Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3274 results about "Magnetic separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scanning electron microscope

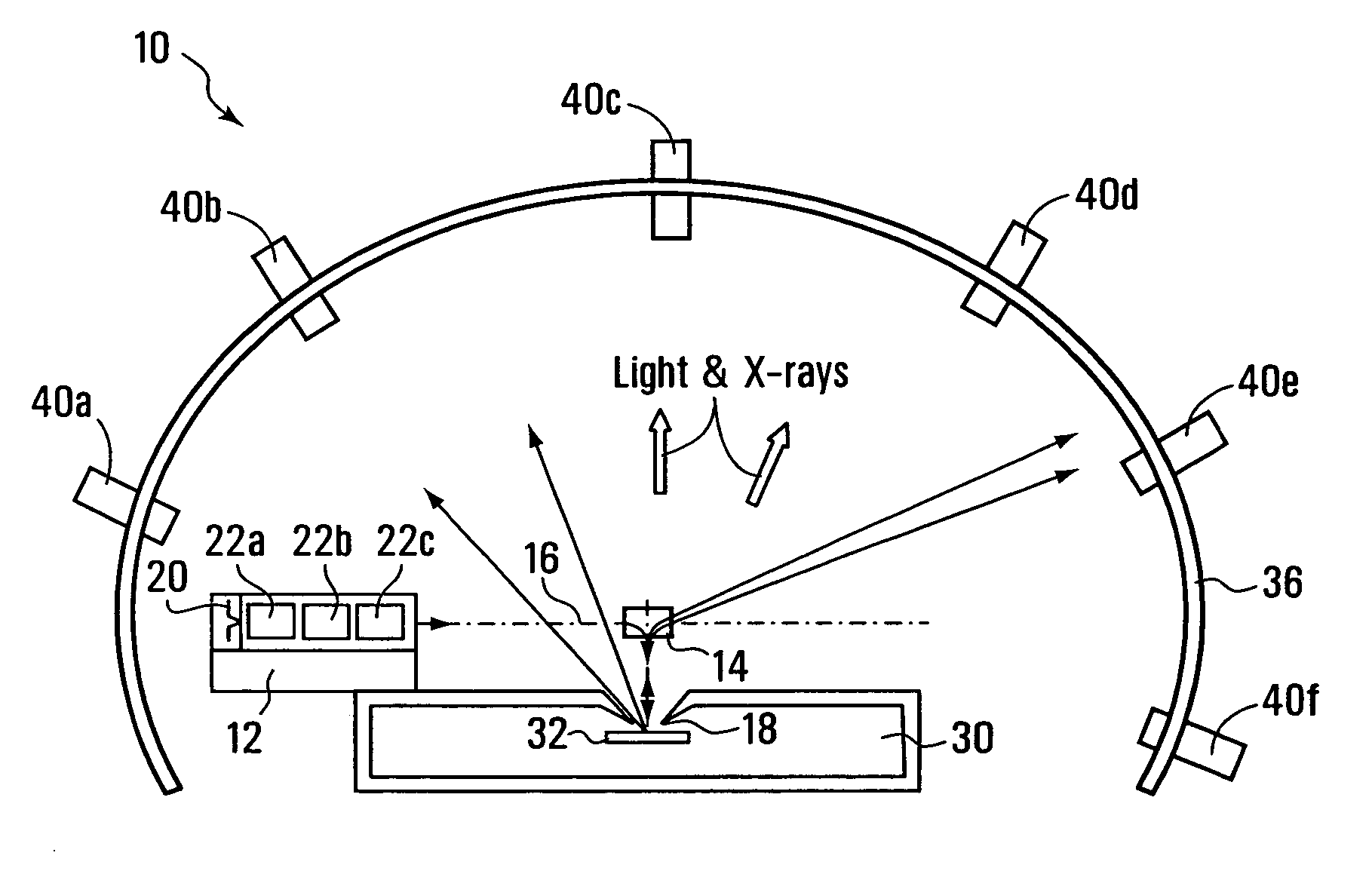

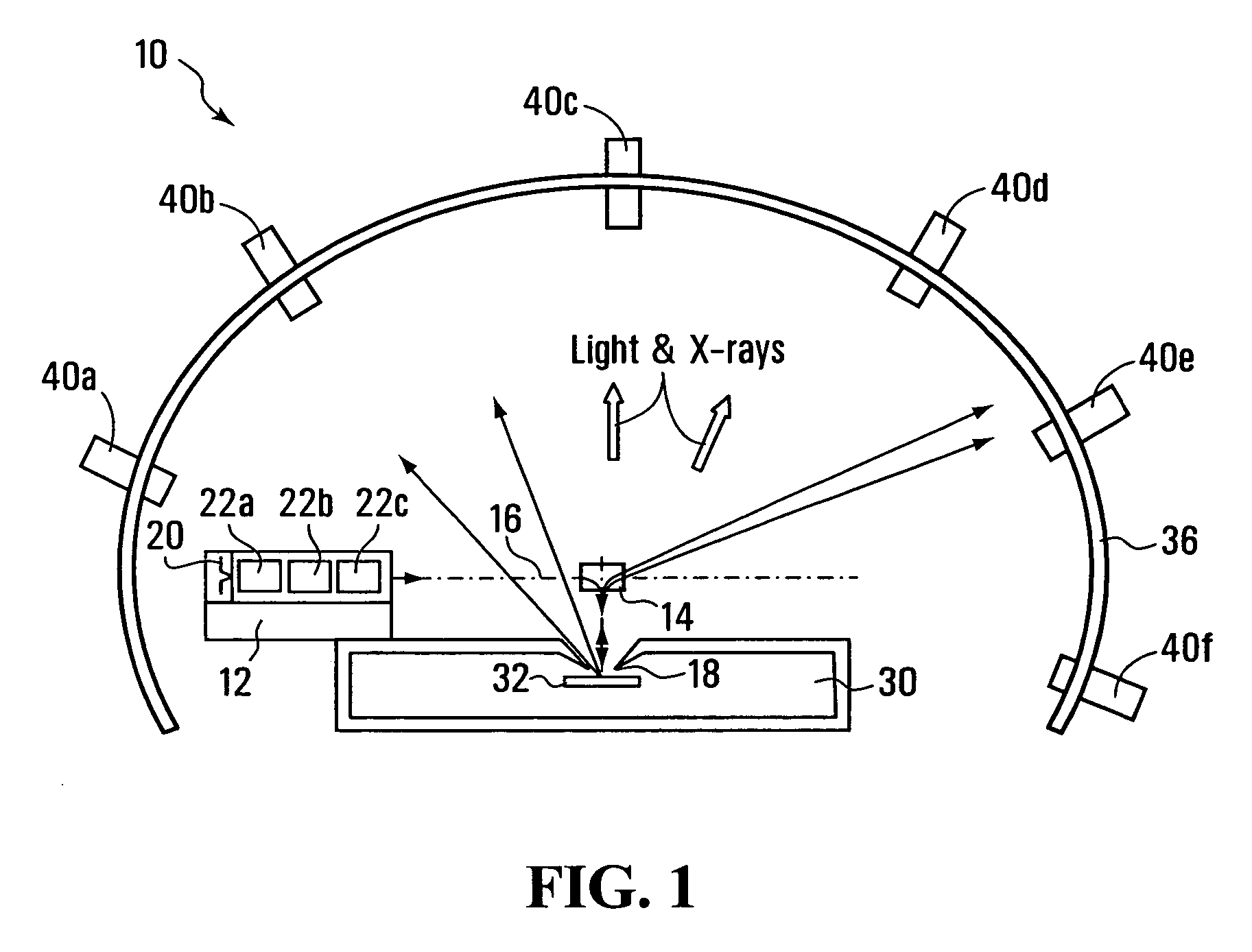

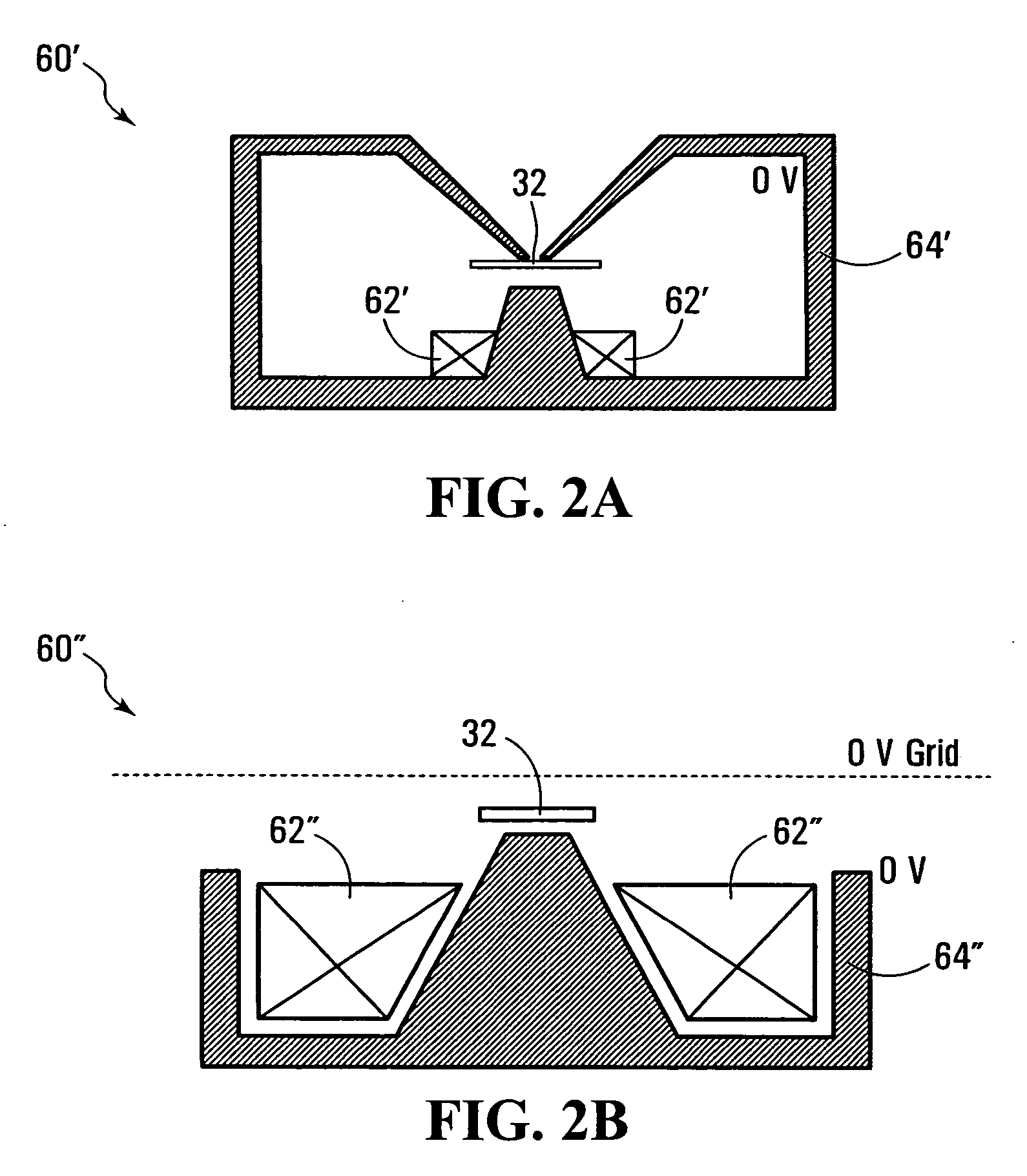

ActiveUS20060060782A1Improve transport efficiencyImprove efficiencyMaterial analysis using wave/particle radiationElectric discharge tubesAngle of incidenceElectron source

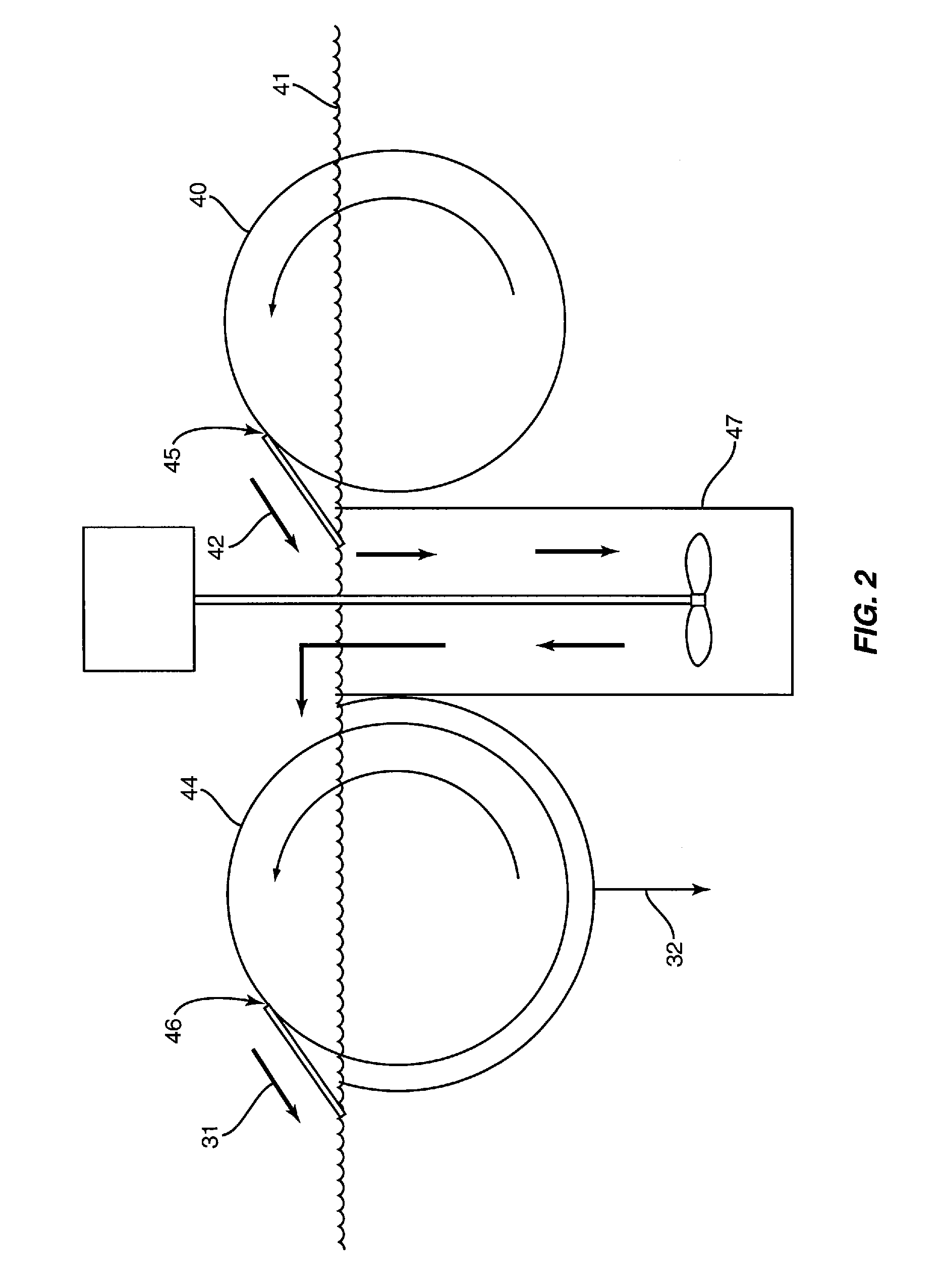

In a scanning electron microscope, an emitted primary electron beam is diverted by an angle of at least about 45 degrees prior to incidence with a specimen. The beam may be bent by a magnetic separator. The separator may also serve to deflect secondary electron and back scattered electrons. As the angle of emissions and reflections from the specimen is close to the angle of incidence, bending the primary electron beam prior to incidence, allows the electron source to be located so as not to obstruct the travel of emissions and reflections to suitable detectors.

