Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1300 results about "Dry cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry cleaning is any cleaning process for clothing and textiles using a chemical solvent other than water. The modern dry cleaning process was developed and patented by Thomas L. Jennings. Despite its name, dry cleaning is not a "dry" process; clothes are soaked in a liquid solvent.

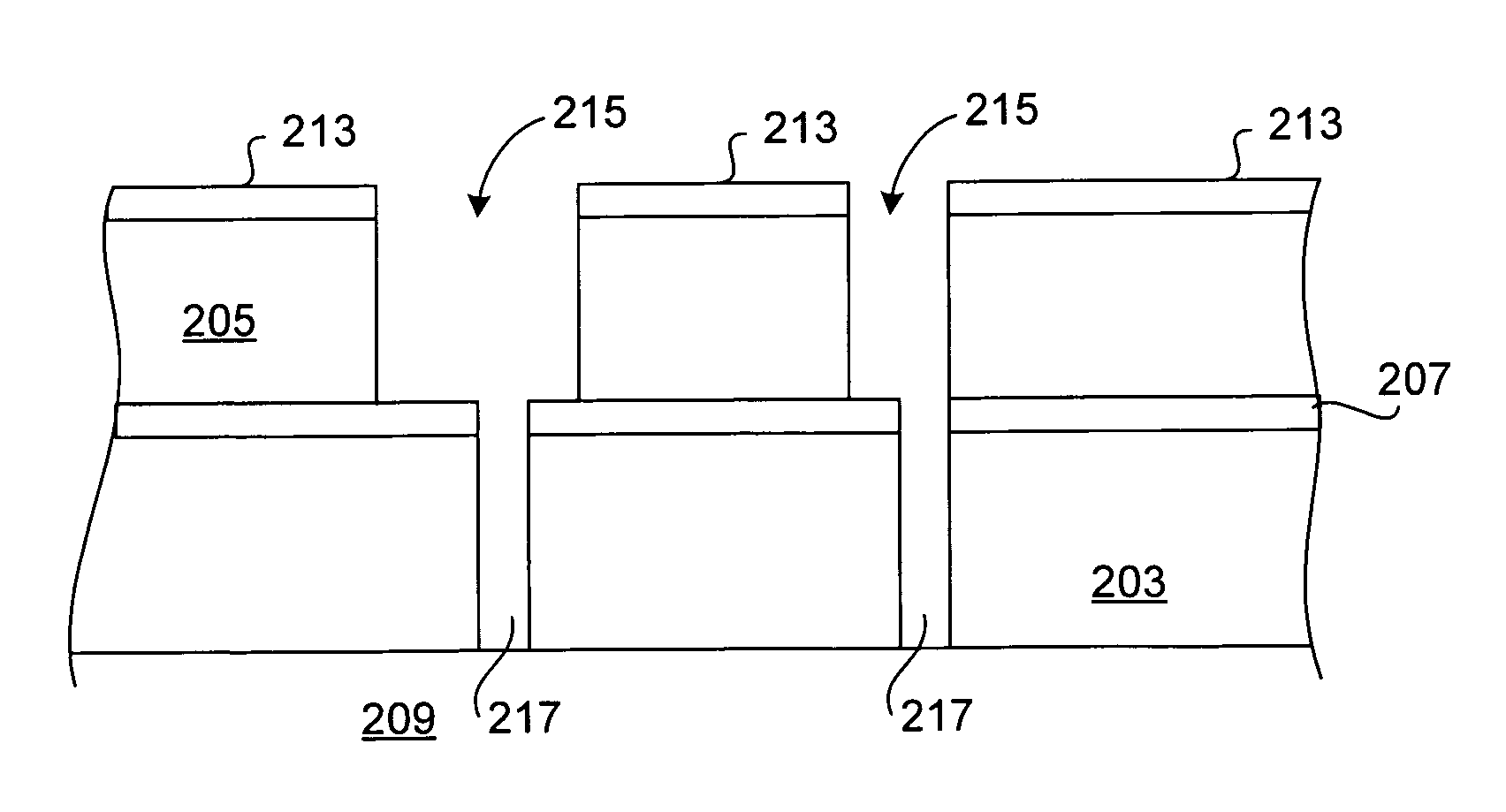

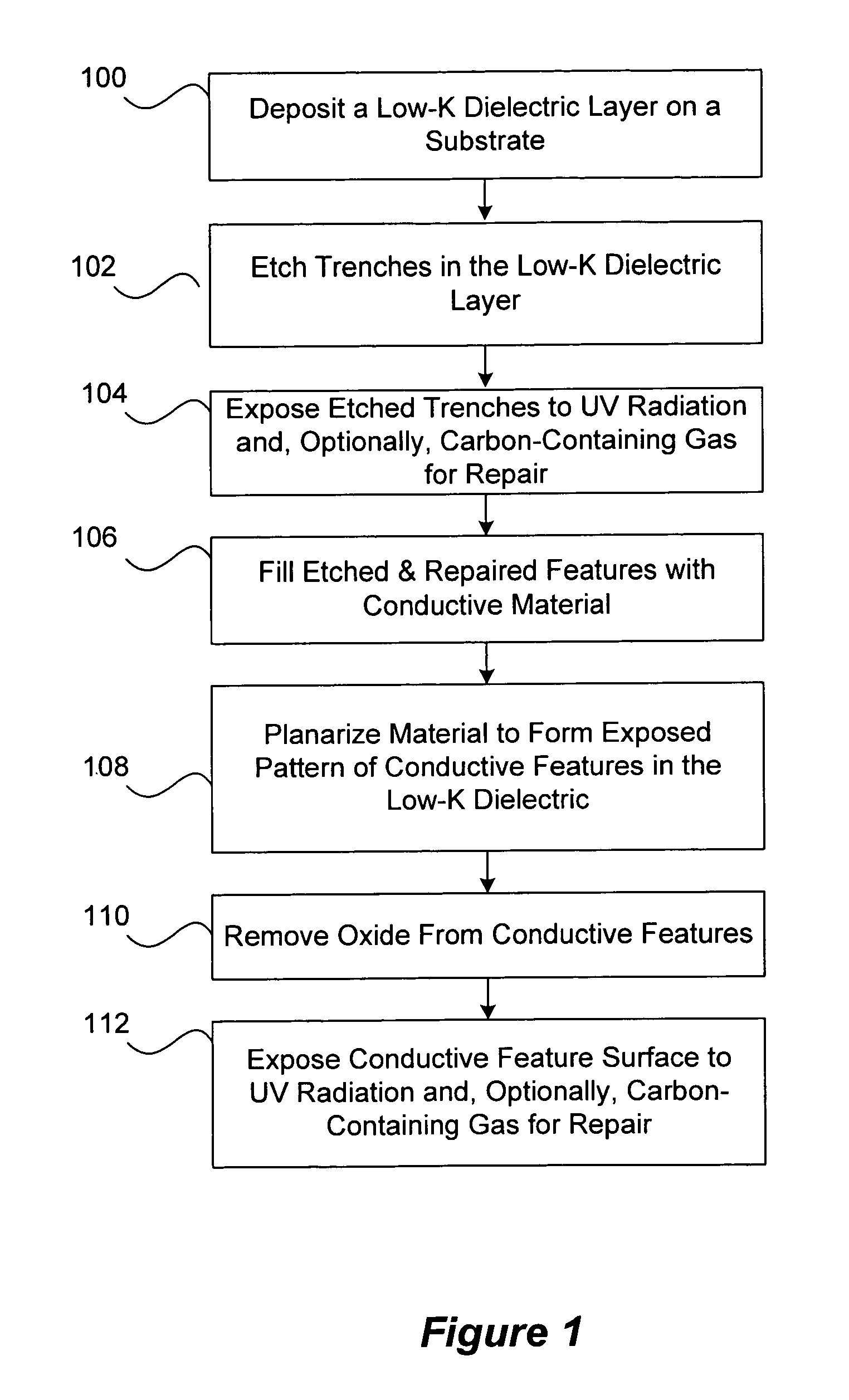

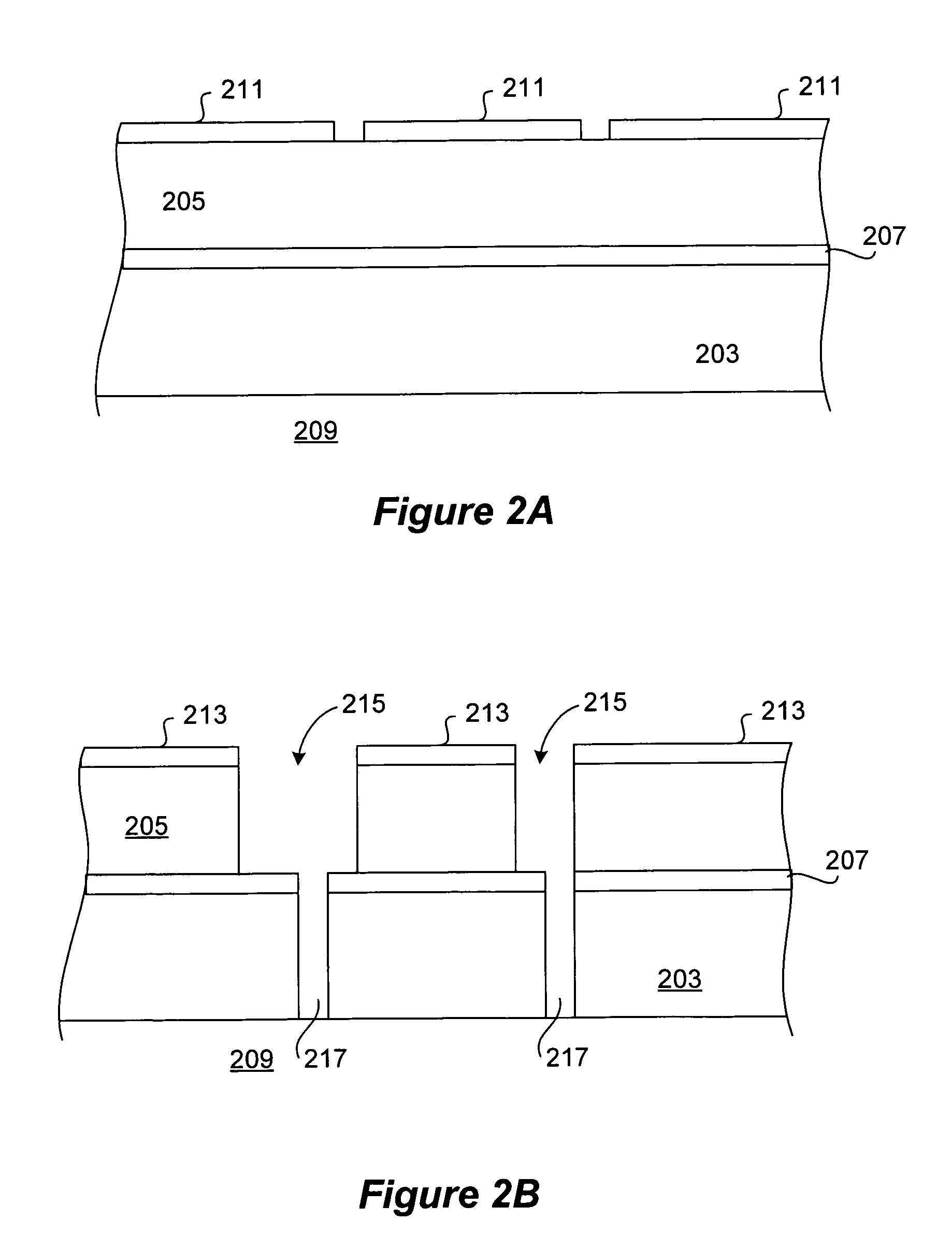

UV treatment for carbon-containing low-k dielectric repair in semiconductor processing

