One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

A technology for knitting fabrics that absorb moisture and generate heat. It is applied in the field of knitted garment fabrics. It can solve the problems of large cutting loss and poor lateral elasticity, and achieve the effect of strengthening moisture absorption performance and strong discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

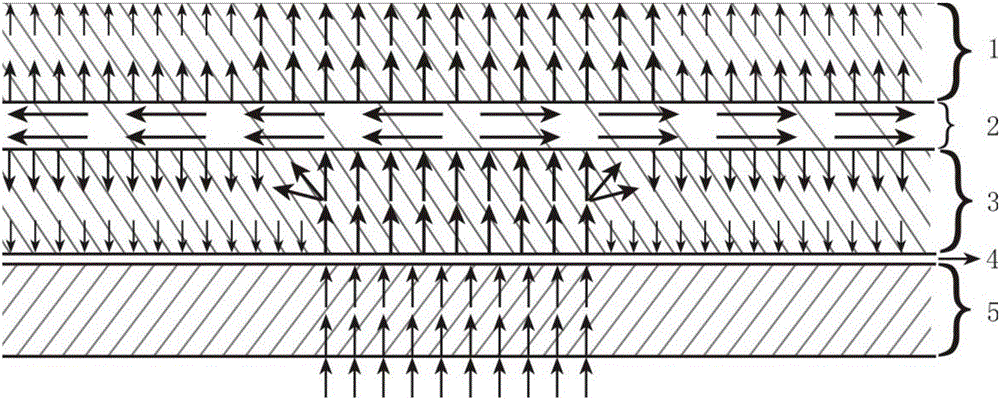

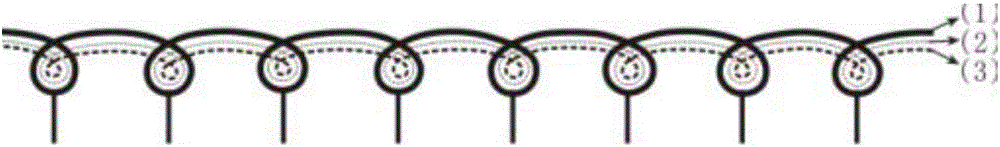

[0059] A unidirectional moisture-wicking, moisture-absorbing and heat-generating knitted fabric, which is woven with three kinds of yarns. The first yarn is a core-spun yarn with a specification of 40 British counts. The core yarn of the core-spun yarn is 30D / 24F COOLDRY, which is a cross-section modified polyester low elastic yarn produced by Shanghai Haitian Yingjie Textile Technology Co., Ltd. The twist direction is Z twist, and the outer wrapping part of the core-spun yarn is wool fiber blended fiber, which is a blend of wool fiber and Lenzing Modal fiber (a kind of regenerated cellulose fiber), of which, according to the weight percentage, wool fiber accounts for 70% , Lenzing Modal fiber accounts for 30%, and the twist direction of the outer wrapped part of the fiber is Z twist; the second yarn is 40D polyurethane elastic fiber yarn produced by Hyosung Spandex (Jiaxing) Co., Ltd. of Korea Co., Ltd.; the third yarn is all Cotton yarn, the specification is 60 pounds, twist...

Embodiment 2

[0074] A unidirectional moisture-wicking, moisture-absorbing and heat-generating knitted fabric, which is woven with three kinds of yarns. The first yarn is a core-spun yarn with a specification of 40 British counts. The core yarn of the core-spun yarn is 40D / 48F Dashuanglun, which is a cross-section high moisture-absorbing and sweat-wicking polyamide fiber provided by Guangdong Xinhui Meida Nylon Co., Ltd. Low elastic yarn, twist direction S twist, the outer wrapping part of the core-spun yarn is pure flax fiber, and the twist direction of the outer wrapping part fiber is S twist; the second yarn is 30D winding yarn ROICA produced by Asahi Kasei Co., Ltd. of Japan, which is A low-temperature hot-melt polyurethane elastic fiber yarn; the third yarn is cotton fiber blended yarn, which is a blended fiber yarn of cotton fiber and polyamide fiber, of which cotton fiber accounts for 80%, Guangdong Xinhui Meida The cross-section high moisture absorption and perspiration polyamide fi...

Embodiment 3

[0089] A unidirectional moisture-wicking, moisture-absorbing and heat-generating knitted fabric, which is woven with three kinds of yarns. The first yarn is a core-spun yarn with a specification of 36 British counts. The core yarn of the core-spun yarn is 50D / 48F Yilun fiber yarn, which is a special-shaped cross-section polyester fiber low elastic yarn provided by Sinopec Yizheng Chemical Fiber Co., Ltd. The twist direction is Z twist, and the outer wrapping part of the core-spun yarn is a blended fiber of regenerated cellulose fiber, which is a blend of ultrafine Lenzing Modal fiber (a kind of regenerated cellulose fiber) and flax fiber. Fine Lenzing modal fiber accounts for 70%, flax fiber accounts for 30%, and the twist direction of the outer wrapped part of the fiber is Z twist; the second yarn is T562B Easy Set LYCRA40D polyurethane fiber elastic yarn produced by INVISTA Fiber Co., Ltd. It is a low-temperature heat-setting polyurethane fiber elastic yarn; the third yarn i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com