Owner:NAT UNIV OF SINGAPORE

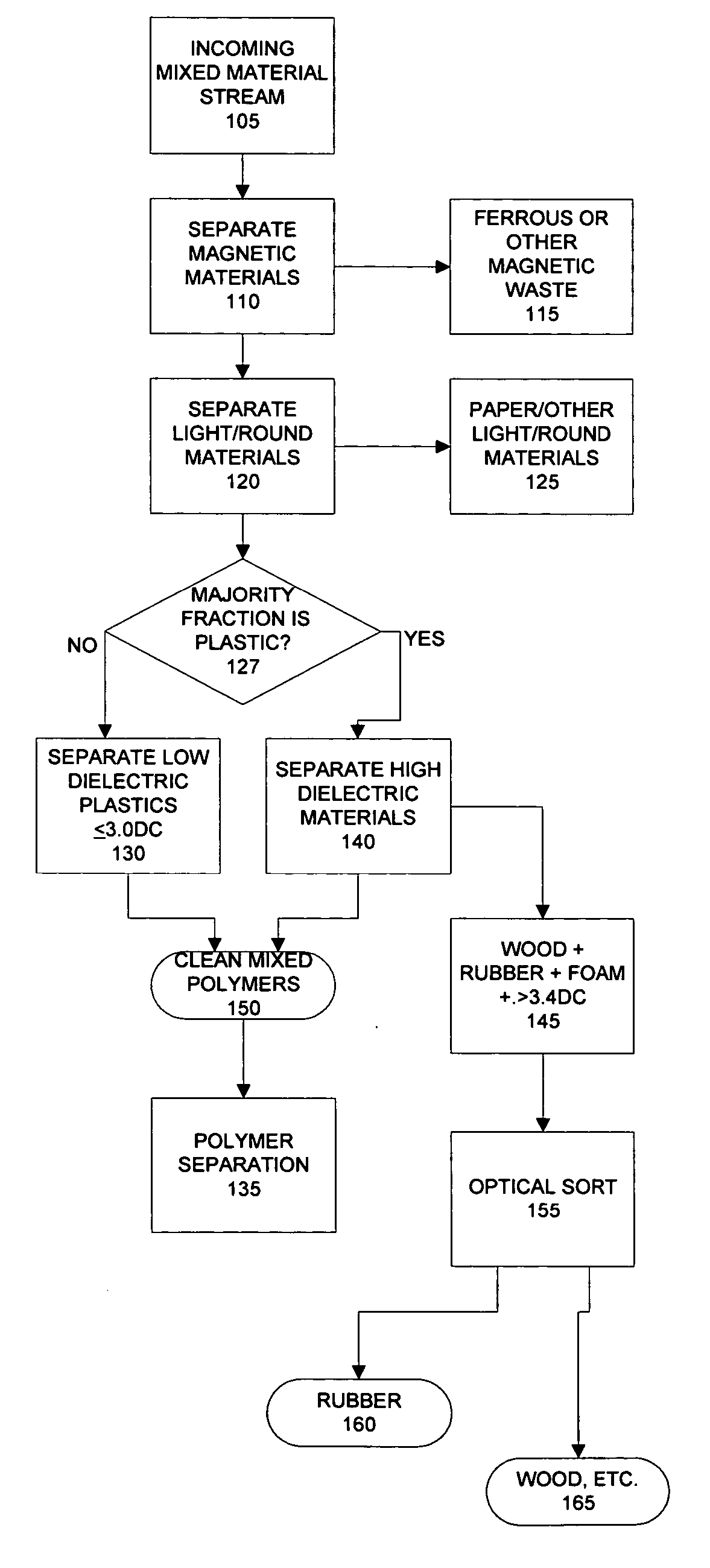

Dissimilar materials sorting process, system and apparata

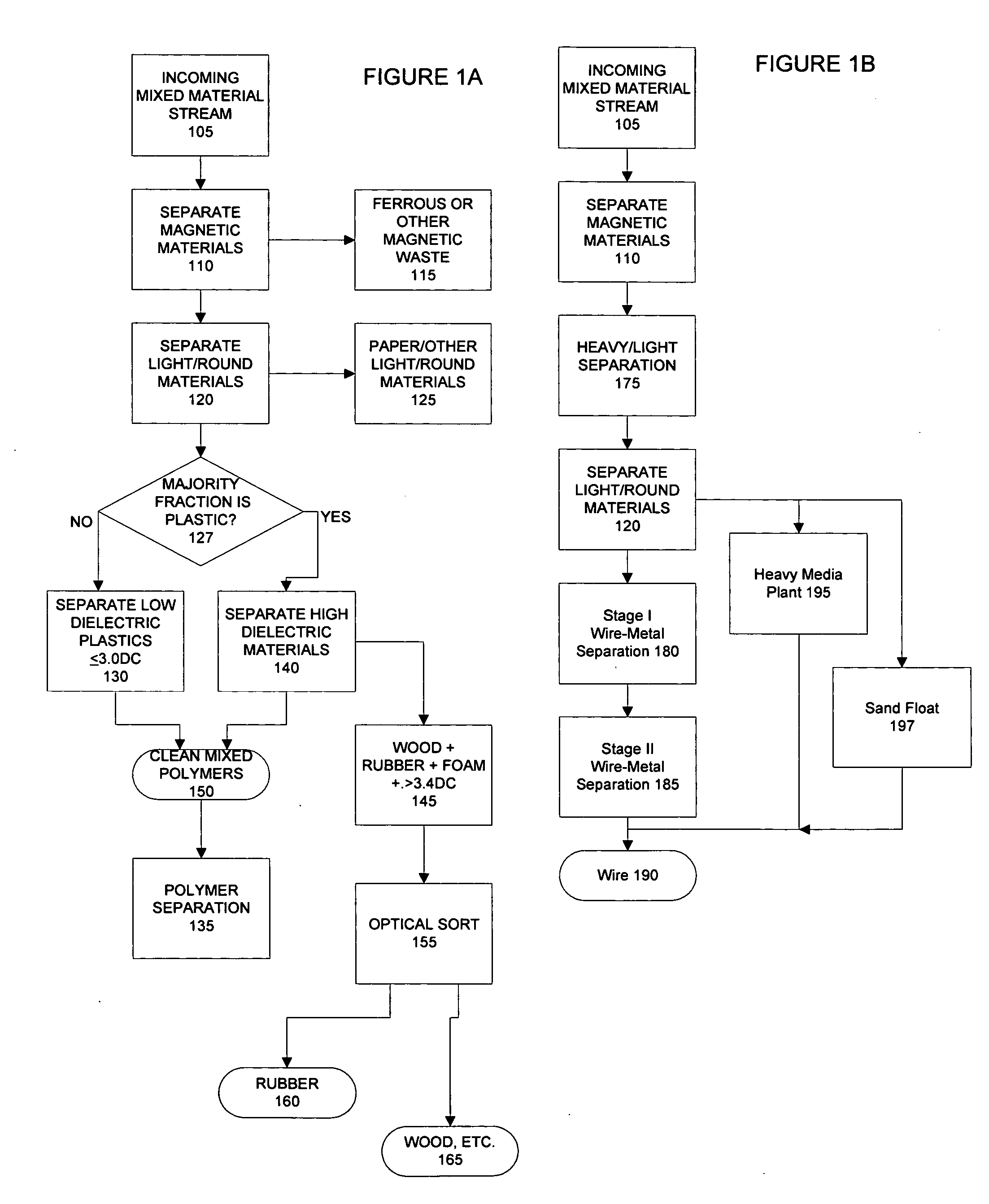

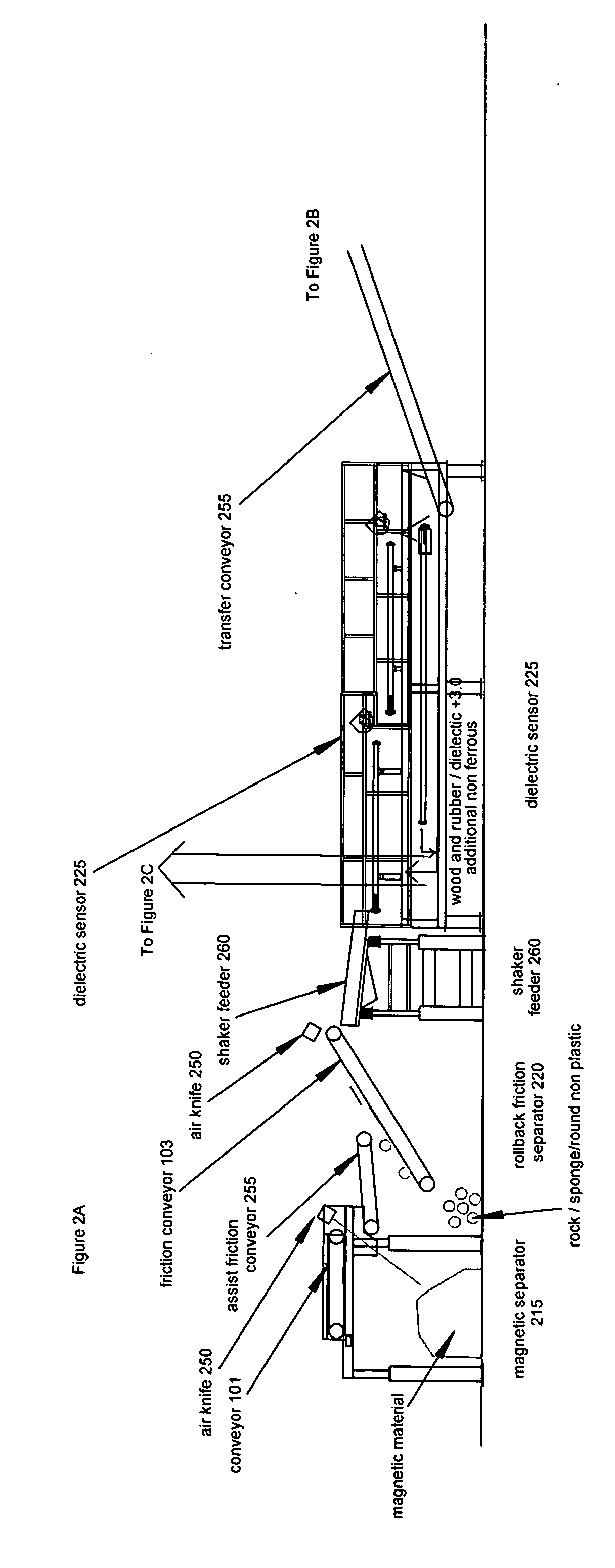

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

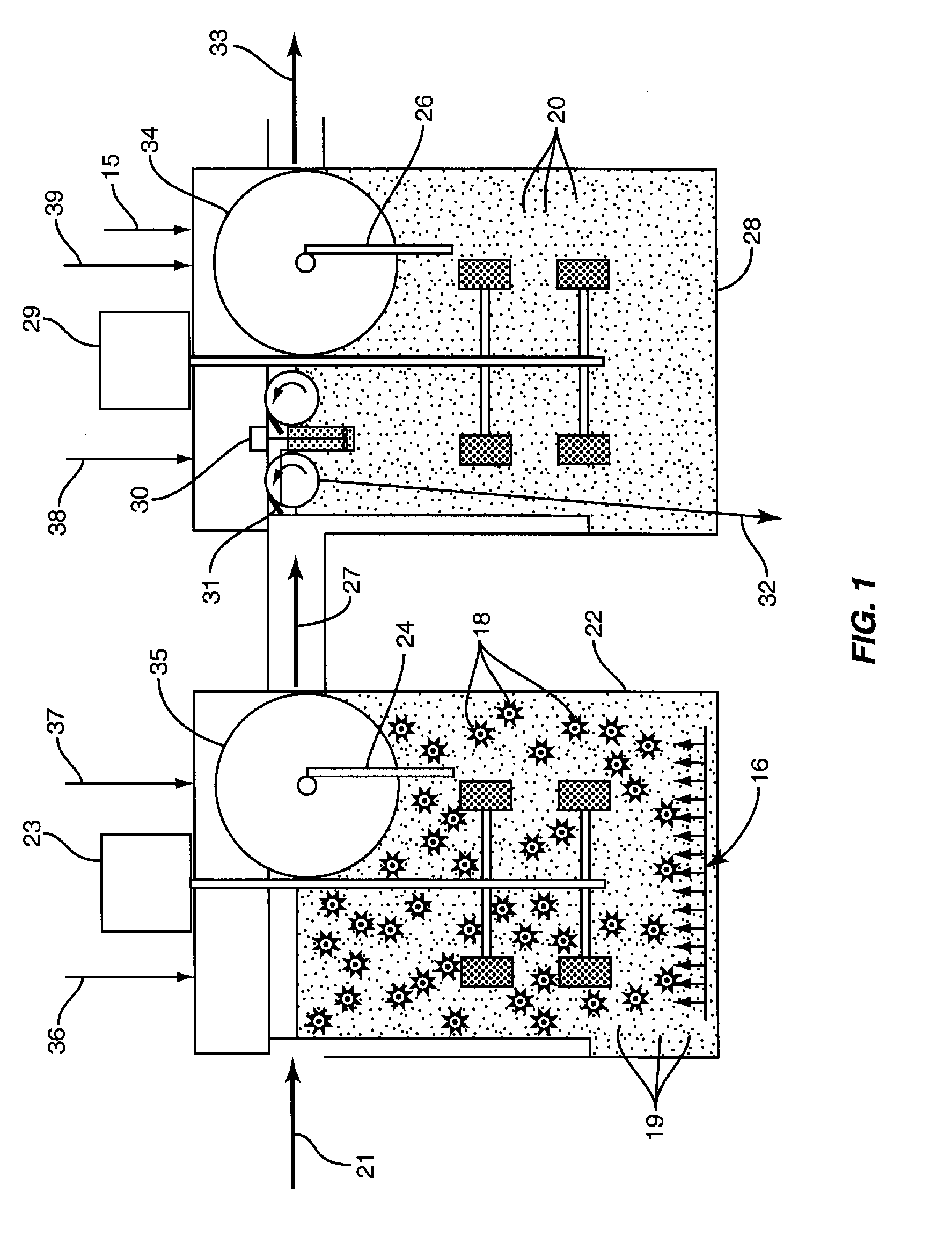

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

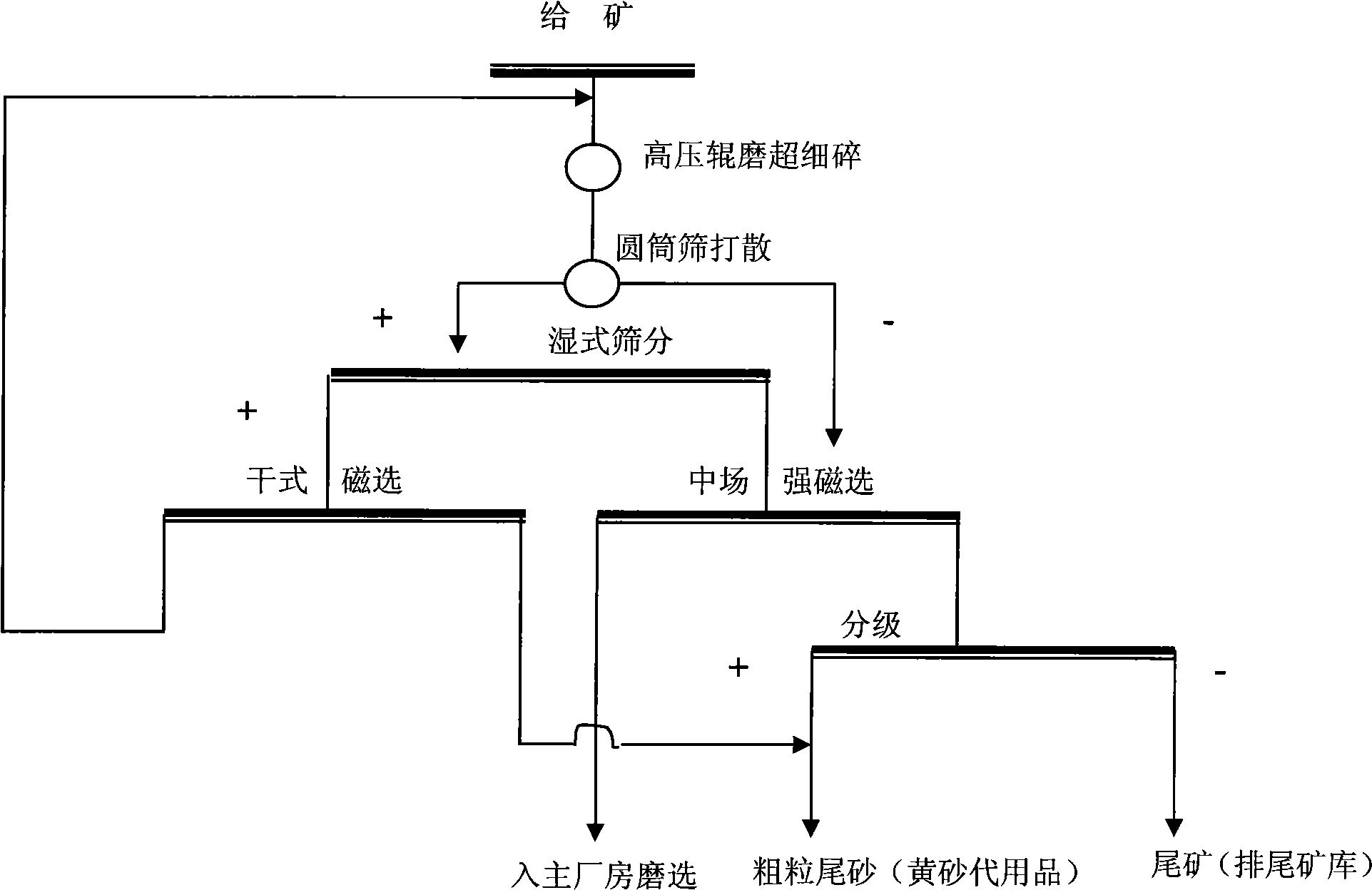

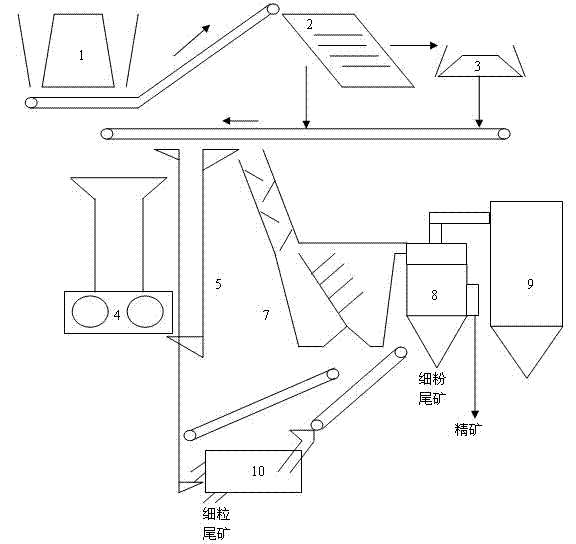

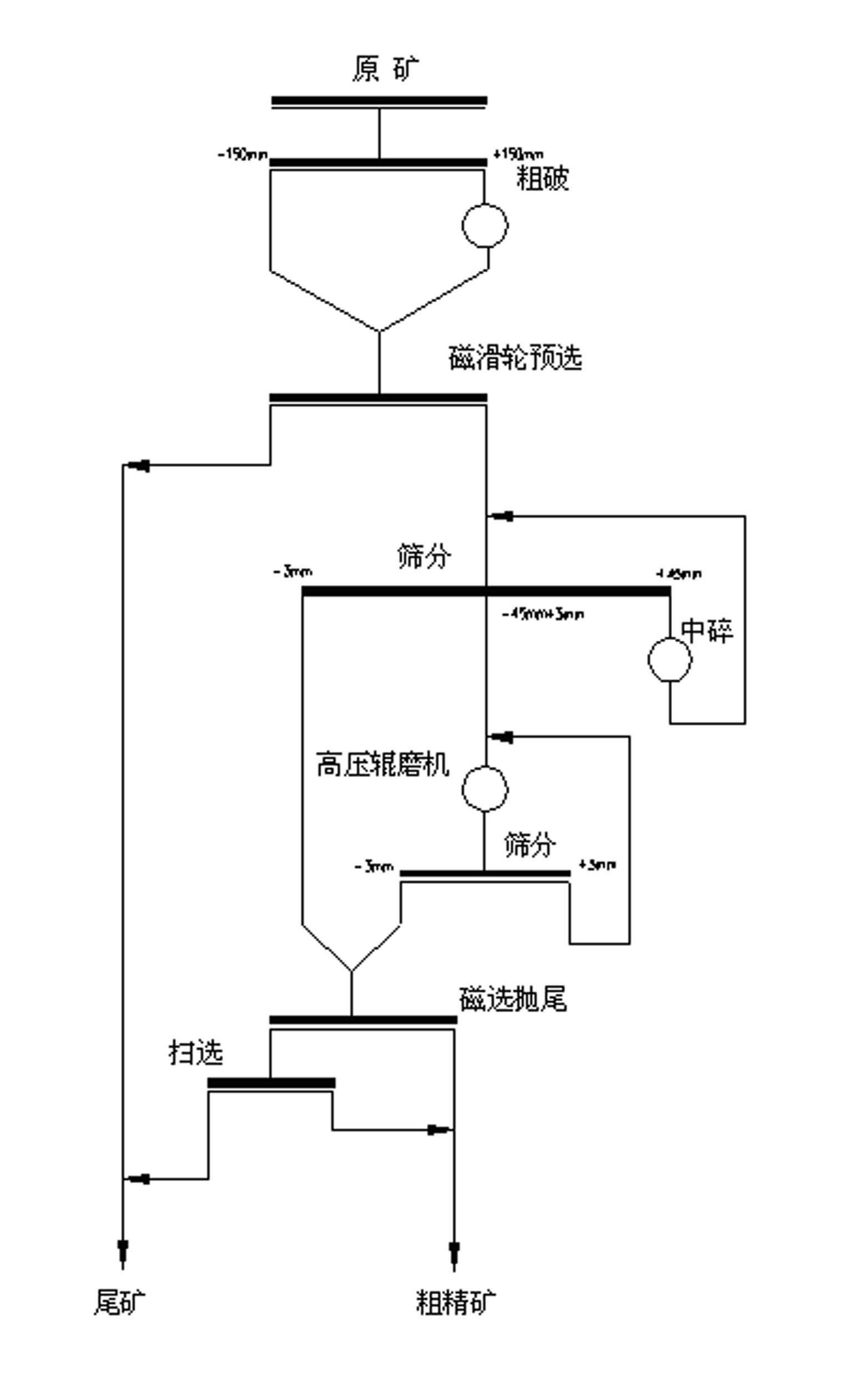

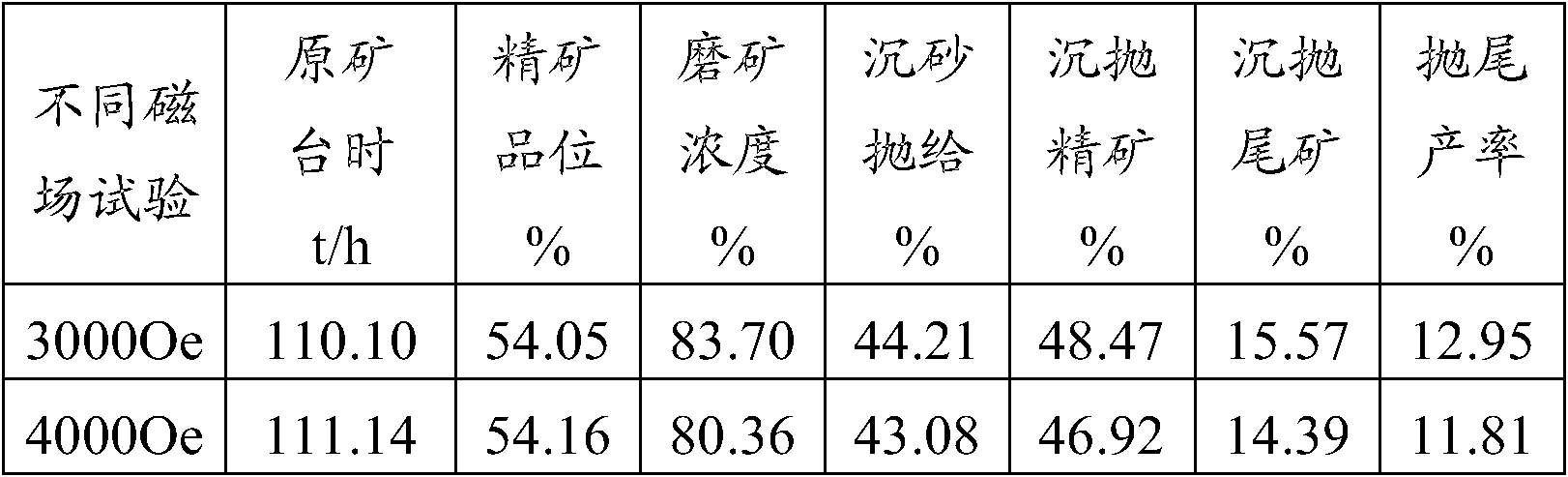

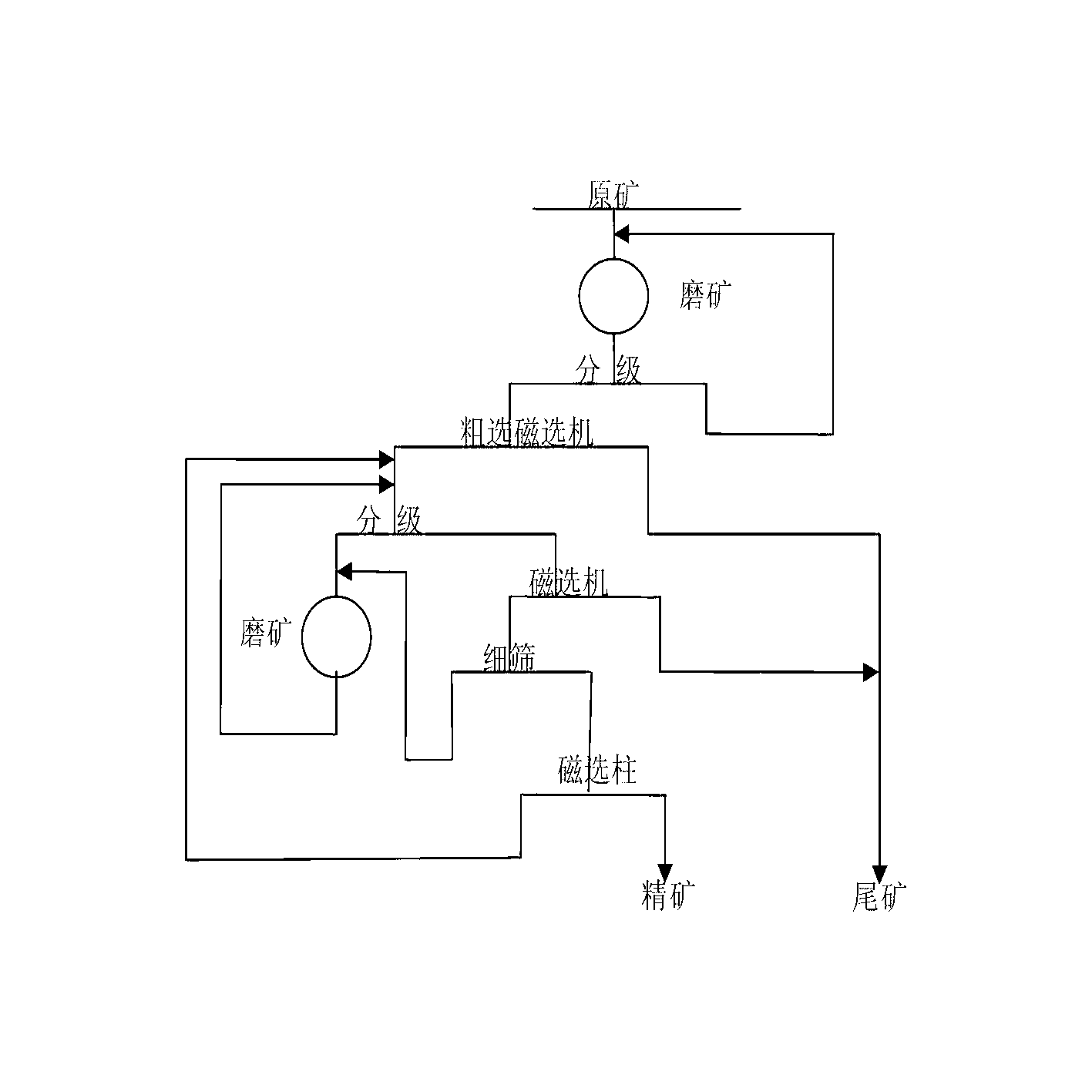

Pre-selection method of low-ore grade magnetic iron ore

InactiveCN101502819ASolve the costSolve the problem of large tailingsSievingScreeningSeparation technologyMagnetite

The invention discloses a preselecting method of low-grade magnetic iron ore, comprising the steps of crushing the raw ore of the magnetic iron ore by coarse crushing, intermediate crushing and fine crushing operations, conveying to subject to ultra-fine crushing operation, and then crushing by a high-pressure roller mill, scattering the crushed product by a wet cylindrical sieve, conveying the ore on the cylindrical sieve to the vibrating sieve by a belt to perform wet gradation, conveying the ore on the vibrating sieve to a dry magnetic separator by the belt to discard the waste, returning the ore concentrate of the dry magnetic separator to the high-pressure roller mill to crush the ore concentrate again, perform magnetic separation and discarding tailings of the ore concentrate below the vibrating sieve and the ore concentrate below the cylindrical sieve in a wet coarse grain intermediate-field intensity magnetic separator, and selecting the coarse ore concentrate of the intermediate-field intensity magnetic separator by a grinding separation technology. The invention has the advantages that the invention selects quantities of qualified mine tailings by wet magnetic separation before grinding ore, reduces ore grinding work, reduces ore grinding energy consumption and has high system processing capacity; the invention can be widely used in magnetic ore dressing plant, and in particular suitable for treatment of preselecting low-grade magnetic iron ore with the iron grade lower than or equal to 22%.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