Owner:NOVELLUS SYSTEMS

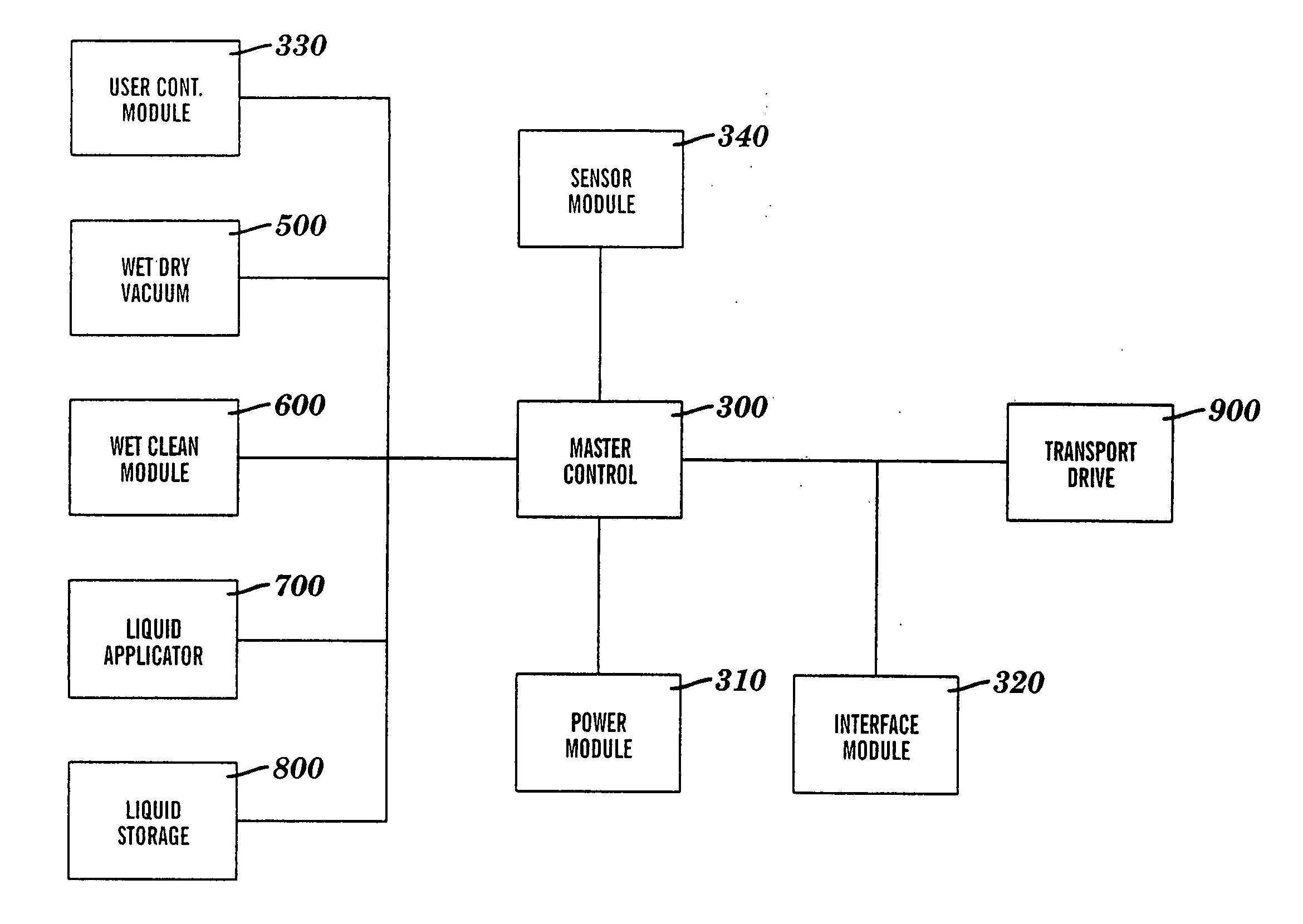

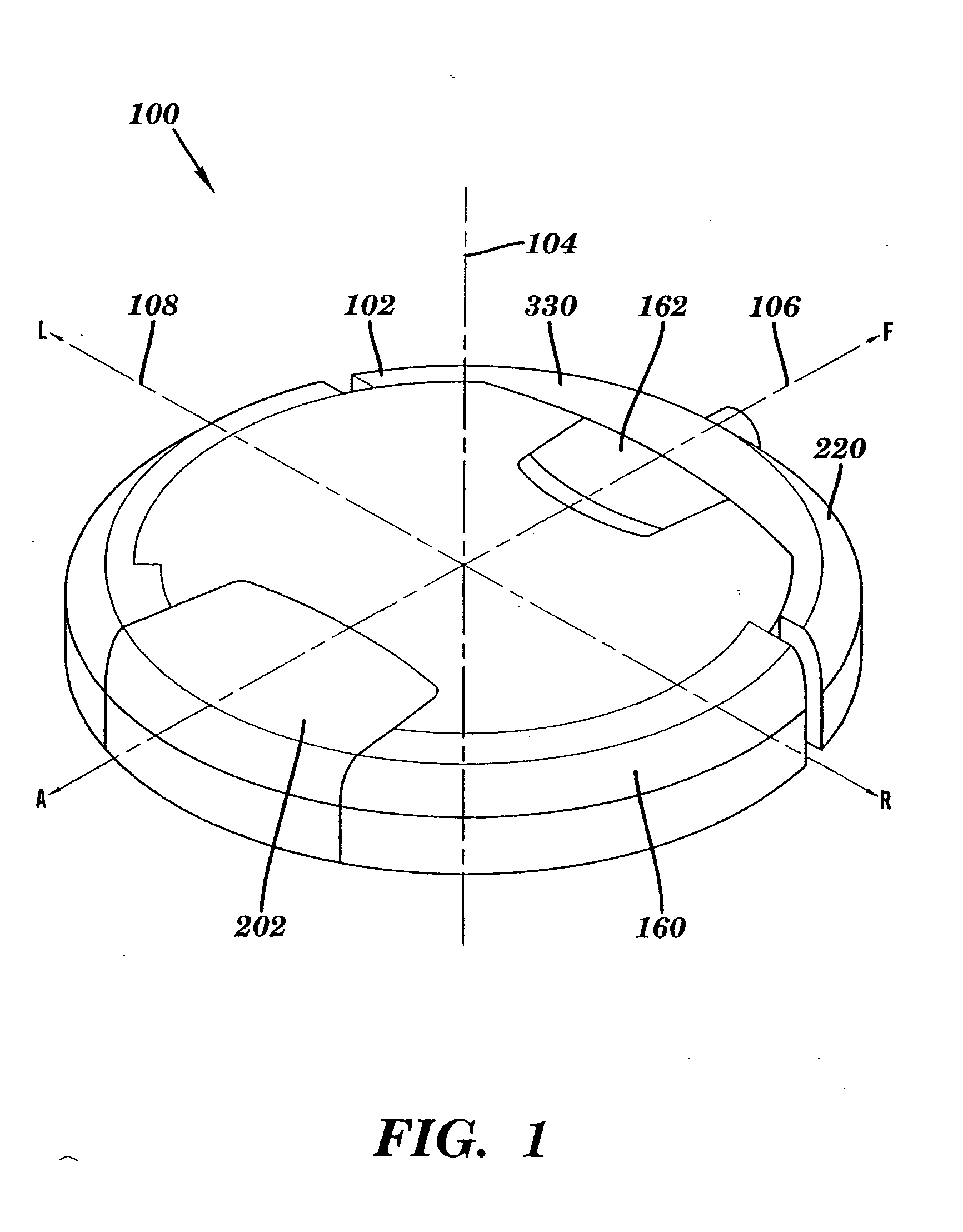

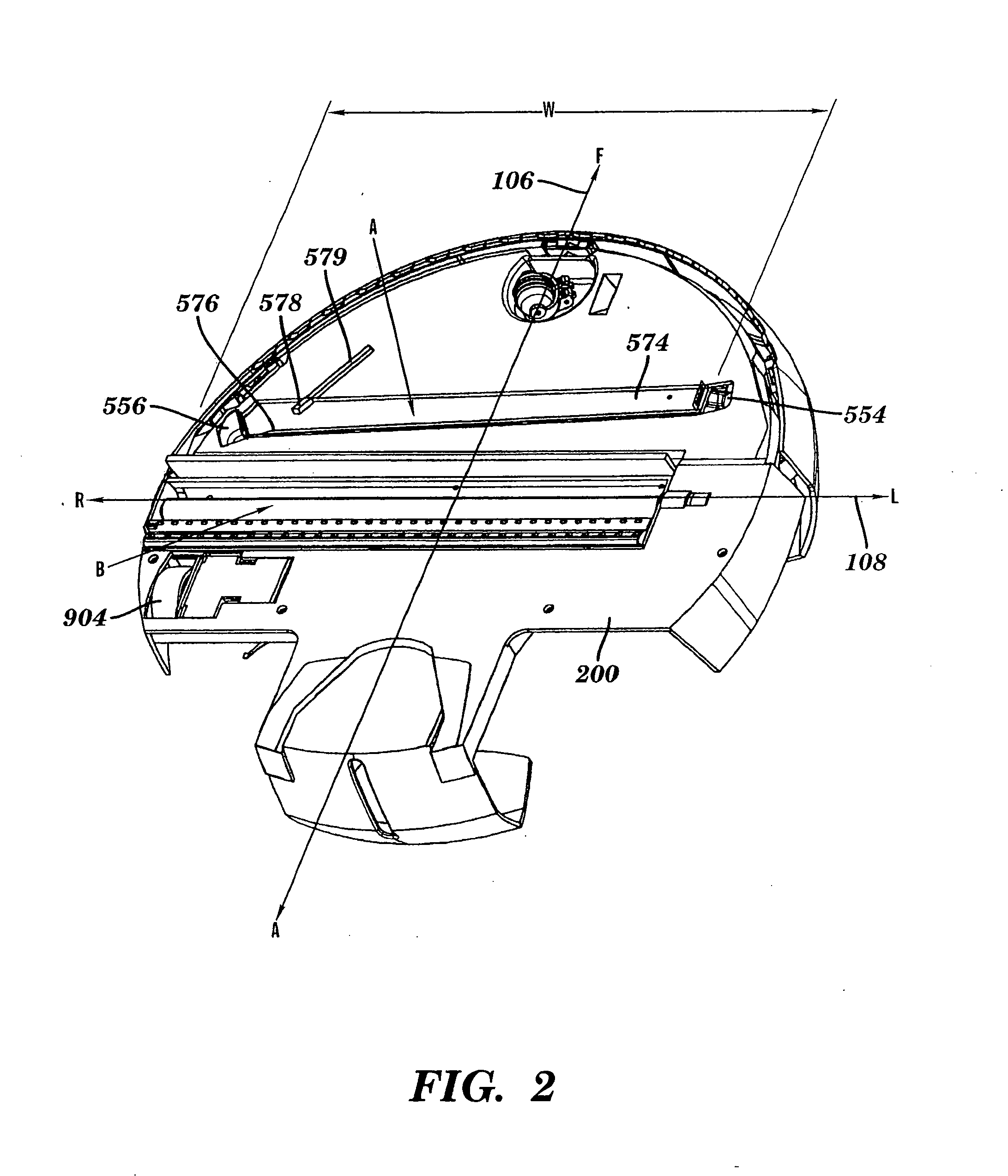

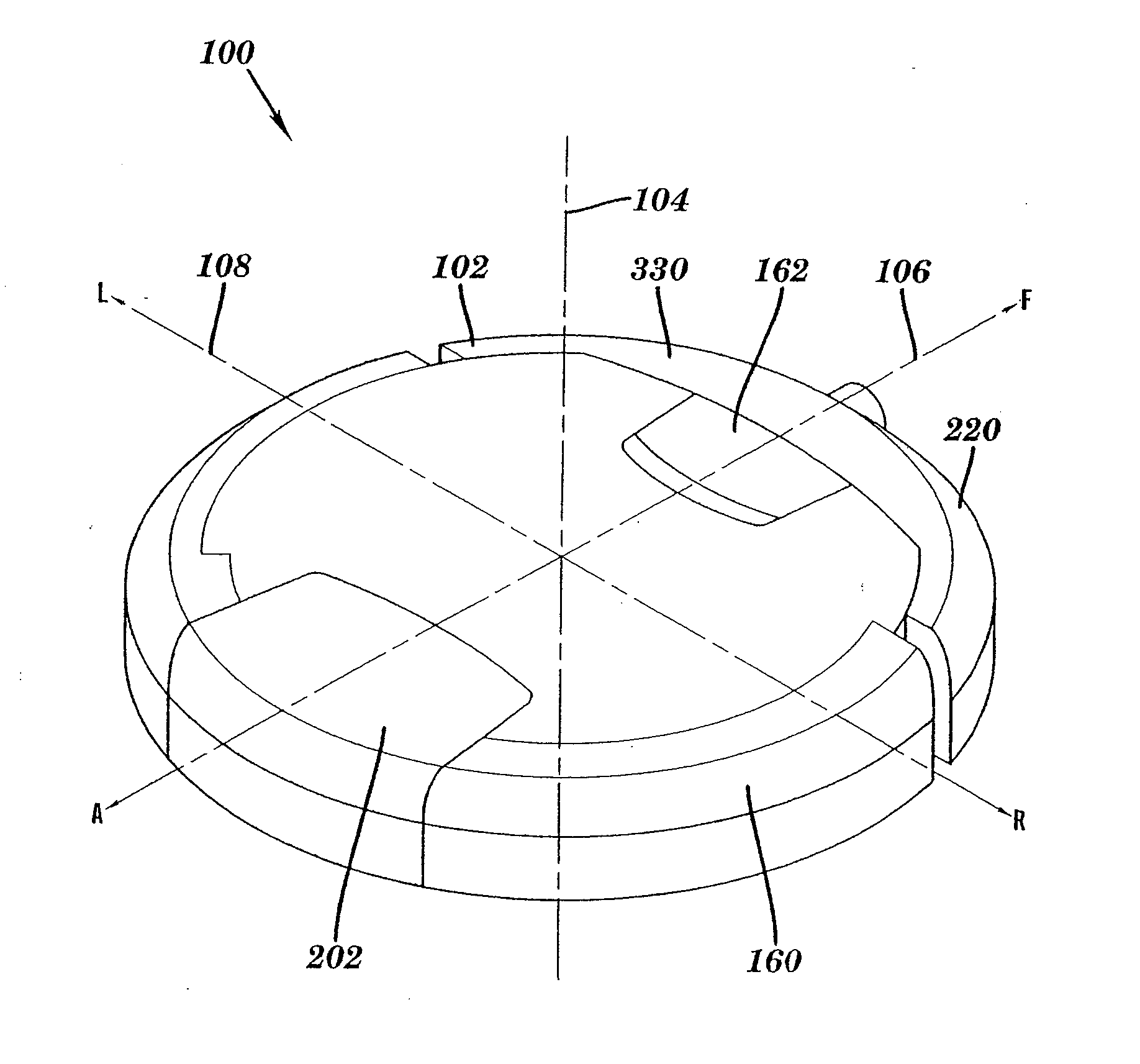

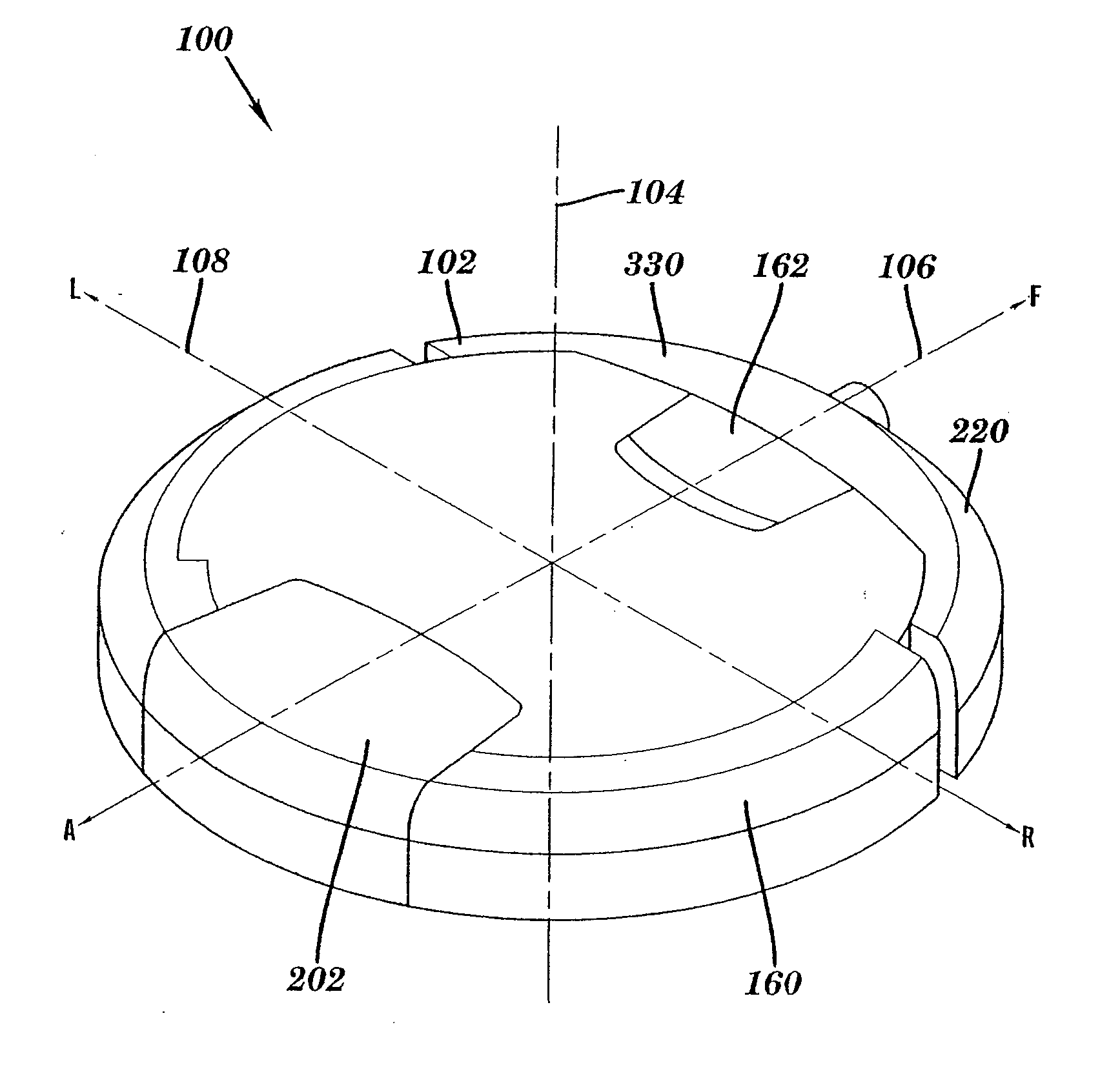

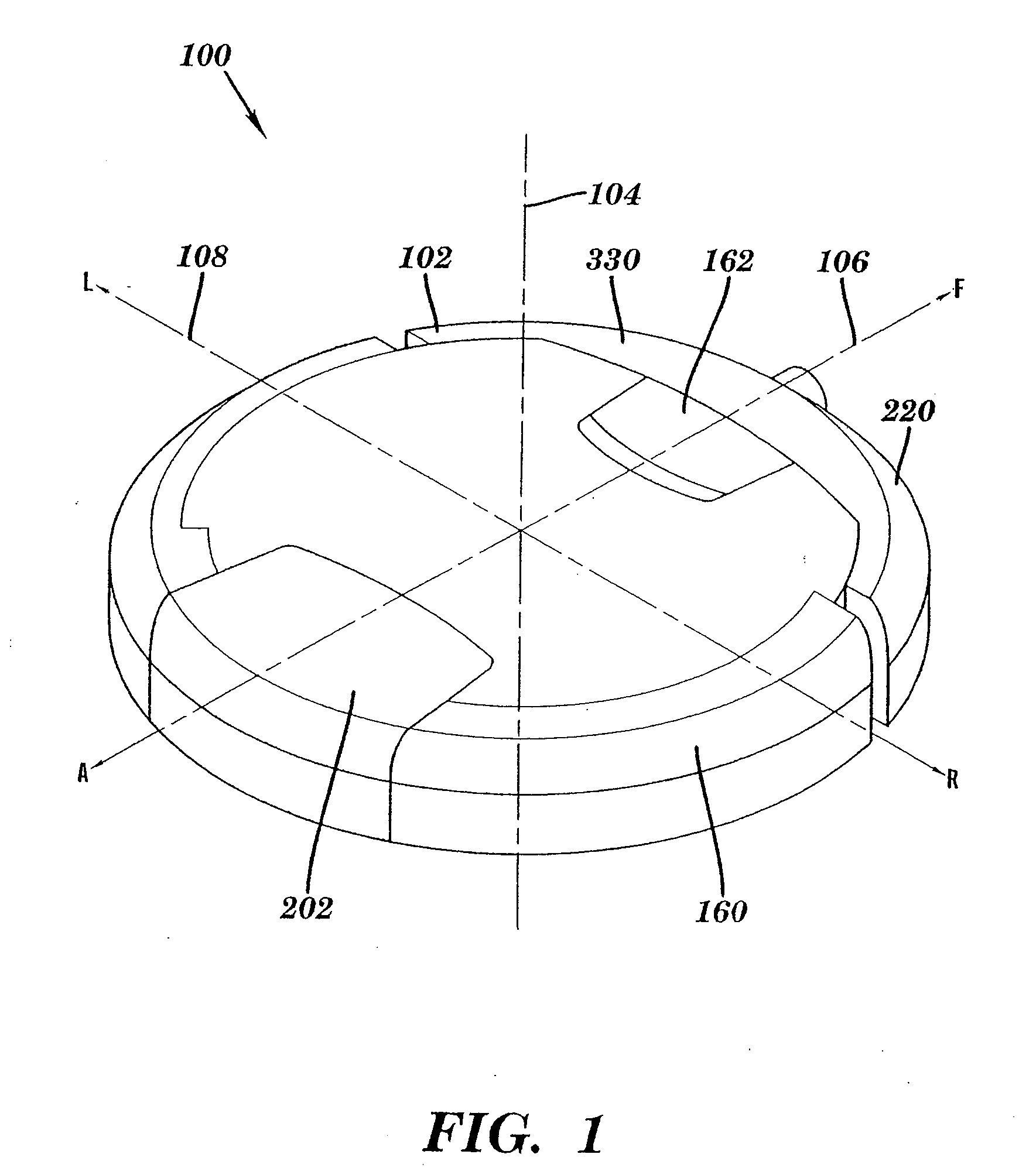

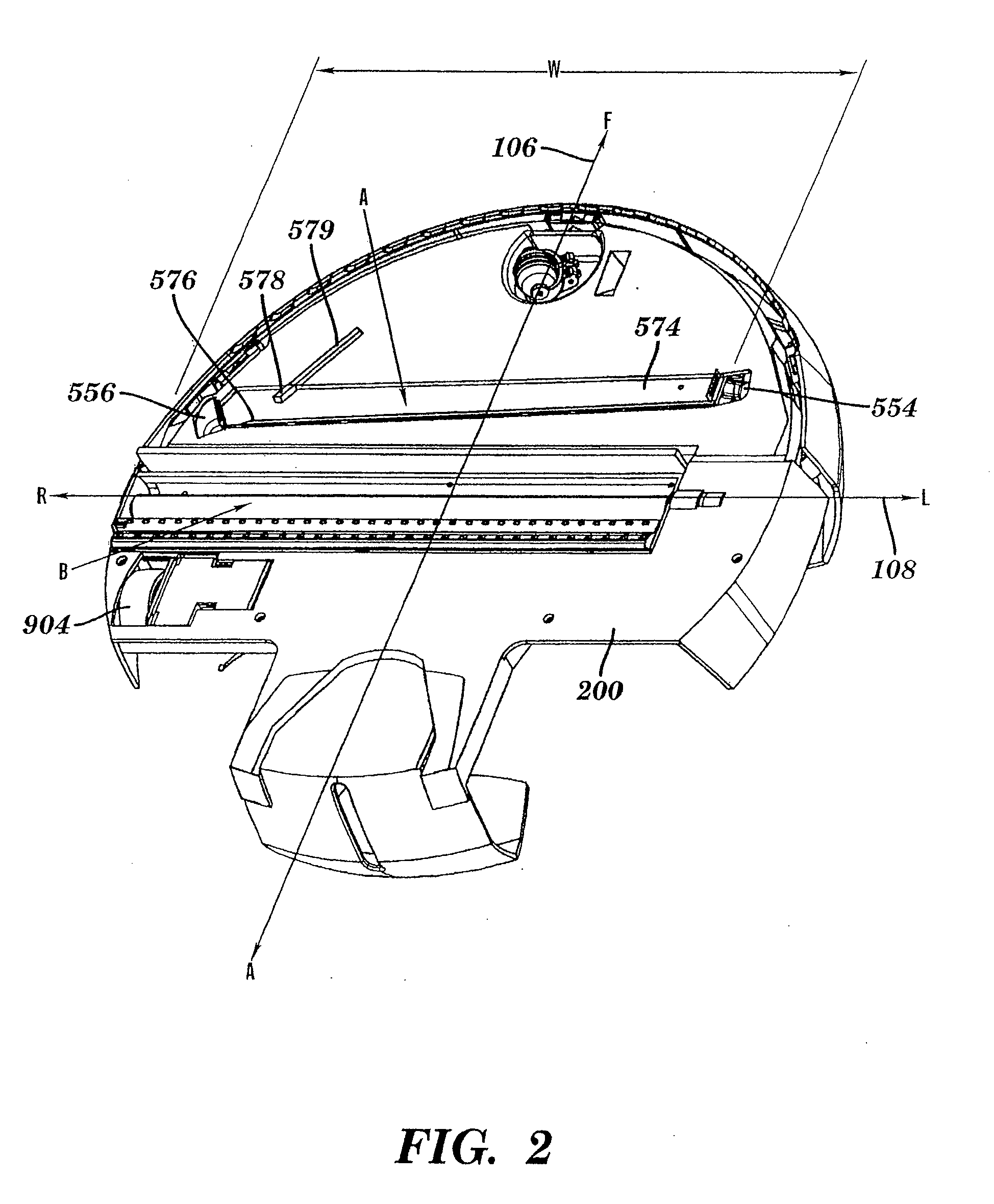

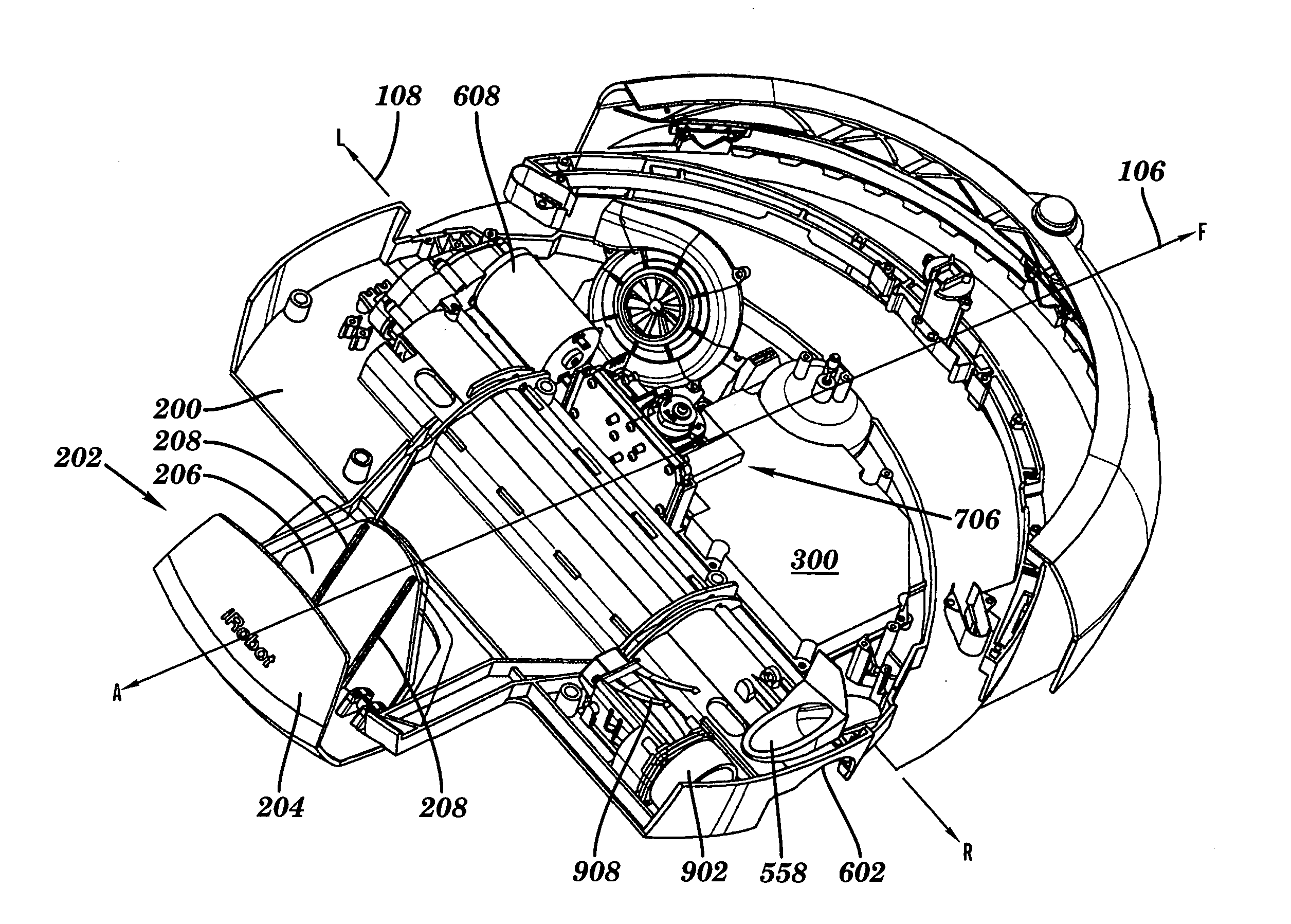

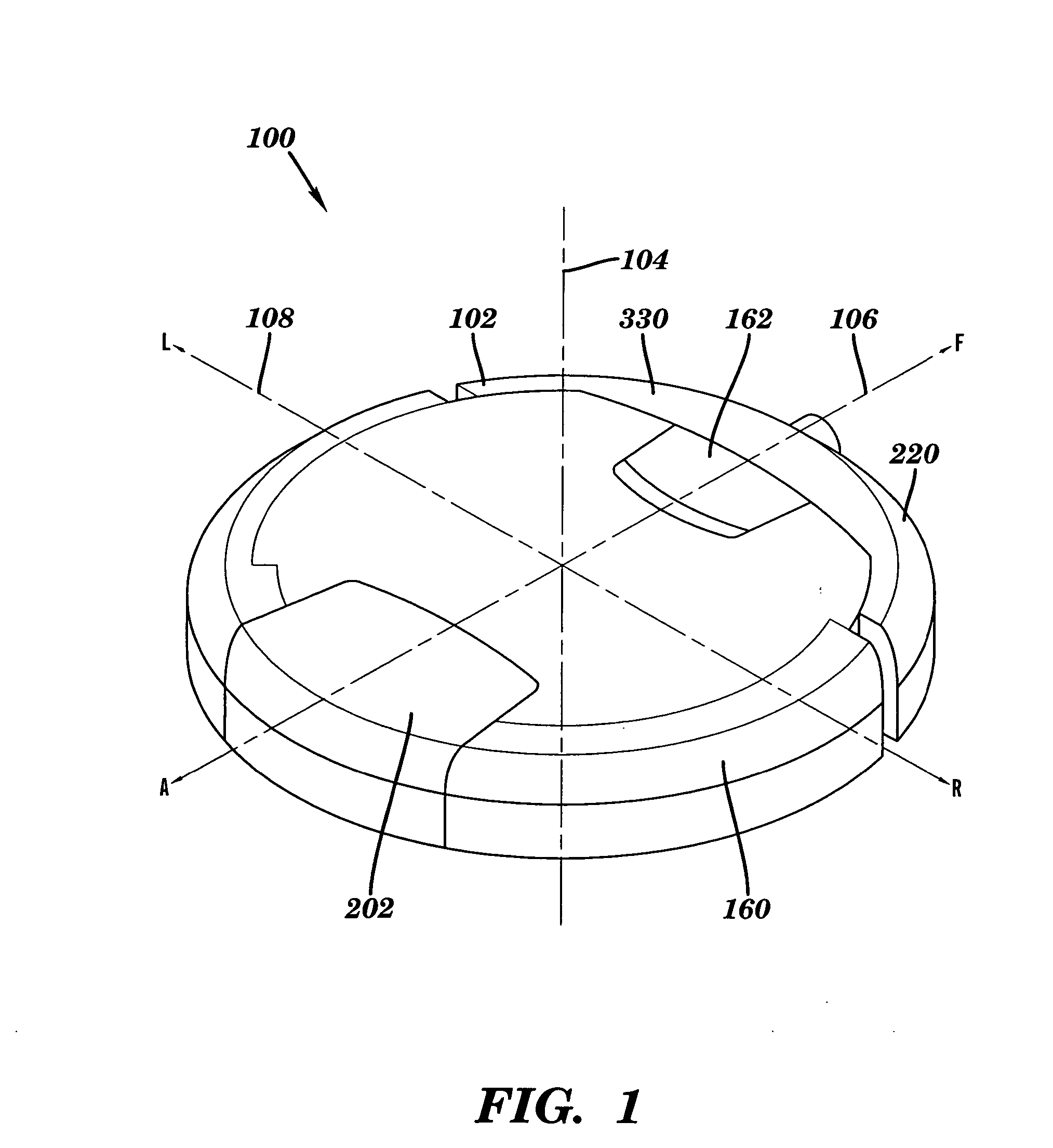

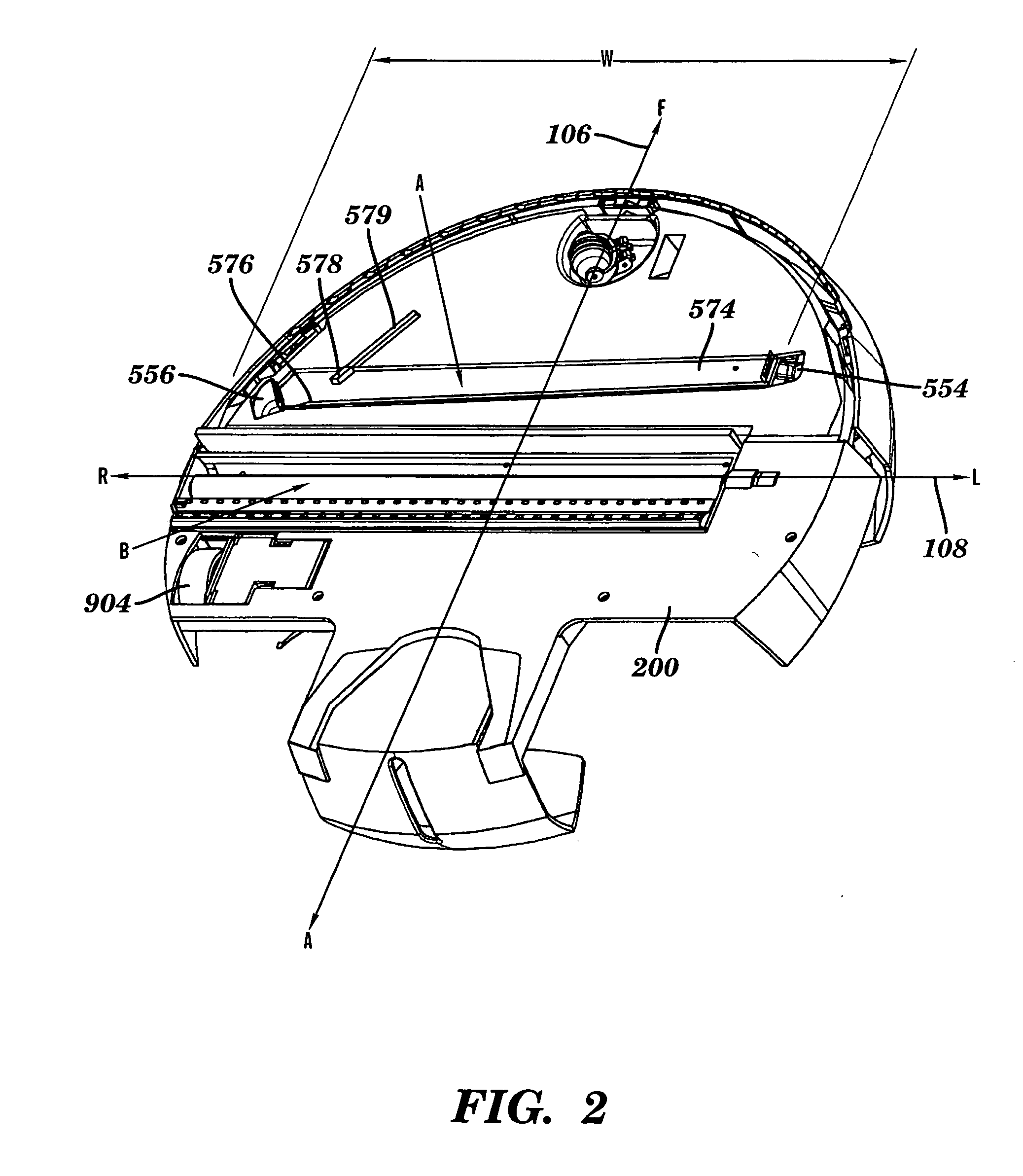

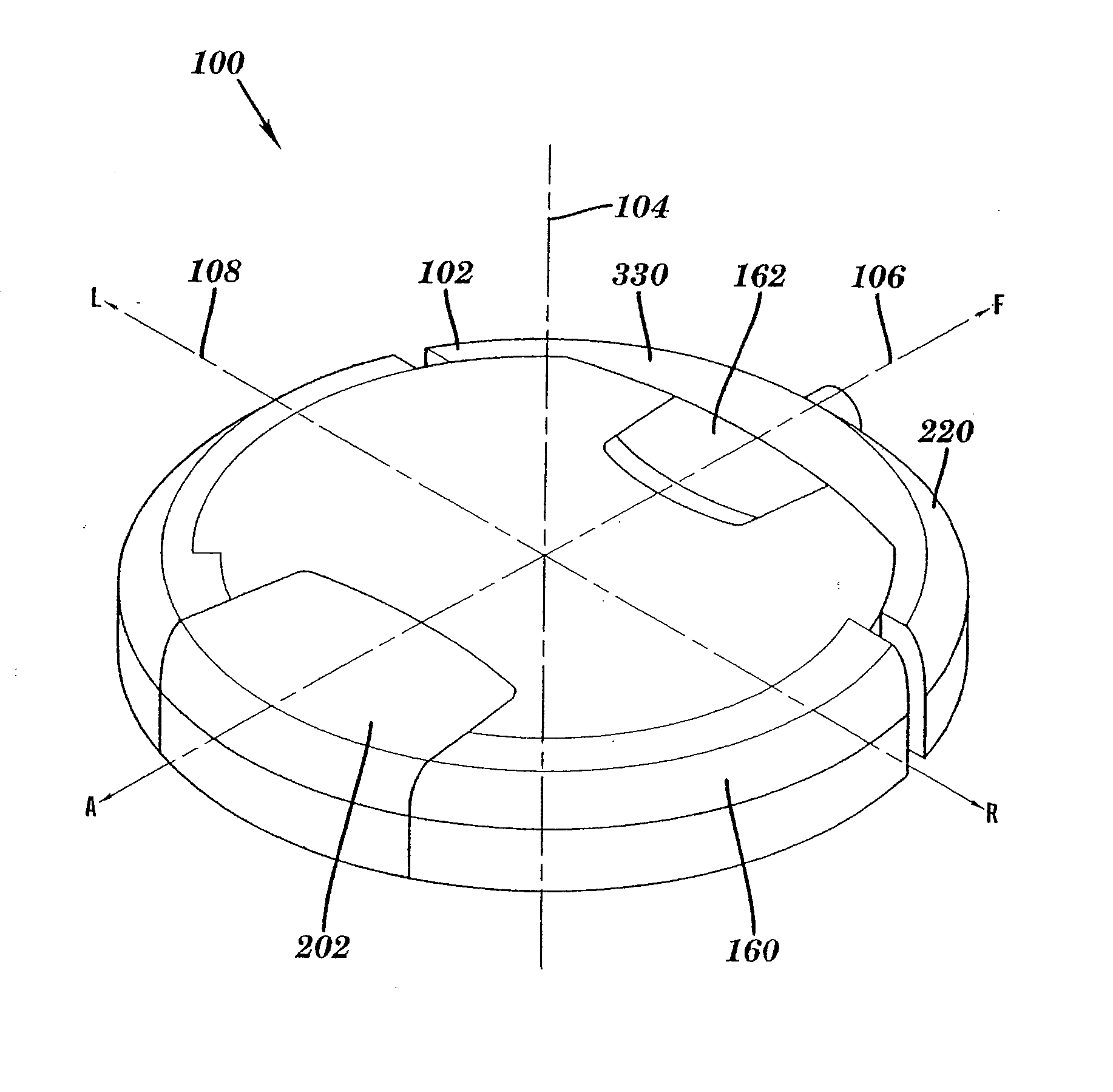

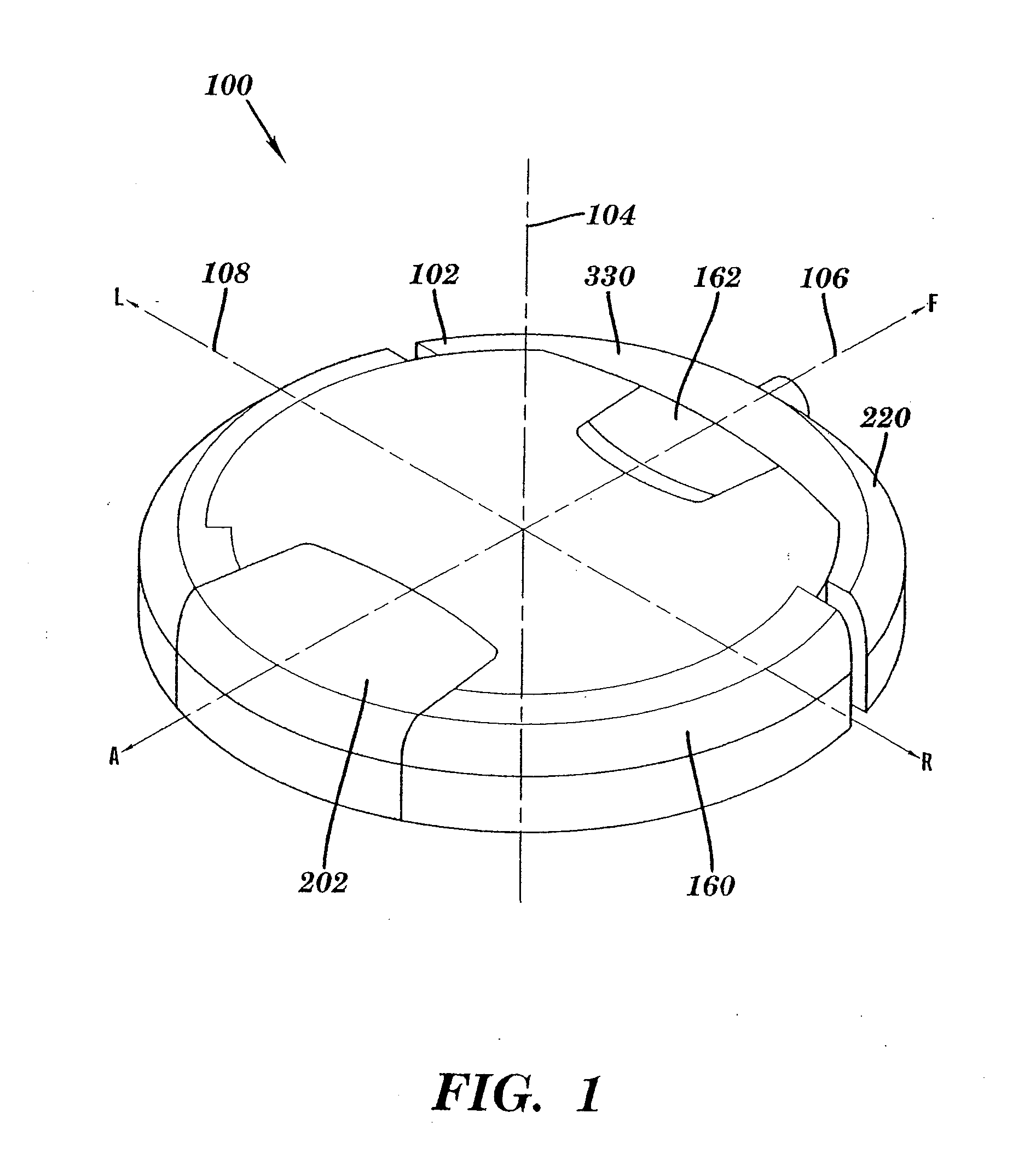

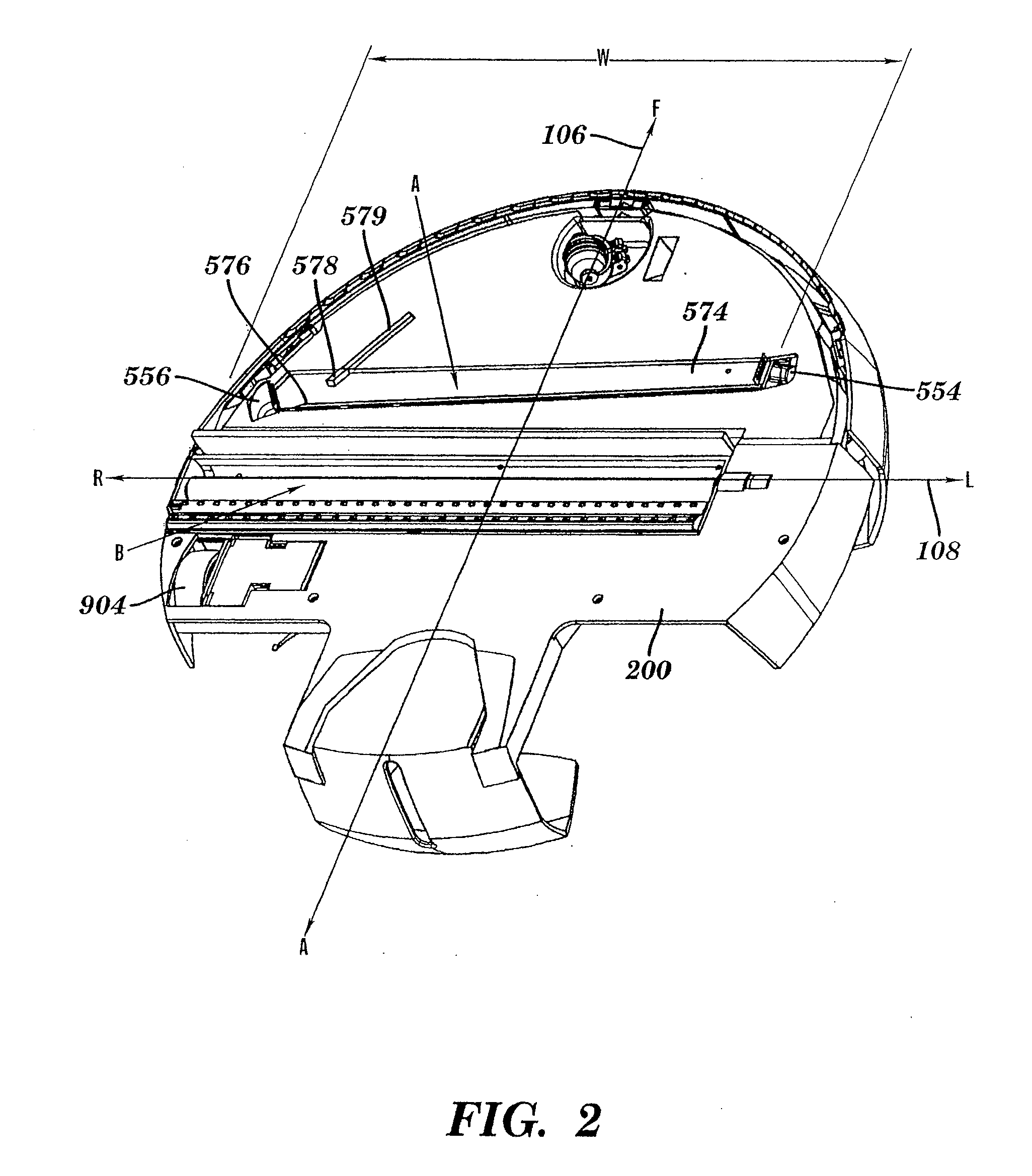

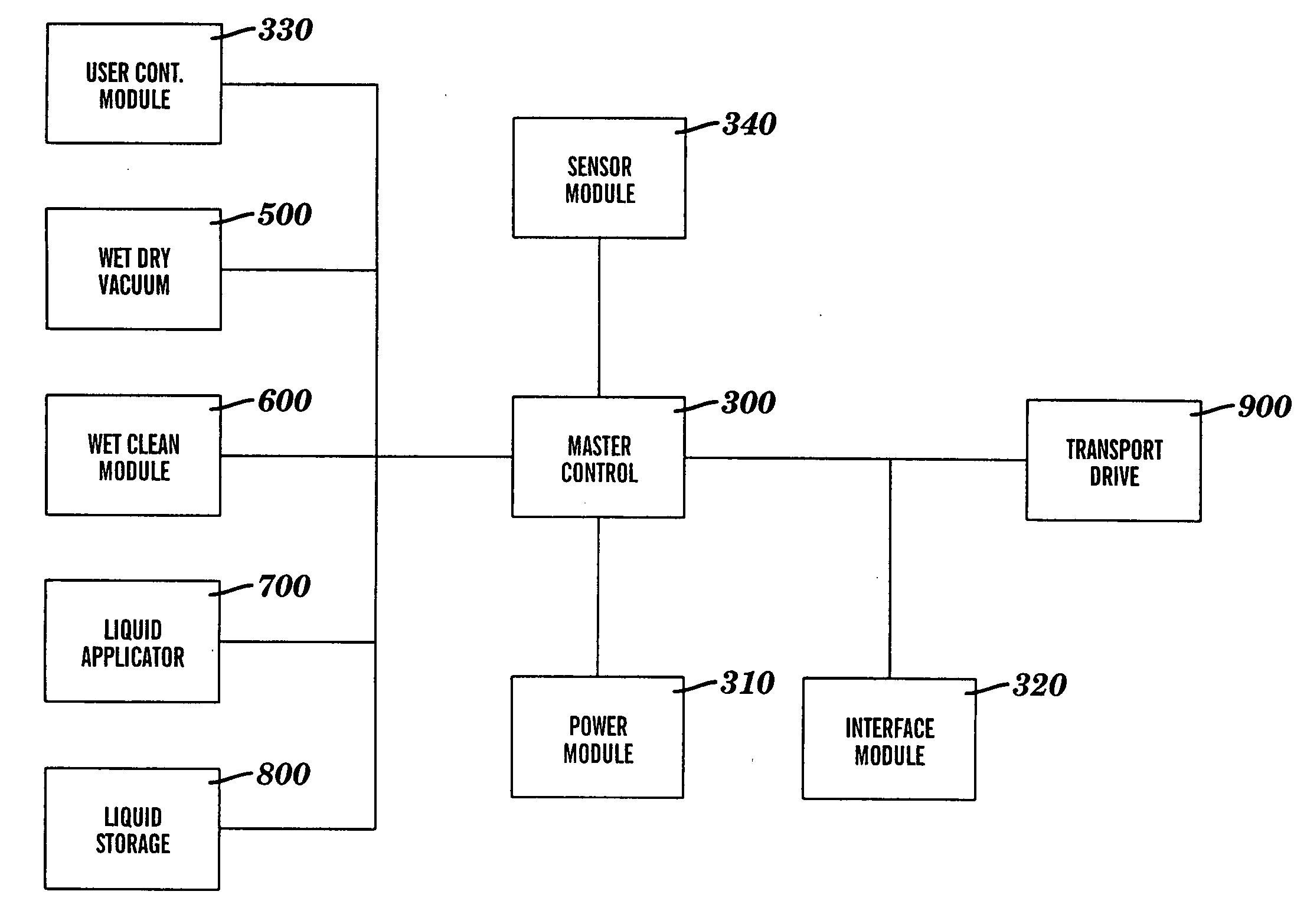

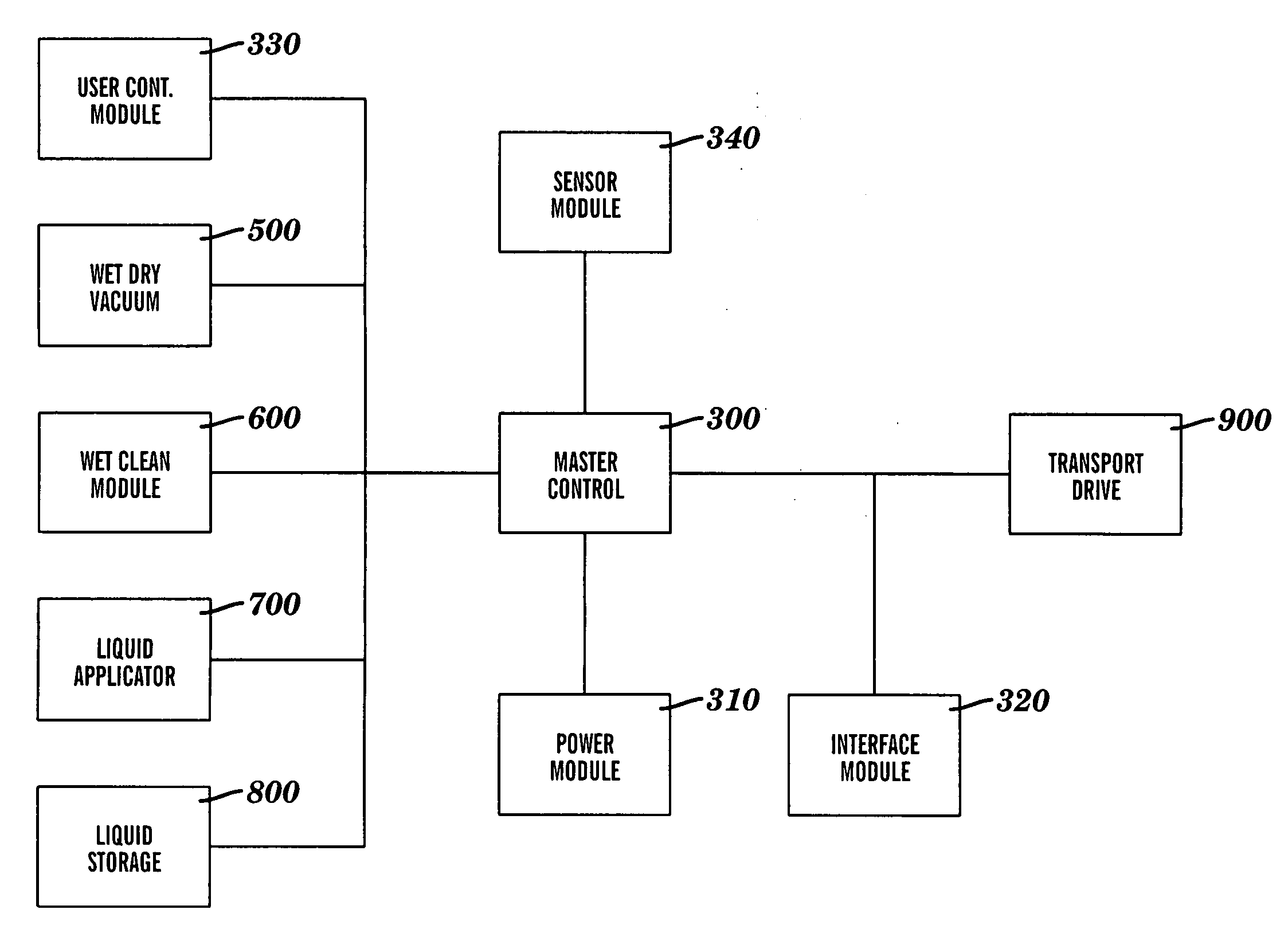

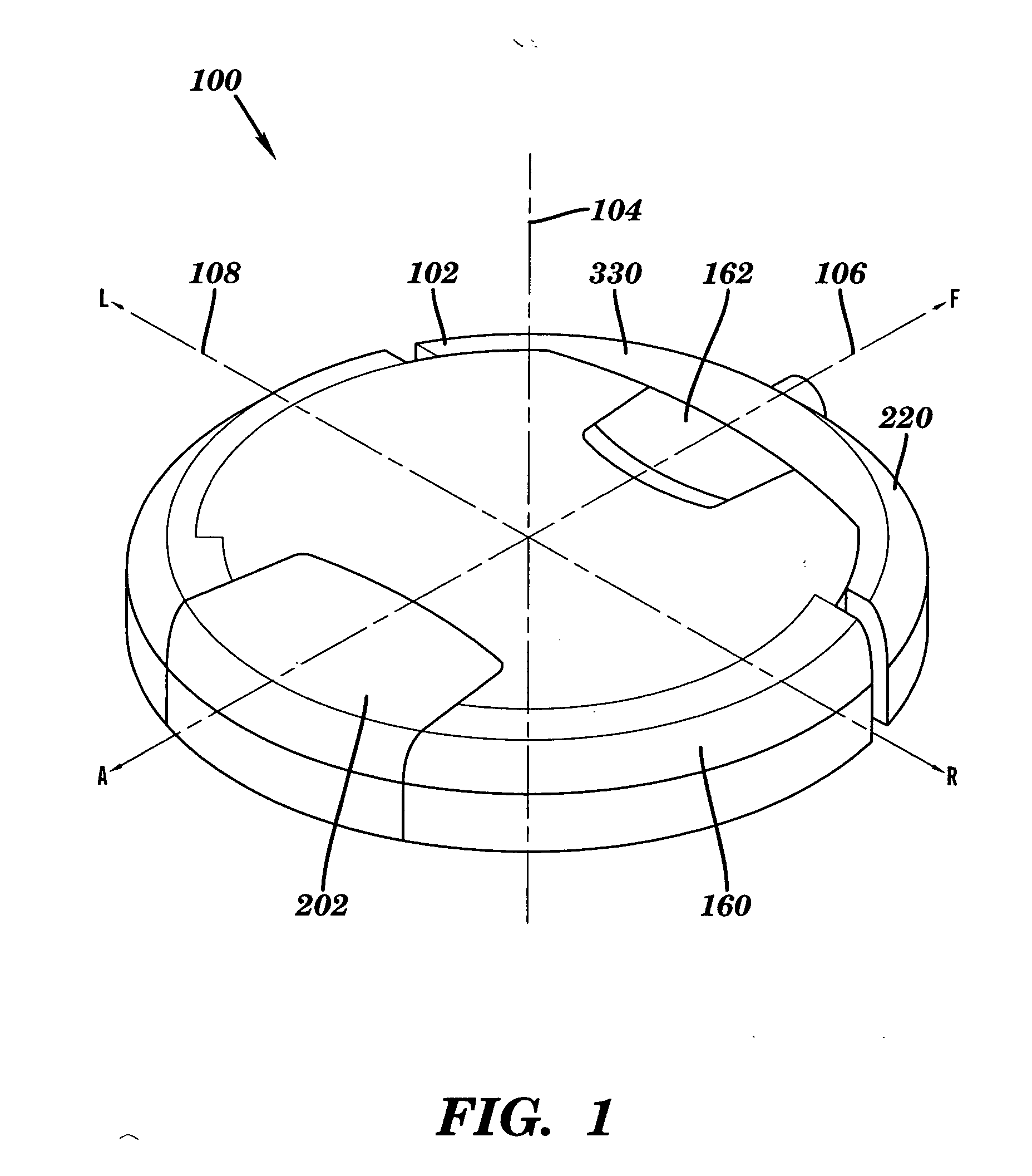

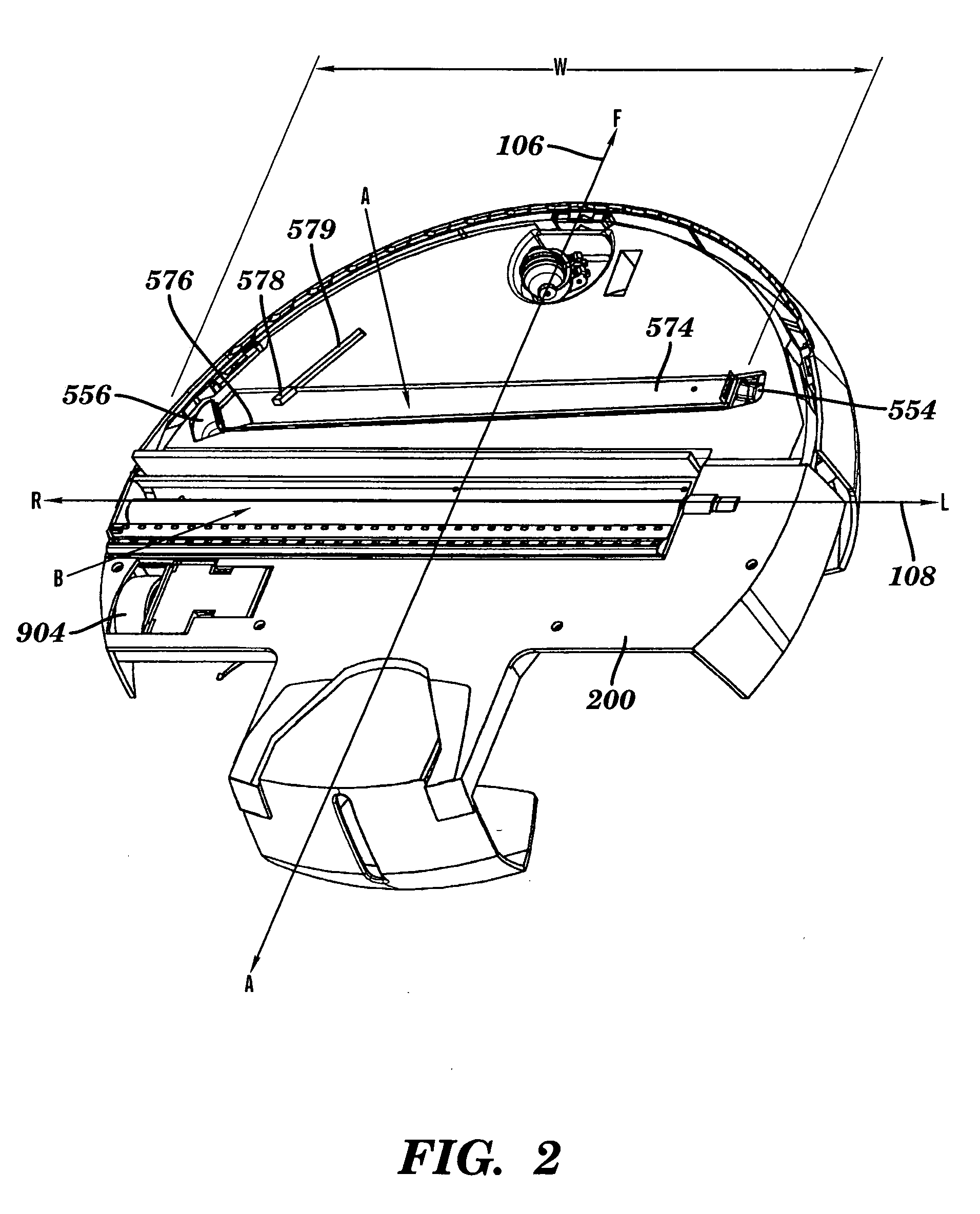

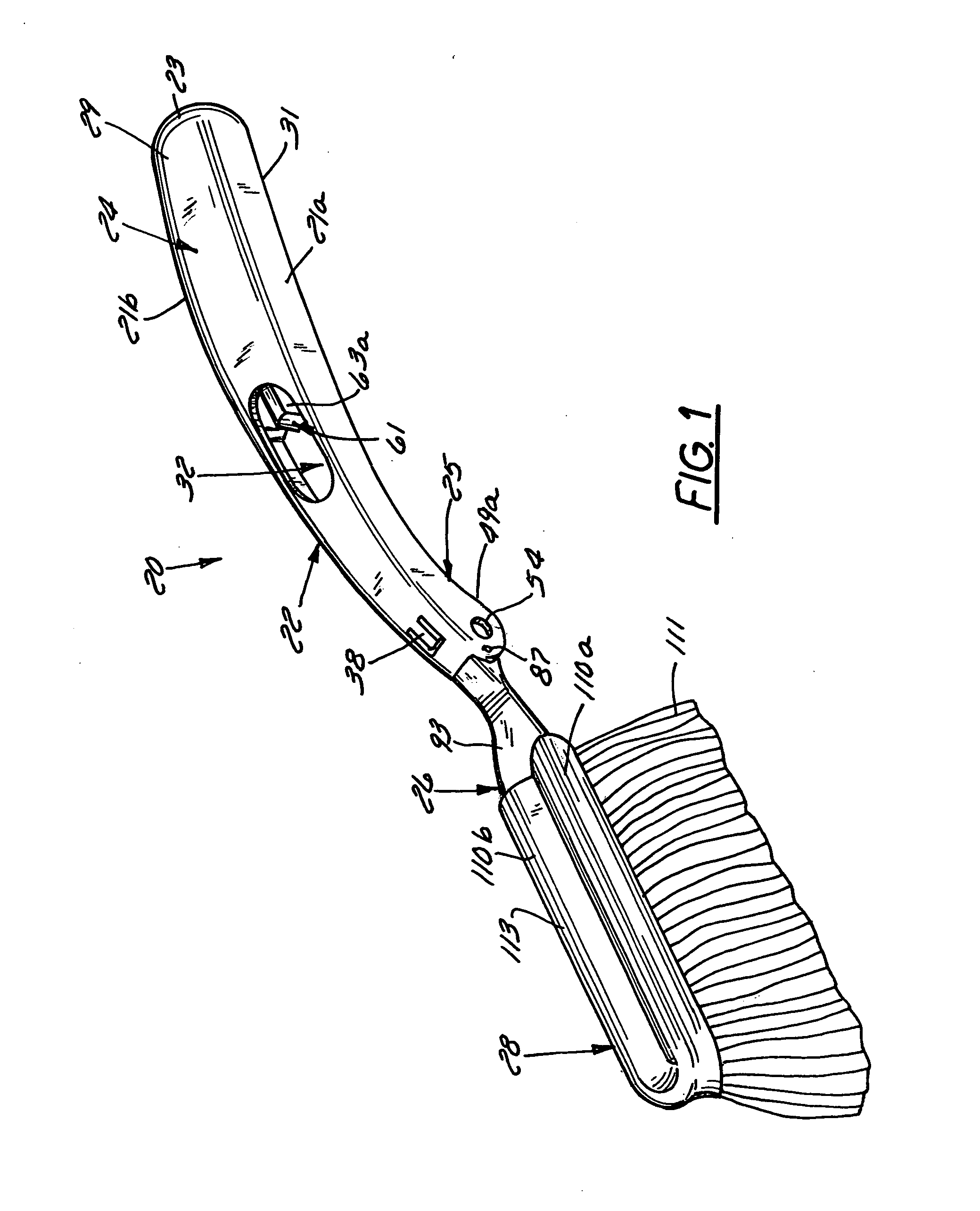

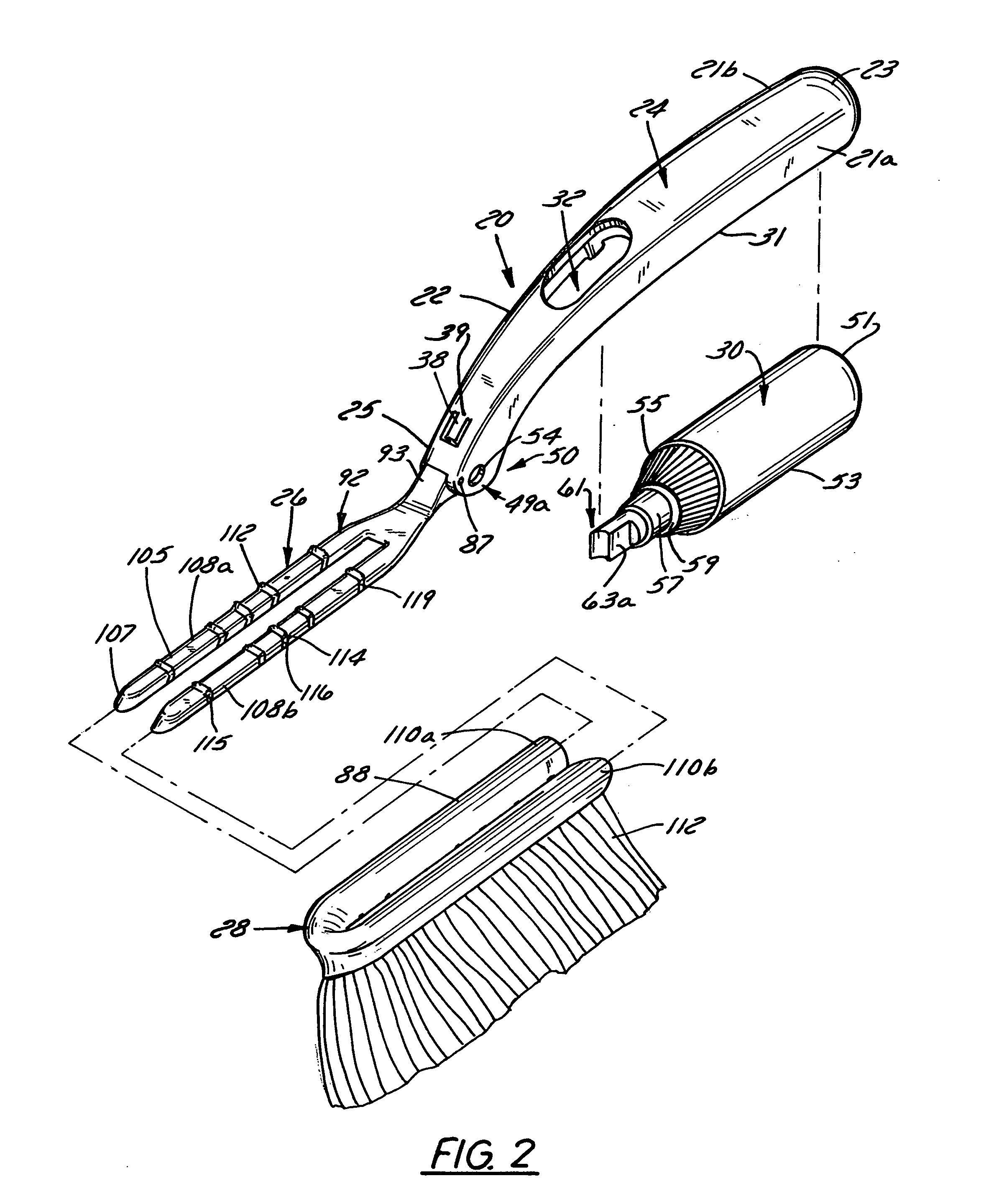

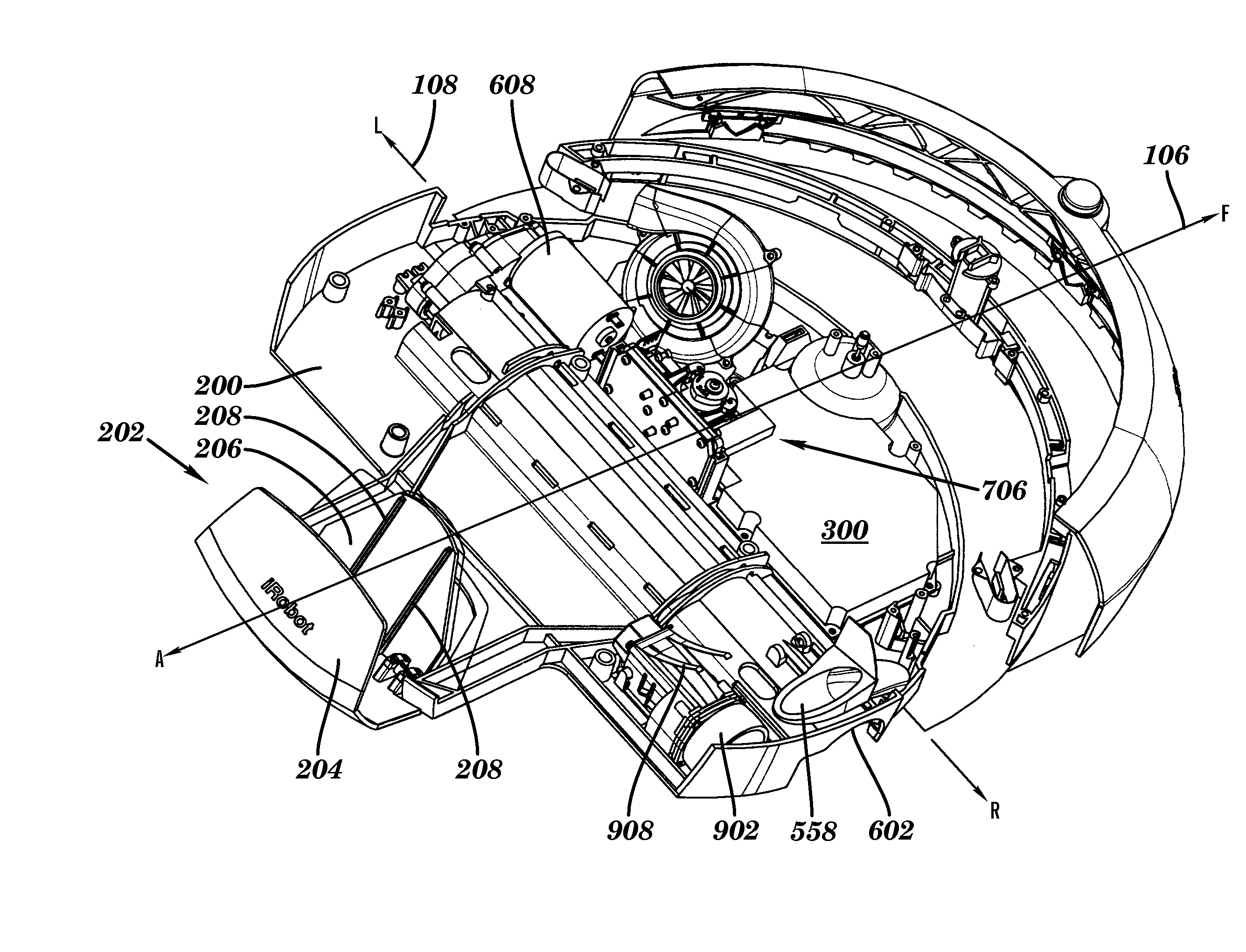

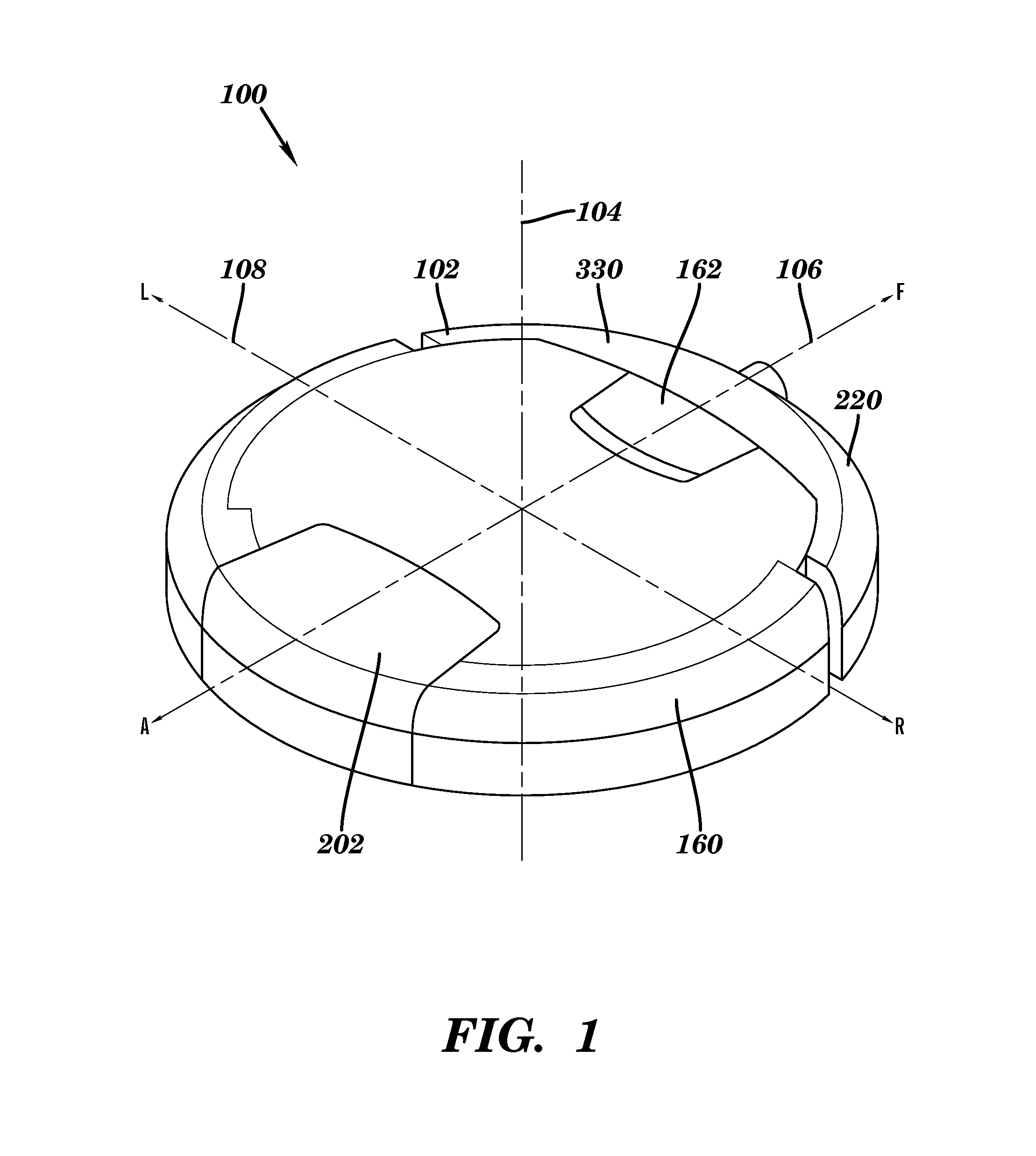

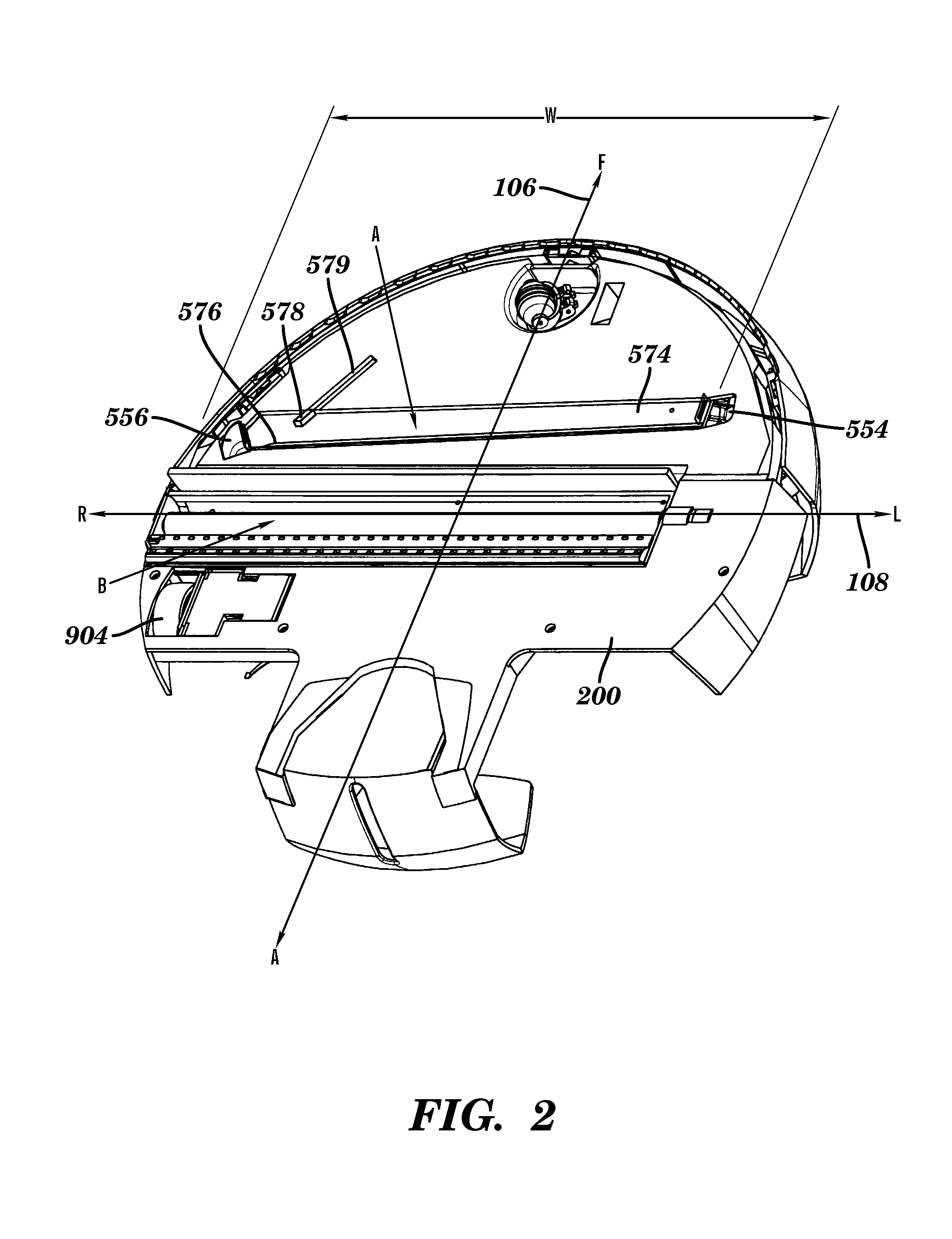

Autonomous surface cleaning robot for wet and dry cleaning

ActiveUS20070016328A1Improve balanceLow costAutomatic obstacle detectionTravelling automatic controlParticulatesSurface cleaning

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

