Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7397results about "Liquid/gas/vapor textile treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

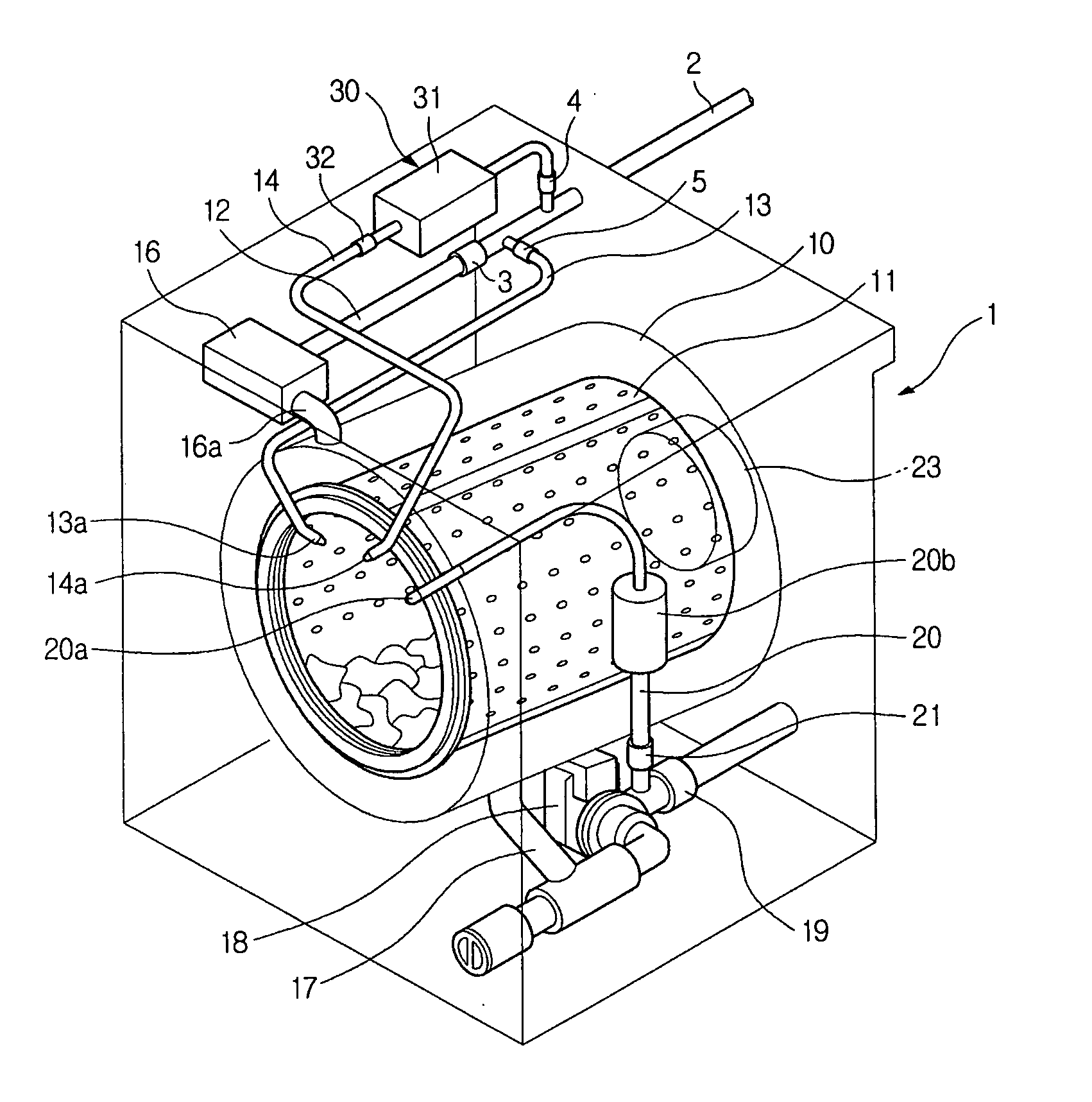

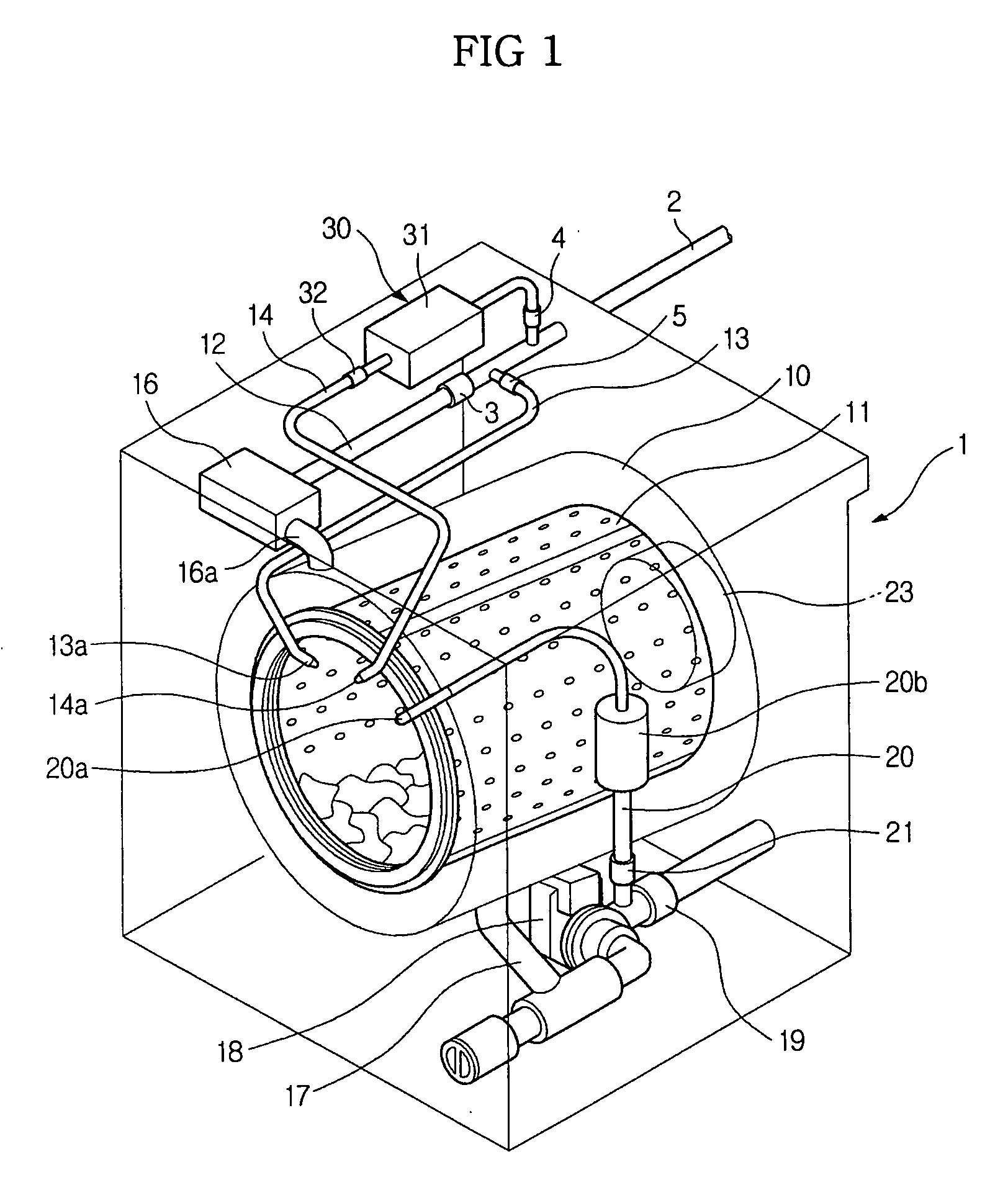

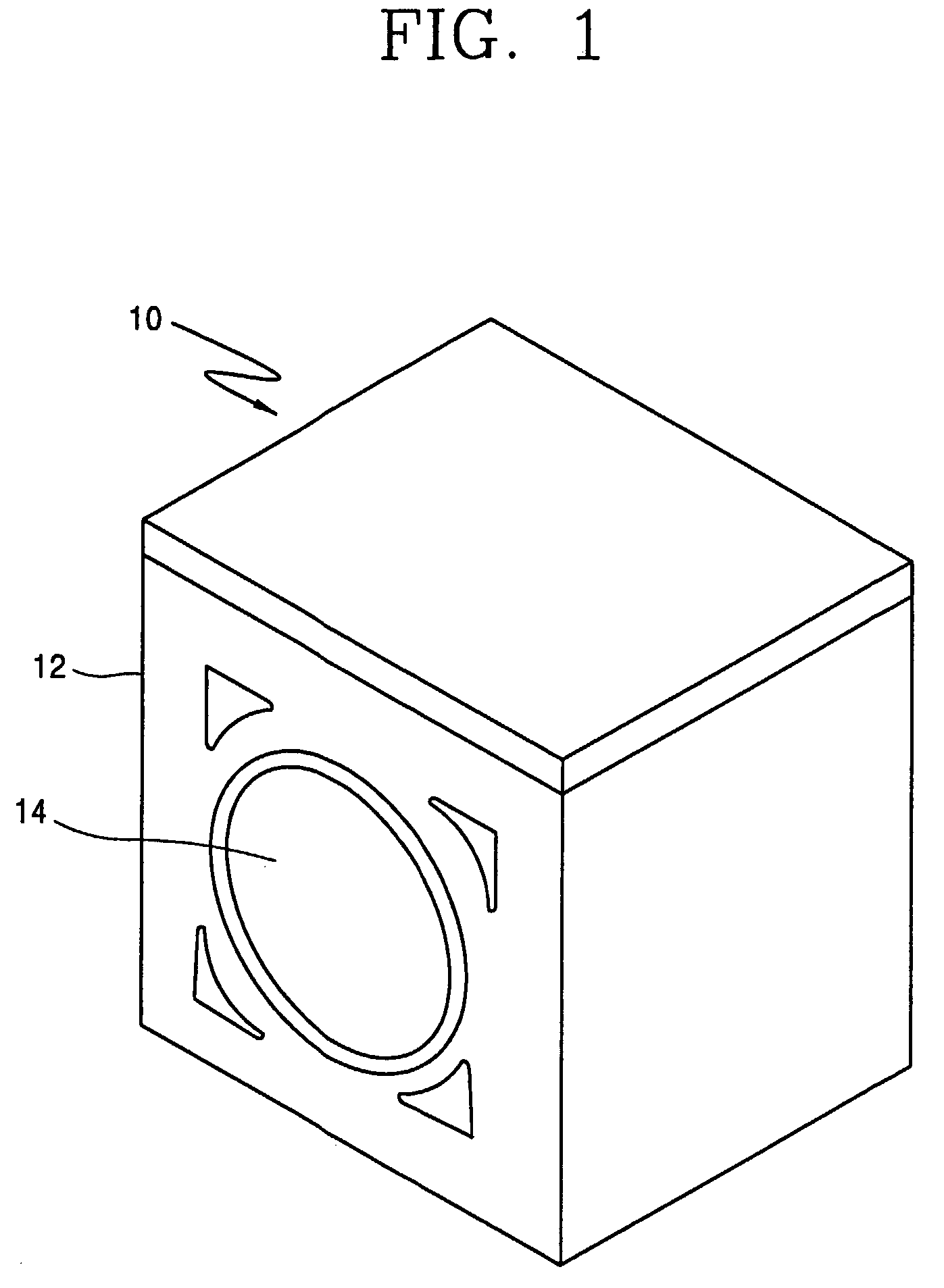

Washing machine

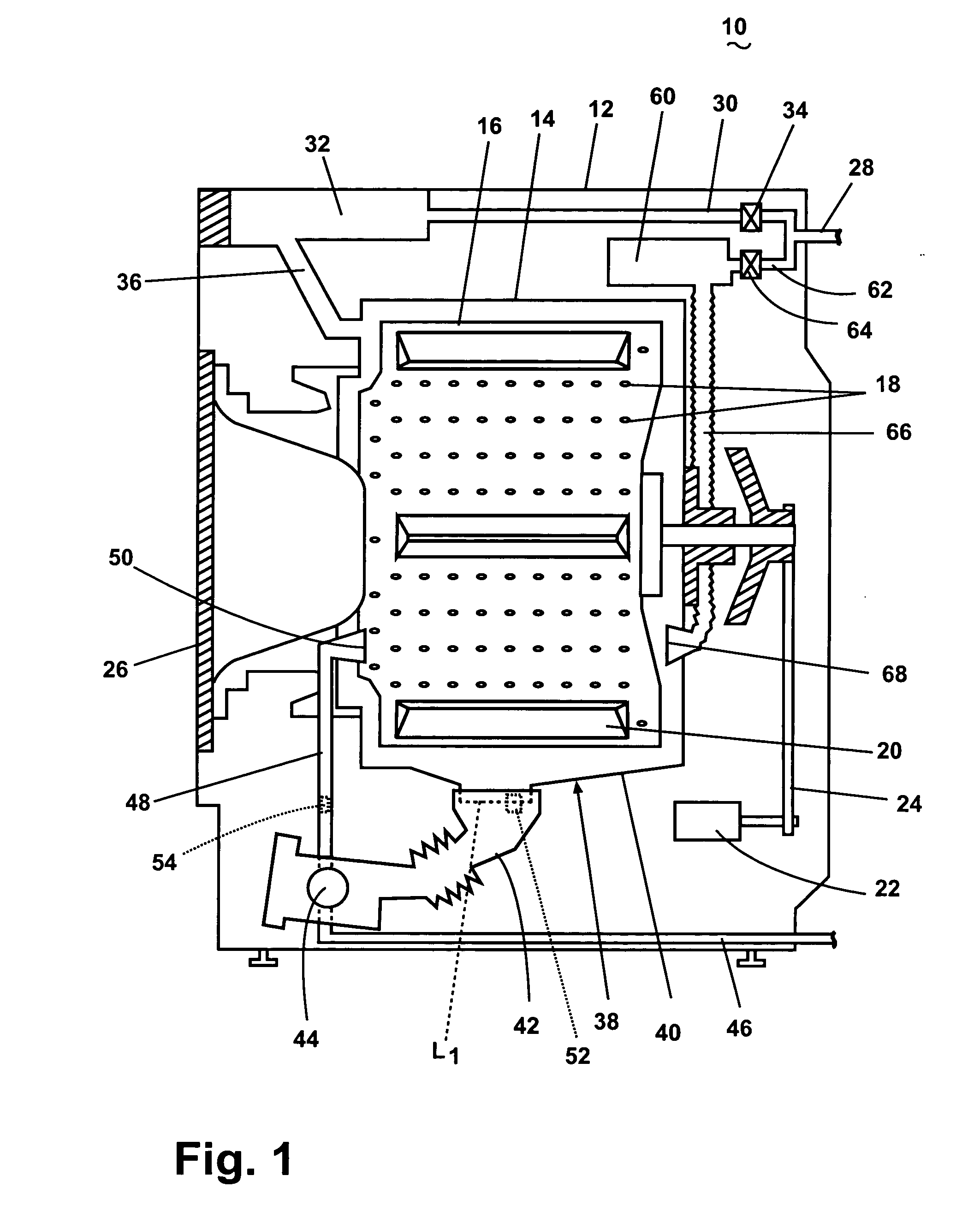

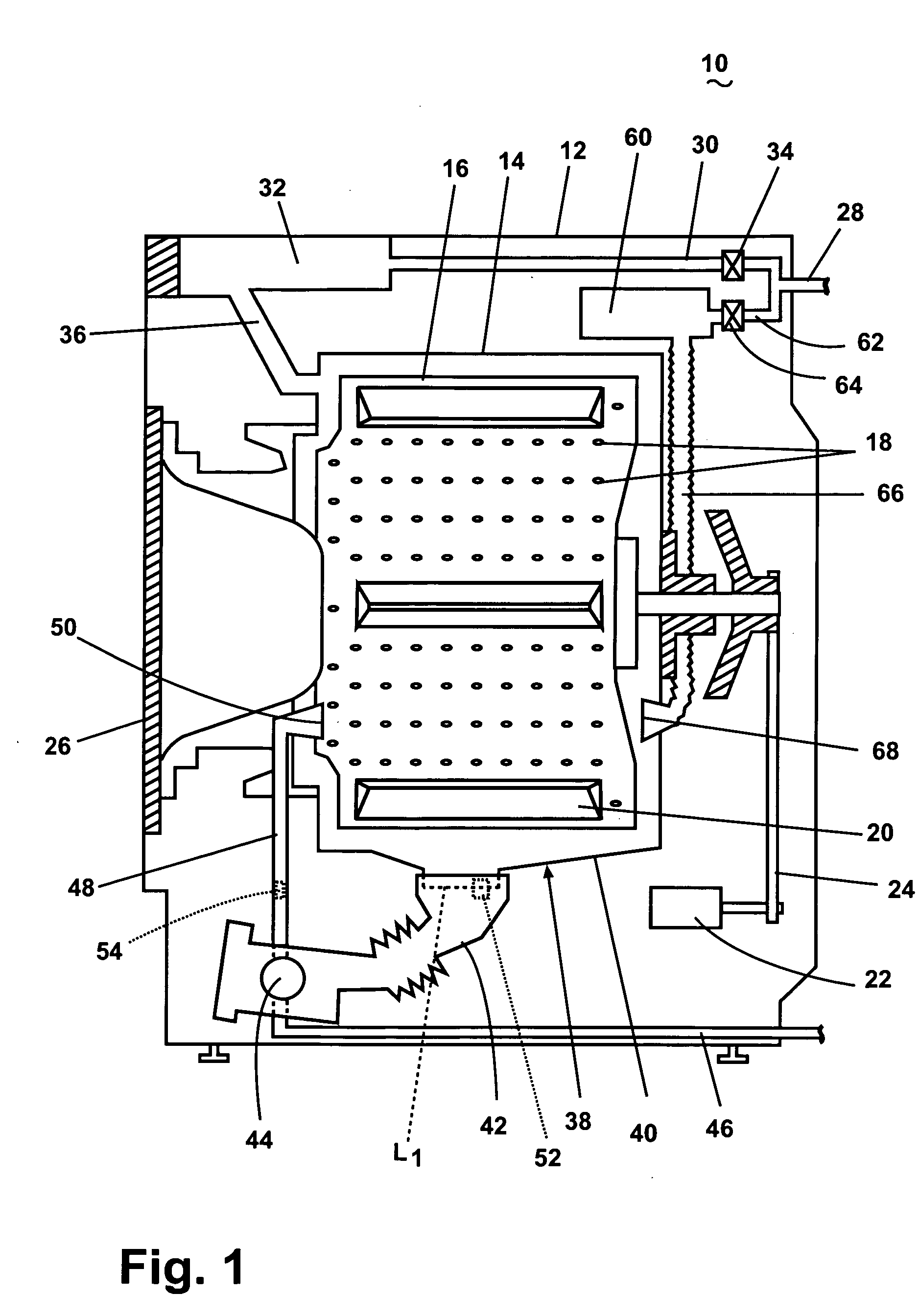

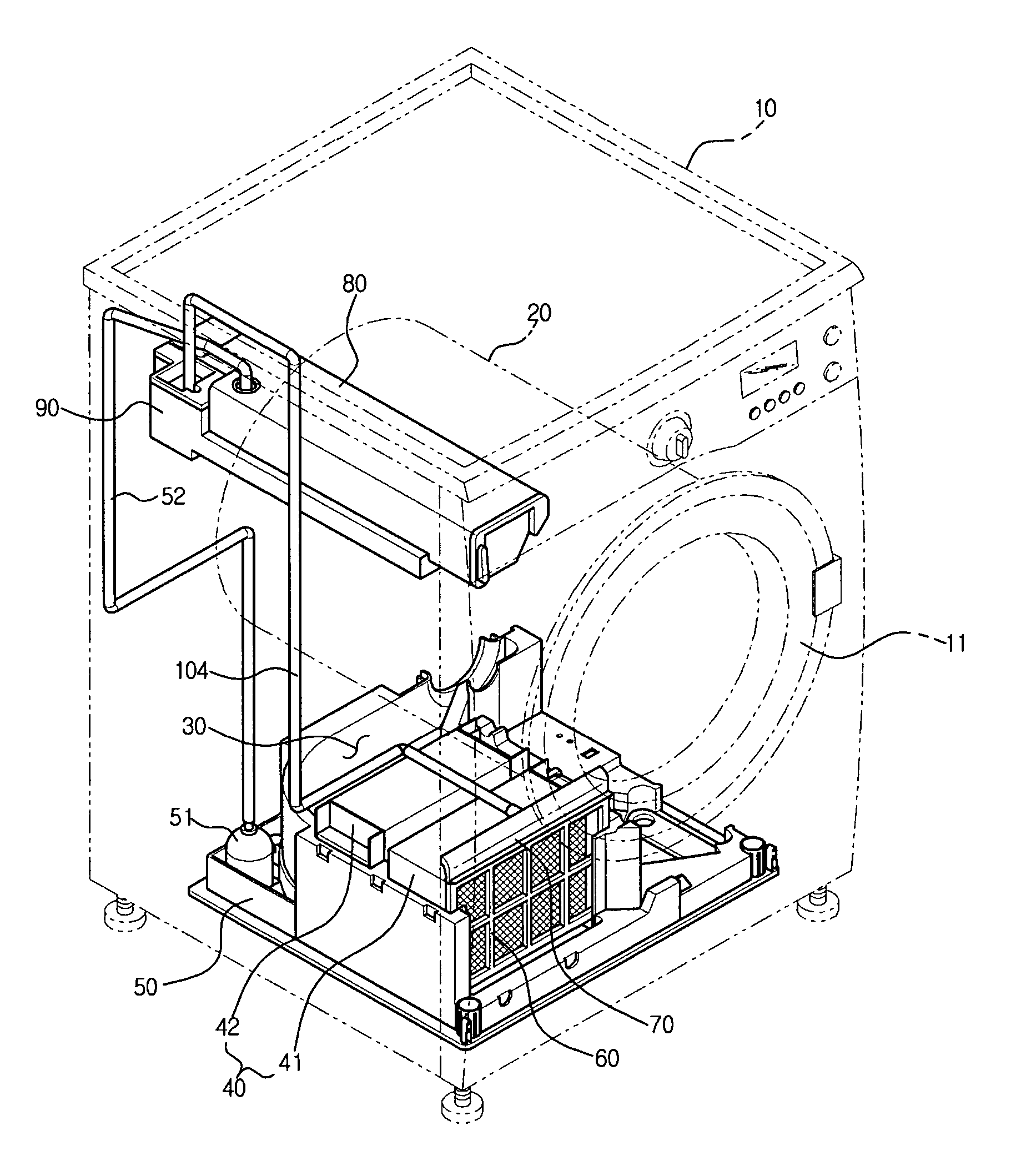

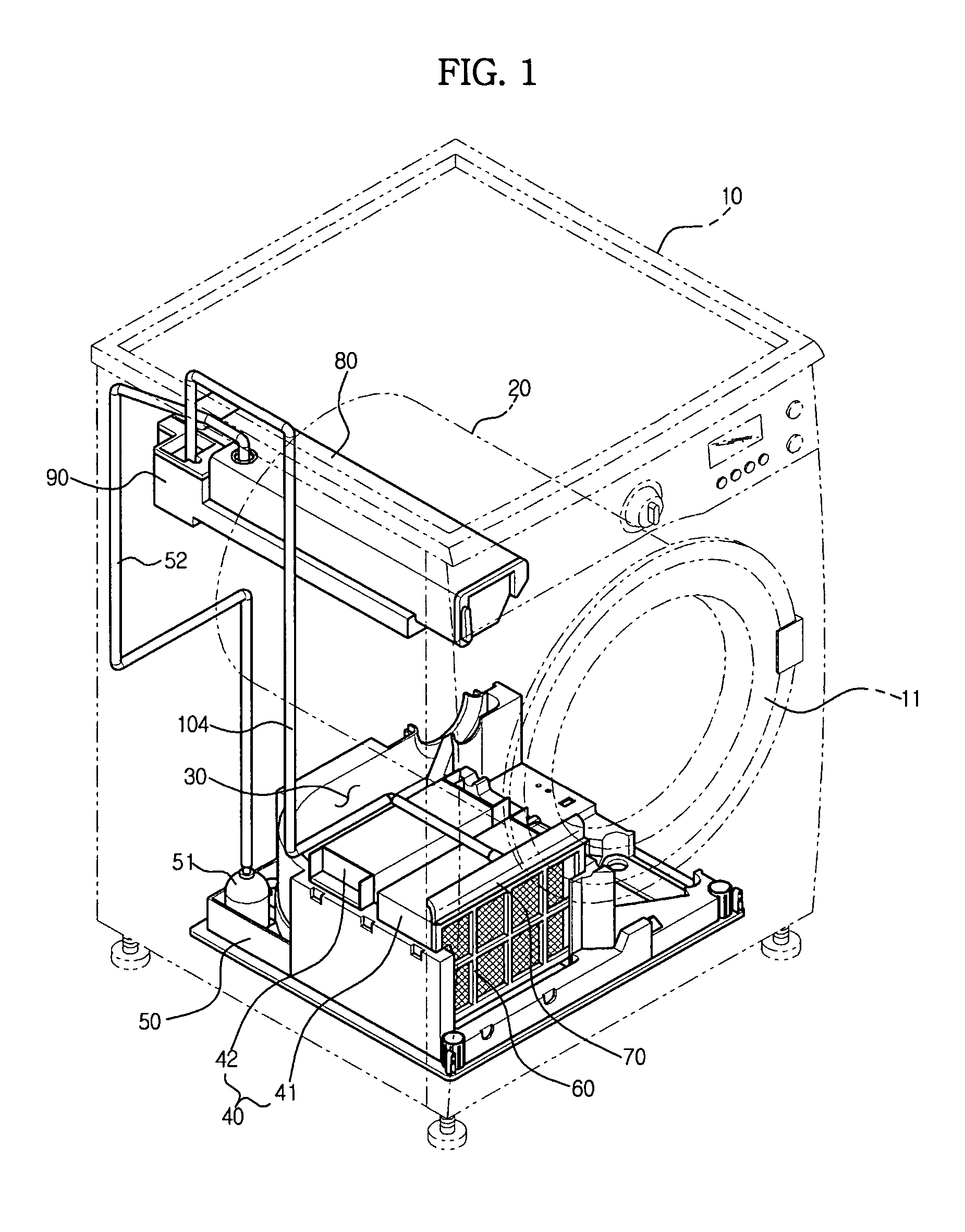

InactiveUS20090249840A1Improve rinsing efficiencyImprove washing efficiencyTextile treatment machine partsOther washing machinesWash waterEngineering

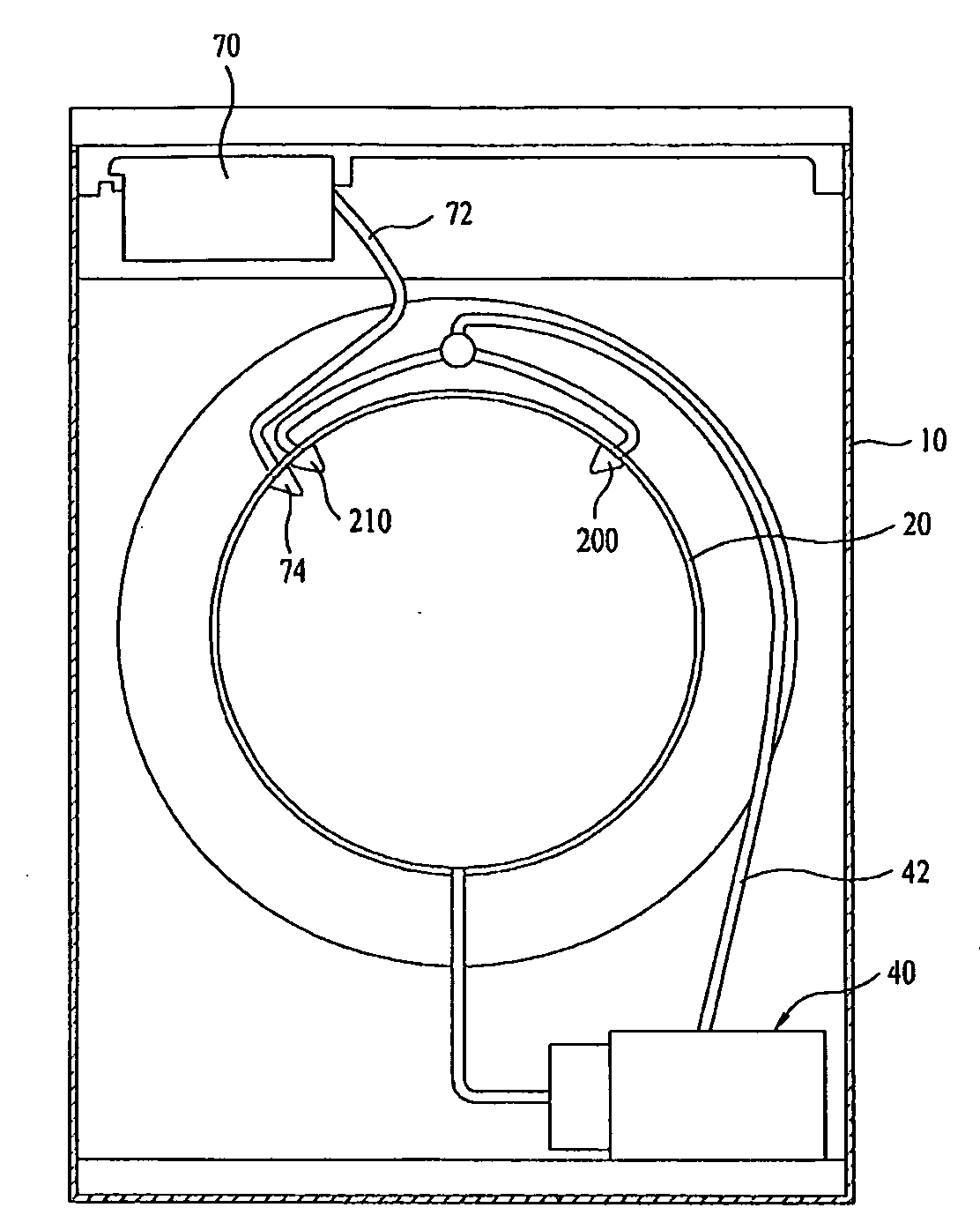

A washing machine includes a cabinet constituting the external appearance of the washing machine, a tub mounted in the cabinet for receiving wash water, a drum rotatably mounted in the tub for receiving laundry to be washed, a circulation unit for circulating wash water in the inner lower part of the tub through the upper part of the tub, and at least one circulation nozzle for spraying the wash water, supplied by the circulation unit, inwardly of the drum along a rotation axis of the drum in a longitudinal direction of the drum. According to the present invention, it is possible to improve washing or rinsing efficiency of the washing machine.