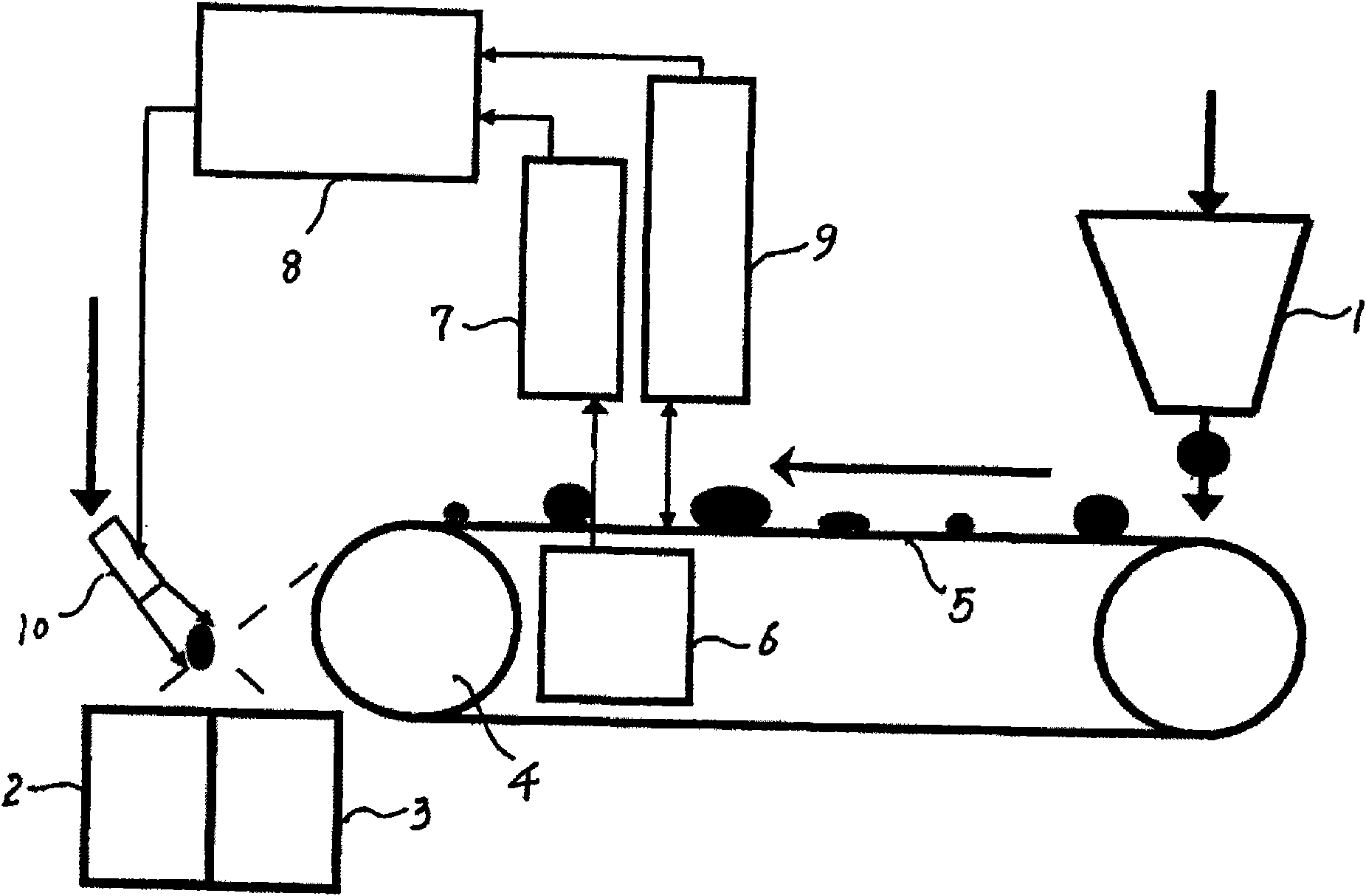

Automatic separator of coal gangue

ActiveCN101637765ANo mutual interferenceSolve the technical problems of poor sorting effectSortingConveyor partsX-rayGamma ray

The invention relates to an automatic separator of coal gangue, which comprises a raw material feeding copper, a coal receiving copper, a gangue receiving copper, a conveying-belt conveyor, an identification and separation controlling mechanism and an executing mechanism, wherein the conveying-belt conveyer is arranged among the raw material feeding copper, the coal receiving copper and the gangue receiving copper; the identification and separation controlling mechanism comprises a single-energy gamma ray source, an X-ray sensor, a measure and control instrument and an ultrasonic transmitter-receiver; the single-energy gamma ray source is arranged below a conveying belt, the X-ray sensor is arranged above the conveying belt and corresponds to the single-energy gamma ray source, the measure and control instrument is electrically connected with the X-ray sensor, and the ultrasonic transmitter-receiver is arranged above the conveying belt and electrically connected with the measure and control instrument; the executing mechanism is a high-frequency air valve arranged above the coal receiving copper and the gangue receiving copper; and the valve port of the high-frequency air valve isarranged towards a throwing track of coal and gangue. As the single-energy gamma ray source is adopted, only one nuclear radiation material exists, and only one spectral line is radiated, the mutualinterference among a plurality of spectral lines can not be generated; and the invention has accurate measurement and good separation effect.

Owner:GREAT DRAGON RISING ELECTROMECHANICAL TECH BEIJING

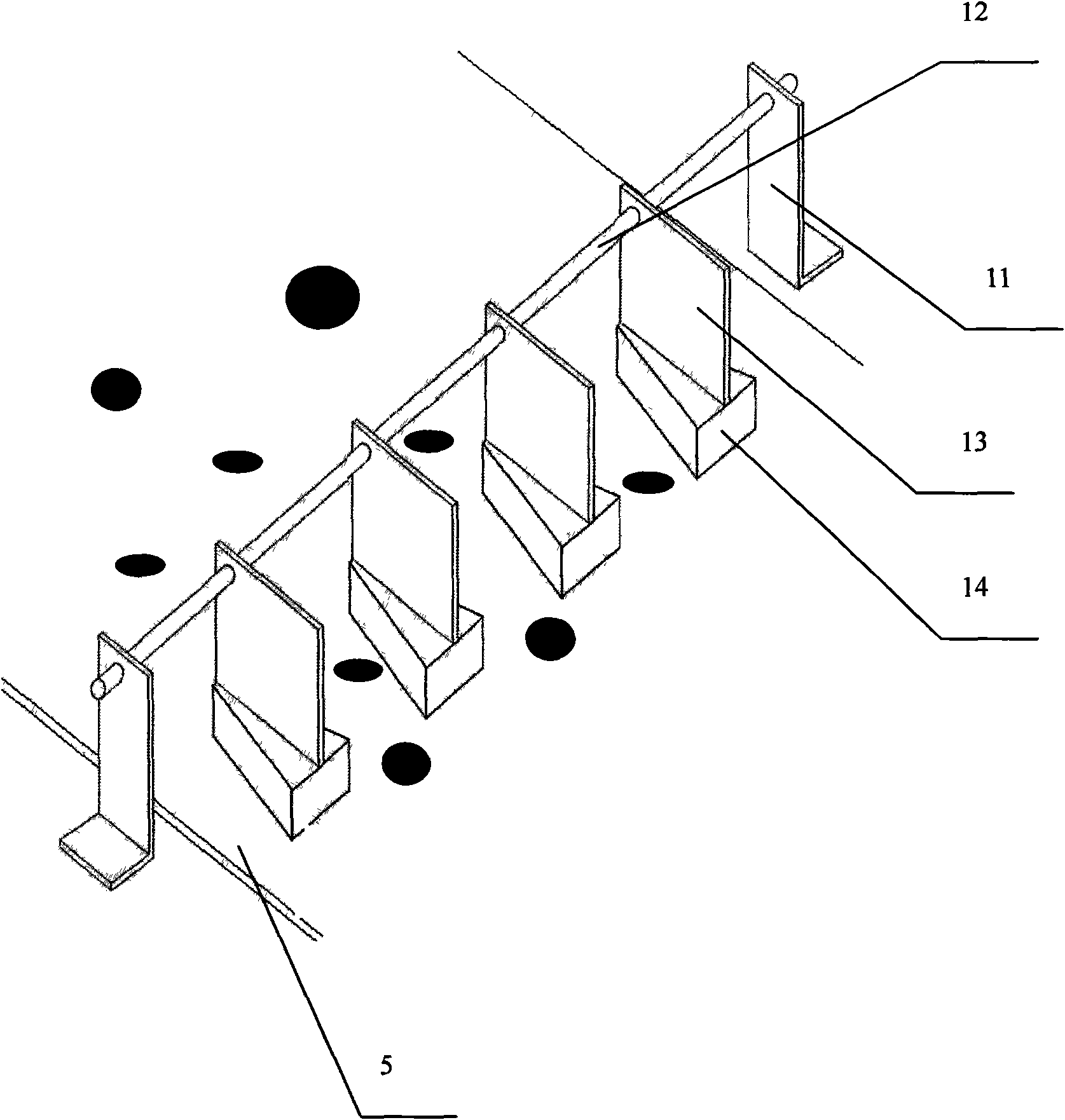

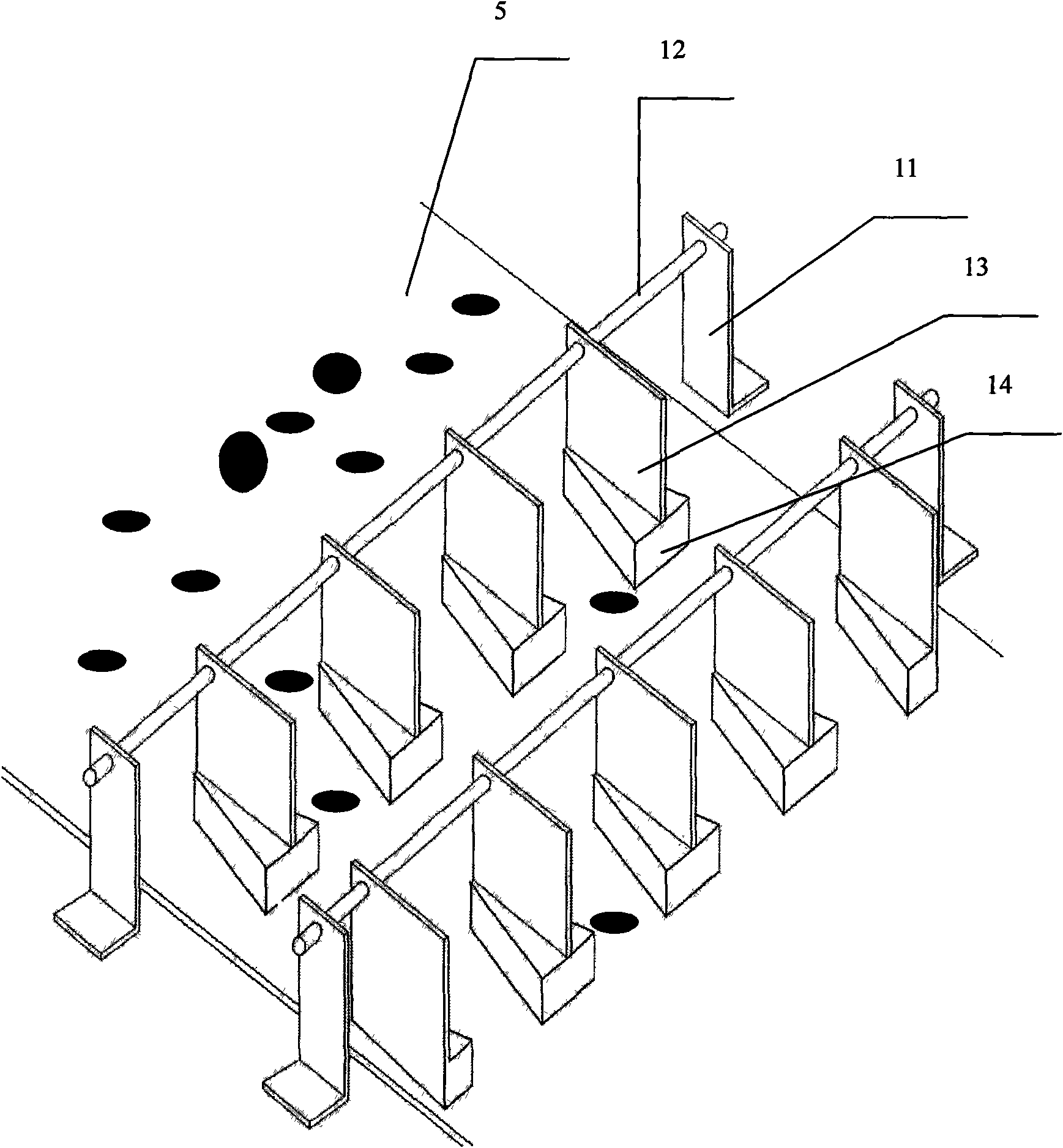

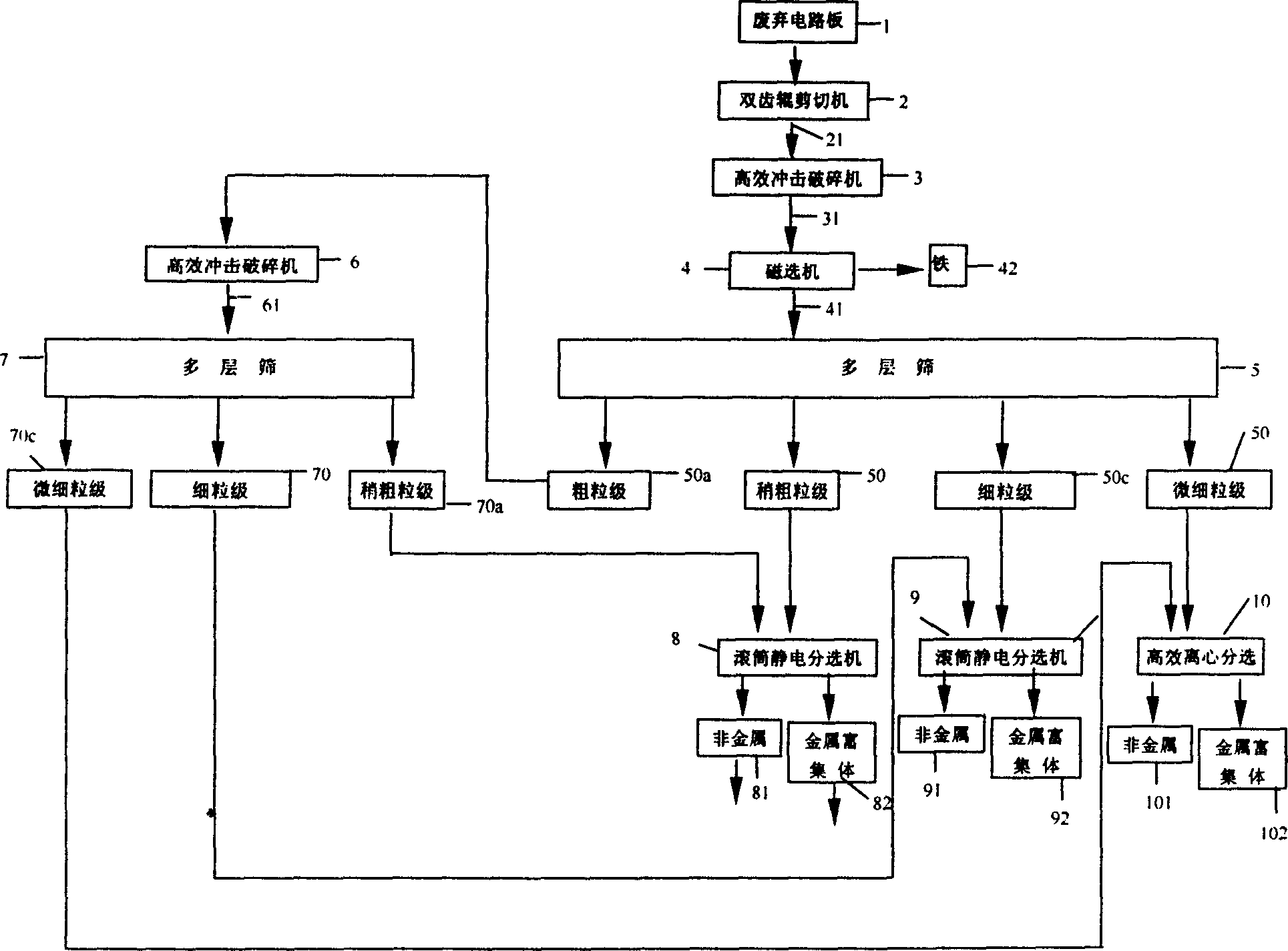

Techhnique for reclaiming metal concentrate in obsolete PCB physically

InactiveCN1563440ASolve resource problemsAchieve recyclingSolid waste disposalProcess efficiency improvementDouble teethMagnetic separator

A physical recovery technology of metal enriched materials from waste CB applies a mechnanical and physical sorting method to cut, crush, screen, sort and separate the waste CB by a double tooth roll shearer, a punch crusher, a magnetic separator, a separating screen, a rotary static separator, high efficient centrifugal separator to get a multicomponent of metal rich collection and a nonmetal enriched material to recover all valuable components from waste CB.