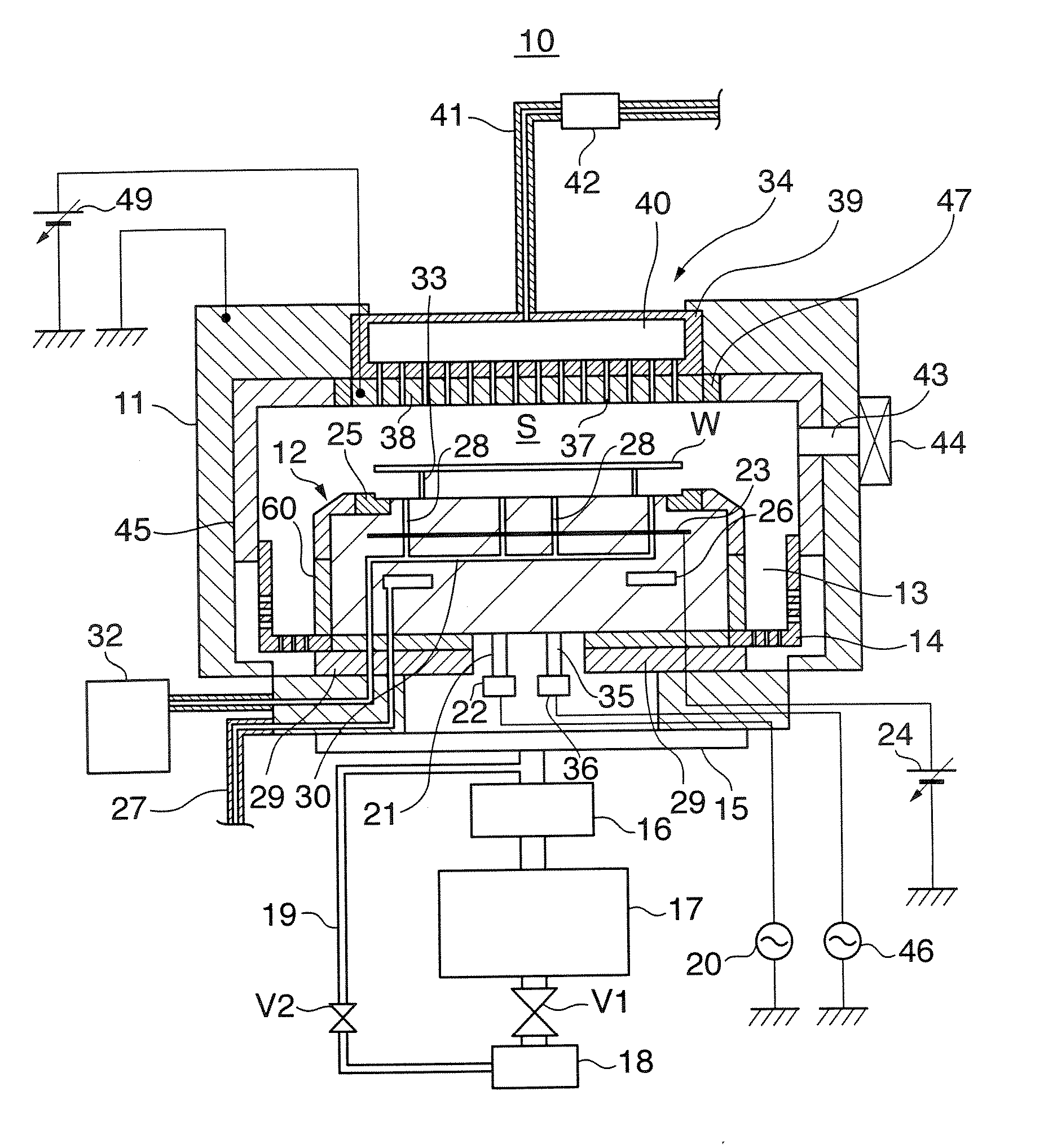

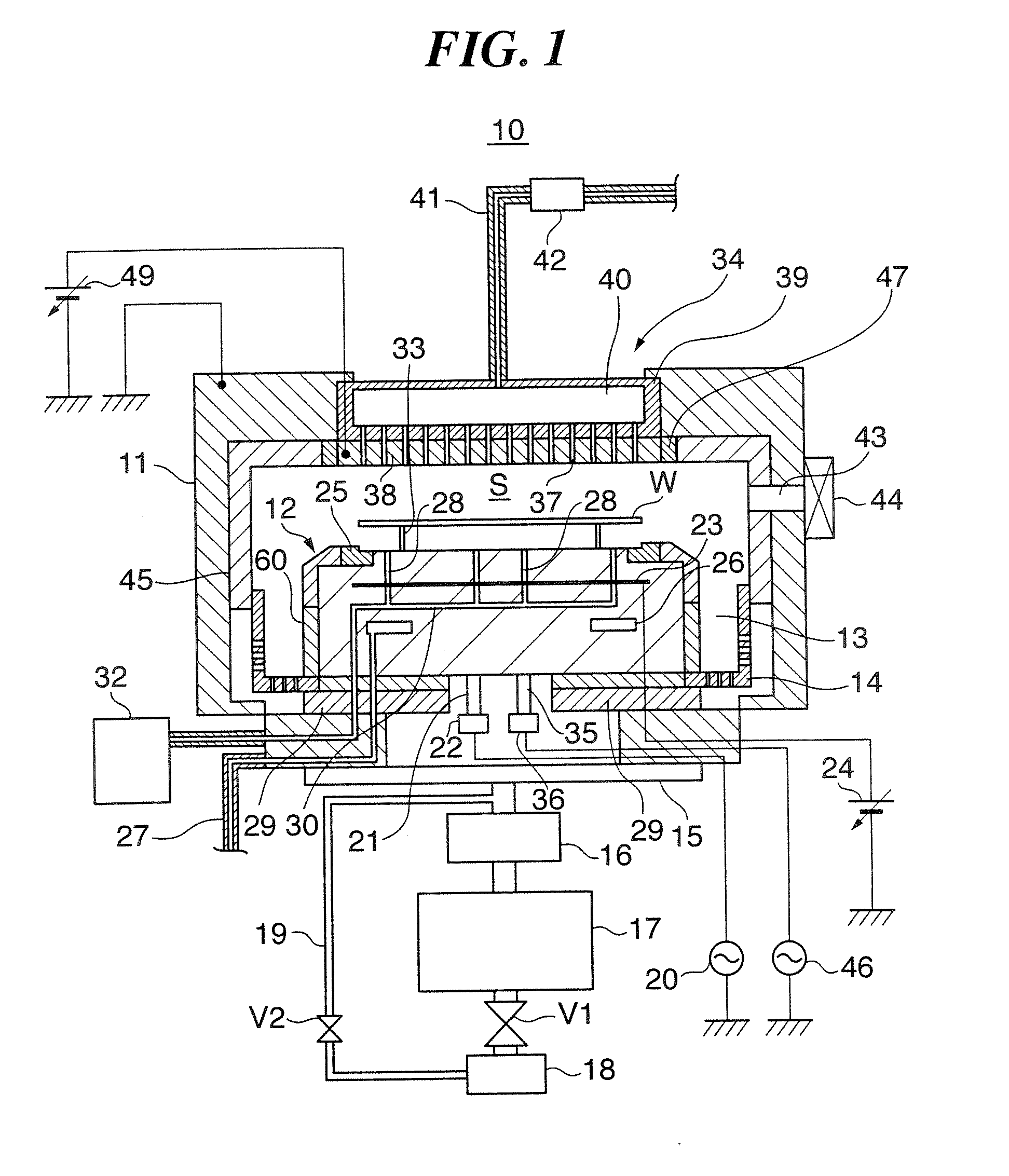

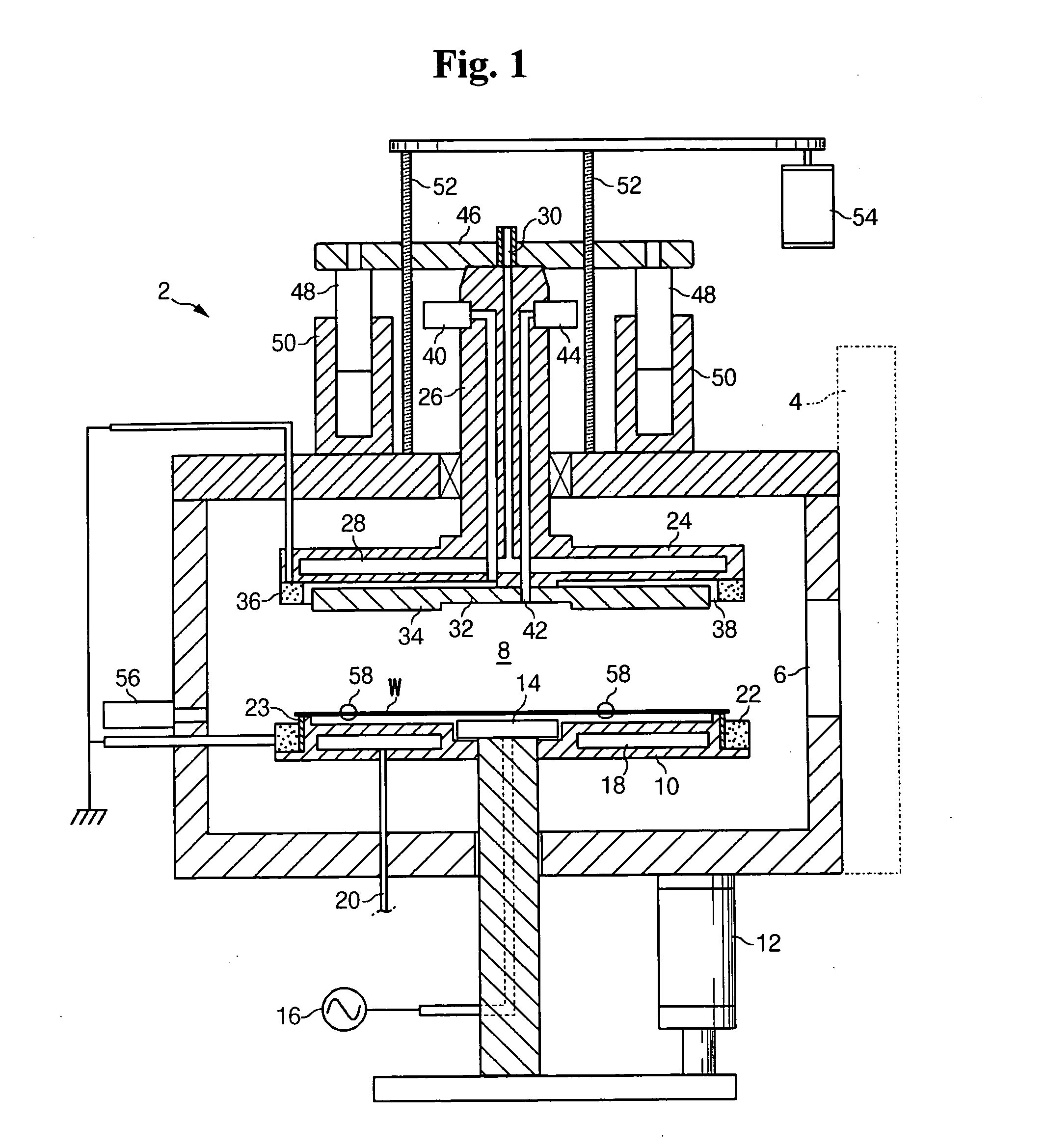

Method of cleaning substrate processing chamber, storage medium, and substrate processing chamber

ActiveUS20070186952A1Inhibition formationElectric discharge tubesHollow article cleaningElectricityReactive-ion etching

A method of cleaning a substrate processing chamber that enables formation of an oxide film on a surface of a processing chamber inside component to be prevented. A substrate processing chamber 11 has therein a processing space S into which a wafer W is transferred and carries out reactive ion etching on the wafer W in the processing space S. The substrate processing chamber 11 has an upper electrode plate 38 that comprises silicon and a lower surface of which is exposed to the processing space S. A dry cleaning is carried out on the upper electrode plate 38 using oxygen radicals produced from oxygen gas introduced into the processing space S. An oxide removal processing is carried out on the upper electrode plate 38 using fluorine ions and fluorine radicals produced from carbon tetrafluoride gas introduced into the processing space S.

