Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1479 results about "Secondary electrons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary electrons are electrons generated as ionization products. They are called 'secondary' because they are generated by other radiation (the primary radiation). This radiation can be in the form of ions, electrons, or photons with sufficiently high energy, i.e. exceeding the ionization potential. Photoelectrons can be considered an example of secondary electrons where the primary radiation are photons; in some discussions photoelectrons with higher energy (>50 eV) are still considered "primary" while the electrons freed by the photoelectrons are "secondary".

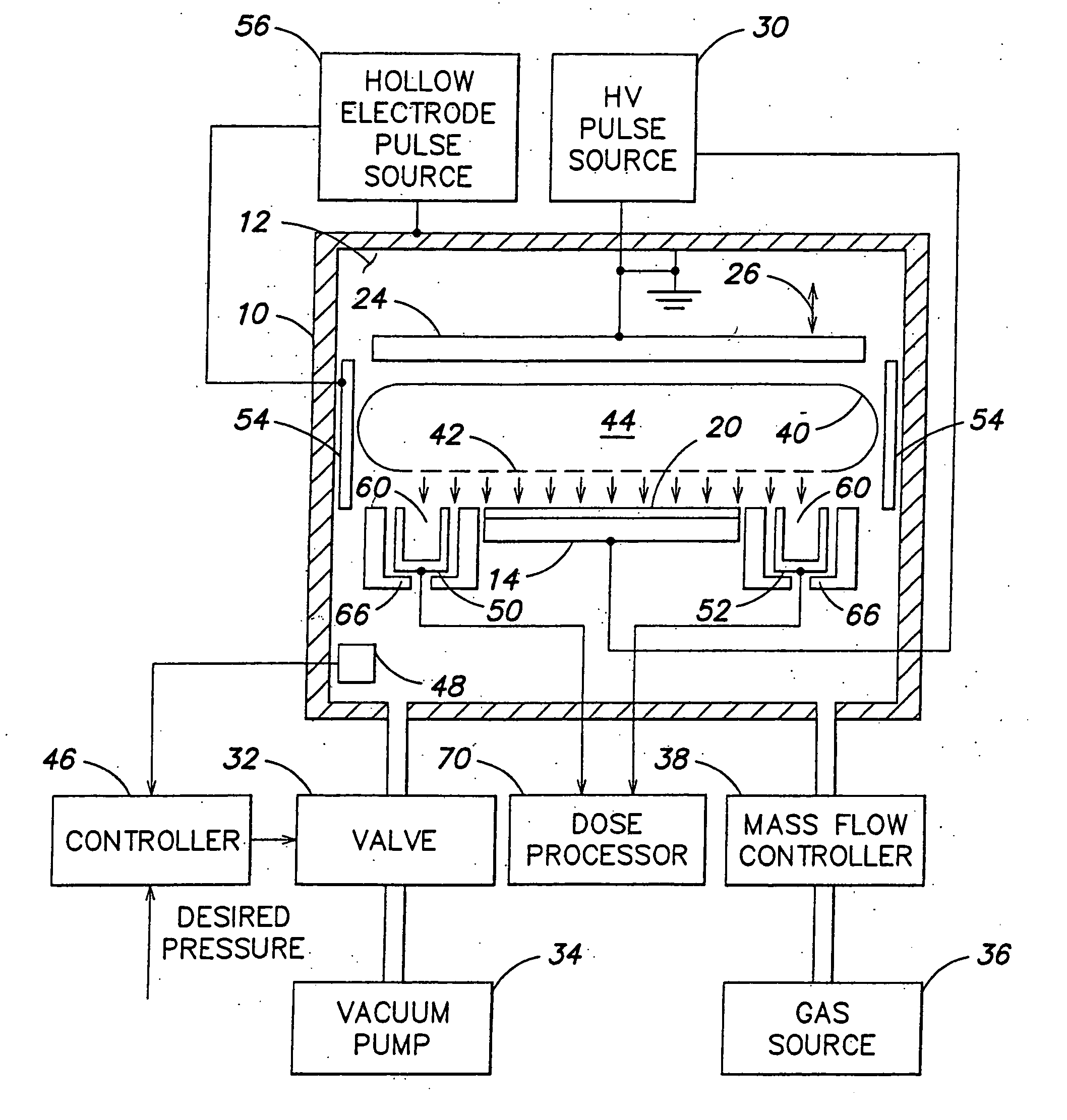

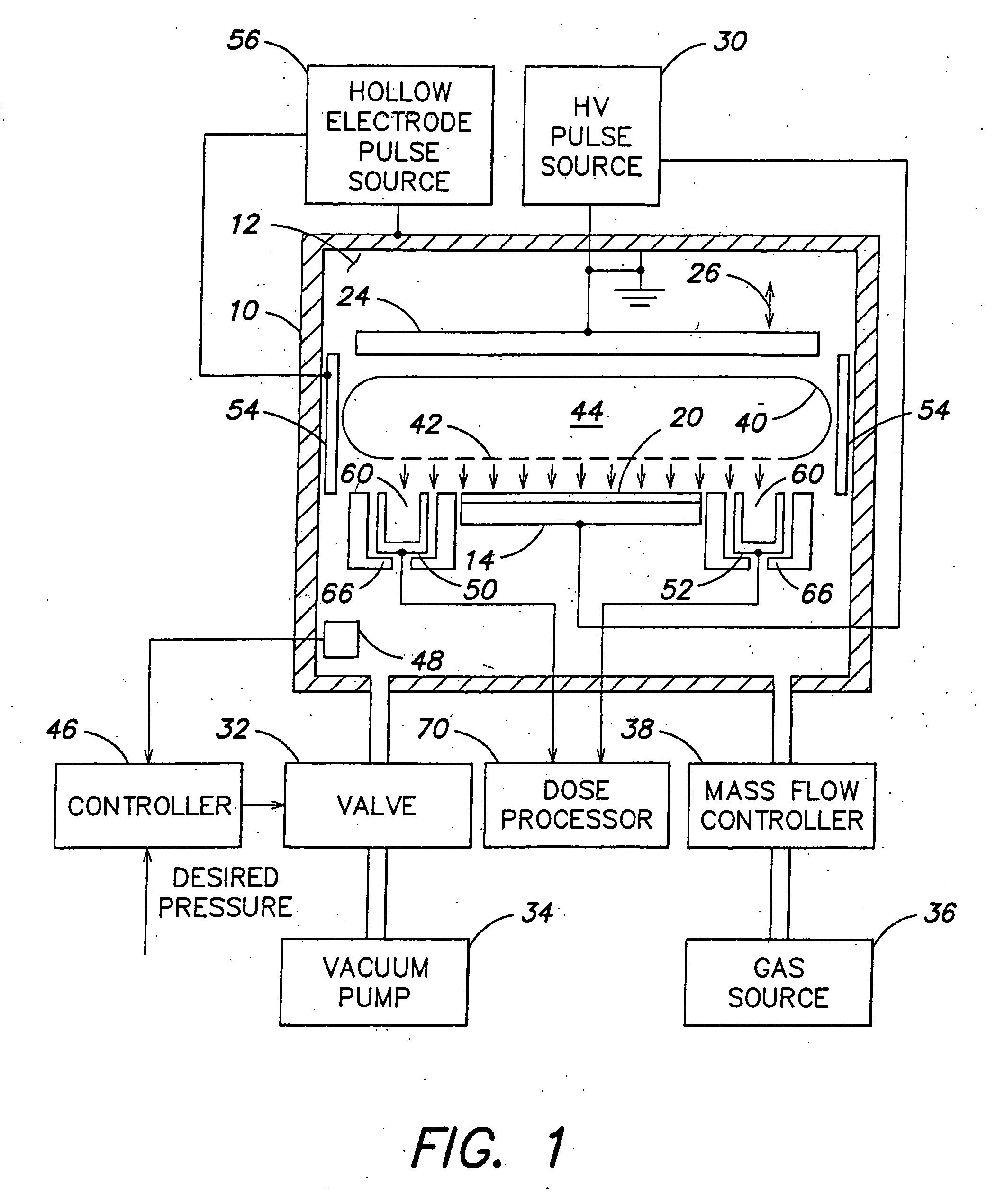

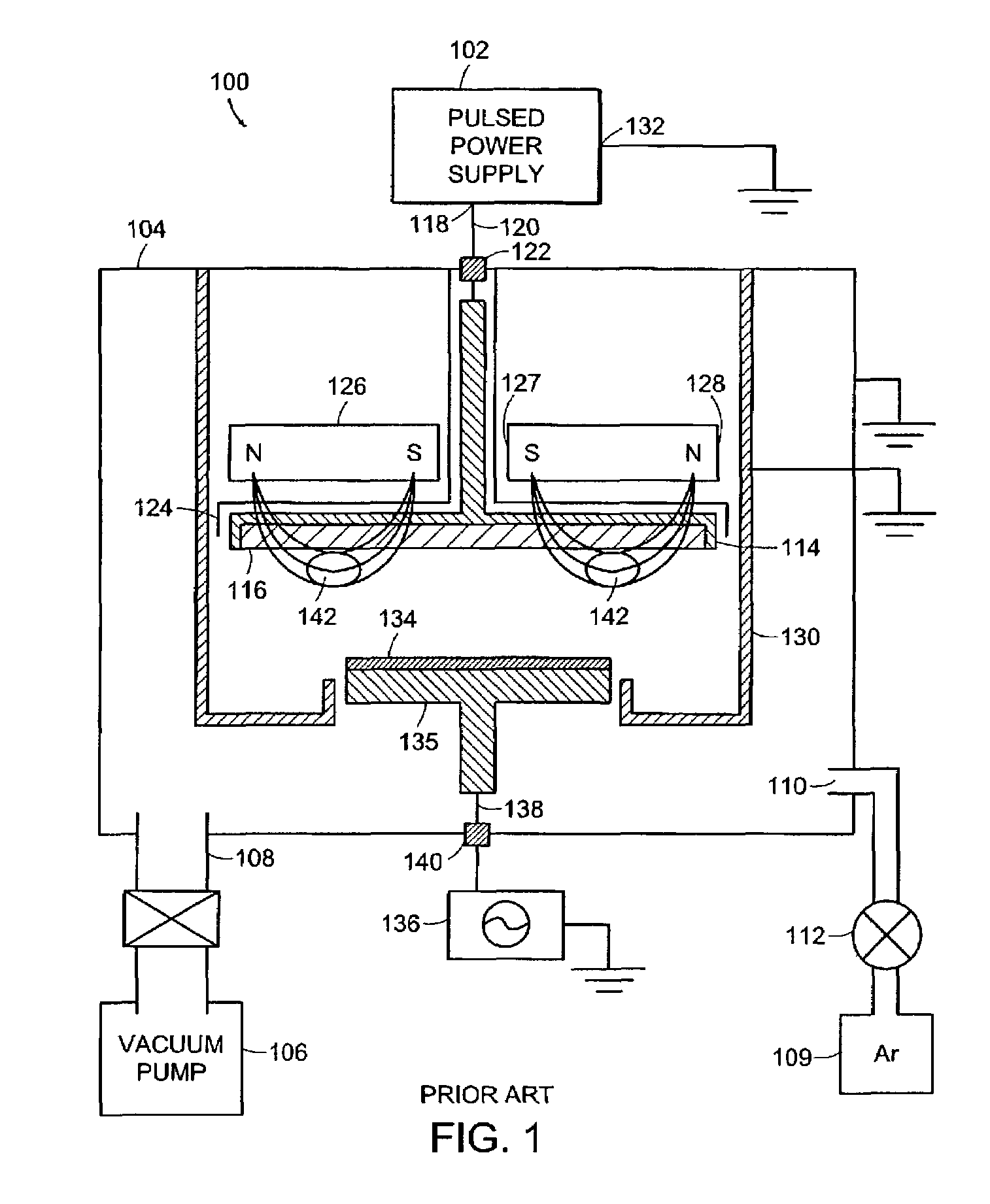

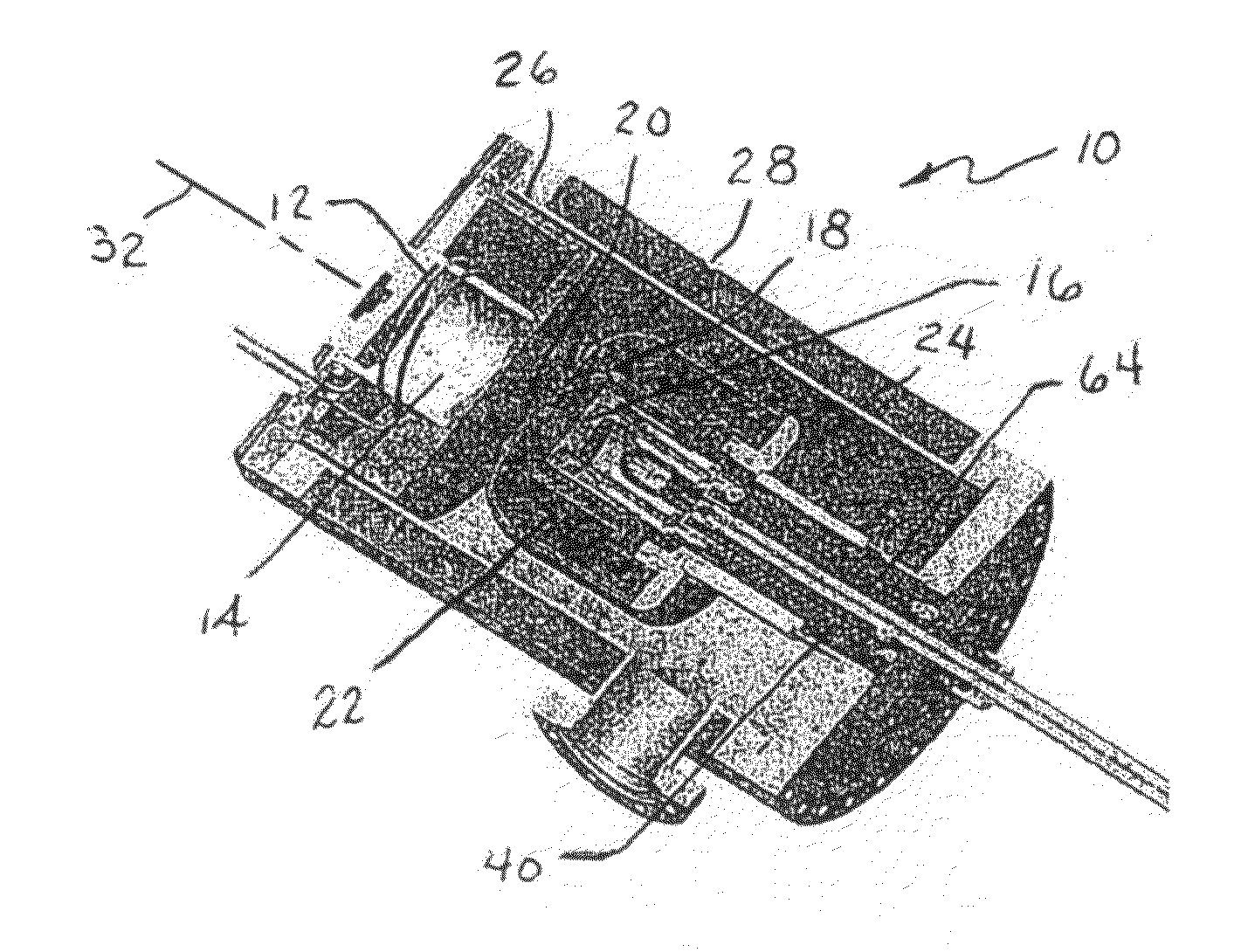

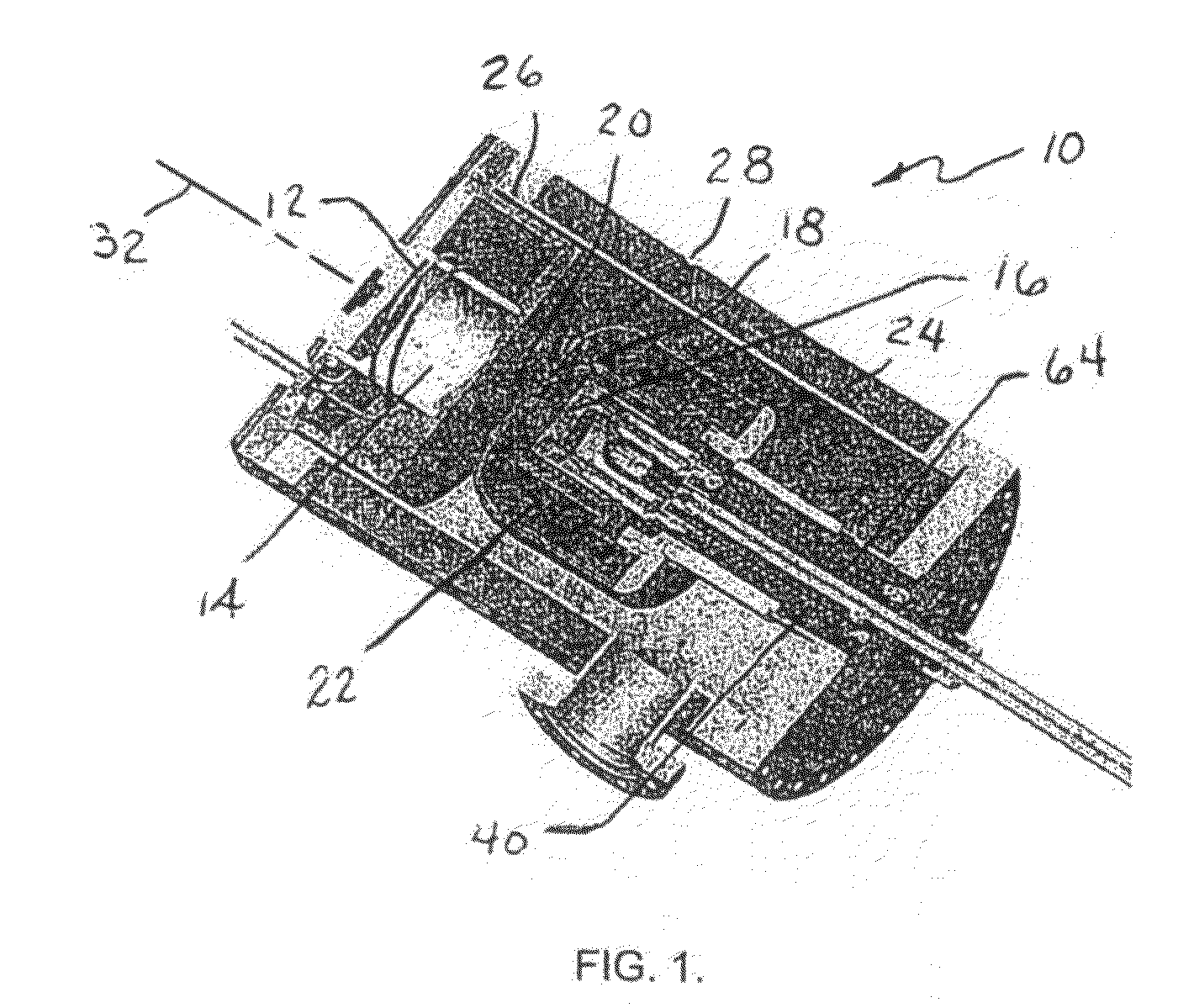

Methods for stable and repeatable ion implantation

A method for plasma ion implantation of a substrate includes providing a plasma ion implantation system having a process chamber, a source for producing a plasma in the process chamber, a platen for holding a substrate in the process chamber, an anode spaced from the platen, and a pulse source for generating implant pulses for accelerating ions from the plasma into the substrate. In one aspect, a parameter of an implant process is varied to at least partially compensate for undesired effects of interaction between ions being implanted and the substrate. For example, dose rate, ion energy, or both may be varied during the implant process. In another aspect, a pretreatment step includes accelerating ions from the plasma to the anode to cause emission of secondary electrons from the anode, and accelerating the secondary electrons from the anode to a substrate for pretreatment of the substrate.

