Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Plasma exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

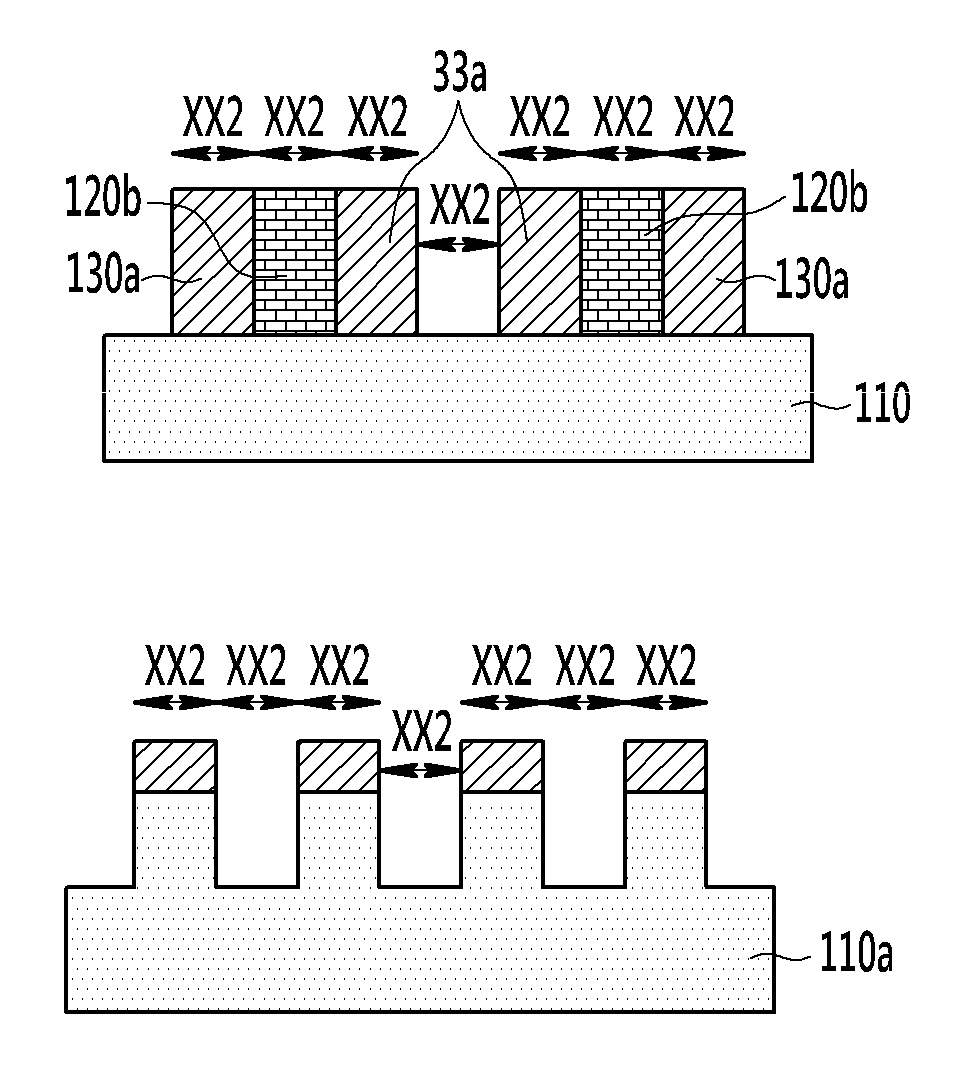

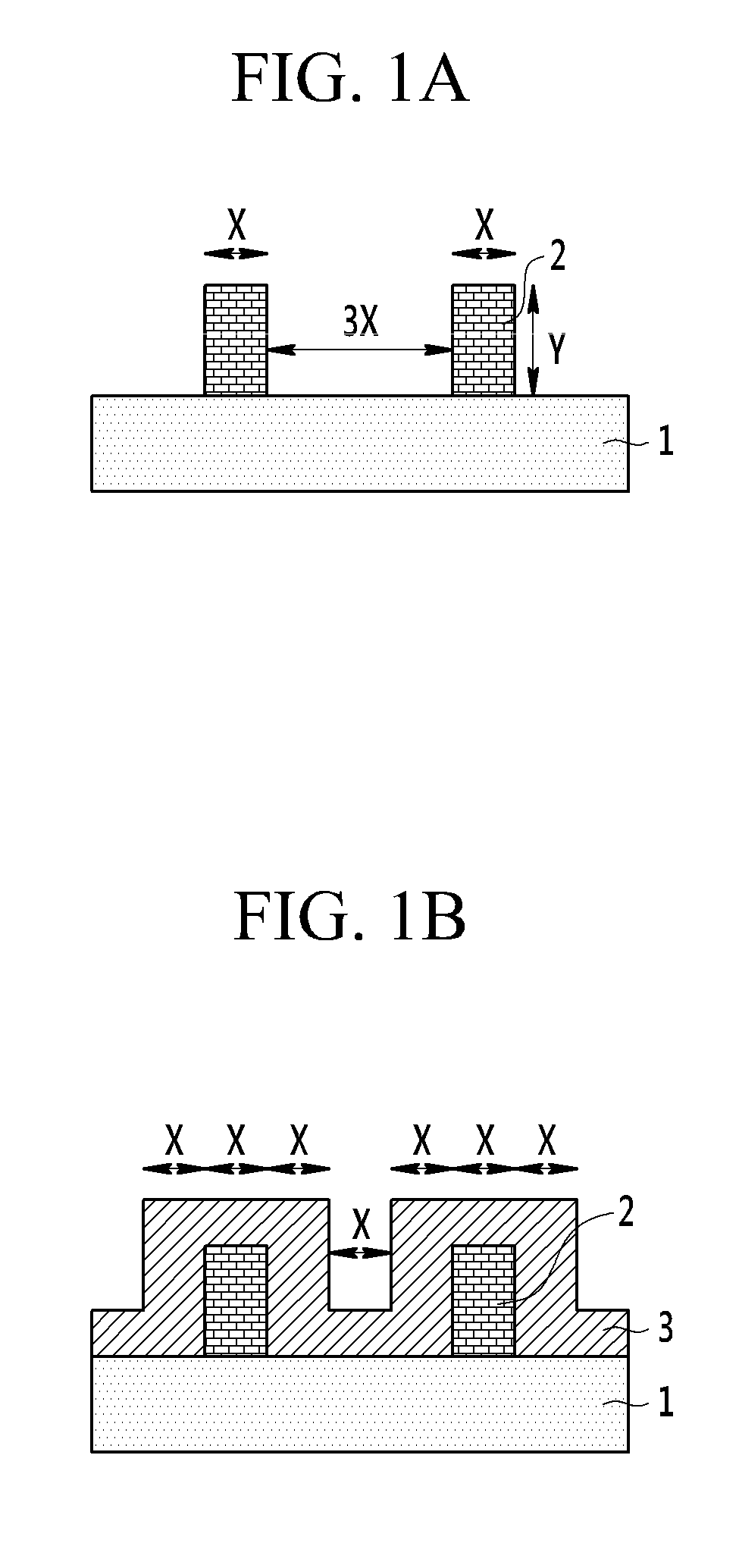

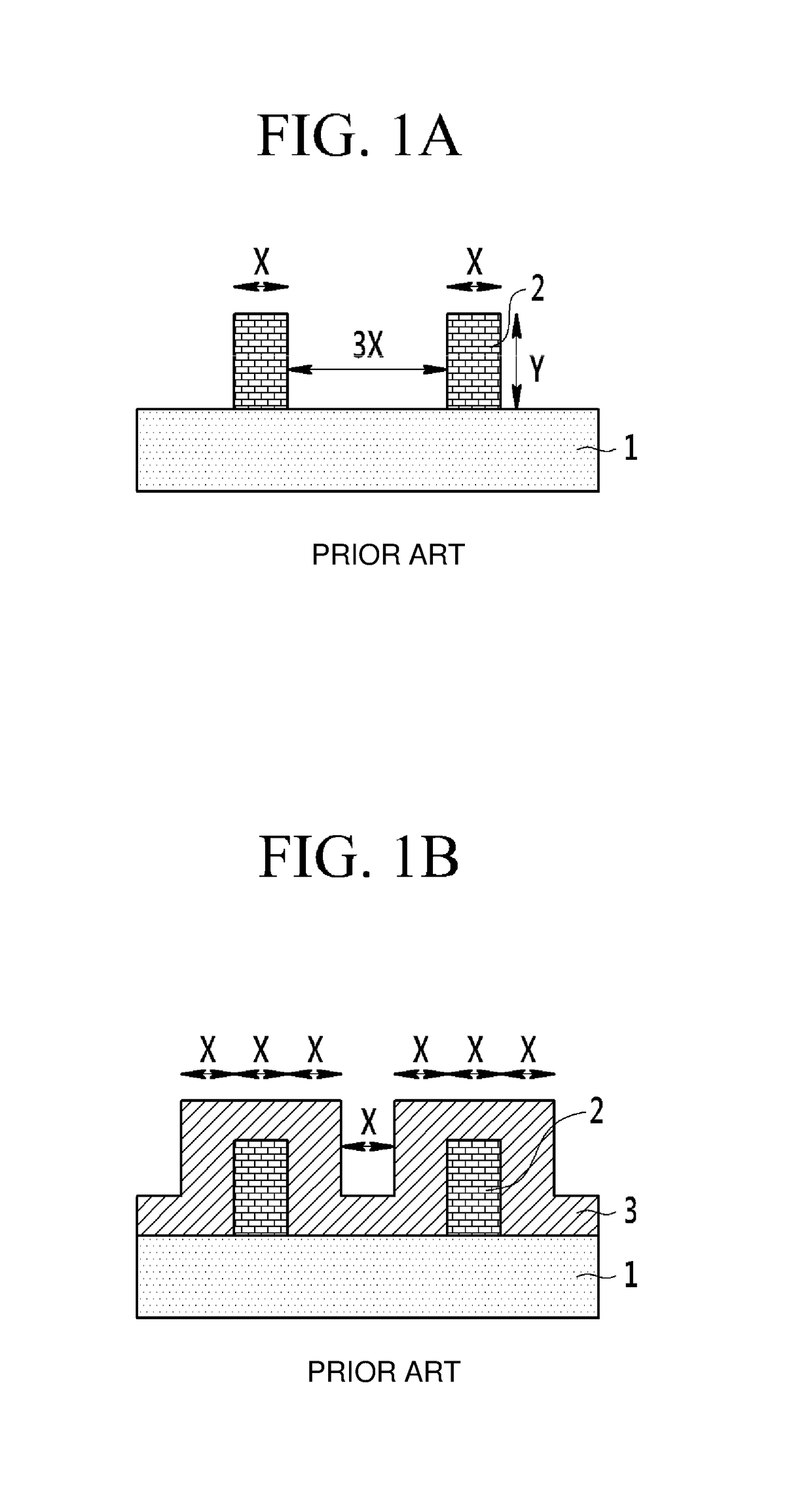

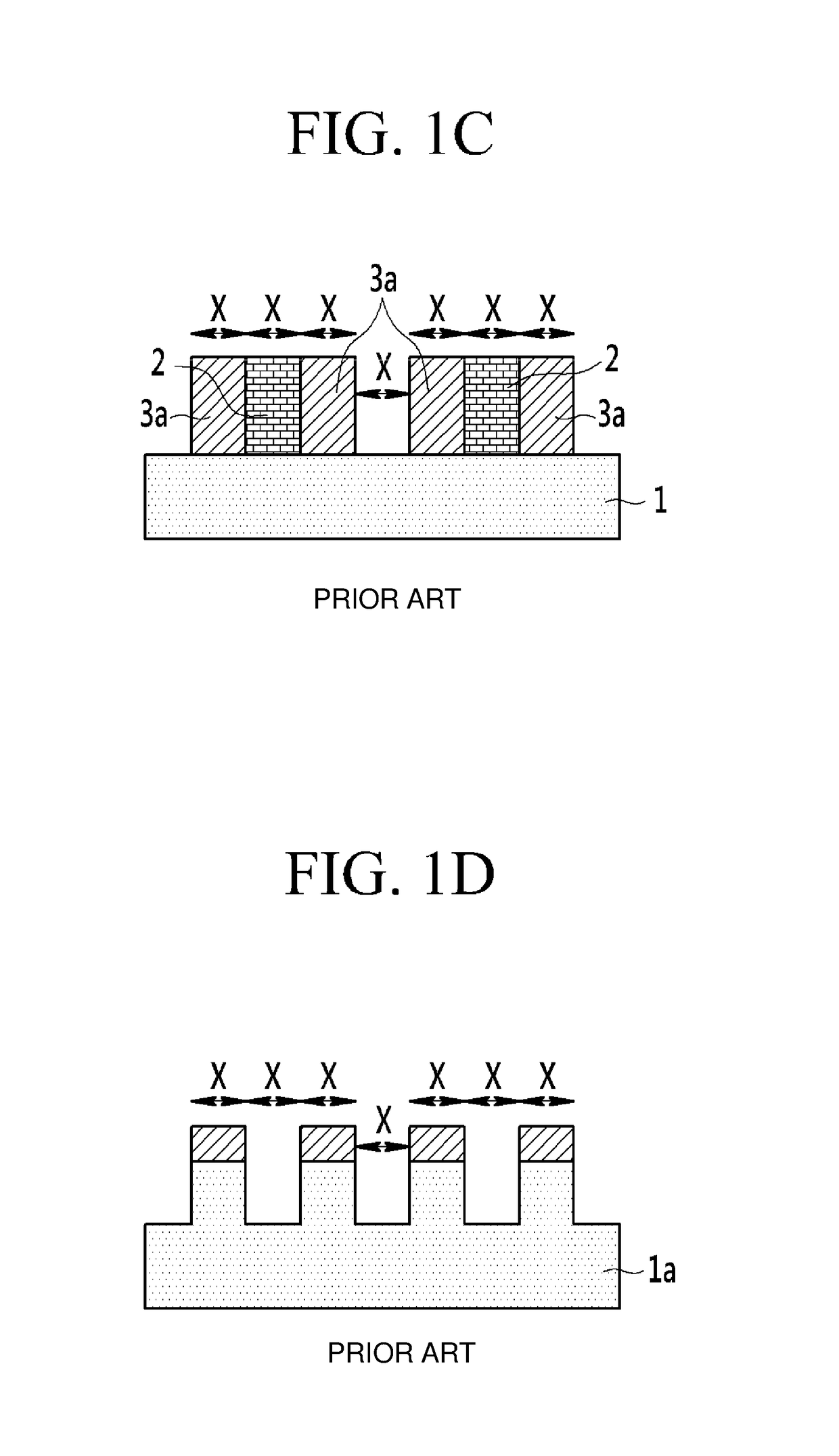

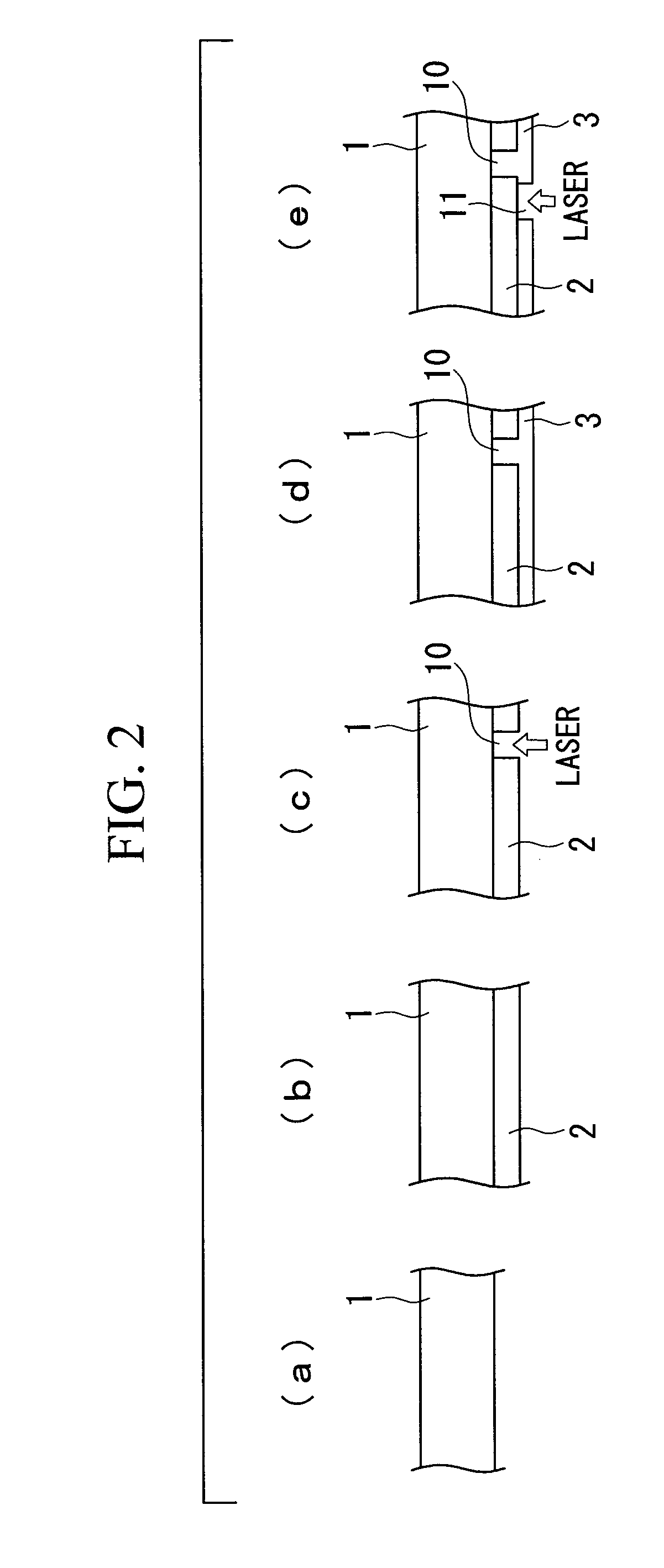

Method of forming semiconductor patterns

ActiveUS8252691B2High ratePR footing remaining in the bottom of PR is reducedSemiconductor/solid-state device manufacturingEngineeringPlasma exposure

Semiconductor patterns are formed by performing trimming simultaneously with the process of depositing the spacer oxide. Alternatively, a first part of the trimming is performed in-situ, immediately before the spacer oxide deposition process in the same chamber in which the spacer oxide deposition is performed whereas a second part of the trimming is performed simultaneously with the process of depositing the spacer oxide. Thus, semiconductor patterns are formed reducing PR footing during PR trimming with direct plasma exposure.

Owner:ASM KOREA LTD

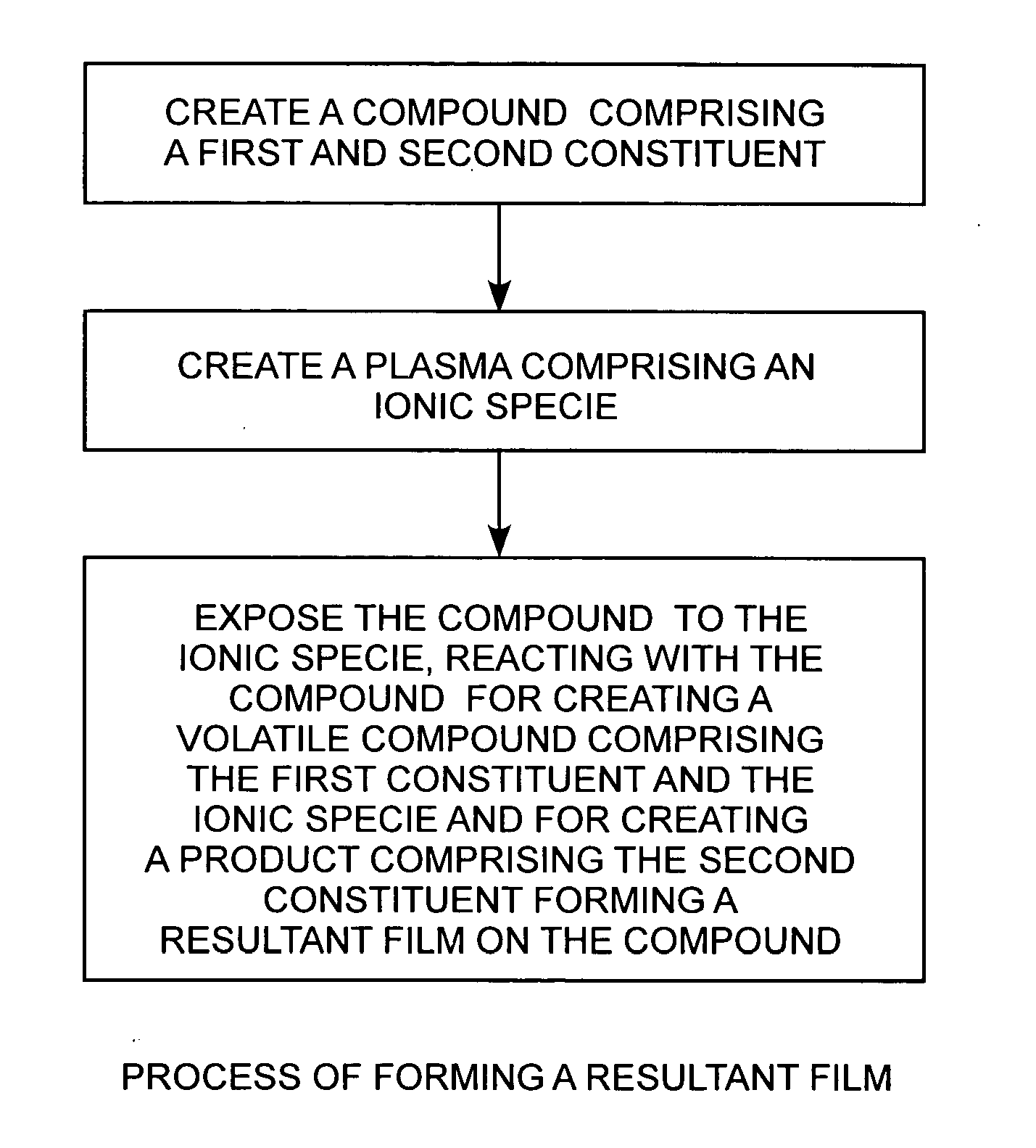

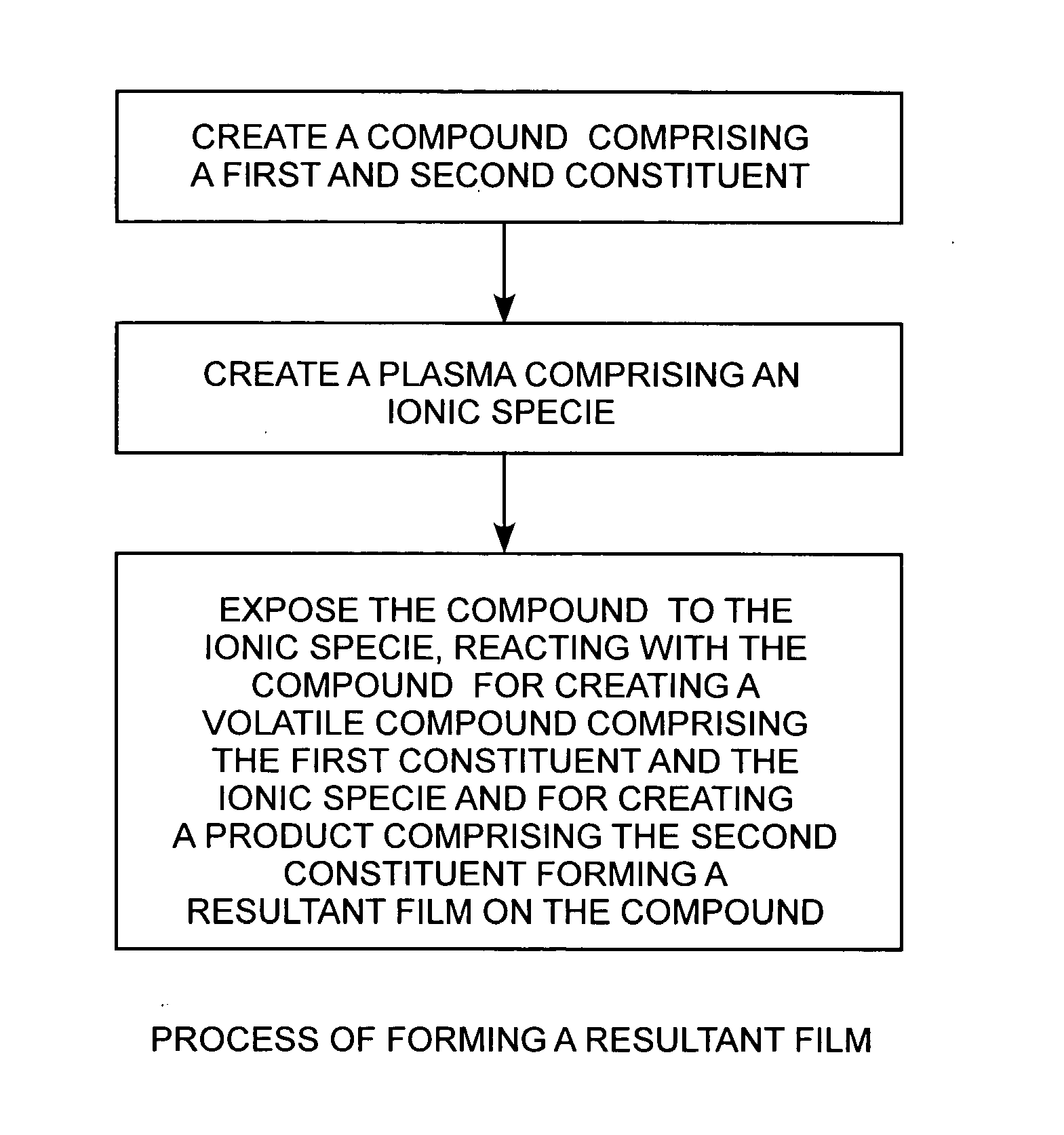

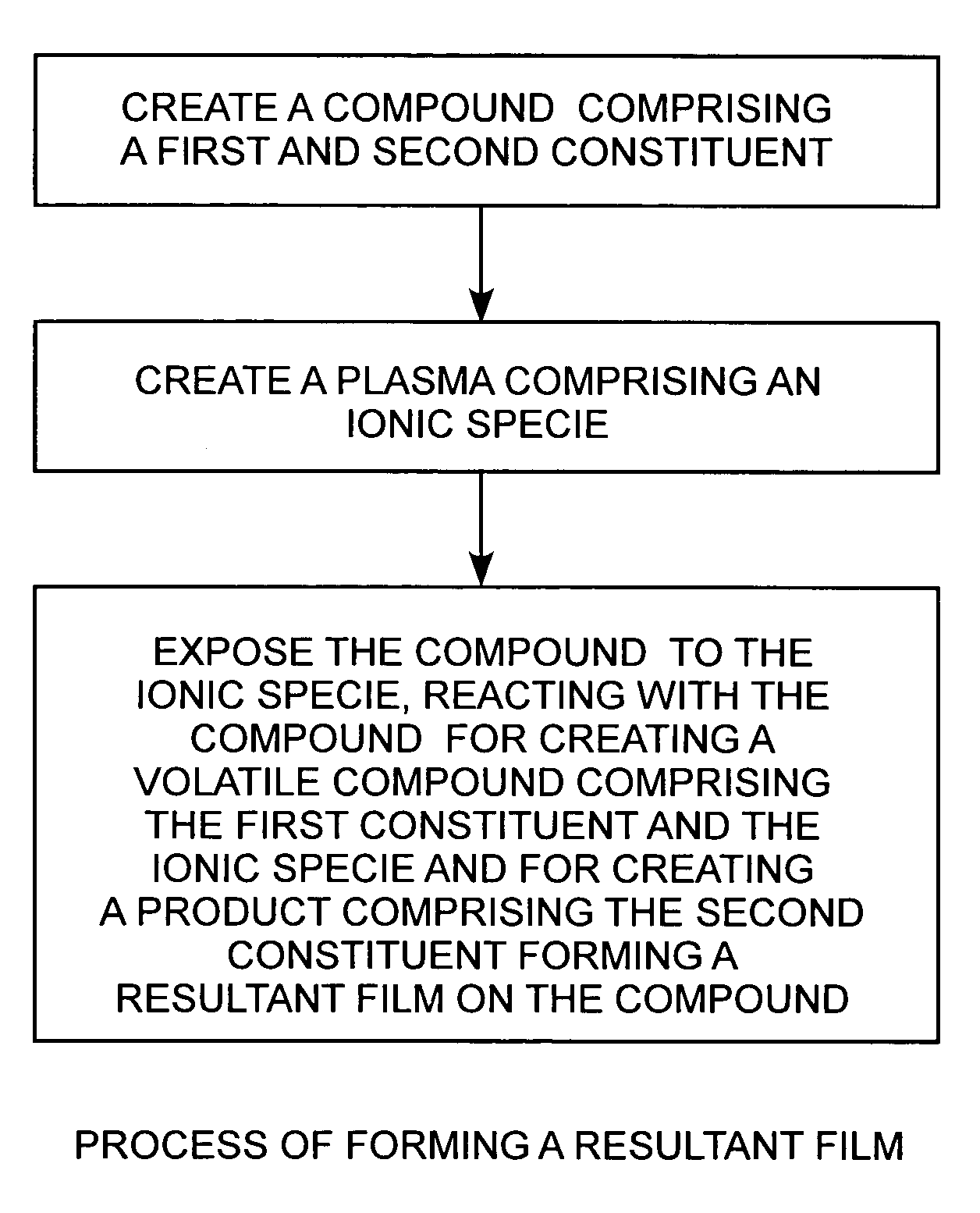

Method for producing carbon surface films by plasma exposure of a carbide compound

InactiveUS20060068125A1Reduce frictionEasy to controlChemical vapor deposition coatingFlexible microstructural devicesCarbon filmCarbon coating

Reactive halogen-ion plasmas, having for example, generating chloride ions, generated from low-pressure halogen gases using a radio-frequency plasma are employed for producing low-friction carbon coatings, such as a pure carbon film, at or near room temperature on a bulk or thin film of a compound, such as titanium carbide.

Owner:THE AEROSPACE CORPORATION

Method of forming semiconductor patterns

ActiveUS20110256727A1High trimming rateHigh rateSemiconductor/solid-state device manufacturingEngineeringPlasma exposure

Semiconductor patterns are formed by performing trimming simultaneously with the process of depositing the spacer oxide. Alternatively, a first part of the trimming is performed in-situ, immediately before the spacer oxide deposition process in the same chamber in which the spacer oxide deposition is performed whereas a second part of the trimming is performed simultaneously with the process of depositing the spacer oxide. Thus, semiconductor patterns are formed reducing PR footing during PR trimming with direct plasma exposure.