Owner:CHINA UNIV OF MINING & TECH

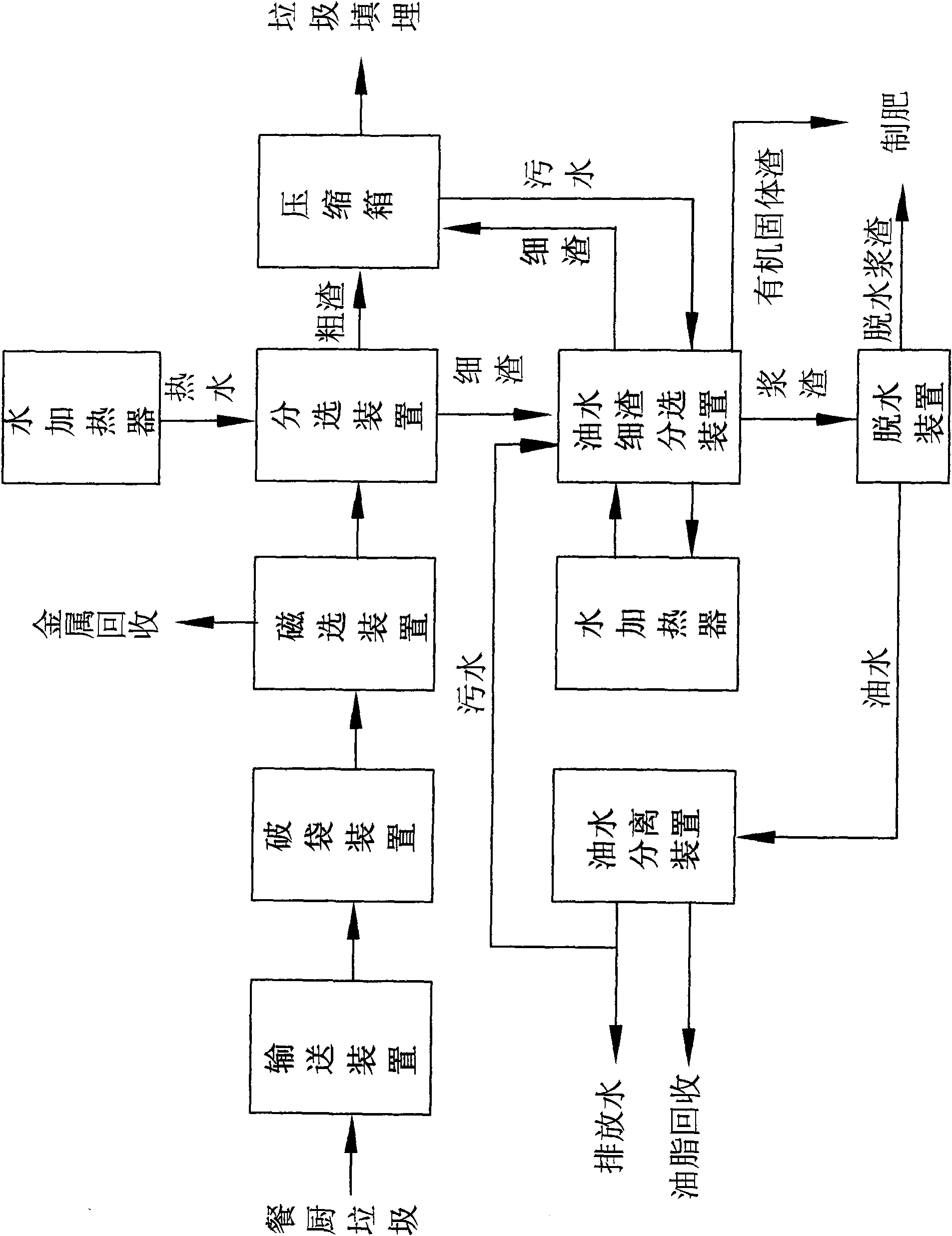

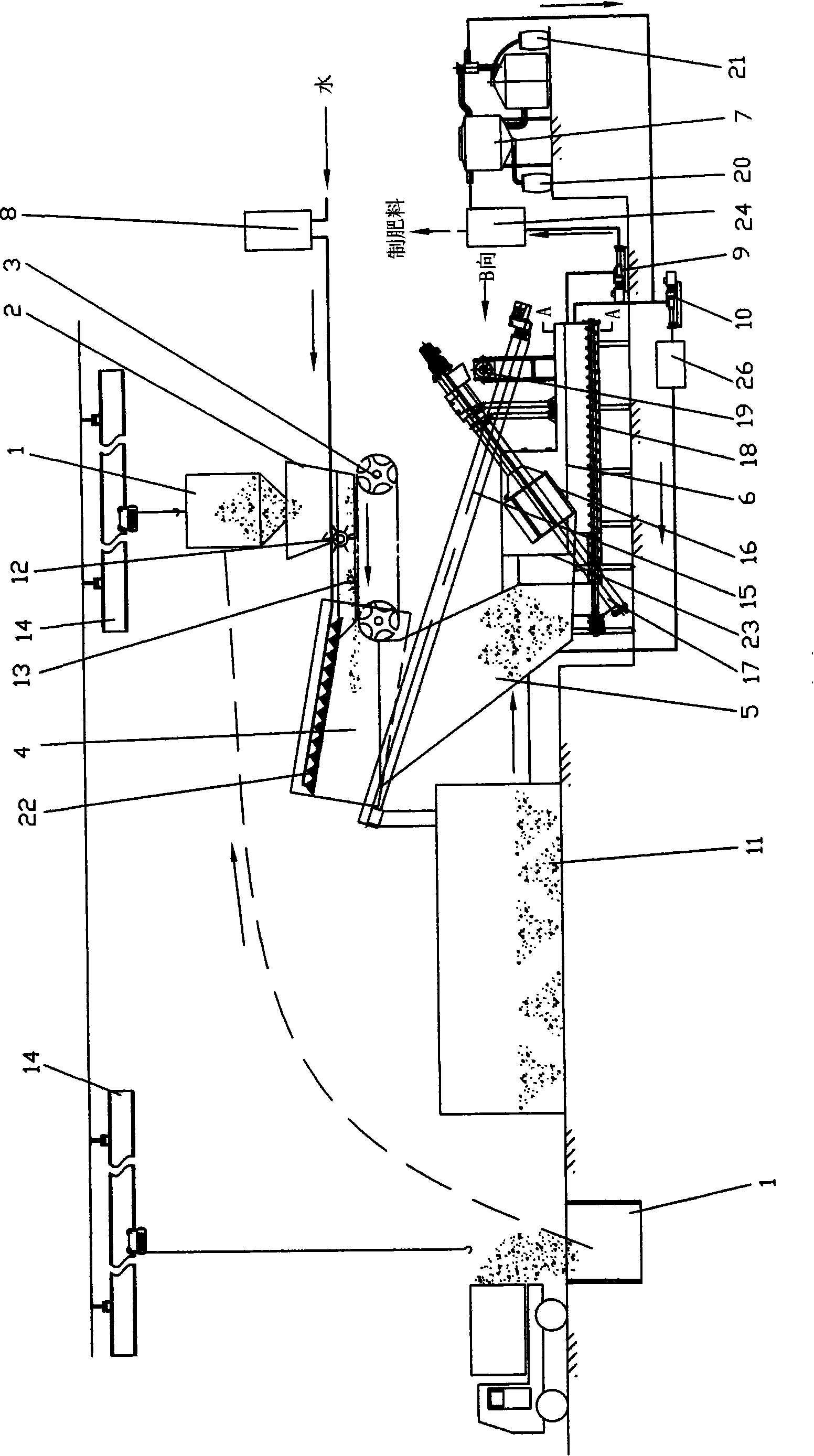

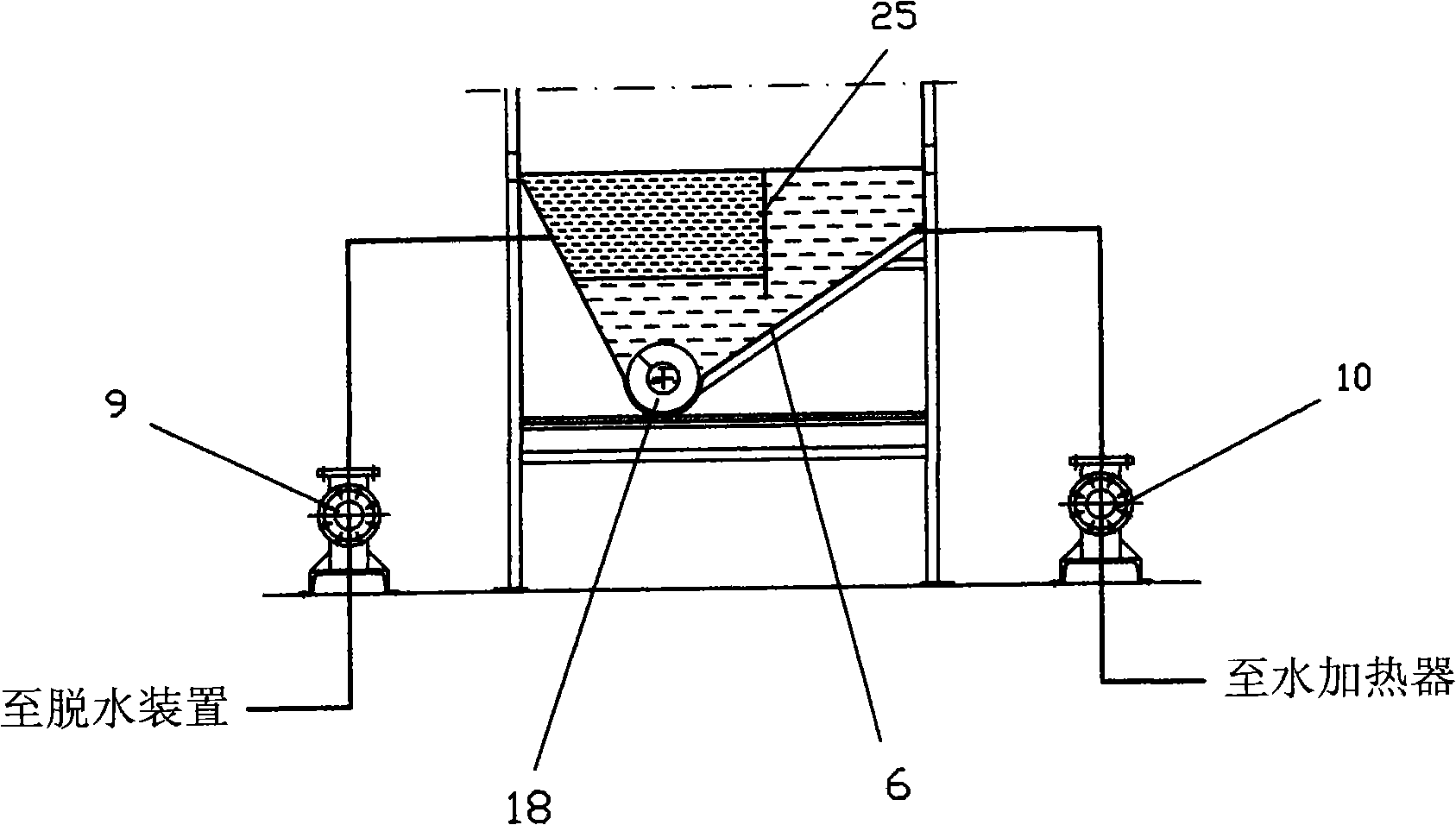

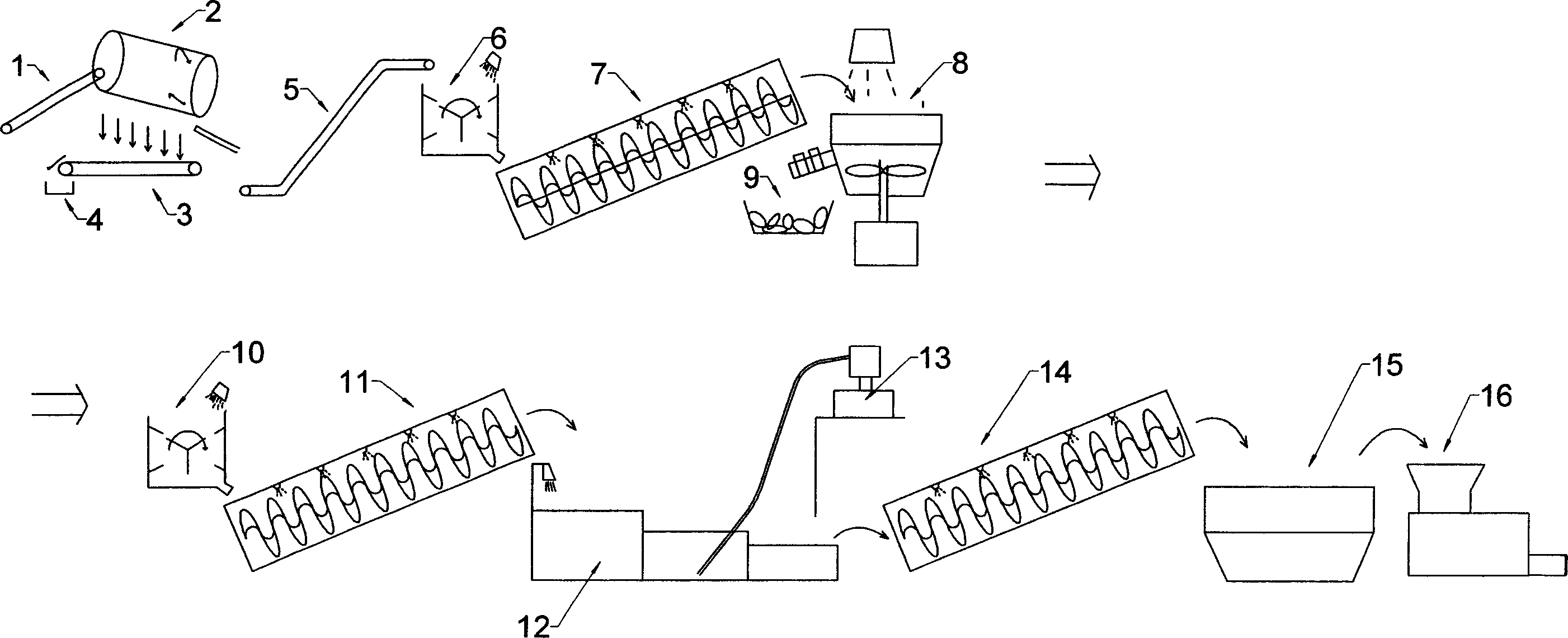

Treating technical method for food wastes and treating equipment

InactiveCN101524700AHarmlessReduce consumptionSolid waste disposalMagnetic separatorEnvironmental engineering

The invention discloses a treating technical method for food wastes and treating equipment, which relate to the technical field of screening and oil water separation in food waste treatment; the technique method comprises the following steps: the food waste is recycled by bag crushing, magnetic separation, coarse residue screening, hot water washing, solid-liquid separation of fine residue and secondary oil water separation with water in a separator of oil, water and fine residue. The treating equipment of food wastes for realizing the technique method mainly comprises a charging part, a conveying part, a bag-crushing device, a magnetic separator, a coarse residue separating part, a solid-liquid separator, a dehydrating unit, an oil water separator and the like. The invention can carry out grading screening, solid-liquid separation, oil water separation and resource recycling on food wastes, has continuous operation in use, thorough treatment and high efficiency and can protect environment.

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH +1

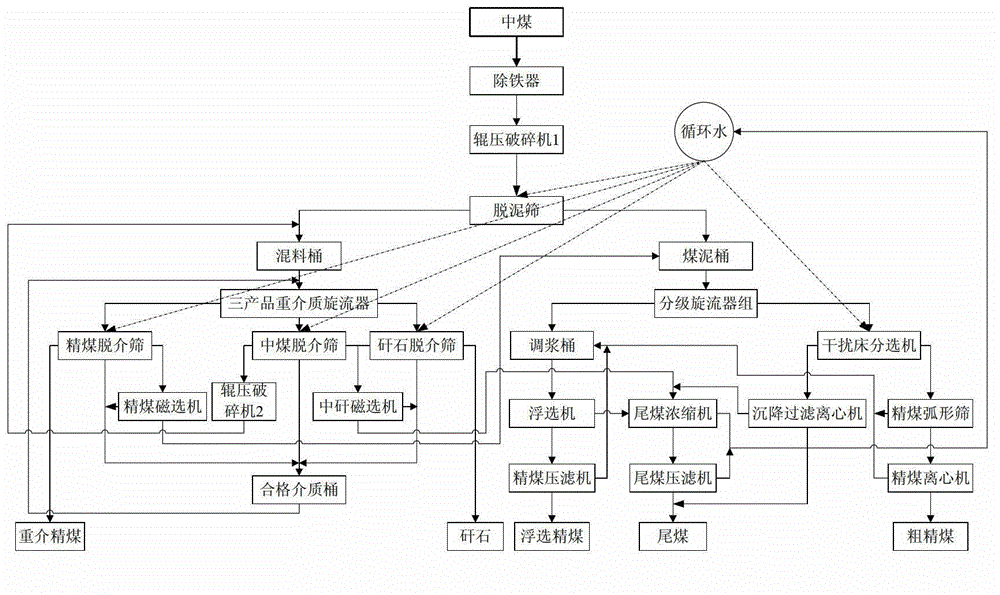

Efficient crushing and three-section type screening method of coking coal gravity middings

An efficient crushing and three-section type screening method of coking coal gravity middings belongs to coal crushing, dissociating and screening processes. Gravity middings in a coking coal preparation plant are taken as a raw material to be crushed through rolling to the fraction being below 6 mm or 3 mm; a desliming screen is used to deslime a material with the fraction being 1 mm, a material with the fraction being 6 to 1 mm or 3 to 1 mm enters into a three-product dense medium cyclone, and clean coal, middings and gangues are respectively obtained after two sections are subjected to medium drainage; the material with the fraction being 1 mm is mixed with tailings in a clean coal magnetic separator, fine coal slimes with the fraction being 0.25 mm are deslimed by a classifying cyclone; coarse coal slimes with the fractions being 1 to 0.25 mm enter into a teetered bed separator for screening, light products are dewatered by a sieve bend and a coal slime centrifuge to obtain coarse clean coal, and heavy products are dewatered by a screen bowl centrifuge to obtain tailings; the fine coal slimes with the fractions being 0.25 mm enter into a flotation machine for flotation, and foamed clean coal and the tailings are sequentially subjected to concentration and pressure filtration dewatering to obtain flotation clean coal and the tailing product; and after the gravity middings are crushed through rolling, the product returns to a mixing barrel. The method has the advantages that the graded screening is carried out on the preselected coal slimes with coarse fraction and fine fraction, and the equipment screening precision is improved.

Owner:CHINA UNIV OF MINING & TECH

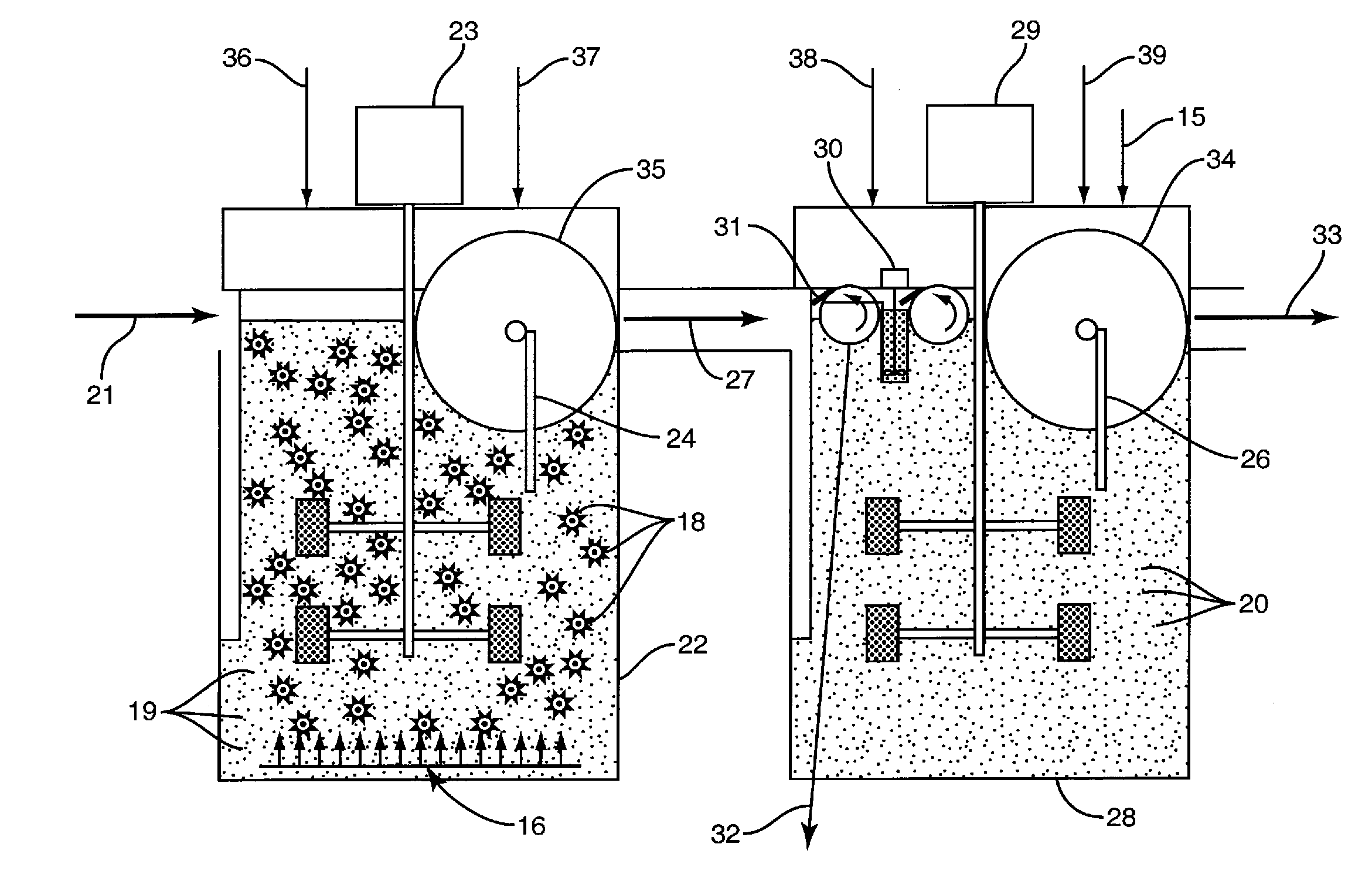

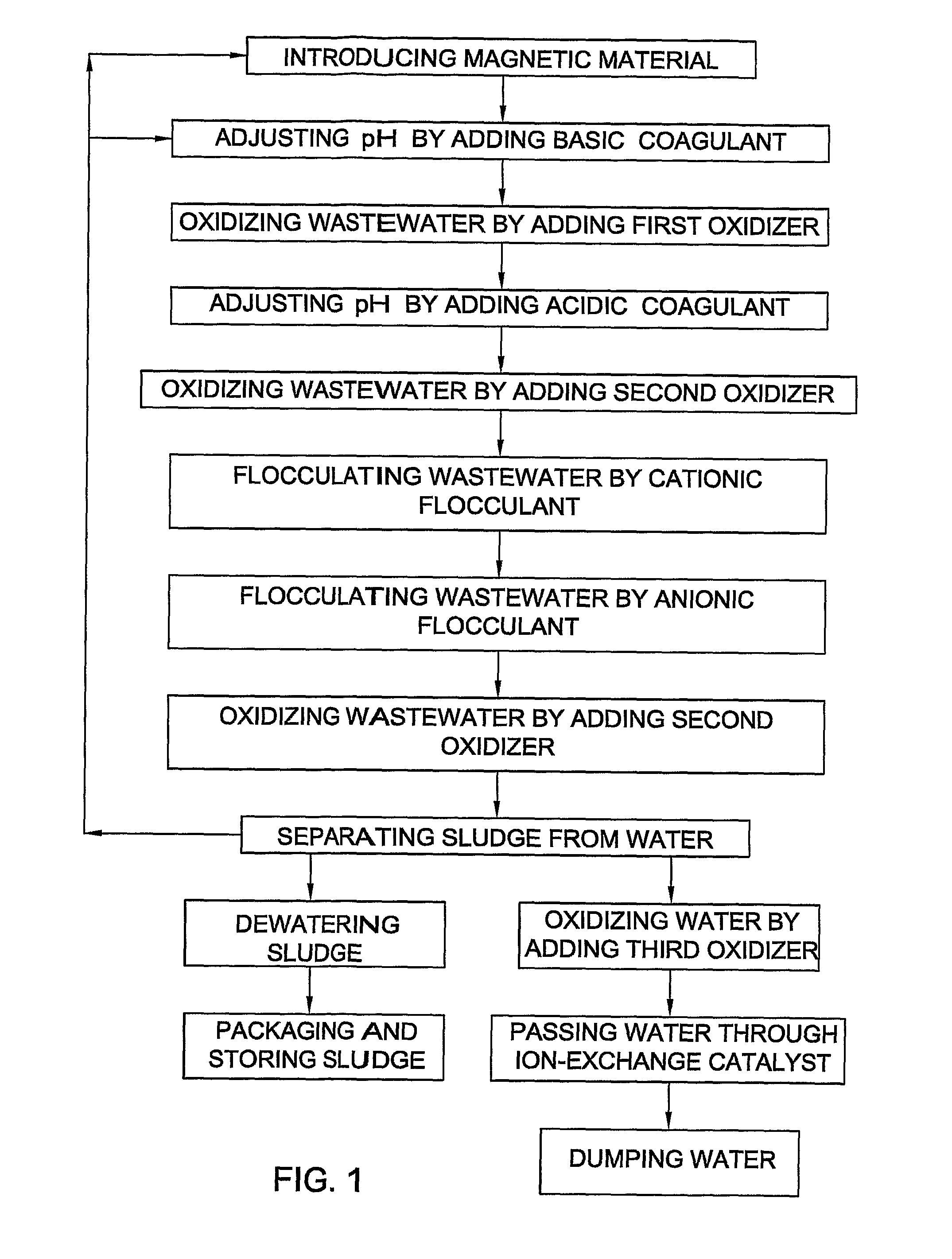

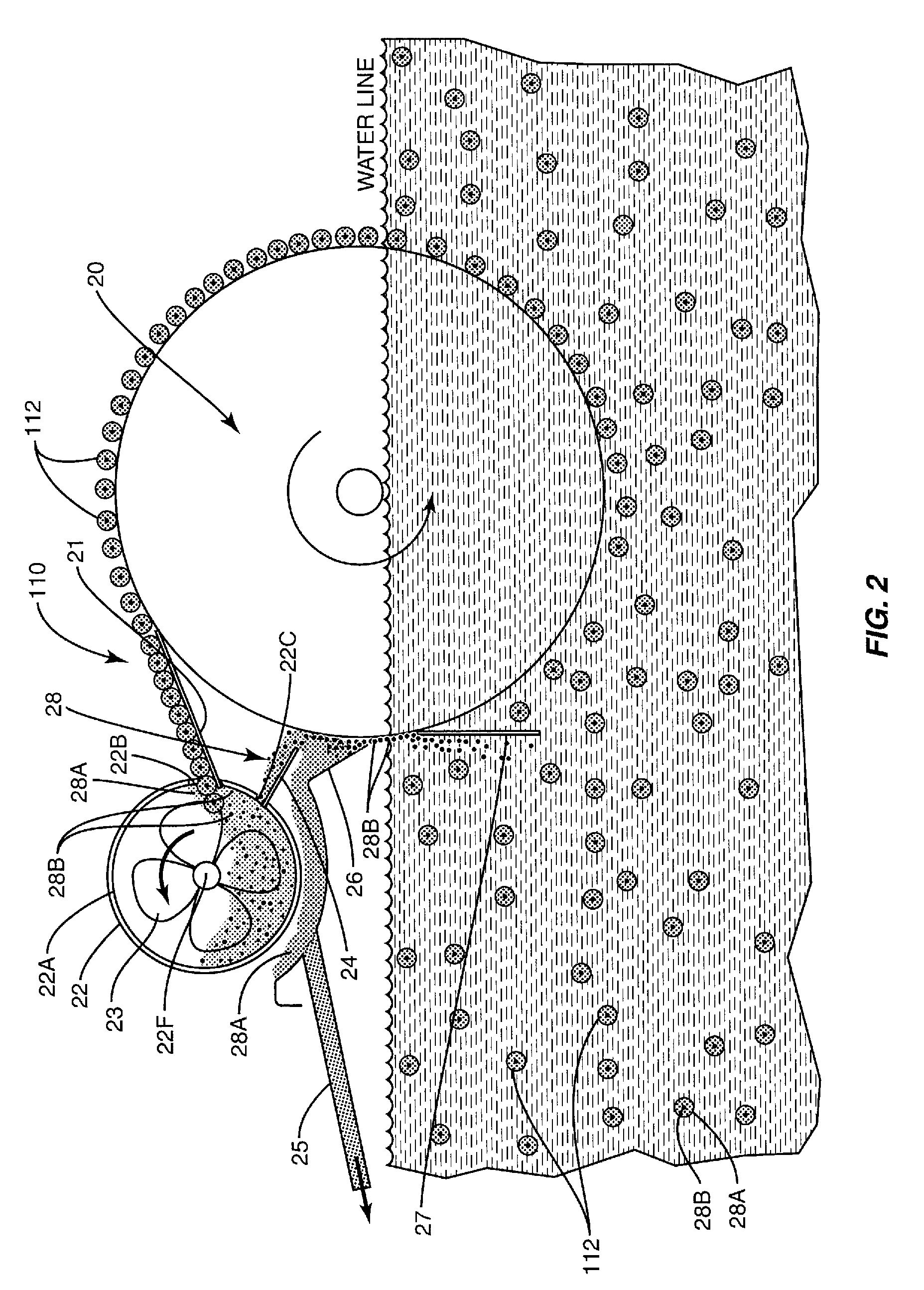

Use of a magnetic separator to biologically clean water

InactiveUS20080073268A1Treatment using aerobic processesWater/sewage treatment by magnetic/electric fieldsNitrateMagnetic separator

A nitrification-denitrification process using magnetic seeding and magnetic separation to treat water is provided. The process includes biologically converting ammonia to nitrates with a biofilm disposed on magnetic seed. Suspended solids are removed by mixing flocculant and magnetic seeds with the water and magnetically removing floc formed floc from the water.

