Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

351 results about "Actual weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Actual weight. Actual weight means the actual unladen weight of a vehicle or combination of vehicles as operated and certified to by a weighmaster.

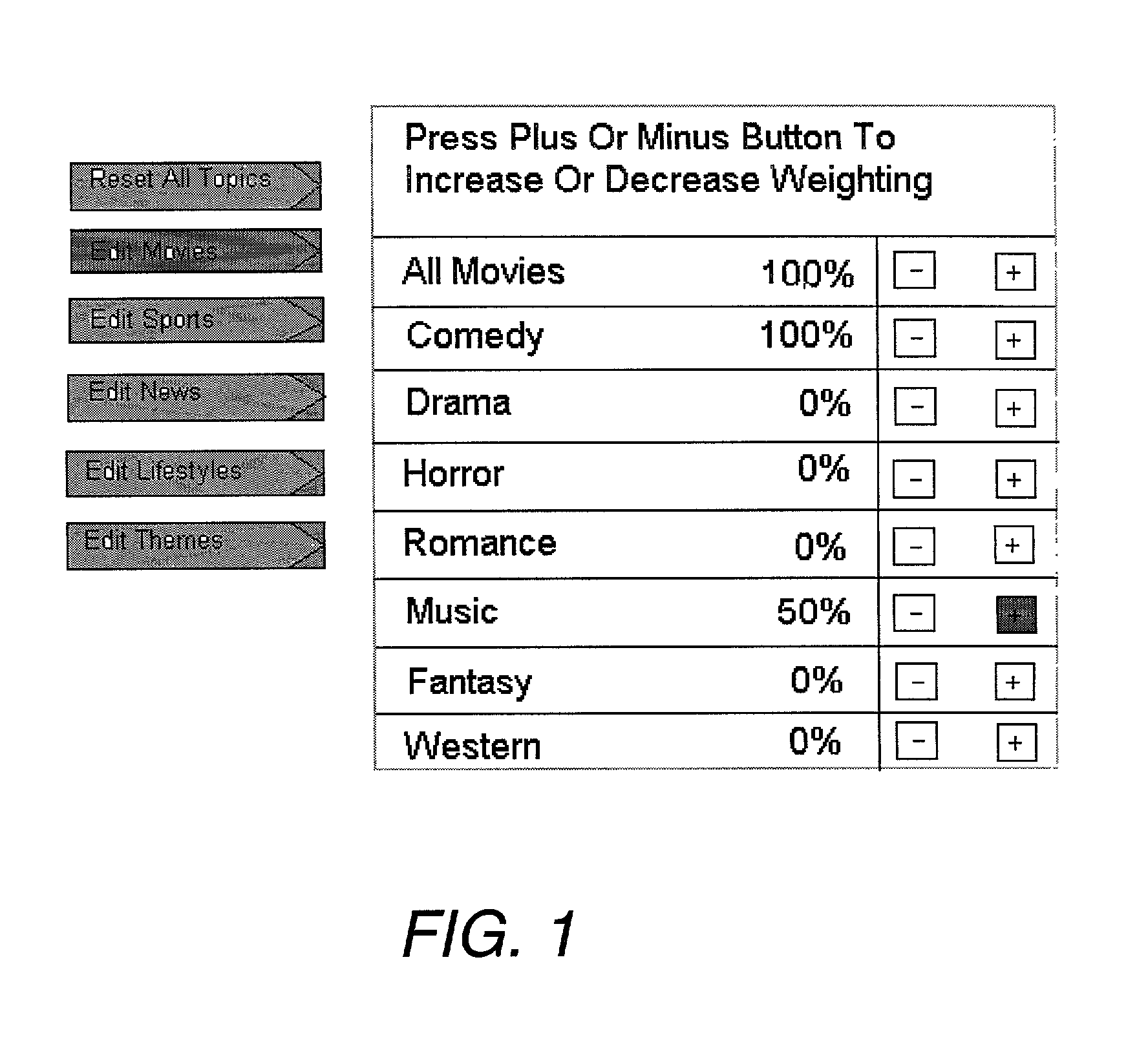

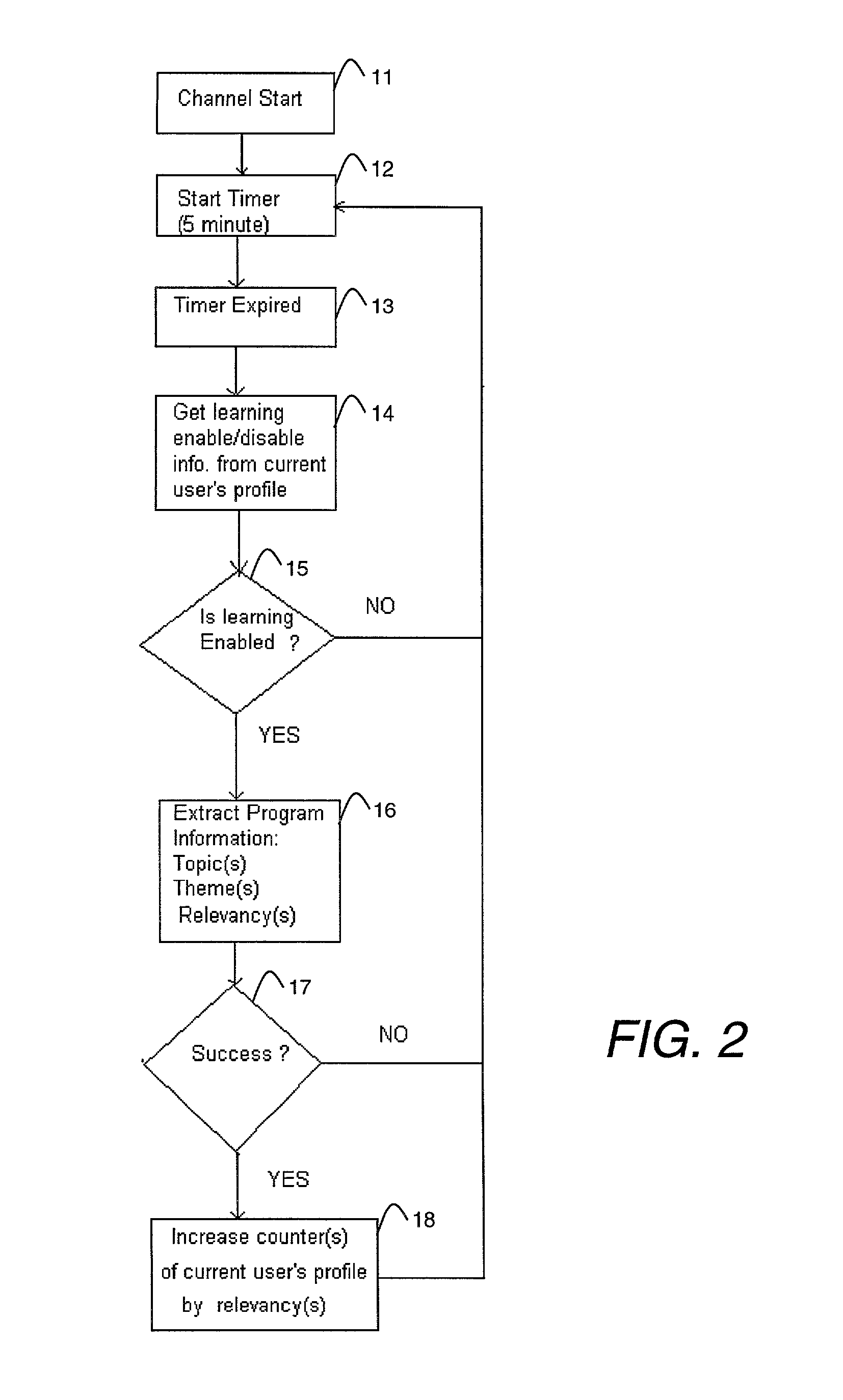

Method and apparatus for generating a list of suggested scheduled television programs

ActiveUS7380262B2Overcome problemsTelevision system detailsColor television detailsPersonal detailsUser profile

A system and method for generating a list of suggested scheduled television programs wherein television schedule guide data which comprises characteristics of scheduled programs and optionally relevancy of those characteristics is obtained from broadcast information. User profiles comprising characteristics of television programs previously viewed, the cumulative amount of time programs having those characteristics has been previously viewed, and optionally the relevancy of the previously viewed characteristics is stored. The user is allowed to manually adjust the weights assigned to characteristics so as to override the system assigned weight values. The system calculates the suggested program list from the schedules it receives from broadcast or other means, using the characteristic weights in the user profiles. The user interface displays percentage values currently assigned to characteristics in that user's profile, but smoothes the percentage values by calculating them based on a ratio of characteristic weights to the greater of a preset value such as 500 or the actual weight of the highest weighted characteristic in that user's profile.

Owner:INTERDIGITAL MADISON PATENT HLDG

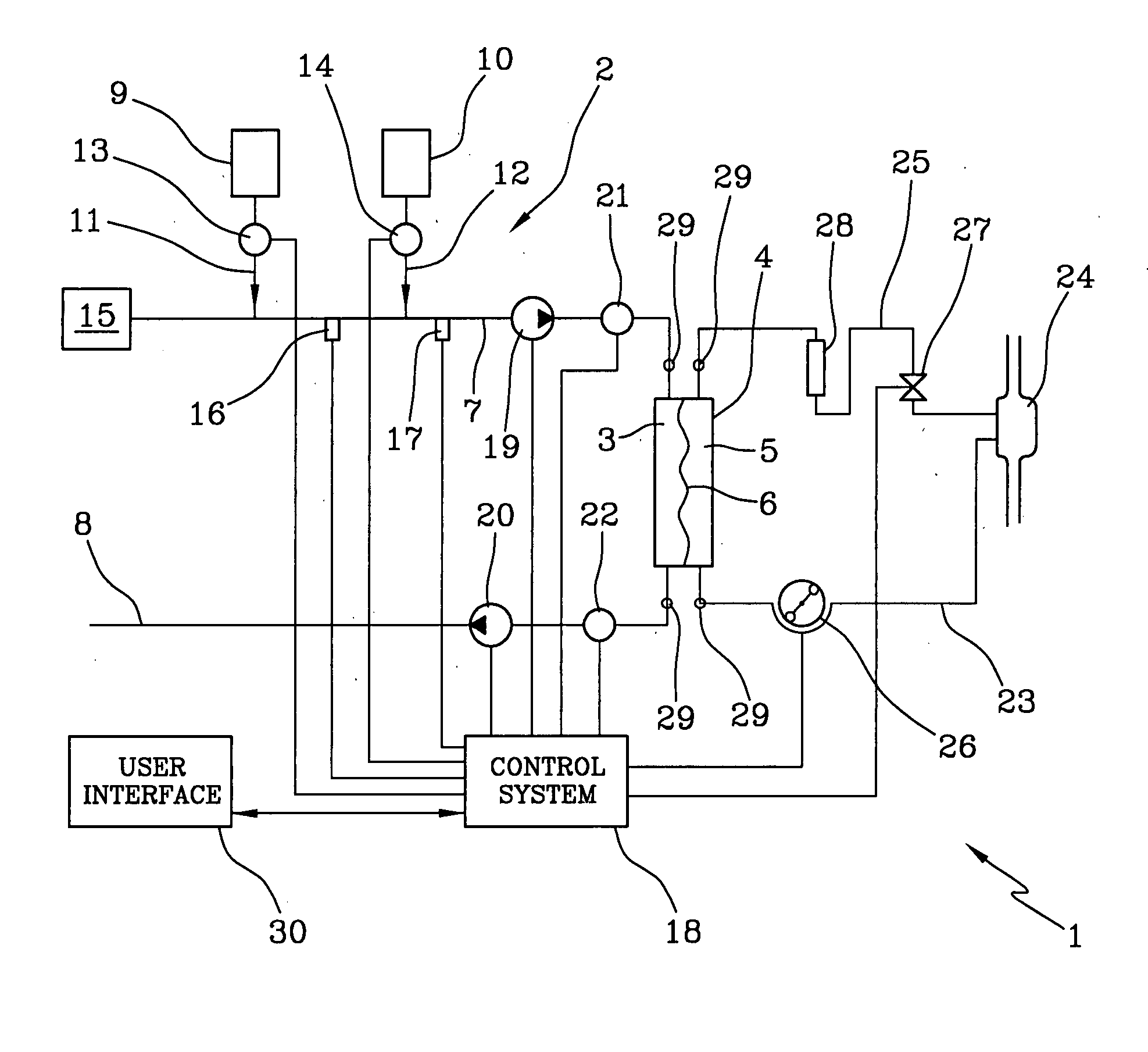

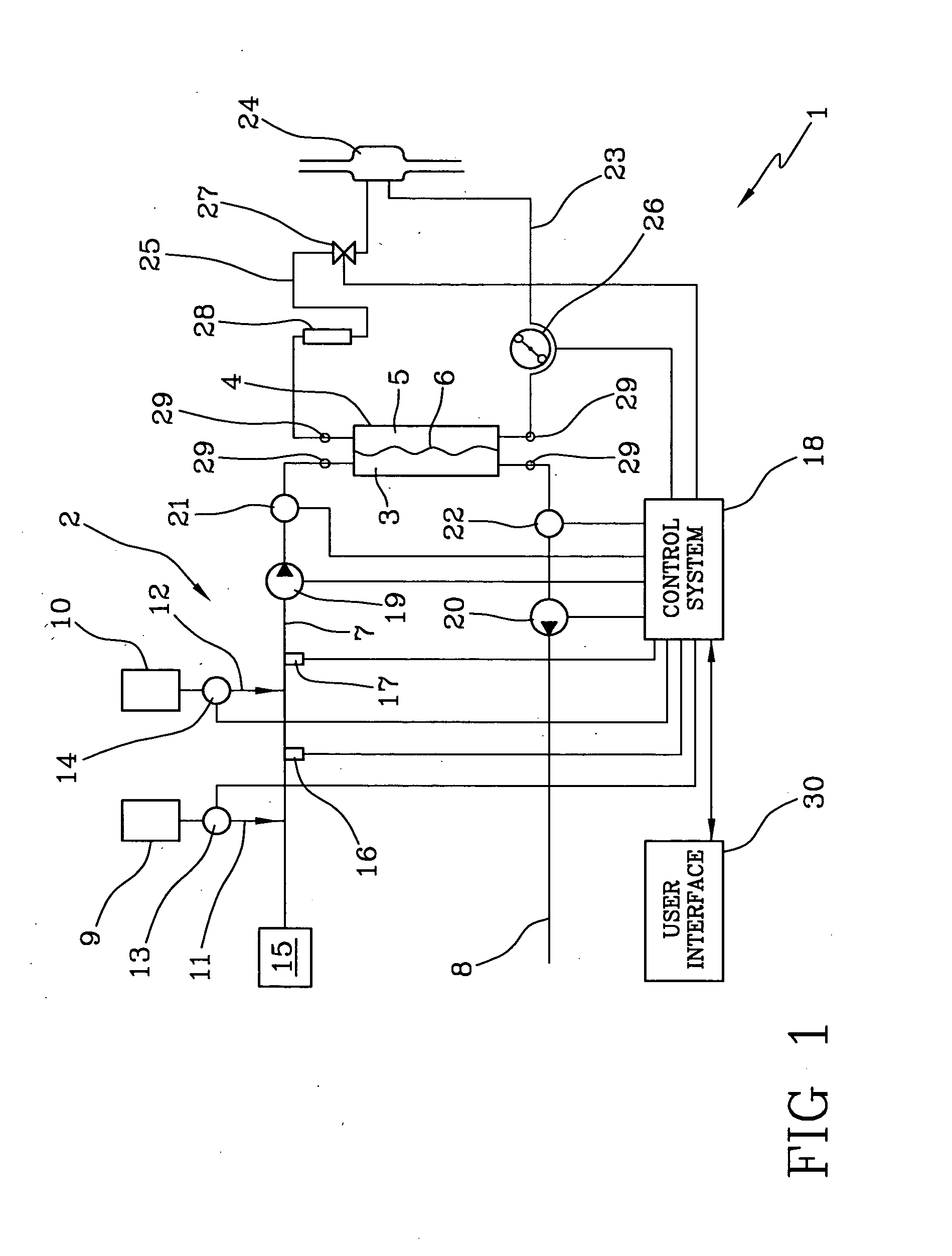

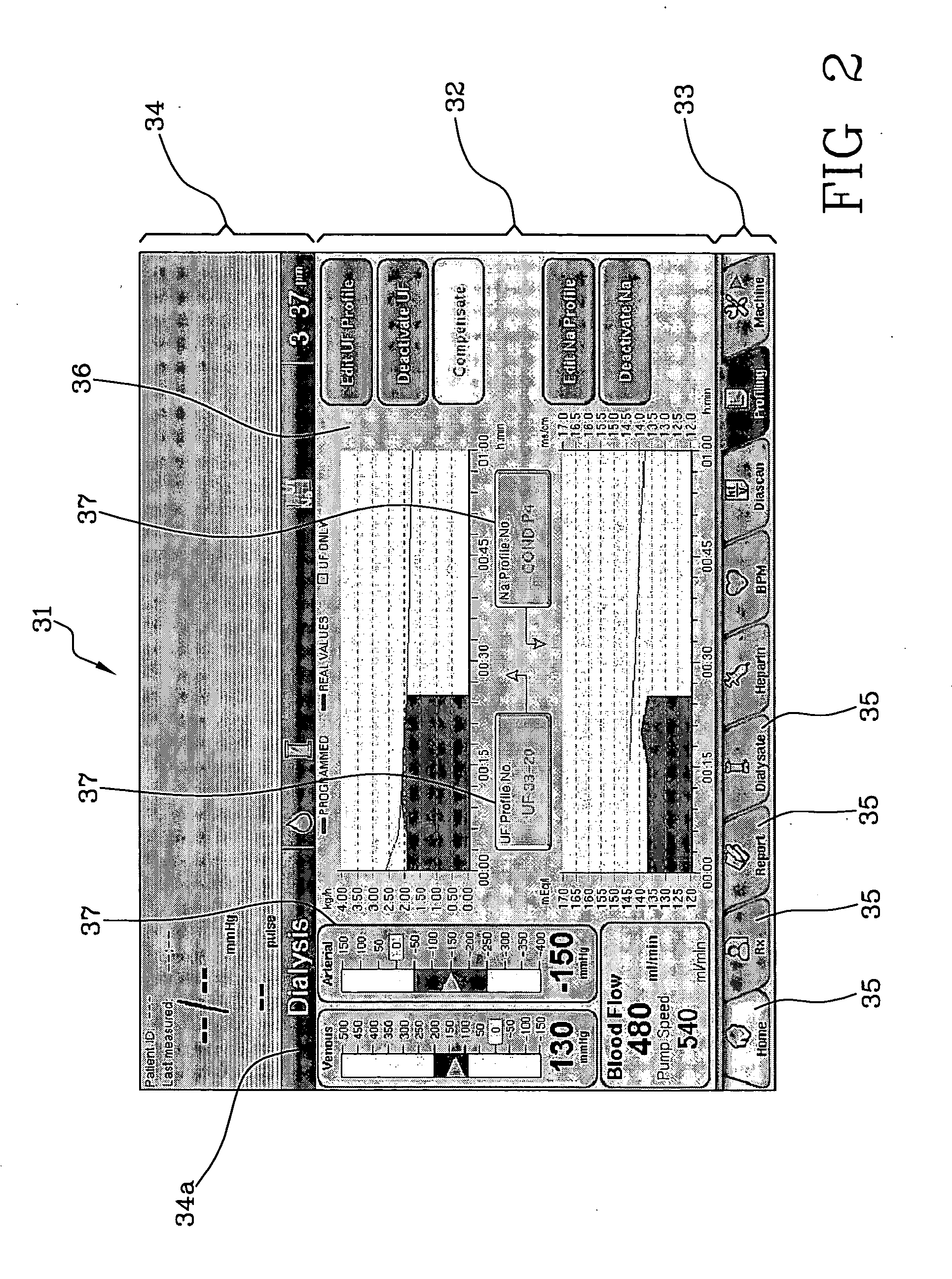

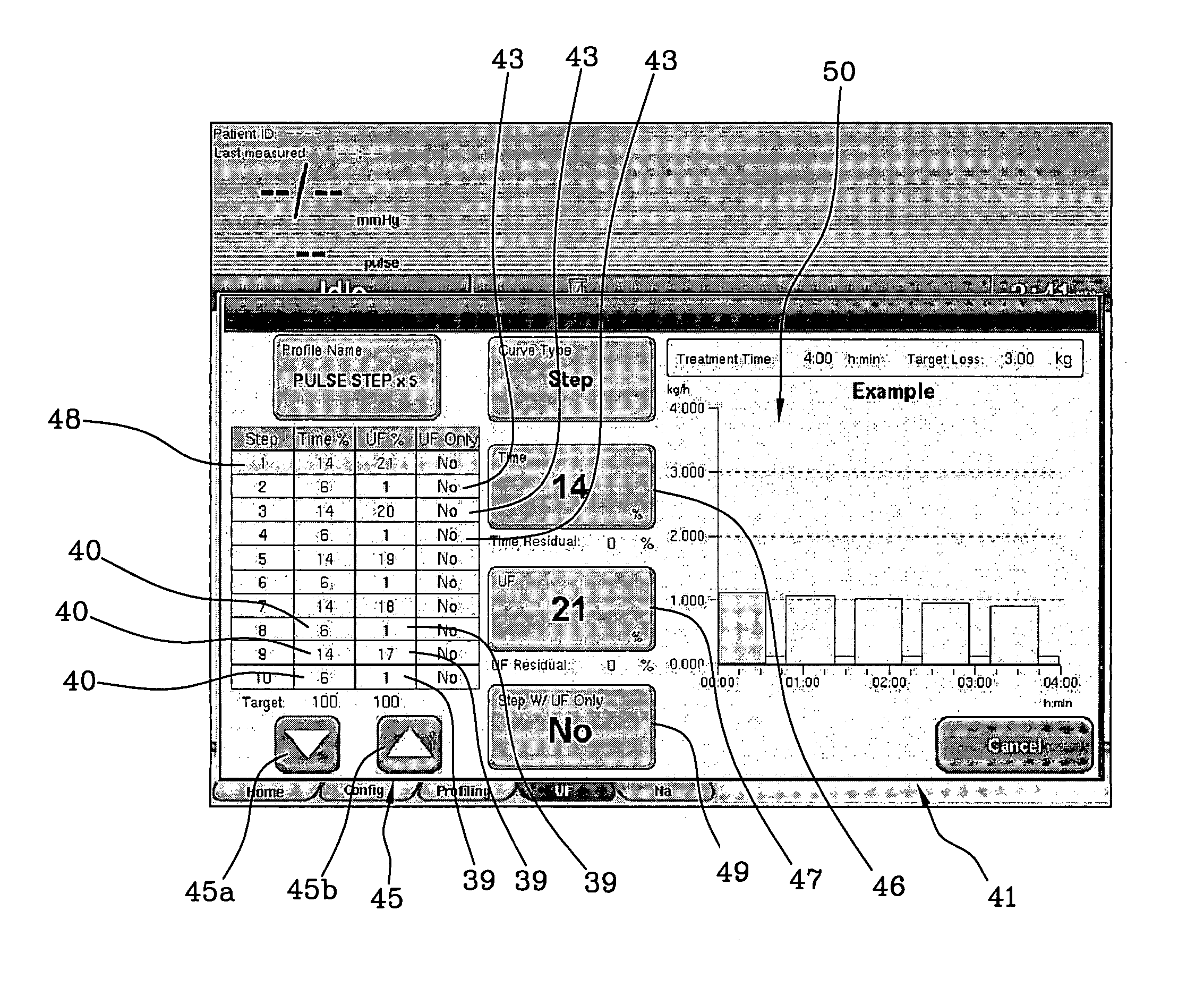

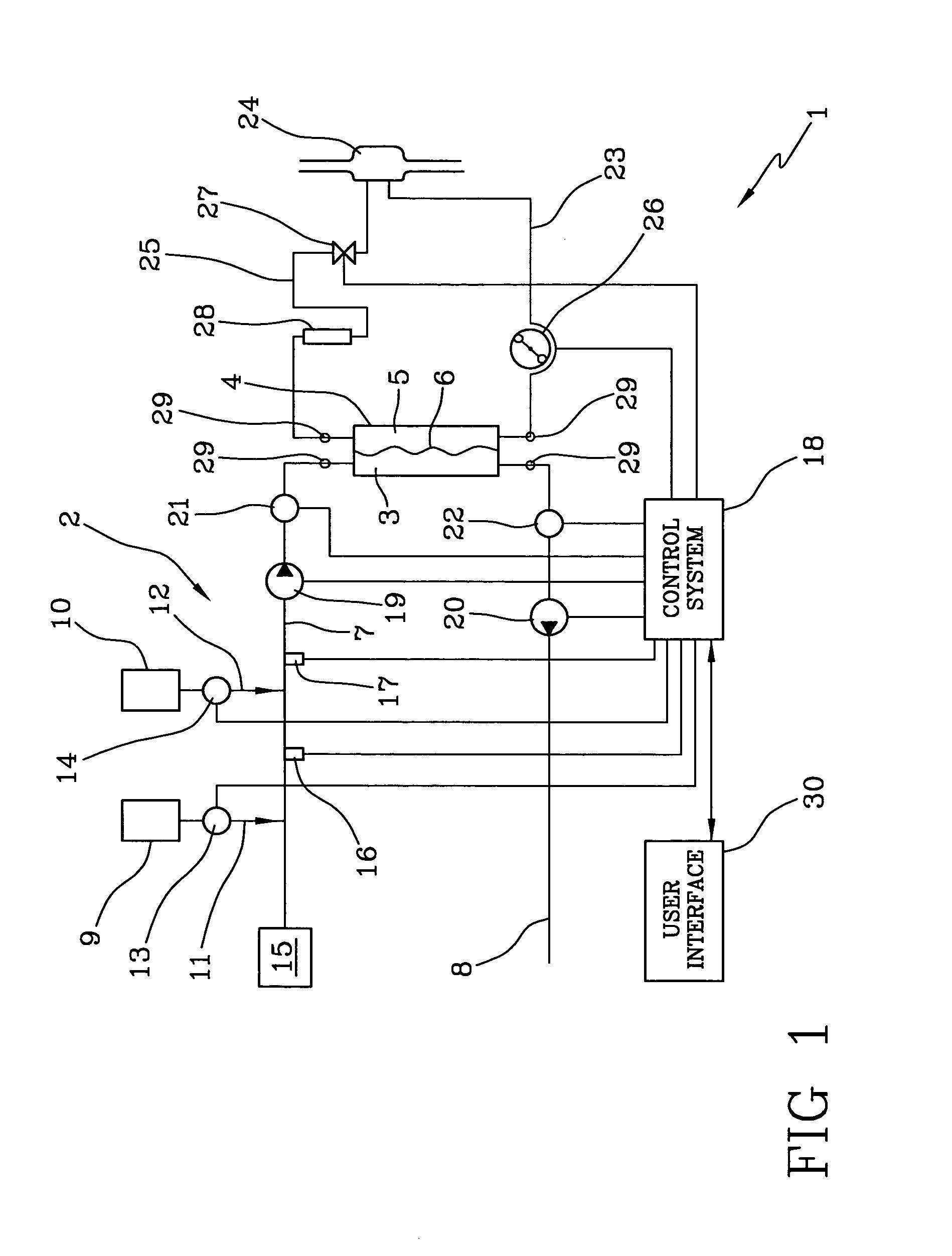

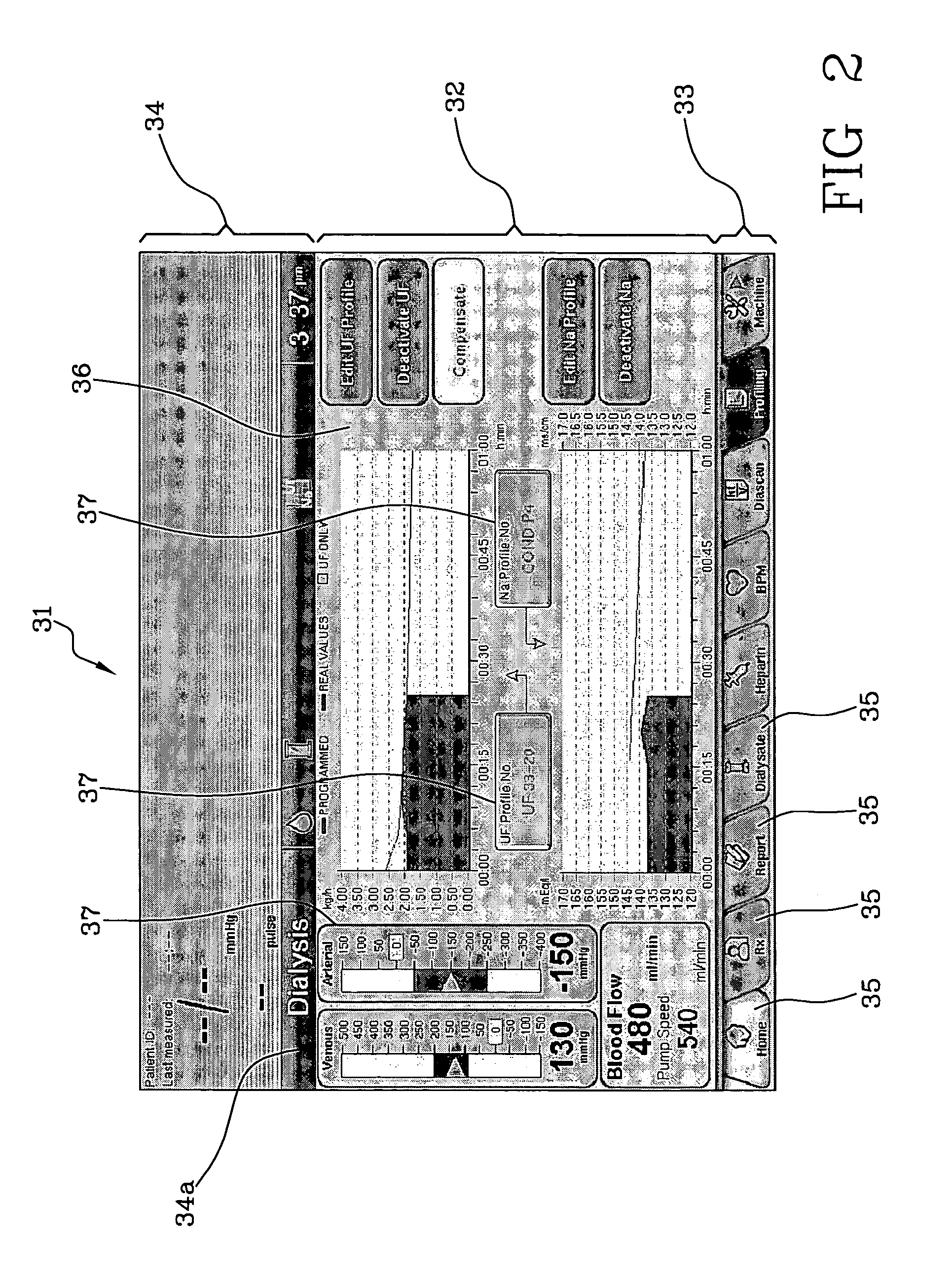

Medical apparatus with improved user interface

ActiveUS20070138069A1Improve easeImprove reliabilityMechanical/radiation/invasive therapiesSolvent extractionLoss rateMedicine

A medical apparatus comprises a control system allowing storage of a number of shaping profiles. Each shaping profile is stored as a plurality of pairs, including a shaping profile reference value and a time interval value. The reference value is represented as fraction, for instance a percentage, of the total weight loss the apparatus should achieve at the end of a treatment time. Each time interval value is represented either as fraction of the total treatment time or as a prefixed actual time interval. The control system calculates the actual weight loss rate versus time profile based on the desired total weight loss, on the desired total treatment time as well as on selected desired shaping profile.

