Surfacing electrode for repairing hot forged mould

A technology for surfacing welding electrodes and hot forging dies, which is applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of large machining costs and heat treatment costs, reduced mechanical properties, and low economic benefits, and is conducive to machining. , Excellent performance, stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The components of the coating used in the surfacing electrode of the present invention and their mass parts are as follows: marble: 30%; fluorite: 20%; zircon sand: 3%; soda ash: 2%; silicon micropowder: 5%; White powder: 3%; phlogopite: 3%; rare earth fluoride: 2%; metal manganese: 3%; ferrosilicon: 2%; ferro-titanium: 4%; chromium metal: 8%; : 6%; aluminum-magnesium alloy: 1%.

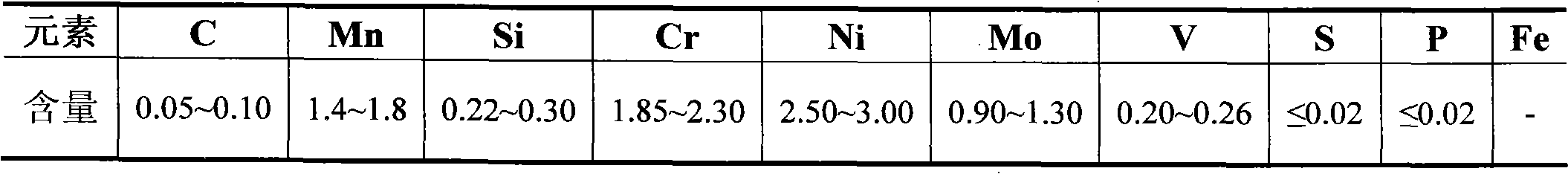

[0039] The mass percentage of the chemical composition of the deposited metal in this example is: C: 0.068; S: 0.0085; P: 0.016; Si: 0.259; Mn: 1.54; Cr: 2.06; Ni: 2.87; margin.

[0040] After mixing the above-mentioned skin raw materials evenly, add 43-48Be (20°C) pure sodium water glass accounting for 20-30% of the mass content of the solid component according to the mass of the solid component to prepare a paste for the skin. Process Electrode preparation is carried out on electrode production equipment.

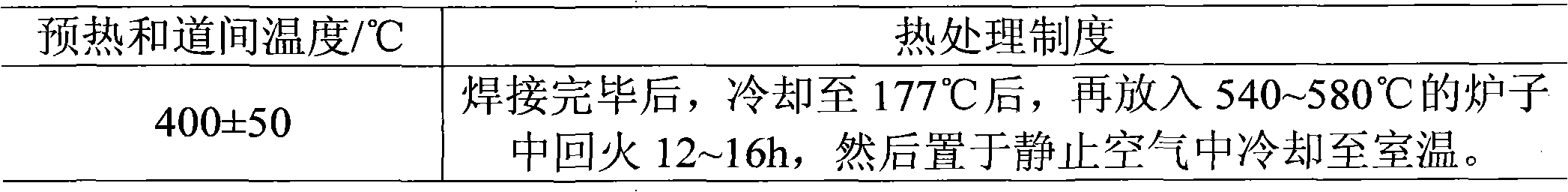

[0041] The welding rod produced according to the above process has excellent produc...

Embodiment 2

[0043] The components and parts by mass of the coating are as follows: marble: 36%; fluorite: 14%; zircon sand: 2%; soda ash: 1%; silicon micropowder: 2%; 1%; rare earth fluoride: 1%; manganese metal: 5%; ferrosilicon: 5%; ferro-titanium: 6%; chromium metal: 4%; 2%.

[0044] Other conditions are identical with embodiment 1.

[0045] The welding rod produced according to the above process has excellent production process performance, smooth surface of the welding rod, high yield and stable eccentricity; the arc is easy to ignite and burns smoothly during the welding process; Beautiful, slag is easy to remove; the hardness of the deposited metal surfacing layer is moderate.

Embodiment 3

[0047] The components of the coating and their parts by mass are as follows: marble: 40%; fluorite: 12%; zircon sand: 1.5%; soda ash: 0.5%; silicon micropowder: 3%; 0.5%; rare earth fluoride: 1%; manganese metal: 7%; ferrosilicon: 3%; ferro-titanium: 5%; chromium metal: 8%; 1.5%.

[0048] Other conditions are identical with embodiment 1.

[0049] The welding rod produced according to the above process has excellent production process performance, smooth surface of the welding rod, high yield and stable eccentricity; the arc is easy to ignite and burns smoothly during the welding process; Beautiful, slag is easy to remove; the hardness of the deposited metal surfacing layer is moderate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com