Owner:ASM KOREA LTD

Method of forming semiconductor patterns

ActiveUSRE47170E1High ratePR footing remaining in the bottom of PR is reducedSemiconductor/solid-state device manufacturingEngineeringPlasma exposure

Owner:ASM IP HLDG BV

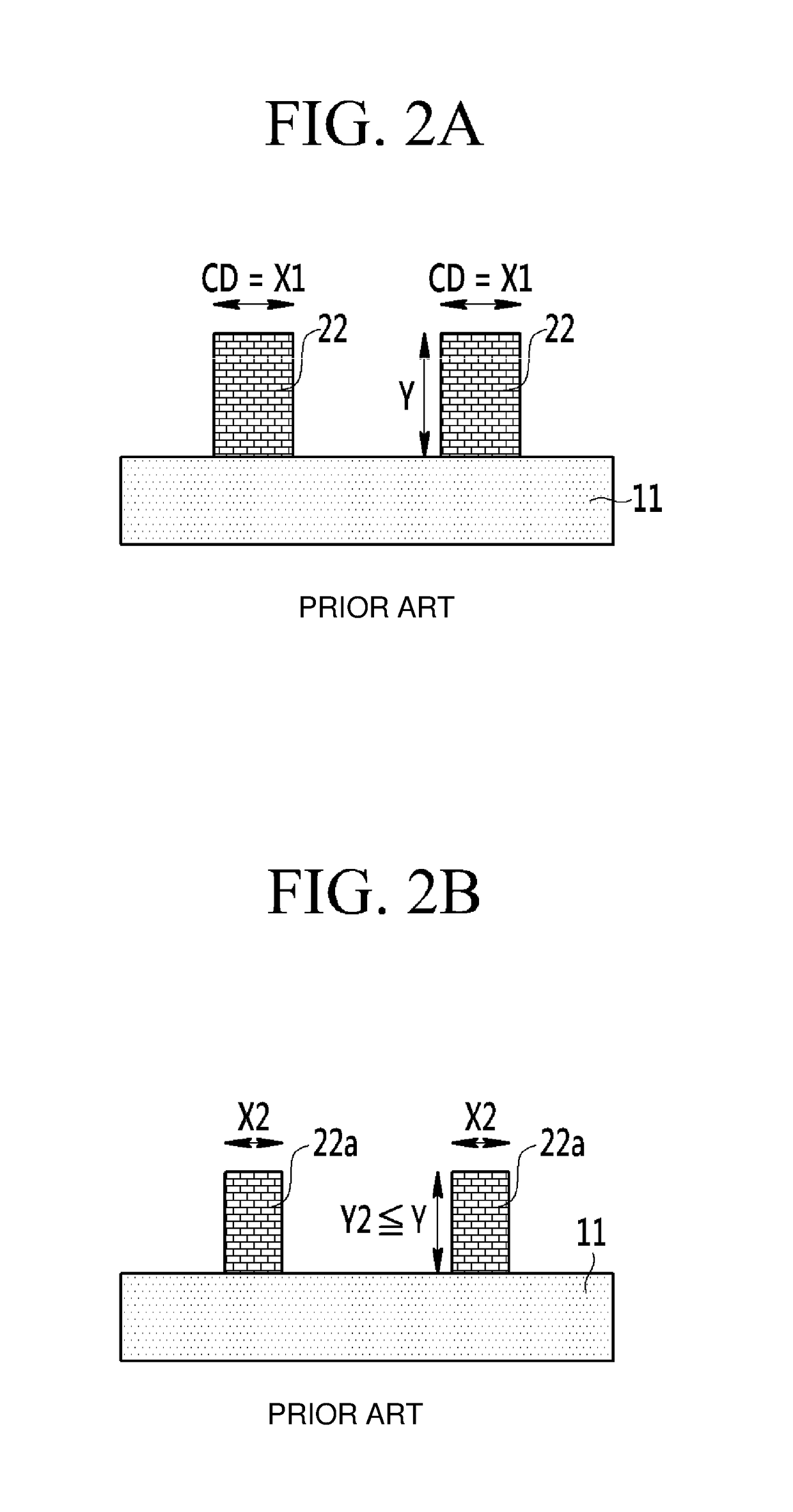

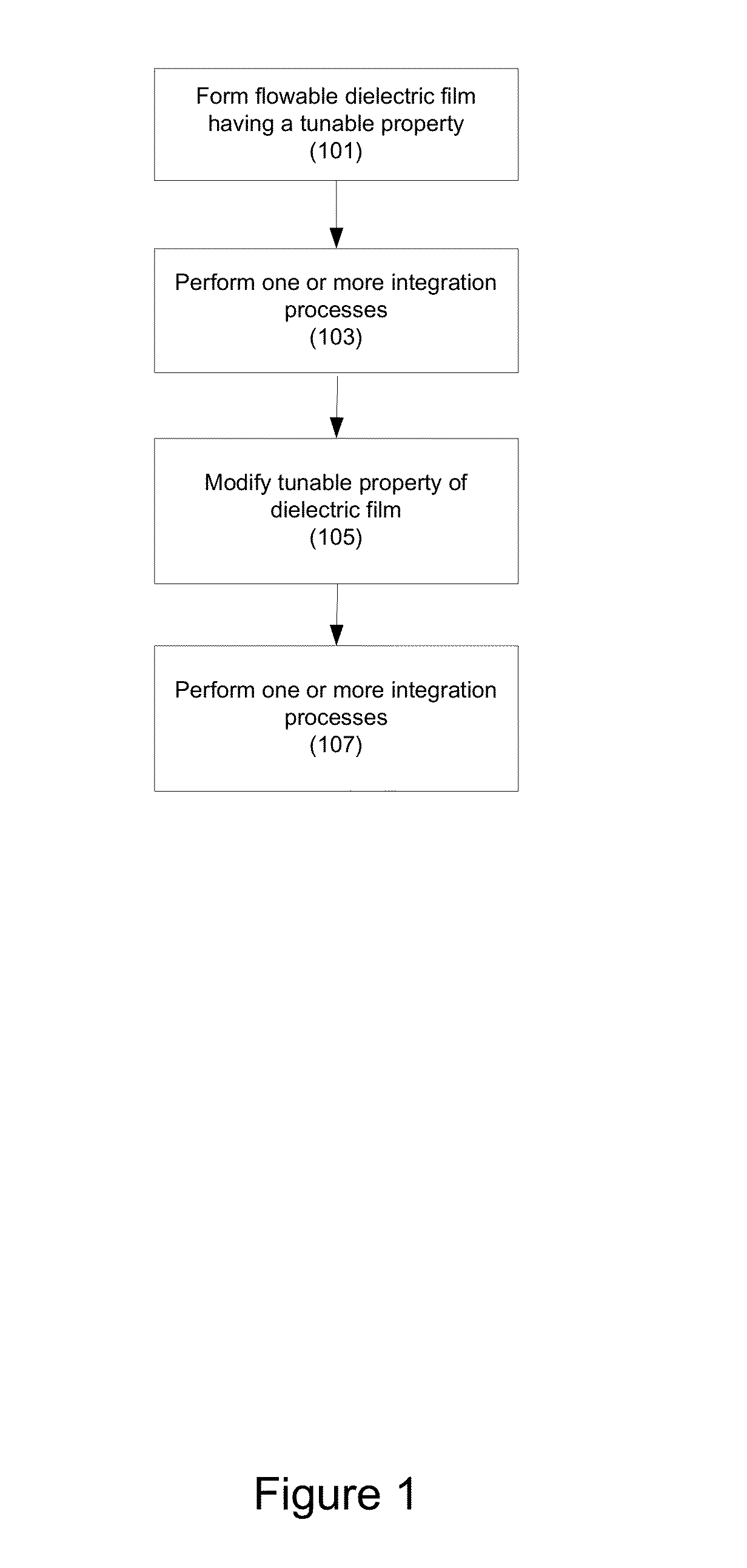

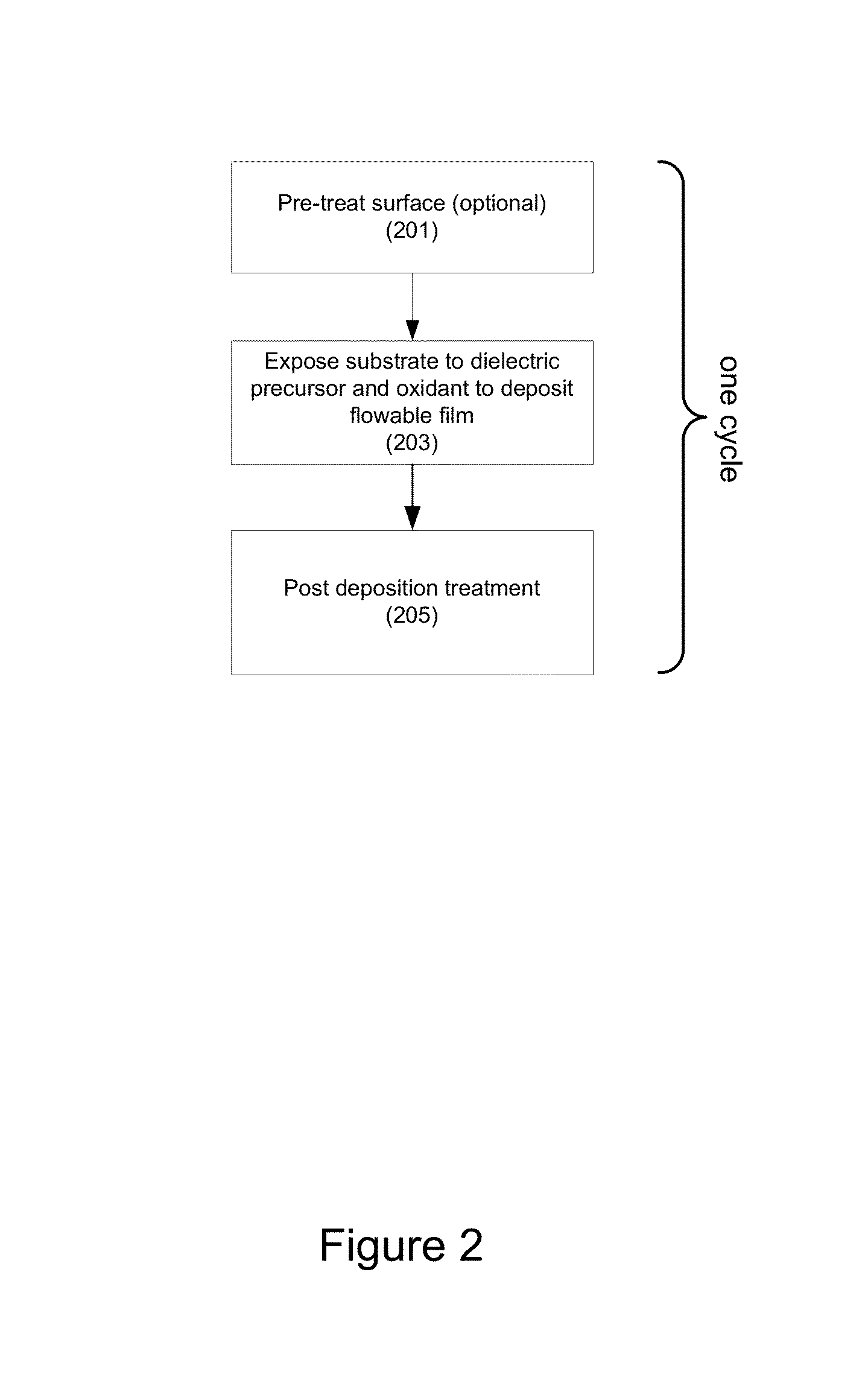

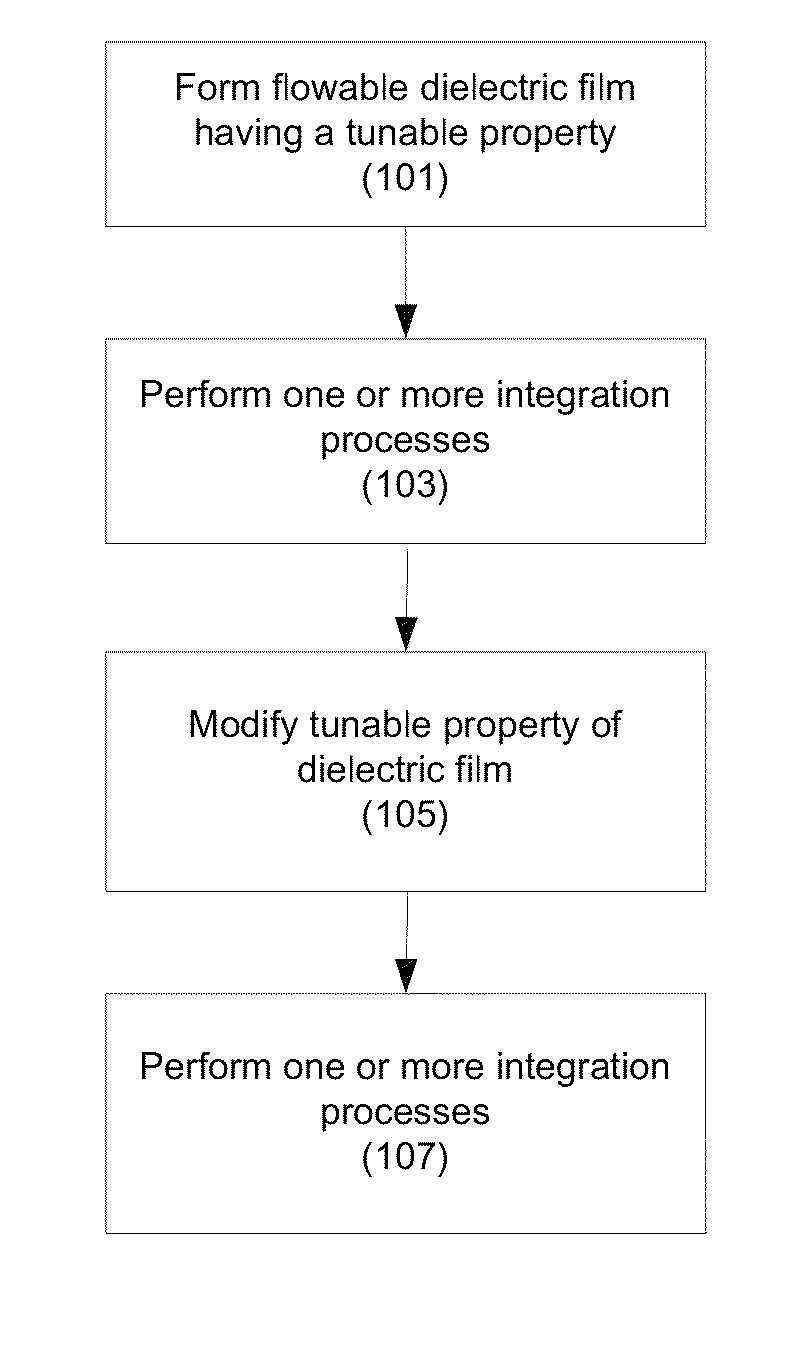

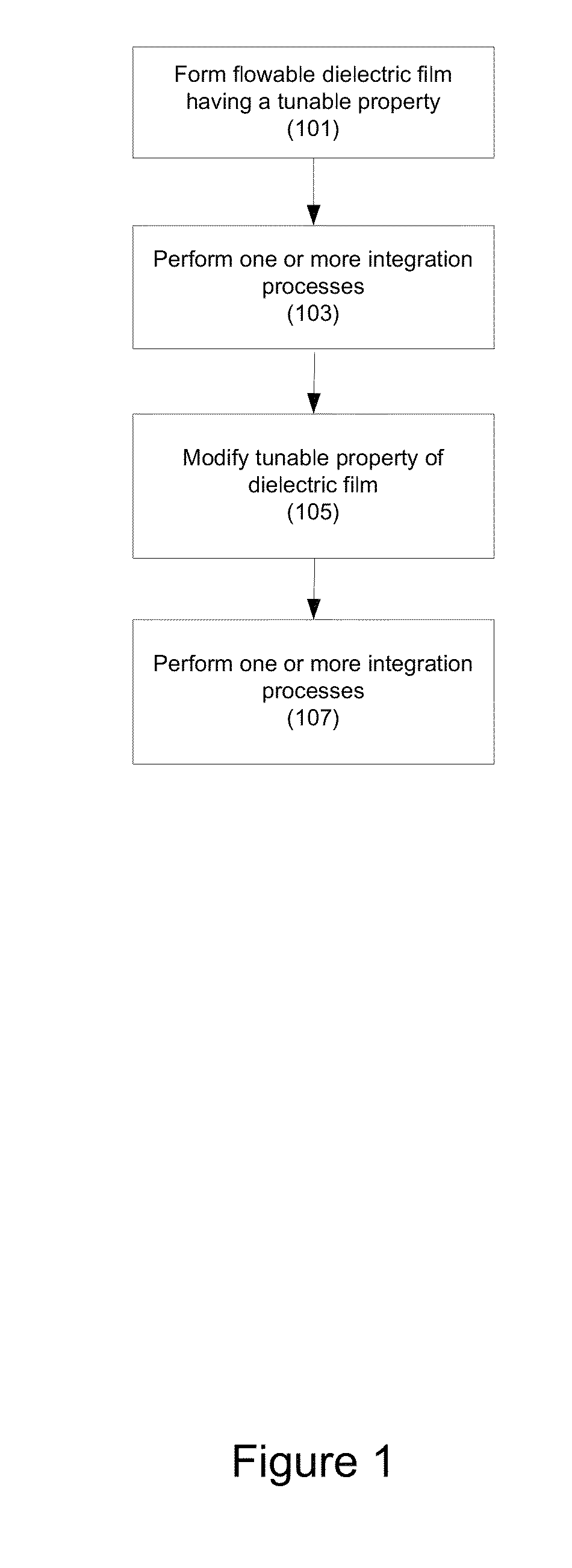

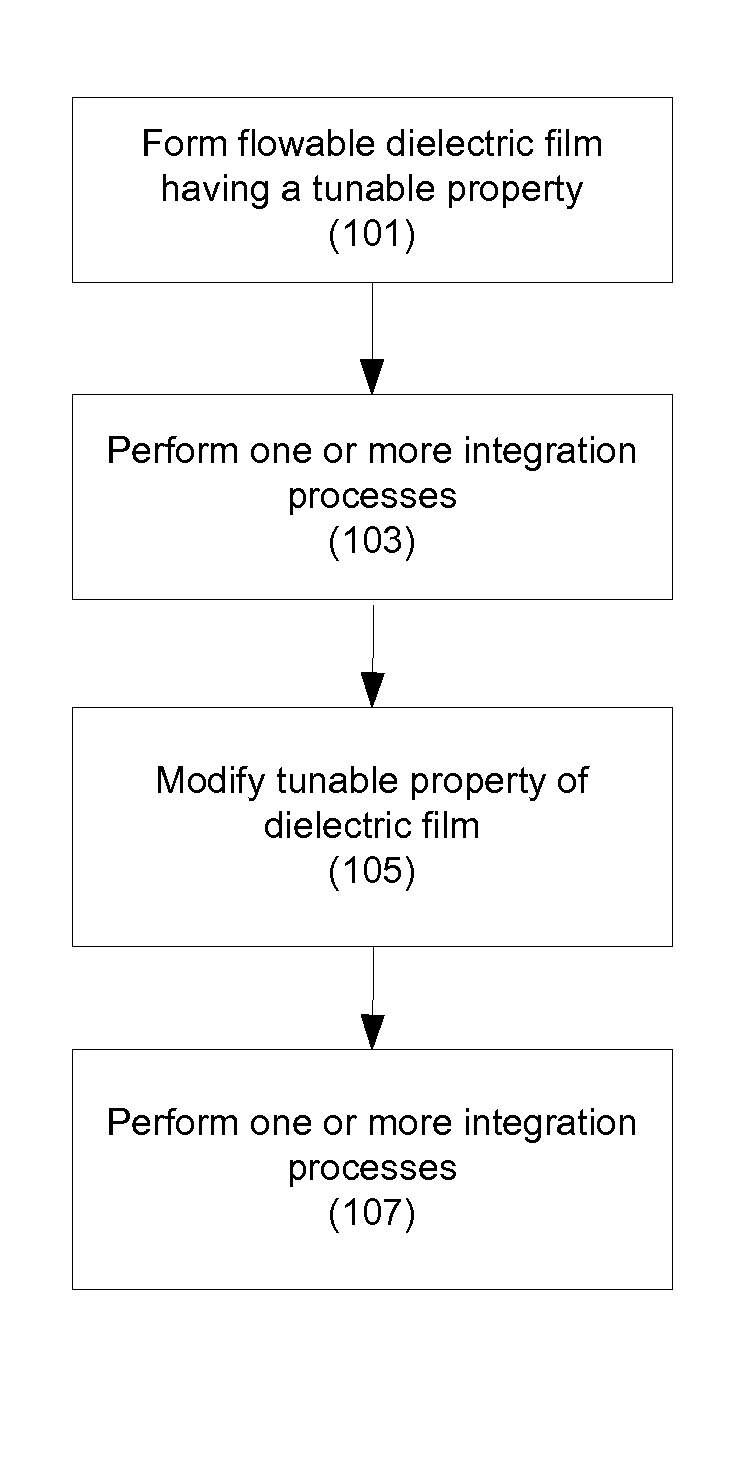

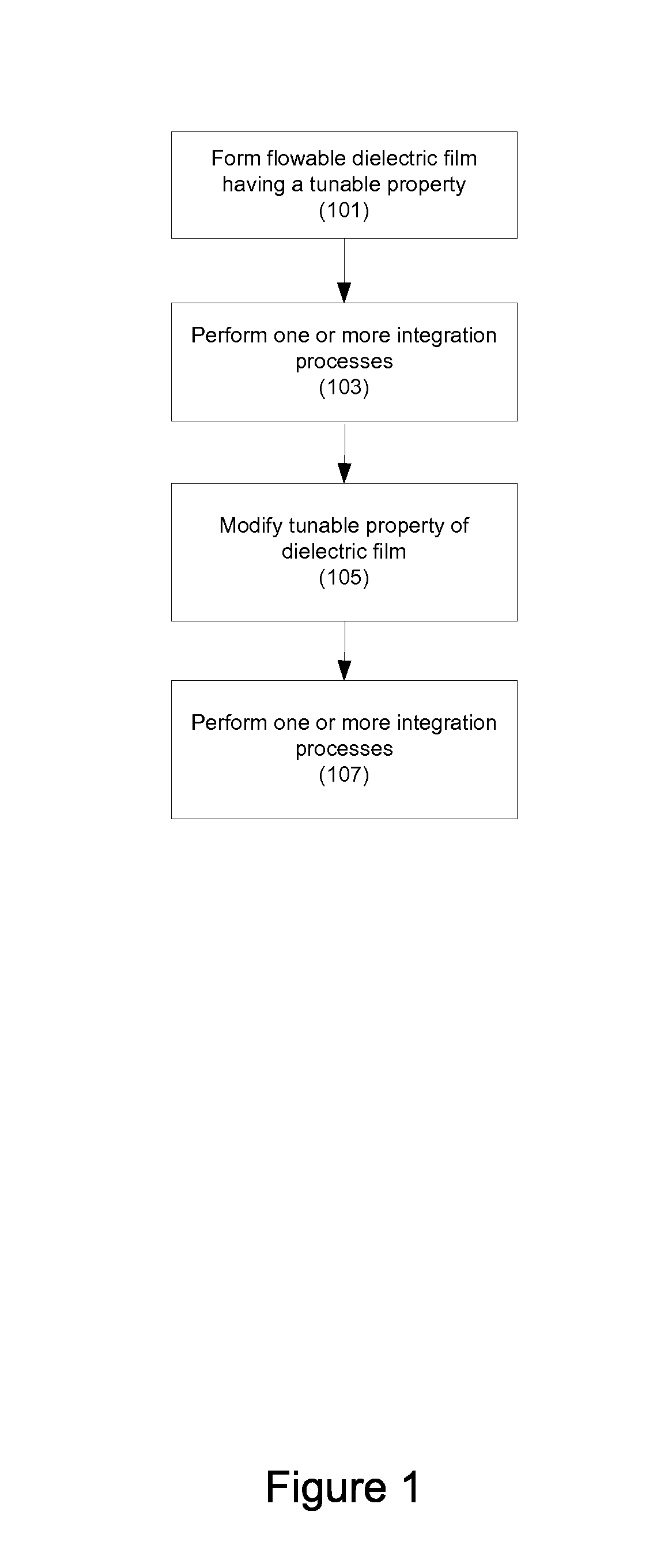

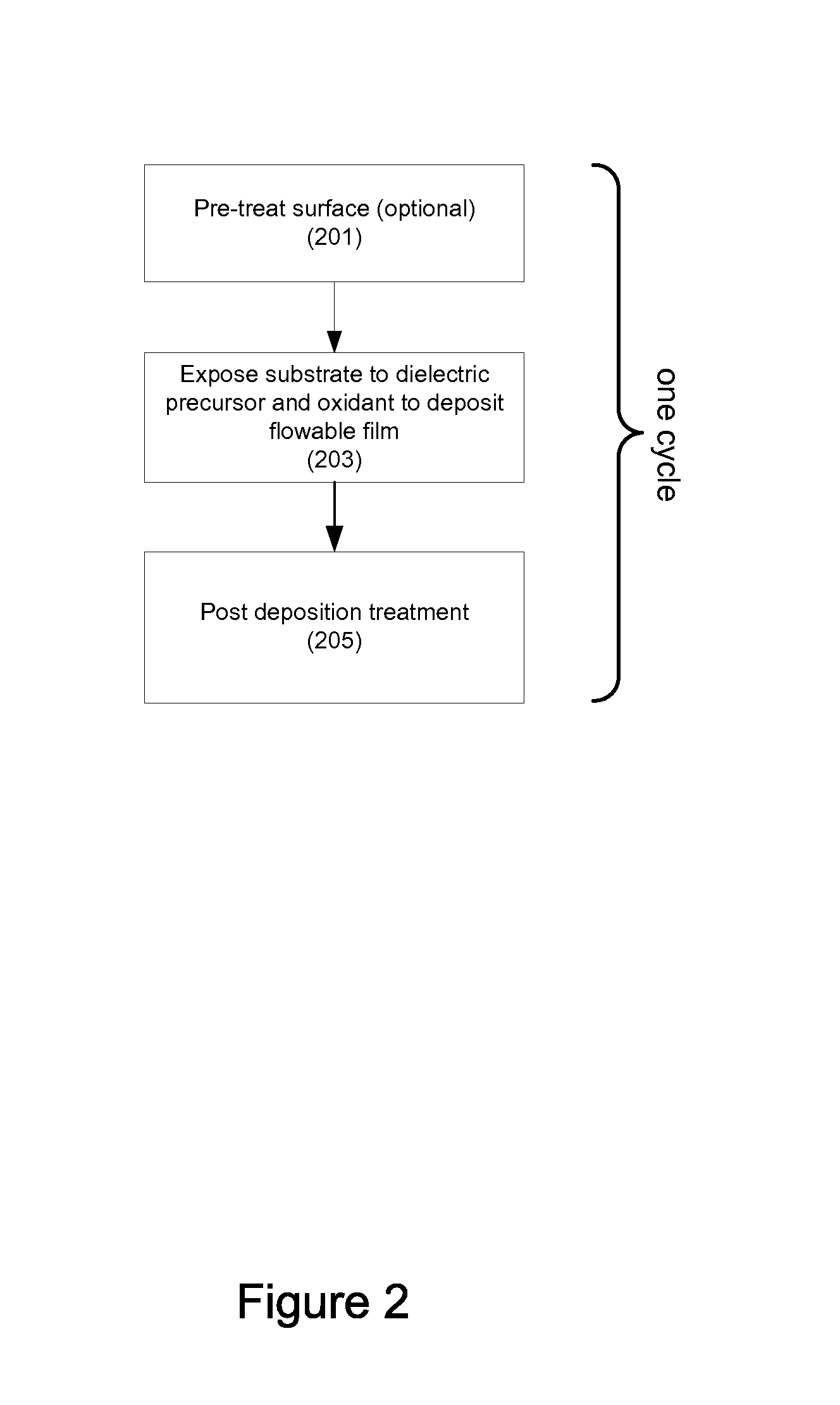

Flowable oxide film with tunable wet etch rate

ActiveUS20130230987A1Increase and decrease WERSemiconductor/solid-state device manufacturingDielectricPlasma exposure

Provided herein are integration-compatible dielectric films and methods of depositing and modifying them. According to various embodiments, the methods can include deposition of flowable dielectric films targeting specific film properties and / or modification of those properties with an integration-compatible treatment process. In certain embodiments, methods of depositing and modifying flowable dielectric films having tunable wet etch rates and other properties are provided. Wet etch rates can be tuned during integration through am integration-compatible treatment process. Examples of treatment processes include plasma exposure and ultraviolet radiation exposure.

Owner:NOVELLUS SYSTEMS

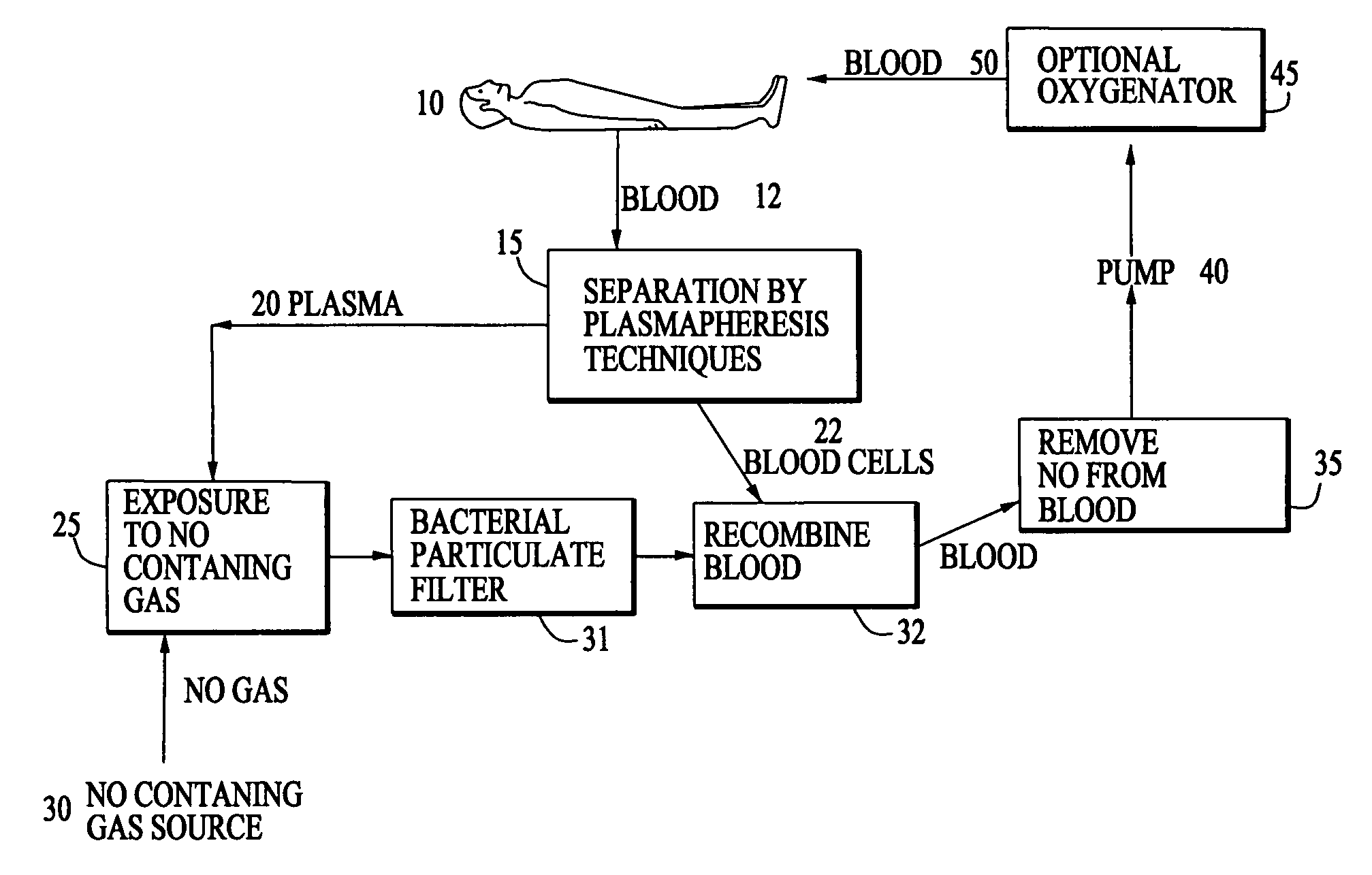

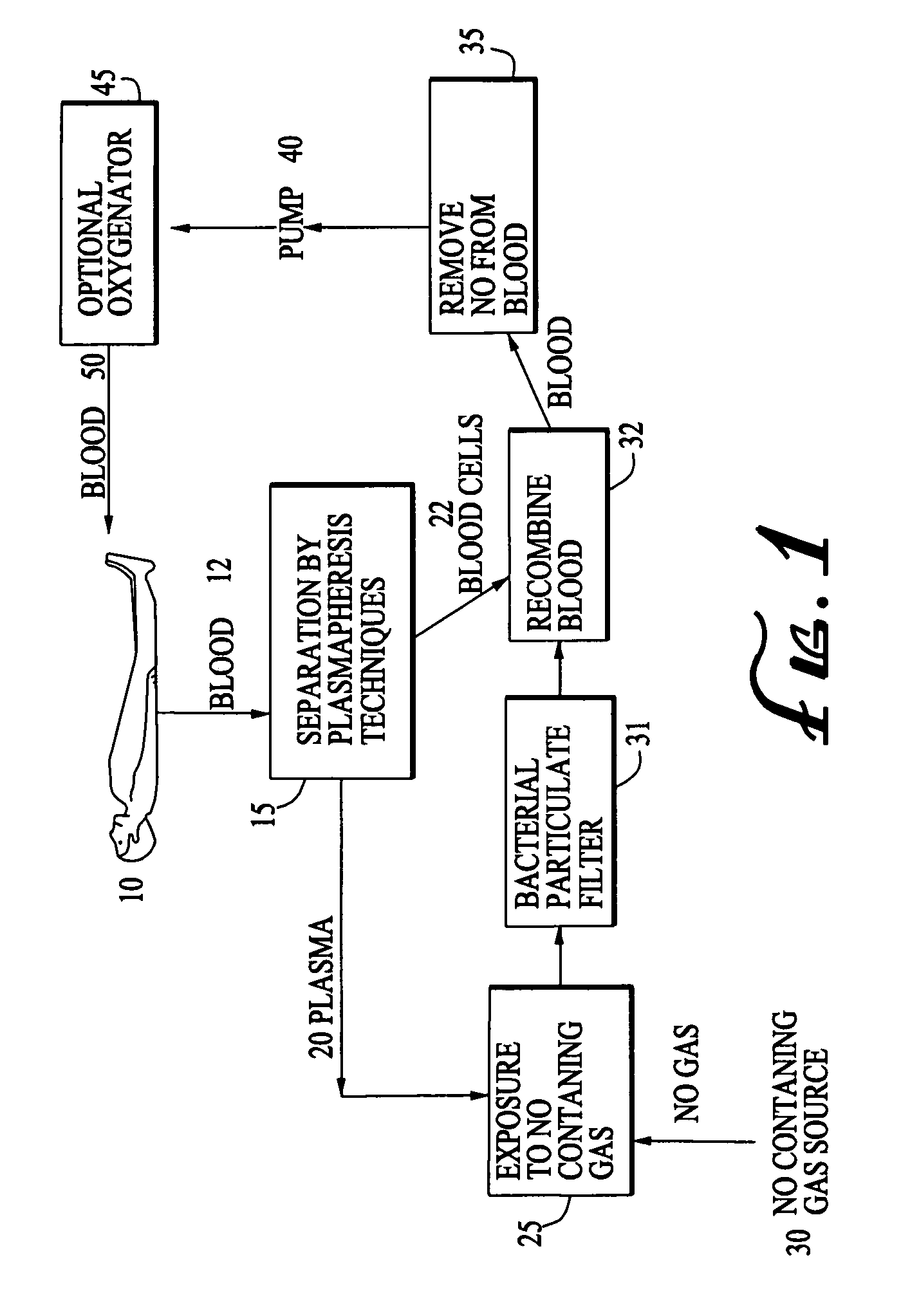

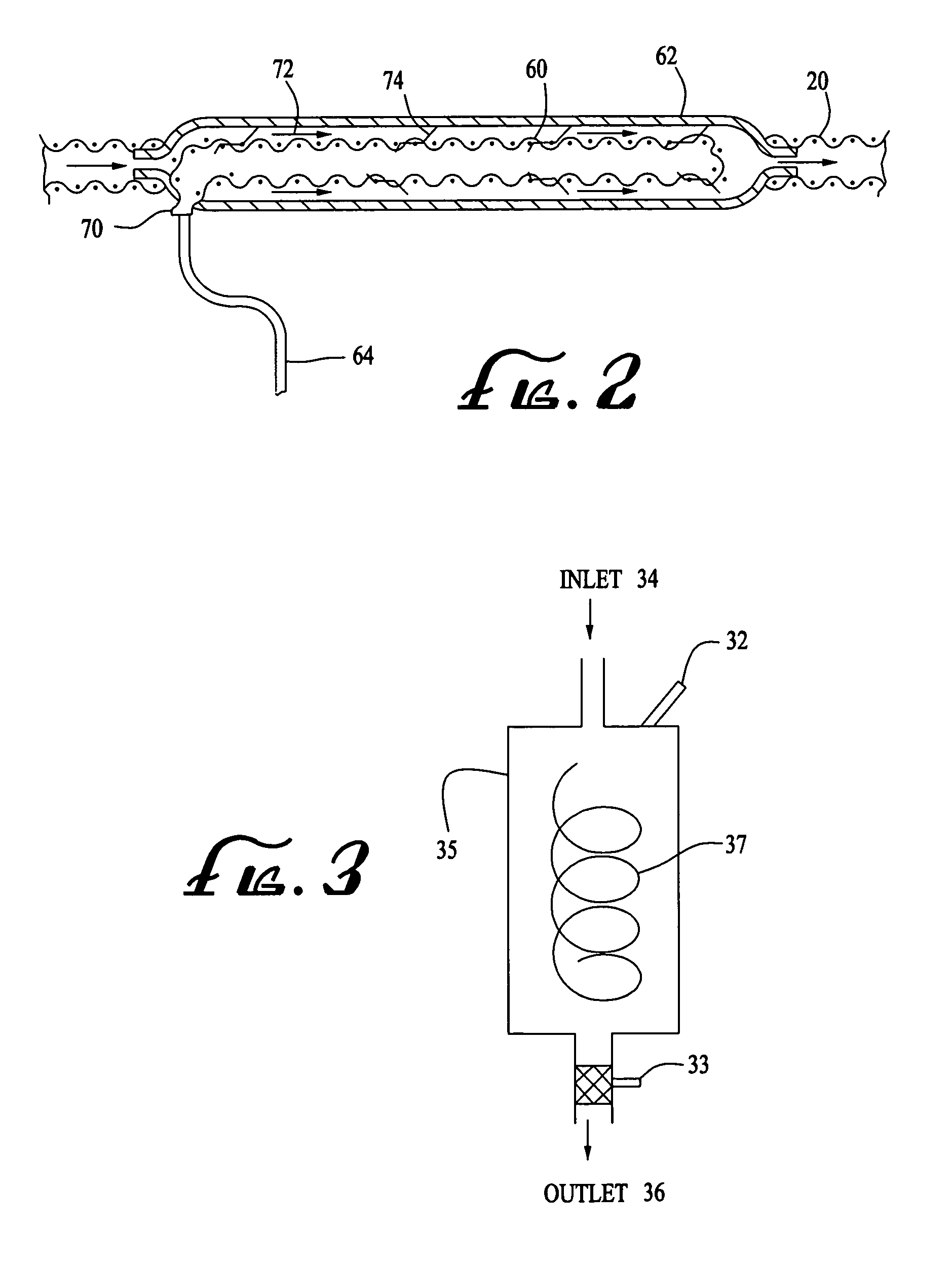

Use of nitric oxide gas in an extracorporeal circuitry to treat blood plasma

InactiveUS7531133B2Reduce pathogensReducing nitric oxide contentSemi-permeable membranesSolvent extractionPlasma exposureNitric oxide gas

A method of reducing pathogens in blood by exposure to a nitric oxide containing gas in an extracorporeal circuitry is provided. The method includes: obtaining blood from a mammal or a blood source, separating the blood into plasma and blood cells, exposing the plasma to nitric oxide containing gas, combining the exposed plasma with the blood cells, reducing nitric oxide content in the recombined blood, and returning the blood to the mammal or blood source.

