Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1823 results about "Elastic fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elastic fibers (or yellow fibers) are bundles of proteins (elastin) found in extracellular matrix of connective tissue and produced by fibroblasts and smooth muscle cells in arteries. These fibers can stretch up to 1.5 times their length, and snap back to their original length when relaxed. Elastic fibers include elastin, elaunin and oxytalan.

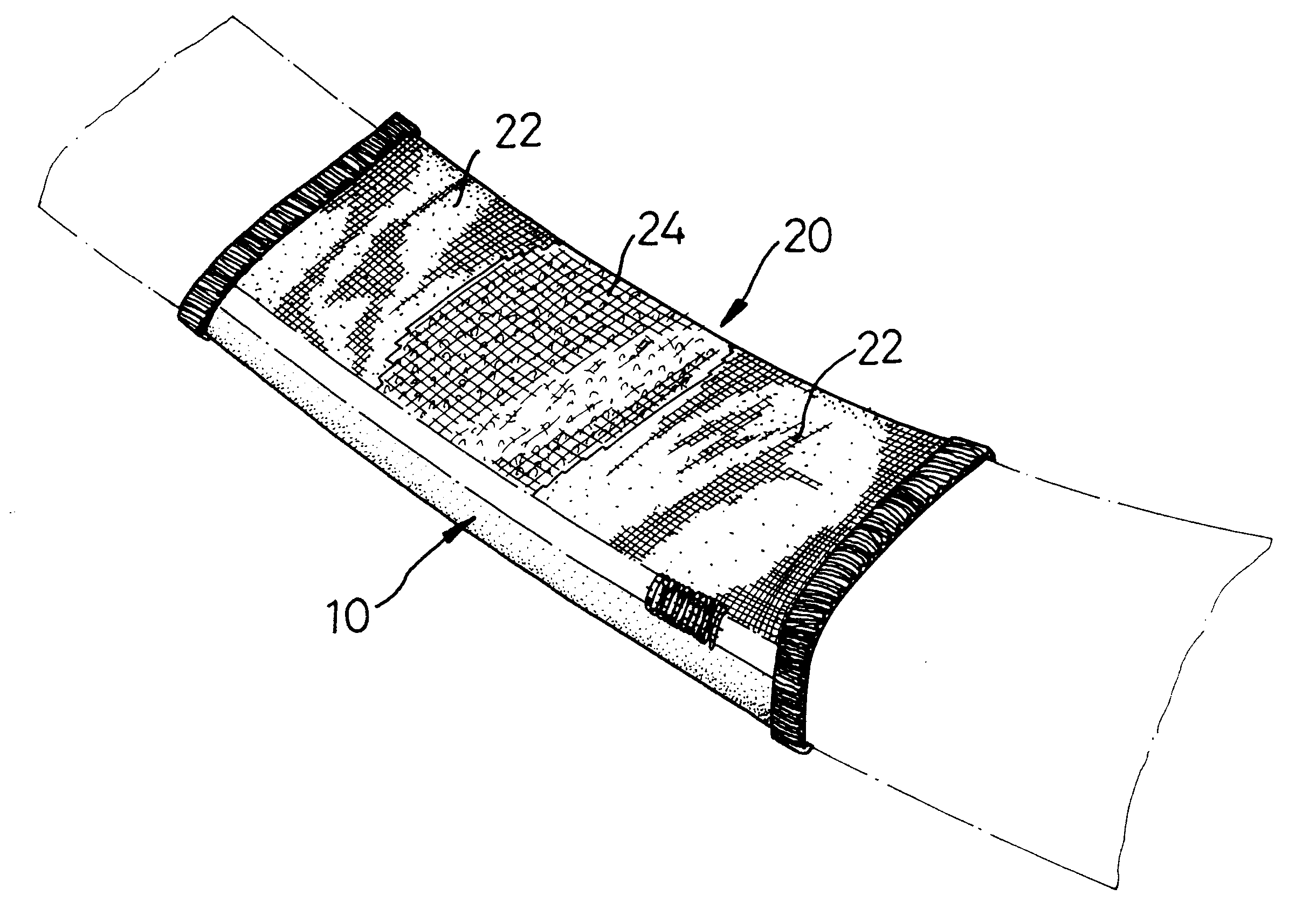

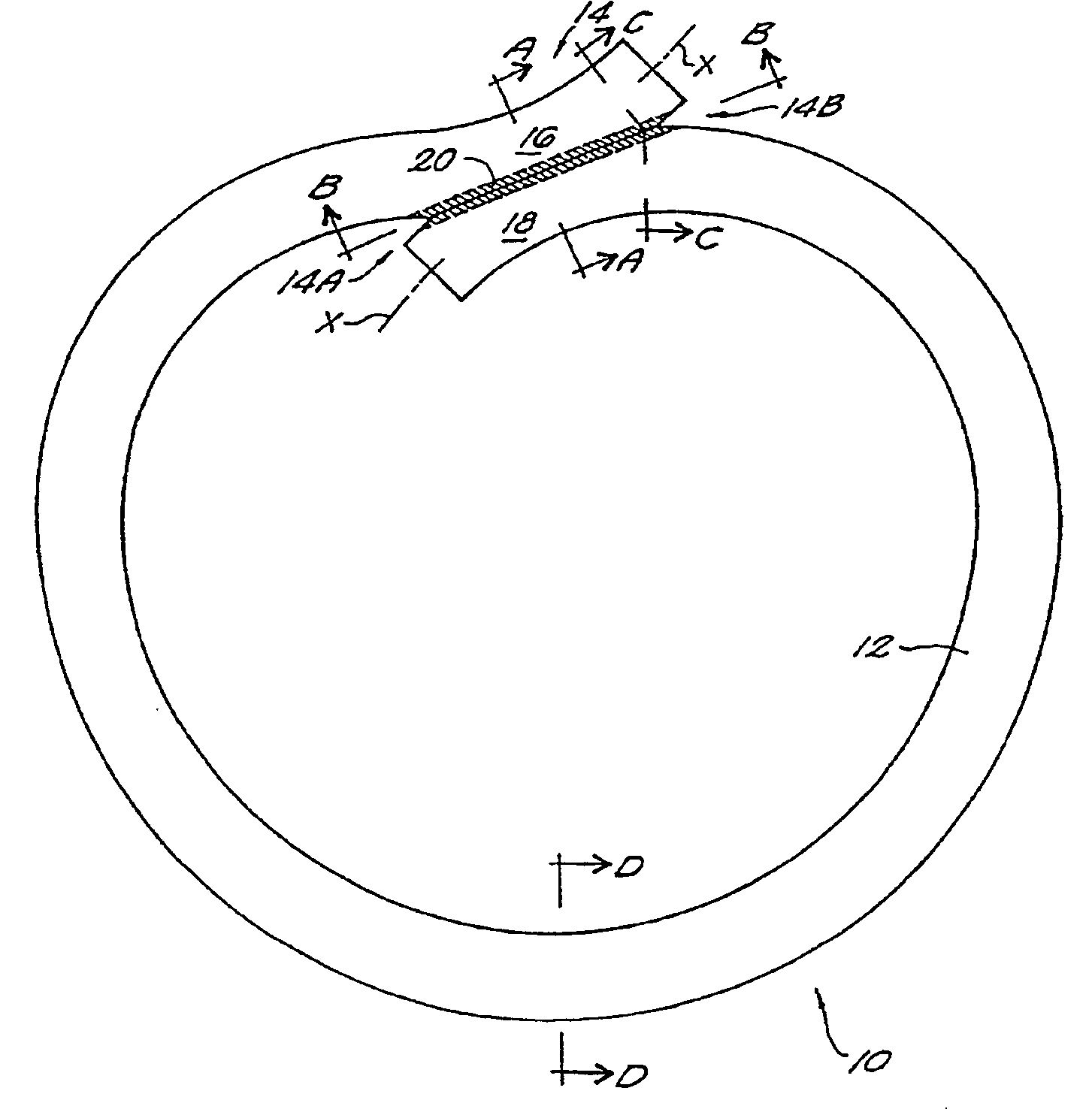

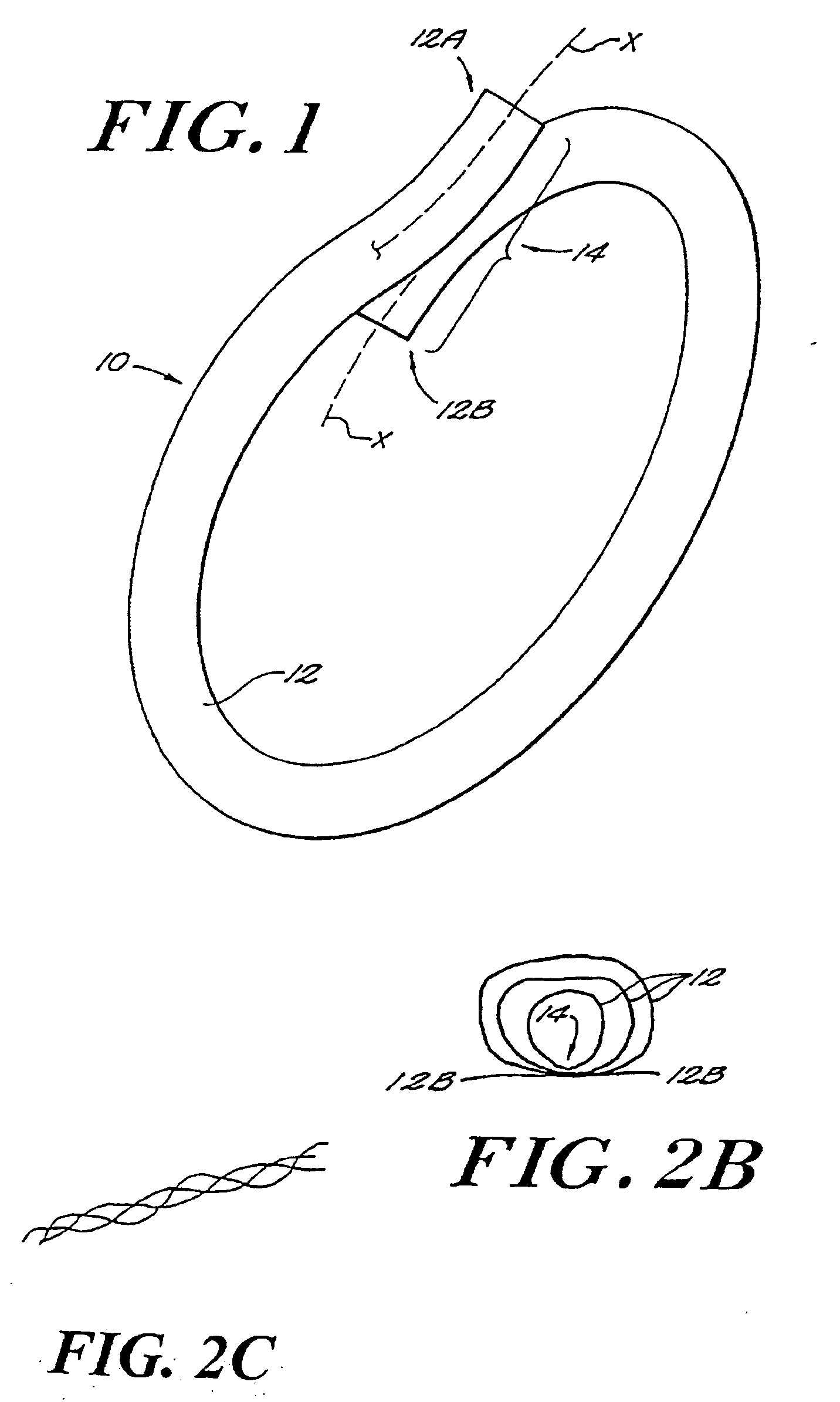

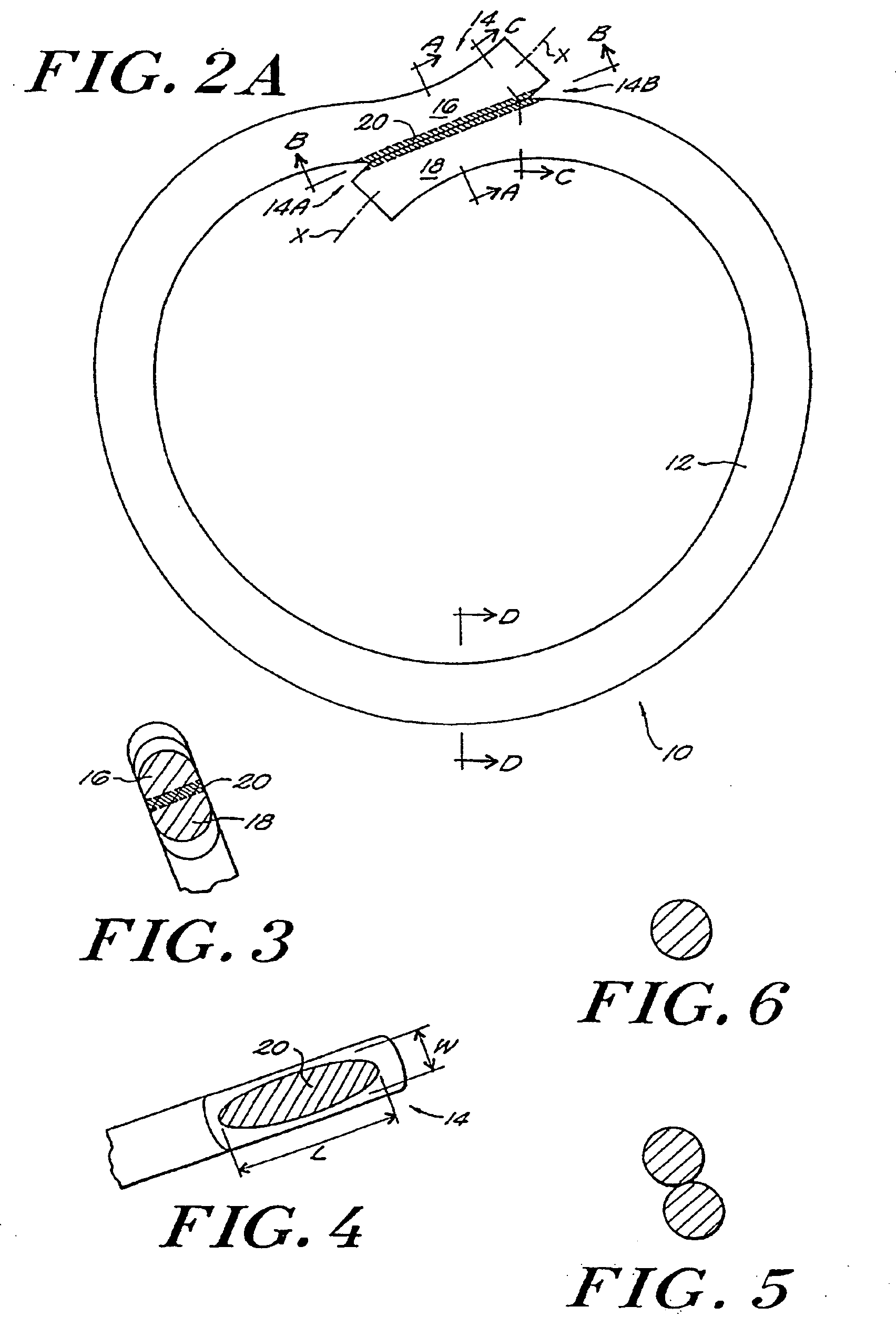

Ventilative joint guard

A ventilative joint guard is composed of a neoprene outer portion (10) and an elastic fiber textile inner portion (20). The joint guard provides a physical heating treatment, however, variation in the texture of the elastic fiber textile of the inner portion (20) makes the joint guard have excellent ventilation and makes users still feel comfortable after having worn the joint guard for a period of time.

