Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2045results about How to "Good emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

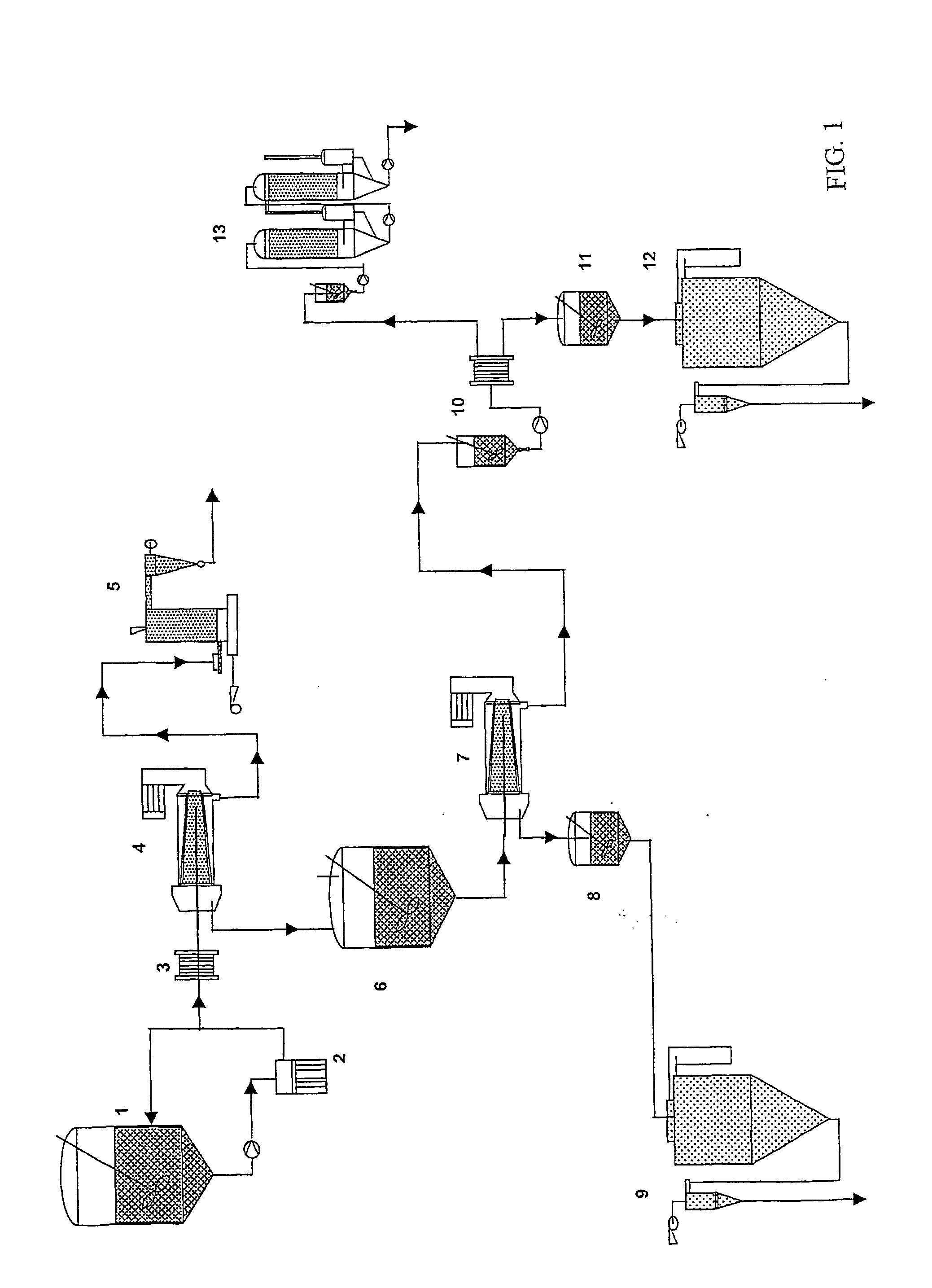

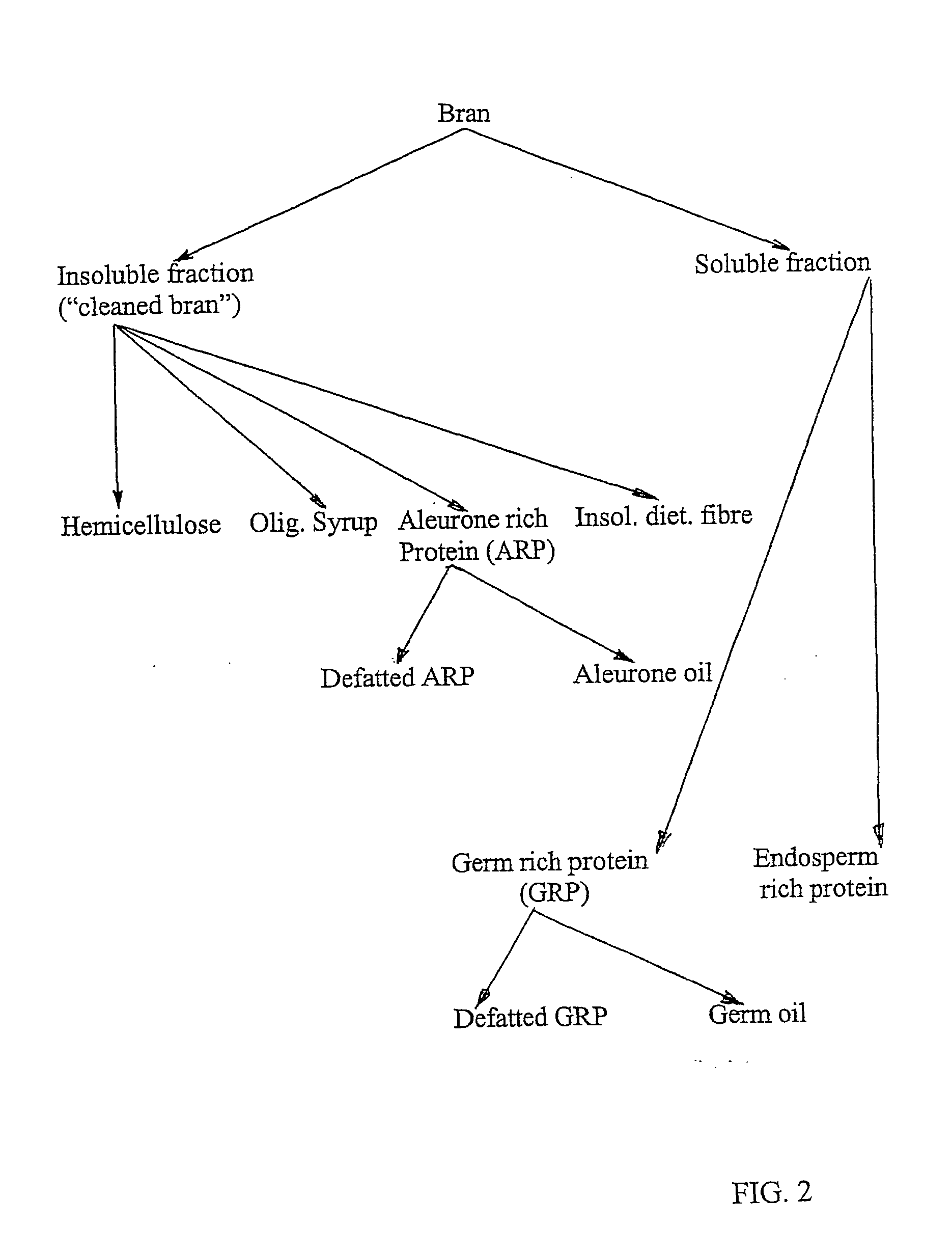

Process for the fractionation of cereal brans

InactiveUS20050089602A1Minimal contaminationImprove efficiencyTea extractionProtein composition from vegetable seedsUltrafiltrationHordeum vulgare

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

Konjac jelly powder and method for making jellies by using same

InactiveCN102106495AGood physical and chemical propertiesImprove water holding capacityFood preparationLocust bean gumFiltration

The invention discloses konjac jelly powder. The konjac jelly powder comprises the following components in part by weight: 30 to 40 parts of konjac powder, 10 to 25 parts of carrageenin, 0 to 10 parts of xanthan gum, 0 to 15 parts of locust bean gum, 0 to 20 parts of guar gum, 5 to 12.5 parts of sodium citrate, 8 to 15 parts of potassium chloride, 0 to 7 parts of xylitol and 2 to 5 parts of citric acid. A method for preparing jellies by using the konjac jelly powder comprises the following steps of: mixing the konjac jelly powder and white granulated sugar uniformly; pouring the mixed white granulated sugar and konjac jelly powder into a stirred cold water proportioning cylinder; continuously adding the white granulated sugar or syrup, opening steam and heating; and performing filtration, packing and sterilization to obtain konjac jelly finished products. The konjac jelly powder provided by the invention has low production cost, adjustable taste and high dietary fiber content; the prepared konjac jellies do not need to be treated by alkali; and the method for preparing the jellies by using the konjac jelly powder has simple making process and low making cost.

Owner:HUBEI YIZHI KONJAC BIOTECH

Detergent mixture

InactiveUS20040048766A1Good cleaning and foaming propertyProcess economyCationic surface-active compoundsOrganic detergent compounding agentsActive agentSugar amine

A process for making a surfactant composition involving: (a) providing a starting mixture containing: (i) an aqueous alkali solution; (ii) at least one amino acid and / or a salt thereof; (iii) a fatty acid chloride; (iv) an acylatable surfactant precursor selected from the group consisting of a protein hydrolyzate, a polyamino acid, an aminosulfonic acid, an amino sugar, a nonionic surfactant, and mixtures thereof; and (v) up to about 15% by weight, based on the weight of the starting mixture, of a polyol component; (b) providing a stirring mechanism; and (c) reacting (ii) and (iii), with stirring, to form the surfactant composition.

Owner:COGNIS DEUT GMBH & CO KG

Modified emulsified asphalt waterproof sealant and preparation method thereof

InactiveCN102898850AImprove stabilityImprove bindingOther chemical processesBuilding insulationsBituminous waterproofingPolypropylene

The invention aims to provide a modified emulsified asphalt waterproof sealant and a preparation method thereof. The modified emulsified asphalt waterproof sealant comprises asphalt, a modifying agent, an emulsifying agent, a thickening agent and water. In a formula system of the modified emulsified asphalt waterproof sealant, more modifying agent in an appropriate amount is adopted than that of the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and a large amount of the thickening agent is used to adjust the appropriate viscosity of a modified emulsified asphalt waterproof sealant system, so that the modified emulsified asphalt waterproof sealant can be well adhered to the surface of a relatively smooth polypropylene random copolymer (PPR) or polyvinyl chloride (PVC) pipe to well seal the connection part of a PPR or PVC water supply and drainage pipe and a concrete base.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Reaction bonding modified emulsified asphalt waterproof paint and preparation method thereof

ActiveCN102898947AImprove stabilityImprove bindingConjugated diene hydrocarbon coatingsChloropene polymer coatingsCross-linkBituminous waterproofing

The invention aims to provide a reaction bonding modified emulsified asphalt waterproof paint and a preparation method thereof. The reaction bonding modified emulsified asphalt waterproof paint comprises asphalt, a modifying agent, an emulsifying agent, a cross-linking agent and water. In the formula system of the reaction bonding modified emulsified asphalt waterproof paint, more modifying agents in an appropriate amount are adopted compared with the prior art, so that a rubber-asphalt mixture can achieve a good emulsifying effect, the elasticity and strength of a dried sealing layer are greatly improved, and the sealing effect can be better and lasting; and by using the cross-linking agent, a chemical coupling effect is achieved between the paint and concrete, so that the cohesive force of the concrete is promoted. The reaction bonding modified emulsified asphalt waterproof paint can be applied to waterproof construction of wall surfaces, roofs, roads, bridges and the like, and has a very high practical value.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Environmentally Friendly Solvent Systems/Surfactant Systems For Drilling Fluids

InactiveUS20140005079A1Good for healthImprove securityFlushingDrilling compositionGlutaric acidActive agent

A oil field production fluid, namely a drilling mud composition, comprising a mixture of: (a) at least one base oil component; and (b) an additive component comprising a blend of dibasic esters. The functional fluid can optionally comprise additional additive components. The blend of dibasic esters comprises two or more of dialkyl methylglutarate, dialkyl adipate, dialkyl ethylsuccinate, dialkyl succinate, dialkyl glutarate.