Owner:GAMBRO LUNDIA AB

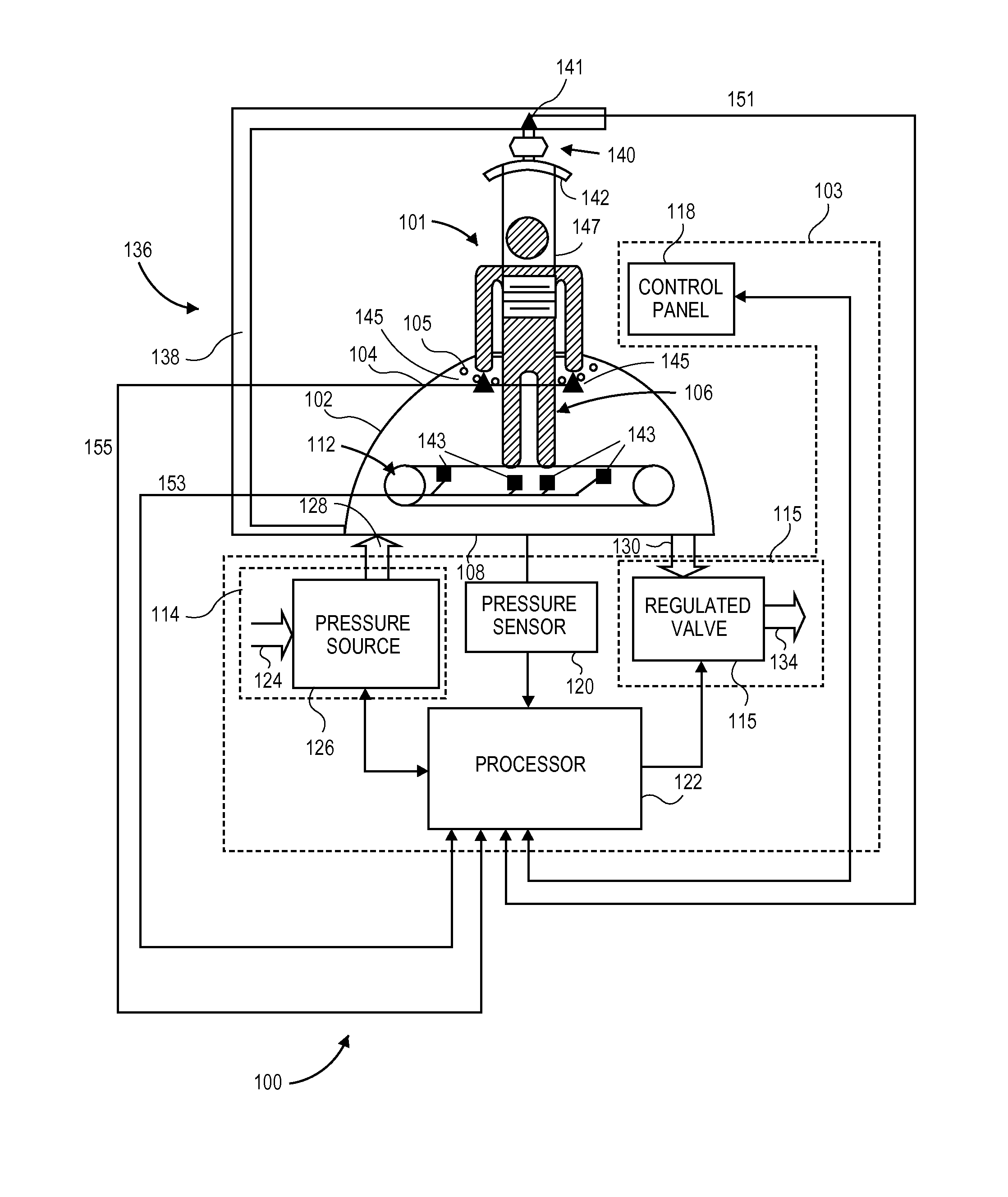

Differential air pressure systems and methods of using and calibrating such systems for mobility impaired users

InactiveUS20120238921A1Improve cardiovascular functionImprove mobilityPneumatic massageDiagnosticsPressure systemPositive pressure

Described herein are various embodiments of differential air pressure systems and methods of using and calibration such systems for individuals with impaired mobility. The differential air pressure systems may comprise an access assist device configured to help a mobility impaired user to stand in a pressure chamber configured to apply a positive pressure on a portion of the user's body in the seals pressure chamber. The system may further comprise load sensors configured to measure the user's weight exerted inside and outside the chamber. The system may be calibrated by determining a relationship between the actual weight of the user and the pressure in the chamber, where the actual weight of the user may be measured by more than one load sensor and at least one load sensor is not in the chamber.

Owner:ALTERG INC

Medical apparatus with improved user interface

ActiveUS7988850B2Improve ease and reliability in data entryReduce data entryMechanical/radiation/invasive therapiesDialysis systemsMedical equipmentTime profile

A medical apparatus comprises a control system allowing storage of a number of shaping profiles. Each shaping profile is stored as a plurality of pairs, including a shaping profile reference value and a time interval value. The reference value is represented as fraction, for instance a percentage, of the total weight loss the apparatus should achieve at the end of a treatment time. Each time interval value is represented either as fraction of the total treatment time or as a prefixed actual time interval. The control system calculates the actual weight loss rate versus time profile based on the desired total weight loss, on the desired total treatment time as well as on selected desired shaping profile.

Owner:GAMBRO LUNDIA AB

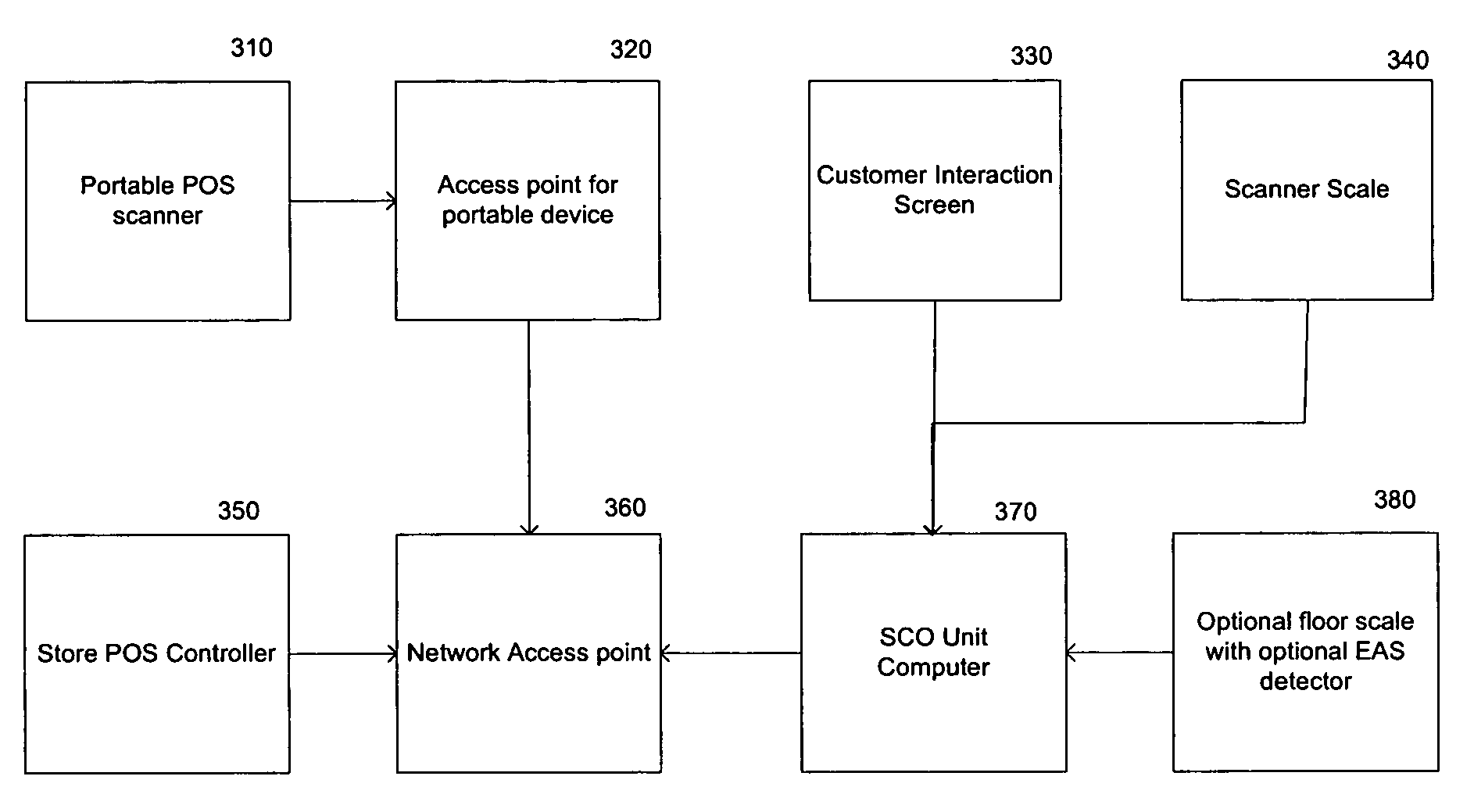

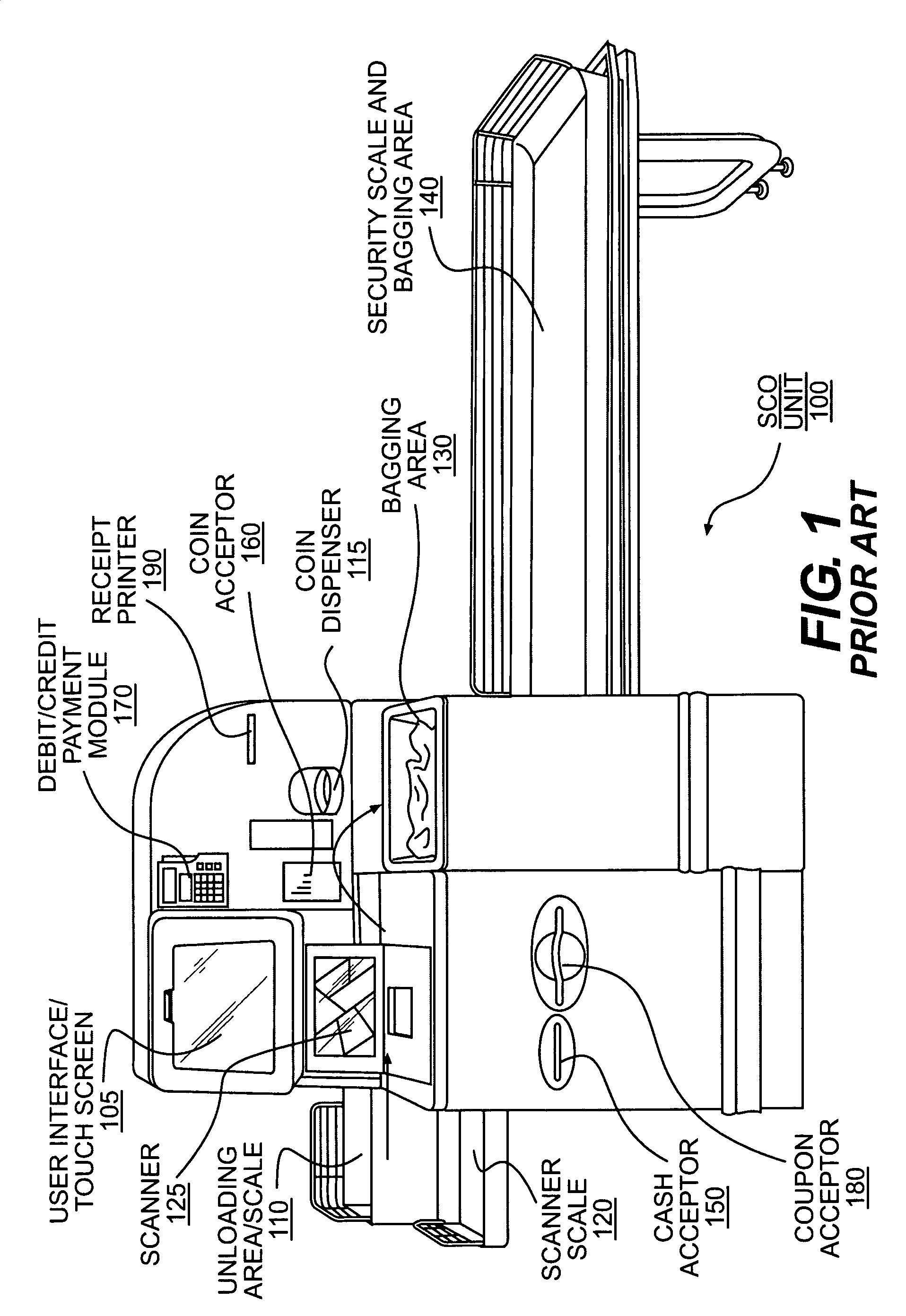

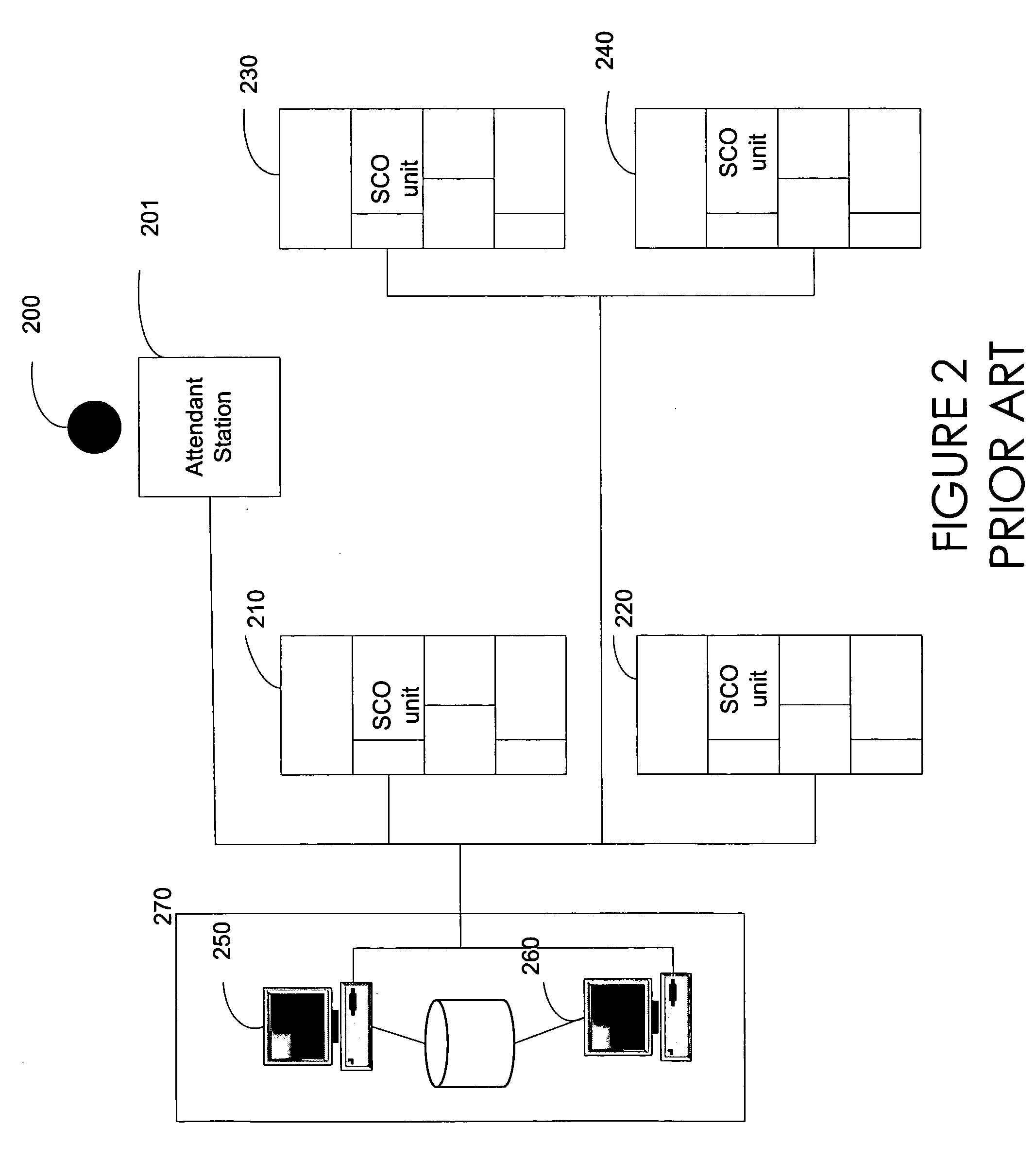

Self-checkout security system and method therefor

A system and method for enhanced security for a self-checkout system is disclosed where predicted weights of items are used to predict the total order weight. The predicted total order weight is compared to an actual weight of the order based on a weighing of the total order, and an output provided indicating whether the comparison is within acceptable limits or if a security alert or attendant assistance is needed.

Owner:FUJITSU FRONTECH NORTH AMERICA

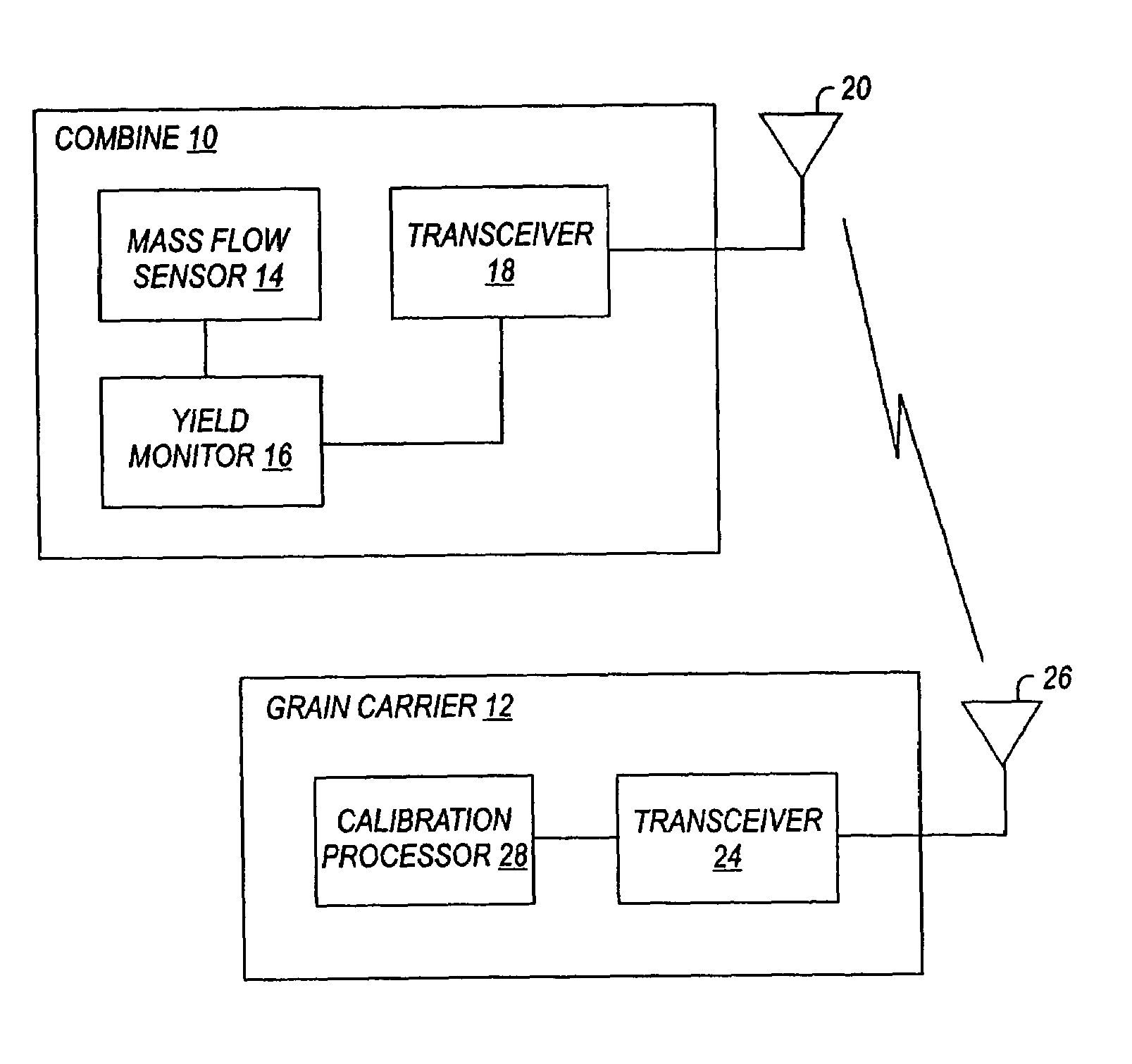

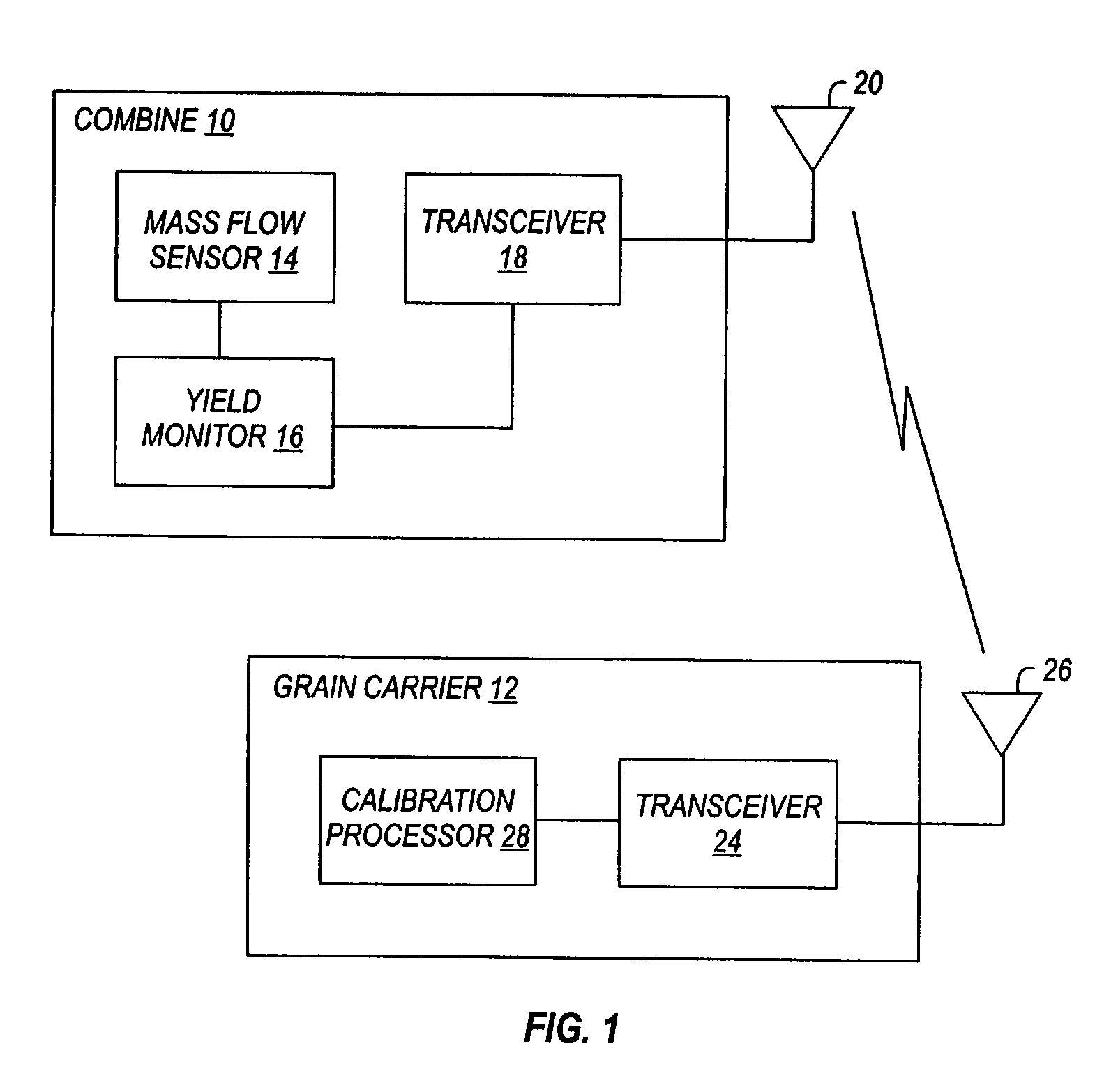

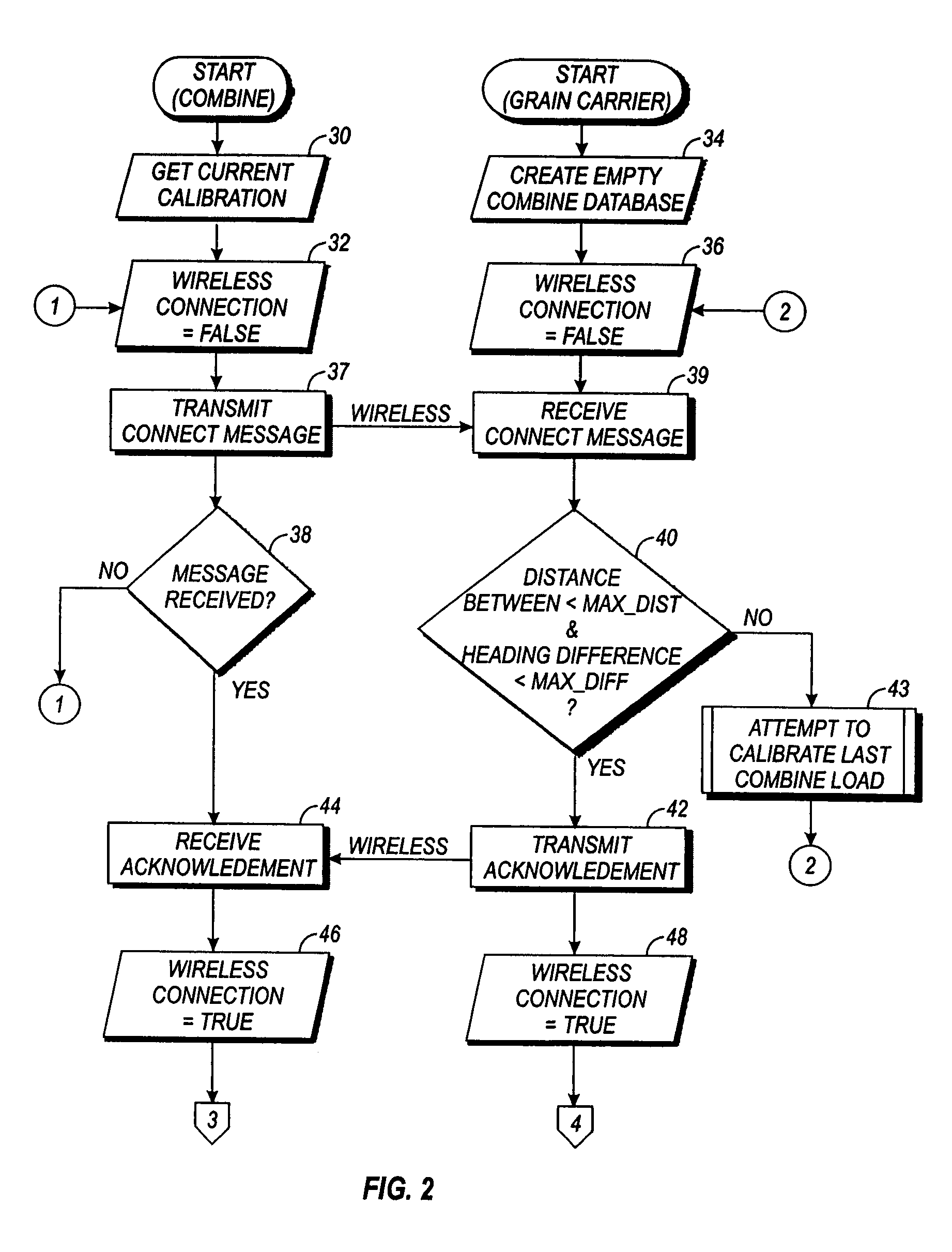

Automatic mass-flow sensor calibration for a yield monitor

A system and method is provided for remotely and automatically calibrating a mass-flow sensor in a yield monitor of a combine. The invention uses a wireless communication device installed on a combine and a remote wireless communication device installed on a grain carrier or truck carrier. Once an actual weight is obtained, calibration information is sent to the combine to calibrate the mass-flow sensor.

