Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25686 results about "Mesh grid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

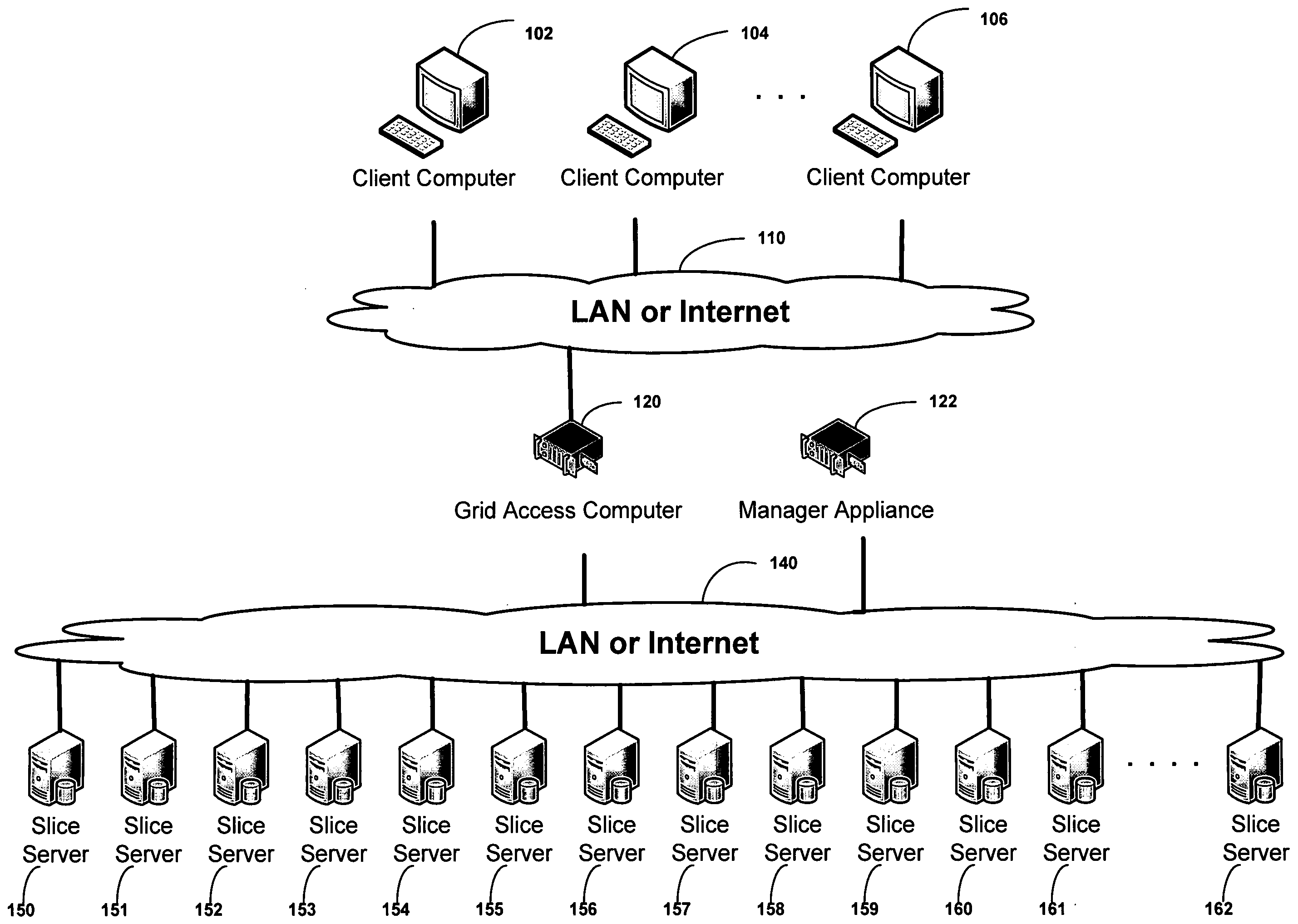

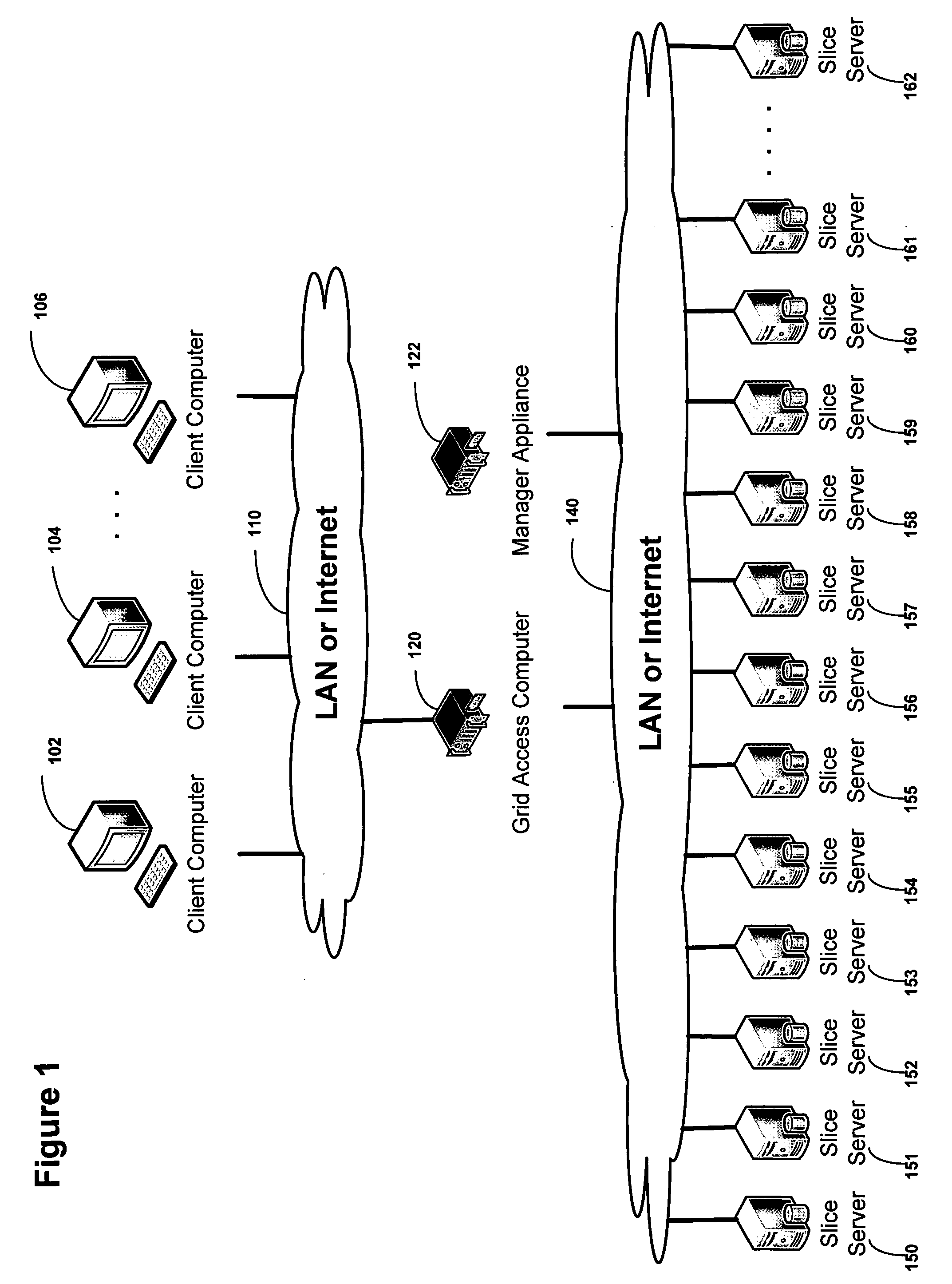

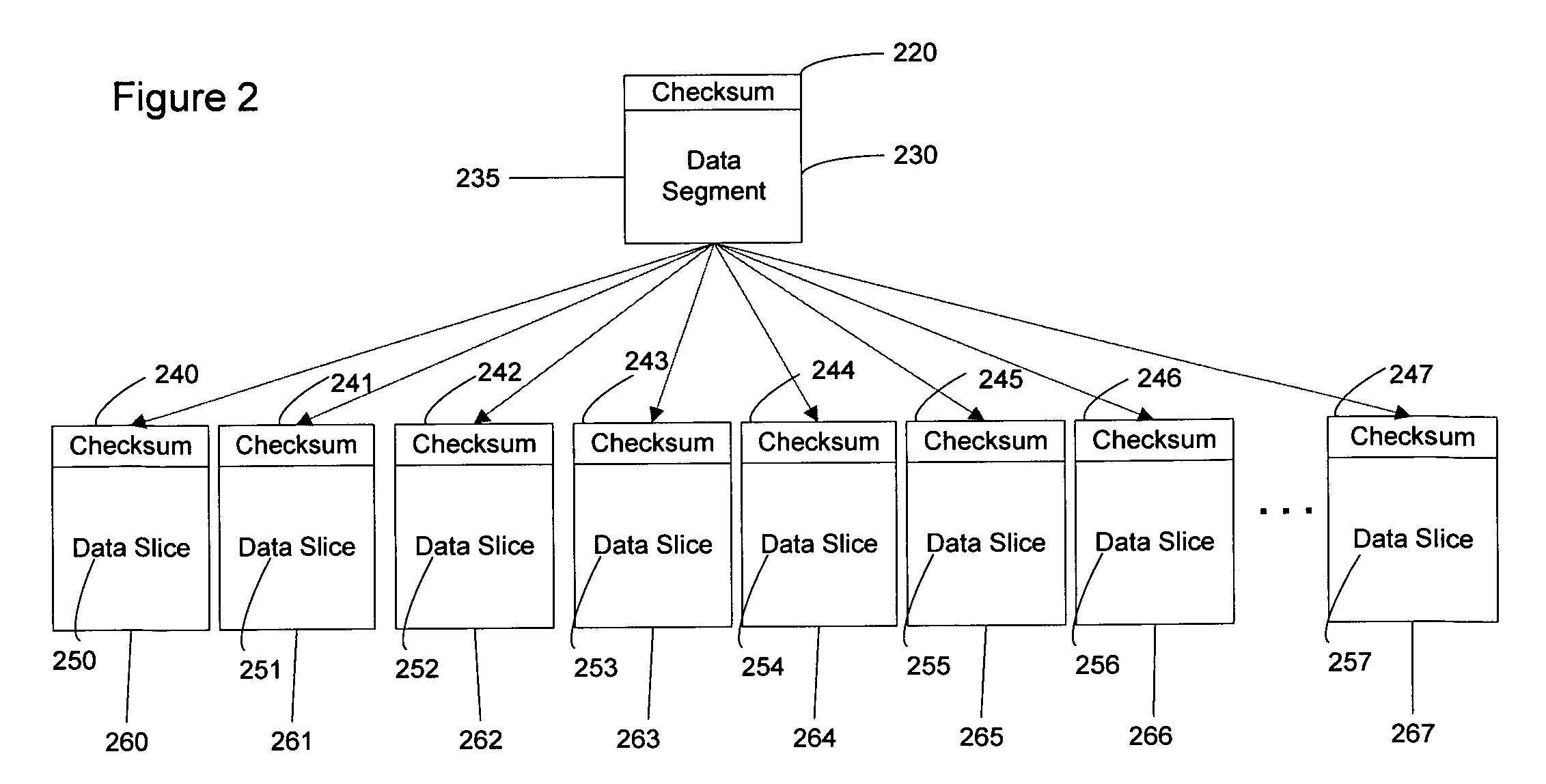

System for rebuilding dispersed data

ActiveUS20070079082A1Reliably and securely protectImprove privacyError detection/correctionDigital data protectionGrid resourcesInformation dispersal

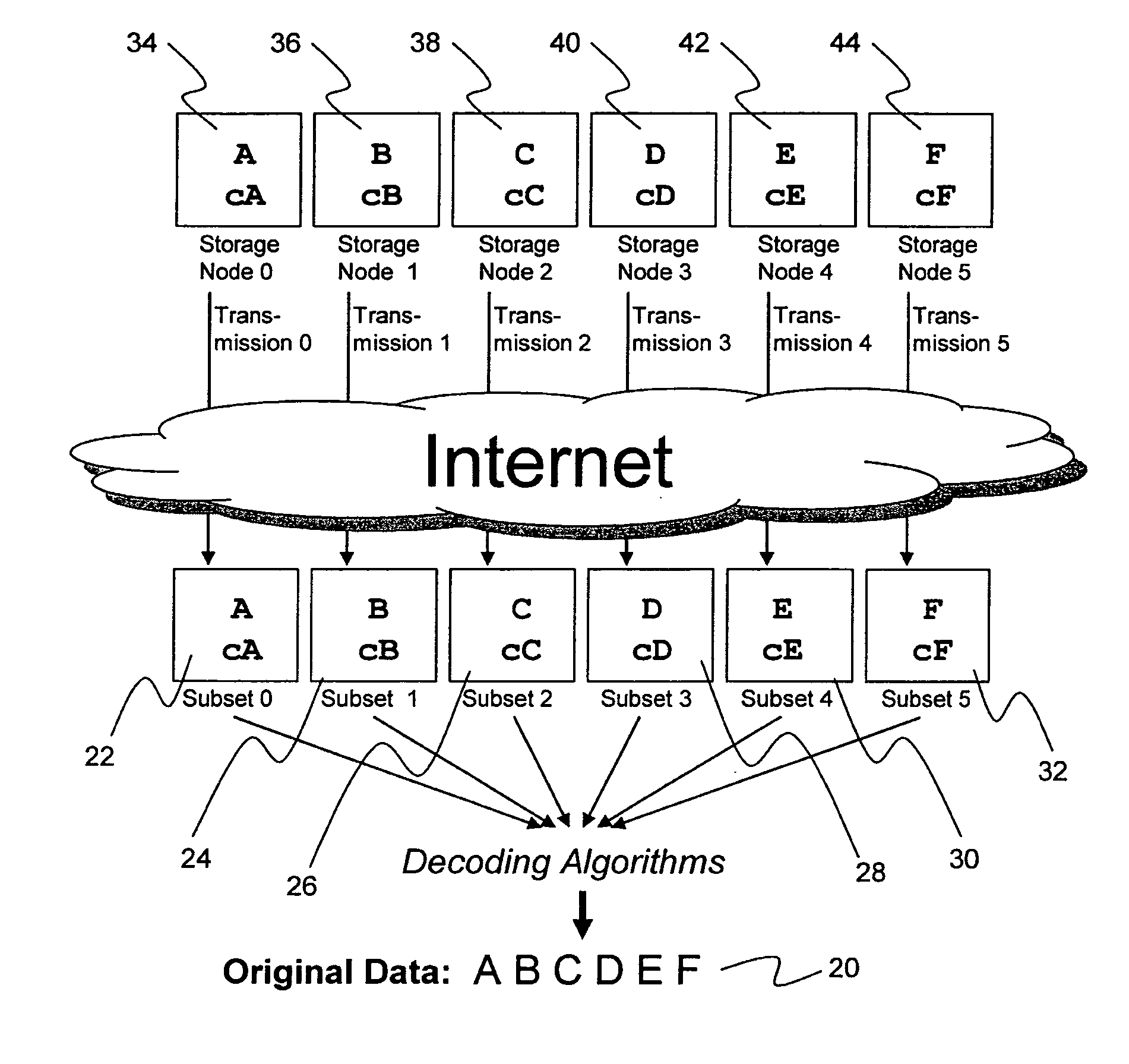

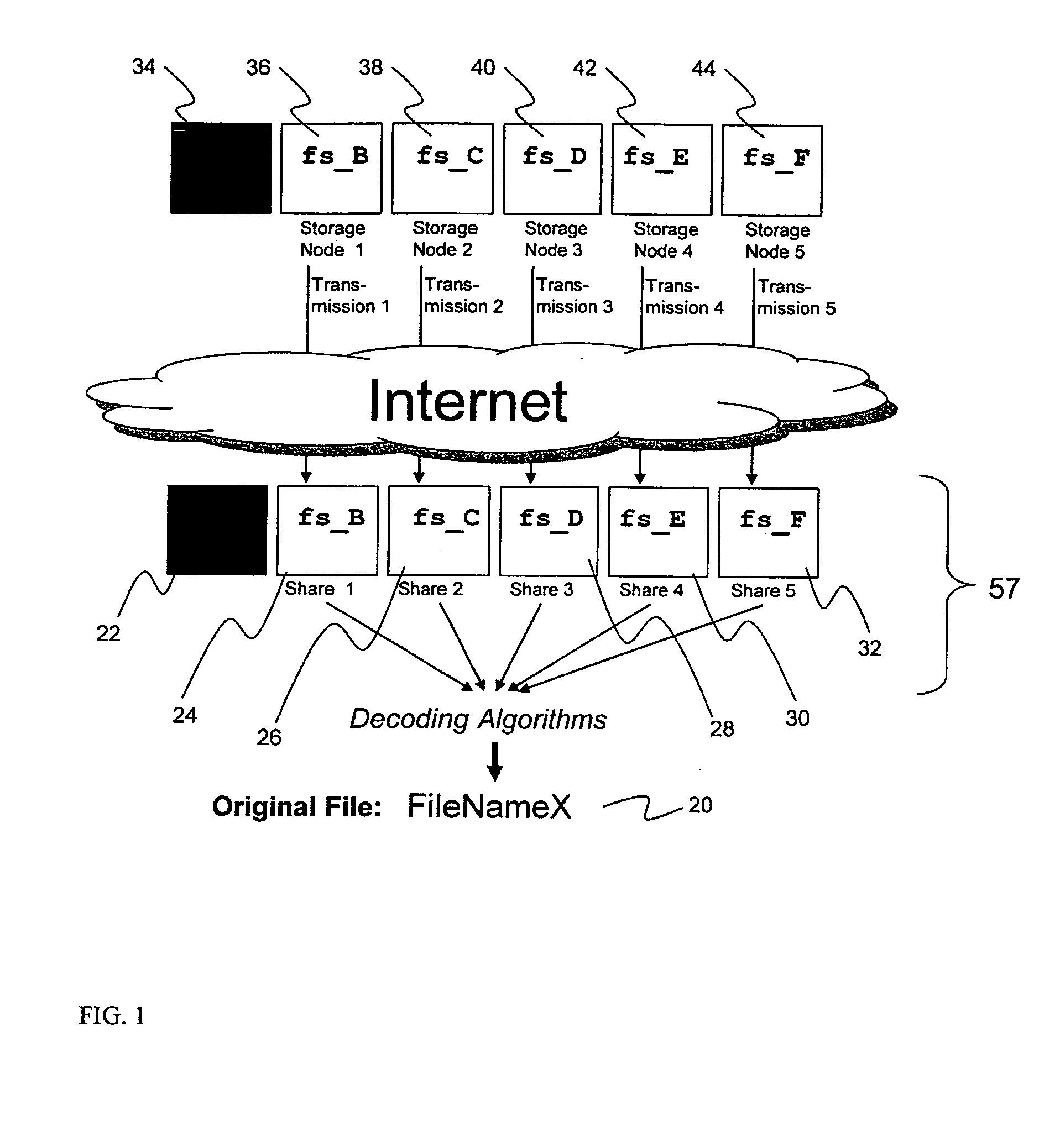

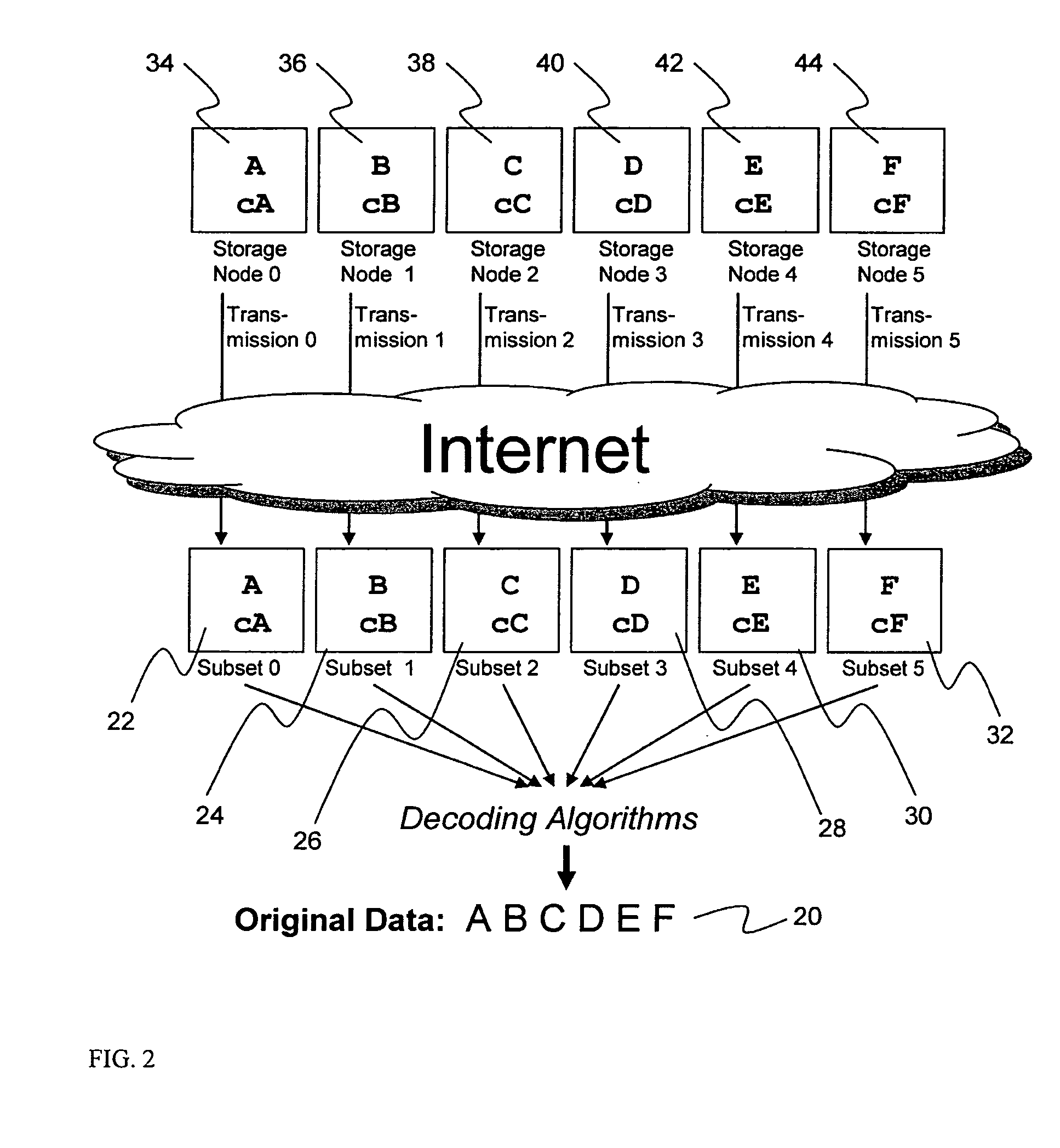

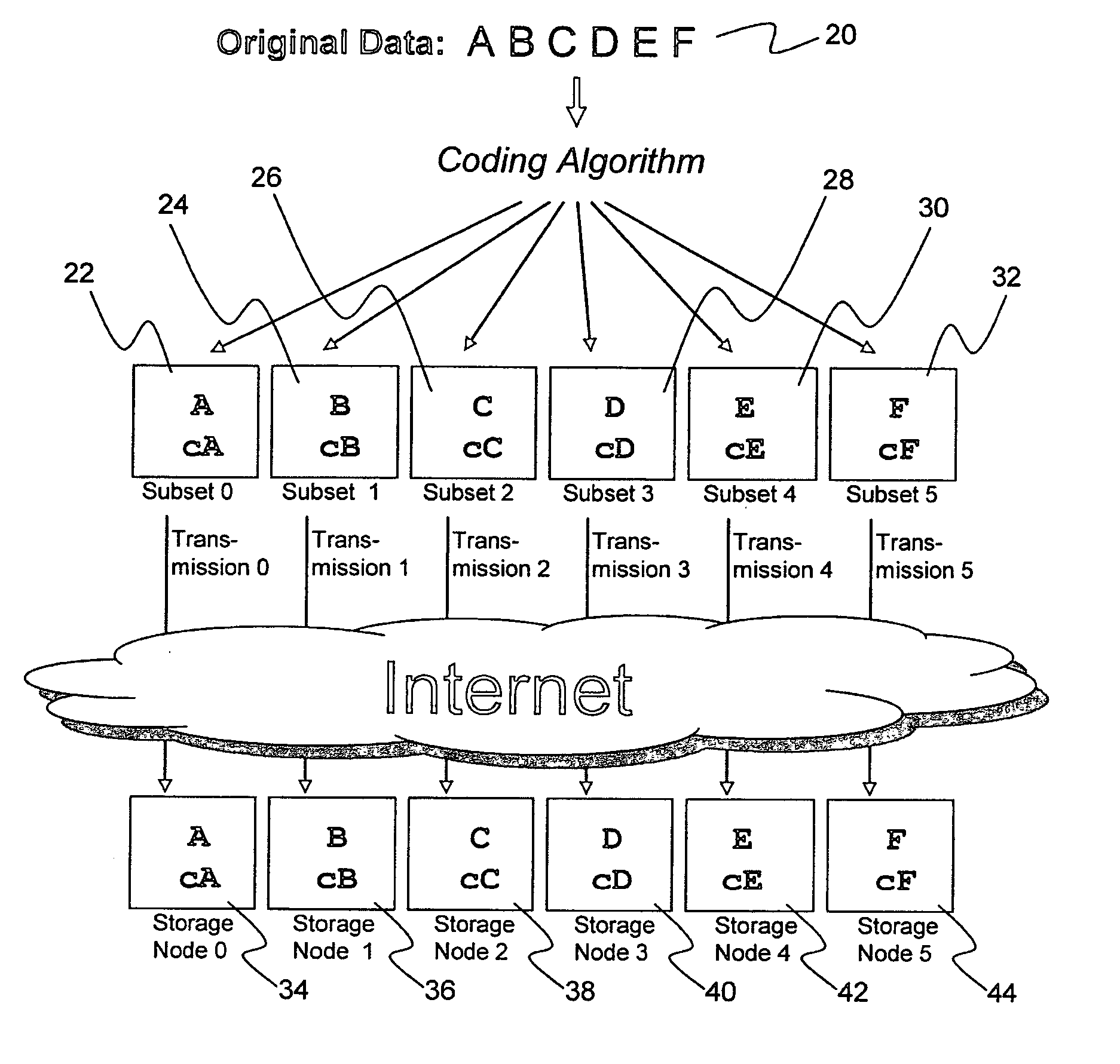

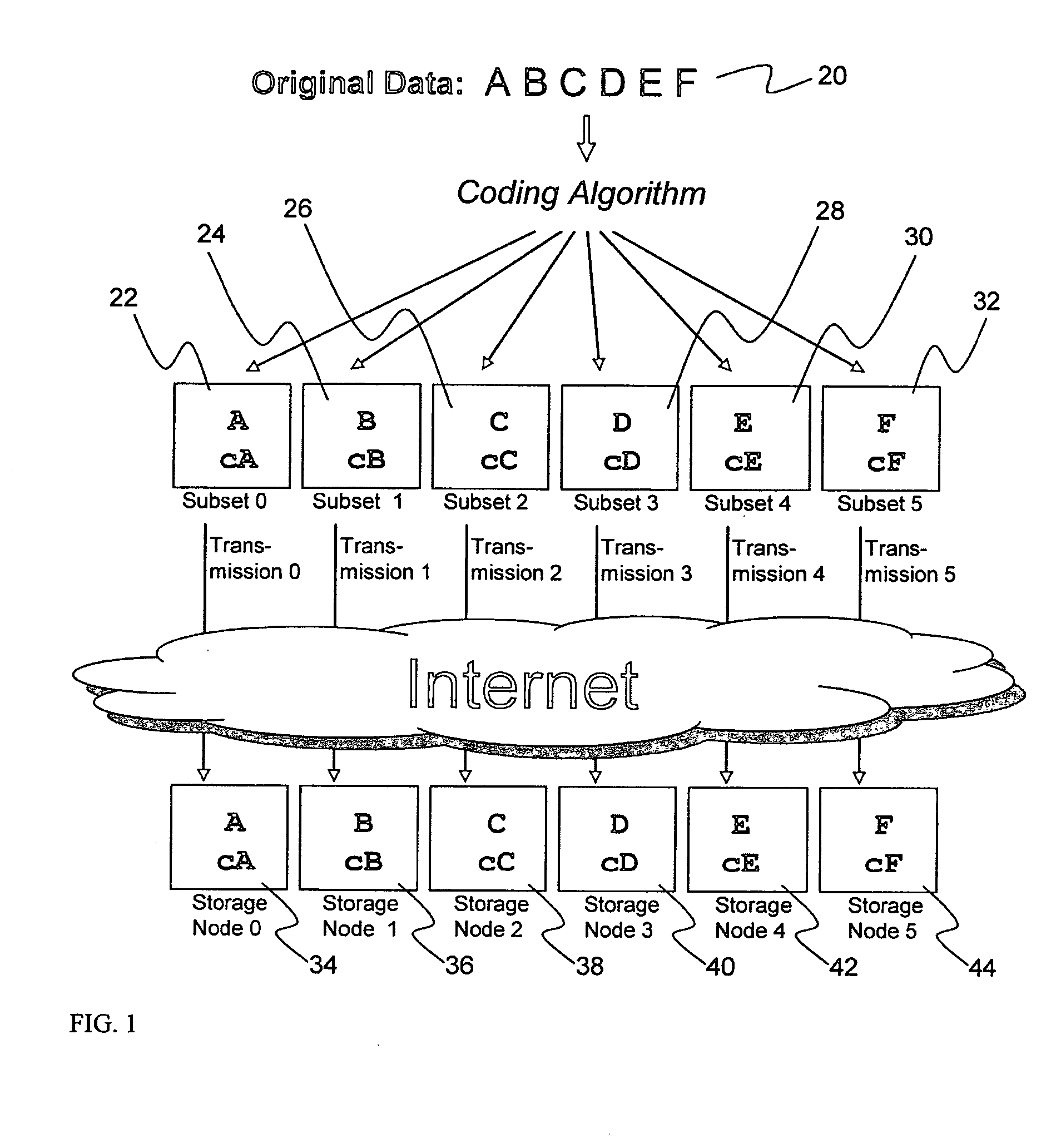

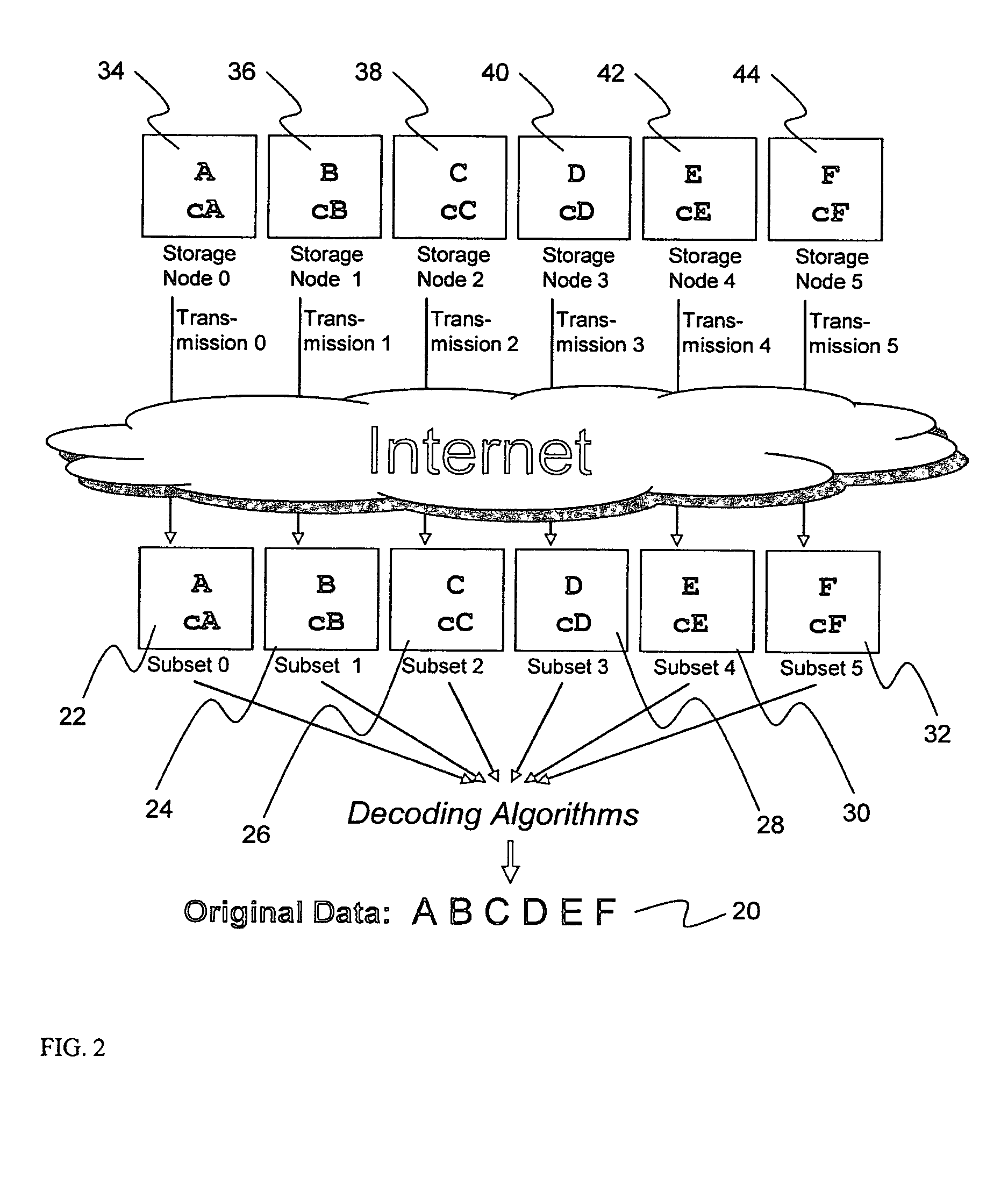

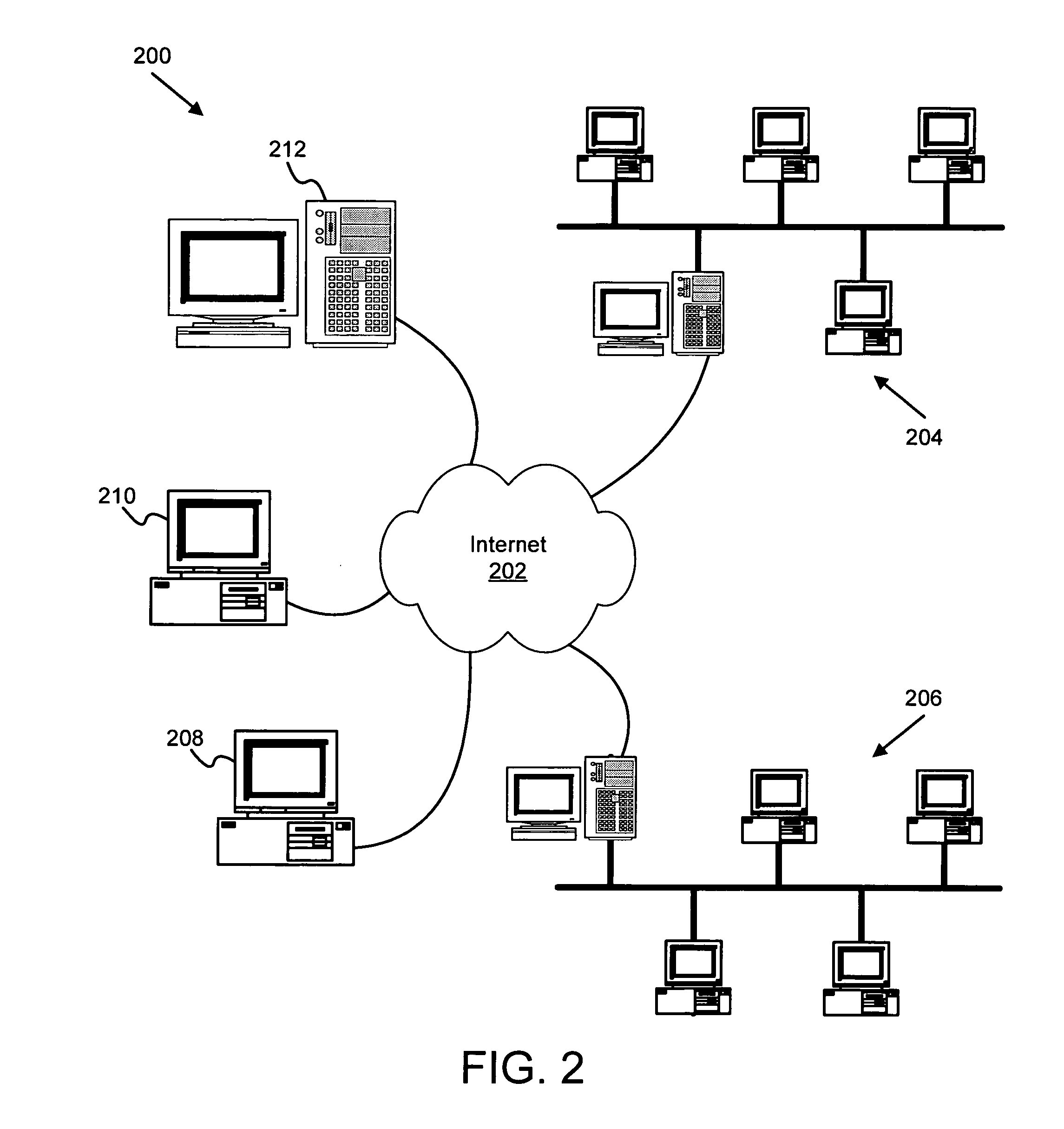

A digital data file storage system is disclosed in which original data files to be stored are dispersed using some form of information dispersal algorithm into a number of file “slices” or subsets in such a manner that the data in each file share is less usable or less recognizable or completely unusable or completely unrecognizable by itself except when combined with some or all of the other file shares. These file shares are stored on separate digital data storage devices as a way of increasing privacy and security. As dispersed file shares are being transferred to or stored on a grid of distributed storage locations, various grid resources may become non-operational or may operate below at a less than optimal level. When dispersed file shares are being written to a dispersed storage grid which not available, the grid clients designates the dispersed data shares that could not be written at that time on a Rebuild List. In addition when grid resources already storing dispersed data become non-available, a process within the dispersed storage grid designates the dispersed data shares that need to be recreated on the Rebuild List. At other points in time a separate process reads the set of Rebuild Lists used to create the corresponding dispersed data and stores that data on available grid resources.

Owner:PURE STORAGE

Billing system for information dispersal system

ActiveUS20070174192A1Less usableLess recognizableFinanceComputer security arrangementsInformation dispersalOriginal data

A billing process is disclosed for a information dispersal system or digital data storage system. In one embodiment of the invention, the original data to be stored is separated into a number of data “slices” or shares in such a manner that the data in each subset is less usable or less recognizable or completely unusable or completely unrecognizable by itself except when combined with some or all of the other data subsets. These data subsets are stored on separate digital data storage devices as a way of increasing privacy and security. As dispersed file shares are being stored or removed from a grid of distributed storage locations, a set of metadata tables are created, separate from the dispersed file share storage, to maintain information about the original data size of each block, file or set of file shares dispersed on the grid. The original data size information in these separate metadata tables is used to determine usage information based upon the original file size even though the file has been dispersed onto a storage grid that contains file slices who size may not relate to the original file size and the file slices may have been compressed by the system in order to reduce storage space or improve transmission time. As such, the billing process is able to enable a broad range of commercial billing options for billing for commercial data services on an information dispersal grid.

