Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172 results about "Plasma-immersion ion implantation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

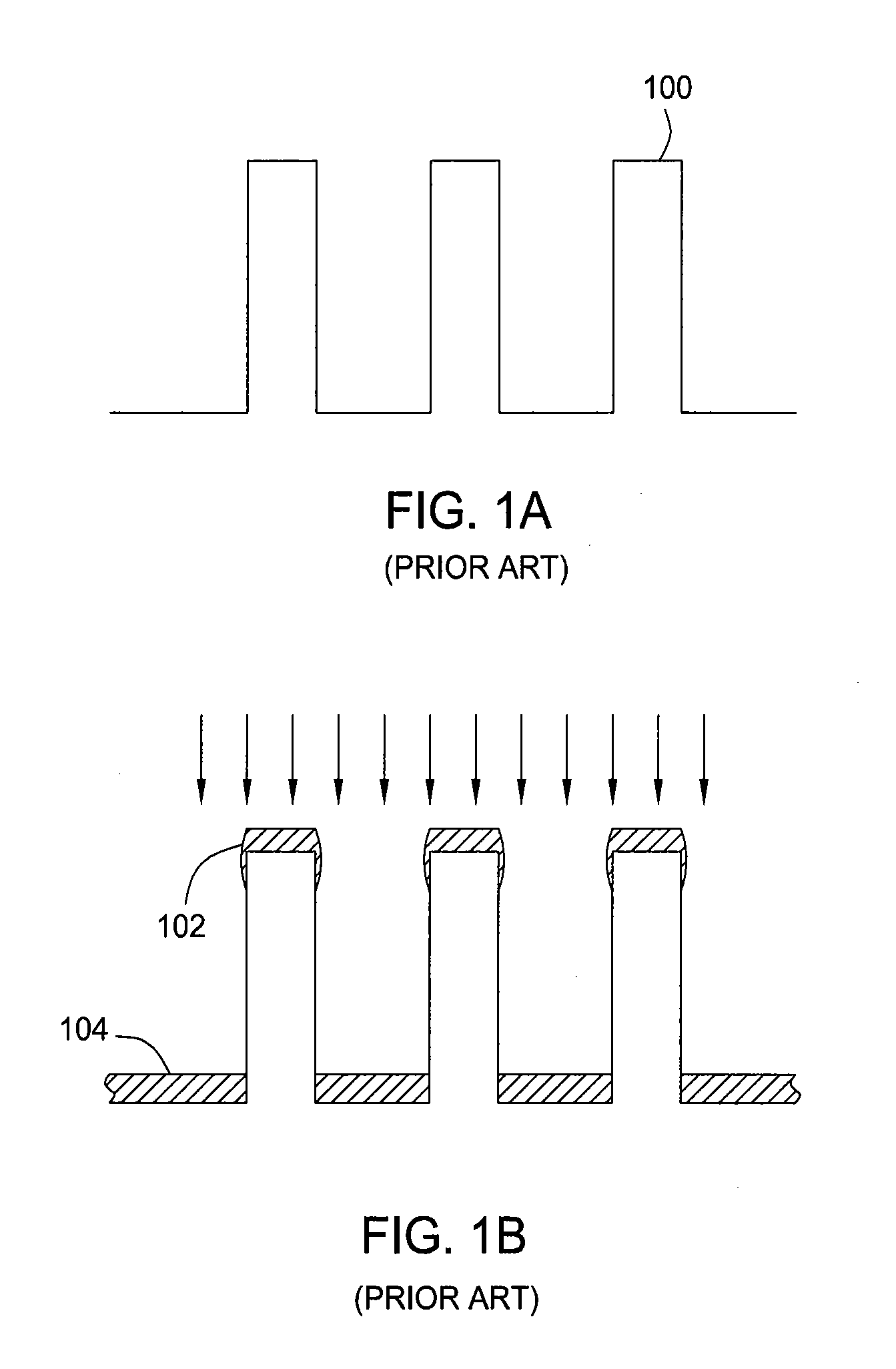

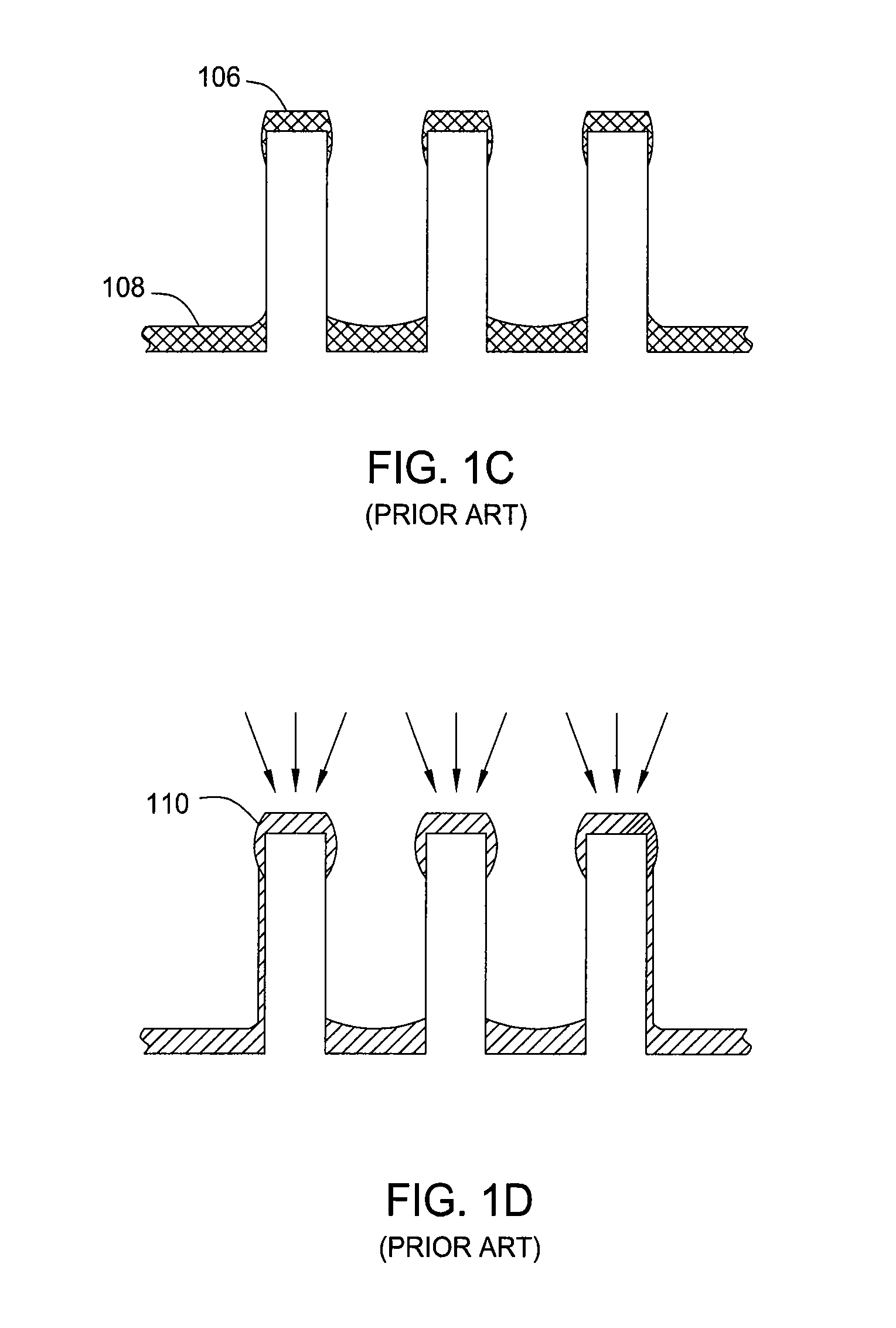

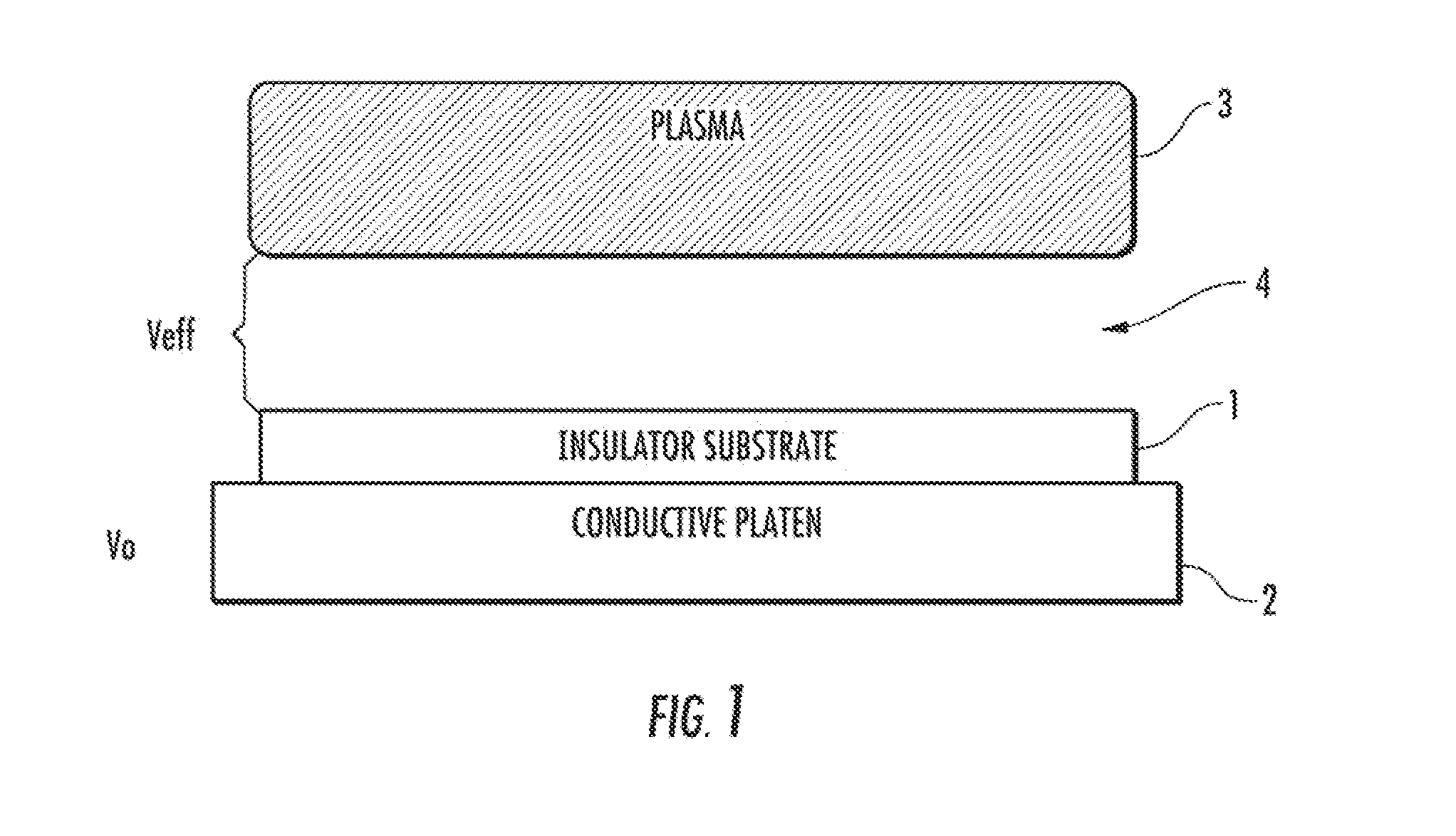

Plasma-immersion ion implantation (PIII) or pulsed-plasma doping (pulsed PIII) is a surface modification technique of extracting the accelerated ions from the plasma by applying a high voltage pulsed DC or pure DC power supply and targeting them into a suitable substrate or electrode with a semiconductor wafer placed over it, so as to implant it with suitable dopants. The electrode is a cathode for an electropositive plasma, while it is an anode for an electronegative plasma. Plasma can be generated in a suitably designed vacuum chamber with the help of various plasma sources such as Electron Cyclotron Resonance plasma source which yields plasma with the highest ion density and lowest contamination level, helicon plasma source, capacitively coupled plasma source, inductively coupled plasma source, DC glow discharge and metal vapor arc(for metallic species). The vacuum chamber can be of two types - diode and triode type depending upon whether the power supply is applied to the substrate as in the former case or to the perforated grid as in the latter.

Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

ActiveUS20110159673A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSource material

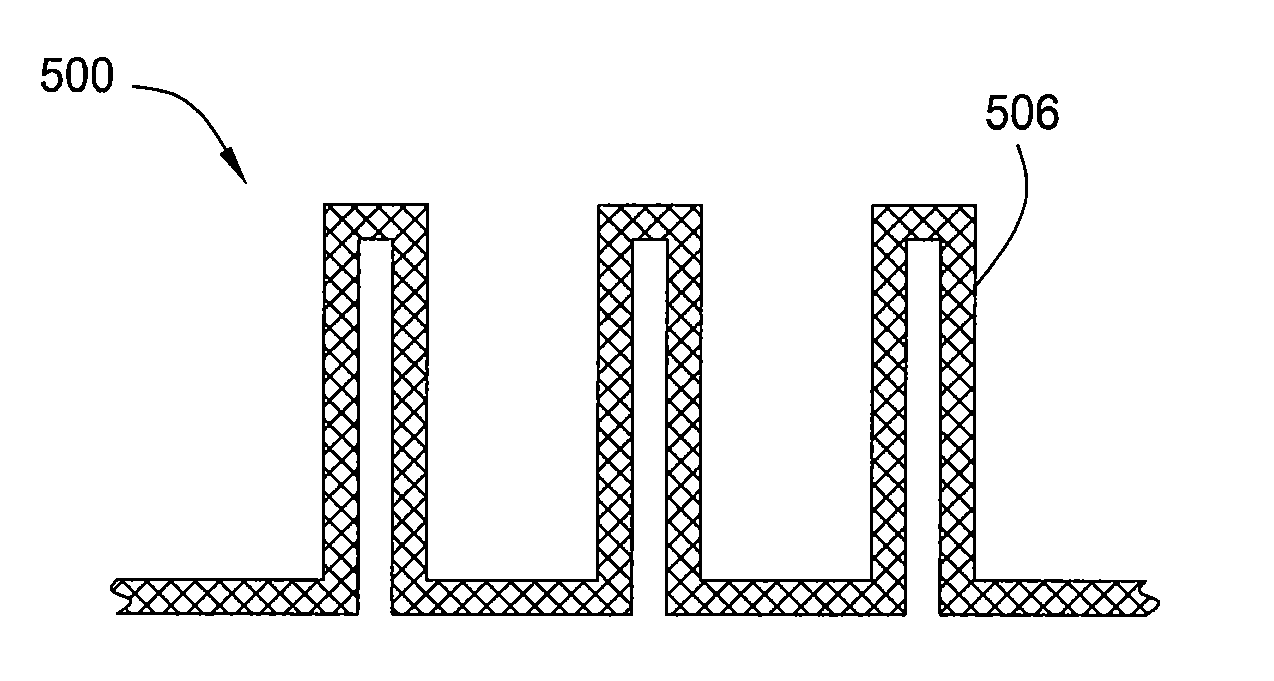

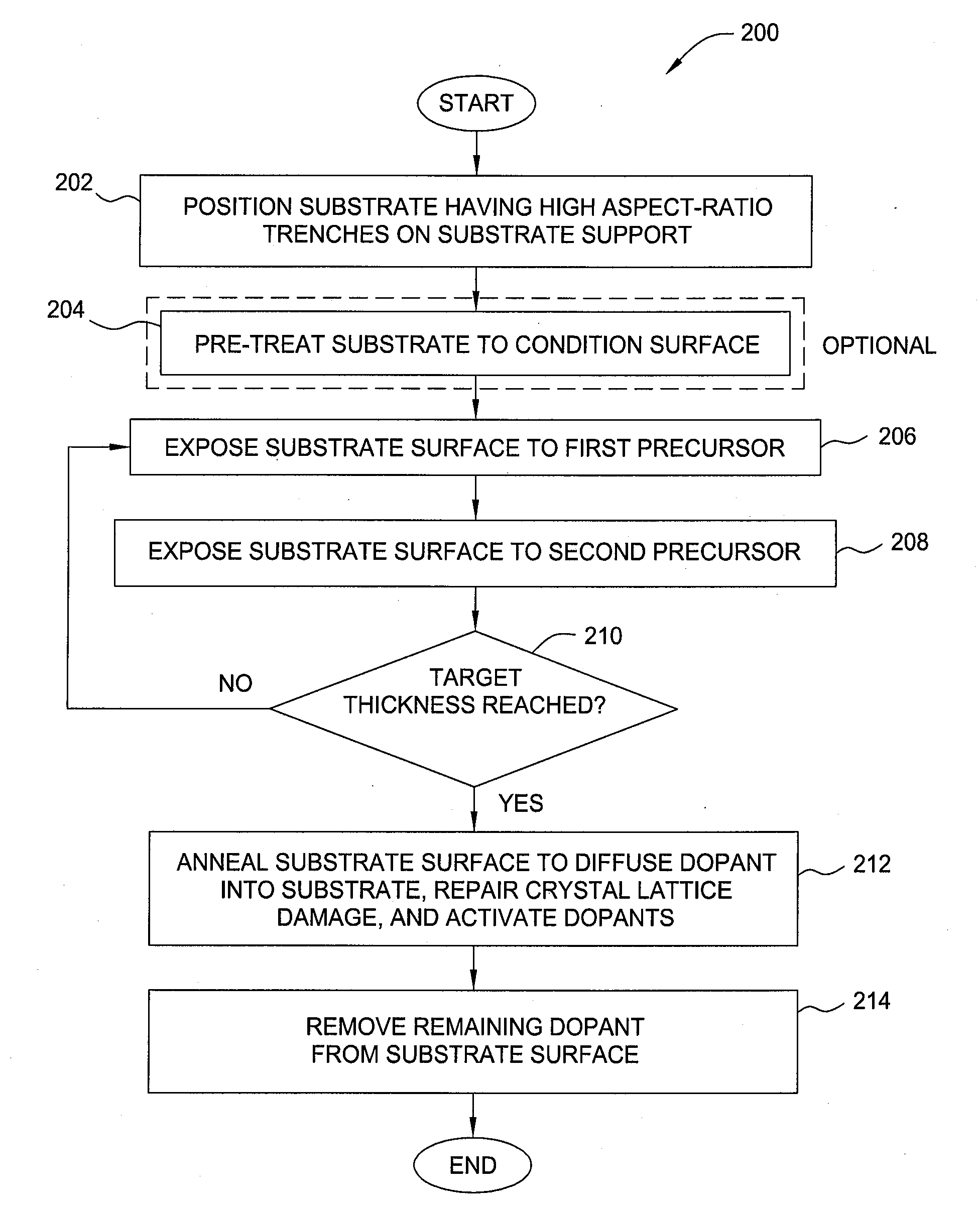

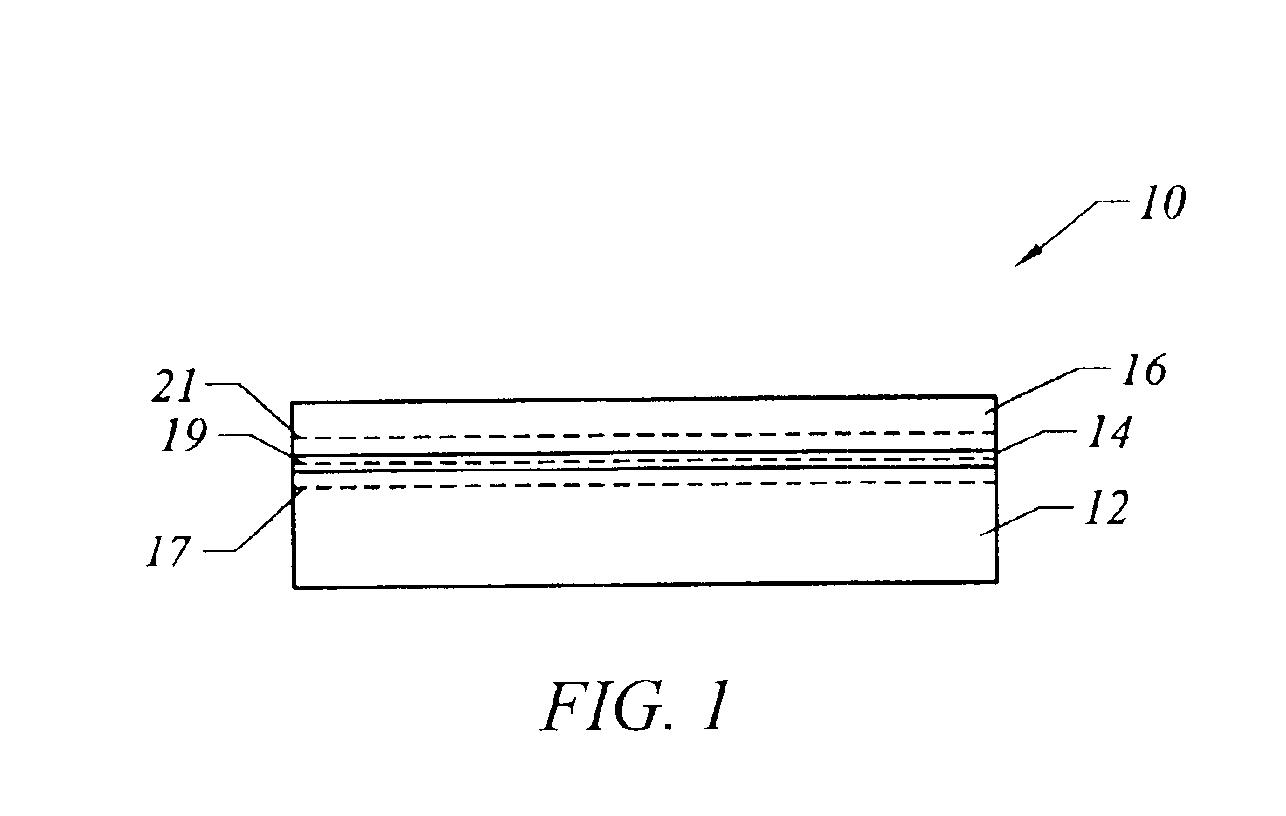

Embodiments of the invention provide a novel apparatus and methods for forming a conformal doped layer on the surface of a substrate. A substrate is provided to a process chamber, and a layer of dopant source material is deposited by plasma deposition, atomic layer deposition, or plasma-assisted atomic layer deposition. The substrate is then subjected to thermal processing to activate and diffuse dopants into the substrate surface.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process

InactiveUS20060081558A1Electric discharge tubesDecorative surface effectsRemote plasmaPlasma-immersion ion implantation

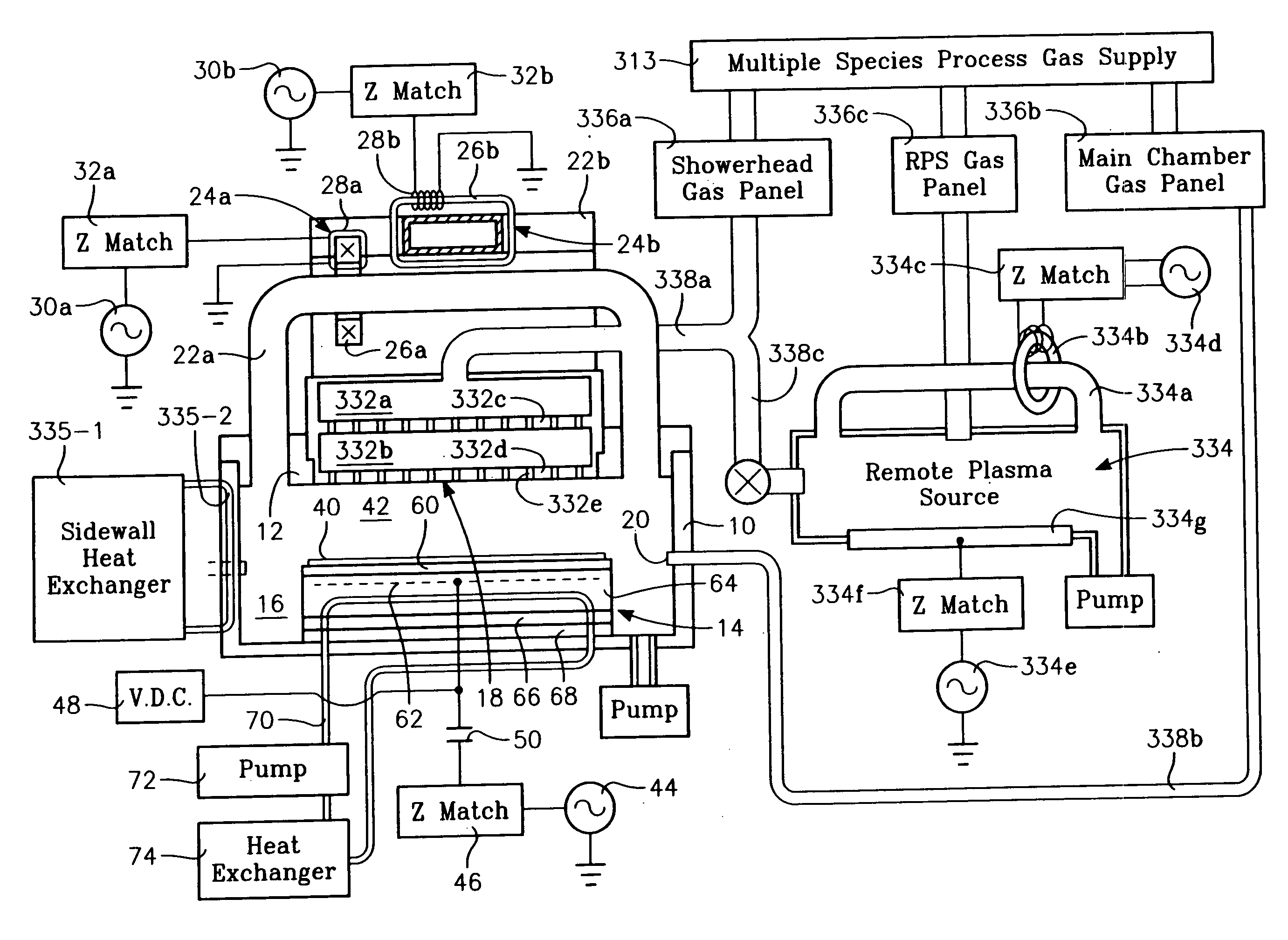

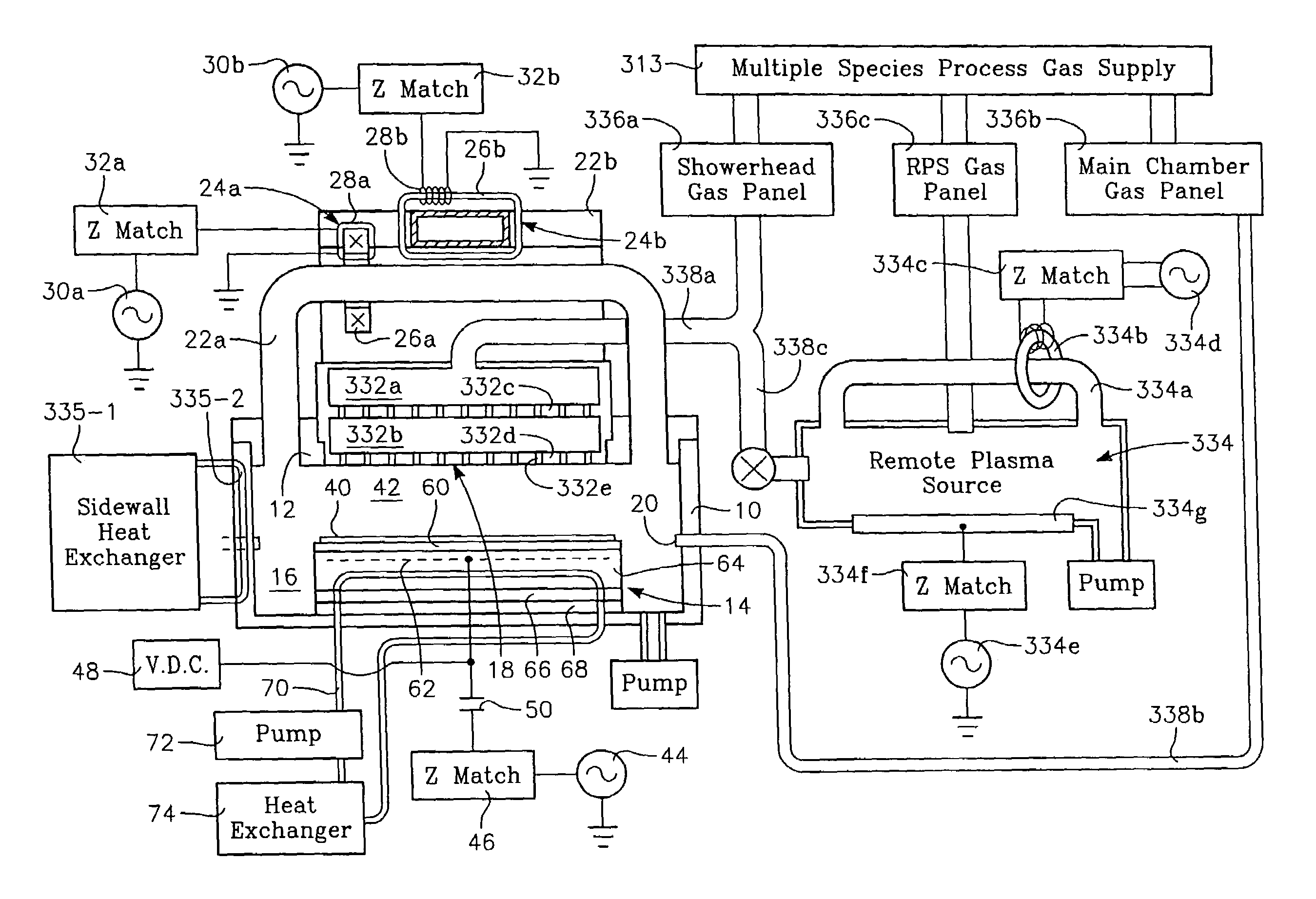

A method of processing a workpiece includes placing the workpiece on a workpiece support pedestal in a main chamber with a gas distribution showerhead, introducing a process gas into a remote plasma source chamber and generating a plasma in the remote plasma source chamber, transporting plasma-generated species from the remote plasma source chamber to the gas distribution showerhead so as to distribute the plasma-generated species into the main chamber through the gas distribution showerhead, and applying plasma RF power into the main chamber.

