Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8931 results about "Laundry washing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

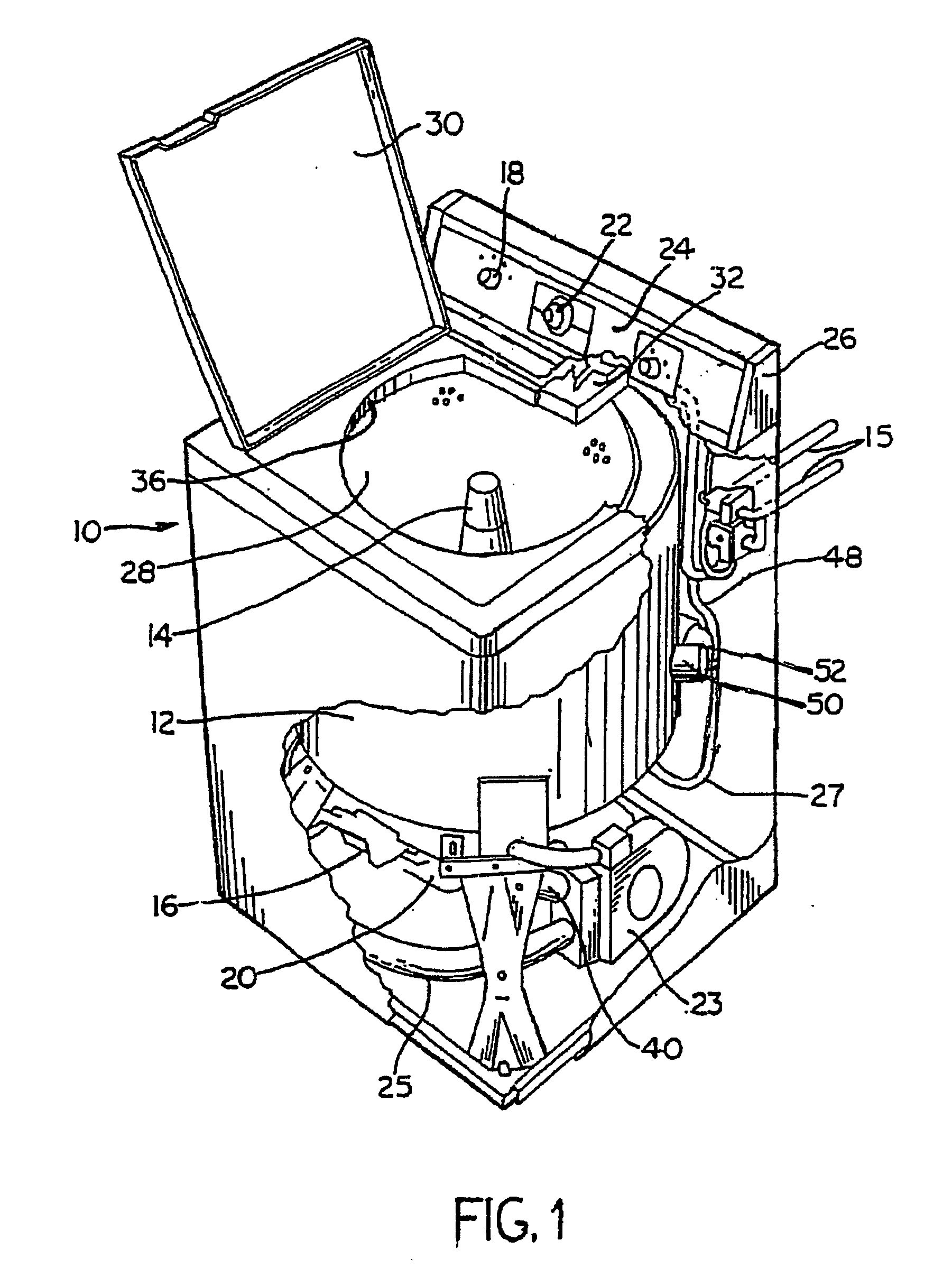

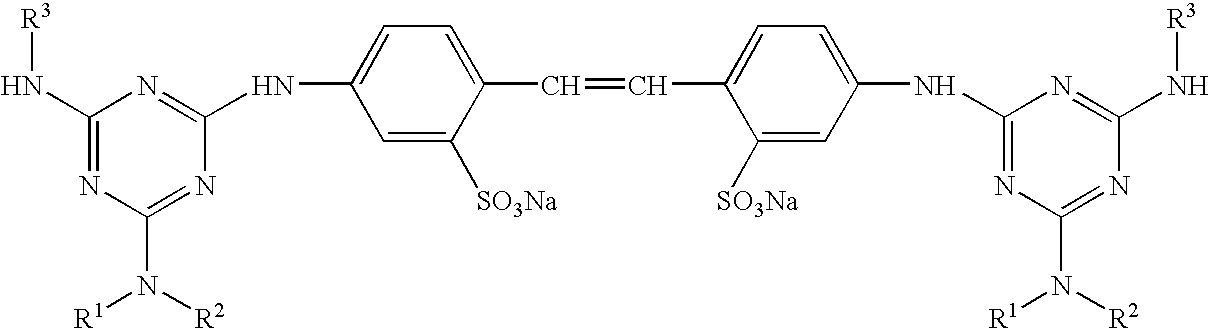

Laundry system having unitized dosing

InactiveUS20030104969A1Facilitated releaseOrganic detergent compounding agentsWrappersPolymer scienceLaundry

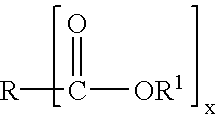

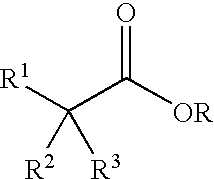

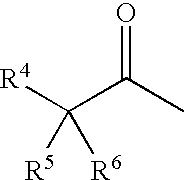

Compositions, articles and methods are provided for supplying fabric care benefits to clothing or fabrics in an automated washing machine and by manual washing. The fabric care compositions preferably have less than about 5% detergent surfactants, more preferably less than 3%, even more preferably less than 1% and are most preferably free of detergent surfactants. Similarly, the fabric care compositions preferably have less than about 5% fabric softener actives, more preferably less than 3%, even more preferably less than 1% and are most preferably free of detergent surfactants. The laundry articles can take a variety of forms in a variety of physical states all of which will rapidly dispense a unitized amount of one or more selected fabric care agents to a wash and / or rinse bath solution during the laundering process under a variety of conditions. The invention also pertains to laundry kits that contain a variety of such articles and instructions concerning their use. Likewise, methods for preparing a customized laundry solution to obtain a specific; fabric care benefit selected based on the user's personal preferences and / or the fabric care needs of the fabrics being laundered are also provided. Further, the present invention also concerns methods for assisting a consumer in identifying the unitized articles to be used in preparing a laundry solution that will impart desired fabric care benefits as well as merchandising displays for dispensing the articles, assembling customized laundry kits and instructing the consumer on the selection and use of laundry articles.

Owner:THE PROCTER & GAMBLE COMPANY

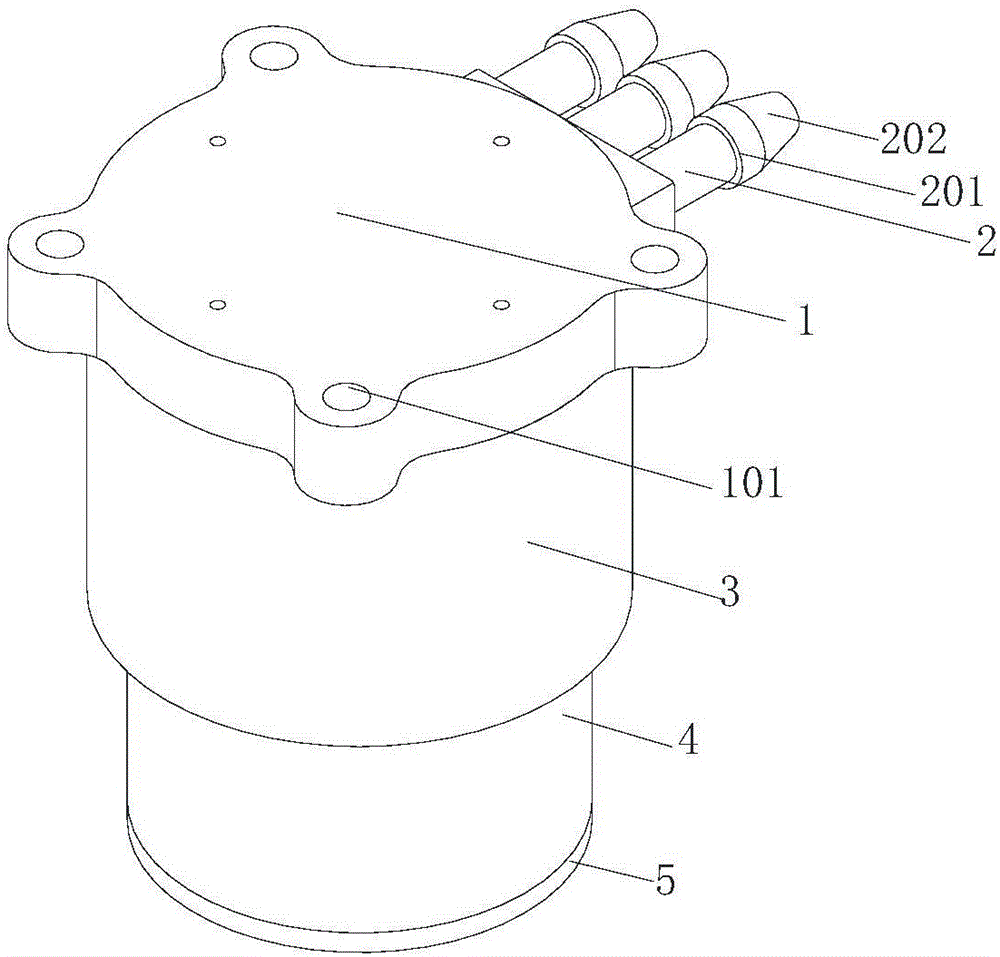

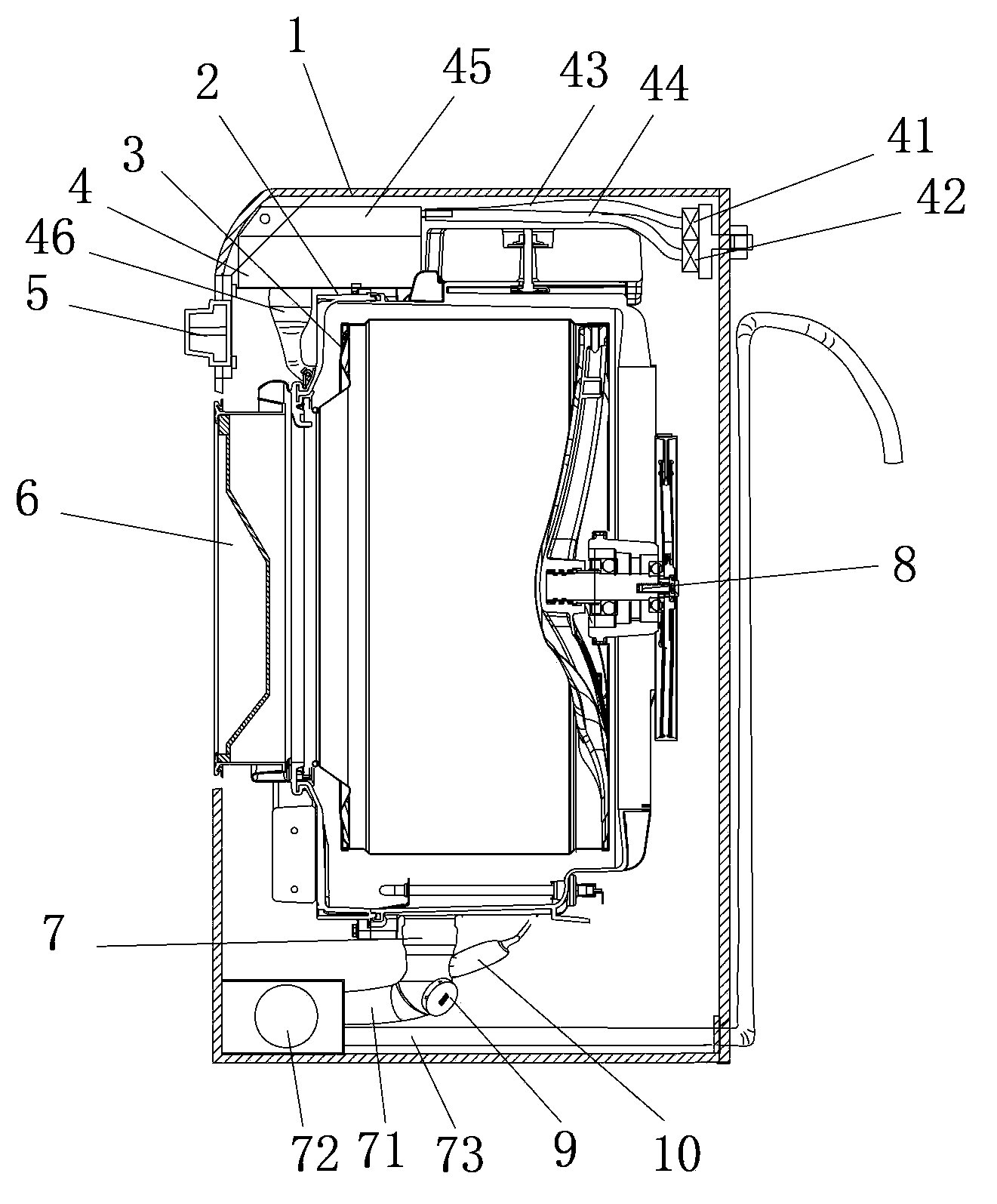

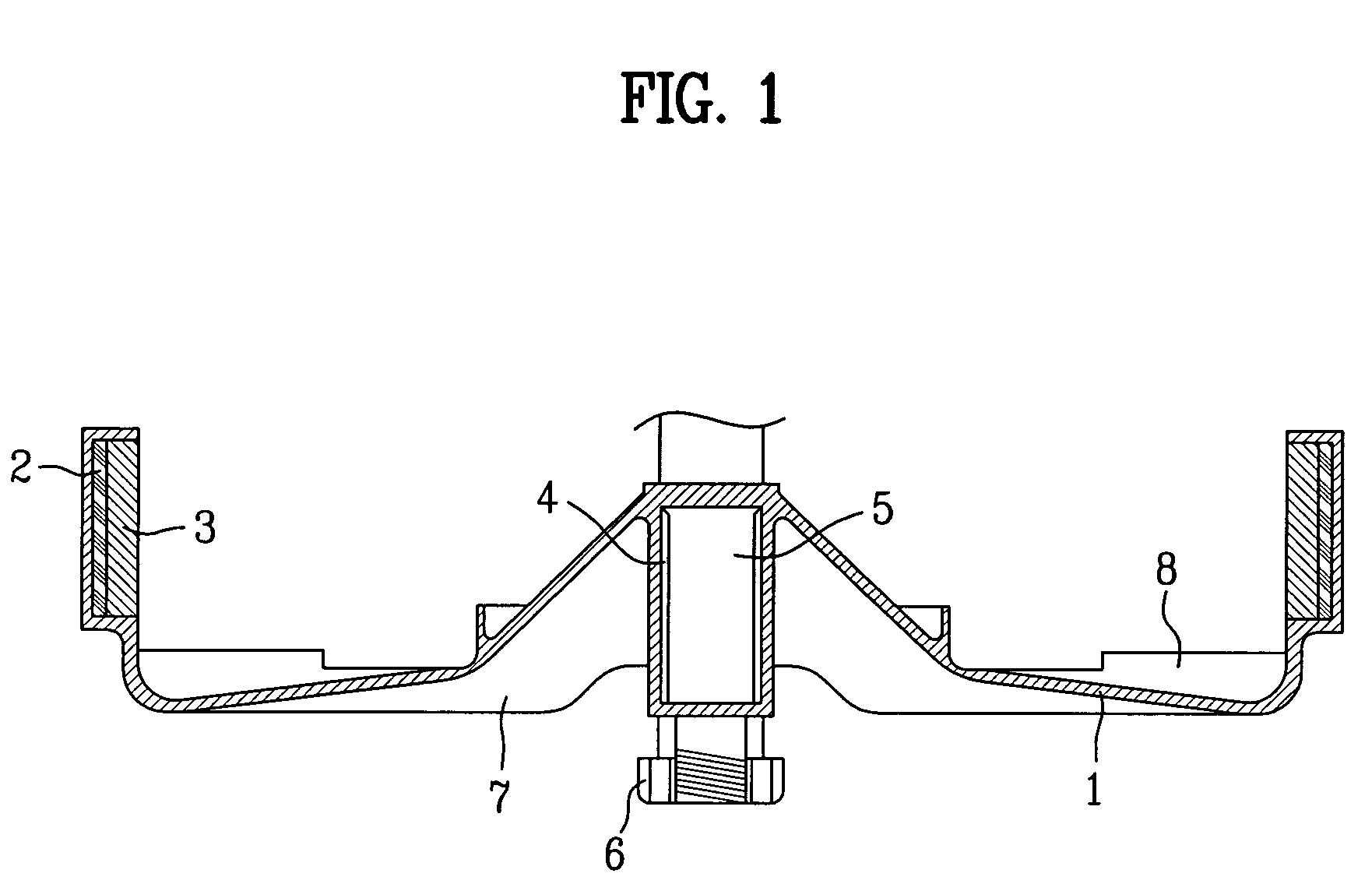

Washing machine feet with automatic levelling function and washing machine

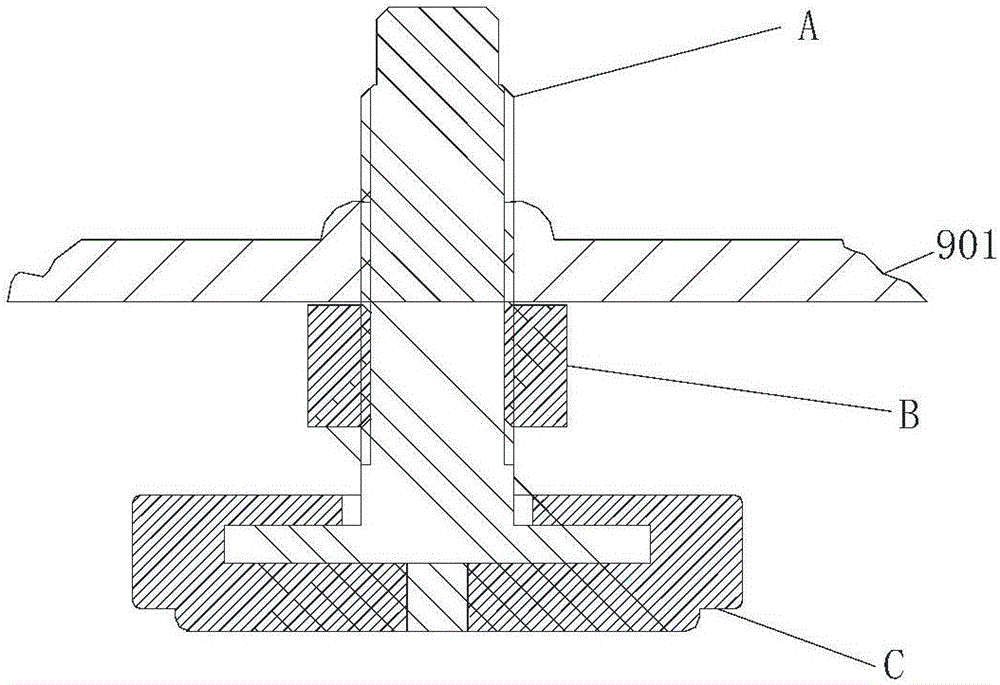

ActiveCN105755757ALarge adjustment rangeEasy to adjustMachine framesOther washing machinesLaundry washing machineLiquid medium

The invention provides washing machine feet with an automatic levelling function and a washing machine. The bottom of the washing machine is provided with the multiple feet; each foot comprises a fixed part and a moving part, a hollow chamber is formed between each fixed part and the corresponding moving part, and each hollow chamber is filled with a hydraulic medium; every two related feet are mutually connected by a high-pressure oil pipe, so that the hollow chambers of the two feet are mutually communicated, or all the feet are respectively connected to a communicating device by high-pressure oil pipes, so that the hollow chambers of all the feet are mutually communicated; under the action of pressure, the hydraulic medium can flow among the mutually-communicated hollow chambers of the feet to enable the moving parts to stretch and retract, and automatic levelling is performed. The washing machine feet with the automatic levelling function has the advantages that according to a hydraulic principle, each foot is filled with the hydraulic medium, and is enabled to perform adaptive adjustment because of the fluidity of the hydraulic medium under different pressures, the hydraulic medium can flow among the feet, the adjustment range is bigger, and the effect is better.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

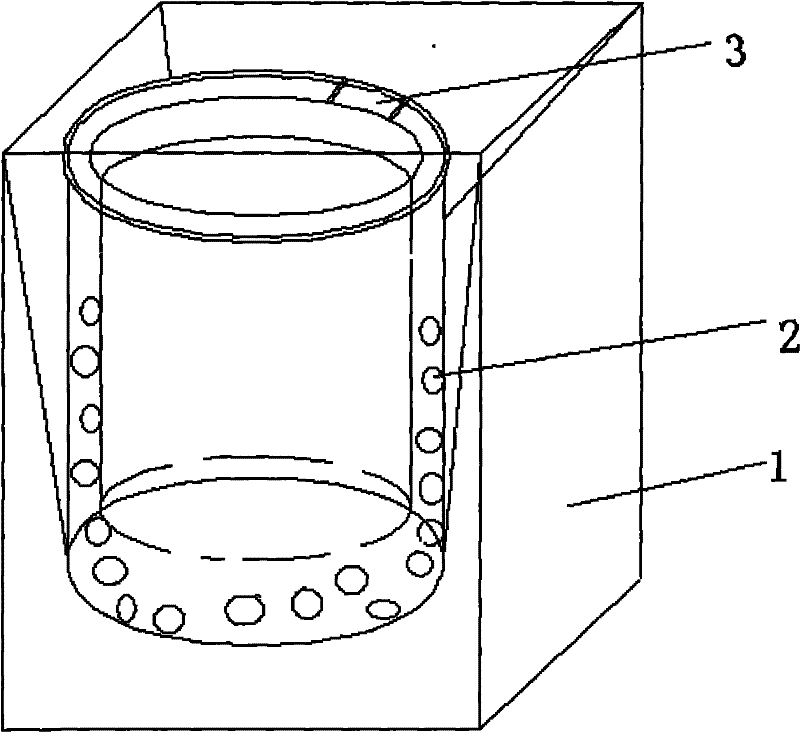

Method for cleaning space between inner and outer tubs of washing machine with flexible particles and washing machine capable of implementing same

ActiveCN102234902AEffect of washing processSimple methodHollow article cleaningOther washing machinesUser needsEngineering

The invention discloses a method for cleaning the space between inner and outer tubs of a washing machine with flexible particles and a washing machine capable of implementing the same. The washing machine is characterized in that flexible particles are arranged between the inner and outer tubs of the washing machine, and are driven by the regular flow of water to impact and rub the walls of the inner and outer tubs of the washing machine in the clothes washing process so as to clean the space between the inner and outer tubs of the washing machine. Sterilization and disinfection substances can be added into the flexible particles, so that the clothes and washing machine can be sterilized and disinfected when the space between the inner and outer tubs is cleaned. The method disclosed by the invention can be selectively implemented according to the user needs; and the method is simple and easy to popularize.

