Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4594results about "Animal fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

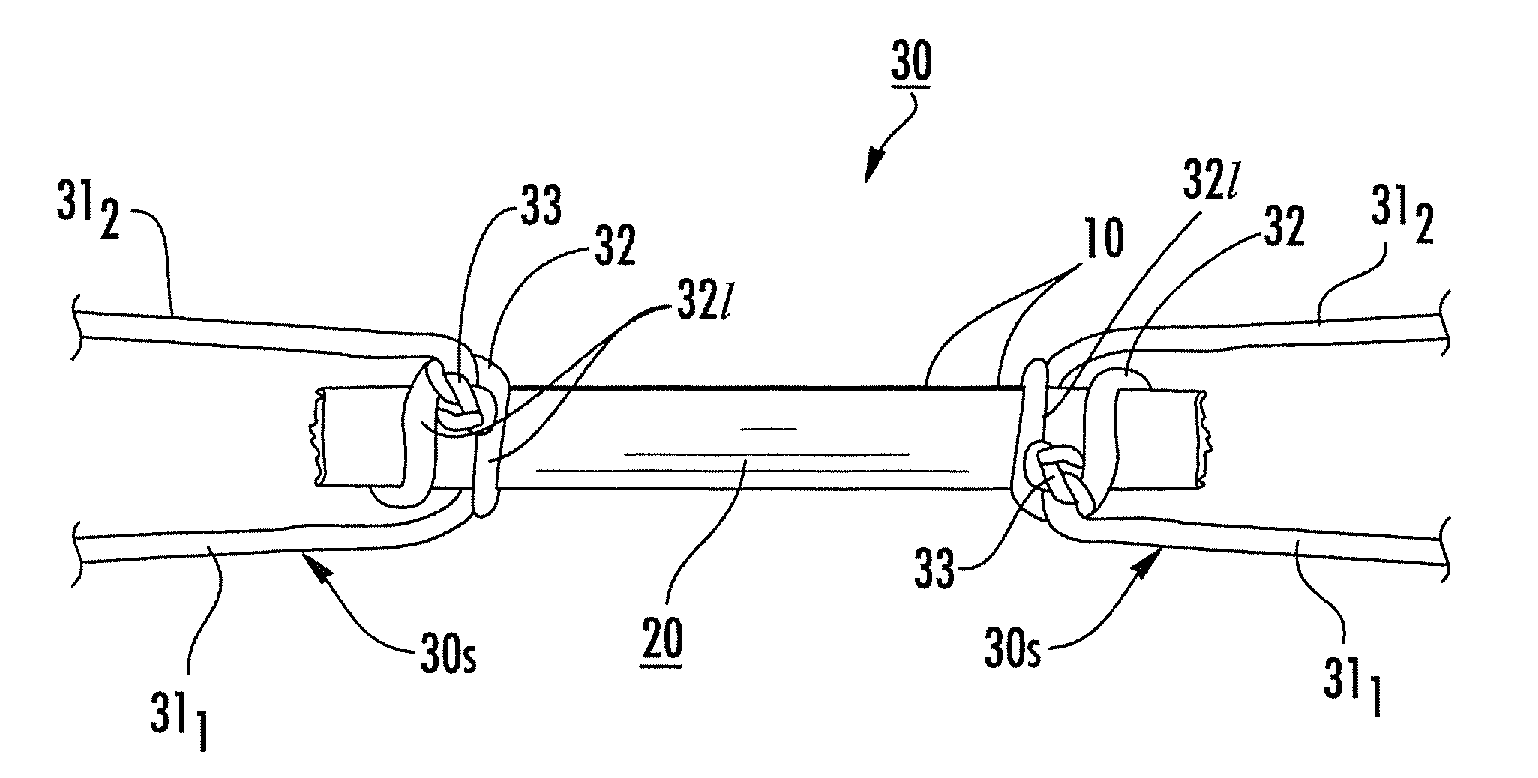

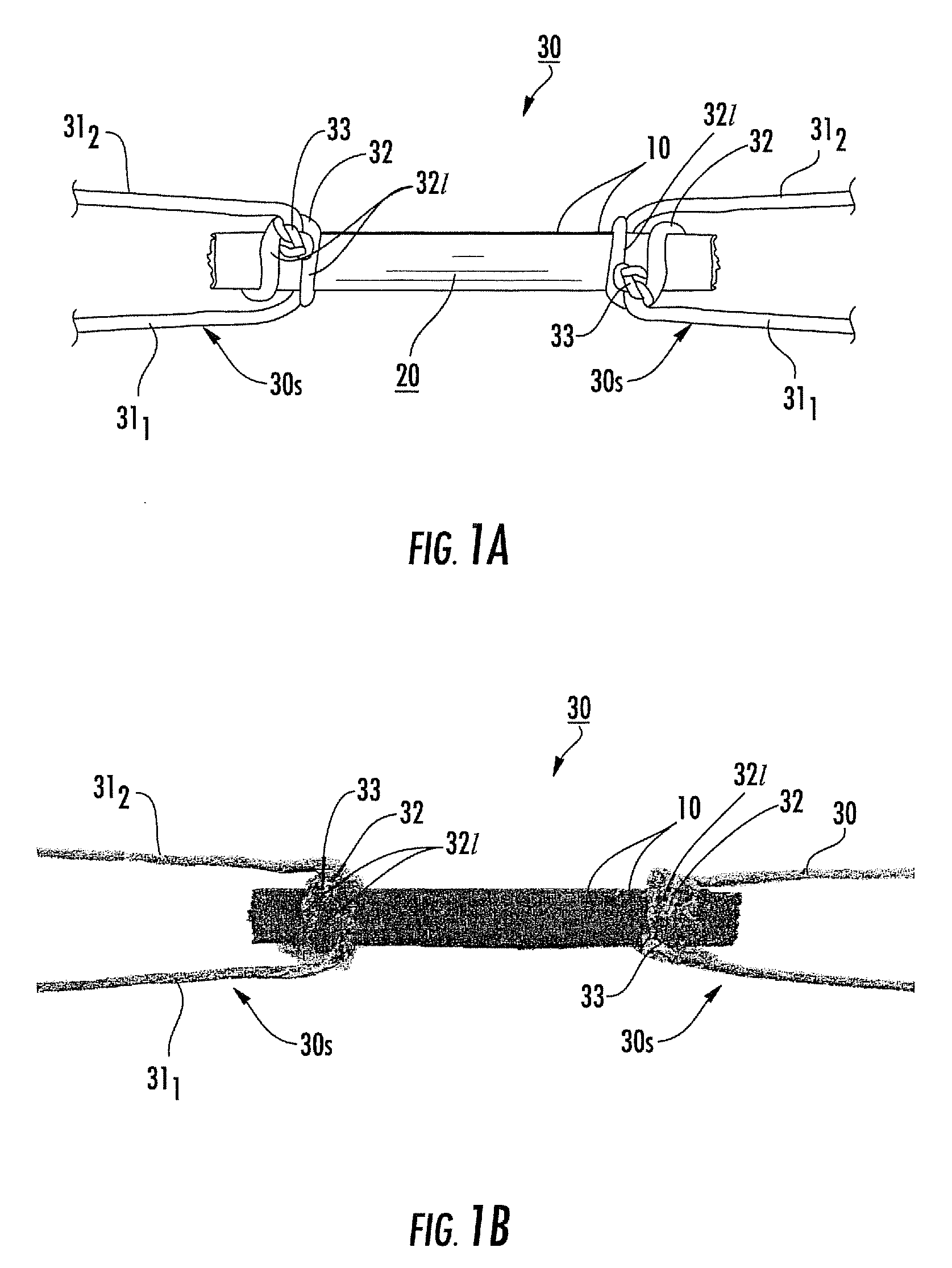

Woven and/or braided fiber implants and methods of making same

Owner:SHRINERS HOSPITALS FOR CRIPPLED CHILDREN

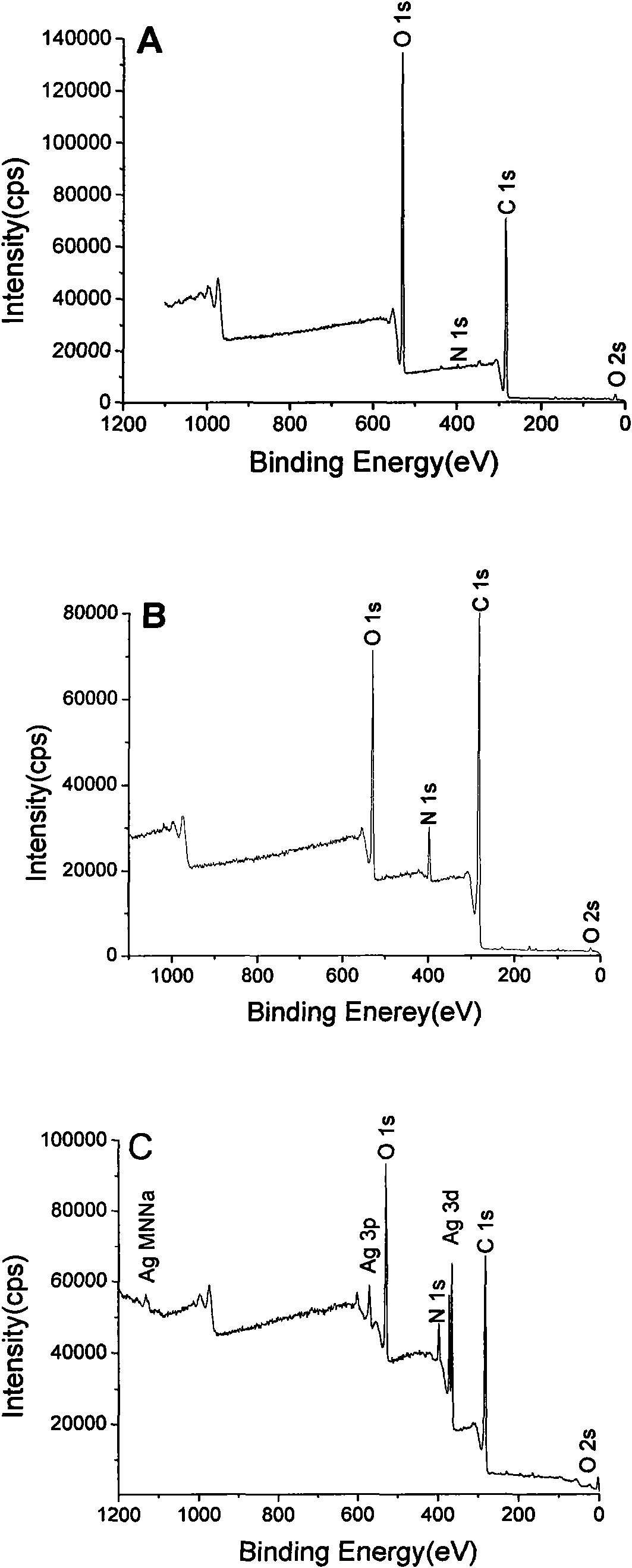

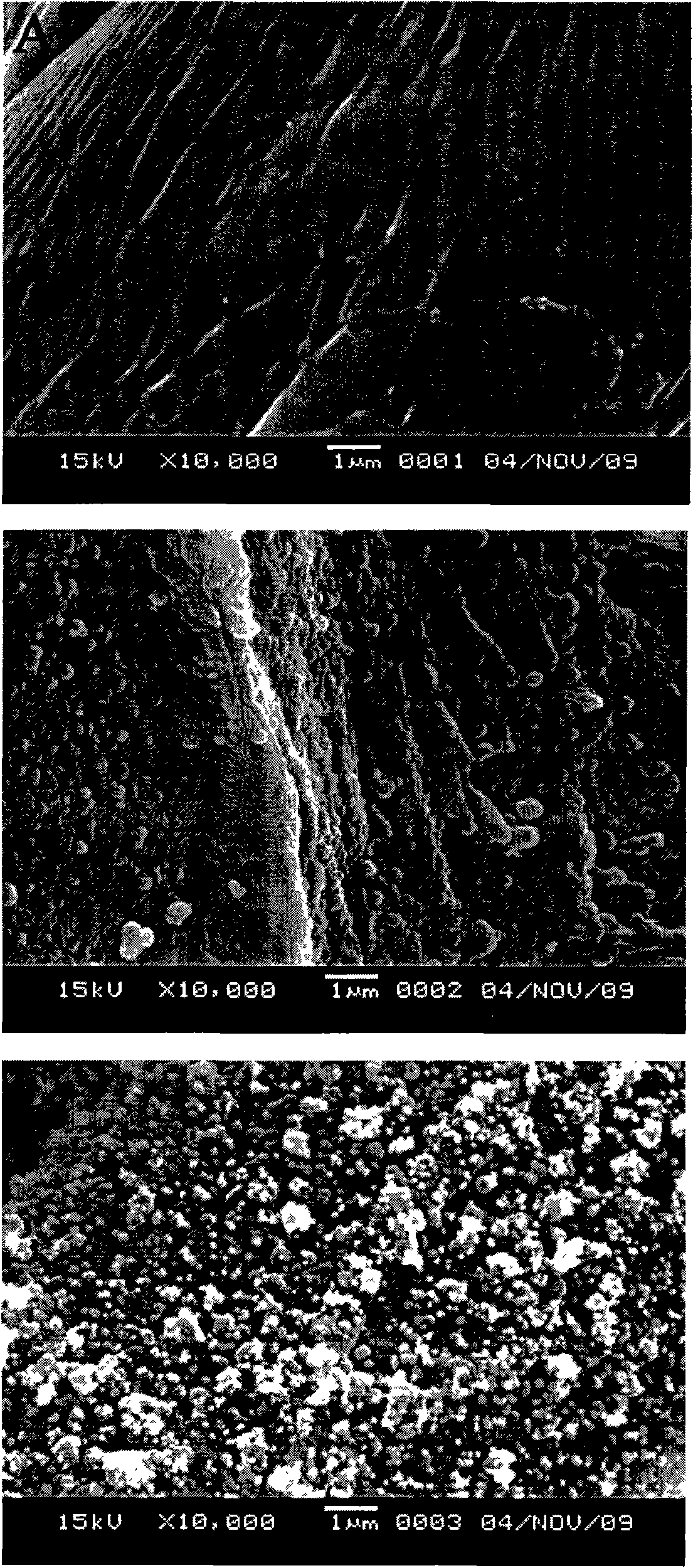

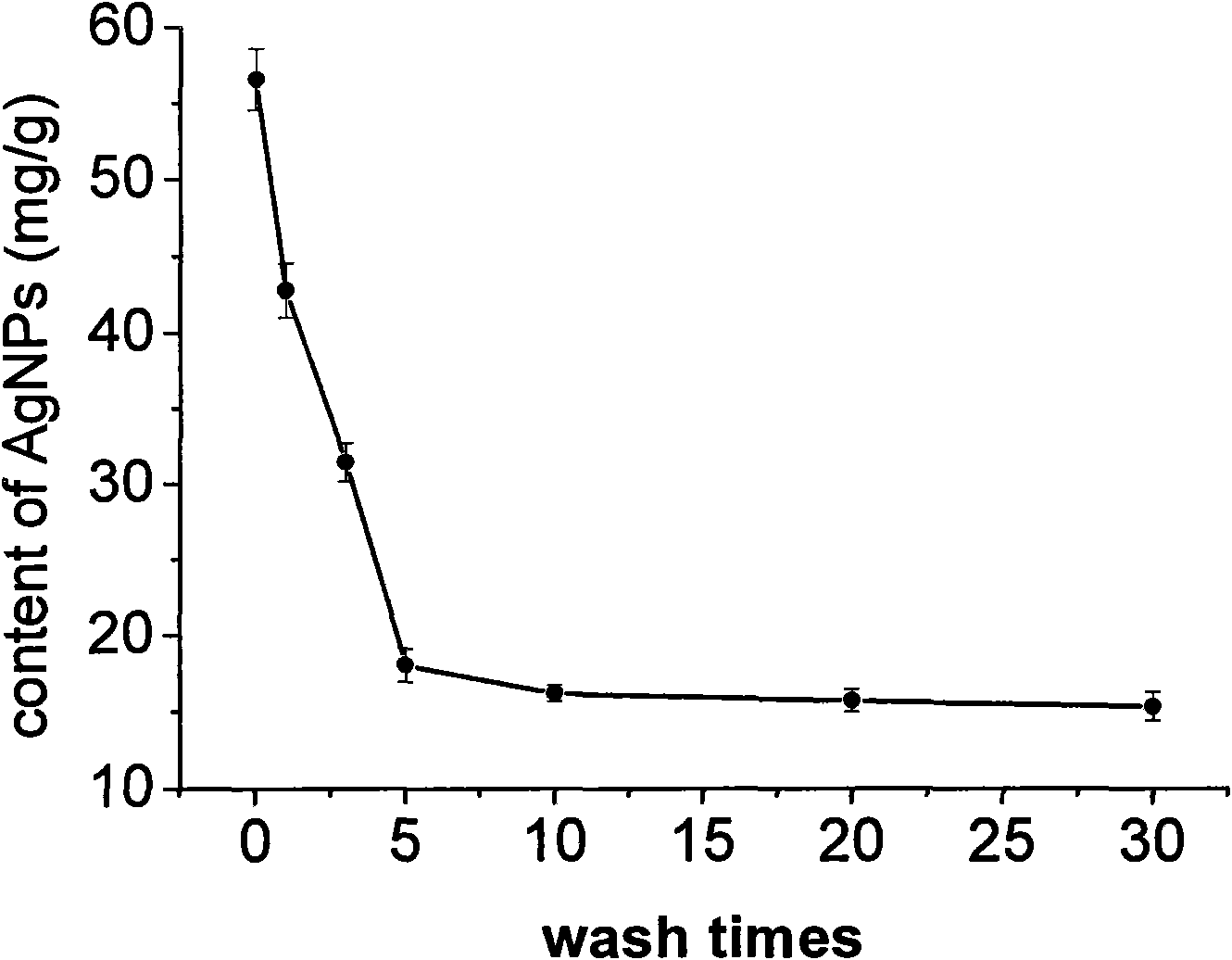

Method for preparing nano silver-containing anti-bacterial fabric by immersion process

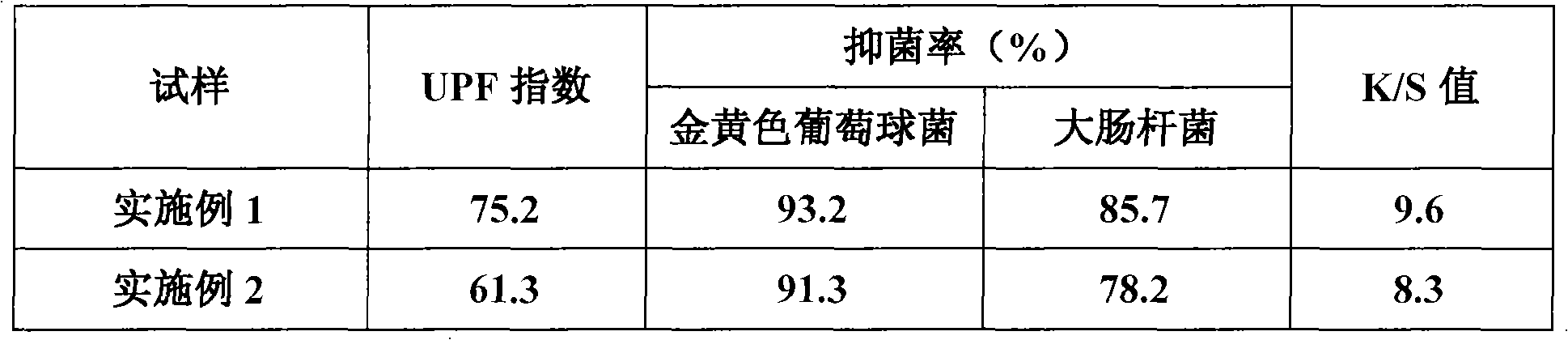

ActiveCN101864670AGood soaping fastnessEfficient and durable antibacterialVegetal fibresAnimal fibresChemistryAnti bacterial

The invention relates to a method for preparing a nano silver-containing anti-bacterial fabric by an immersion process. The method comprises the following steps: dissolving dopamine hydrochloride in Tris buffer solution; adjusting the pH value of solution to be between 7 and 10 by using hydrochloric acid; immerging a fabric into prepared dopamine solution in a bath ratio of 1:30; after stirring for reacting at the temperature of between 20 and 40 DEG C for 20 to 30 hours, taking the fabric out and washing to obtain a poly dopamine film-coated fabric; putting the fabric into silver nitrate aqueous solution; and after immerging for 8 to 10 hours, washing and drying the fabric to obtain the nano silver-containing fabric. The nano silver-containing fabric prepared by the method has the characteristics of high soaping fastness resistance and lasting antibiotic property; a sterilizing rate is still up to 100 percent after the fabric is washed with water for 30 times; and the preparation method has the characteristics of simple process, no pollution to the environment, low cost and large-scale production.