Owner:APPLIED MATERIALS INC

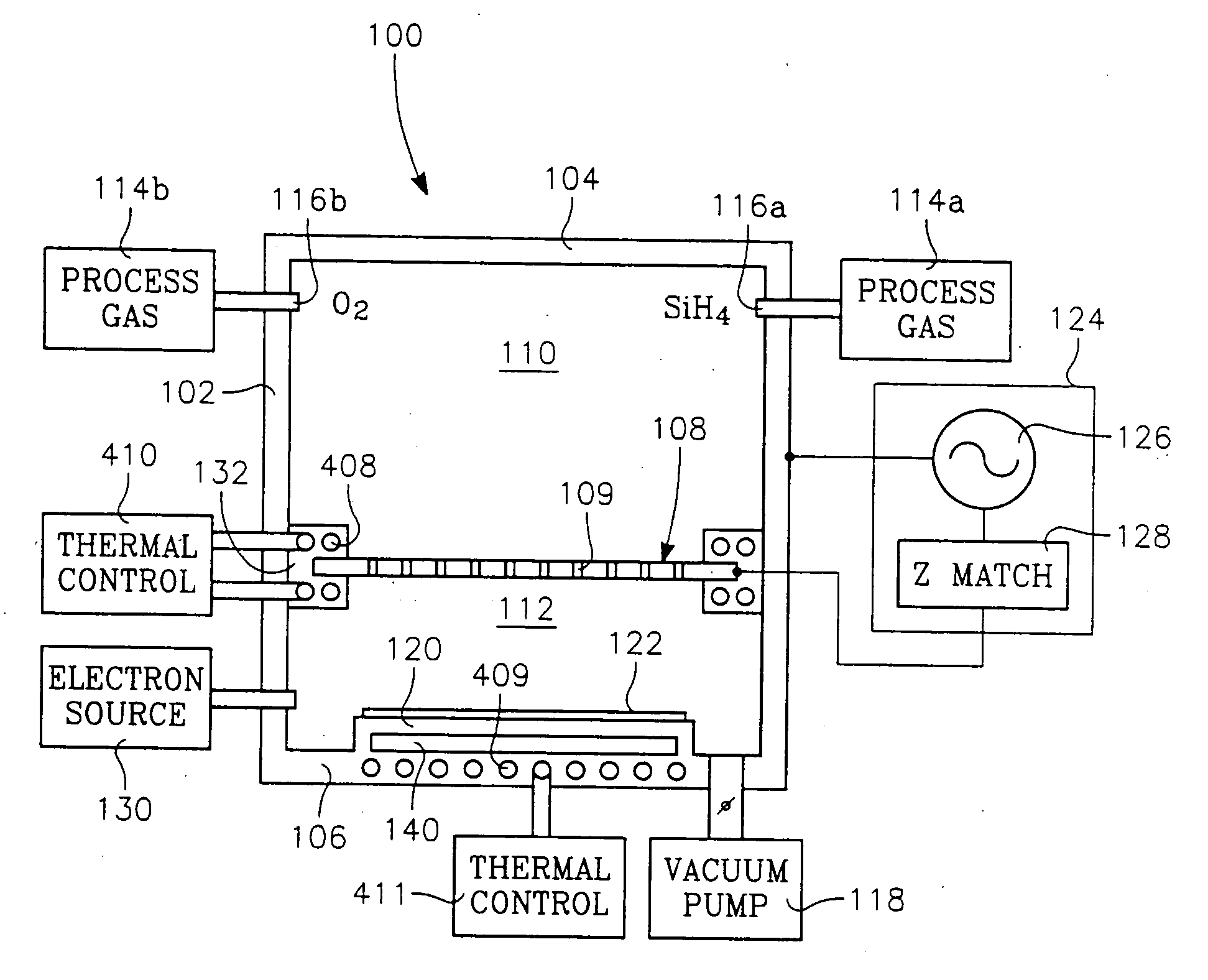

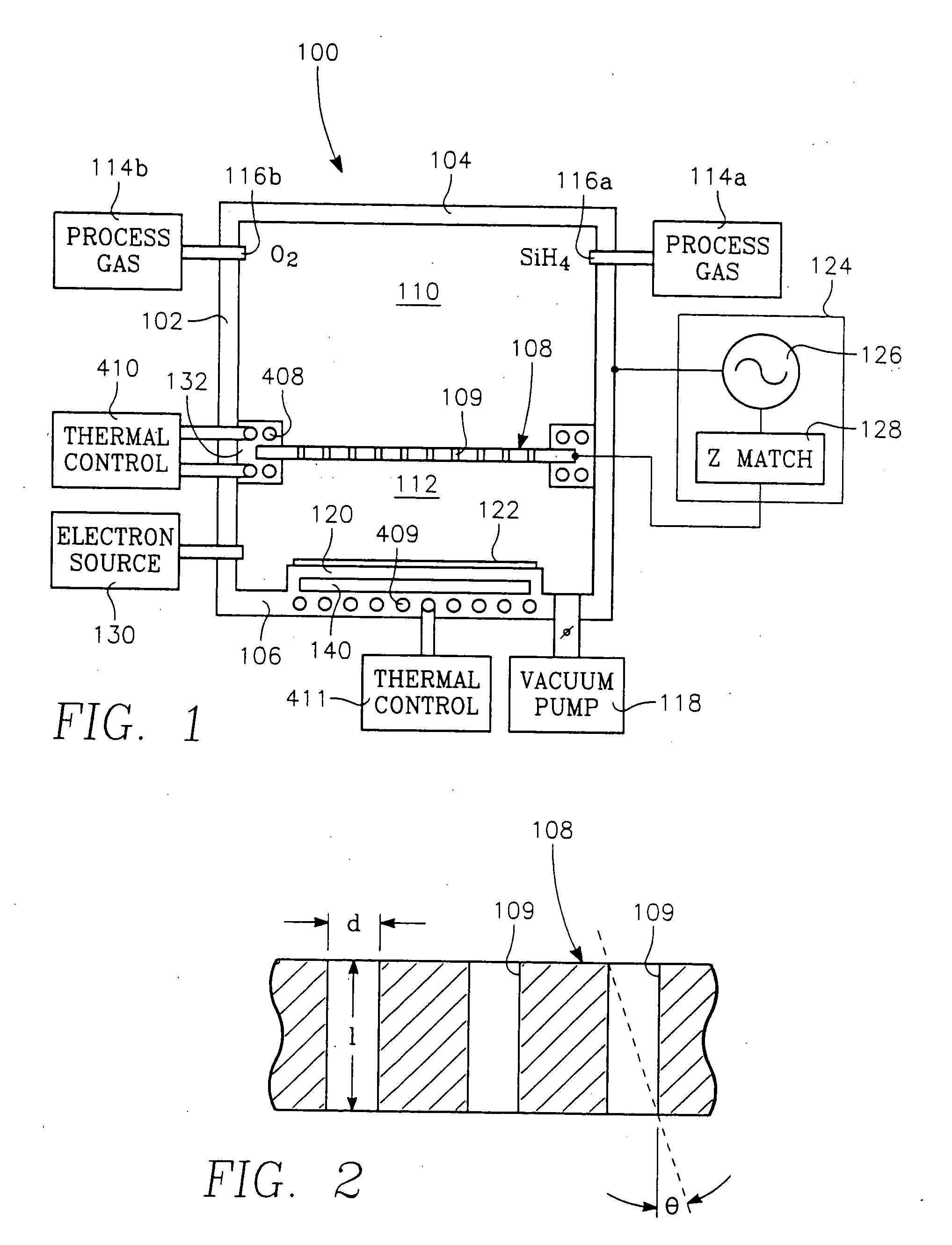

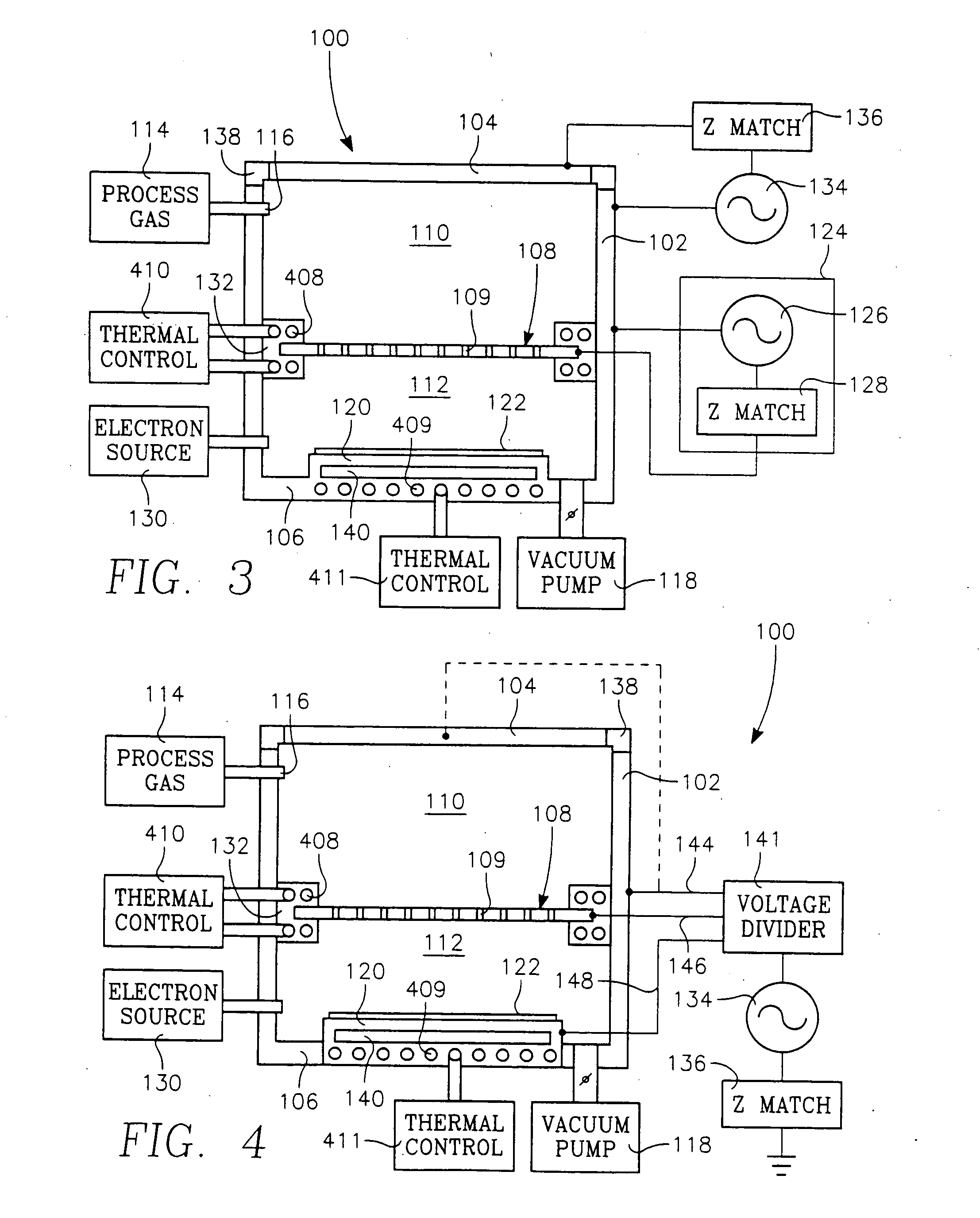

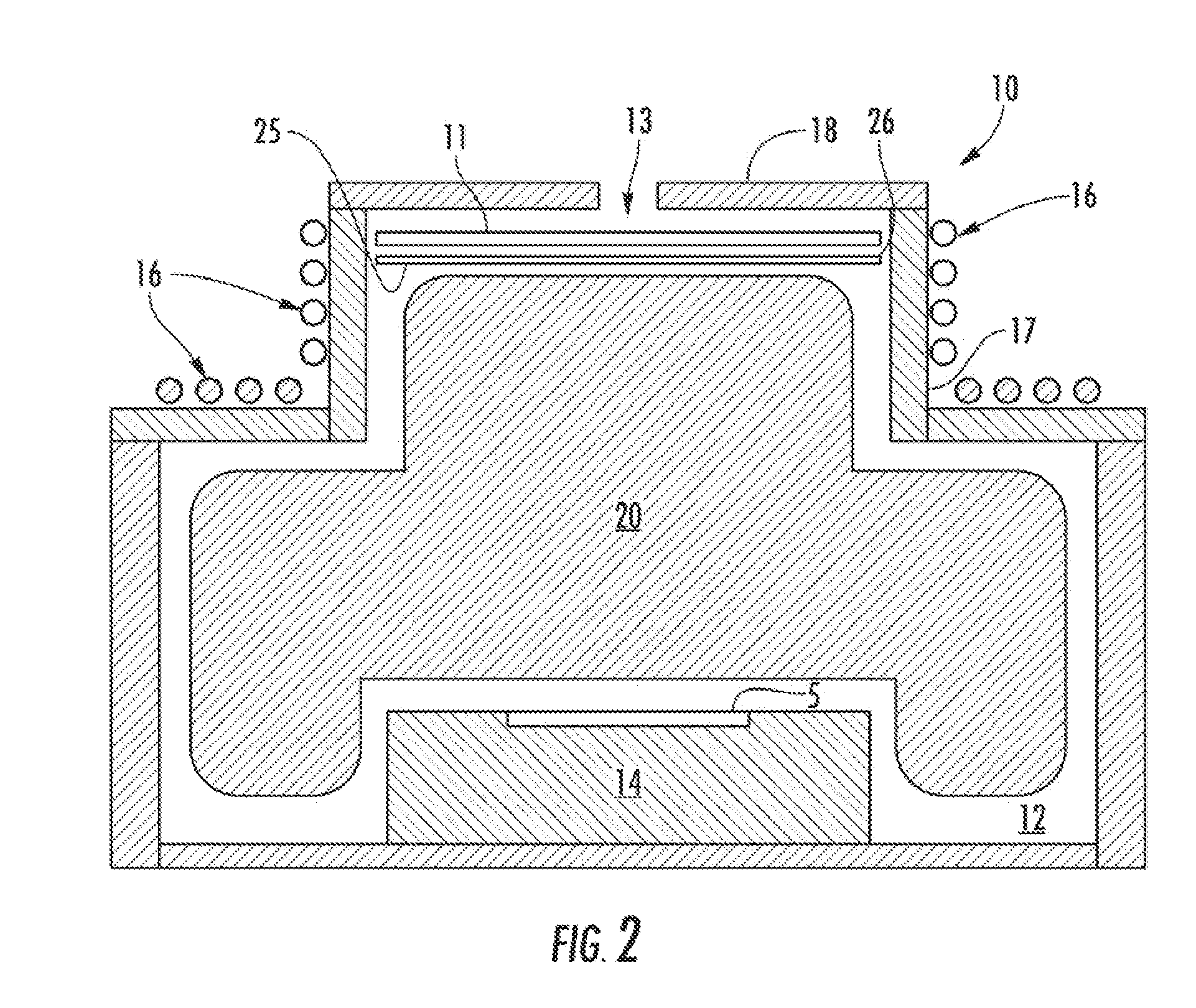

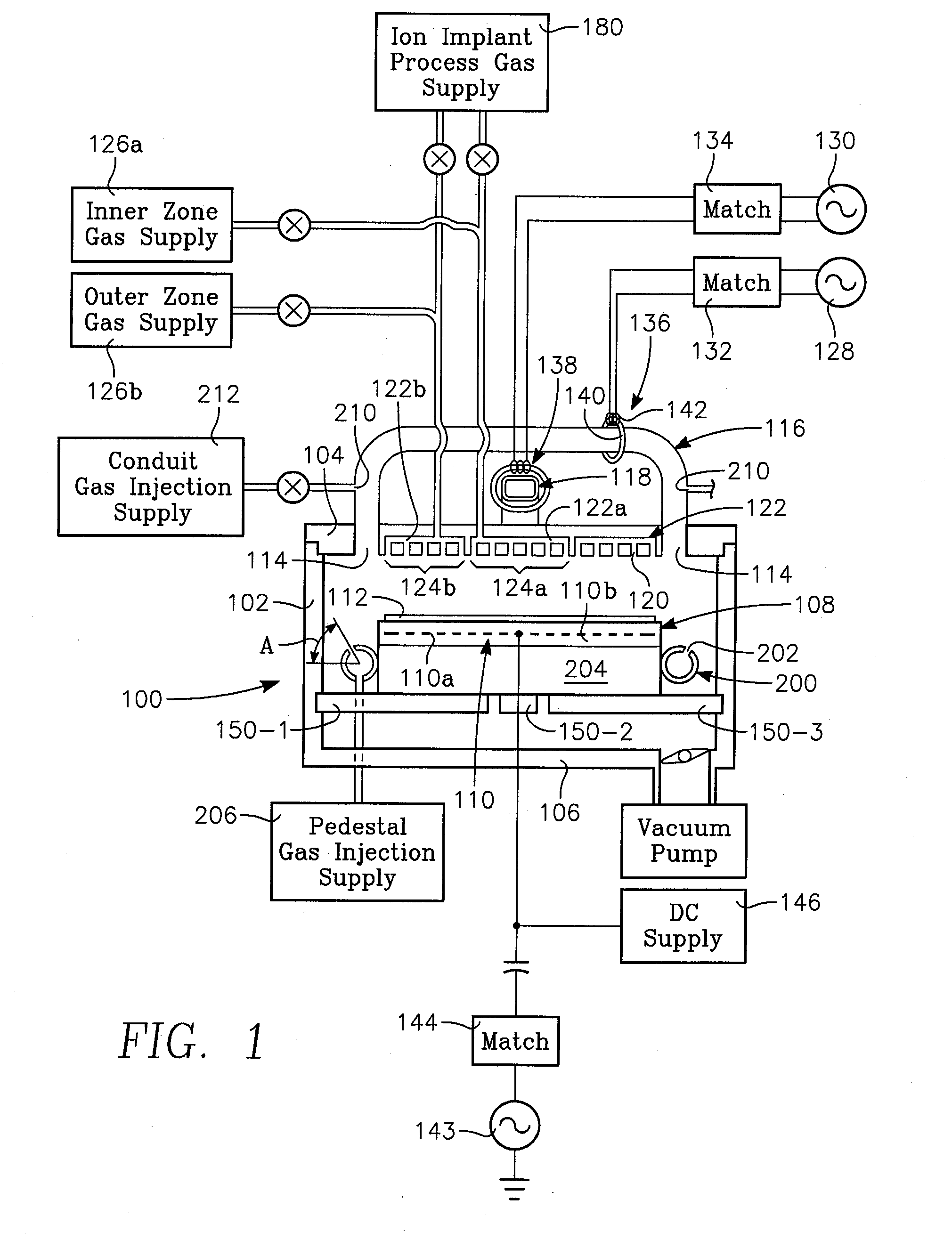

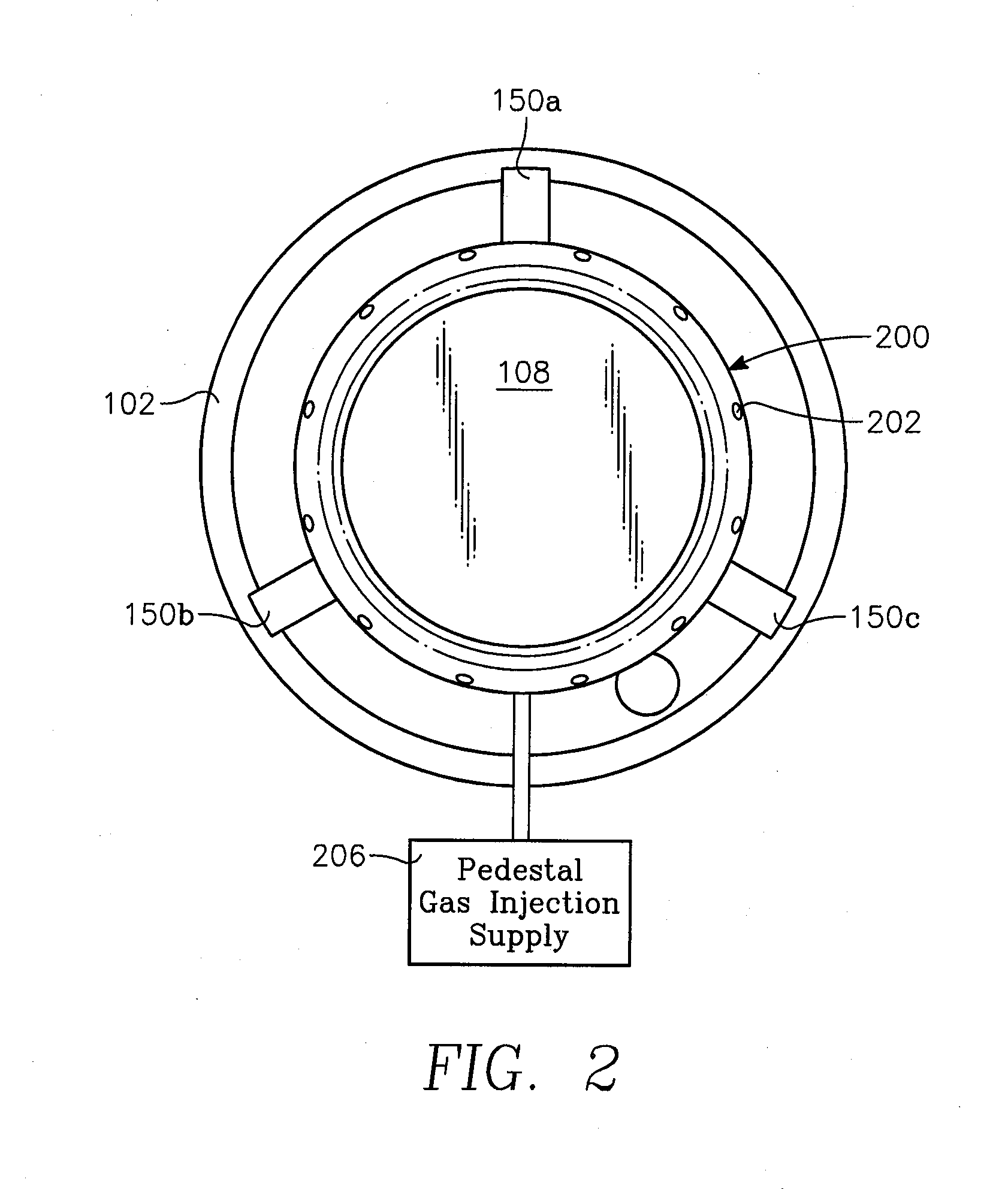

Plasma immersion ion implantation reactor having an ion shower grid

InactiveUS20060019477A1High ion fluxElectric discharge tubesVacuum evaporation coatingProcess regionPlasma-immersion ion implantation

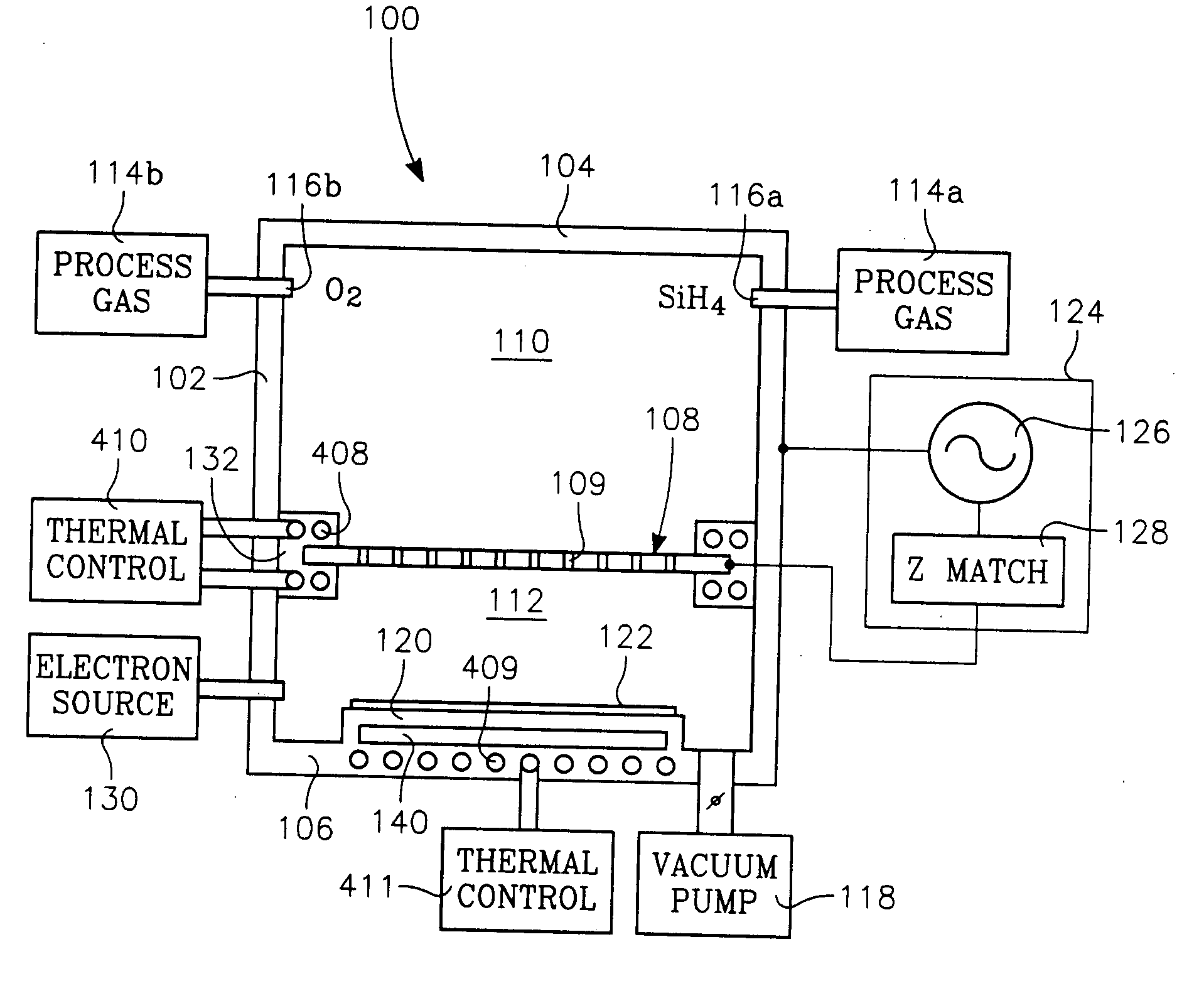

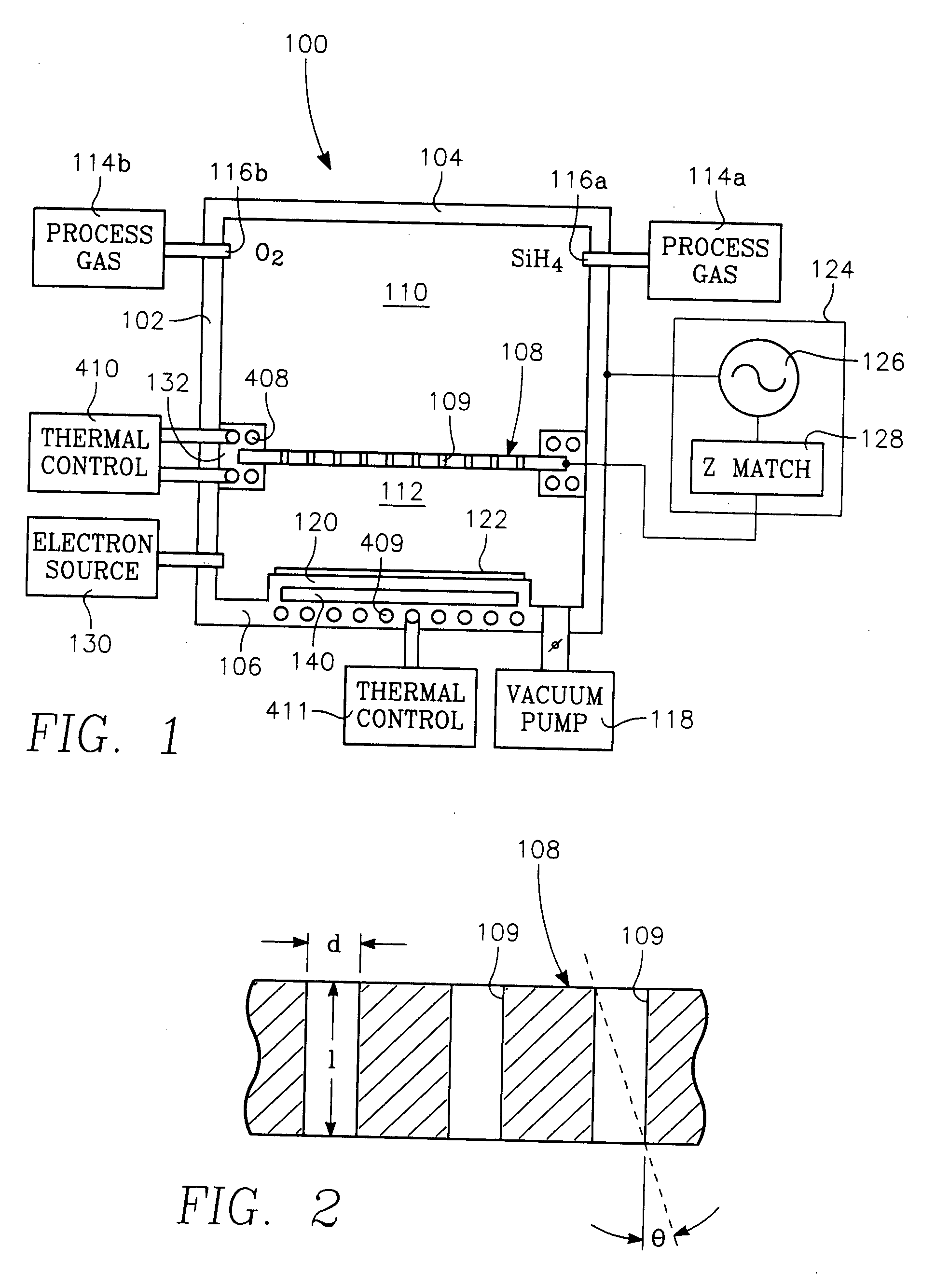

A plasma immersion ion implantation process for implanting a selected species at a desired ion implantation depth profile in a workpiece is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural elongate orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. The process includes placing a workpiece in the process region, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid, and furnishing the selected species into the ion generation region in gaseous, molecular or atomic form and evacuating the process region at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region of about a factor of at least four. The process further includes applying plasma source power to generate a plasma of the selected species in the ion generation region, and applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region. The process also includes applying a sufficient bias voltage to at least one of: (a) the workpiece, (b) the grid, relative to at least one of: (a) the workpiece, (b) a plasma in the ion generation region, (c) a surface of the chamber, to accelerate the flux of ions to a kinetic energy distribution generally corresponding to the desired ion implantation depth profile in the workpiece.