Owner:DEERE & CO

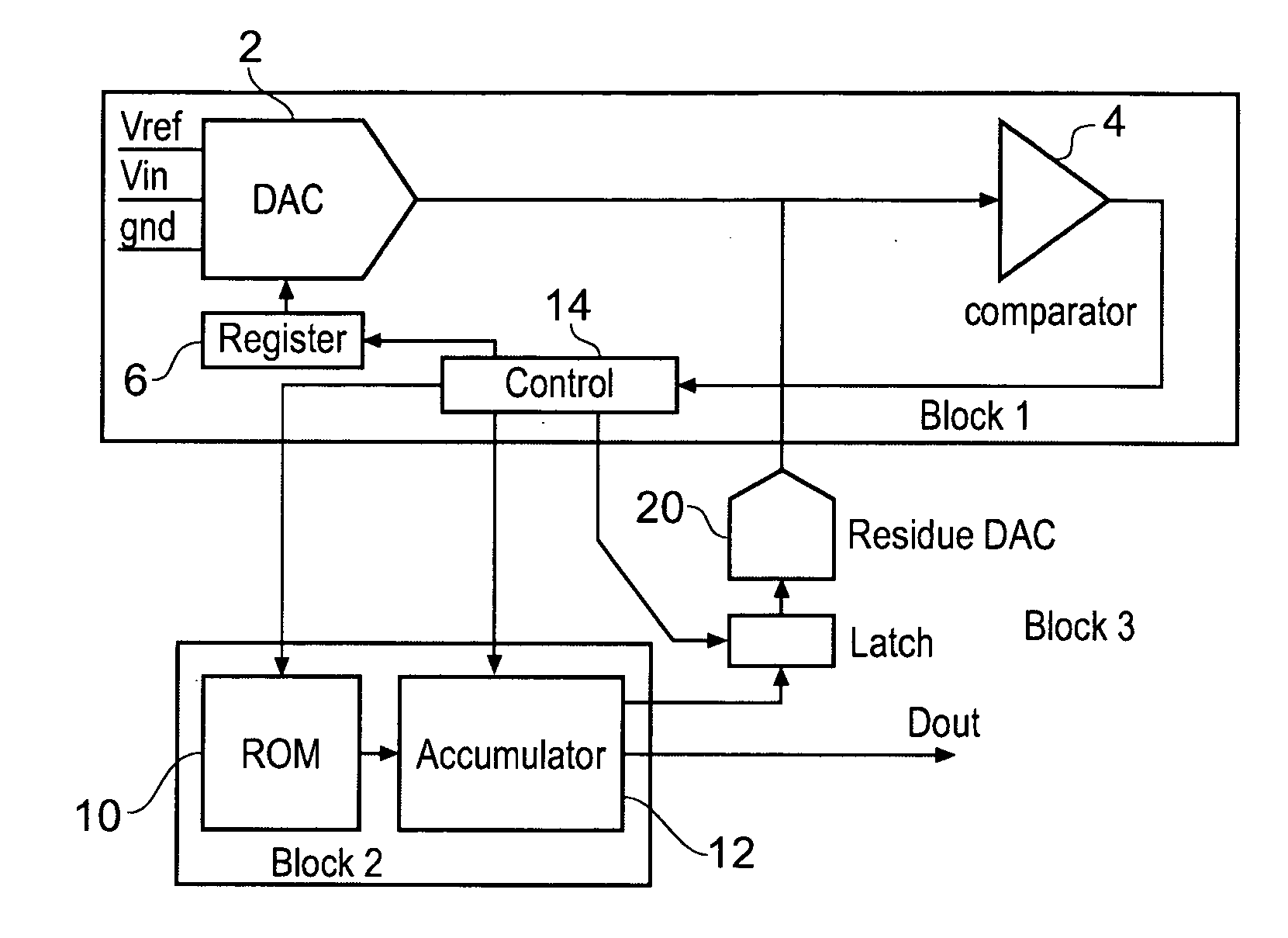

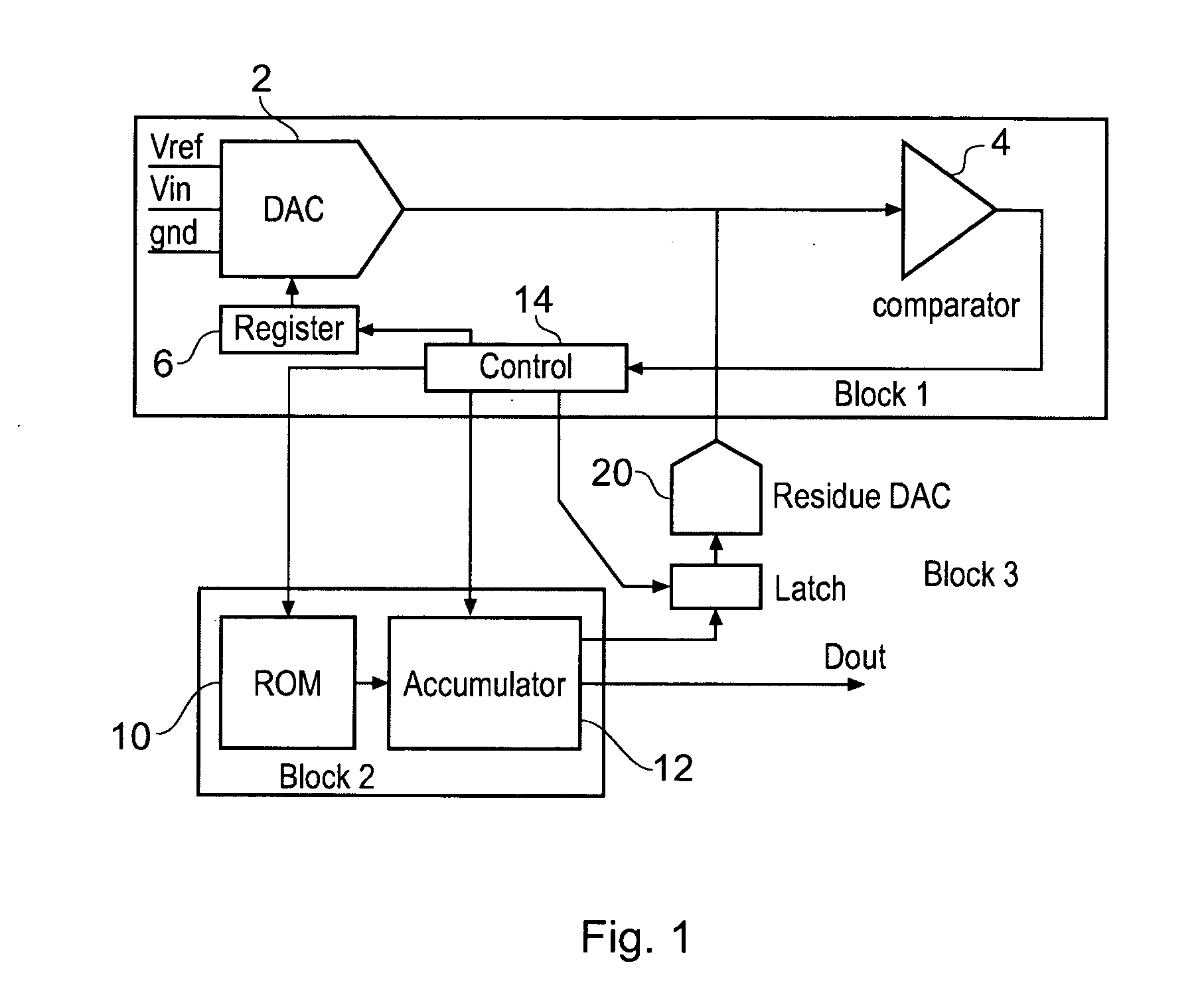

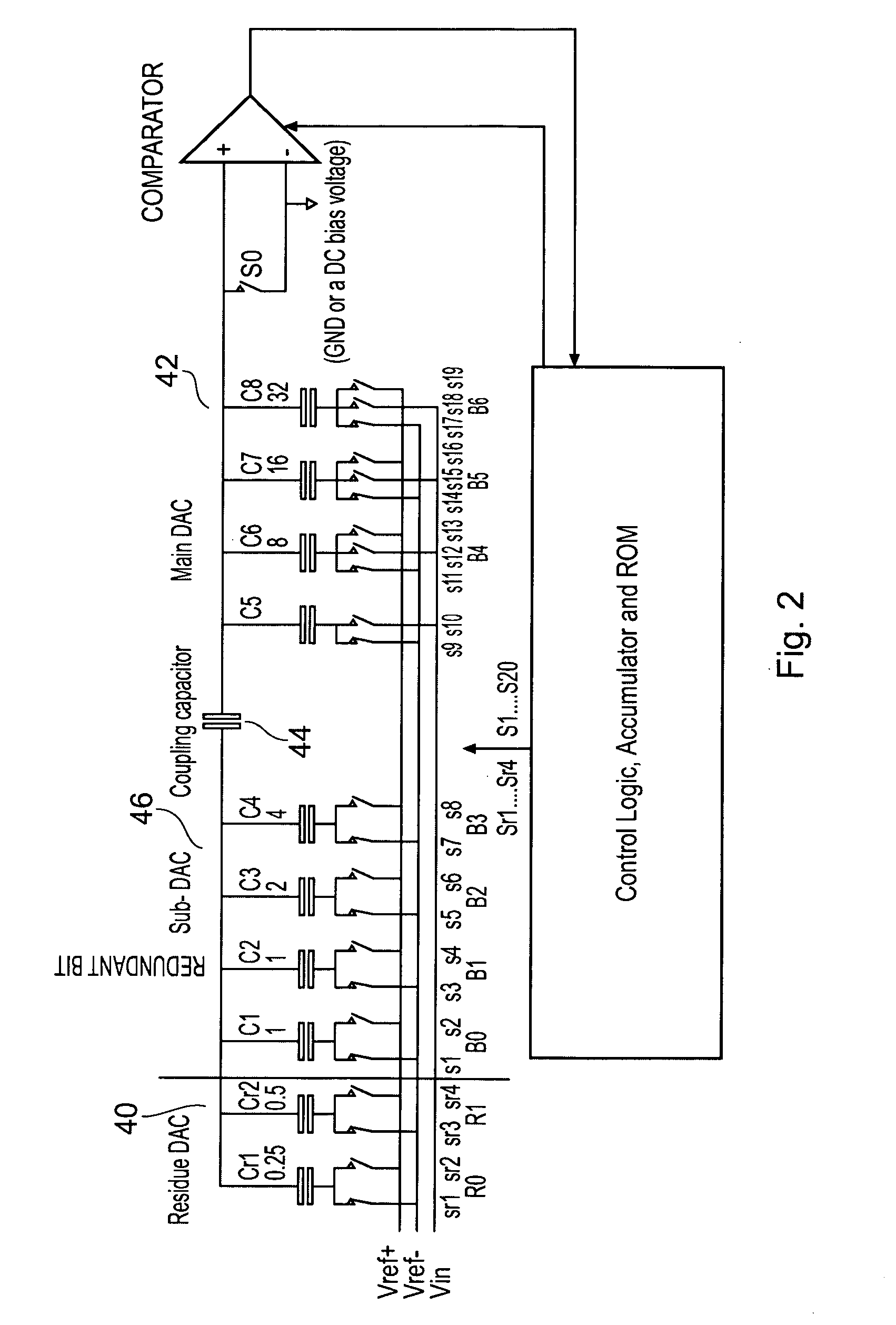

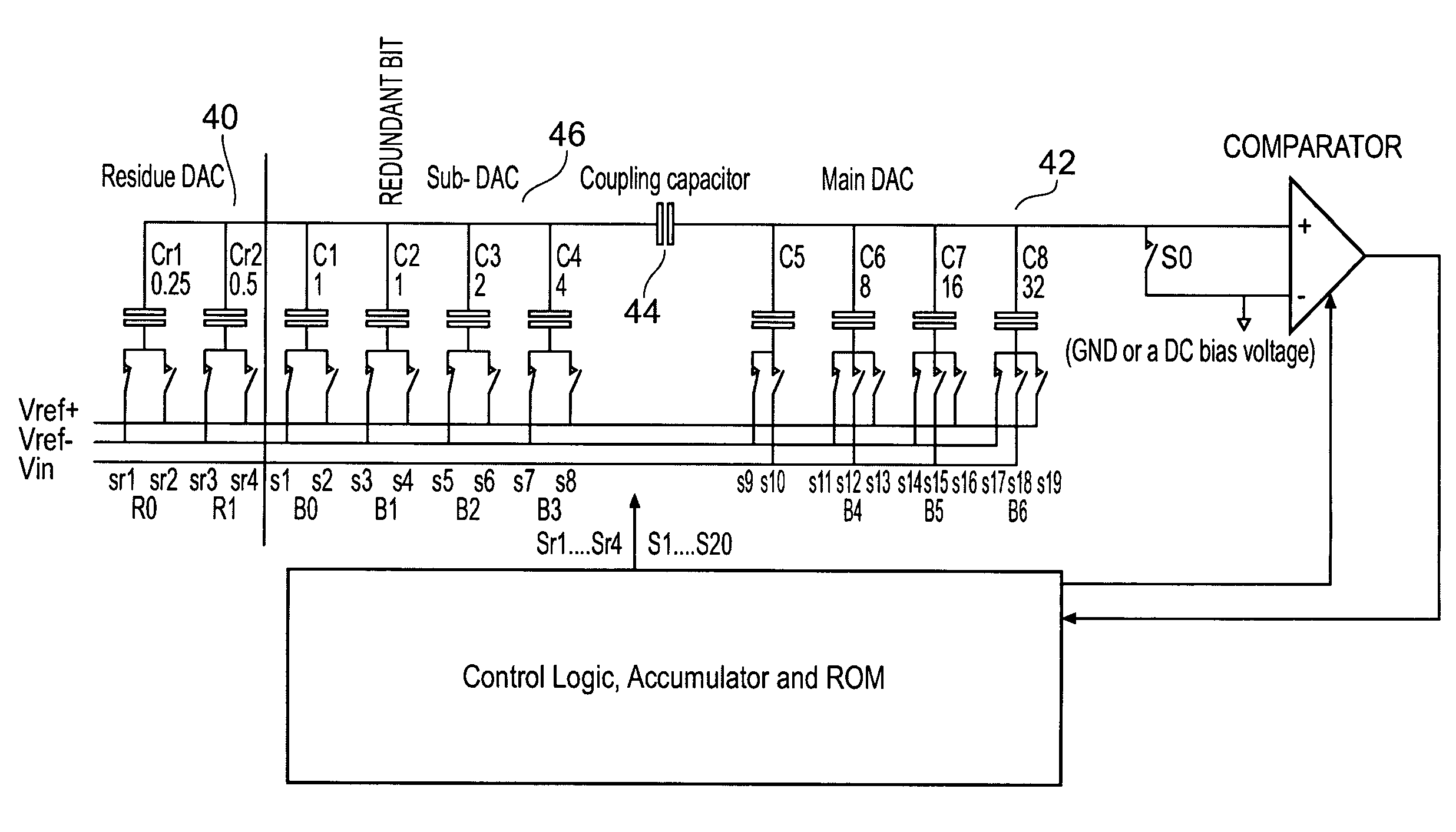

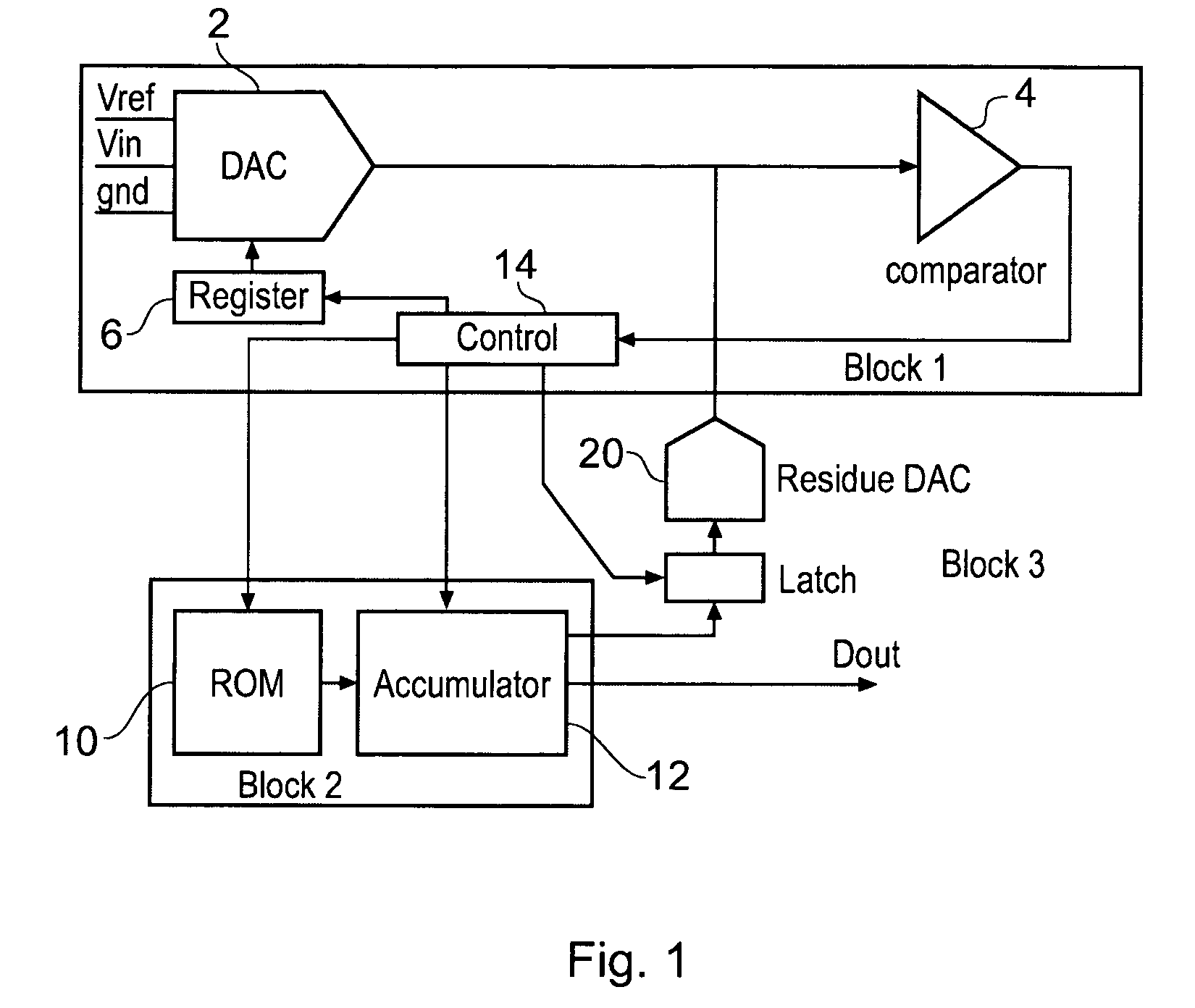

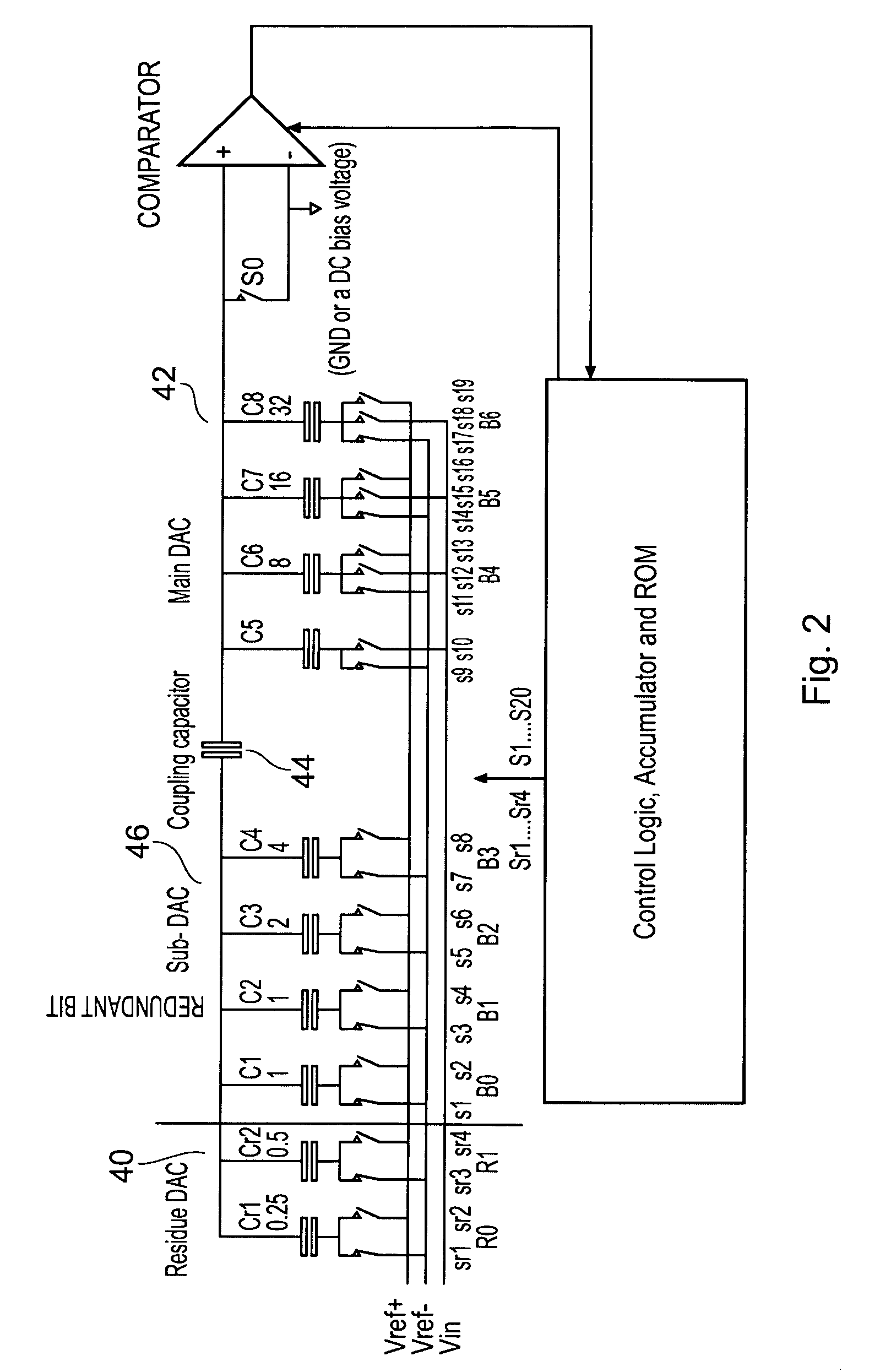

Digitally corrected SAR converter including a correction DAC

ActiveUS20070132626A1Eliminate errorsElectric signal transmission systemsAnalogue-digital convertersA d converterEngineering

An analog to digital converter having improved differential non-linearity is provided. The converter has a memory which is used to look up the actual weight or a weight error corresponding to the bits that have been kept as part of the SAR process to form an output correction value A part of this, for example a residue (the part following the decimal point in a decimal representation) is used to drive a correction DAC which causes a correction to be applied to the trial value presented to a comparator used by the ADC.

Owner:ANALOG DEVICES INC

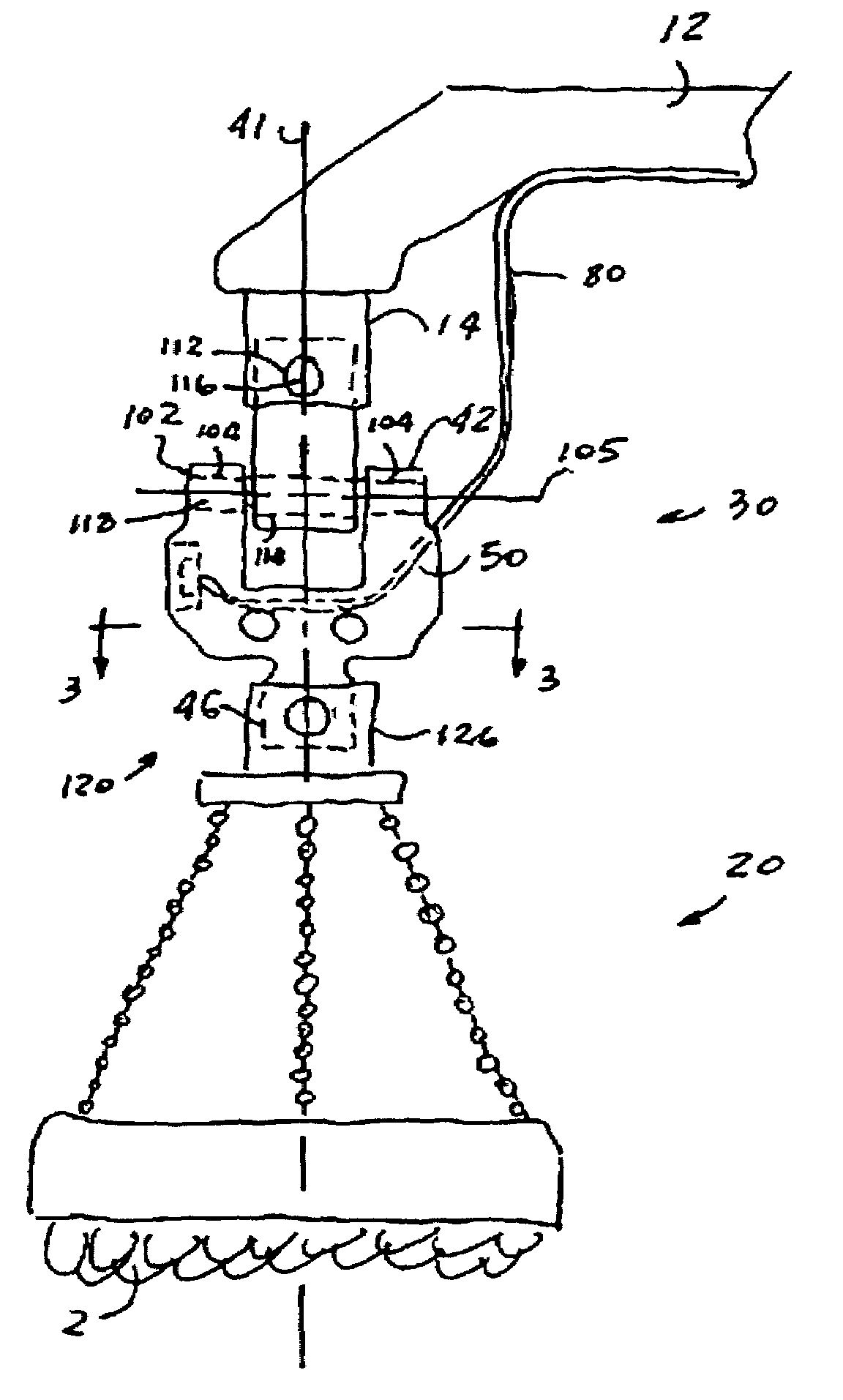

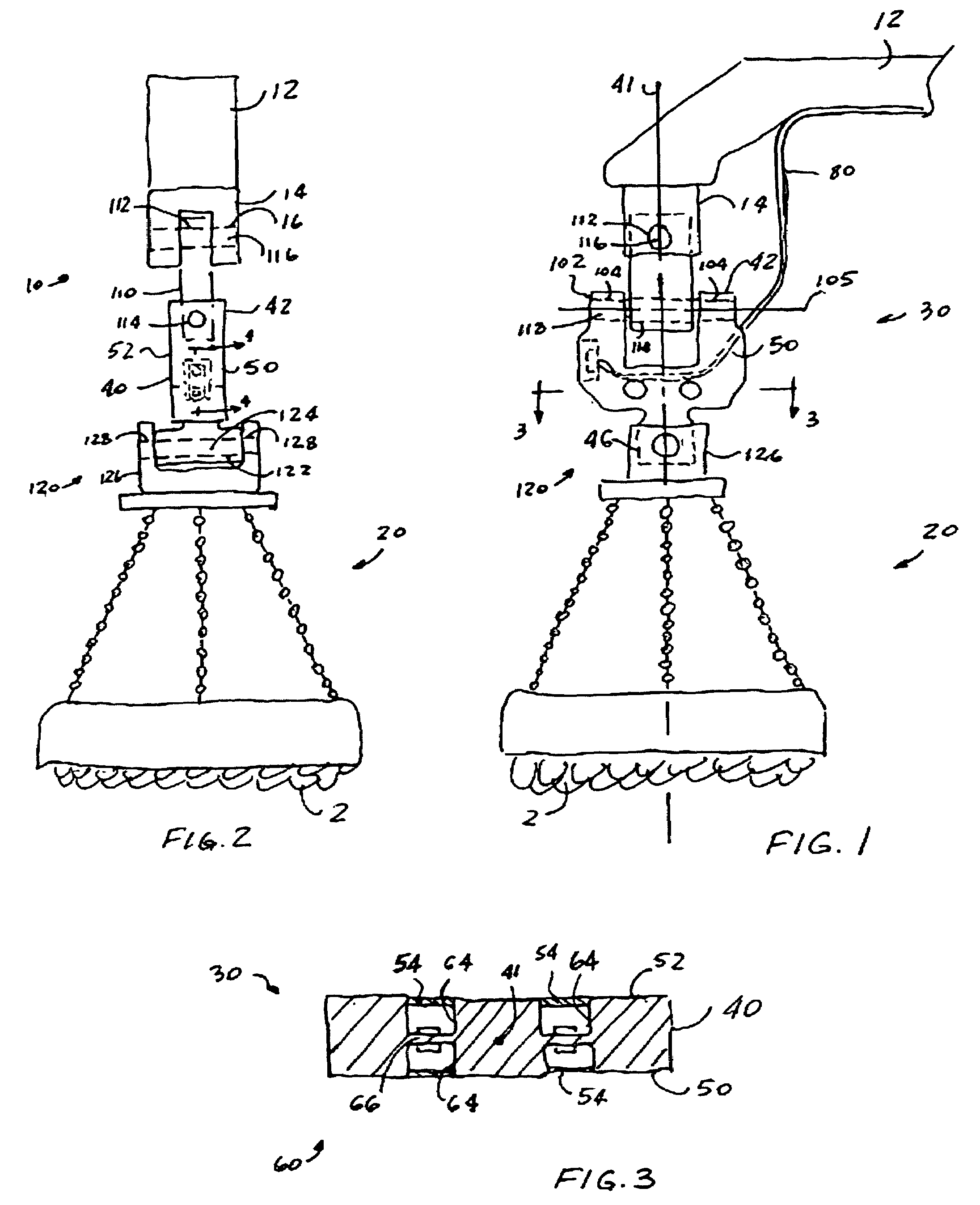

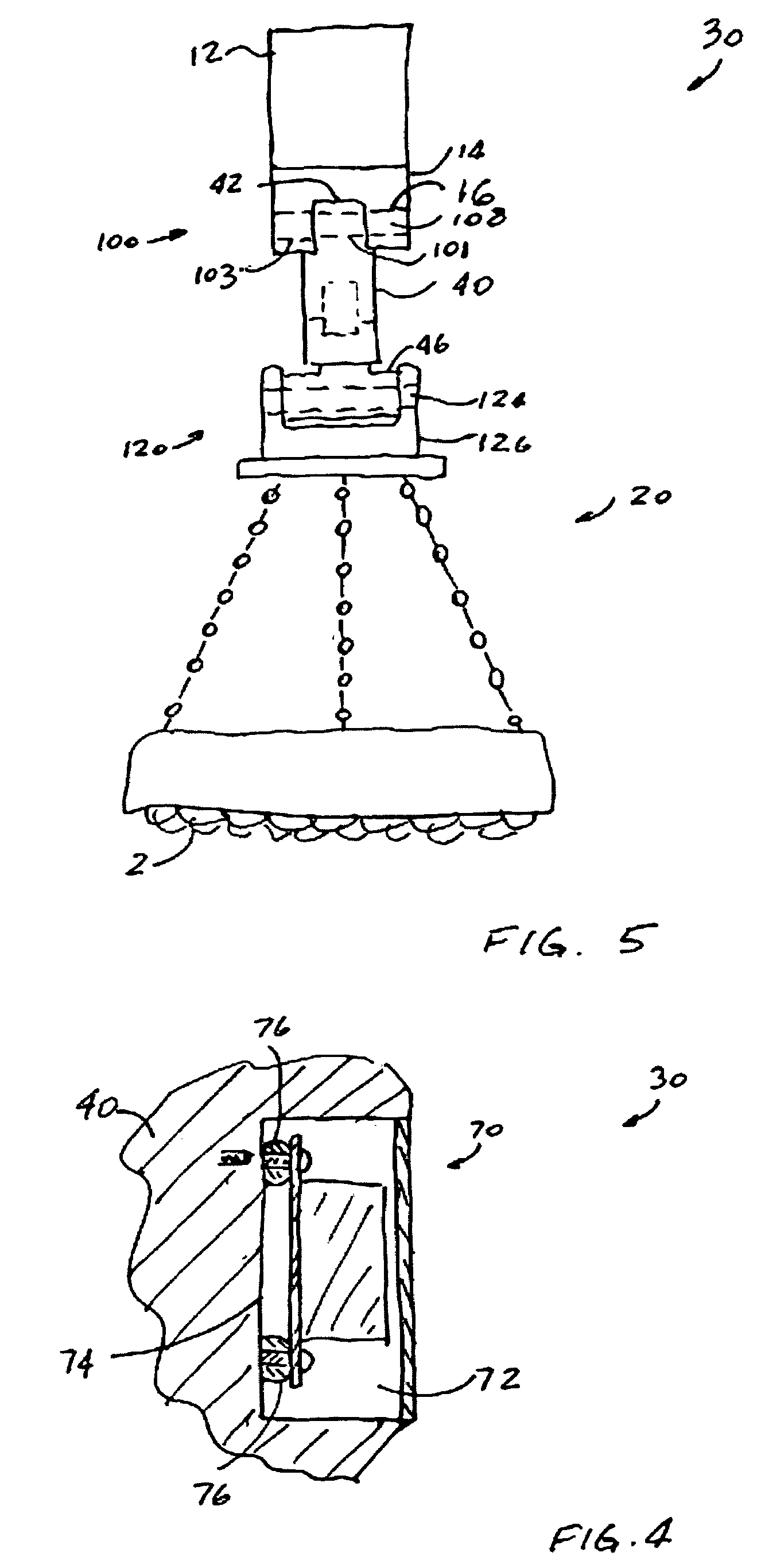

Apparatus, system and method for weighing loads in motion

ActiveUS20080073129A1High precisionEasy to modifyWeighing auxillary devicesLoad-engaging elementsAccelerometerEngineering

The apparatus for weighing a load in motion includes a rigid member, a plurality of strain gages mounted within the rigid member and forming a Wheatstone bridge network for measuring a force exerted by such load onto the rigid member and an accelerometer mounted within the rigid member for measuring gravitational acceleration of the load. A controller mounted in remote location compensates the measured force according to a measurement from the accelerometer and according to a predetermined algorithm to determine the actual weight of the load. Strain gages and accelerometer are connected to the controller by way of a wiring connection. The apparatus can be easily retrofitted into existing applications, particularly for loading scrap metal by way of a crane.