Owner:CHIANG PANG CHING

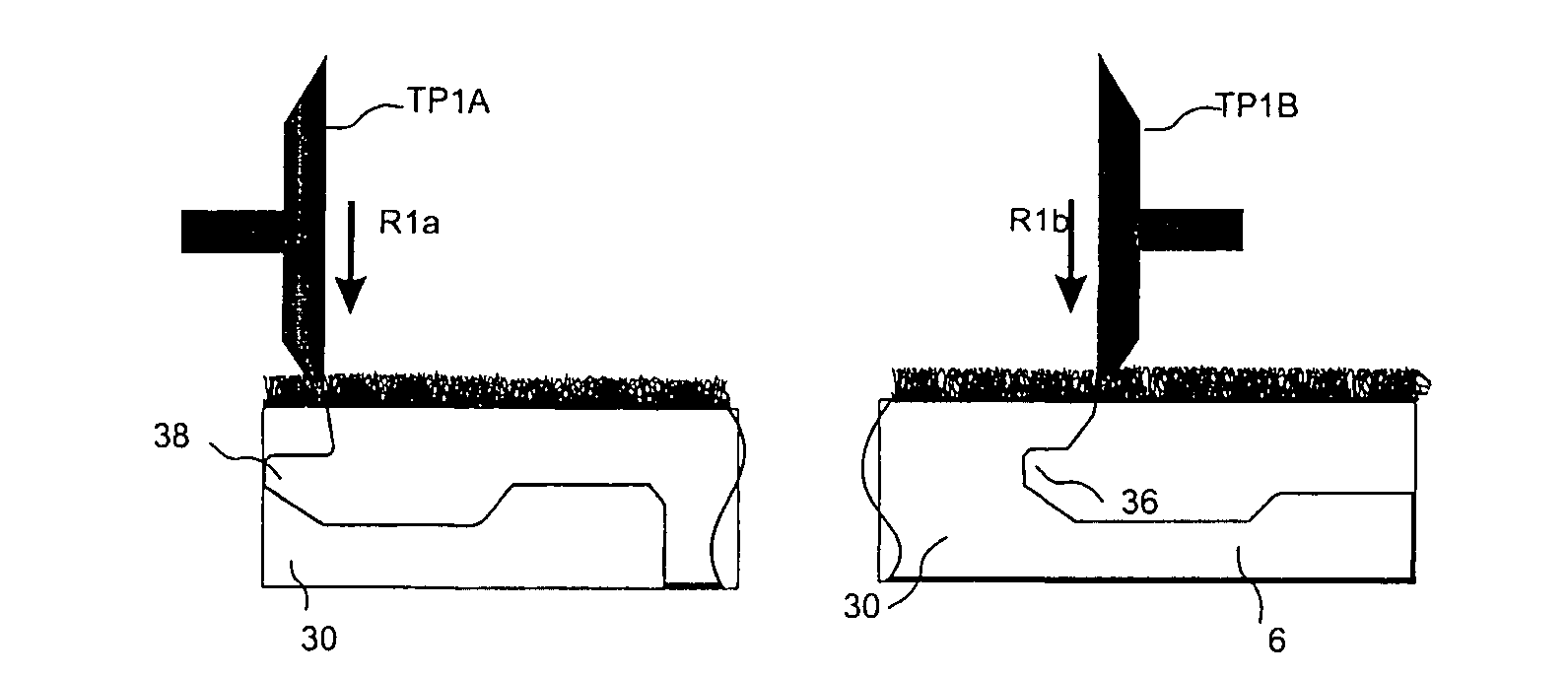

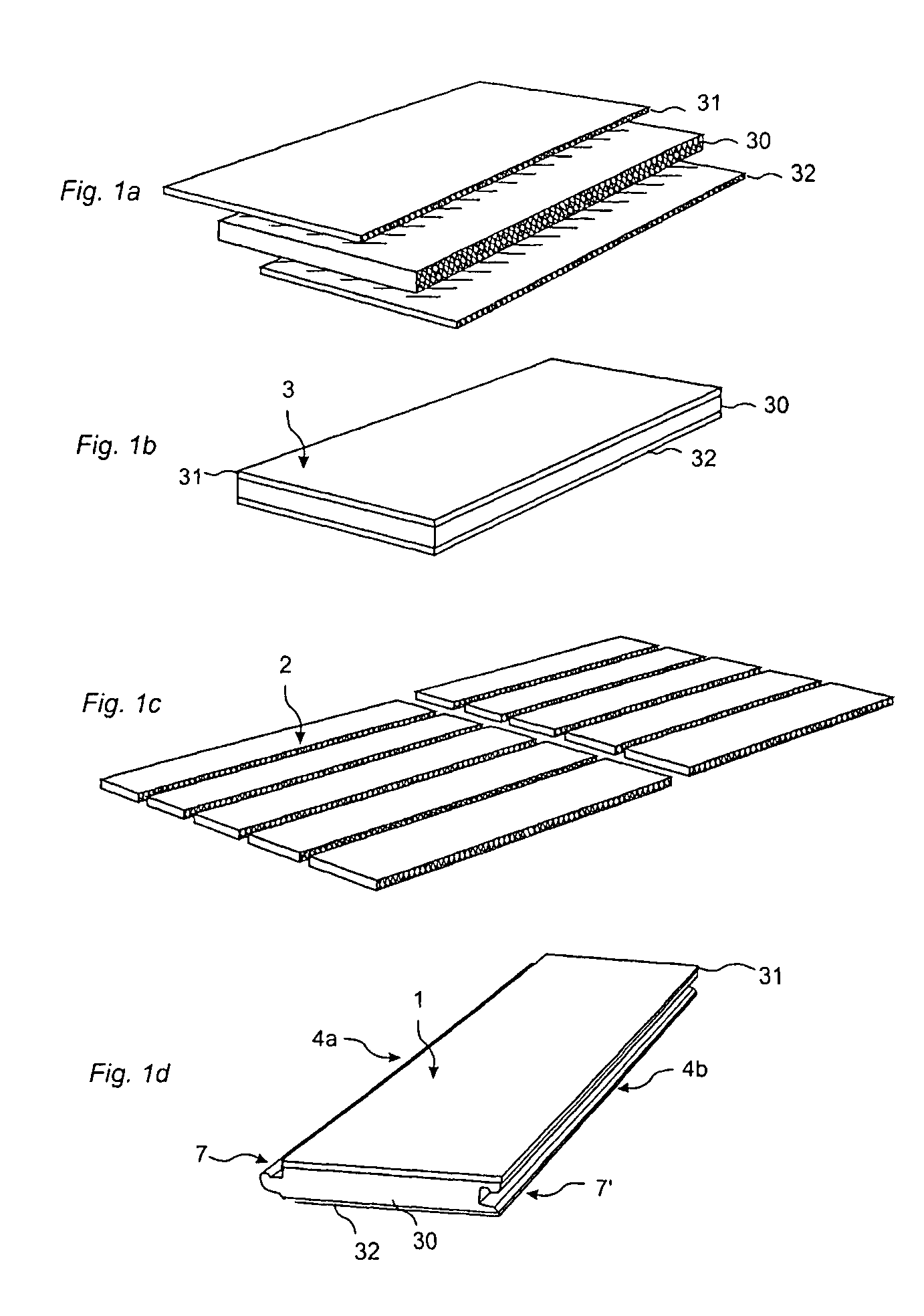

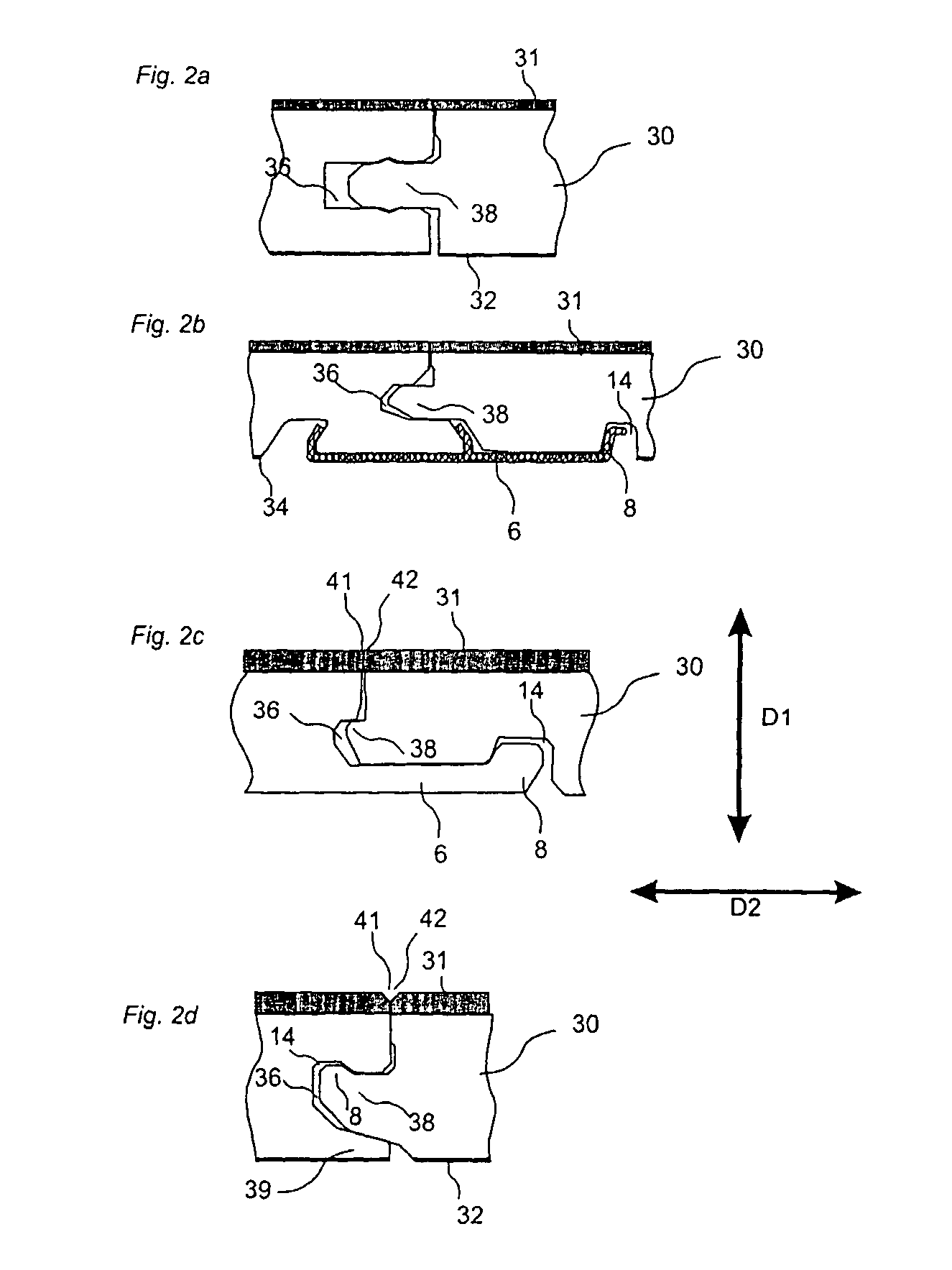

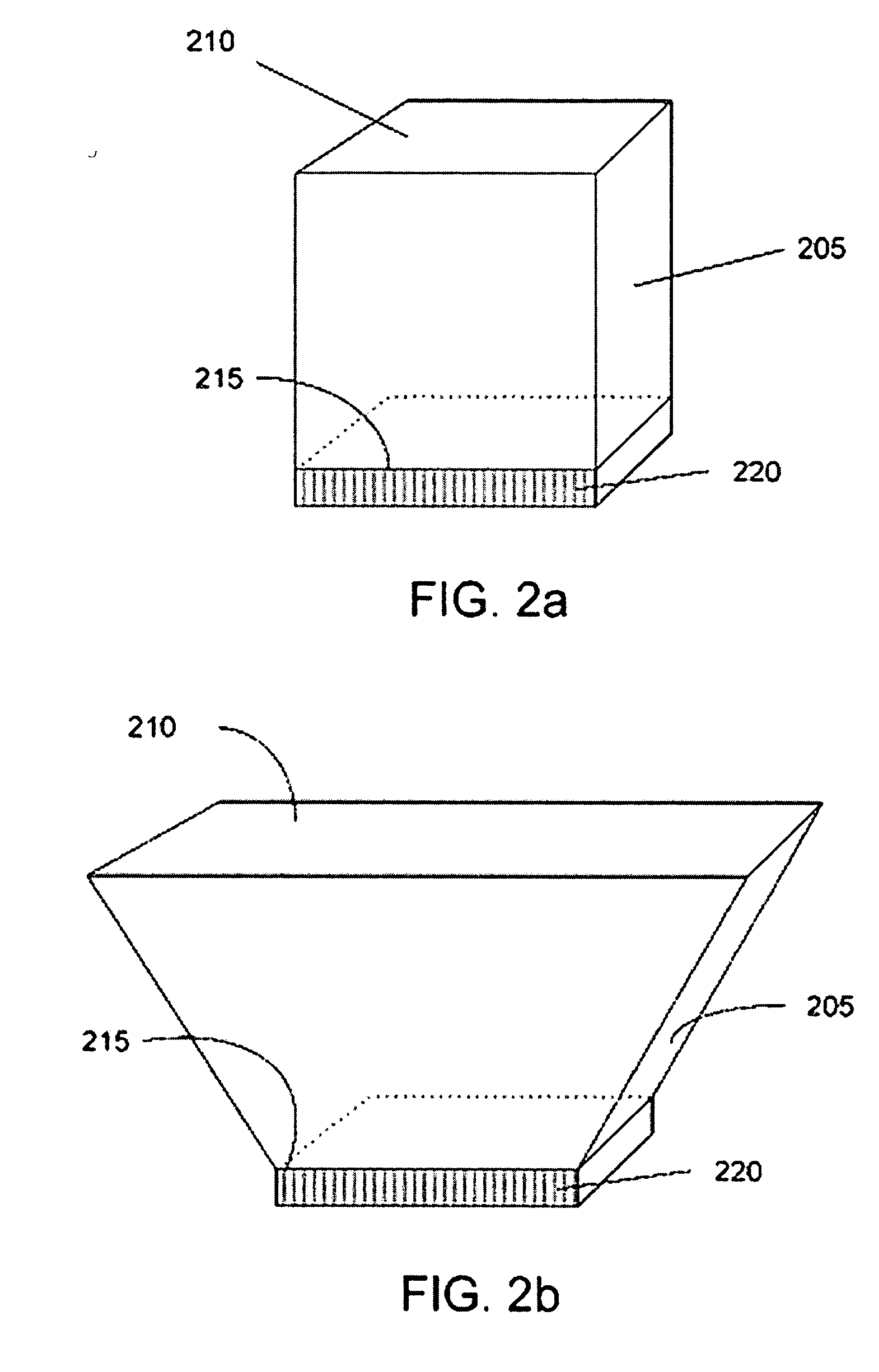

Method for manufacturing floorboard having surface layer of flexible and resilient fibers

ActiveUS8112891B2Reduce sound levelAttractive appearanceTongue/grooves making apparatusWallsFiberMoving floor