Owner:RHODIA OPERATIONS SAS

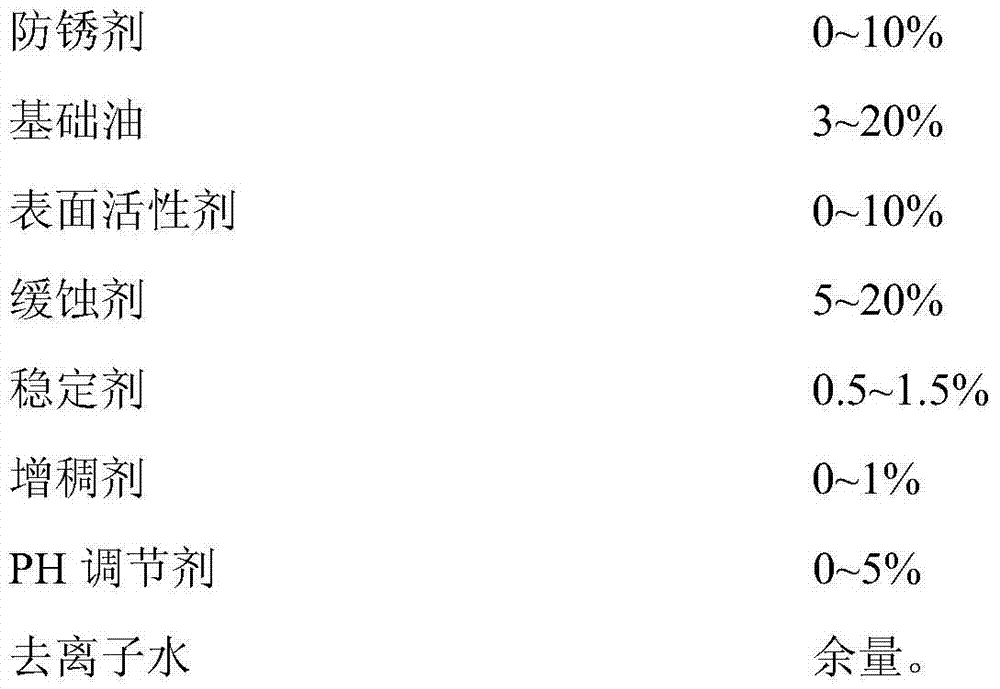

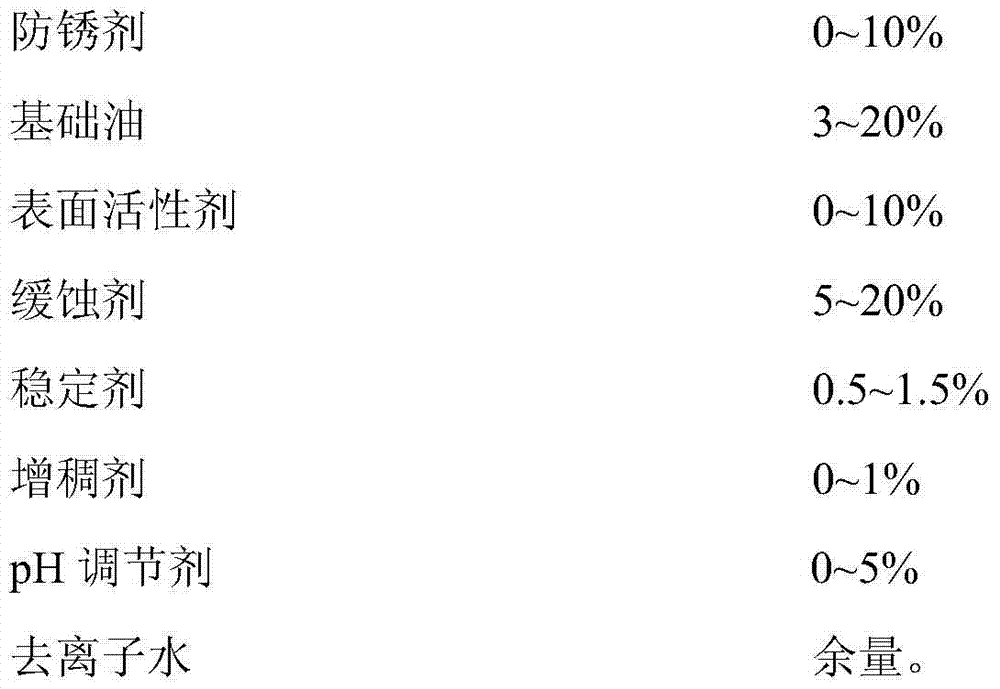

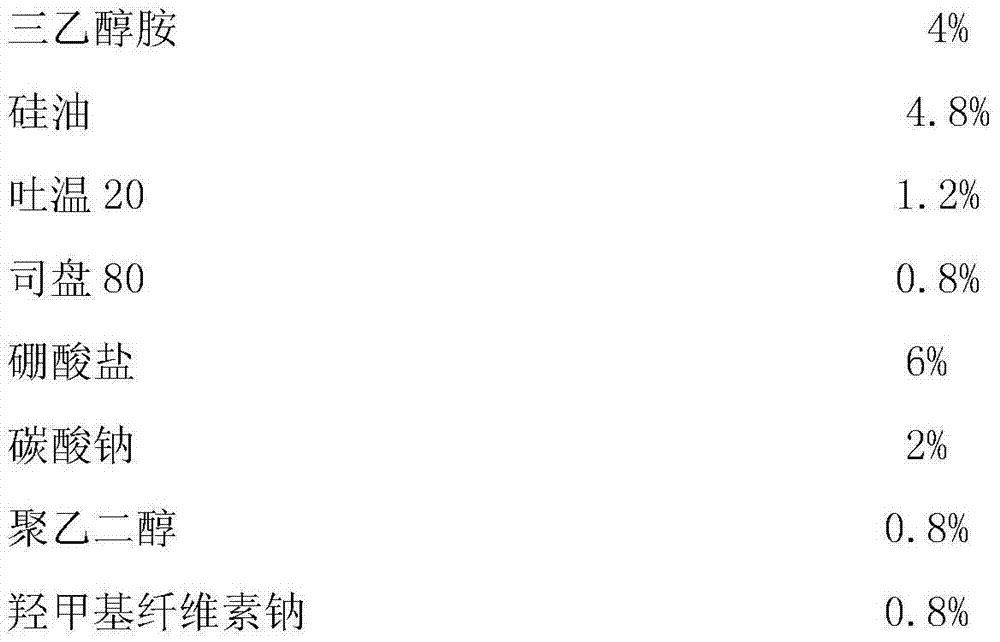

Micro emulsion type water-based metal anti-rusting liquid

The invention discloses a micro emulsion type water-based metal anti-rusting liquid which is prepared from the following raw materials in percentage by mass: 0-10% of anti-rusting agent, 3-20% of base oil, 0-10% of surfactant, 5-20% of corrosion inhibitor, 0.5-1.5% of stabilizing agent, 0-1% of thickening agent, 0-5% of pH adjusting agent and the balance of deionized water. By adopting the anti-rusting liquid, both the defect that an existing anti-rusting liquid such as an oil-based anti-rusting liquid is large in elimination difficulty and not easy to decompose and the defect that the anti-rusting effect of an existing water-based anti-rusting liquid cannot meet the anti-rusting effect of an oil-based anti-rusting liquid are solved, and the advantages of two anti-rusting liquids are integrated, so that the anti-rusting liquid disclosed by the invention has good functions of lubrication, cooling, anti-rusting and the like, and meanwhile the requirements of environmental-friendliness, economy and high efficiency are met.

Owner:ZHONGBEI UNIV

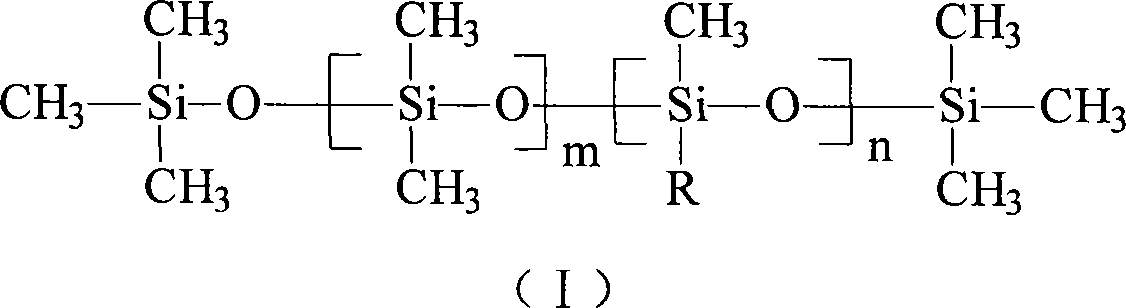

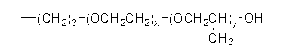

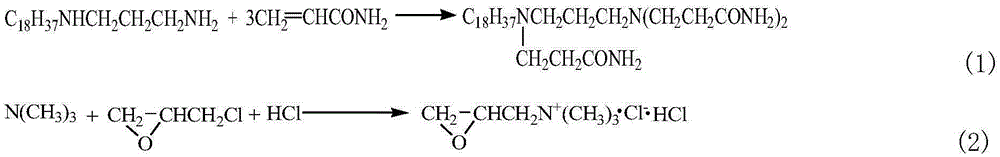

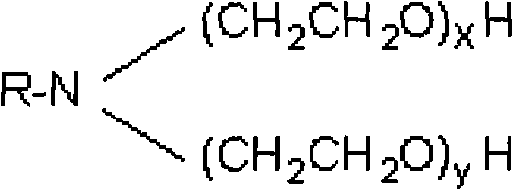

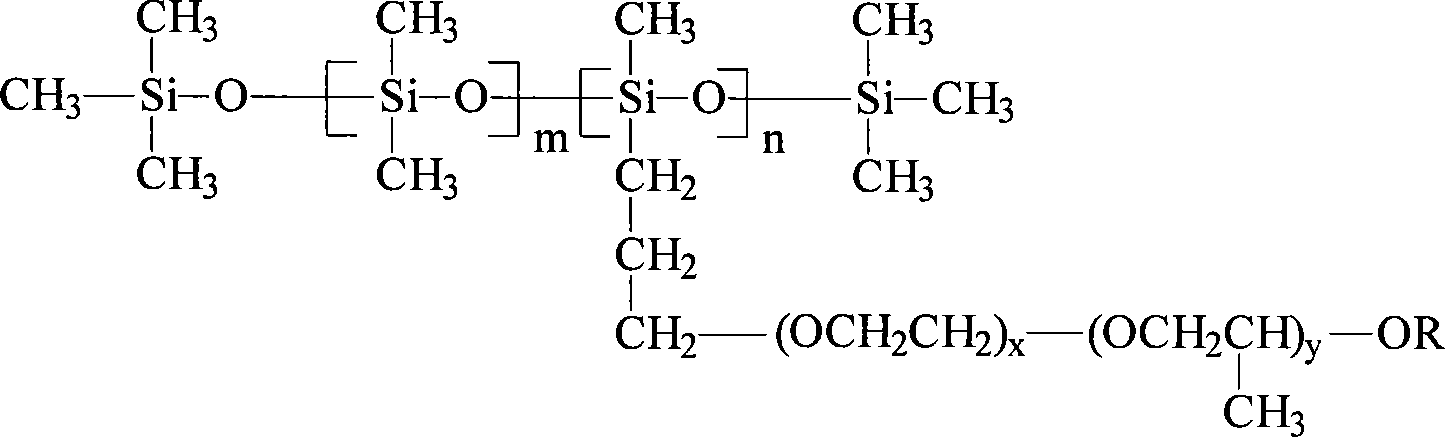

Masked non-ionic surfactant, preparation method and application thereof

ActiveCN101099926AMolecular weight controllableNarrow molecular weight distributionTransportation and packagingMixingPolymer scienceDouble bond

The present invention discloses one kind of terminated non-ionic surfactant and its preparation process and application. The surfactant is allyl terminated polyether with molecular weight controllable in 700-9500 Da, narrow molecular weight distribution and high reaction activity. It has methylol terminating rate up to 95 % and double bond terminating rate up to 93 %, and possesses structure as shown.

Owner:JIANGSU MAYSTA CHEM

Preparation method of high-viscosity organic silicon defoamer

InactiveCN104069654AIncrease the molecular chain lengthGood defoaming performanceFoam dispersion/preventionRoom temperatureOil phase

The invention discloses a preparation method of a high-viscosity organic silicon defoamer. The preparation method comprises the following steps of preparing a silicon grease by using organopolysiloxane, dewatering particles, catalysts and silicon resin under 180-240 DEG C, and stirring and uniformly mixing the silicon grease, polyether modified silicone oil and an emulsifying agent under 72-78 DEG C so as to obtain an oil phase mixture, dissolving a dispersing thickening agent in water; then adding a sodium hydroxide solution to uniformly stir to obtain emulsifying thickening water, adding the emulsifying thickening water into an oil-phase mixture, and carrying out emulsifying stir on the oil-phase mixture under 72-78 DEG C to obtain a coarse emulsifying object; and homogenizing the coarse emulsifying object under 50-55 DEG C to obtain a fine emulsifying object, adding residue water into the fine emulsifying object, stirring and uniformly mixing the fine emulsifying object under room temperature so as to obtain the high-viscosity organic silicon defoamer. The preparation method provided by the invention has the advantages that high-viscosity simethicone is utilized as an emulsifying main raw material, and thus, the obtained high-viscosity organic silicon defoamer has an ultra-strong defoaming speed and an anti-foam effect.

