Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11497 results about "Shower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A shower is a place in which a person bathes under a spray of typically warm or hot water. Indoors, there is a drain in the floor. Most showers have temperature, spray pressure and adjustable showerhead nozzle. The simplest showers have a swivelling nozzle aiming down on the user, while more complex showers have a showerhead connected to a hose that has a mounting bracket. This allows the showerer to hold the showerhead by hand to spray the water at different parts of their body. A shower can be installed in a small shower stall or bathtub with a plastic shower curtain or door. Showering is common in Western culture due to the efficiency of using it compared with a bathtub. Its use in hygiene is, therefore, common practice. A shower uses less water on average than a bath: 80 litres (18 imp gal; 21 US gal) for a shower compared with 150 litres (33 imp gal; 40 US gal) for a bath.

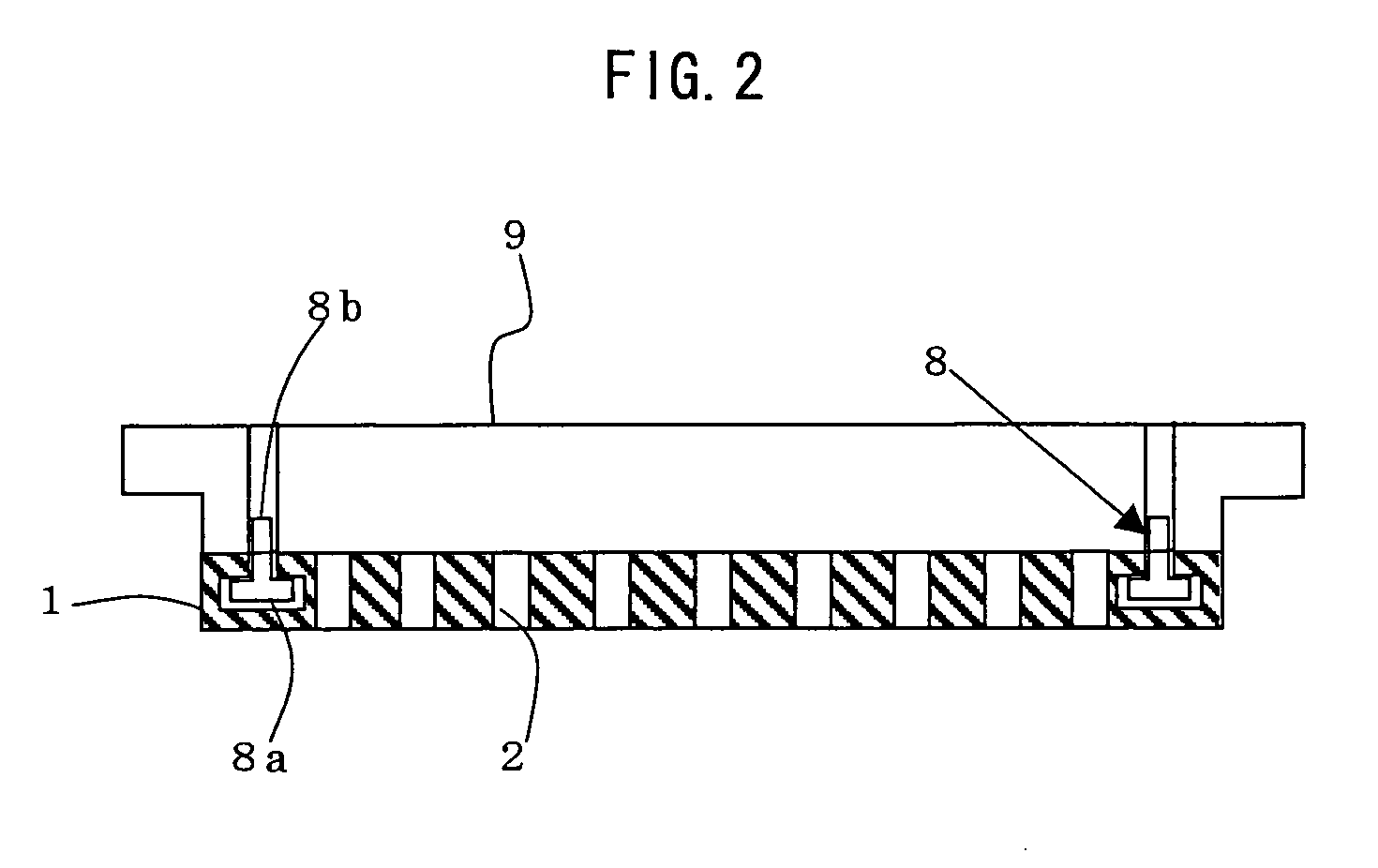

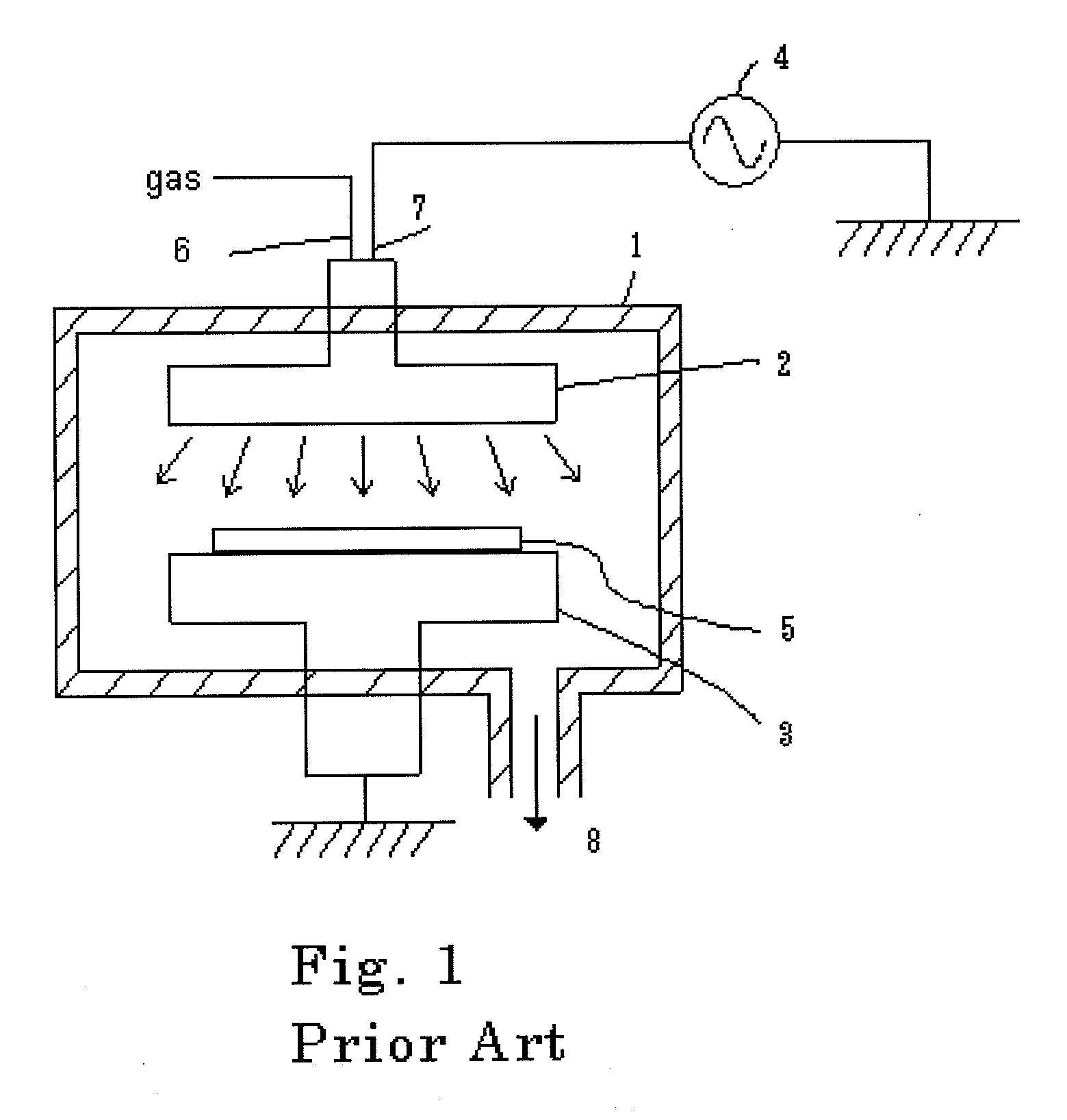

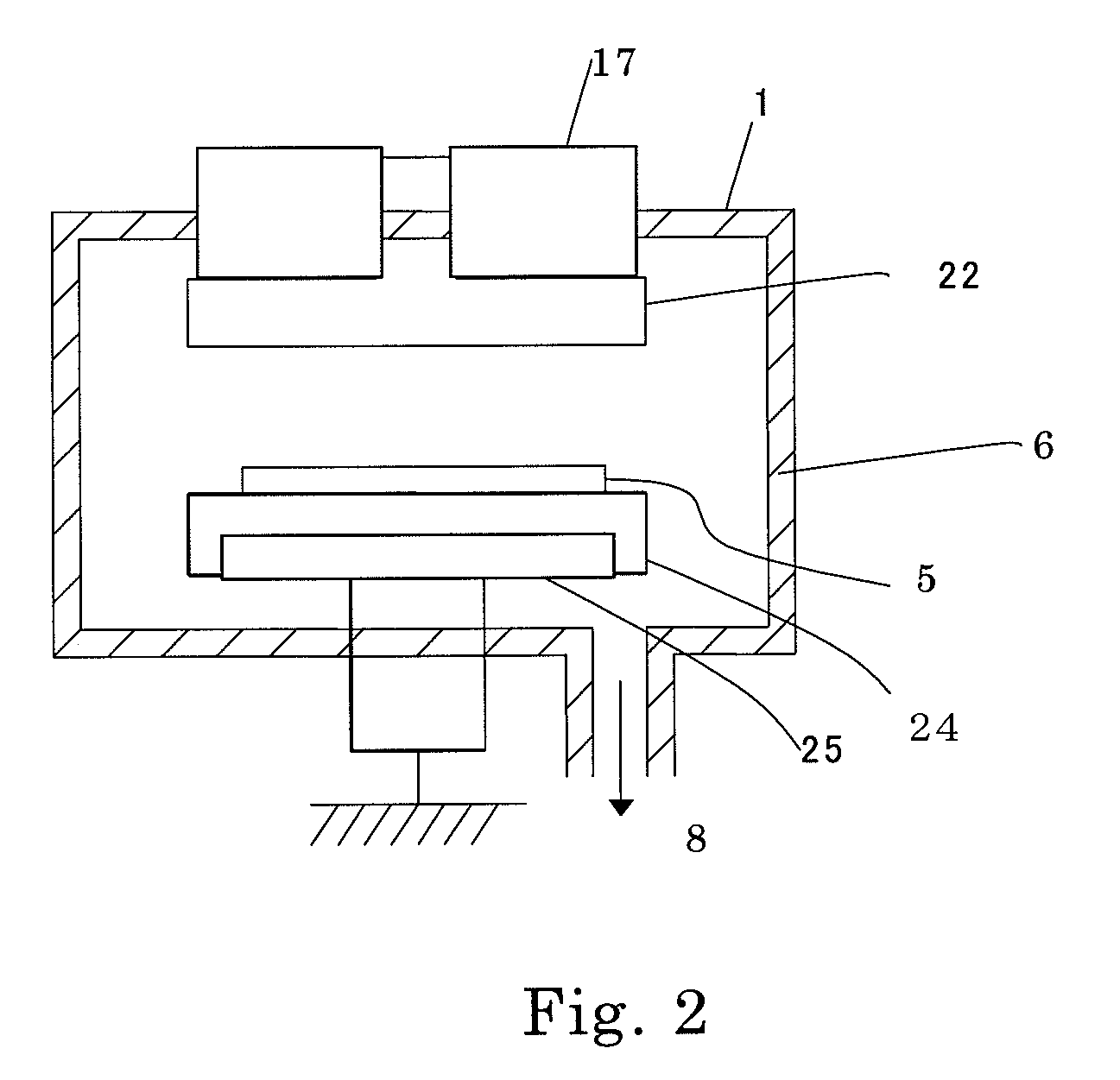

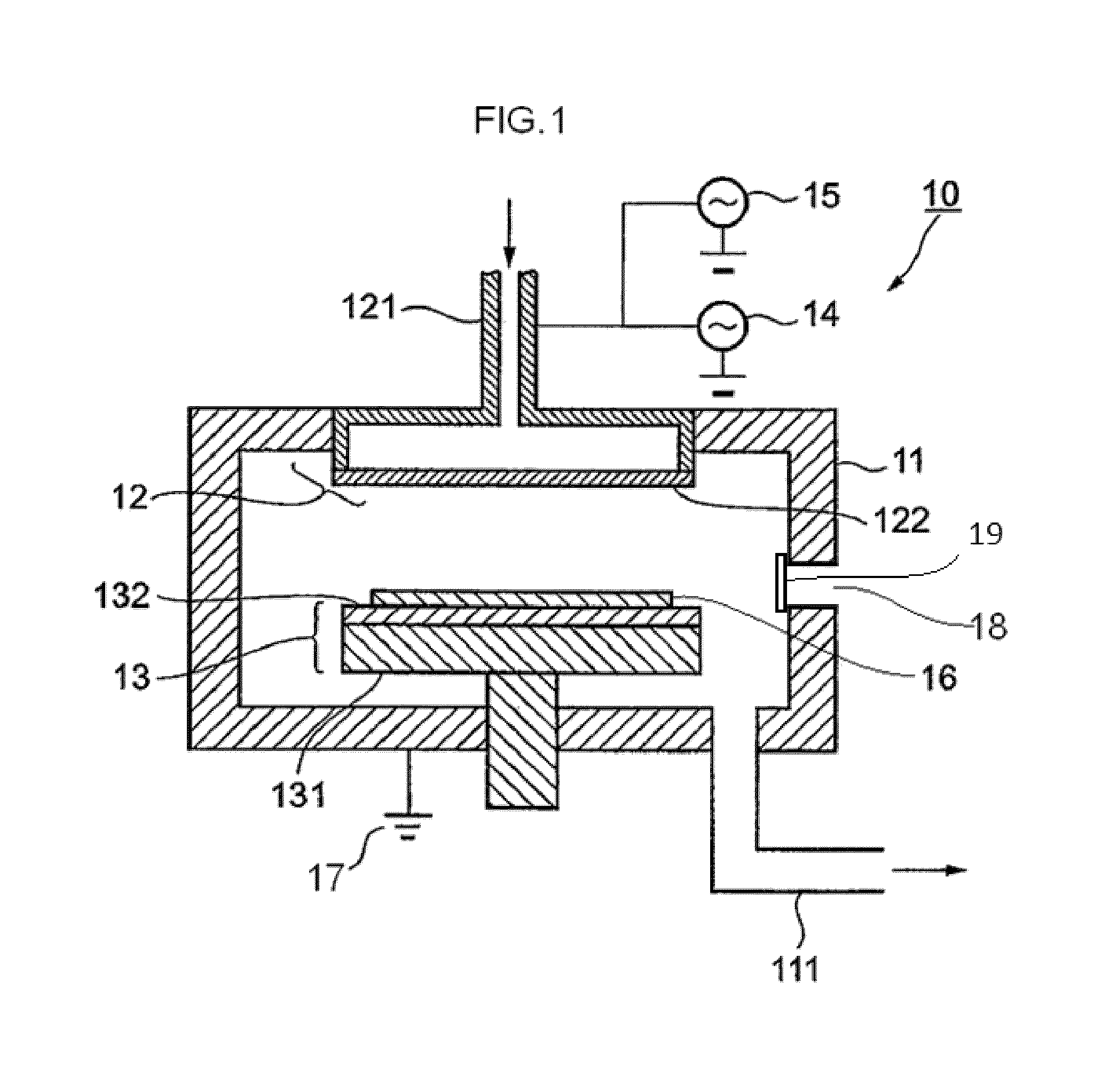

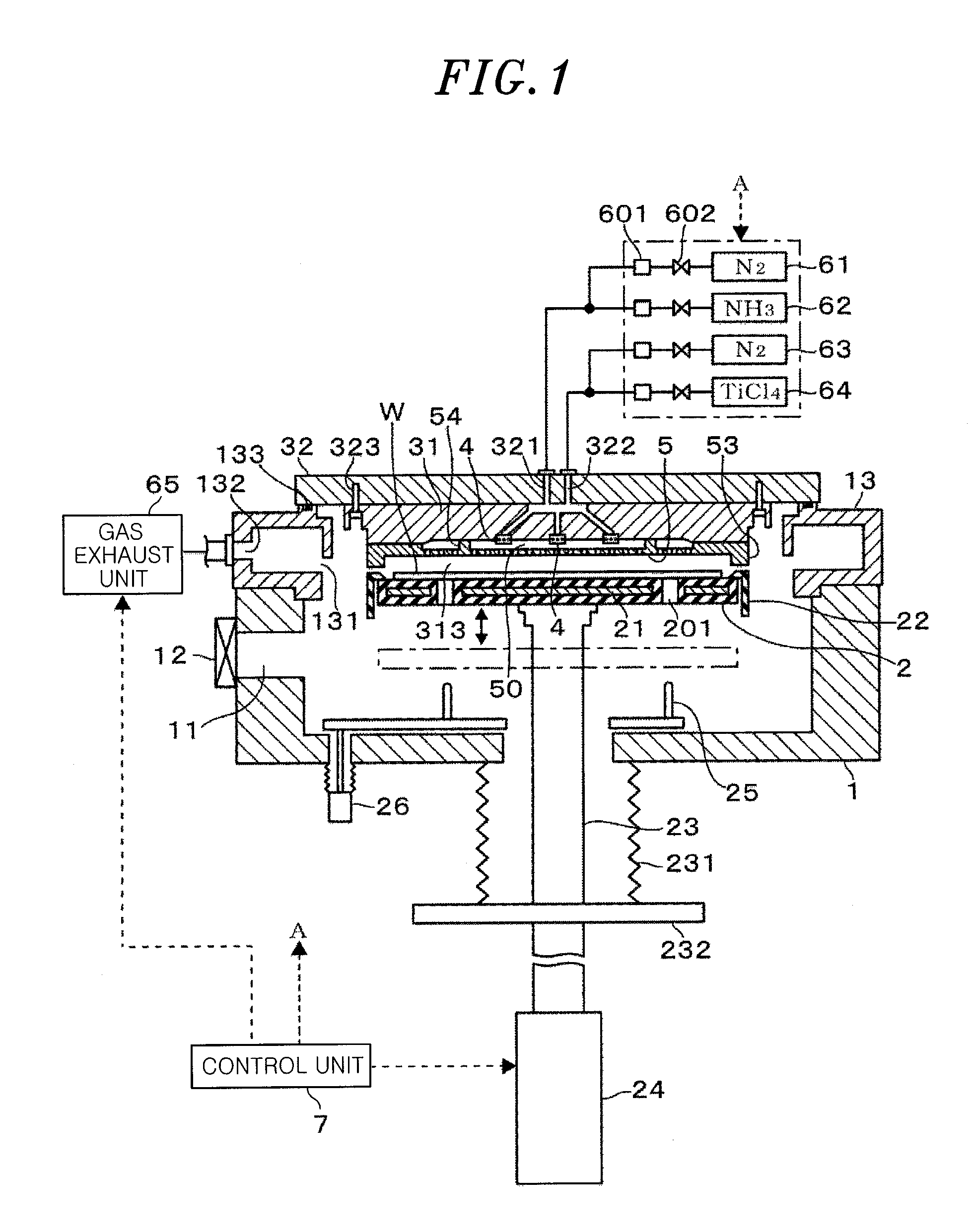

Gas treatment device and heat readiting method

InactiveUS20070022954A1Improve cooling efficiencyInhibit temperature riseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringRadiant heat

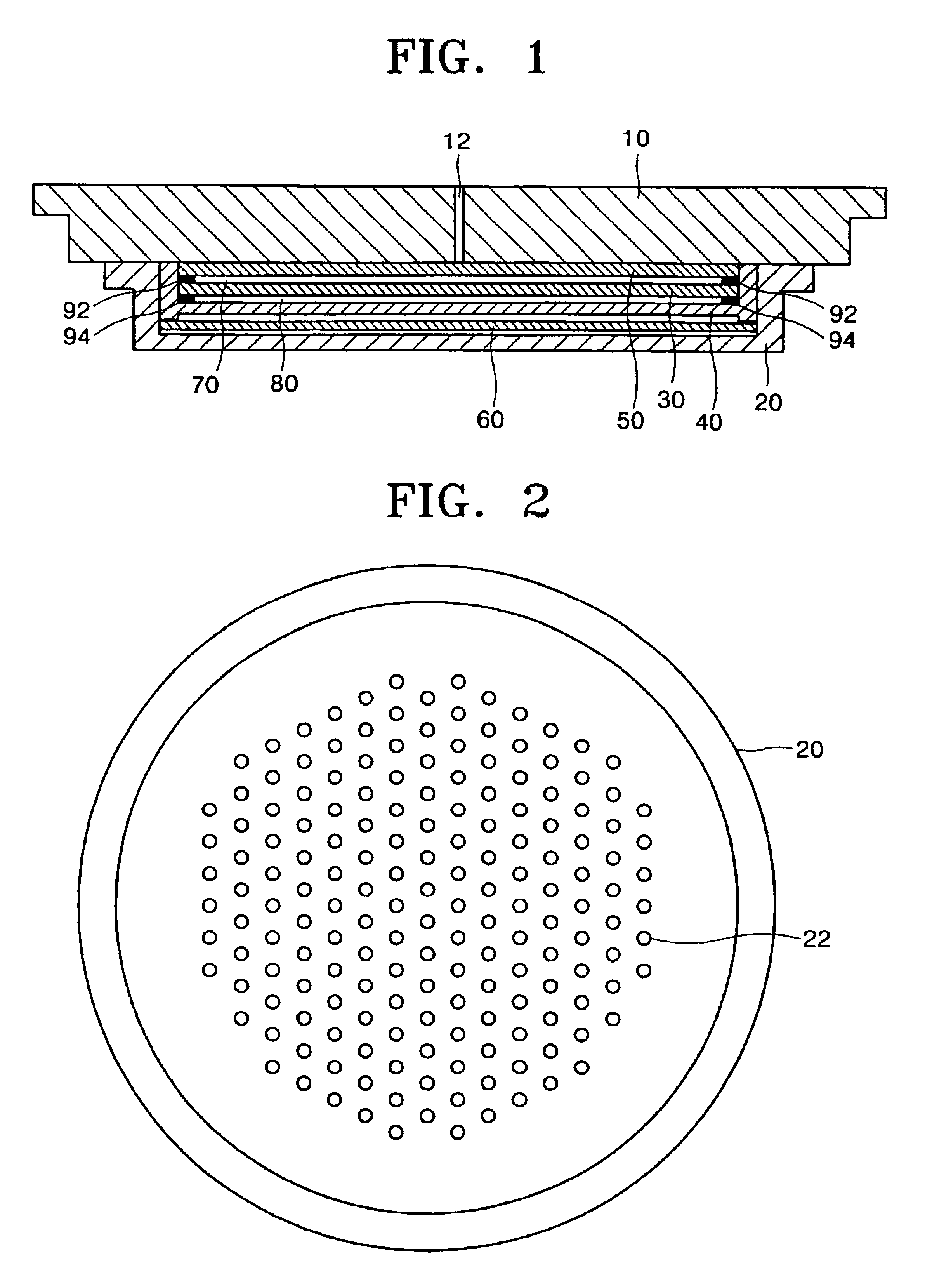

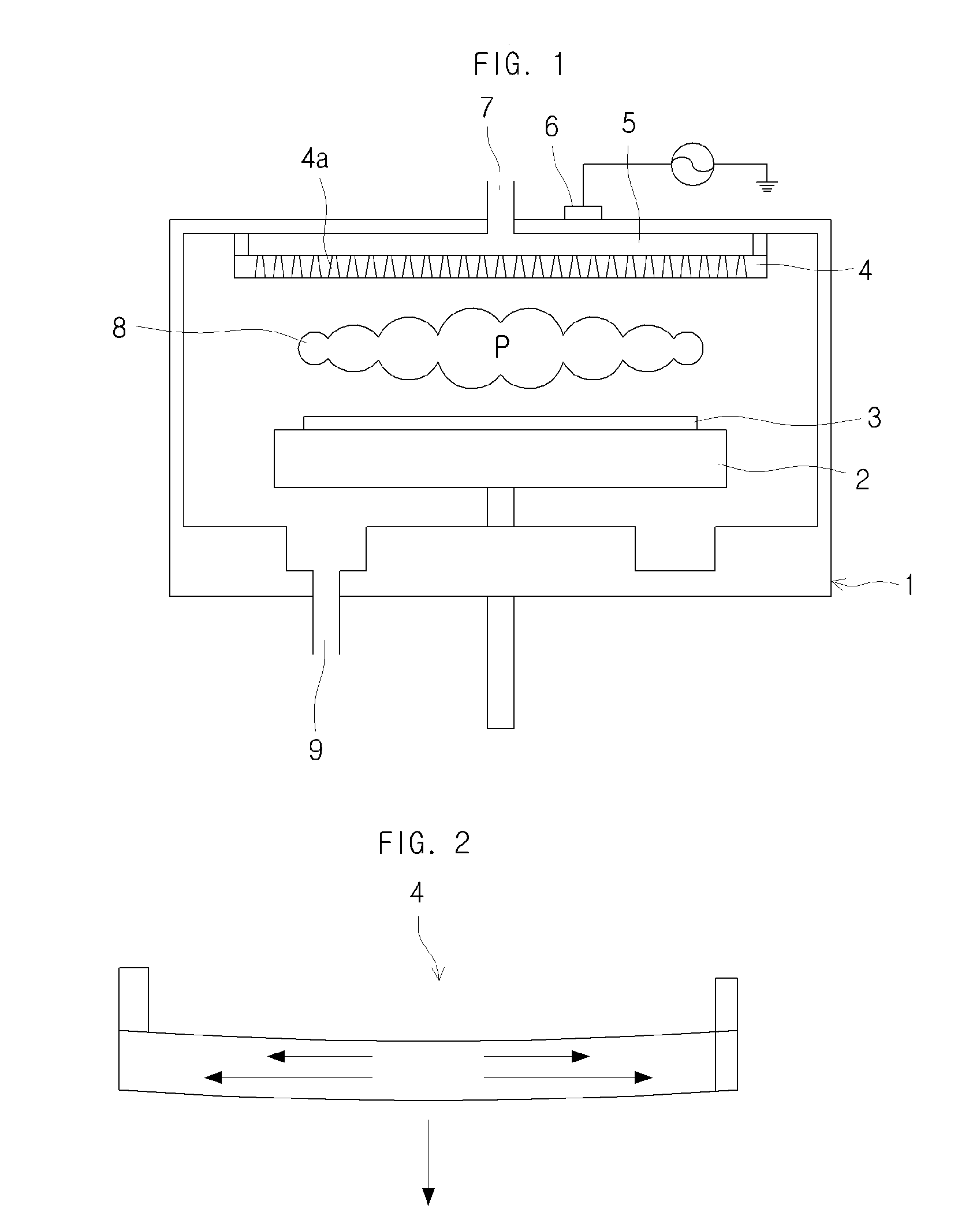

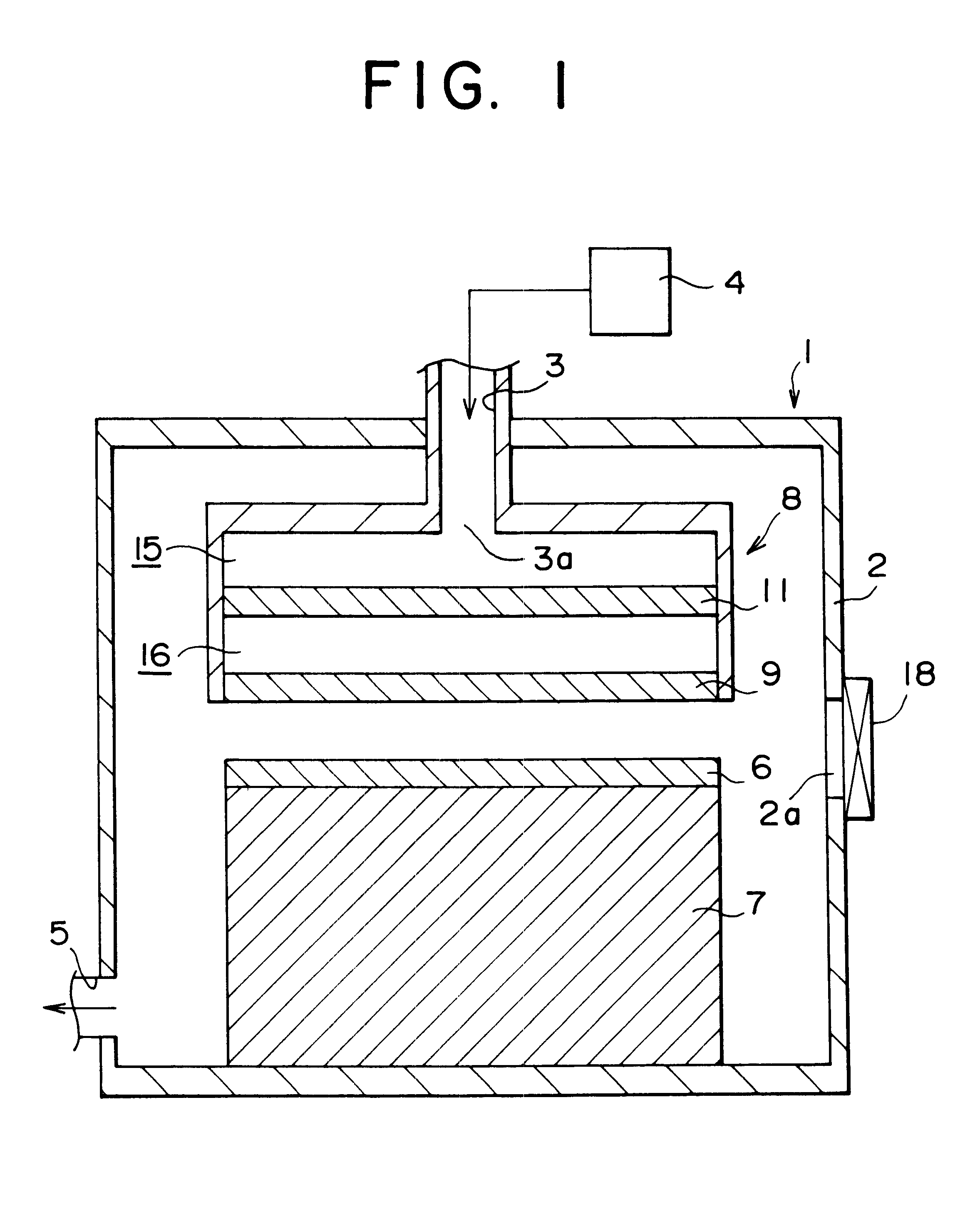

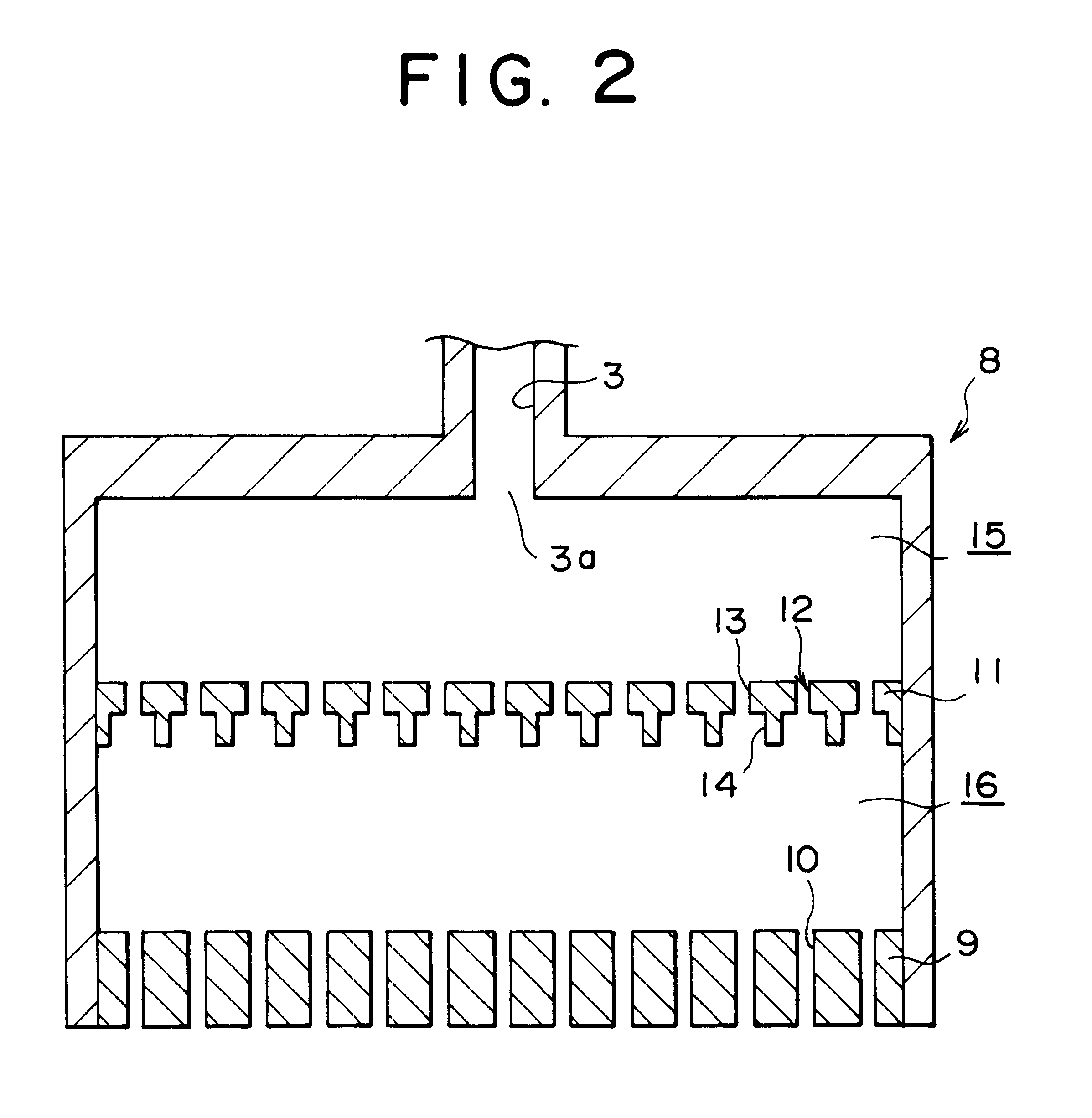

A shower head formed by stacking a shower base, a gas diffusion plate, and a shower plate and supplying material gas and oxidizer gas to a wafer on a loading table through a first gas diffusion part and a second gas diffusion part formed in both faces of the gas diffusion plate, first gas outlets formed in the shower plate and communicating with a first gas diffusion space, and second gas outlets formed in the shower plate and communicating with a second gas diffusion space. A plurality of heat transfer columns fitted closely to the lower surface of the shower base are installed in the first gas diffusion part so that portions therebetween can form the first gas diffusion space, and radiant heat from the loading table is transmitted by the heat transfer columns in the thickness direction of the shower head.