Owner:VARIAN SEMICON EQUIP ASSOC INC

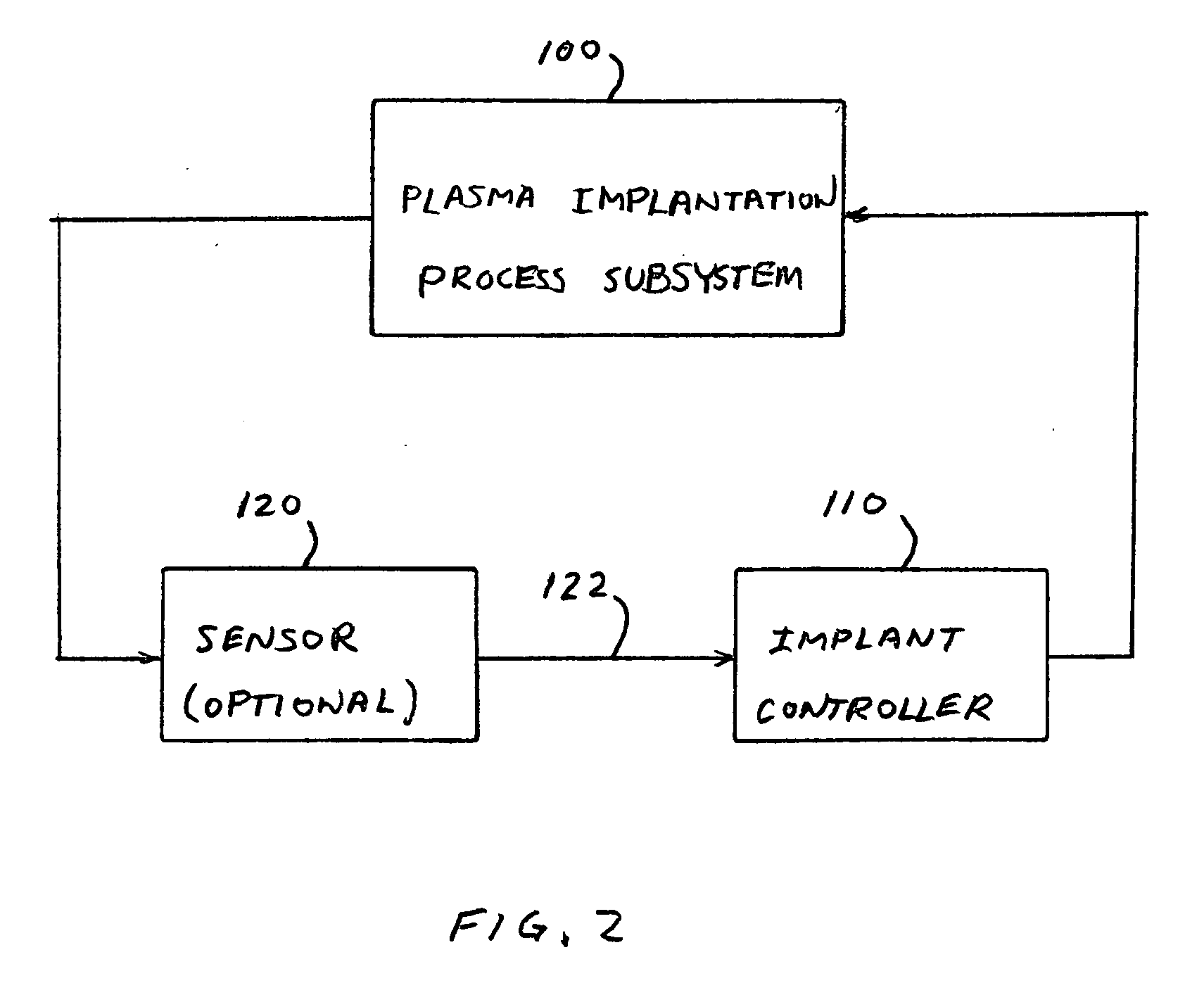

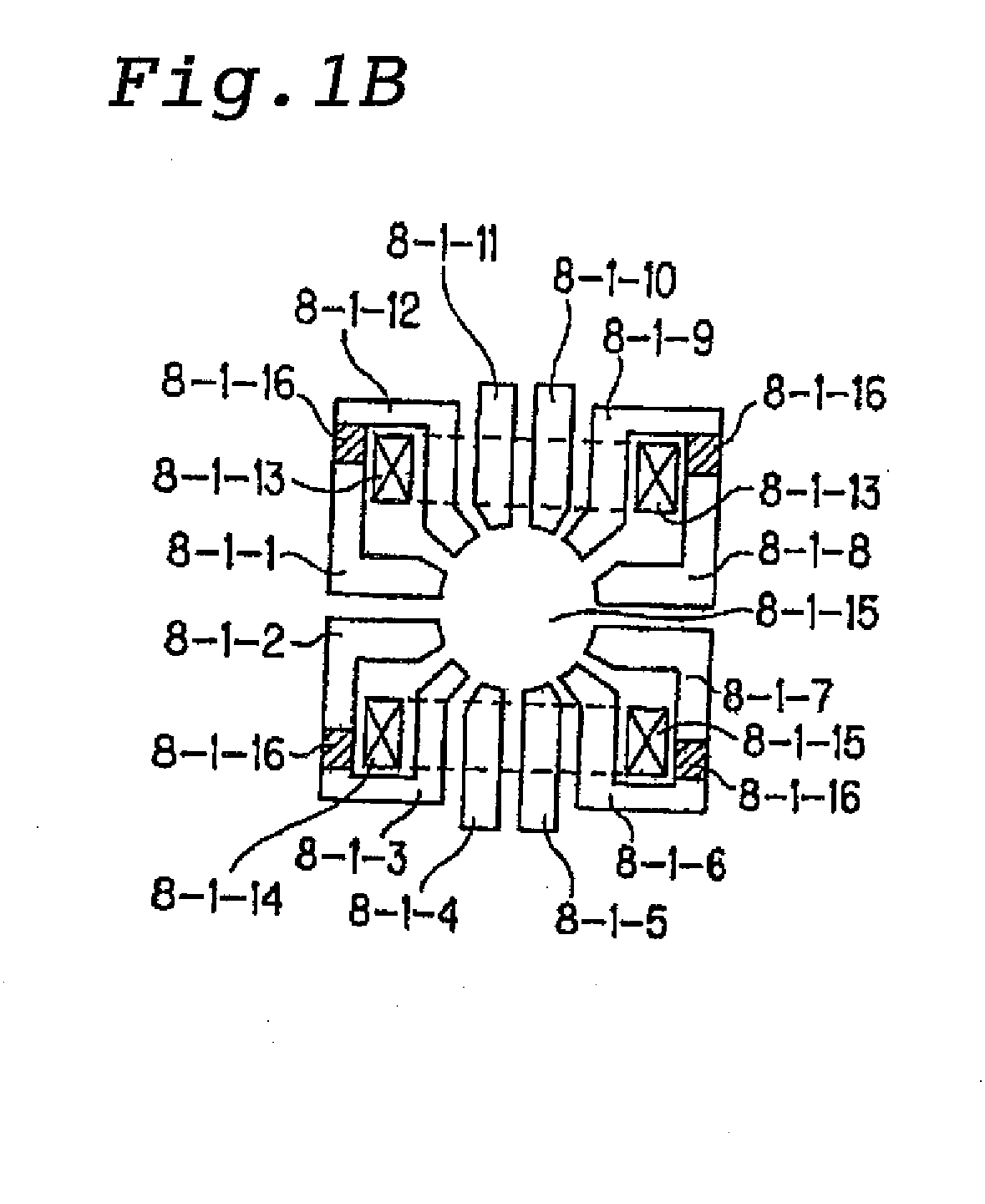

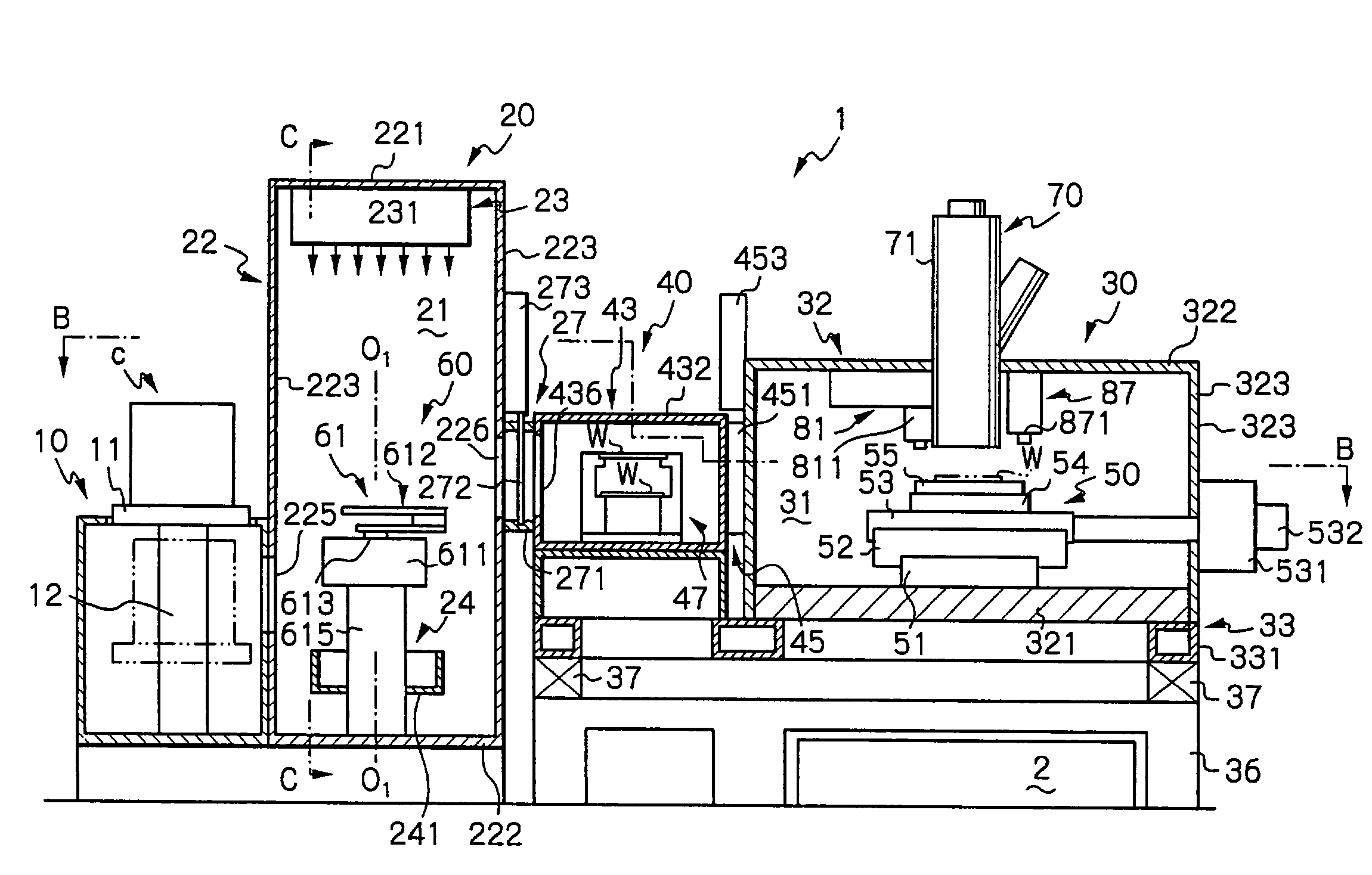

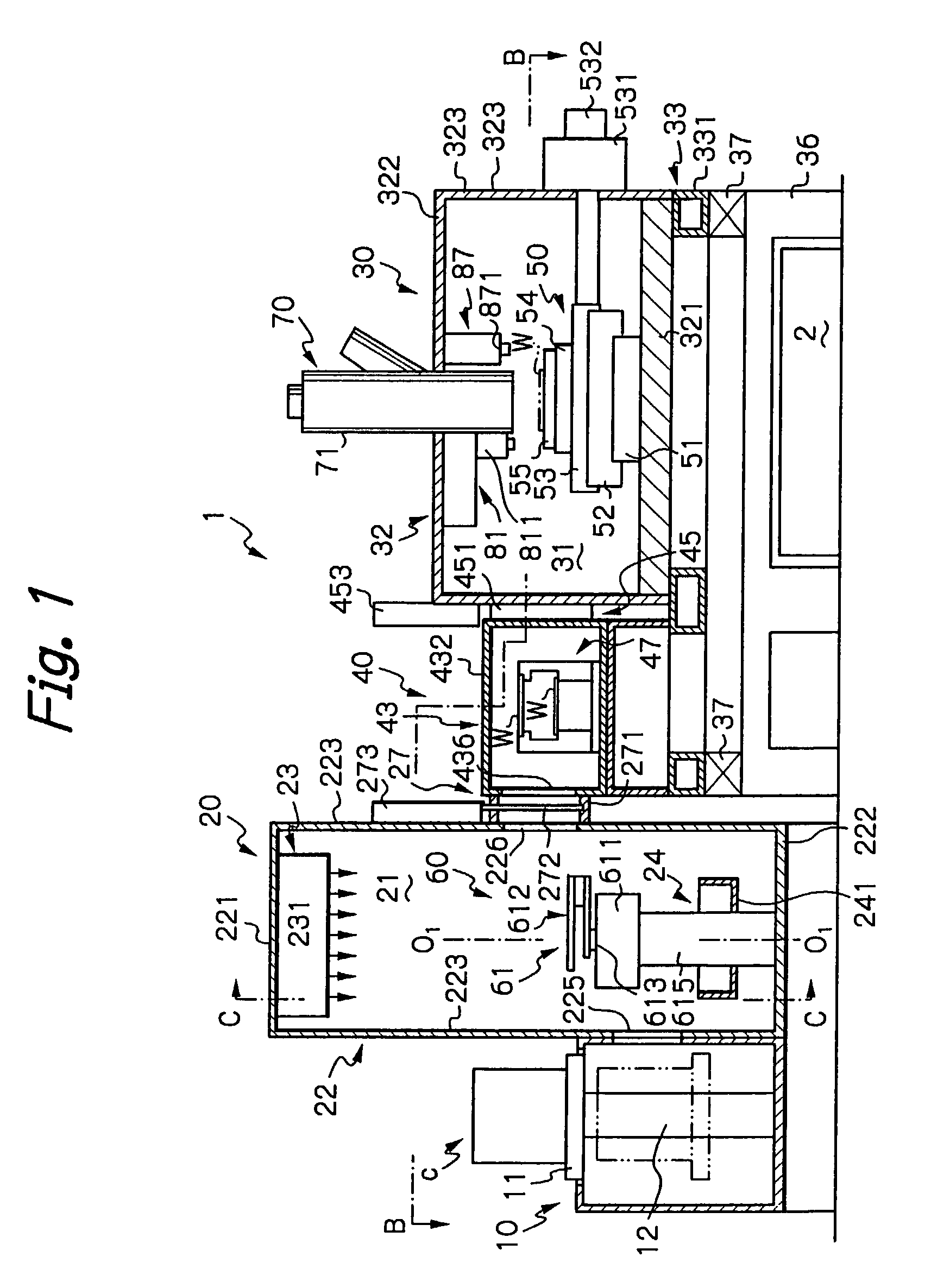

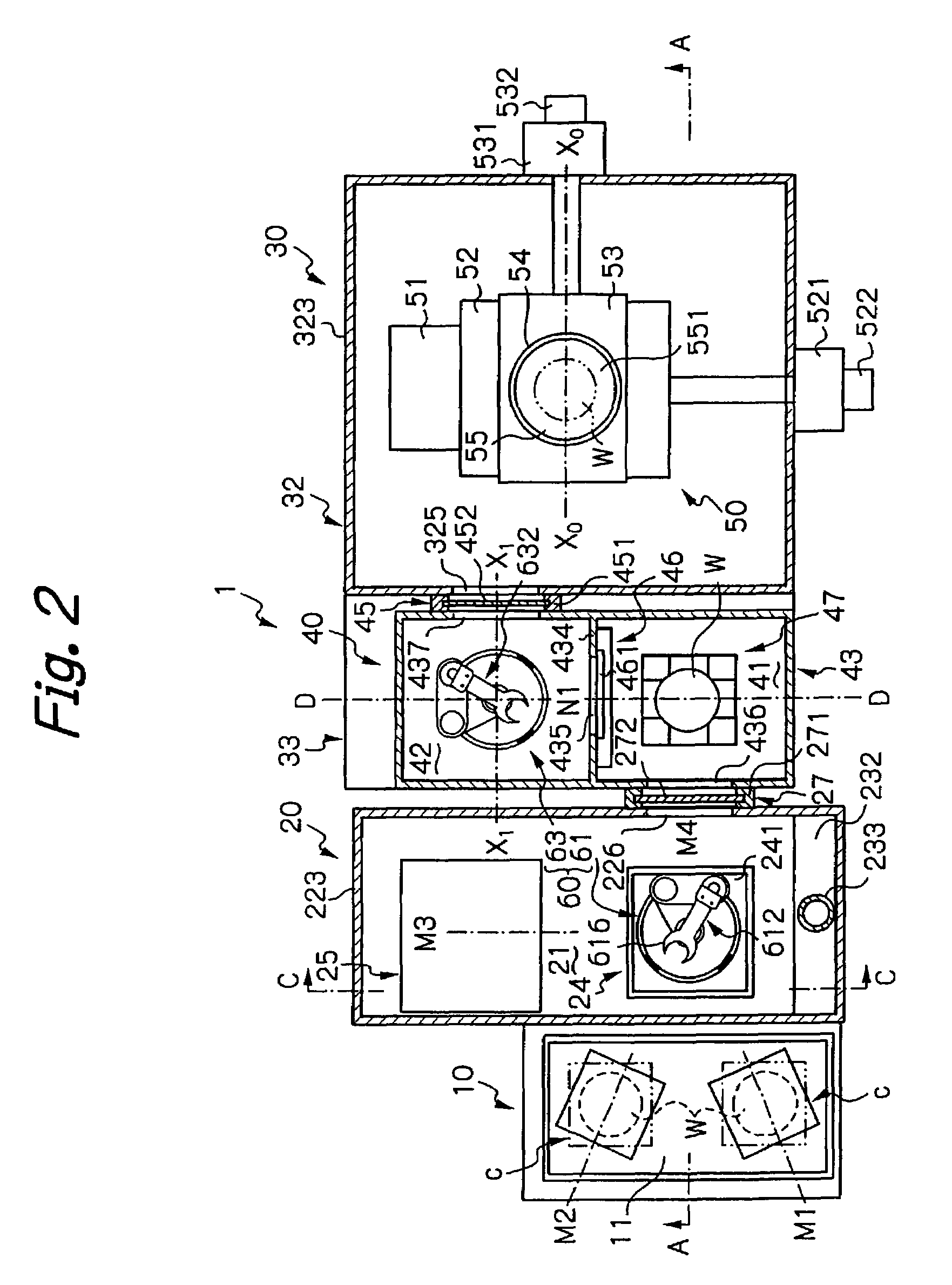

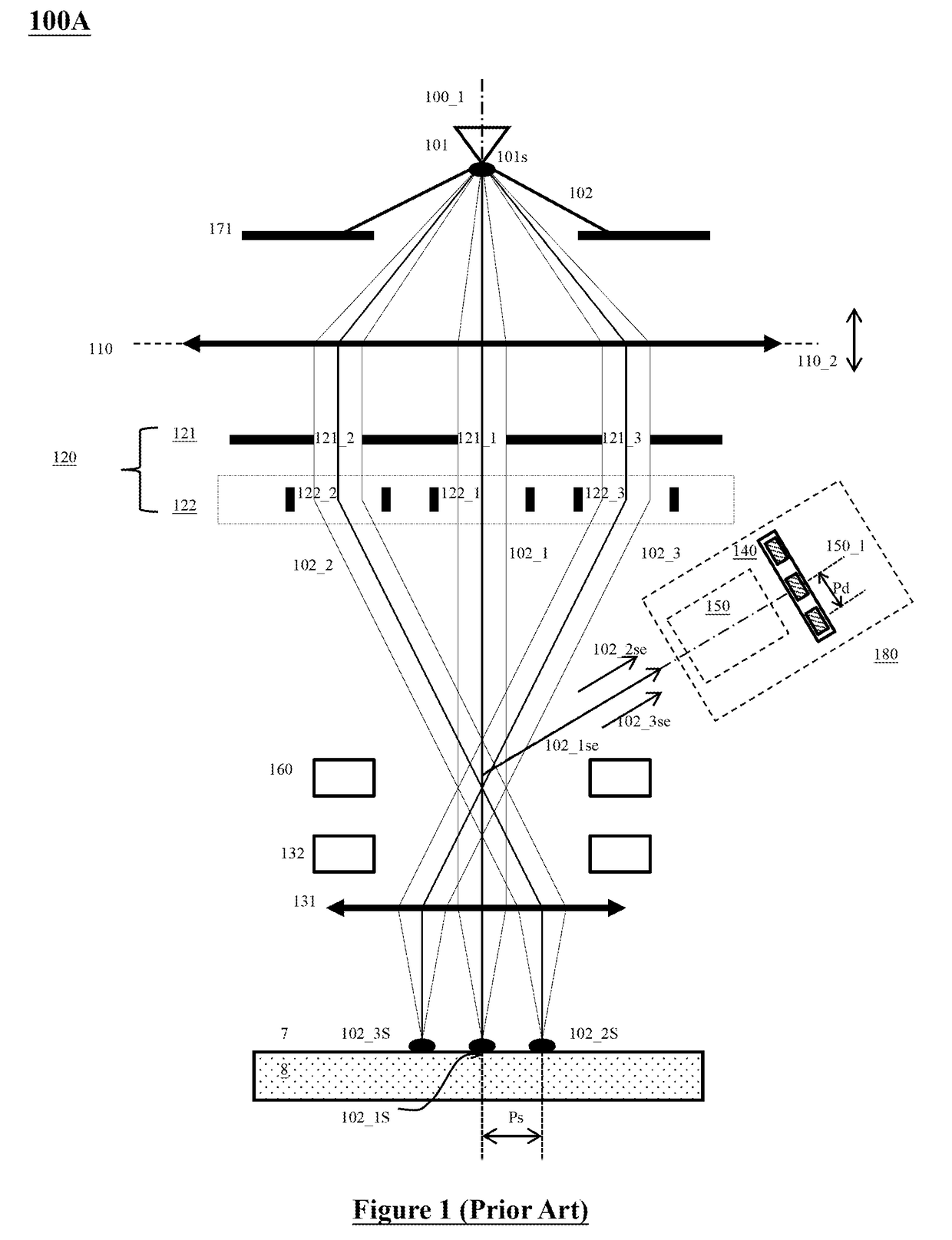

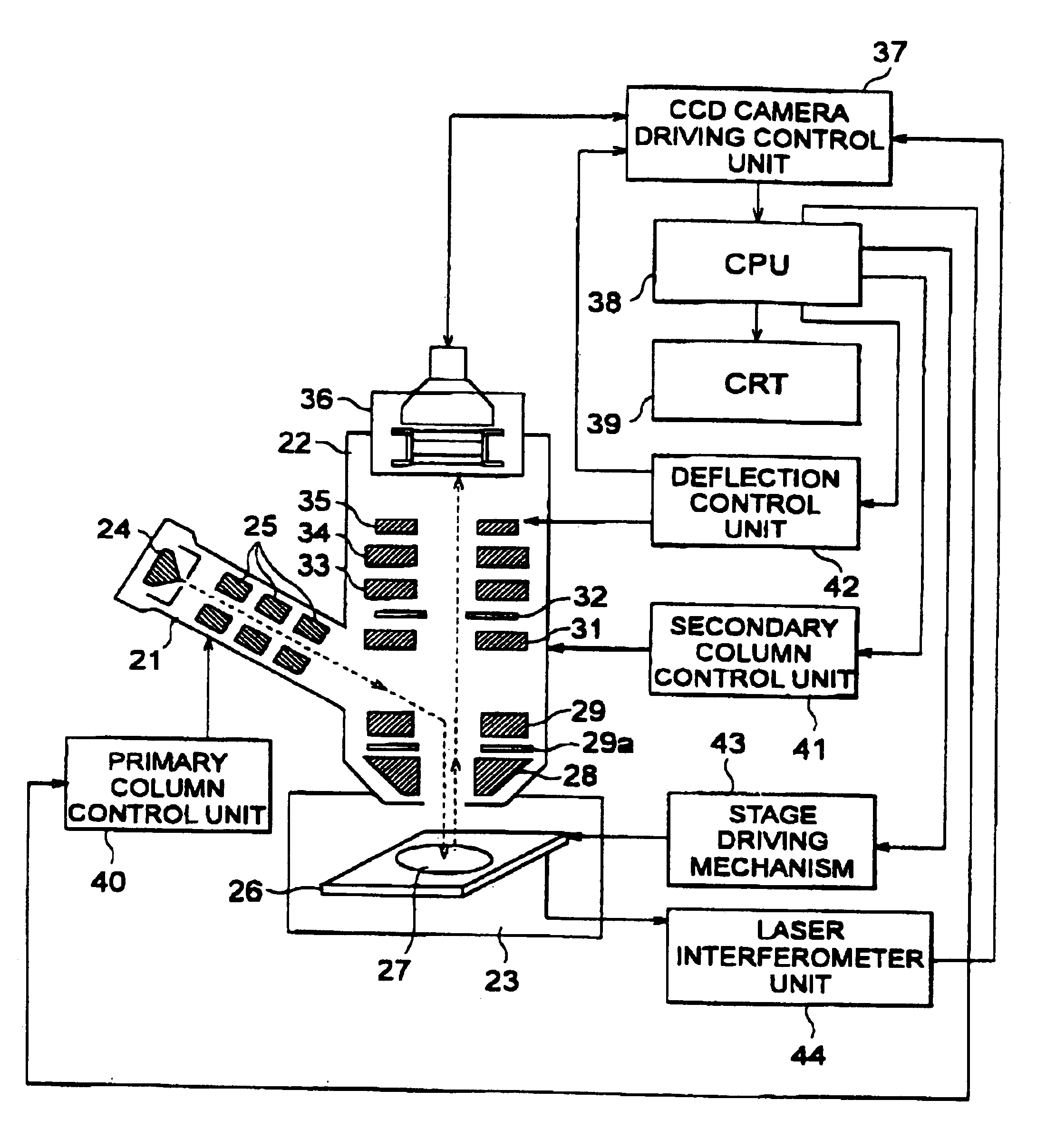

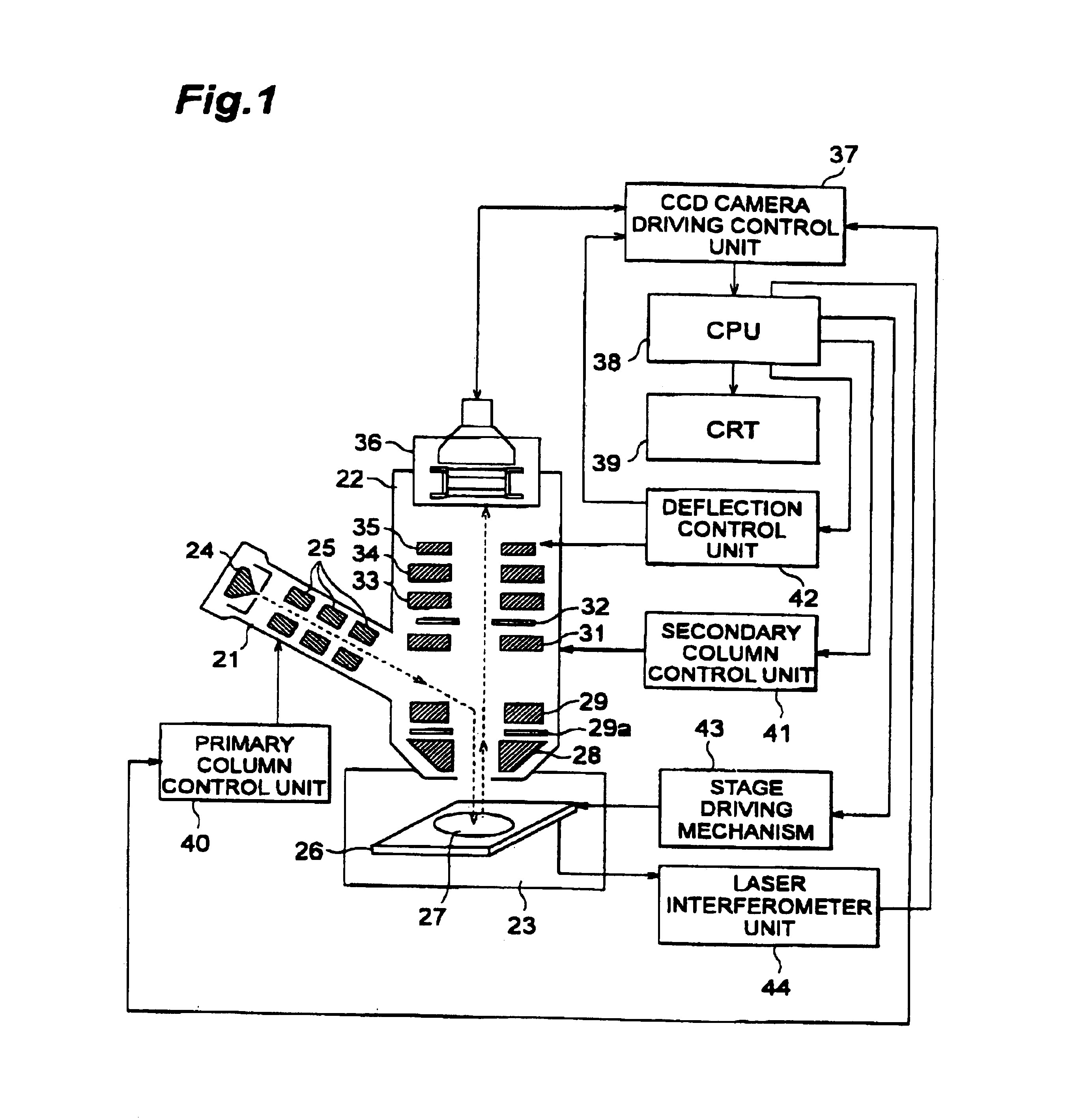

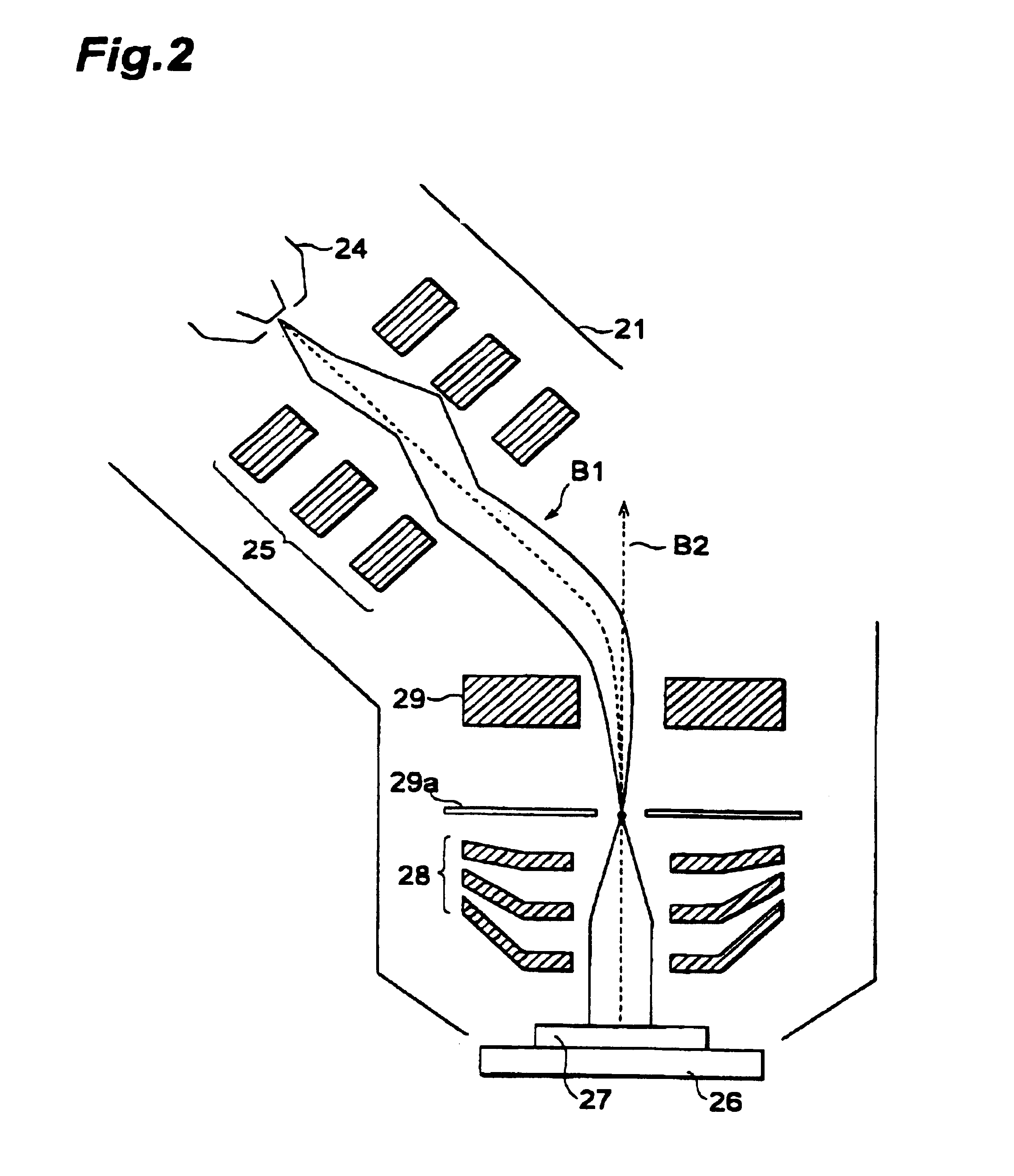

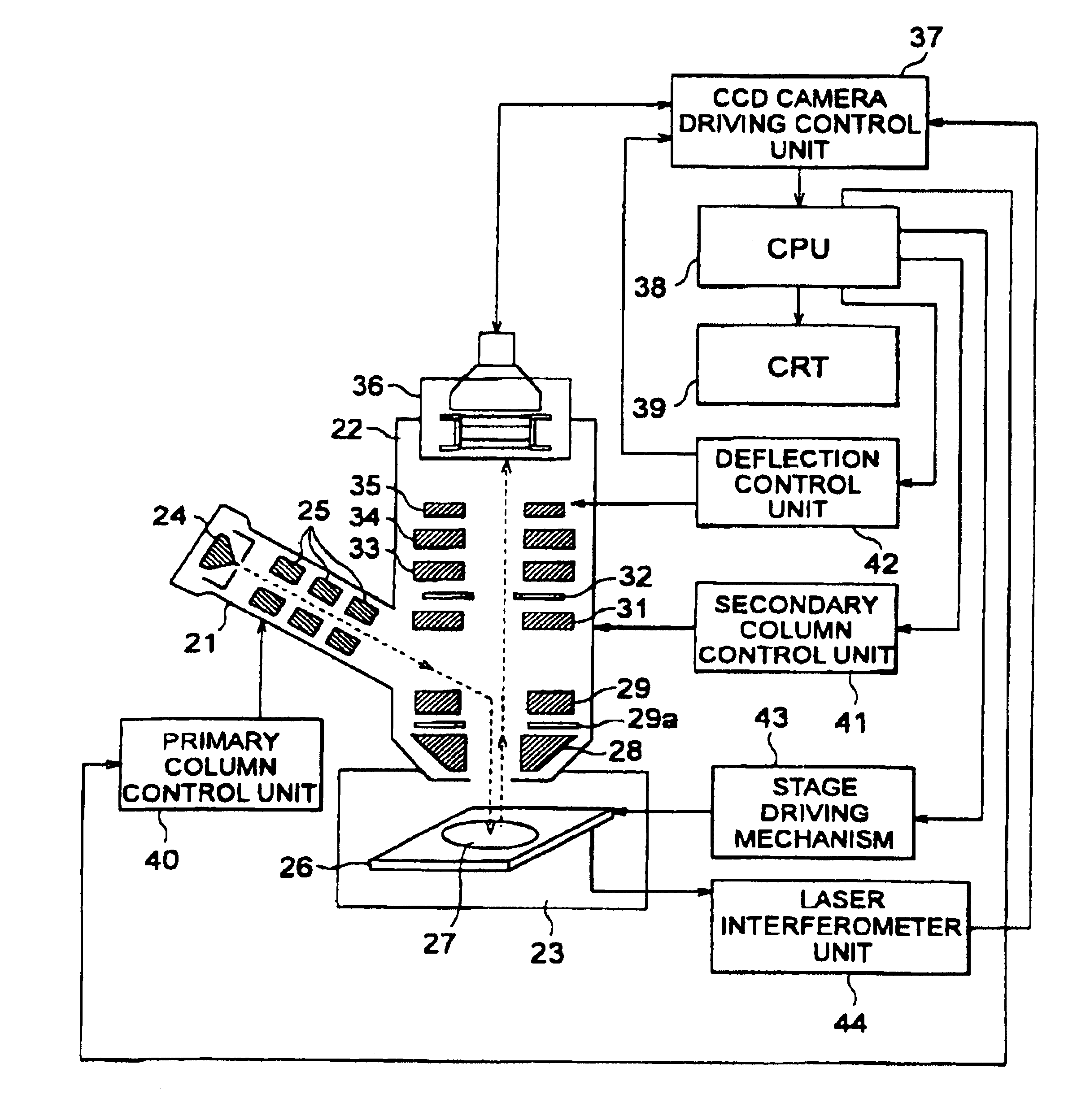

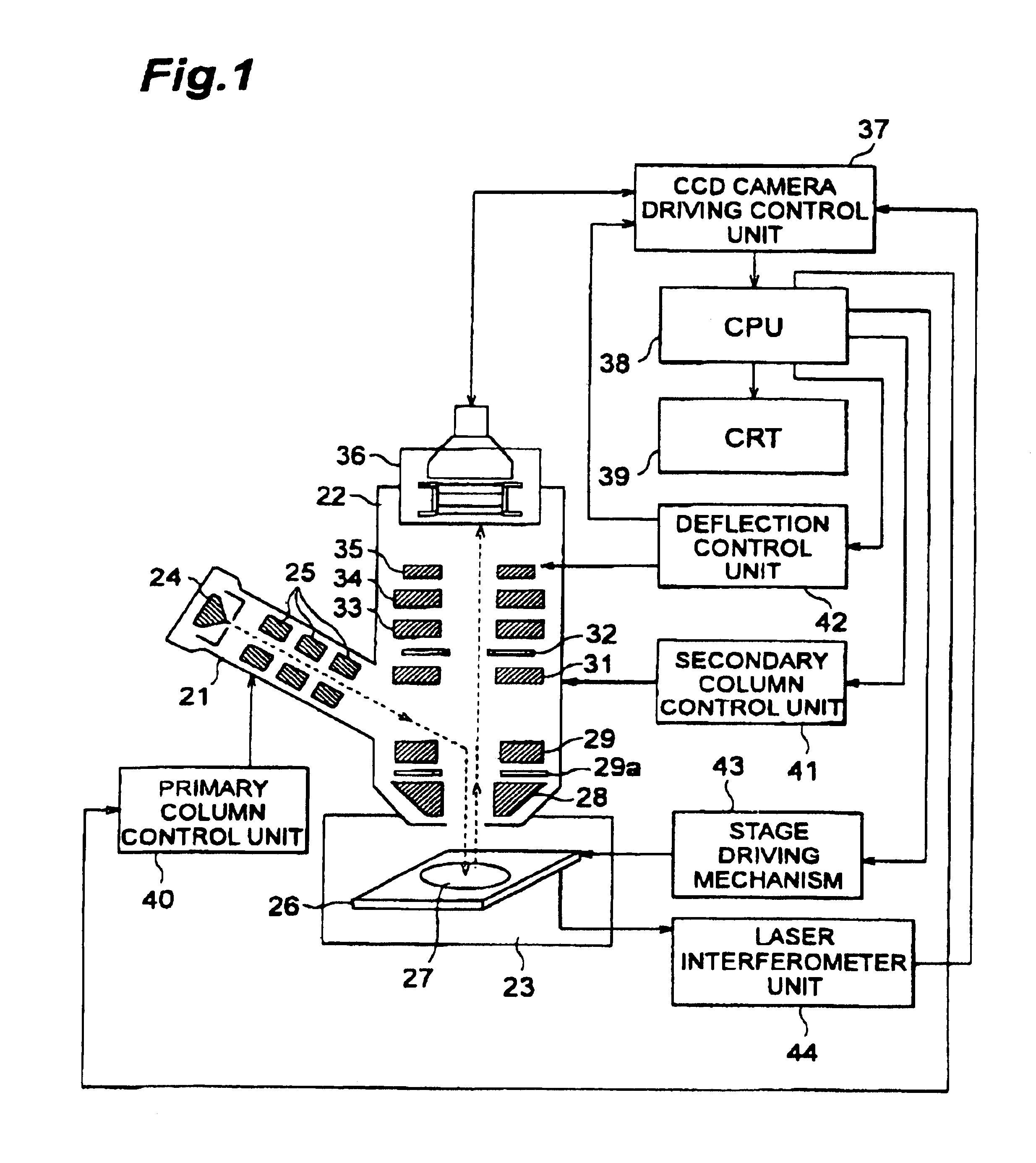

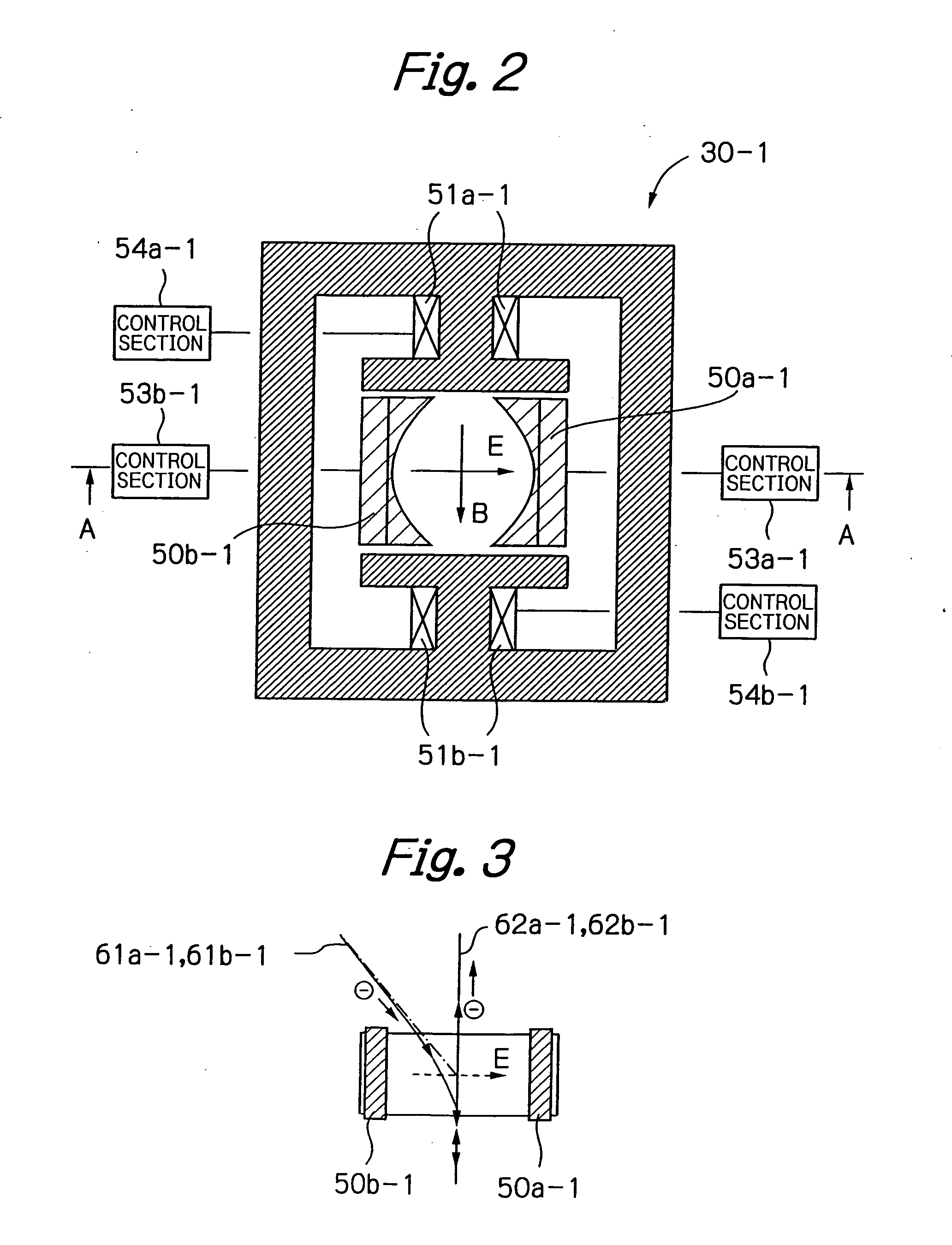

Inspection system by charged particle beam and method of manufacturing devices using the system

InactiveUS20020028399A1Efficiently and accurately inspecting objectAccurately inspect an objectMaterial analysis using wave/particle radiationElectrode and associated part arrangementsBeam sourceSecondary electrons

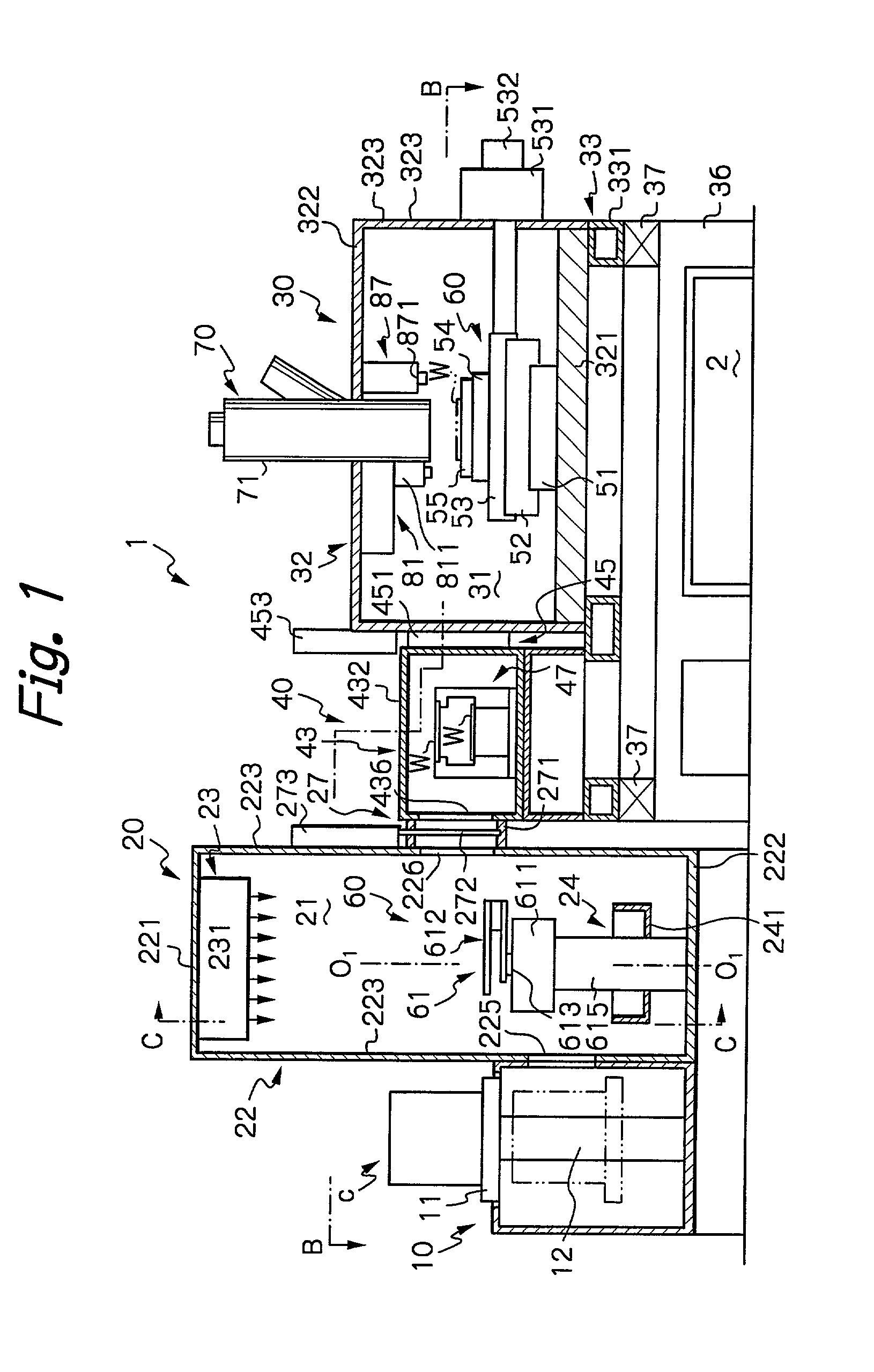

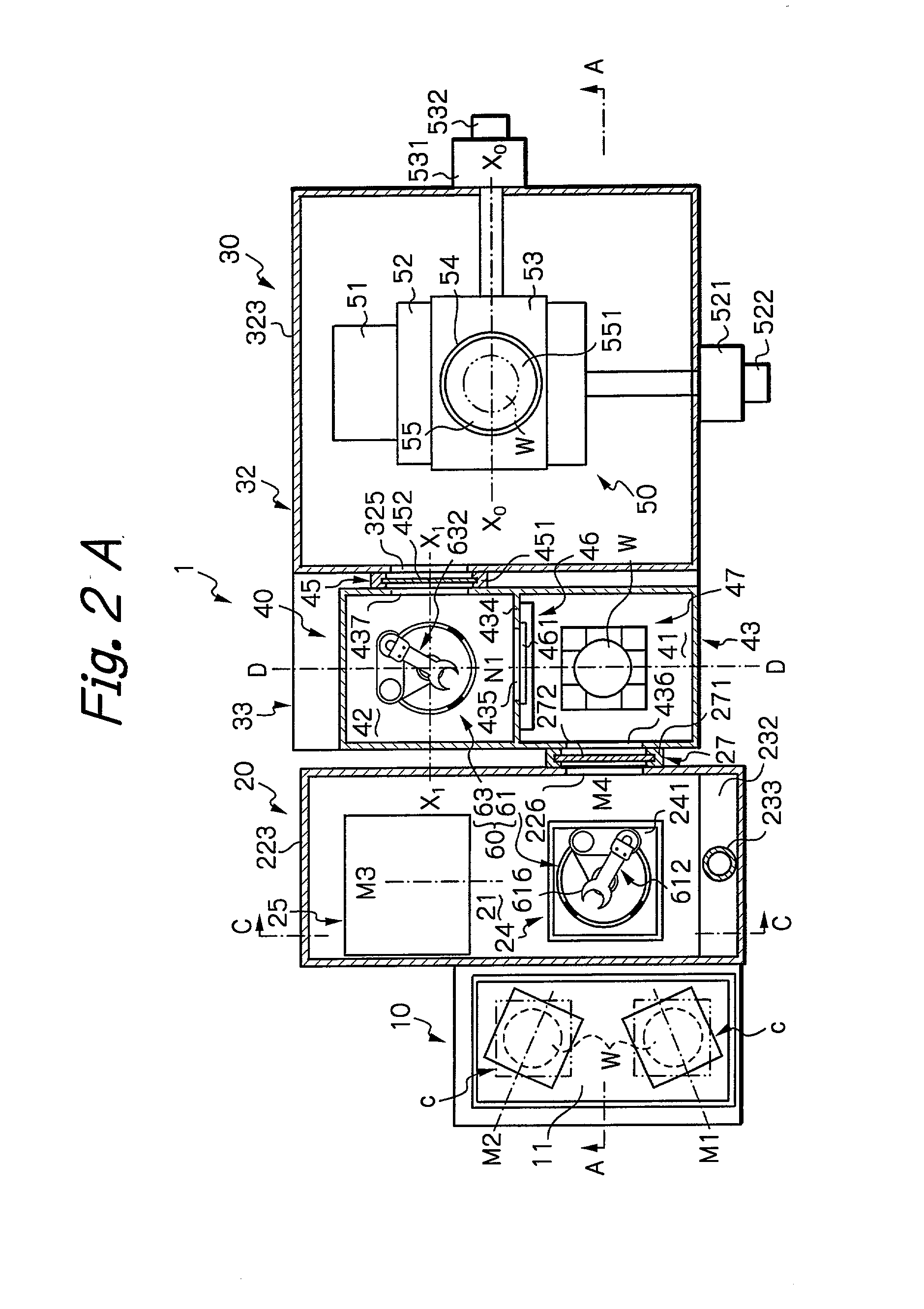

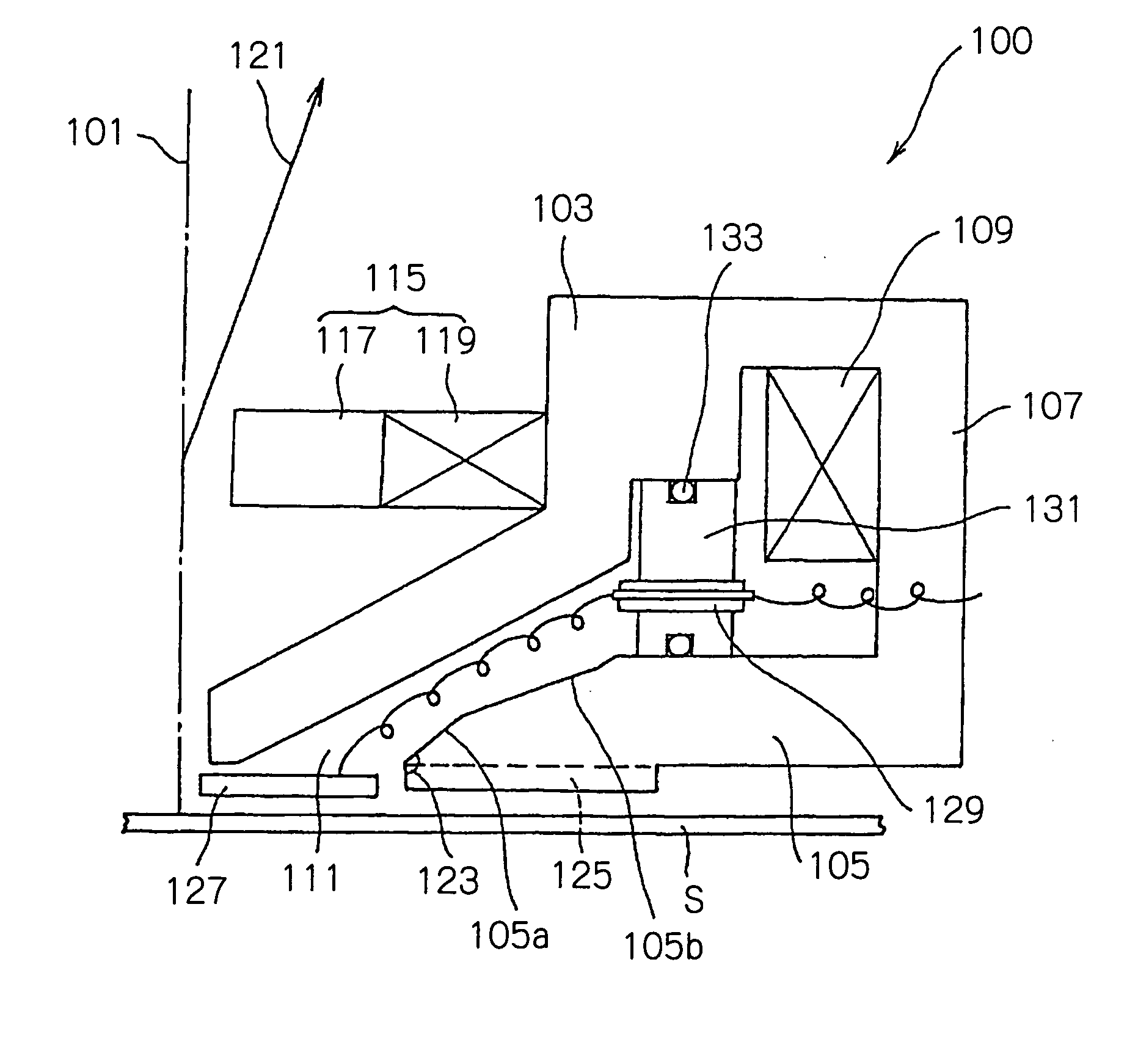

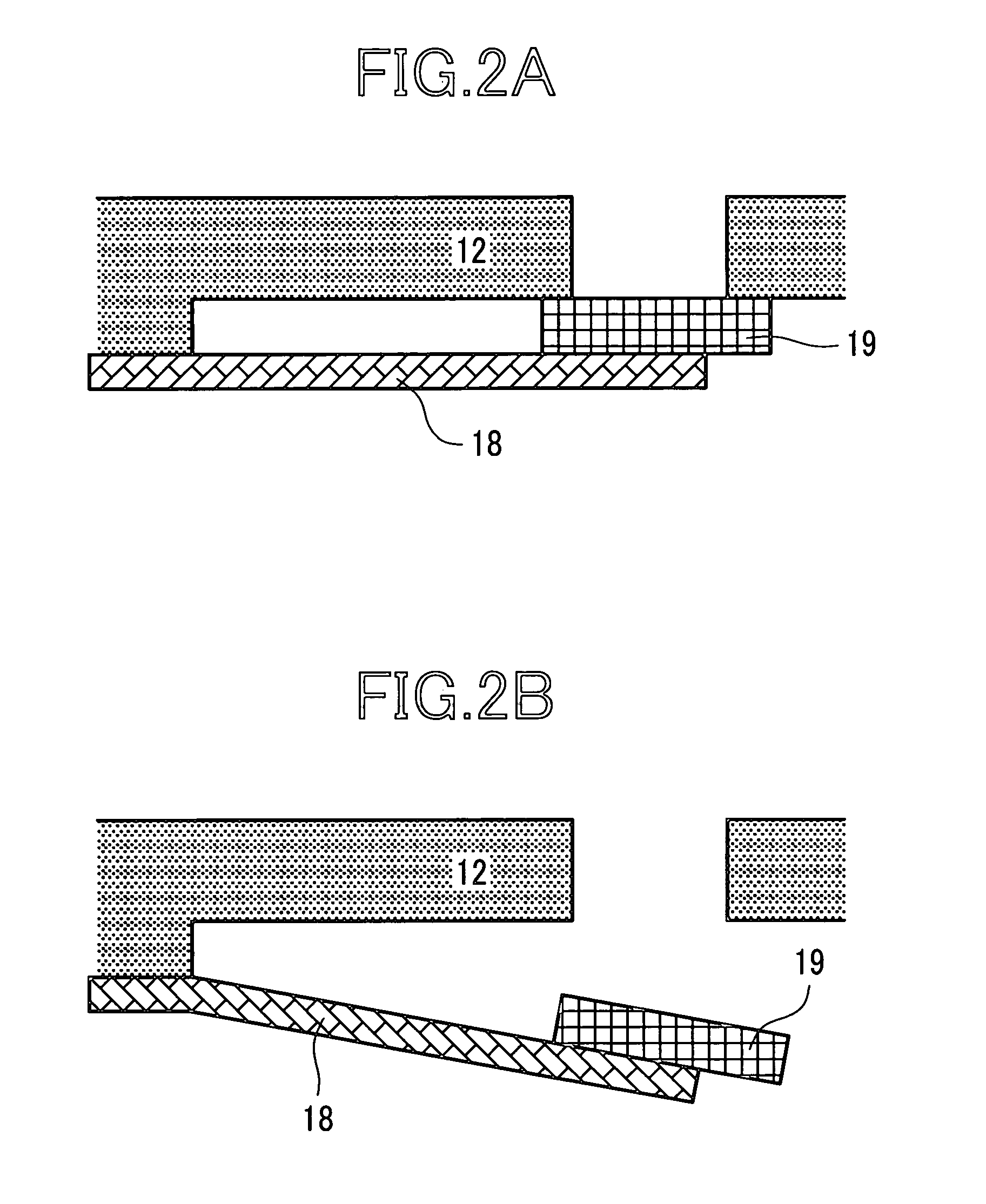

An inspection apparatus by an electron beam comprises: an electron-optical device 70 having an electron-optical system for irradiating the object with a primary electron beam from an electron beam source, and a detector for detecting the secondary electron image projected by the electron-optical system; a stage system 50 for holding and moving the object relative to the electron-optical system; a mini-environment chamber 20 for supplying a clean gas to the object to prevent dust from contacting to the object; a working chamber 31 for accommodating the stage device, the working chamber being controllable so as to have a vacuum atmosphere; at least two loading chambers 41, 42 disposed between the mini-environment chamber and the working chamber, adapted to be independently controllable so as to have a vacuum atmosphere; and a loader 60 for transferring the object to the stage system through the loading chambers.

