the pure oxygen and the natural gas are large in flow, the silicon dioxide particles can be effectively dispersed, the clustering possibility of the silicon dioxide particles of which the surfaces are melted is reduced and the sphericity of final products is guaranteed.

Owner:ZHEJIANG HUAFEI ELECTRONICS BASE MATERIAL

Continuous combusting regenerative industrial furnace

InactiveCN102878817AOptimize layoutStable combustionCombustion processIndirect carbon-dioxide mitigationCombustorProcess engineering

The invention discloses a continuous combusting regenerative industrial furnace, which includes a rotary regenerative heat exchanger, wherein the rotary regenerative heat exchanger includes a rotary cylinder, an upper cover and a lower cover, and the rotary cylinder is internally provided with a regenerator; the high-temperature smoke outlet on the furnace body is connected with an induced draft fan through the high-temperature smoke inlet and the low-temperature smoke outlet of the rotary regenerative heat exchanger in sequence; an air blower is connected with an combustor on the furnace body through the normal temperature air inlet and the preheated air outlet of the rotary regenerative heat exchanger in sequence; and the rotary cylinder is connected with a rotary driving device. The regenerator in the rotary regenerative heat exchanger rotates to continuously preheat the air, the preheated air can be continuously fed into the furnace, the whole combusting process needs no reversing, the pipeline arrangement is simple, the continuous regenerative heat exchange between the high-temperature smoke and the normal temperature air can be realized, and the whole combusting process needs no reversing and is stable.