Owner:TOKYO ELECTRON LTD

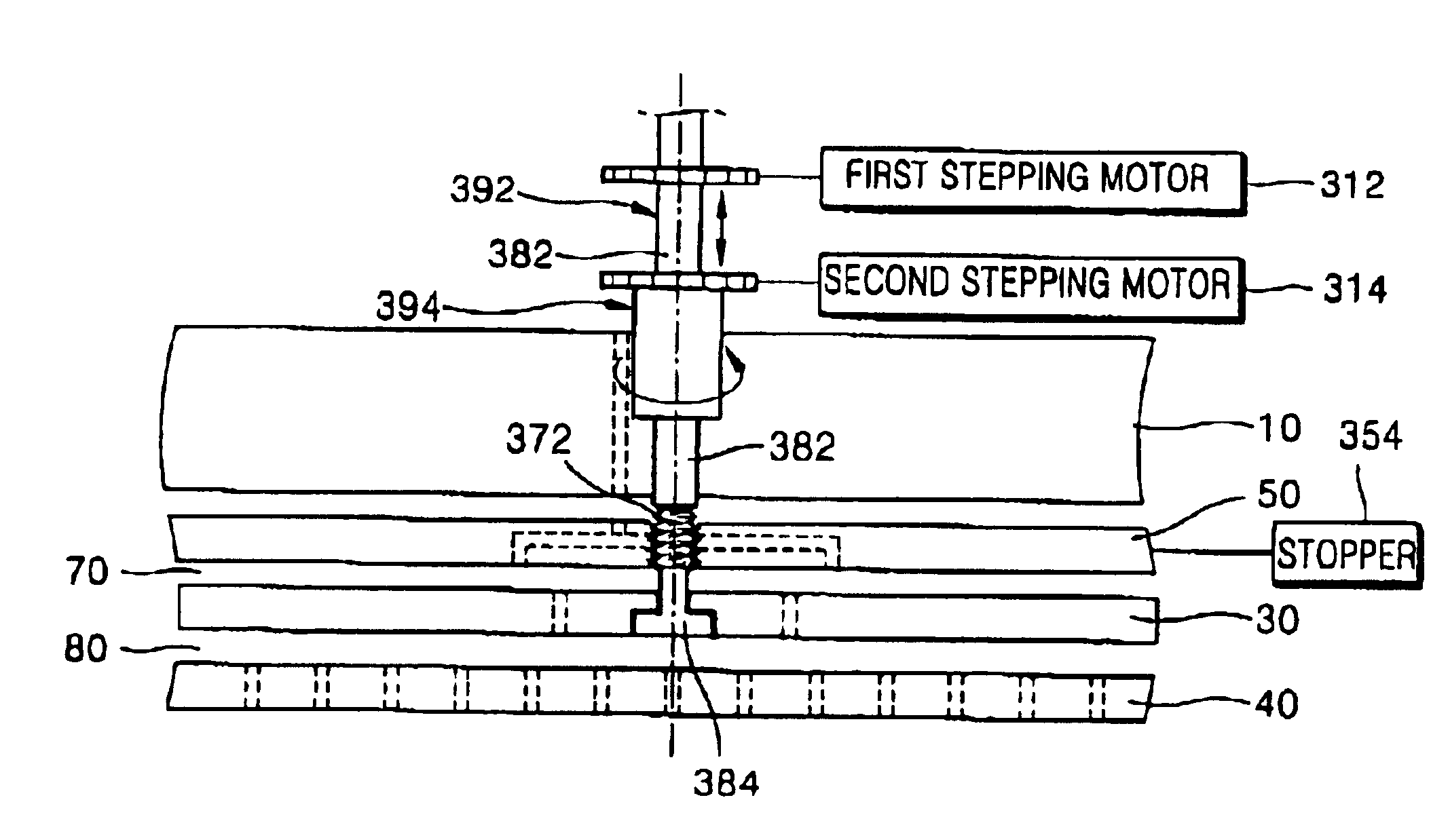

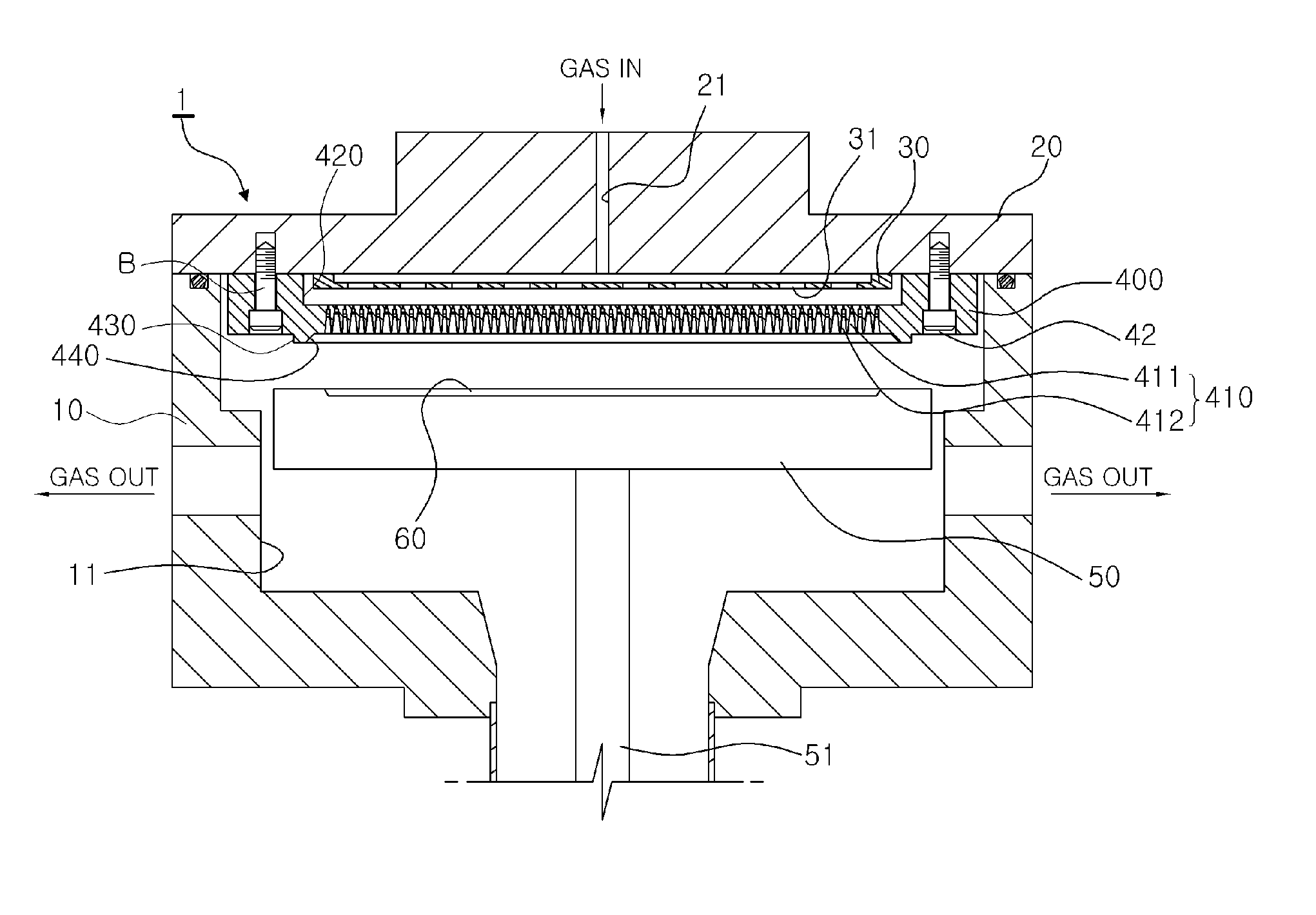

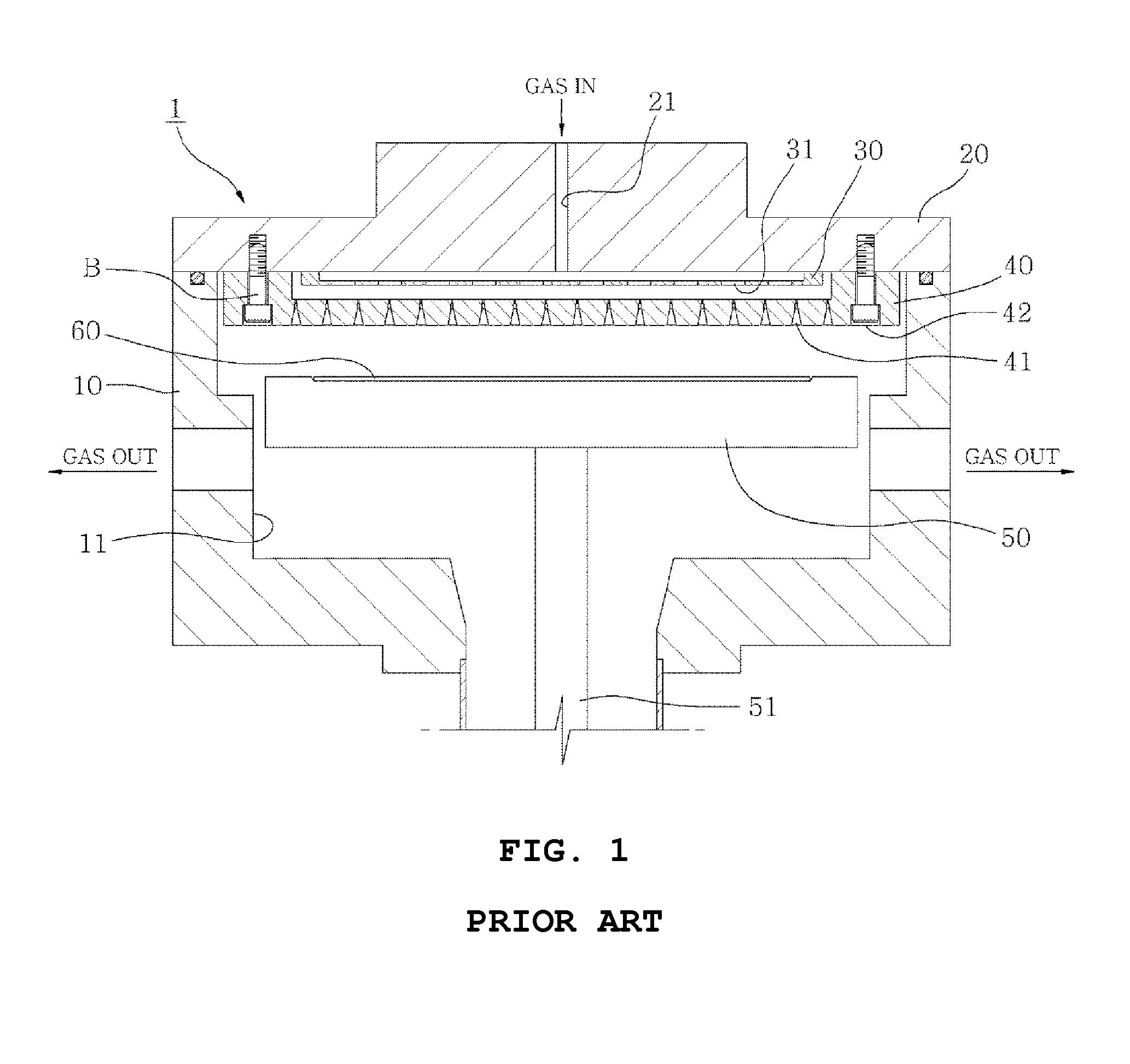

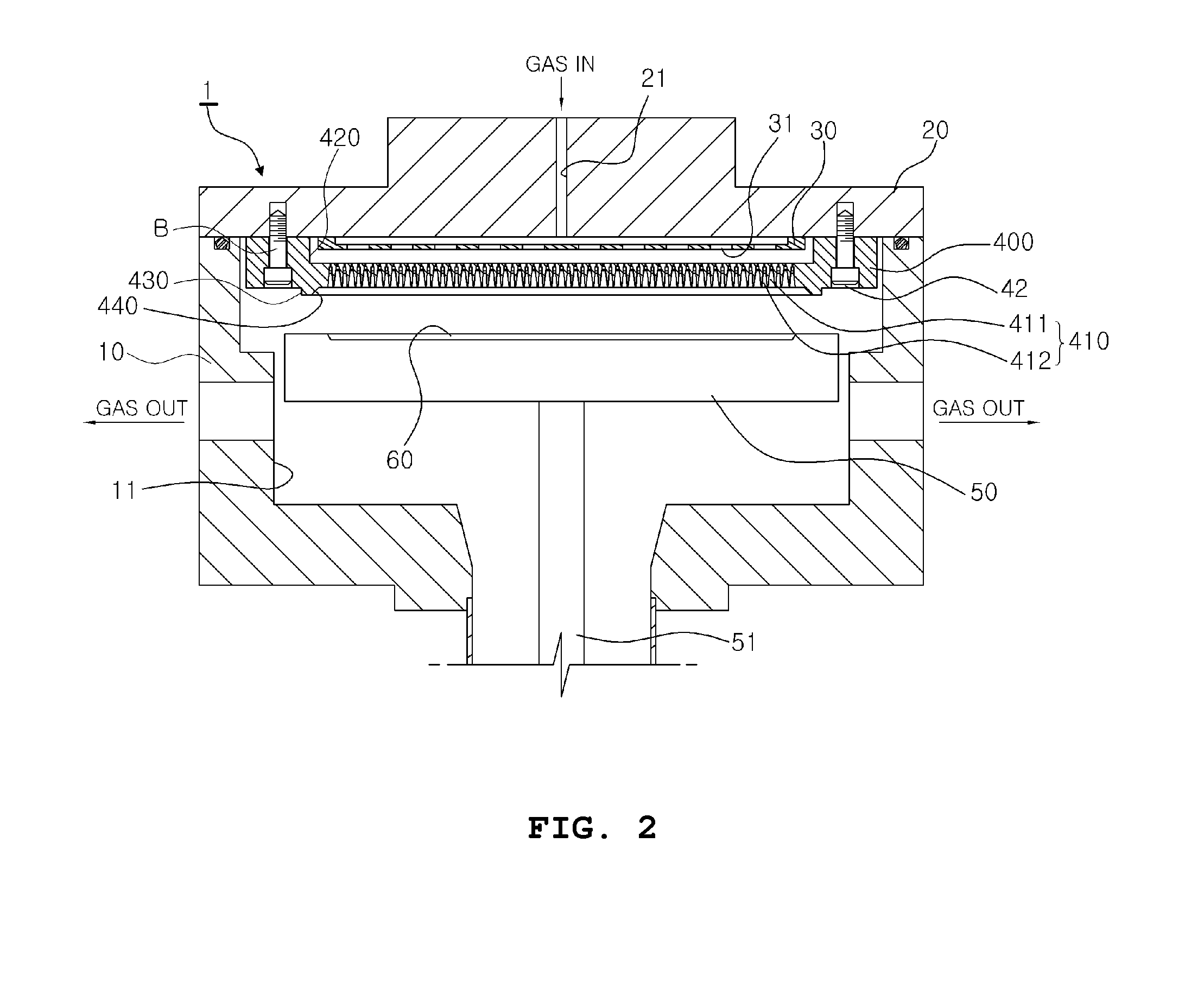

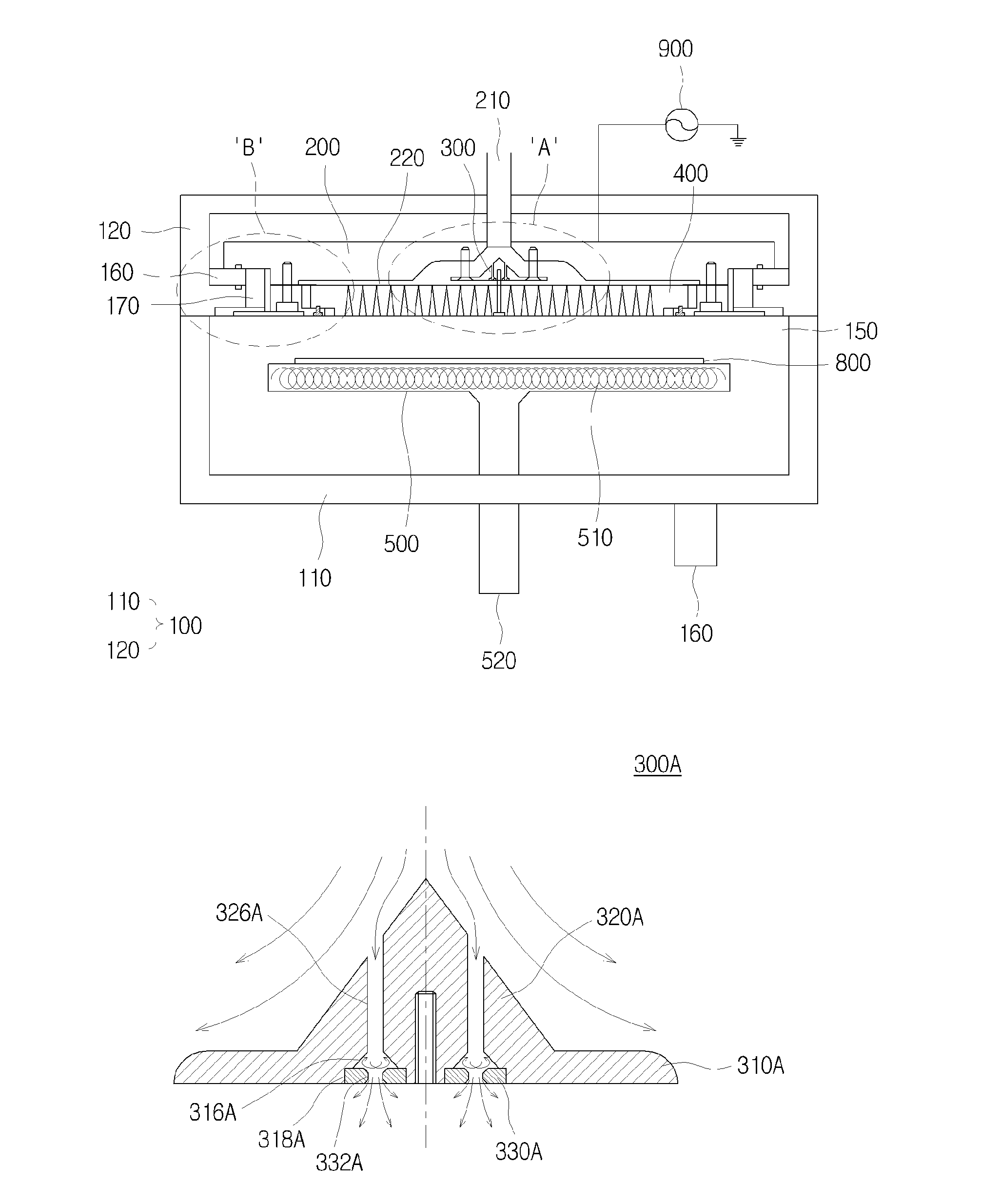

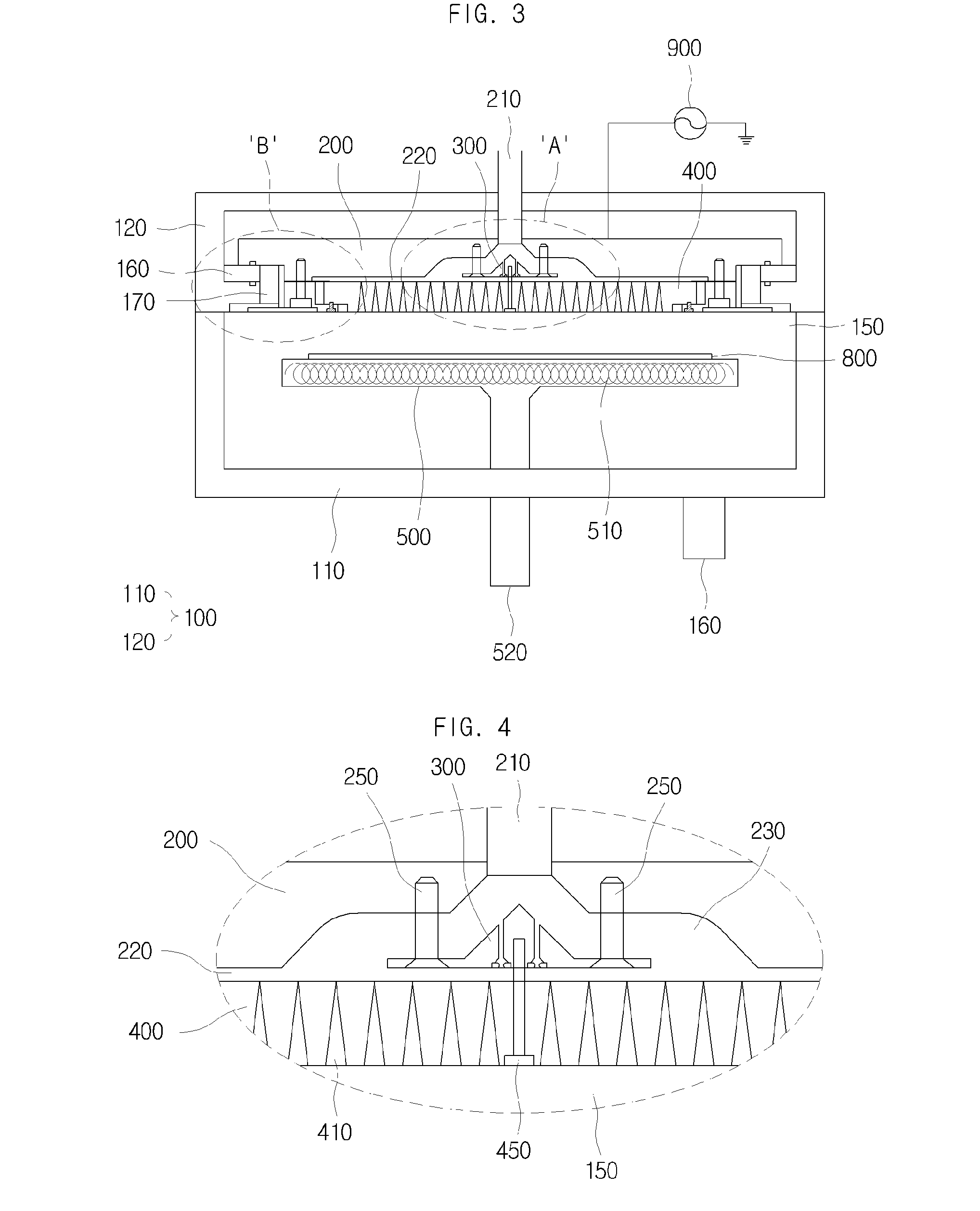

Shower head of a wafer treatment apparatus having a gap controller

InactiveUS6872258B2Improve uniformityEtch rate be optimizedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess regionSemiconductor

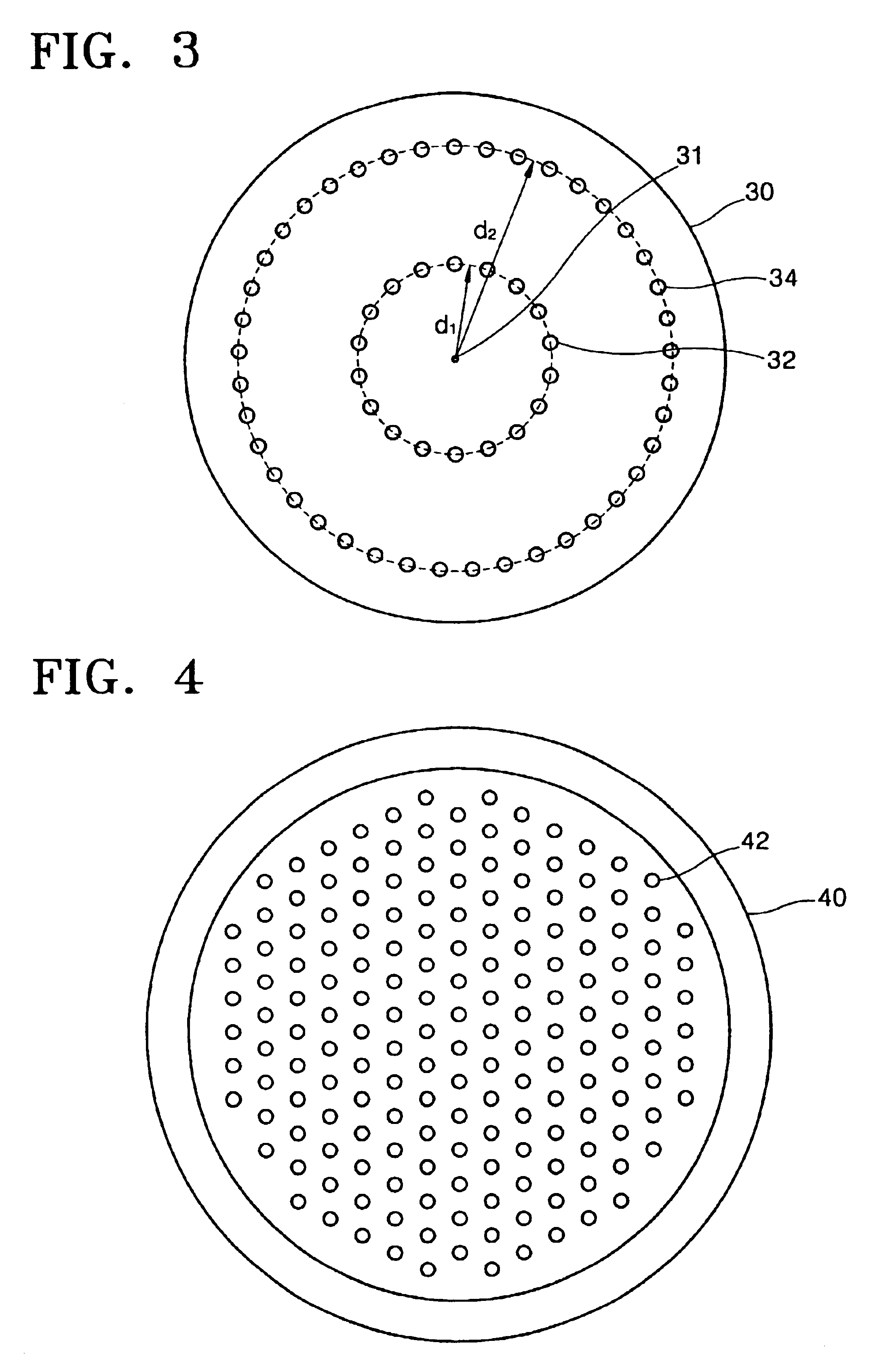

A shower head for adjusting distribution of a reactant gas in a process region of a semiconductor manufacturing reaction chamber, wherein a top plate has a gas port for introducing the reactant gas into the reaction chamber; a face plate, having through holes, disposed opposite the process region; a first baffle plate, having through holes, disposed between the top plate and the face plate and capable of moving up or down, wherein the first baffle plate has a top surface that defines a first gap for forming a first lateral flow passage; a second baffle plate, having through holes, disposed between the first baffle plate and the face plate and capable of moving up or down, wherein the second baffle plate has a top surface that defines a second gap for forming a second lateral flow passage; and a gap controller for determining widths of the first and second gaps.

Owner:SAMSUNG ELECTRONICS CO LTD

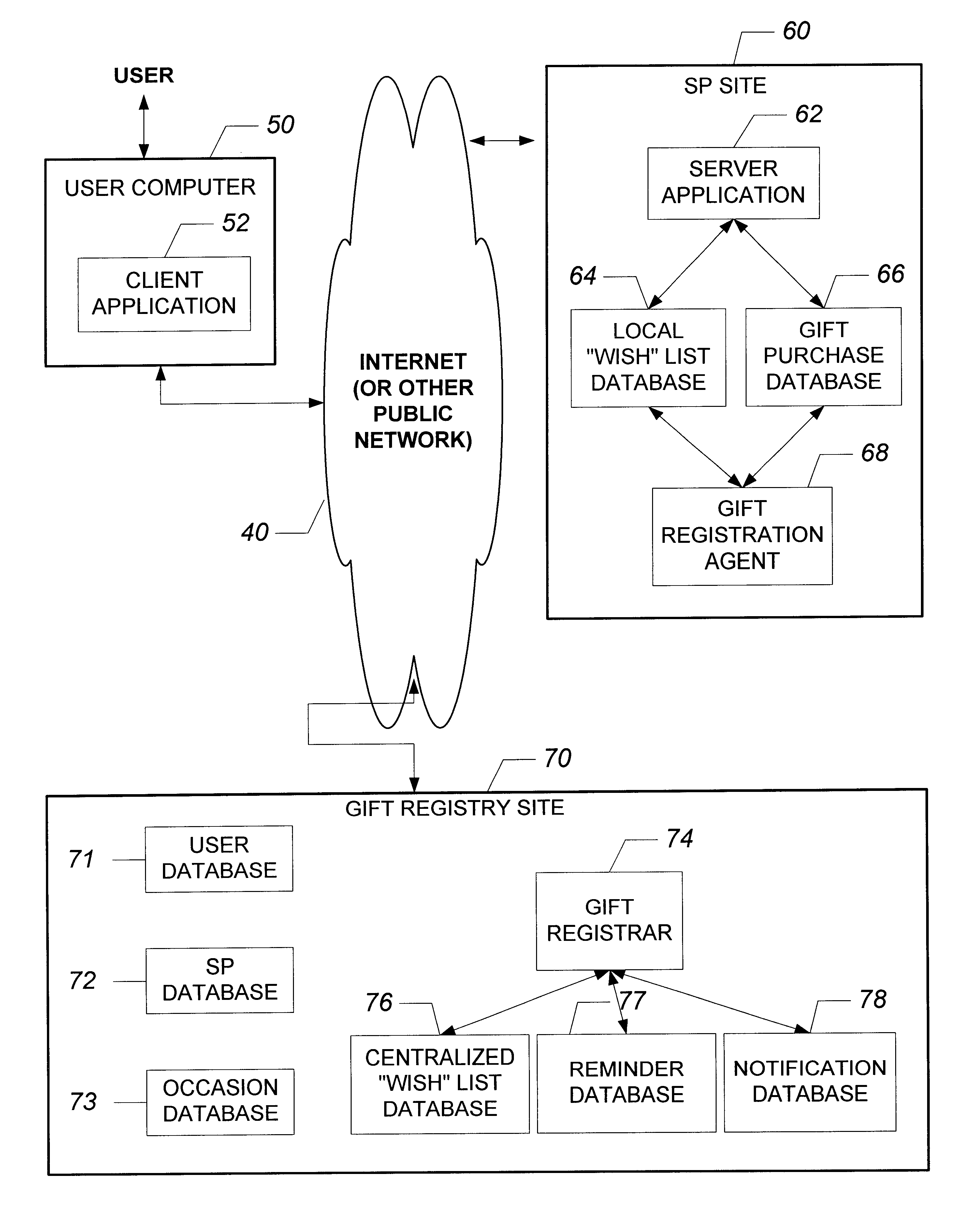

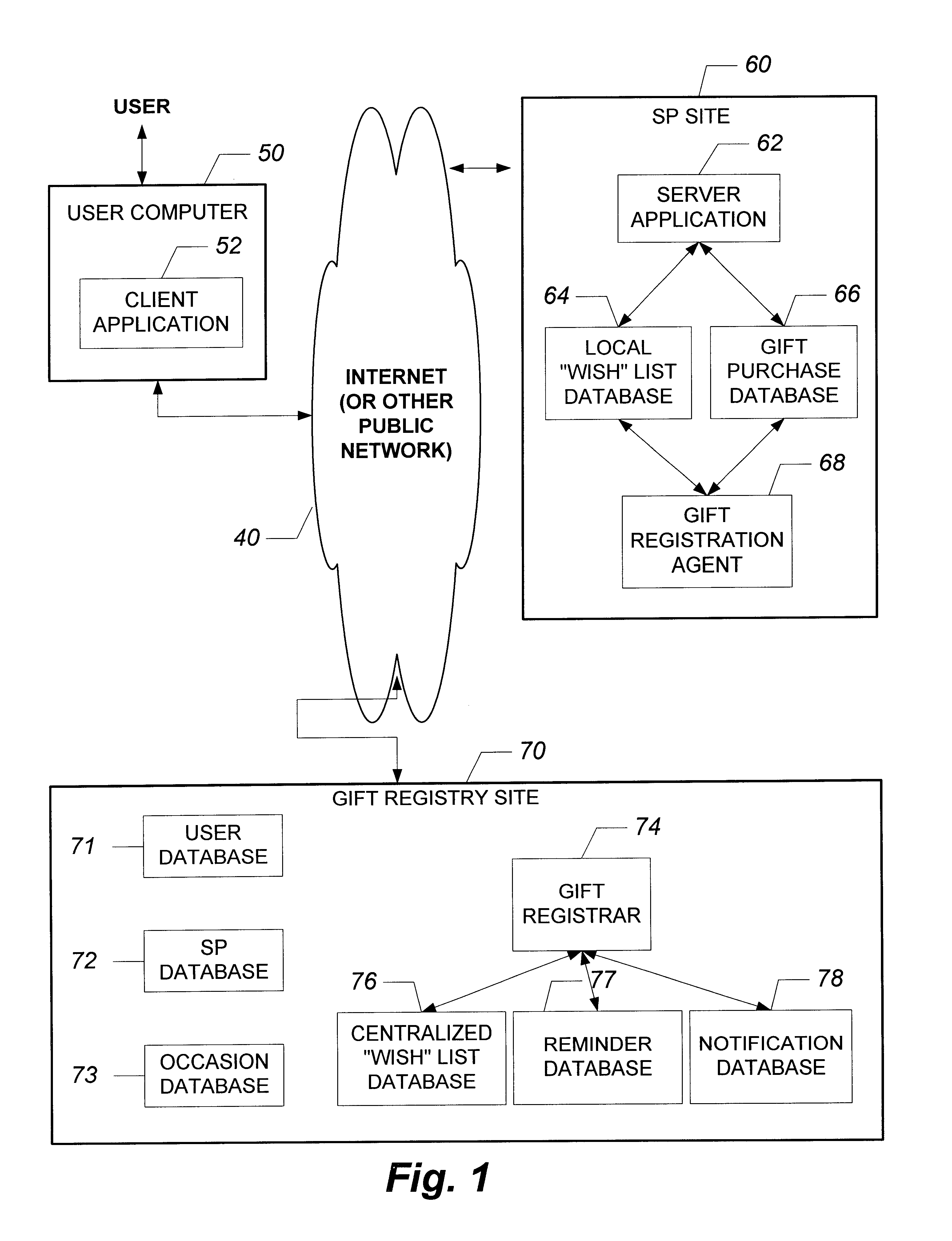

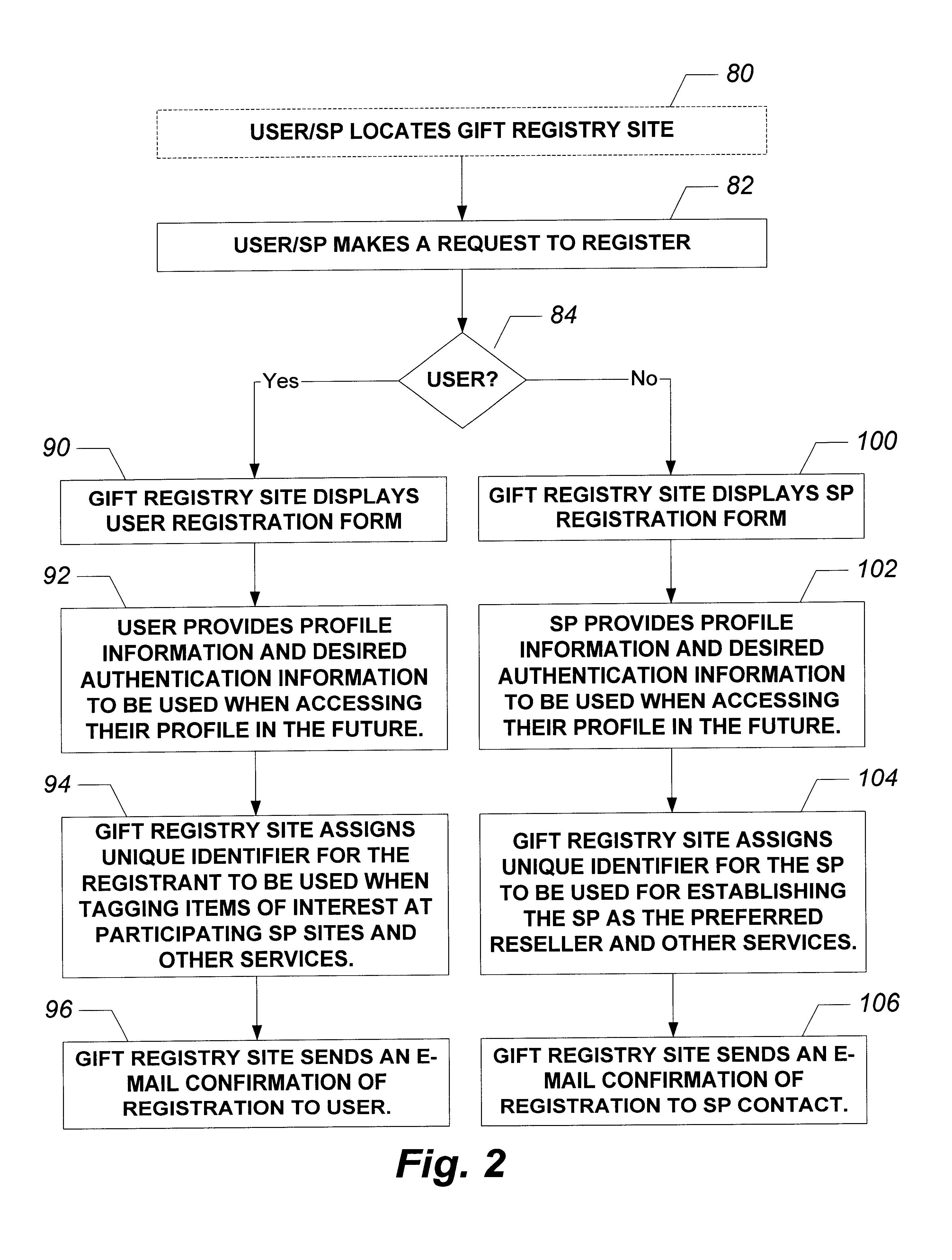

System and method for providing electronic multi-merchant gift registry services over a distributed network

InactiveUS6609106B1Minimal costMethod is fastReservationsBuying/selling/leasing transactionsWeb siteService provision

An online Gift Registry Service provides registration of information for a gift registrant and allows access to the registry by potential gift giver users. In addition, users can tag items of interest at participating Service Provider (SP) sites and the SP sites will register these items with the Gift Registry Service on the user's behalf. It further provides a streamlined checkout process for purchasing these gift items with the registered SP sites (e.g. World Wide Web sites) over a distributed public network. Users and Service Providers (SP) initially register with the Gift Registry Service and are provided additional functionality. For users, a reminder service is provided to notify individuals automatically upon the trigger of certain events, such as important dates or product sales from online merchants. In addition, there are various occasion planning services available such as distribution lists, discussion groups, and other related resources for multiple events including weddings, baby showers, etc. These other resources include sending out announcements, reserving halls, and contracting services of related businesses for the occasion. A distinct advantage of this system is that users can perform all the planning for the event online in the comfort of their home or office. Service Providers on the other hand, can register system notification messages to be triggered on pre-determined events. In addition, Service Providers can obtain marketing information to tailor their products and services.