Owner:LG ELECTRONICS INC

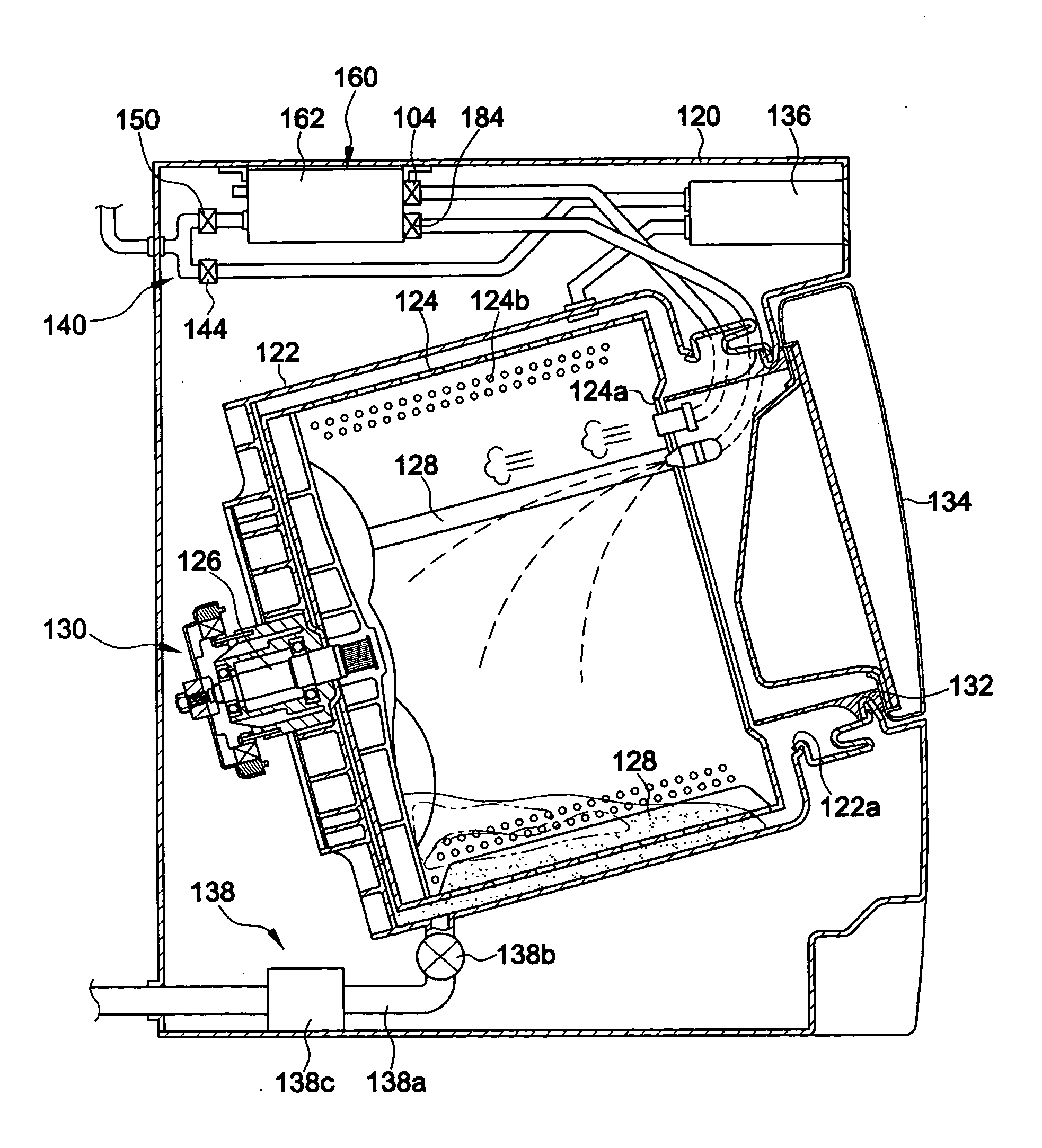

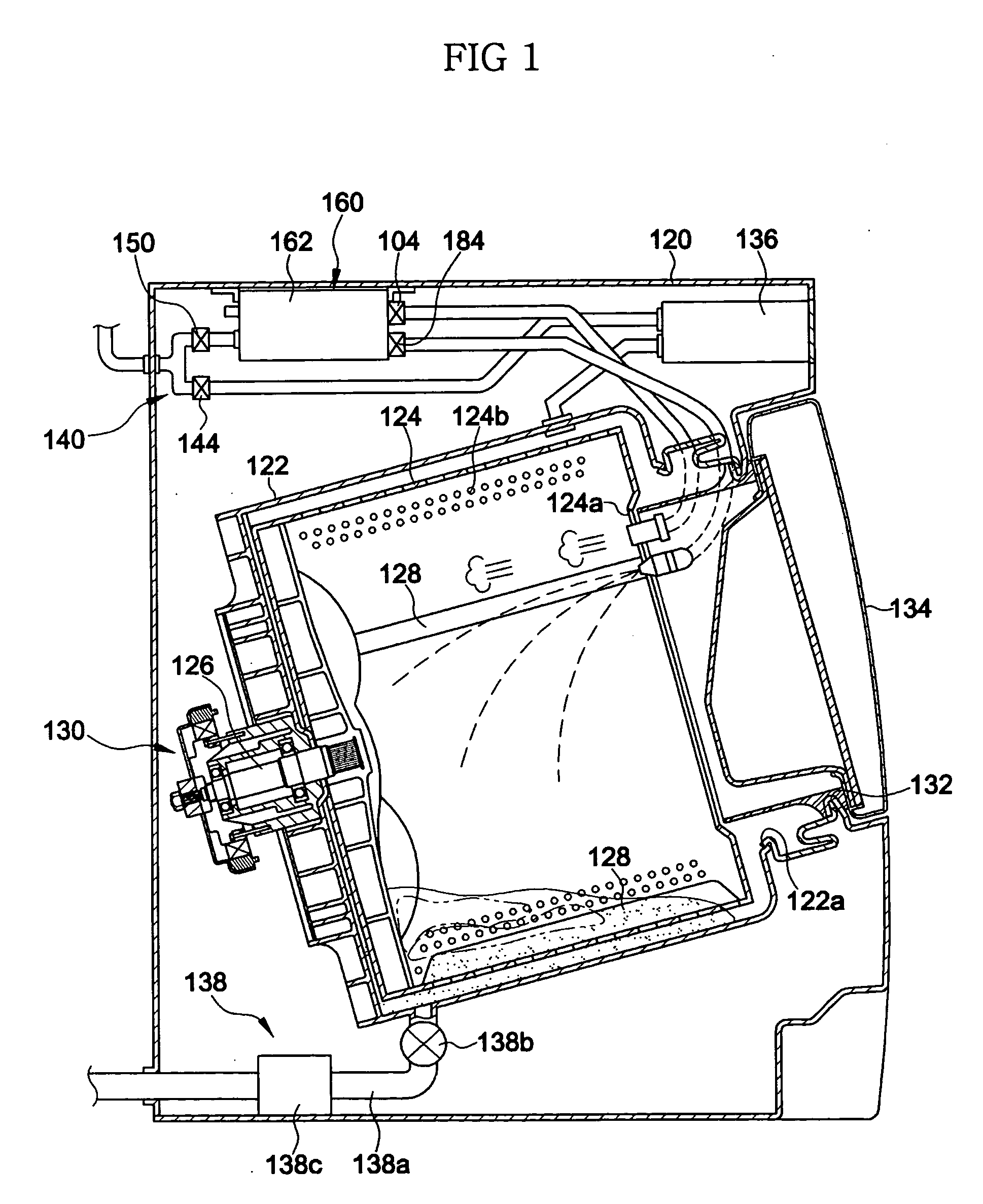

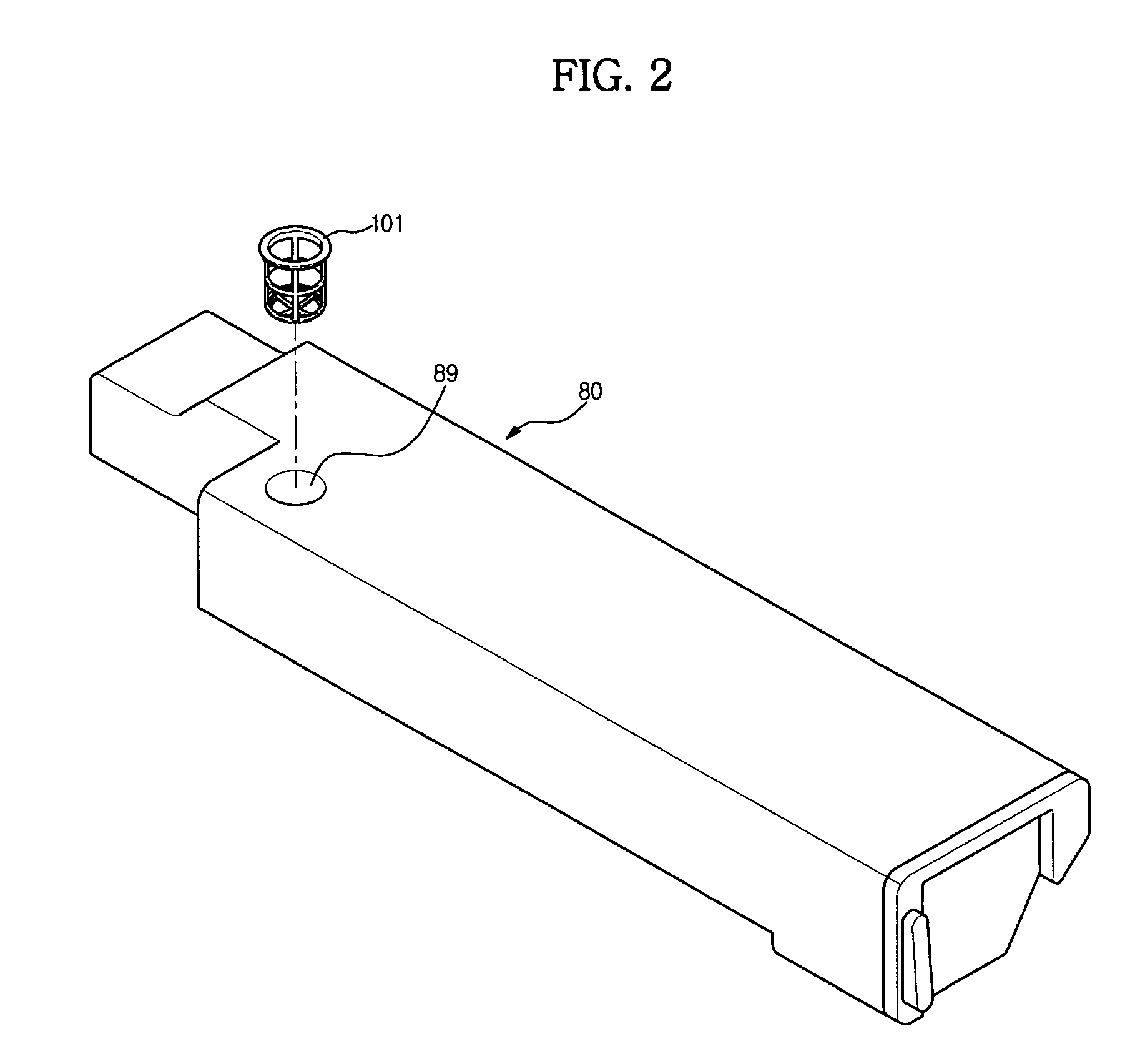

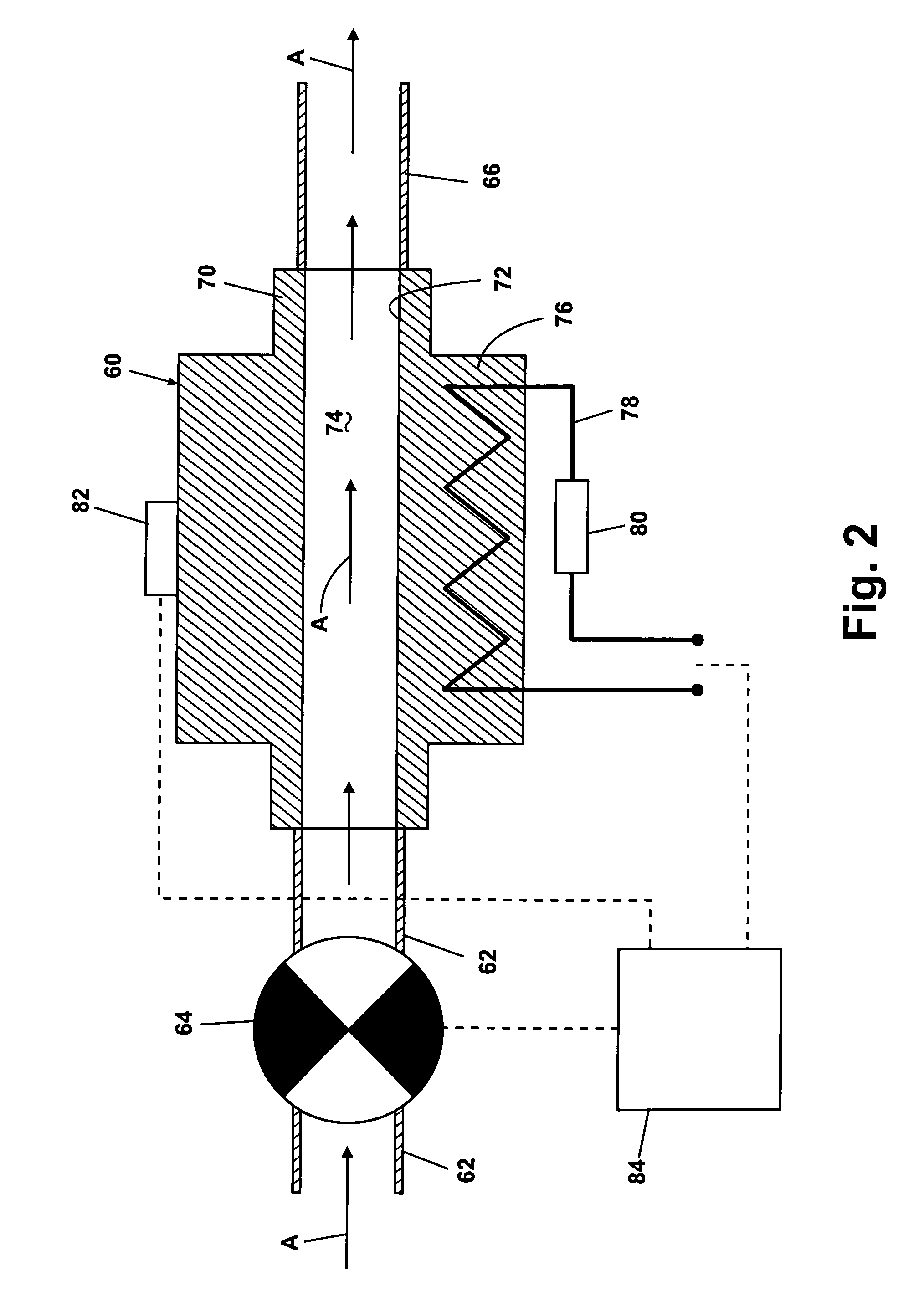

Washing machine and method for controlling the same

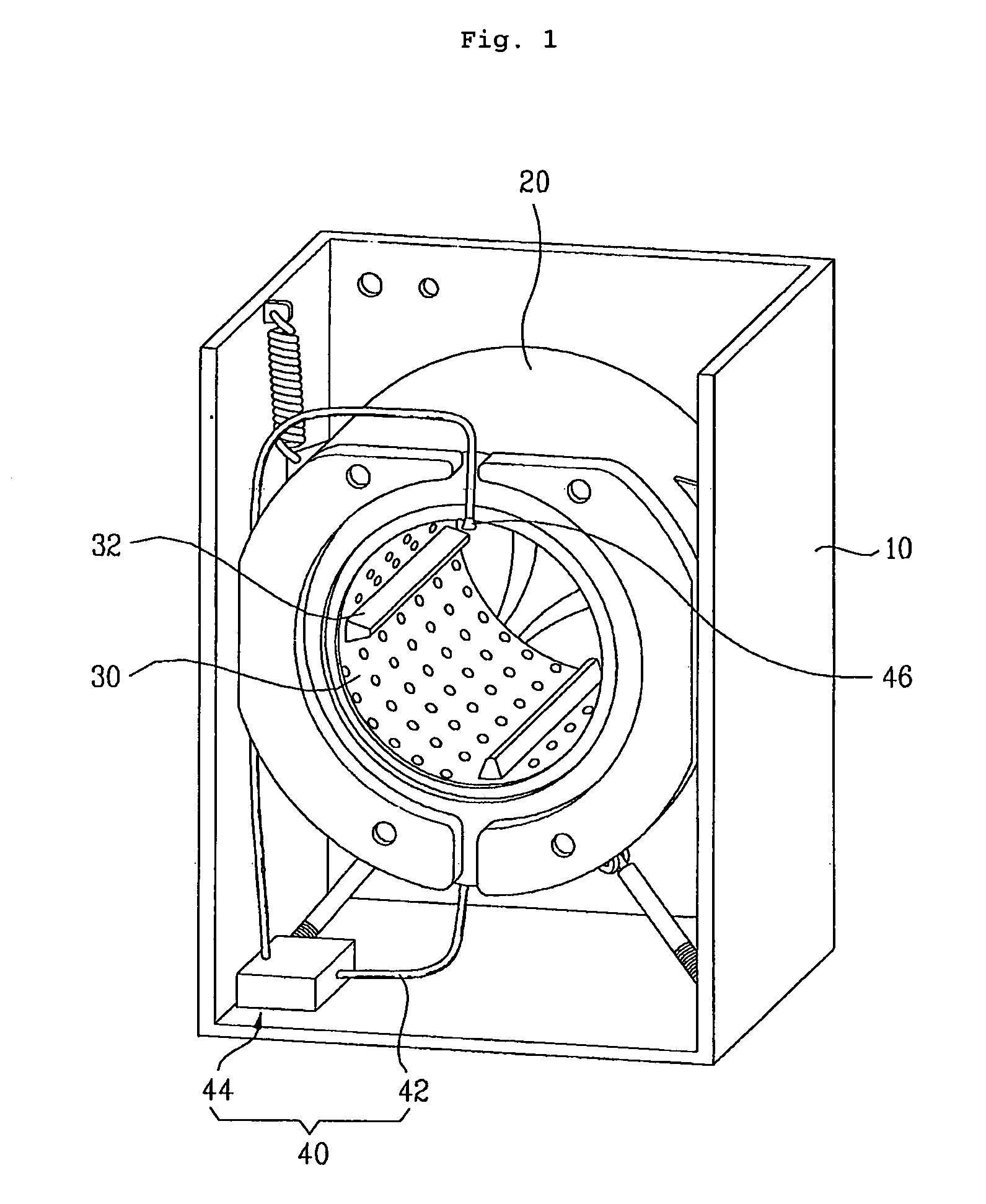

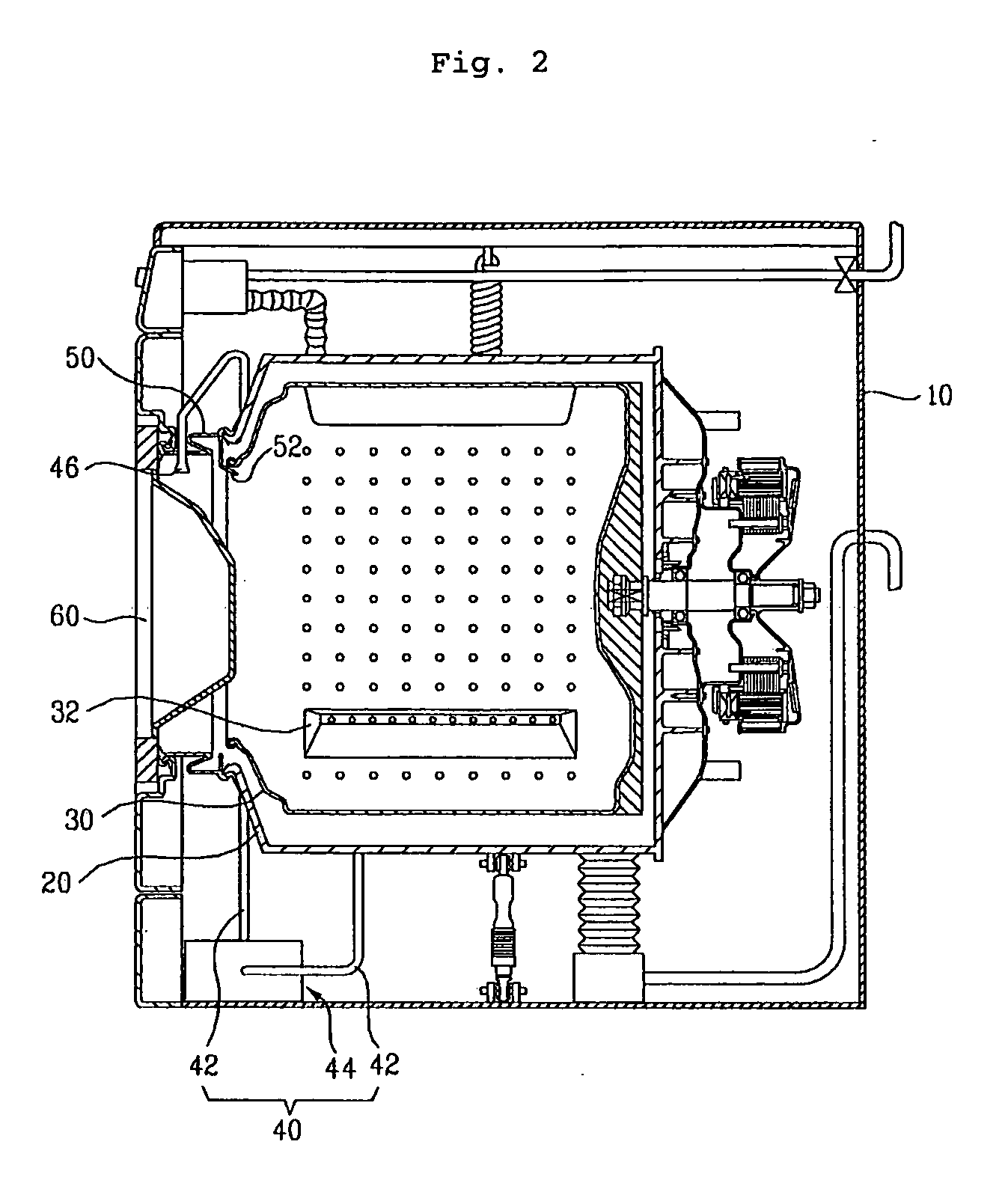

ActiveUS20060016020A1Save washing waterAvoid damageOther washing machinesWashing machine with receptaclesCirculating pumpMechanical engineering

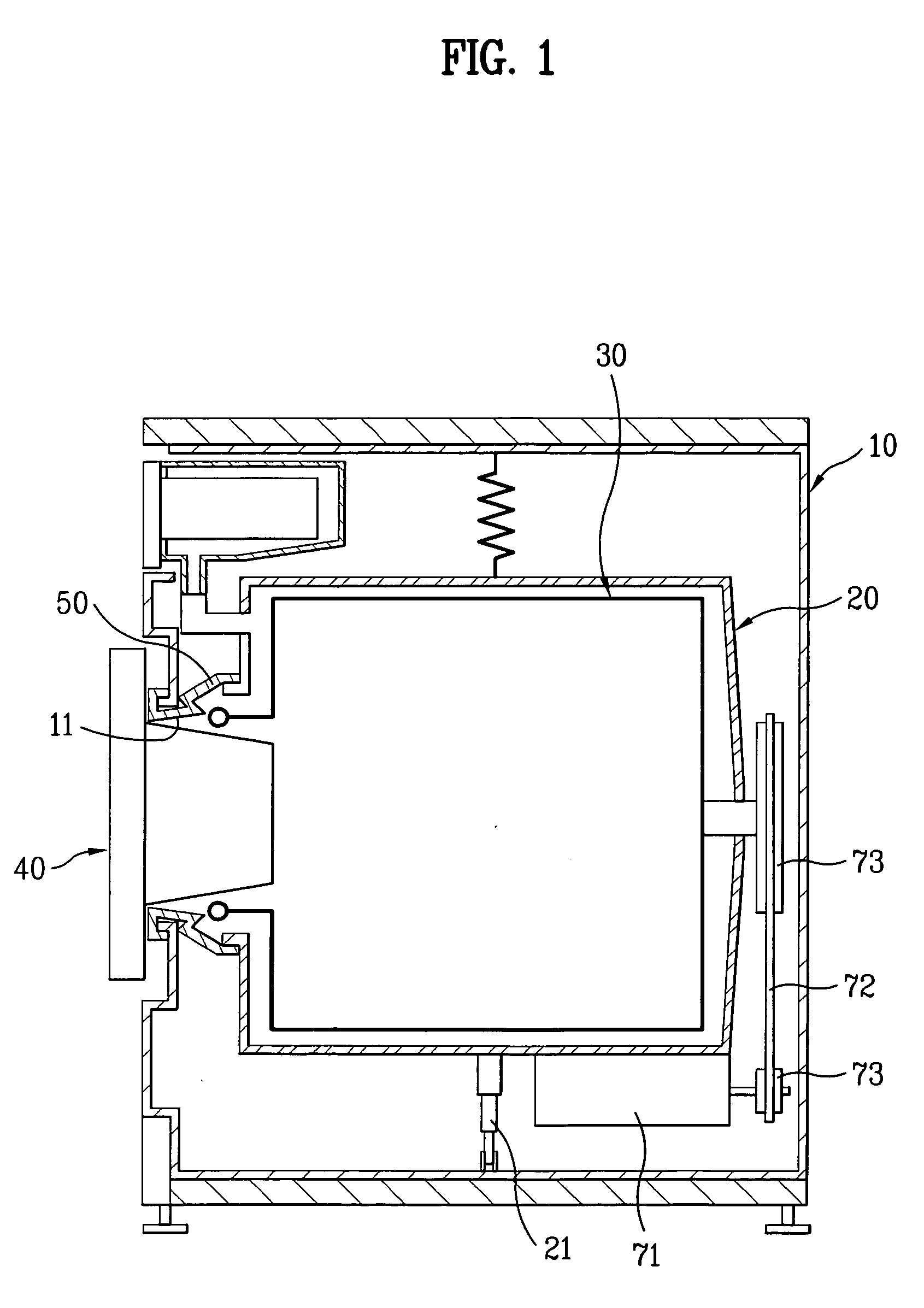

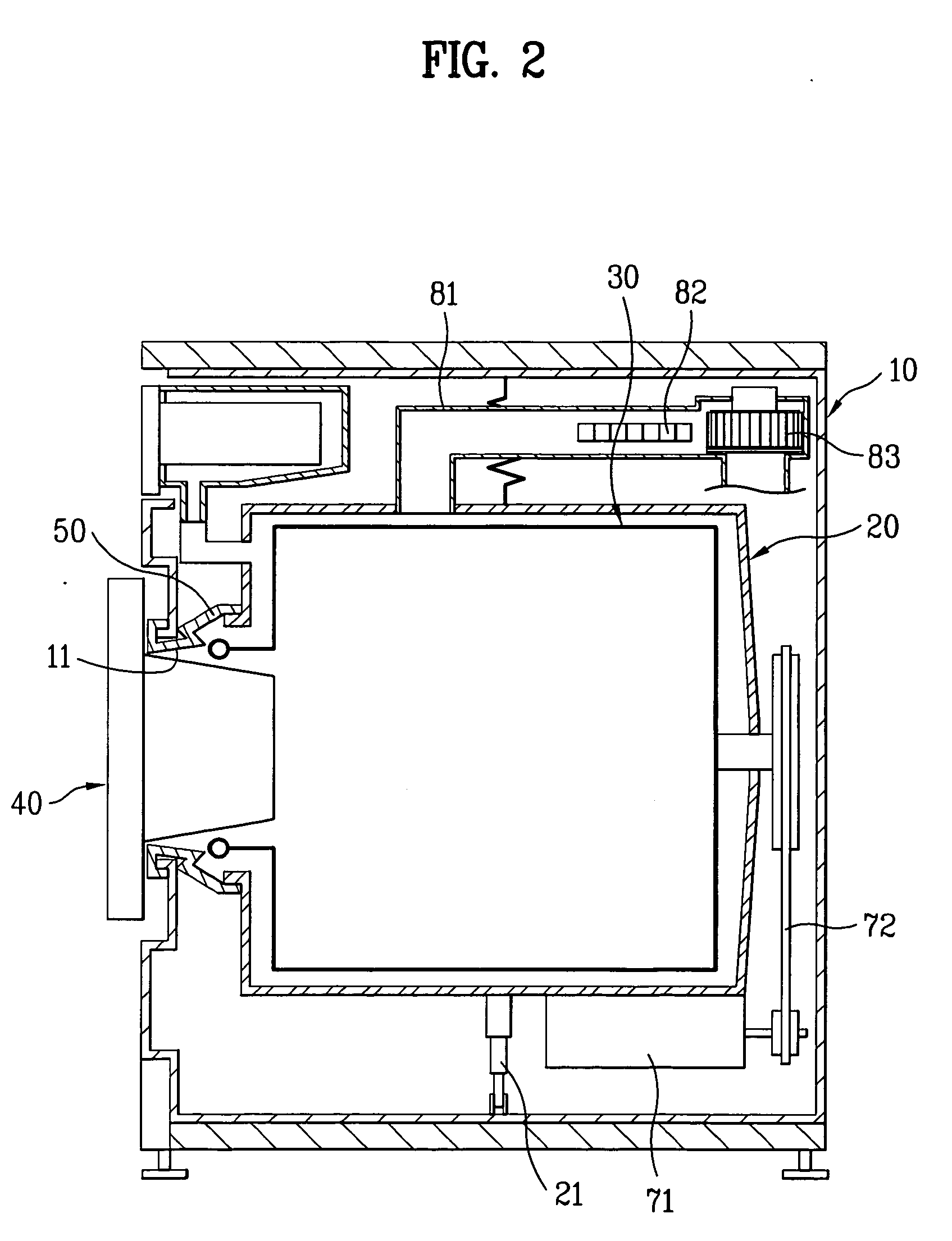

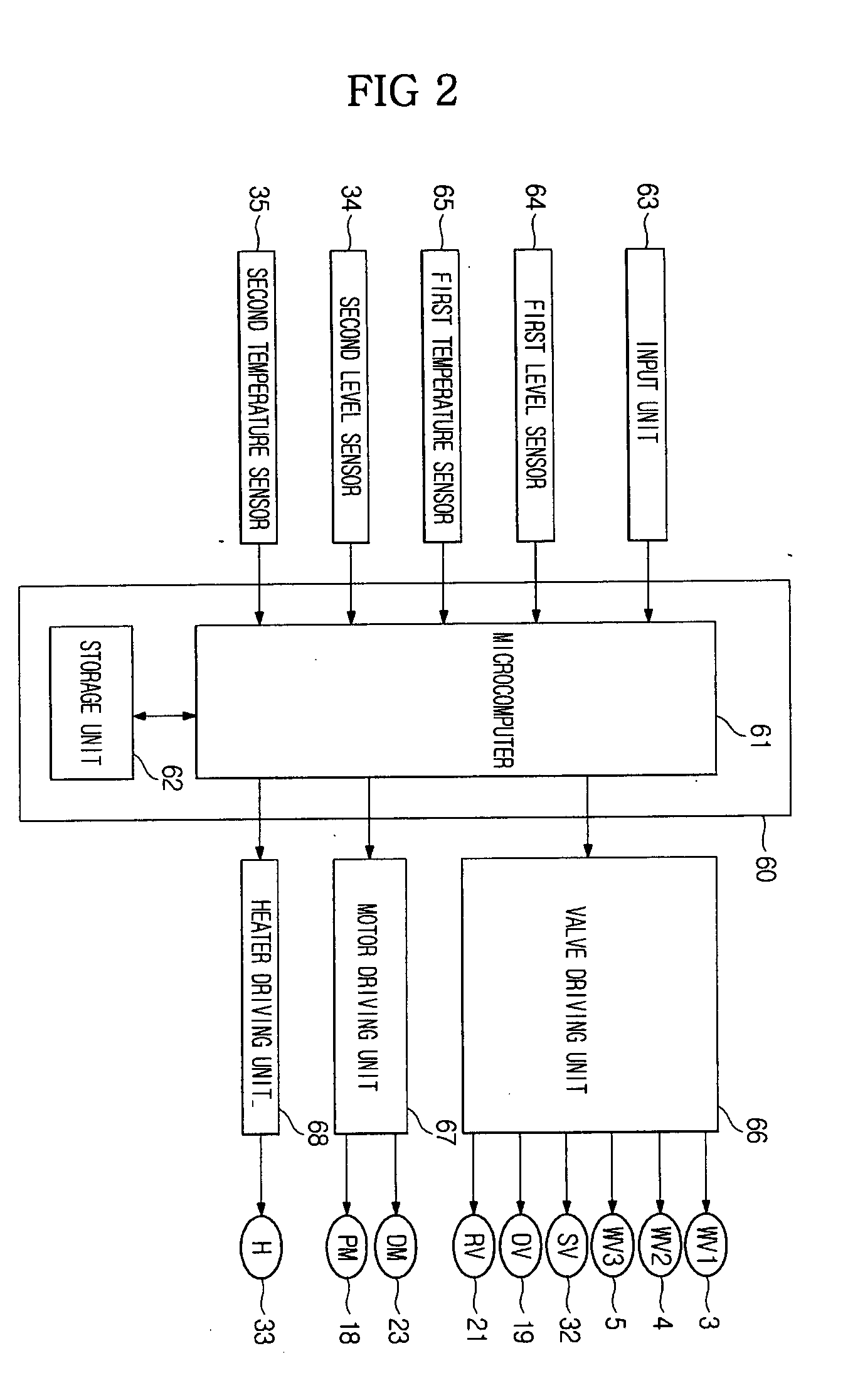

A washing machine includes a main body defining an outer appearance, a tub supported in the main body, a drum rotatably installed in the tub, a steam generating unit supplying steam into the drum, and a circulation pump returning washing water exhausted from a first side of the tub to a second side of the tub.