Owner:EBARA CORP +1

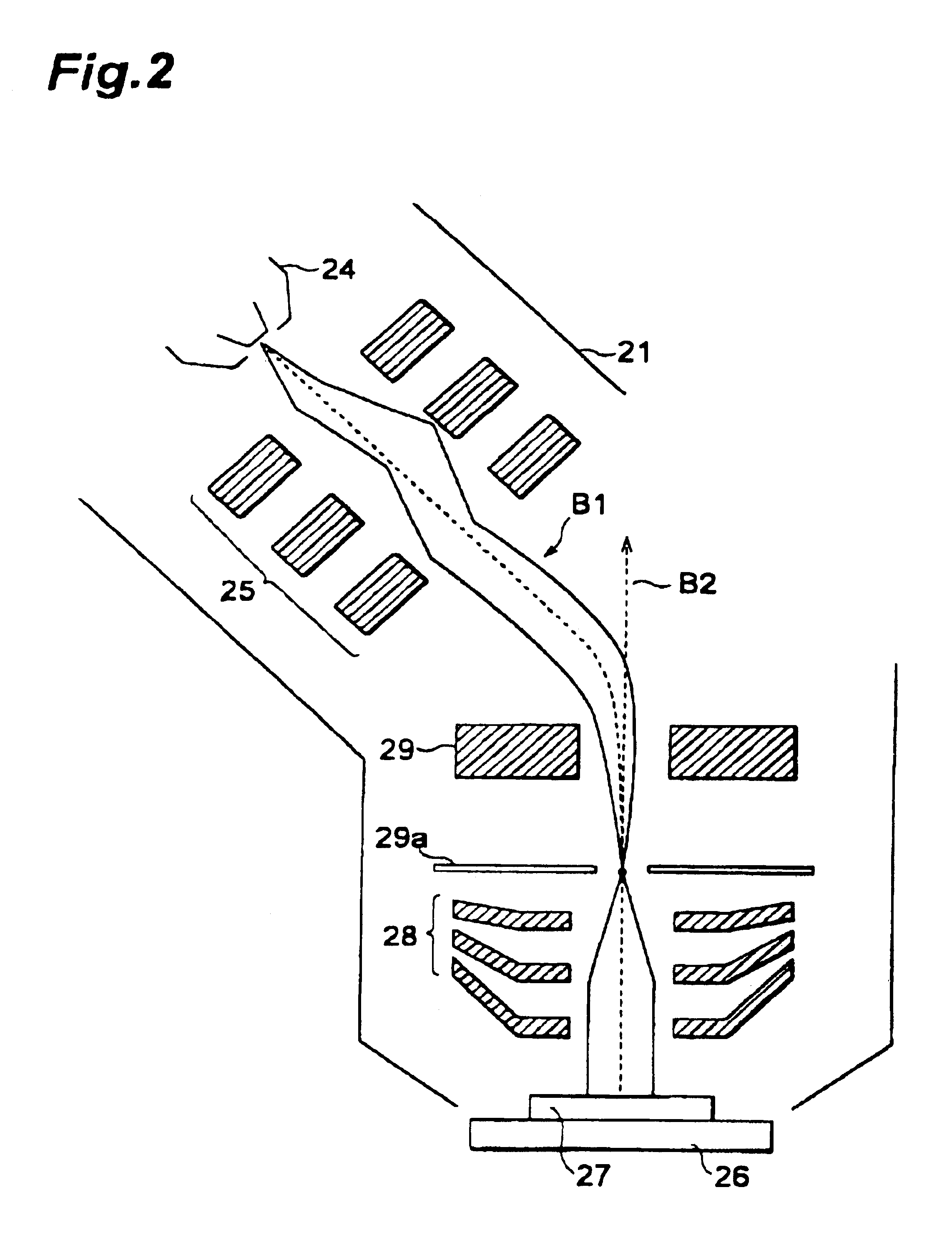

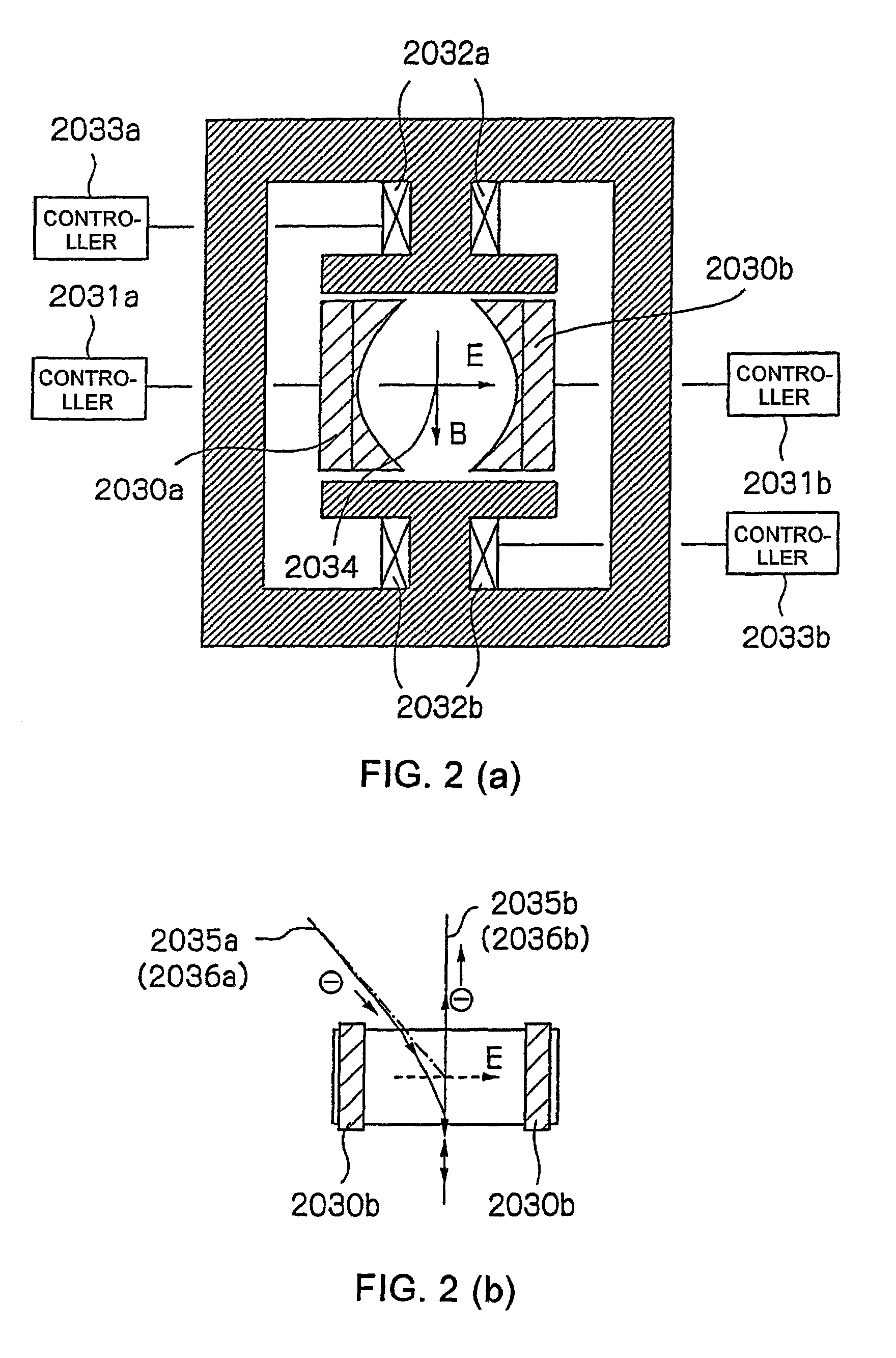

Particle-optical systems and arrangements and particle-optical components for such systems and arrangements

ActiveUS7244949B2High accuracy of focusingMaintain propertiesStability-of-path spectrometersSemiconductor/solid-state device testing/measurementSecondary electronsAtomic physics

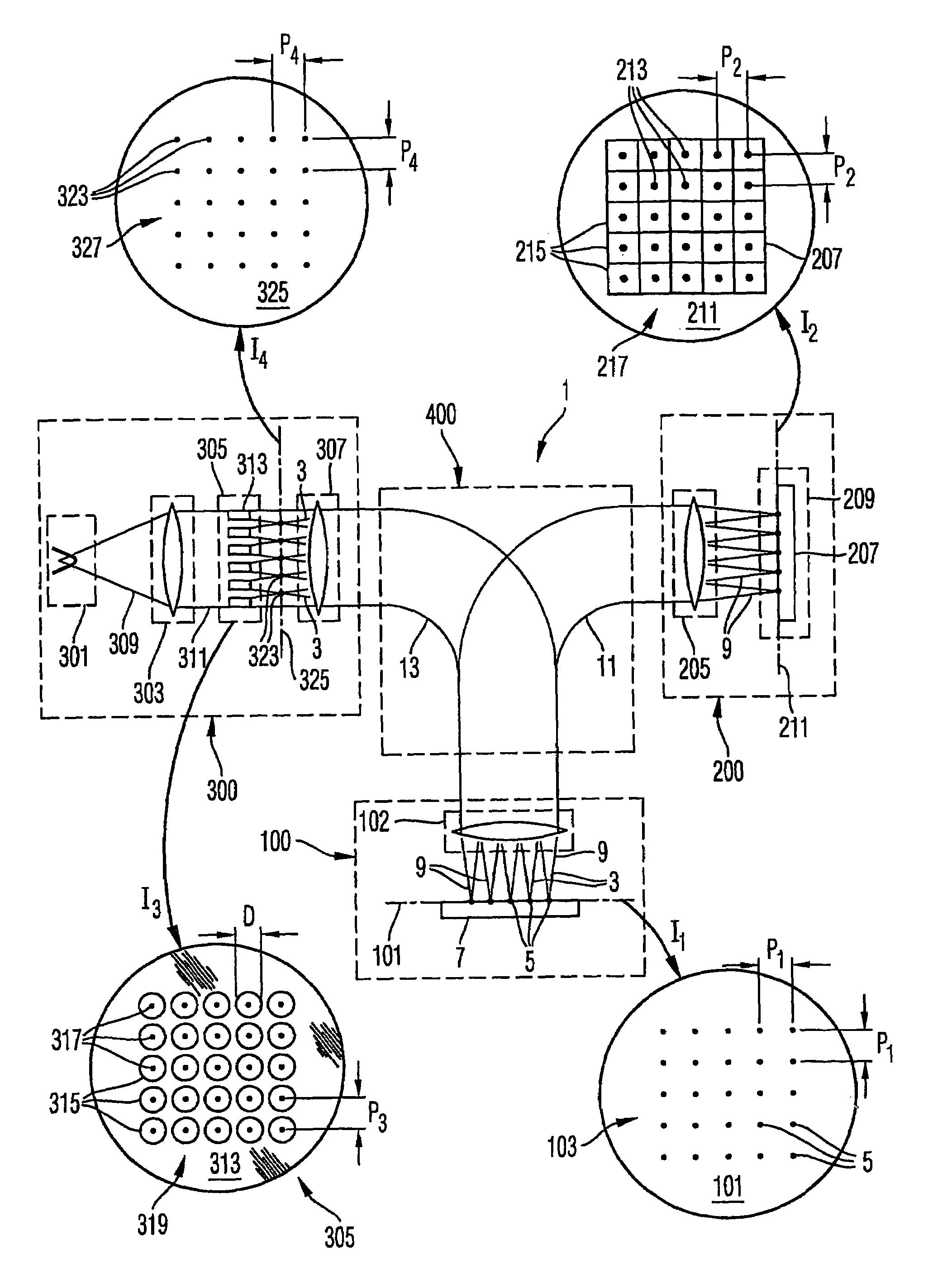

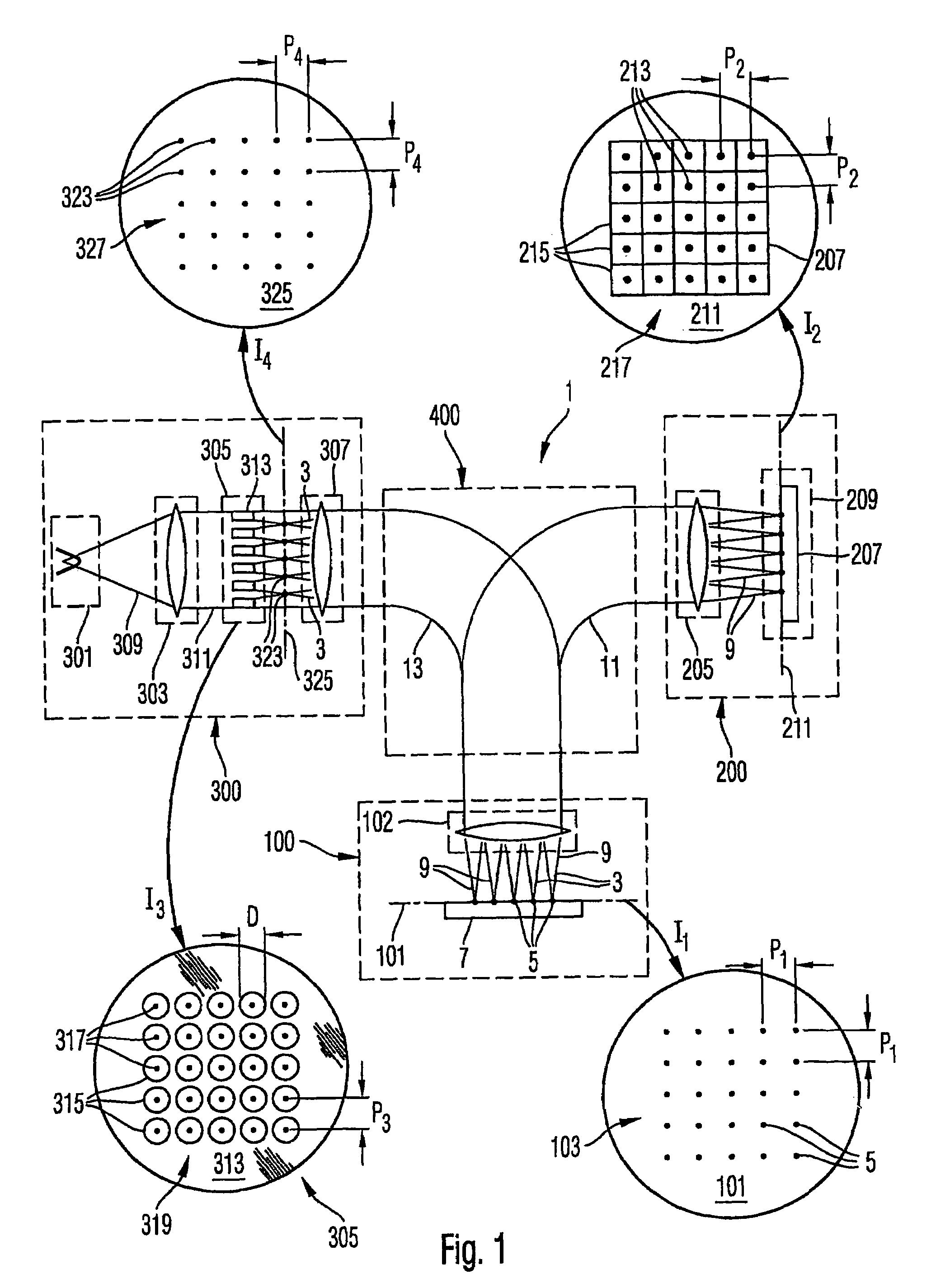

An electron-optical arrangement provides a primary beam path for a beam of primary electrons and a secondary beam path for secondary electrons. The electron-optical arrangement includes a magnet arrangement having first, second and third magnetic field regions. The first magnetic field region is traversed by the primary beam path and the secondary beam path. The second magnetic field region is arranged in the primary beam path upstream of the first magnetic field region and is not traversed by the secondary beam path. The first and second magnetic field regions deflect the primary beam path in substantially opposite directions. The third magnetic field region is arranged in the secondary beam path downstream of the first magnetic field region and is not traversed by the first beam path. The first and third magnetic field regions deflect the secondary beam path in a substantially same direction.

Owner:CARL ZEISS MICROSCOPY GMBH +1

Multi-beam multi-column electron beam inspection system

InactiveUS6844550B1Material analysis using wave/particle radiationRadiation/particle handlingSystems designData stream

A multi-column electron beam inspection system is disclosed herein. The system is designed for electron beam inspection of semiconductor wafers with throughput high enough for in-line use. The system includes field emission electron sources, electrostatic electron optical columns, a wafer stage with six degrees of freedom of movement, and image storage and processing systems capable of handling multiple simultaneous image data streams. Each electron optical column is enhanced with an electron gun with redundant field emission sources, a voltage contrast plate to allow voltage contrast imaging of wafers, and an electron optical design for high efficiency secondary electron collection.

Owner:MULTIBEAM CORP

Scanning electron microscope

ActiveUS20060060782A1Improve transport efficiencyImprove efficiencyMaterial analysis using wave/particle radiationElectric discharge tubesAngle of incidenceElectron source

In a scanning electron microscope, an emitted primary electron beam is diverted by an angle of at least about 45 degrees prior to incidence with a specimen. The beam may be bent by a magnetic separator. The separator may also serve to deflect secondary electron and back scattered electrons. As the angle of emissions and reflections from the specimen is close to the angle of incidence, bending the primary electron beam prior to incidence, allows the electron source to be located so as not to obstruct the travel of emissions and reflections to suitable detectors.

Owner:NAT UNIV OF SINGAPORE

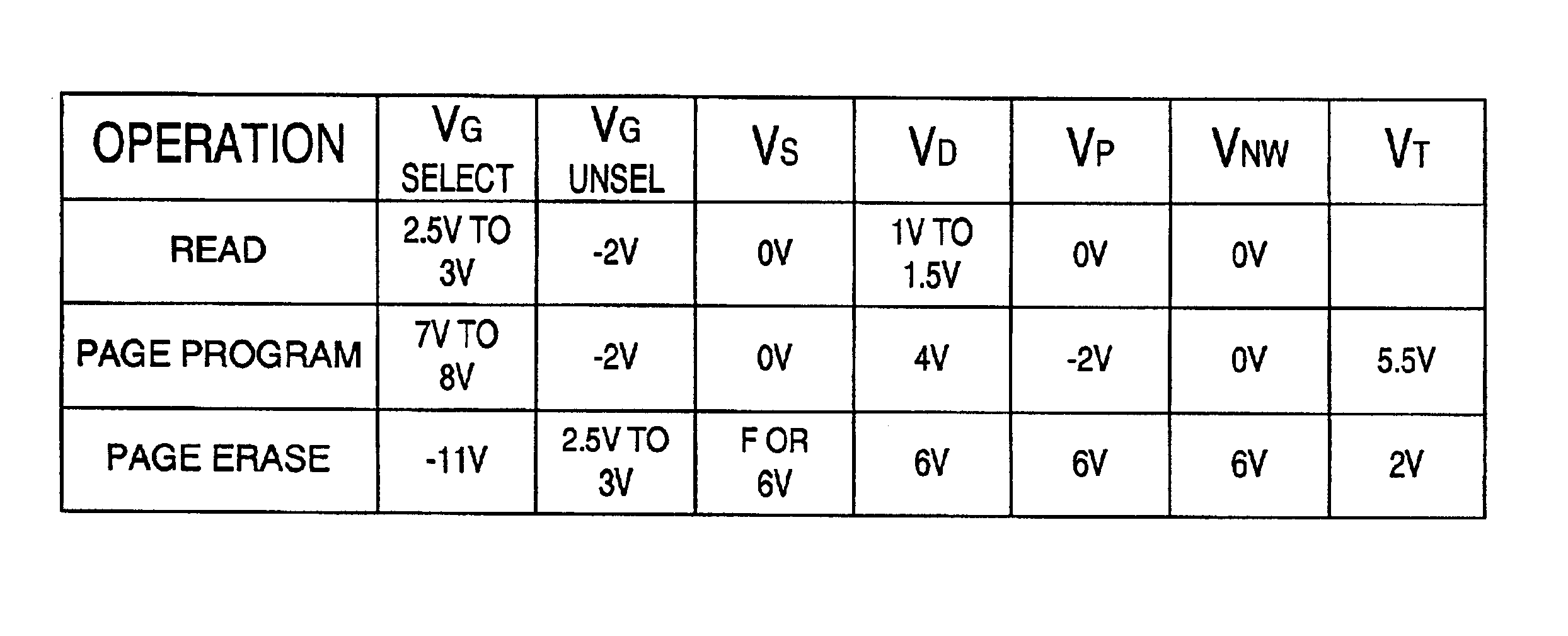

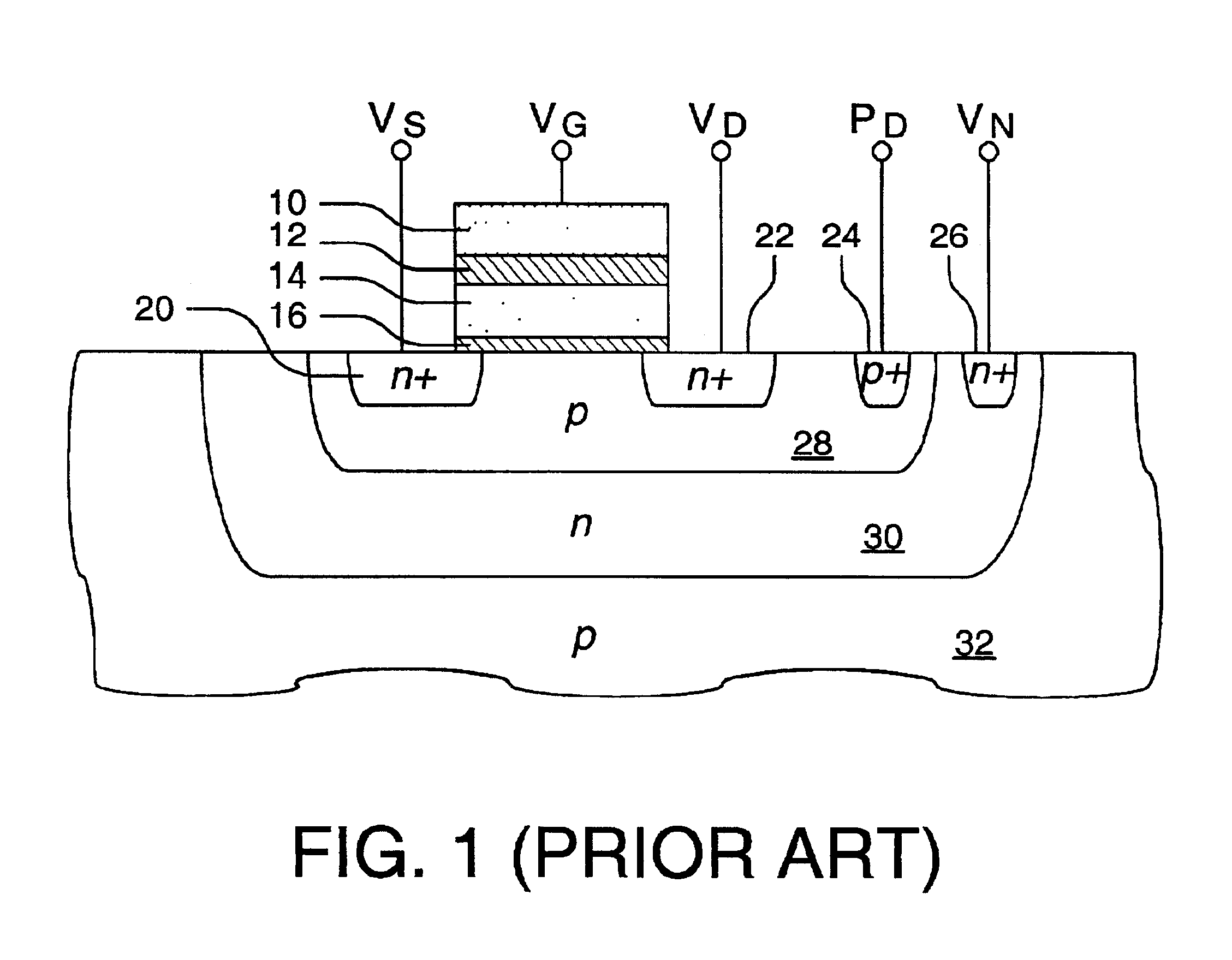

Method and apparatus for multiple byte or page mode programming and reading and for erasing of a flash memory array

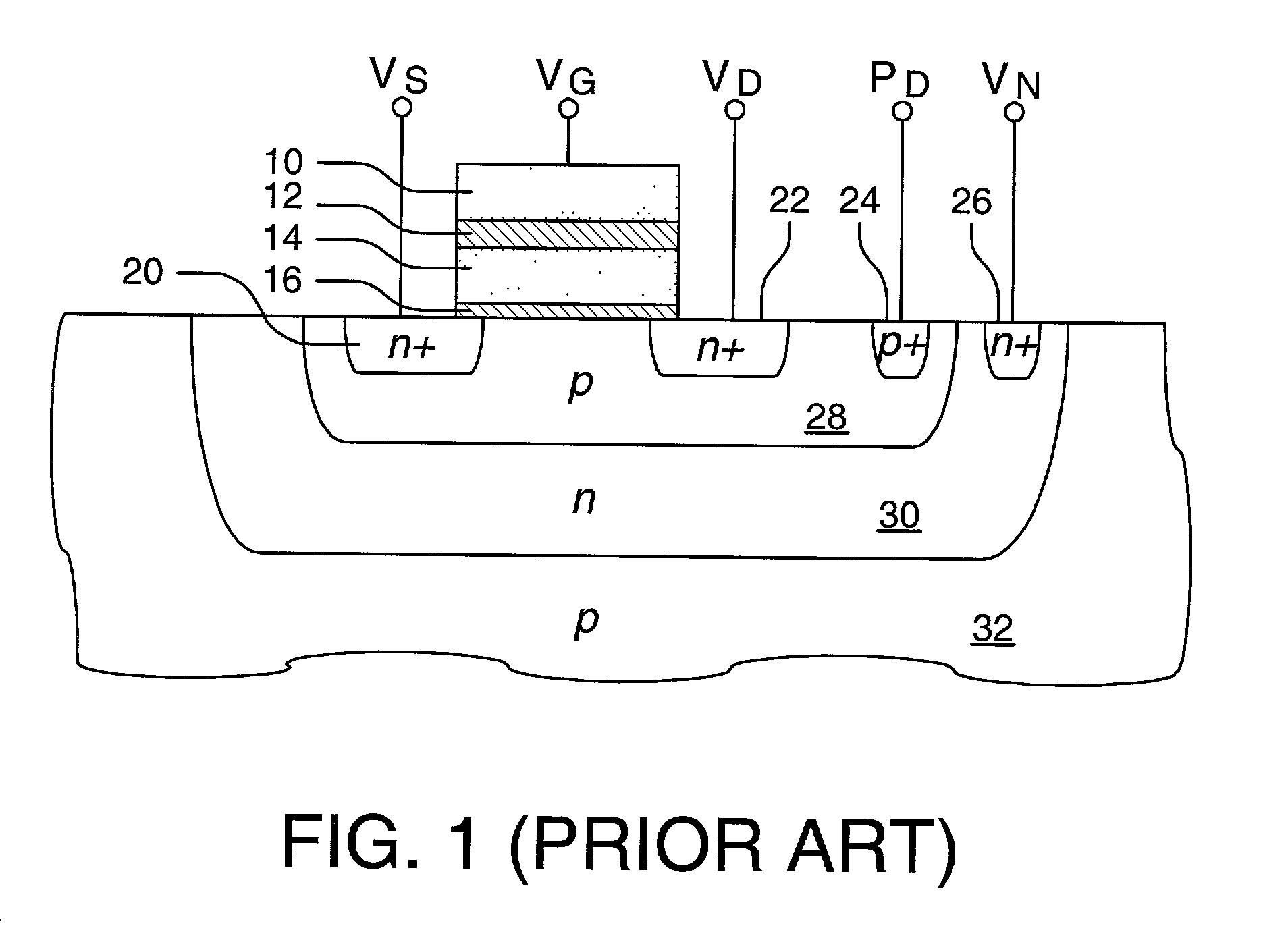

A memory array contains memory cells designed to be erased using Fowler-Nordheim ("FN") tunneling through the channel area, and programmed using either channel hot electron injection ("CHE") or channel-initiated secondary electron injection ("CISEI"). To reduce disturbance of the floating gate potential of unselected memory cells during programming operations and read operations, the unselected word lines are brought to a negative potential rather than ground potential. To reduce disturbance of the floating gate potential of unselected memory cells during FN erase operations, the unselected word lines are brought to a positive potential rather than ground potential.