Owner:VÄLINGE INNOVATION AB

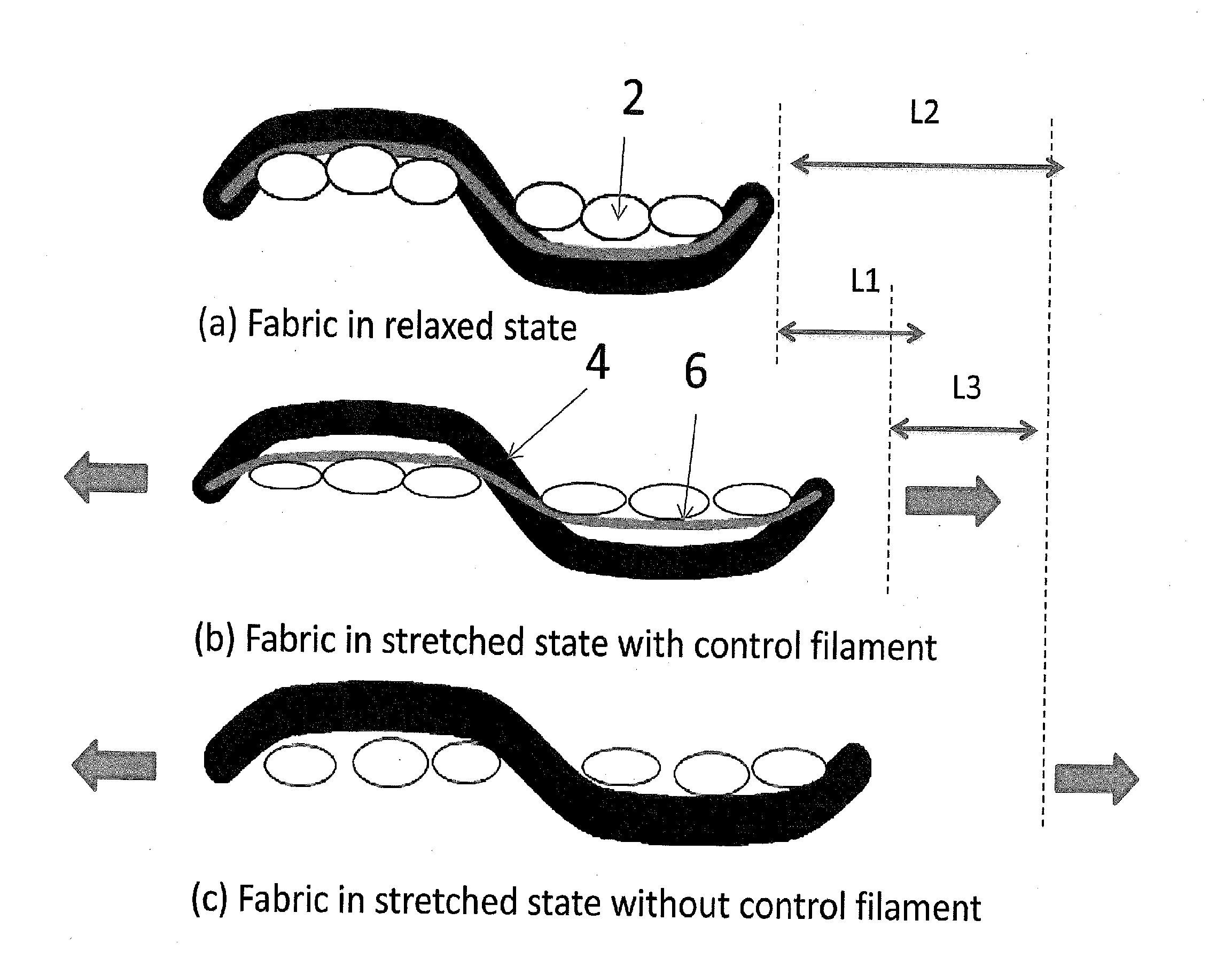

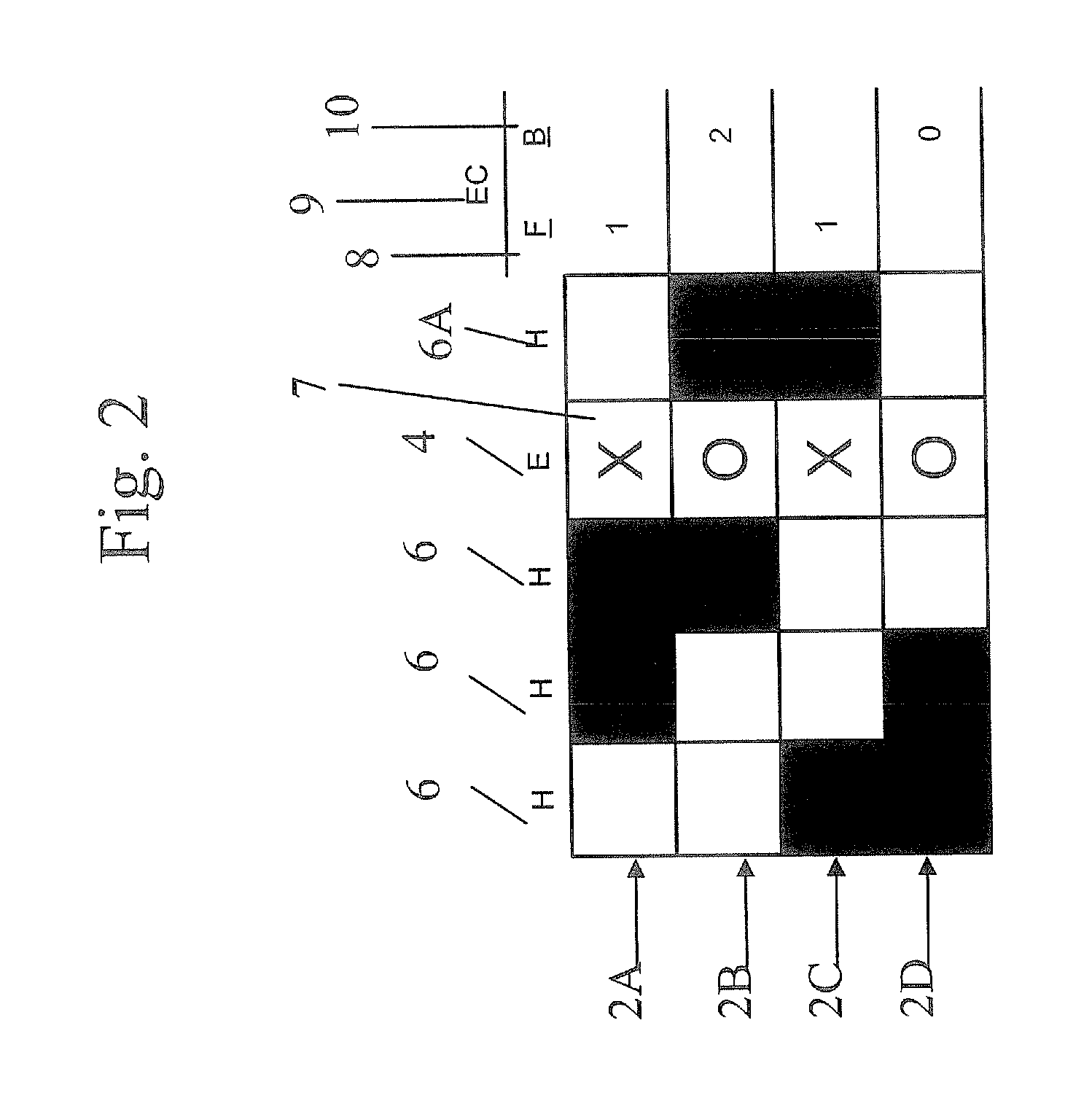

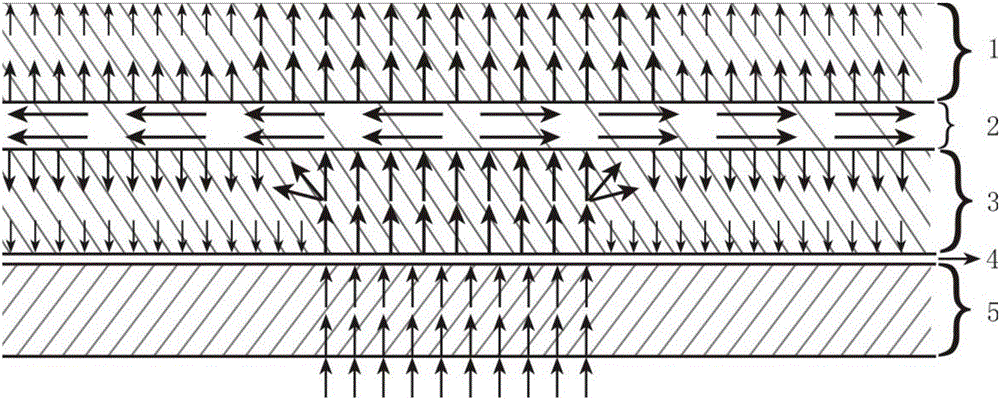

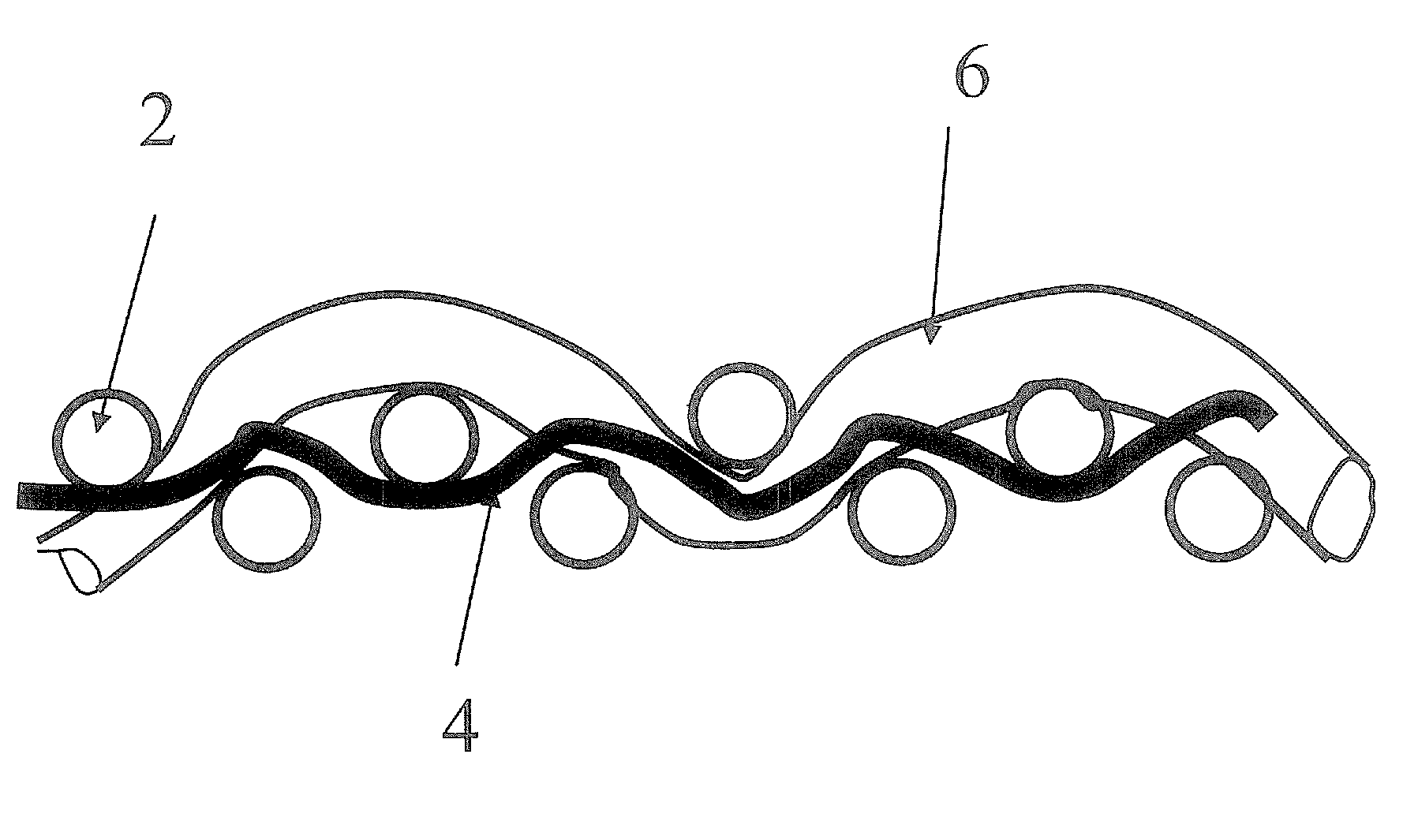

Stretch wovens with a control yarn system

ActiveUS20150133017A1Better recovery powerImprove the level ofShrinkingPattern makingEngineeringElastic fiber

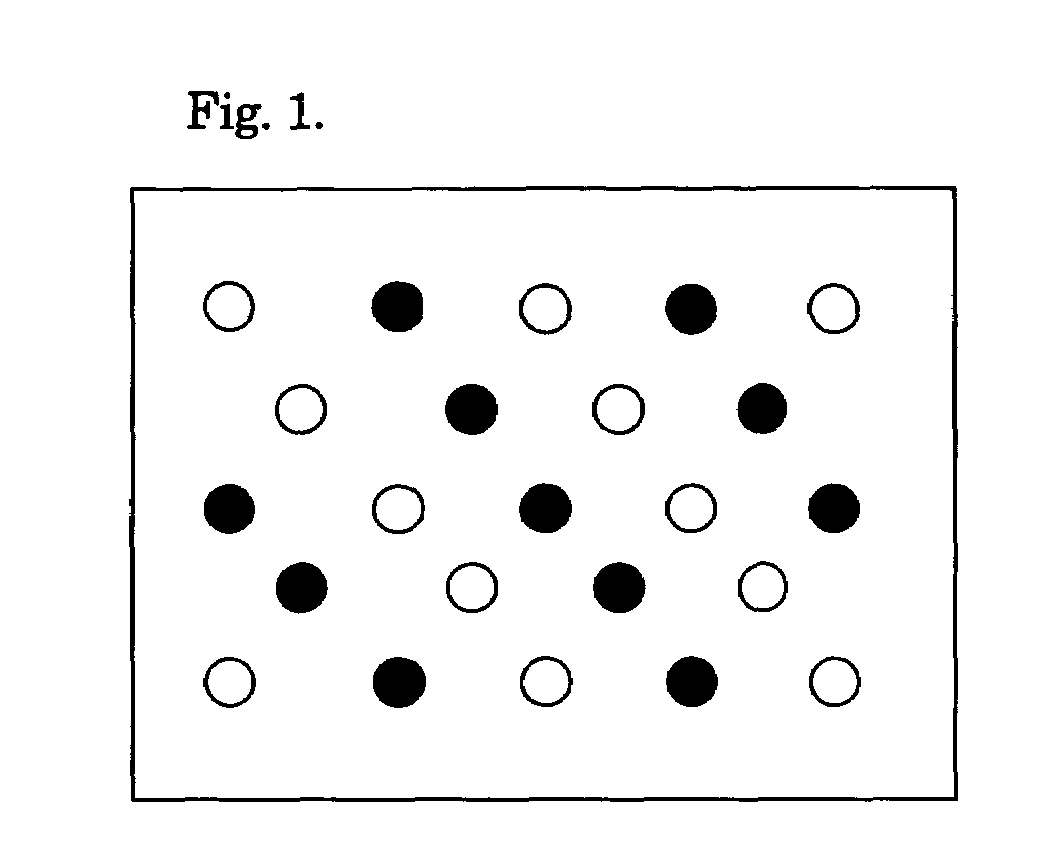

An article including a woven fabric comprising warp yarns and weft yarns, wherein at least one of either the warp yarns or the weft yarns includes: (a) a corespun elastic base yarn having a denier and including staple fiber and an elastic fiber core; and (b) a separate control yarn selected from the group consisting of a single filament yarn, a multiple filament yarn, a composite yarn, and combinations thereof; having a denier greater than zero to about 0.8 times the denier of the corespun elastic base yarn; wherein the woven fabric includes (1) a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; or (2) a ratio of corespun base yarn picks to control yarn picks of up to about 6:1; or (3) both a ratio of corespun base yarn ends to control yarn ends of up to about 6:1; and a ratio of corespun base yarn picks to control yarn picks of up to about 6:1.

