Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2278results about "Physical treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

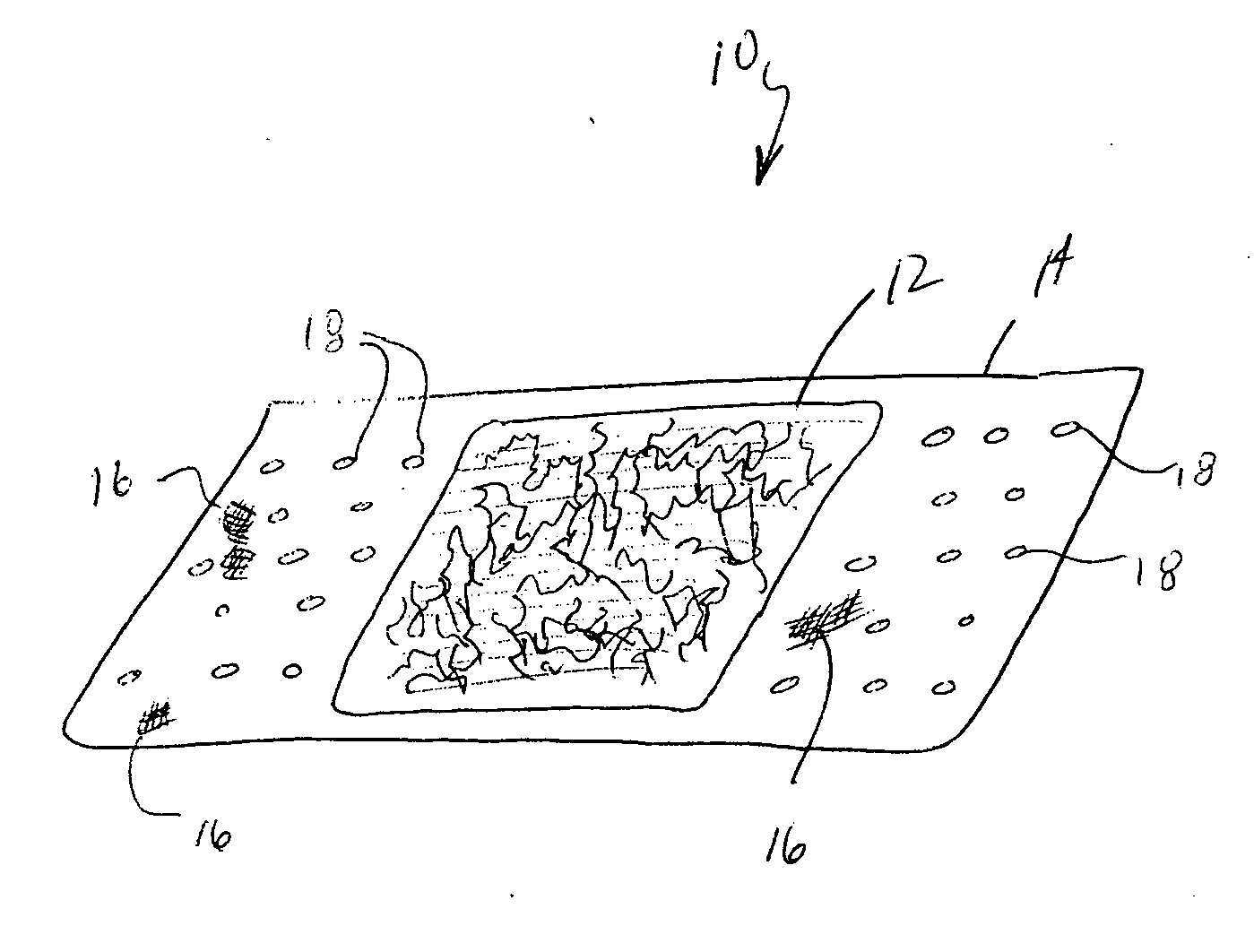

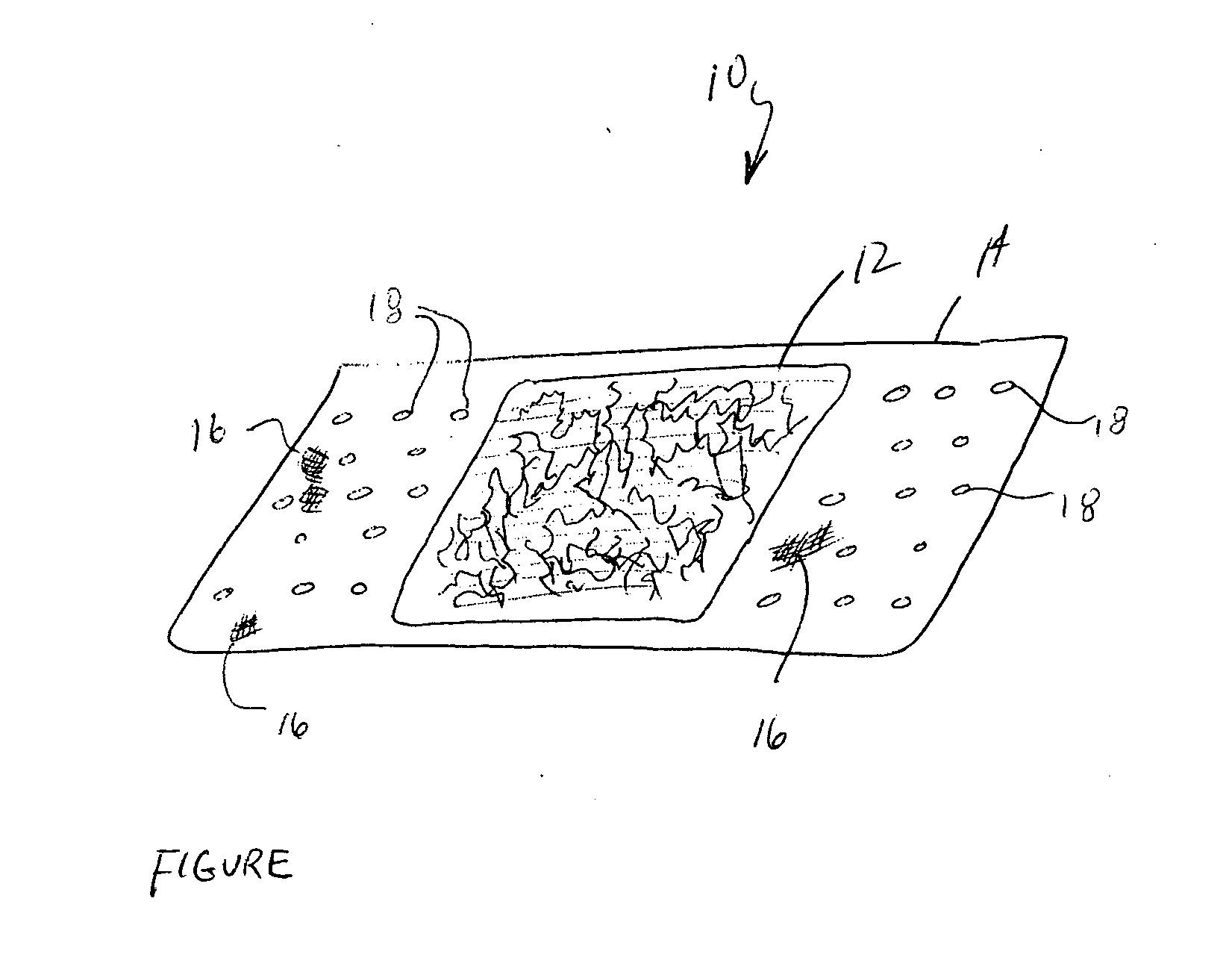

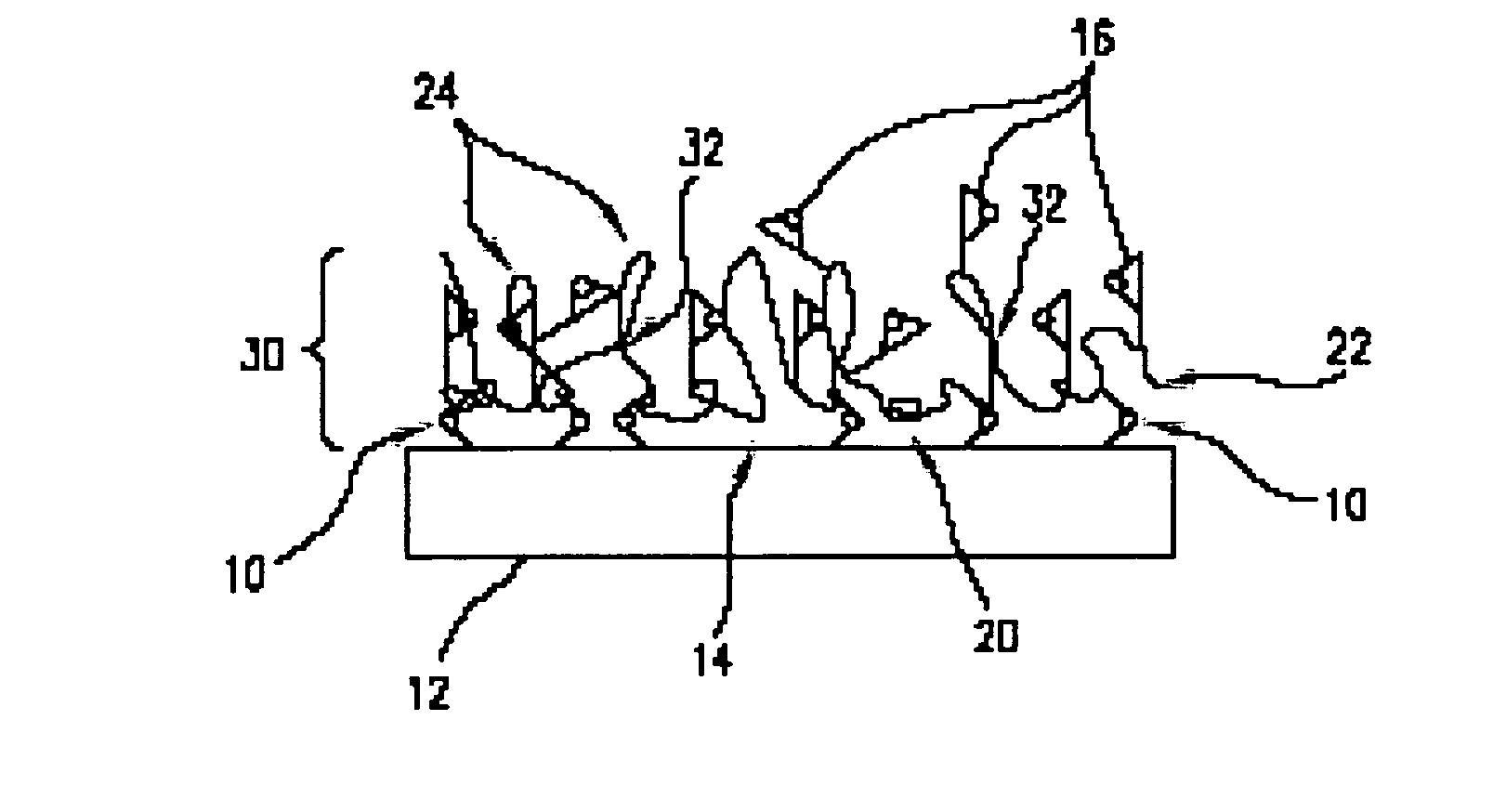

Agents and devices for providing blood clotting functions to wounds

InactiveUS20070190110A1Promote healingShorten the timePhysical treatmentAntithrombogenic treatmentNitrogen dioxideMedicine

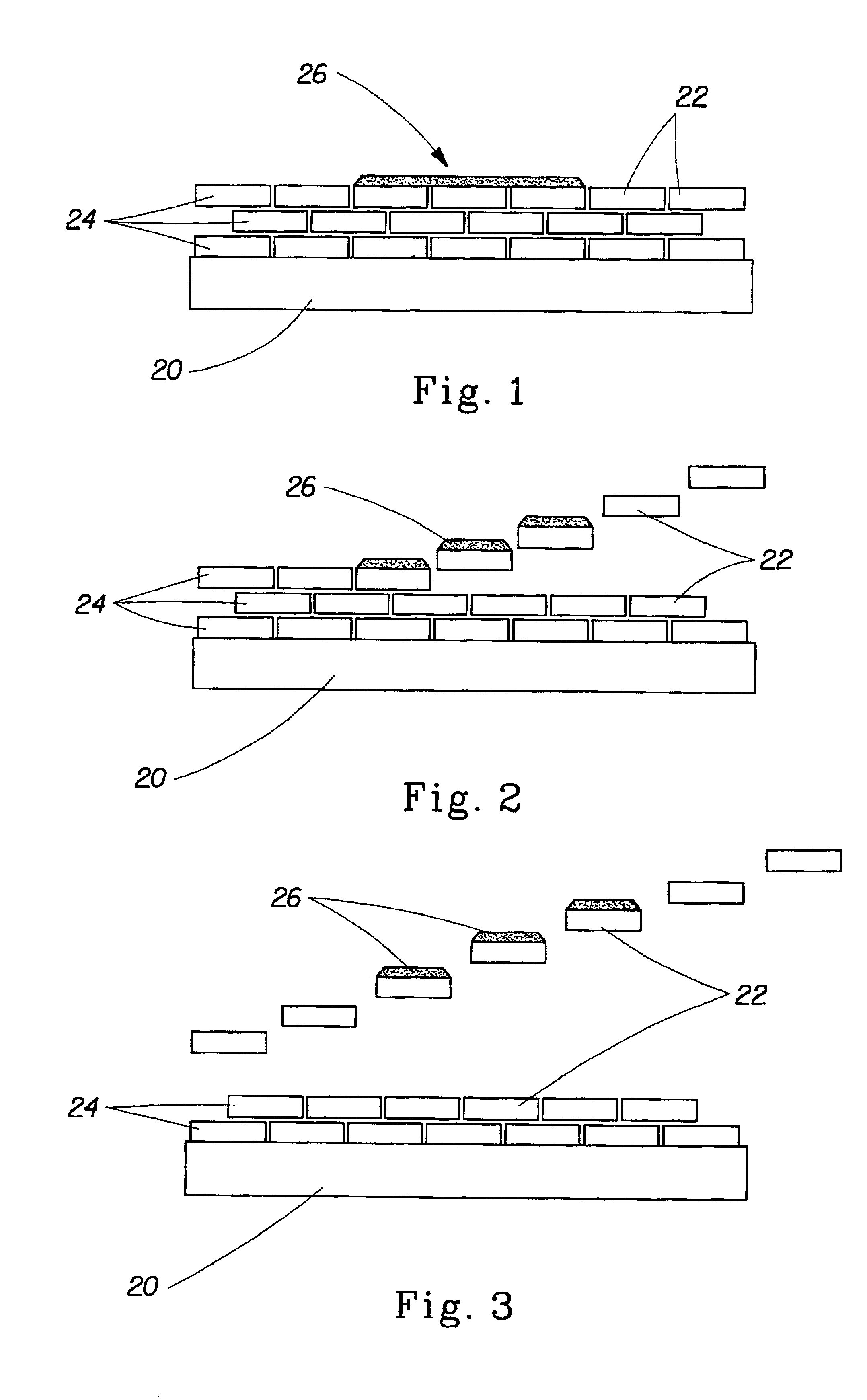

Hemostatic agents and devices are made from oxidized cellulose fiber, the oxidized cellulose having a carboxylation content increased by the action of nitrogen dioxide on virgin cellulose fiber. A composition may be incorporated into the oxidized cellulose fiber to cause a pharmacological effect on a wound to which the hemostatic agents and devices are applied. When applied, the oxidized cellulose fiber causes blood emanating from the wound to clot. The oxidized cellulose fiber can either be resorbed into the wound or removed from the wound after healing. A hemostatic bandage includes a pad of unwoven oxidized cellulose fibers mounted on a substrate. Methods of arresting a flow of blood emanating from a wound using such devices are also disclosed. Methods of fabricating oxidized cellulose are also disclosed.

Owner:PAMEIJER CORNELIS H +1

Method of hydrophilizing materials

InactiveUS6863933B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsRadiation applicationsPolymer scienceNanoparticle