Owner:WINBOND ELECTRONICS CORP

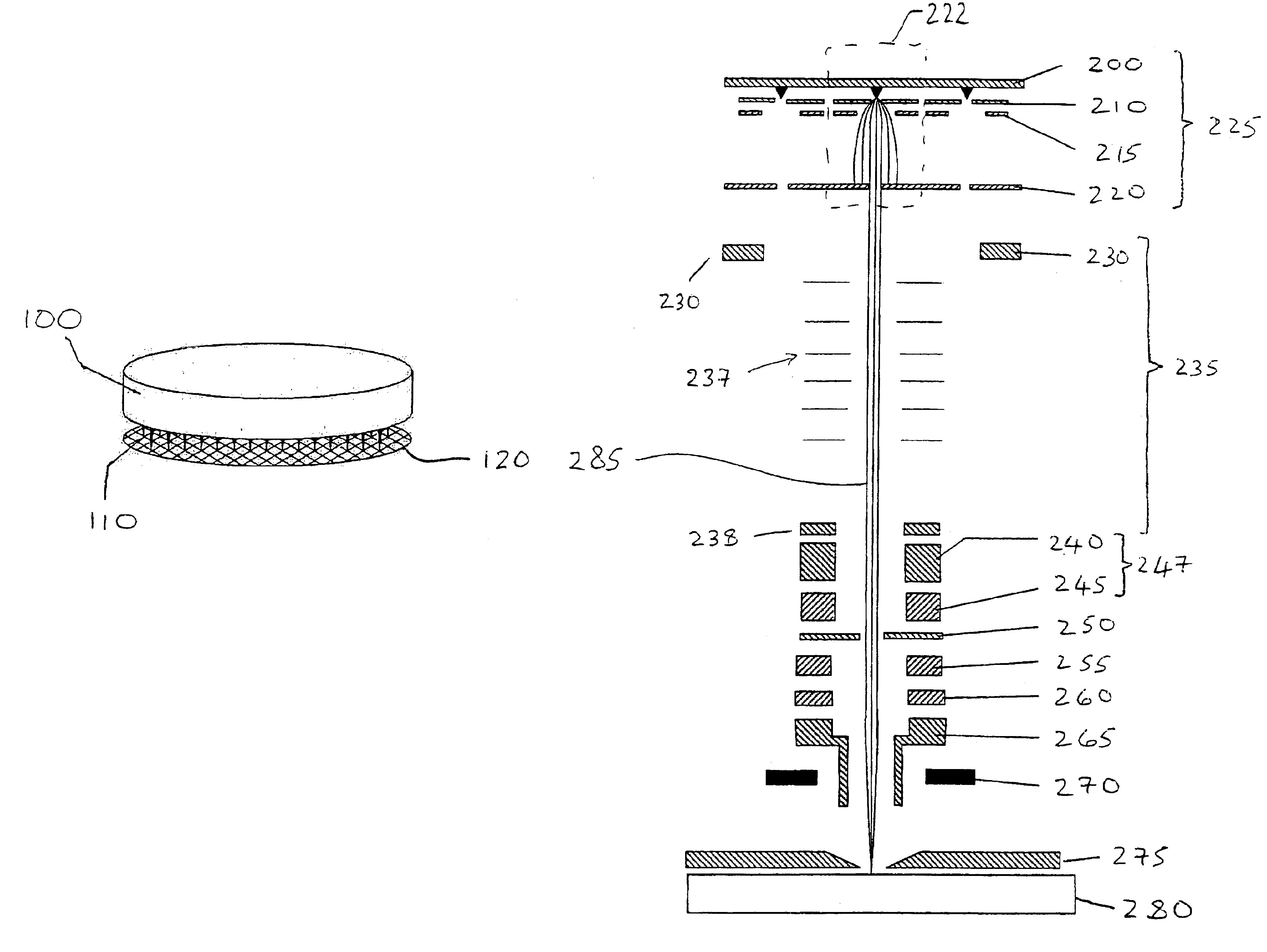

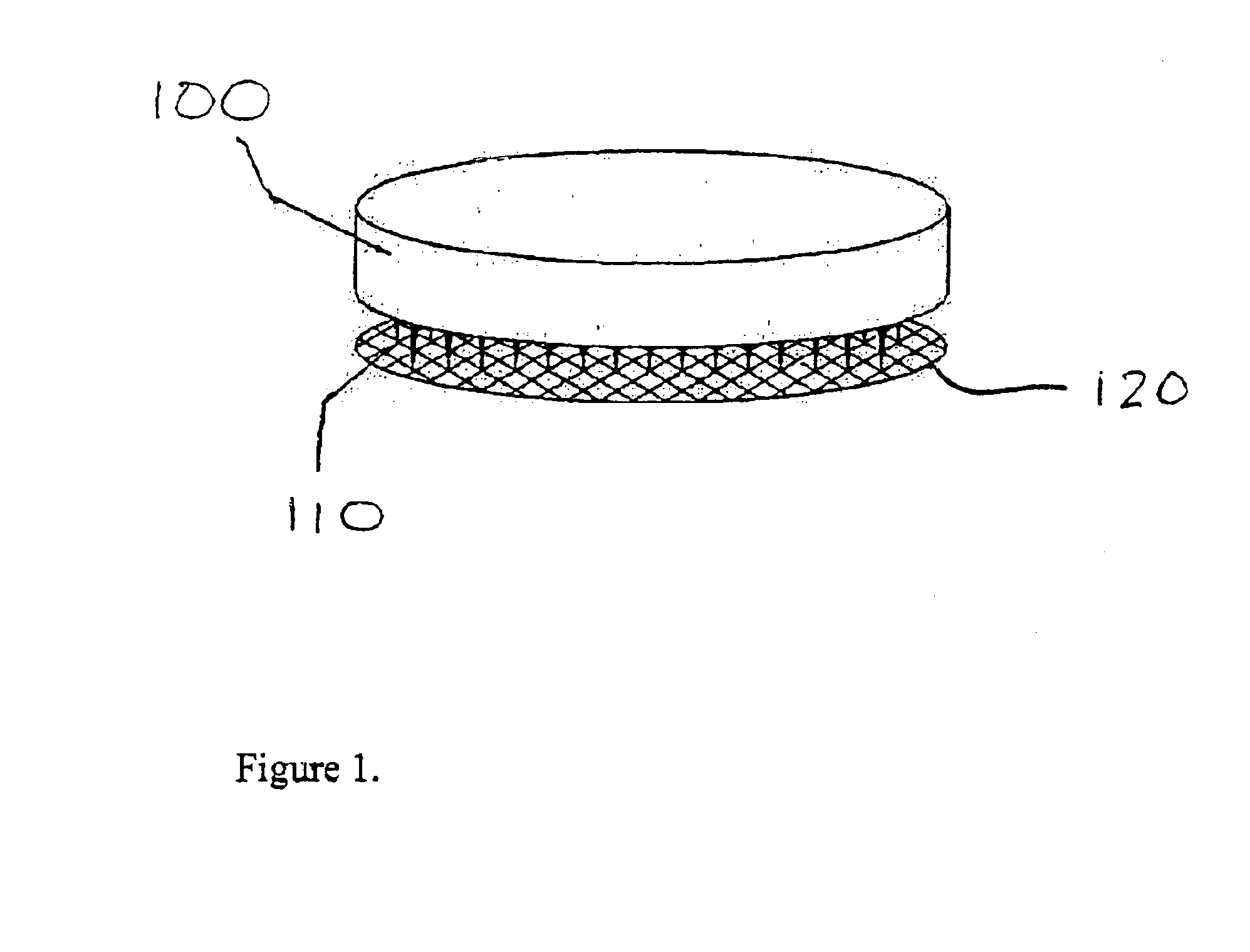

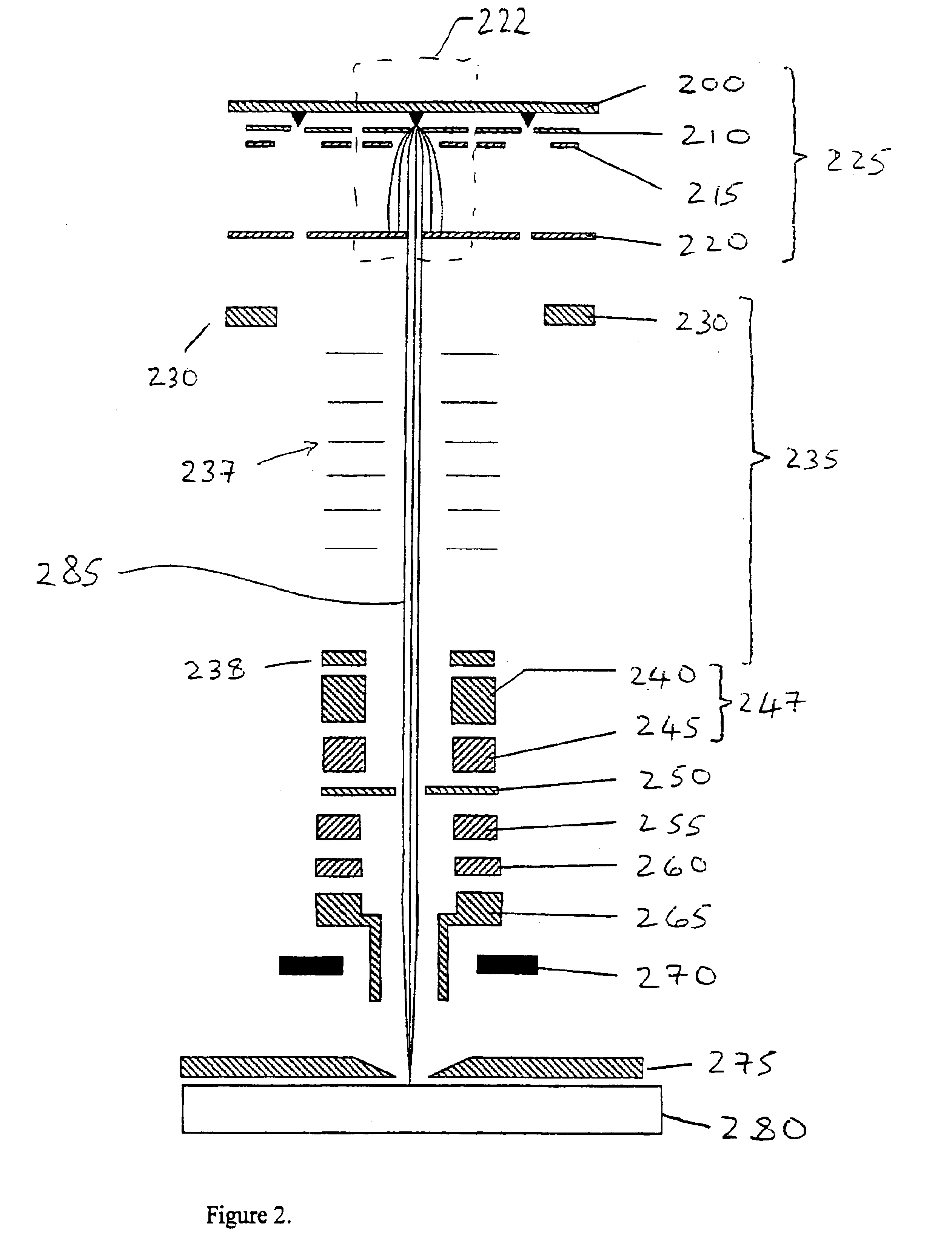

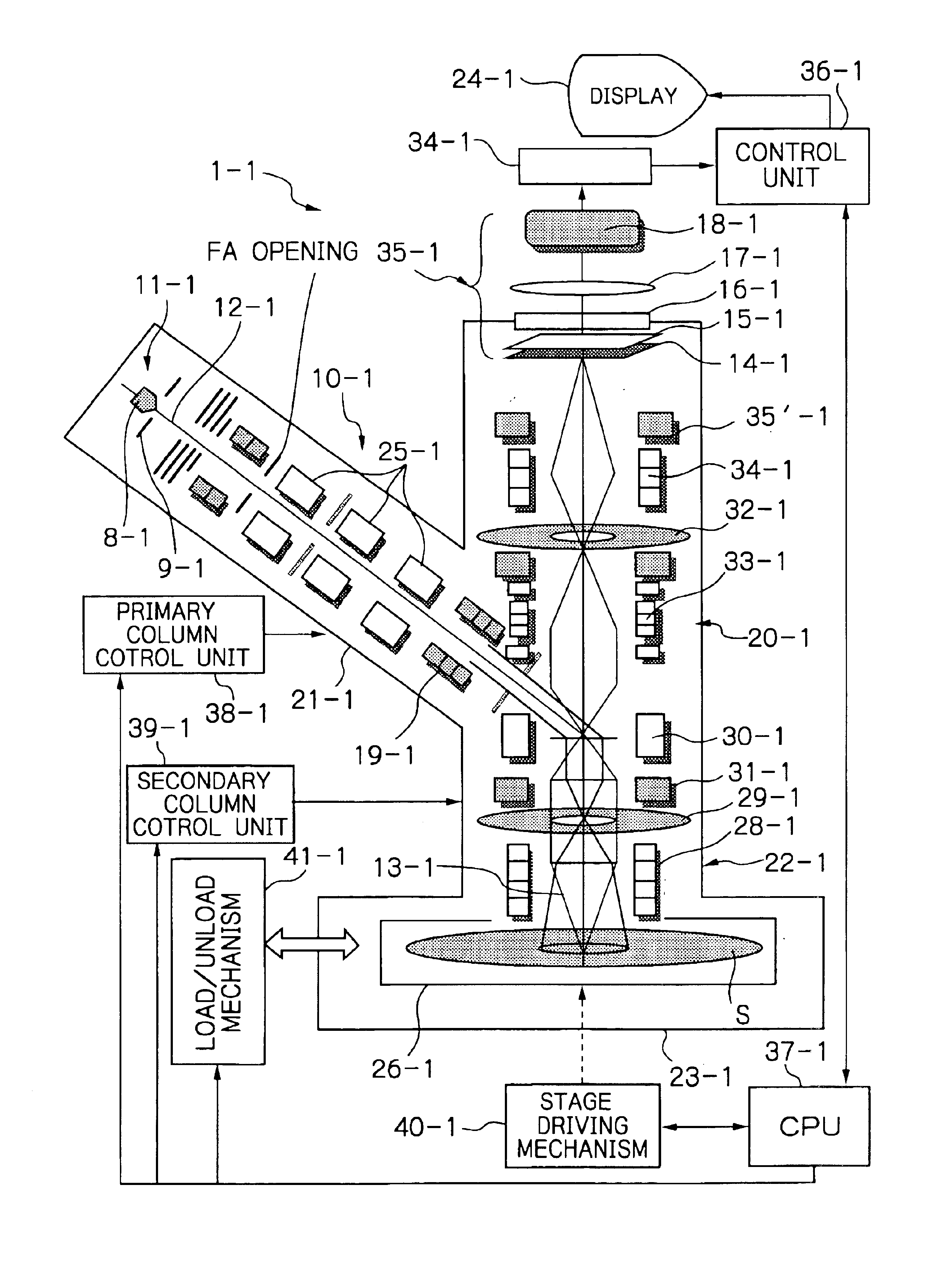

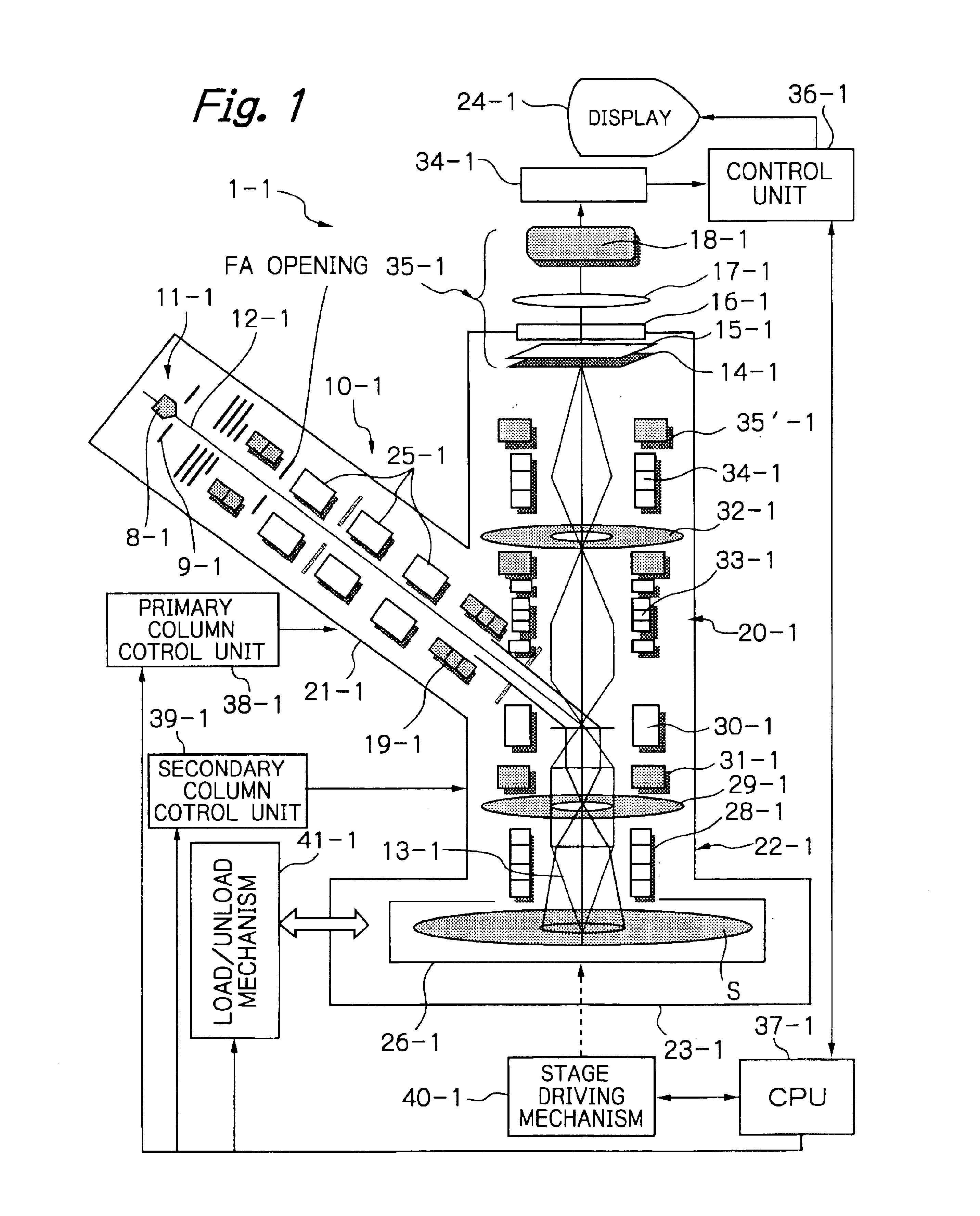

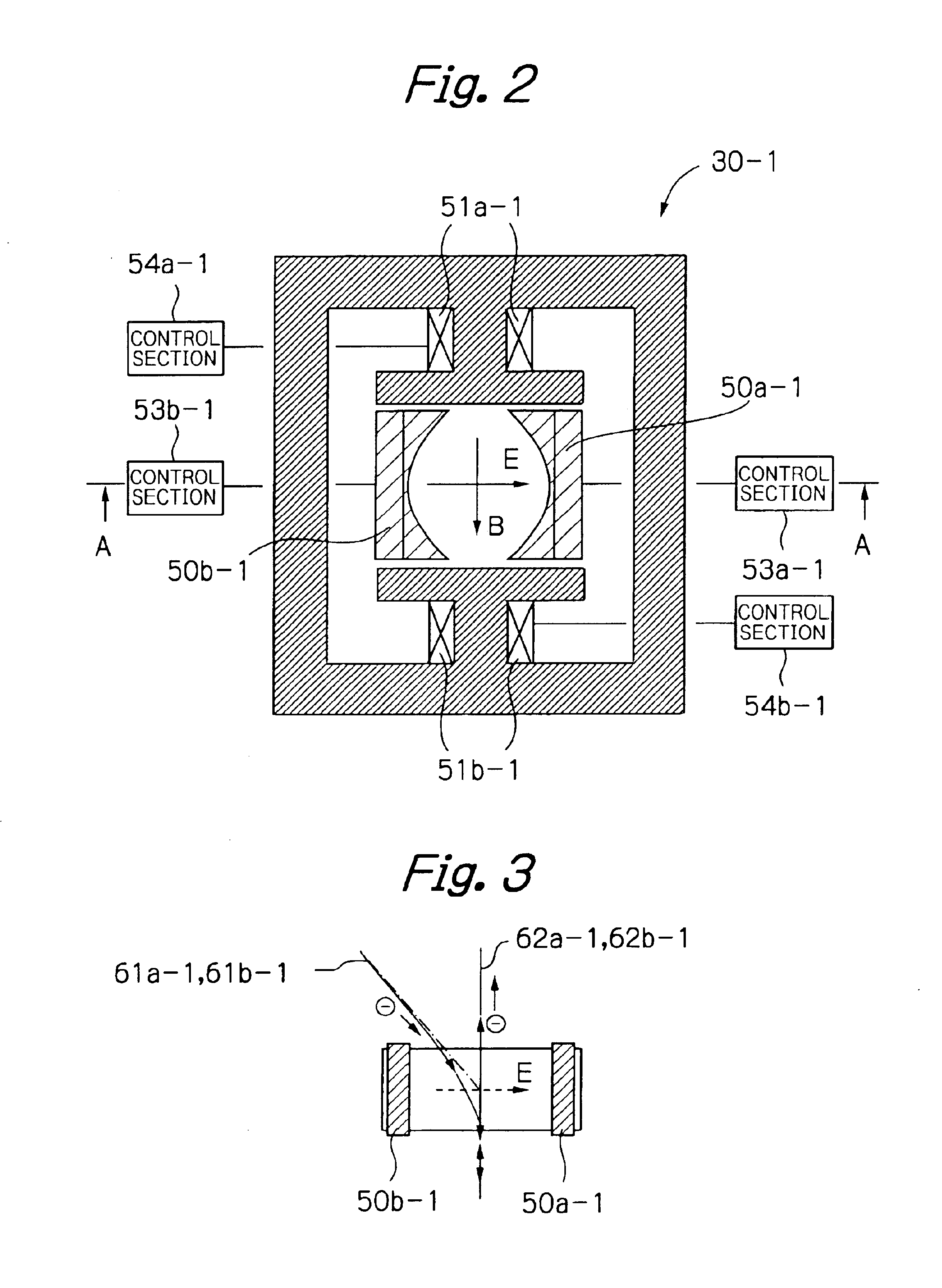

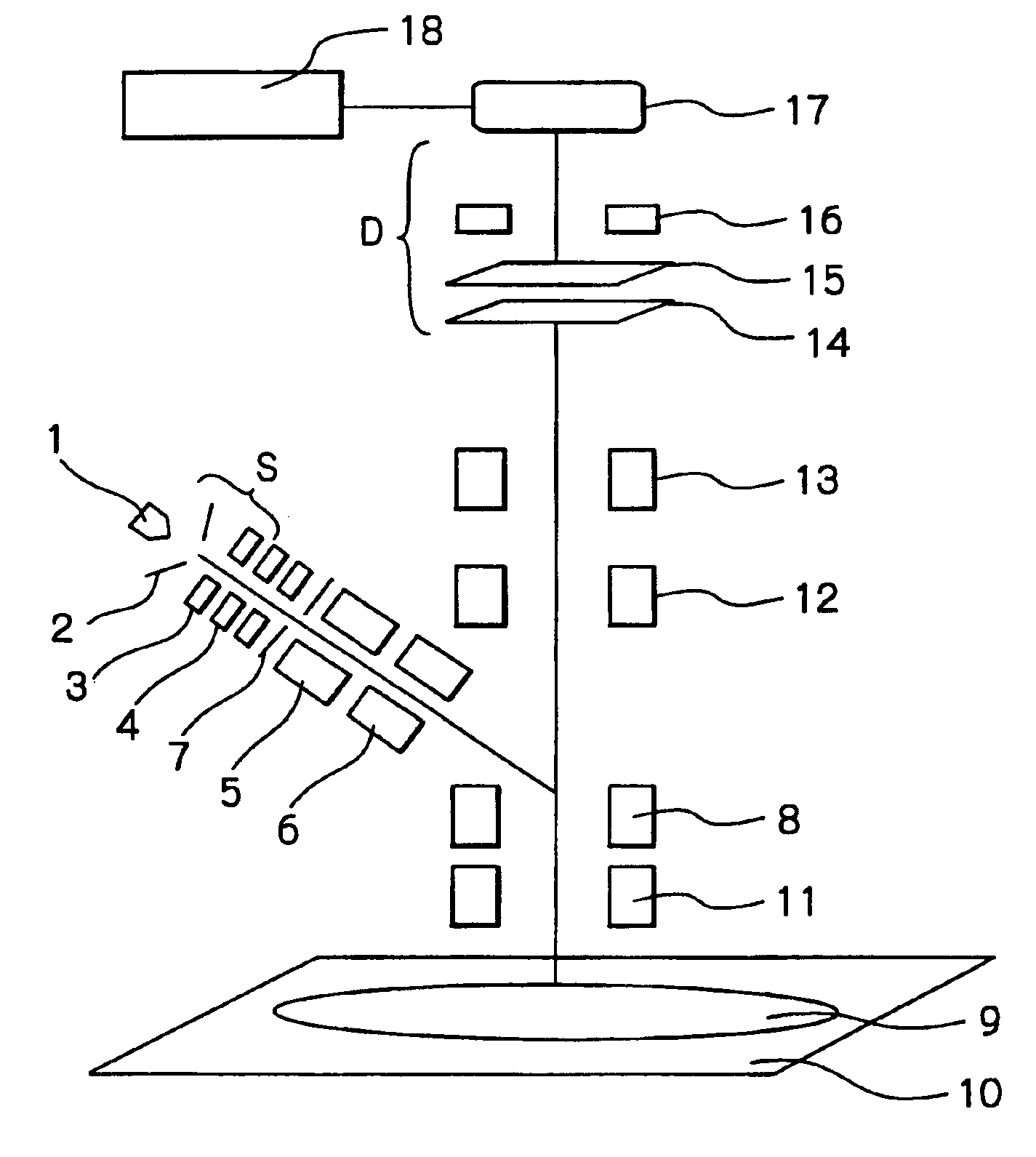

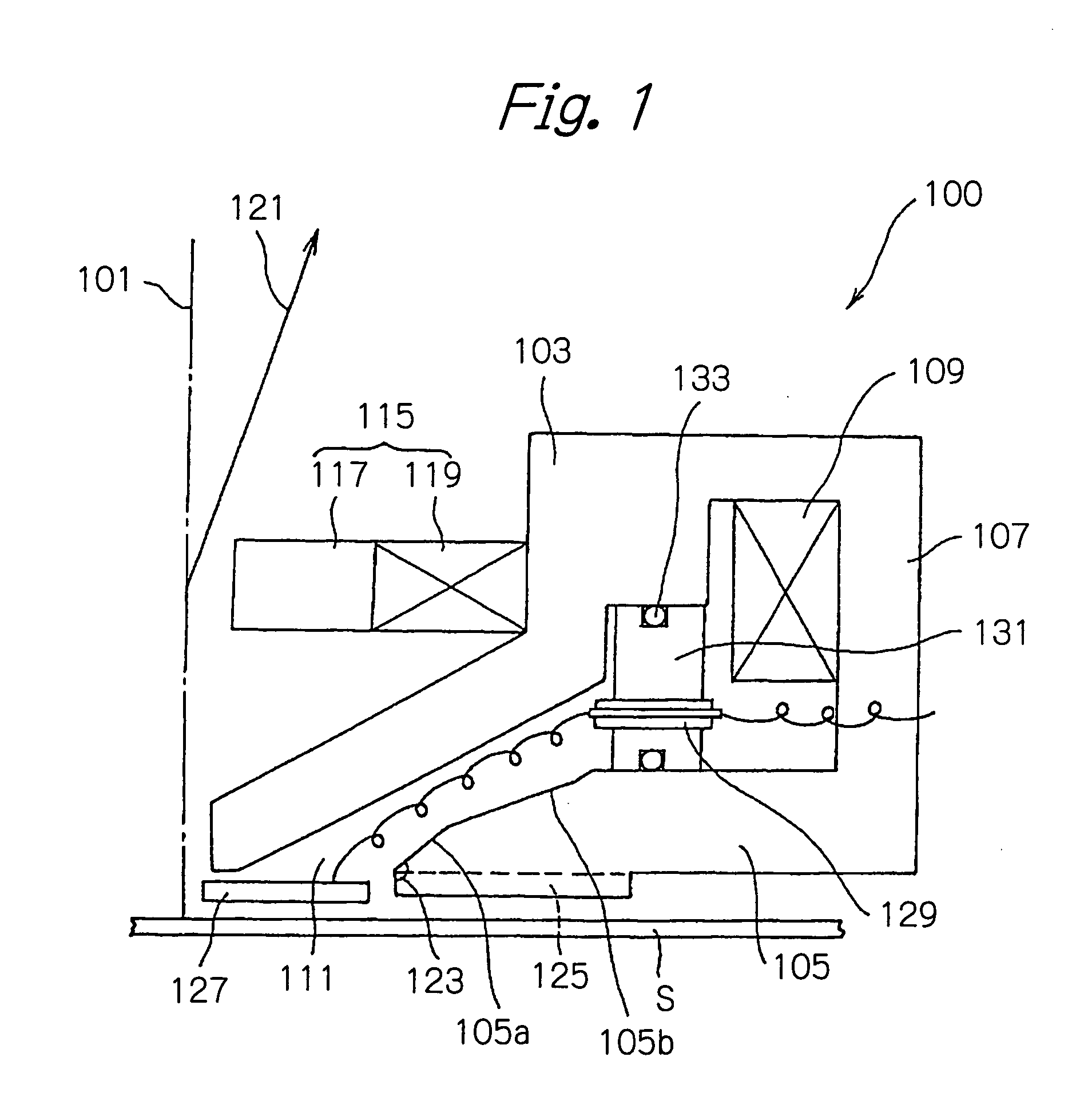

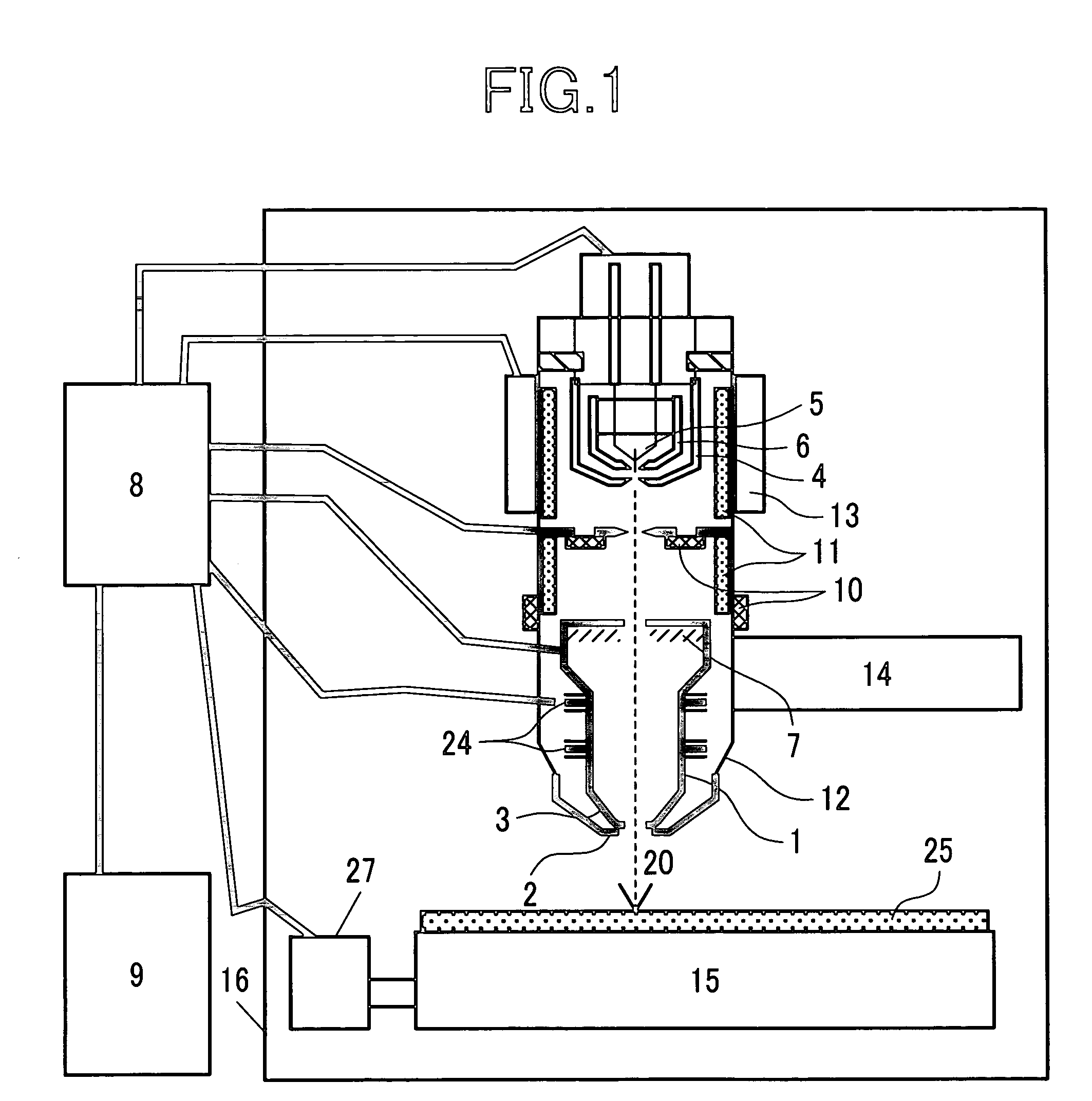

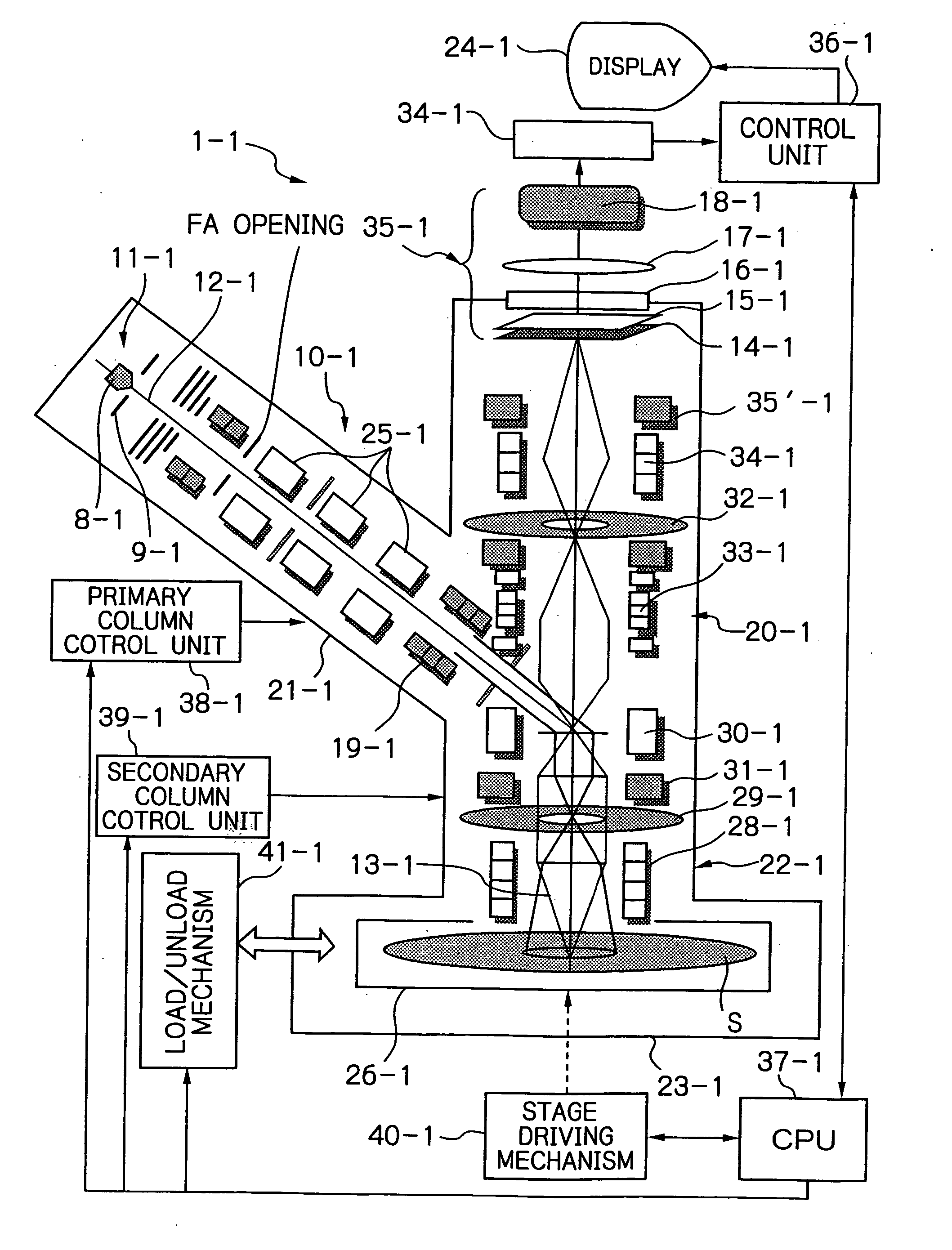

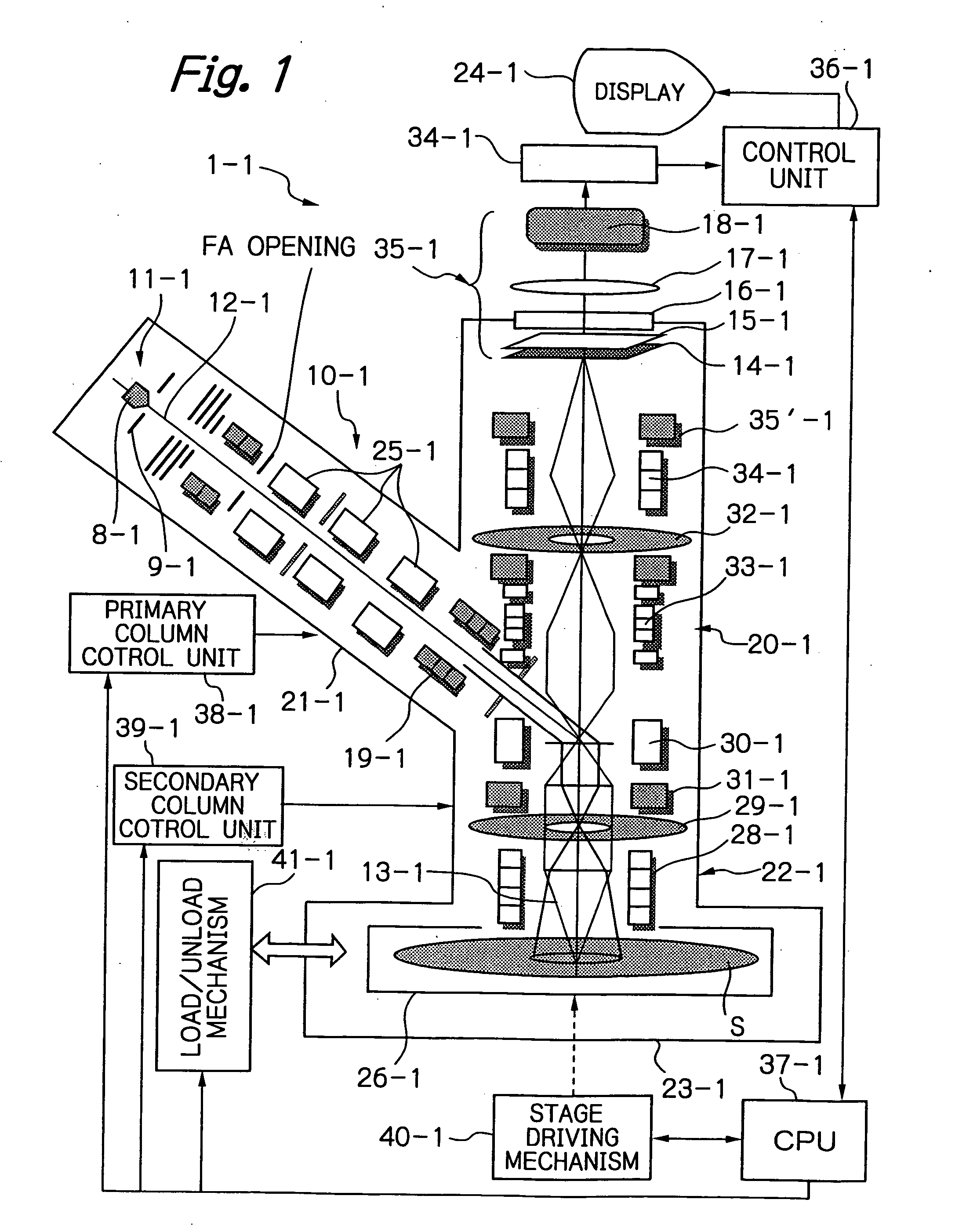

Apparatus for inspection with electron beam, method for operating same, and method for manufacturing semiconductor device using former

InactiveUS6855929B2Avoid low detection accuracyAvoid mistakesElectric discharge tubesSolid-state devicesImaging processingSecondary electrons

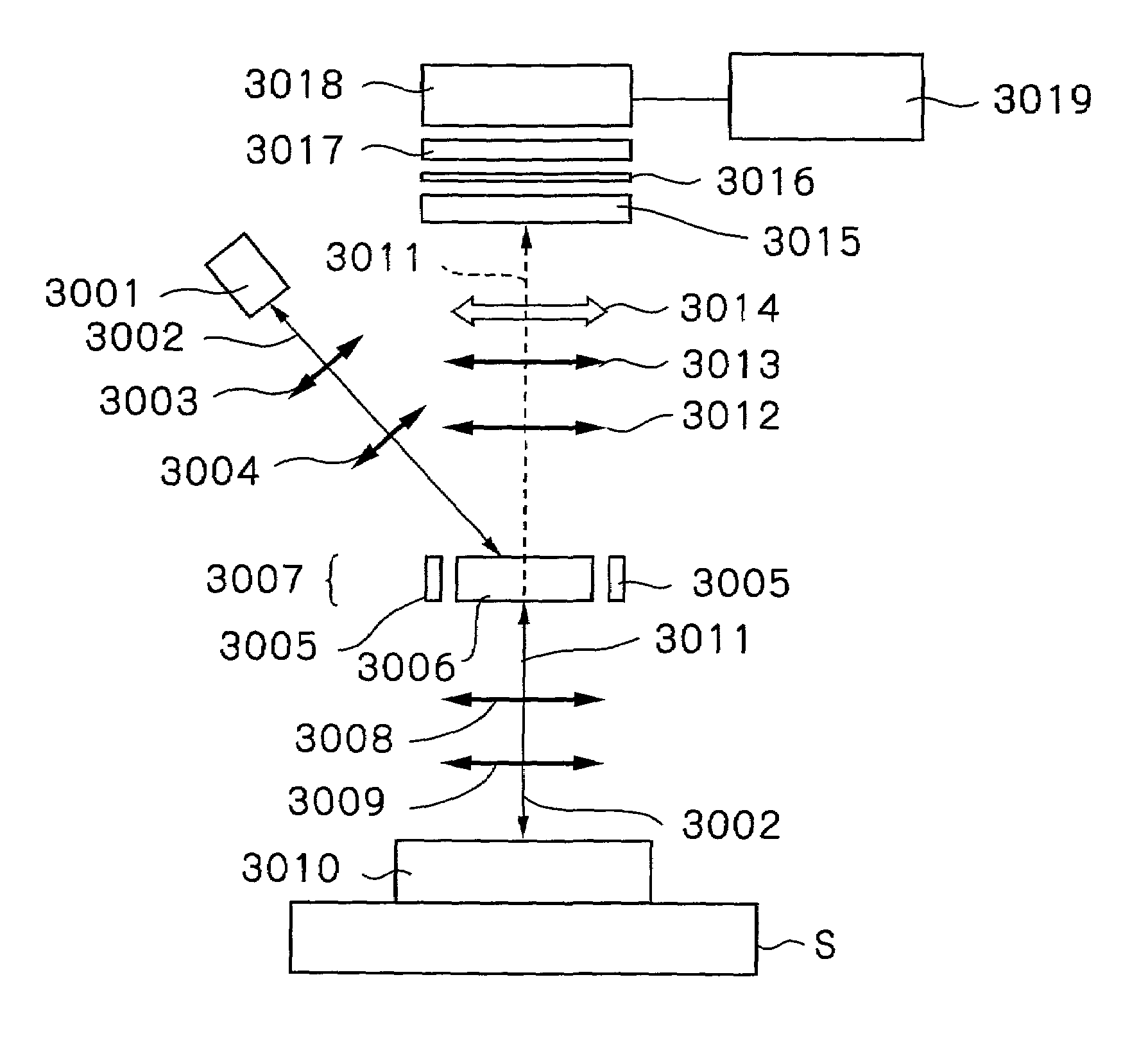

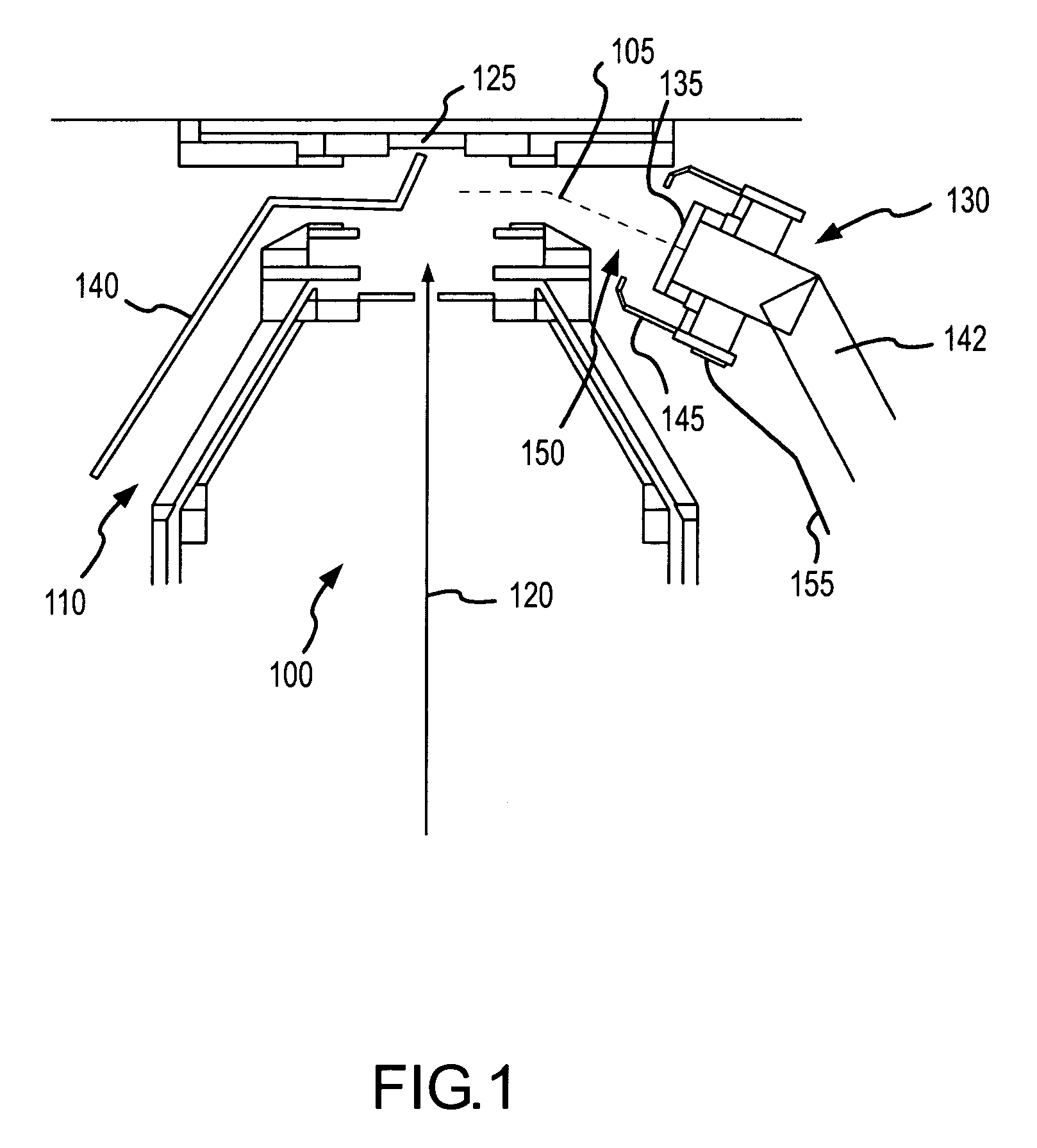

A substrate inspection apparatus 1-1 (FIG. 1) of the present invention performs the following steps of: carrying a substrate “S” to be inspected into an inspection chamber 23-1 maintaining a vacuum in said inspection chamber; isolating said inspection chamber from a vibration; moving successively said substrate by means of a stage 26-1 with at least one degree of freedom; irradiating an electron beam having a specified width; helping said electron beam reach to a surface of said substrate via a primary electron optical system 10-1; trapping secondary electrons emitted from said substrate via a secondary electron optical system 20-1 and guiding it to a detecting system 35-1; forming a secondary electron image in an image processing system based on a detection signal of a secondary electron beam obtained by said detecting system; detecting a defective location in said substrate based on the secondary electron image formed by said image processing system; indicating and / or storing said defective location in said substrate by CPU 37-1; and taking said completely inspected substrate out of the inspection chamber. Thereby, the defect inspection on the substrate can be performed successively with high level of accuracy and efficiency as well as with higher throughput.

Owner:EBARA CORP

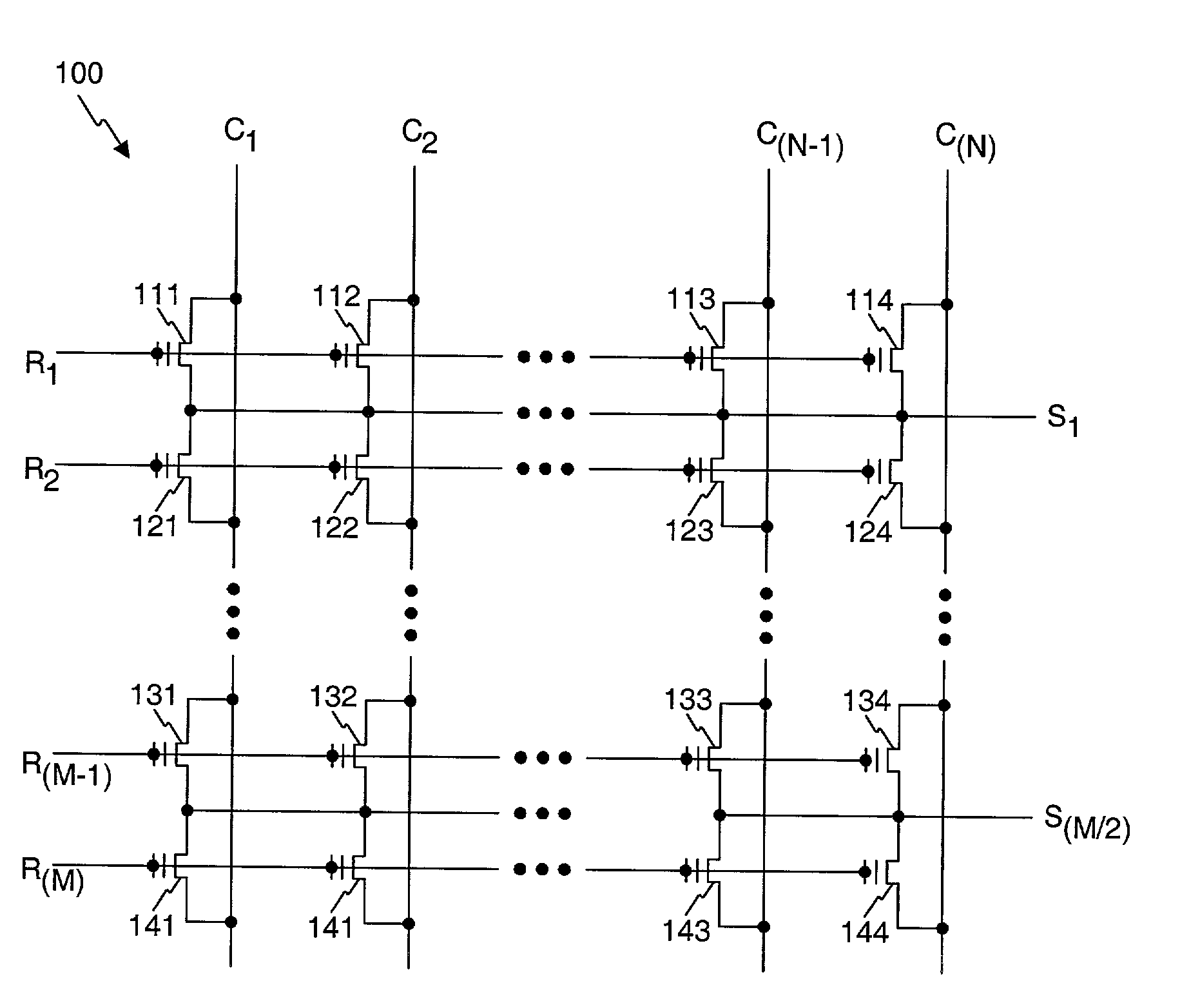

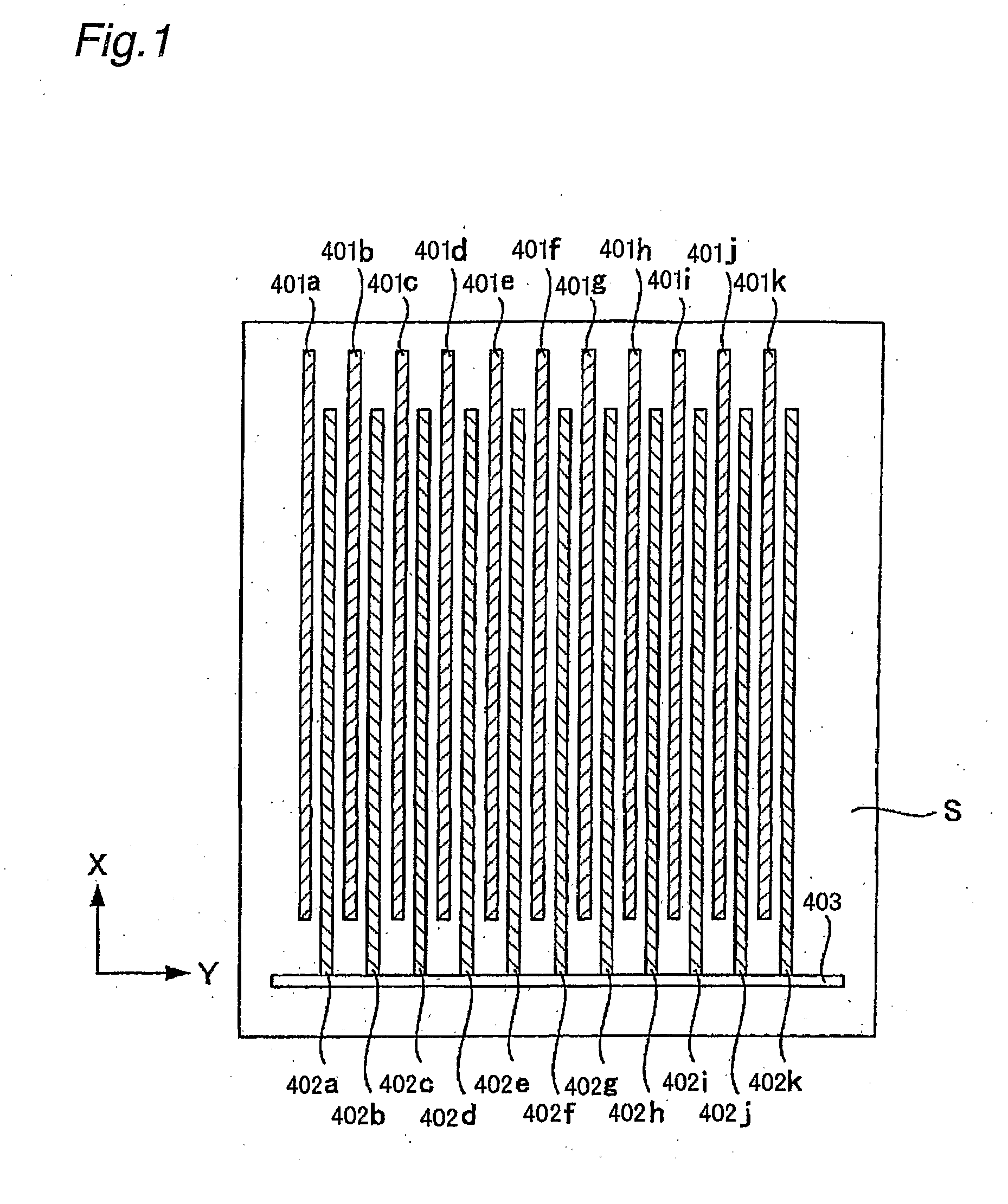

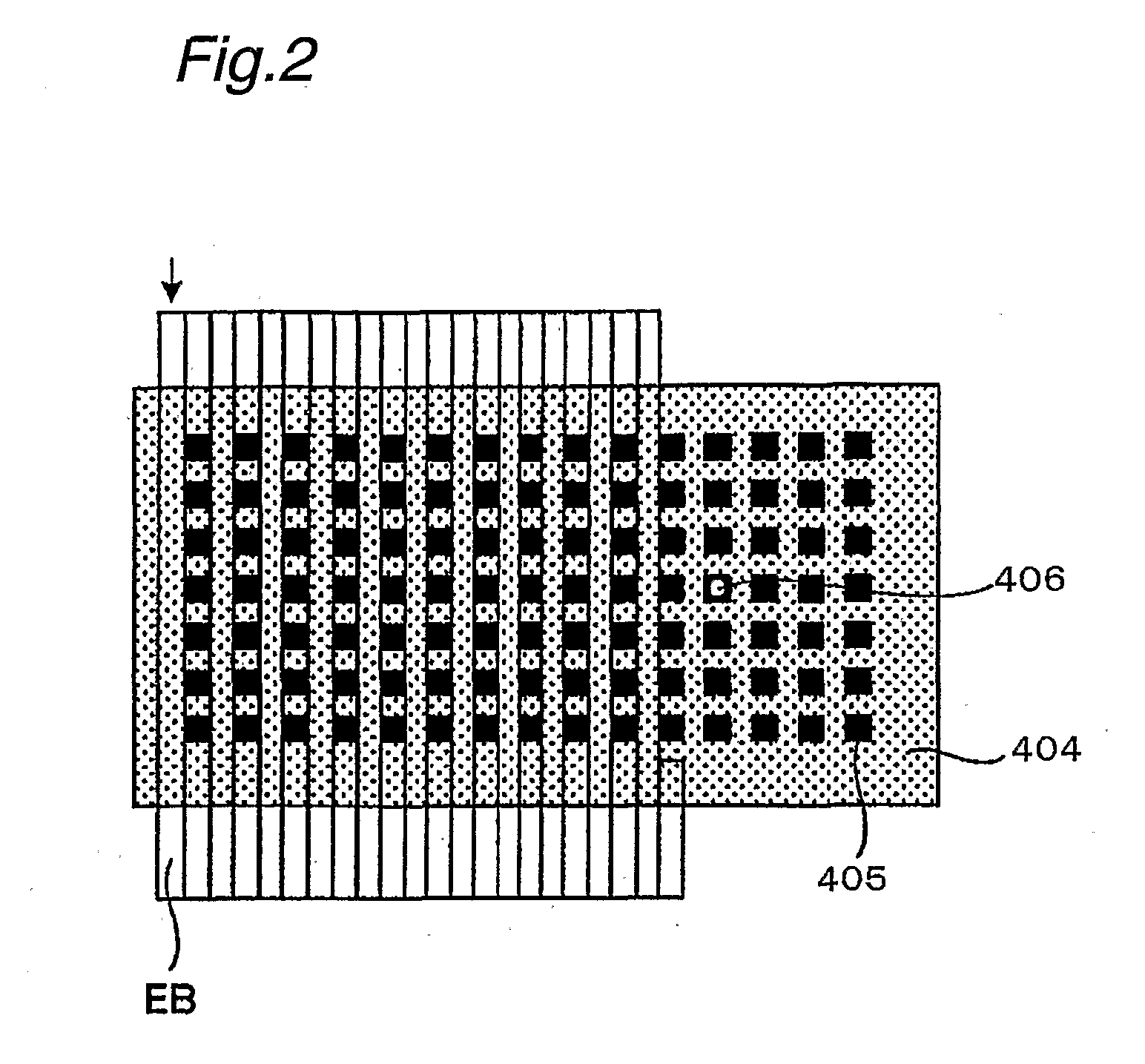

Semiconductor devices and method of testing same

InactiveUS20090152595A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectricityElectrical conductor

There are provided a semiconductor device having a pattern which allows electric failures to be sensitively detected at high speeds, and a method of testing the same. In one embodiment, the semiconductor device comprises a pair of row wires including a plurality of first wires arranged in a first layer at predetermined intervals in a row direction, where the first wires have ends connected to second wires arranged in a second layer at a predetermined intervals through vias, and the first wire and second wire are at the same potential. In the pair of row wires, a first wire positioned at a right end of one row wire is connected to a first conductor, and a first wire positioned at a left end in the other row wire is connected to a second conductor. By sequentially scanning the first conductor and second conductor using an electron beam, a change in the amount of emitted secondary electrons due to a difference in potential between these conductors is detected to detect electric anomalies.