Owner:DONGHUA UNIV

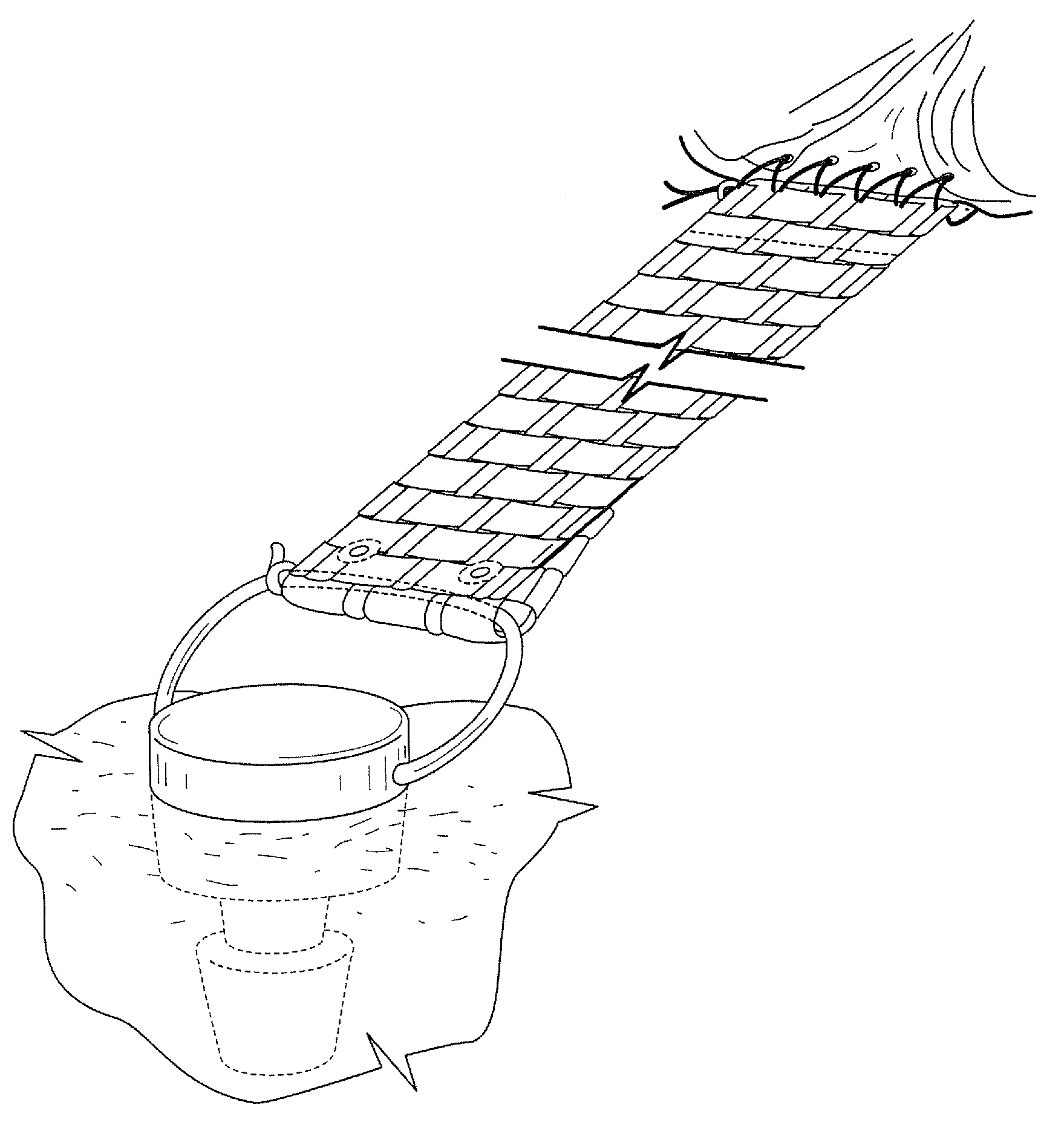

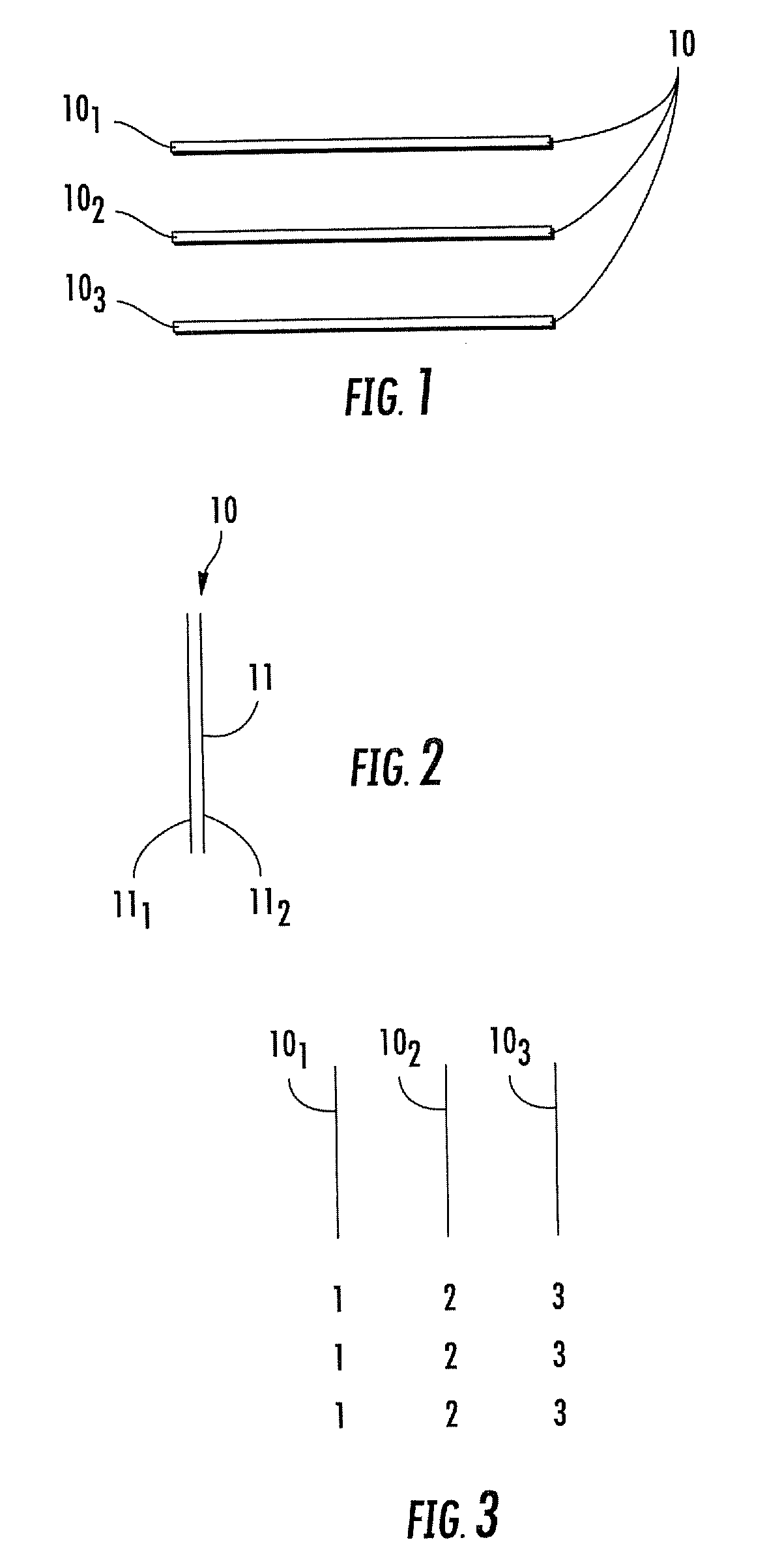

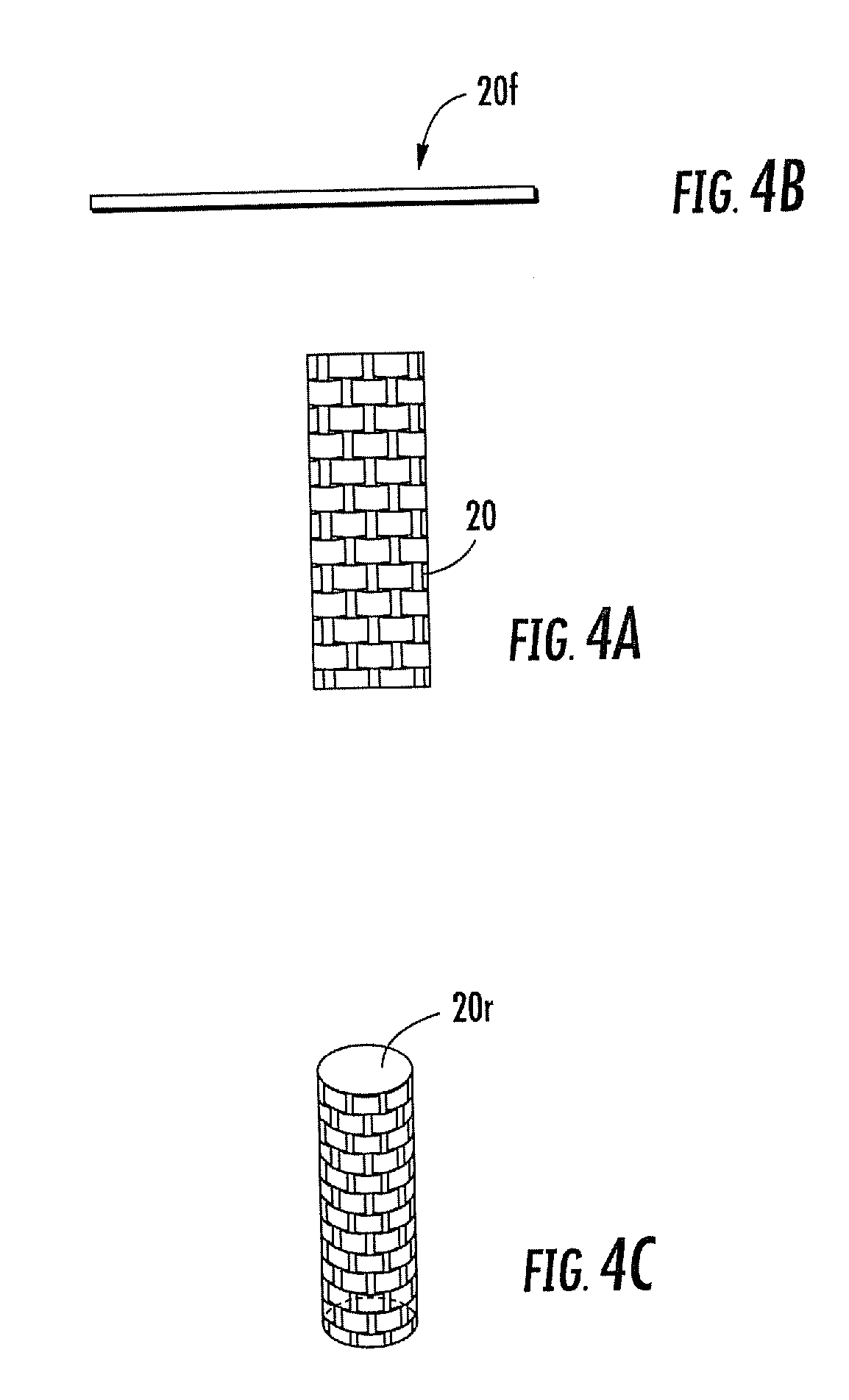

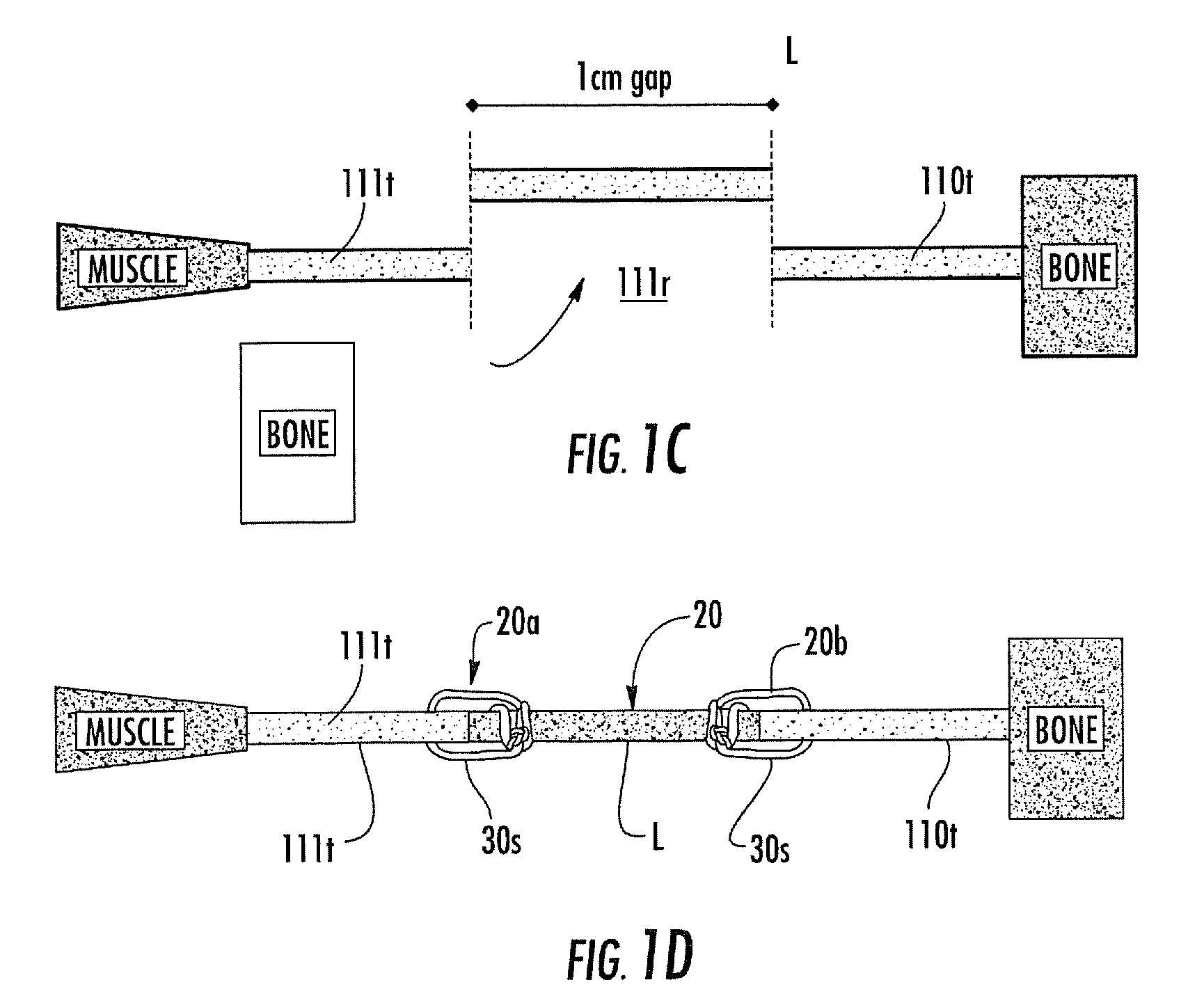

Tendon or ligament bioprostheses and methods of making same

The disclosure describes implantable bioprosthesis having an implantable construct with a multi-fiber array of collagen fibers attached together.

Owner:SHRINERS HOSPITALS FOR CRIPPLED CHILDREN

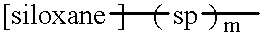

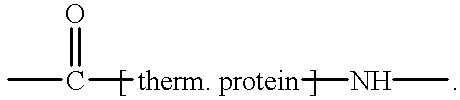

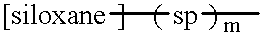

Polypeptide-polysiloxane copolymers

InactiveUS6358501B1Simple processWithout usingCosmetic preparationsHair cosmeticsOrganic chemistryCopolymer

The present invention relates to polypeptide-polysiloxane copolymers, to their preparation by thermal copolymerization of amino acids with organofunctional polysiloxanes, and to their use as interface-active substances. The polypeptide-polysiloxane copolymers consist of at least one polysiloxane unitand of at least one polypeptide unit

Owner:GOLDSCHMIDT GMBH

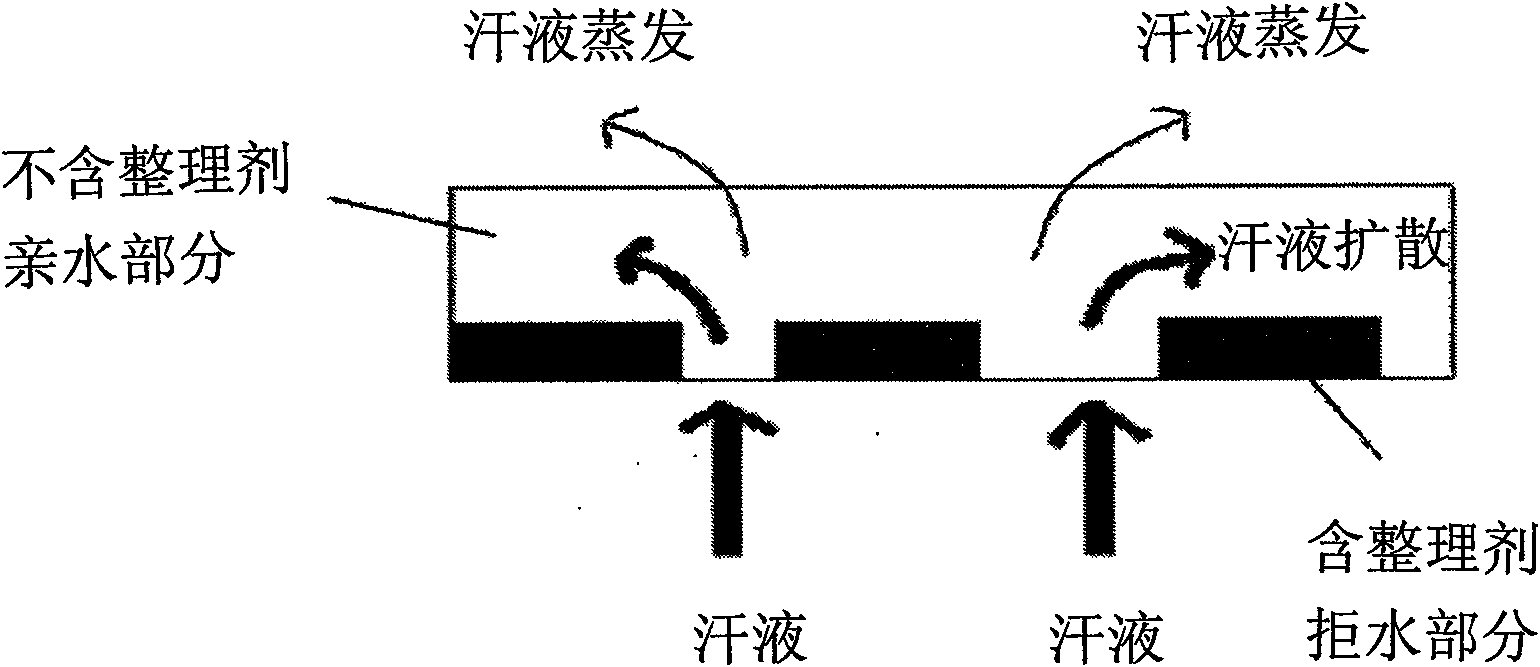

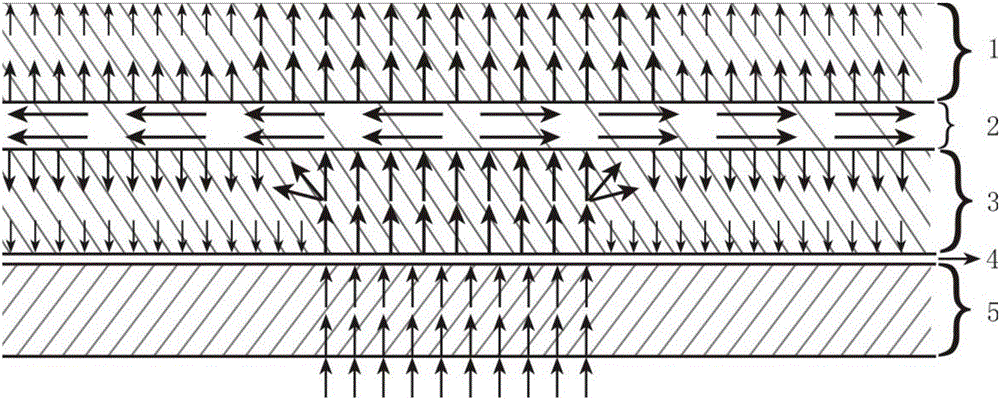

One-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and processing method thereof

InactiveCN101649558ASolve moisture absorptionSolve the contradiction of dehumidificationVegetal fibresAnimal fibresEngineeringMoisture absorption

The invention relates to a one-way moisture-conducting cashmere and cashmere blended woven fabric or knitted product and a processing method thereof. A double-lateral surface structure with differenthydrophilic and hydrophobic properties is constructed at the front and reverse sides of the woven fabric product in a single-face liquid feeding way, wherein the front sides of the products are all hydrophilic sides with favorable hygroscopic property, hydrophobic areas with a hydrophobic structure are discontinuously distributed at the reverse side of the product, and the hydrophobic area occupies 20-80 percent of the total area of the lateral side. The processing method comprises the steps of preprocessing fabric, mixing printing paste and finishing agent, printing or feeding liquid at single side, drying, washing and shrinking, processing flexibly, drying again and finally ironing. The invention has the advantages of reasonably solving the contradiction between moisture absorption and moisture discharge as well as the contradiction between hydrophilic and hydrophobic of the fabric, ensuring favorable one-way moisture-conducting effect, achieving the aim of conducting sweat from oneside clinging to the skin to outside and maintaining relatively dry and comfortable efficiency at one side of the skin.