Owner:THE LYCRA CO LLC

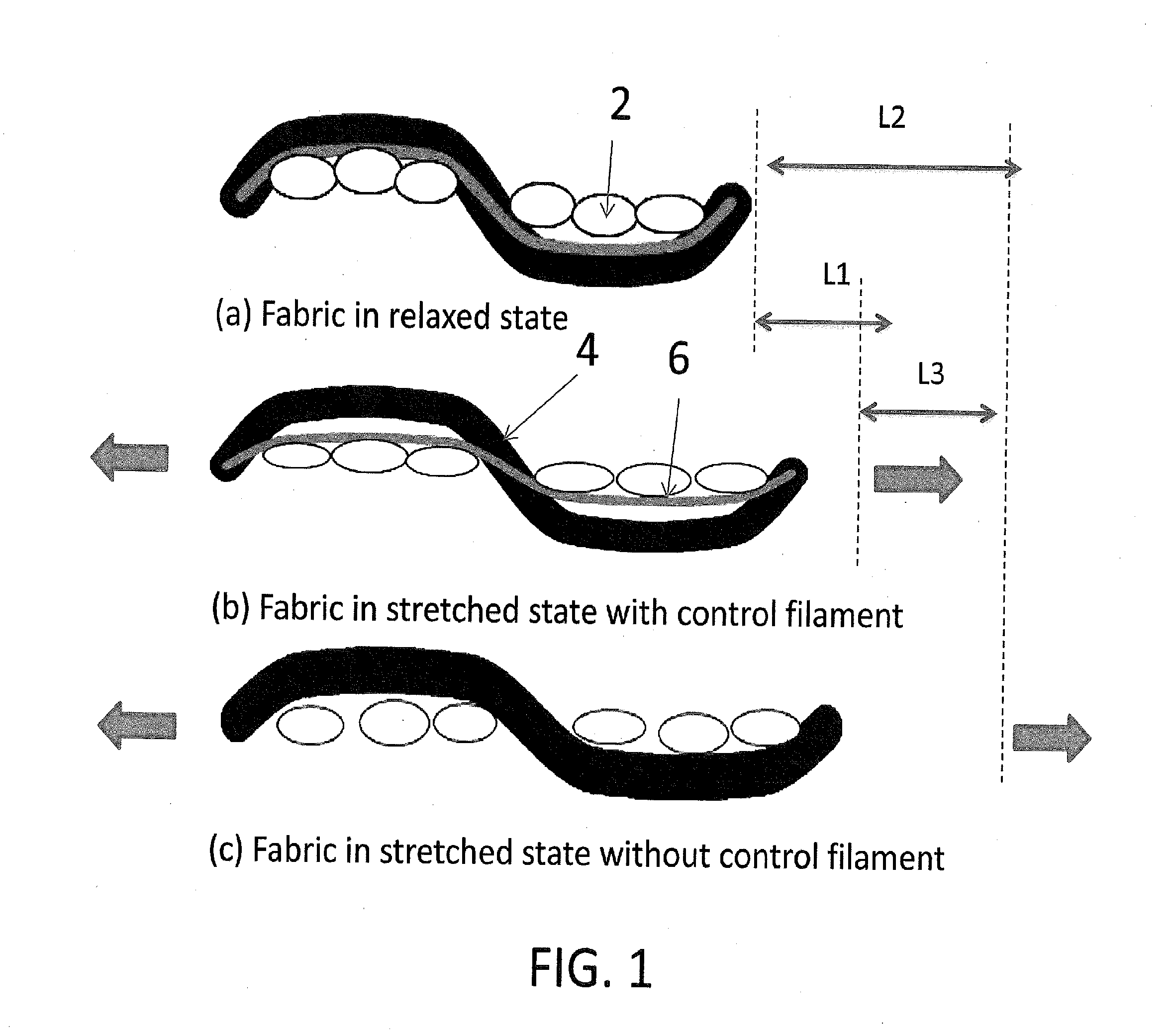

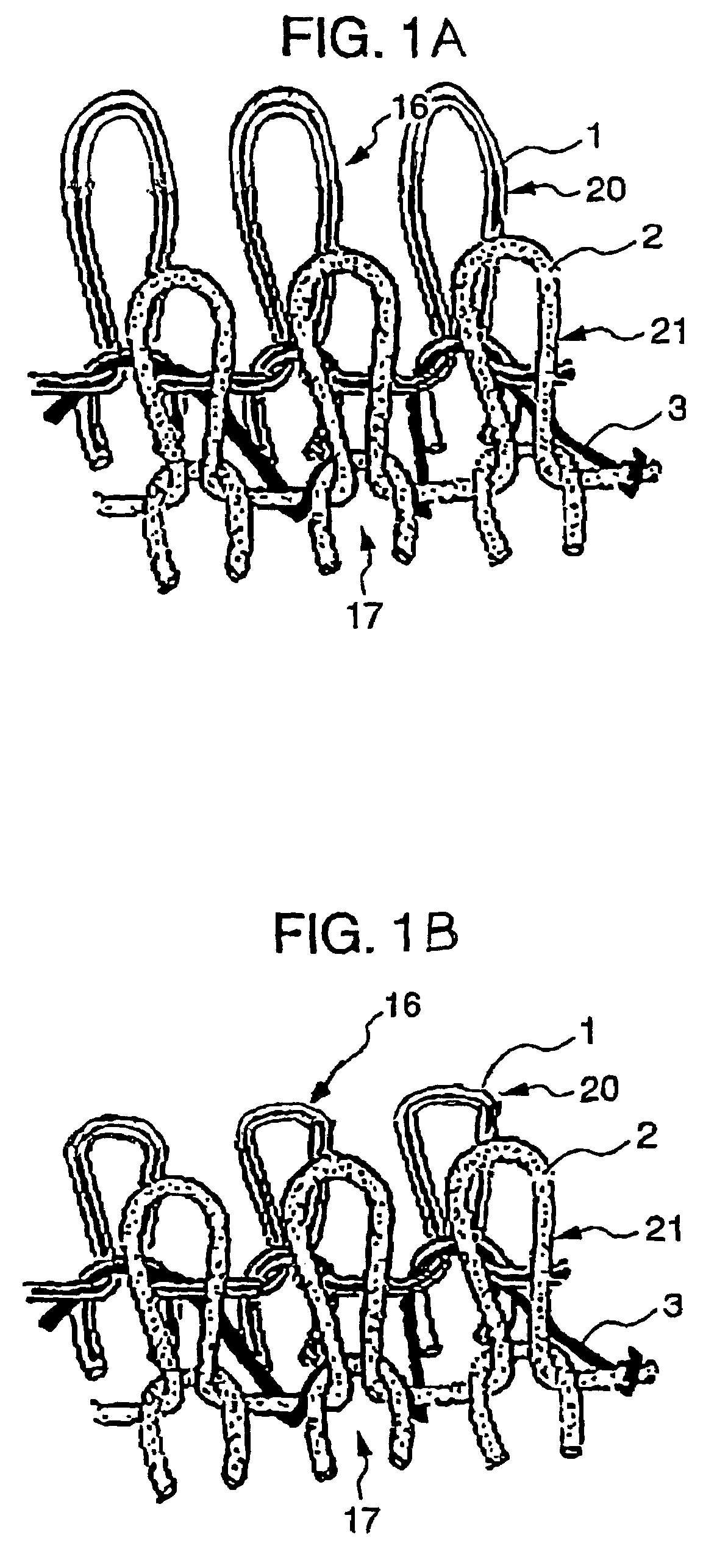

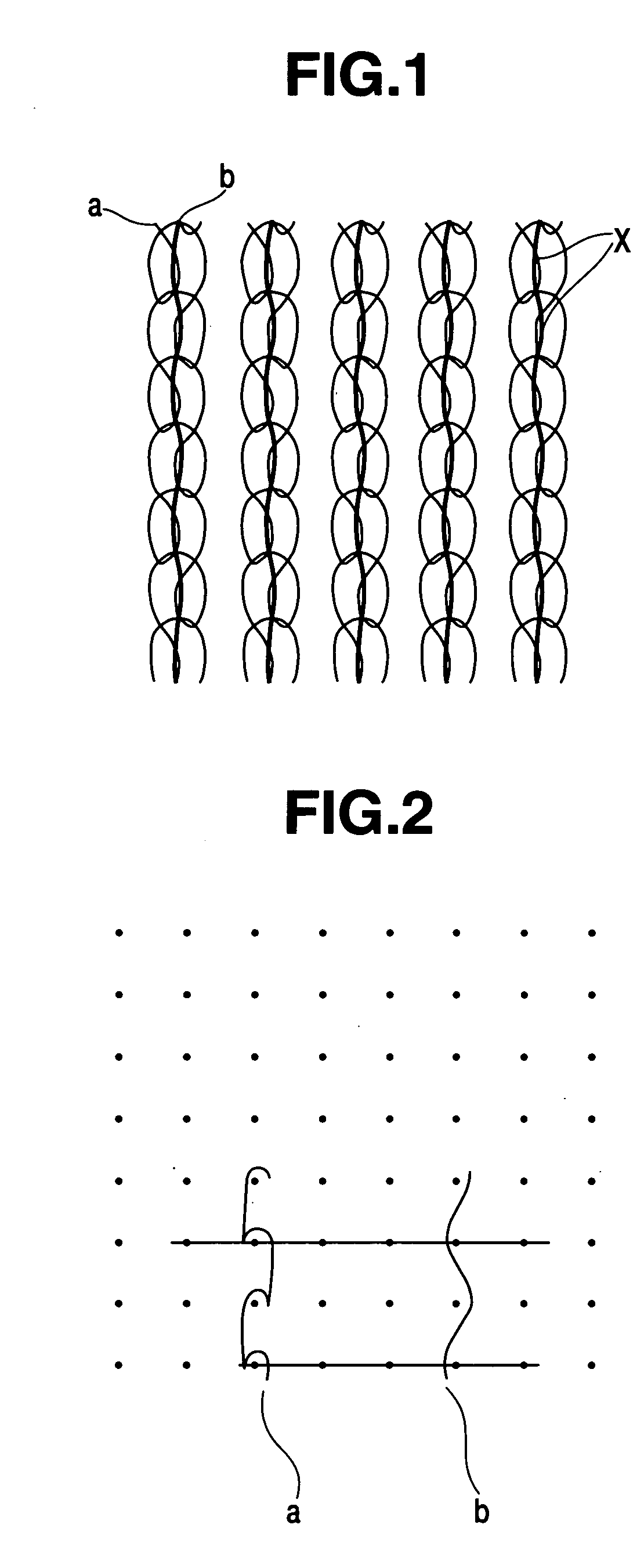

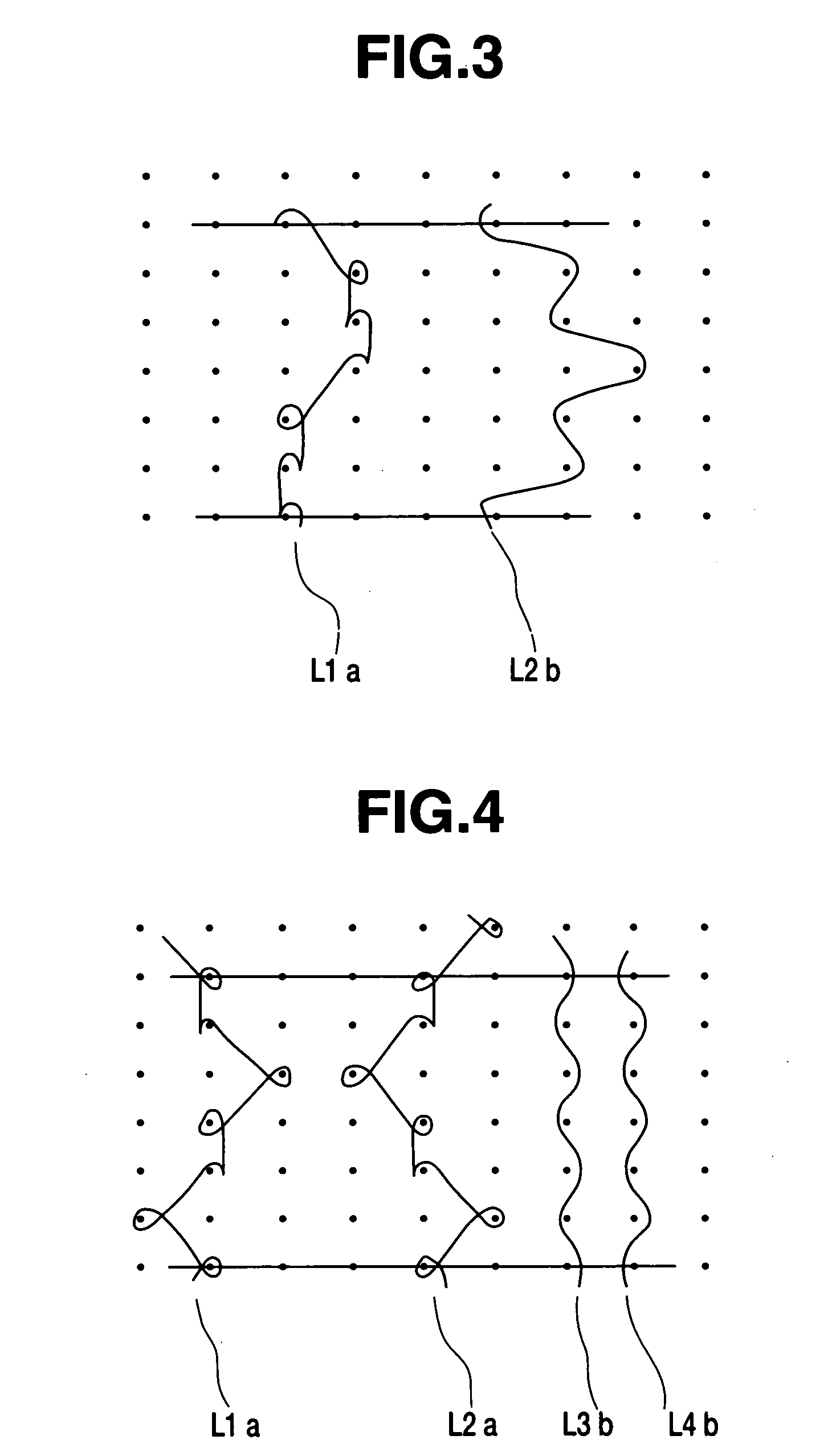

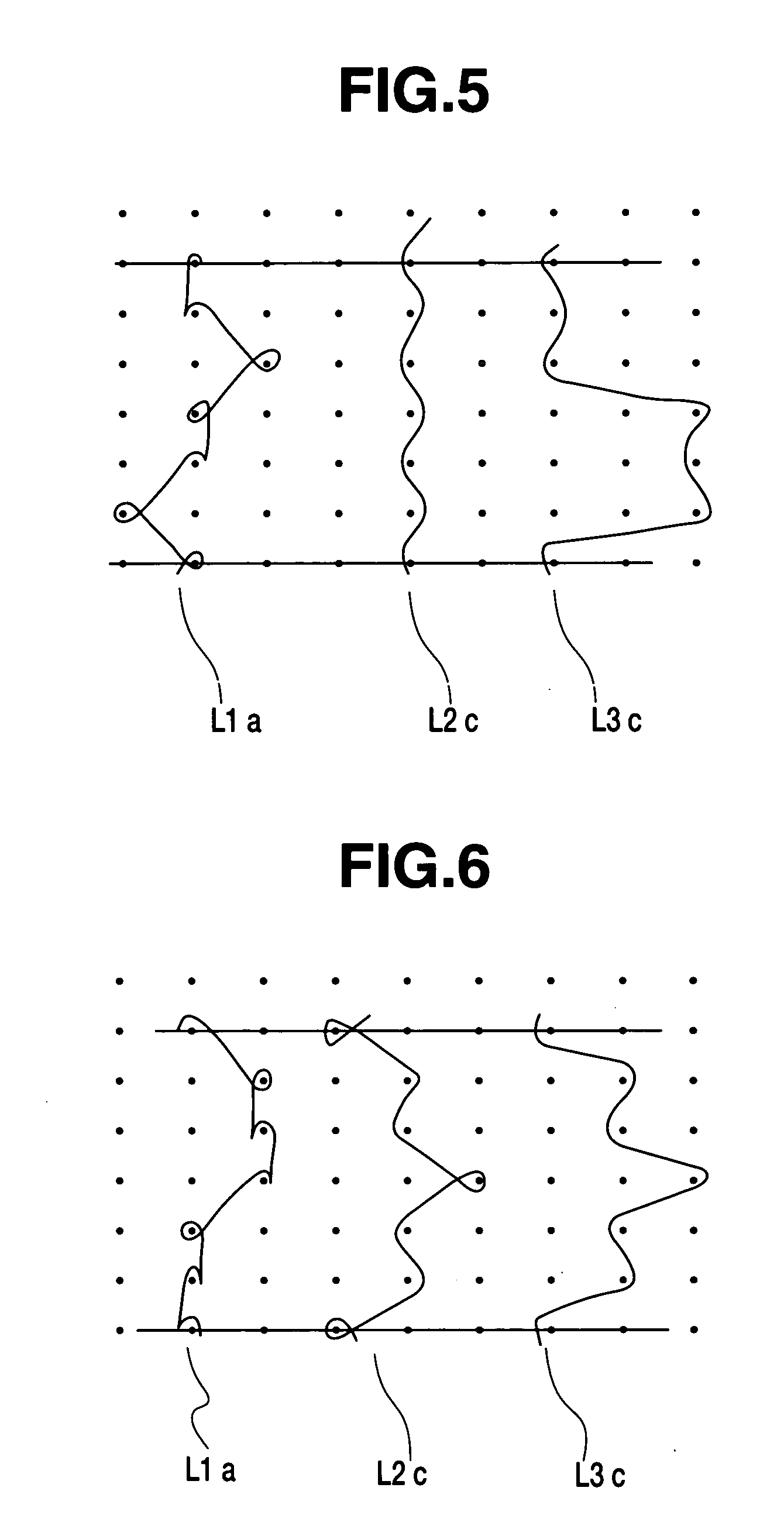

Elastic knitting fabric having multilayer structure

InactiveUS7240522B2Improve tensile propertiesImproved shape stabilityOrnamental textile articlesStraight-bar knitting machinesFiberElastic fiber bundle

An elastic knitted fabric having a multilayer structure, made by binding separate front and back two-layer ground knitted fabrics together, wherein the above described two-layer ground knitted fabrics are bound together with only a bare string(s) of polyurethane based elastic fibers of 17 to 3000 decitexes.

Owner:ASAHI KASEI FIBERS CORPORATION

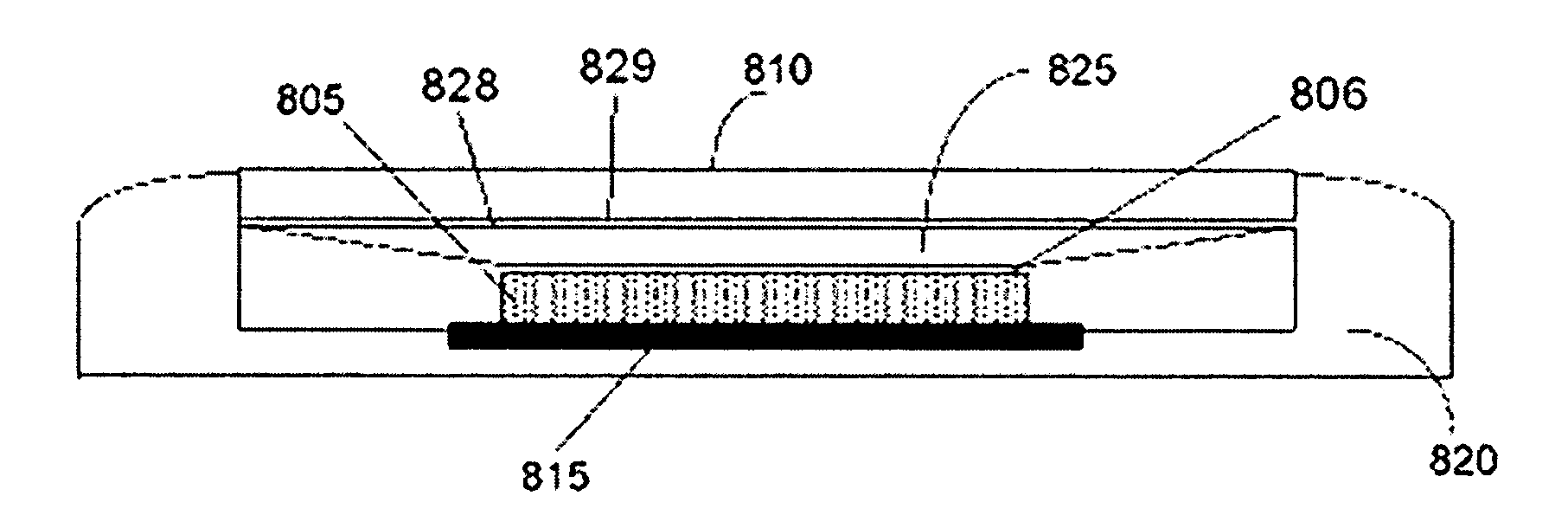

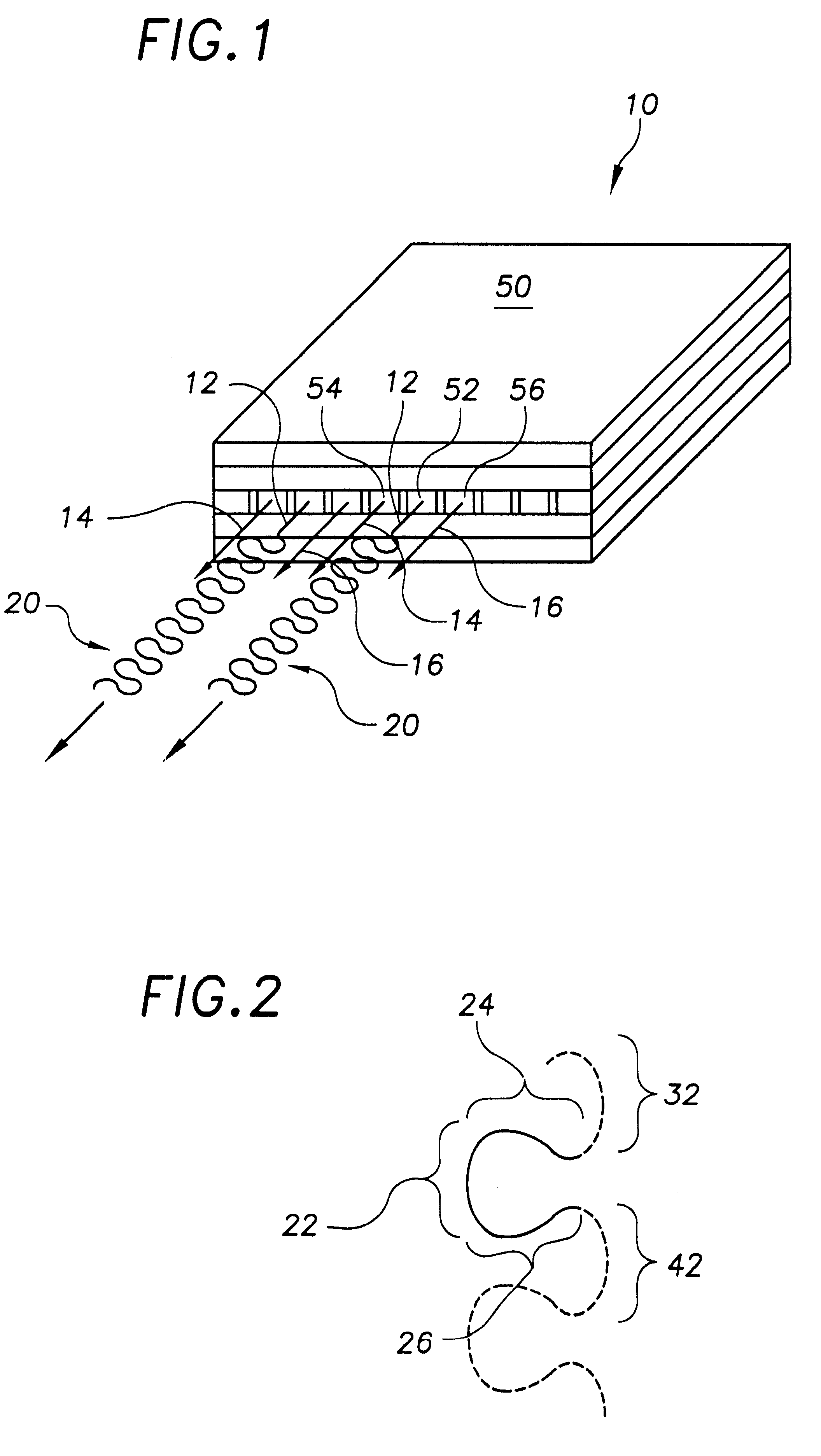

Elastic fiber optic image guide

InactiveUS20070097108A1Increase brightnessCathode-ray tube indicatorsDetails for portable computersDisplay deviceEngineering

There is disclosed a mobile consumer electronic device comprising a display capable of providing information at an external display surface. The device further includes an elastic fiber optic image guide extending between a first end and a second end. The first end of the elastic fiber optic image guide is optically coupled to the external display surface. The second end of the elastic fiber optic image guide having a first configuration in a first mode and a second configuration in a second mode. The second end may be rotated and / or enlarged in the second mode when compared to the first mode.

Owner:SONY COMPUTER ENTERTAINMENT INC

Mechanically strong absorbent non-woven fibrous mats

The present invention is generally directed to a liquid entrapping device having the capacity to absorb liquids. More particularly, the present invention is directed to a liquid entrapping device comprising an absorbent component, hydrophilic elastomeric fibrous component in fluid communication therewith, and optionally an adhesive component. The present invention is also directed to a liquid entrapping device having the capacity to absorb liquids while maintaining a suitable degree of mechanical strength. Furthermore, the present invention is generally directed to methods for making and using the foregoing devices and materials.

Owner:AKRON UNIV OF

Stretch wovens with separated elastic yarn system

In some embodiments are an article including a woven fabric having warp yarns and weft yarns. Either warp yarn or weft yarn or both warp and weft yarns have two separate systems of yarns. The systems of yarns include a hard yarn forming the main body of fabric and a composite covered elastic yarn with an elastic fiber core; wherein the fabric has an outer face side, a back side, and the fabric includes at least one of: (a) a weaving pattern where the composite yarn and at least one adjacent hard yarn pass over the same pick when the composite yarn is on the outer surface; (b) the ratio of hard yarn denier to composite yarn denier is at least 1:1; and (c) the composite yarn floats over no more than 5 picks on the outer face side.

Owner:THE LYCRA CO LLC

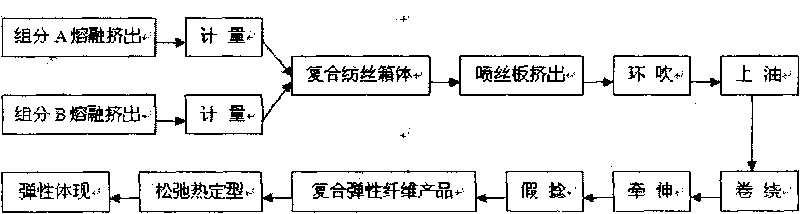

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

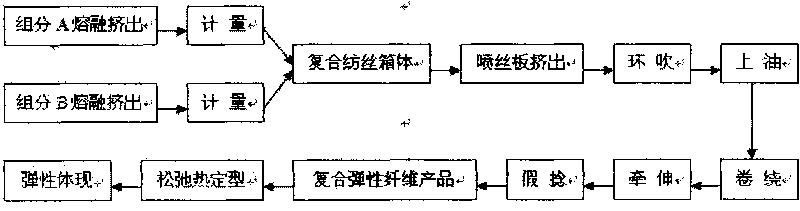

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

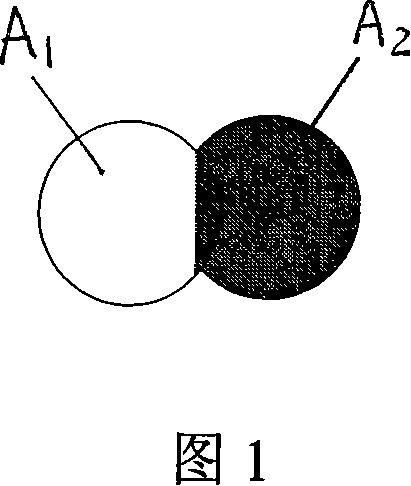

High-performance polyester composite elastic fiber and manufacturing method thereof

InactiveCN101718008AGood dyeabilityGood wrinkle resistance and shape retentionMelt spinning methodsConjugated synthetic polymer artificial filamentsCopolyesterViscosity

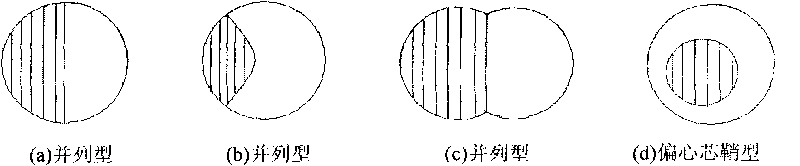

The invention provides a high-performance polyester composite elastic fiber with good dyeability. The composite fiber is prepared from two polyester or copolyester components with viscosity differences through a composite spinning process, wherein the high-viscosity component accounts for 30 to 70 percent by weight, and the low-viscosity component accounts for 70 to 30 percent by weight. The composite fiber has a parallel or eccentric core sheath type structure, and has good curling property, natural resilience and dyeability; meanwhile, the manufacturing process is simple and convenient and easy to operate; the low-temperature dyeing property of the composite fiber has the functions of environmental protection and energy conservation; and the composite fiber of the invention can be widely applied to various woven and knitted elastic fabrics.