Owner:CORT CHERYL J

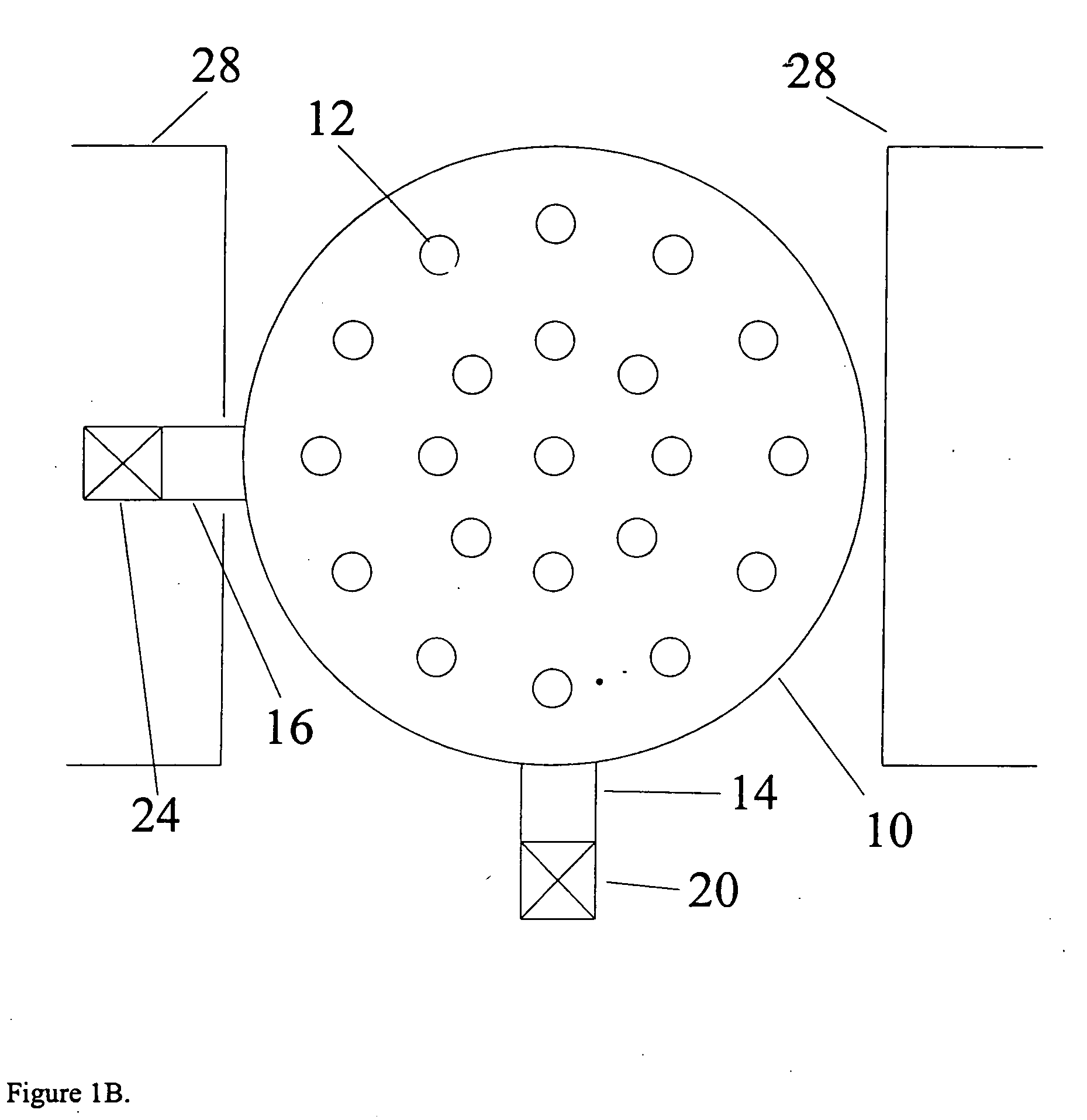

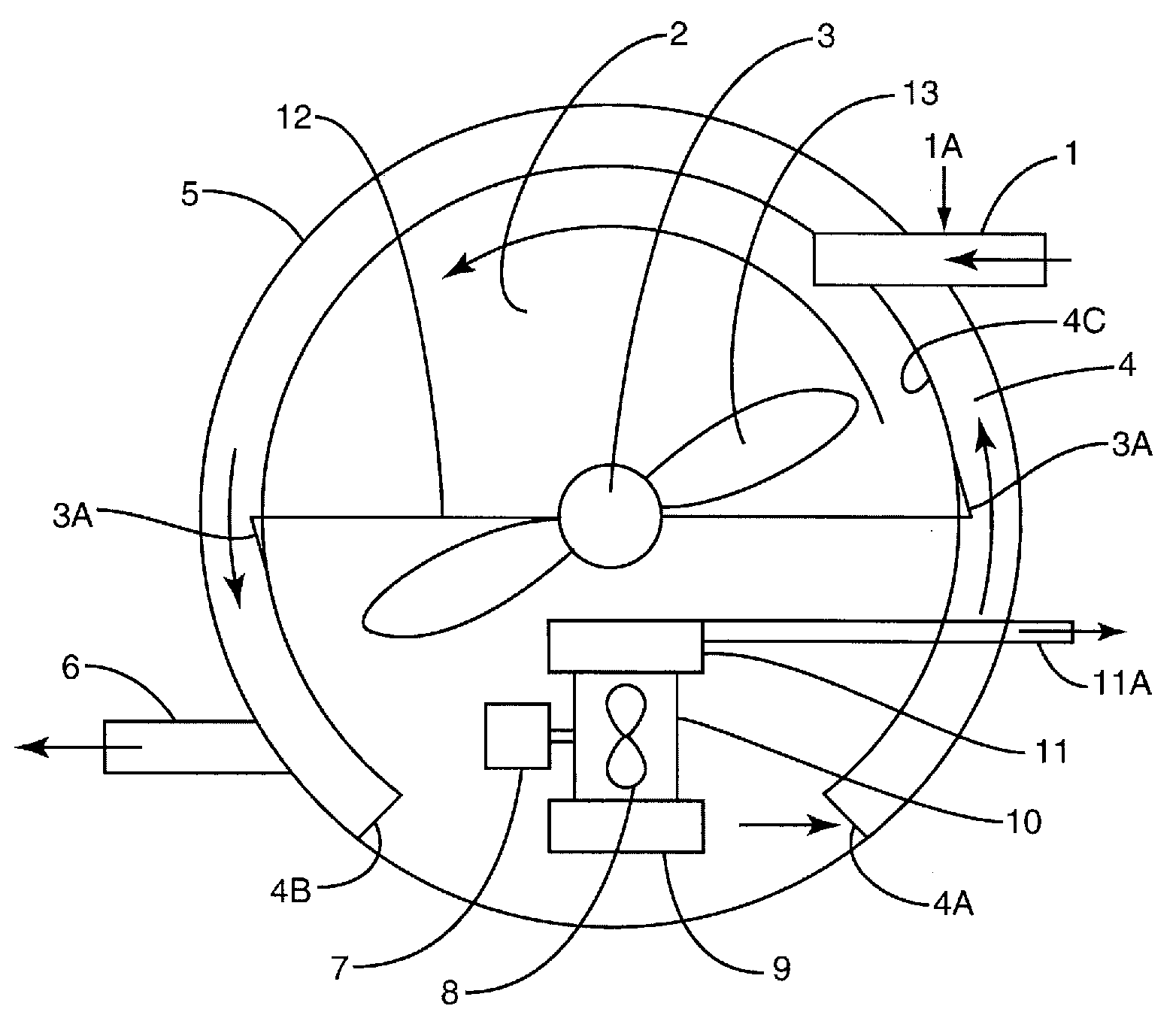

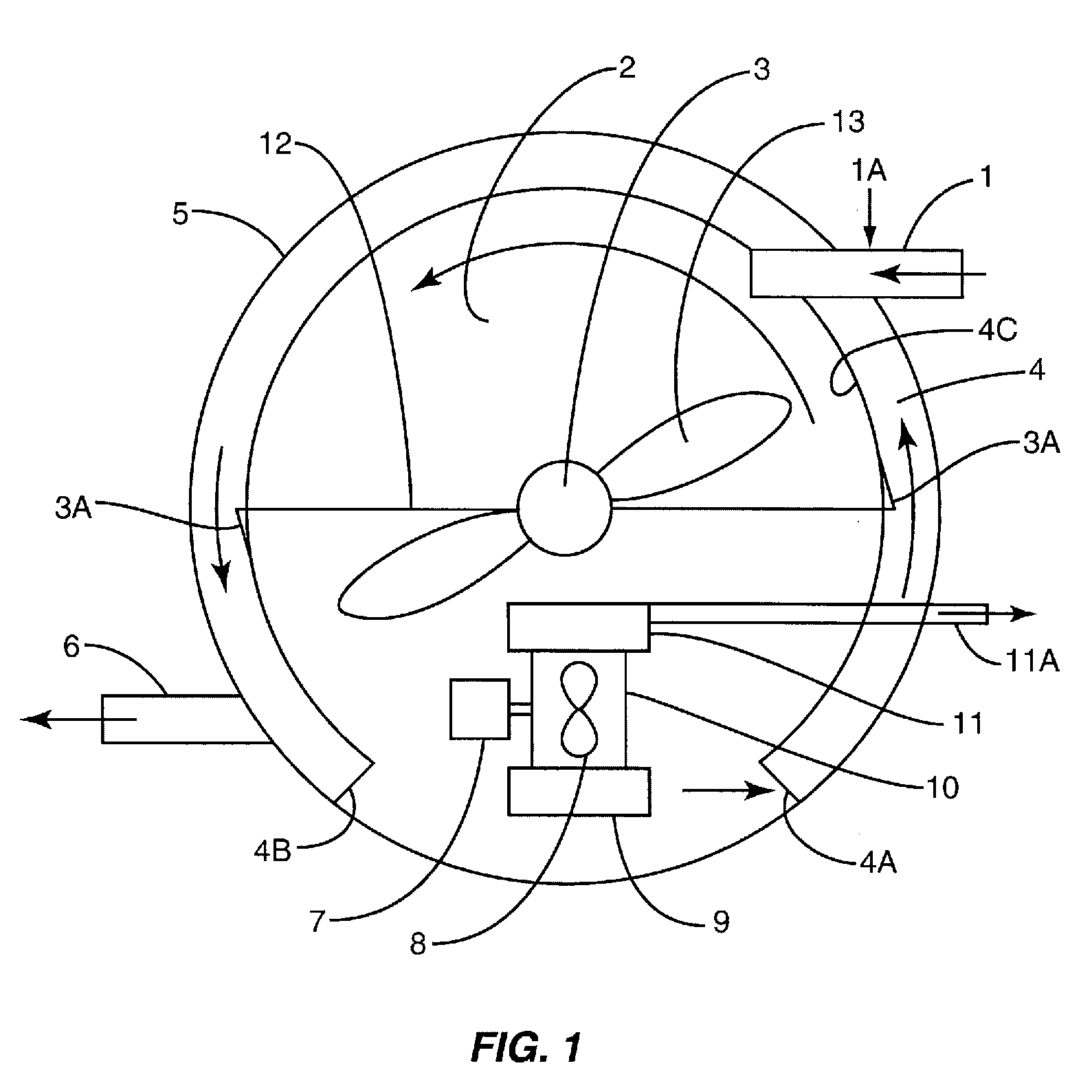

Continuous magnetic seperator and process

InactiveUS20050035030A1High gradient magnetic separatorsFiltration separationMagnetic separatorSlurry

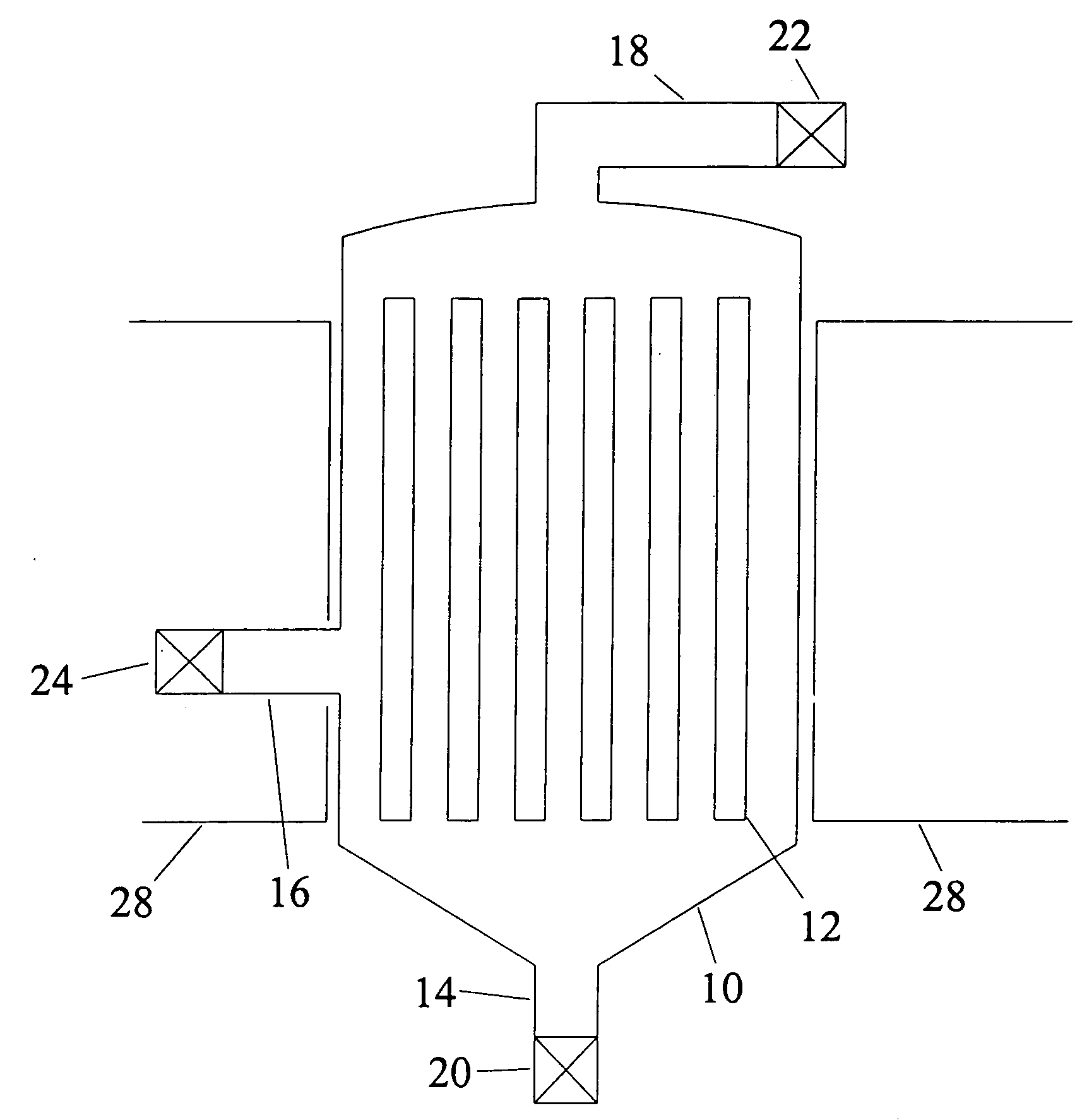

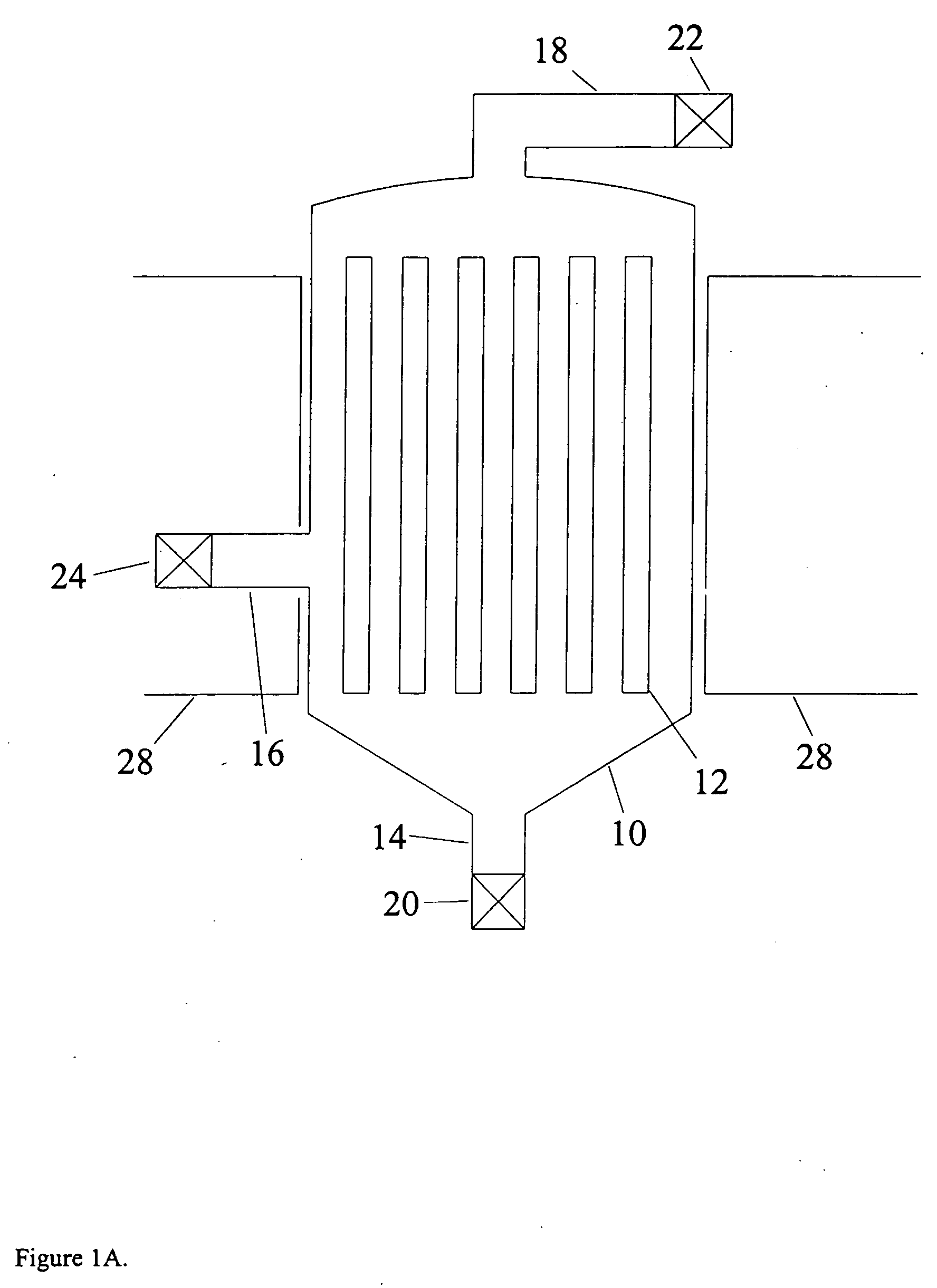

A continuous magnetic separator and process for separating a slurry comprising magnetic particles into a clarified stream and a thickened stream. The separator has a container with a slurry inlet, an overflow outlet for the discharge of the clarified slurry stream, and an underflow outlet for the discharge of a thickened slurry stream. Magnetic particles in the slurry are attracted to, and slide down, magnetic rods within the container. The slurry is thus separated into magnetic concentrate and clarified slurry. Flow control means can be used to control the ratio of the rate of magnetic concentrate to the rate of clarified slurry. Feed control means can be used to control the rate of slurry feed to the slurry inlet.

Owner:RES USA LLC

Separating method and system for waste paper and waste plastic mixture

InactiveCN1834340AReduce energy consumptionReduce loadGas current separationWashing/displacing pulp-treating liquorsFiberSingle stage

A method for separating out waste paper and waste plastic form their mixture including preliminary selecting, using magnetic separator to select out magnetic impurities, using hand to pick up large impurity block without plastic, using fan to blow impurities with different gravities into different grooves at different distance, using mechanical rubbing machine to separate paper fiber from plastic, using single stage floating tank to beat floating matters for releasing paper fiber off, storing floated out plastic and palletizing them for reutilization.