Owner:ROBERTSON STEVEN C

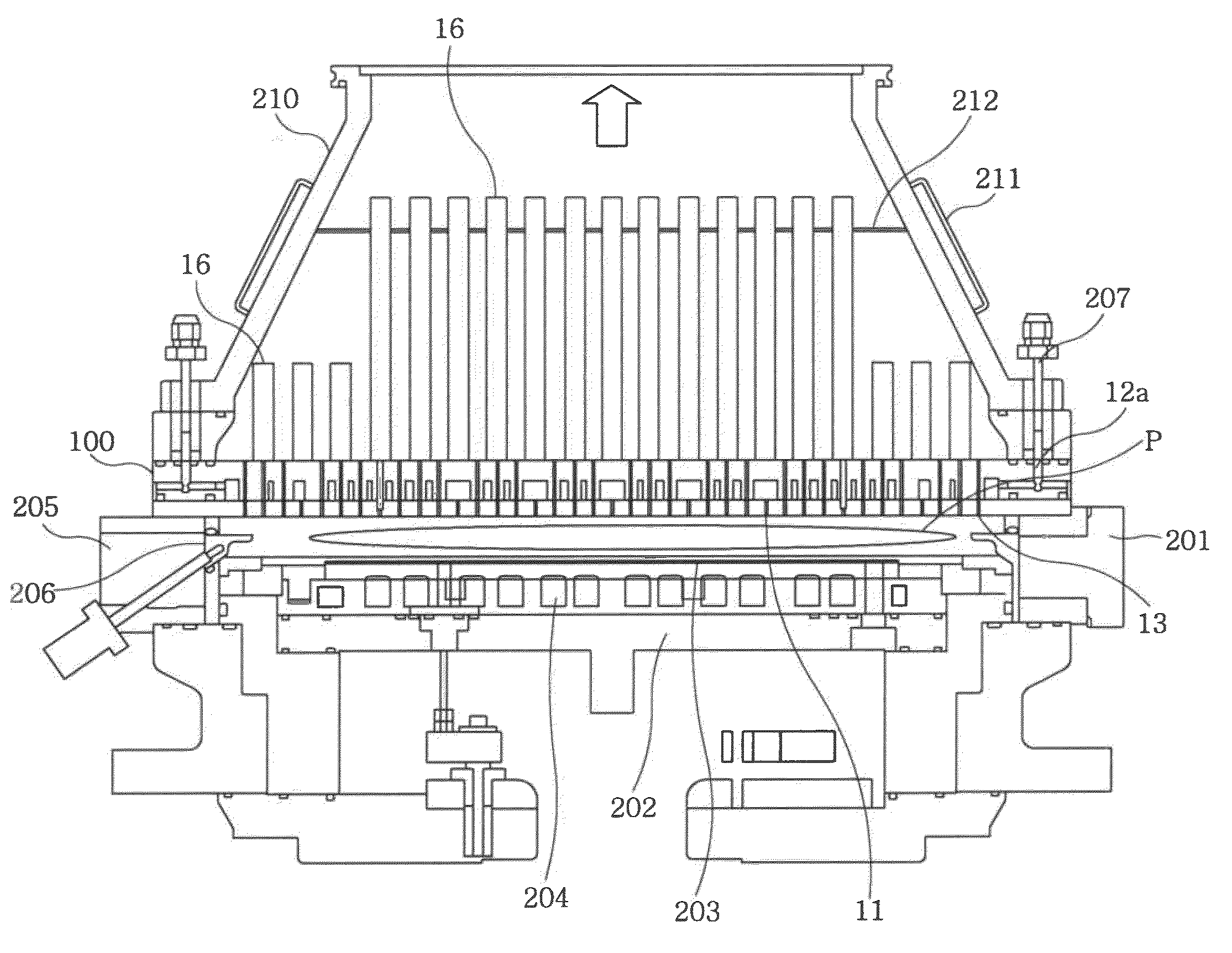

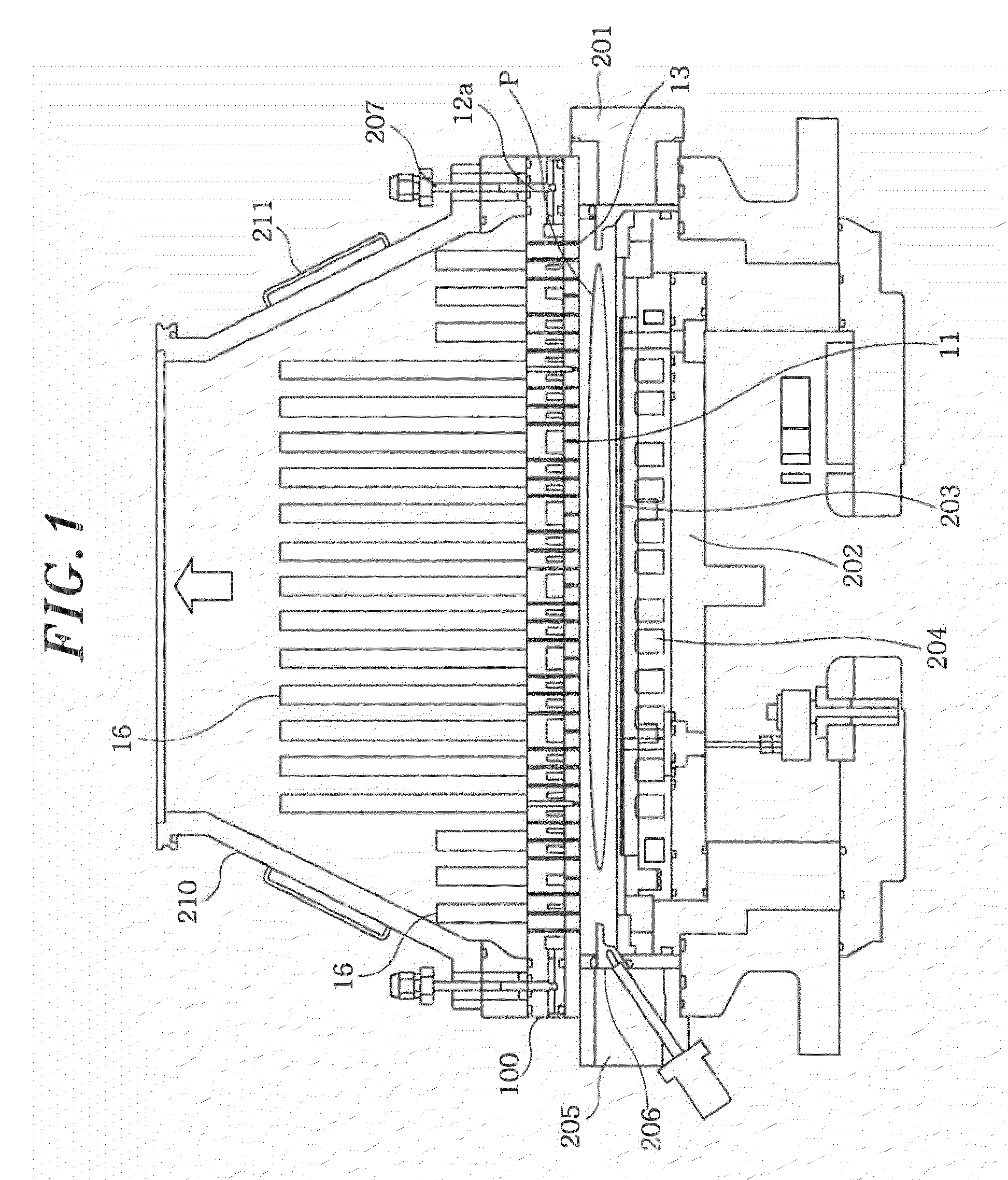

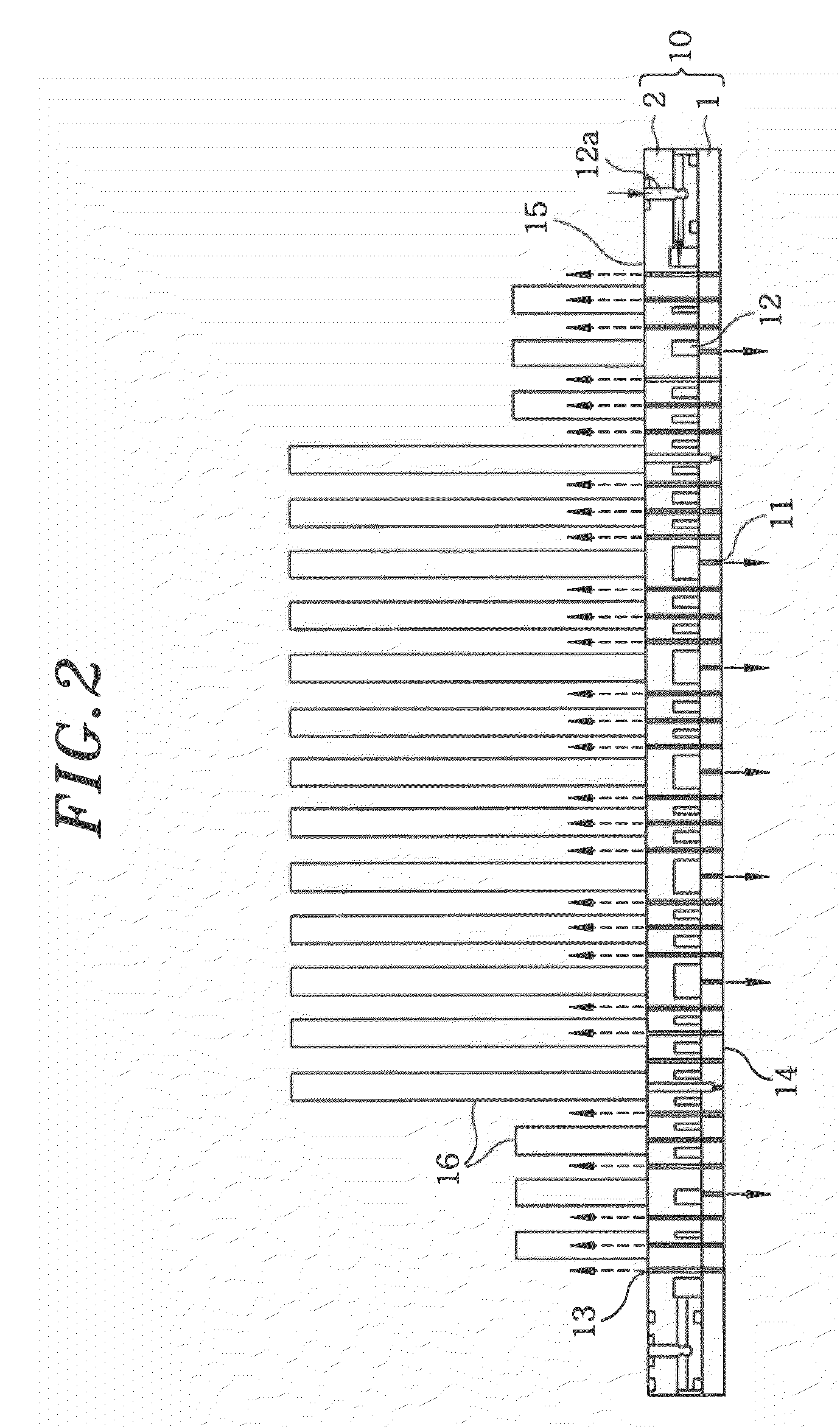

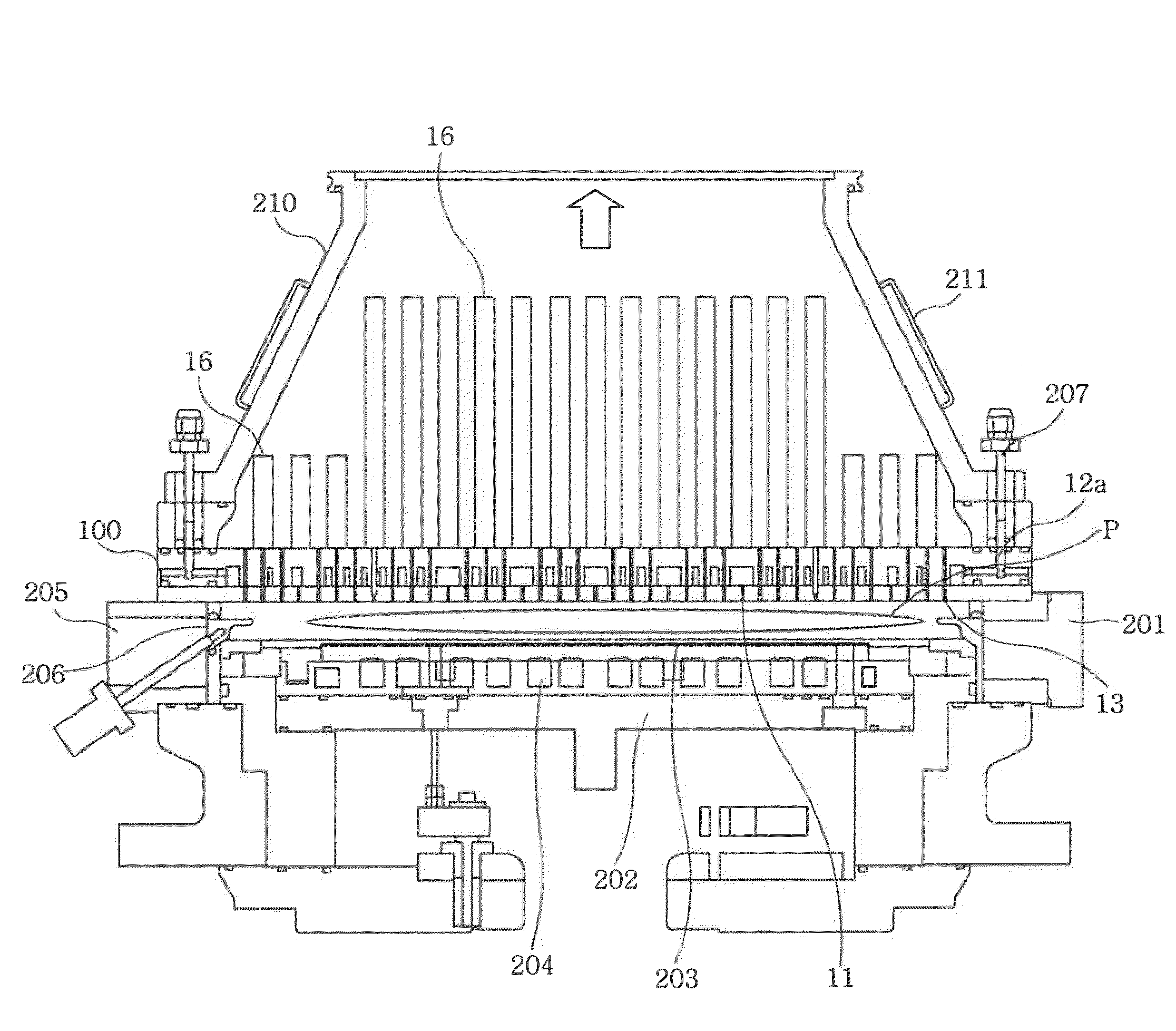

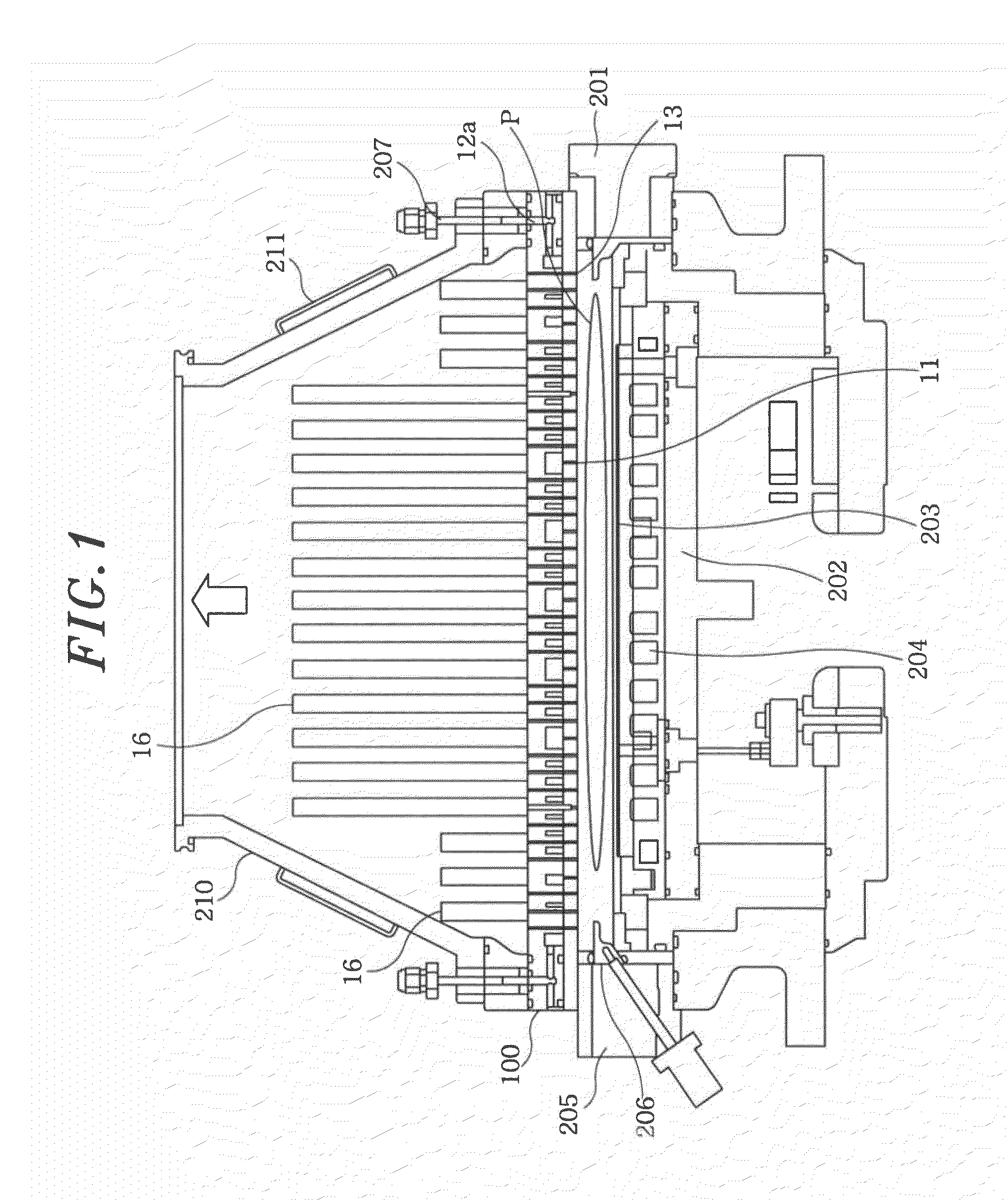

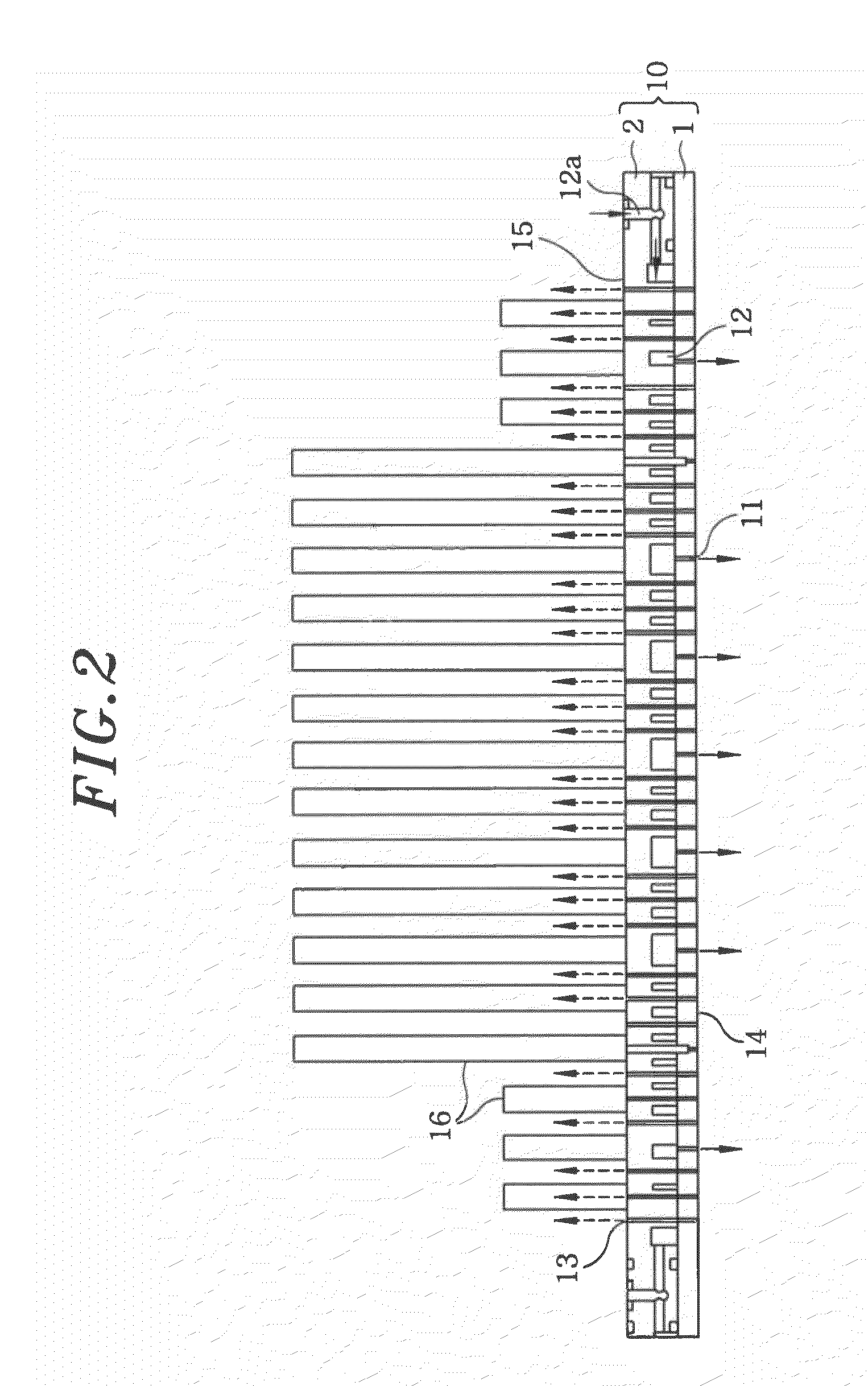

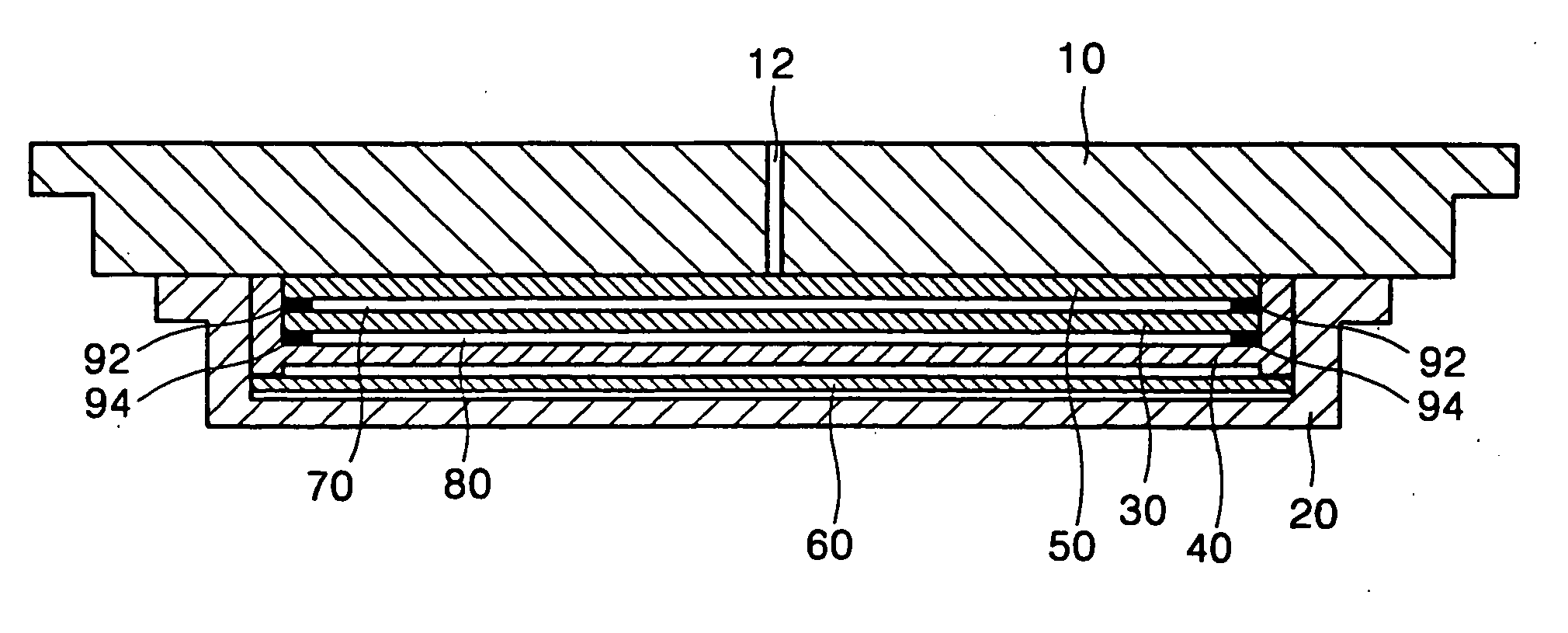

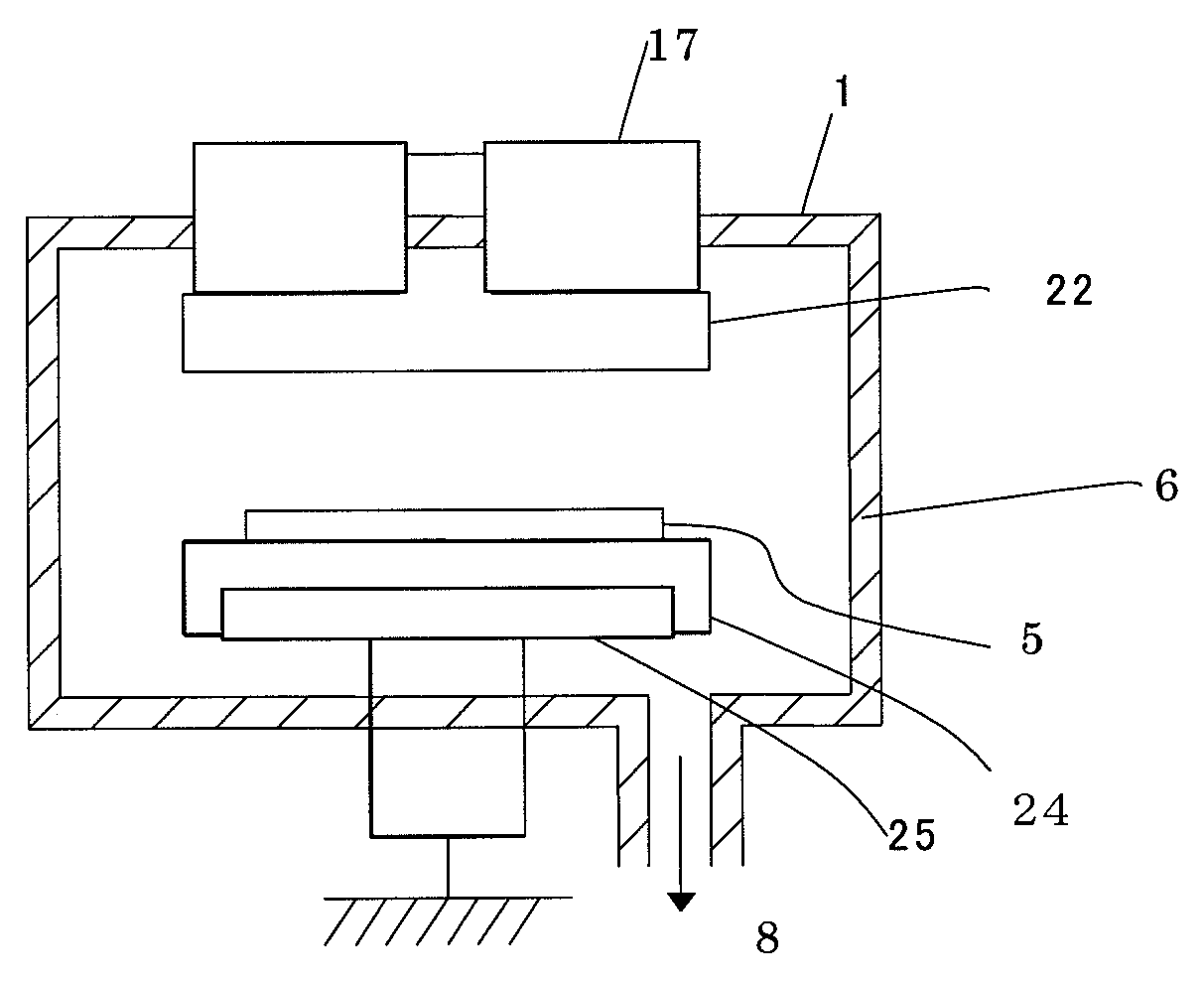

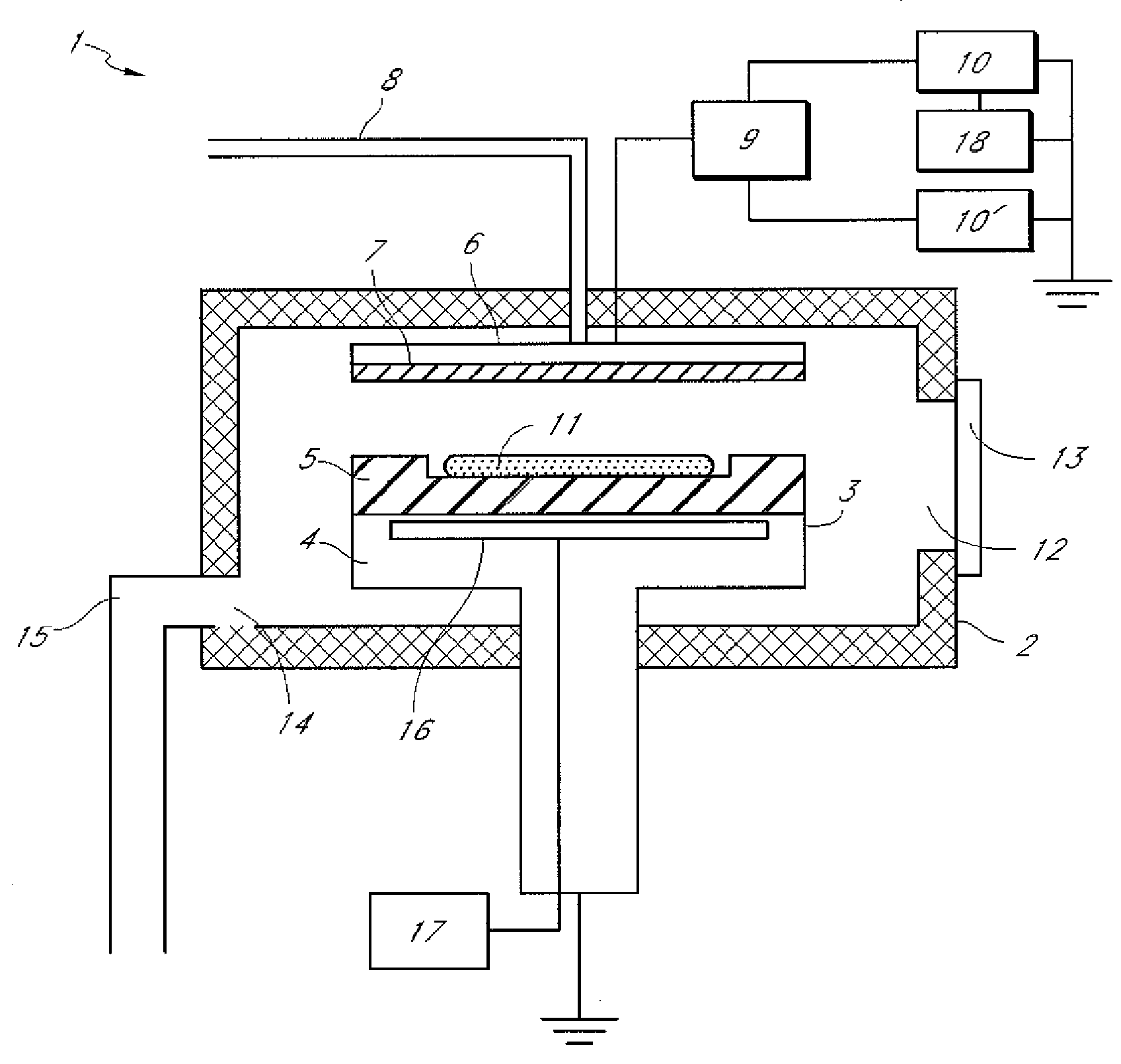

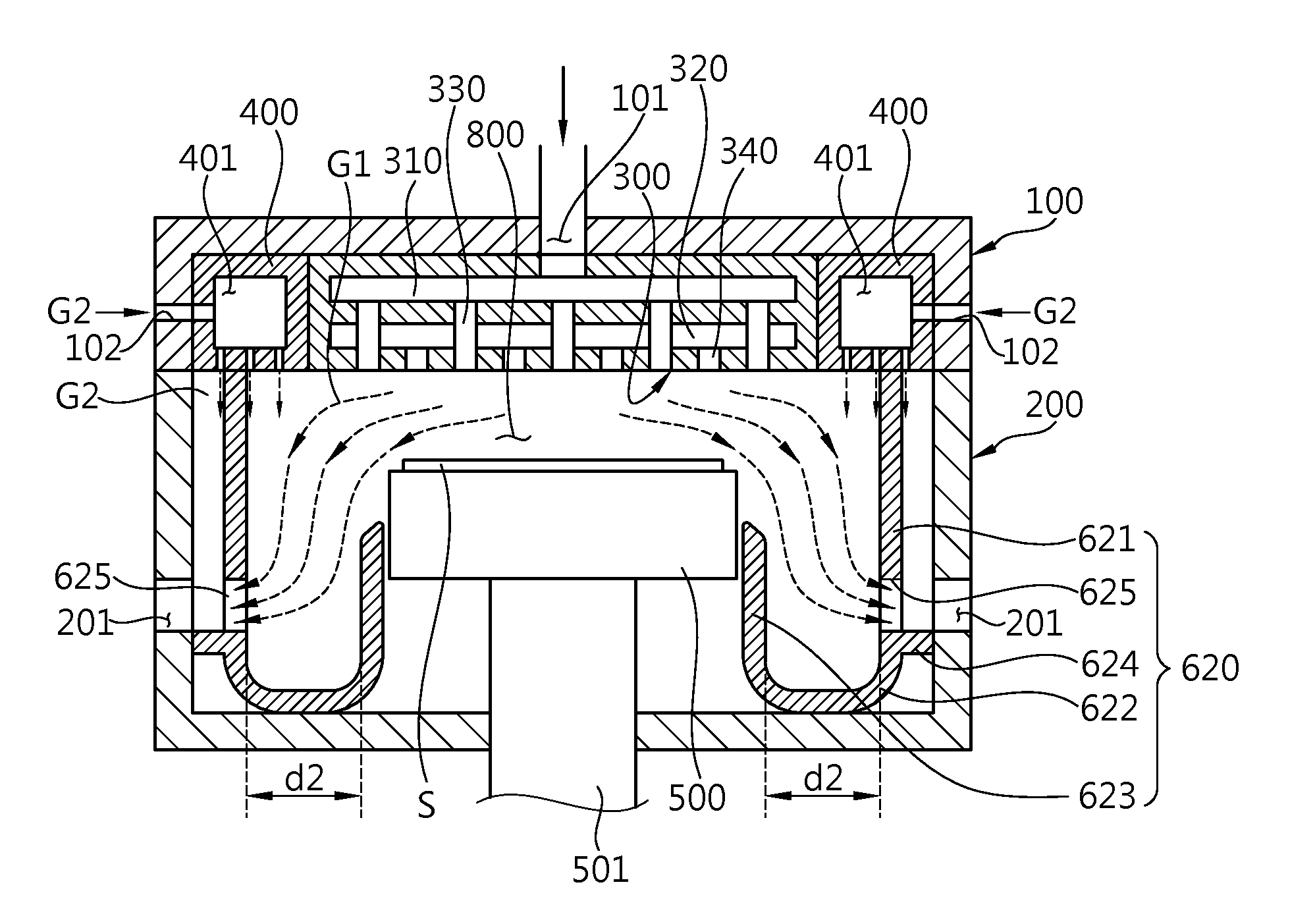

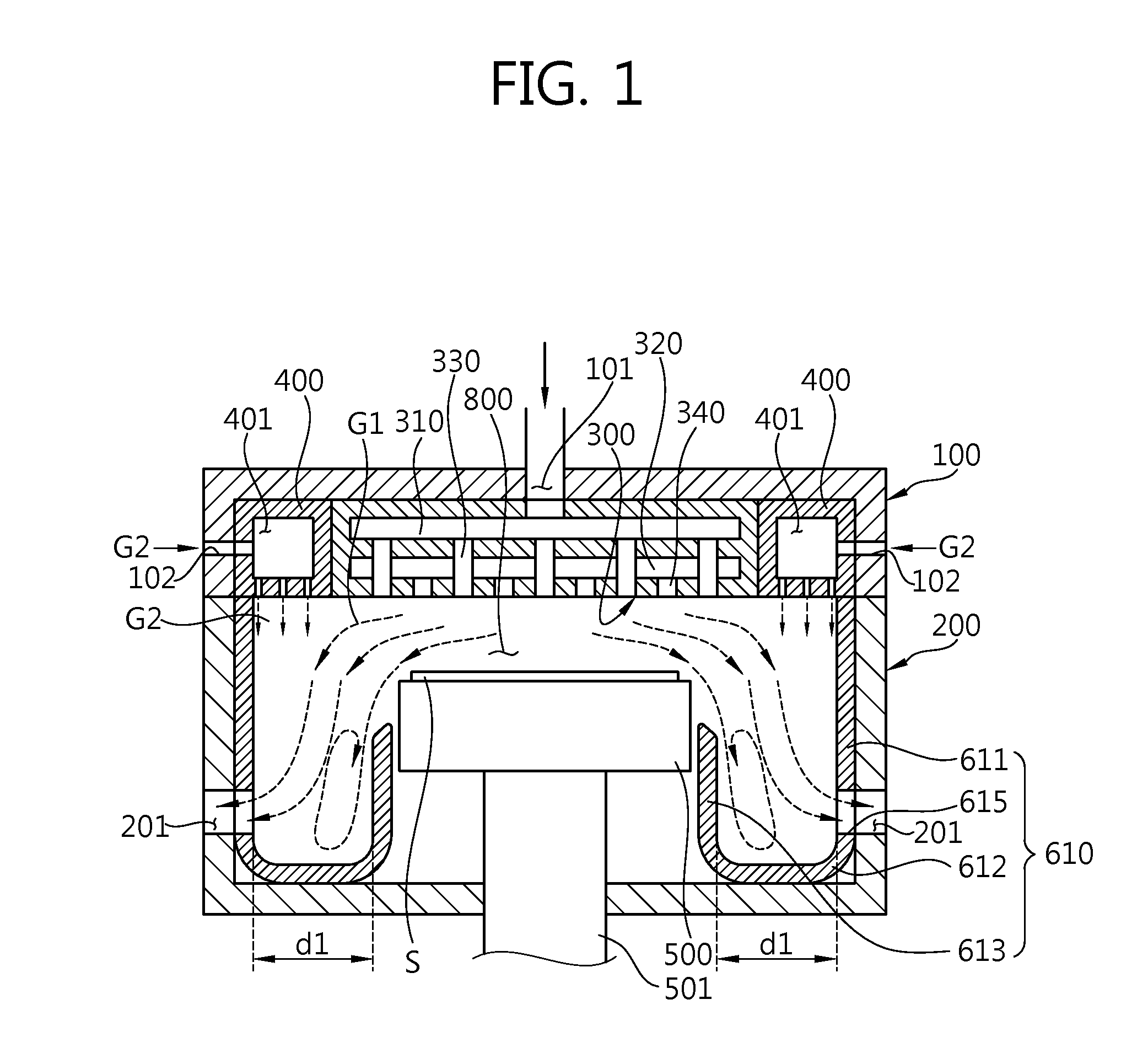

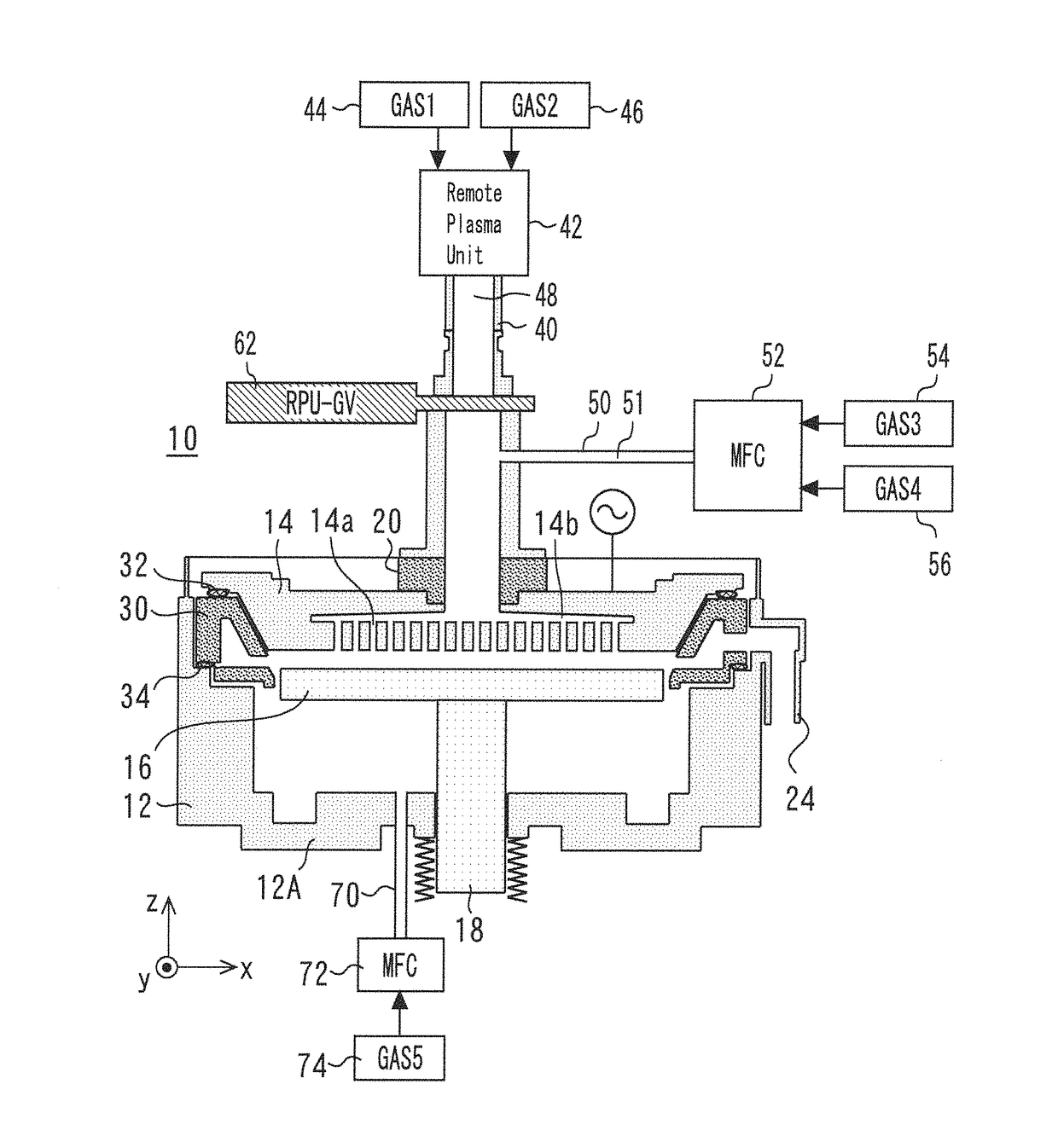

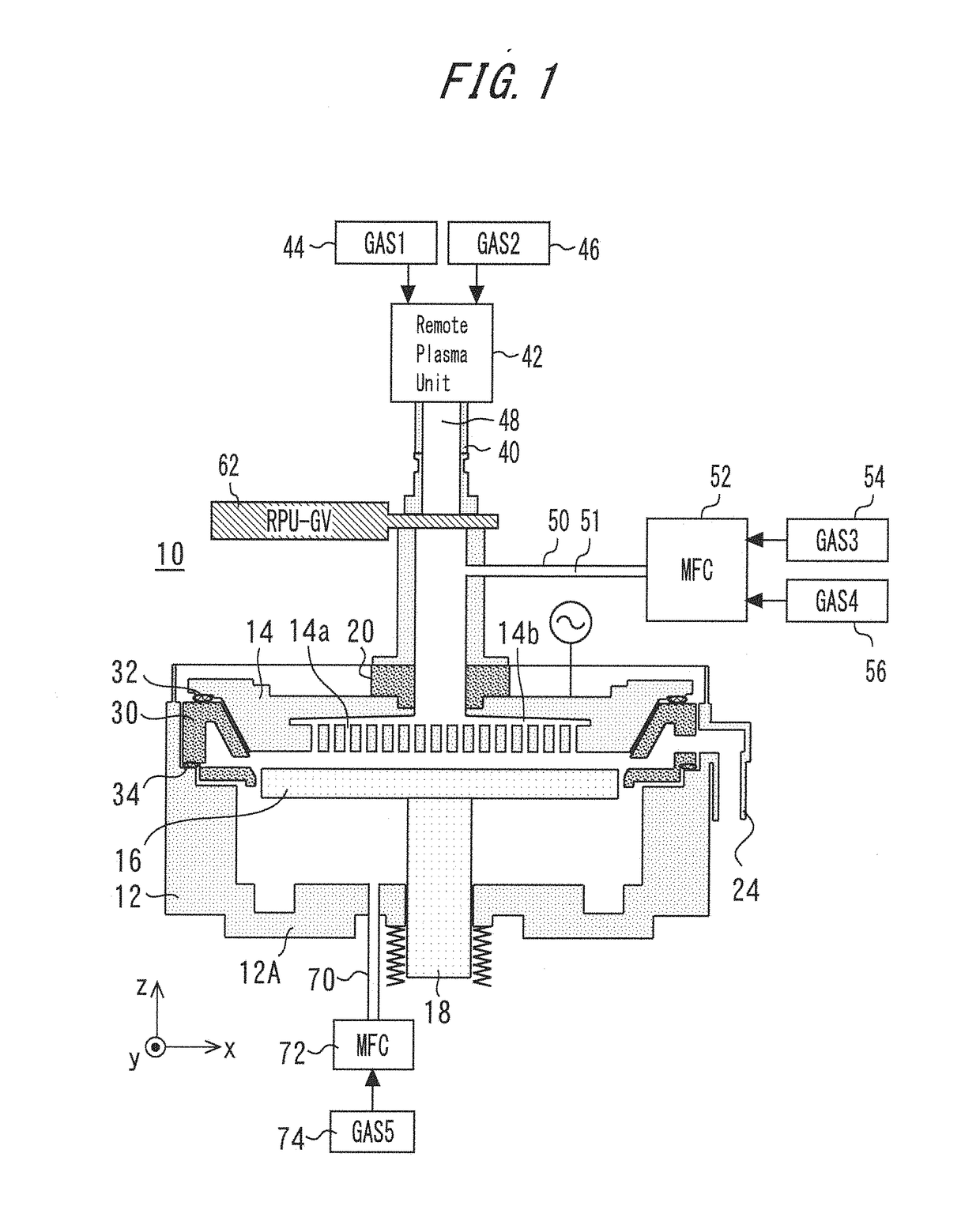

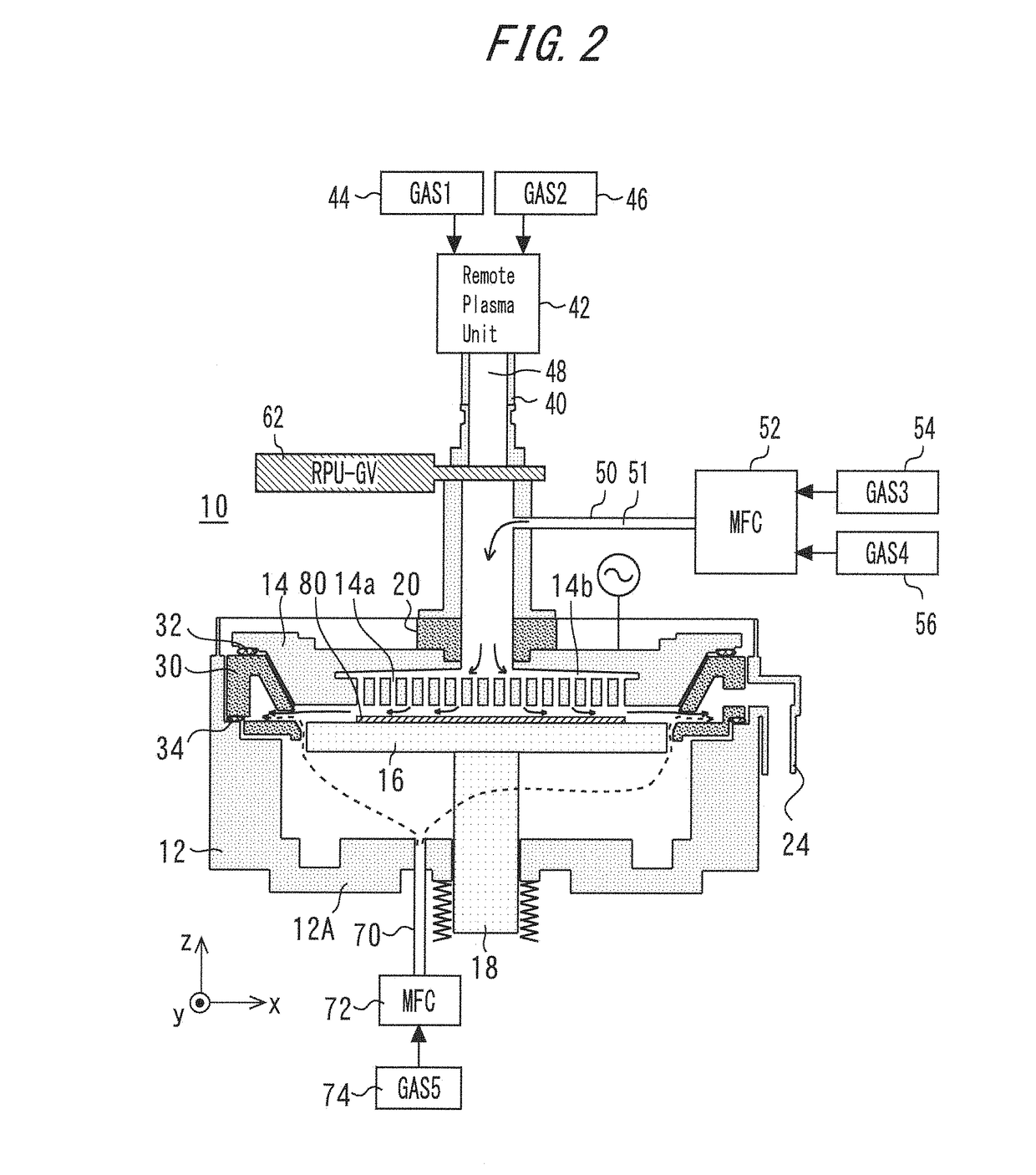

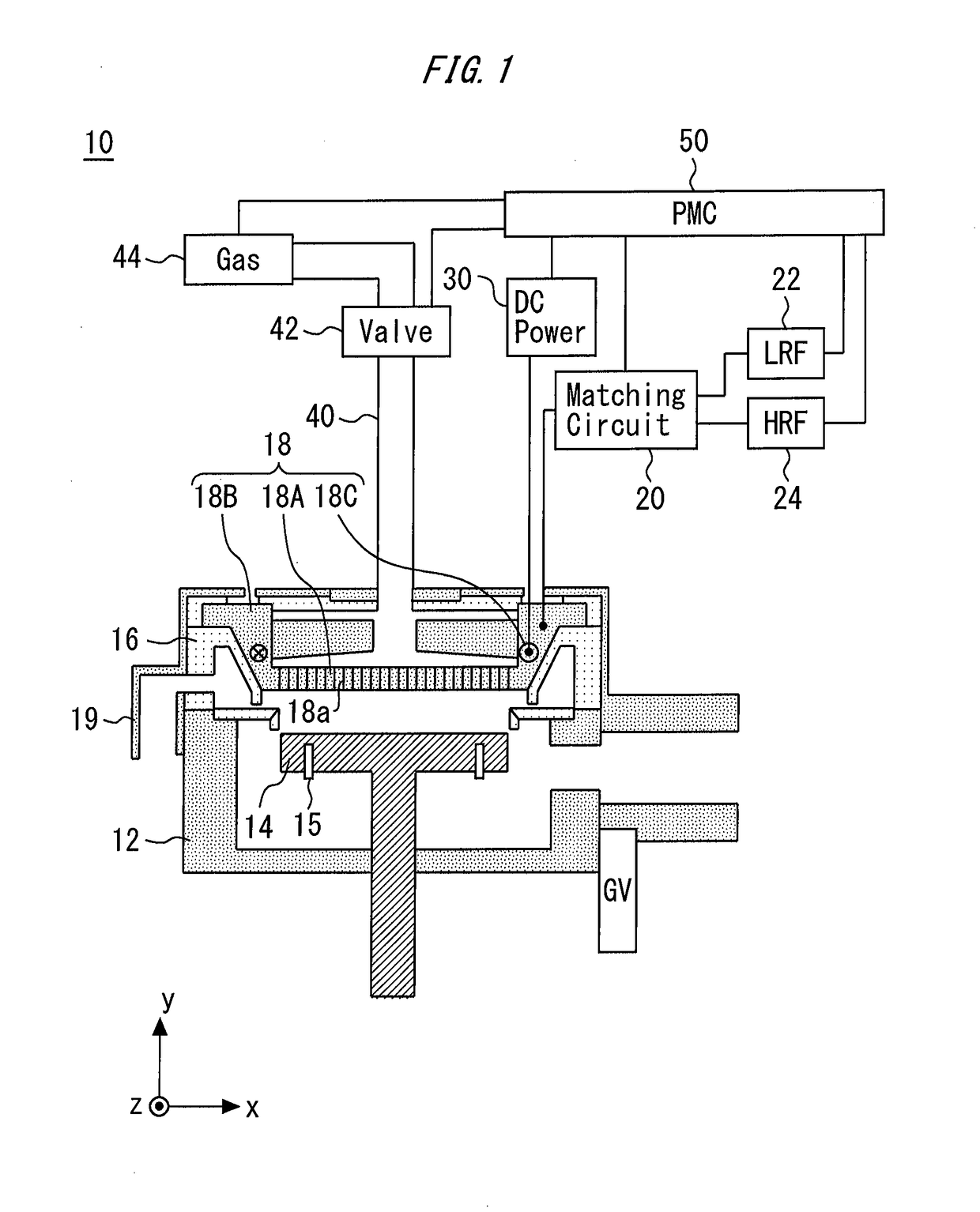

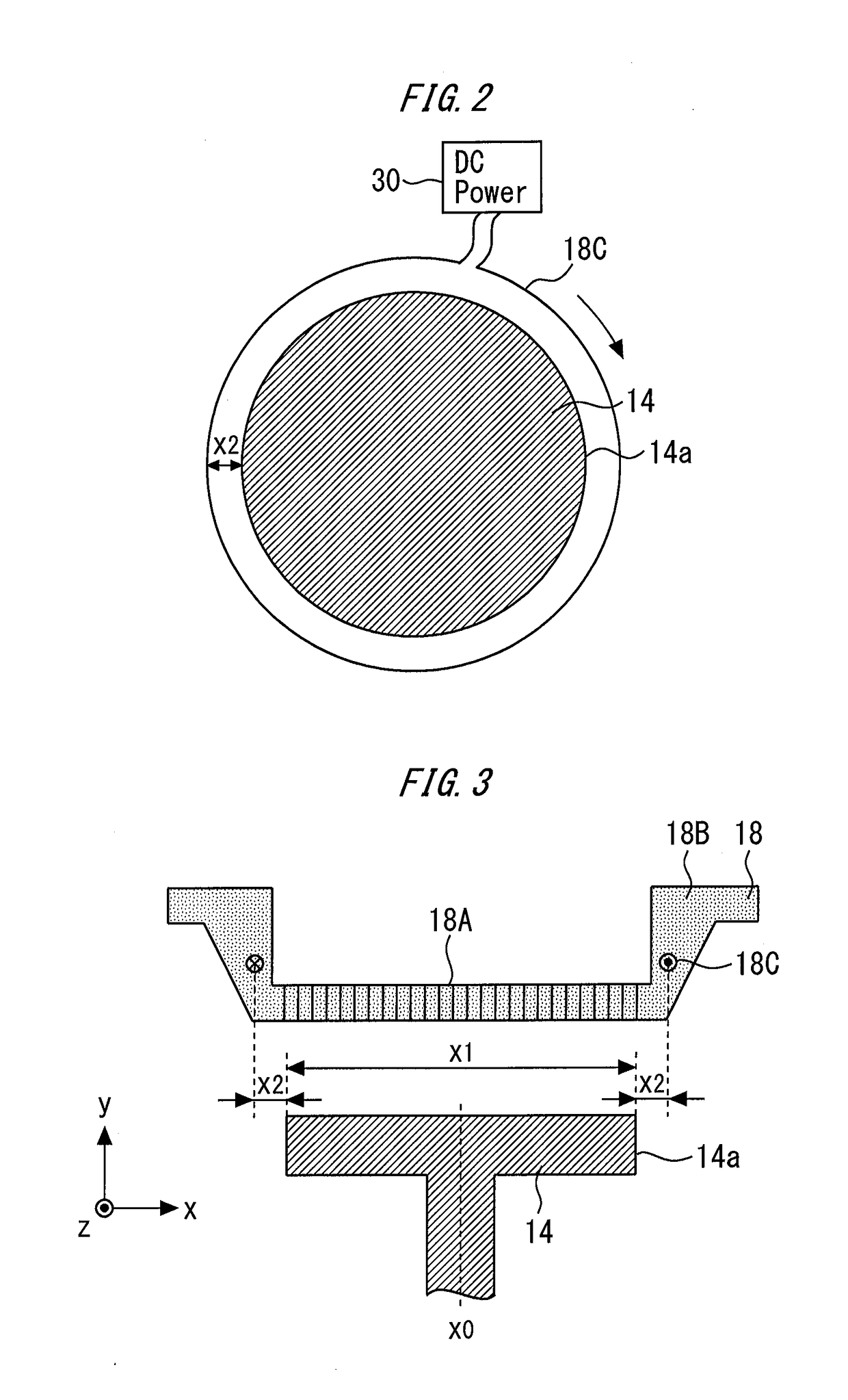

Shower head and plasma processing apparatus having same

InactiveUS8282769B2Avoid temperature riseImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCopper

A shower head is provided, in a processing chamber in which a substrate is processed, to face a mounting table for mounting the substrate thereon. The shower head includes: a facing surface that faces the mounting table to supply a gas to the substrate in a form of shower through a plurality of gas injection holes formed on the facing surface; an opposing surface provided opposite to the facing surface; and a plurality of bar-shaped heat transfer columns standing on the opposing surface. Here, the heat transfer columns have varying lengths and / or thicknesses to adjust heat capacities thereof. The heat transfer columns are made of one of aluminum, stainless steel, and copper.