Owner:SHANGHAI VITA SCI & TECH

Elastic nonwoven fabric and fiber products manufactured therefrom

InactiveUS7405171B2Improve productivityEase of productionEngine sealsSynthetic resin layered productsNonwoven fabricUltimate tensile strength

PROBLEM TO BE SOLVED: To provide an elastic nonwoven fabric with a good elasticity, adequate strength under elongation, good antiblocking property and favorable feeling, suitable for fiber products, at low cost, as well as fiber products using the same.SOLUTION: An elastic nonwoven fabric comprising long elastomeric fiber and nonelastomeric fiber in a weight ratio within a range from 50 / 50 to 95 / 5, which has an elongation recovery rate of the elastic nonwoven fabric after 50% elongation equal to or higher than 70%, and a resistance to peel two sheets of the nonwoven fabric apart equal to or lower than the strength of the fabric under 50% elongation; as well as fiber products using the same.

Owner:JNC CORP

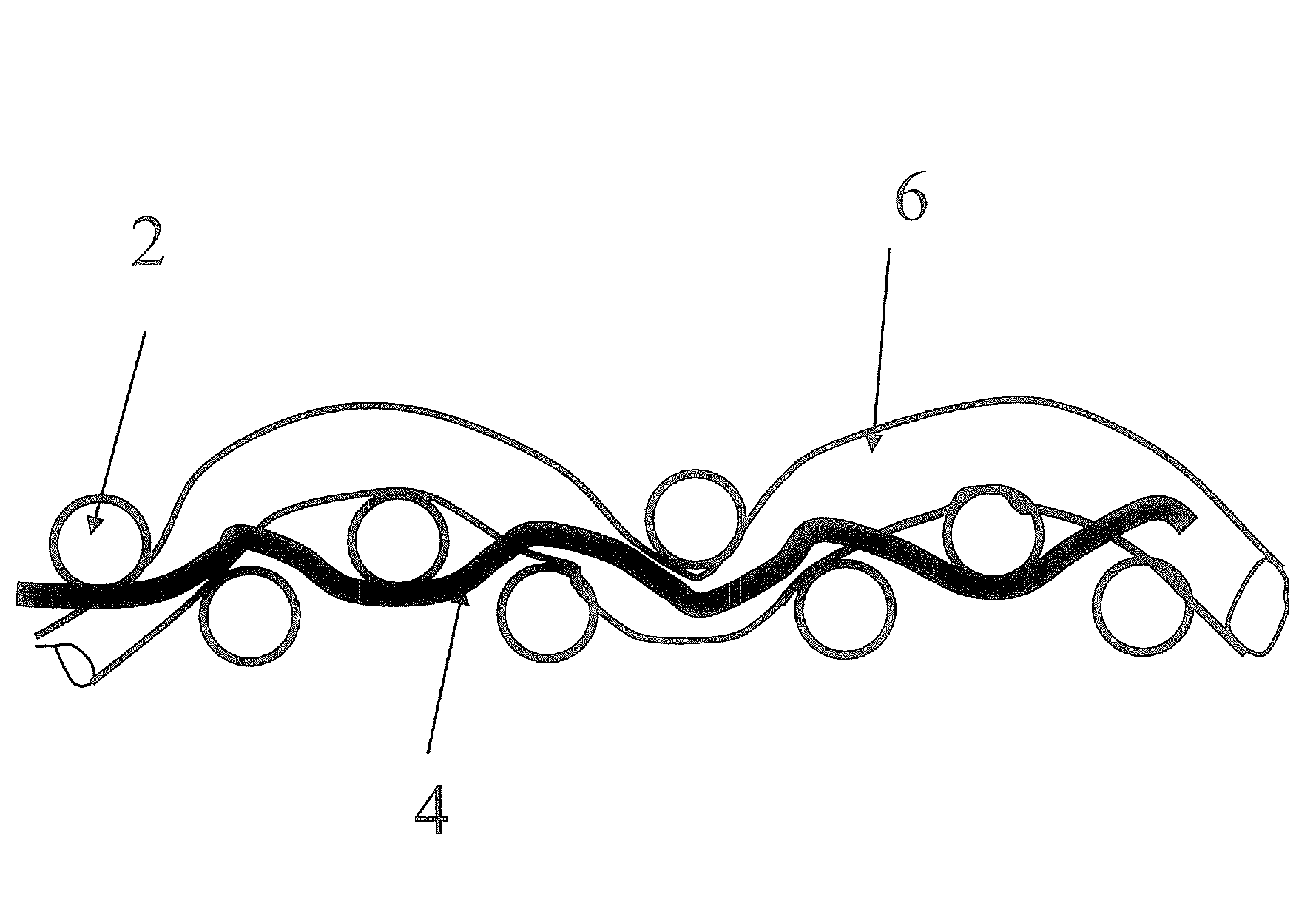

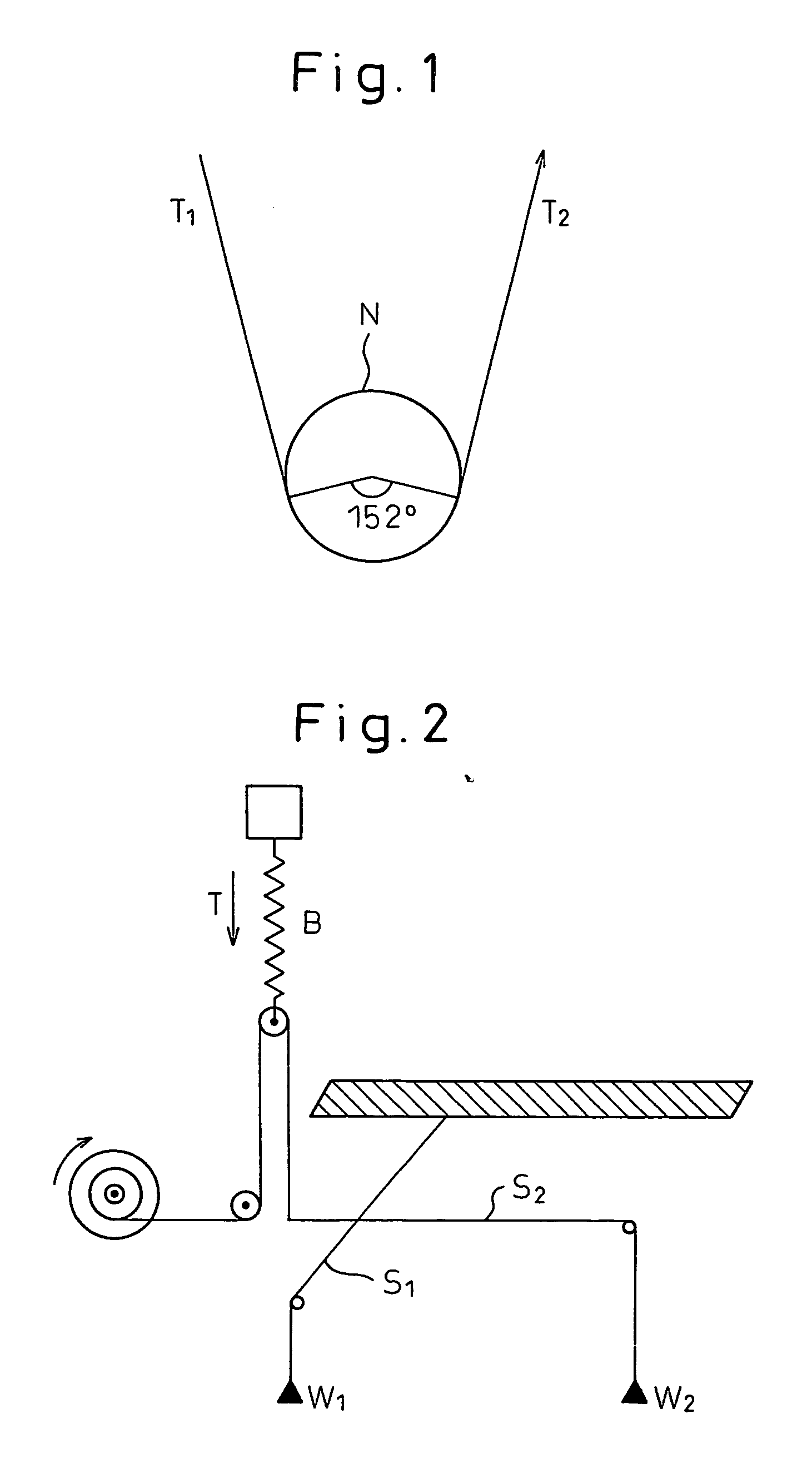

Blended woven or knitted fabrics containing polyerethane elastic fibers and process for the production thereof

A blended woven or knitted fabric which contains both highly fusible polyurethane elastic fibers exhibiting a retention of tenacity of 50% or above after the dry heat treatment at 150° C. for 45 s at 100% elongation and a melting point of 180° C. or below and at least one kind of non-elastic yarns and which is produced by fusing the polyurethane elasotomeric fibers to each other or the polyurethane elastic fibers to the non-elastic yarns at the crossover points by dry- or wet-heat setting; and a process for the production thereof.

Owner:NISSHINBO IND INC

Parallel composite elastic fiber and manufacture method thereof

ActiveCN101851812ALow costElastic Elongation GuaranteedFilament/thread formingConjugated synthetic polymer artificial filamentsExtensibilityPolytetramethylene terephthalate

The invention discloses parallel composite elastic fiber and a manufacture method thereof. The parallel composite elastic fiber is obtained through false twisting process after parallel composite spinning of valox and polyethylene glycol terephthalate according to a weight ratio of 70 / 30 to 30 / 70, wherein the inherent viscosity of the valox is between 0.45 to 0.60 dl / g, and the difference of the inherent viscosity of the valox and the inherent viscosity of the polyethylene glycol terephthalate is between 0.40 and 1.05 dl / g. The elastic extensibility of the elastic fiber of the invention is between 130 and 220 percent, and the elastic recovery rate is higher than 85 percent.

Owner:TORAY IND INC

Extensible and elastic conjugate fibers and webs having a nontacky feel

Extensible bicomponent fibers and webs particularly adapted for disposable personal care product component applications. Sheath / core configurations providing desirable feel properties for elastic embodiments when compared with conventional elastic fibers and webs are obtained with specific olefin polymer combinations and sheath configurations.

Owner:DOW GLOBAL TECH LLC

Fused loop of filamentous material and apparatus for making same

InactiveUS20050216058A1Maximize joint strengthSuture equipmentsSurgical needlesElastic fibresPolymer science

A method of forming an elastic cloth structure comprising fibers of synthetic, organic, relatively elastomeric polymer and fibers of a synthetic, organic, elongatable, but relatively nonelastic polymer. The relatively elastomeric fibers and the elongatable but relatively nonelastic fibers are forwarded for well dispersed random lay down of an unbonded web with random fiber crossings on a porous forming surface. Some of the fiber crossings are then bonded to provide a coherent bonded cloth web and the web is stretched to elongate some of the fibers in at least one direction. The web is then released so that retraction by the relatively elastomeric fibers provides looping and bunching of the elongated relatively nonelastic fibers to thereby provide a low modulus of elasticity in the direction in which the web was worked.

Owner:HOWMEDICA OSTEONICS CORP

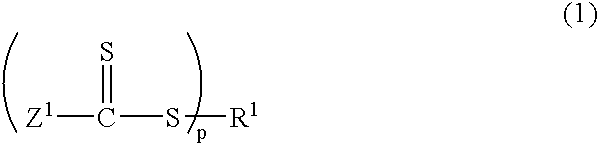

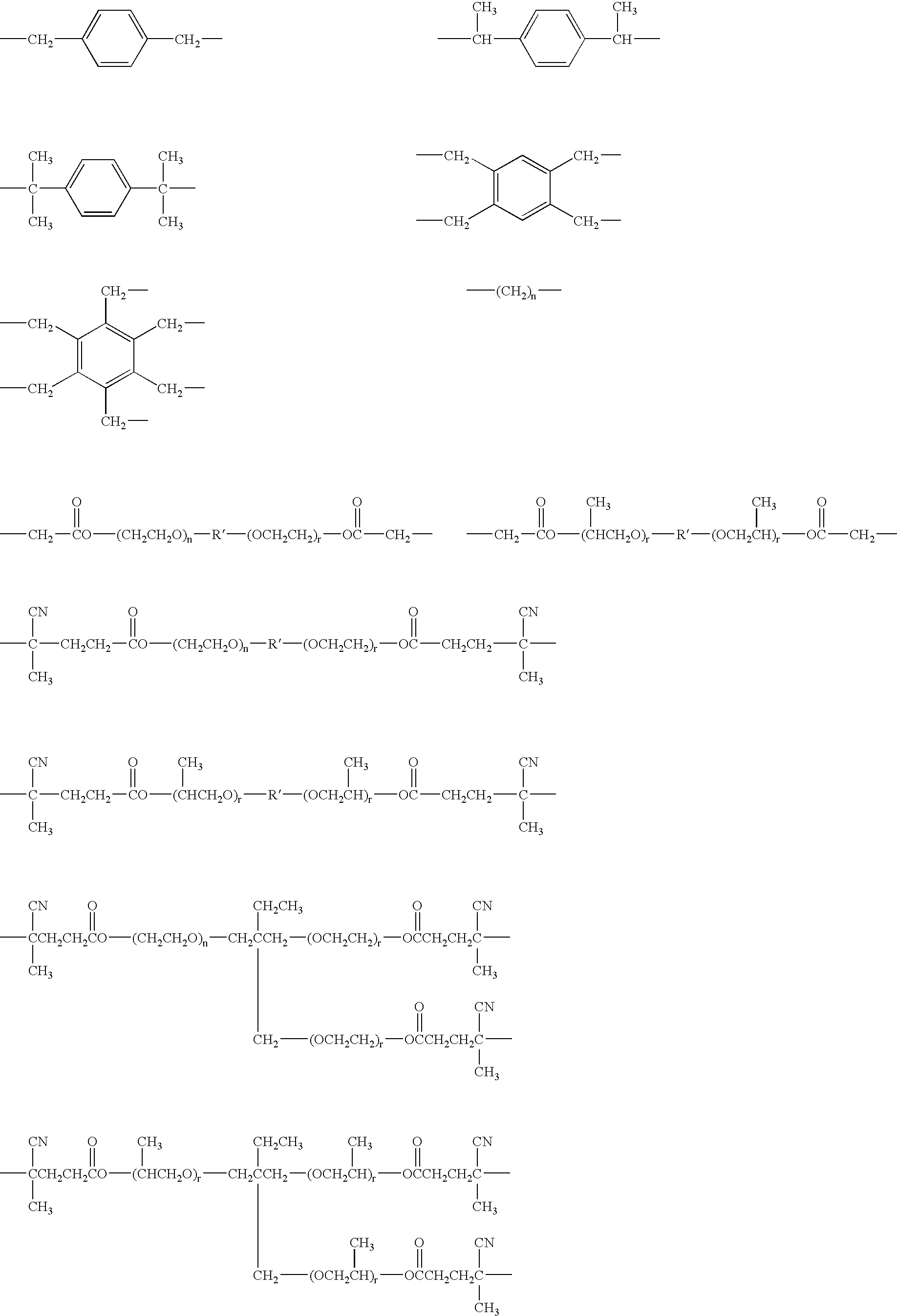

Polyurethane polymer

InactiveUS20040171765A1Good chemical resistanceImprove chlorine resistanceMonocomponent polyurethanes artificial filamentHeat resistanceReversible addition−fragmentation chain-transfer polymerization

Provided is a polyurethane polymer which is excellent in oil resistance, weatherability, light resistance, heat resistance, hot water resistance, hydrolysis resistance, strength, chlorine resistance, and chemical resistance, and which can be produced simply and economically. The polyurethane polymer is produced by polymerizing at least two components: a vinyl polymer (A) having a mercapto group at each end of the molecular chain produced by a reversible addition-fragmentation chain transfer polymerization method, and an organic polyisocyanate (B). Also provided are polyurethane-based materials containing the polyurethane polymer, and polyurethane elastic fiber.