Owner:APPLIED MATERIALS INC

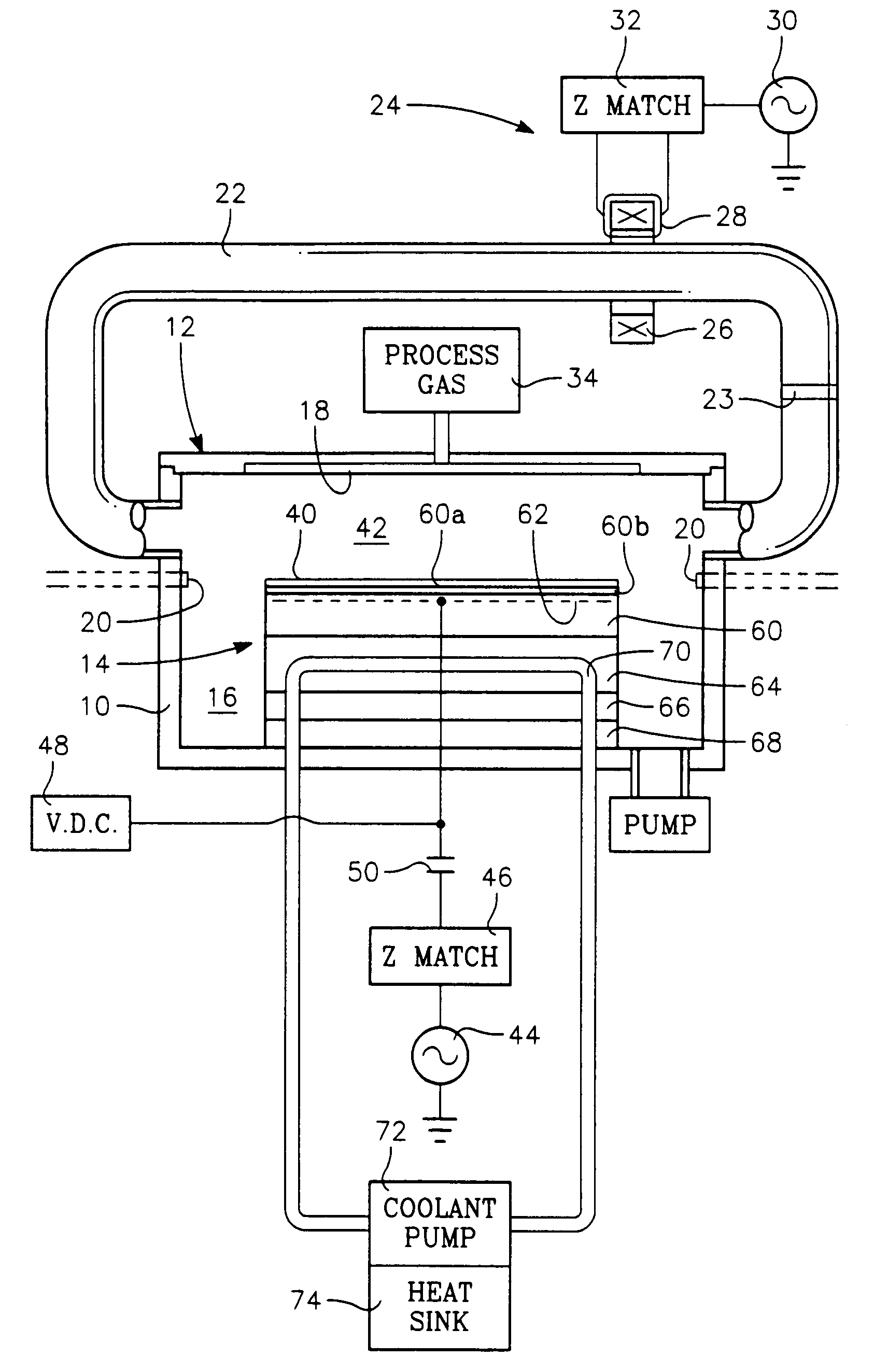

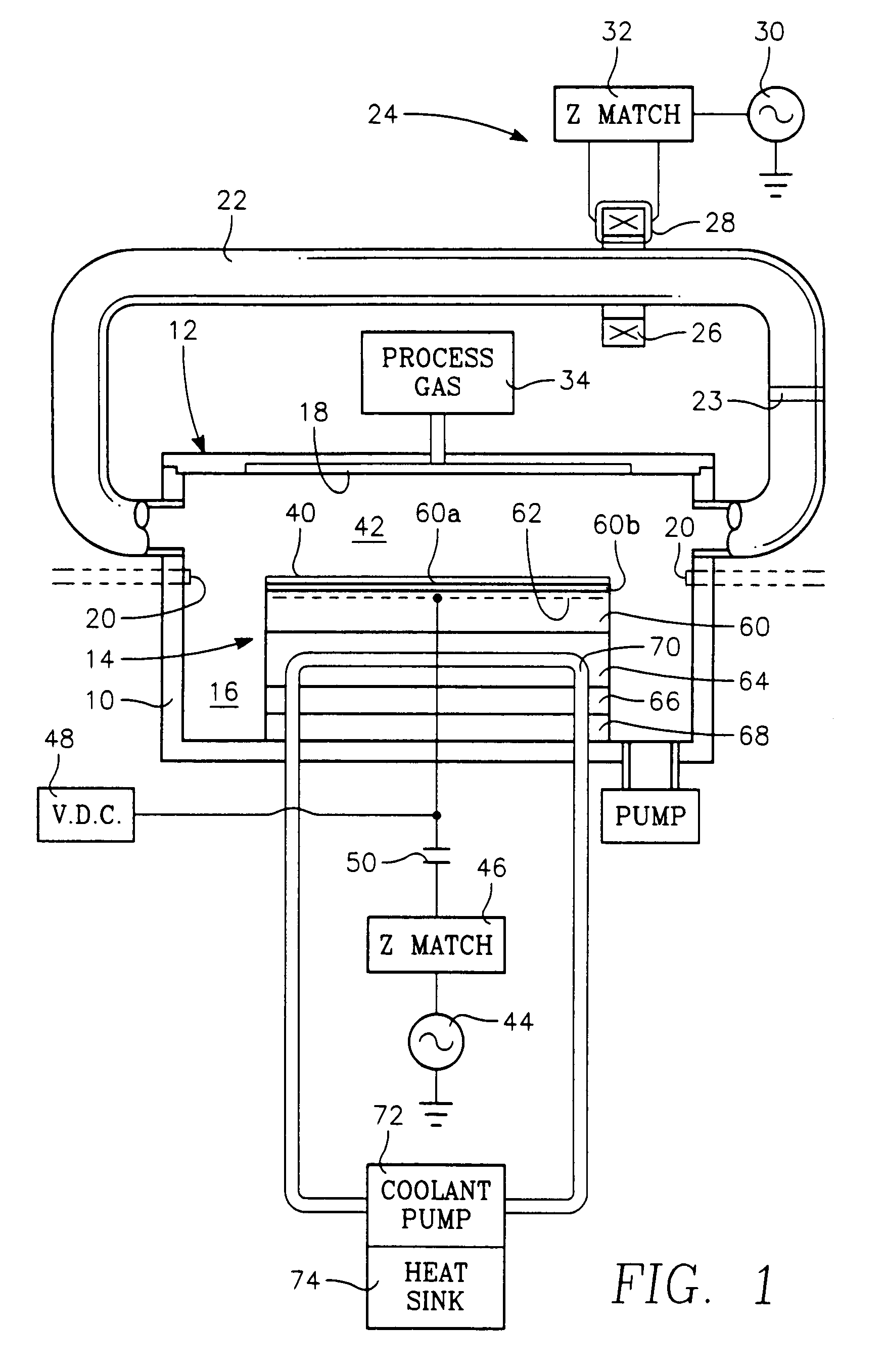

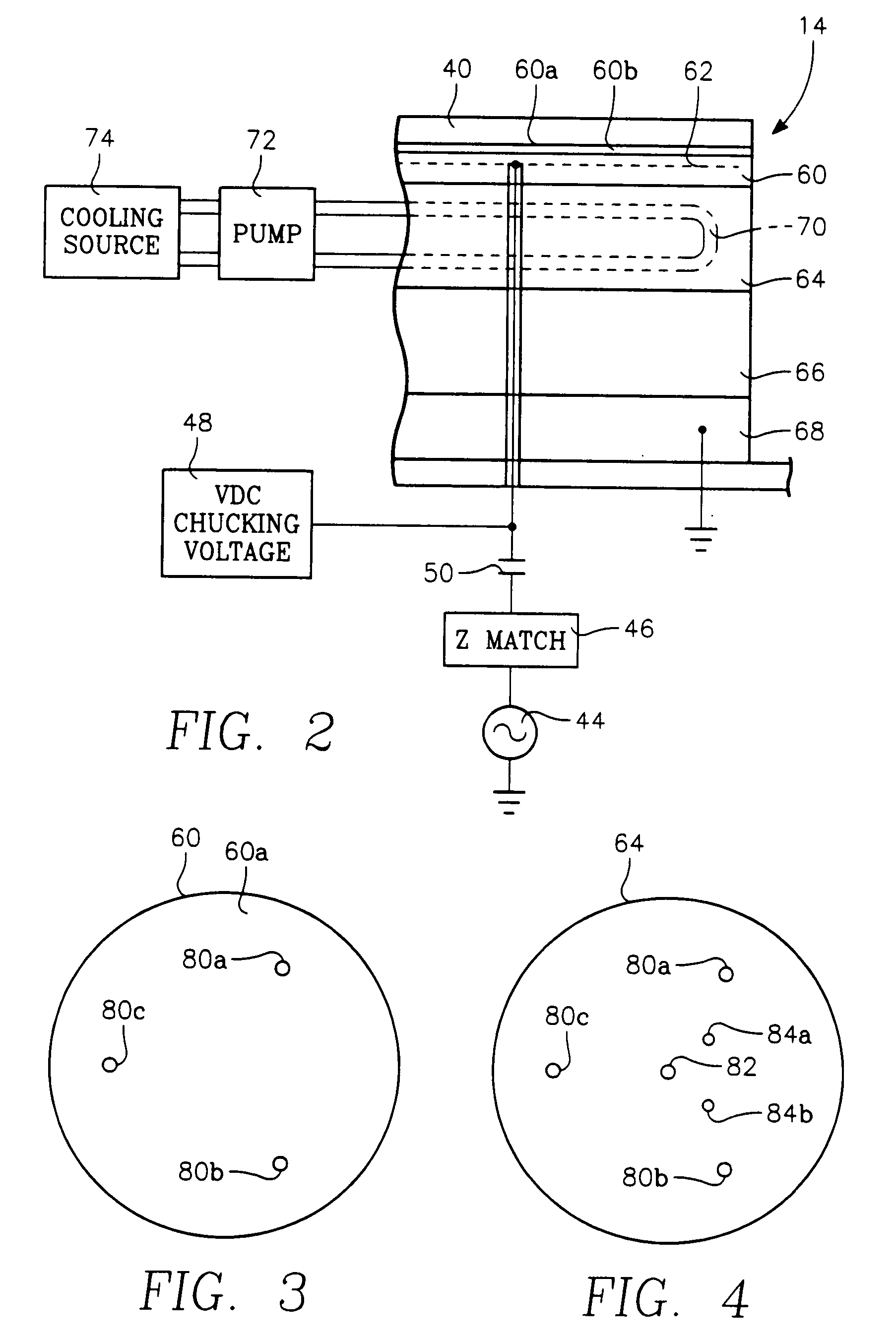

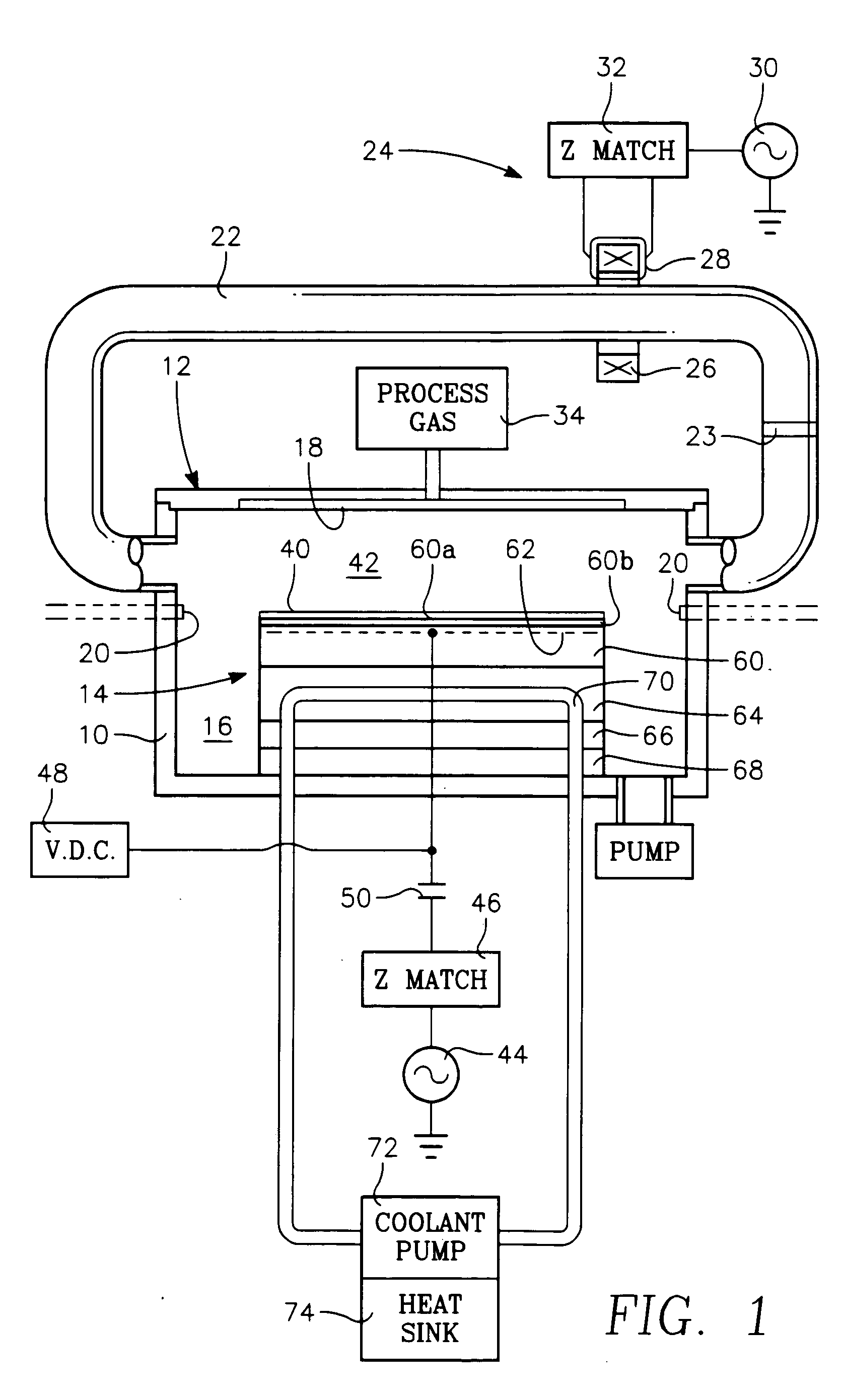

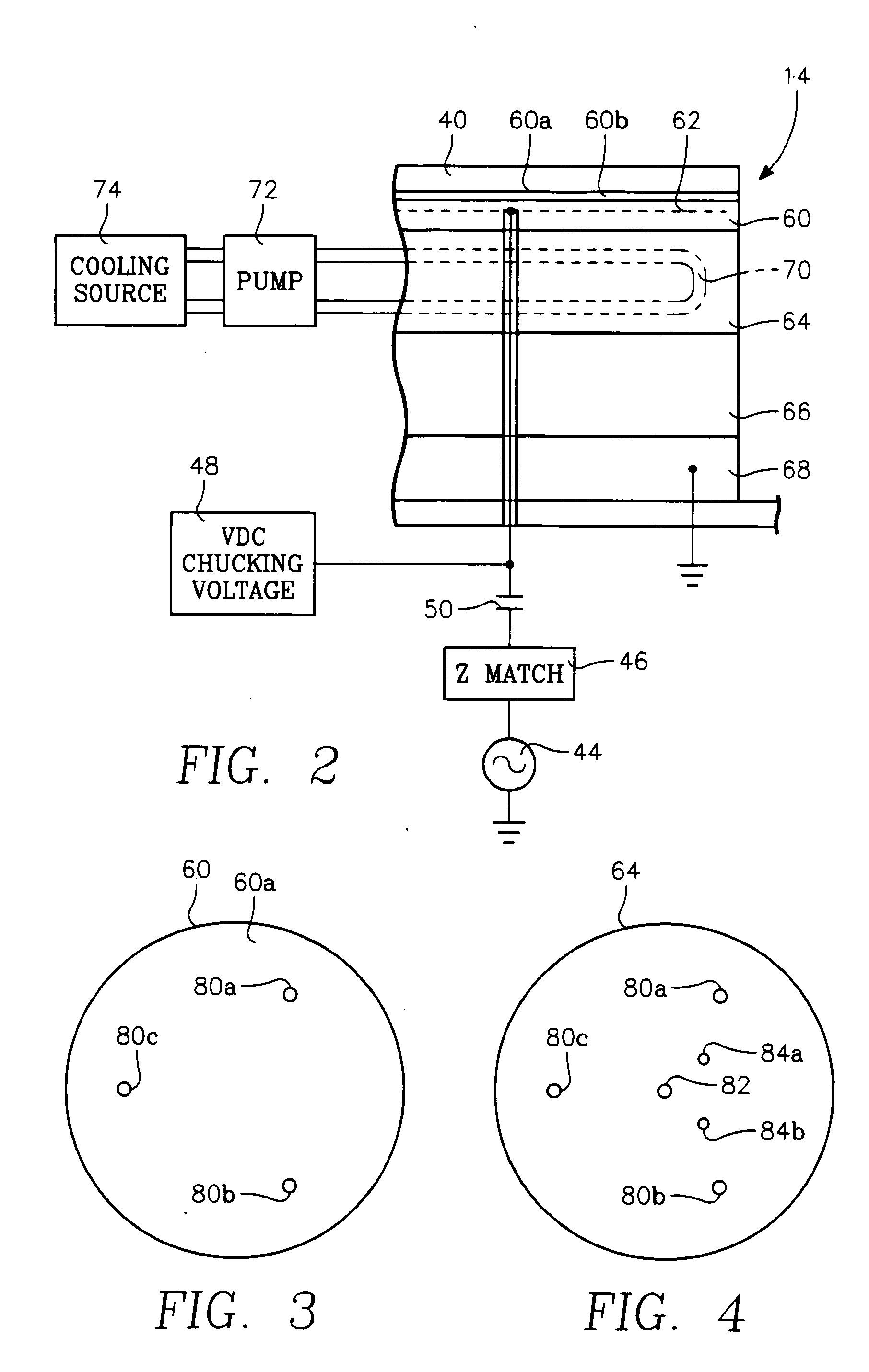

Plasma immersion ion implantation apparatus

InactiveUS20050230047A1Electric discharge tubesDecorative surface effectsSemiconductor materialsEngineering