Owner:TOKYO ELECTRON LTD

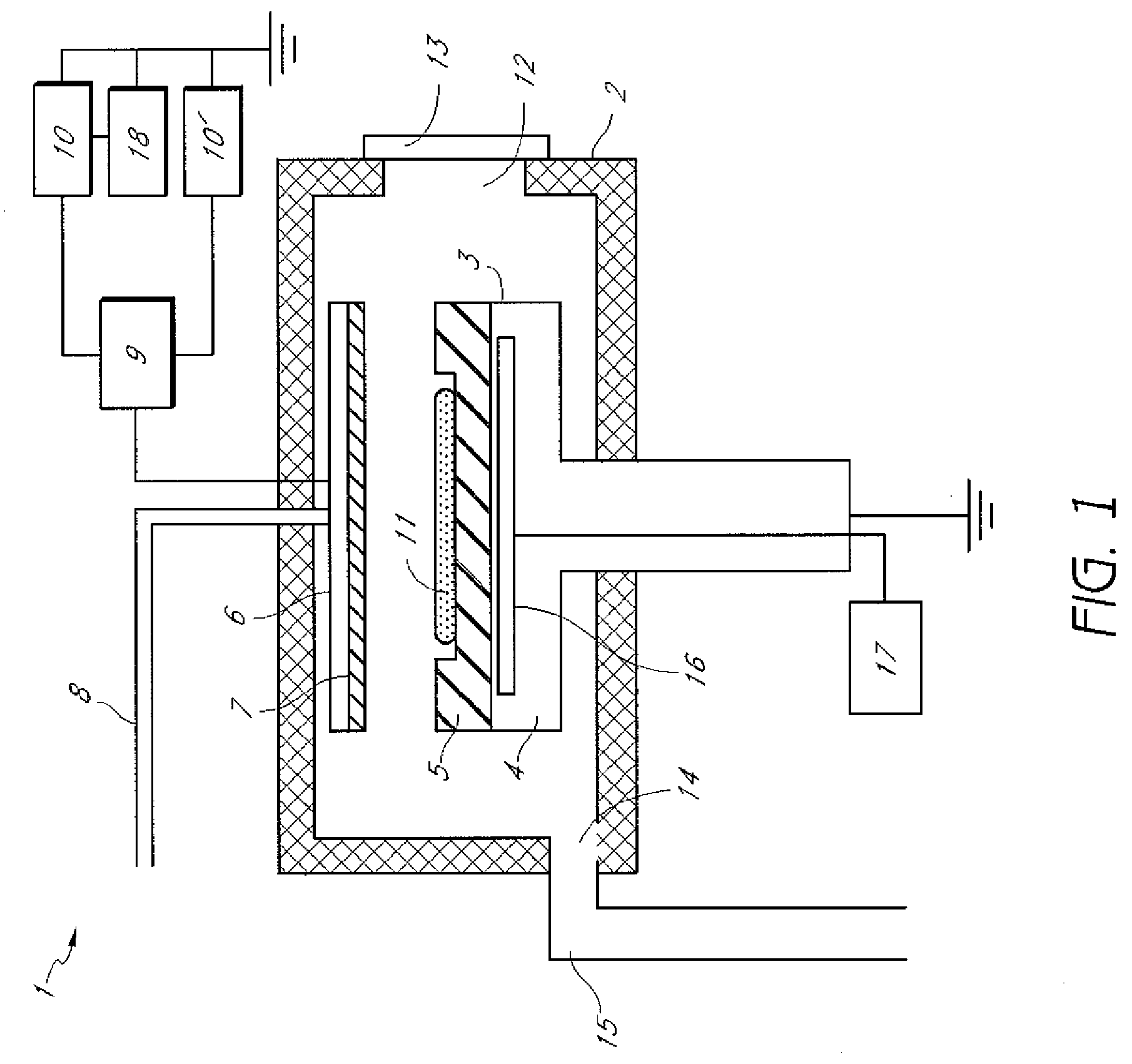

Shower head and plasma processing apparatus having same

InactiveUS20100230051A1Improve uniformityUniform temperature distributionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCopper

A shower head is provided, in a processing chamber in which a substrate is processed, to face a mounting table for mounting the substrate thereon. The shower head includes: a facing surface that faces the mounting table to supply a gas to the substrate in a form of shower through a plurality of gas injection holes formed on the facing surface; an opposing surface provided opposite to the facing surface; and a plurality of bar-shaped heat transfer columns standing on the opposing surface. Here, the heat transfer columns have varying lengths and / or thicknesses to adjust heat capacities thereof. The heat transfer columns are made of one of aluminum, stainless steel, and copper.

Owner:TOKYO ELECTRON LTD

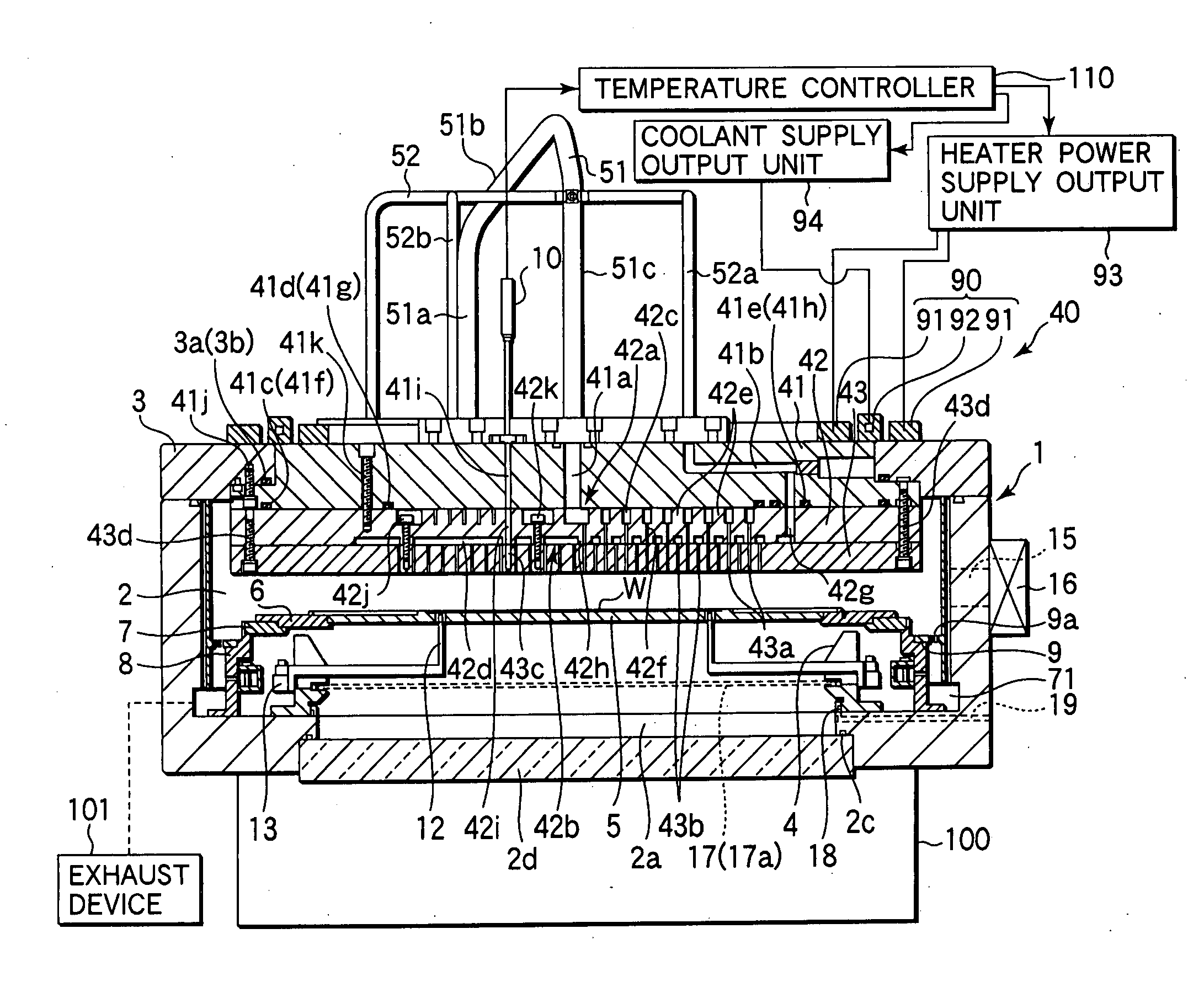

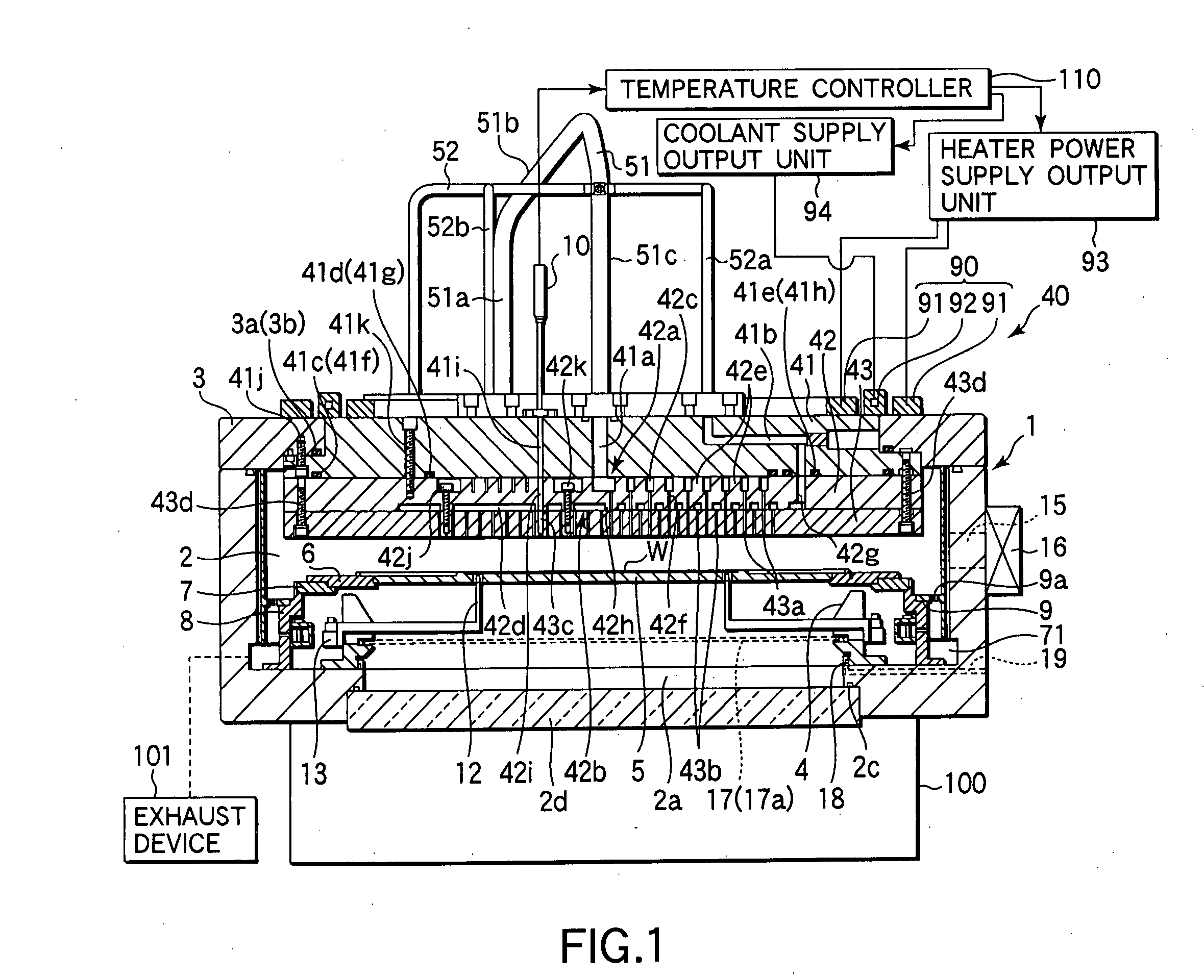

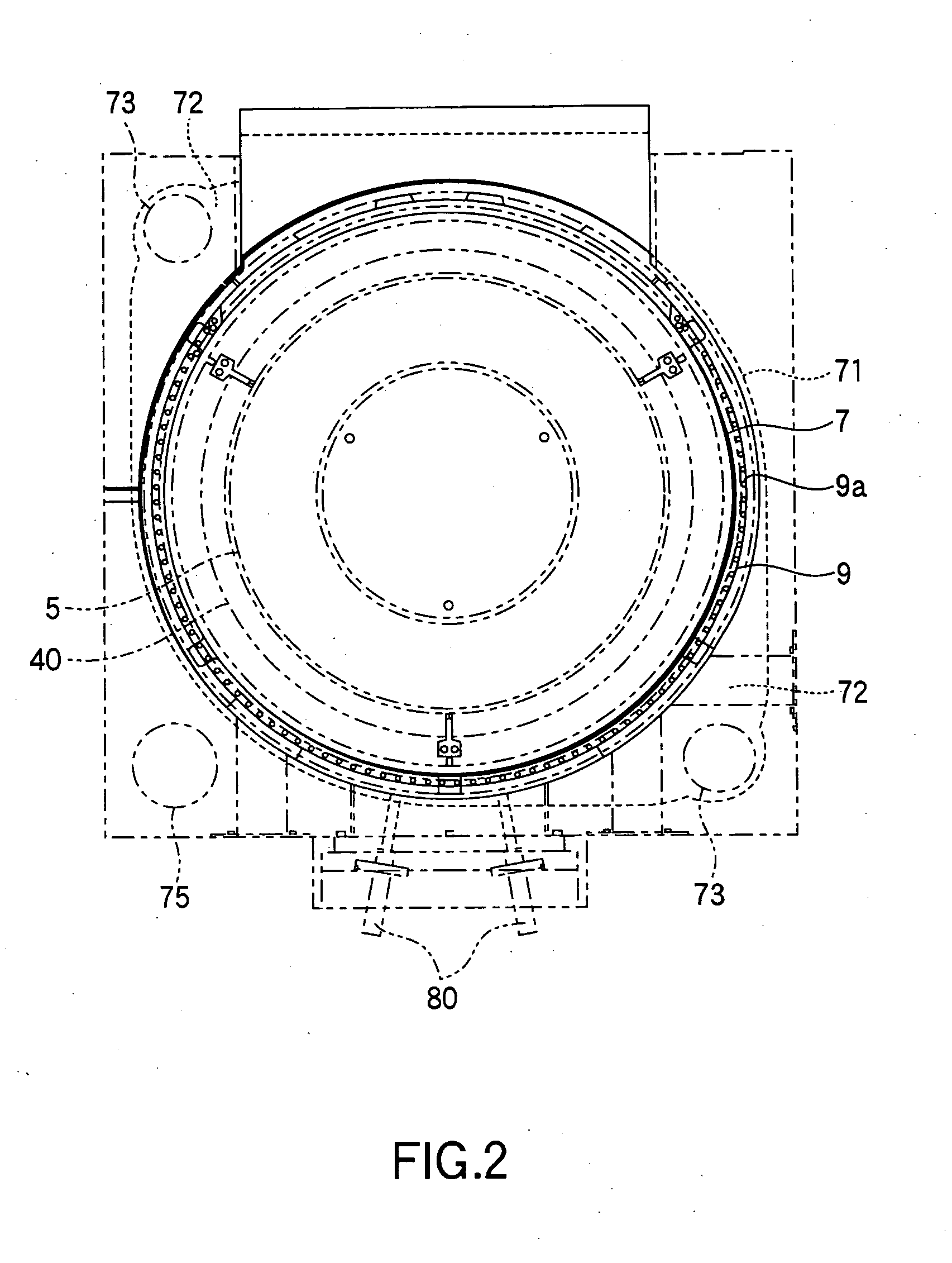

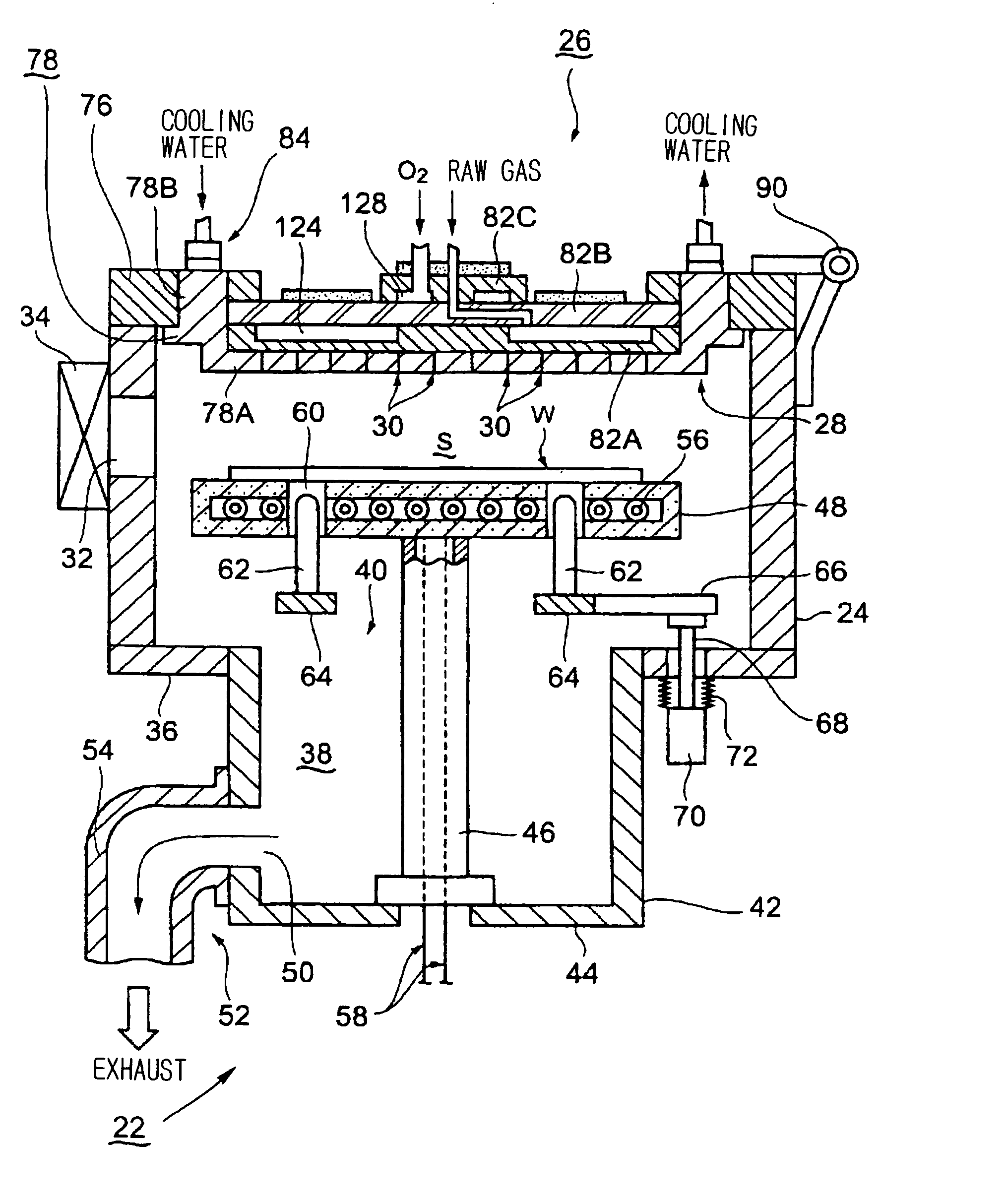

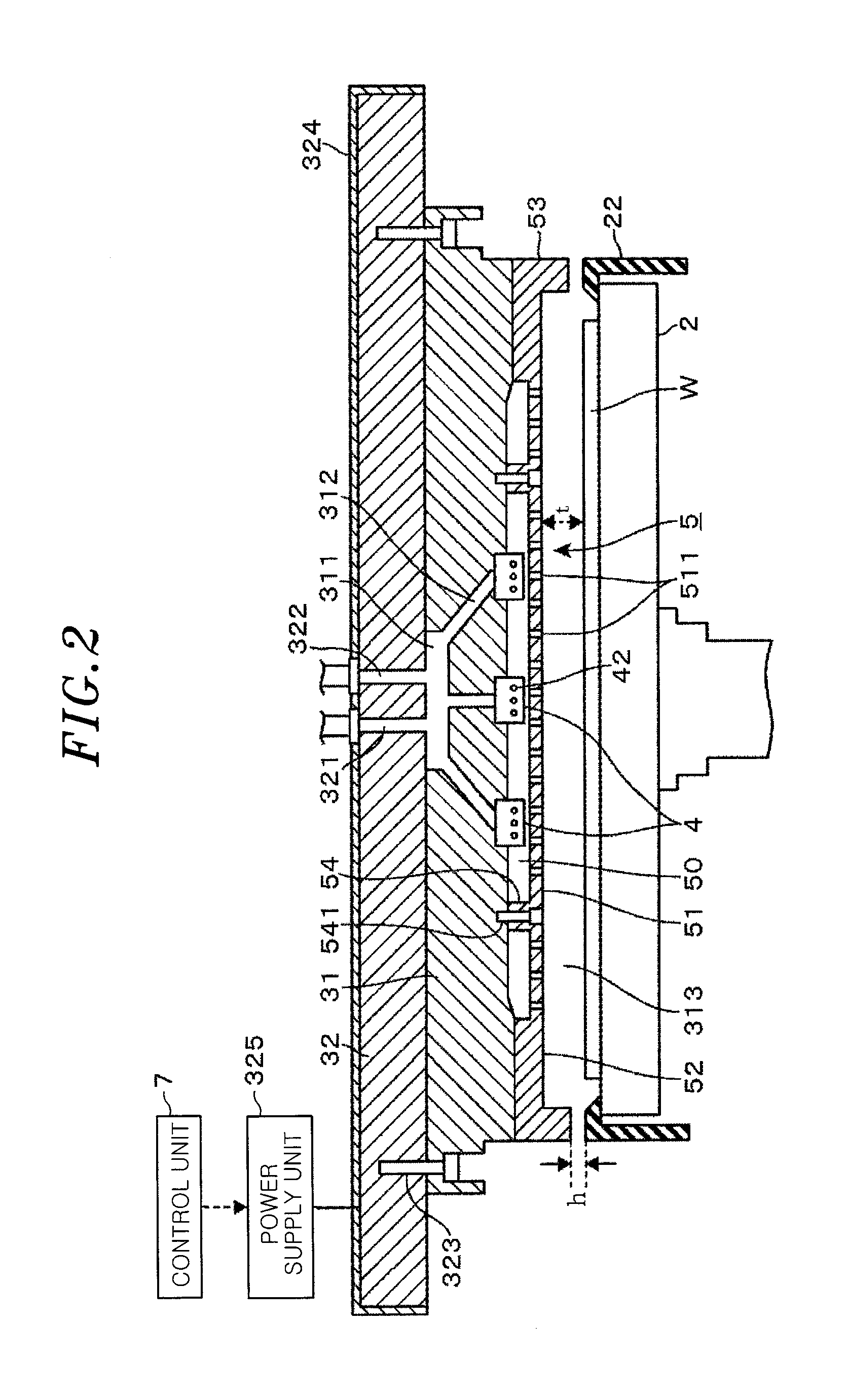

Processing apparatus

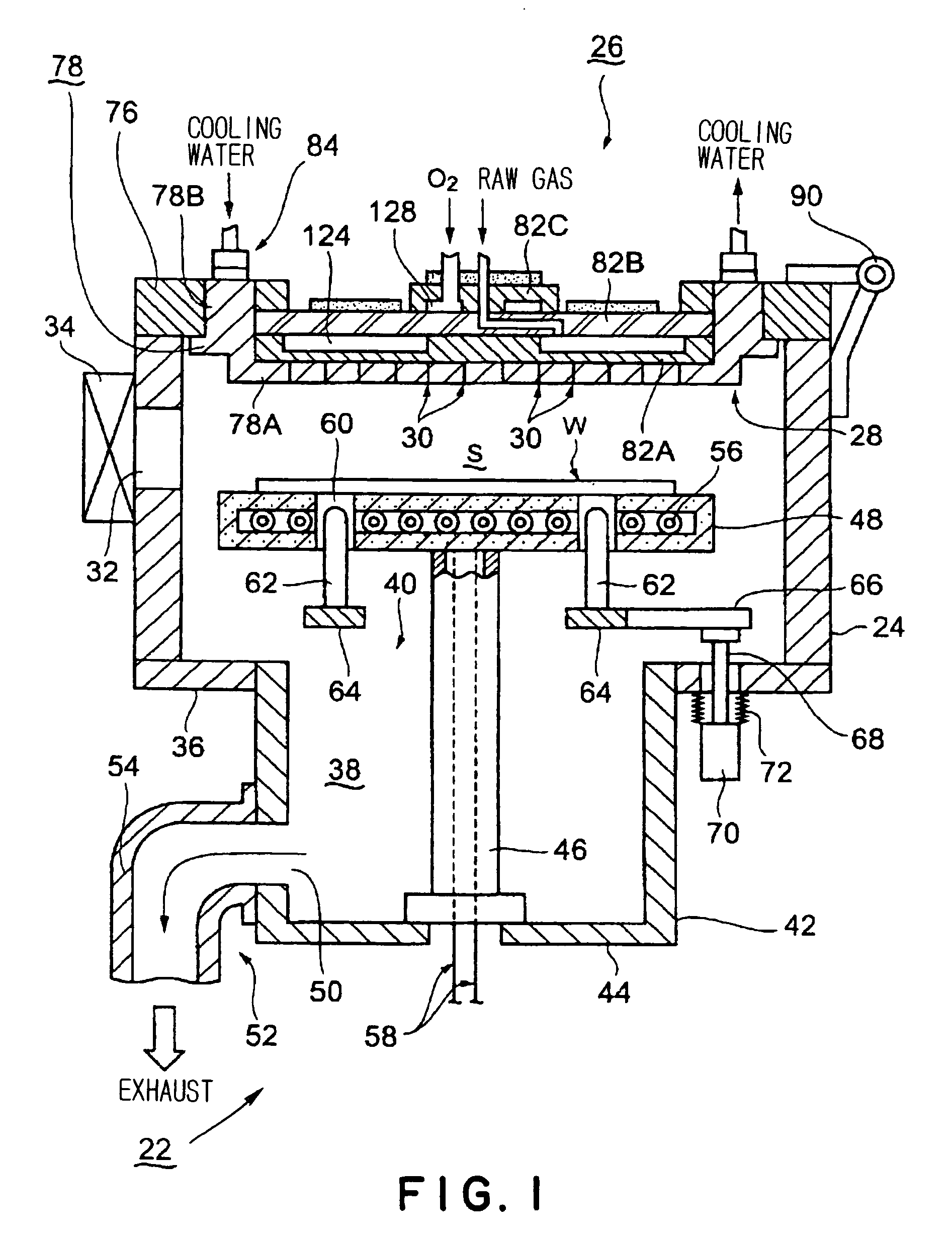

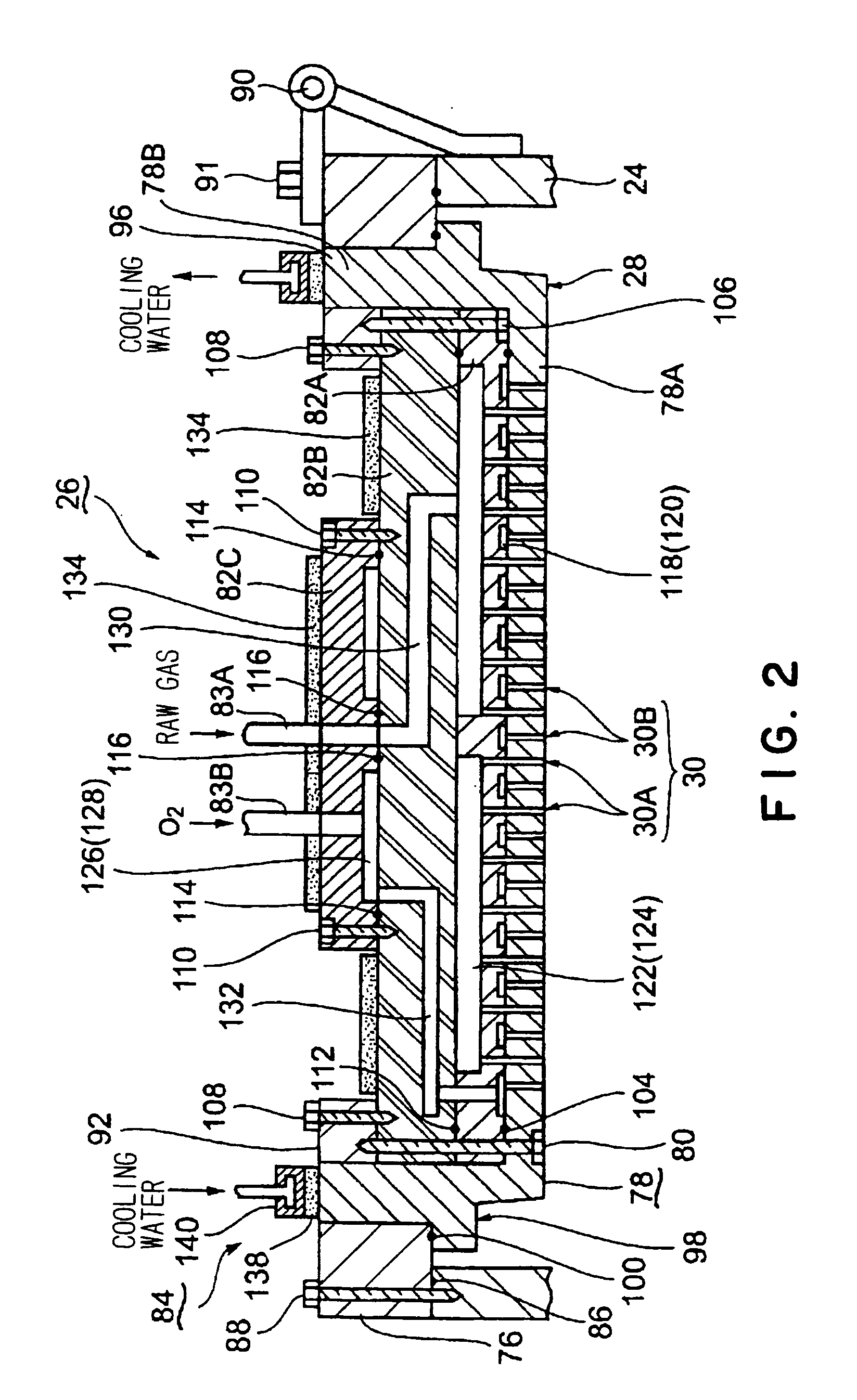

InactiveUS20070158026A1High temperature controllabilityEasy maintenanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

A shower head structure (26) includes a shower head main body (78) of a one-piece structure formed in a generally cup shape and having a bottom wall (78A) provided with a plurality of gas injection holes (30A, 30B) formed therein and a side wall (78B) rising from a peripheral portion of the bottom wall. A plurality of gas diffusion chamber forming plates (82A-82C) are housed in the shower head main body (78). A through-hole is formed in a head mounting frame (76) disposed on a ceiling of a processing vessel (24). An upper portion of the side wall (78B) of the shower head main body (78) is inserted into the through-hole, so that a part of the side wall (78B) is exposed to the exterior of the processing vessel. A cooling mechanism (84) is disposed at the upper end portion of the side wall (78B). Heat transfer between the cooling mechanism (84) and the bottom wall (78A) is enhanced, so that the temperature of the bottom wall (78A) can be controlled at a proper value, thereby preventing any adhesion of an unnecessary film onto the bottom wall (78A).