Owner:道尔达(西安)新材料有限公司

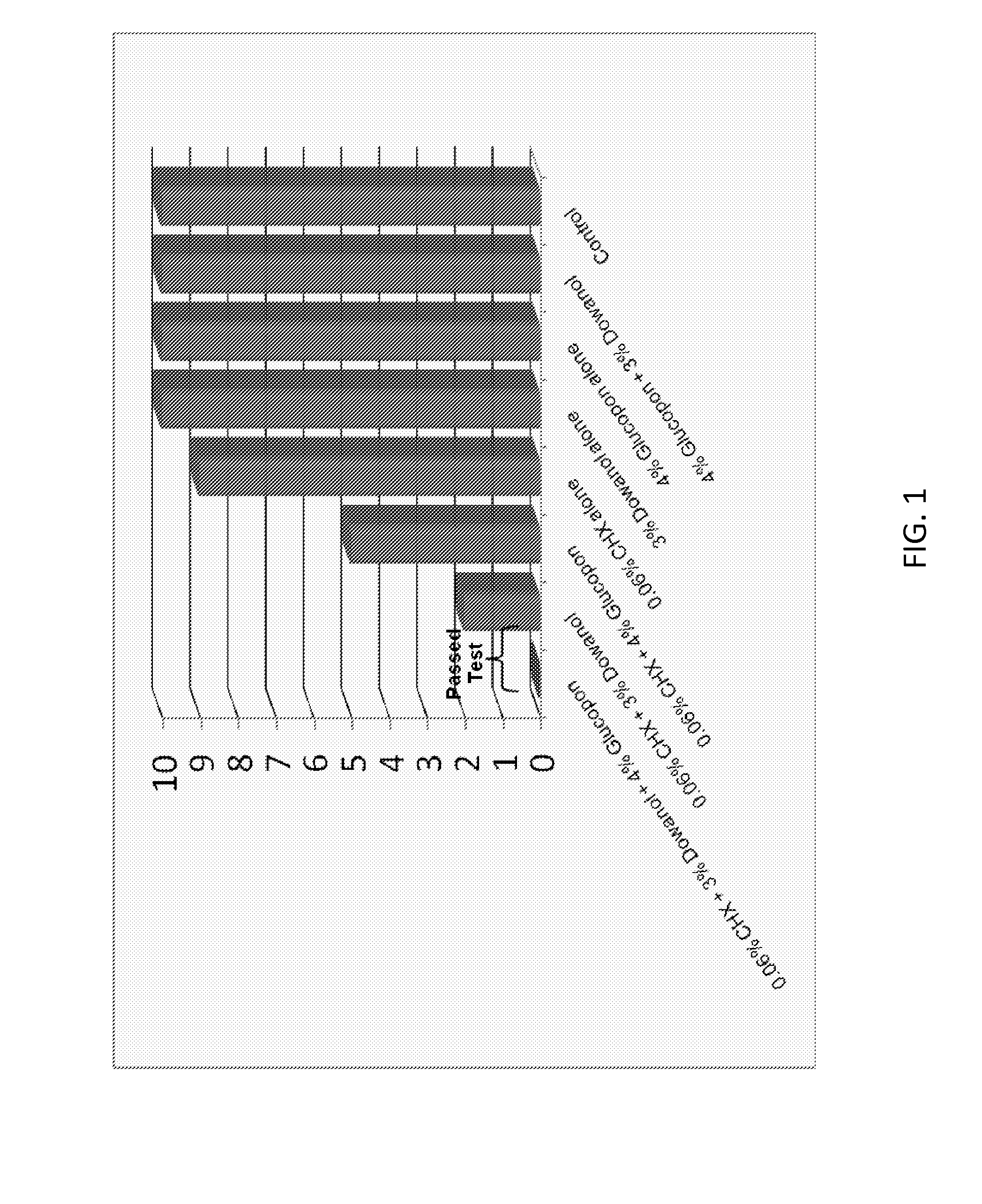

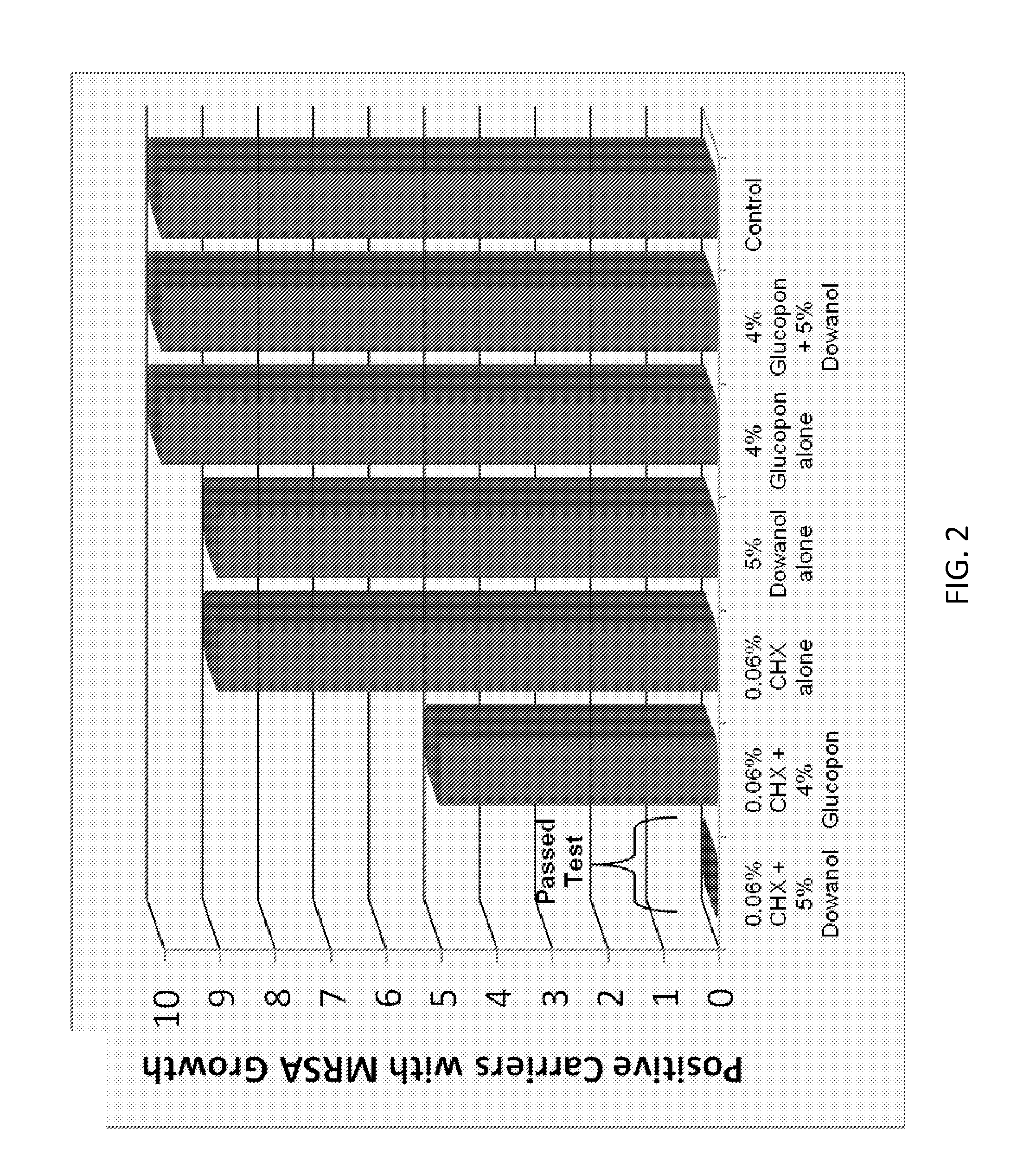

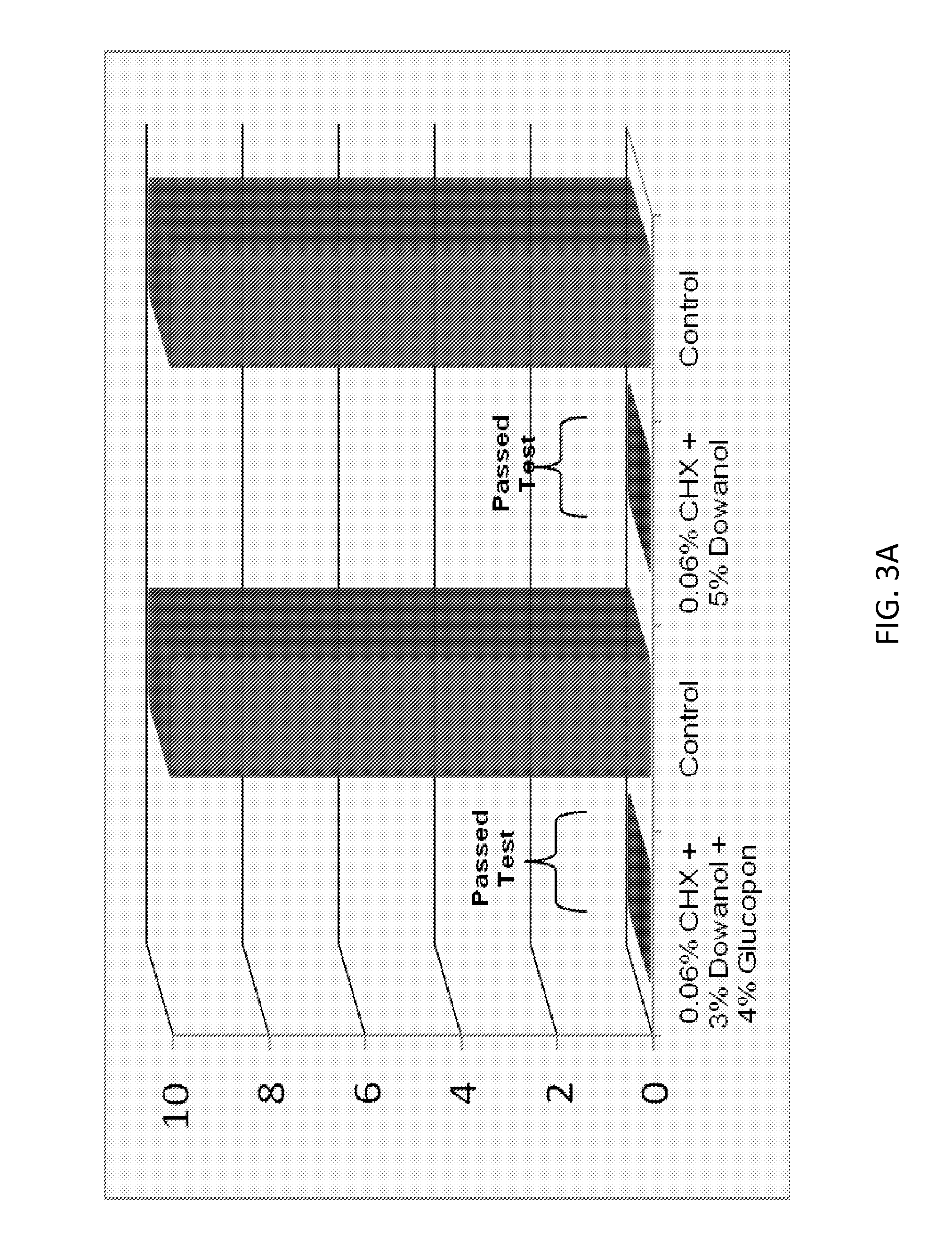

Antimicrobial solutions

ActiveUS20130231302A1Excellent surface tension lowering activityImprove film qualityOrganic active ingredientsBiocideAlcoholMedicine

The present invention provides antimicrobial solutions that in certain cases comprise a biguanide and a glycol ether and, in some cases, optionally also includes combinations of at least one an alcohol, at least one chelator, glycerol, deoxycholate, and / or at least one alkylpolyglucoside. In certain aspects the invention comprises a biguanide and deoxycholate or a combination of chelator, ethanol, and alkylpolyglucoside. Also provided are methods for rapidly killing and / or reducing bacteria, fungi, or virus from surfaces, for example, including surfaces of indwelling medical devices and organic surfaces such as skin and sutures, and inorganic surfaces such as medical equipment, pipelines etc.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

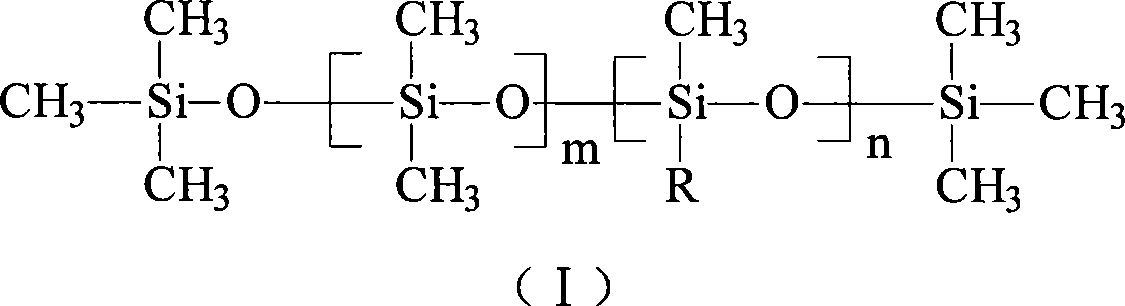

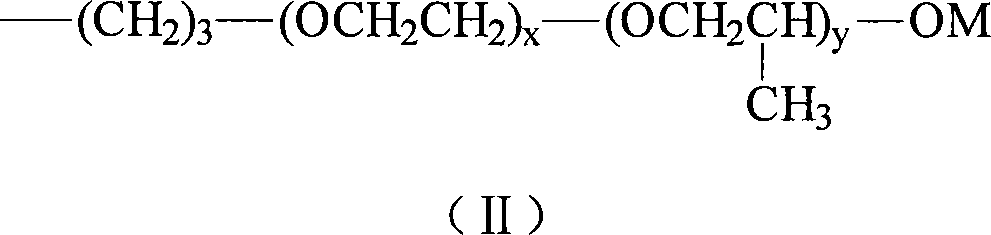

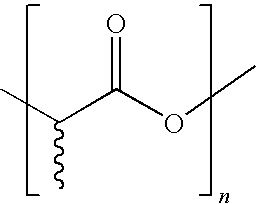

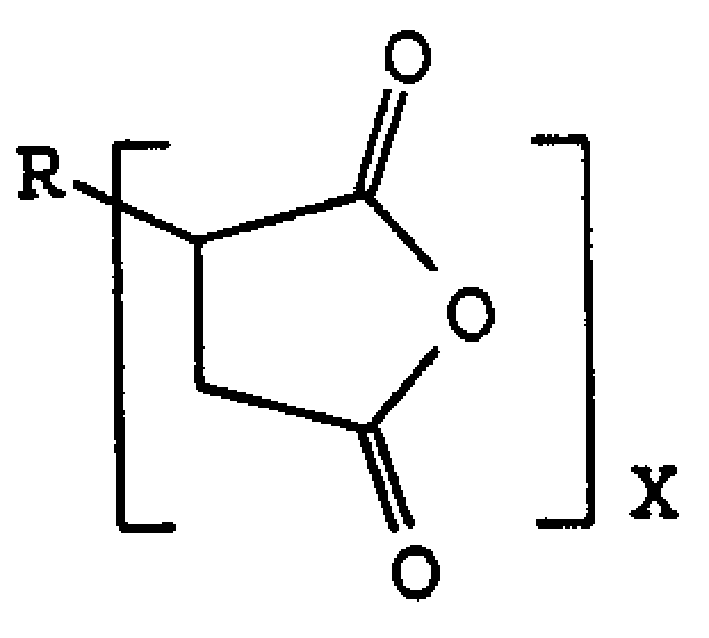

Preparation method of polyether modified polysiloxane foam stabilizer

The invention discloses a preparation method of a polyether modified polysiloxane foam stabilizer and relates to a preparation method of a foam stabilizer for flexible polyurethane foam. The polyether modified polysiloxane foam stabilizer is generated through reaction between allyl epoxyethane and methyloxirane methyl ethers with different molecular weights and silicone oil with low hydrogen content under the conditions that methylbenzene as a solvent and chloroplatinic acid as a catalyst. Through controlling the degree of polymerization of a hydrophilic polyether chain segment and a hydrophobic polysiloxane chain segment of polyether modified polysiloxane, the foam stabilizer has precise hydrophilic-lipophilic balance property, better emulsifying property and a favorable foam stabilizing effect, so that a flexible polyurethane foam mixture has enough stability in a coring stage, a form hole growing stage, a punching stage and an early-stage crosslinking stage, and foam collapse cannot be caused.