Owner:ADVANCED INHILATION THERAPIES AIT LTD

Flowable oxide film with tunable wet etch rate

ActiveUS8846536B2Decorative surface effectsSemiconductor/solid-state device manufacturingDielectricPlasma exposure

Provided herein are integration-compatible dielectric films and methods of depositing and modifying them. According to various embodiments, the methods can include deposition of flowable dielectric films targeting specific film properties and / or modification of those properties with an integration-compatible treatment process. In certain embodiments, methods of depositing and modifying flowable dielectric films having tunable wet etch rates and other properties are provided. Wet etch rates can be tuned during integration through am integration-compatible treatment process. Examples of treatment processes include plasma exposure and ultraviolet radiation exposure.

Owner:NOVELLUS SYSTEMS

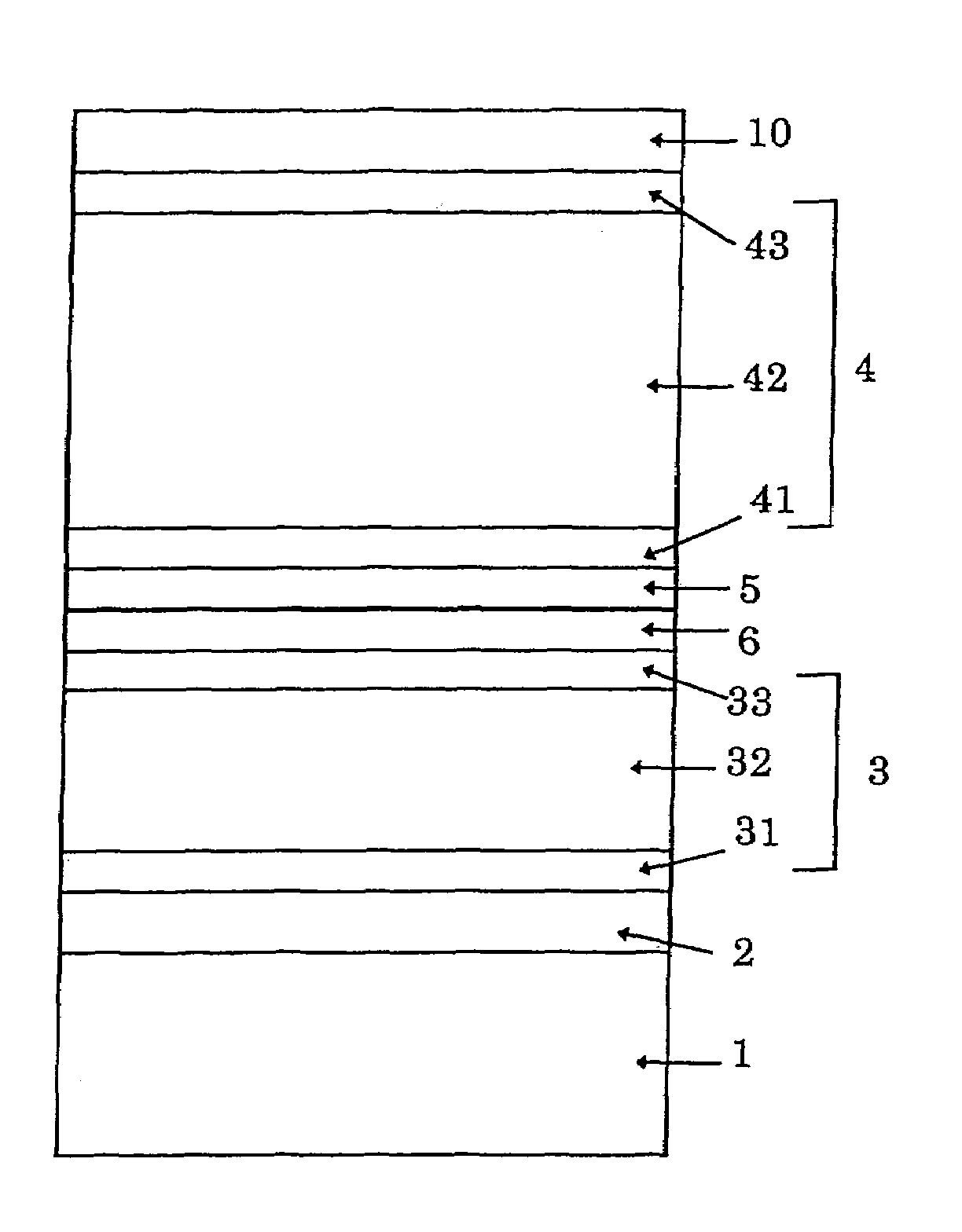

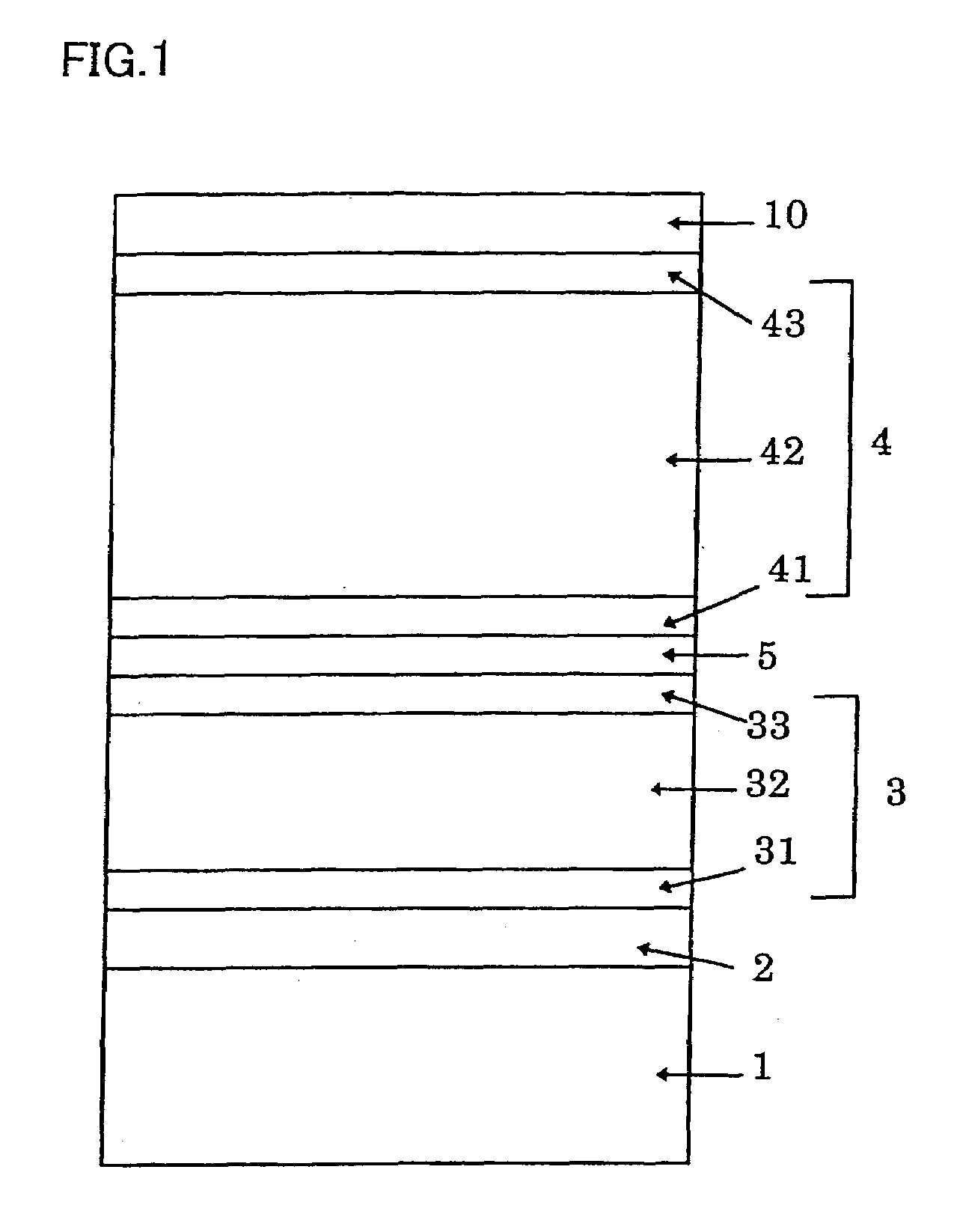

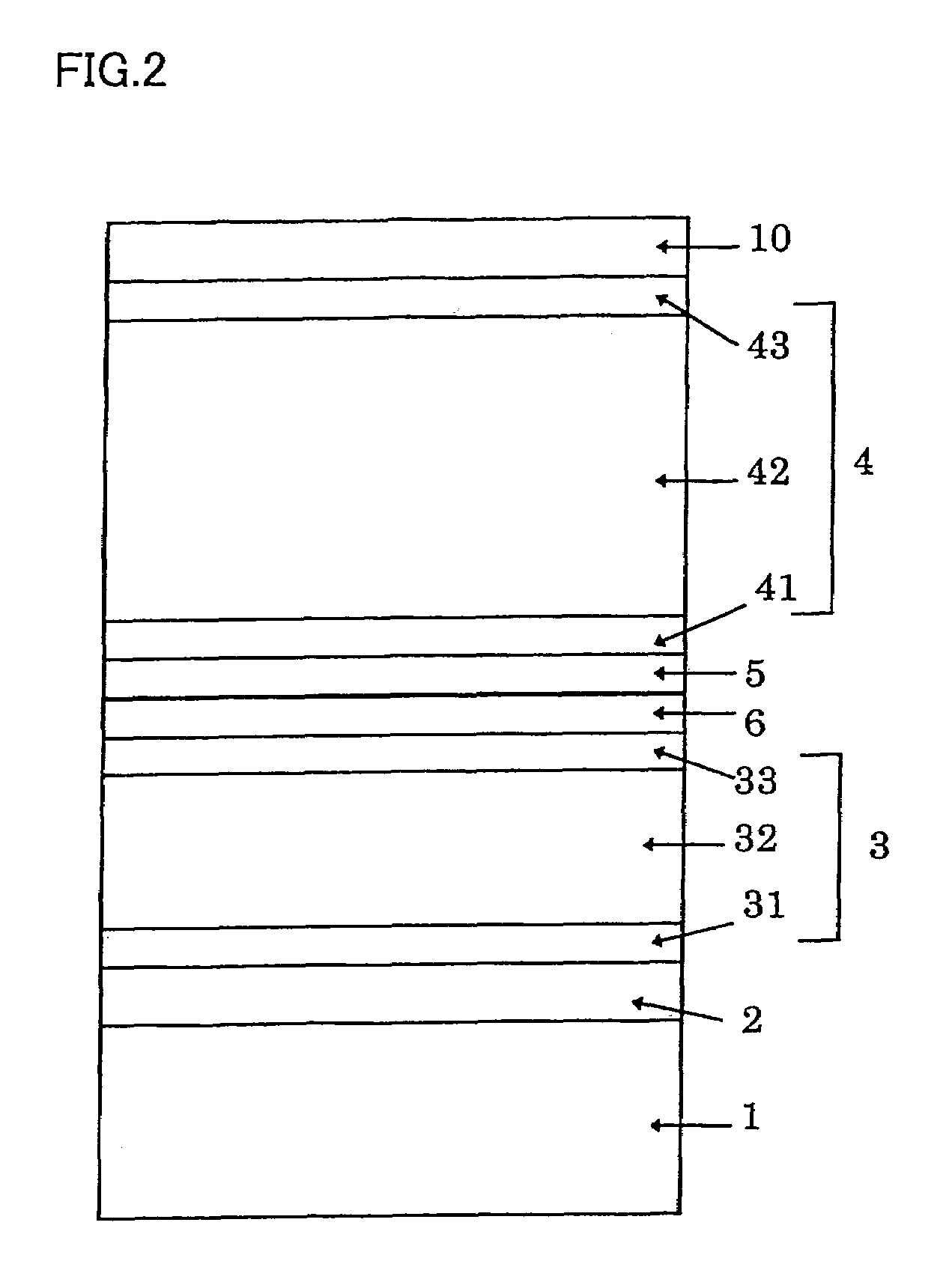

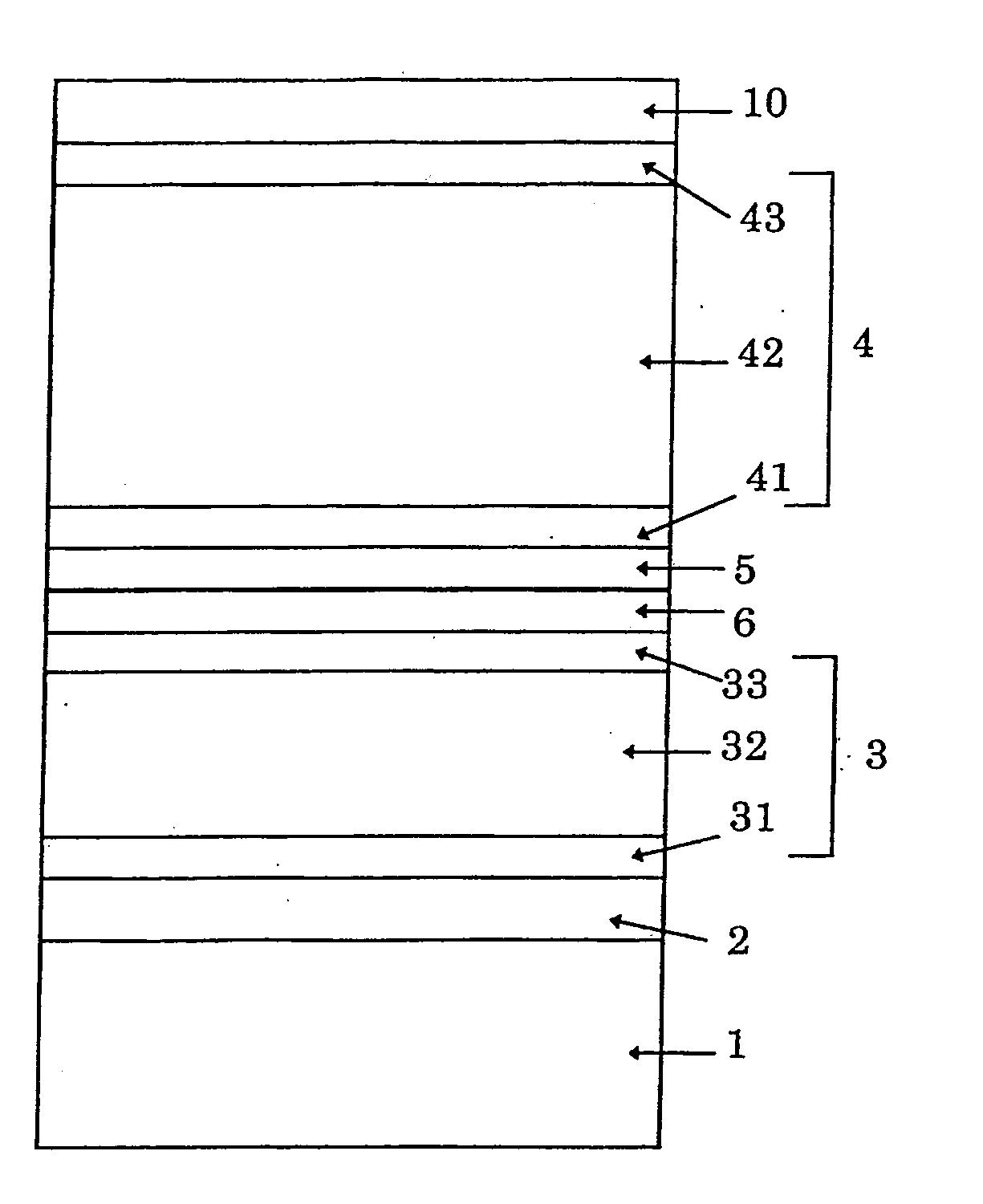

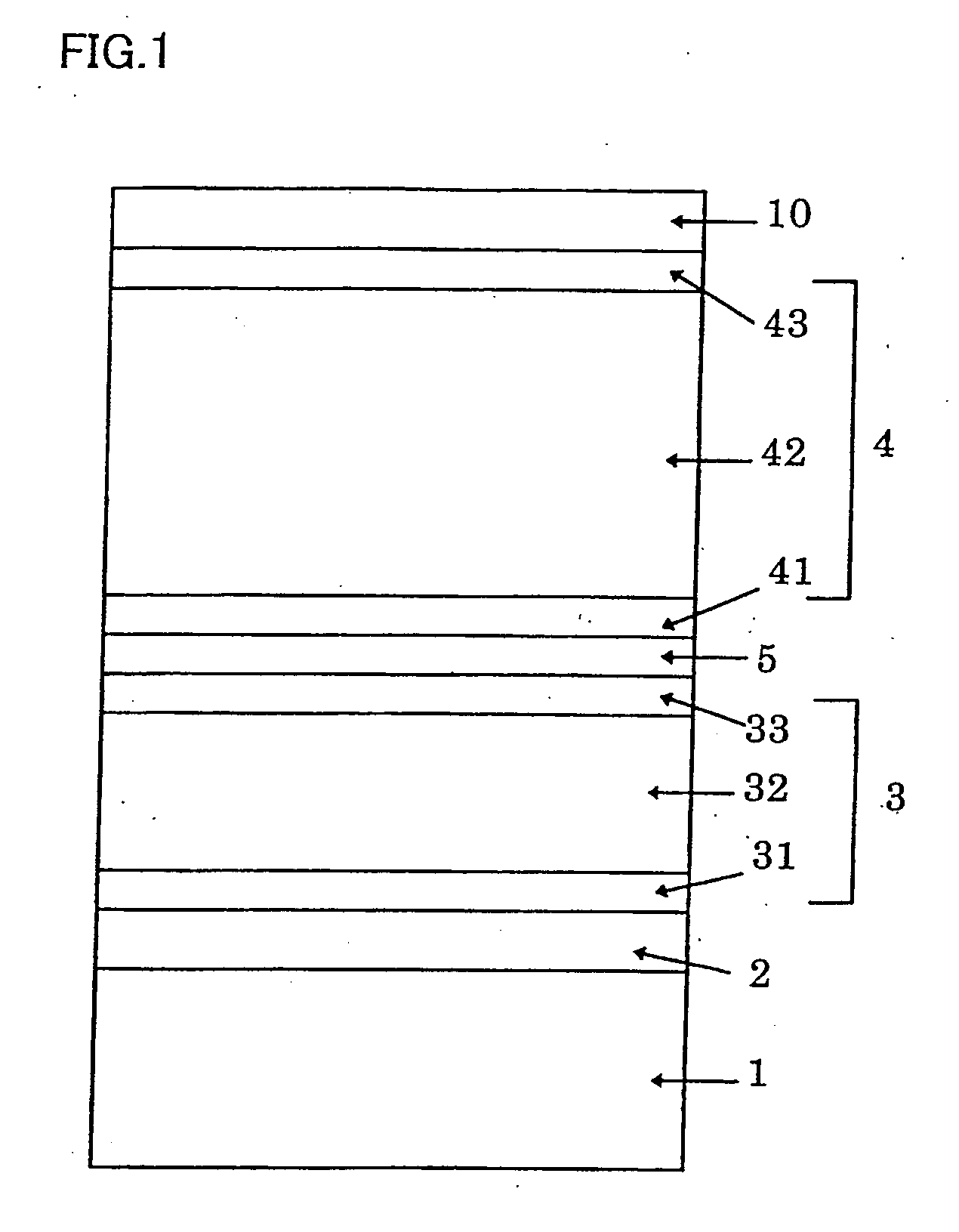

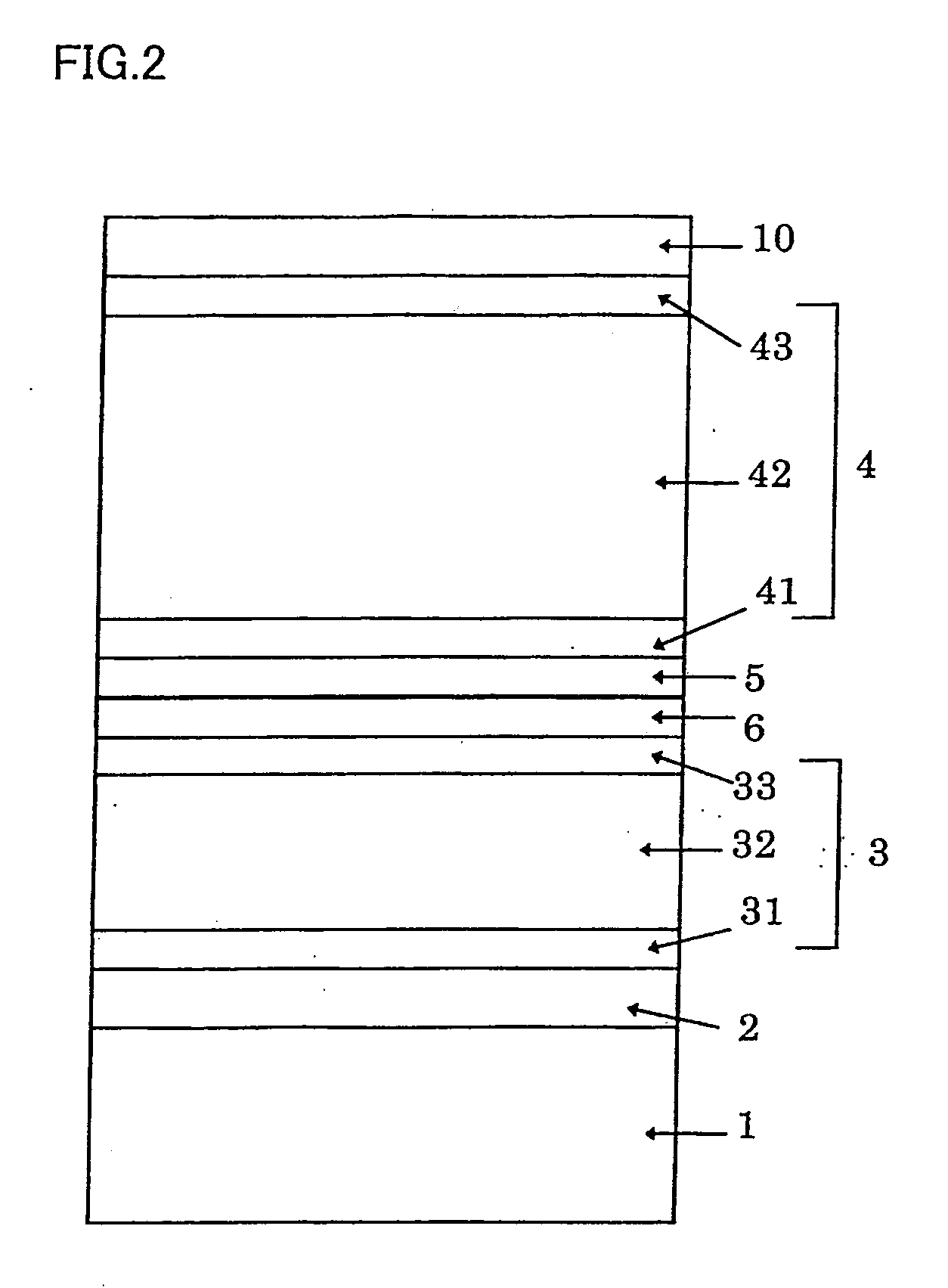

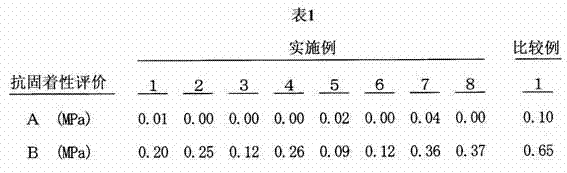

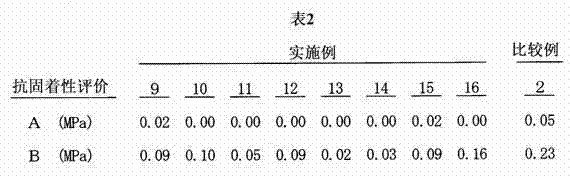

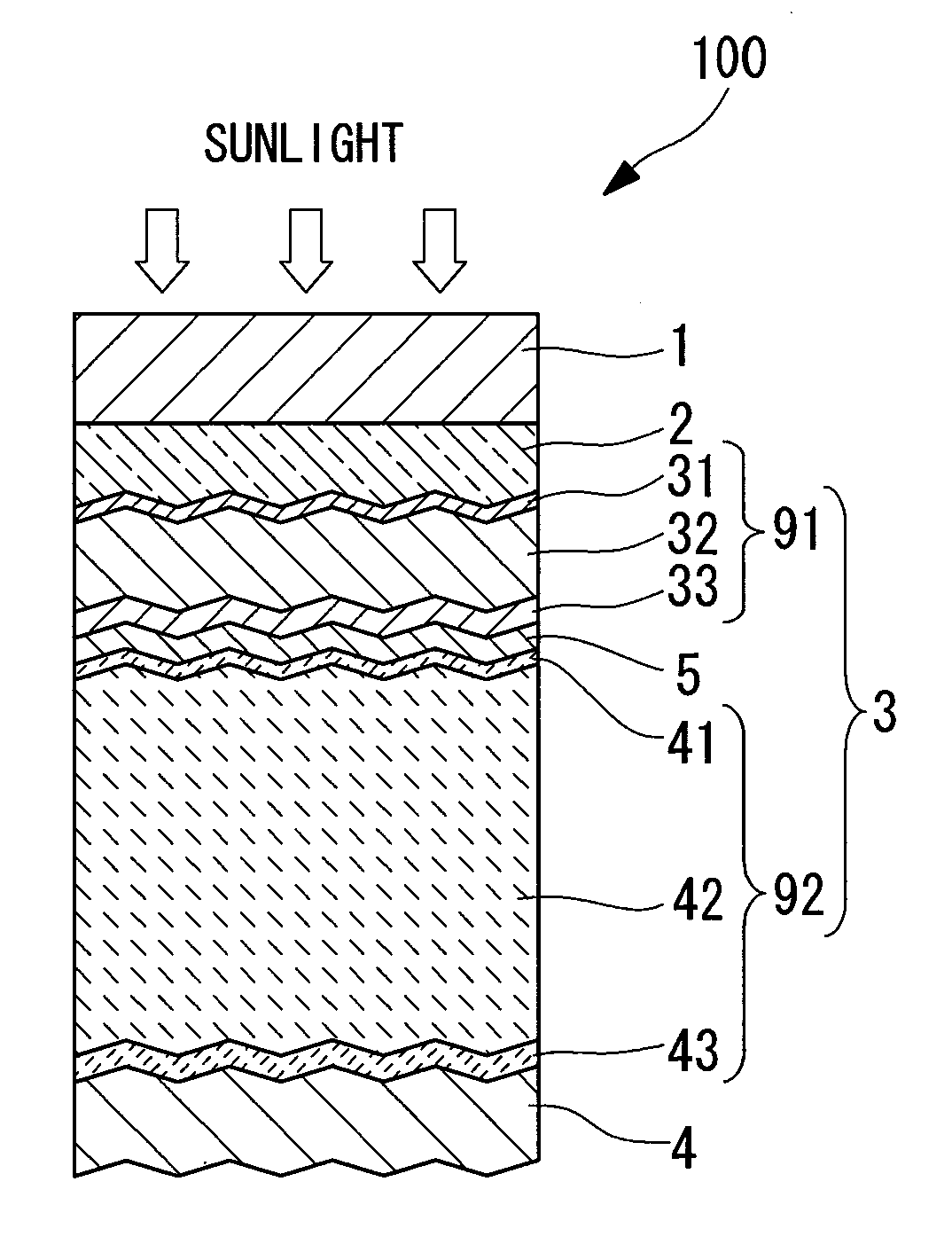

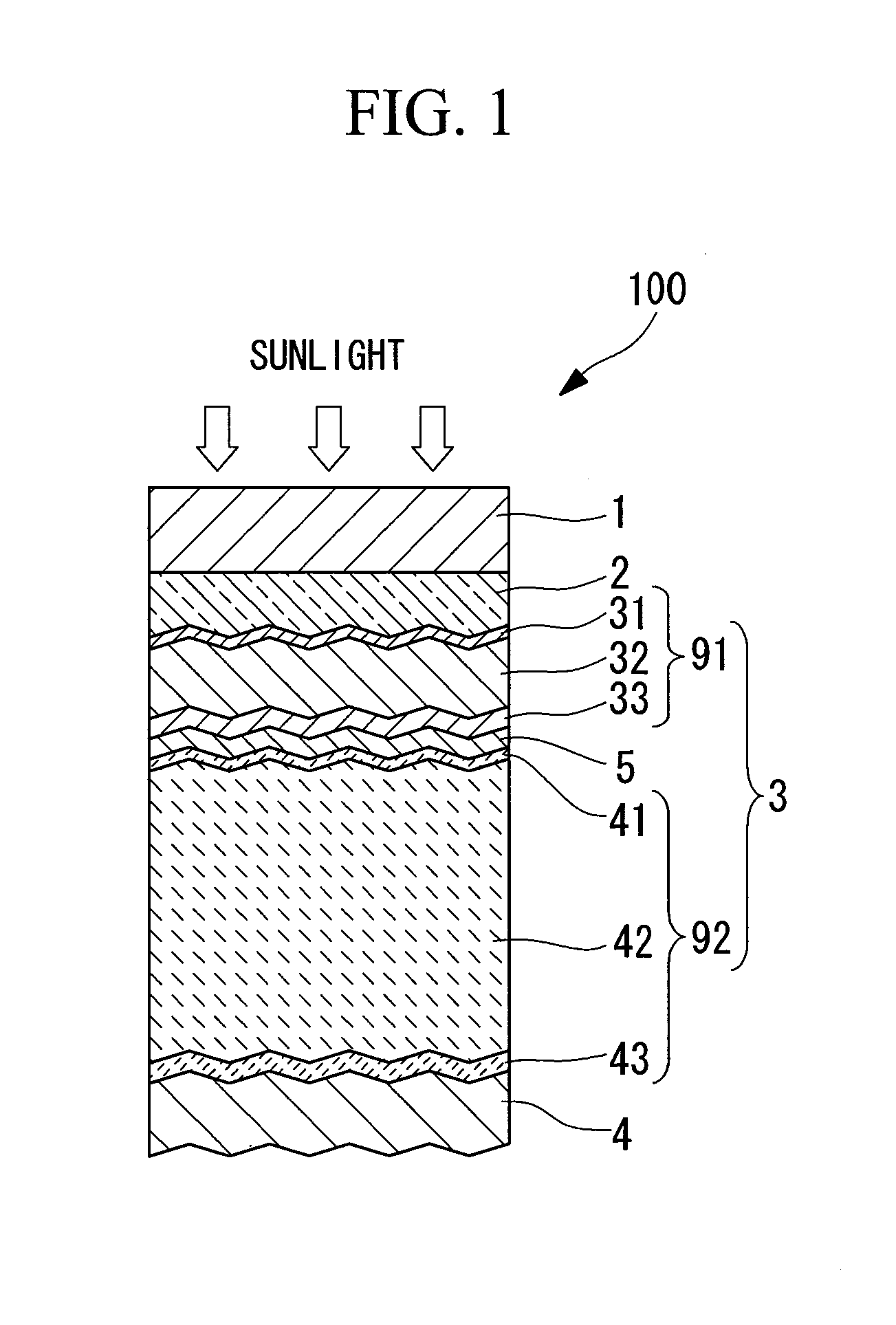

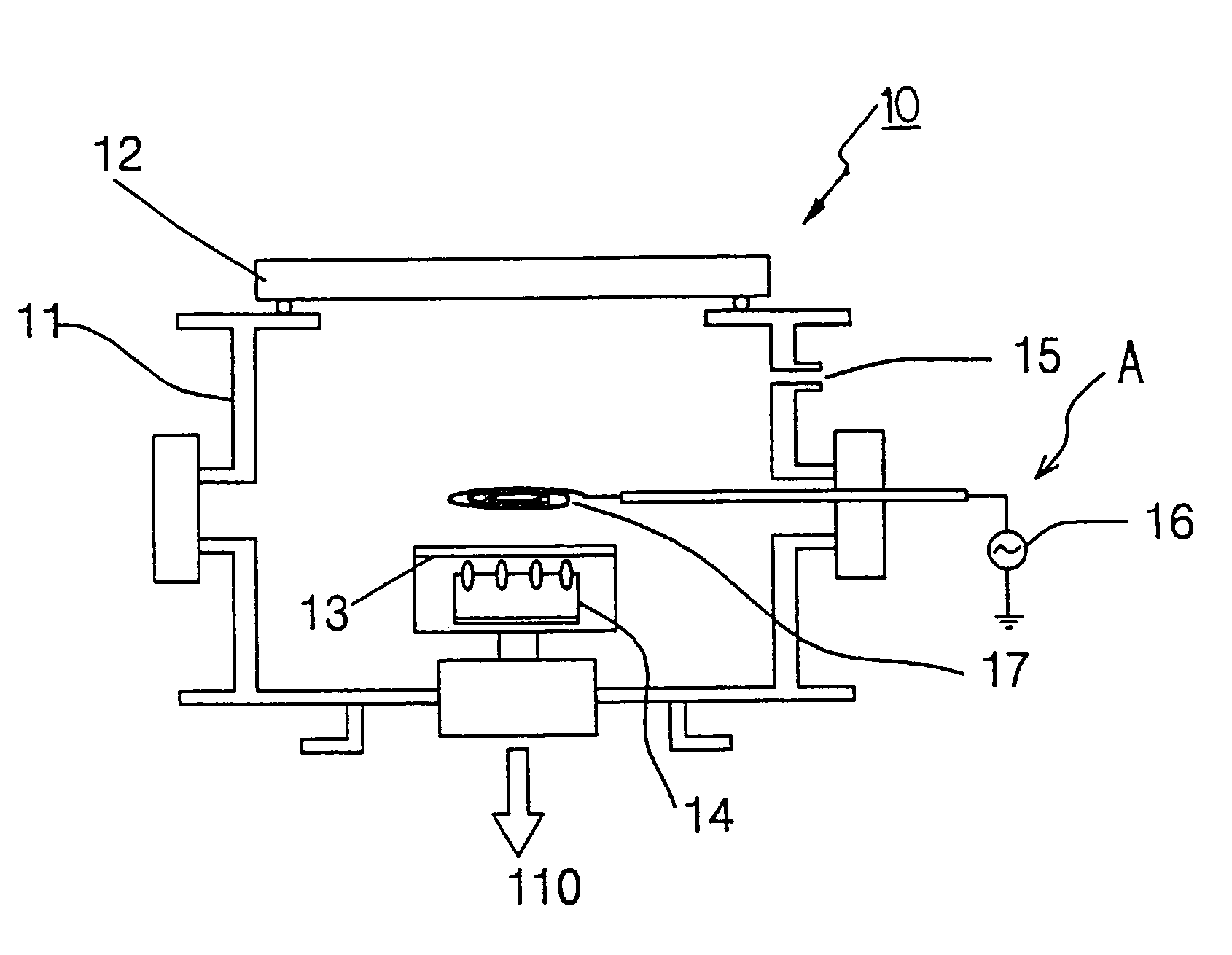

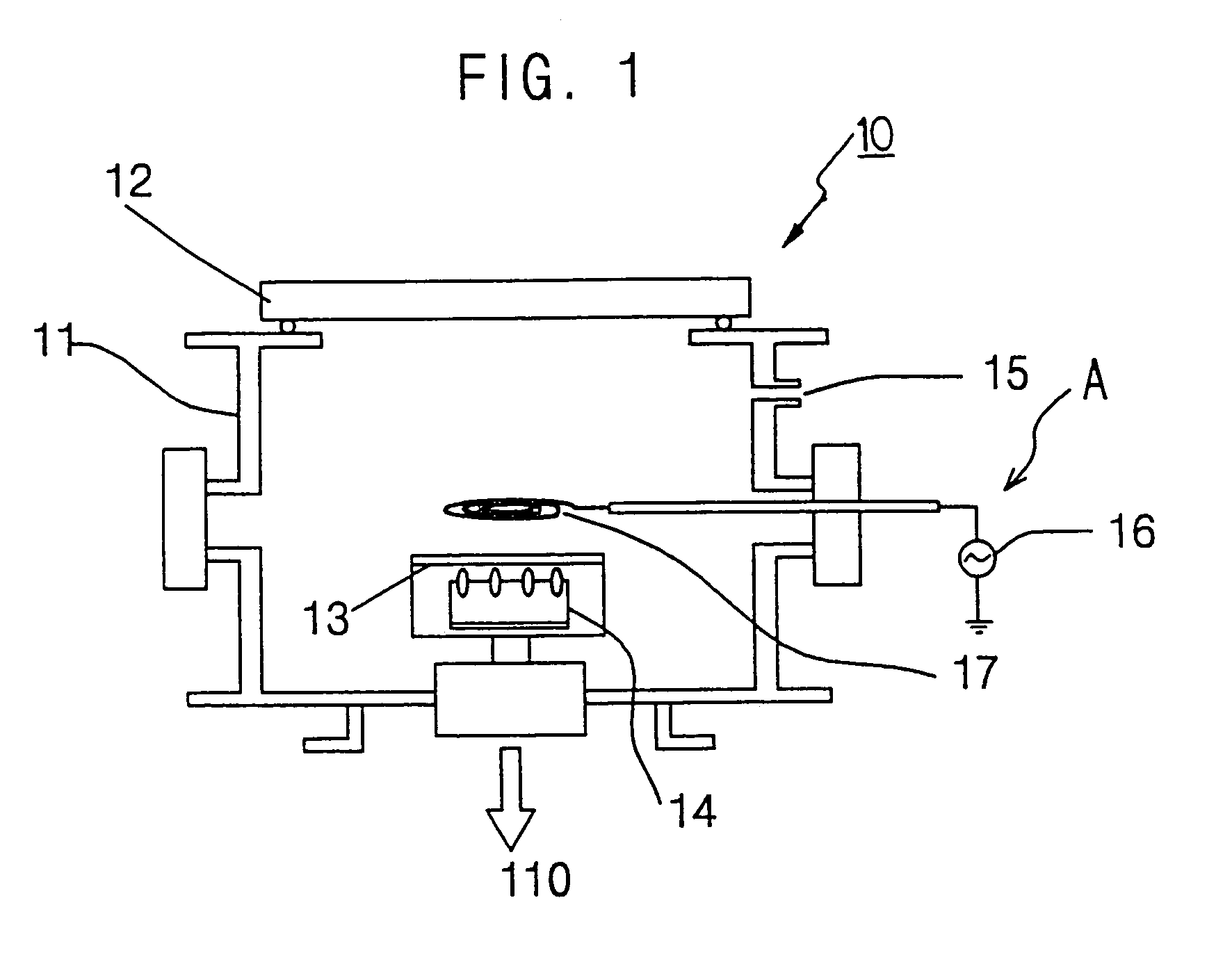

Method for fabricating tandem thin film photoelectric converter

InactiveUS7238545B2Minimize conversionFinal product manufactureSemiconductor/solid-state device manufacturingHydrogenPhotoelectric conversion

A method of manufacturing a tandem-type thin film photoelectric conversion device includes the steps of forming at least one photoelectric conversion unit (3) on a substrate (1) in a deposition apparatus, taking out the substrate (1) having the photoelectric conversion unit (3) from the deposition apparatus to the air, introducing the substrate (1) into a deposition apparatus and carrying out plasma exposure processing on the substrate (1) in an atmosphere of a gas mixture containing an impurity for determining the conductivity type of the same conductivity type as that of the uppermost conductivity type layer (33) and hydrogen, forming a conductivity type intermediate layer (5) by additionally supplying semiconductor raw gas to the deposition apparatus, and then forming a subsequent photoelectric conversion unit (4).

Owner:KANEKA CORP

Method for fabricating tandem thin film photoelectric converter

InactiveUS20050181534A1Minimize conversionFinal product manufactureSemiconductor/solid-state device manufacturingHydrogenPhotoelectric conversion