Owner:LG ELECTRONICS INC

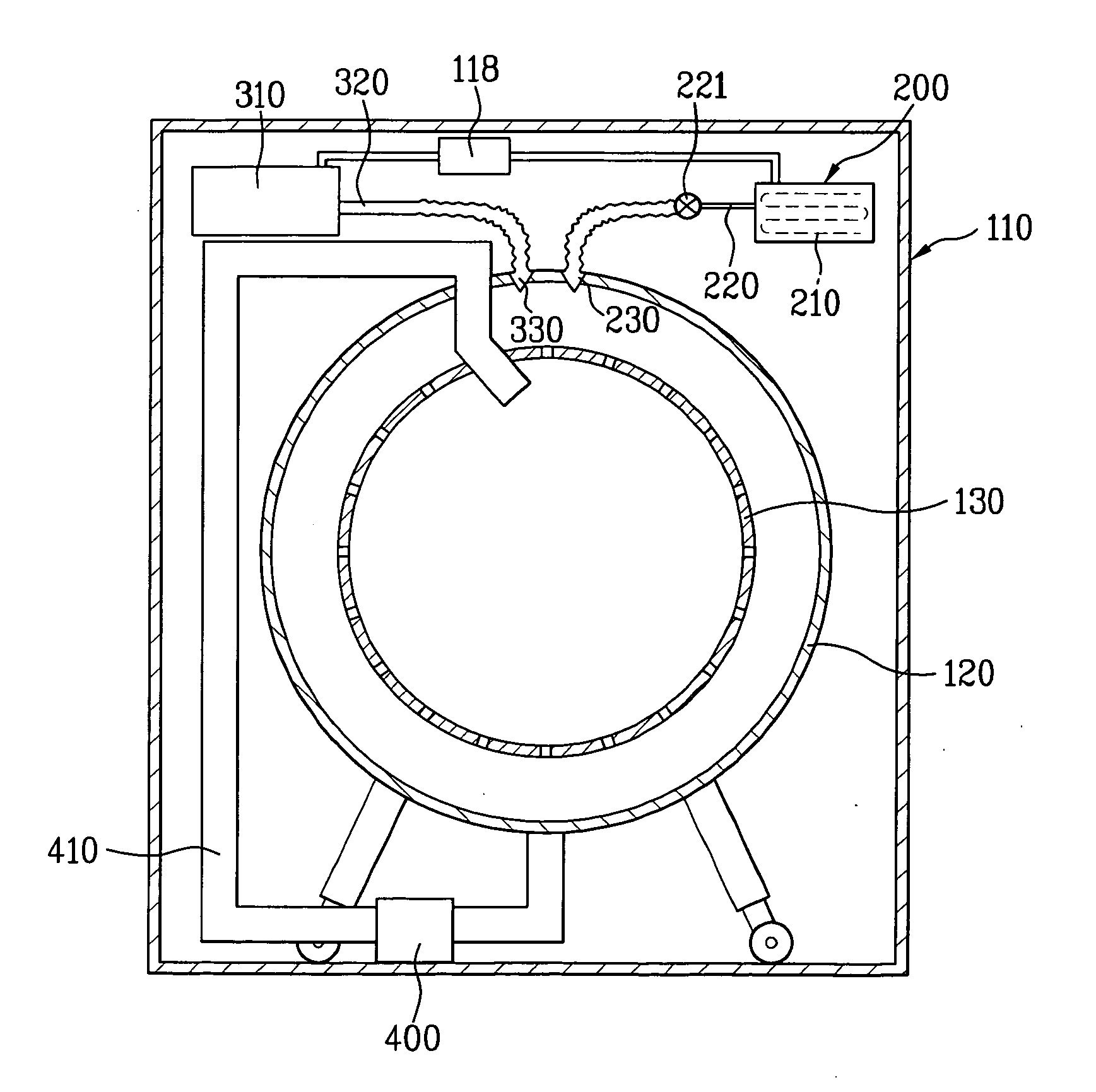

Washing machine and method of controlling the same

ActiveUS20050144734A1Preventing the laundry of poor heat-resistanceOther washing machinesControl devices for washing apparatusHeat resistanceEngineering

A washing machine in which the laundry of poor heat-resistance is sufficiently wet so that a water curtain layers are formed at the laundry, thereby preventing the laundry from being stained and damaged when the laundry contacts the steam. According to the present invention, cold water is supplied simultaneously with injection of the steam so that the real temperature of the steam contacting the surfaces of the laundry is lowered, thereby preventing the laundry from being stained and damaged when the laundry contacts the steam.