Owner:扬州晨化新材料股份有限公司

Oil-in-Water Emulsified Composition, and External Preparation for Skin and Cosmetics Using the Composition

InactiveUS20080311234A1Maintain good propertiesImprove retentionCosmetic preparationsBiocideSurfactinNon ionic

An oil-in-water emulsified composition suitable for external preparation for skin and cosmetic product, which comprised 0.1 to 5% by mass of (A) lipopeptide compound derived from a microorganism such as surfactin and its analogous compound, 0.05 to 1.5% by mass of (B) xanthan gum, 25 to 70% by mass of (C) oil component and (D) water, free from non-ionic surfactants and acrylic water-soluble polymers, and is excellent in feeling upon use, moisture retention, emollient property and stability as well as environmental suitability and safety for living organisms, and external preparation for skin and cosmetic product using the composition.

Owner:SHOWA DENKO KK

Polyacrylamide microsphere deep profile control agent and preparation method and application thereof

ActiveCN108315003AHigh solid contentHigh effective solid contentDrilling compositionMicrosphereEngineering

The invention relates to a polyacrylamide microsphere deep profile control agent and a preparation method thereof, and mainly solves the problems that in the prior art polymer microspheres used for profile control, plugging oil displacement of medium-high-permeability oil reservoirs are poor in effects, deep profile control cannot be realized, and cost is increased by increasing of the concentration of the polymer microspheres. The polyacrylamide microsphere deep profile control agent includes the following components by weight: 0.05-0. 5 parts of a polymer microsphere emulsion, 0.1 to 1 partof an oil-displacing surfactant, and 0 to 99.85 parts of water; wherein the polymer microsphere core-shell structure comprises a core and a shell, the core is a crosslinked polymer gel microsphere containing an ionic monomer structural unit, the shell is a crosslinked polymer gel containing an ionic monomer structural unit different or same in electrical property with the ionic monomer structuralunit in the core. The polyacrylamide microsphere deep profile control agent solves the problems well and can be used for field enhanced oil recovery application such as deep profile control, water shutoff and oil displacement in the medium-high-permeability oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

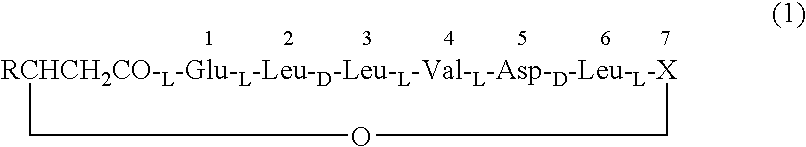

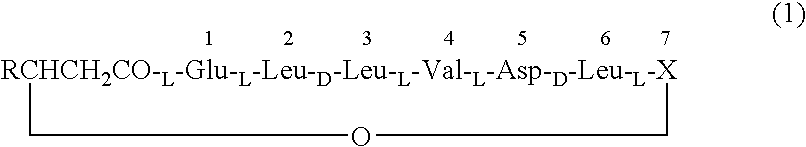

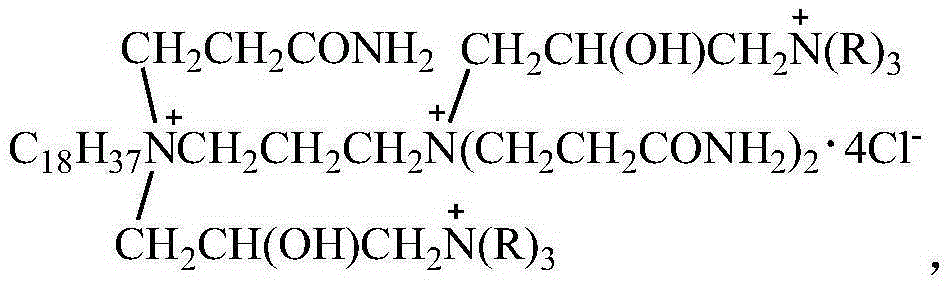

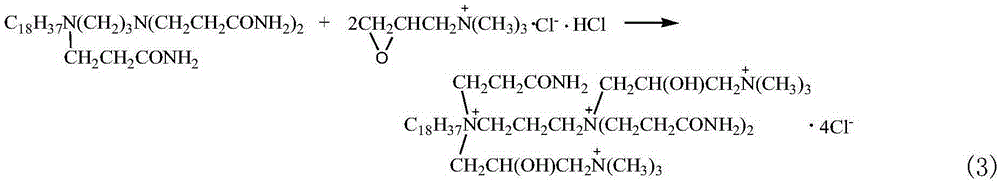

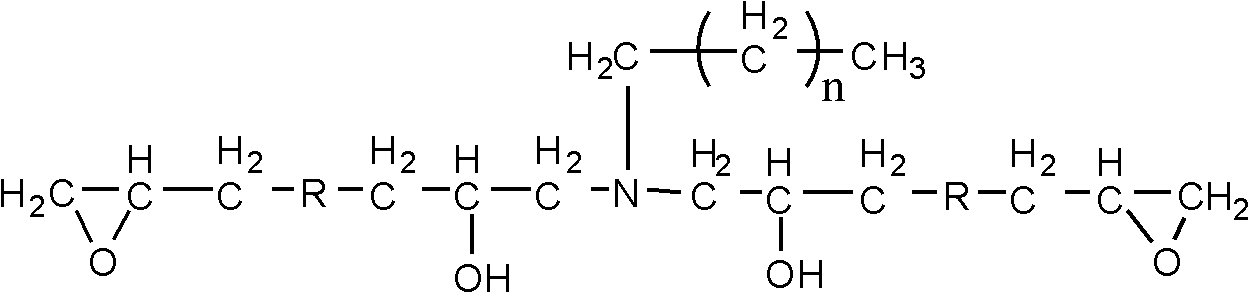

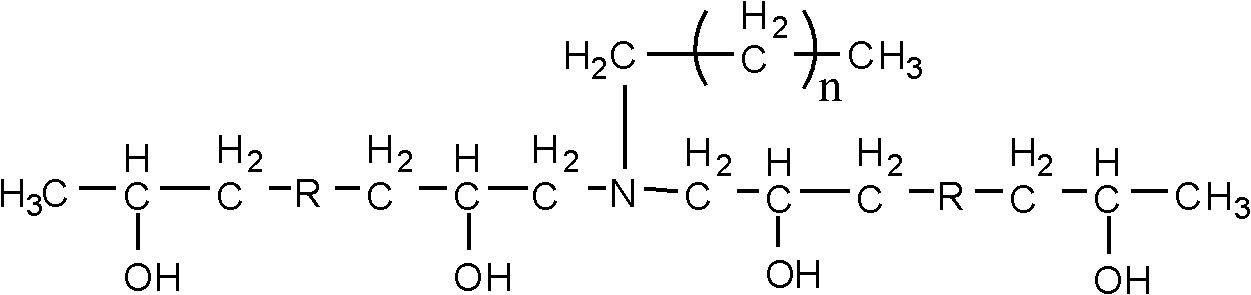

Multi-positive-ion amide-type asphalt emulsifier and preparation method thereof

InactiveCN105399645AGood emulsifying effectImprove hydrophilicityOrganic compound preparationCarboxylic acid amides preparationSolventHigh heat

The present invention discloses a multi-positive-ion amide-type asphalt emulsifier and a preparation method thereof, and the asphalt emulsifier is prepared from raw materials of N-hydrogenated tallow-1,3-propylene diamine, an alcohol solvent, acrylamide, a low-carbon tertiary amine, industrial hydrochloride and epichlorohydrin in the molar ratio of N-hydrogenated tallow-1,3-propylene diamine to alcohol solvent to acrylamide to low-carbon tertiary amine to industrial hydrochloride to epichlorohydrin of 1mol: (5.00-11.00) mol: (3.00-3.10) mol: (2.02-2.10) mol: (2.02-2.10) mol: (2.02-2.08) mol. The alcohol solvent is ethanol, methanol or isopropanol. The low-carbon tertiary amine is a trimethylamine aqueous solution, triethylamine or triethanolamine. The asphalt emulsifier synthetic raw materials are readily available, production cost is low, a process is simple, and a high temperature reaction is not required. The asphalt emulsifier can emulsify a variety of different types of asphalt, the prepared emulsified asphalt is fine, uniform, and good in storage stability, and positive-ion-type emulsified asphalt can be prepared.

Owner:SHANDONG UNIV

Wet process refractory mortar

The invention relates to wet process refractory mortar which comprises the following raw materials by weight: 25-50 parts of white fused alumina powder with the granularity of not more than 180 meshes, 40-65 parts of the white fused alumina powder with the granularity of not more than 320 meshes, 1-5 parts of phosphate binder, 1-4 parts of plasticizer, 1-3 parts of water retention agent, 0.1-1 part of resin type preservative, 0.05-0.5 part of preservative agent and 0-10 parts of Cr2O3 powder with the granularity of not more than 320 meshes, the wet process refractory mortar is prepared by uniformly stirring the raw materials, adding 12-18 parts of water, continuously uniformly stirring, and then loading into a plastic bag for sealing and preserving, and the preservation period is a year and a half to two years.

Owner:PUYANG REFRACTORIES GRP CO LTD

Fabric one-bath deoiling agent

ActiveCN101629130AHigh affinityGood emulsificationNon-ionic surface-active compoundsDry-cleaning apparatus for textilesFiberPolymer science

The invention relates to a fabric deoiling agent, in particular to a fabric one-bath deoiling agent not only suitable for the single deoiling treatment of fabrics, such as terylene, chinlon, cotton, and the like, but also particularly suitable for treating chemical fiber fabrics, such as the terylene, the chinlon, and the like by a deoiling dyeing one-bath method. The invention provides the fabric one-bath deoiling agent with favorable deoiling effect under acidic conditions and an application thereof. The fabric one-bath deoiling agent comprises the following ingredients in percentage by weight: 10-60 polyoxyethylene alkyl amine, 5-40 alkyl sulfonate, 10-50 sulfate surface active agent or / and phosphate salt surface active agent and the balance of water. The fabric one-bath deoiling agent can be used for treating the fabrics of the terylene, the chinlon, the cotton, and the like by the deoiling dyeing one-bath method.