Owner:PURE STORAGE

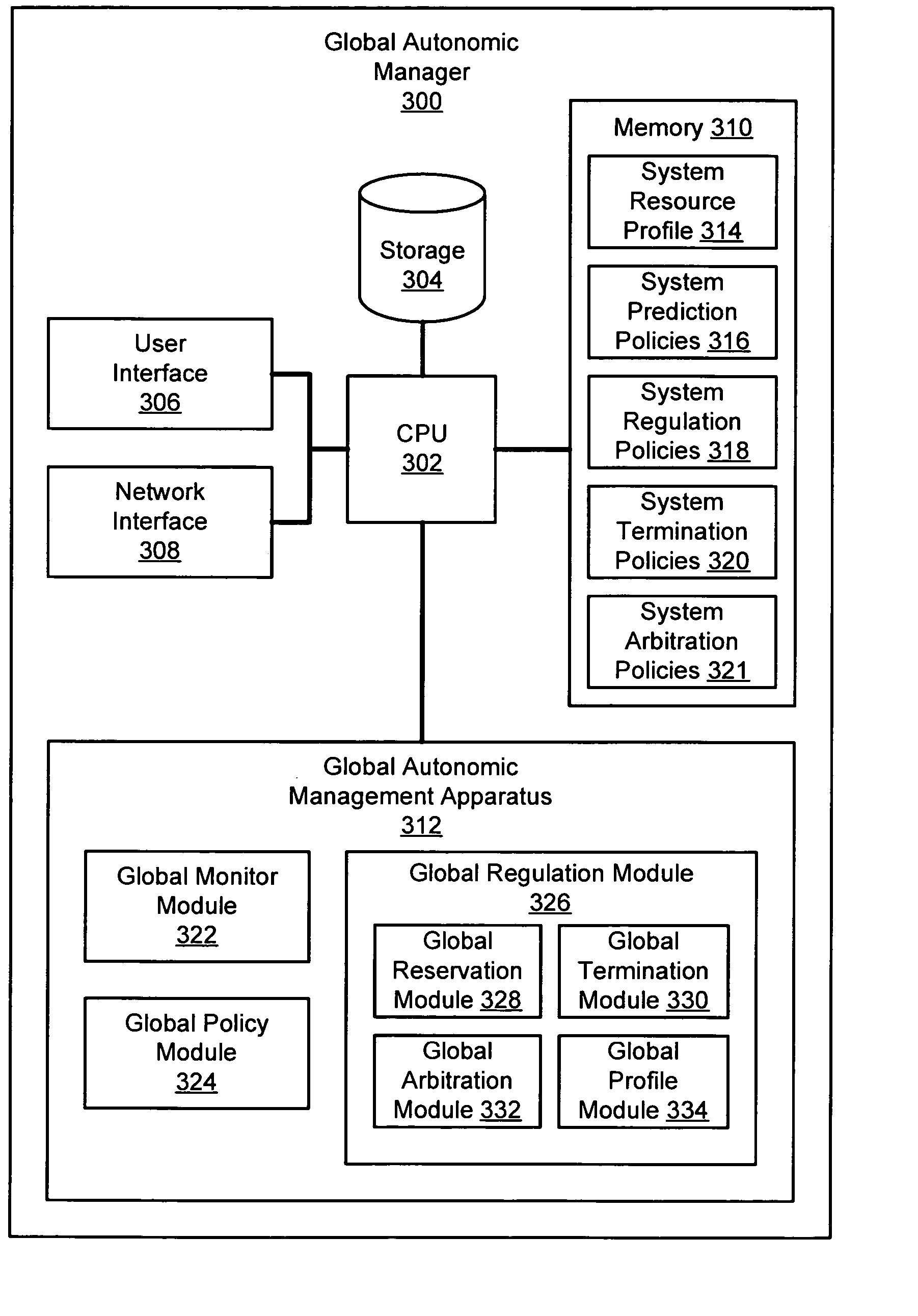

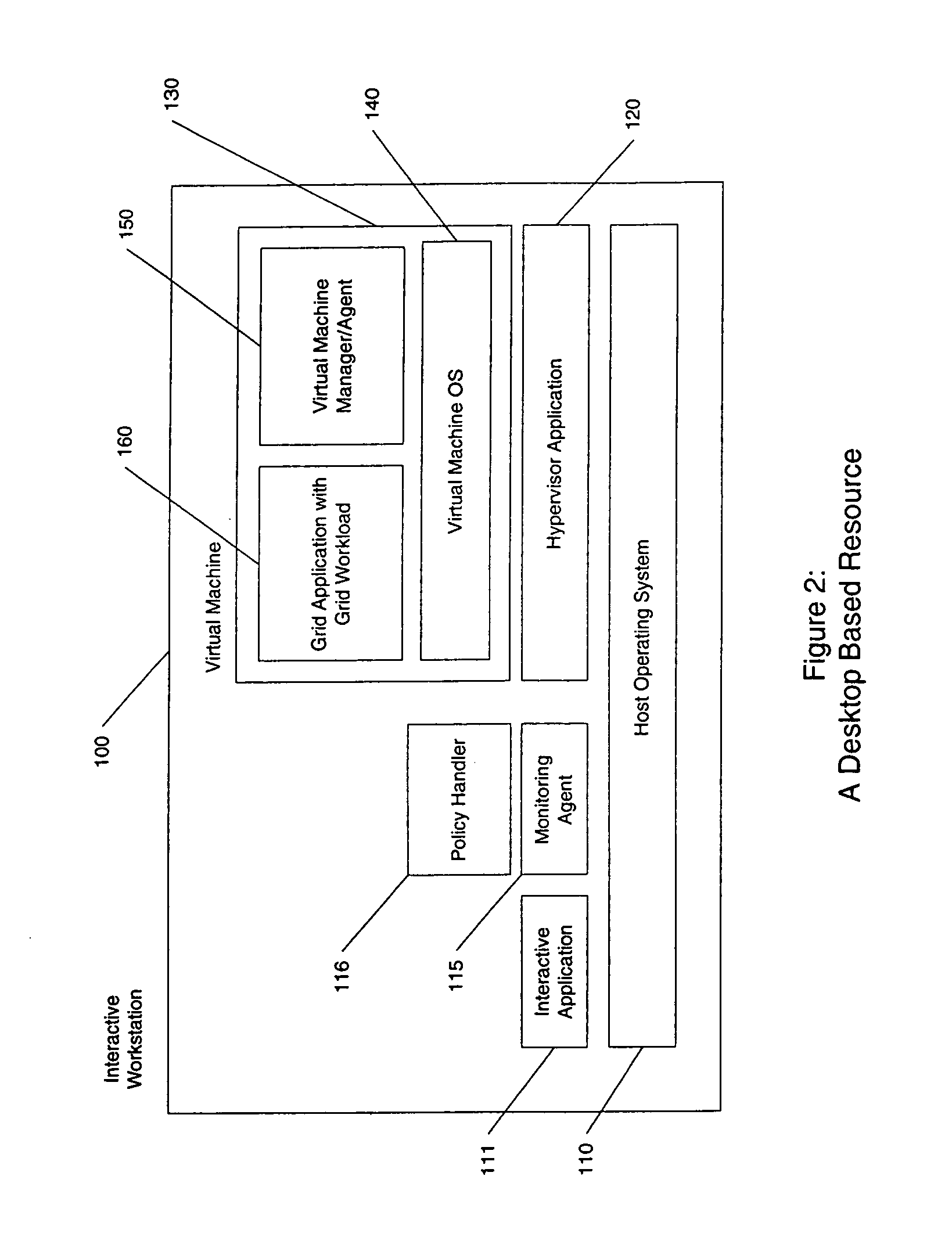

Apparatus, system, and method for autonomic control of grid system resources

ActiveUS20050131993A1Resource allocationMultiple digital computer combinationsAutomatic controlData operations

An apparatus, system, and method are disclosed for autonomic management of data operations and performance resources on a grid computing system. An autonomic management apparatus includes a monitor module, a policy module, and a regulation module. The monitor module is configured to monitor the grid computing system for a trigger event. The policy module is configured to access one of a plurality of system policies. Each of the plurality of system policies corresponds to an operational control parameter of a system resource of the grid computing system. The regulation module is configured to autonomically regulate the system resource in response to a recognized trigger event according to one of the plurality of system policies. The trigger event may be a prediction trigger event, an initiation trigger event, a regulation trigger event, or a termination trigger event.

Owner:WESTERN DIGITAL TECH INC

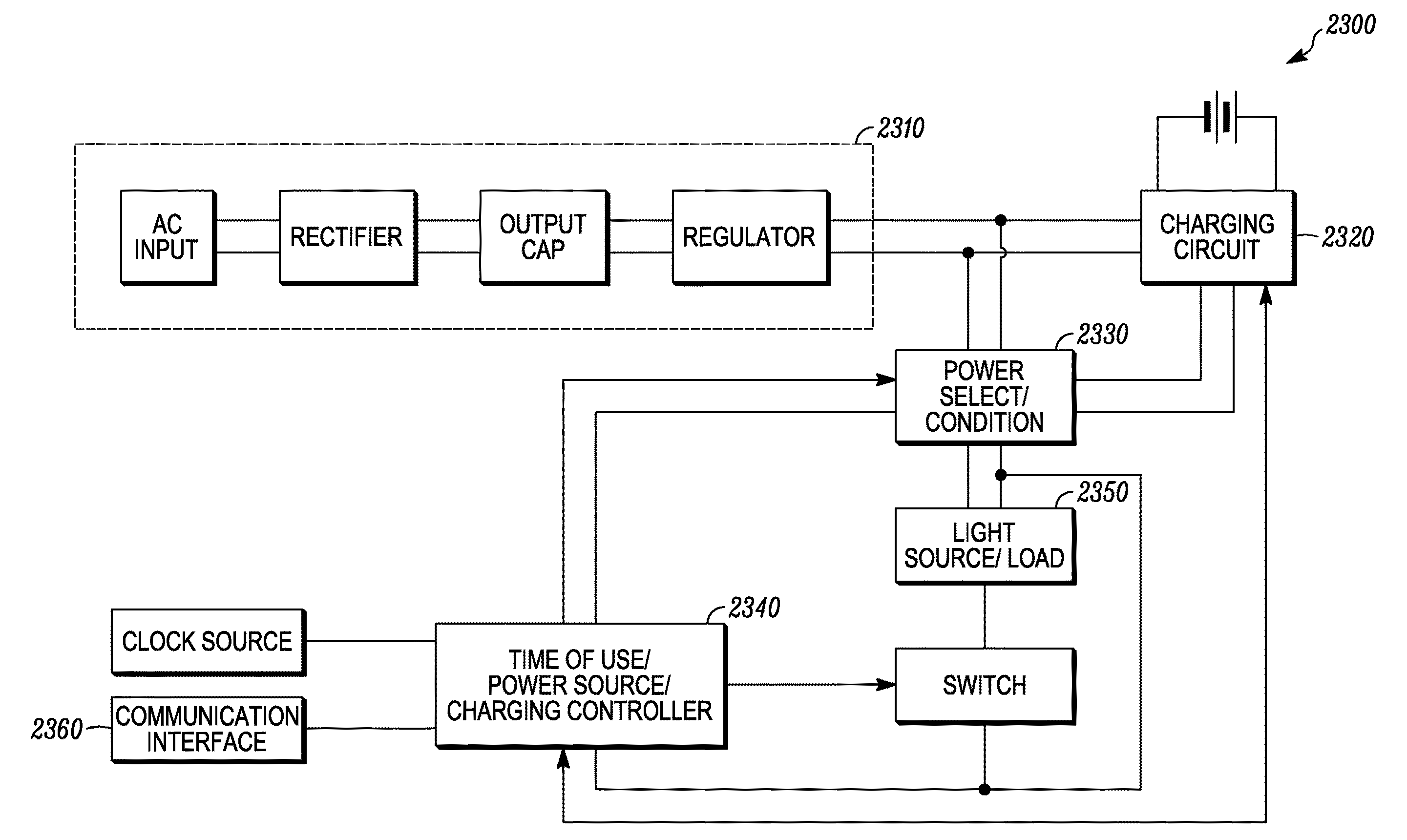

Autonomous grid shifting lighting device

InactiveUS20110133655A1Advantage in easeLow costElectroluminescent light sourcesSemiconductor lamp usageElectricityEffect light

In embodiments of the present invention improved capabilities are described for autonomous shifting of at least a portion of a lighting load off an energy distribution grid, comprising electrically connecting a lighting device to the energy distribution grid; causing the lighting device to interpret information obtained from an information source proximate the lighting device; and causing the lighting device to select from at least two different power sources based on the interpretation, where selecting may include a sharing of the load between the two different power sources, and where one power source may be the energy distribution grid.

Owner:RING LLC

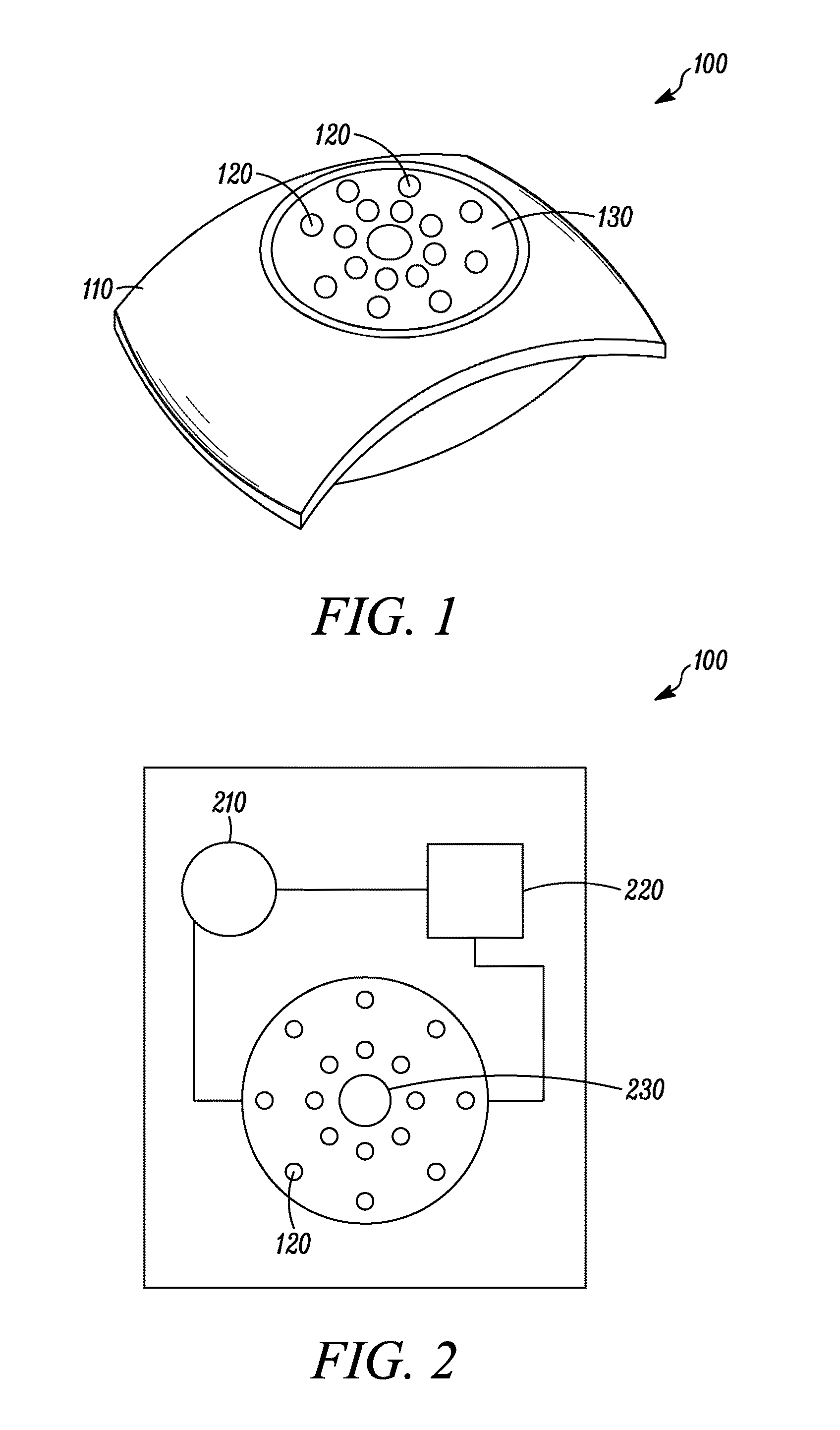

Multi-touch display screen with localized tactile feedback

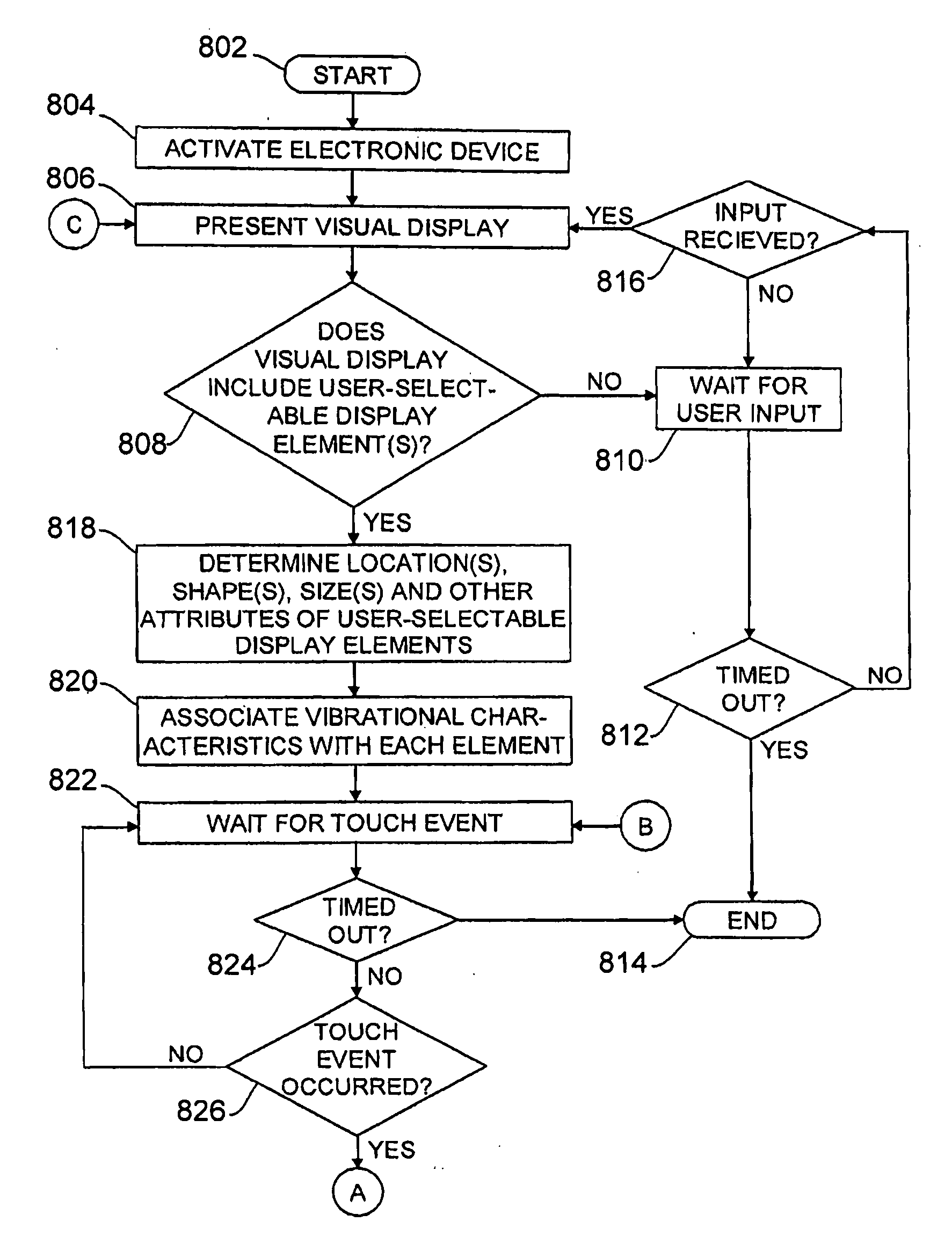

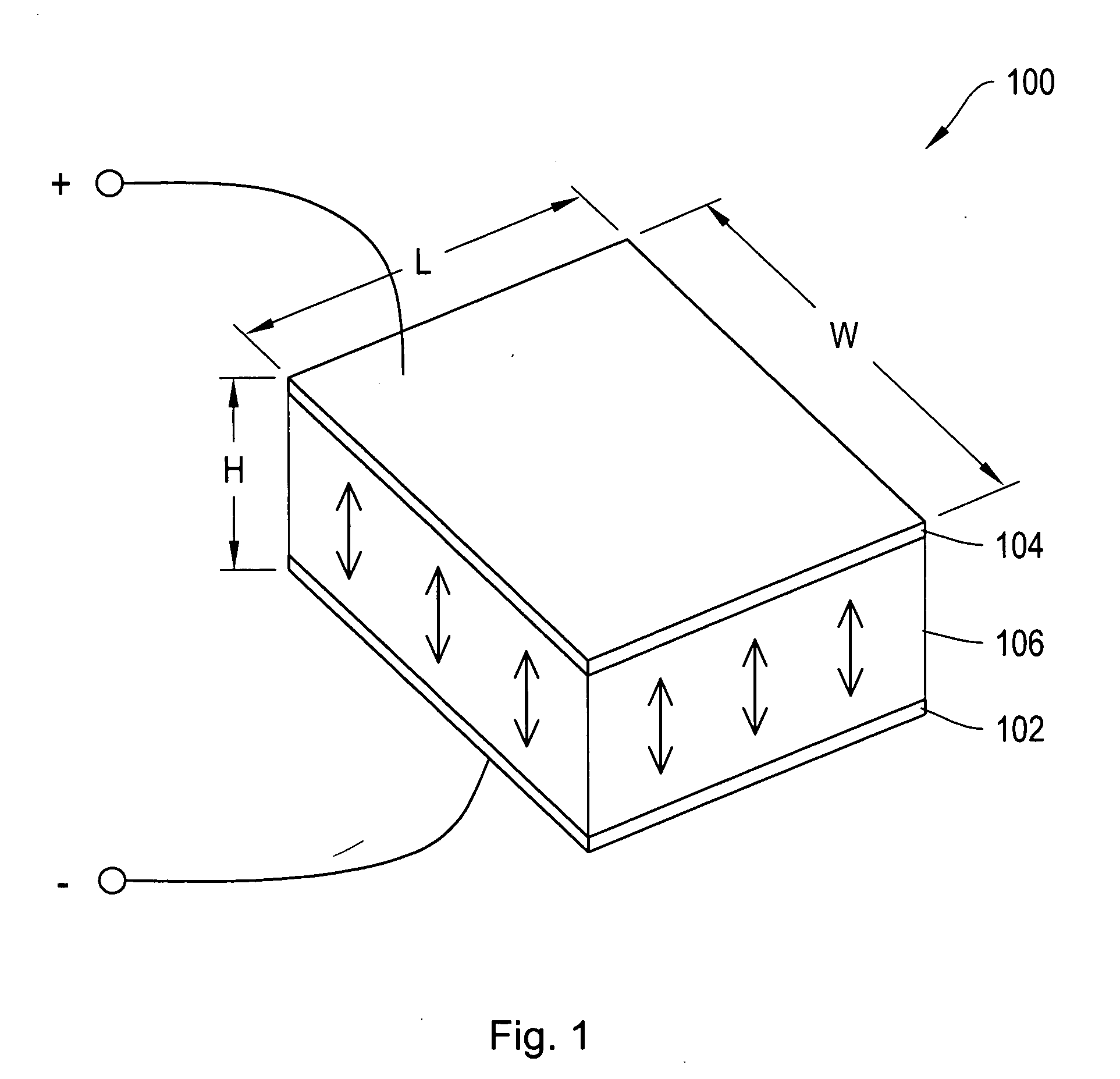

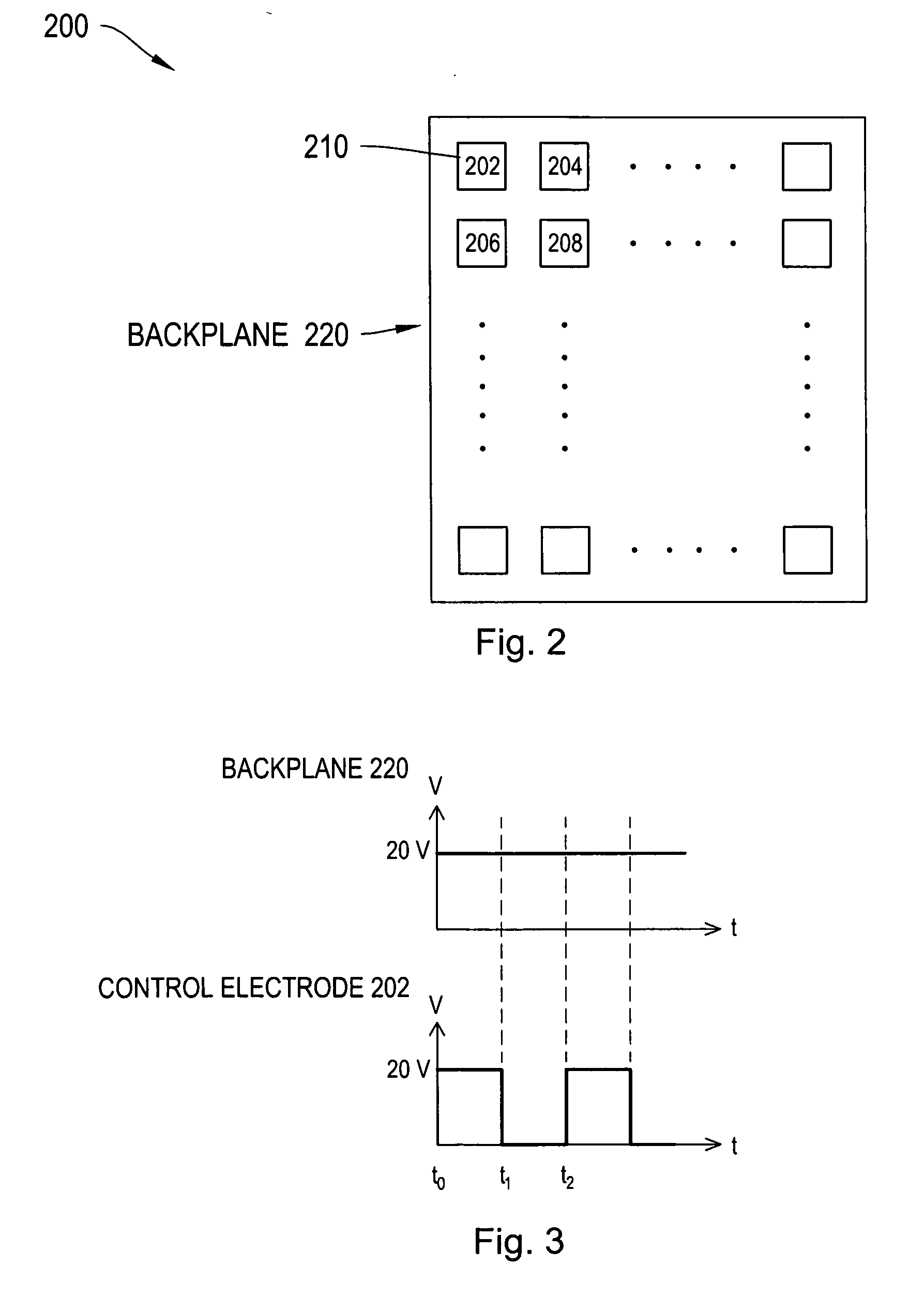

Systems, methods, computer-readable media, and other means are described for utilizing touch-based input components that provide localized haptic feedback to a user. The touch-based input components can be used and / or integrated into any type of electronic device, including laptop computers, cellular telephones, and portable media devices. The touch-based input components can use, for example, a grid of piezoelectric actuators to provide vibrational feedback to a user, while the user scrolls around a click wheel, slides across a trackpad, or touches a multi-touch display screen.

Owner:APPLE INC

Smart filtering

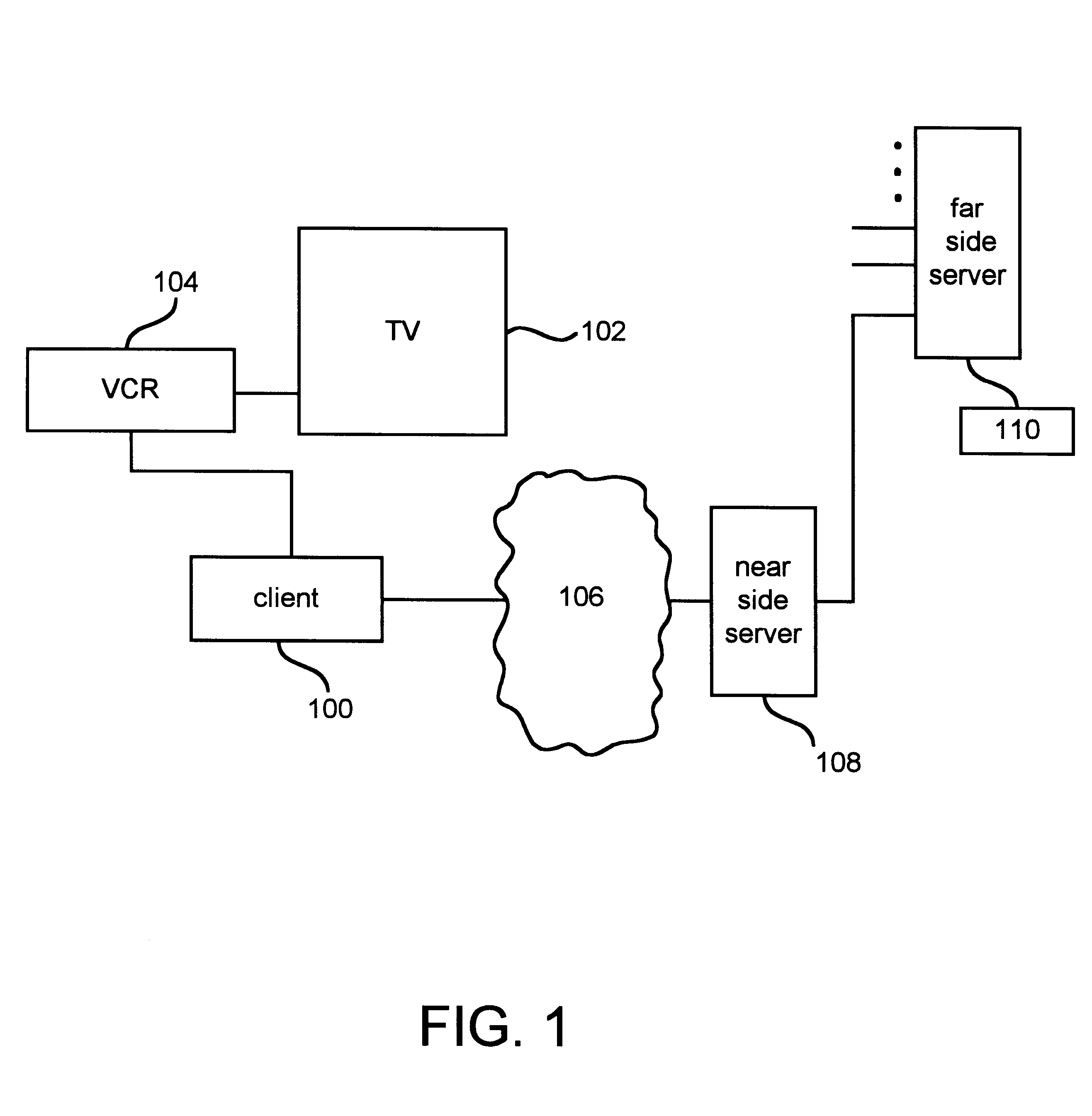

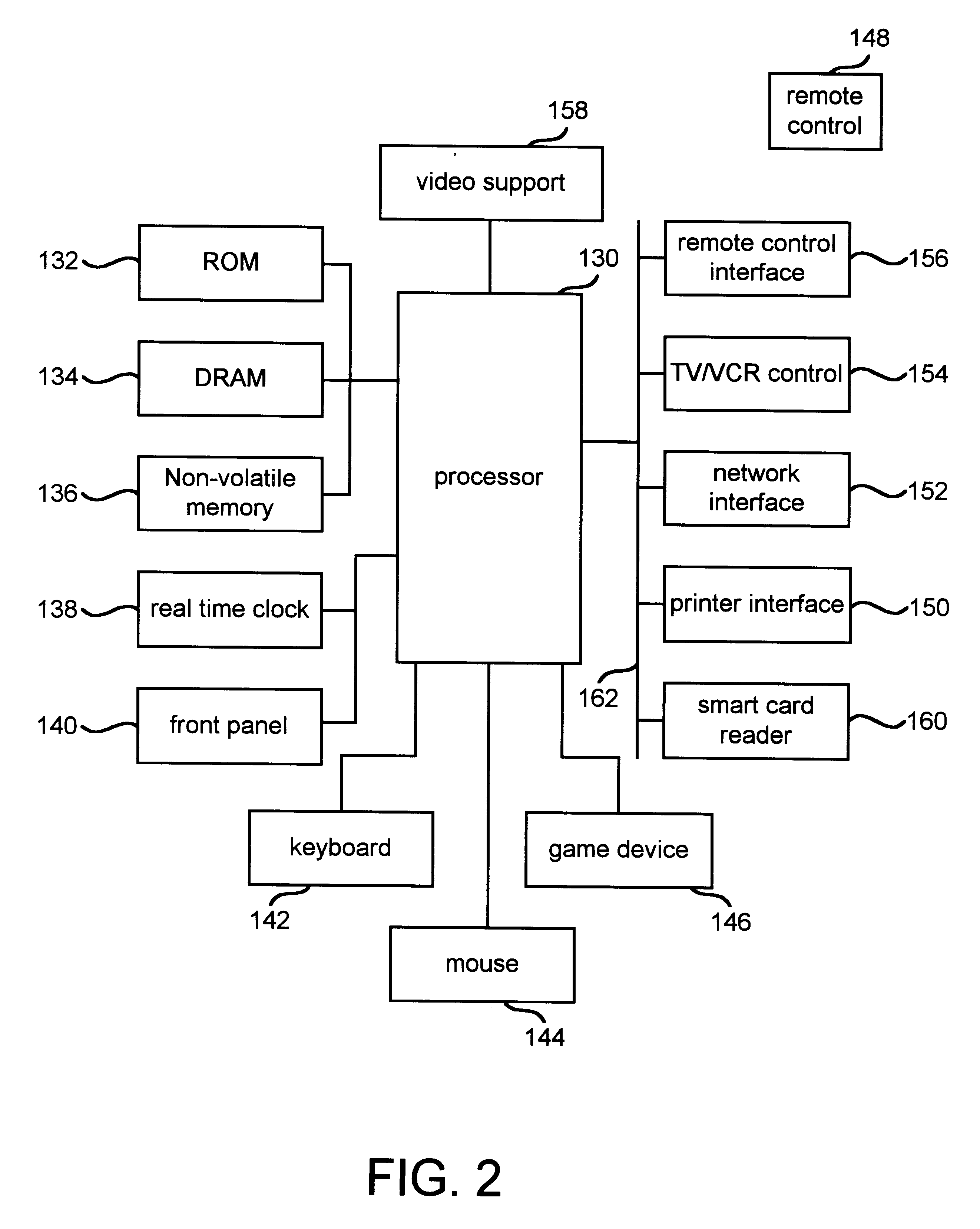

InactiveUS6172674B1Reduce settingsFind quicklyTelevision system detailsAnalogue secracy/subscription systemsComputer scienceElectronic program guide

A system and method for implementing an electronic programming guide that allows a television viewer to access and interact with television scheduling information. The electronic programming guide provides the viewer with a grid which lists channels, titles and show times. To help the viewer locate information about shows the viewer is interested in, the guide can filter the data prior to display. Only the data that meets certain filter criteria will be displayed. The filter criteria are set by the viewer. The filter criteria can be changed by manipulating a variable selection element such as a slider.

Owner:COMCAST CABLE COMM MANAGEMENT LLC

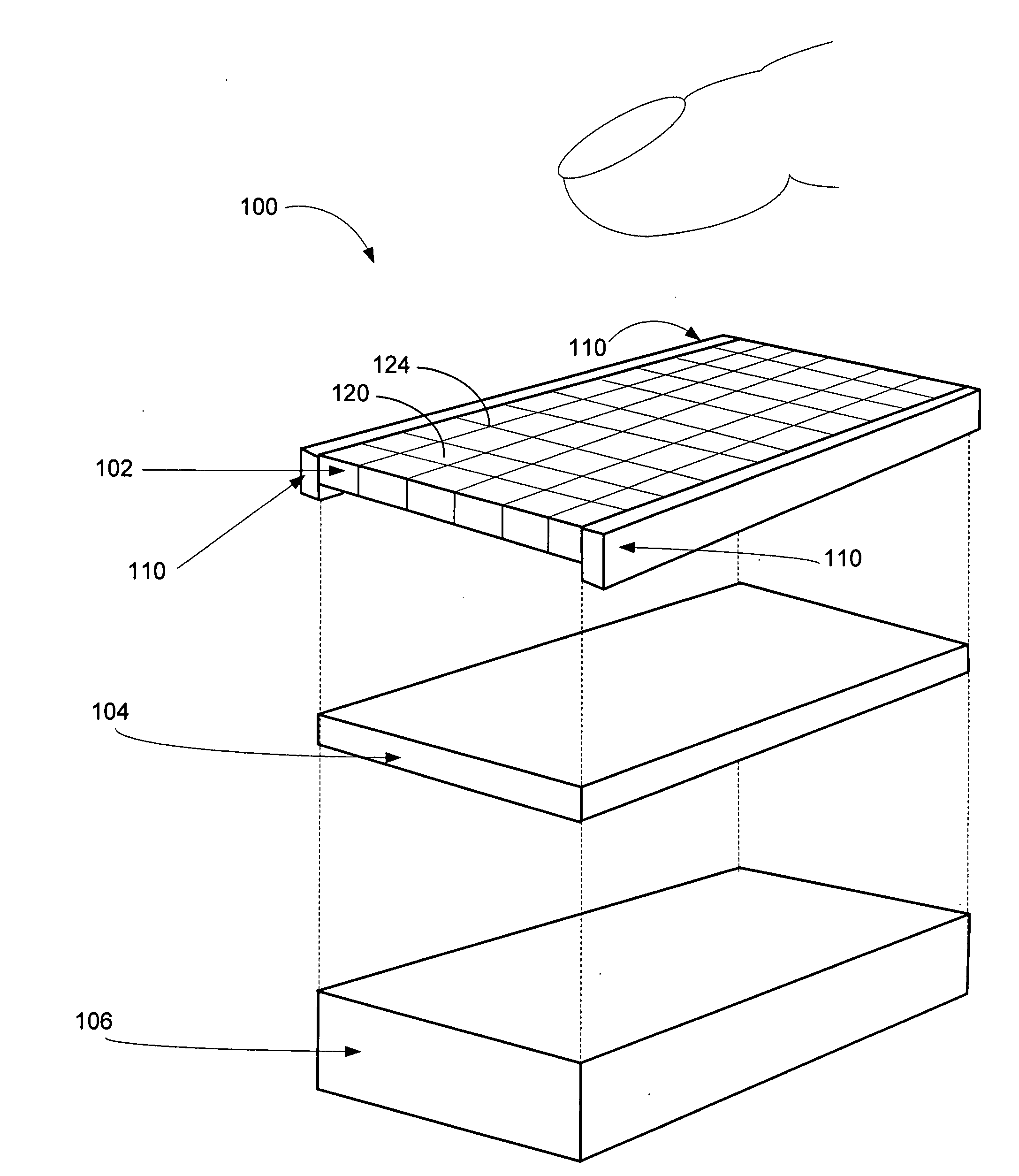

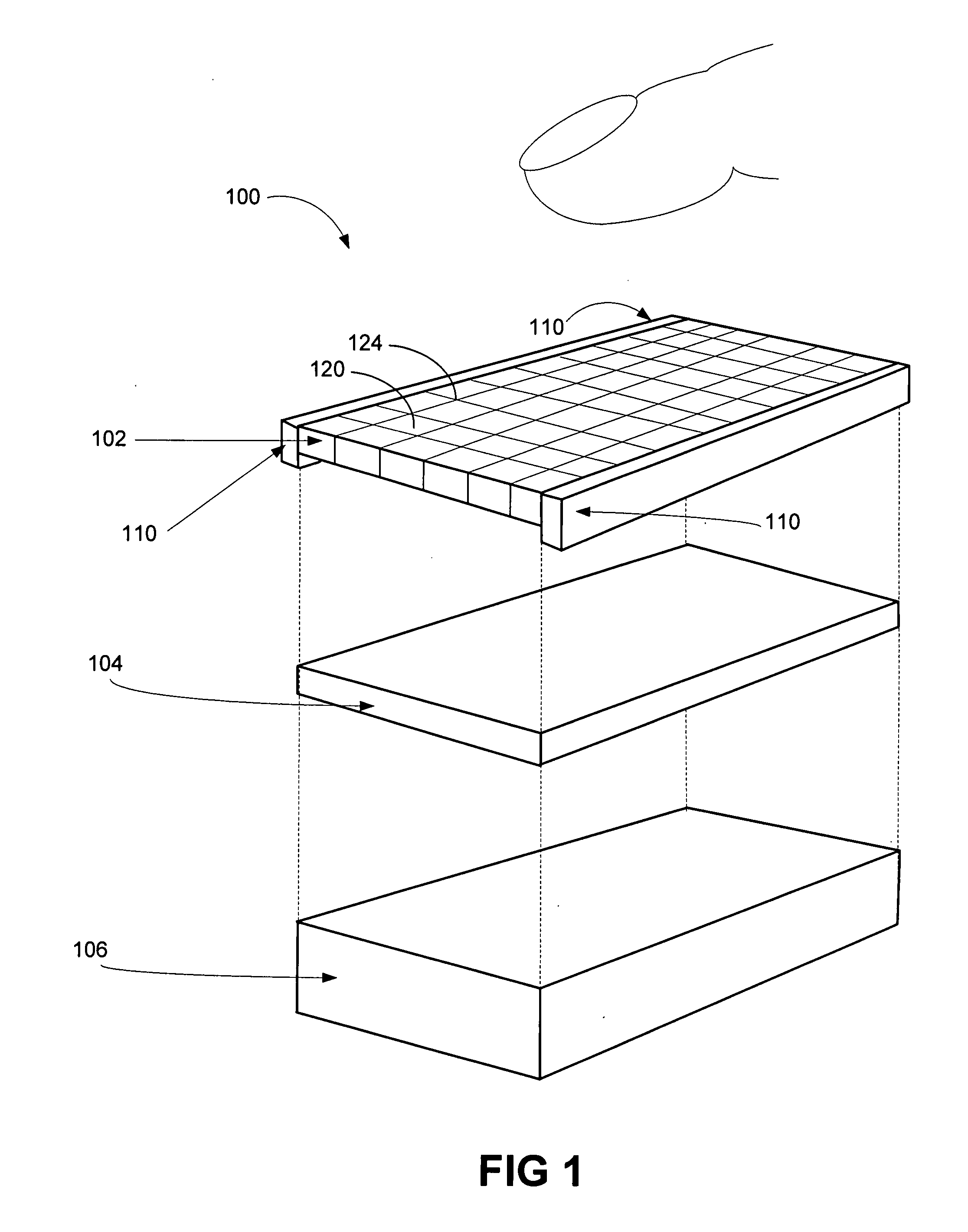

Method and apparatus for multi-touch tactile touch panel actuator mechanisms

A method and apparatus of actuator mechanisms for a multi-touch tactile touch panel are disclosed. The tactile touch panel includes an electrical insulated layer and a tactile layer. The top surface of the electrical insulated layer is capable of receiving an input from a user. The tactile layer includes a grid or an array of haptic cells. The top surface of the haptic layer is situated adjacent to the bottom surface of the electrical insulated layer, while the bottom surface of the haptic layer is situated adjacent to a display. Each haptic cell further includes at least one piezoelectric material, Micro-Electro-Mechanical Systems (“MEMS”) element, thermal fluid pocket, MEMS pump, resonant device, variable porosity membrane, laminar flow modulation, or the like. Each haptic cell is configured to provide a haptic effect independent of other haptic cells in the tactile layer.