Owner:SHENWU TECH GRP CO LTD

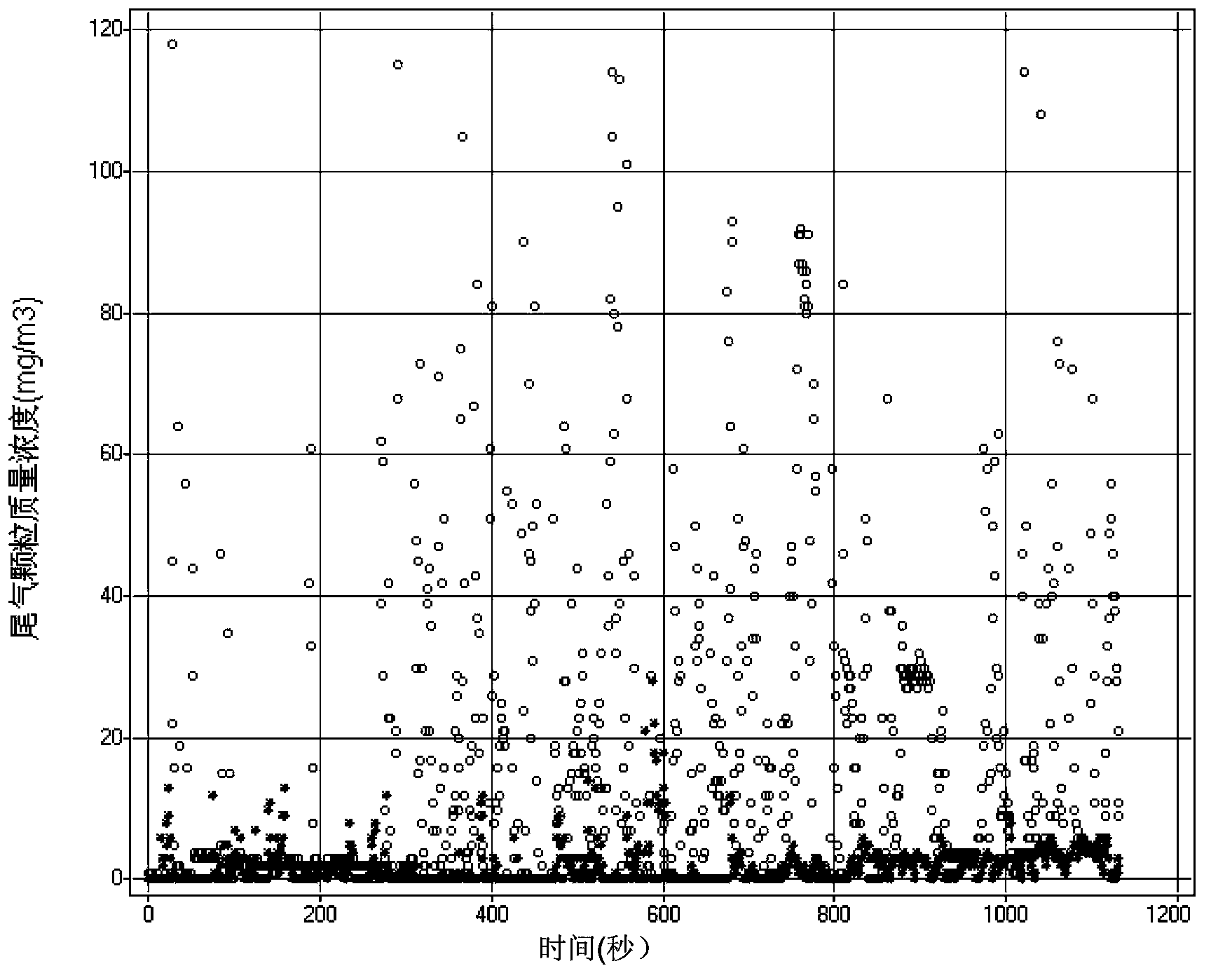

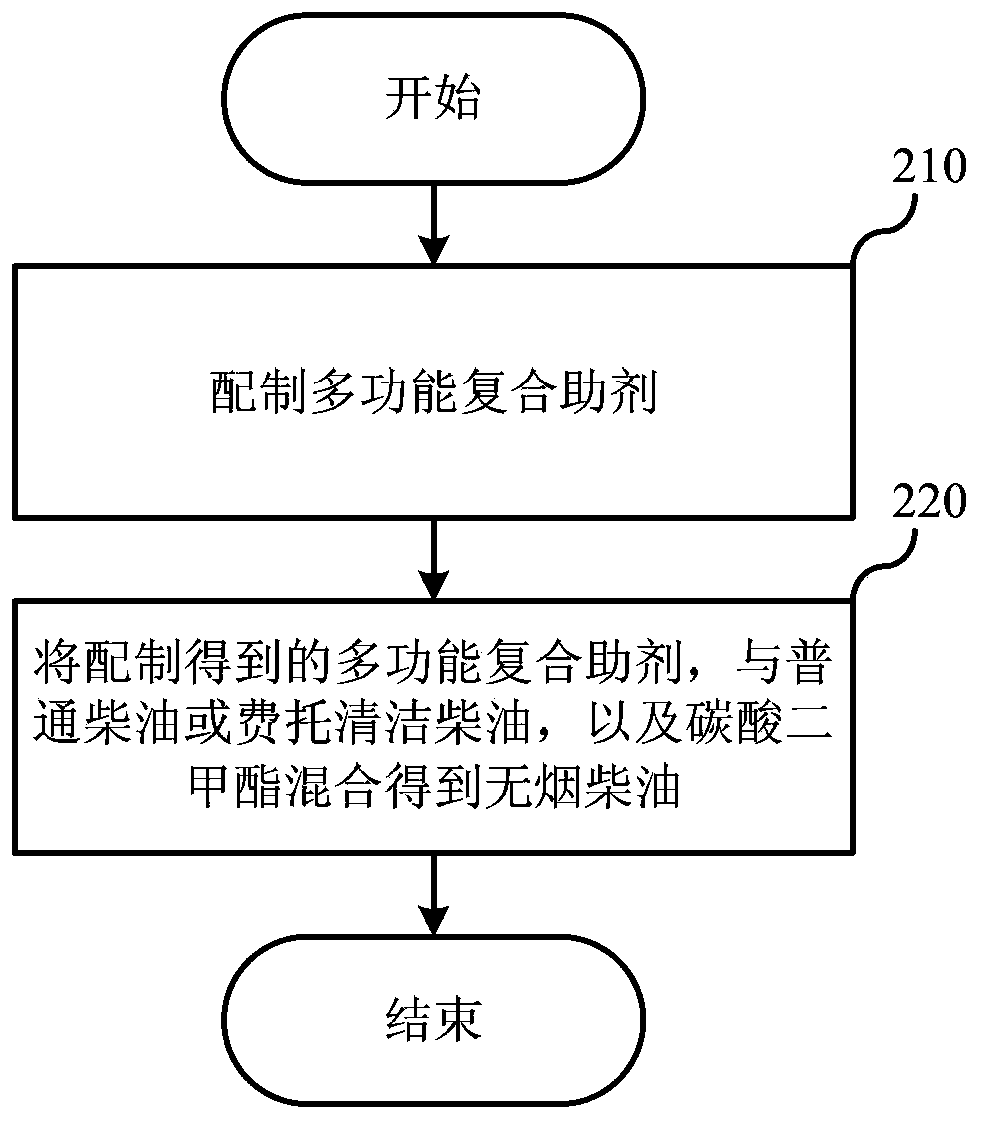

Smokeless diesel oil and preparation method thereof

ActiveCN103805297AEliminate emissionsImprove combustion effectLiquid carbonaceous fuelsParticulatesMethyl carbonate

The invention relates to the field of fuels, and discloses smokeless diesel oil and a preparation method thereof. The smokeless diesel oil comprises 70-95wt% of common diesel oil, 2-25wt% of dimethyl carbonate and 0-10wt% of a multifunctional compound additive. According to the smokeless diesel oil provided by the invention, particulate matter emission in the using process of means of conveyance (comprising various motor vehicles and ships) taking diesel oil as a fuel and machinery for engineering, mining and agriculture and forestry taking diesel engines as power can be greatly reduced or even eliminated without affecting other emission indexes. The smokeless diesel oil is clean and environment-friendly diesel oil, and is simple and convenient and feasible. The fuel system of the diesel engine needs not to be changed.