Owner:福建省晋江新德美化工有限公司

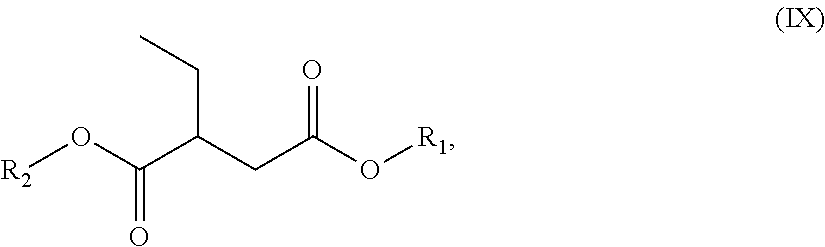

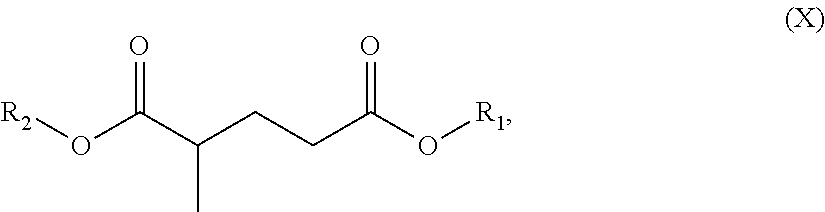

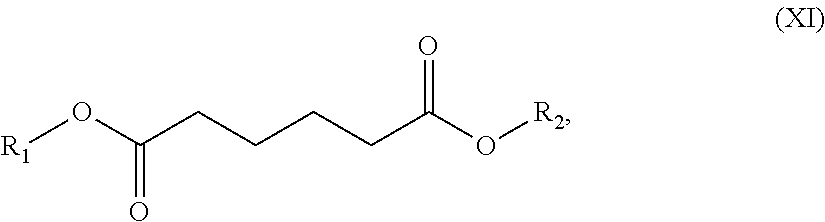

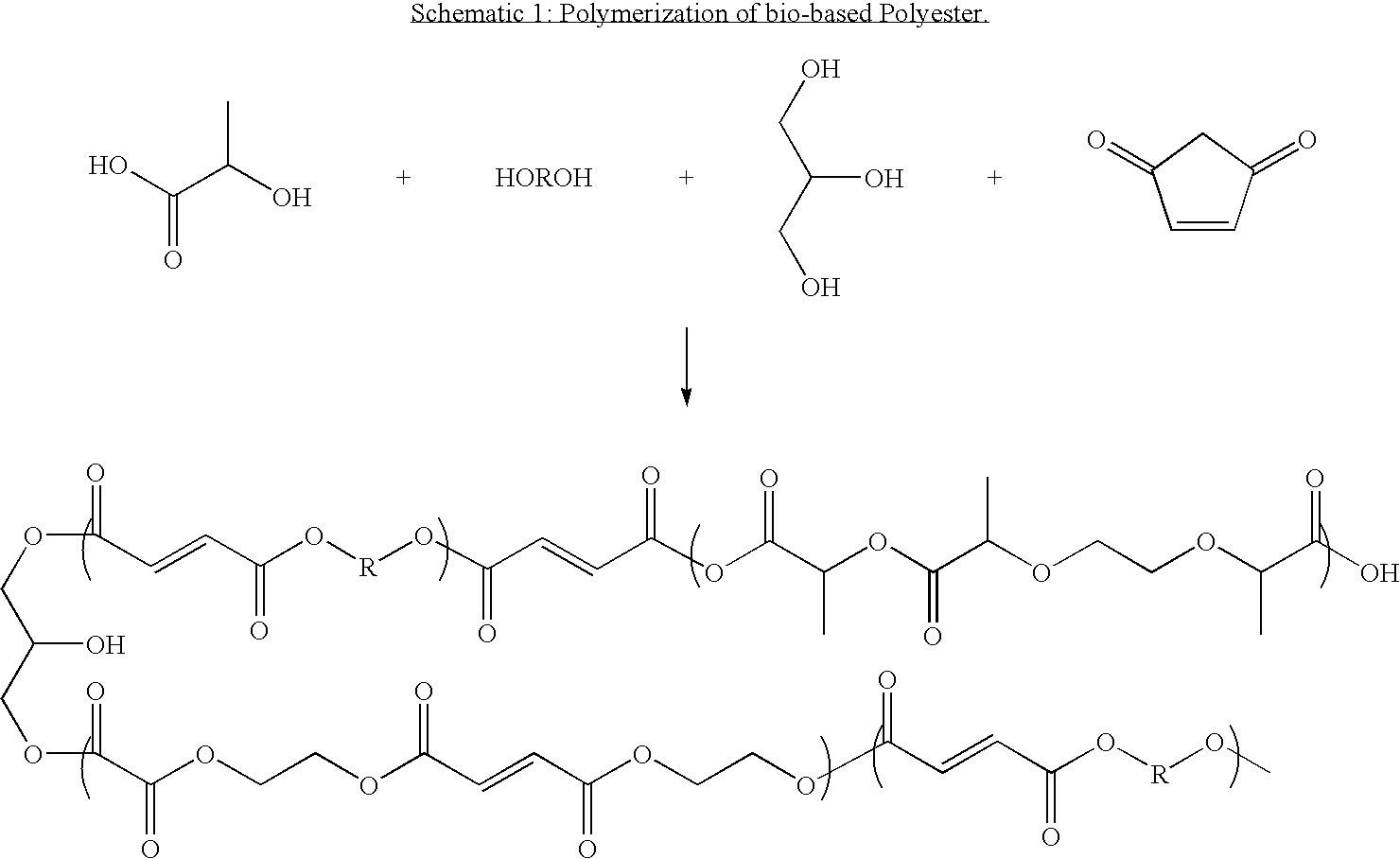

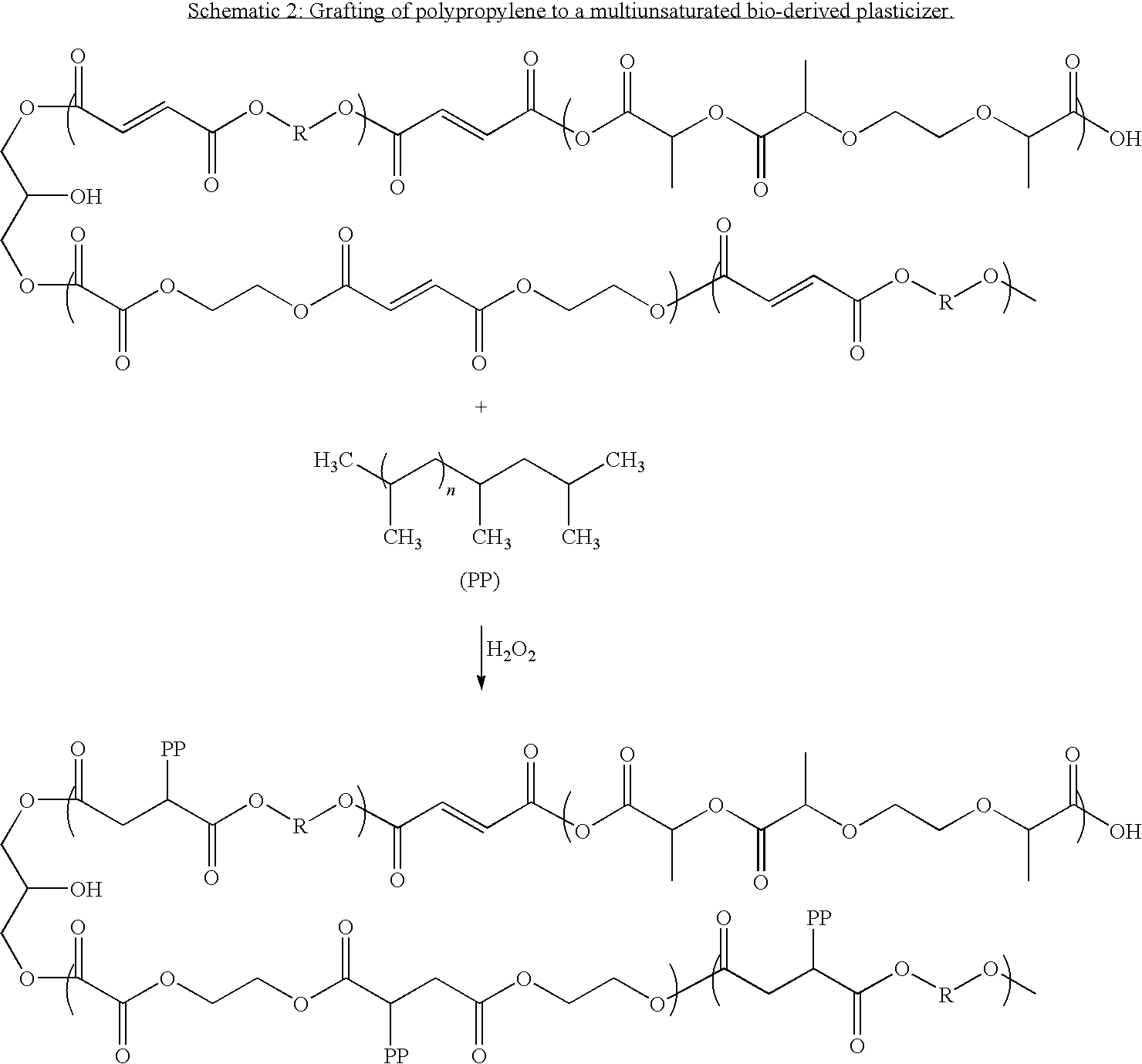

Bioderived plasticizer for biopolymers

A bioderived plasticizer for biopolymers includes a compatibilizing unit and a polyester plasticizing unit. The plasticizer improves the flexibility of biopolymers while not adversely affecting their modulus. The compatibilizing unit renders the plasticizer more miscible with the desired base biopolymer and includes a lower alkyl (C3 to C7) organic acid. The polyester plasticizing unit is formed from monomers comprising a multifunctional alcohol and an aliphatic anhydride or its equivalent dicarboxylic acid and ester derivatives. The polyester plasticizing unit may optionally include one or more difunctional alcohols in combination with the multifunctional alcohol. The resulting the bioderived plasticizer has a low glass transition temperature (Tg), preferably between −20° C. to 30° C. The plasticizer is preferably amorphous.

Owner:LAPOL

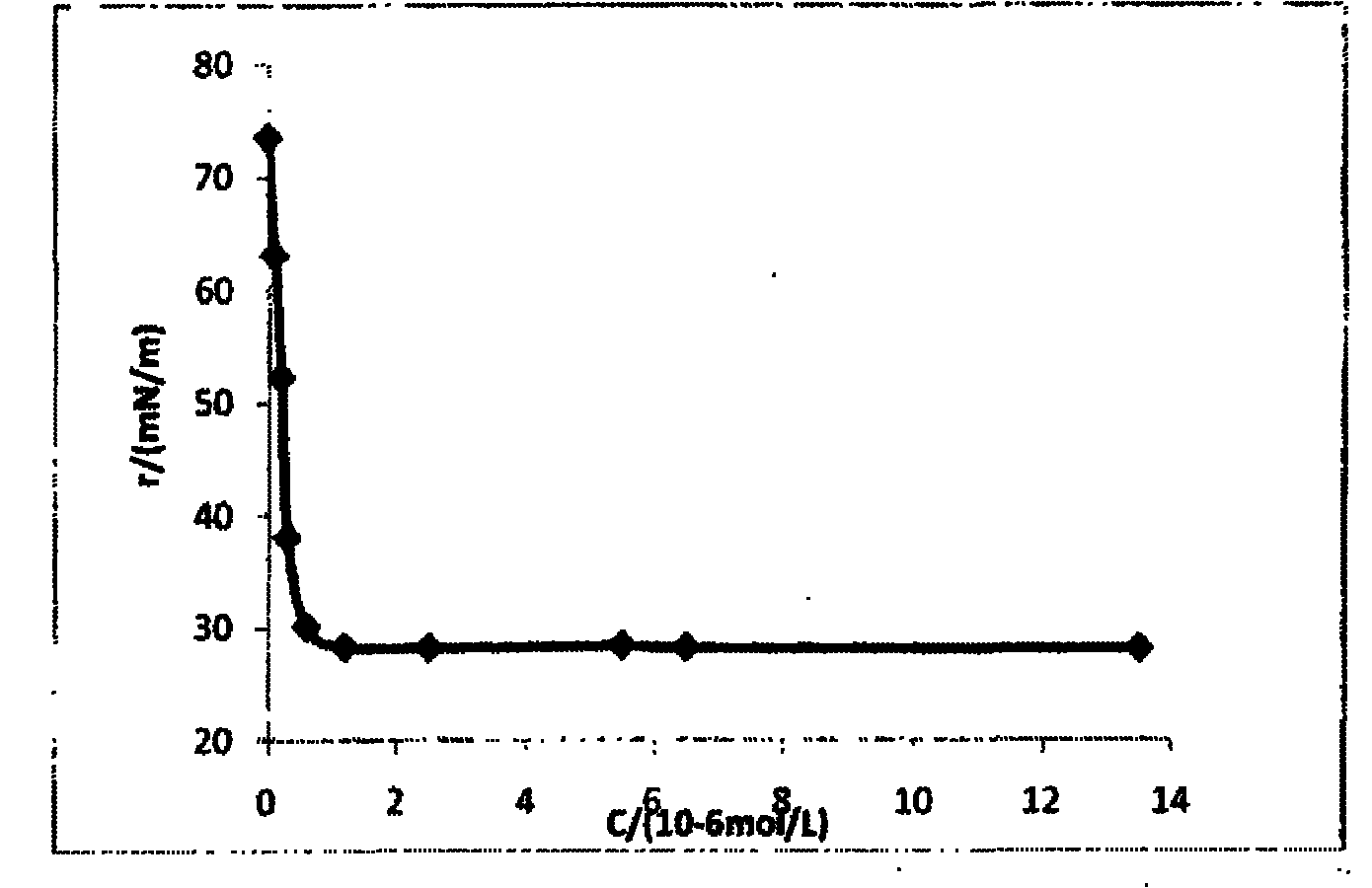

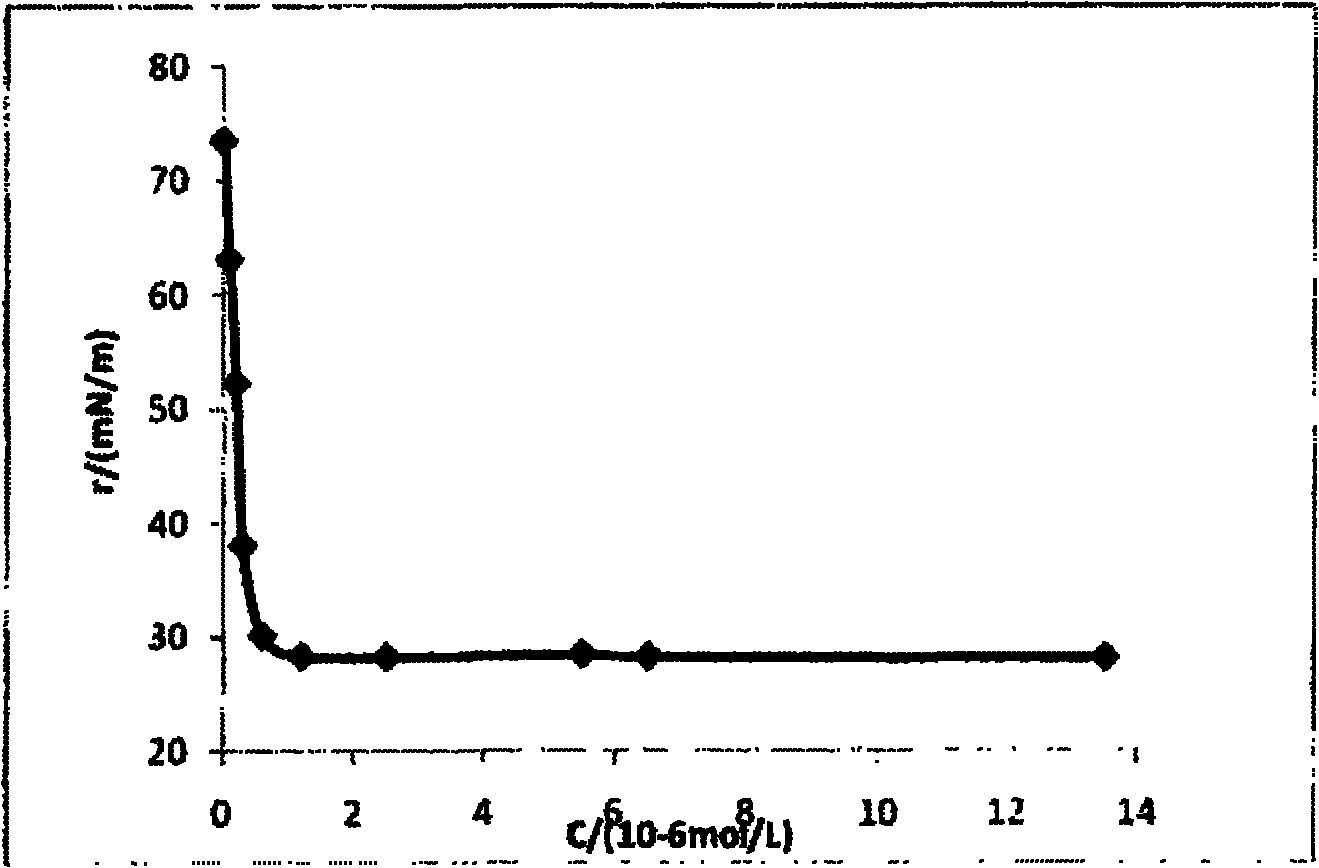

Method for preparing rosin-based surfactant

InactiveCN101831066AImprove surface activityRaw materials are cheap and easy to getCosmetic preparationsBiocideCritical micelle concentrationPolymer science

