Repair method of uneven surface in golf head and manufacturing method of golf head

A golf head and uniform surface technology, which is applied to manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of waste of Ti alloy raw materials, high production cost, low production efficiency, etc., and achieves good welding effect and simple manufacturing method. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A golf head manufacturing method specifically includes the following steps:

[0033] (1) First prepare the golf head with the Ti alloy raw material less than the normal amount of 1-2g according to the conventional investment casting method;

[0034] (2) Measure the actual weight of the golf head, and determine the weight that is expected to be added later according to the difference between the theoretical weight and the actual weight;

[0035] (3) Select the uneven and thinner part as the part to be repaired by measuring the golf head;

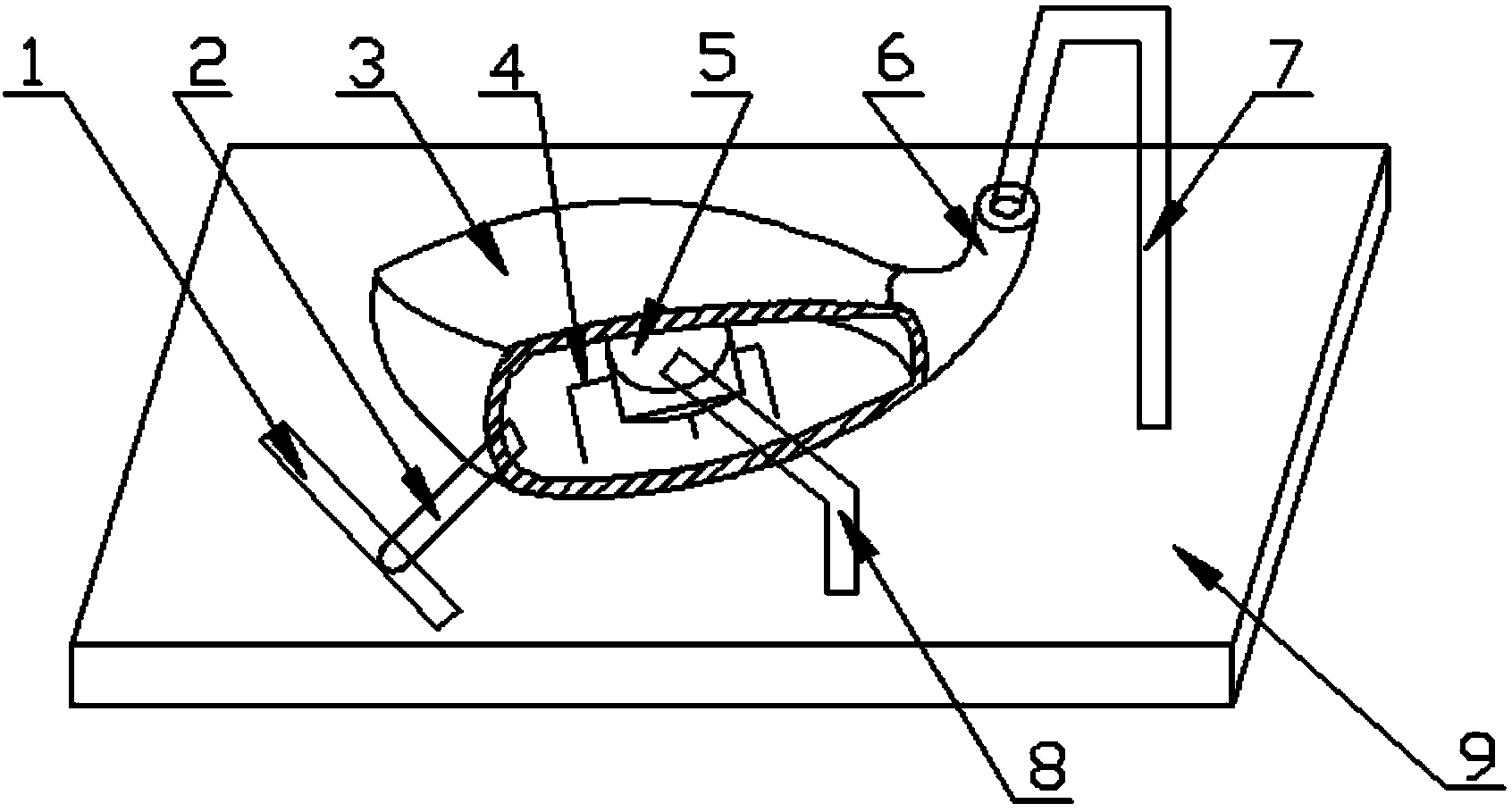

[0036] (4) Al with a purity of 99.9% and a grain size of 1 μm 2 o 3 Make a ceramic mold for the raw material with a fitting surface that matches the shape of the curved surface of the golf head to be repaired;

[0037] (5) Grind the part of the golf head to be repaired with sandpaper, and then clean it with acetone, so as to facilitate the better combination of Ti-based amorphous solder and the ball head;

[0038] (6) ...