Owner:HAIER GRP CORP +2

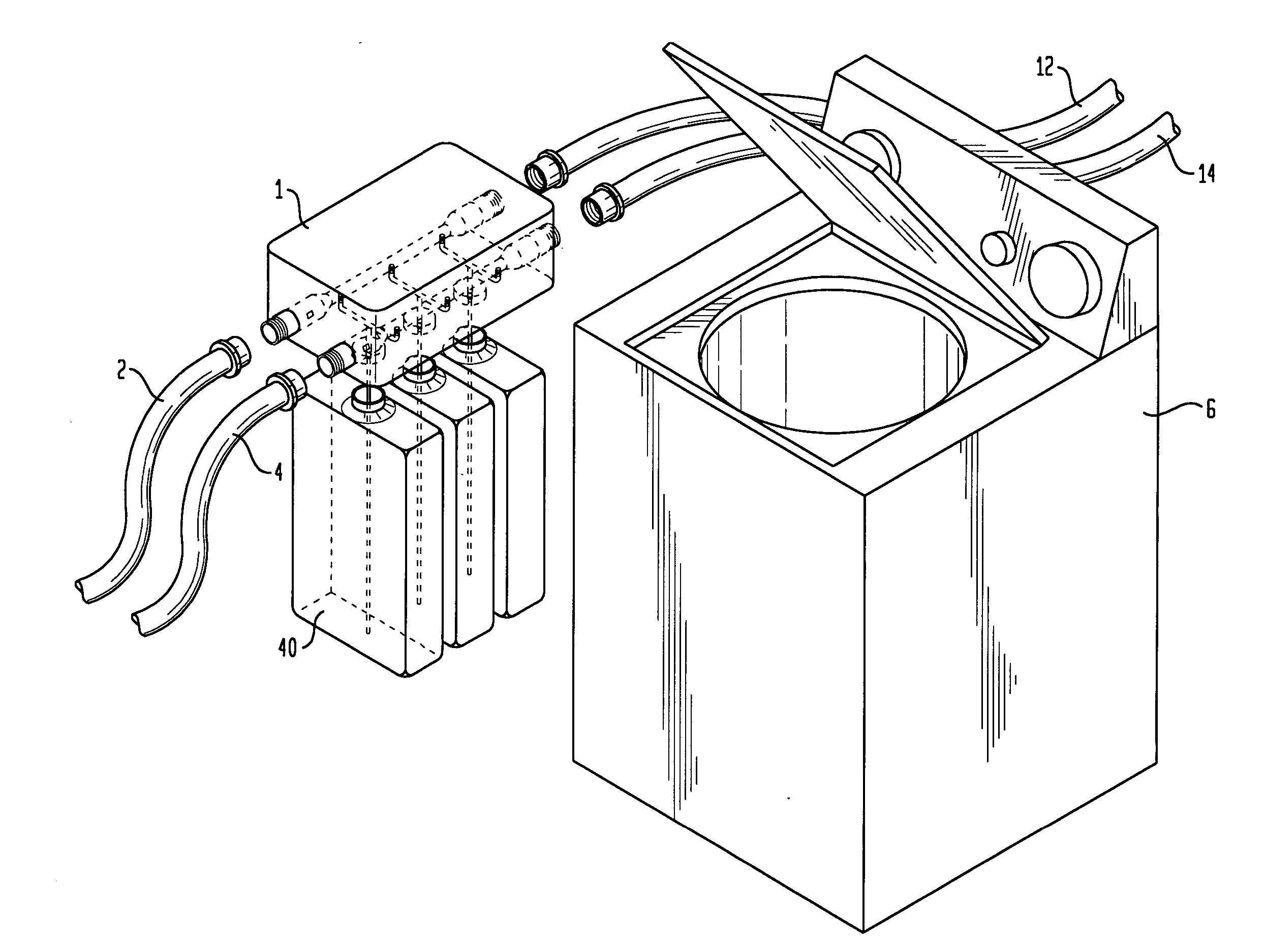

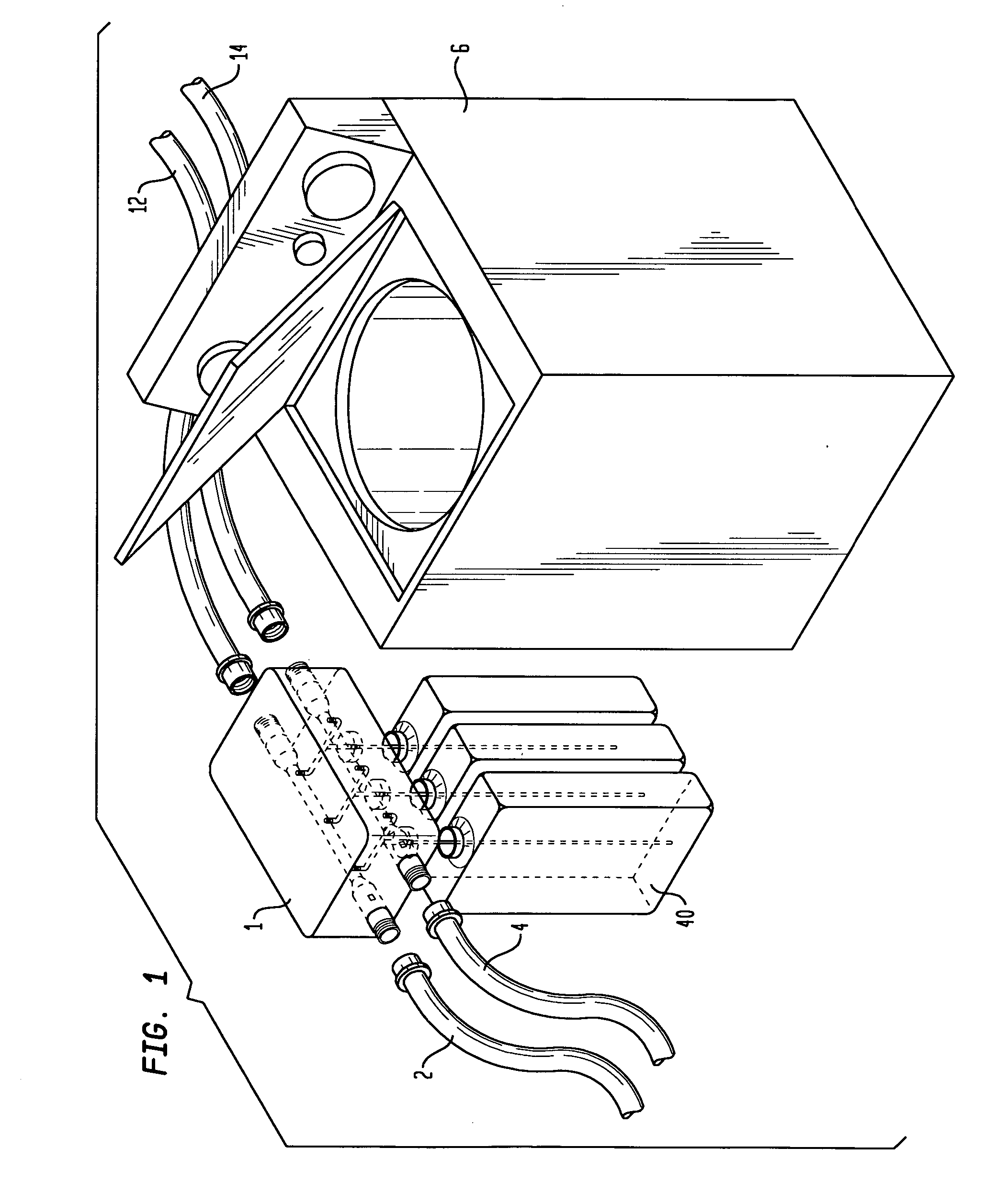

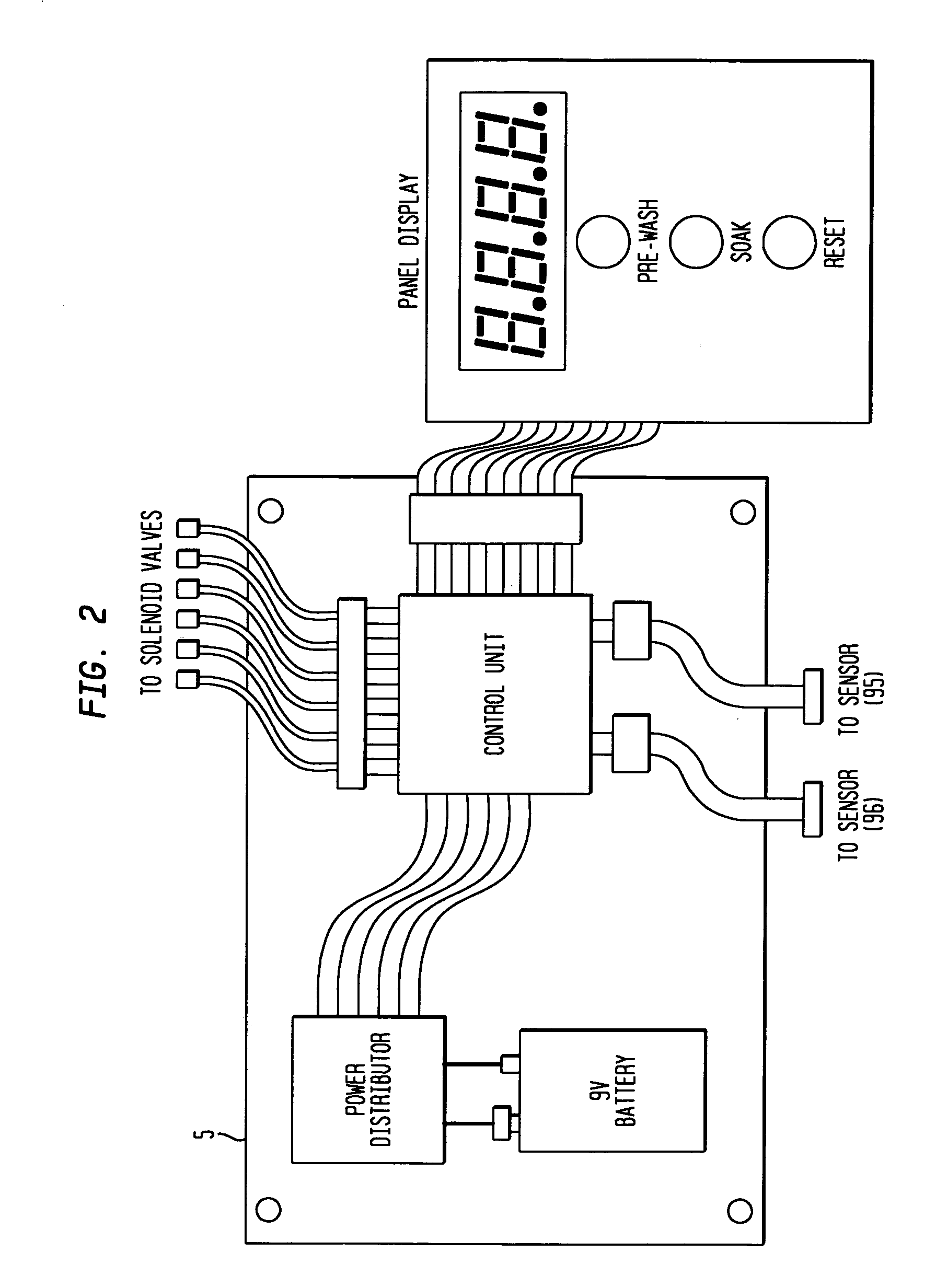

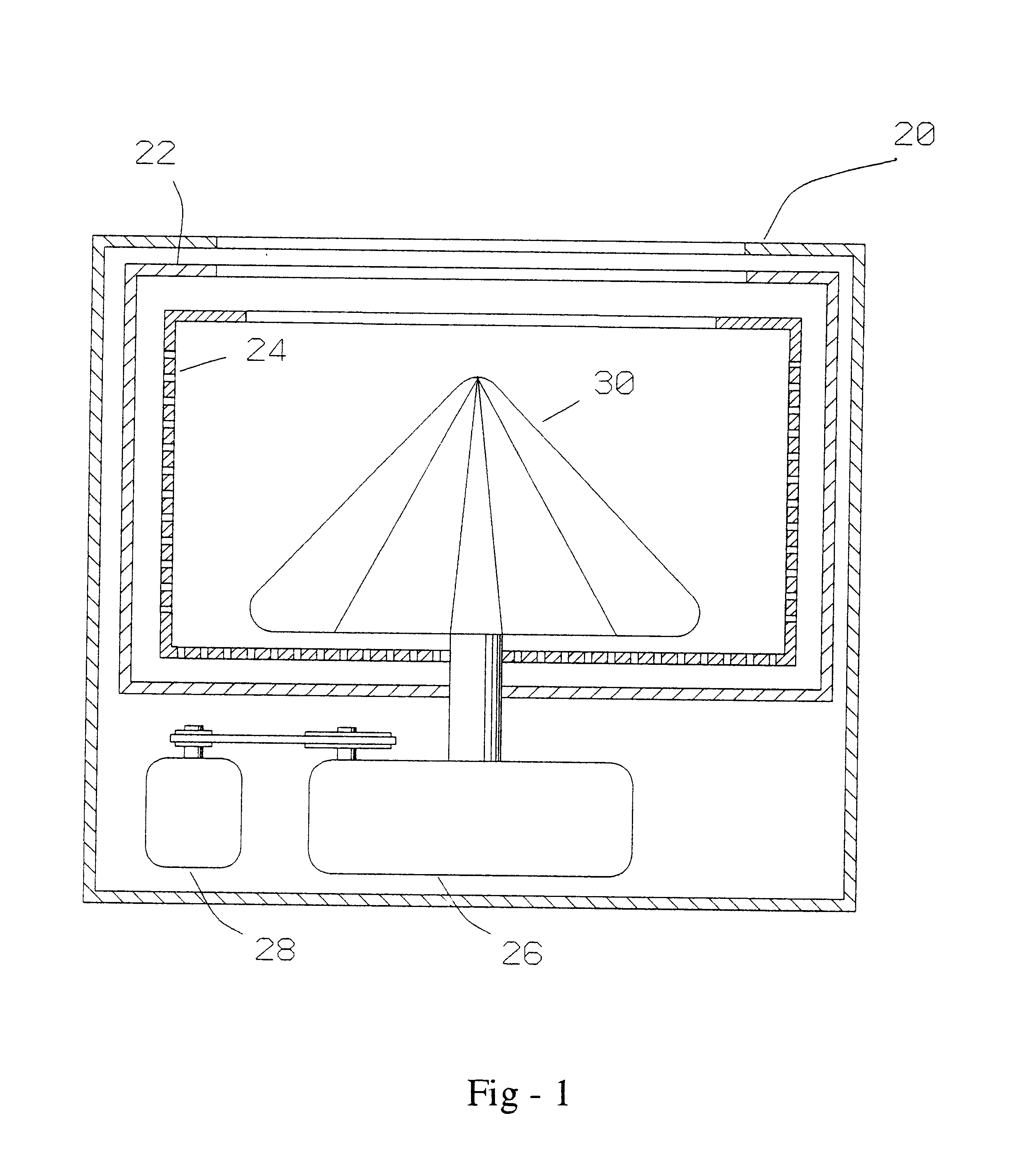

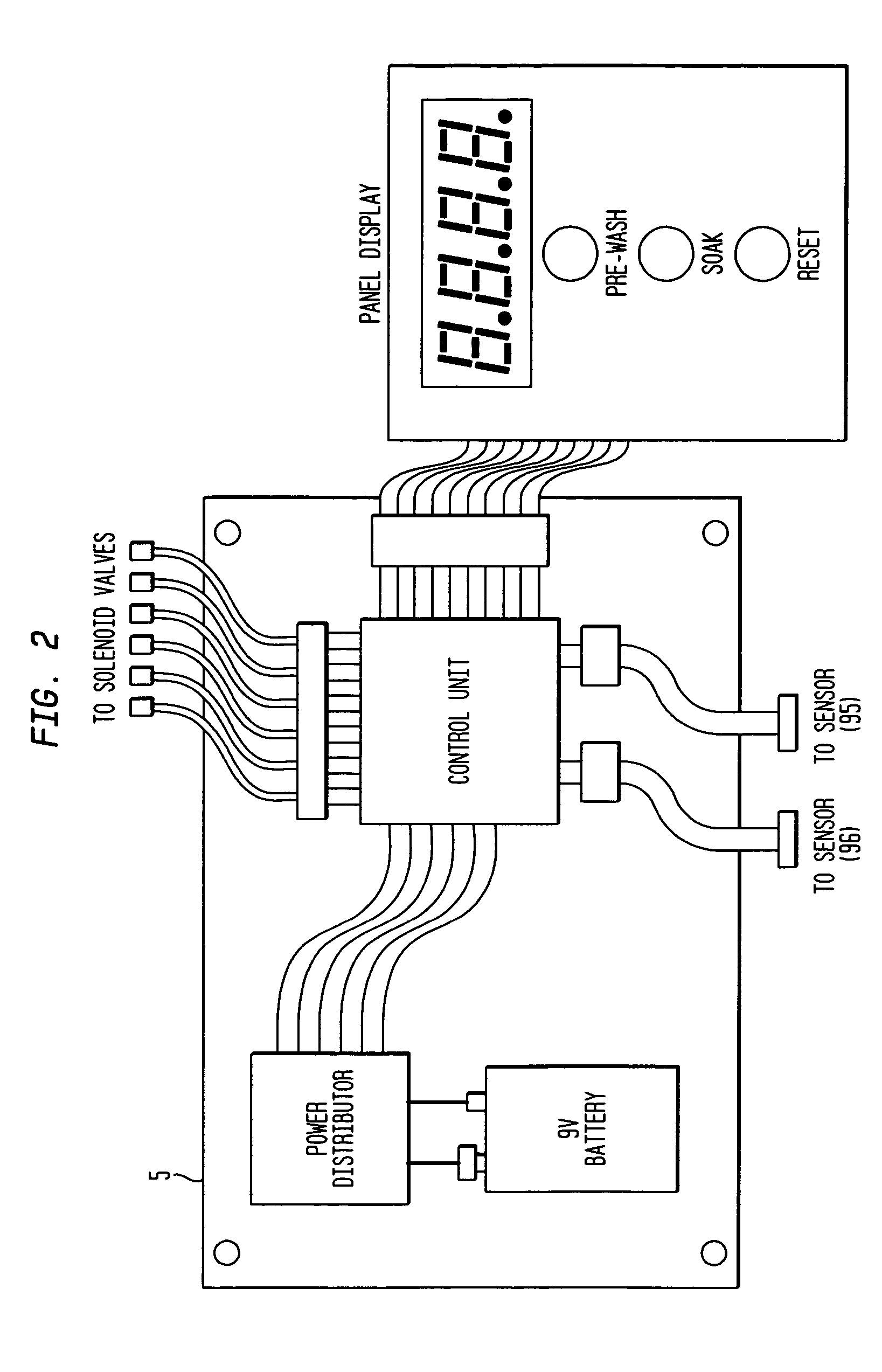

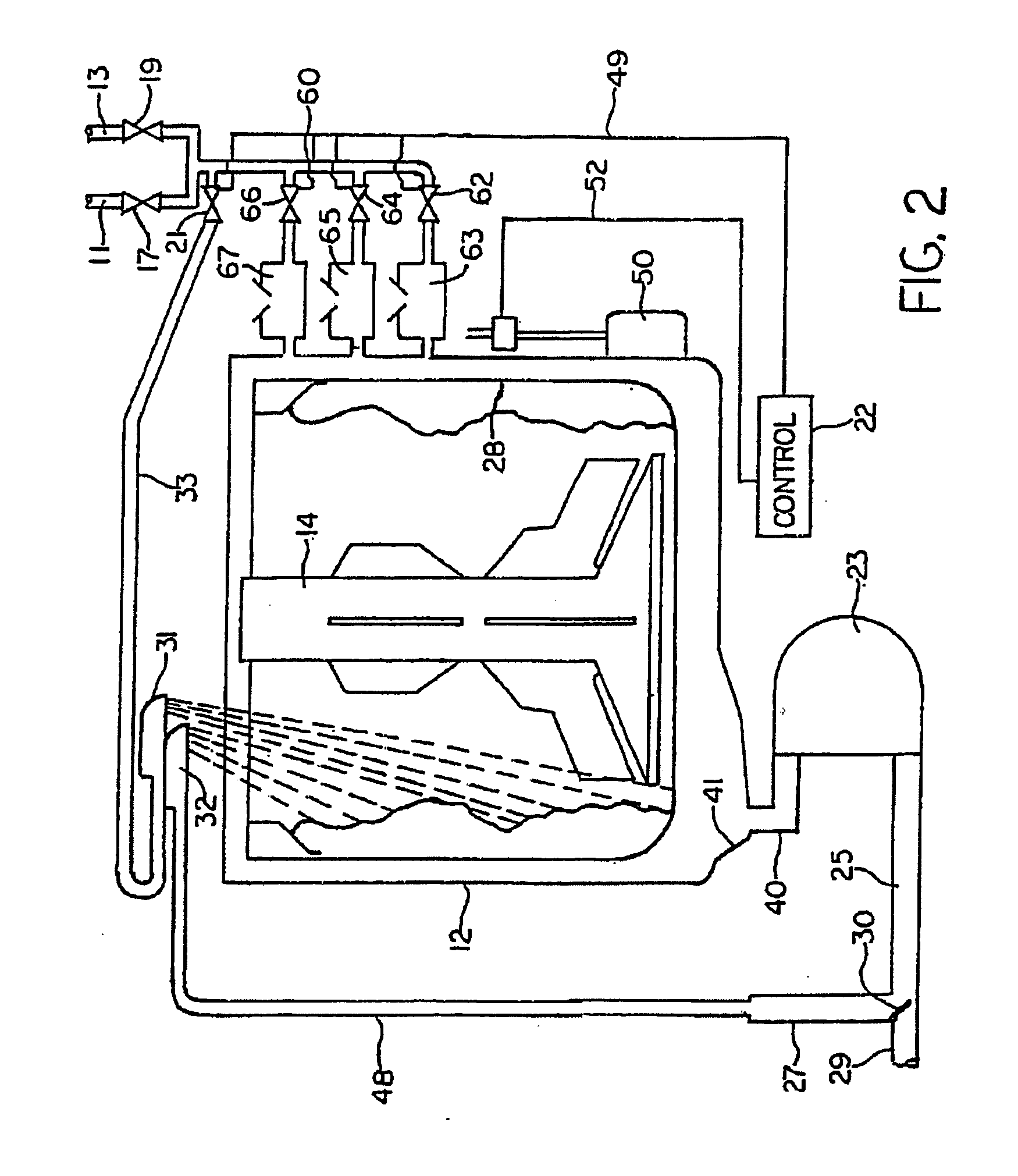

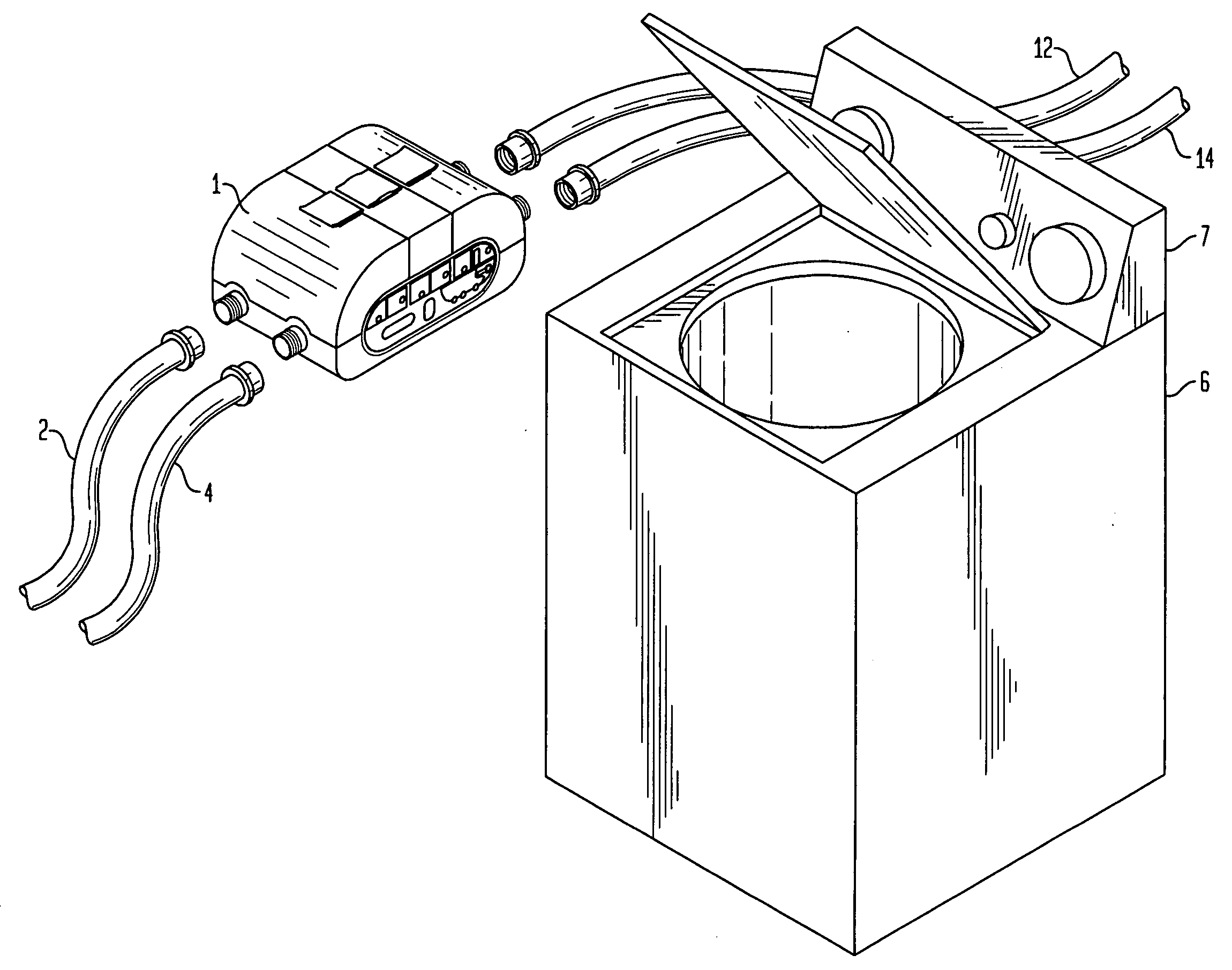

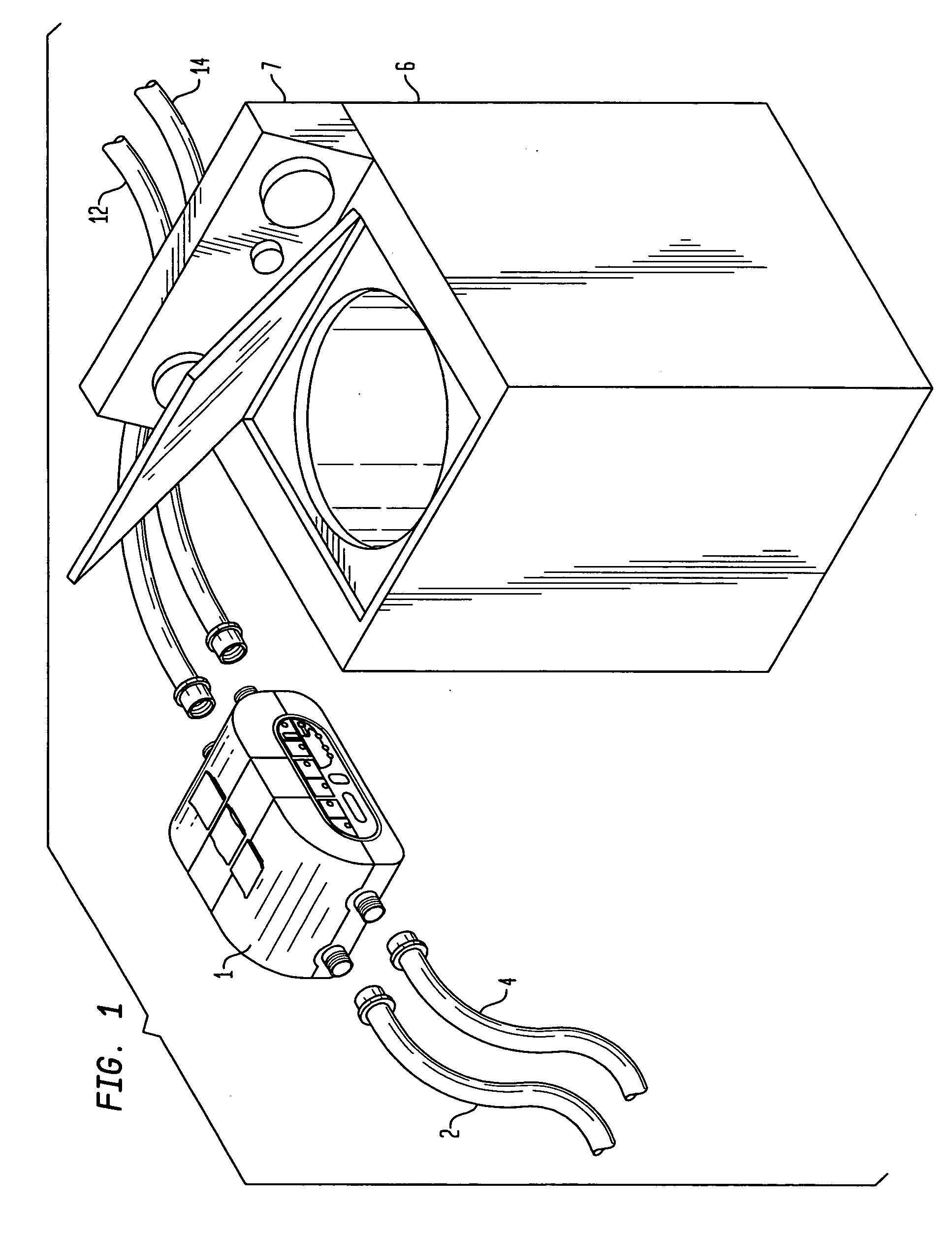

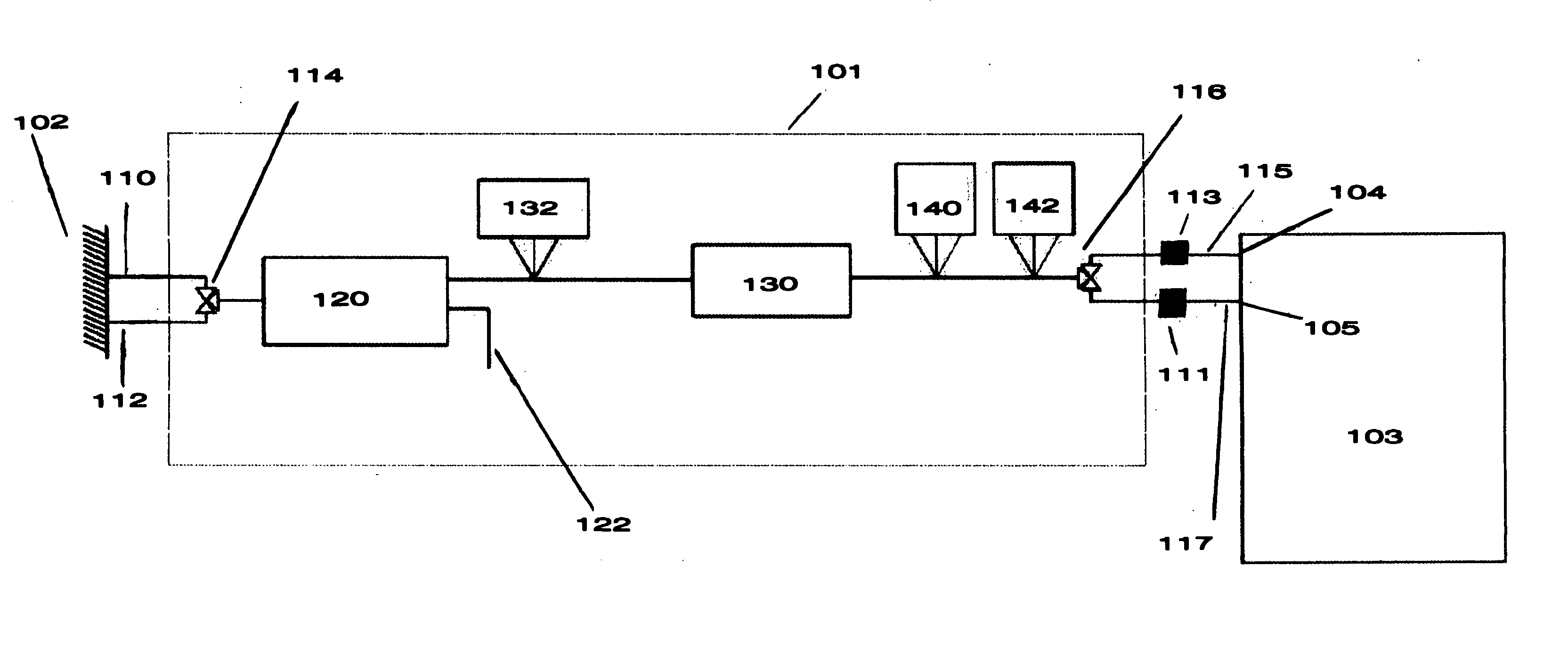

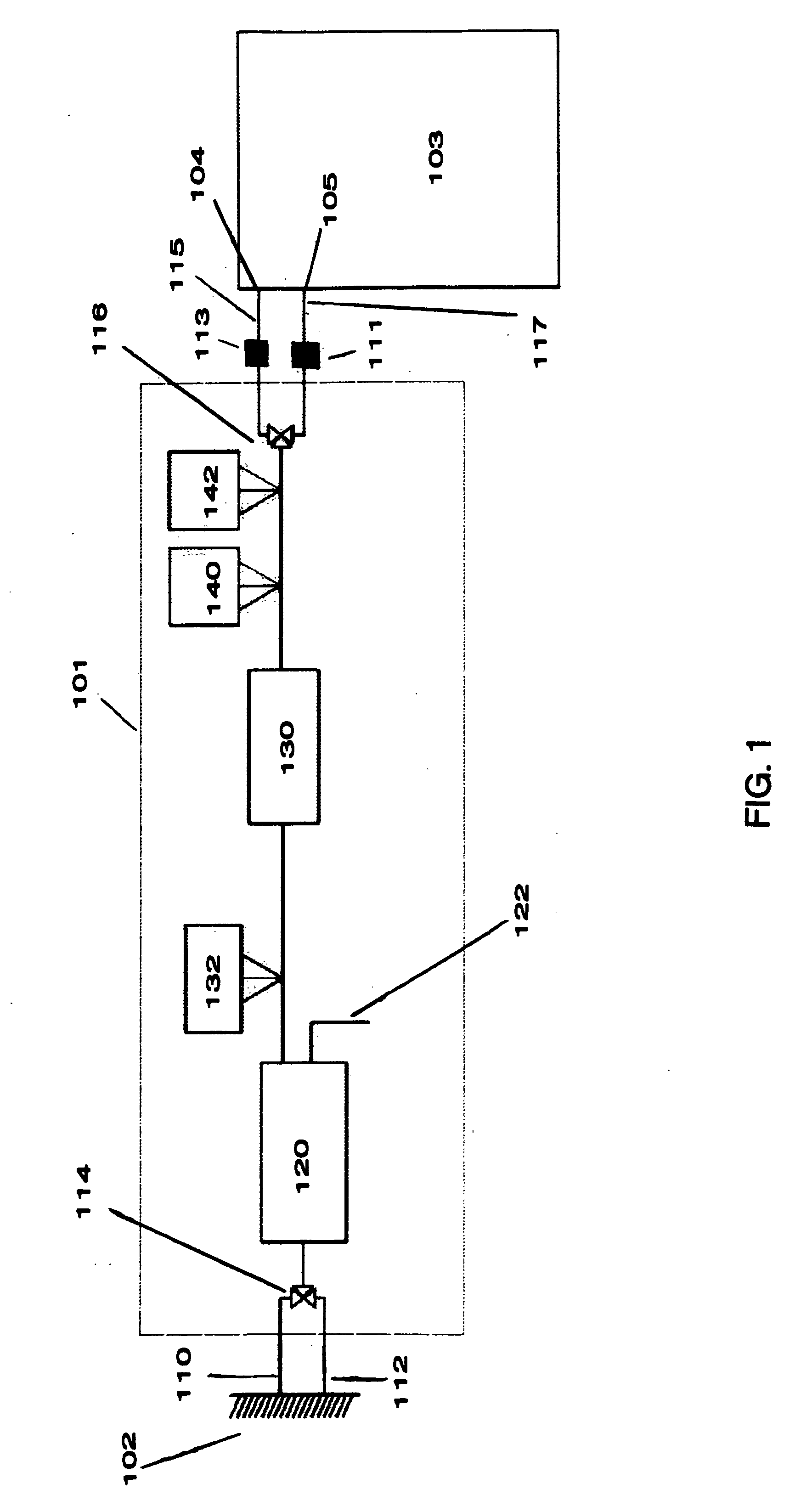

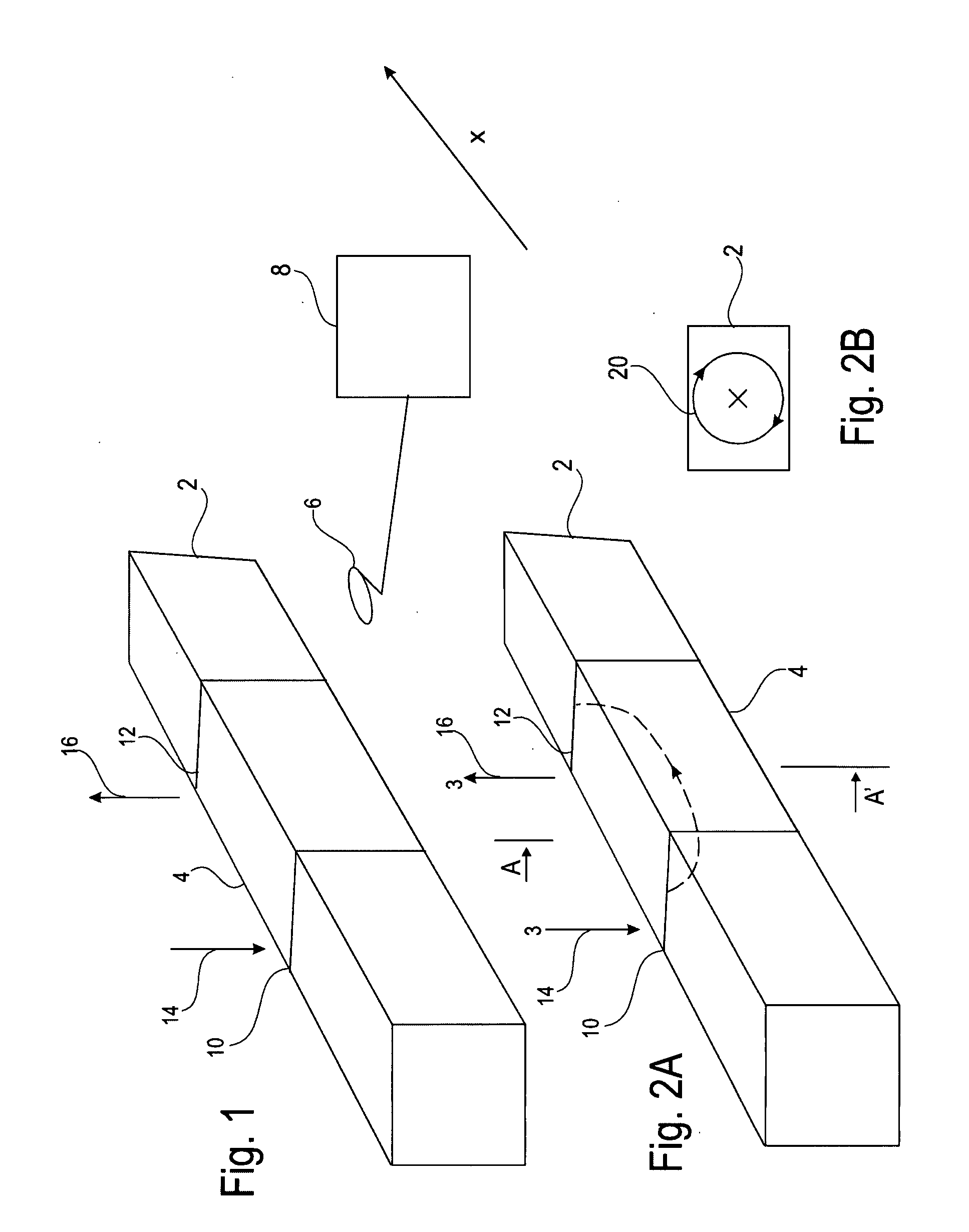

Automatic stand-alone dispensing device for laundry care composition

InactiveUS20060107705A1Other washing machinesControl devices for washing apparatusLaundry washing machineEngineering

A non-intrusive device for automatically dosing at least one liquid laundry care composition to an automatic laundry washing machine. The device employs a Venturi tube mechanism or a pump to dose the laundry detergent care composition. The dosing is controlled by a machine-generic algorithm capable of determining the actual cycle at any duration of wash for various cycle designs from various washing machines, without the input of precise cycle design; and dose the correct products correctly and is capable of distinguishing between major water addition and a water pulse.