Owner:EBARA CORP

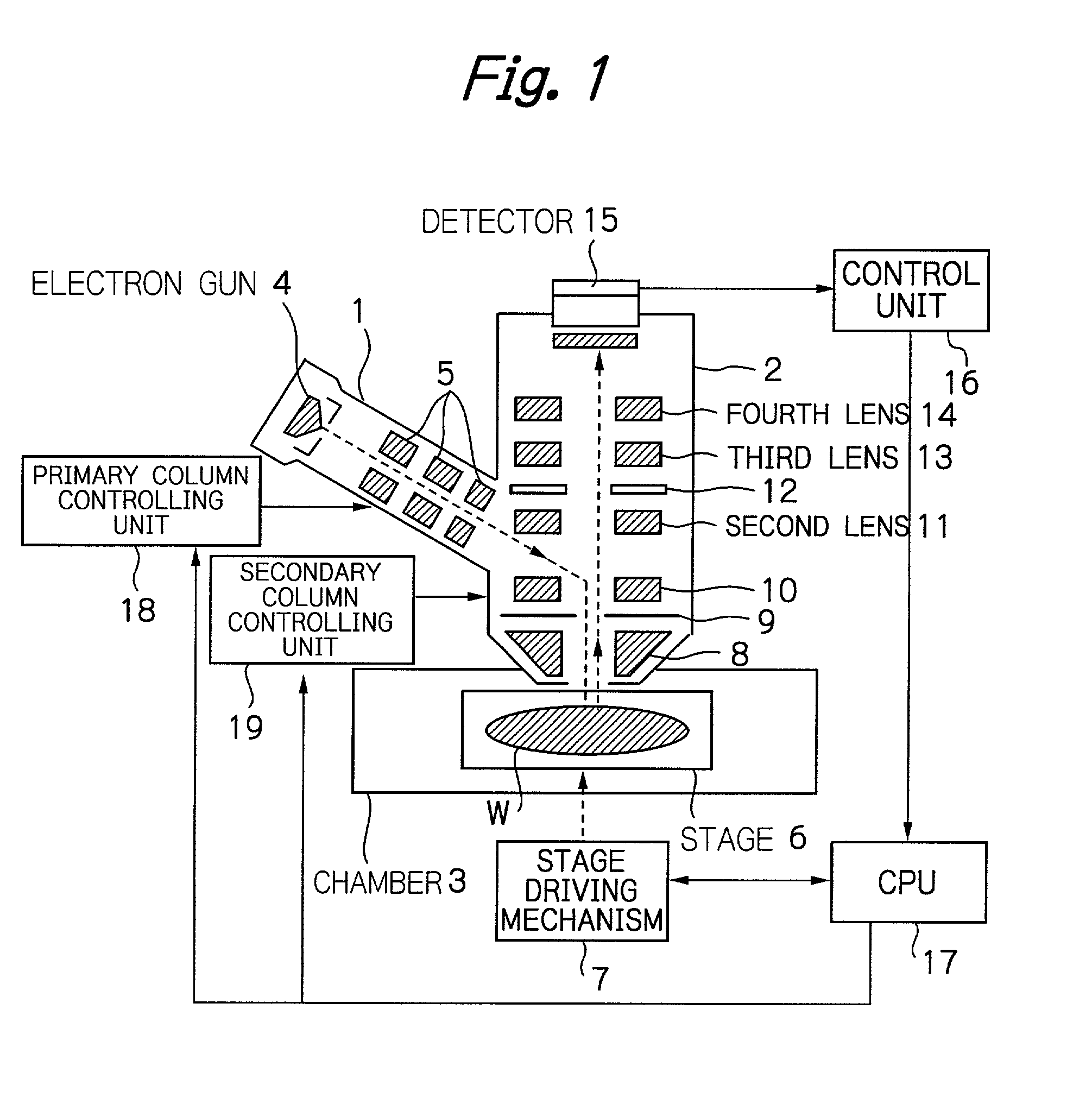

Electron beam apparatus and device manufacturing method using same

InactiveUS6909092B2Reduce image distortionLess aberrationThermometer detailsBeam/ray focussing/reflecting arrangementsElectron sourceImaging processing

A defect inspecting apparatus is provided for generating a less distorted test image to reliably observe a surface of a sample for detecting defects thereon. The defect detecting apparatus comprises a primary electron beam source for irradiating a sample, electrostatic lenses for focusing secondary electrons emitted from the surface of the sample irradiated with the primary electron beam, a detector for detecting the secondary electrons, and an image processing unit for processing a signal from the detector. Further, a second electron source may be provided for emitting an electron beam irradiated to the sample, wherein the sample may be irradiated with the electron beam from the second electron source before it is irradiated with the primary electron beam from the first electron source for observing the sample. A device manufacturing method is also provided for inspecting devices under processing with high throughput using the defect detecting apparatus.

Owner:EBARA CORP

Evaluation method and manufacturing method of semiconductor device

InactiveUS20060022295A1Accurate measurementQuick measurementSemiconductor/solid-state device testing/measurementElectric discharge tubesDevice materialSecondary electrons

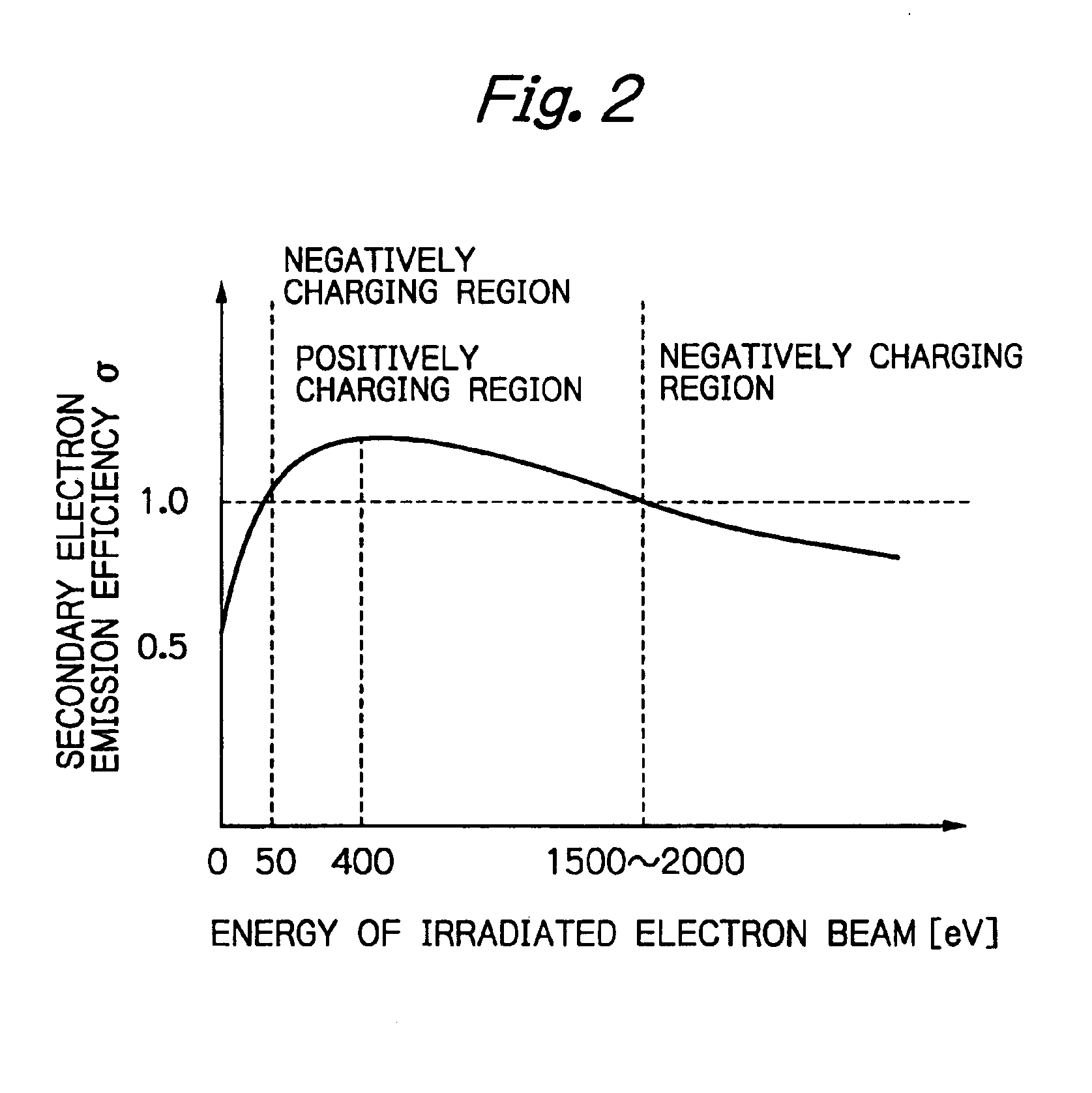

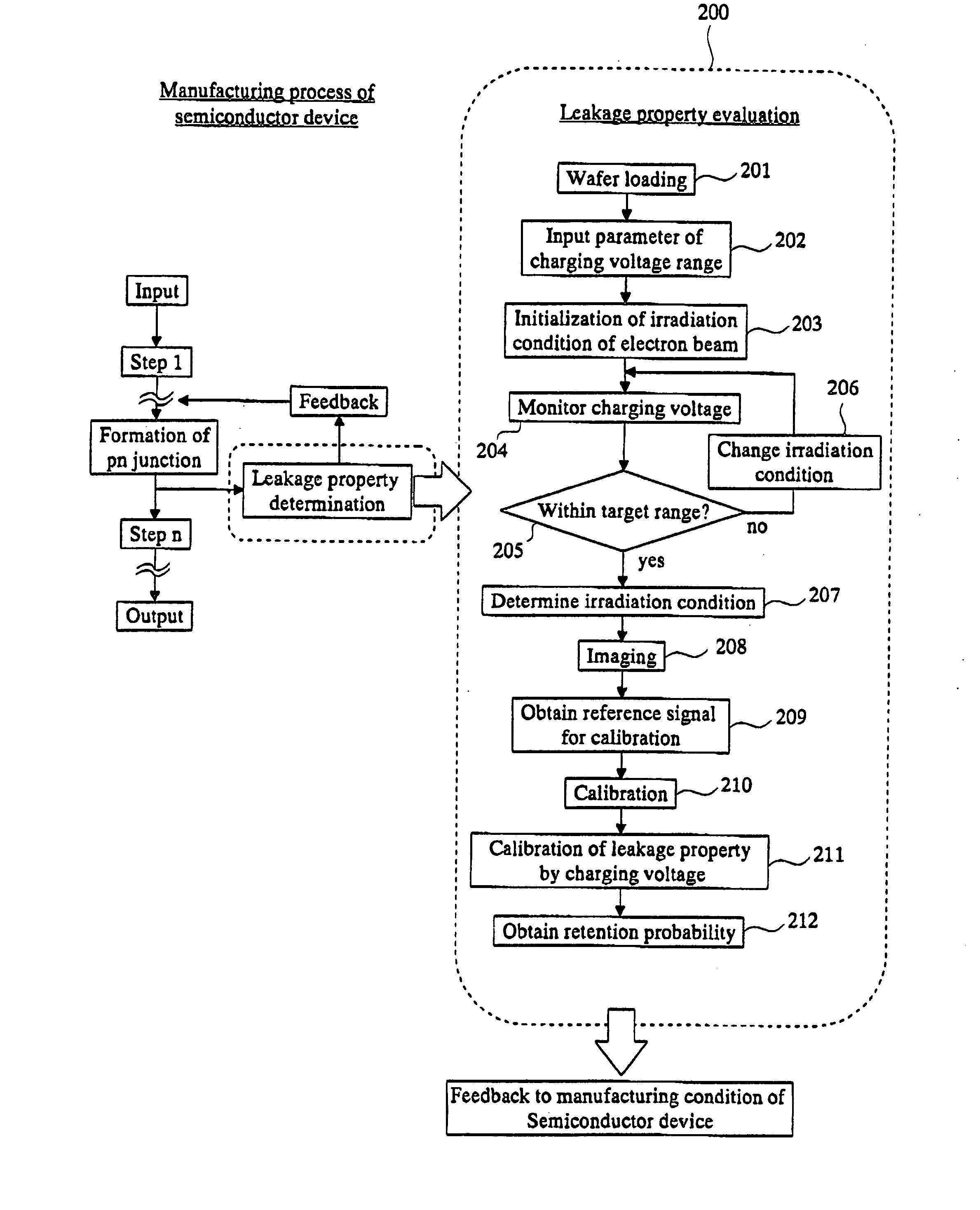

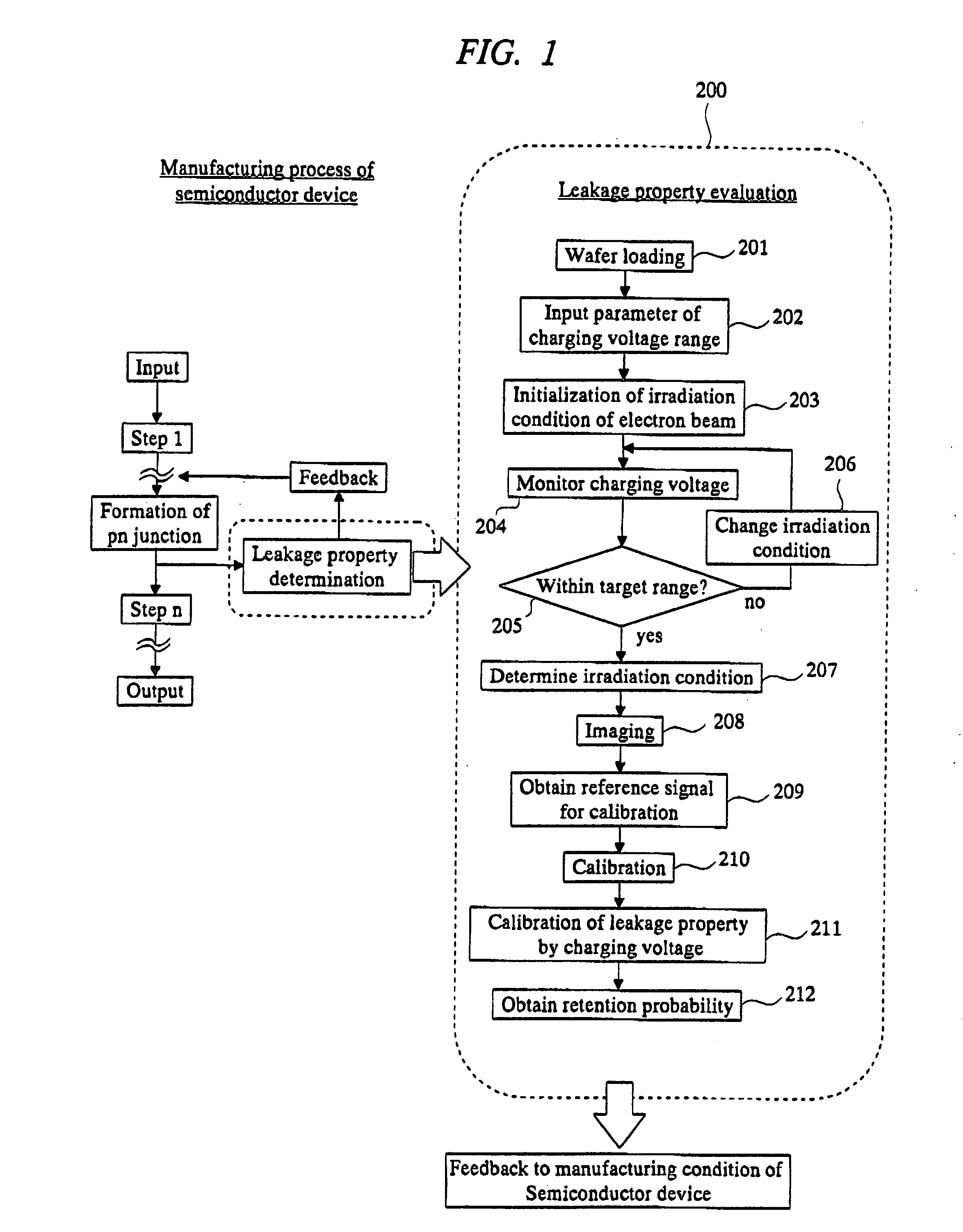

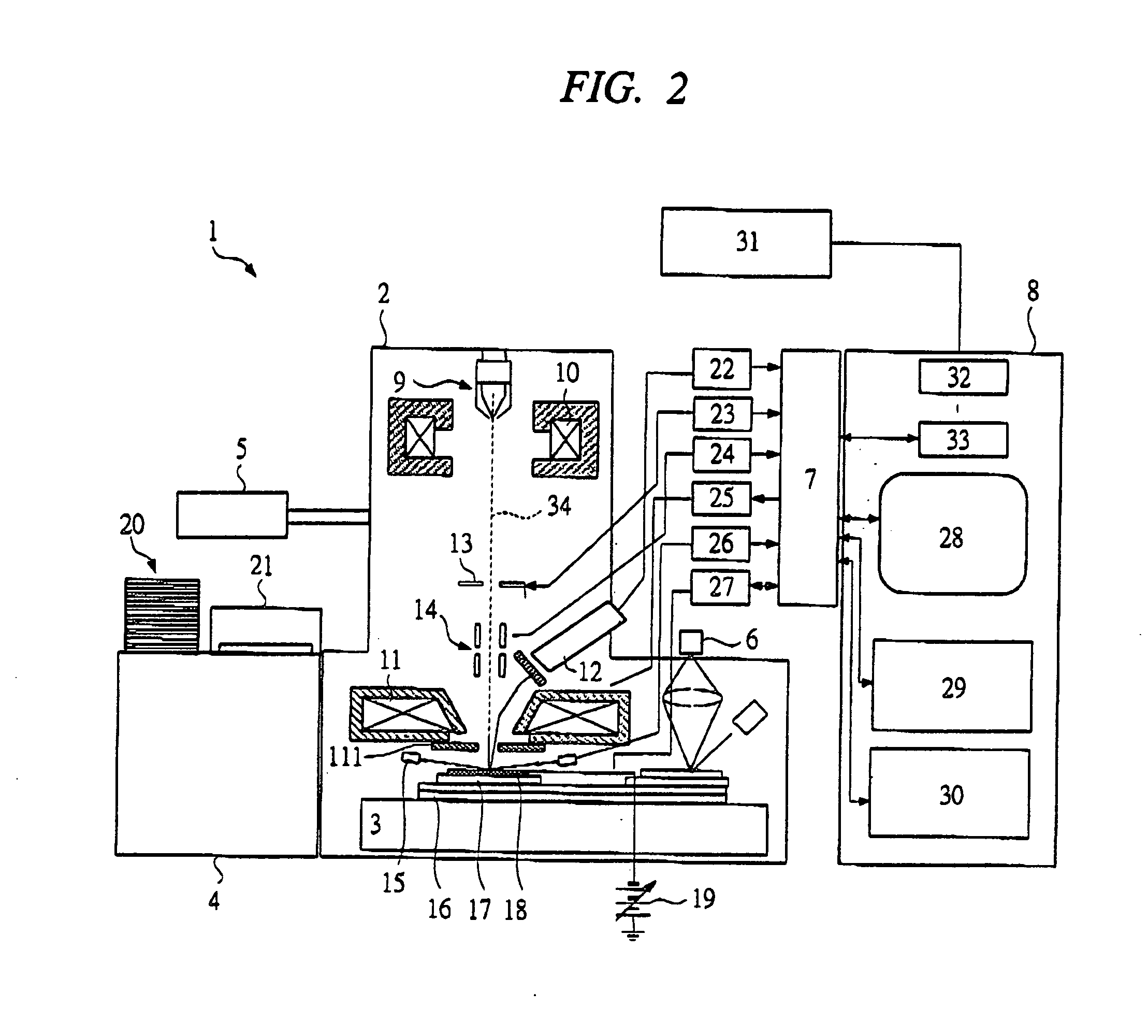

The electron beam is irradiated several times at predetermined intervals to the wafer surface on which the plugs are exposed in the course of the manufacturing process so that the pn junction is in the reverse bias state. Then, the irradiation conditions of the electron beam are changed while monitoring the charging voltage on the plug surface, and the secondary electron signals of the circuit pattern are obtained under the irradiation conditions that the charging is within a desired range, thereby evaluating the leakage property. Since the charging voltage of the pn junction is relaxed depending on the magnitude of the leakage current during the interval, the leakage property is evaluated based on the luminance signals of the voltage contrast image. By measuring the charging voltage and setting it within a desired range, the evaluation result reflects the state in the actual operation. Therefore, the accuracy is enhanced.

Owner:HITACHI LTD +1

Electron beam inspection system and inspection method and method of manufacturing devices using the system

InactiveUS6992290B2Inspection speed is fastImprove inspection speedMaterial analysis using wave/particle radiationElectric discharge tubesLine sensorSecondary electrons

An electron beam inspection system of the image projection type includes a primary electron optical system for shaping an electron beam emitted from an electron gun into a rectangular configuration and applying the shaped electron beam to a sample surface to be inspected. A secondary electron optical system converges secondary electrons emitted from the sample. A detector converts the converged secondary electrons into an optical image through a fluorescent screen and focuses the image to a line sensor. A controller controls the charge transfer time of the line sensor at which the picked-up line image is transferred between each pair of adjacent pixel rows provided in the line sensor in association with the moving speed of a stage for moving the sample.

Owner:EBARA CORP

Objective lens, electron beam system and method of inspecting defect

InactiveUS20050263715A1Reduce penetrationIncrease in space charge effectMaterial analysis using wave/particle radiationElectric discharge tubesHigh current densityOptical axis

An electron beam system or a method for manufacturing a device using the electron beam system in which an electron beam can be irradiated at a high current density and a ratio of transmittance of a secondary electron beam of an image projecting optical system can be improved and which can be compact in size. The surface of the sample S is divided into plural stripe regions which in turn are divided into rectangle-shaped main fields. The main field is further divided into plural square-shaped subfields. The irradiation with the electron beams and the formation of a two-dimensional image are repeated in a unit of the subfields. A magnetic gap formed by the inner and outer magnetic poles of the objective lens is formed on the side of the sample, and an outer side surface and an inner side surface of each of the inner magnetic pole and the outer magnetic pole, respectively, forming the magnetic gap have each part of a conical shape with a convex having an angle of 45° or greater with respect to the optical axis.