Owner:INNER MONGOLIA ERDUOSI CASHMERE PRODS

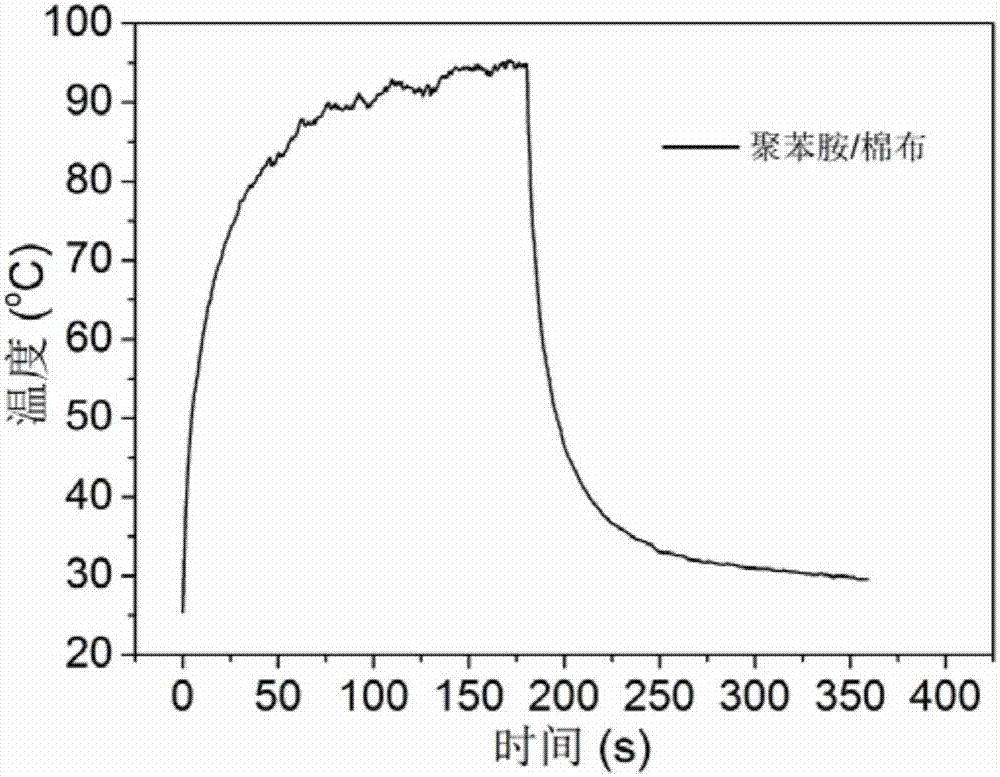

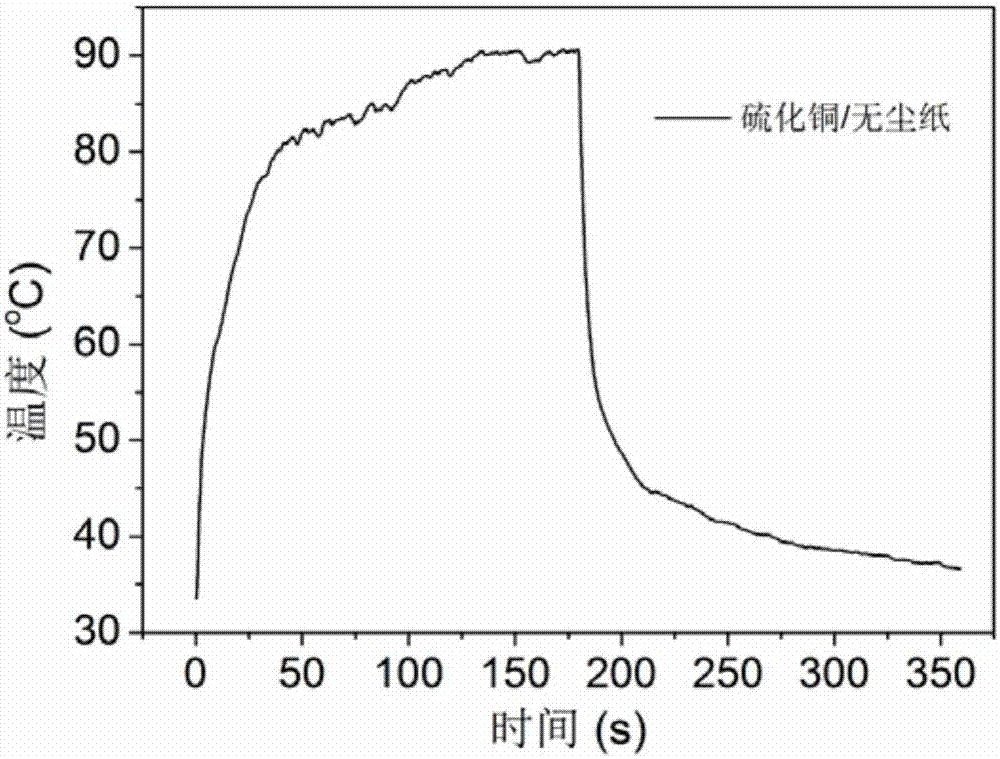

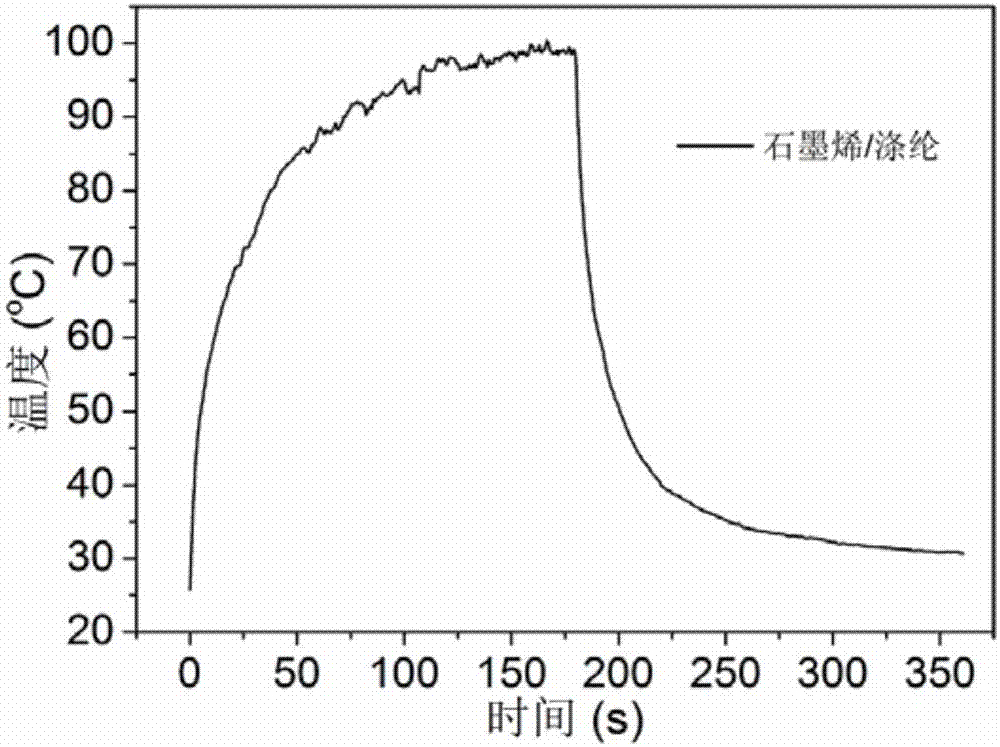

Method for preparing photothermal conversion textile

InactiveCN106958141AImprove photothermal efficiencyImprove mechanical propertiesVegetal fibresAnimal fibresPhotothermal conversionEngineering

The invention relates to a method for preparing a light-to-heat conversion fabric. The light-to-heat conversion fabric uses the fabric as a matrix to attach photothermal nanomaterials to the surface of the fabric matrix. The method includes the following steps: dispersing the photothermal nanomaterials into a solvent to obtain light thermal nanometer material dispersion liquid; uniformly distributing the photothermal nanometer material dispersion liquid on the fabric substrate; drying to obtain light heat conversion fabric. The invention expands the photothermal nano-material from the solution to the surface of the fabric, has the characteristics of rapid temperature rise and high temperature rise, greatly improves the application range, simple operation, mild conditions, low cost, and the obtained photothermal conversion fabric has high photothermal efficiency , with good mechanical properties, it is expected to have great application value in the fields of winter heating, a new generation of solar thermal insulation clothing, new solar heating equipment and new solar desalination.

Owner:DONGHUA UNIV

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

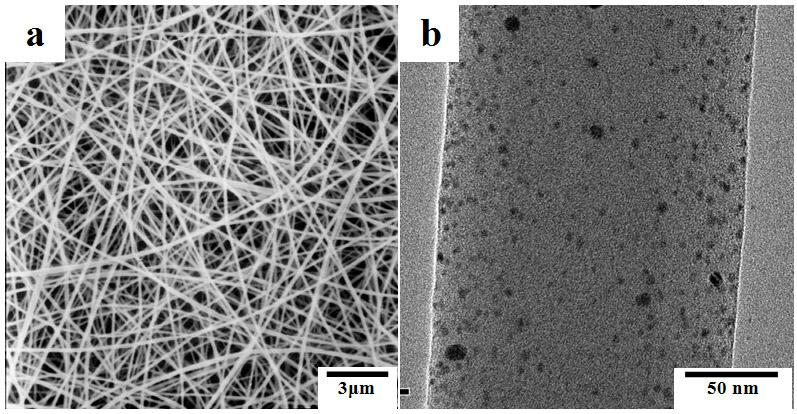

Strengthened toughened regenerated silk fibers and preparation method thereof

ActiveCN103572395ASimple preparation processMonocomponent protein artificial filamentAnimal fibresMolar concentrationGraphite oxide

The invention relates to strengthened toughened regenerated silk fibers and a preparation method thereof. The preparation method comprises the following steps of 1, degumming silkworm cocoons, and dissolving the degummed silkworm cocoons to obtain a regenerated silk fibroin aqueous solution, 2, blending a graphene oxide aqueous solution subjected to ultrasonic treatment and the regenerated silk fibroin aqueous solution according to a certain ratio, 3, adding metal-oxide hydrosol into the mixture according to a certain ratio, 4, adding a CaCl2 solution into the mixture obtained by the step 3 to adjust a calcium ion molar concentration to 0.15-0.3mol / L, and sequentially carrying out concentration, 5, carrying out dry spinning on the concentrated solution as a spinning liquid at a room temperature, and 6, after-treating the composite fibers by an ethanol-water solution. The preparation method has simple processes and utilizes the raw materials having wide sources. The treated composite fibers have good strength and good toughness and have breaking strength of 70-380MPa, breaking elongation of 20-150% and breaking energy of 30-100J / g.

Owner:DONGHUA UNIV

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

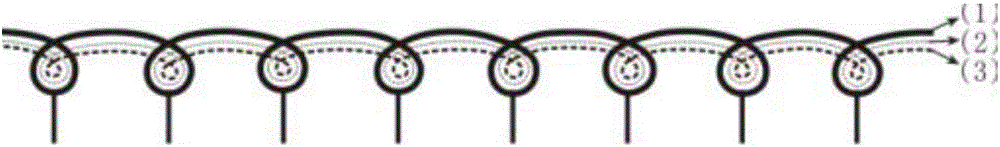

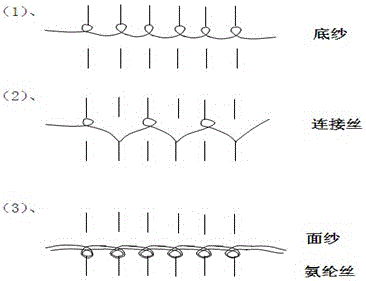

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

Mercerization and shrinkproof finishing method for woven fabric

InactiveCN101418515AReduce yellowingGood reproducibilityAnimal fibresBiochemical engineeringReducing agent

The invention discloses a mercerizing and shrinkproof finishing method for a wool fabric, which comprises the following steps of: step one, washing fluffiness of the wool fabric; step two, scale stripping by chloridizing or chloridizing plus oxidizing; step three, reduction dechlorination, in which a reducing agent is added into a container; step four, alkali washing neutralization; step five, water washing; step six, softening and fluid removal; and step seven, dehydration and drying. The method is characterized in that: 1. the whole process of the process is finished in water environment, which is suitable for uniform processing of ready-made clothes and has good reproducibility; 2. the appropriate stripping of wool scales improves dimensional stability and achieves the aim of machine washing; 3. the method combining the chlorination and the oxidization greatly reduces the yellowing of the fabric; and 4. the method greatly improves hand feel and luster, and meets the requirement of people on the comfort and beauty.