Owner:IMMERSION CORPORATION

Simulation gridding method and apparatus including a structured areal gridder adapted for use by a reservoir simulator

InactiveUS6106561AHigh simulationSimulation results are accurateElectric/magnetic detection for well-loggingComputation using non-denominational number representationHorizonTriangulation

A Flogrid Simulation Gridding Program includes a Flogrid structured gridder. The structured gridder includes a structured areal gridder and a block gridder. The structured areal gridder will build an areal grid on an uppermost horizon of an earth formation by performing the following steps: (1) building a boundary enclosing one or more fault intersection lines on the horizon, and building a triangulation that absorbs the boundary and the faults; (2) building a vector field on the triangulation; (3) building a web of control lines and additional lines inside the boundary which have a direction that corresponds to the direction of the vector field on the triangulation, thereby producing an areal grid; and (4) post-processing the areal grid so that the control lines and additional lines are equi-spaced or smoothly distributed. The block gridder of the structured gridder will drop coordinate lines down from the nodes of the areal grid to complete the construction of a three dimensional structured grid. A reservoir simulator will receive the structured grid and generate a set of simulation results which are displayed on a 3D Viewer for observation by a workstation operator.

Owner:SCHLUMBERGER TECH CORP

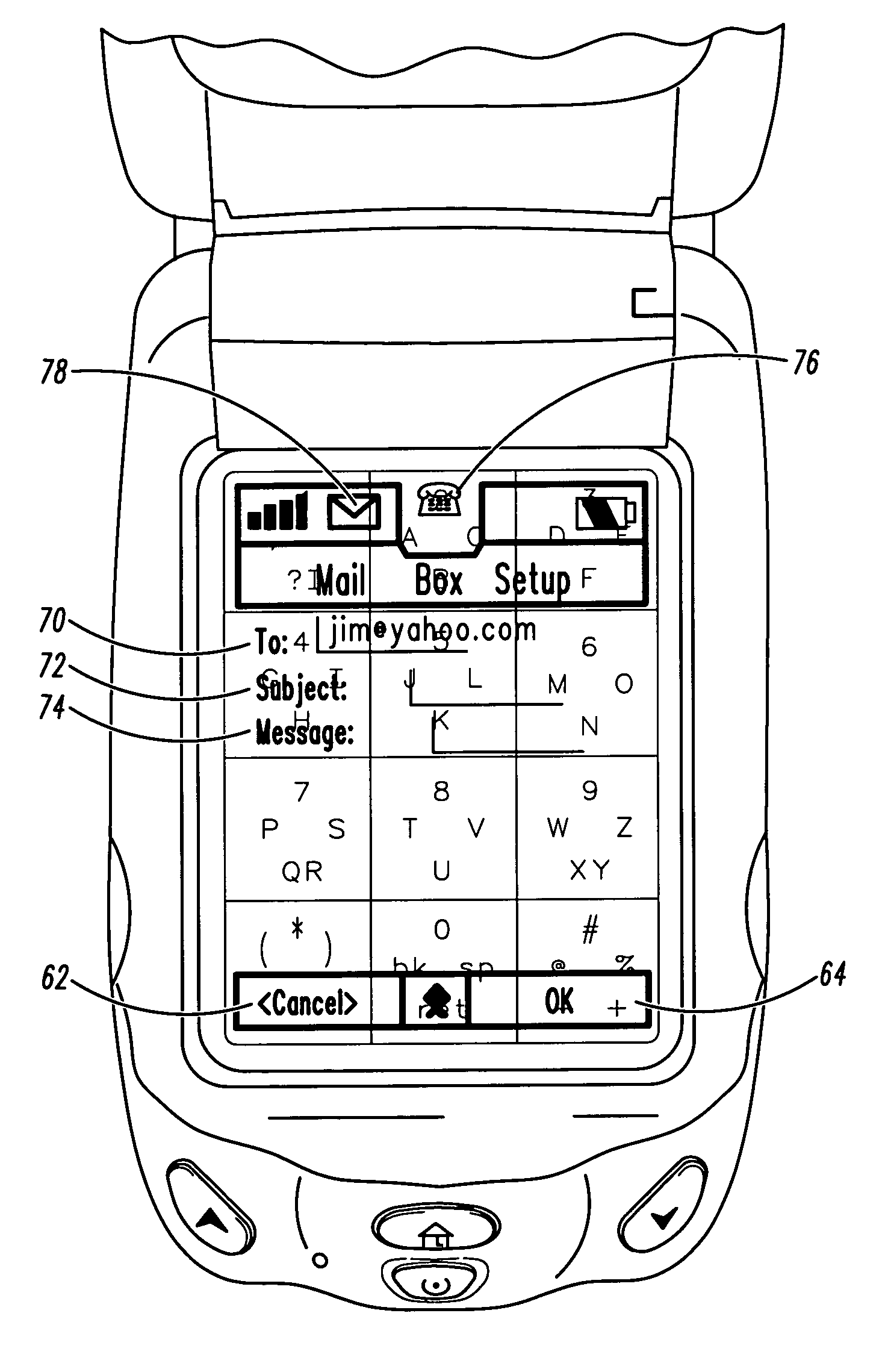

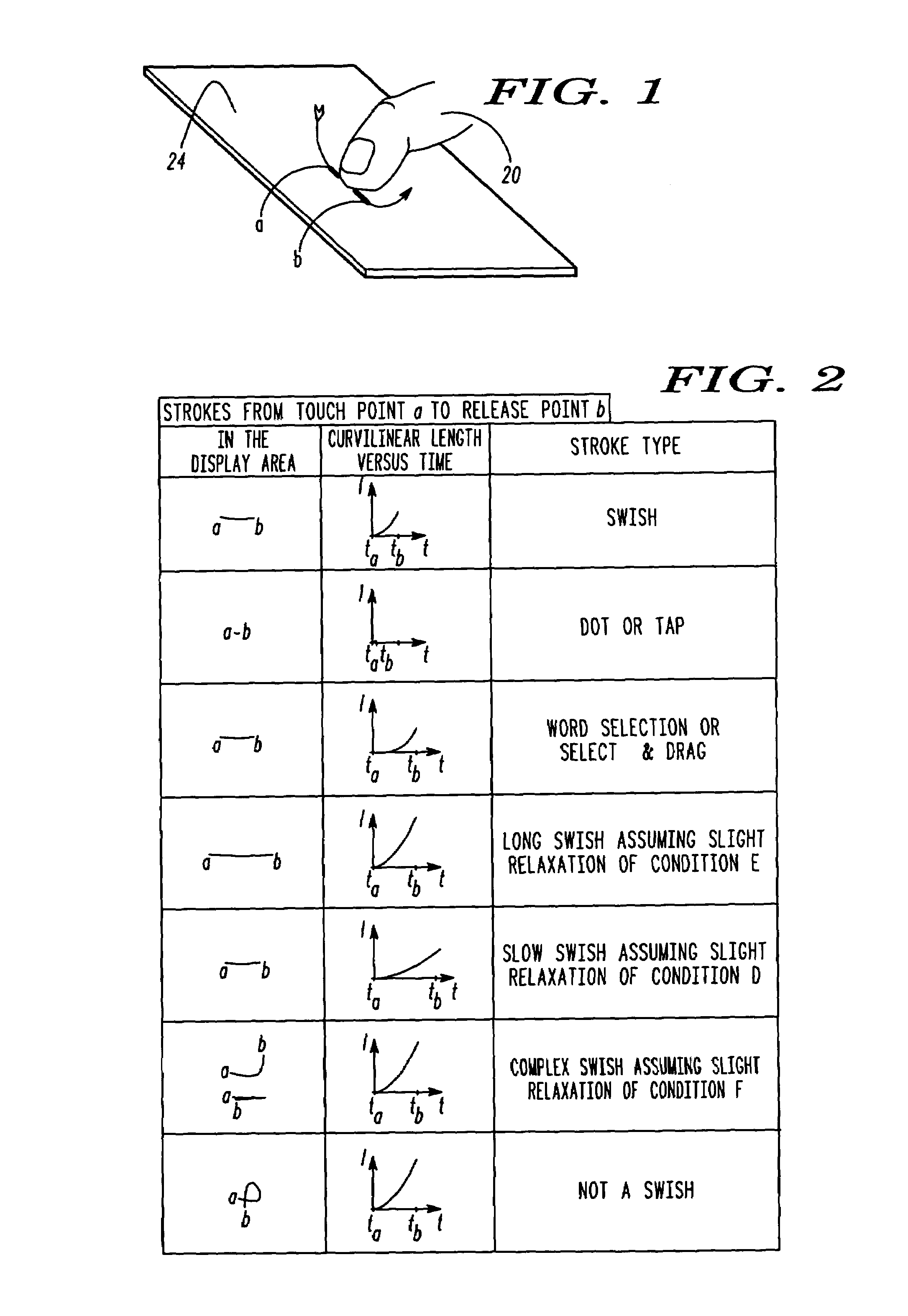

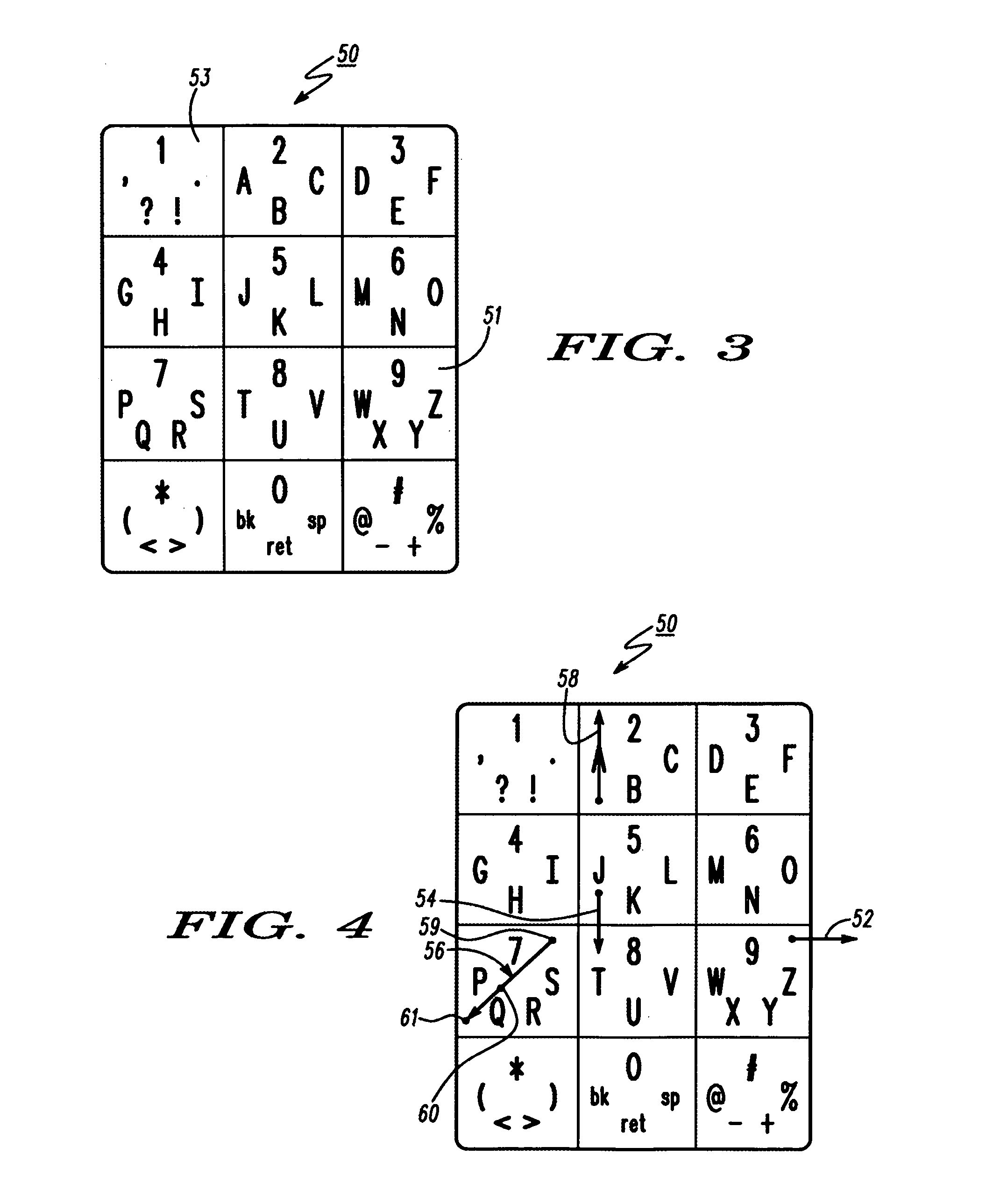

Application-independent text entry for touch-sensitive display

A user interface method and apparatus for an electronic device operates by detecting (108) a stroke of a touch sensitive display (170) forming a part of the electronic device. The stroke is categorized (116) as one of a swish type stroke and a non-swish type stroke. If the stroke is a non-swish stroke, it is translated (132) into an application function. If the stroke is a swish stroke, it is converted (128) to a character input function. The touch sensitive display (170) has a grid (50) containing cells (51, 53, etc.), with each cell containing a plurality of characters, and the grid can overlay application interface to thereby occupying a common area, up to and including the entire area, of the touch sensitive display (170).

Owner:GOOGLE TECH HLDG LLC

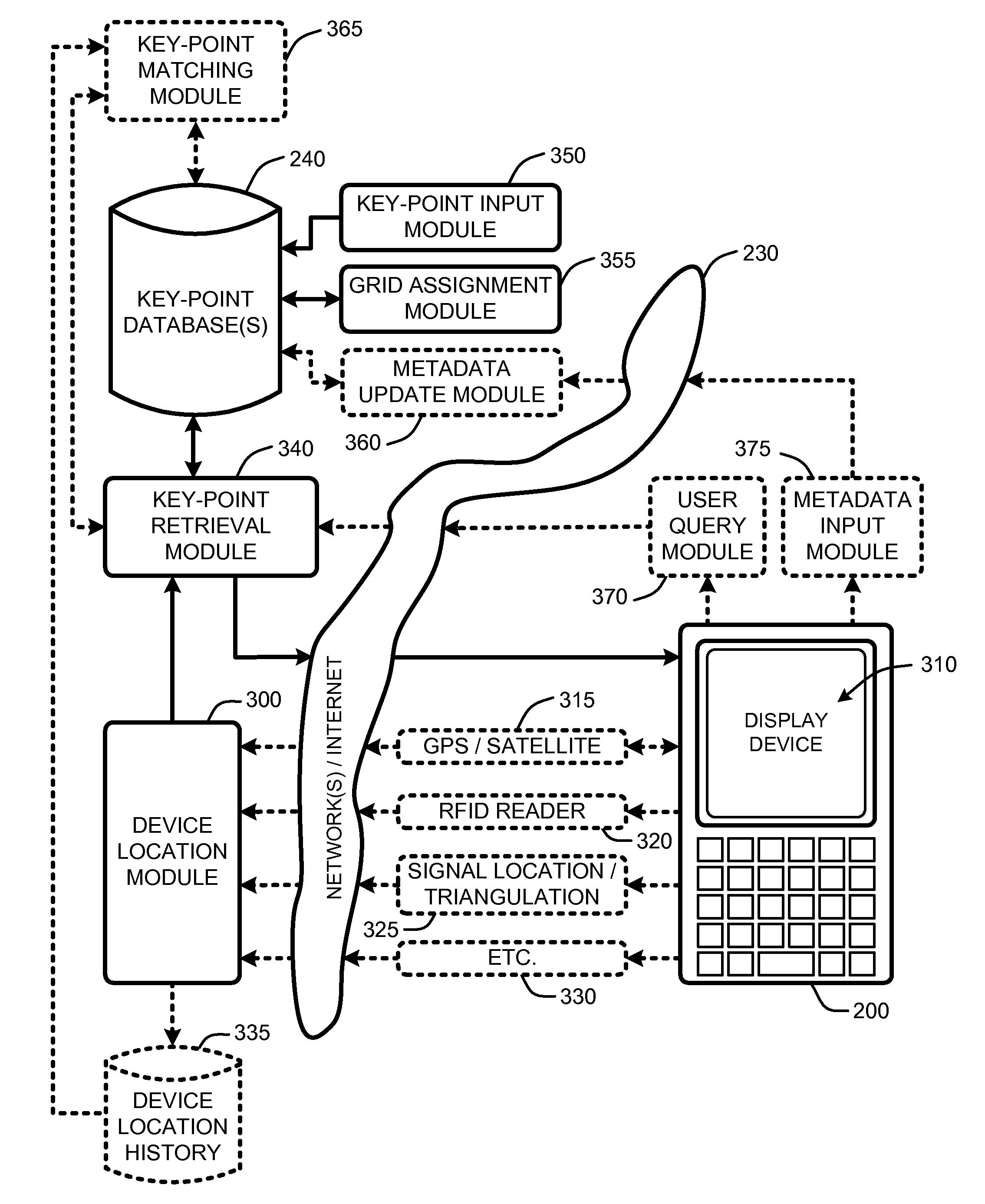

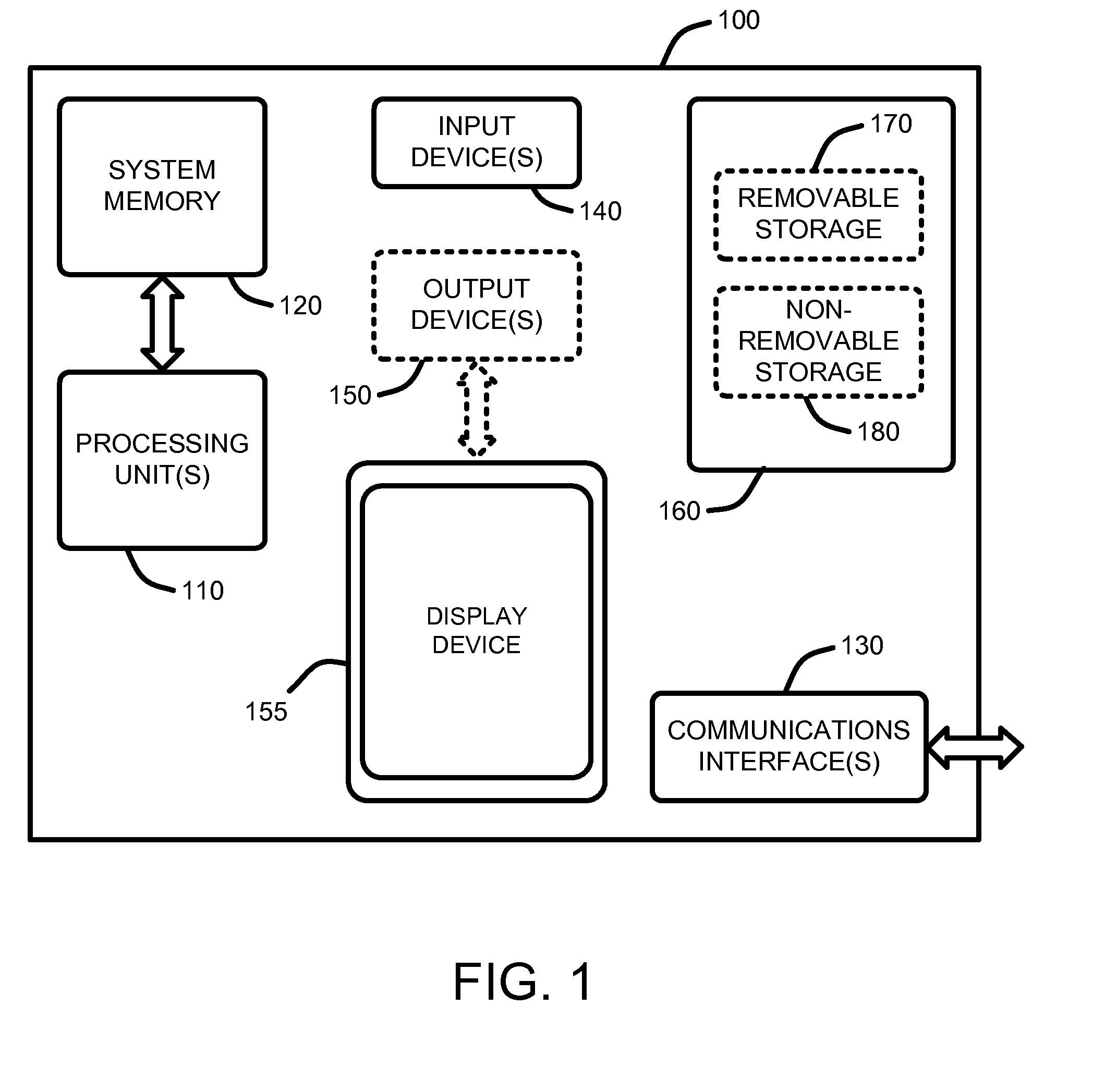

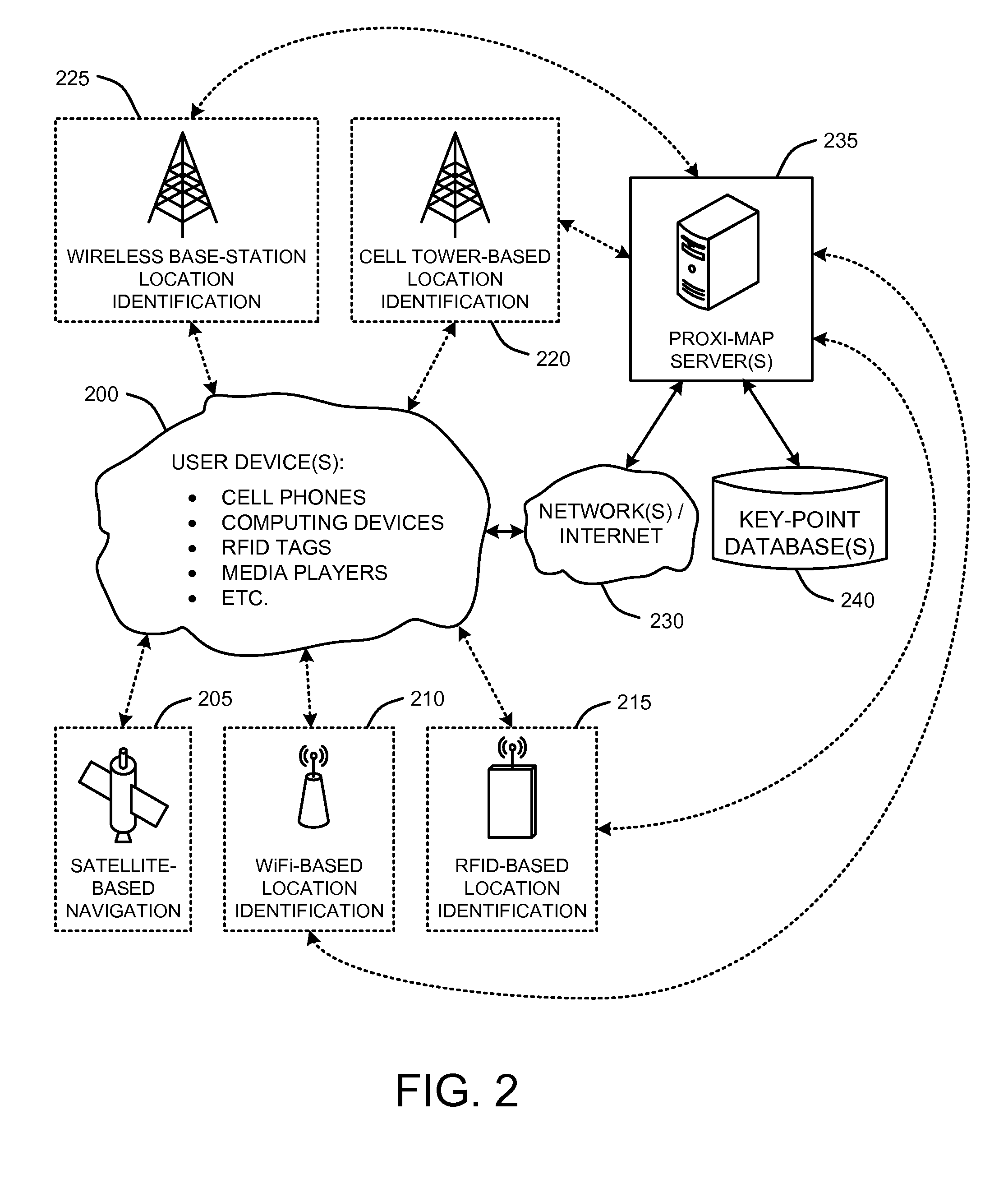

Location mapping for key-point based services

ActiveUS20080172173A1Minimizes bandwidth requirementMaximize user experienceInstruments for road network navigationRoad vehicles traffic controlCrucial pointUser device

A “Proxi-Mapper” combines location based services (LBS), local searching capabilities, and relative mapping in a way that minimizes bandwidth requirements and maximizes user experience. The Proxi-Mapper automatically determines approximate locations of one or more local user devices (cell phones, PDA's, media players, portable computing devices, etc.) and returns a lightweight model of local entities (“key-points”) representing businesses, services or people to those devices. Key-points are maintained in one or more remote databases in which key-points are assigned to predetermined grid sections based on the locations of the corresponding entities. Metadata associated with the key-points provides the user with additional information relating to the corresponding entities. In various embodiments, user query options allow the Proxi-Mapper to pull or push relevant local key-point based information to user devices via one or more wired or wireless networks.