Owner:SAMSUNG ELECTRONICS CO LTD

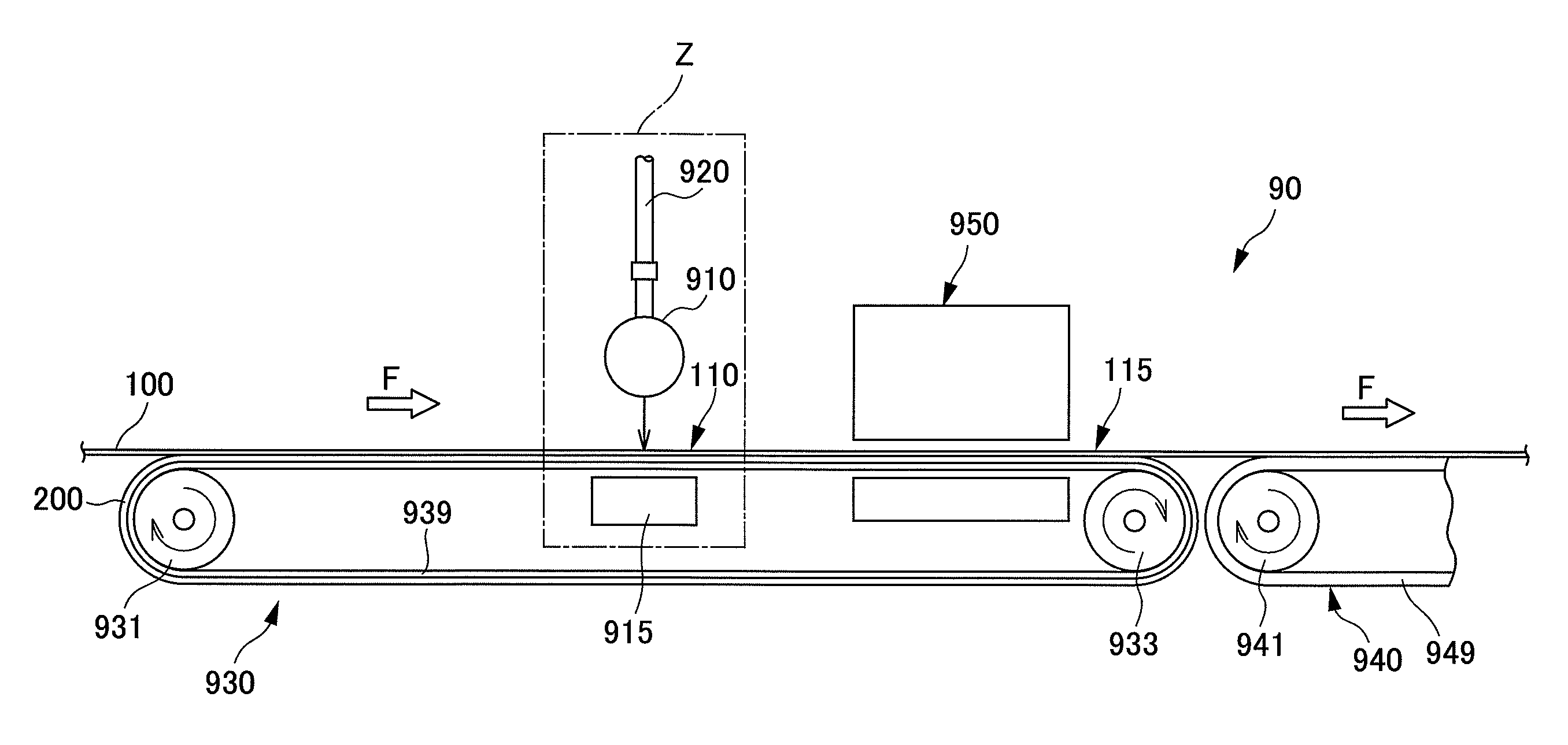

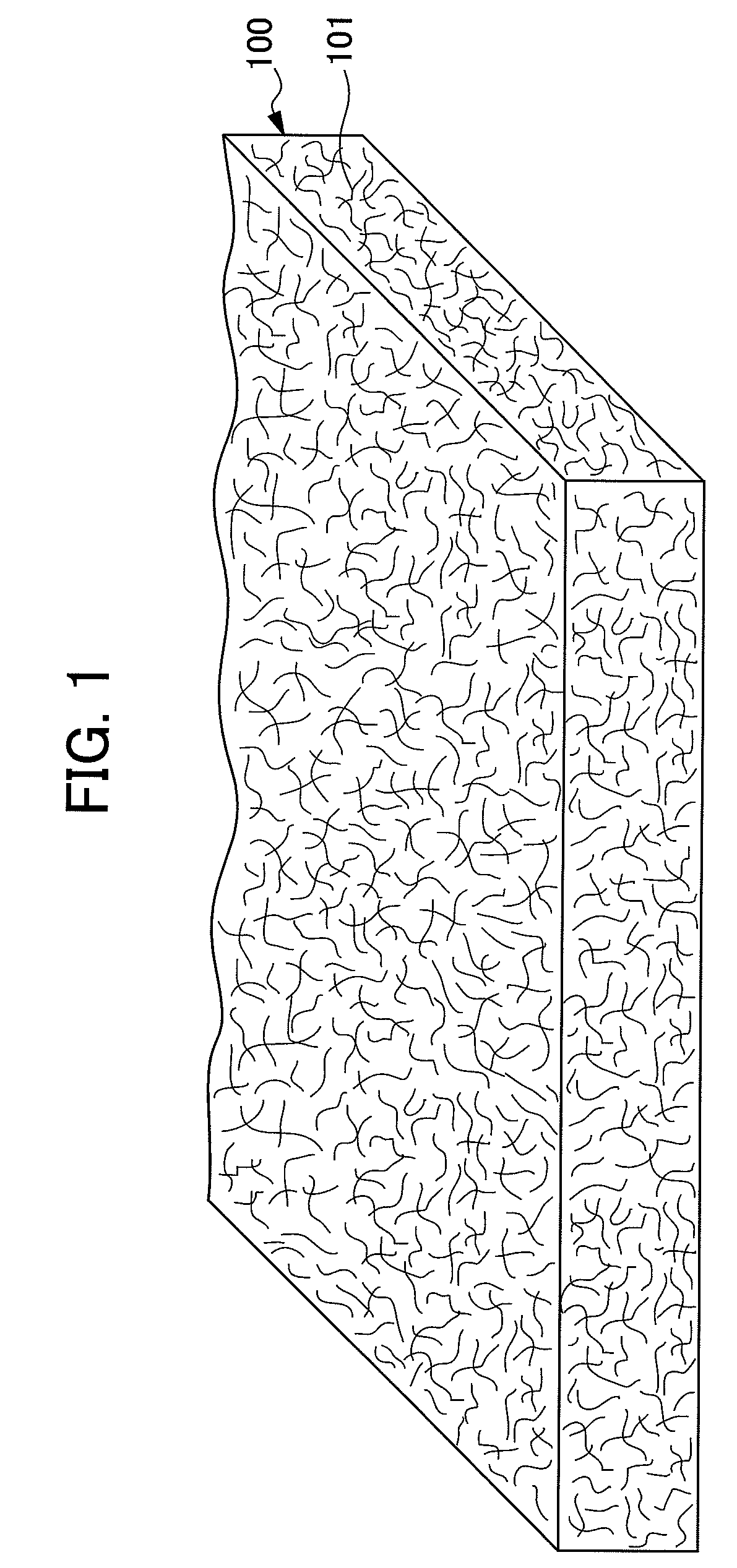

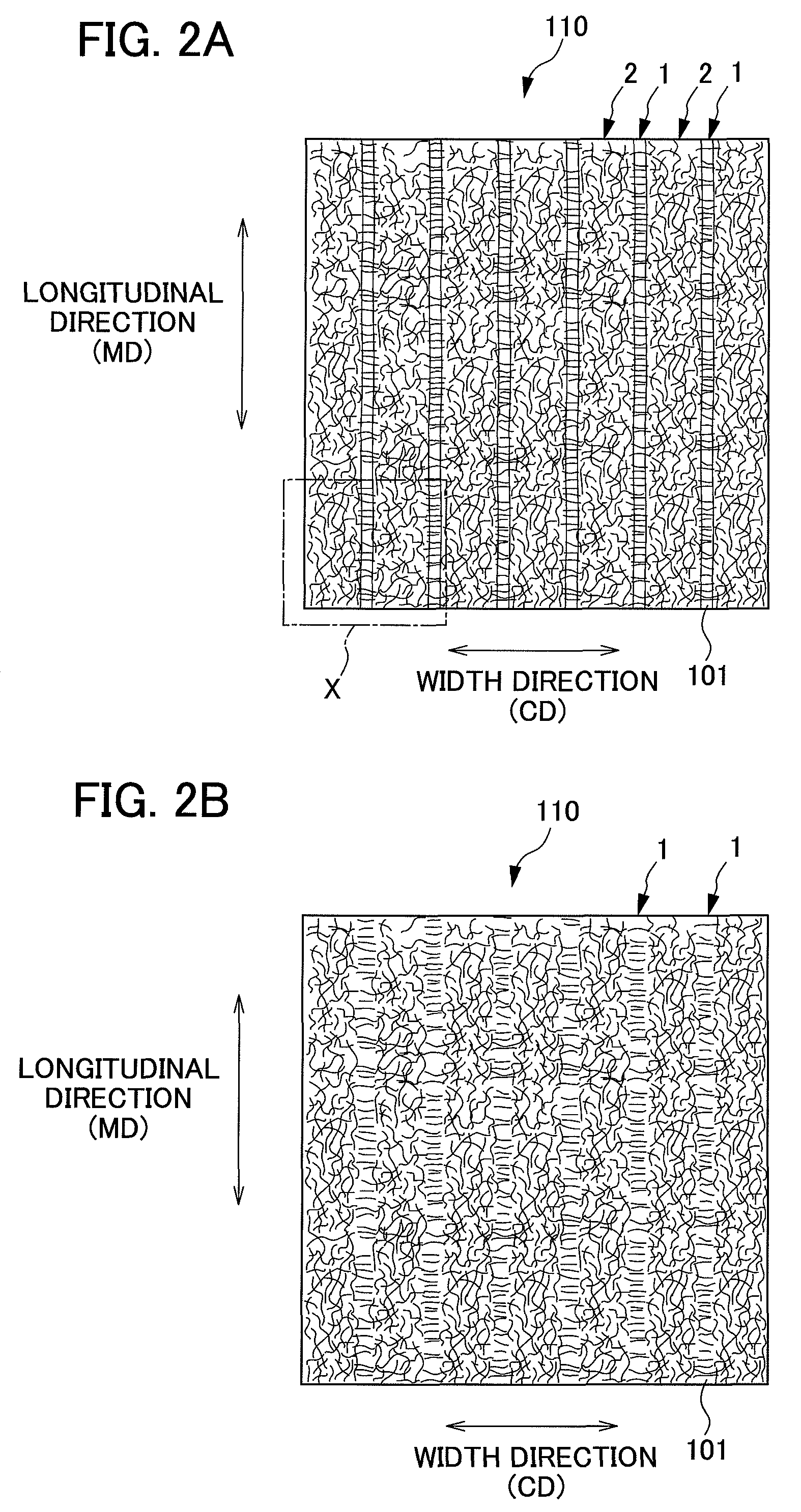

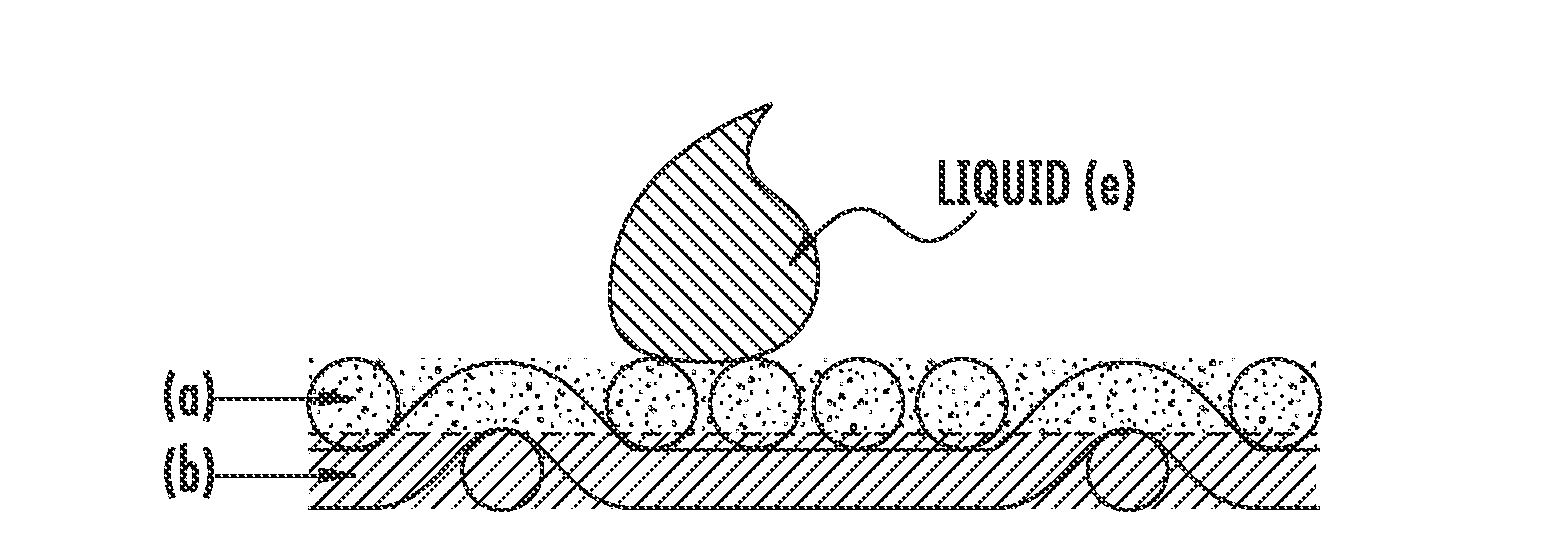

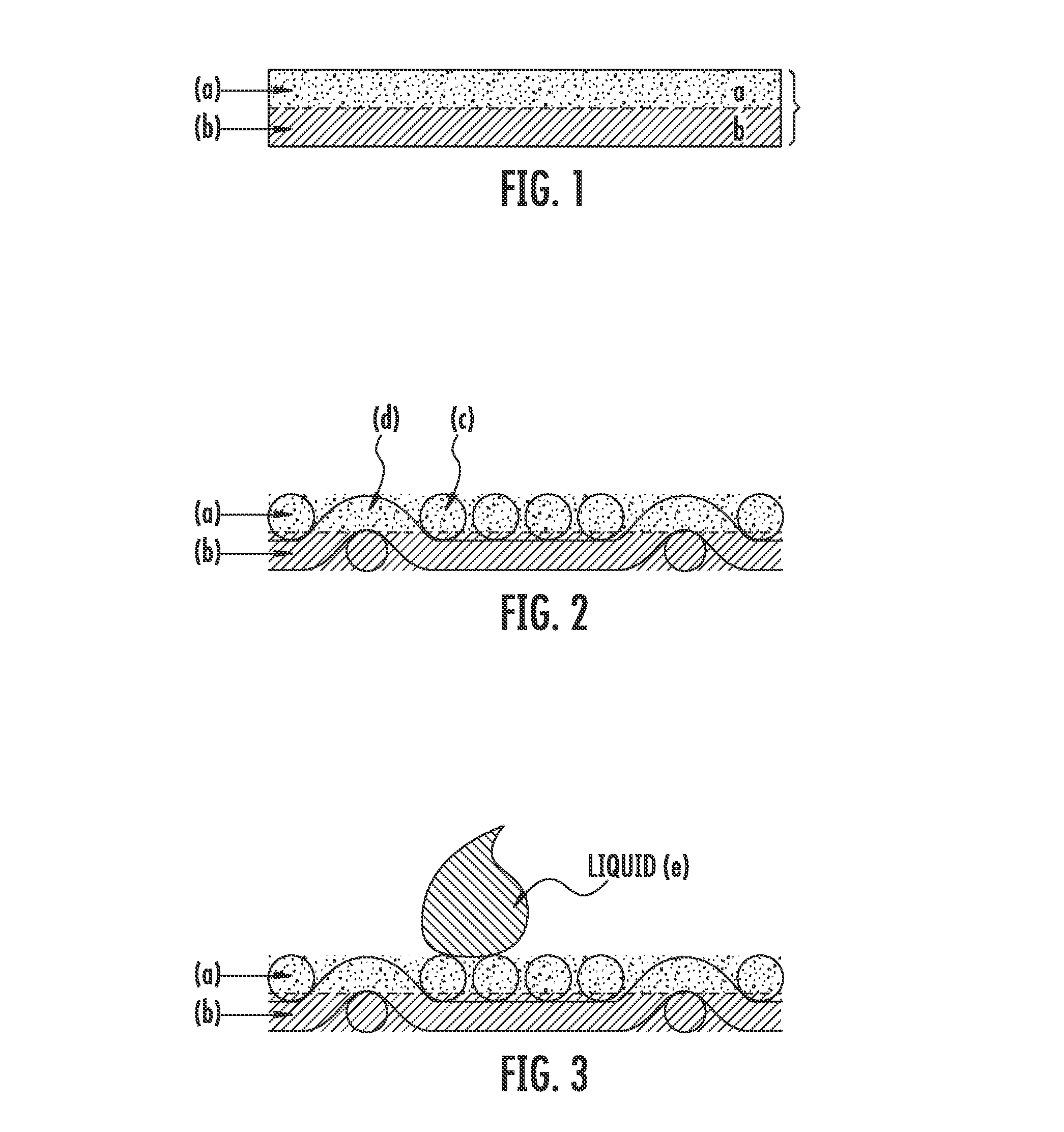

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

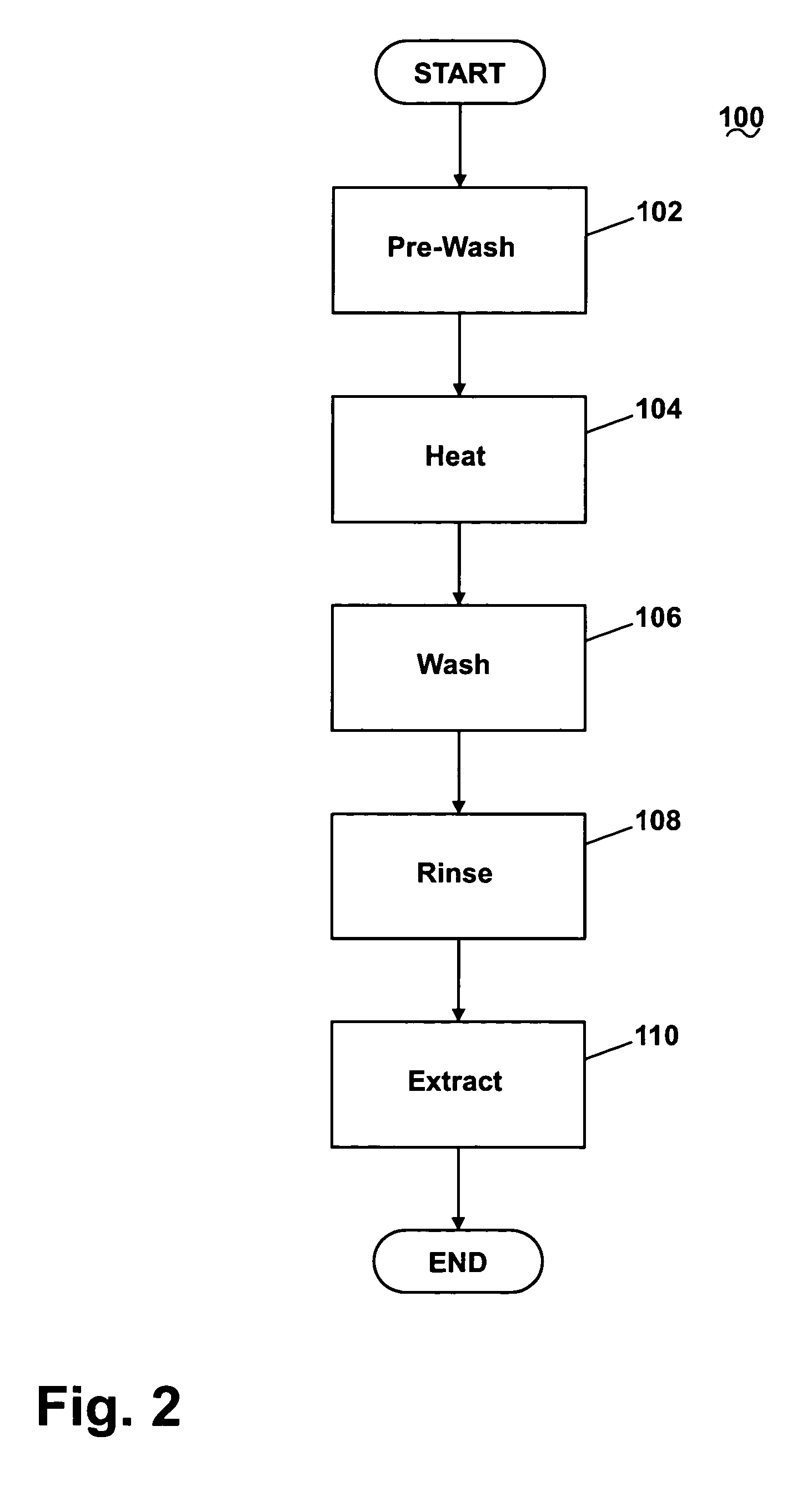

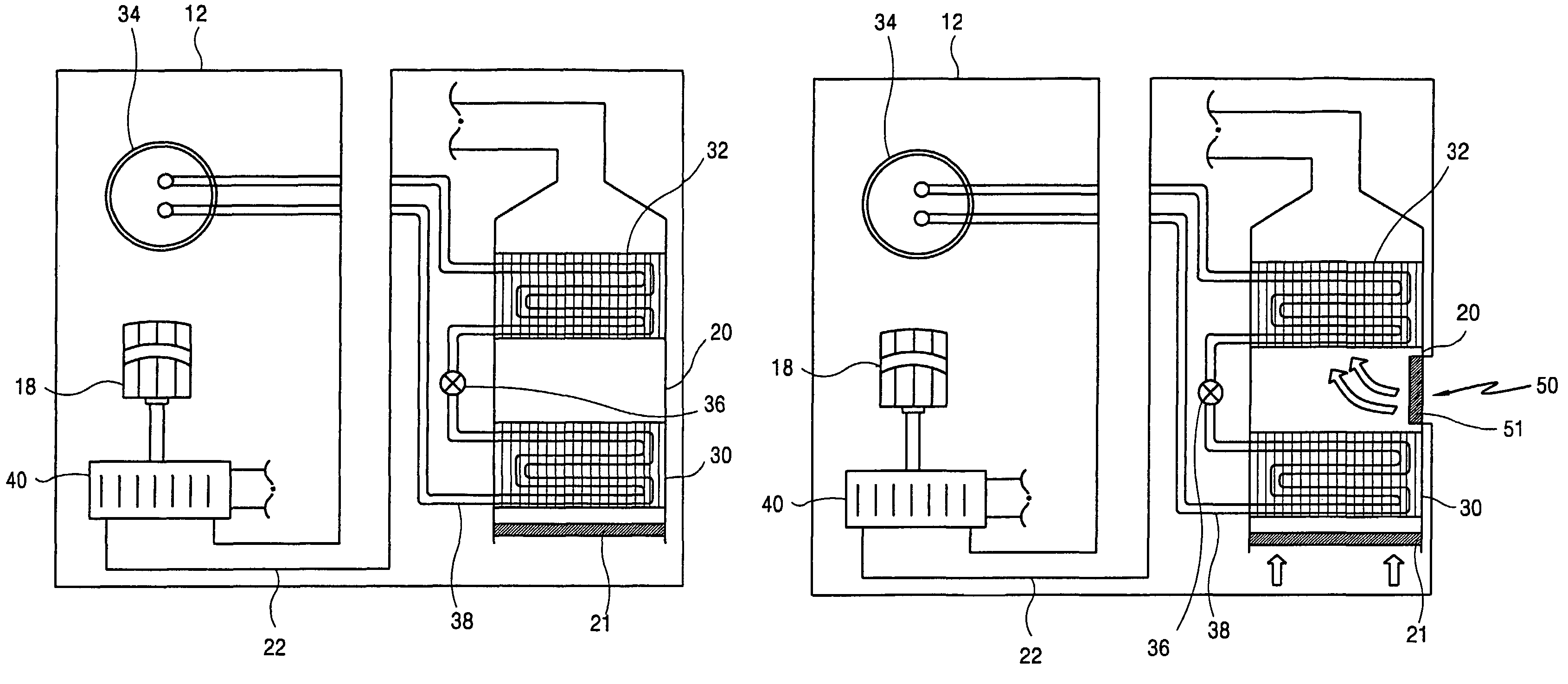

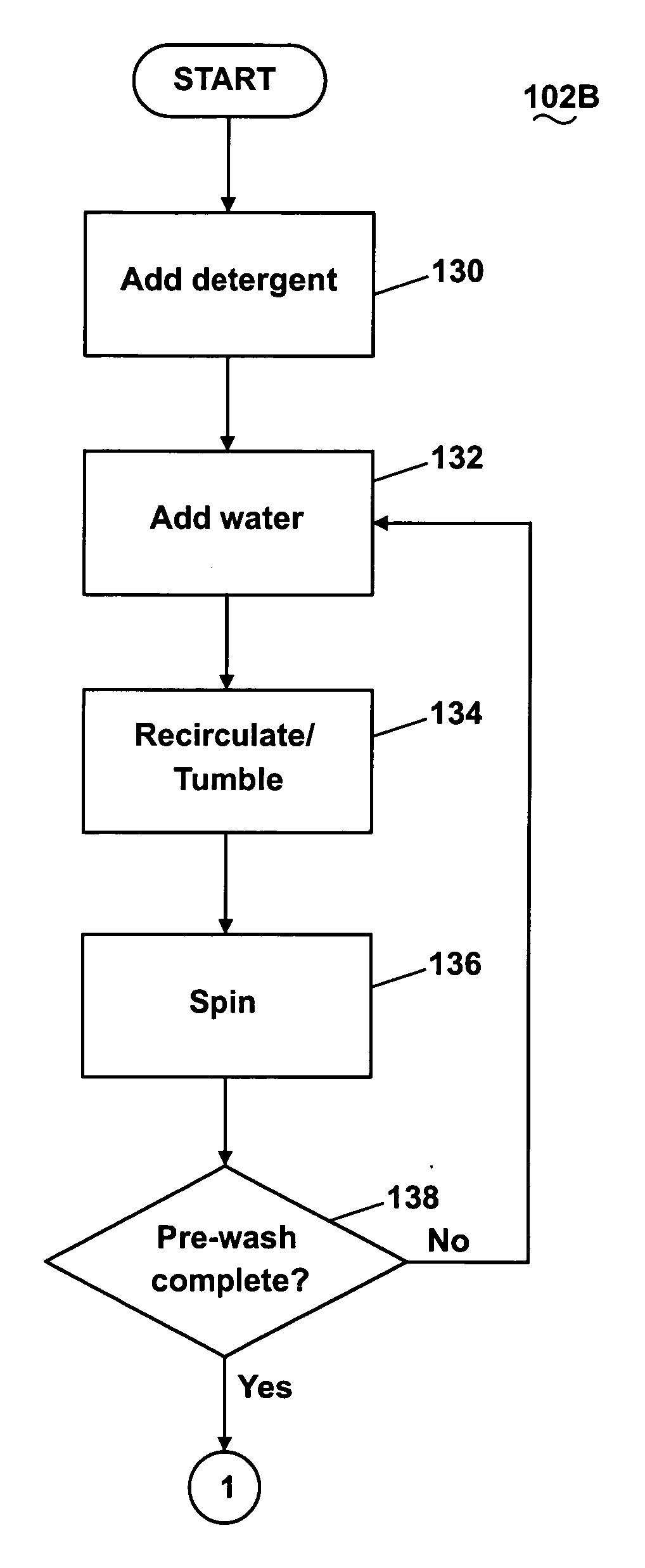

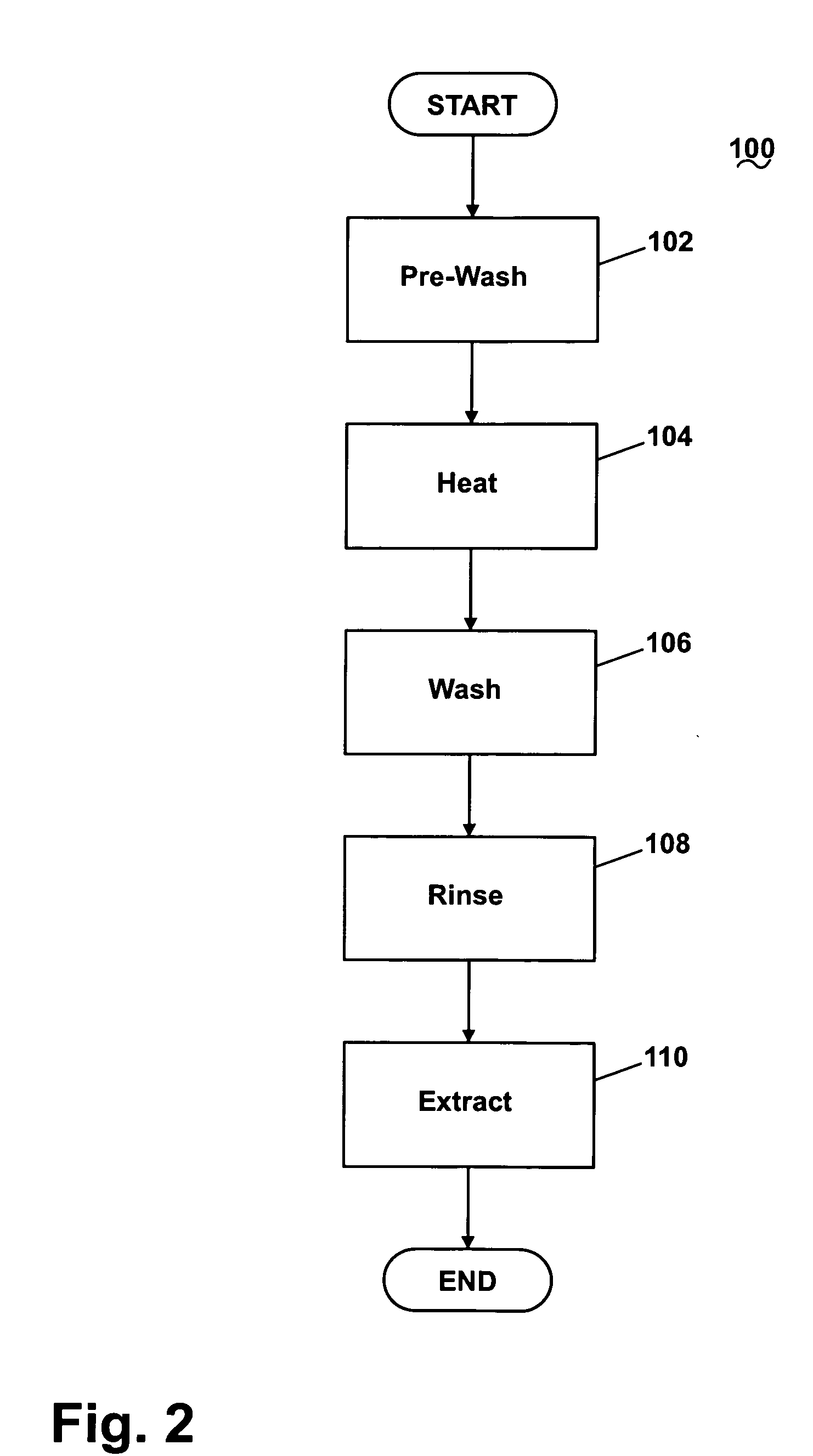

Method of operating a washing machine using steam

ActiveUS20070283508A1Decrease fabric load weightReduce load weightOther washing machinesControl devices for washing apparatusProcess engineering

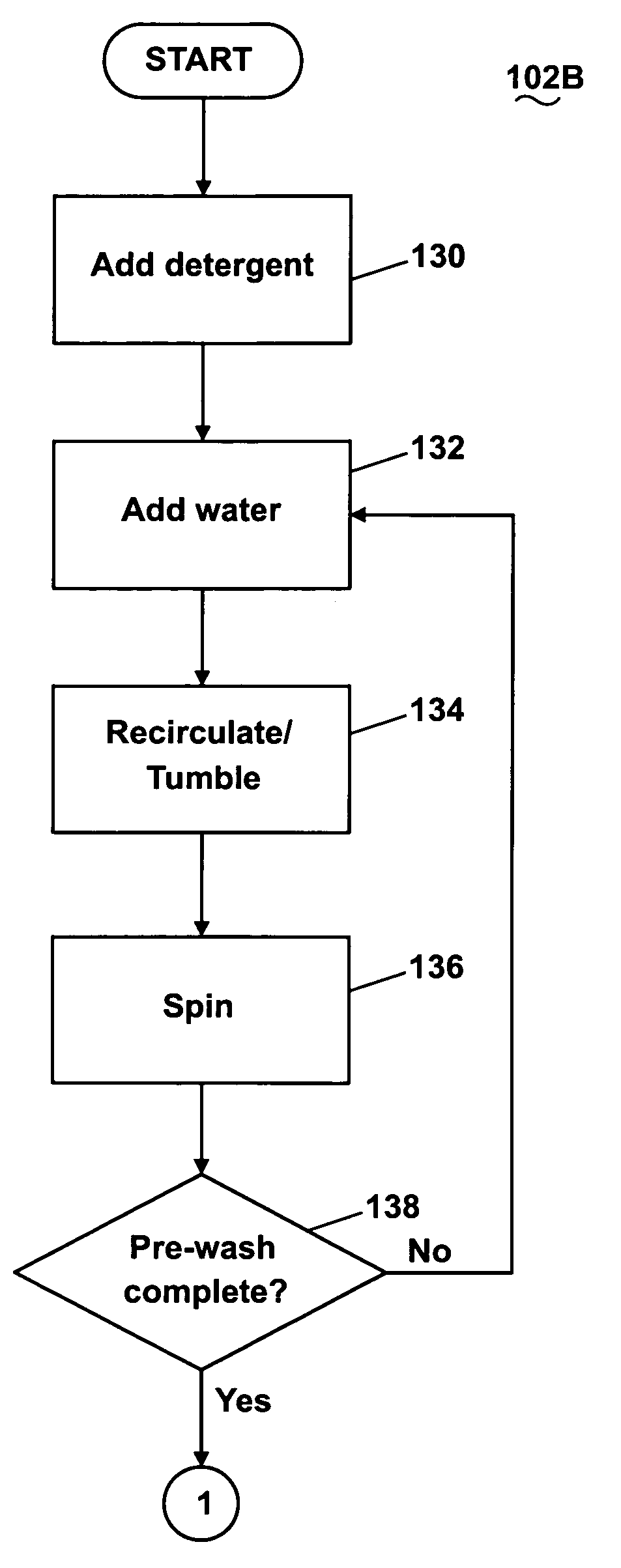

A method for operating a washing machine having a tub with a drum rotatably mounted in the tub and configured to hold a fabric load and a liquid recirculation system configured to recirculate liquid from the tub to the drum comprises a pre-wash step; a heating step comprising introducing steam into the tub and / or the drum; and a washing step comprising washing the fabric load with a second volume of liquid greater than the first volume of liquid. The pre-wash step can comprise recirculating a first volume of liquid between the tub and the drum without submerging a portion of the drum in the liquid and rotating the drum. In another embodiment, the pre-wash step can comprise recirculating a first volume of liquid between the tub and the drum to achieve a fabric load weight to liquid weight ratio of between about 1:0.5 and 1:2.7.

Owner:WHIRLPOOL CORP

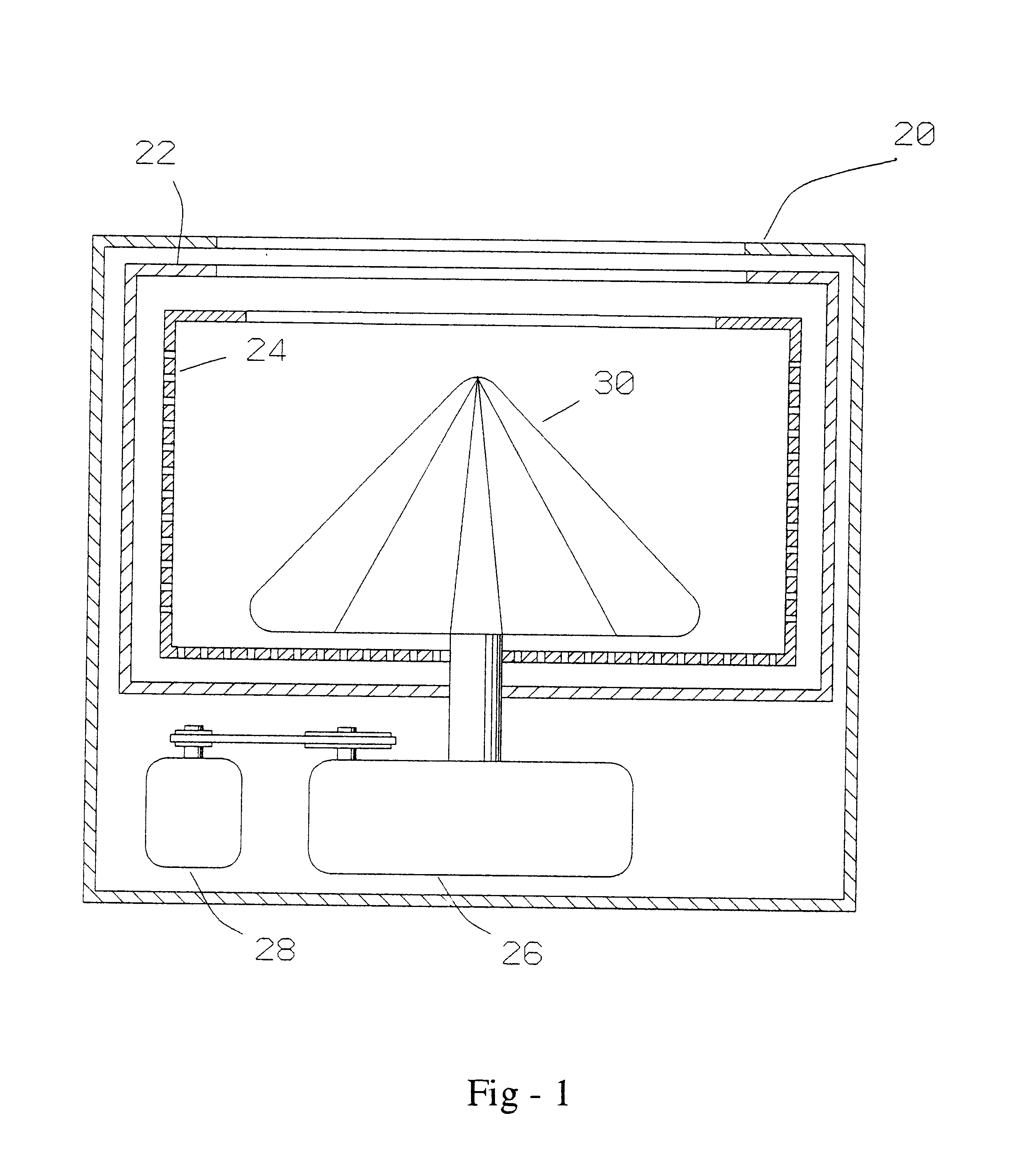

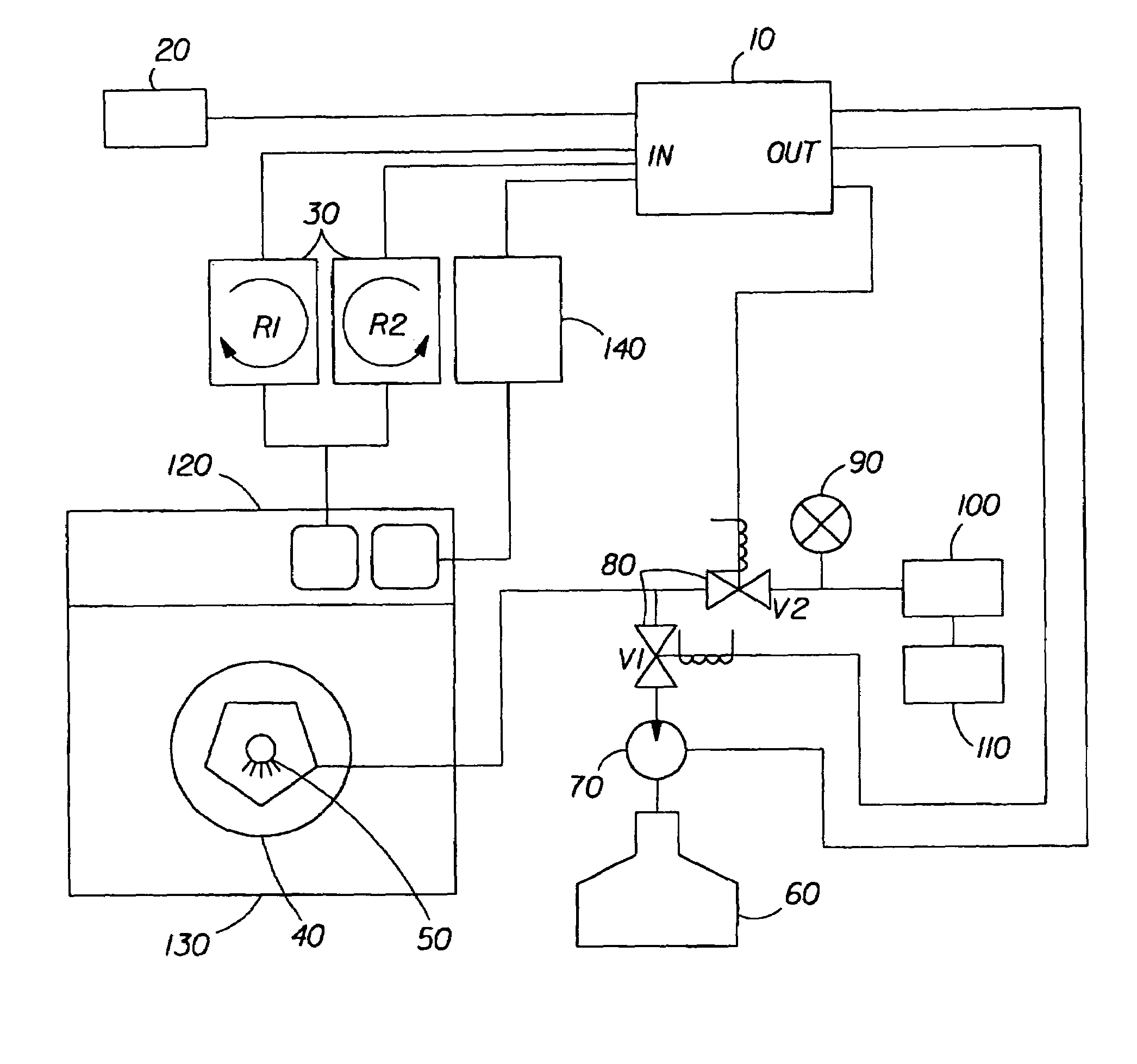

Washing apparatus and method utilizing flexible container to improve cleaning efficiency and minimize space occupancy

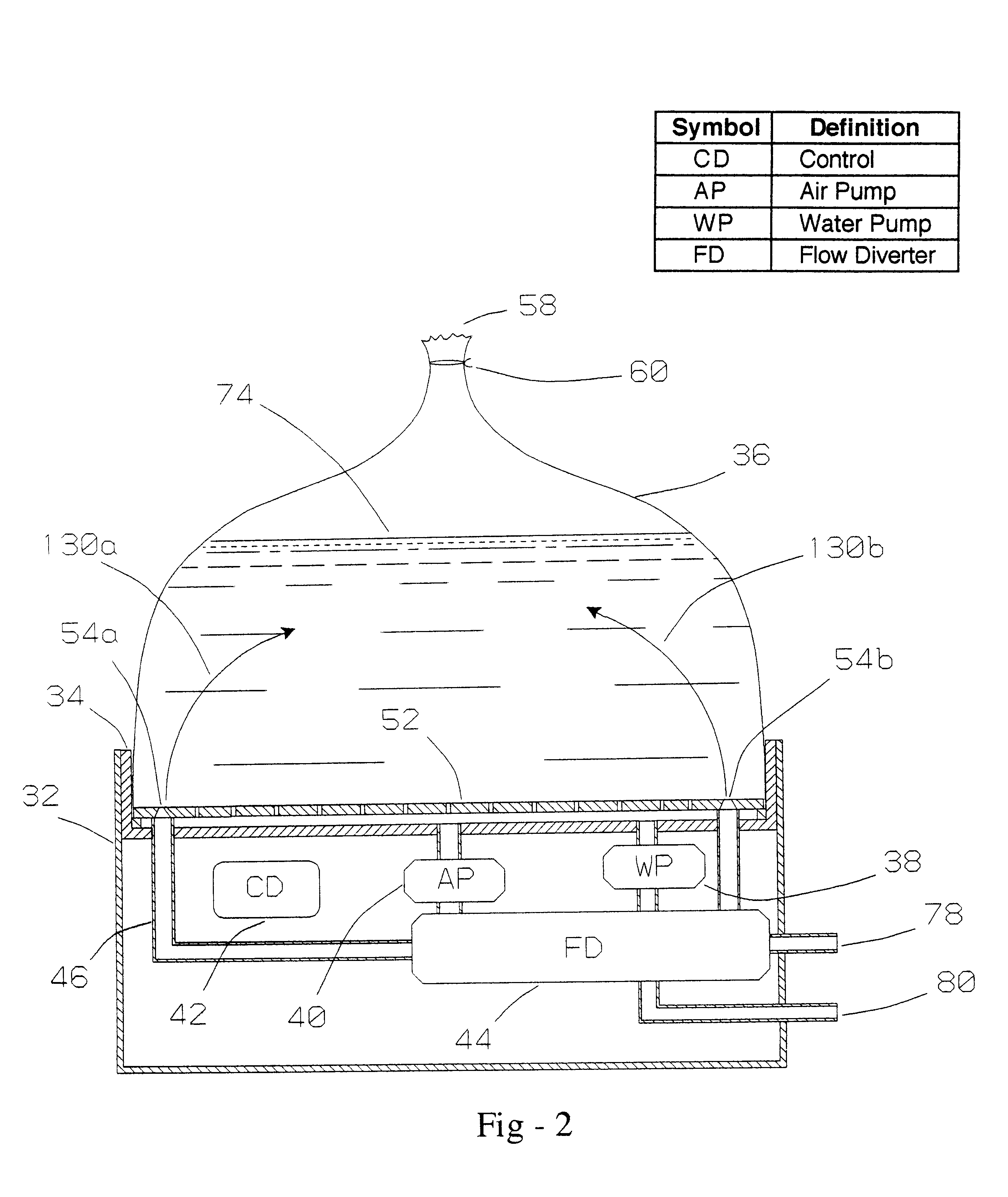

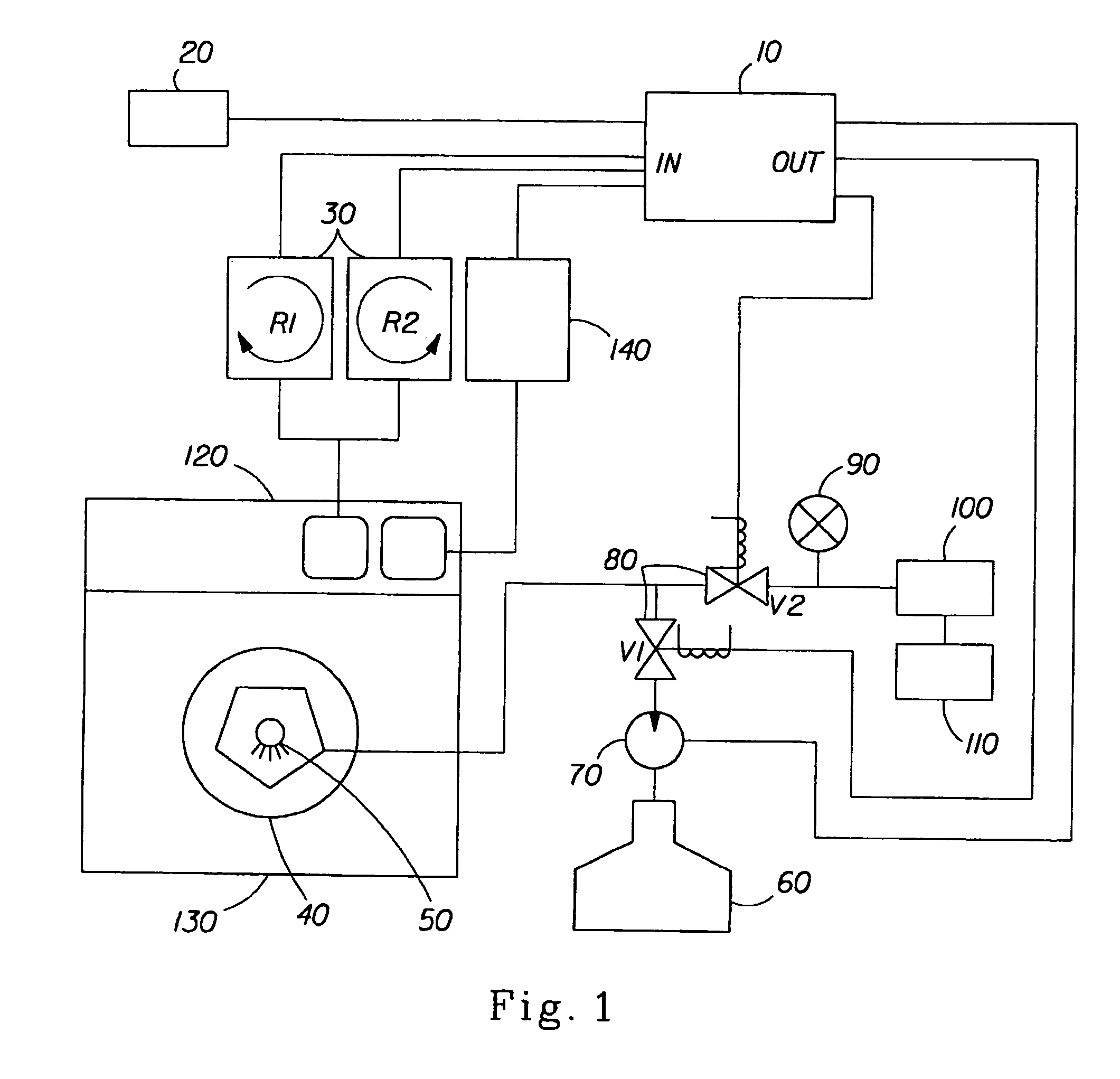

InactiveUS6219871B1Suitable for useSufficient capabilityOther washing machinesWashing machine with receptaclesCavitationLaundry washing machine

An automatic laundry washing machine that is suitable for use in living units having no area set aside for laundry facilities is achieved by replacing the heavy bulky parts of the currently popular automatic washing machine design with a light flexible bag. A large portion of the volume of any washing machine is the vessel for containing the laundry solution and articles to be washed. That vessel is a flexible bag made of modern durable material so as to be collapsible both while in use and for storage. The method of use includes the complete process of washing, rinsing, and extracting excess water in an automatic cycle analogous to standard automatic washing machines popular today. The vessel containing the items being laundered is a waterproof laundry bag with automatic washing apparatus attached. Items are automatically washed in that bag. The automatic process includes cycles of filling, washing, rinsing and extracting such that the clothes are ready for a drying process such as hanging out to dry or putting into a tumble dryer. The agitating of the washing and rinsing cycles is accomplished without the familiar bulky agitator thereby reducing the volume requirements and the traditional wear and tear on the garments. By eliminating the bulky agitator and the spin water extraction method, the heavy transmission is also eliminated. The water extraction cycle is done in a much less violent way than the conventional spin cycle by allowing atmospheric pressure to collapse the washing vessel and press the water from the articles as the water and air are pumped from the vessel in the draining portion of the cycle. The cleaning ability of the water is enhanced by built in ionic processing of the water thereby reducing the required amount of laundry detergent. The agitating in the non-electrically conductive vessel generates static electric charges in the process and ions thus produced further enhance the cleaning ability of the water. Cavitation produced in a multi-frequency washing action further enhances the washing ability of the water. The washing machine is light, compact and collapsible and is as portable as a piece of luggage. The set up procedure is simple and no assembly is required beyond attaching a quick connect fastener to a water faucet and plugging in a power cord. The washing machine is light and takes little storage space. It can be put in a small closet or on a shelf when not in use. The minimum capacity of the washing machine is a single garment. The normal capacity of the washing machine is comparable to that of a standard household washing machine.