Owner:TOKYO ELECTRON LTD

Process and method for in-situ dry cleaning of thin film deposition reactors and thin film layers

ActiveUS20150218695A1Efficient dry etching.Easy to useLighting and heating apparatusVacuum evaporation coatingHalogenChemical vapor deposition

The invention relates to the use of thionyl chloride and related materials for dry etching of internal surfaces of metalorganic vapour phase epitaxy (MOVPE) reactors to remove deposits. The method is also useful for the dry etching of process substrates within such reactors for cleaning and processing of those substrates. The invention may be particularly adaptable to chemical vapor deposition reactors used in the manufacture of high brightness LED's based on III-V semiconductors such as GaN and related materials. Features of the process include thermal, UV, and plasma activated dry cleaning, and the use of etchant gases such as COCl2, COBr2, COl2, SOl2, SOCl2, SOBr2, SO2Cl2, SO2Br2, NOCI, NOBr, NOl, S2Cl2, S2Br2, SCI2, SBr2, SOClBr, SOClF and SOFBr, either formed from neat materials or combinations of constituent gases such as CO, SO, SO2 or NO with halogens, to achieve the desired effect.

Owner:SEASTAR CHEM

Autonomous surface cleaning robot for wet and dry cleaning

ActiveUS20080155768A1Low costWet cleaningAutomatic obstacle detectionTravelling automatic controlSurface cleaningControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

Autonomous surface cleaning robot for wet and dry cleaning

InactiveUS20080140255A1Low costWet cleaningAutomatic obstacle detectionTravelling automatic controlSurface cleaningControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

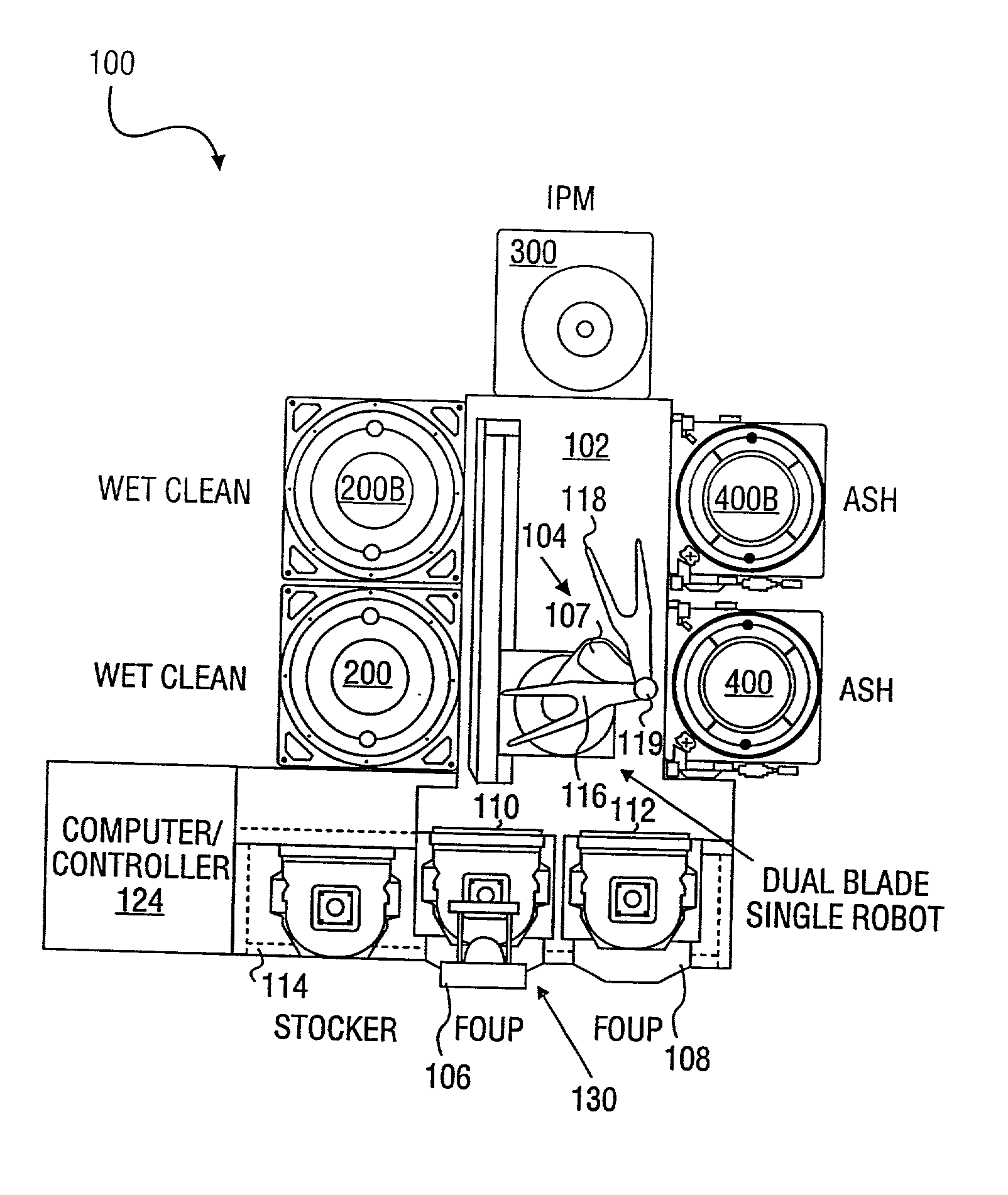

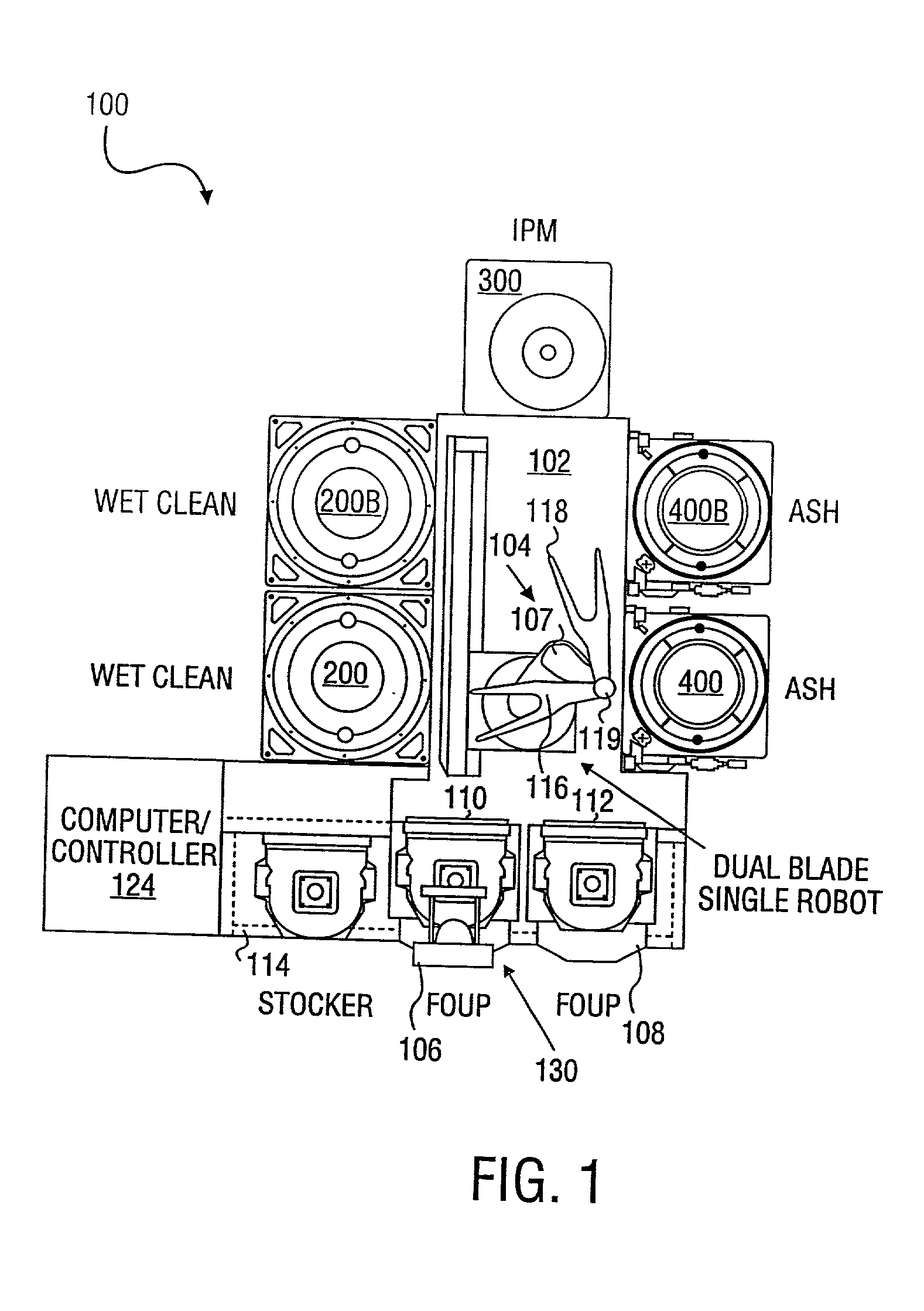

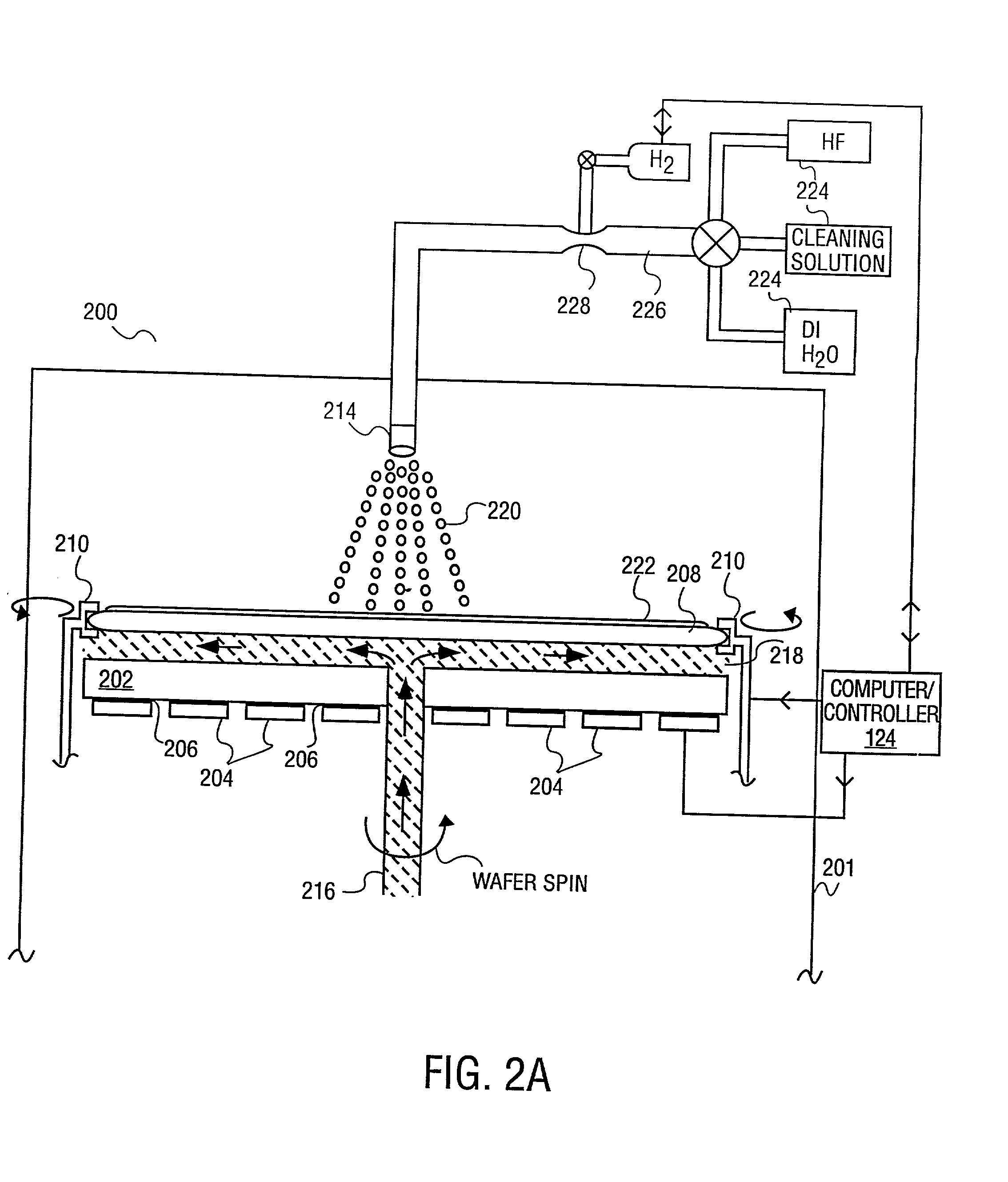

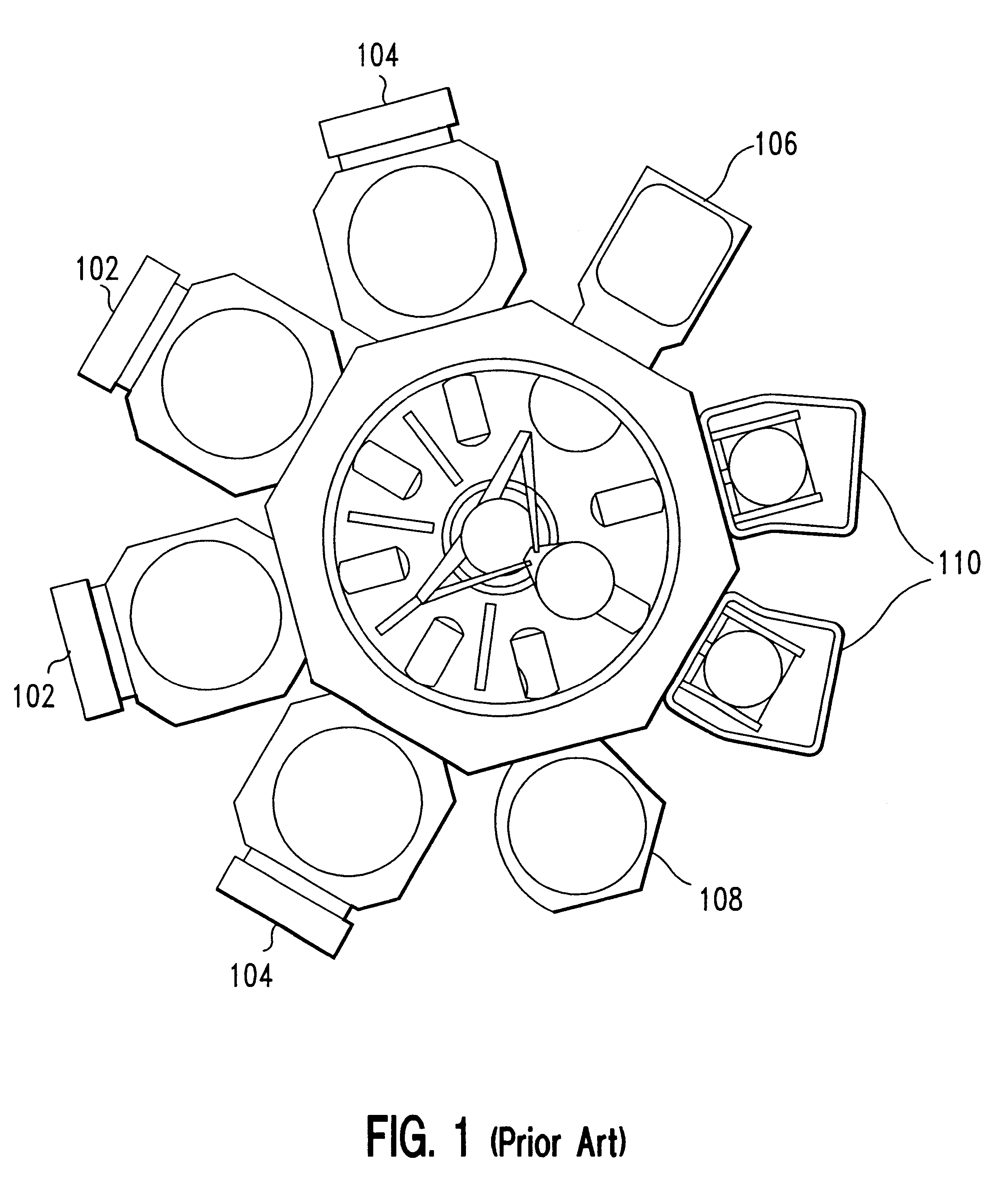

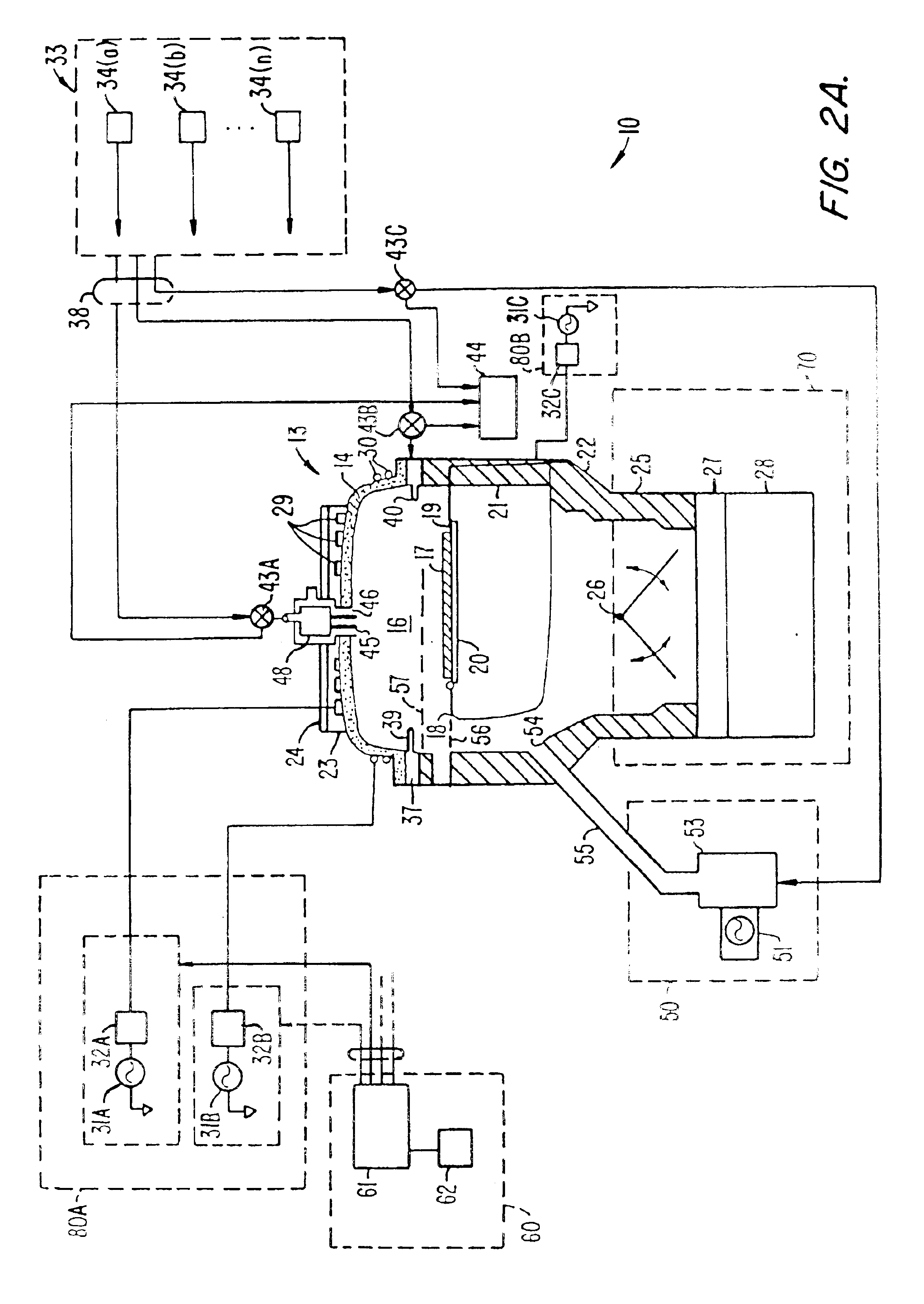

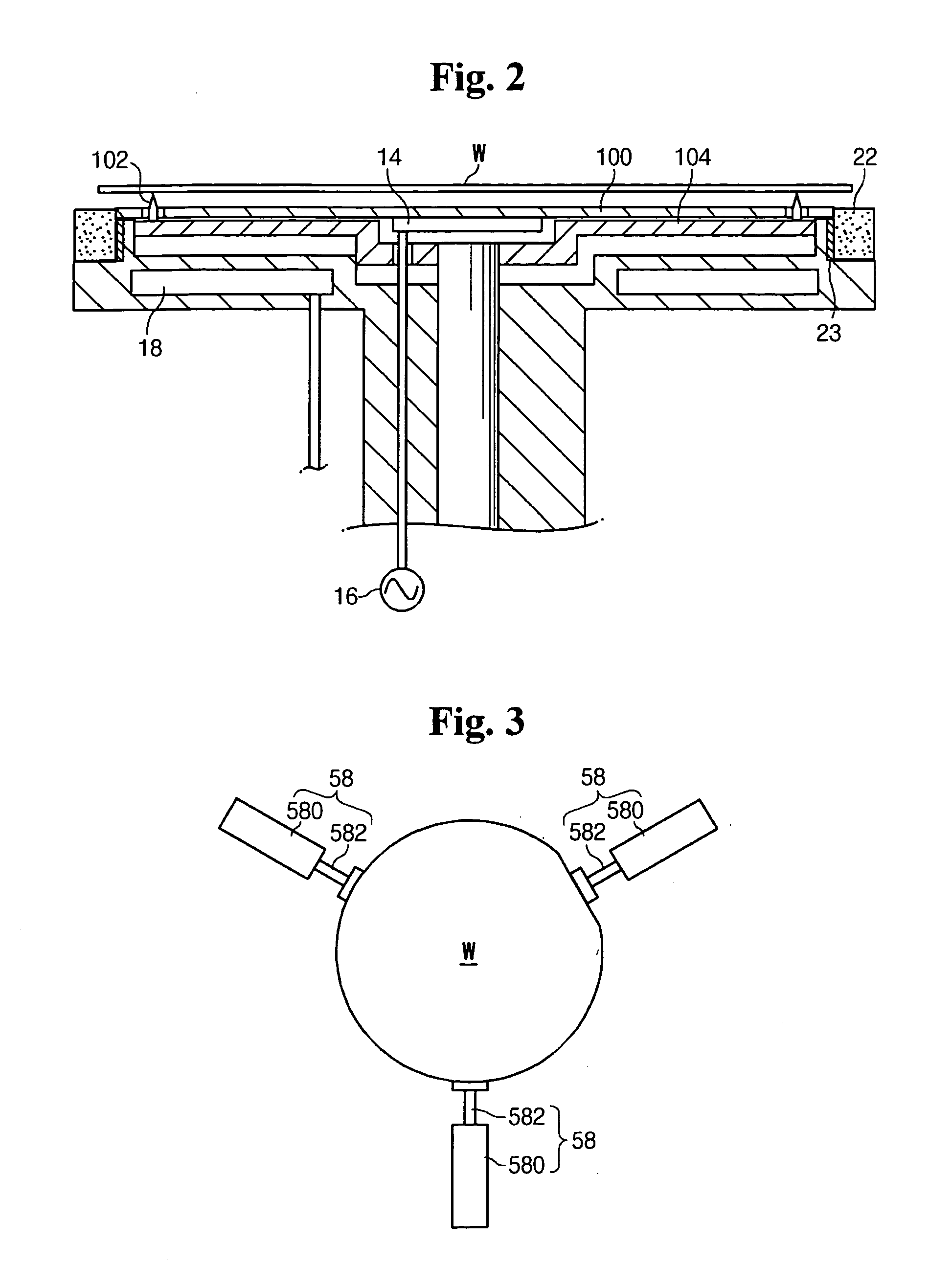

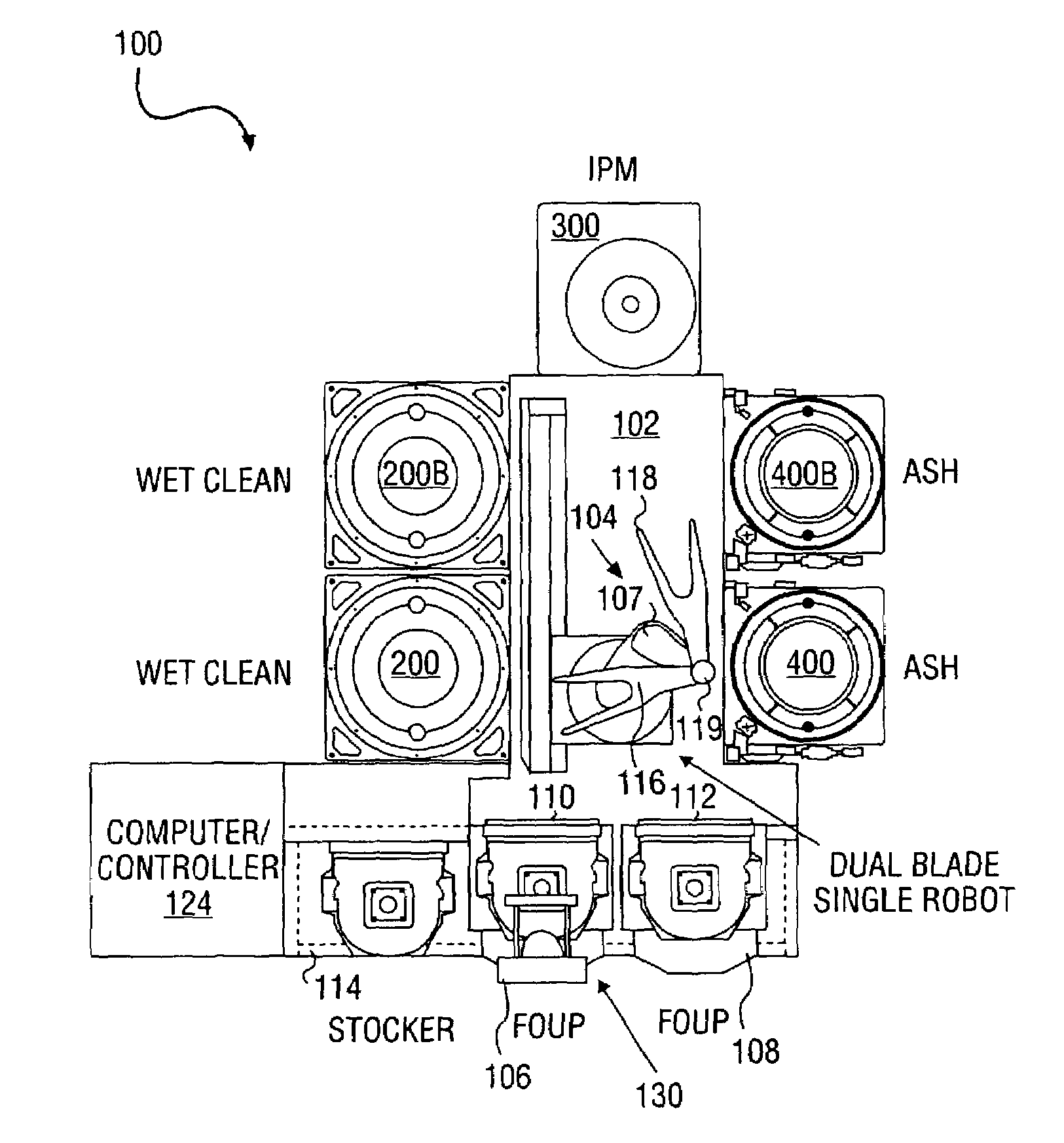

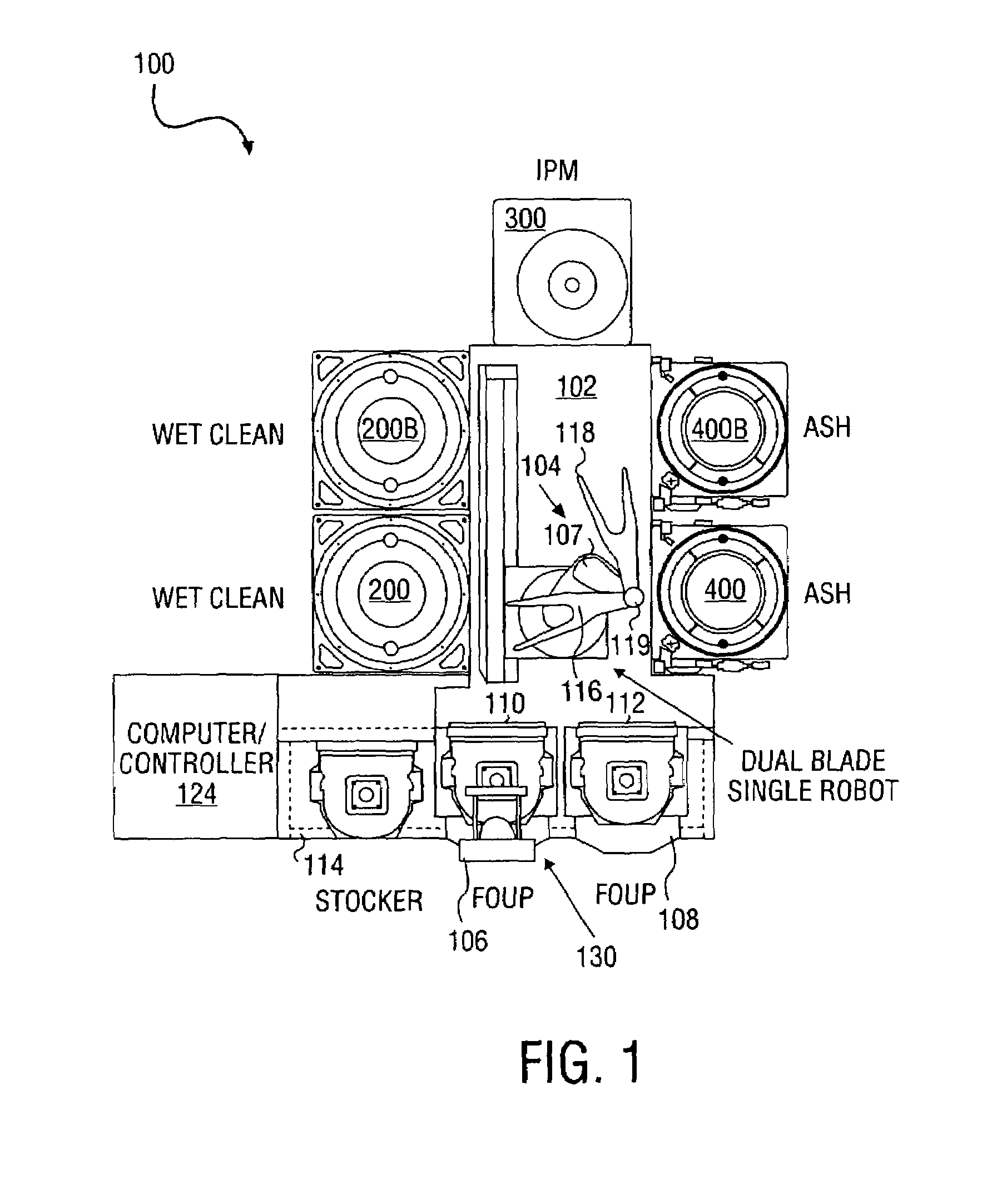

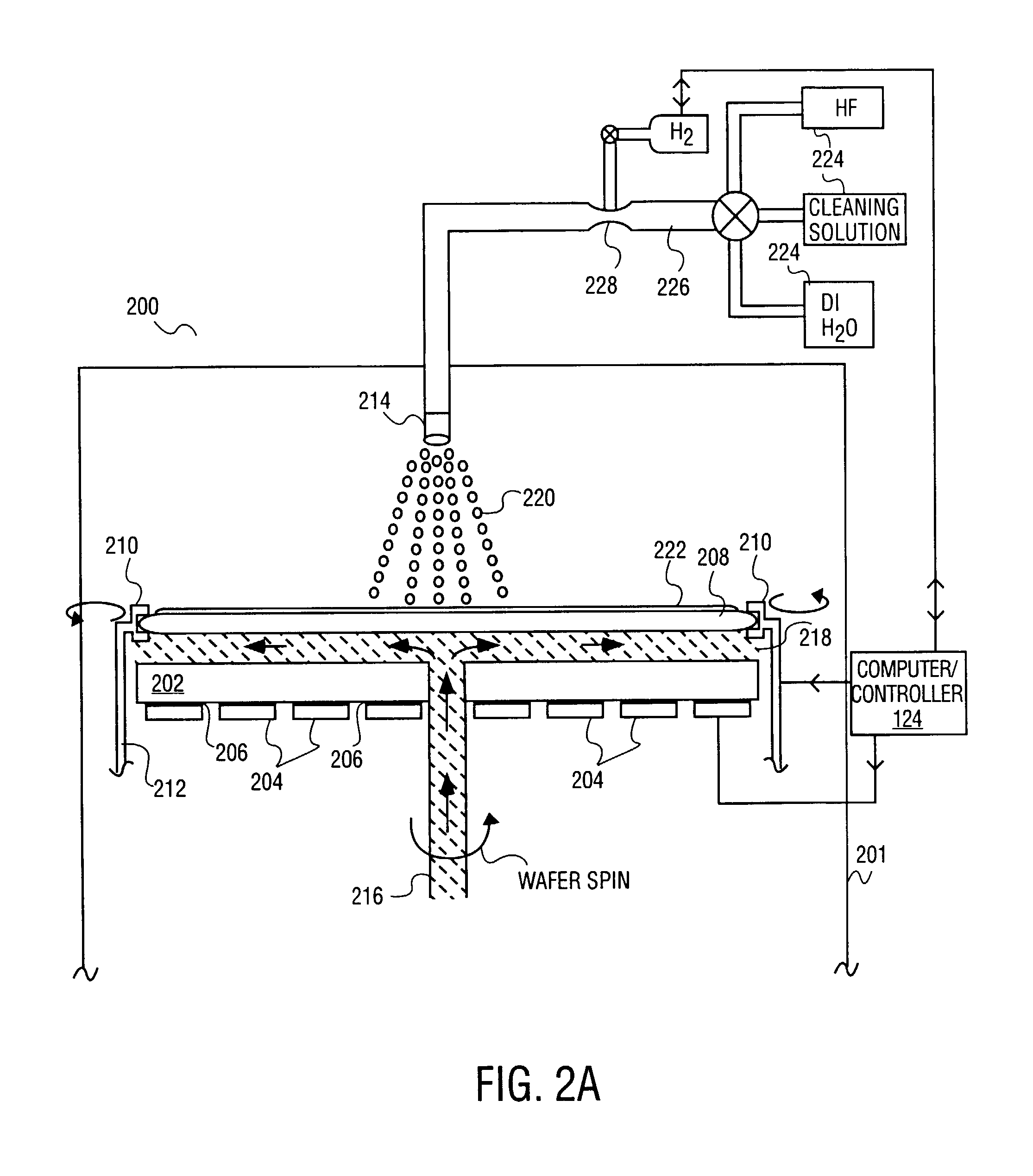

Method and apparatus for processing a wafer

InactiveUS20030045098A1Vacuum evaporation coatingPhotomechanical apparatusEngineeringMechanical engineering

A method of a single wafer wet / dry cleaning apparatus comprising: a transfer chamber having a wafer handler contained therein; a first single wafer wet cleaning chamber directly coupled to the transfer chamber; and a first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:APPLIED MATERIALS INC

Method of cleaning a semiconductor device processing chamber after a copper etch process

The present invention is a method for removing deposited etch byproducts from surfaces of a semiconductor processing chamber after a copper etch process. The method of the invention comprises the following general steps: (a) an oxidation step, in which interior surfaces of the processing chamber are contacted with an oxidizing plasma; (b) a first non-plasma cleaning step, in which interior surfaces of the processing chamber are contacted with an H+hfac-comprising gas; and (c) a second cleaning step, in which interior surfaces of the processing chamber are contacted with a plasma containing reactive fluorine species, whereby at least a portion of the copper etch byproducts remaining after step (b) are volatilized into gaseous species, which are removed from the processing chamber. The method of the invention is preferably performed at a chamber wall temperature of at least 150° C. in order to achieve optimum cleaning of the chamber at the chamber operating pressures typically used during the cleaning process. The dry cleaning method of the invention can be performed between wafer processing runs without opening the processing chamber, thereby minimizing potential contamination to the chamber as well as chamber downtime.