The invention discloses a method for preparing a rosin-based surfactant, which comprises the following steps: 1, adding a catalyst in an amount of 0.1 to 1.0 percent based on the mass of the rosin or a rosin derivative and polyethylene glycol or alkylene oxide in an amount of 2 to 3,000 percent based on the mass of the rosin or a rosin derivative into the molten rosin or a rosin derivative to allow the polyethylene glycol or alkylene oxide to react with the rosin or a rosin derivative at the temperature of 230 to 290 DEG C for 2 to 5 hours; 2, perform reduced pressure vacuumization and keeping a vacuum degree of less than or equal to 2kPa for 5 to 60 minutes to remove low-boiling-point substances; and 3, decreasing the temperature to 60 to 120 DEG C, adding antioxygen in an amount of 0.1 to 1 percent based on the mass of the rosin or a rosin derivative and an esterifying agent in an amount of 5 to 12 percent based on the mass of the rosin or a rosin derivative in batch into the product obtained by the step, performing a reaction at the temperature of 65 to 110 DEG C for 2 to 6 hours, and discharging the resulting material to obtain the rosin-based surfactant. The product has low surface tension, low critical micelle concentration, high emulsifying performance and low Krafft point and can be used as an emulsifier, a dispersant and an oil field assistant.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

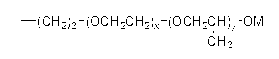

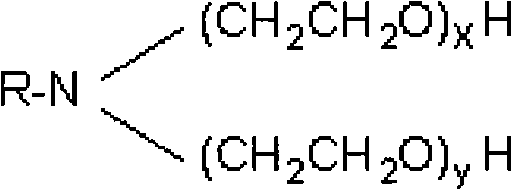

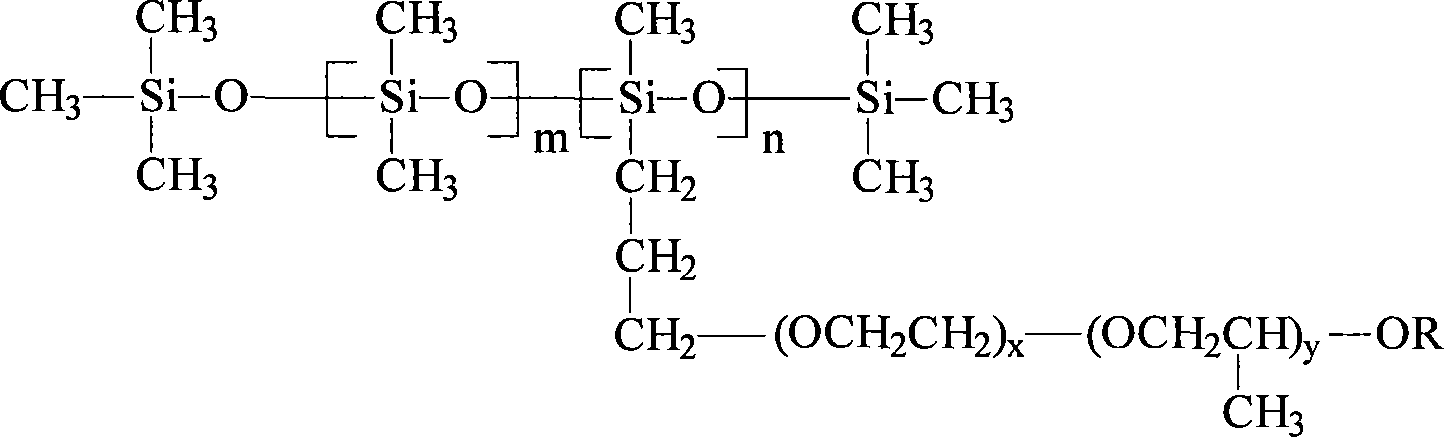

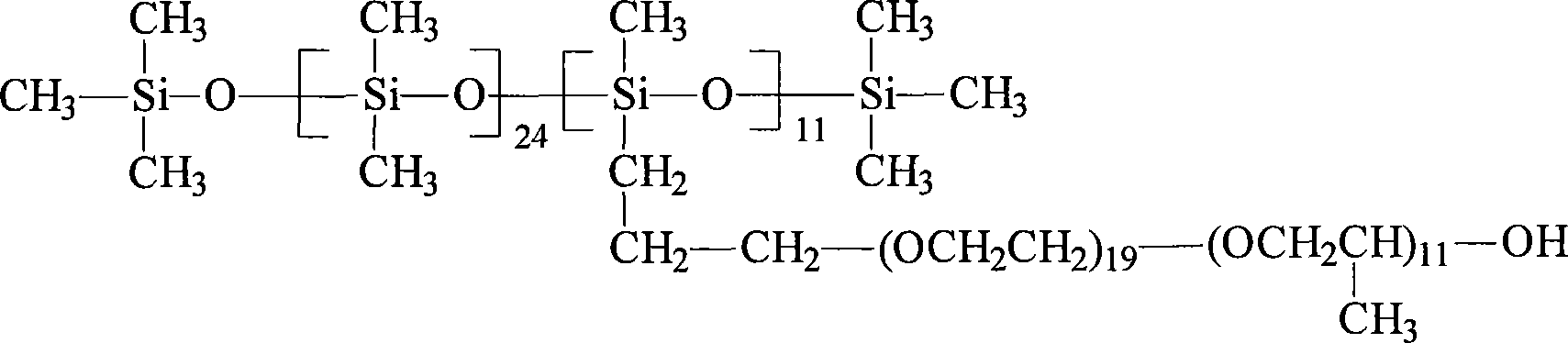

Polyurethane foam stabilizer with low density and low thermal conductivity factor and preparation method thereof

The invention discloses a low-density and low thermal-conduction-index polyurethane foam stabilizer and a preparation method thereof. The stabilizer can be widely used in polyurethane blowing technique, and enable the thermal conduction index of the pentane-blowing polyurethane foam to be lowered down to 0.0195-0.0200W / m.K, and has excellent functions of heat protection and heat preservation. The low-density and low thermal-conduction-index polyurethane foam stabilizer of the invention is provided with the structures: wherein, the figure of m is 10-80, the figure of n is 1-10, the figure of x is 10-70, the figure of y is 0-30, and m plus n is 11-90, x plus y is 10-100; R can be paraffin, radical aromatic, acyloxy or hydrogen atom that contains 1-4 carbon atoms.

Owner:JIANGSU MAYSTA CHEM

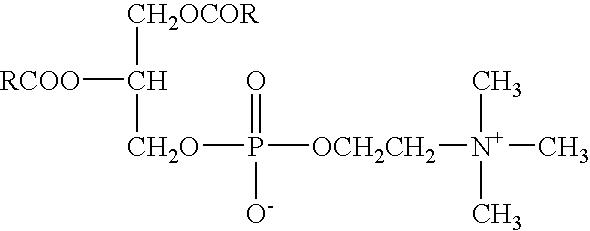

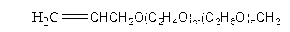

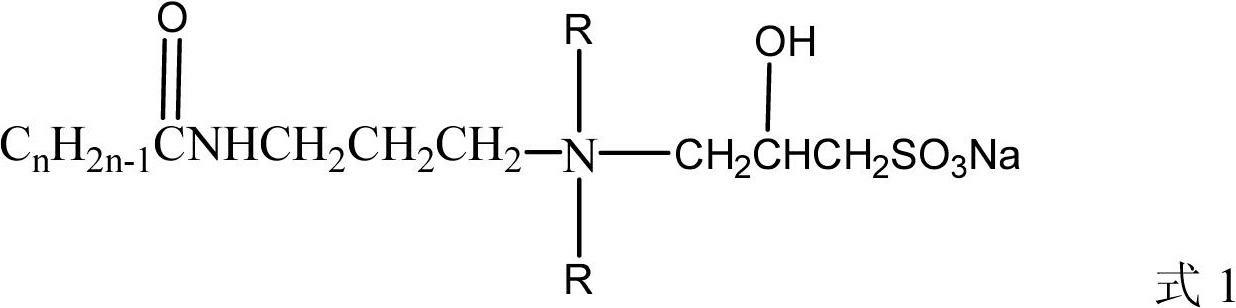

Emulsifier utilized for emulsion explosive and its preparation method

InactiveCN1415588AGood emulsificationEasy to emulsifyTransportation and packagingMixingEmulsion explosiveStructural formula

An emulsifier for preparing emusified explosive with long storage time is prepared by the reaction of acylating agent on alkylol amine. Its advantage is high emulsifying performance. Its structural formula is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

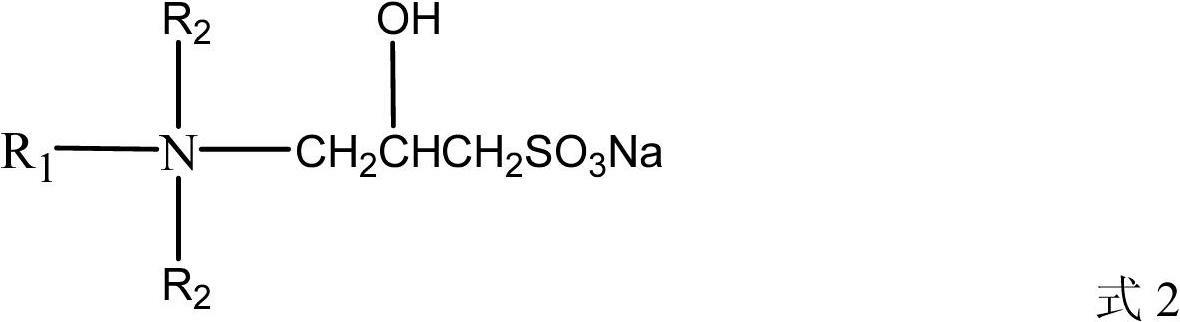

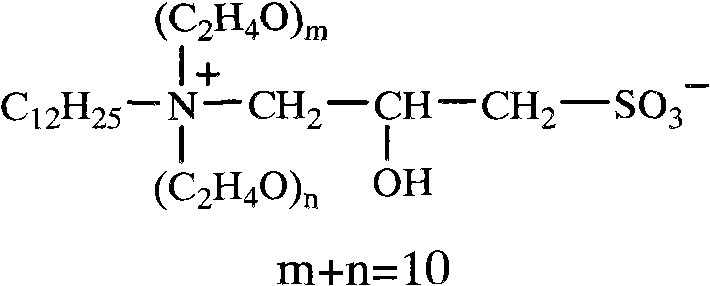

Binary alkali-free complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application thereof

ActiveCN102690644ALow costOvercoming the defect of interfacial tension recoveryFluid removalDrilling compositionAlkali freeMass ratio

The invention relates to a binary alkali-free complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application of the composition. The binary alkali-free complex composition for flooding is composed of the following components measured by total weight of the binary alkali-free complex composition for flooding: 0.05-0.3% of complex surfactants, 0.1-0.25% of polymers and the balance of water; wherein the compound surfactants are composed of two kinds of hydroxysulfobetaine with different structures and a mass ratio of 9: 1-4: 6. The invention further provides the application of the binary alkali-free complex composition for flooding in tertiary oil recovery. According to the binary alkali-free complex flooding composition provided by the invention, interface performance exceeds the performance of the composition simply utilizing erucamide hydroxysulfobetaine as surfactants to achieve ultralow interfacial tension, and at the same time, the interfacial tension of the composition in a long term can be kept at an ultralow state; and oil recovery cost also can be reduced.

Owner:PETROCHINA CO LTD

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045AGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyRoad surface

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

Preparation method for oil-in-water type soybean isolated protein

InactiveCN101317623AAvoid excessive protein denaturationHigh protein recoveryProtein composition from vegetable seedsFood preparationProteolysisOil in water

The invention discloses a preparation method for emulsion-typed soybean protein isolate, which comprises the steps as follows: pre-crushed low-temperature defatted soybean flour (DSF) is taken as raw material and mixed with deionized water with the water / material ratio of 5-20w / w, is heated to 40-60 DEG C under alkali condition and leached for 20-30min so as to lead the soybean meal to expand by absorbing water; Acalase alkaline protease is added to carry out the enzymolysis; the bottom residue is removed by centrifuging so as to obtain soybean proteolysis supernatant; furthermore, the soybean proteolysis supernatant is homogenized and acidity is adjusted to PH 4.5; the protein in the soybean proteolysis supernatant is deposited and centrifuged for 10-20min; the obtained deposition is mixed with the deionized water by the water / material ratio of 3-5w / w; the mixed solution is adjusted to neutral by adding NaOH and frozen dryly or sprayed dryly so as to obtain the emulsion-typed soybean protein isolate. The process of the invention is simple and reliable, which remarkably improves the emulsion performance of the soybean protein.