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

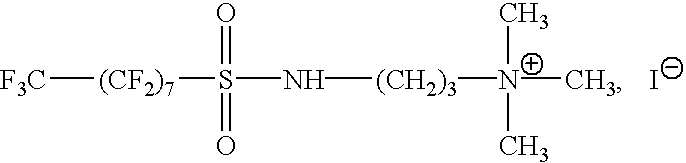

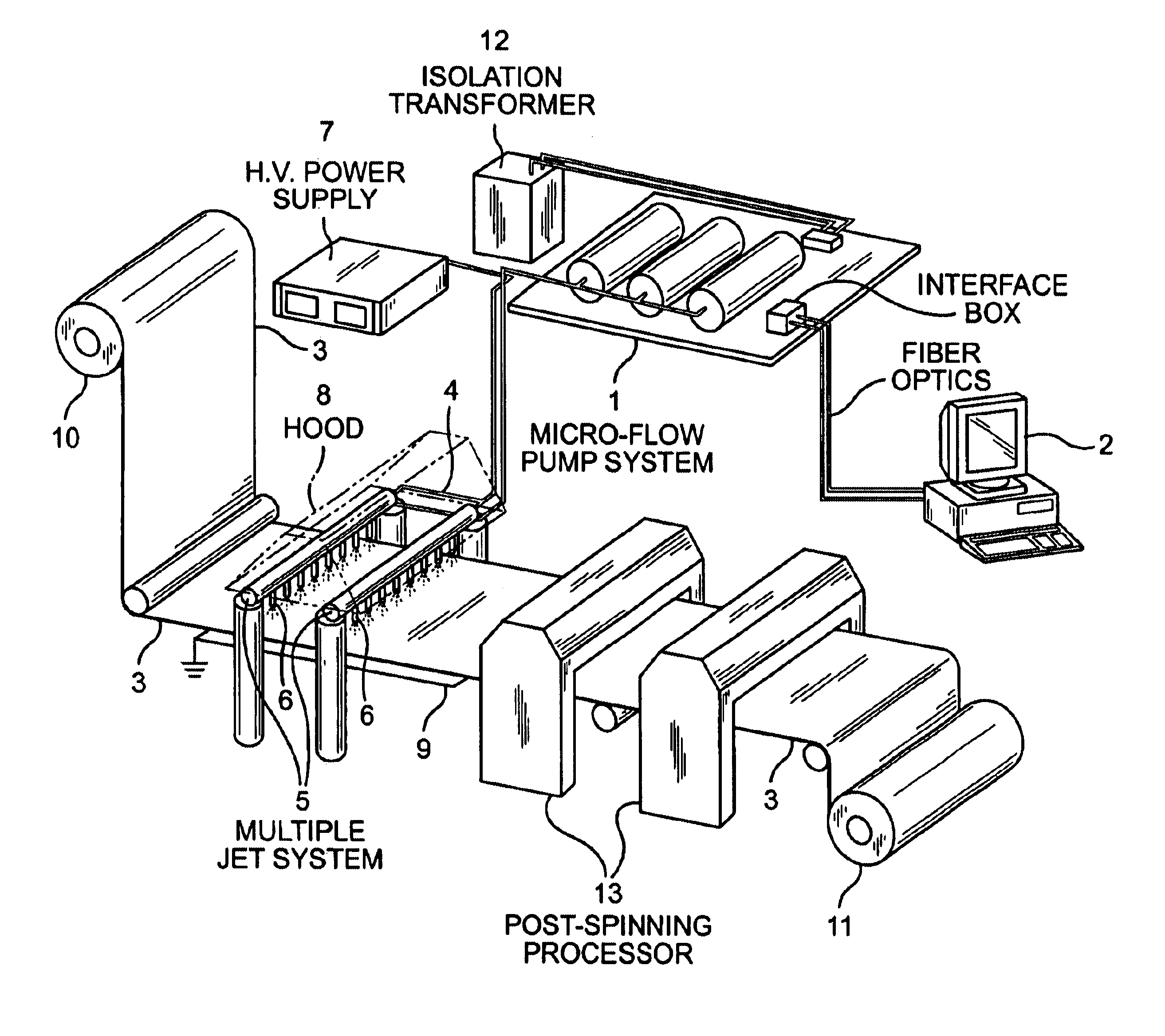

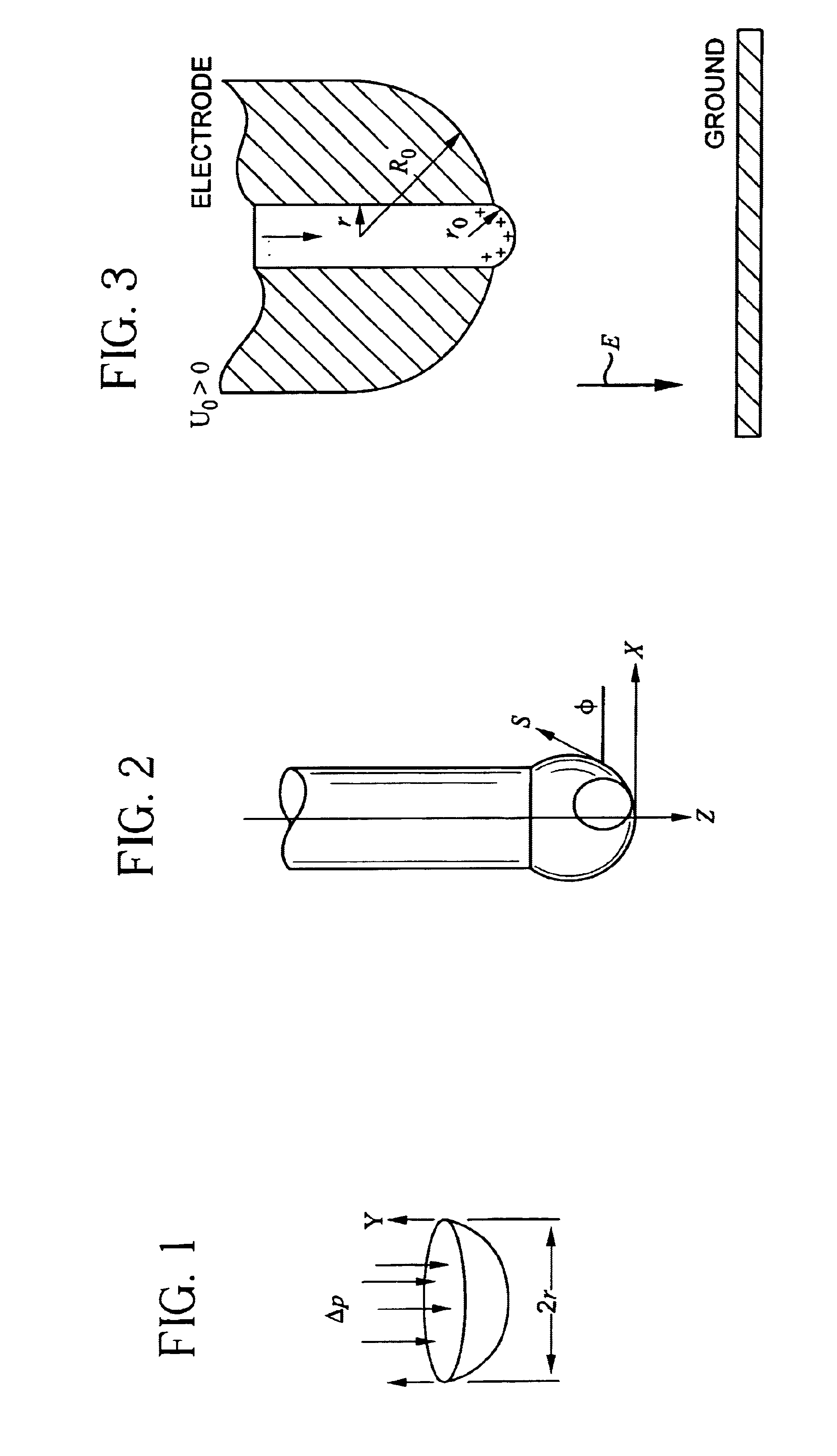

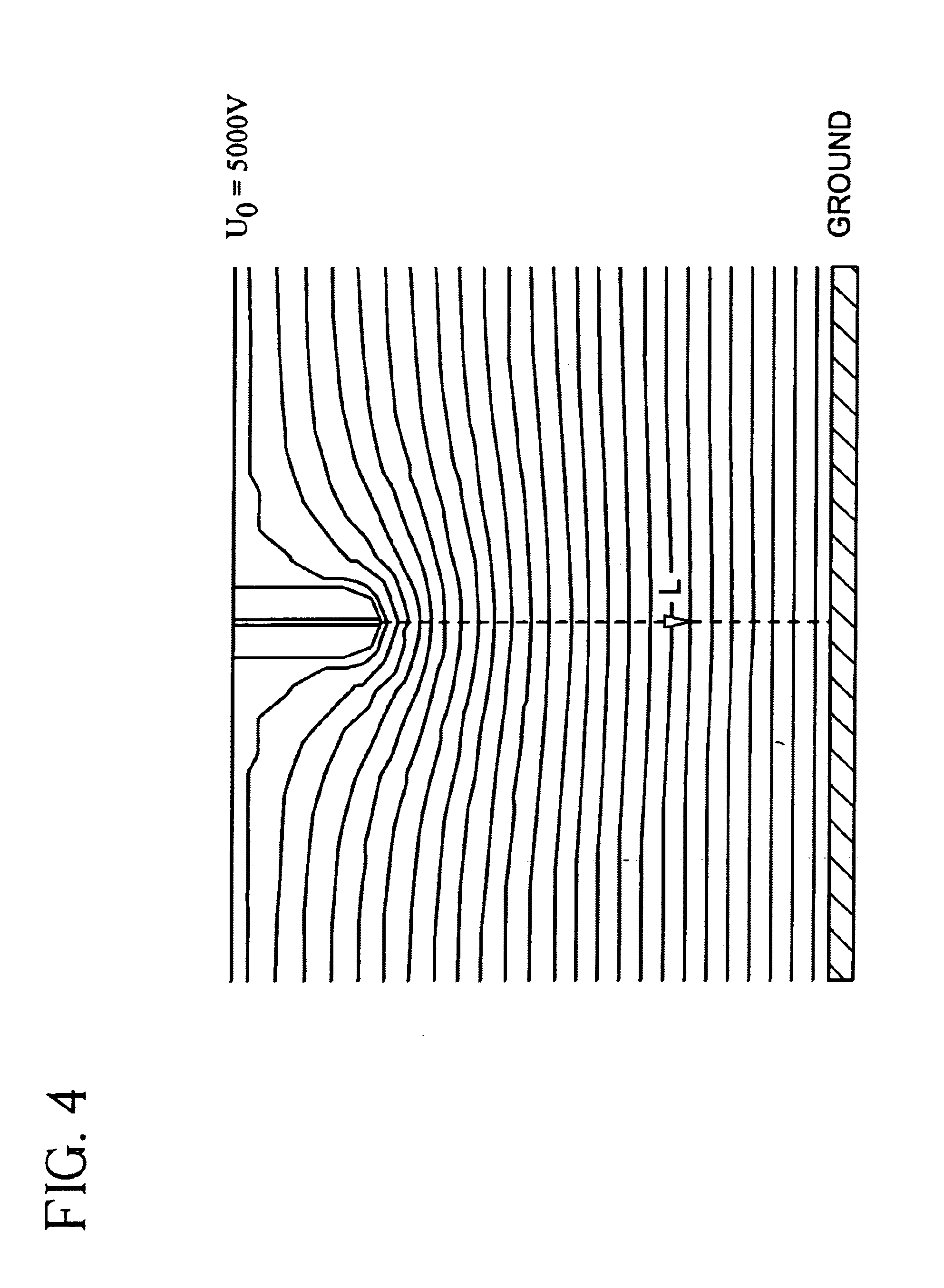

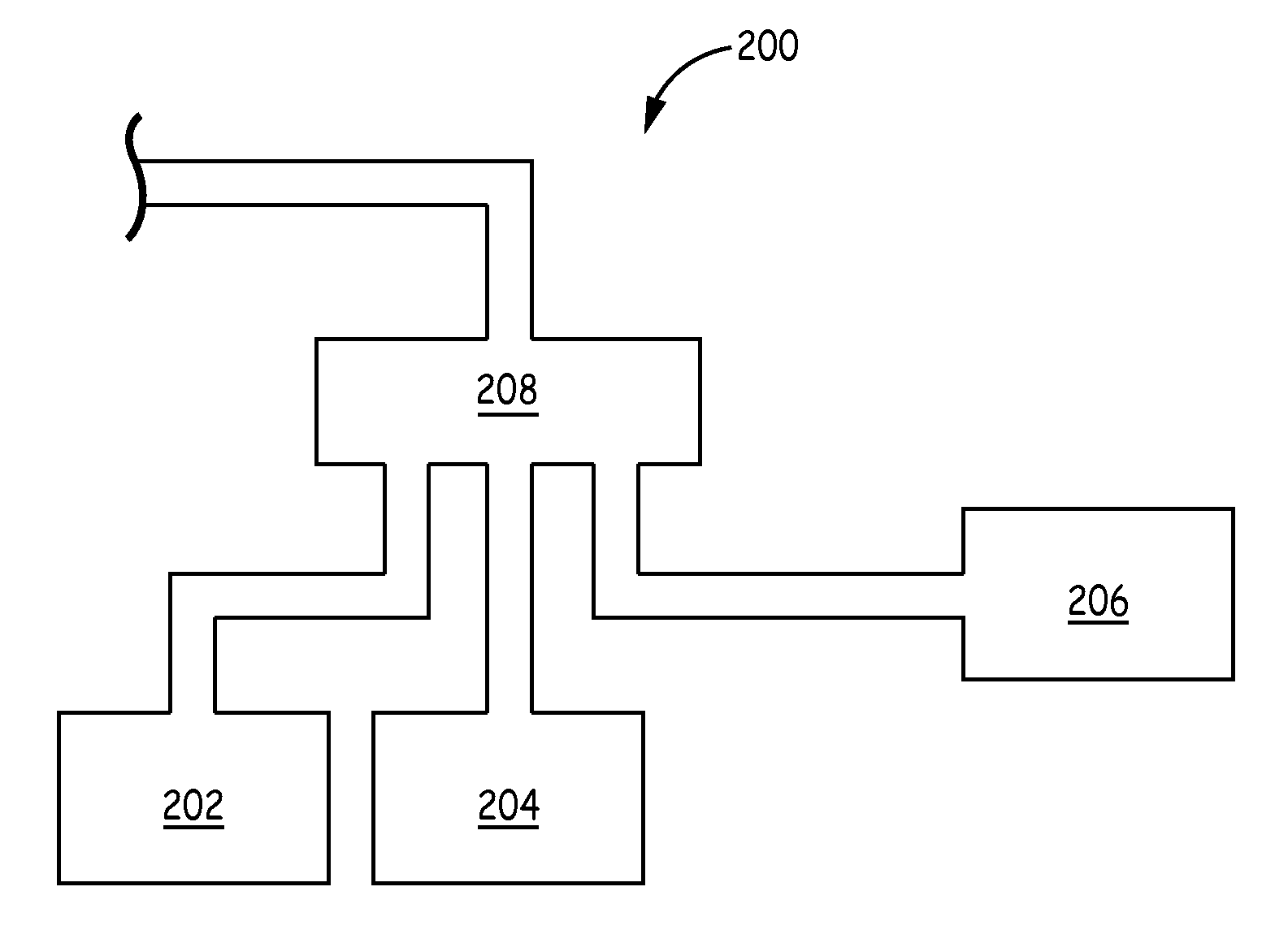

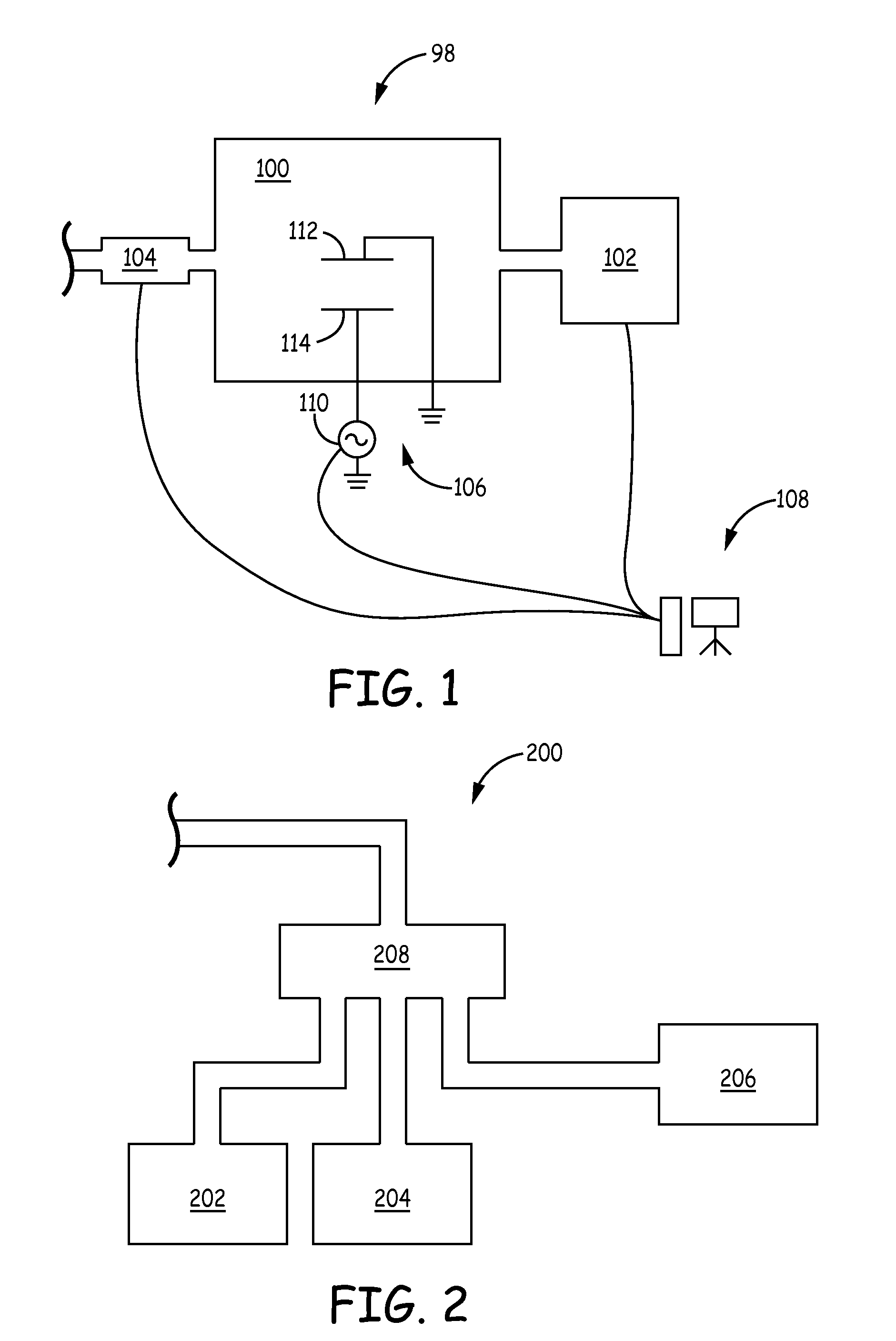

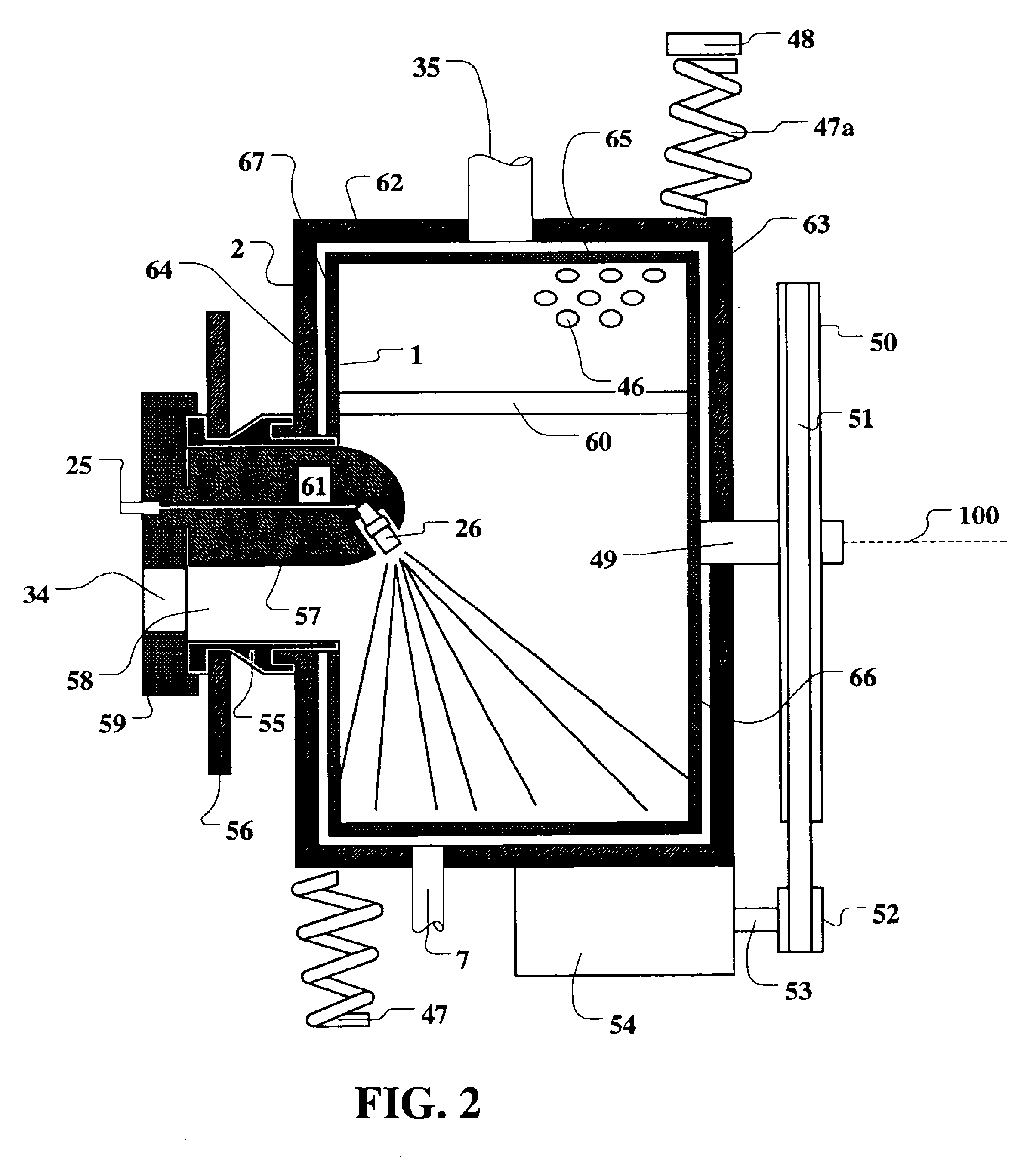

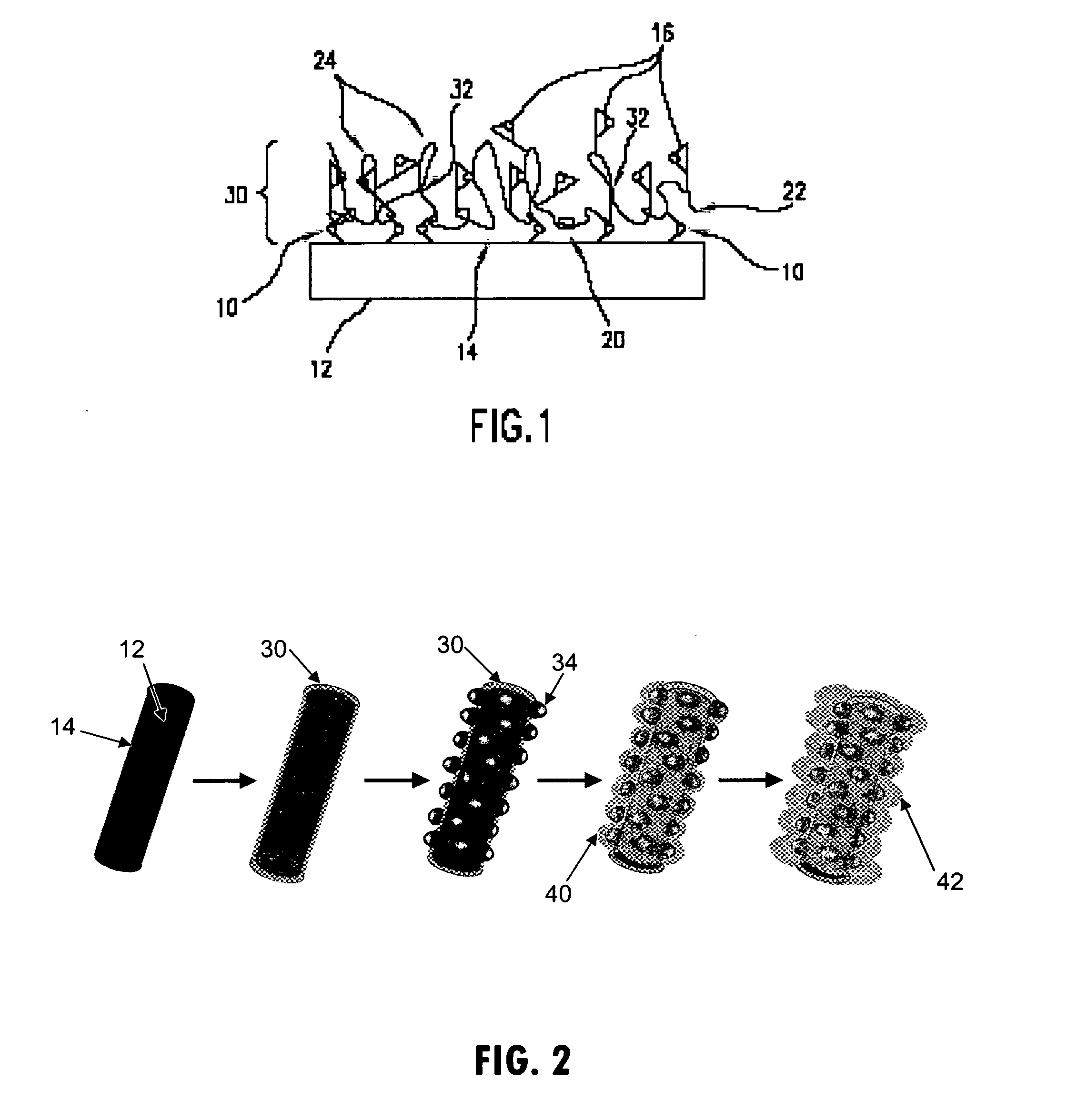

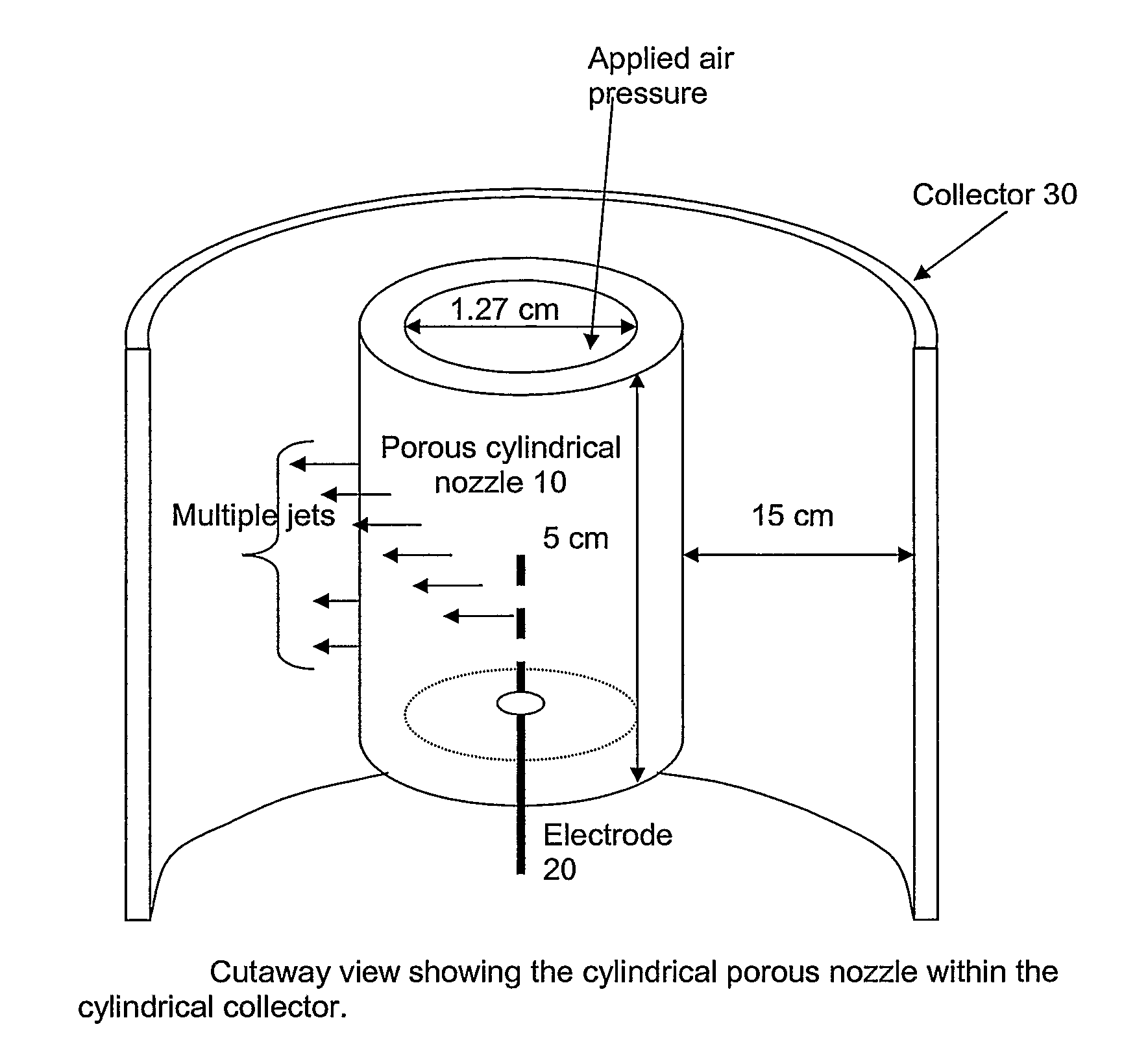

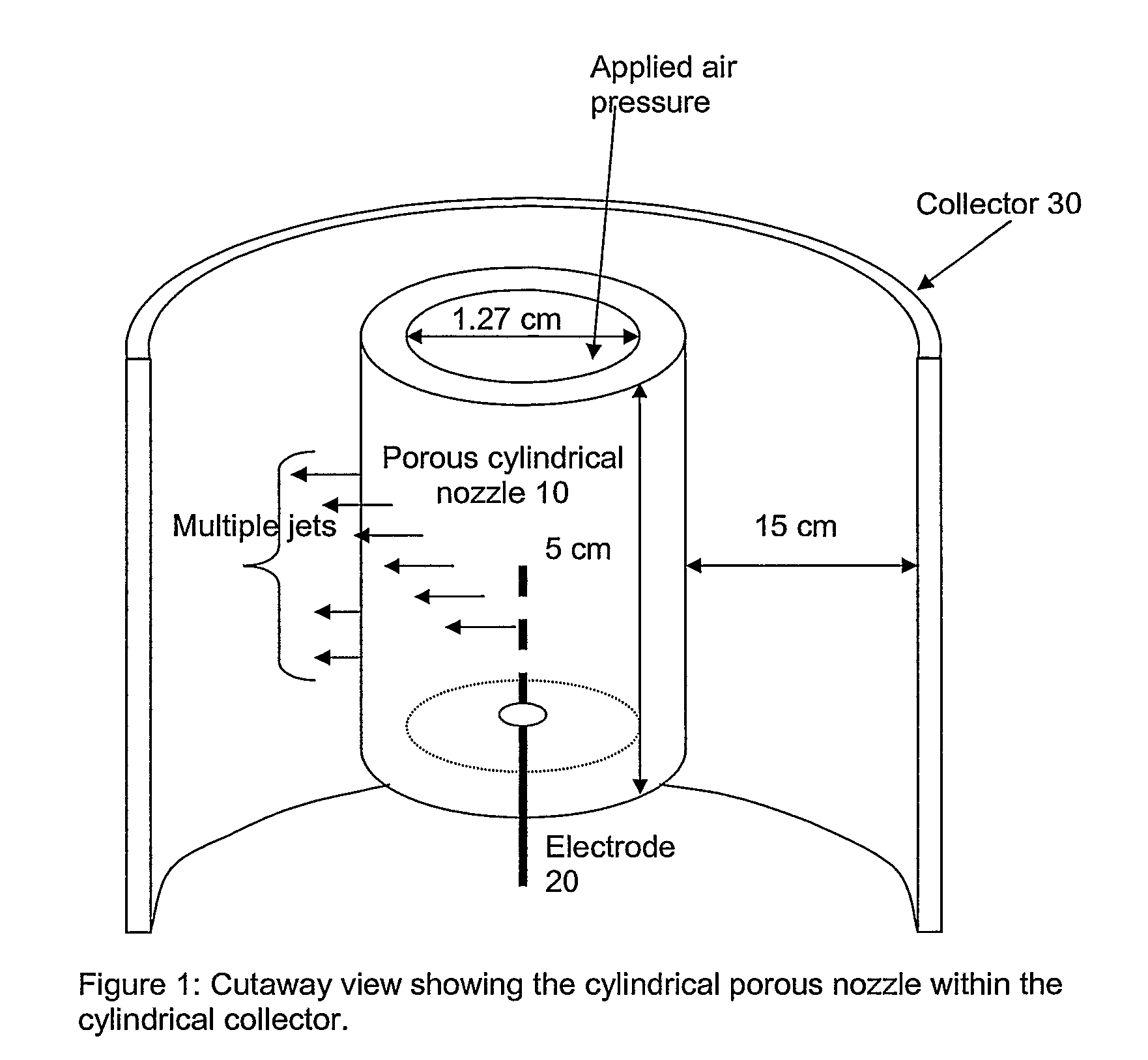

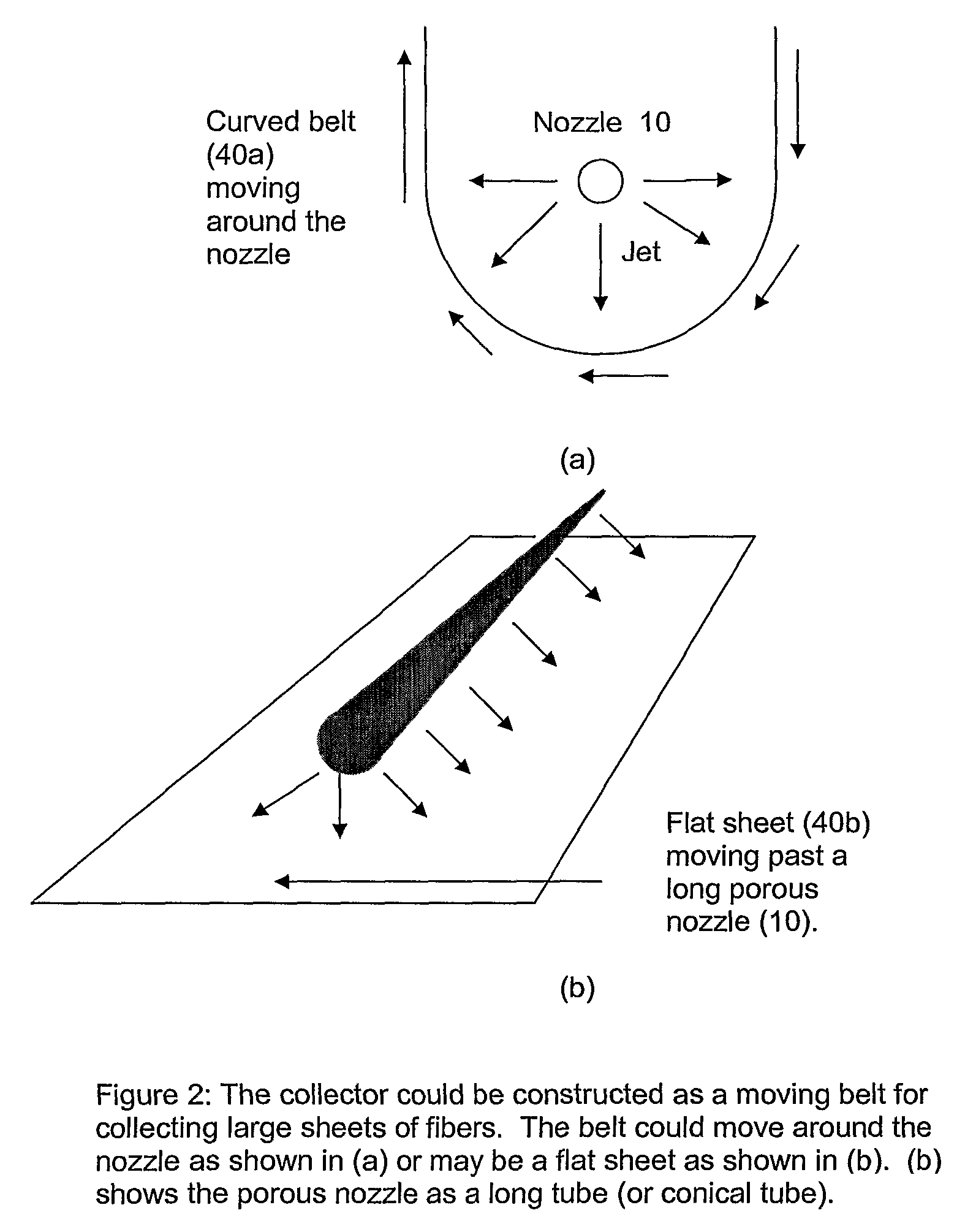

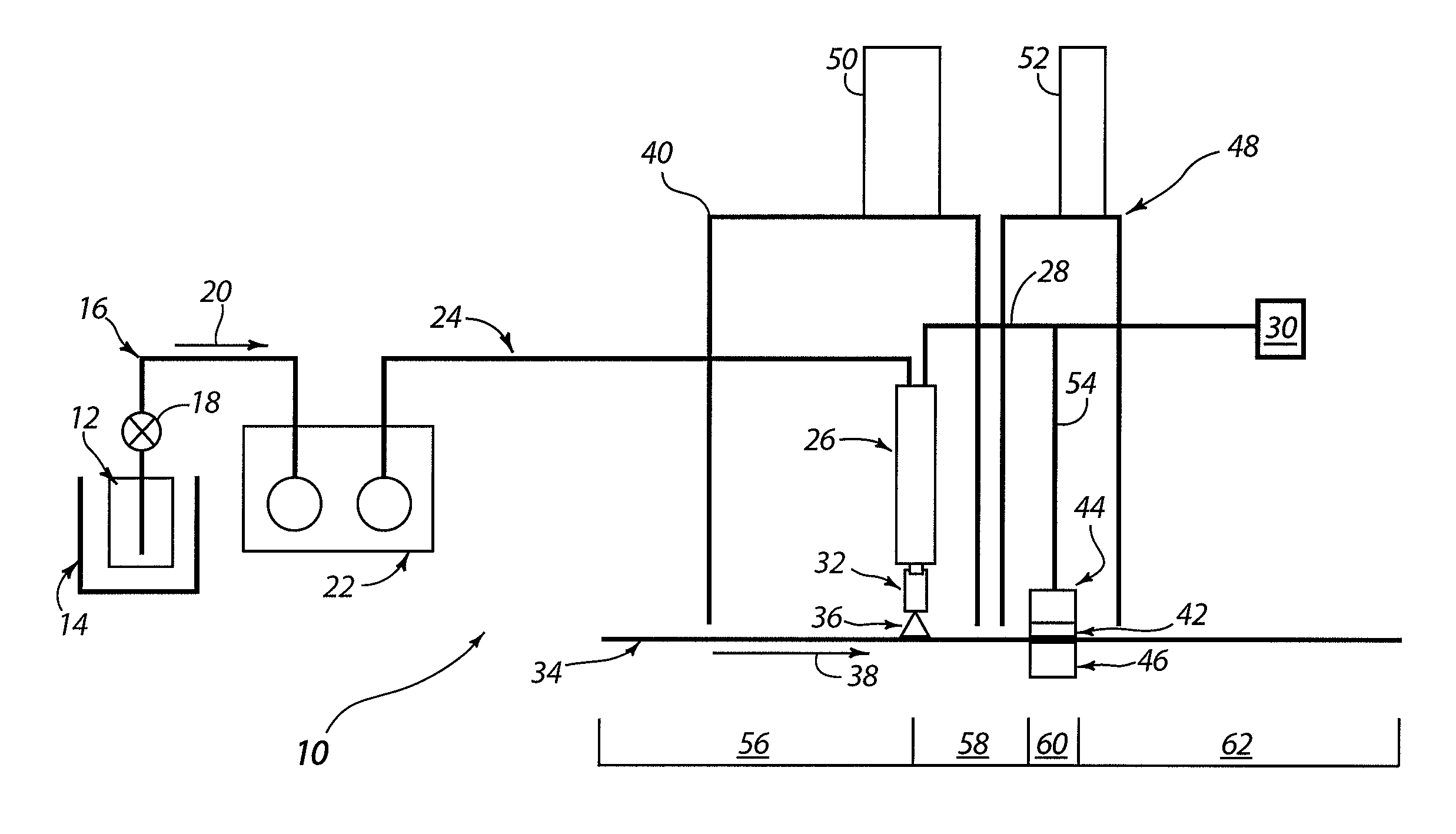

Apparatus and methods for electrospinning polymeric fibers and membranes

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

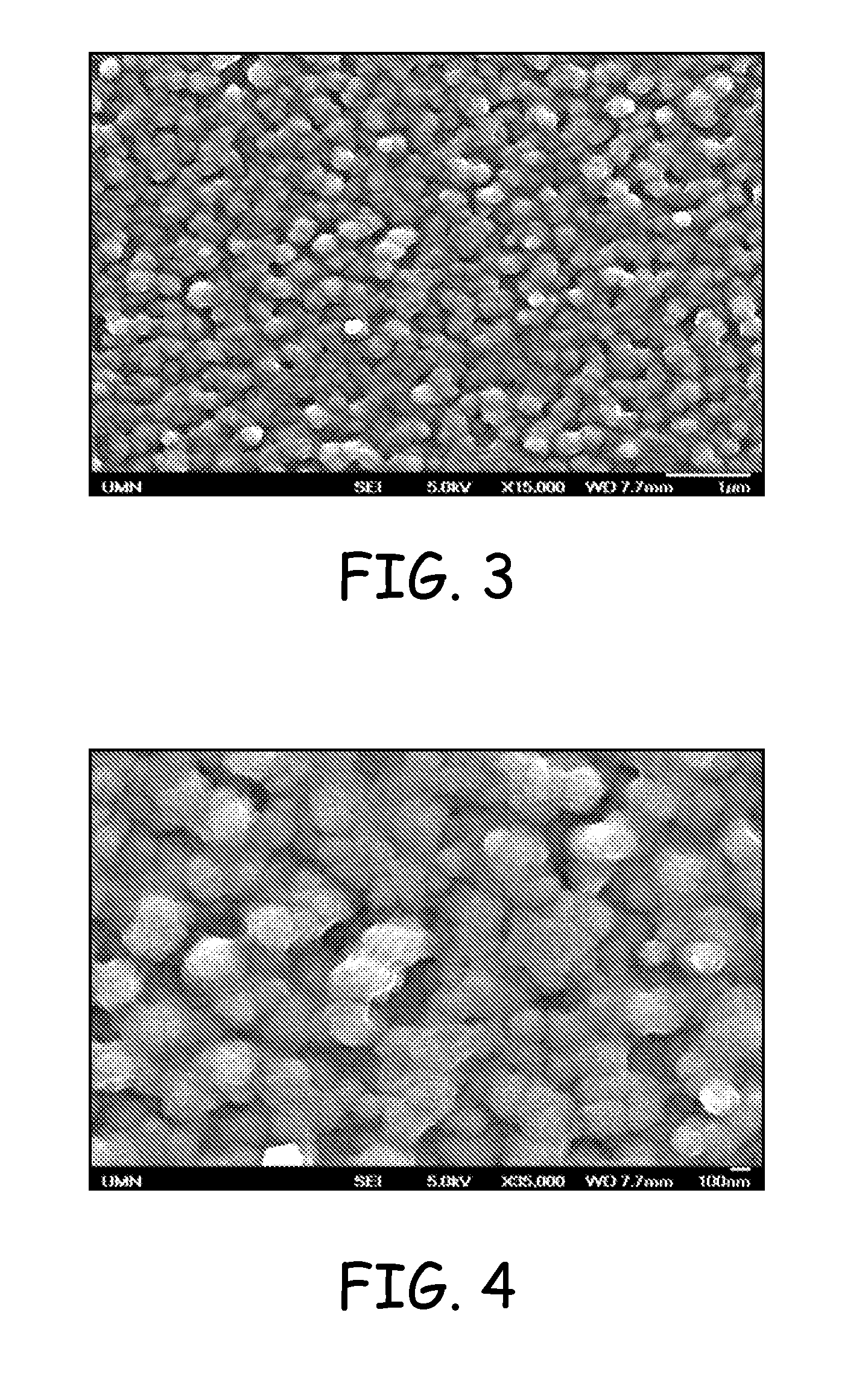

Apparatus and methods for plasma enhanced chemical vapor deposition of polymer coatings

Apparatuses and methods are described that involve the deposition of polymer coatings on substrates. The polymer coatings generally comprise an electrically insulating layer and / or a hydrophobic layer. The hydrophobic layer can comprise fused polymer particles have an average primary particle diameter on the nanometer to micrometer scale. The polymer coatings are deposited on substrates using specifically adapted plasma enhanced chemical vapor deposition approaches. The substrates can include computing devices and fabrics.