Owner:HENKEL IP & HOLDING GMBH

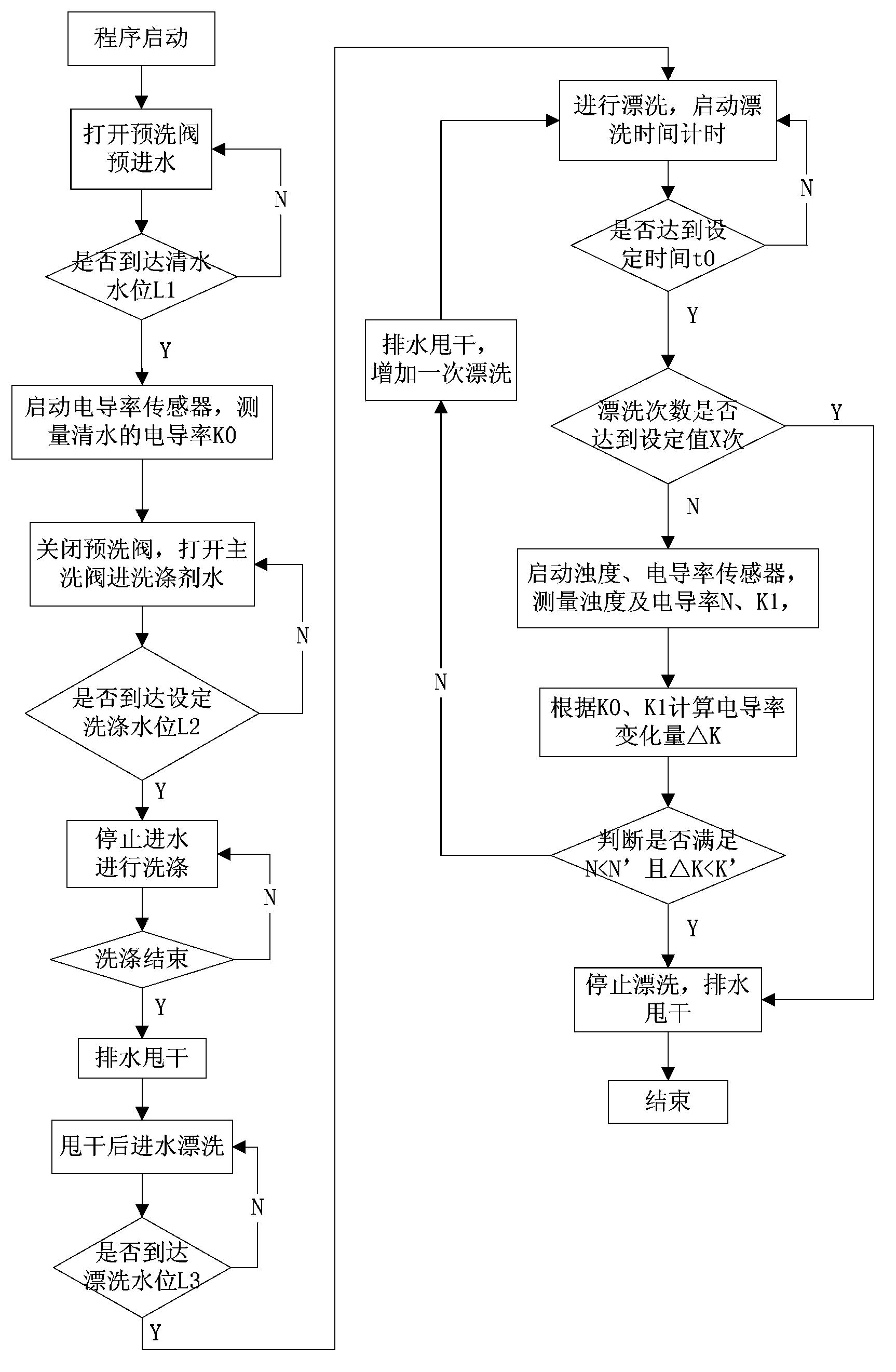

Washing machine control method and washing machine

ActiveCN104233700AExpand the scope of detectionAccurate detection and judgmentOther washing machinesControl devices for washing apparatusLaundryProcess engineering

Owner:QINGDAO HAIER WASHING MASCH CO LTD

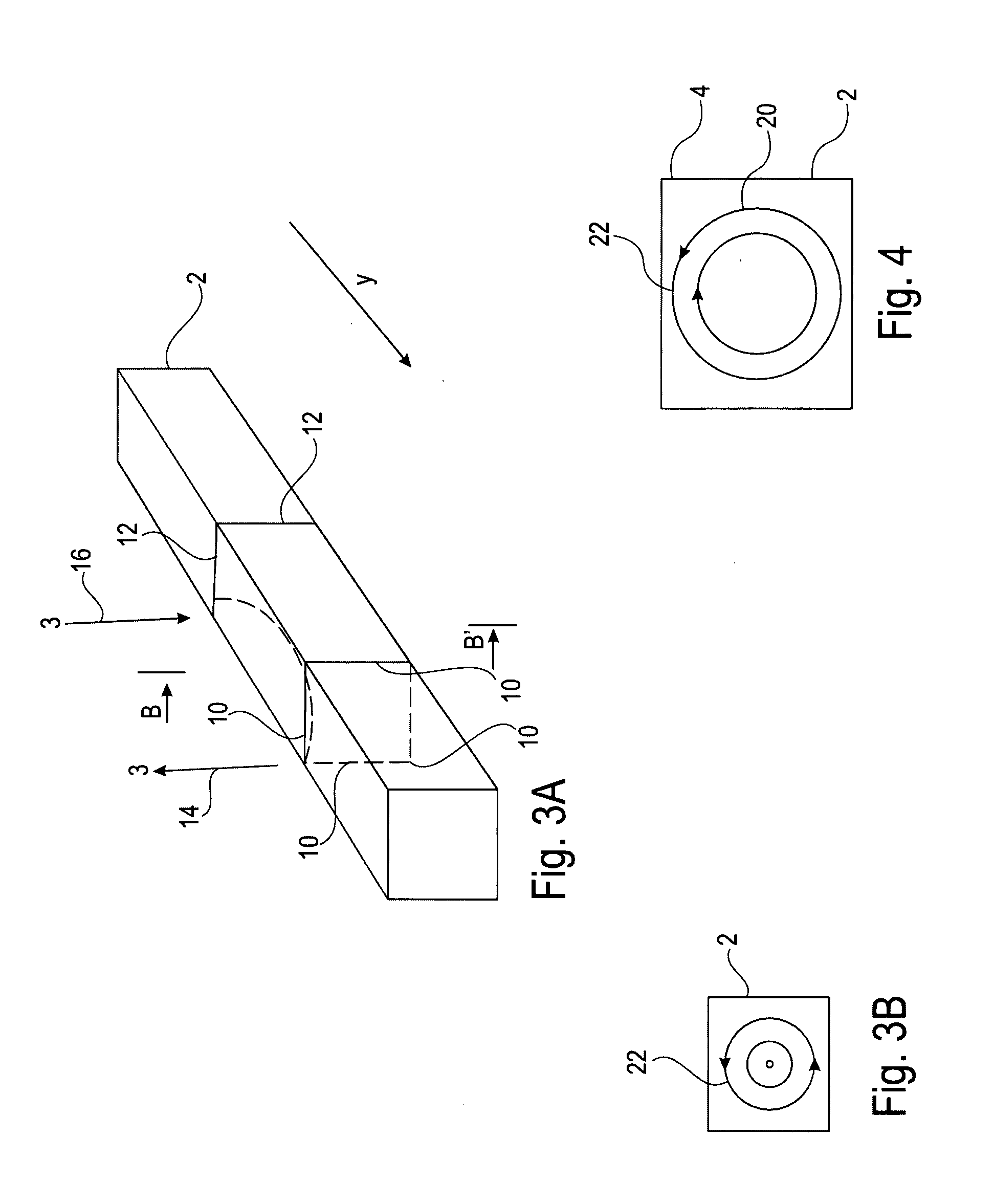

Method and apparatus for monitoring load size and load imbalance in washing machine

InactiveUS20060242768A1Vibration minimizationOther washing machinesControl devices for washing apparatusHorizontal axisEngineering

A method of determining static and dynamic imbalance conditions in a horizontal axis washing machine is disclosed. The method utilizes a number of algorithms to automatically determine the total load size, the magnitude of any static load imbalance, and the magnitude of any dynamic load imbalance for any given load in a given washing machine based on power measurements from the washing machine motor. Methods of obtaining the algorithms for the given washing machine are disclosed.

Owner:WHIRLPOOL CORP

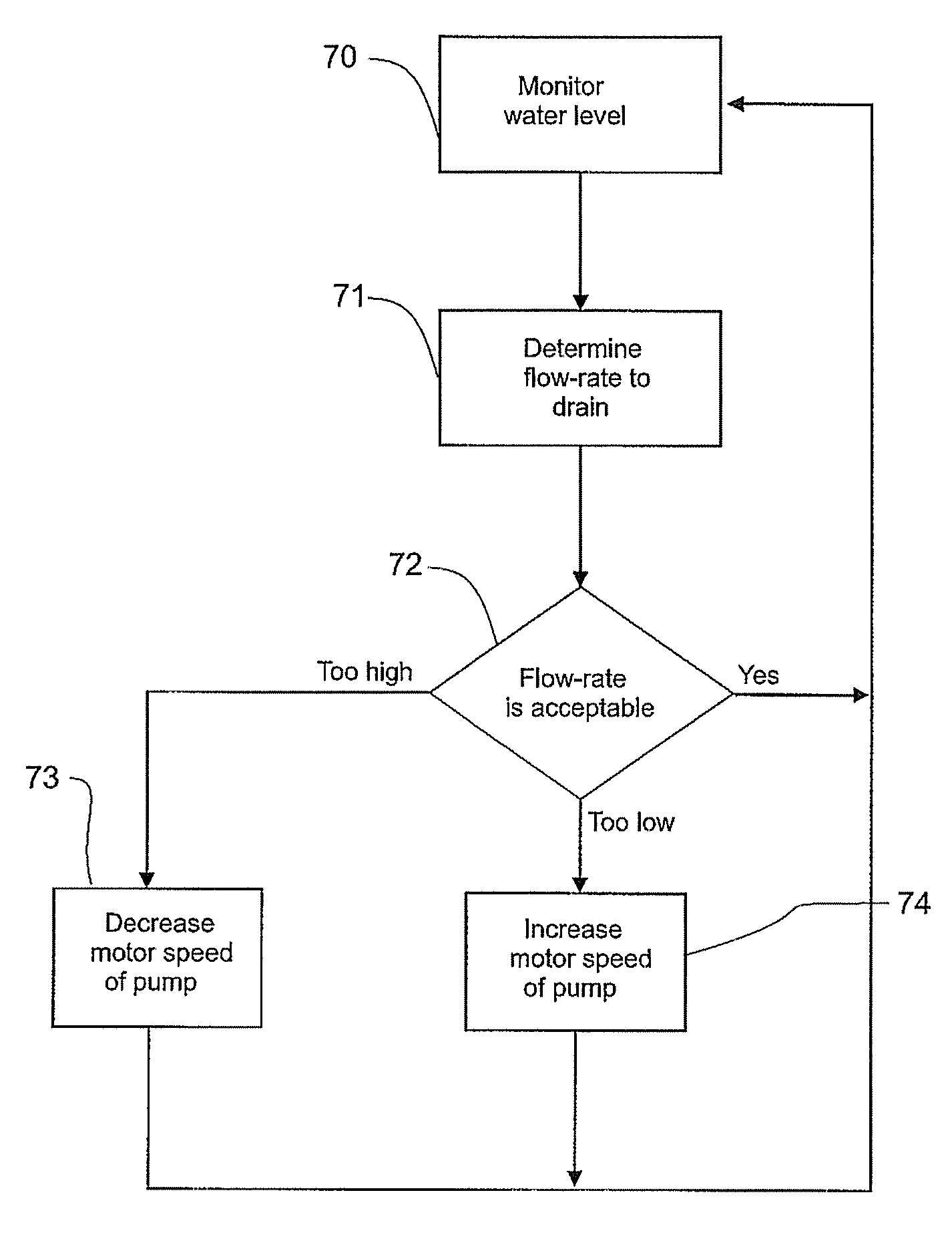

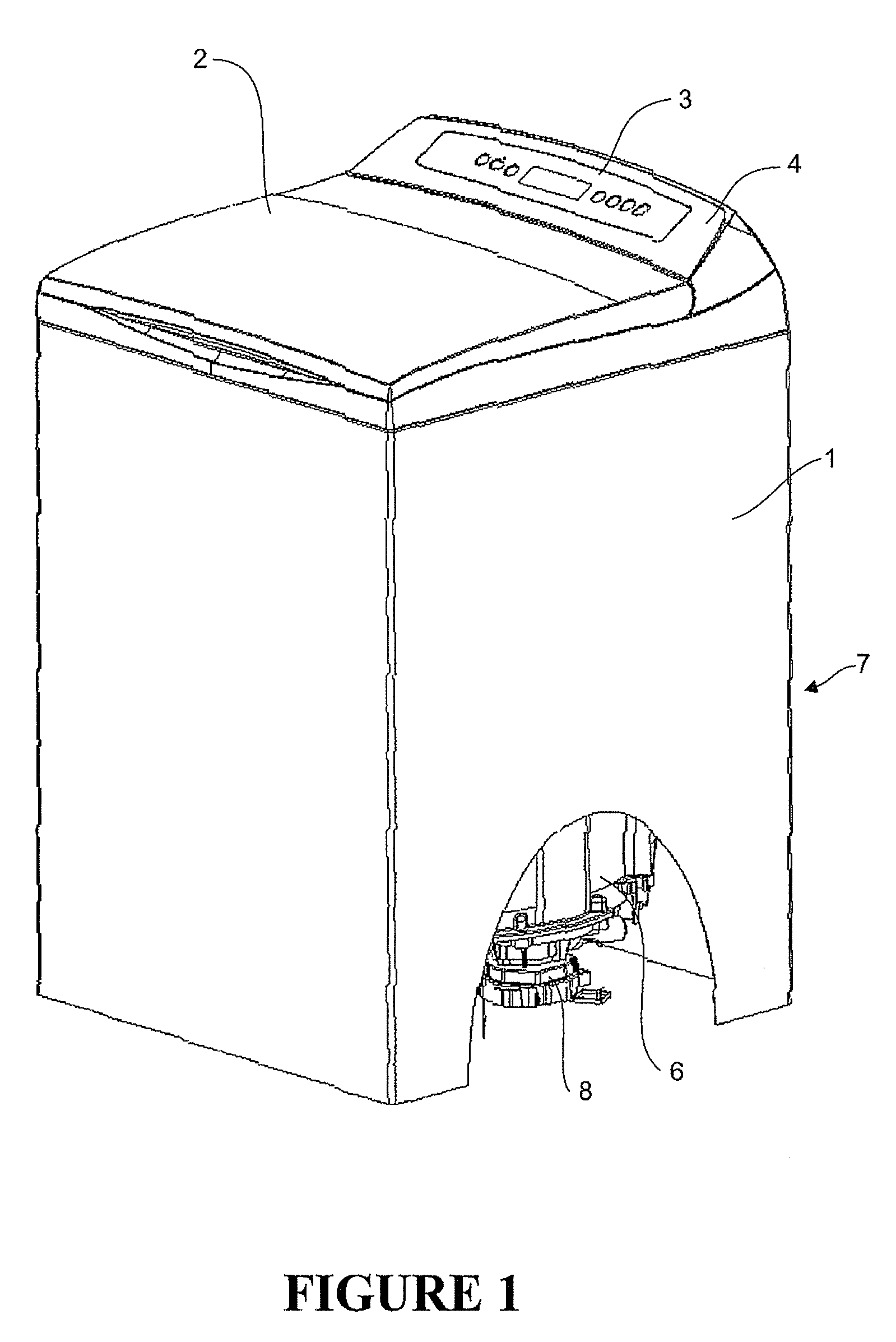

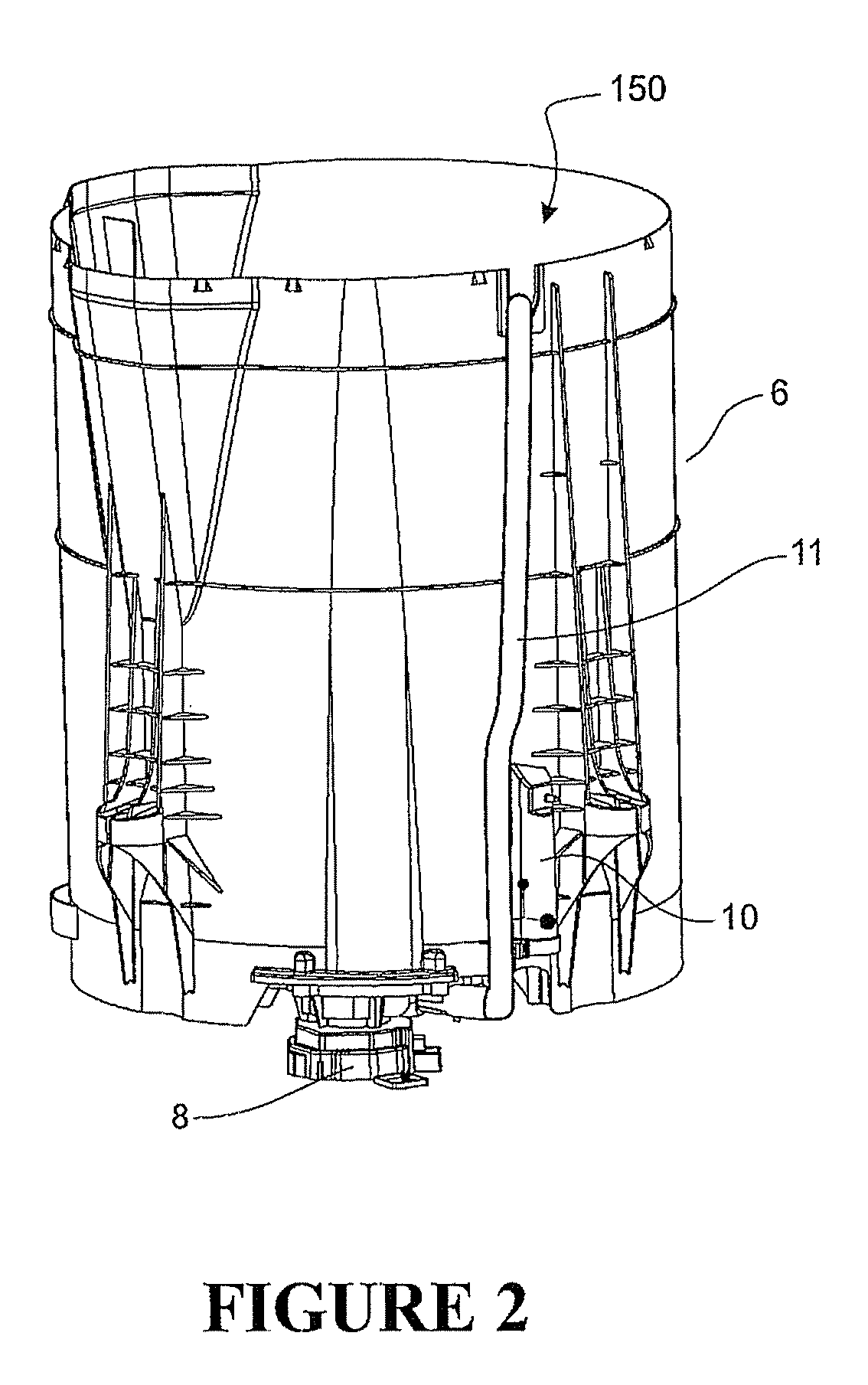

Washing machines

ActiveUS20070113595A1Increase water flowReduce stressOther washing machinesControl devices for washing apparatusWastewaterEngineering

The present invention relates to a washing machine (7) and pump (8) for a washing machine (7). The pump is driven by a brushless DC motor (38). The pump can be controlled to improve the operation of the washing machine. In one aspect the invention comprises a washing machine (7) with a variable speed pump (8) for pumping out wastewater, a controller (50) for controlling the speed of the pump and a sensor (10) for determining the flow-rate of water being pumped from the washing machine, wherein the controller (50) controls the speed of the pump to maintain the flow-rate at a desirable level.

Owner:FISHER & PAYKEL APPLIANCES LTD

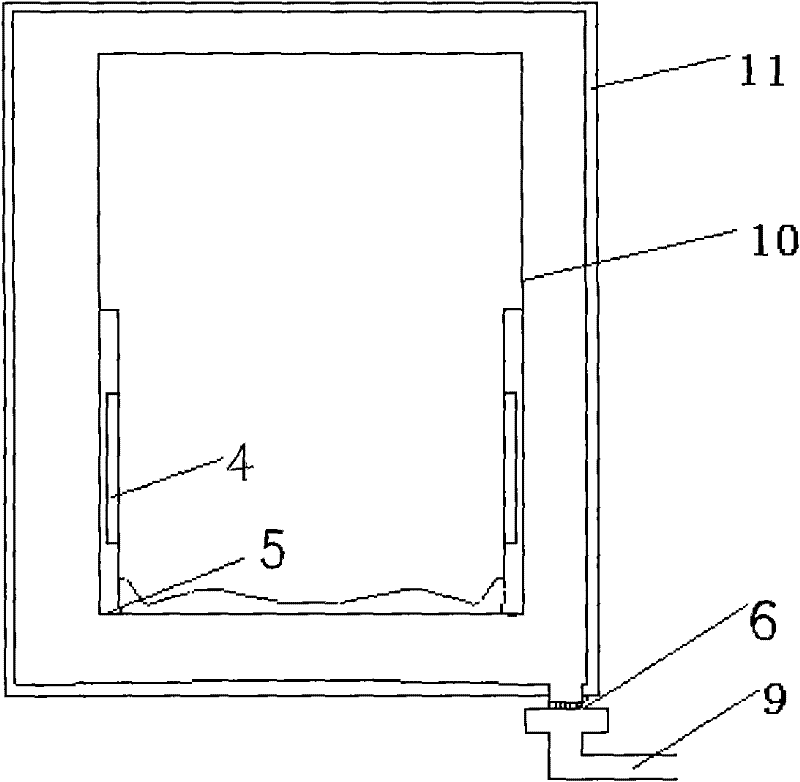

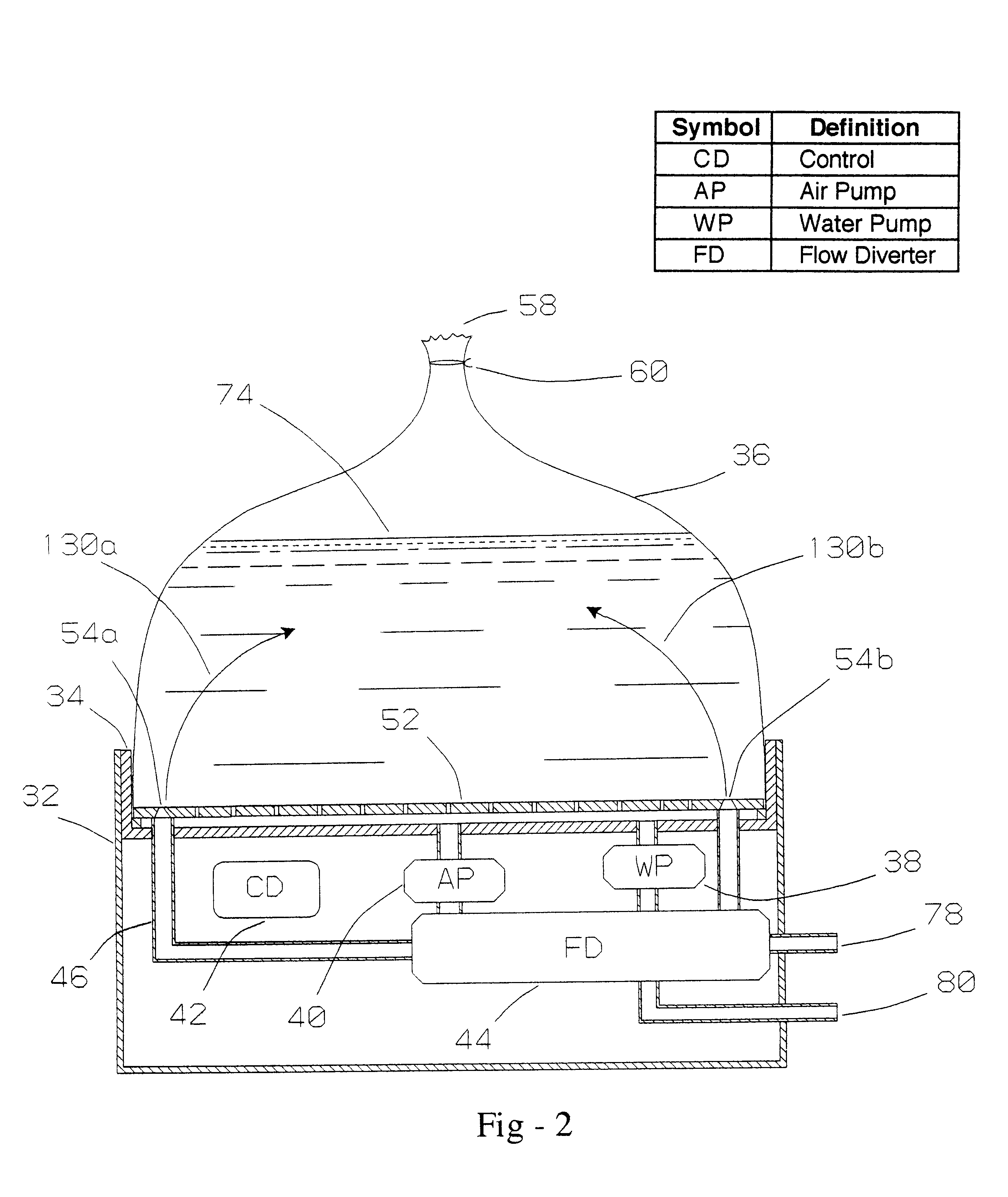

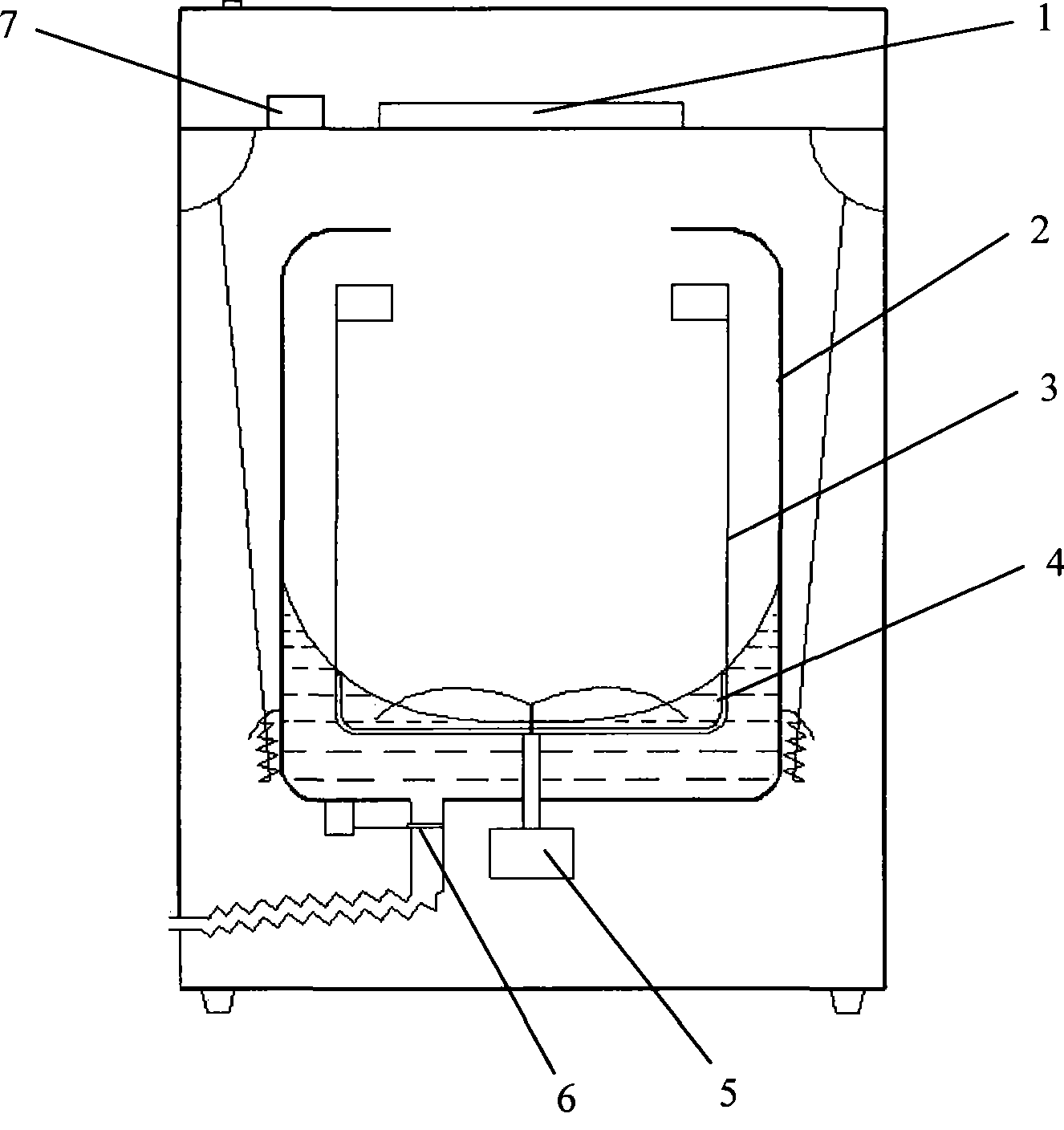

Washing apparatus and method utilizing flexible container to improve cleaning efficiency and minimize space occupancy

InactiveUS6219871B1Suitable for useSufficient capabilityOther washing machinesWashing machine with receptaclesCavitationLaundry washing machine

An automatic laundry washing machine that is suitable for use in living units having no area set aside for laundry facilities is achieved by replacing the heavy bulky parts of the currently popular automatic washing machine design with a light flexible bag. A large portion of the volume of any washing machine is the vessel for containing the laundry solution and articles to be washed. That vessel is a flexible bag made of modern durable material so as to be collapsible both while in use and for storage. The method of use includes the complete process of washing, rinsing, and extracting excess water in an automatic cycle analogous to standard automatic washing machines popular today. The vessel containing the items being laundered is a waterproof laundry bag with automatic washing apparatus attached. Items are automatically washed in that bag. The automatic process includes cycles of filling, washing, rinsing and extracting such that the clothes are ready for a drying process such as hanging out to dry or putting into a tumble dryer. The agitating of the washing and rinsing cycles is accomplished without the familiar bulky agitator thereby reducing the volume requirements and the traditional wear and tear on the garments. By eliminating the bulky agitator and the spin water extraction method, the heavy transmission is also eliminated. The water extraction cycle is done in a much less violent way than the conventional spin cycle by allowing atmospheric pressure to collapse the washing vessel and press the water from the articles as the water and air are pumped from the vessel in the draining portion of the cycle. The cleaning ability of the water is enhanced by built in ionic processing of the water thereby reducing the required amount of laundry detergent. The agitating in the non-electrically conductive vessel generates static electric charges in the process and ions thus produced further enhance the cleaning ability of the water. Cavitation produced in a multi-frequency washing action further enhances the washing ability of the water. The washing machine is light, compact and collapsible and is as portable as a piece of luggage. The set up procedure is simple and no assembly is required beyond attaching a quick connect fastener to a water faucet and plugging in a power cord. The washing machine is light and takes little storage space. It can be put in a small closet or on a shelf when not in use. The minimum capacity of the washing machine is a single garment. The normal capacity of the washing machine is comparable to that of a standard household washing machine.