A method of manufacturing a tandem-type thin film photoelectric conversion device includes the steps of forming at least one photoelectric conversion unit (3) on a substrate (1) in a deposition apparatus, taking out the substrate (1) having the photoelectric conversion unit (3) from the deposition apparatus to the air, introducing the substrate (1) into a deposition apparatus and carrying out plasma exposure processing on the substrate (1) in an atmosphere of a gas mixture containing an impurity for determining the conductivity type of the same conductivity type as that of the uppermost conductivity type layer (33) and hydrogen, forming a conductivity type intermediate layer (5) by additionally supplying semiconductor raw gas to the deposition apparatus, and then forming a subsequent photoelectric conversion unit (4).

Owner:KANEKA CORP

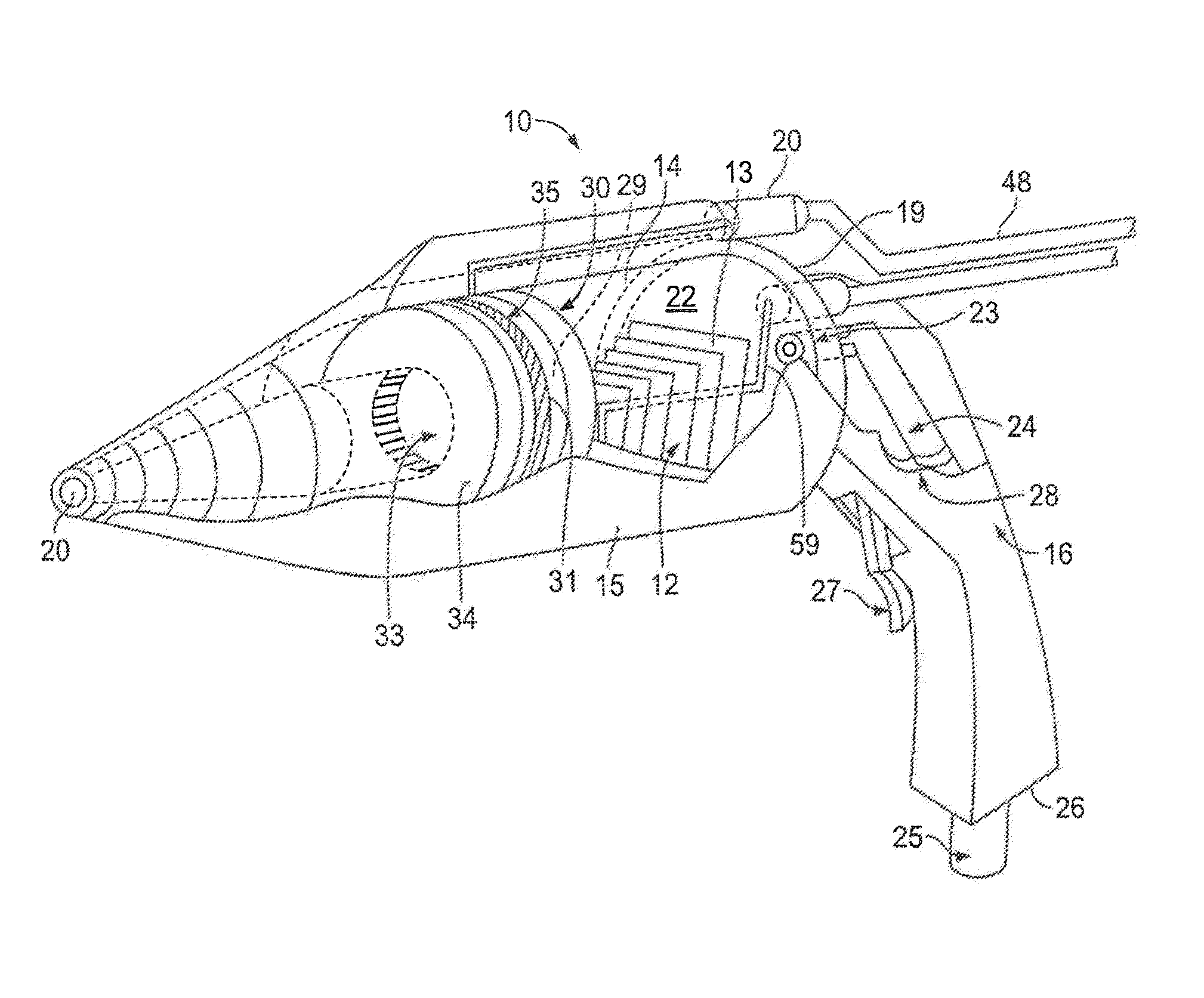

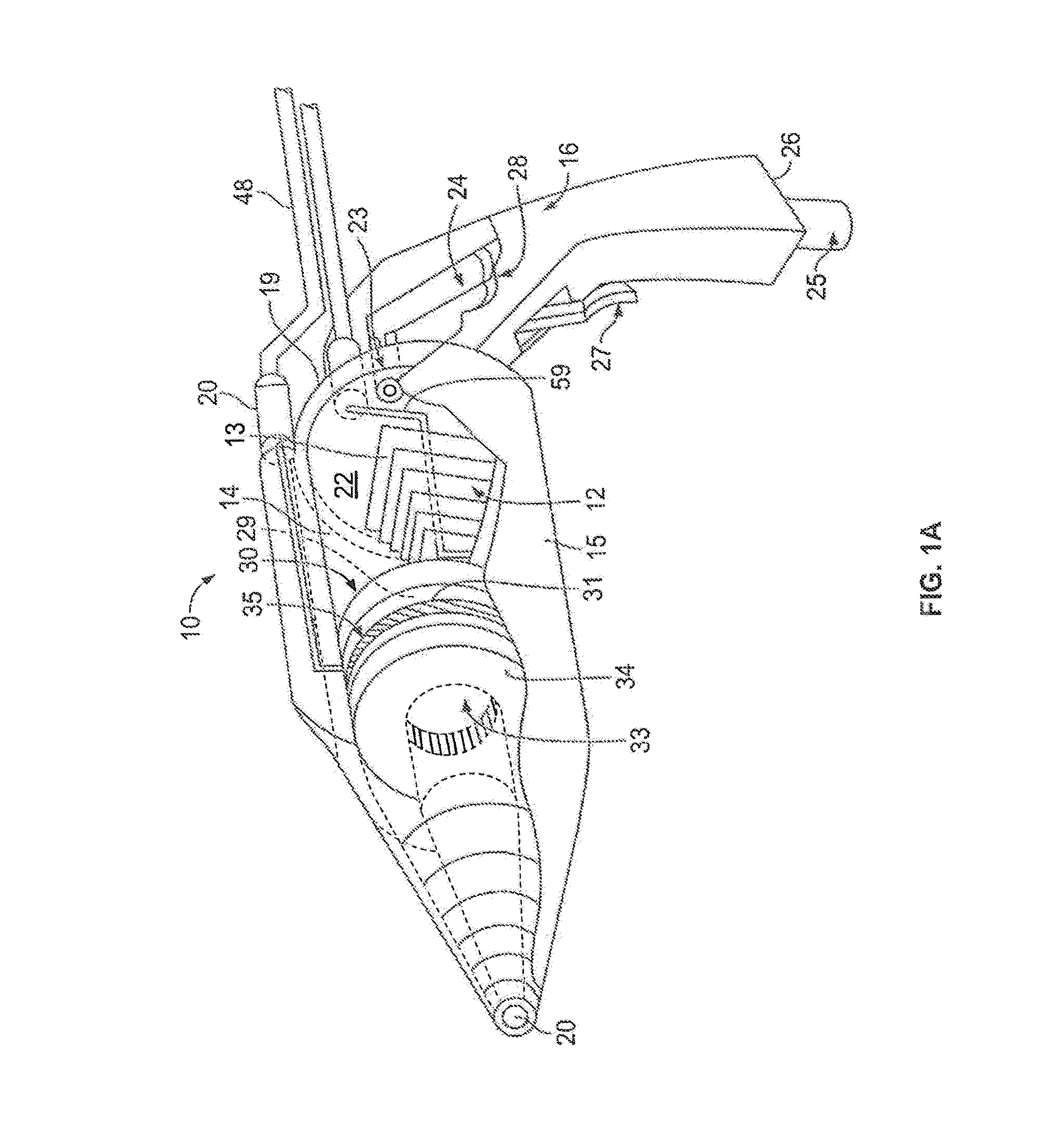

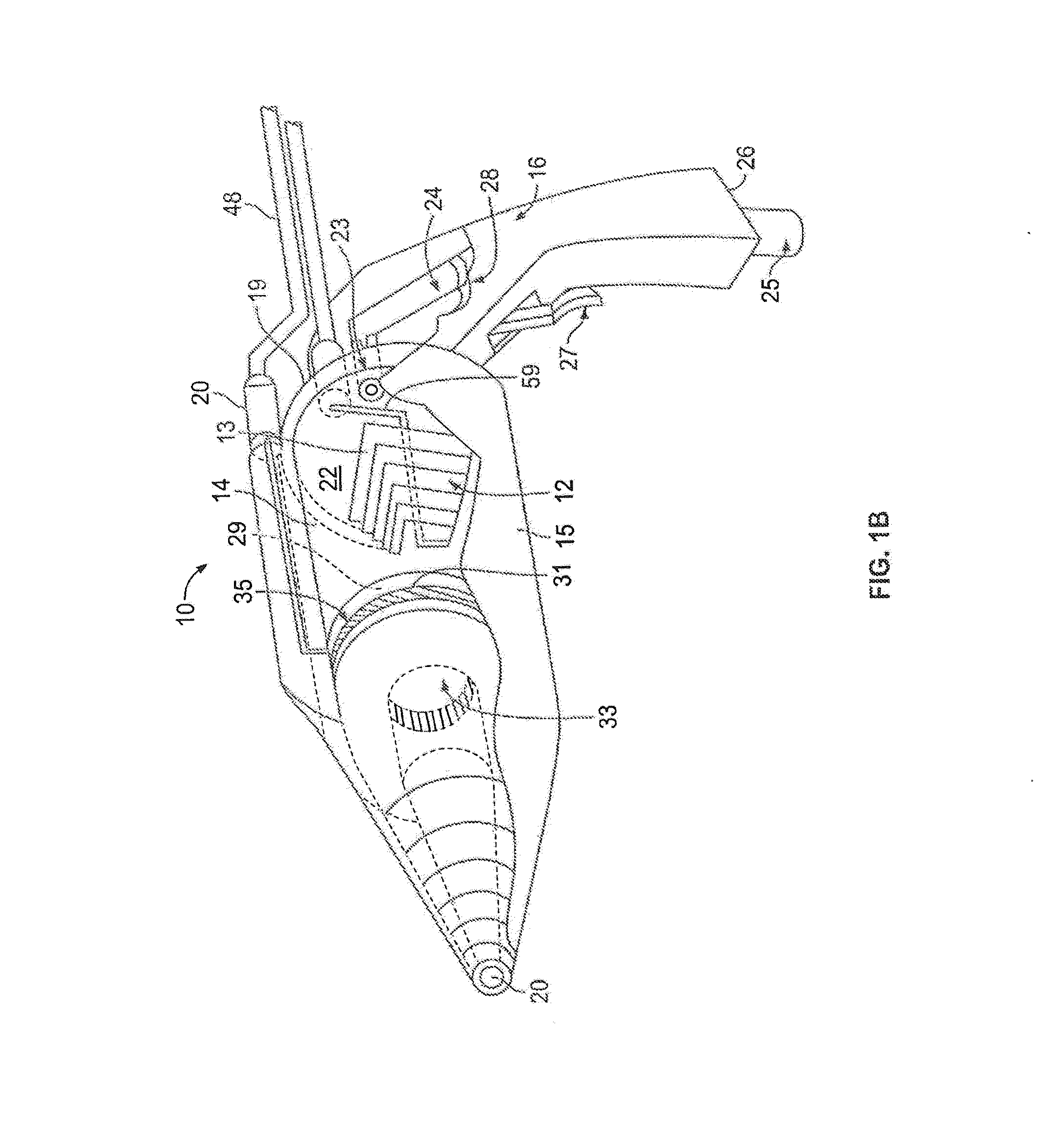

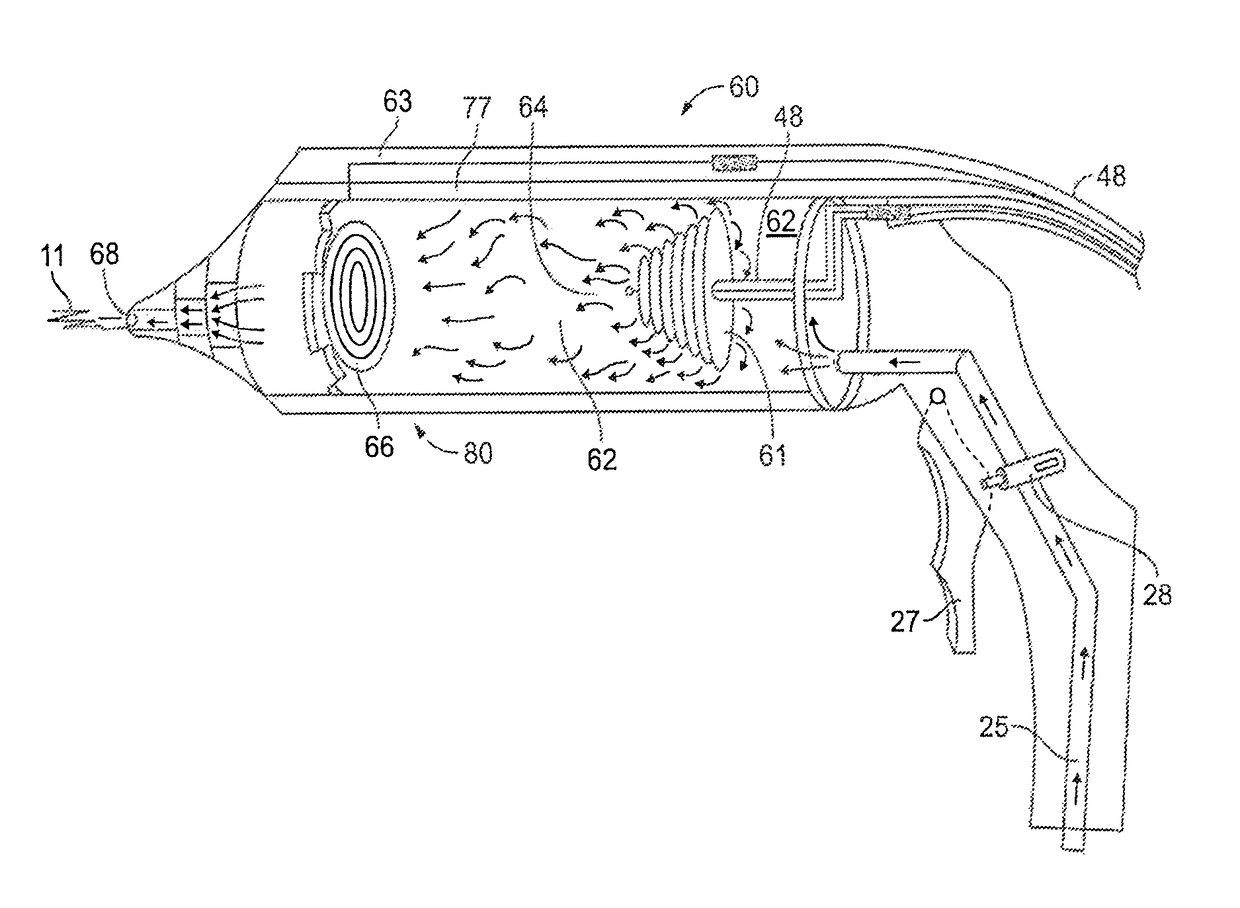

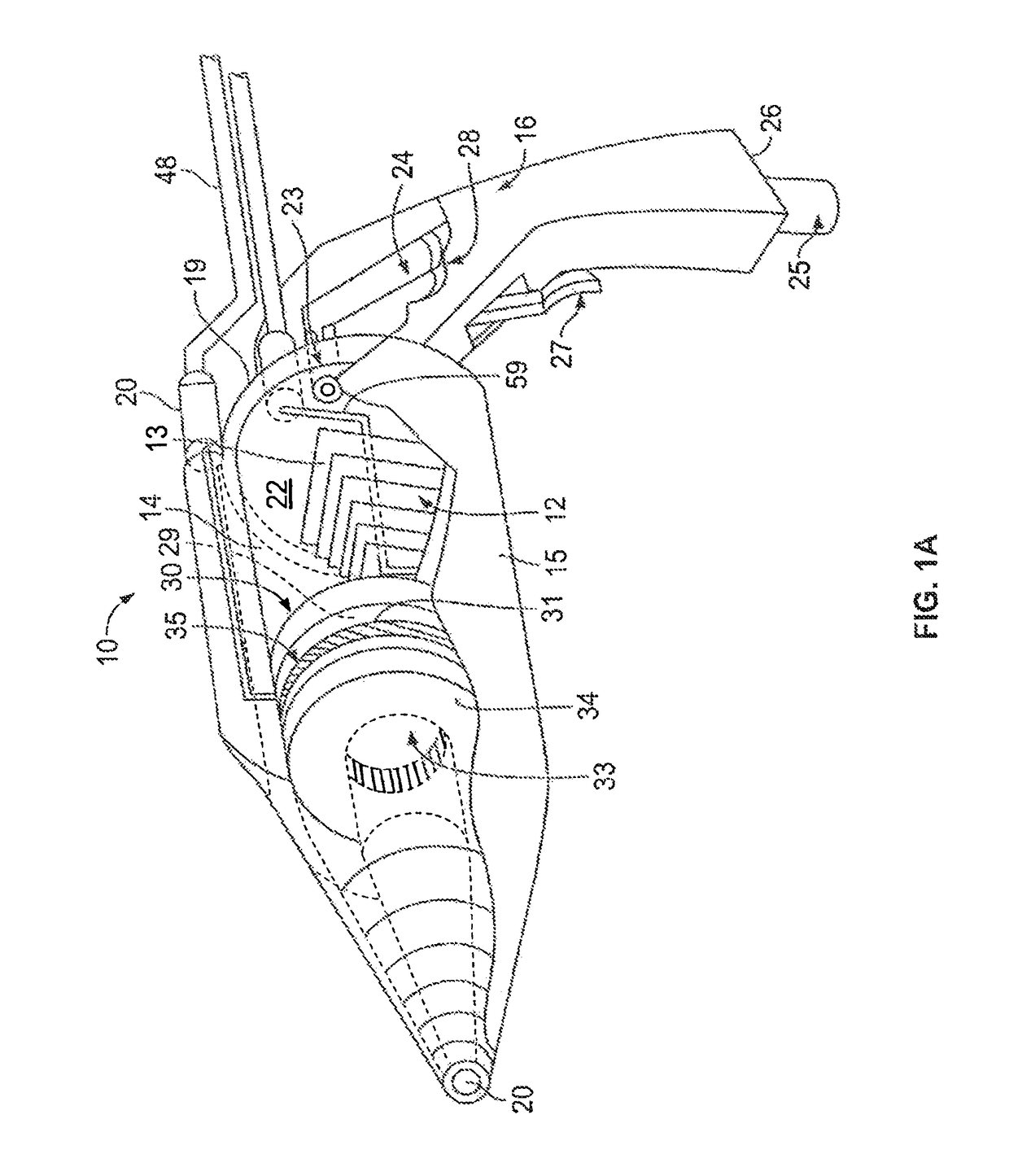

Harmonic Cold Plasma Devices and Associated Methods

A nozzle for attachment to a cold plasma device configured to maintain delivery of a stable cold plasma. The nozzle can have many different shaped apertures to support different applications requiring different shaped cold plasma plumes. Use of a disc of foam material within a nozzle can expand the size of aperture of a nozzle while maintaining delivery of a stable cold plasma. The nozzle can be an elongated cannula tube for internal delivery of a cold plasma treatment. The cannula tube can provide an aperture at its distal end or one or more apertures along its length. A shroud can partially enclose the distal aperture of the nozzle. A sterile sleeve can be used in conjunction with a nozzle to provide a sterile means of attachment and operation of the nozzle with a cold plasma device. In addition, various shaped apertures may be deployed to provide selective targeting of the cold plasma to a treatment area, while shielding other biological structures from cold plasma exposure. Such apertures also provide an opportunity for manual manipulation of tissues in the treatment area prior to or during cold plasma treatment.

Owner:COLD PLASMA MEDICAL TECH

Flowable oxide film with tunable wet etch rate

Provided herein are integration-compatible dielectric films and methods of depositing and modifying them. According to various embodiments, the methods can include deposition of flowable dielectric films targeting specific film properties and / or modification of those properties with an integration-compatible treatment process. In certain embodiments, methods of depositing and modifying flowable dielectric films having tunable wet etch rates and other properties are provided. Wet etch rates can be tuned during integration through am integration-compatible treatment process. Examples of treatment processes include plasma exposure and ultraviolet radiation exposure.