Owner:LIQUIPEL IP

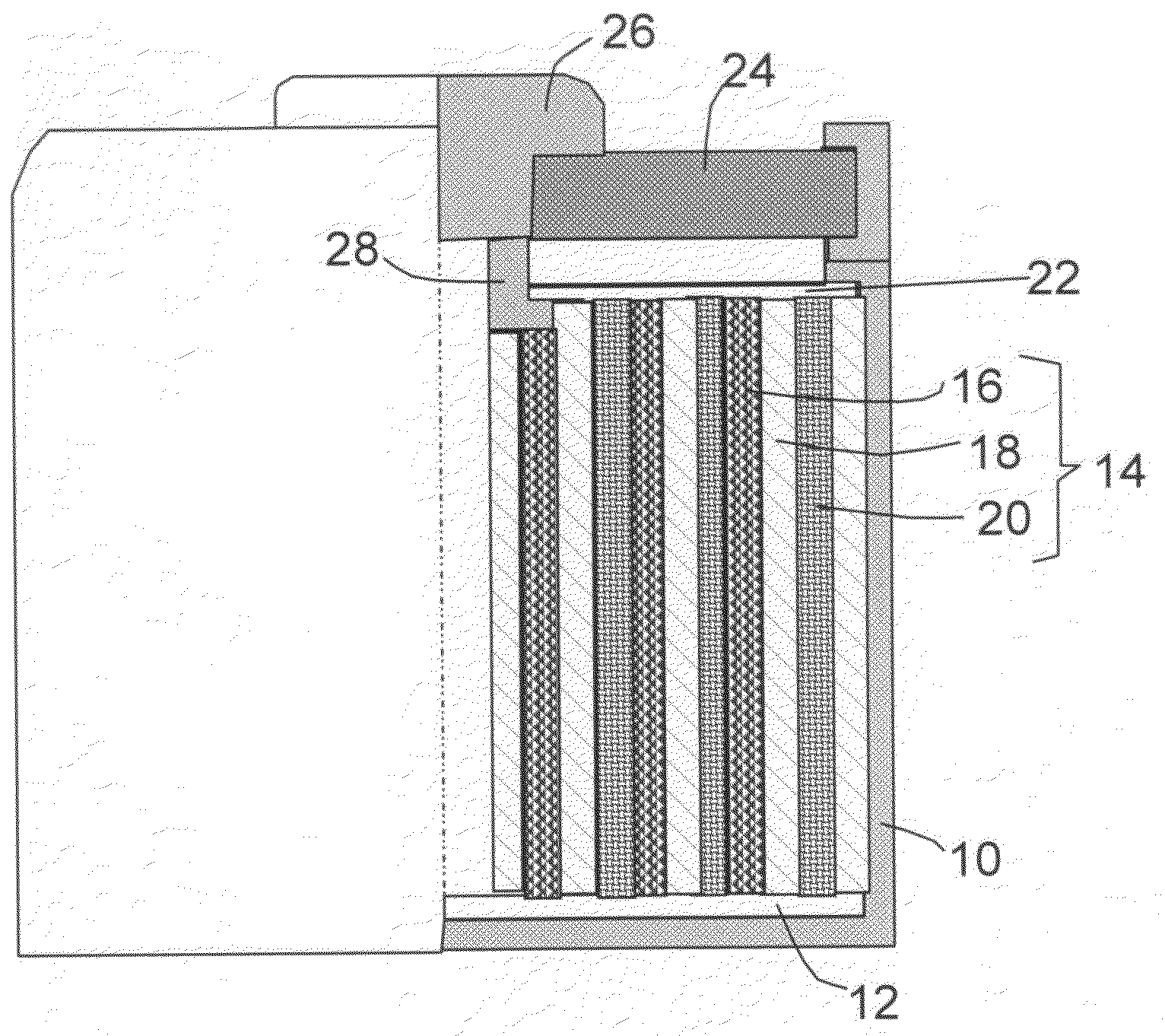

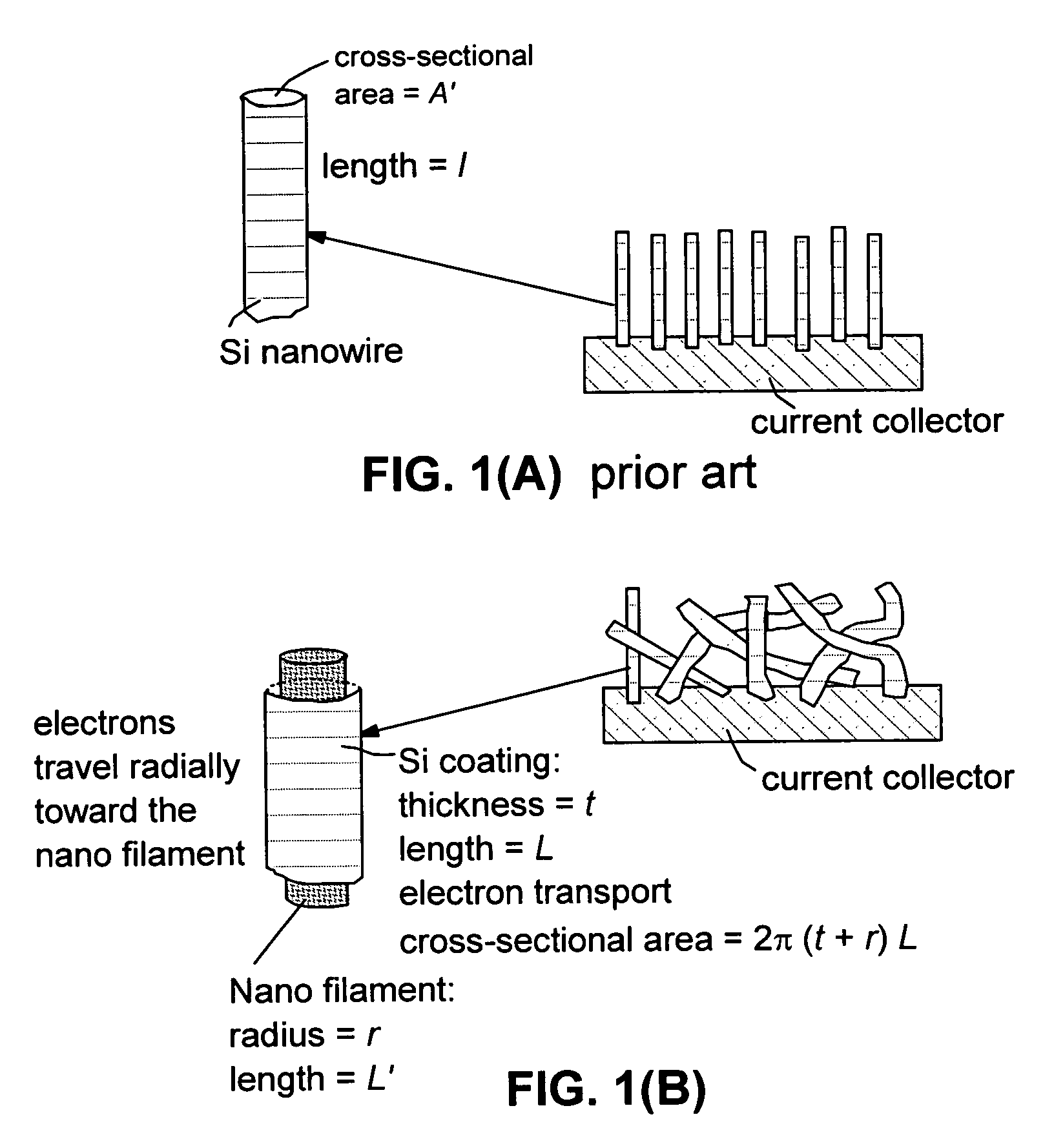

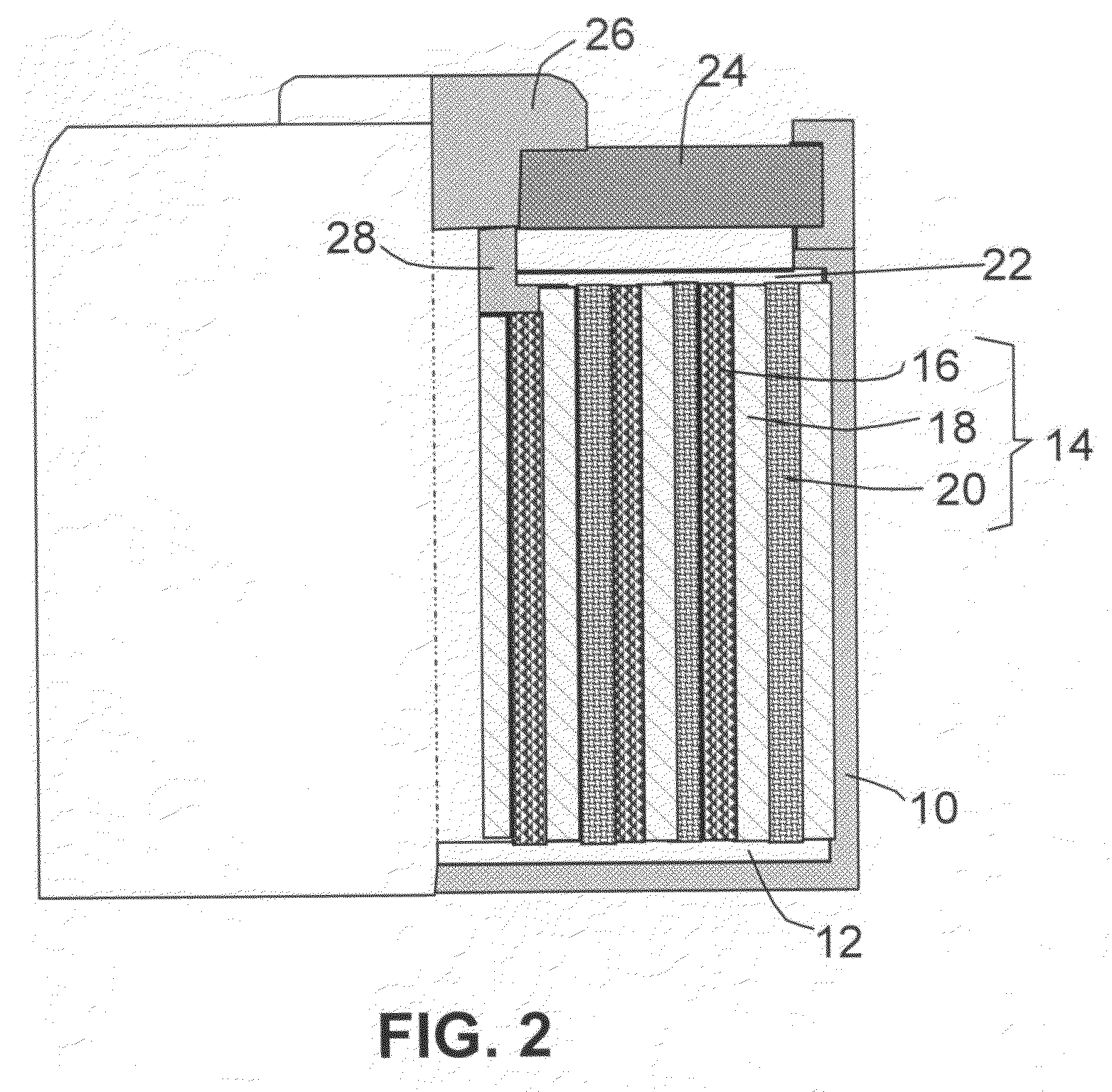

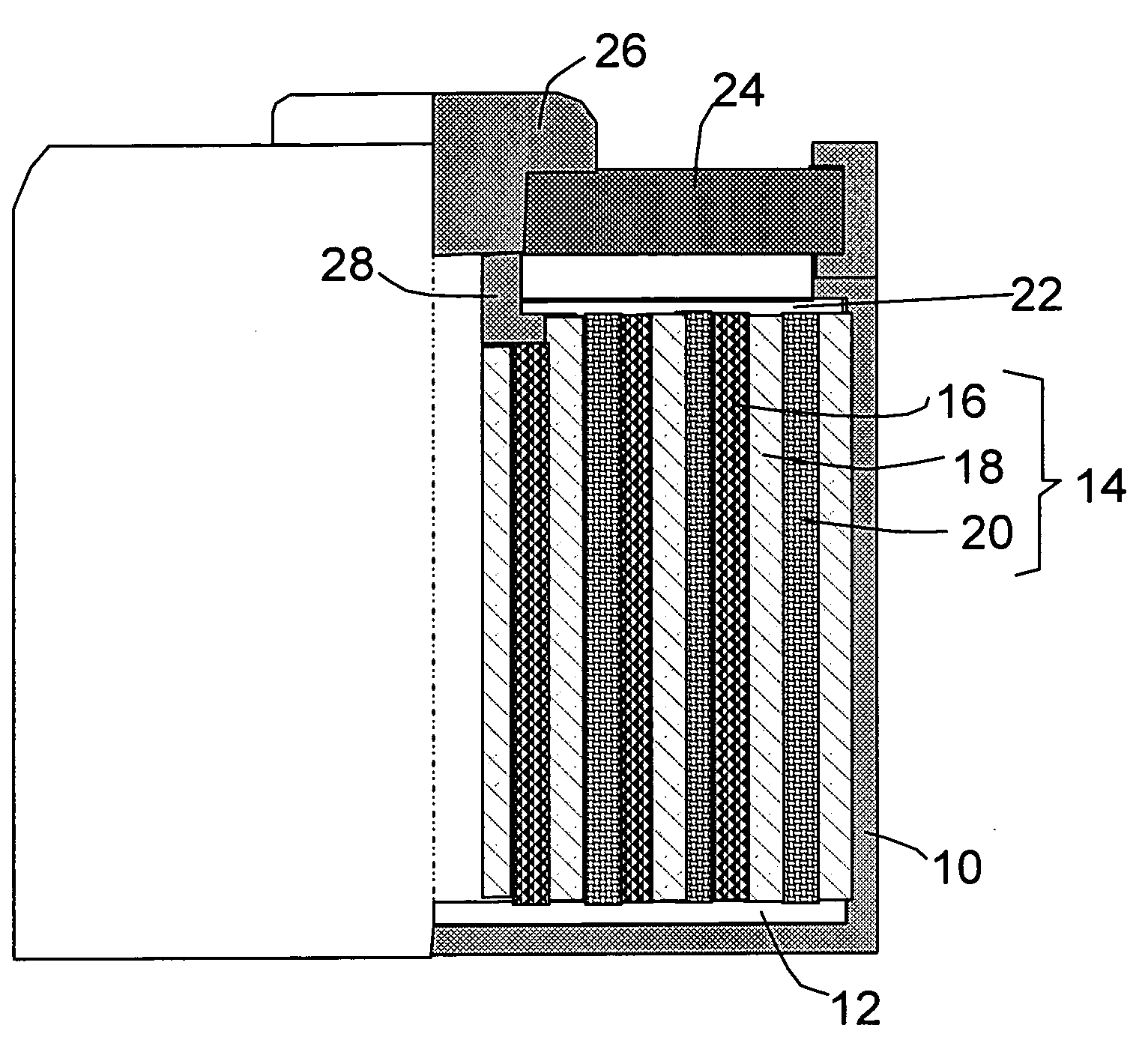

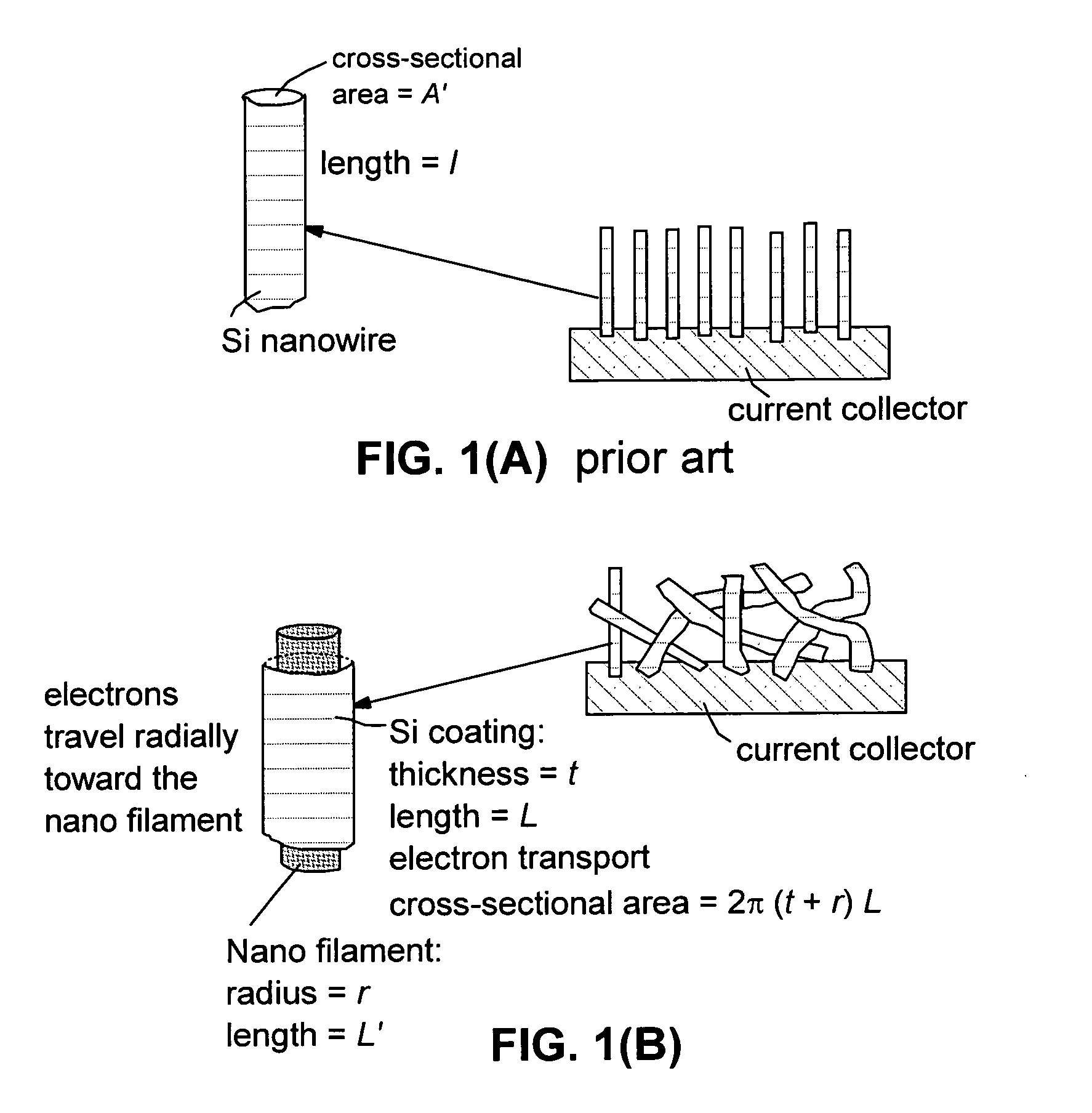

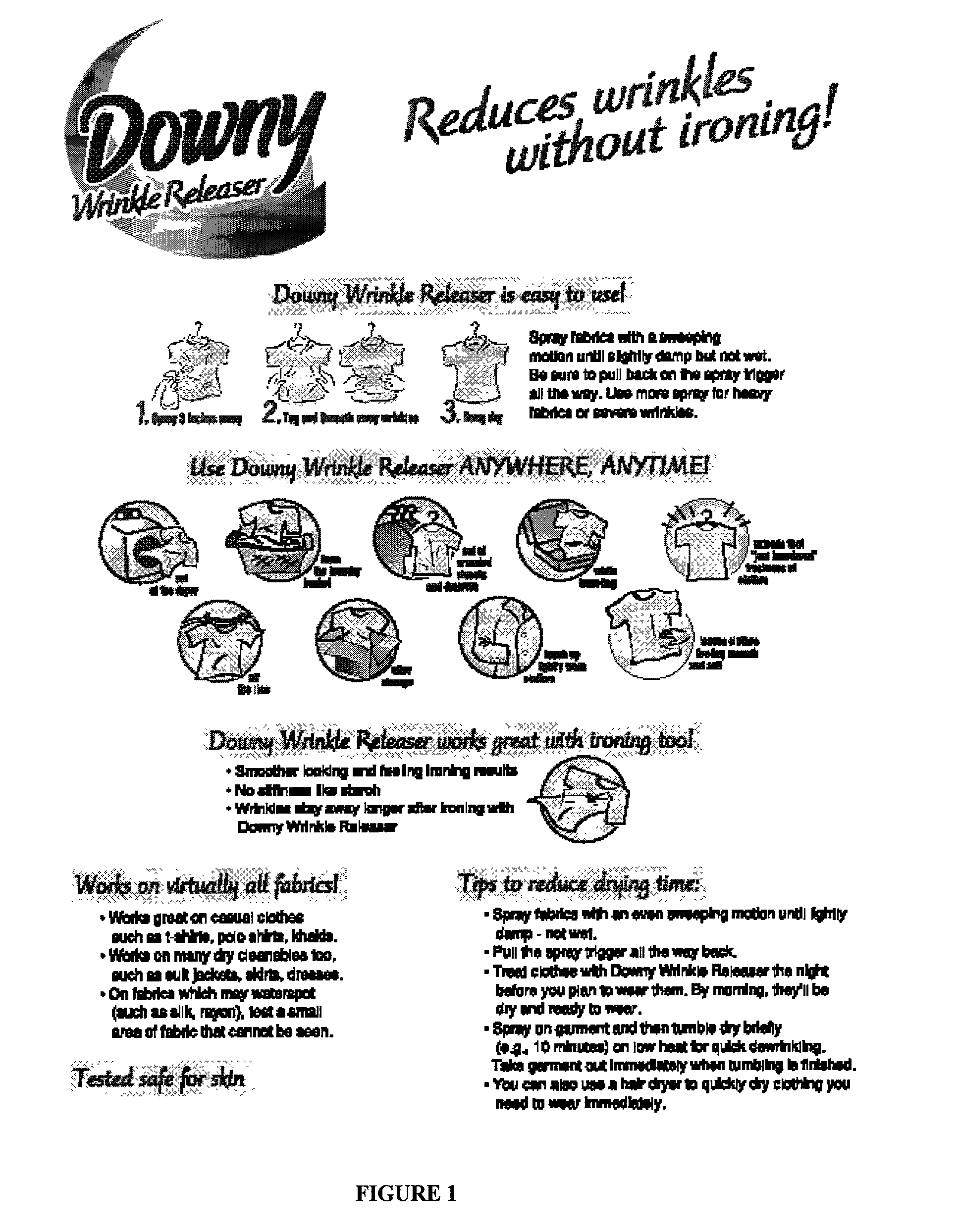

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

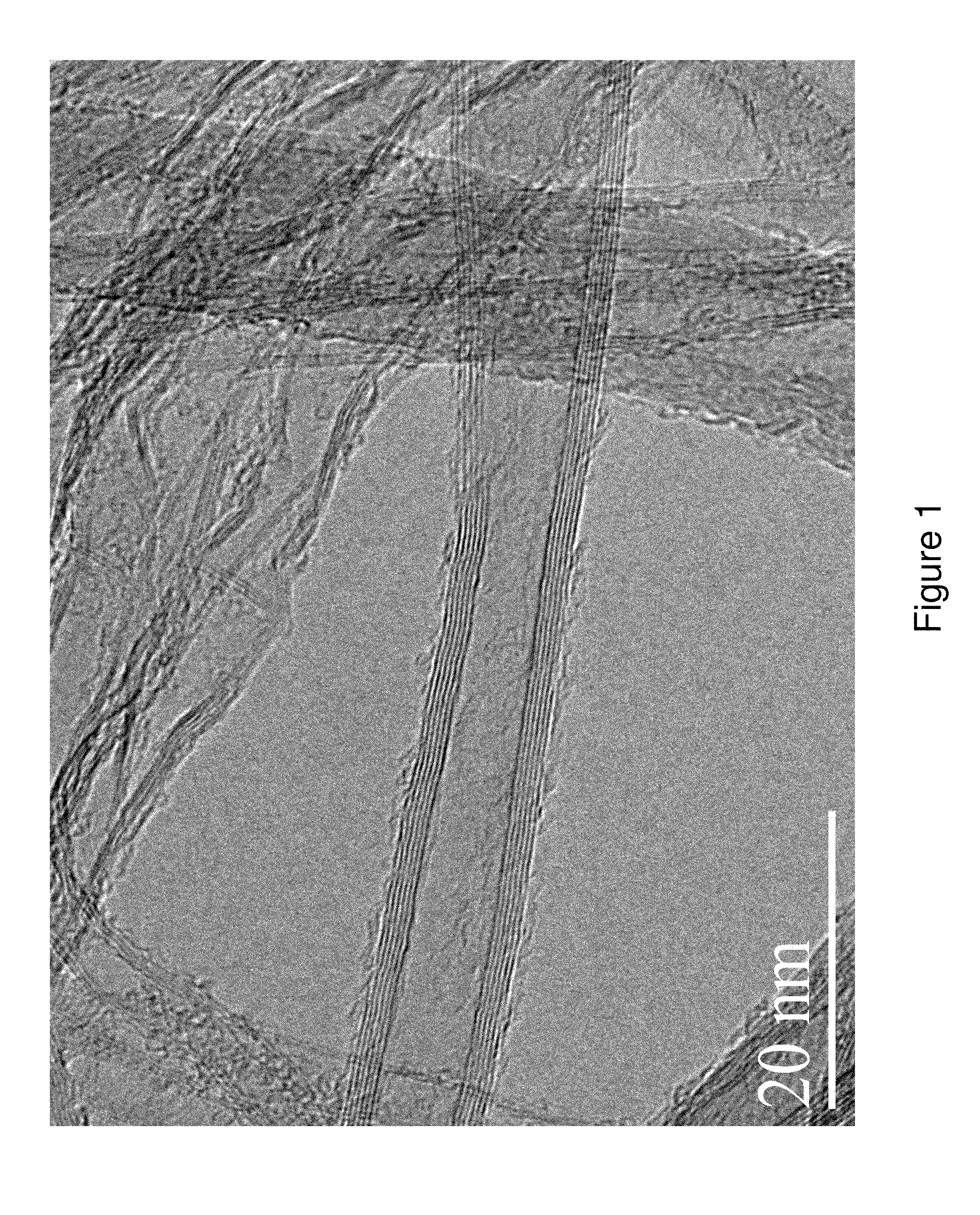

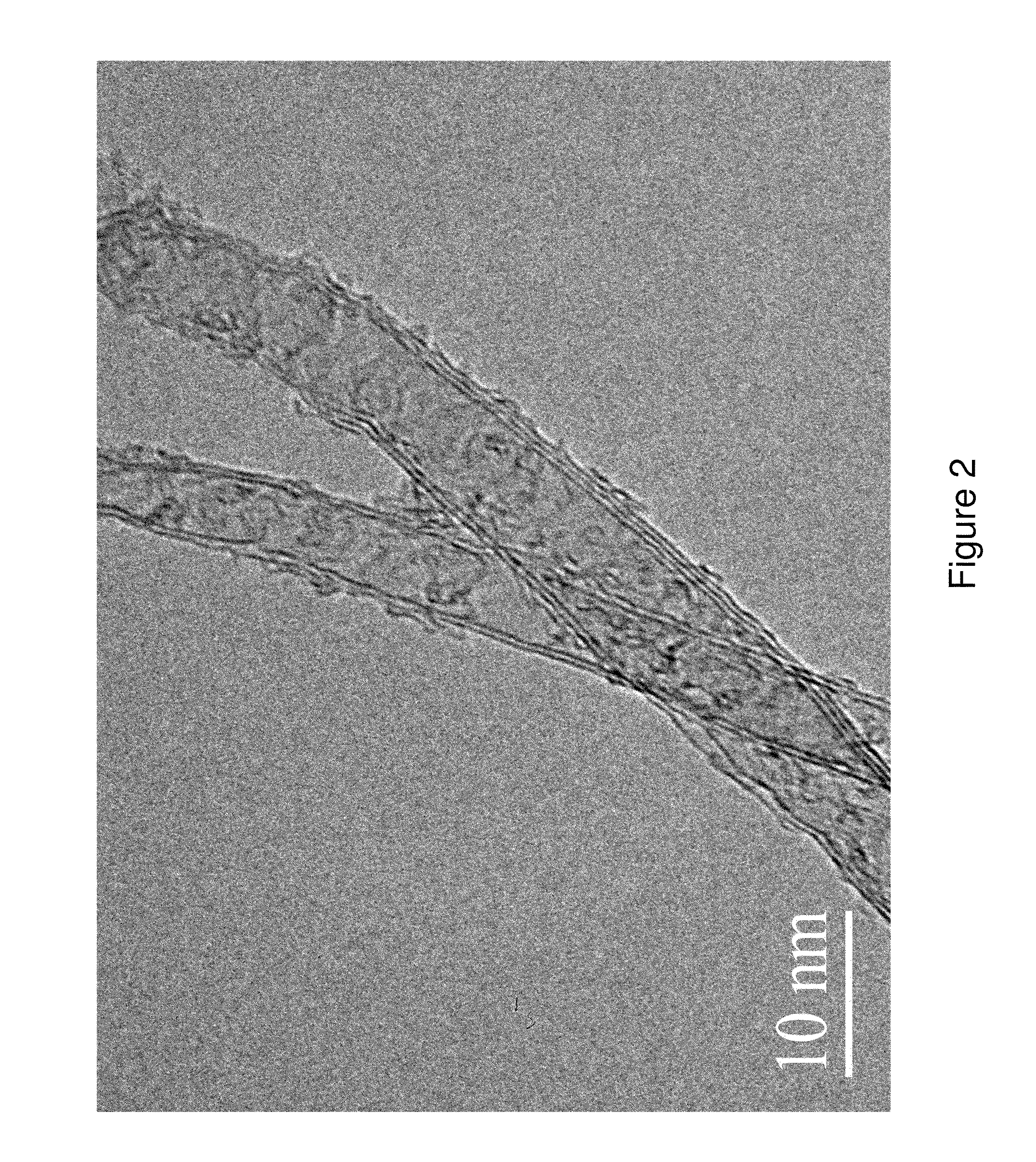

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Fluoropolymer fine fiber

ActiveUS20090032475A1Advantageously employedHeat stableDispersed particle filtrationLiquid suspension thickening by filtrationPolymer scienceFiltration

A layer of fluoropolymer fine fiber can be made. The fine fiber can be made by electrospinning from a solvent or a solvent blend. The layers of the invention are useful in general filtration of fluid streams including gaseous and liquid streams. The fine fiber layers are also useful as hydrophobic filtration layers that can be used to separate water from a hydrocarbon stream.

Owner:DONALDSON CO INC

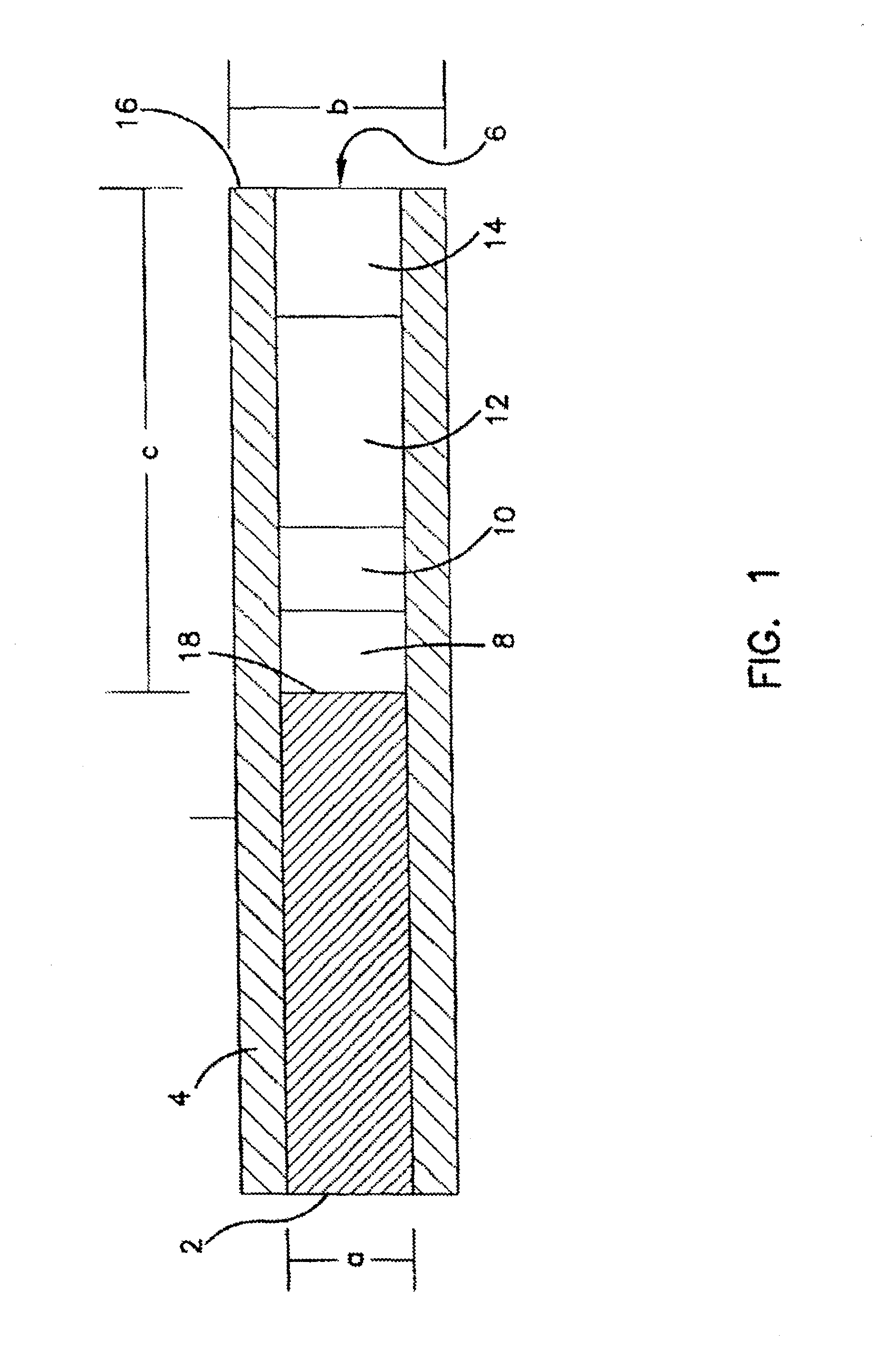

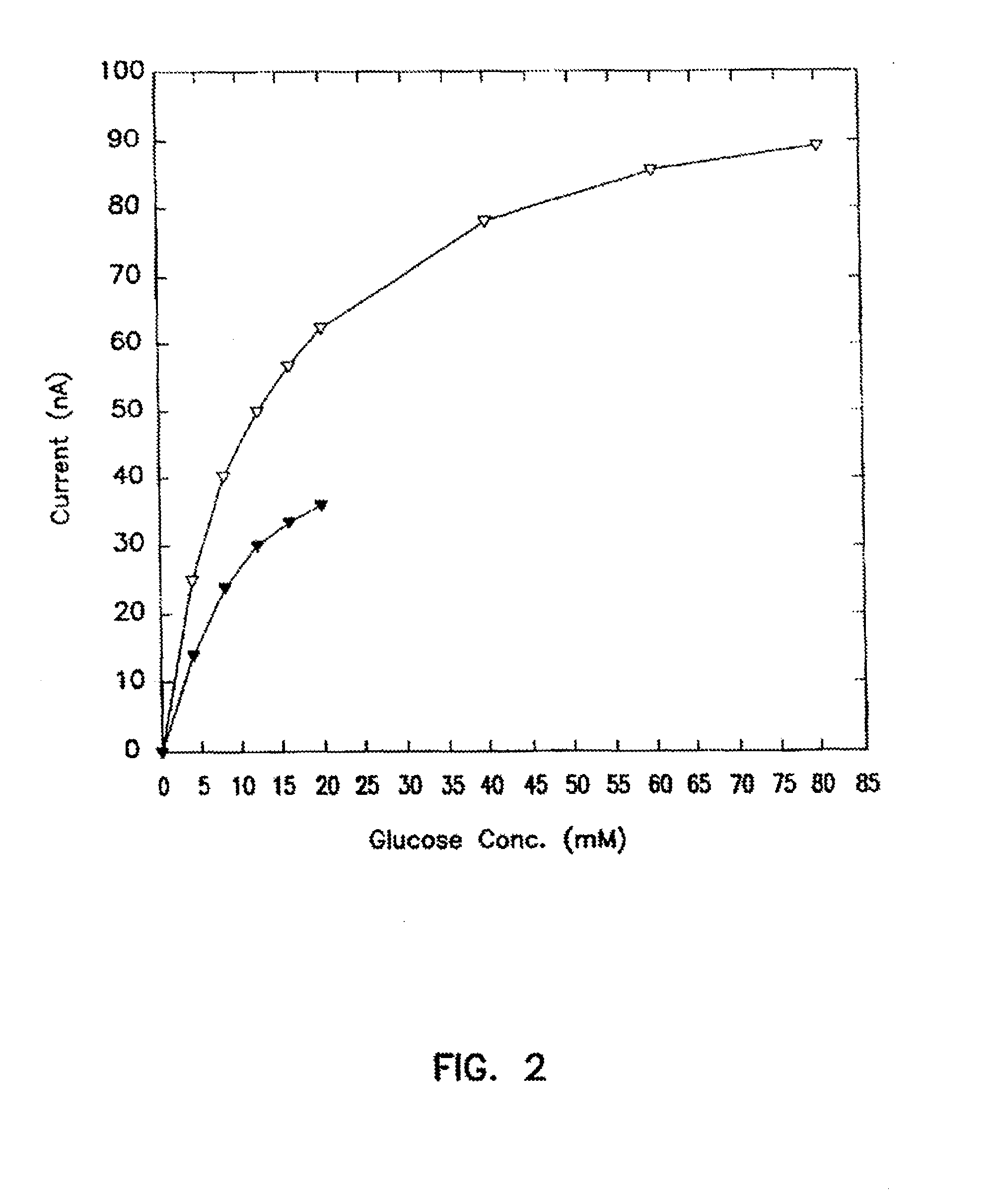

Subcutaneous glucose electrode

InactiveUS20080210557A1Reduce transportationAccurate measurementImmobilised enzymesBioreactor/fermenter combinationsPower flowConcentrations glucose

A small diameter flexible electrode designed for subcutaneous in vivo amperometric monitoring of glucose is described. The electrode is designed to allow “one-point” in vivo calibration, i.e., to have zero output current at zero glucose concentration, even in the presence of other electroreactive species of serum or blood. The electrode is preferably three or four-layered, with the layers serially deposited within a recess upon the tip of a polyamide insulated gold wire. A first glucose concentration-to-current transducing layer is overcoated with an electrically insulating and glucose flux limiting layer (second layer) on which, optionally, an immobilized interference-eliminating horseradish peroxidase based film is deposited (third layer). An outer (fourth) layer is biocompatible.