Owner:FREDERICK MAX B +2

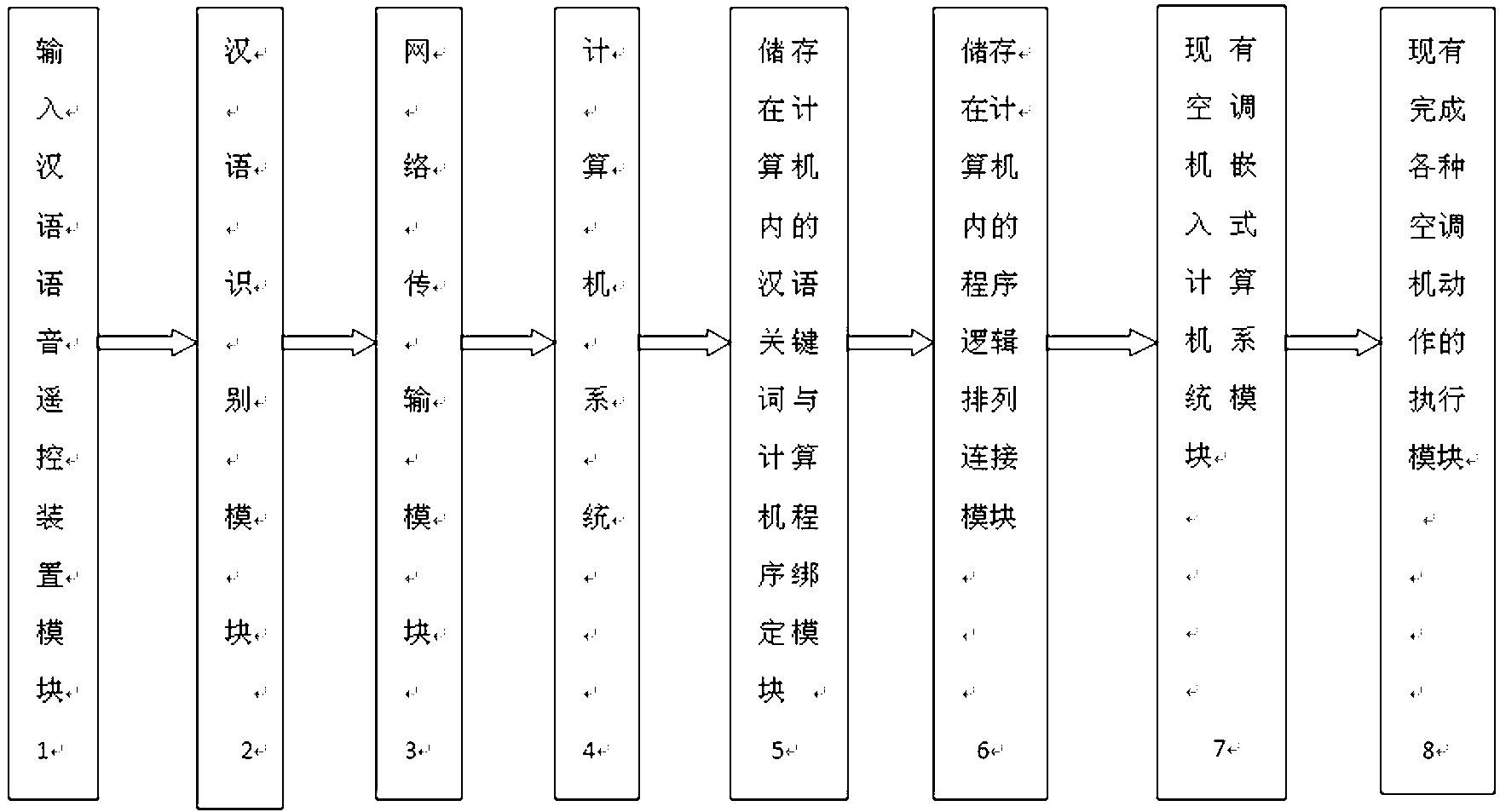

Device for nonspecific persons to remotely control intelligent air conditioner by Chinese speech

InactiveCN103277874ASpace heating and ventilation safety systemsLighting and heating apparatusSmart applianceSpeech sound

The invention relates to a device for nonspecific persons to remotely control an intelligent air conditioner by Chinese speech and belongs to the technical field of intelligent electrical appliances. The technical scheme is that the device comprises an input Chinese speech remote control device module 1, a Chinese speech recognition module 2, a network transmission module 3, a computer system 4, a computer program module 5 pre-stored in the computer system 4 and bound with input Chinese speech codes or keywords in Chinese characters, a module 6 for arranging and being connected with bound programs according to an executed successive logic sequence, an existing intelligent air conditioner embedded computer system module 7 and an existing execution module 8 for finishing various movements of the intelligent air conditioner, wherein the input Chinese speech remote control device module 1, the Chinese speech recognition module 2, the network transmission module 3, the computer system 4, the computer program module 5, the module 6, the existing intelligent air conditioner embedded computer system module 7 and the execution module 8 are sequentially connected with each other according to an order of a computer for processing information and work. Due to the technical scheme, people can conveniently use various remote control devices in non-real time off site by the Chinese speech to control an intelligent washing machine to work.

Owner:江苏华音信息科技有限公司

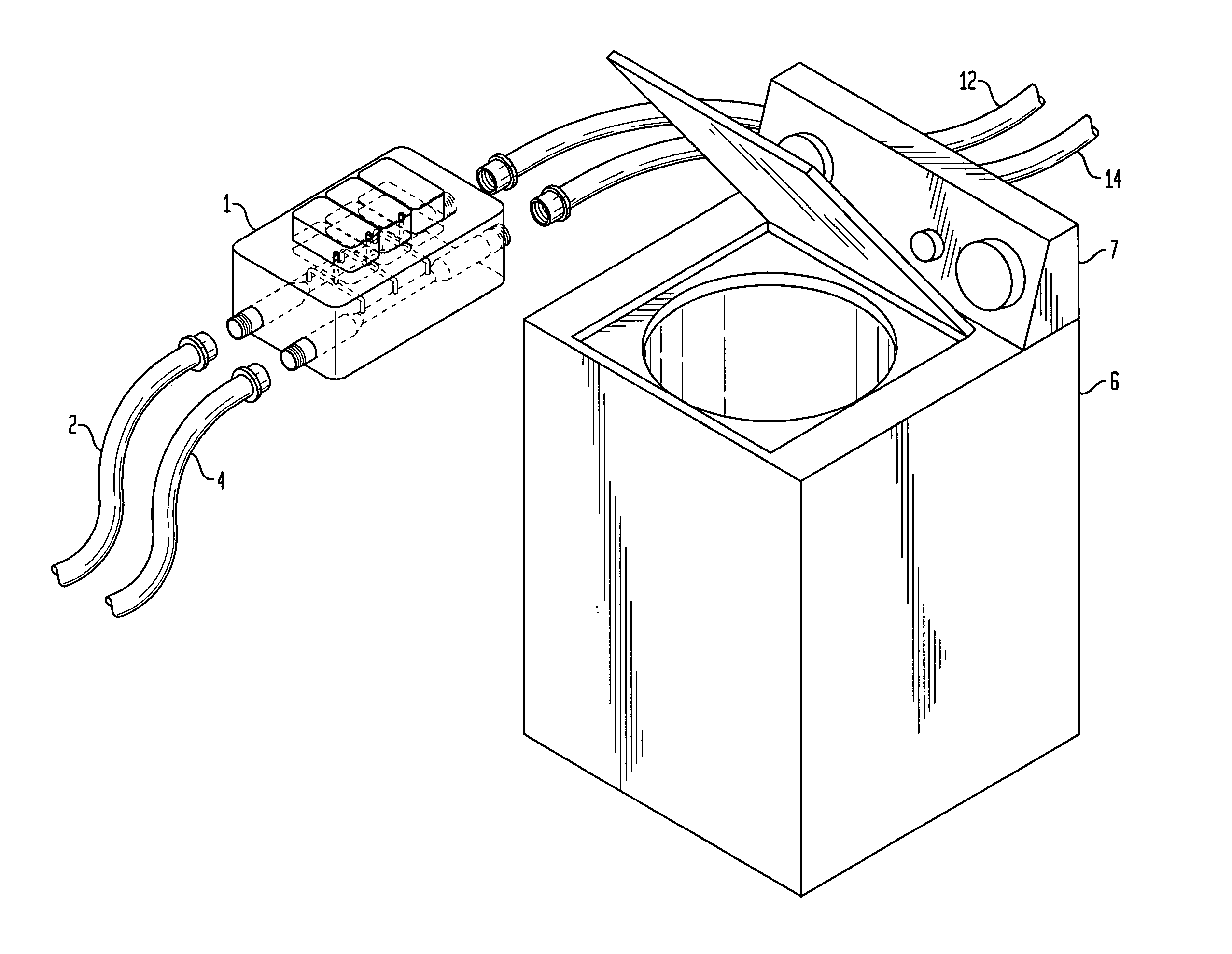

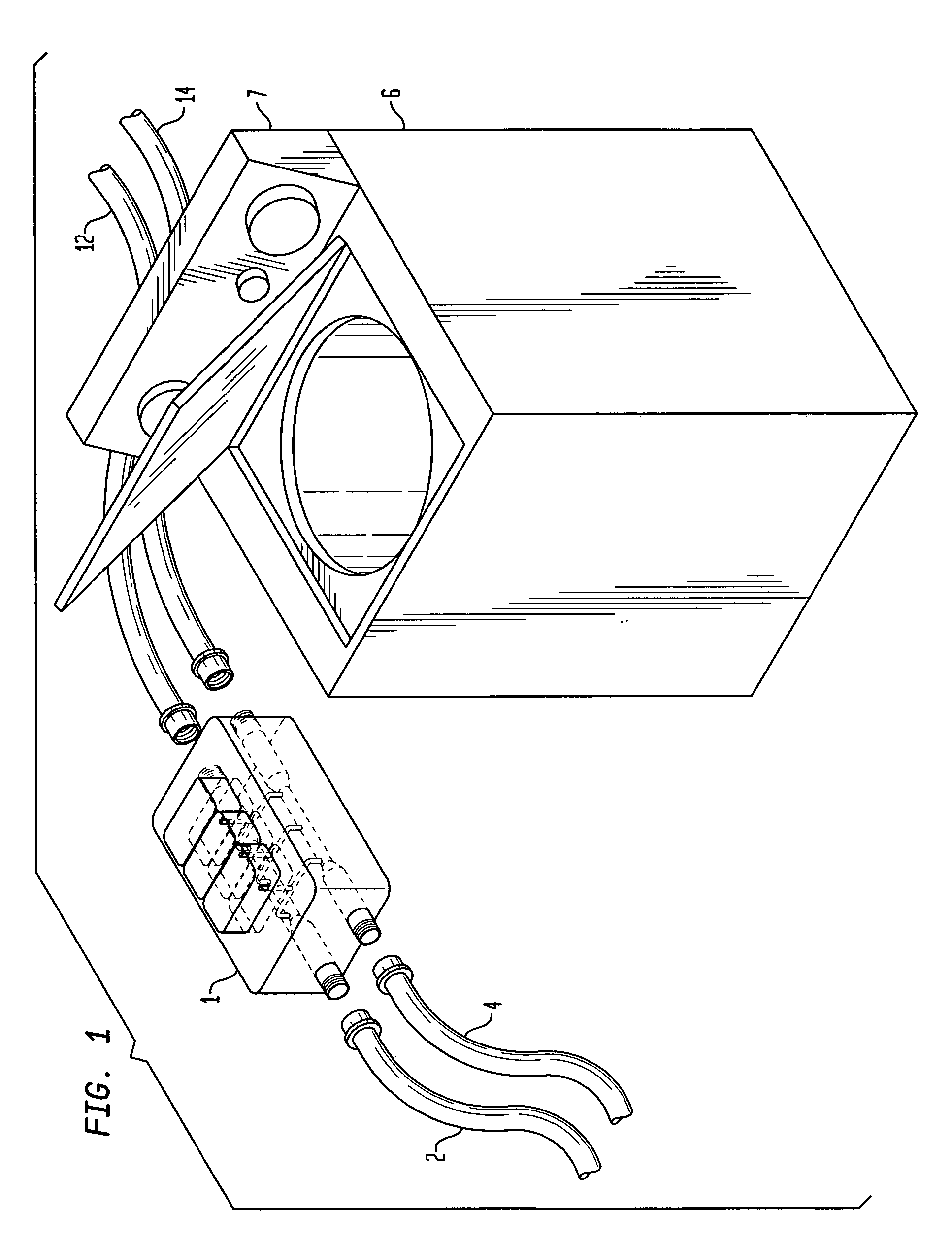

Automatic dispensing device for laundry care composition

InactiveUS20060081016A1Other washing machinesControl devices for washing apparatusLaundry washing machineEngineering

A non-intrusive device for automatically dosing at least one liquid laundry care composition to an automatic laundry washing machine. The device employs a Venturi tube mechanism or a pump to dose the laundry detergent care composition. The dosing is controlled by a machine-generic algorithm capable of determining the actual cycle at any duration of wash for various cycle designs from various washing machines, without the input of precise cycle design; and dose the correct products correctly and is capable of distinguishing between major water addition and a water pulse.

Owner:HENKEL IP & HOLDING GMBH

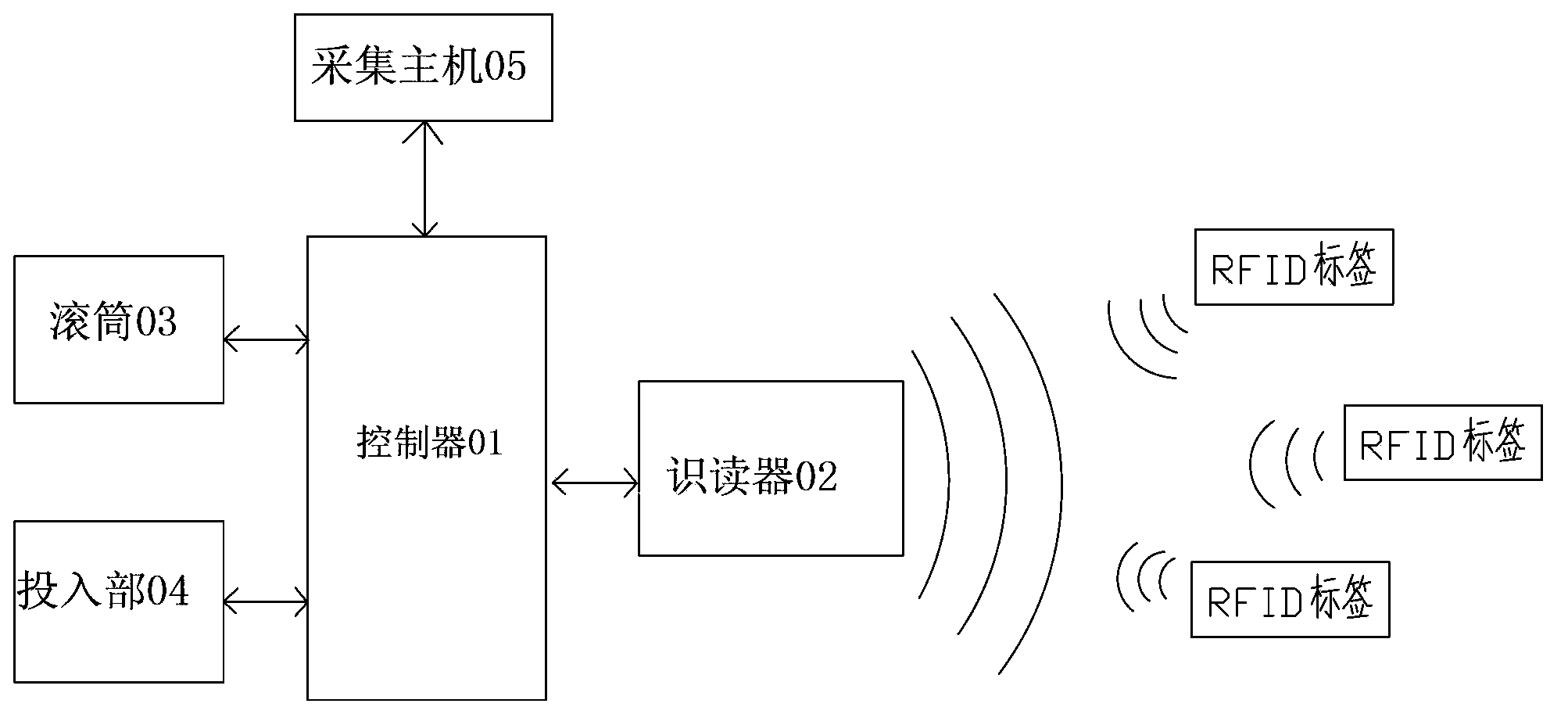

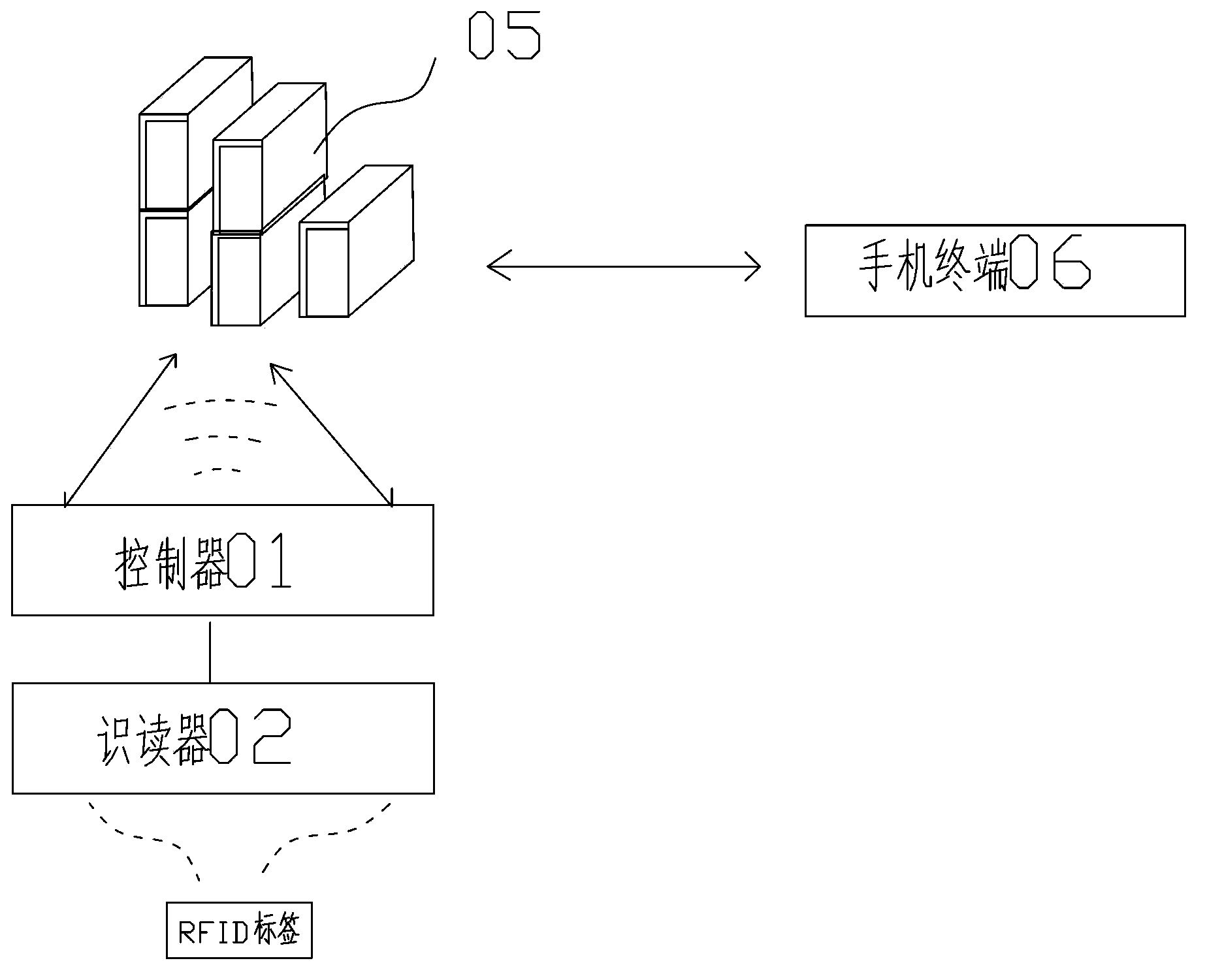

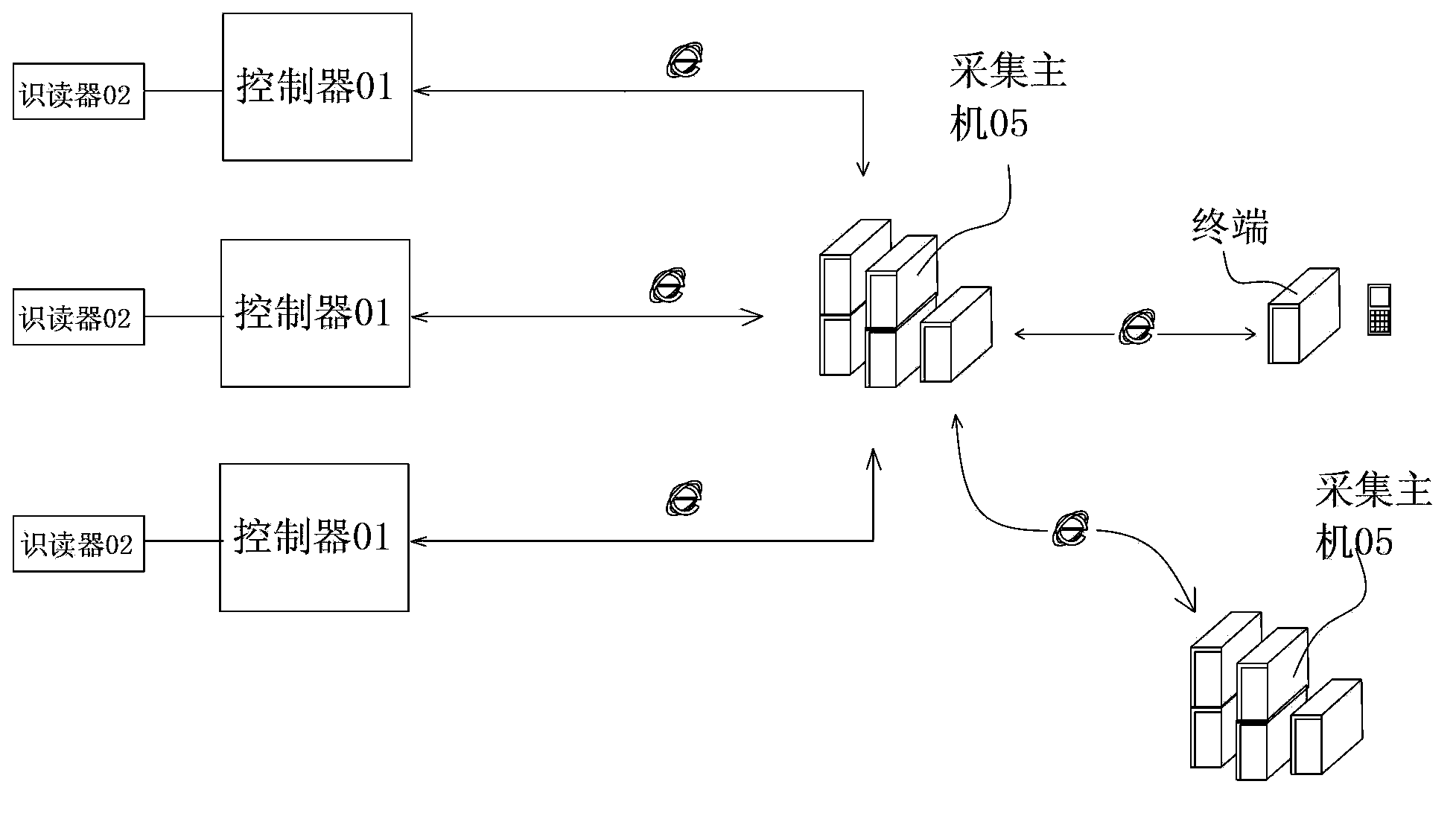

Washing machine based on RFID technology and clothes washing information collecting system

ActiveCN103726262AAvoid cross-colorAverage wearing frequencyControl devices for washing apparatusCo-operative working arrangementsRadio frequencyWork status

The invention discloses a washing machine based on the RFID technology and a clothes washing information collecting system. The washing machine comprises a recognizer and a controller. The recognizer is used for reading clothes information from an RFID tag of clothes, and the clothes information is stored in the RFID tag and comprises the unique code of the clothes. The controller is used for recording the clothes information read by the recognizer. The number of times of washing the clothes is recorded through a counting unit inside the controller, compensation is made for a control stroke according to the number of times of washing the clothes, and the controller is used for controlling the working states of driving parts through the compensated stroke. The clothes washing information collecting system based on the washing machine comprises a collecting main machine which is connected with the controller in a wired or wireless mode, the controller is used for sending the information of the number of times of washing the different clothes to the collecting main machine, and the collecting main machine is used for obtaining clothes using tendency data, personal clothes loving data and / or clothes matching data according to the number of times of washing the different clothes.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG +1

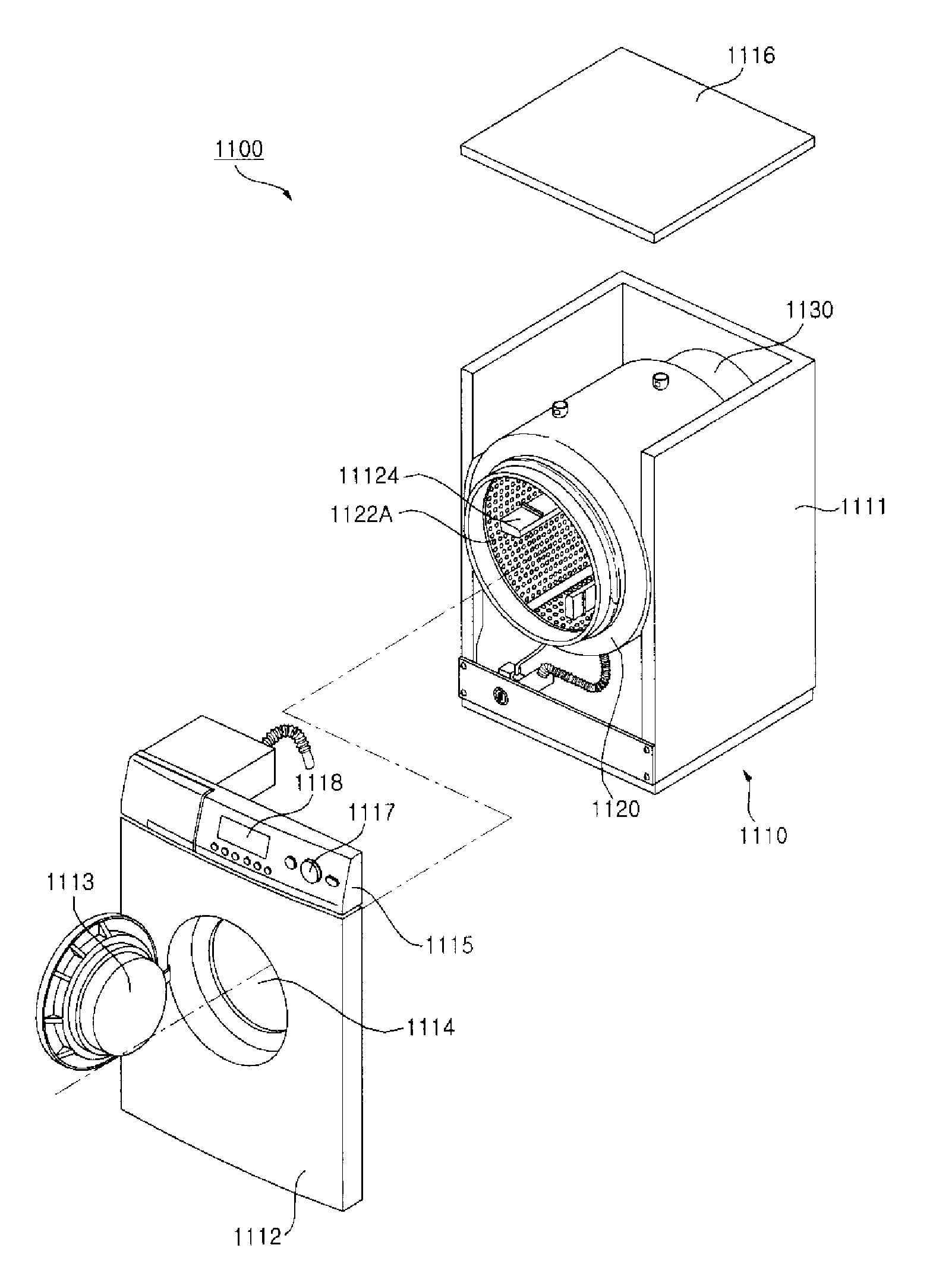

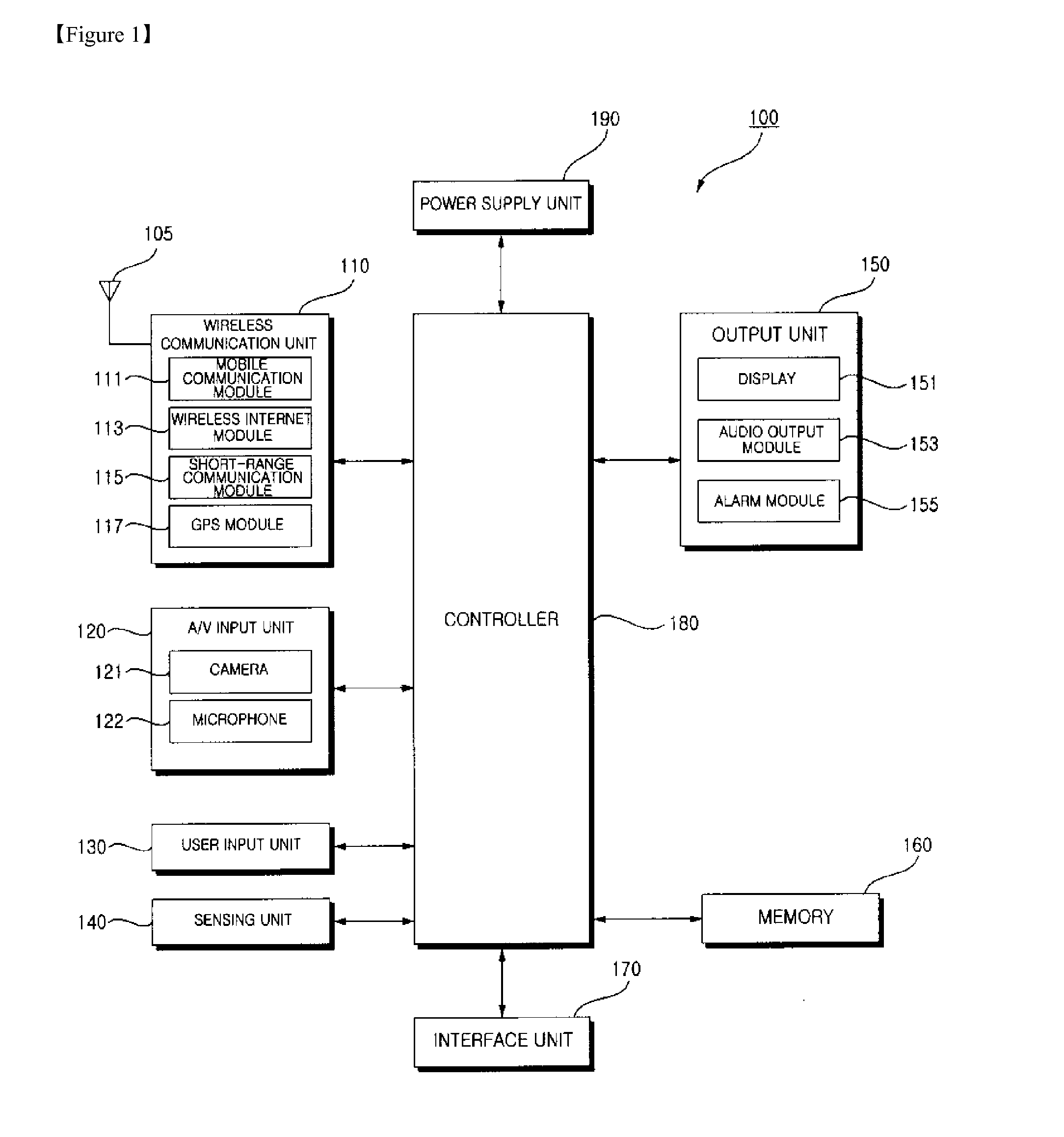

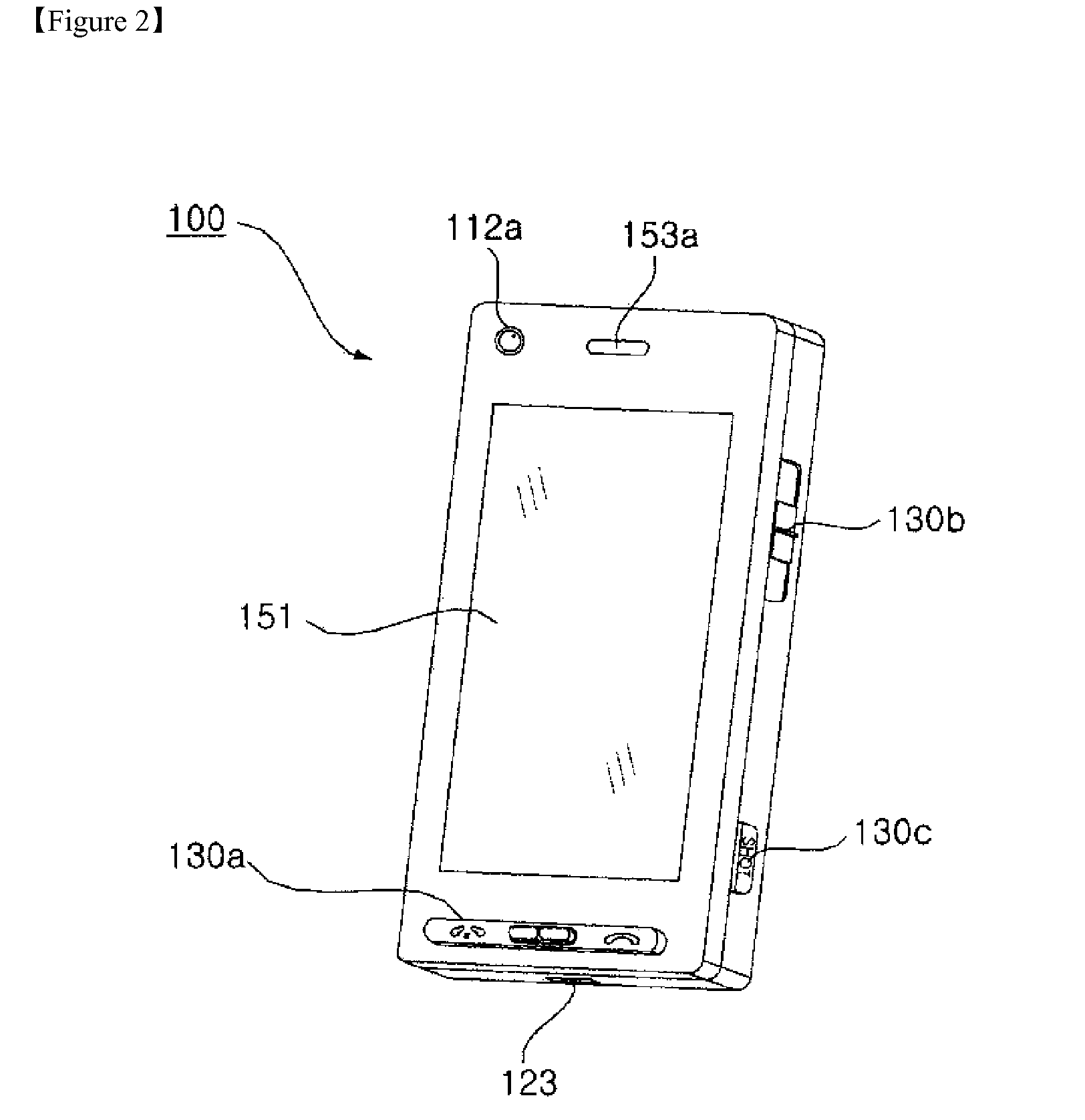

Mobile Terminal Controlling Washing Machine, Method Of Operating The Mobile Terminal, Washing Machine, And Method Of Operating The Washing Machine