Owner:曾碚凯

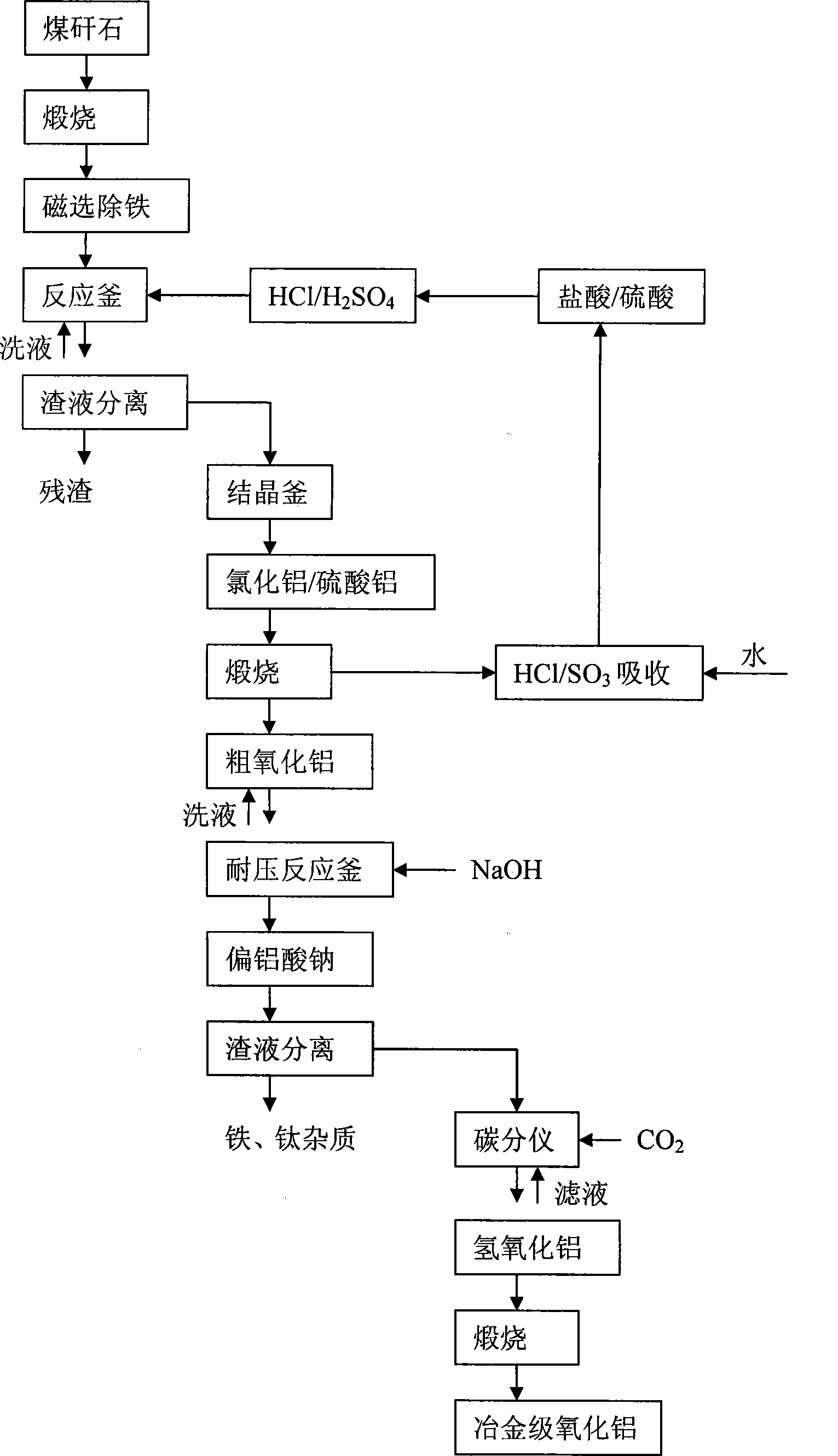

Method for extracting alumina from coal gangue

InactiveCN101450811AAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

The invention mainly relates to a method for extracting alumina from coal gangue. The coal gangue is ground, and then is calcined through a fluidized furnace and iron is removed through a magnetic separator, the coal gangue with the iron removal reacts with an acid to obtain an aluminum chloride solution without silicon impurities, the solution containing the aluminum is concentrated and crystallized and then is subjected to low-temperature calcination to obtain crude aluminum oxide, then the crude aluminum oxide reacts with sodium hydroxide to obtain a sodium aluminate mother solution, impurities such as iron and titanium are removed, an aluminum hydroxide crystal seed is added to the mother solution, and carbon dioxide gas is introduced for seed precipitation to obtain an aluminum hydroxide precipitate, and metallurgical grade alumina can be obtained through the calcinations. The method does not use any auxiliary agent at normal pressure, and uses hydrochloric acid and sulfuric acid to directly leach and extract alumina; the content of the alumina prepared by the method can reach more than 99 percent; and the method has the advantages of simple process flow, adequate raw material sources, less energy consumption, low cost, and high utilization value of the coal gangue.

Owner:CHANGCHUN CHAOWEI NEW MATERIALS TECH

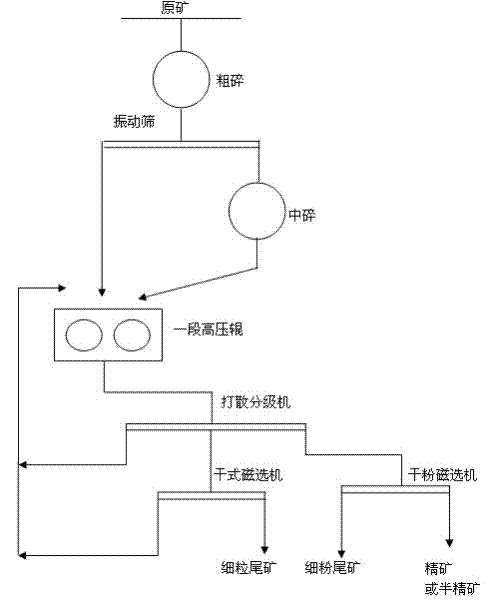

Dry-grinding and dry-separation method of magnetite

ActiveCN102240588ASimplify the crushing processSave moneyGas current separationGrain treatmentsMagnetiteClosed loop

The invention discloses a dry-grinding and dry-separation method of magnetite, which comprises the following steps of: feeding the crude ore of magnetite into a crusher for coarse crushing, and then feeding the crushed magnetite into a vibrating sieve for sieving; controlling the sieve meshes within a range of 35-75 mm; feeding the oversize product to the crusher for intermediate crushing and then feeding the crushed oversize product into a high-pressure roller mill along with the undersize product for fine crushing; breaking and grading the fine-crushed ore by a breaking-grading machine, thereby obtaining the products of three grain grades, i.e. coarse grains, fine grains and fine powder; returning the coarse-grain grade product to the high-pressure roller mill through an elevator, and feeding the fine-grain grade product to a dry type magnetic separator for magnetic separation and discarding tailings, wherein the magnetic field intensity is controlled within a range of 1200-3000 Gs; directly dryly stacking the discarded fine-grain grade tailings, and returning the fine-grain grade concentrate to the high-pressure roller mill through a belt conveyor and the elevator to form a closed loop; and feeding the fine-powder grade product into a cyclone magnetic separator, wherein the magnetic field intensity is controlled within a range of 600-1200 Gs, thereby obtaining concentrate or semi-concentrate. The dry-grinding and dry-separation method is low in power consumption, steel consumption and water consumption, and the tailings are easy to be disposed of.

Owner:CHENGDU LEEJUN IND

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

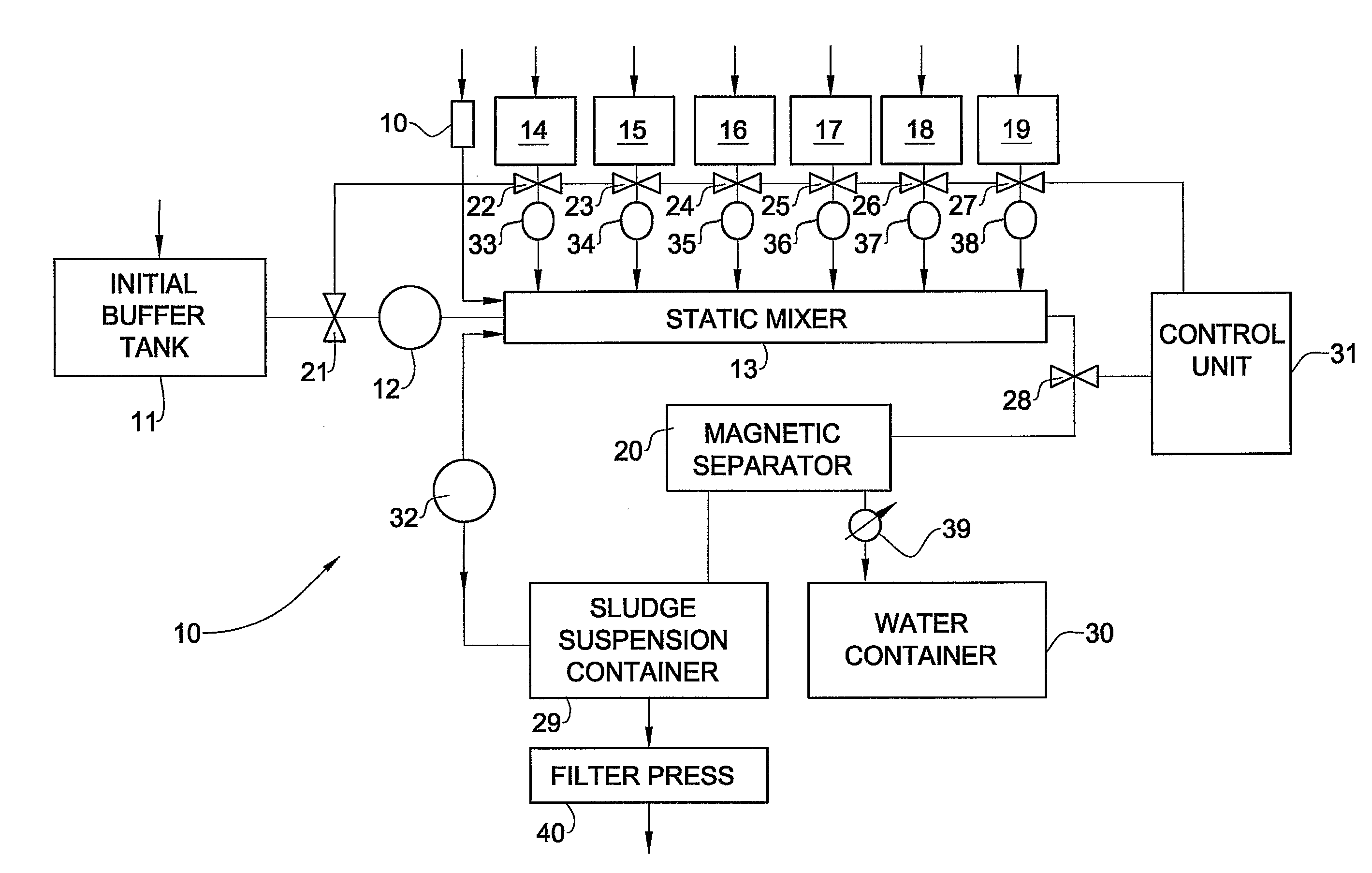

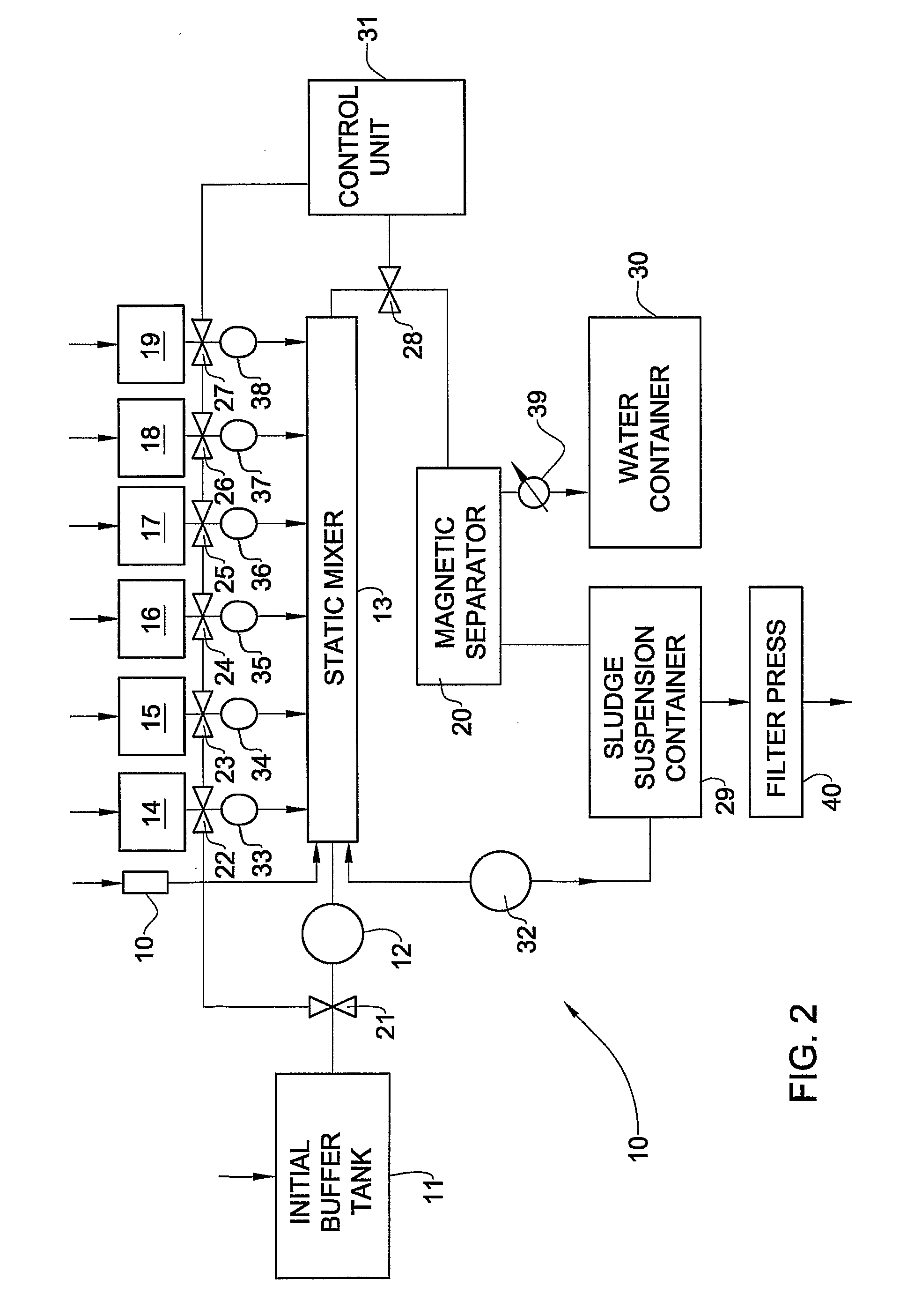

System and Method for Treatment of Industrial Wastewater

InactiveUS20080035577A1Improve efficiencyImprove standardsSolid sorbent liquid separationWaste water treatment from metallurgical processPHENOL LIQUIDSludge

Owner:UNIQKLEEN WASTEWATER TREATMENT

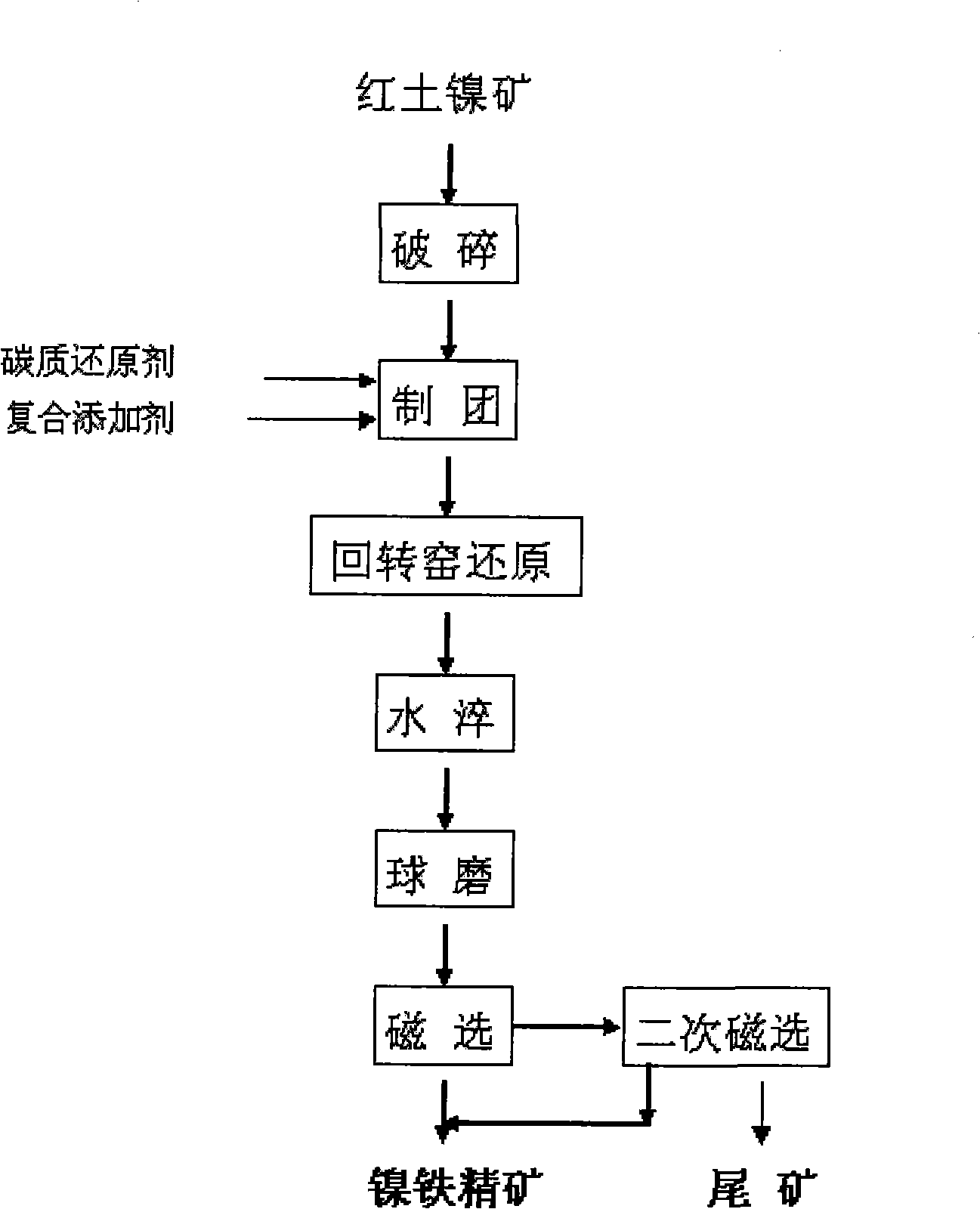

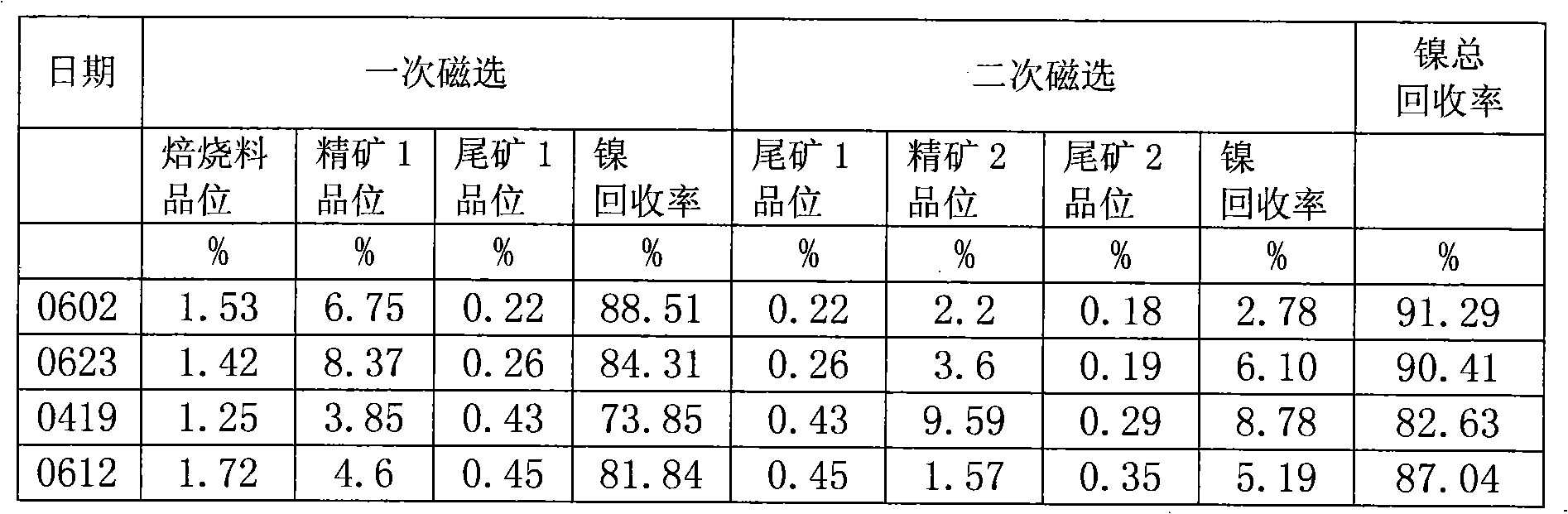

Method for enriching nickel iron ore concentrate from laterite type nickel ore by means of rotary kiln

InactiveCN101323904ANo pollution in the processSimple processRotary drum furnacesMagnetic separatorLaterite

The invention relates to a method for collecting ferronickel concentrate from lateritic nickel ores by a rotary kiln. The lateritic nickel ores are crushed, stirred and mixed with a carbonaceous reducing agent and a compound additive, made into pellets by a ball press or a marble machine and put into the rotary kiln for reducing and roasting; waste heat at the front part of the rotary kiln is used for carrying out the drying and preheating of the pellets; the high-temperature area of the rotary kiln is 9 to 10 meters away from a kiln outlet; the temperature of the high-temperature area is controlled to be 1000 to 1300 DEG C; roasting time is 0.5 to 2 hours; the dried pellets enter the high-temperature area of the rotary kiln for reducing and roasting; a magnetic separator with a magnetic field intensity of 3000 to 5000 gauss is adopted to sort roasted material obtained after water quenching and wet ball milling, thus obtaining high-content ferronickel concentrate; the method can realize the simultaneous recycling of nickel and iron and obtain the high-content ferronickel concentrate; the content of nickel is 5 to 13 percent and the recycling rate of nickel is 85 to 93 percent; the content of iron is 30 to 75 percent and the recycling rate of nickel is 60 to 85 percent; the reasonable utilization of the waste heat during process procedure achieves the purposes of saving energy and reducing discharge and greatly reduces pollution to the environment.