Owner:ABBOTT LAB INC

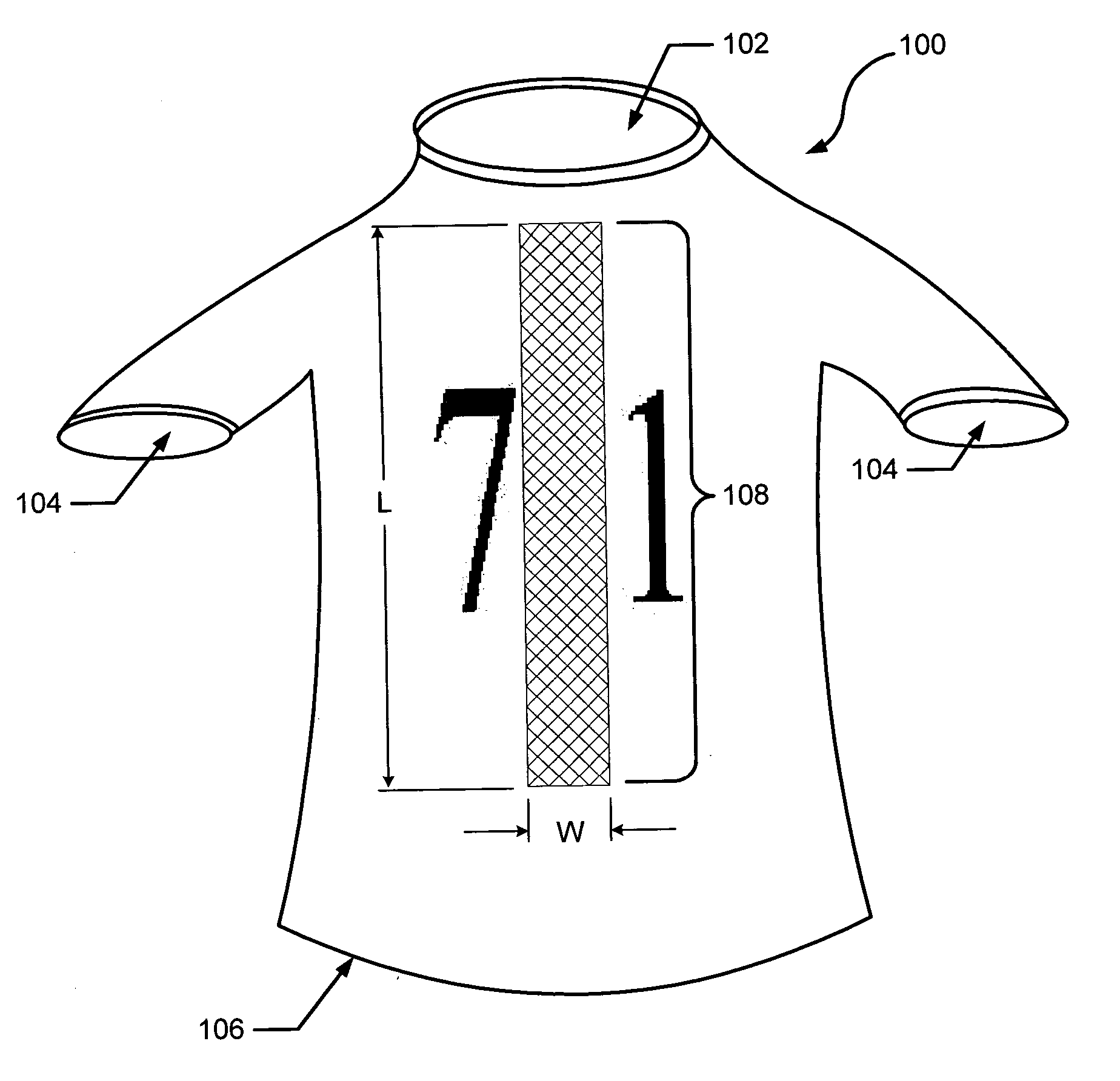

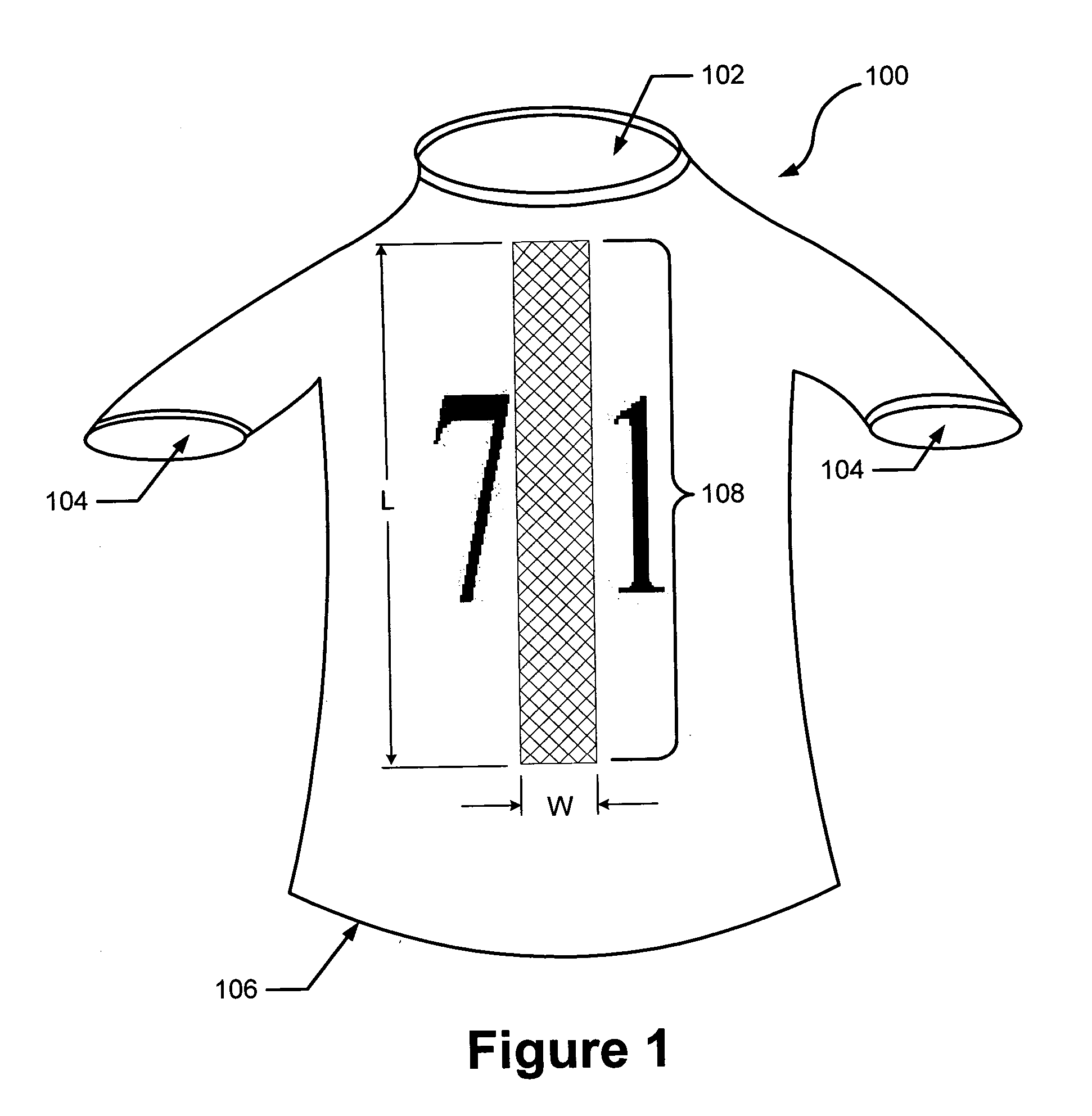

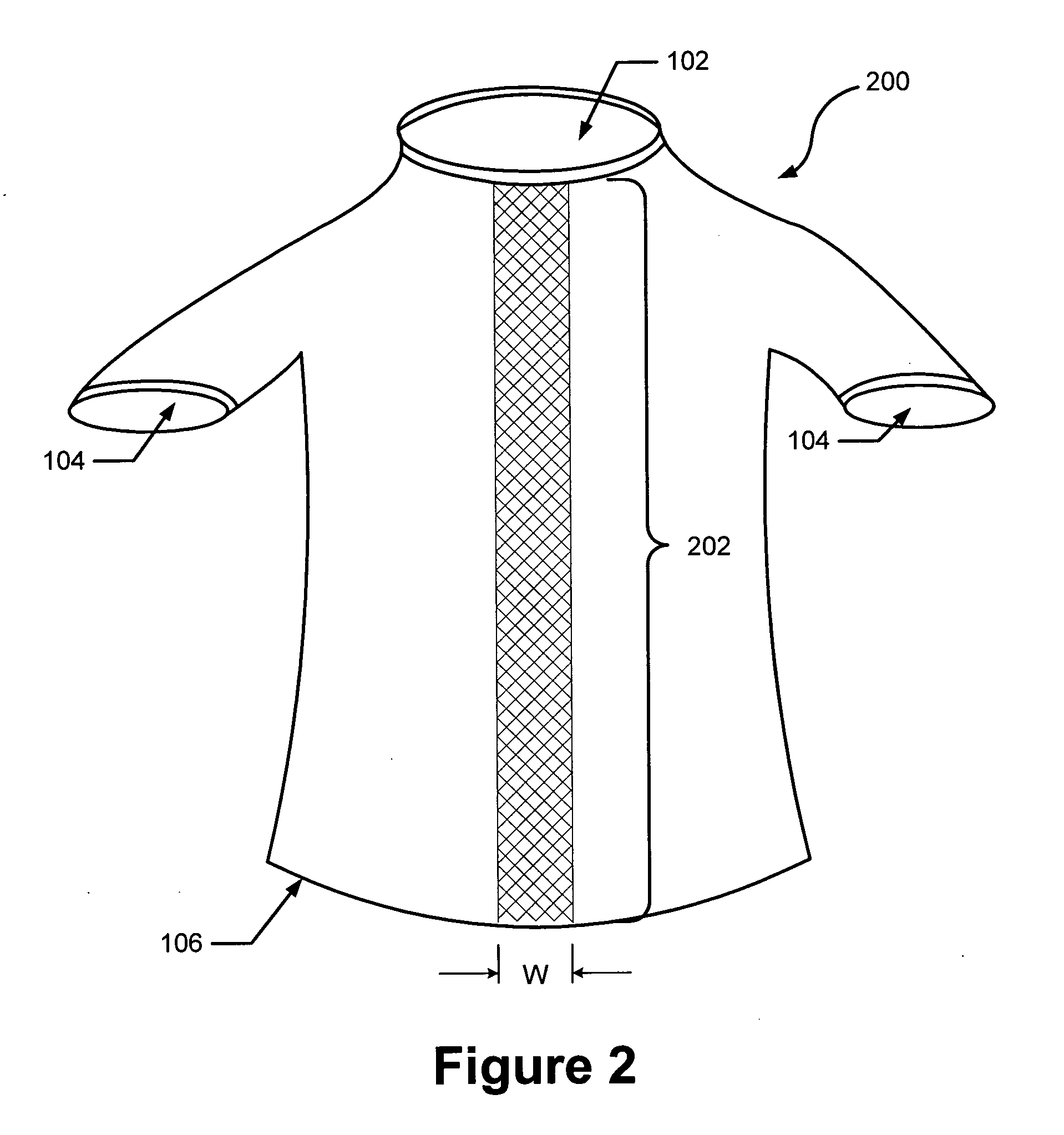

Article of apparel incorporating a zoned modifiable textile structure

ActiveUS20050204449A1Improve understandingGarment special featuresWeft knittingEngineeringE-textiles

An article of apparel is disclosed that includes zones with a textile having a structure that changes or is otherwise modified by a physical stimulus, such as the presence of water or a temperature change, to modify a property of the textile. The zones may be along a center back area and side areas of the apparel, and the textile may increase in air permeability when exposed to water. The zones may also be in an upper area of the torso and in a lower back area, and the textile may increase in texture when exposed to water. In some embodiments, slits are formed in the textile.

Owner:NIKE INC

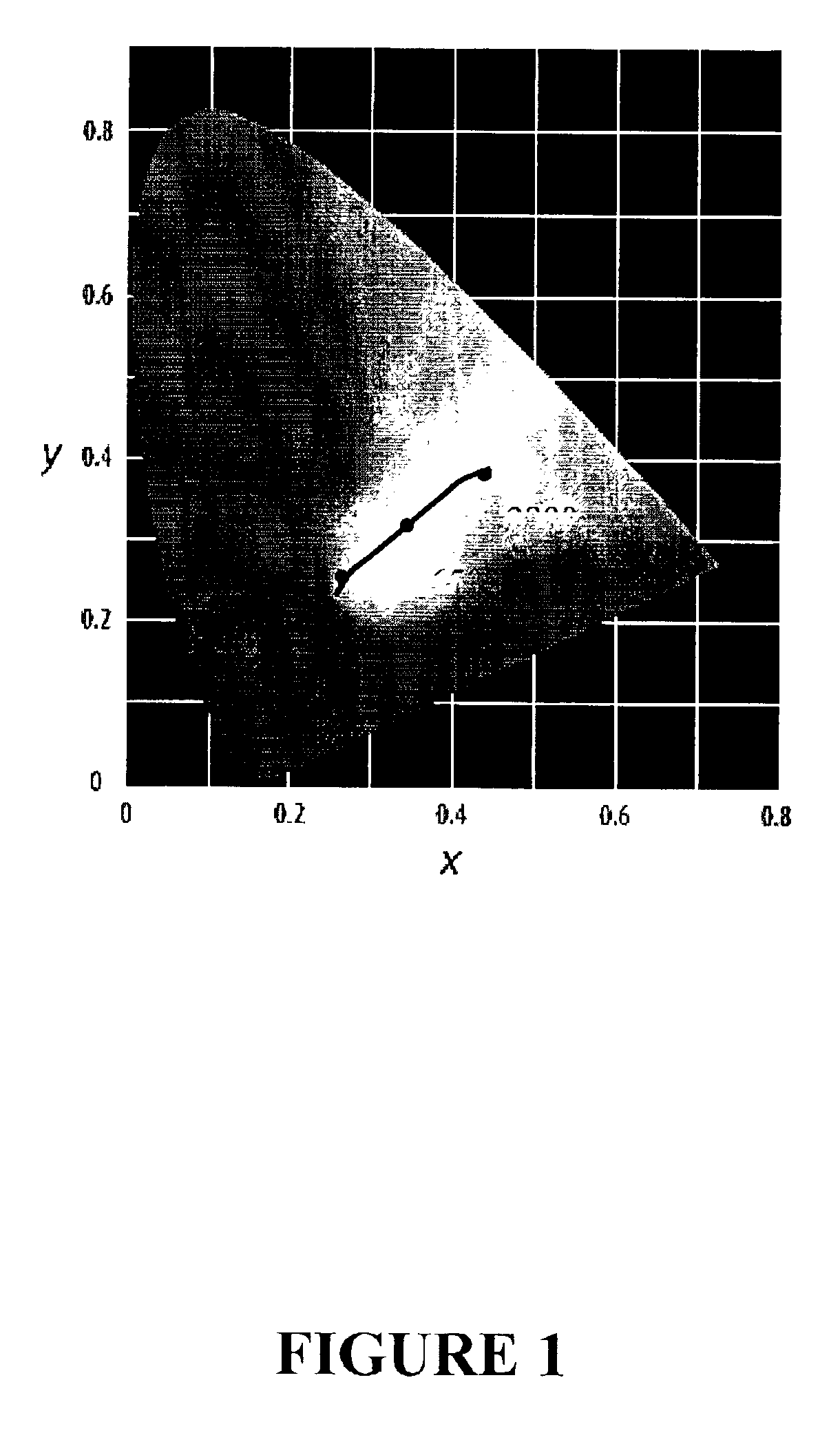

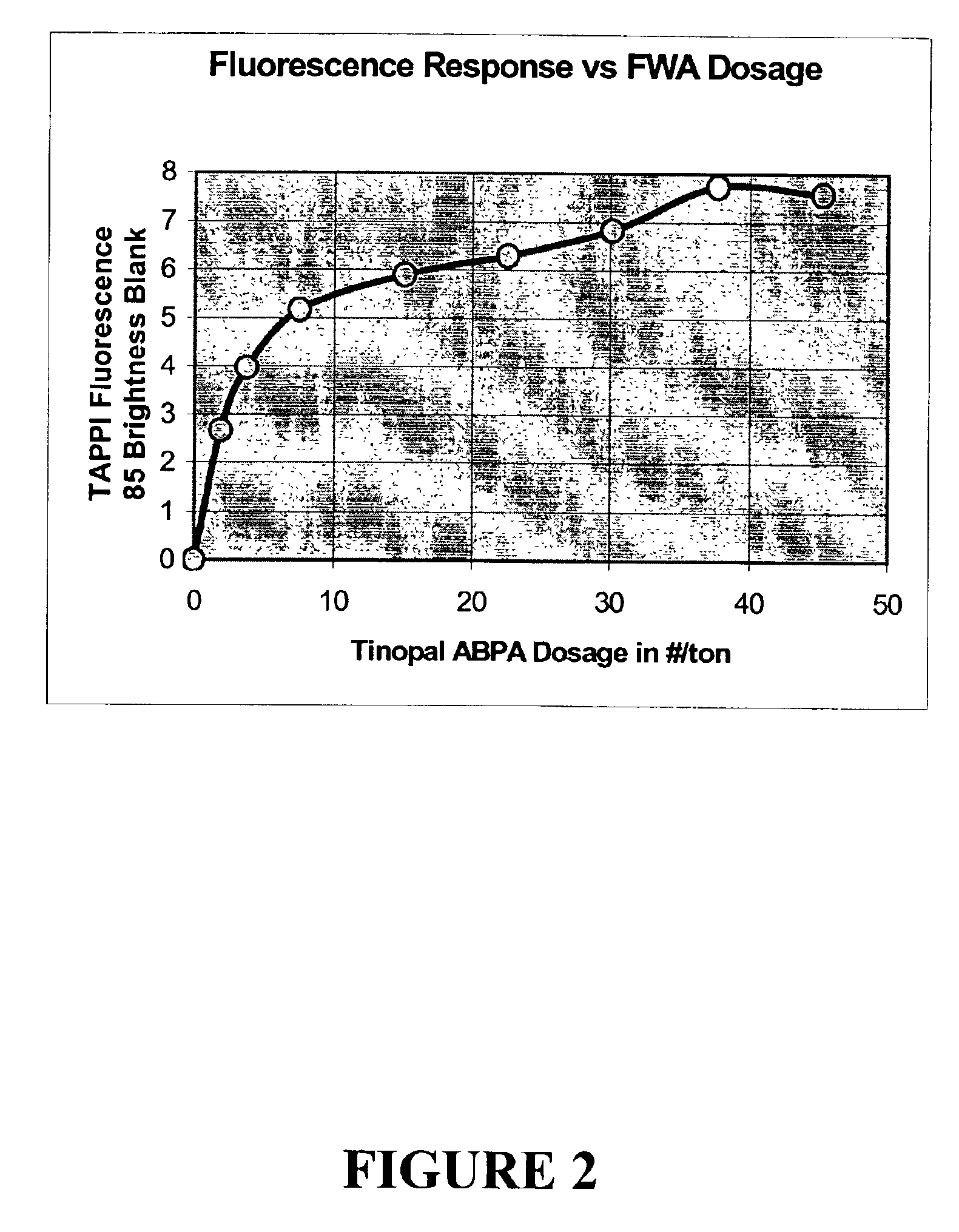

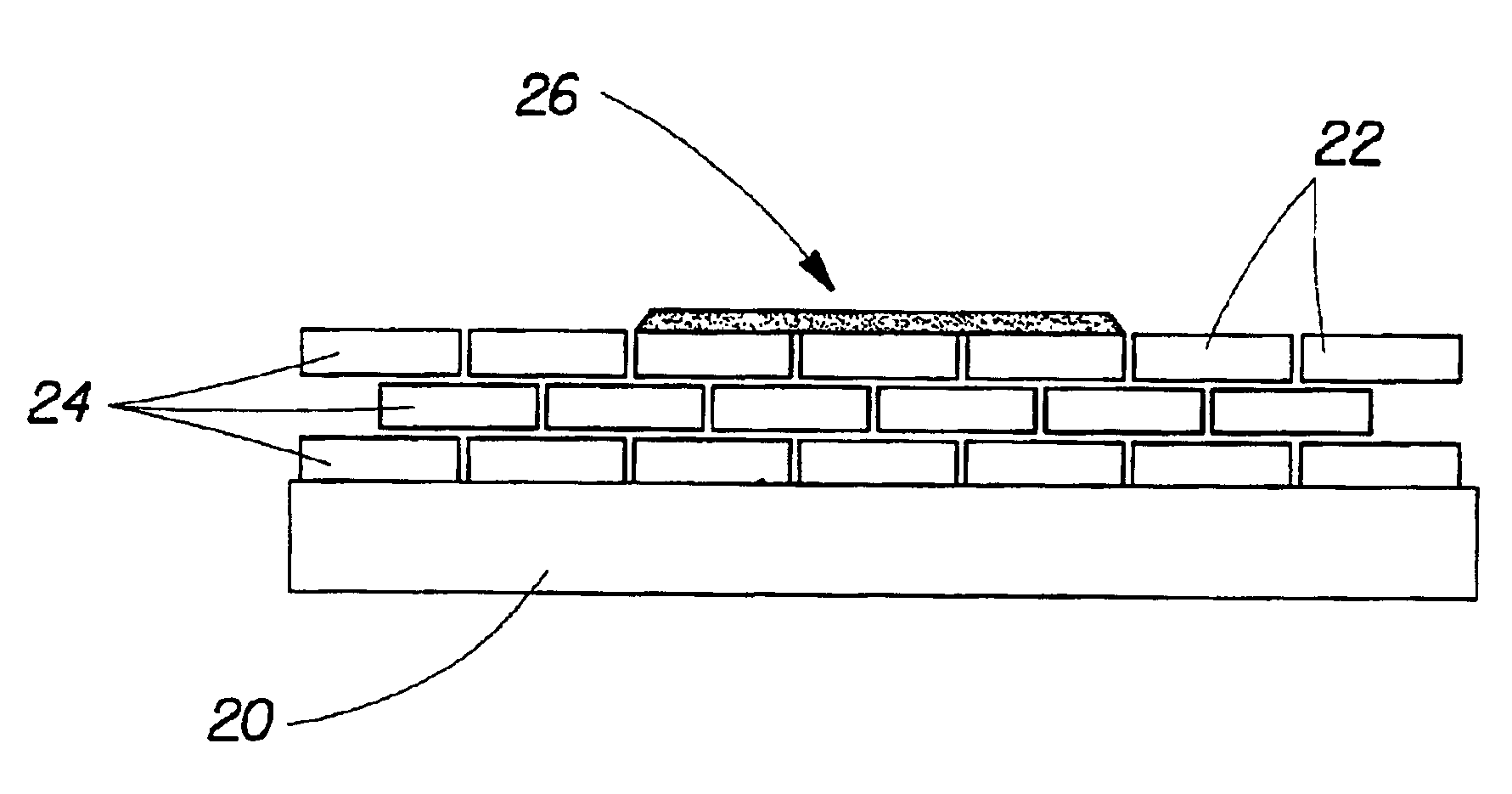

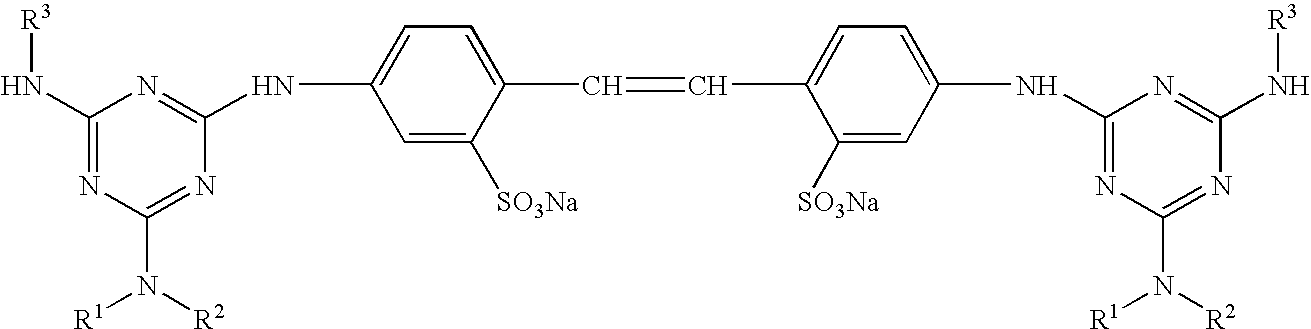

Whitened fluff pulp

InactiveUS6893473B2Luminescent/fluorescent substance additionPaper/cardboardWhitening AgentsFluff pulp

Whitened fluff pulp and methods for making whitened fluff pulp. The whitened pulp is a fluff pulp that has been treated with one or more of a white pigment, a colorant, or a fluorescent whitening agent.