ActiveUS20120110747A1Washing controlling processesOther washing machinesProcess engineeringTerminal operation

The present invention relates to a mobile terminal capable of displaying recommended washing machine operation information to control a washing machine, a method of operating the mobile terminal, a washing machine capable of operating the recommended washing machine operation information, and a method of operating the washing machine.The method of operating the mobile terminal to control a washing machine includes displaying a menu screen including a washing machine management menu, and displaying recommended washing machine operation information which is set according to external environment information when a recommended operation item is selected from the washing machine management menu. Thus since the recommended washing machine operation information is displayed using the mobile terminal according to external conditions such as weather, time, and season irrespective of time and place, convenience is provided.

Owner:LG ELECTRONICS INC

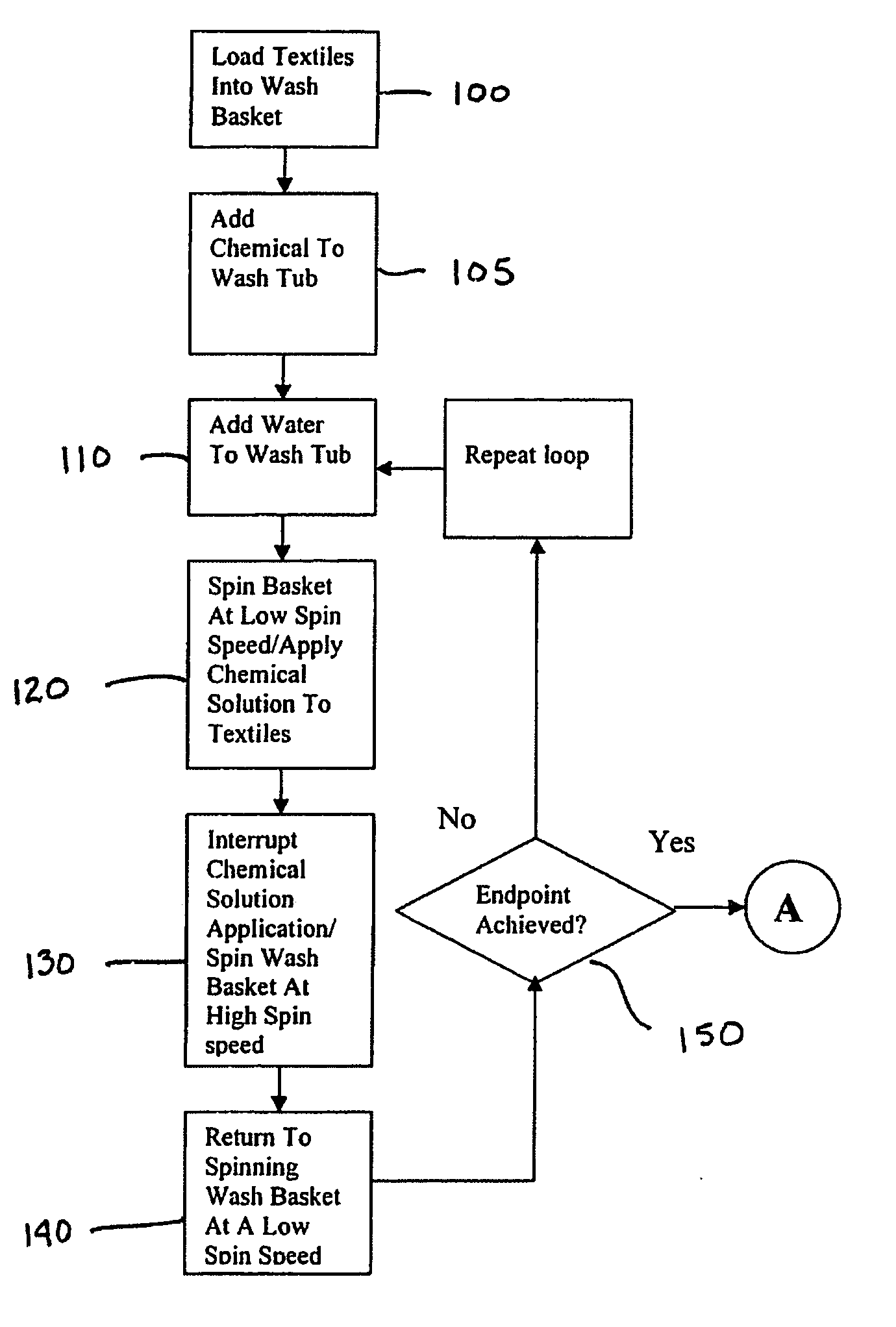

Stain removal process using combination of low and high speed spin

An improved method for treating textiles such as clothing with a concentrated solutions in an automatic washer by alternating the speed of rotation of the automatic washer wash basket from a low spin speed to a high spin speed and applying the concentrated solution to the textiles when the wash basket is spinning at the low spin speed.

Owner:WHIRLPOOL CORP

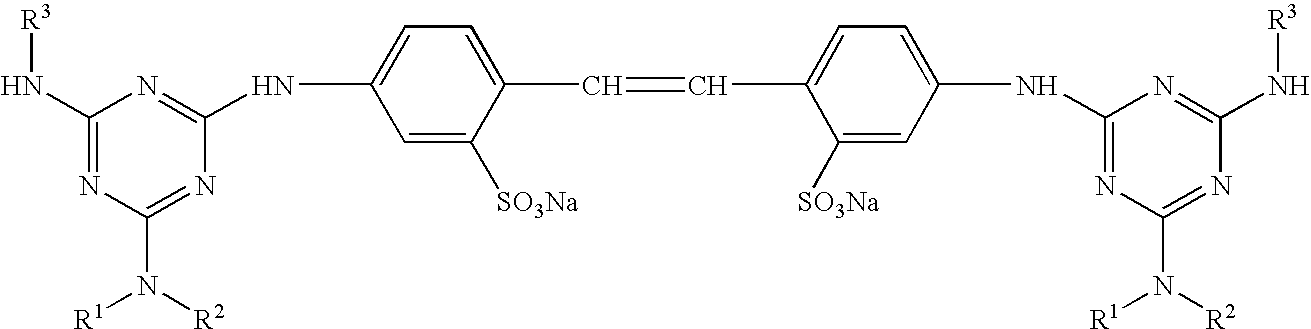

Fabric treatment for stain release

InactiveUS20050204477A1Extended service lifeImprove the protective effectOrganic detergent compounding agentsPhysical treatmentWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Particularly preferred compositions include at least one zeta potential modifier in an amount sufficient to adjust the zeta potential of the composition to be positive and greater than zero millivolts. Particularly preferred compositions also include a fluoropolymer. The composition can be used as a pretreatment prior to washing, through soaking or direct spray application, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, or used prior to or during the drying cycle of an automatic drying machine or refresher machine, or used prior to or in conjunction with an ironing device. The fabric treatment is complete when the fabric is cured by drying and / or heating.

Owner:VAN BUSKIRK GREGORY

Warewashing system containing low levels of surfactant

ActiveUS20070017553A1Reduce thicknessFast dryingTableware washing/rinsing machine detailsSurface-active detergent compositionsOrganic chemistrySURFACTANT BLEND

A method of washing ware in an automatic institutional warewashing machine, using a cleaning composition containing a surfactant which eliminates the need for a surfactant in the rinse step. A surfactant is employed in the wash step in an amount not to exceed 15 wt % based on weight of the detergent. The amount of surfactant is sufficient to provide a layer of surfactant on the ware so as to afford a sheeting action in an aqueous rinse step without any added rinse agent.

Owner:JOHNSONDIVERSEY INC

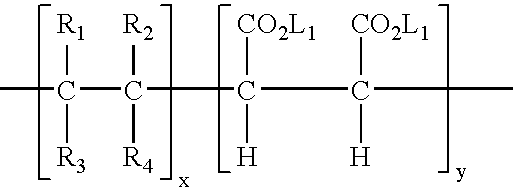

Laundry pre-treatment or pre-spotting compositions used to improve aqueous laundry processing

InactiveUS6204233B1Good water solubilitySubstantial thickening capacityOrganic detergent compounding agentsSurface-active detergent compositionsEthylene oxidePre treatment

The ability of aqueous laundry compositions to remove organic hydrophobic soils, such as oily, greasy or particulate soils, from a laundry item is substantially improved by pre-spotting or pre-treating such a soiled item with a treatment composition having a surfactant comprising a unique hydrophillic ethoxylate surfactant with less than two moles of ethylene oxide or a or blend of at least two surfactant compositions with a blended HLB value of about 7-12. The blend of surfactants with this HLB value penetrates soils and renders the soil more easily removed from the item using aqueous laundry detergent. The treatment composition can be used in a liquid or solid form and can be applied to individual laundry items in the form of a solid stick or liquid spray prior to introduction to the laundry machine. Laundry items can also be contacted in the laundry machine with the pre-spot or pre-treatment composition in the form of an aqueous presoak, preflush, prewash, or other step prior to the cleaning step. A preferred laundry machine comprises an institutional tunnel washer.

Owner:ECOLAB USA INC

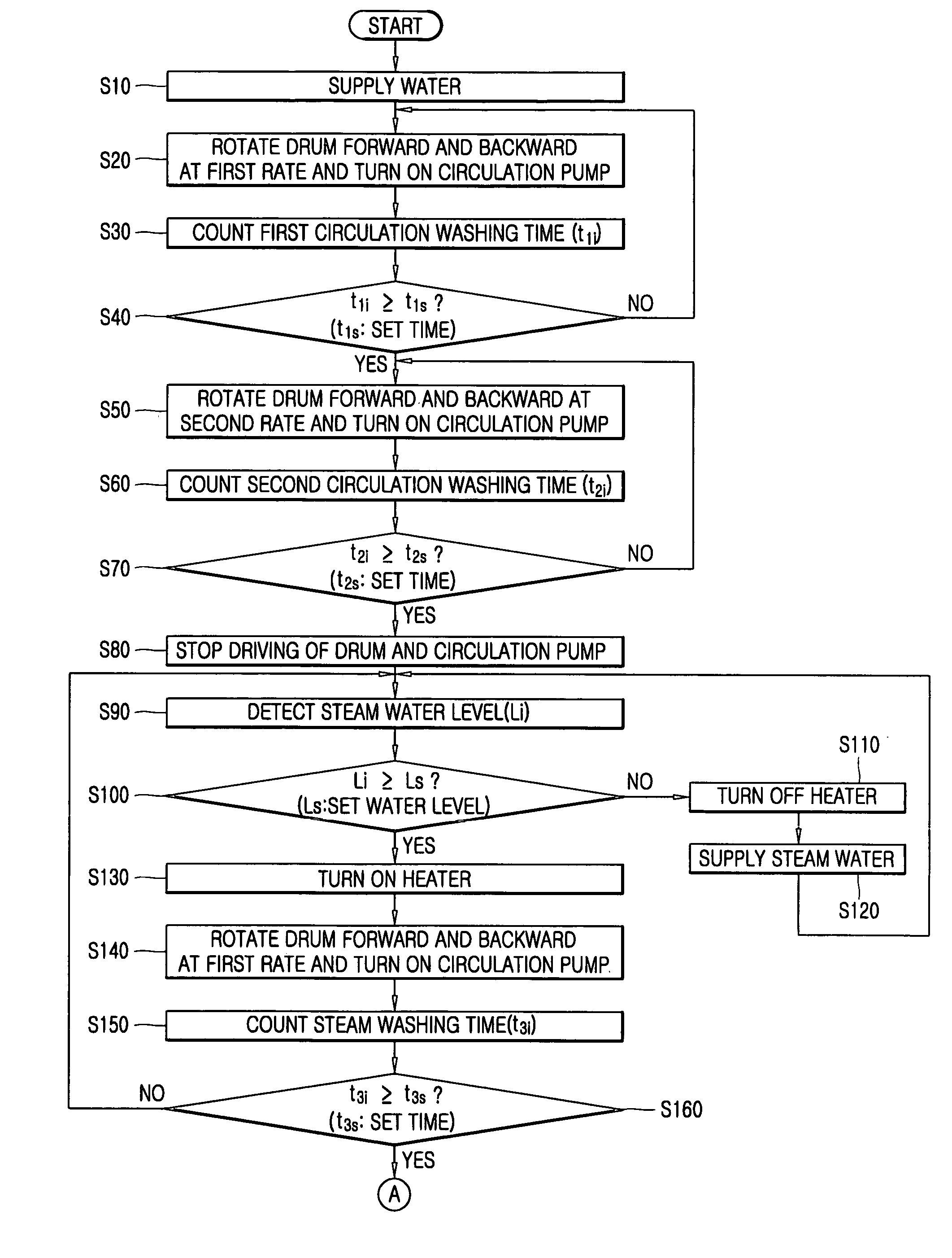

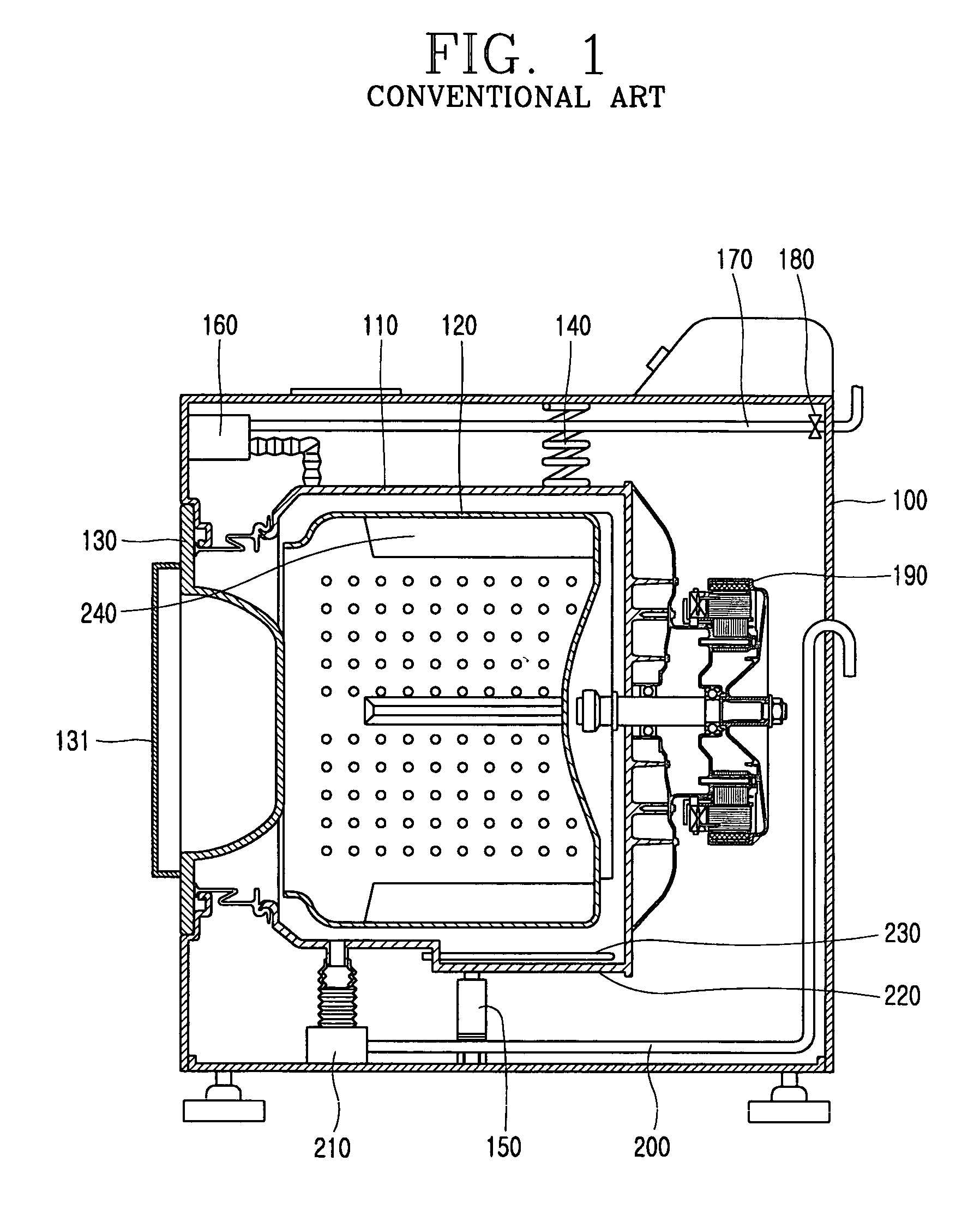

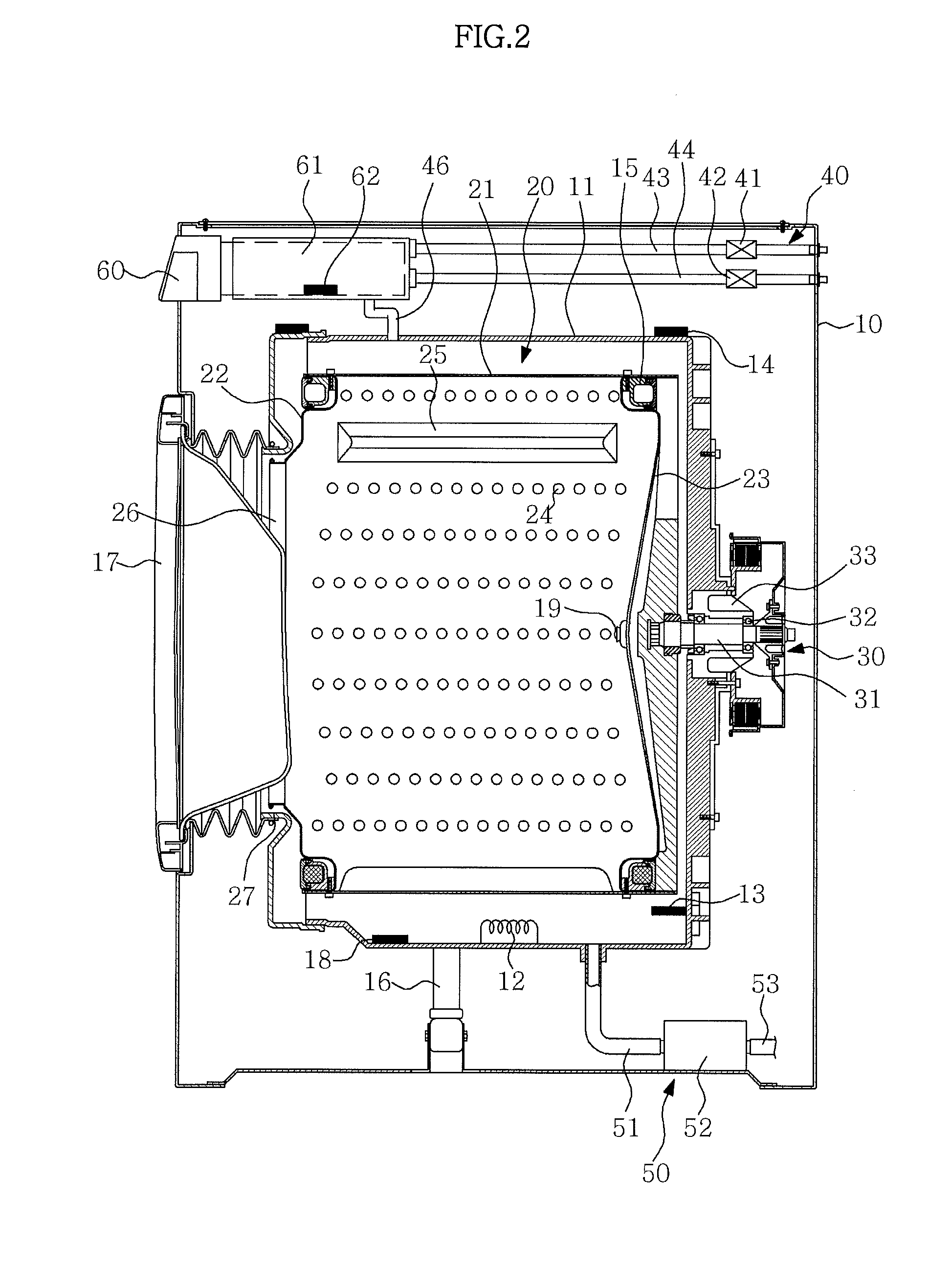

Method of washing laundry in drum washing machine

ActiveUS20060010613A1Reduce the amount requiredOther washing machinesControl devices for washing apparatusWash waterWater level

Disclosed is a method of washing laundry in a drum washing machine by which the amount of wash water used and the amount of power use can be decreased when doing washing in the drum washing machine. The method comprises supplying wash water to a tub up to a first preset water level; and washing laundry in a drum by rotating the drum of the drum washing machine forward and backward simultaneously while drawing the wash water and supplying the drawn wash water to the drum.

Owner:LG ELECTRONICS INC

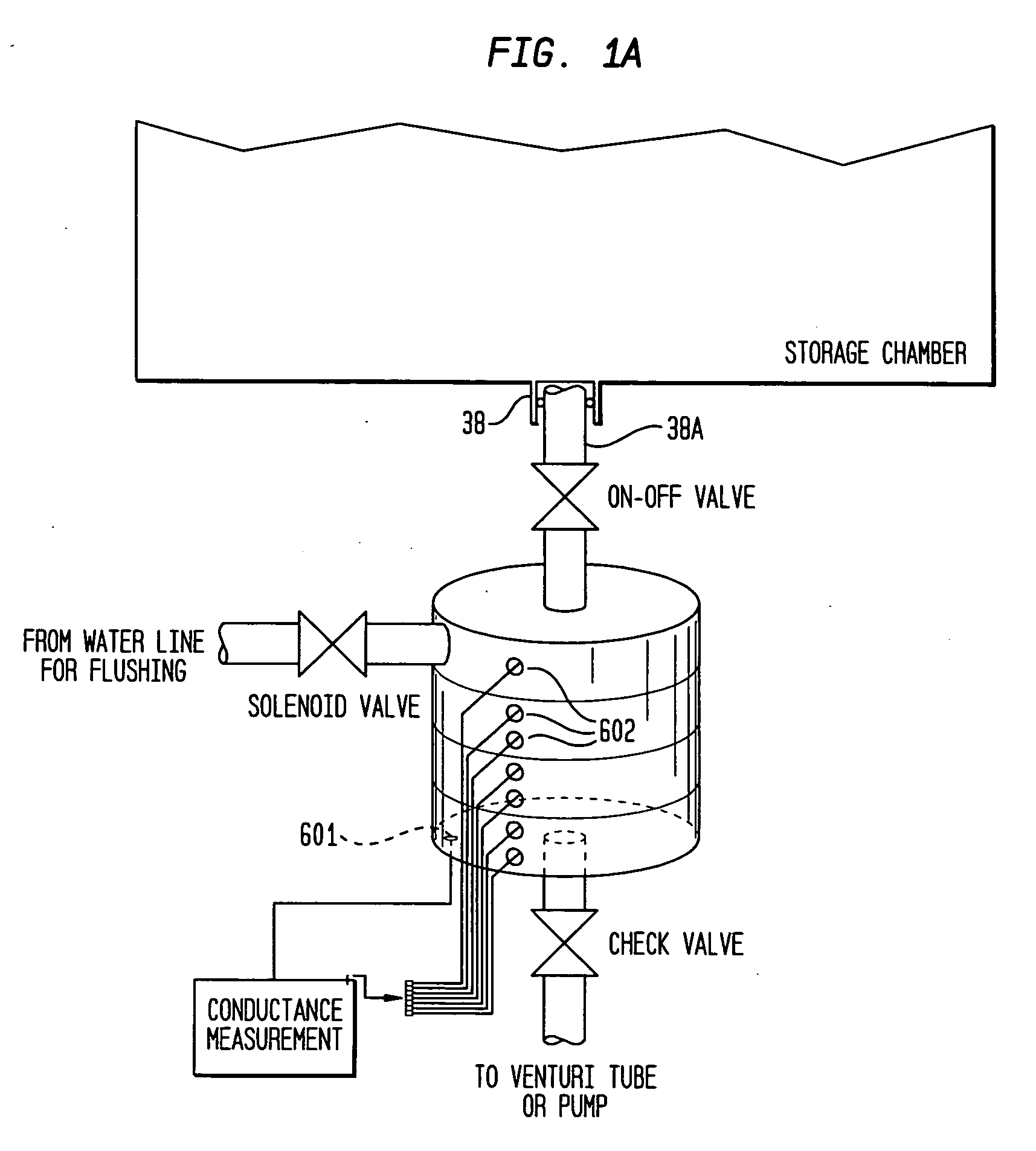

Automatic dispensing device for laundry detergent composition with intermediate chamber

InactiveUS20060272360A1Other washing machinesControl devices for washing apparatusLaundry washing machineProcess engineering

A non-intrusive device for automatically dispensing at least one liquid laundry care composition to an automatic laundry washing machine. The device employs a Venturi tube mechanism or a pump to dose the laundry detergent care composition. The dosing is either manually controlled or controlled by a machine-generic algorithm capable of determining the actual cycle at any duration of wash for various cycle designs from various washing machines, without the input of precise cycle design; and dose the correct products correctly and is capable of distinguishing between major water addition and a water pulse.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Device and system for improved cleaning in a washing machine

A washing system for cleaning within a washing zone comprising at least one inlet capable of fluid communication with a feed water; at least one treatment zone in fluid communication with the at least one inlet, said at least one treatment zone comprising a water softening zone, an electrolysis zone, a dosing zone and combinations thereof; and at least one outlet in fluid communication the at least treatment zone capable of being in fluid communication with a washing zone.

Owner:THE PROCTER & GAMBLE COMPANY

Fabric Treatment For Stain Release

ActiveUS20080148491A1Feel goodMinimizing fiber wearNon-ionic surface-active compoundsOrganic detergent compounding agentsWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Treatment compositions can be used as a pretreatment prior to washing, through soaking, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, to first provide and then maintain and restore the beneficial fabric protection benefits imparted to the fabrics during a first treatment operation. The fabric treatment is complete when the fabric is cured by drying and / or heating. Following use of a first treatment composition, protective benefits are maintained and restored by means of a second treatment operation employing a second treatment composition with lower active levels of the protective agents to provide for economical and continual maintenance of the imparted fabric protection benefits through a delivered second fabric treatment benefit with each subsequent treatment operation employing the fabric treatment compositions.