Owner:TECHN WEIGHING SERVICES

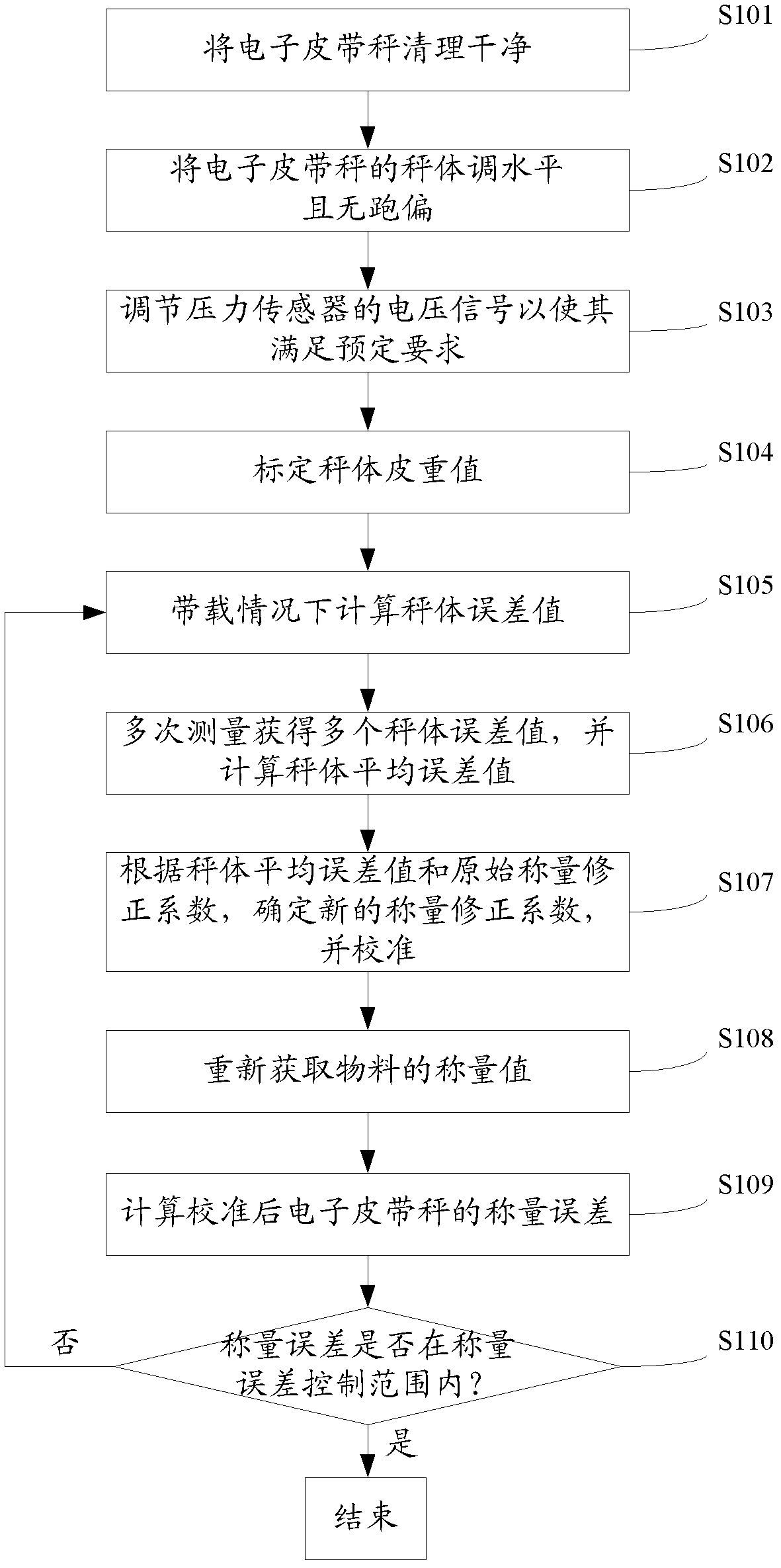

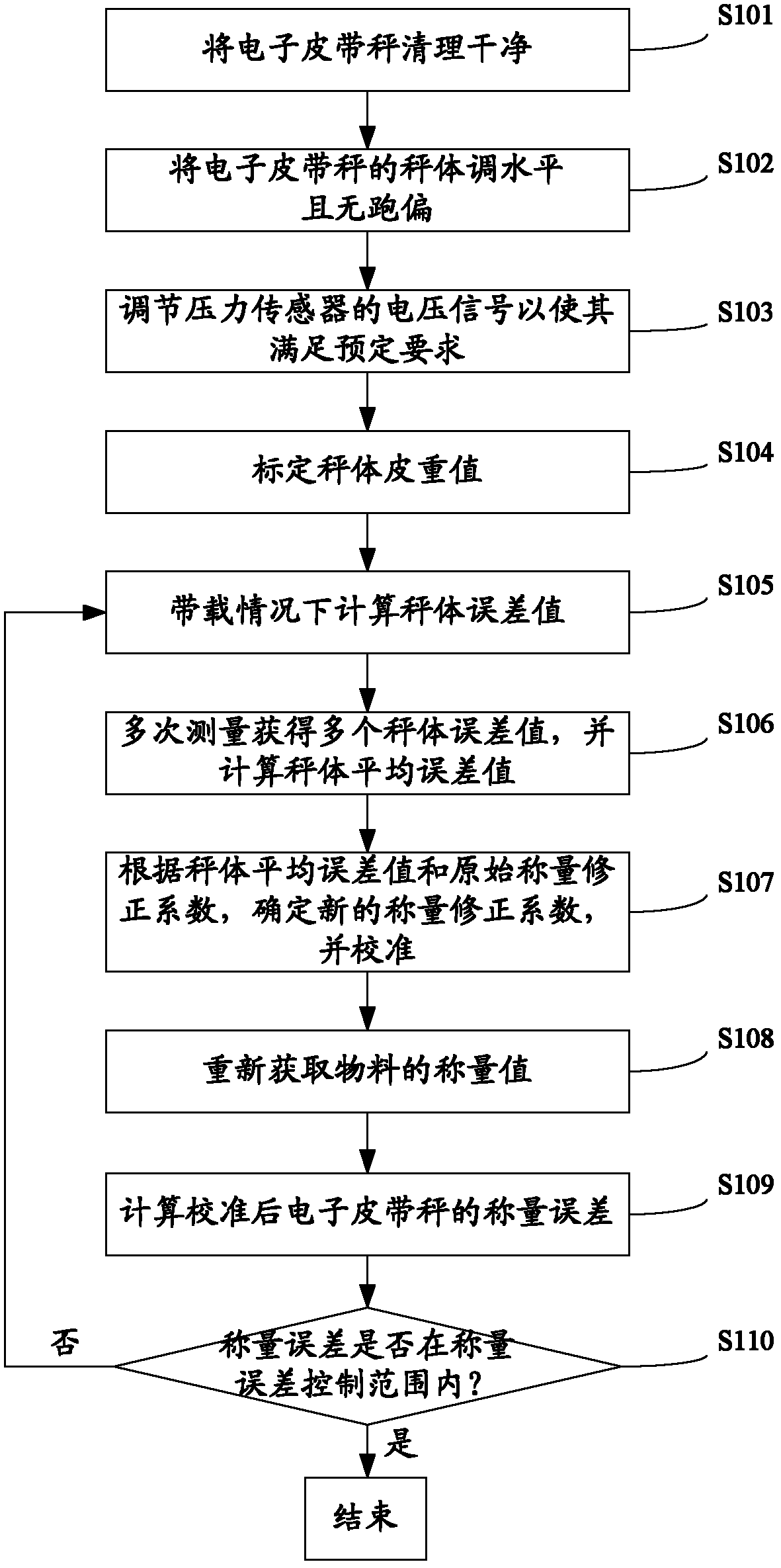

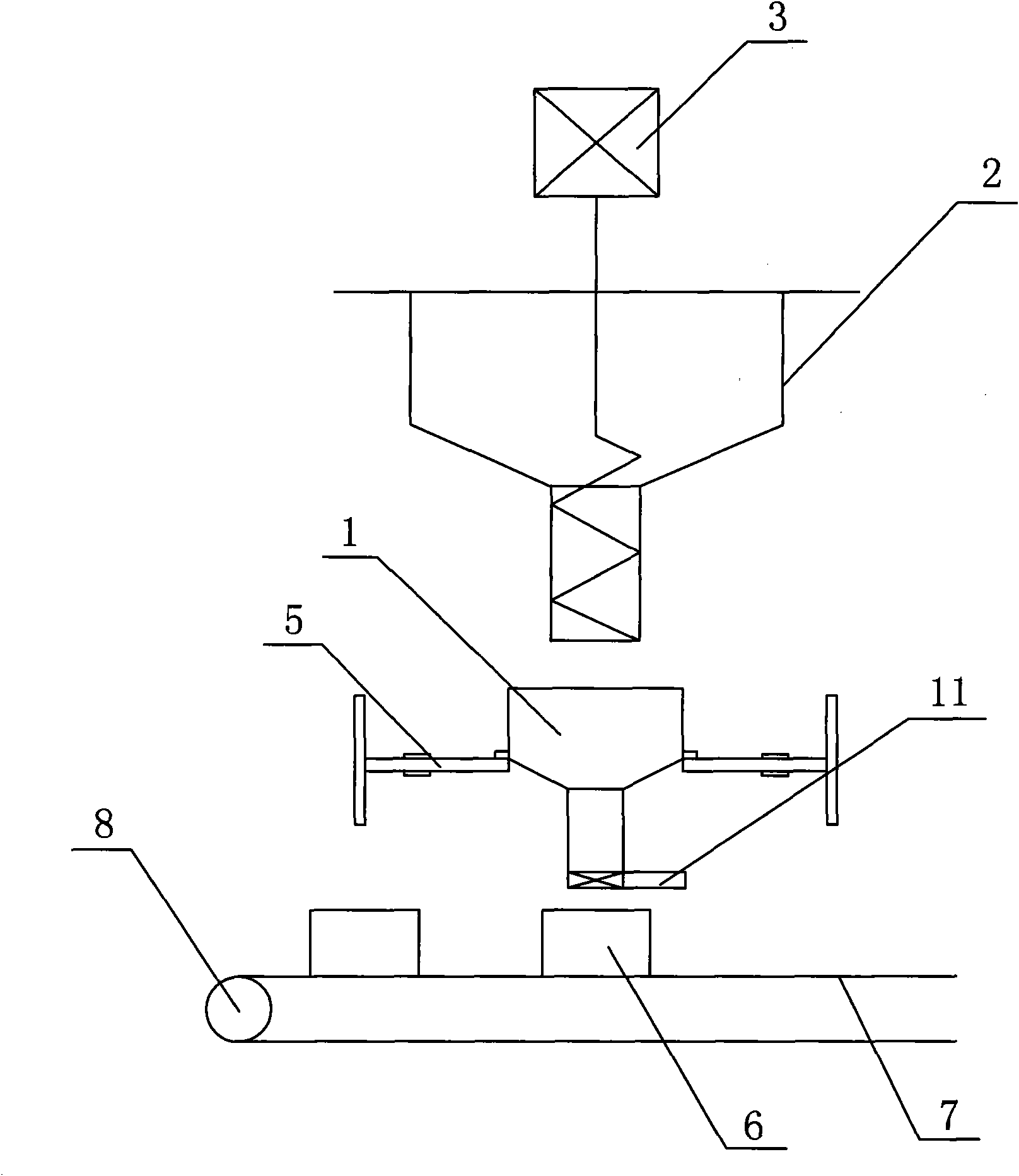

Method for calibrating electronic belt scale

InactiveCN102494753AHigh precisionEasy to operateWeighing apparatus testing/calibrationEngineeringScale error

The invention provides a method for calibrating an electronic belt scale. The method comprises the following steps of: making preparation for calibration, namely cleaning and adjusting the electronic belt scale, adjusting a pressure sensor and calibrating a tare value; on the condition that the electronic belt scale operates normally, obtaining the weighed value of a material of which the actual weight is known, and determining a scale error valve according to the actual weight and the weighed valve of the material; repeating the above measuring step so as to obtain multiple scale error values and determining an average scale error value according to the multiple scale error values; and determining a new weighed value correction factor according to the average scale error valve and an original weighed value correction factor and calibrating the electronic belt scale. The method is simple and has an obvious effect; and the calibrated electronic belt scale has high measurement accuracy and can be used for weighing large granular materials.

Owner:YUNNAN JIANSHUI MANGANESE

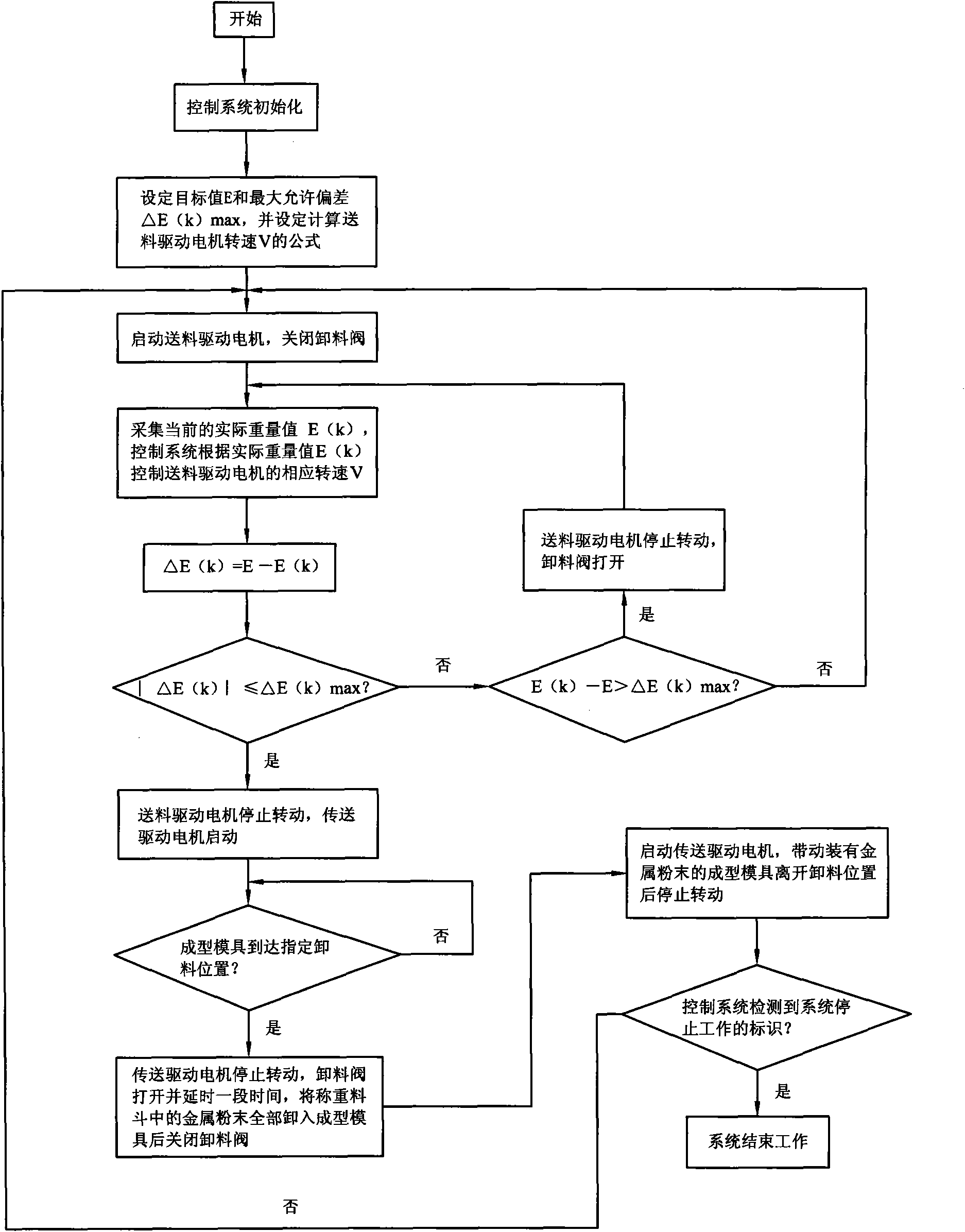

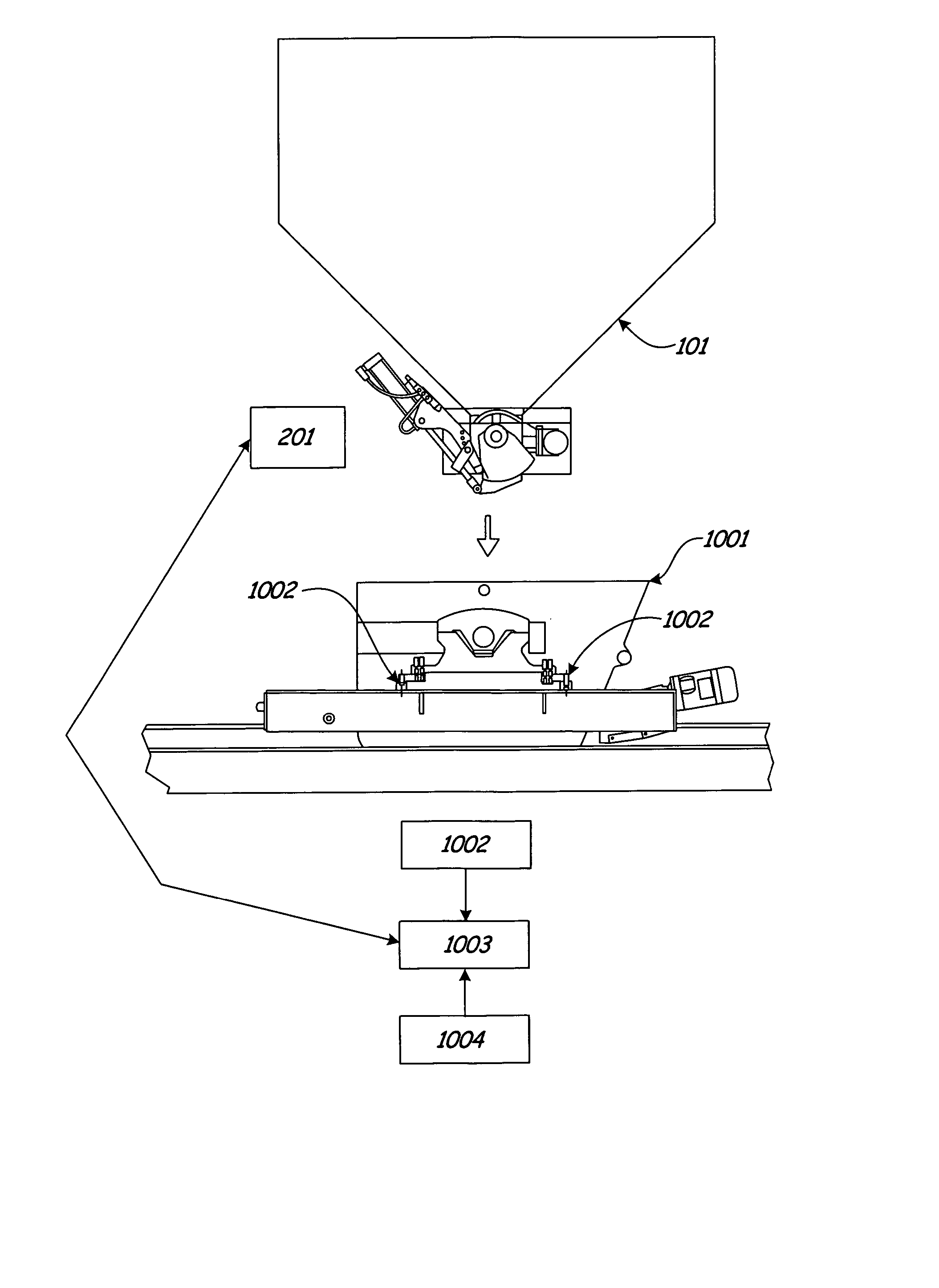

Control method for automatic weighting of metal powder

InactiveCN101620001AImprove uniformityImprove stabilityWeighing apparatus with automatic feed/dischargeContinuous/uninterruptedControl system

The invention discloses a control method for automatic weighting of metal powder, which has the advantages that the rotation speed of a feeding and driving motor is controlled by an improved proportion pulse width speed adjusting and control method, thus when the actual weight value of the metal powder in a weighting hopper is small, the rotation speed of the feeding and driving motor is high, and the feeding speed of the feeding and driving motor to the weighting hopper is high; when the actual weight value approaches to a target value; the rotation speed of the feeding and driving motor is low, and the feeding speed of the feeding and driving motor to the weighting hopper is low; the speed change of the feeding and driving motor is continuous, and the efficiency and the precision for feeding are both considered; a single microcomputer control system is adopted for the control system, so that the control method is relatively simple, and the cost is simultaneously reduced; in addition, as the feeding direction and the gravity direction of a screw feed mechanism arranged in a material storage hopper are consistent, the self gravity action of the metal powder is utilized while feeding, the uniformity and the stability for feeding are improved, and the system for achieving the whole control method is relatively simple.

Owner:NINGBO UNIV

Digitally corrected SAR converter including a correction DAC

ActiveUS7605741B2Eliminate errorsElectric signal transmission systemsAnalogue-digital convertersEngineeringAnalog-to-digital converter

An analog to digital converter having improved differential non-linearity is provided. The converter has a memory which is used to look up the actual weight or a weight error corresponding to the bits that have been kept as part of the SAR process to form an output correction value A part of this, for example a residue (the part following the decimal point in a decimal representation) is used to drive a correction DAC which causes a correction to be applied to the trial value presented to a comparator used by the ADC.

Owner:ANALOG DEVICES INC

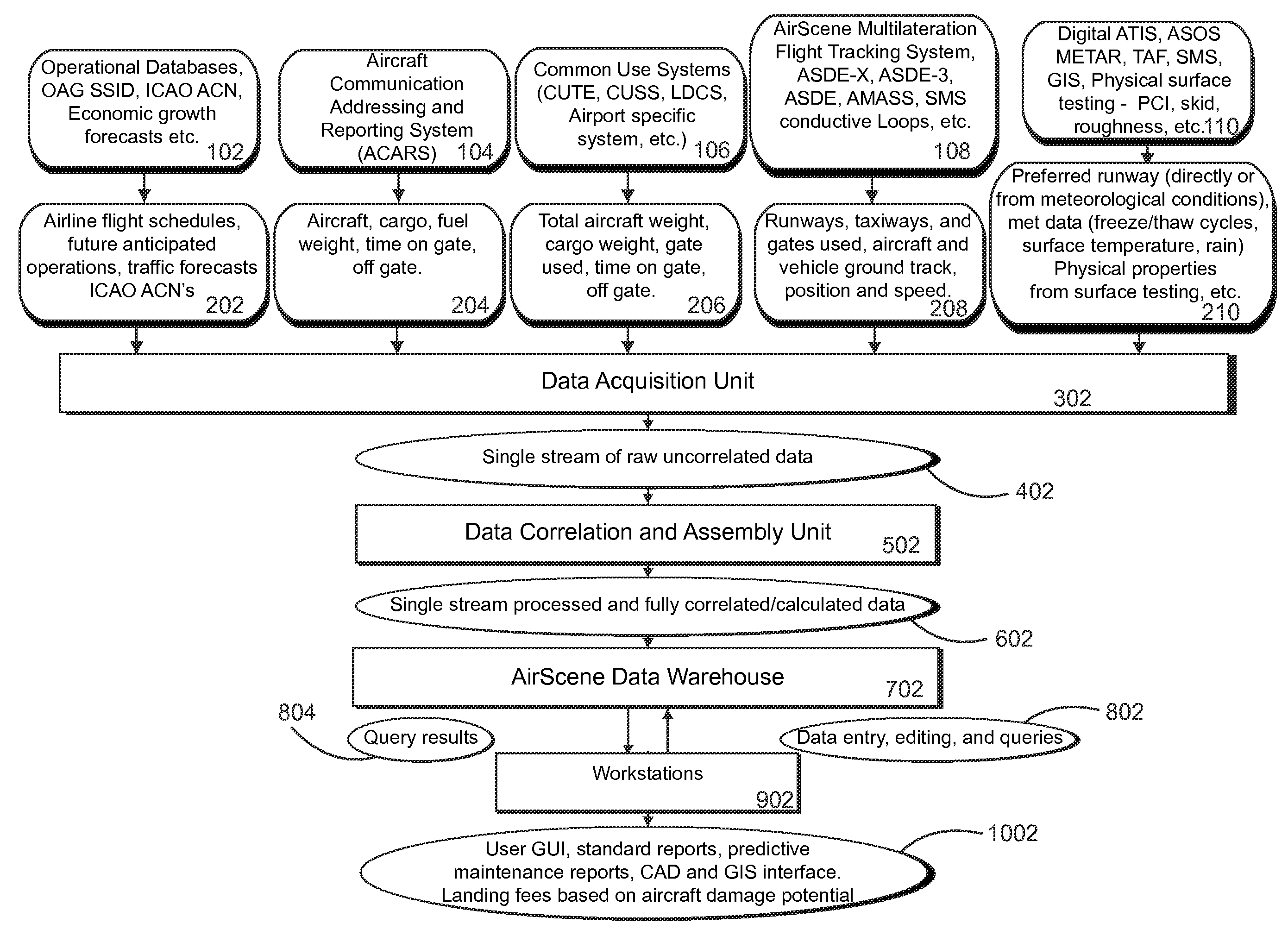

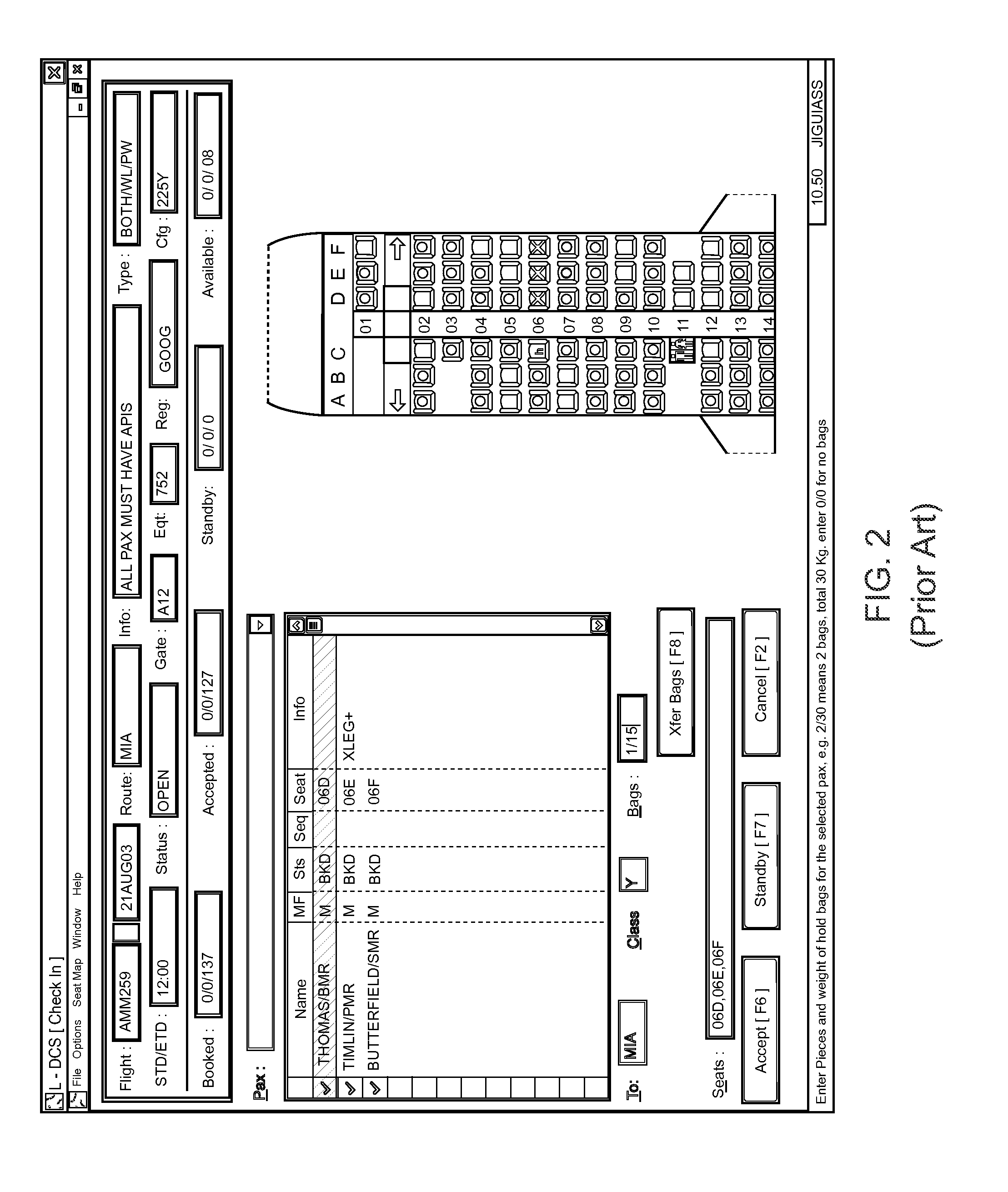

Airport pavement management system

InactiveUS7437250B2Accurately determineAccurate predictionPlug gaugesIn situ pavingsVehicle dynamicsData warehouse

The AirScene™ Pavement Management System of the present invention automatically tracks data required to determine various factors in an assessment of current and future pavement maintenance needs and utilizes this data to quantify the pavement damage caused by each individual aircraft movement and thus compute pavement condition based on an initial survey and the calculations of accrued damage over time. This information can be displayed through AirScene™ in the form of tables, graphs, or graphically represented on an airport diagram showing present conditions, rates of accruing damage, and future wear rates and areas. The system draws on the data from the AirScene™ Data Warehouse (ADW), a single repository for all the information acquired from a number of different sources. These data include: Aircraft or vehicle type (wheel layout, weight, vehicle specific parameters, and the like), Aircraft or vehicle location (ground track, position, gate used, and the like), Aircraft or vehicle dynamics (velocity, acceleration, take off, touchdown, and the like), Aircraft or vehicle actual weight (cargo load, fuel load, and the like), as well as Future operational data (flight schedules, increasing flight loads and demand, and the like).