Owner:NOVELLUS SYSTEMS

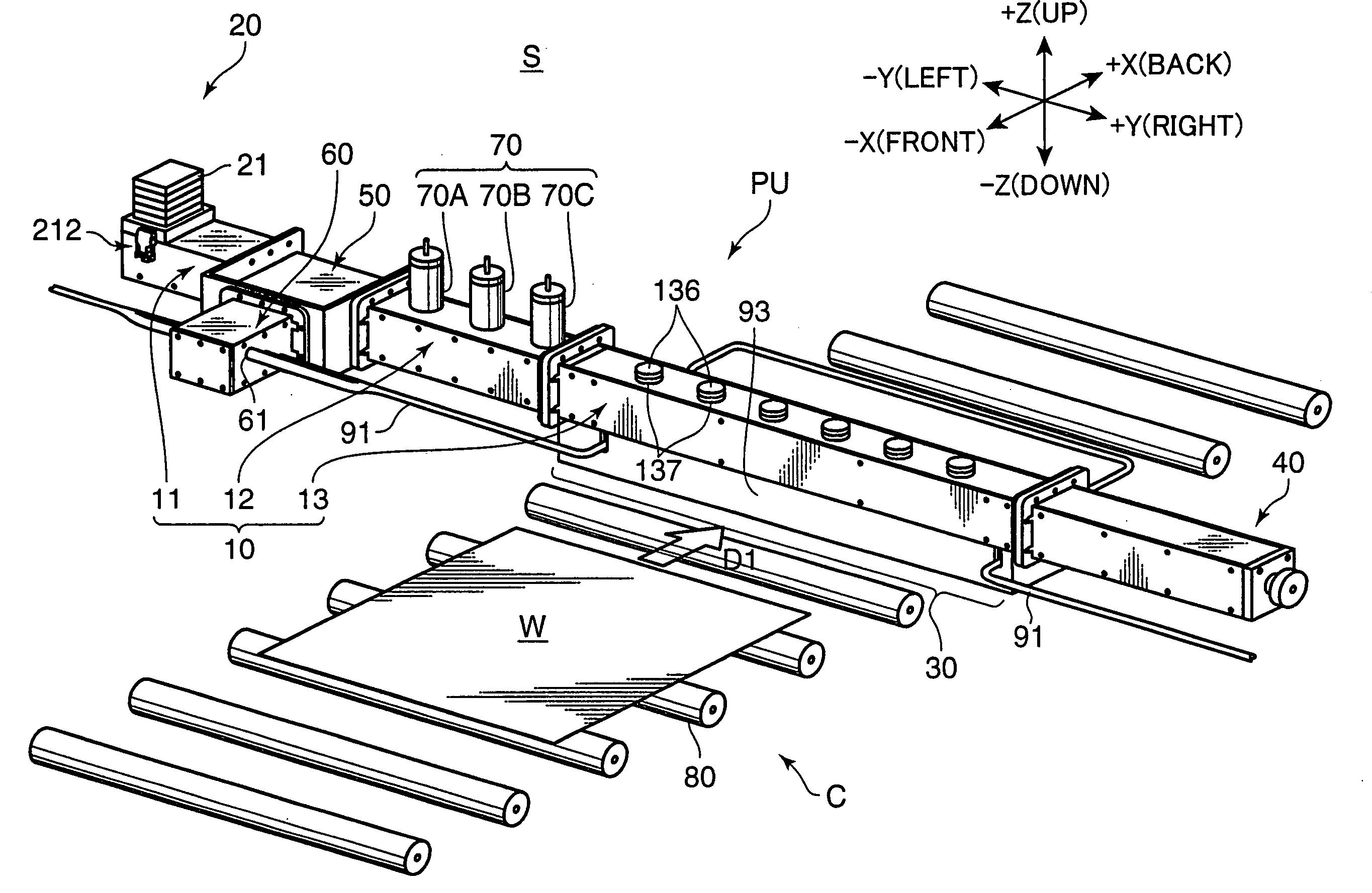

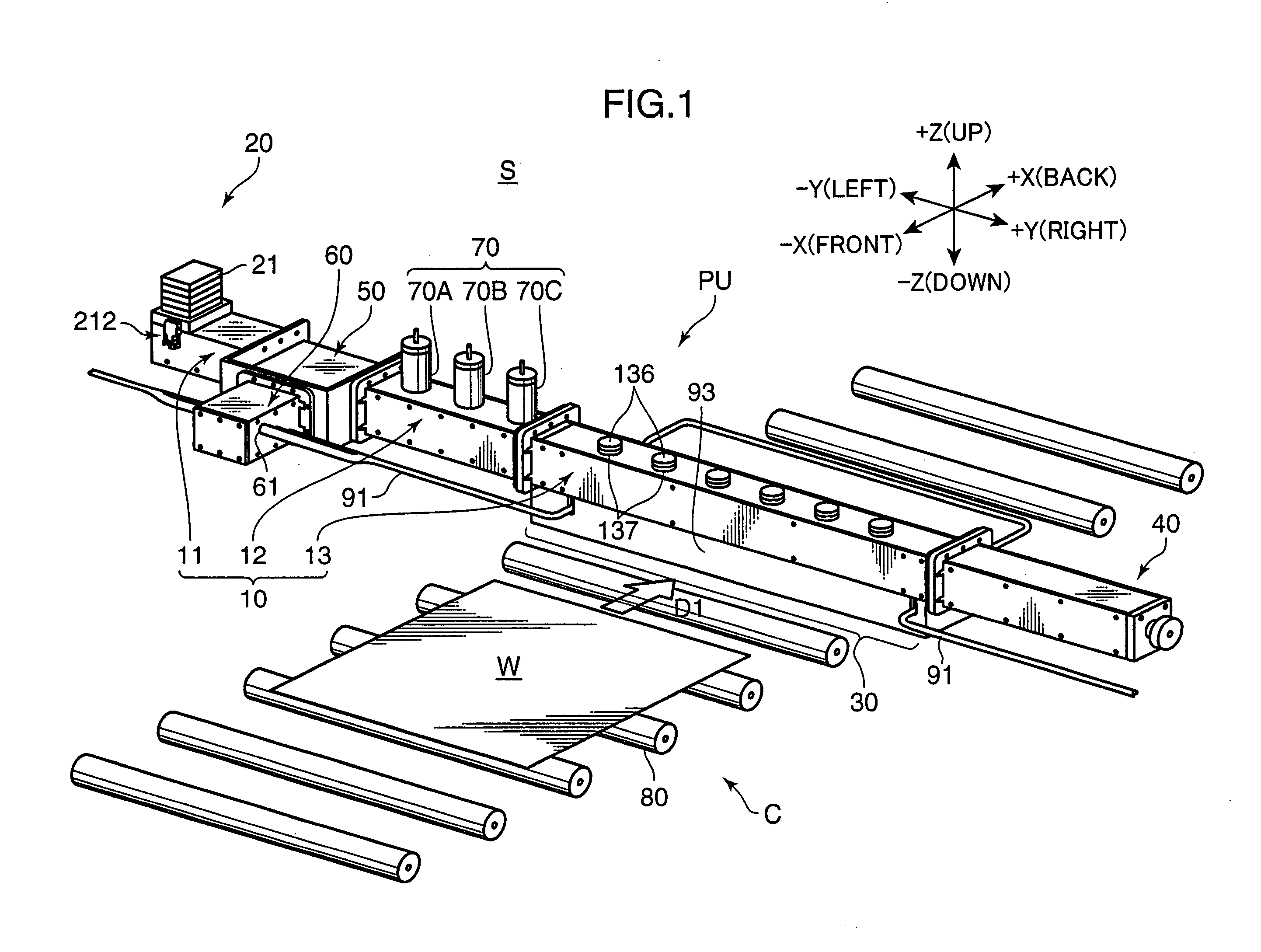

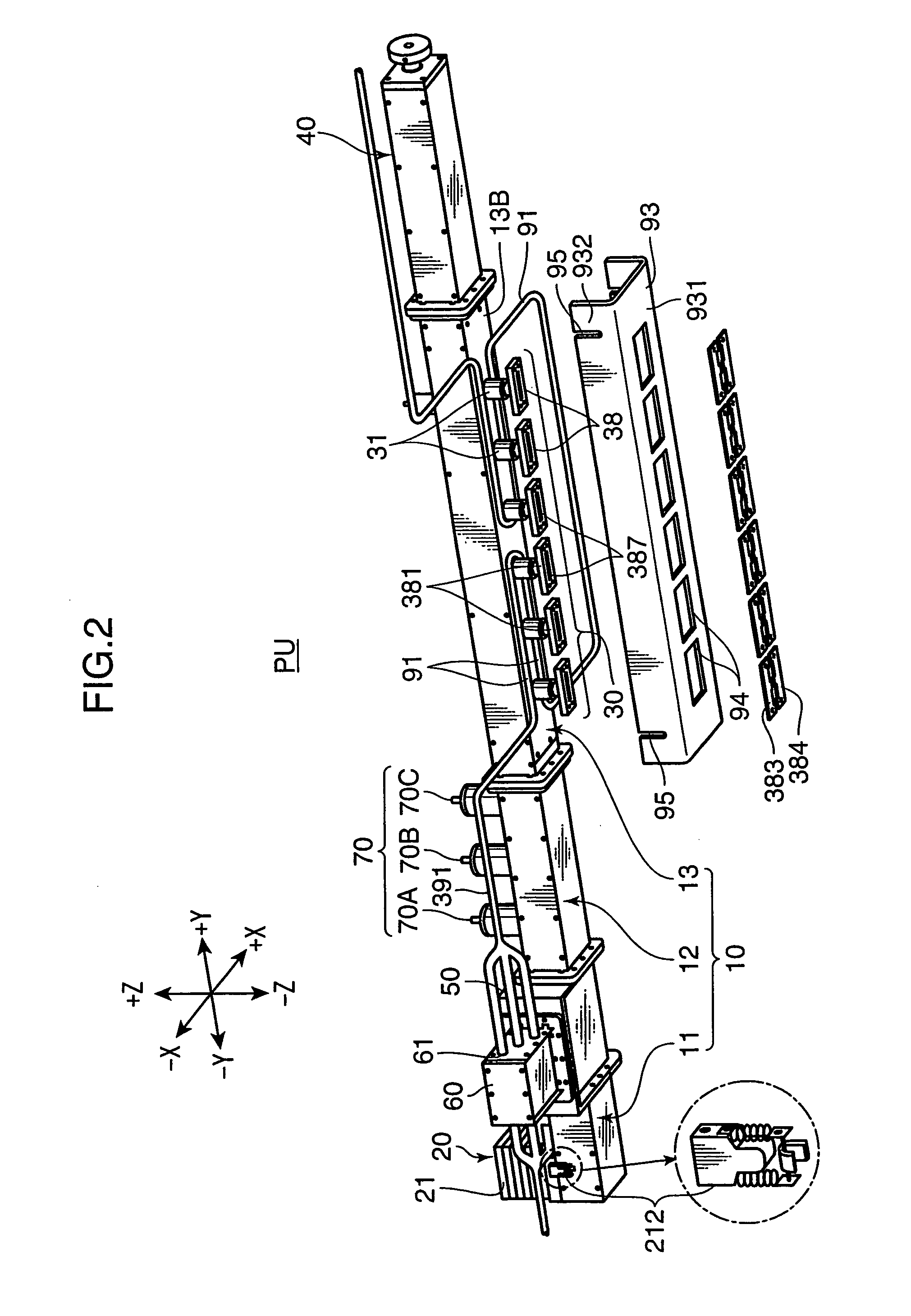

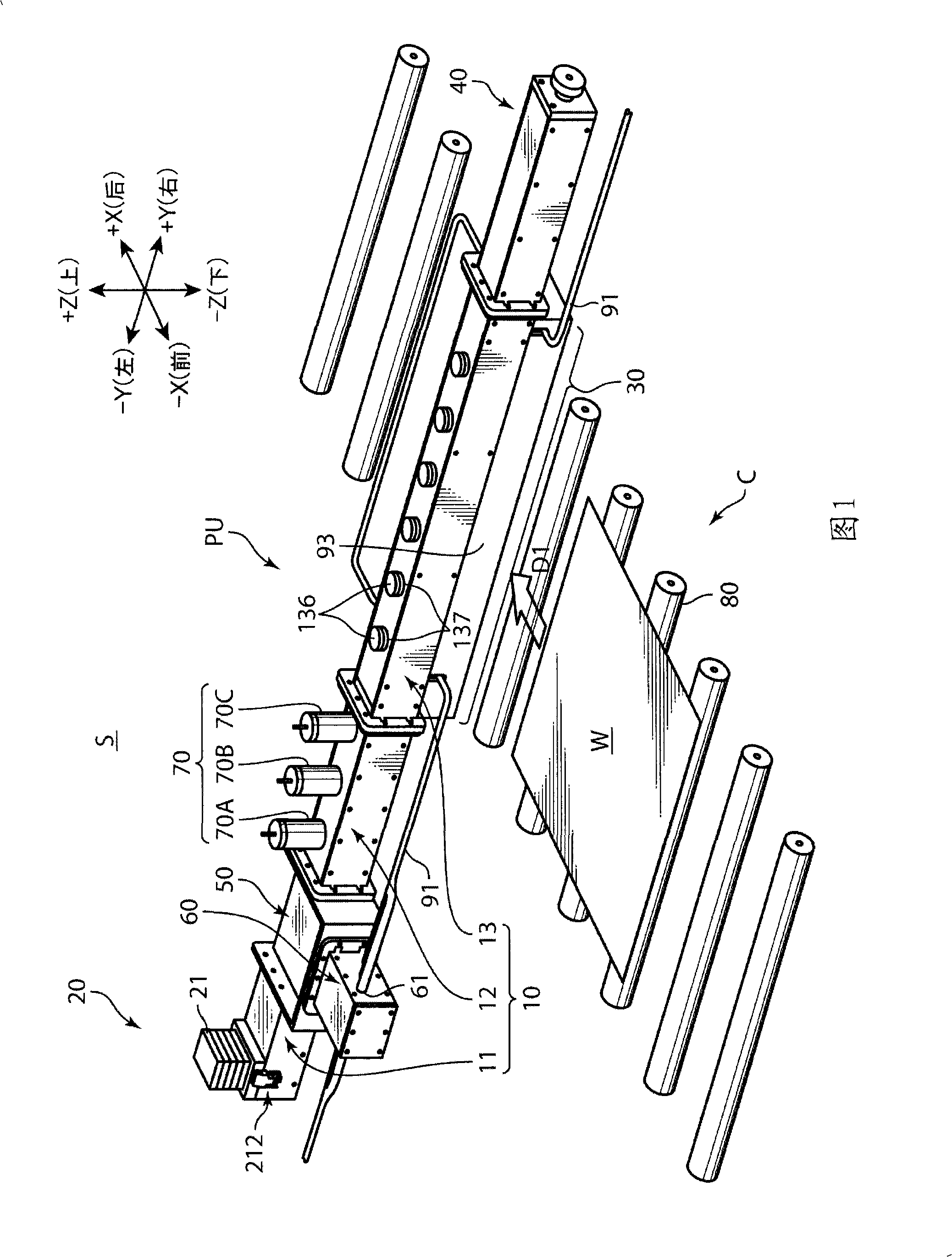

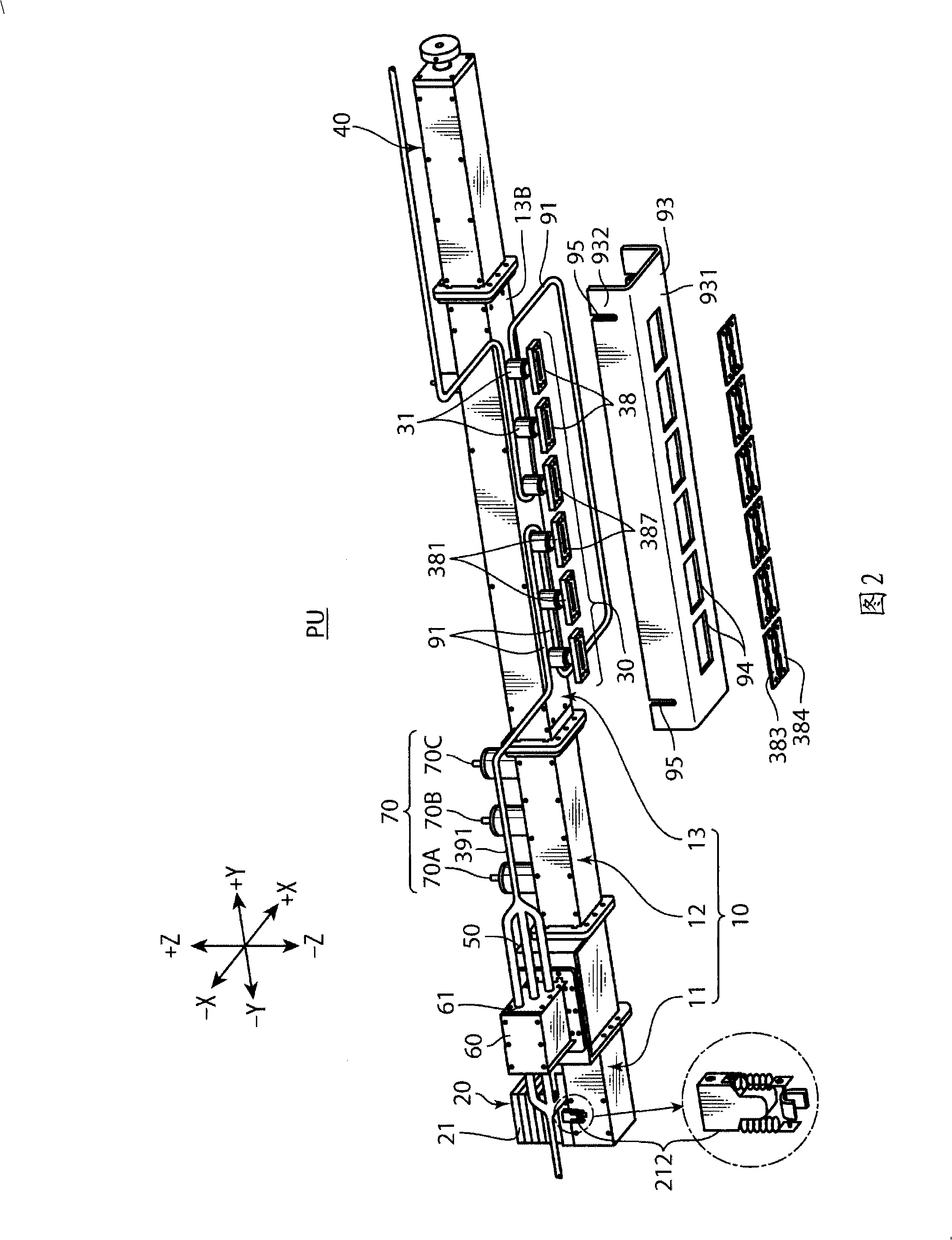

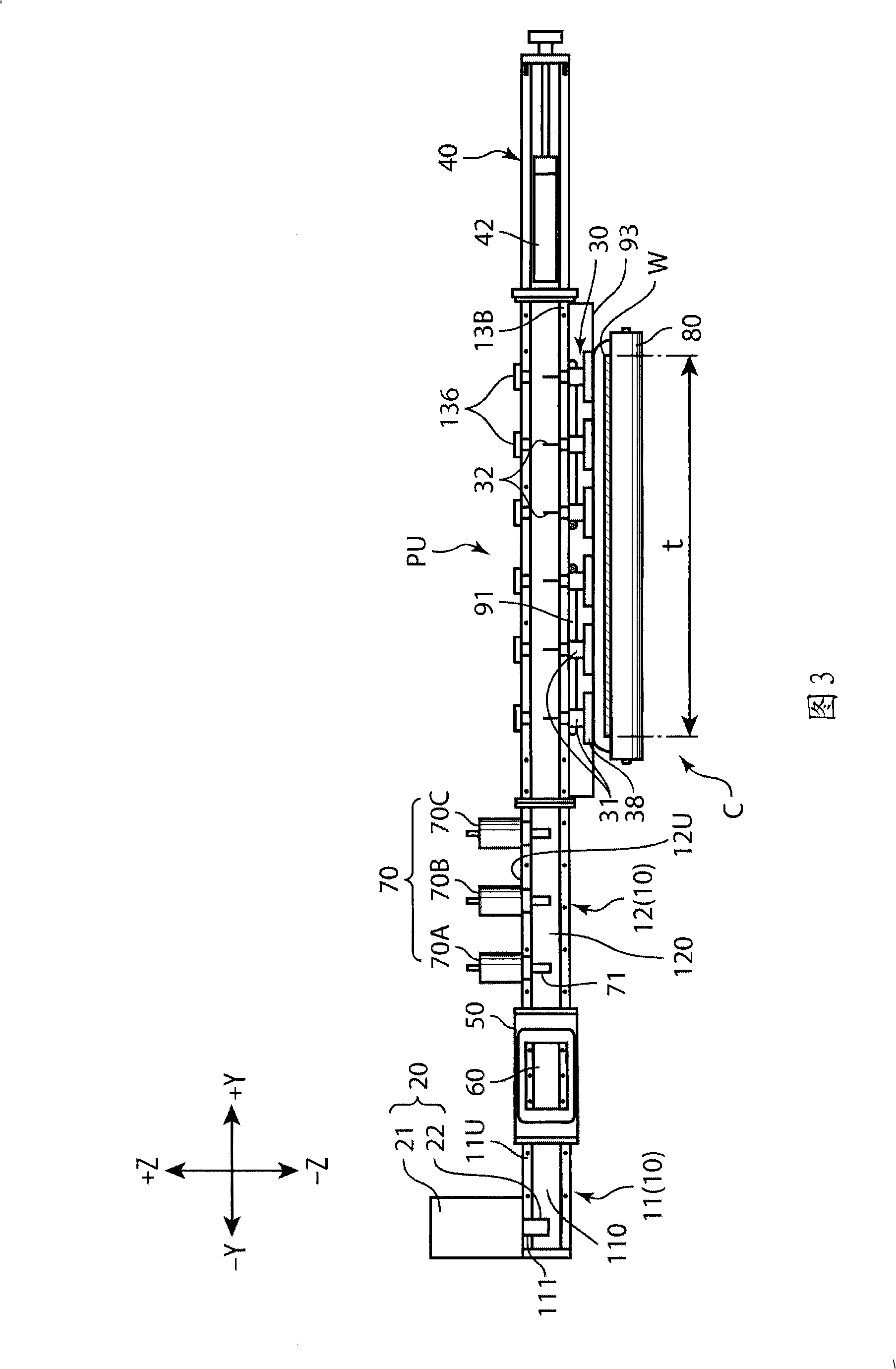

Plasma generator and workpiece processing apparatus using the same

InactiveUS20080296268A1Suppress scatterAvoid coolingElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma disappearance ratePlasma generator

Disclosed are a plasma generator and a workpiece processing apparatus, wherein an adapter 38 is attached to a distal end of each of a plurality of plasma generation nozzles 31 to convert a spot-shaped spout port of the plasma generation nozzle 31 to a lengthwise sport port 387, and a cover member 93 is provided to cover the plasma generation nozzles 31 so as to allow a narrow space to be defined between the cover member 93 and a workpiece, whereby plasma spouted from the spout port 387 is retained in the space in such a manner as to hit against and rebound from the workpiece into the space. This makes it possible to subject a workpiece having a relatively large surface area to plasma exposure in a uniform manner, while suppressing cooling of plasma in the space to allow the plasma to survive for a relatively long period of time (reduce a plasma disappearance rate) so as to provide enhanced efficiency of plasma exposure.

Owner:SAIAN CORP

Harmonic cold plasma devices and associated methods

A nozzle for attachment to a cold plasma device configured to maintain delivery of a stable cold plasma. The nozzle can have many different shaped apertures to support different applications requiring different shaped cold plasma plumes. Use of a disc of foam material within a nozzle can expand the size of aperture of a nozzle while maintaining delivery of a stable cold plasma. The nozzle can be an elongated cannula tube for internal delivery of a cold plasma treatment. The cannula tube can provide an aperture at its distal end or one or more apertures along its length. A shroud can partially enclose the distal aperture of the nozzle. A sterile sleeve can be used in conjunction with a nozzle to provide a sterile means of attachment and operation of the nozzle with a cold plasma device. In addition, various shaped apertures may be deployed to provide selective targeting of the cold plasma to a treatment area, while shielding other biological structures from cold plasma exposure. Such apertures also provide an opportunity for manual manipulation of tissues in the treatment area prior to or during cold plasma treatment.

Owner:COLD PLASMA MEDICAL TECH

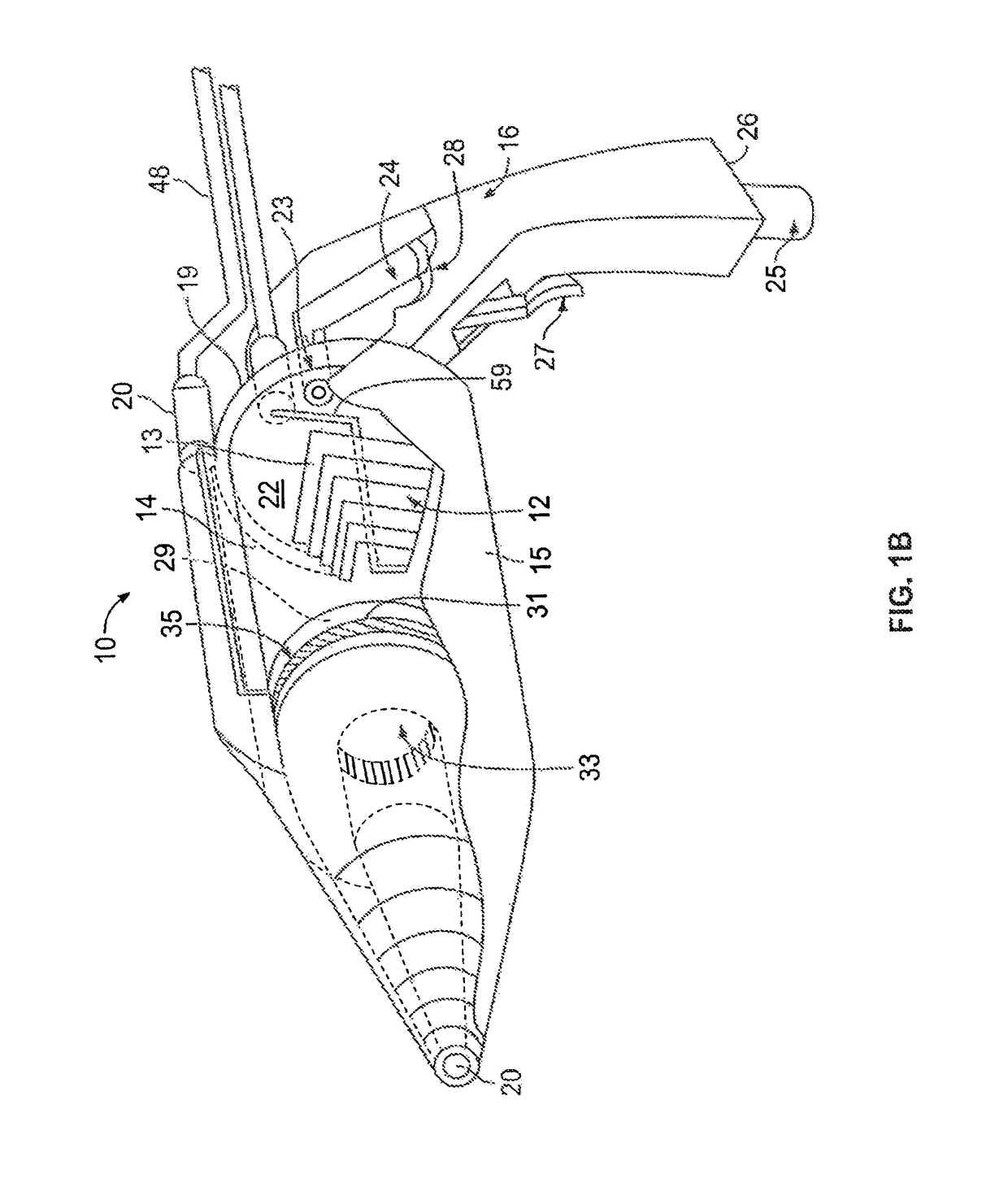

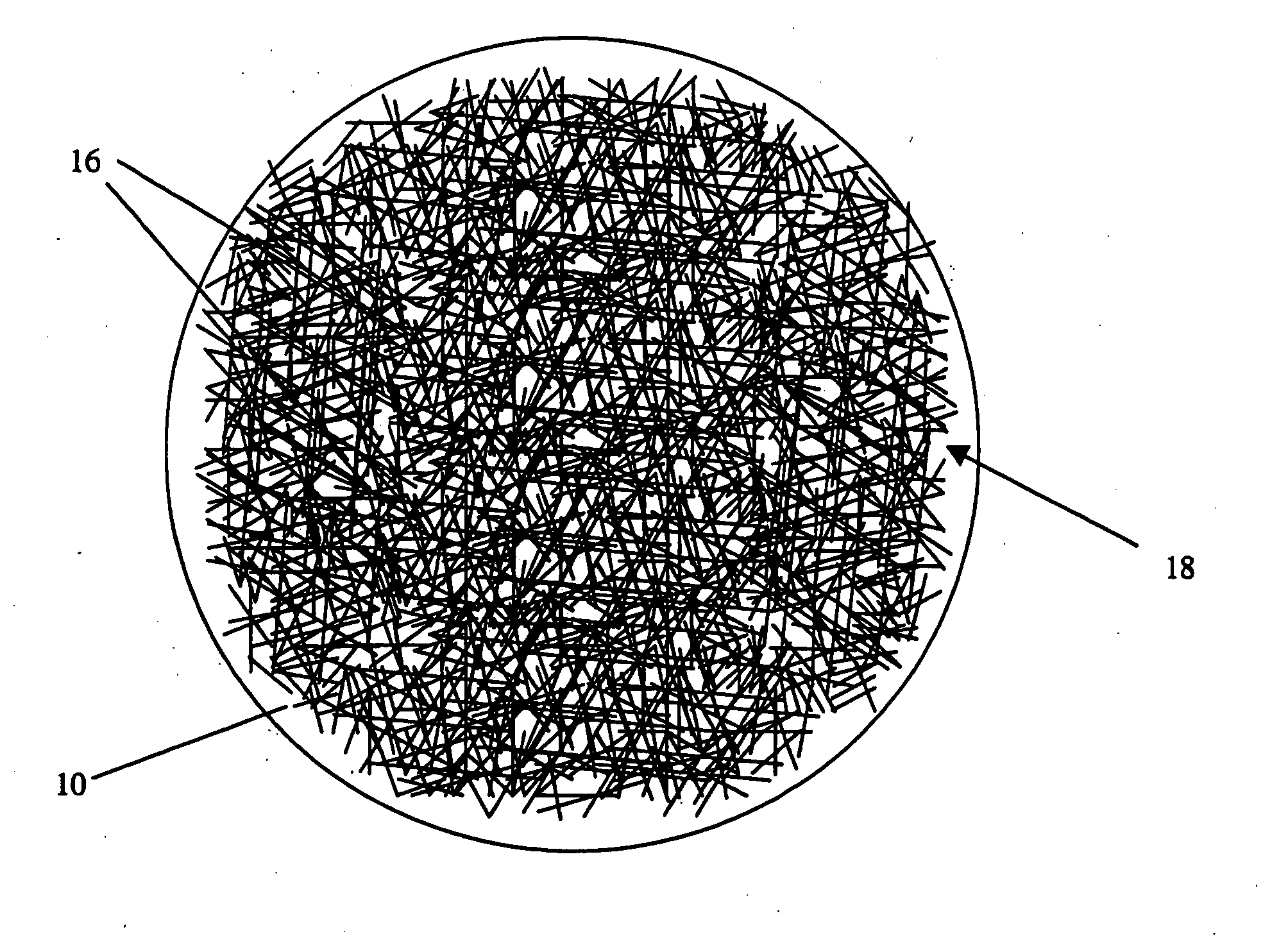

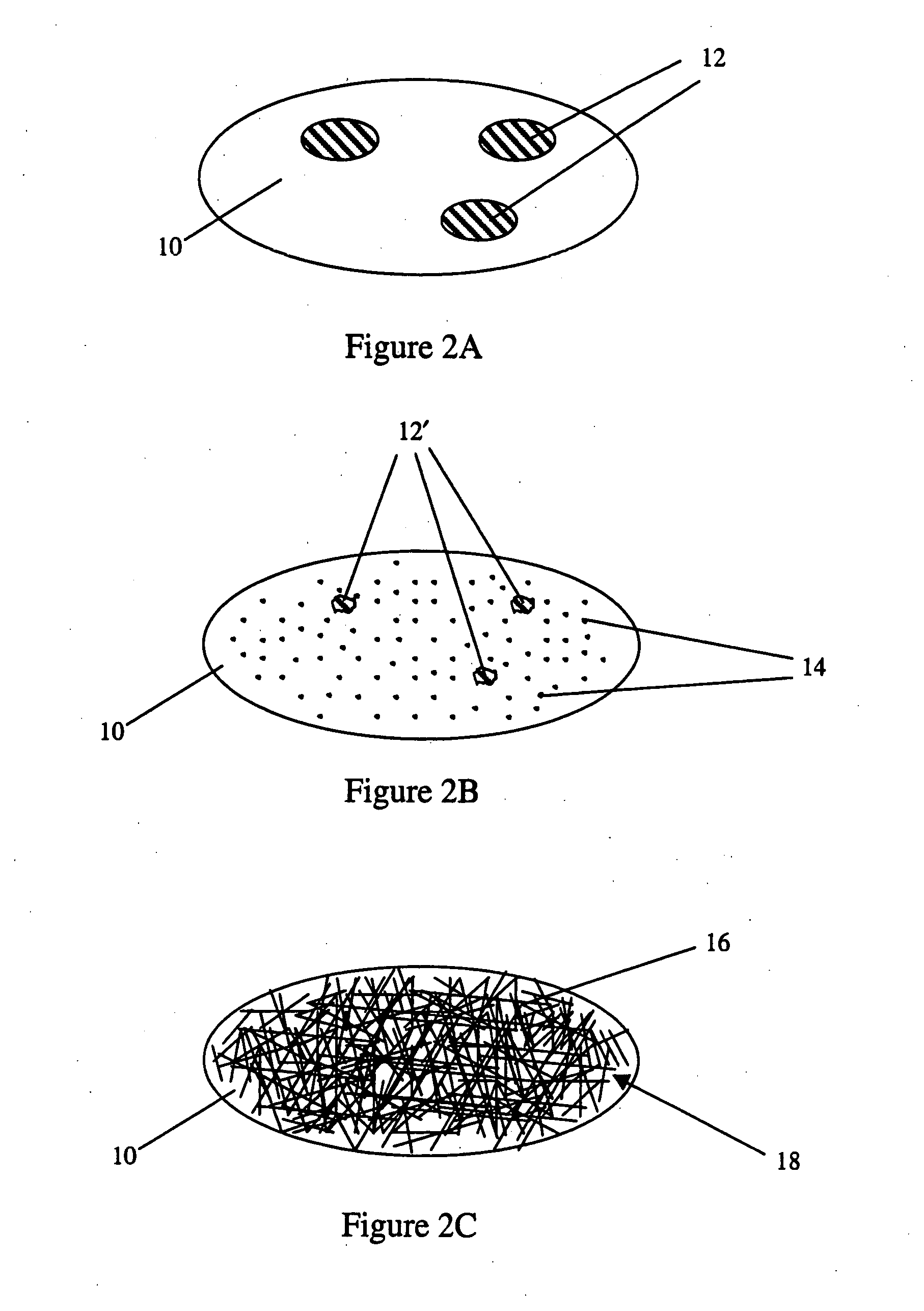

Dispersed growth of nanotubes on a substrate

Methods of forming a dispersion of nanostructures, a distribution of carbon nanotubes, and an array of nanostructure devices are described. The methods involve providing a substrate, applying growth promoter to at least a portion of the substrate, exposing the substrate and the growth promoter to a plasma, and forming a dispersion of nanostructures from the growth promoter after the plasma exposure. Exposing the substrate and the growth promoter to a plasma disperses at least a portion of the growth promoter as distinct, isolated growth promoter areas over the substrate. Preferably, the growth promoter areas are nanoparticles between about 1 nm and 50 nm in size and they are dispersed approximately uniformly over the substrate. An array of nanostructure devices is also described. The array of devices includes a substrate, a dispersion of nanostructures disposed discontinuously on the substrate and an array of electrodes in contact with the dispersion of nanostructures. The nanostructures may be nanotubes or nanowires. Preferably, the dispersion of nanostructures is approximately planar and substantially in contact with the substrate. Regions containing nanostructures can provide electrical communication between two or more electrodes.