Owner:WEYERHAEUSER CO

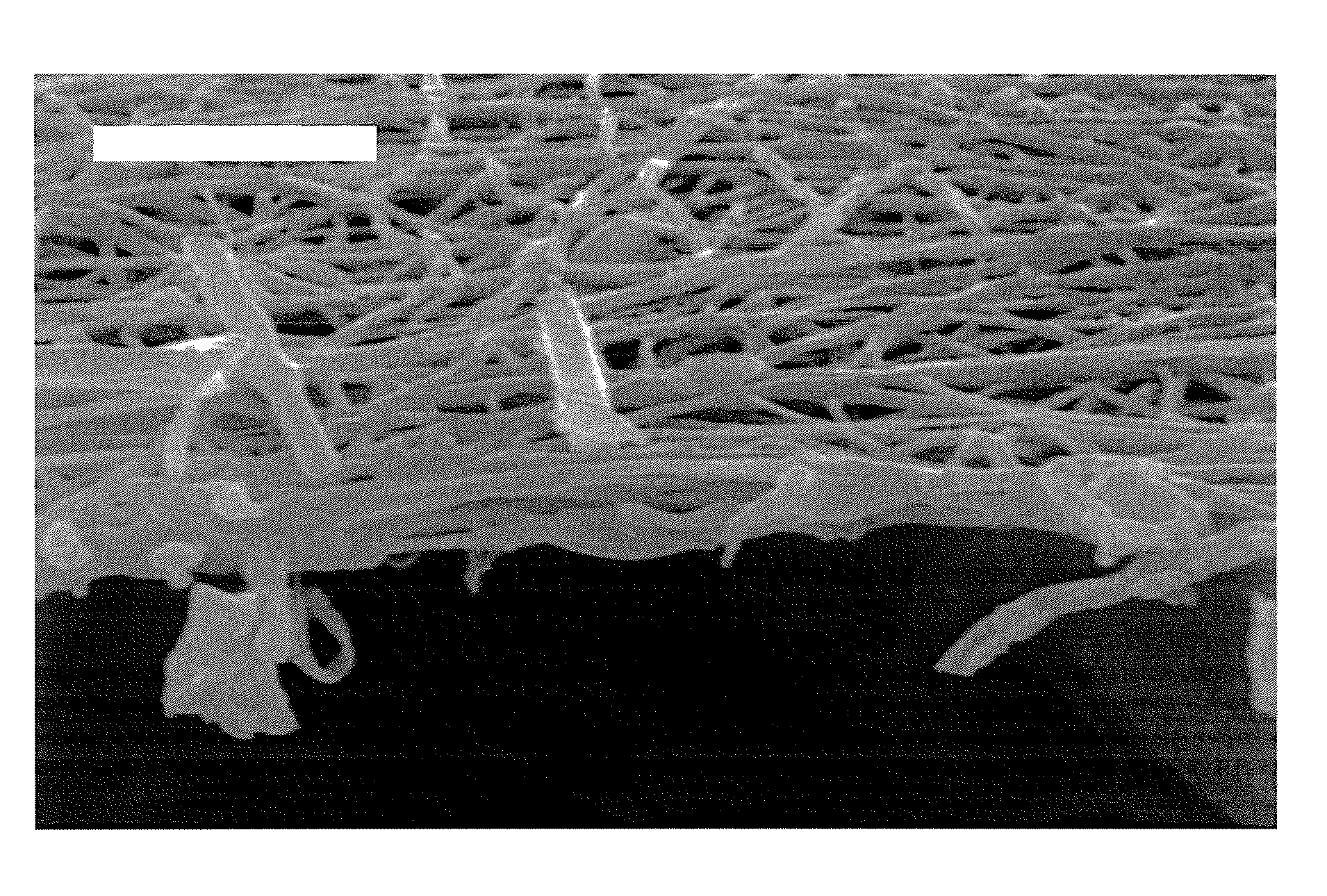

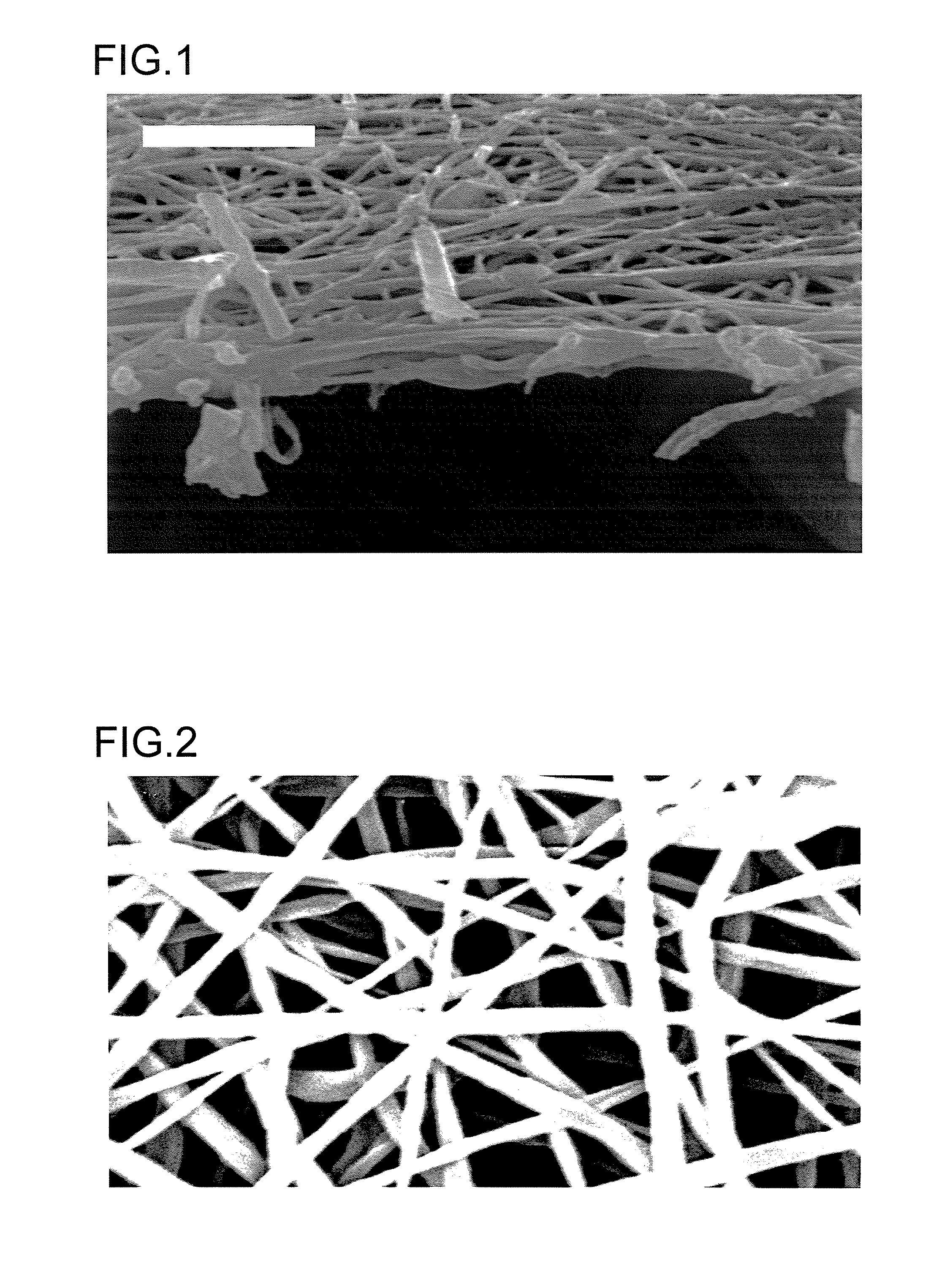

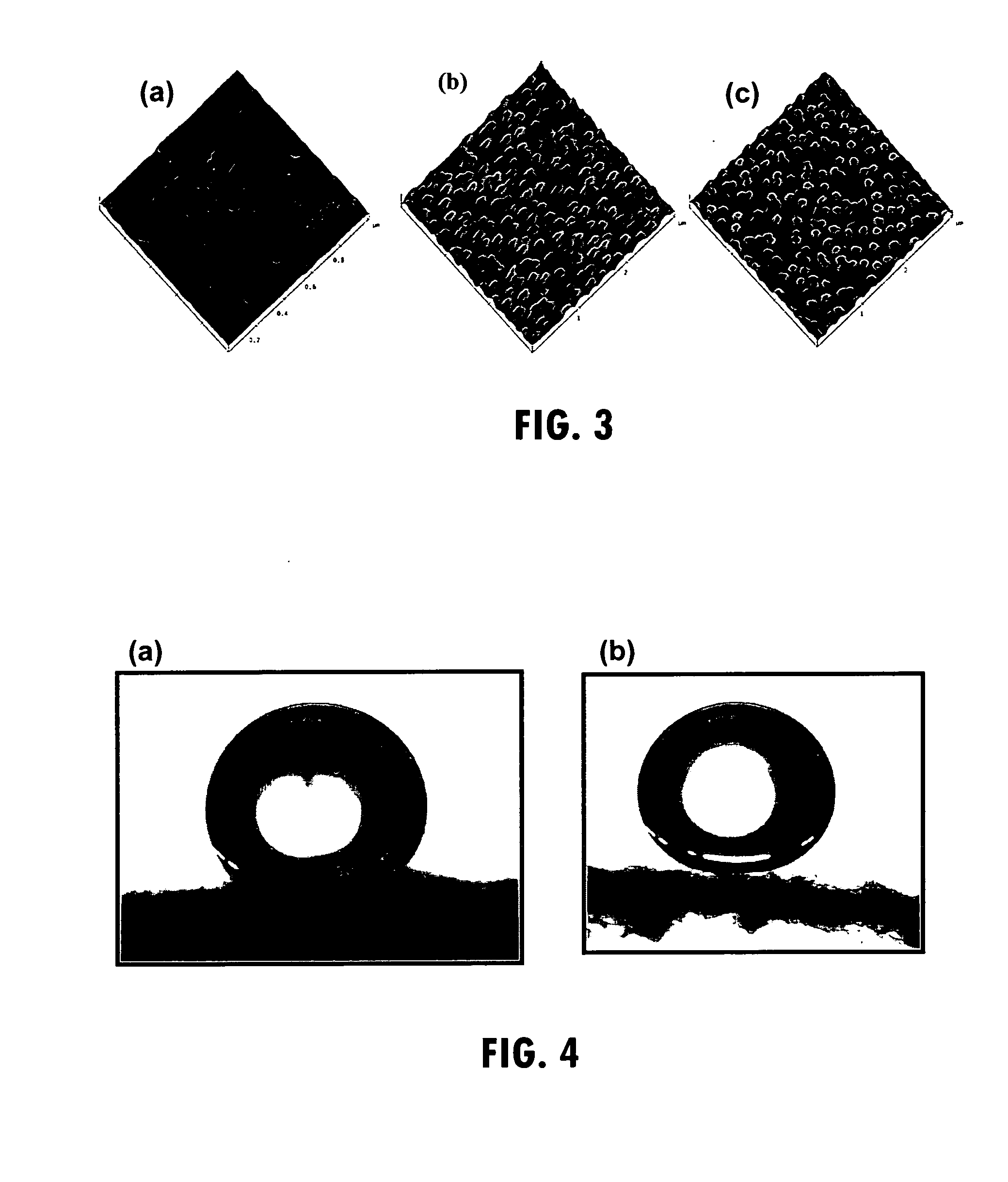

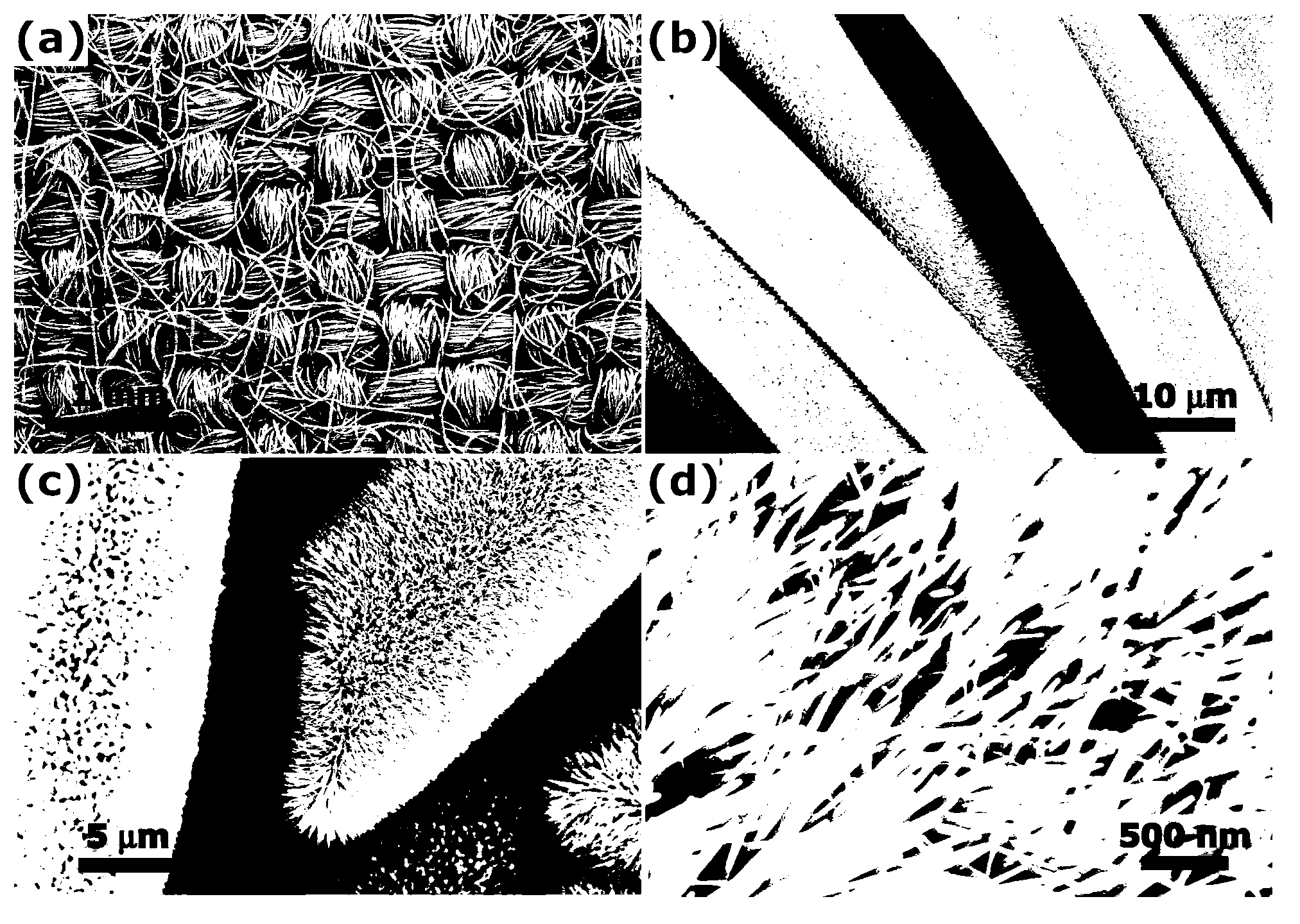

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

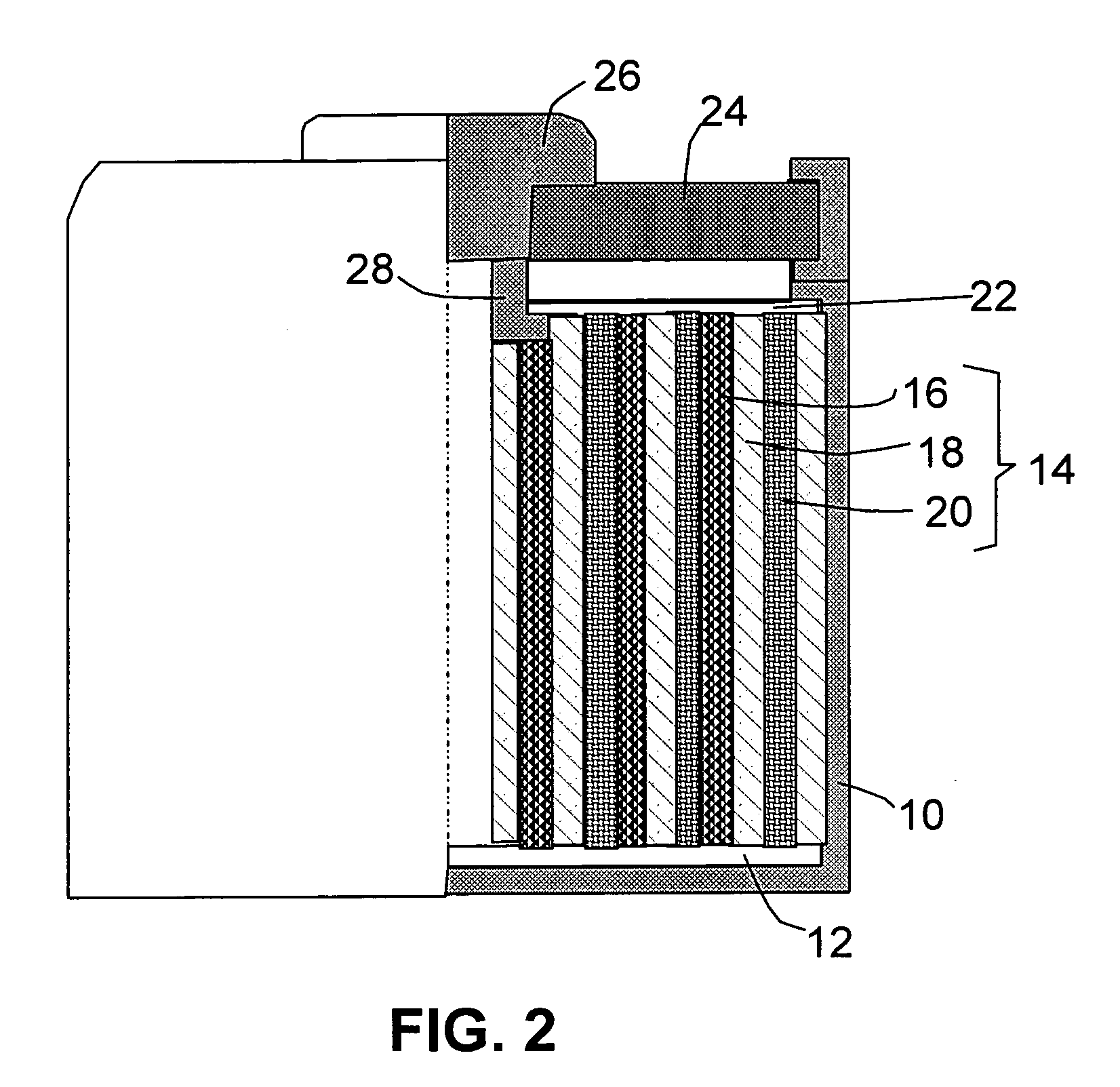

Methods for improving the performance of fabric wrinkle control compositions

InactiveUS20050098759A1Improve performanceGood dispersionPhysical treatmentWrinkle resistant fibresFiberWrinkle skin

The present invention provides methods for improving the performance of a consumer wrinkle control composition by making the composition available to the consumer and providing information to the consumer concerning the use of the composition to control wrinkles in fabrics without the application of heat. Information may be provided by teaching educational elements and disseminating educational elements to consumers in an efficient, effective, and affordable manner as well as techniques for heightening consumer awareness of the product. The information that is provided to the consumer may concerns the use of the composition to remove or control wrinkles in fabrics without the application of heat, instructions for the proper use of the product, the product's effectiveness, the appearance of the fabric in the finished state after treatment, how the product can be incorporated into the consumer's everyday habits and lifestyles, additional non-wrinkle related benefits that may be achieved with the product and how the composition can be effectively and safely used by most members of the consumer's household. Also provided are methods for prolonging or extending the useful life of fabric items that require frequent and repeated laundering processes and that are prone to cause incremental damage to fabric fibers. The useful life of such fabric items is prolonged by enabling the item to be revitalized or renewed for rewear without laundering, thus reducing the number of launderings and the resulting damage to fabric fibers over a given period of time.

Owner:THE PROCTER & GAMBLE COMPANY

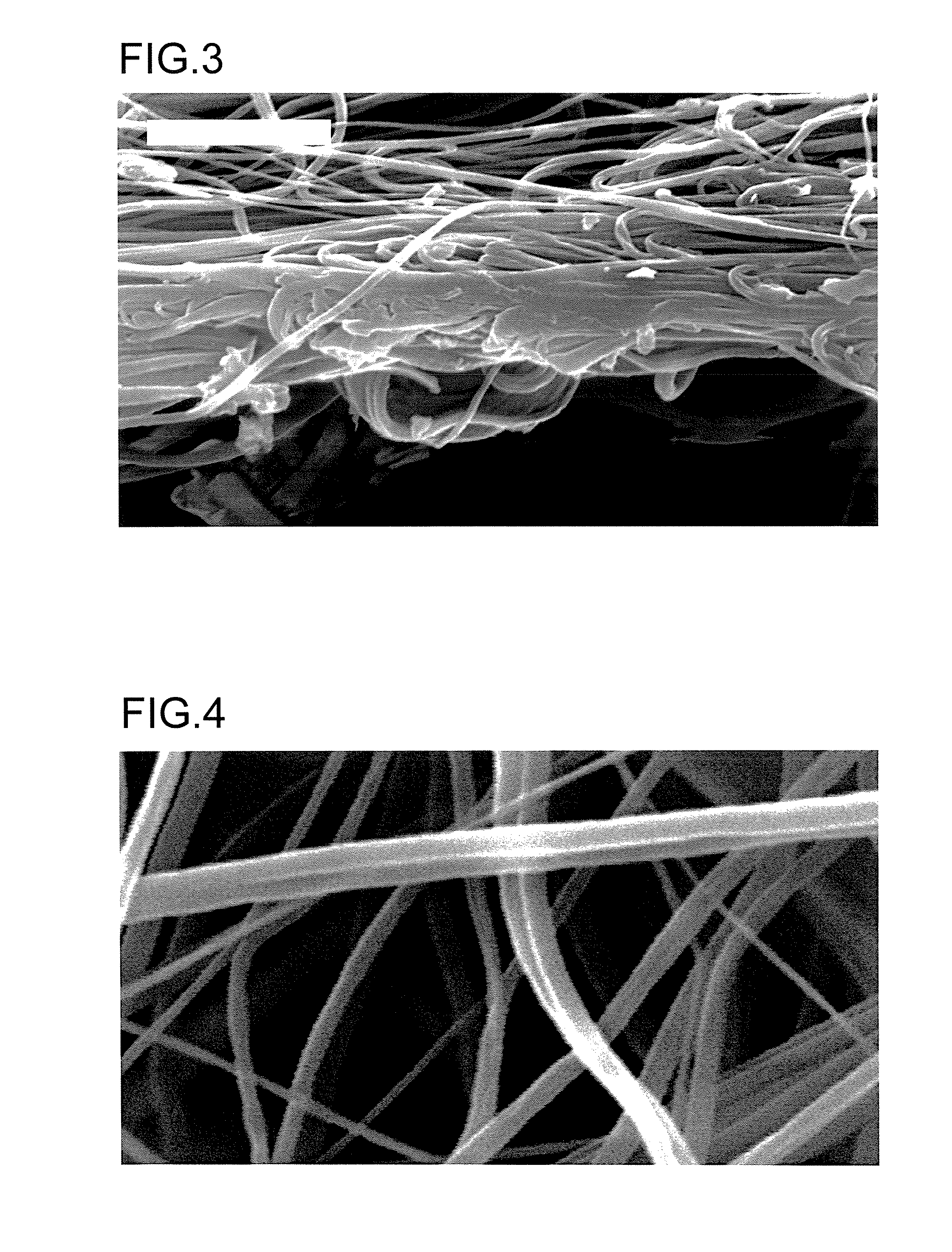

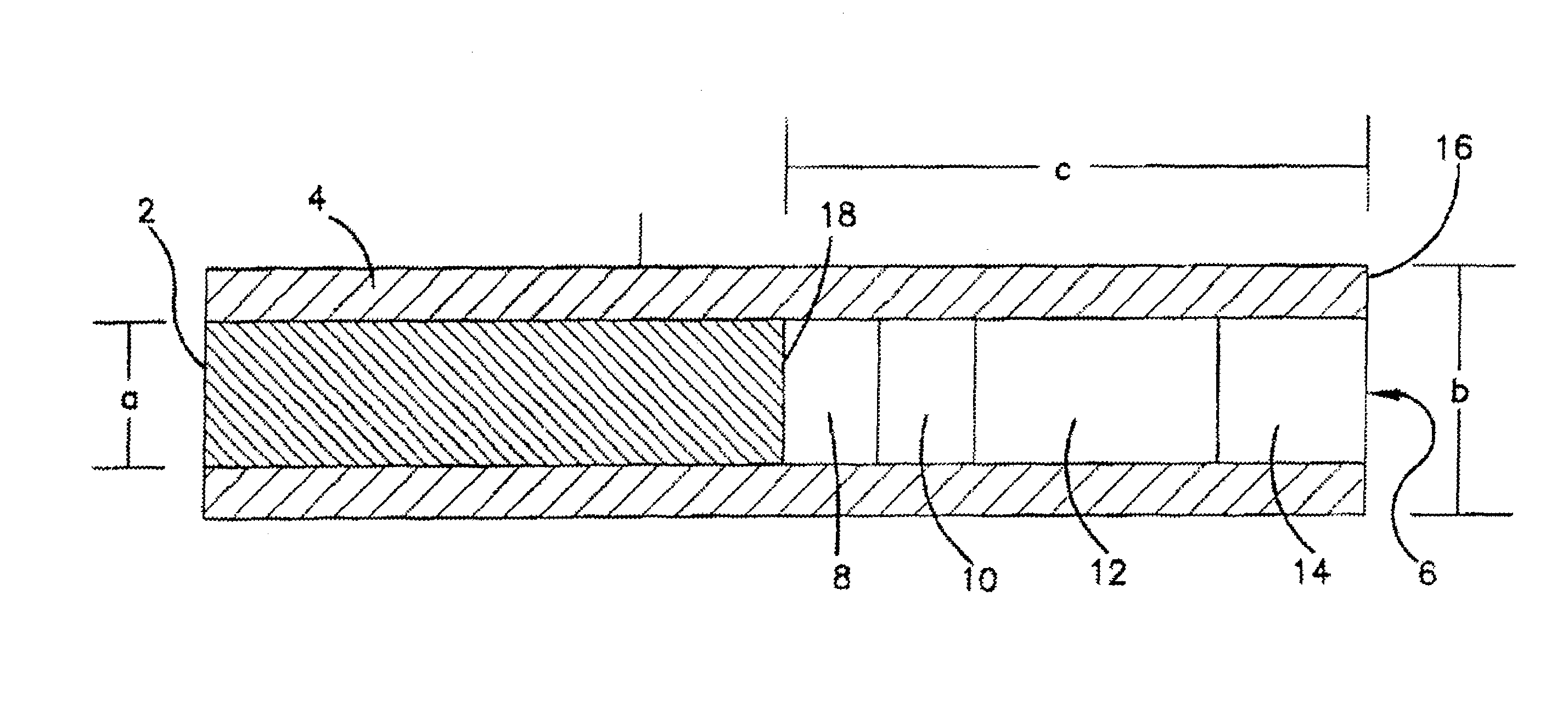

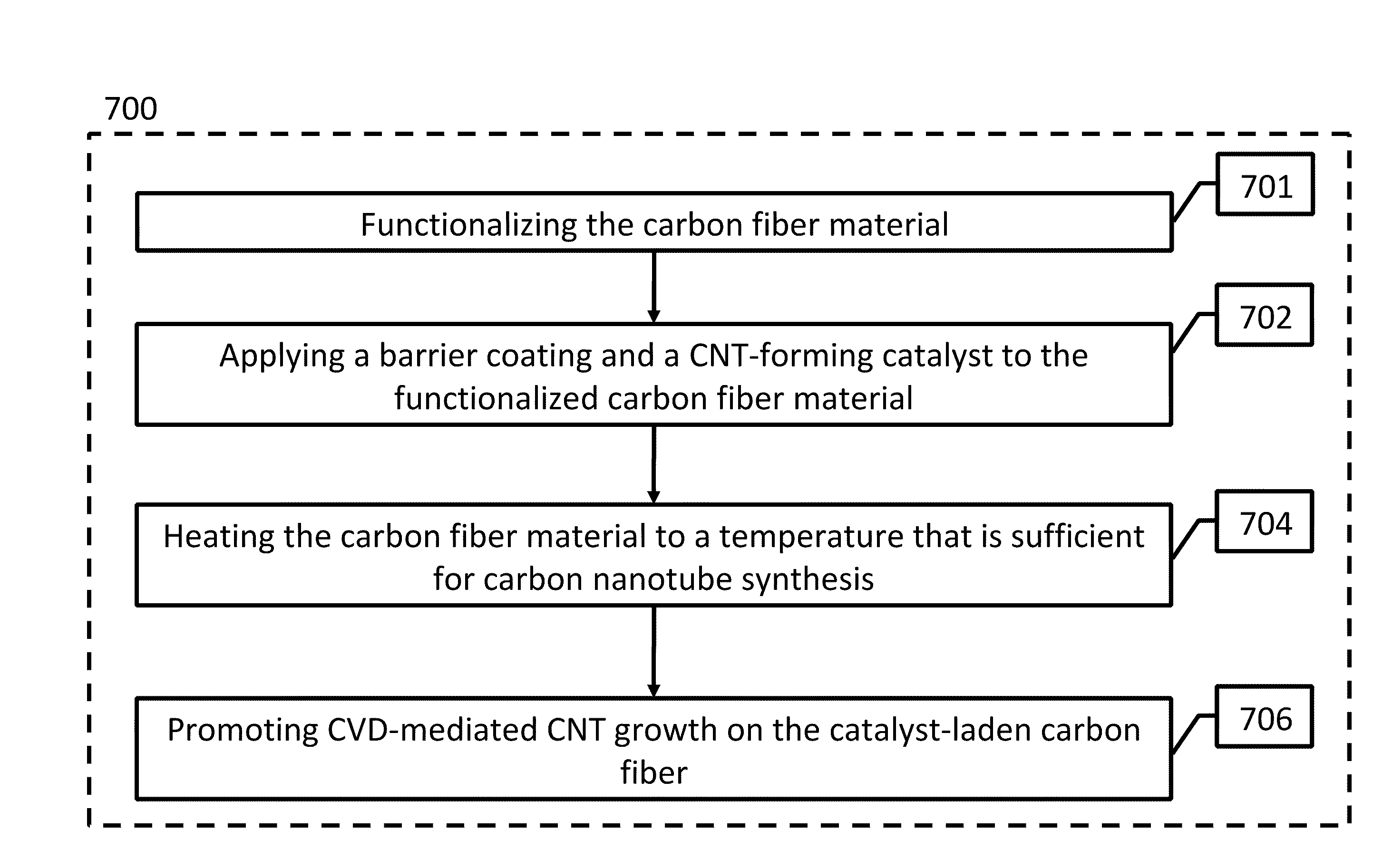

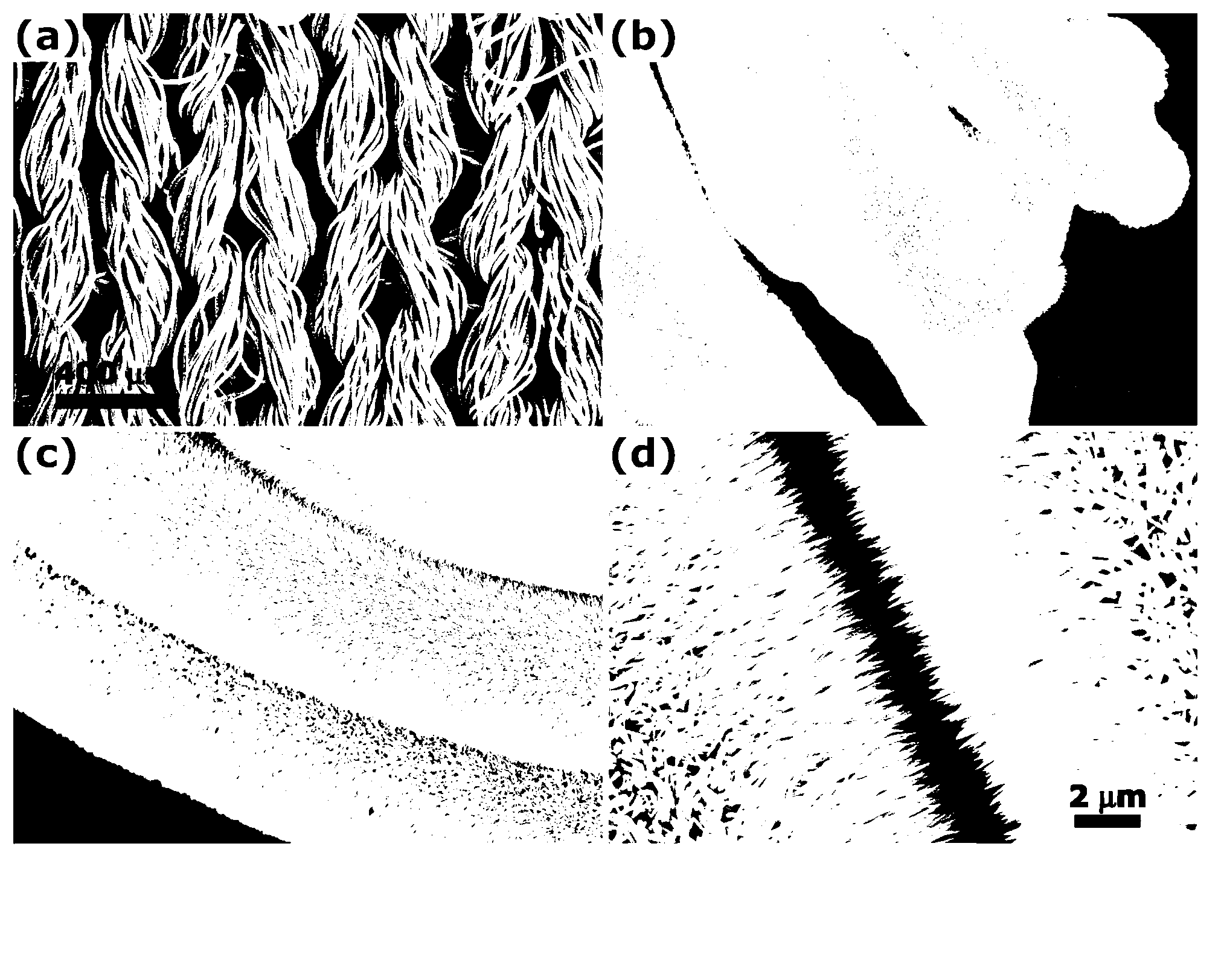

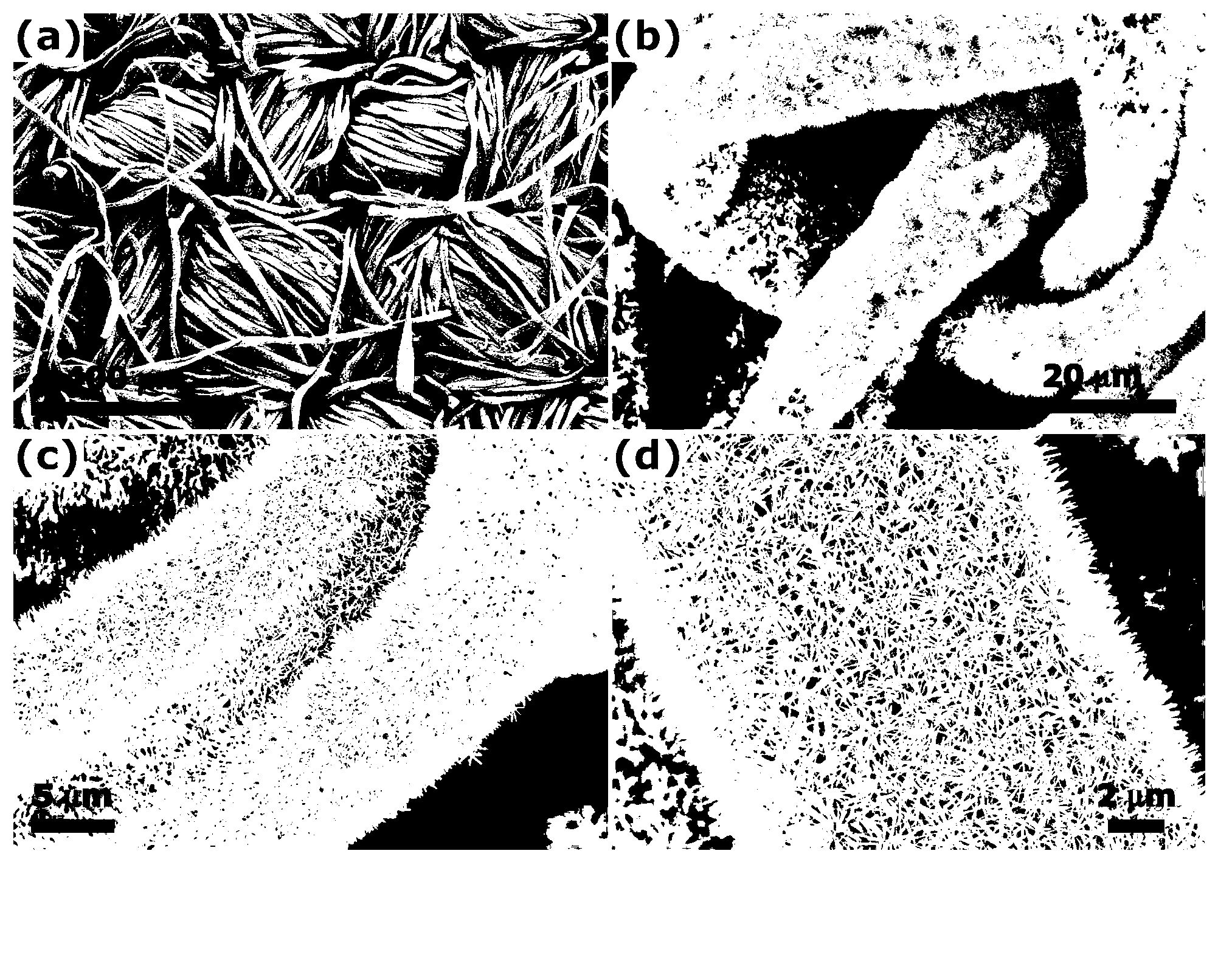

Cnt-infused carbon fiber materials and process therefor

A composition includes a carbon nanotube (CNT)-infused carbon fiber material that includes a carbon fiber material of spoolable dimensions and carbon nanotubes (CNTs) infused to the carbon fiber material. The infused CNTs are uniform in length and uniform in distribution. The CNT infused carbon fiber material also includes a barrier coating conformally disposed about the carbon fiber material, while the CNTs are substantially free of the barrier coating. A continuous CNT infusion process includes: (a) functionalizing a carbon fiber material; (b) disposing a barrier coating on the functionalized carbon fiber material (c) disposing a carbon nanotube (CNT)-forming catalyst on the functionalized carbon fiber material; and (d) synthesizing carbon nanotubes, thereby forming a carbon nanotube-infused carbon fiber material.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