Owner:HONGHE HENGHAO MINING

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

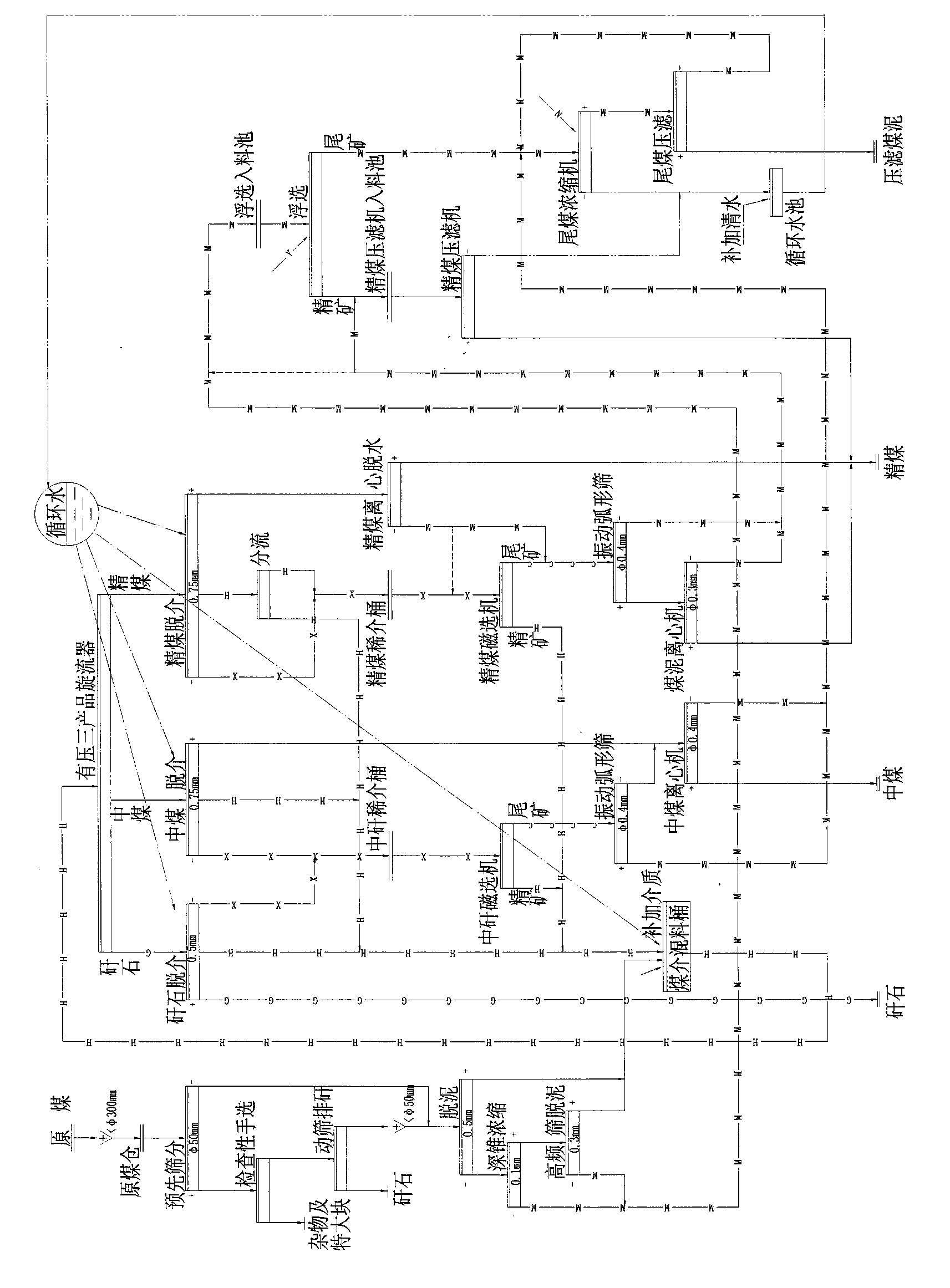

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

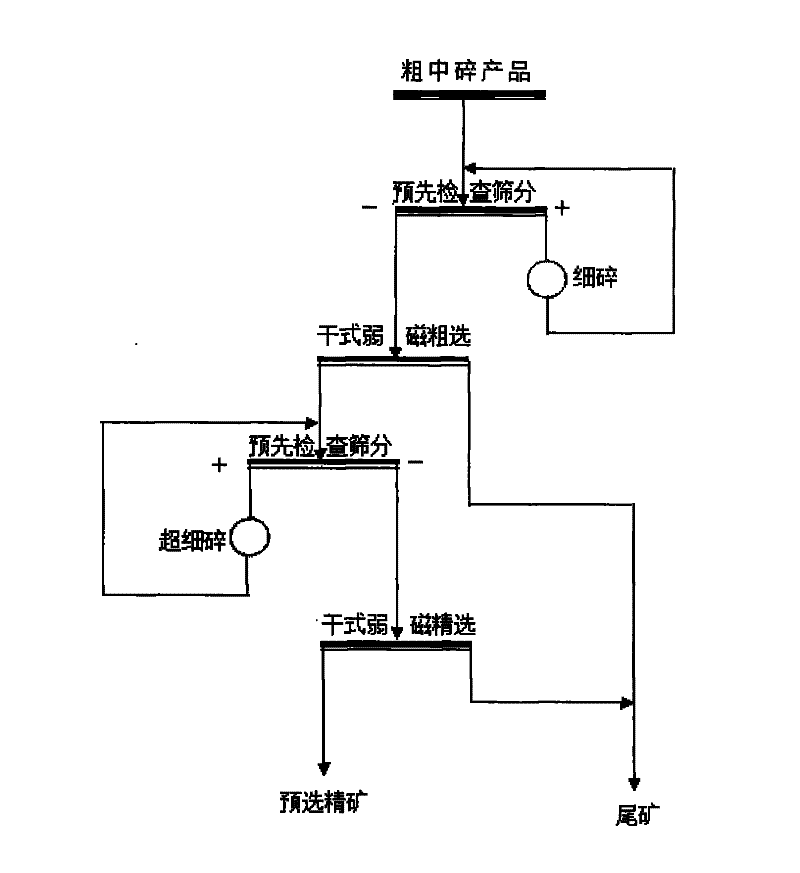

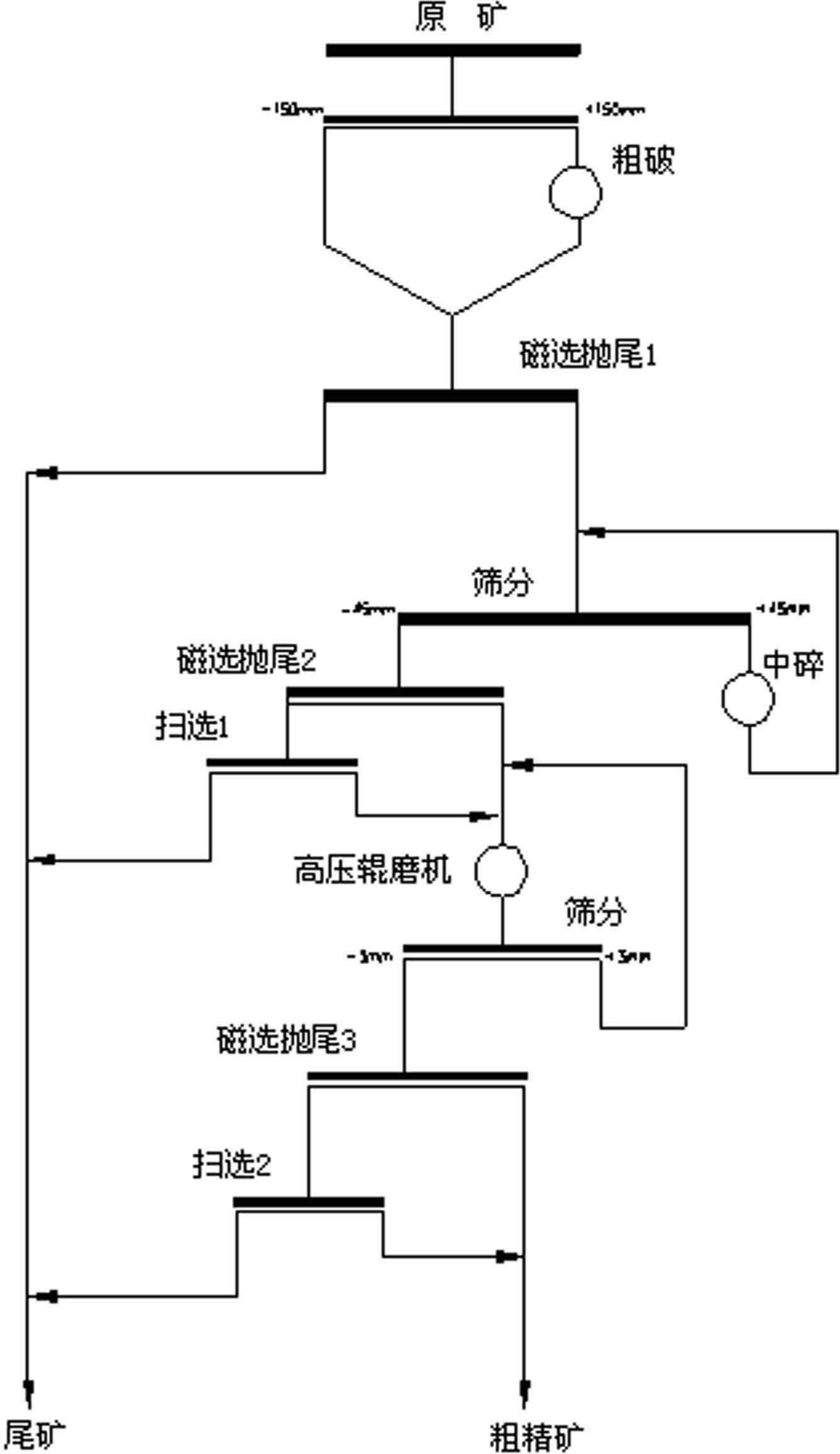

Dry presorting and tailings discarding process for ultra-poor magnetite

Owner:INNER MONGOLIA UNIV OF SCI & TECH

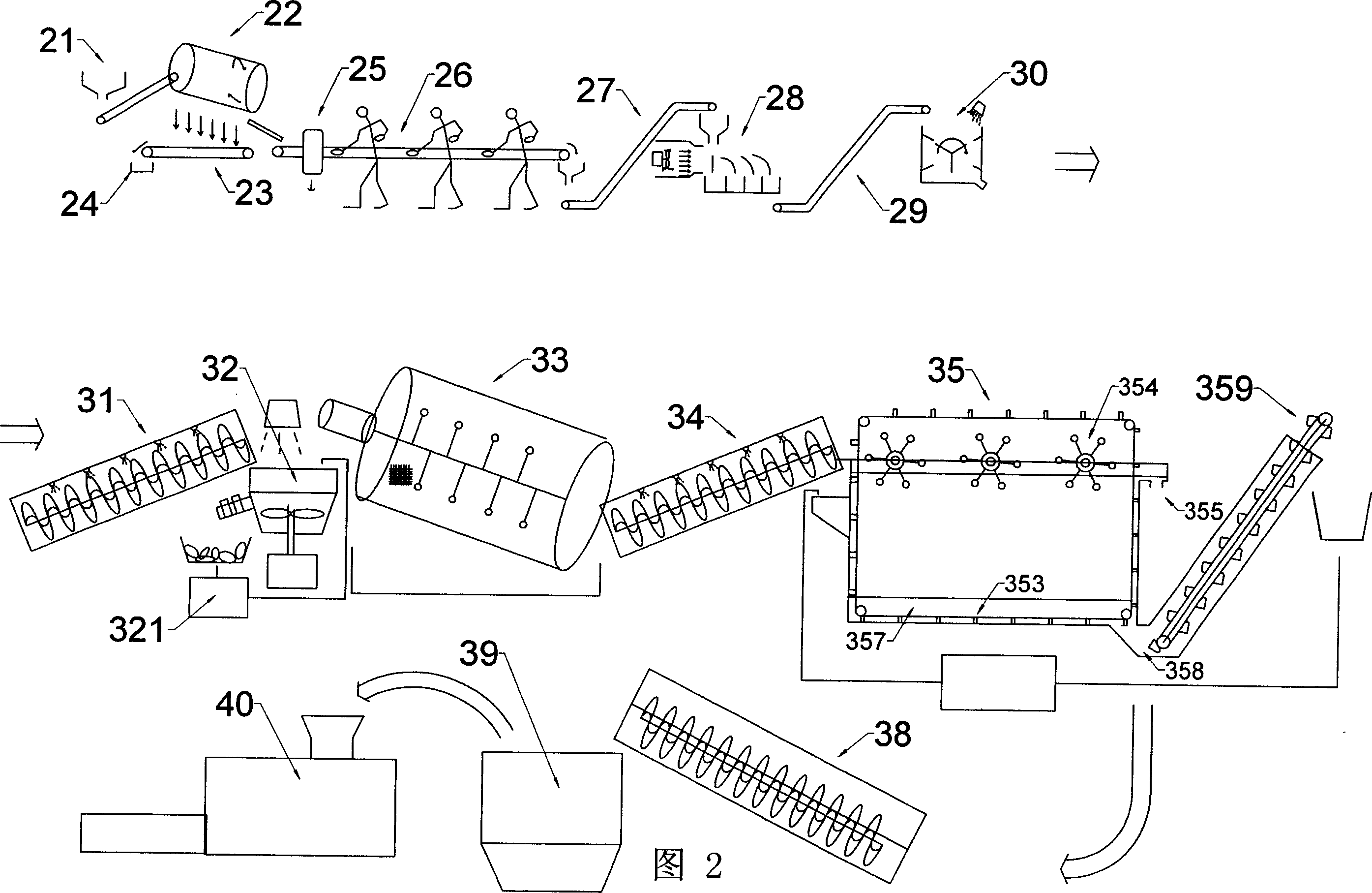

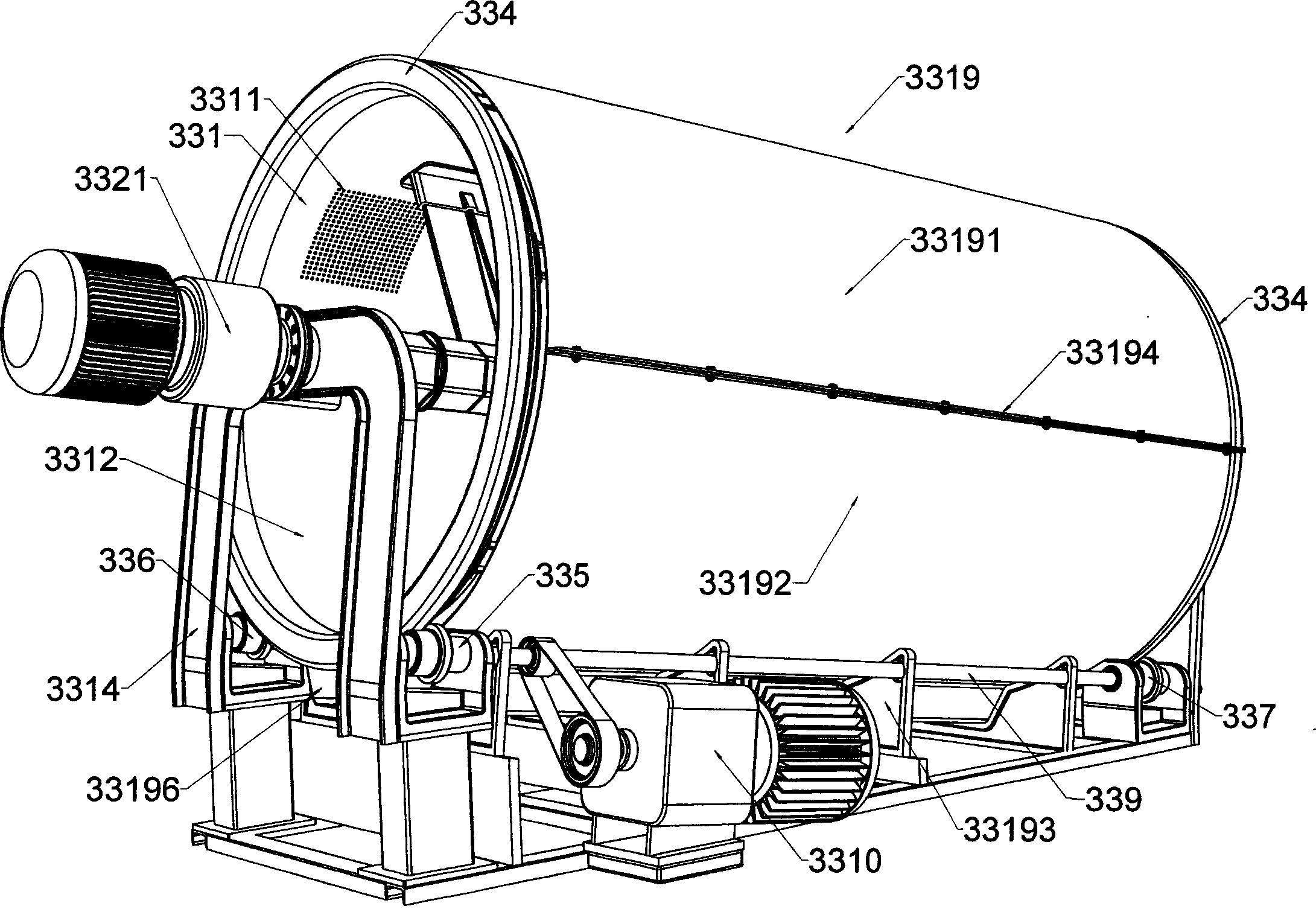

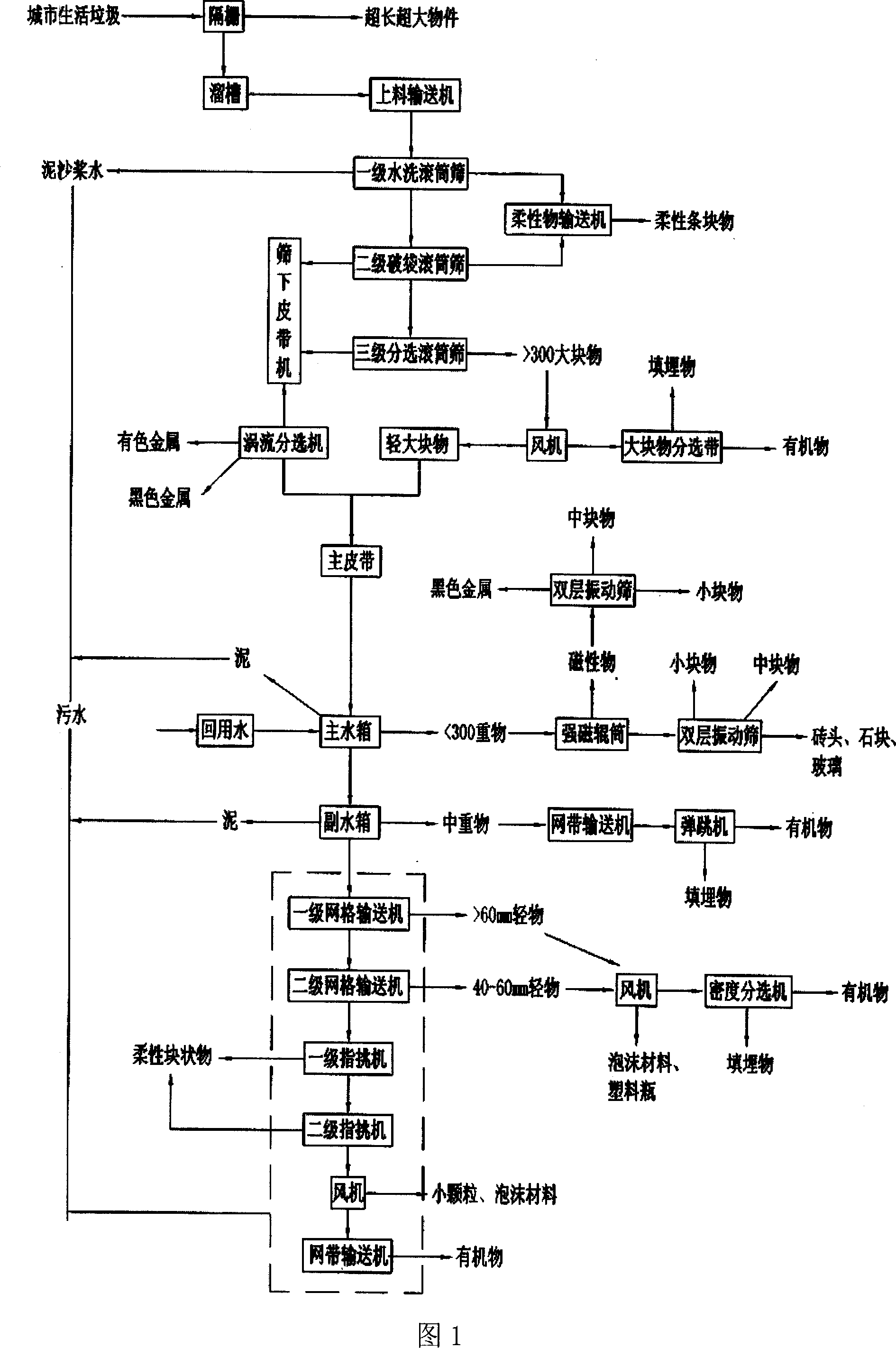

City life-garbage automatic sorting system and apparatus of becoming garbage into resource and without harm

InactiveCN101069871AReach resourcesReach disposalSolid waste disposalMechanical conveyorsProduction lineLitter

The present invention relates to an automatic separation system for making urban domestic refuse be changed into reusable resorce and making harmless treatment. Said system includes the following several portions: partition grille, chute, charging conveying machine, three-stage drum sieve composed of water-washing drum sieve, bag-breaking drum sieve and sorting drum sieve, flexible material conveying machine, undersieve belt conveyer, whirlpool separator, main belt, main water tank, rear-mounted water tank, double-layer vibration sieve, magnetic separator and desinty separator, etc.