Owner:NANOMIX

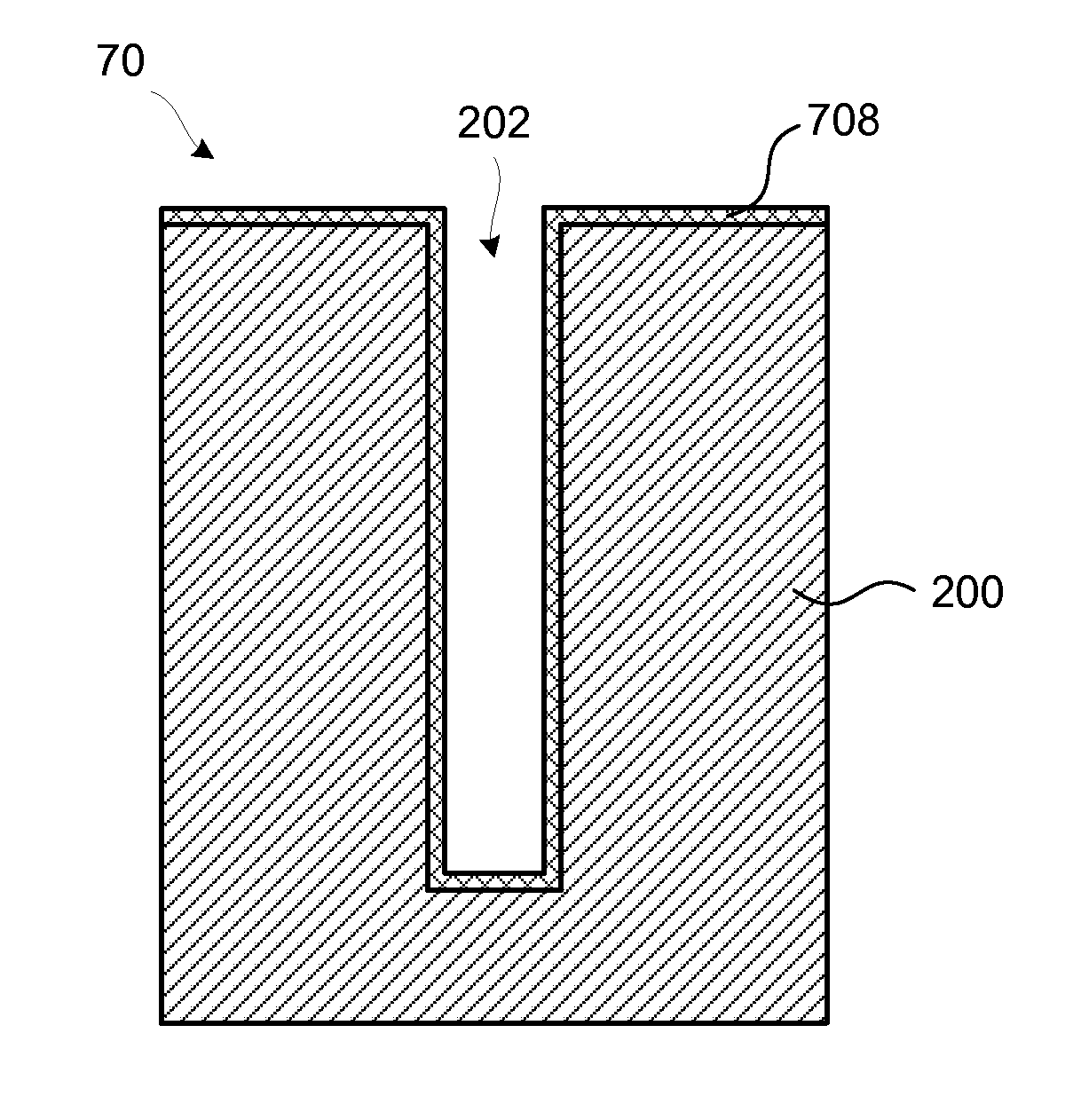

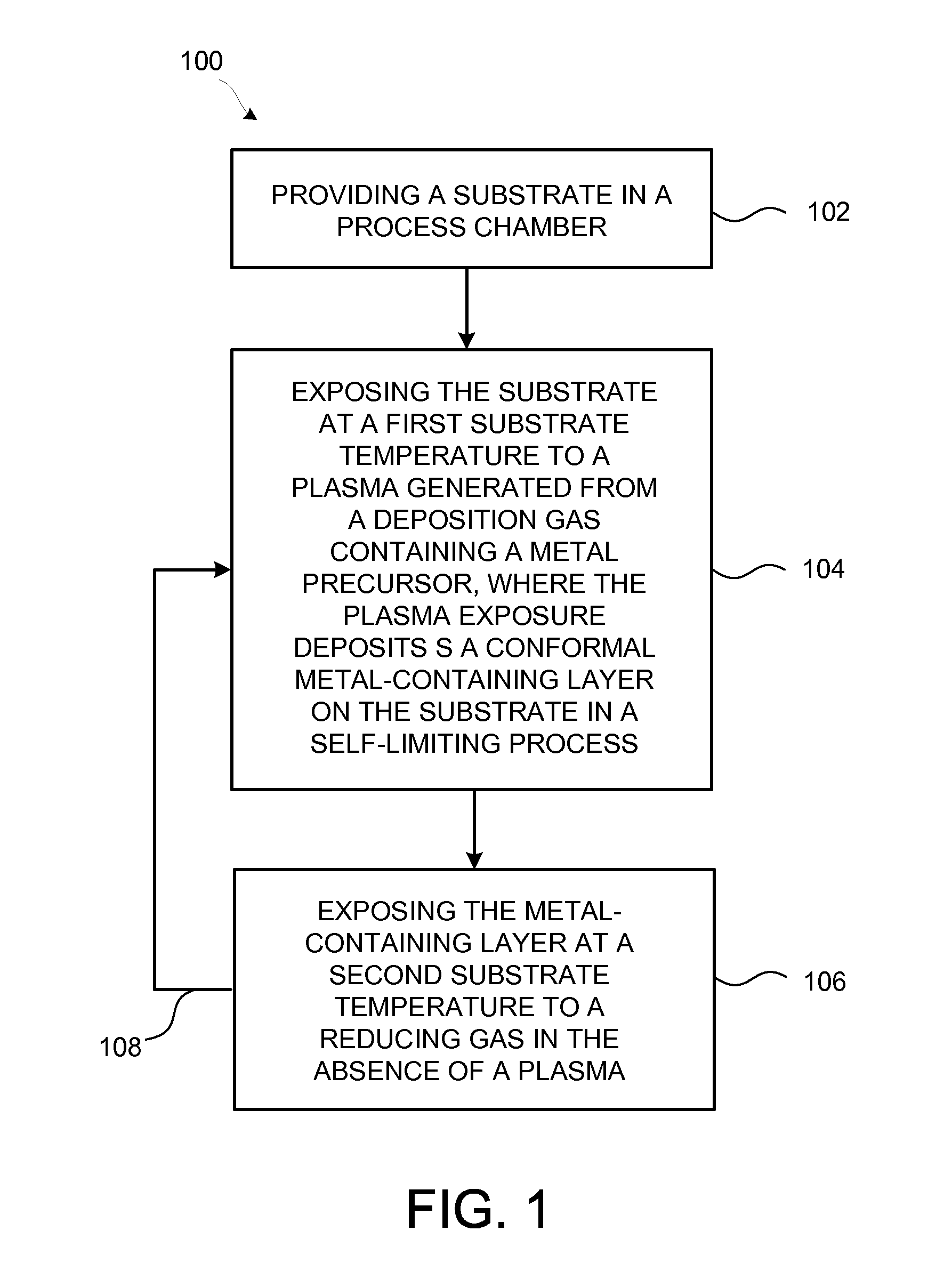

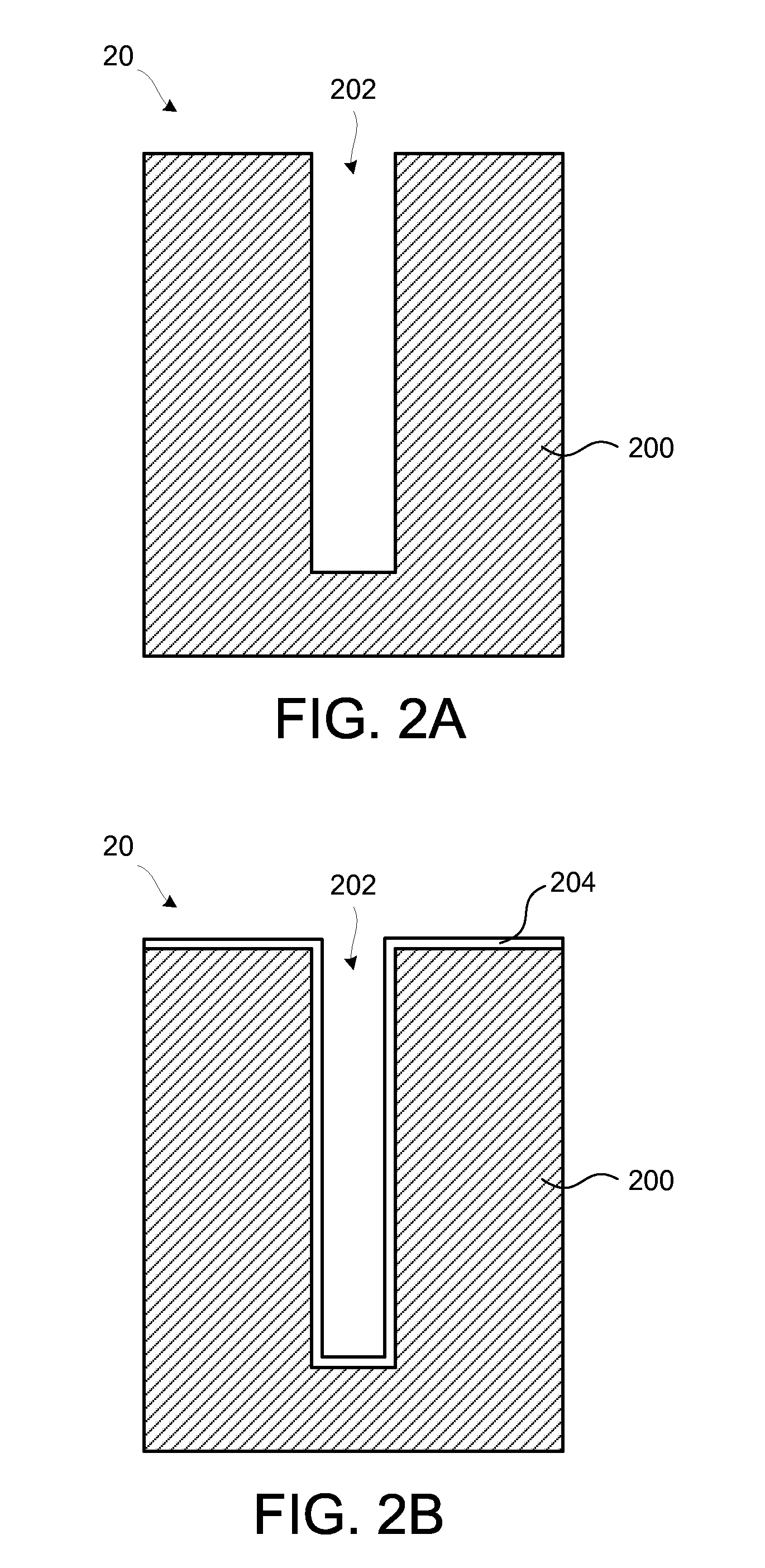

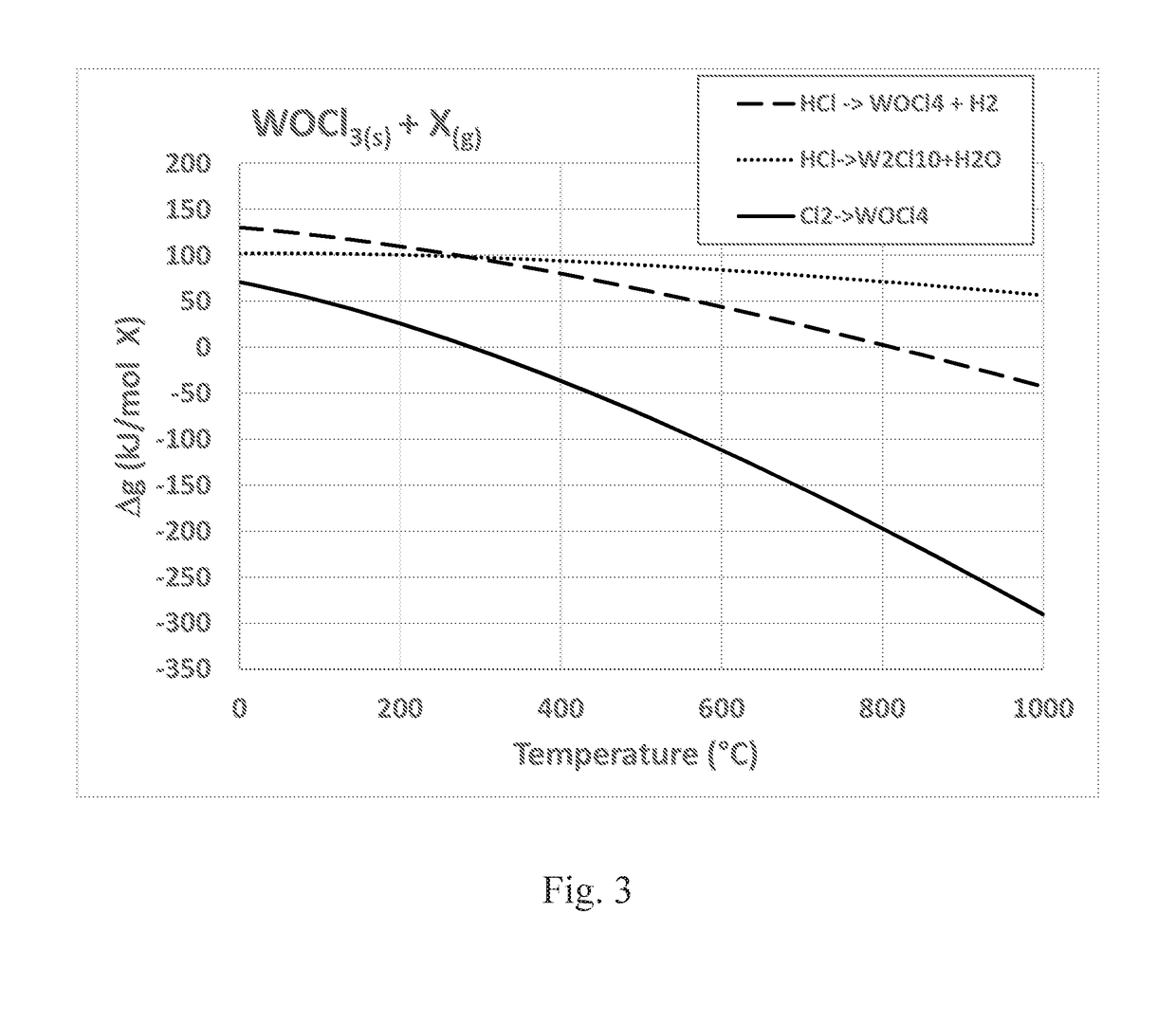

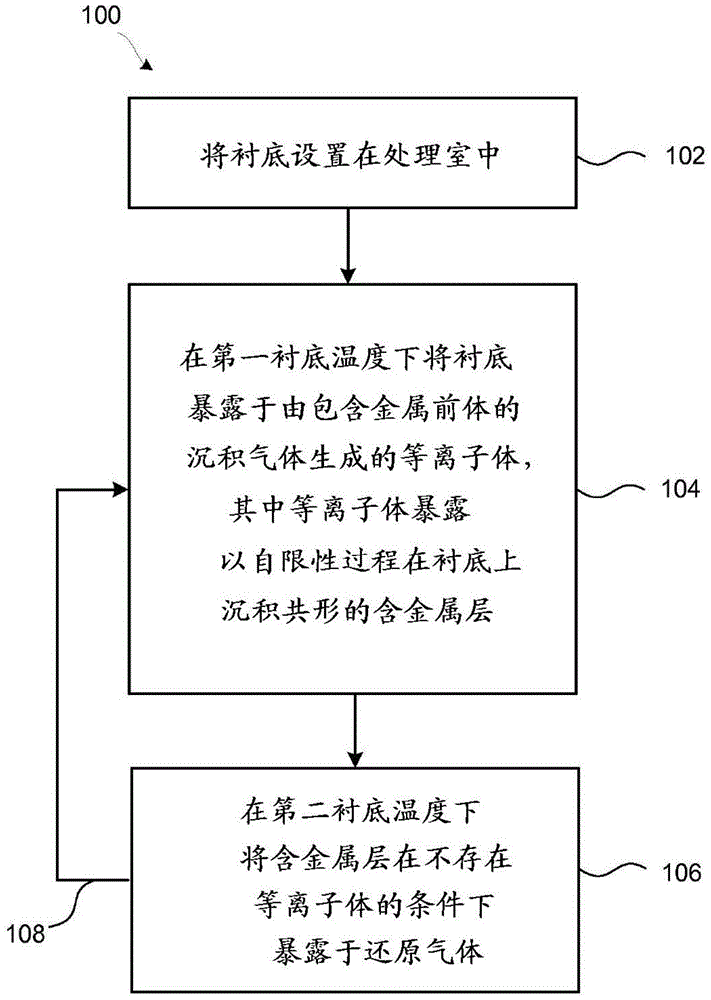

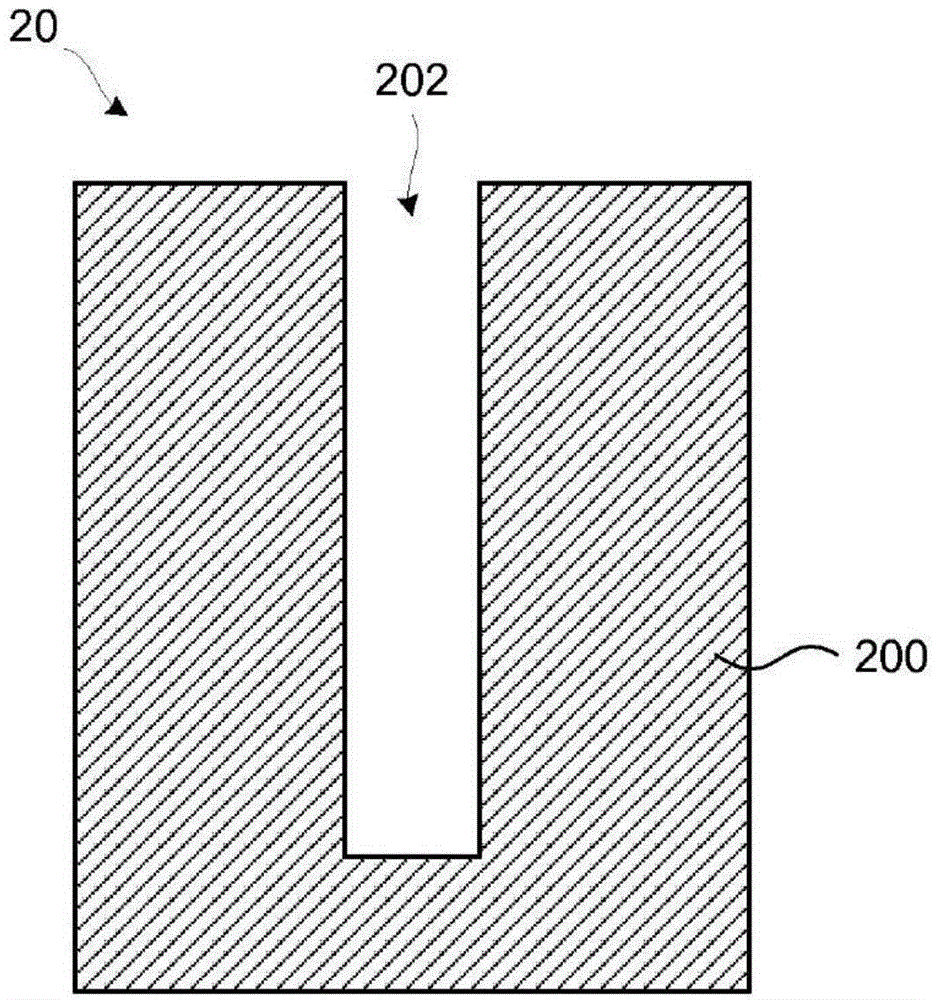

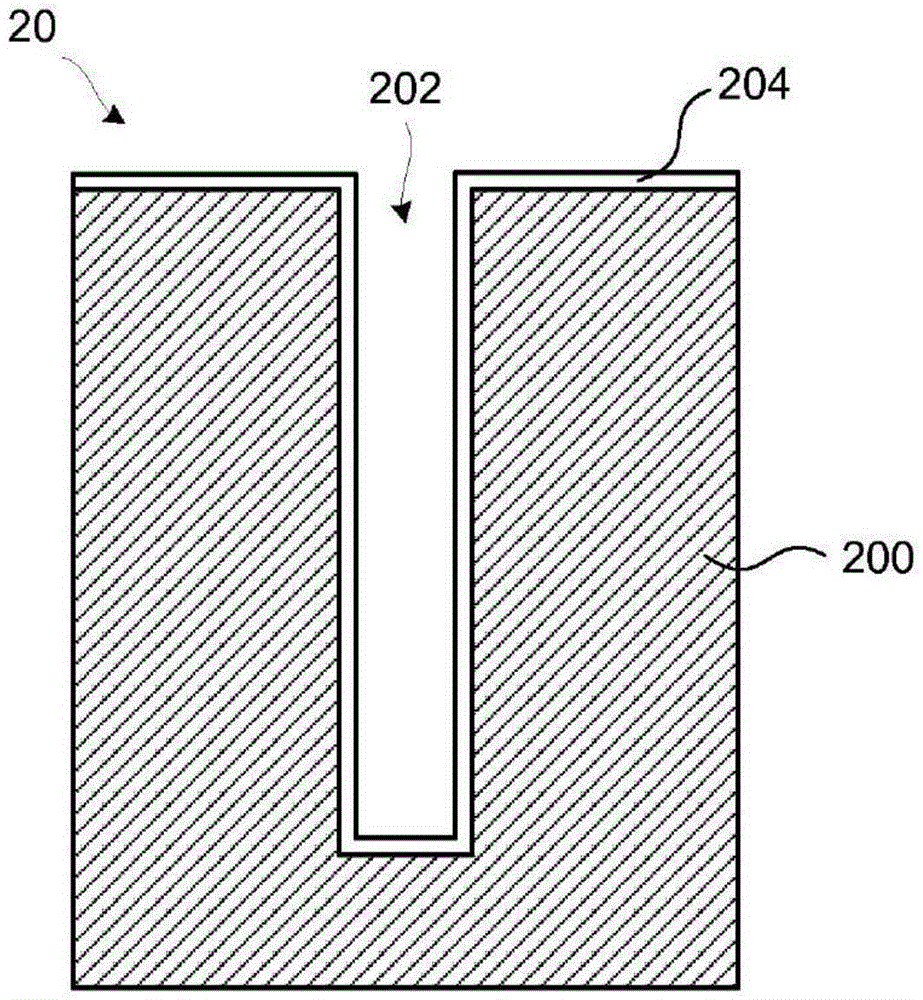

Method of forming conformal metal silicide films

InactiveUS20130196505A1Semiconductor/solid-state device manufacturingCapacitorsSelf limitingMetal silicide

A method is provided for forming a metal silicide layer on a substrate. According to one embodiment the method includes providing the substrate in a process chamber, exposing the substrate at a first substrate temperature to a plasma generated from a deposition gas containing a metal precursor, where the plasma exposure forms a conformal metal-containing layer on the substrate in a self-limiting process. The method further includes exposing the metal-containing layer at a second substrate temperature to a reducing gas in the absence of a plasma, where the exposing steps are alternatively performed at least once to form the metal silicide layer, and the deposition gas does not contain the reducing gas. The method provides conformal metal silicide formation in deep trenches with high aspect ratios.

Owner:TOKYO ELECTRON LTD

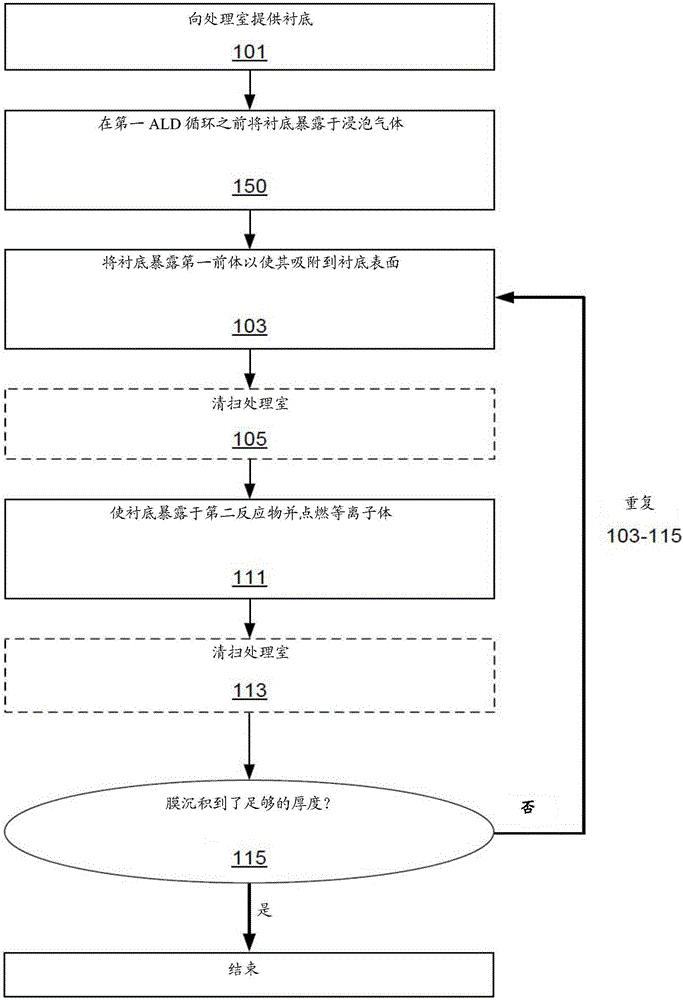

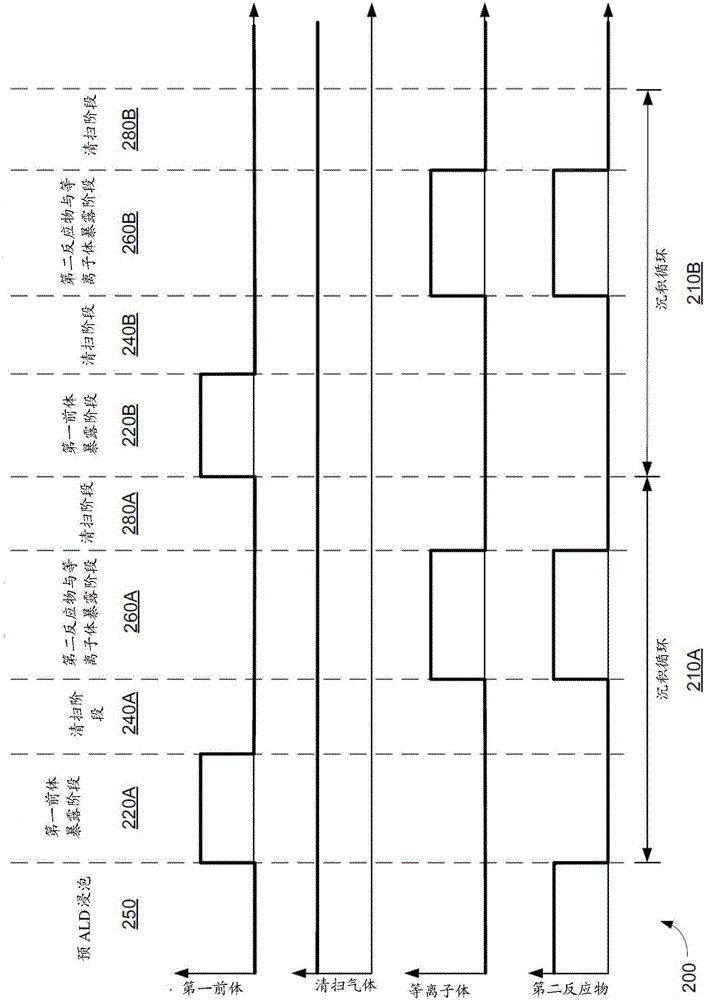

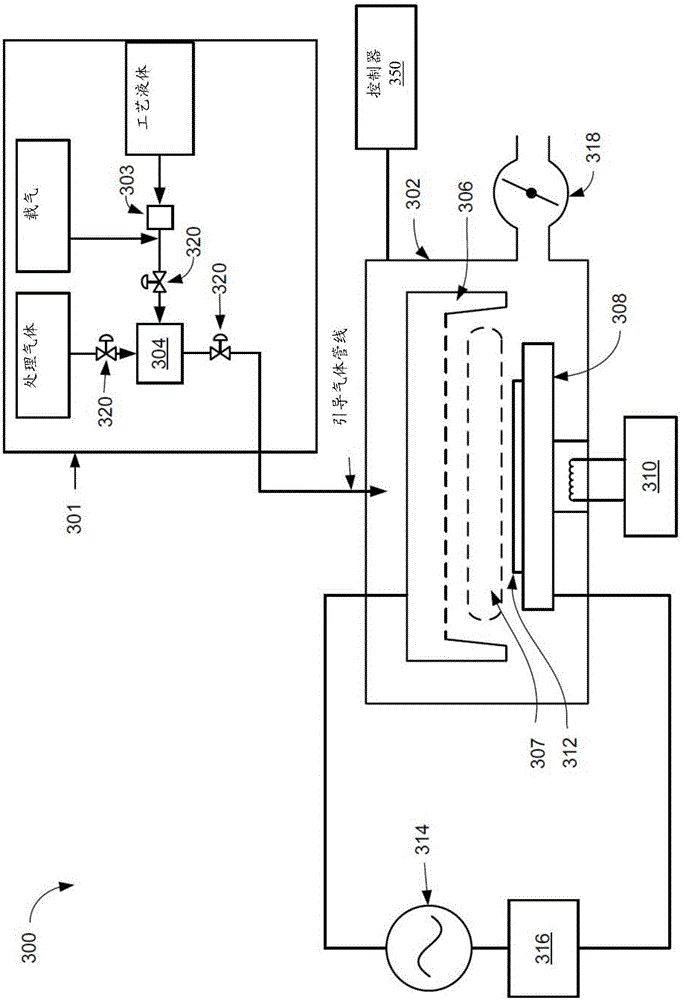

Ultrathin atomic layer deposition film accuracy thickness control

ActiveCN105990108AElectric discharge tubesSemiconductor/solid-state device manufacturingDeposition temperatureOptoelectronics

The present invention relates to ultrathin atomic layer deposition film accuracy thickness control. Methods for depositing ultrathin films by atomic layer deposition with reduced wafer-to-wafer variation are provided. Methods involve exposing the substrate to soak gases including one or more gases used during a plasma exposure operation of an atomic layer deposition cycle prior to the first atomic layer deposition cycle to heat the substrate to the deposition temperature.

Owner:LAM RES CORP

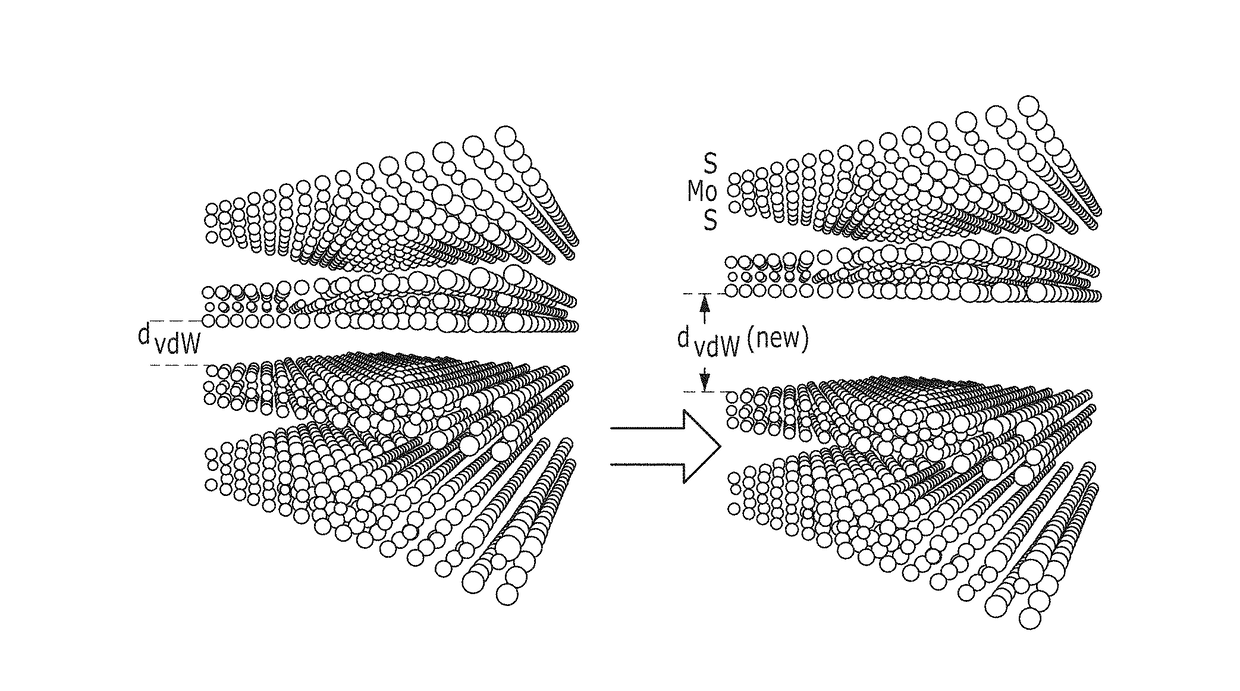

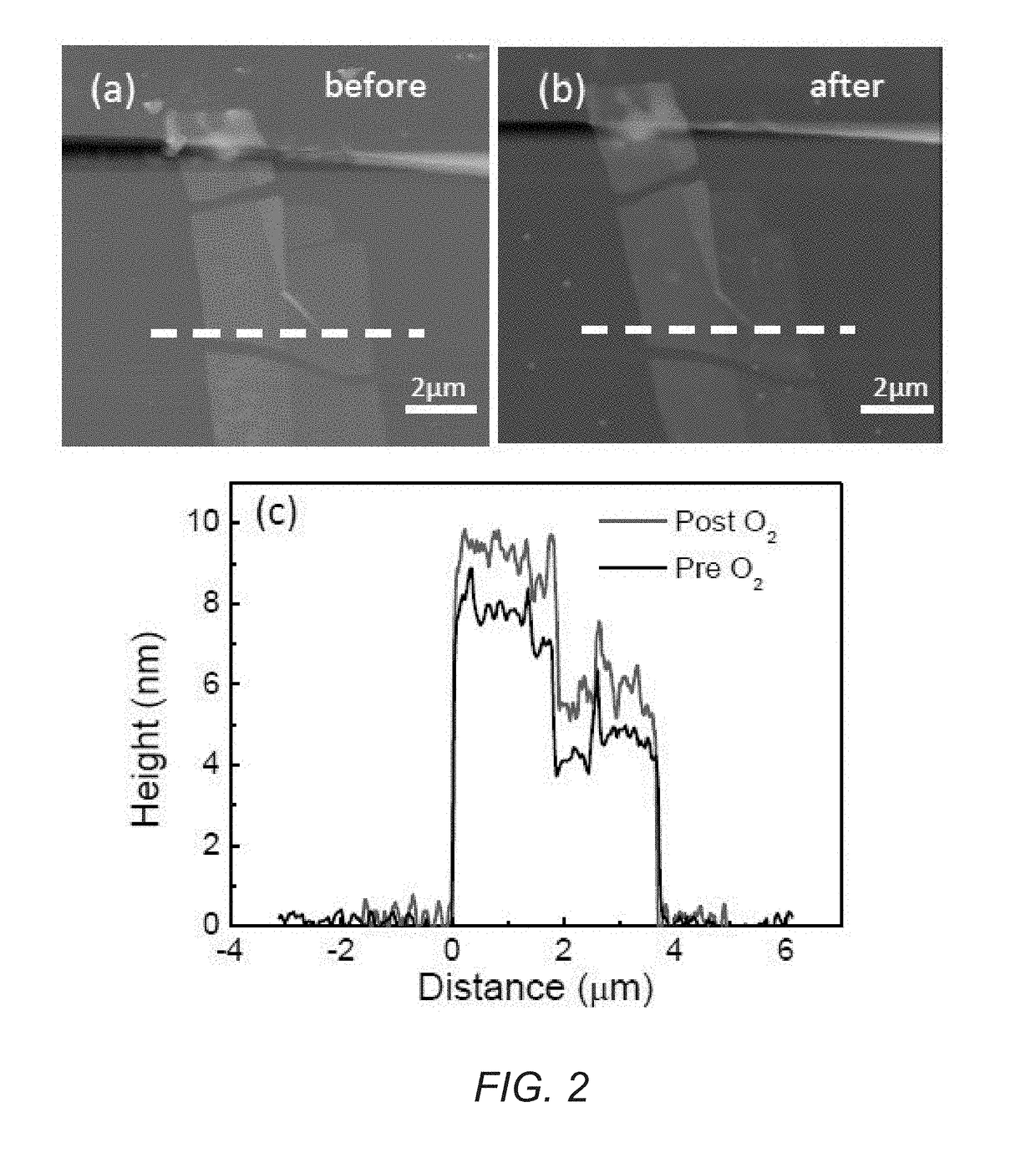

Bulk direct gap mos2 by plasma induced layer decoupling

ActiveUS20180026422A1Increased interlayer separationLong photo-excited carrier lifetimeNon-metal conductorsLaser detailsPhotoluminescencePhotodetector