Owner:EBARA CORP

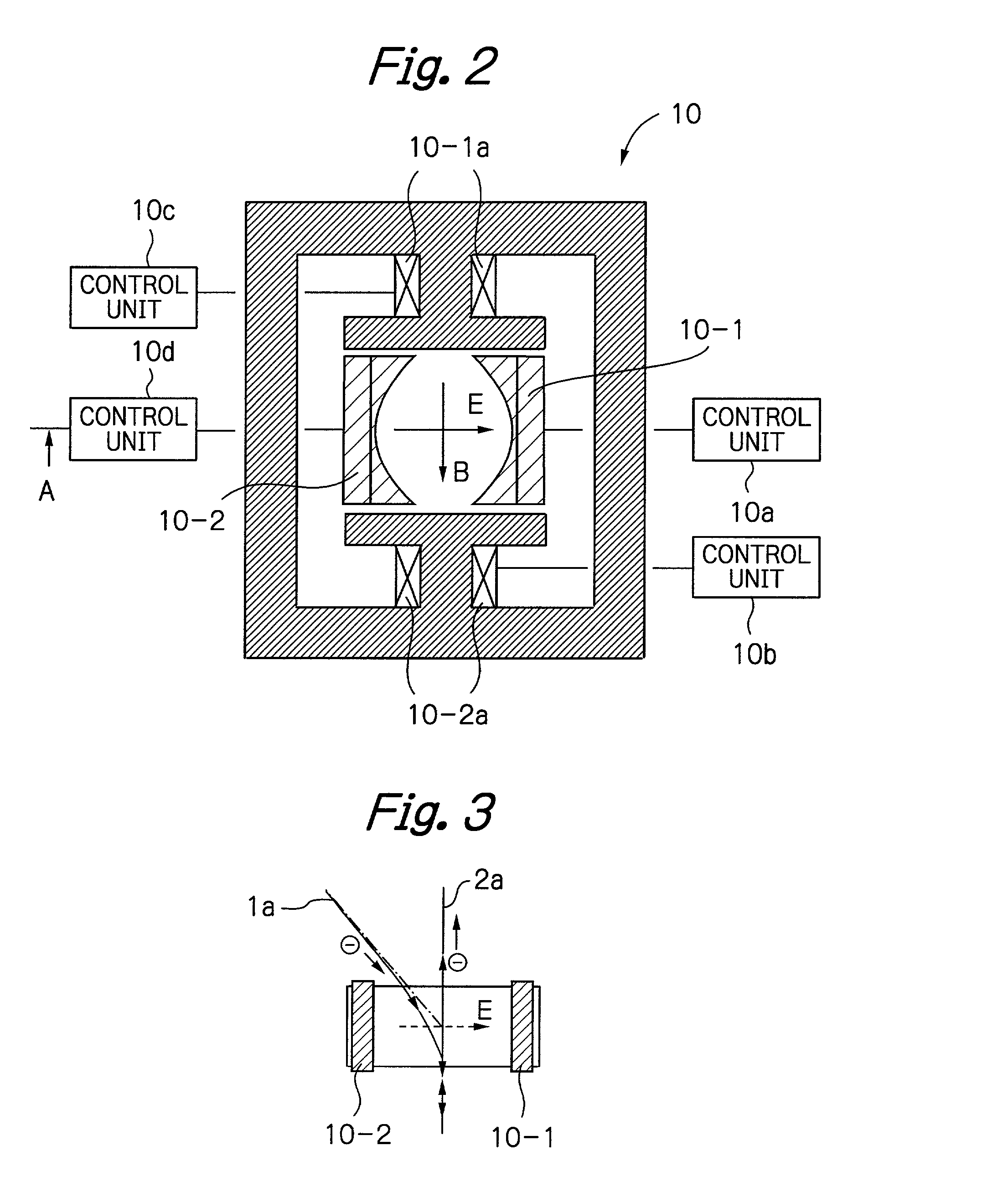

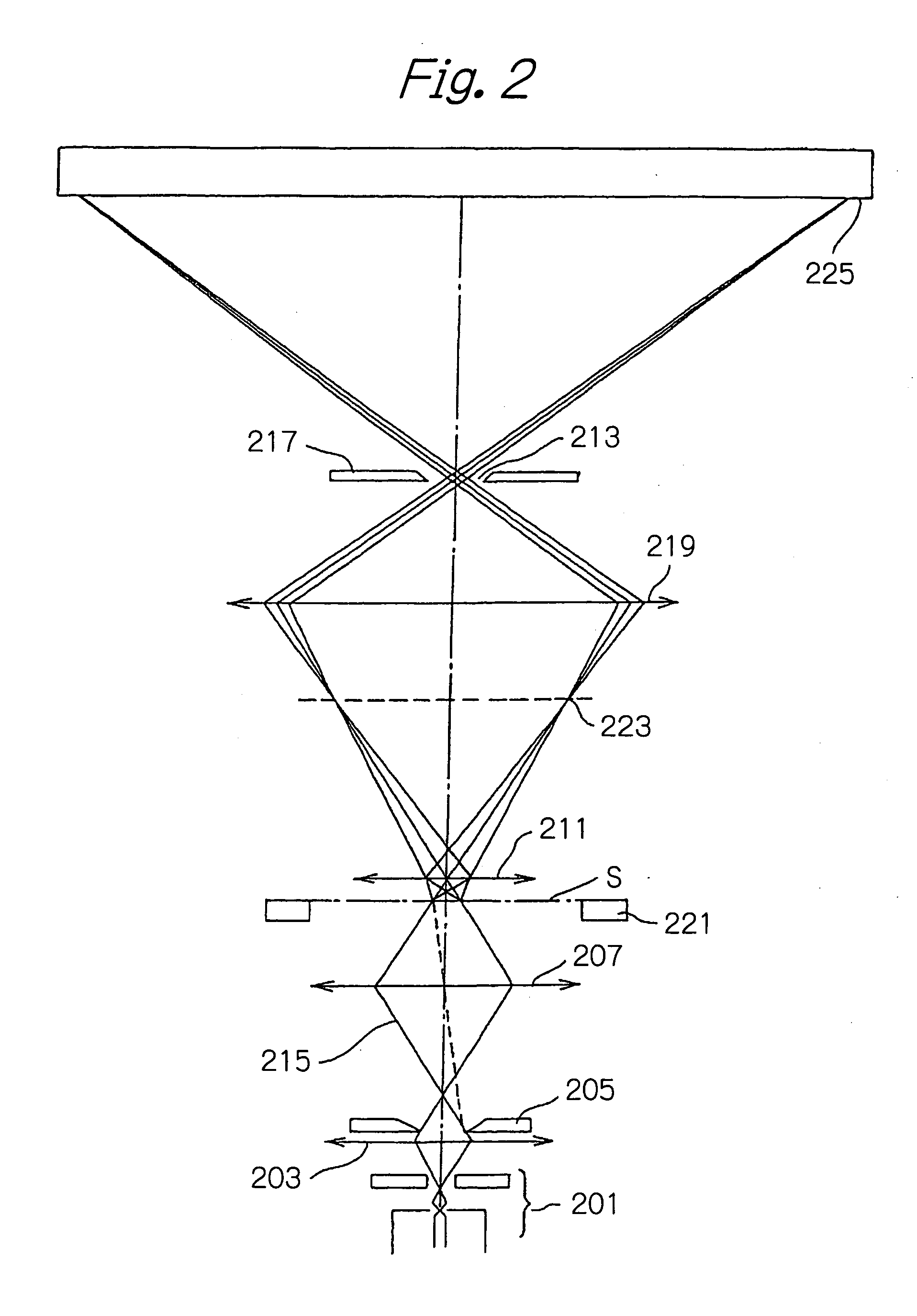

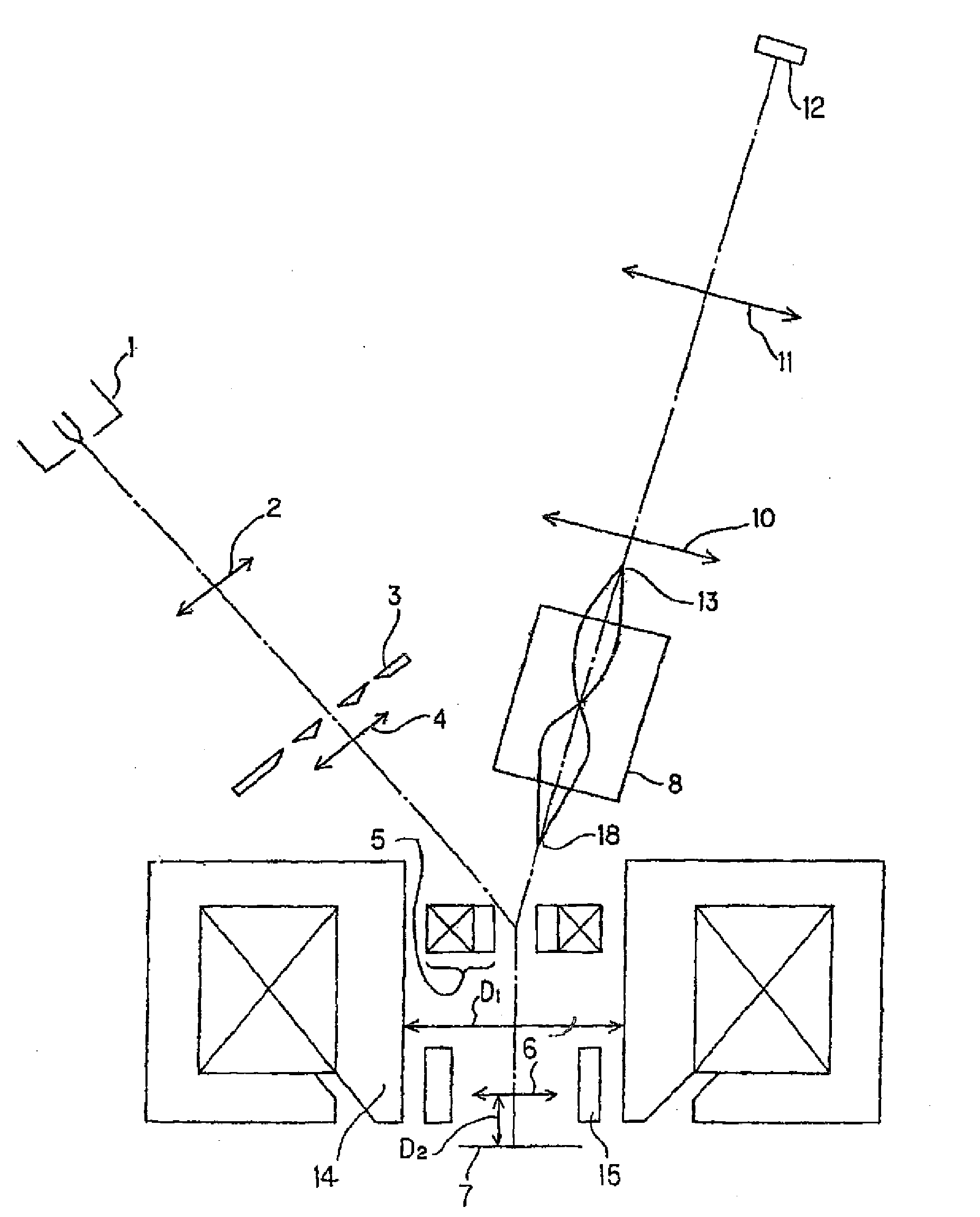

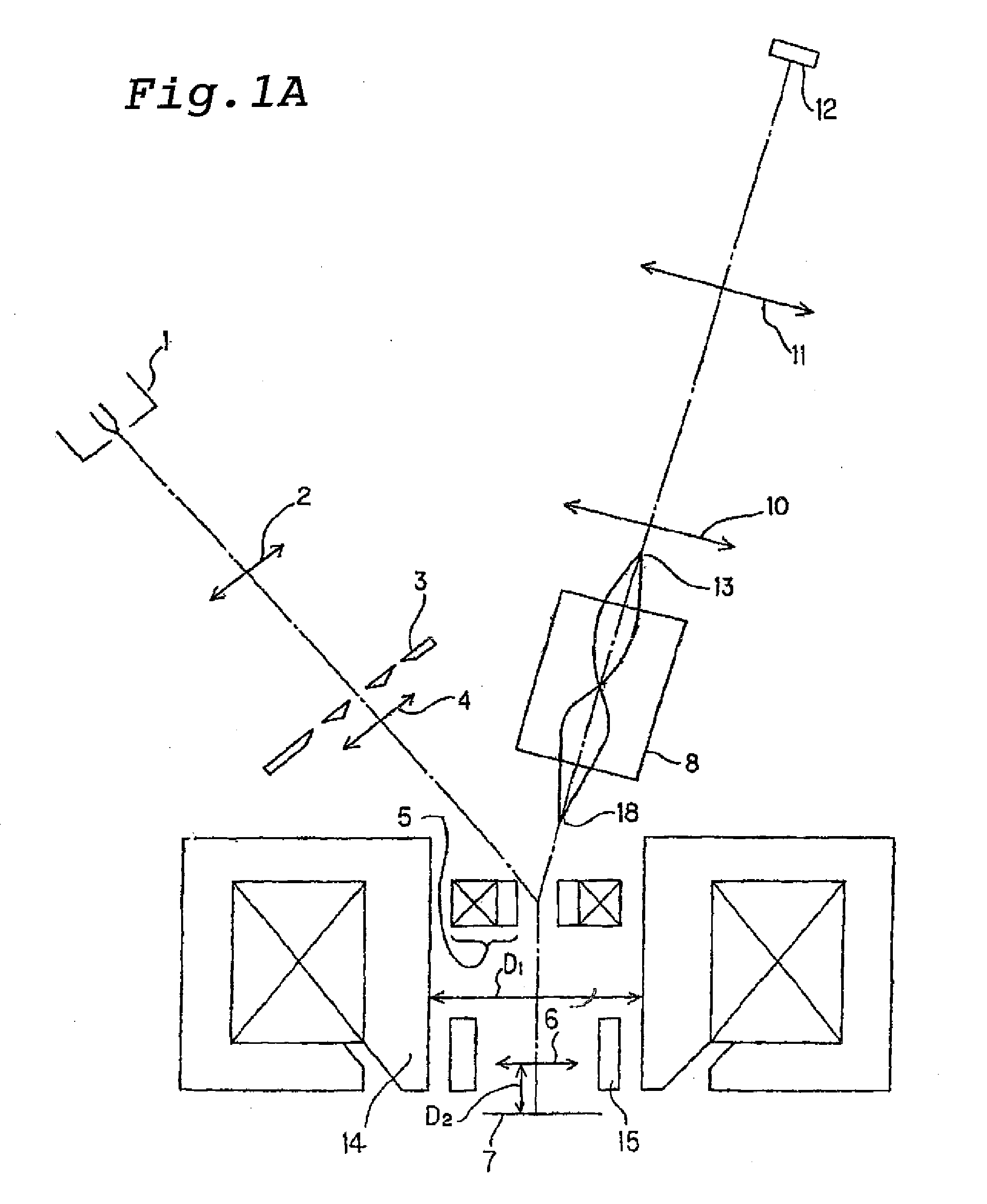

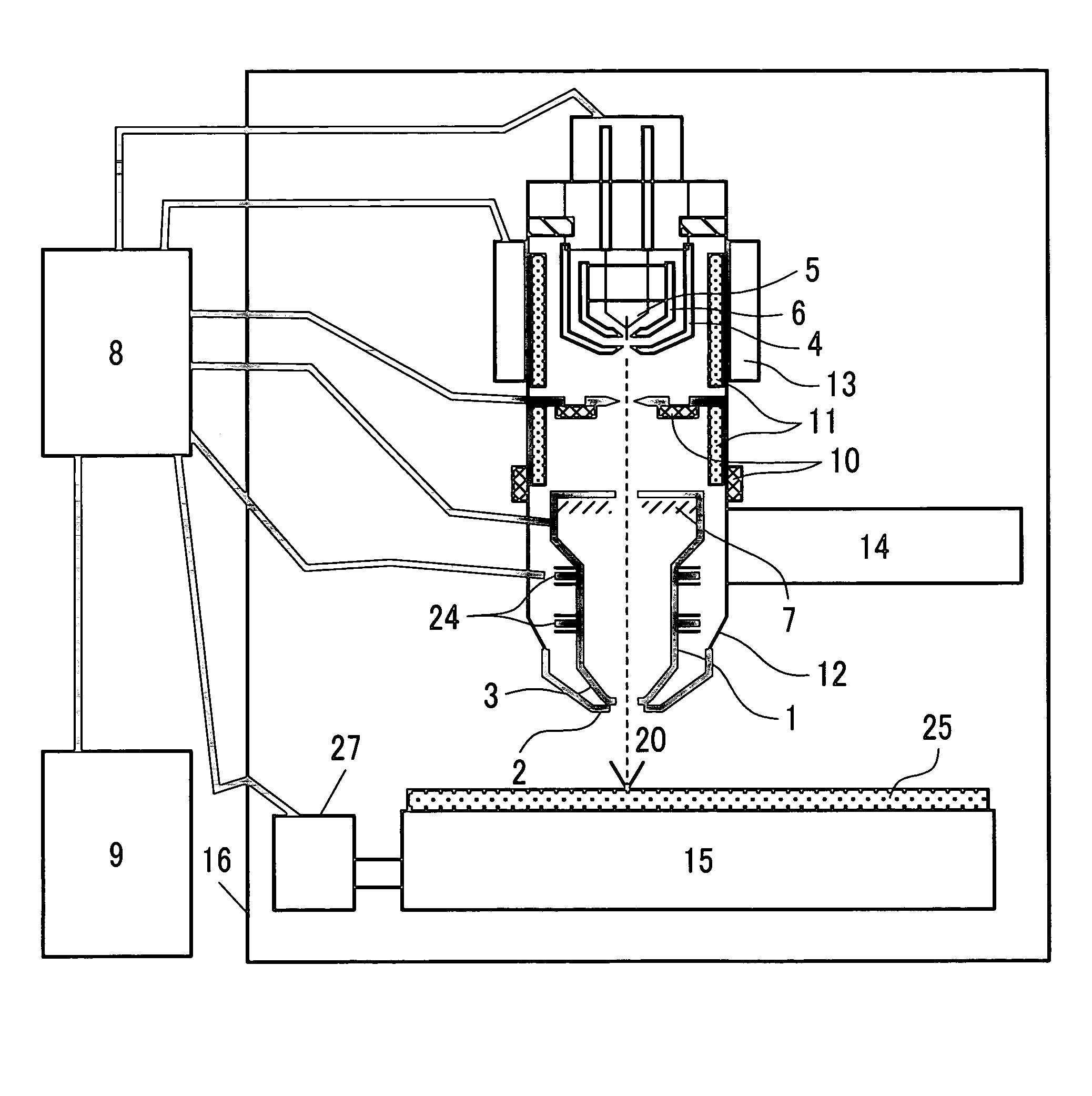

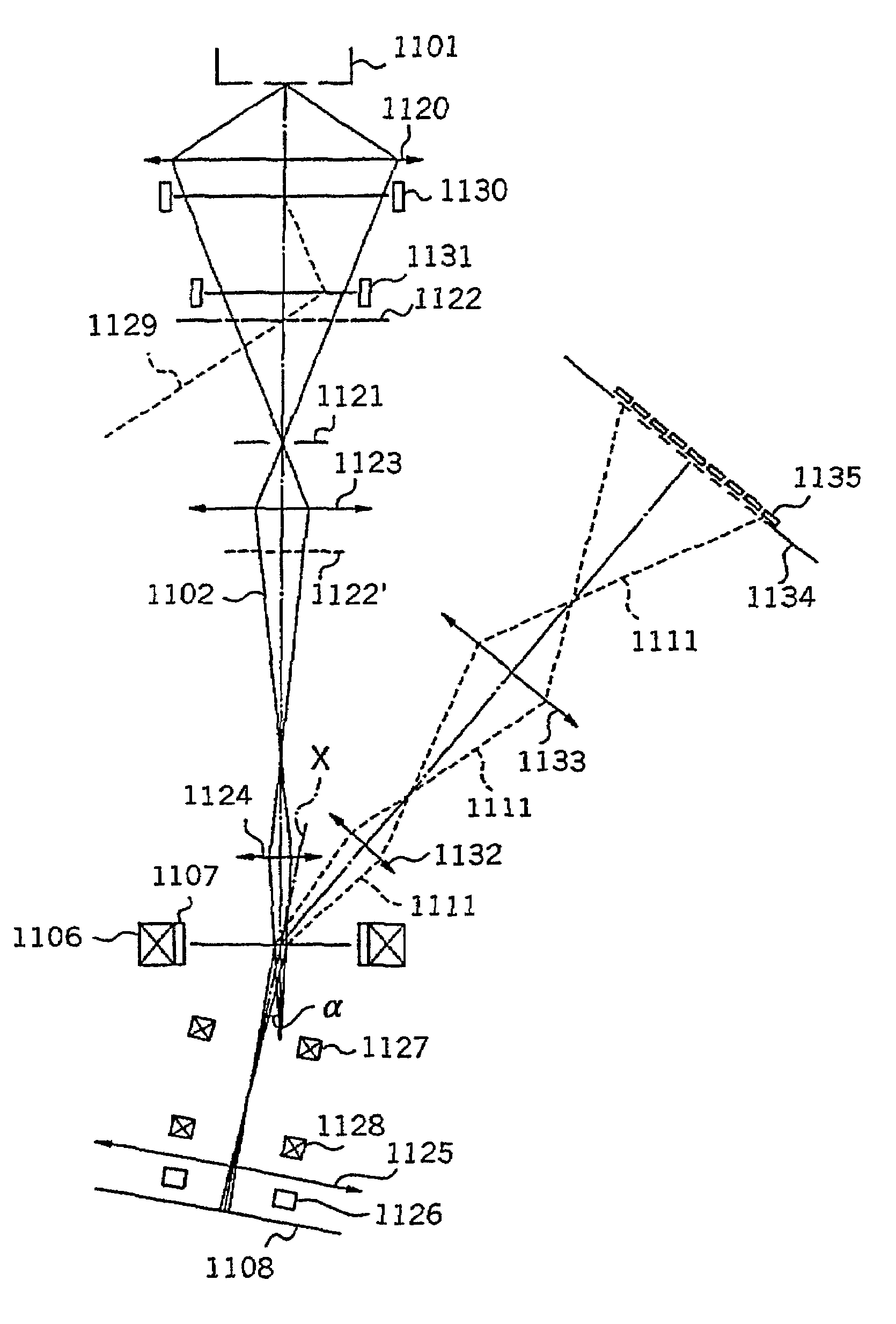

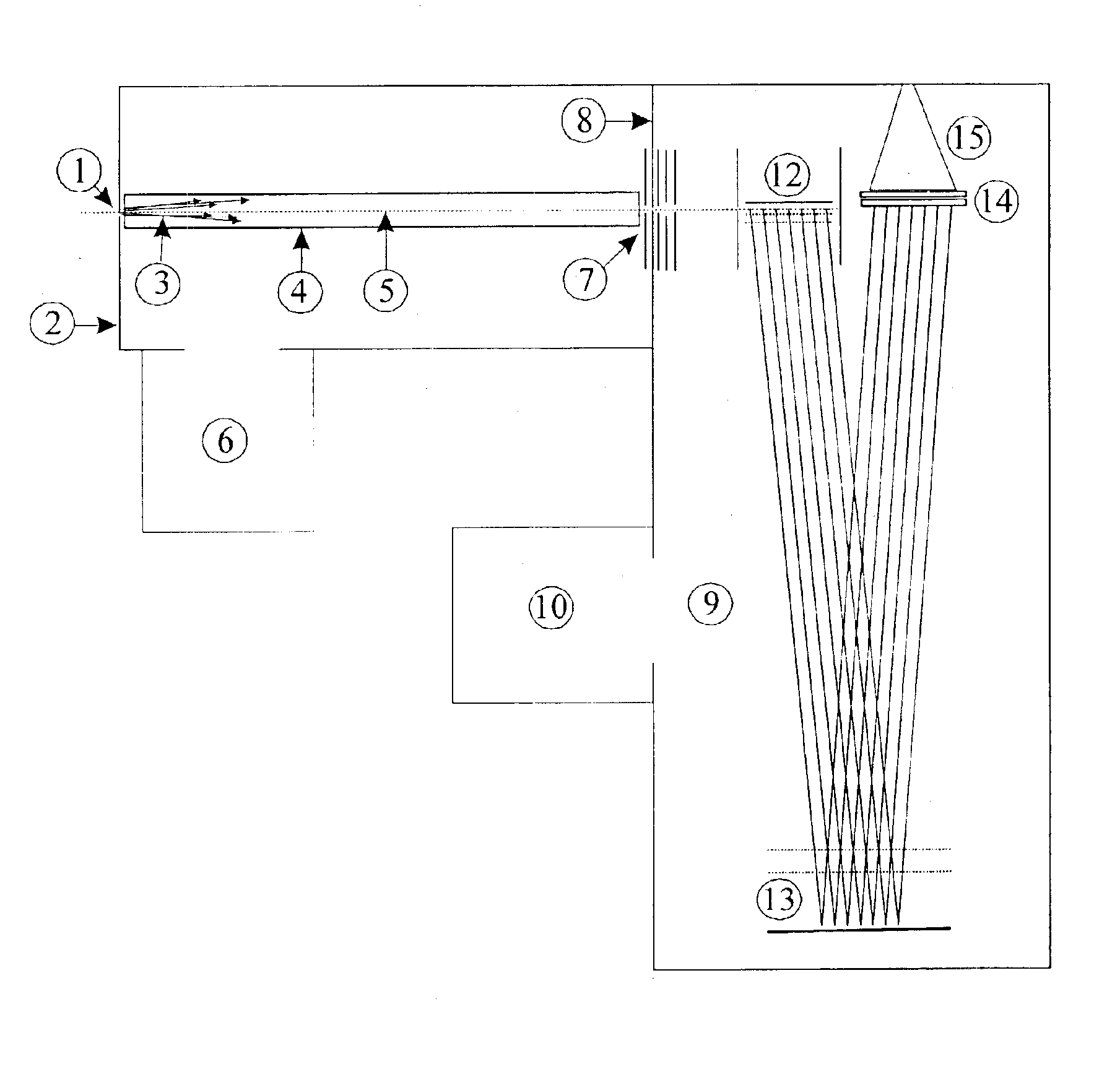

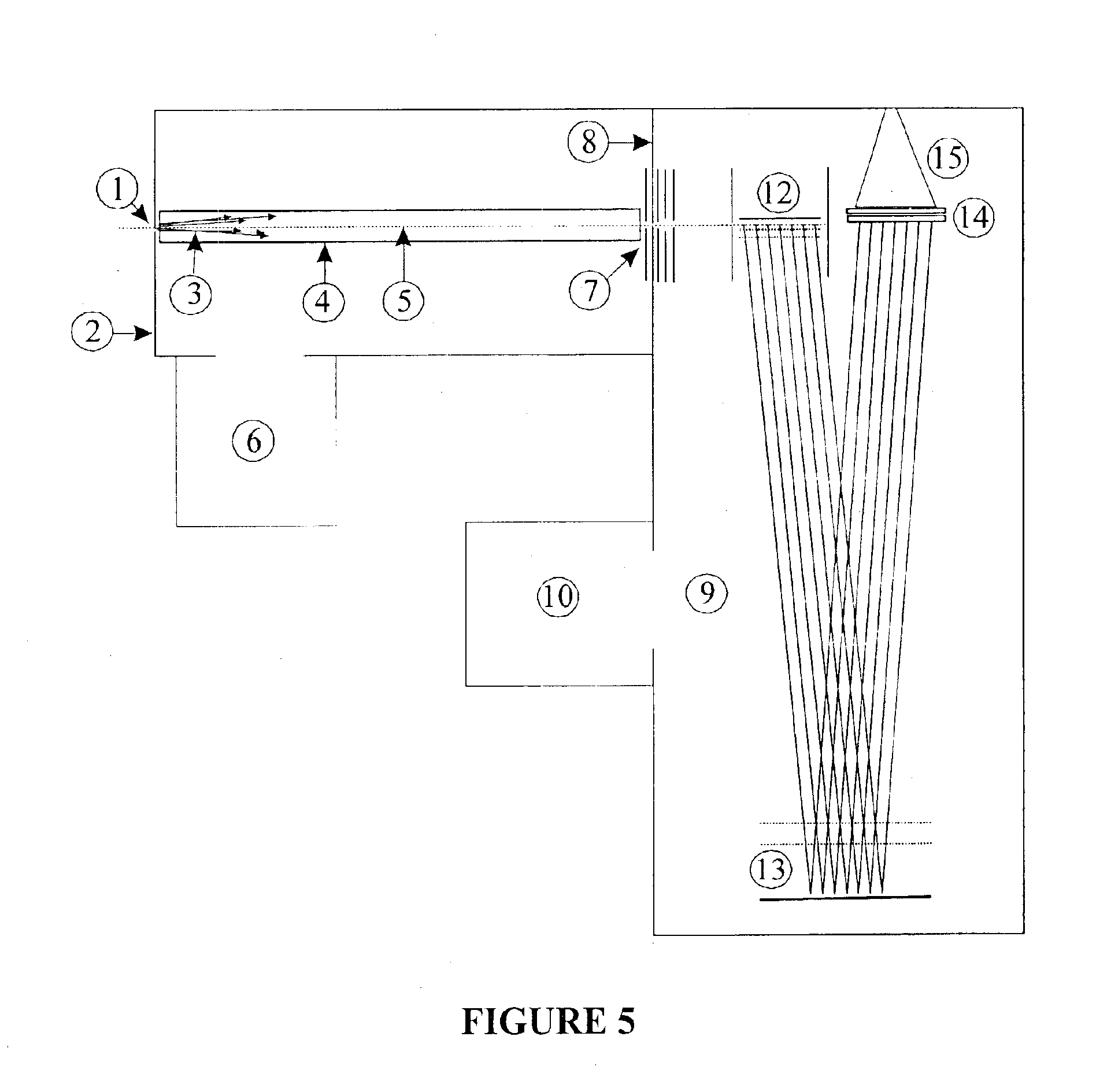

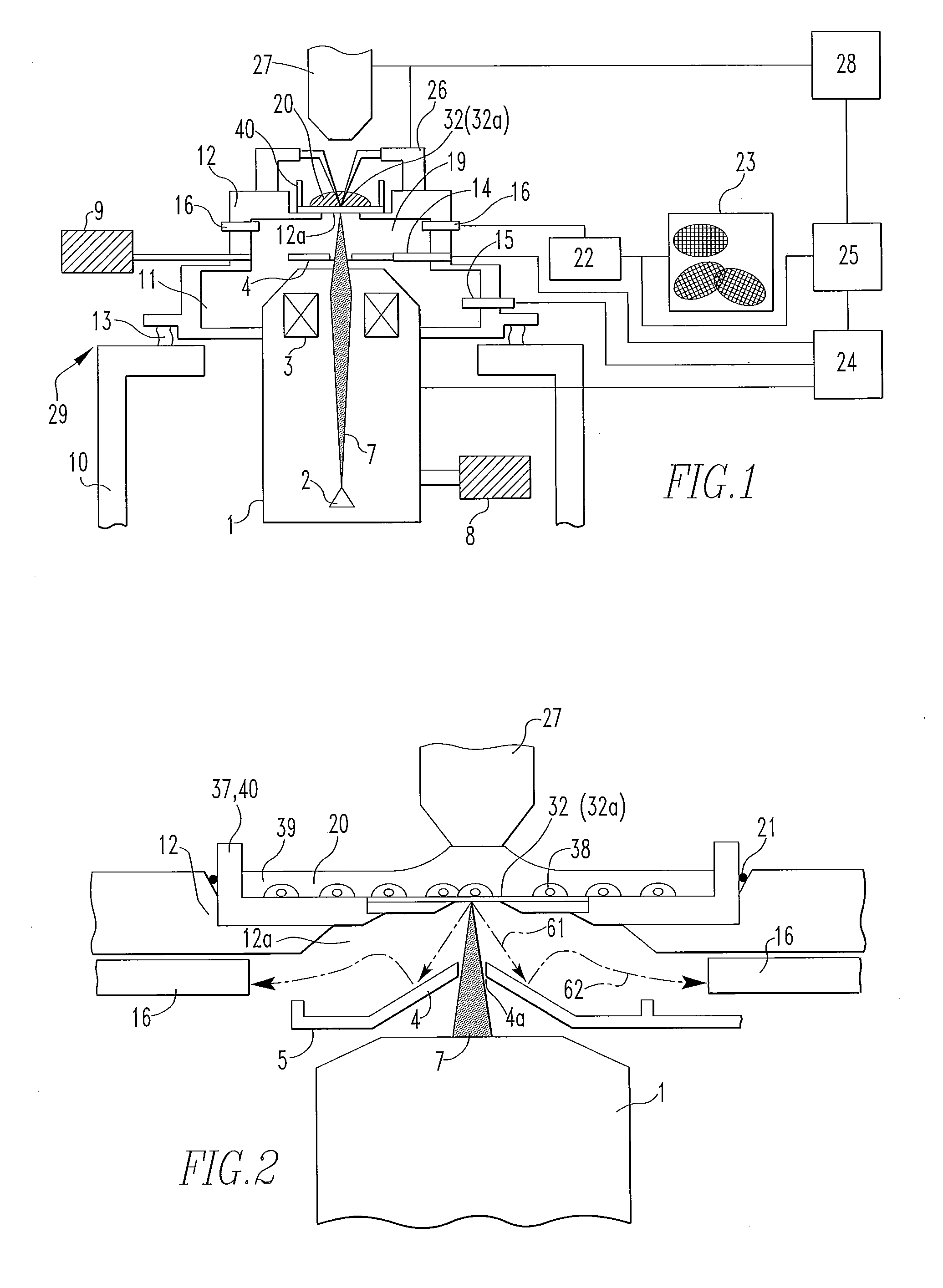

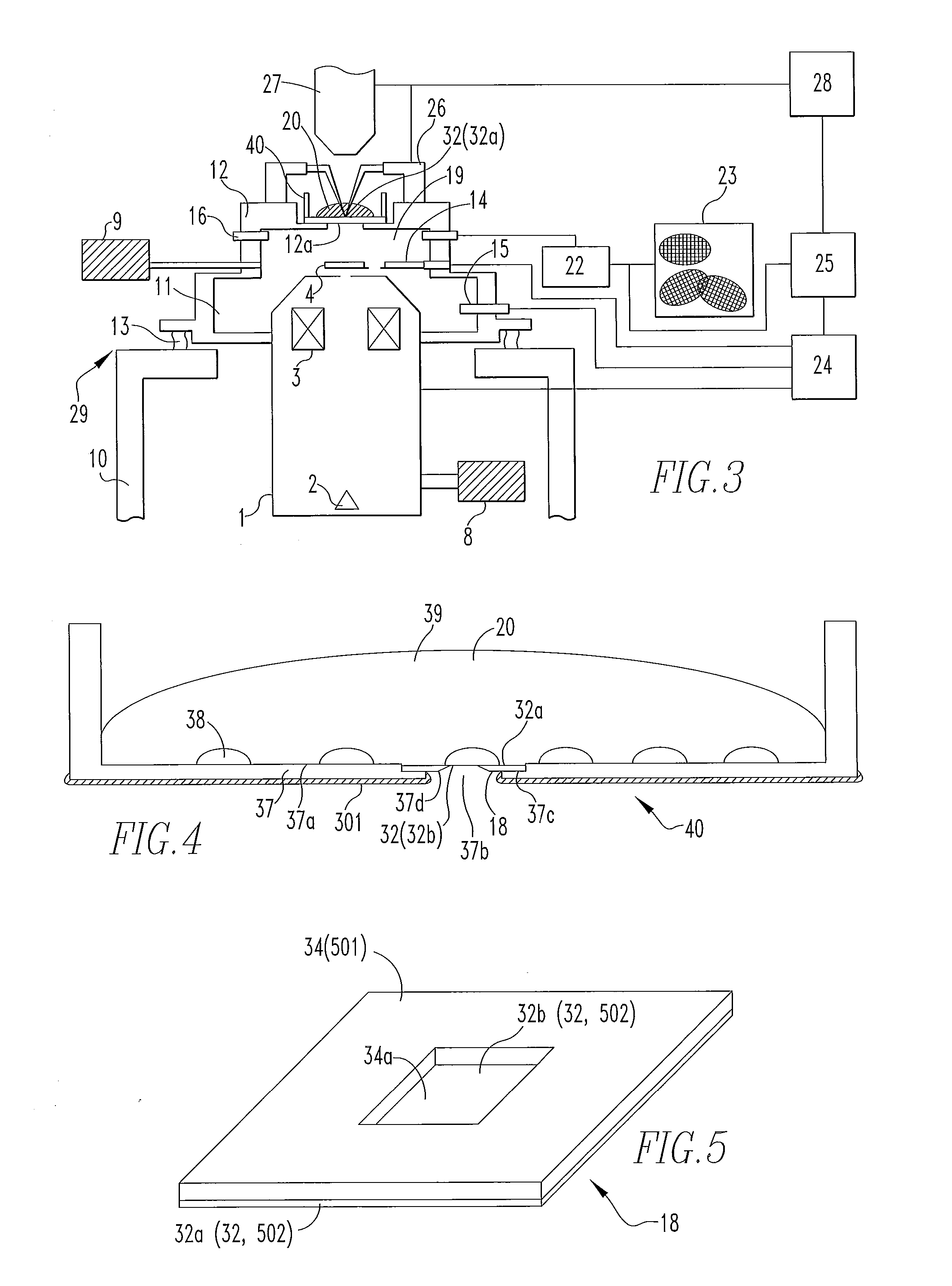

Projection electron beam apparatus and defect inspection system using the apparatus

InactiveUS20090212213A1Increase currentImprove throughputMaterial analysis using wave/particle radiationElectric discharge tubesWien filterTransmittance

A sample is evaluated at a high throughput by reducing axial chromatic aberration and increasing the transmittance of secondary electrons. Electron beams emitted from an electron gun 1 are irradiated onto a sample 7 through a primary electro-optical system, and electrons consequently emitted from the sample are detected by a detector 12 through a secondary electro-optical system. A Wien filter 8 comprising a multi-pole lens for correcting axial chromatic aberration is disposed between a magnification lens 10 in the secondary electro-optical system and a beam separator 5 for separating a primary electron beam and a secondary electron beam, for correcting axial chromatic aberration caused by an objective lens 14 which comprises an electromagnetic lens having a magnetic gap defined on a sample side.

Owner:KK TOSHIBA

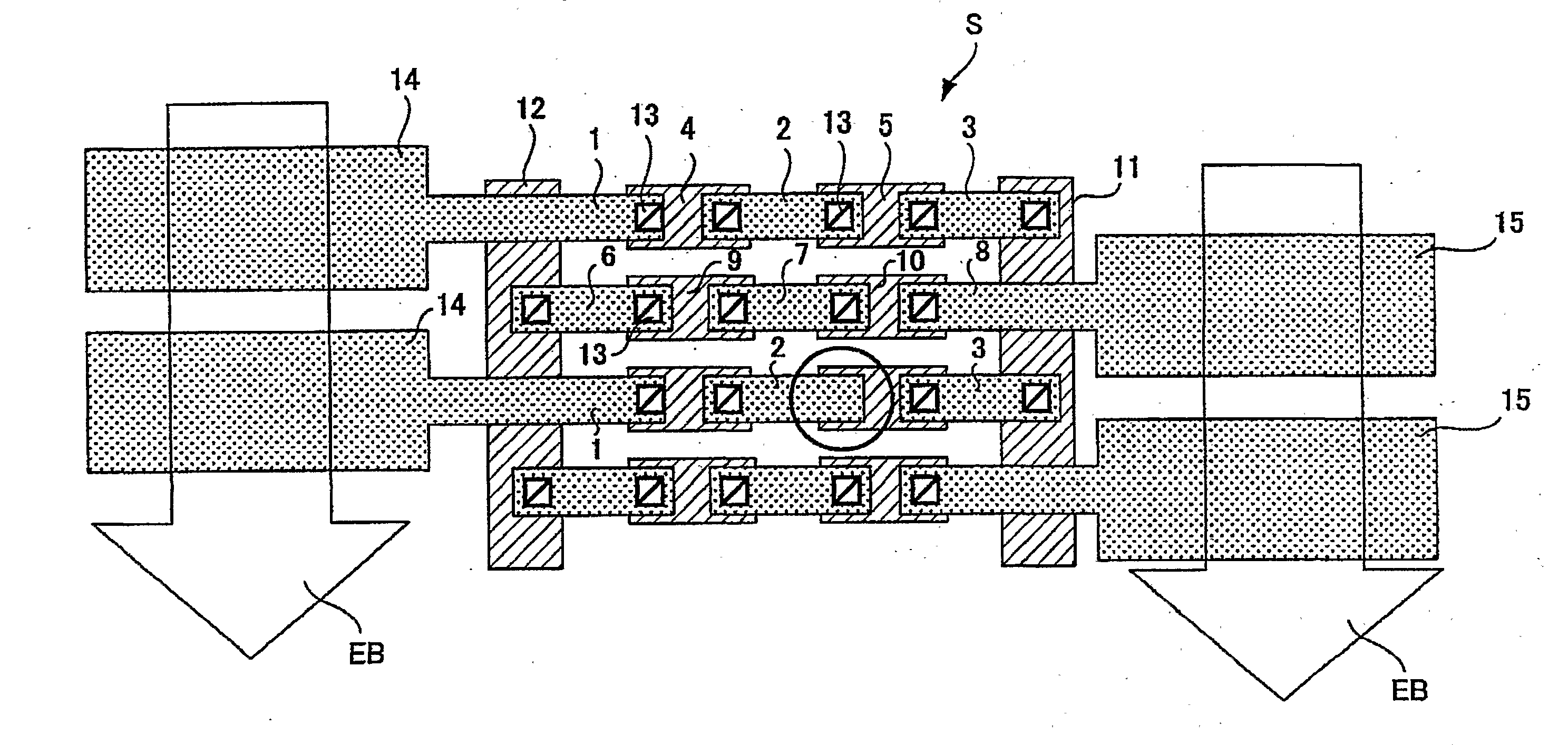

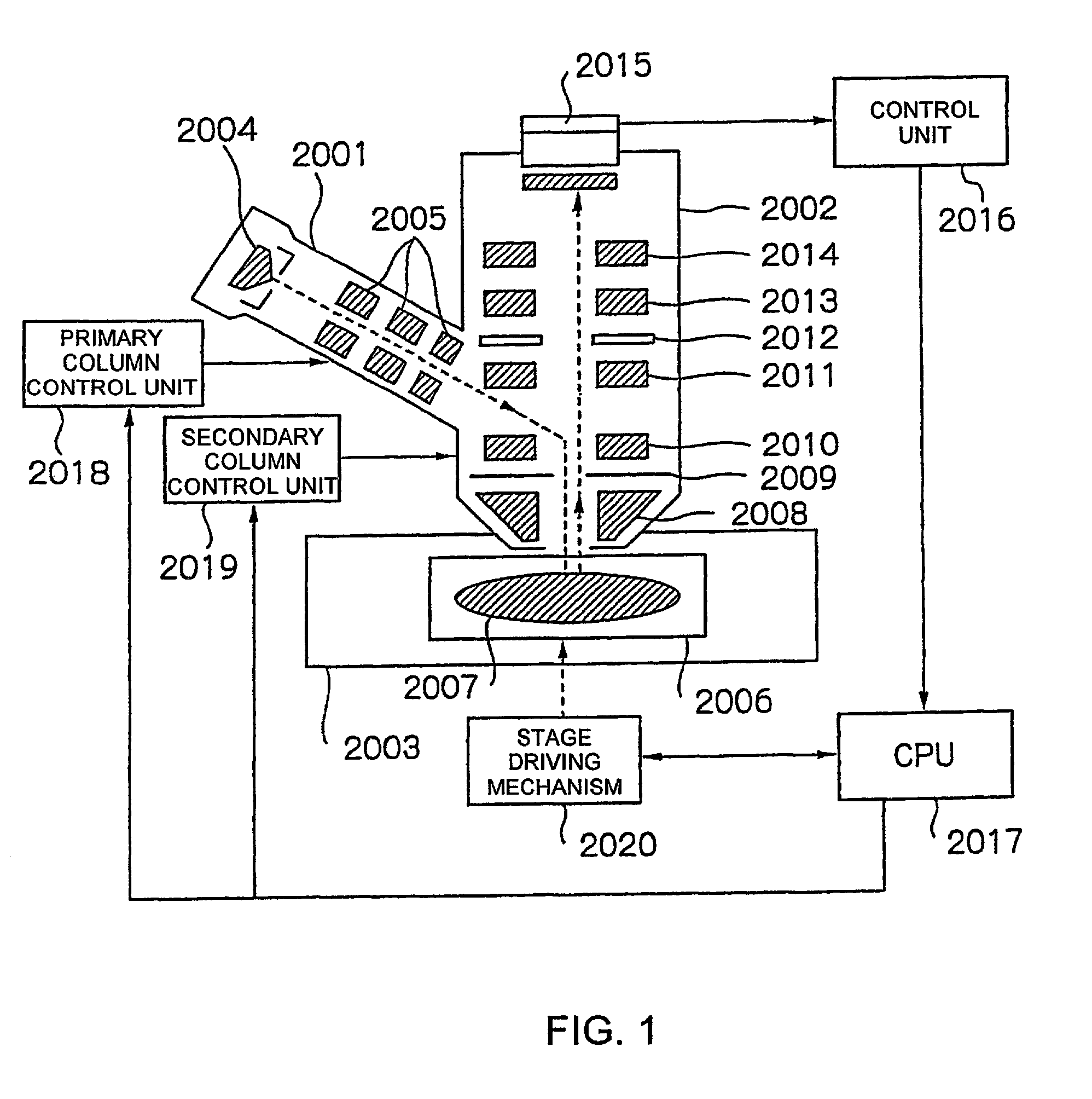

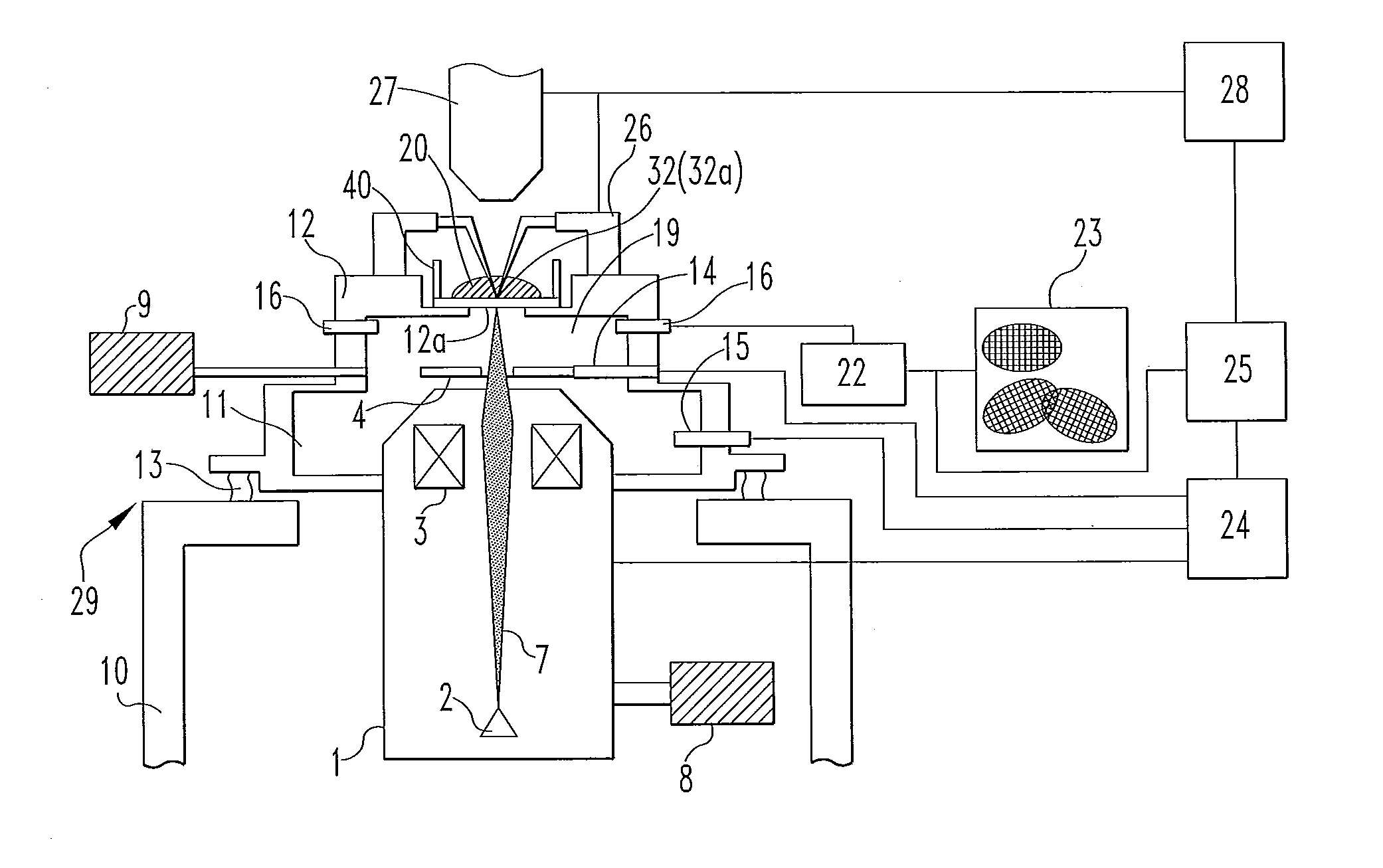

Electron beam apparatus and device fabrication method using the electron beam apparatus

InactiveUS7244932B2Improve throughputImprove accuracyThermometer detailsStability-of-path spectrometersSecondary electronsThroughput

The purpose of the invention is to provide an improved electron beam apparatus with improvements in throughput, accuracy, etc. One of the characterizing features of the electron beam apparatus of the present invention is that it has a plurality of optical systems, each of which comprises a primary electron optical system for scanning and irradiating a sample with a plurality of primary electron beams; a detector device for detecting a plurality of secondary beams emitted by irradiating the sample with the primary electron beams; and a secondary electron optical system for guiding the secondary electron beams from the sample to the detector device; all configured so that the plurality of optical systems scan different regions of the sample with their primary electron beams, and detect the respective secondary electron beams emitted from each of the respective regions. This is what makes higher throughput possible. To provide high accuracy, the apparatus is configured such that the axes of its optical systems can be aligned, and aberrations corrected, by a variety of methods.

Owner:EBARA CORP

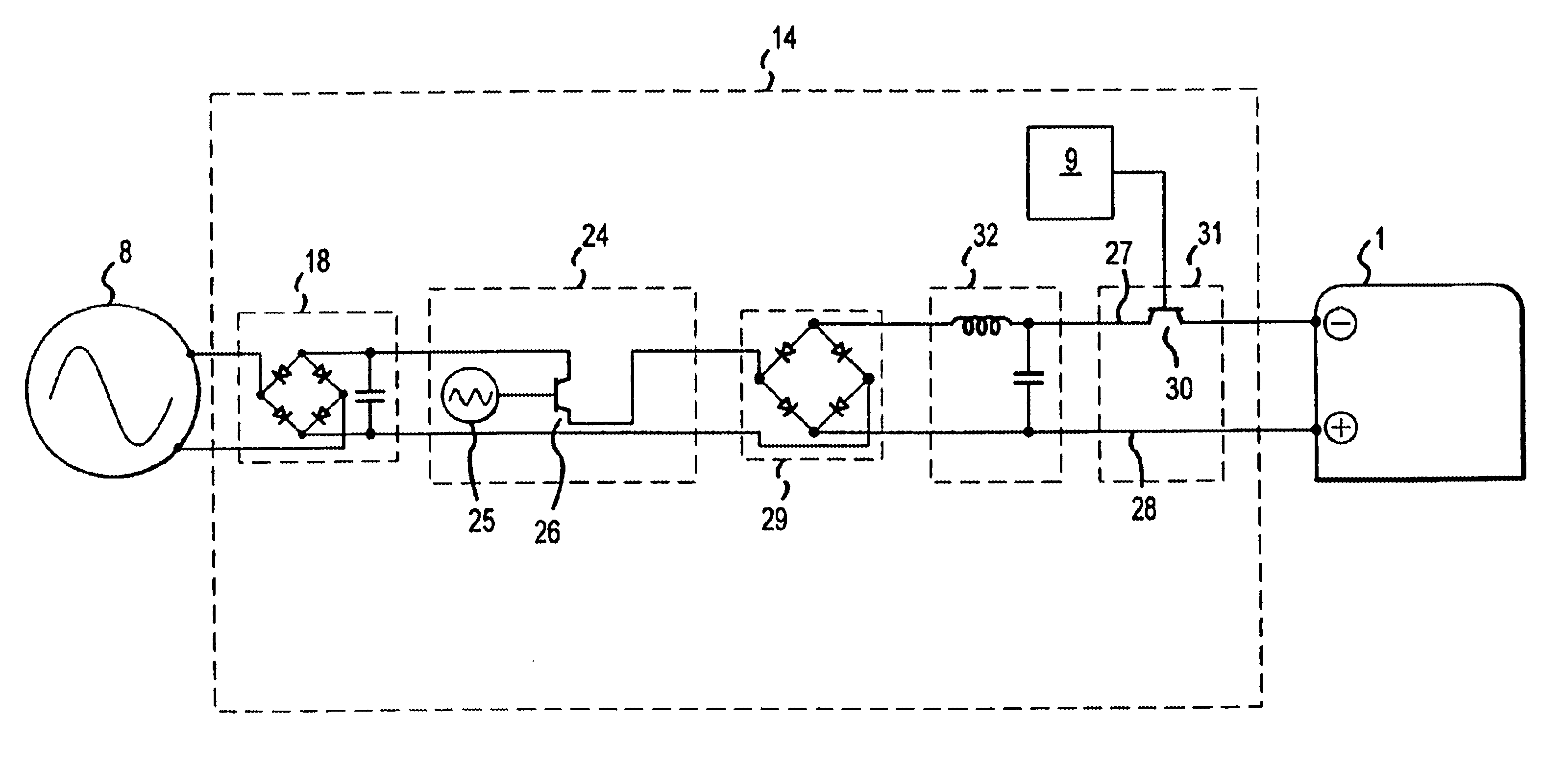

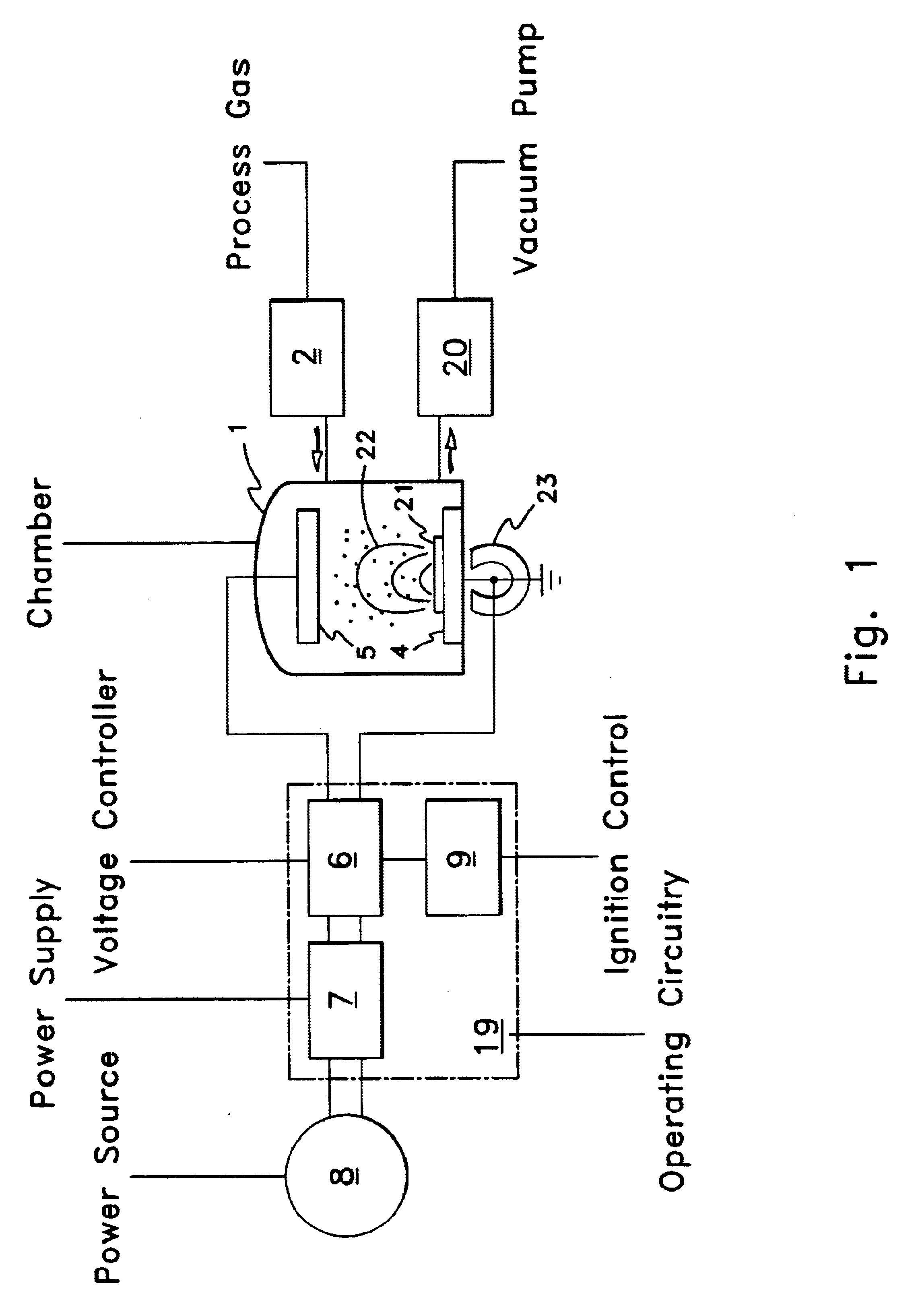

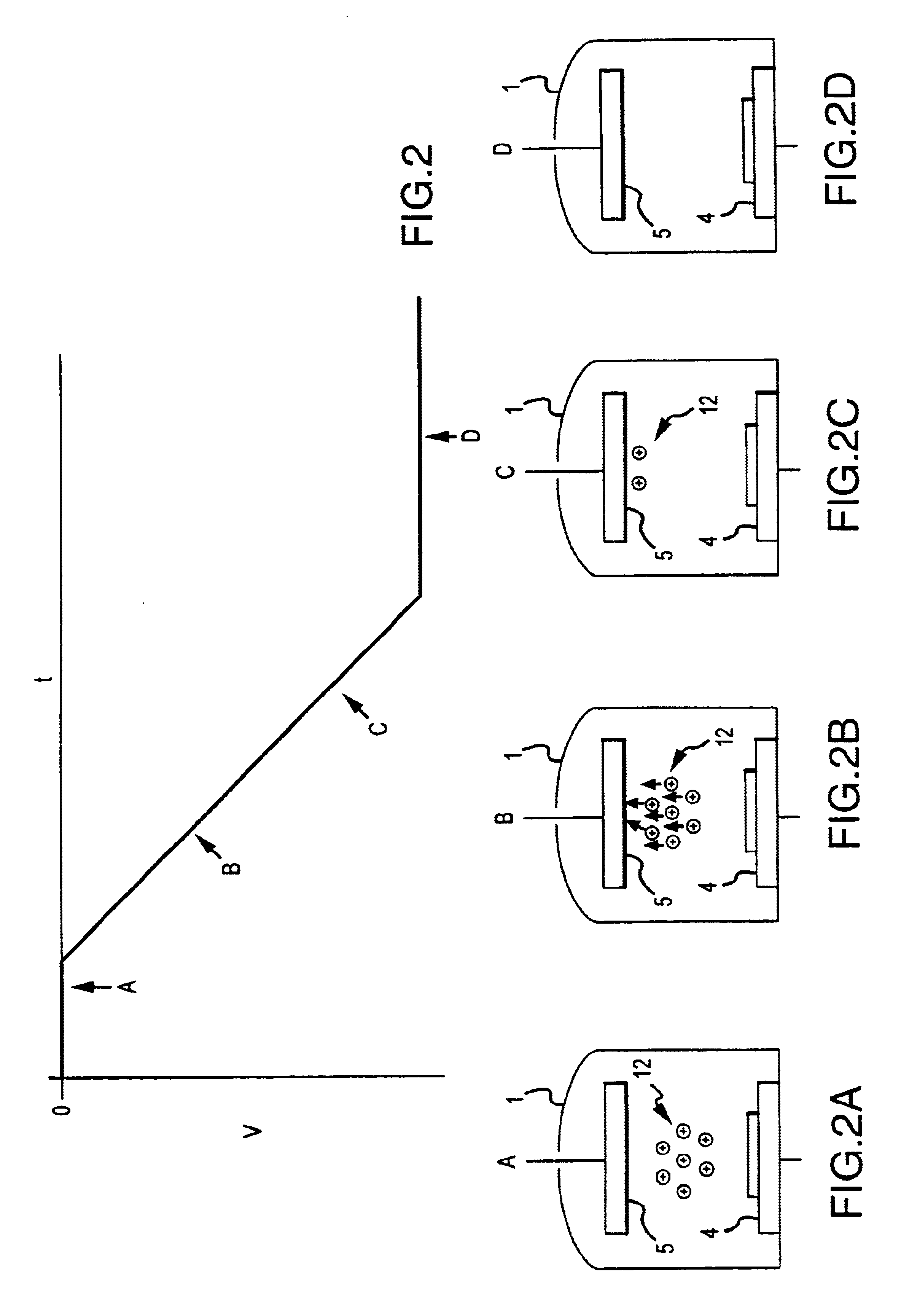

System for plasma ignition by fast voltage rise

InactiveUS6633017B1Increase probabilityIncrease variabilityElectric discharge tubesArc welding apparatusSecondary electronsEngineering