Owner:SOUTH CHINA UNIV OF TECH

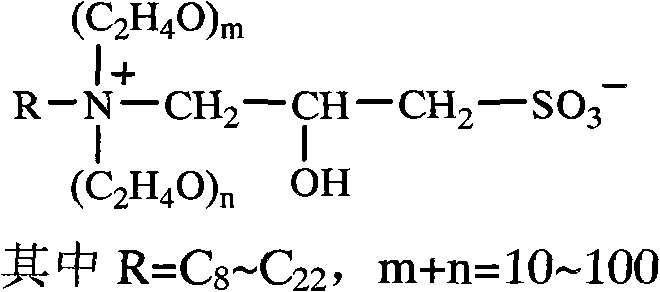

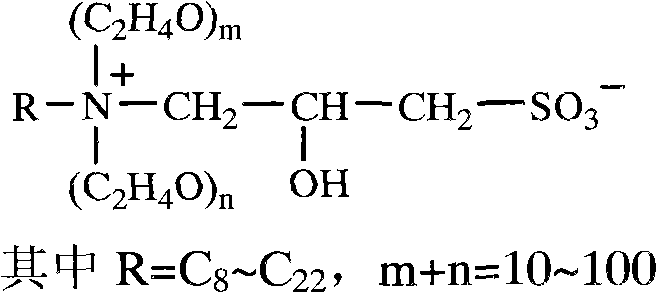

Method for preparing gydroxysulfobetaine amphoteric surface active agent including polyether chain segment

InactiveCN102304067AHigh selectivityReduce pollutionTransportation and packagingSulfonic acids salts preparationSolubilityFatty amine

The invention relates to a method for preparing a gydroxysulfobetaine amphoteric surface active agent including a polyether chain segment, belonging to the technical field of preparation of surface active agents. The gydroxysulfobetaine amphoteric surface active agent including the polyether chain segment is prepared by taking fatty amine polyoxyethylene ether and 3-chlorine-2-hydroxyl propane sodium sulfonate as raw materials. The gydroxysulfobetaine amphoteric surface active agent including the polyether chain segment is shown as a chemical structural formula in the specification. According to the gydroxysulfobetaine amphoteric surface active agent including the polyether chain segment synthesized by using the method disclosed by the invention, three hydrophilic groups consisting of polyoxyethenyl, quaternary ammonium salt and sulfonyl and hydrophobic alkyl are included; the gydroxysulfobetaine amphoteric surface active agent including the polyether chain segment has the two good surface activities of the non-ionic and amphoteric surface active agent; in addition, besides the good performance of the traditional gydroxysulfobetaine amphoteric surface active agent, the performances, such as water solubility, detergency, emulsifiability, dispersibility, solubilising power and the like, are improved obviously.

Owner:HENAN TITANING CHEM TECH

Pure plant type antibacterial cleanser and preparation method thereof

ActiveCN102559408AImprove antibacterial and antiviral effectsNo stimulationAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsSolubilityIrritation

The invention provides a pure plant type antibacterial cleanser and a preparation method thereof. The cleanser is prepared from a Chinese medicinal plant preparation, alkyl polyglucoside, coco glucoside amphoteric surfactant, polyol, acidity regulator, flavor, and deionized water. The pure plant preparation is used as the raw material, so the pure plant type antibacterial cleanser is mild in usability, low in irritation and high in efficiency, and can be used safely, and used for sterilizing the surfaces of household rooms, clothes, kitchen ware, gymnasium equipment, infant toys and the like. According to the cleanser, the raw material system has a synergistic effect, and the pure plant type antibacterial cleanser is high in stability and water solubility, low in toxicity, can be washed easily, does not have irritation, and can be applied to the surfaces of various objects.

Owner:北京绿伞科技股份有限公司

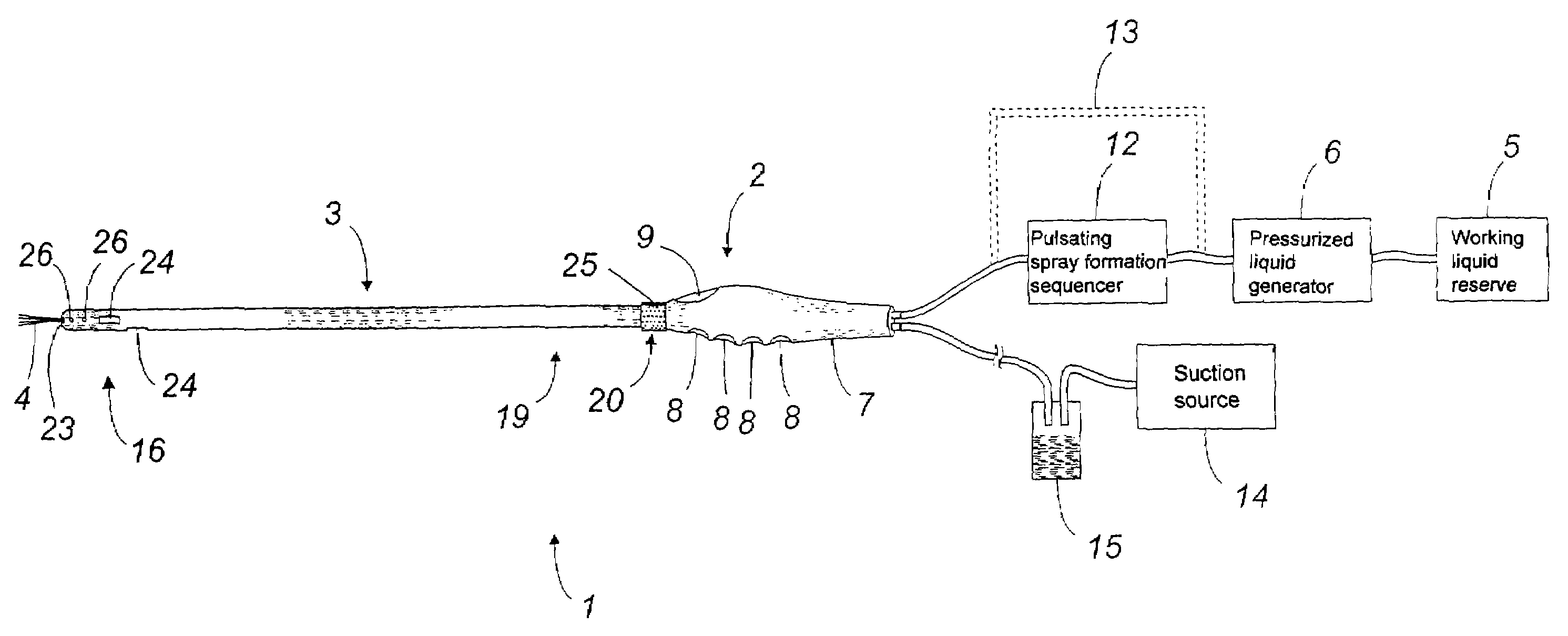

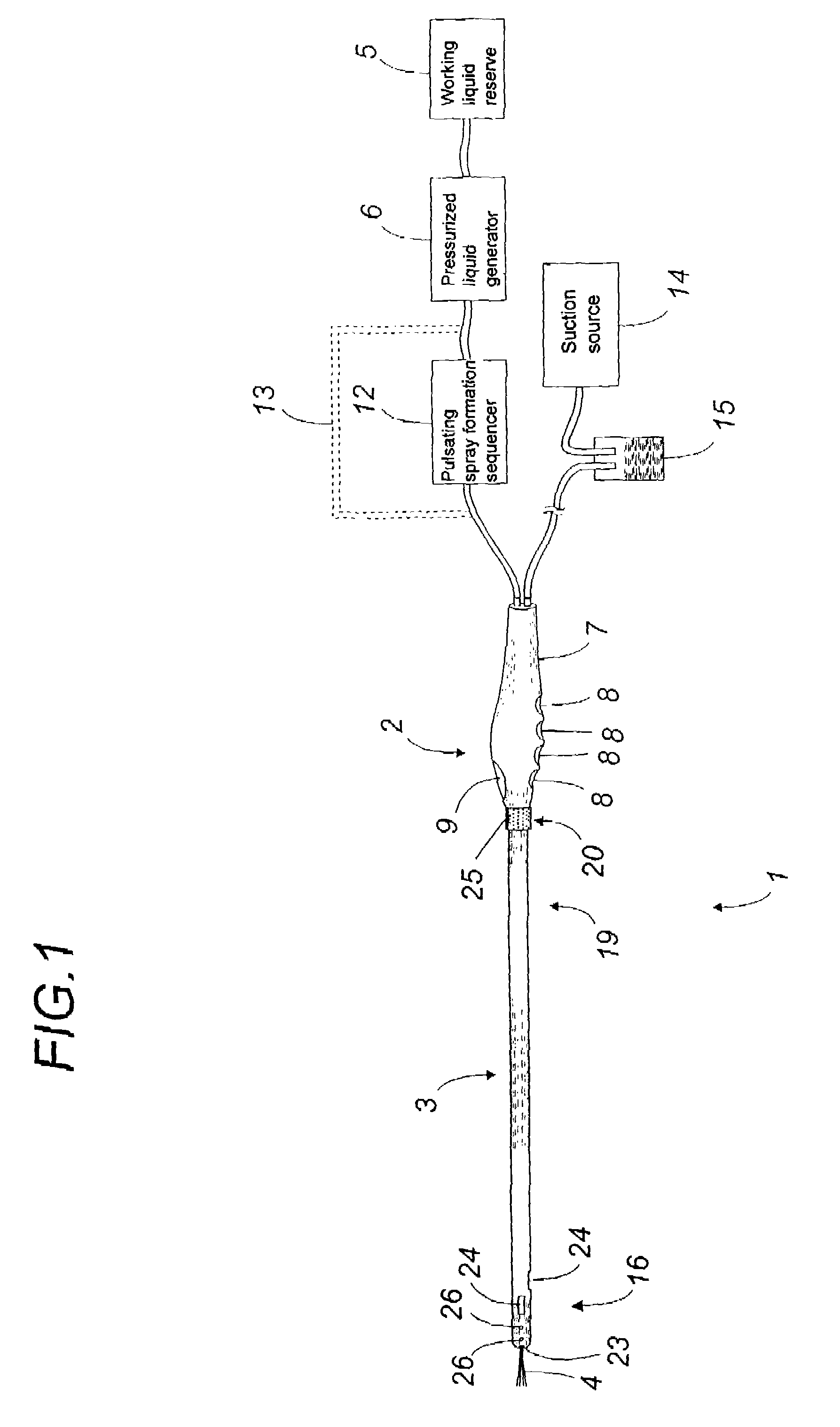

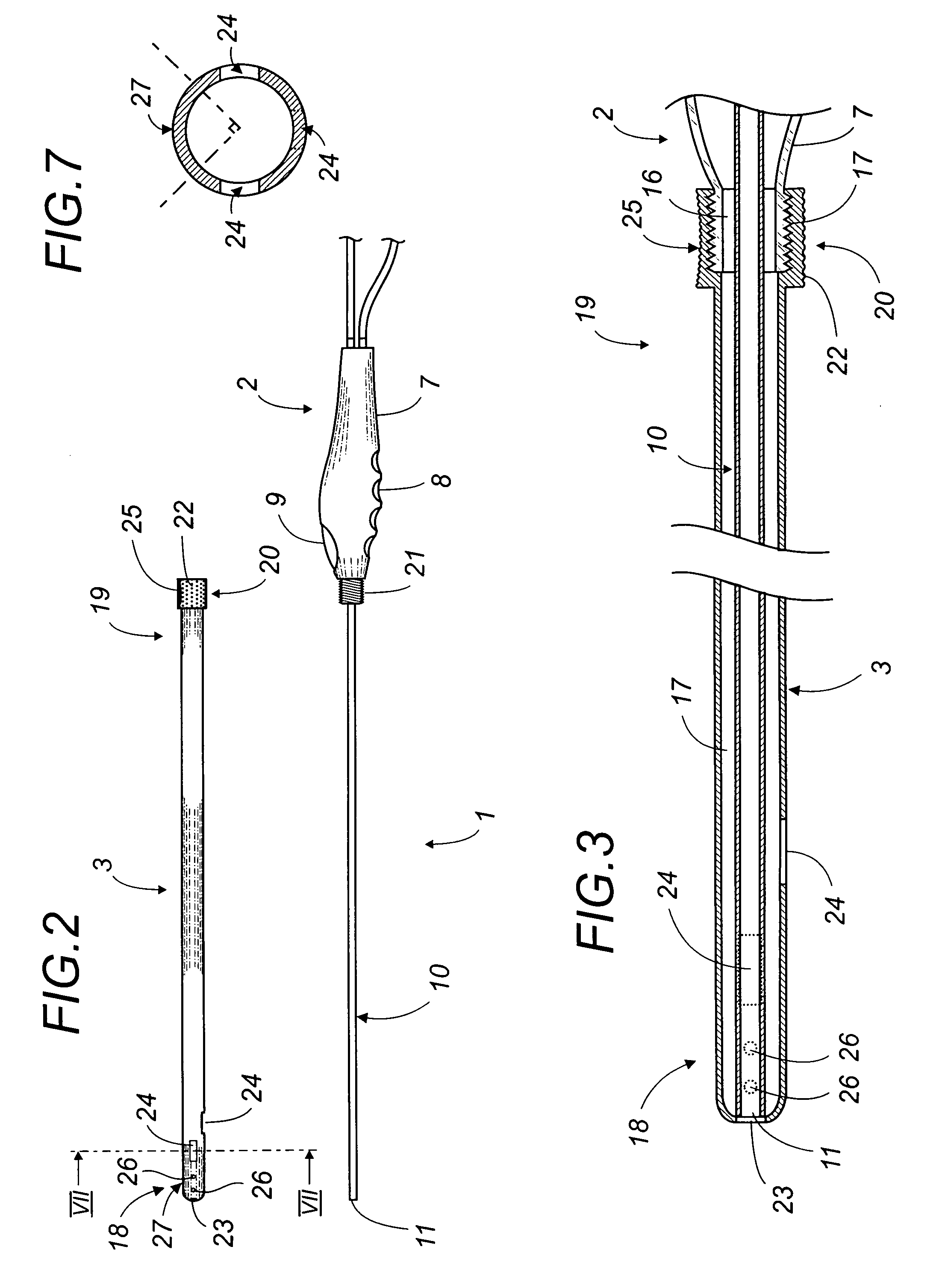

Liposuction apparatus with pressurized liquid spray and liposuction method using the apparatus

InactiveUS7056315B2Less blood lossComfortable handlingElectrotherapyInfusion syringesProximateLiposuction

The liposuction apparatus (1) comprises in combination a tubular canula (3) having at its distal extremity (18) one or more suction orifices (24) and connected at its proximate extremity (19) to a suction source (14) in communication with these orifices, and a hand piece (2) delivering a spray of working liquid (4) under pressure. The hand piece delivers the spray of liquid under pressure using a conduit opening into an ejection orifice which, when the canula is attached to the hand piece, is located opposite an ejection orifice in the canula located at its distal extremity. A liposuction method using the apparatus is also taught. This invention is of interest to manufacturers and users of surgical equipment.