Embodiment 2

[0043] Embodiment 2 A method for manufacturing a golf head is basically the same as Embodiment 1, the difference lies in:

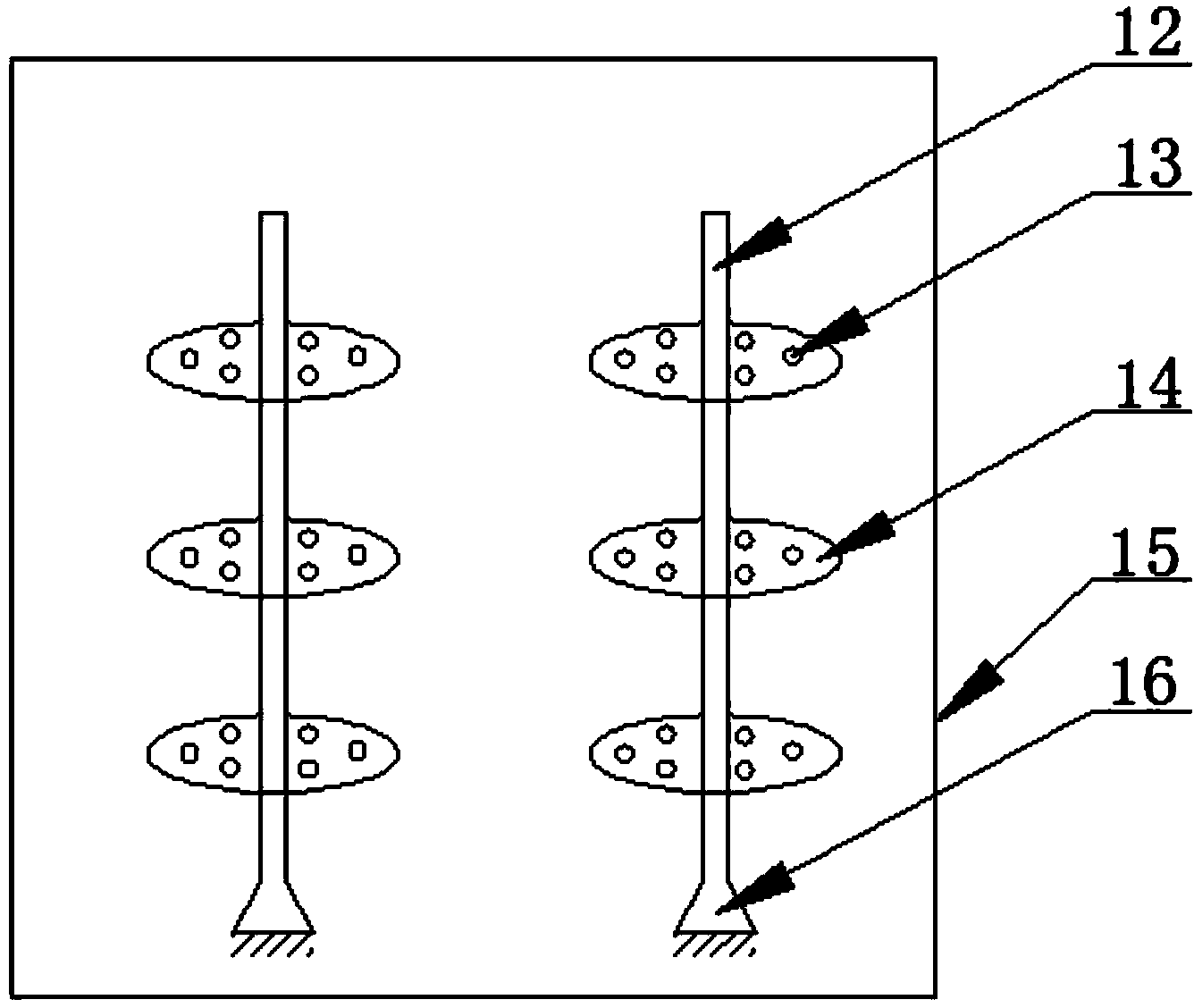

[0044]In the above step (8), a plurality of fixed ceramic molds and golf heads are first placed on the disk of the batch rack and fixed, and then put into an oven or a roasting furnace for batch roasting. The batch rack consists of The support shaft, the base and a certain number of discs are installed on the support shaft, and the lower end of the support shaft is fixed on the base, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com