Owner:TOKYO ELECTRON LTD

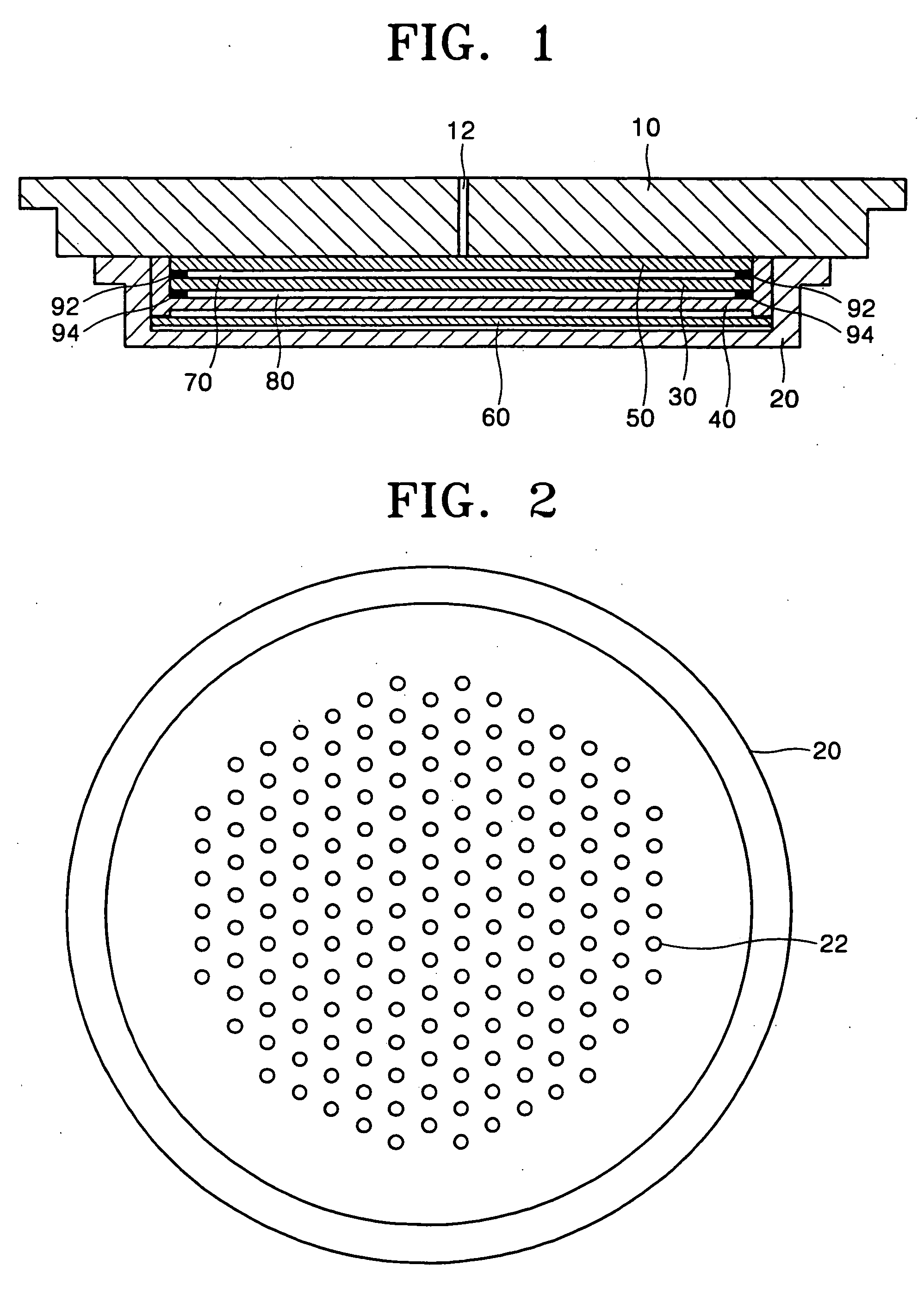

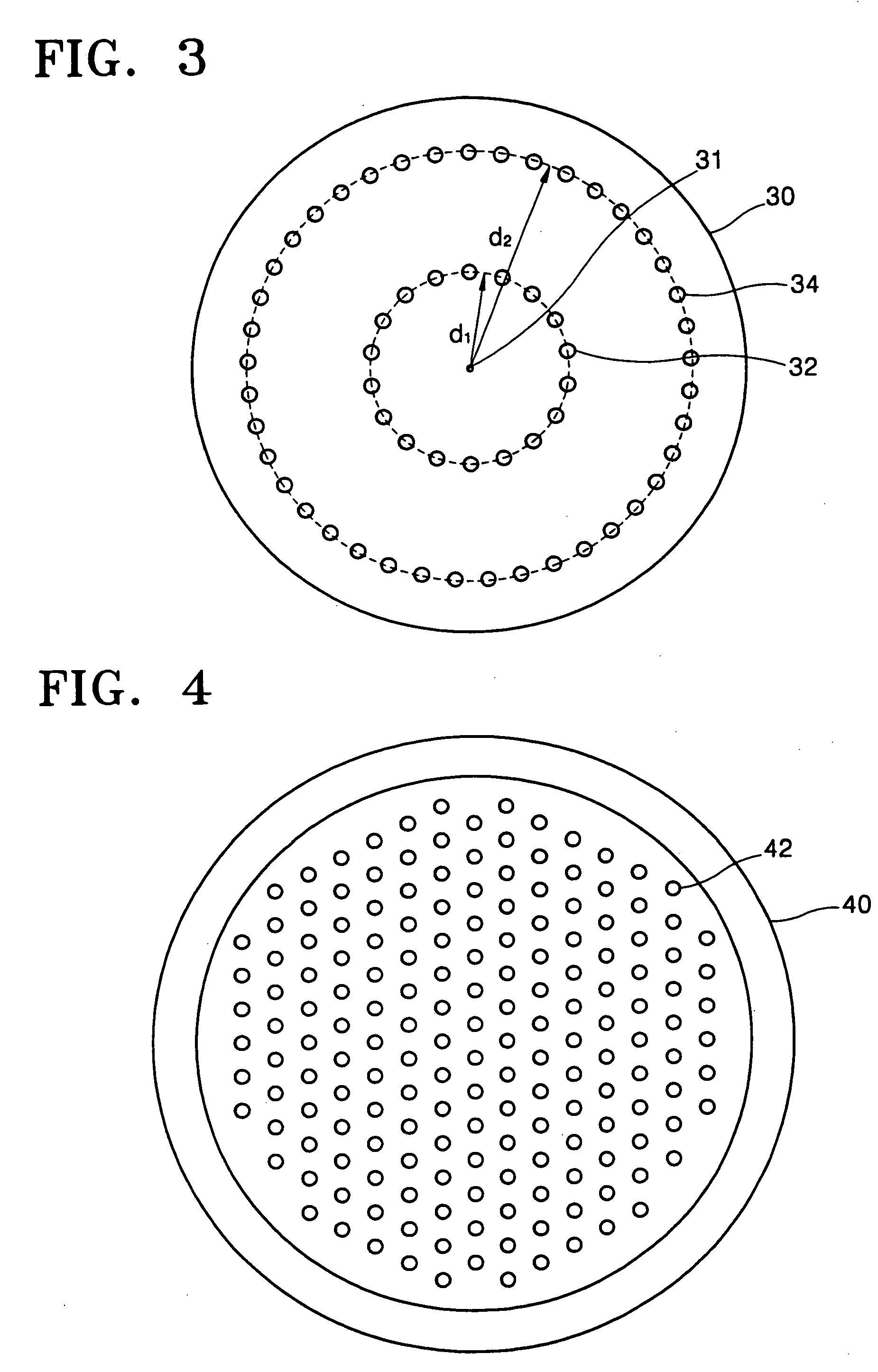

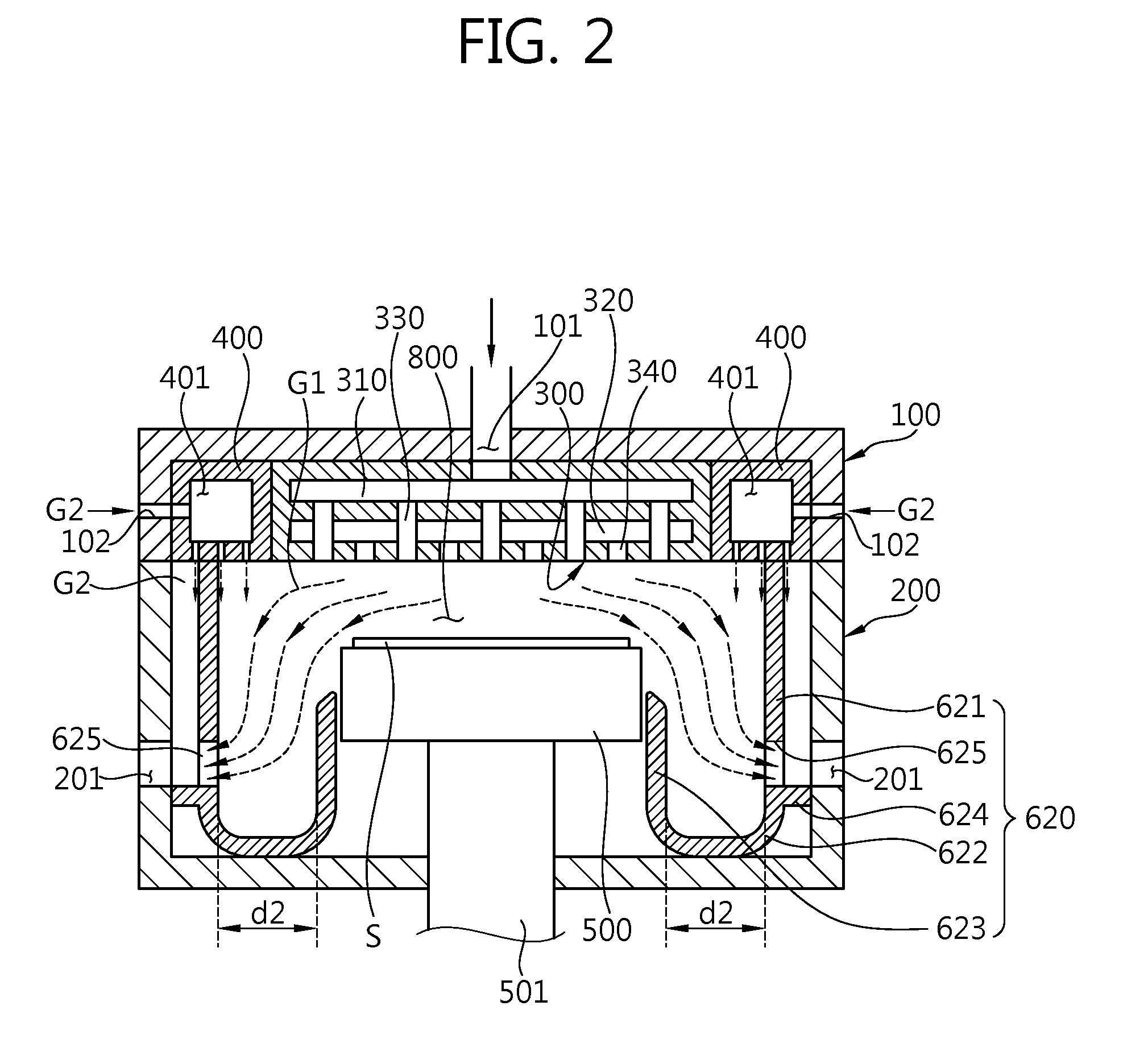

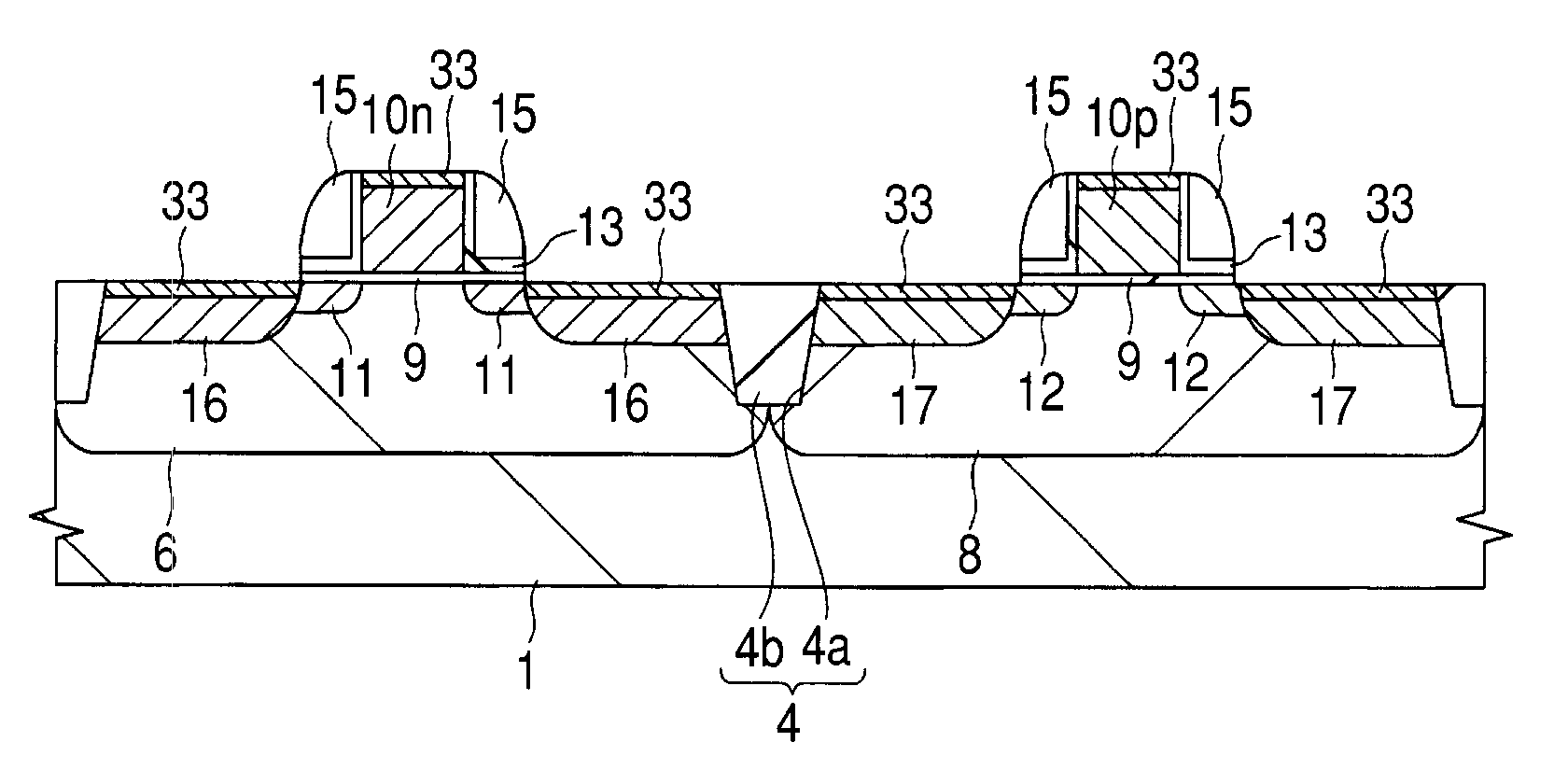

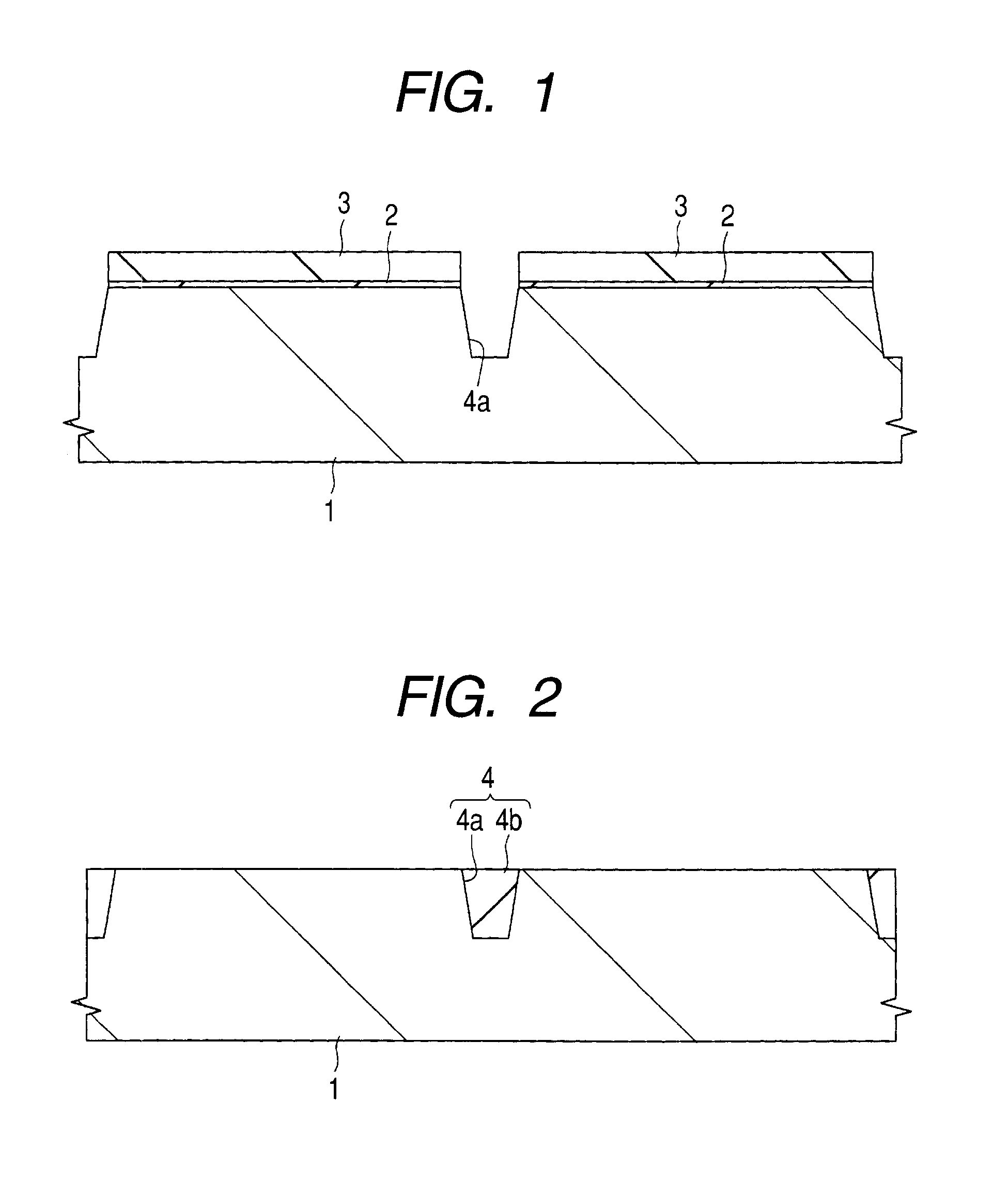

Shower plate for plasma processing apparatus and plasma processing apparatus

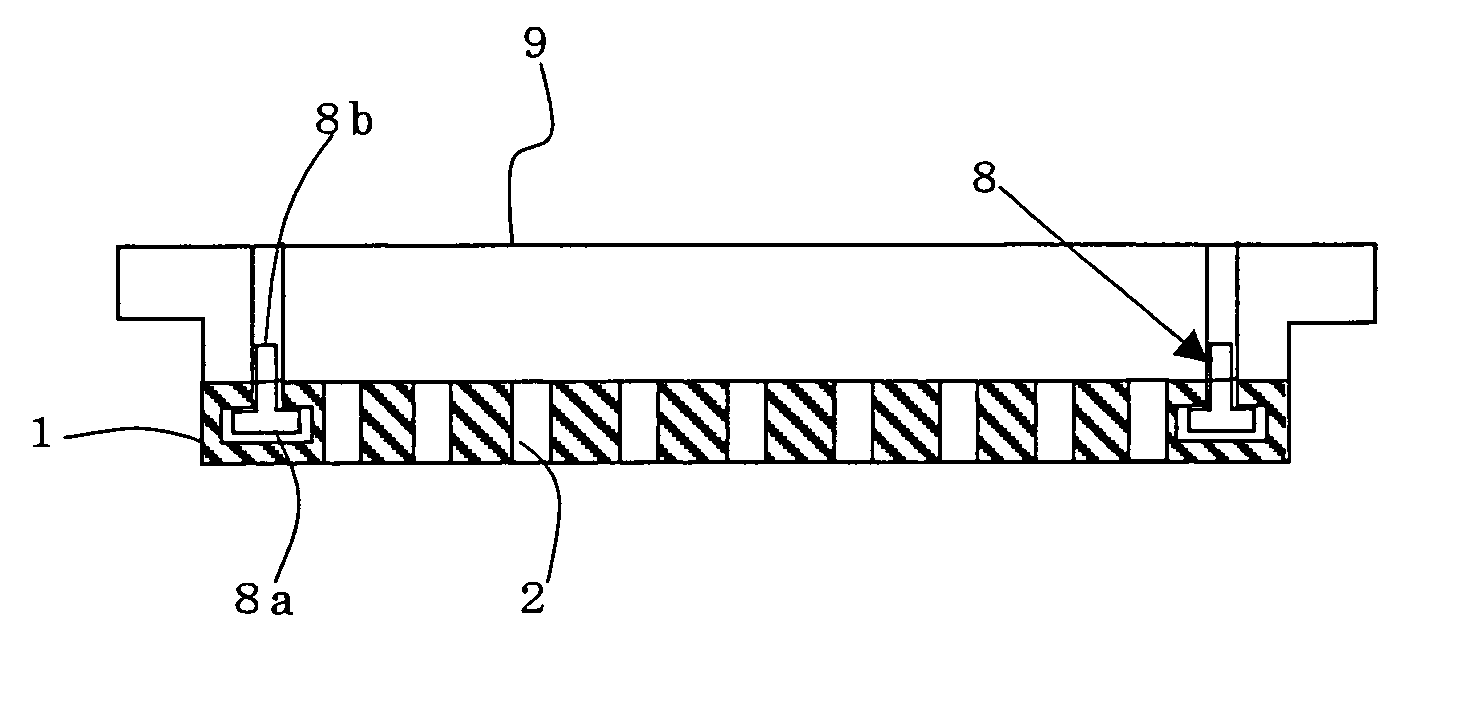

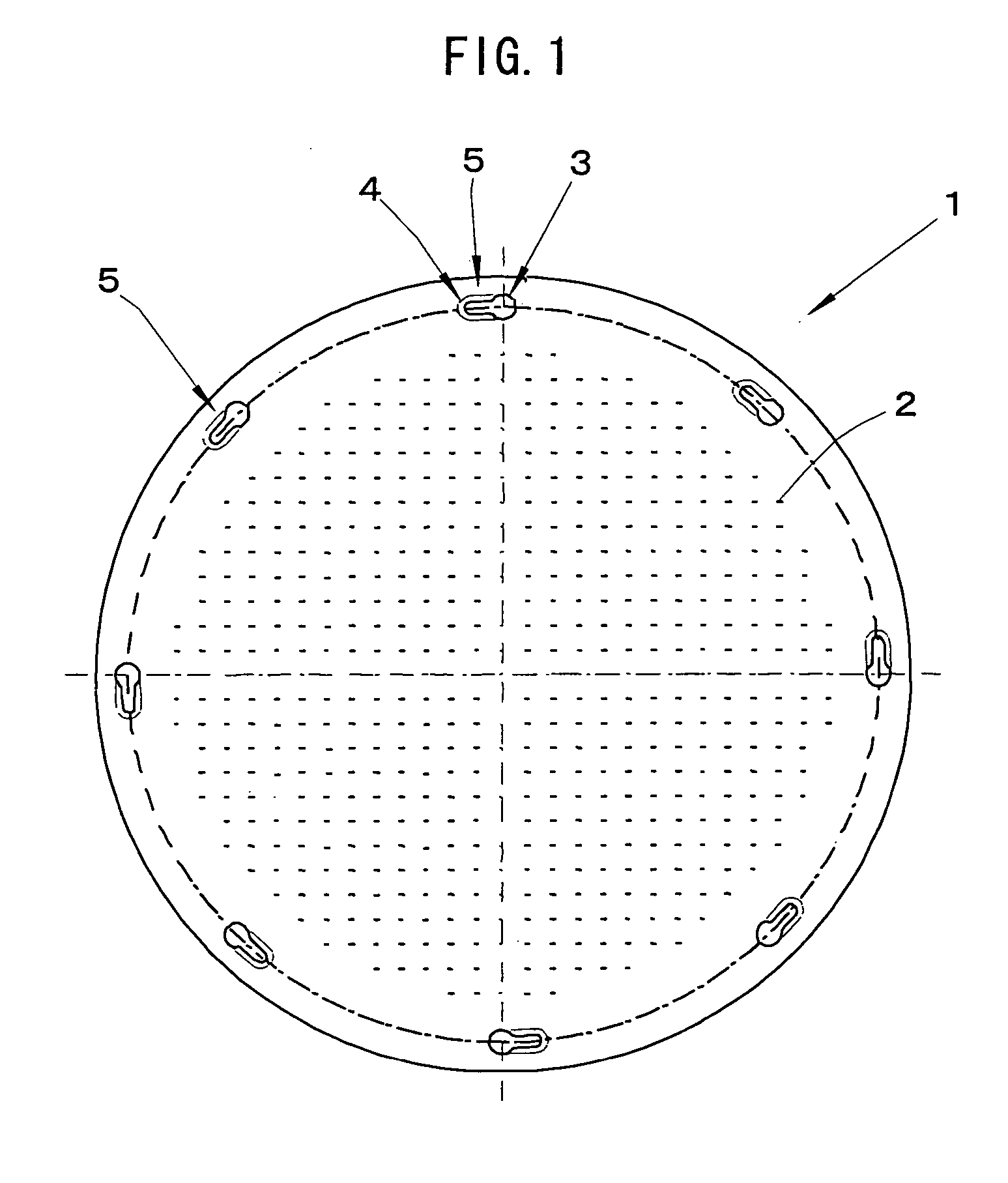

InactiveUS20050258280A1Easy to manufactureAvoid pollutionElectric discharge tubesMovable spraying apparatusEngineeringContamination

There is disclosed a shower plate 1, wherein the shower plate has a plurality of holes 3 for inserting the head of the fastening member and holes 4 for fitting the head are formed integrally along a concentric circle in the outside region of the gas feeding holes 2 on a side facing the supporting member, each hole for fitting extending in one direction of the concentric circle from each hole for insertion, each hole for fitting has a groove portion 4b through which the shank of the fastening member is to pass and a fitting portion 4a which is wider than the groove portion and in which the head of the fastening member is to be fitted, and the head of the fastening member fixed in the supporting member is inserted into the hole for insertion of the shower plate and the shower plate is turned so that the head of the fastening member is fitted in the fitting portion, and thereby the shower plate is supported by the supporting member without exposure of the fastening member. There can be provided a shower plate for a plasma processing apparatus, wherein effective diameter is large enough, contamination of a substrate to be treated can be prevented, it is easy to manufacture, and it is easy to fix to a supporting member.

Owner:SHIN ETSU CHEM IND CO LTD

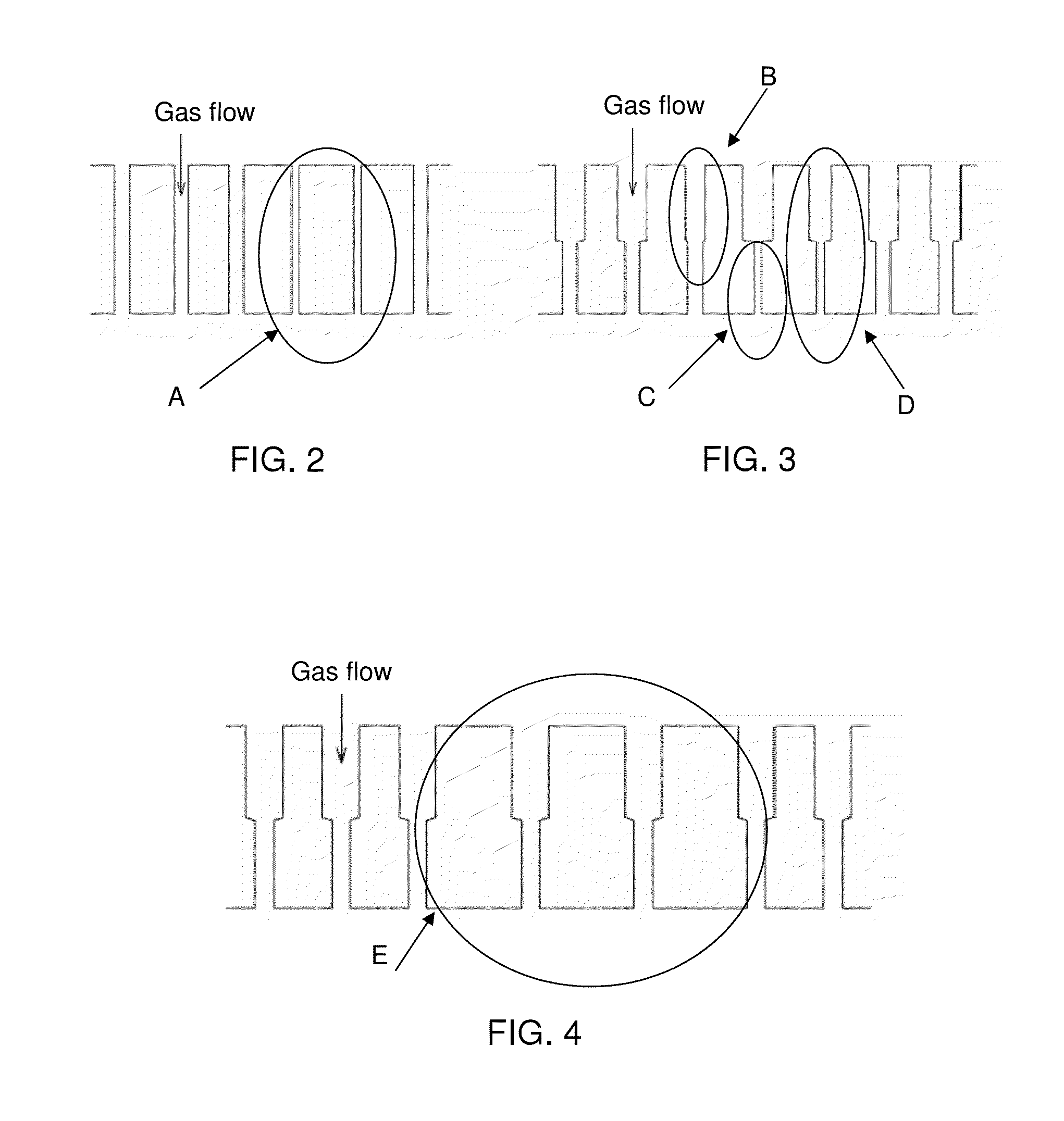

Shower head of a wafer treatment apparatus having a gap controller

InactiveUS20050145338A1Improve uniformityIncrease widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess regionEngineering

A shower head for adjusting distribution of a reactant gas in a process region of a semiconductor manufacturing reaction chamber, wherein a top plate has a gas port for introducing the reactant gas into the reaction chamber; a face plate, having through holes, disposed opposite the process region; a first baffle plate, having through holes, disposed between the top plate and the face plate and capable of moving up or down, wherein the first baffle plate has a top surface that defines a first gap for forming a first lateral flow passage; a second baffle plate, having through holes, disposed between the first baffle plate and the face plate and capable of moving up or down, wherein the second baffle plate has a top surface that defines a second gap for forming a second lateral flow passage; and a gap controller for determining widths of the first and second gaps.

Owner:SAMSUNG ELECTRONICS CO LTD

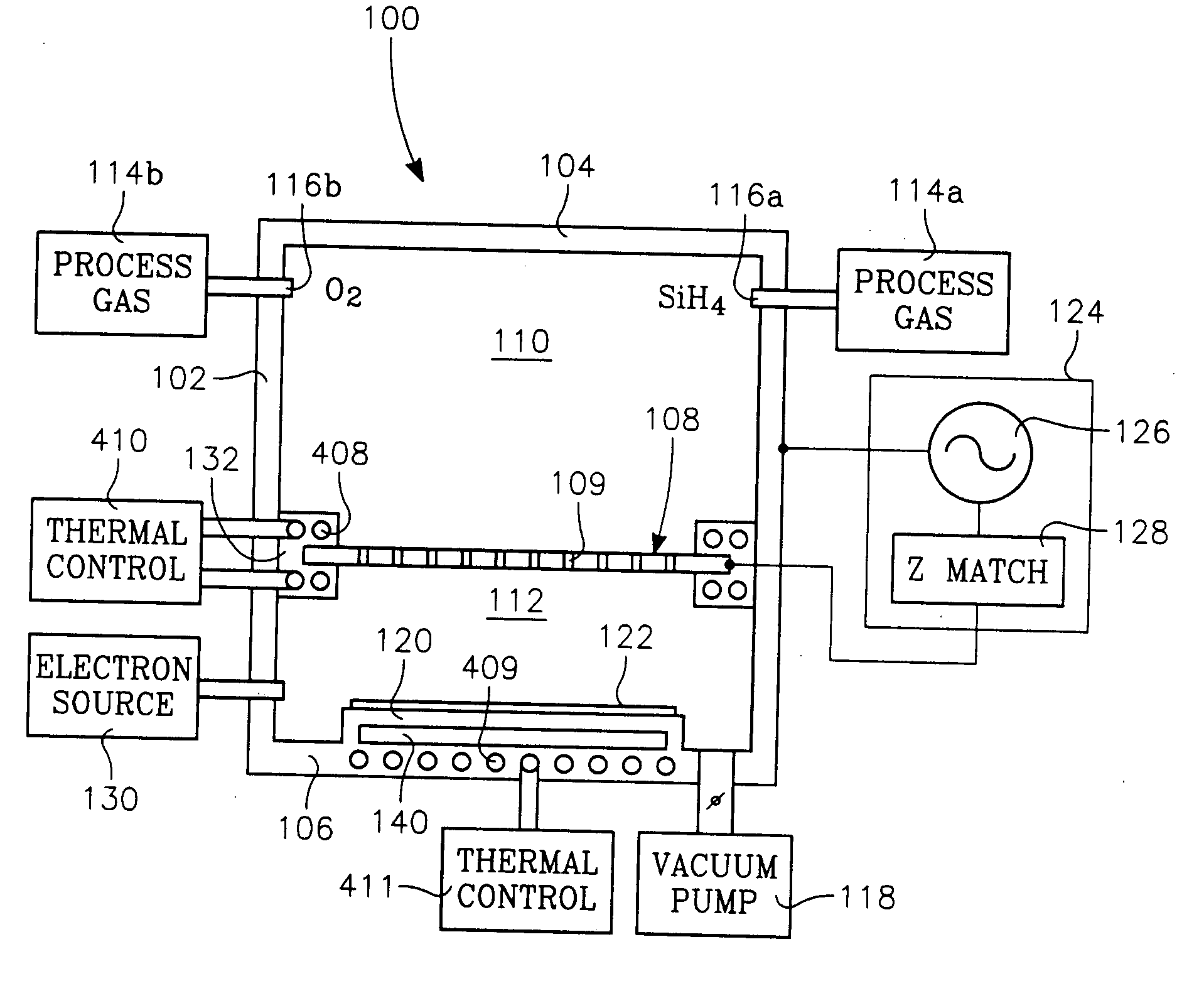

Plasma CVD apparatus having non-metal susceptor

InactiveUS20080299326A1Avoid Metal ContaminationConcerning long-term stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorMetallurgy

A plasma CVD apparatus includes: a cooling susceptor for placing a substrate thereon and serving as an electrode; and a shower plate for introducing gas toward the susceptor via multiple throughholes formed therein. The shower plate serves as an electrode and is disposed in parallel to the susceptor. The cooling susceptor is made of a ceramic material provided with a cooling fluid flow path for passing a cooling fluid therethrough.

Owner:ASM JAPAN

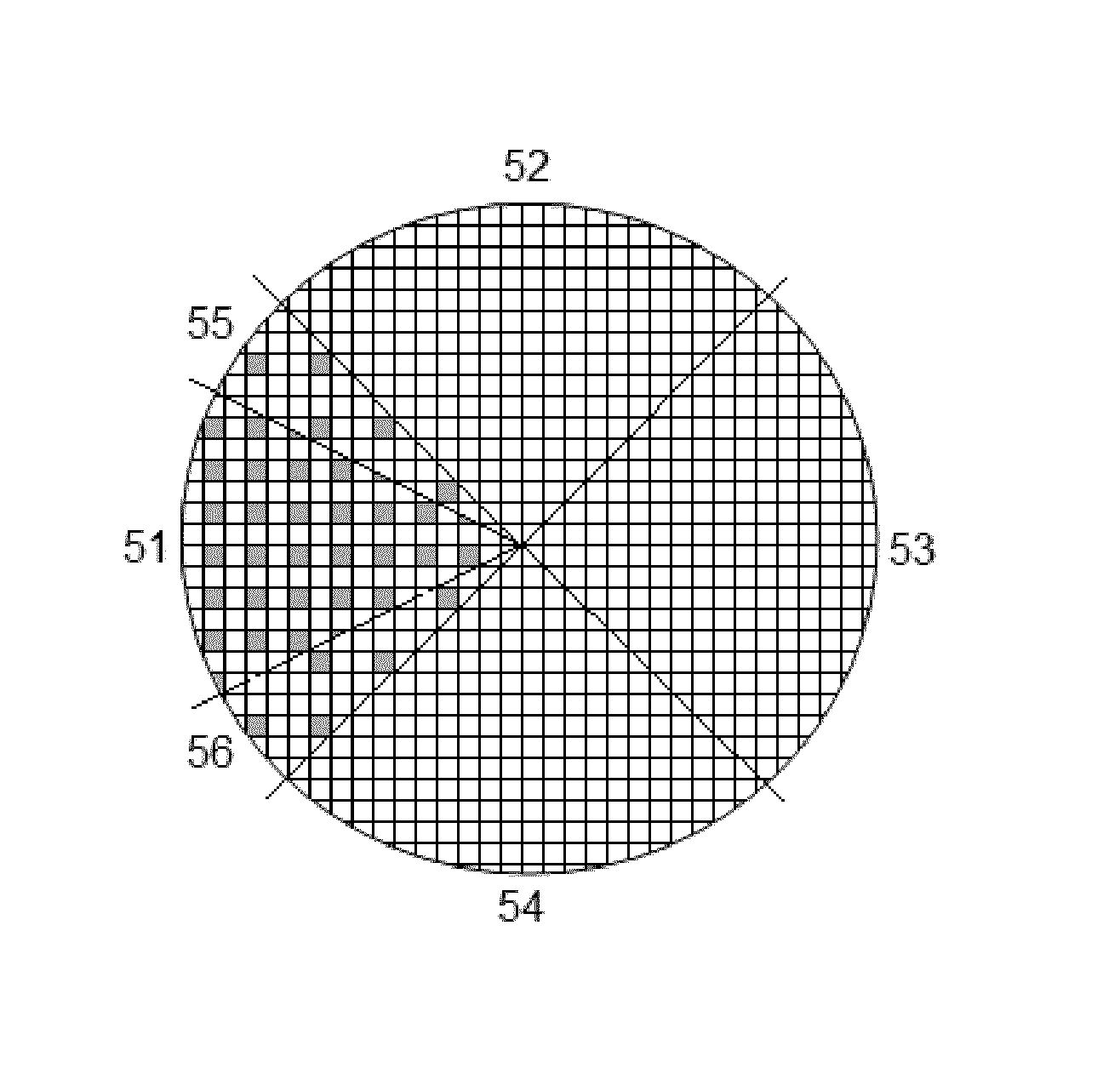

Shower plate having different aperture dimensions and/or distributions

ActiveUS8845806B2Improve uniformityUniform propertyElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

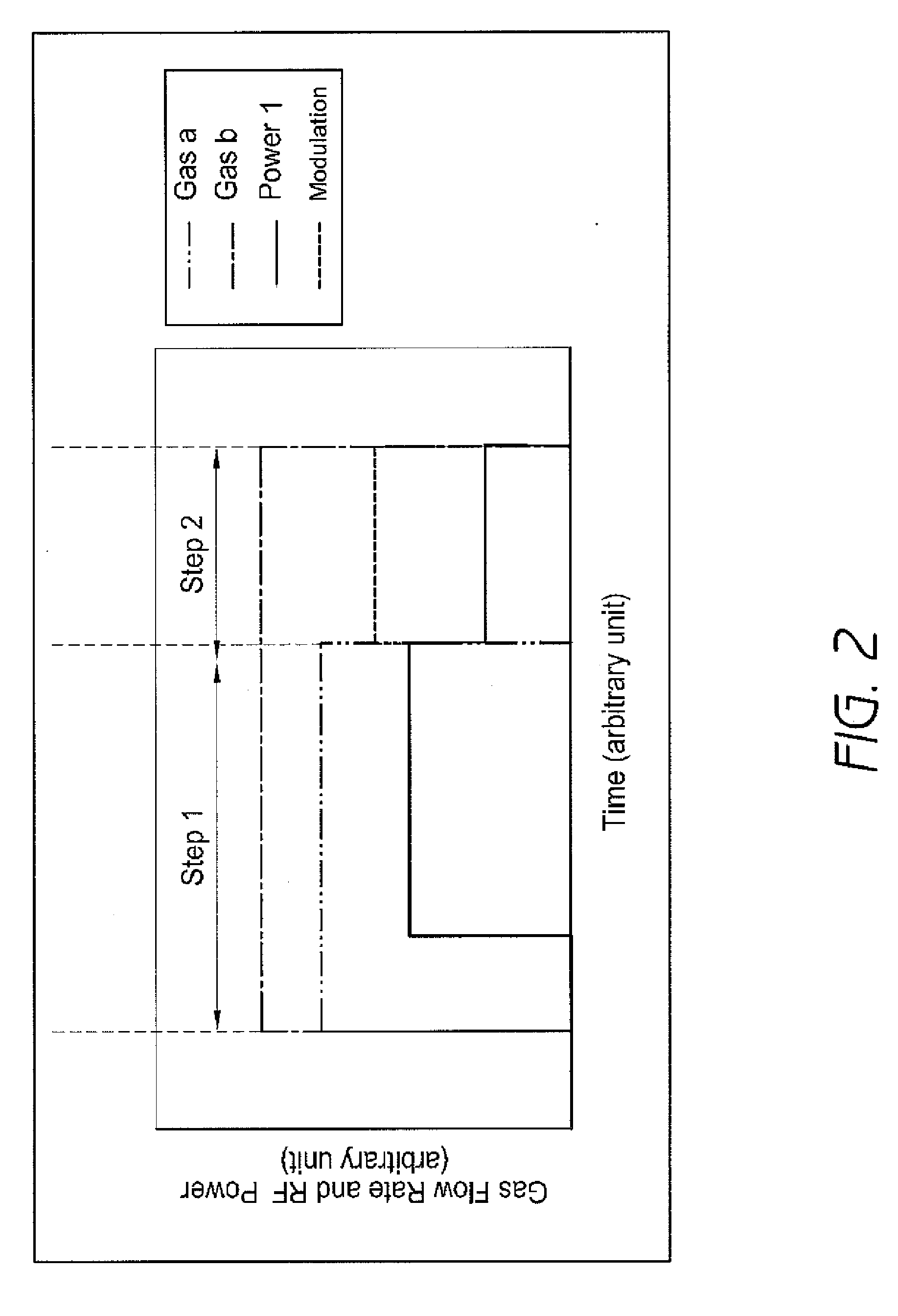

Method of plasma treatment using amplitude-modulated RF power

ActiveUS20090136683A1Reduce floating potentialSufficient voltageElectric discharge tubesVacuum evaporation coatingSusceptorForming gas

A method for processing a substrate by plasma CVD includes: (i) forming a film on a substrate placed on a susceptor by applying RF power between the susceptor and a shower plate in the presence of a film-forming gas in a reactor; and (ii) upon completion of step (i), without unloading the substrate, applying amplitude-modulated RF power between the susceptor and the shower plate in the absence of a film-forming gas but in the presence of a non-film-forming gas to reduce a floating potential of the substrate.

Owner:ASM JAPAN

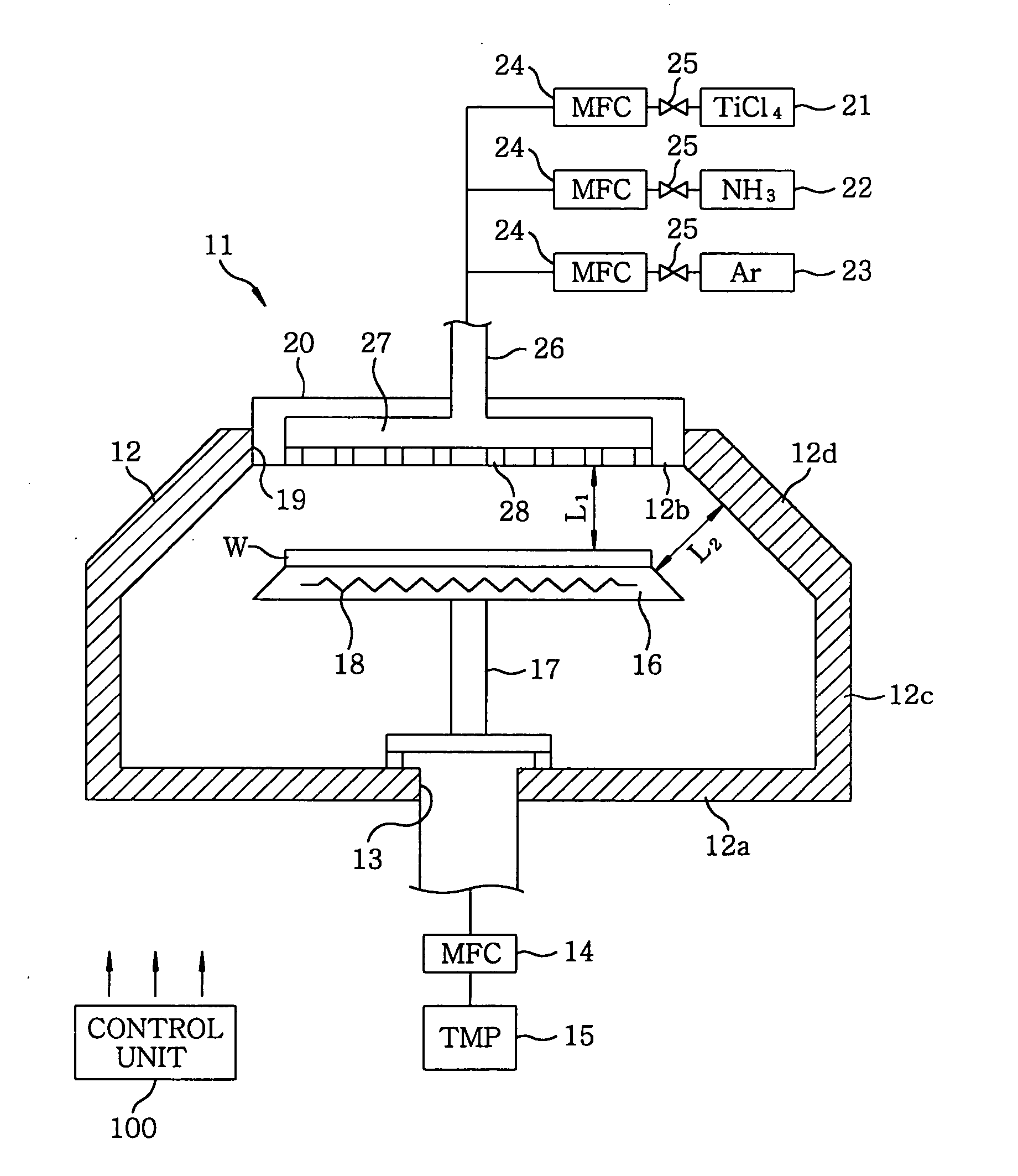

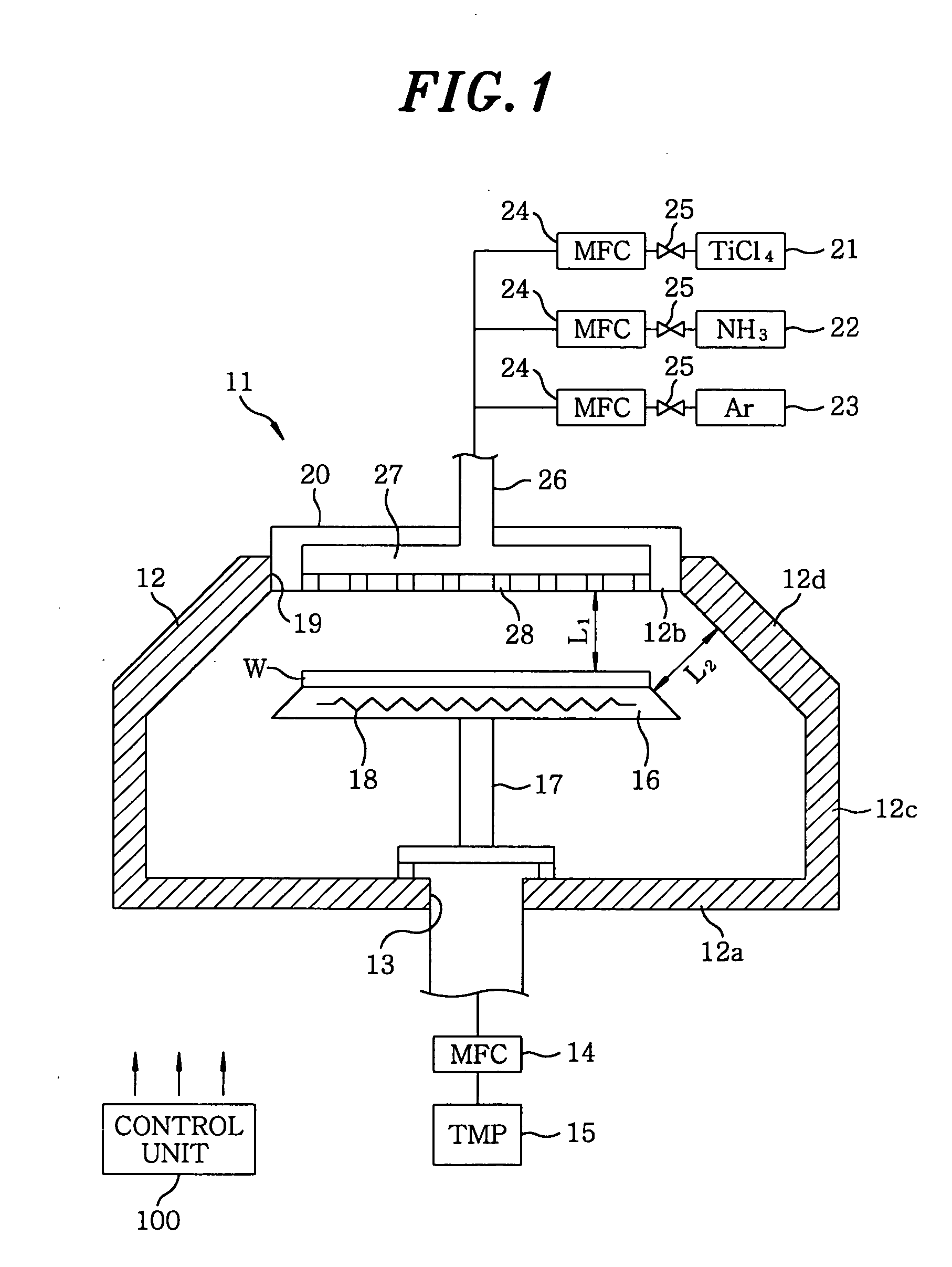

Processing device and processing method

InactiveUS20050211167A1Increase speedHigh productSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorEngineering

The ceiling surface (12b) of a chamber (12) is substantially entirely formed with a gas supply port (19). Further, the gas supply port (19) has shower head (20) fitted therein. The peripheral edge of the ceiling surface (12b) has connected thereto a second side wall (12d) forming an angle greater than 90 degrees with ceiling surface (12b). Further, the side surface of a susceptor (16) is formed such that it forms an angle greater than 90 degrees with a mounting surface for a wafer (W) and is substantially parallel with the second side wall (12d) of the chamber (12). Further, the susceptor (16) is disposed such that the distance (L2) between its side surface and the second side wall (12d) is greater than the distance (L1) between the shower head (20) and the wafer (W).

Owner:TOKYO ELECTRON LTD

Shower head unit and chemical vapor deposition apparatus

A chemical vapor deposition apparatus comprises a chamber, a chamber lead having a gas in port configured to receive a reaction gas, the chamber lead connected to a top surface of the chamber to seal up the chamber, a shower head connected to the chamber lead, the shower head having a plurality of spray holes separated from each other for spraying the reaction gas onto the surface of a wafer in the chamber, and a protrusion surrounding the spray holes on the bottom surface of the shower head so that an induction groove is provided inside the protrusion, wherein the plurality of spray holes have a plurality of main holes and a plurality of supplementary holes, each of the main holes is uniformly arranged in each corner of a square-grid pattern across the shower head and each of the supplementary holes is disposed at each centerpoint of the square-grid pattern.

Owner:EUGENE TECH CO LTD

Substrate processing apparatus

PendingUS20190062907A1Improve cooling efficiencySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringThermodynamics

Provided is a cooling device capable of controlling the temperature of an upper portion of a reactor, or more particularly, a gas supply device, for example, a shower head. The cooling device includes a separator configured to uniformly and efficiently cool the gas supply device.