Owner:HARRIS CORP

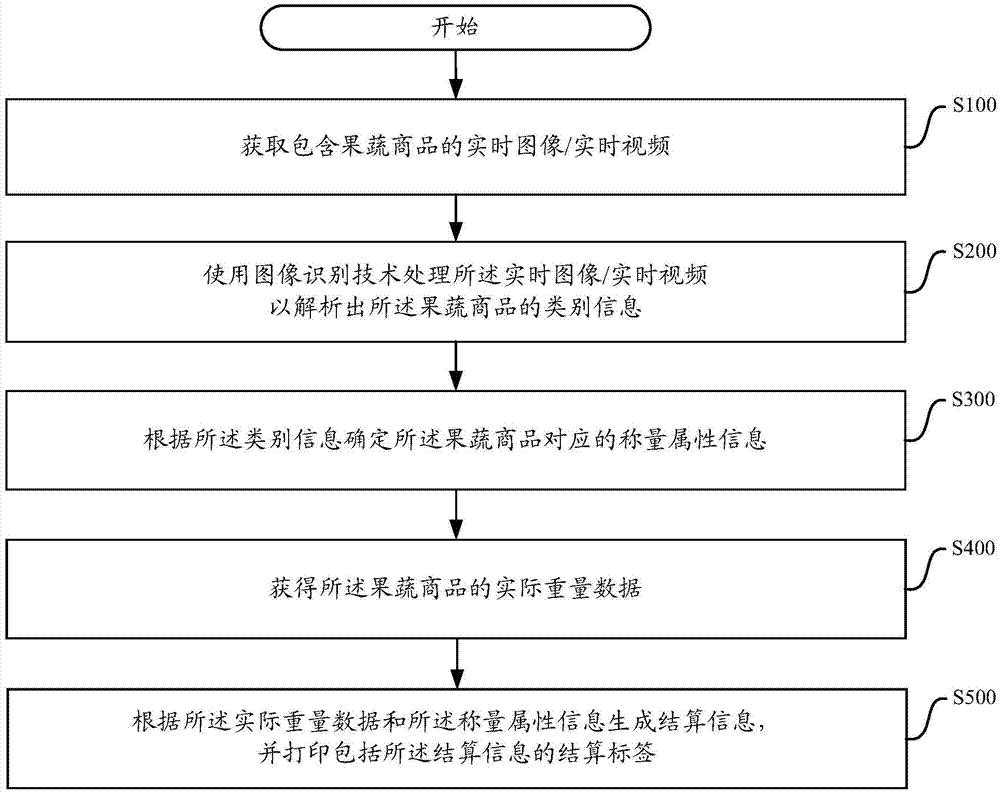

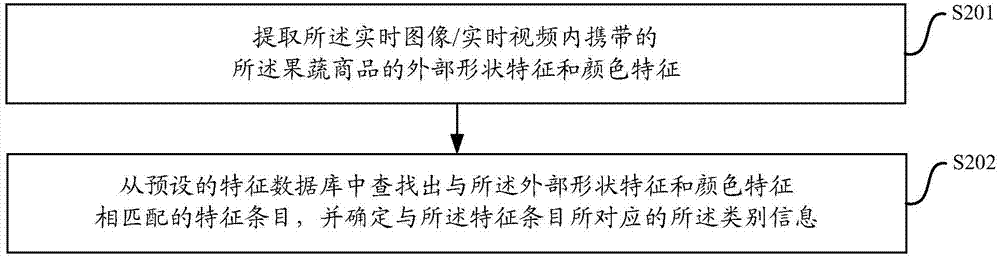

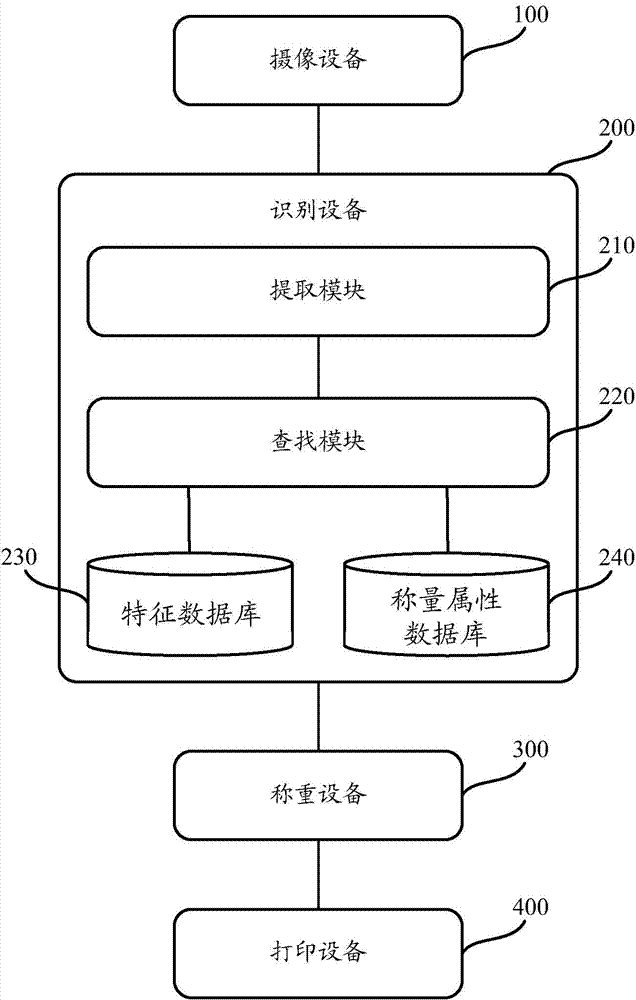

Self-service weighing method and apparatus for fruit and vegetable commodities

InactiveCN104296852AImprove shopping experienceReduce labor costsSpecial purpose weighing apparatusSelf-serviceComputer science

The invention provides a self-service weighing method for fruit and vegetable commodities. The method comprises: obtaining real-time images / real-time videos containing fruit and vegetable commodities; carrying out processing on the real-time images / real-time videos by using an image identification technology to parse class information of the fruit and vegetable commodities; according to the class information, determining weighing attribute information corresponding to the fruit and vegetable commodities; obtaining actual weight data of the fruit and vegetable commodities; and generating settlement information based on the actual weight data and the weighing attribute information and printing settlement tags containing the settlement information. Correspondingly, the invention also provides a self-service weighing apparatus for fruit and vegetable commodities. With the method and the apparatus, the labor cost can be saved; the customer shopping experience can be improved; and the work efficiency can be enhanced.

Owner:赵肖肖

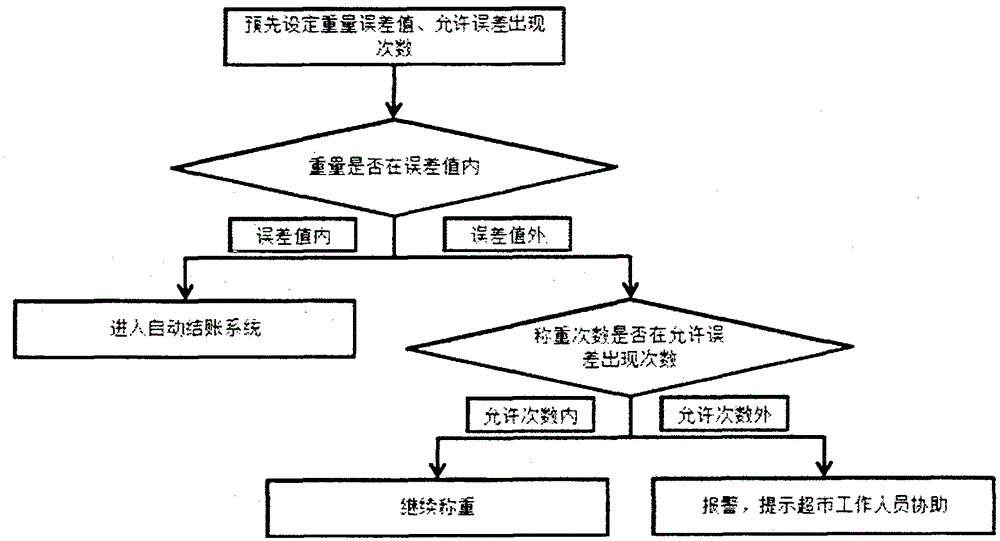

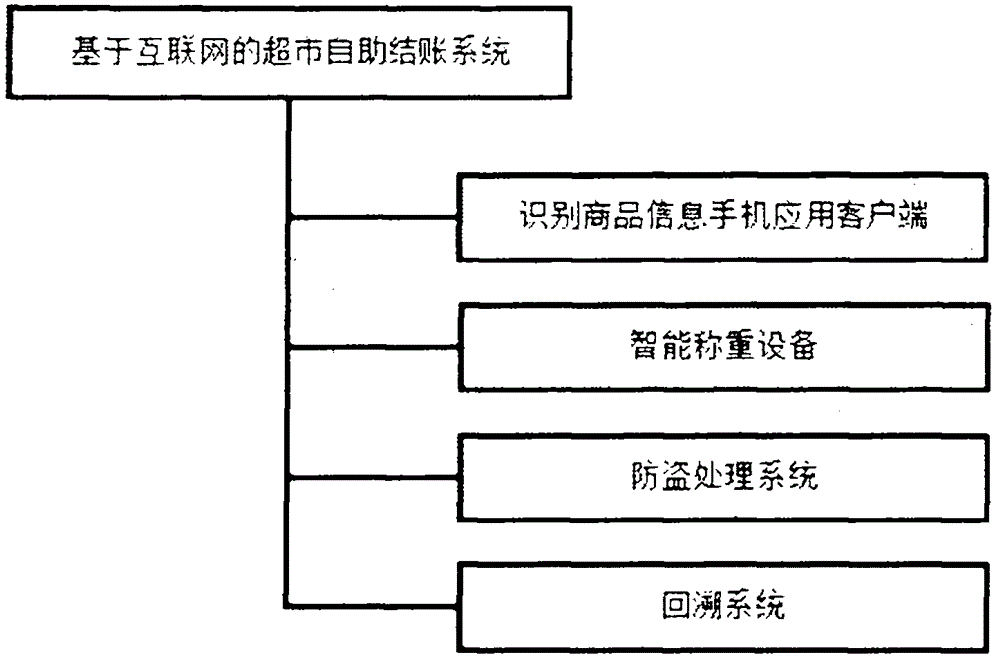

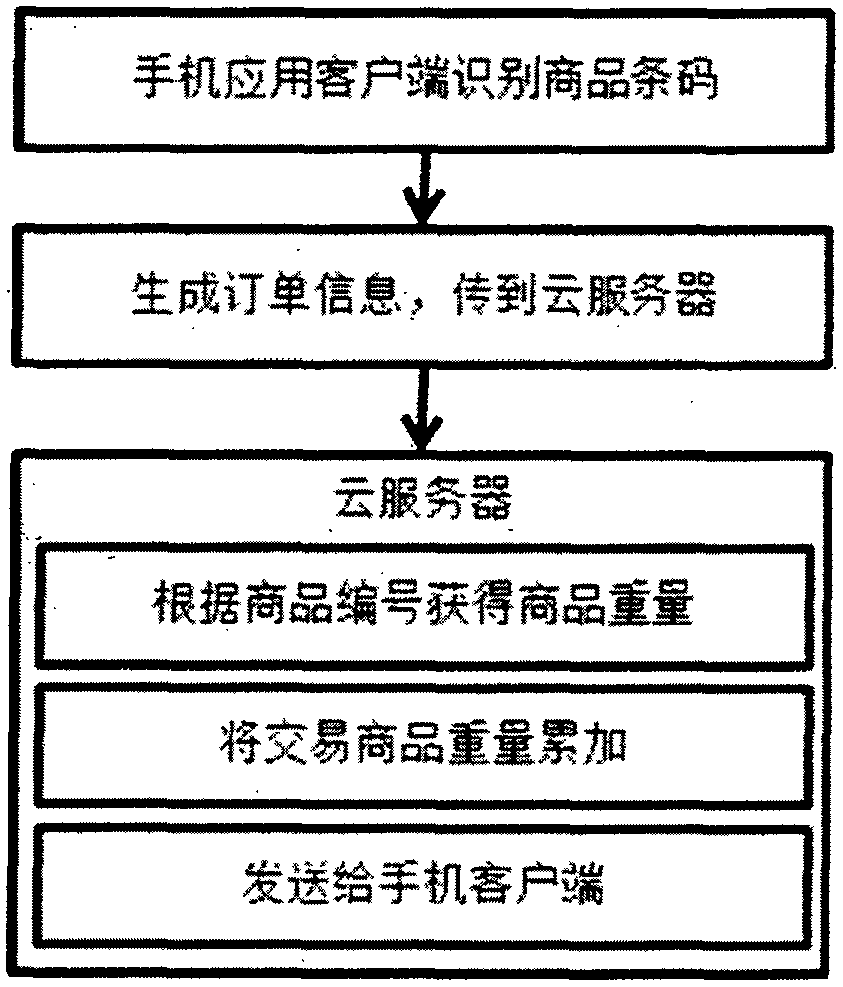

Self-service shopping system and self-service shopping method of supermarket

InactiveCN106127538APayment architectureBuying/selling/leasing transactionsInformation repositoryApplication software

The invention discloses a mobile internet payment-based self-service shopping system and method of a supermarket, and solves the problems in customer queuing for payment during peak shopping hours, theft prevention in self-service shopping, rights protection of purchased commodities by consumers and overtime accurate sales existent in the supermarket. The self-service shopping system comprises a mobile phone self-service shopping application, a cloud server and an intelligent weighing device. The mobile phone self-service shopping application is used for identifying and recording the commodities and generating order barcodes that contain prices and weights of the purchased commodities; the cloud server comprises a commodity information library and is used for obtaining information such as the prices, the weights and the like of the commodities; the intelligent weighing device is used for comparing the weights, obtained by scanning the order barcodes, of the commodities purchased by the consumers with actual weights of the commodities, and giving an alarm when difference occurs; meanwhile, the system records shopping records of the consumers, and the shopping records can serve as rights protection evidences when a rights protection event occurs; and the supermarket can perform big data analysis through shopping data to make an accurate sales plan.

Owner:唐琳娜

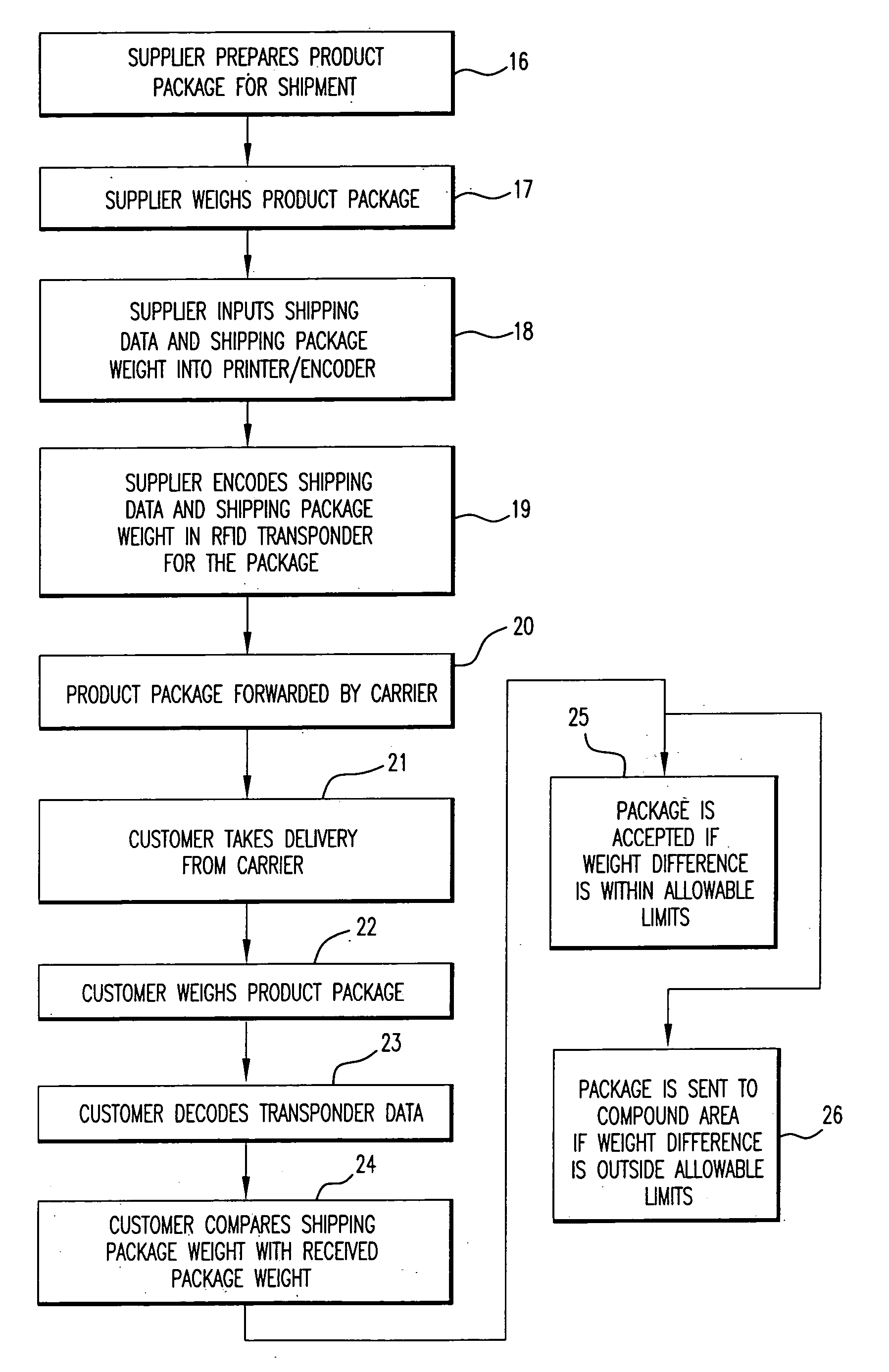

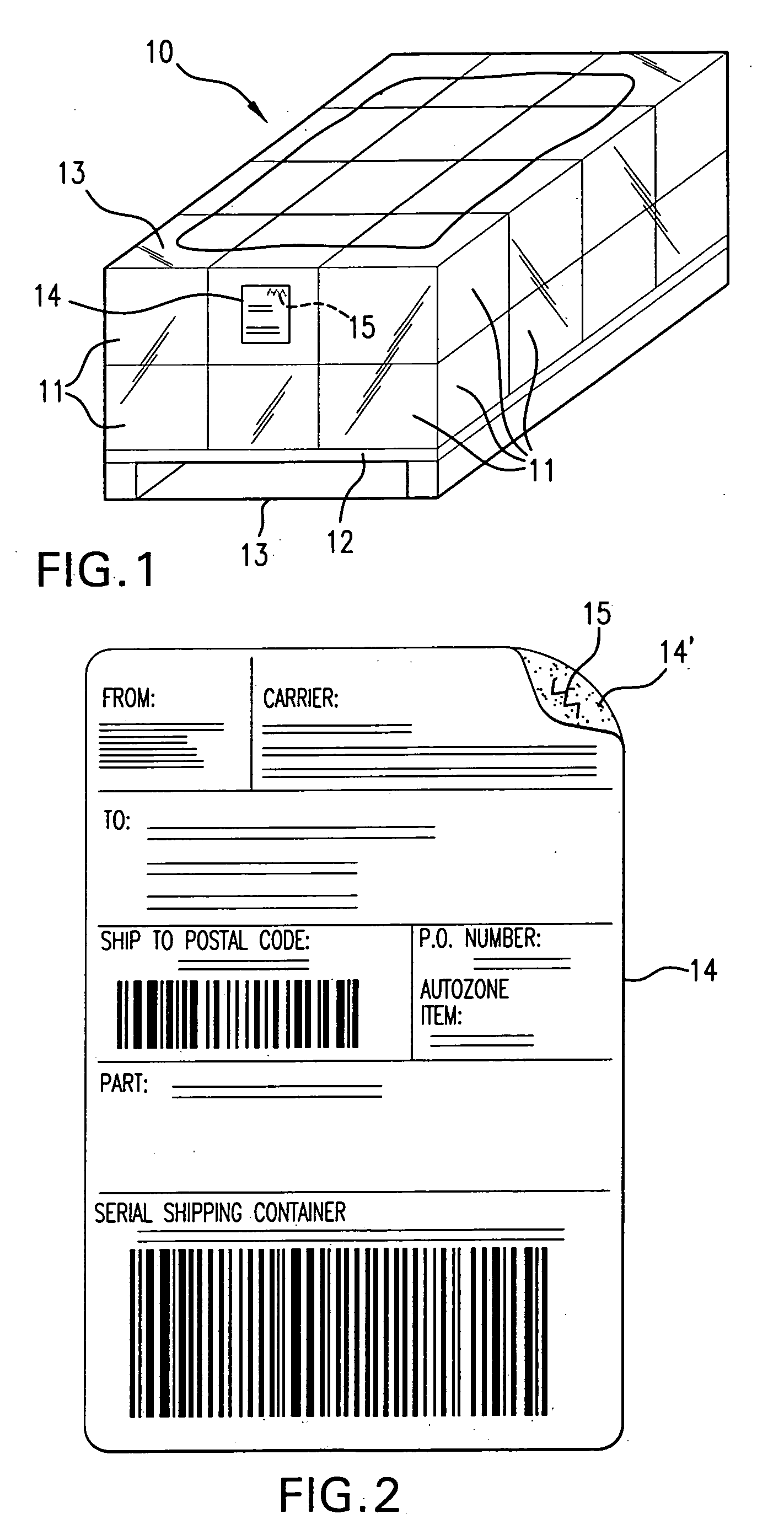

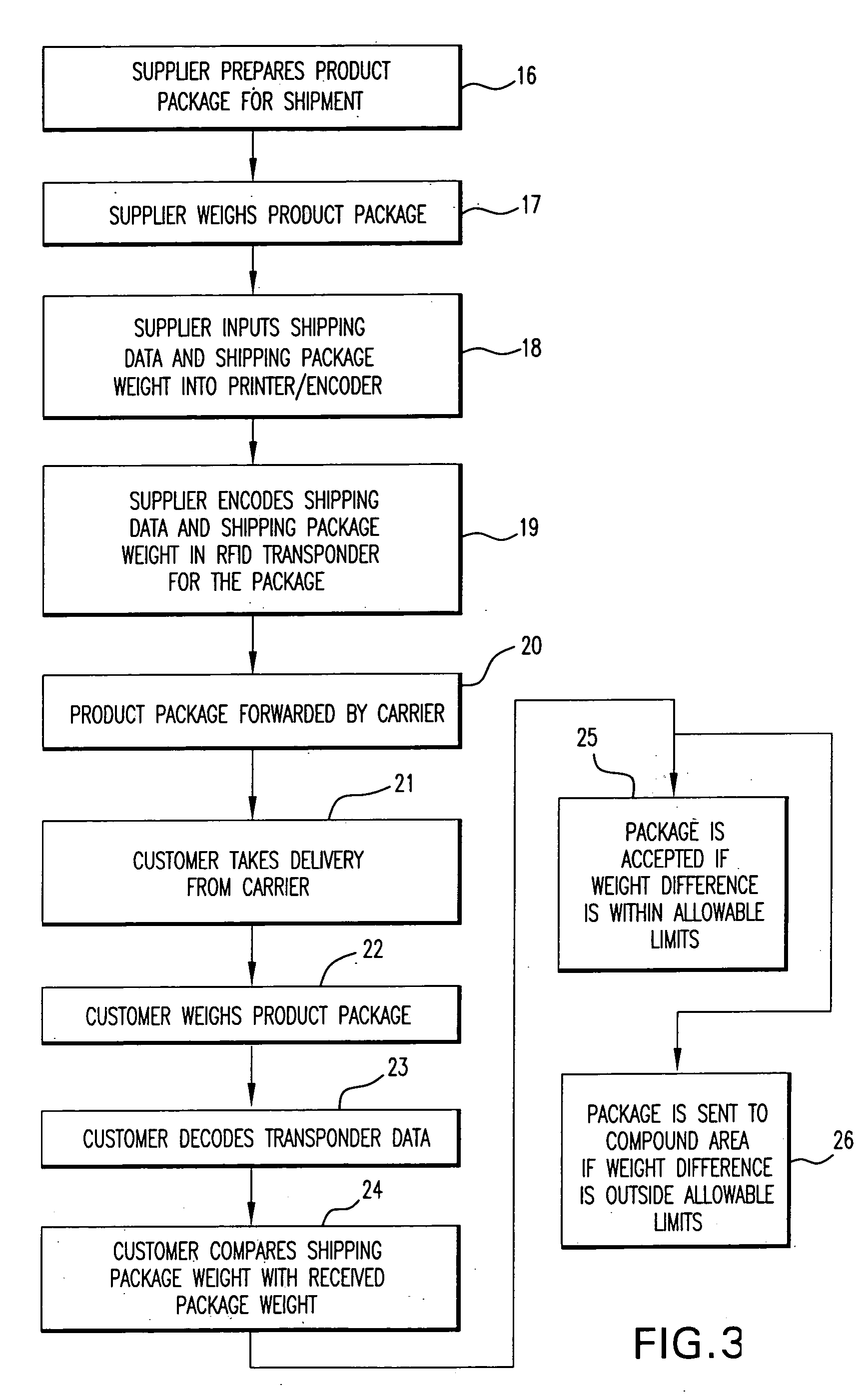

Method for verifying and/or detecting tampering

There is disclosed method of shipment verification and / or tamper detection, wherein a purchaser generates an ordering document such as a purchase order RFID-encoded with data identifying items on the order. The supplier gathers the items into a package or packages for the shipment and RFID encodes the shipment with both data relating to the items ordered and to the shipping package weight. When the shipment arrives at the customer's location, the customer decodes the RFID package transponder and compares the items ordered with the items received and / or compares the decoded shipping package weight with the actual weight of the shipment and if there is an unallowable discrepancy in either or both, the customer is on notice that the shipment may be erroneous.

Owner:AVERY DENNISON CORP

Airport pavement management system

InactiveUS20060036378A1Easy to wearEasy to tearPlug gaugesIn situ pavingsVehicle dynamicsData warehouse

The AirScene™ Pavement Management System of the present invention automatically tracks data required to determine various factors in an assessment of current and future pavement maintenance needs and utilizes this data to quantify the pavement damage caused by each individual aircraft movement and thus compute pavement condition based on an initial survey and the calculations of accrued damage over time. This information can be displayed through AirScene™ in the form of tables, graphs, or graphically represented on an airport diagram showing present conditions, rates of accruing damage, and future wear rates and areas. The system draws on the data from the AirScene™ Data Warehouse (ADW), a single repository for all the information acquired from a number of different sources. These data include: Aircraft or vehicle type (wheel layout, weight, vehicle specific parameters, and the like), Aircraft or vehicle location (ground track, position, gate used, and the like), Aircraft or vehicle dynamics (velocity, acceleration, take off, touchdown, and the like), Aircraft or vehicle actual weight (cargo load, fuel load, and the like), as well as Future operational data (flight schedules, increasing flight loads and demand, and the like).

Owner:HARRIS CORP

Bin gate for providing variable output flow rates

InactiveUS20070215238A1Precise and Efficient ControlPromote sportsClosuresMovable measuring chambersEngineeringTarget weight

An assembly for controlling delivery of material from a bin opening includes a movable bin gate for closing the bin opening and providing a high flow rate of material when the movable gate is open, wherein a low flow aperture is formed in the bin gate to provide a low flow rate of material when the bin gate is positioned such that only the low flow aperture is open. A two-stage flow enhancer within the bin includes a first stage for impelling material in the direction of the low flow aperture and a second stage for impelling material to exit through the low flow aperture. A controller controls operation of the bin gate to adjust a flow rate of material from the bin opening. The controller may include a sensor for providing an actual weight value of material present in a receiving bin and a memory for storing a target weight value for the amount of material in the receiving bin, wherein the controller adjusts the position of the bin gate and the low flow aperture in response to the actual weight value and the target weight value. The bin gate may also be adjusted in response to one or more tolerance values defining proximity to the target weight value and / or in response to one or more threshold weight values, wherein the threshold weight values are less than the target weight value. A method for controlling delivery of material from a bin opening includes the steps of providing at the bin opening a movable bin gate with a low flow aperture and selectively positioning the bin gate using a single actuator to expose only the low flow aperture to the bin opening for material flow or to expose substantially all of the bin opening for material flow.