Owner:ESCHMANN HLDG LTD

Silk afterfinishing compound softening agent and preparation method

The invention relates to a silk afterfinishing compound softening agent and a preparation method. The softening agent is nontoxic, nonirritating, very low in yellowing possibility, good in re-wettability, biodegradable, and completely harmless to an environment. The method comprises the steps that required water temperature is selected between 0 DEG C and 100 DEG C according to used different quaternization raw materials; 1-30% of ester quaternary ammonium salt is added to water, and stirred; and then 1-30% of hydrophilic amino silicone oil is added and stirred uniformly after ester quaternary ammonium salt is completely dissolved or dispersed in the water and forms a uniform white viscous emulsion. The softening agent has the advantages that 1, the softening agent adopts raw animal or plant synthetic chemicals as main components of the softening agent, and is completely nontoxic, nonirritating, very low in yellowing possibility, and good in re-wettability, and 2, the softening agent is biodegradable and completely harmless to the environment, and is an ideal silk fabric afterfinishing softening agent.

Owner:ZHEJIANG HSDP SILK TECH

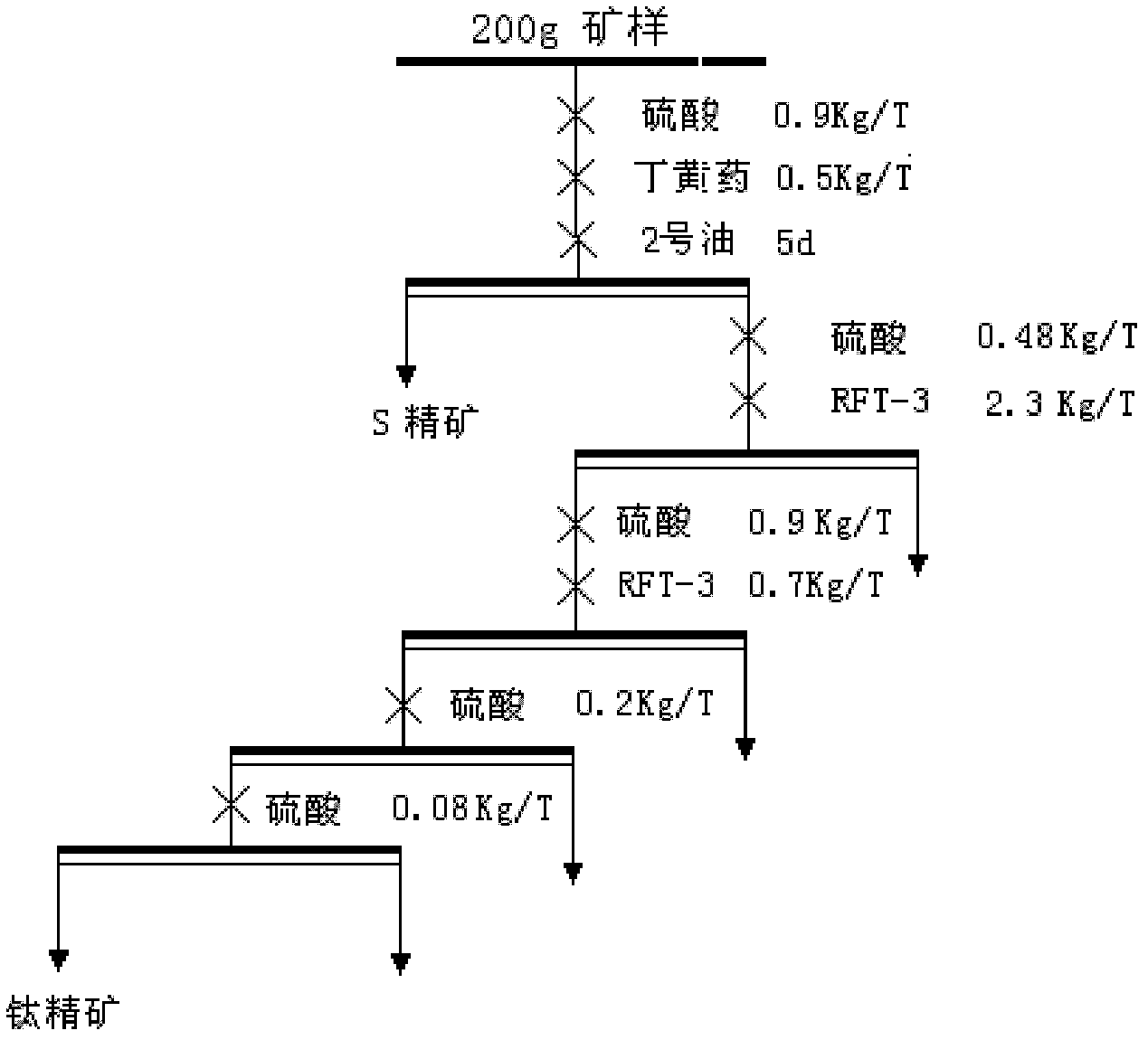

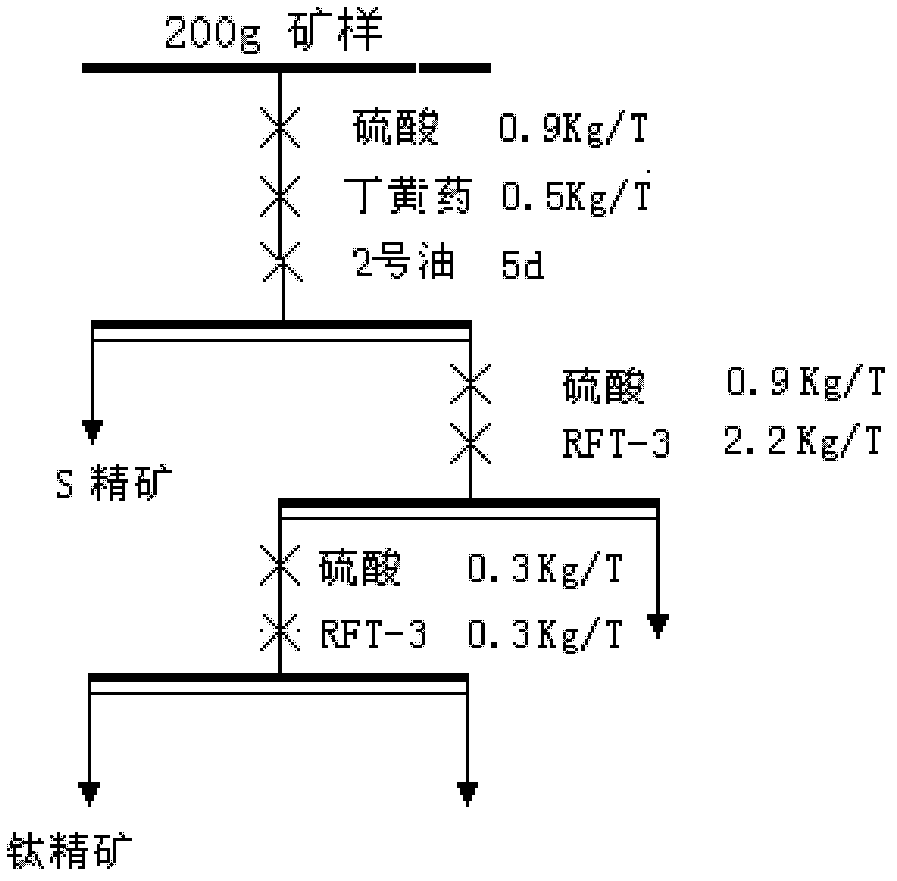

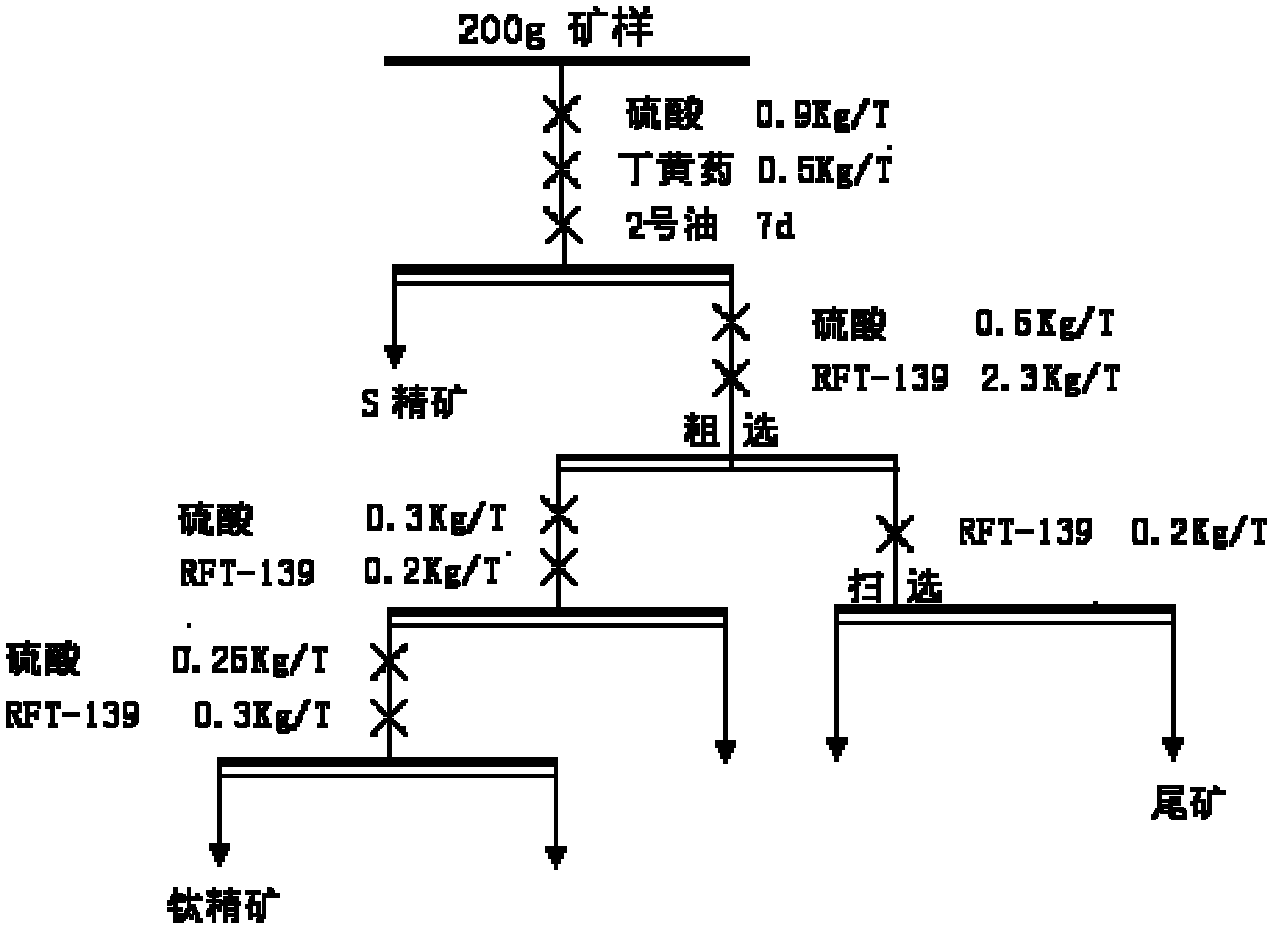

Collector for floating ilmenite and preparation method thereof

The invention discloses a collector for floating ilmenite and a preparation method thereof. The collector is mainly prepared from the following components by mass percent: 40-60% of peroxide fatty acid soup, 5-15% of emulsifiers, 10-30% of oil substance and the balance of water. The preparation method comprises the following steps: mixing the components uniformly according to the mass percent ratio, throwing the mixture into a reaction kettle and stirring the mixture for 0.5-1 hour, thus obtaining the collector. The collector has the advantages of small amount, low cost, strong collecting capability, safety, nontoxicity, capability of reducing the amount of media such as modifiers.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

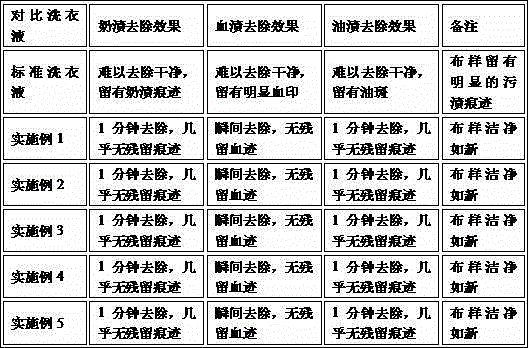

Protease super-concentrated laundry detergent and preparation method thereof

ActiveCN105062703AMild in natureGentle to the touchOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentBiology

The present invention discloses a protease super-concentrated laundry detergent, which mainly comprises, by mass, 3-38% of a non-ionic surfactant, 1-22% of an anionic surfactant, 0.1-1% of protease, 0.1-2% of triethanolamine, 0.1-2% of sodium citrate, 0.1-2% of refined salt and 60-70% of deionized water, wherein the protease comprises biological protease and compound protease. According to the present invention, the protease super-concentrated laundry detergent product is neutral and has characteristics of mild nature, no stimulation, soft hand-feeling, no alkaline residue after washing, no skin allergy and other symptoms, no damage on fabrics, water solubility, easy use, easy use amount control, easy storage, and easy use; and the process operation of the preparation method is simple, and the method is easily subjected to industrial production.

Owner:DONGGUAN XIANGYU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com