Owner:ASM IP HLDG BV

Film forming apparatus

ActiveUS20150267298A1High in-plane uniformityEfficient replacementChemical vapor deposition coatingGas supplyForming processes

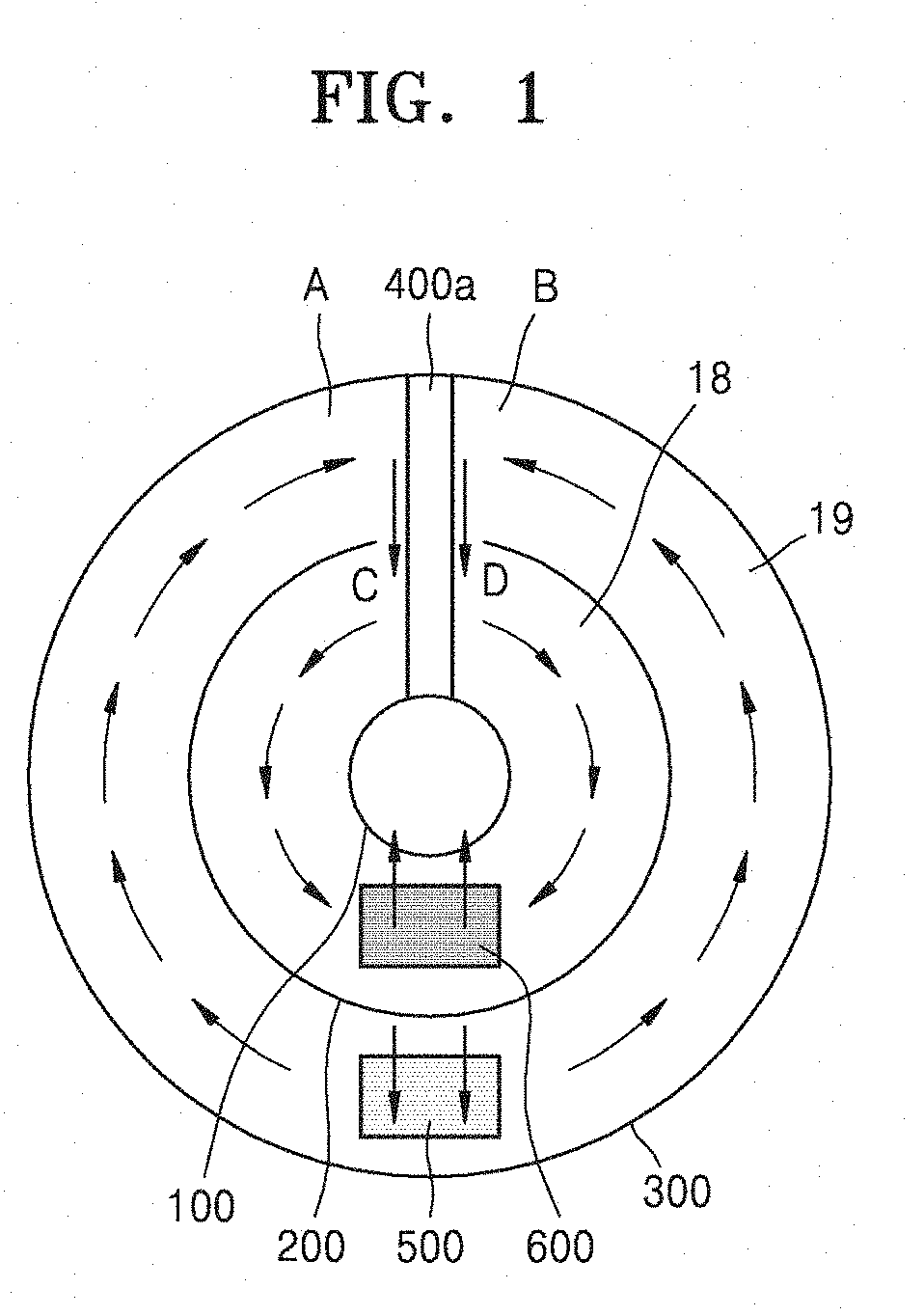

A film forming apparatus for performing a film forming process by sequentially supplying a plurality of reactant gases to a substrate and supplying a replacement gas includes a mounting table configured to mount thereon a substrate, and a shower head having a flat surface facing the mounting table and a plurality of gas supply opening. An annular protrusion is provided at the shower head to form a gap between the annular protrusion and a top surface of the mounting table. A plurality of gas supply units is provided at a ceiling portion at an upper side of the shower head. Each gas supply unit has gas discharge openings formed along a circumferential direction. The diffusion space is disposed such that an outer periphery of the diffusion space is located at an inner side of an outer periphery of the substrate mounted on the mounting table in a plan view.

Owner:TOKYO ELECTRON LTD

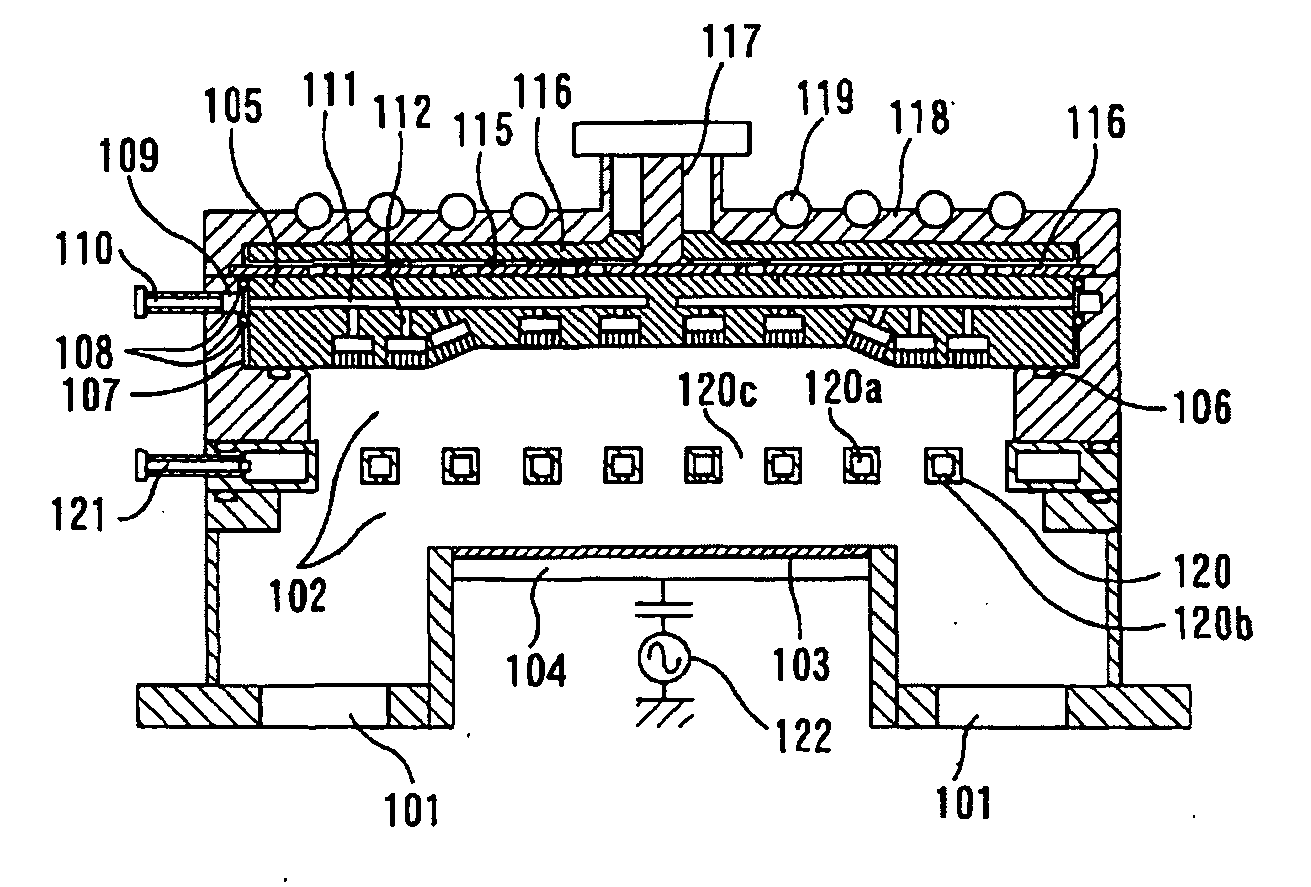

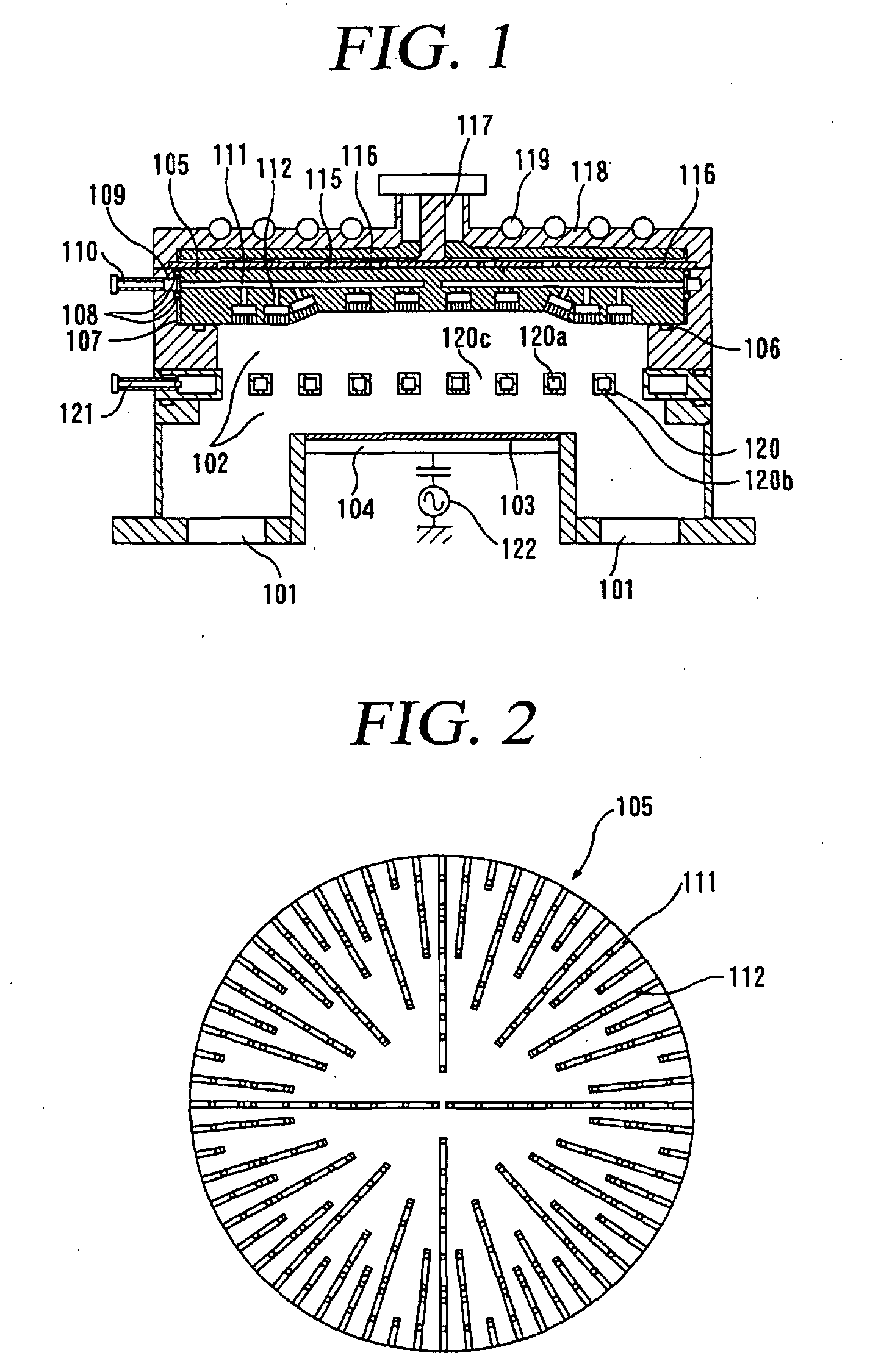

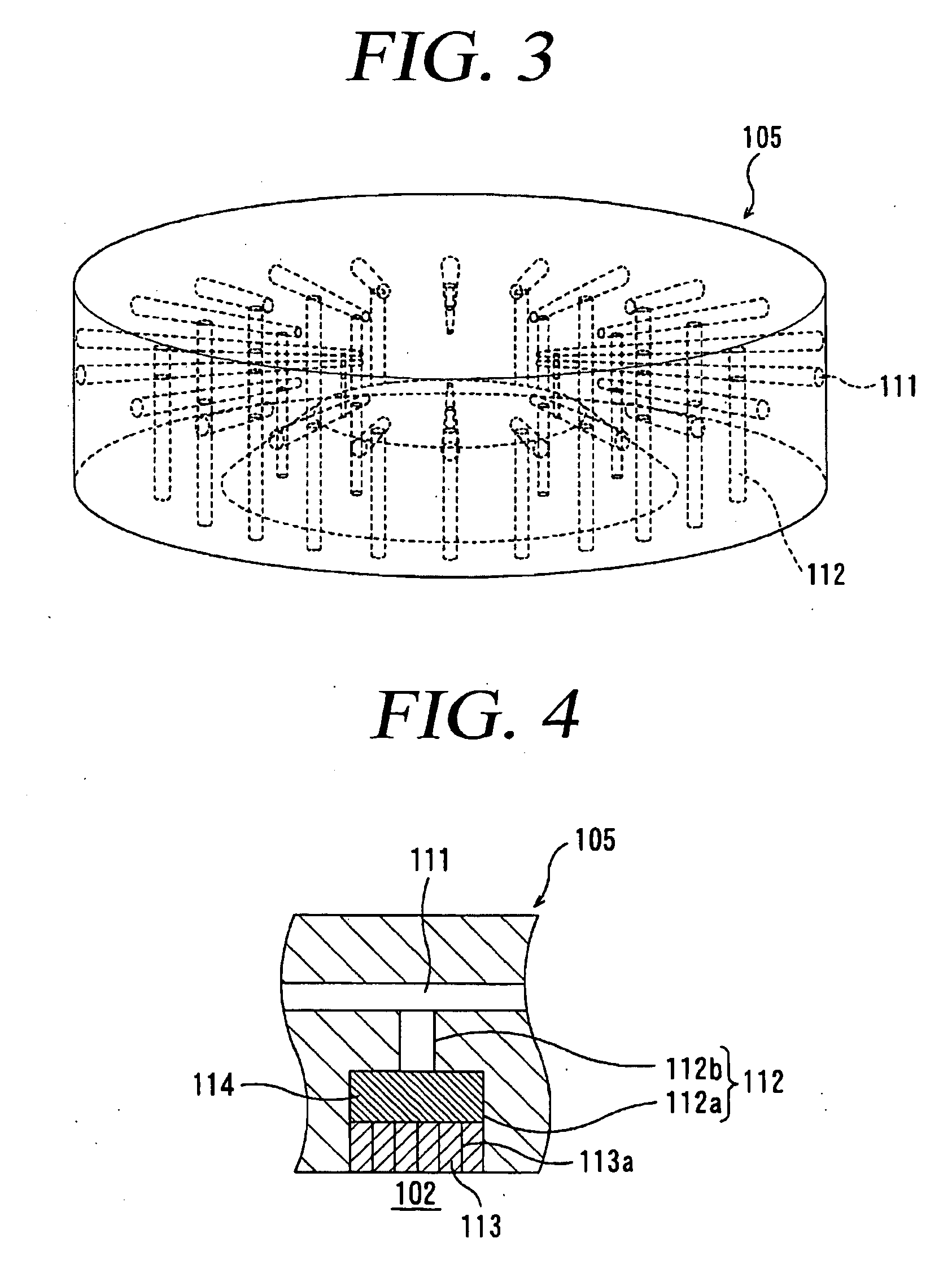

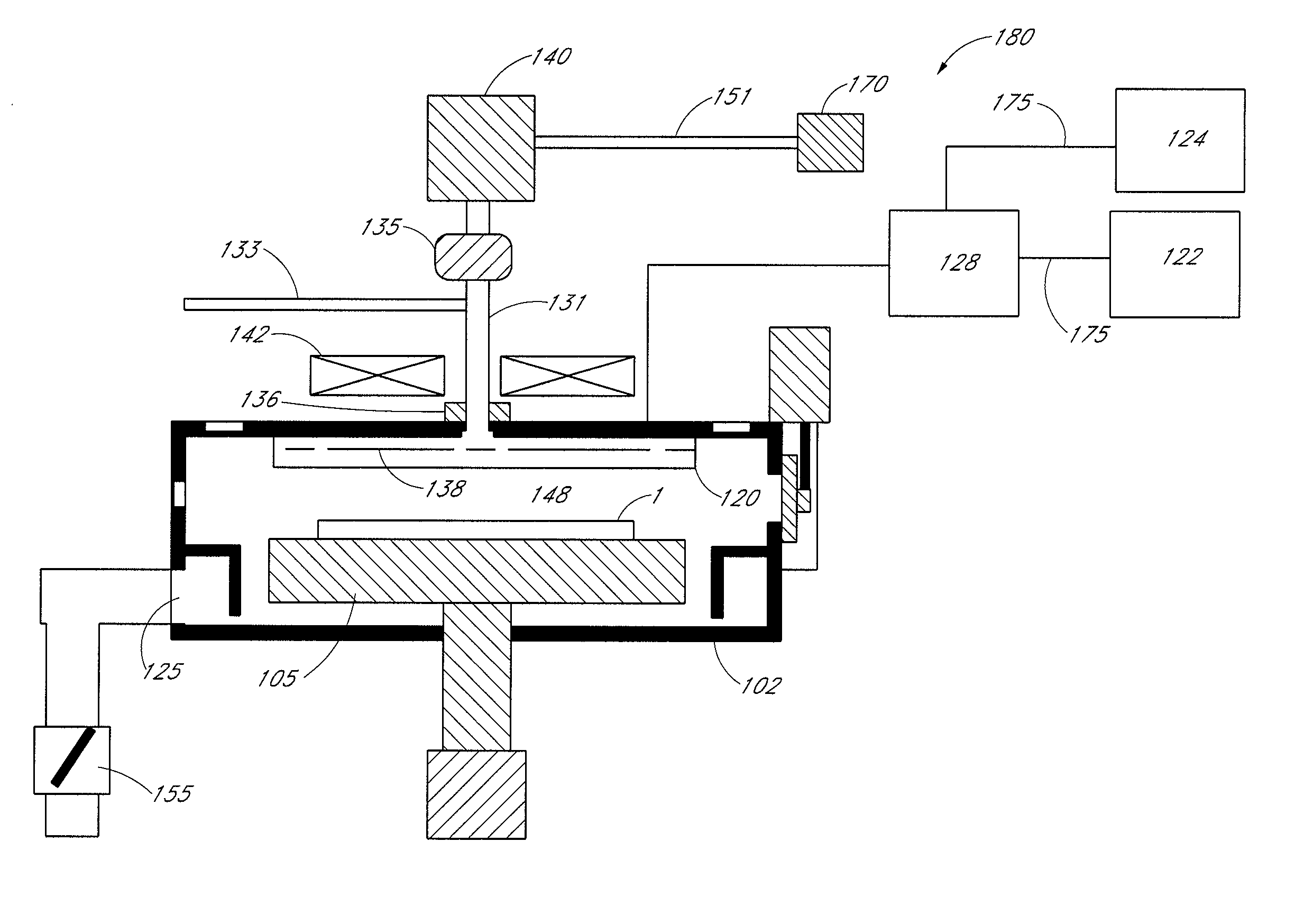

Shower plate, and plasma processing apparatus, plasma processing method and electronic device manufacturing method using the shower plate

InactiveUS20090286405A1Improve stabilityConvenience to workElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectron

Provided is a shower plate in which there's no need for a cover plate. The shower plate 105 is disposed in a processing chamber 102 of a plasma processing apparatus, for discharging a plasma excitation gas to generate plasma in the processing chamber 102, and the shower plate 105 includes a horizontal hole 111 for introducing the plasma excitation gas into the shower plate 105 from a gas inlet port 110 of the plasma processing apparatus; and a vertical hole 112 communicating with the horizontal hole 111, wherein the shower plate 105 is formed as a single body.

Owner:TOKYO ELECTRON LTD +1

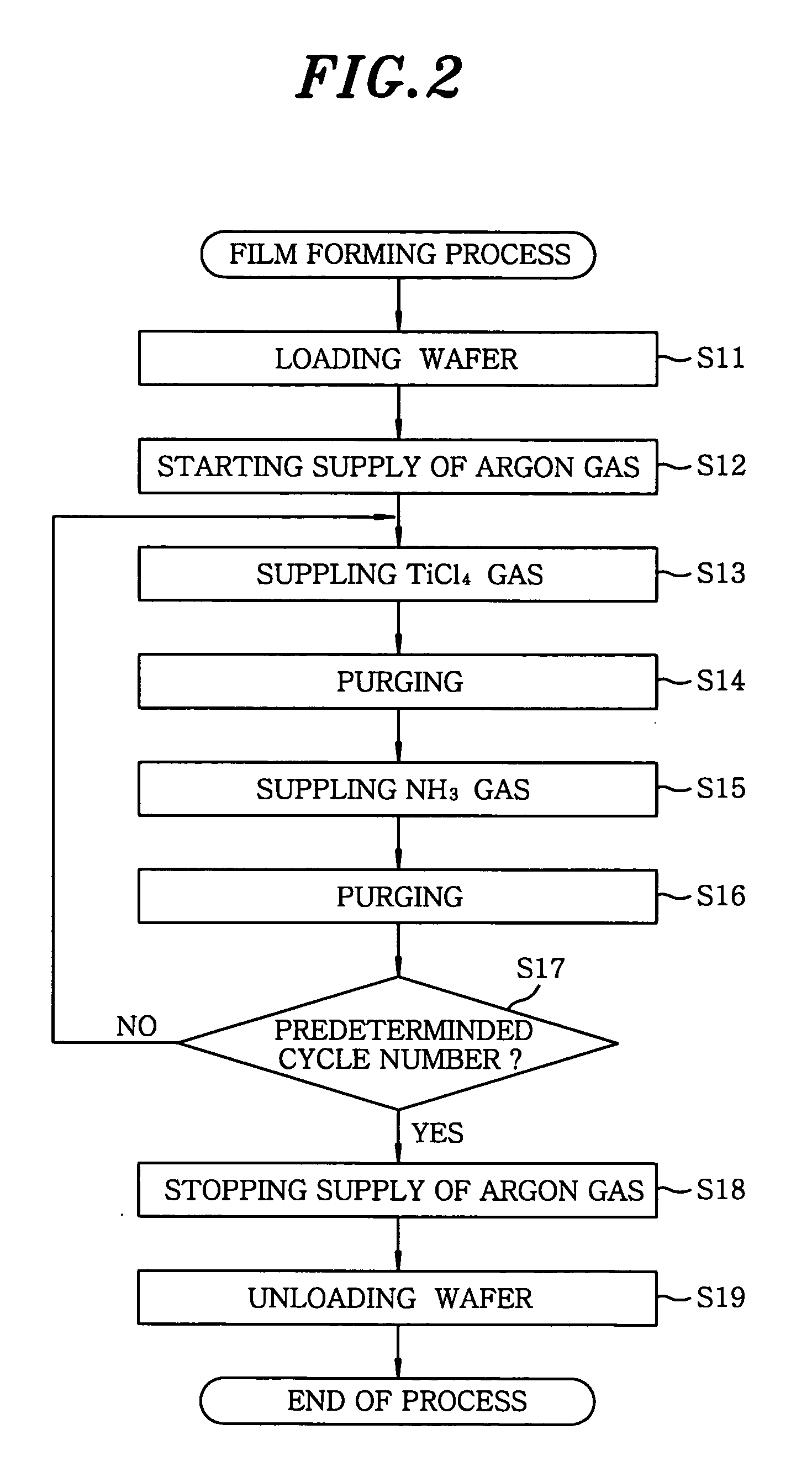

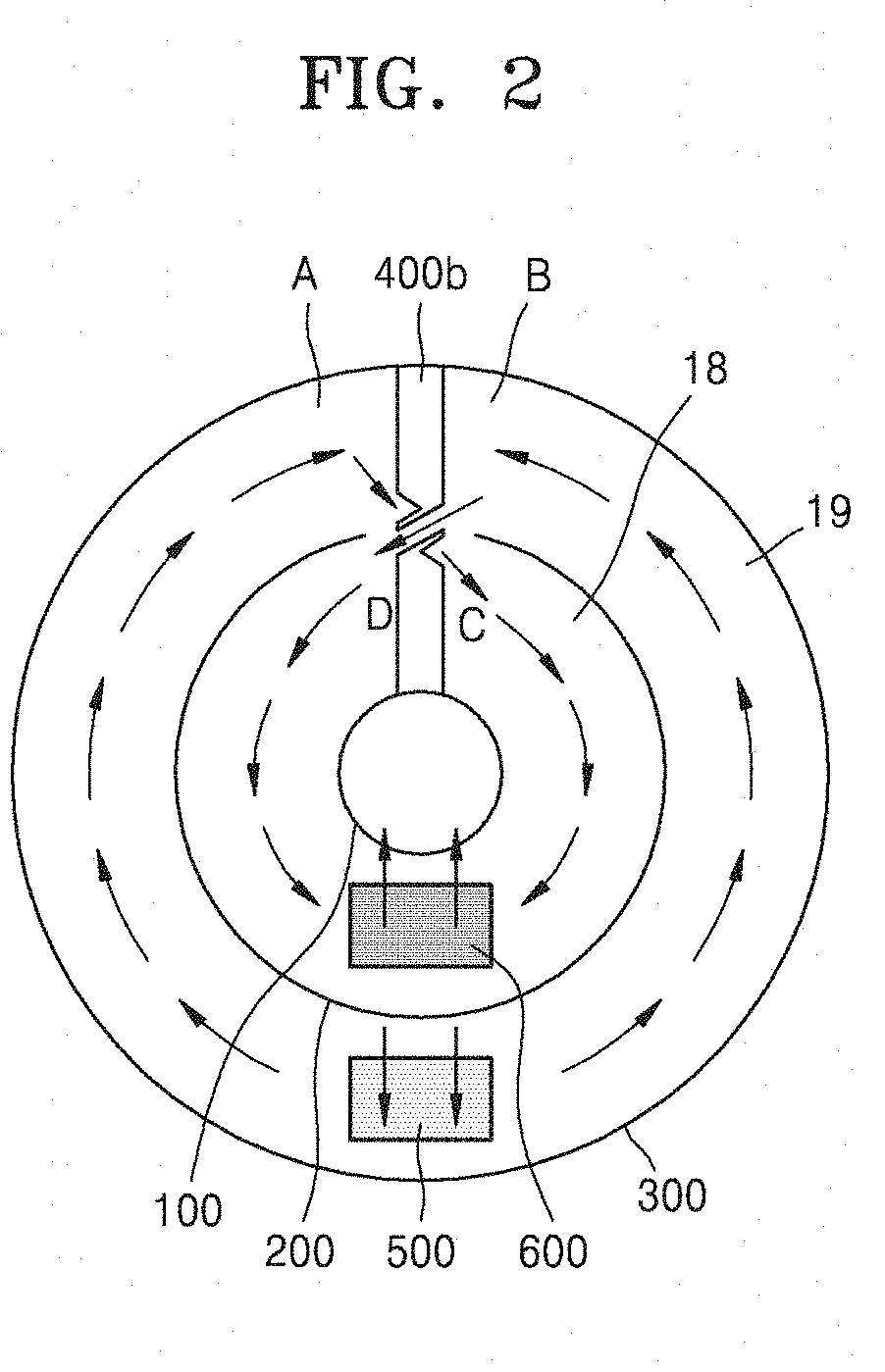

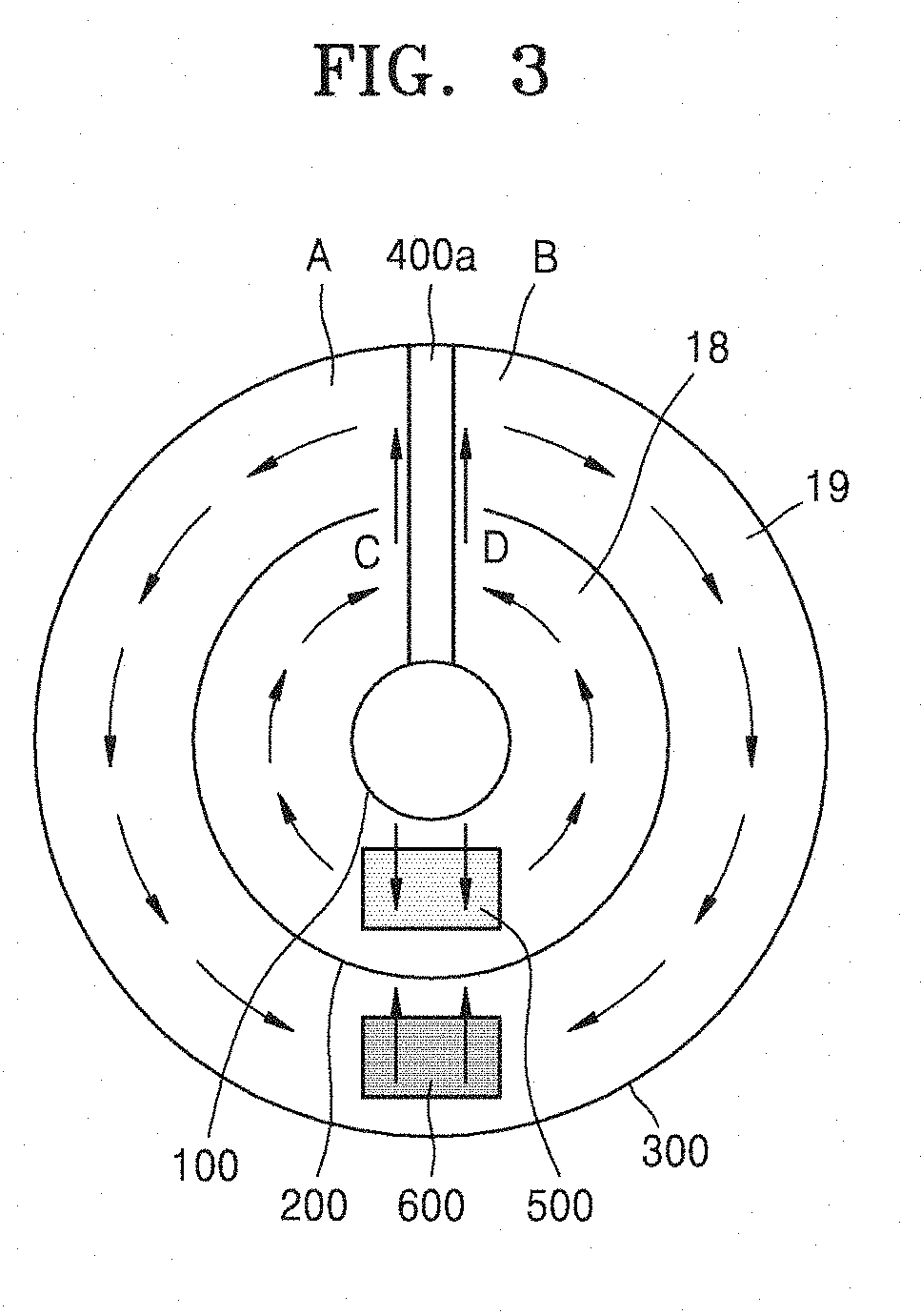

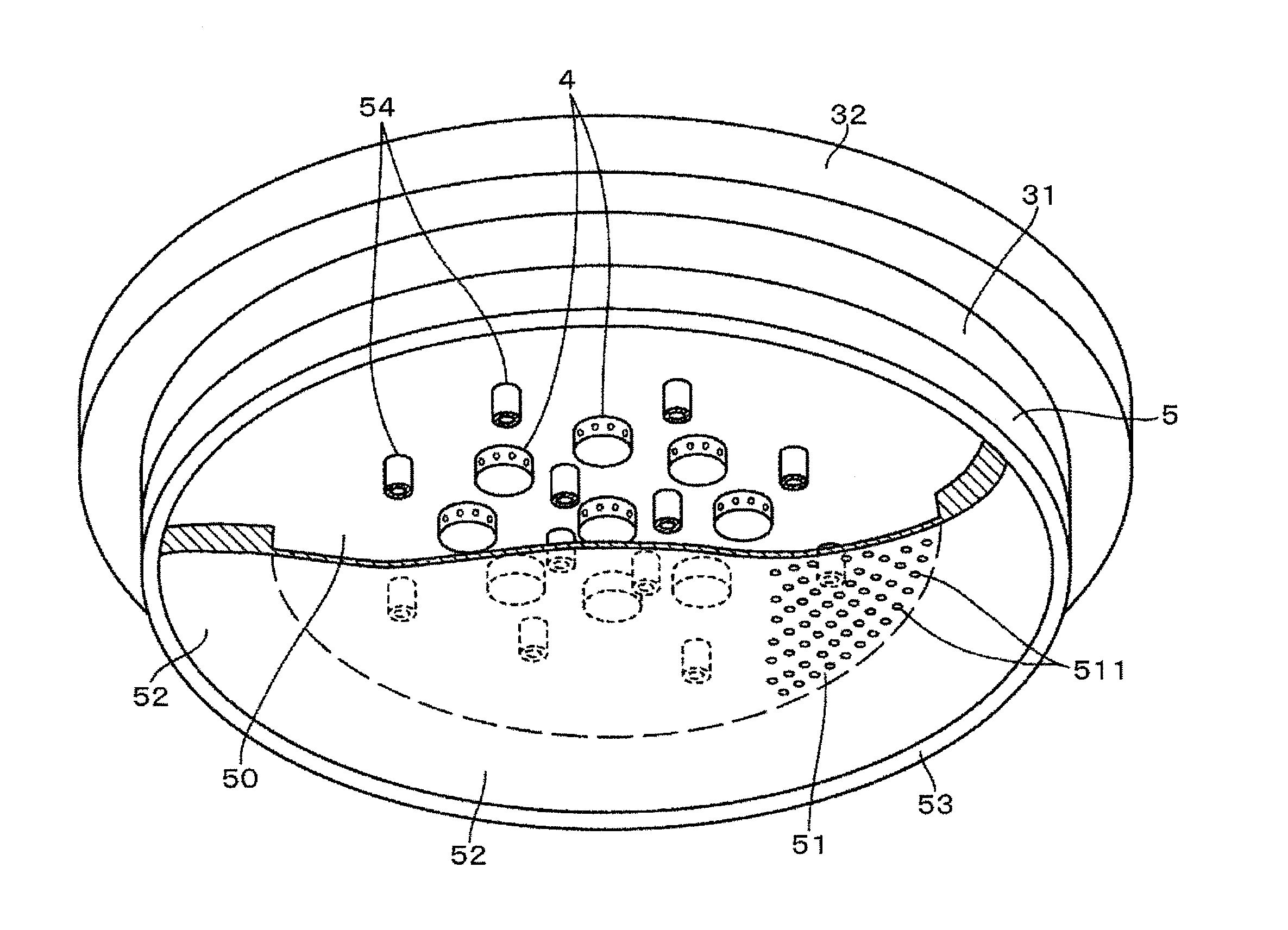

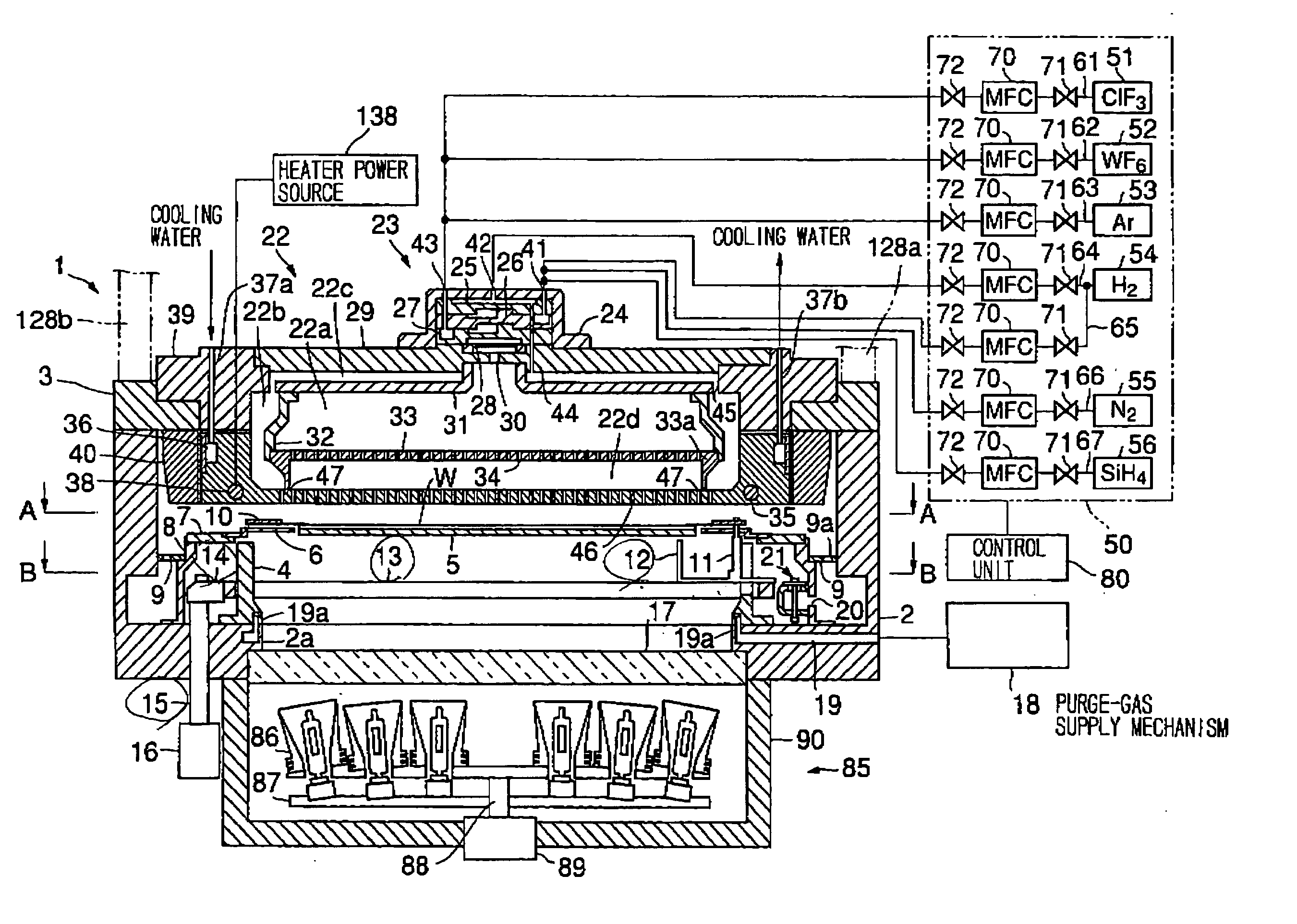

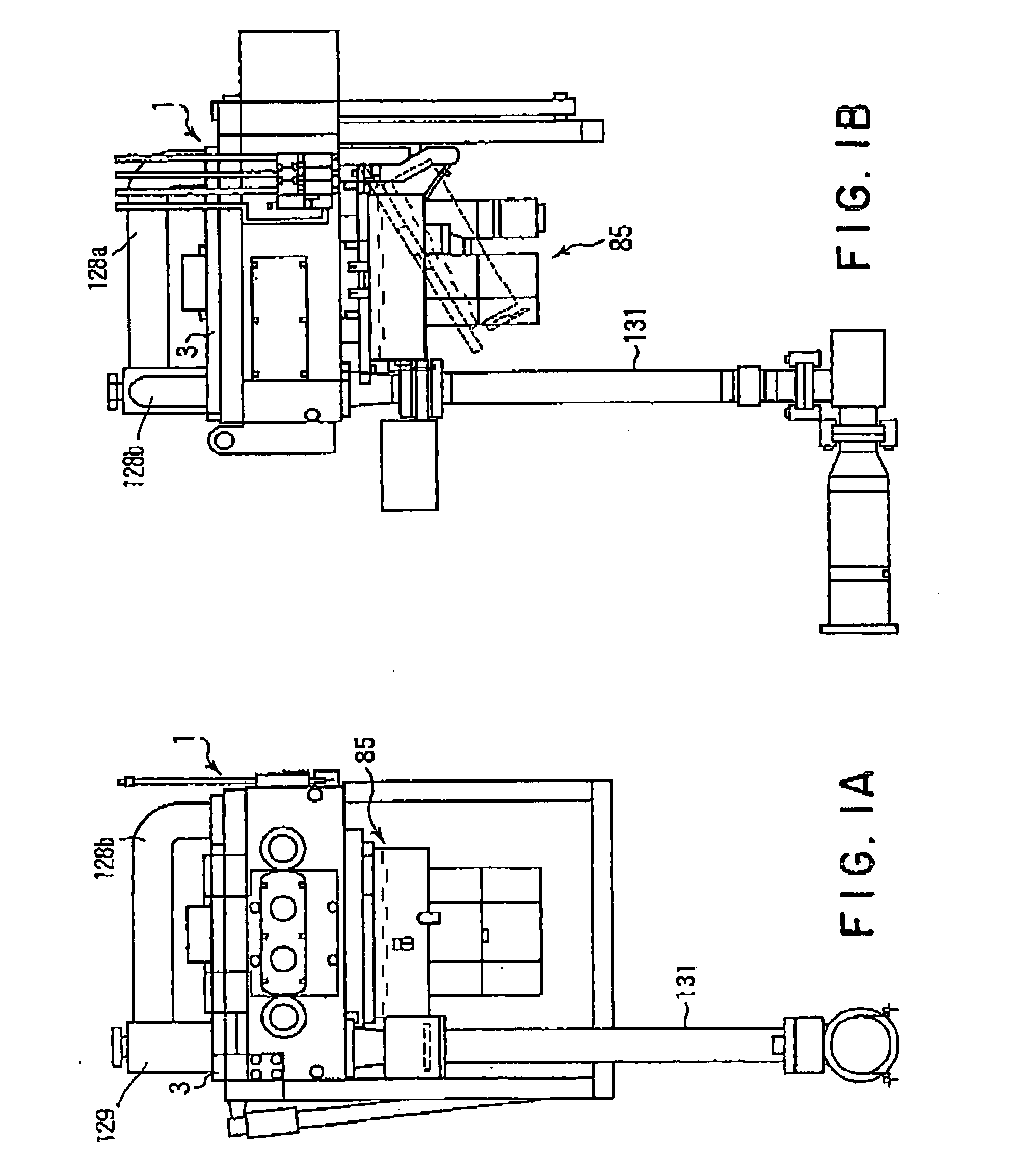

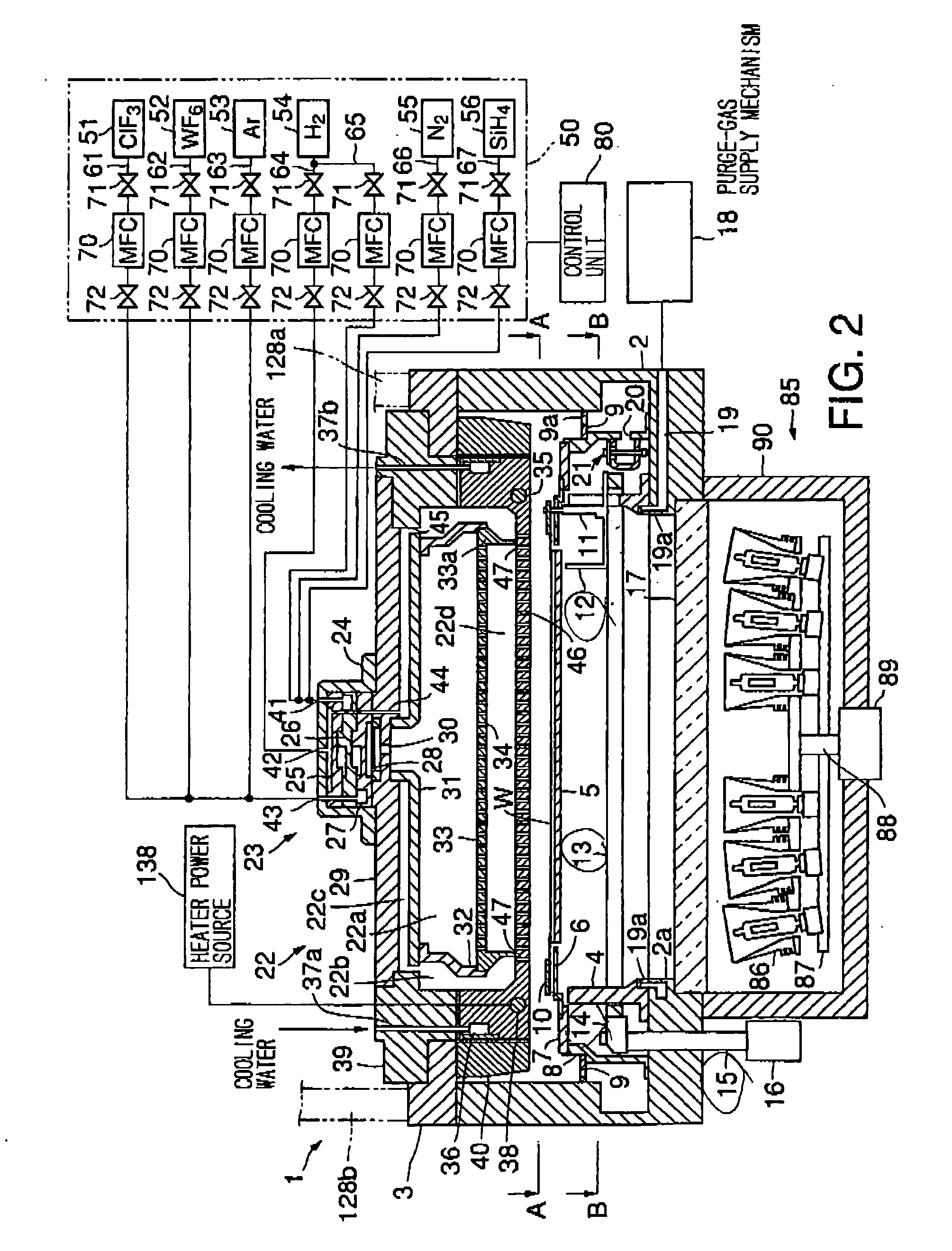

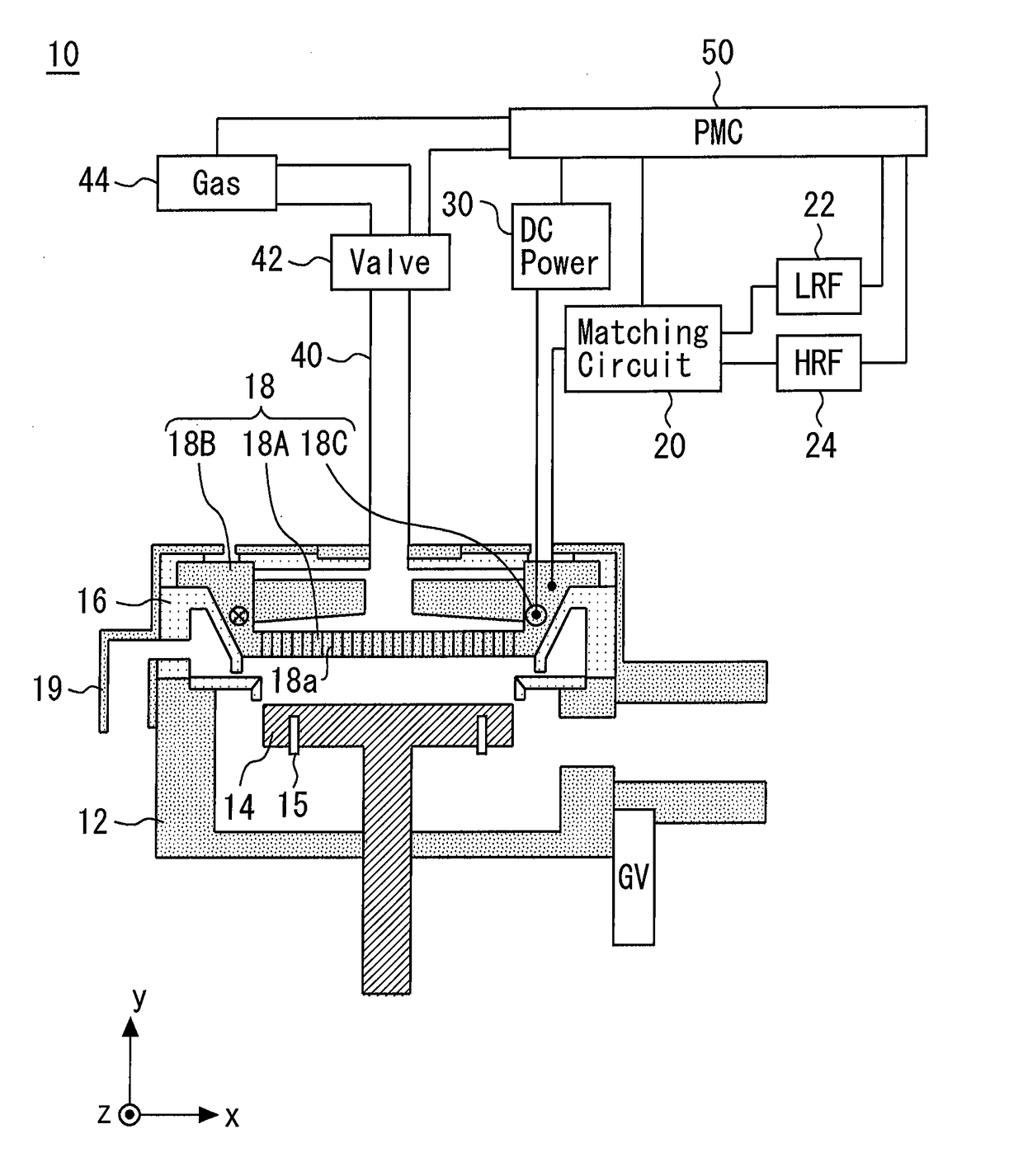

Gas treating device and gas treating method

InactiveUS20050003600A1Inhibition formationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas supplyShower

A gas processing apparatus 1 includes a processing container 2 for applying a processing to a wafer W while using a processing gas, a mount table 5 arranged in the processing container 2 to mount the wafer W, a shower head 22 arranged corresponding to the wafer W on the mount table 5 to discharge the processing gas into the processing container 2 and exhausting means 132 for exhausting the interior of the processing container 2. The shower head 22 has first gas discharging holes 46 arranged corresponding to the wafer W mounted on the mount table 5 and second gas discharging holes 47 arranged around the first gas discharging holes 46 independently to discharge the processing gas to the peripheral part of the wafer W. Thus, with a uniform gas supply to a substrate, it is possible to perform a uniform gas processing.

