Manufacture method of steel ingot for million multikilowatt nuclear electricity pile core component

A manufacturing method and nuclear power stack technology, applied in the field of steel ingot manufacturing, can solve the problems of inability to meet large austenitic stainless steel forgings and unsatisfactory physical and chemical properties, and achieve strong resistance to neutron radiation embrittlement sensitivity, excellent high temperature resistance and Corrosion resistance, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

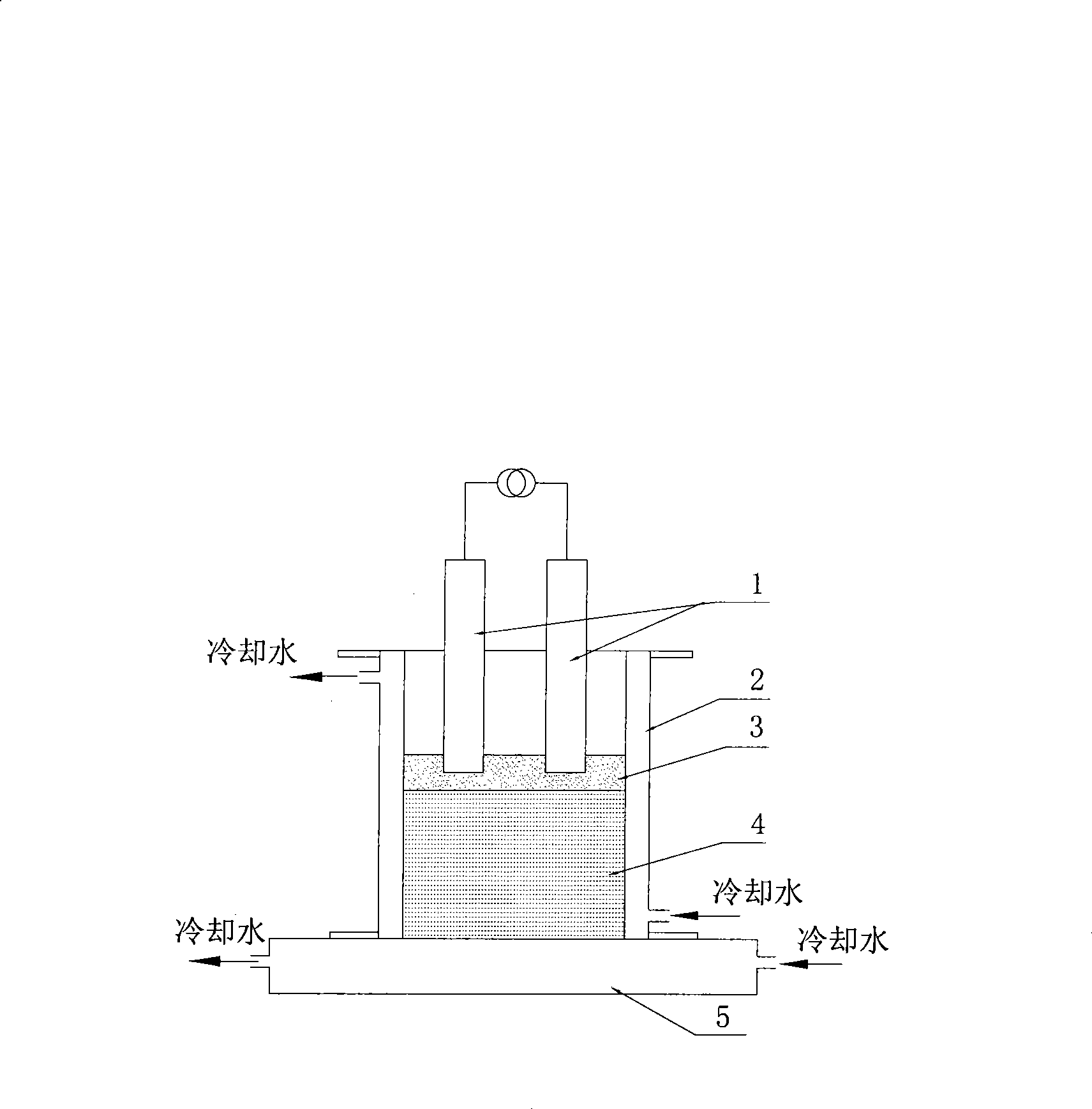

Image

Examples

Embodiment Construction

[0026] The invention adopts the electroslag remelting method to manufacture steel ingots for nuclear power reactor core components of the million-kilowatt class. According to the requirements of relevant nuclear power technical specifications, the steel ingots used for large austenitic stainless steel forgings for million-kilowatt nuclear power reactor core components must meet the requirements of Z3CN18-10NS materials, that is, the physical and chemical properties should meet the following indicators:

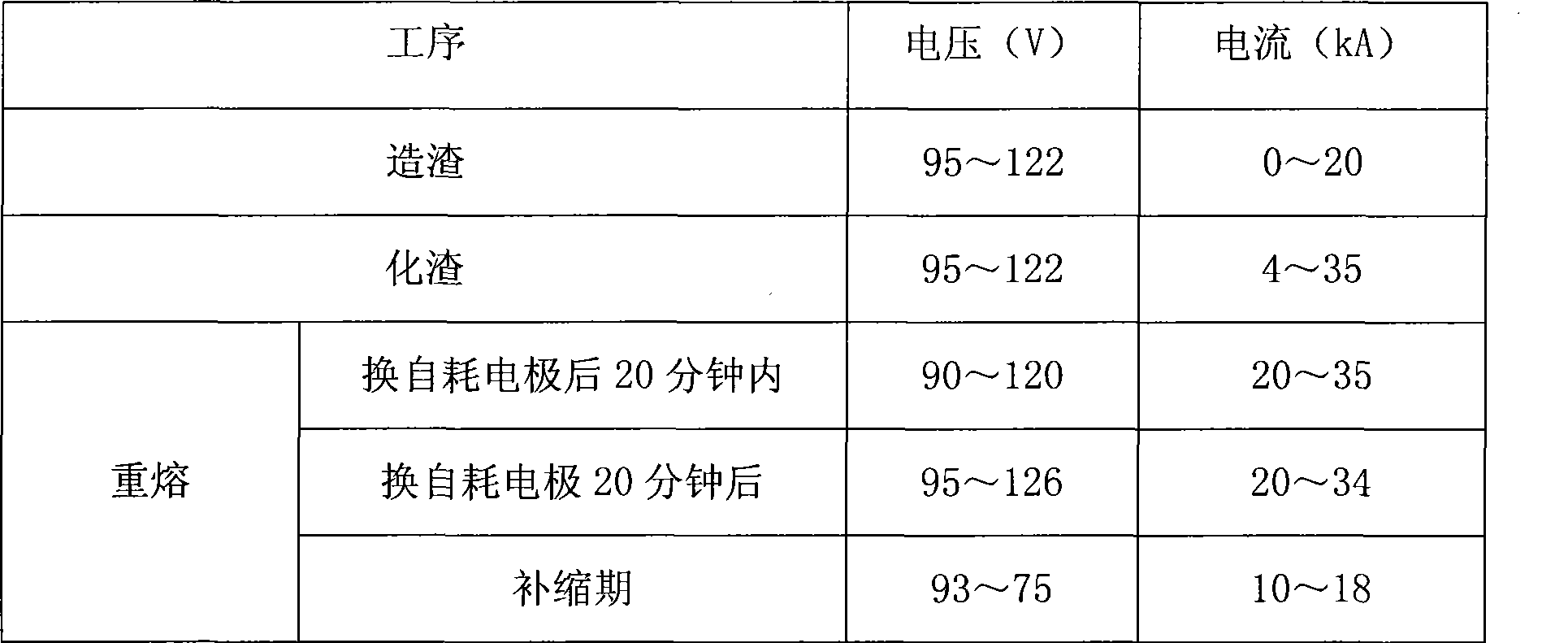

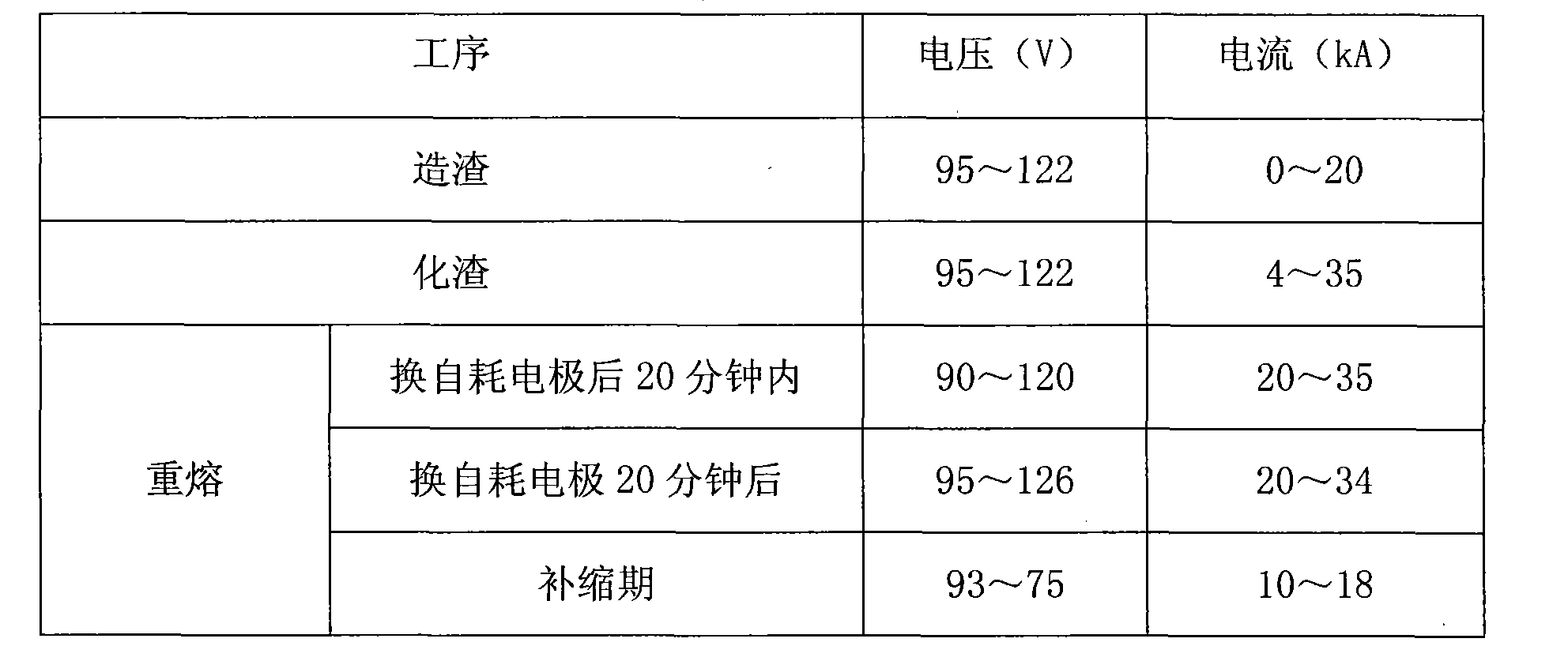

[0027] 1. The chemical composition should meet the indicators in Table 1:

[0028] element Melting analysis (%) Analysis value of finished product (%) C ≤0.038 ≤0.040 Cr 18.50~20.00 18.50~20.00 Ni 9.00~11.00 9.00~11.00 Si ≤1.00 ≤1.00 mn ≤2.00 ≤2.00 S ≤0.015 ≤0.020 P ≤0.030 ≤0.035 Cu ≤1.00 ≤1.00 co ≤0.06 ≤0.10 N ≤0.080 ≤0.080 B ≤0.0018 ≤0.0018

[0029] Table 1

[0030] 2. The mechanical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com