Owner:ZHEJIANG QUEPING TEXTILE CHEM

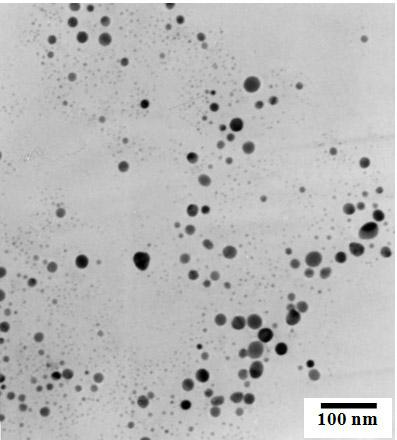

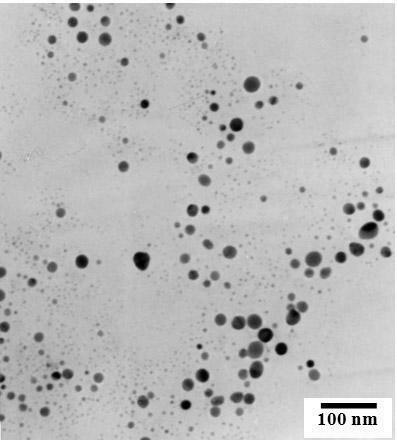

Fibroin-silver-nanoparticle composite material and preparation method thereof

The invention belongs to the technical field of composite materials and particularly provides a fibroin-silver-nanoparticle composite material and a preparation method thereof. The fibroin-silver-nanoparticle composite material comprises fiber (including electrospinning fiber), film, hydrogel and three dimensional porous materials. The preparation method comprises the following steps: after fibroin solution and silver nitrate solution are mixed, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight, and then the material is formed and prepared; or fibroin is prepared into different forms of materials first, then the materials are soaked in silver nitrate water solution, and finally, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight. According to the invention, fibroin is taken as material matrix and the reducing agents and stabilizing agents of silver-nanoparticles, and no other chemical agent is required to be added; and the preparation process is simple, energy-saving and environment-friendly, and the material has various forms.

Owner:FUDAN UNIV

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

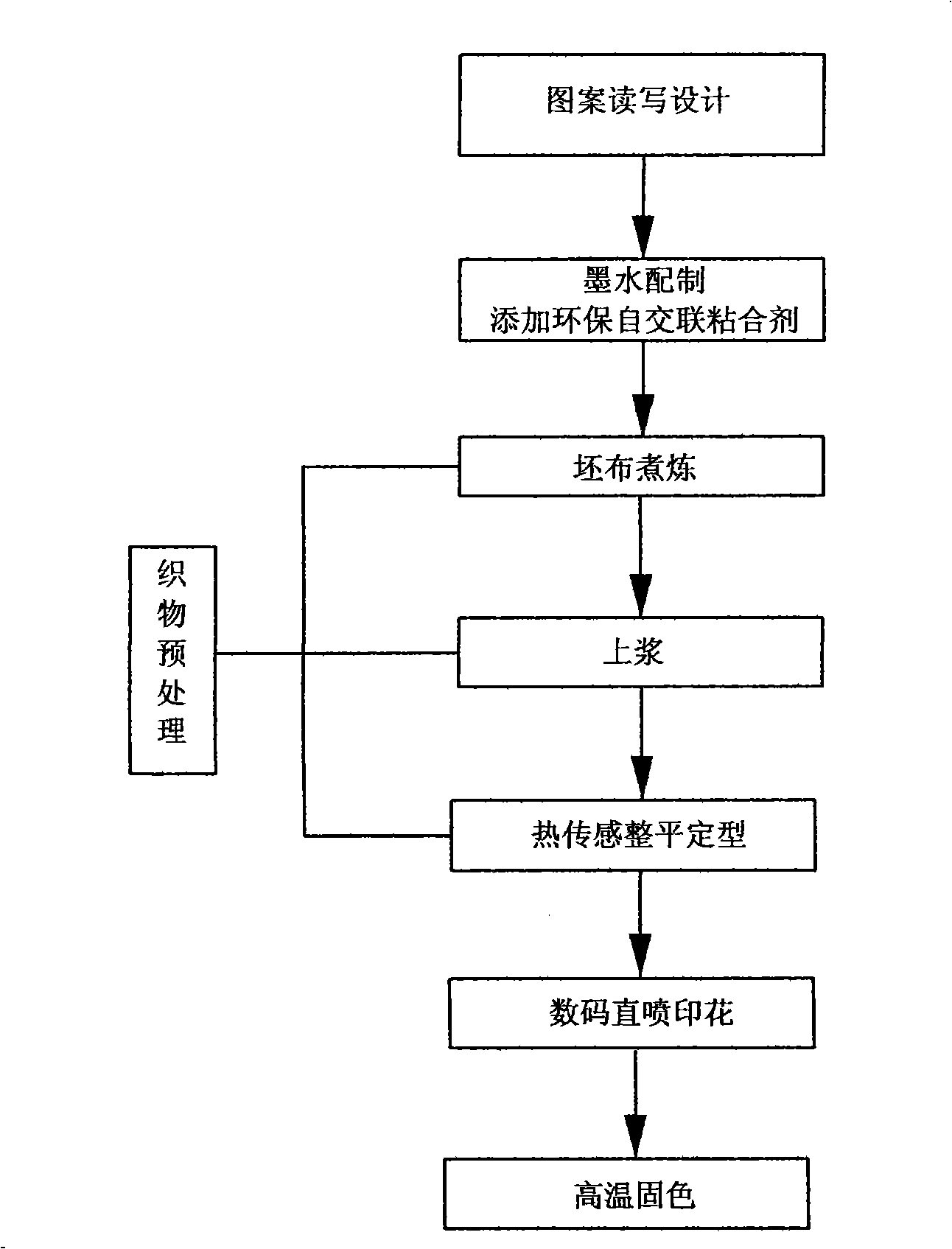

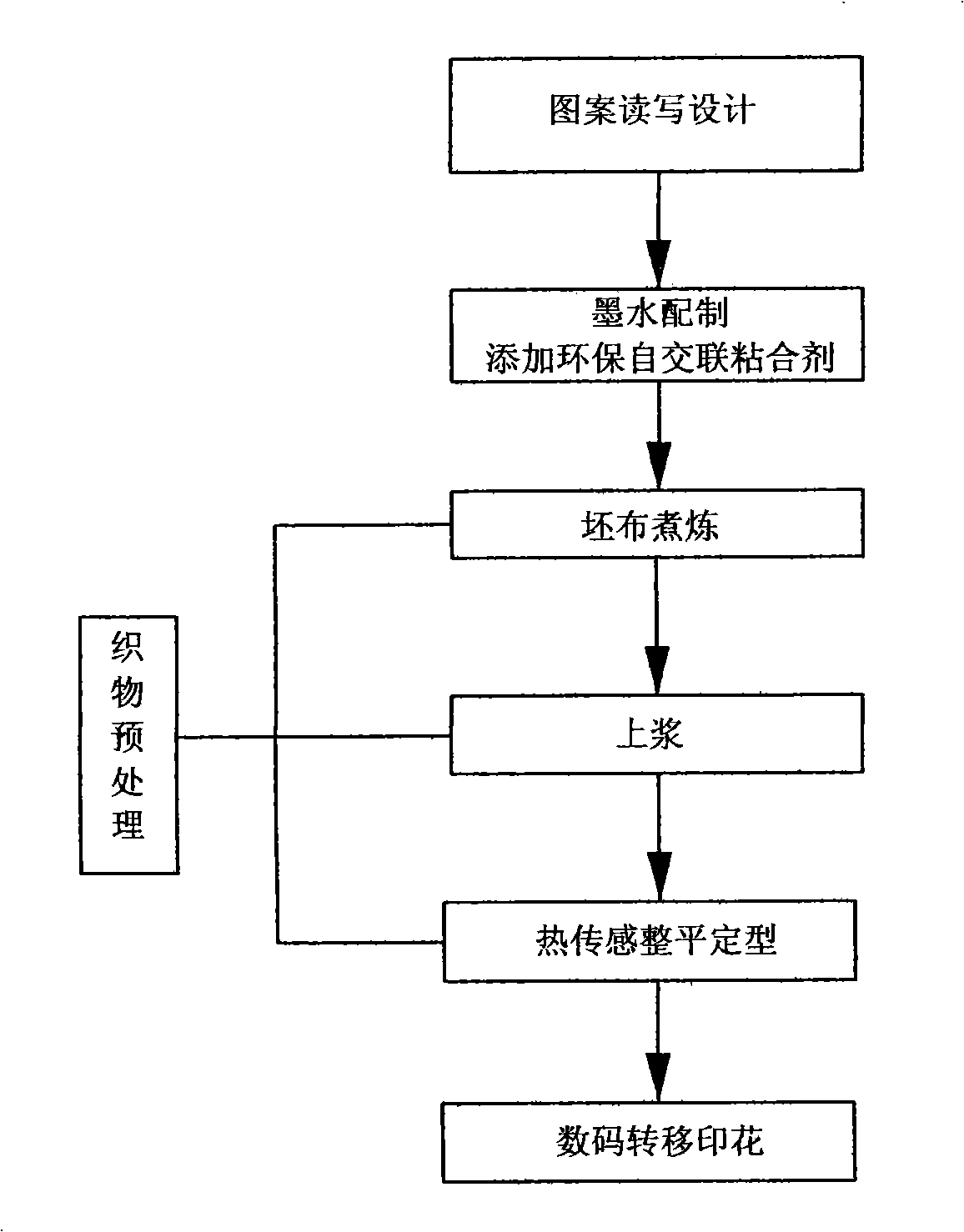

Real silk and real silk intimating digit printing process

The invention discloses a natural silk and artificial silk digital printing technique, which belongs to the printing technical field. The technique comprises the following steps: read-write design of patterns, preparation of ink, pretreatment of textile fabrics, digital jet printing and so on. By addition of an environment-friendly self-crosslinking adhesive into the ink and adoption of the special heat-setting technique, the upper part and the lower part of a blank after sizing are tightly pressed and heated by two electric blankets; and the pressure is between 2 and 3kgf / cm<2>, and the heating temperature is between 200 and 280 DEG C. Products prepared by adoption of the technique still can not be faded after water scrubbing for a plurality of times and even under more severe experimental environments and maintain the prior color and the prior brightness.

Owner:SHAOXING COUNTY YONGTONG SILK PRINTING

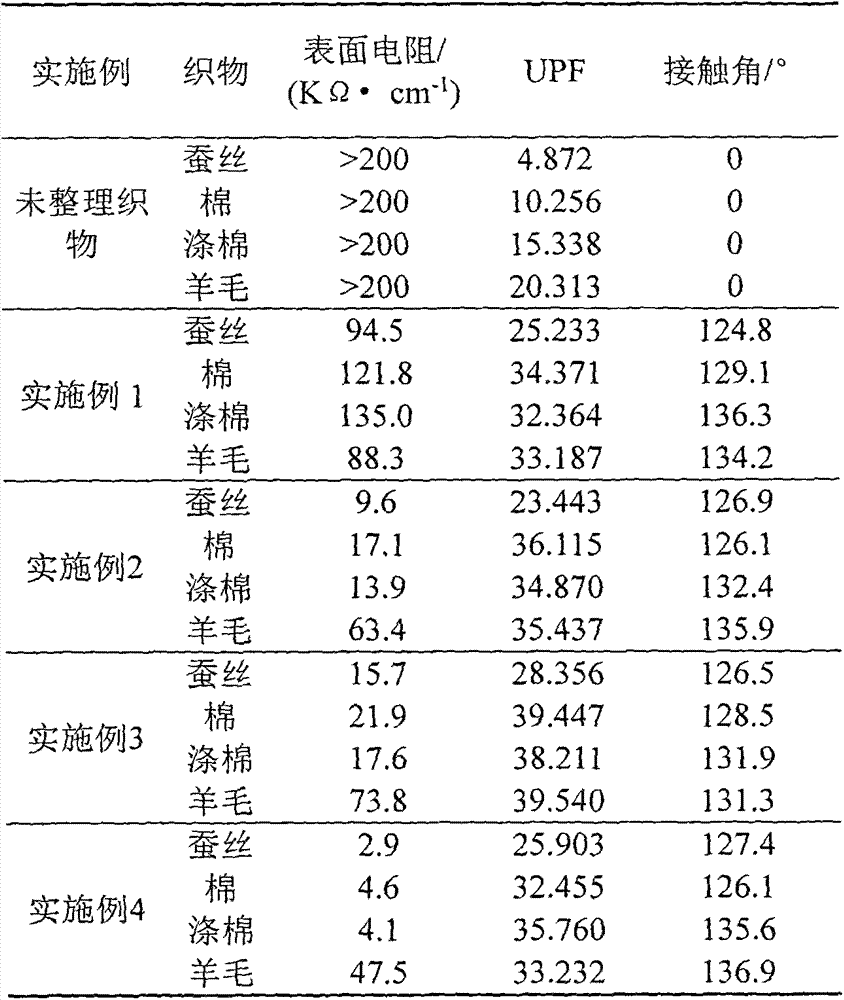

Method for multifunctional sorting of textile by using graphene oxide derivative

ActiveCN104328653ASimple technical solutionEasy to operateVegetal fibresAnimal fibresUltravioletSmart transducer

The invention discloses a method for multifunctional sorting of a textile by using a graphene oxide derivative, belonging to the technical field of textile chemistry. The method comprises the following steps: immersing the textile with a graphene oxide derivative water solution; drying the textile and carrying out reduction so that the surface of the textile is covered with one layer of a reduced graphene oxide derivative; and repeating the steps to obtain the multifunctional textile with good conductive, anti-ultraviolet and water-repelling functions. By virtue of the method, the textile can obtain a lot of functions by one type of sorting and the multifunctional sorting of common textiles including cotton, wool, silk, dacron, chinlon and the like, and blended textiles or intertextures thereof can be realized; and the textile can be used for the fields including medical treatment, intelligent sensors, mobile power generation, military affairs and the like.