Bulk direct transition metal dichalcogenide (TMDC) may have an increased interlayer separation of at least 0.5, 1, or 3 angstroms more than its bulk value. The TMDC may be a bulk direct band gap molybdenum disulfide (MoS2) or a bulk direct band gap tungsten diselenide (WSe2). Oxygen may be between the interlayers. A device may include the TMDC, such as an optoelectronic device, such as an LED, solid state laser, a photodetector, a solar cell, a FET, a thermoelectric generator, or a thermoelectric cooler. A method of making bulk direct transition metal dichalcogenide (TMDC) with increased interlayer separation may include exposing bulk direct TMDC to a remote (aka downstream) oxygen plasma. The plasma exposure may cause an increase in the photoluminescence efficiency of the TMDC, more charge neutral doping, or longer photo-excited carrier lifetimes, as compared to the TMDC without the plasma exposure.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

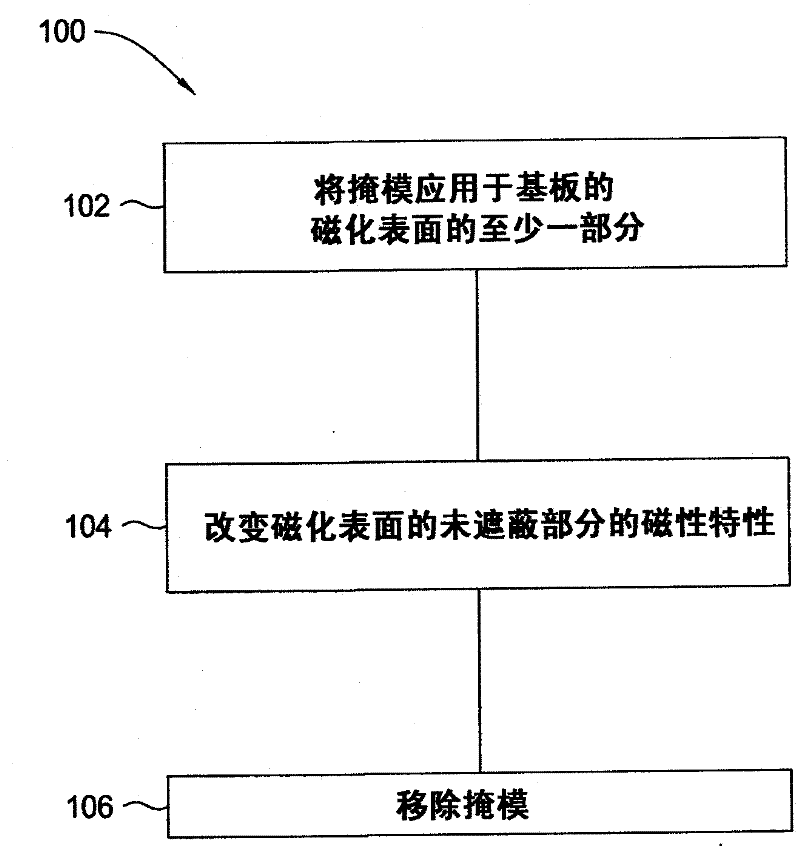

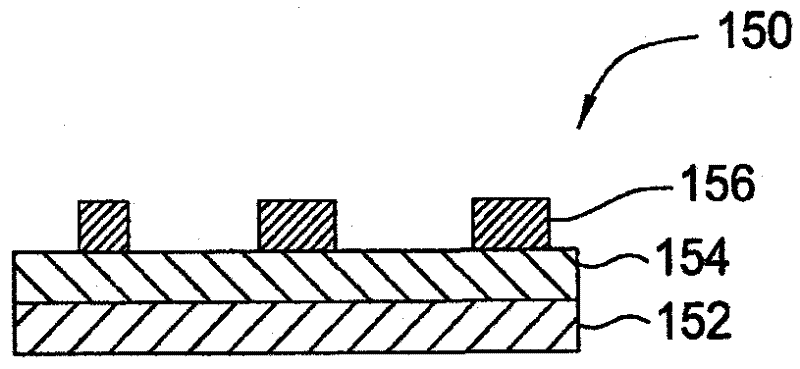

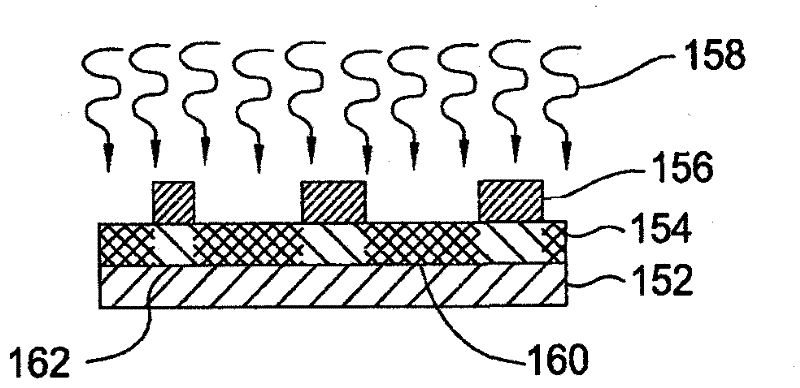

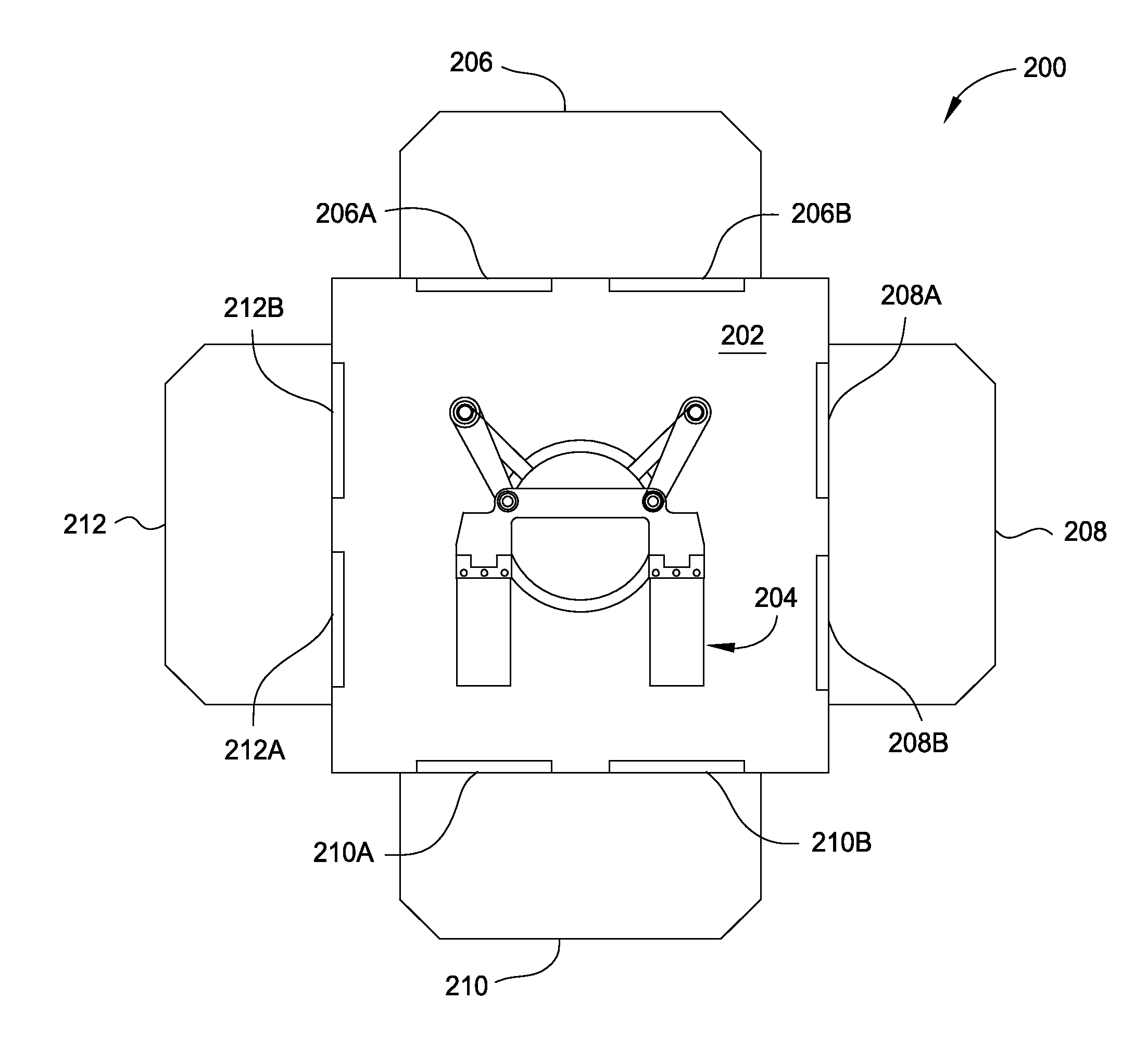

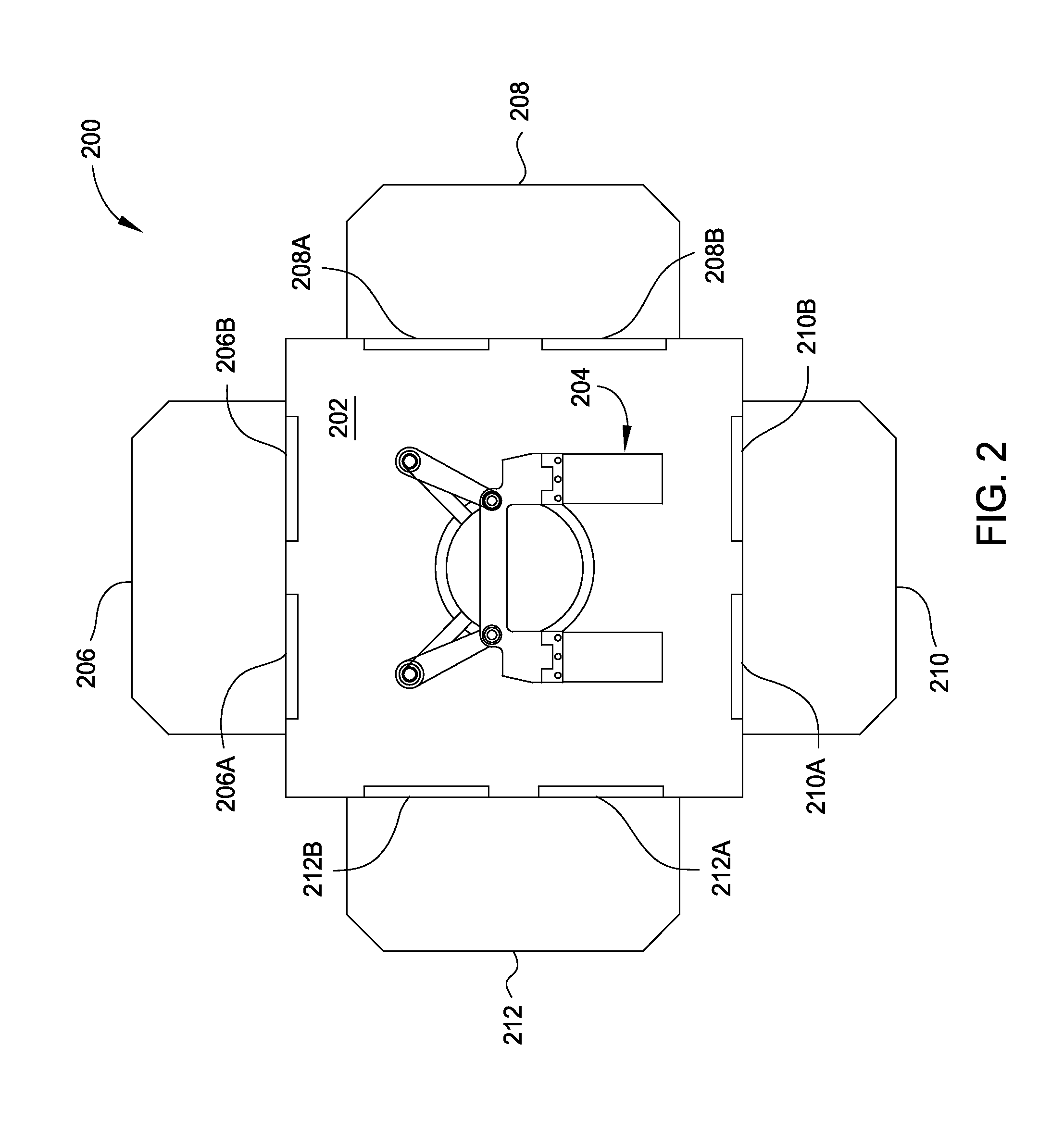

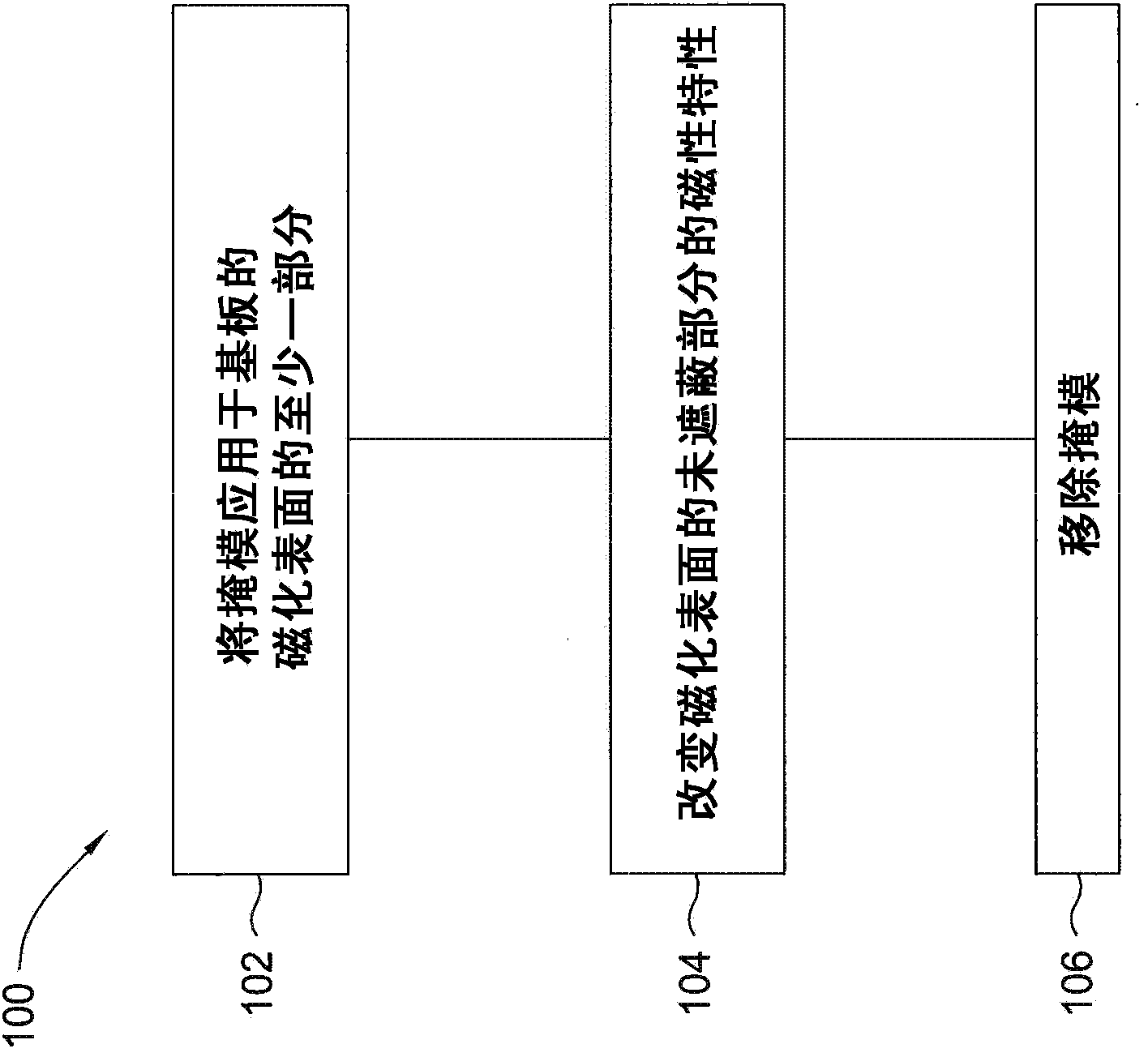

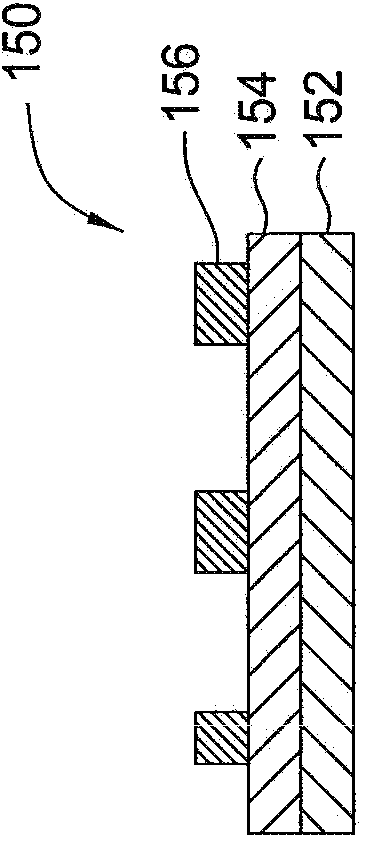

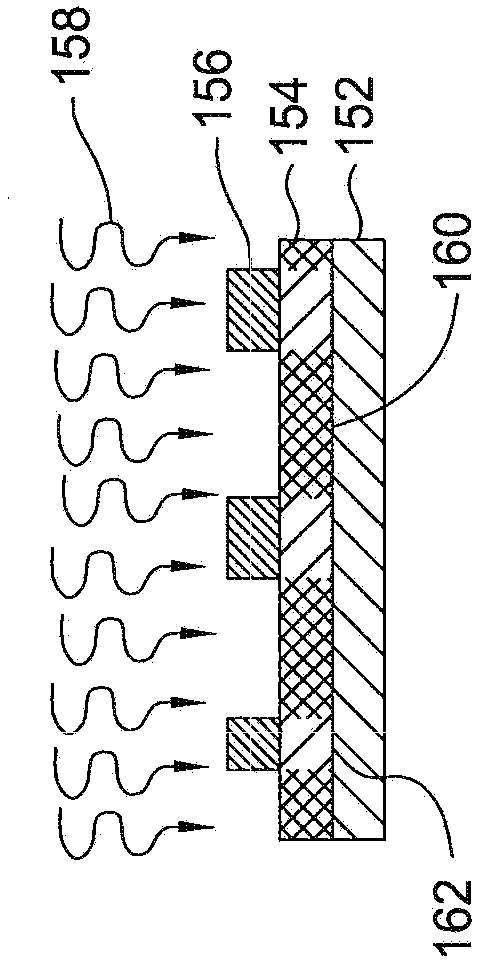

Hdd pattern implant system

InactiveCN102334161ABase layers for recording layersVacuum evaporation coatingPlasma exposureTopography

Methods and apparatus for forming substrates having magnetically patterned surfaces is provided. A magnetic layer comprising one or more materials having magnetic properties is formed on a substrate. The magnetic layer is subjected to a patterning process in which selected portions of the surface of the magnetic layer are altered such that the altered portions have different magnetic properties from the non-altered portions without changing the topography of the substrate. A protective layer and a lubricant layer are deposited over the patterned magnetic layer. The patterning is accomplished through a number of processes that expose substrates to energy of varying forms. Apparatus and methods disclosed herein enable processing of two major surfaces of a substrate simultaneously, or sequentially by flipping. In some embodiments, magnetic properties of the substrate surface may be uniformly altered by plasma exposure and then selectively restored by exposure to patterned energy.

Owner:APPLIED MATERIALS INC

Fluorine-resin sealing ring

InactiveCN104508334AGuaranteed tightnessEnsure slidingEngine sealsOther chemical processesAutomatic transmissionReciprocating motion

A PTFE resin sealing ring in which at least one surface of an abutting part that forms a discontinuity in the sealing ring has been subjected to a plasma-modification treatment using a non-polymerizable gas and a pressure during plasma exposure of 10 to 500 Pa. Since the abutting surface(s) of this PTFE resin sealing ring has / have been subjected to a low-pressure plasma treatment, changing the states of the C-F bonds in the surface region(s), the abutting part does not stick even after a steady load has been applied at a high temperature, producing the prominent effect of ensuring both sealing performance under pressure and the ability to slide when not under pressure. This sealing ring is effective as a sealing material used with rotation or reciprocal motion, including a hydraulic circuit in a continuously variable transmission (CVT) or an automatic transmission (A / T) in an automobile, for example.

Owner:NOK CORP

Photoelectric conversion device

InactiveUS20110120521A1Suppress leakage currentReduce contact resistancePV power plantsVacuum evaporation coatingHydrogenCell layer

Provided is a photoelectric conversion device in which the conductivity after hydrogen-plasma exposure is set within an appropriate range, thereby suppressing the leakage current and improving the conversion efficiency. A photoelectric conversion device includes, on a substrate, a photoelectric conversion layer having at least two power generation cell layers, and an intermediate contact layer provided between the power generation cell layers. The intermediate contact layer mainly contains a compound represented by Zn1-xMgxO (0.096≦x≦0.183).

Owner:MITSUBISHI HEAVY IND LTD

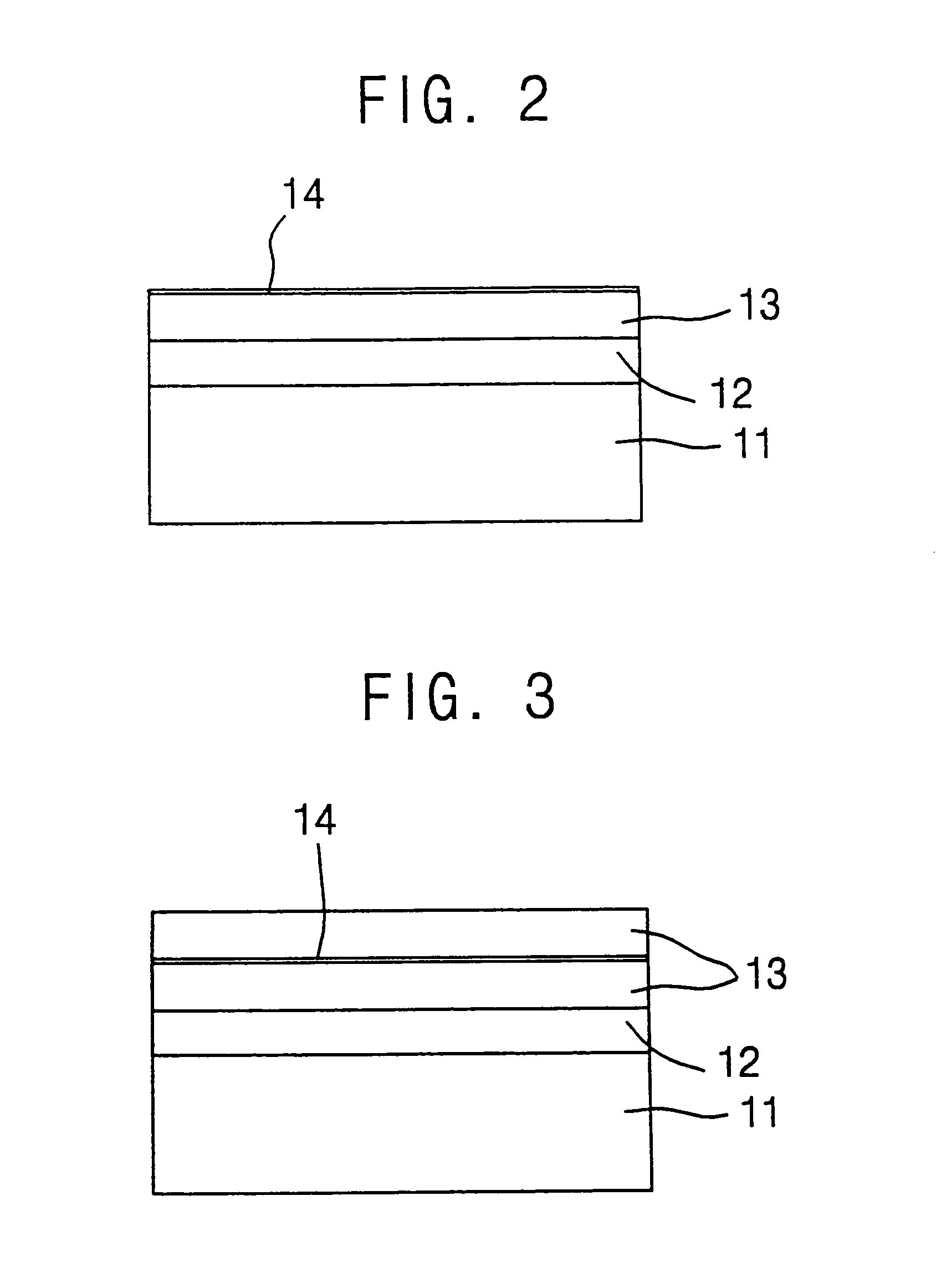

Method of crystallizing amorphous silicon layer and crystallizing apparatus thereof

InactiveUS7022191B2Improve crystallizationDecrease in crystallization temperatureAfter-treatment apparatusPolycrystalline material growthAmorphous siliconPlasma exposure

The present invention is related to a method of crystallizing an amorphous silicon layer and a crystallizing apparatus thereof which crystallize an amorphous silicon layer using plasma. The present invention includes the steps of depositing an inducing substance for silicon crystallization on an amorphous silicon layer by plasma exposure, and carrying out annealing on the amorphous silicon layer to the amorphous silicon layer. The present invention includes a chamber having an inner space, a substrate support in the chamber wherein the substrate support supports a substrate, a plasma generating means in the chamber wherein the plasma generating means produces plasma inside the chamber, and a heater at the substrate support wherein the heater supplies the substrate with heat.

Owner:JANG JIN

Plasma generator and workpiece processing apparatus using the same

InactiveCN101315875AElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma disappearance ratePlasma generator

Owner:SAIAN CORP

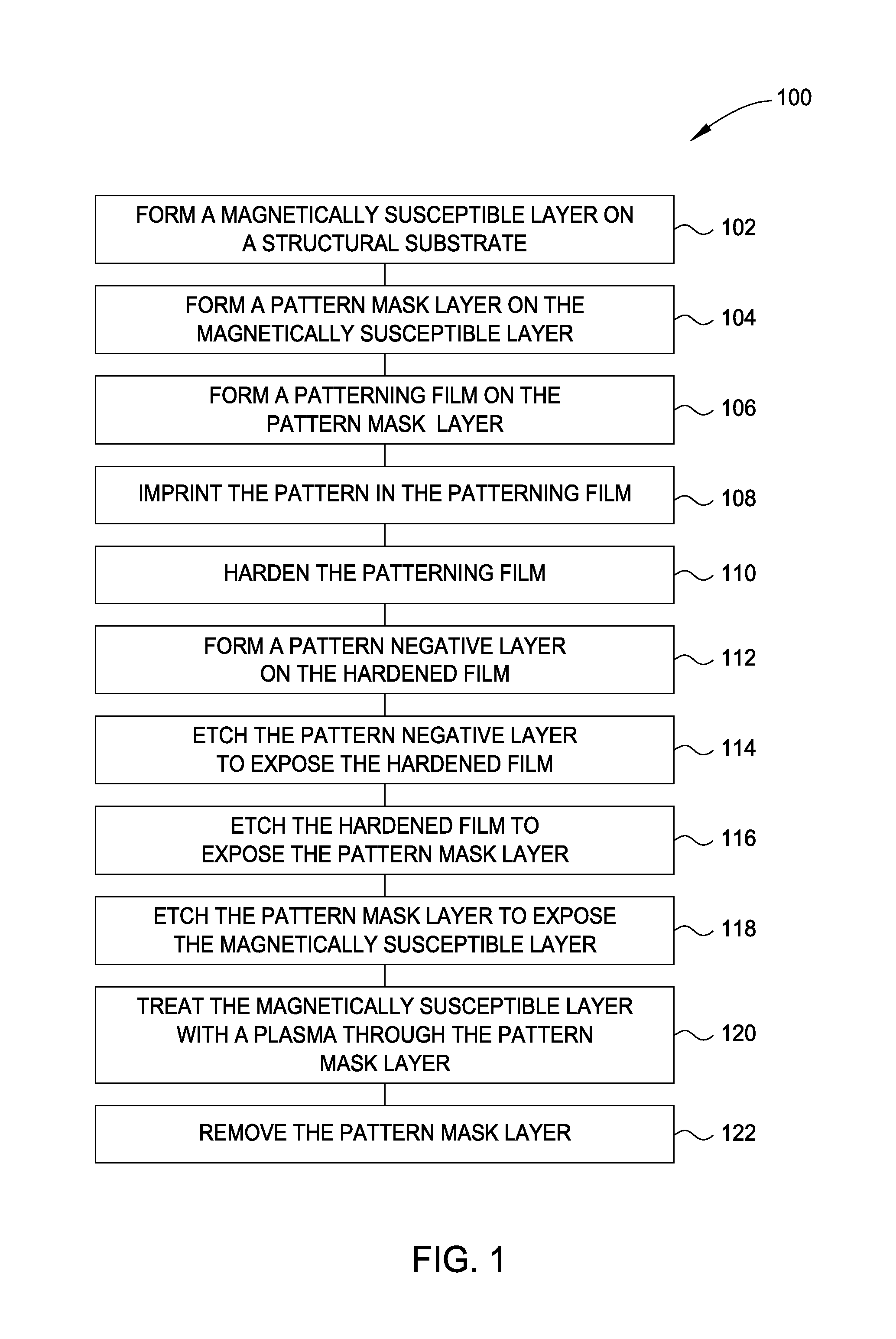

Pattern fortification for HDD bit patterned media pattern transfer

InactiveUS20140131308A1Decorative surface effectsPatterned record carriersRemote plasmaPlasma exposure

A method and apparatus for forming a magnetic layer having a pattern of magnetic properties on a substrate is described. The method includes using a metal nitride hardmask layer to pattern the magnetic layer by plasma exposure. The metal nitride layer is patterned using a nanoimprint patterning process with a silicon oxide pattern negative material. The pattern is developed in the metal nitride using a halogen and oxygen containing remote plasma, and is removed after plasma exposure using a caustic wet strip process. All processing is done at low temperatures to avoid thermal damage to magnetic materials.

Owner:APPLIED MATERIALS INC

Method for producing carbon surface films by plasma exposure of a carbide compound

InactiveUS7241475B2Reduce frictionEasy to controlChemical vapor deposition coatingFlexible microstructural devicesCarbon coatingCarbon film

Reactive halogen-ion plasmas, having for example, generating chloride ions, generated from low-pressure halogen gases using a radio-frequency plasma are employed for producing low-friction carbon coatings, such as a pure carbon film, at or near room temperature on a bulk or thin film of a compound, such as titanium carbide.