Owner:YASHENTECH CORP

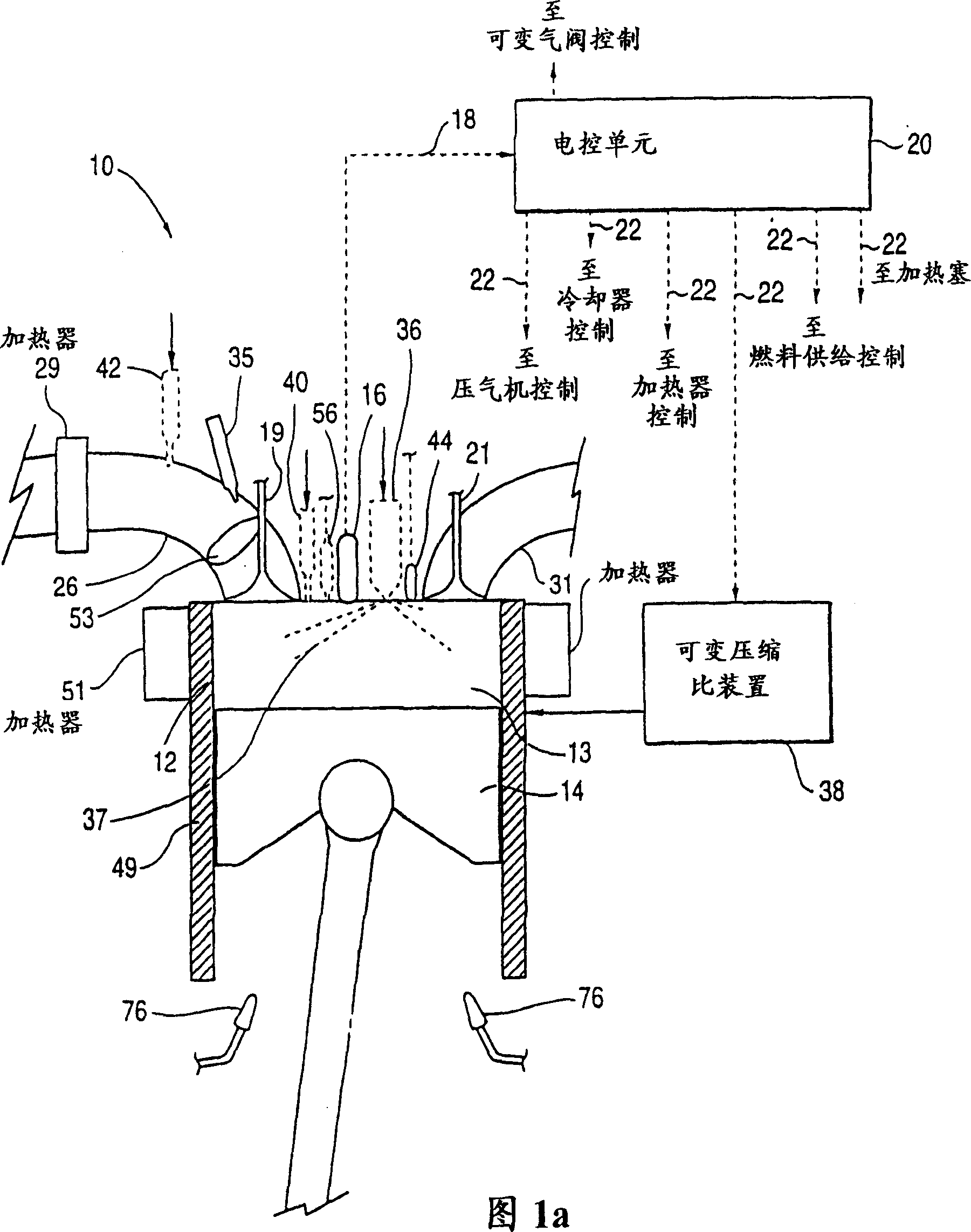

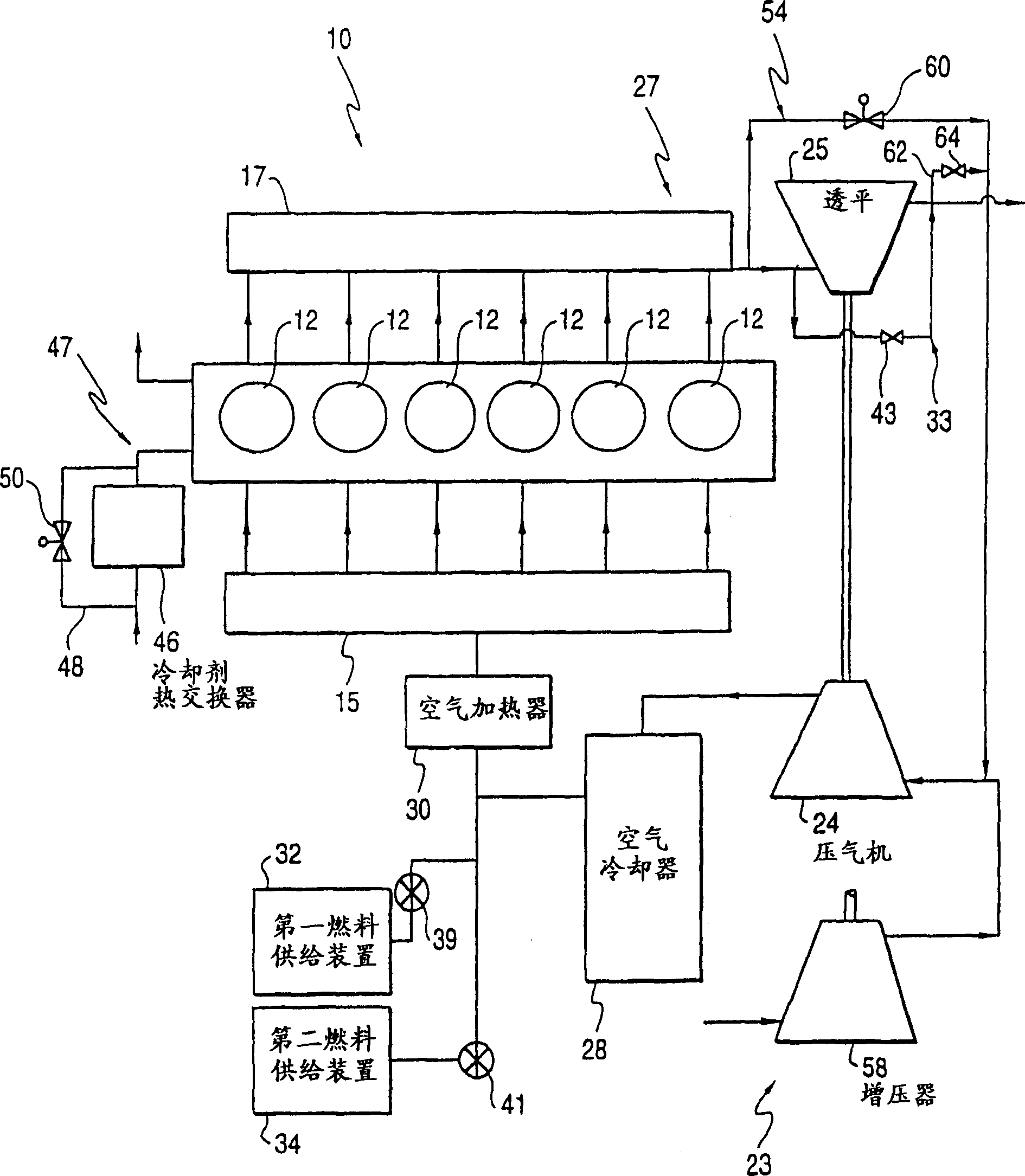

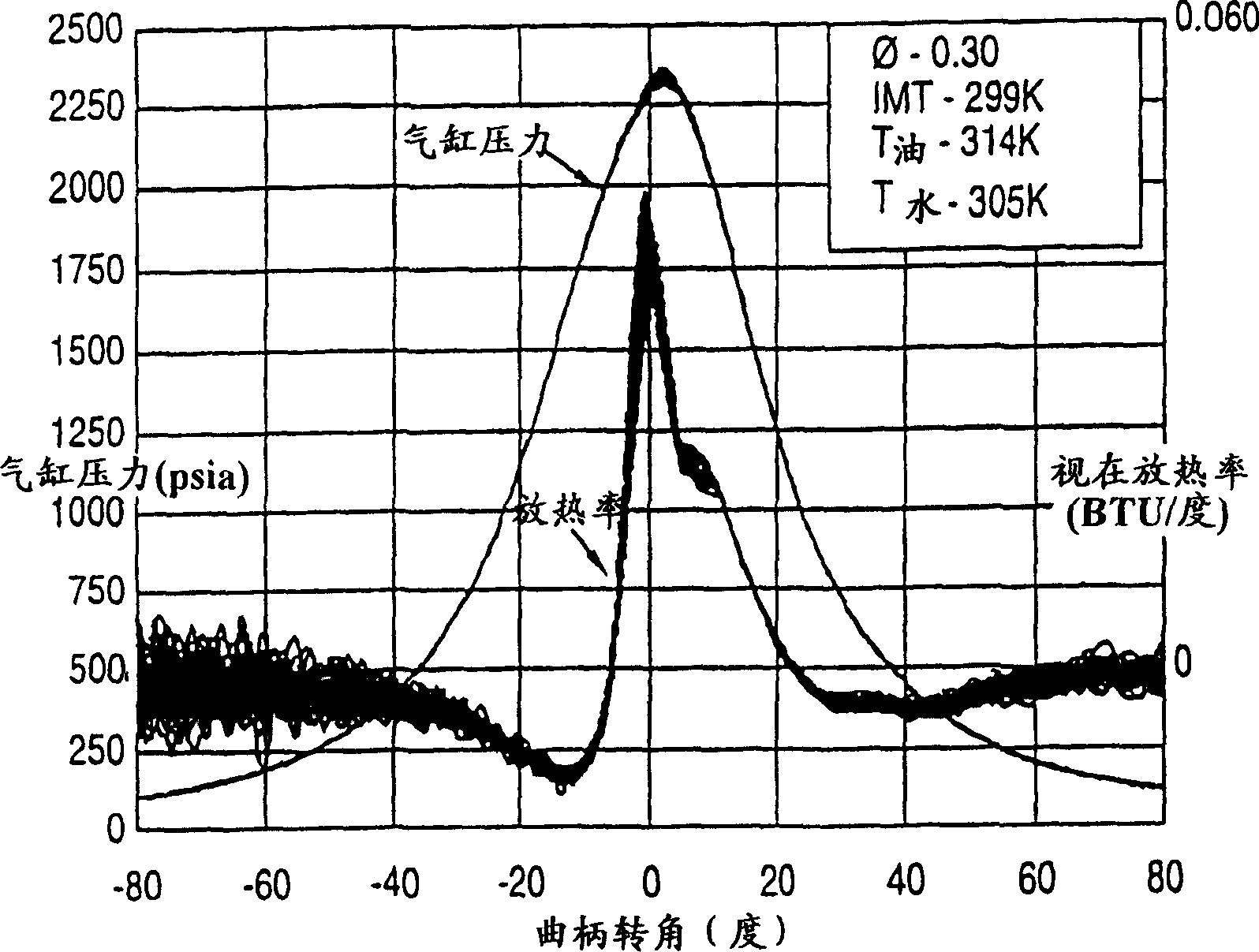

Premixed charge compression ignition engine with optimal combustion control

InactiveCN1624305AControl control systemEffective controlElectrical controlInternal combustion piston enginesTemperature controlActive feedback

The present invention provides a premixed charge compression ignition engine and control system (10), which can effectively trigger combustion and maintain stable combustion by means of compression ignition, while achieving extremely low nitrogen oxide emissions, good overall efficiency and Acceptable combustion noise and cylinder pressure. The engine and control system (10) of the present invention can effectively control the combustion process by controlling certain control variables of temperature control, pressure control, mixture self-ignitability control and equivalence ratio control, that is, the time