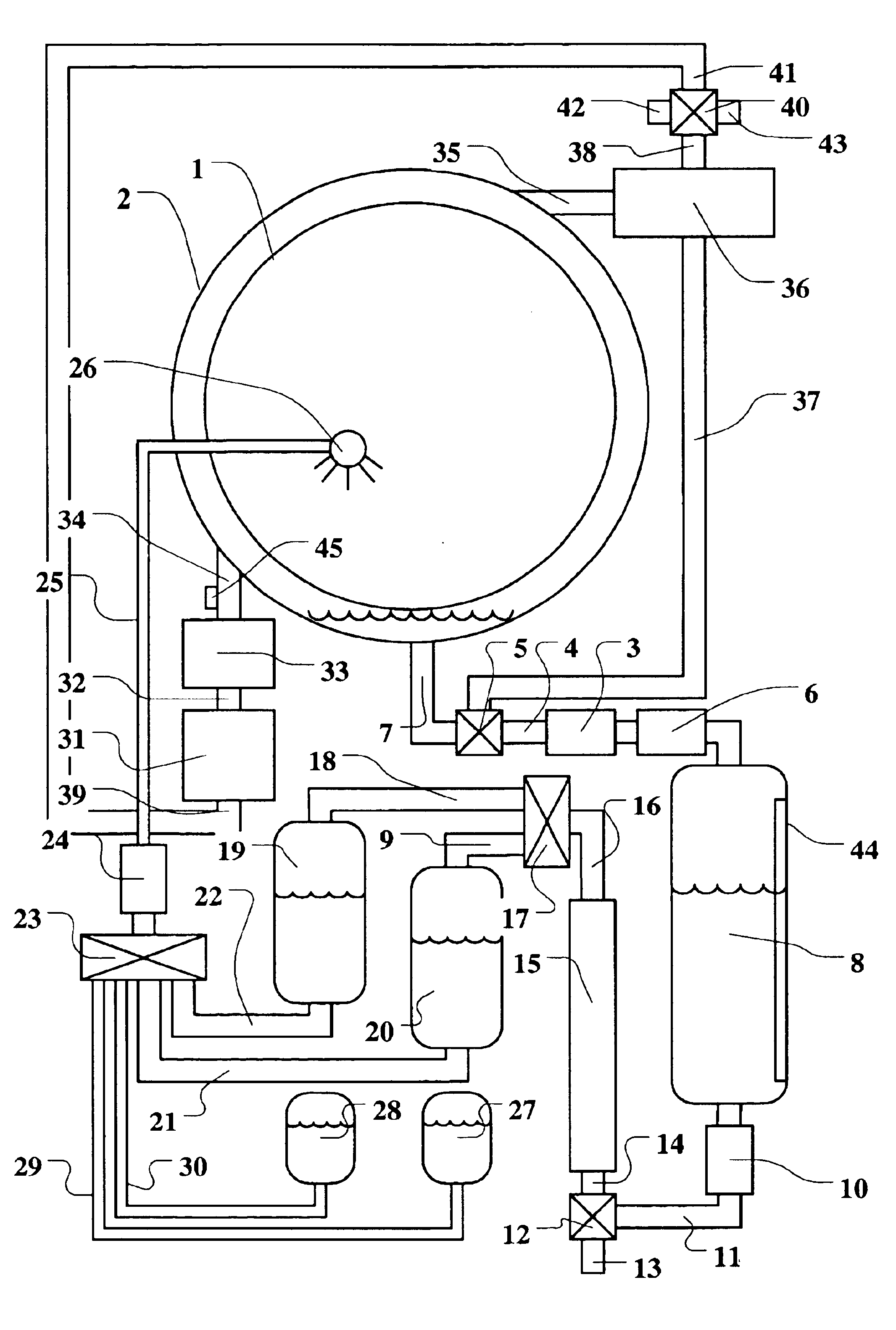

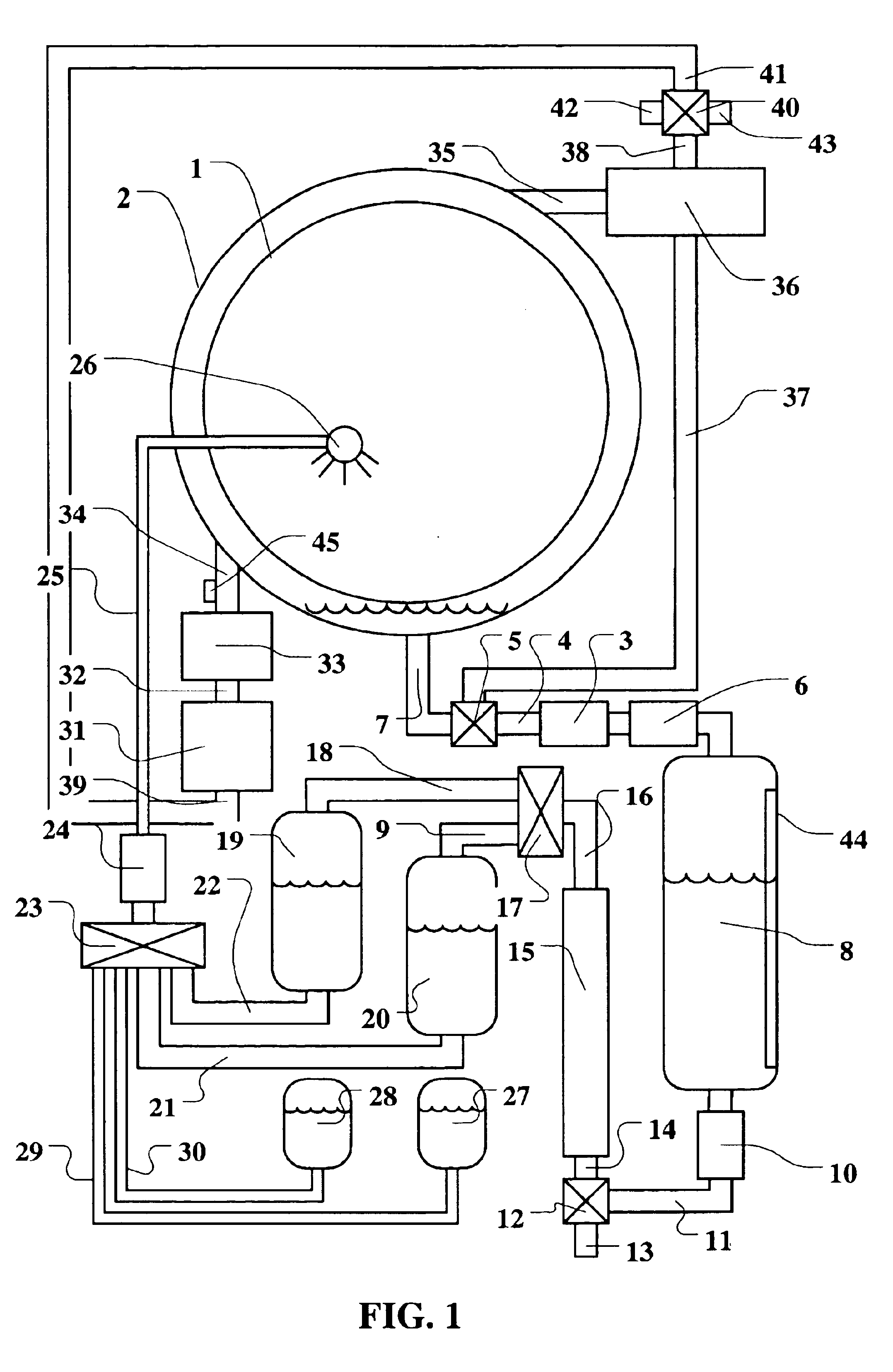

Washing apparatus

InactiveUS6898951B2Organic detergent compounding agentsDry-cleaning apparatusMechanical engineeringSurgery

Owner:THE PROCTER & GAMBLE COMPANY

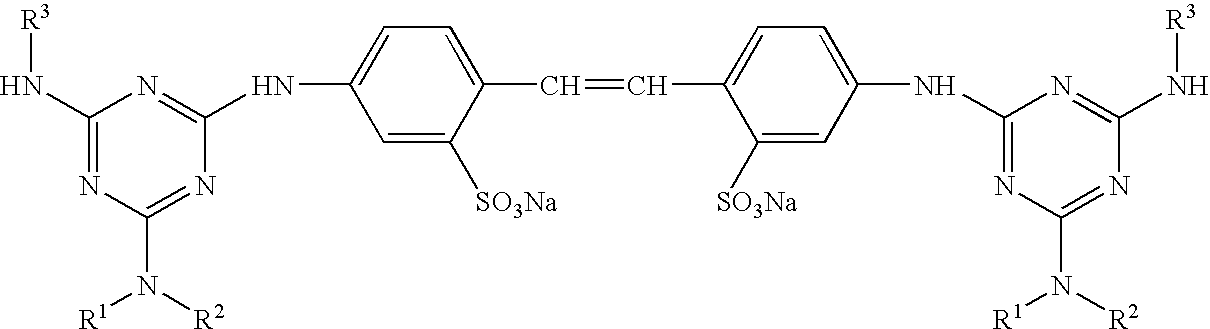

Ultrahydrophobic substrates

ActiveUS20070026193A1Improve surface roughnessImprove surface hydrophobicityFouling preventionLotus effect fibresSurface roughnessEngineering

Disclosed is a process for modification of a substrate so as to form an ultrahydrophobic surface on the substrate. Also disclosed are surface-modified substrates that can be formed according to the disclosed processes. The process includes attachment of a multitude of nano- and / or submicron-sized structures to a surface to provide increased surface roughness. In addition, the process includes grafting a hydrophobic material to the surface in order to decrease the surface energy and decrease wettability of the surface. The combination of increase surface roughness and decreased surface energy can provide an ultrahydrophobic surface on the treated substrate.

Owner:CLEMSON UNIVERSITY

Fabric treatment for stain release

InactiveUS20050229327A1Minimizing fiber wearMaintain fabric appearancePhysical treatmentDry-cleaning apparatus for textilesZeta potentialWrinkle skin

A fabric treatment composition that includes a hydrophobic agent with a melting point or glass transition temperature below 100° C. and optionally, a fluoropolymer, that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Compositions may further include a zeta potential modifier in an amount sufficient to adjust the zeta potential of the composition to be positive and greater, than zero millivolts. The composition can be used as a pretreatment prior to drying or ironing, through soaking or direct spray application, or used prior to or during the drying cycle of an automatic drying machine or clothing refresher machine, or used prior to or in conjunction with an ironing device. The fabric treatment is complete when the fabric treated by contact with the protective composition is then cured by drying and / or heating. The invention further includes a kit providing a means for convenient dispensing of the protective composition to effect treatment and curing of fabric articles.

Owner:THE CLOROX CO

Enhancement of color on surfaces

InactiveUS6872444B2Easy to controlGood removal effectInorganic/elemental detergent compounding agentsPigmenting treatmentNanoparticleMaterials science

Coating compositions, methods and articles of manufacture comprising a nanoparticle system employing same to impart surface modifying benefits for all types of soft surfaces, and in some cases, hard surfaces, are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to the modified surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that, in some embodiments, may include at least one of the following improved surface properties: cleaning, wettability, liquid strike-through, comfort, stain resistance, soil removal, malodor control, modification of surface friction, reduced damage to abrasion and color enhancement, relative to the surfaces unmodified with such nanoparticle systems.

Owner:THE PROCTER & GAMBLE COMPANY

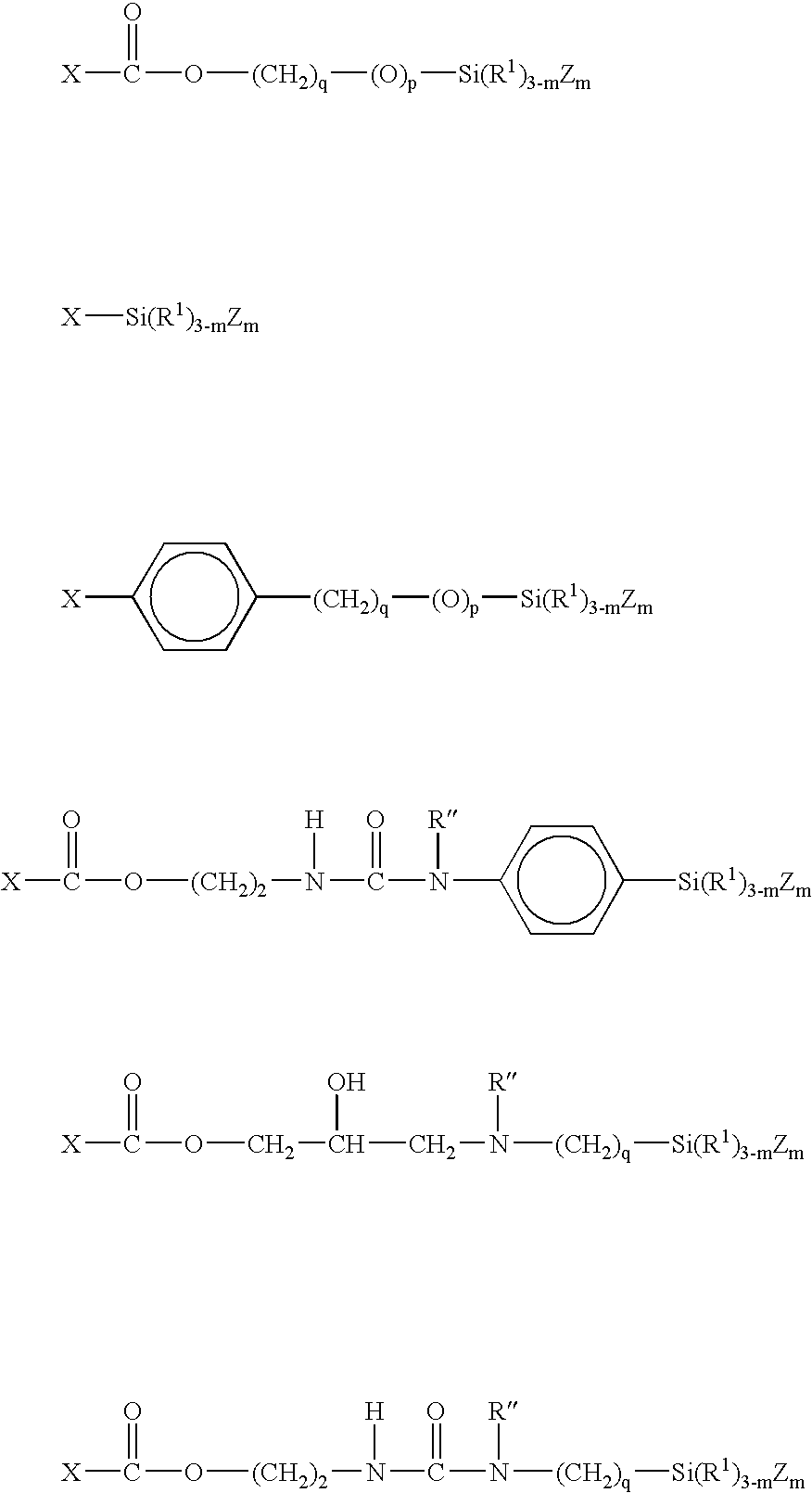

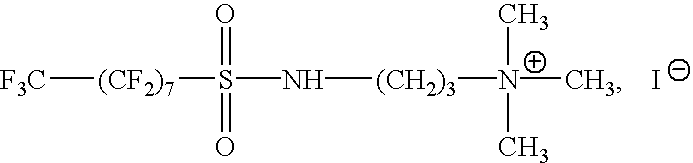

Finishing of textile fibers, tissues and fabrics

InactiveUS7056845B2Improve the level ofImprove functional propertiesOther chemical processesPhysical treatmentTextile fiberEngineering

A method is provided for the application of a finishing layer to a textile support material. A water repellent or oil repellent layer, a so-called finishing layer, is applied to a textile support material selected from the group of fibers, tissues, and fabrics. The water repellent or oil repellent finishing layer comprises at least two water repellent or oil repellent components wherein a first component comprises one or more dispersants and a second component comprises one or more dispersed phases or colloids, and wherein the dispersant and the dispersed phase are present in the gel state.