Owner:APPLIED MATERIALS INC

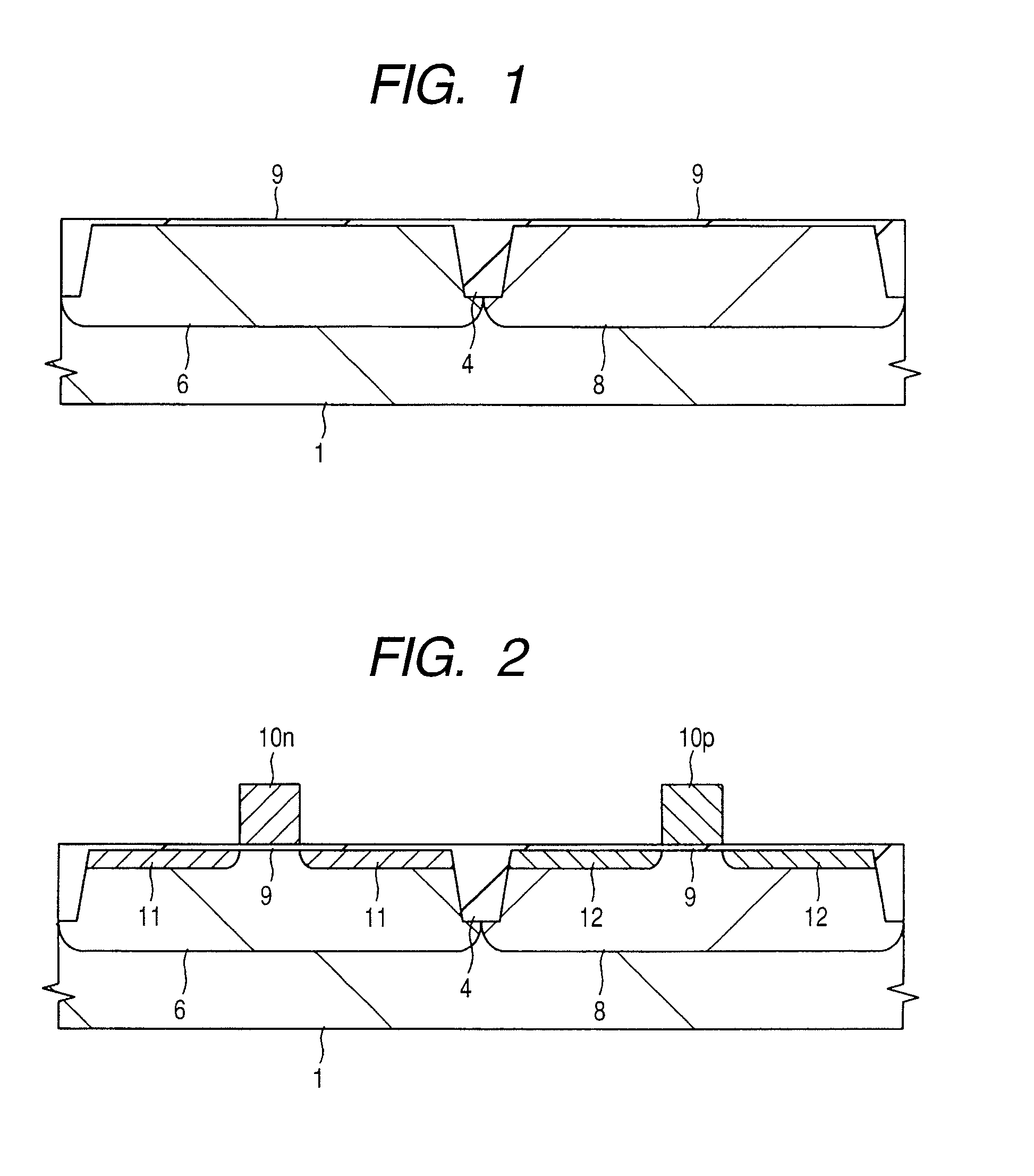

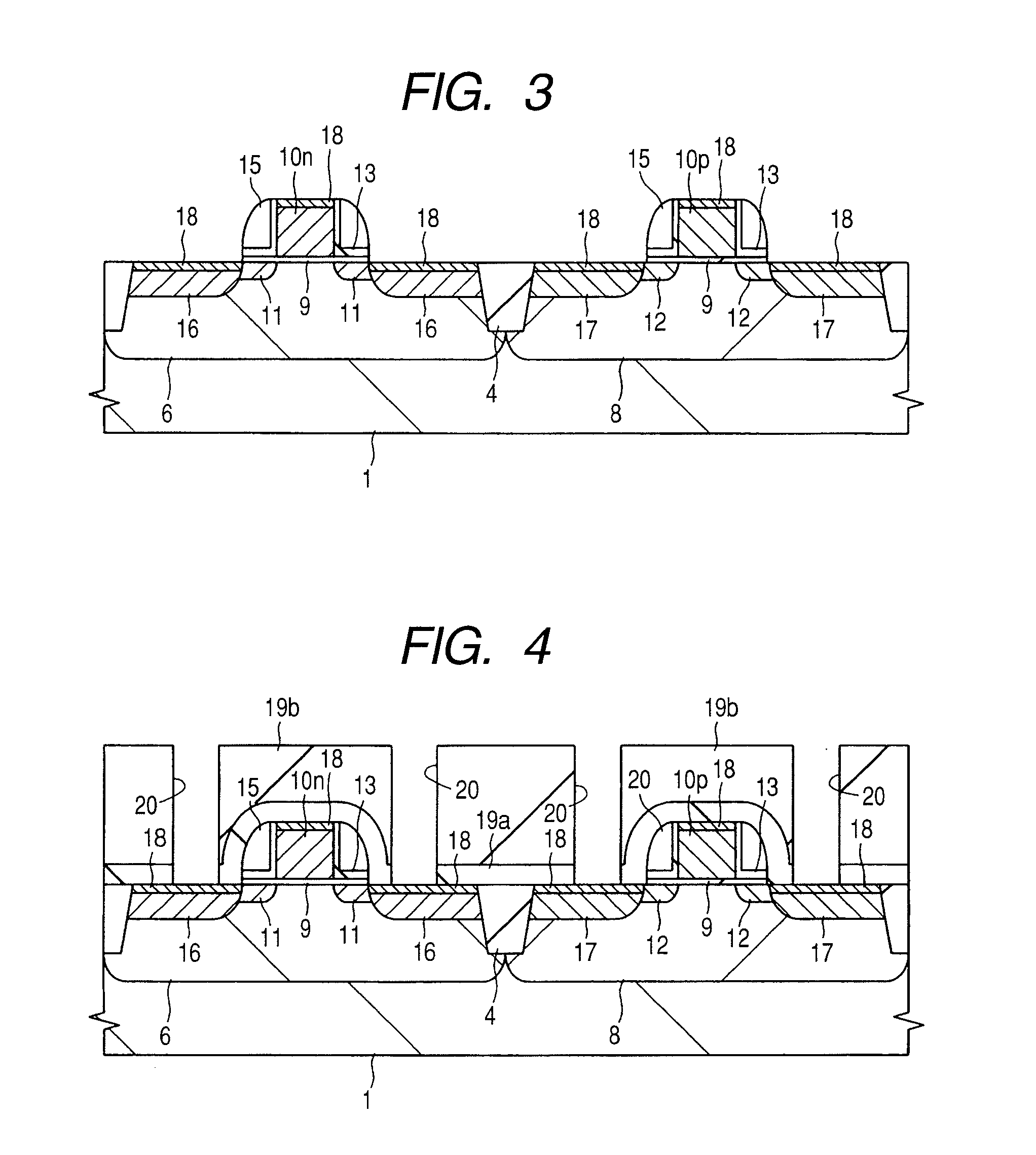

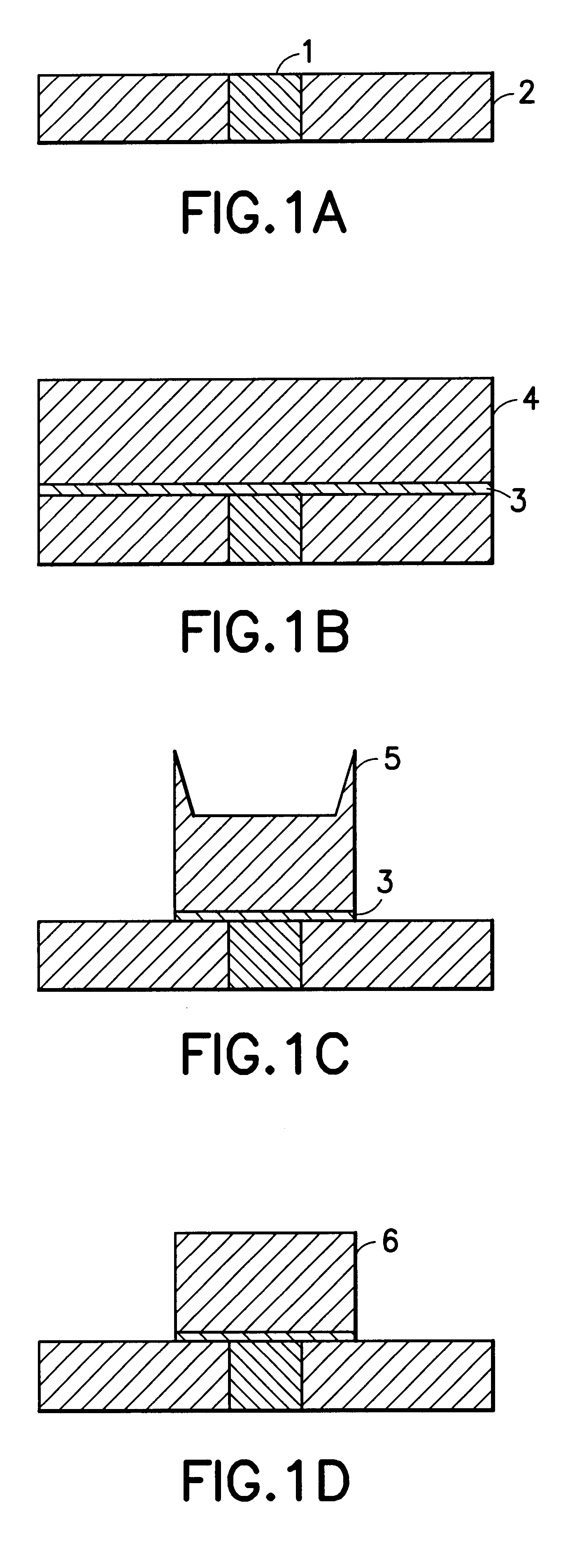

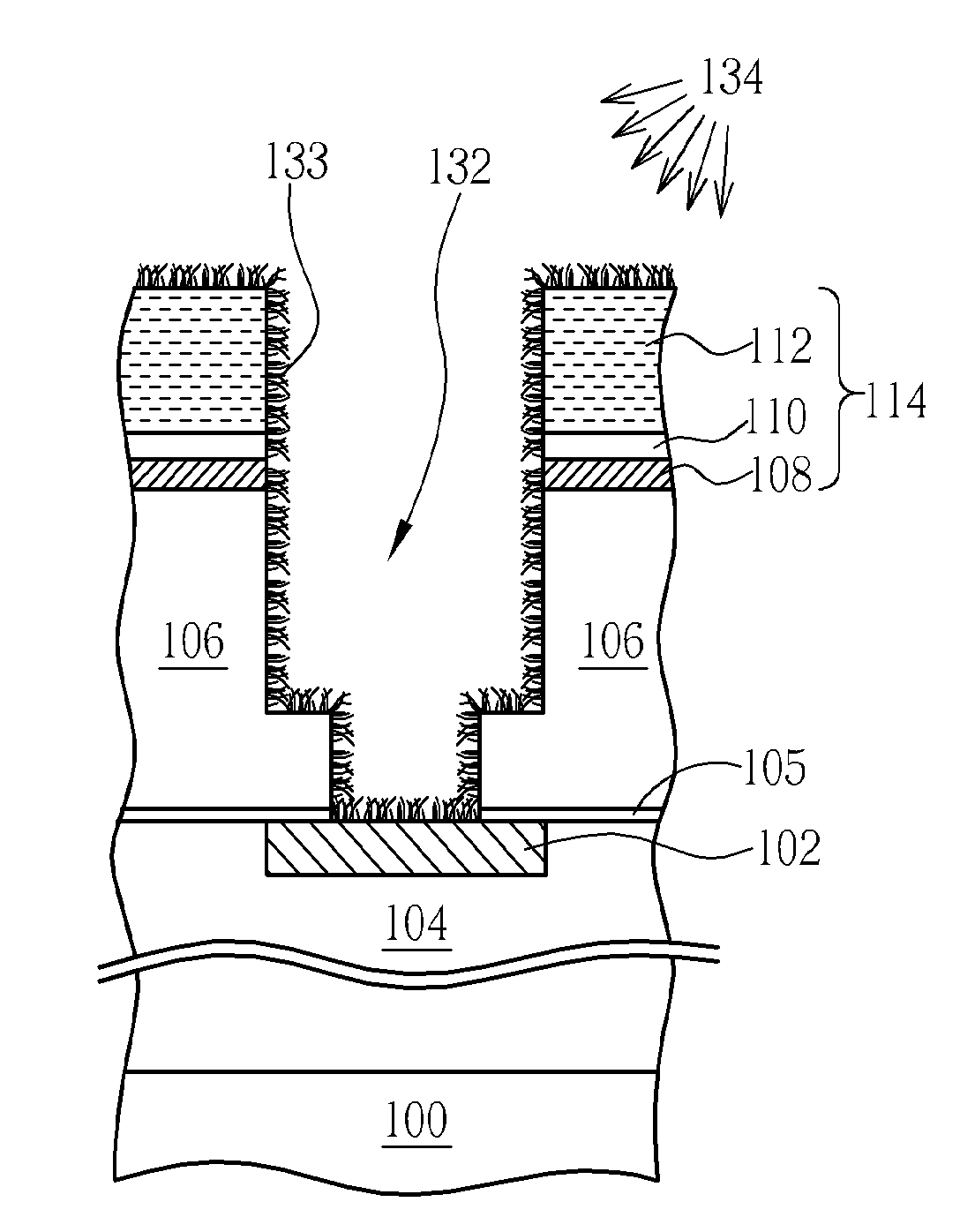

Method of manufacturing semiconductor device

ActiveUS20070238321A1Improve reliabilityVariation in electrical propertyTransistorElectrostatic cleaningEngineeringSemiconductor

Provided is a method of manufacturing a semiconductor device. After a semiconductor wafer is placed over a wafer stage with which a dry cleaning chamber of a film forming apparatus is equipped, dry cleaning treatment is given over the surface of the semiconductor wafer with a reducing gas. Then, the semiconductor wafer is heat treated at a first temperature of from 100 to 150° C. by using a shower head kept at 180° C. The semiconductor wafer is then vacuum-transferred to a heat treatment chamber, wherein the semiconductor wafer is heat treated at a second temperature of from 150 to 400° C. A product remaining over the main surface of the semiconductor wafer is thus removed. The present invention makes it possible to manufacture a semiconductor device having improved reliability and production yield by reducing variations in the electrical properties of a nickel silicide layer.

Owner:RENESAS ELECTRONICS CORP

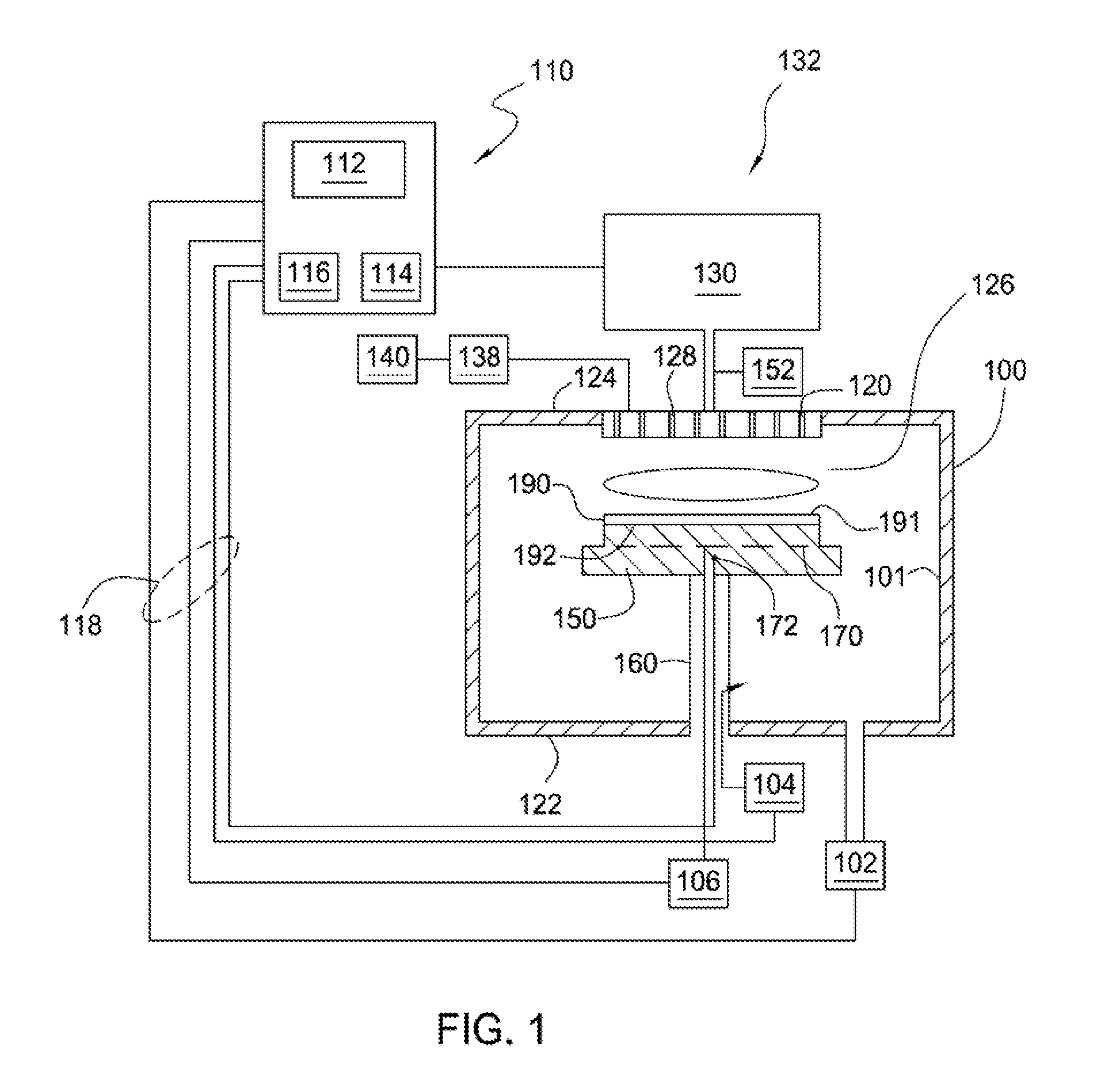

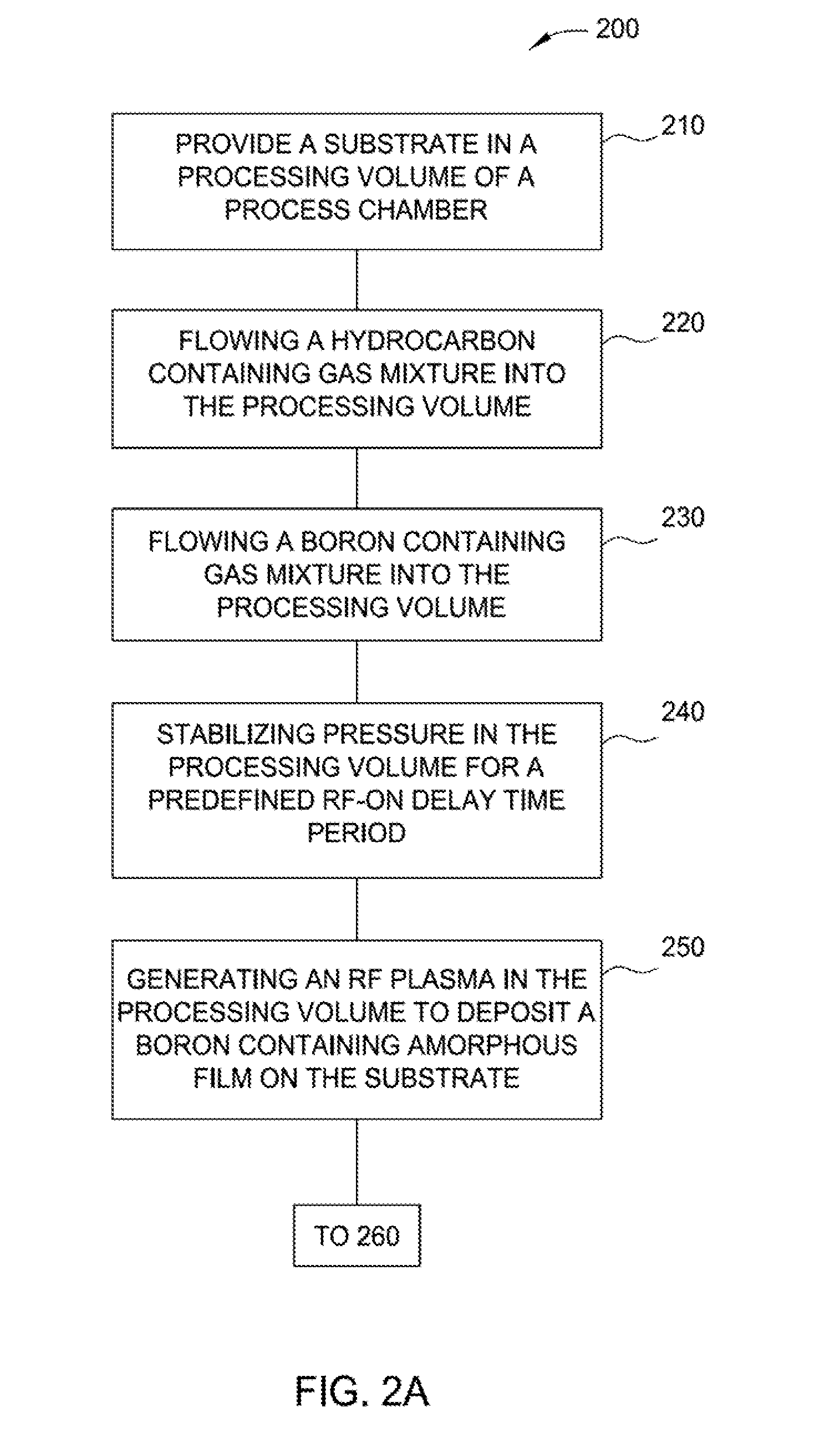

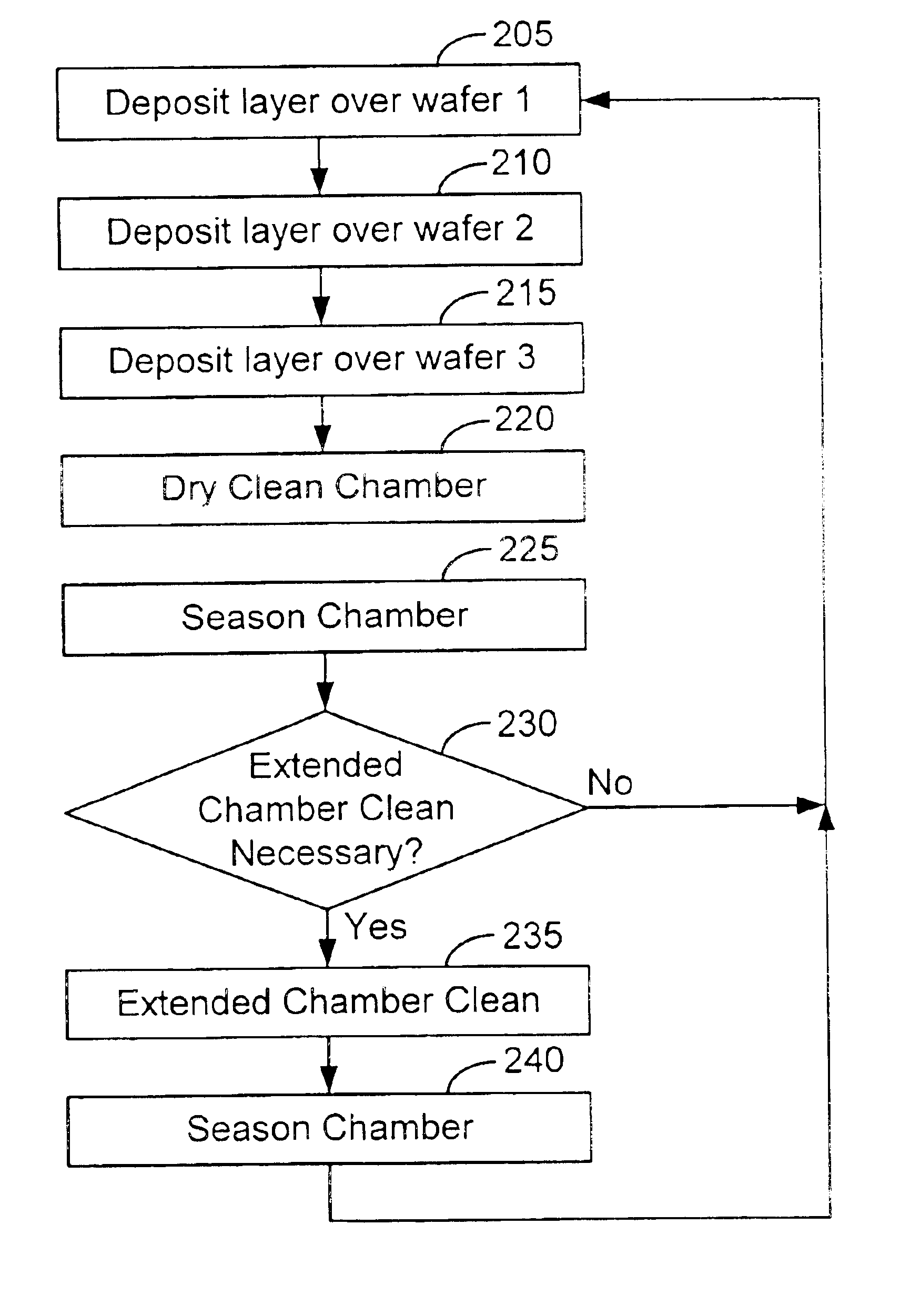

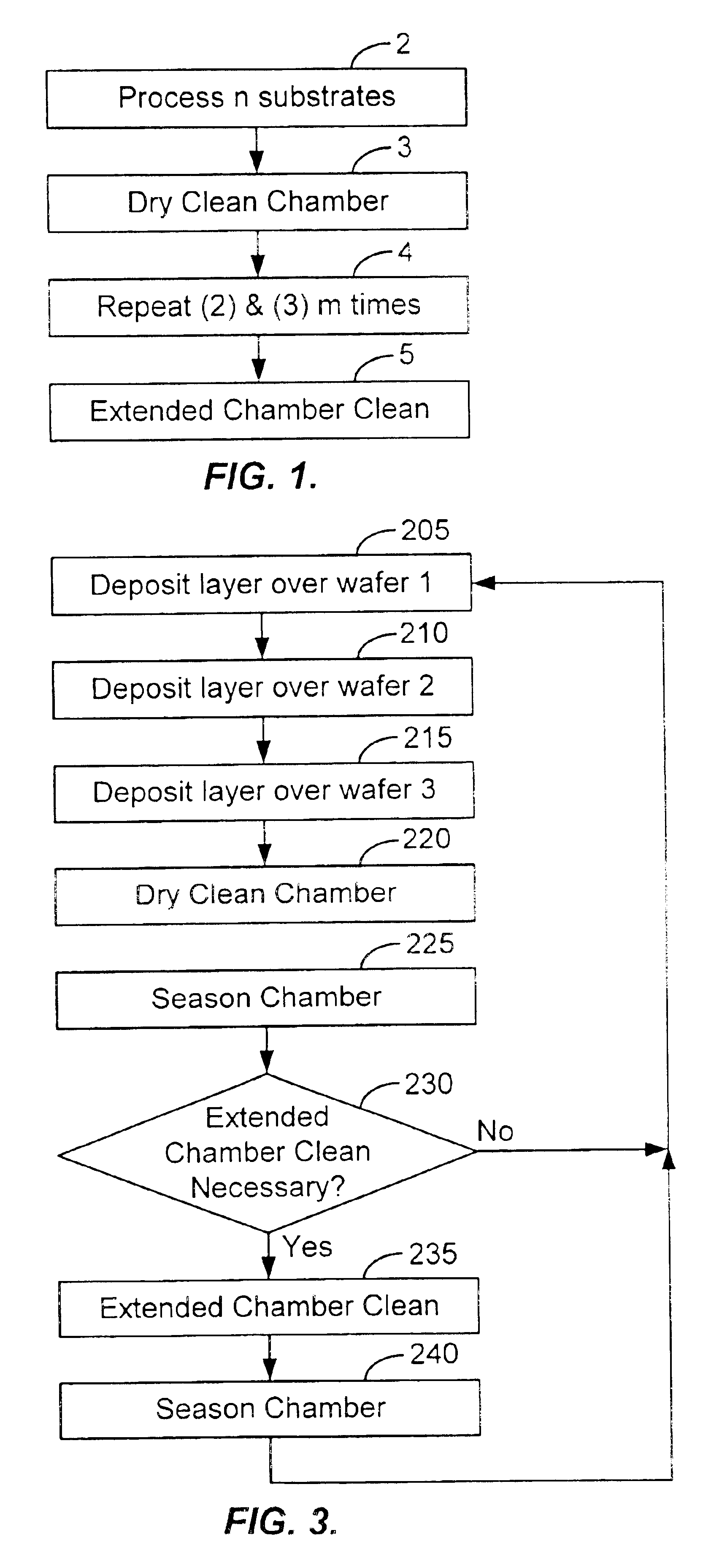

Methods to improve in-film particle performance of amorphous boron-carbon hardmask process in pecvd system

ActiveUS20170062218A1Reduce particle pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron containingDelayed time

Implementations of the present disclosure generally relate to the fabrication of integrated circuits. More particularly, the implementations described herein provide techniques for deposition of boron-containing amorphous carbon films on a substrate with reduced particle contamination. In one implementation, the method comprises flowing a hydrocarbon-containing gas mixture into a processing volume having a substrate positioned therein, flowing a boron-containing gas mixture into the processing volume, stabilizing the pressure in the processing volume for a predefined RF-on delay time period, generating an RF plasma in the processing volume after the predefined RF-on delay time period expires to deposit a boron-containing amorphous film on the substrate, exposing the processing volume of the process chamber to a dry cleaning process and depositing an amorphous boron season layer over at least one surface in the processing volume of the process chamber.