Owner:FREDERICK MAX B +2

Coating selective zones of thin webs to change the pervious character thereof

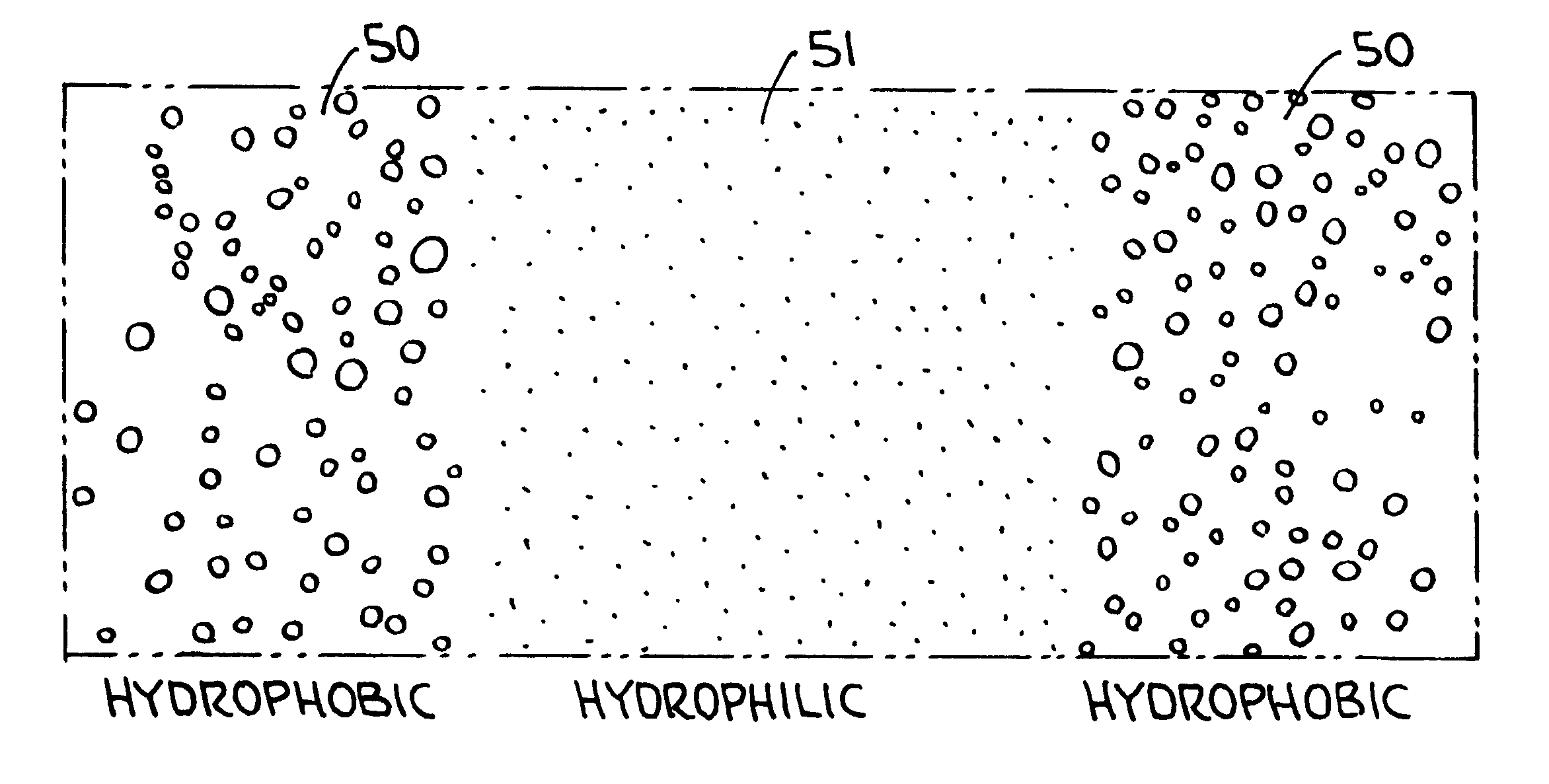

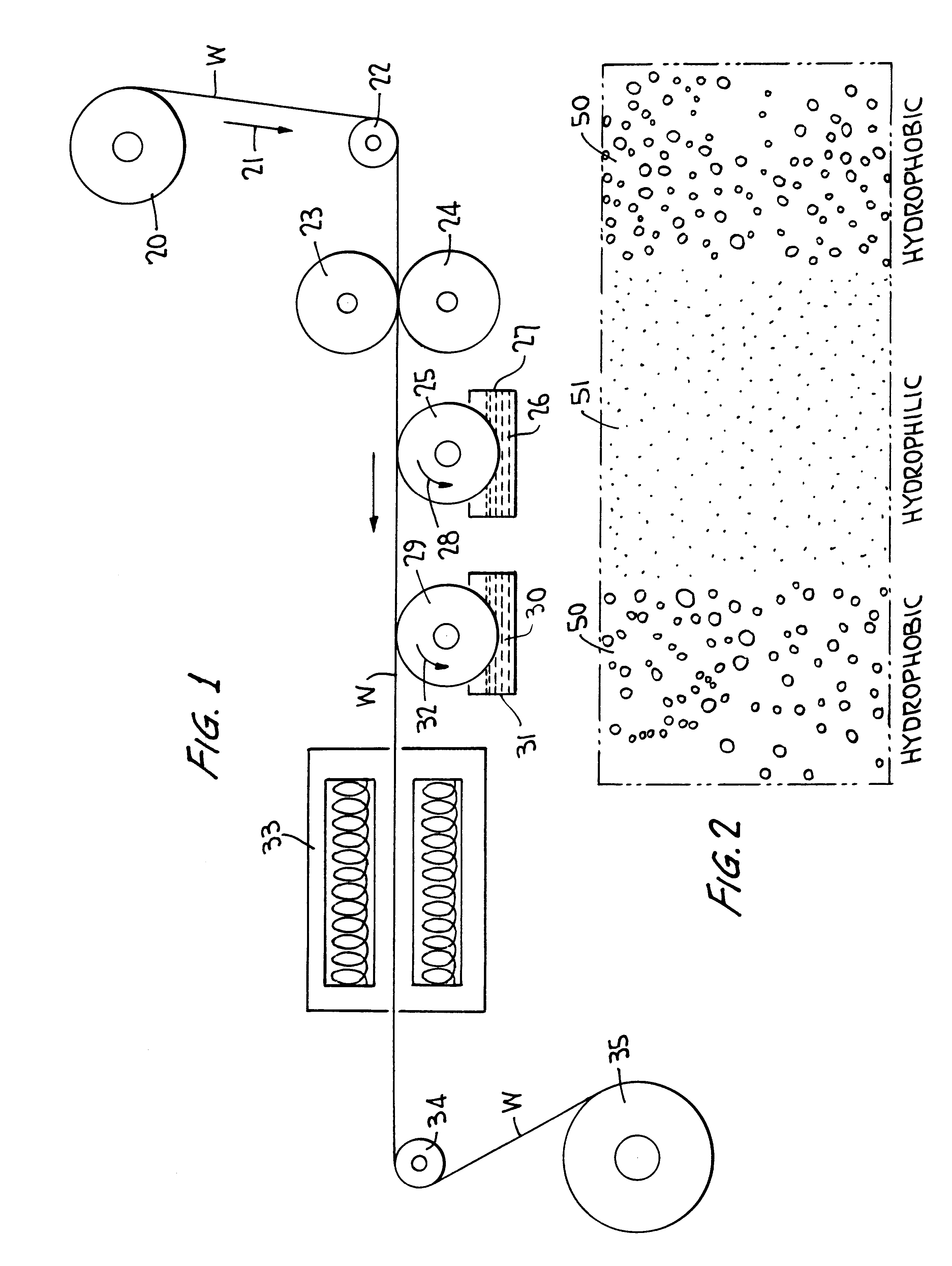

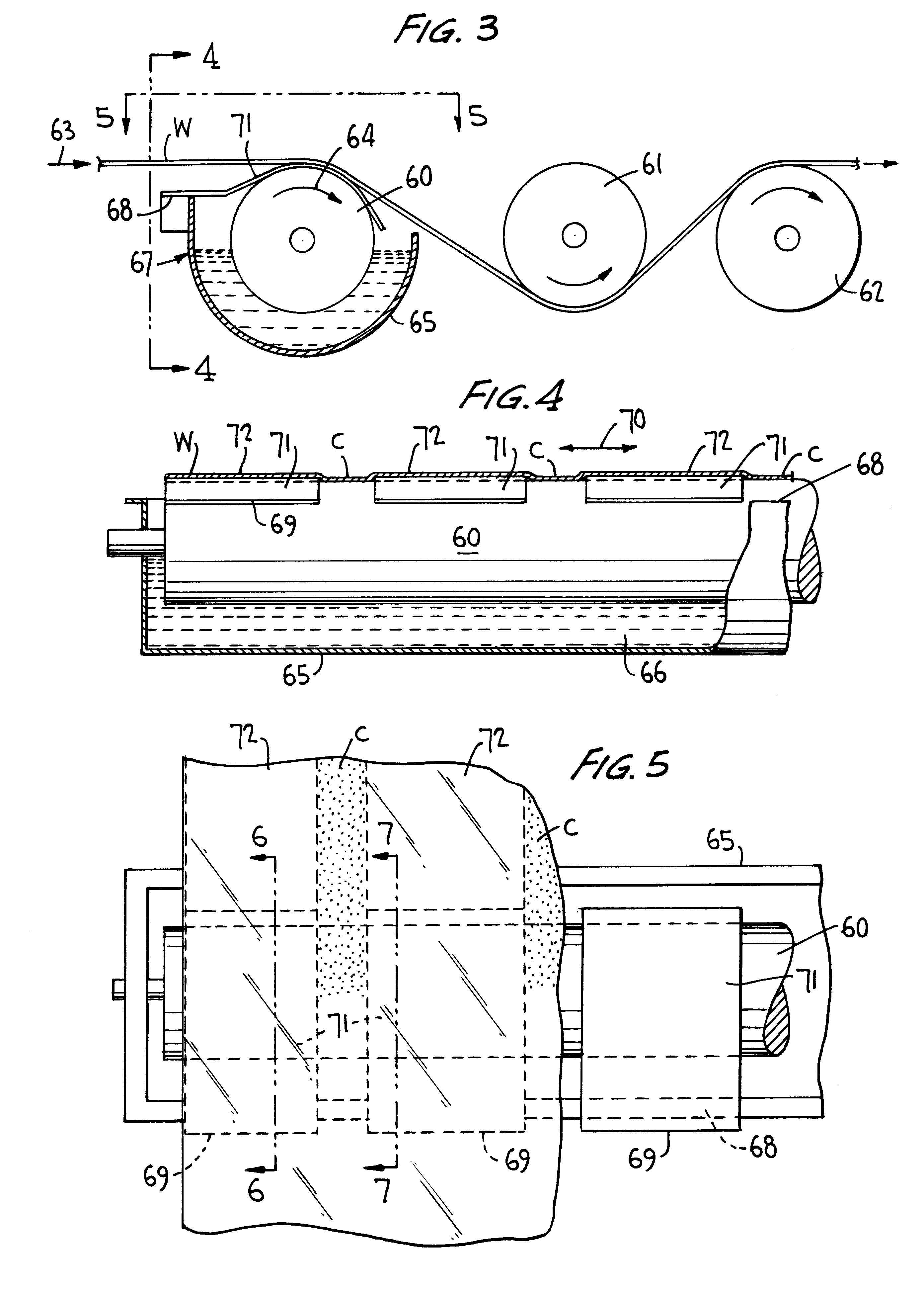

InactiveUS6183847B1Easy to transportExcellent impregnationNon-adhesive dressingsDecorative surface effectsEngineeringPolypropylene

The process and apparatus of the present invention involves treating a well-integrated woven or non-woven web of hydrophobic fibers to make selected areas hydrophilic. It also can be used to make a web of hydrophilic fibers selectively hydrophobic. It uses a plurality of selectively adjustable covers on an applicator roll rotating in a bath of liquid to place the liquid material on selected areas of the web as the web moves over the roll. In a preferred embodiment the web is non-woven and the fibers are hydrophobic in nature, e.g., dry-laid or melt-blown polypropylene or polyethylene fibers or spun-bonded hydrophobic filaments. A woven web made of cotton or other hydrophilic fibers may also be used if the end result is to create partially hydrophobic areas on a hydrophilic web. The areas of liquid are positioned on the web only where desired so as to eliminate the excessive cost of unwanted and unnecessary coating material. If the web is hydrophobic, the liquid makes that area hydrophilic. If the web is hydrophilic, the liquid makes that area hydrophobic. Enhanced liquid containment and transport is obtained when at least one discontinuous fine fiber layer is utilized in the web and the fine fiber layer has a melt-blown content greater than zero but less than 1.5 gsm.

Owner:AVGOL NONWOVEN INDS

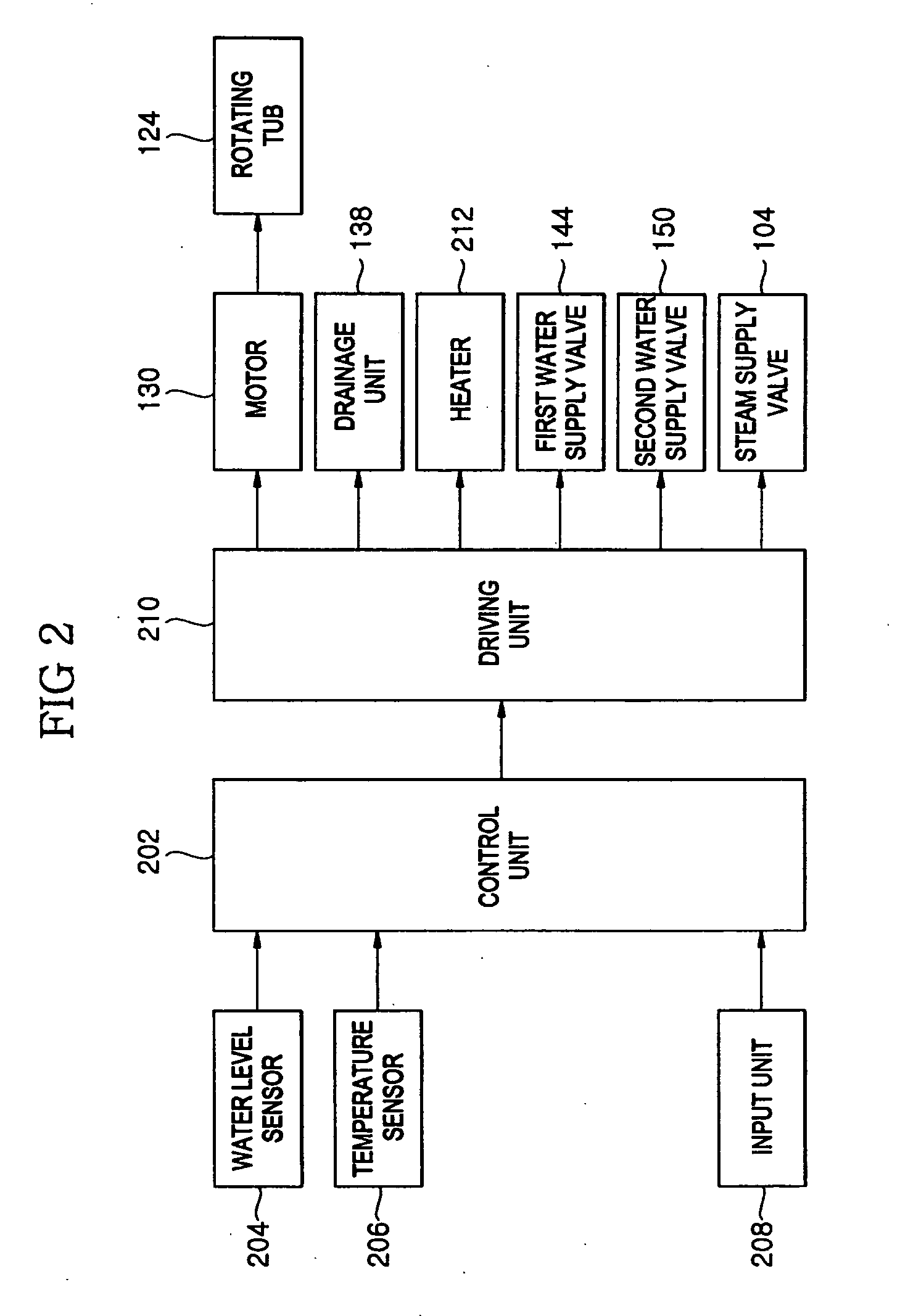

Washing machine and control method thereof

InactiveUS20050132503A1Grow fastShorten washing timeOther washing machinesControl devices for washing apparatusWash waterEngineering

A drum type washing machine in which wash water and laundry contained in a rotating tub are heated by steam supplied into the rotating tub, so as to rapidly increase the temperature of the wash water and laundry, thereby being capable of reducing the total wash time while reducing the amount of wash water to be used, and reducing the consumption of energy caused by heating of the wash water. The washing machine includes a steam generating unit for heating water supplied thereto, thereby generating steam, and a control unit for rotating the rotating tub at a high speed to cause the laundry contained in the rotating tub to be in constant contact with an inner peripheral surface of the rotating tub without falling down, by virtue of a centrifugal force generated during the rotation of the rotating tub, the control unit supplying the steam from the steam generating unit into the rotating tub during the high-speed rotation of the rotating tub, to increase the internal temperature of the rotating tub and the temperature of the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Fabric coating dyeing process

InactiveCN1936148ASimple pad dyeing processSave energyHeating/cooling textile fabricsDyeing processAdhesiveSurface-active agents

The invention relates to a fabric pigment dyeing technology. The dye liquor is made up of dope color paste, anode ion modifying agent, surface active agent, pH regulator and adhesive. After mixing equal according to certain order, the dye liquor would be used to take pad dyeing, and the pigment dyeing fabric product would be gained after drying and fixation. The invention has the advantages of good color deepness and vividness, low consumption of adhesive and improved handle of fabric.