Owner:TOKYO ELECTRON LTD

Apparatus for chemical vapor deposition

ActiveUS8980006B2Minimize thermal expansionUniform and good qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorCoupling

An apparatus for chemical vapor deposition is disclosed. An aspect of the present invention provides an apparatus for chemical vapor deposition that includes: a process chamber configured to demarcate a reaction space; a back plate placed above the reaction space and having a gas inlet in a middle thereof; a gas diffusion member arranged below and separated from the gas inlet and coupled to the back plate by a first coupling member and configured to diffuse process gas supplied through the gas inlet; a shower head placed below and separated from the back plate and the gas diffusion member and having a middle part thereof coupled to the gas diffusion member by a second coupling member and having a plurality of spray holes perforated therein; and a susceptor arranged below and separated from the shower head and supporting a substrate. The gas diffusion member has a plurality of gas guiding holes that vertically penetrate the gas diffusion member such that the process gas supplied through the gas inlet is diffused toward a lower side of the gas diffusion member.

Owner:DMS CO LTD

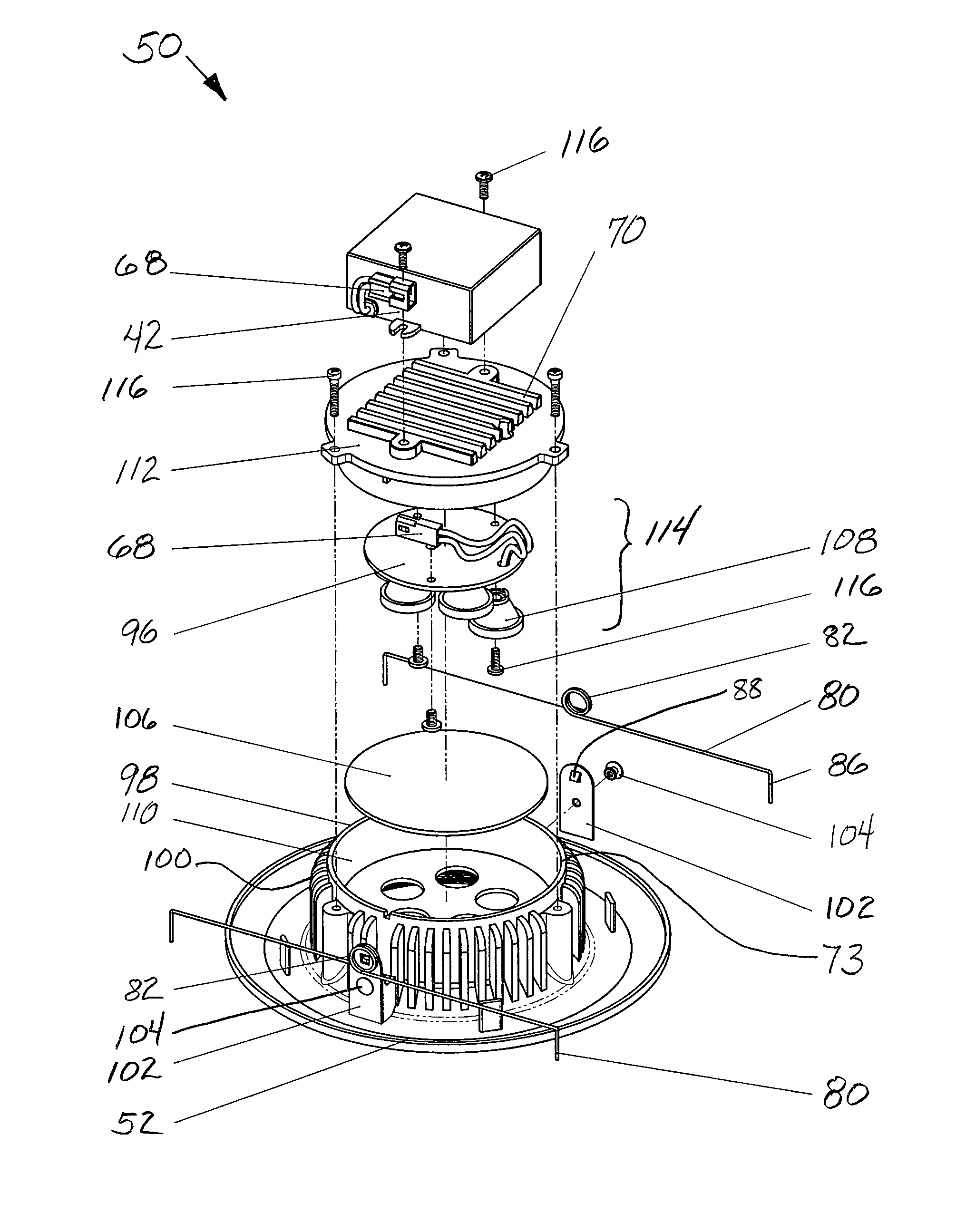

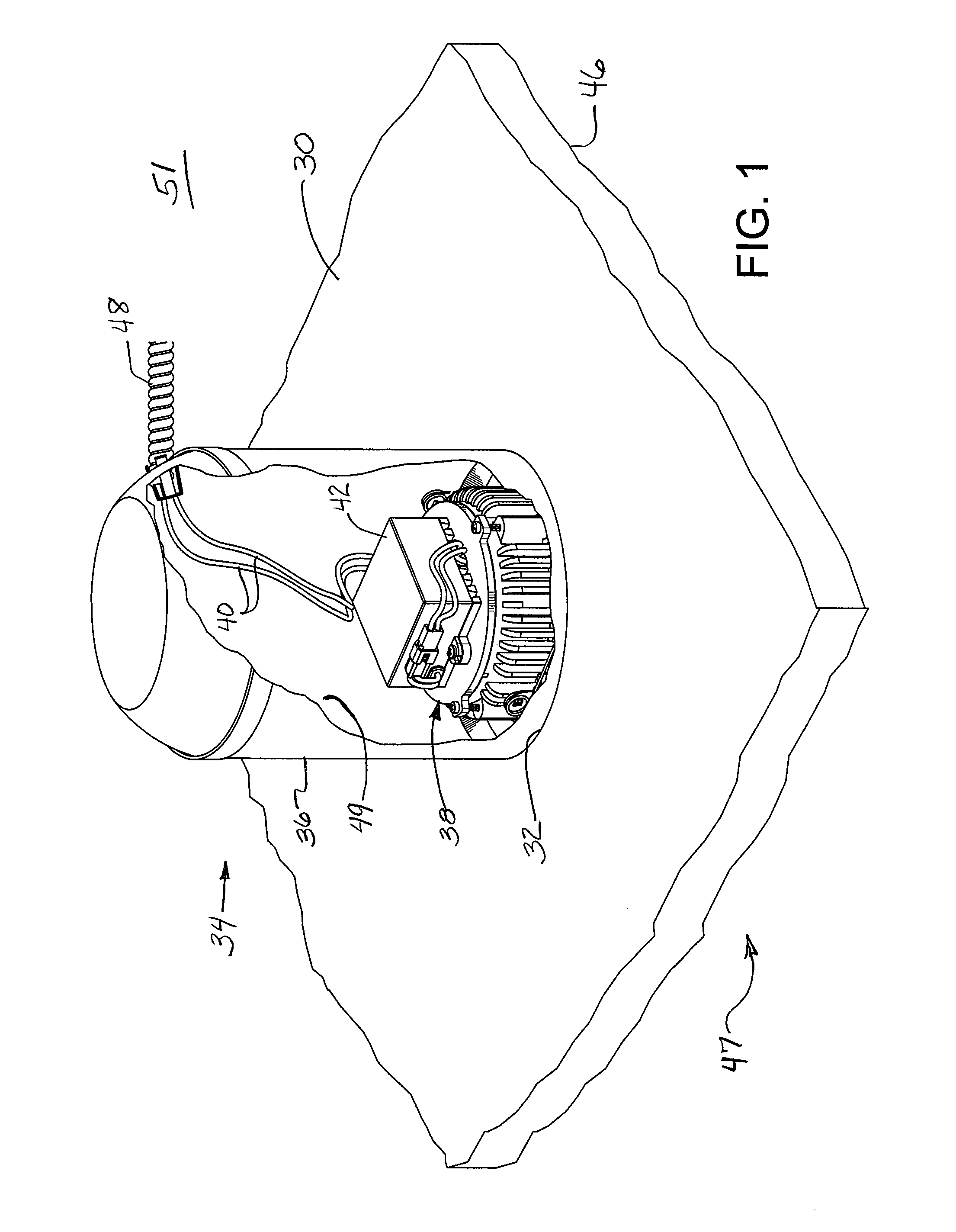

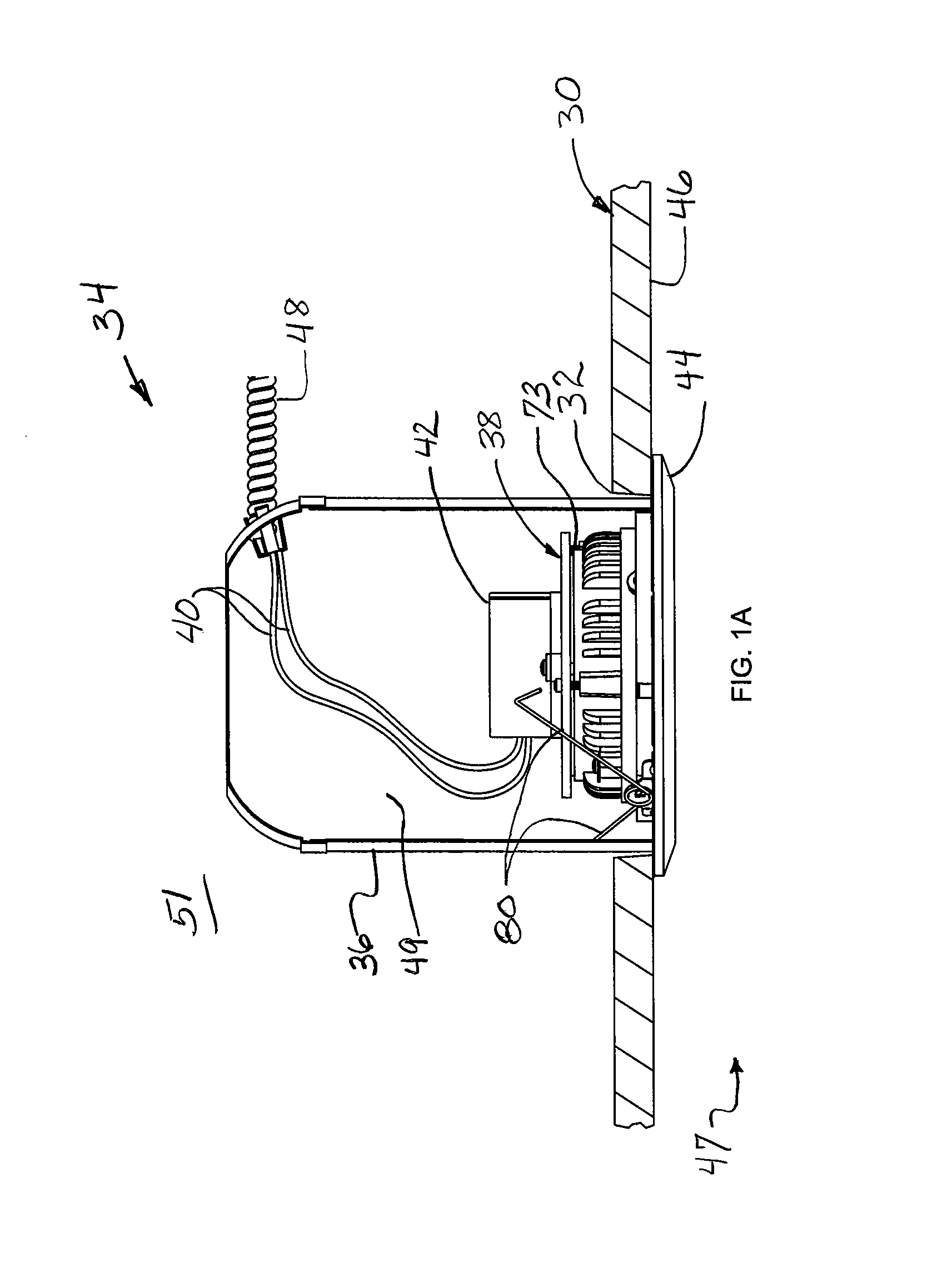

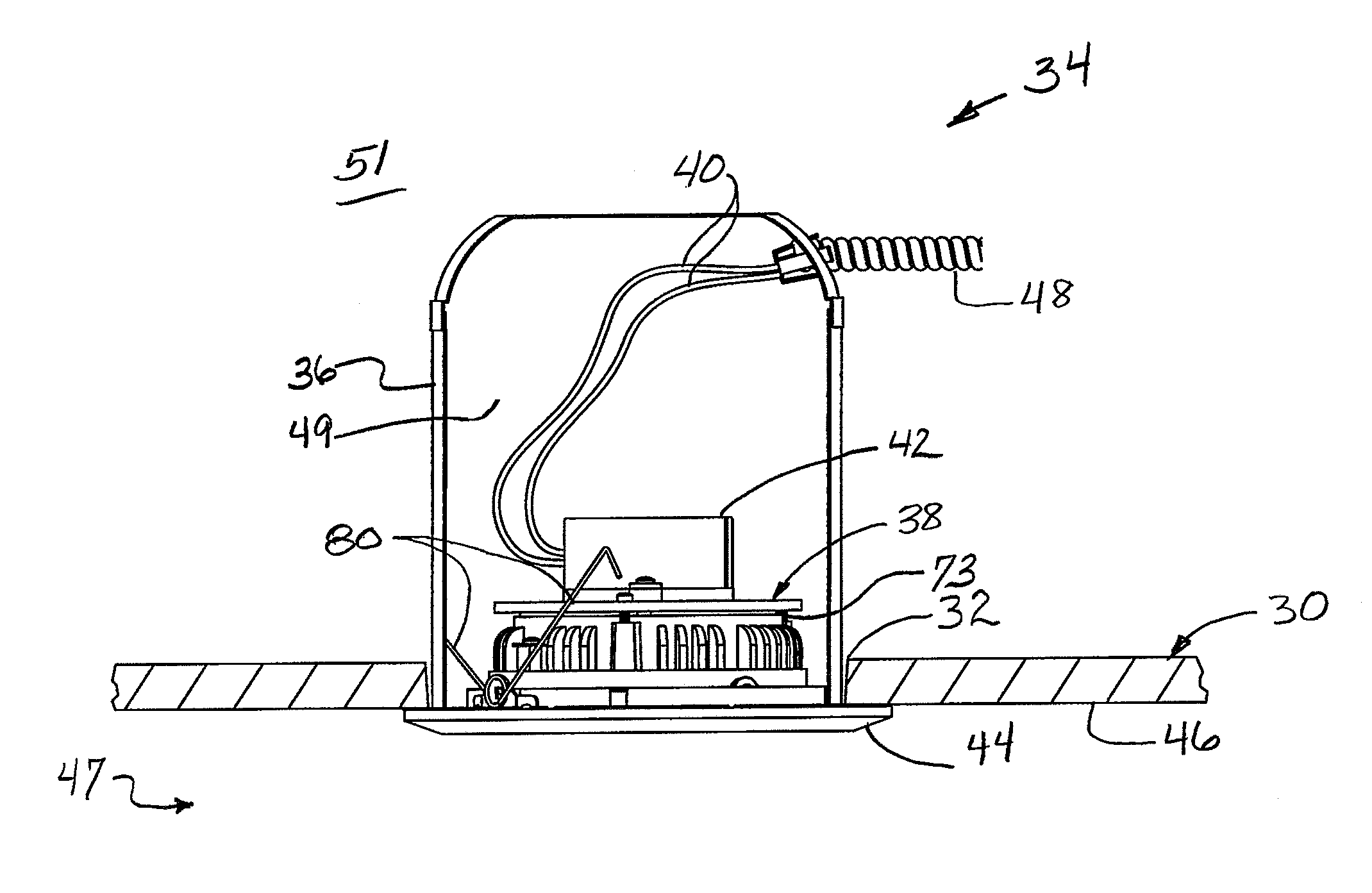

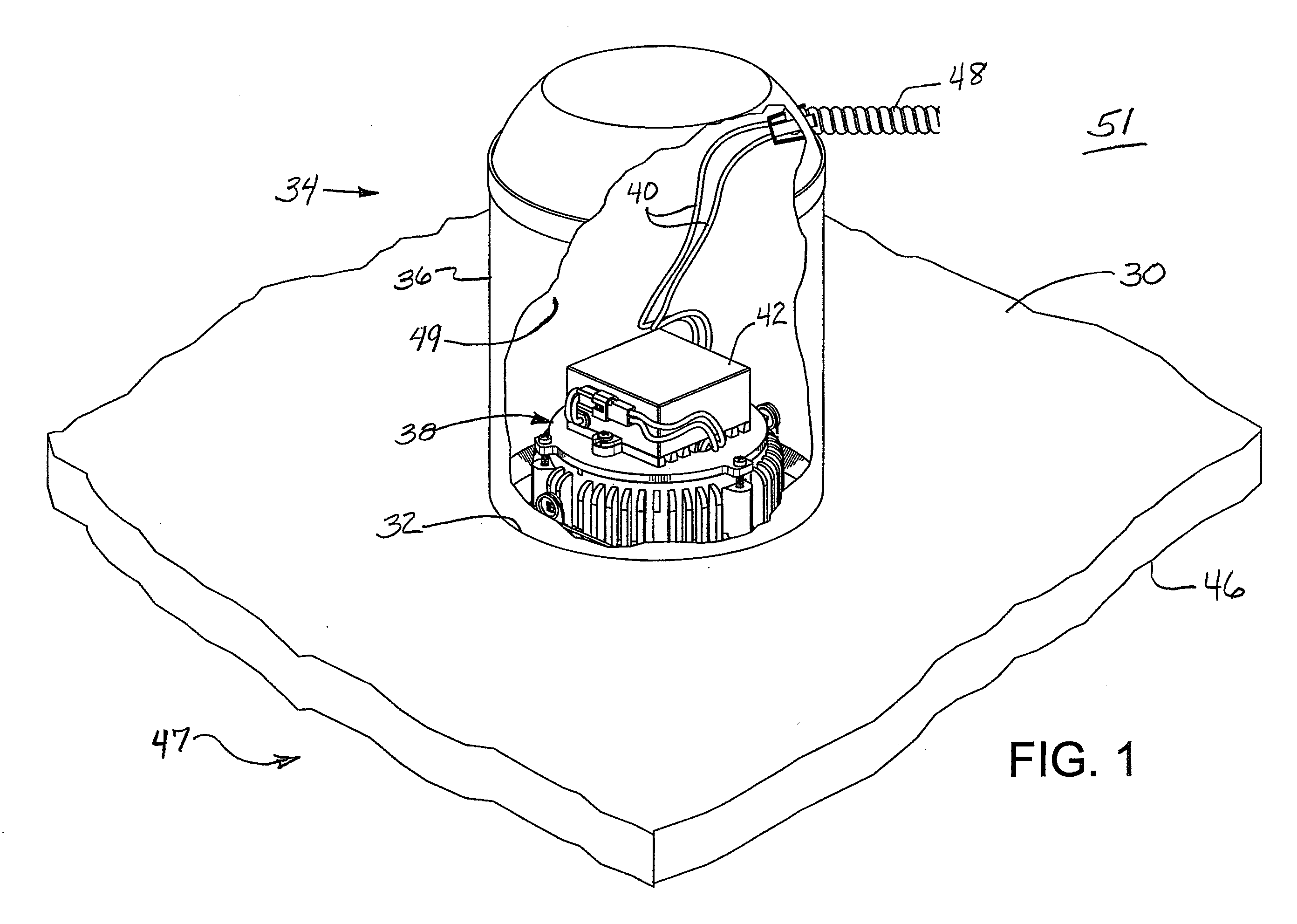

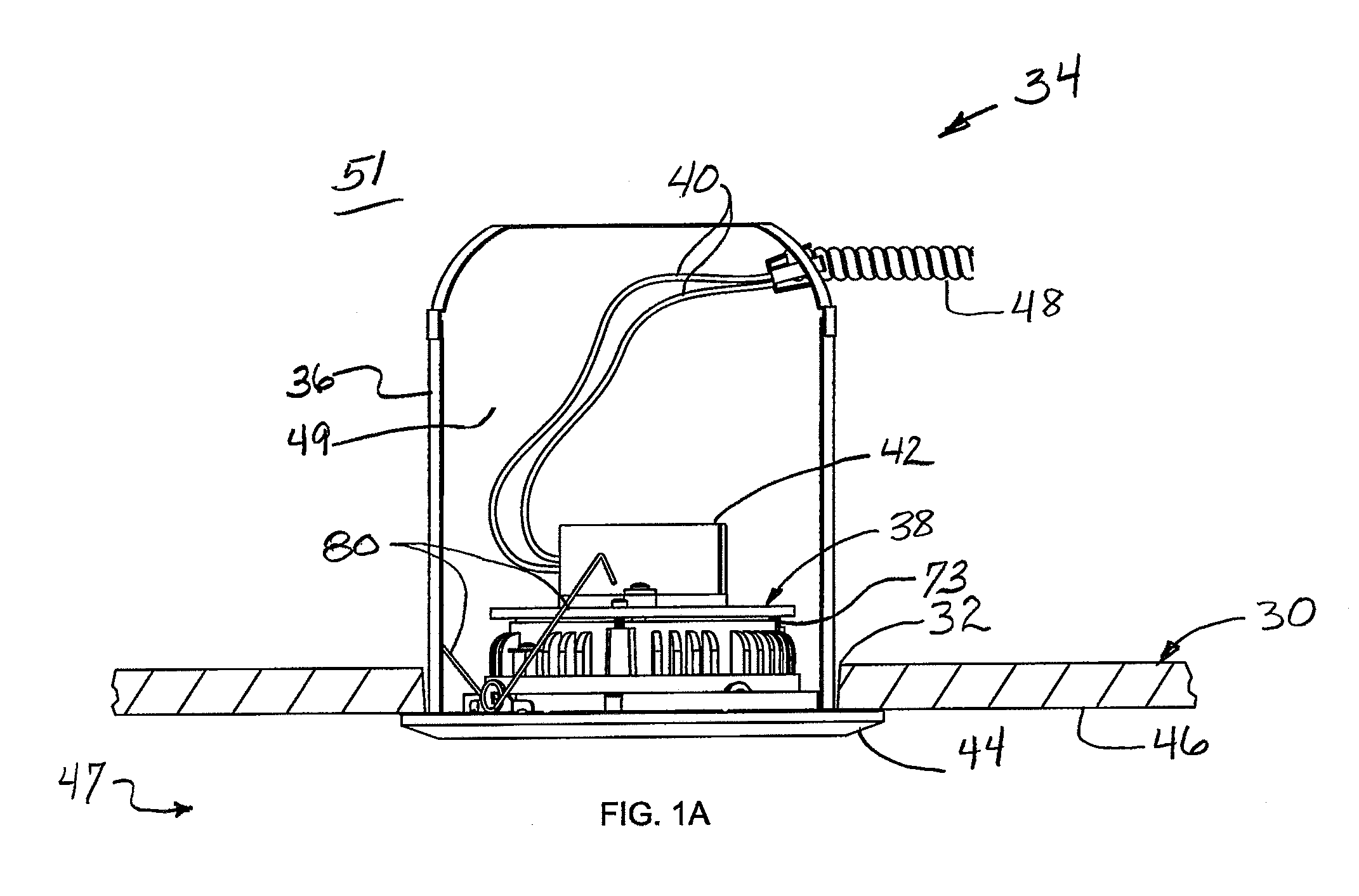

Lighting fixture with recessed baffle trim unit

InactiveUS7722227B2Easy to GrindGood thermal controlLighting support devicesPoint-like light sourceEffect lightEngineering

A recessed lighting fixture providing illumination from a light source comprising a plurality of light emitting diodes (LEDs) placed within a cavity of a planar surface, such as a ceiling, wall, or shower. The fixture comprises a baffle integrated with a low profile heat sink that is used to draw heat out of the fixture and communicate that heat to a trim ring of the fixture for dissipation of the heat in the room so that higher intensity light sources can be used. Improved grounding of the recessed trim unit to the recessed housing is provided with combination support and grounding springs. One embodiment of the light source is fixed in position while a second embodiment is gimbal mounted for aiming the light produced by the fixture.

Owner:CORDELIA LIGHTING

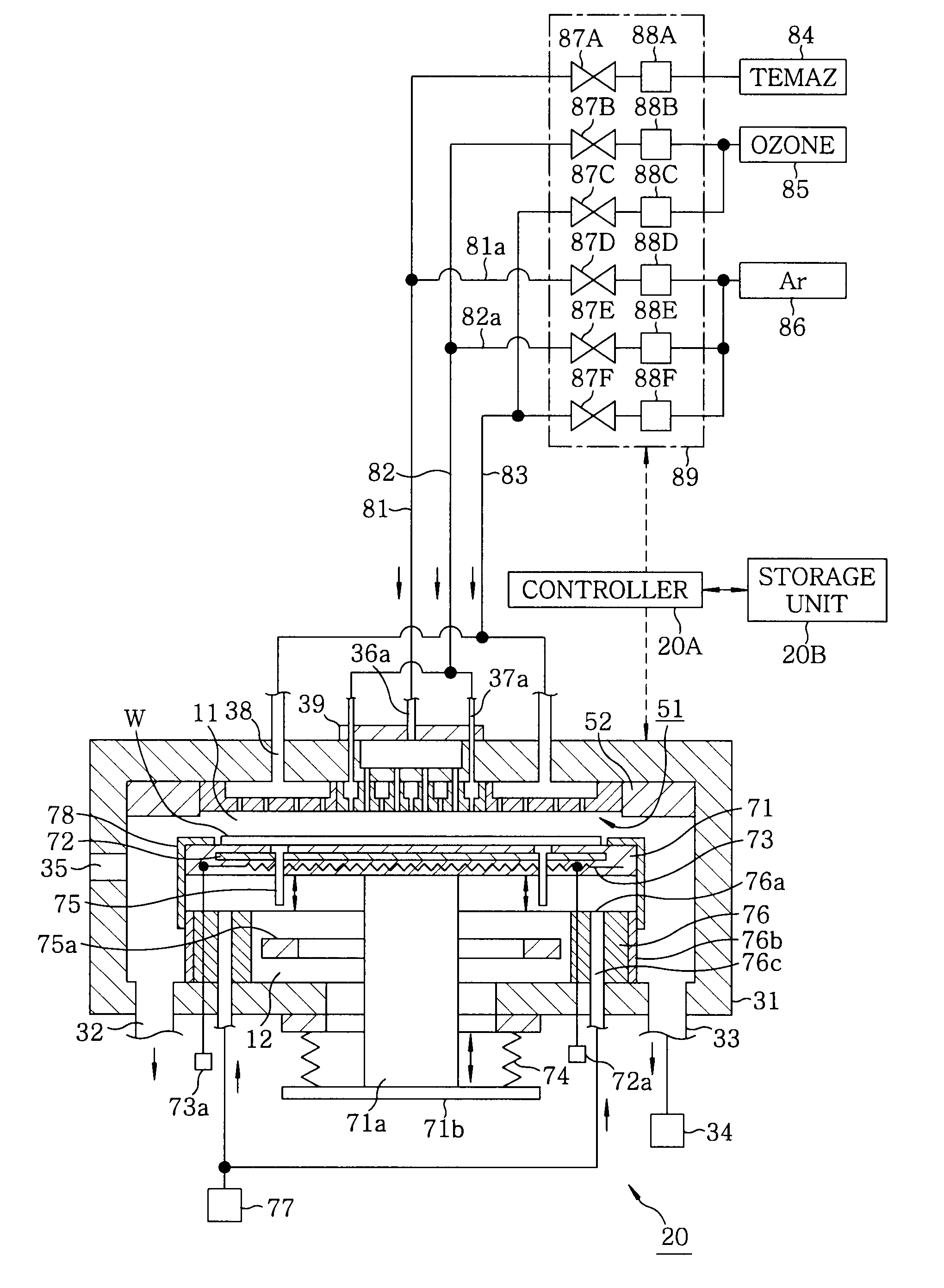

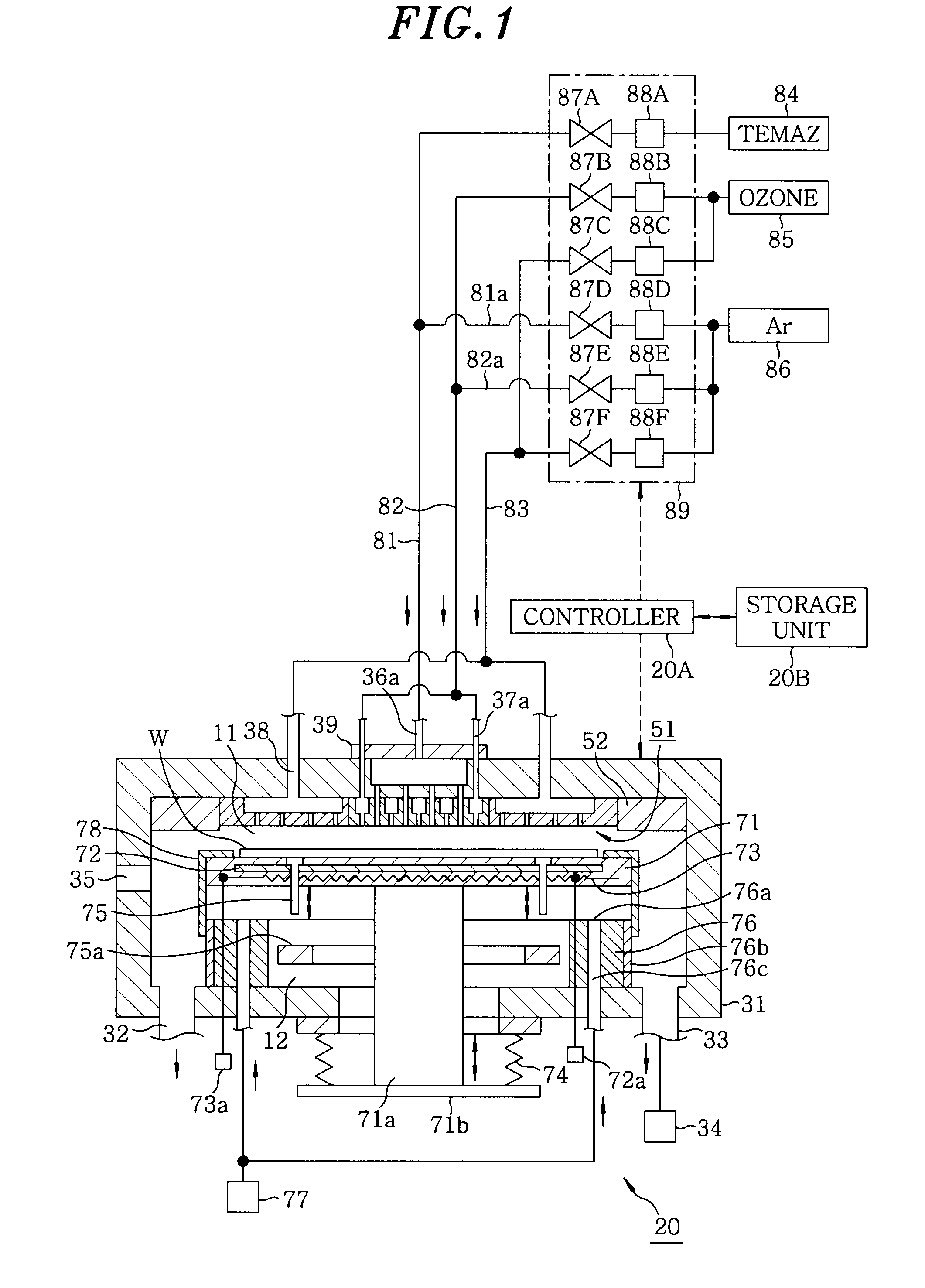

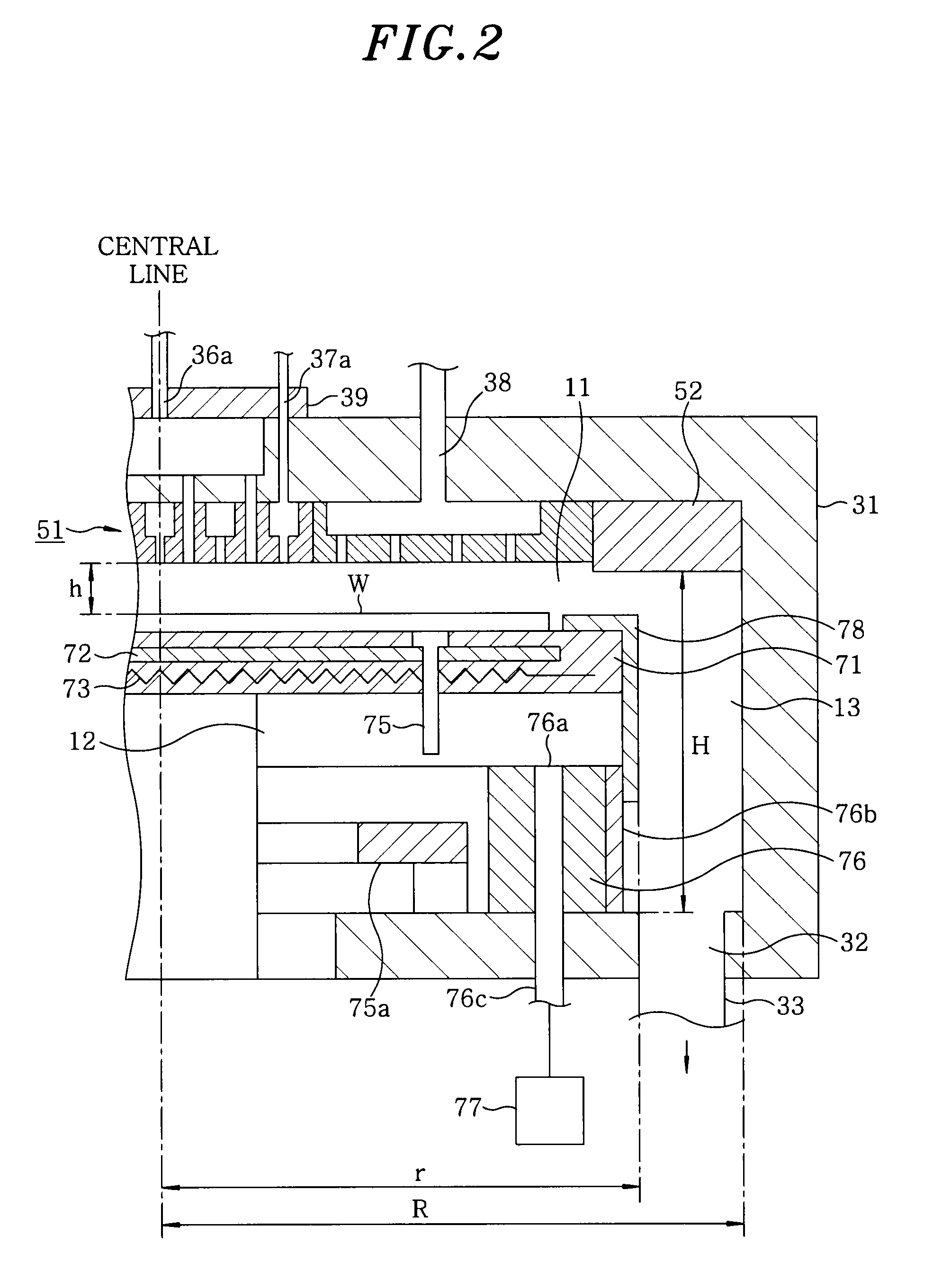

Film forming apparatus, film forming method and storage medium

ActiveUS20100119727A1Reduce gas volumeShorten the timeComputer controlPretreated surfacesEnergy supplyProduct gas

A film forming apparatus includes a processing chamber, and a mounting table disposed in the processing chamber to mount a substrate thereon. The film forming apparatus further includes a gas shower head having gas supply holes and including a central region facing a central portion of the substrate and a peripheral region facing a peripheral portion of the substrate, a first processing gas supply unit for supplying a first processing gas to the central region, a second processing gas supply unit for supplying a second processing gas to the central region, an energy supply unit for supplying energy to react the first processing gas with the second processing gas on the substrate, and a purge gas supply unit for supplying a purge gas to the central region and the peripheral region when one of the first and the second processing gas is switched by the other.

Owner:TOKYO ELECTRON LTD

Chemical vapor deposition apparatus capable of controlling discharging fluid flow path in reaction chamber

InactiveUS8876974B2Reduce widthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorGas phase

A chemical vapor deposition apparatus is equipped to control the width of a gas discharge path between a susceptor and an inner surface of a chamber without having to resort to redesign and remanufacturing of the apparatus. The chemical vapor deposition apparatus includes: a chamber; a susceptor positioned inside the chamber and on which a substrate can be loaded; a shower head injecting a processing gas toward the substrate; and a guide unit detachably installed inside the chamber to guide the processing gas such that the processing gas injected from the shower head is discharged through a chamber hole formed in the chamber.