Owner:MIXER SYST

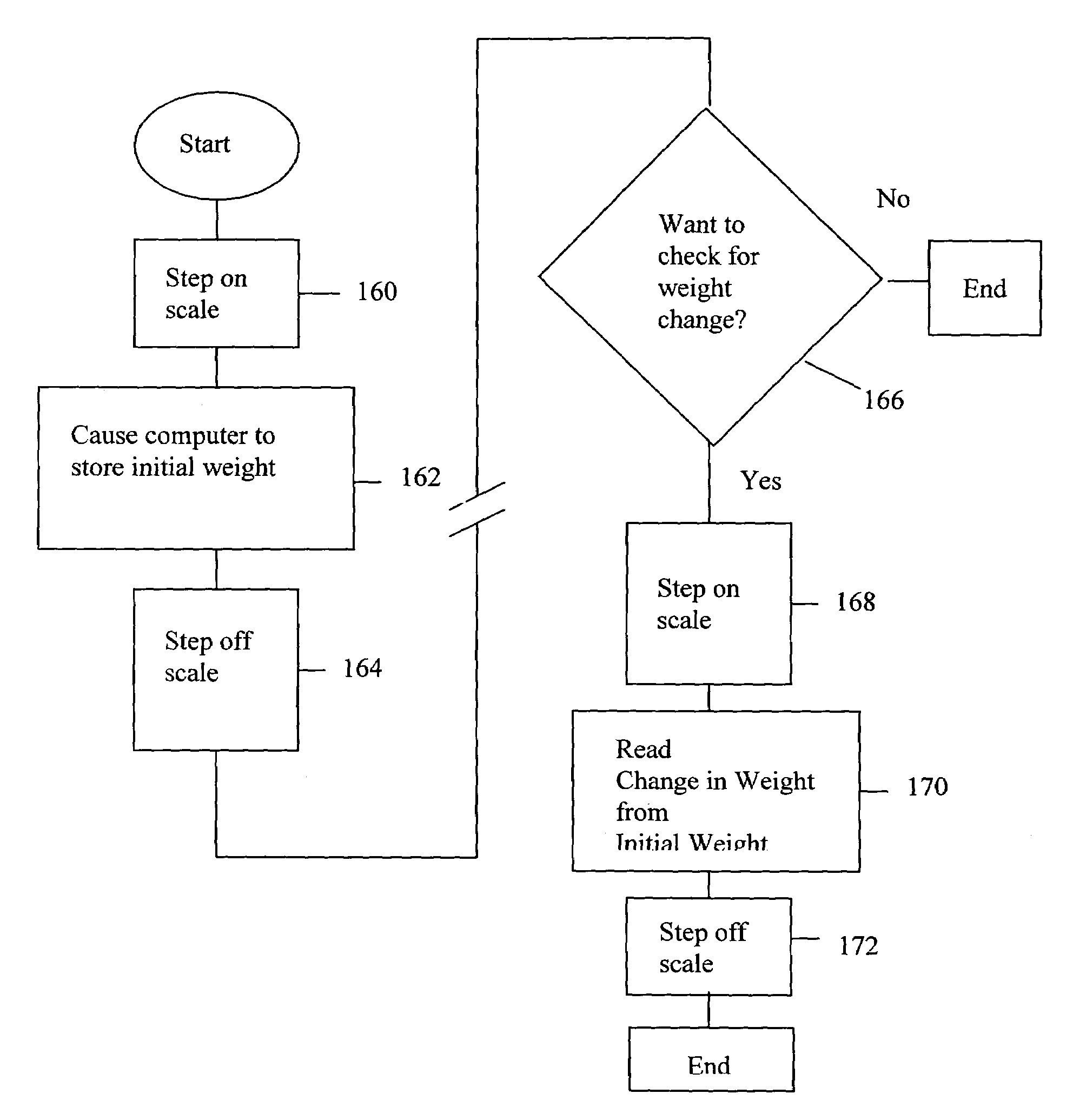

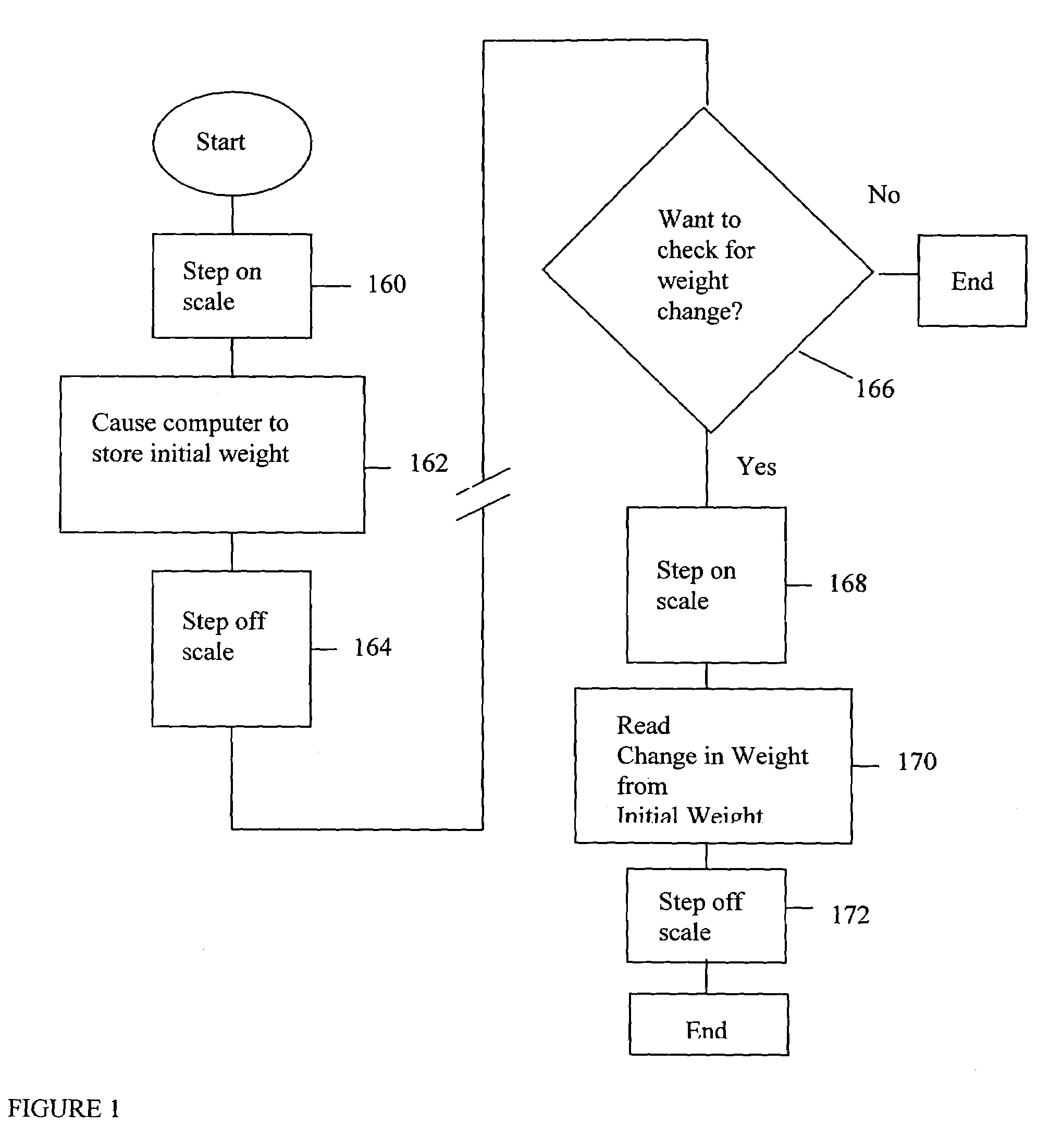

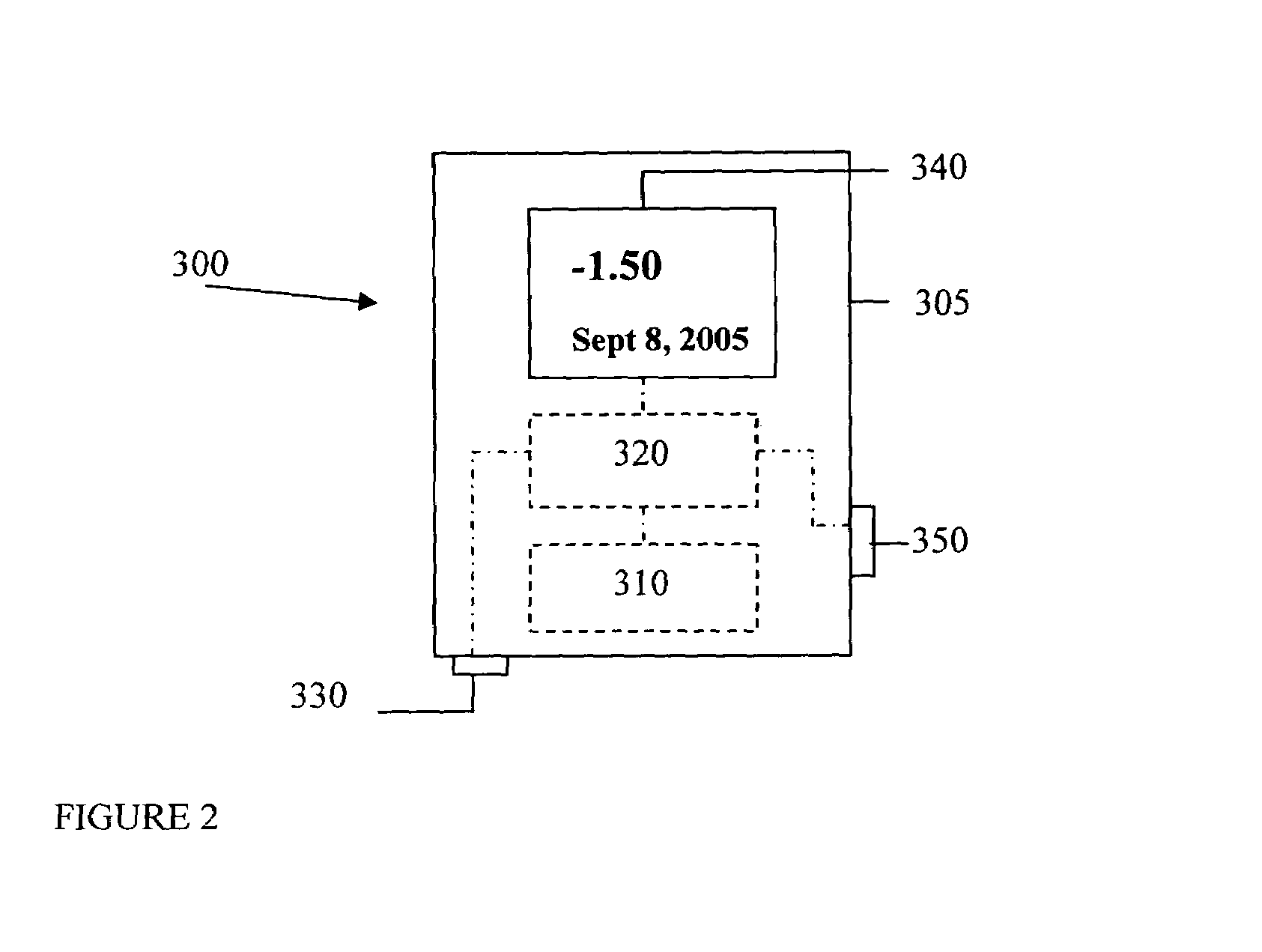

Weight tracking scale and method of use

InactiveUS7265301B2Rapidly and easily determiningSurgeryWeighing indication devicesComputer scienceActual weight

The present invention provides an improved scale that only shows a user how much weight he or she has gained or lost. The scale includes a weight sensing apparatus and a numerical display. A computer stores a user's initial pre-diet weight, and then compares that weight to the user's weight from time to time as the user progresses through his or her diet. The only information displayed is the current date and the magnitude of the weight differential (e.g. “+5” lbs or kg). In this way, the user can avoid learning, and possibly fixating, on his or her actual weight.

Owner:SIMBERG BRITTANI

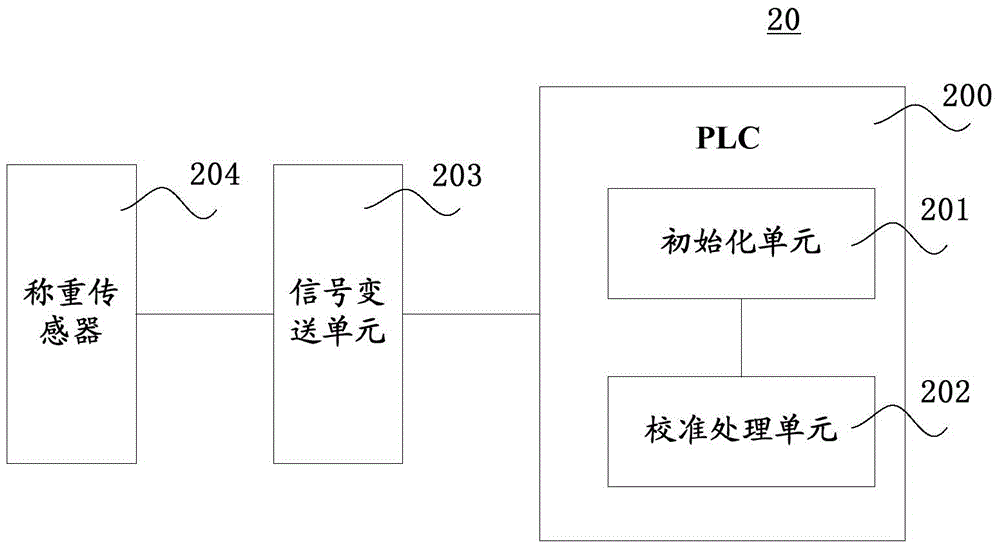

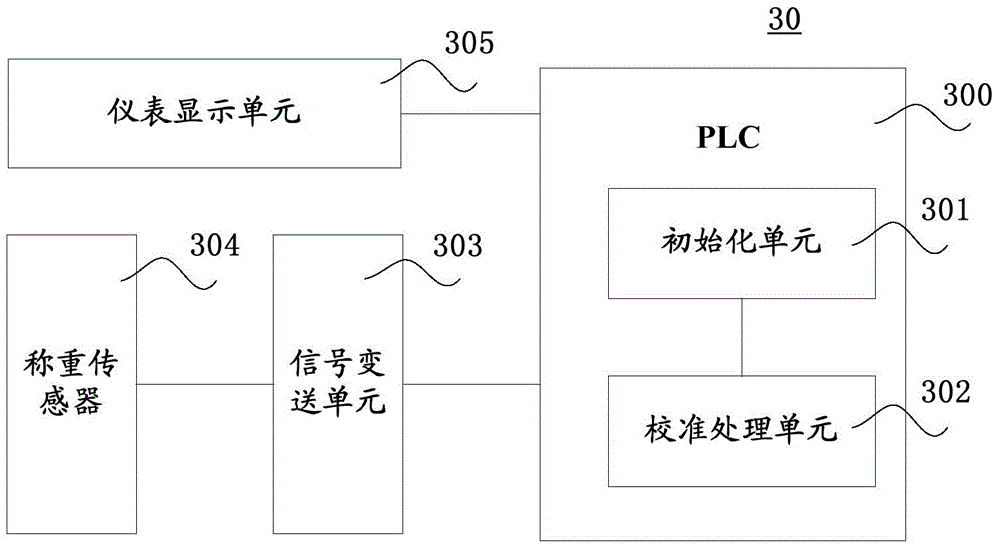

Weighing system and weighing method having self-calibration function

ActiveCN105527009ARealize automatic judgmentAchieve calibrationWeighing apparatus testing/calibrationComputer scienceCalibration function

The invention discloses a weighing system and a weighing method having the self-calibration function. The system comprises an initiation unit and a calibration processing unit, wherein the initiation unit is used for storing effective zones, the effective zones comprise multiple data points confirmed by object weight values and current values, the calibration processing unit is used for acquiring a standard weight value of any standard object and determining whether data points confirmed by the standard weight value of the standard object and a current value acquired during measuring the actual weight value of the standard object are in the effective zones, if yes, weighing precision satisfies requirements, otherwise, weighing precision does not satisfy the requirements, and the standard object is a weighing empty bucket or the weighing empty bucket plus known-weight objects. Through the system, whether weighing precision satisfies the requirements is automatically determined.

Owner:XCMG CONSTR MACHINERY

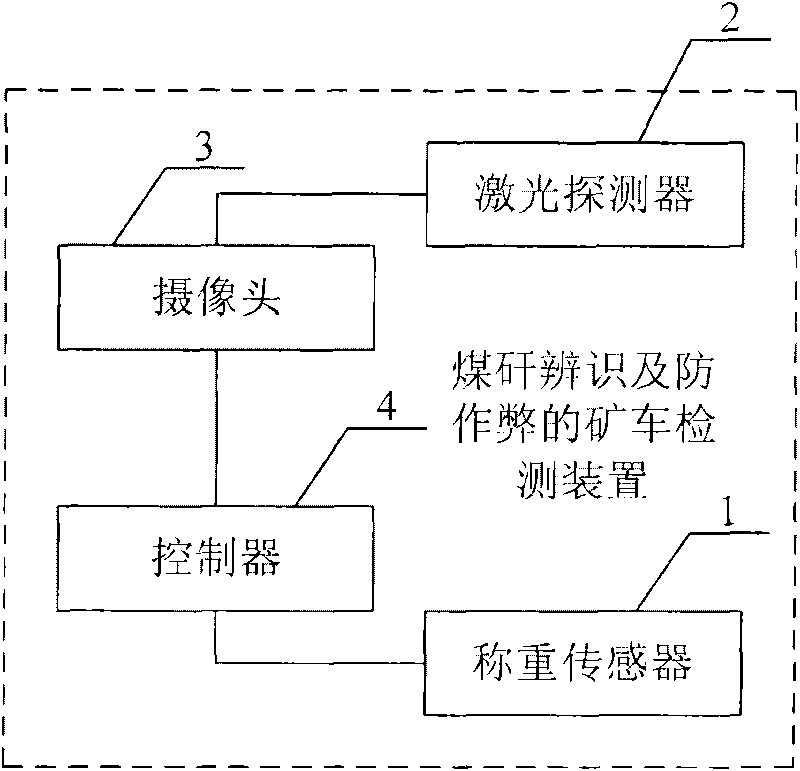

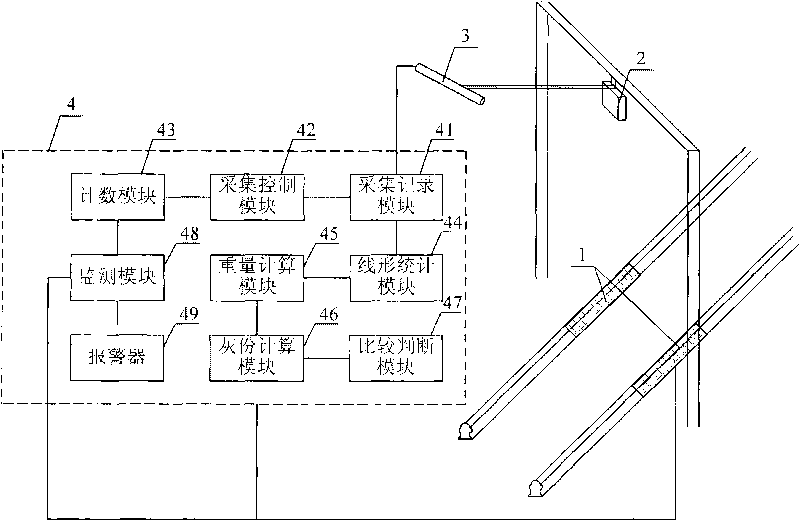

Mine car detection device and method for identifying coals and gangues and preventing cheating

InactiveCN101726348AEfficient identificationEffective detectionWeighing apparatus for materials with special property/formSpecific gravity measurementEngineeringLoad cell

The invention discloses a mine car detection device and a method for identifying coals and gangues and preventing cheating. The device comprises a weighing sensor arranged on a track, a laser detector positioned right above the weighing sensor, a camera arranged laterally above the track, and a controller connected with the camera and the weighing sensor, wherein the weighing sensor is used for detecting the actual weight of materials carried by mine cars; the laser detector is used for generating line laser rays for calibrating the top line shape of the materials carried by the mine cars; the camera is used for acquiring image data having the top line shape calibrated by the laser detector in real time; and the controller is used for receiving the actual weight detected by the weighing sensor, counting the running mine cars according to the received image data from the camera, and calculating the standard weight of the materials carried by the mine cars according to the received image data from the camera. The device and the method can realize the accurate identification of the coals and the gangues, and prevent cheating behaviors in weighing the materials carried by the mine cars.

Owner:北京斯凯尔工业科技有限公司

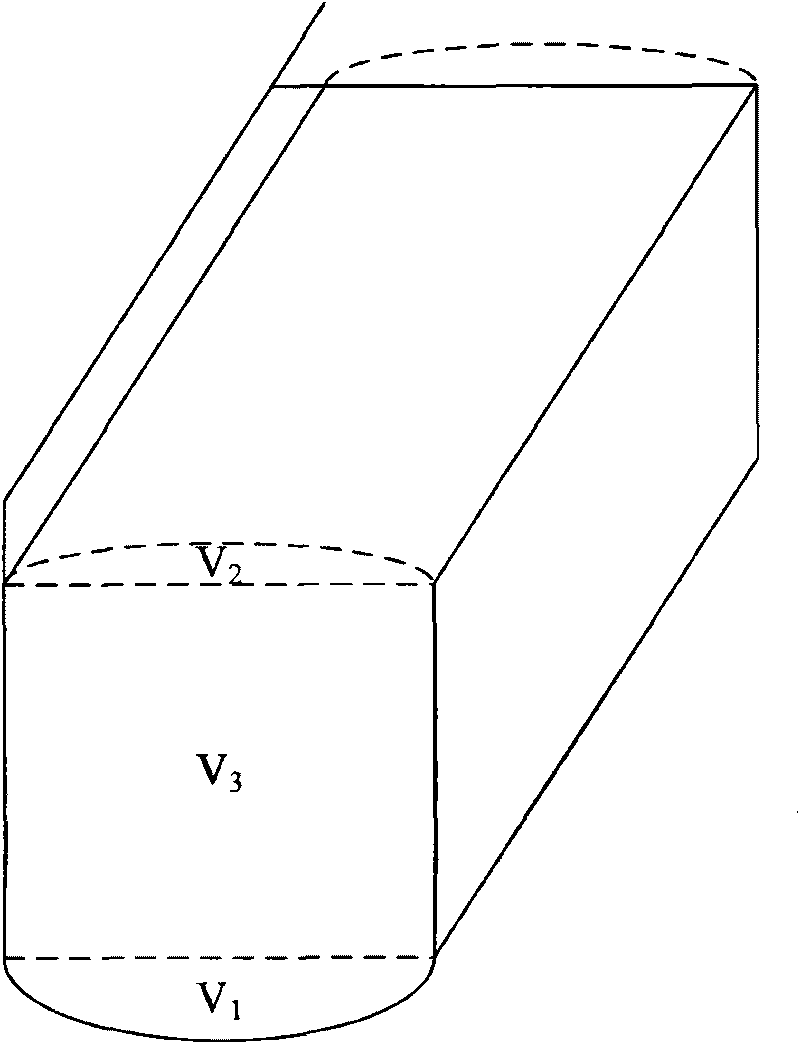

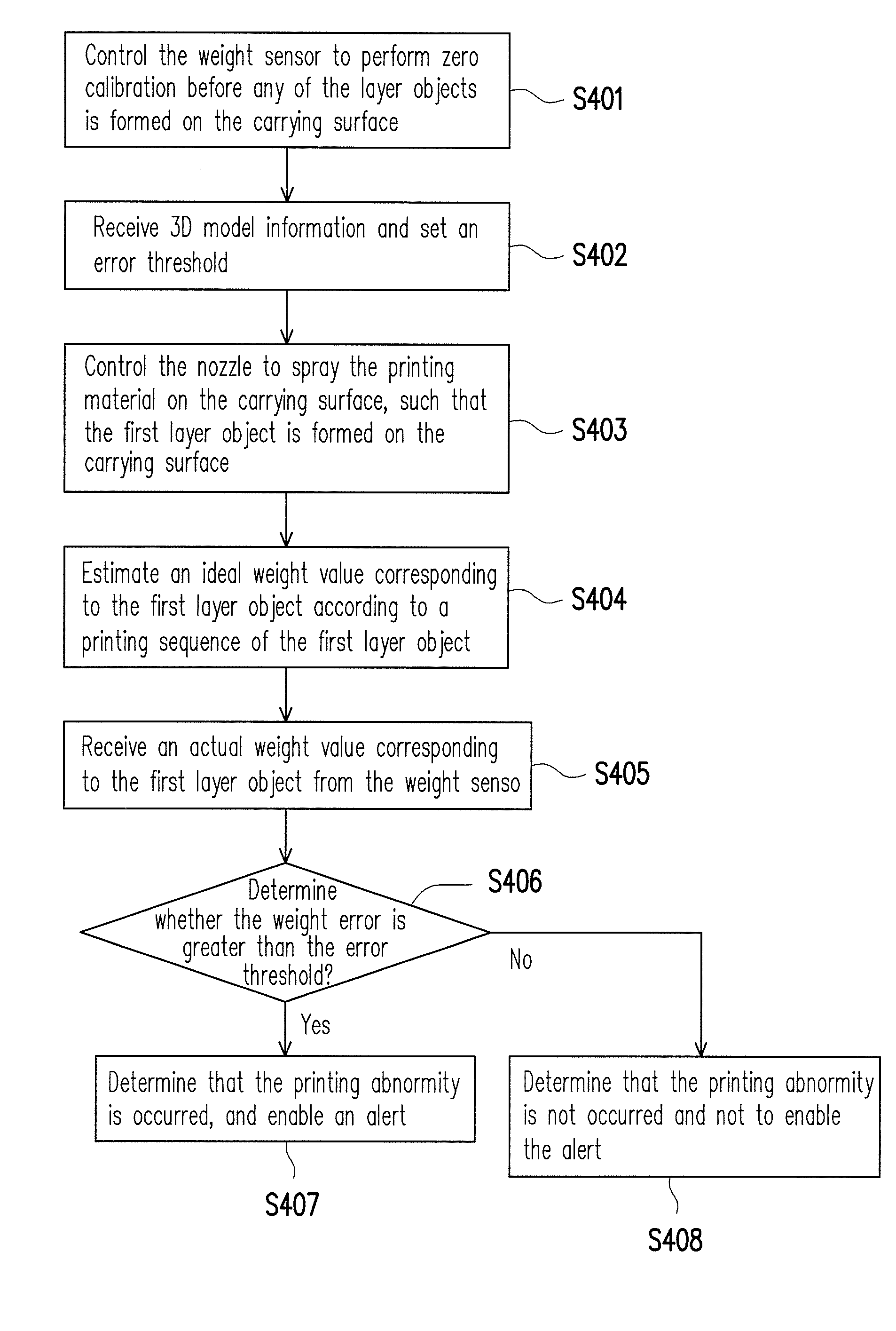

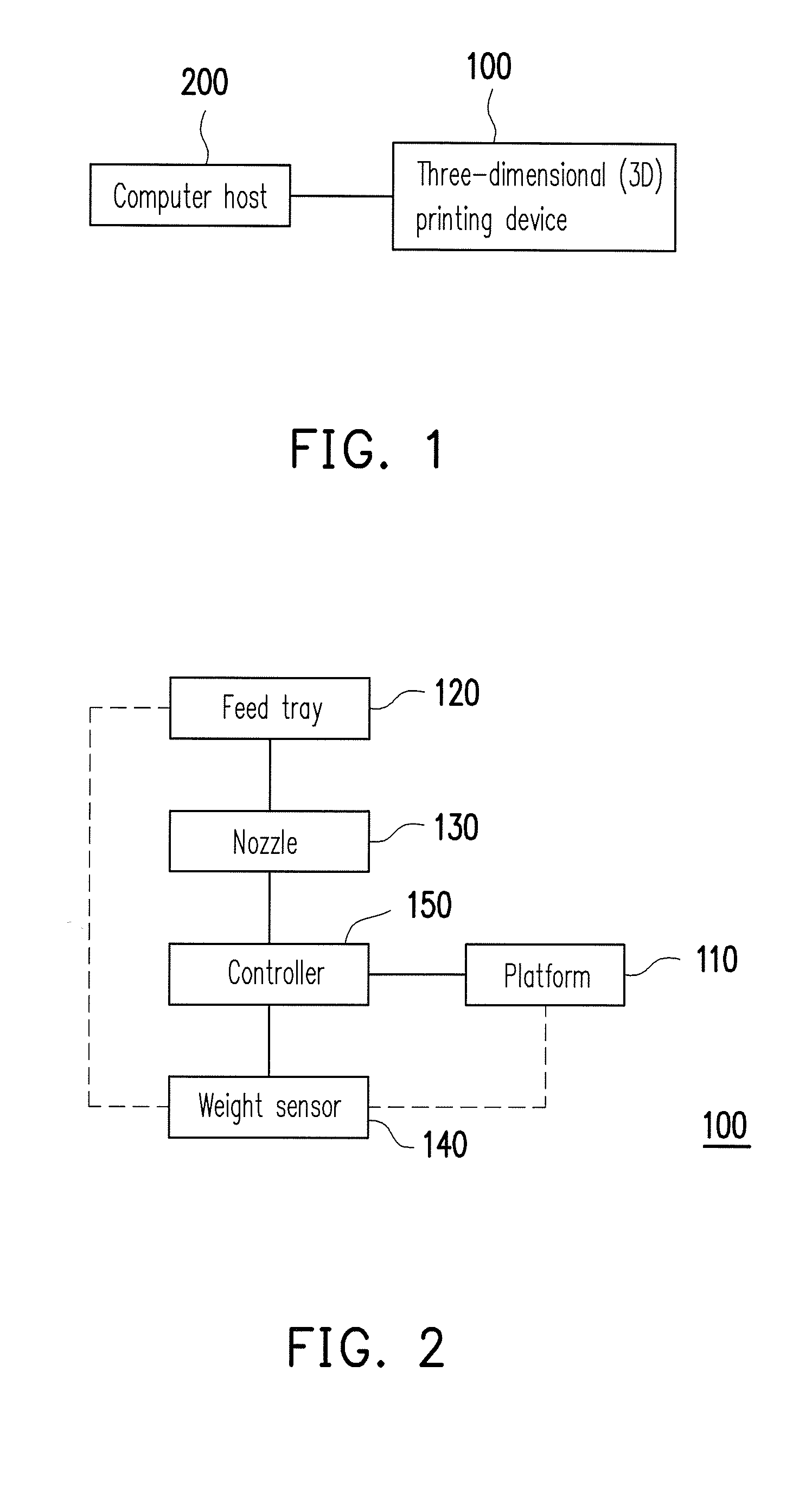

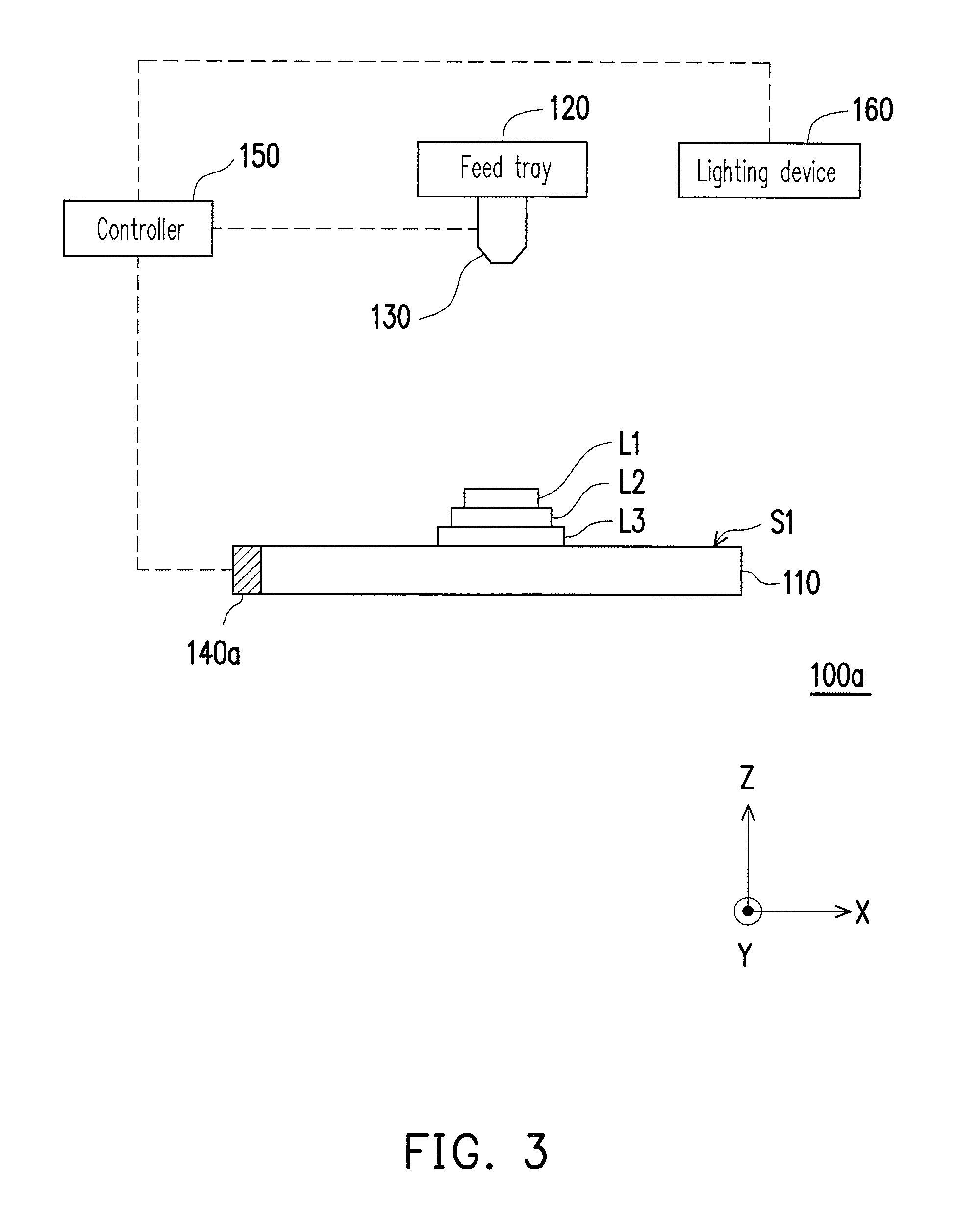

Three-dimensional printing device

InactiveUS20170028646A1Improve printing qualityAdditive manufacturing apparatus3D object support structuresIdeal weightEngineering

A 3D printing device is provided. The 3D printing device is adapted to print a 3D object including a plurality of layer objects. The 3D printing device includes a weight sensor, which is configured to measure an actual weight value of the layer objects formed on a carrying surface or configured to measure an actual weight value of a feed tray. A controller of the 3D printing device estimates an ideal weight value corresponding to a first layer object according to a printing sequence of the first layer object in the layer objects. The controller receives the actual weight value corresponding to the first layer object from the weight sensor, and compares the ideal weight value with the actual weight value to determine whether printing abnormity is occurred. According to the disclosure, the printing quality of the 3D printing device is improved.