Owner:SUNVIM GROUP

Methods and apparatus for applying a treatment fluid to fabrics

Owner:THE PROCTER & GAMBLE COMPANY

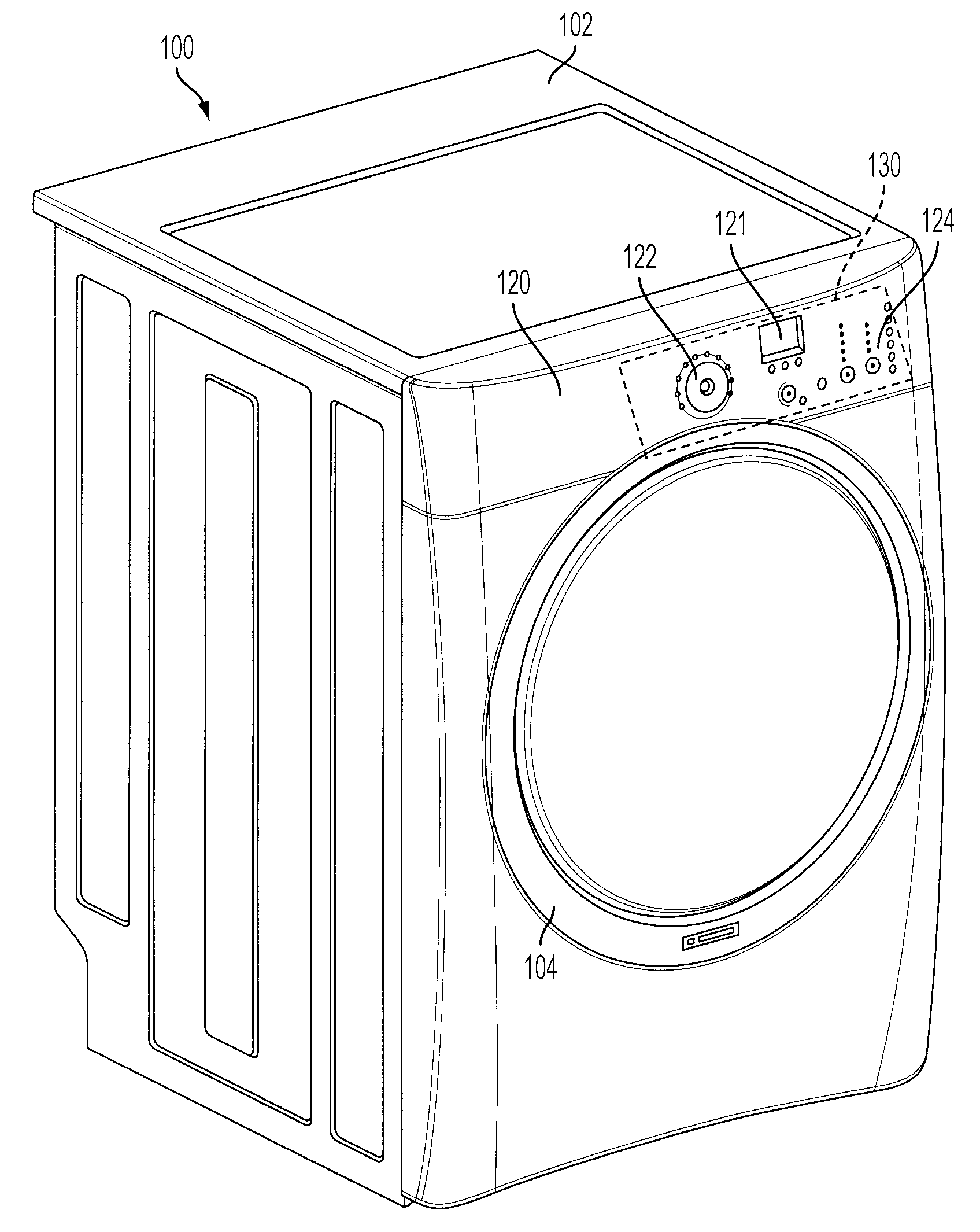

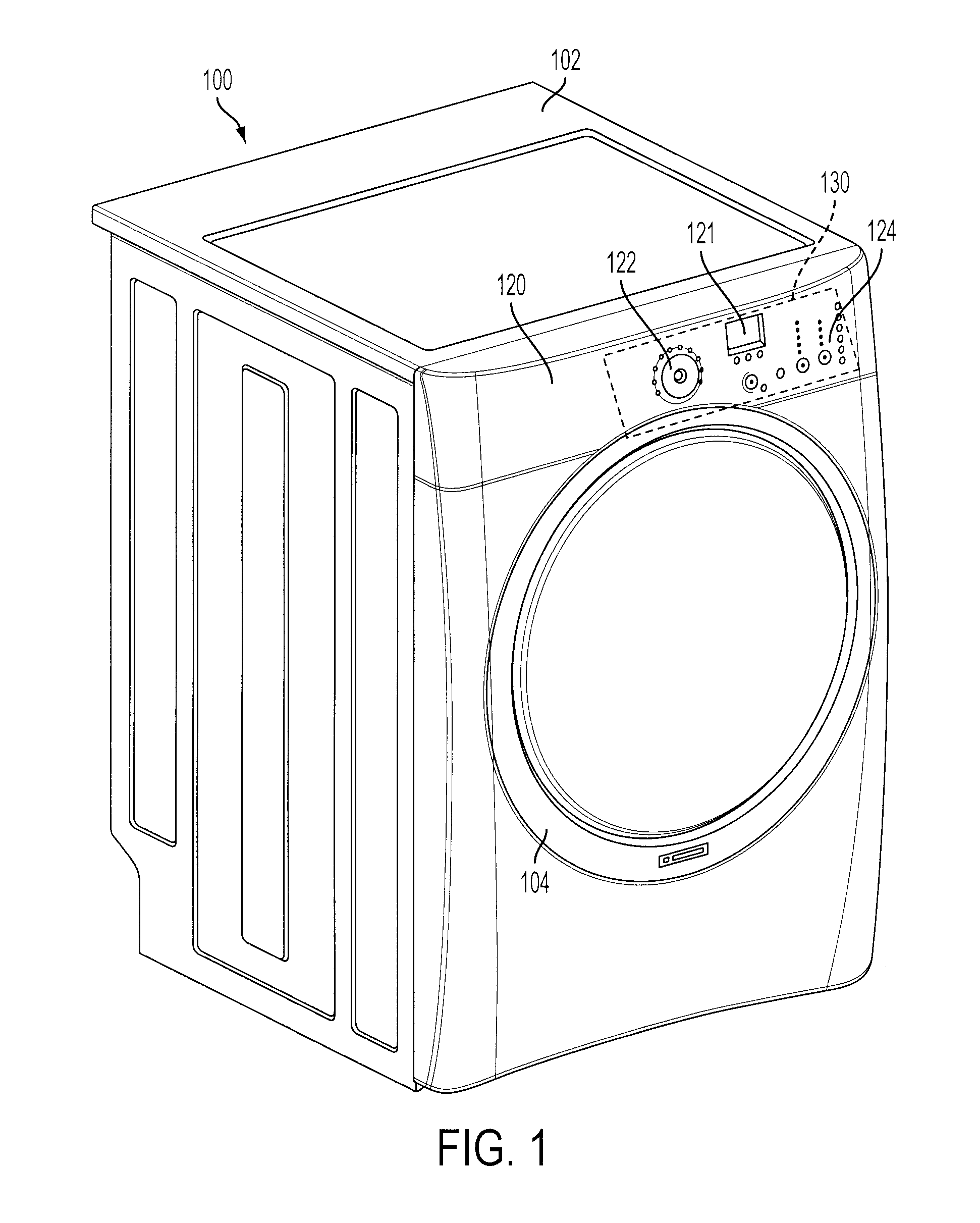

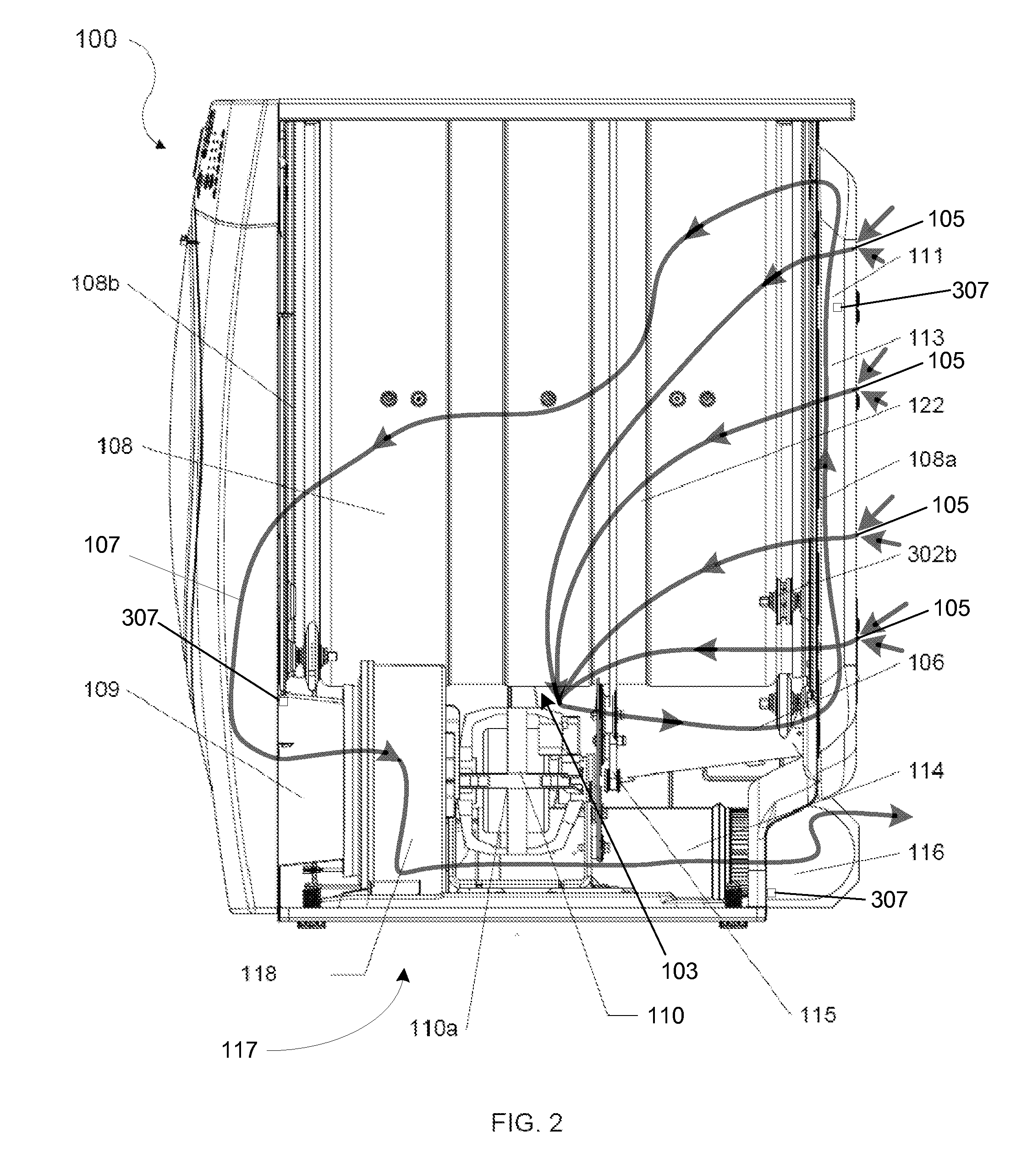

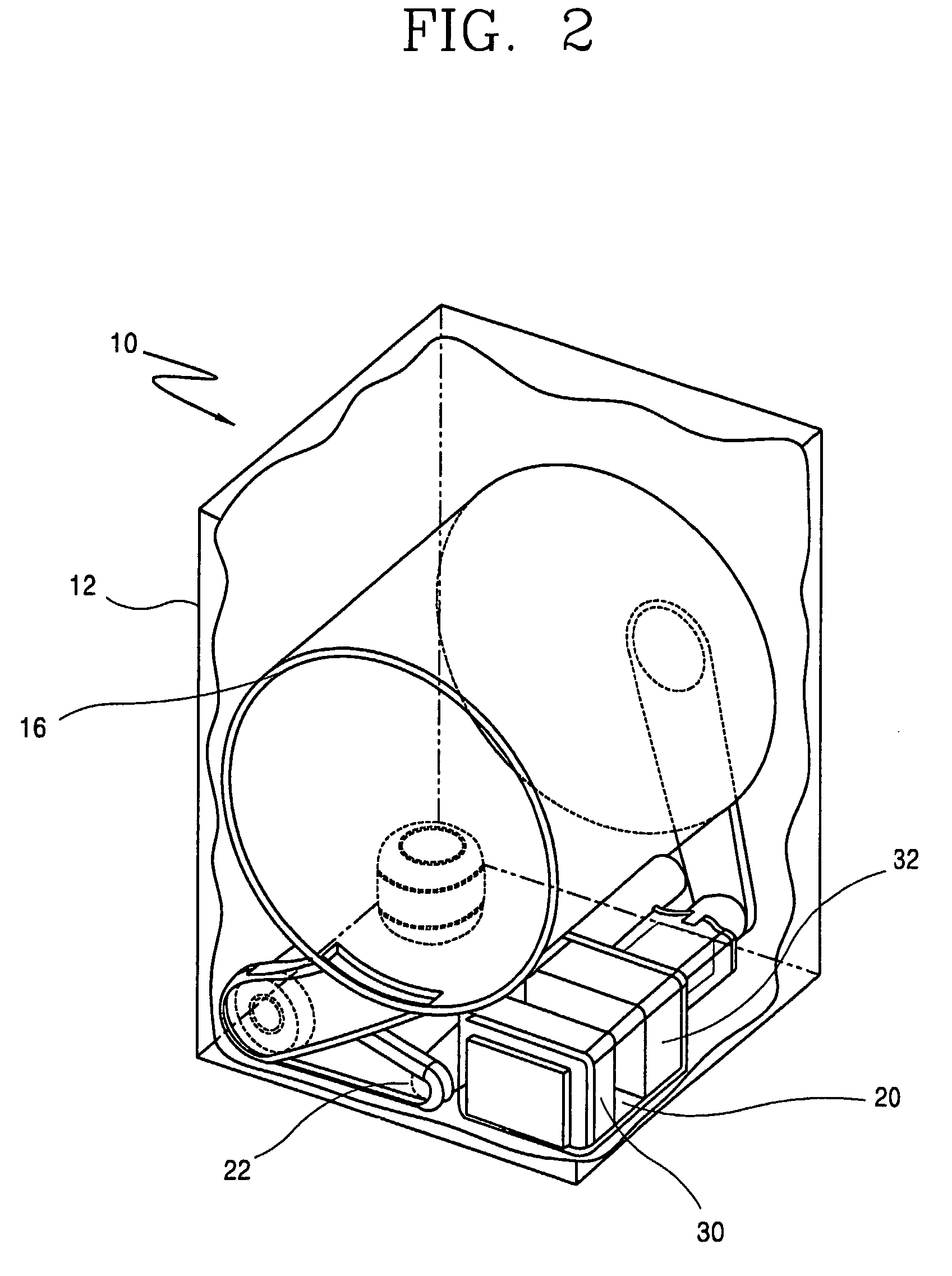

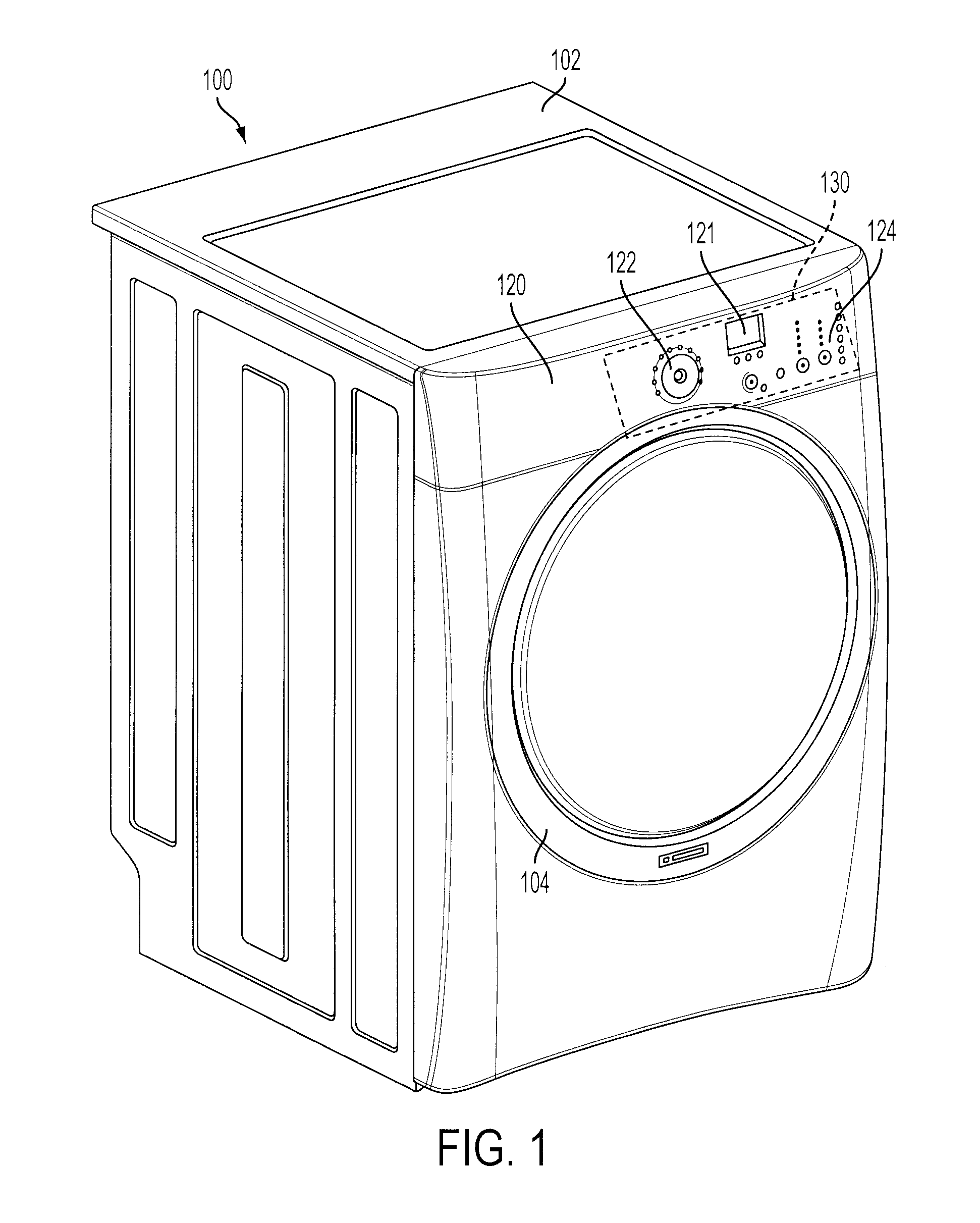

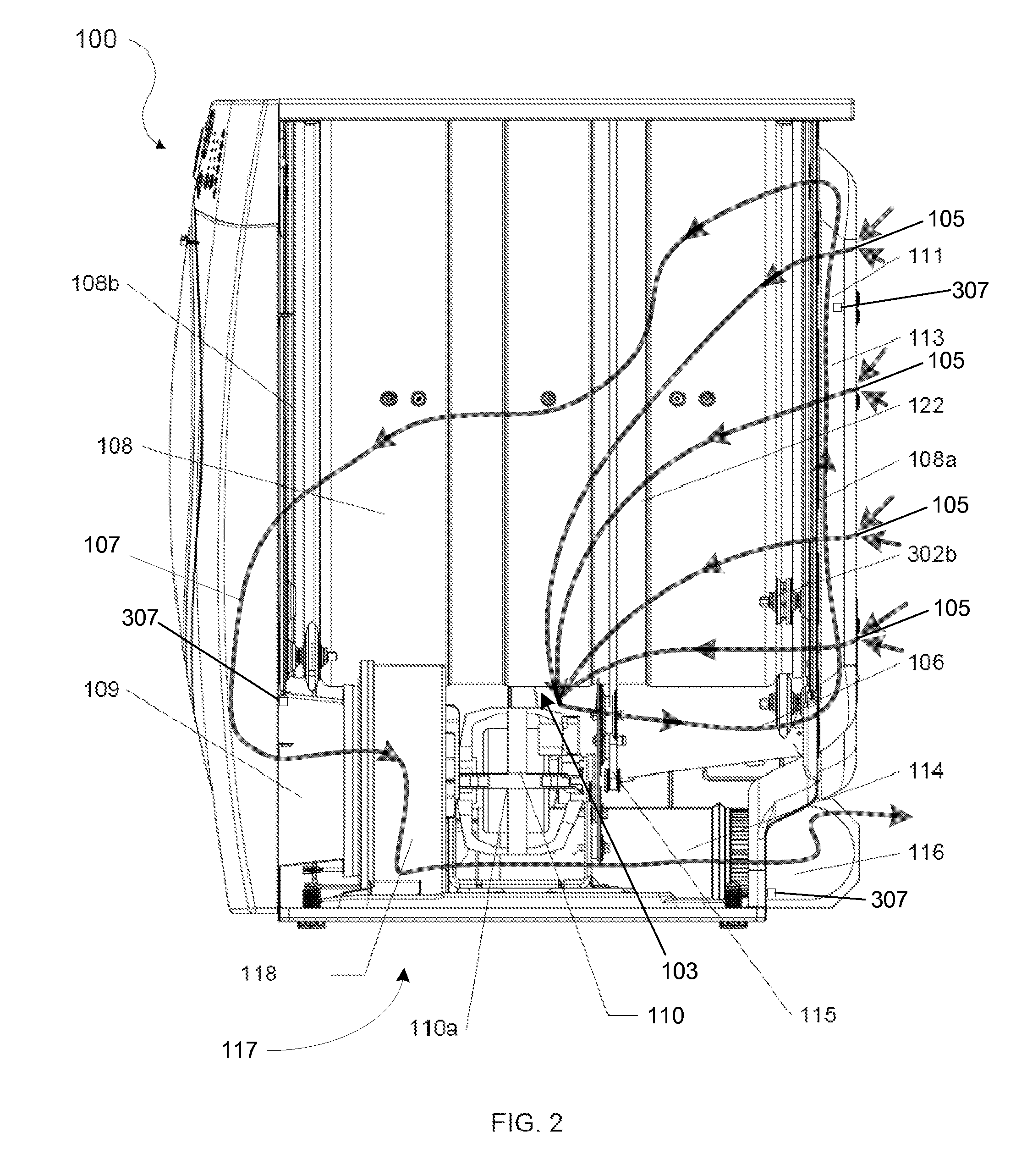

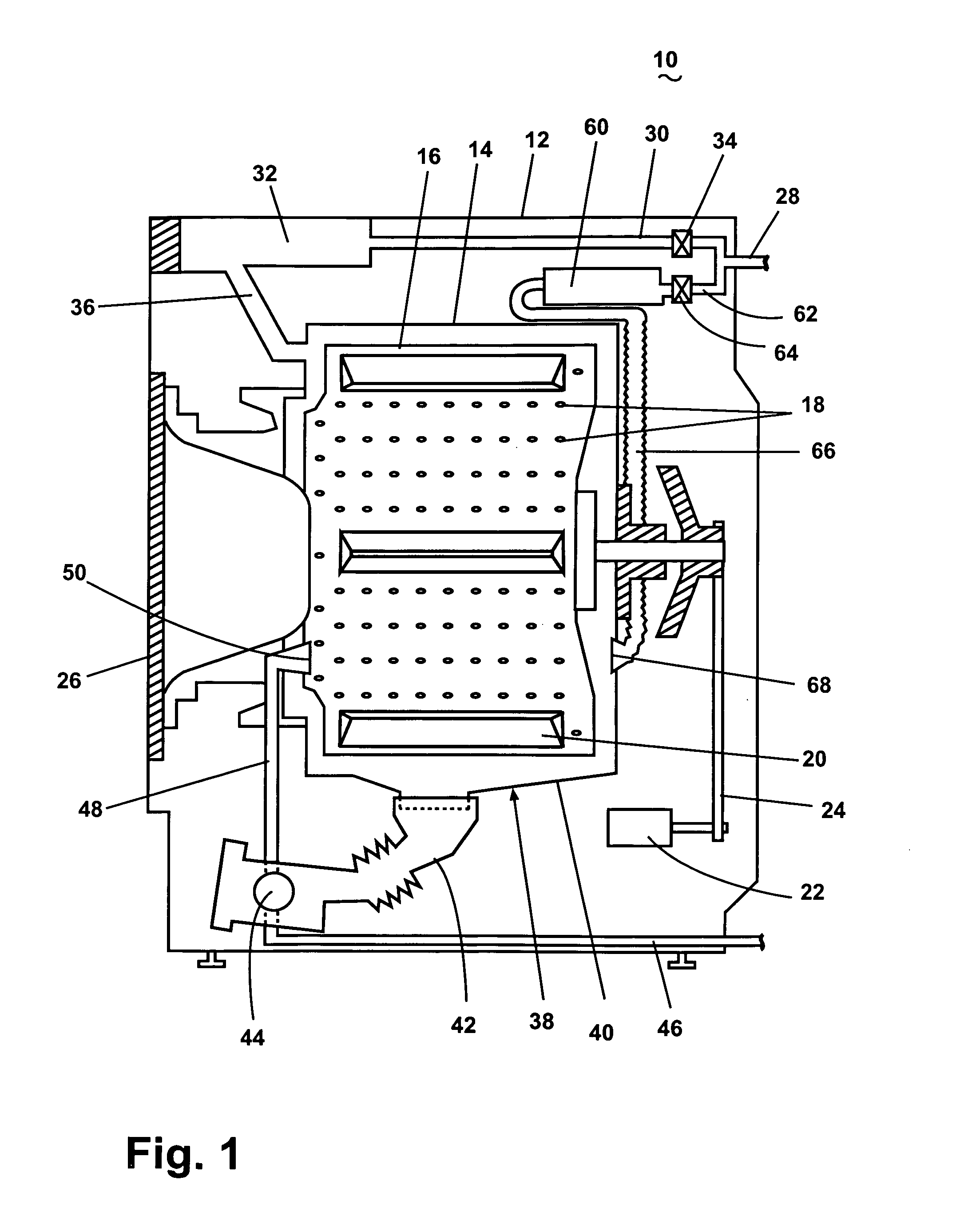

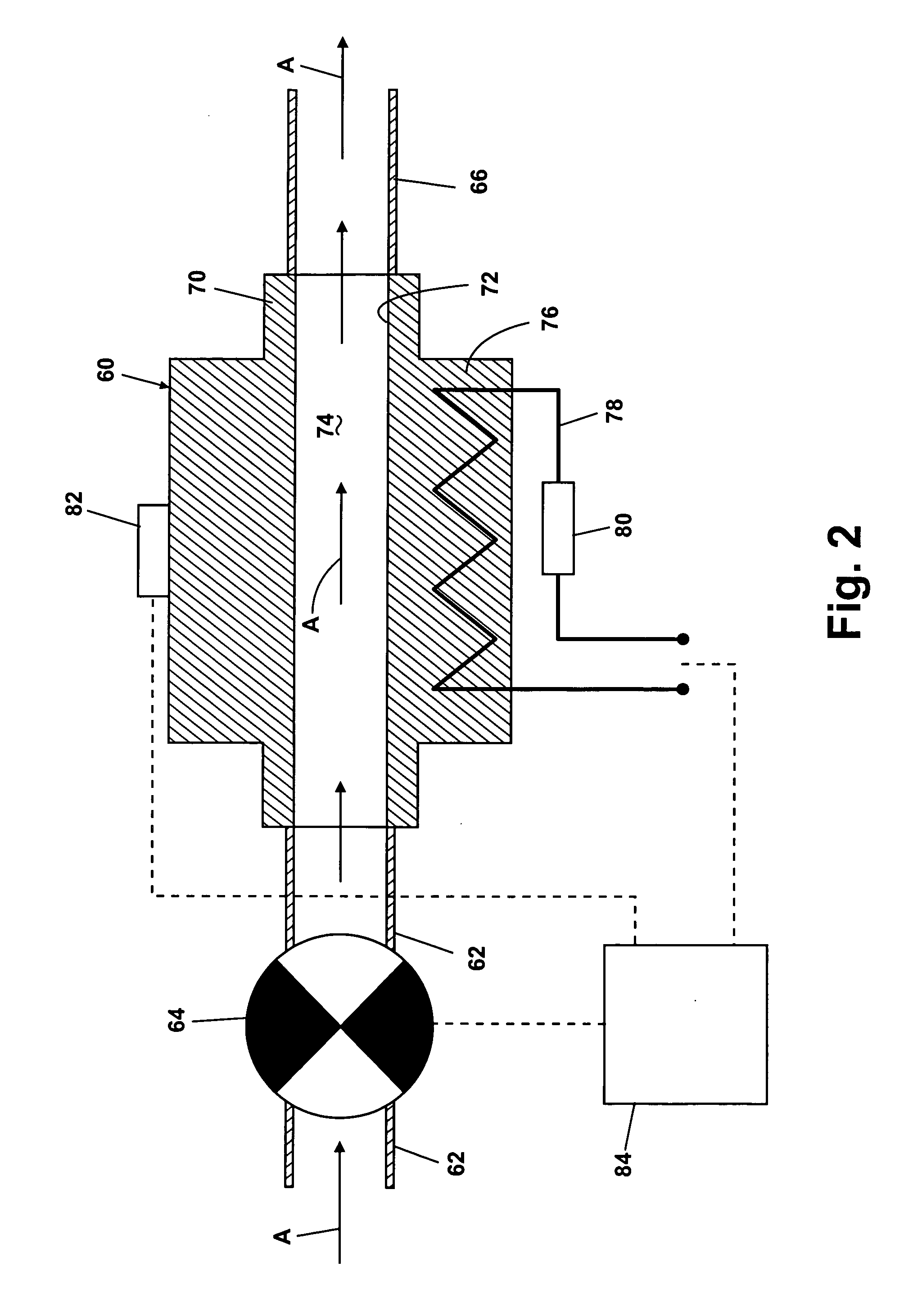

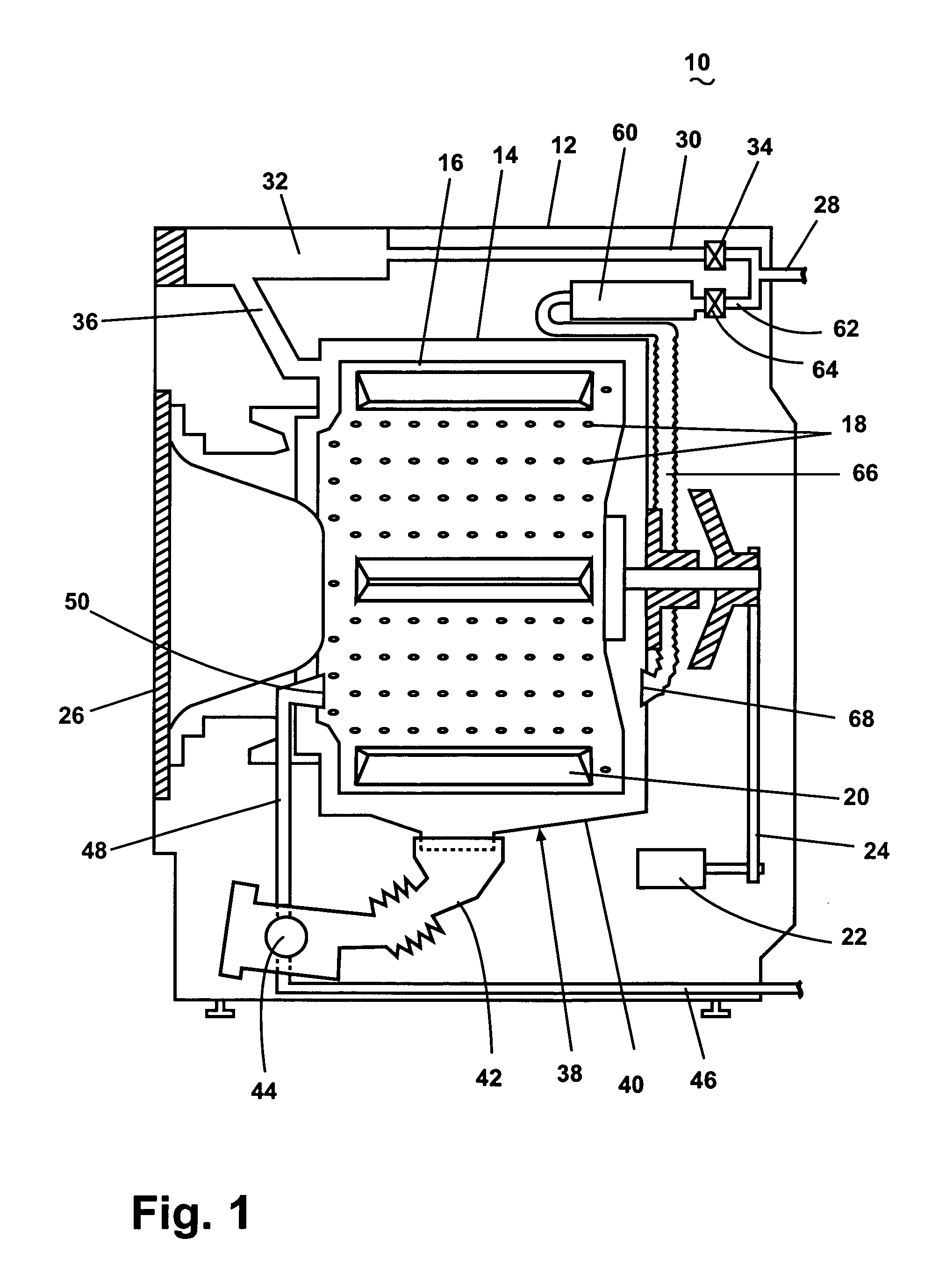

Laundry dryer providing moisture application during tumbling and reduced airflow

ActiveUS20100024243A1Efficient removalStay hydratedDrying solid materials with heatDrying gas arrangementsEngineeringDrive motor

A laundry dryer includes a rotatable drum, an air delivery system selectively operable to provide air into the drum at a first flow rate and a second flow rate that is less than the first flow rate, and a moisture delivery system operable to provide moisture (e.g., water mist or steam) into the drum while air is being provided at the lower second flow rate, and during drum rotation (tumbling), to thus enhance dispersion of the moisture into the fabrics of the load, and the attendant dewrinkling / refresh benefits. The air delivery system can include a reversible blower that provides air at the first flow rate when operated in a first direction and provides air at the second flow rate when operated in an opposite second direction. The drum can be a reversibly rotatable drum that is rotatable in a first and an opposite second direction, and the dryer can include a drive motor that both rotates the drum and operates the blower. The moisture delivery system can include a nozzle to provide moisture directly into the drum.

Owner:ELECTROLUX HOME PROD CORP NV

Process for treating a lipophilic fluid in the form of a siloxane emulsion

InactiveUS6914040B2Cost-effective and efficient and safeLiquid separation auxillary apparatusSemi-permeable membranesEmulsionPre treatment

The present invention relates to a process for treating a lipophilic fluid contained in an emulsion of water and lipophilic fluid. The process includes the steps of pretreating the emulsion, removing lipophilic fluid from the emulsion, and purifying the lipophilic fluid to remove at least a portion of the impurities collected during the use of the emulsion. Method options are provided for each of the aforementioned steps.

Owner:THE PROCTER & GAMBLE COMPANY

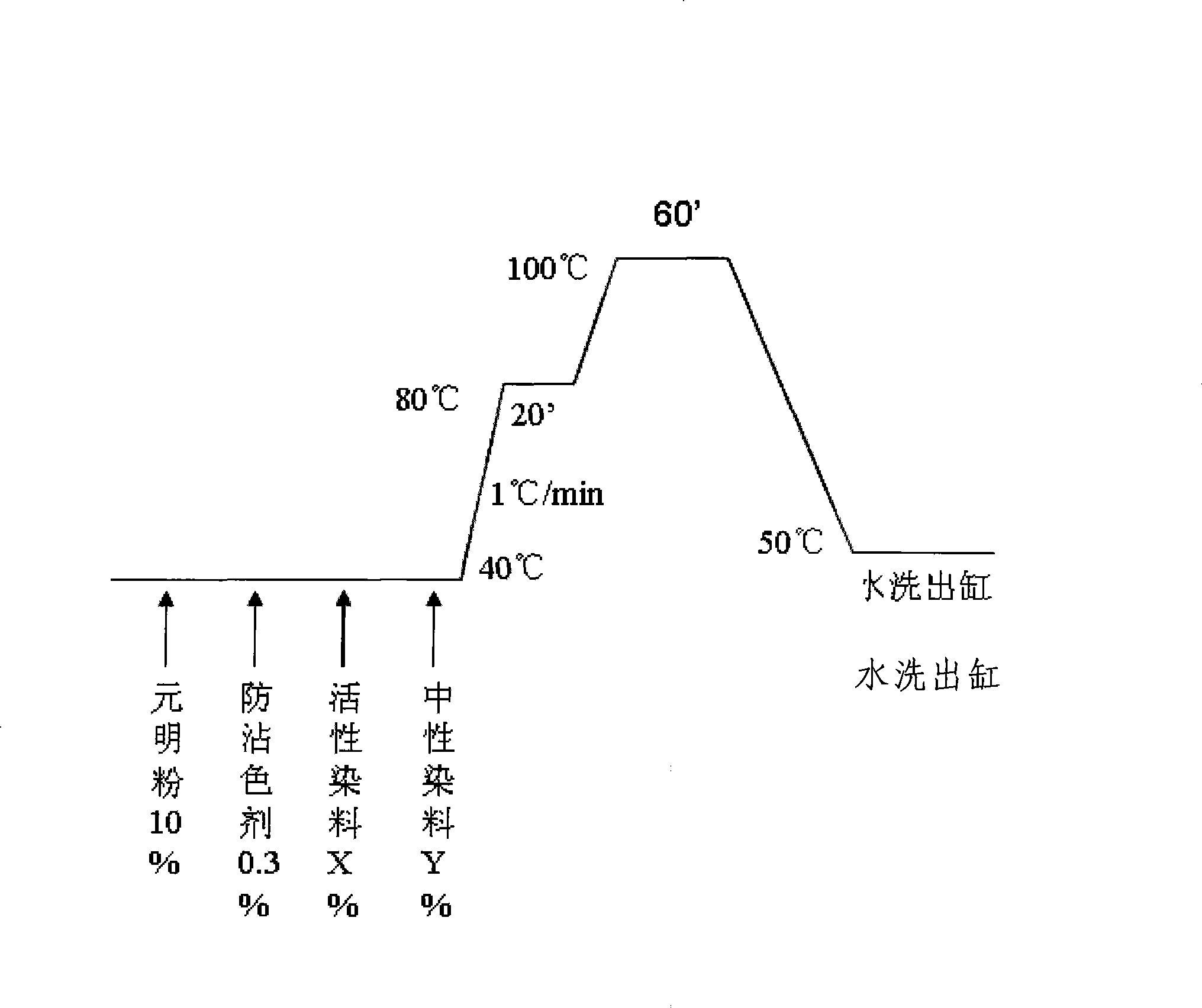

Cold-rolling heap staining method for textile fabric

ActiveCN101016682AImprove solubilityGood compatibilityBiochemical fibre treatmentDyeing processSewageWater washing

The invention discloses a cold rolling stack dying method of face fabric, comprising immerging, stacking and water washing. The immerging step comprises cold rolling stack pretreatment, obtaining half finished product and drying rolling. The stacking step comprises coiling and stacking. The water washing step comprises washing with water, washing soap, washing with water and drying. The inventive method has advanced and reasonable process, with stable quality, energy-saving and environment friend functions, while the invention has simple process, low cost, and high fixation yield, or the like.

Owner:YUYUE HOME TEXTILE

Clothes dryer

ActiveUS7908766B2Improve energy efficiencySmall possibilityDomestic stoves or rangesBaking ovenEngineeringMechanical engineering

A clothes dryer is provided. In the dryer, air flowing into a drying container is provided with heat from heat pump. The clothes dryer comprises a cabinet, a drying container rotationally mounted in the cabinet, a motor providing the container with rotational force, a first air path connected to a side of the container, a second air path connected to another side of the container and to the outside of the cabinet, and a first heat exchanging member and a second heat exchanging member in the first air path. A damper may be additionally included in the second air path.

Owner:LG ELECTRONICS INC

Method for fabricating multifunctional protective face fabric

InactiveCN101092776AImprove antistatic performanceSolve the existing illsSingeingHeating/cooling textile fabricsYarnEngineering

This invention discloses a processing method for multifunction safety fabrics including: 1, process of anti-static fabrics: a, spinning, b, merging to anti-static yarn, c, weaving them to anti-static fabrics, 2, dying and arrangement of the fabrics: a, pretreatment of the fabrics, b, dying, 3, functional arrangement to the fabrics: a, preparing flammable inhibitor, b, flammable arrangement, c, waterproof, oil-proof and dust proof.

Owner:JINQIU TEXTILE ARRANGEMENT

Steam washing machine operation method having dry spin pre-wash

ActiveUS20070283507A1Other washing machinesControl devices for washing apparatusHorizontal axisMechanical engineering

A method for operating a horizontal axis washing machine having a tub with a drum rotatably mounted in the tub and configured to hold a fabric load comprises introducing liquid into the drum to wet the fabric load and spinning the drum to distribute the fabric load about the drum prior to the introducing of the liquid.

Owner:WHIRLPOOL CORP

Preparation method of zinc oxide nano-rod film on fibre product

InactiveCN101012621ASmall granularityHigh purityFibre treatmentLiquid/gas/vapor textile treatmentFiberChemical solution

The invention relates to a manufacturing method for nanometer rod film of zinc oxide on fiber product, comprising (1) by sol-gel method ZnO nano-crystal grain is prepared and a great deal of ZnO seed crystal is deposited on the surface of fiber product, molar concentrations of zinc salt and alkaline agent are all 0.001M-0.75M; (2) by hydrothermal method or precipitation of chemical solution pool, nanometer rod film of zinc oxide grows on fiber product, molar concentrations of zinc salt solution and complexing agent solution are all 0.001M-0.05M; ZnO nanometer rod film with equal surface and good directivity is obtained. The manufacturing method is provided with simple method and low cost. It is suitable for industrial production.

Owner:DONGHUA UNIV

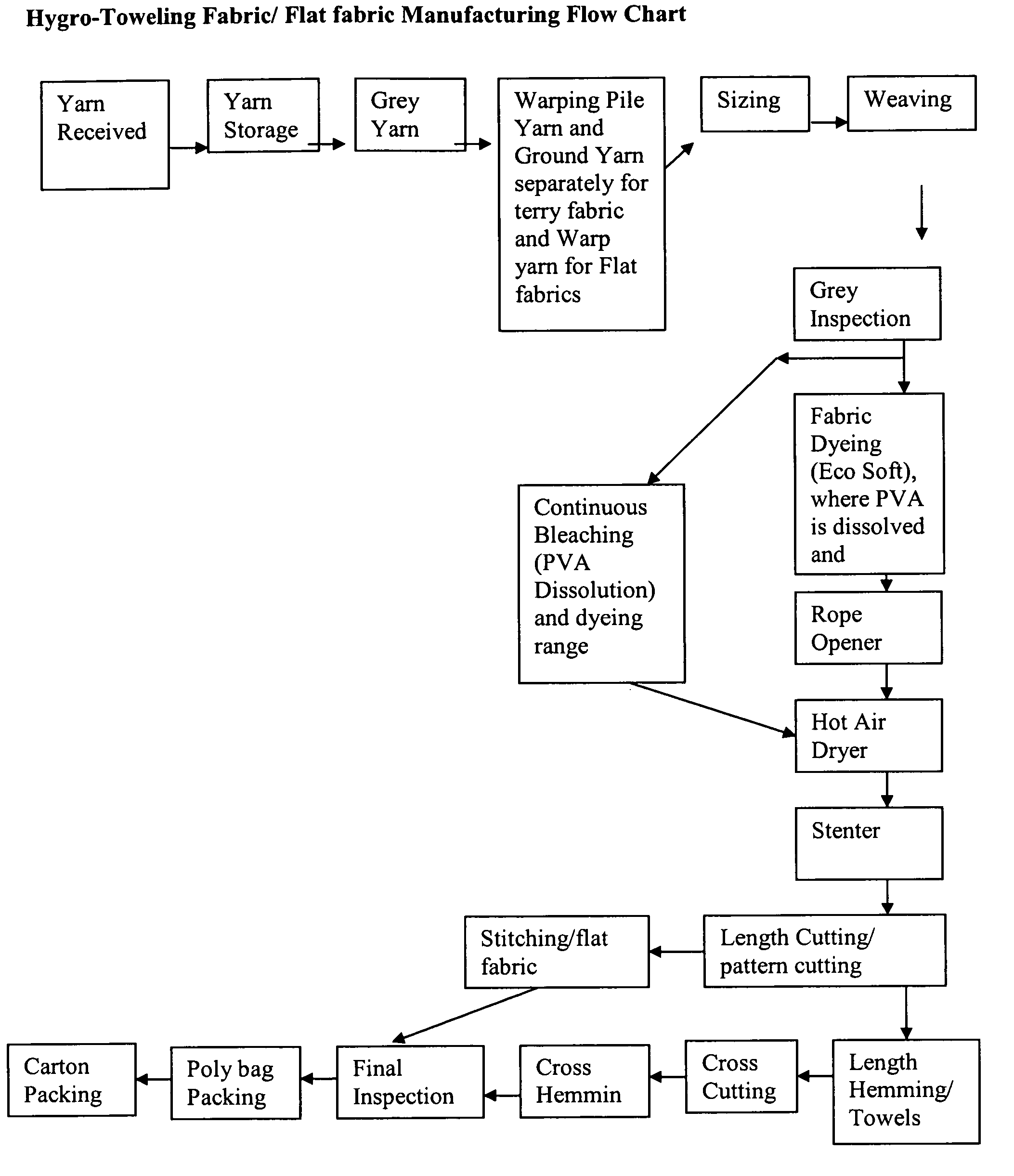

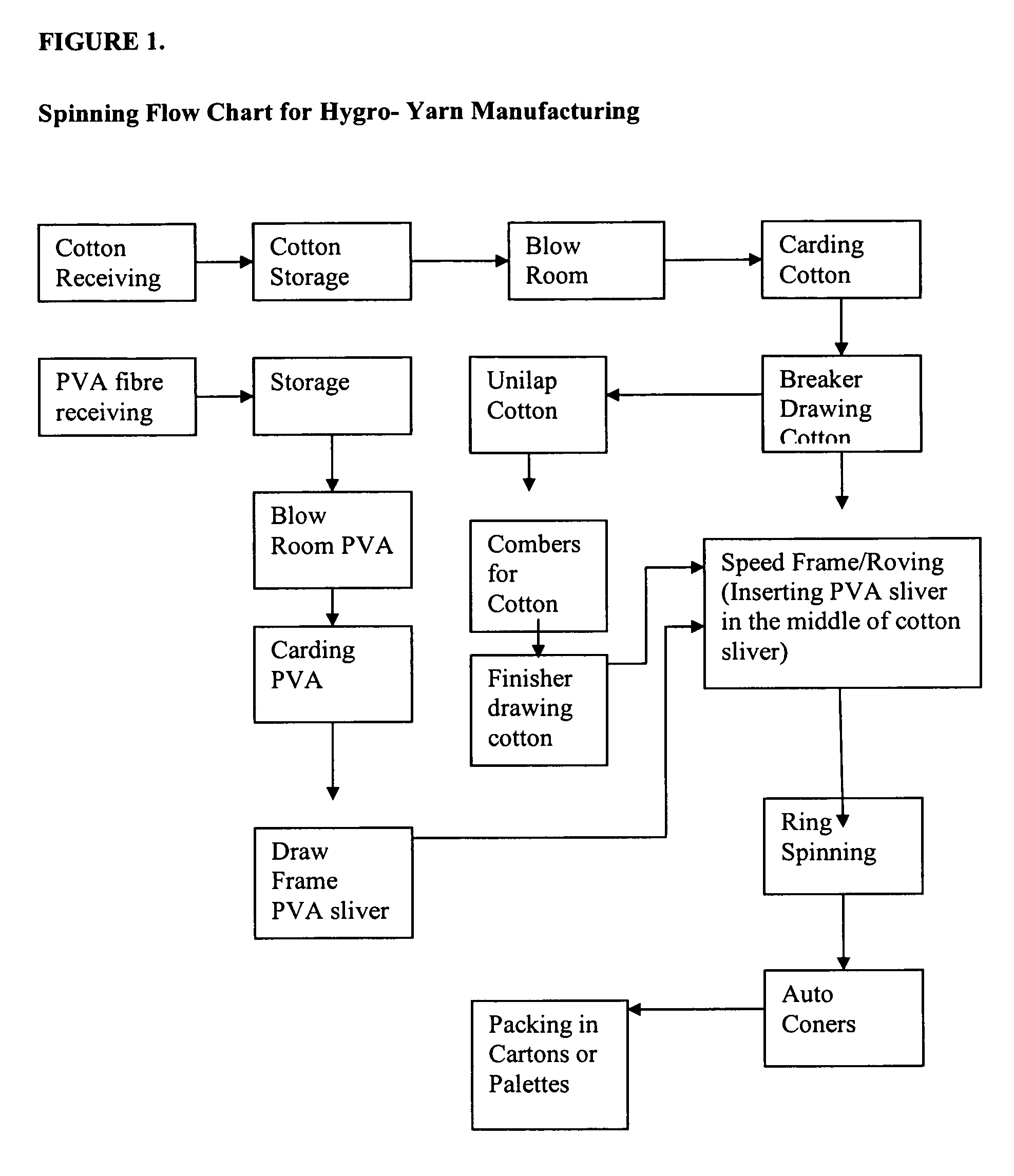

Hygro materials for use in making yarns and fabrics

ActiveUS20070087162A1Fast dryingIncrease in sizeFabric breaking/softeningLayered productsFiberWarm water