Owner:JIANGNAN UNIV

Method for clearing up nanometer uvioresistant antibacterial self-cleaning fabric

The invention relates to a method for clearing up a nanometer uvioresistant antibacterial self-cleaning fabric. The method comprises the steps of: (1) mixing a titanium slat with an organic acid in a mass ratio of 10:(1-3), stirring the mixed solution uniformly, then adding the mixed solution into an inorganic acid solution to react at 50-60 DEG C for 30-60 minutes, so as to obtain nanometer TiO2clearing up liquid; (2) soaking and rolling the fabric twice in the nanometer TiO2 clearing up liquid; (3) mixing stearate, hydrolyst, water and alcohol at room temperature to react for 0.5-2 hour toobtain a water repellent; and (4) padding or soaking the fabric mentioned in step (2) in the water repellent, pre-drying and baking the fabric cleared up in a manner of water repellence, thus obtaining a nanometer uvioresistant antibacterial self-cleaning fabric. The method disclosed by the invention is simple and easy to industrialize, and the treated fabric has good self-cleaning performance and also has good uvioresistant and antibacterial performances, so the nanometer uvioresistant antibacterial self-cleaning fabric has good application prospect.

Owner:DONGHUA UNIV

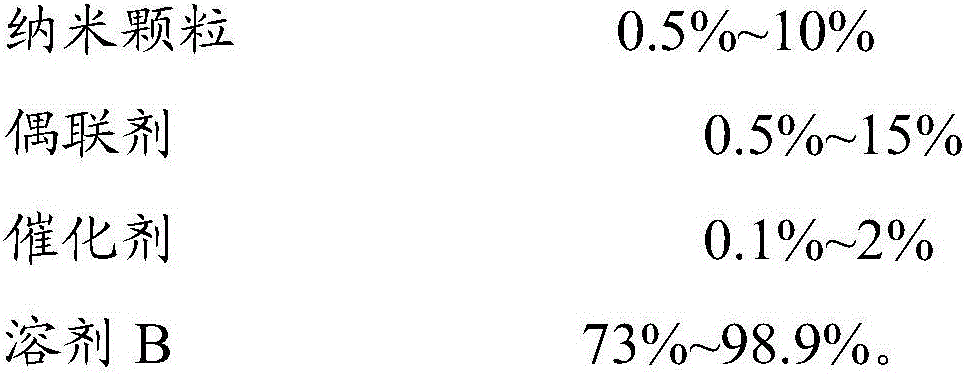

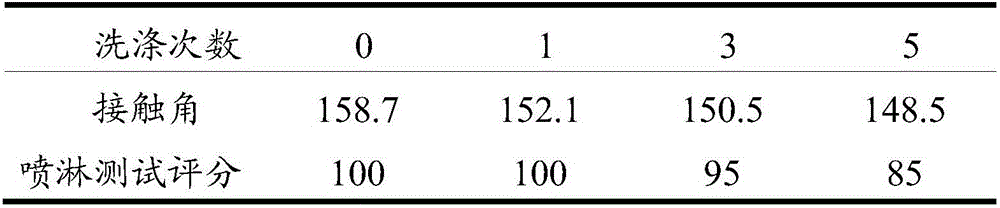

Super-hydrophobic fabric and preparation method thereof

ActiveCN105780468AImprove wear resistanceMaintain superhydrophobic effectLiquid repellent fibresVegetal fibresNanoparticleWear resistant

The invention discloses a super-hydrophobic fabric and a preparation method thereof and belongs to the technical field of super-hydrophobicity. The super-hydrophobic fabric comprises a fabric body, wherein a coupling agent wear-resistant layer is stuck to the surface of the fabric body, a super-hydrophobic layer is stuck to the surface of the coupling agent wear-resistant layer, the coupling agent wear-resistant layer contains a coupling agent A, and the super-hydrophobic layer is a coupling agent B modified nanoparticle layer. The super-hydrophobic fabric disclosed by the invention contains the coupling agent wear-resistant layer and the super-hydrophobic layer, and the coupling agent wear-resistant layer can be used for improving the wear resistance of the super-hydrophobic layer, so that the super-hydrophobic fabric can keep a super-hydrophobic effect in a long-acting manner.