Owner:THE AEROSPACE CORPORATION

Hdd pattern implant system

InactiveCN103824569ABase layers for recording layersVacuum evaporation coatingMulti materialPlasma exposure

Owner:APPLIED MATERIALS INC

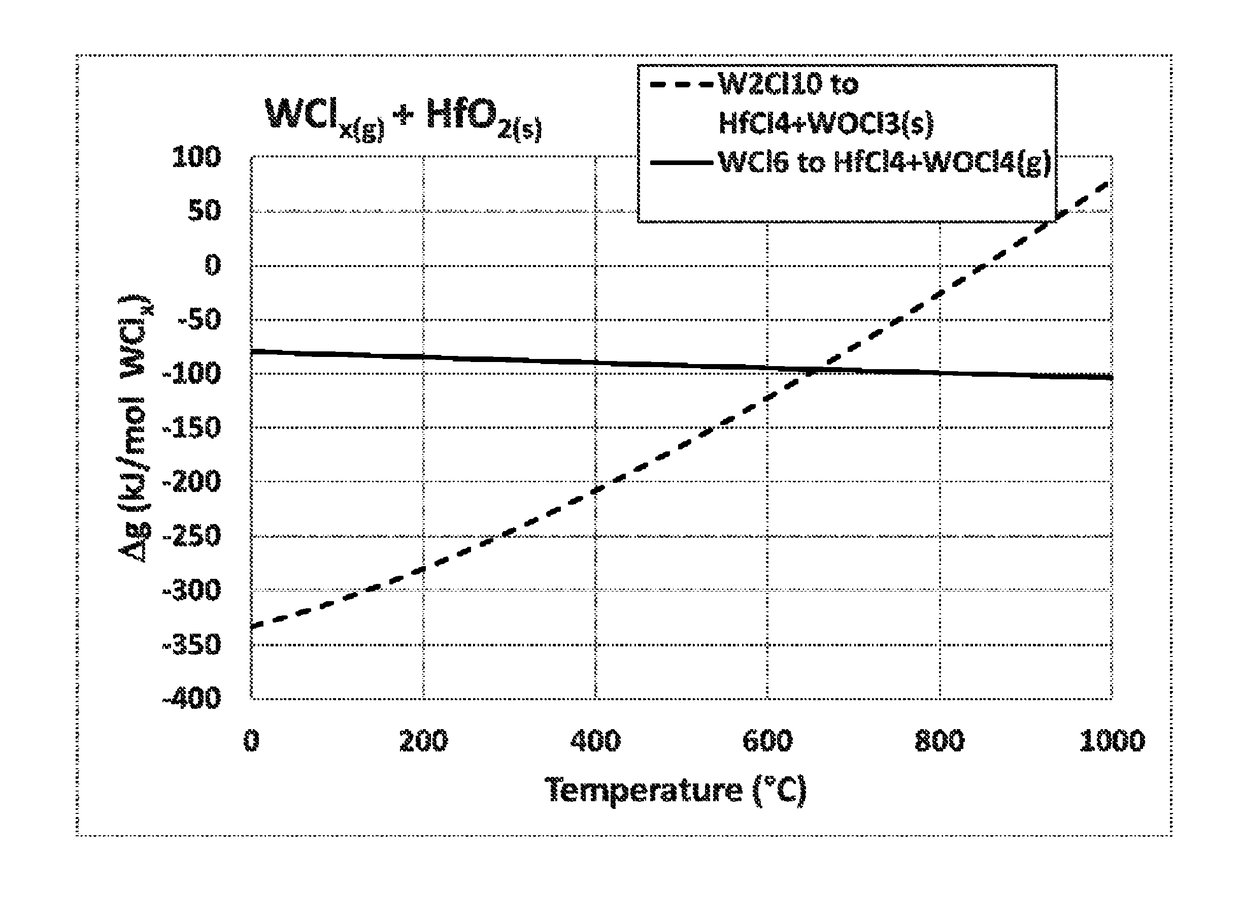

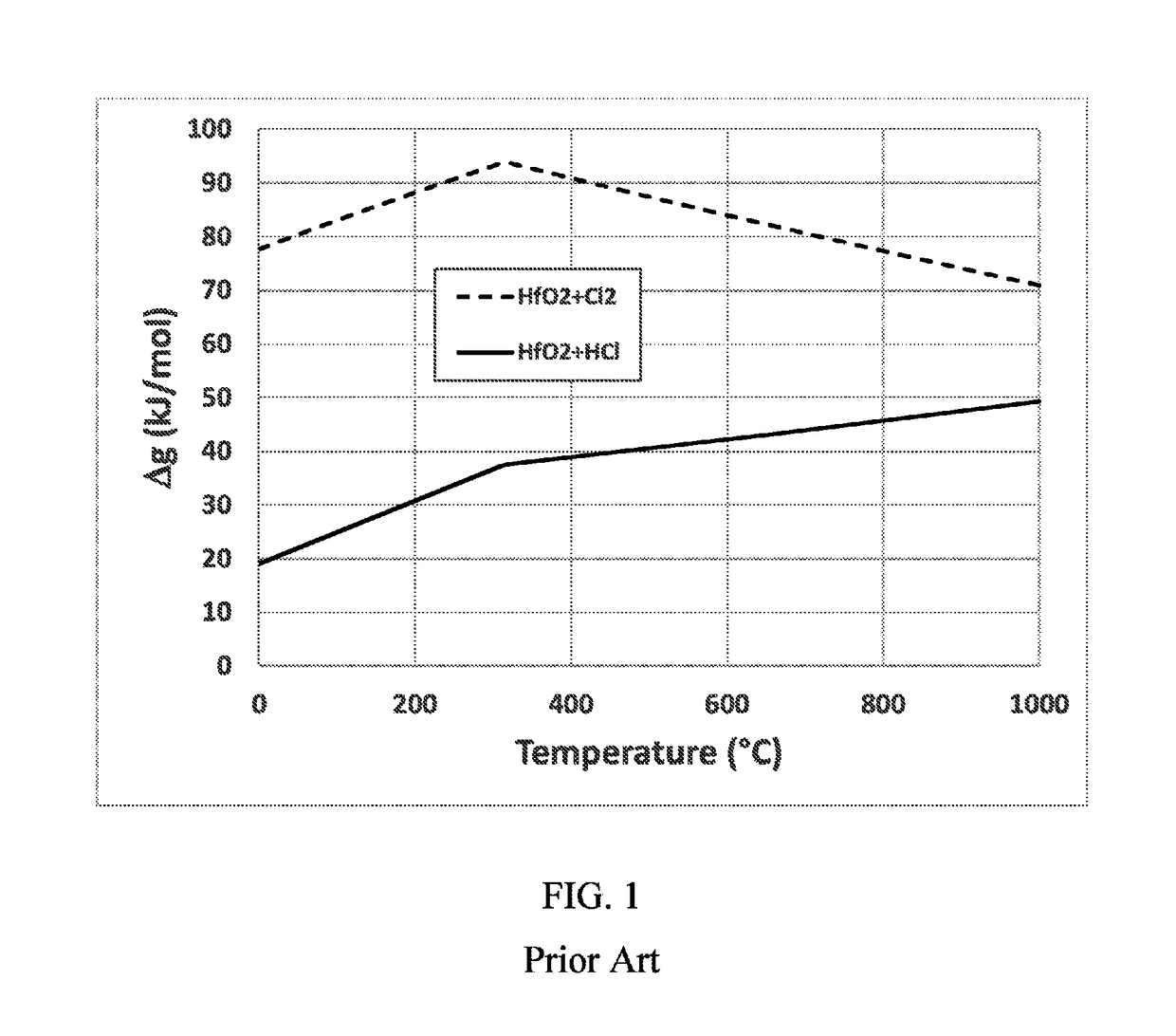

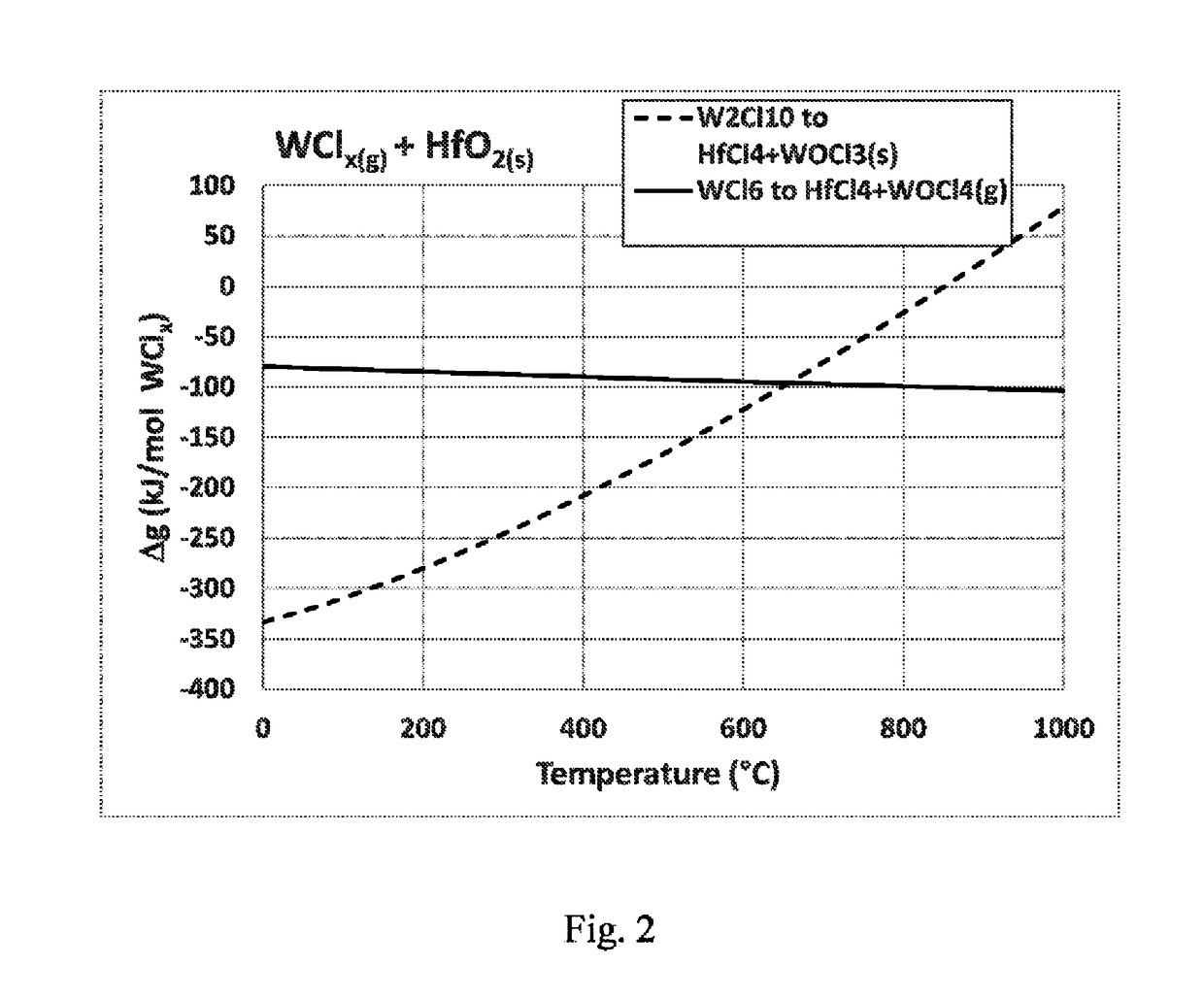

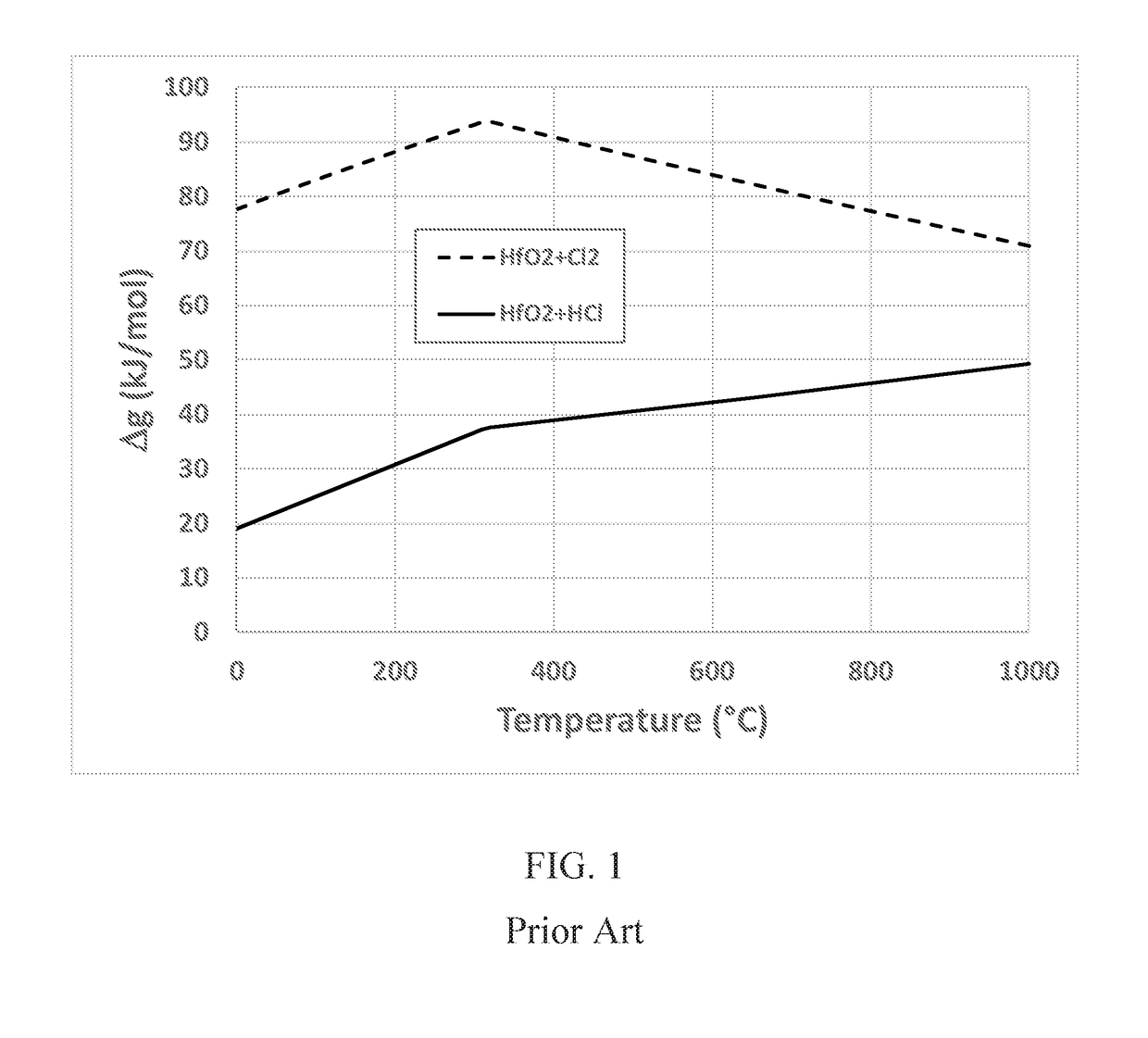

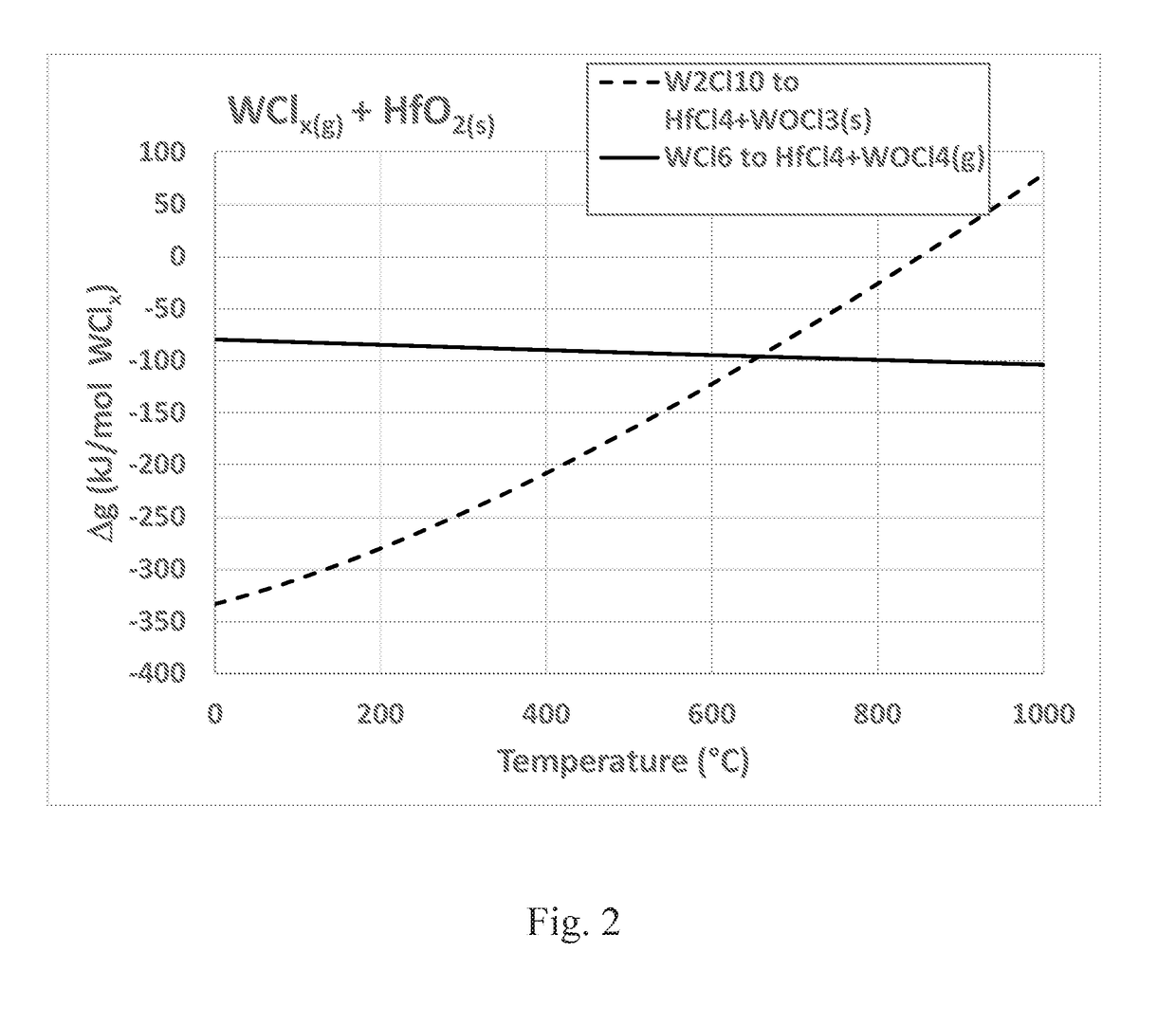

Vapor phase etching of hafnia and zirconia

ActiveUS10002772B2Decorative surface effectsSemiconductor/solid-state device manufacturingEtchingPhosphorus chloride

A method is described for vapor phase etching of oxide material including at least one of hafnia (HfO2) and zirconia (ZrO2), in the absence of plasma exposure of the oxide material. The method involves contacting the oxide material with an etching medium including at least one of phosphorus chloride and tungsten chloride under conditions producing a removable fluid reaction product, and removing the removable fluid reaction product. The etching process may be controllably carried out by use of pressure swings, temperature swings, and / or modulation of partial pressure of Hf or Zr chloride in the reaction, e.g., to achieve precision etch removal in the manufacture of semiconductor devices such as 3D NAND, sub-20 nm DRAMs, and finFETs.

Owner:ENTEGRIS INC

Vapor phase etching of hafnia and zirconia

ActiveUS20170352549A1Control depthControl rateSemiconductor/solid-state device manufacturingEtchingPhysical chemistry

A method is described for vapor phase etching of oxide material including at least one of hafnia (HfO2) and zirconia (ZrO2), in the absence of plasma exposure of the oxide material. The method involves contacting the oxide material with an etching medium including at least one of phosphorus chloride and tungsten chloride under conditions producing a removable fluid reaction product, and removing the removable fluid reaction product. The etching process may be controllably carried out by use of pressure swings, temperature swings, and / or modulation of partial pressure of Hf or Zr chloride in the reaction, e.g., to achieve precision etch removal in the manufacture of semiconductor devices such as 3D NAND, sub-20 nm DRAMs, and finFETs.

Owner:ENTEGRIS INC

Method of forming conformal metal silicide films

A method is provided for forming a metal silicide layer on a substrate. According to one embodiment the method includes providing the substrate in a process chamber, exposing the substrate at a first substrate temperature to a plasma generated from a deposition gas containing a metal precursor, where the plasma exposure forms a conformal metal-containing layer on the substrate in a self-limiting process. The method further includes exposing the metal-containing layer at a second substrate temperature to a reducing gas in the absence of a plasma, where the exposing steps are alternatively performed at least once to form the metal silicide layer, and the deposition gas does not contain the reducing gas. The method provides conformal metal silicide formation in deep trenches with high aspect ratios.

Owner:TOKYO ELECTRON LTD

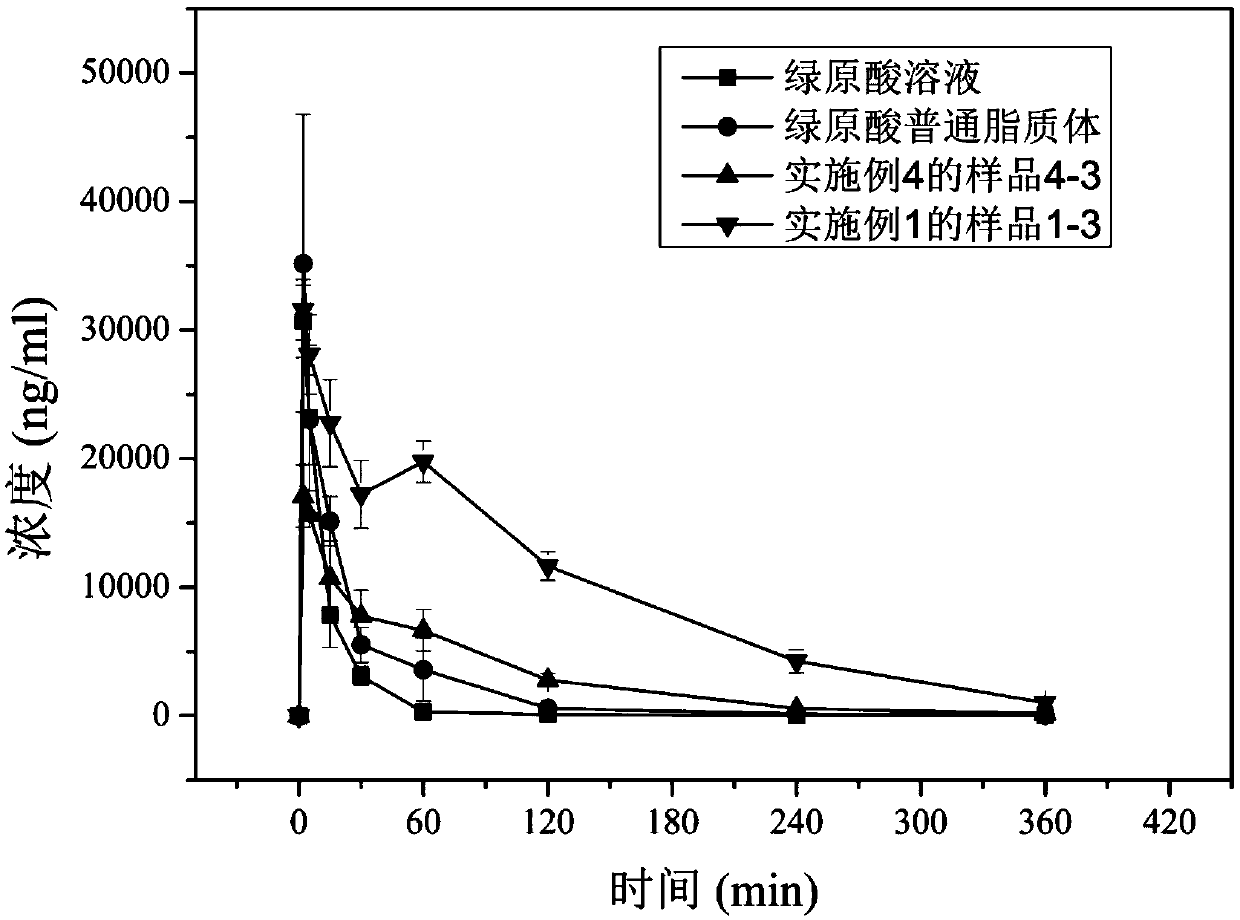

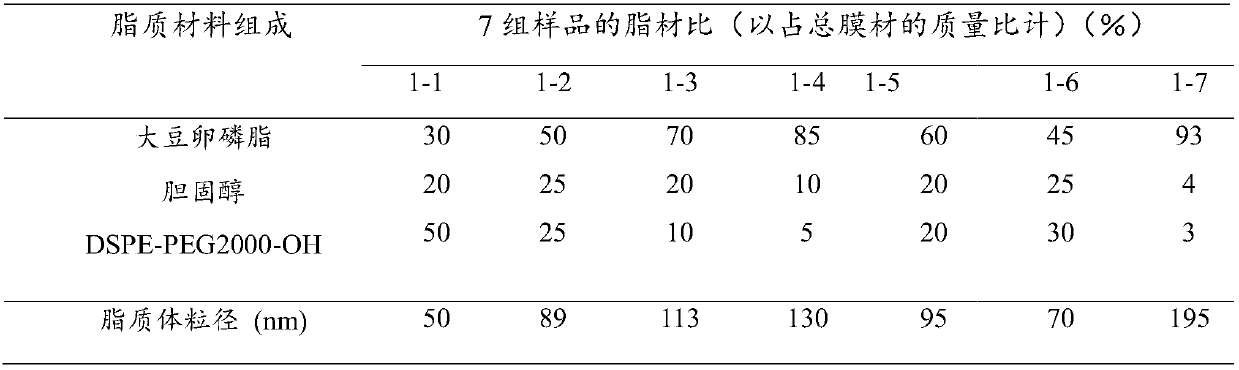

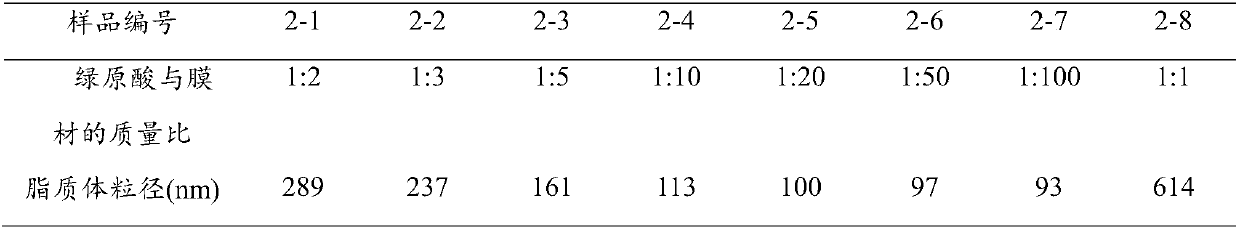

Chlorogenic acid long-circulating liposome as well as preparation method and application thereof

PendingCN111067867ASlow removal rateSignificant long-circulation effect in the bodyOrganic active ingredientsPharmaceutical non-active ingredientsChlorogenic acidPharmaceutical drug

The invention belongs to the technical field of medicines, and particularly relates to a chlorogenic acid long-circulating liposome as well as a preparation method and application thereof. According to the chlorogenic acid liposome disclosed by the invention, a lipid material containing PEGylated phospholipid is used as a membrane material, and chlorogenic acid active ingredients are entrapped, sothat the liposome with the average particle size of 50-500nm is prepared. The chlorogenic acid long-circulating liposome provided by the invention can prolong the residence time (MRT) of chlorogenicacid in blood, slow down the drug clearance rate (CLz) and improve the plasma exposure (AUC under a drug-time curve), and is beneficial to better exerting the biological effect of chlorogenic acid.

Owner:INST OF MATERIA MEDICA CHINESE ACAD OF MEDICAL SCI

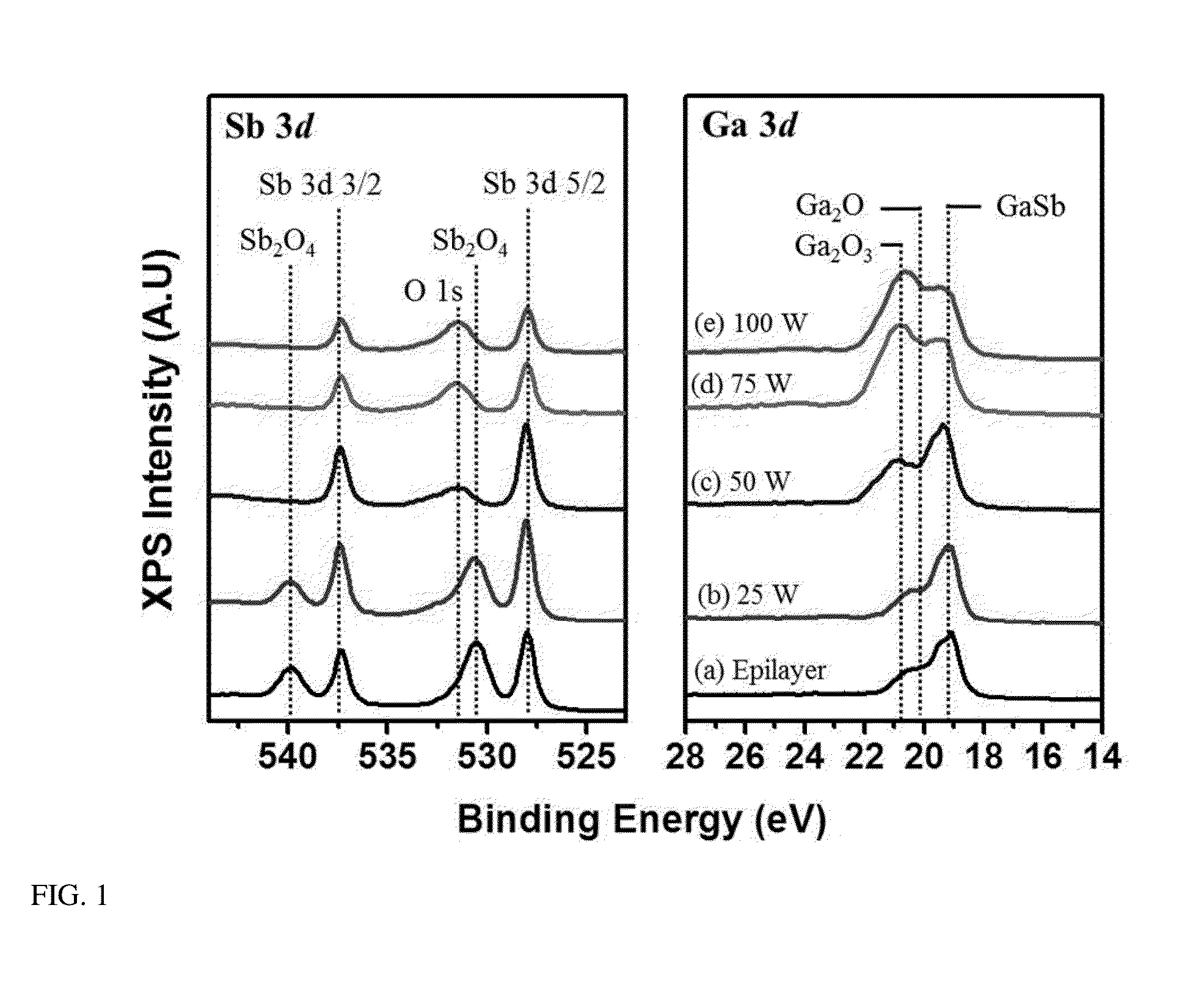

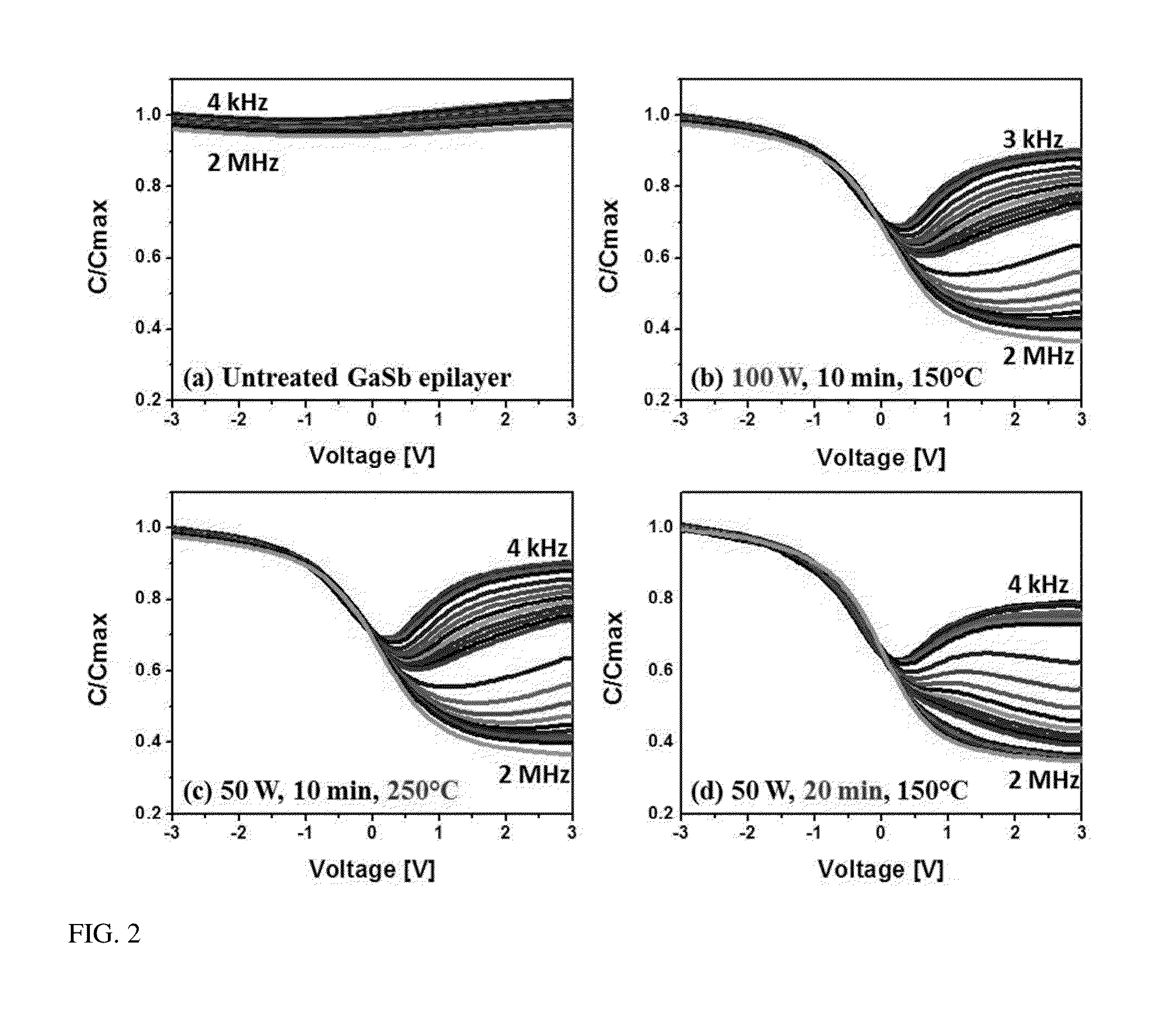

Hydrogen-plasma process for surface preparation prior to insulator deposition on compound semiconductor materials

InactiveUS20140273519A1Reduce the possibilityExcellent charge modulationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricSemiconductor materials

A method of making a semiconductor material by pretreating a semiconductor substrate having a native oxide on the substrate surface under vacuum with hydrogen plasma to remove and / or modify the native oxide. After plasma exposure, a high-k dielectric is deposited in-situ onto the substrate using atomic layer deposition. There is no break in the vacuum between the plasma exposure and the atomic layer deposition. Also disclosed is the related semiconductor / dielectric material stack.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com