of combustion initiation, the combustion rate , duration of combustion and / or completeness of combustion. The combustion control system (10) provides active feedback control of combustion and includes a sensor for detecting engine operating conditions representative of a combustion process, such as ignition of combustion, and generating a corresponding engine operating condition signal (18) , such as the pressure sensor (16).

Owner:CUMMINS INC

Dense Phase Swirl Pulverized Coal Burner

InactiveUS20130112120A1Simple primary air channel structureImprove wear resistancePulverulent fuel combustion burnersCombustionFlue gas

A dense phase swirl pulverized coal burner comprises a primary air channel, a direct flow secondary air channel and a outermost swirl secondary air channel; and multiple levels of pulverized coal concentration rings are arranged axially at intervals along the oil gun casing in a straight tube section of the primary air channel, so that pulverized coal air flow is distributed thickly outside and thinly inside the primary air nozzle. In the invention, dense phase pulverized coal outside the primary air nozzle passes through guide vanes, forms disturbed flow, is ejected into a furnace and mixes with high temperature backflow flue gas rapidly and sufficiently at an outlet. Meanwhile, dilute pulverized coal air flow at the center is ejected into the furnace by direct flow, ensuring subsequent mixing and combustion of pulverized coal flow. The primary air nozzle and the secondary air nozzle are provided with cone flaring structures with certain angle to effectively control appropriate mixing of secondary air and pulverized coal. The invention has advantages of strong ignition and combustion stability, good coal adaptability, low nitric oxide emission, simple primary air channel structure and small resistance, which effectively slows wear rate of parts.

Owner:LI YUEHUA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com