Owner:BEIJING NEATRITION TECH CO LTD

Antibacterial processing method for wool fiber

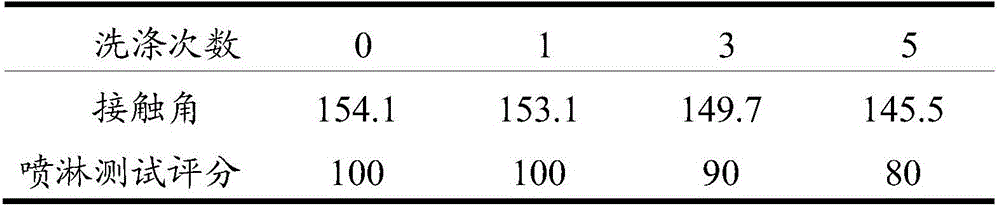

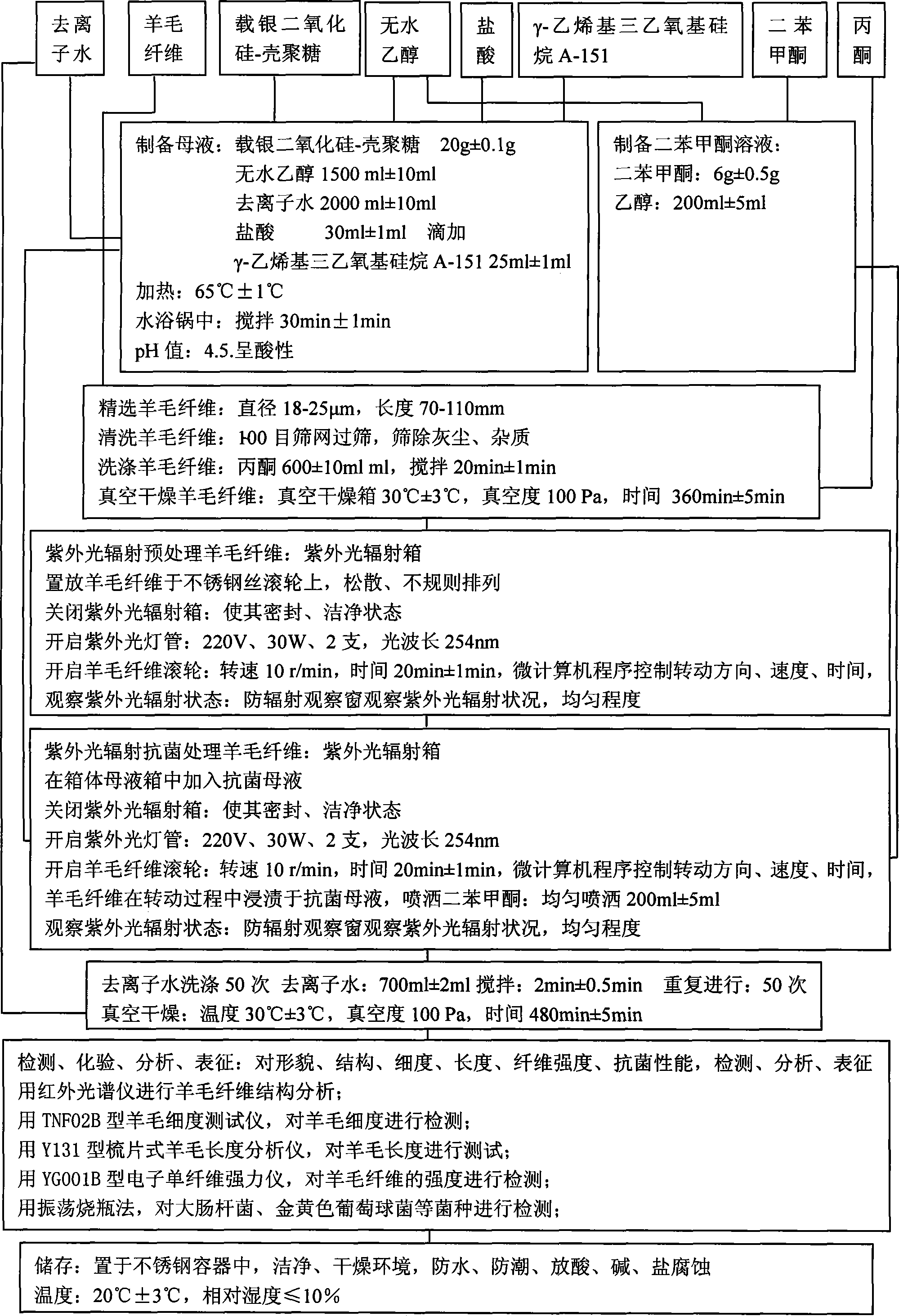

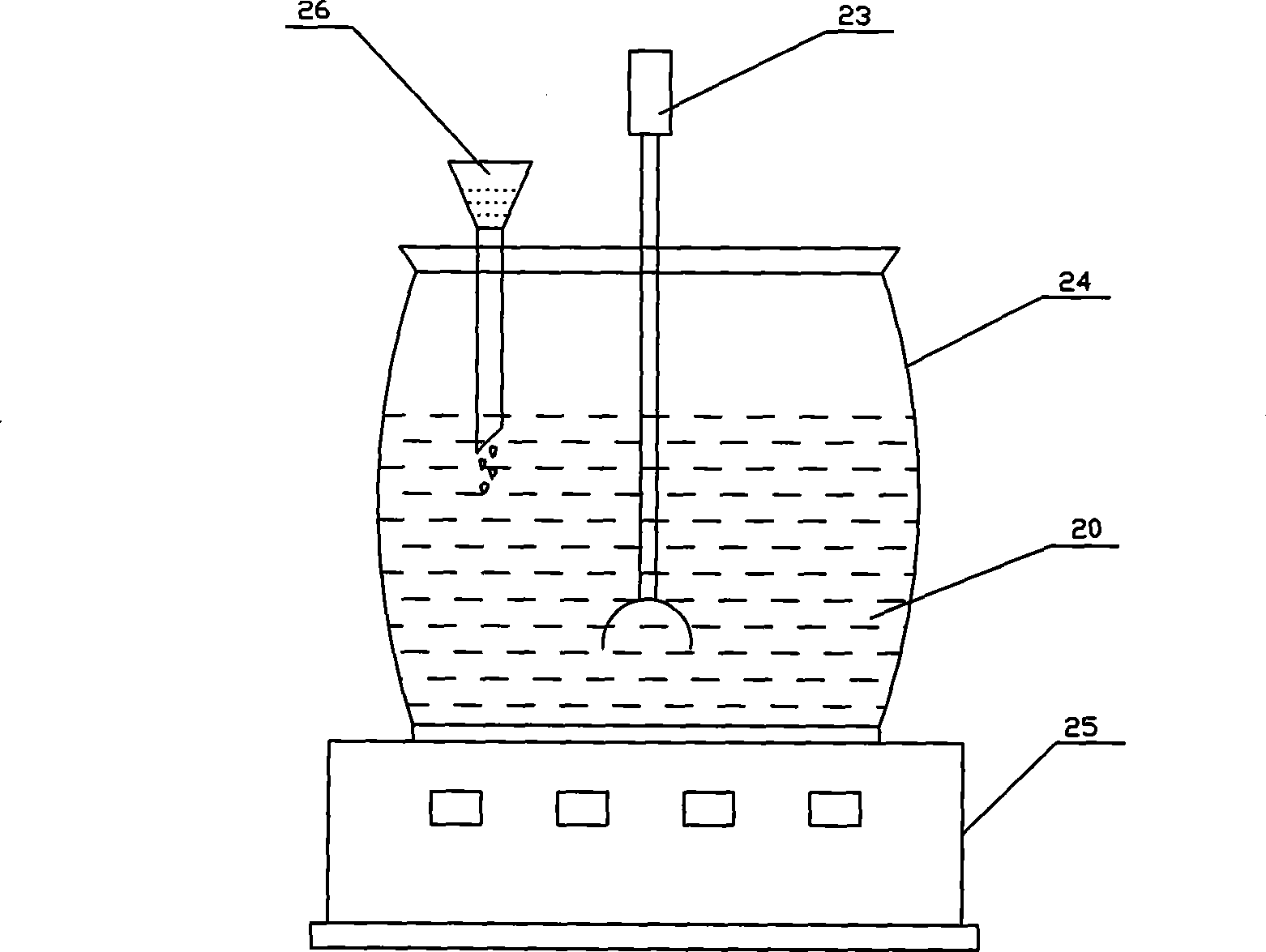

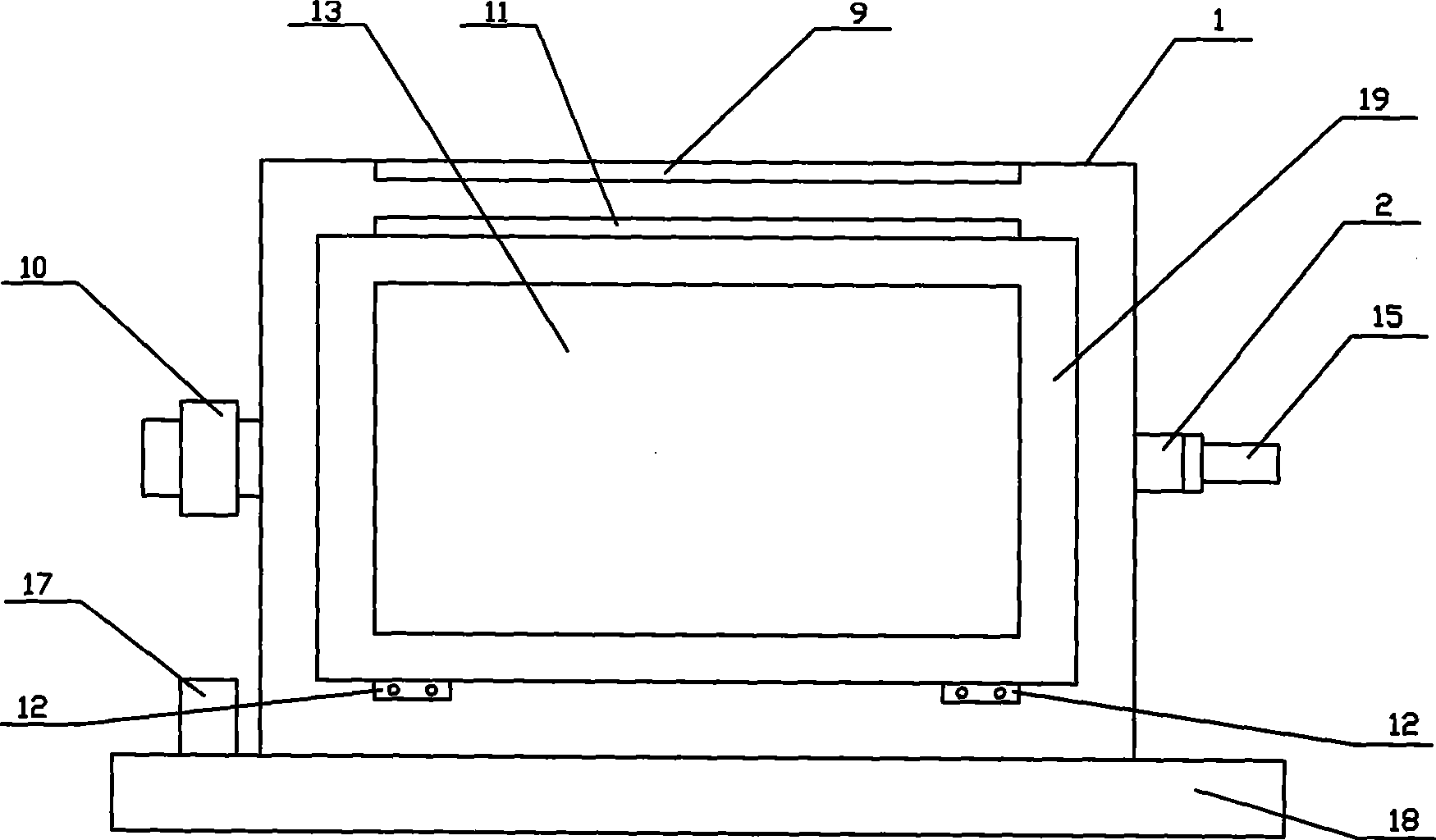

InactiveCN101413208AImprove durabilityEasy to manufacturePhysical treatmentAnimal fibresPre irradiationChemical reaction

The invention relates to an antibacterial treatment method for wool fiber, which comprises the following steps: an organic-inorganic composite antibacterial agent, namely silver-bearing silicon dioxide-chitosan is taken as an antibacterial agent and prepared into a pentabasic antibacterial mother liquor with anhydrous alcohol, deionized water, a diluted hydrochloric acid, a dispering / coupling agent and gamma-vinyltriethoxysilane A-151; the wool fiber is subjected to pre-irradiation of the ultraviolet light, and then immersed into the antibacterial mother liquor for secondary irradiation; and the wool fiber and the silver-bearing silicon dioxide-chitosan composite antibacterial agent generate chemical reaction under the action of a light trigger benzophenone and are combined by means of valence linkage to form an antibacterial film with the thickness of 200 nanometers. The antibacterial treatment method improves the persistence of antibacterial functions of the wool fiber, and the antibacterial rate of the wool fiber is still 98.6 percent after being washed for 50 times. Moreover, the antibacterial treatment method has short process flow, small number of equipment used, quick antibacterial speed, high efficiency and good effect, is easy to prepare the mother liquor, is particularly suitable for performing antibacterial treatment on the wool fiber and pashm fiber, and improves the efficiency by 90 percent compared with the prior antibacterial technology.

Owner:TAIYUAN UNIV OF TECH

Piecedyed jet black fine-spun facing and preparation method thereof

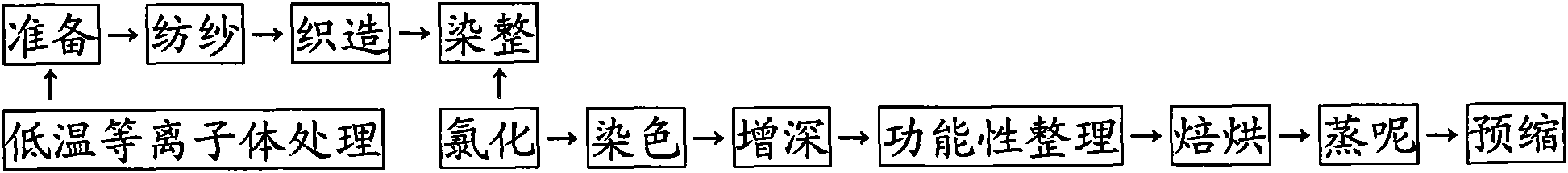

InactiveCN101671950AImprove hydrophilicityImprove dye uptakePhysical treatmentDyeing processTextile technologyNatural fiber

The invention discloses a piecedyed jet black fine-spun facing and a preparation method thereof, and relates to the technical field of wool spinning. Raw fiber used comprises natural wool fiber. The preparation method comprises steps of preparation, spinning, weaving, dyeing, finishing and the like. The method is characterized in that the raw fiber used further comprises wool natural fiber, and non-wool natural fiber or / and chemical fiber blended spinning material. The preparation method comprises a step of wool top chlorination treatment in the preparation step, or fabric chlorination treatment in the step of dyeing and finishing, further comprises steps of low-temperature plasma treatment in the steps of preparation, spinning or dyeing and finishing to generate obvious dyed color to enhance effect, so even jet black wool and blended-spun and fine-spun facing without dyeing defect can be obtained. Detection by a computer color photometer shows that blackness of the facing is deep, L value is up to 3.5-9.5, chromatic aberration between pieces is small, and delta E is equal to or less than 0.5. No expensive piece goods treating machine is needed, and the method has the advantages oflow cost, simple process and stable quality.