Owner:KANEKA CORP

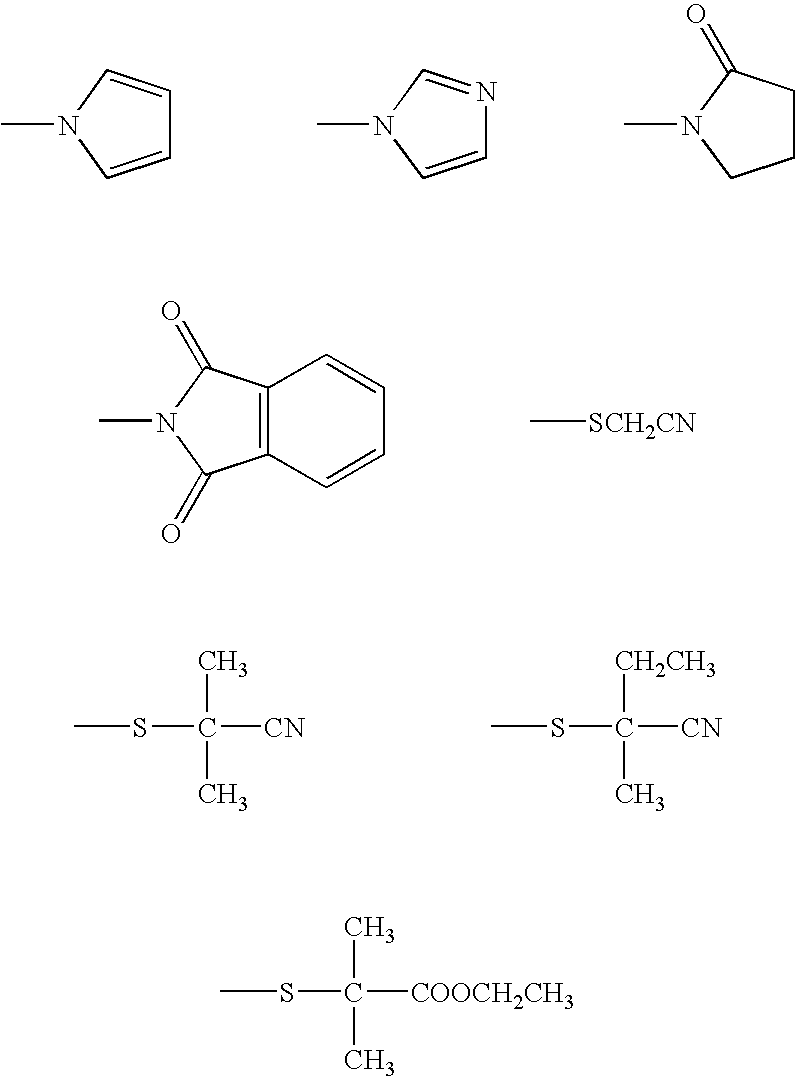

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

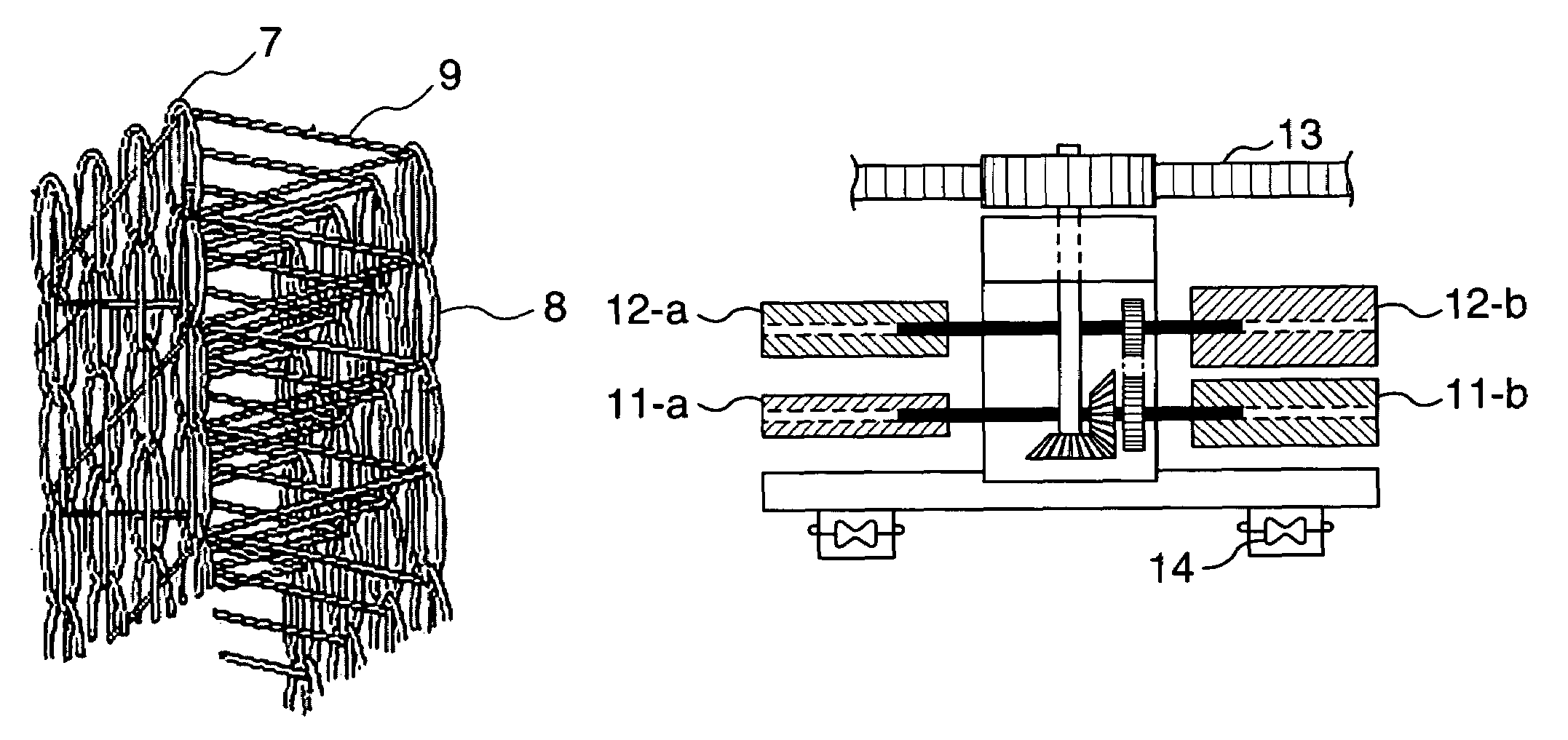

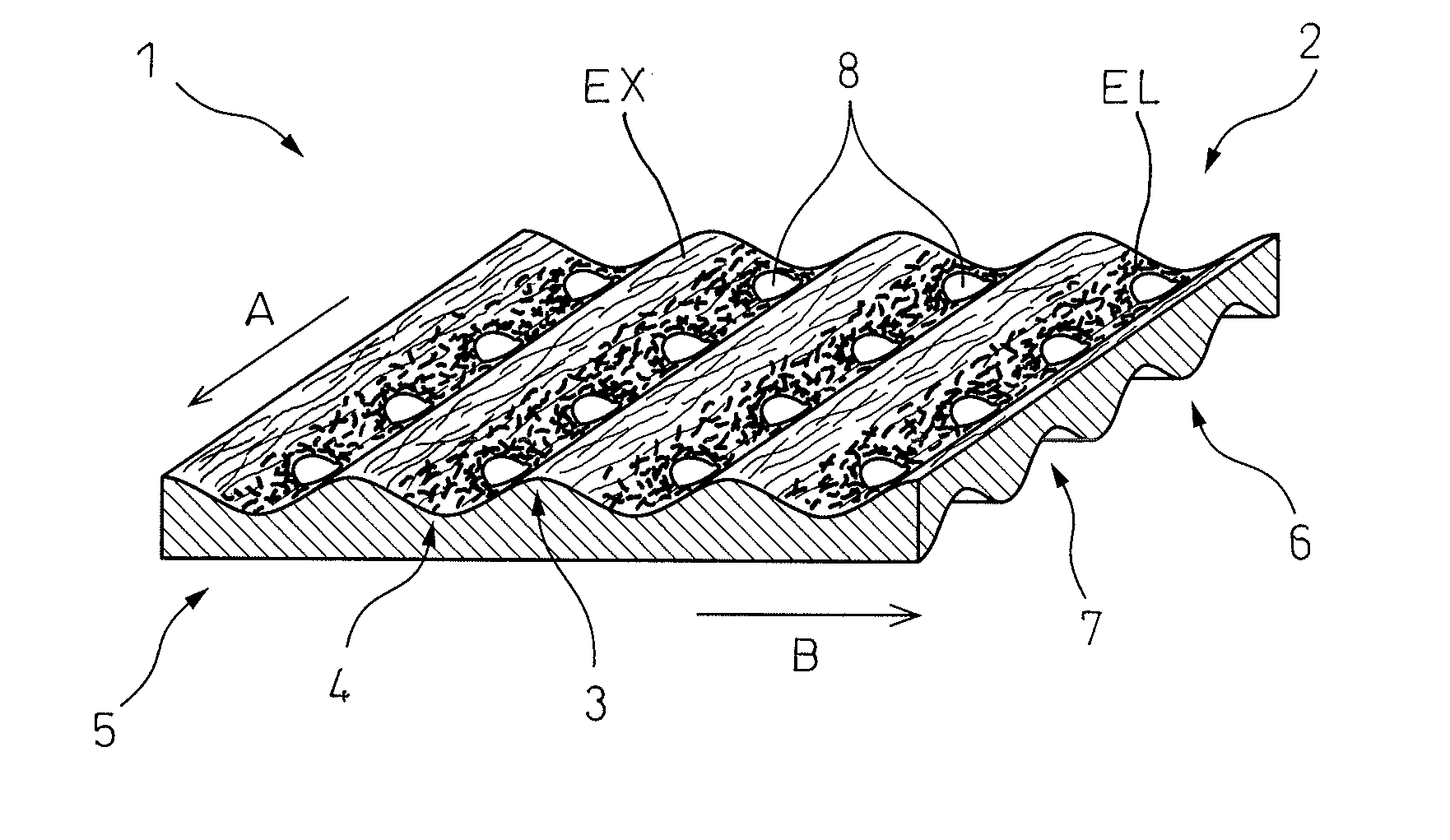

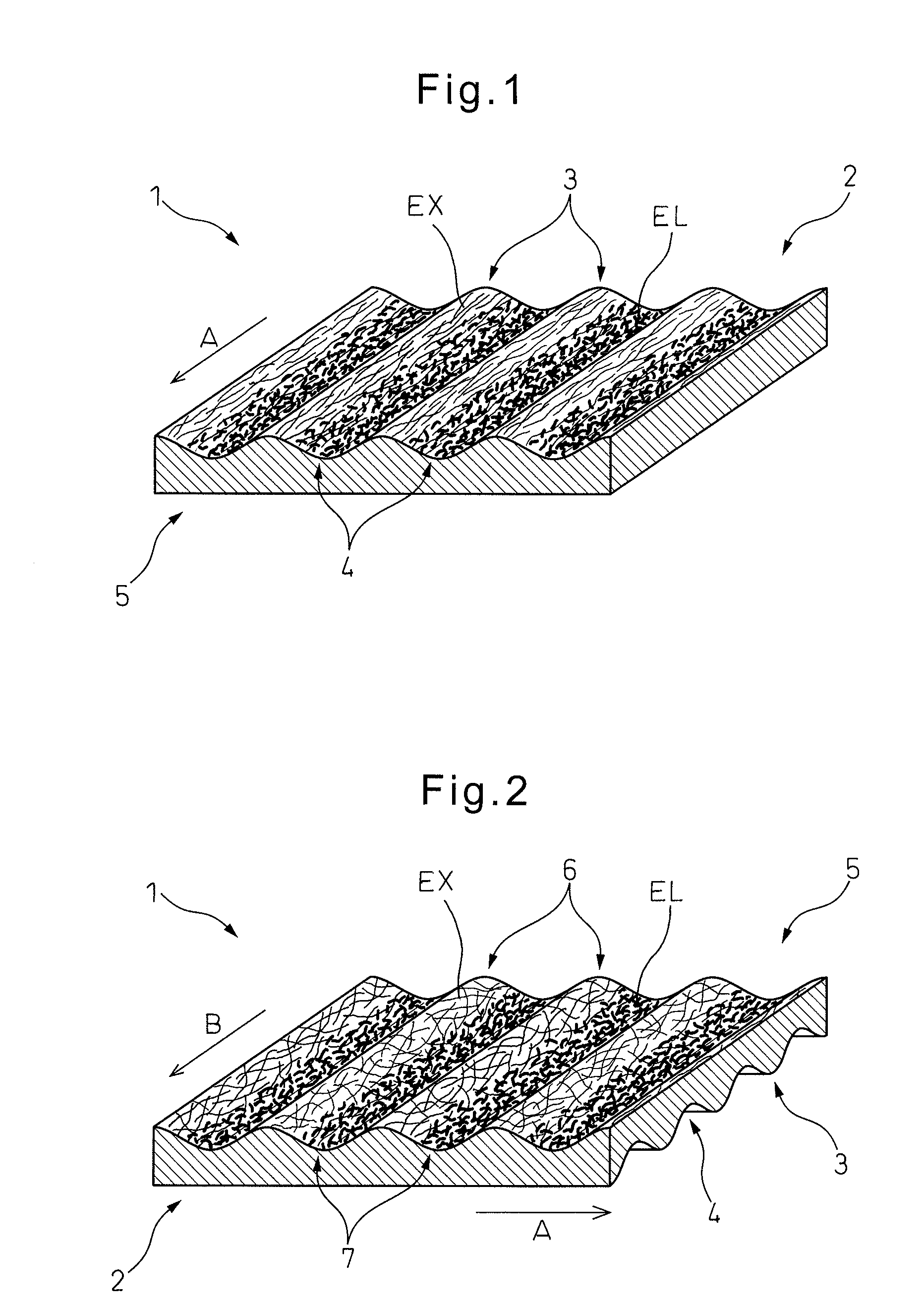

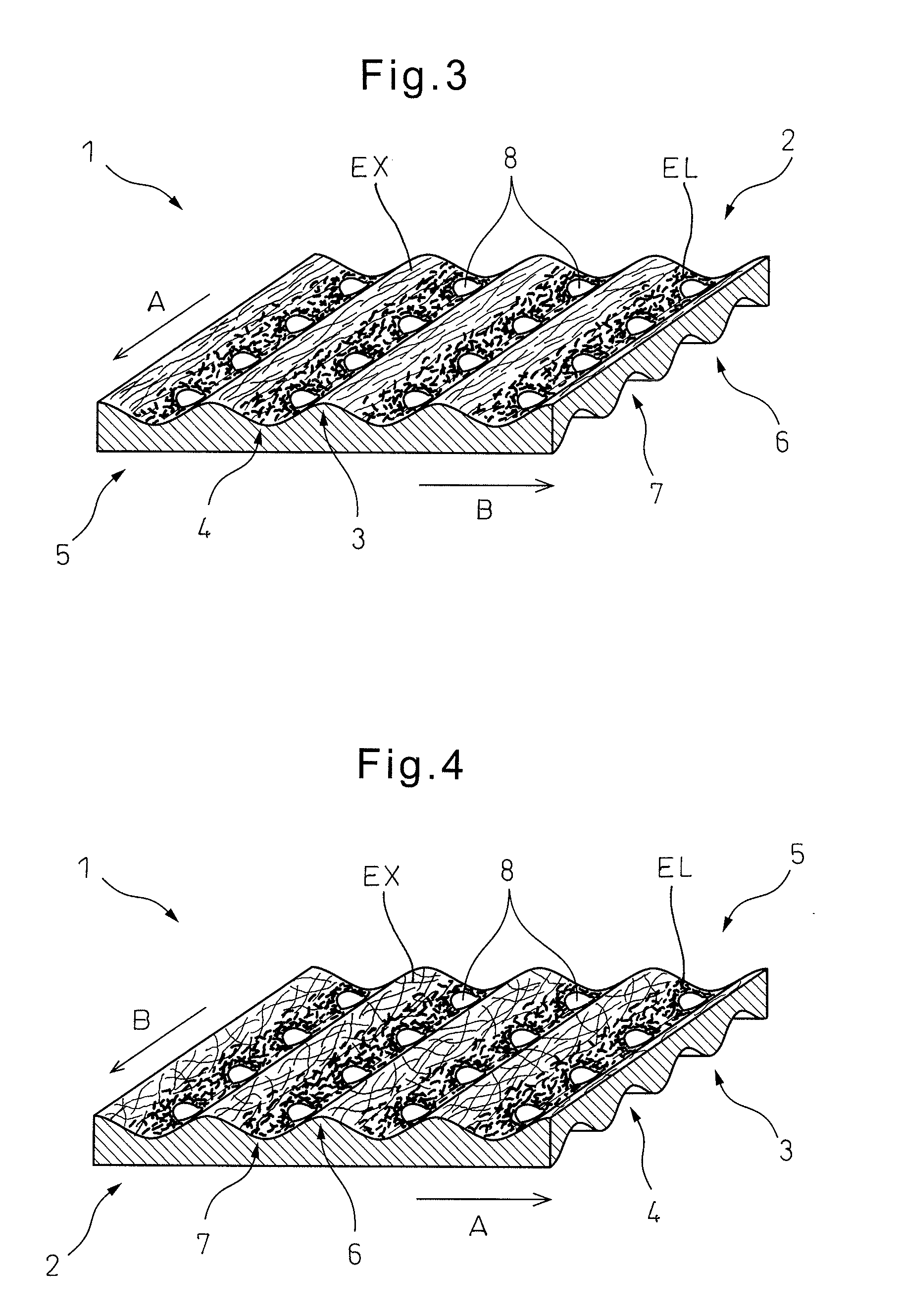

Nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, and method of producing nonwoven fabric

InactiveUS20130034686A1Good skin feelIncrease elasticityPattern makingLayered productsNonwoven fabricElastic fiber

It is an object of the invention to provide a nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, which has excellent feel on the skin and elasticity, and excellent air permeability in the planar directions and the thickness direction, as well as a method of producing the nonwoven fabric.A nonwoven fabric having projections and recesses, comprising extensible fiber and elastic fiber, wherein the first surface of the nonwoven fabric has a plurality of projections and a plurality of recesses, and the proportion of extensible fiber in the projections is higher than the proportion of extensible fiber in the recesses.

Owner:UNI CHARM CORP

Composite fiber structure and method for producing the same

ActiveUS7387976B2Good flexibilityIncrease elasticityLamination ancillary operationsLaminationElastomerPolyester

A web containing comprising side-by-side or eccentric core / shell conjugate short fibers A, which contain two kinds of polyester different from each other in intrinsic viscosity, and elastic conjugate fibers B, which contain a thermoplastic elastomer having a melting point lower by 40° C. or more than the two kinds of polyester, and a nonelastic polyester, with at least the thermoplastic elastomer being exposed on a surface of the fibers, is subjected to a heat treatment at a temperature equal to or higher than the melting point of the thermoplastic elastomer, so as to obtain a polyester elastic fiber structure, and then polyester woven or knitted fabrics are laminated adhered on both surfaces of the polyester elastic fiber structure with a polyester adhesive, followed by heat molding into a curved shape by a molding process depending on necessity, so as to obtain a composite fiber structure.

Owner:TEIJIN FRONTIER CO LTD

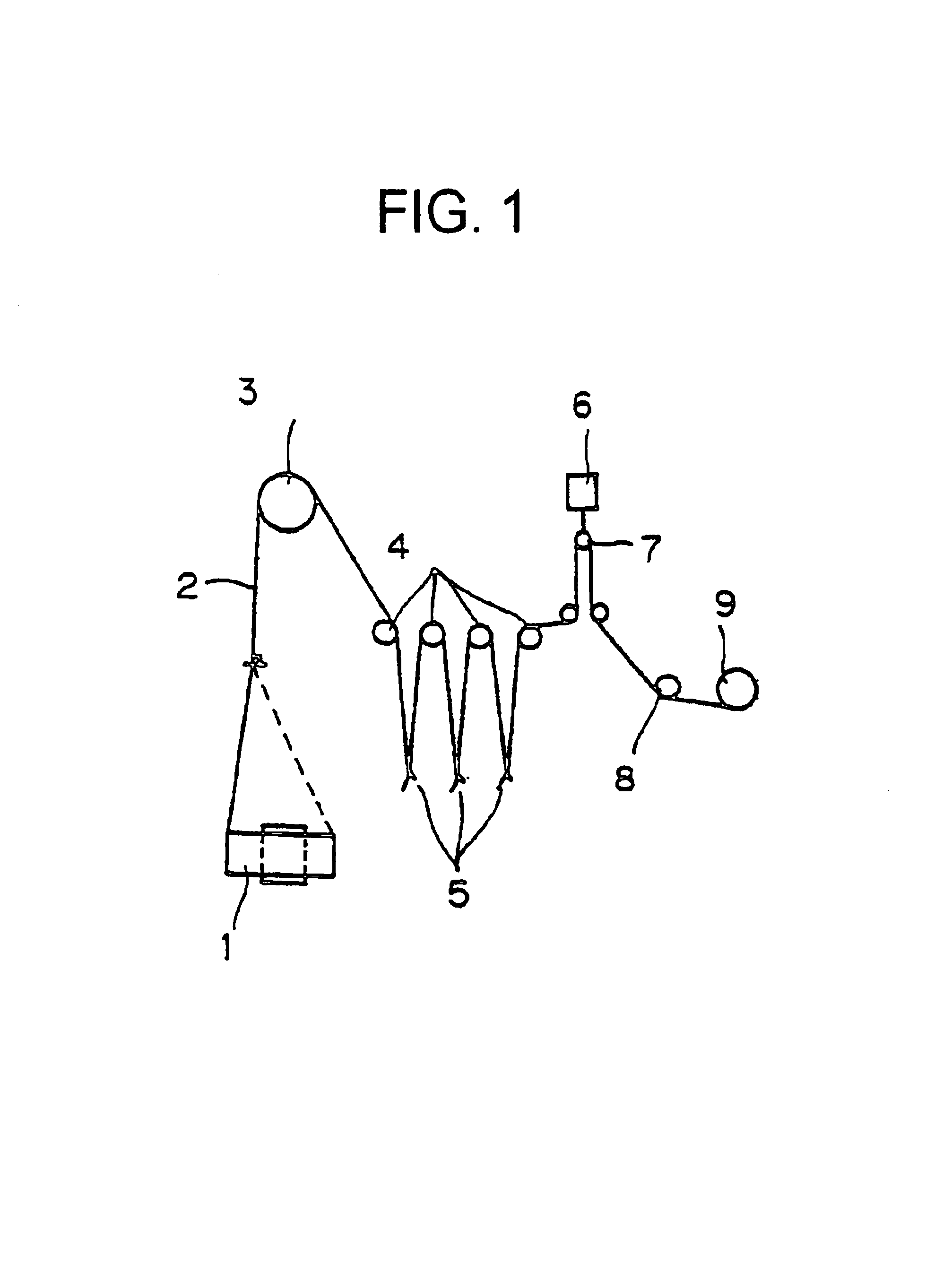

Production method of double-component spinneret outside composite parallel self-crimping elastic short fiber

ActiveCN106149071AIncrease elasticityImprove curling effectArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsFiberElastic fiber

The invention relates to a production method of double-component spinneret outside composite parallel self-crimping elastic short fiber. The production method includes: adopting high molecular polymer components A and B different in shrinkage characteristics as raw materials; subjecting AB melt to outside compositing through a double-passage spinneret to obtain an AB parallel composite filament bundle; subjecting the AB parallel composite filament bundle sequentially to air-blowing cooling, oiling, winding traction and filament carrying to obtain AB parallel composite fiber protofilament; subjecting the AB parallel composite fiber protofilament sequentially to inter-cluster balance, drafting, thermal setting, oiling, crimping, loosening and drying and cutting to obtain the double-component spinneret outside composite parallel self-crimping elastic fiber. The fiber has excellent and lasting crimping performance, is high in elasticity, elastic recovery rate and spinnability, wide in application range and suitable for nonwoven filling.

