Emulsifier utilized for emulsion explosive and its preparation method

A technology of emulsified explosives and emulsifiers, which is applied in chemical instruments and methods, non-explosive/non-thermal agent components, explosives, etc. It can solve the problems of high emulsification conditions and poor storage stability of emulsified explosives, and achieve good emulsification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

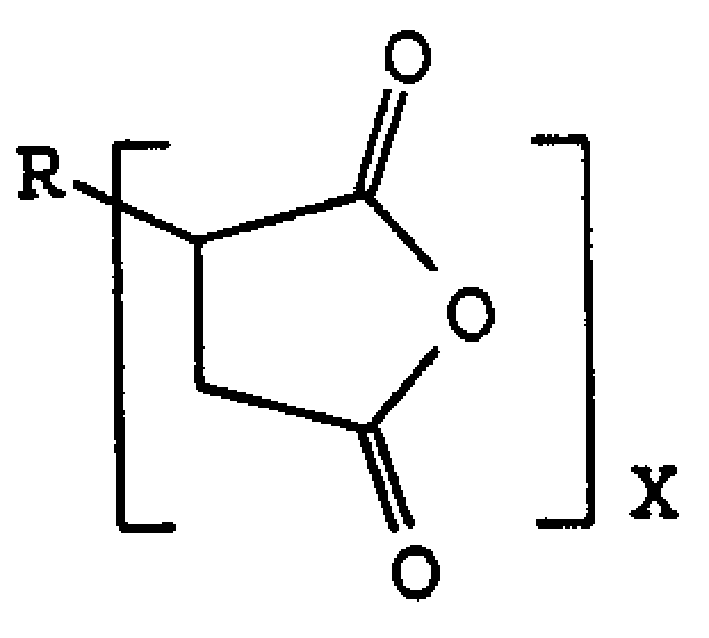

Image

Examples

example 1

[0021] Put 100 g of polyisobutene with terminal olefin content of number average molecular weight Mn=1000 (BASF company product, terminal olefin content is 85%) into a closed autoclave, feed nitrogen, then feed air oxidation at 150° C. for 2 hours, and react The air partial pressure in the kettle is 0.04MPa. Then, the molar ratio of polyisobutylene to maleic anhydride is 1:2.4, maleic anhydride is added at 150°C, the reaction temperature rises to 210°C within 2 hours, and the reaction is continued for 5 hours. Then add 2% tert-butyl peroxide, react at 150° C. for 1 hour, remove unreacted maleic anhydride to obtain acylating agent A, and the degree of substitution of the acylating agent is 1.6.

example 2

[0023] 100 g of polyisobutylene with terminal olefin content of number average molecular weight Mn=2300 (BASF company product, terminal olefin content is 85%) 100g is put into airtight autoclave, feeds air oxidation at 200 ℃ subsequently for 2 hours, the air in the reactor The pressure is 0.04MPa. Then, the molar ratio of polyisobutene to maleic anhydride is 1:2.4, maleic anhydride is added at 150°C, the temperature rises to 230°C within 3 hours, and the reaction is continued for 3 hours. Then add 2% tert-butyl peroxide, react at 155° C. for 2 hours, remove unreacted maleic anhydride to obtain acylating agent B, and the degree of substitution of the acylating agent is 1.8.

example 3

[0025] Put 100 g of polyisobutylene with terminal olefin content of number average molecular weight Mn=2300 (BASF company product, terminal olefin content is 85%) 100g into airtight autoclave, pass into air oxidation at 180 ℃ subsequently for 2 hours, the air in the reactor The pressure is 0.08MPa. Then, the molar ratio of polyisobutene to maleic anhydride is 1:2.4, maleic anhydride is added at 160°C, and the temperature rises to 190°C within 3 hours for reaction, and the reaction time is 6 hours. Then add 2% tert-butyl peroxide, react at 140° C. for 2 hours, remove unreacted maleic anhydride to obtain acylating agent C, and the degree of substitution of the acylating agent is 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com