Owner:XYZPRINTING +2

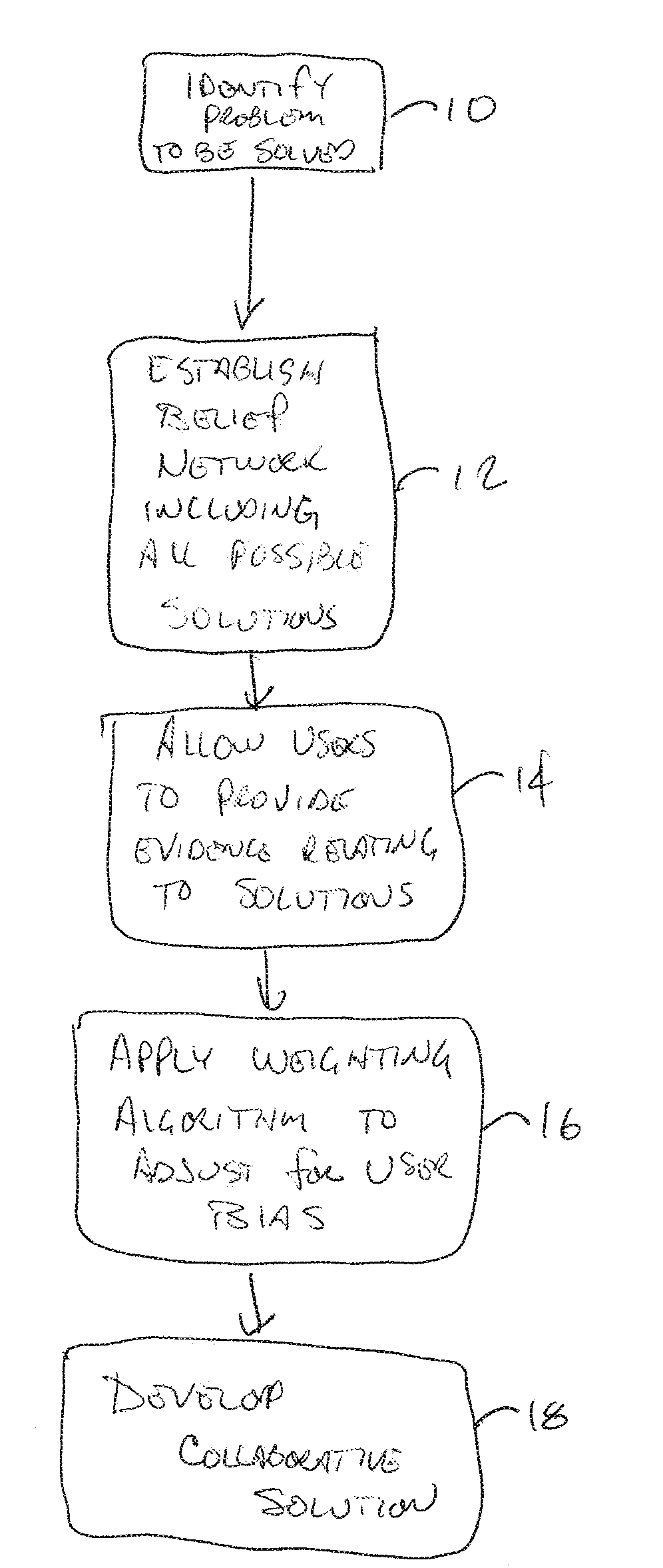

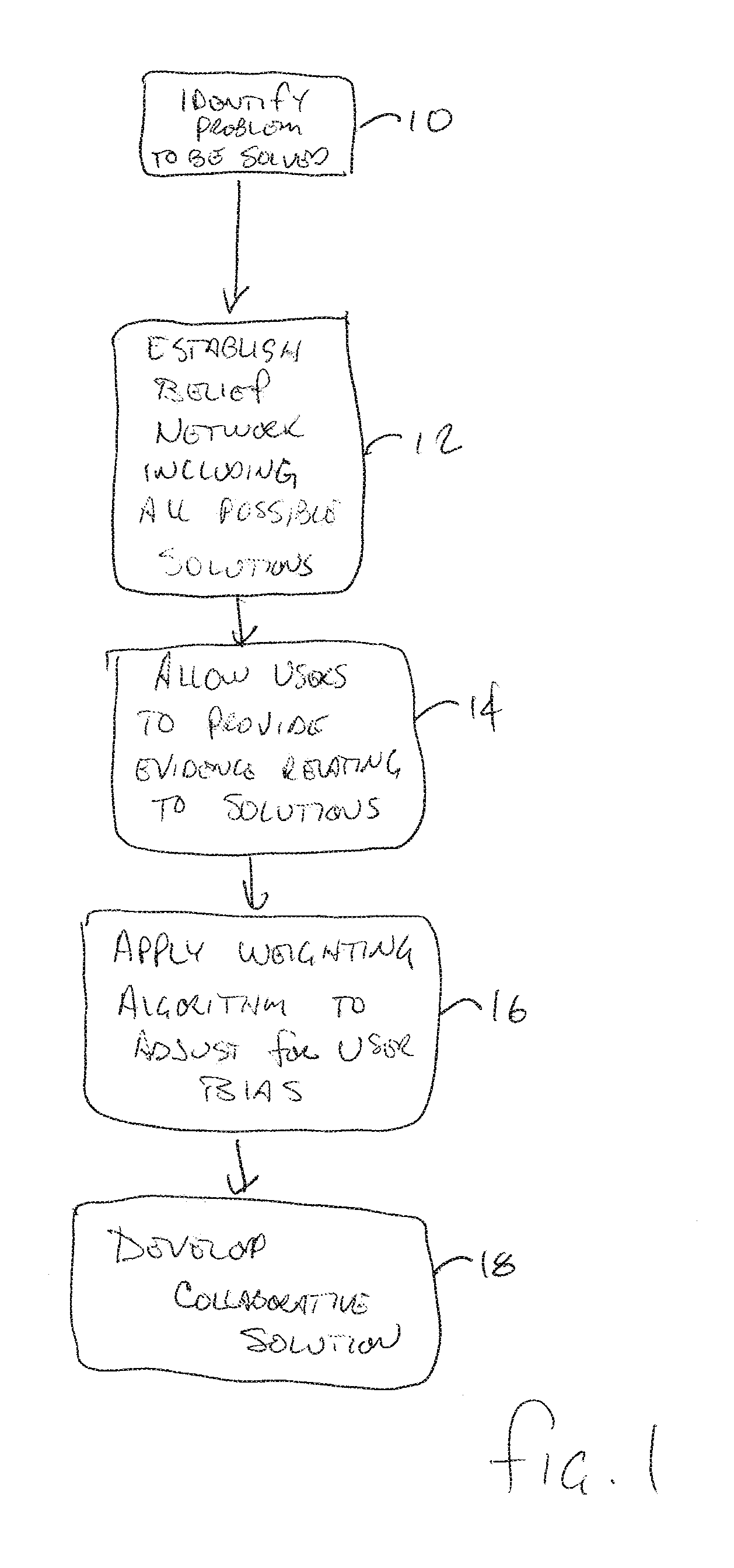

Objective decision making application using bias weighting factors

A method and system for implementing a weighted belief network that assists collaborative users in making decisions. A belief network structure is employed that further includes user controlled weighting and biasing factors to adjust the probabilities for the various nodes. The various participants have the opportunity to make adjustments to the weighting and credibility of the evidence and participants in the decision making process in order to arrive at what may be perceived as a more objective outcome. As the collaborative environment is established and the belief network is built, each user can apply various weighting and bias scenarios from their own perspective thereby allowing each discrete user to work out their various suspicions regarding the bias of other participants or the actual weight of a discrete piece of supporting evidence in the context of the entire belief network.

Owner:CHARLES RIVER ANALYTICS INC A MASSACHUSETTS

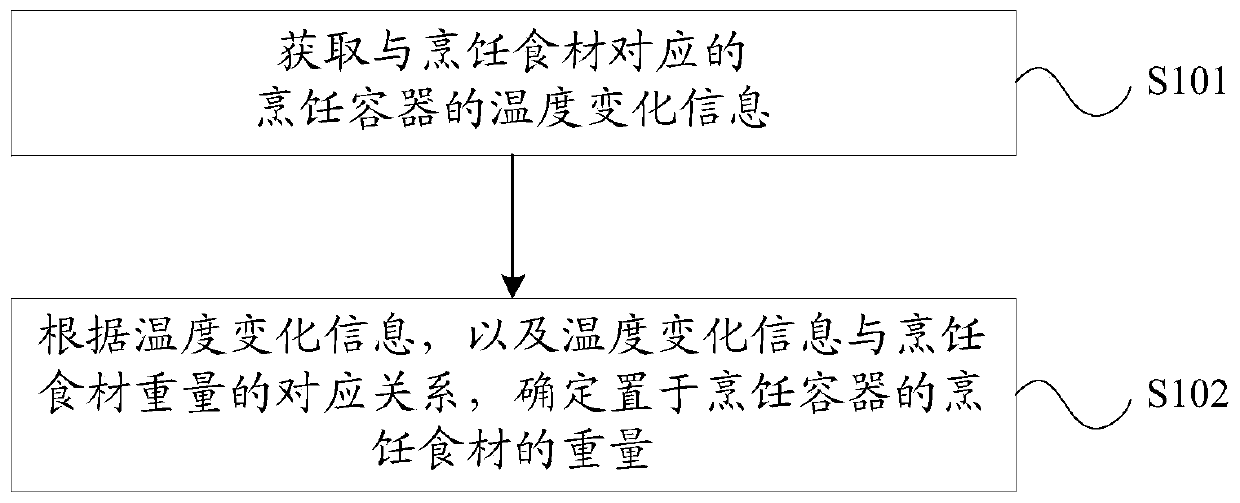

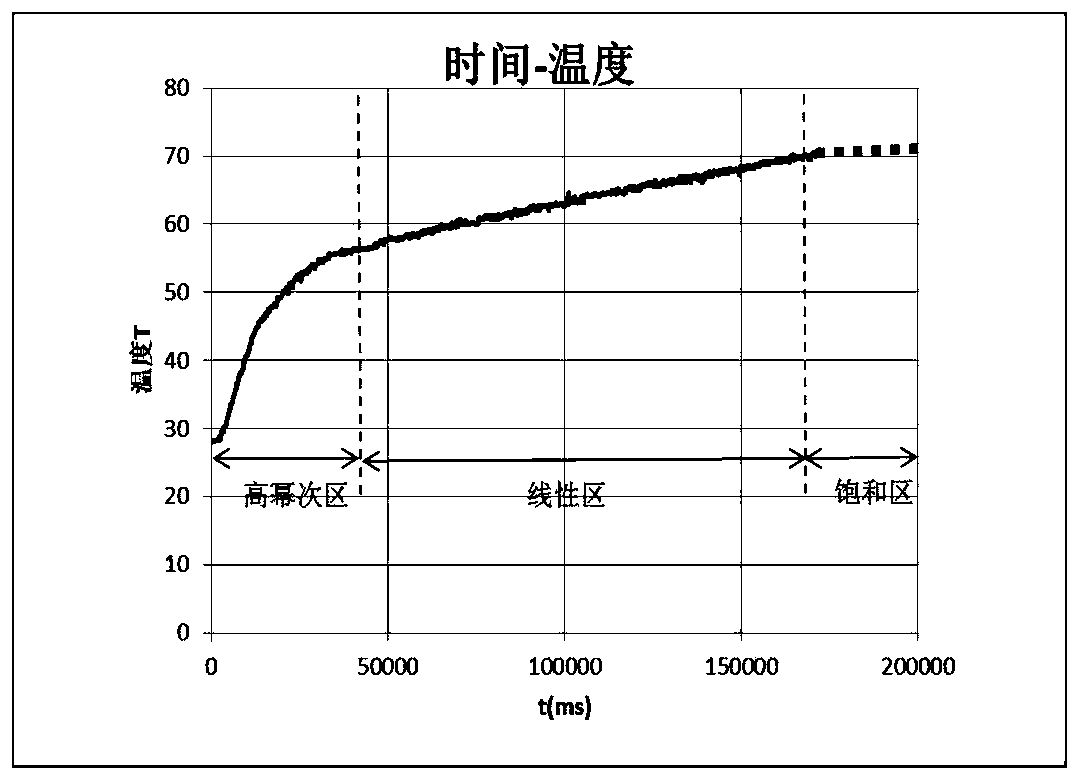

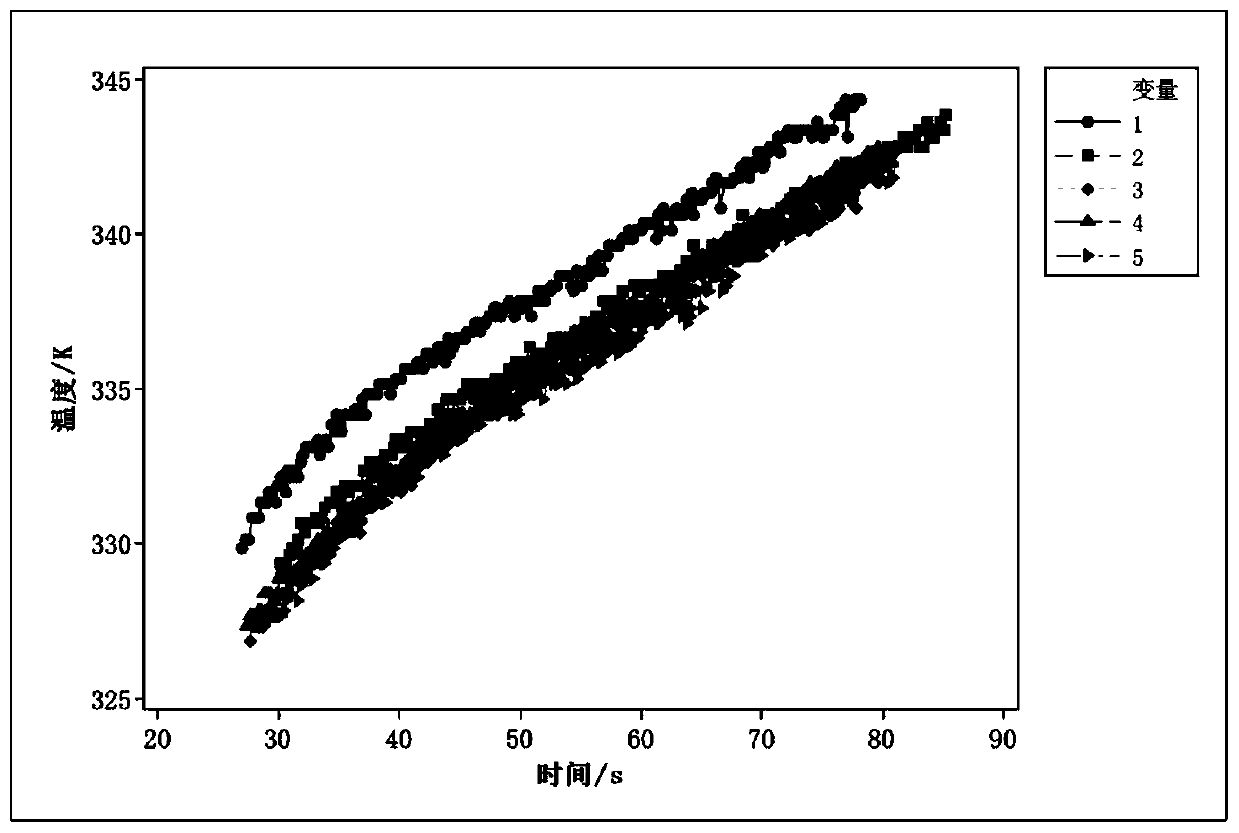

Food weight detecting method, cooking method and device

ActiveCN109717724AGuaranteed cooking effectSmart and easy to useMeasurement devicesCooking vesselsEngineeringCooking methods

The invention discloses a food weight detecting method, a cooking method and a device. The device is used for detecting the actual weight of food placed into the cooking device and therefore performing cooking according to the actual weight to meet the food cooking requirement as much as possible. The food weight detecting method comprises the steps of obtaining temperature change information of acooking container corresponding to the cooking food; according to the temperature change information and the corresponding relation between the cooked food weight of the prestored temperature changeinformation, determining the weight of the cooked food placed into the cooking container.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Billet intelligent cutting method and system

The present invention relates to a billet intelligent cutting method and system. The method comprises: obtaining a target cutting weight for cutting a to-be-cut billet, and the theoretical density, actual cross sectional area and actual length of the to-be-cut billet, and calculating a theoretical weight per unit length of the to-be-cut billet; calculating theoretical cut lengths for cutting the to-be-cut billet according to the target cutting weight and the theoretical weight; cutting the to-be-cut billet according to the theoretical cut lengths and obtaining a preliminary cut billet; detecting the actual weight of the preliminary cut billet; calculating a density weight coefficient of the to-be-cut billet according to the actual weight, the actual cross sectional area and the theoretical cut lengths; calculating actual cut lengths for cutting the to-be-cut billet according to the density weight coefficient, the theoretical density, the actual cross sectional area and the target cutting weight; and cutting the to-be-cut billet again according to the actual cut lengths. The billet intelligent cutting method and system are mainly applied to billet continuous casting production processes.

Owner:ELECTRON CO LTD

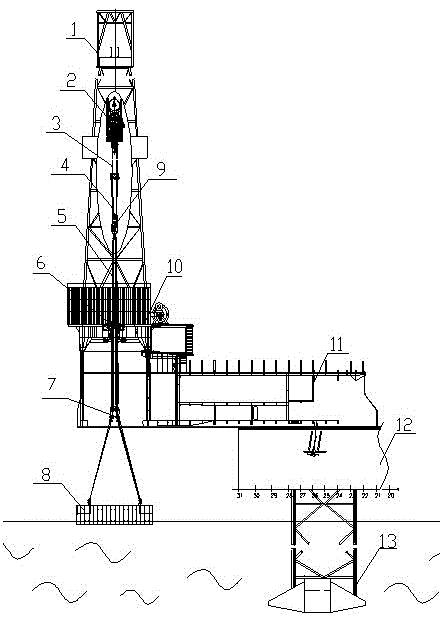

System and method for cantilever beam heavy-duty test of self-elevating drilling platform

ActiveCN105464064ALow costImprove work efficiencyMachine part testingArtificial islandsTop driveSea level

The invention relates to a system and a method for cantilever beam heavy-duty test of a self-elevating drilling platform. The system comprises a main boat body, a cantilever beam, a drilling platform, a derrick, a top drive and a water ballasting type barge, wherein the main boat body is supported by pile legs and positioned above the sea level, the cantilever beam is horizontally positioned on the main boat body and extends above the sea level, the drilling platform and the derrick are positioned at the end part of the cantilever beam, the top drive is positioned at the top of the derrick, and the water ballasting type barge is connected with the top drive and floats on the sea level; a stand zone simulating actual weight is arranged on the drilling platform; and the top drive is connected with the barge through a steel wire rope. Three tests are carried out by using the system. The system and the method have the advantages that the correct implementation of the test scheme can be ensured, and at the same time, the test cycle can be shortened; and through the universalization of tool design, the system and the method can adapt to the cantilever beam heavy-duty tests of various self-elevating drilling platforms, thereby reducing cost.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

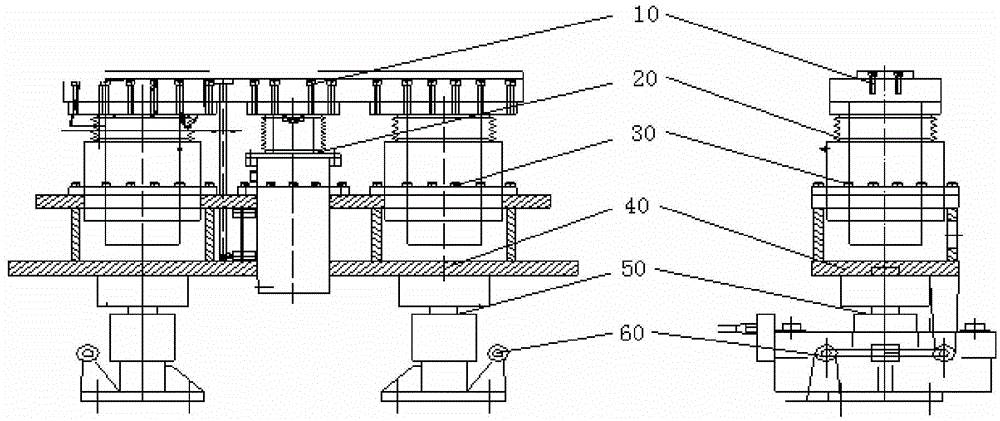

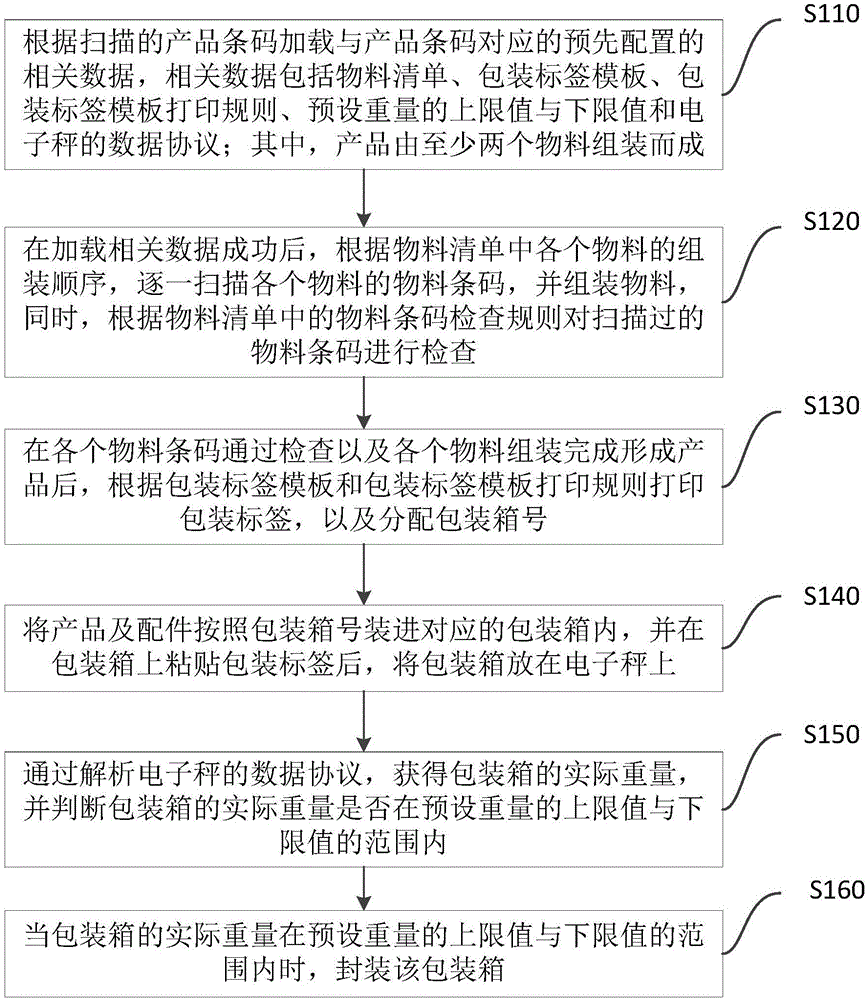

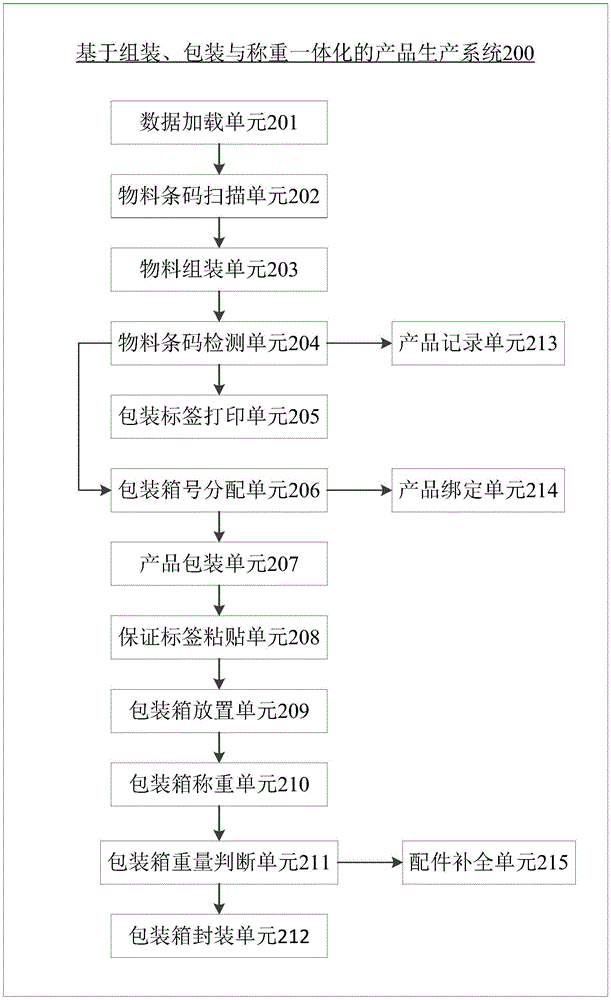

Product production method and system based on assembling, packaging and weighing integration

InactiveCN106275644ALow costIncrease productivityPackaging automatic controlPackaging machinesBarcodeActual weight

The invention provides a product production method and system based on assembling, packaging and weighing integration. The method comprises the following steps: according to the scanned product barcode, loading pre-allocated related data corresponding to the product barcode; according to the assembling sequence of each material in a material list of related data, scanning the material barcodes and assembling the materials, and at the same time, inspecting the scanned material barcodes according to the inspection rule; according to a packaging label template of related data and the printing rule of the packaging label template, printing packaging labels and distributing packaging box numbers; putting products and accessories in corresponding packaging boxes according to the packaging box numbers, pasting packaging labels on the packaging boxes, putting the packaging boxes on an electronic balance to obtain actual weight of the packaging boxes, and sealing the packaging boxes when actual weight of the packaging boxes is within the ranges of upper limiting value and lower limiting value of preset weight. With adoption of the product production method and system, the cost is greatly reduced, and the production efficiency is improved.