Owner:VAN BUSKIRK GREGORY

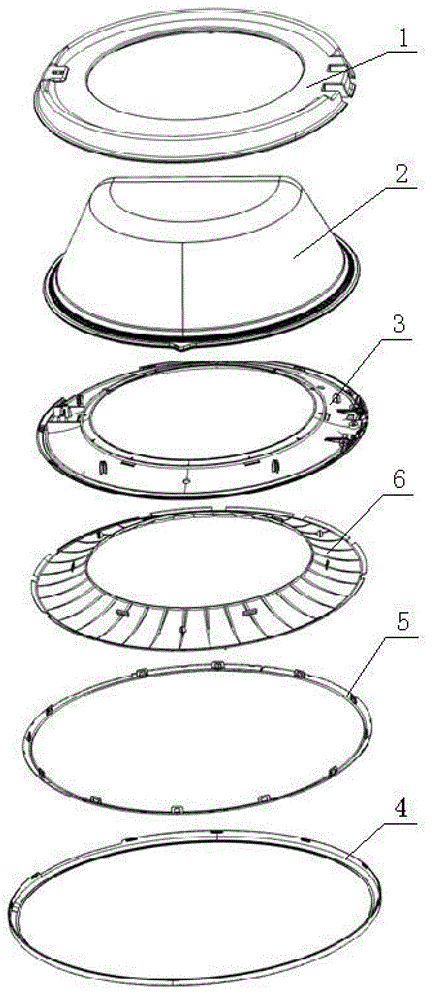

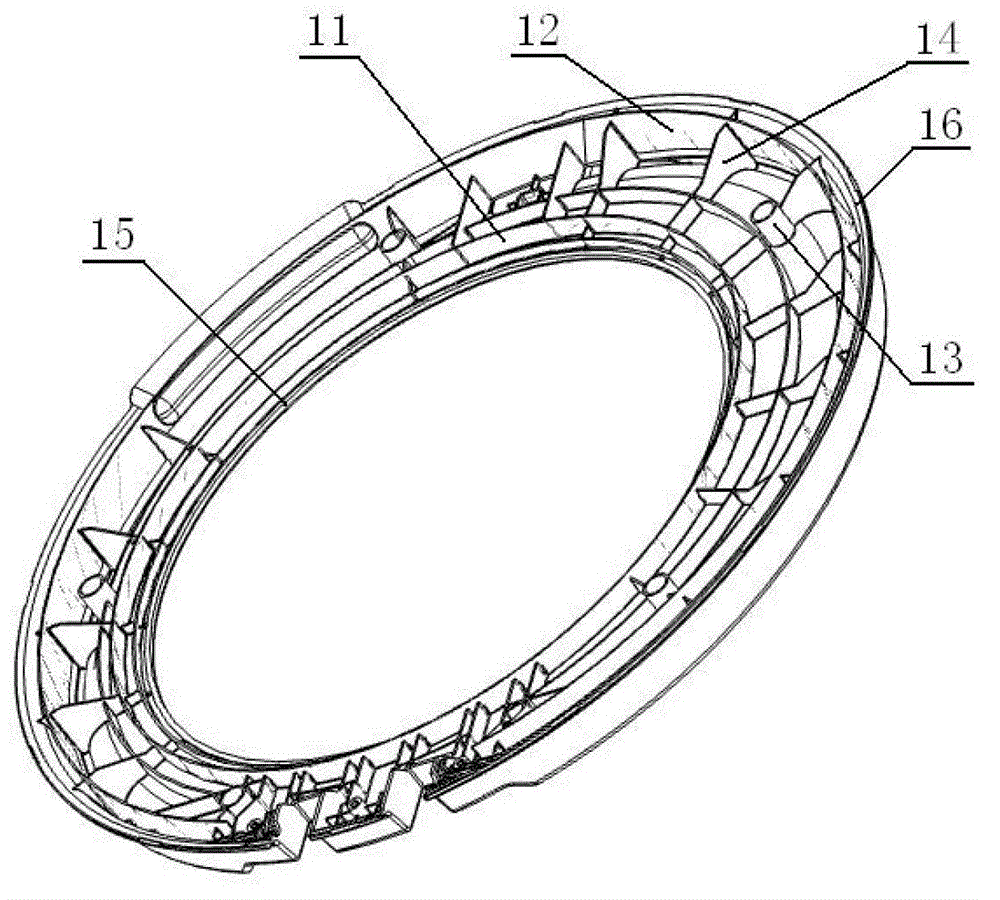

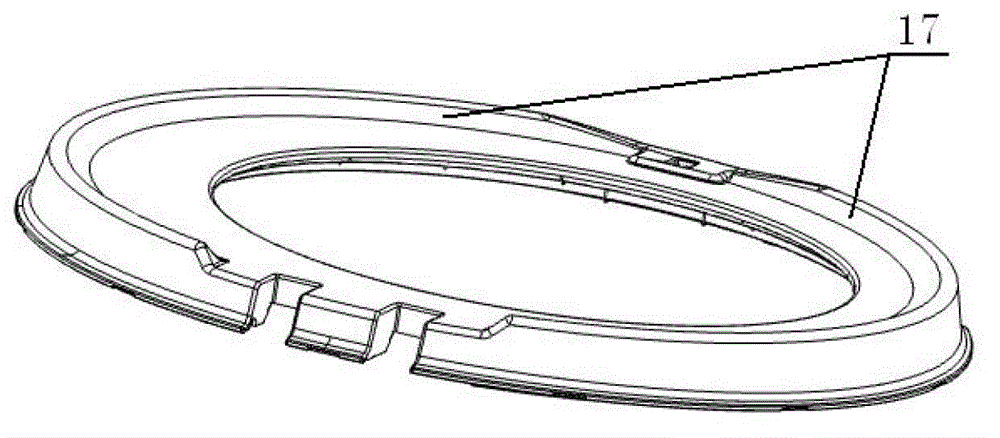

Door of front-loading washer and assembly method thereof

ActiveCN104372569AImprove reliabilityIncreased durabilityOther washing machinesTextiles and paperEngineeringFront loading

The invention discloses a door of a front-loading washer and belongs to the field of parts for front-loading washers. The door comprises an inner frame, a transparent basin, a middle frame and an outer frame which are arranged in order from inside of the door to the outside of the door; a window screen is disposed between the outer frame and the middle frame; the middle frame is in welded connection with the inner frame; the outer frame and the window screen are fastened to the middle frame; a decoration is provided between the window screen and the middle frame. The door is compact in structure and convenient to mechanically assemble; parts of the door are flexible to combine and select; personalized needs of different users can be met. An assembly method of the door includes assembling the parts of the door by plastics welding; production is highly effective; products are more reliable and durable.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD

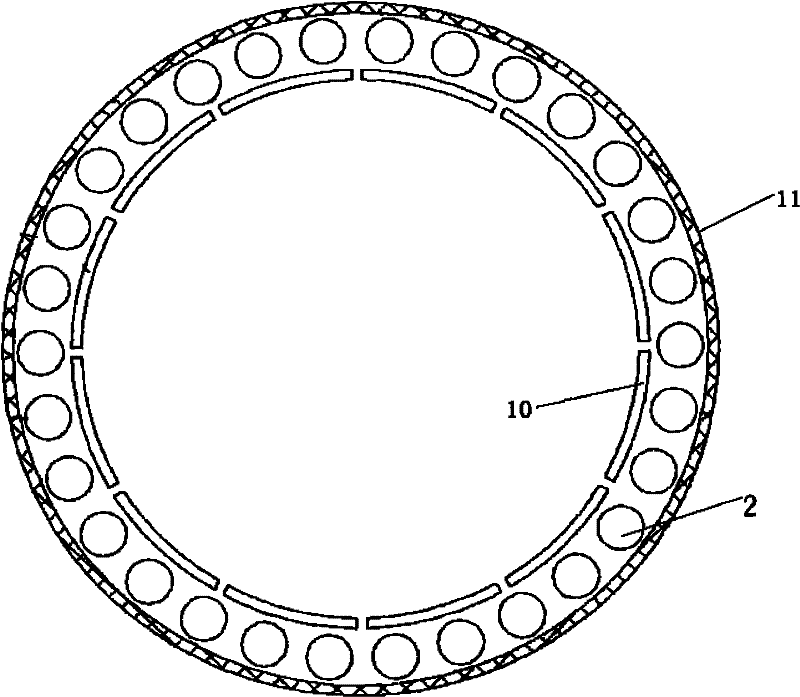

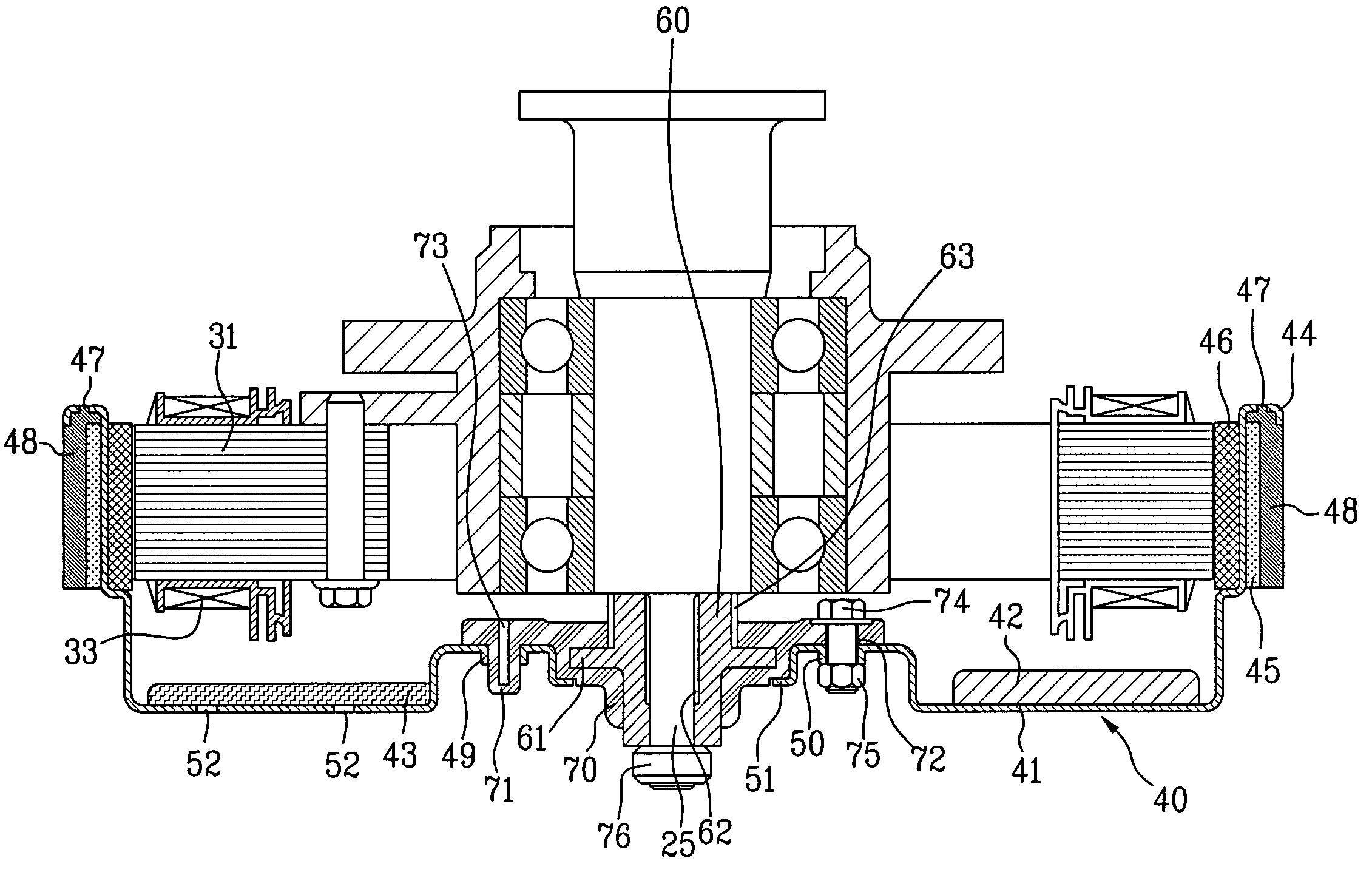

Motor for washing machine

InactiveUS20050140232A1Improve securityEasy to manufactureMagnetic circuit rotating partsOther washing machinesDrive shaftMagnet

A motor for a washing machine including a driving shaft coupled to a drum, a stator for forming a magnetic field with a coil wound on a core, and a rotor rotatably mounted on an outside of the stator coupled to the driving shaft for driving the driving shaft, wherein the rotor includes a rotor frame having magnets attached to an inside surface of an outer end, a back yoke on an outside surface of the outer end for reinforcing the rotor frame and forming a magnetic path, a shaft supporting housing at a center of the rotor frame having one end portion of the driving shaft secured thereto, a bushing of a non-conductive resin having the shaft supporting housing formed as one body at a center, the bushing being secured to the rotor frame, and fastening members for fastening the bushing to the rotor frame.

Owner:LG ELECTRONICS INC

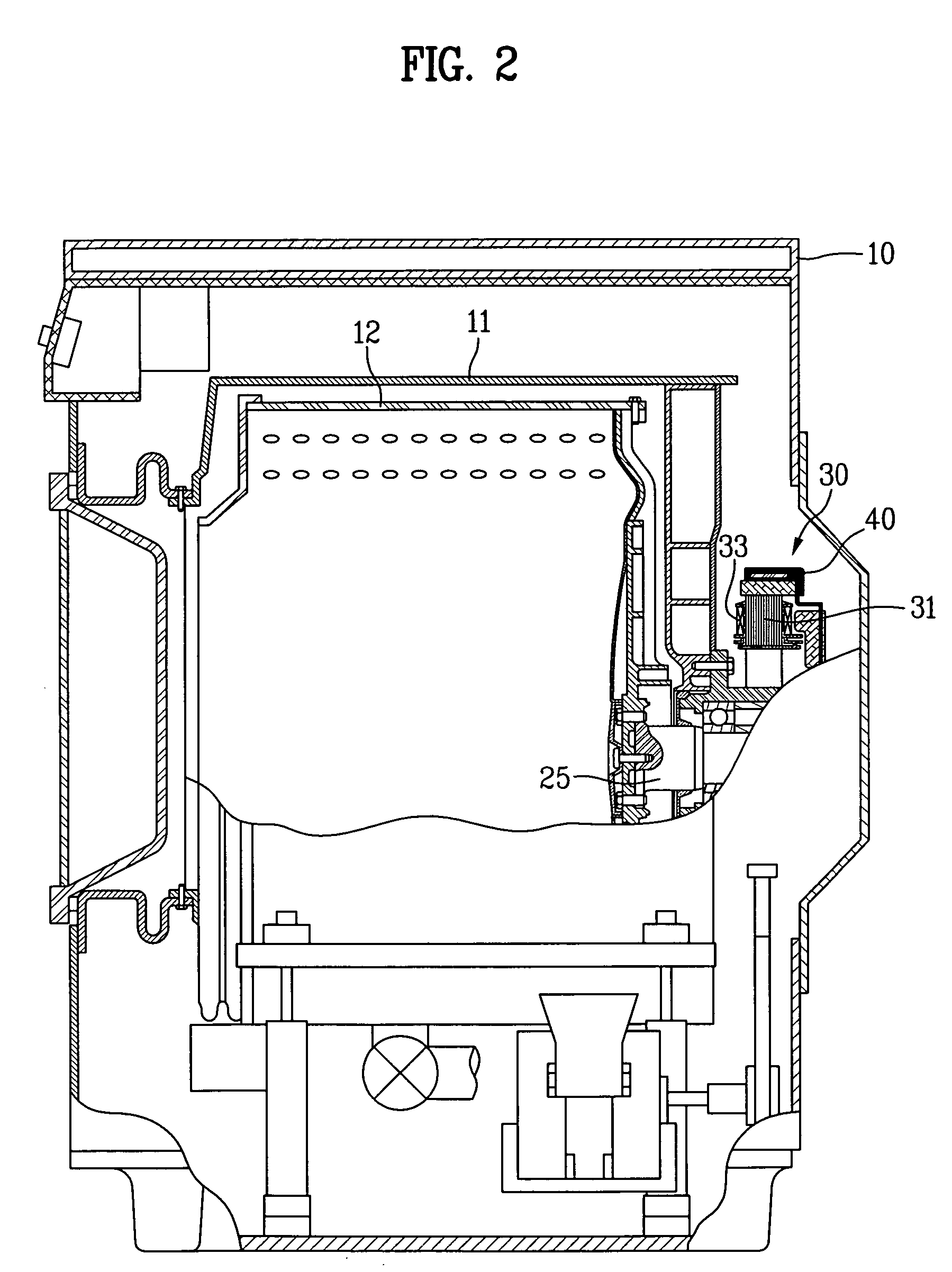

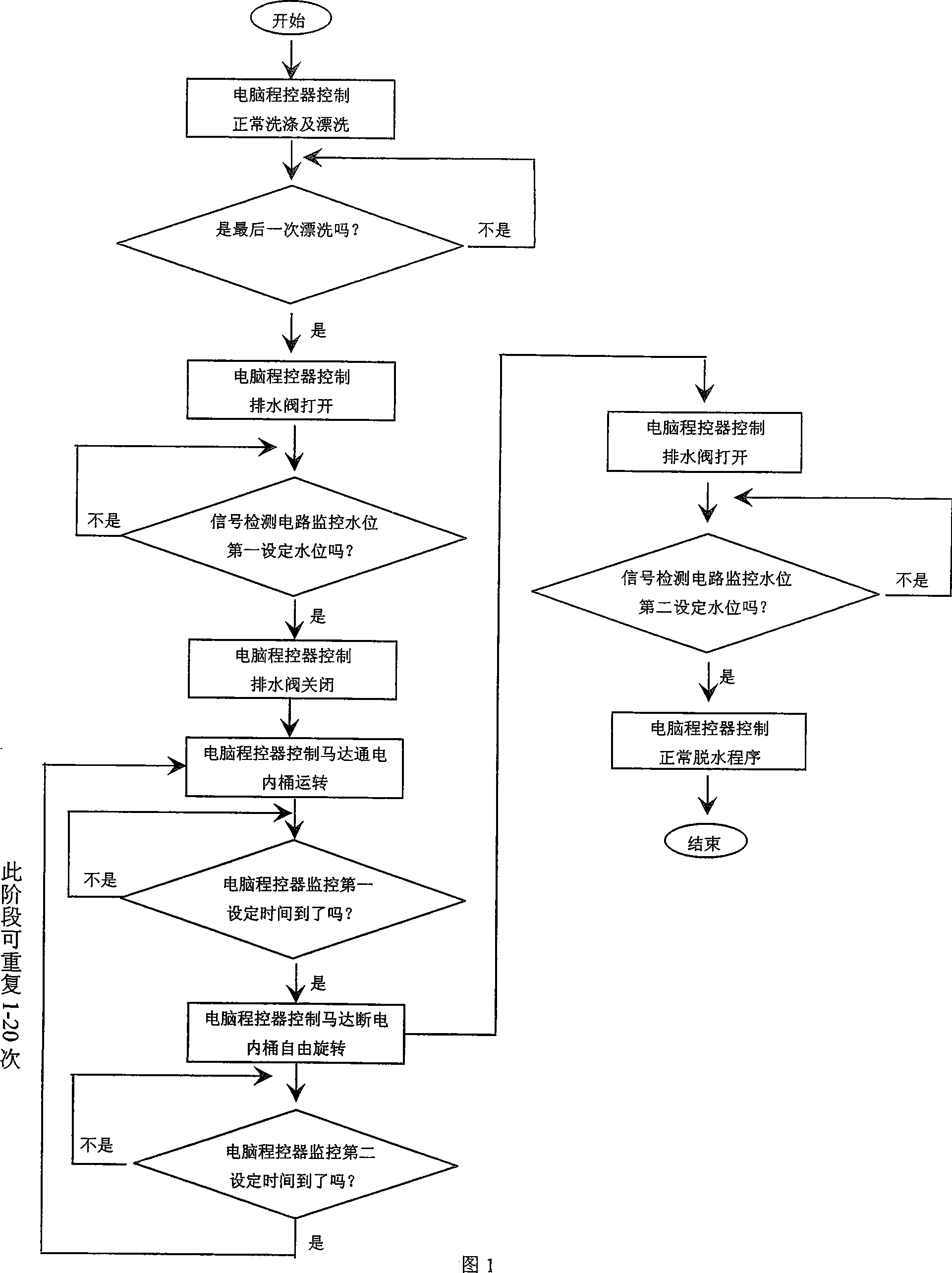

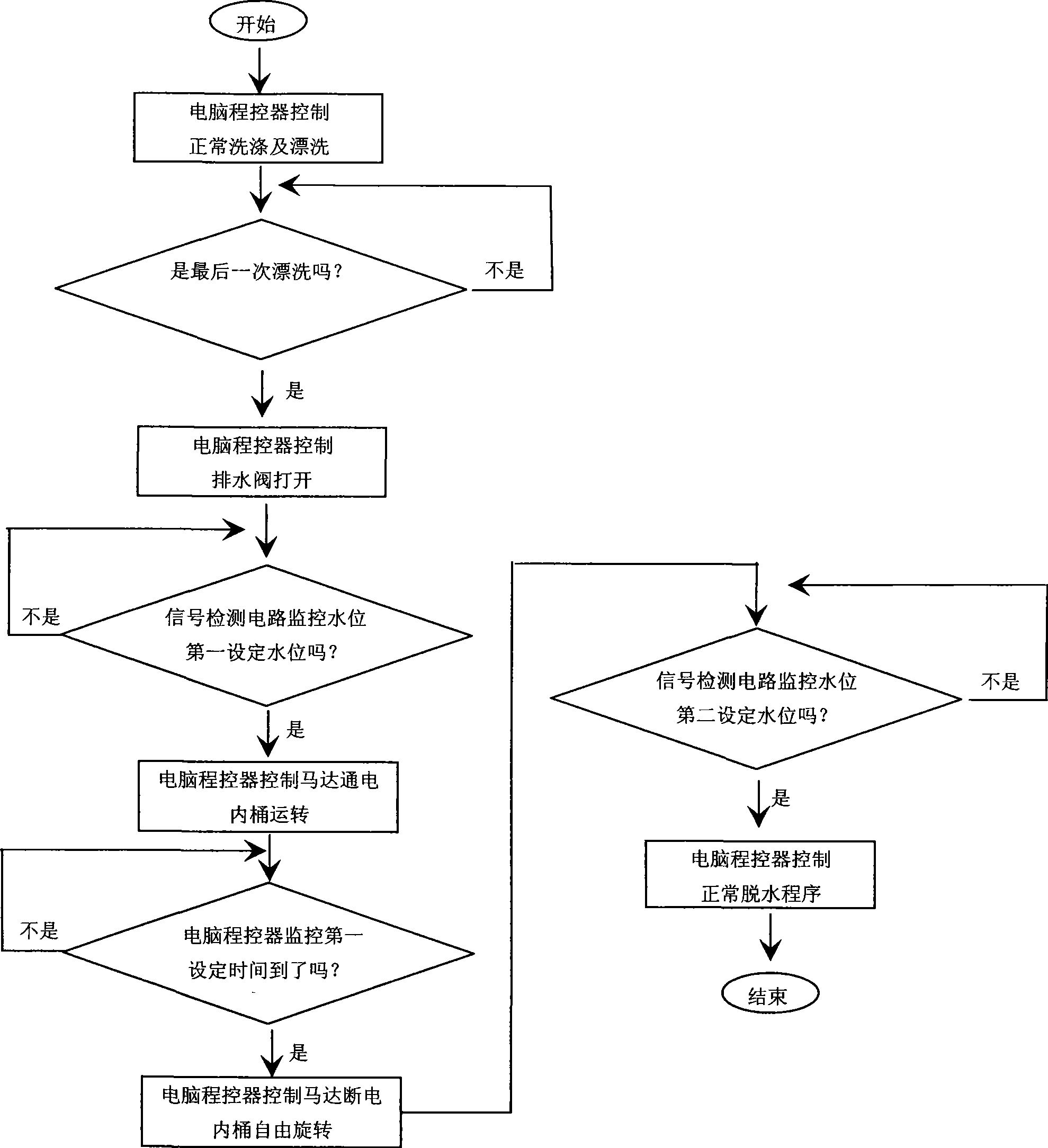

Drum cleaning program control method for full automatic washing machine

InactiveCN101413198AKeep the internal environment cleanDo not cause secondary pollutionOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

The invention discloses a method for controlling the cleaning procedure of an automatic washing machine drum, which is characterized in that drainage is begun after completion of final rinsing until the water level in a monitoring outer drum of a water level controller of a signal detection circuit reaches a first set water level; a computer programmed controller controls a drainage valve to close, and drainage stops; the computer programmed controller controls a motor to be electrified, and an inner drum rotates until a time controller of the computer programmed controller detects a first set time; the computer programmed controller controls the motor to be power-down, and the inner drum rotates freely until the time controller of the computer programmed controller detects a second set time; the computer programmed controller controls the drainage valve to open, and drainage begins until the water level in the monitoring outer drum of the water level controller of the signal detection circuit reaches a second set water level; and normal dehydration procedure is performed. The control method which changes rinsing, drainage and dehydration cleans the outside of the inner drum and the inside and the bottom surface of the outer drum of an automatic washing machine, removes residual soil, and maintains a clean internal environment for washing clothes.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU +1

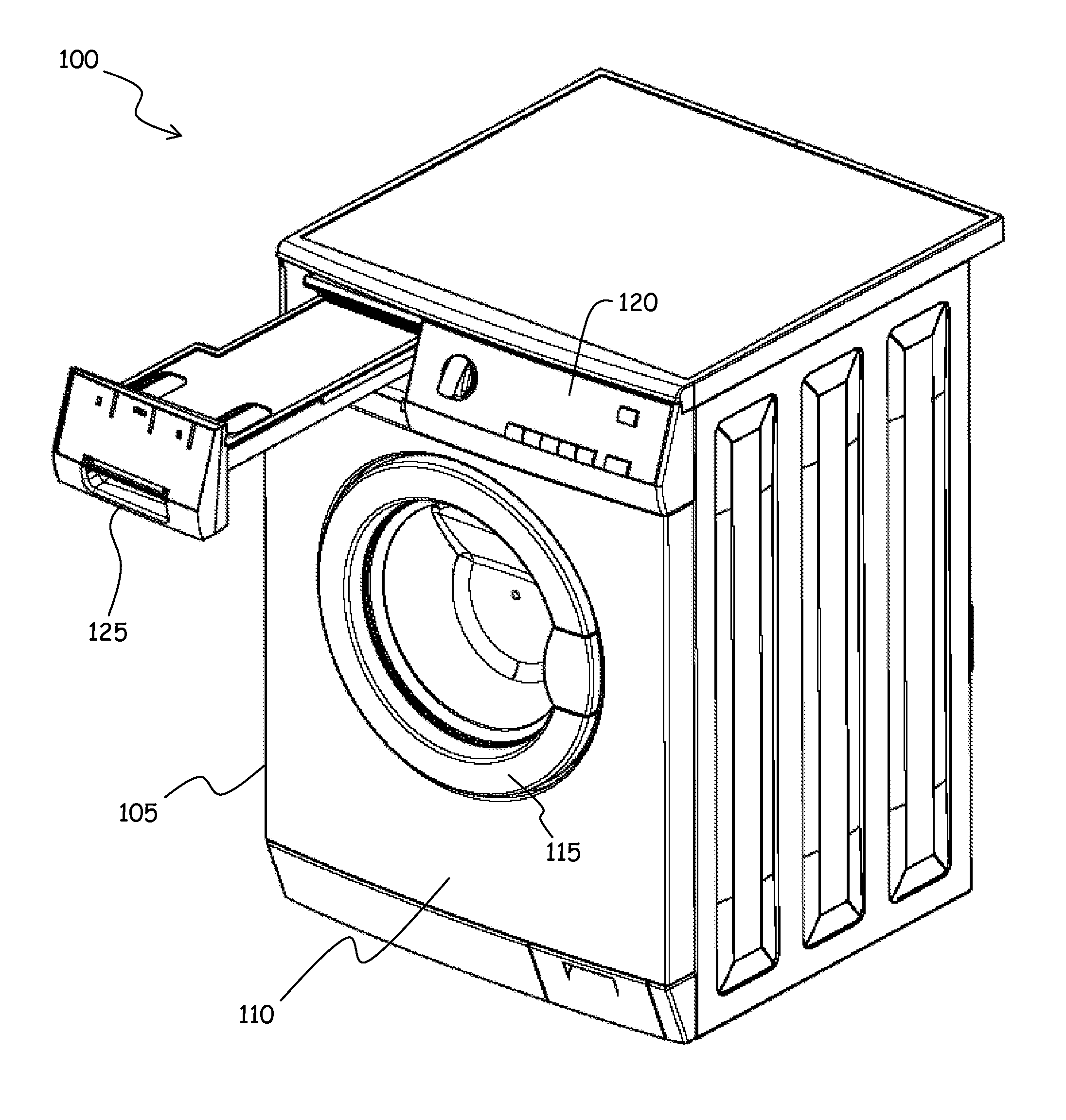

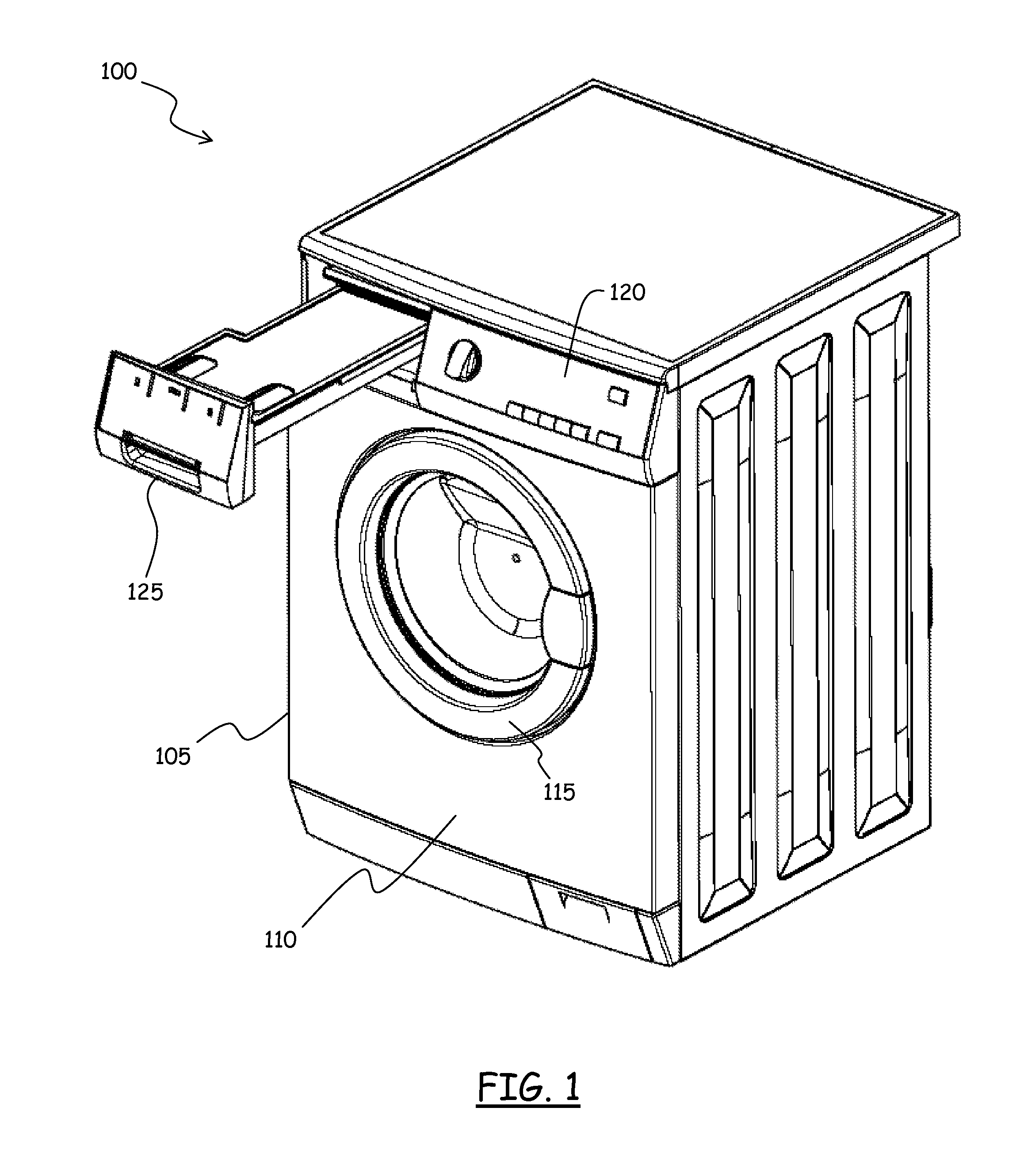

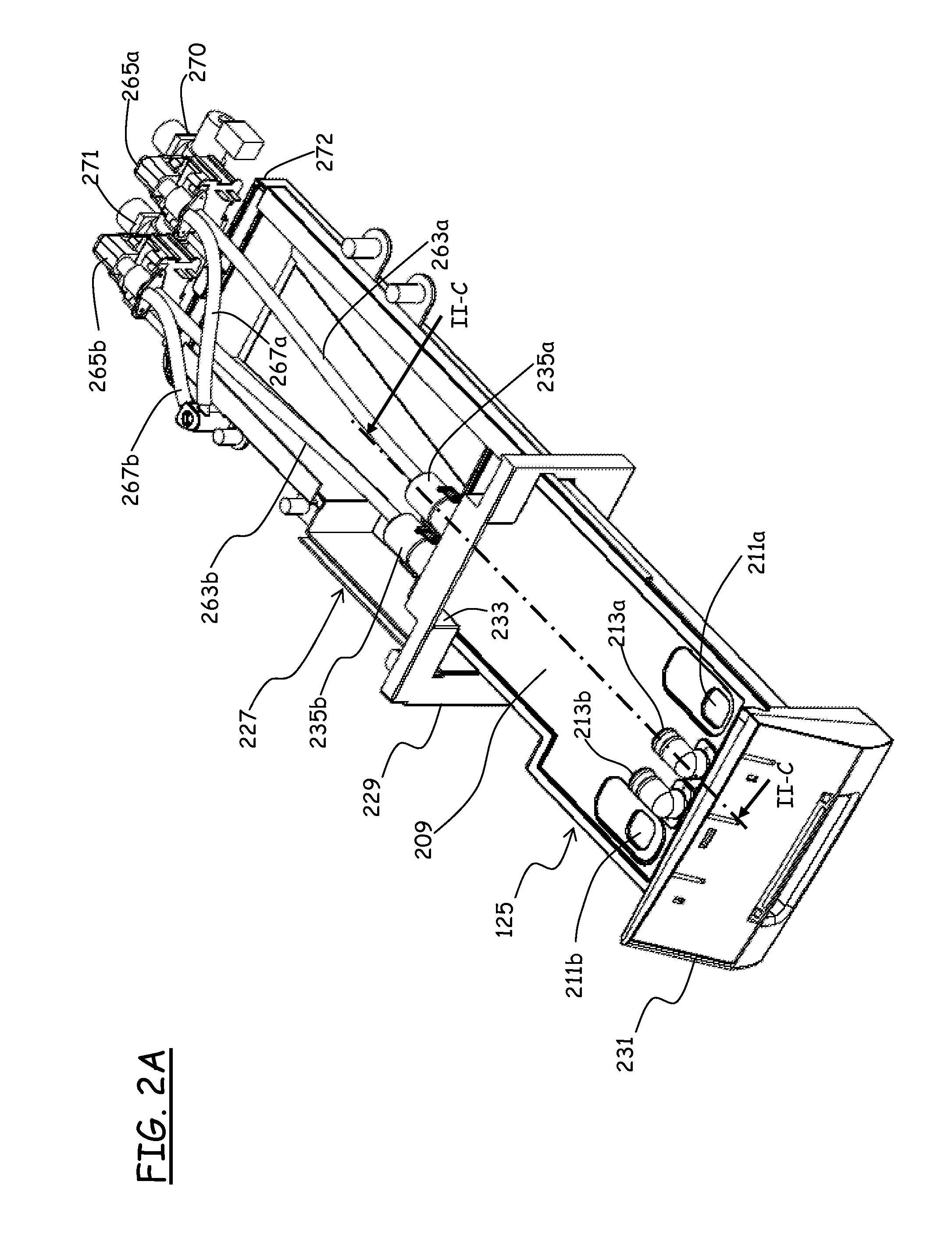

Laundry Washing Appliance

ActiveUS20120096901A1Efficient solutionOther washing machinesTextiles and paperLaundryBiomedical engineering

A laundry washing appliance (100) includes a cabinet (105) accommodating a laundry washing tub and a dispensing arrangement for dispensing laundry washing treatment products to be used during laundry washing. The dispensing arrangement includes a drawer (125) slidable within a seat (227) provided in the cabinet (105). The drawer (125) defines at least one container (201a, 201b) for laundry washing treatment products. At least one suction pump (265a, 265b, 365a, 365b) is associated with the at least one container (201a, 201b) and is fluidly connected to the laundry washing tub for delivering thereto dosed amounts of the treatment products. Suction pipes (213a, 213b, 331) are connected between the at least one suction pump (265a, 265b, 365a, 365b) and the at least one container (201a, 201b). The at least one suction pump (265a, 265b, 365a, 365b) and the suction pipes (213a, 213b, 331) are arranged so as to enable the suction of the dosed amounts of treatment product from above a surface of the treatment product contained in the container (201a, 201b).