Owner:LIGADP

Gas processing apparatus baffle member, and gas processing method

A gas processing apparatus is disclosed, that comprises a processing chamber that is airtightly structured, a gas delivery pipe connected to the processing chamber, a gas supply source for supplying gas to the processing chamber through the gas delivery pipe, a holding table for holding a workpiece loaded to the processing chamber, a shower member disposed at a gas outlet of the gas delivery pipe connected to the processing chamber, a spray plate structured as a partition wall of the shower member that faces the holding plate, the spray plate having a plurality of spray holes, and a baffle member disposed between the spray plate in the shower member and the gas outlet and having a plurality of through-holes formed perpendicular to the surface of the baffle member, wherein each of the through-holes of the baffle member has a first opening portion and a second opening portion facing the gas outlet, the second opening portion facing the spray plate, the opening area of the second opening portion being larger than the opening portion of the first opening portion. Thus, a gas processing apparatus and a gas processing method that allow gas to be uniformly supplied to the entire surface of a workpiece are provided. In addition, a baffle member for use with the gas processing apparatus and the gas processing method is provided.

Owner:TOKYO ELECTRON LTD

Shower plate electrode for plasma CVD reactor

InactiveUS20090155488A1Uniform cross-sectional areaElectrostatic cleaningChemical vapor deposition coatingMachined surfaceEngineering

Methods and apparatuses for plasma chemical vapor deposition (CVD). In particular, a plasma CVD apparatus having a cleaning function, has an improved shower plate with holes having a uniform cross-sectional area to yield a high cleaning rate. The shower plate may serve as an electrode, and may have an electrically conductive extension connected to a power source. The shower plate, through which both cleaning gases and reaction source gases flow, may include a hole machined surface area with a size different than conventionally used to ensure a good film thickness uniformity during a deposition process. The size of the hole machined surface area may vary based on the size of a substrate to be processed, or the size of the entire surface of the shower plate.

Owner:ASM JAPAN

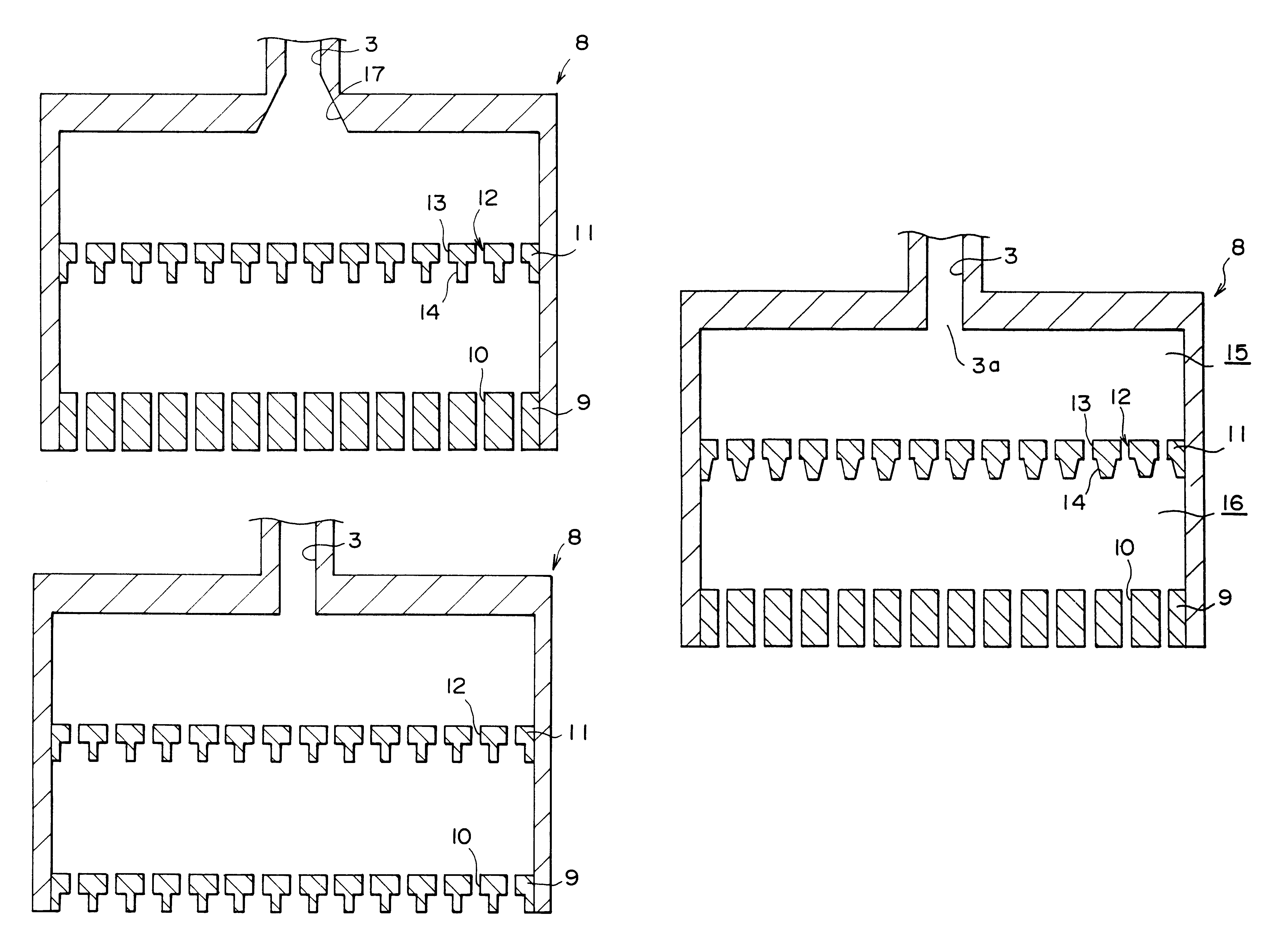

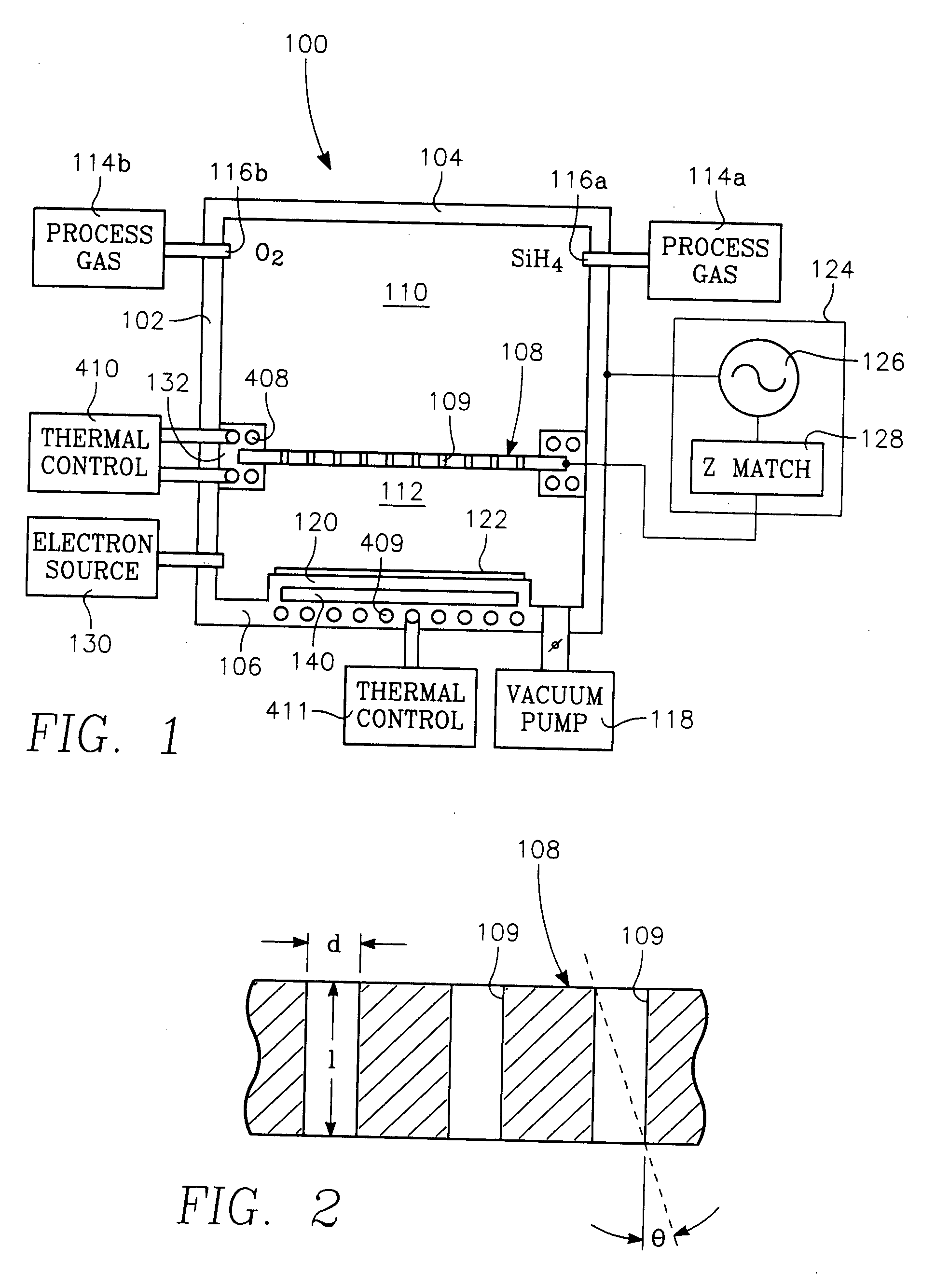

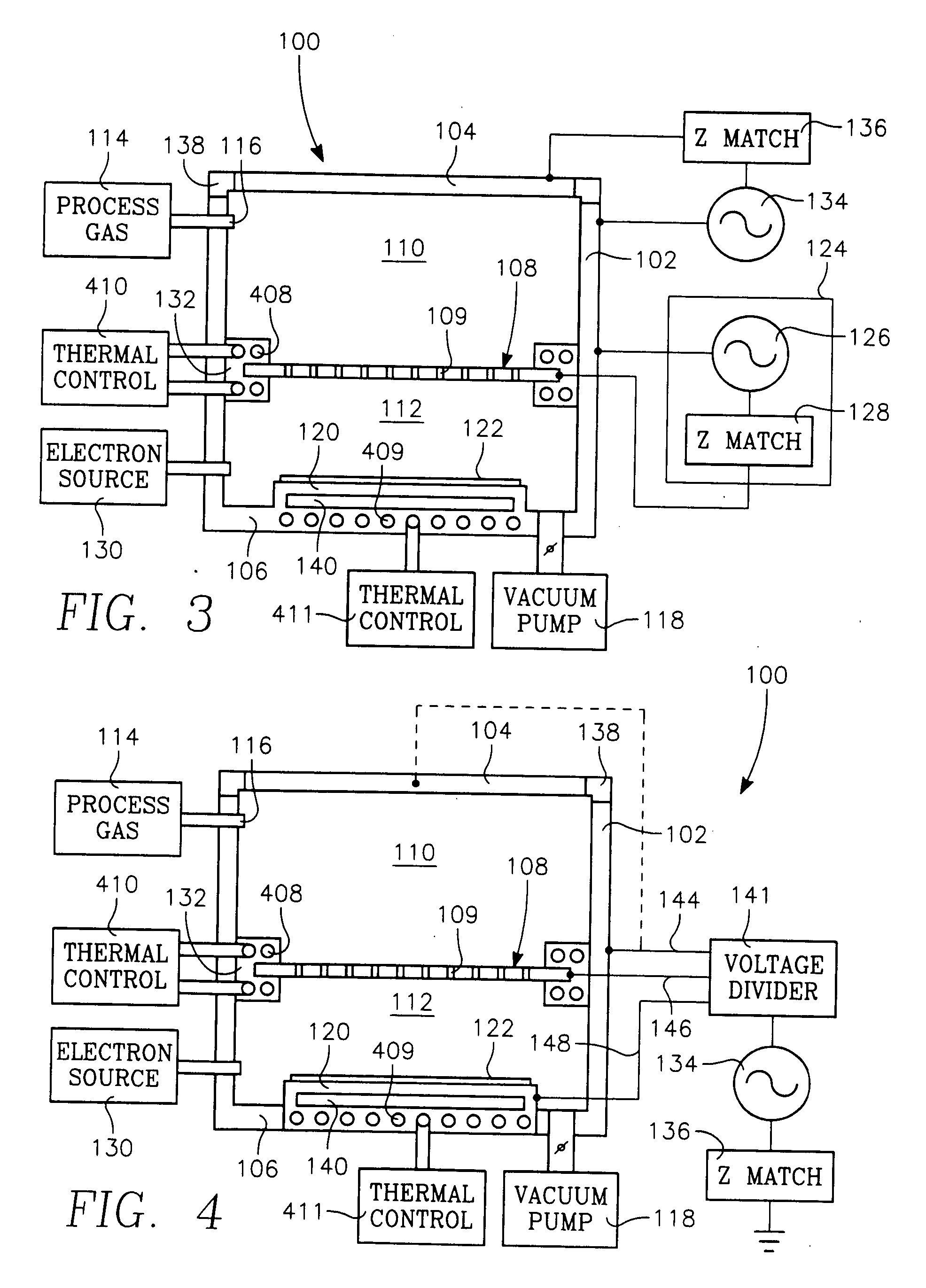

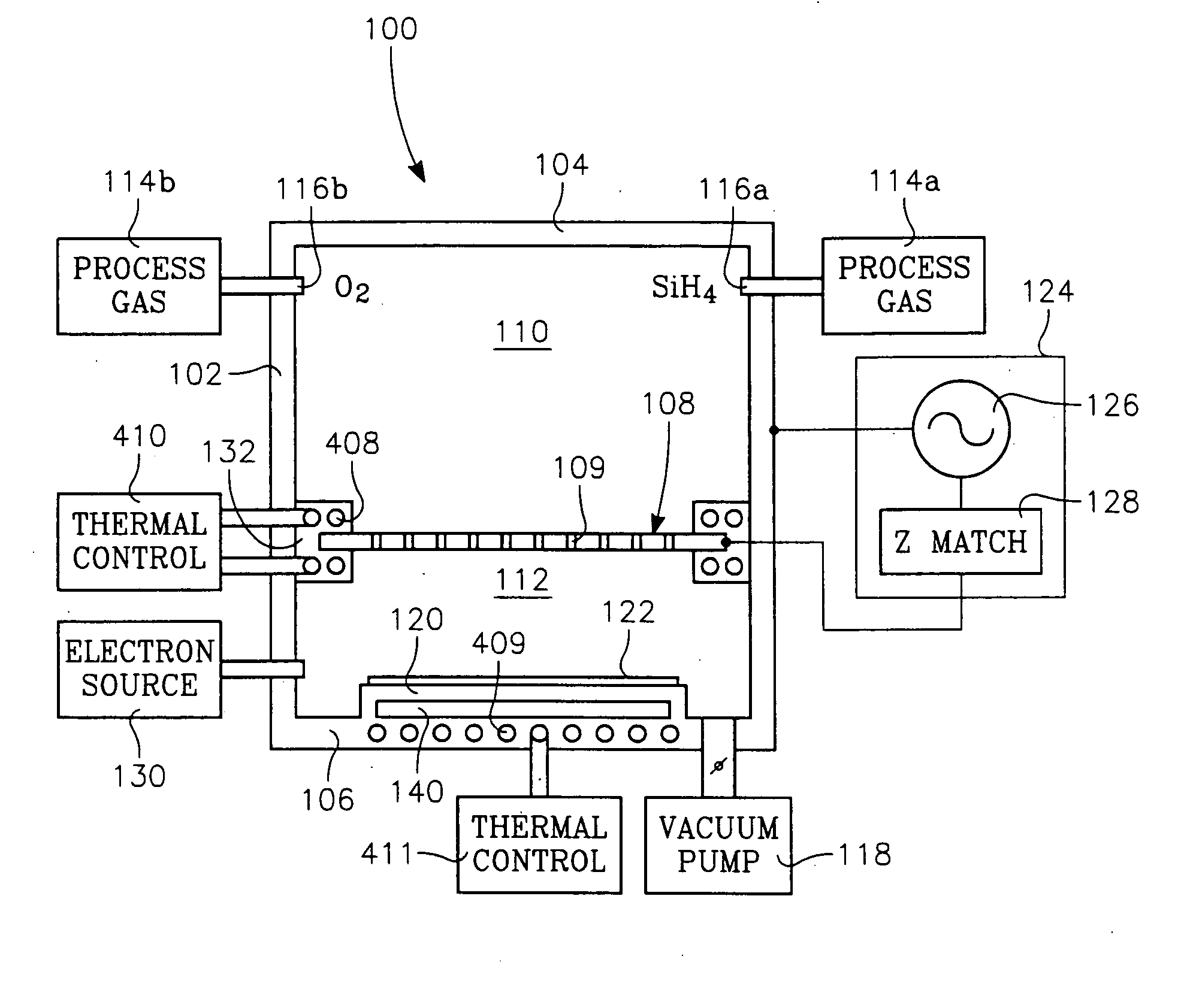

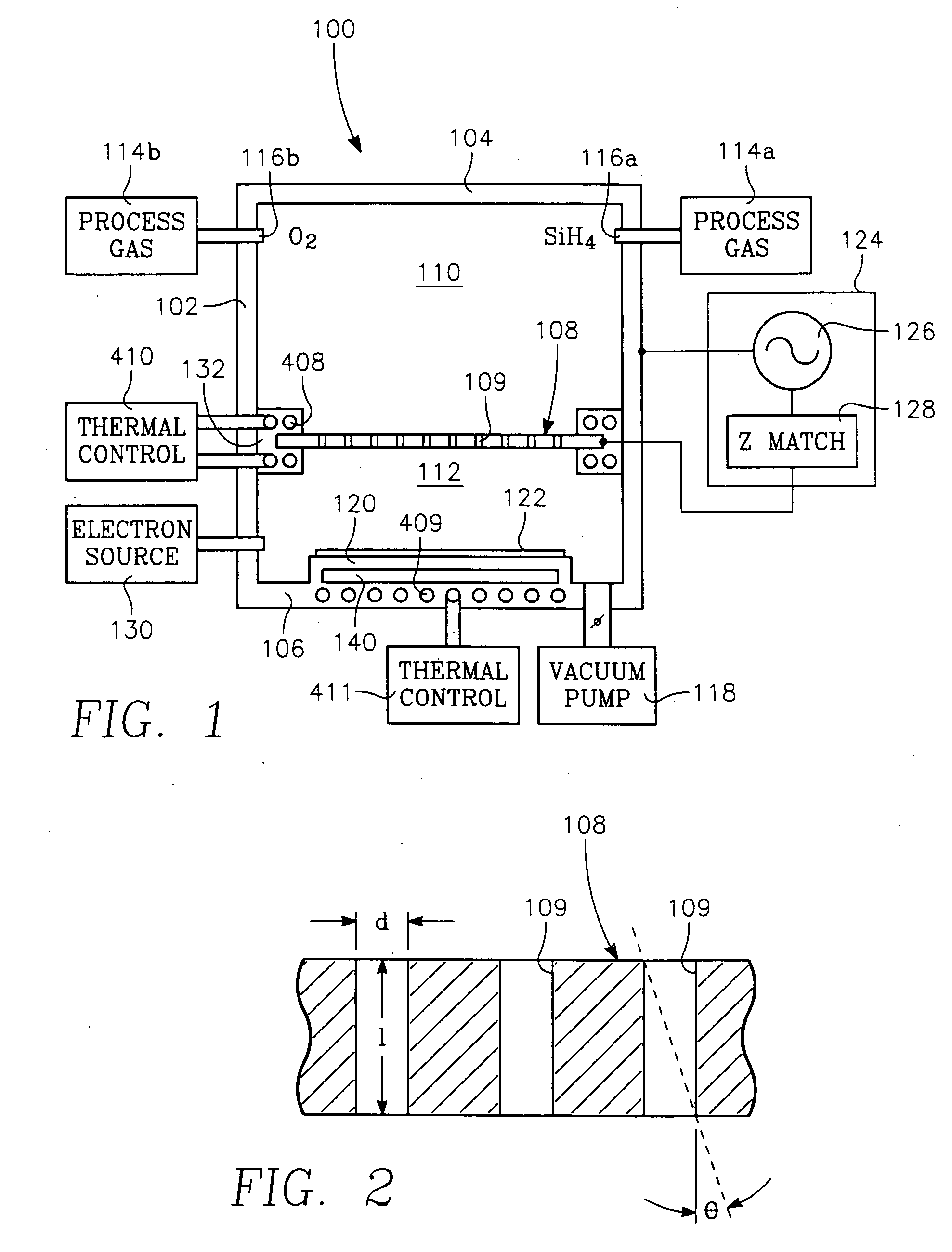

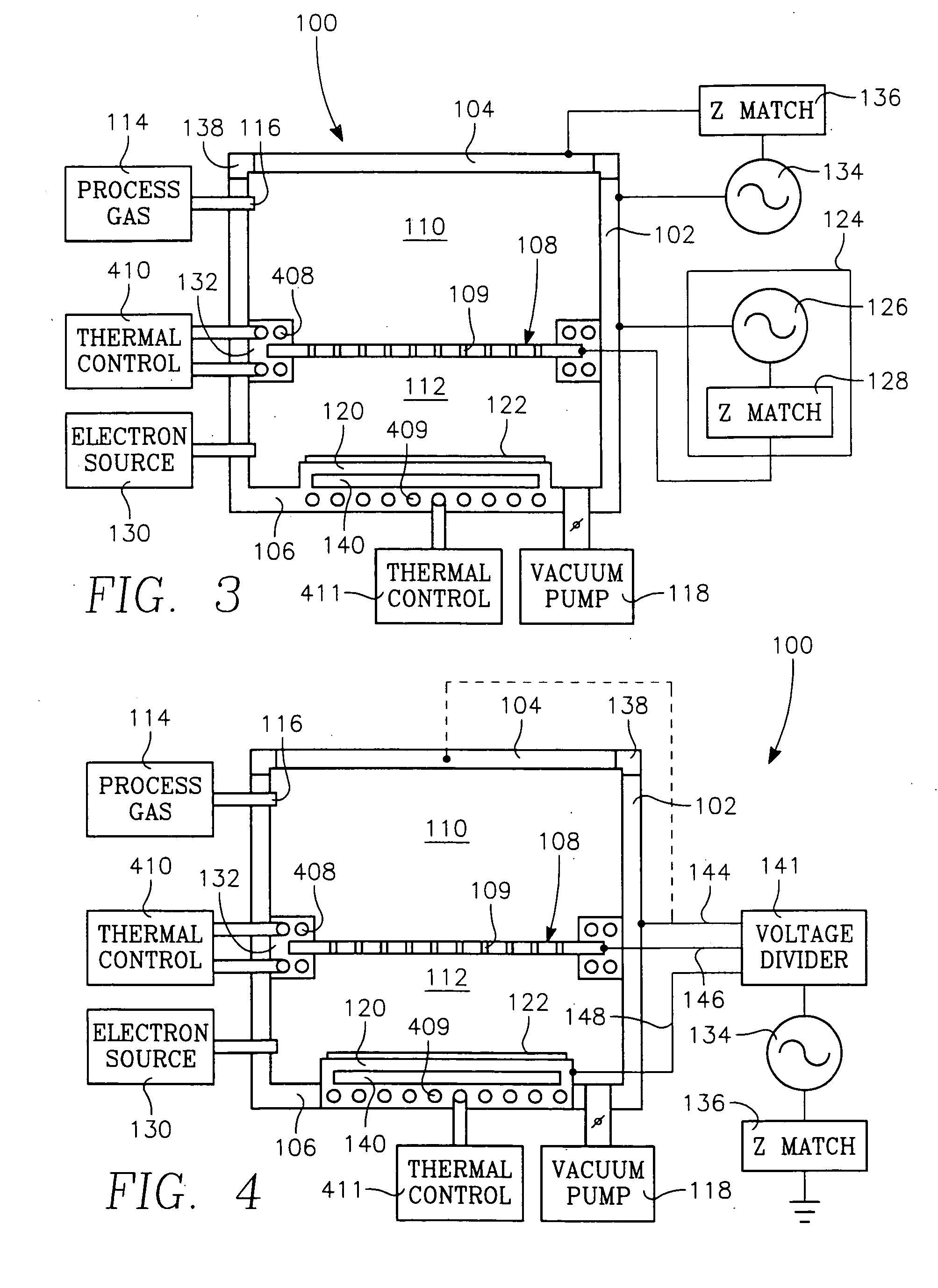

Plasma immersion ion implantation reactor having an ion shower grid

InactiveUS20060019477A1High ion fluxElectric discharge tubesVacuum evaporation coatingProcess regionPlasma-immersion ion implantation

A plasma immersion ion implantation process for implanting a selected species at a desired ion implantation depth profile in a workpiece is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural elongate orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. The process includes placing a workpiece in the process region, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid, and furnishing the selected species into the ion generation region in gaseous, molecular or atomic form and evacuating the process region at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region of about a factor of at least four. The process further includes applying plasma source power to generate a plasma of the selected species in the ion generation region, and applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region. The process also includes applying a sufficient bias voltage to at least one of: (a) the workpiece, (b) the grid, relative to at least one of: (a) the workpiece, (b) a plasma in the ion generation region, (c) a surface of the chamber, to accelerate the flux of ions to a kinetic energy distribution generally corresponding to the desired ion implantation depth profile in the workpiece.

Owner:APPLIED MATERIALS INC

Chemical vapor deposition plasma process using an ion shower grid

A chemical vapor deposition process is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. A workpiece is placed in the process region facing the ion shower grid, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid. A gas mixture is furnished comprising deposition precursor species into the ion generation region and the process region is evacuated at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region whereby the pressure in the ion generation region is at least several times the pressure in the process region. A layer of material of a desired thickness is deposited on the workpiece by: (a) applying plasma source power to generate a plasma of the deposition precursor species in the ion generation region, and (b) applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region.

Owner:APPLIED MATERIALS INC

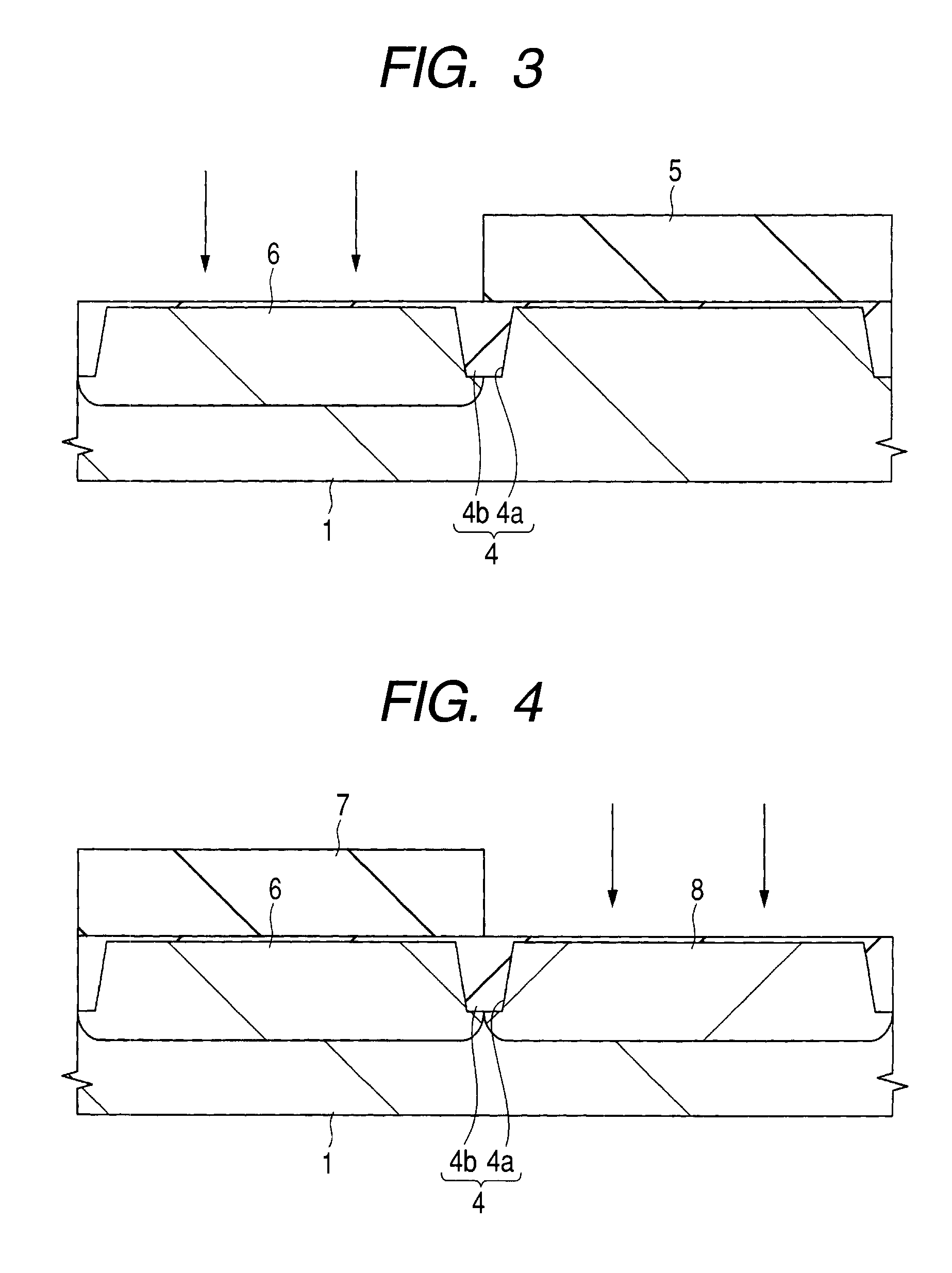

Method of manufacturing semiconductor device

ActiveUS20070238321A1Improve reliabilityVariation in electrical propertyTransistorElectrostatic cleaningEngineeringSemiconductor

Provided is a method of manufacturing a semiconductor device. After a semiconductor wafer is placed over a wafer stage with which a dry cleaning chamber of a film forming apparatus is equipped, dry cleaning treatment is given over the surface of the semiconductor wafer with a reducing gas. Then, the semiconductor wafer is heat treated at a first temperature of from 100 to 150° C. by using a shower head kept at 180° C. The semiconductor wafer is then vacuum-transferred to a heat treatment chamber, wherein the semiconductor wafer is heat treated at a second temperature of from 150 to 400° C. A product remaining over the main surface of the semiconductor wafer is thus removed. The present invention makes it possible to manufacture a semiconductor device having improved reliability and production yield by reducing variations in the electrical properties of a nickel silicide layer.

Owner:RENESAS ELECTRONICS CORP

Substrate processing apparatus and method of processing substrate

PendingUS20180155836A1Avoid dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingNoble gasProduct gas

A substrate processing apparatus includes a stage provided in a chamber, a shower head in which a plurality of slits are formed and which is opposed to the stage, a first gas supply part which supplies a first gas to a space between the stage and the shower head via the plurality of slits, and a second gas supply part which supplies a second gas which is not a noble gas to a region below the stage, wherein the second gas is the same gas as one of a plurality of kinds of gases constituting the first gas in a case where the first gas is a mixture gas constituted of the plurality of kinds of gases, and the second gas is the same gas as the first gas in a case where the first gas is a single kind of gas.

Owner:ASM IP HLDG BV

Substrate processing apparatus and method for processing substrate

ActiveUS20180286638A1Electric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A substrate processing apparatus includes a chamber, a susceptor provided in the chamber, a shower plate having a plate part provided with a plurality of through holes and formed of a conductor, a ring-shaped part connected to an outer edge of the plate part, surrounding the plate part and formed of a conductor and a lead wire embedded in the ring-shaped part and surrounding the plate part and the susceptor in plan view, the shower plate being provided so as to face the susceptor in the chamber, and a DC power supply that supplies a direct current to the lead wire.

Owner:ASM IP HLDG BV

Lighting fixture with recessed baffle trim unit

InactiveUS20100061108A1Easy to GrindGood thermal controlLighting support devicesElectric circuit arrangementsEffect lightEngineering

A recessed lighting fixture providing illumination from a light source including a plurality of light emitting diodes (LEDs) placed within a cavity of a planar surface, such as a ceiling, wall, or shower. The fixture comprises a baffle integrated with a low profile heat sink that is used to draw heat out of the fixture and communicate that heat to a trim ring of the fixture for dissipation of the heat in the room so that higher intensity light sources can be used. Improved grounding of the recessed trim unit to the recessed housing is provided with combination support and grounding springs. One embodiment of the light source is fixed in position while a second embodiment is gimbal mounted for aiming the light produced by the fixture.

Owner:CORDELIA LIGHTING

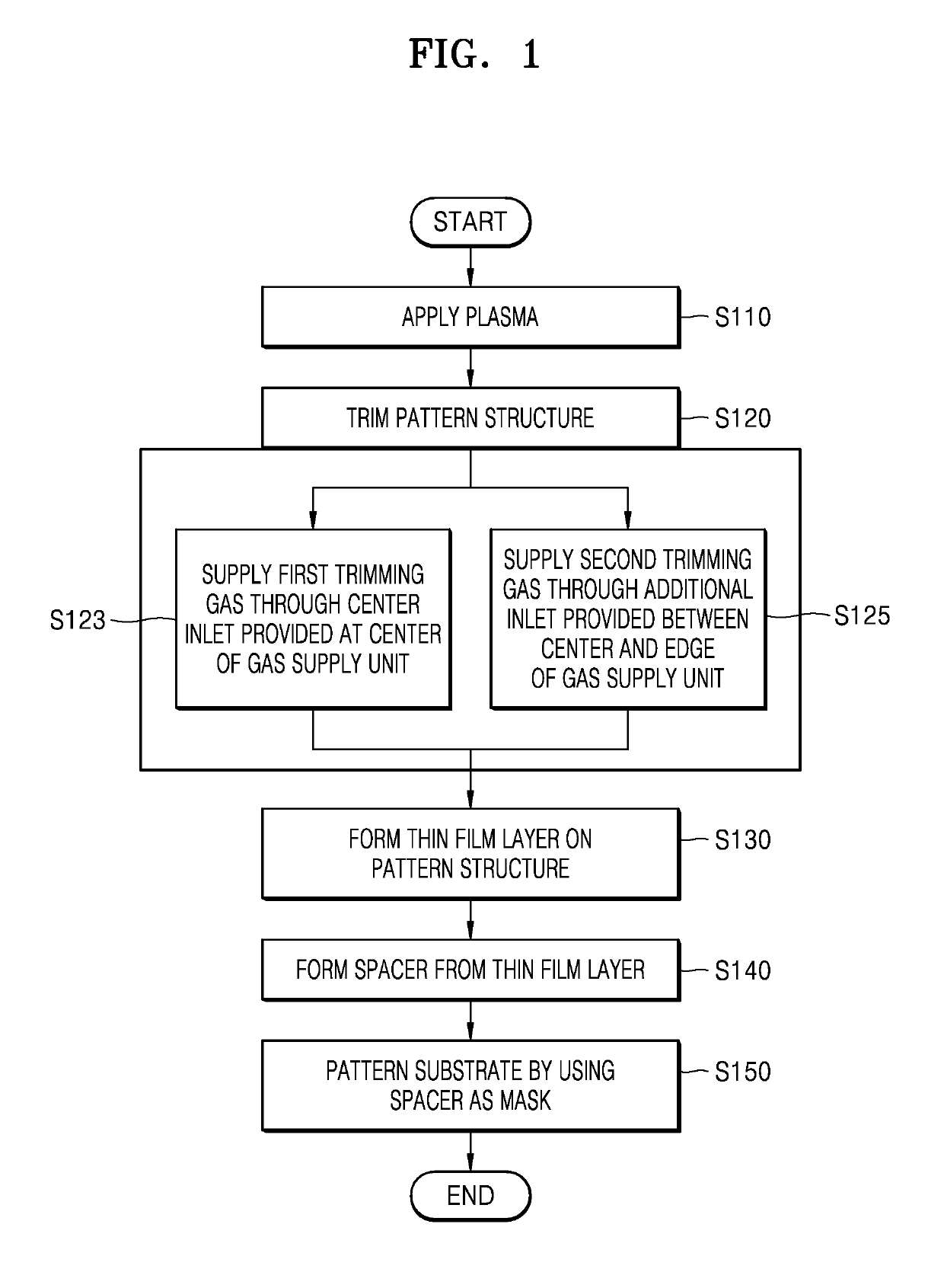

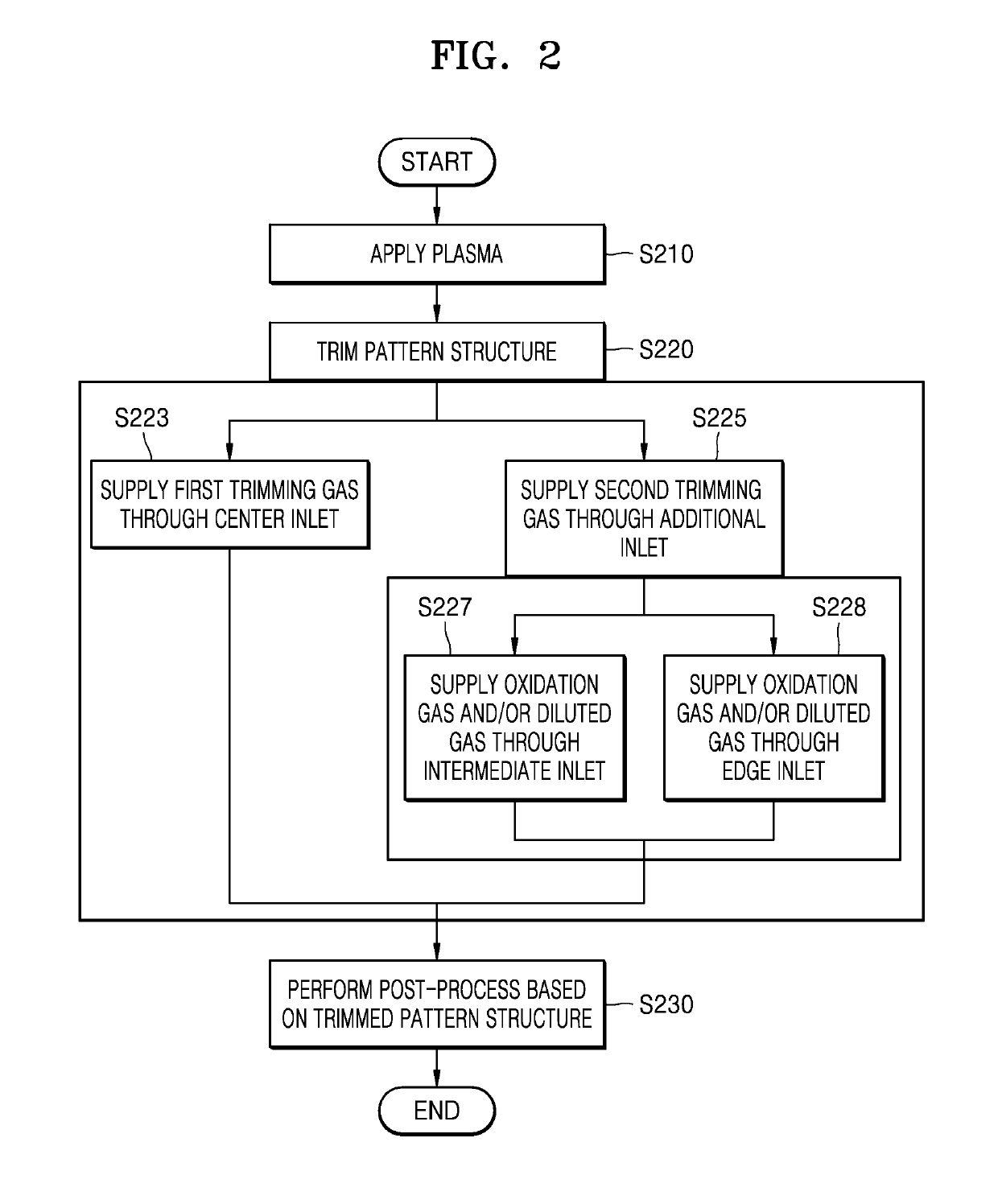

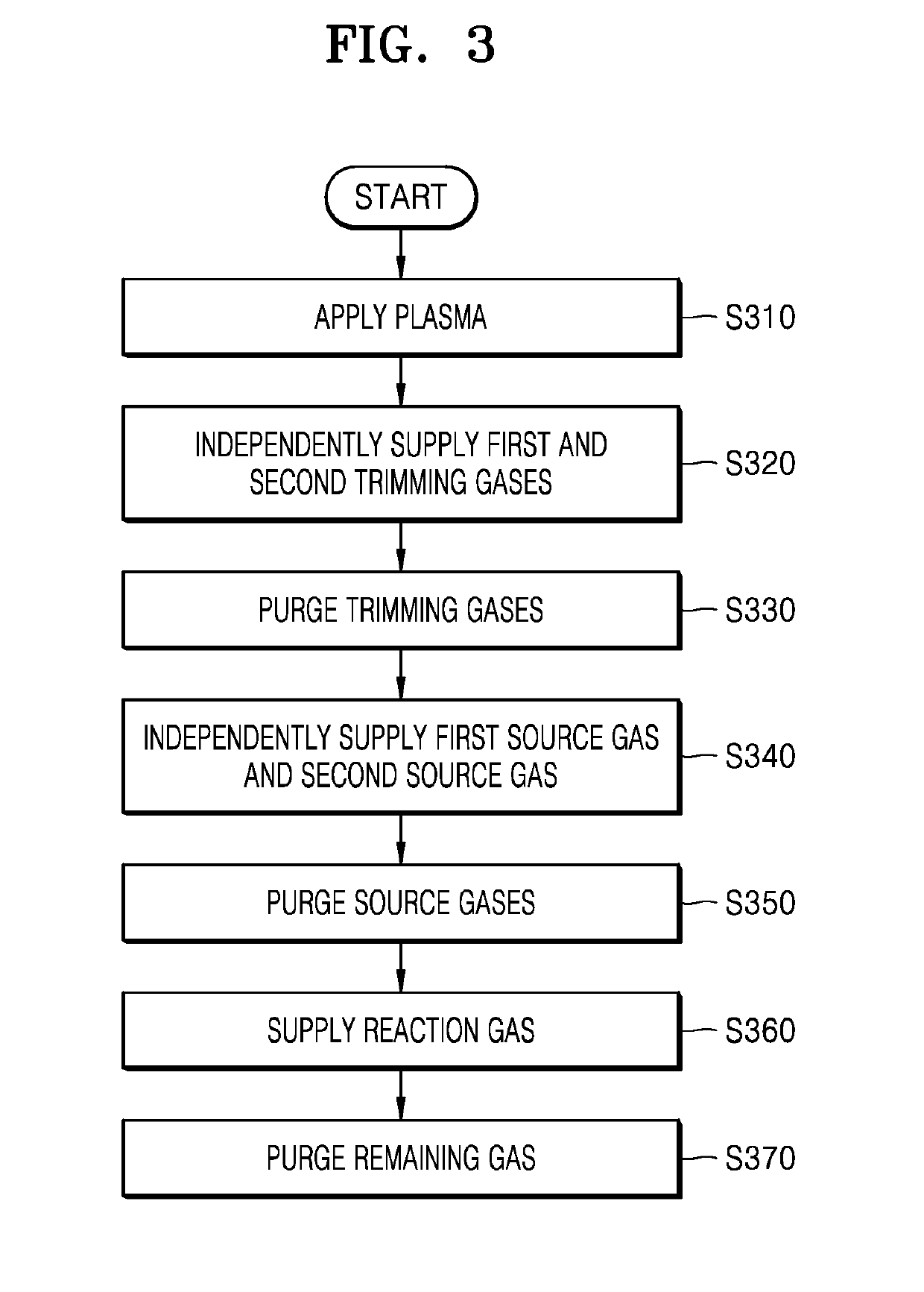

Substrate processing method and apparatus

ActiveUS20190259611A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringShower

Provided are a substrate processing apparatus and a substrate processing method capable of achieving uniform trimming throughout an entire surface of a substrate. The substrate processing apparatus includes a gas channel including a center gas inlet and an additional gas inlet spaced apart from the center gas inlet, and a shower plate including a plurality of holes connected to the center gas inlet and the additional gas inlet, wherein a gas flow channel is formed having a clearance defined by a lower surface of the gas channel and an upper surface of the shower plate, the lower surface and the upper surface being substantially parallel.

Owner:ASM IP HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com