An improved system of igniting a plasma using a rapid voltage rise and thus causing ions that may be pre-existing to create secondary electron emission or the like is provided. In one embodiment, the voltage rise can be timed to be comparable to the transit time of the electrons across the plasma. It can also be arranged to achieve a voltage rise in less than 1000 microseconds, to result in a transition time that is less than one hundred times the transit time, to maximize the emission of secondary electrons, or even to merely result in collision energies ranging from 5 to 500 electron volts. The transition time can be controlled through an ignition control that may be programmable, may involve charging output storage devices, or may involve delayed switching to supply the increased voltage to the plasma after the storage elements have been more fully charged.< / PTEXT>

Owner:ADVANCED ENERGY IND INC

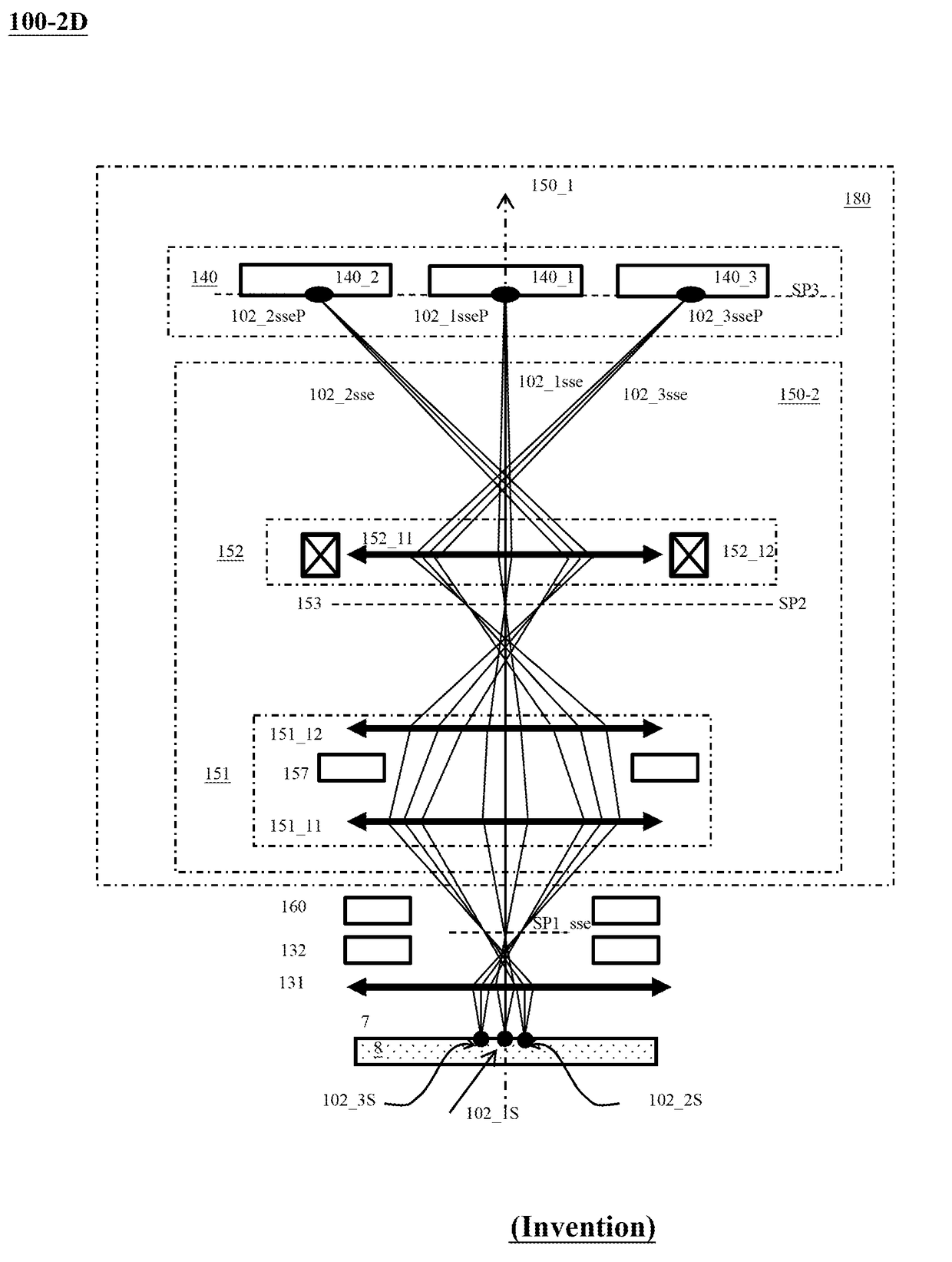

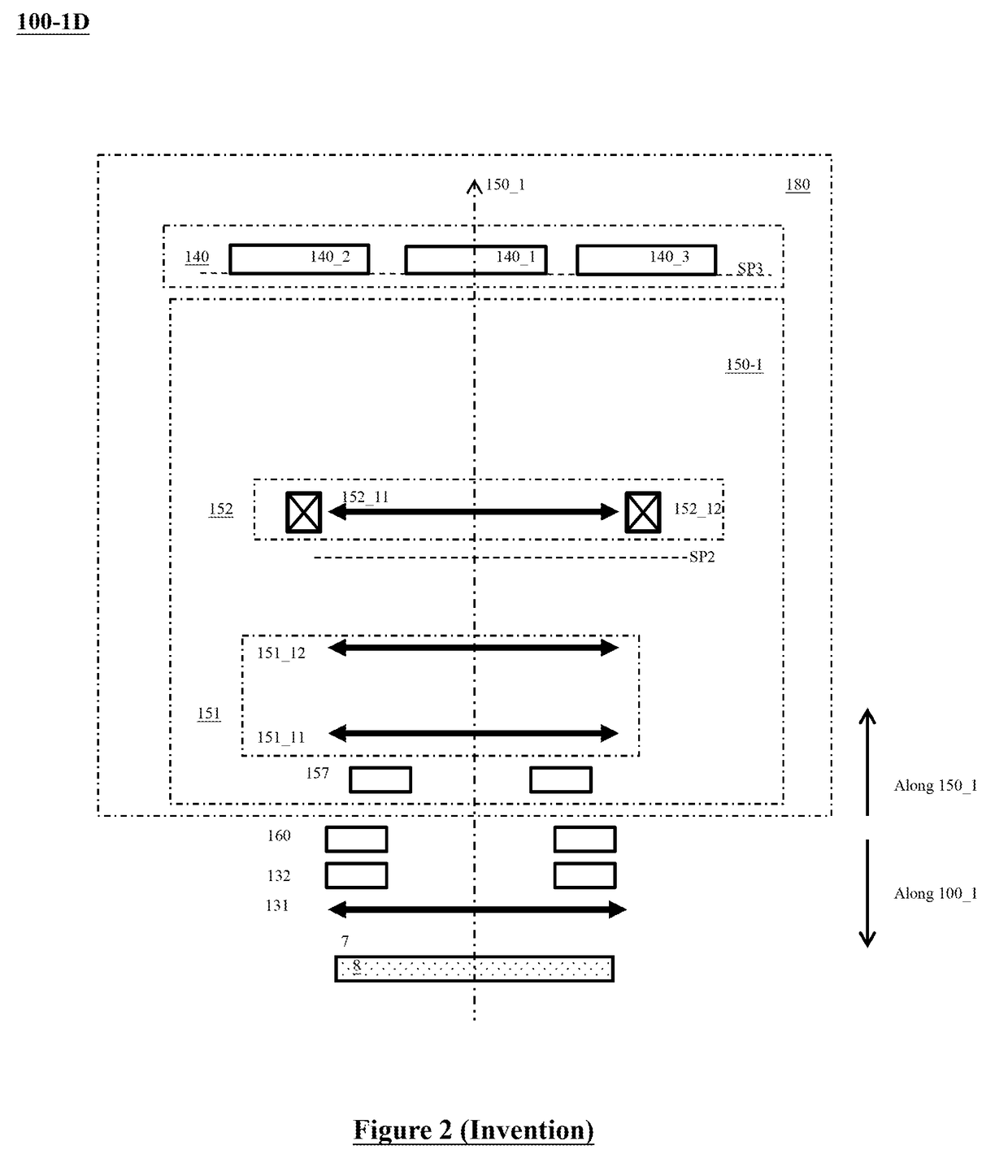

Apparatus of Plural Charged-Particle Beams

ActiveUS20170154756A1Improve collection efficiencyLower levelMaterial analysis using wave/particle radiationElectric discharge tubesRotation functionLight beam

A secondary projection imaging system in a multi-beam apparatus is proposed, which makes the secondary electron detection with high collection efficiency and low cross-talk. The system employs one zoom lens, one projection lens and one anti-scanning deflection unit. The zoom lens and the projection lens respectively perform the zoom function and the anti-rotating function to remain the total imaging magnification and the total image rotation with respect to the landing energies and / or the currents of the plural primary beamlets. The anti-scanning deflection unit performs the anti-scanning function to eliminate the dynamic image displacement due to the deflection scanning of the plural primary beamlets.

Owner:ASML NETHERLANDS BV

Charged particle beam apparatus

InactiveUS20060076489A1FunctionalMaterial analysis using wave/particle radiationParticle separator tubesElectron sourceSecondary electrons

A charged particle beam apparatus in which an electrostatic lens is used as a main focusing element to obtain a subminiature high-sensitivity high-resolution SEM, a drift tube for an electron beam is located inside a column between an electron source and a sample, and a detector for secondary electrons is located inside the drift tube. This solves the problem associated with the provision of a secondary electron detector, which heretofore has been a bottleneck in making a subminiature high-resolution SEM column.

Owner:HITACHI HIGH-TECH CORP

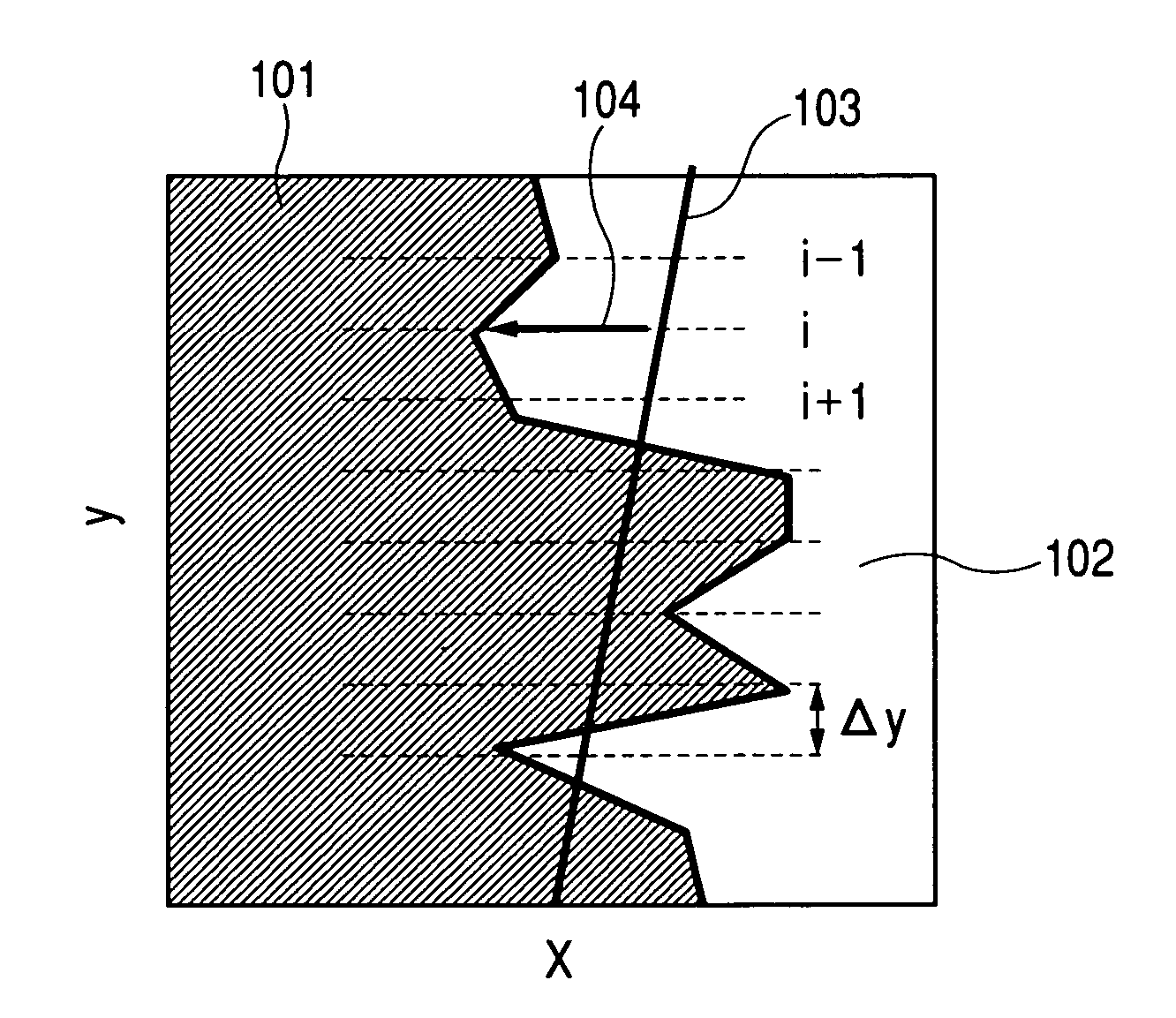

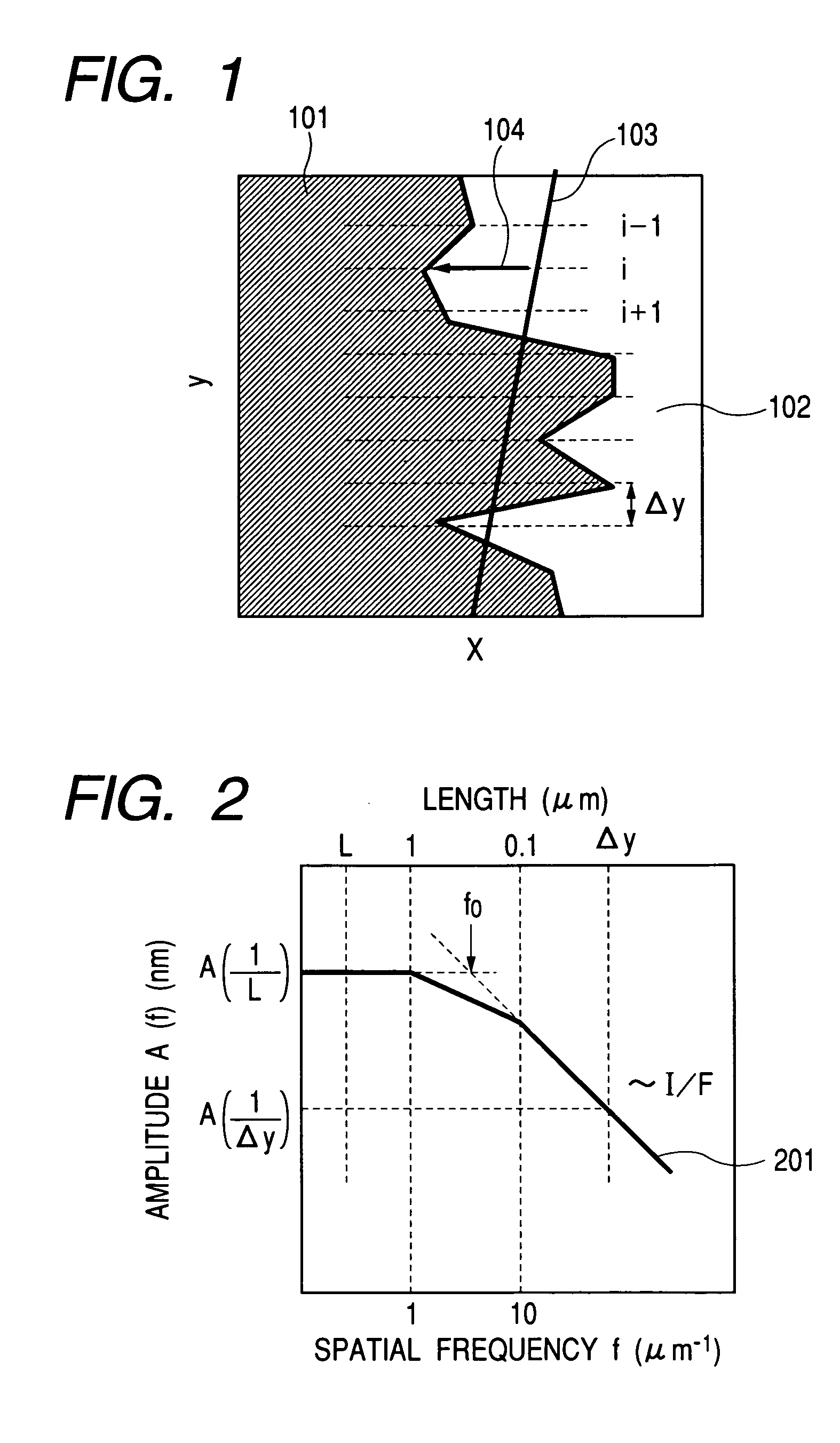

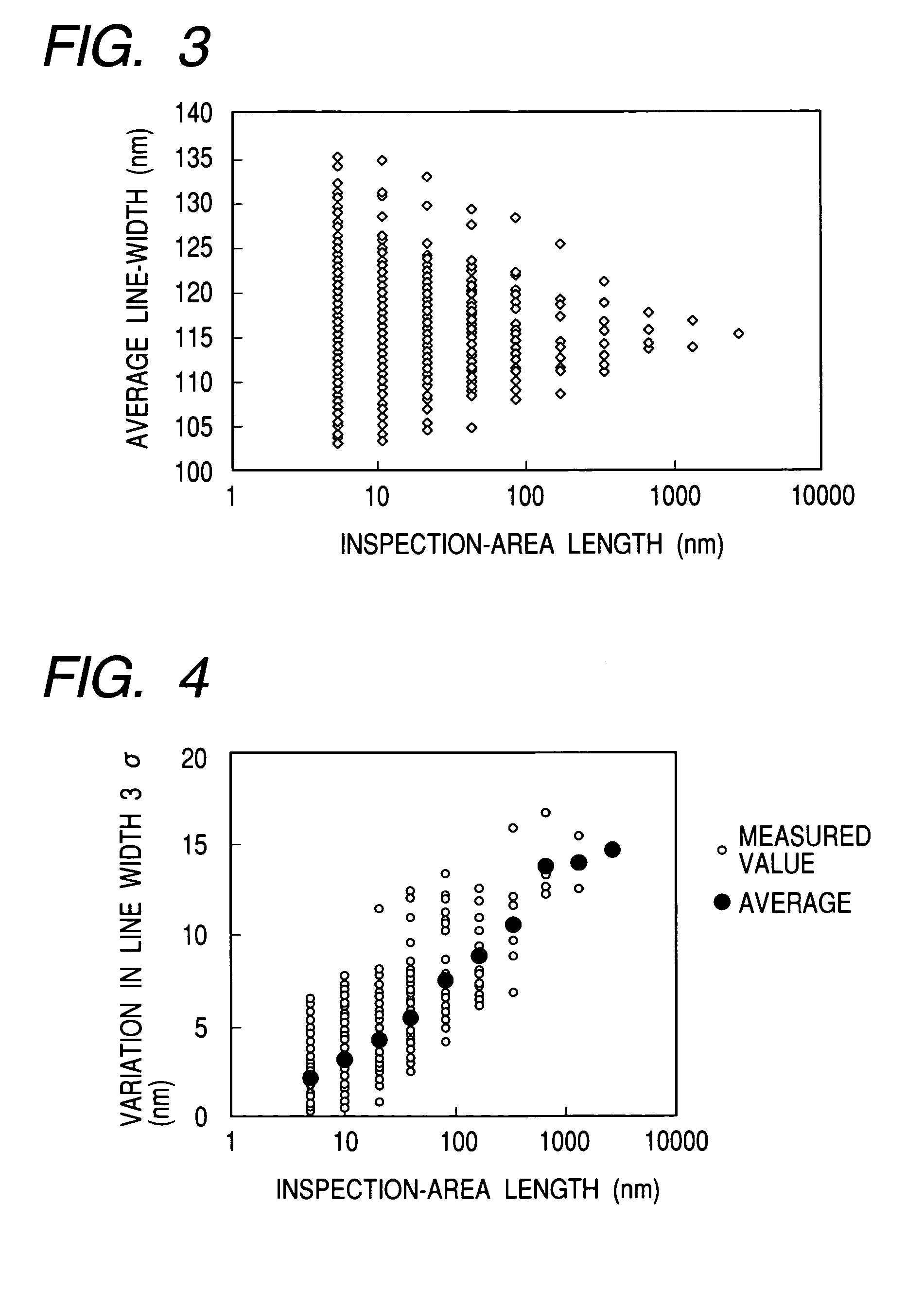

Pattern inspection method

InactiveUS7049589B2Highly accurately estimateAccurately and quickly effectMaterial analysis using wave/particle radiationUsing wave/particle radiation meansSecondary electronsEngineering

The present invention may include a pattern inspection method of extracting a pattern edge shape from an image obtained by a scanning microscope and inspecting the pattern. A control section and a computer of the scanning microscope process the intensity distribution of reflected electrons or secondary electrons, find the distribution of gate lengths in a single gate from data about edge positions, estimate the transistor performance by assuming a finally fabricated transistor to be a parallel connection of a plurality of transistors having various gate lengths, and determine the pattern quality and grade based on an estimated result. In this manner, it is possible to highly, accurately and quickly estimate an effect of edge roughness on the device performance and highly accurately and efficiently inspect patterns in accordance with device specifications.

Owner:HITACHI LTD +1

Object observation apparatus and object observation

InactiveUSRE40221E1Improve accuracyThermometer detailsMaterial analysis using wave/particle radiationLight beamOperation mode

This invention relates to an object observation apparatus and observation method. The object observation apparatus is characterized by including a drivable stage on which a sample is placed, an irradiation optical system which is arranged to face the sample on the stage, and emits an electron beam as a secondary beam, an electron detection device which is arranged to face the sample, causes to project, as a primary beam, at least one of a secondary electron, reflected electron, and back-scattering electron generated by the sample upon irradiation of the electron beam, and generates image information of the sample, a stage driving device which is adjacent to the stage to drive the stage, and a deflector arranged between the sample and the electron detection device to deflect the secondary beam, the electron detection device having a converter arranged on a detection surface to convert the secondary beam into light, an array image sensing unit which is adjacent to the converter, has pixels of a plurality of lines each including a plurality of pixels on the detection surface, sequentially transfers charges of pixels of each line generated upon reception of light of an optical image obtained via the converter to corresponding pixels of an adjacent line at a predetermined timing, adds, every transfer, charges generated upon reception of light after the transfer at the pixels which received the charges, and sequentially outputs charges added up to a line corresponding to an end, and a control unit connected to the array image sensing unit to output a transfer signal for sequentially transferring charges of pixels of each line to an adjacent line, and the control unit having a stage scanning mode in which the array image sensing unit is controlled in accordance with a variation in projection position of the secondary beam projected on the electron detection device that is generated by movement of the stage device, and a deflector operation mode in which the array image sensing unit is controlled in accordance with a variation in projection position of the secondary beam projected on the detection device by the deflector.

Owner:NIKON CORP

Object observation apparatus and object observation

InactiveUSRE41665E1Improve accuracyThermometer detailsMaterial analysis using wave/particle radiationLight beamOperation mode

Owner:NIKON CORP

Method and apparatus for multiple byte or page mode programming of a flash memory array

Owner:WINBOND ELECTRONICS CORP

Radiation detector with converters

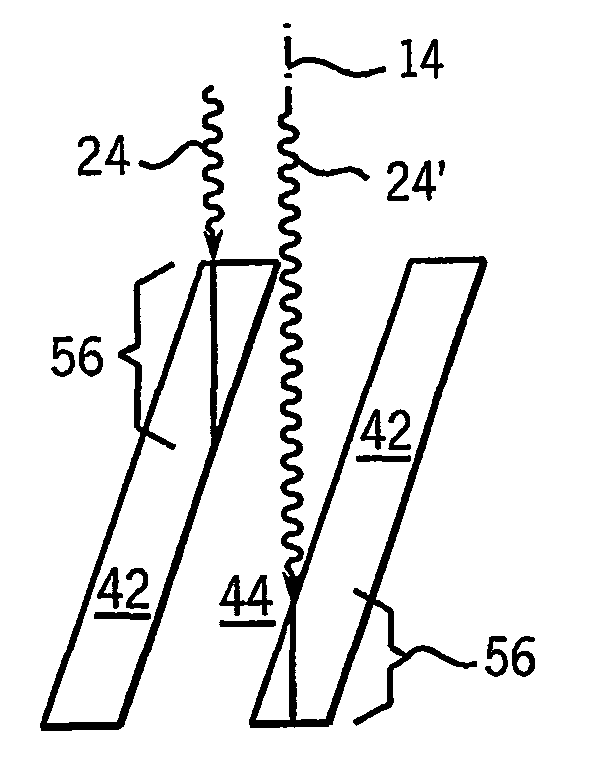

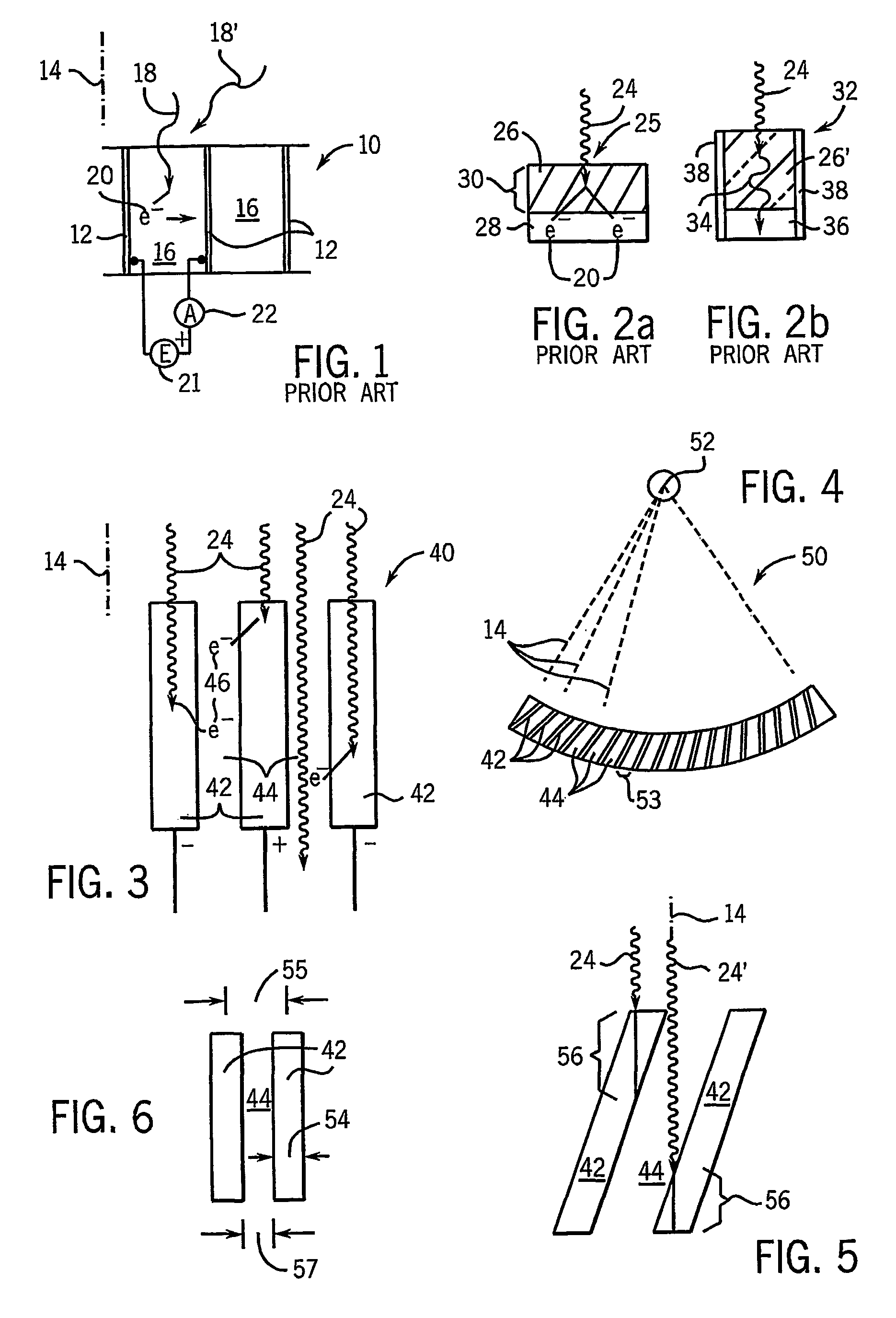

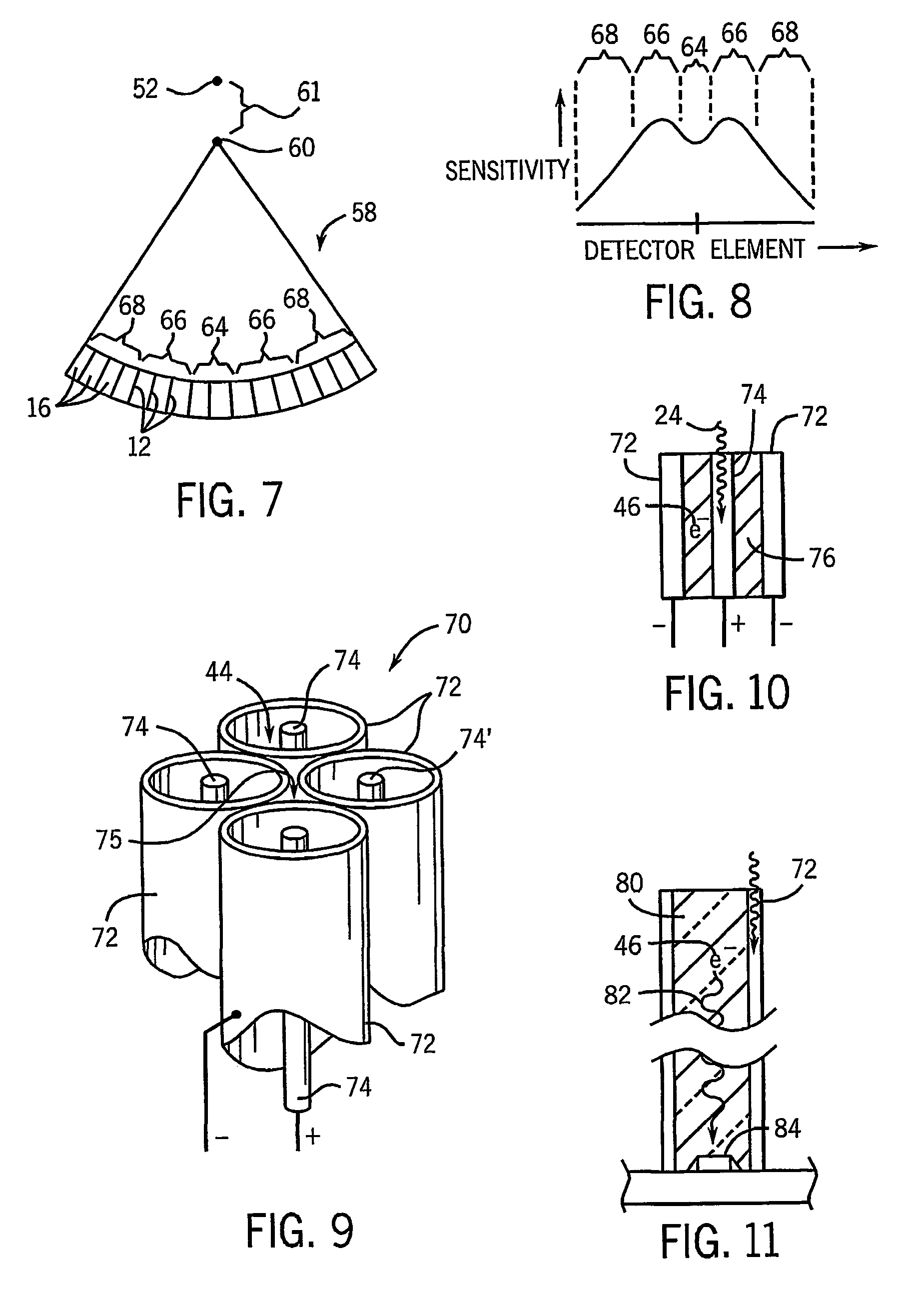

InactiveUS7186986B2Avoid reabsorptionSolve the lack of heightElectric discharge tubesMaterial analysis by optical meansSecondary electronsReady to use

A high efficiency radiation detector employs longitudinally extending converter elements receiving longitudinally propagating radiation to produce high-energetic electrons received by detector structures in interstitial spaces. The secondary electron generation in this architecture allows great freedom in selection of converter materials and thickness. A variety of detector mechanisms may be used including ionization-type detectors or scintillation-type detector.

Owner:WISCONSIN ALUMNI RES FOUND

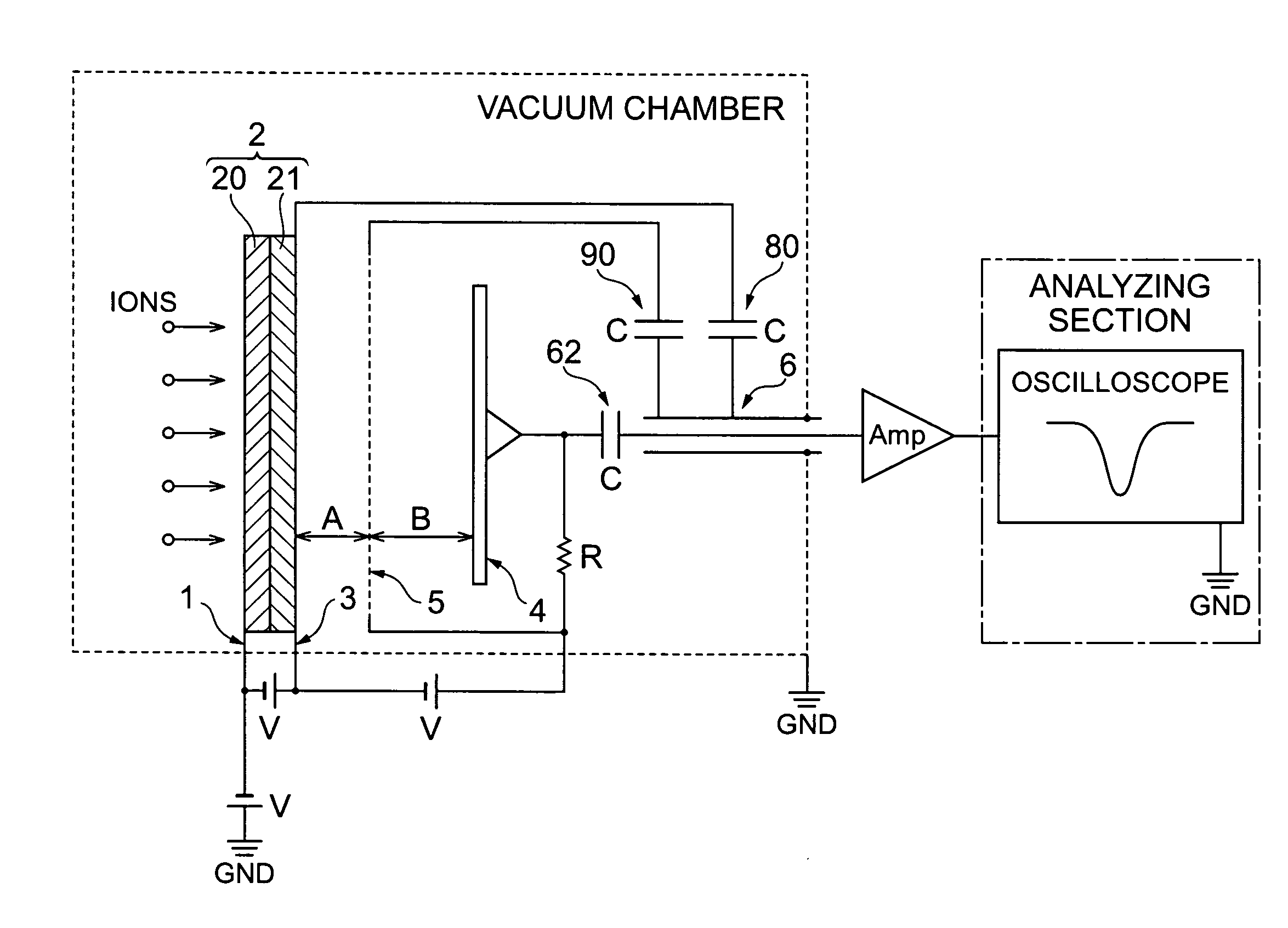

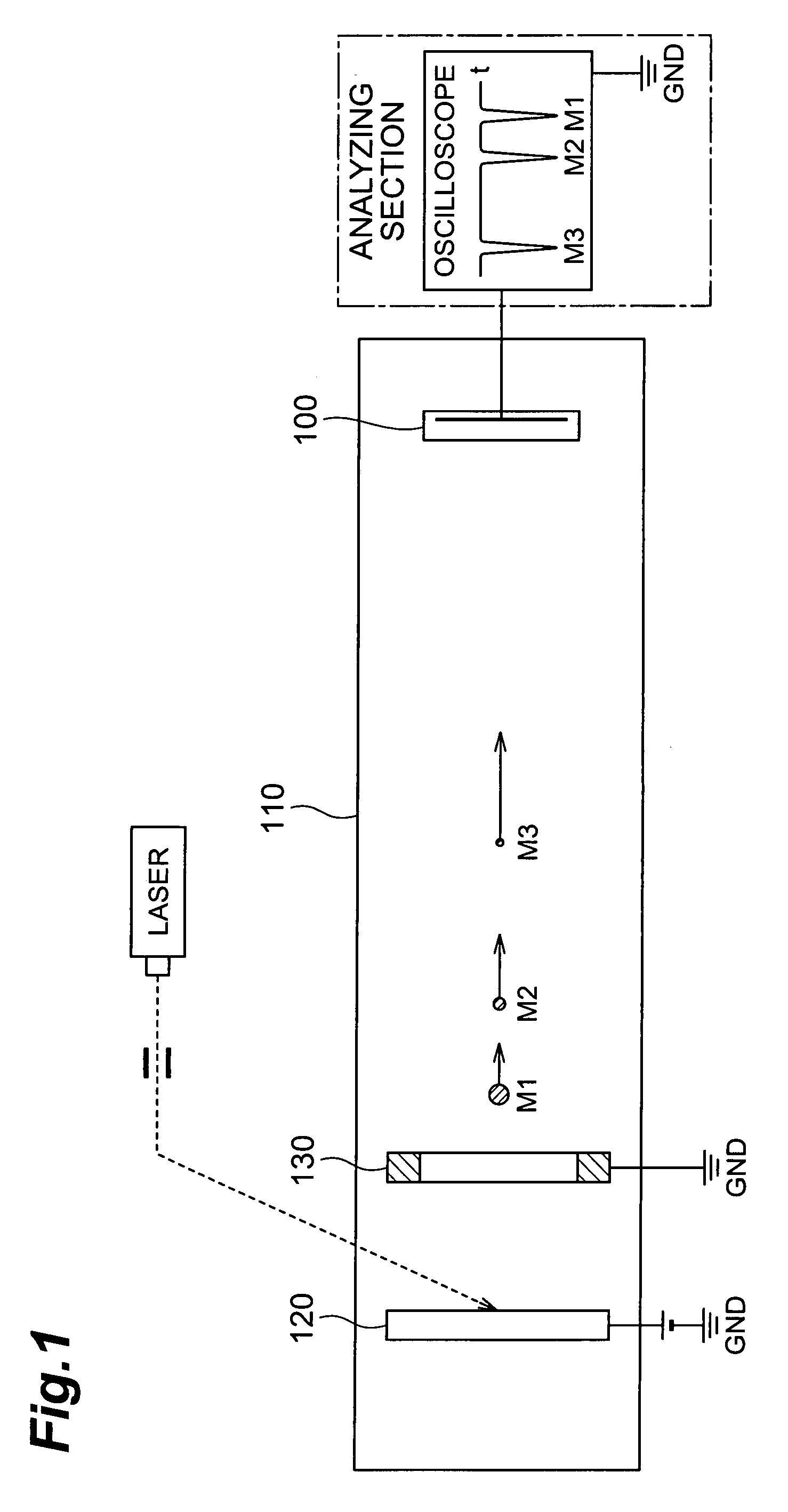

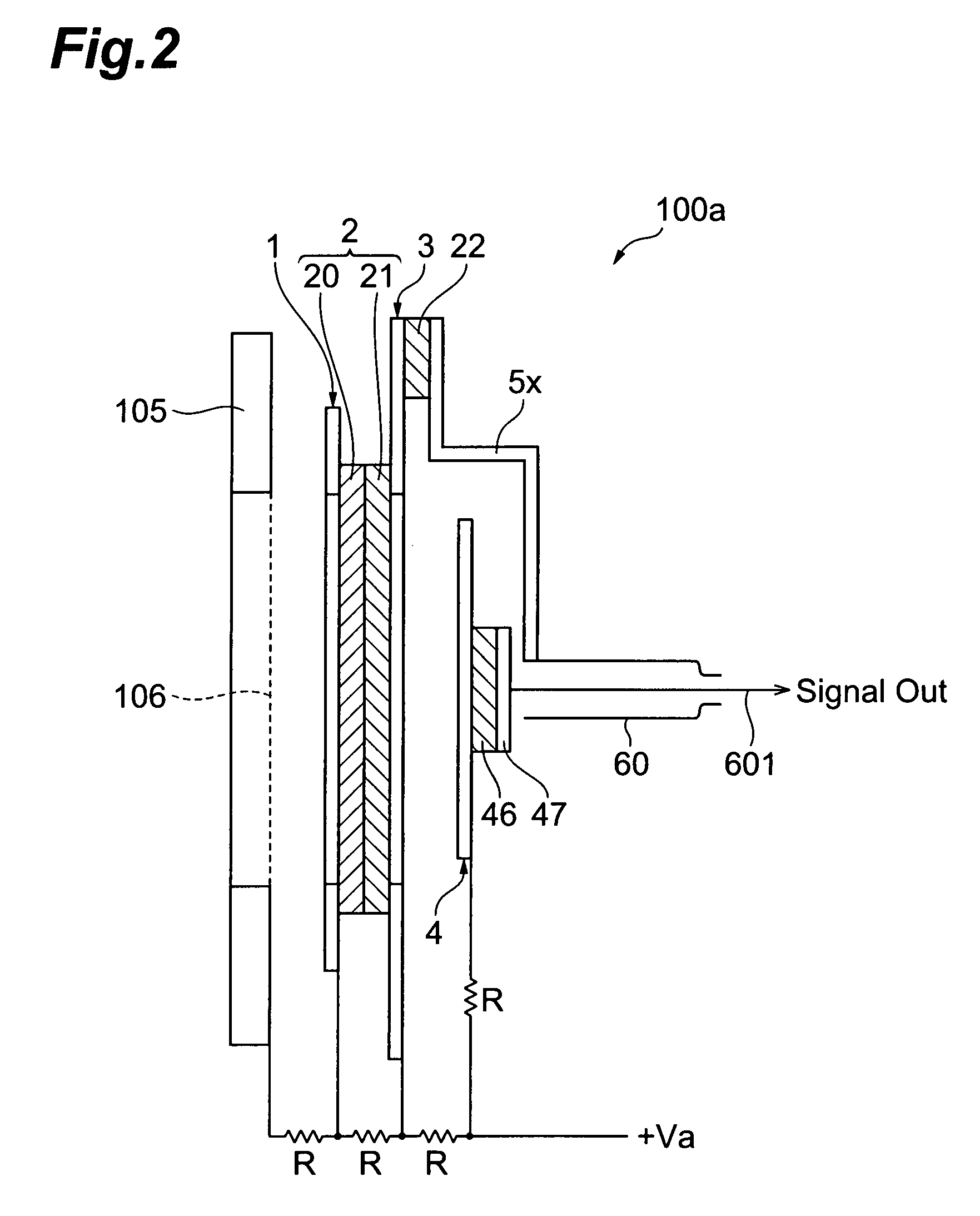

MCP unit, MCP detector and time of flight mass spectrometer

ActiveUS7564043B2Reduce widthShortened fall timeThermometer detailsSpectrometer detectorsTime-of-flight mass spectrometryTime response

The present invention relates to an MCP unit or the like having a structure intended to achieve a desired time response characteristic, without depending on a limitation imposed by a channel diameter of MCP. The MCP unit comprises the MCP for releasing secondary electrons internally multiplied in response to incidence of charged particles, an anode arranged in a position where the secondary electrons reach, and an acceleration electrode arranged between the MCP and the anode. In particular, the acceleration electrode includes a plurality of openings which permit passing of the secondary electrons migrating from the MCP toward the anode. Further, the acceleration electrode is arranged such that the shortest distance B between the acceleration electrode and the anode is longer than the shortest distance A between the MCP and the acceleration electrode. Thus, an FWHM of a detected peak appearing in response to the incidence of the charged particles is remarkably shortened.