Owner:ELECTROLUX HOME PROD CORP NV

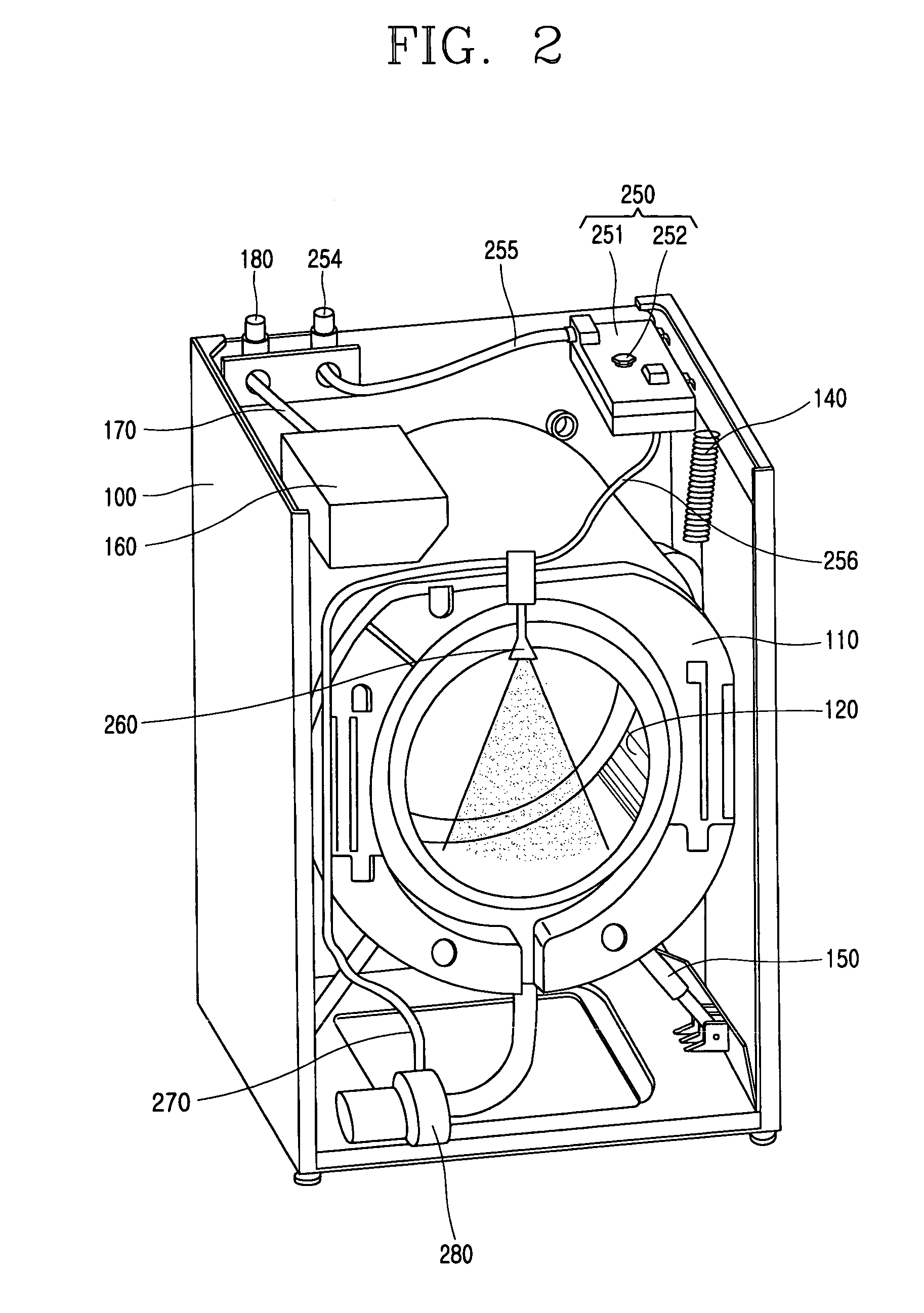

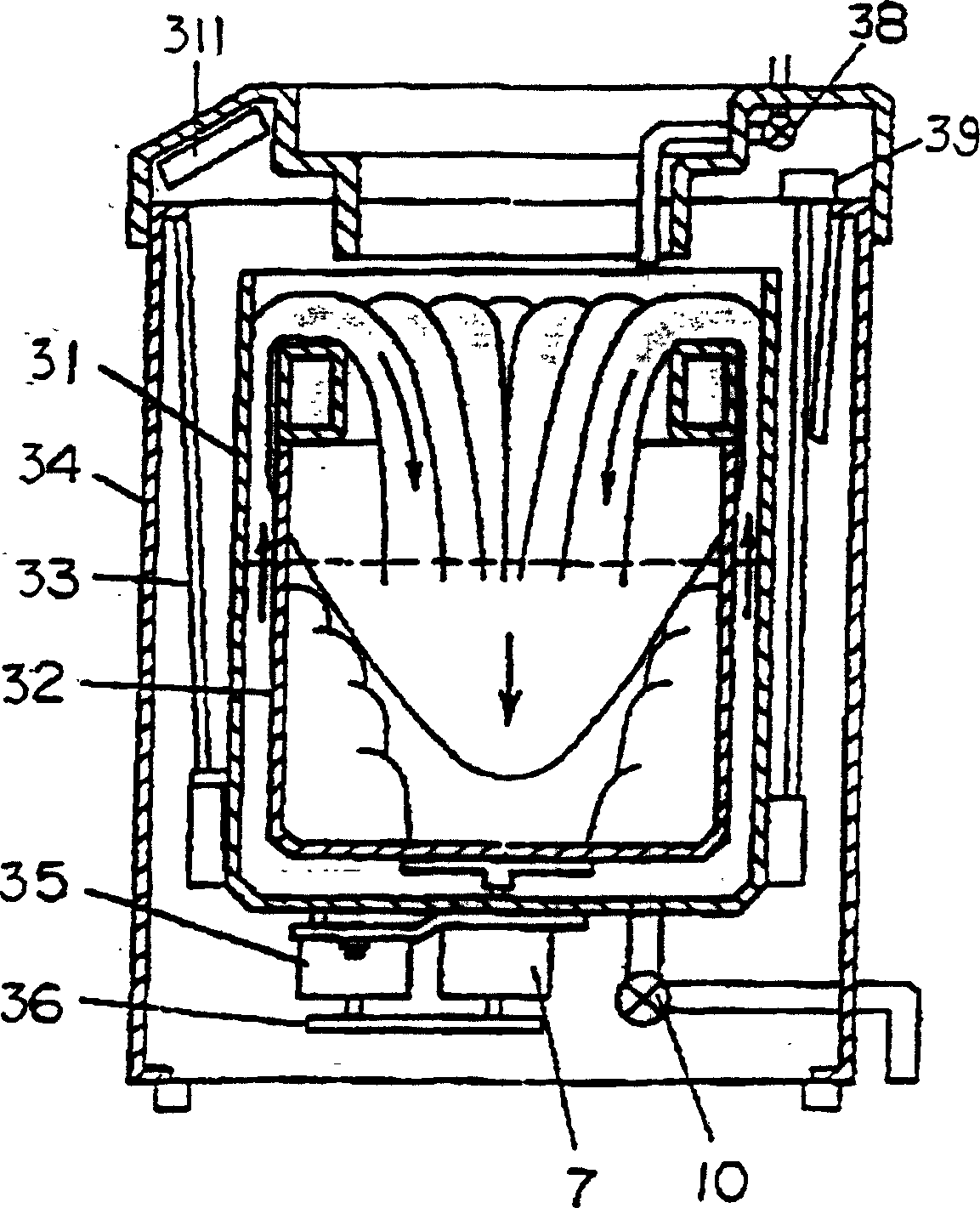

Method for washing clothes under sprinkling internal circulation and washing machine

ActiveCN1661155ASimple structureSmall design areaOther washing machinesWashing machine with receptaclesEngineeringWater level

A washer with internal circulated spray adds a spraying device on inner dully tube top of existing washer. The spraying device consists of water injection tube with its one end being connected to circulation tube and another end being water inlet of water cavity, position for forming waterfall as its space height being samaller then that of water cavity and its horizontal width being greater than that of water cavity as well as spacing baffle set at opposite side of water outlet on position for forming waterfall.

Owner:HAIER GRP CORP +1

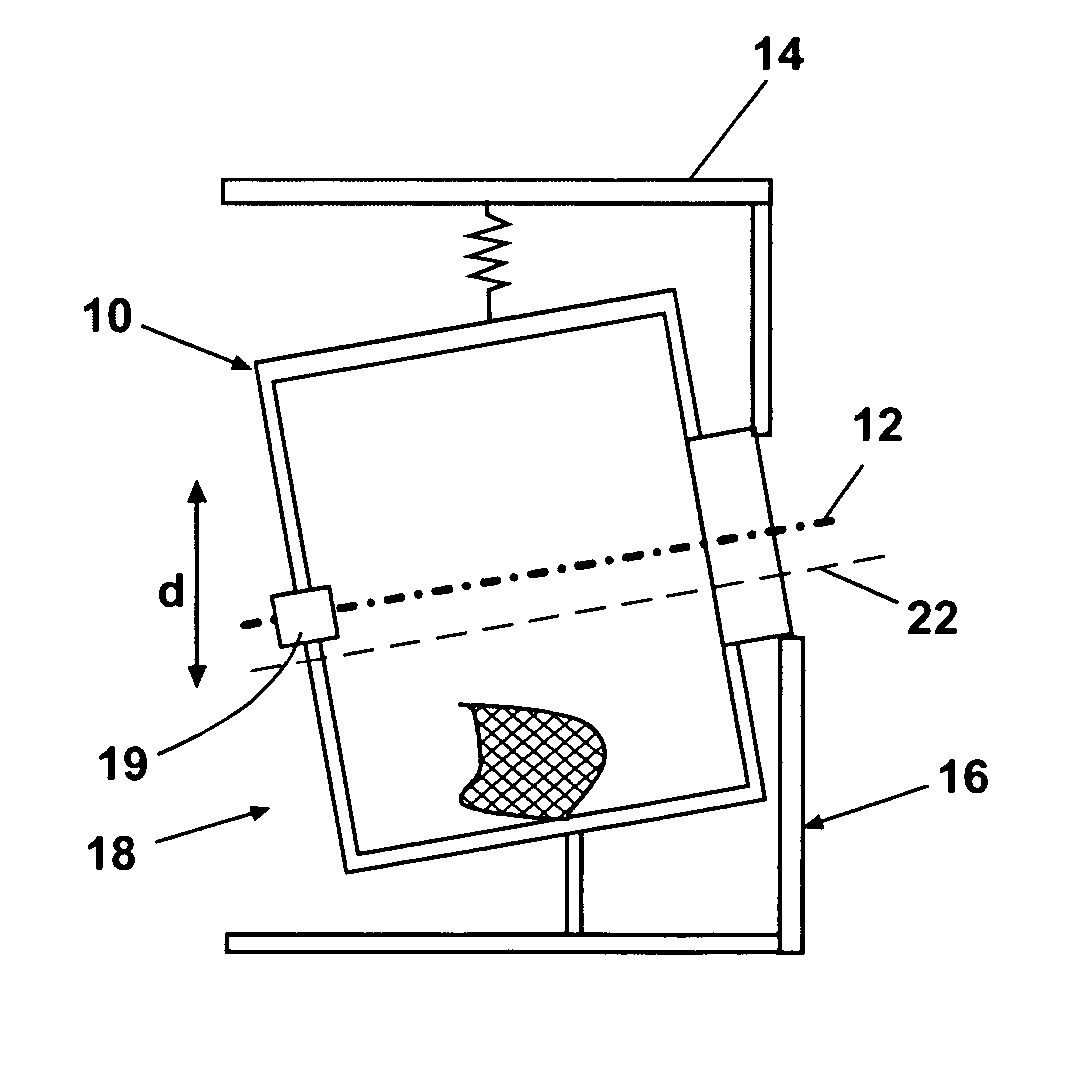

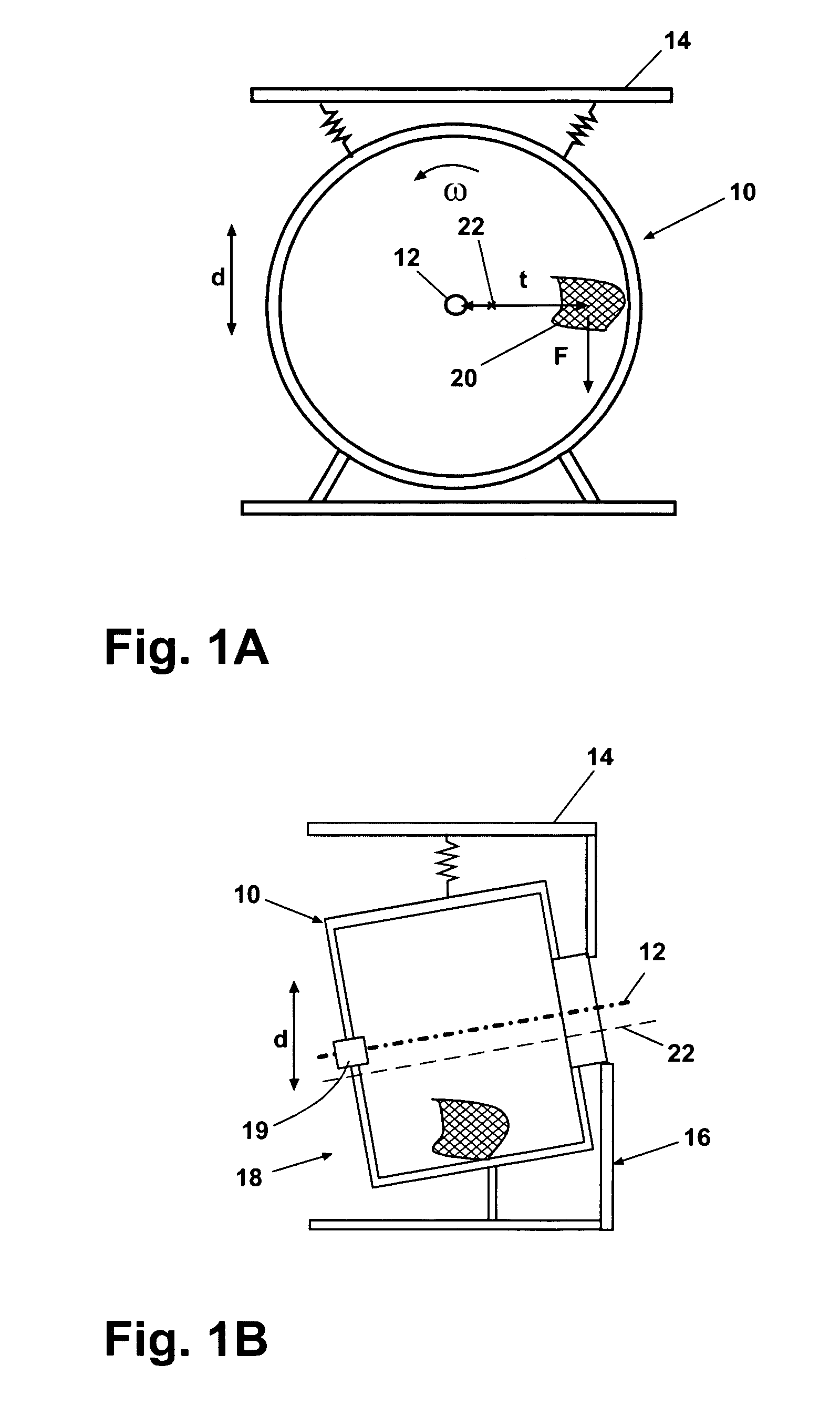

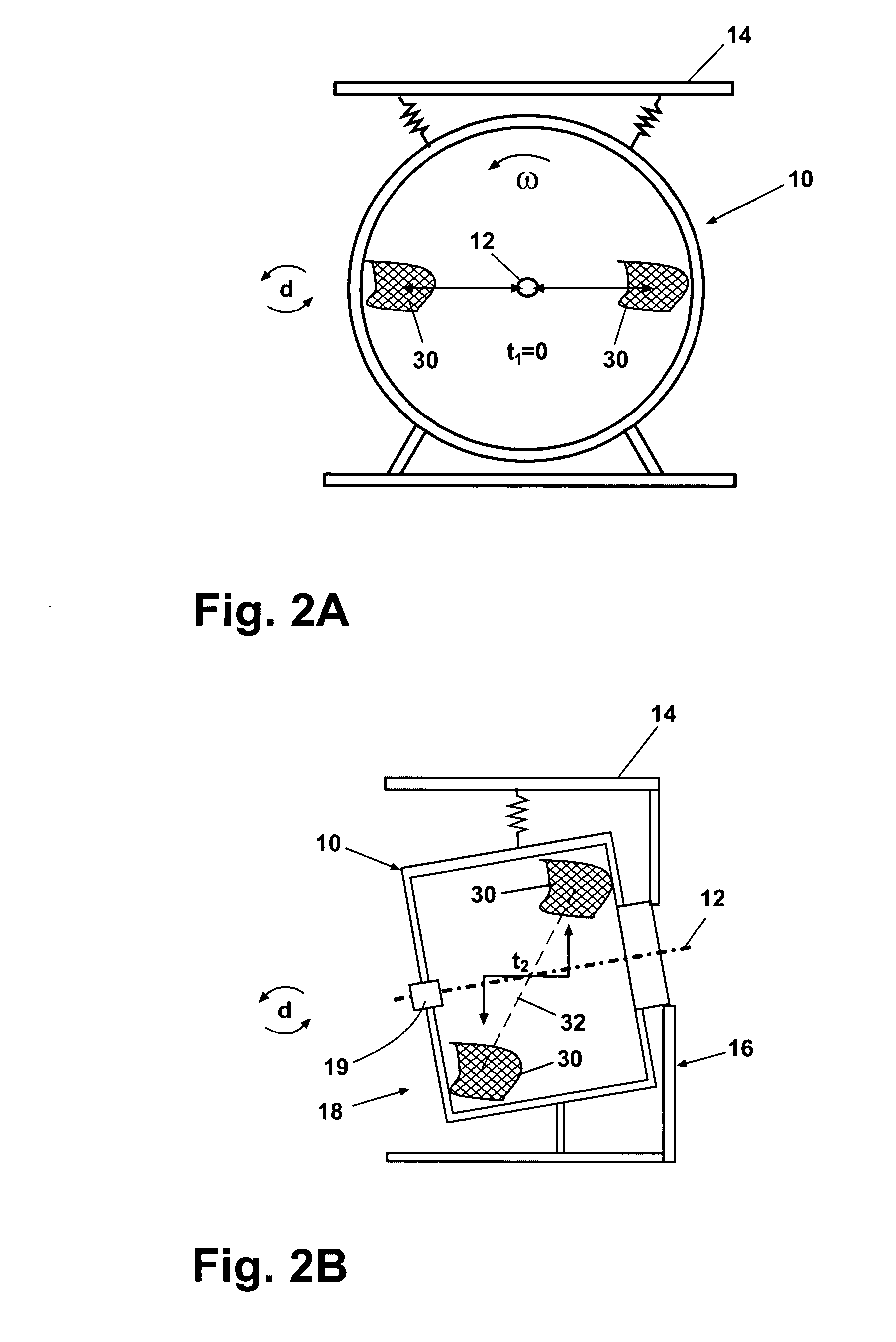

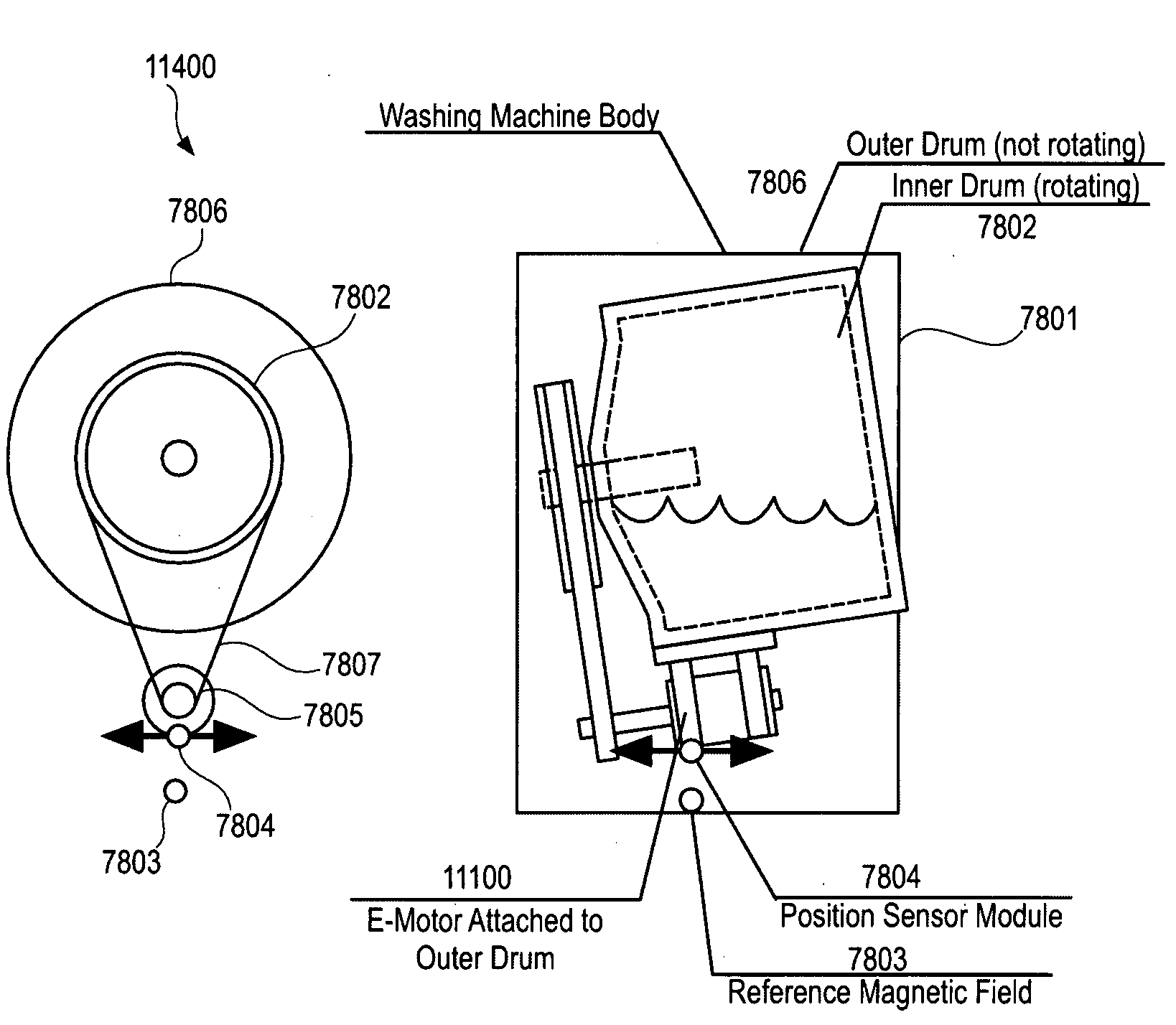

Position Sensor and Washing Machine

InactiveUS20080134727A1Cheap and accurateAccurate and cheap of determiningPermanent magnetsOther washing machinesPosition sensorCondensed matter physics

Described is a position sensor device for determining a position of a movable object. The position sensor device includes (a) a magnetic field source fixed on a movable object, (b) a first magnetic field detector located at a first position and detecting a first magnetic field signal characteristic for a magnetic field generated by the magnetic field source at the first position, (c) a second magnetic field detector located at a second position and detecting a second magnetic field signal characteristic for a magnetic field generated by the magnetic field source at the second position, and (d) a position determining unit determining a position of the magnetic field source based on a comparison of the first magnetic field signal and the second magnetic field signal.