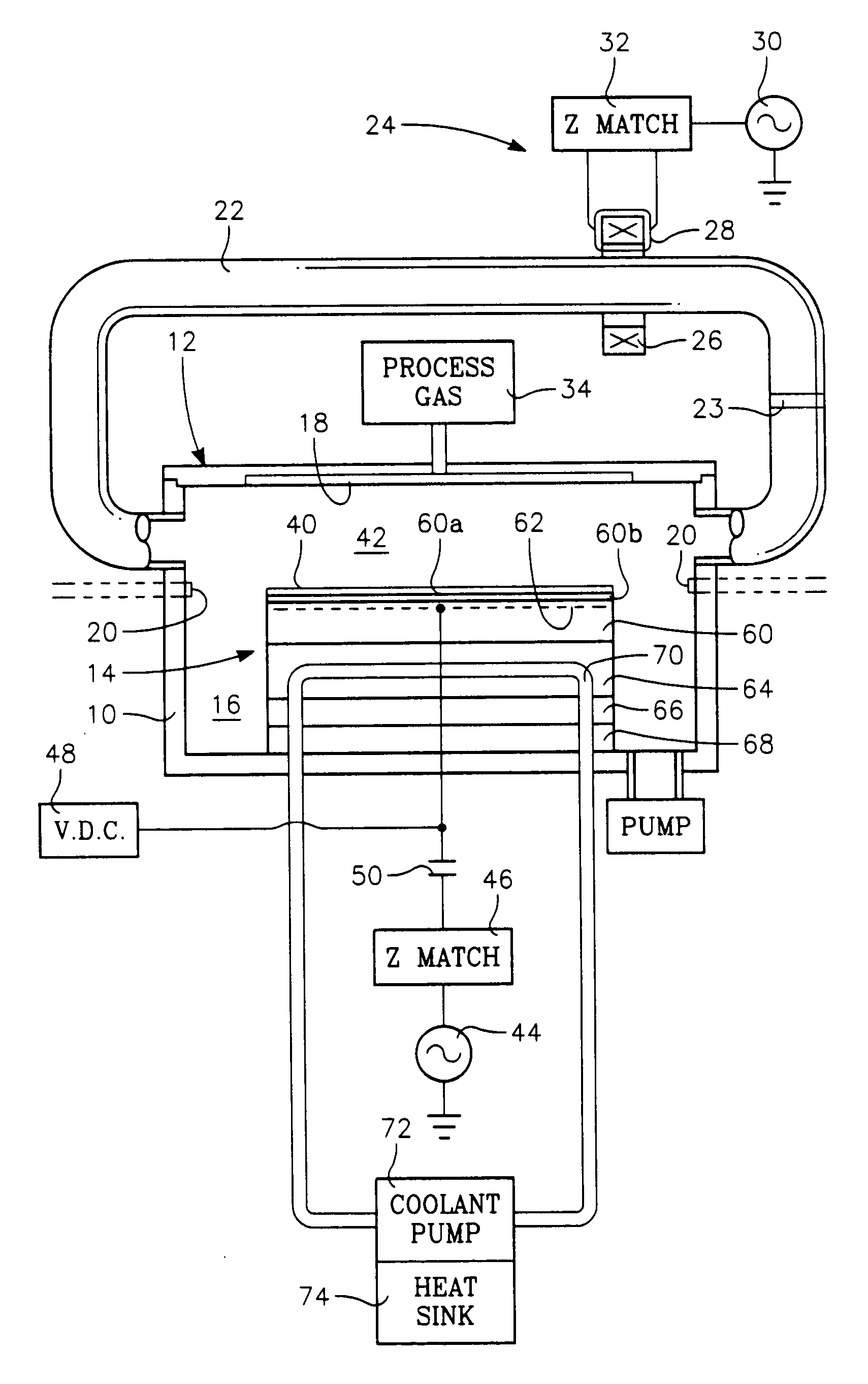

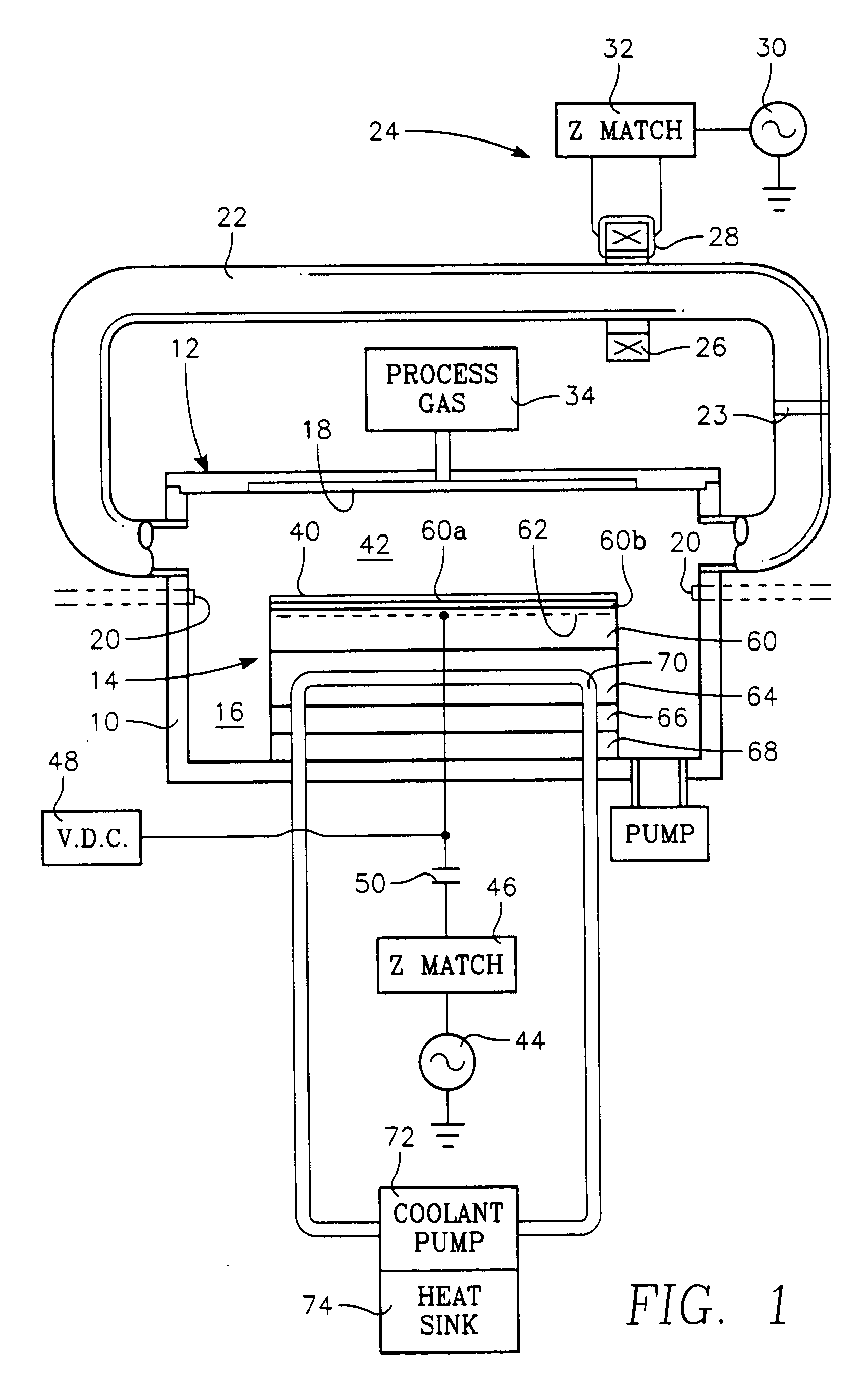

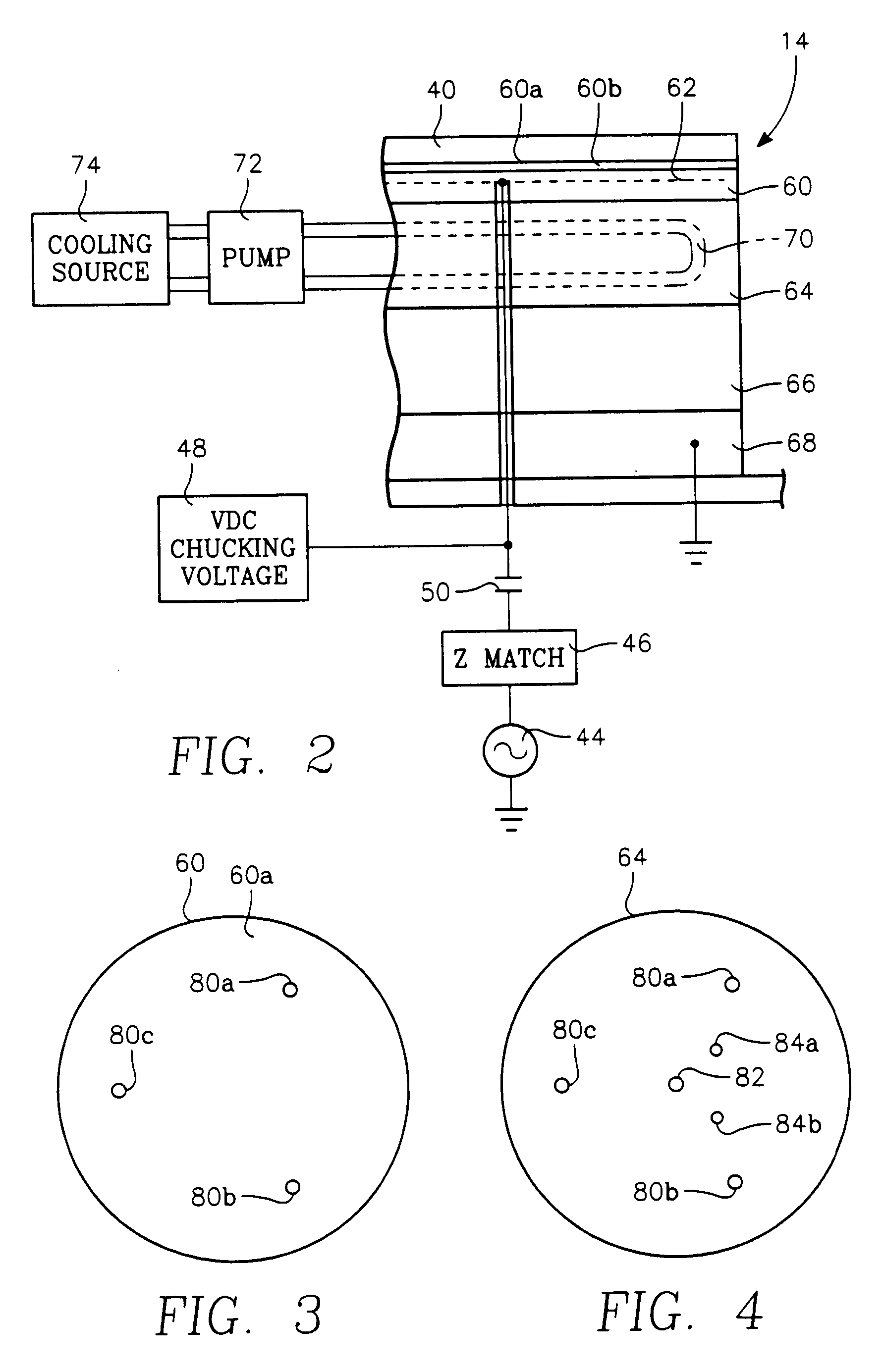

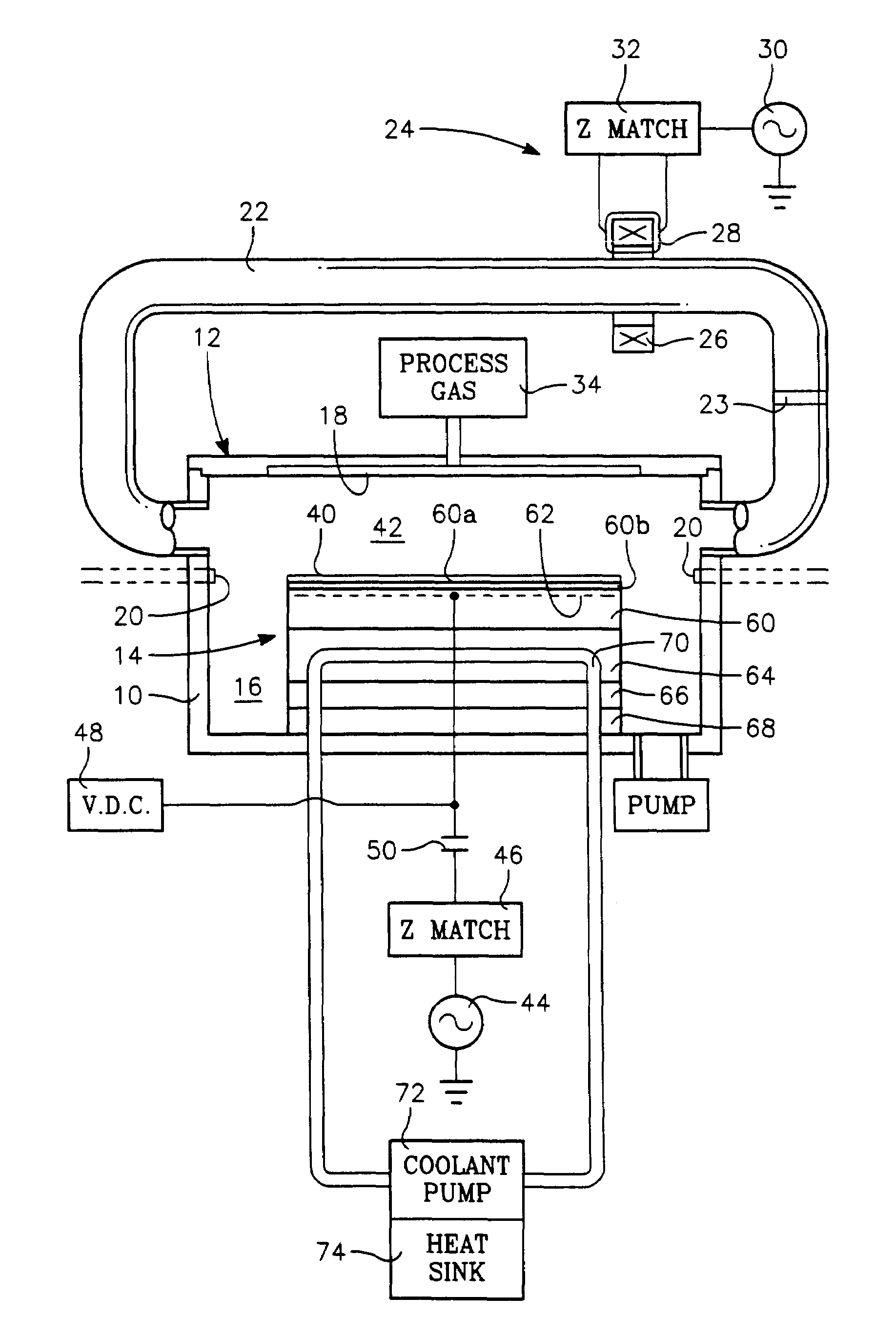

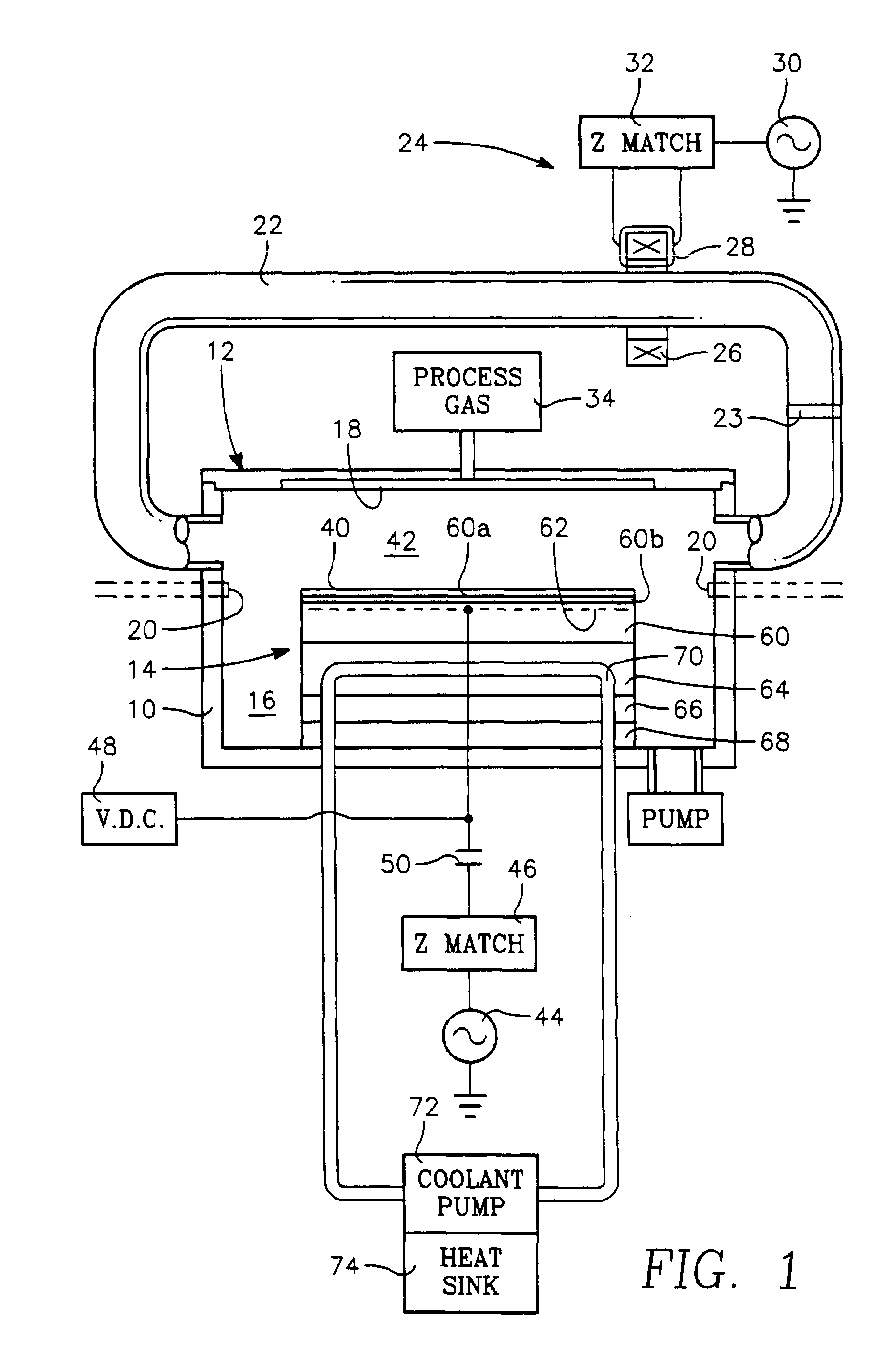

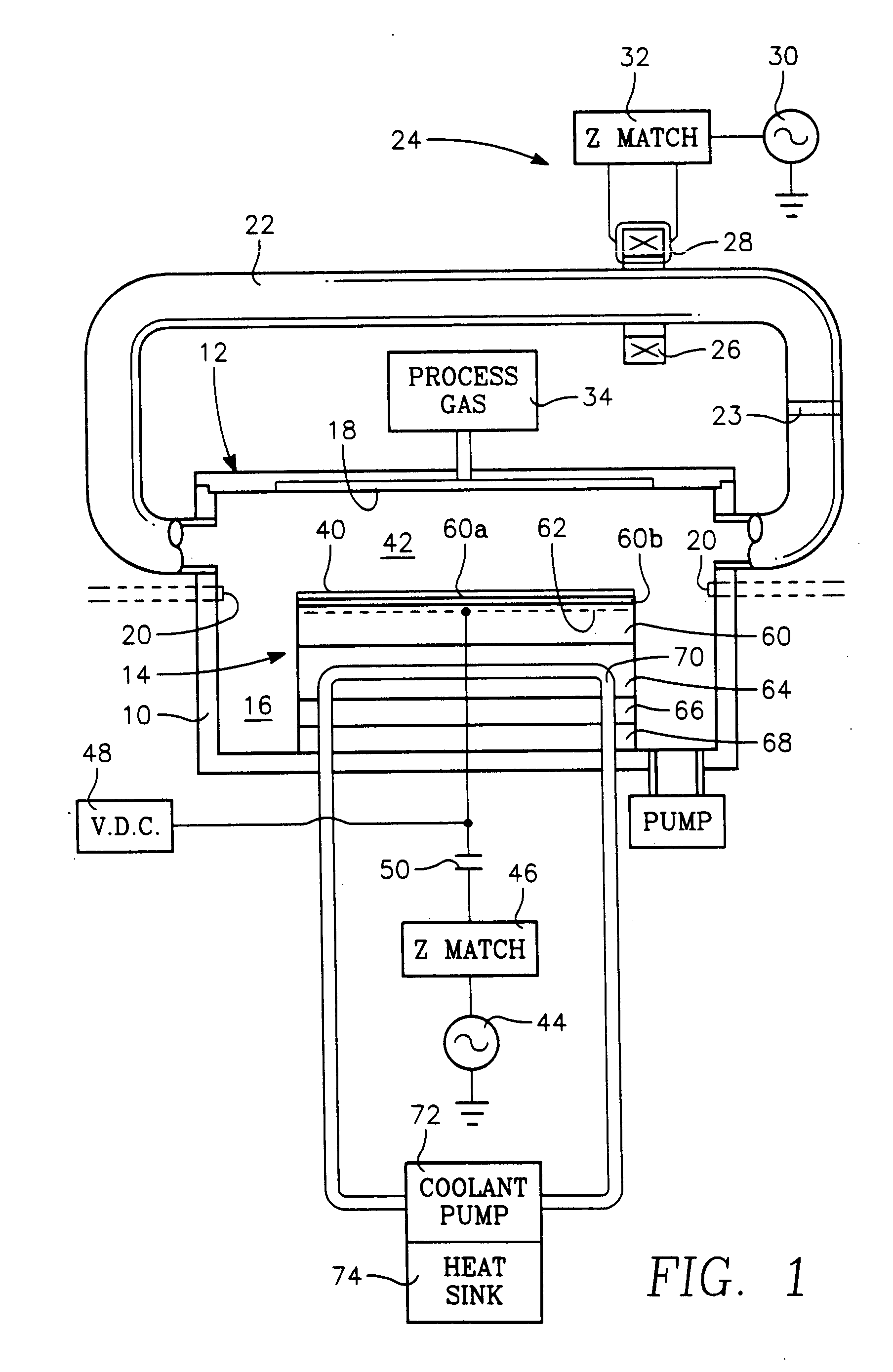

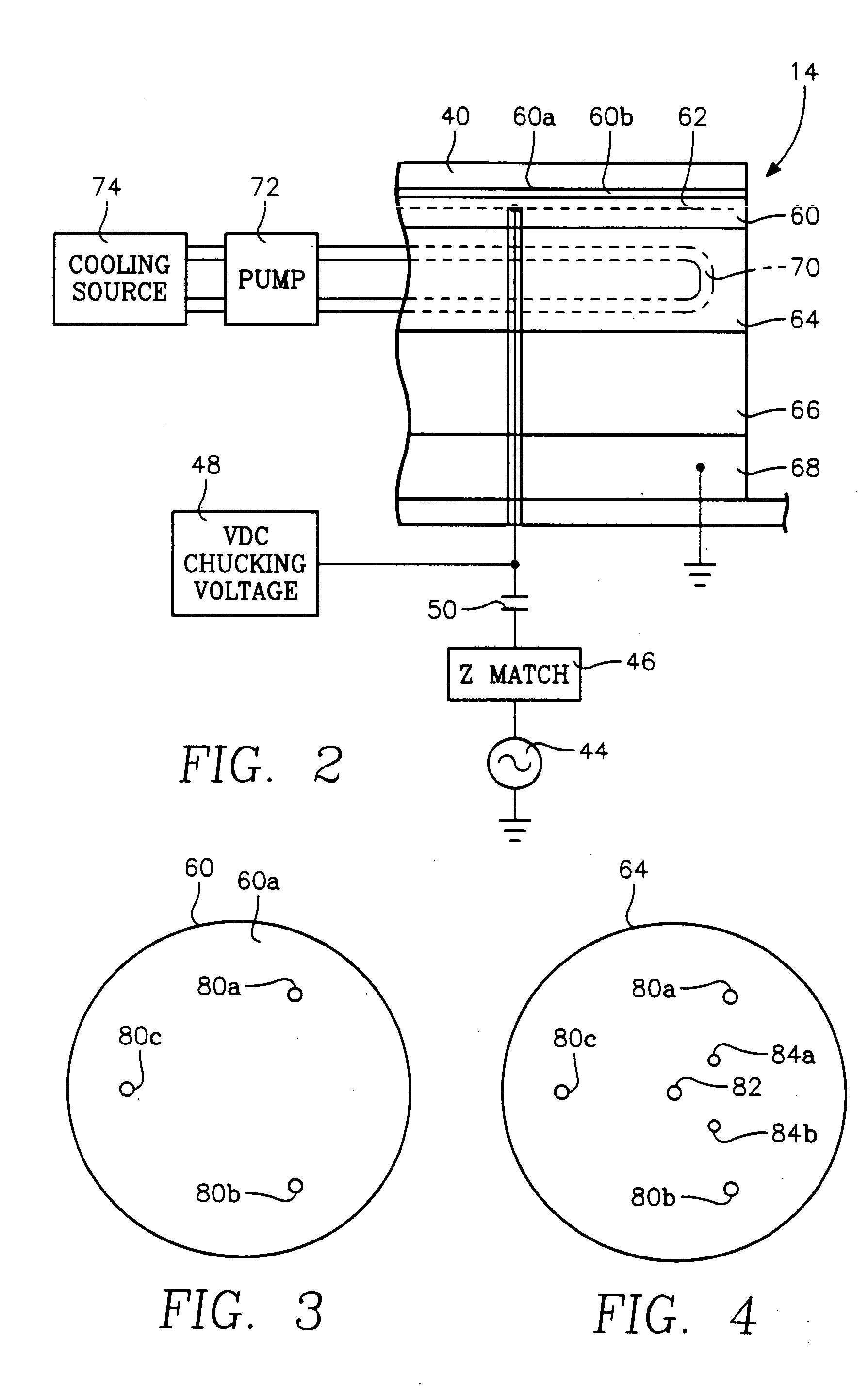

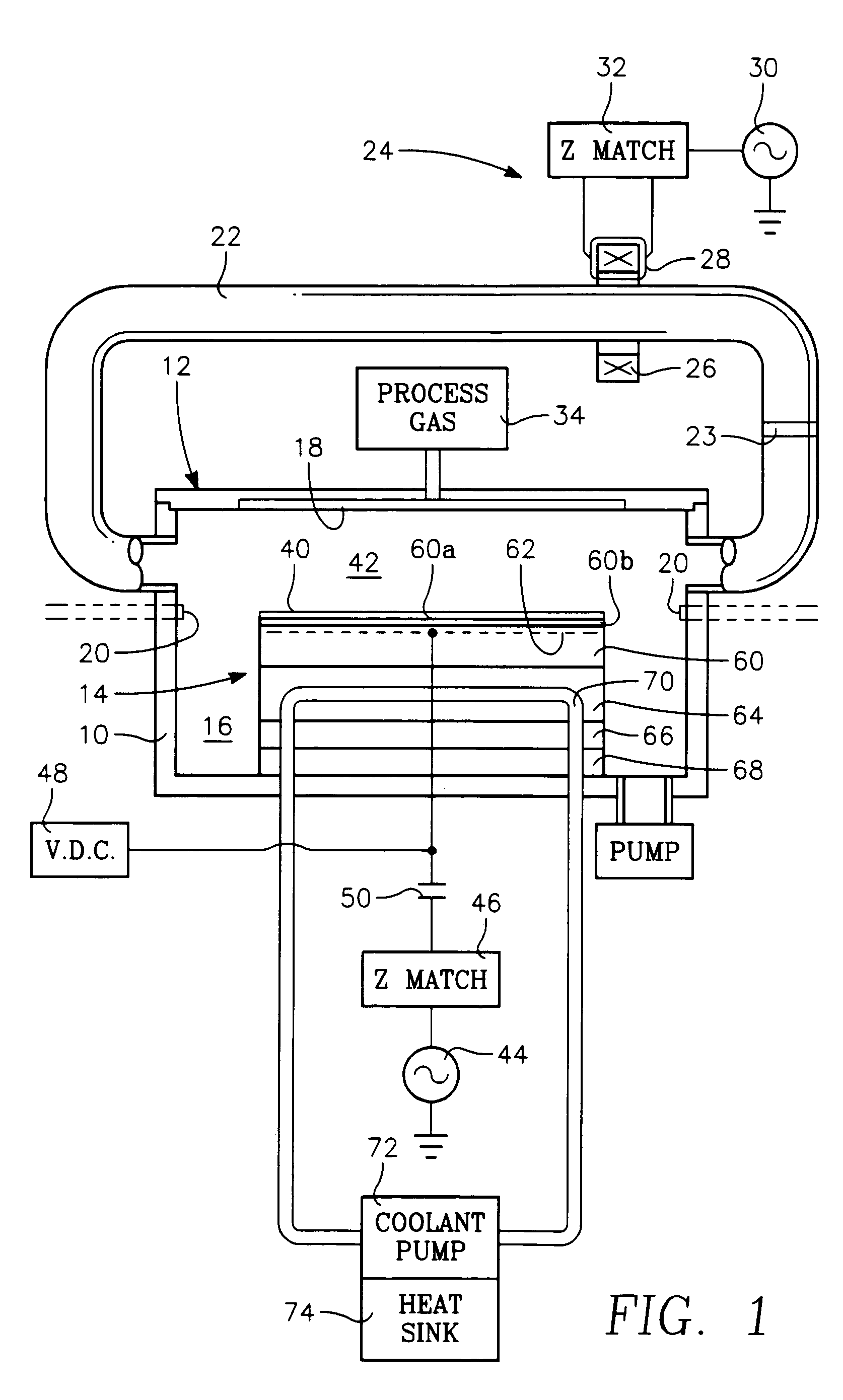

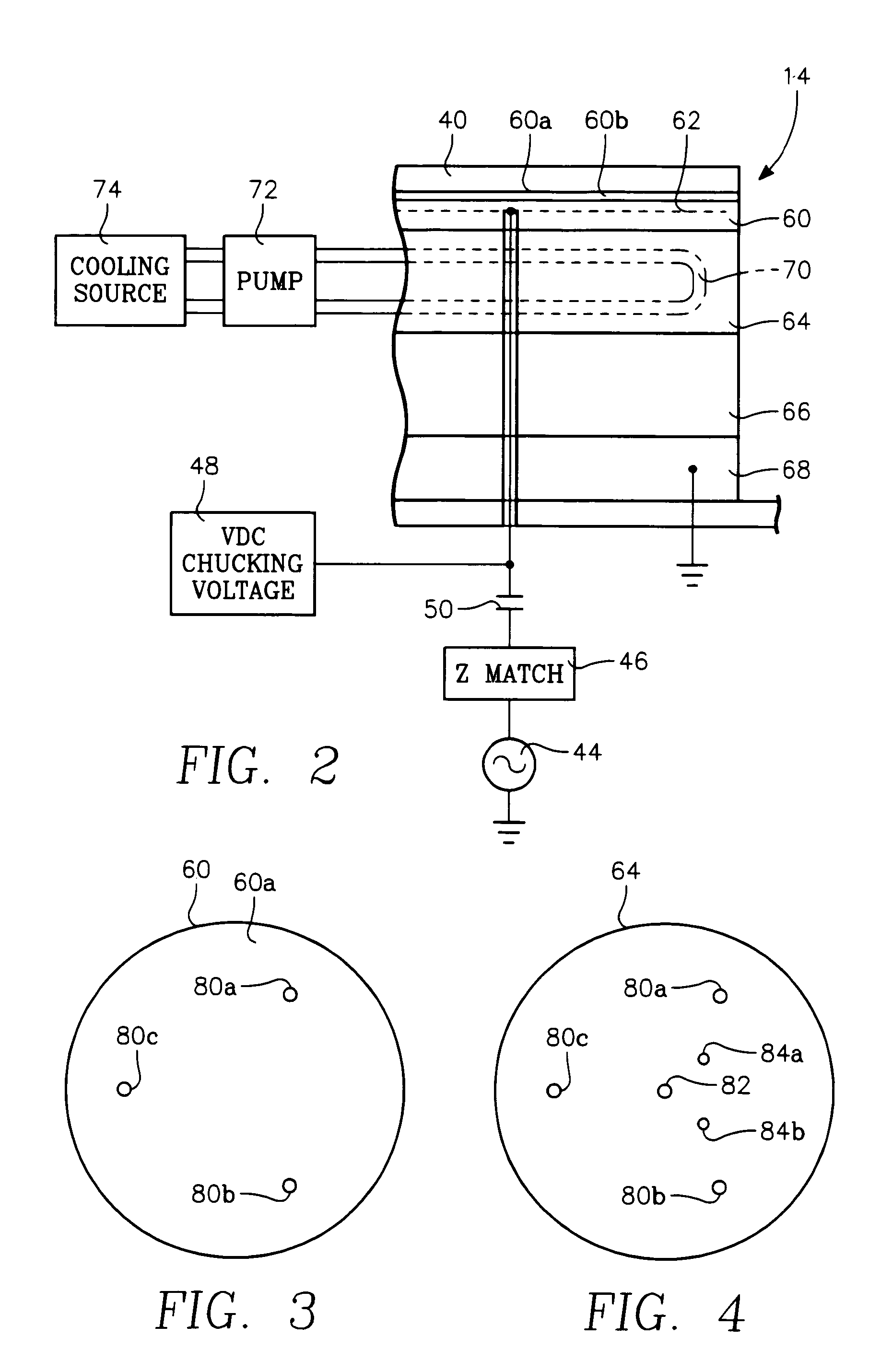

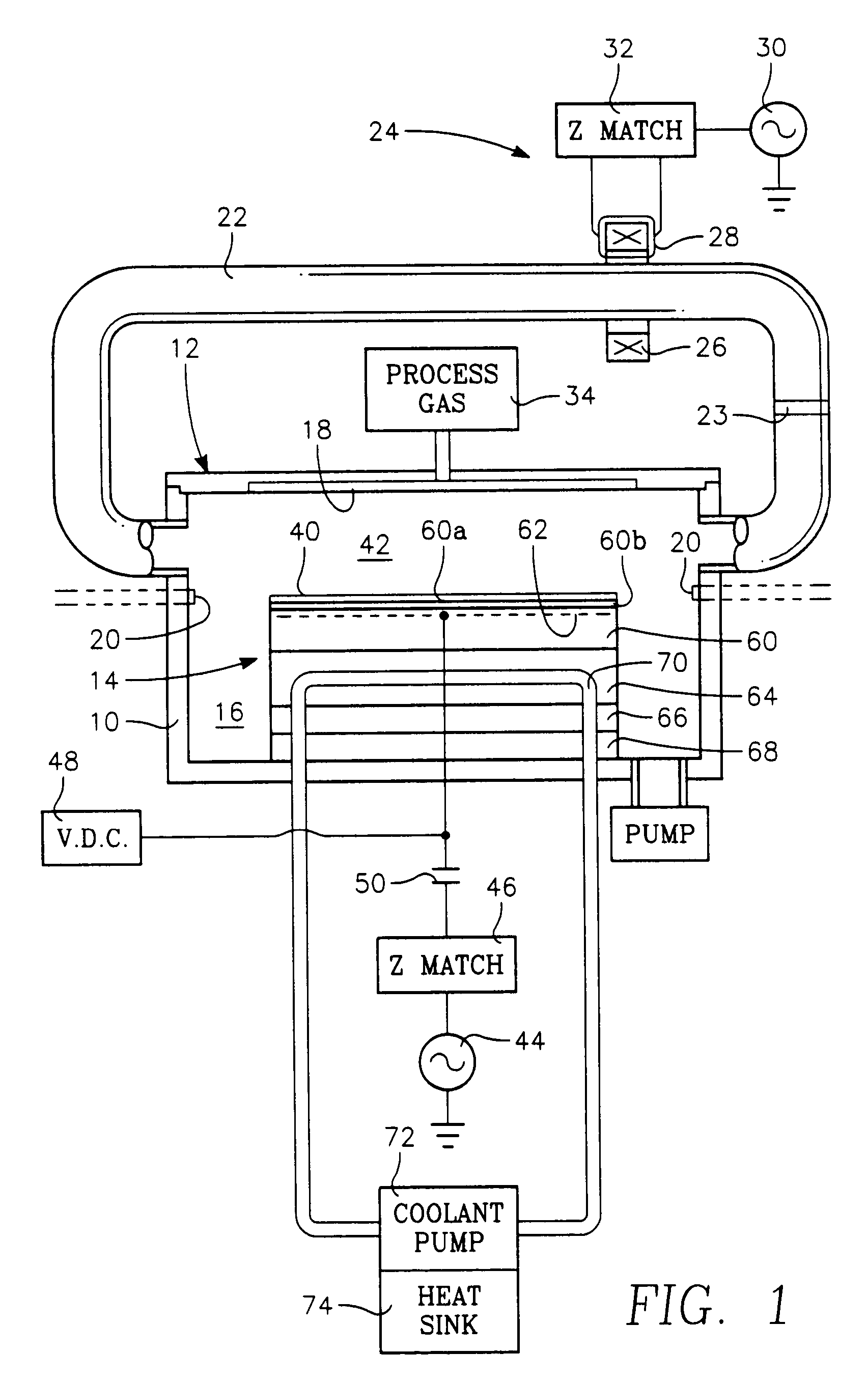

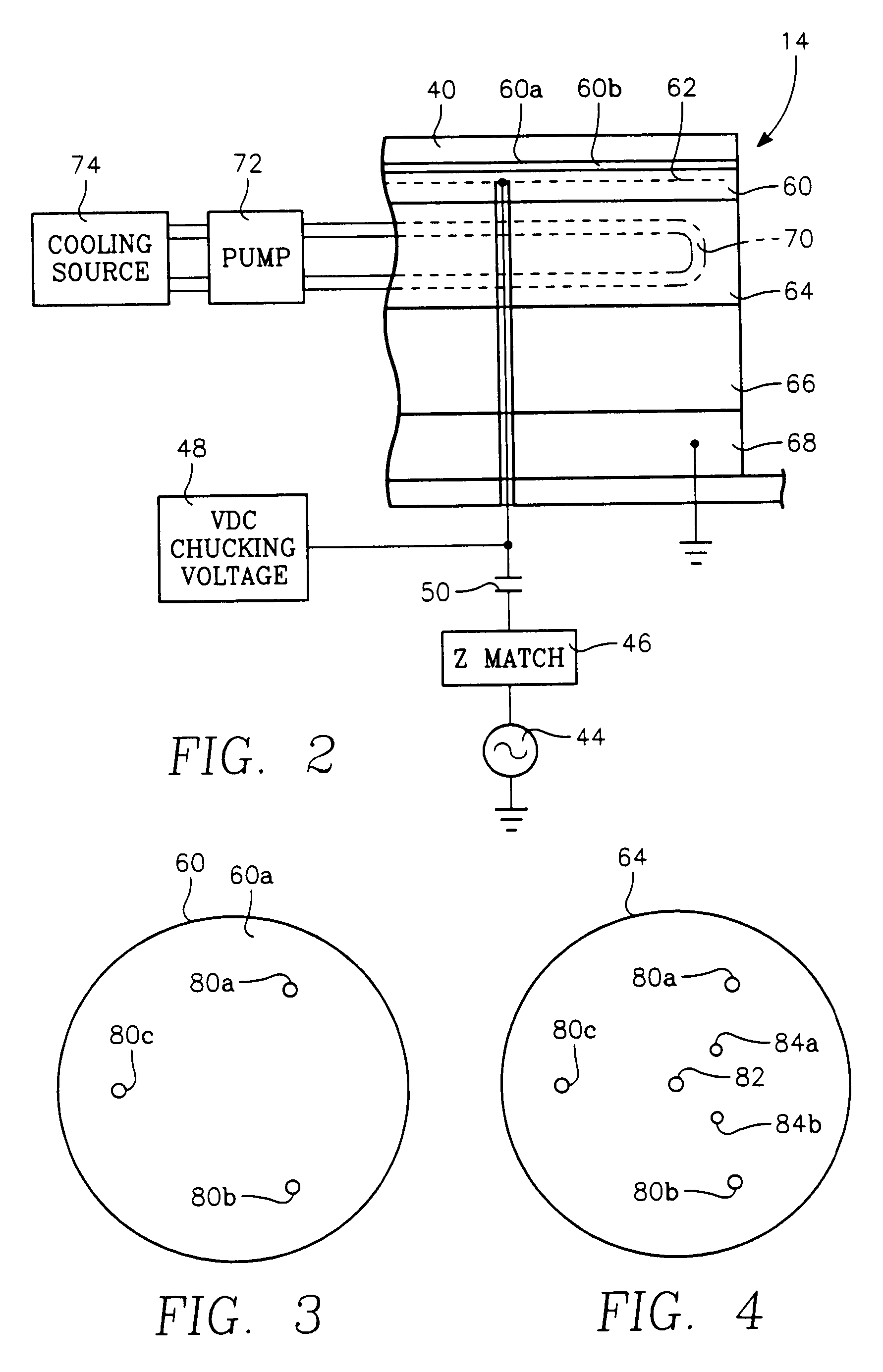

A plasma reactor for performing plasma immersion ion implantation, dopant deposition or surface material enhancement, includes a vacuum chamber, a wafer support pedestal or electrostatic chuck having an insulated electrode underlying a wafer support surface within said chamber, a chucking voltage source coupled to the insulated electrode, a thermal sink coupled to the electrostatic chuck, an RF bias power generator coupled to said electrostatic chuck, and a process gas supply and gas inlet ports coupled to the chamber and coupled to the gas supply. The process gas supply contains either (a) a gas containing a dopant species to be ion implanted in a semiconductive material of workpiece, (b) a gas containing a dopant species to be deposited on a surface of a semiconductive material of a workpiece, or (c) a gas containing a material enhancement species to be ion implanted into a workpiece.

Owner:APPLIED MATERIALS INC

Fabrication of silicon-on-insulator structure using plasma immersion ion implantation

InactiveUS6893907B2Reduce oxygen concentrationElectric discharge tubesSemiconductor/solid-state device manufacturingSurface layerPlasma-immersion ion implantation

A method of fabricating a silicon-on-insulator structure having a silicon surface layer in a semiconductor workpiece, is carried out by maintaining the workpiece at an elevated temperature and producing an oxygen-containing plasma in the chamber while applying a bias to the workpiece and setting the bias to a level corresponding to an implant depth in the workpiece below the silicon surface layer to which oxygen atoms are to be implanted, whereby to form an oxygen-implanted layer in the workpiece having an oxygen concentration distribution generally centered at the implant depth and having a finite oxygen concentration in the silicon surface layer. The oxygen concentration in the silicon surface layer is then reduced to permit epitaxial silicon deposition.