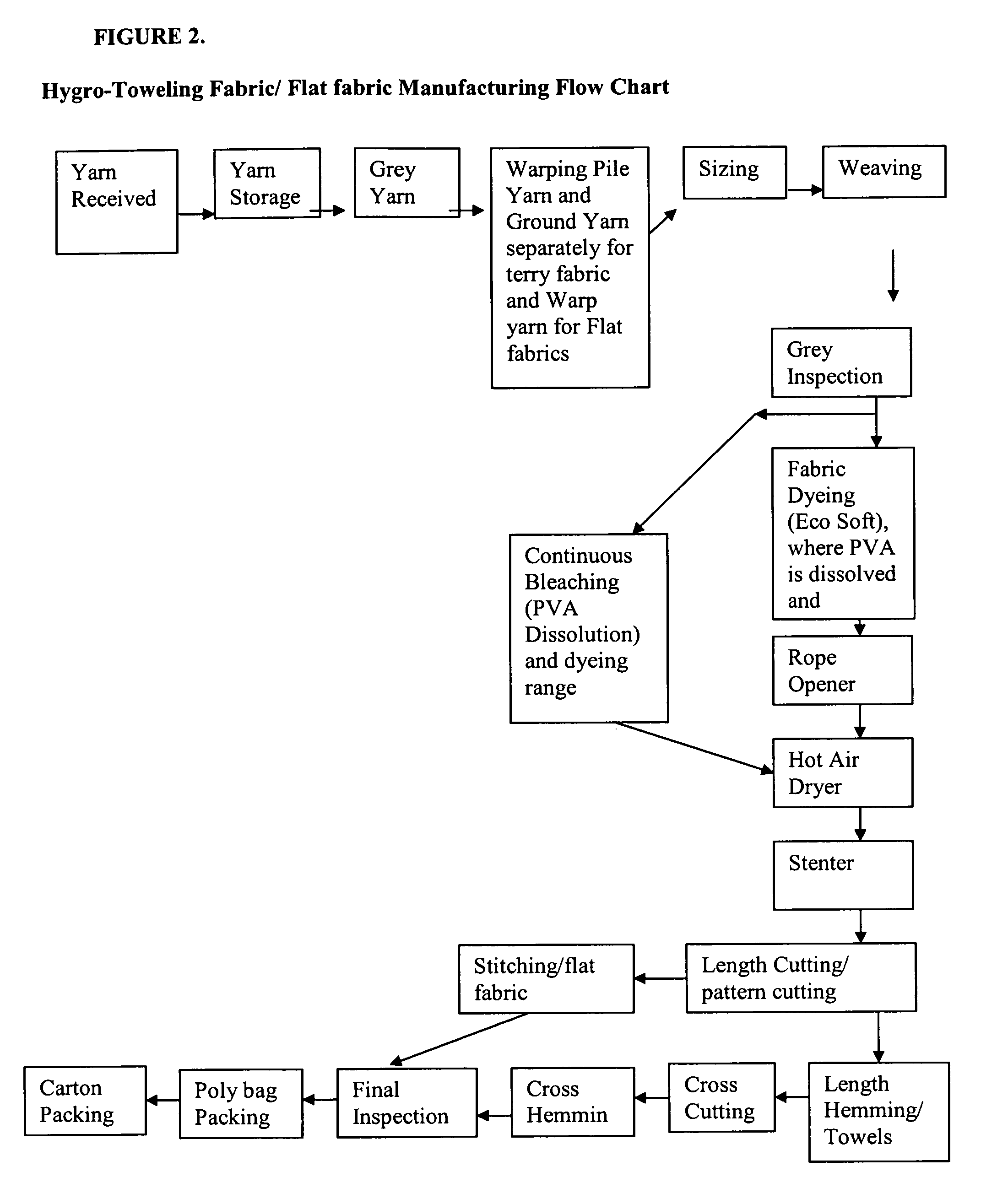

A process is described wherein pile yarn is woven with cotton weft and warp yarns to produce terry fabrics, such as towels. The fabric is then washed in warm water to dissolve the PVA fibers. The amount of fibers dissolved, depends upon the count of the yarn or yarns used. By dissolving the PVA fibers, a hollow air space is produced throughout the pile yarn, corresponding to an increase in the air space in the pile yarn. By increasing the air space in the pile yarn, the resulting towels are softer and bulkier than standard cotton towels. The present invention further relates to pile yarn in terry woven fabric (warp yarn), or weft yarn, in the case of flat fabrics.

Owner:WELSPUN INDIA LTD

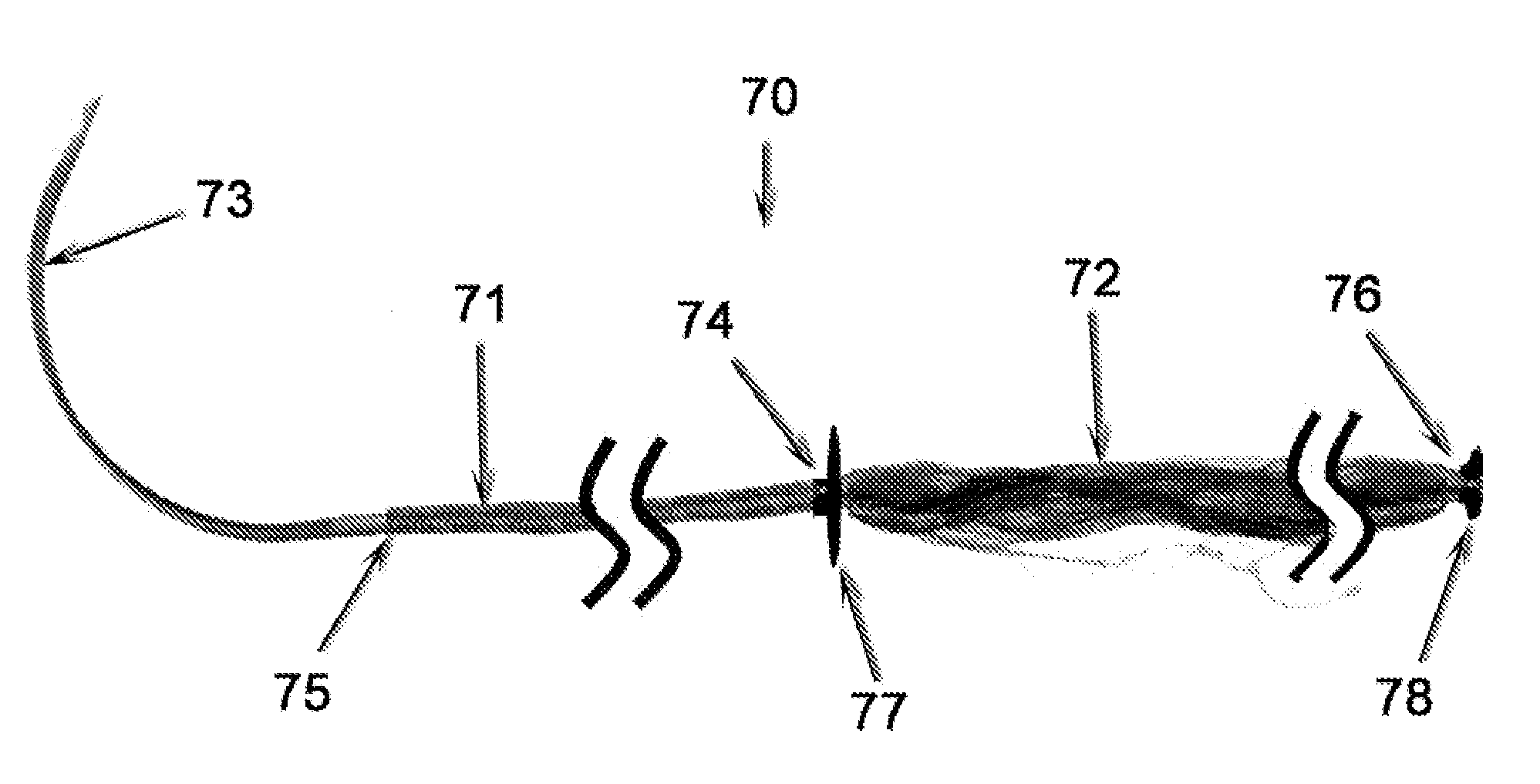

Surgical sutures incorporated with stem cells or other bioactive materials

InactiveUS20090318962A1Reduce concentrationReducing cell migrationSuture equipmentsSurgical needlesSurgical siteSurgical department

Materials and Methods for immobilizing bioactive molecules, stem and other precursor cells, and other agents of therapeutic value in surgical sutures and other tissue scaffold devices are described herein. Broadly drawn to the integration and incorporation of bioactive materials into suture constructs, tissue scaffolds and medical devices, the present invention has particular utility in the development of novel systems that enable medical personnel performing surgical and other medical procedures to utilize and subsequently reintroduce bioactive materials extracted from a patient (or their allogenic equivalents) to a wound or target surgical site.

Owner:BIOACTIVE SURGICAL

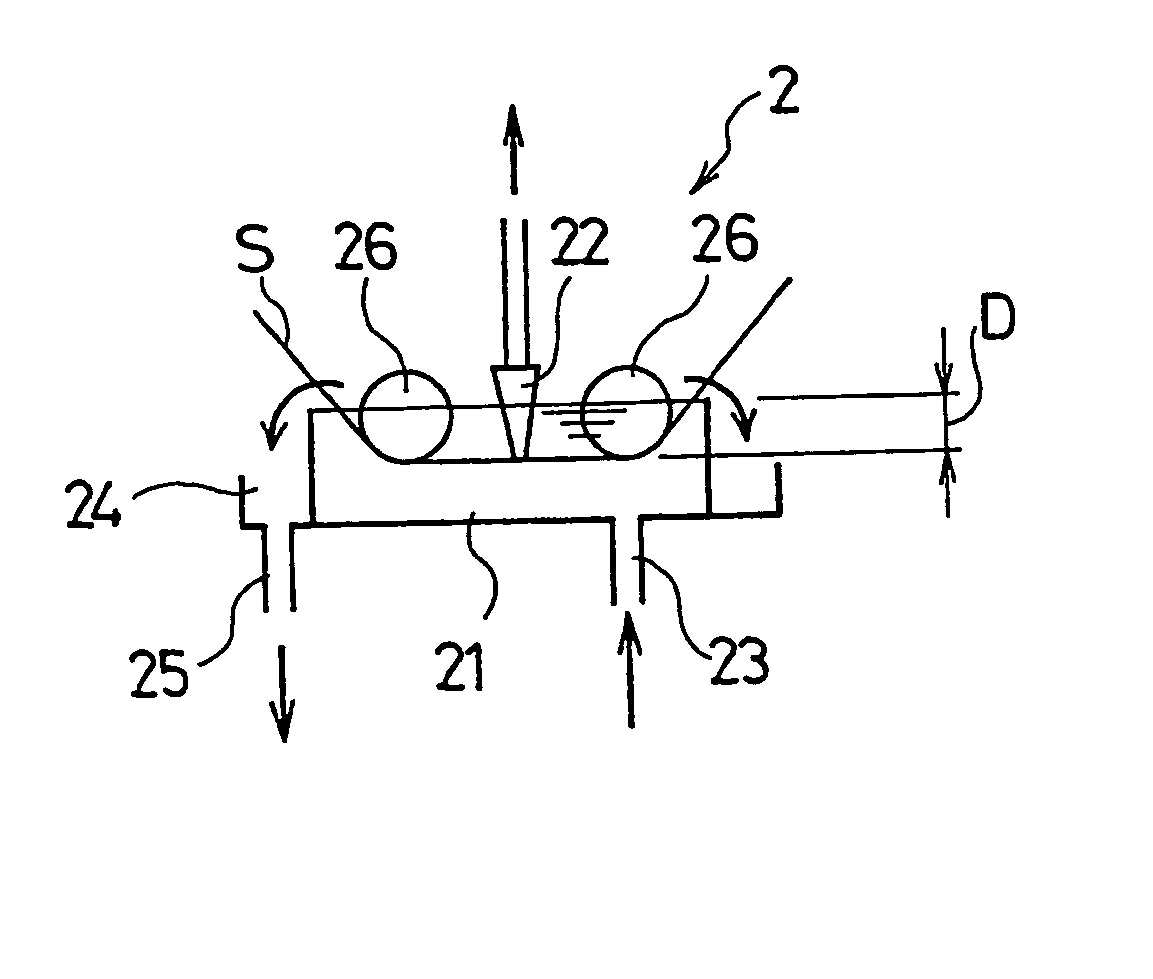

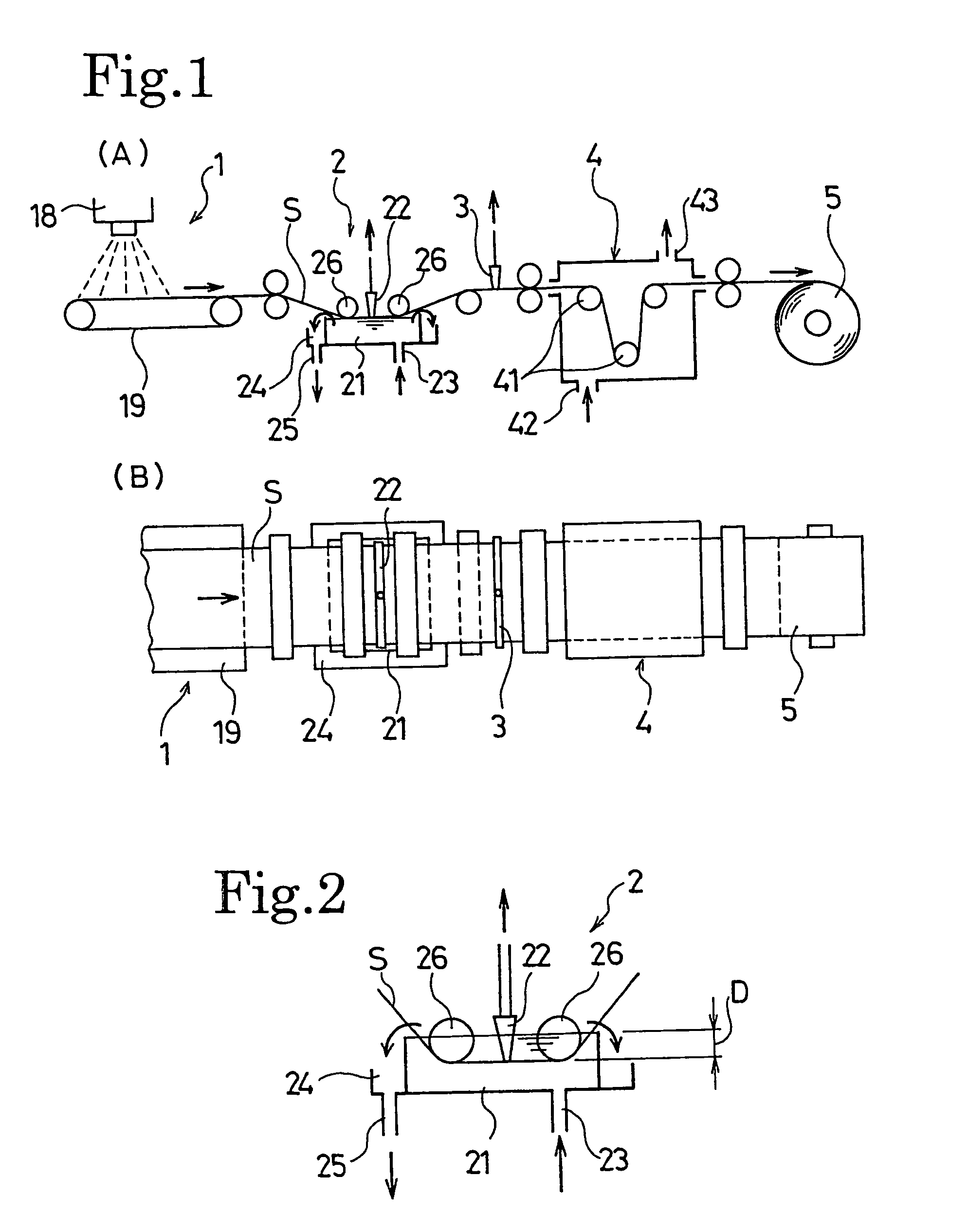

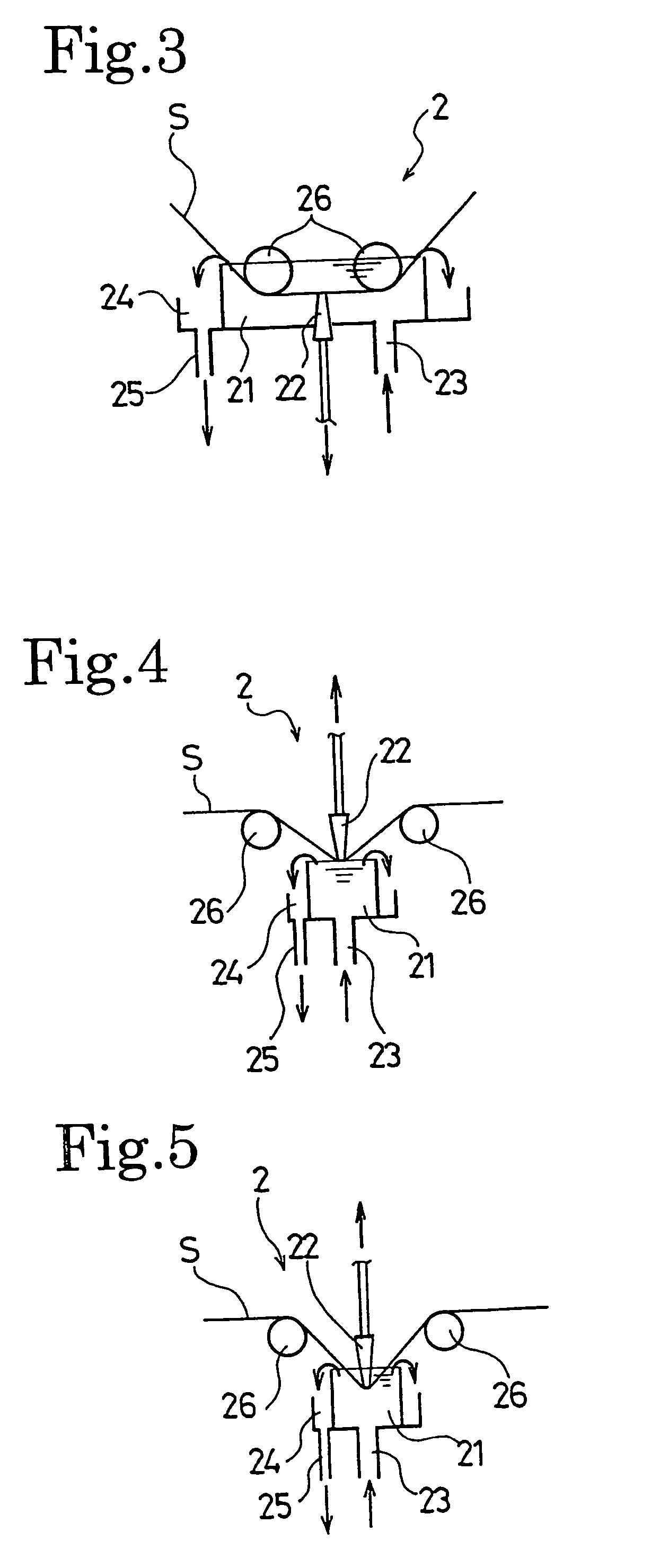

Manufacturing method and device for electret processed product

A manufacturing method of an electret processed product, comprising the steps of allowing a section nozzle (22) to come into contact with a nonconductive fiber sheet (S) so as to cross in the lateral direction of the sheet while running the sheet, allowing the surface of the sheet on the opposite side of the contact portion to come into contact with or to immerse into a water surface, sucking water from the suction nozzle (22) so that the water can be passed through the sheet in the thickness direction of the sheet to penetrate the water into the nonconductive fiber sheet (S), and drying the nonconductive fiber sheet (S), whereby a high quality and high performance electret processed product can be manufactured at a low cost.

Owner:TORAY IND INC

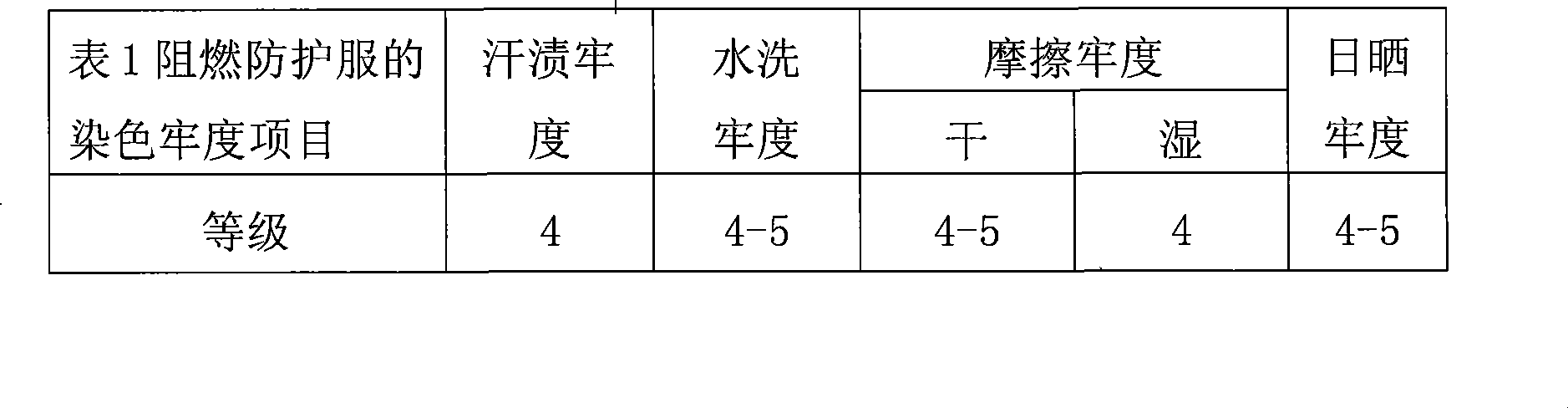

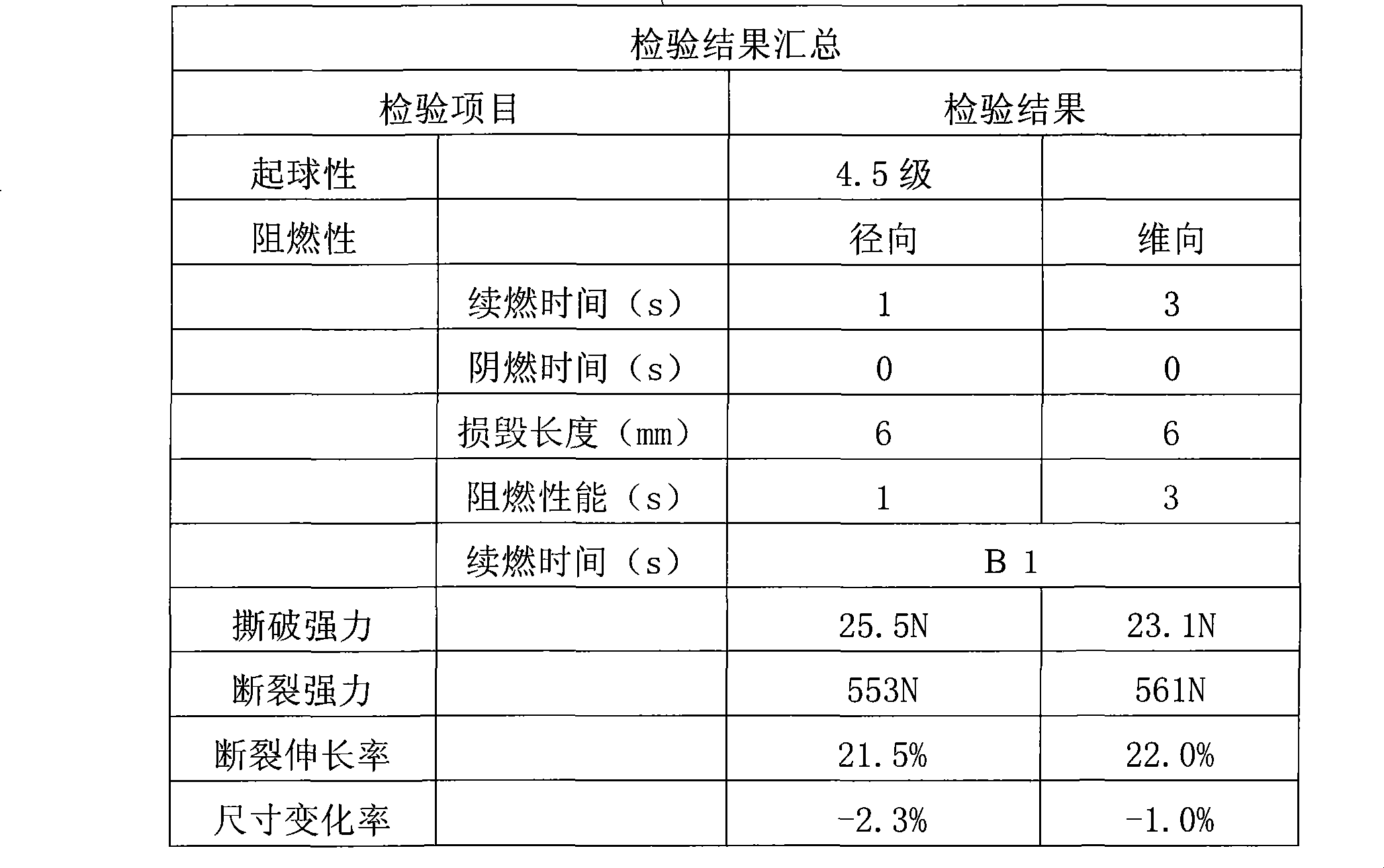

Industrial flame-retardant protection suit fabric, production method thereof and flame-retardant protection suit thereof

The invention relates to an industrial anti-flaming exposure suit fabric and a manufacturing method and an exposure suit thereof. Yarns used in the industrial anti-flaming exposure suit fabric are formed by the blending of anti-flaming viscose, wool fibers and nylon fibers. The blending proportions (weight percentage) of the anti-flaming viscose, the wool fibers and the nylon fibers are respectively 45 percent to 55 percent, 35 percent to 45 percent and 5 percent to 15 percent. The industrial anti-flaming exposure suit fabric used in front of electric welding and metallurgy smelting furnaces has the functions of permanent anti-flaming performance, high temperature resistance, heat convection resistance, molten metal splashing resistance, and the like. The fabric is not only suitable for firefighter uniforms, flying protective clothing, and the like, realizes permanent anti-flaming performance and high temperature resistance, but also meets the requirements of the anti-flaming exposure suit fabric used in front of the electric welding and metallurgy smelting furnaces for the functions of heat convection resistance, molten metal splashing resistance, and the like.

Owner:SHANGHAI IBENA TEXTILE PROD

Laundry dryer providing moisture application during tumbling and reduced airflow

ActiveUS8104191B2Efficient removalStay hydratedDrying solid materials with heatDrying gas arrangementsSpray nozzleEngineering

A laundry dryer includes a rotatable drum, an air delivery system selectively operable to provide air into the drum at a first flow rate and a second flow rate that is less than the first flow rate, and a moisture delivery system operable to provide moisture (e.g., water mist or steam) into the drum while air is being provided at the lower second flow rate, and during drum rotation (tumbling), to thus enhance dispersion of the moisture into the fabrics of the load, and the attendant dewrinkling / refresh benefits. The air delivery system can include a reversible blower that provides air at the first flow rate when operated in a first direction and provides air at the second flow rate when operated in an opposite second direction. The drum can be a reversibly rotatable drum that is rotatable in a first and an opposite second direction, and the dryer can include a drive motor that both rotates the drum and operates the blower. The moisture delivery system can include a nozzle to provide moisture directly into the drum.

Owner:ELECTROLUX HOME PROD CORP NV

Ultra-soft Raschel plush fabric and method for making same

InactiveCN101113547AImprove insulation effectWith perspirationWarp knittingHeating/cooling textile fabricsPolyesterYarn

The invention relates to a Raschel plush fabric and a production method thereof, in particular to a plush fabric taken terylene as raw materials and the fabricating method thereof, pertaining to weaving science field. The invention adopts terylene with a single fiber fineness of 0.52 to 1.0D, a polyester / polyamide compound DTY or terylene FDY with a fiber fineness of 100-250D / 36-48F; the silk is terylent and polyester / polyamide compound draw textured yarns or fully drawn yanrs (FDY) made through a direct spun method or a section cutting method. The invention adopts special production technologies and has the advantages of heat preservation, easy perspiration, lightness, softness, anti-static and being not easy to be dirty, etc, which can be applied to clothes fabrics, blanket, bedgown, slipper and bath towel, etc.