Owner:APPLIED MATERIALS INC

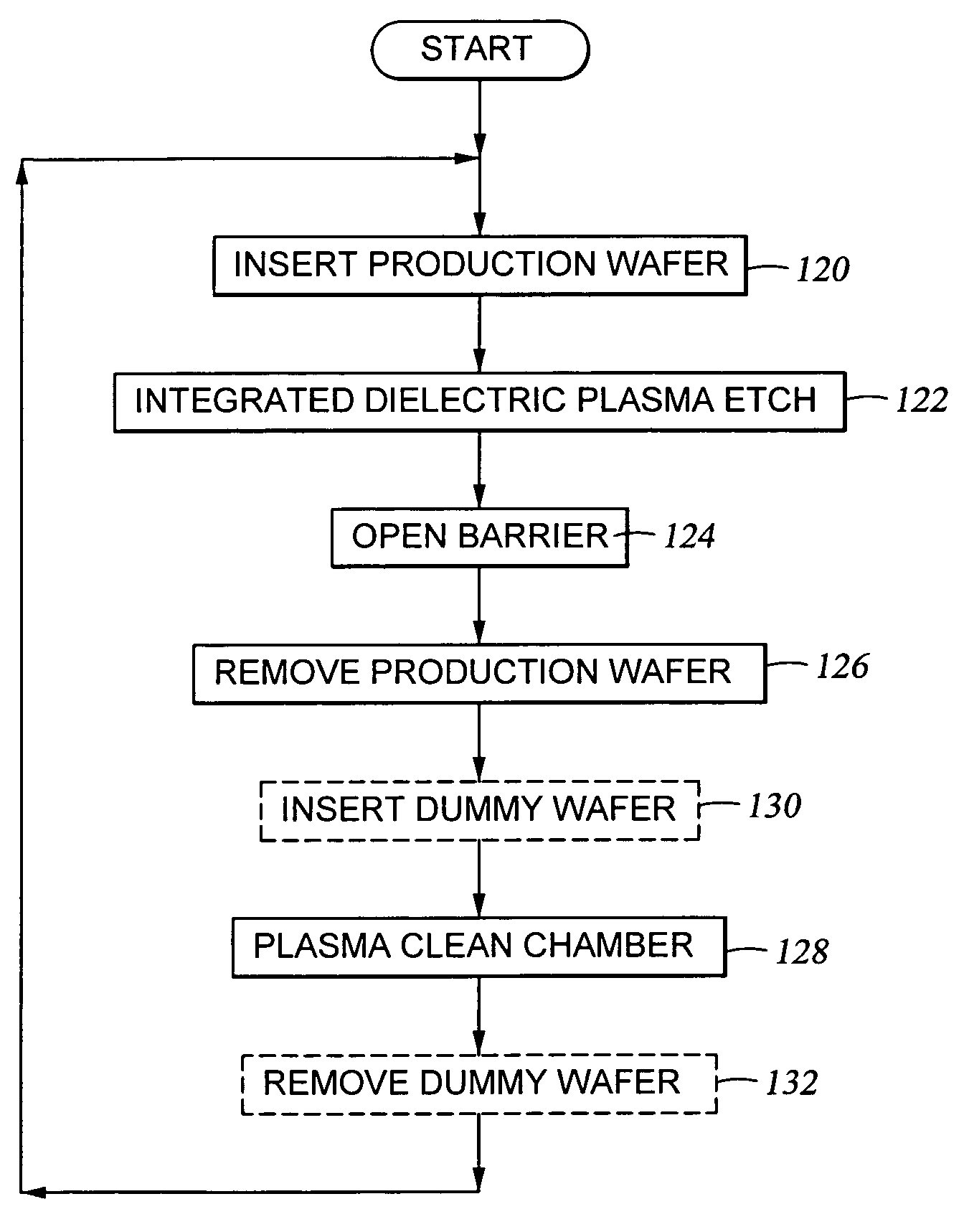

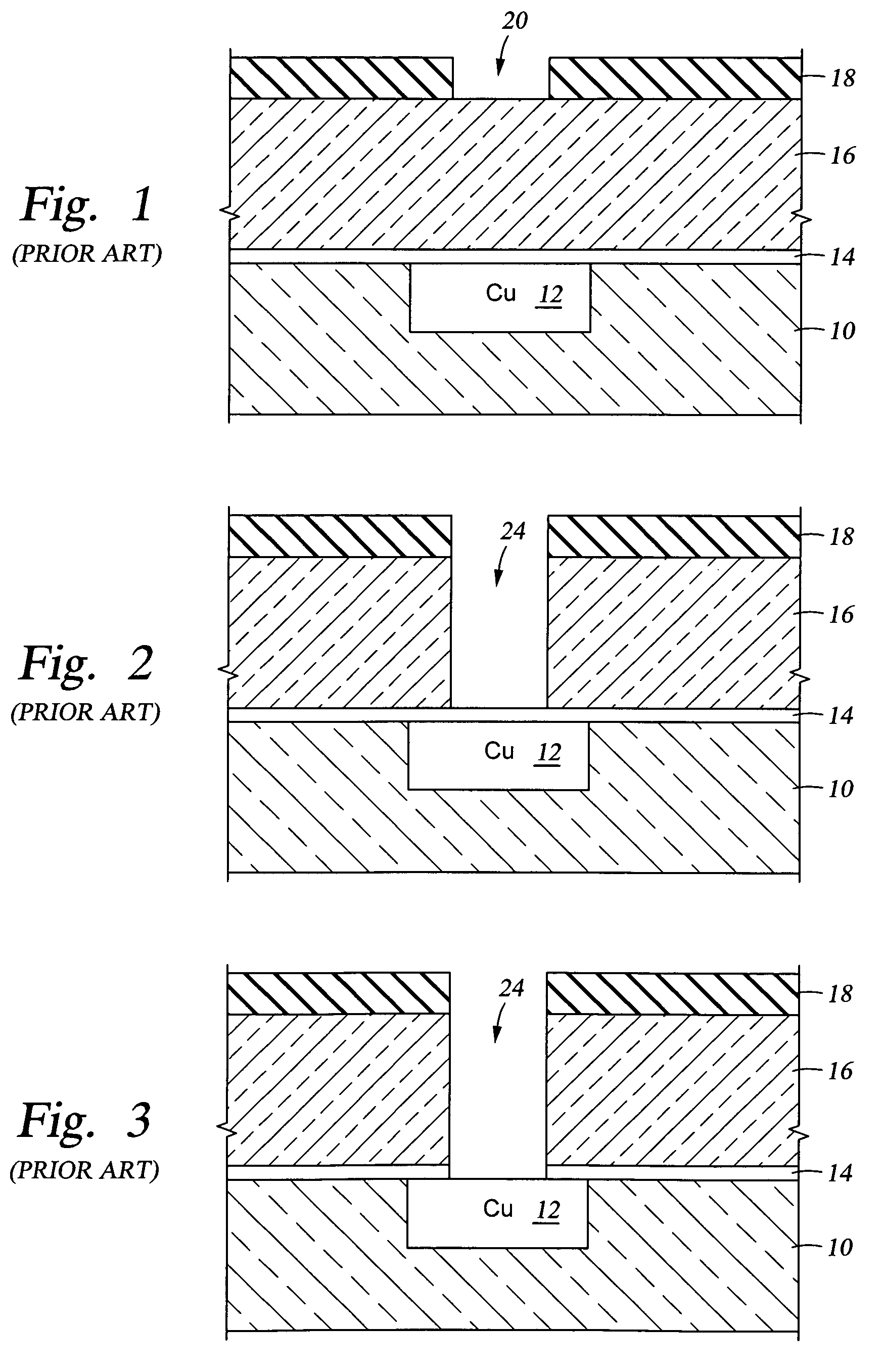

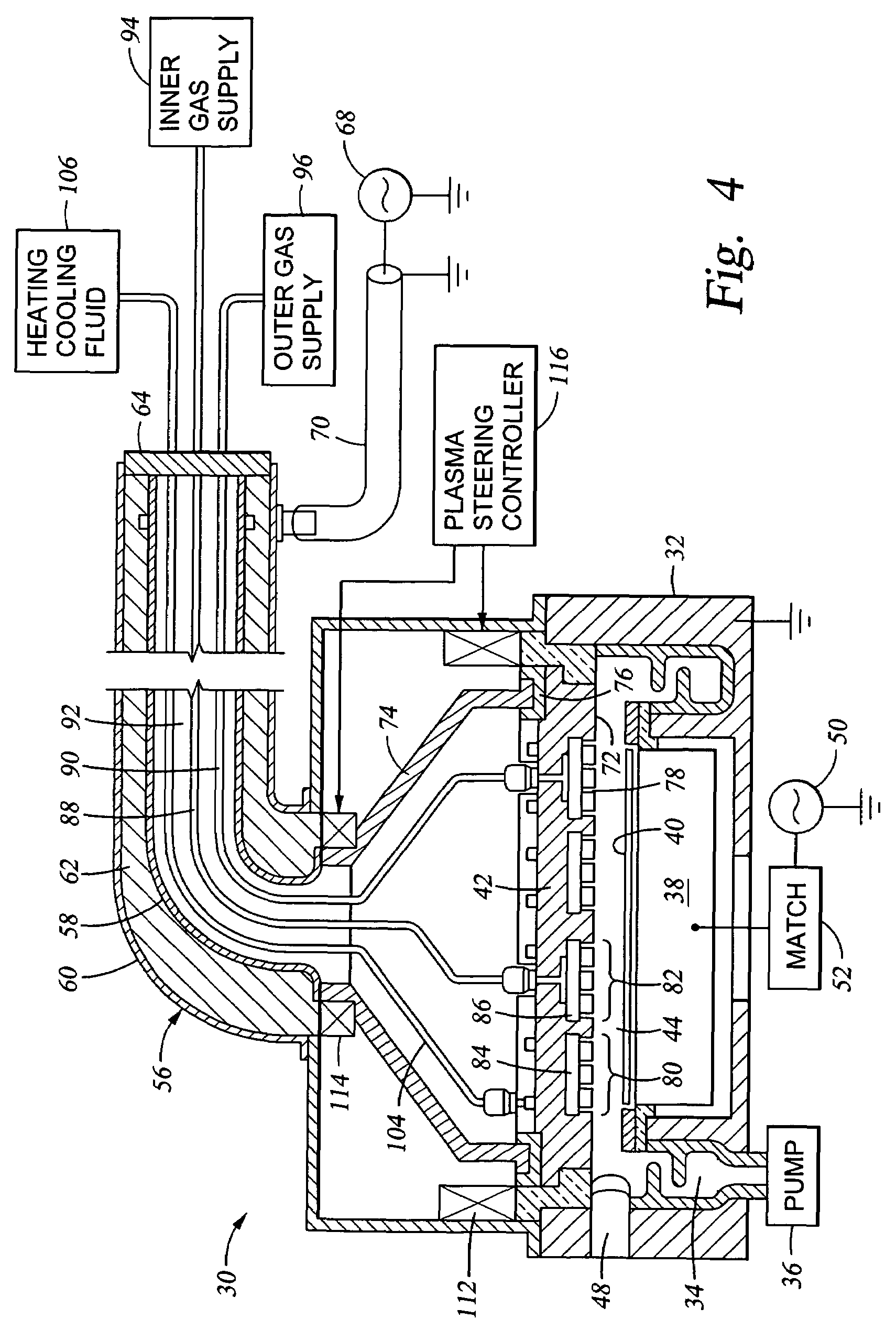

Chamber recovery after opening barrier over copper

A chamber dry cleaning process particularly useful after a dielectric plasma etch process which exposes an underlying copper metallization. After the dielectric etch process, the production wafer is removed from the chamber and a cleaning gas is excited into a plasma to clean the chamber walls and recover the dielectric etching characteristic of the chamber. Preferably, the cleaning gas is reducing such as hydrogen gas with the addition of nitrogen gas. Alternatively, the cleaning gas may an oxidizing gas. If the wafer pedestal is vacant during the cleaning, it is not electrically biased. If a dummy wafer is placed on the pedestal during cleaning, the pedestal is biased. The cleaning process is advantageously performed every wafer cycle.

Owner:APPLIED MATERIALS INC

Autonomous surface cleaning robot for dry cleaning

InactiveUS20060190146A1Low costWet cleaningProgramme-controlled manipulatorActuated automaticallyParticulatesControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

Cleaning tools with UV flash unit

A combination tool for cleaning and sanitizing a surface is disclosed. The tool includes a cleaning device and at least one UV flash unit. The cleaning device can be adapted for either wet or dry cleaning. The combination tool can also include a dispensing unit that can dispense a treatment agent. The tool can also include a sensor that can detect surface properties. In some arrangements, the tool includes a motive component that can propel the tool robotically.

Owner:THE CLOROX CO

Method of cleaning a semiconductor processing chamber

A method of operating a substrate processing chamber. In one embodiment the method includes processing one or more substrates in the substrate processing chamber and subsequently cleaning the chamber using a dry cleaning process. This substrate processing and dry cleaning sequence is then repeated multiple times before chamber is further cleaned by flowing a cleaning gas into the chamber and forming a plasma within the chamber from the cleaning gas in an extended cleaning process. During the extended cleaning process the plasma is maintained within the chamber for a total of at least 5 minutes before the chamber is reused to process a substrate.

Owner:APPLIED MATERIALS INC

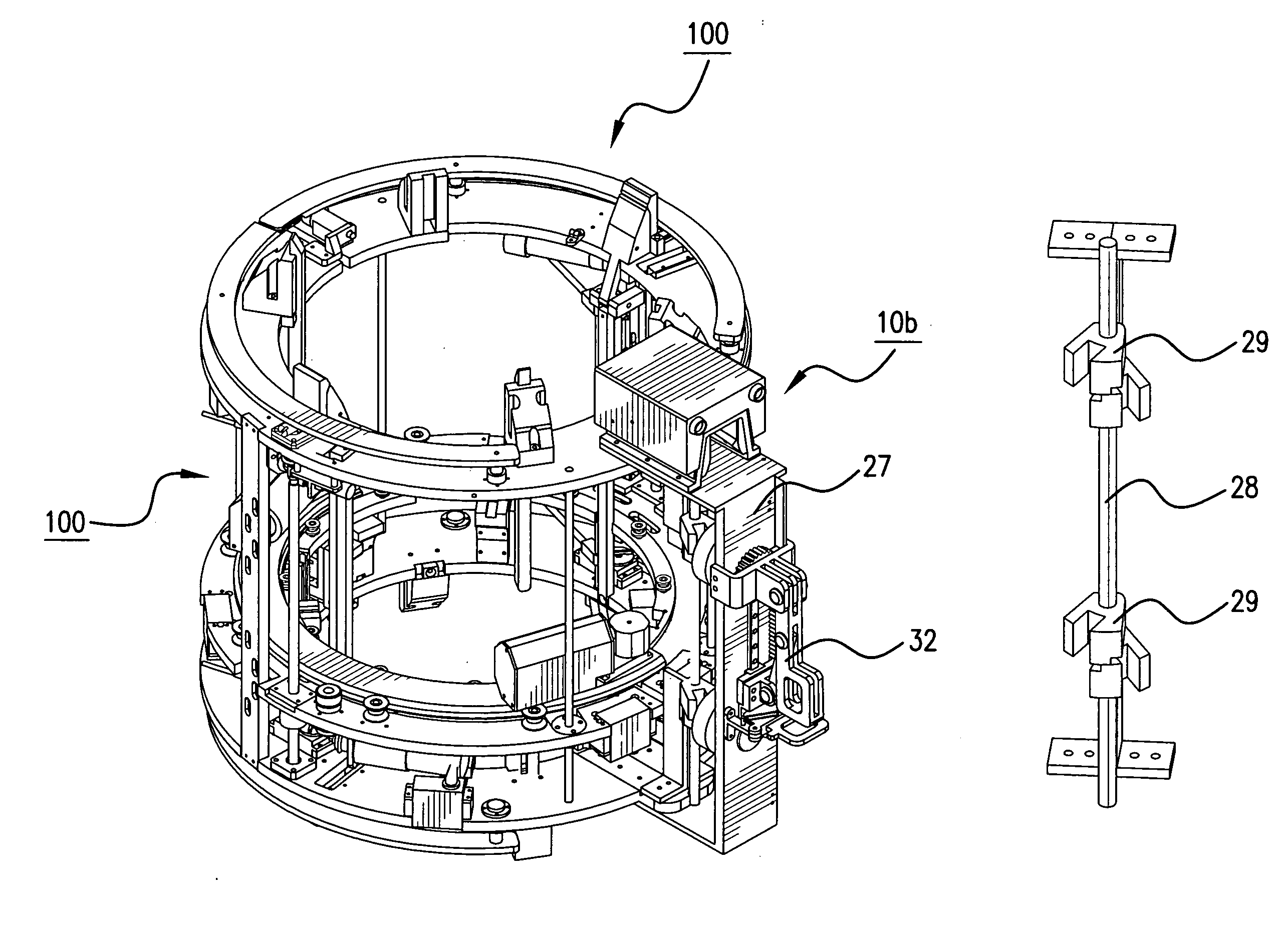

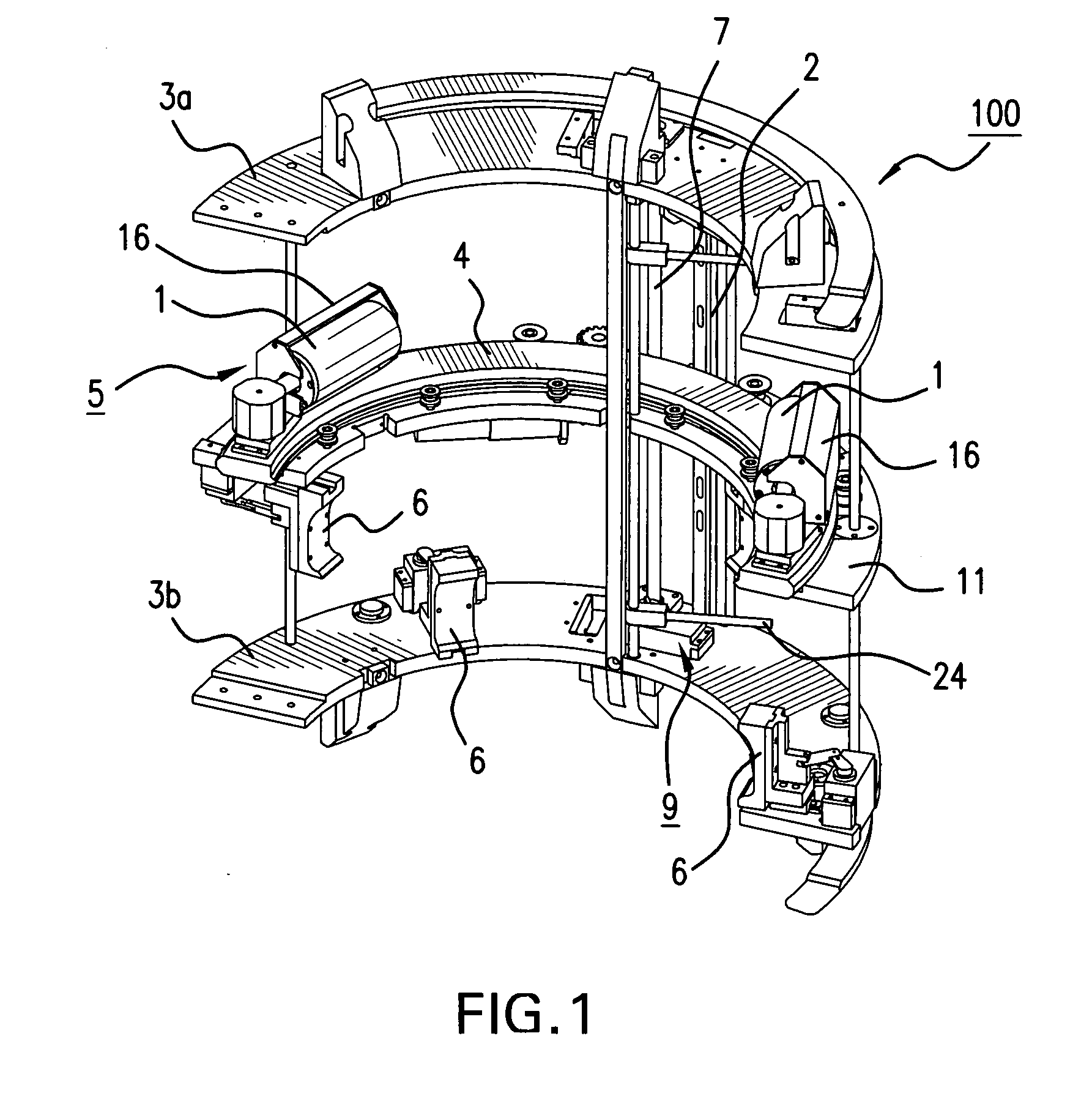

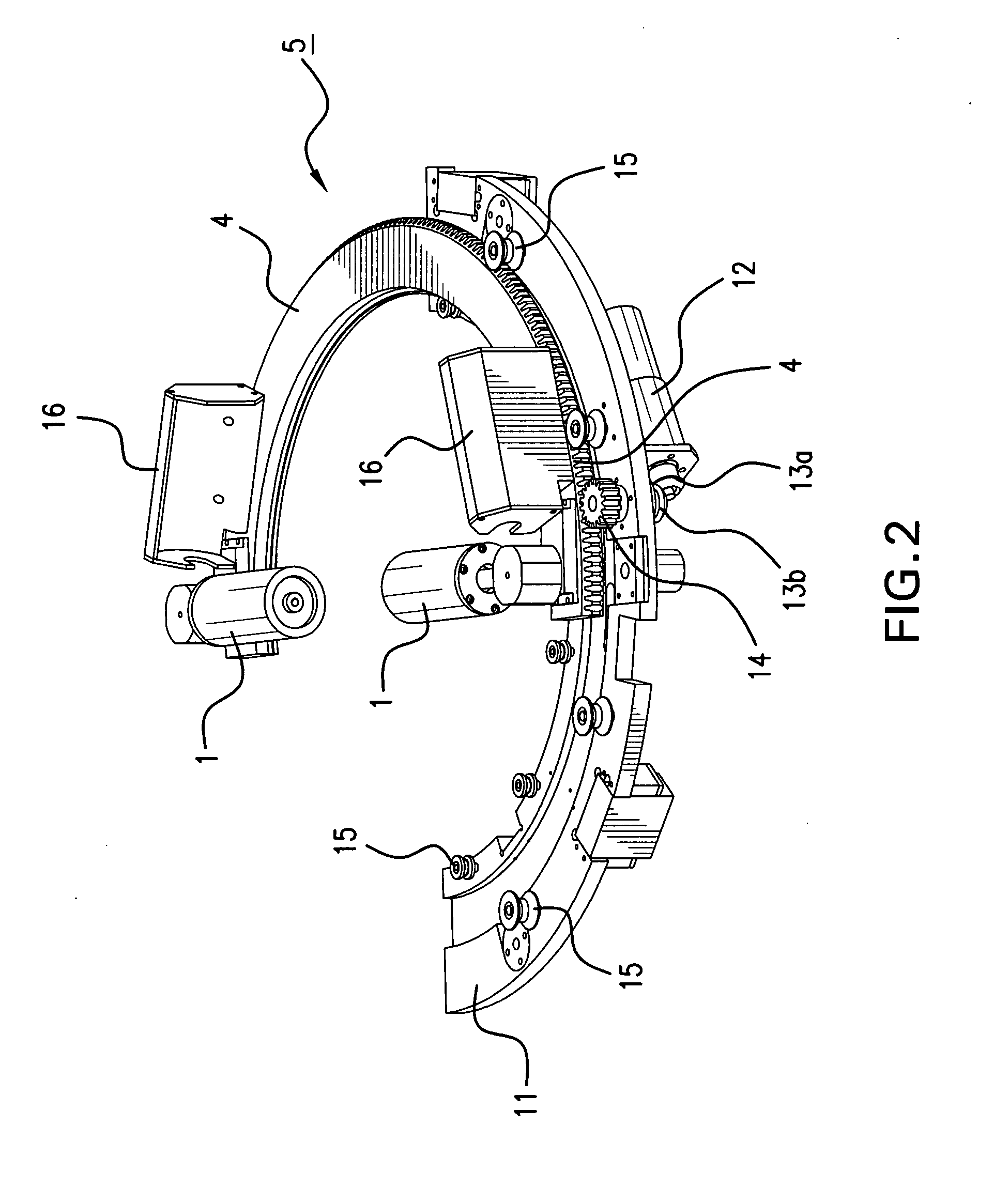

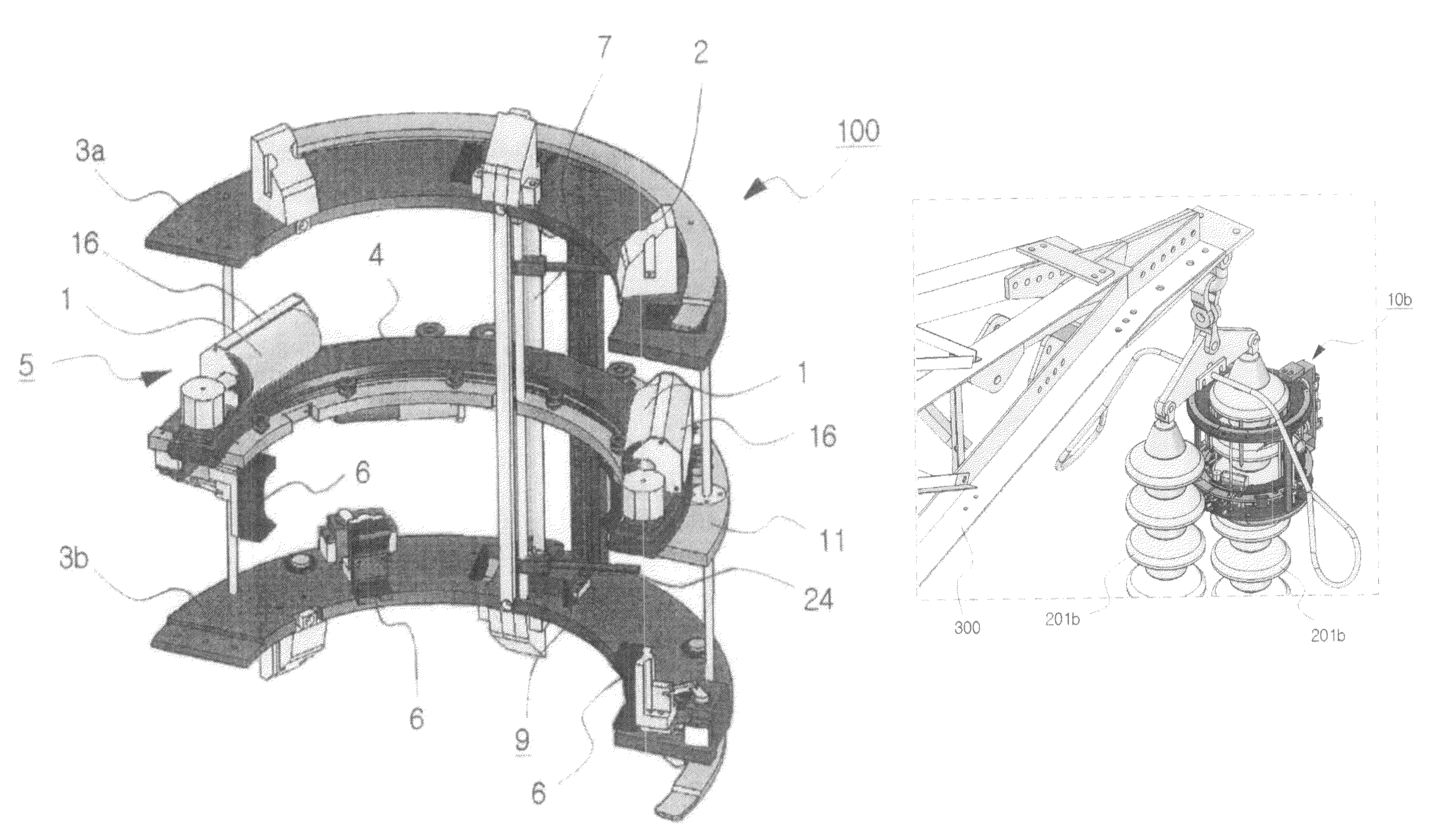

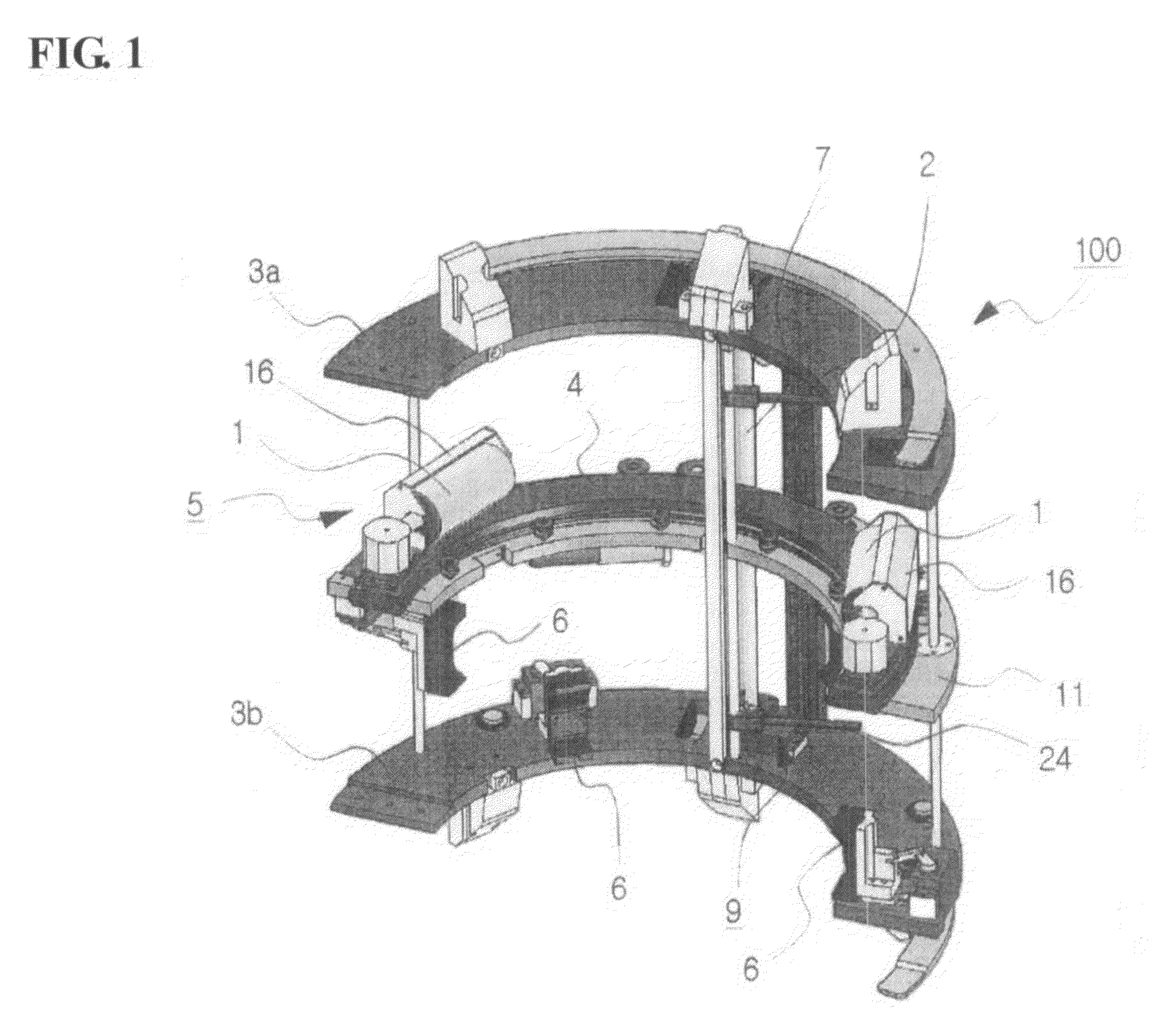

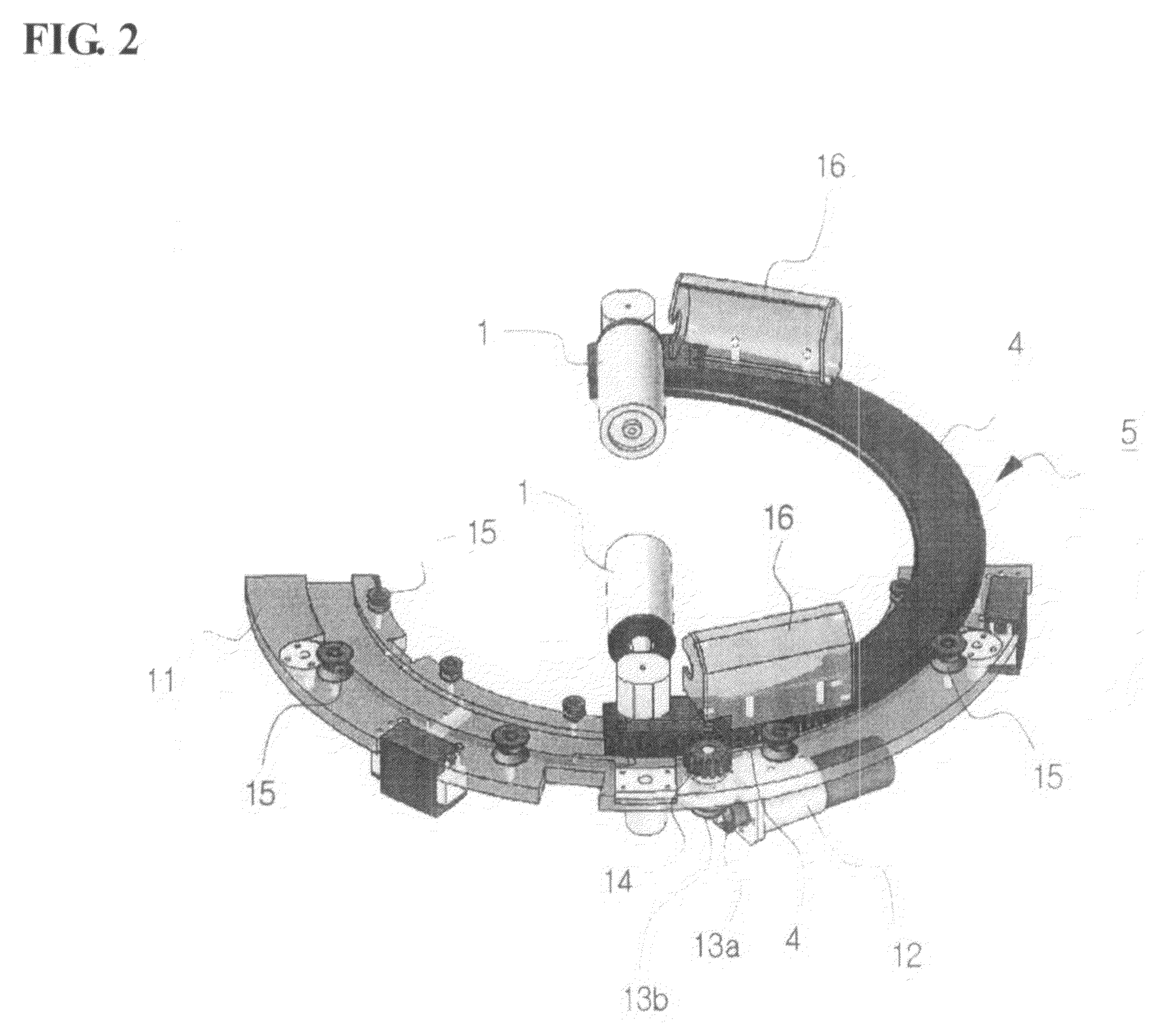

Robot mechanism for cleaning and inspection of live-line insulators

ActiveUS20080301891A1Improve efficiencyImprove securityBowling gamesCarpet cleanersBall bearingMechanical engineering

A robot mechanism adopts a dry cleaning method to clean the surface of live-line insulators without: using water and can perform cleaning and inspection of the surface of the live-line insulators while automatically moving along an insulator string. The robot mechanism includes a main unit having upper and lower wing frames connected with each other by a connecting bracket to surround the insulator string, a cleaning unit disposed between the upper and lower wing frames and including a base frame to perform dry cleaning with a rotational brush and a CM guide, a lift unit including a clamp and a ball-bearing screw to move the main unit up or down, and an inspection unit to electrically inspect the insulators; and a coupling unit to couple a pair of the main units to allow the pair of main units to move along a tension insulator string or a suspension insulator string.