Owner:APPLIED MATERIALS INC

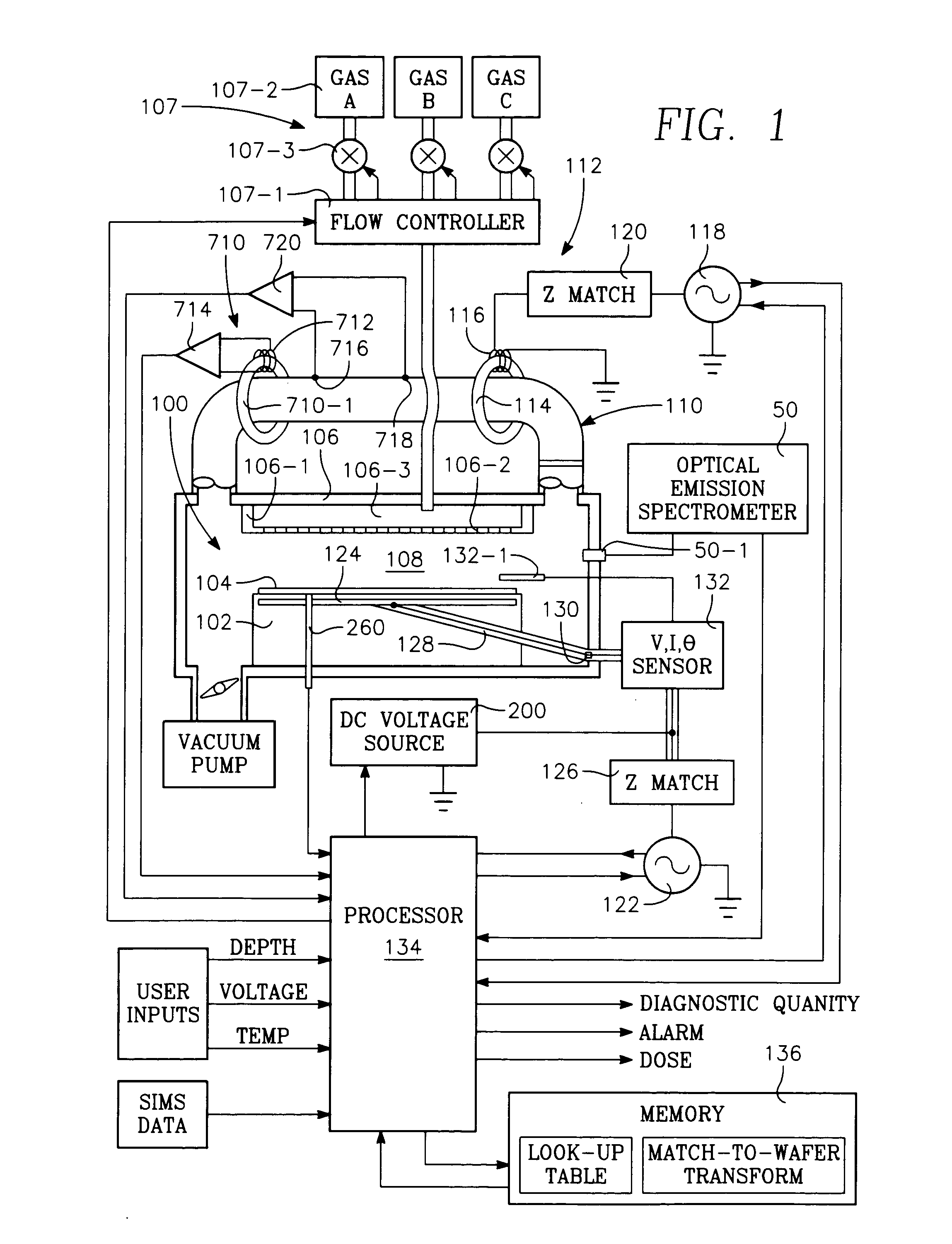

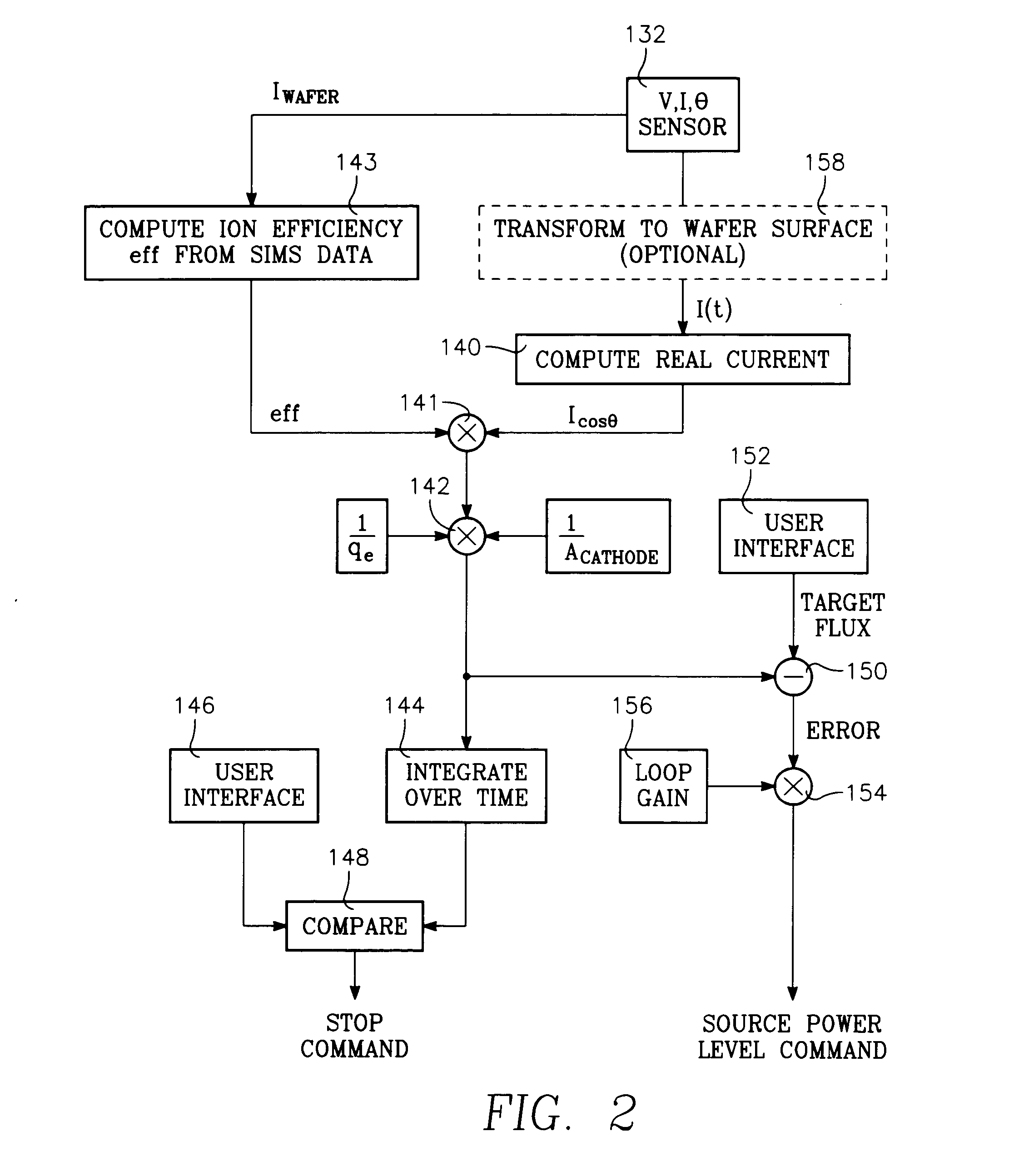

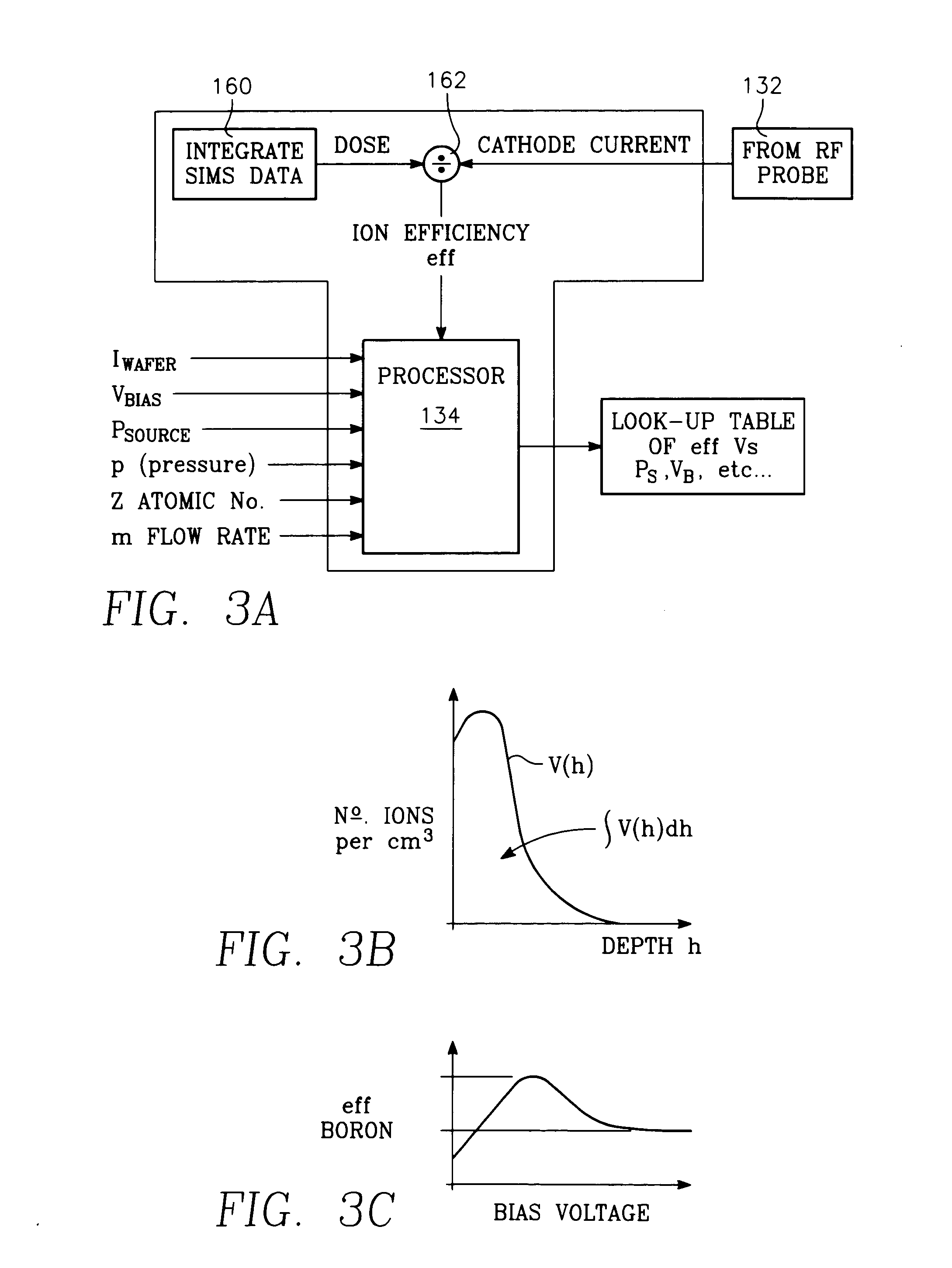

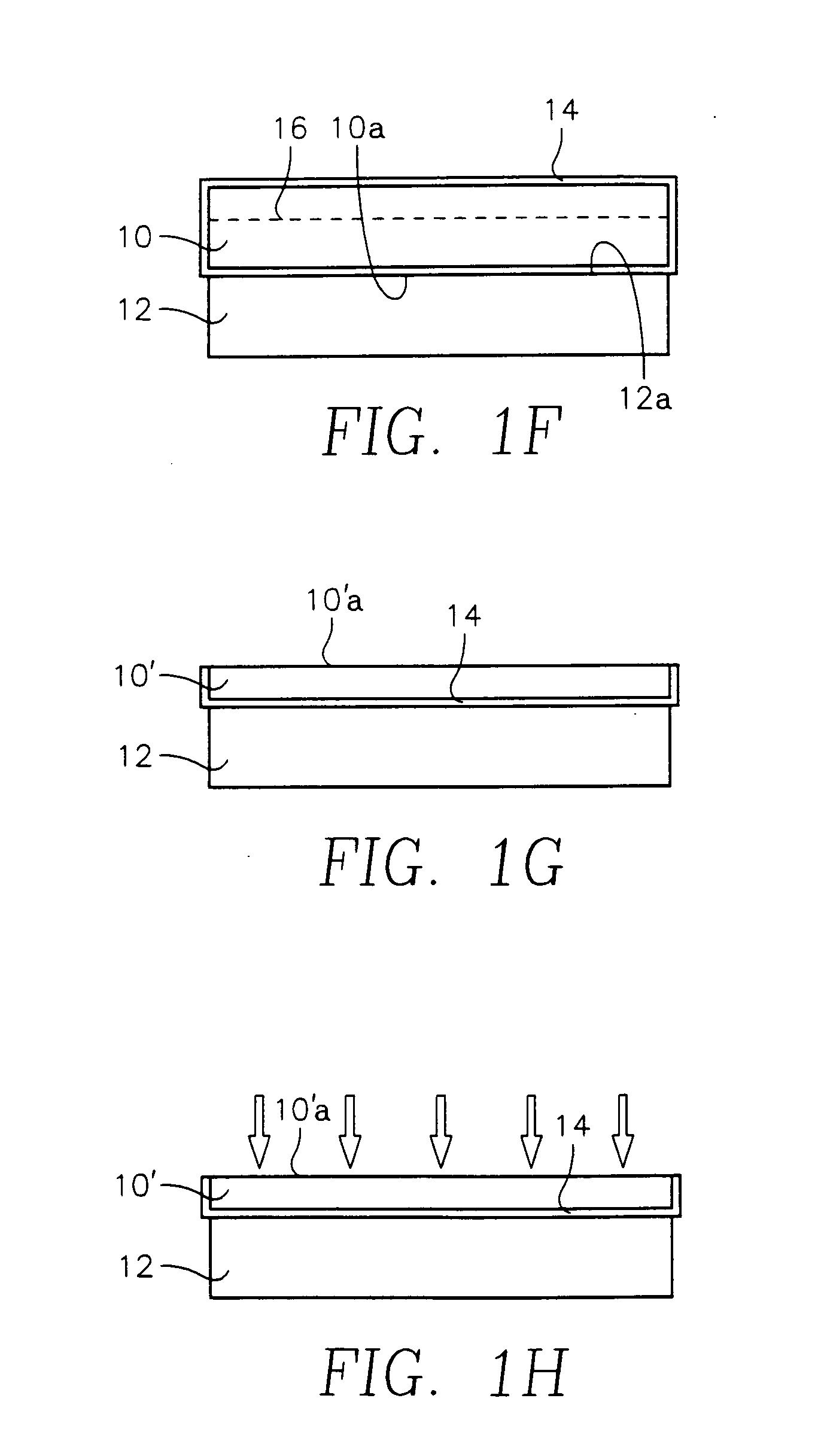

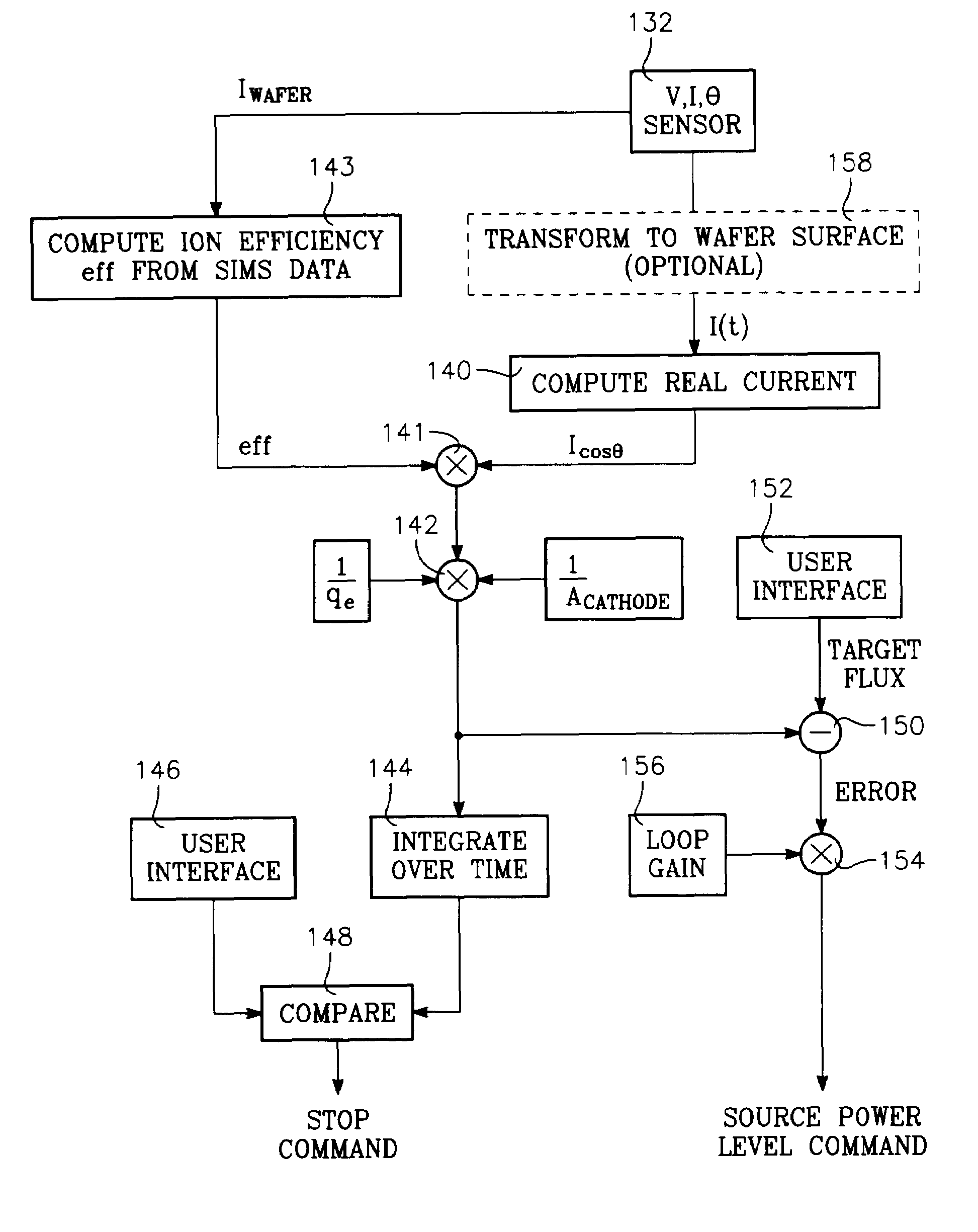

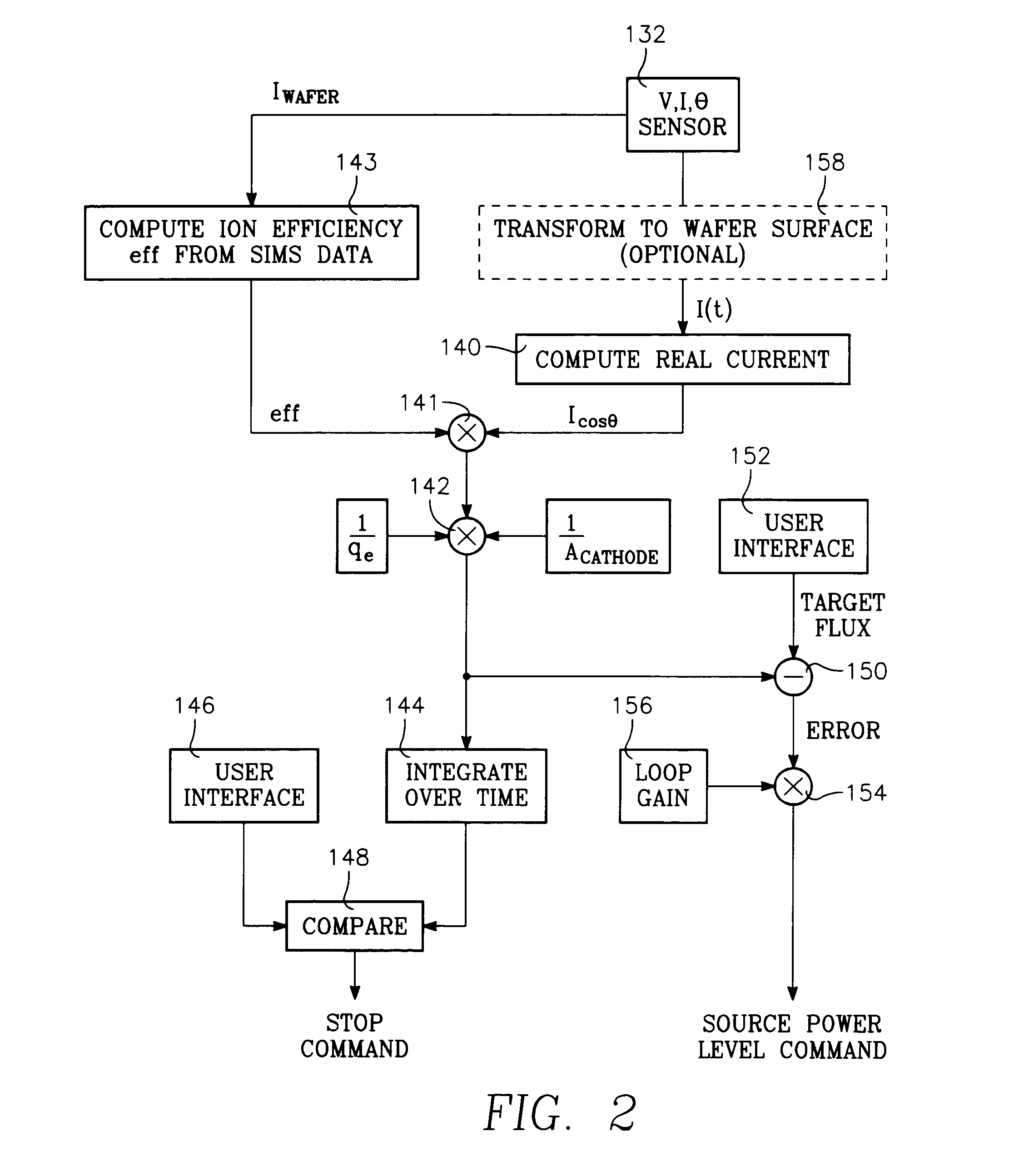

RF measurement feedback control and diagnostics for a plasma immersion ion implantation reactor

InactiveUS20060088655A1Improve accuracySemiconductor/solid-state device testing/measurementElectric discharge tubesCouplingPlasma-immersion ion implantation

A method of measuring ion dose in a plasma immersion ion implantation reactor during ion implantation of a selected species into a workpiece includes placing the workpiece on a pedestal in the reactor and feeding into the reactor a process gas comprising a species to be implanted into the workpiece, and then coupling RF plasma source power to a plasma in the reactor. It further includes coupling RF bias power to the workpiece by an RF bias power generator that is coupled to the workpiece through a bias feedpoint of the reactor and measuring RF current at the feedpoint to generate a current-related value, and then integrating the current-related over time to produce an ion implantation dose-related value.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation reactor having multiple ion shower grids

ActiveUS20060019039A1High ion fluxElectric discharge tubesVacuum evaporation coatingProcess regionPlasma-immersion ion implantation

A plasma immersion ion implantation process for implanting a selected species at a desired ion implantation depth profile in a workpiece is carried out in a reactor chamber having a set of plural parallel ion shower grids that divide the chamber into an upper ion generation region and a lower process region, each of the ion shower grids having plural orifices in mutual registration from grid to grid, the plural orifices oriented in a non-parallel direction relative to a surface plane of the respective ion shower grid. The process includes placing a workpiece in the process region, the workpiece having a workpiece surface generally facing the surface plane of the closest one of the plural ion shower grids, and furnishing the selected species into the ion generation region. The process further includes evacuating the process region, and applying plasma source power to generate a plasma of the selected species in the ion generation region. The process also includes applying successive grid potentials to successive ones of the grids and applying a bias potential to the workpiece. The combination of the grid and bias potentials corresponds to the desired ion implantation depth profile in the workpiece.

Owner:APPLIED MATERIALS INC

Novel method for conformal plasma immersed ion implantation assisted by atomic layer deposition

InactiveUS20090203197A1Maximize penetrationVacuum evaporation coatingSputtering coatingDopantSource material

Embodiments of the invention provide a novel apparatus and methods for forming a conformal doped layer on the surface of a substrate. A substrate is provided to a process chamber, and a layer of dopant source material is deposited by plasma deposition, atomic layer deposition, or plasma-assisted atomic layer deposition. The substrate is then subjected to thermal processing to activate and diffuse dopants into the substrate surface.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process

InactiveUS7094670B2Electric discharge tubesDecorative surface effectsPlasma-immersion ion implantationThreshold temperature

A method of performing plasma immersion ion implantation on a workpiece in a plasma reactor chamber, includes placing the workpiece on a workpiece support in the chamber, controlling a temperature of the wafer support near a constant level, performing plasma immersion ion implantation on the workpiece by introducing an implant species precursor gas into the chamber and generating a plasma while minimizing deposition and minimizing etching by holding the temperature of the workpiece within a temperature range that is above a workpiece deposition threshold temperature and below a workpiece etch threshold temperature.

Owner:APPLIED MATERIALS INC

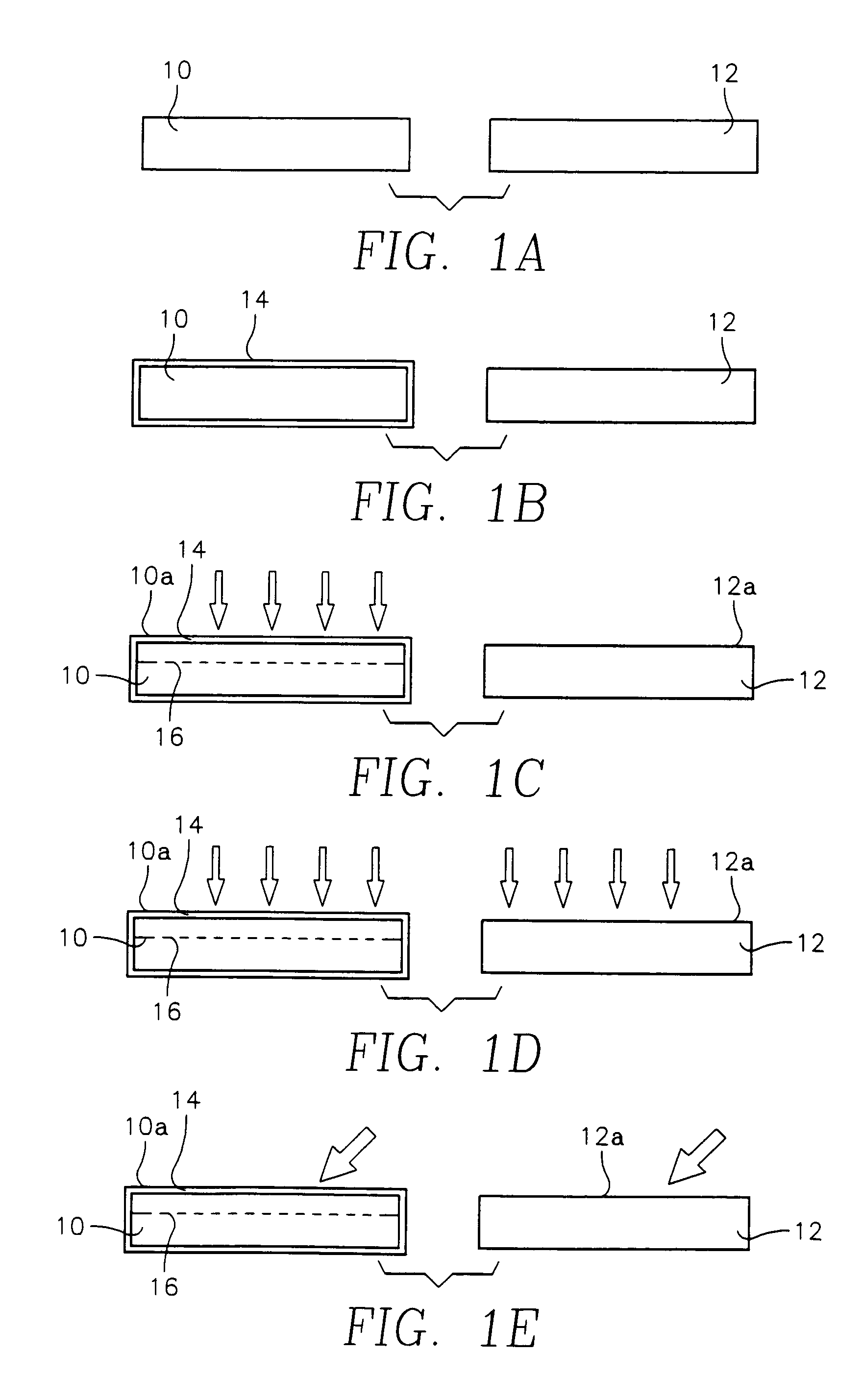

Silicon-on-insulator wafer transfer method using surface activation plasma immersion ion implantation for wafer-to-wafer adhesion enhancement

InactiveUS7183177B2TransistorElectric discharge tubesSemiconductor structurePlasma-immersion ion implantation

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process using a capacitively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS7037813B2Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSurface layer

A method for implanting ions in a surface layer of a workpiece includes placing the workpiece on a workpiece support in a chamber with the surface layer being in facing relationship with a ceiling of the chamber, thereby defining a processing zone between the workpiece and the ceiling, and introducing into the chamber a process gas including the species to be implanted in the surface layer of the workpiece. The method includes generating from the process gas a plasma by capacitively coupling RF source power across the workpiece support and the ceiling or the sidewall from an RF source power generator. The method further includes applying an RF bias from an RF bias generator to the workpiece support.

Owner:APPLIED MATERIALS INC

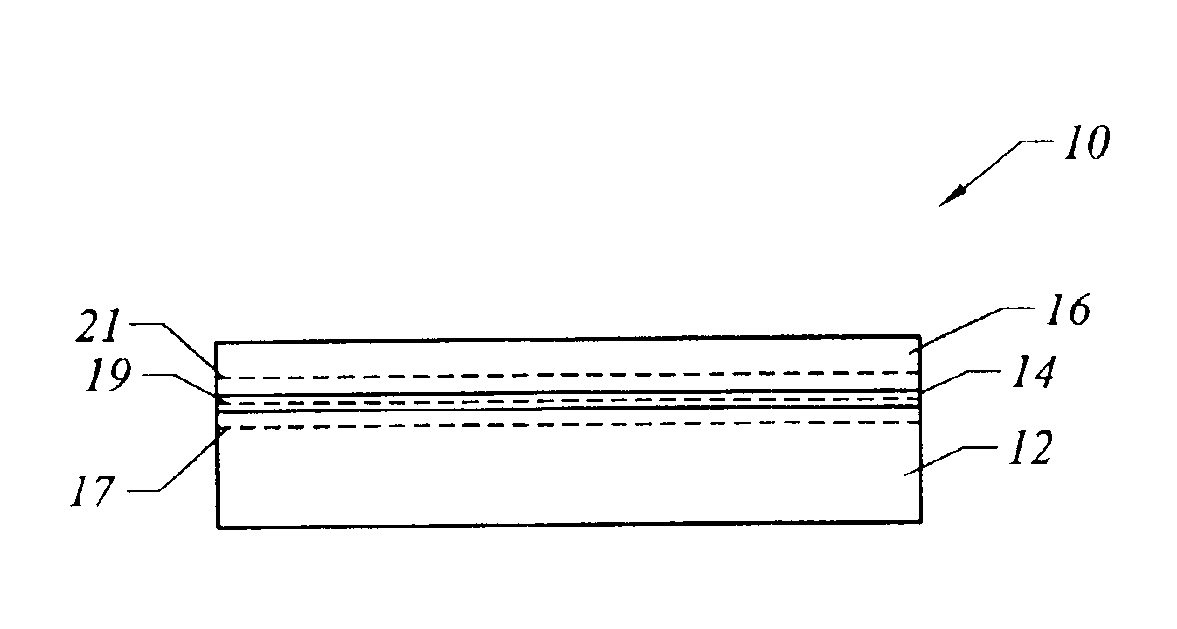

Gettering technique for wafers made using a controlled cleaving process

InactiveUS6890838B2Lower breakdown voltageImprove leakage currentSemiconductor/solid-state device manufacturingIntegrated circuitPlasma-immersion ion implantation

A technique for forming a gettering layer in a wafer made using a controlled cleaving process. The gettering layer can be made by implanting using beam line or plasma immersion ion implantaion, or made by forming a film of material such as polysilicon by way of chemical vapor deposition. A controlled cleaving process is used to form the wafer, which is a multilayered silicon on insulator substrate. The gettering layer removes and / or attracts impurities in the wafer, which can be detrimental to the functionality and reliability of an integrated circuit device made on the wafer.

Owner:SILICON GENERAL CORPORATION

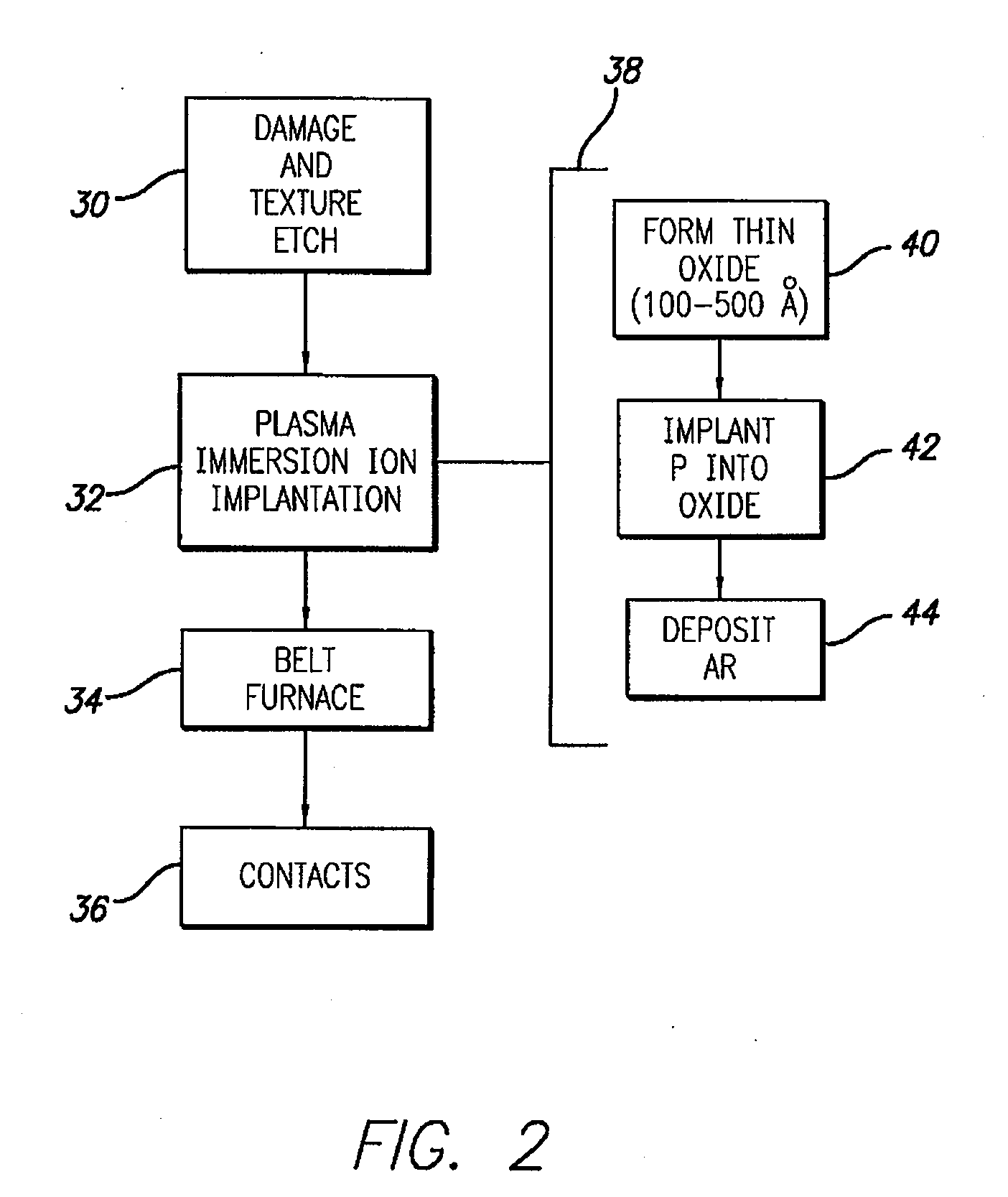

Method of making an improved selective emitter for silicon solar cells

InactiveUS20090142875A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationPlasma-immersion ion implantationSilicon solar cell

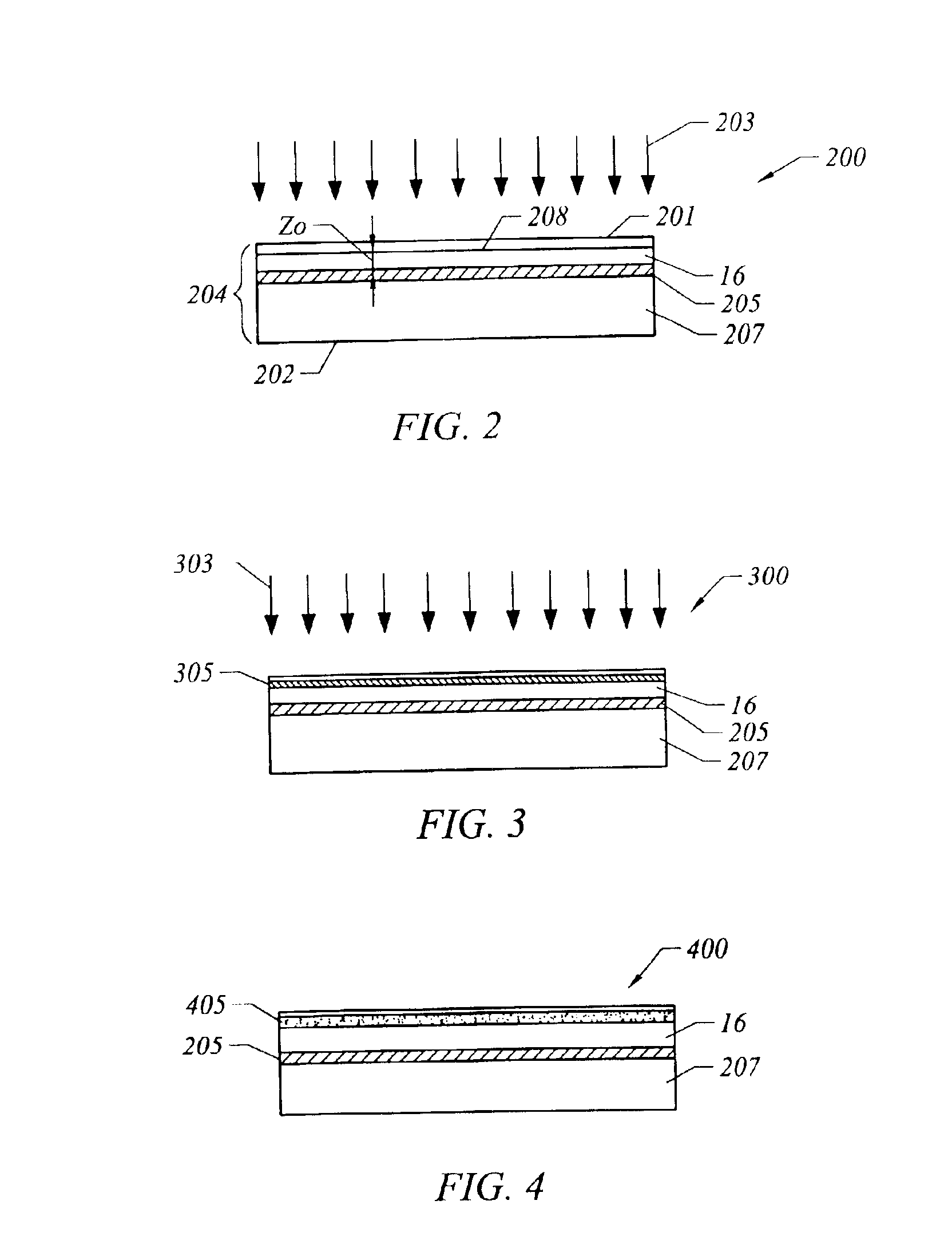

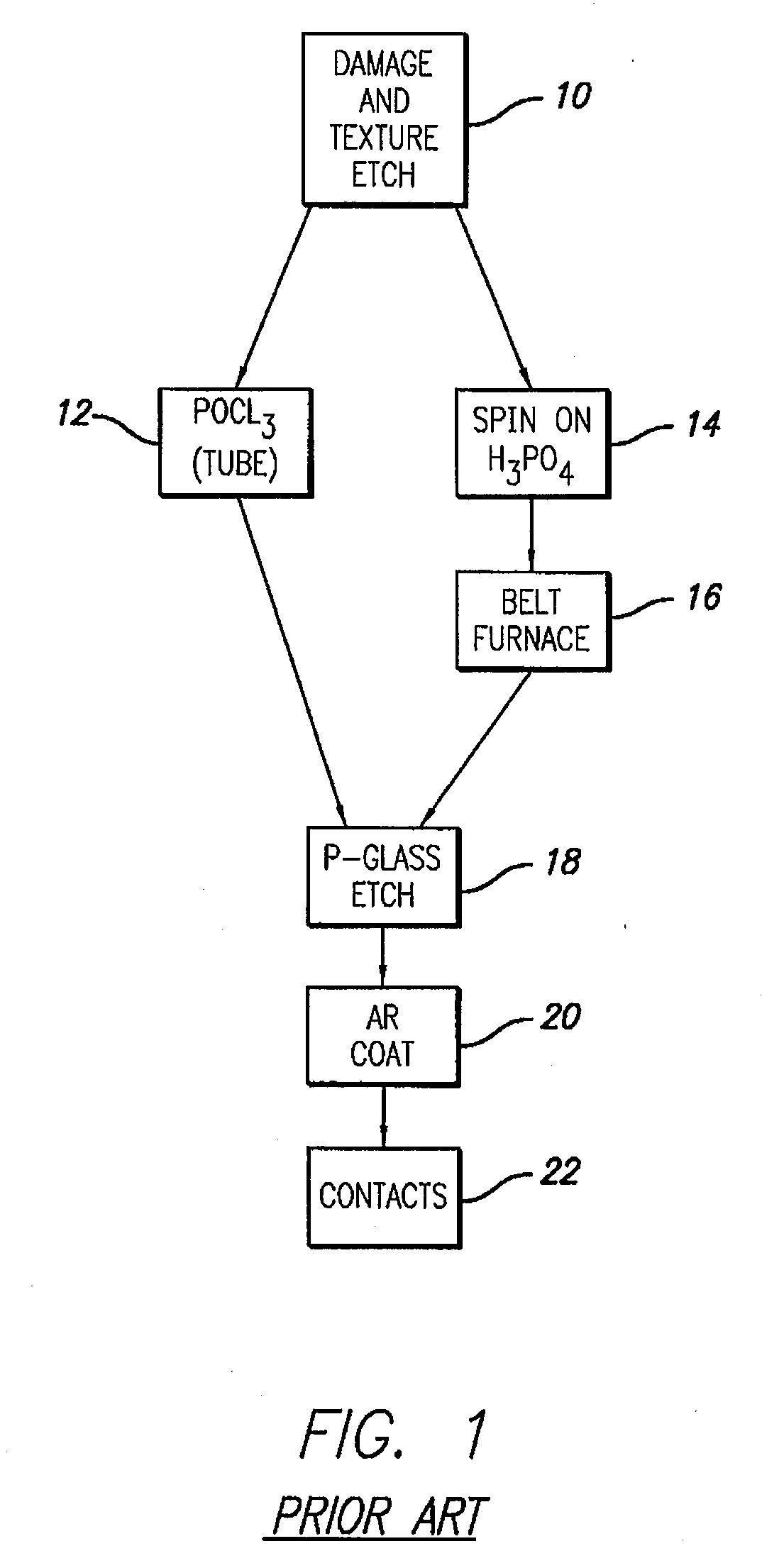

A method for forming a selective emitter on a silicon solar cell is provided including forming an oxide layer on a surface of the P-type silicon substrate, implanting phosphorus doping atoms into the oxide layer on the substrate using plasma immersion ion implantation, patterning the oxide layer, annealing the substrate to provide heavily doped regions in the patterned regions and a lightly doped region between the patterned regions, and providing metal contacts to the heavily doped regions.

Owner:APPLIED MATERIALS INC

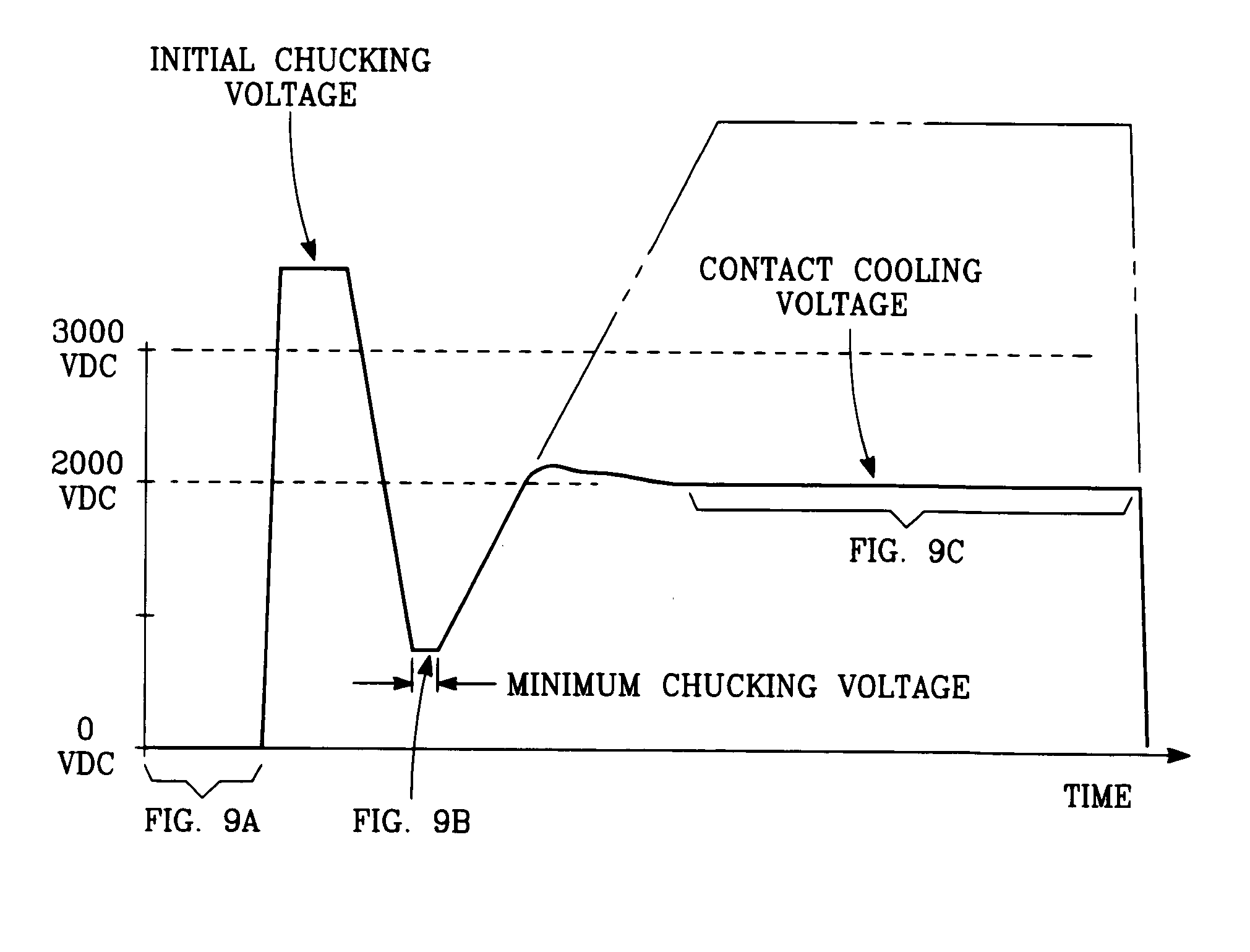

Plasma immersion ion implantation process using a capacitively couple plasma source having low dissociation and low minimum plasma voltage

InactiveUS7291545B2Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor materials

A method of ion implanting a species in a workpiece to a selected ion implantation profile depth includes placing a workpiece having a semiconductor material on an electrostatic chuck in or near a processing region of a plasma reactor chamber and applying a chucking voltage to the electrostatic chuck. The method further includes introducing into the chamber a precursor gas including a species to be ion implanted in the workpiece and applying an RF bias to the electrostatic chuck, the RF bias having a bias level corresponding to the ion implantation profile depth.

Owner:APPLIED MATERIALS INC

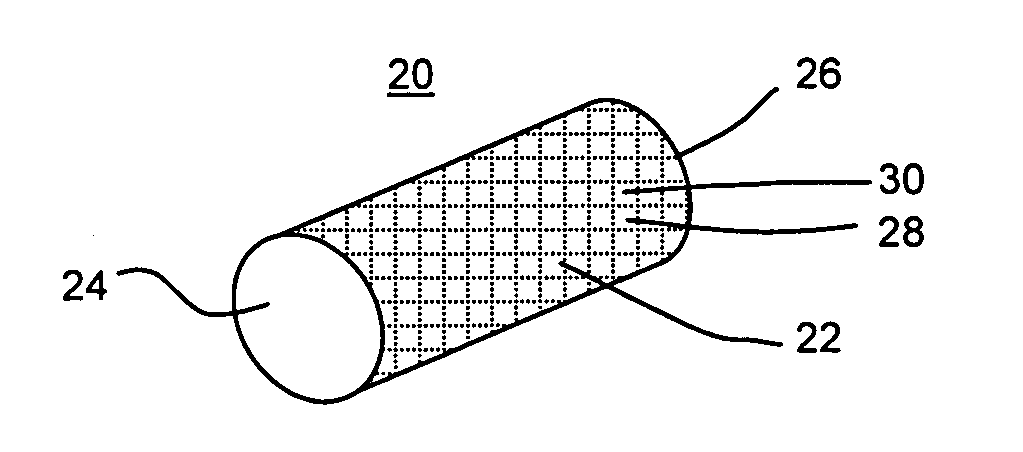

Surface modification of ePTFE and implants using the same

A method for modifying an ePTFE surface by plasma immersion ion implantation includes the steps of providing an ePTFE material in a chamber suitable for plasma treatment; providing a continuous low energy plasma discharge onto the sample; and applying negative high voltage pulses of short duration to form a high energy ion flux from the plasma discharge to generate ions which form free radials on the surface of the ePTFE material without changing the molecular and / or physical structure below the surface to define a modified ePTFE surface. The step of applying the high voltage pulses modifies the surface of the ePTFE without destroying the node and fibril structure of the ePTFE, even when the step of applying the high voltage pulses etches and / or carburizes the surface of the ePTFE. The modified surface may have a depth of about 30 nm to about 500 nm. The ions are dosed onto the ePTFE sample at concentrations or doses from about 1013 ions / cm2 to about 1016 ions / cm2.

Owner:LIFESHIELD SCI

Plasma immersion ion implantation reactor having an ion shower grid

InactiveUS7767561B2Electric discharge tubesVacuum evaporation coatingProcess regionPlasma-immersion ion implantation

A plasma immersion ion implantation process for implanting a selected species at a desired ion implantation depth profile in a workpiece is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural elongate orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid.