Owner:JIANGSU DANMAO TEXTILE

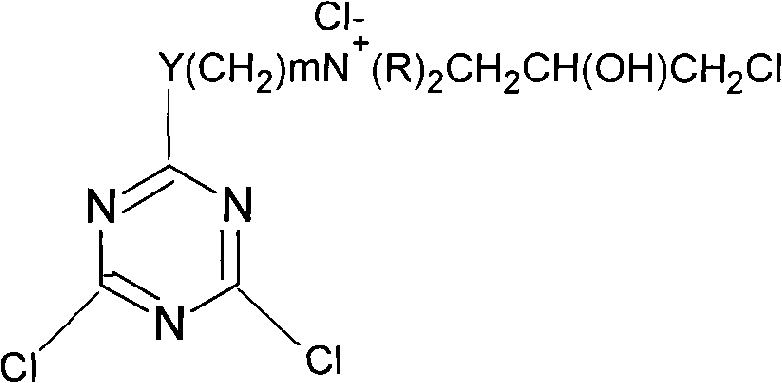

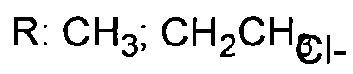

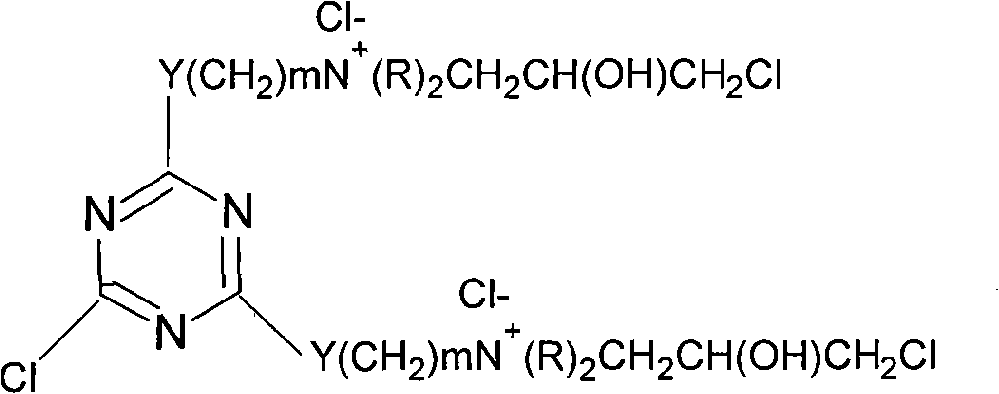

Fabric graft modified full-fixation printing method

InactiveCN101403185AReduced charge repulsionReduce processing burdenDyeing processVegetal fibresSodium bicarbonateWorking fluid

The invention relates to a whole fixation printing method for the graft modification of textiles, and aims at providing the whole fixation printing method that can promote the dye fixation rate from 70 percent to 80 percent to more than 90 percent to 98 percent. The technical proposal is as follows: 1) the pretreatment of a textile, the textile is treated according to the processes of desizing, boiling, smelting and bleaching; 2) the preparation of the graft modification working fluid, the working fluid comprises 0.1 percent to 10 percent of cationic graft agent, 0.1 percent to 20 percent of alkali agent and 0 percent to 1 percent of penetrating agent, and the rest is water; 3) the treatment of the graft modification, the pretreated textile is put into a dyeing machine, and the graft modification working fluid is added; or the pretreated textile is padded with the graft modification working fluid in a padder; the printing formula of the invention comprises 50 grams of protoplasm, 2 grams to 5 grams of urea, 0.5 gram to 8 grams of dye, 1 gram to 2.5 grams of sodium bicarbonate and 0.5 gram to 1.5 grams of reserve salt, and the rest amount of water in every 100 grams according to weight; and 4) the printing technology, the printing is carried out according to the conventional technology. The whole fixation printing method for the graft modification of the textiles is used in the whole fixation printing.

Owner:ZHEJIANG JIAXIN SILK

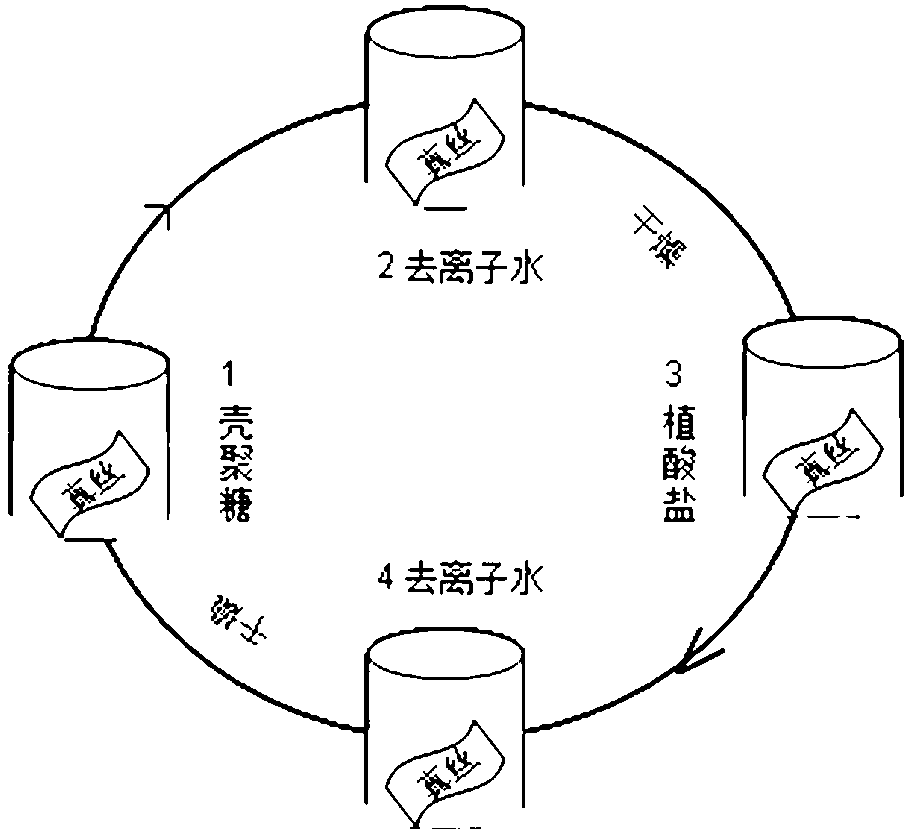

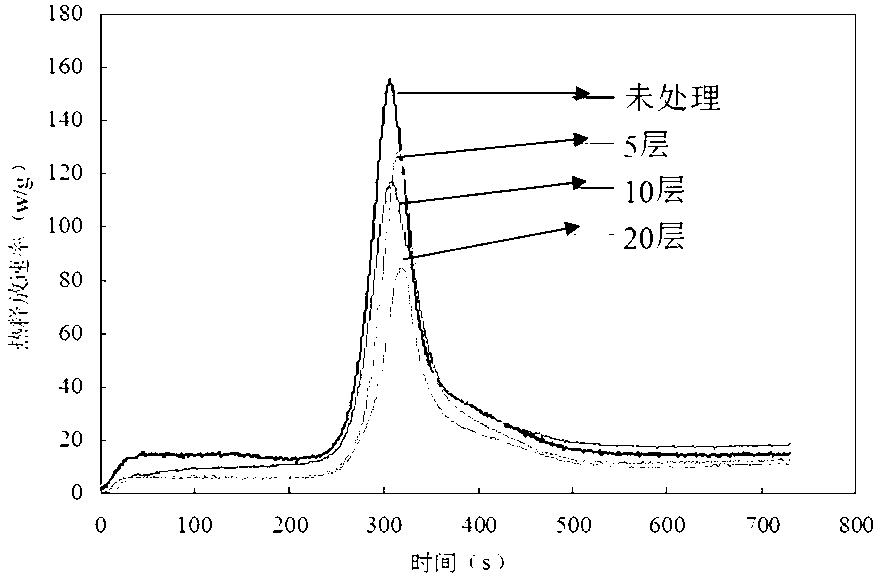

Flame-retardant pure silk and preparation method thereof

ActiveCN103321044AEasy to operateMeet environmental protection requirementsAnimal fibresEnvironmental resistanceRoom temperature

The invention discloses a flame-retardant pure silk and a preparation method of the flame-retardant pure silk. The preparation method comprises the following steps of: firstly, soaking the pure silk into a low molecular weight chitosan solution, washing by using deionized water, drying the washed pure silk, then soaking the dried pure silk into a sodium phytate solution, then taking the pure silk out, washing the pure silk with deionized water and then drying; and repeating the steps till the flame-retardant pure silk is obtained. A flame retardant comes from natural animals and plants, is nontoxic and belongs to an ecological type flame-retardant finishing agent; the flame-retardant pure silk is prepared by adopting an electrostatic self-assembling technology at room temperature, the preparation method is simple to operate and accords with an environment-friendly requirement, energy is saved and emission is reduced; and the prepared flame-retardant pure silk has a favorable flame-retardant effect.