Owner:UBER TECH INC

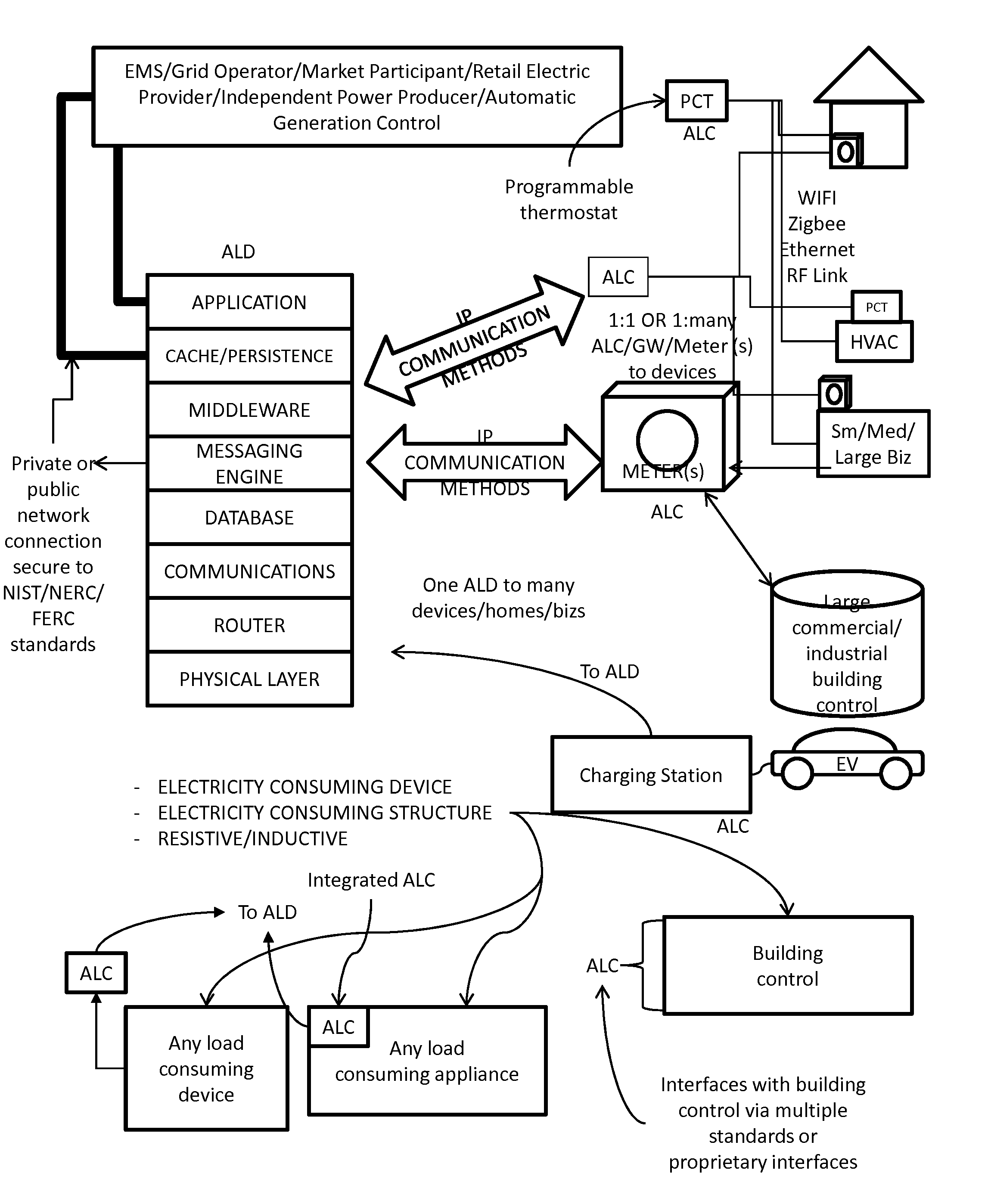

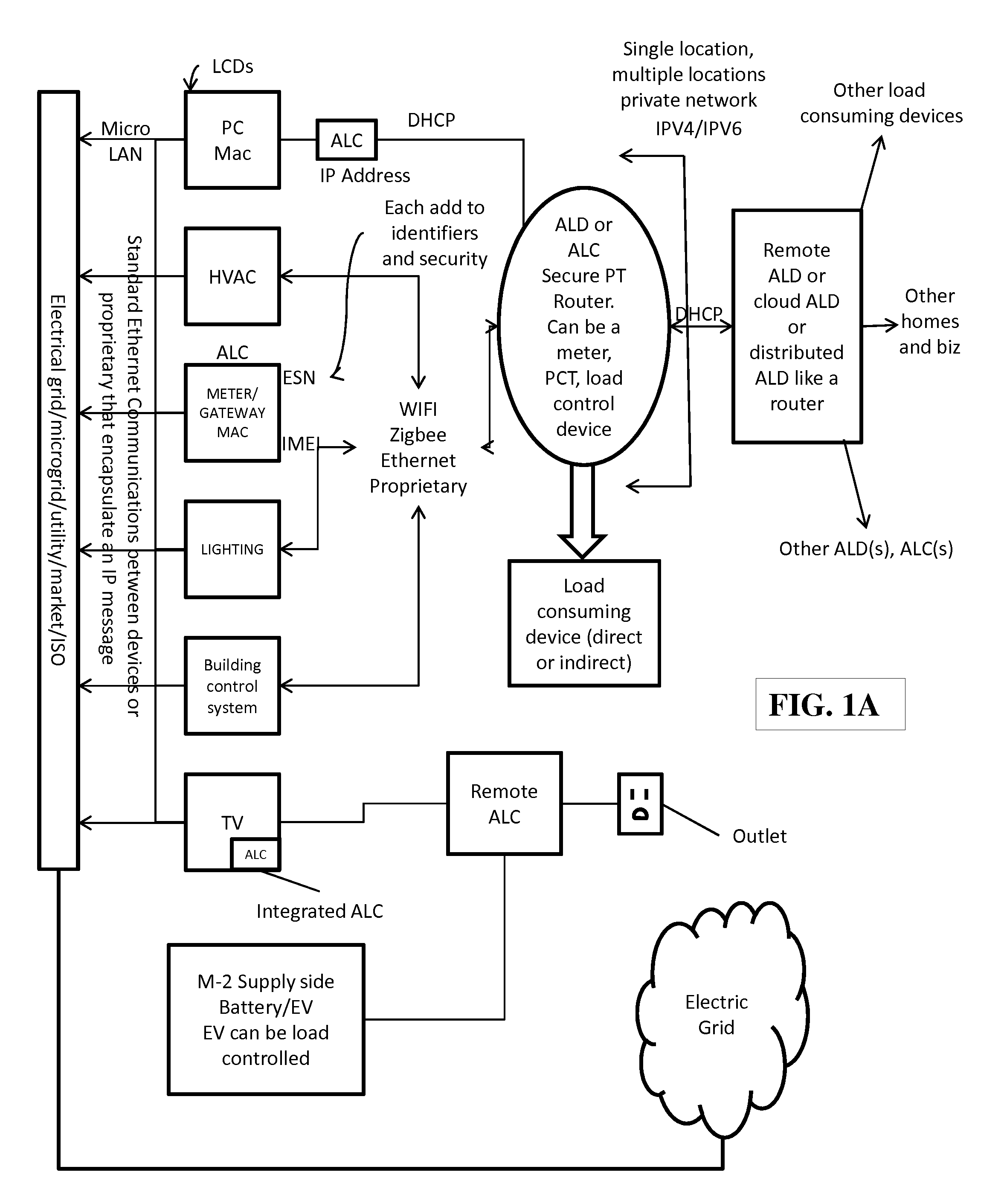

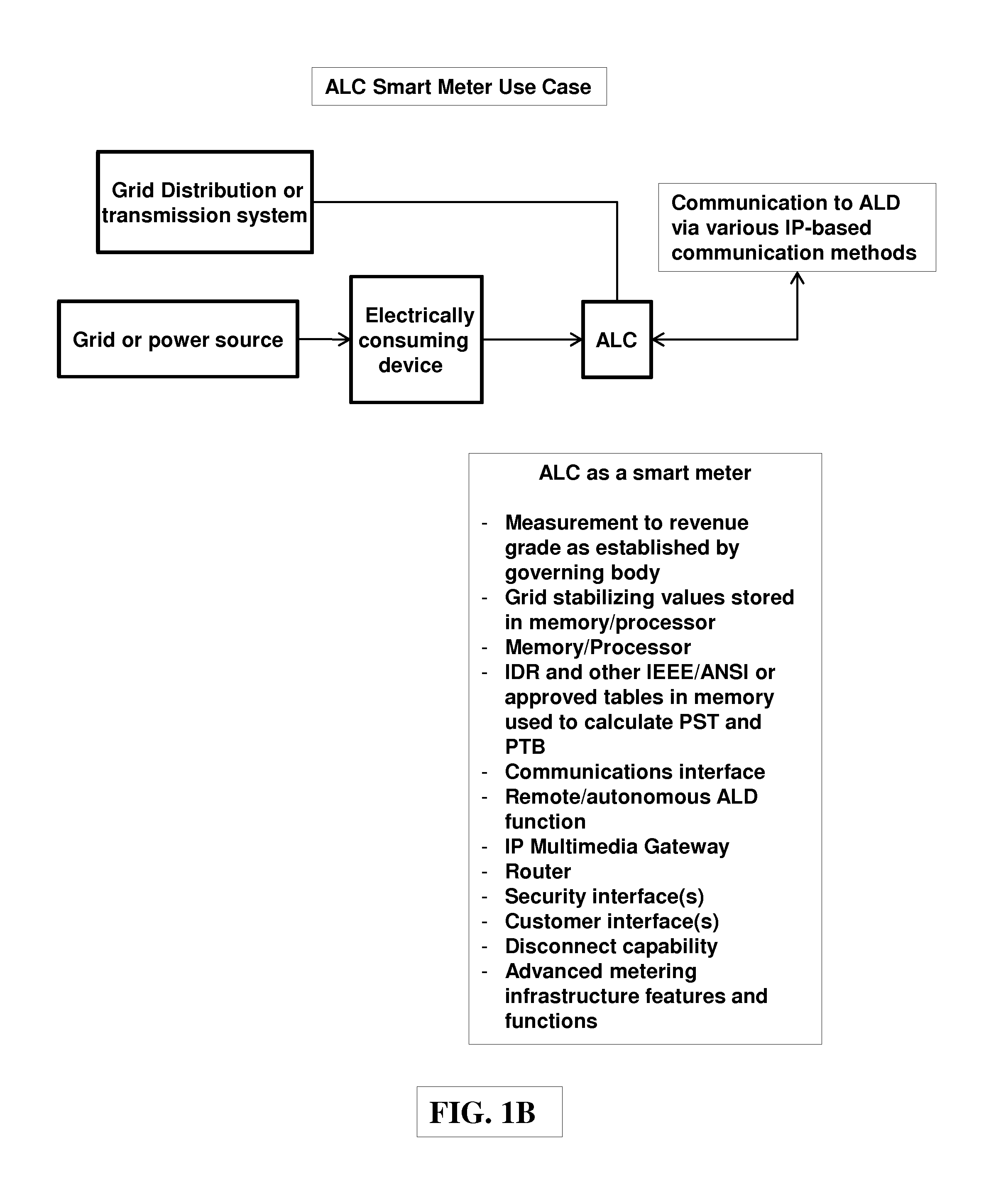

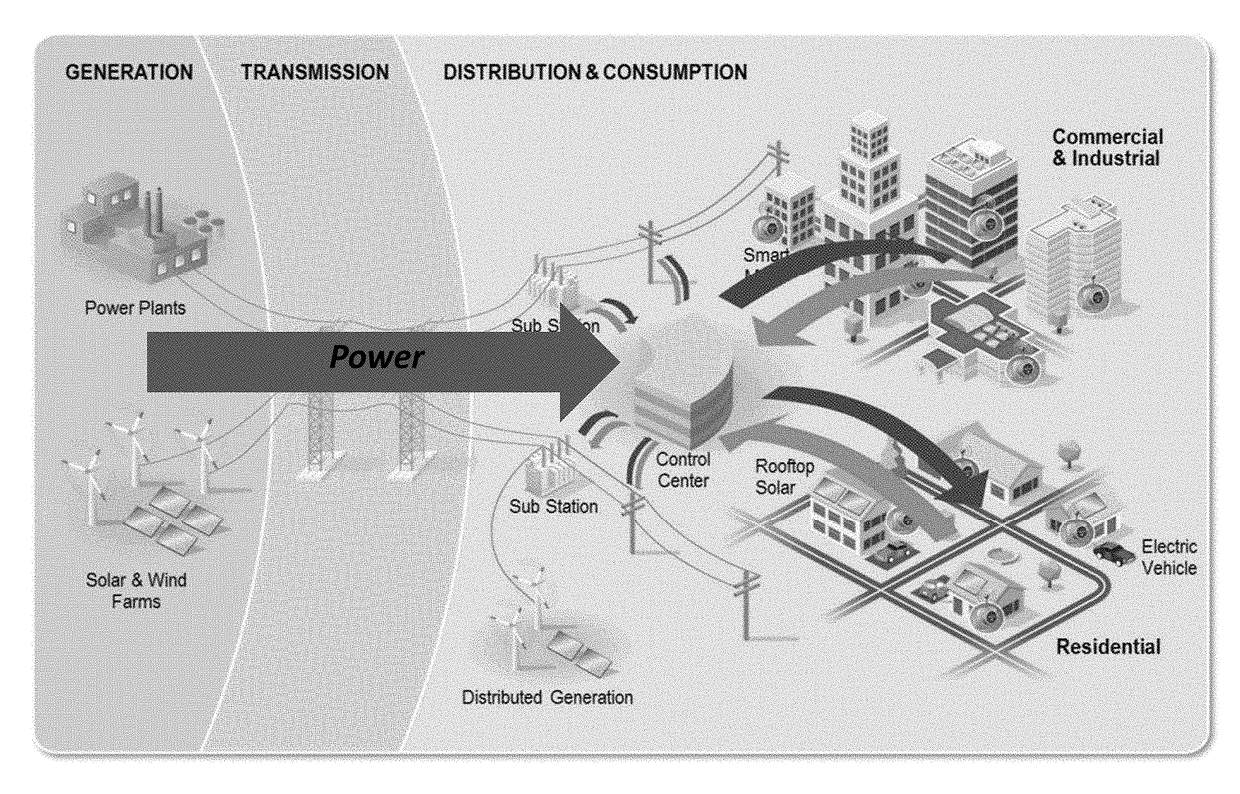

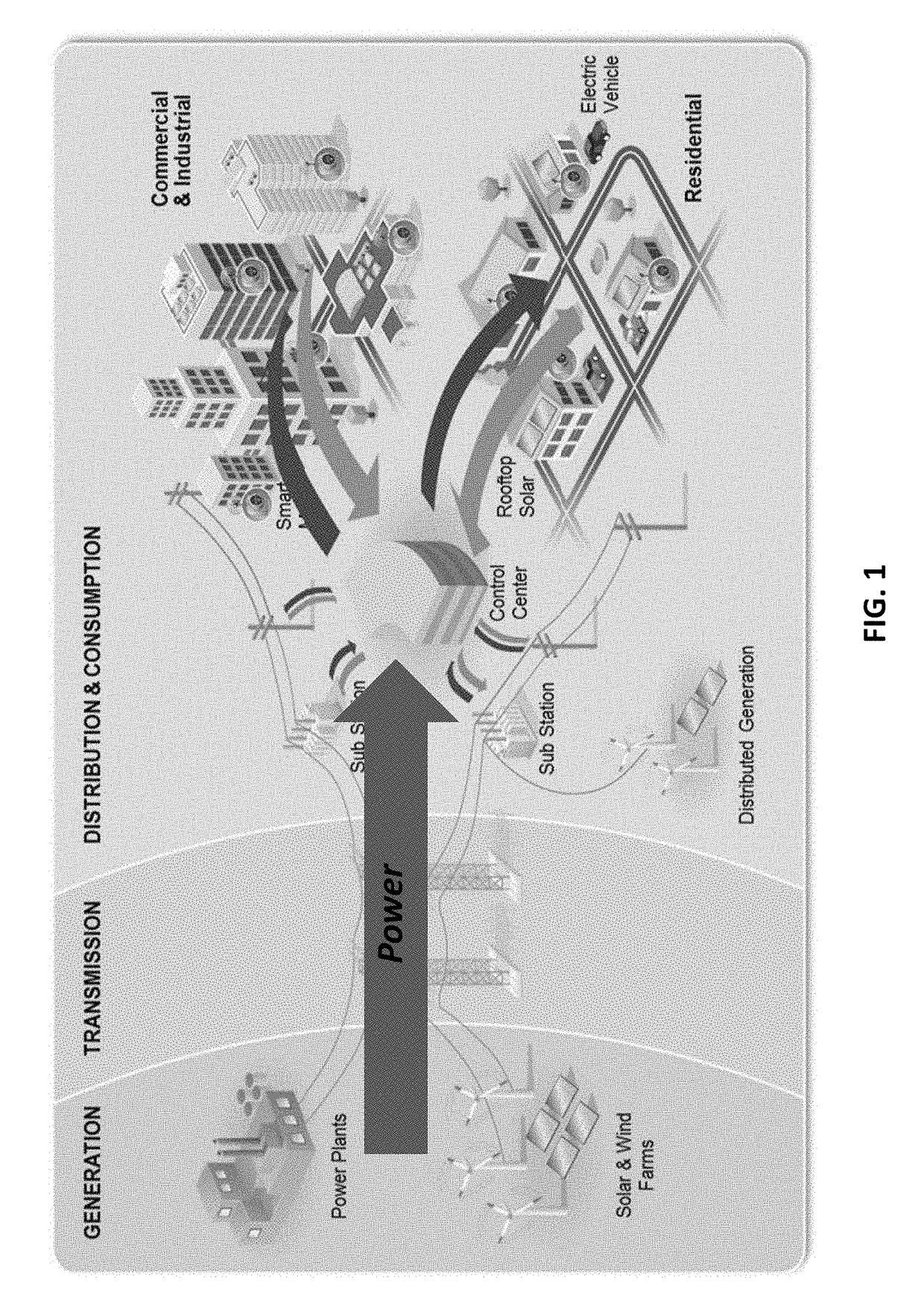

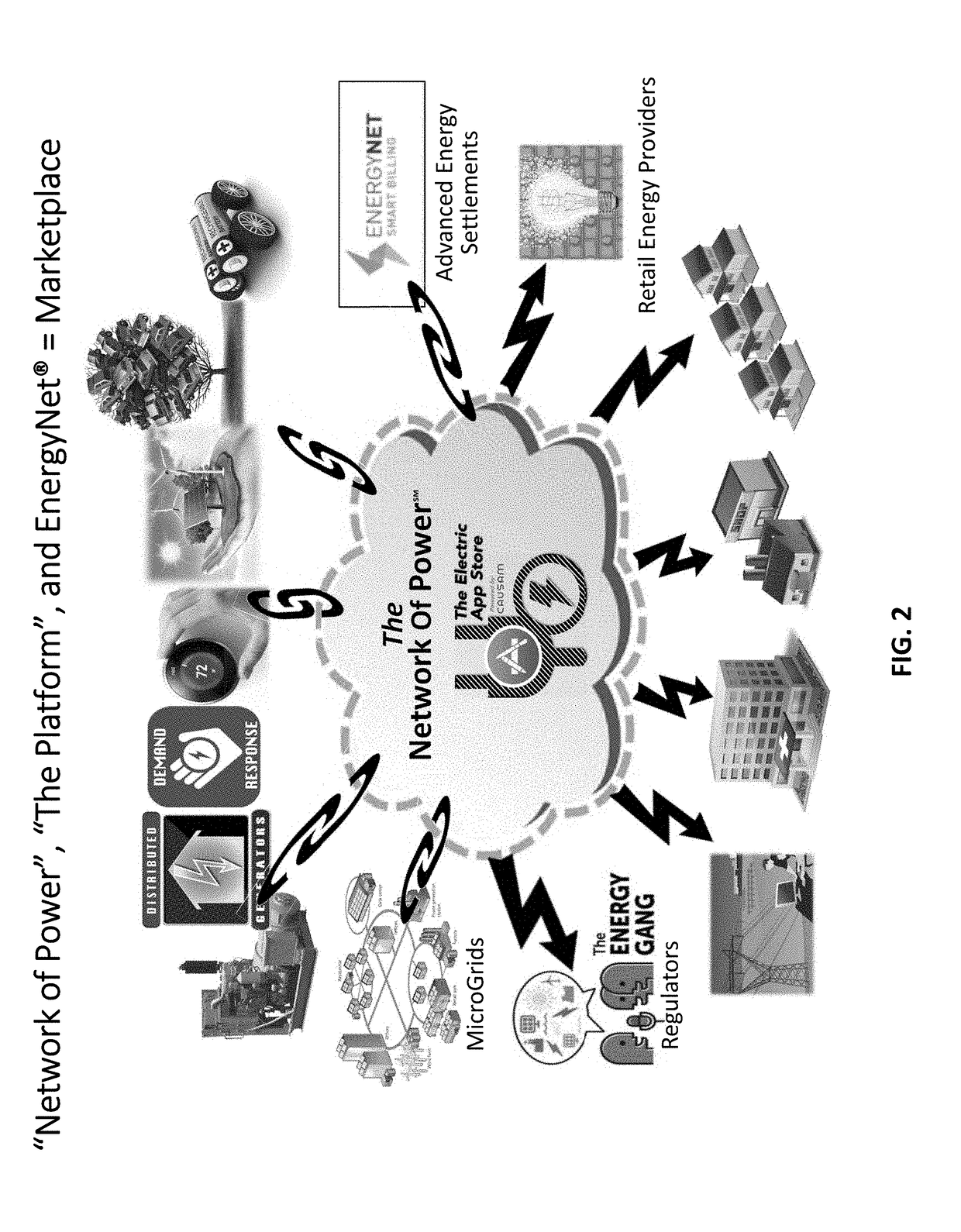

Method and Apparatus for Actively Managing Electric Power Supply for an Electric Power Grid

ActiveUS20140018969A1Improve grid stabilityLevel controlVolume/mass flow measurementGrid operatorPower grid

Systems and methods for managing power supplied over an electric power grid by an electric utility and / or other market participants to multiplicity of grid elements and devices for supply and / or load curtailment as supply, each of which having a Power Supply Value (PSV) associated with its energy consumption and / or reduction in consumption and / or supply, and wherein messaging is managed through a network by a Coordinator using IP messaging for communication with the grid elements and devices, with the energy management system (EMS), and with the utilities, market participants, and / or grid operators.

Owner:CAUSAM ENERGY INC

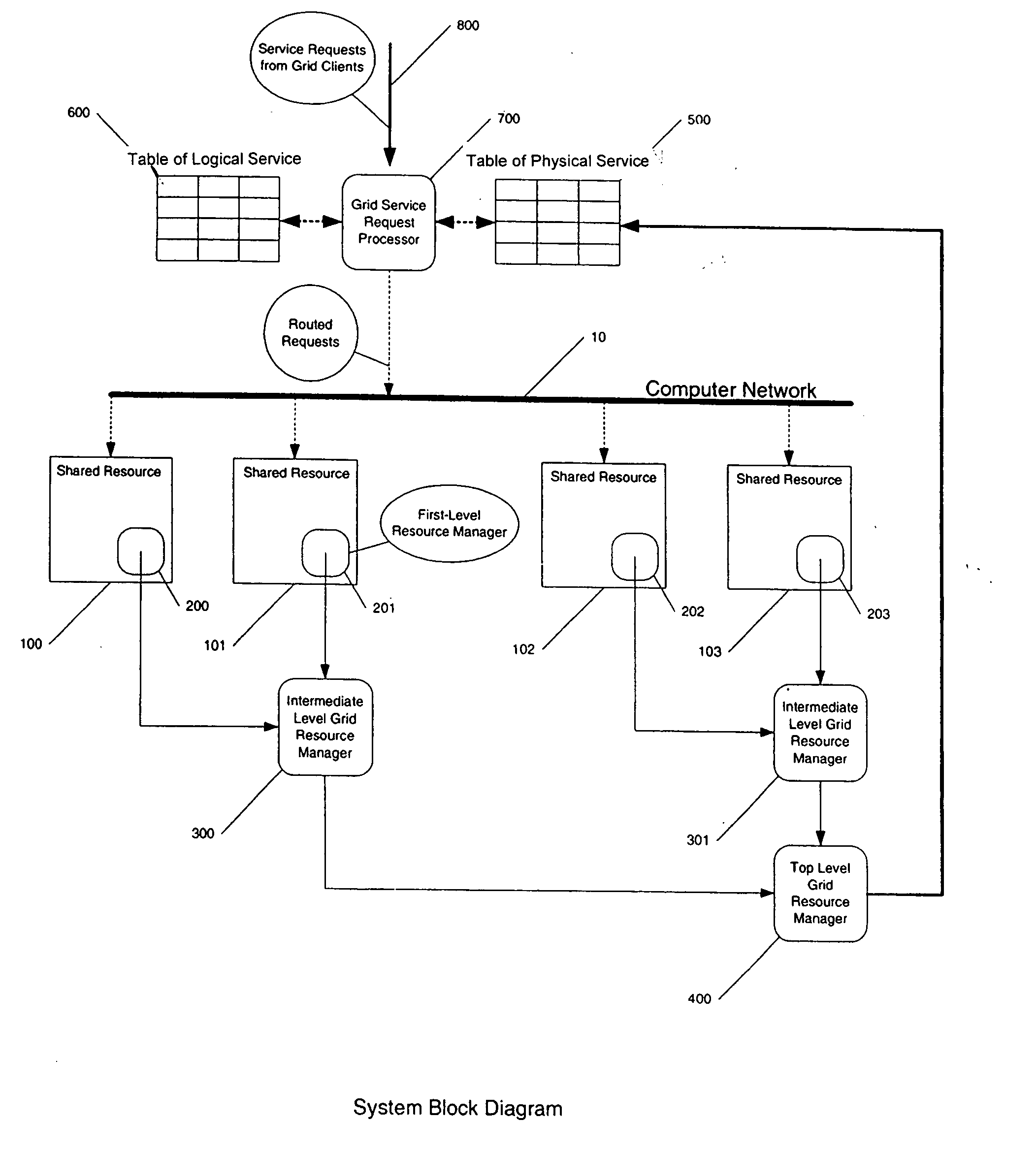

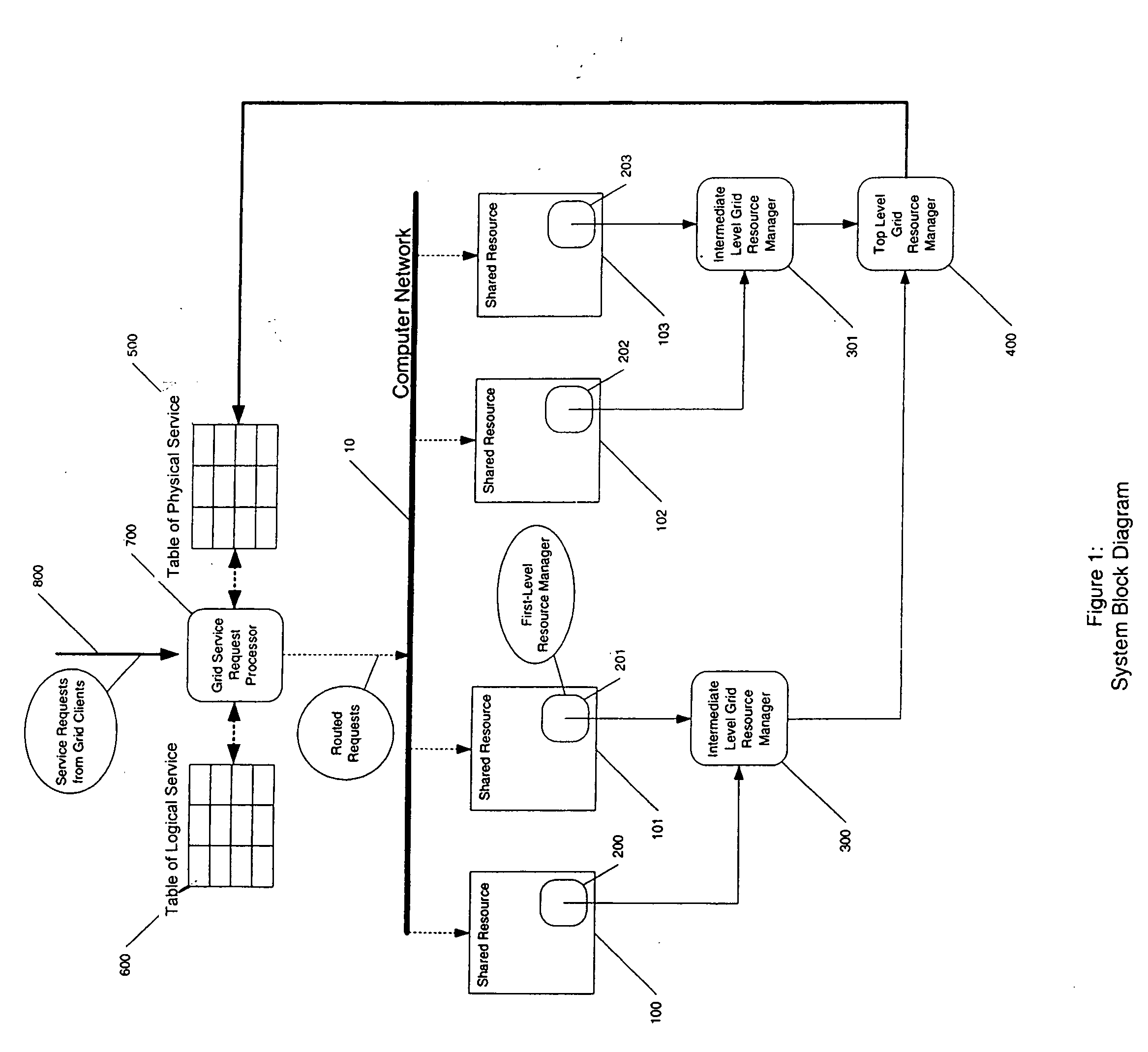

Policy-based hierarchical management of shared resources in a grid environment

InactiveUS20060294238A1Facilitates efficient means for routingDigital computer detailsProgram controlService guaranteeClient-side

The invention relates to controlling the participation and performance management of a distributed set of resources in a grid environment. The control is achieved by forecasting the behavior of a group of shared resources, their availability and quality of their performance in the presence of external policies governing their usage, and deciding the suitability of their participation in a grid computation. The system also provides services to grid clients with certain minimum levels of service guarantees using resources with uncertainties in their service potentials.

Owner:IBM CORP

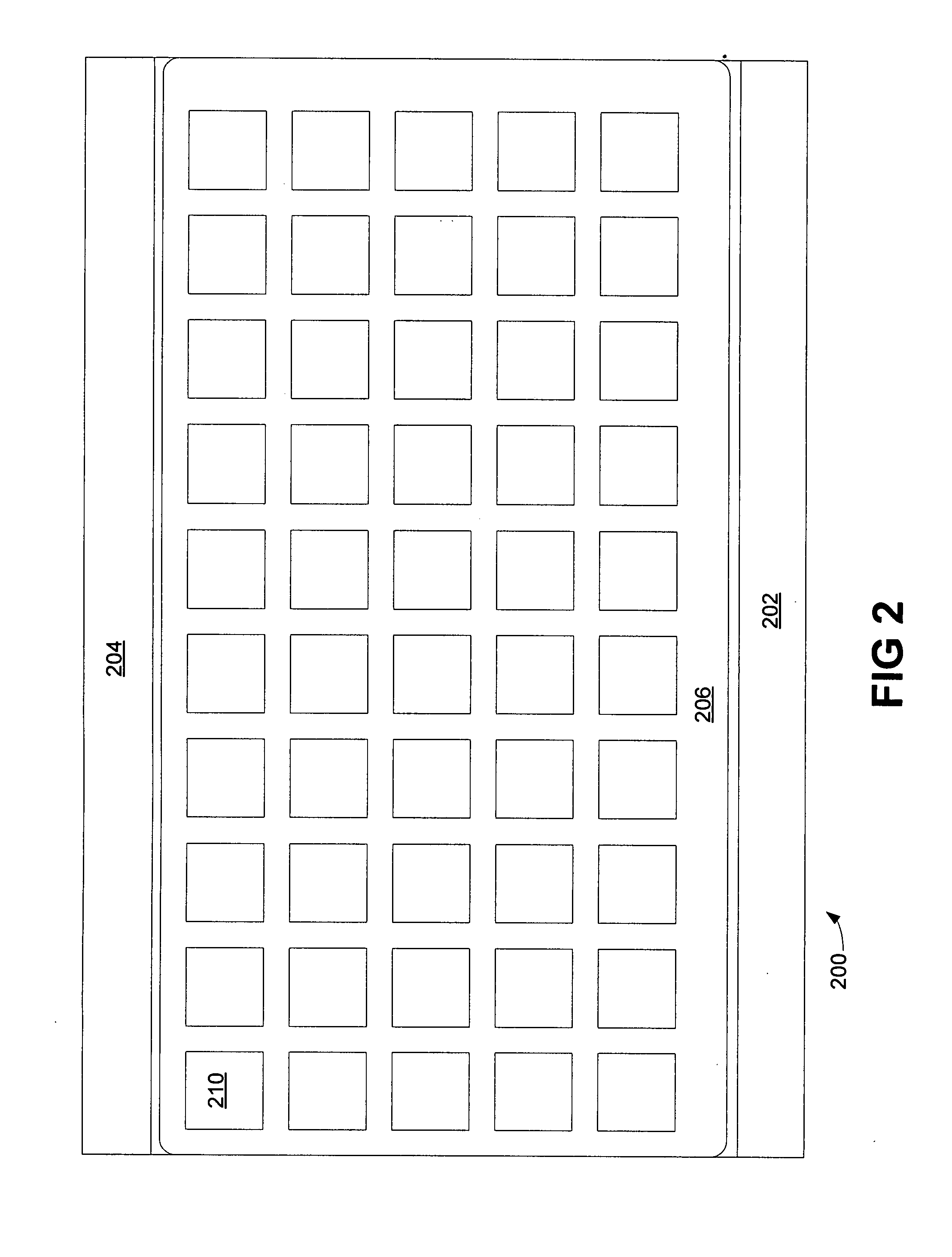

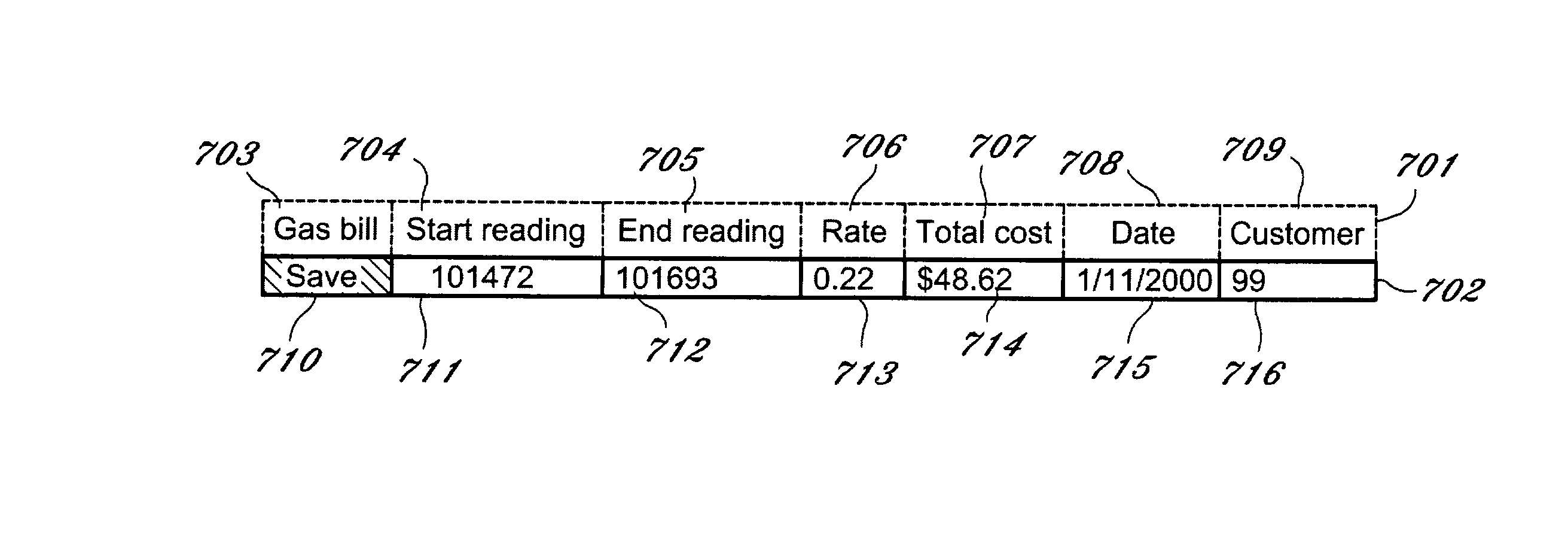

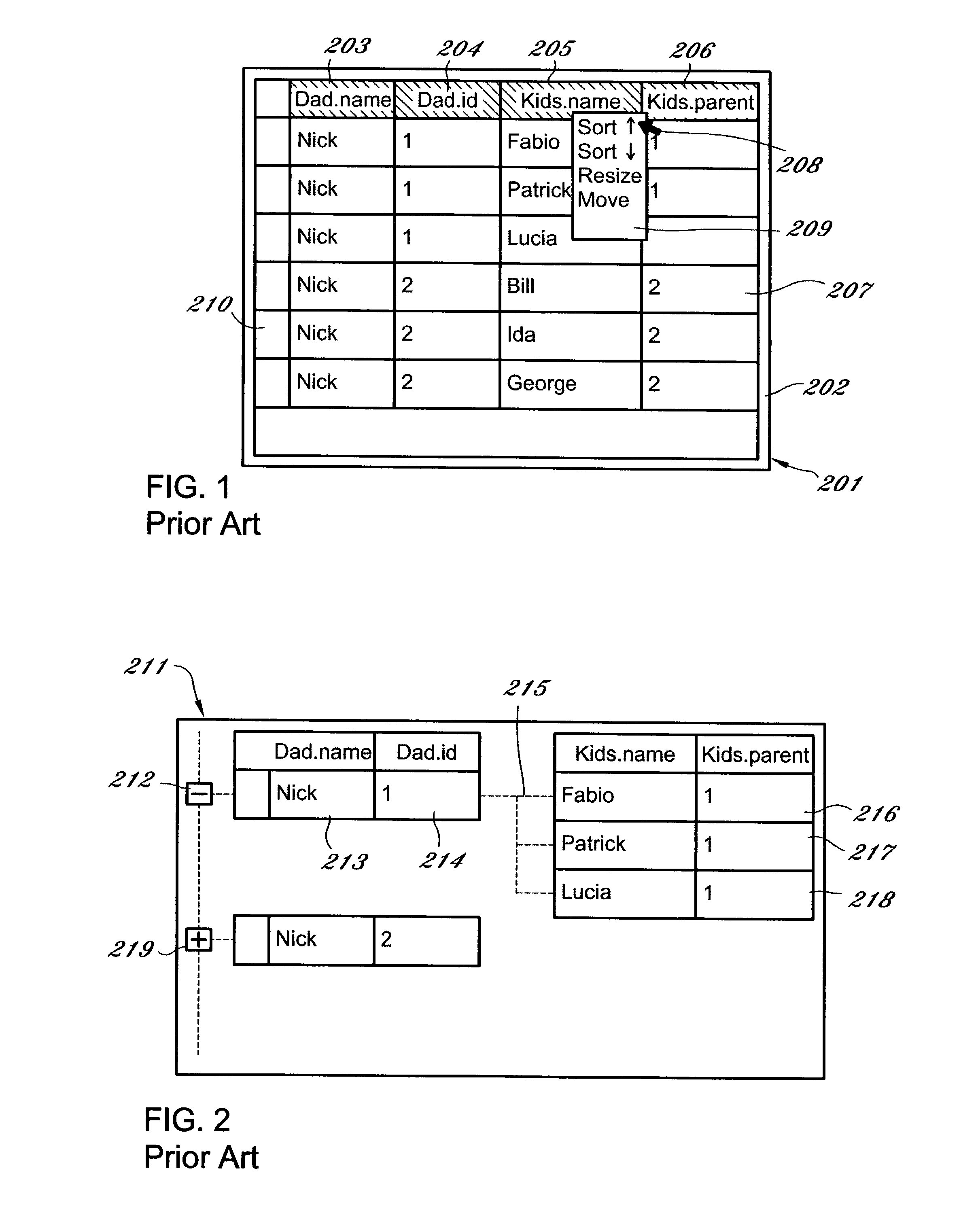

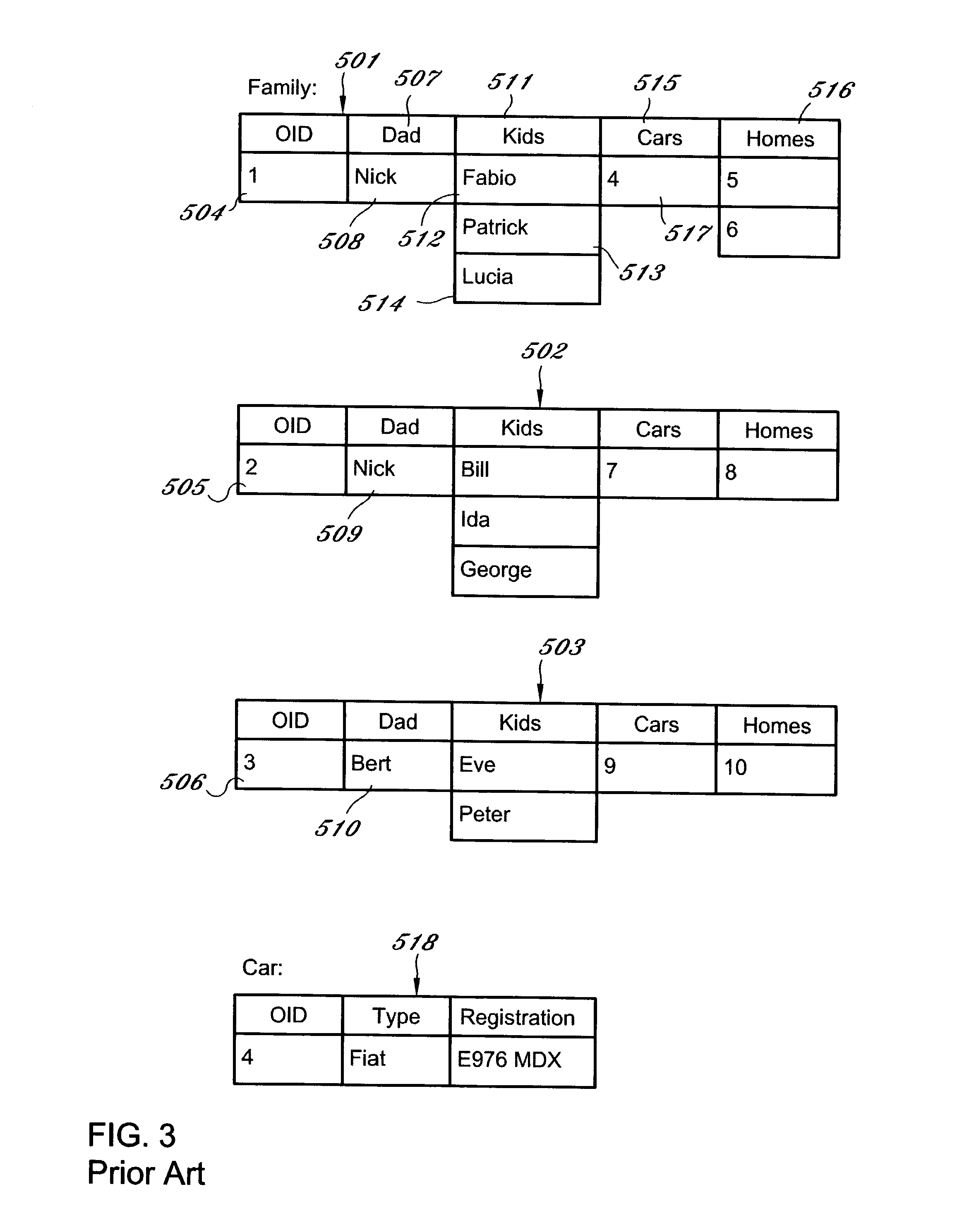

Representation of data records

ActiveUS7461077B1Easy to browseConsistent interfaceDigital data information retrievalSpecial data processing applicationsData sourceDisplay device

A computerized method for representing a data record comprising: querying a data source to obtain data selected from the group consisting of a data element in a record, and metadata concerning the record; presenting in a display a record handle for manipulation of the record; presenting in the display a data item wherein the data item is a list of data items or a reference to another record; and, optionally, presenting on the display the metadata above the data item. In some embodiments, the method includes the step of retrieving one or more heterogeneous records from a plurality of databases for display and manipulation. The invention is also a grid control programmed to implement a disclosed method and is a computer-readable medium having computer-executable instructions for performing a disclosed method. The invention links the grid control of the invention with automatic query generation using hierarchical data schema trees. Both the trees and the grid records represent relational foreign keys as extra reference columns. In the grid control, these reference columns are additional embedded record handles.

Owner:MUSICQUBED INNOVATIONS LLC

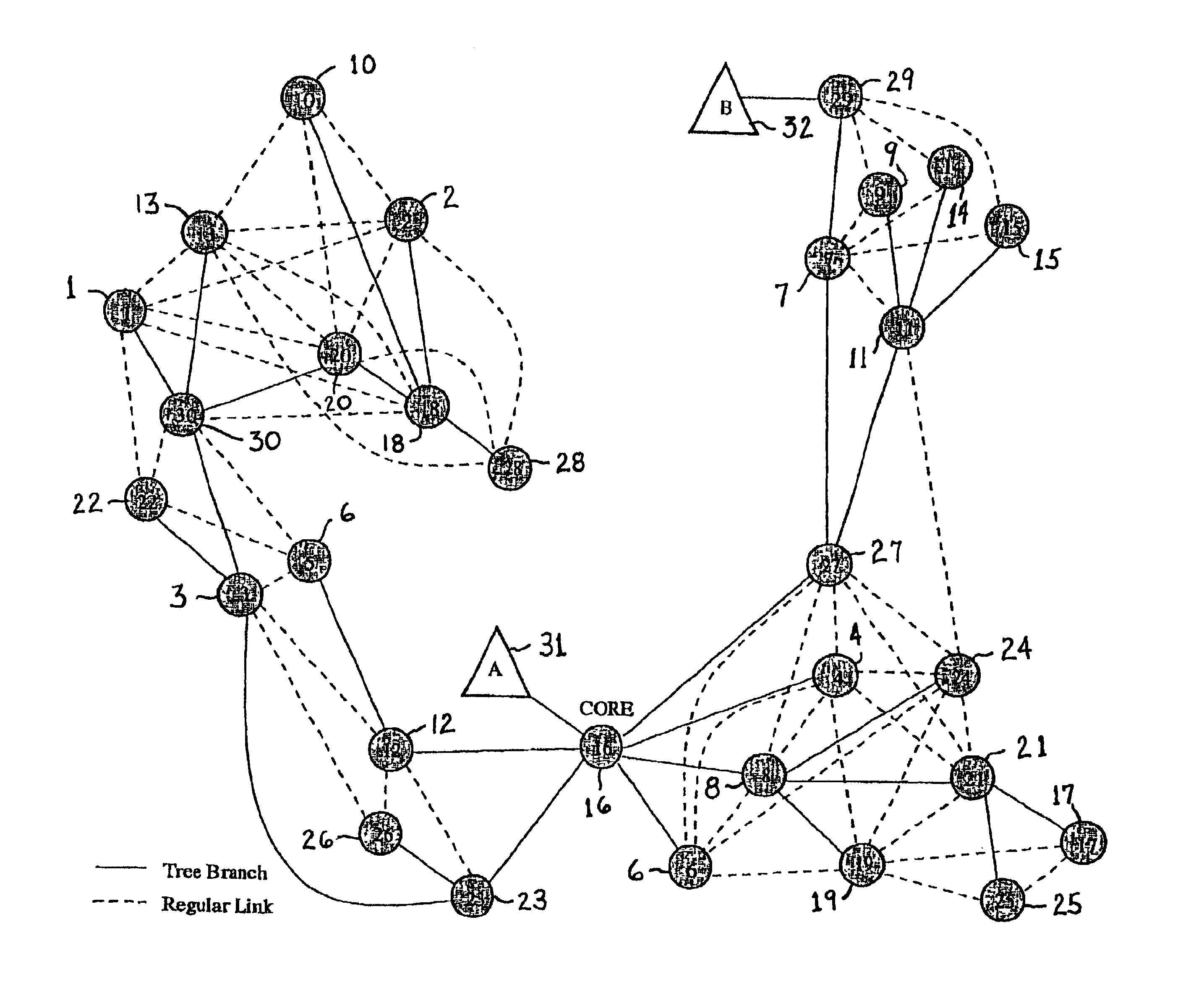

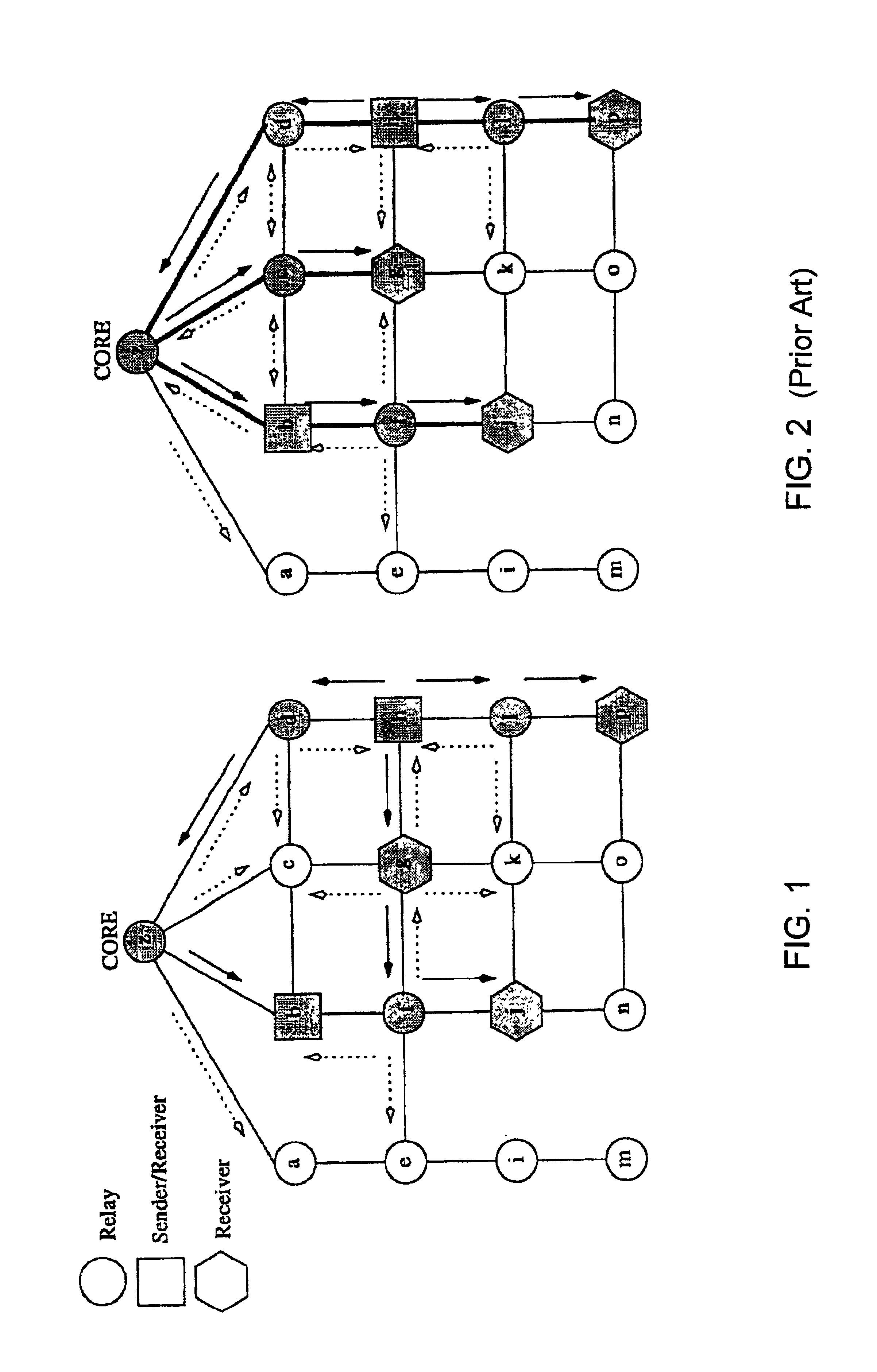

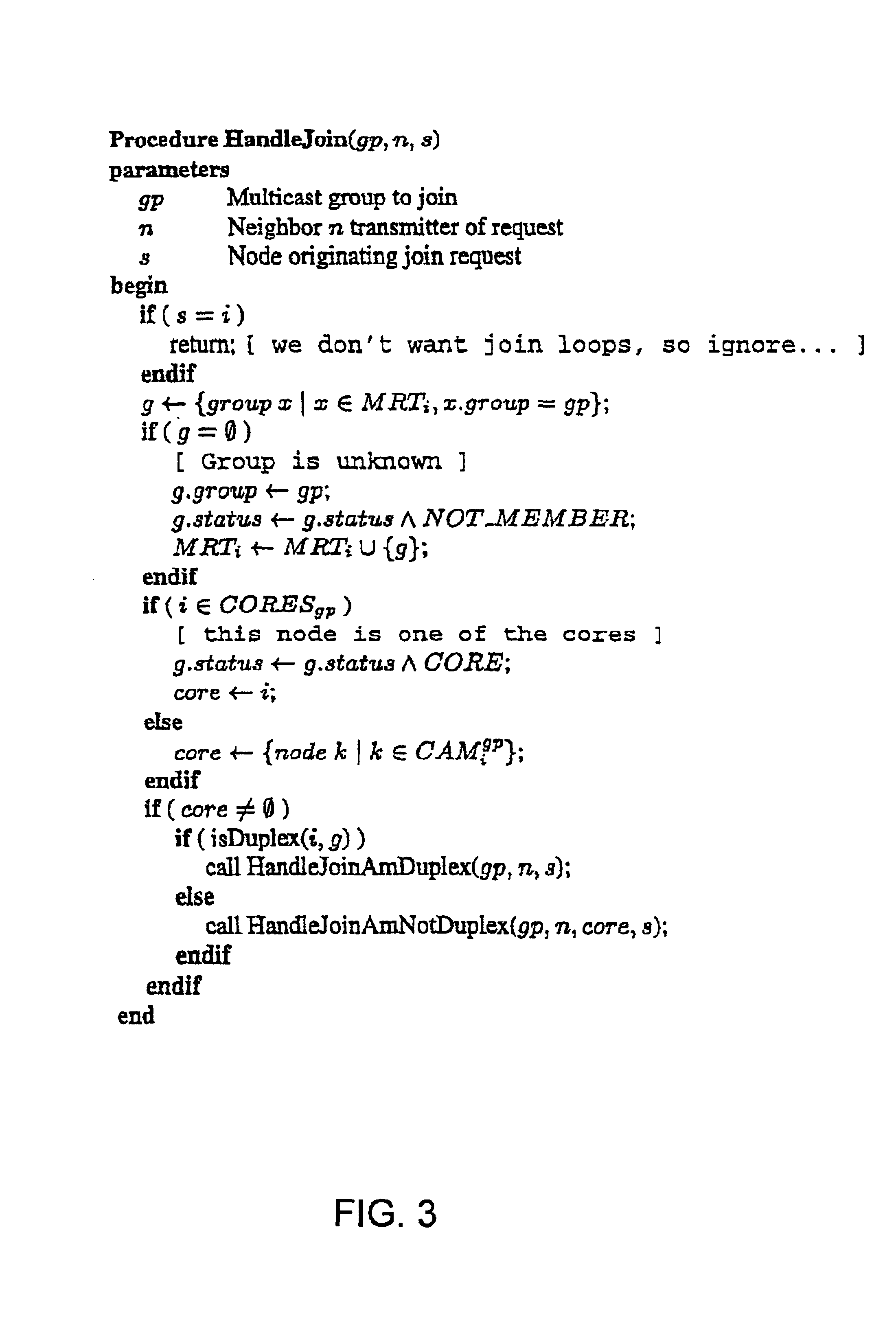

Core assisted mesh protocol for multicast routing in ad-hoc Networks

InactiveUS6917985B2Enrich connectivityStay connectedSpecial service provision for substationError preventionIP multicastBroadcasting

A method of providing multicast routing for use in ad hoc broadcast networks, such as wireless and mobile networks. The method is described within a protocol referred to as core-assisted mesh protocol, or CAMP. The method departs from traditional tree-structured multicast protocols and utilizes multicast meshes in which the network need not be flooded with control or data packets to establish routing paths. Each router configured for CAMP is capable of accepting unique packets arriving from any neighbor in the mesh, wherein packets are forwarded along reverse shortest paths to the receiver. Multiple cores may be defined for a group wherein the loss of a single core does not prevent packet flow. Routers for sender-only hosts are allowed to join the multicast mesh in simplex mode, and in certain cases may join without the sending of a join request.