Owner:HAMAMATSU PHOTONICS KK

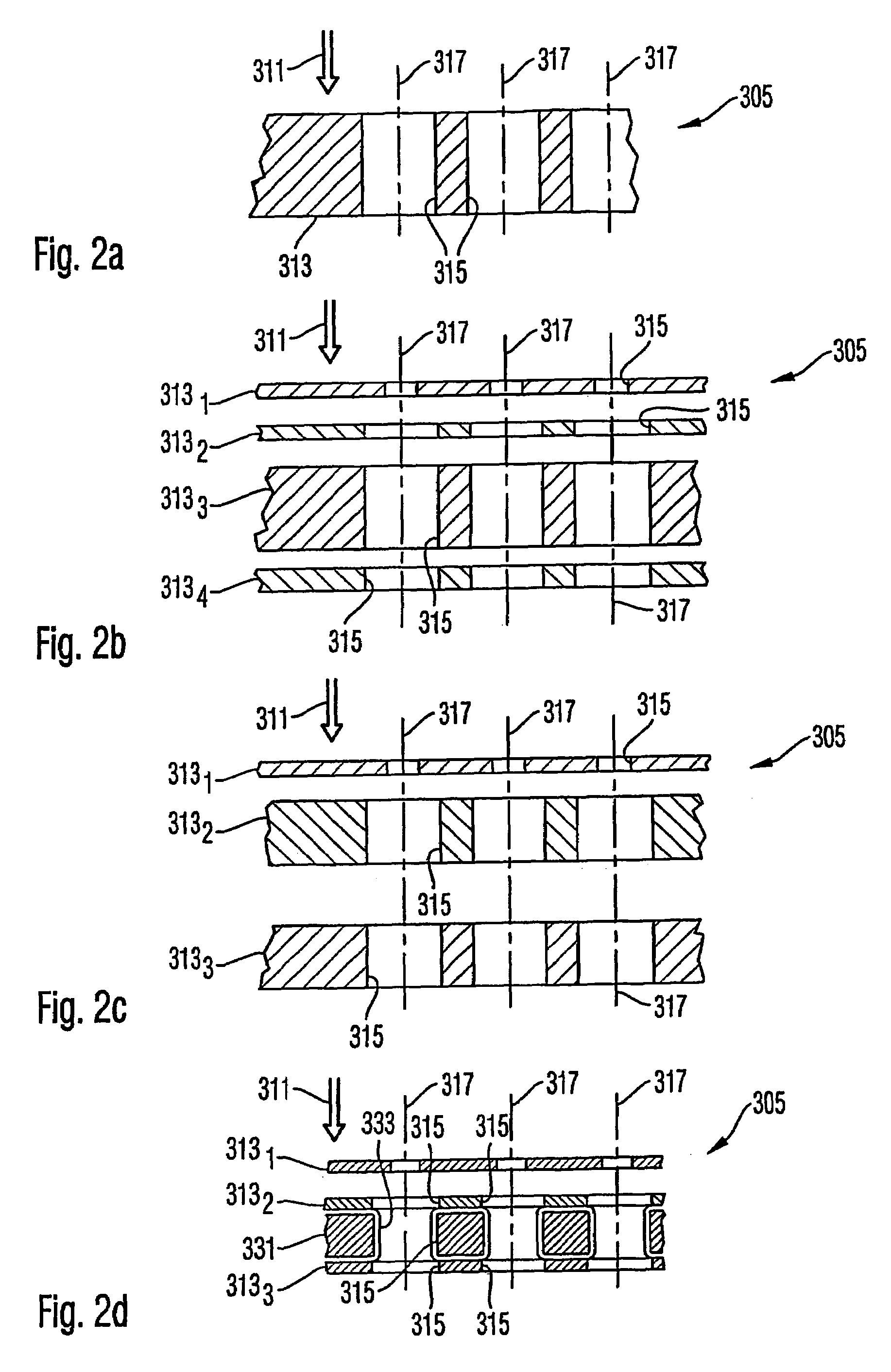

Sheet beam-type testing apparatus

InactiveUS7049585B2Inhibition of attachmentMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingBeam source

Owner:EBARA CORP

High resolution detection for time-of-flight mass spectrometers

InactiveUS6870156B2High resolutionInhibit transferSpectrometer detectorsTime-of-flight spectrometersEngineeringMass analyzer

The invention covers a method for detecting ions in high resolution time-of-flight mass spectrometers which operate with secondary electron multiplier multichannel plates and in which many single spectra are acquired and added to produce a sum spectrum. The invention involves (a) using an analog digital converter (ADC) for converting electron currents from secondary electron multipliers, instead of a time-to-digital converter (TDC) which was previously used for highest possible signal resolution, (b) performing a separate rapid peak recognition procedure for the ion signals of each spectrum by a fast calculation method, thereby collecting flight time and intensity value pairs for the ion peaks, and (c) constructing a time-of-flight / intensity histogram, which is further processed as a composite time-of-flight spectrum. The invention retains the significantly higher measurement dynamics of an ADC and achieves the improved resolution capability of a TDC, but without showing the latter's known signal distortion due to dead times.

Owner:BRUKER DALTONIK GMBH & CO KG

Apparatus and Method for Inspecting Samples

InactiveUS20100243888A1Easy maintenanceLow costElectric discharge tubesGamma-ray/x-ray microscopesLight beamEngineering

An inspection apparatus and method capable of well observing or inspecting a specimen contained in a liquid. The inspection apparatus has a film including first and second surfaces. Furthermore, the apparatus has a vacuum chamber for reducing the pressure in the ambient in contact with the second surface of the film, primary beam irradiation column connected with the vacuum chamber, and a shutter for partially partitioning the space between the film and the primary beam irradiation column within the vacuum chamber. A liquid sample is held on the first surface of the film. The primary beam irradiation column irradiates the sample. Backscattered electrons (a secondary beam) produced from the sample by the primary beam irradiation are directed at the shutter, producing secondary electrons (a tertiary signal).

Owner:JEOL LTD

Apparatus for inspection with electron beam, method for operating same, and method for manufacturing semiconductor device using former

InactiveUS20050121611A1Improve throughputImprove efficiencyMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingDevice material

A substrate inspection apparatus 1-1 (FIG. 1) of the present invention performs the following steps of: carrying a substrate “S” to be inspected into an inspection chamber 23-1; maintaining a vacuum in said inspection chamber; isolating said inspection chamber from a vibration; moving successively said substrate by means of a stage 26-1 with at least one degree of freedom; irradiating an electron beam having a specified width; helping said electron beam reach to a surface of said substrate via a primary electron optical system 10-1; trapping secondary electrons emitted from said substrate via a secondary electron optical system 20-1 and guiding it to a detecting system 35-1; forming a secondary electron image in an image processing system based on a detection signal of a secondary electron beam obtained by said detecting system; detecting a defective location in said substrate based on the secondary electron image formed by said image processing system; indicating and / or storing said defective location in said substrate by CPU 37-1; and taking said completely inspected substrate out of the inspection chamber. Thereby, the defect inspection on the substrate can be performed successively with high level of accuracy and efficiency as well as with higher throughput.

Owner:EBARA CORP

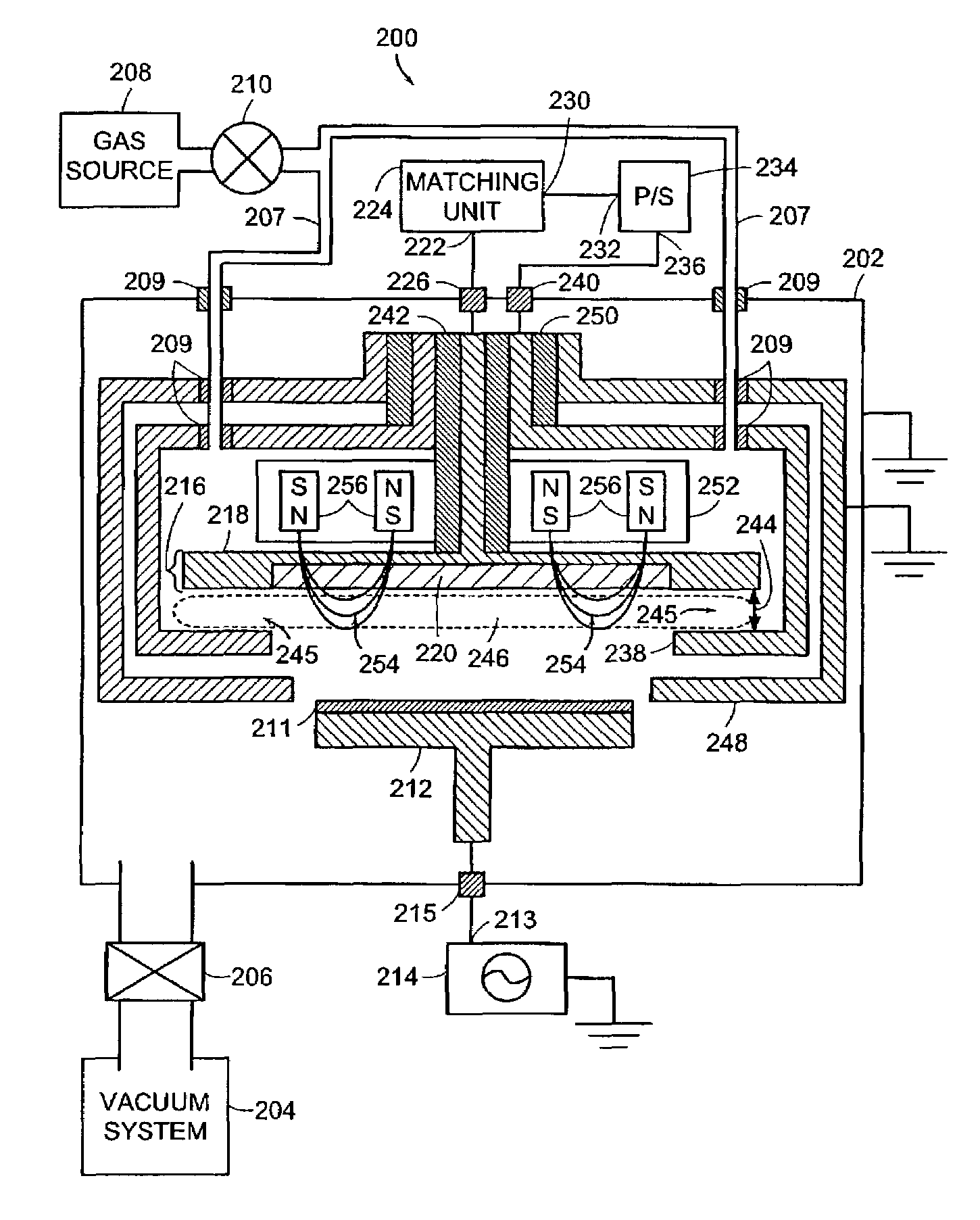

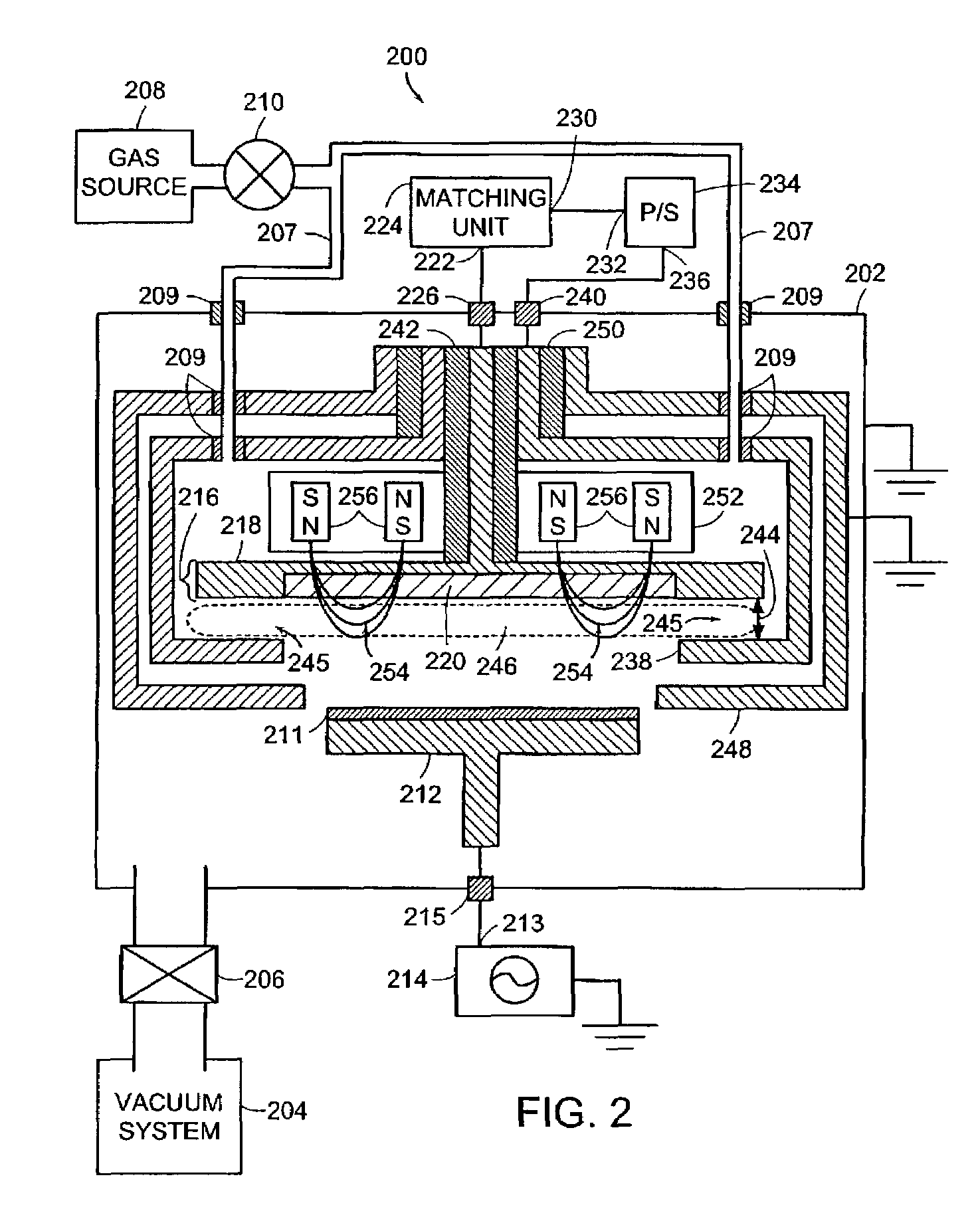

High-power pulsed magnetron sputtering

Magnetically enhanced sputtering methods and apparatus are described. A magnetically enhanced sputtering source according to the present invention includes an anode and a cathode assembly having a target that is positioned adjacent to the anode. An ionization source generates a weakly-ionized plasma proximate to the anode and the cathode assembly. A magnet is positioned to generate a magnetic field proximate to the weakly-ionized plasma. The magnetic field substantially traps electrons in the weakly-ionized plasma proximate to the sputtering target. A power supply produces an electric field in a gap between the anode and the cathode assembly. The electric field generates excited atoms in the weakly ionized plasma and generates secondary electrons from the sputtering target. The secondary electrons ionize the excited atoms, thereby creating a strongly-ionized plasma having ions that impact a surface of the sputtering target to generate sputtering flux.

Owner:ZOND CORP +1

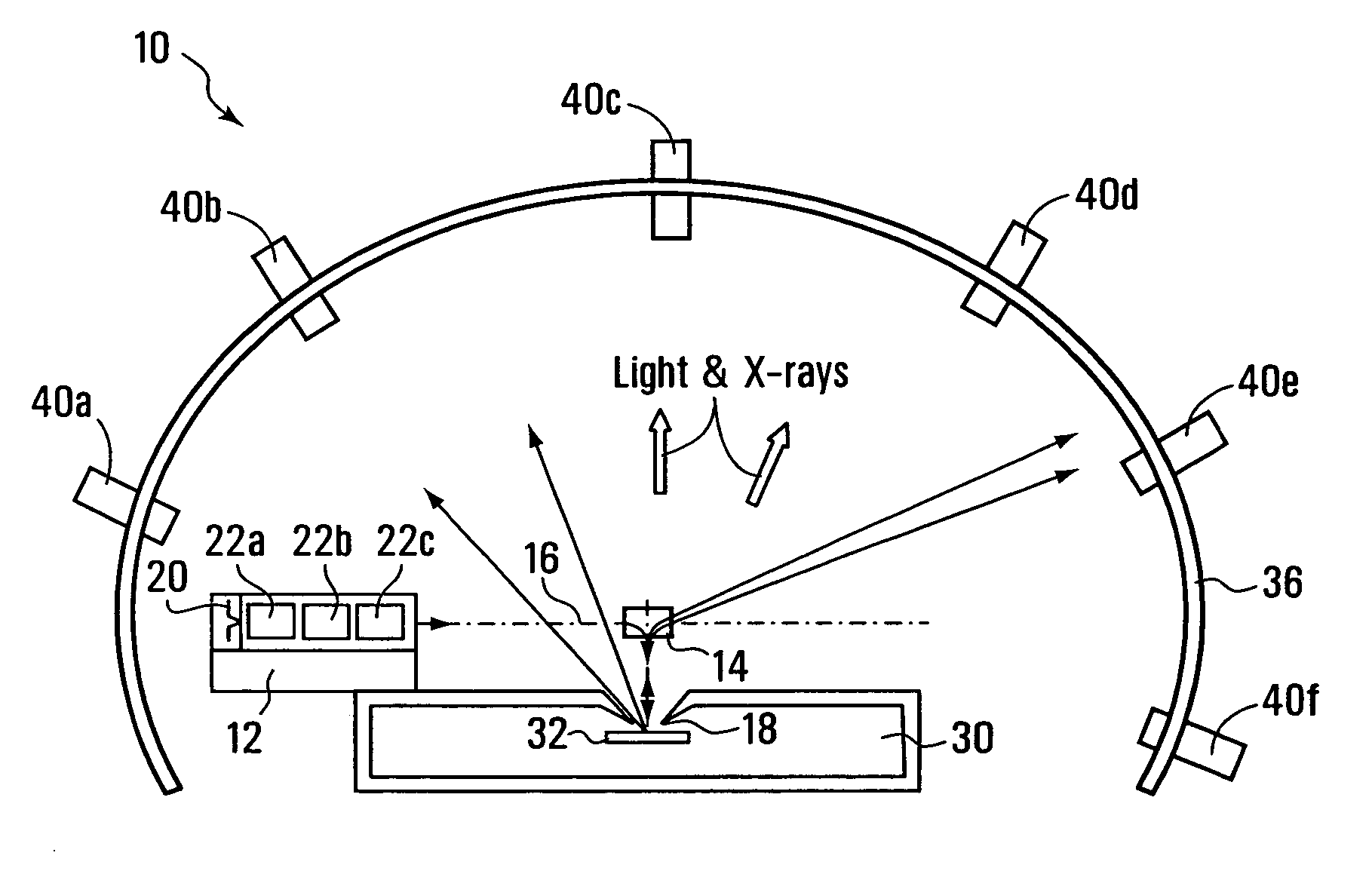

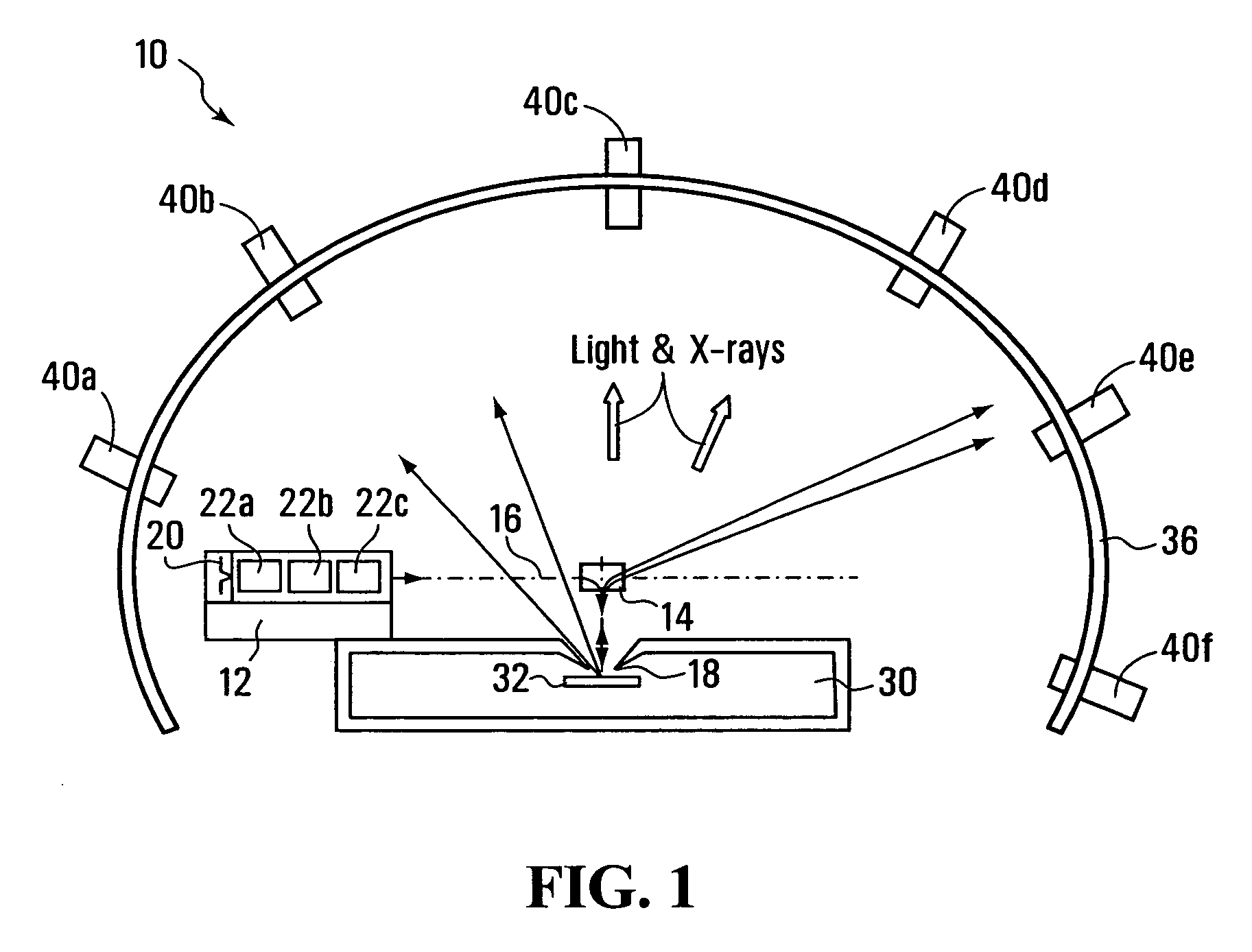

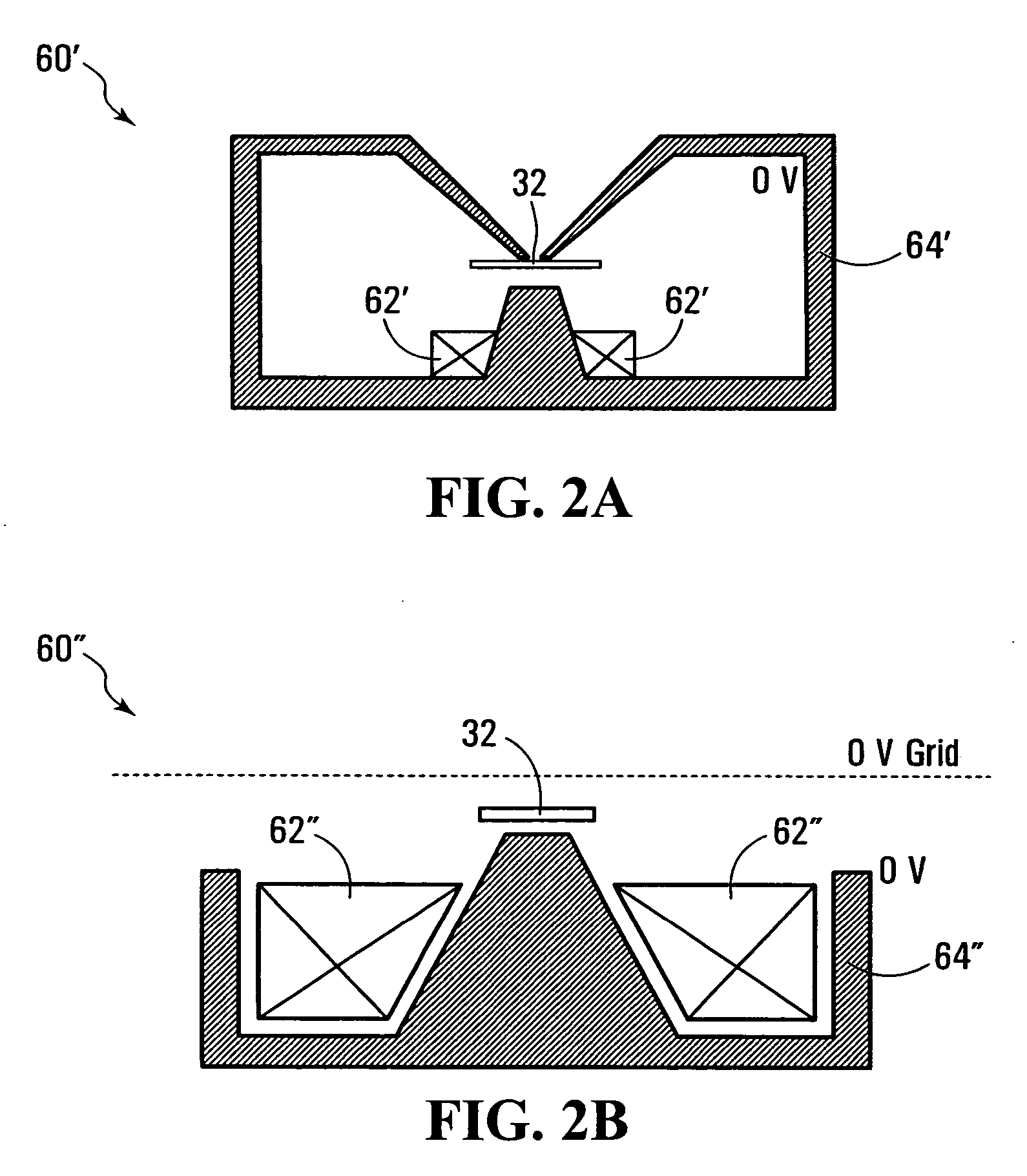

Compact neutron source and moderator

InactiveUS20100061500A1Nuclear energy generationDirect voltage acceleratorsSecondary electronsIon source

A novel method and compact neutron source for generating thermal neutrons is described that uses an ion source to emit ions toward a target where neutrons are generated. Surrounding the target is a secondary electron shield, and surrounding the target is a first stage moderator to reduce the energy of generated fast neutrons. Enclosing the first stage moderator is a second stage moderator with a thermal neutron port.

Owner:RGT UNIV OF CALIFORNIA

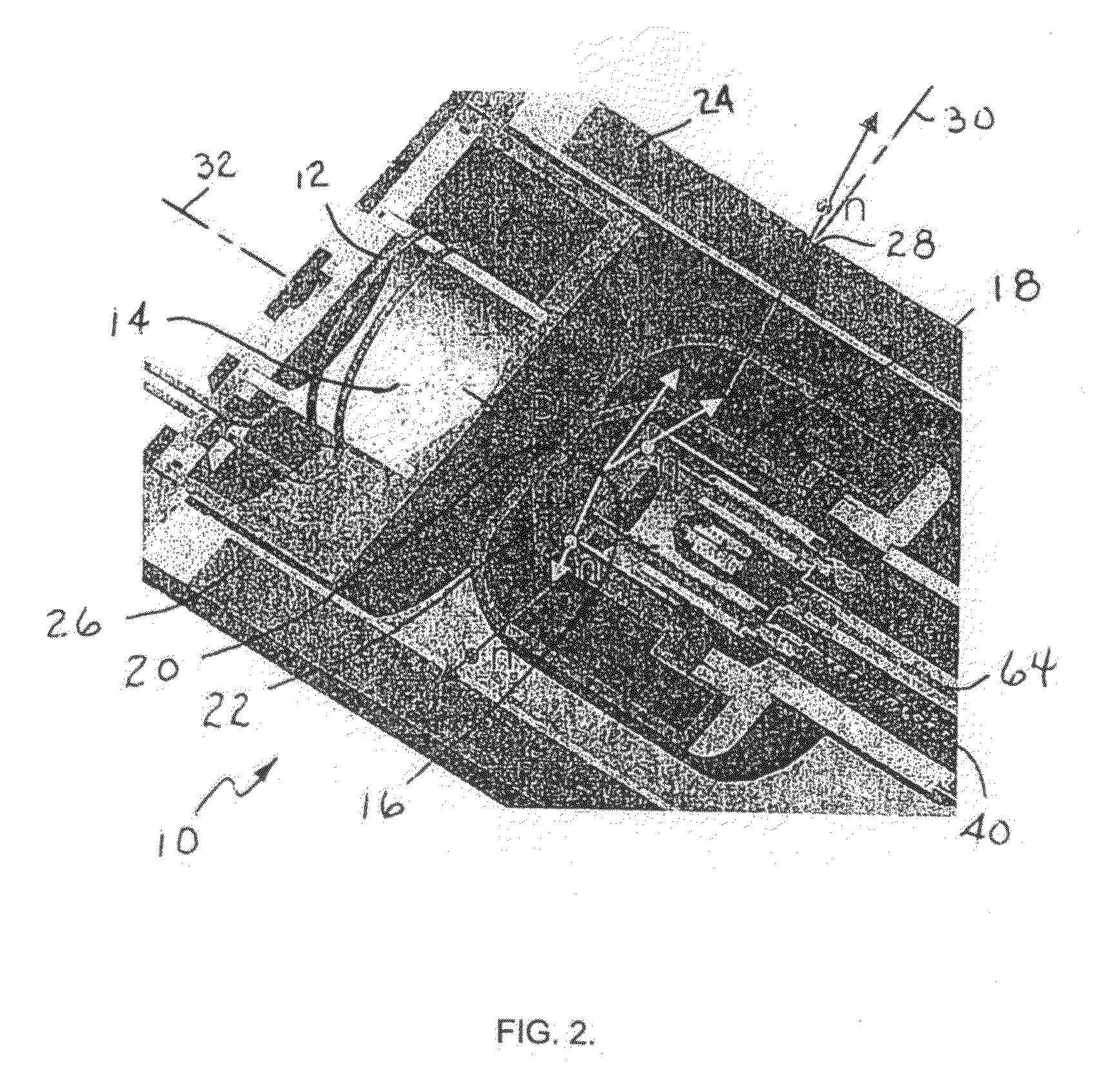

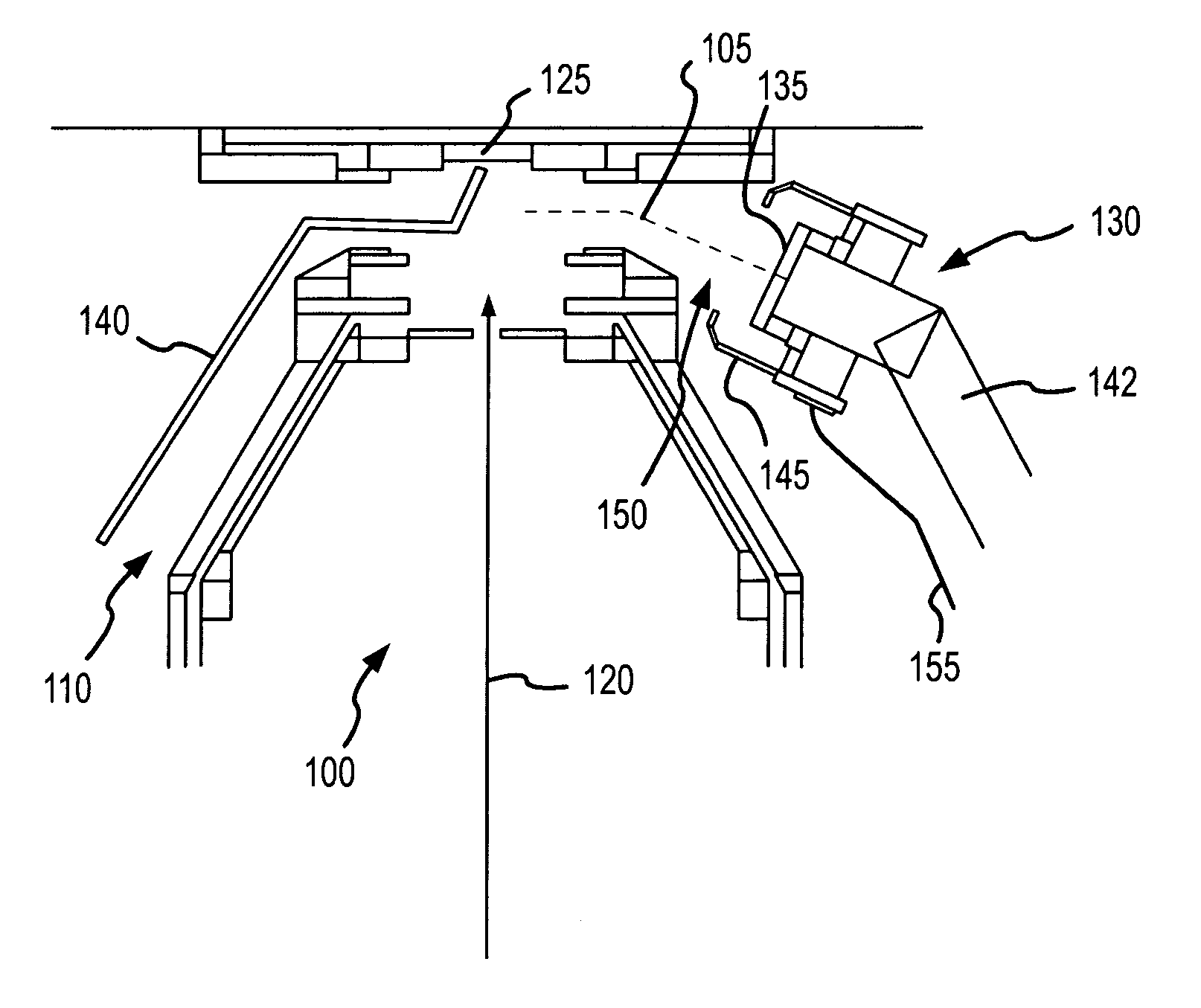

Charged particle guide

ActiveUS7135678B2Reduce wearIncrease generationThermometer detailsMaterial analysis using wave/particle radiationCharged particle detectorsSecondary electrons

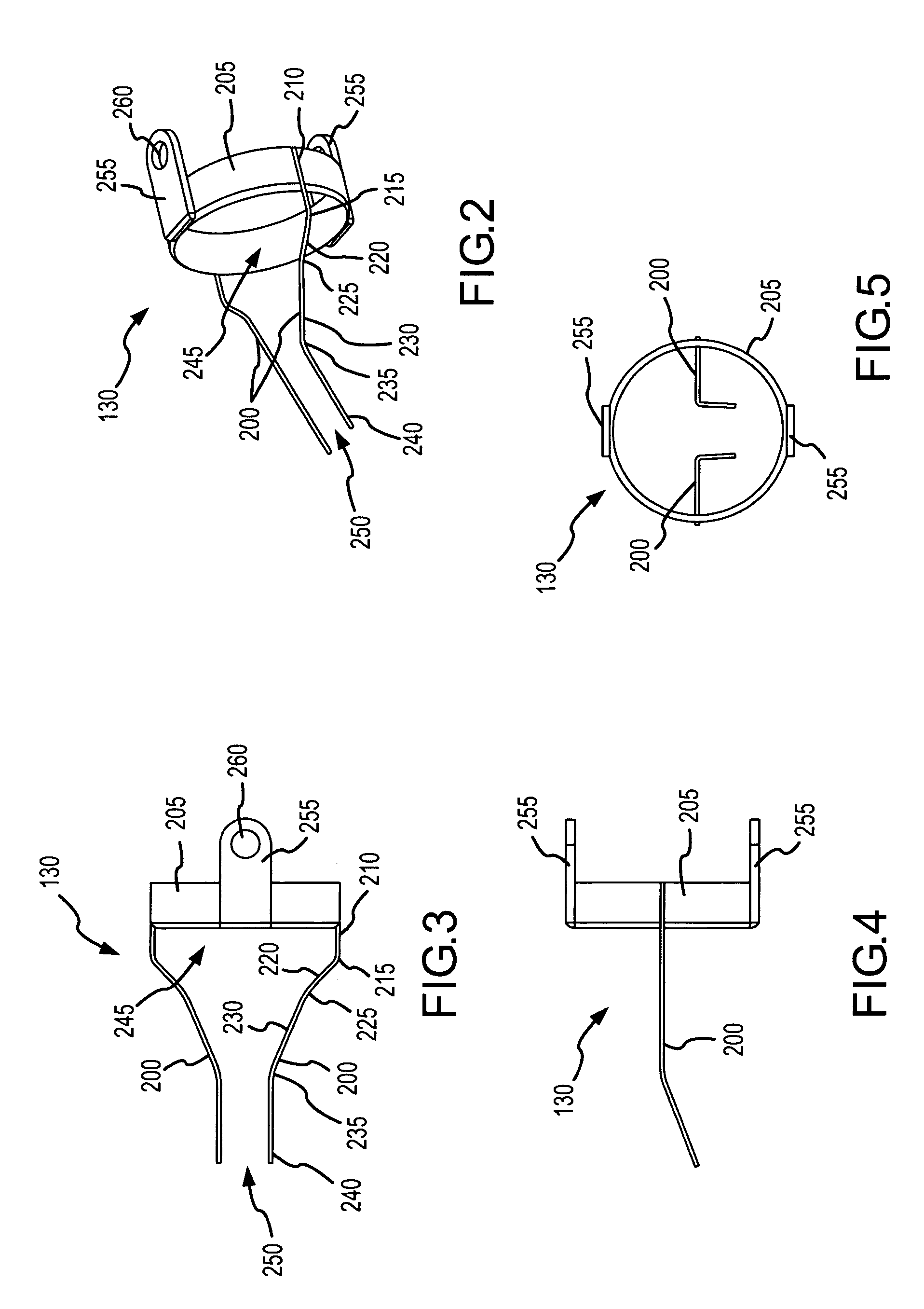

A charged particle guide adapted to be coupled with a charged particle detector, such as a secondary electron detector. The charged particle guide, in one example, comprising two wires extending from the charged particle detector toward a source of charged particles, such as secondary electrons emitted from an IC upon application of a focused ion beam. Upon application of a bias voltage, the charged particle guide introduces a collecting electric field that attracts charged particles and directs the charged particles to the charged particles detector.

Owner:DCG SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com