Owner:ZHEJIANG TRUELOVE GROUP

Clothes dryer

Owner:SAMSUNG ELECTRONICS CO LTD

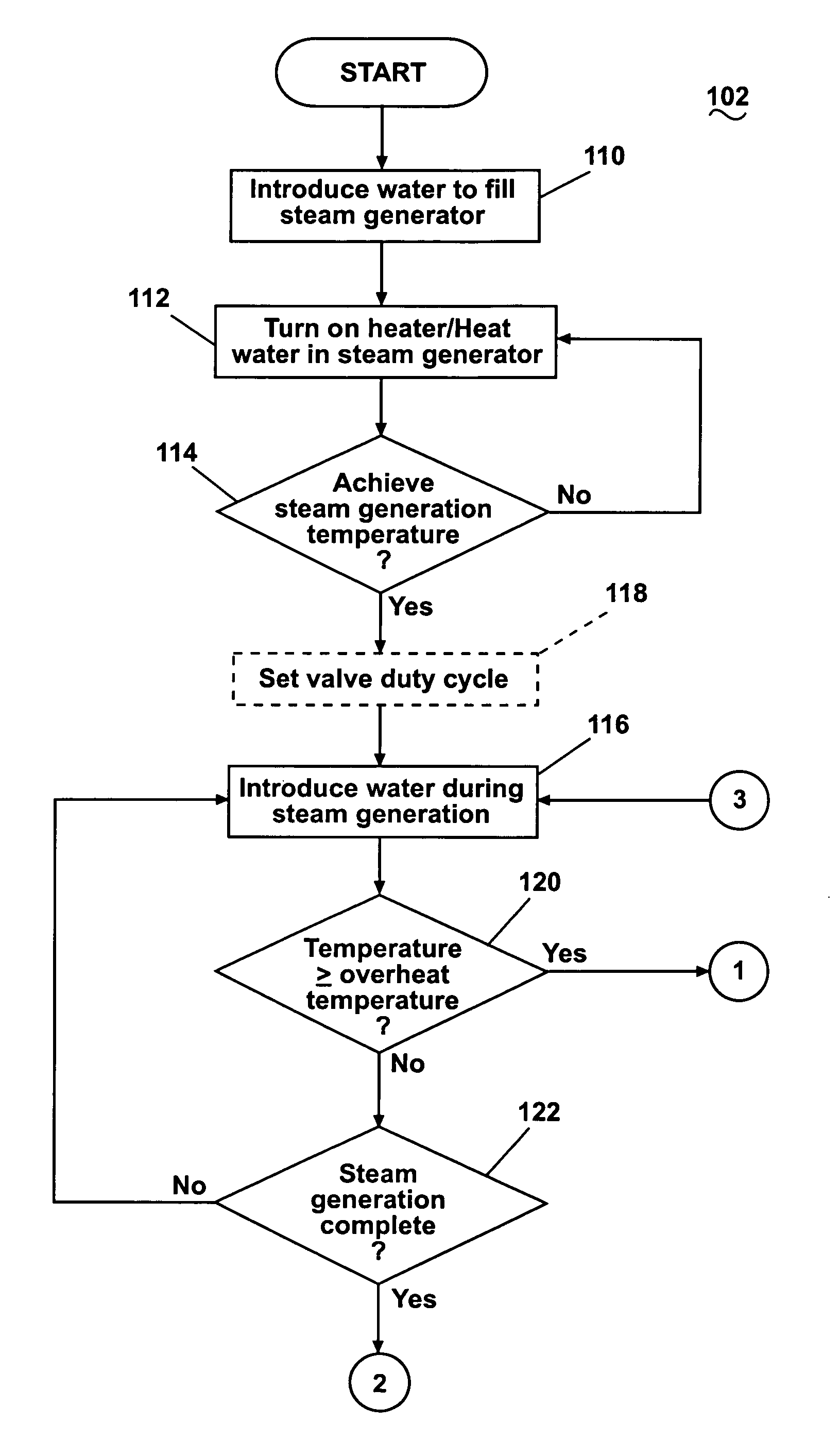

Draining liquid from a steam generator of a fabric treatment appliance

InactiveUS20070283509A1Other washing machinesCleaning using liquidsNuclear engineeringSteam generation

A method of operating a fabric treatment appliance comprises a steam generation step and, after the completion of the steam generation step, a draining step comprising draining liquid remaining in a chamber of the steam generator to a tub of the fabric treatment appliance. The steam generator in one embodiment can comprise the chamber, an inlet configured to introduce liquid into the chamber, an outlet configured to exhaust steam from the chamber, and a drain coupling the chamber to the tub and configured to drain liquid from the chamber to the tub.

Owner:WHIRLPOOL CORP

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

Removal of scale and sludge in a steam generator of a fabric treatment appliance

ActiveUS20070283505A1Other washing machinesLiquid/gas/vapor textile treatmentNuclear engineeringSludge

A method of operating a fabric treatment appliance comprises a steam generation step and a steam generator cleaning step. In the steam generator cleaning step, a chamber of the steam generator can be flushed by introducing a volume of liquid into the chamber greater than the internal volume. The steam generator cleaning step can also involve thermally shocking scale formed within the chamber.

Owner:WHIRLPOOL CORP

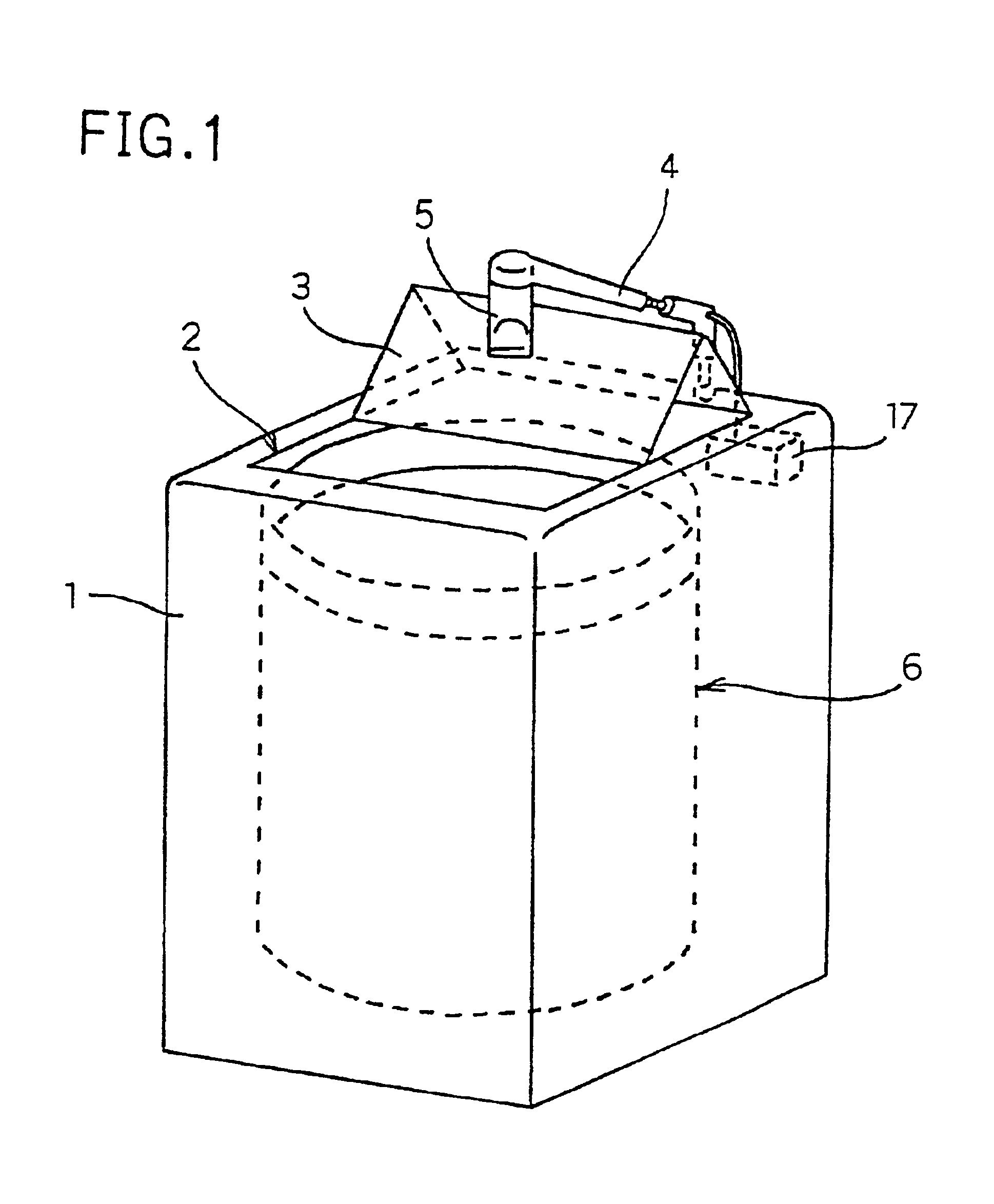

Washer having a partial washing apparatus, and washing apparatus

InactiveUS6886371B2Improve solubilityImprove transmission efficiencyOther washing machinesVibration washing machinesSupersonic wavesProcess engineering

A washing machine has a partial washing apparatus, which has a supersonic resonator, which is driven by an oscillator to generate supersonic vibration and a supersonic vibration horn. A washing liquid is fed to the partial washing apparatus so as to be agitated by supersonic waves, which are then fed to an article to be washed to achieve partial washing of the article. The partial washing apparatus is detachably fitted to the washing machine proper at approximately the center of a lid of the washing machine proper. The partial washing apparatus may be used as a handy-type partial washing apparatus when held at a grip portion of the partial washing apparatus.

Owner:SHARP KK

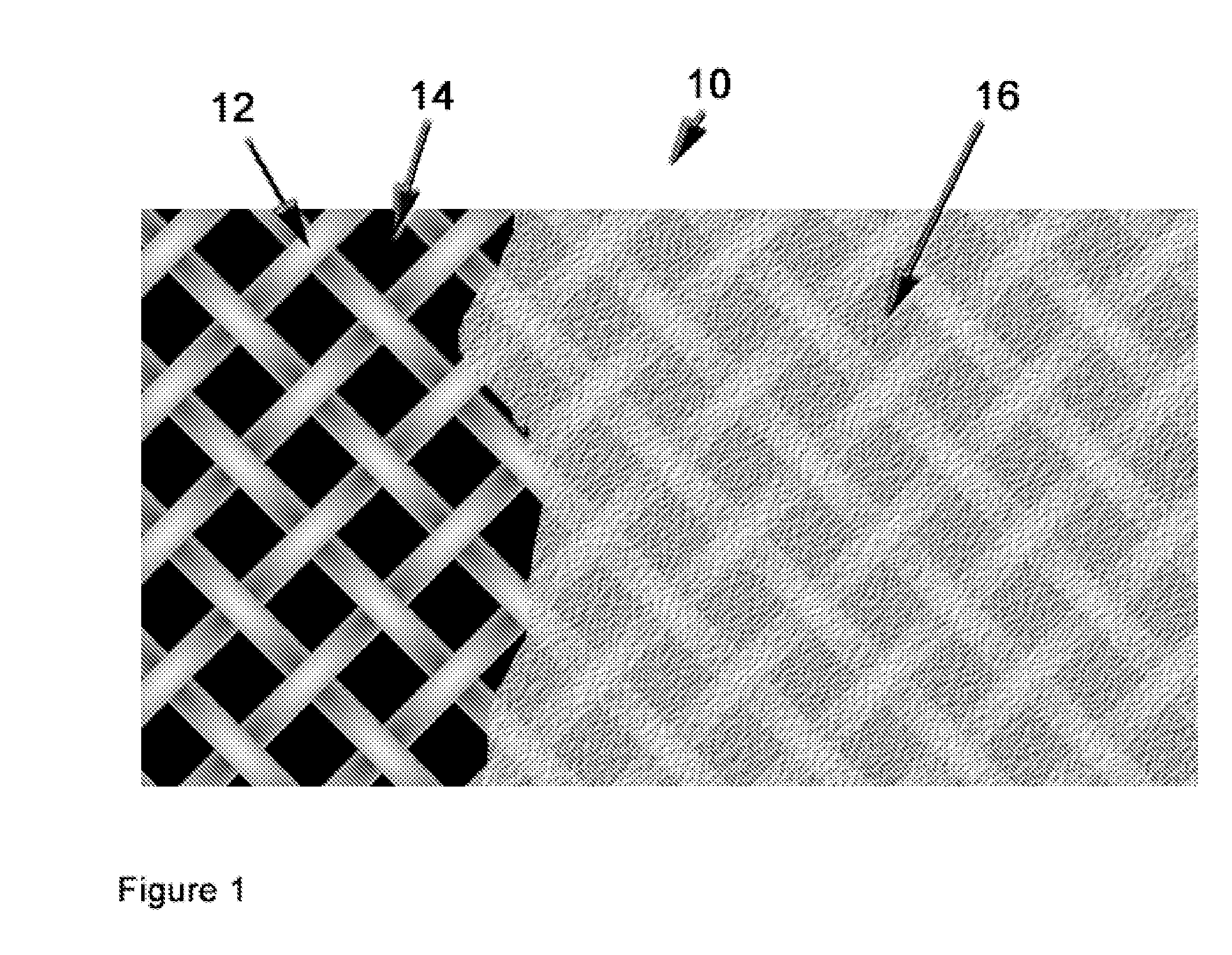

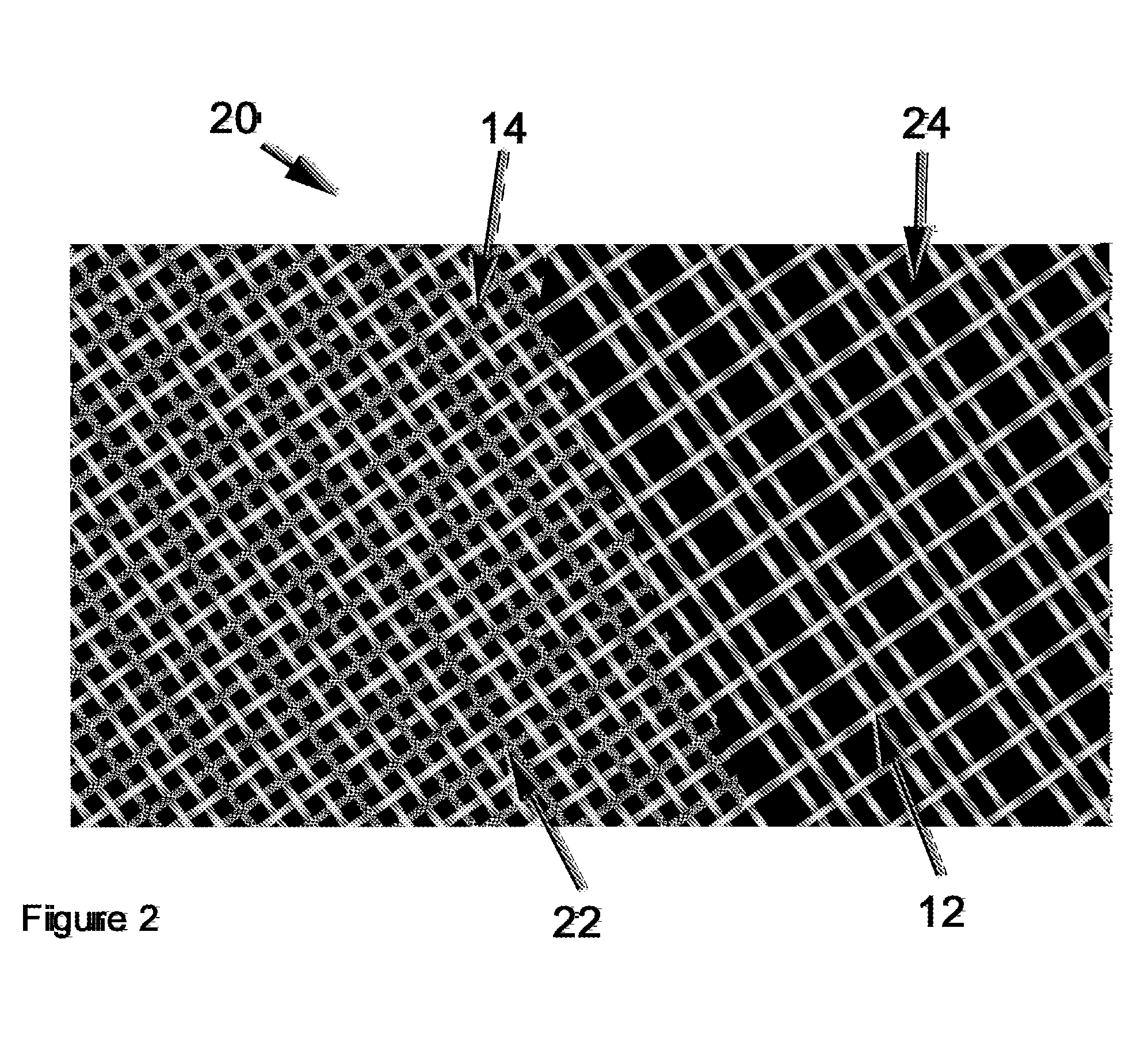

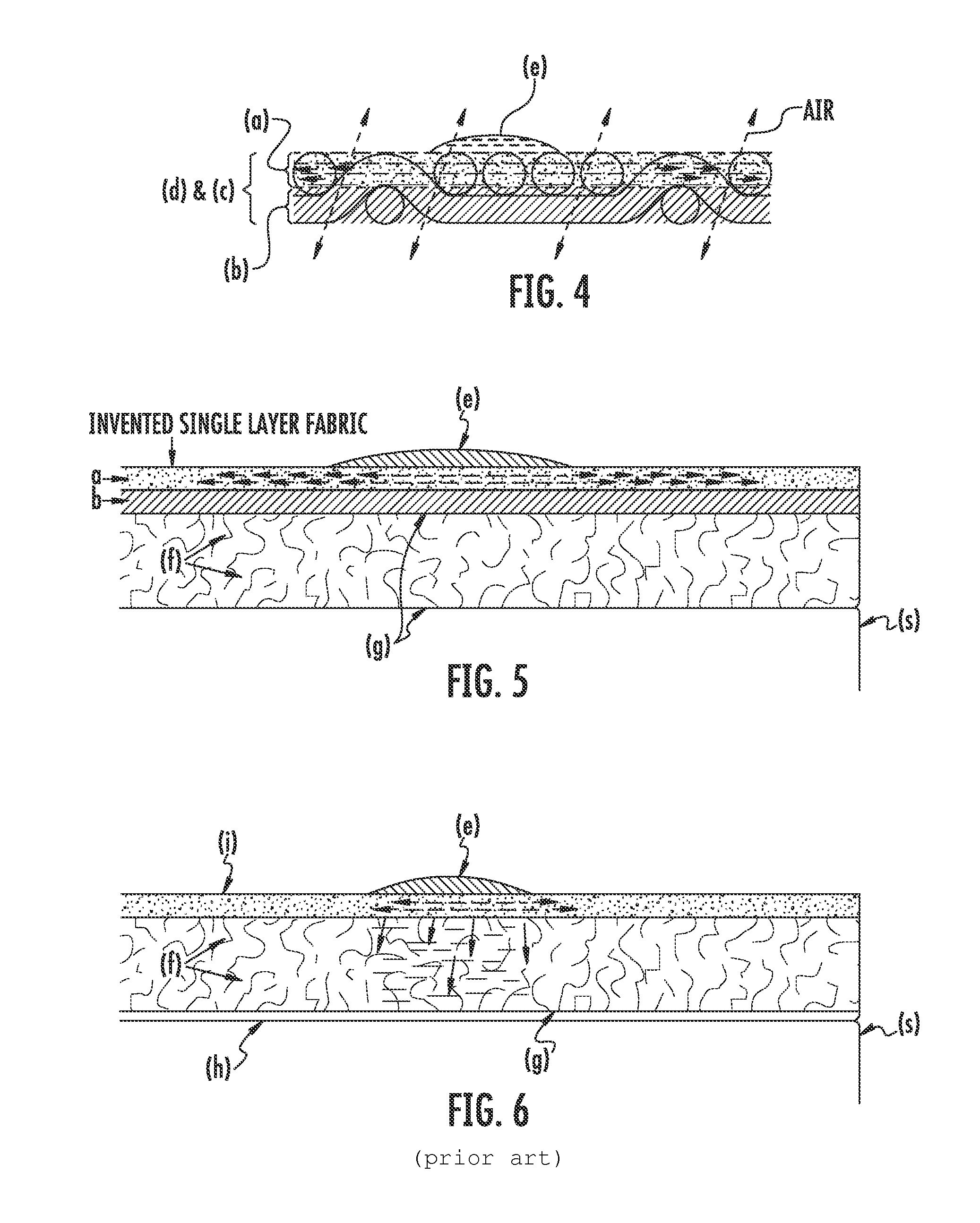

Semi-absorbent, semi-resistant, breathable fabric

A semi-absorbent, semi-resistant, breathable fabric includes a single-layer having a first, hydrophilic side that absorbs water, and a second, hydrophobic side; wherein the first, hydrophilic side of the single-layer fabric quickly spreads out a liquid that is absorbed laterally to a wider area such that the absorbed liquid does not seep or pass through to the second, hydrophobic side of the single-layer fabric under gravitational force. A method of making a semi-absorbent, semi-resistant, breathable fabric includes: subjecting a first side of a single-layer fabric to a hydrophilic amino functional polysiloxane softener; treating a second opposite side of the fabric with a fluorocarbon compound under low pressure such that the fluorocarbon compound penetrates no more than half of the fabric thickness; and drying and curing the fabric, preferably at a temperature of about 145° C. to 155° C. for about three minutes to about five minutes.

Owner:WELSPUN INDIA LTD

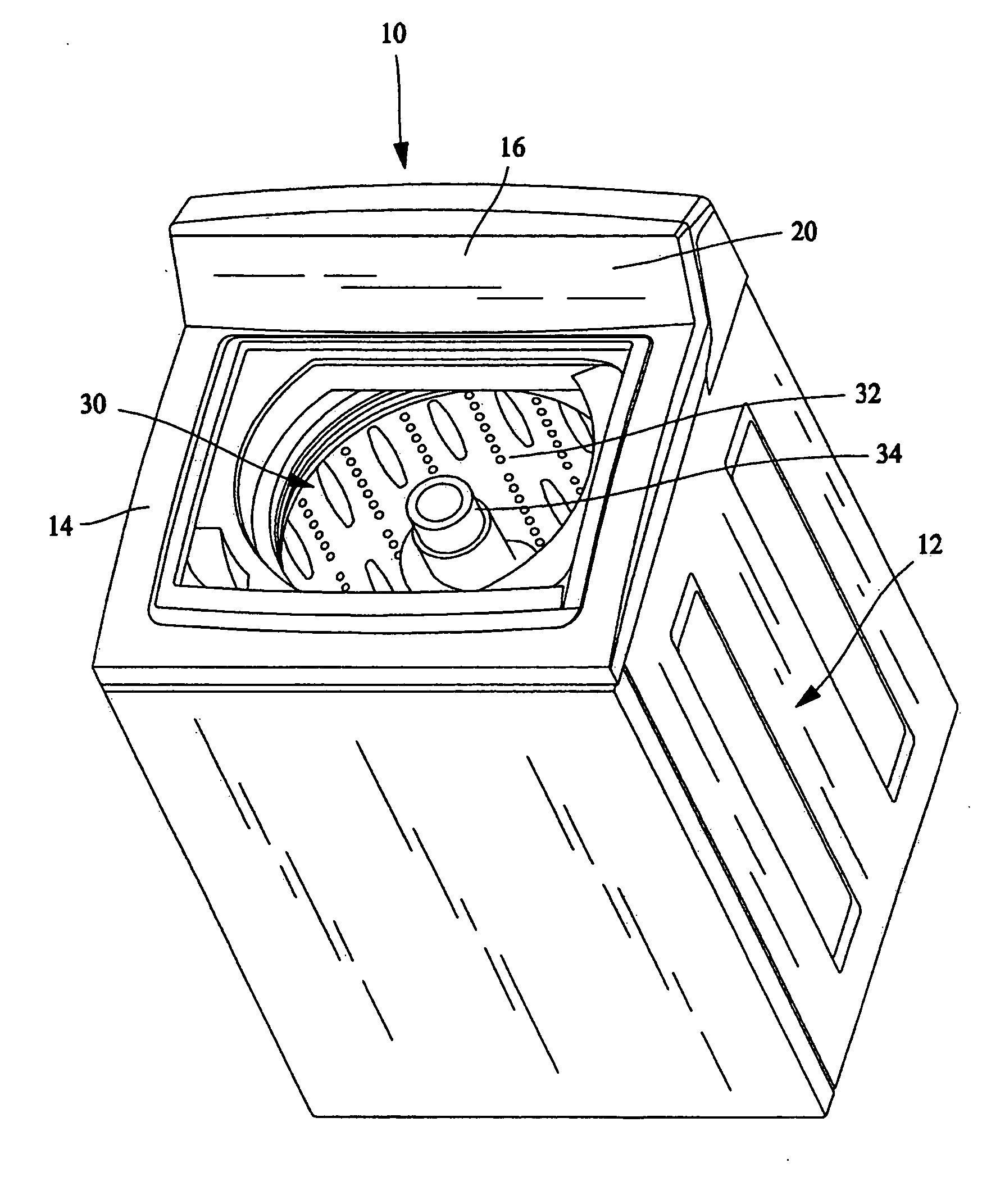

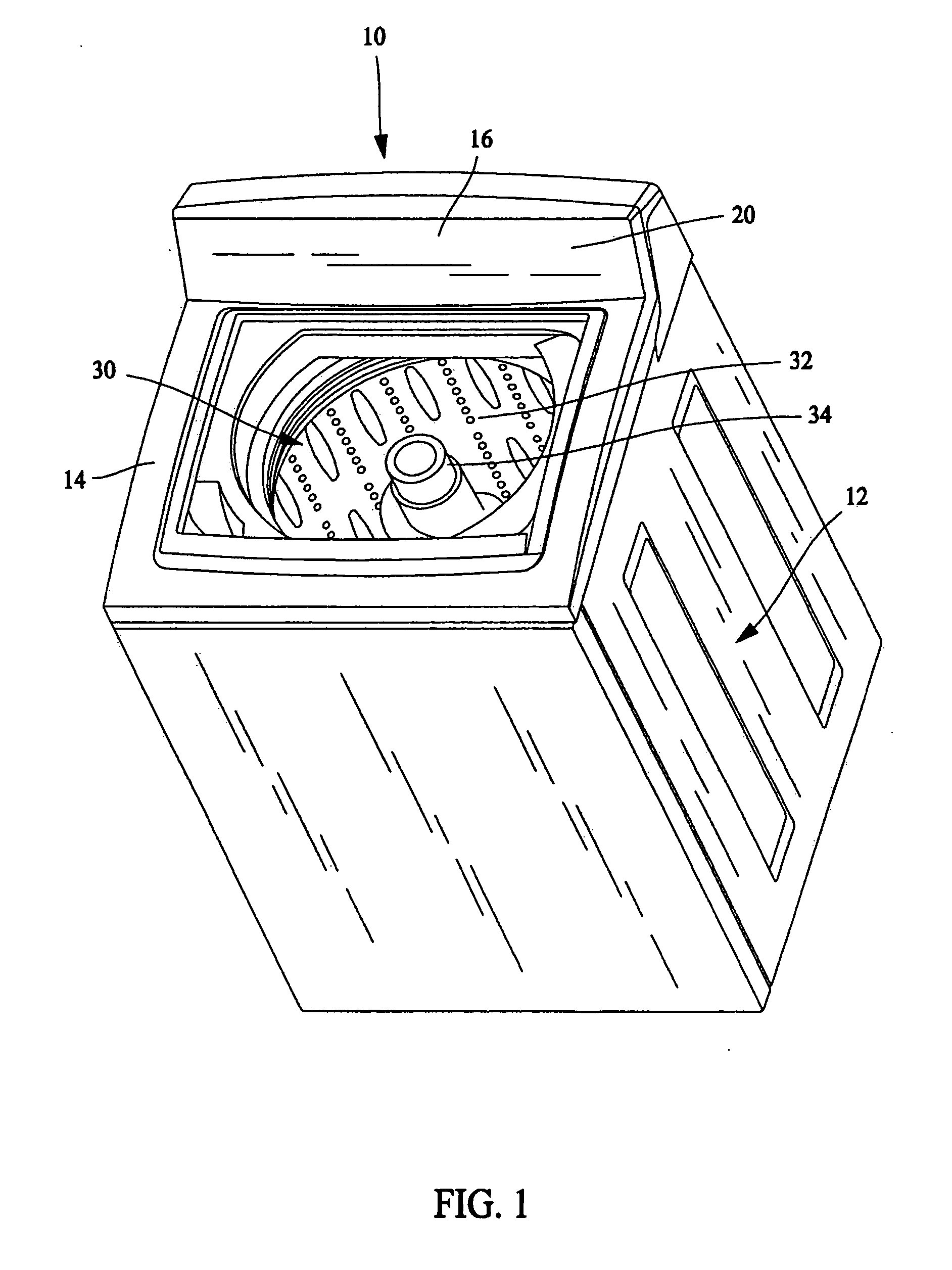

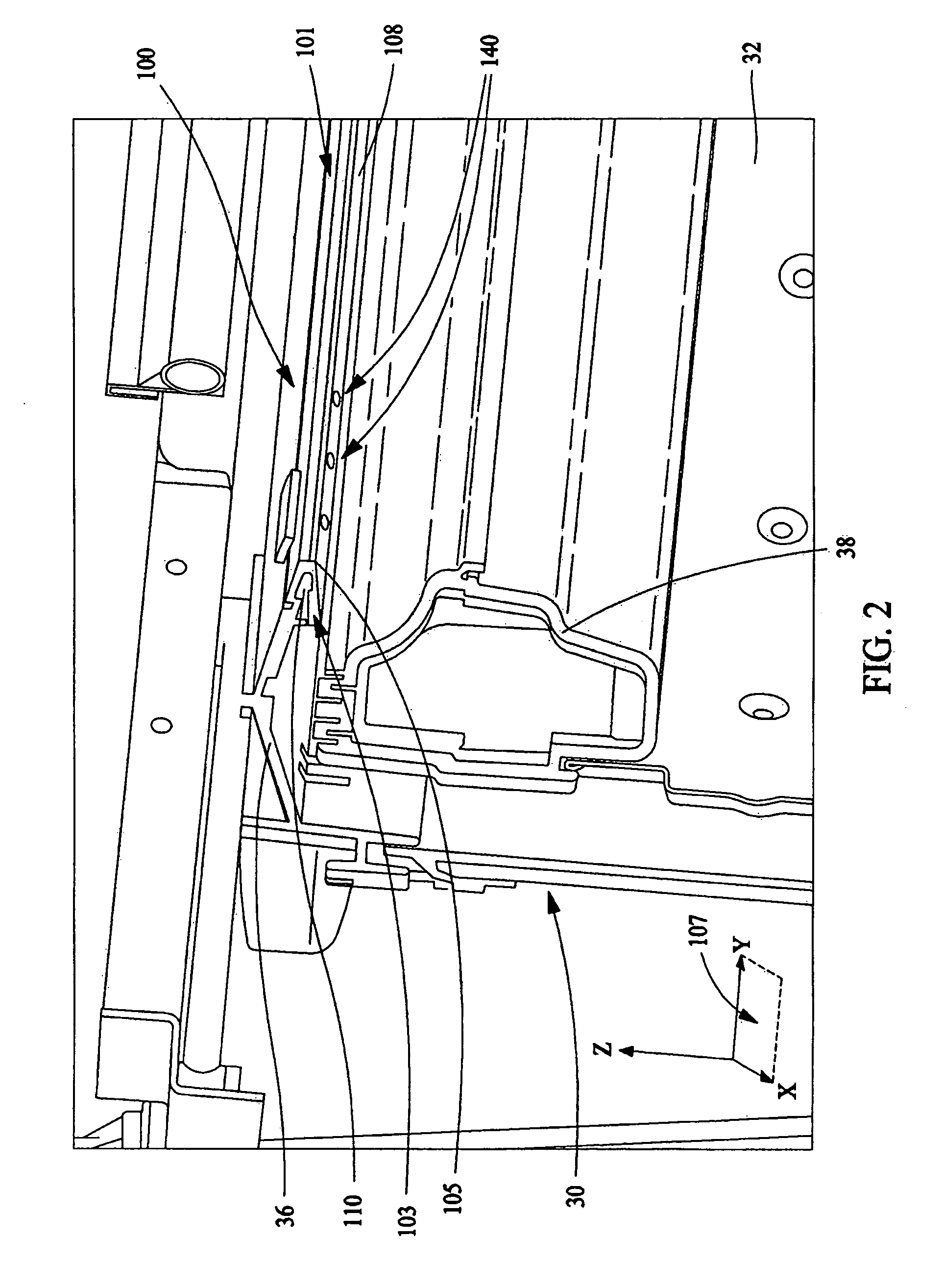

Methods and apparatus for washing machine

A spraying device for a washing machine includes a body including a wall having an outer surface, a water inlet and a channel defined therein. The channel is in flow communication with the water inlet, and a plurality of nozzles extend through the wall and in flow communication with the channel. The washing machine includes a wash tub and a basket mounted within the wash tub. The basket is configured to rotate. The nozzles include an inlet, an outlet, an inner diameter, and an outer diameter. At least a portion of the outlet includes a surface substantially perpendicular to a flow of water through the nozzle, and the nozzles have a length longer than a thickness of the wall. At least a portion of the outlet is unitary with the wall outer surface.

Owner:MICROSOFT CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com