Owner:RGT UNIV OF CALIFORNIA

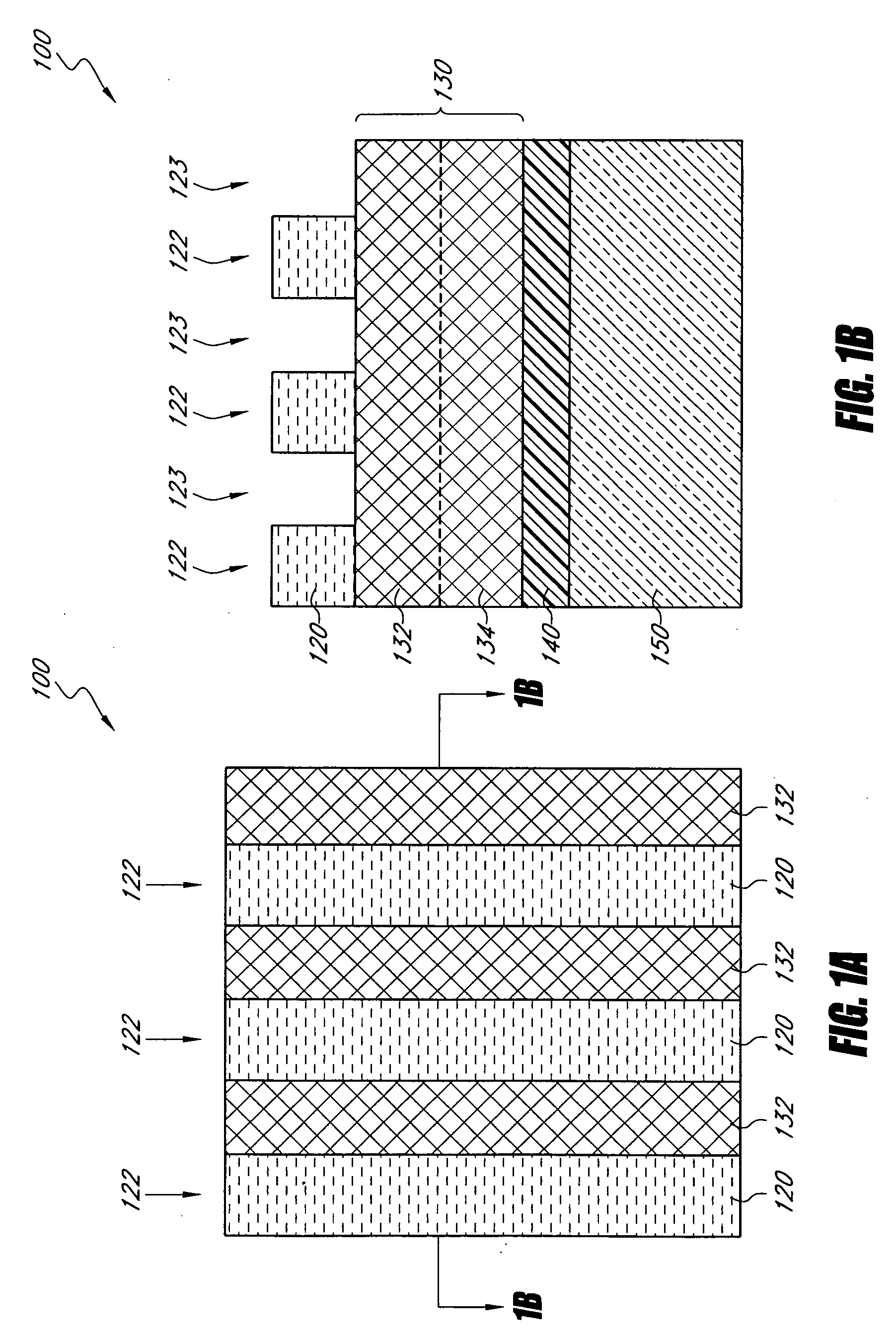

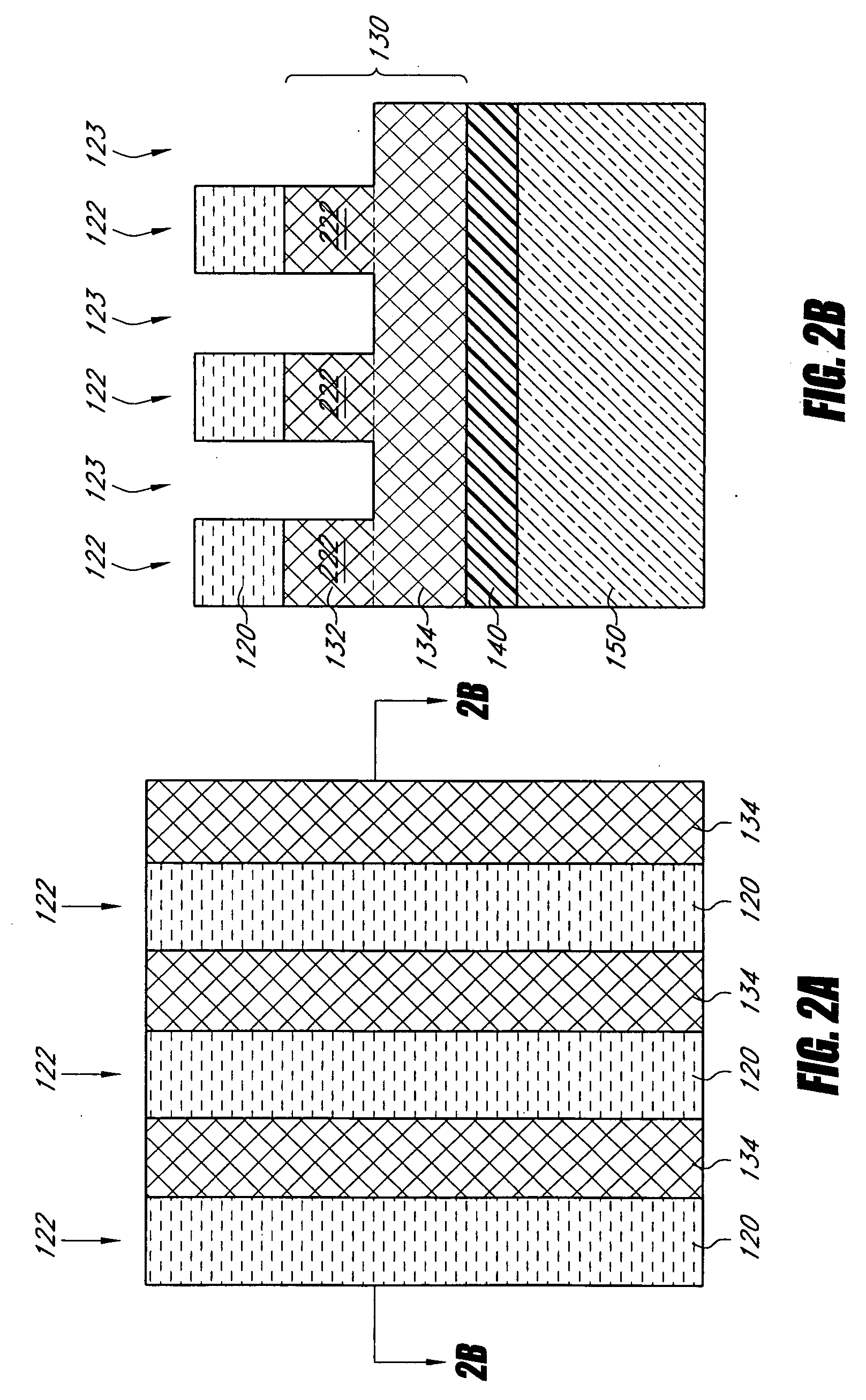

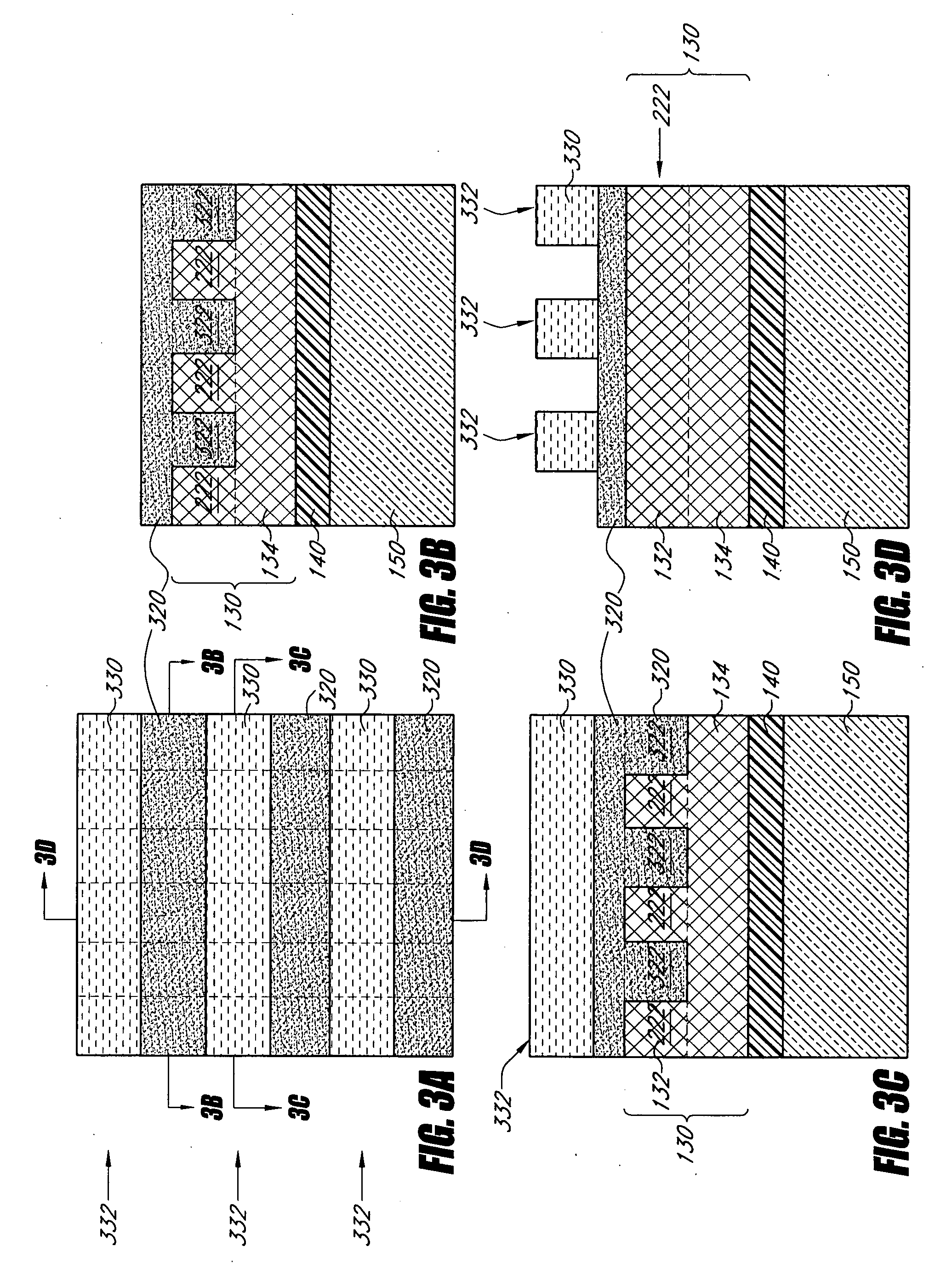

Methods for forming arrays of small, closely spaced features

Methods of forming arrays of small, densely spaced holes or pillars for use in integrated circuits are disclosed. Various pattern transfer and etching steps can be used, in combination with pitch-reduction techniques, to create densely-packed features. Conventional photolithography steps can be used in combination with pitch-reduction techniques to form superimposed patterns of crossing elongate features with pillars at the intersections. Spacers are simultaneously applied to sidewalls of both sets of crossing lines to produce a pitch-doubled grid pattern. The pillars facilitate rows of spacers bridging columns of spacers.

Owner:MICRON TECH INC

Rebuilding data on a dispersed storage network

A rebuilder application operates on a dispersed data storage grid and rebuilds stored data segments that have been compromised in some manner. The rebuilder application actively scans for compromised data segments, and is also notified during partially failed writes to the dispersed data storage network, and during reads from the dispersed data storage network when a data slice is detected that is compromised. Records are created for compromised data segments, and put into a rebuild list, which the rebuilder application processes.

Owner:PURE STORAGE

Systems and methods for advanced energy settlements, network-based messaging, and applications supporting the same on a blockchain platform

Systems and methods for financial settlement of transactions within an electric power grid network are disclosed. A multiplicity of active grid elements are constructed and configured for electric connection and network-based communication over a blockchain-based platform. The multiplicity of active grid elements are operable to make peer-to-peer transactions based on their participation within the electric power grid by generating and executing a digital contract. The multiplicity of active grid elements generate messages autonomously and / or automatically within a predetermined time interval. The messages comprise energy related data and settlement related data. The energy related data of the multiplicity of active grid elements are based on measurement and verification. The energy related data and the settlement related data are validated and recorded on a distributed ledger with a time stamp and a geodetic reference.

Owner:CAUSAM ENERGY INC

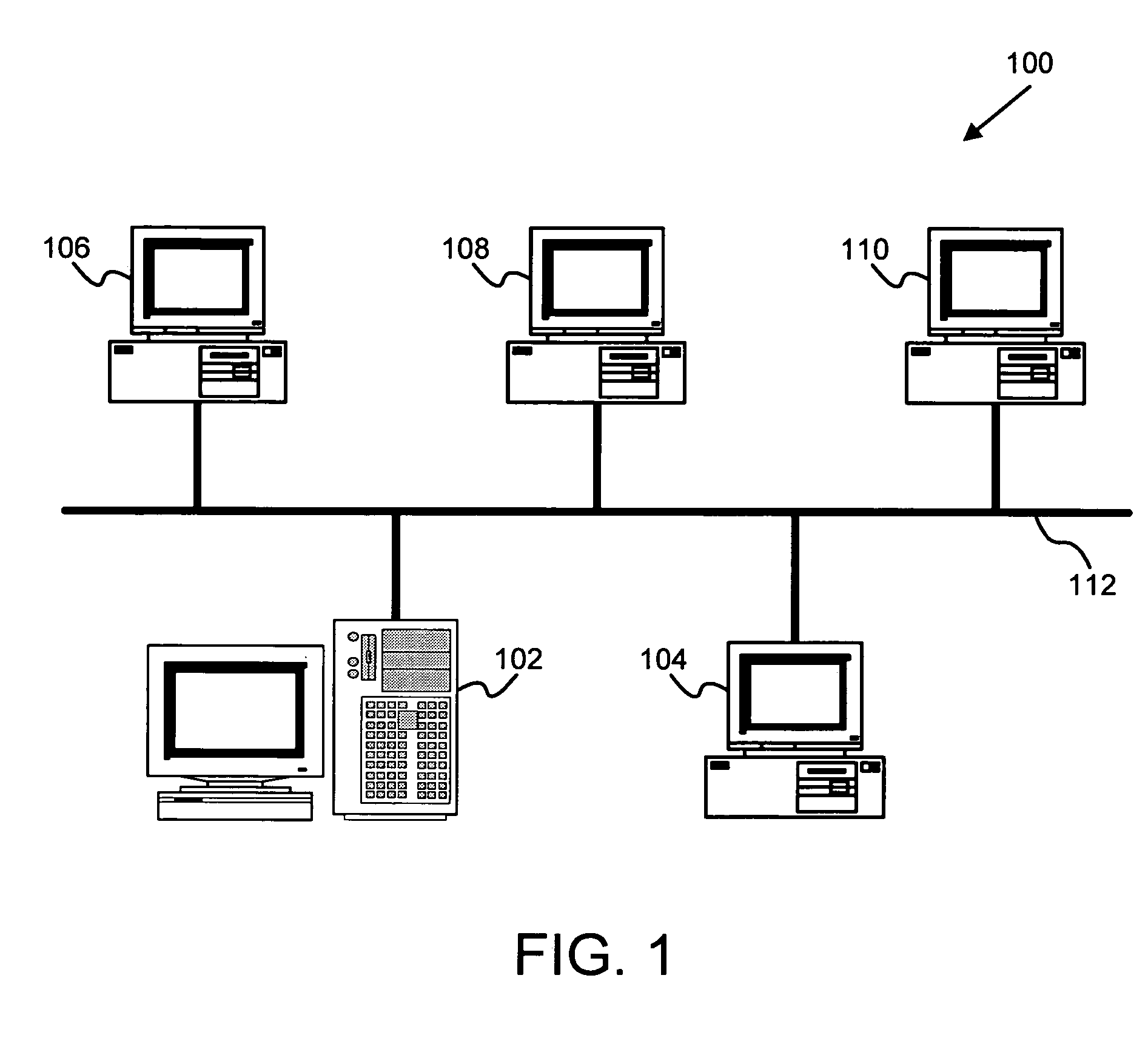

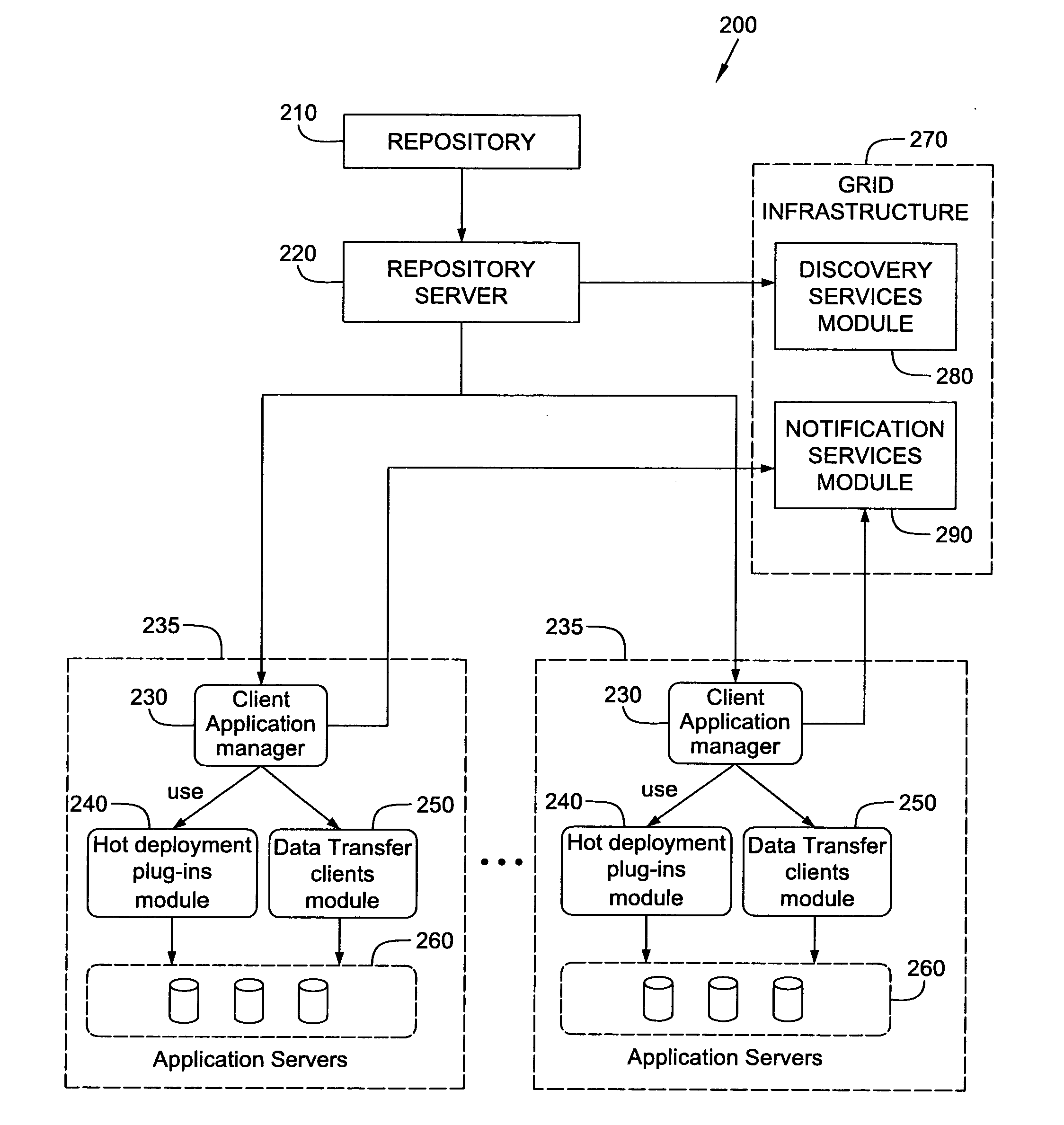

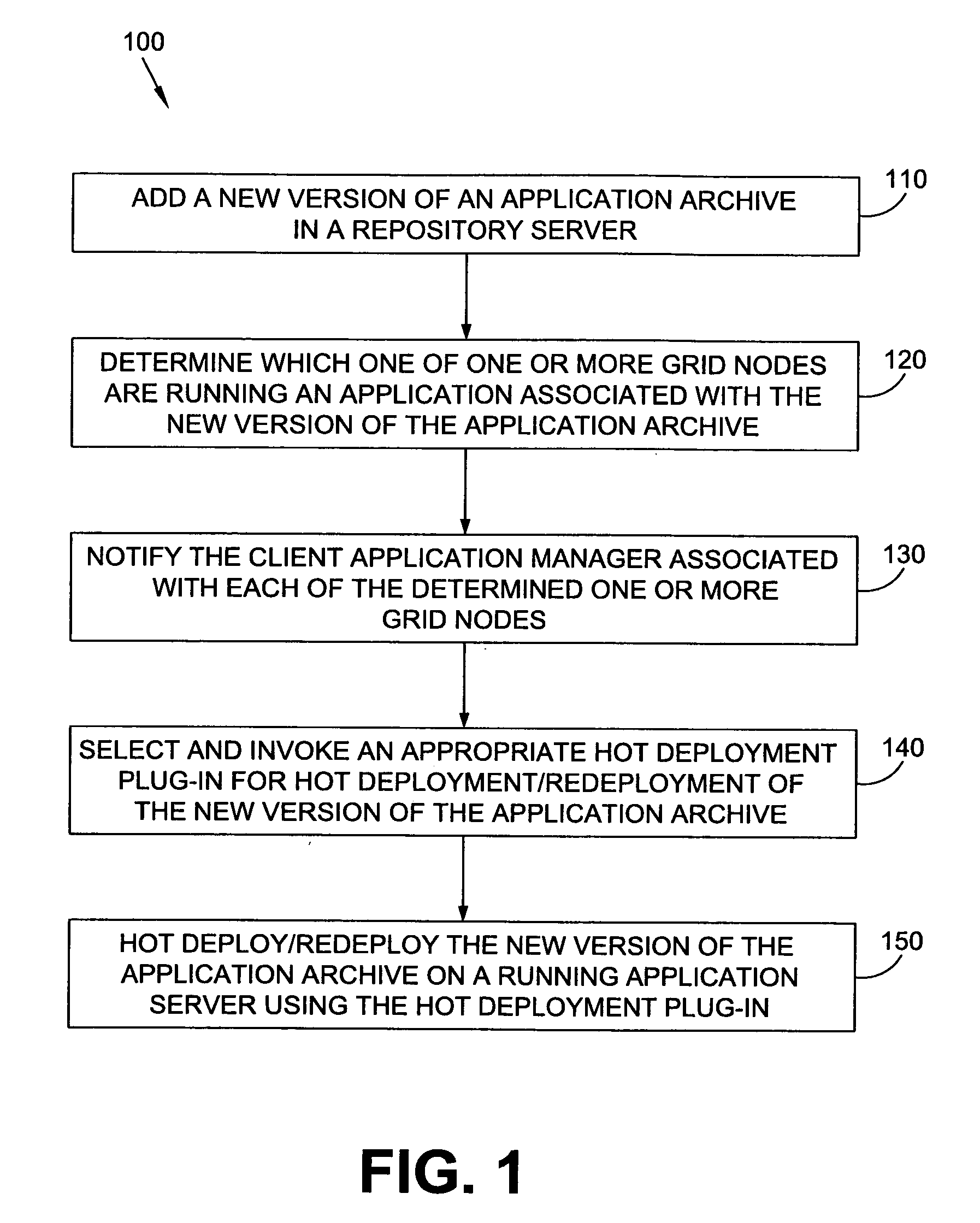

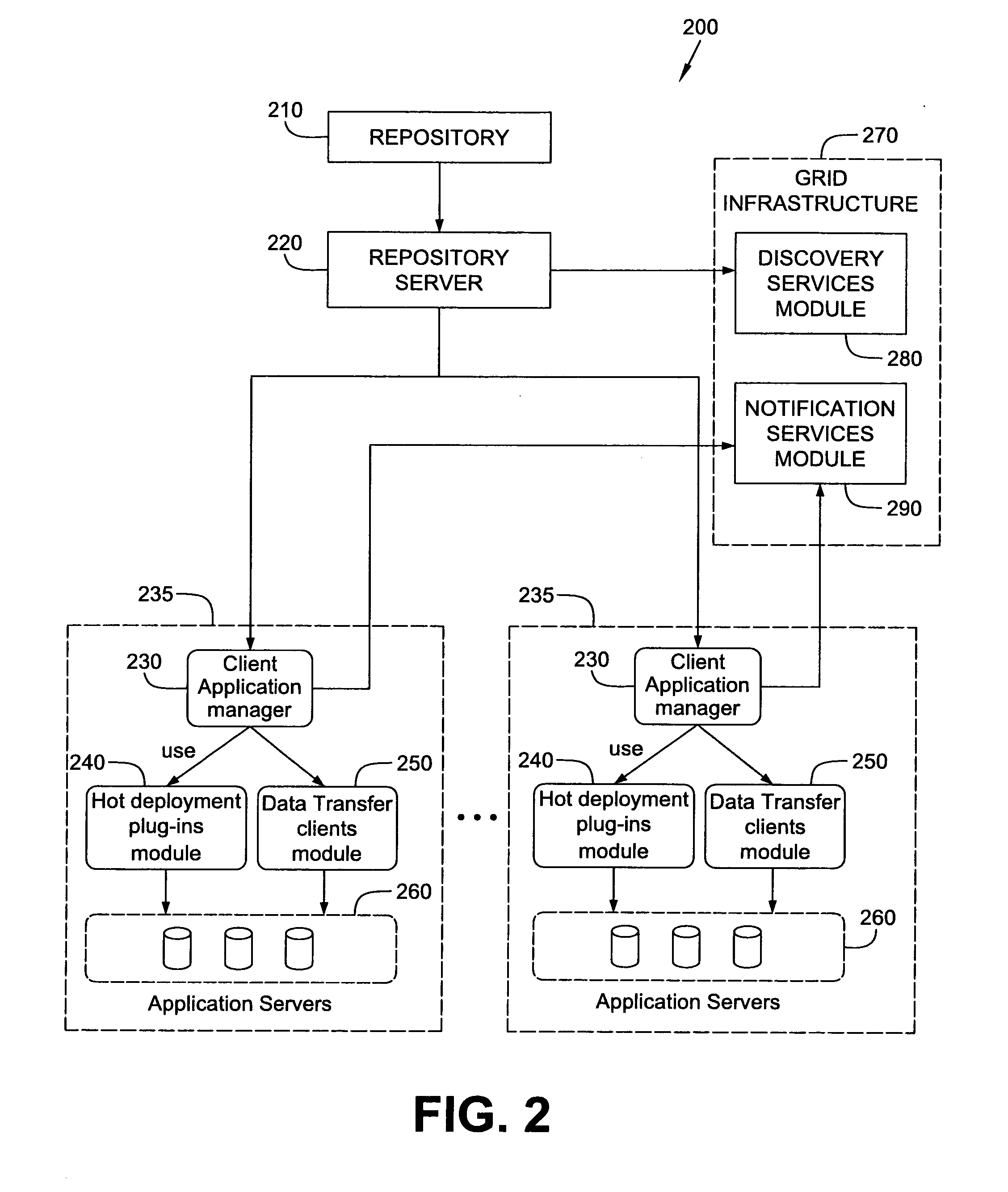

System and method for hot deployment/redeployment in grid computing environment

ActiveUS20080162674A1Reduce chanceReduce overheadSoftware engineeringDigital computer detailsApplication serverProgram management

A technique for hot deploying / redeploying applications in a grid computing environment to improve operating efficiency and reduced overhead. In one example embodiment, this is accomplished by notifying a client application manager associated with each of one or more grid nodes about a type of data transfer protocol to use upon receiving a new version of an application release bundle by a repository server. The new version of the application release bundle is then hot deployed / redeployed on running one or more application servers in the associated grid using an appropriate hot deployment plug-in based on the data transfer protocol by each client application manager.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

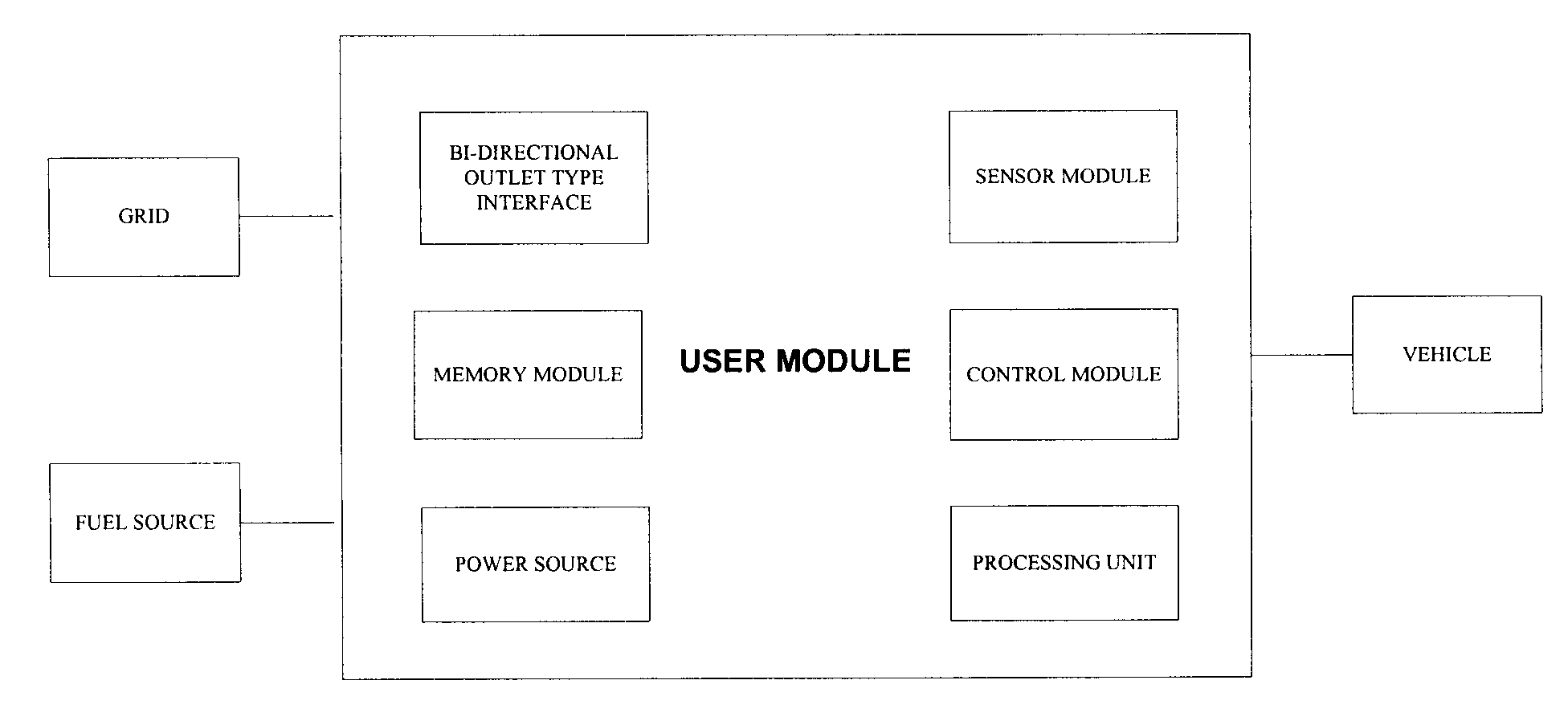

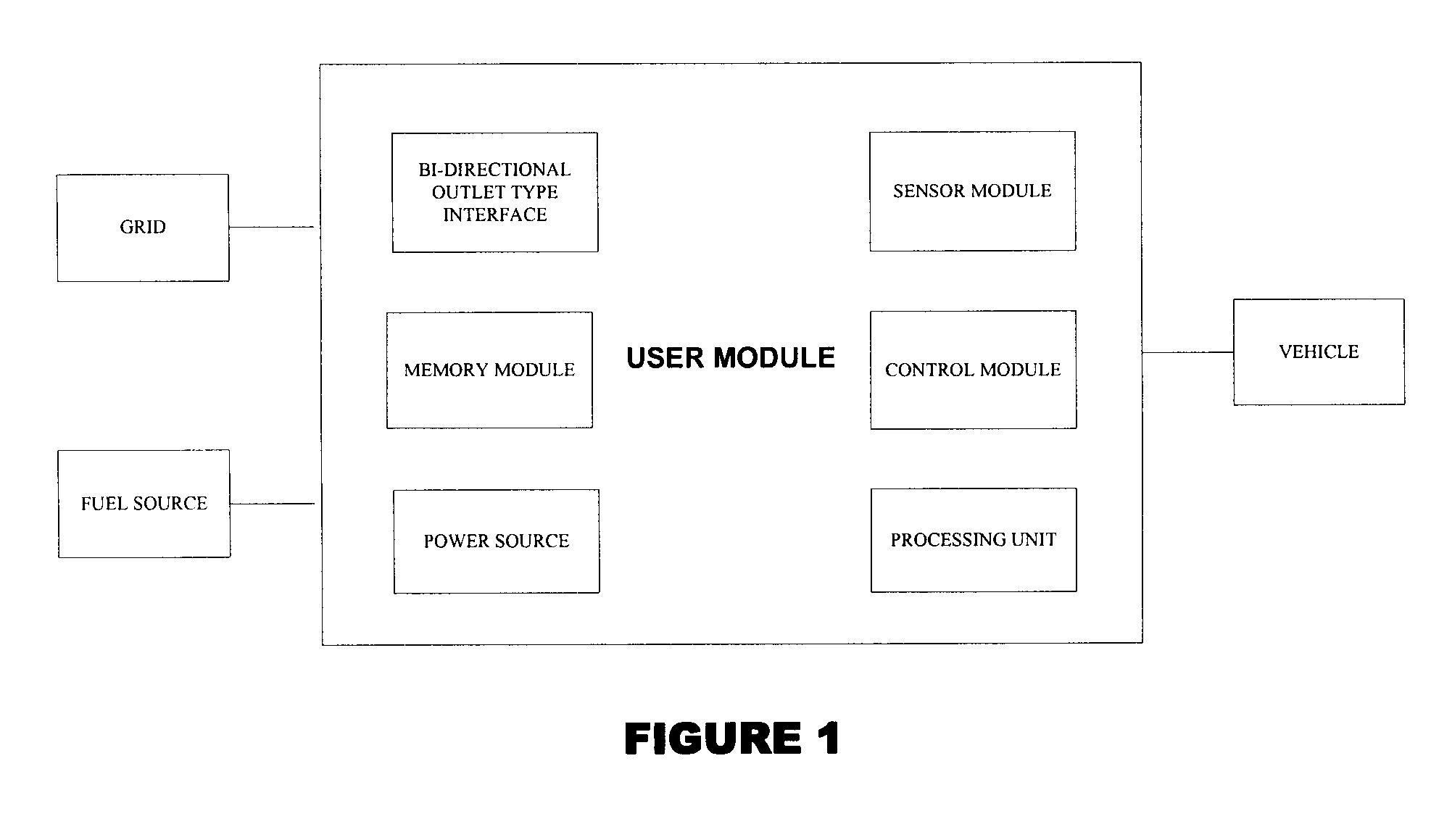

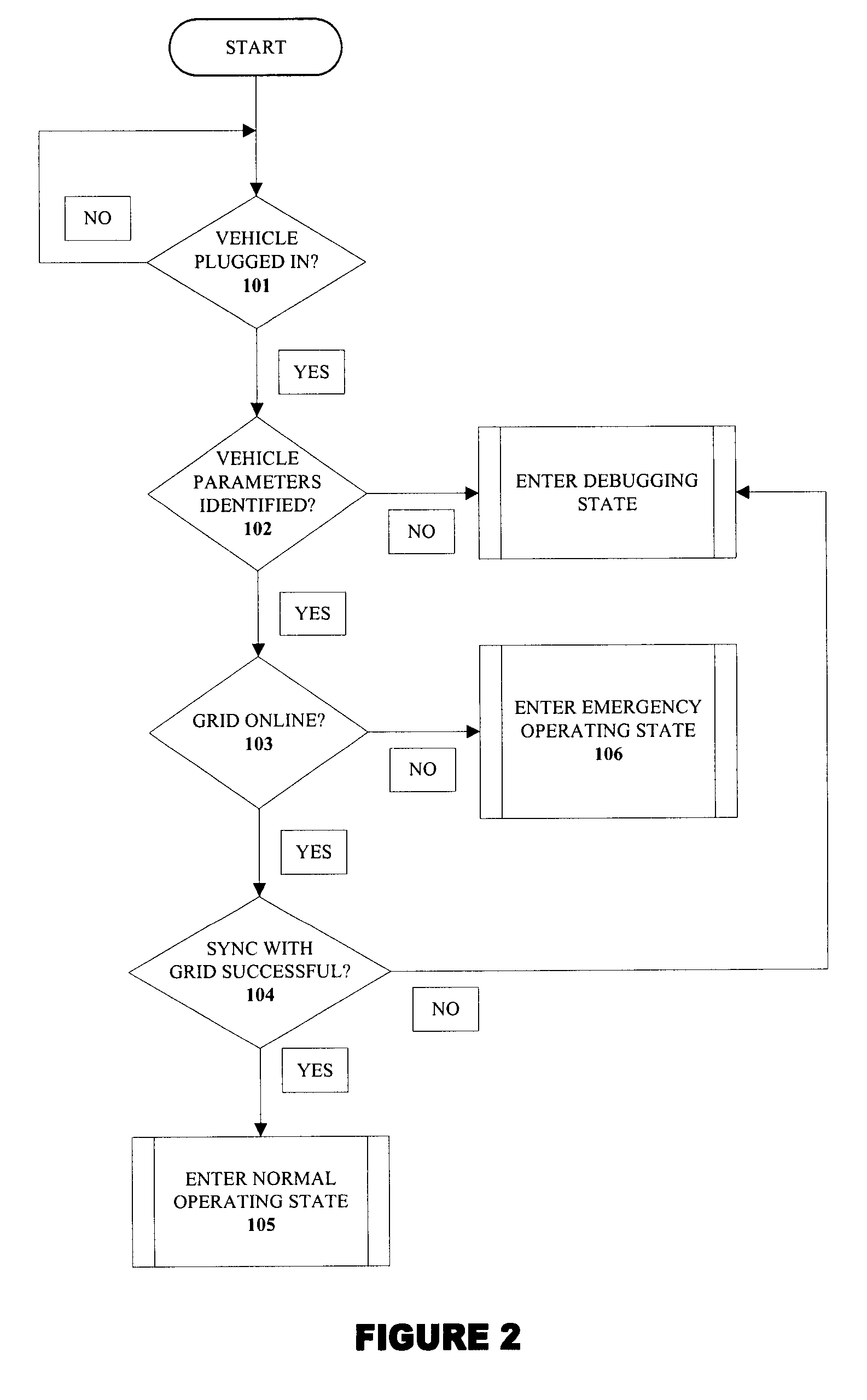

System and method for transferring electrical power between grid and vehicle

InactiveUS20090030712A1Low loading amountIncrease available powerBatteries circuit arrangementsRoad vehicles traffic controlElectric power transmissionElectrical battery

The present invention discloses a system for transferring electrical power between a grid and at least one vehicle. The vehicle can be Battery Electric Vehicle (BEV), Plug-in Hybrid Electric Vehicle (PHEV) or Fuel Cell Vehicle (FCV). The type of vehicle will be recognized and controlled by the system to support demand response and supply side energy management. Vehicle recognition can be carried out by load signature analysis, power factor measurement or RFID techniques. In an embodiment of the invention, the grid is a Smart Grid. The present invention also discloses a method for facilitating electrical power transfer between the grid and the vehicle.