Owner:NCT ENG

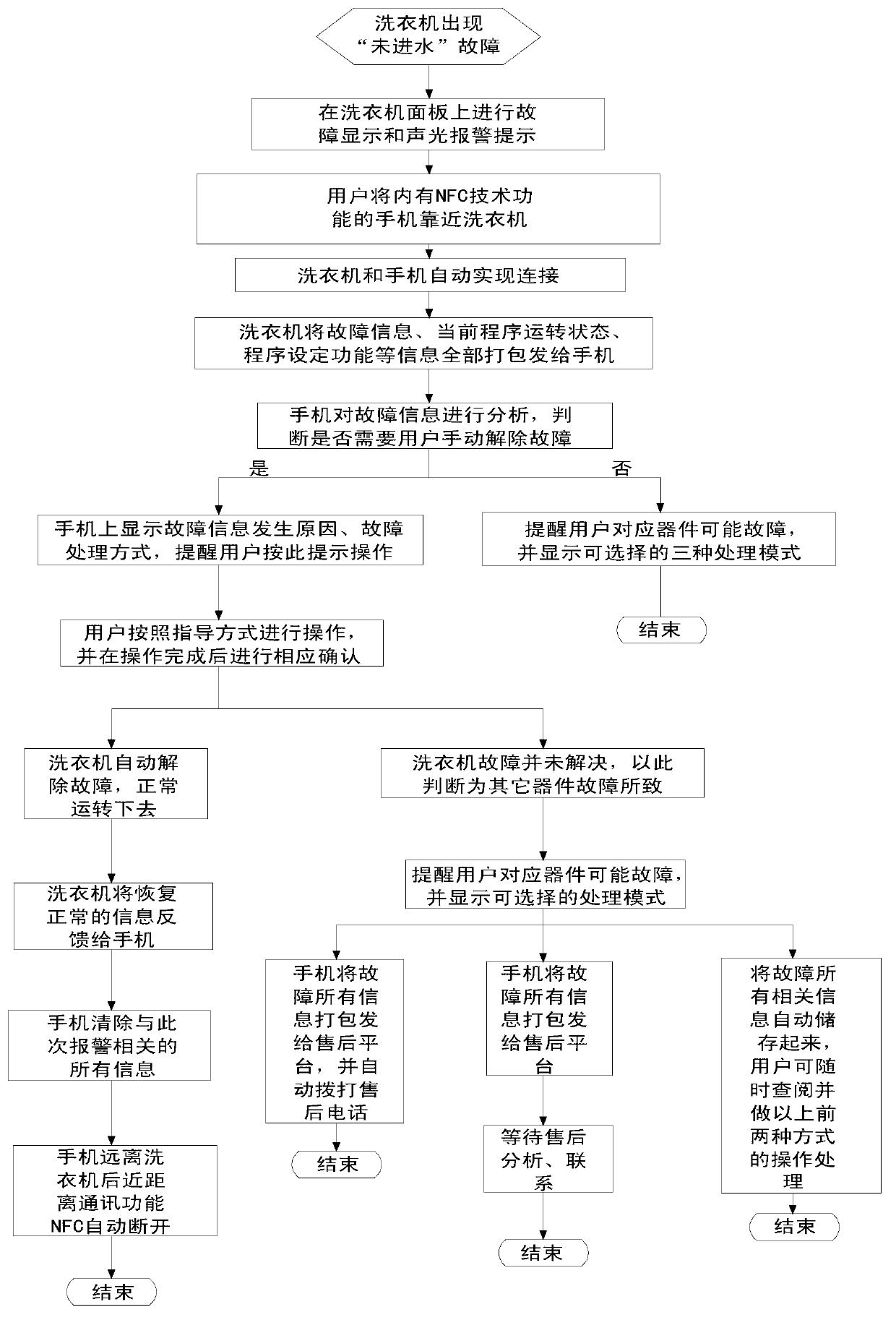

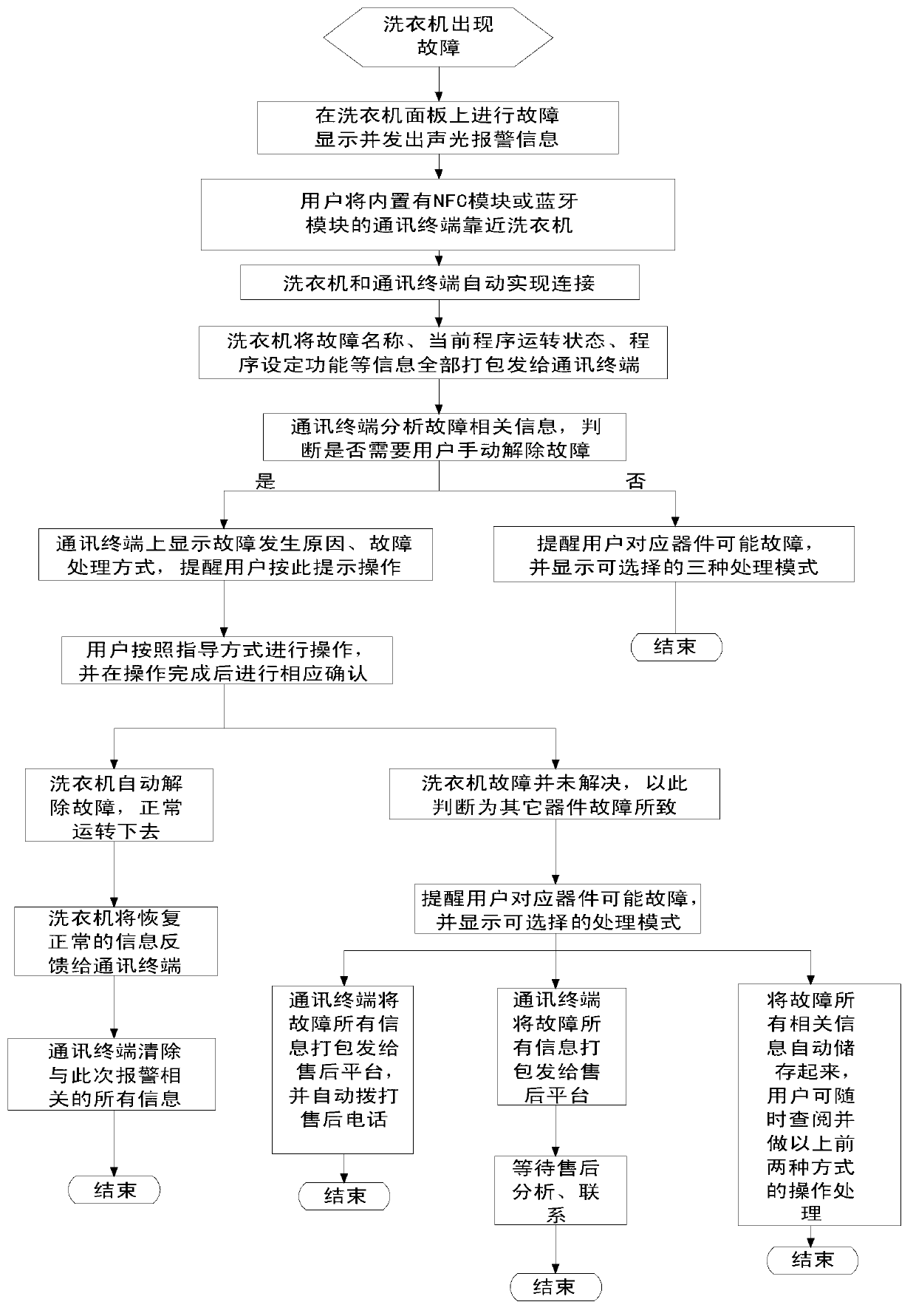

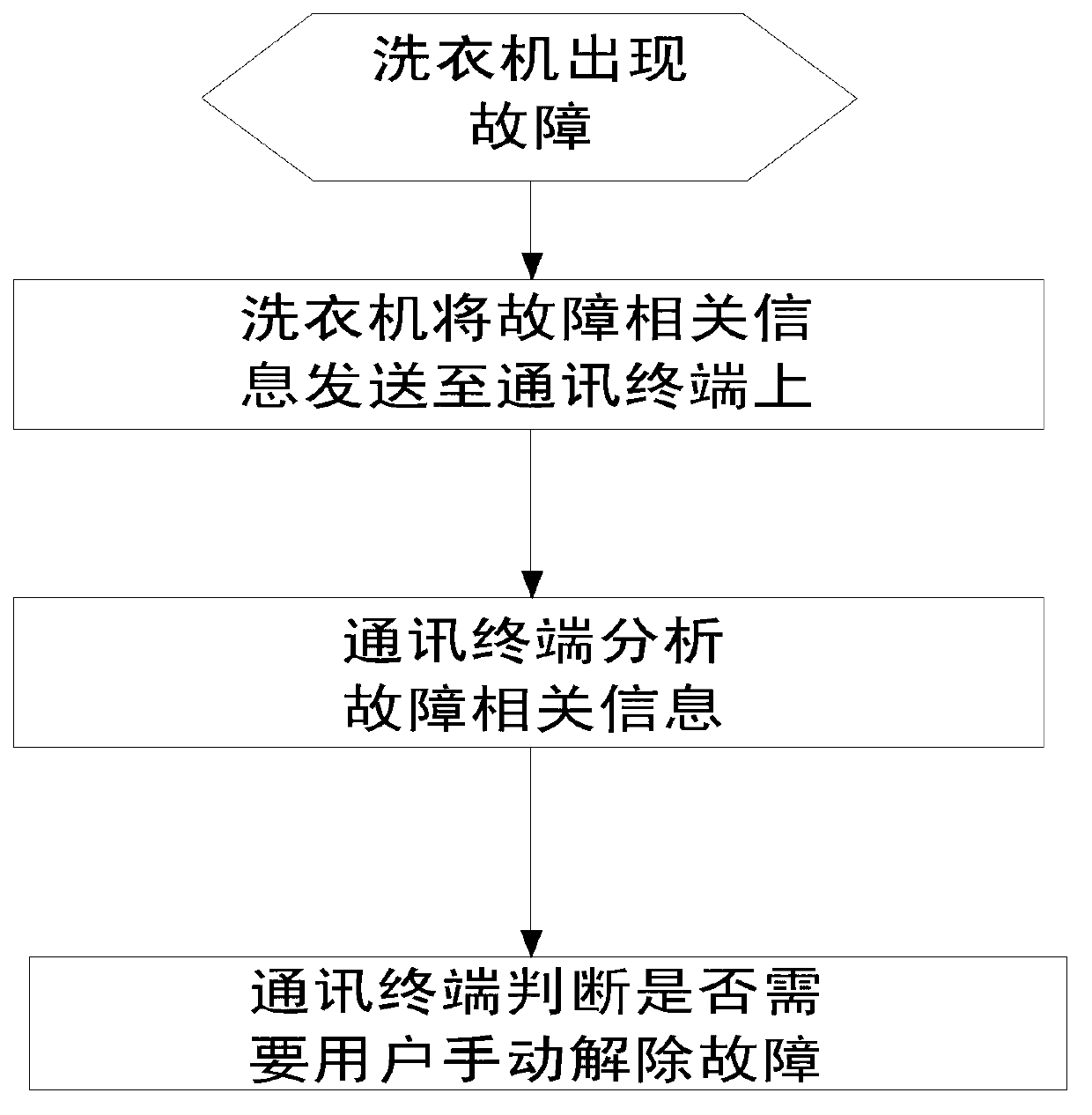

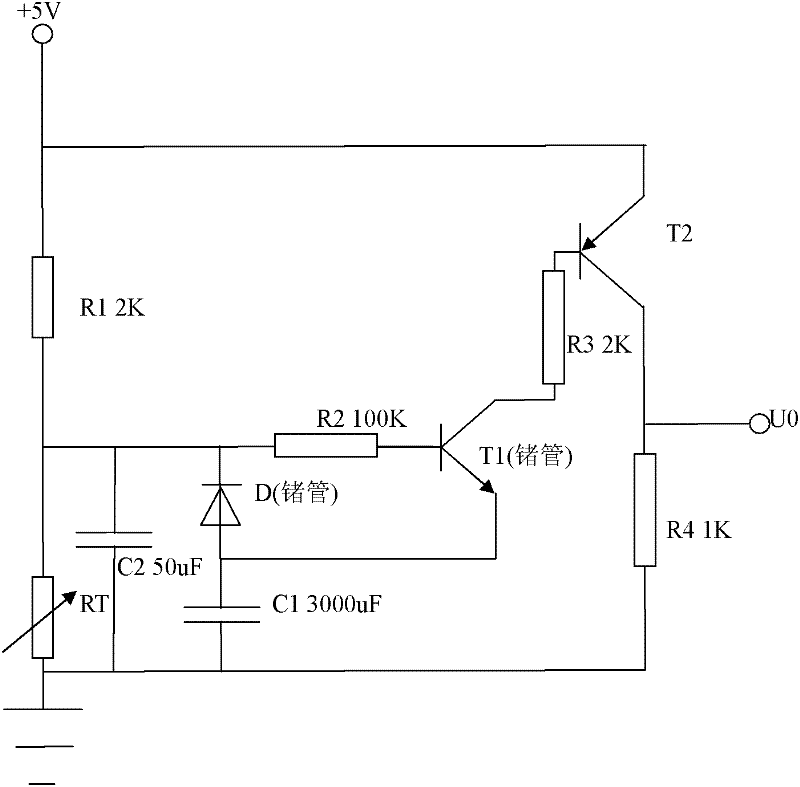

Washing machine malfunction warning and judging method, washing machine and washing machine malfunction warning and judging system

ActiveCN103276557AEasy to useRealize short-distance communication functionOther washing machinesControl devices for washing apparatusRelevant informationMessage passing

The invention discloses a washing machine malfunction warning and judging method, a washing machine and a washing machine malfunction warning and judging system. The washing machine failure warning and judging method includes the steps that when a malfunction occurs, the washing machine sends malfunction relevant information to a specified communication terminal, and the communication terminal analyzes and judges whether the malfunction needs to be eliminated by a user according to the received malfunction relevant information. The washing machine comprises a washing machine body and a communication module, and message passing can be conducted between the communication module and a communication terminal of the user. The washing machine malfunction warning and judging system comprises the communication terminal and the washing machine, and communication models which are mutually matched are arranged in the communication terminal and the washing machine respectively. The washing machine malfunction warning and judging method and the washing machine malfunction warning and judging system can solve an occurred malfunction problem within shortest time, improve user satisfaction degree, feed the malfunction problem back to a design source, and prevent the problem from happening again.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

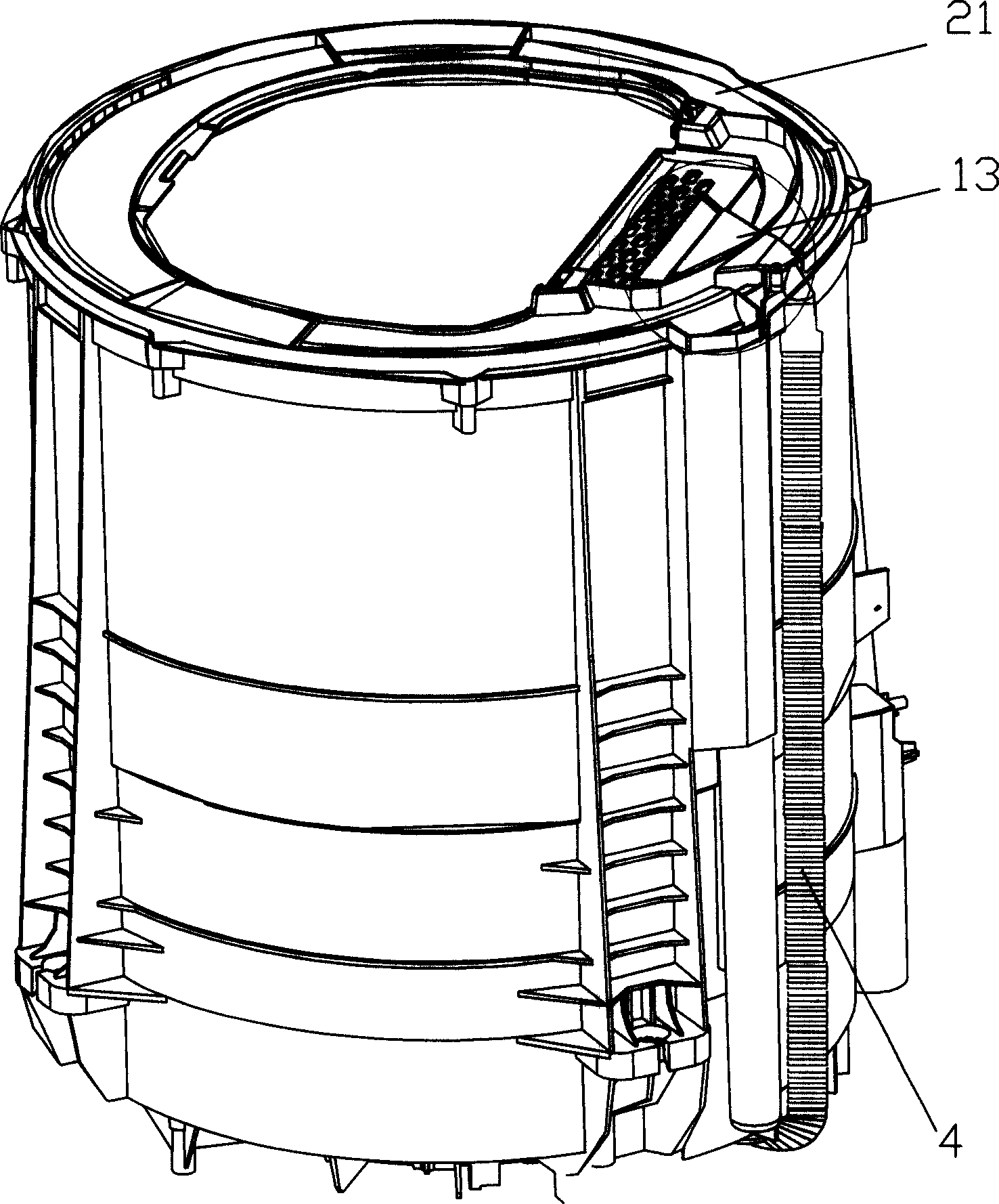

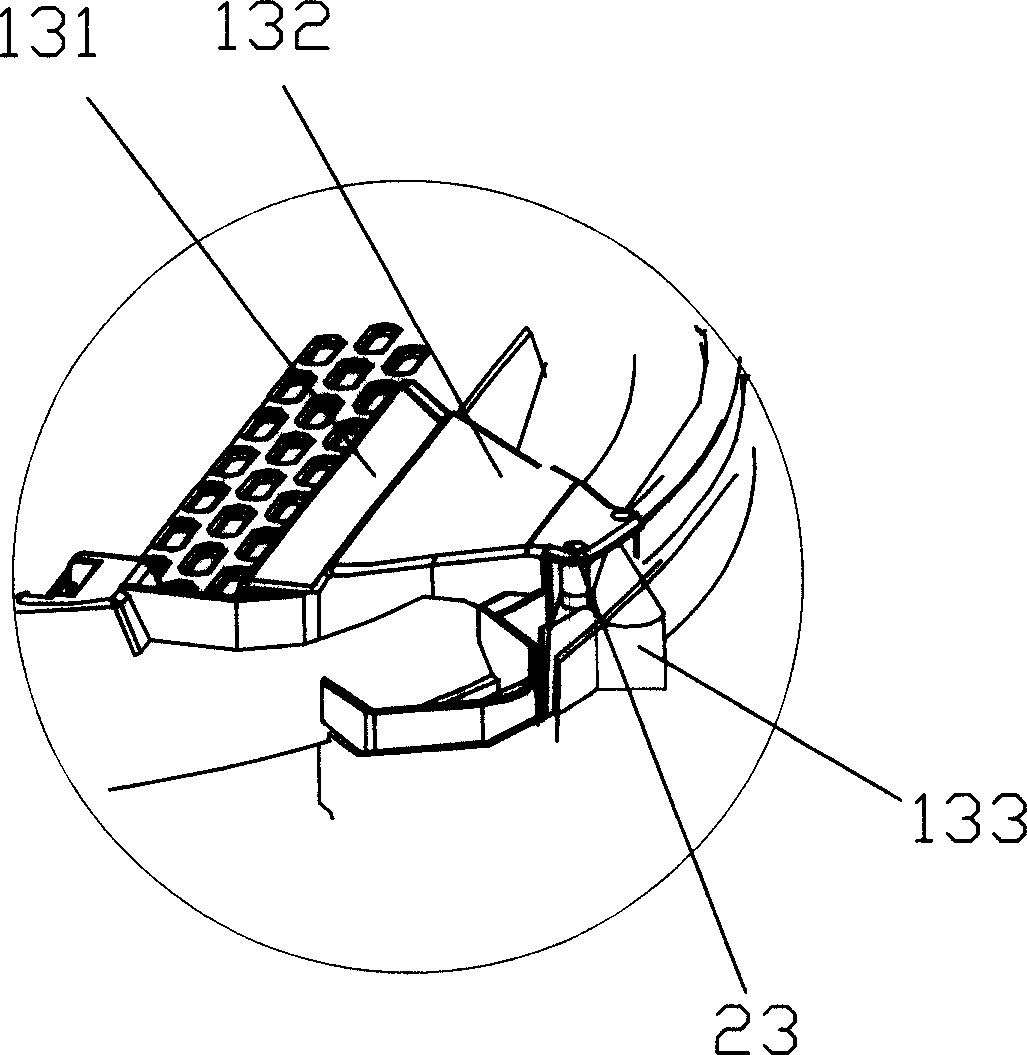

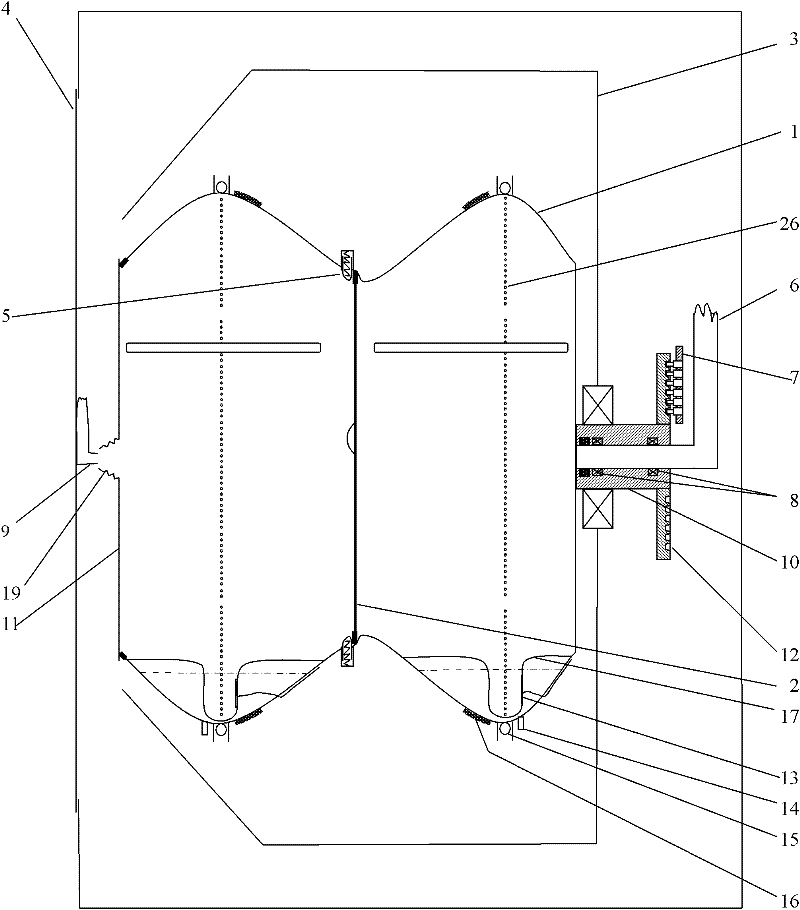

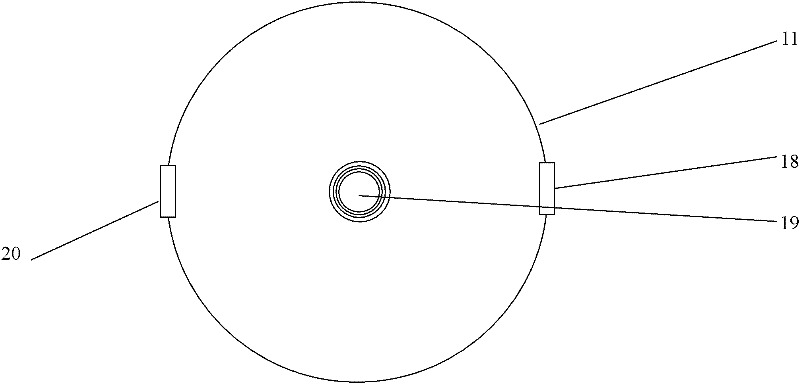

Category washing single barrel drum washing machine

InactiveCN102268800AAvoid cross infectionAvoid stainsOther washing machinesControl devices for washing apparatusLaundry washing machineEngineering

The invention relates to an improvement of a drum of a classification washing single-tub drum washing machine. When people wash clothes, they always hope that underwear and outerwear, decolorized clothes, and clothes for adults and children can be washed separately, so as to avoid cross-contamination and dyeing between clothes. However, the current single-tub drum washing machine washes one type of clothing first and then washes another type of clothing, which not only wastes water, electricity and time, but also requires manual intervention in the middle, which brings inconvenience to users. In the present invention, a detachable partition 22 is added in the single-tub drum 21, and the inner space of the single-tub drum 21 is divided into two independent washing spaces with different sizes on the left and right (the front and rear can also be separated), and different kinds of clothes can be placed at the same time Wash in 2 independent washing spaces, and take off the partition 22 when you need to wash bulky clothes. Among the figure, two of 25 are the washing ribs that the top is provided with grooves and are sealingly connected with the cylinder inwall, 23 and 24 are washing ribs, and 27 is a water level sensor.

Owner:任文涛

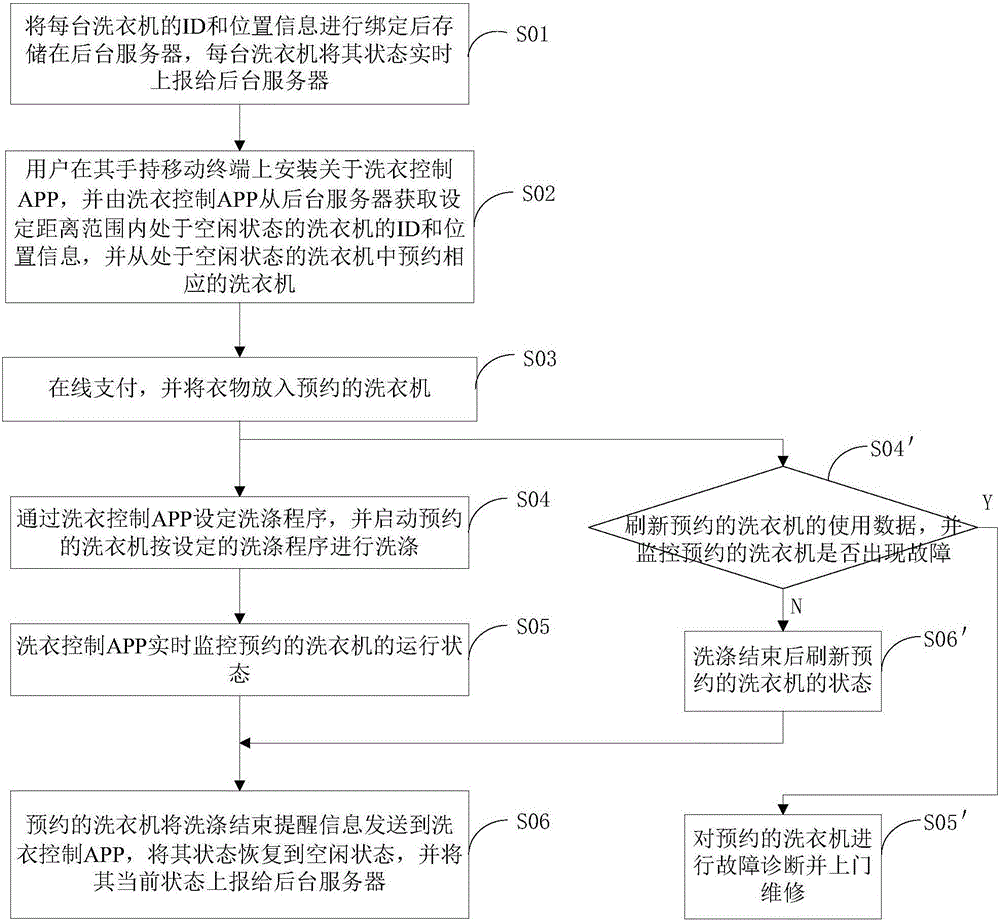

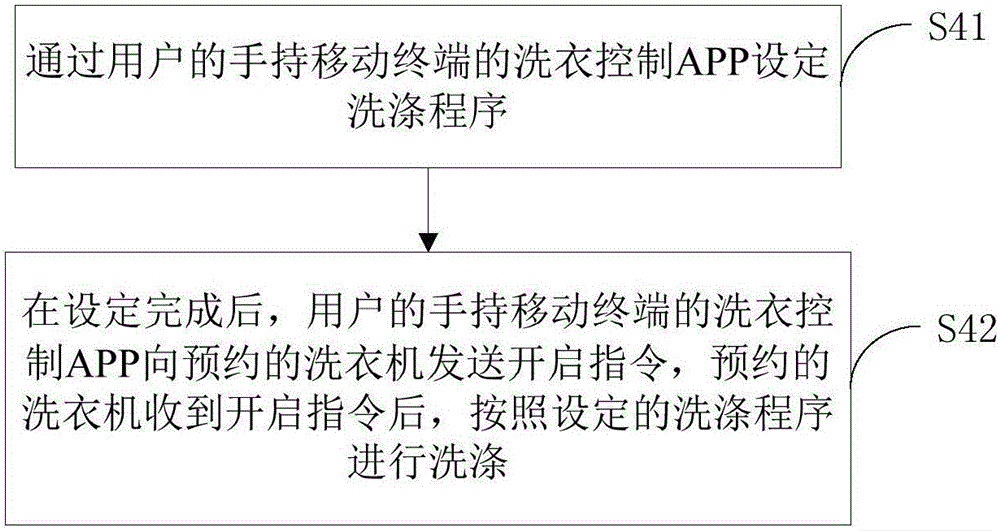

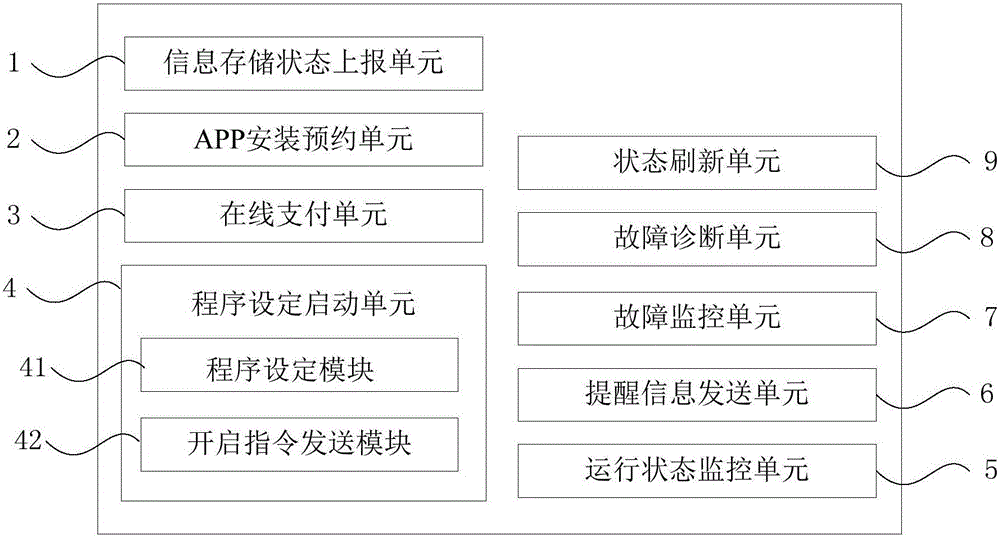

Method and device for remotely controlling washing machines to wash clothes

InactiveCN105133249AImprove experienceOvercome deficienciesControl devices for washing apparatusTextiles and paperComputer terminalComputer science

The invention provides a method and device for remotely controlling washing machines to wash clothes. The method includes the steps of bonding ID and position information of each washing machine and then storing the ID and position information in a background server, reporting the state to the background server by each washing machine, installing a clothes washing control APP on a handheld mobile terminal by a user, obtaining the ID and position information of the washing machines, in the idle states, within the set distance range from the background server, booking a certain washing machine, making a pavement online, putting clothes in the booked washing machine, setting a washing program through the clothes washing control APP, making the booked washing machine wash the clothes according to the set washing program, monitoring the running state of the booked washing machine in real time through the clothes washing control APP, and sending the washing finishing prompt information to the clothes washing control APP by the booked washing machine. The method and device have the advantages of being beneficial to user experience and convenient to manage.

Owner:田菲

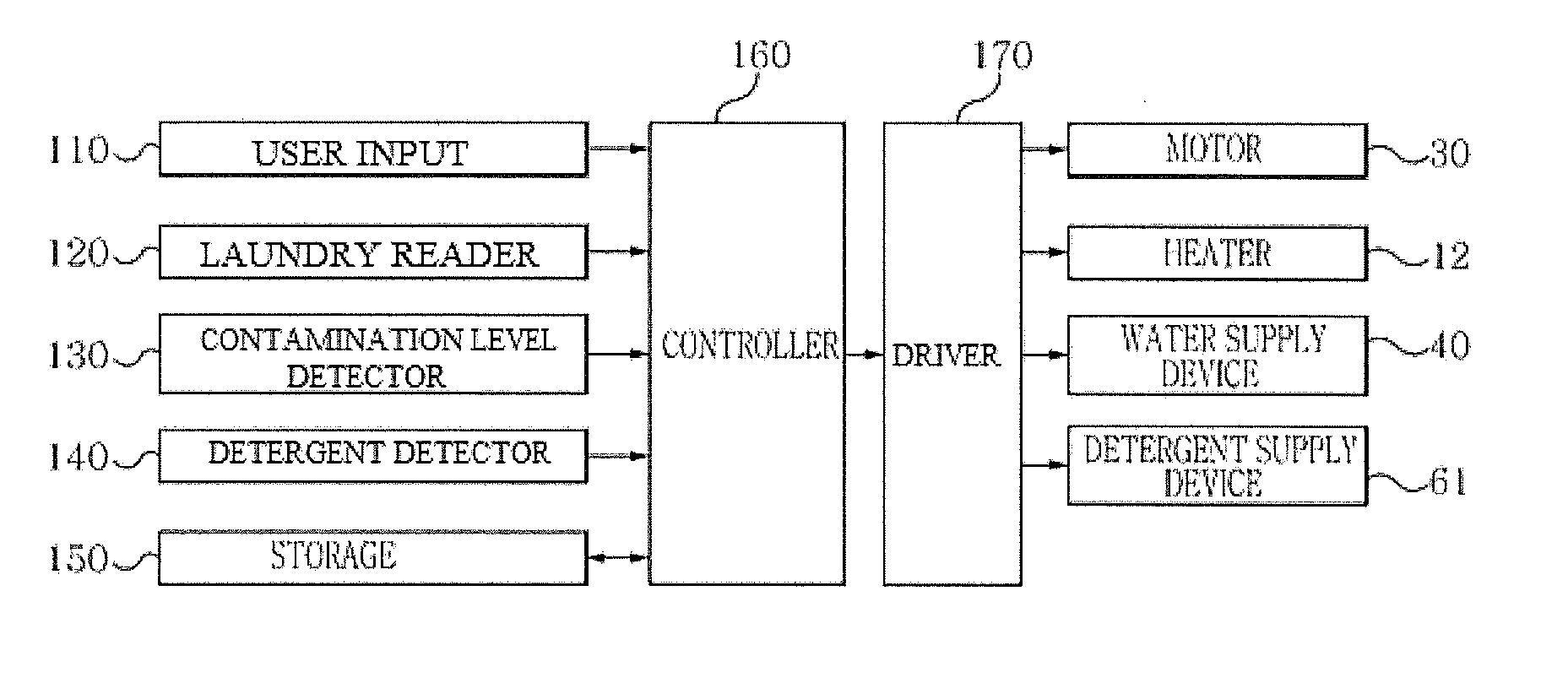

Washing machine and controlling method thereof

InactiveUS20130239337A1Other washing machinesControl devices for washing apparatusUser inputProcess engineering

A washing machine and a controlling method thereof may automatically set a customized washing cycle according to a wearing environment of laundry. The washing machine includes a user input configured to receive wearing environment information of the laundry from a user, and a controller configured to determine washing characteristics of the laundry based on the wearing environment information of the laundry and automatically set a washing cycle based on the washing characteristics of the laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com