Owner:KOREA ELECTRIC POWER CORP

Autonomous surface cleaning robot for wet and dry cleaning

ActiveUS20080134458A1Low costWet cleaningAutomatic obstacle detectionTravelling automatic controlSurface cleaningControl system

Owner:IROBOT CORP

Autonomous surface cleaning robot for wet and dry cleaning

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

Autonomous surface cleaning robot for wet and dry cleaning

ActiveUS20060190134A1Low costWet cleaningProgramme-controlled manipulatorControl initiation meansParticulatesSurface cleaning

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

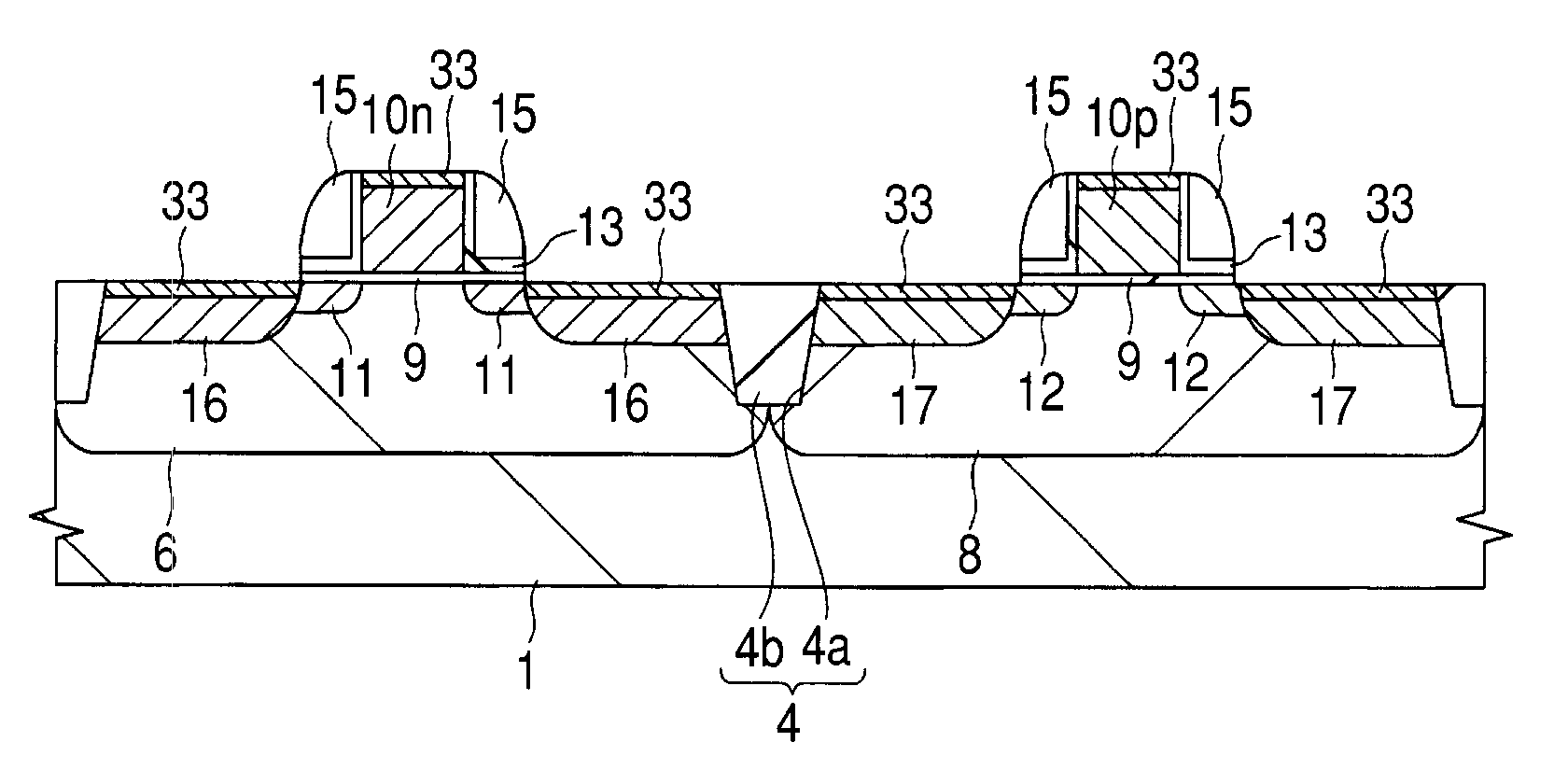

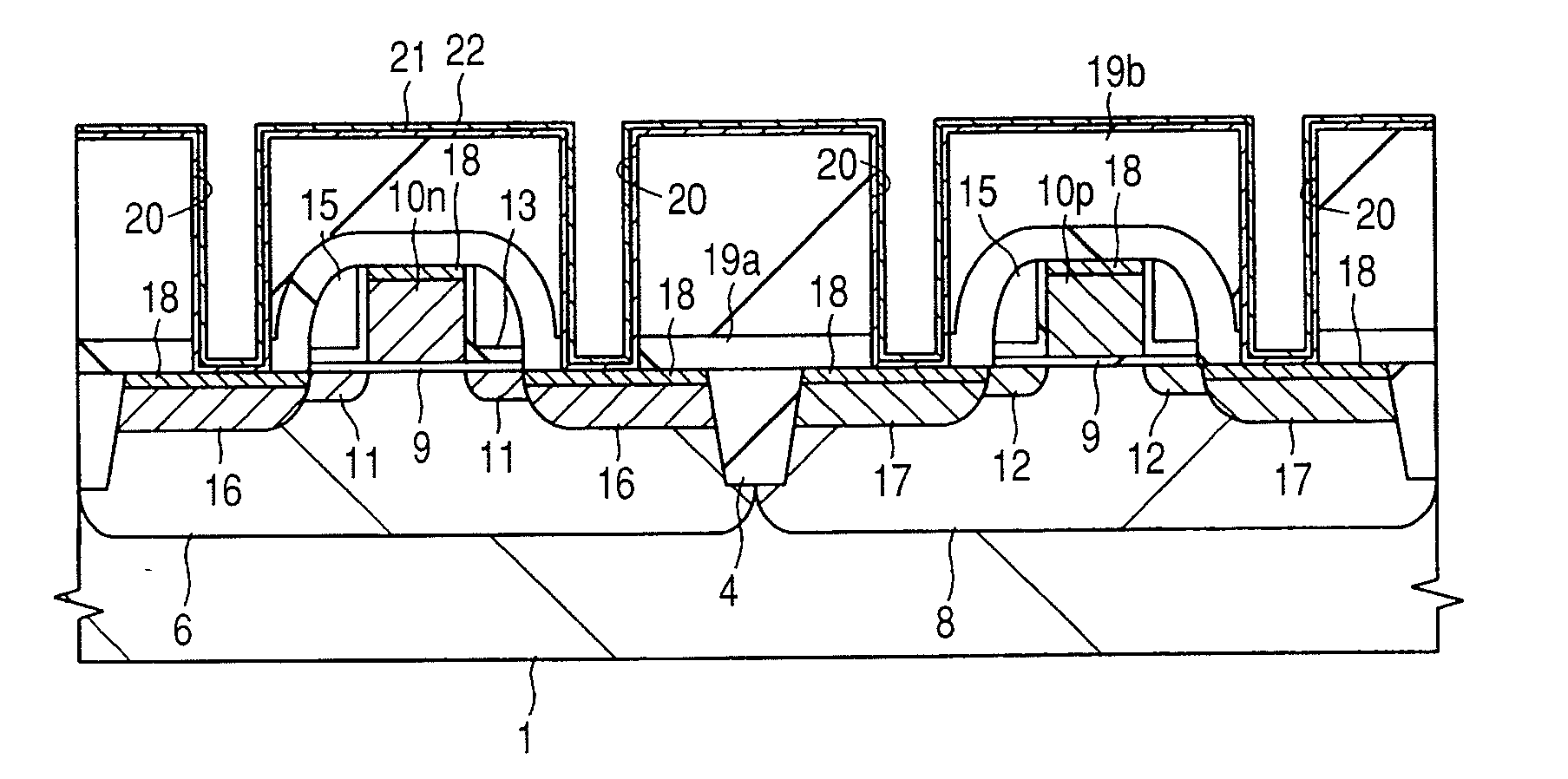

Method of manufacturing semiconductor device

ActiveUS20070269976A1Decrease its variation of electrical characteristicImprove reliabilitySemiconductor/solid-state device manufacturingEngineeringSemiconductor

To provide a technology capable of improving reliability and manufacturing yield of a semiconductor device by reducing variations of electrical characteristics in connection hole portions. After a semiconductor wafer is placed over a wafer stage provided in a chamber for dry cleaning treatment of a deposition system, dry cleaning treatment is performed to a principal surface of the semiconductor wafer by supplying reducing gas, sequentially, heat treatment is performed to the semiconductor wafer at a first temperature of 100 to 150° C. by a showerhead which is maintained at 180° C. Next, after the semiconductor wafer is vacuum transferred from the chamber to a chamber for heat treatment, heat treatment is performed to the semiconductor wafer at a second temperature of 150 to 400° C. in the chamber, thereby removing a product remaining over the principal surface of the semiconductor wafer.

Owner:RENESAS ELECTRONICS CORP

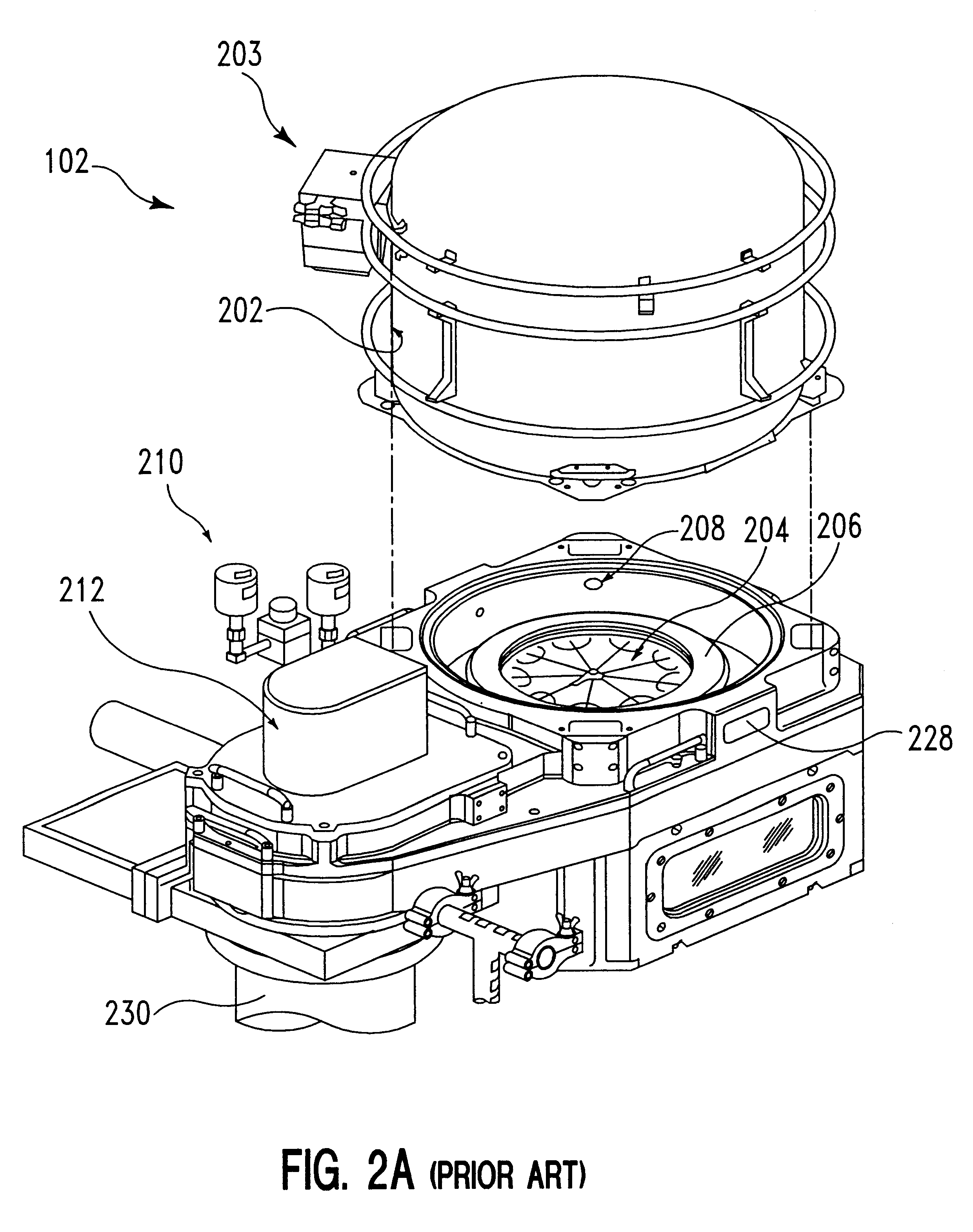

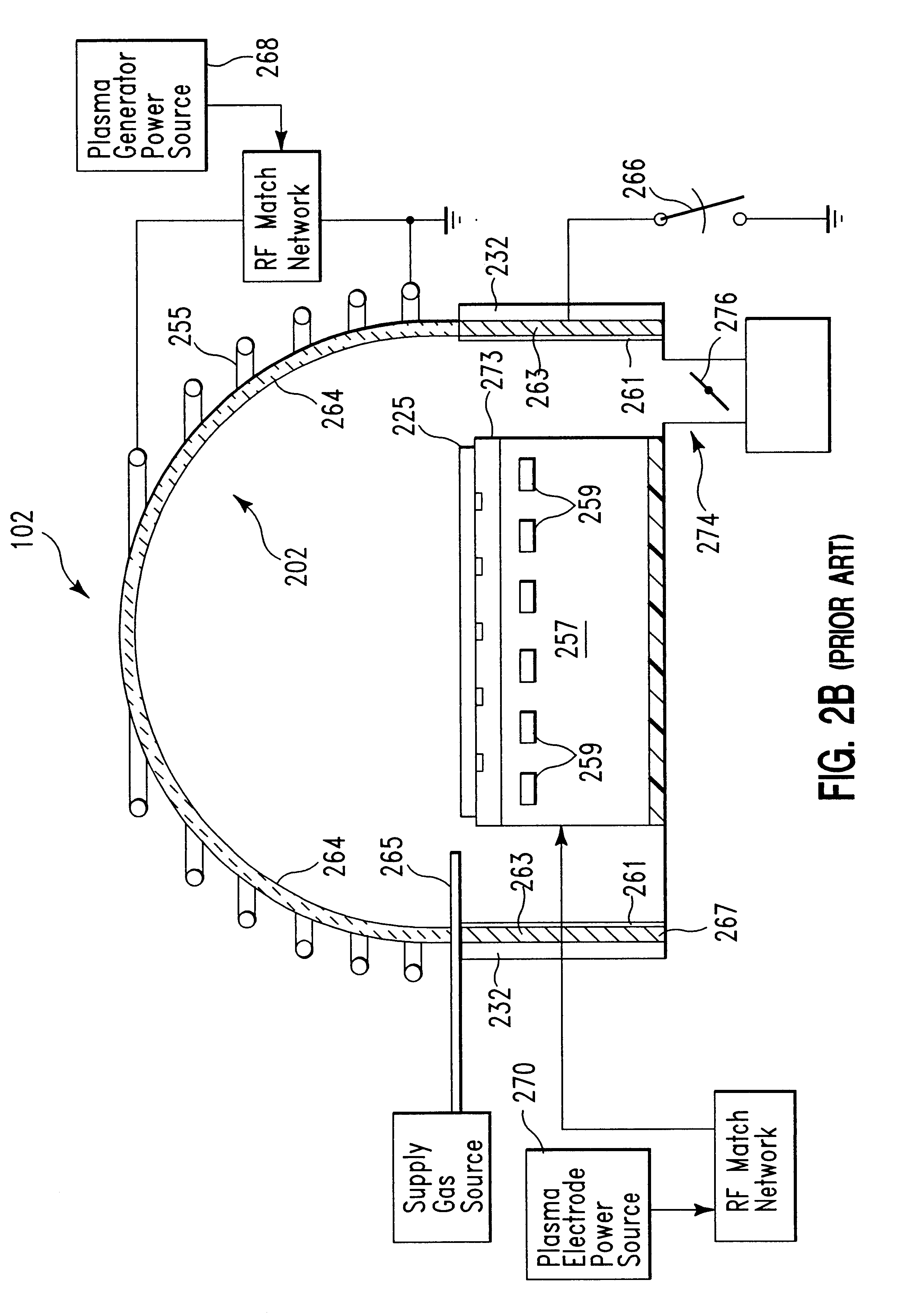

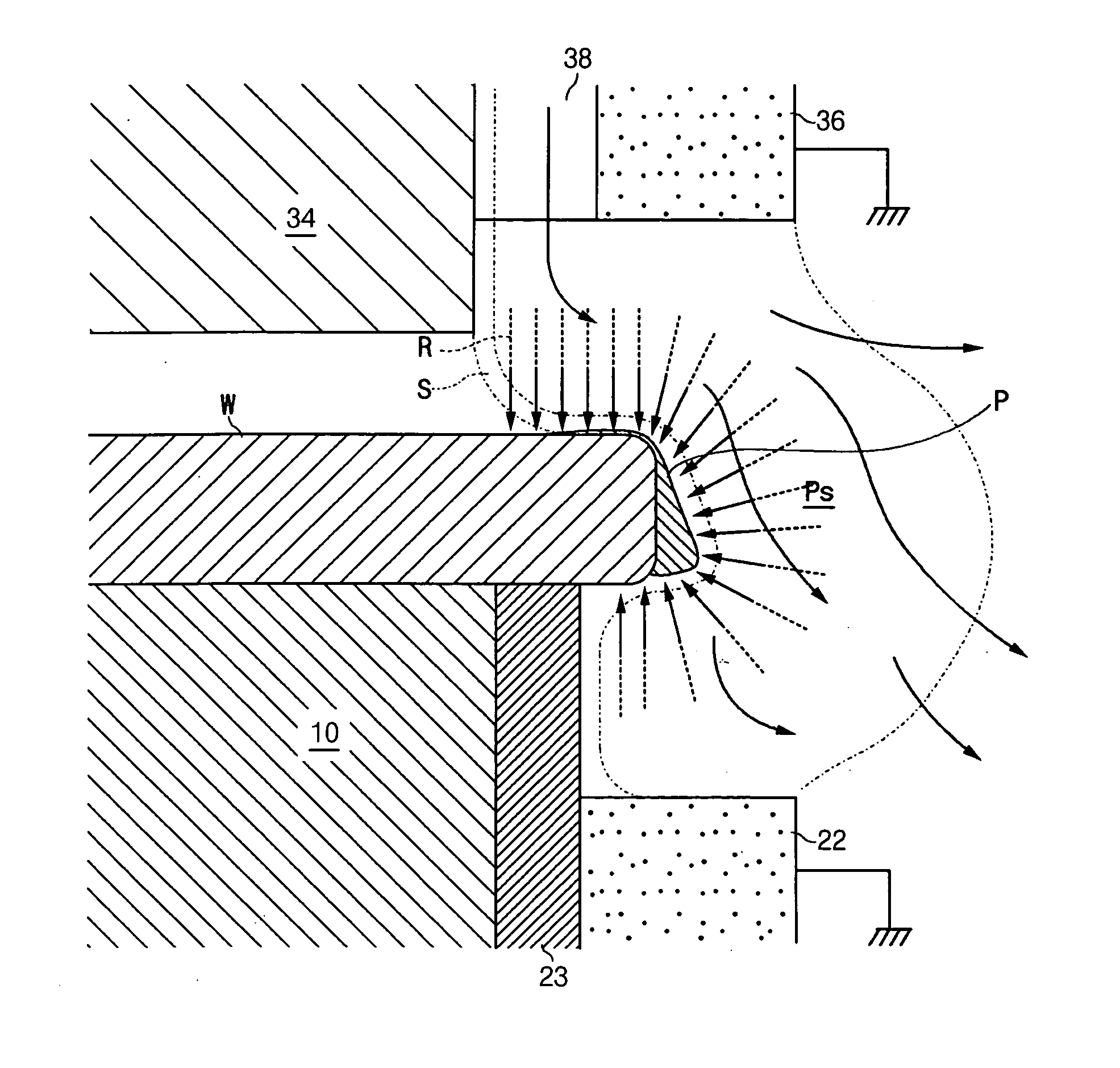

Plasma etching chamber and plasma etching system using same

ActiveUS20050173067A1Limited spaceImprove throughputElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyFilm material

Disclosed is a plasma etching chamber for completely dry-cleaning a film material and particles deposited at the periphery of a wafer through plasma etching while generating plasma at the top to the bottom sides of the periphery of the wafer. A pair of top and bottom anodes facing each other is placed around the periphery of the wafer under the application of radio frequency through a cathode. Alternatively, a top cathode and a bottom anode are placed around the periphery of the wafer while facing each other and a view-ring shields the area of the cathode, the anode and the wafer from the outside. A plasma etching system includes a plurality of the above-structured etching chambers. A handler takes wafers from a plurality of cassette stands or load ports, and posture-corrects the orientation frat locations of the wafers by a wafer alignment unit. The wafers are charged into the plasma etching chambers directly or via load lock chambers. The handler takes the etched wafers from the chambers, and returns the wafers to the cassettes or the load ports directly or via the load lock chambers.

Owner:SOSUL

Method and apparatus for processing a wafer

InactiveUS7159599B2Semiconductor/solid-state device manufacturingCleaning using liquidsDirect couplingEngineering

A method of a single wafer wet / dry cleaning apparatus comprising:a transfer chamber having a wafer handler contained therein;a first single wafer wet cleaning chamber directly coupled to the transfer chamber; anda first single wafer ashing chamber directly coupled to the transfer chamber.

Owner:APPLIED MATERIALS INC

Isotropic dry cleaning process for noble metal integrated circuit structures

A method for removing from a microelectronic device structure a noble metal residue including at least one metal selected from the group consisting of platinum, palladium, iridium and rhodium, by contacting the microelectronic device structure with a cleaning gas including a reactive halide composition, e.g., XeF2, SF6, SiF4, Si2F6 or SiF3 and SiF2 radicals. The method may be carried out in a batch-cleaning mode, in which fresh charges of cleaning gas are successively introduced to a chamber containing the residue-bearing microelectronic device structure. Each charge is purged from the chamber after reaction with the residue, and the charging / purging is continued until the residue has been at least partially removed to a desired extent. Alternatively, the cleaning gas may be continuously flowed through the chamber containing the microelectronic device structure, until the noble metal residue has been sufficiently removed.

Owner:FELLOWS RES B V +1

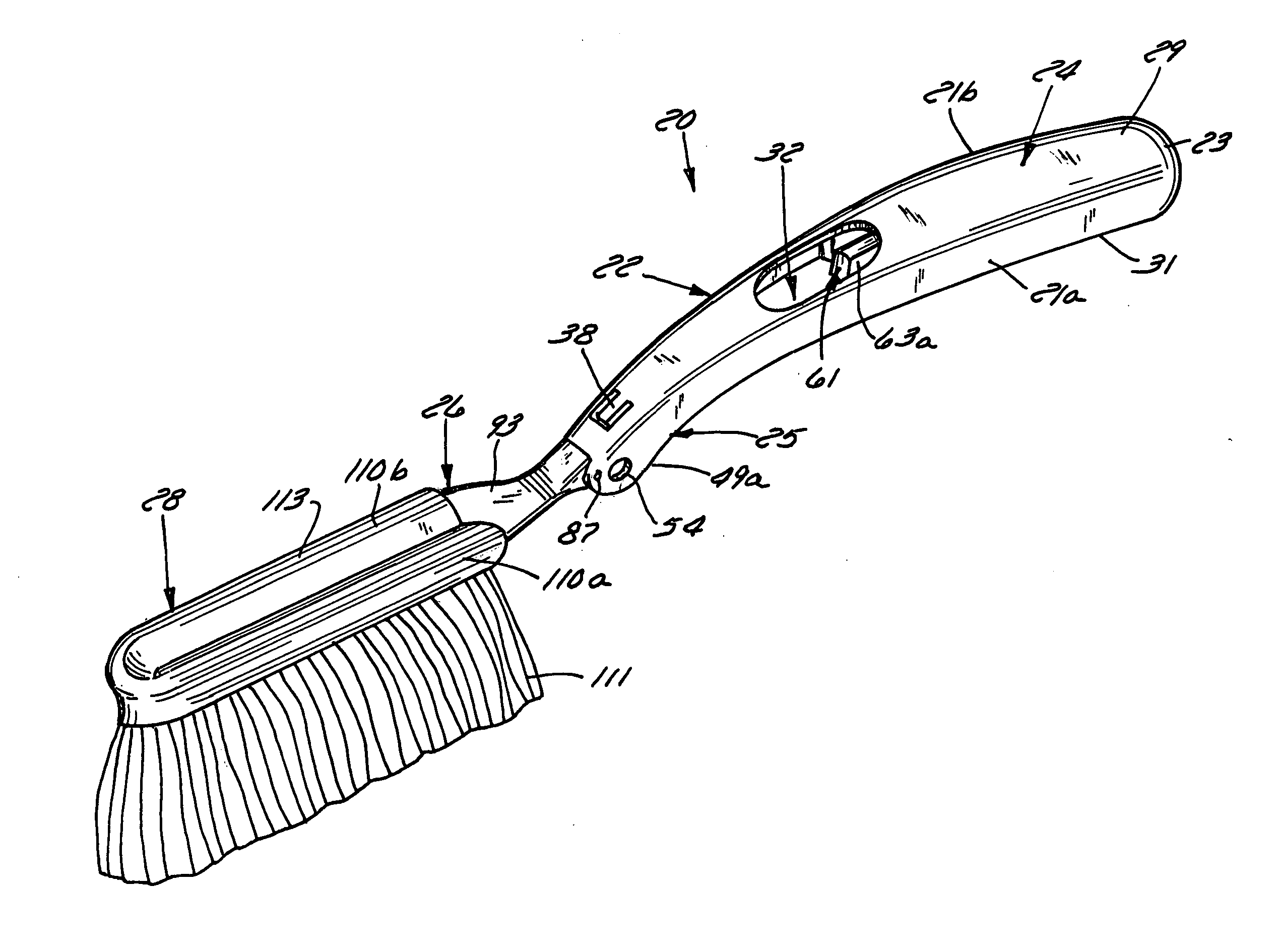

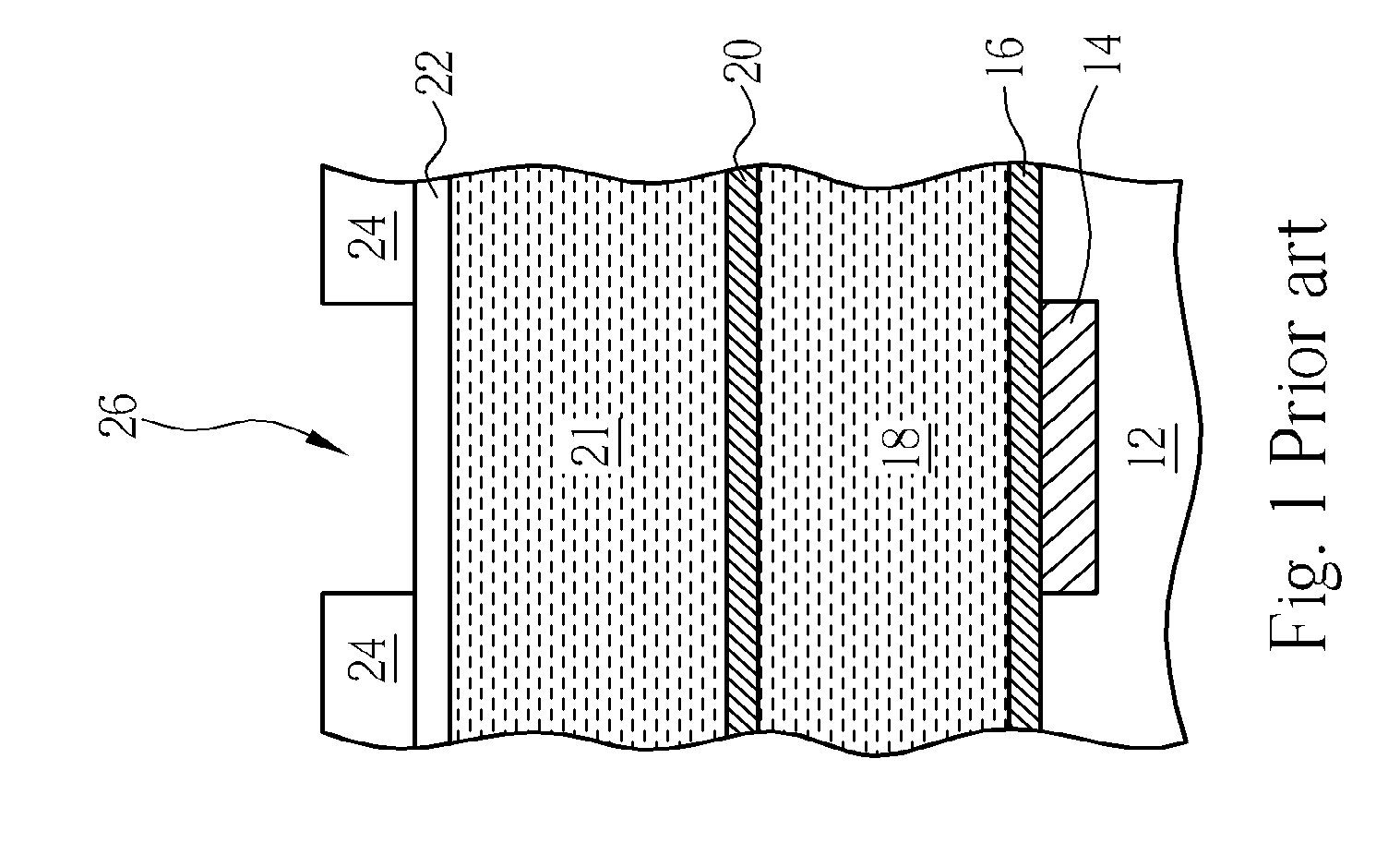

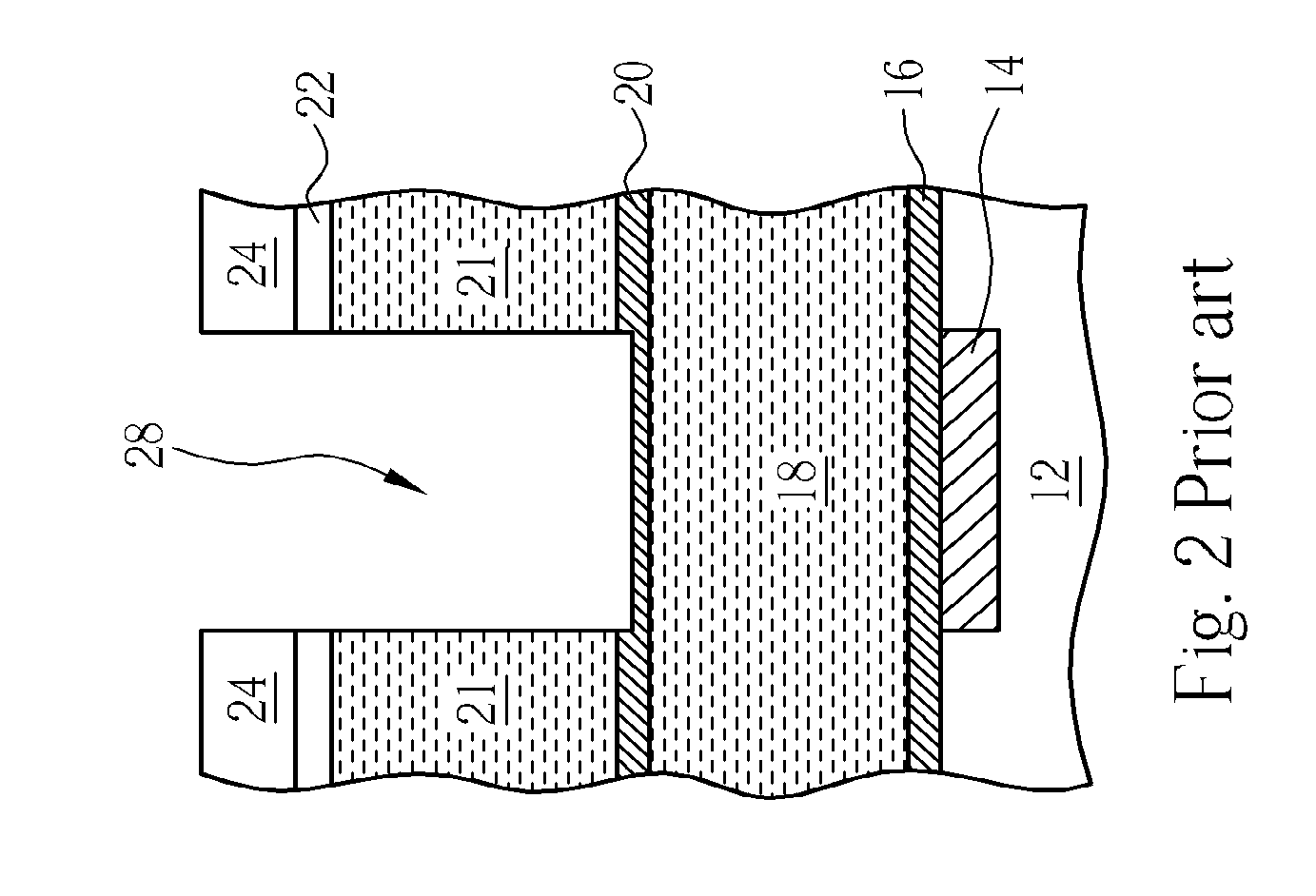

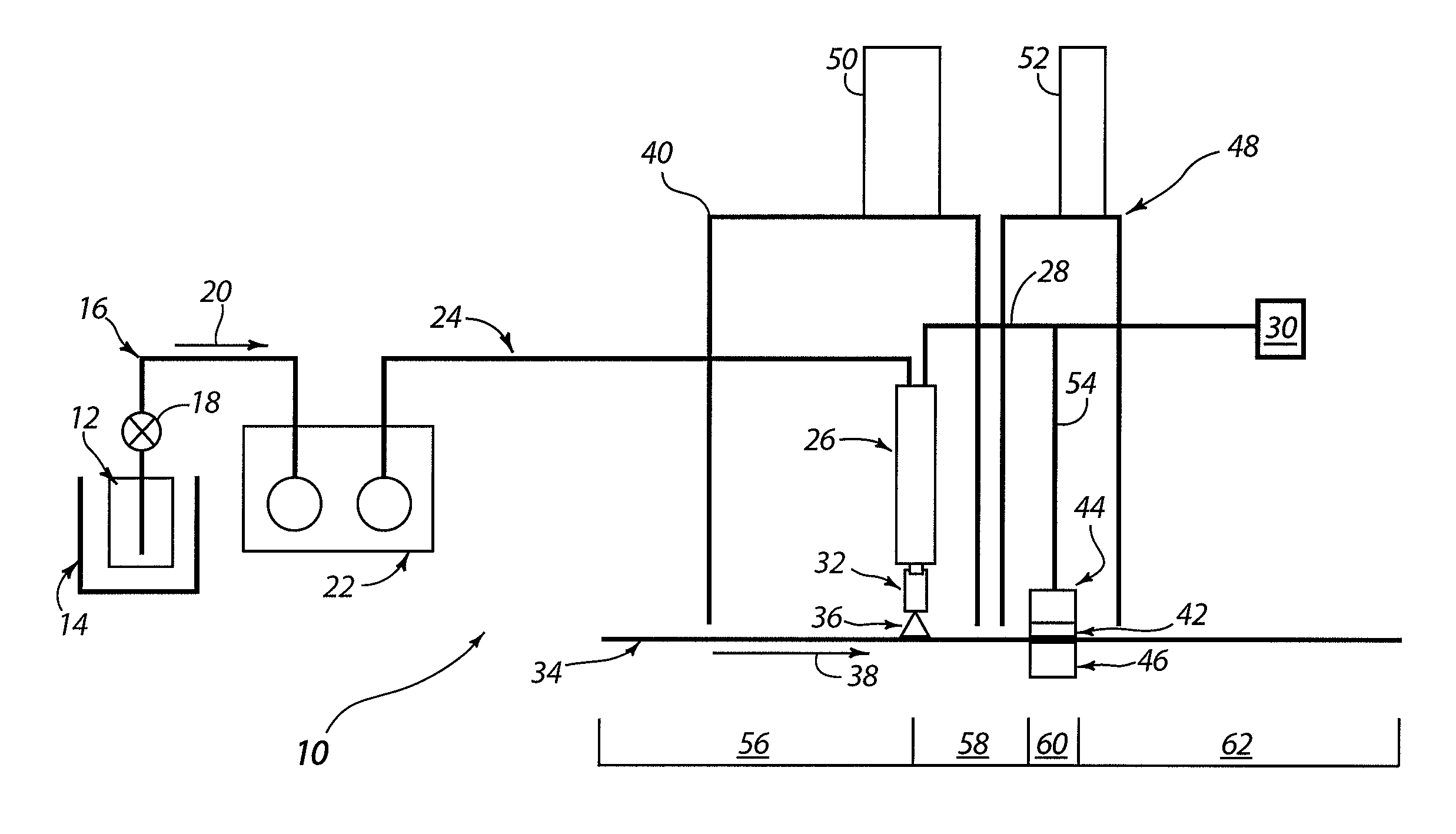

Cleaning pad for wet, damp or dry cleaning

ActiveUS20060171764A1Improved dust retentionImproved debris retentionCarpet cleanersFloor cleanersFiberEngineering

A cleaning pad (28) is disclosed. The cleaning pad (28) includes a base sheet (202) bonded to a fiber mat (203) and exhibits improved debris retention when a liquid is applied to the pad (28) or the surface to be cleaned. The pad (28) is preferably used with a cleaning system that includes a fluid source (30) in communication with a cleaning tool (22) such that fluid may be selectively applied to a surface to be cleaned or directly to the fiber mat (203) of the cleaning pad (28).