Owner:APPLIED MATERIALS INC

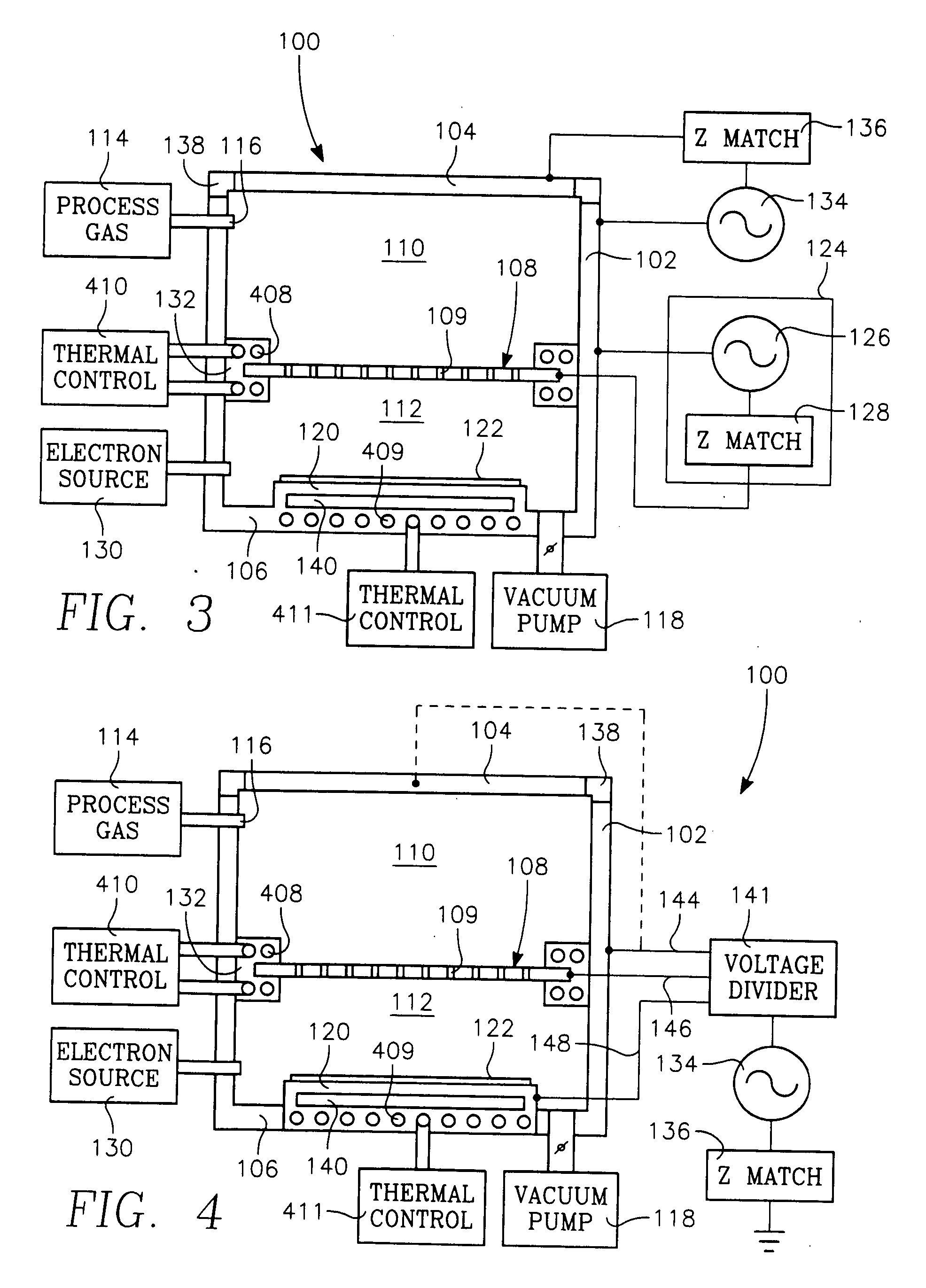

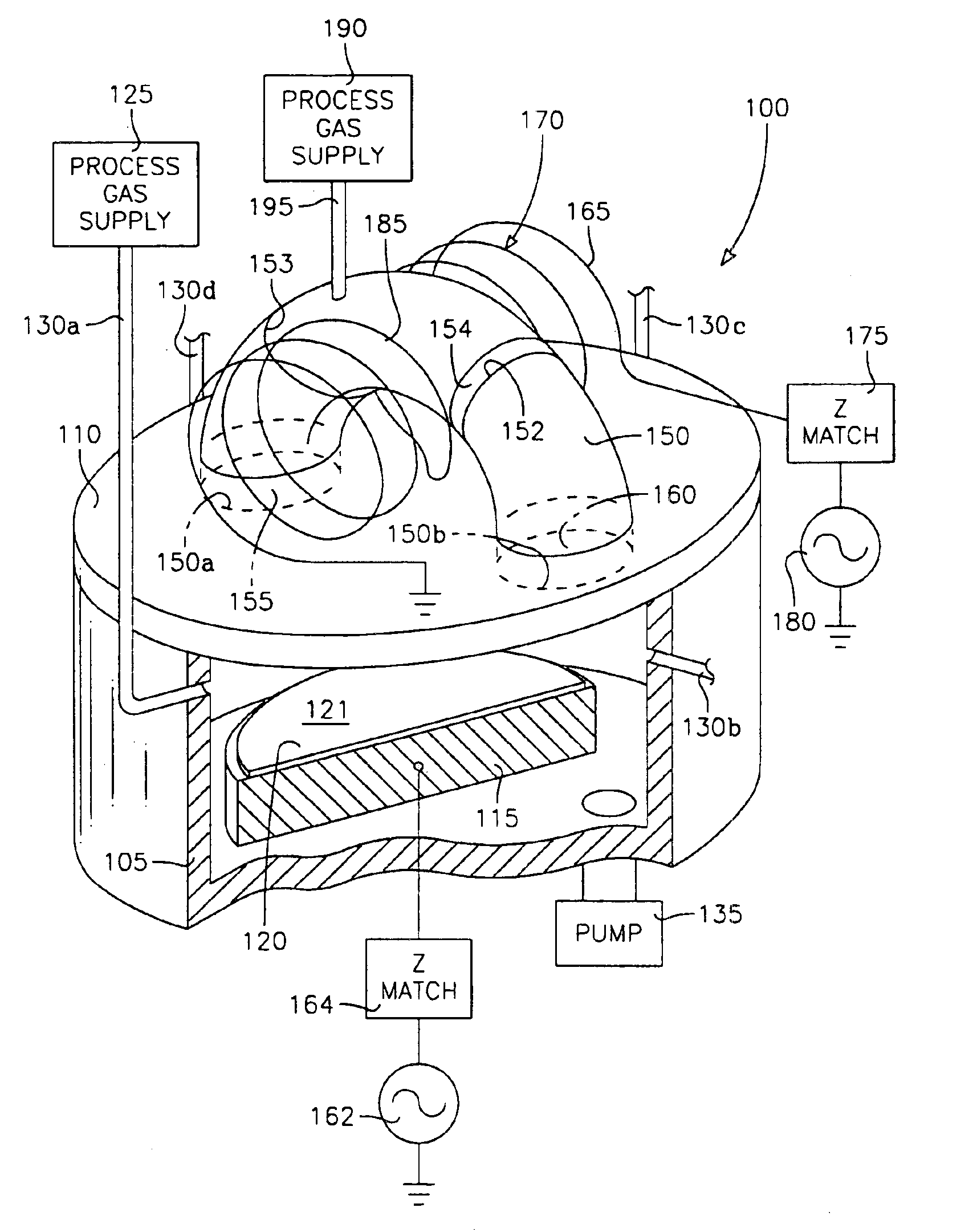

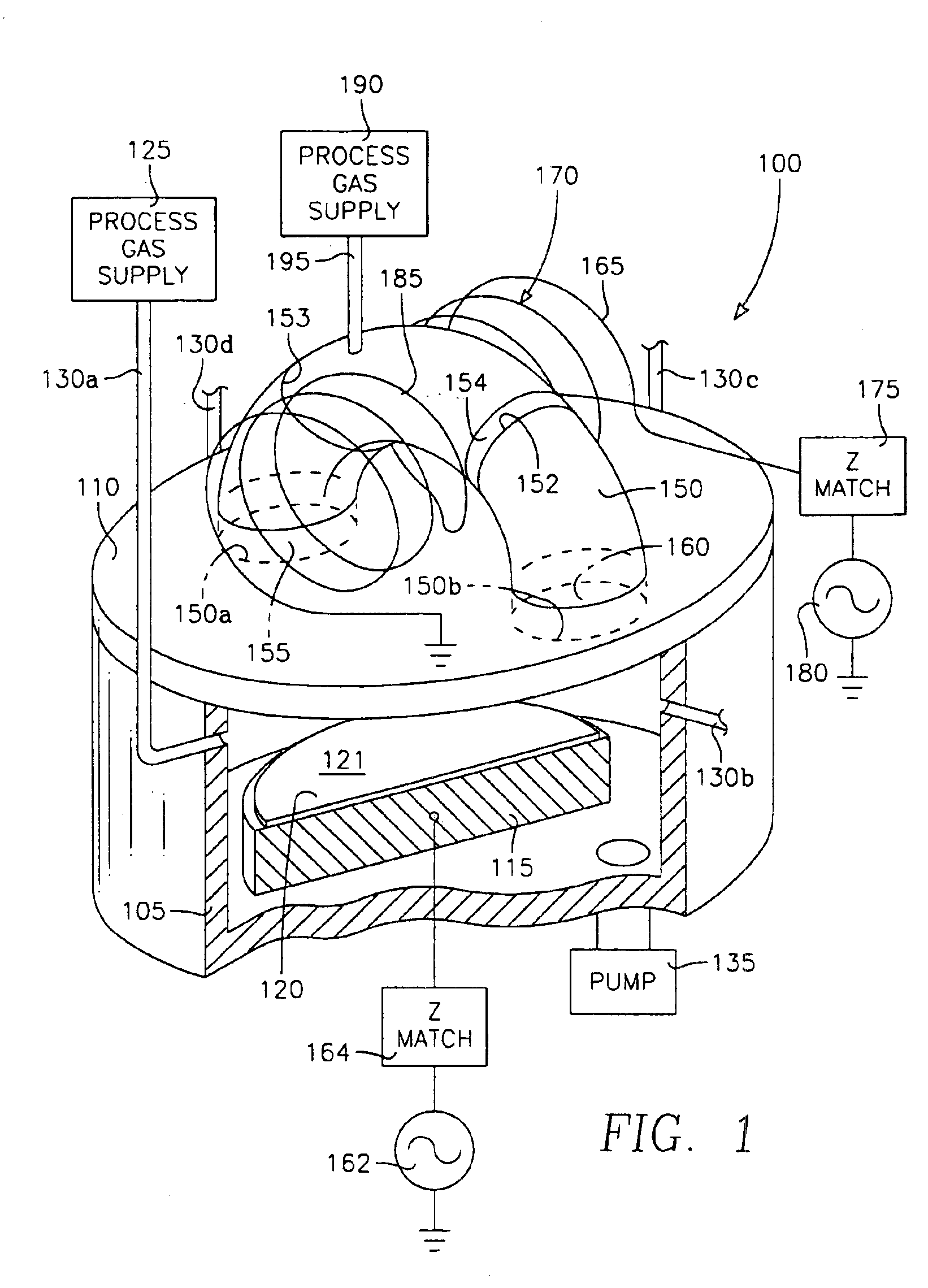

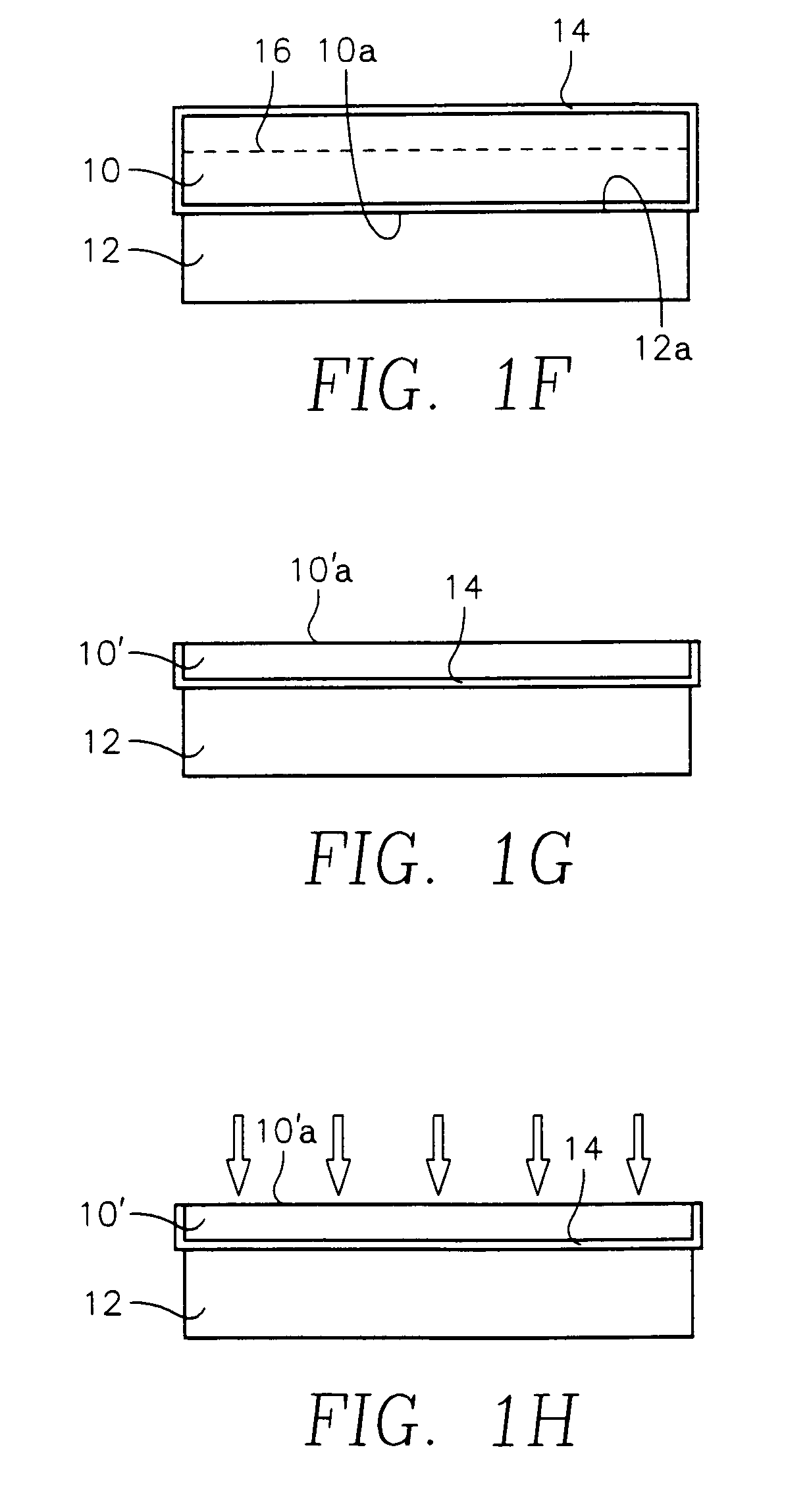

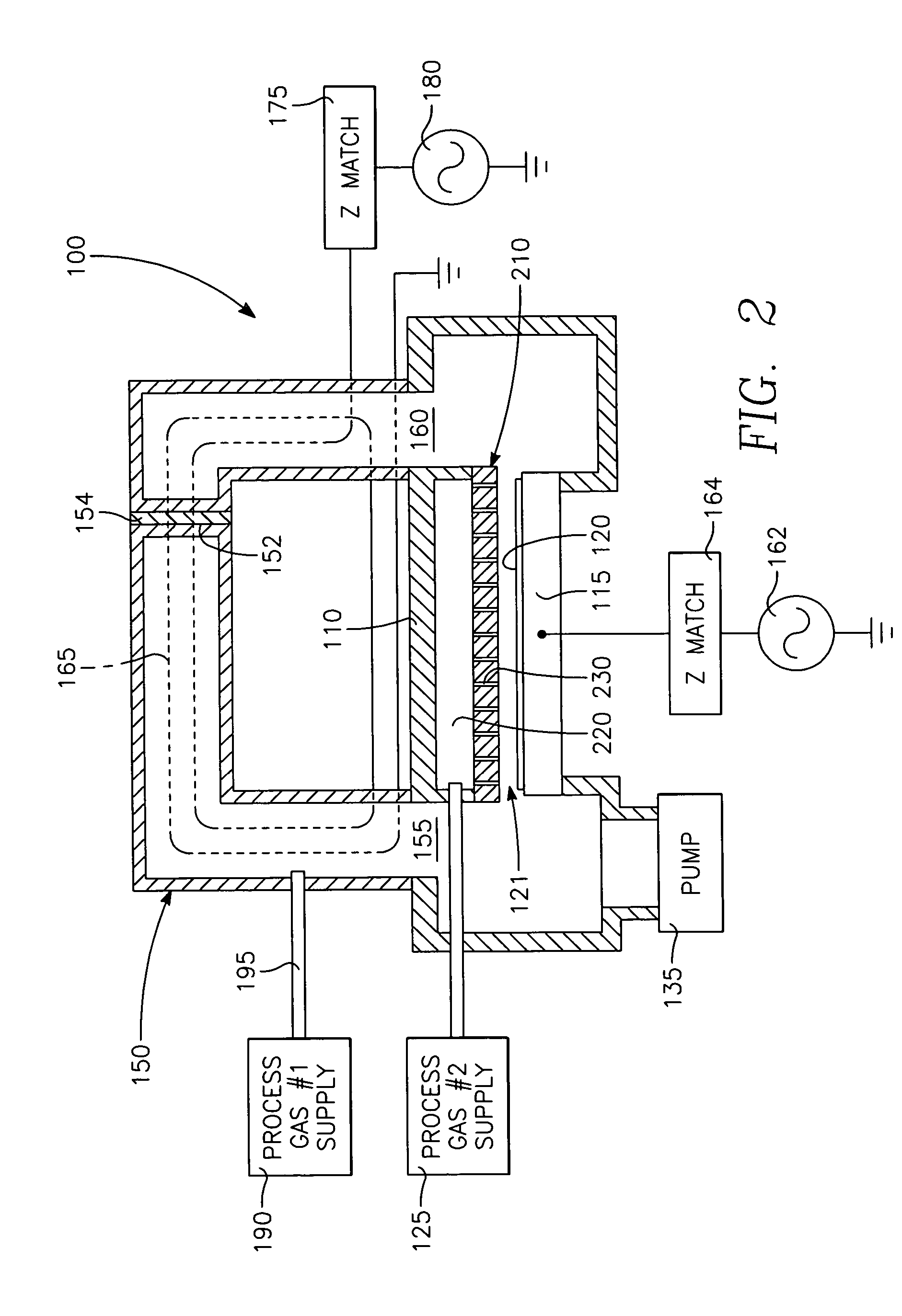

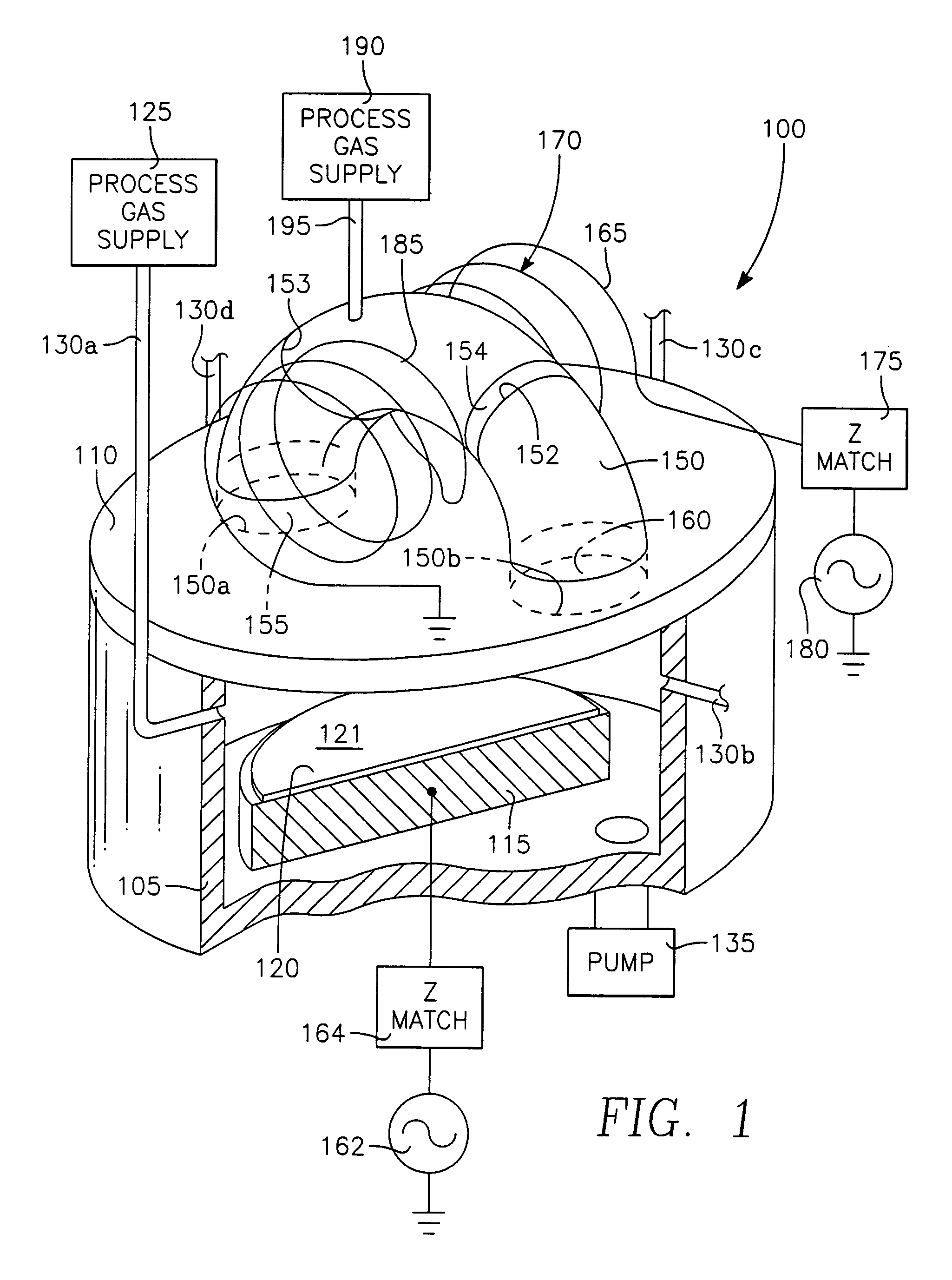

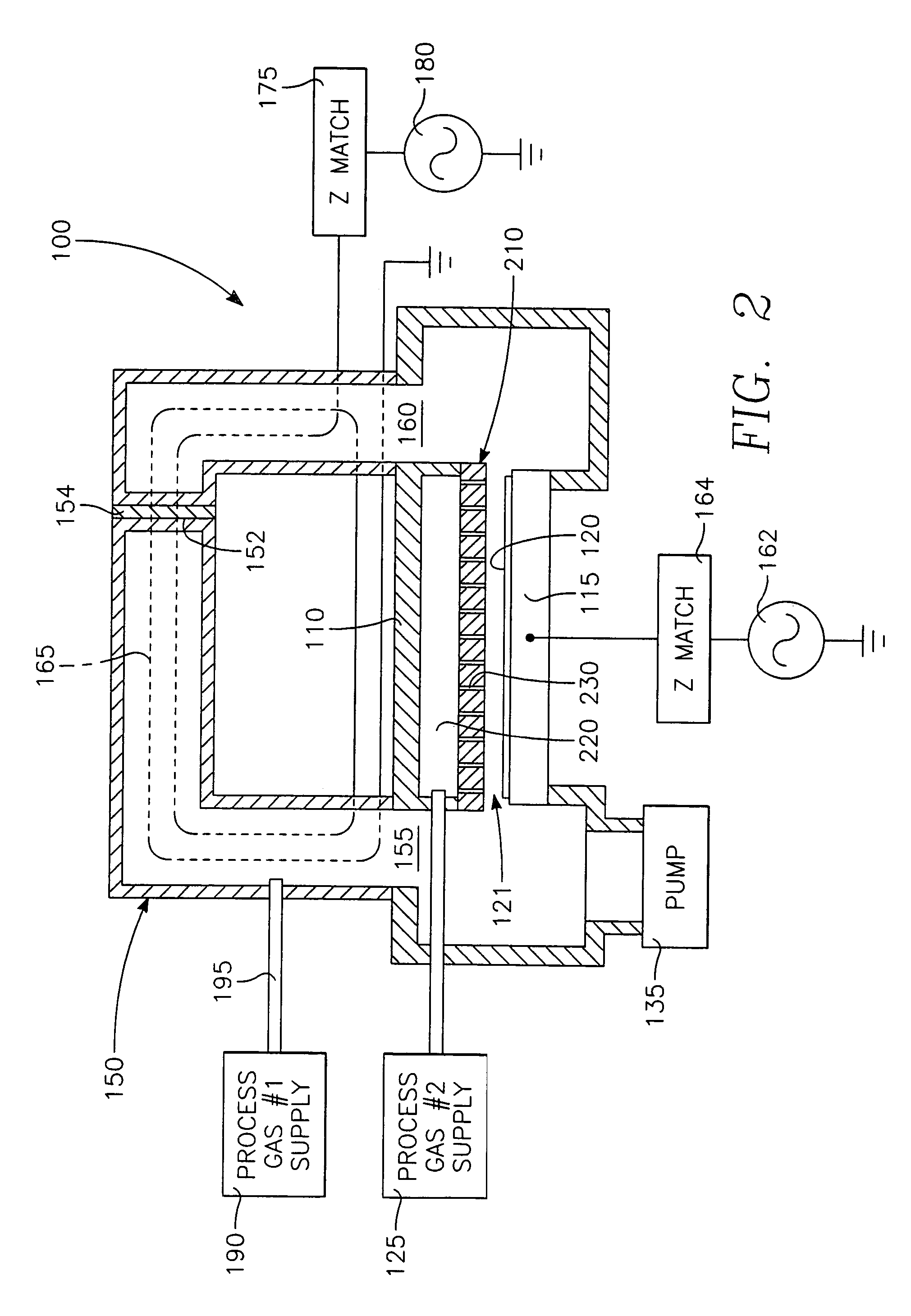

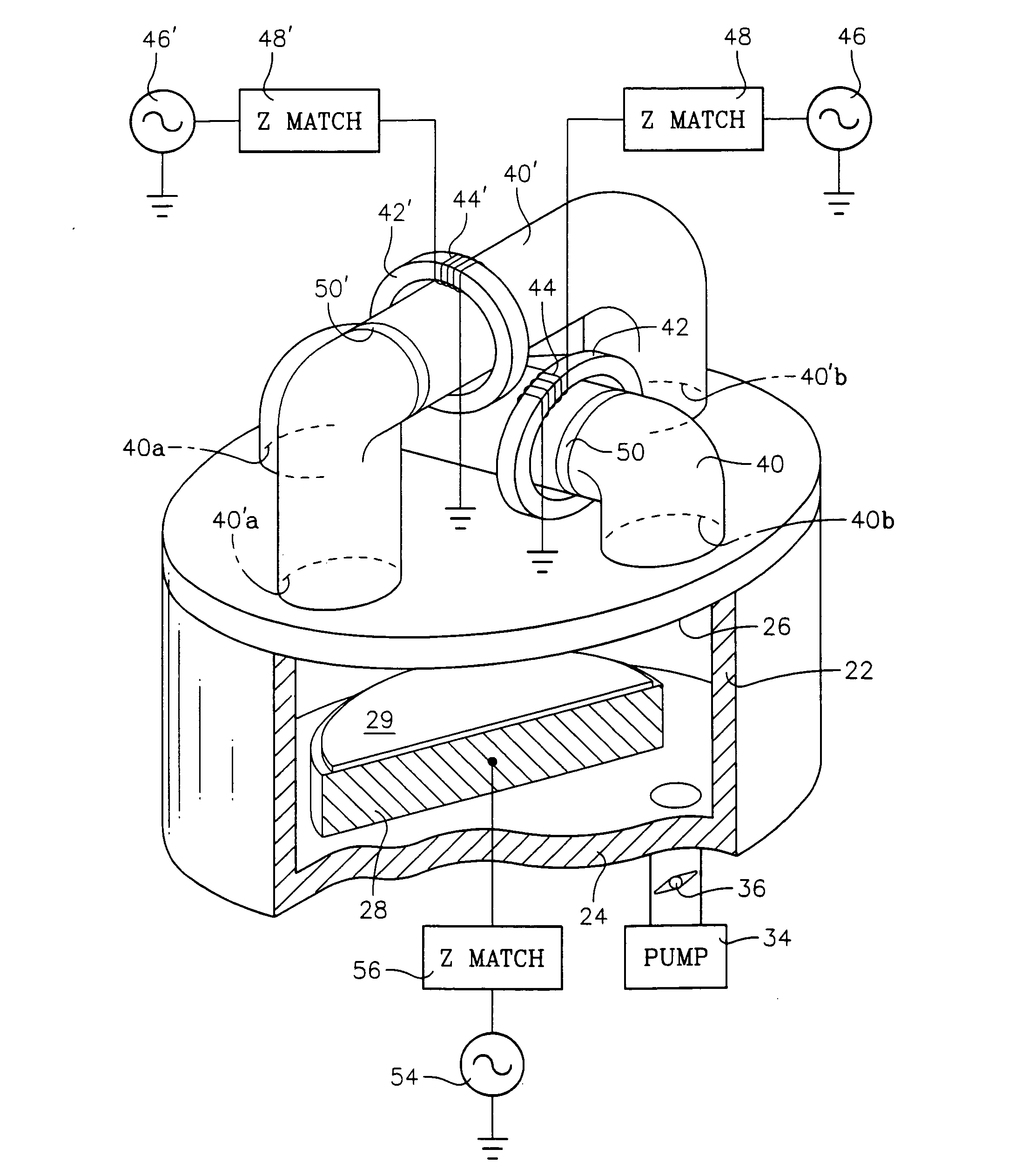

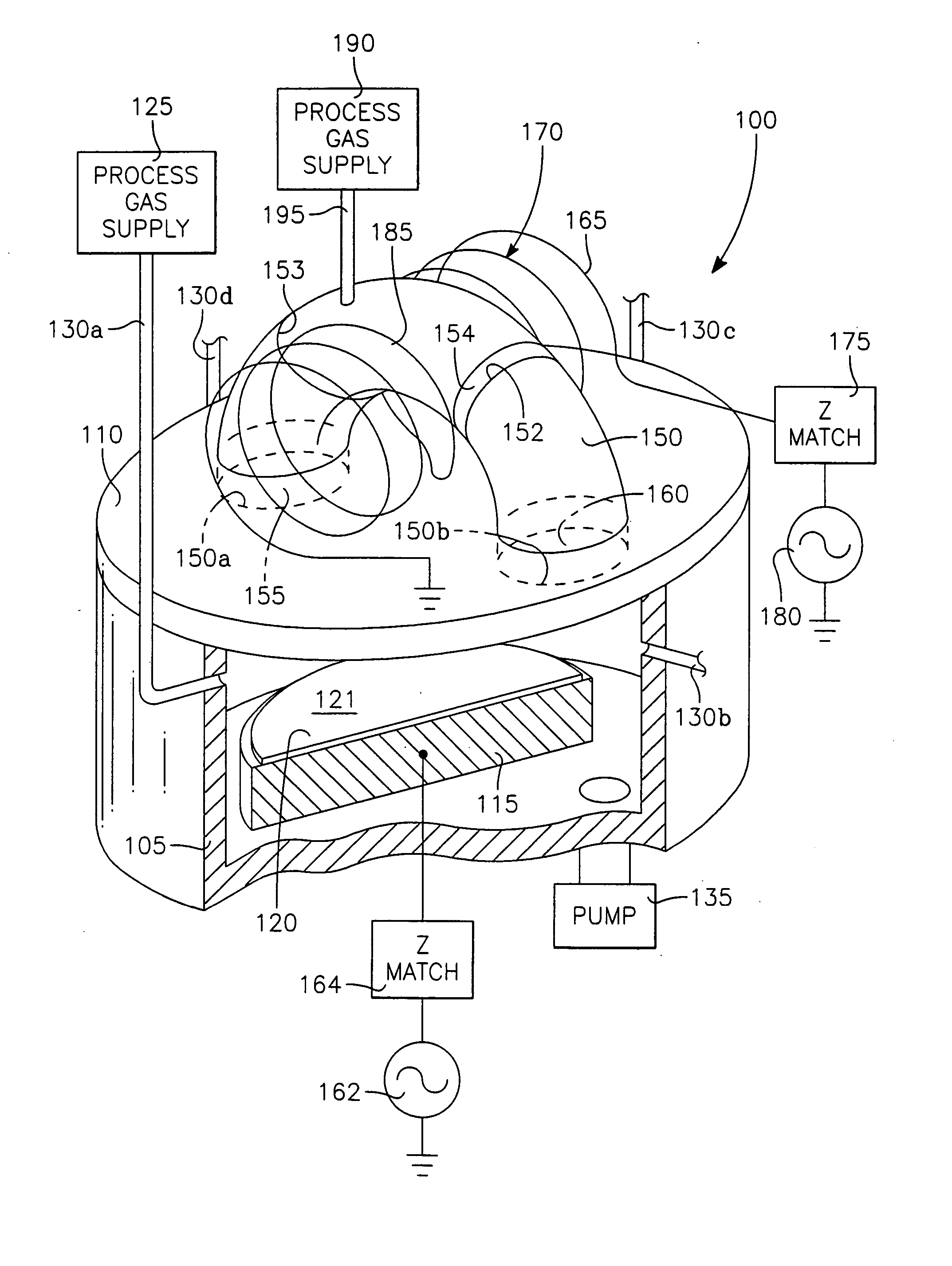

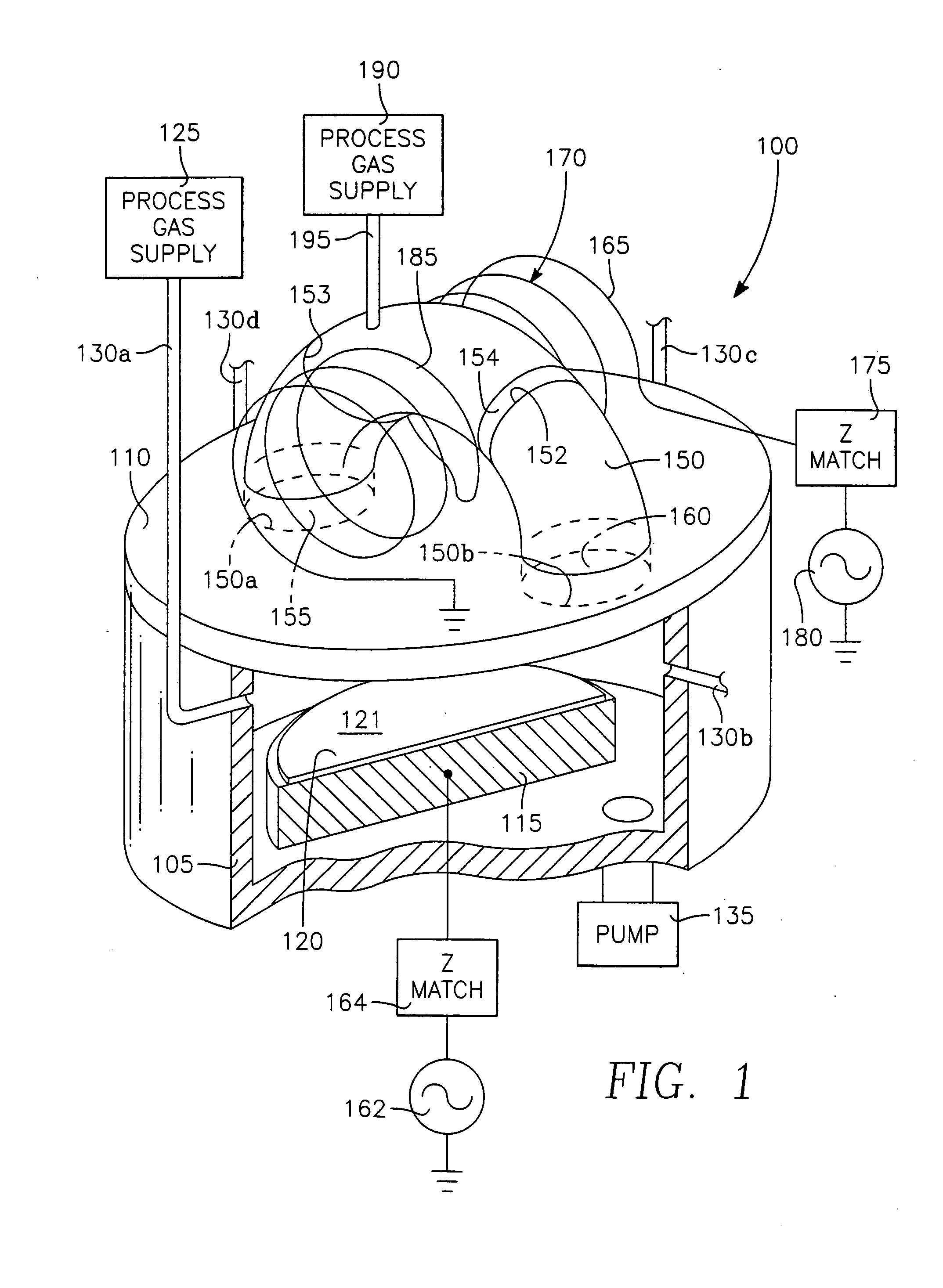

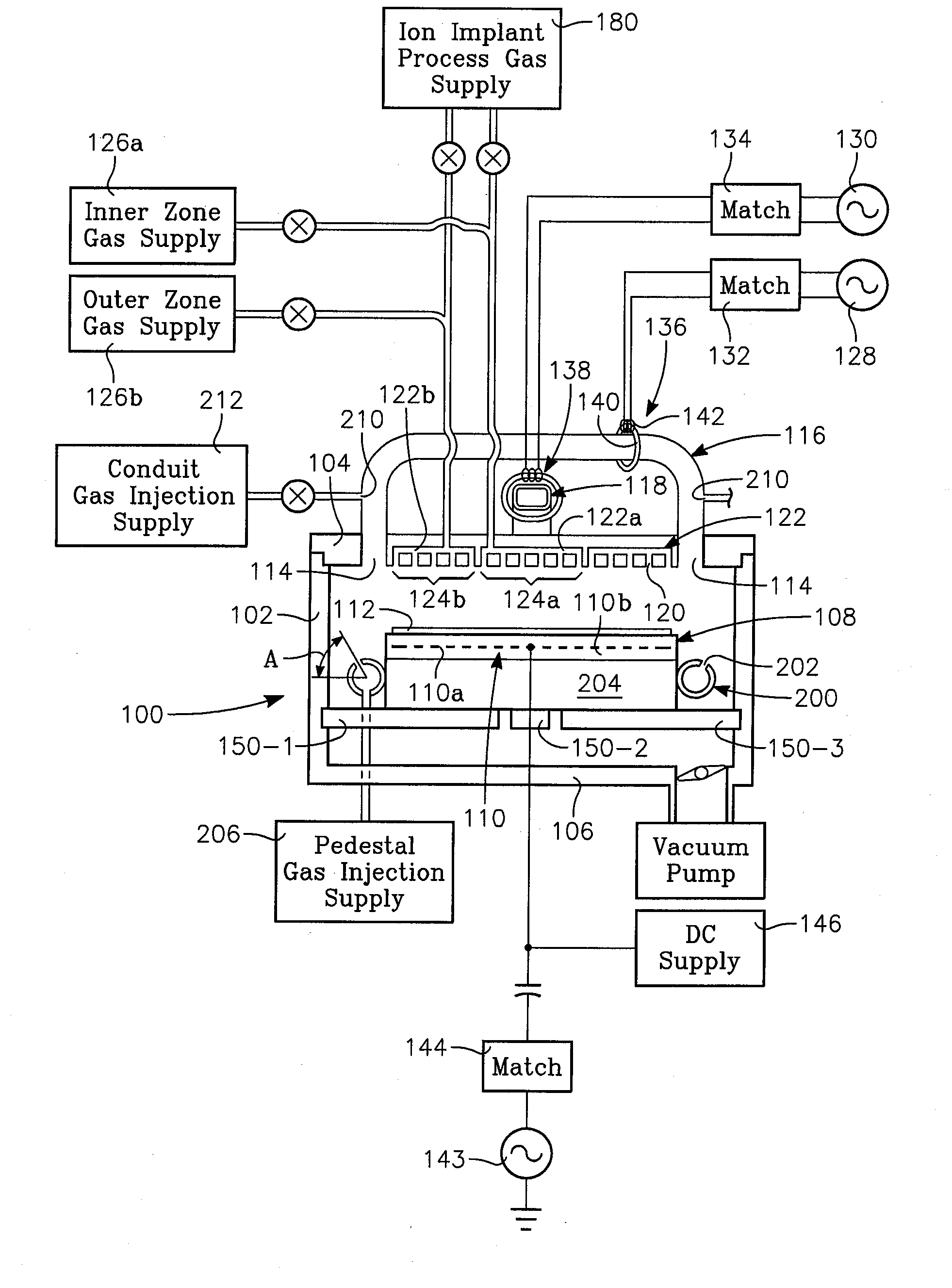

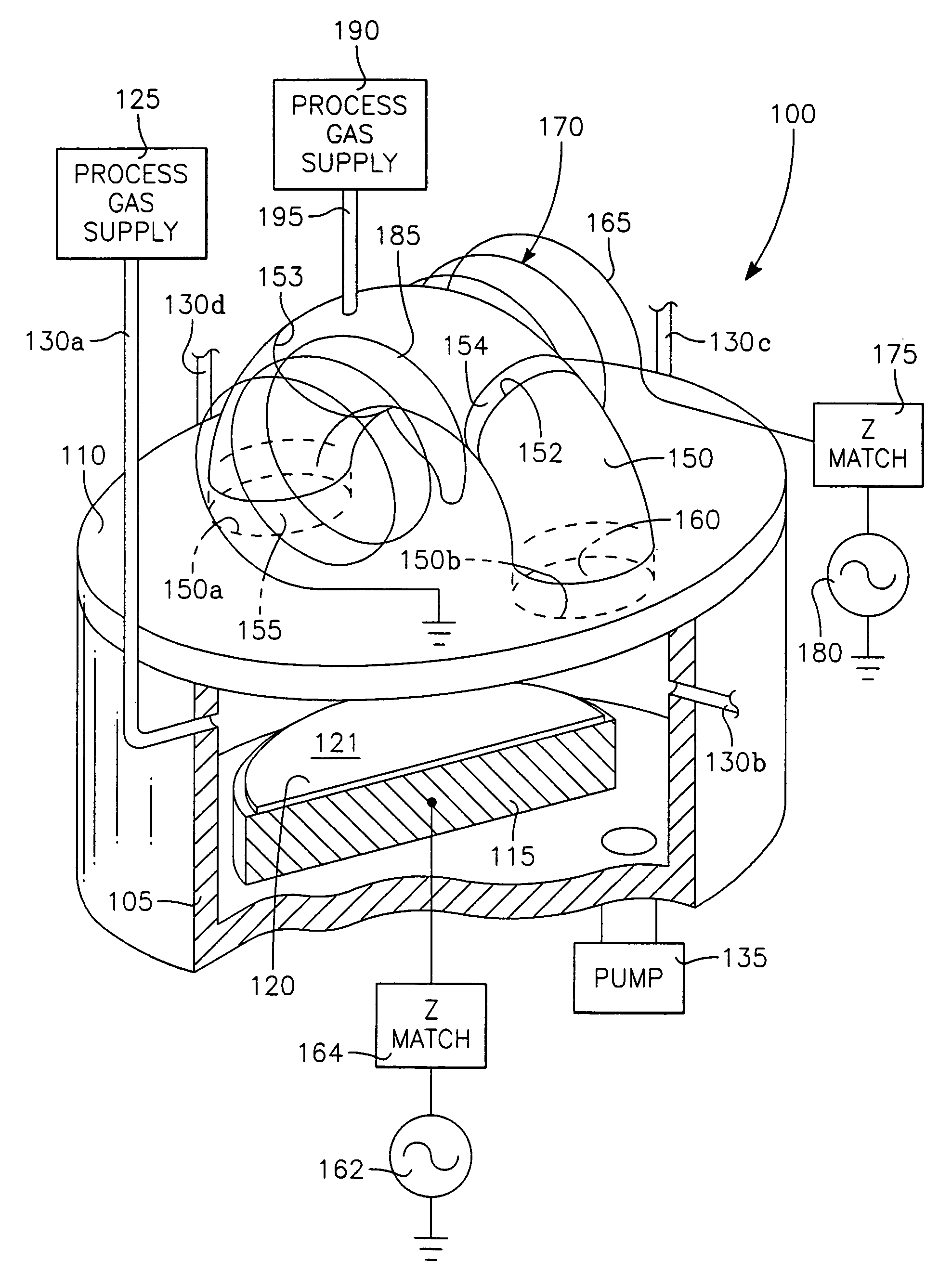

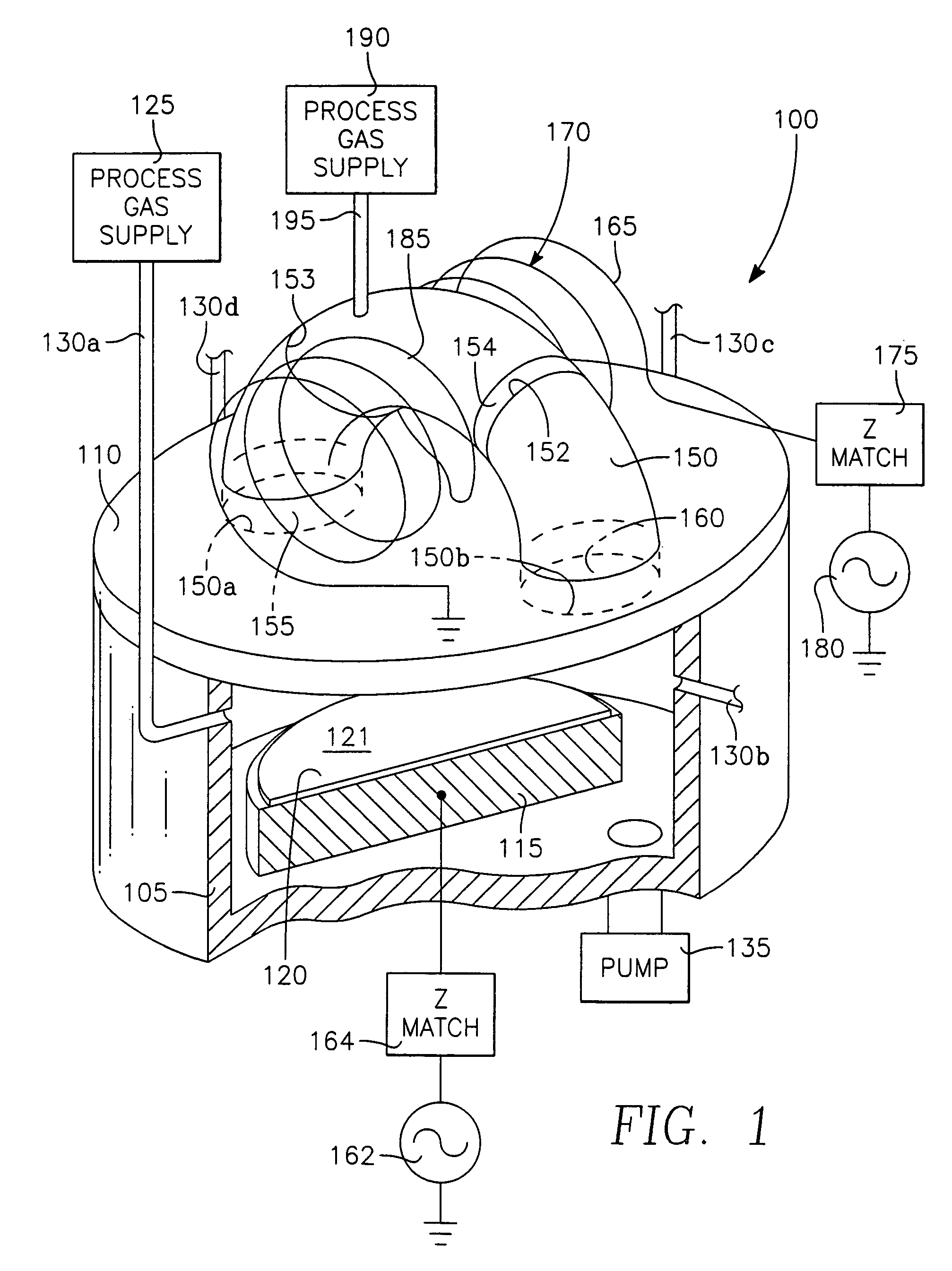

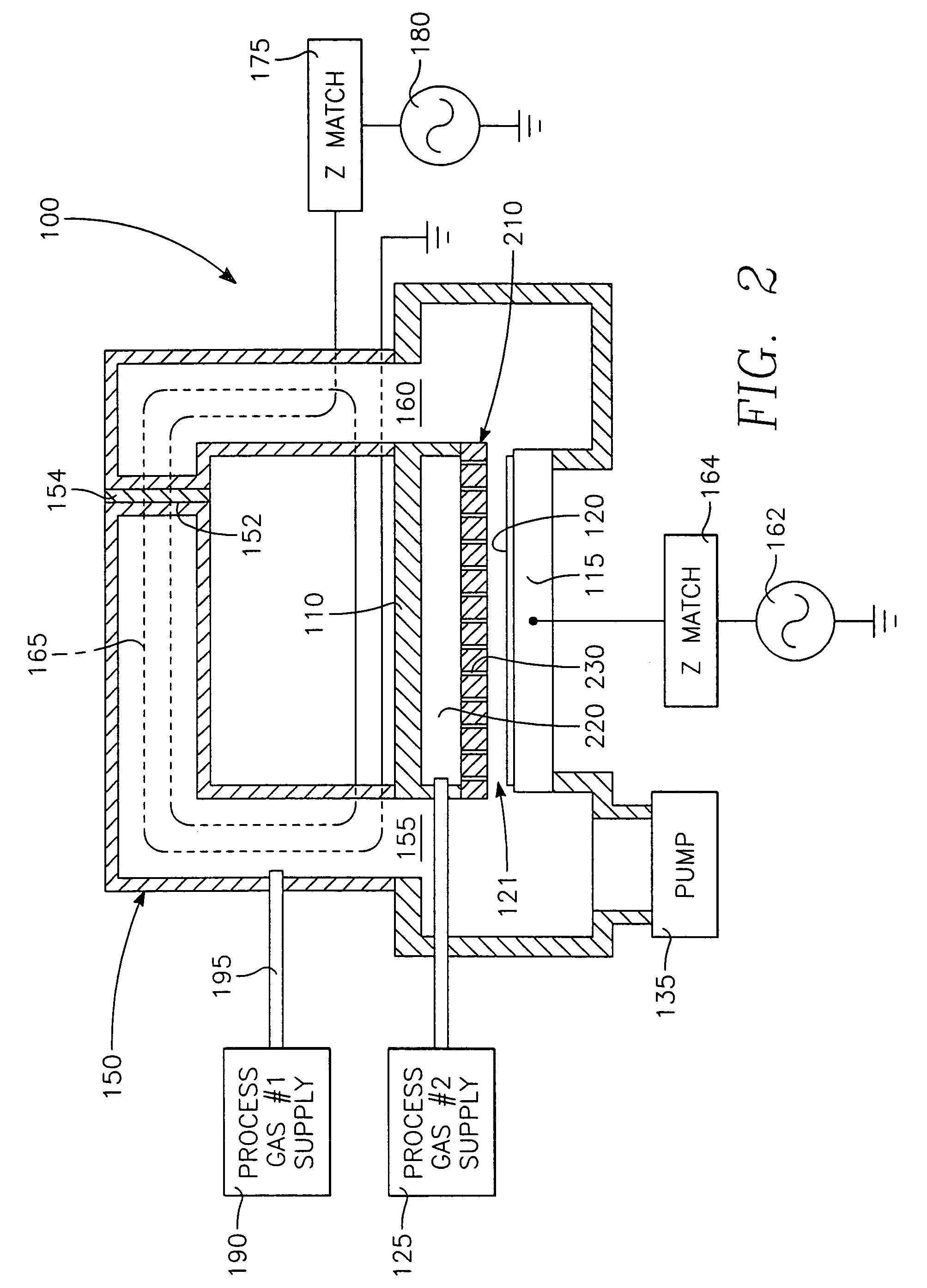

Plasma immersion ion implantation apparatus including a plasma source having low dissociation and low minimum plasma voltage

InactiveUS7137354B2High ion fluxElectric discharge tubesSemiconductor/solid-state device manufacturingSurface layerProcess region

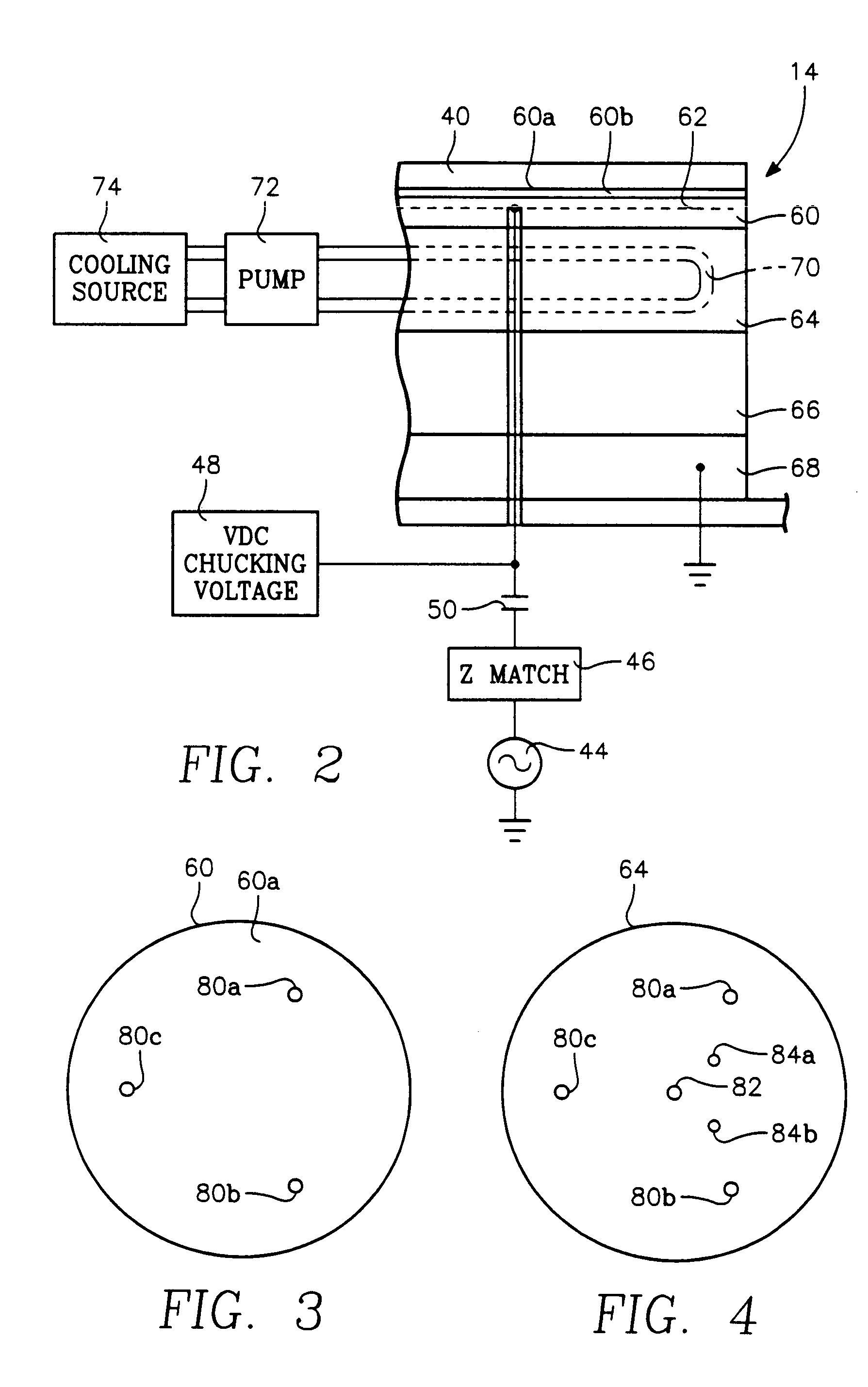

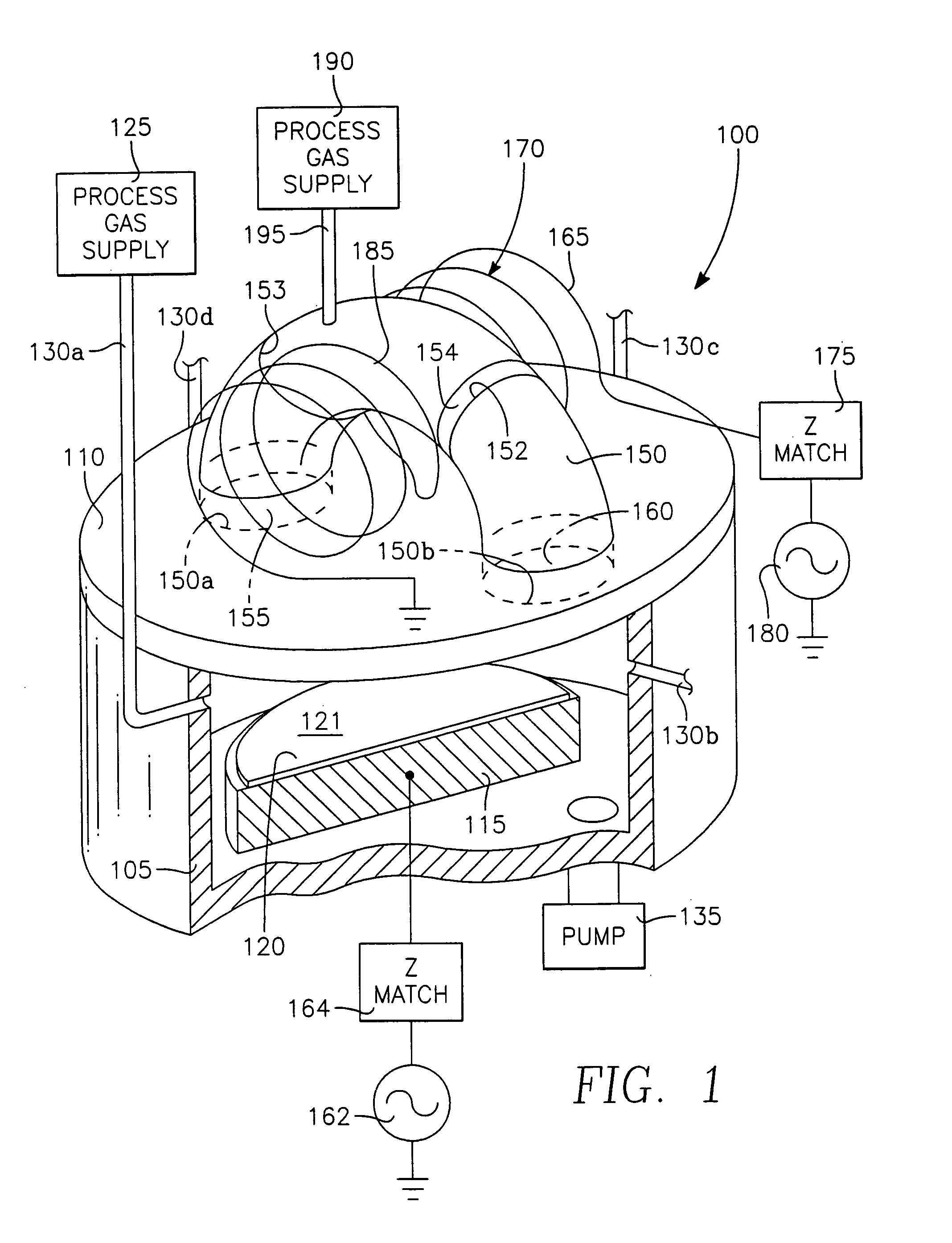

A plasma immersion ion implantation reactor for ion implanting a species into a surface layer of a workpiece includes an enclosure which has a side wall and a ceiling defining a chamber and a workpiece support pedestal within the chamber having a workpiece support surface facing the ceiling and defining a process region extending generally across the wafer support pedestal and confined laterally by the side wall and axially between the workpiece support pedestal and the ceiling. The enclosure has at least a first pair of openings at generally opposite sides of the process region and a first hollow conduit outside of the chamber having first and second ends connected to respective ones of the first pair of openings, so as to provide a first reentrant path extending through the conduit and across said process region. A gas distribution apparatus is provided on or near an interior surface of the reactor for introducing a process gas containing the species to be ion implanted and a first RE plasma source power applicator for generating a plasma in the chamber.