Owner:SCHOELLER TEXTIL

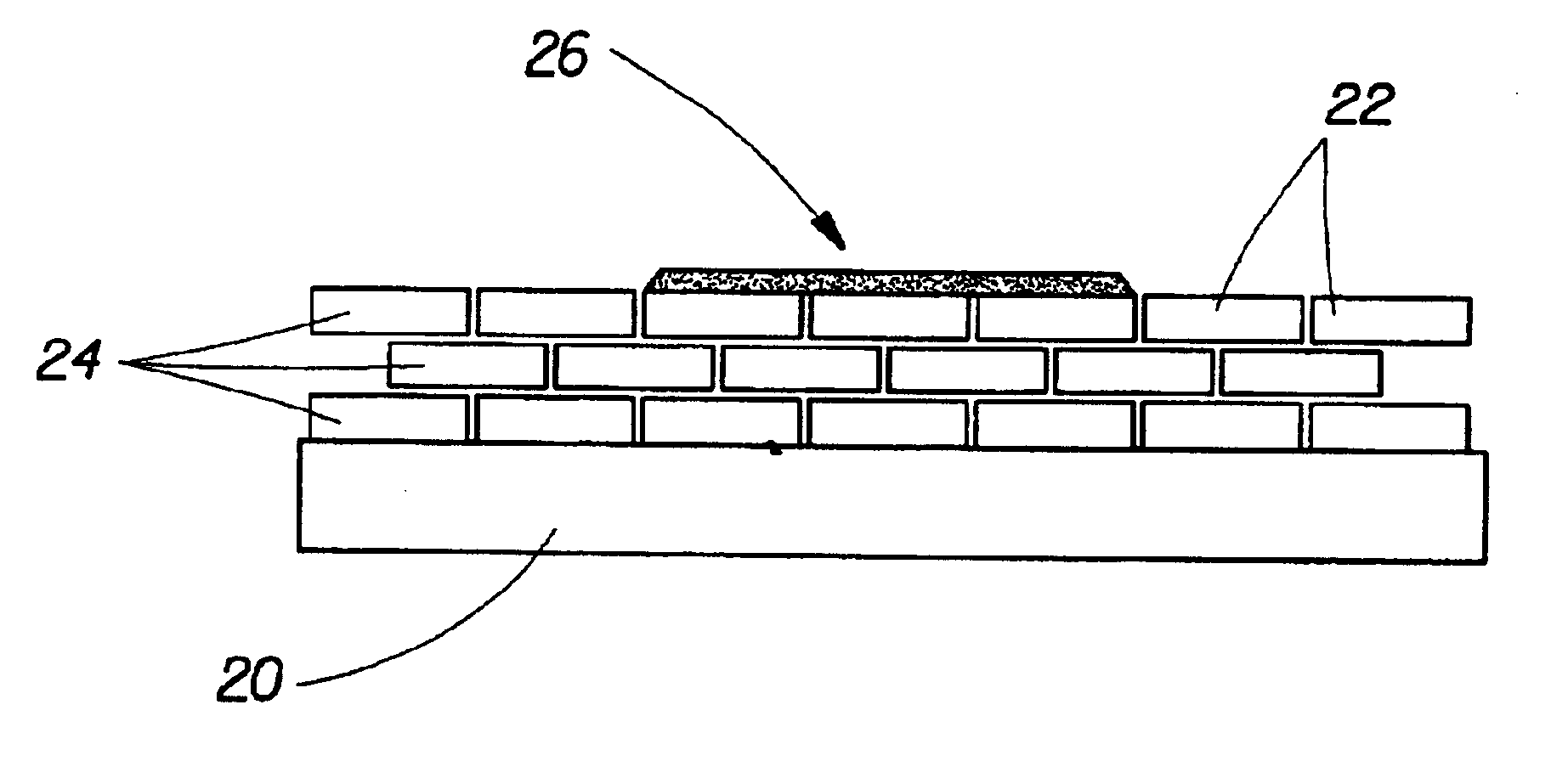

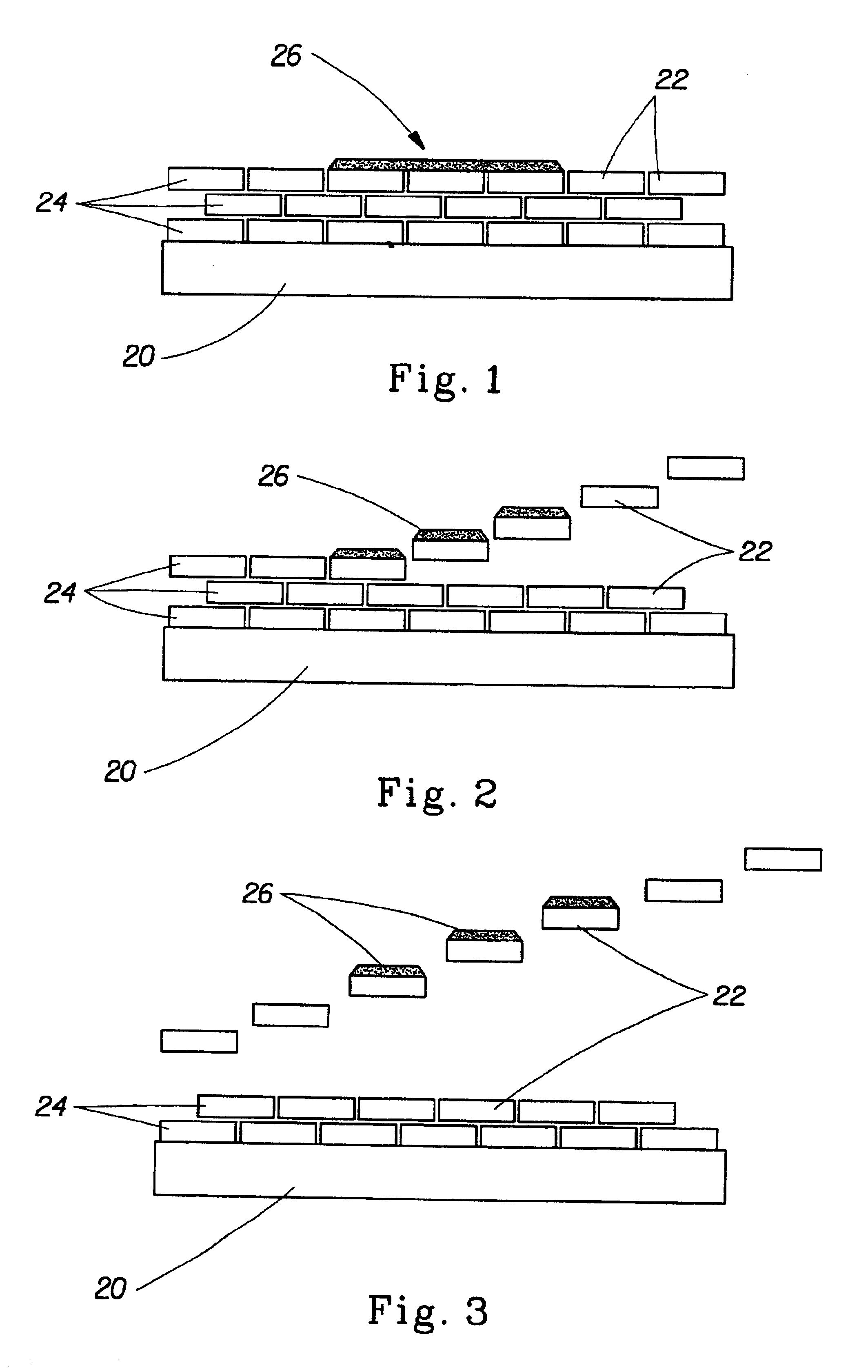

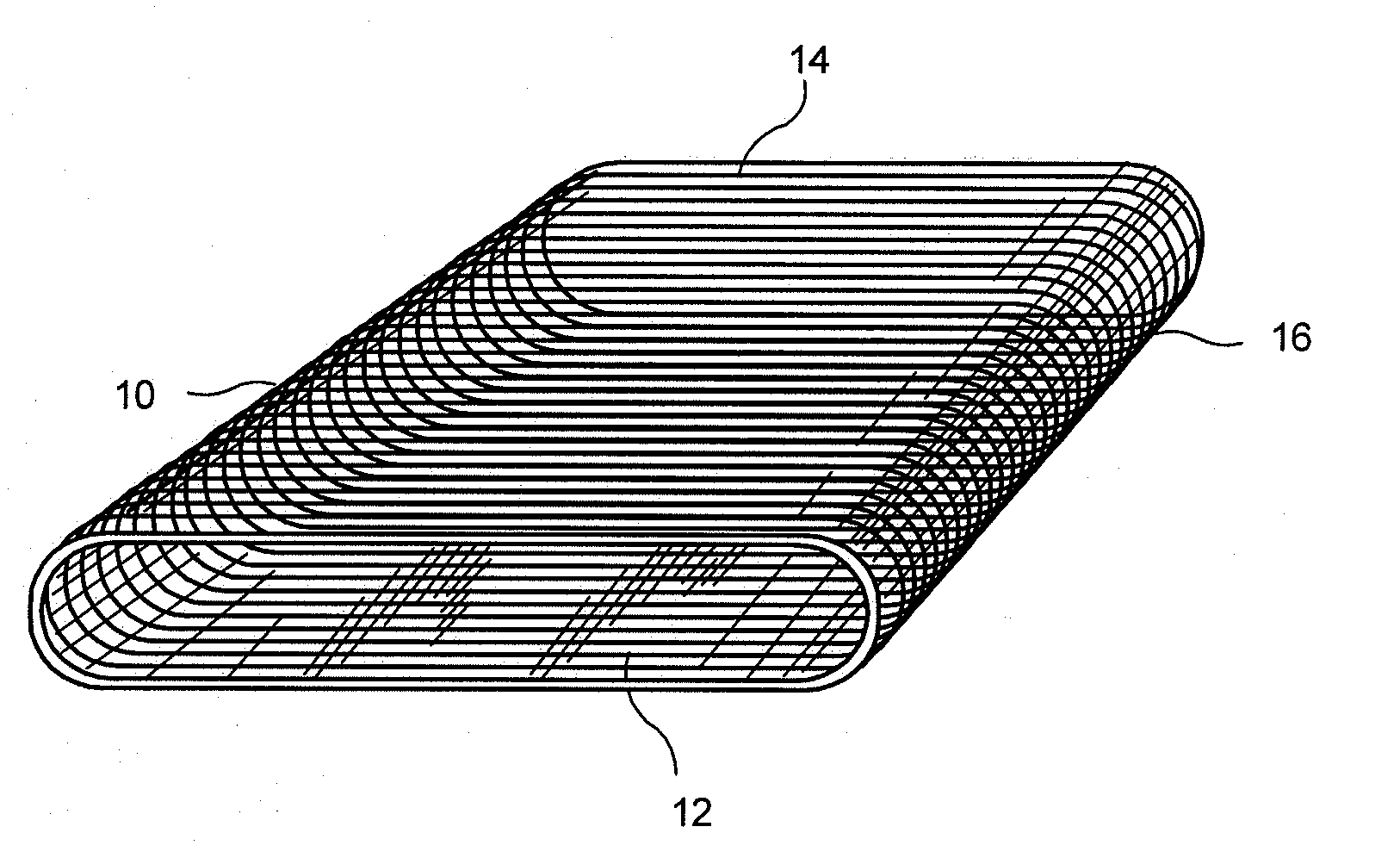

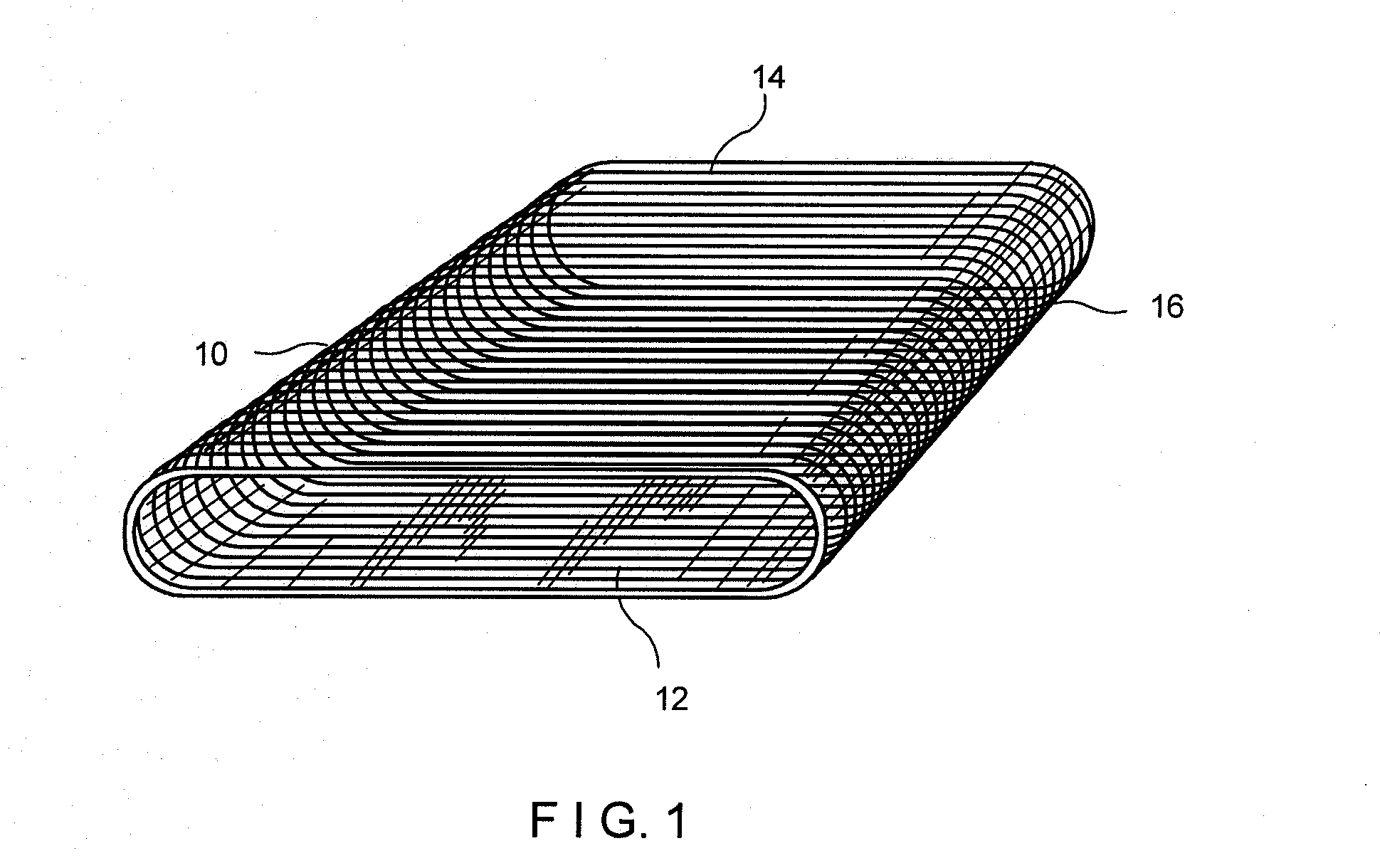

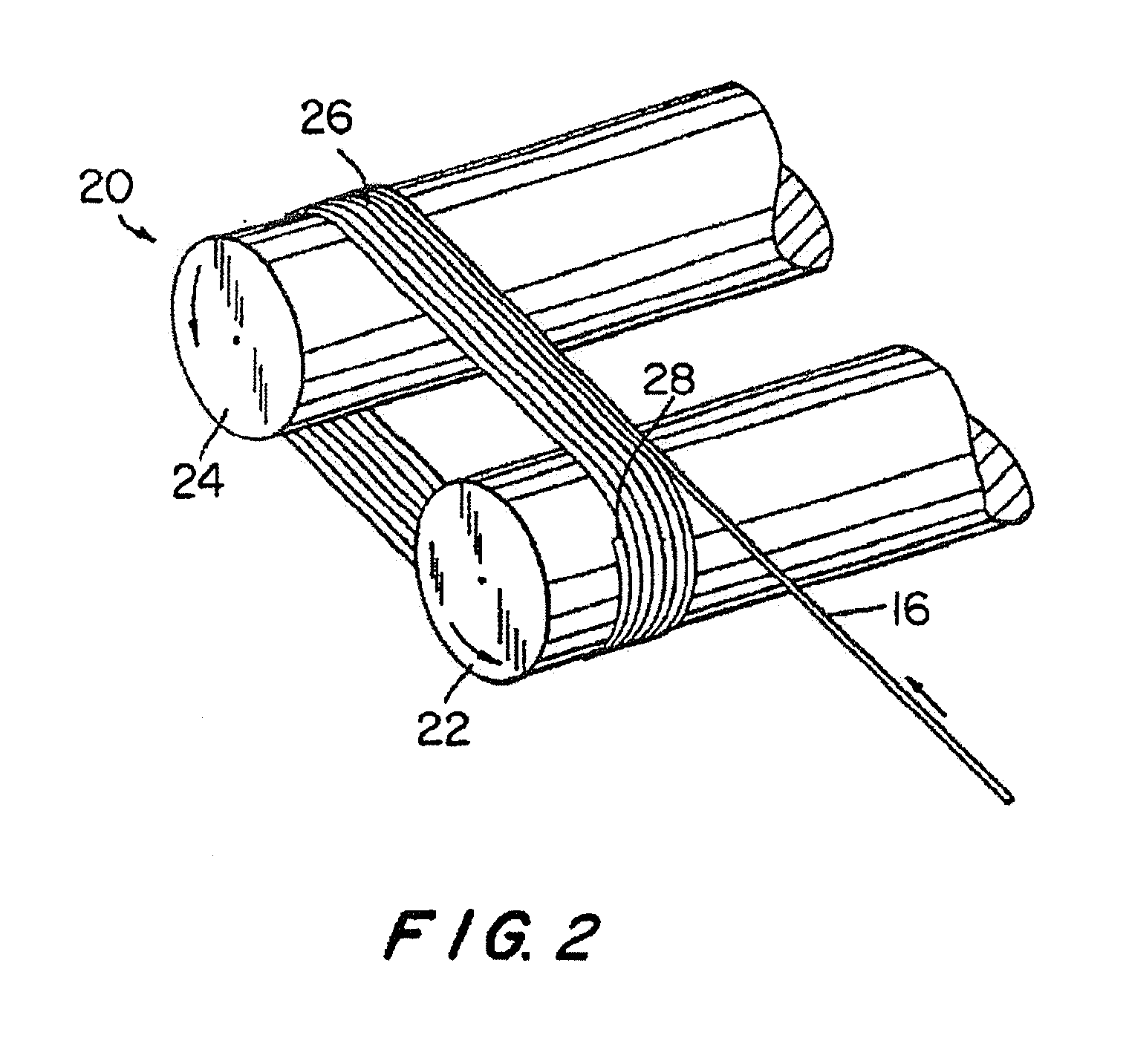

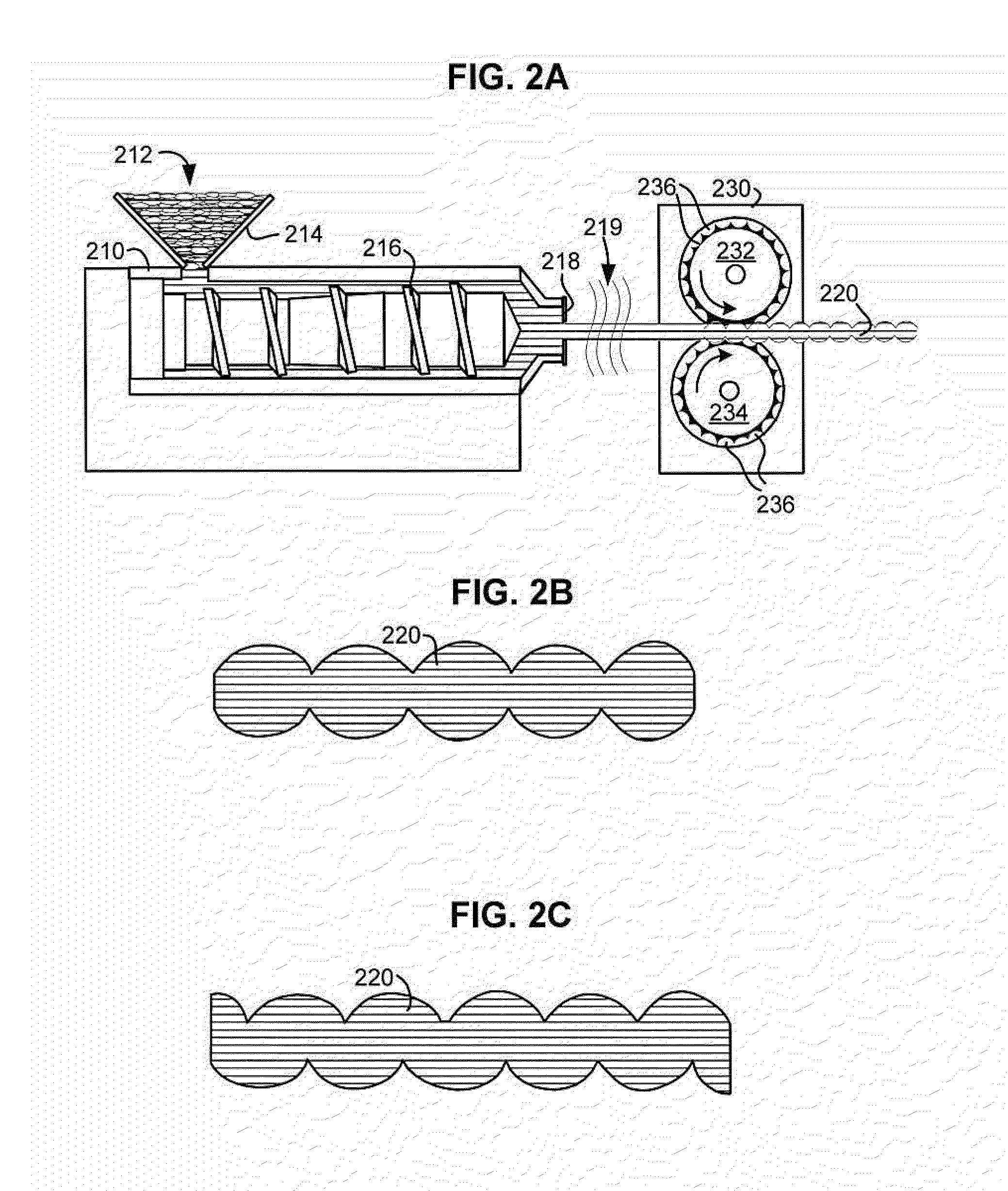

Industrial fabric including spirally wound material strips

ActiveUS20100236034A1Facilitated releaseStable supportNon-fibrous pulp additionNatural cellulose pulp/paperUltrasonic weldingStrapping

An industrial fabric such as an endless belt or sleeve for use in the production of nonwovens, and a method of making thereof are disclosed. The industrial fabric is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

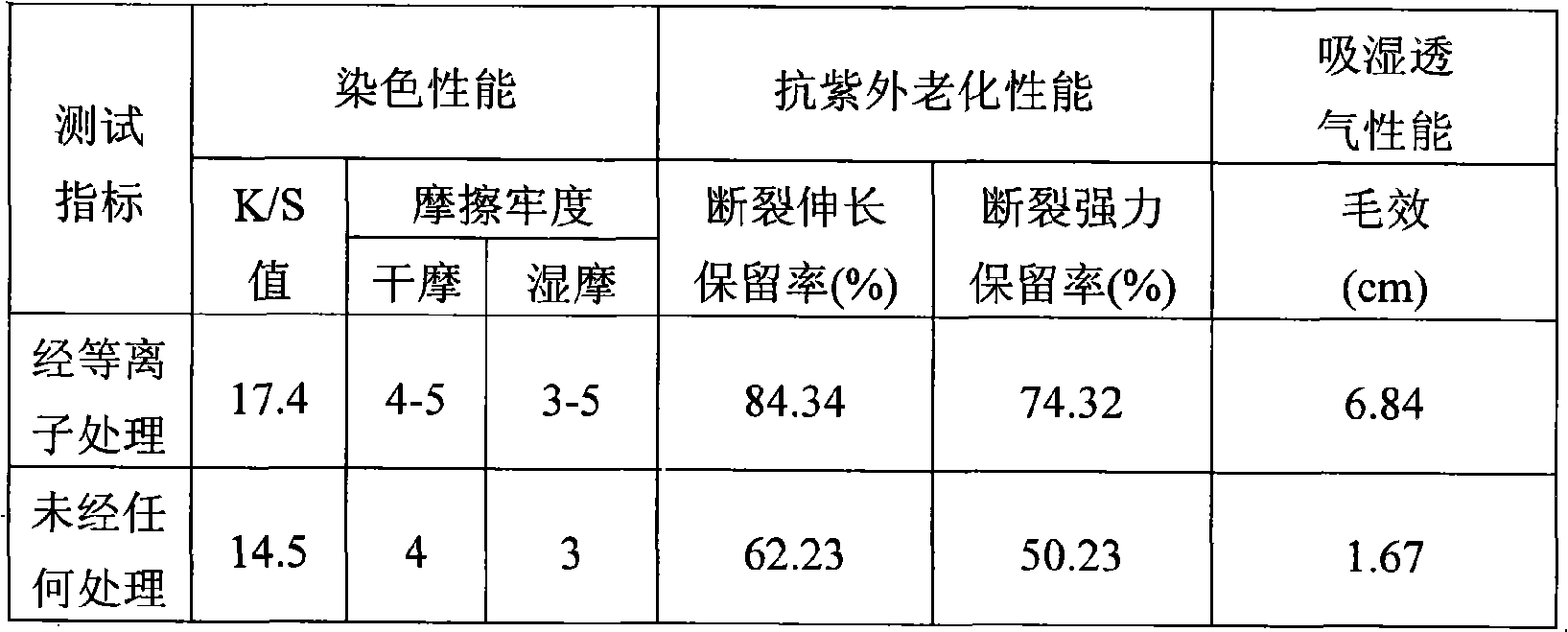

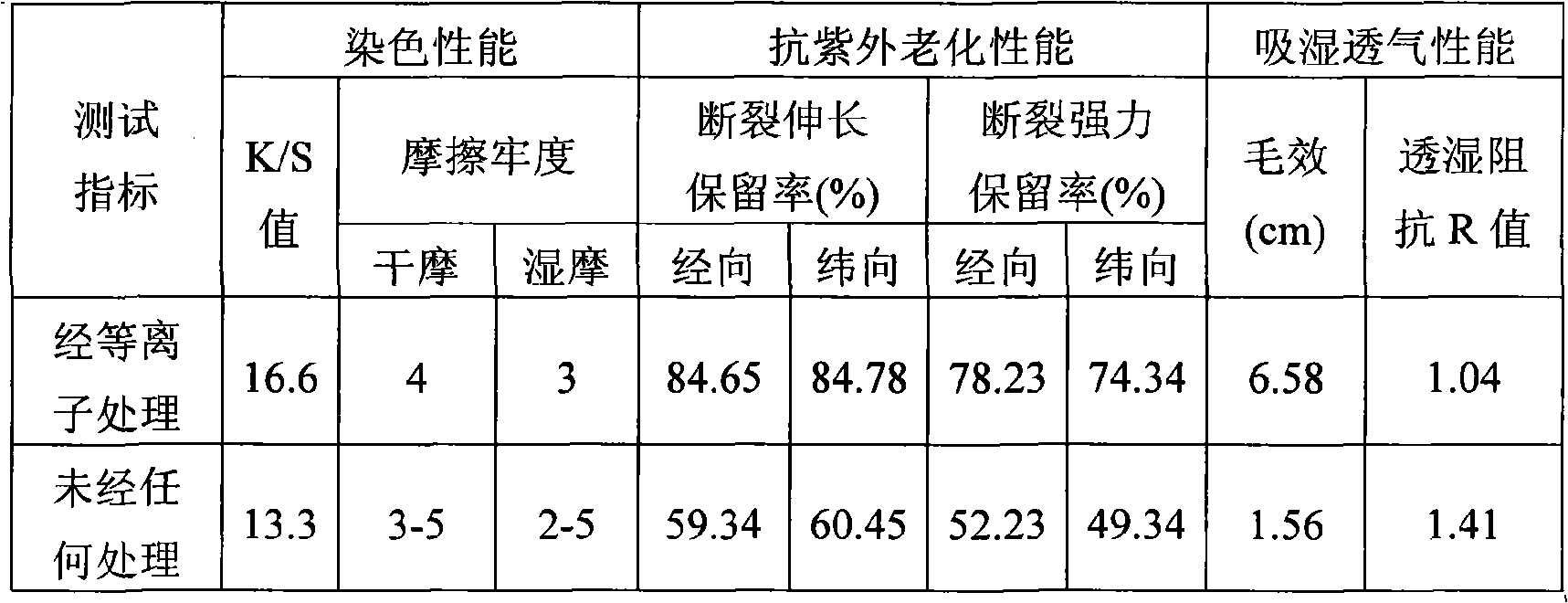

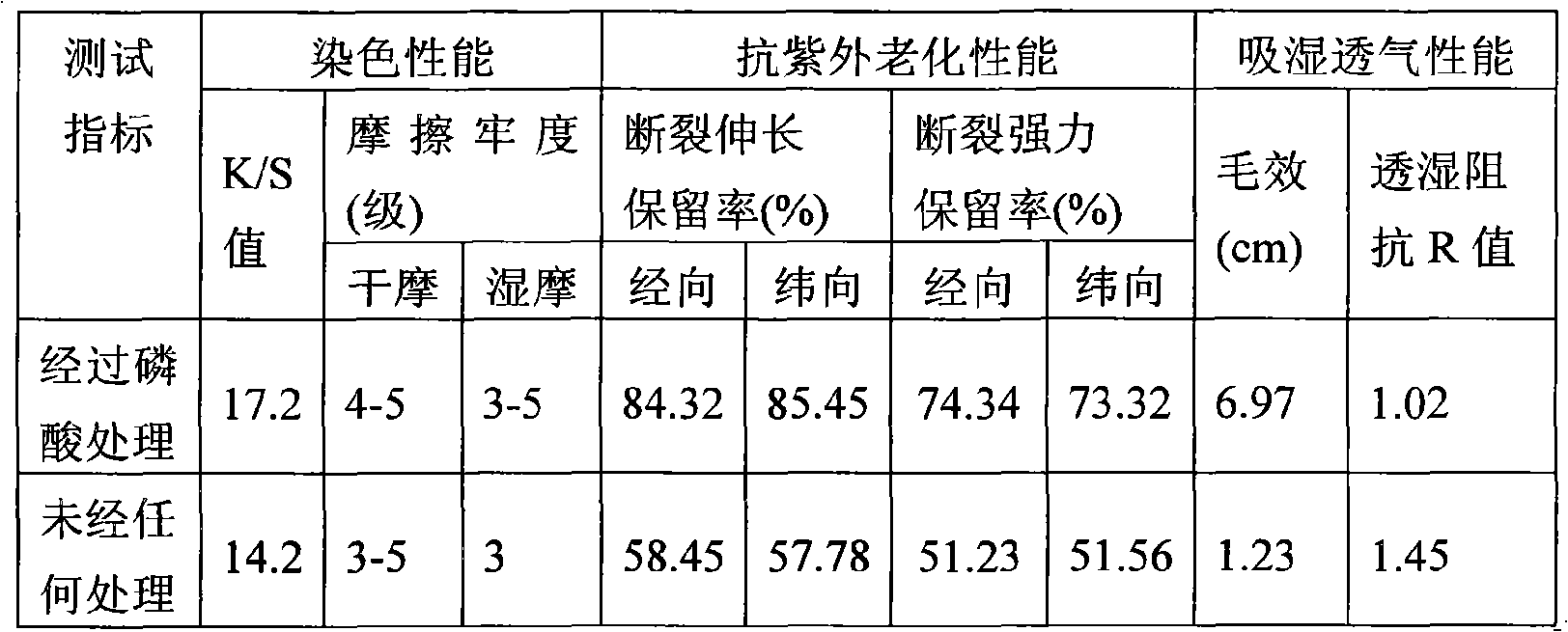

Method for modification, dyeing and multifunctional composite finishing of aramid fiber

InactiveCN101570940ALittle impact on physical and mechanical properties such as strengthEnhanced interactionPhysical treatmentDyeing processChemical industryMoisture permeability

The invention discloses a method for modification, dyeing and multifunctional composite finishing of aramid fiber, and belongs to the technical field of textile chemical industry. Through surface physical and chemical modification for the aramid fiber, the method improves the physical and chemical states of the aramid fiber surface and is favorable for the dyeing and after finishing of the aramid fiber. The specific process flow comprises the following steps of cleaning before the dyeing of the aramid fiber, pretreatment of the aramid fiber, dyeing of the aramid fiber, and multifunctional composite finishing of the aramid fiber. Not only the dyeing property of the aramid fiber treated by the method is remarkably improved, but also the dyeing fastness is good, the aramid fiber has good moisture permeability particularly, and simultaneously the aramid fiber is endued with good anti-ultraviolet ageing function. Moreover, the aramid fiber is subjected to composite finishing by adopting a nano composite sol, and the method has wide applicability, simple process, relatively low treatment cost, and low requirements on the applied technology and equipment.

Owner:JIANGNAN UNIV

Graphite felt watch surface modified method and modified mineral carbon felt

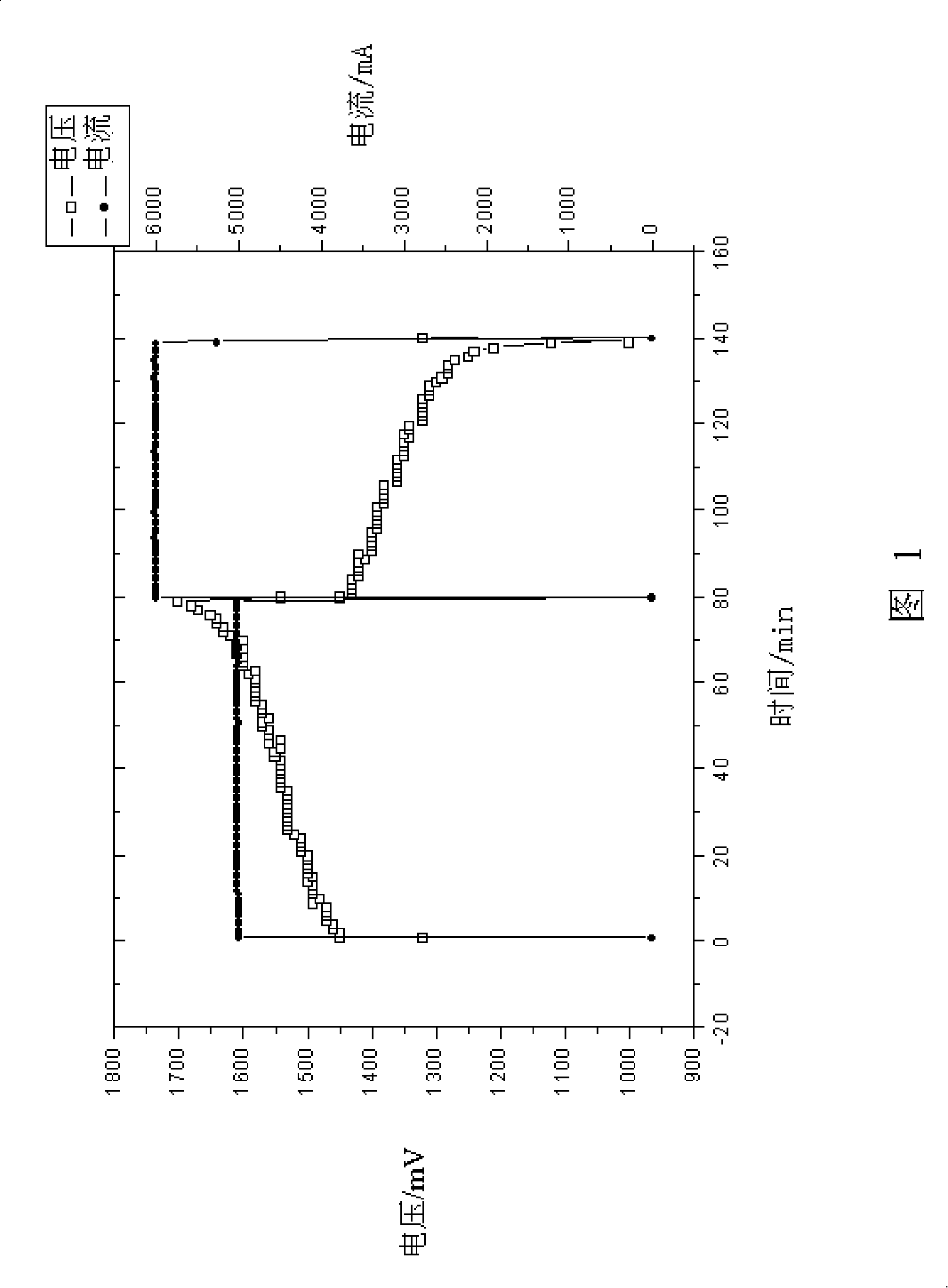

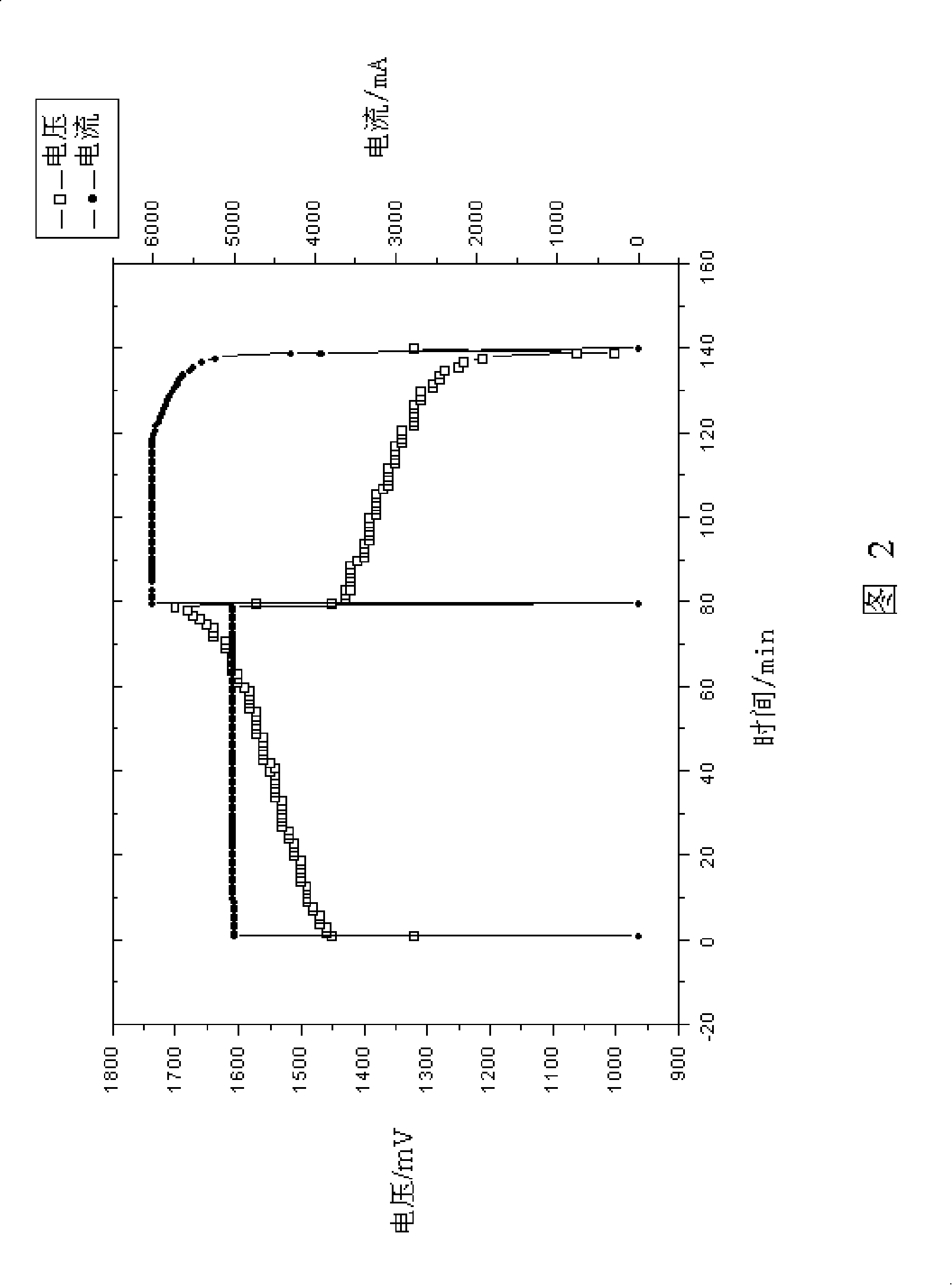

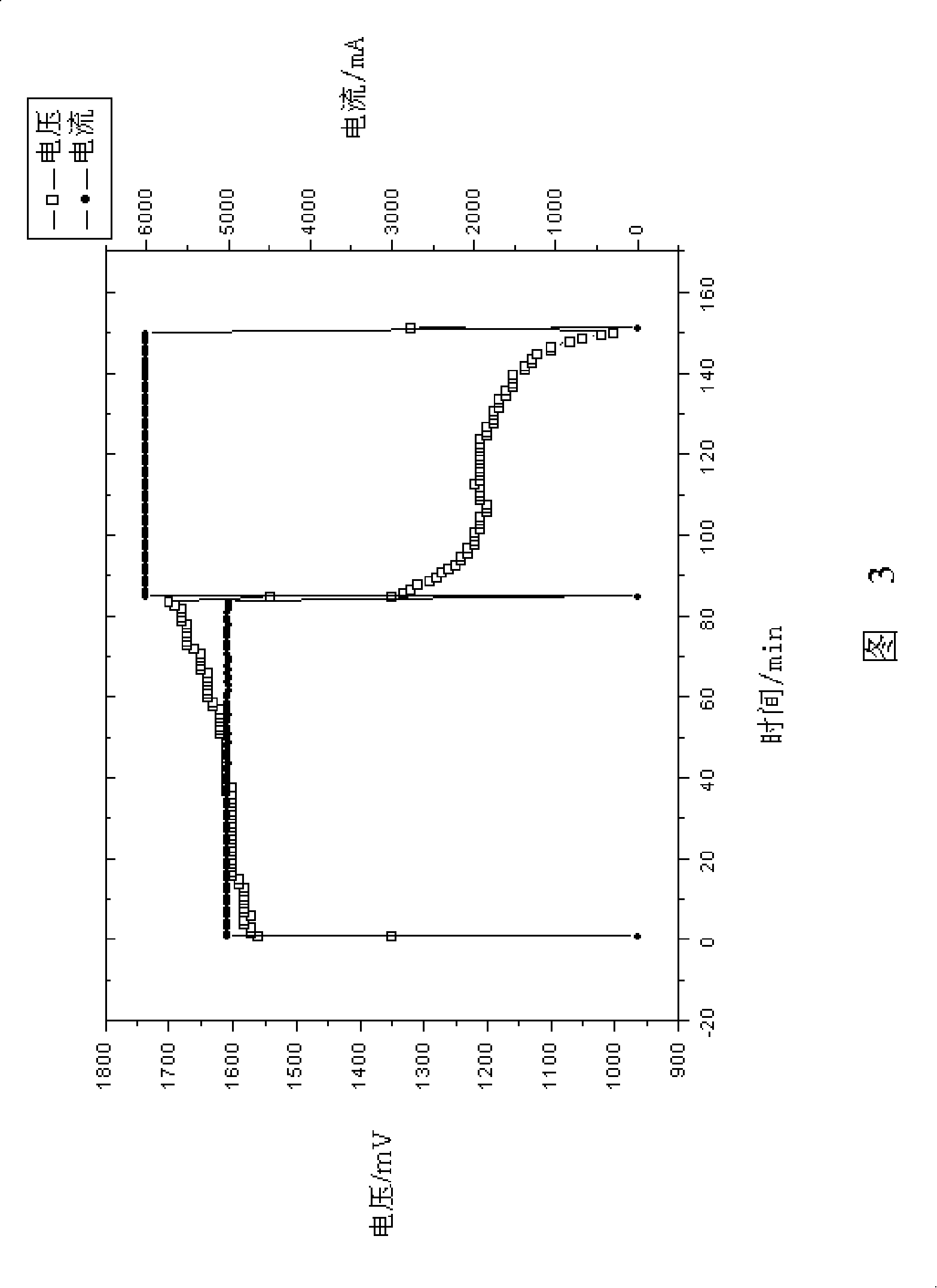

InactiveCN101182678AImprove wettabilityImprove charge and discharge performanceElectrode manufacturing processesPhysical treatmentFiberVanadium redox battery

The invention relates to a graphite fiber felt surface modification method and a modified graphite fiber felt, and belongs to the all vanadium redox flow battery electrode manufacture technical field. The method step is that the electrochemical cathode modification treatment is conducted before the anode oxidation treatment. When used as an electrode, a modified graphite fiber felt greatly improves the electrochemical activity in the preparation of an all vanadium redox flow battery, promotes the voltage efficiency and the battery energy efficiency during the battery discharging, and increases the stable discharging time, so the recharging and discharging performance of the all vanadium redox flow battery is greatly improved. Moreover, the method is easy for implantation and low in the cost. No particular devices are required. The invention provides a good-performance electrode material for the battery manufacture field.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Fabric treatment for stain release

InactiveUS20050204477A1Extended service lifeImprove the protective effectOrganic detergent compounding agentsPhysical treatmentWrinkle skinZeta potential

A fabric treatment composition that includes at least one zeta potential modifier and a hydrophobic agent with a melting point or glass transition temperature below 100° C. that imparts fabric protection benefits, including improved stain and soil resistance, oil repellency, water repellency, softness, wrinkle and damage resistance, and better handfeel to treated fabrics. Particularly preferred compositions include at least one zeta potential modifier in an amount sufficient to adjust the zeta potential of the composition to be positive and greater than zero millivolts. Particularly preferred compositions also include a fluoropolymer. The composition can be used as a pretreatment prior to washing, through soaking or direct spray application, or added to the treatment liquor, that is either the wash or rinse cycle of an automatic washing machine, or used prior to or during the drying cycle of an automatic drying machine or refresher machine, or used prior to or in conjunction with an ironing device. The fabric treatment is complete when the fabric is cured by drying and / or heating.

Owner:VAN BUSKIRK GREGORY

Preparation method of functional fabric

InactiveCN104805680AOvercome strong adsorptionDestruction of the entangled bonded statePhysical treatmentEcological environmentProcess equipment

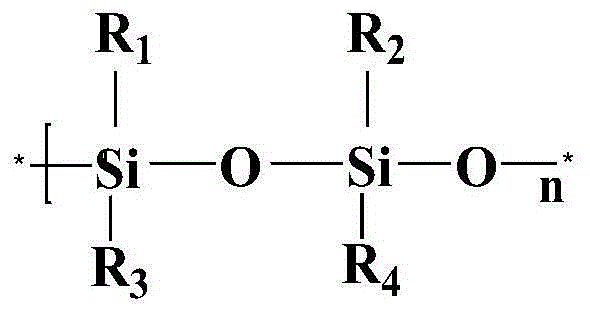

The invention relates to a preparation method of a functional fabric, and belongs to the technical field of textile materials. Functional nanoparticles are compounded on the surface of the fabric through the preparation of the functional nanoparticles and the preparation of the functional fabric. The existence of vinyl polysiloxane overcomes high adsorption capacity of functional nanoparticle aggregate, so that the uniformly dispersed functional nanoparticles are firmly adhered to the surface of the fabric, and the fabric has multiple functions of ultraviolet resistance, super-hydrophobicity, pollution resistance, antibacterial property, health and the like through the synergistic effect of the vinyl polysiloxane and the functional nanoparticles. According to the preparation method of the functional fabric disclosed by the invention, the vinyl polysiloxane is efficiently utilized, the productive value of the vinyl polysiloxane is improved, and the application of the vinyl polysiloxane to other fields is developed; moreover, the whole process is simple in equipment, relatively low in cost and free of pollution to ecological environment, and has a great application prospect.