Owner:王家铭

Elastomeric fibers comprising controlled distribution block copolymers

InactiveUS20070055015A1High melt flowIncrease chanceWoven fabricsConjugated synthetic polymer artificial filamentsProduction rateYarn

Bicomponent fibers comprising a thermoplastic polymer and an elastomeric compound are made which can be continuously extruded from the melt at high production rates. The elastomeric compound comprises a selectively hydrogenated block copolymer having a controlled distribution elastomeric block which has a mono alkenyl arene blockiness index of less than 40 mol % and high flow. Elastomeric fibers are also provided which comprise a controlled distribution block copolymer and a slip agent. The fibers are useful for the manufacture of articles such as woven fabrics, spunbond non-woven fabrics or filters, staple fibers, yarns and bonded, carded webs. The bicomponent fibers can be made using a process comprising coextrusion of the thermoplastic polymer and elastomeric compound to produce fibers at spinning speeds of at least 1000 mpm and having a denier from 0.1 to 50 g / 9000 m.

Owner:KRATON POLYMERS US LLC

Stretch wovens with separated elastic yarn system

Included is a woven fabric having warp yarns and weft yarns. Either warp yarn or weft yarn or both warp and weft yarns have two separate systems of yarns. The systems of yarns include a hard yarn forming the main body of fabric and a composite covered elastic yarn with an elastic fiber core; wherein the fabric has an outer face side, a back side, and the fabric includes at least one of: (a) a weaving pattern where the composite yarn and at least one adjacent hard yarn pass over the same pick when the composite yarn is on the outer surface; (b) the ratio of hard yarn denier to composite yarn denier is at least 1:1; and (c) the composite yarn floats over no more than 5 picks on the outer face side.

Owner:THE LYCRA CO LLC

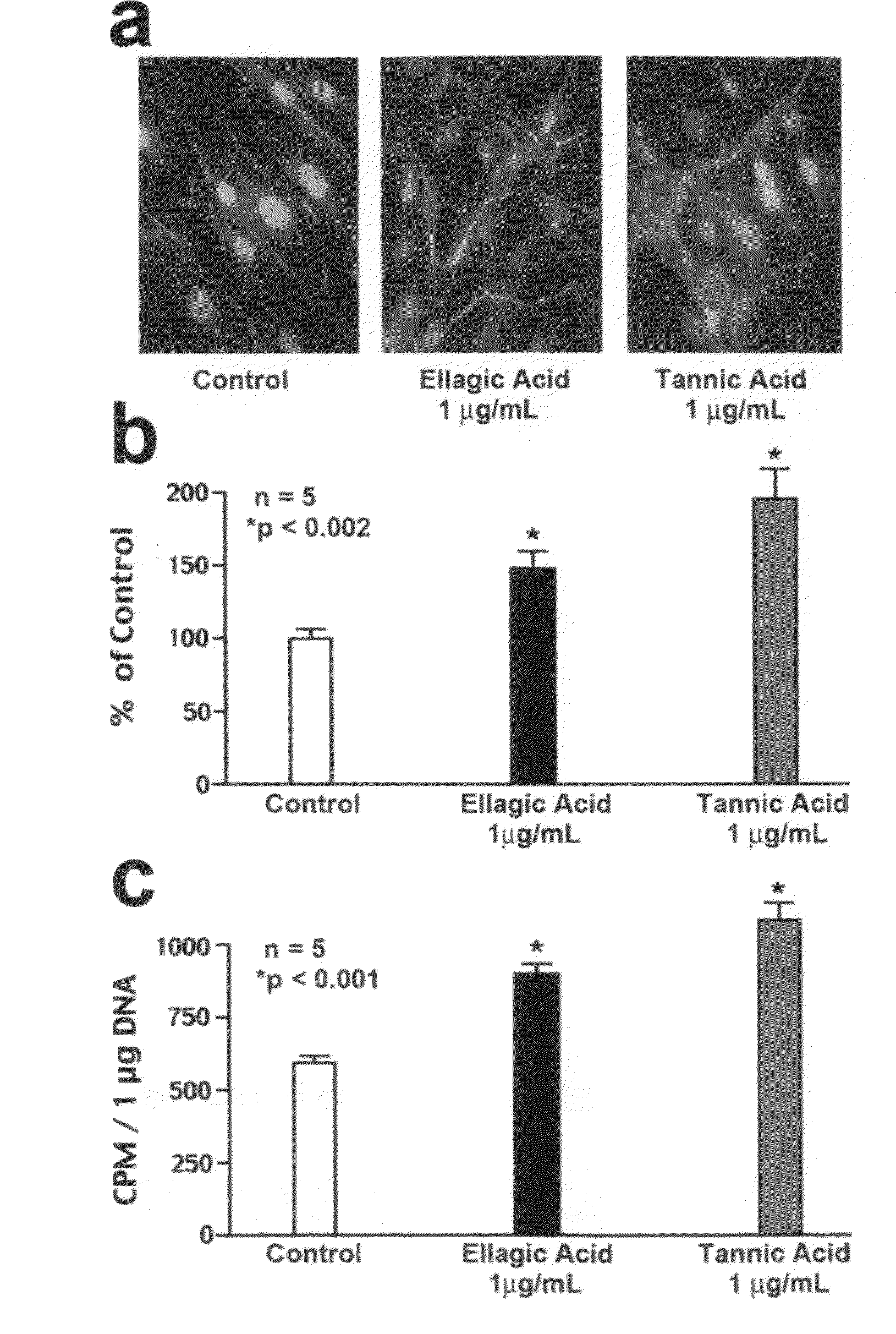

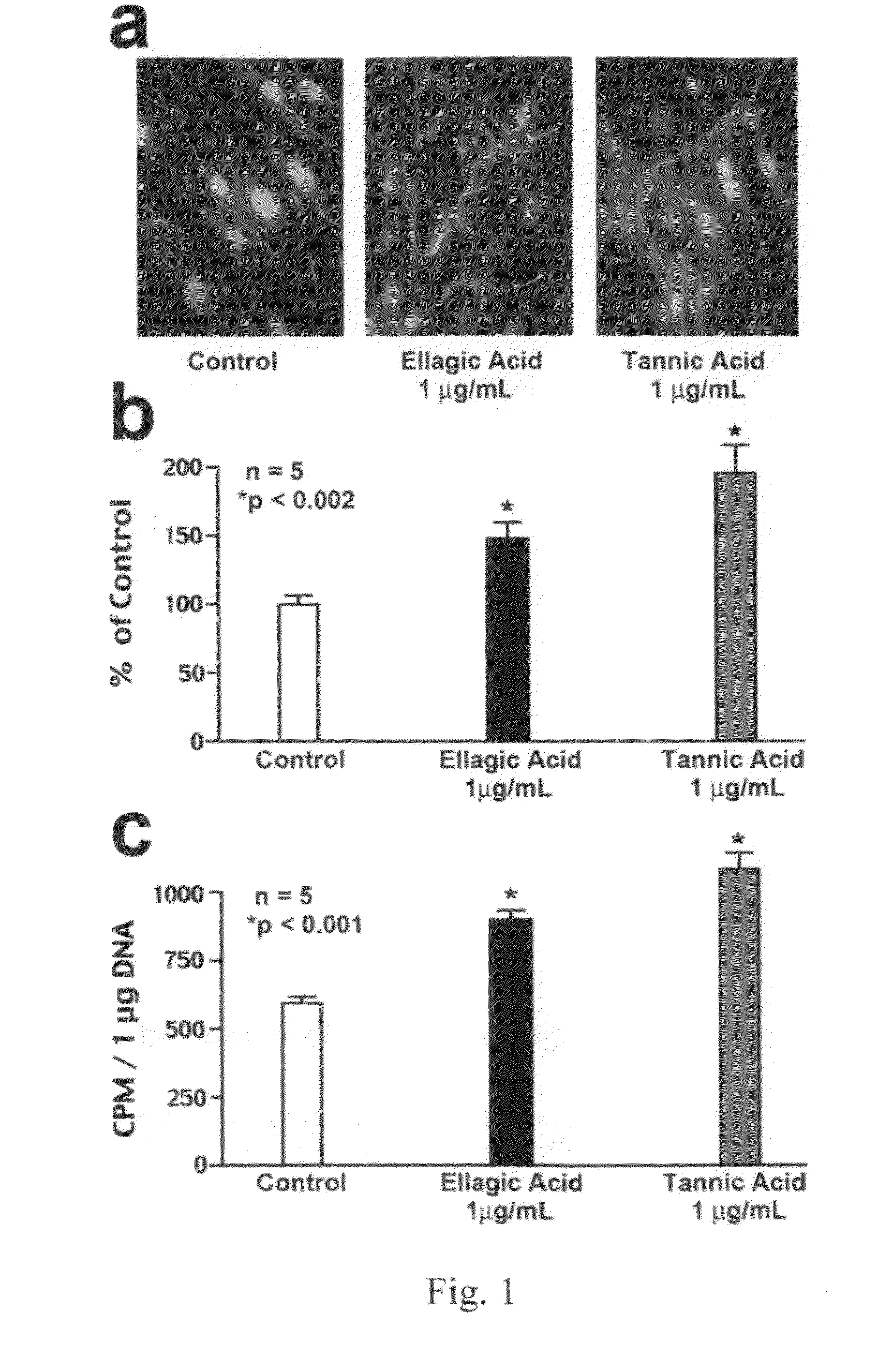

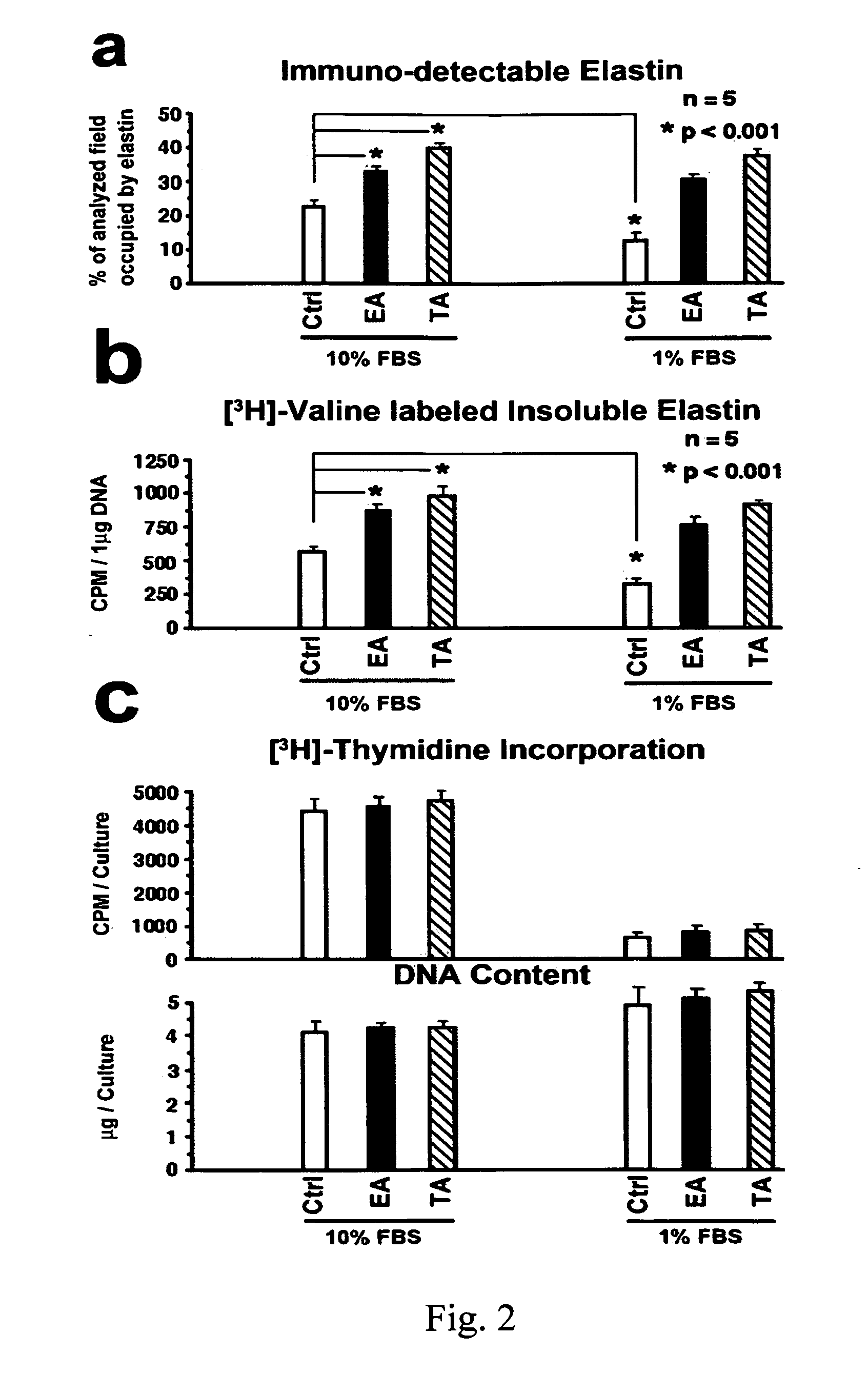

Elastin protective polyphenolics and methods of using the same

ActiveUS20090110709A1Prevent premature proteolyticEfficient elastogenesisCosmetic preparationsBiocideFiberPolyphenol

Dermal fibroblasts permanently loose their ability to synthesize elastin, the major component of elastic fibers, shortly after puberty. This progressive loss of elastic fibers cannot be replaced, resulting in the physical signs of aging. The present invention provides methods and compositions containing the polyphenols ellagic acid and / or tannic acid for protection against degradation of cutaneous elastic fibers by the elastolytic enzymes. The use of ellagic acid and / or tannic acid increased the overall deposition of elastic fibers in healthy and damaged skin cells. The protection of both intra-tropoelastin and extra-cellular mature elastic fibers from proteolytic enzymes by ellagic acid and tannic acid caused an increase in the net deposition of elastic fibers. Therefore, embodiments of the present invention provide methods and composition for the treatment of skin and prevention and treatment of degradation of dermal elastic fibers.

Owner:ELASTOGENESIS LLC +1

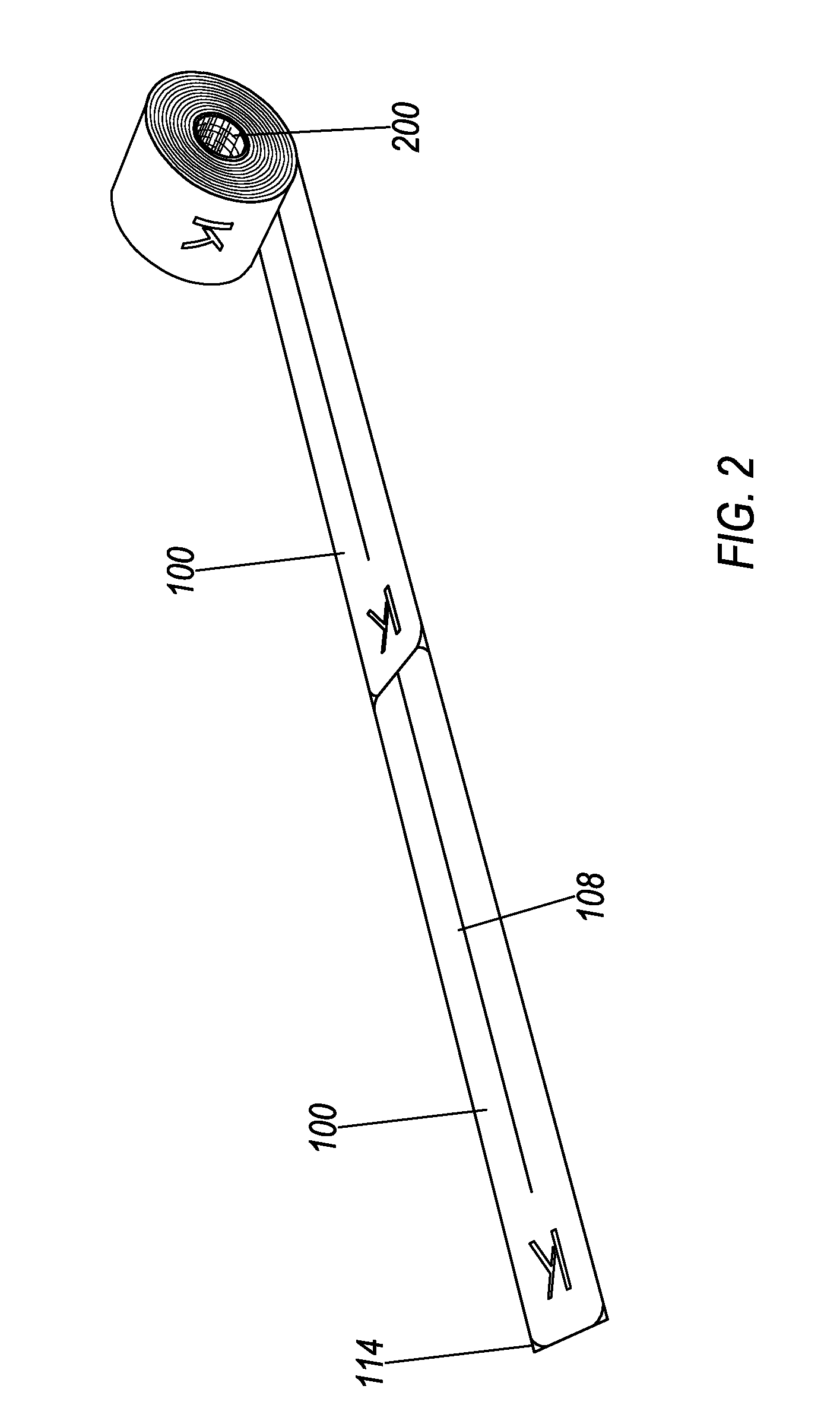

Pre-cut strips of kinesiology tape

One example embodiment includes a pre-cut strip of kinesiology tape. The pre-cut strip of kinesiology tape includes a fabric. The fabric includes a weave of fibers, where the fibers include an elastic fiber covered by a covering material. The fabric also includes a first end and a second end, where the second end is opposite the first end. The fabric further includes one or more rounded corners. The pre-cut strip of kinesiology tape also includes a longitudinal cut in the fabric. The longitudinal cut passes through at least a portion of the fabric and extends from the first end to a pre-determined distance from the second end. The pre-cut strip of kinesiology tape also includes adhesive on a first surface of the fabric, where the adhesive is configured to adhere the fabric to a human body.