Owner:APPLIED MATERIALS INC

Silicon-on-insulator wafer transfer method using surface activation plasma immersion ion implantation for wafer-to-wafer adhesion enhancement

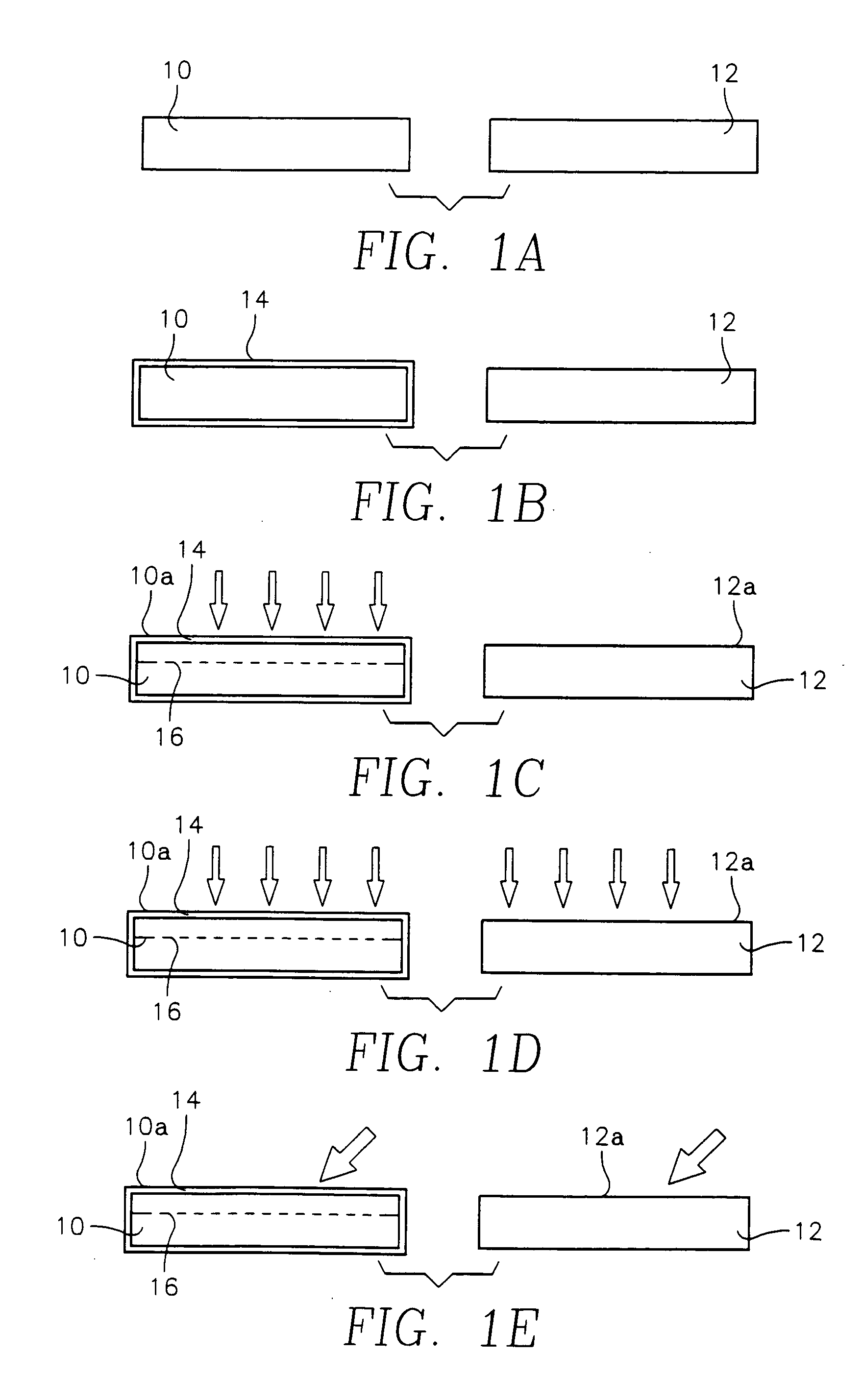

InactiveUS20050070073A1TransistorElectric discharge tubesSemiconductor structurePlasma-immersion ion implantation

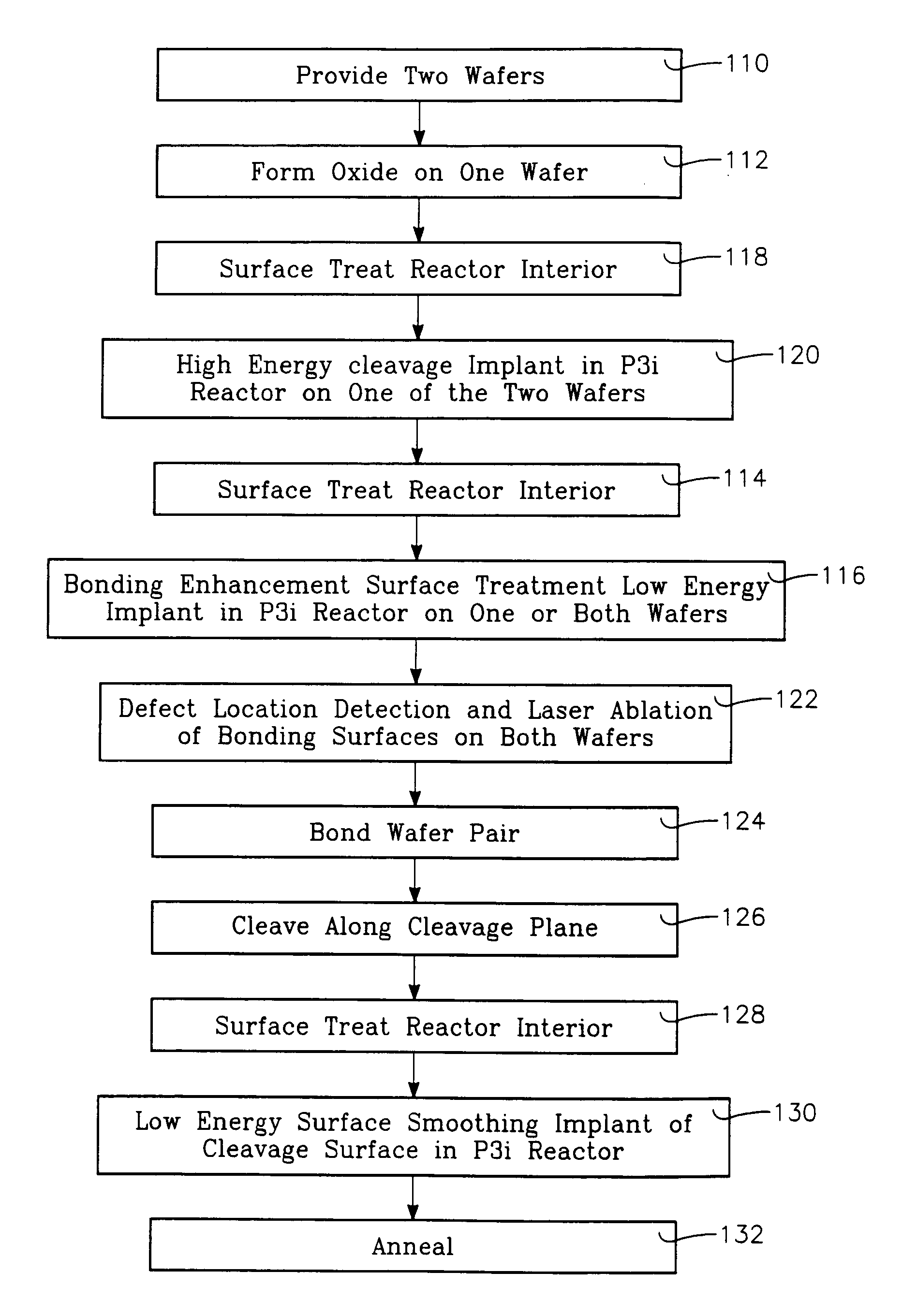

A method of fabricating a semiconductor-on-insulator structure from a pair of semiconductor wafers, includes forming an oxide layer on at least a first surface of a first one of the wafers and performing a bonding enhancement implantation step by ion implantation of a first species in the first surface of at least either of the pair of wafers. The method further includes performing a cleavage ion implantation step on one of the pair of wafers by ion implanting a second species to define a cleavage plane across a diameter of the wafer at the predetermined depth below the top surface of the one wafer. The wafers are then bonded together by placing the first surfaces of the pair of wafers onto one another so as to form an semiconductor-on-insulator structure. The method also includes separating the one wafer along the cleavage plane so as to remove a portion of the one wafer between the second surface and the cleavage plane, whereby to form an exposed cleaved surface of a remaining portion of the one wafer on the semiconductor-on-insulator structure. Finally, the cleaved surface is smoothed, preferably by carrying out a low energy high momentum ion implantation step.