Owner:ITRON NETWORKED SOLUTIONS INC

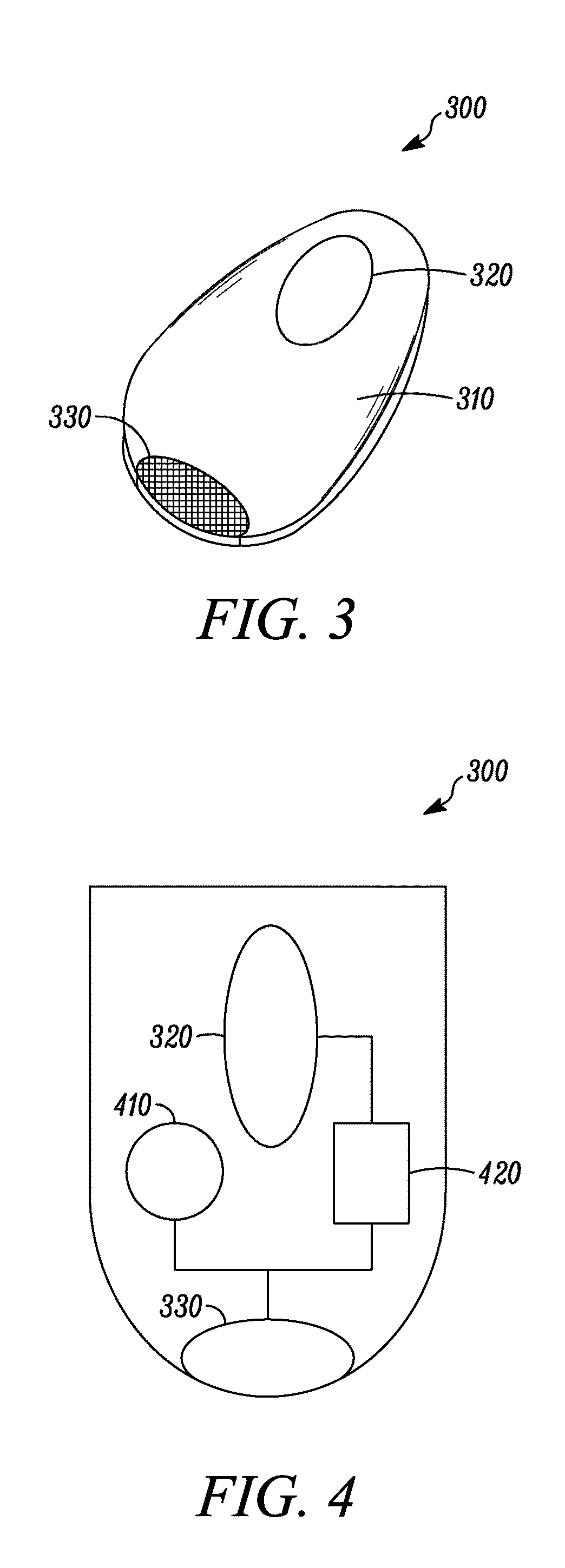

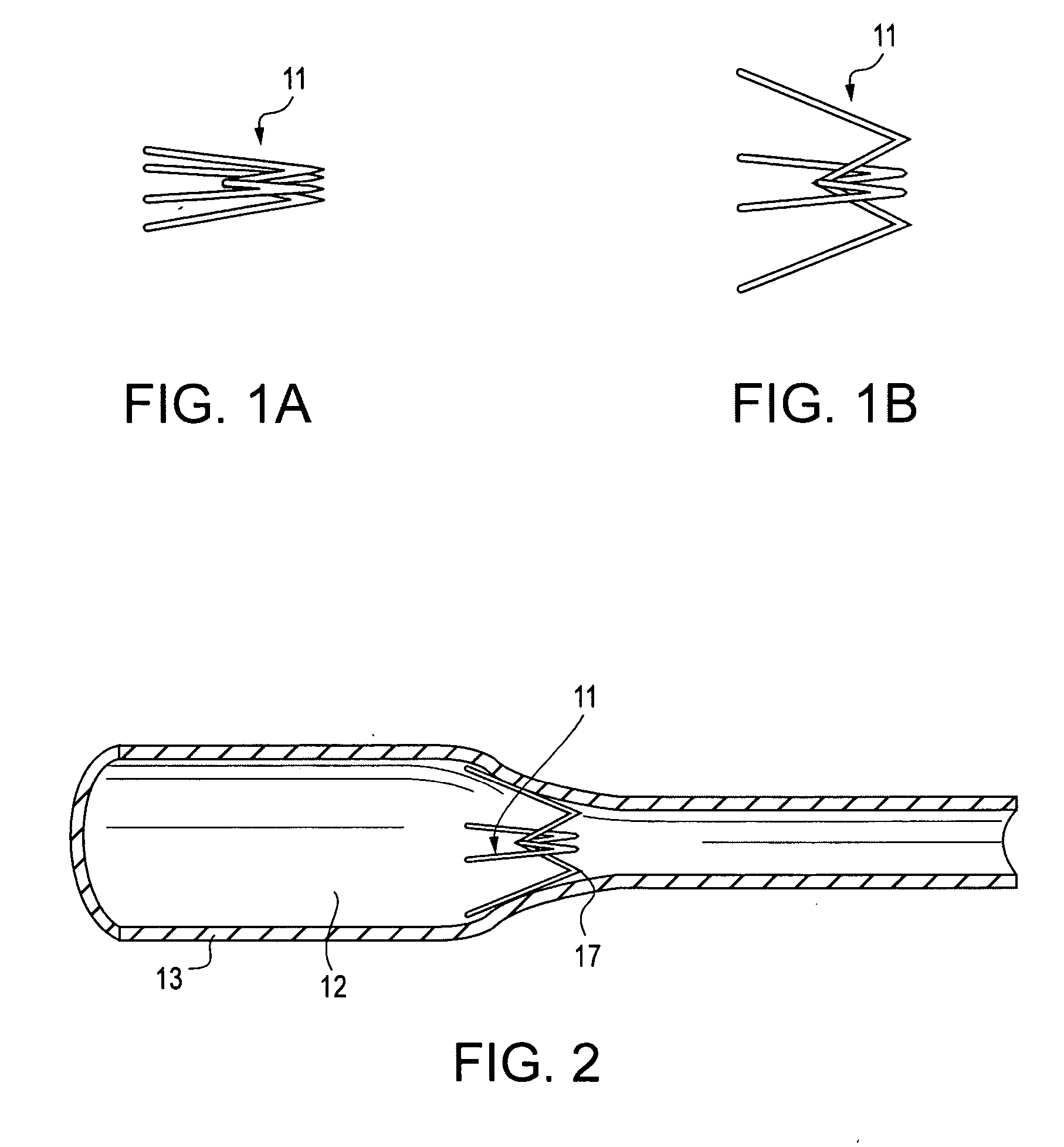

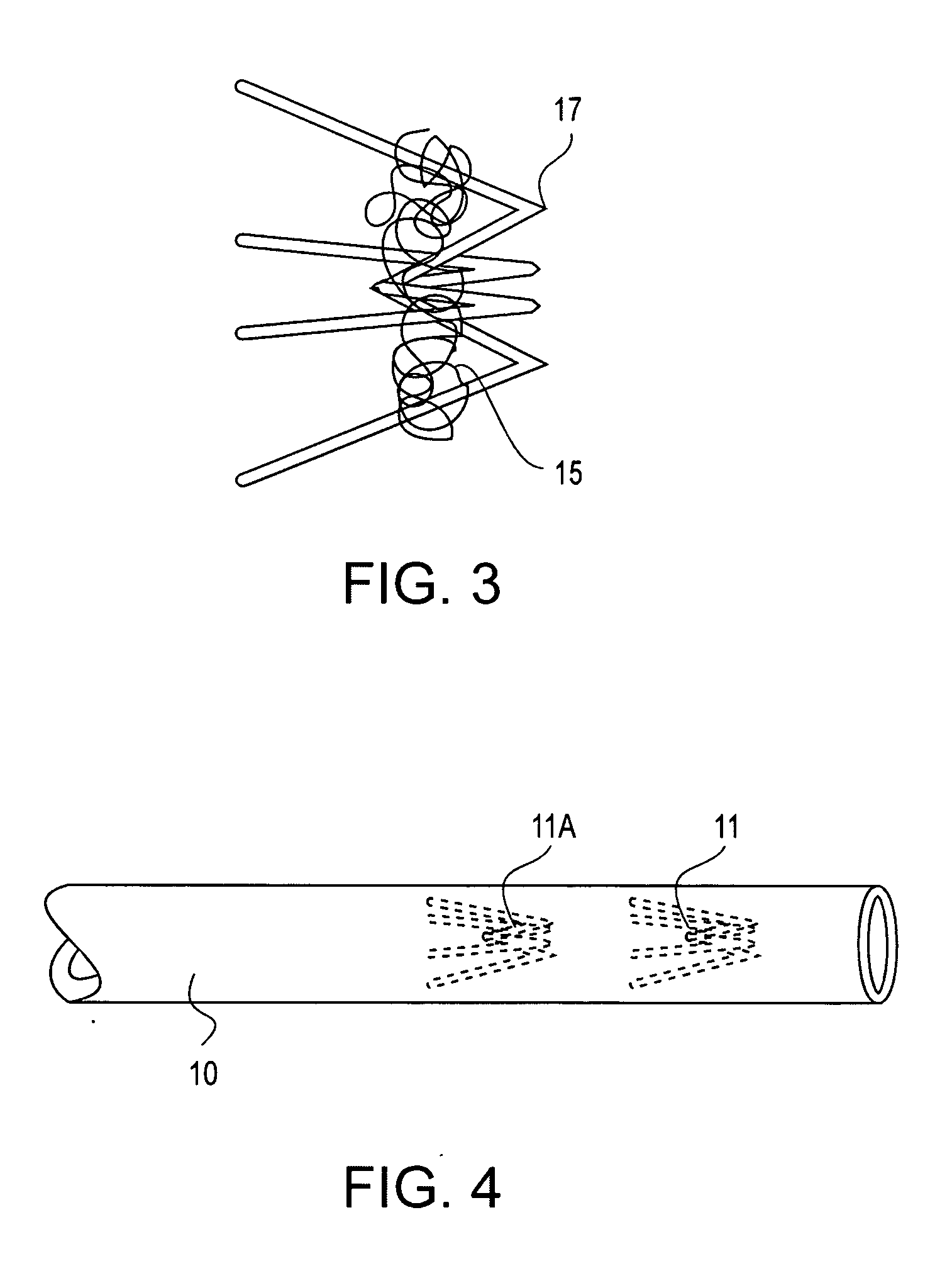

Methods and devices for occluding body lumens and/or enhancing tissue ingrowth

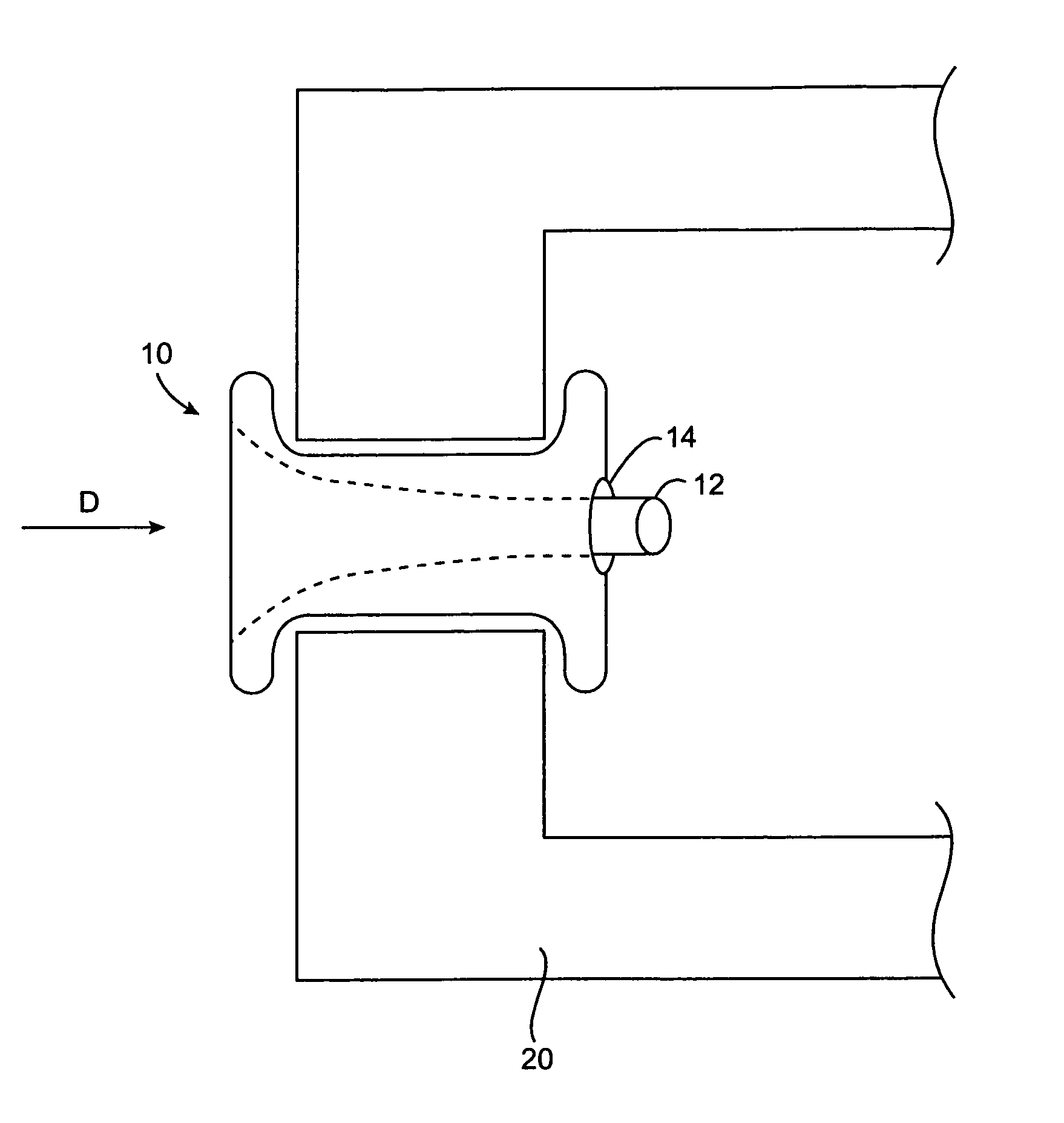

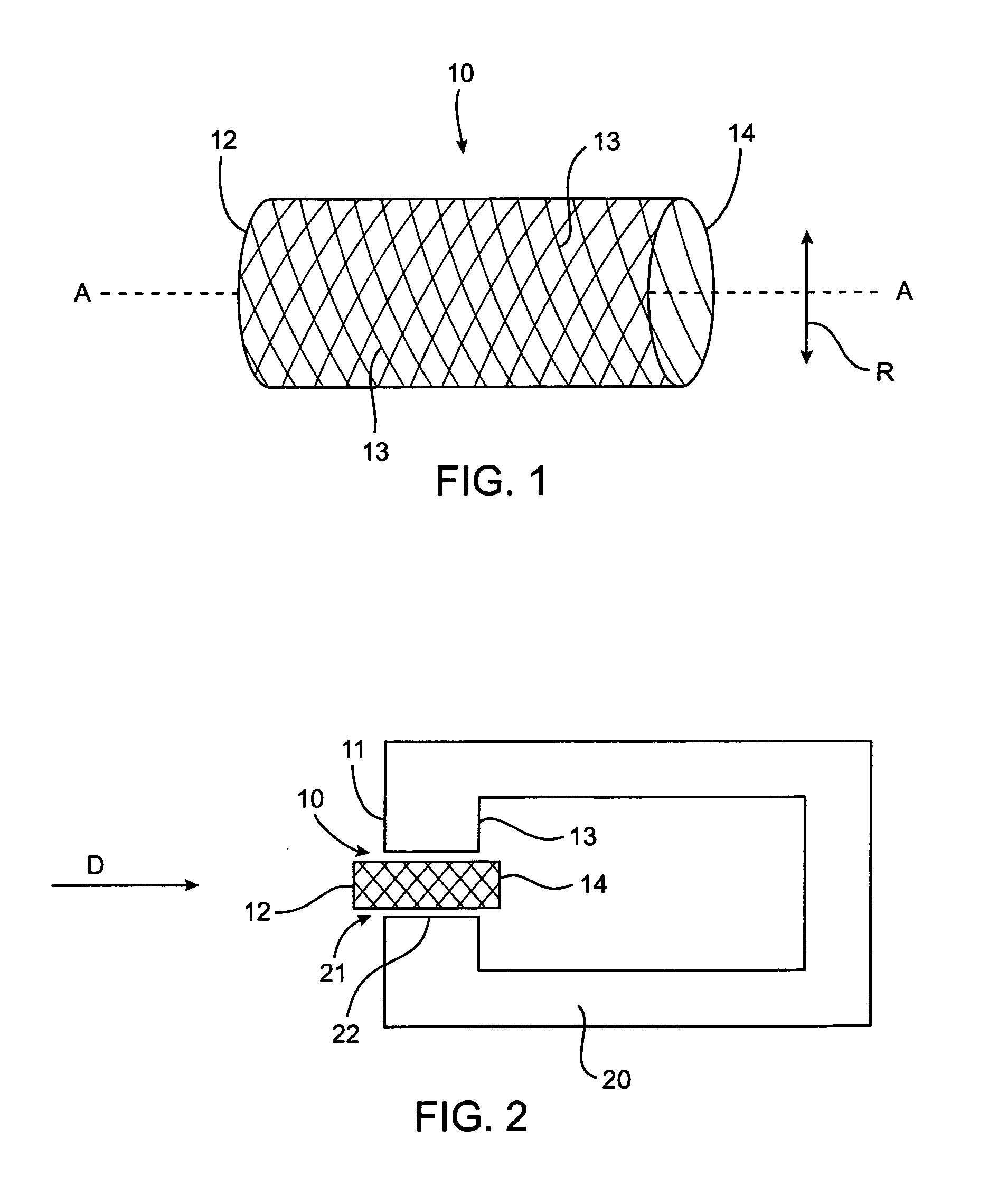

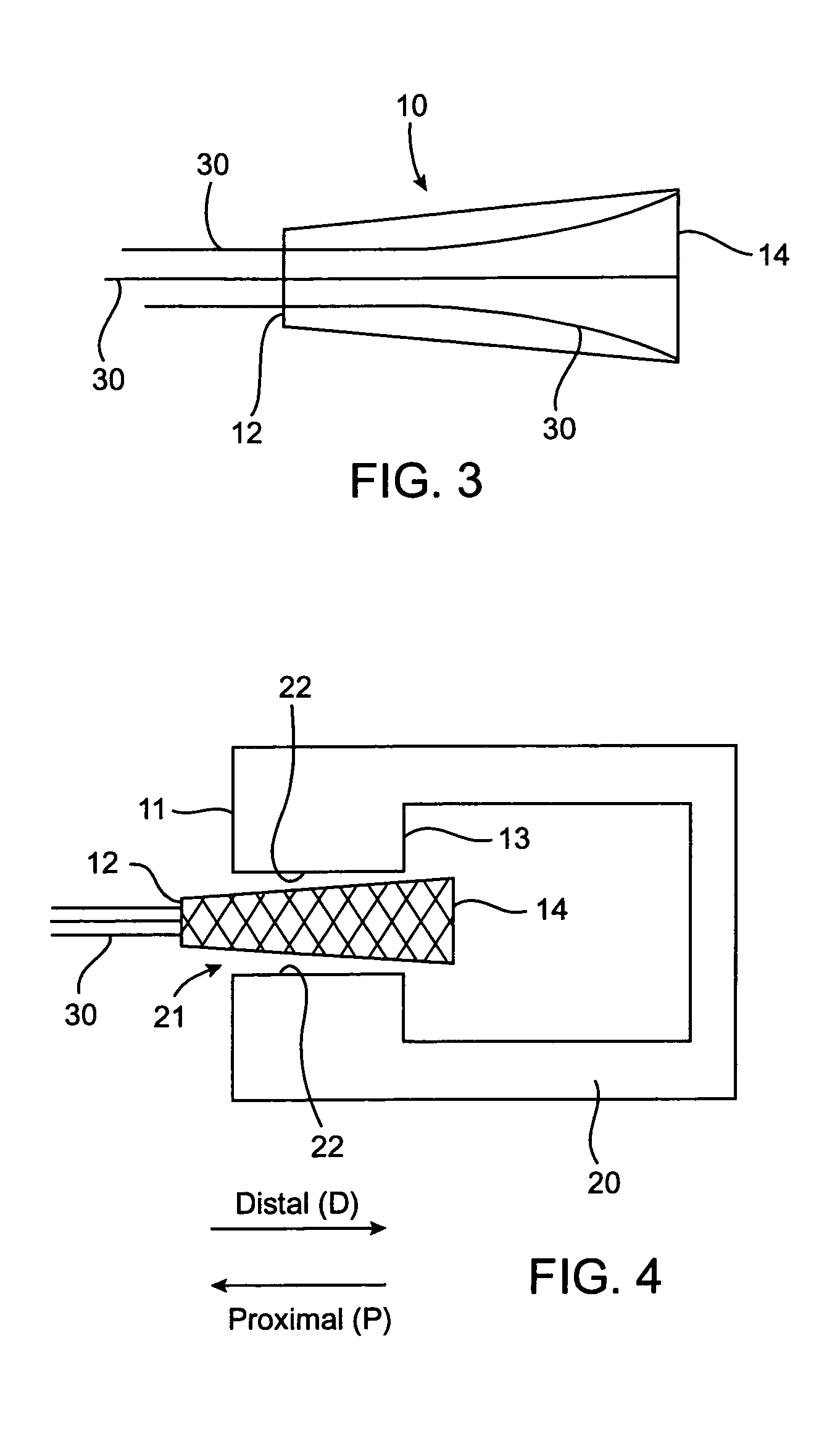

InactiveUS20060009798A1Enhance ingrowthTissue ingrowth is further enhancedStentsFallopian occludersMesh gridEpithelial tissue

The present invention provides devices, methods and systems for the occlusion of various lumens in a body of a patient including devices and methods for enhancing tissue ingrowth, particularly endothelial tissue growth within an occlusive device. The system includes an occlusive device and a delivery device for placing the occlusive device in a body lumen. The occlusive device is generally a tubular member with a mesh member disposed thereon. The occlusive device is configured to be radially expandable along a longitudinal axis of the tubular member and implantable with a delivery catheter such that the occlusive device is in a collapsed state when positioned in the delivery catheter and in an expanded state when positioned in a lumen of a patient. The mesh member of the occlusive device is configured to promote epithelial tissue ingrowth.

Owner:BAYER ESSURE

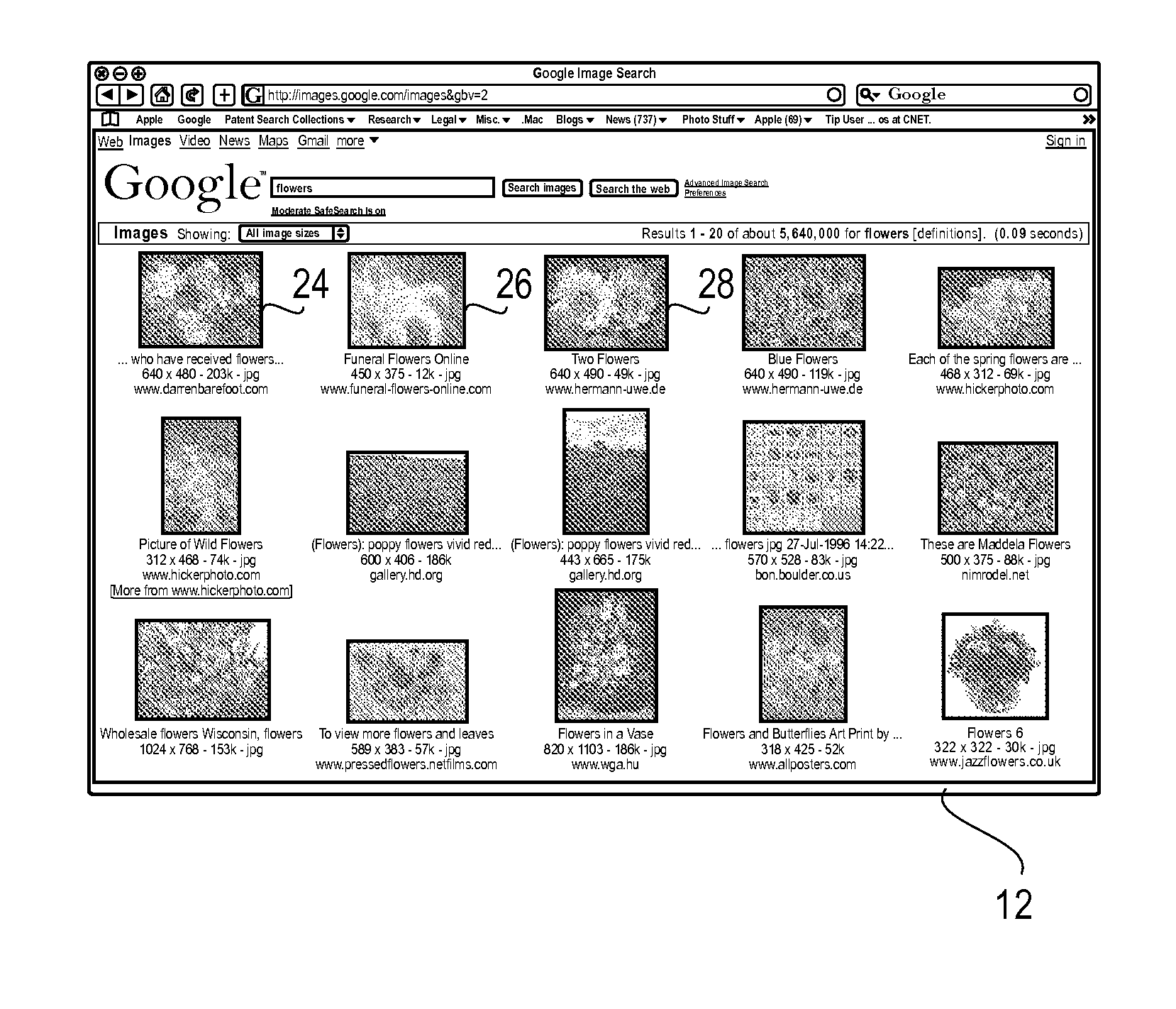

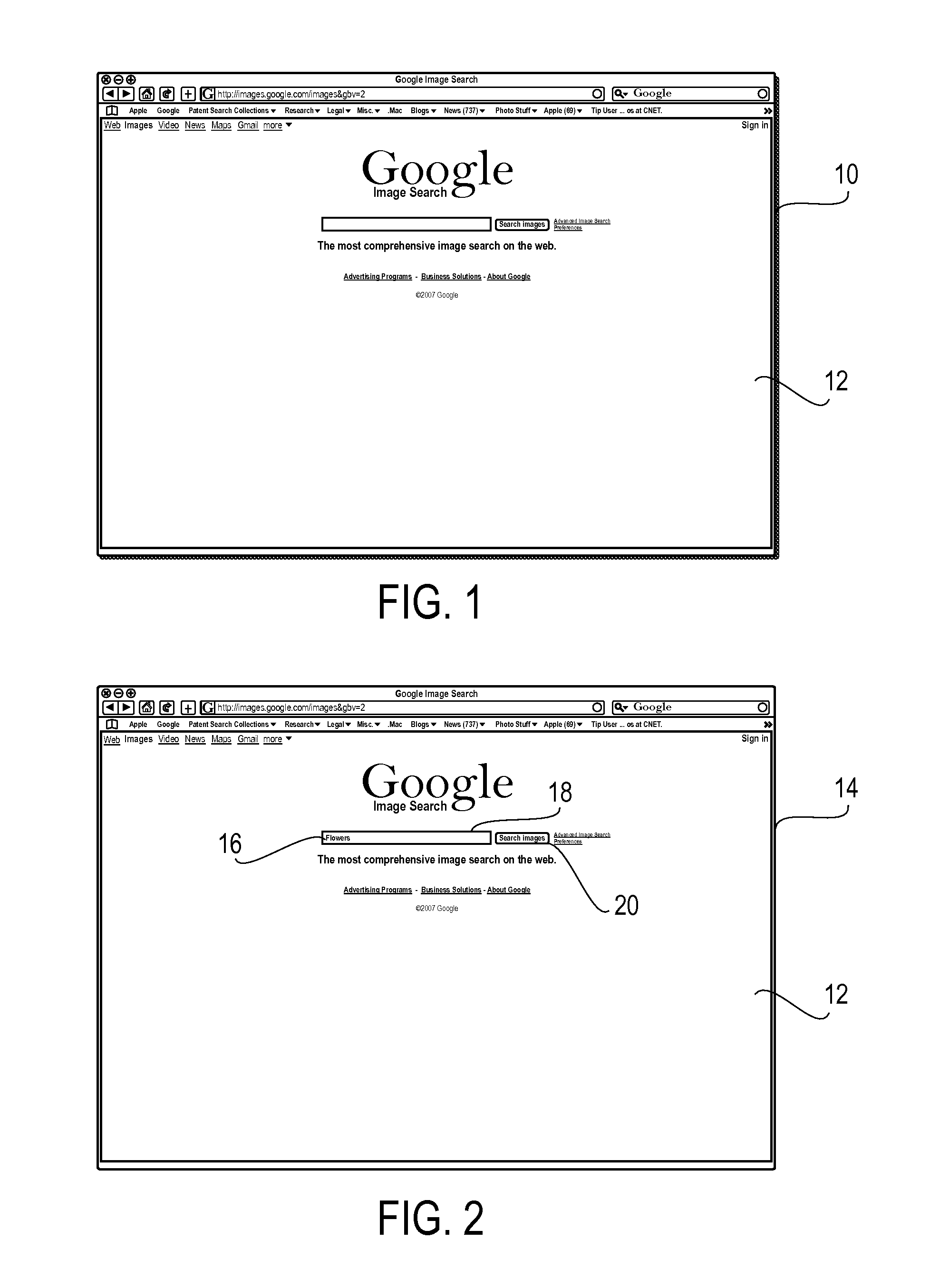

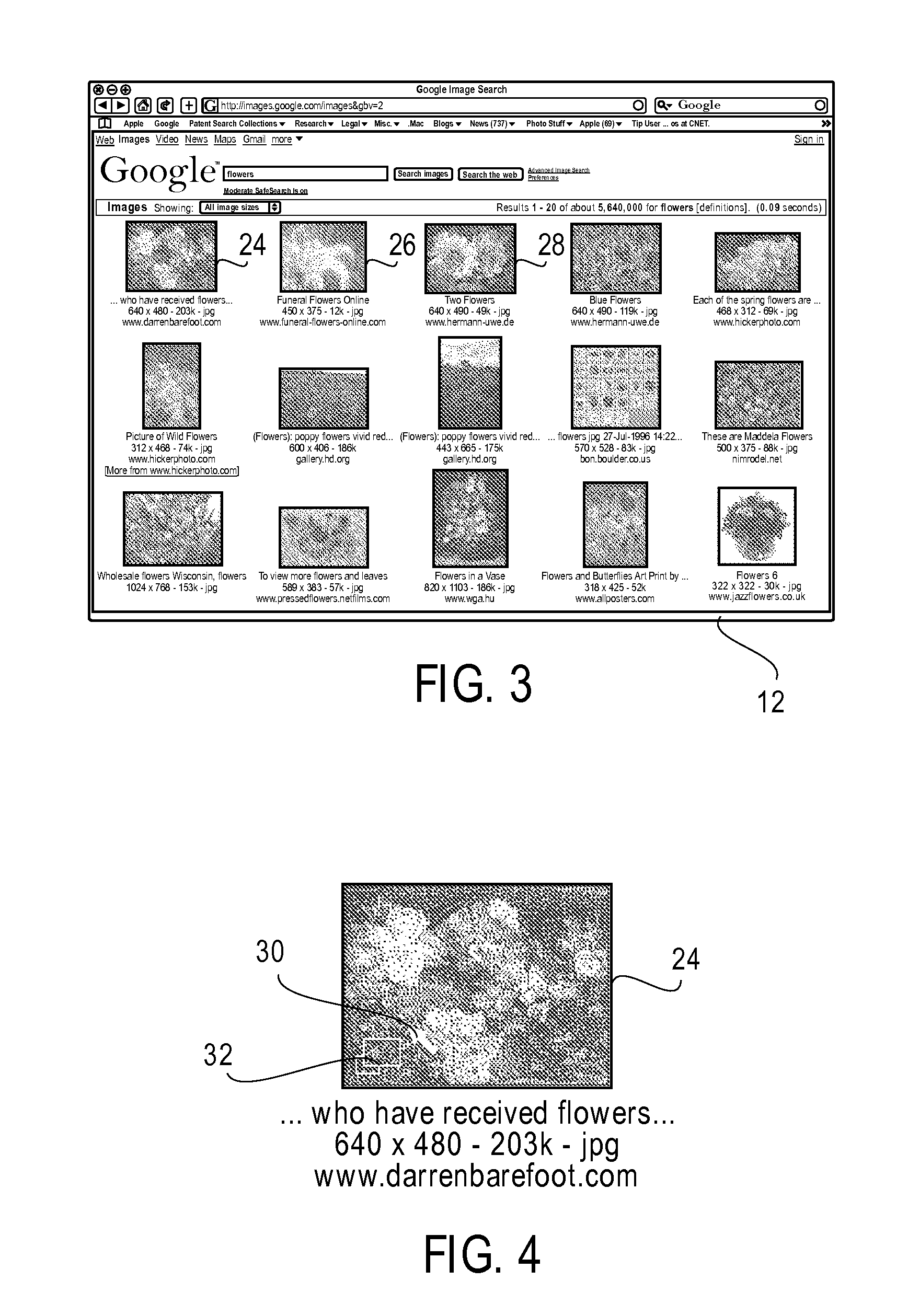

Method and system for displaying photos, videos, rss and other media content in full-screen immersive view and grid-view using a browser feature

User-initiated or intelligently automated acquisition, extraction and presentation of content such as photos, videos, and / or other content (e.g., news stories, product displays, advertisements, etc.), from a Web site in a full-screen slideshow via client-side software, which may be implemented as a stand-alone application, an extension (a.k.a. plug-in, or add-on), a Web browser feature (a.k.a. function), or as an embedded component associated with the content.