Owner:GOERTEK INC

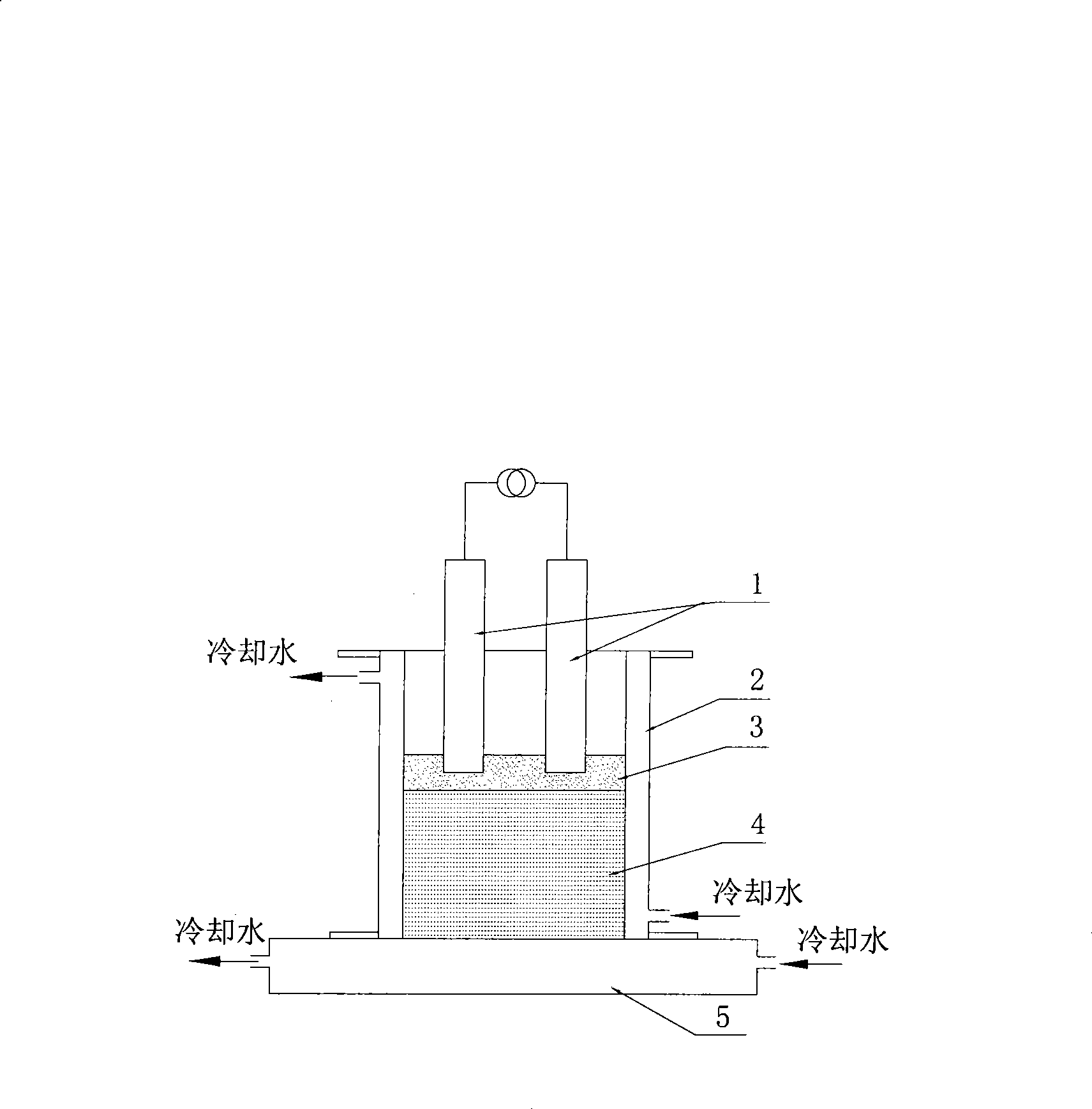

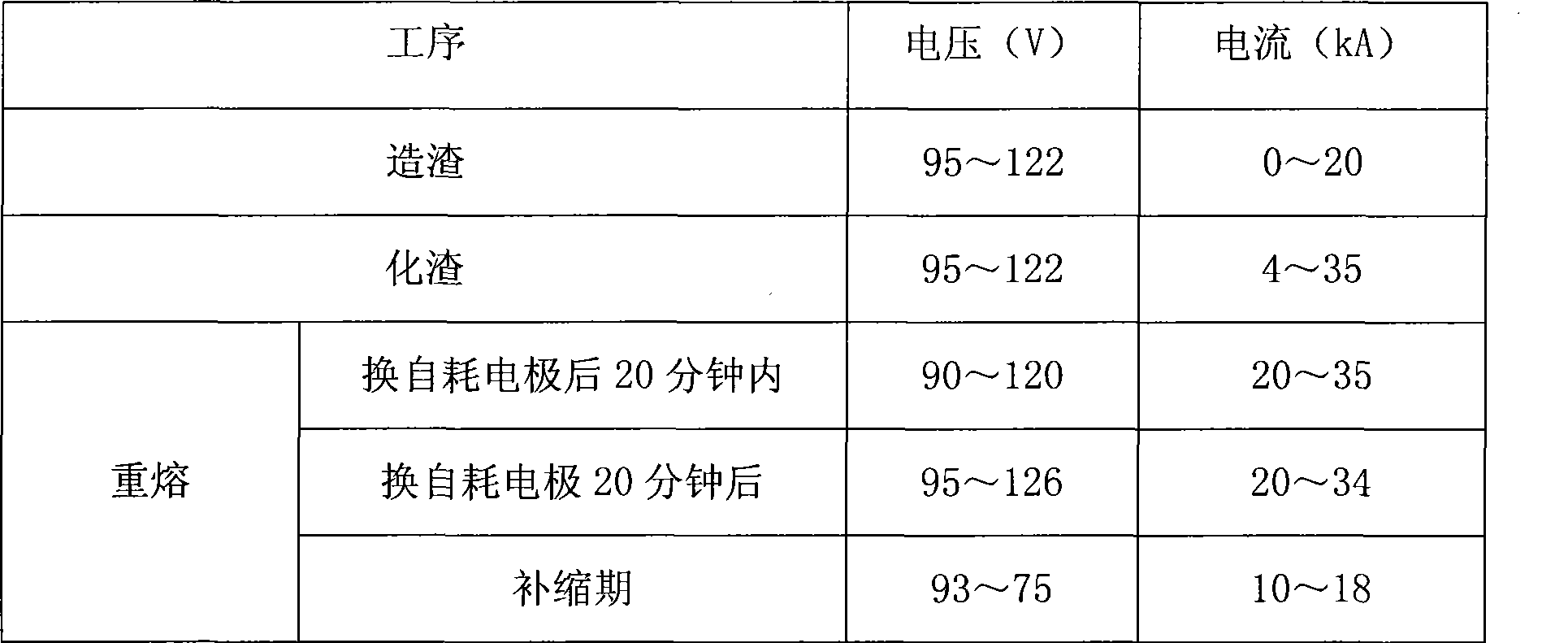

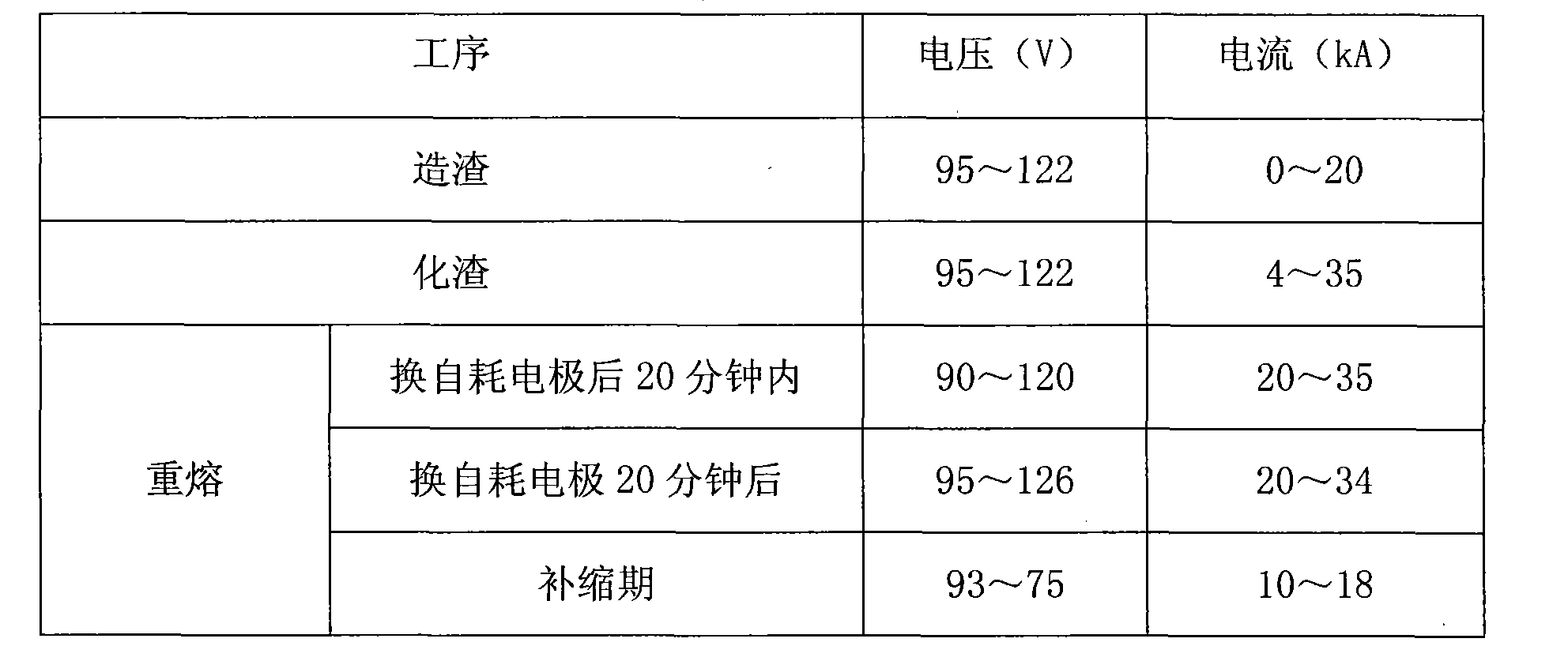

Manufacture method of steel ingot for million multikilowatt nuclear electricity pile core component

The invention discloses a method for manufacturing a steel ingot used for million-kilowatt nuclear power reactor core structural component, austenitic stainless steel ingot that weighs over 25 tons is manufactured by electroslag remelting process: firstly, preparation: a single-phase bipolar series connected or triphase bipolar series connected electroslag remelting furnace is adopted; a copper wall water-cooling crystallizer and a water-cooled base plate are adopted; a consumable electrode is assembled; slag charge is matched; SiGa and Al powder are adopted for deoxidation; secondly, refinement and fusion casting: a graphite electrode is picked up and replaced by the consumable electrode to remelt the fully melted slag charge after slagging and slugging. When the actual weight of the steel ingot is 2 tons less than the preset weight, the electric power is reduced and feeding operation in telophase is carried out; thirdly, the steel ingot is stripped. The steel ingot manufactured by the invention has extremely high purity, extremely fine uniformity, excellent high temperature resistance and tarnish resistance, as well as strong anti neutron radiation embrittlement sensibility.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

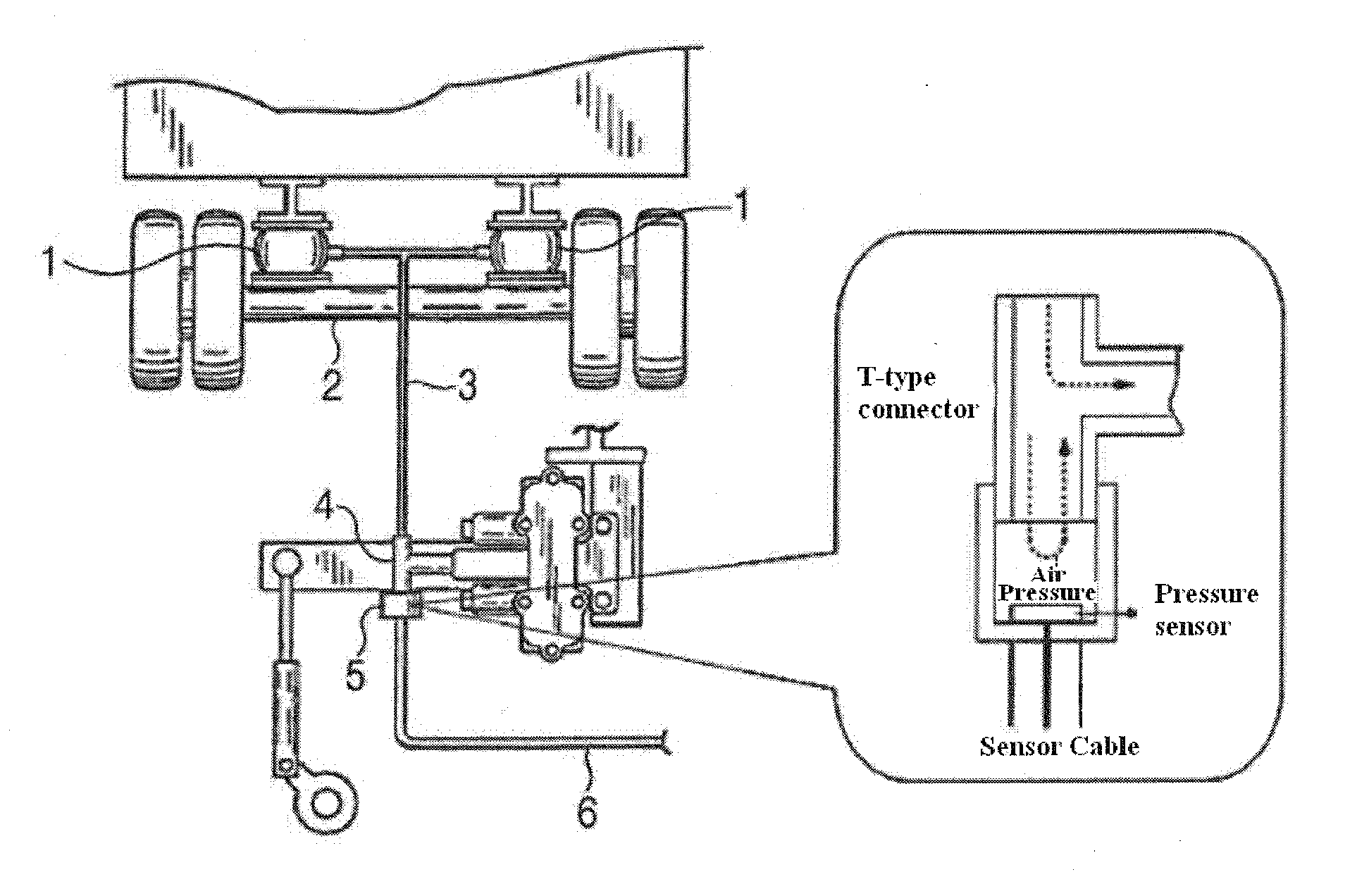

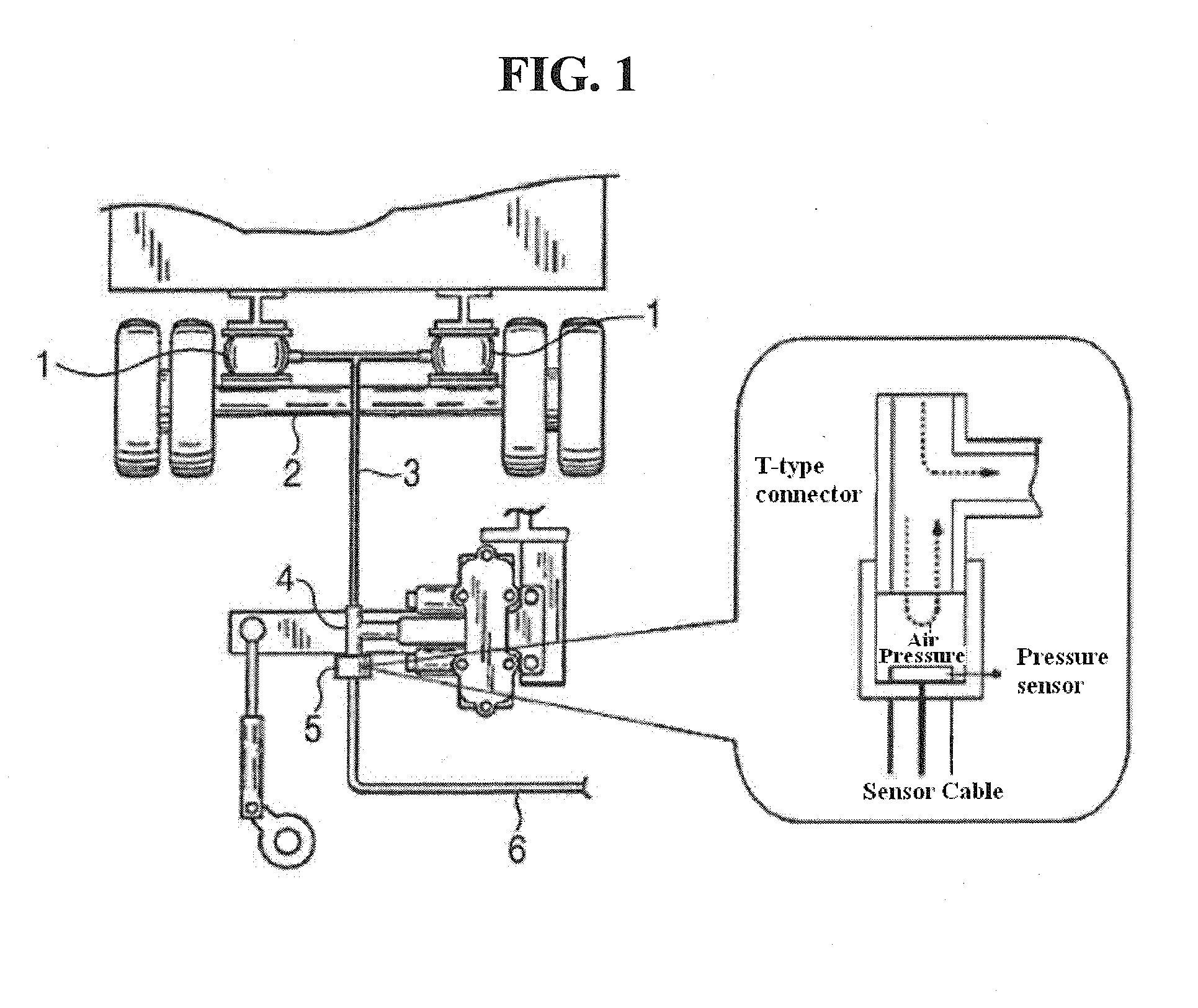

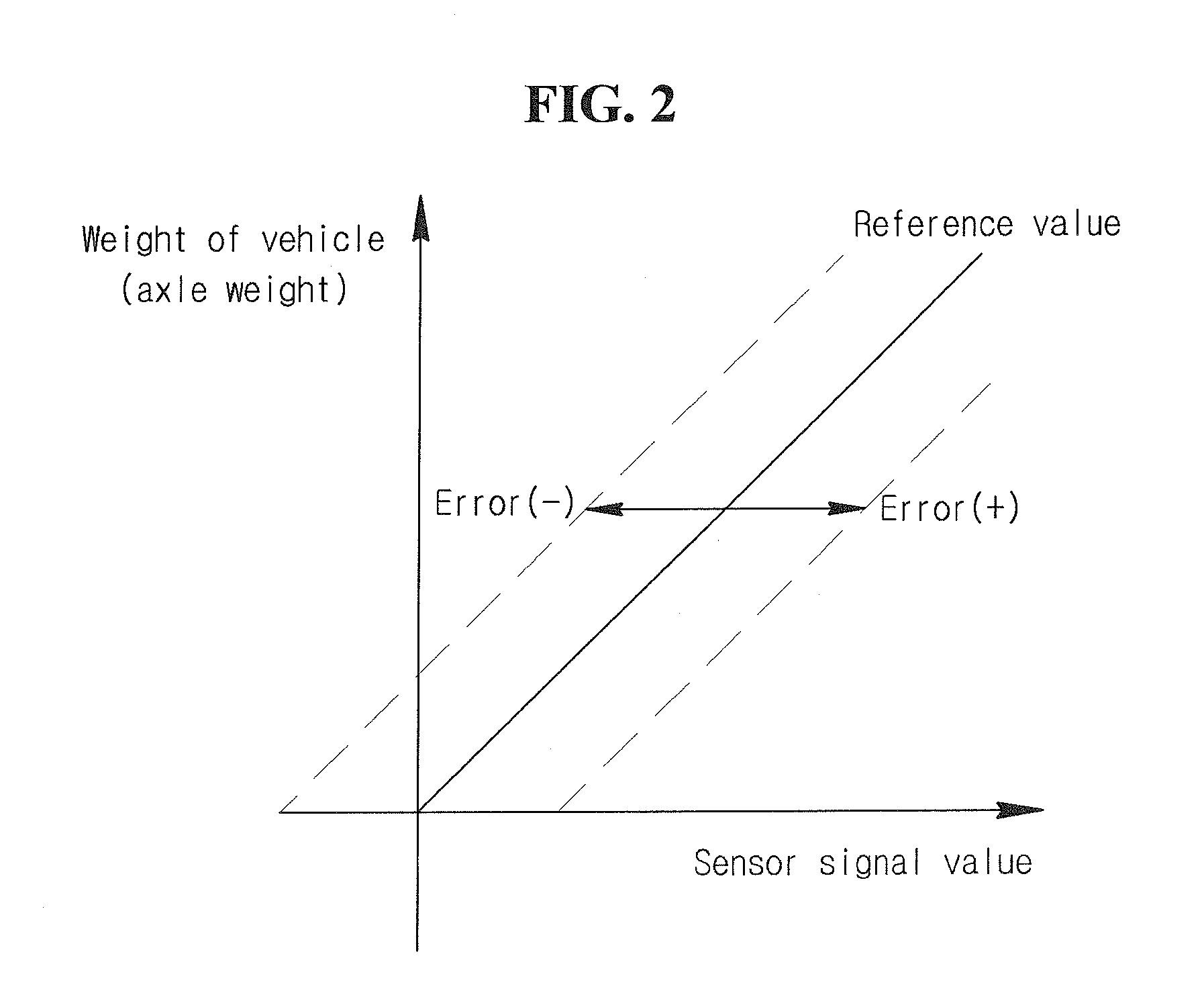

Method of displaying weight of vehicle and pressure in tires on one display unit

InactiveUS20130081883A1Error can be prevented and minimizedReduce pressureTyre measurementsWeighing apparatus for materials with special property/formEngineeringActual weight

Disclosed is a method of displaying weight of a vehicle and pressure in tires on one display unit, and more specifically, a method of displaying weight of a vehicle and pressure in tires on one display unit, in which the weight of a vehicle is measured based on pressure values of air suspensions. The weight of a vehicle is measured precisely by compensating properties of the material of the air suspension according to temperature. Pressure values of the tires and the compensated weight of the vehicle are displayed on one display unit, an actual weight is measured more precisely compared with conventional methods.

Owner:NAE WOI KOREA LTD

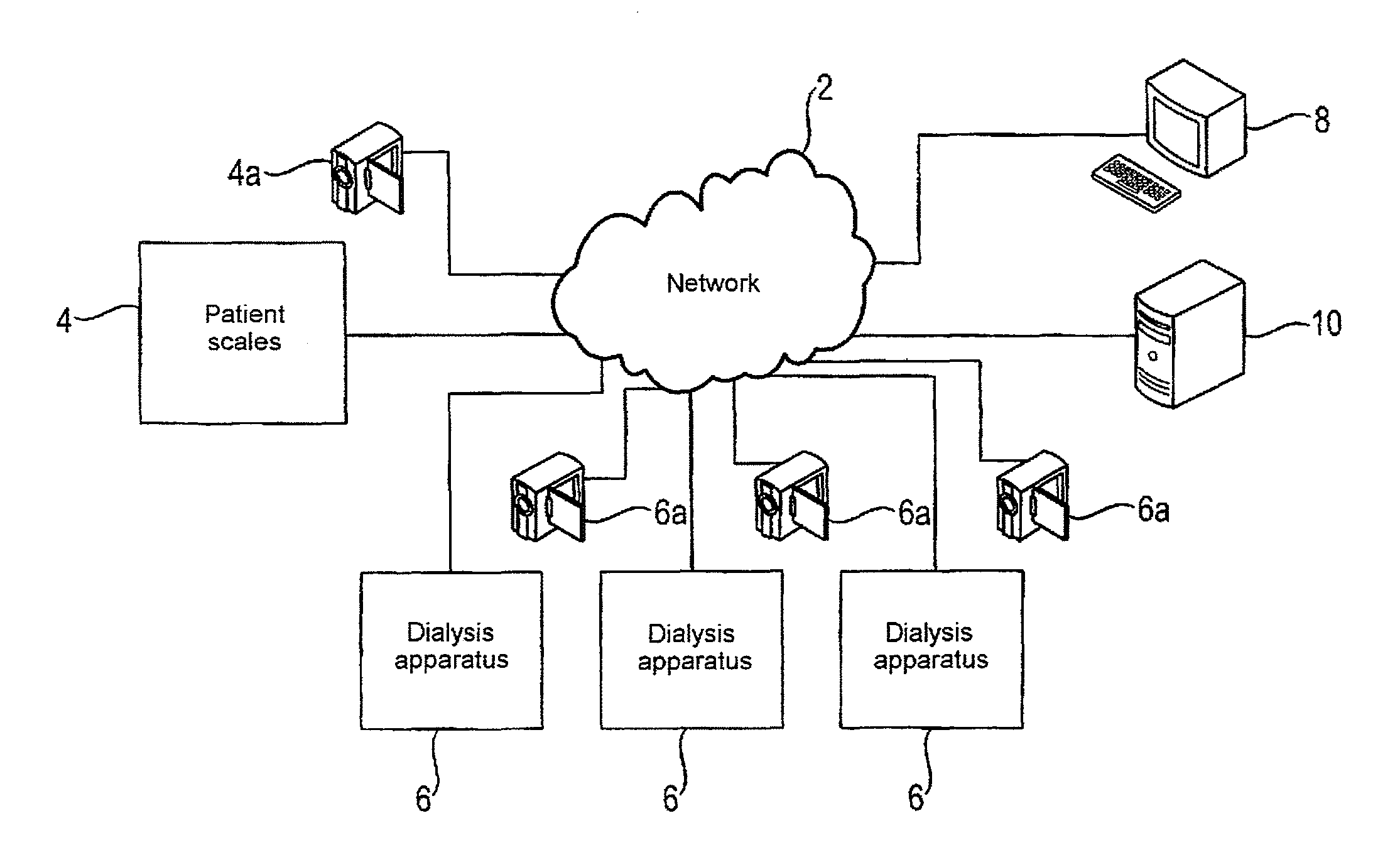

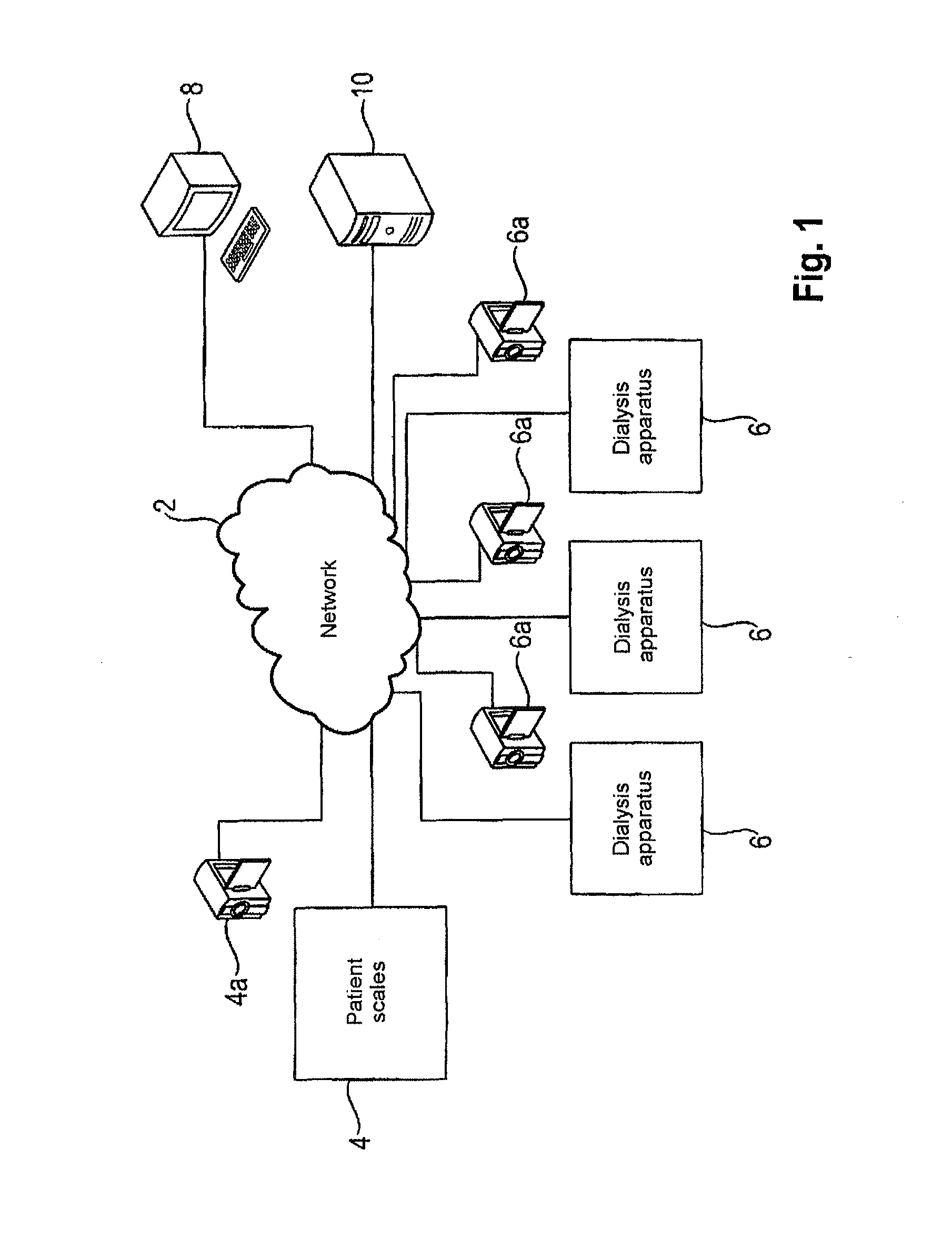

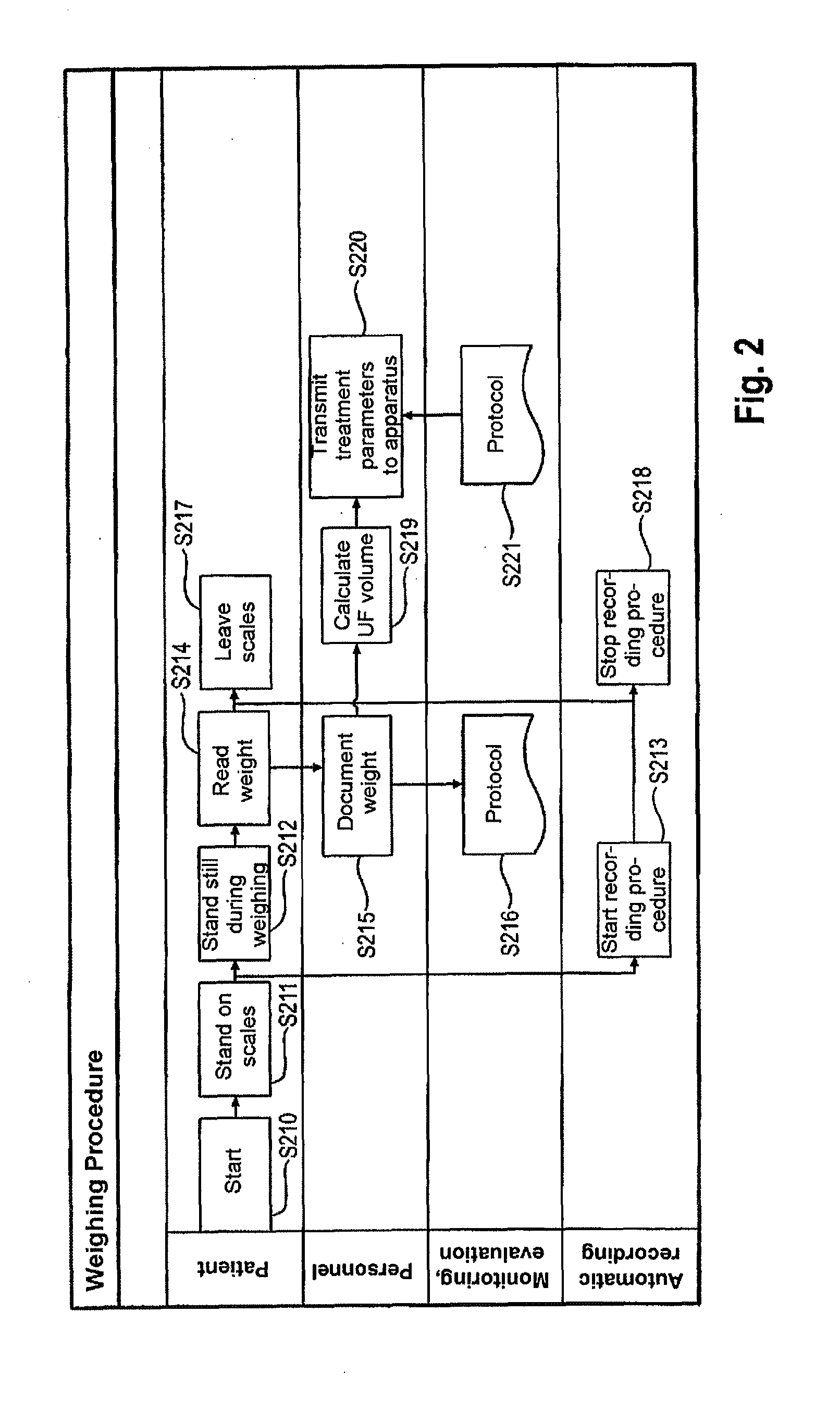

Patient scales with camera-supported monitoring and a dialysis therapy system with camera-controlled weighing process

InactiveUS20140102957A1Easy to optimizeEvaluate and correct the possible misbehavior of a patientWeighing indication devicesDiagnostic recording/measuringCamera controlNetwork connection

A weight detection device is disclosed for determining a patient's weight, for dialysis treatment, that includes patient scales arranged to carry out a weighing procedure to detect the actual weight of a patient, preferably a network connection arranged to connect a component of the weight detection device, generating information and / or data related to the determining of the patient's weight and / or to the weighing procedure, to a data network, an output device arranged to output the actual weight of the patient, and an image information recording device that includes a field of view directed to the patient scales for the visual detection of weighing procedures arranged to record the course of a weighing procedure such that a cause of a change in the actual weight occurring in the course of dialysis therapy can be determined from a recording of the weighing procedure.

Owner:B BRAUN AVITUM

Dynamic weighing correction method of vehicle weighing module

ActiveCN105865607AAddressing the Effects of Weighing WeightThe operation principle is simpleWeighing apparatus testing/calibrationSpecial purpose weighing apparatusGyroscopeAngular variation

The invention provides a dynamic weighing correction method of a vehicle weighing module. The method is used for correcting vehicle weight detected when a vehicle runs. Firstly, a vehicle-mounted weighing module provided with a gyroscope sensor, a storage unit and a processing unit is provided, installed on the vehicle and used for detecting the weight of the vehicle, an angular variation correction coefficient A and an acceleration correction coefficient B are calculated through the processing unit according to a deviation angle theta O, the lateral force coefficient kx in the X-axis direction, the lateral force coefficient ky in the Y-axis direction, acceleration components ax, ay and az, gravity acceleration g and the included angle theta, detection weight S of the vehicle at a certain dynamic moment is obtained through the vehicle-mounted weighing module, and the actual weight G of the vehicle is calculated through the formula satisfying G=S / (A*B). The dynamic weighing correction method of the vehicle weighing module is simple in computation principle, high in operating speed and high in detection precision.

Owner:KELI SENSING TECH NINGBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com