Owner:SC JOHNSON & SON INC

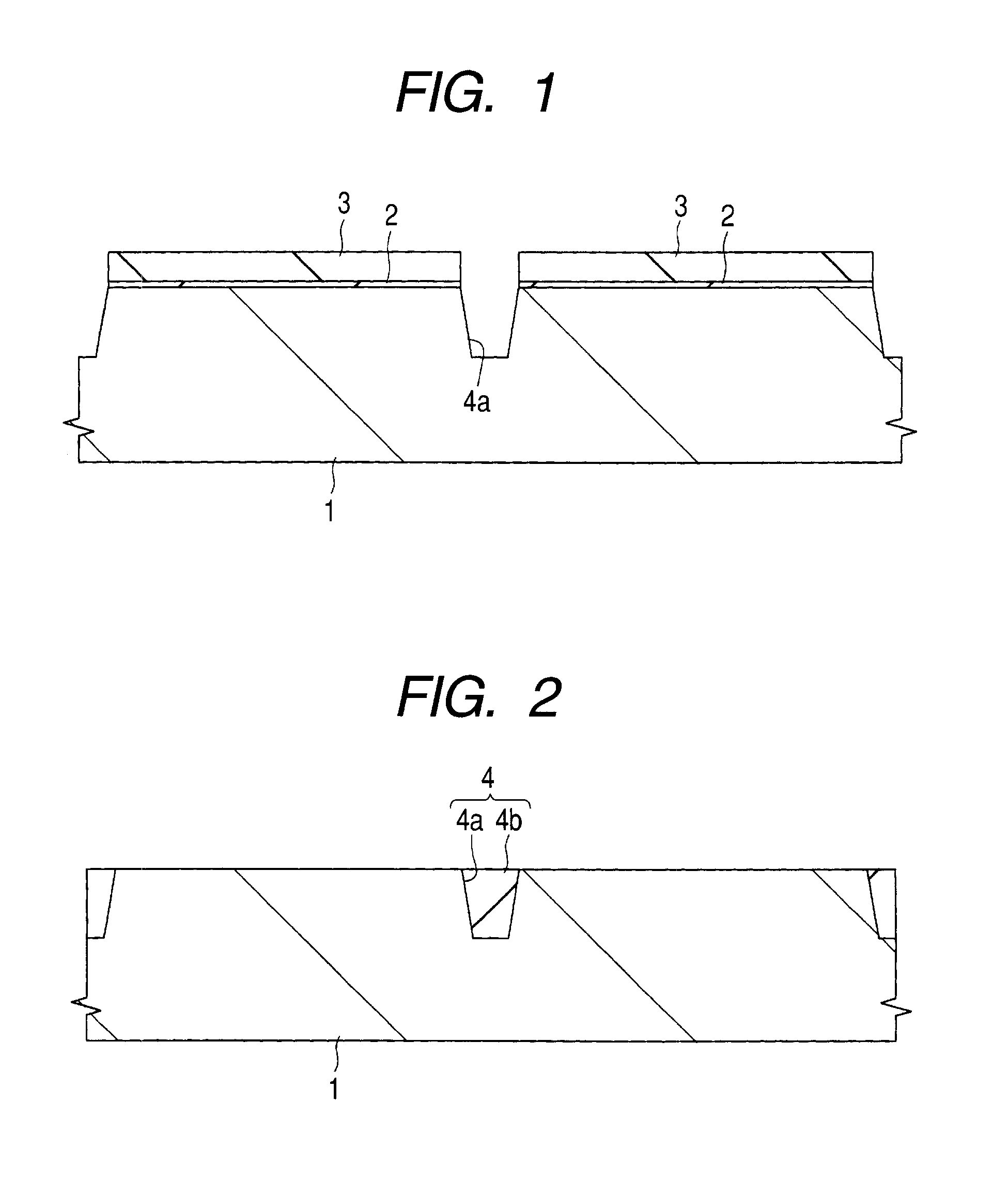

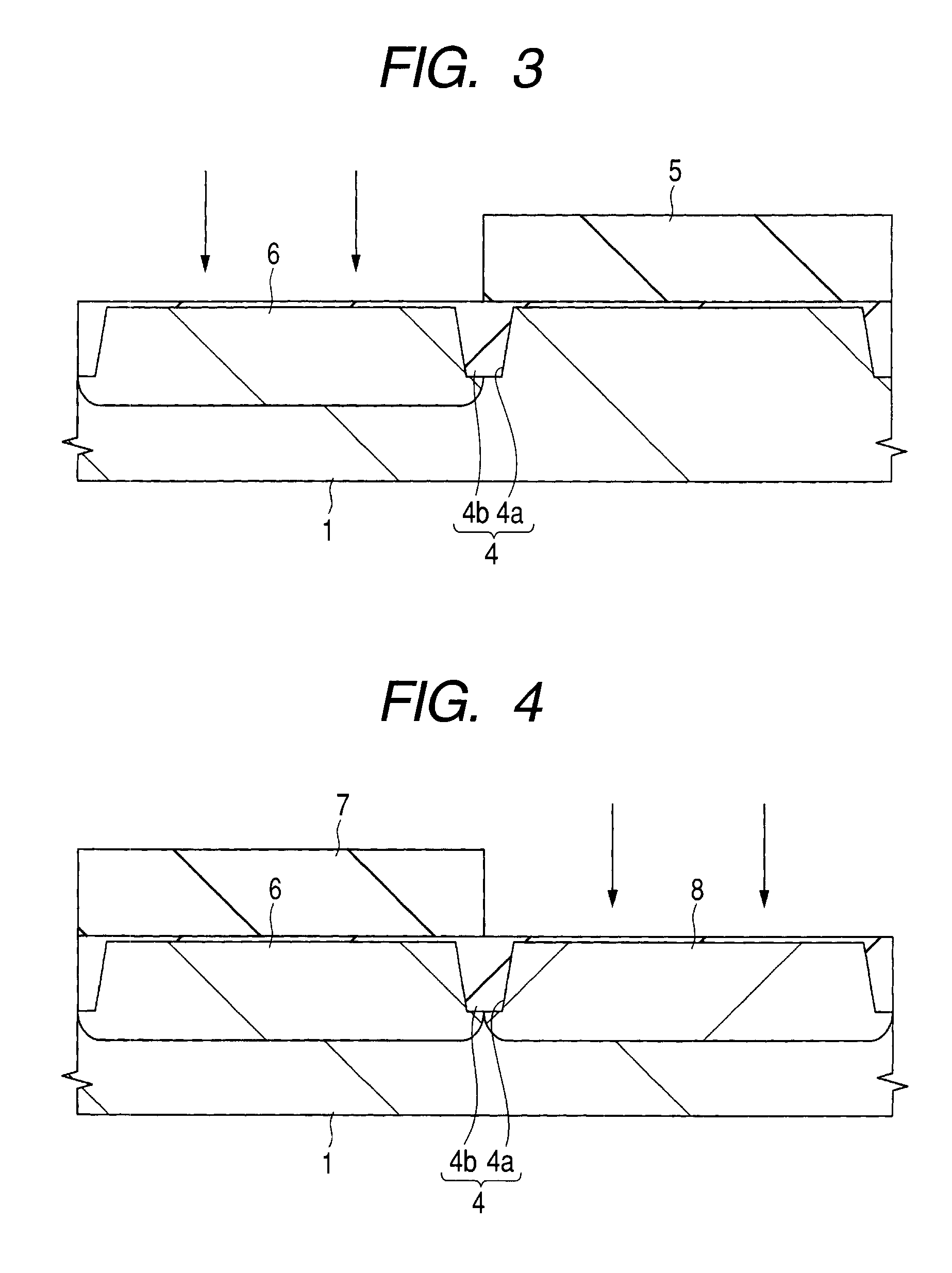

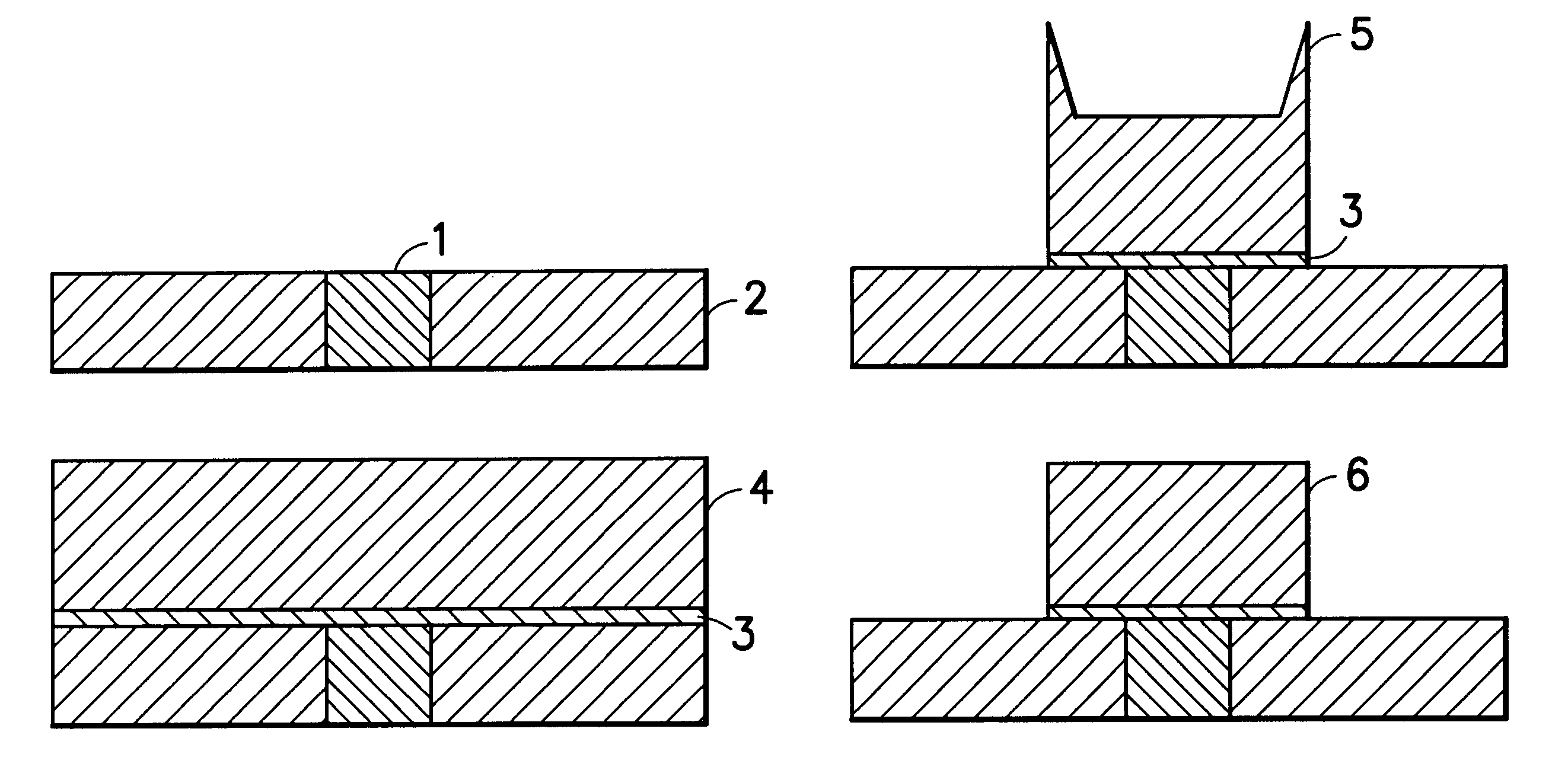

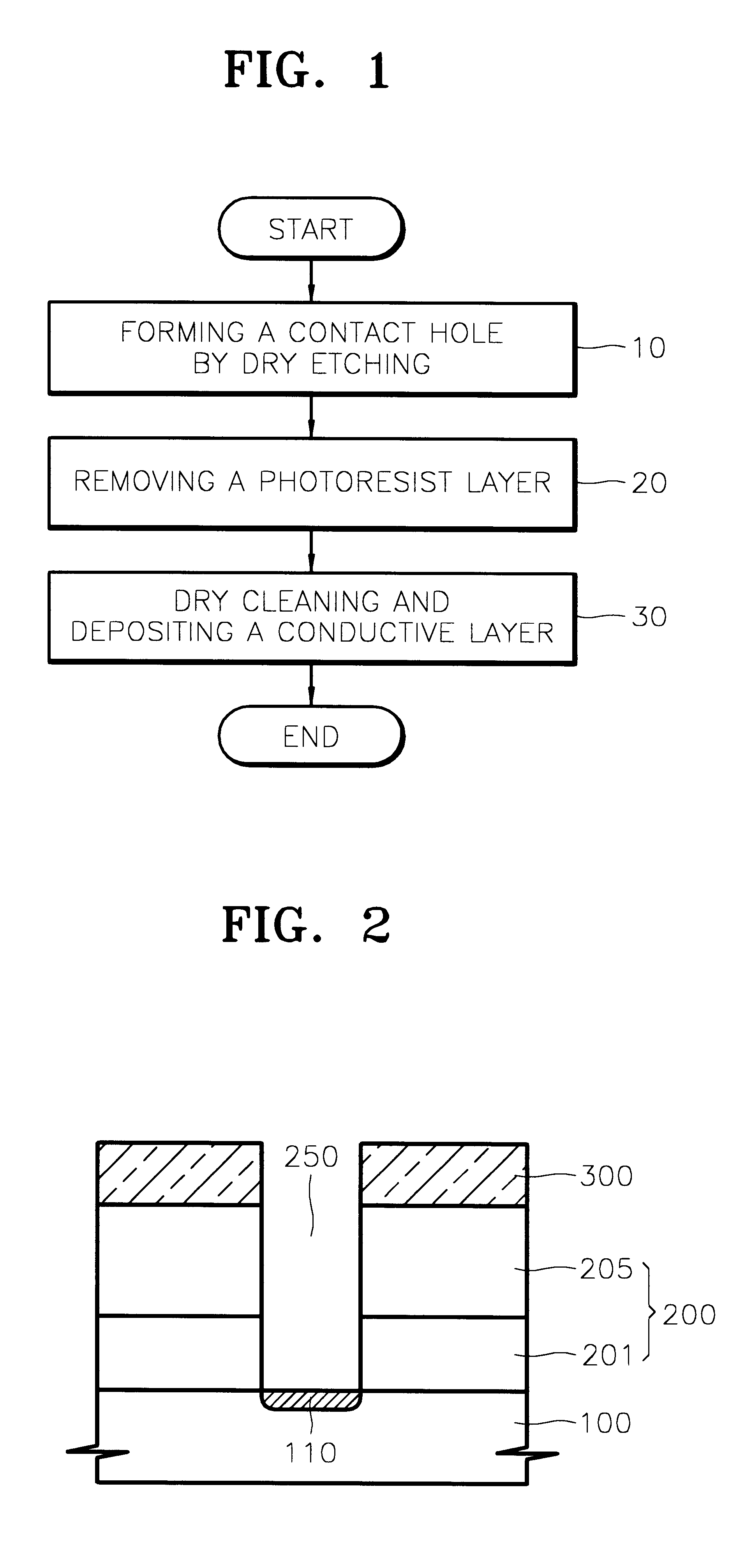

Method of filling contact hole of semiconductor device

InactiveUS6638855B1Reduce contact resistanceRecontamination of the cleaned inside of a contact holeSemiconductor/solid-state device manufacturingSemiconductor devicesDry etchingContamination

A method of filling a contact hole of a semiconductor device preceded by dry cleaning for removing a damaged layer resulting from dry etching is provided. The method includes selectively exposing an underlying material layer by a dry etch and dry cleaning including passing plasma excited from a source gas over the exposed underlying material layer to remove the damaged layer formed from the dry etch. Subsequently, an electrically conductive layer with which to fill the contact hole is formed. The formation of the electrically conductive layer is performed in a separate chamber connected sequentially to a chamber for performing the dry cleaning to prevent the exposed underlying material layer inside the dry cleaned contact hole from being exposed to a source of contamination.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for fabricating a dual damascene and polymer removal

InactiveUS20060246717A1Easy to disassembleLow costSemiconductor/solid-state device manufacturingPhotoresistPolymer

A method for fabricating a dual damascene includes a partial etching process, a photoresist layer stripping process, and a blanket etching process. After the blanket etching process, an in-situ dry cleaning process is performed to remove residual polymers resulting from the etching processes.

Owner:UNITED MICROELECTRONICS CORP

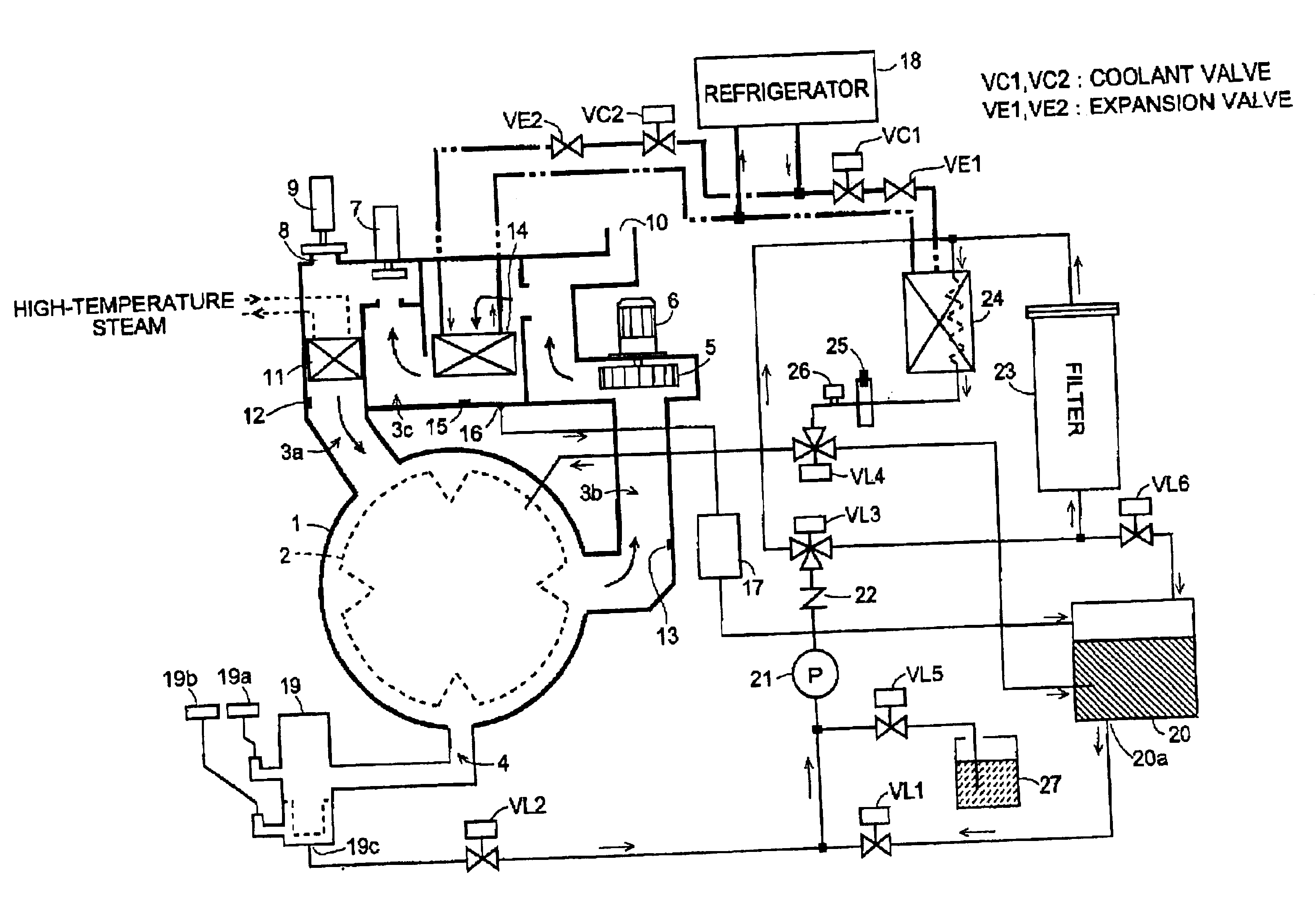

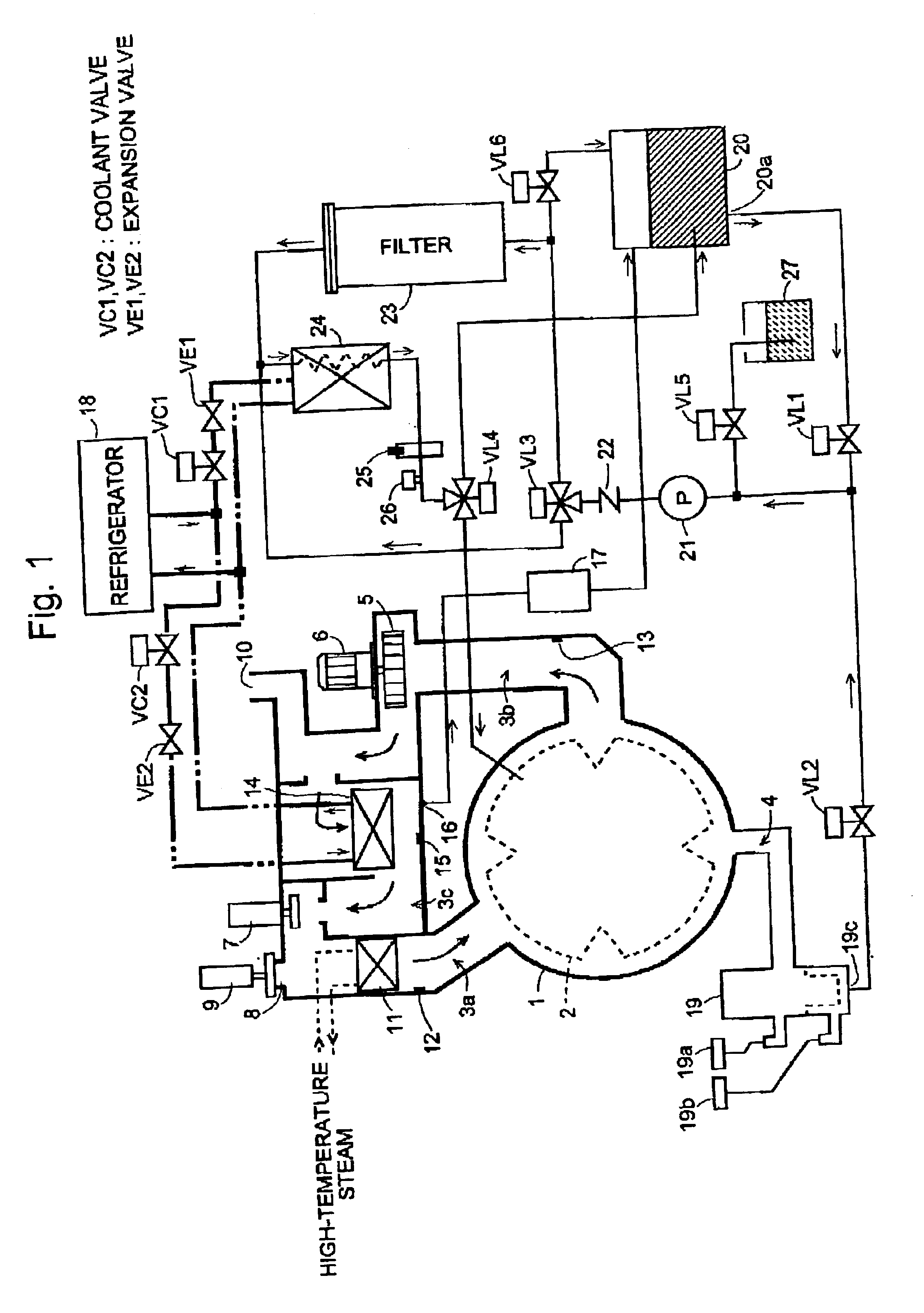

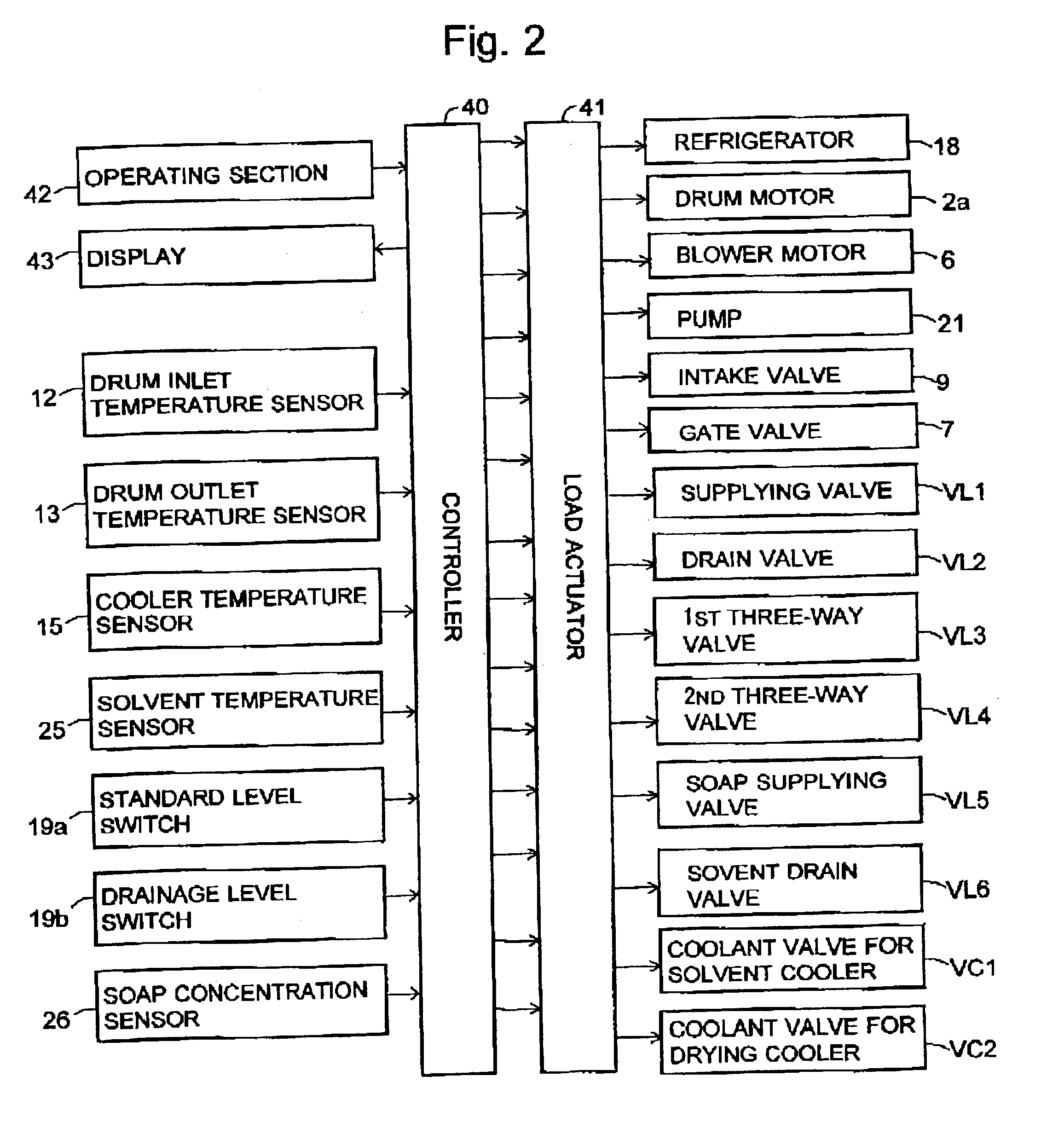

Dry cleaning machine

ActiveUS6904703B2Prevent overloadProlong lifeDry-cleaning apparatusOther washing machinesEngineeringSolvent

In the dry clearing machine, a common refrigerator is used for both the solvent cooler and the drying cooler, and the coolant compressed and liquefied in the refrigerator is supplied either one of the heat exchanger of the solvent cooler or that of the drying cooler, depending on the state of a switch. In the heat exchanger selected by the switch, the coolant is supplied and the solvent or the air is cooled when the coolant evaporates. That is, only the cooler selected by the switch works, but the other cooler not selected by the switch does not work. While the laundry is washed, normally, it is not necessary to supply air to the outer tub through the air path, and the drying cooler need not be operated. Thus, in the process of washing, the solvent is adequately cooled because an enough amount of coolant is supplied to the solvent cooler, and the temperature rise of the solvent is prevented.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Treatment of fibrous materials using atmospheric pressure plasma polymerization

ActiveUS20080107822A1Suitable for useLiquid surface applicatorsPhysical treatmentTextile industryDry cleaning

An apparatus and method for plasma finishing of fibrous materials including paper and knitted, woven and non-woven fibrous substrates such that desired characteristics are imparted are described. The method includes depositing a monomer comprising at least one fluorocarbon monomer with chemical additives, as required, at atmospheric pressure onto the paper or knitted, woven or non-woven substrate; exposing the monomer on a single surface of the fibrous material to an inert gas, atmospheric-pressure plasma, thereby causing polymerization of the monomer species; and repeating this sequence using multiple sequential deposition and plasma discharge steps to create a layered surface having durability against abrasion for both water-based laundry methods and dry-cleaning methods, and normal wear, without affecting the feel, drape, appearance or breathability of the substrate material. The present method uses a high-power, continuously operating plasma that is 104 times more powerful than the prior art plasma sources utilized in the textile industry, and produces a durable finish with between 0.5 and 2 s of plasma exposure. This is sufficiently rapid to meet commercial fabric processing throughput, and repeated cleaning of the electrodes is not required.

Owner:APJET INC

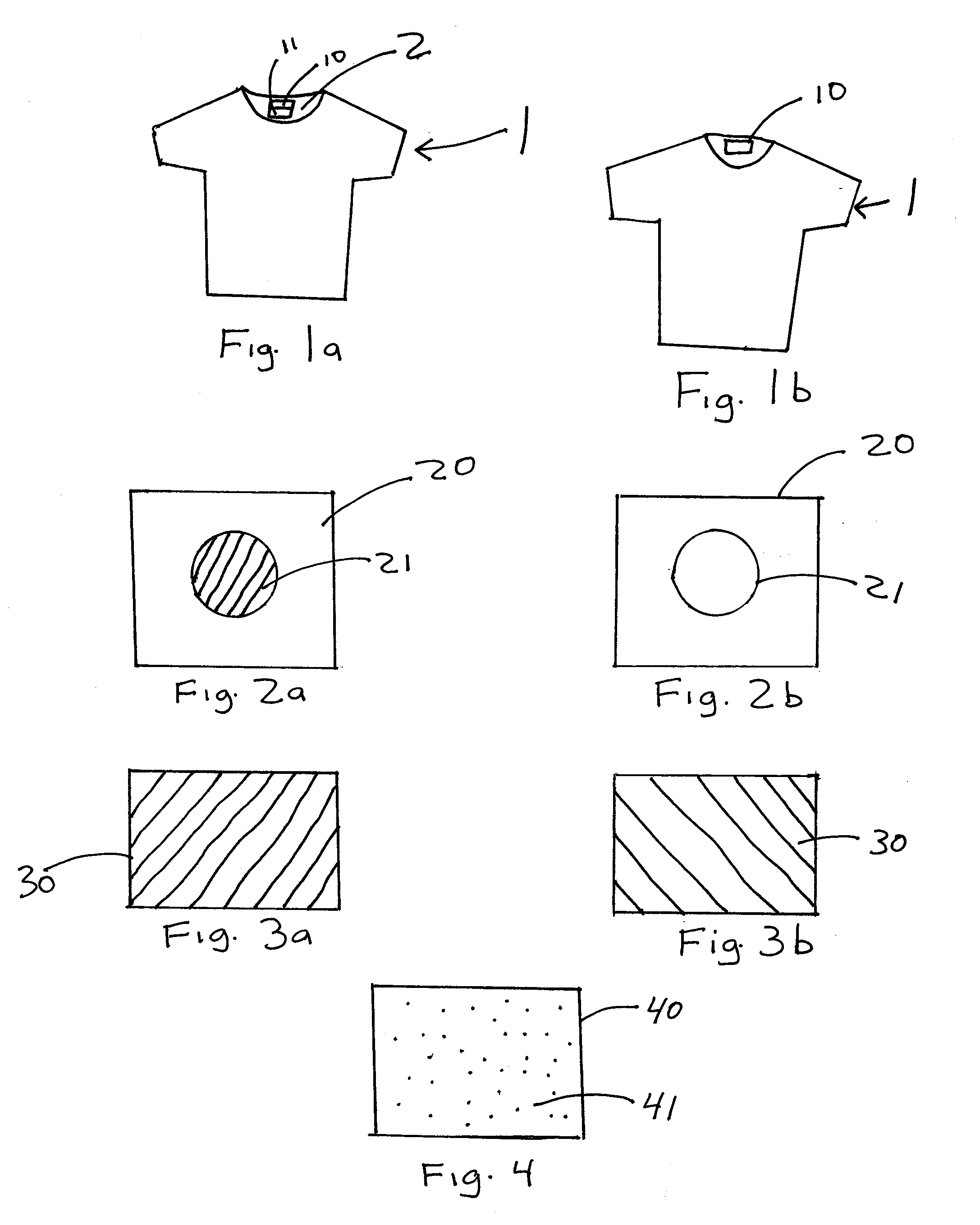

Indication tags

InactiveUS20090064919A1Sure easyMeasuring points markingMeasurement apparatus componentsEngineeringDry cleaning

A method for determining whether a garment has been used comprising integrating an indicator tag to a garment having an indicator material which reacts with any one of body sweat, water or dry cleaning chemicals or provides wear down indication to provide a visual indication of such use. A garment with an indicator tag having an indicator material which reacts with any one of body sweat, water or dry cleaning chemicals or provides wear down indication to provide a visual indication of such use.

Owner:GREENWALD MOSHE

Autonomous surface cleaning robot for wet and dry cleaning

InactiveUS20080127446A1Low costWet cleaningBrush bodiesVehicle cleaning apparatusParticulatesControl system

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries a first cleaning zone comprising cleaning elements arranged to suction loose particulates up from the cleaning surface and a second cleaning zone comprising cleaning elements arraigned to apply a cleaning fluid onto the surface and to thereafter collect the cleaning fluid up from the surface after it has been used to clean the surface. The robot chassis carries a supply of cleaning fluid and a waste container for storing waste materials collected up from the cleaning surface.

Owner:IROBOT CORP

Robot mechanism for cleaning and inspection of live-line insulators

ActiveUS7797781B2Improve safety and efficiencyReduce weightBrush bodiesVehicle cleaning apparatusBall bearingEngineering

A robot mechanism adopts a dry cleaning method to clean the surface of live-line insulators without using water and can perform cleaning and inspection of the surface of the live-line insulators while automatically moving along an insulator string. The robot mechanism includes a main unit having upper and lower wing frames connected with each other by a connecting bracket to surround the insulator string, a cleaning unit disposed between the upper and lower wing frames and including a base frame to perform dry cleaning with a rotational brush and a CM guide, a lift unit including a clamp and a ball-bearing screw to move the main unit up or down, and an inspection unit to electrically inspect the insulators; and a coupling unit to couple a pair of the main units to allow the pair of main units to move along a tension insulator string or a suspension insulator string.

Owner:KOREA ELECTRIC POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com