Owner:苏州盛泽科技创业园发展有限公司

Method for protease-method wool felt-proofing treatment by using ultrasonic technology

InactiveCN103924439AHelps catalyze hydrolysisReduce processing timeBiochemical fibre treatmentUltrasonic/sonic fibre treatmentEngineeringUltrasonic technology

The invention discloses a method for protease-method wool felt-proofing treatment by using an ultrasonic technology, belongs to the application technical filed of wool fabric dyeing and finishing in the wool manufacturing industry and aims at solving the problems that the treating time is long, the felt-proofing rate is high and the fiber damage is large in a single protease method so as to realize the effect of optimizing wool fiber / wool top / wool fabric biological enzyme-method felt-proofing finishing. The felt proofing can be performed on wool under an ultrasonic condition, the protease catalytic hydrolysis speed is increased, the shedding off of a wool scale layer is accelerated, the protease method treating time is shortened, and the degradation of the protease to the inferiors of fibers is reduced. The synergistic effect of ultrasonic waves and the protease can replace a conventional chlorination method or single protease method felt-proofing method, so that the felt-proofing performance of wool fabrics is improved.

Owner:JIANGNAN UNIV

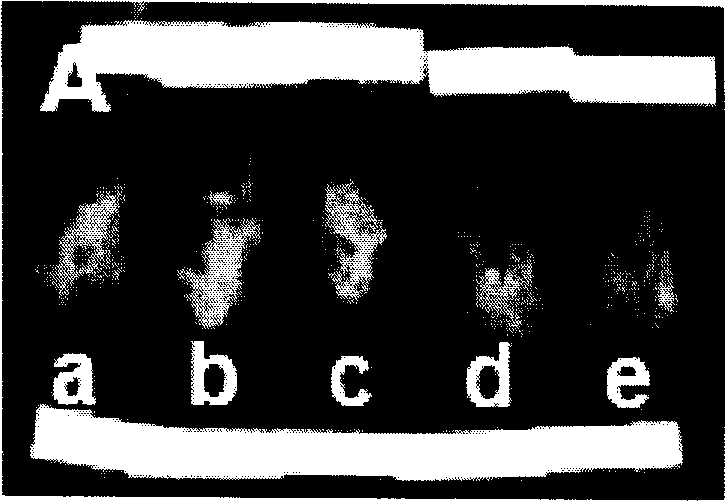

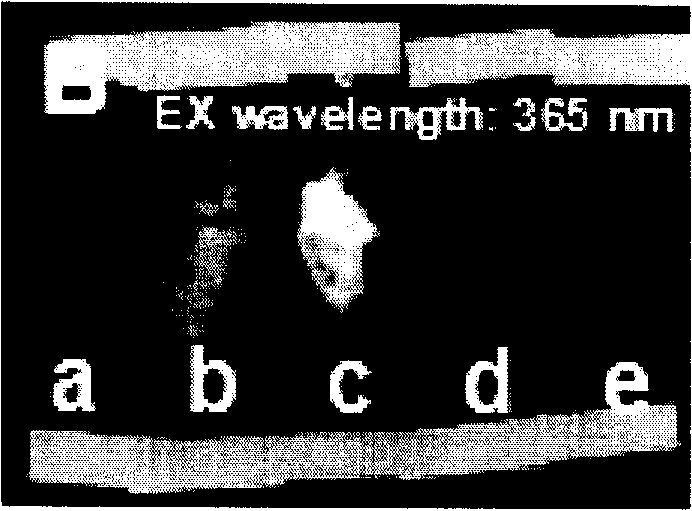

Preparation for silk with quantum dot nano-particles

A preparing method of fluorescent cocoon fibre assembled with quantum point nano particles, takes the quantum point nano particles as fluorescent particles, takes cocoon fibre as nuclear, adopts an electrostatic absorption method to connect one layer of organic high molecule on the cocoon fibre surface, and then adopts an electrostatic absorption method to connect one layer of quantum point nano particles on the organic high molecule surface, or alternately repeats steps for multitime, and then uses an electrostatic absorption method to connect one layer of organic high molecule on the quantum point nano particles surface, so as to compose a fluorescent cocoon fibre coated by quantum point nano particles once or many times, wherein, the quantum point nano particles surface is coated by organic small molecule and / or organic high molecule. The invention has advantages that the inventive fluorescent cocoon fibre assembled with quantum point nano particle, not only has large superiority in optical aspects such as fluorescent stability, fluorescent strength and fluorescent color kinds, but also can produce in large under low cost conditions with better product character repetitiveness.

Owner:TONGJI UNIV

Production process for anti-bacterial deodorant textile

InactiveCN104294595AImprove comfortExcellent moisture absorption and sweat absorptionVegetal fibresAnimal fibresMoistureAntibacterial agent

The invention relates to a production process for an anti-bacterial deodorant textile, and relates to the textile technical field. The production process comprises the steps: preparation of a natural textile; preparation of an antibacterial deodorant finishing liquid comprising the steps of blending a micro-powder chitosan aqueous solution, a nano silver solution, a bamboo charcoal micro-powder, a herba houttuyniae extract, an aloe extract, a trehalose aqueous solution and silk fibroin in proportion, mixing evenly, and emulsifying to obtain a finished product; and preparation of the anti-bacterial textile. The finishing liquid mostly selects the natural antibacterial agents, and the textile is made of cotton, hemp or mulberry silks, not only is extremely high in comfortable degree, but also has the moisture-dispelling and sweat-absorbing functions better than those of ordinary fabrics; and with addition of the natural anti-bacterial deodorant finishing liquid, the prepared finished product can be safely used for sterilization, has no harm to human bodies, allows microorganisms not to generate drug resistance, and is suitable for promotion and use.

Owner:JIANGSU SHUANGSHUANG CLOTHING

Method for producing stretch knit warm fabric with high shape preservation property

ActiveCN105970462ANo damage such as melting cracks was foundLess hairyWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention relates to a fabric production method, in particular to a method for producing a stretch knit warm fabric which is small in fiber damage, stable in elasticity, small in shrinkage degree and high in shape preservation property. The method comprises the steps of gray fabric knitting, gray fabric scutching, presetting, dyeing, water pressing and drying, fleecing, setting, lustring and shearing. During gray fabric knitting, ecotype fiber and single-component or multi-component blended yarn containing protein fiber or cellulosic fiber are used as surface yarn, DTY fine-denier polyester interlaced low-stretch long filament subjected to yarn steaming setting at 130 DEG C in a vacuum environment is used as bottom yarn, DTY polyester interlaced low-stretch yarn is used as middle connecting yarn, and 2.5 times drafting 20D spandex yarn is fed together with the surface yarn. In this way, the fabric is high in elasticity and shape preservation property. By reducing presetting temperature and machine speed, the degree of damage to spandex yarn is reduced to the minimum, and it is ensured that the elasticity of spandex yarn is stable.

Owner:ZHEJIANG JIAMING DYEING & FINISHING CO LTD

Regenerated cellulose fiber-real silk jacquard fabric for home textiles and preparation method thereof

The invention discloses a regenerated cellulose fiber-real silk jacquard fabric for home textiles and a preparation method thereof. The regenerated cellulose fiber-real silk jacquard fabric is woven by adopting regenerated cellulose fiber long yarns as warp yarns and real silk yarns as weft yarns in a jacquard interweaving mode. Because the regenerated cellulose fiber long yarns per se have good handfeel and soft gloss, the regenerated cellulose fiber-real silk jacquard fabric formed by interweaving the regenerated cellulose fiber long yarns and the real silk yarns has smooth handfeel comparable with that of a full real silk jacquard fabric; the regenerated cellulose fiber-real silk jacquard fabric is a jacquard fabric with different yarn-dyed effects by a later-bath yarn dyeing method; and compared with separate dyeing, the preparation method can effectively save the cost.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Process for pre-treating, dyeing and settling wool cotton or cashmere cotton printed and dyed fabrics

InactiveCN102102298ASoft touchFeel smoothBiochemical fibre treatmentBleaching apparatusCellulosePulp and paper industry

The invention discloses a process for pre-treating, dyeing and settling wool cotton or cashmere cotton printed and dyed fabrics, wherein the process flows are as follows: preparing a wool cotton or cashmere cotton stock cloth, desizing and cooking the stock cloth with compound bio-enzyme, bleaching in oxygen, grinding with carbon, treating with cellulose, dyeing by using an airflow machine, softening the cloth on a softening machine, and tentering and pre-shrinking in loosening mode, so as to acquire the finished product wool and cotton or cashmere and cotton, the proportion by weight of which is (15-30%):(70-85%). The wool cotton or cashmere cotton printed and dyed fabrics treated by using the process provided by the invention are soft, smooth and fluffy in hand feel, can excellently keep warm, are comfortable and breathable in wearing, have wealthy, noble and elegant appearance, are high-class clothes fabrics, and are suitable for being used as the materials of clothes fabrics such as high-class western-style clothes, western style pants, leisure wear, and the like.

Owner:FUJIAN ZHONGHE

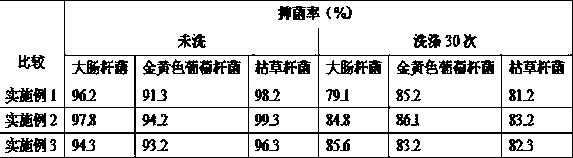

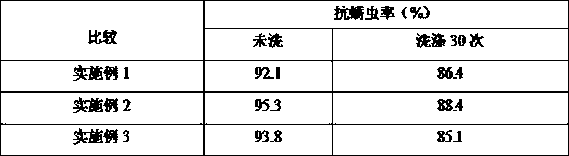

Antibacterial fabric, preparation technology thereof and textile thereof

InactiveCN103255522ANon-irritatingImprove thermal stabilityWeft knittingCarbon fibresBiotechnologyPolyester

The invention relates to the field of functional fabrics, in particular to an antibacterial fabric, a preparation technology of the antibacterial fabric and textile of the antibacterial fabric. The antibacterial fabric comprises, by weight, 10-20 parts of short fiber silk, 20-25 parts of anion polypropylene staple fibers, 15-25 parts of nano bamboo carbon fiber, 2-5 parts of nano-titanium dioxide, 5-10 parts of nano-silver fiber, 2-4 parts of anti-mite finishing agent, 3-8 parts of sweat-absorbent quick-drying processing agent, 12-18 parts of binder, 2-4 parts of dispersing agent, 3-5 parts of fabric softener and 80-85 parts of polyester cotton fiber. Due to the fact that the anion polypropylene staple fibers are added, effects of nerve stability, sleep improvement, inflammation diminishing and pain relief are provided. Due to the fact that the anti-mite finishing agent is added, trouble caused by mites to a human body can be effectively prevented. Due to the fact that the sweat-absorbent quick-drying processing agent is added, sweat generated by the body can be rapidly absorbed, discomfort can be reduced, and breeding of germs under a humid environment can be prevented. The antibacterial fabric can be applied to clothing, home textiles, sports goods, medical care, bacteria resistance and insect prevention textiles.

Owner:广东雄兴内衣实业有限公司

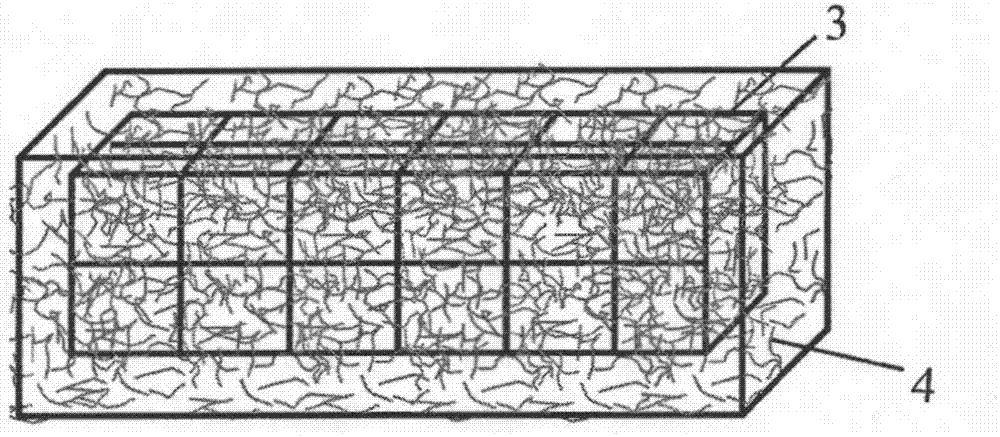

Three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material and preparation thereof

InactiveCN107116857AImproved dissipation capacityAct as a reflectionSynthetic resin layered productsCellulosic plastic layered productsNoise reduction coefficientFiber

The invention provides a three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material and preparation thereof. The three-dimensional porous framework-reinforced fiber sponge containing high-efficiency sound-absorbing material is characterized by comprising three-dimensional porous framework-reinforced fiber sponge and a microporous membrane compounded on the three-dimensional porous framework-reinforced fiber sponge. The sound-absorbing material is the high-efficiency sound-absorbing material obtained by introducing a three-dimensional porous framework with certain mechanical strength as a main body supporting reinforcing structure, putting the three-dimensional porous framework into flame retardant-containing fiber slurry, forming the slurry, drying a solvent, curing to obtain the reinforced fiber sponge with a reinforcing framework therein, and compounding the reinforced fiber sponge with the microporous membrane. The noise reduction coefficient (NRC) of the obtained sound-absorbing material is 0.34-0.59; and the sound-absorbing material shows relatively high sound-absorbing performance.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com