Owner:APPLIED MATERIALS INC

RF measurement feedback control and diagnostics for a plasma immersion ion implantation reactor

InactiveUS7666464B2Improve accuracySemiconductor/solid-state device testing/measurementElectric discharge tubesPower flowCoupling

A method of measuring ion dose in a plasma immersion ion implantation reactor during ion implantation of a selected species into a workpiece includes placing the workpiece on a pedestal in the reactor and feeding into the reactor a process gas comprising a species to be implanted into the workpiece, and then coupling RF plasma source power to a plasma in the reactor. It further includes coupling RF bias power to the workpiece by an RF bias power generator that is coupled to the workpiece through a bias feedpoint of the reactor and measuring RF current at the feedpoint to generate a current-related value, and then integrating the current-related over time to produce an ion implantation dose-related value.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process

InactiveUS20050191827A1Electric discharge tubesElectrostatic cleaningPlasma-immersion ion implantationPlasma reactor

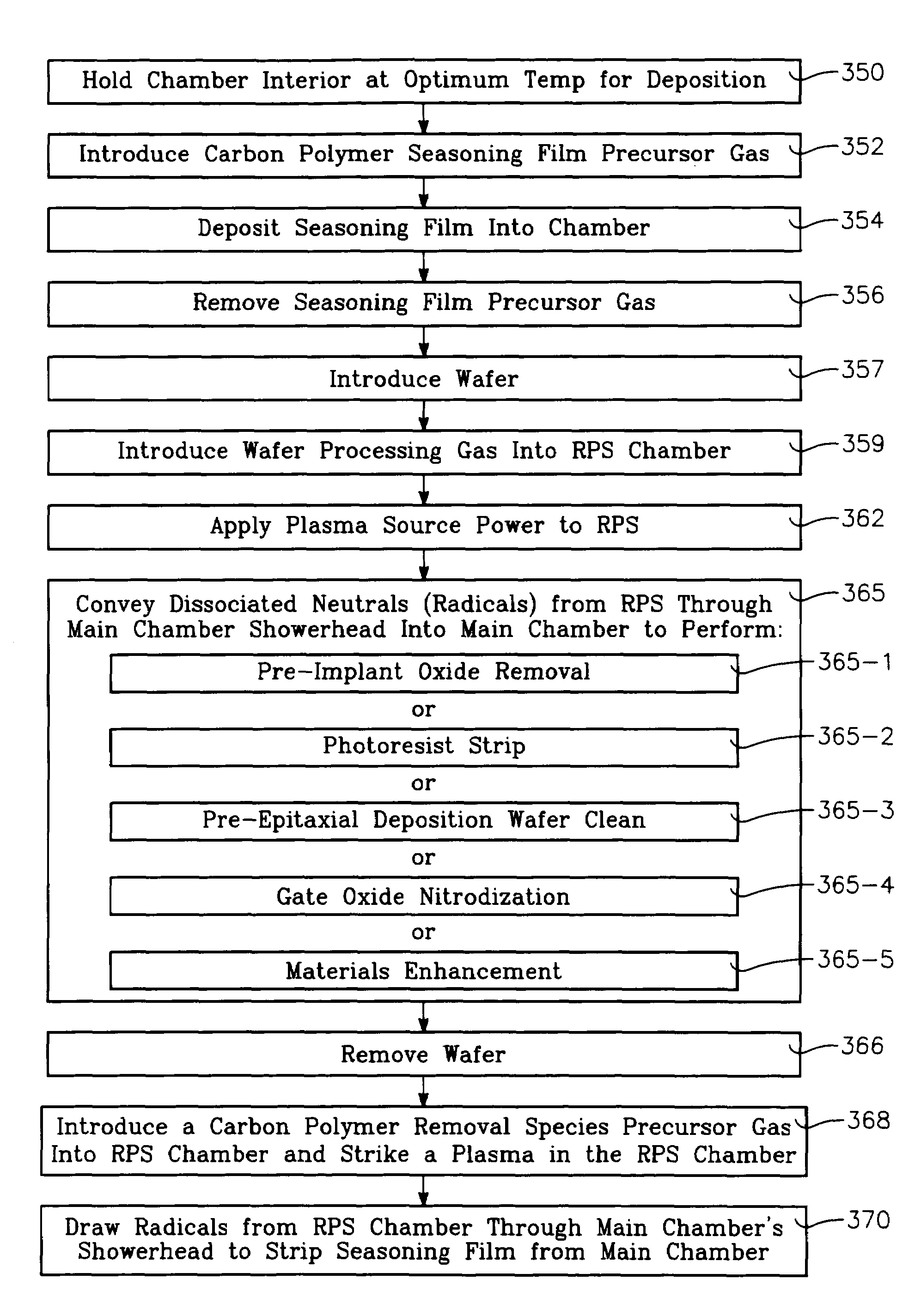

One method of performing plasma immersion ion implantation on a workpiece in a plasma reactor chamber includes initially depositing a seasoning film on the interior surfaces of the plasma reactor chamber before the workpiece is introduced, by introducing a seasoning film precursor gas into the chamber and generating a plasma within the chamber, performing plasma immersion ion implantation on the workpiece by introducing an implant species precursor gas into the chamber and generating a plasma, and then removing the workpiece from the chamber and removing the seasoning film from the chamber interior surfaces.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process

InactiveUS20050191830A1Electric discharge tubesDecorative surface effectsWaferingPlasma-immersion ion implantation

A method of performing plasma immersion ion implantation on a workpiece in a plasma reactor chamber, includes placing the workpiece on a workpiece support in the chamber, controlling a temperature of the wafer support near a constant level; performing plasma immersion ion implantation on the workpiece by introducing an implant species precursor gas into the chamber and generating a plasma while minimizing deposition and minimizing etching by holding the temperature of the workpiece within a temperature range that is above a workpiece deposition threshold temperature and below a workpiece etch threshold temperature.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process

InactiveUS7288491B2Electric discharge tubesElectrostatic cleaningPlasma-immersion ion implantationPlasma reactor

One method of performing plasma immersion ion implantation on a workpiece in a plasma reactor chamber includes initially depositing a seasoning film on the interior surfaces of the plasma reactor chamber before the workpiece is introduced, by introducing a seasoning film precursor gas into the chamber and generating a plasma within the chamber, performing plasma immersion ion implantation on the workpiece by introducing an implant species precursor gas into the chamber and generating a plasma, and then removing the workpiece from the chamber and removing the seasoning film from the chamber interior surfaces.

Owner:APPLIED MATERIALS INC

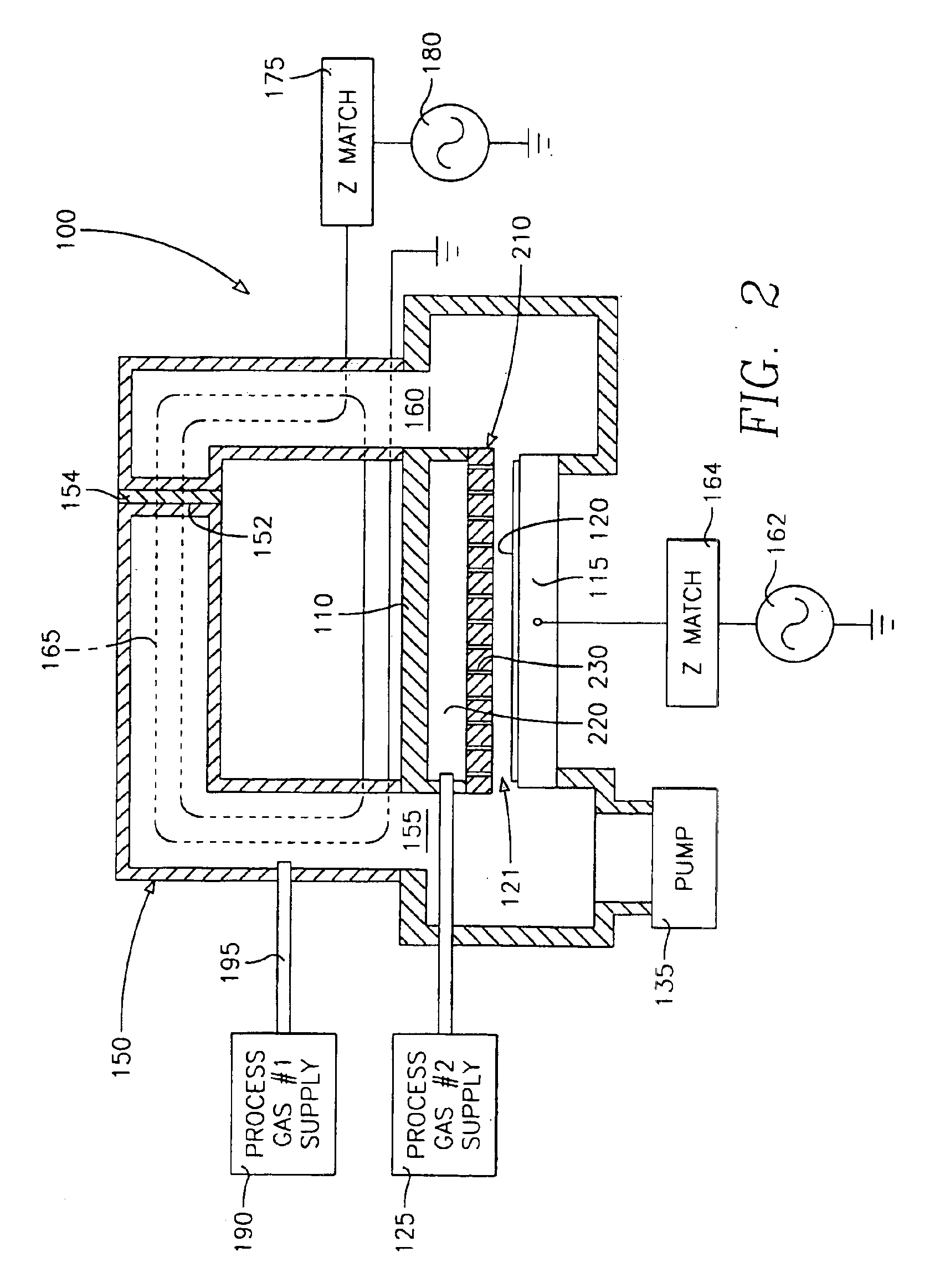

Plasma immersion ion implantation system including an inductively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS20050051271A1Electric discharge tubesSemiconductor/solid-state device manufacturingSurface layerProcess region

A system for processing a workpiece includes a plasma immersion implantation reactor with an enclosure comprising a side wall and a ceiling and defining a chamber, and a workpiece support pedestal within the chamber having a workpiece support surface facing the ceiling and defining a process region extending generally across the wafer support pedestal. The reactor includes a gas distribution apparatus for introducing a process gas containing a first species to be ion implanted into a surface layer of the workpiece, and inductively coupled source power applicator, and an RF plasma source power generator coupled to the inductively coupled source power applicator for inductively coupling RF source power into the process zone. The reactor further includes an RF bias generator having an RF bias frequency and coupled to the workpiece support pedestal for applying an RF bias to the workpiece. The system further includes a second wafer processing apparatus, and a wafer transfer apparatus for transferring the workpiece between the plasma immersion ion implantation reactor and the second wafer processing apparatus.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process using a capacitively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS20060073683A1High ion fluxElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor materials

A method of ion implanting a species in a workpiece to a selected ion implantation profile depth includes placing a workpiece having a semiconductor material on an electrostatic chuck in or near a processing region of a plasma reactor chamber and applying a chucking voltage to the electrostatic chuck. The method further includes introducing into the chamber a precursor gas including a species to be ion implanted in the workpiece and applying an RF bias to the electrostatic chuck, the RF bias having a bias level corresponding to the ion implantation profile depth.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process

InactiveUS7465478B2Electric discharge tubesDecorative surface effectsRemote plasmaPlasma-immersion ion implantation

A method of processing a workpiece includes placing the workpiece on a workpiece support pedestal in a main chamber with a gas distribution showerhead, introducing a process gas into a remote plasma source chamber and generating a plasma in the remote plasma source chamber, transporting plasma-generated species from the remote plasma source chamber to the gas distribution showerhead so as to distribute the plasma-generated species into the main chamber through the gas distribution showerhead, and applying plasma RF power into the main chamber.

Owner:APPLIED MATERIALS INC

Control apparatus for plasma immersion ion implantation of a dielectric substrate

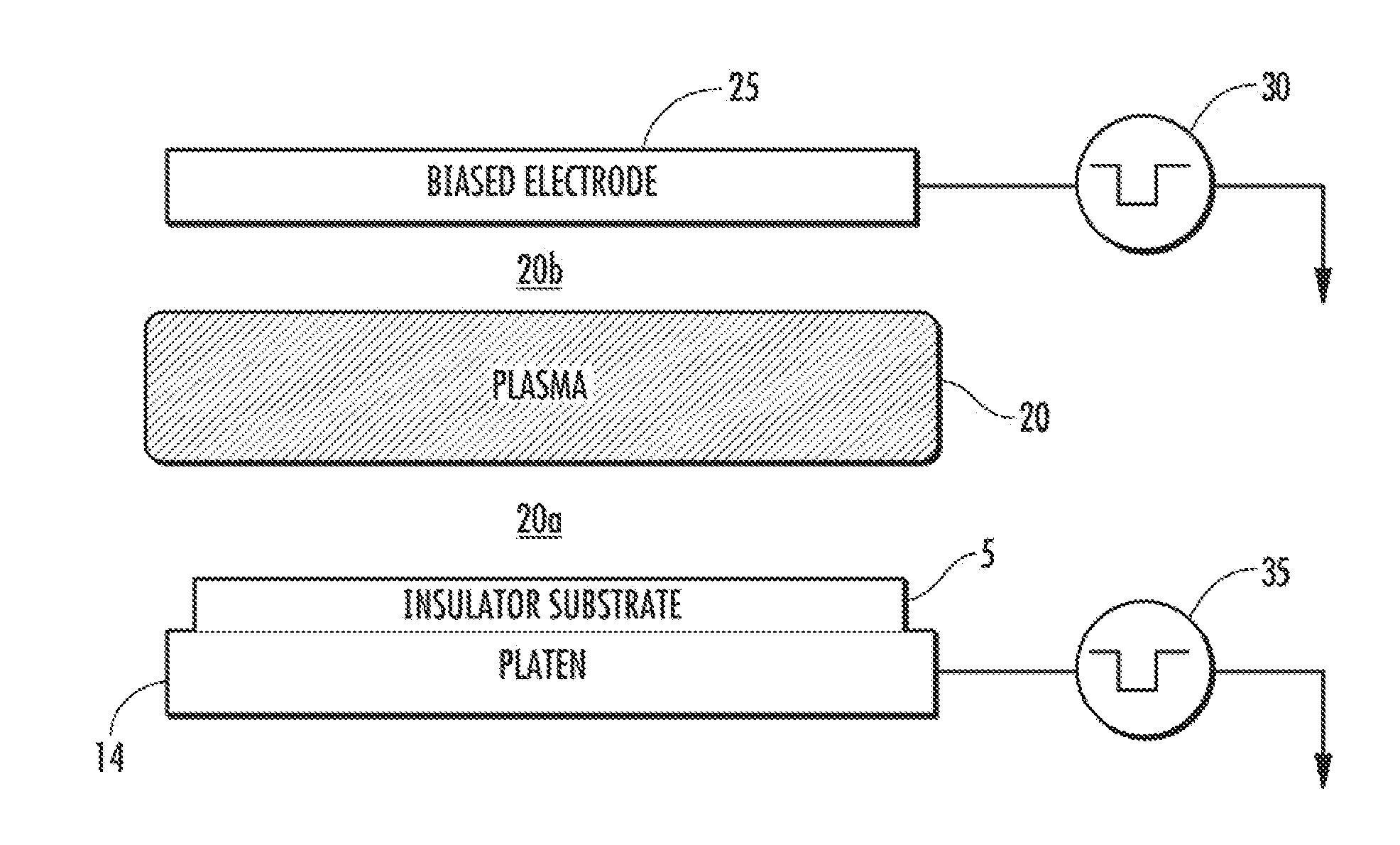

InactiveUS20120000421A1Sufficient energyLiquid surface applicatorsElectric discharge tubesElectricityDielectric substrate

A control apparatus for plasma immersion ion implantation of a dielectric substrate which includes an electrode disposed above a generated plasma in a plasma chamber. The electrode is biased with negative voltage pulses at a potential that is higher than a potential of a substrate or cathode configured to receive ion implantation. The electrode is more negative to give the electrons generated as secondary electrons from the electrode sufficient energy to overcome the negative voltage of the high voltage sheath around the substrate thereby reaching the substrate. These electrons are accelerated toward the substrate to neutralize charge build-up on the substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Plasma immersion ion implantation process using an inductively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS20050051272A1High ion fluxElectric discharge tubesSemiconductor/solid-state device manufacturingSurface layerPlasma-immersion ion implantation

A method for implanting ions in a surface layer of a workpiece includes placing the workpiece on a workpiece support in a chamber with the surface layer being in facing relationship with a ceiling of the chamber, thereby defining a processing zone between the workpiece and the ceiling, and introducing into the chamber a process gas which includes the species to be implanted in the surface layer of the workpiece. The method further includes generating from the process gas a plasma by inductively coupling RF source power into the processing zone from an RF source power generator through an inductively coupled RF power applicator, and applying an RF bias from an RF bias generator to the workpiece support.

Owner:APPLIED MATERIALS INC

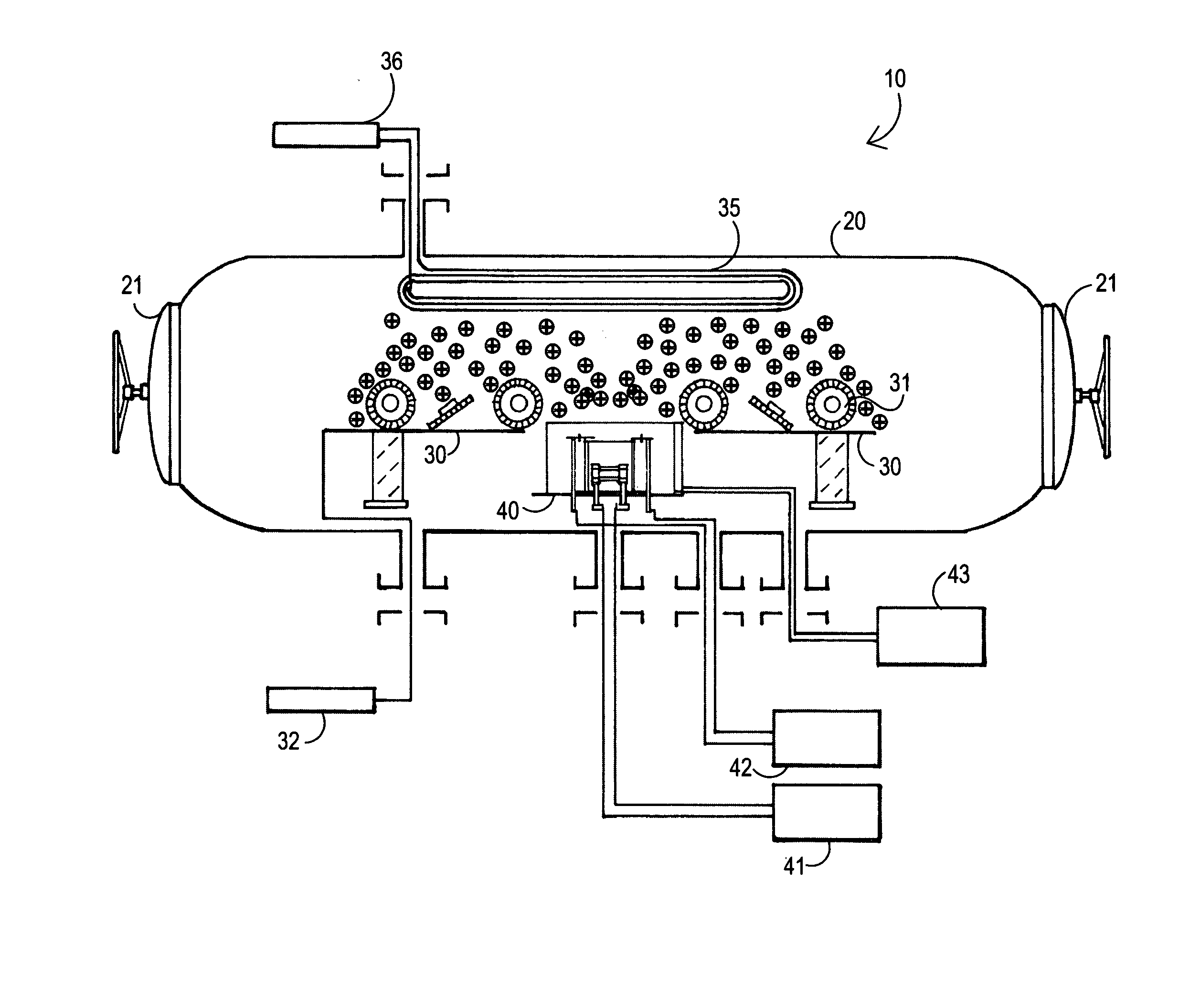

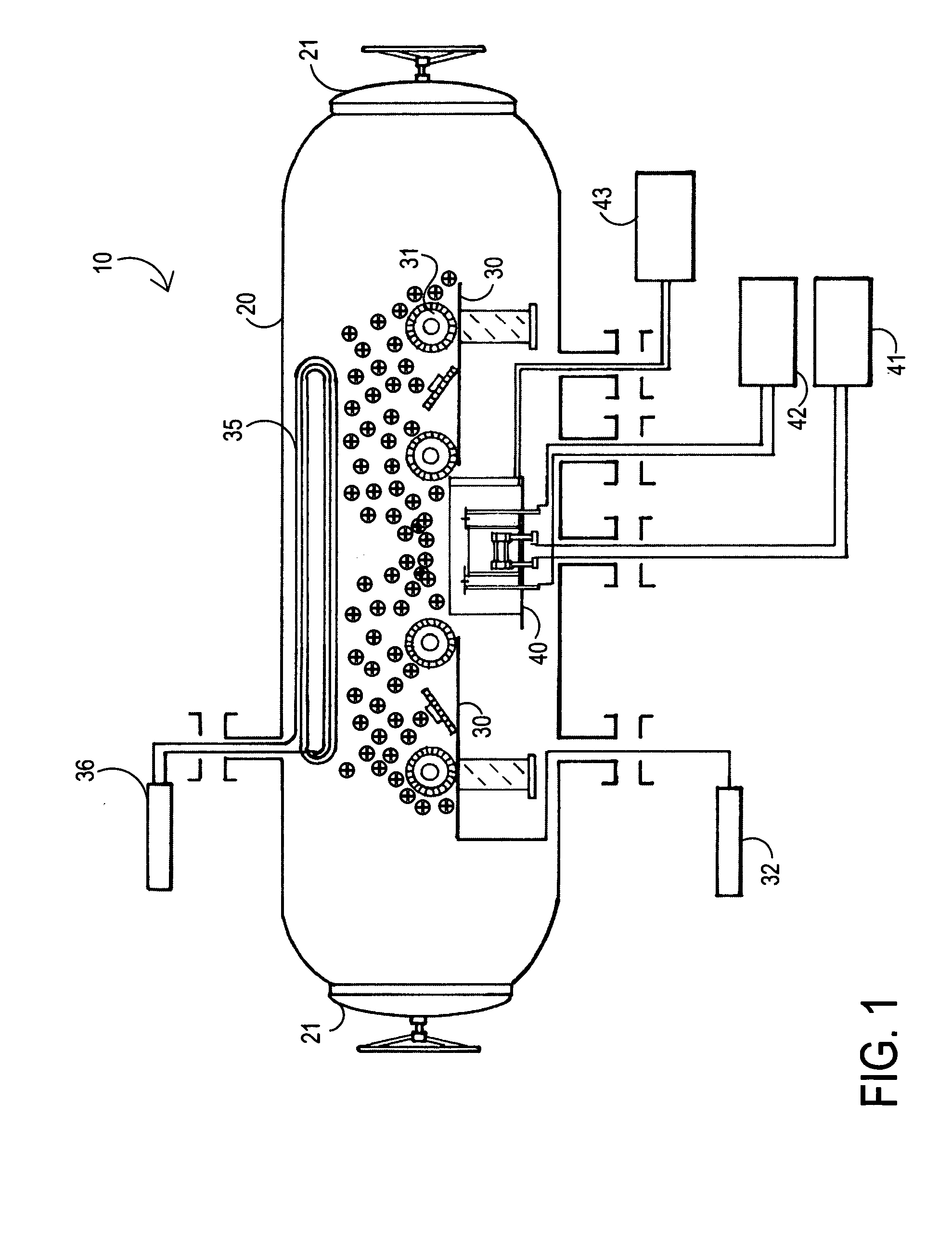

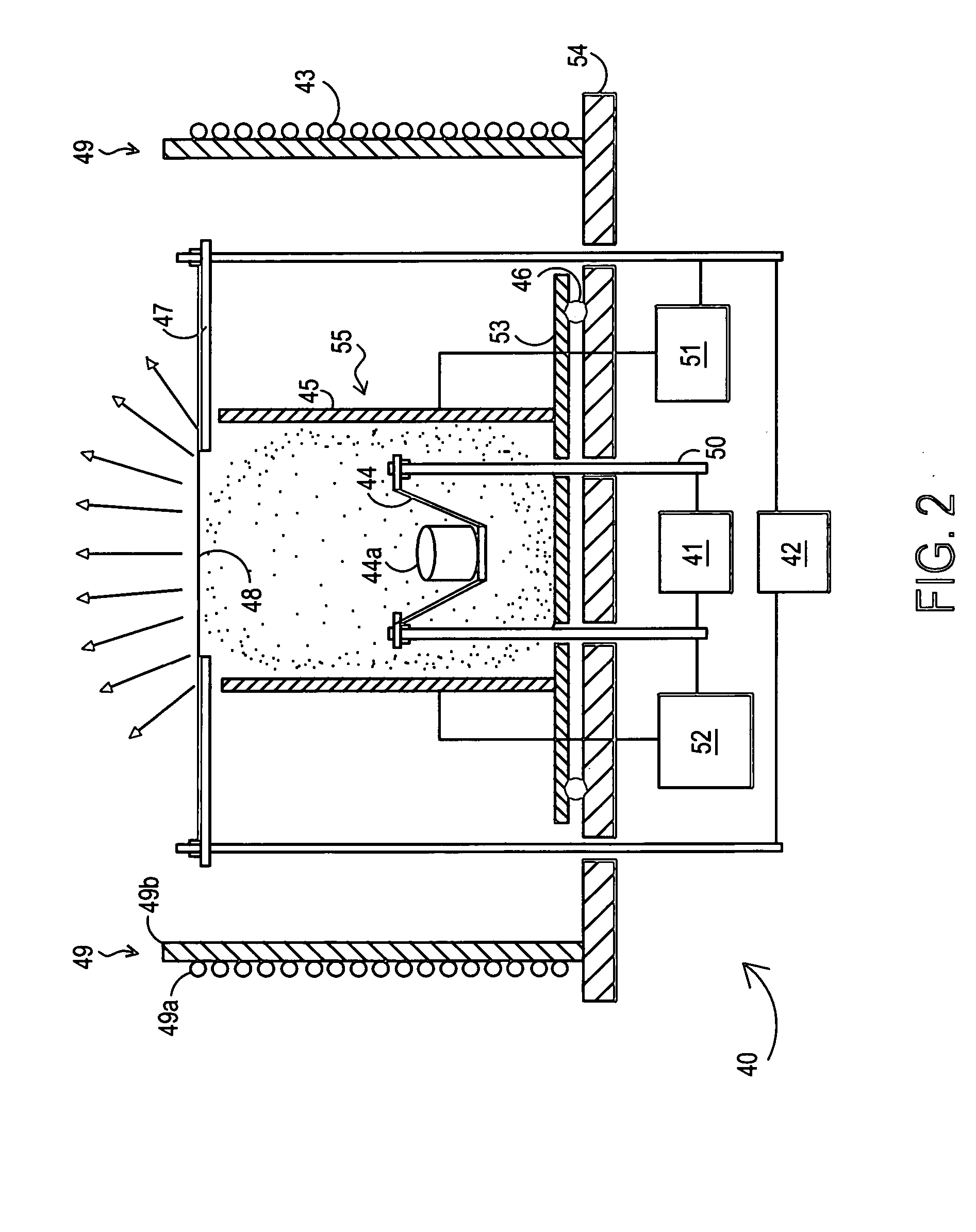

Apparatus and method for metal plasma immersion ion implantation and metal plasma immersion ion deposition

InactiveUS20050061251A1Large-scale processingReduce pressureElectric discharge tubesVacuum evaporation coatingIon depositionPlasma deposition

This invention is a method for metal plasma ion implantation and metal plasma ion deposition, comprising: providing a vacuum chamber with at least one workpiece having a surface positioned on a worktable within the vacuum chamber; reducing the pressure in the vacuum chamber; generating a plasma of metal ions within the vacuum chamber, applying a negative bias to the worktable to thereby accelerate metal ions from the plasma toward at least one workpiece to thereby either implant metal ions into or deposit metal ions onto the workpiece or both. This invention includes an apparatus for metal ion implantation and metal ion plasma deposition, comprising: a vacuum chamber, a metal plasma generator within the vacuum chamber, and at least one worktable within the vacuum chamber.

Owner:SOUTHWEST RES INST

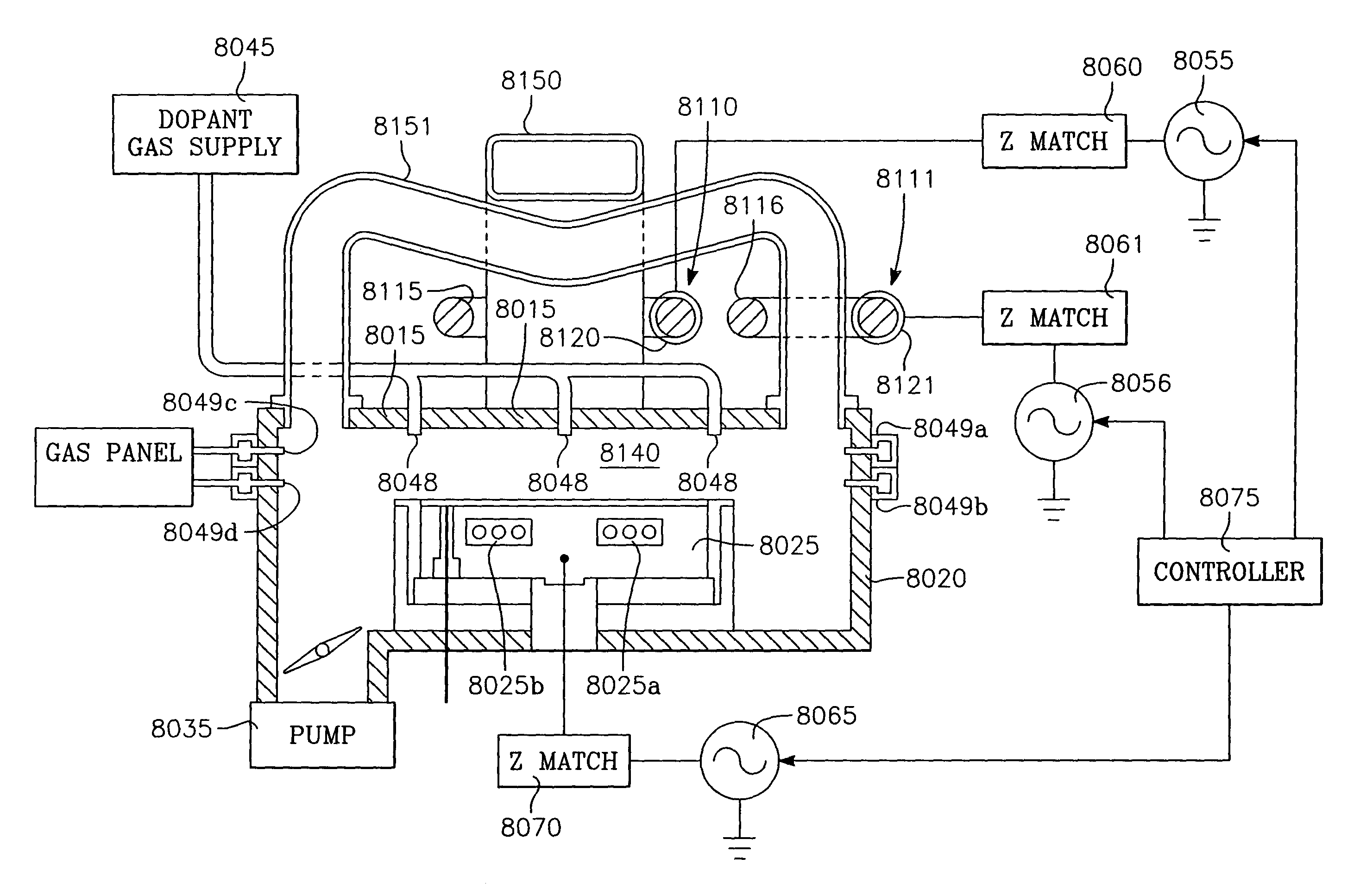

Plasma immersion ion implantation with highly uniform chamber seasoning process for a toroidal source reactor

InactiveUS20080286982A1Electric discharge tubesSemiconductor/solid-state device manufacturingPlasma currentPlasma-immersion ion implantation

A method is provided for performing plasma immersion ion implantation with a highly uniform seasoning film on the interior of a reactor chamber having a ceiling and a cylindrical side wall and a wafer support pedestal facing the ceiling. The method includes providing a gas distribution ring with plural gas injection orifices on a periphery of a wafer support pedestal, the orifices facing radially outwardly from the wafer support pedestal. Silicon-containing gas is introduced through the gas distribution orifices of the ring to establish a radially outward flow pattern of the silicon-containing gas. The reactor includes pairs of conduit ports in the ceiling adjacent the side wall at opposing sides thereof and respective external conduits generally spanning the diameter of the chamber and coupled to respective pairs of the ports. The method further includes injecting oxygen gas through the conduit ports into the chamber to establish an axially downward flow pattern of oxygen gas in the chamber. RF power is coupled into the interior of each of the conduits to generate a toroidal plasma current of SixOy species passing through the chamber to deposit a seasoning layer of a SixOy material on surfaces within the chamber, while leaving the pedestal without a wafer so as to expose a wafer support surface of the pedestal.

Owner:APPLIED MATERIALS INC

Plasma immersion ion implantation process using an inductively coupled plasma source having low dissociation and low minimum plasma voltage

InactiveUS7303982B2Electric discharge tubesSemiconductor/solid-state device manufacturingSurface layerProcess region

A method for implanting ions in a surface layer of a workpiece includes placing the workpiece on a workpiece support in a chamber with the surface layer being in facing relationship with a ceiling of the chamber, thereby defining a processing zone between the workpiece and the ceiling, and introducing into the chamber a process gas which includes the species to be implanted in the surface layer of the workpiece. The method further includes generating from the process gas a plasma by inductively coupling RF source power into the processing zone from an RF source power generator through an inductively coupled RF power applicator, and applying an RF bias from an RF bias generator to the workpiece support.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com