Owner:LUMOS

Method for preparing functional composite woolly elastic fiber

The invention relates to a method for preparing functional composite woolly elastic fiber, comprising the following steps: (1) preparing uvioresistant fine-denier polyester pre-oriented yarn (a) with the method of adding uvioresistant masterbatch; (2) carrying out composite spinning with low viscosity polyester (PET) or modified PET and polyethylene terephthalate (PTT) to prepare fully-drawn self-winding composite elastic fiber (b); and (3) stretching and false twisting the uvioresistant fine-denier polyester pre-oriented yarn (a) on a false-twisting texturing machine, converging the uvioresistant fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) in the position of a second roller, combining the uvioresistant the fine-denier polyesterpre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through an interlacing machine, shaping the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through a second heating box, and winding the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) into a composite yarn, contracting the PET / PTT self-winding composite elastic fiber with the elasticity and the contractibility in the core layer of the composite woolly elastic fiber to show the elasticity of the composite yarn, and making the uvioresistant fine-denier polyester pre-oriented yarn to float on the surface layer of the composite yarn to show the uvioresistant performance of the composite yarn. Therefore, the uvioresistant composite woolly elastic fiber is prepared.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Elastic core fibre and an elastic nonwoven

A bicomponent elastic fiber that includes a core formed of an elastic fiber and having a sheath formed of a non-elastic material surrounding the core. The sheath has at least one cut therein extending at an angle to the length of the fiber to expose and release the elasticity of the core elastic fiber. This provides elasticity to the bicomponent elastic fiber.

Owner:APLIX INC

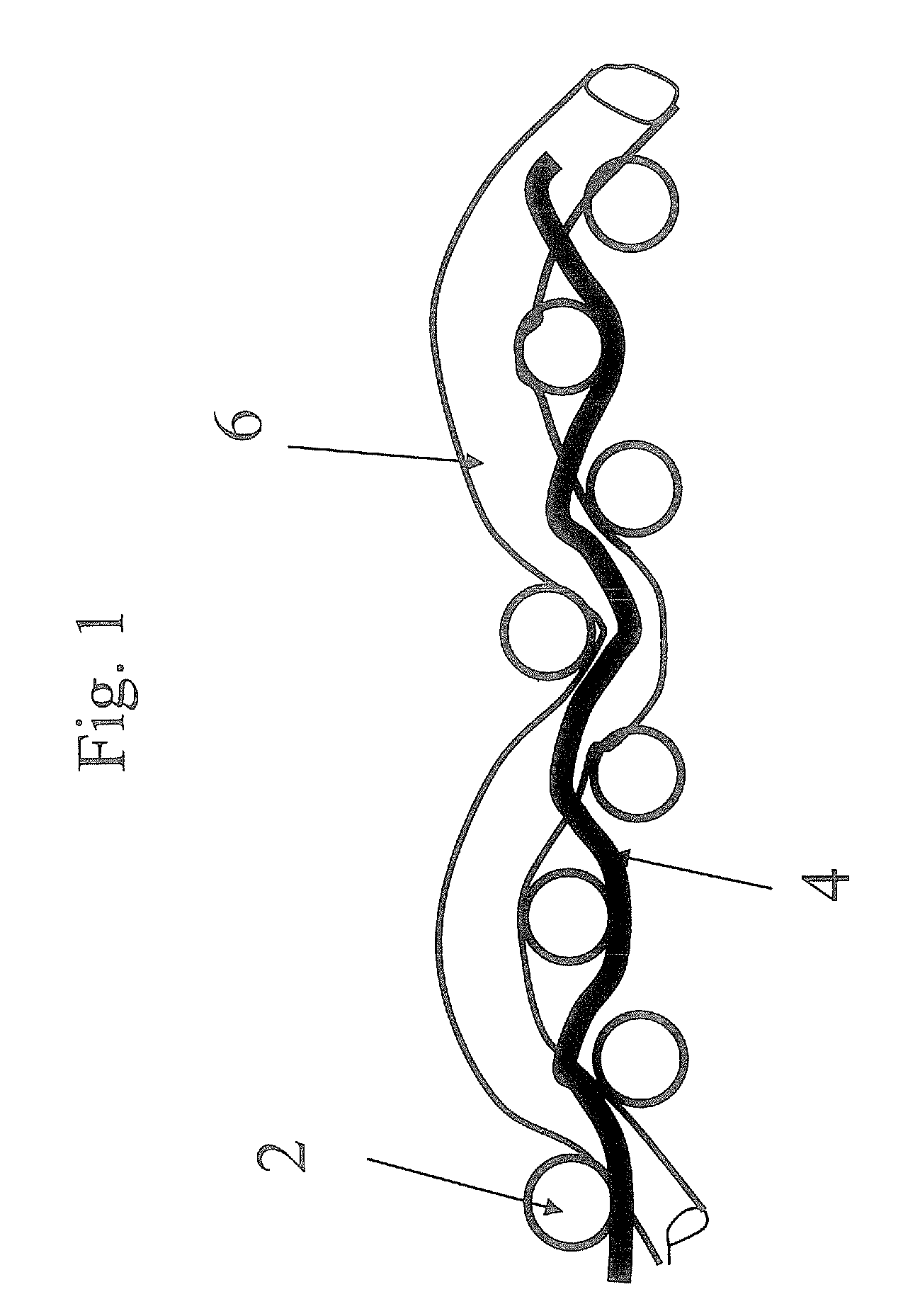

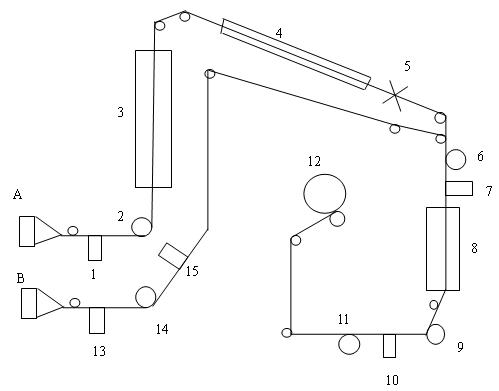

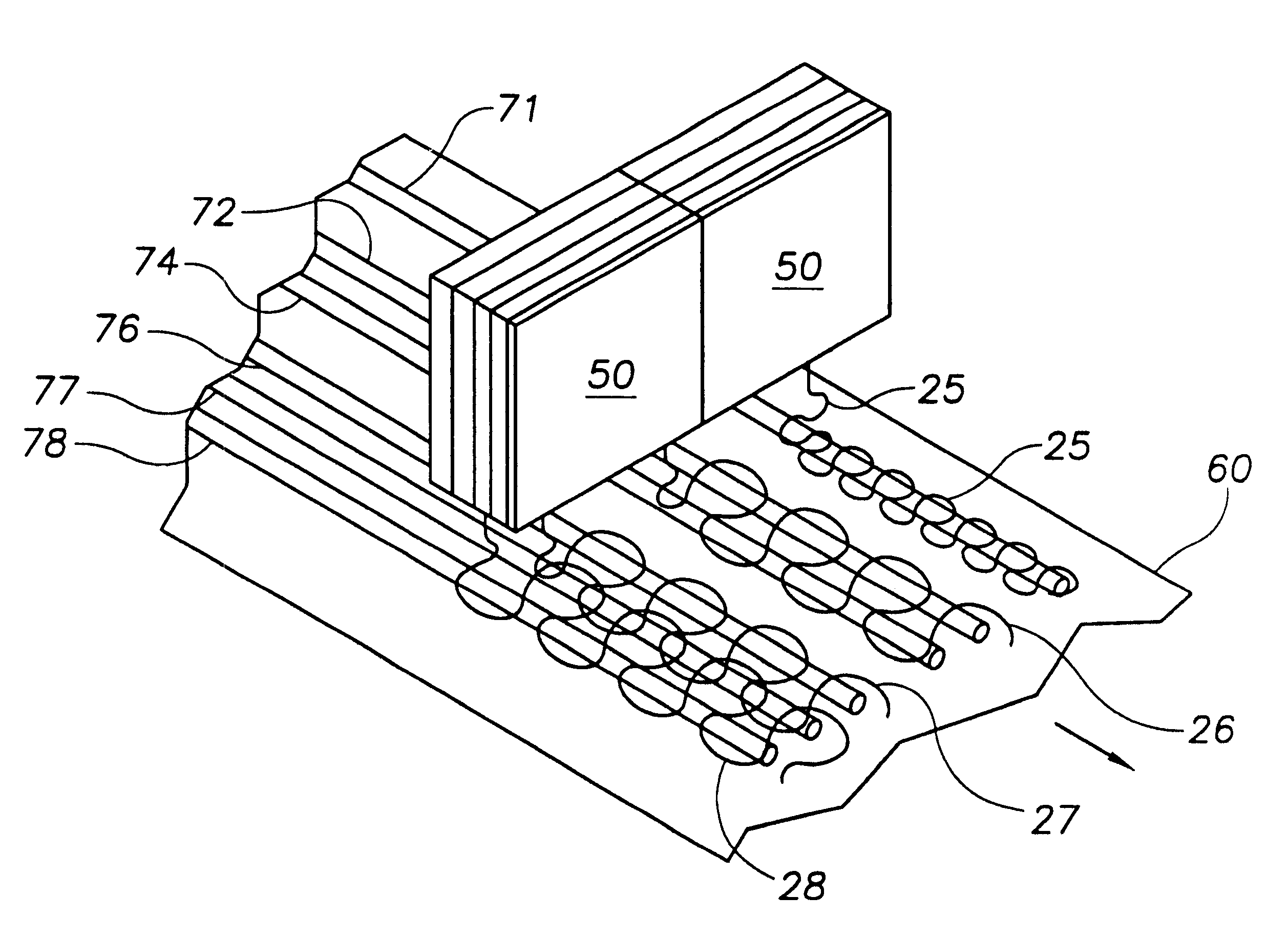

Omega spray pattern and method therefor

A method for producing visco-elastic fluidic material flows by drawing a visco-elastic fluidic material with corresponding separate second fluid flows associated therewith to form a visco-elastic fiber vacillating in a repeating, generally omega-shaped pattern having a bowed portion with first and second side portions that first converge toward each other and then diverge outwardly in generally opposing directions. In one operation, the visco-elastic fiber vacillating in the repeating, generally omega-shaped pattern is an adhesive material deposited onto woven and non-woven fabric substrates and stretched elongated elastic strands in the manufacture of a variety of bodily fluid absorbing hygienic articles.

Owner:ILLINOIS TOOL WORKS INC

Antistatic polyurethane elastic fiber and material for producing the same

InactiveUS6849676B1Monocomponent polyurethanes artificial filamentElectroconductive/antistatic filament manufacturePolymer sciencePhosphate

Inorganic salts are generated in the production process of metal salts, such as sulfonates, sulfates and phosphates. When such metal salts containing inorganic salts are added as an antistatic agent to a polymer for producing polyurethane fiber, the inorganic salts cause fiber breakage or pack choking in fiber extrusion process. In addition, such antistatic agents are highly hygroscopic and contain trace of water. When such an antistatic agent is added to the material for polymerizing polyurethane, the alcohol and water in the agent react with isocyanate to result in lowered degree of polymerization and generation of oligomer. Such polyurethane polymer is spun into fiber of low elongation and tenacity. The material for polyurethane elastic fibers of the present invention comprises a mixture of 5 to 95 weight percent of at least one of the above-mentioned antistatic agents and 95 to 5 weight percent of a isocyanate-free starting material for elastic fibers, and eliminates the above troubles.

Owner:MATSUMOTO YUSHI SEIYAKU

Polyurethane Elastic Fiber And Process For Producing Same

ActiveUS20070196650A1Improve stabilityReduce yarn breakageMonocomponent polyurethanes artificial filamentOther chemical processesFiberInorganic compound

A polyurethane elastic fiber, containing inorganic compound particles that have an average particle size of 0.5 to 5 mm and that show a refractive index of 1.4 to 1.6, having at least one protruded portion that has a maximum width of 0.5 to 5 μm, in the fiber surface, per 120-μm length in the fiber axis direction.

Owner:ASAHI KASEI FIBERS CORPORATION

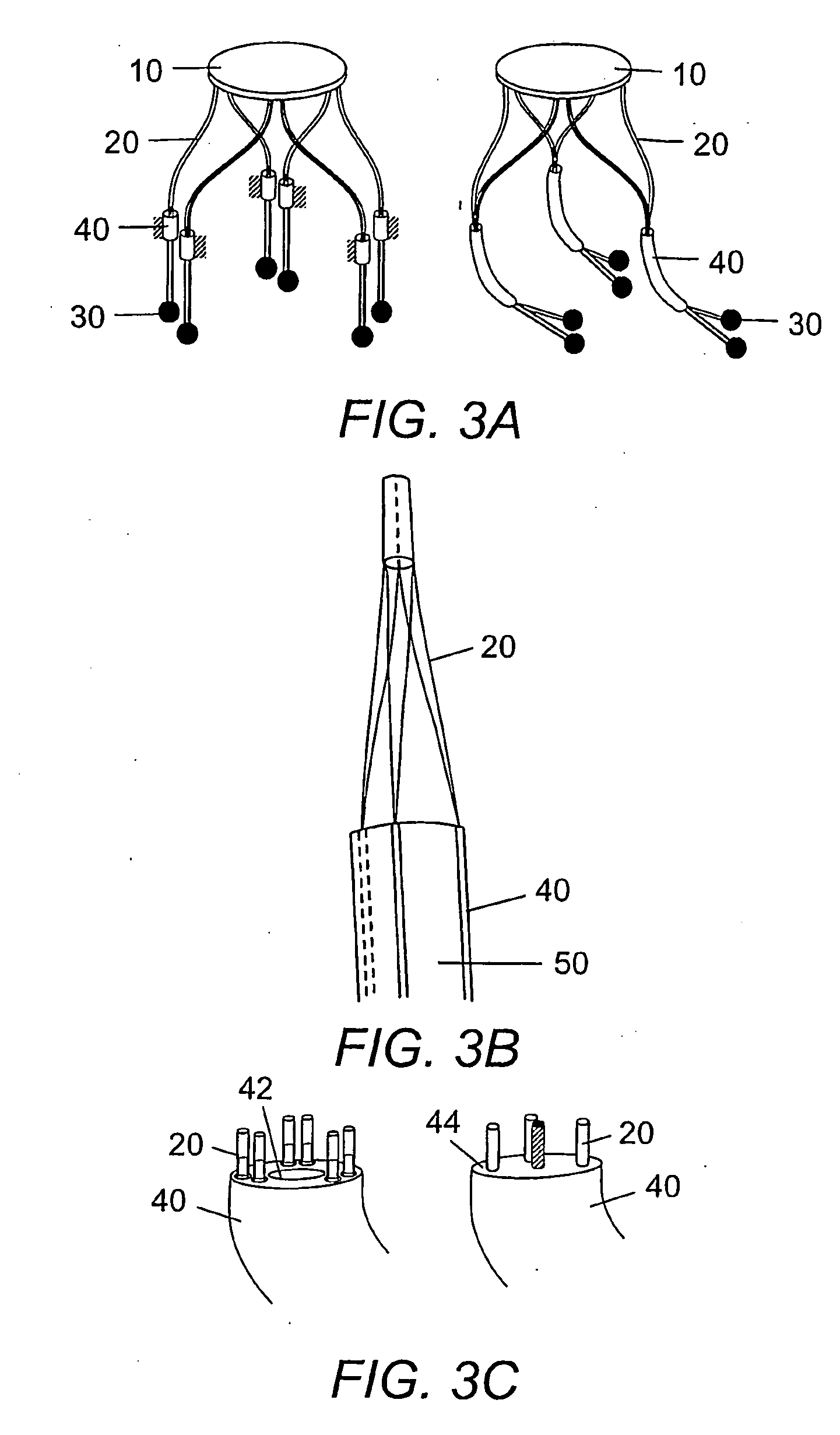

Flexible Parallel Manipulator For Nano-, Meso- or Macro-Positioning With Multi-Degrees of Freedom

The present invention is a friction- and backlash-fee flexible parallel manipulator device. The device is composed of multiple elastic fiber legs with various physical properties, a top platform, and a bottom platform. With multiple degrees of freedom, the motion of the top platform is controlled by the multiple elastic fiber legs whose lengths or curvatures between the top and bottom platforms are controlled based on the required motion of the top platform. The device can be used for nano-, micro-, or meso-manipulation.

Owner:ZHU ZHENQI +2

Human umbilical cord mesenchymal stem cell exosome type external cream and preparation method thereof

InactiveCN107854418AEasy to get materialsA large amountCosmetic preparationsToilet preparationsFiberBase cream

The invention provides human umbilical cord mesenchymal stem cell exosome type external cream and a preparation method thereof, and aims at the solving the problem in effectively inducing human umbilical cord mesenchymal stem cells to massively synthesize and secrete mesenchymal stem cell exosome capable of specifically promoting epidermis cell and hypodermal cell to proliferate, divide and differentiate, promoting the formation of collagenous fibers, reticular fibers and elastic fibers, and adjusting the secreting functions of collagen and mucopolysaccharide. The cream comprises human umbilical cord mesenchymal stem cell exosome extracting liquid and a base cream formula based on the mass ratio ranging from (1:20) to (3:10), wherein the human umbilical cord mesenchymal stem cell exosome extracting liquid is prepared by performing hungry culture on P2-P5 generations of human umbilical cord mesenchymal stem cells and stimulating through epidermal growth factors. The prepared cream has the effects of improving the skin quality, resisting the aging of skin cells, recovering the normal structure and physiological function of the skin, reducing the skin atrophy exsiccosis, and moisturizing the skin tissue.

Owner:南京九圣生物医学科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com