Owner:YAHOO ASSETS LLC

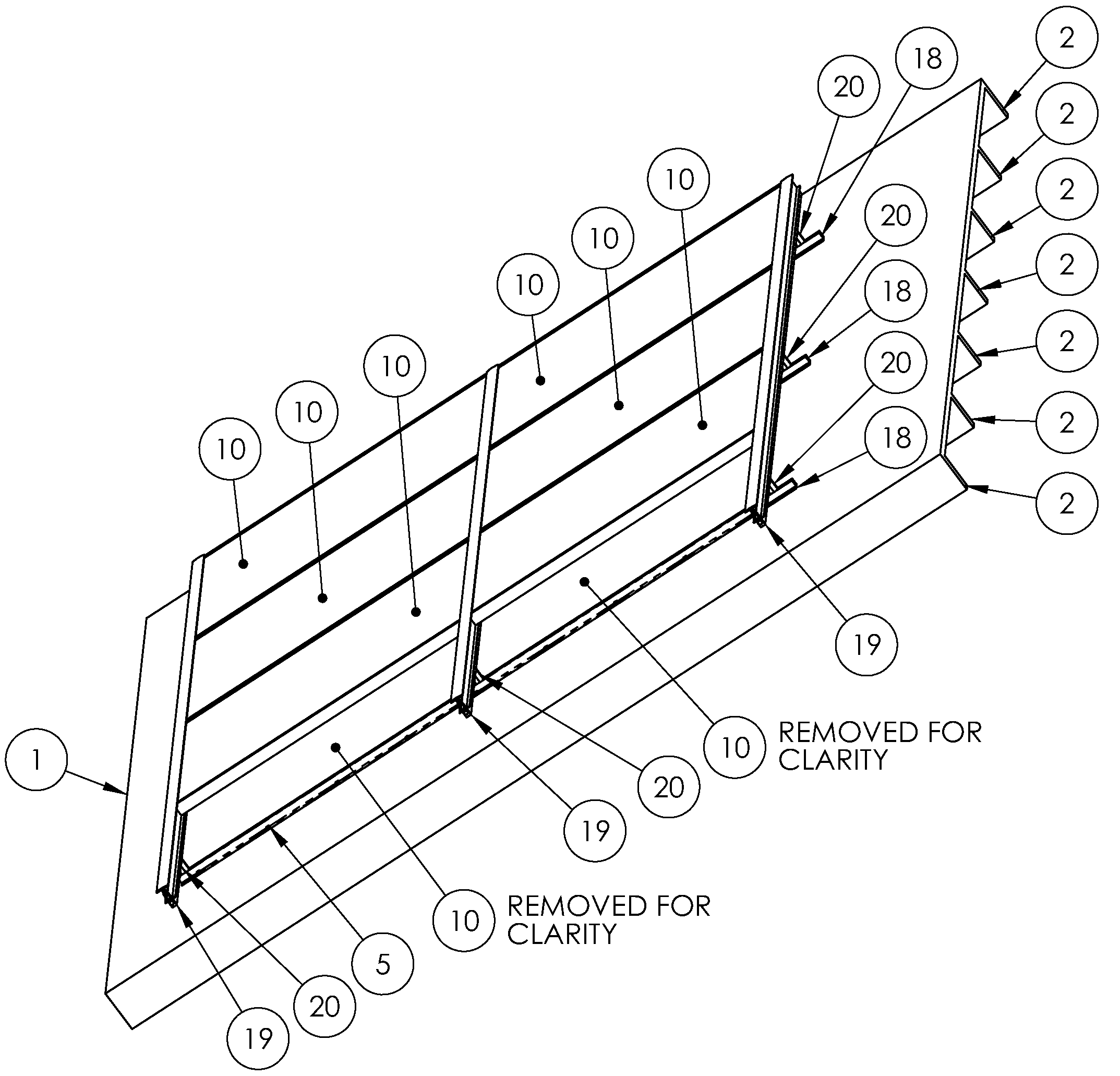

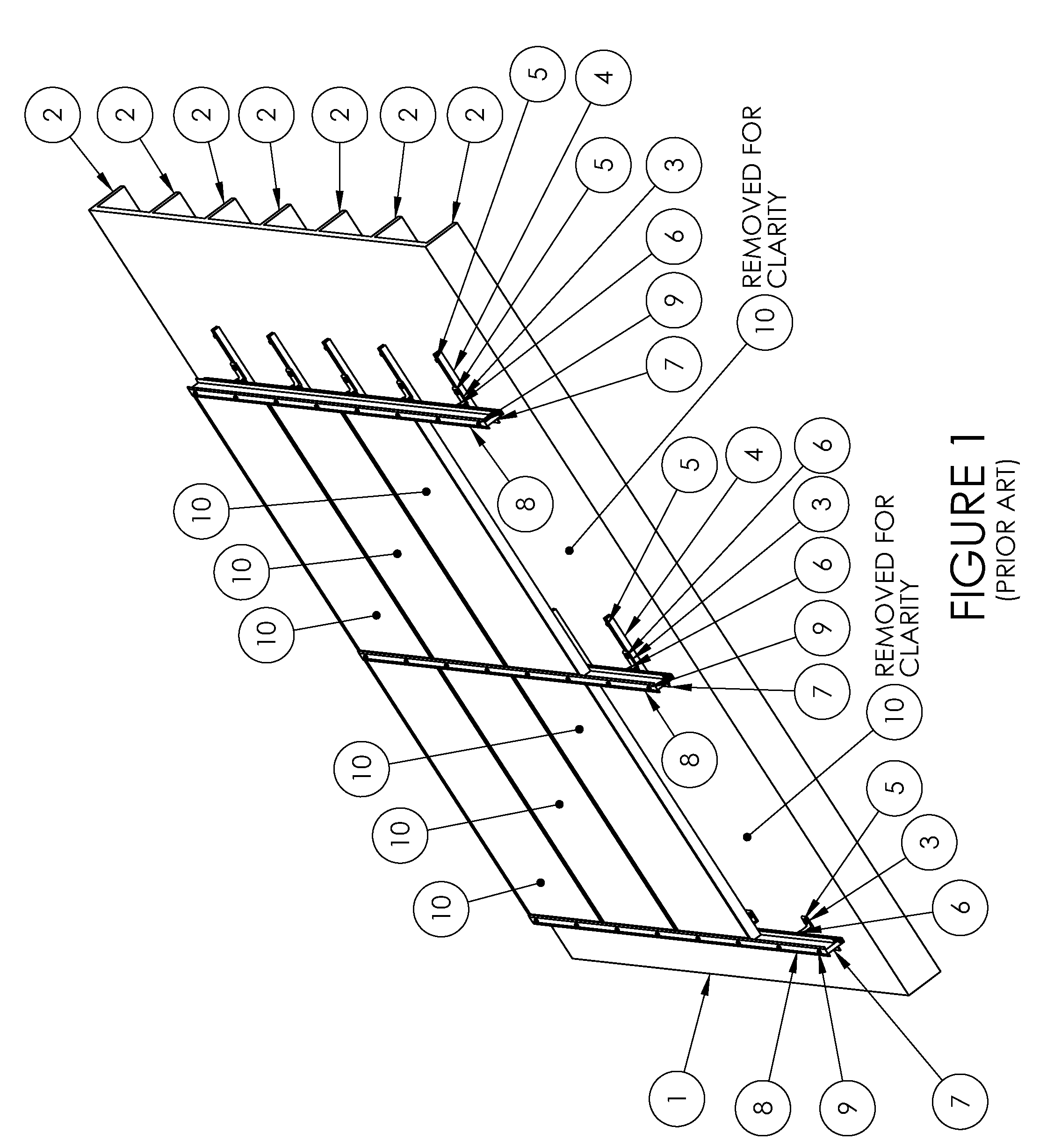

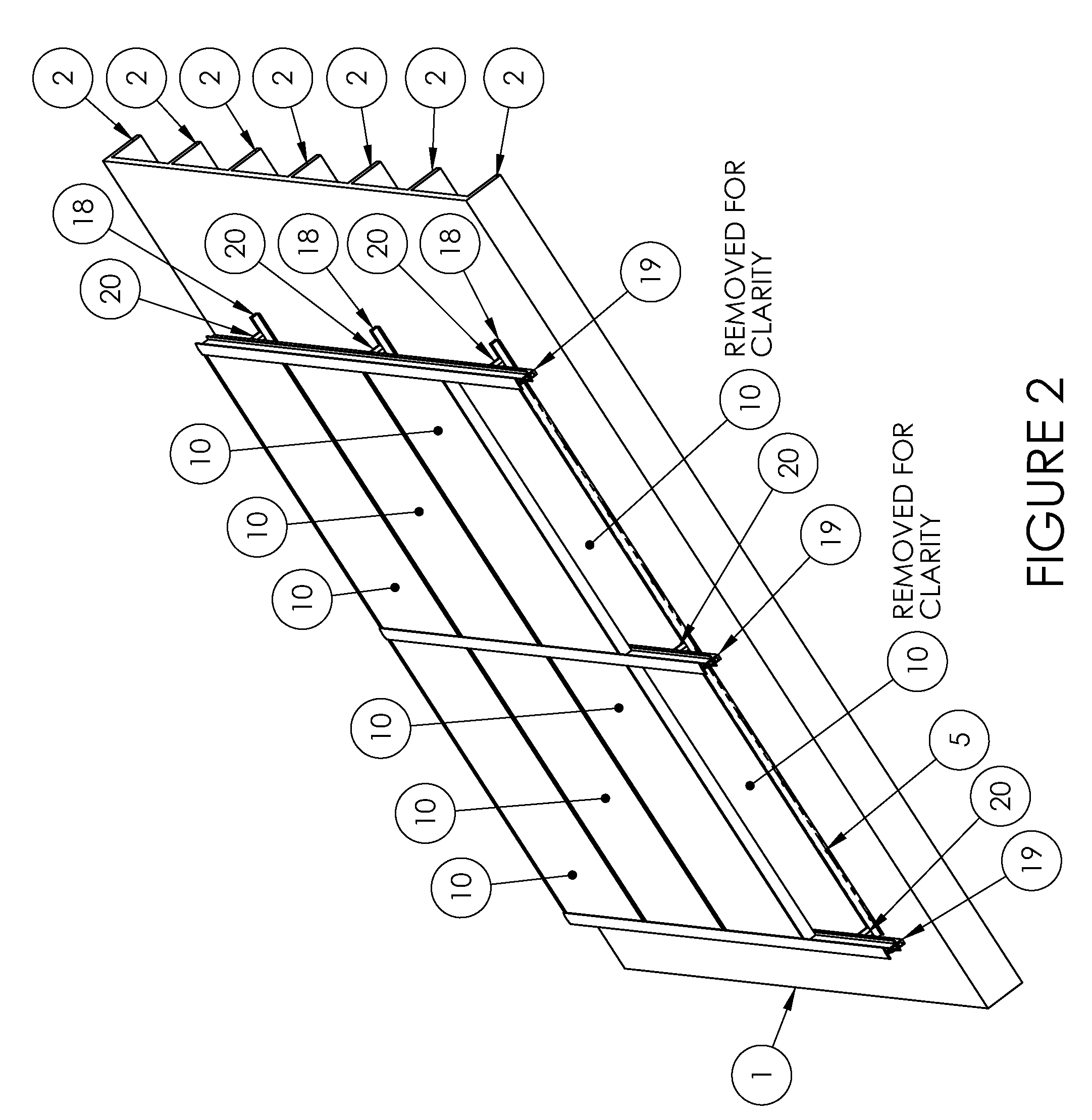

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS20090282755A1Cost-effectiveTurn easilyPhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

A cam-actuated connection device joins rail mounting members of a photovoltaic panel array. The connection device slides within channels of mounting members until the members are in a properly positioned grid. When in position, the connection device is rotated to lock the mounting members in a rigid grid network. The connecting device can be subsequently loosened, repositioned and locked into position. The rail-mounting members create a grid for installation of multiple PV panels. The mounting rail allows the unit to remain relatively compact in nature but still covers a wide range of PV panel thicknesses. The rail system has a hinged connection with the mounting rail that allows an installer to assemble the module in a near perpendicular fashion to the mounting rail, make the required electrical connections and then lower the PV module into its working position. The unit is then locked into its working position.

Owner:POWERMOUNT SYST +1

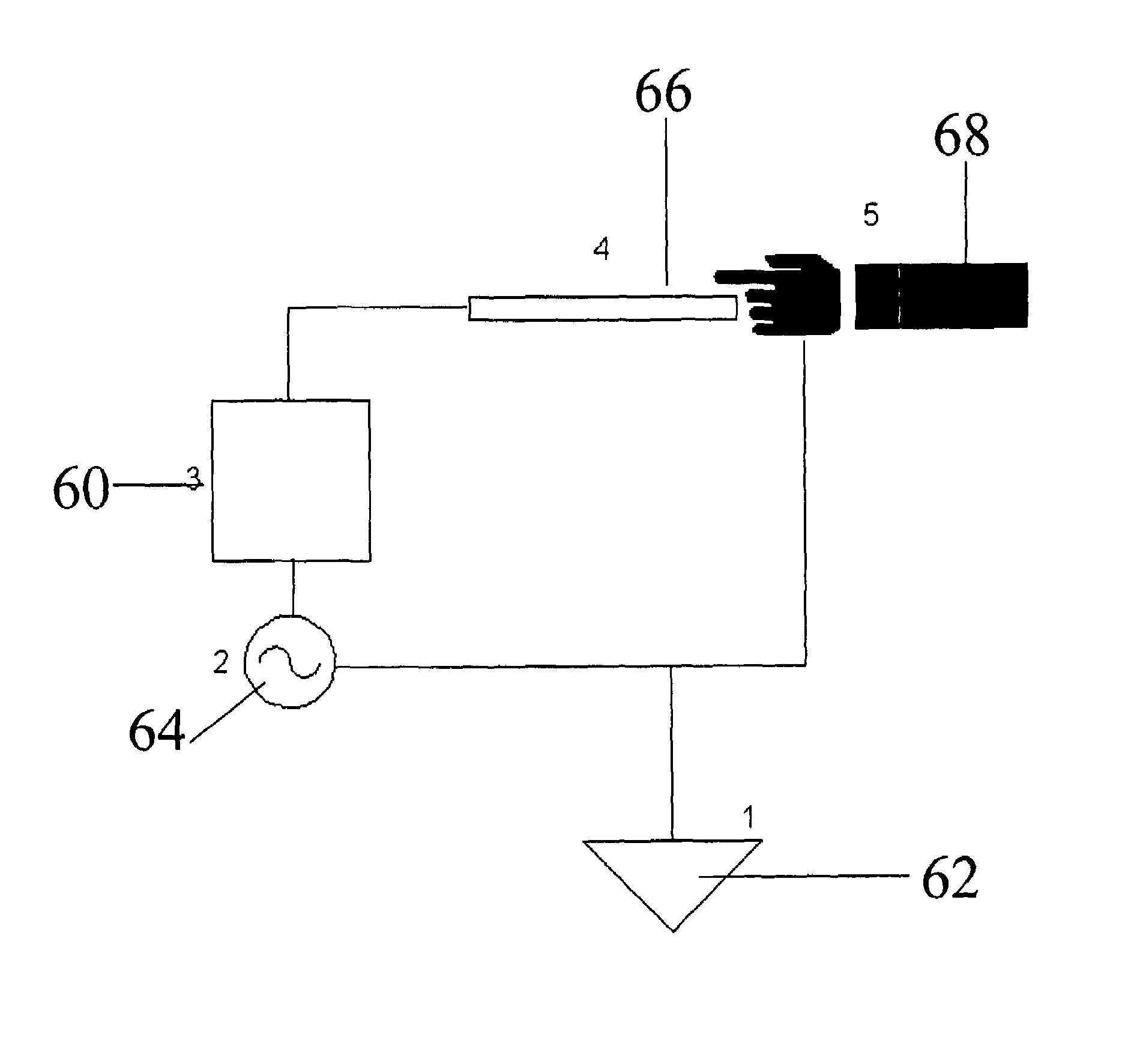

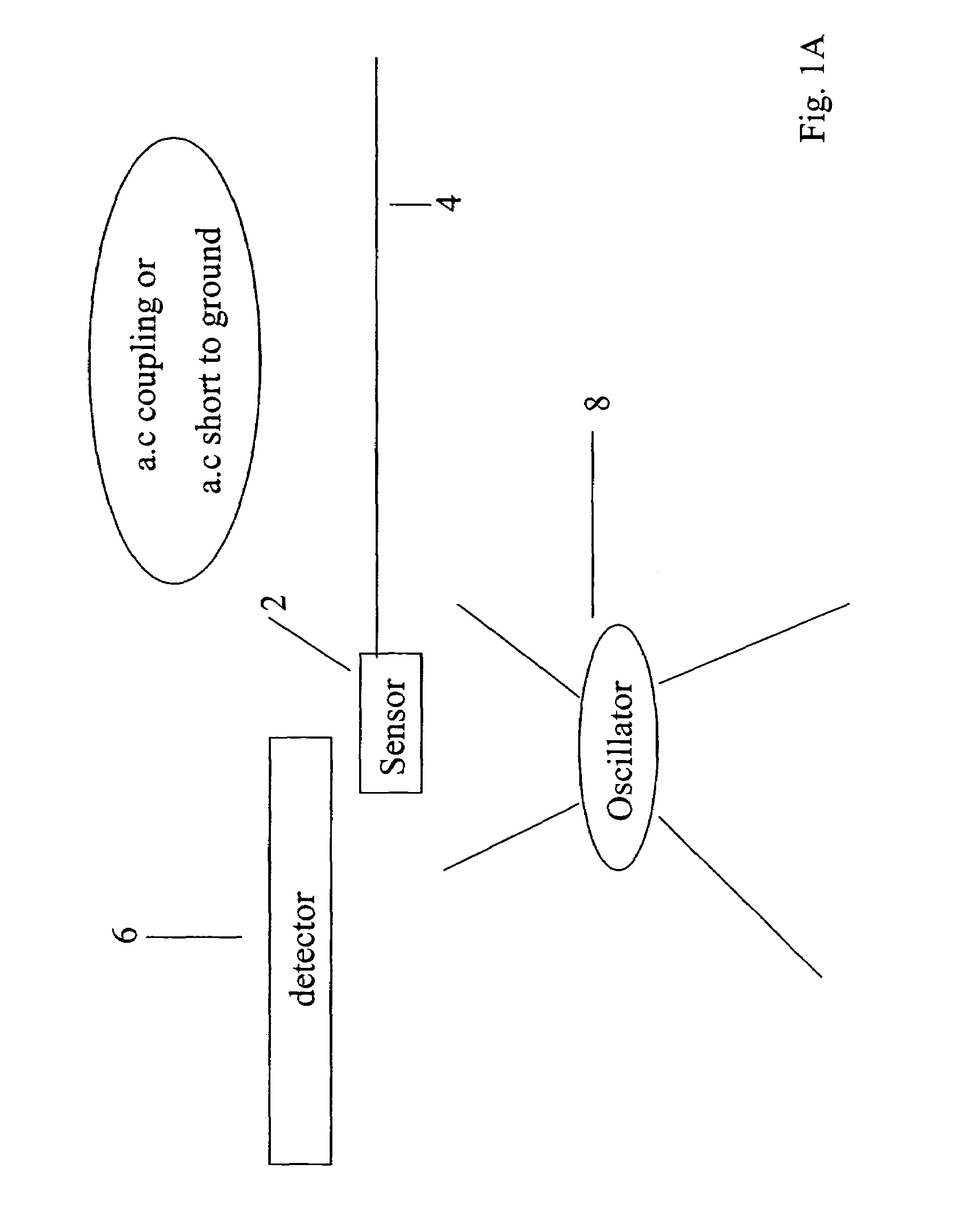

Touch detection for a digitizer

ActiveUS7372455B2Input/output for user-computer interactionCathode-ray tube indicatorsCapacitanceElectrical conductor

A detector for detecting touches by fingers or like body parts on a sensor comprises at least one sensing conductor, typically a grid of such conductors, extending into the sensor, a source of oscillating electrical energy at a predetermined frequency, and detection circuitry for detecting a capacitive influence on the sensing conductor when said oscillating electrical energy is applied, the capacitive influence being interpreted as a touch. The detector is advantageous in that the same sensing conductors can be used both for touch sensing and for detection of an electromagnetic stylus.

Owner:MICROSOFT TECH LICENSING LLC

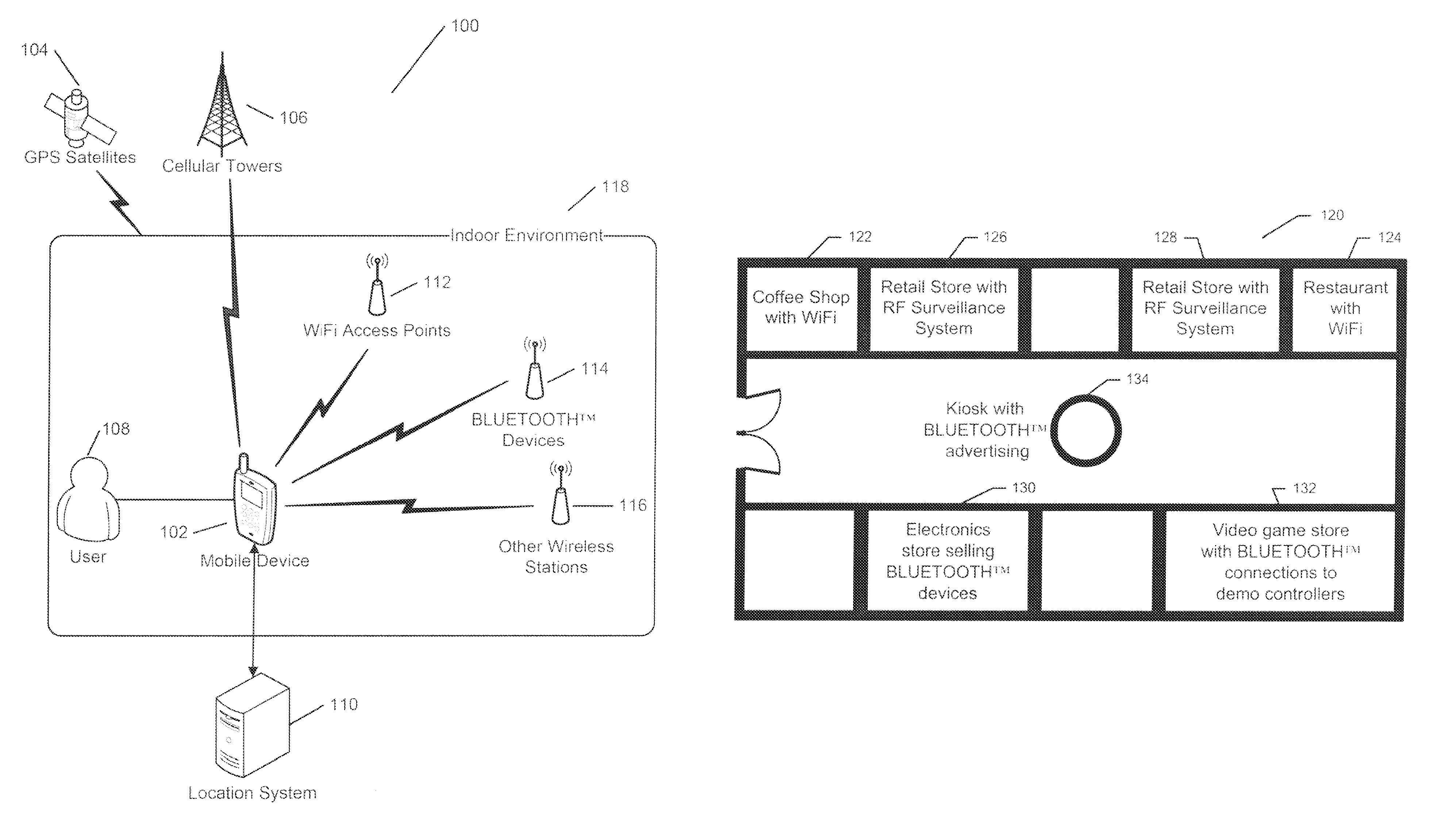

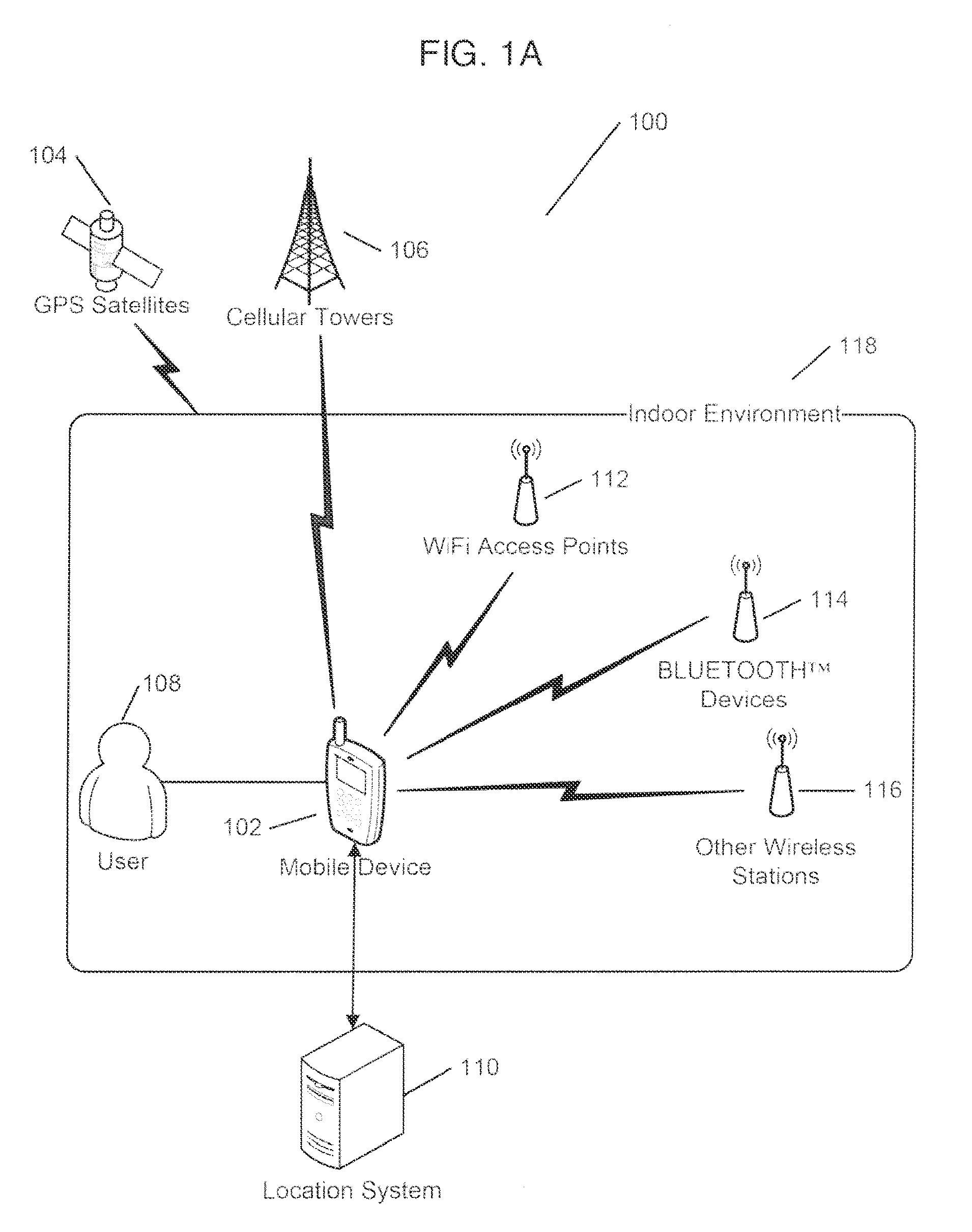

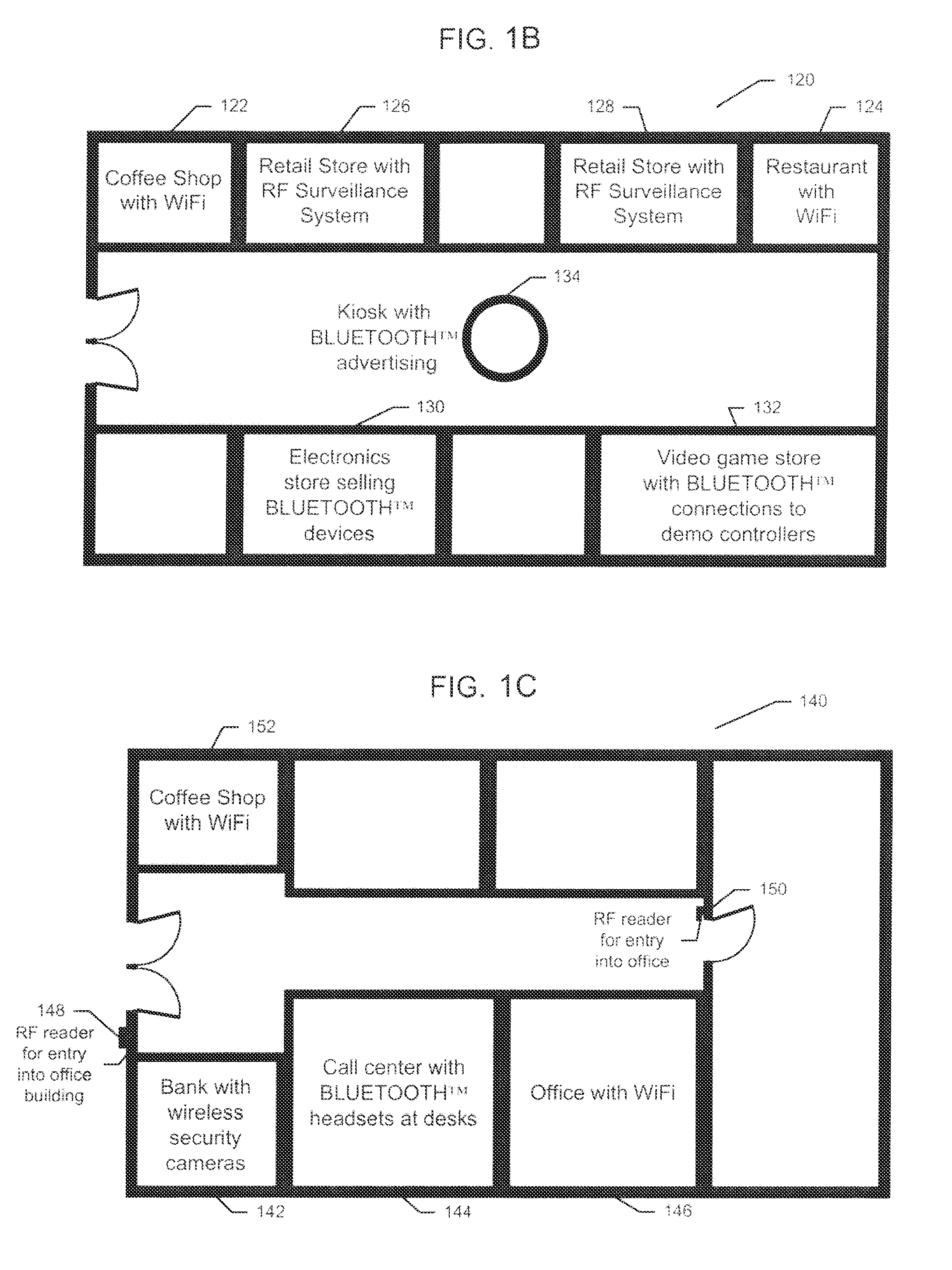

Systems and methods for calibration based indoor geolocation

ActiveUS9439041B2Improve accuracyAccurate CalibrationDirection finders using radio wavesParticular environment based servicesIndoor geolocationSystems analysis

In a system facilitating the calibration of a map-point grid for an indoor location determination, the grid includes several map points, each having a radio frequency (RF) data fingerprint being associated therewith. At least one of: (i) RF signal data from several RF sources, (ii) a user specified location indication, and (ii) tracking data from a sensor, the tracking data indicating a user's movement relative to a base map point, are received. The map-point grid is updated based on, at least in part, at least one of (i) adjusted RF data, the received RF data being adjusted using systematic analysis thereof, (ii) the tracking data, and (iii) the location indication. A user's location may be determined based on the fingerprints associated with the map-point grid, and sensor data.

Owner:LIGHTHOUSE SIGNAL SYST

Annulotomy closure device

A system for sealing a hole in a body, comprising a generally cylindrical mesh formed from a plurality of helical strands which is inserted into the hole, with at least one end of the cylindrical mesh being moved least partially through an interior portion of the cylindrical shaped mesh such that the mesh expands radially outwards against sides of the hole.

Owner:NUVASIVE

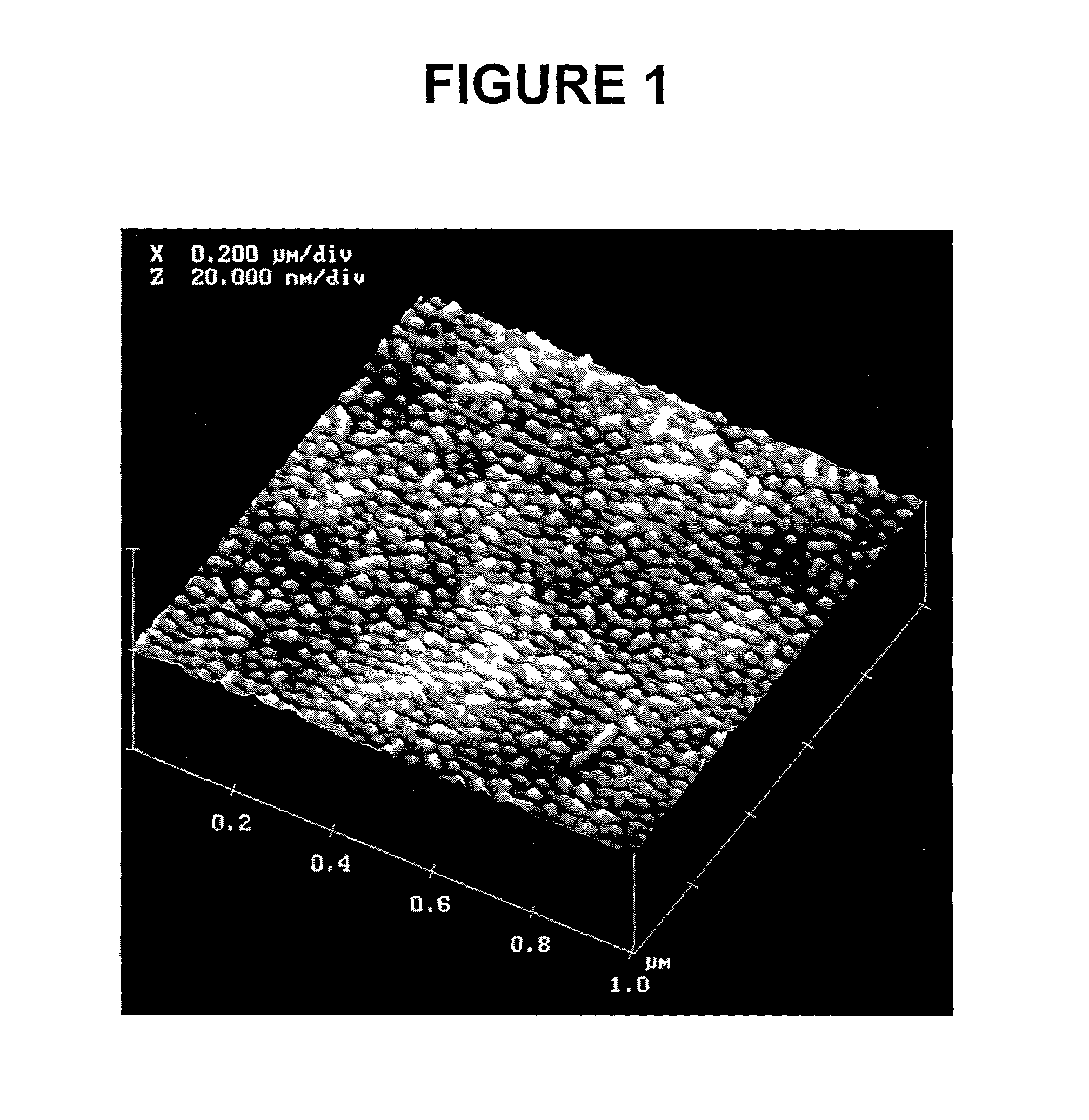

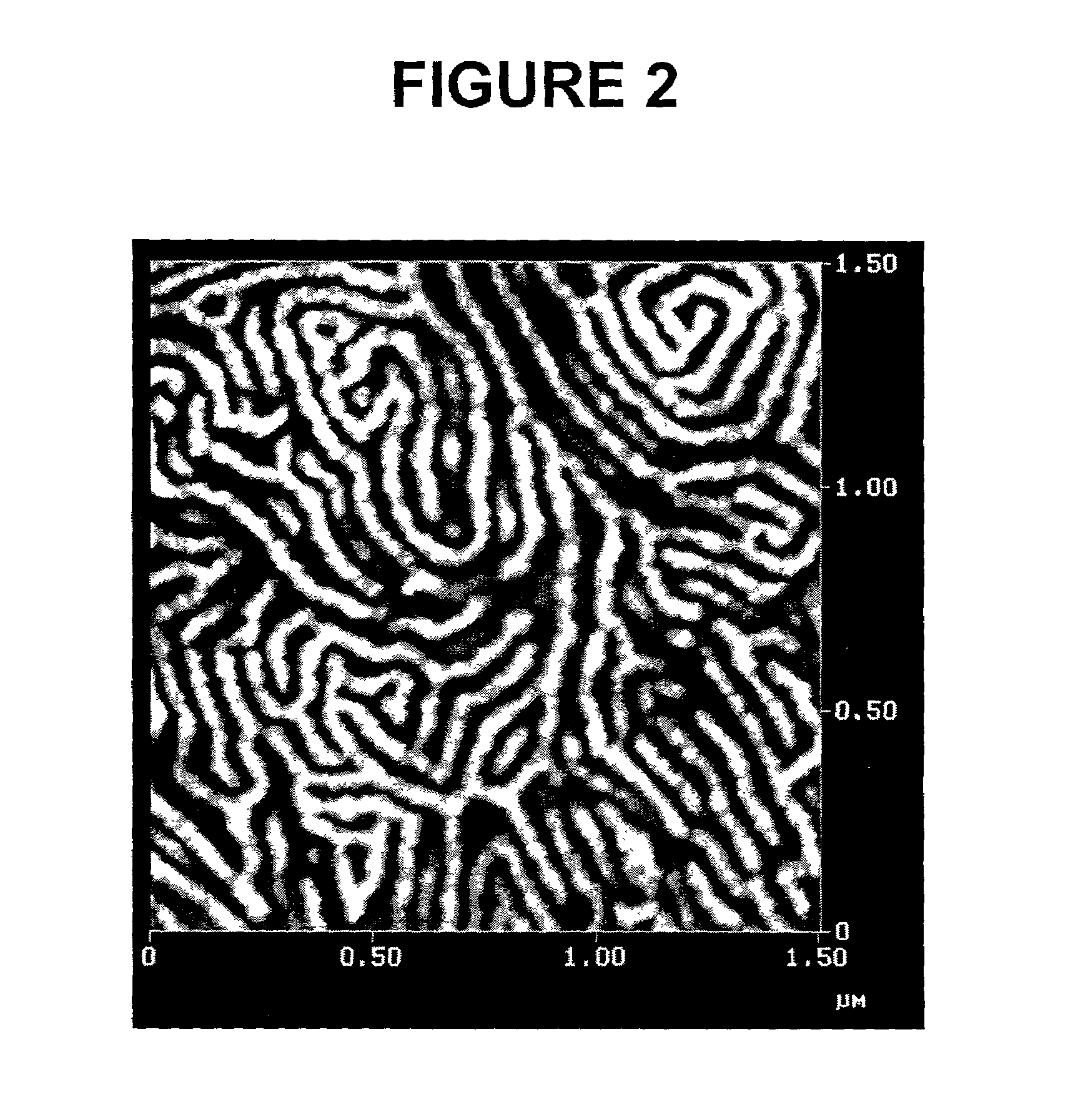

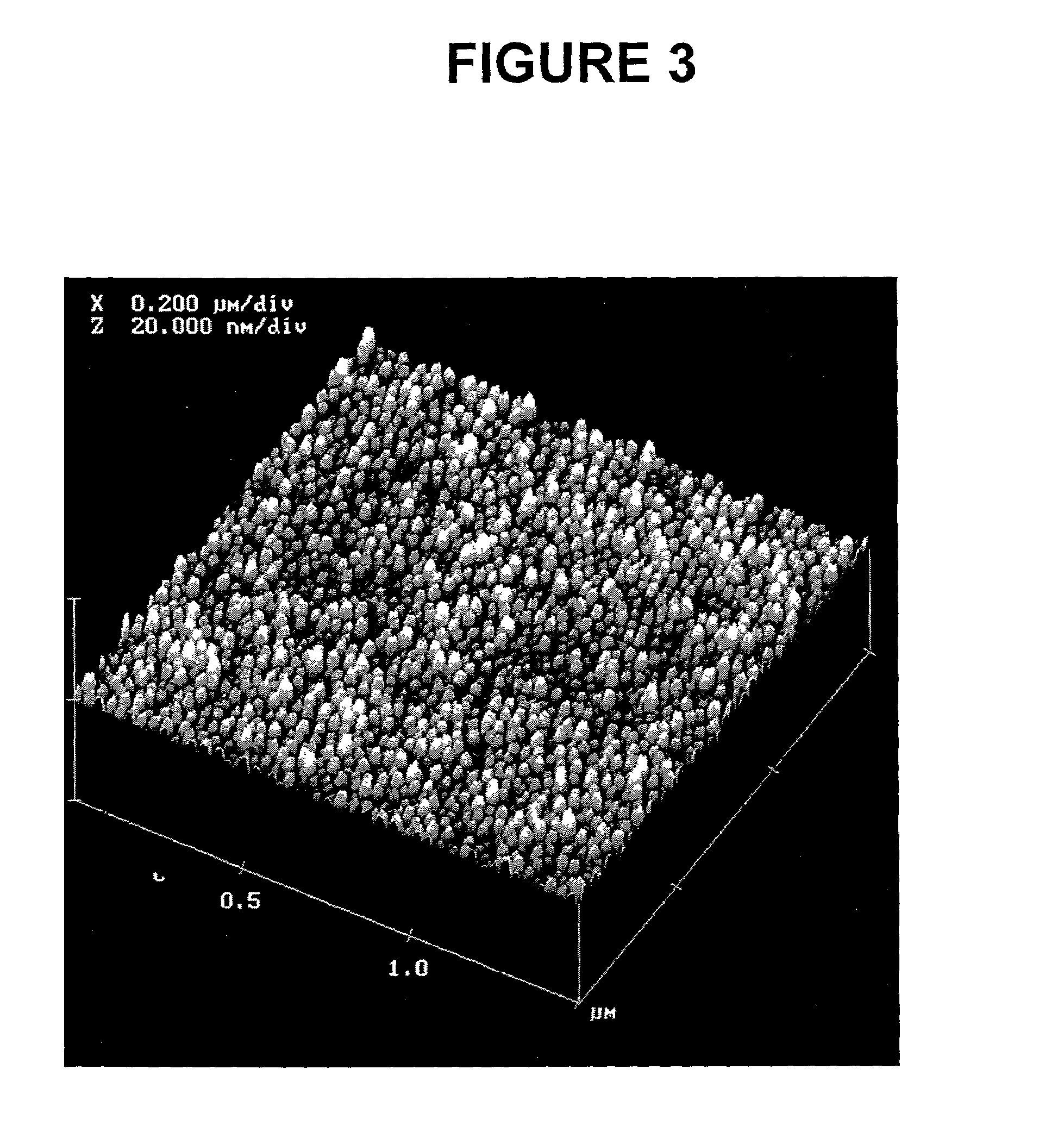

Process for the preparation of nanostructured materials

The present invention comprises a novel process for the preparation of carbon based structured materials with controlled topology, morphology and functionality. The nanostructured materials are prepared by controlled carbonization, or pyrolysis, of precursors comprising phase separated copolymers. The precursor materials are selected to phase separate and self organize in bulk, in solution, in the presence of phase selective solvents, at surfaces, interfaces or during fabrication, into articles, fibers or films exhibiting well-defined, self-organized morphology or precursors of well-defined, self-organized, bi- or tri-phasic morphology. Compositional control over the (co)polymers provides control over the structure of the phase separated precursor whose organization therein dictates the nanostructure of the material obtained after carbonization or pyrolysis, wherein each dimension of the formed structure can be predetermined. When the precursor morphology is selected to comprise cylindrical domains this procedure additionally allows for the direct formation of two dimensional nanowire grids or arrays of oriented nanostructures on surfaces. When these nanowire grids or arrays are perpendicularly oriented to the surface applications include field emitters, high surface area electrodes, electronic devices such as diodes and transistors, tools for AMF tips and elements of molecular electronics. When the first nanostructured morphology is selected to form cylinders parallel to the surface then nanowire arrays are formed after pyrolysis. When the composition of the first nanostructured morphology is selected to comprise a continuous precursor matrix then a continuous carbon based nanostructured material is formed. The internal structure of the carbon based material can be selected to comprise perpendicular pores or an interconnected array of pores. The carbon based structures can additionally find application in photovoltaics, supercapacitors, batteries, fuel cells, computer memory, carbon electrodes, carbon foams, actuators and hydrogen storage.