Owner:WUHAN TEXTILE UNIV

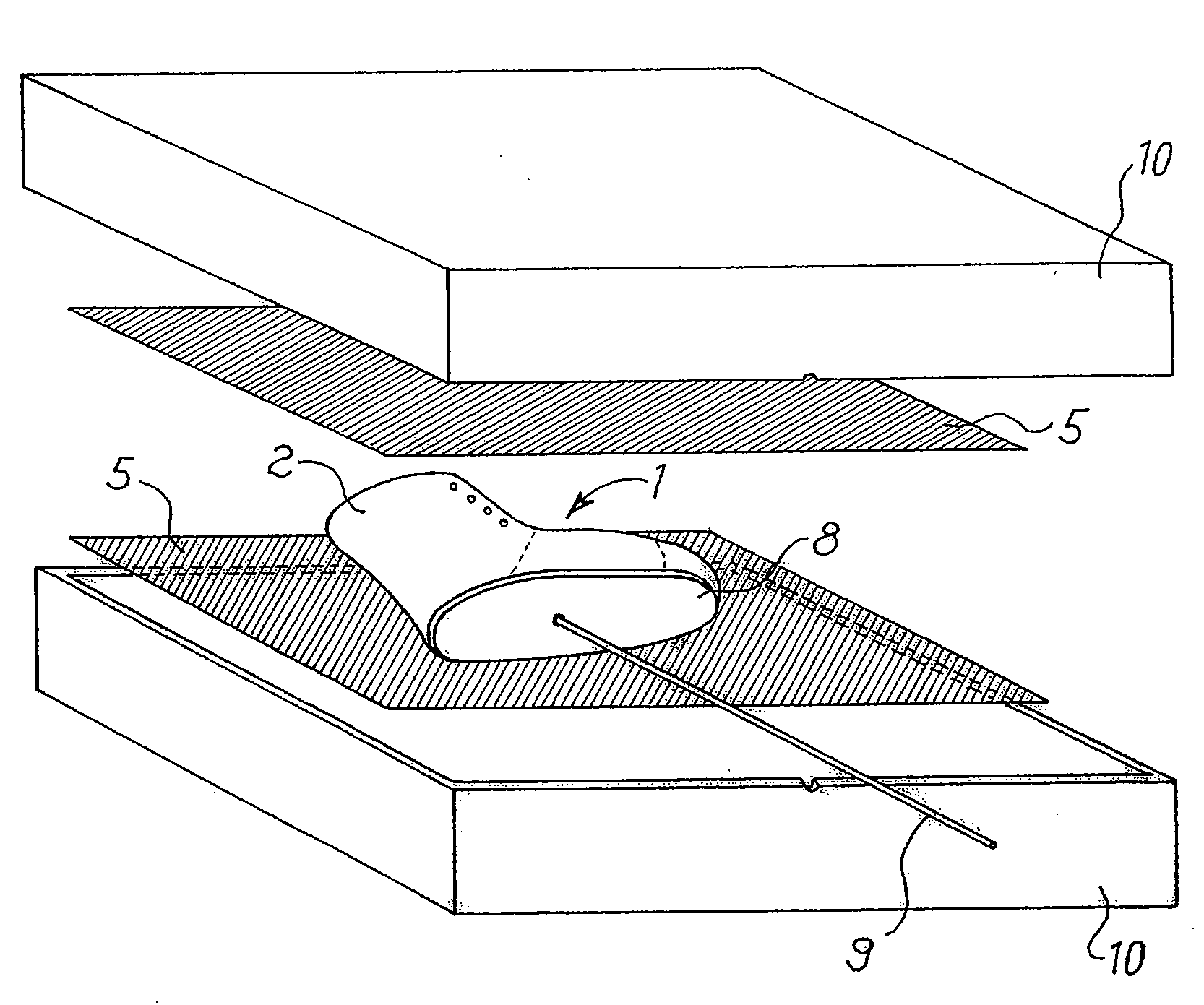

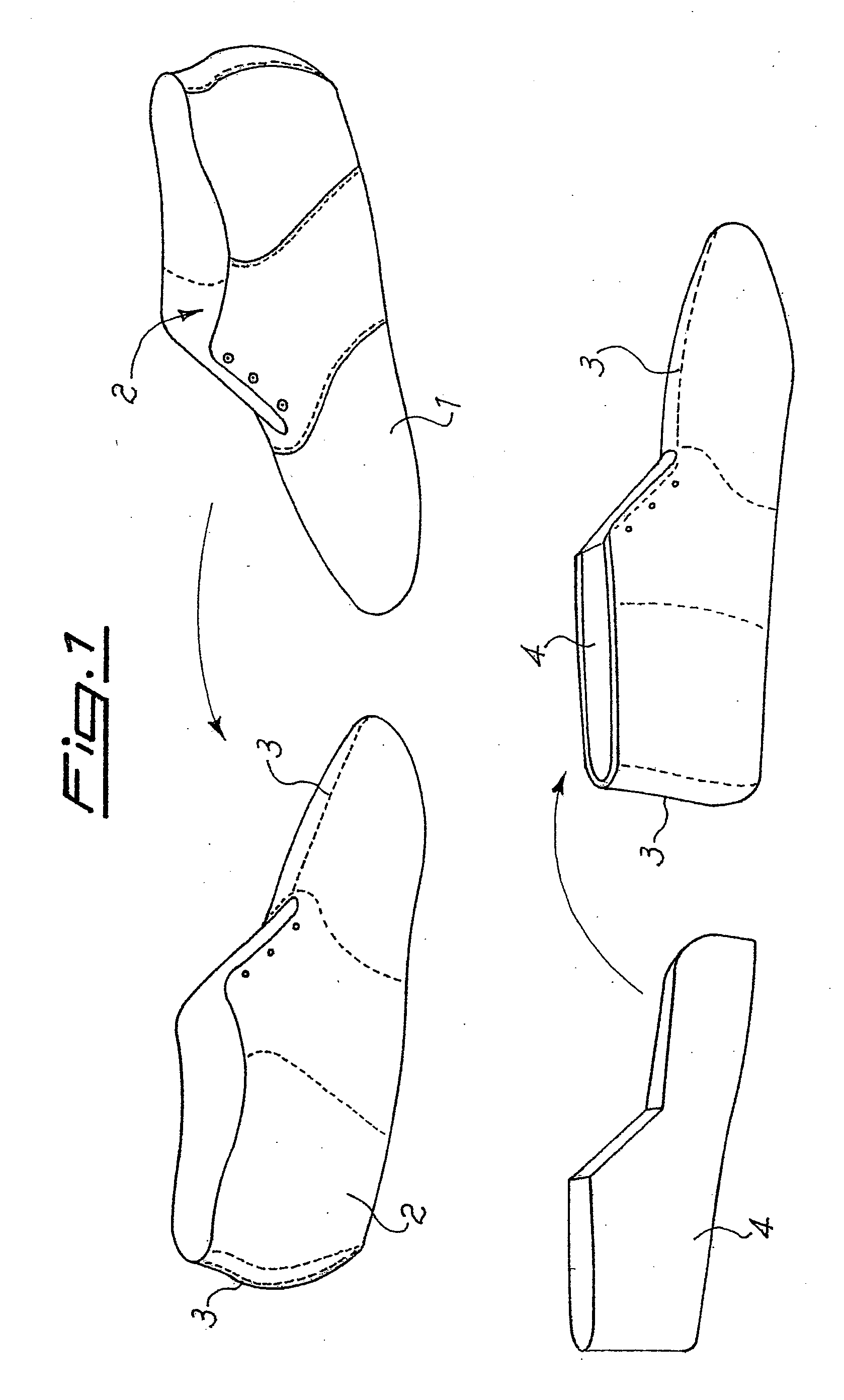

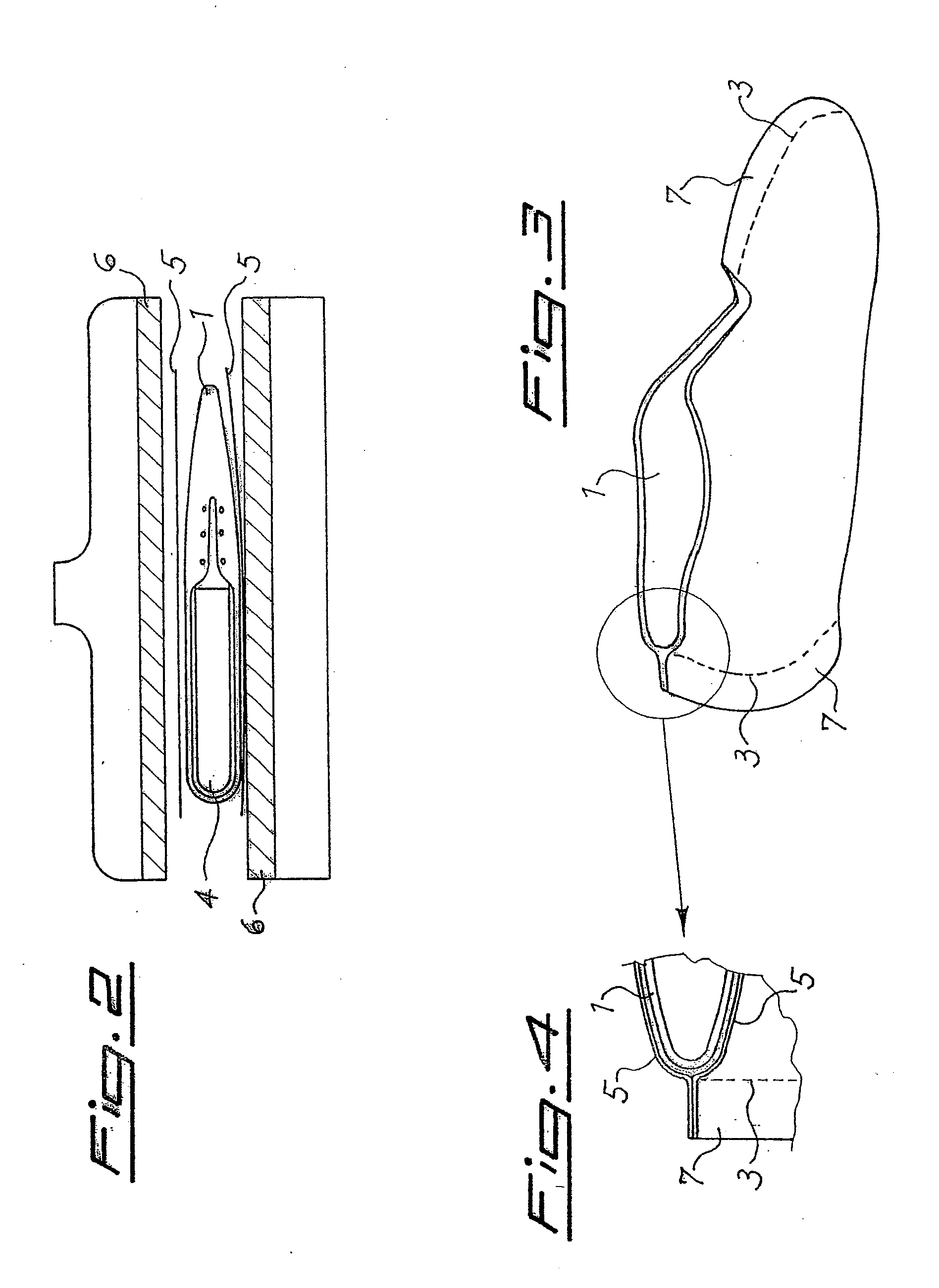

Semimanufactured Waterproofed Products, Particularly Shoes, Clothing Items and Accessories

InactiveUS20080127426A1Improve adhesionPhysical treatmentInsolesWork in processBiomedical engineering

Owner:OUTDRY TECH

Method and device for producing electrospun fibers

The present invention relates to methods for producing fibers made from one or more polymers or polymer composites, and to structures that can be produced from such fibers. In one embodiment, the fibers of the present invention are nanofibers. The present invention also relates to apparatus for producing fibers made from one or more polymers or polymer composites, and methods by which such fibers are made.

Owner:AKRON THE UNIV OF

Electroconductive woven and non-woven fabric and method of manufacturing thereof

ActiveUS20070054577A1Improve adhesionUniform and stableNanotechPhysical treatmentEngineeringBiological activation

The invention relates to an electroconductive textile material and method of preparation thereof. The method consists mainly of two stages: 1) special pretreatment of the fabric substrate for activation and making it suitable for subsequent application and strong attachment of a conductive coating with the use of a layer-by-layer technique (LBL); 2) subsequent application and strong attachment of a conductive coating by means of a layer-by-layer technique. The first stage may be carried out thermally, thermochemically, by treating in hot solutions, or plasma-chemically by plasma treatment. The pre-treatment may be performed, e.g., for swelling and / or for the formation of unsaturated chemical bonds or uncompensated charges in the fabric material. The pretreatment is needed to ensure more efficient penetration of chemical components into the fabric structure during subsequent LBL applications of treatment solutions that contain nano-particles and that determine the density of the molecular layer. The types and amounts of the nano-particles determine their charge density (solution pH is very important for charge density) in the sublayer. Such a pretreatment increases bonds of the applied layers with the substrate material.

Owner:EEONYX CORP

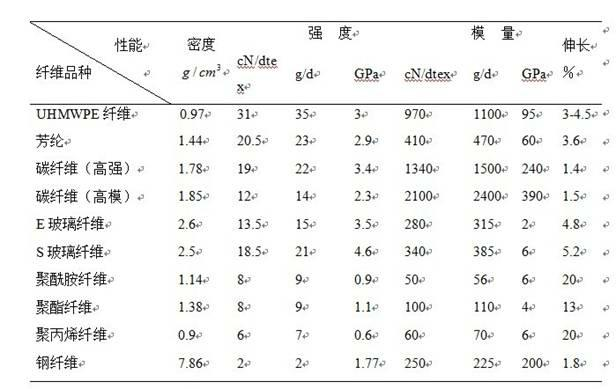

Method for improving creep resistant performance of ultra-high molecular weight polyethylene fiber

ActiveCN102493168AHigh surfaceIncrease internal cross-link pointsPhysical treatmentFibre typesFiberPolymer science

The invention relates to a method for improving the creep resistant performance of an ultra-high molecular weight polyethylene fiber; and the method is characterized by jointly triggering crosslinking by using a photosensitizer and a thermal initiating agent, thereby crosslinking points of the surface and interior of the ultra-high molecular weight polyethylene fiber are increased, the crosslinking efficiency of a cross-linking agent is improved, the relative slippage among molecules of the ultra-high molecular weight polyethylene fiber is effectively impeded and the creep resistant performance of the fiber is increased.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

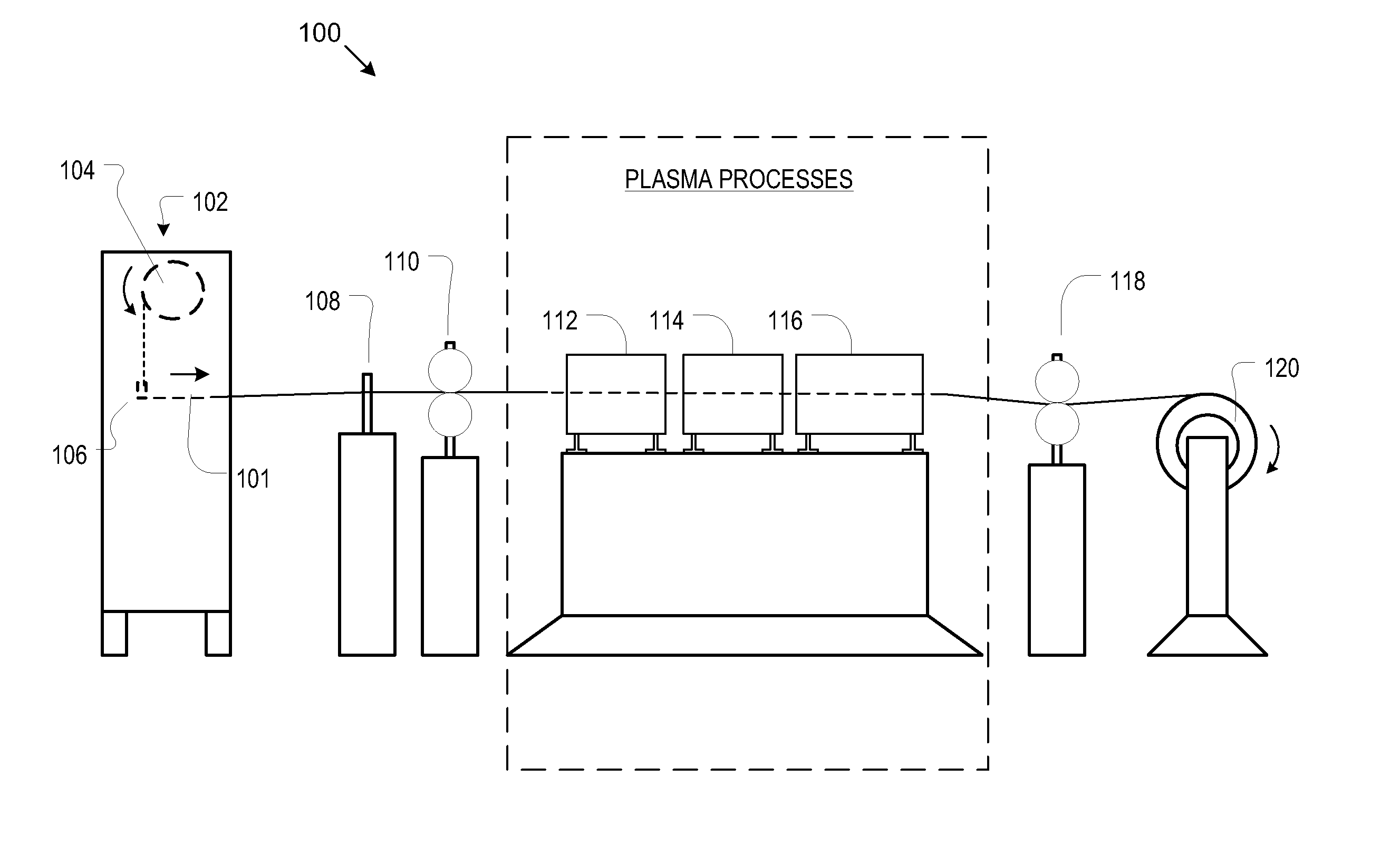

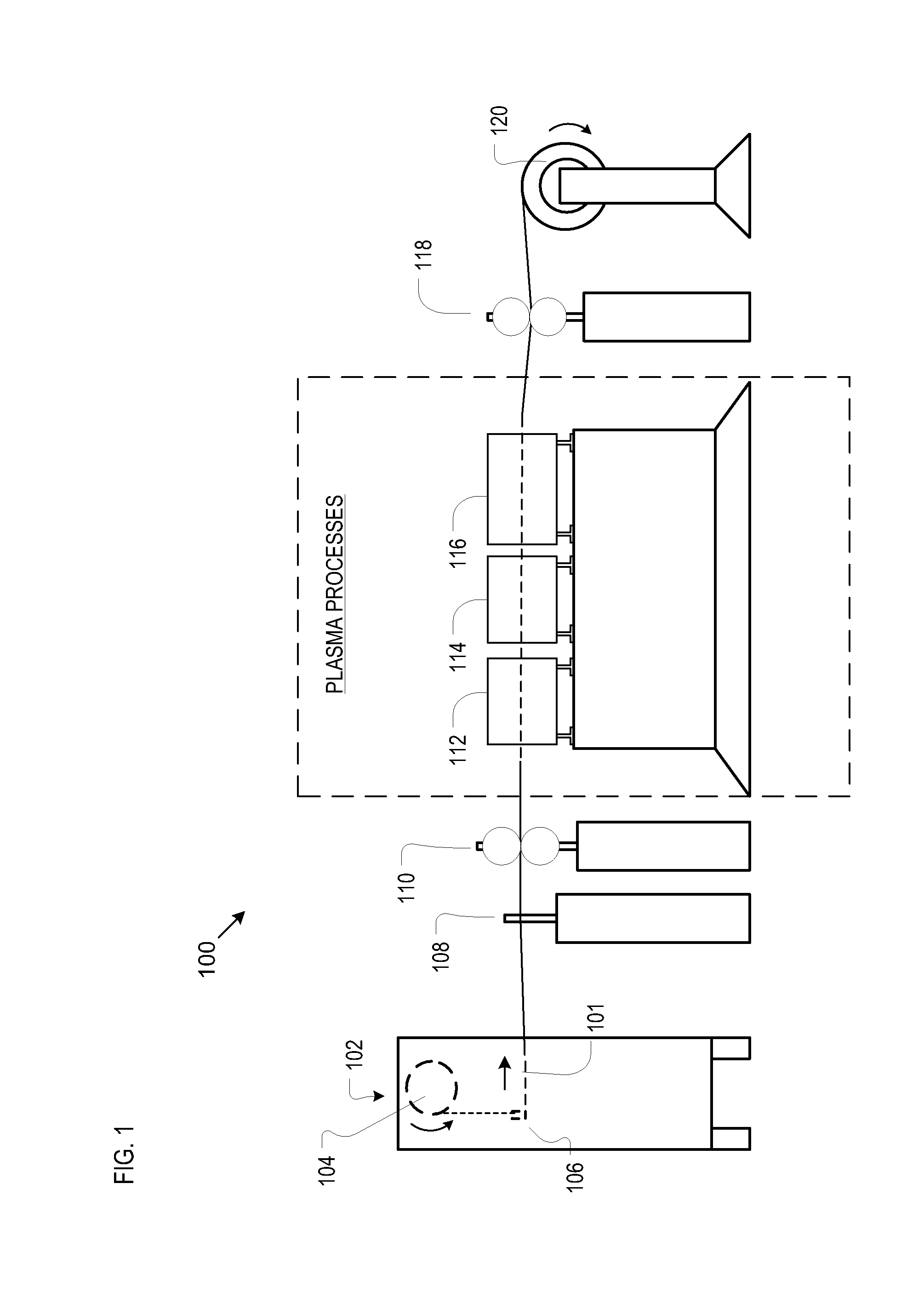

Treatment of fibrous materials using atmospheric pressure plasma polymerization

ActiveUS20080107822A1Suitable for useLiquid surface applicatorsPhysical treatmentTextile industryDry cleaning

An apparatus and method for plasma finishing of fibrous materials including paper and knitted, woven and non-woven fibrous substrates such that desired characteristics are imparted are described. The method includes depositing a monomer comprising at least one fluorocarbon monomer with chemical additives, as required, at atmospheric pressure onto the paper or knitted, woven or non-woven substrate; exposing the monomer on a single surface of the fibrous material to an inert gas, atmospheric-pressure plasma, thereby causing polymerization of the monomer species; and repeating this sequence using multiple sequential deposition and plasma discharge steps to create a layered surface having durability against abrasion for both water-based laundry methods and dry-cleaning methods, and normal wear, without affecting the feel, drape, appearance or breathability of the substrate material. The present method uses a high-power, continuously operating plasma that is 104 times more powerful than the prior art plasma sources utilized in the textile industry, and produces a durable finish with between 0.5 and 2 s of plasma exposure. This is sufficiently rapid to meet commercial fabric processing throughput, and repeated cleaning of the electrodes is not required.

Owner:APJET INC

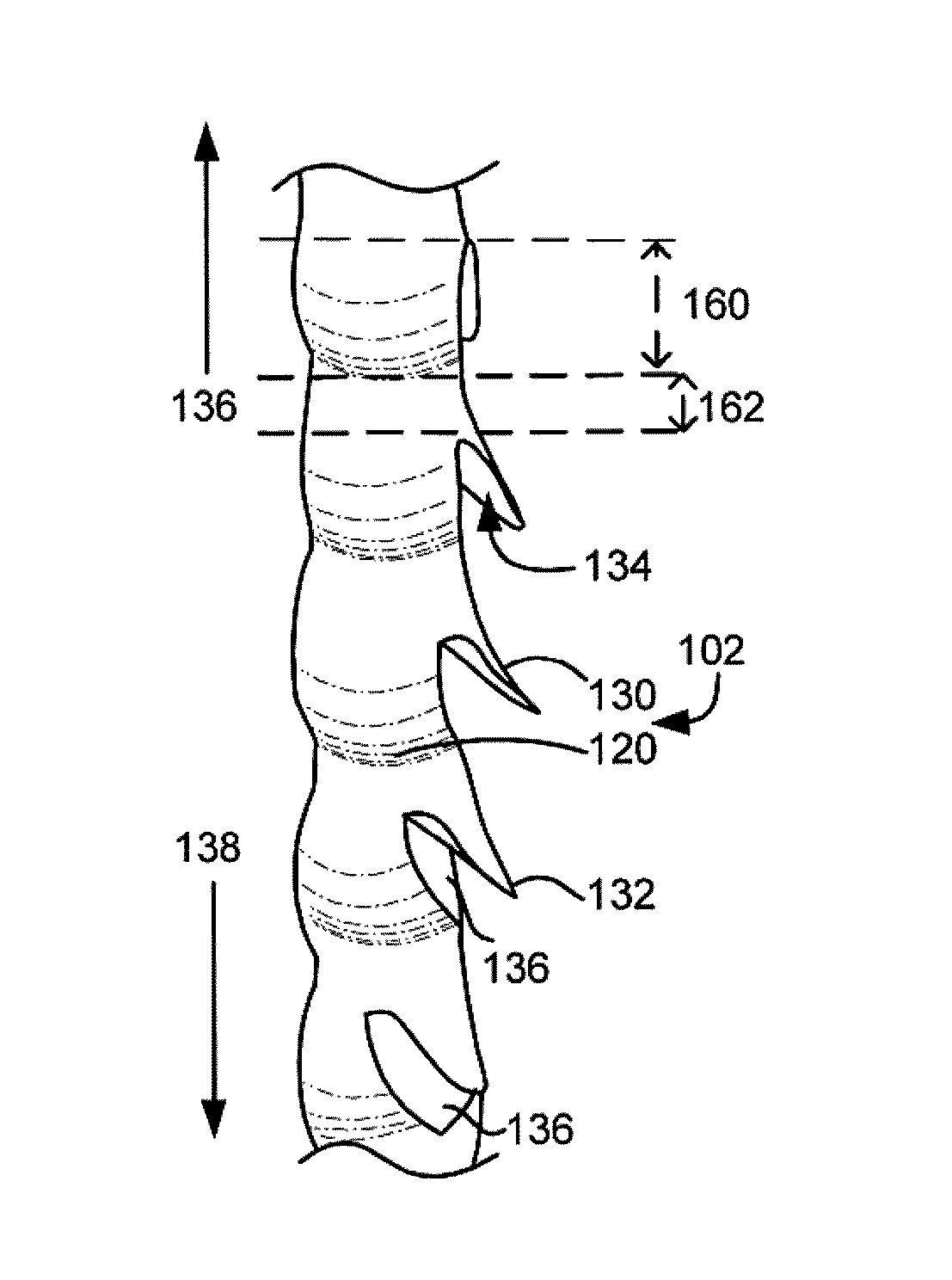

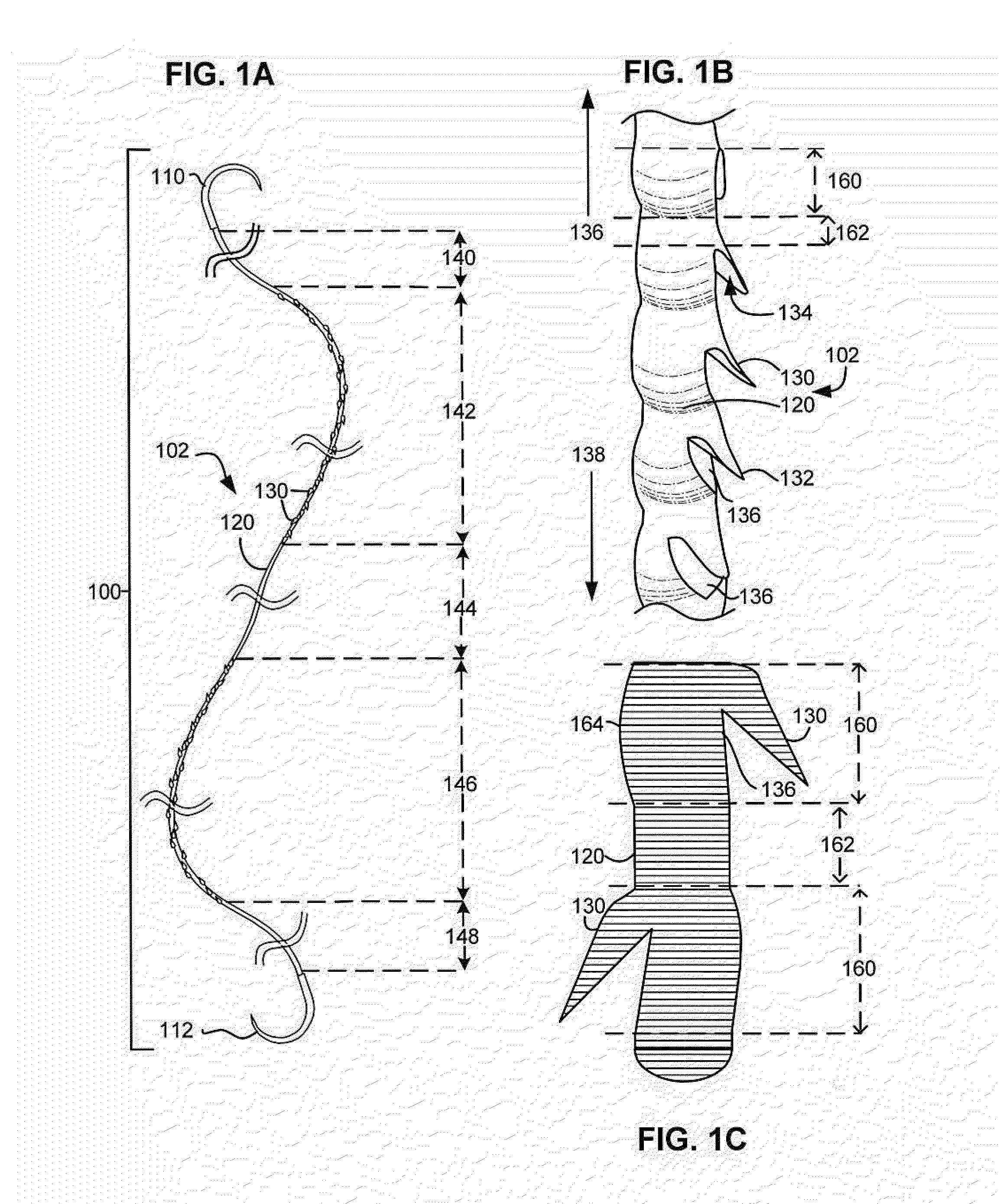

Self-retaining suture with variable dimension filament and method

ActiveUS8641732B1Improved self-retaining suturesImprove abilitiesSuture equipmentsPhysical treatmentMedicineUltimate tensile strength

Owner:ETHICON INC

Nano-silver antibacterial fabric and preparation method thereof

InactiveCN103015166ASmall sizeImprove release efficiencyPhysical treatmentSynthetic fibresAir filtrationBio aerosol

The invention provides a nano-silver antibacterial fabric and a preparation method thereof. The nano-silver antibacterial fabric has the characteristics that a zinc oxide nano line grows on the fabric; and silver nano particles are deposited on the zinc oxide nano line. The zinc oxide nano line is synthesized by a solution chemical method; and the silver nano particles are deposited on the zinc oxide nano line by a simple 'immersion-illumination' method. The nano-silver antibacterial fabric prepared by the method has extremely obvious long-time antibacterial performance; the silver nano particles are small in size and cannot be accumulated; a synthesis process is environment-friendly; and the nano-silver antibacterial fabric can be recycled and reused. The nano-silver antibacterial fabric can be used for single-point water treatment to reduce microorganism content in water and can be suitable for medical surgical dressing and medical fabrics; and the nano-silver antibacterial fabric can be used as an antibacterial air filtration device for preventing bio-aerosol from being gathered on a ventilating, heating and air conditioning system.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com