Owner:CARNEGIE MELLON UNIV

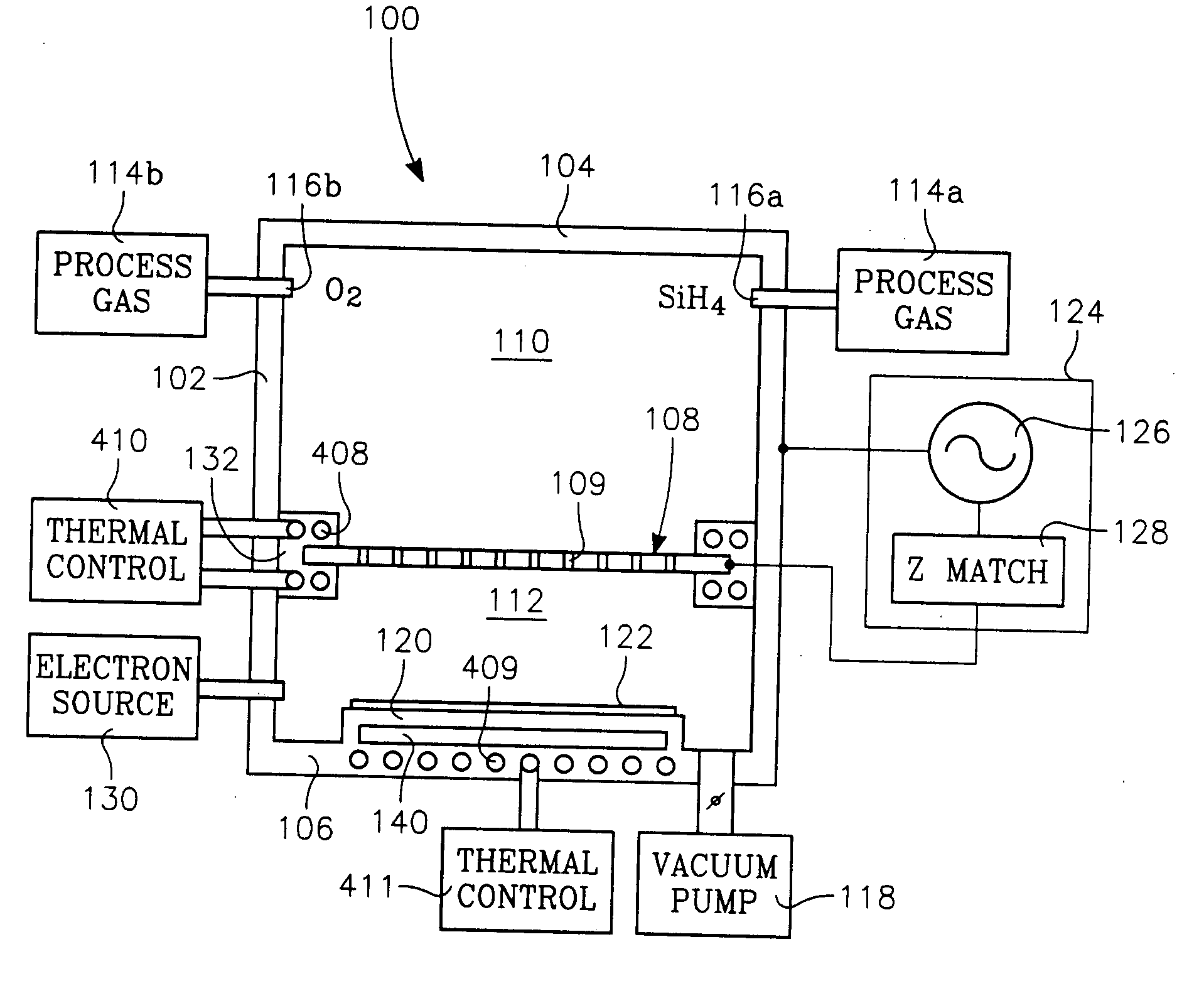

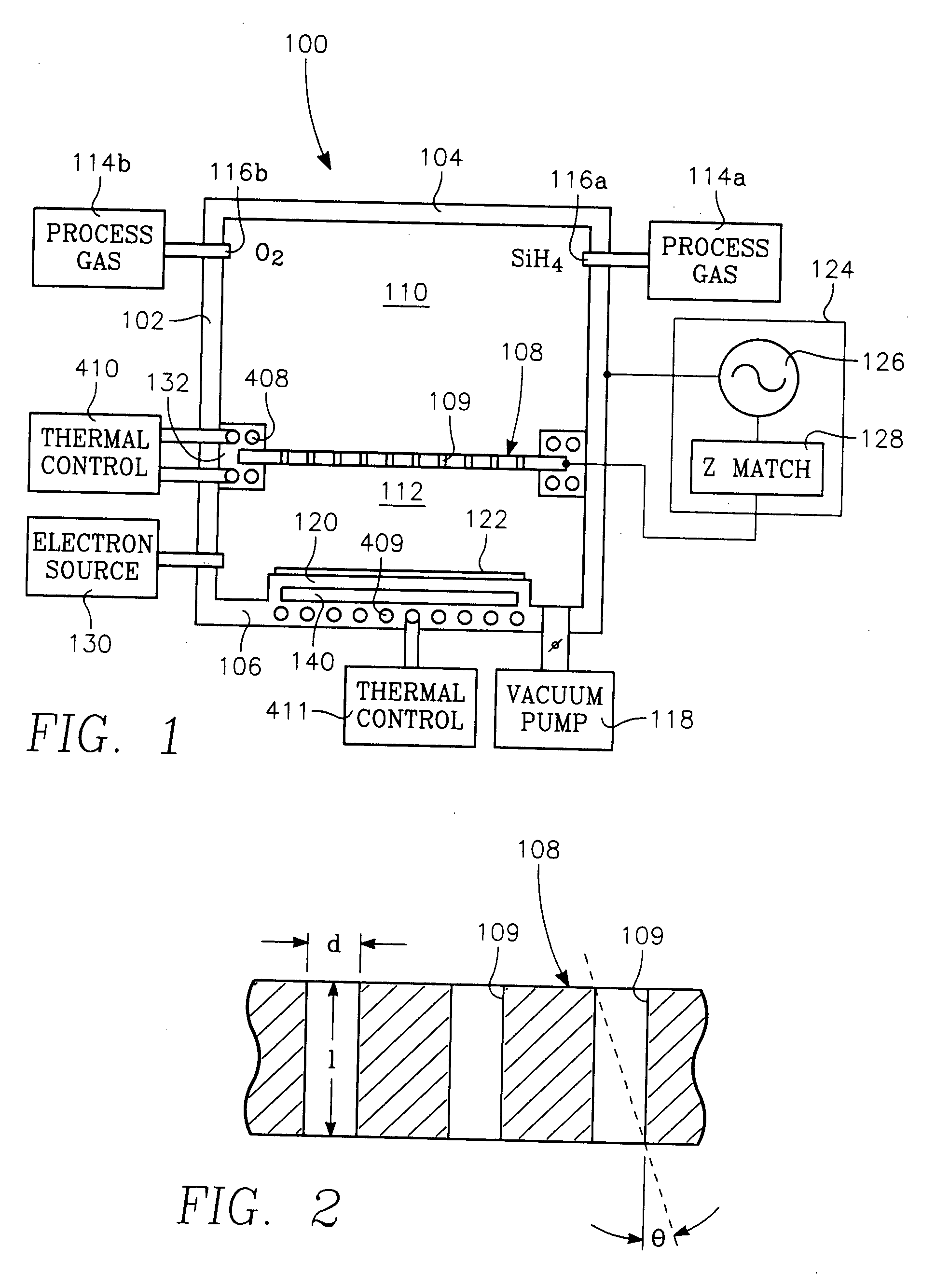

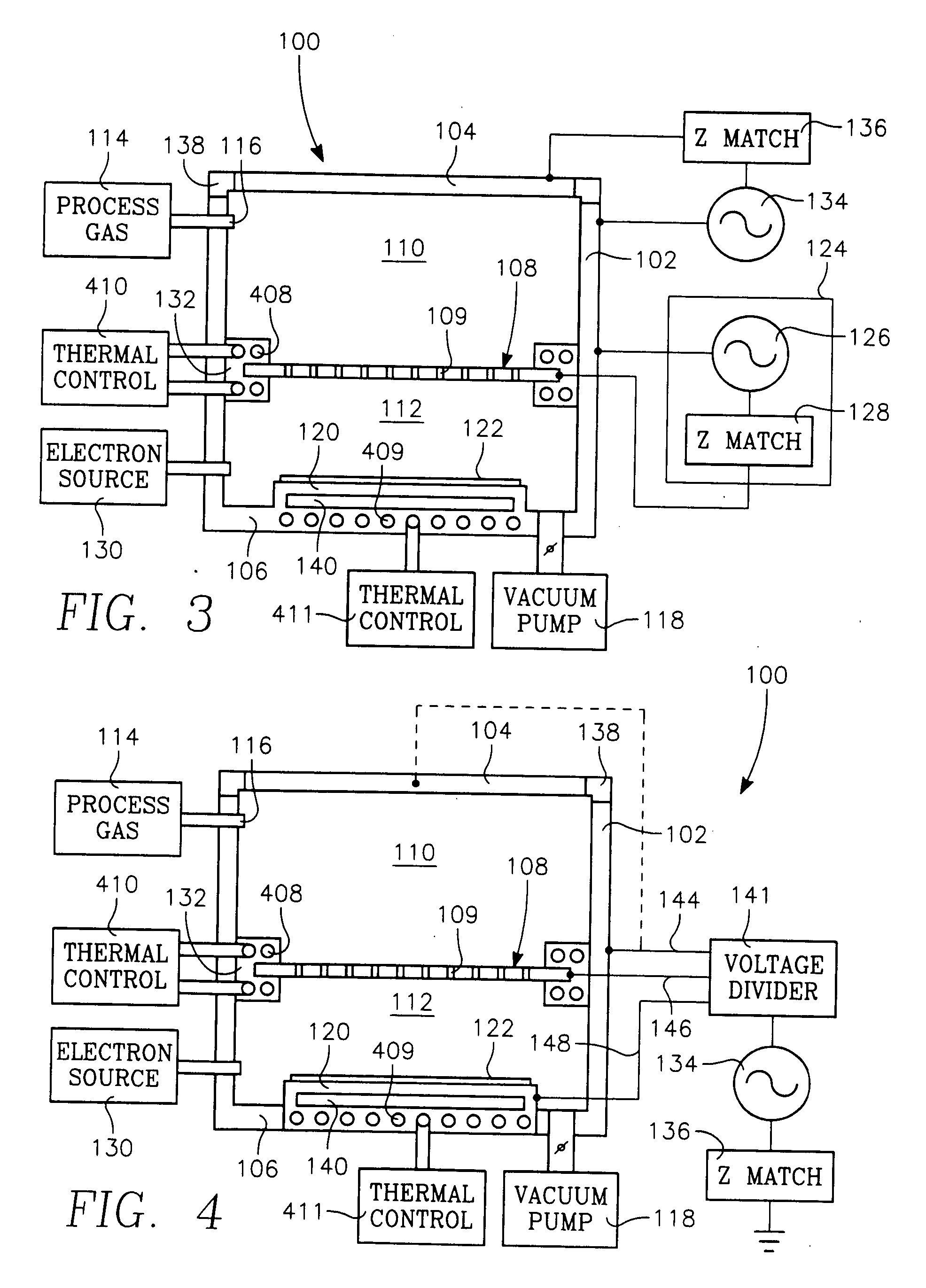

Plasma immersion ion implantation reactor having an ion shower grid

InactiveUS20060019477A1High ion fluxElectric discharge tubesVacuum evaporation coatingProcess regionPlasma-immersion ion implantation

A plasma immersion ion implantation process for implanting a selected species at a desired ion implantation depth profile in a workpiece is carried out in a reactor chamber with an ion shower grid that divides the chamber into an upper ion generation region and a lower process region, the ion shower grid having plural elongate orifices oriented in a non-parallel direction relative to a surface plane of the ion shower grid. The process includes placing a workpiece in the process region, the workpiece having a workpiece surface generally facing the surface plane of the ion shower grid, and furnishing the selected species into the ion generation region in gaseous, molecular or atomic form and evacuating the process region at an evacuation rate sufficient to create a pressure drop across the ion shower grid from the ion generation region to the process region of about a factor of at least four. The process further includes applying plasma source power to generate a plasma of the selected species in the ion generation region, and applying a grid potential to the ion shower grid to create a flux of ions from the plasma through the grid and into the process region. The process also includes applying a sufficient bias voltage to at least one of: (a) the workpiece, (b) the grid, relative to at least one of: (a) the workpiece, (b) a plasma in the ion generation region, (c) a surface of the chamber, to accelerate the flux of ions to a kinetic energy distribution generally corresponding to the desired ion implantation depth profile in the workpiece.

Owner:APPLIED MATERIALS INC

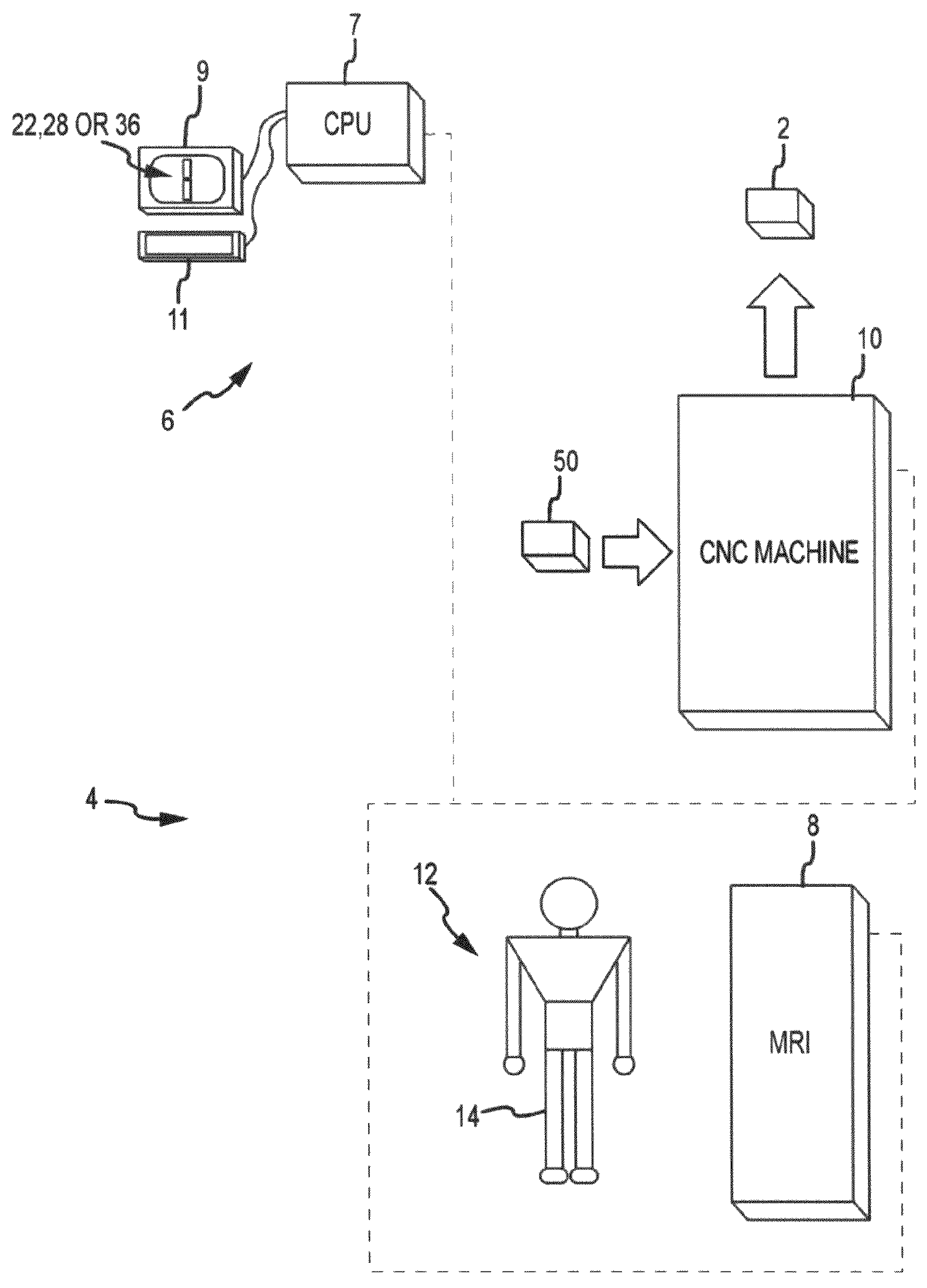

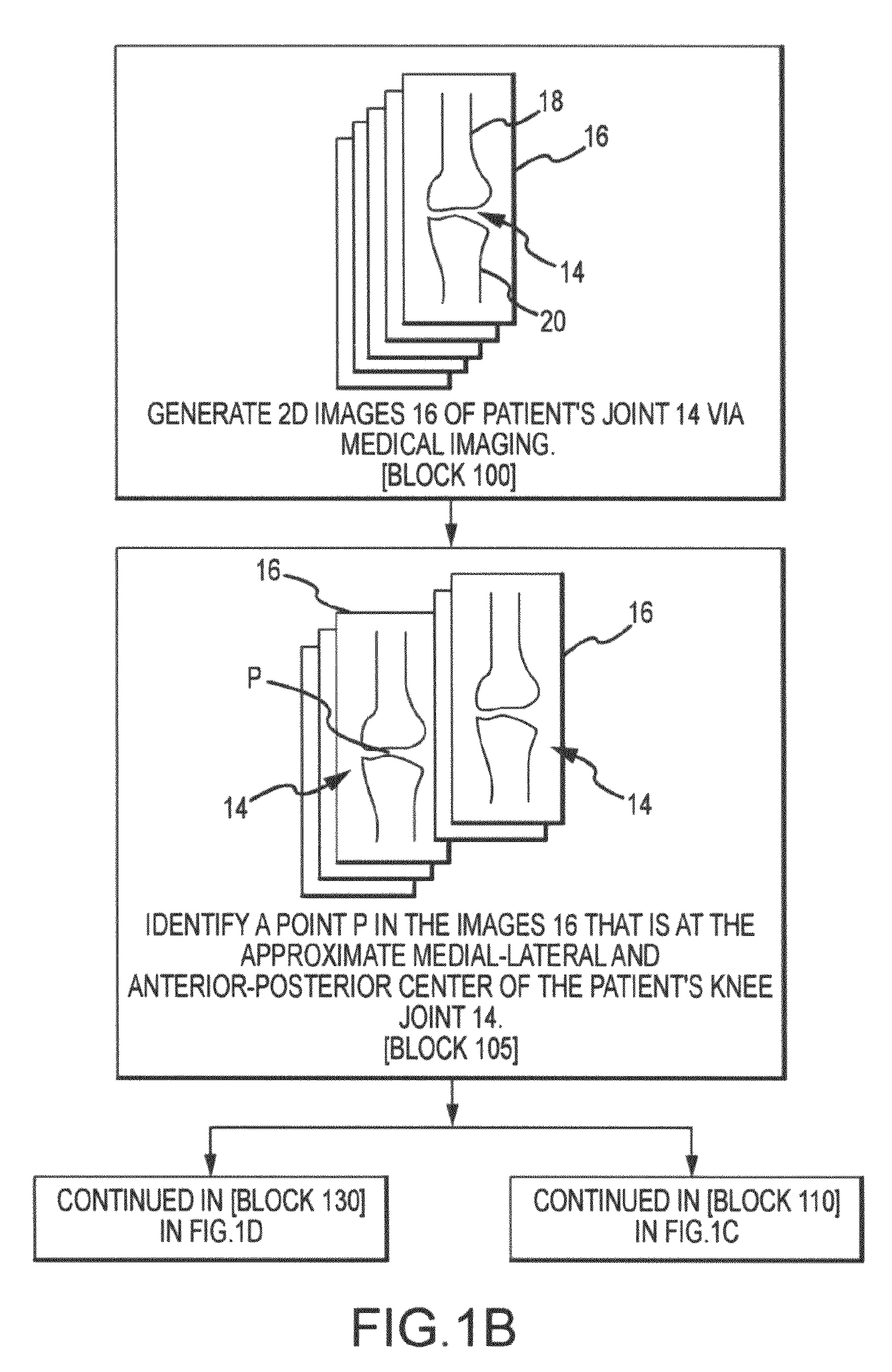

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

Systems and methods for image segmentation in generating computer models of a joint to undergo arthroplasty are disclosed. Some embodiments may include a method of partitioning an image of a bone into a plurality of regions, where the method may include obtaining a plurality of volumetric image slices of the bone, generating a plurality of spline curves associated with the bone, verifying that at least one of the plurality of spline curves follow a surface of the bone, and creating a 3D mesh representation based upon the at least one of the plurality of spline curve.

Owner:HOWMEDICA OSTEONICS CORP

System for audible feedback for touch screen displays

InactiveUS6999066B2Easily and quickly navigateCathode-ray tube indicatorsSound input/outputVisually impairedDisplay device

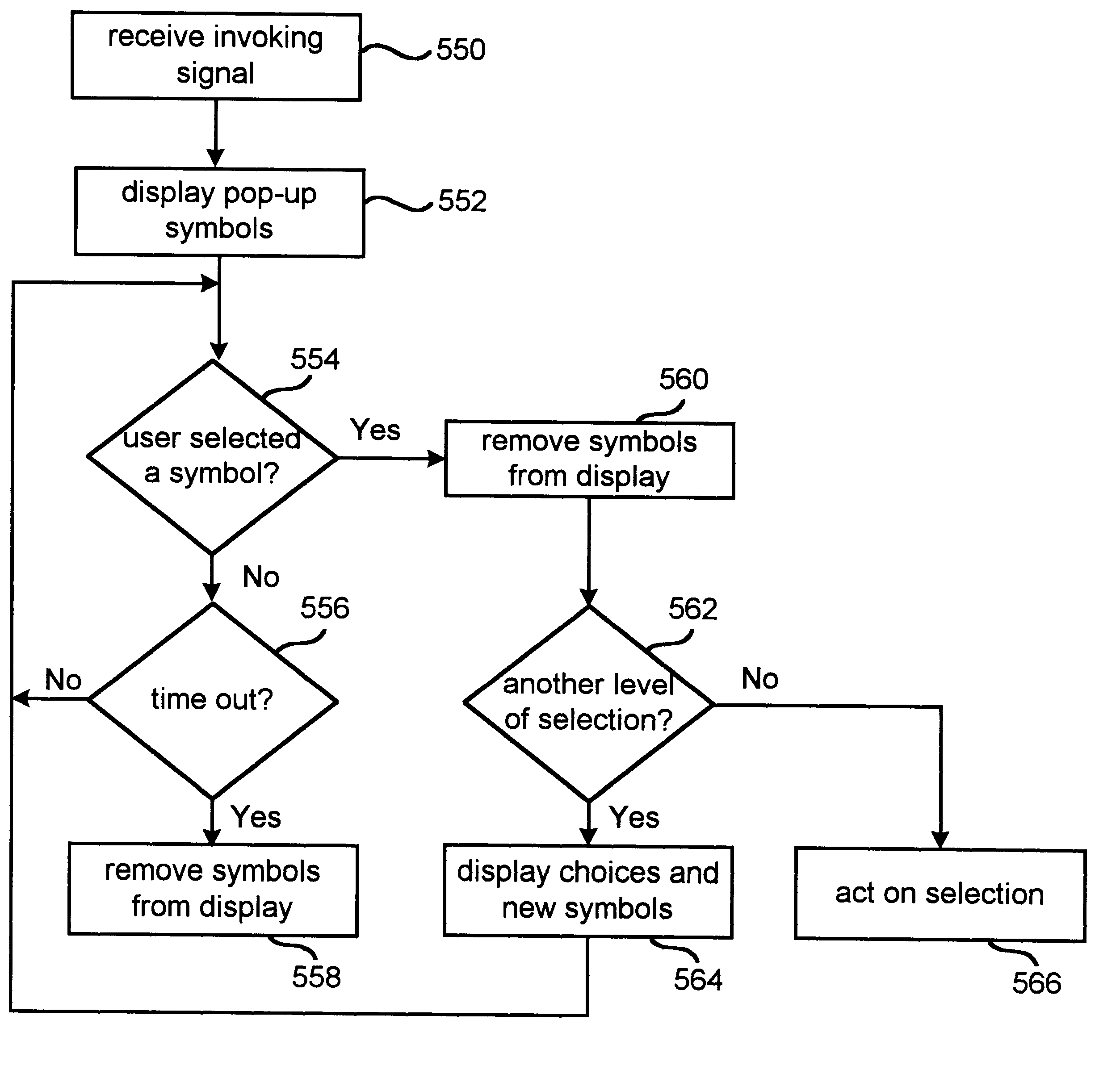

What is presented is a system and method by which a visually impaired worker could easily and quickly navigate menu options on touch screen displays. An Audible Feedback ON / OFF Switch is provided which turns the audible feedback feature of the present invention on or off. The software monitoring which row / column areas of the touch screen's display grid have been touched by the user in response to a menu option selection is made switchable into one of two modes. A first mode is when the audible feedback feature is OFF or otherwise disabled. In this mode the software operates the touch screen's menu selections in the normal manner in which the machine is intended to perform. When a user selects an option, the option is immediately activated whether it be a machine activity or a jump to another level of menus. A second mode is when the audible feedback feature has been turned ON or otherwise activated. In this mode a two step process is activated such that when a user makes a first touch of a menu option a sound or voice is audibly played indicating the nature of the particular menu option just selected. A second consecutive touch of the same menu option then actually activates the machine activity associated with that particular menu option.

Owner:XEROX CORP

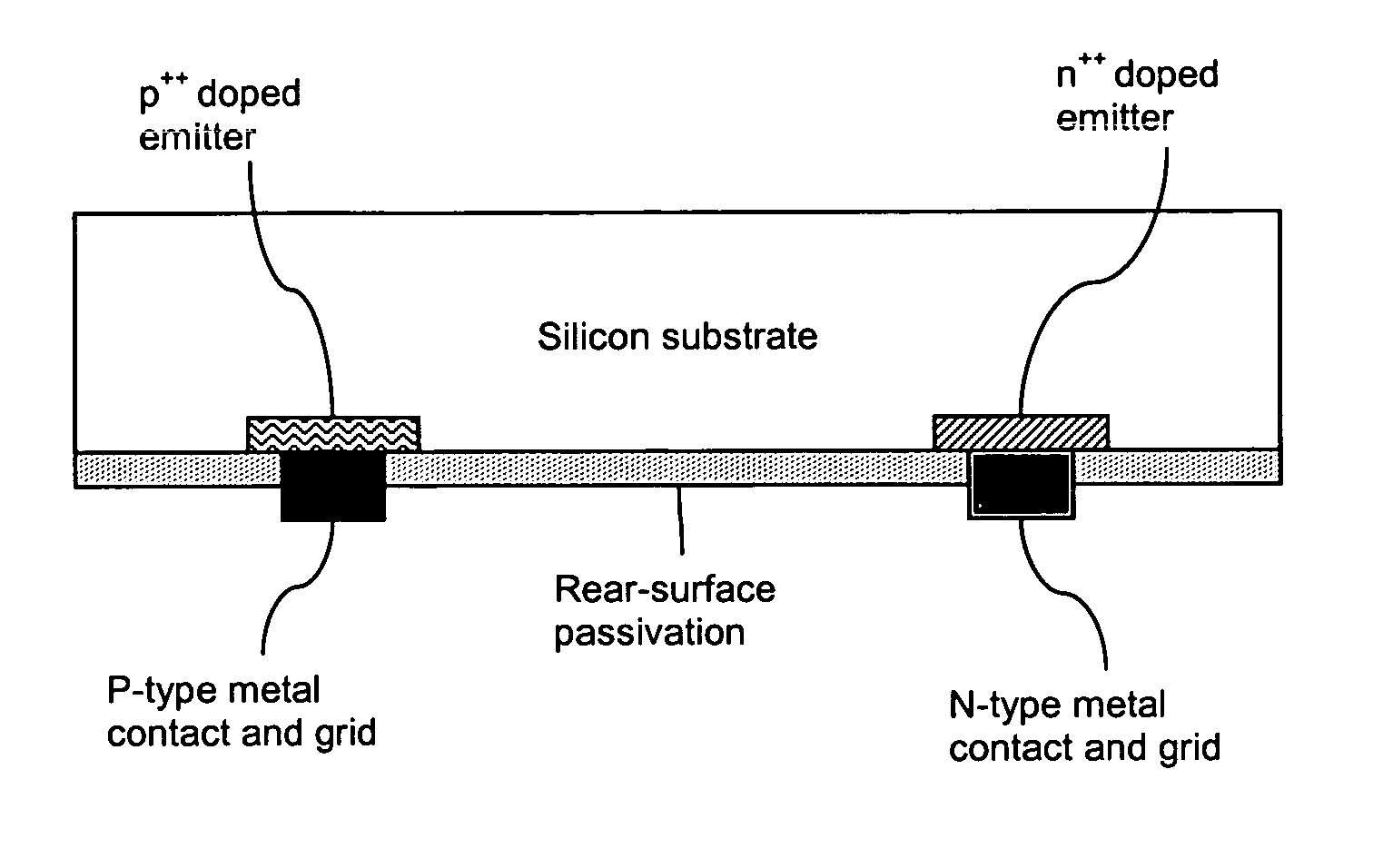

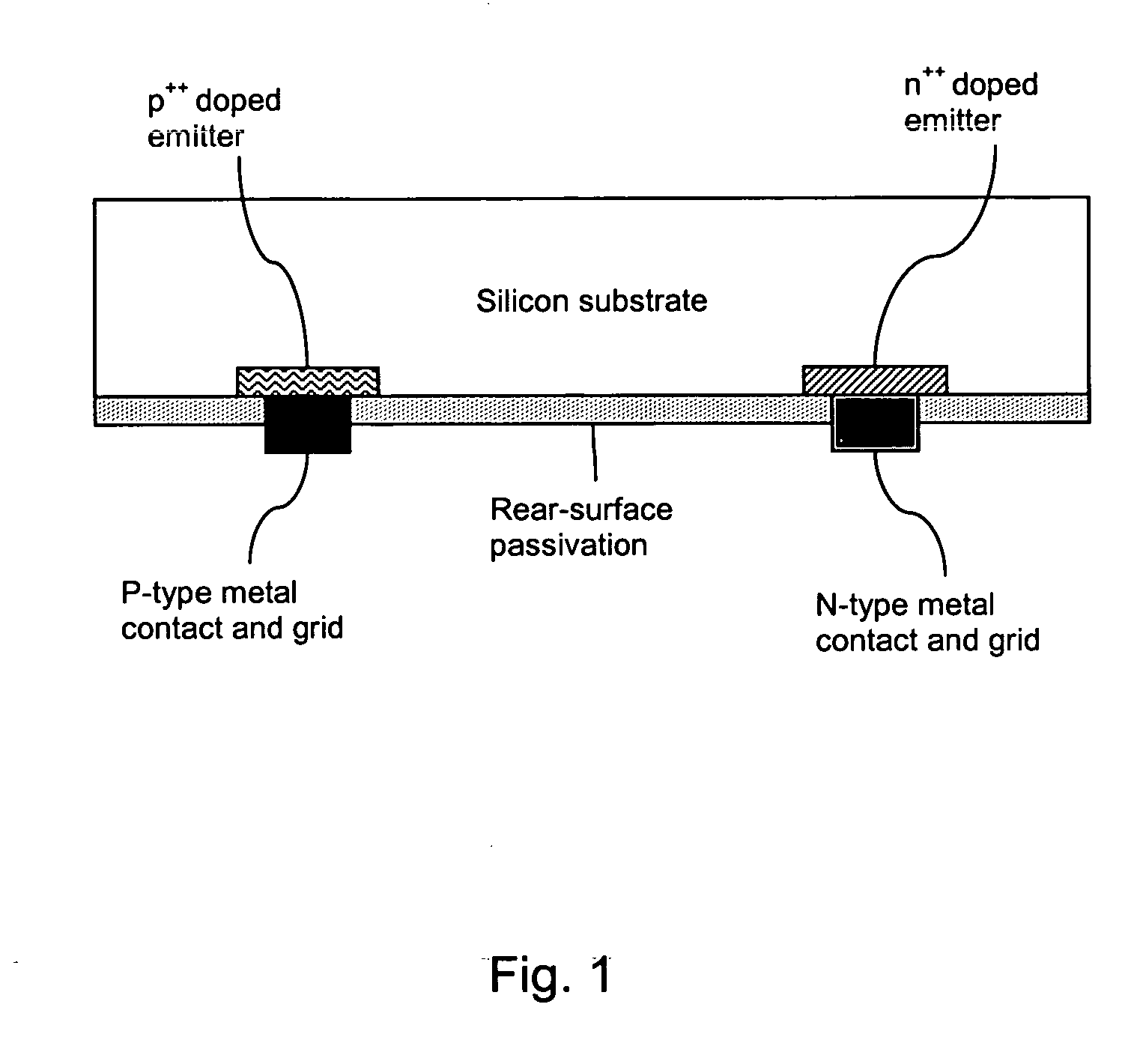

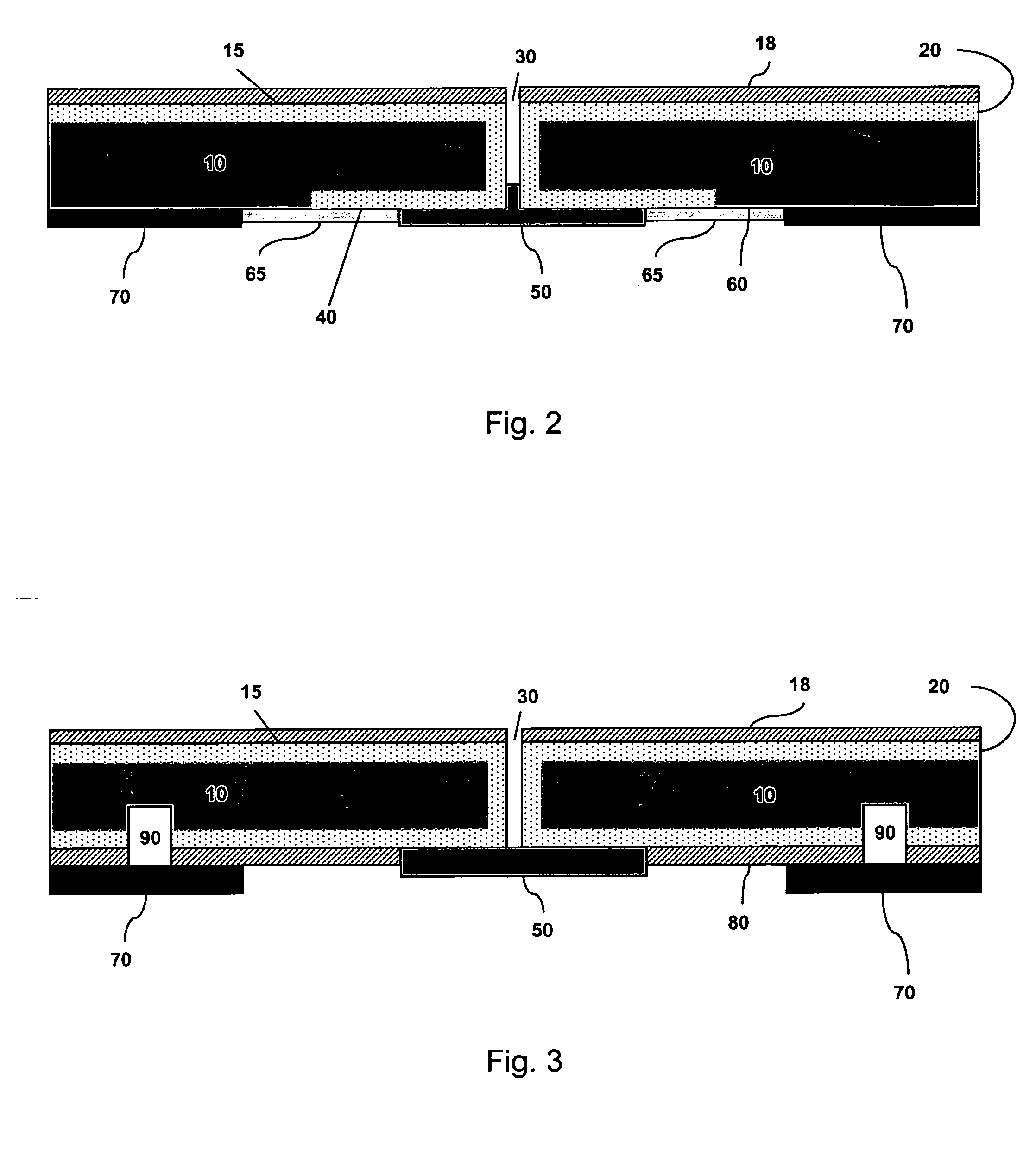

Contact fabrication of emitter wrap-through back contact silicon solar cells

InactiveUS20050172996A1Few and economical process stepImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon solar cell

Back contact solar cells including rear surface structures and methods for making same. The rear surface has small contact areas through at least one dielectric layer, including but not limited to a passivation layer, a nitride layer, a diffusion barrier, and / or a metallization barrier. The dielectric layer is preferably screen printed. Large grid areas overlay the dielectric layer. The methods provide for increasing efficiency by minimizing p-type contact areas and maximizing n-type doped regions on the rear surface of a p-type substrate.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com