Owner:深圳合续环保投资有限公司

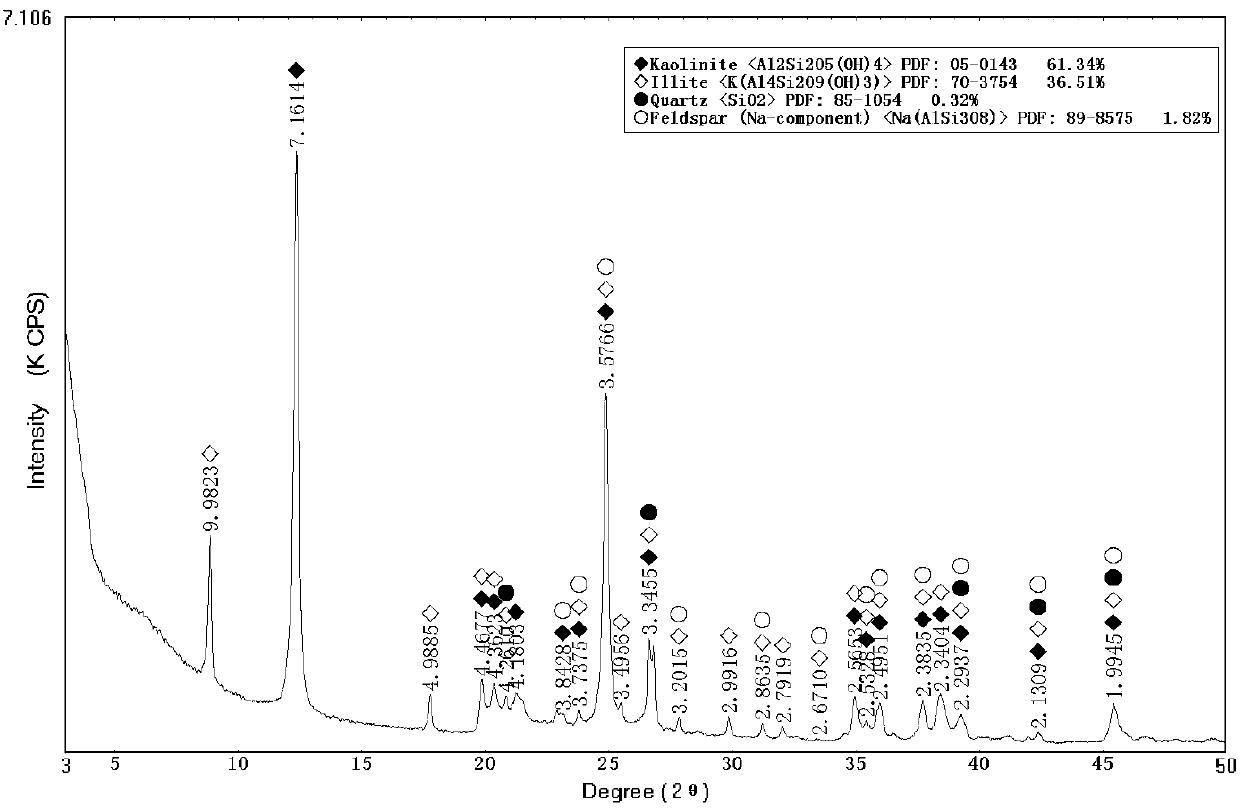

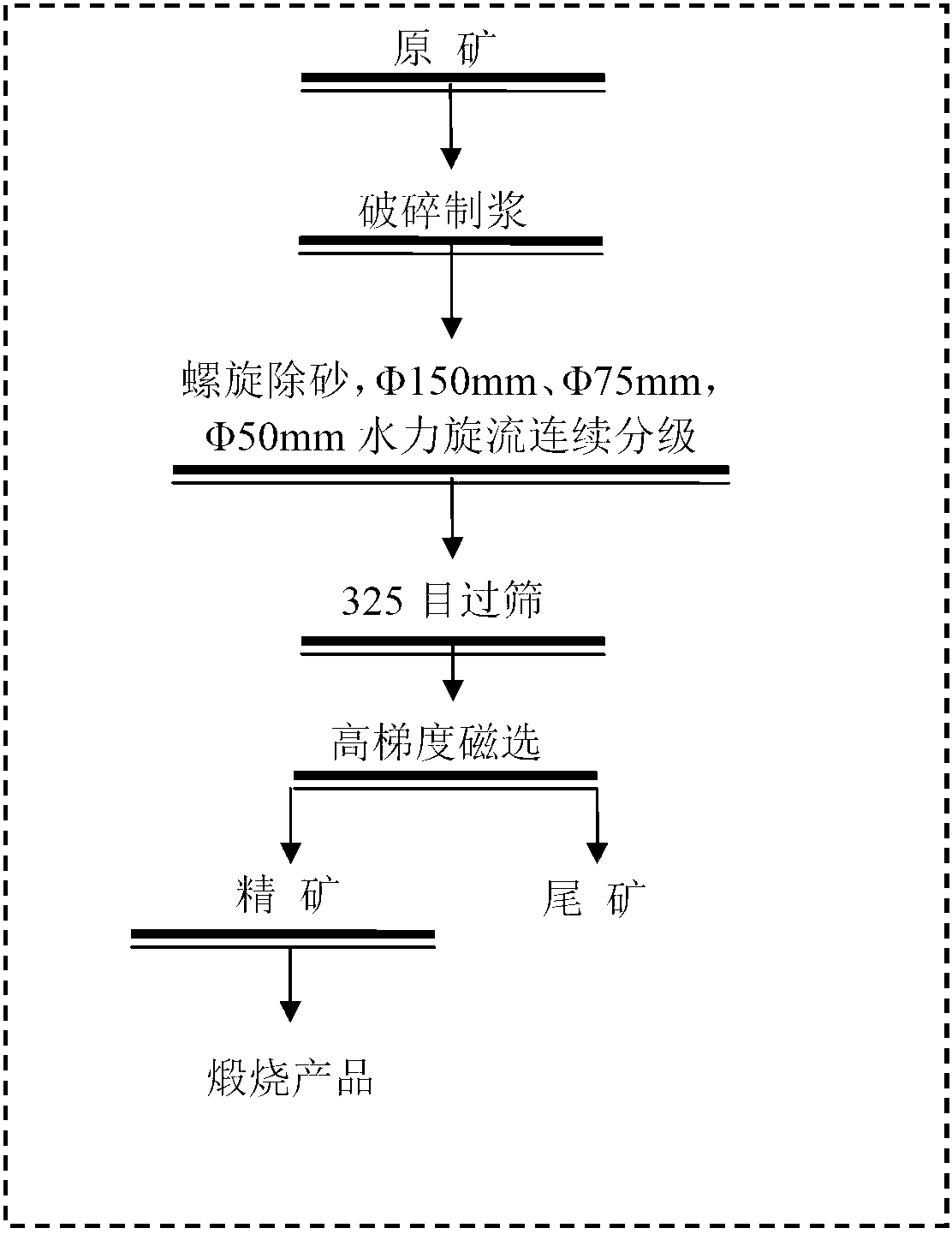

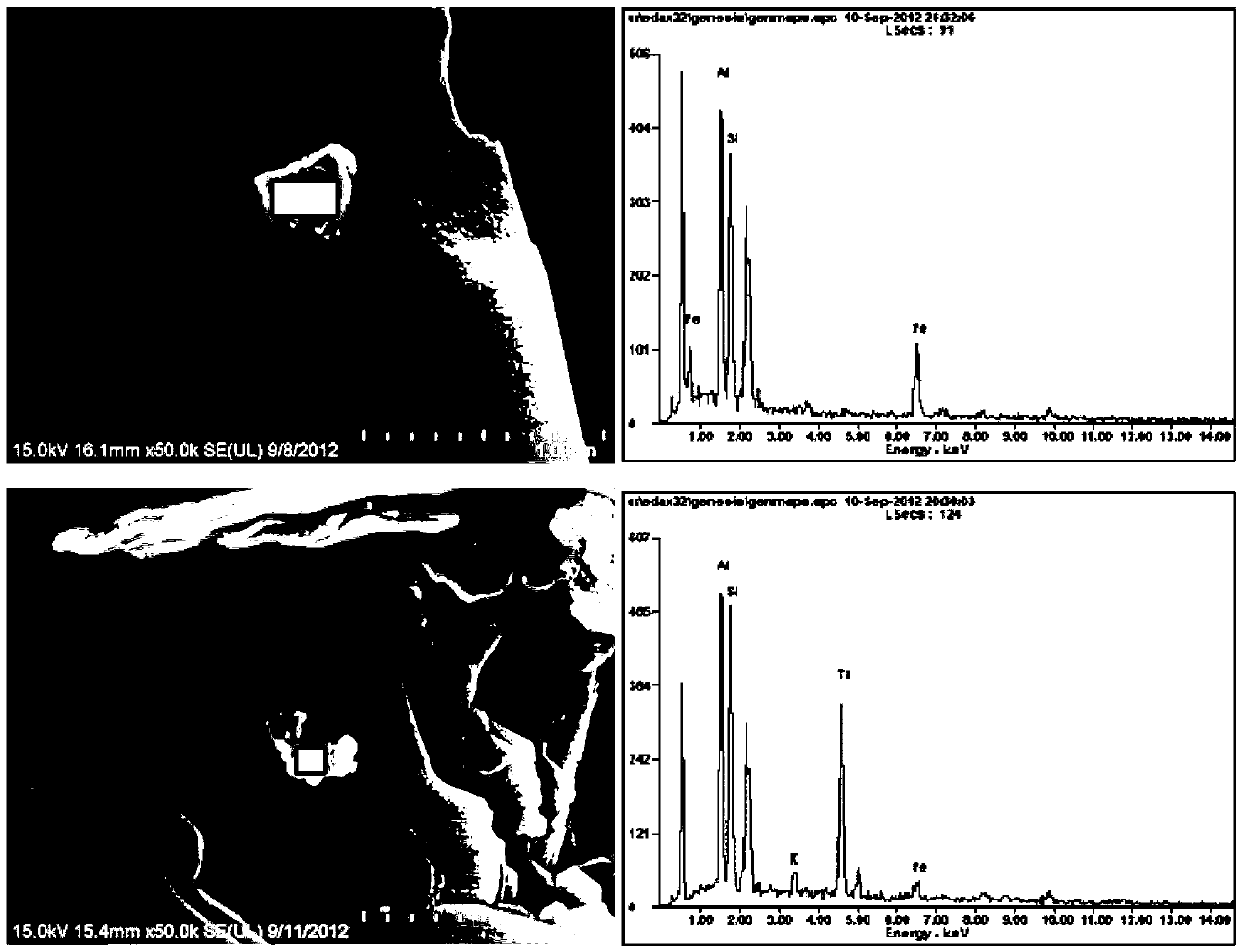

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore to obtain a magnetic separation raw material; (2) adding water to the magnetic separation raw material obtained in the step (1) to prepare a mixed slurry with the solid content of 10-20 wt%, adding sodium hexametaphosphate accounting for 0.2-0.6 wt% of the magnetic separation raw material, slurrying, stirring for 20 minutes, and passing through a 325-mesh wet sieve; (3) carrying out high-gradient magnetic separation on the undersize slurry of the 325-mesh sieve in the step (2): while controlling the magnetic field intensity of the high-gradient magnetic separator at 1.0-1.8T and the slurry flow rate at 0.8-1.8cm / s, the slurry is subjected to magnetic separation by the high-gradient magnetic separator to obtain a concentrate slurry; (4) adding alum accounting for 1-6 wt% of the concentrate slurry into the concentrate slurry obtained in the step (3), flocculating, carrying out pressure filtration, drying, and packaging to obtain a magnetic concentrate; and (5) calcining the magnetic concentrate obtained in the step (4) to obtain the calcined kaolin. The technique has the advantages of high iron removal efficiency and obvious whitening effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

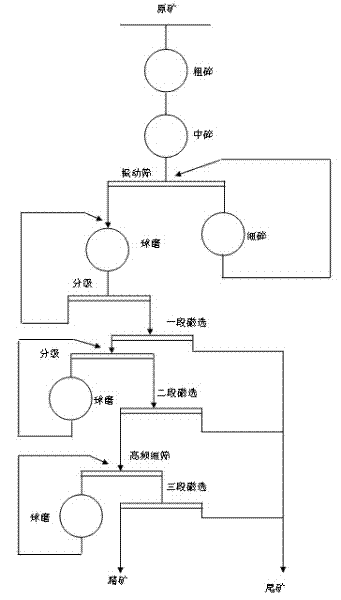

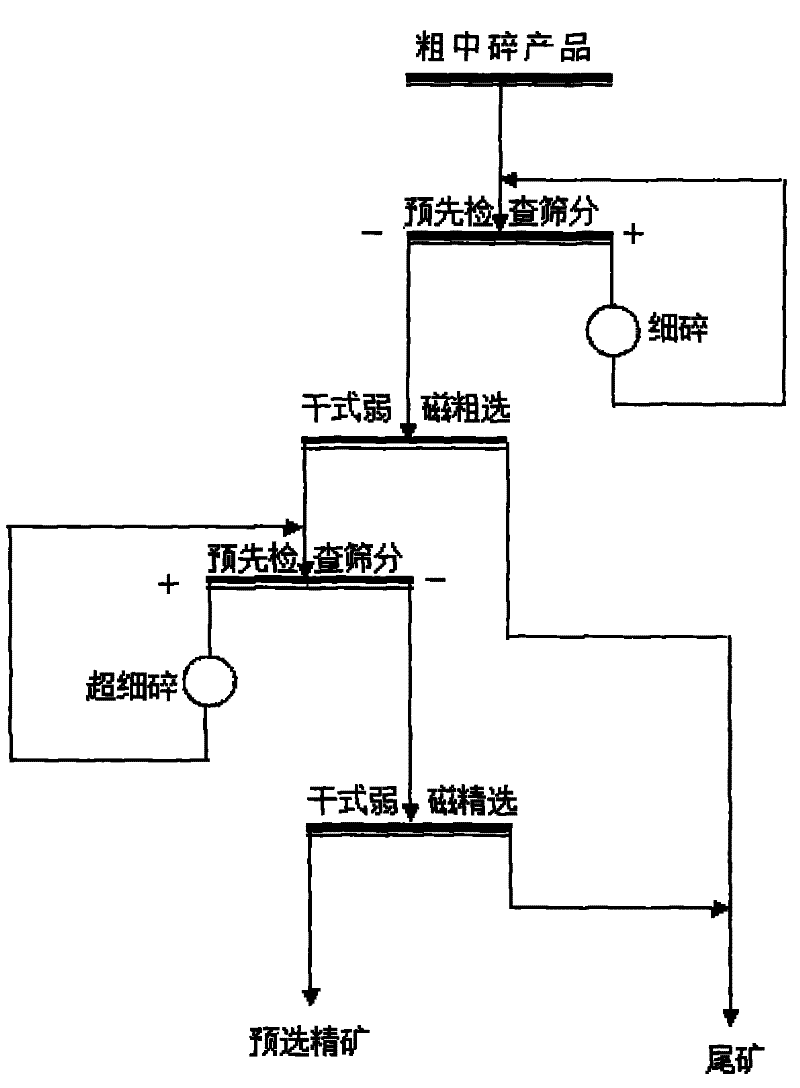

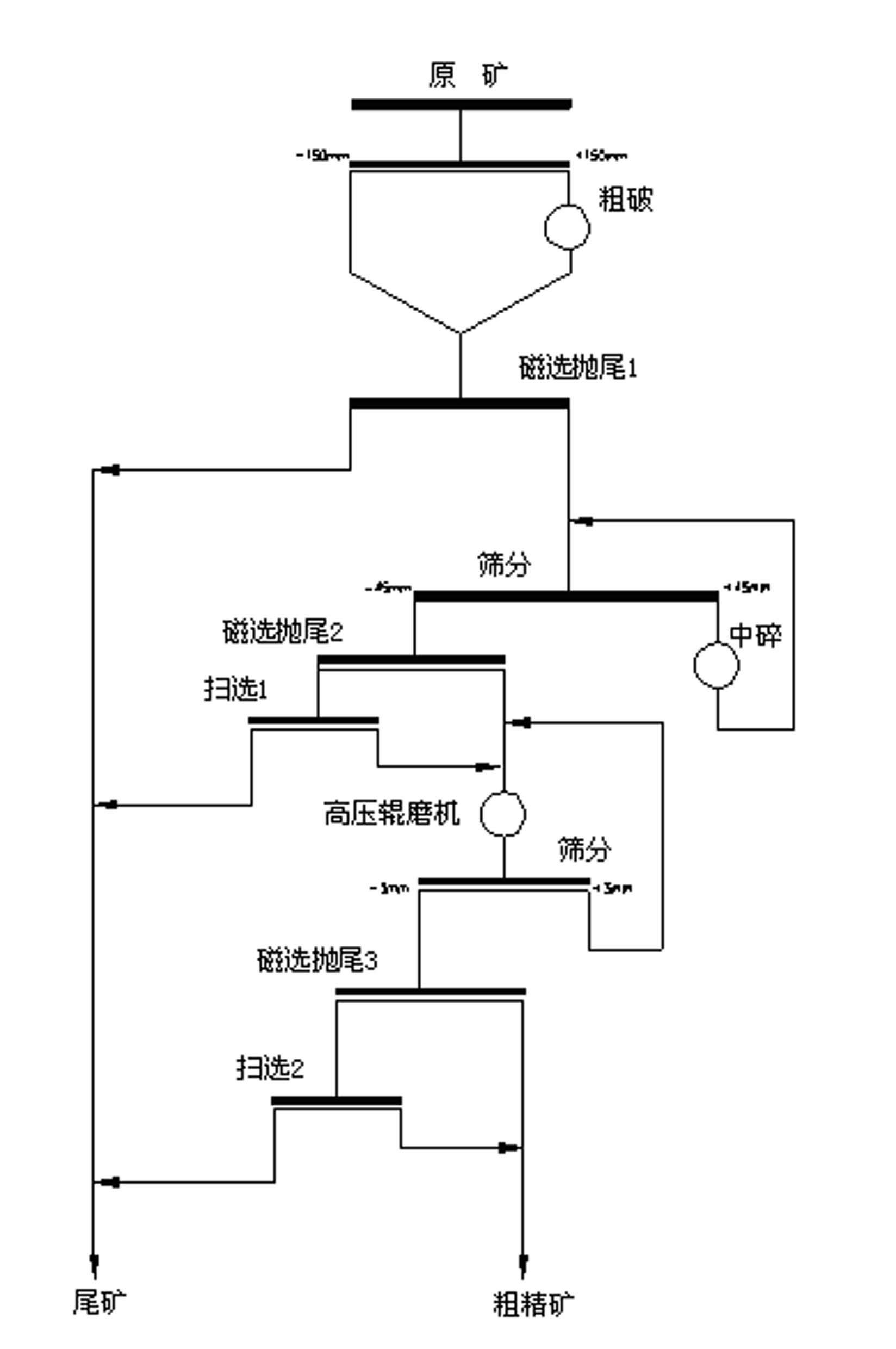

Pre-selecting and tailings discarding process of lean magnetite ores

InactiveCN102430473AImprove the grade of iron for grindingImprove efficiencyMagnetic separationGrain treatmentsMagnetiteMagnetic separator

The invention discloses a pre-selecting and tailings discarding process of lean magnetite ores, comprising three stages: a coarse crushing stage, an intermediate crushing stage and an ultra-fine crushing stage, wherein fine crushing operation stage can be increased before the ultra-fine crushing stage and after the intermediate crushing stage. The staged magnetic pre-separation and tailings discarding work can be executed by different types of magnetic separators according to the difference of granularity of each crushing stage. Surrounding rocks and partial dissociatve gangue which drop in the tailings are removed in the first discarding work; waste stones which are not removed in the first tailings discarding work and the gangue which is further dissociated after the intermediate crushing stage are removed in the secondary tailings discarding work; and the third tailings discarding work is to discard the tailings after the tailings are ultra-finely crushed by a high-pressure roller mill. After the lean magnetite ores in which the fine particles are embedded are ultra-finely crushed by the high-pressure roller mill, the dissociation degree is further improved, and the magnetic separating and tailings discarding effects are good. The tailings discarding work is designed to reduce the loss of ferrous metal. The complete process can effectively improve the grade of grinding ferrous, can ensure the TFe recovery rate of the work, can improve the grinding characteristics of the material in the grinder, can reduce the quantity of the ore to be grinded, and can reduce the energy consumption of grinding the ores and the cost of separating the ores.

Owner:ANHUI UNIV OF SCI & TECH

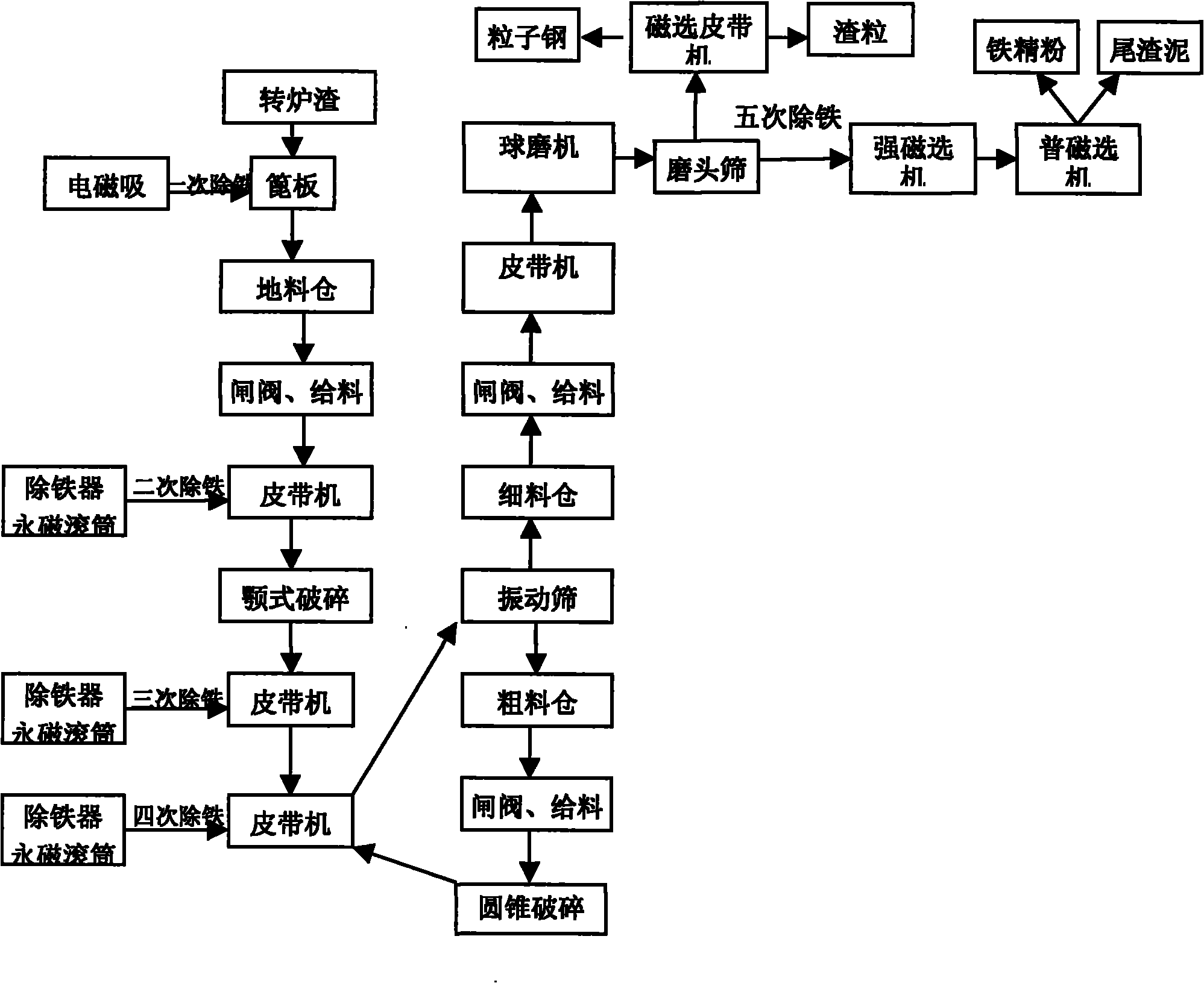

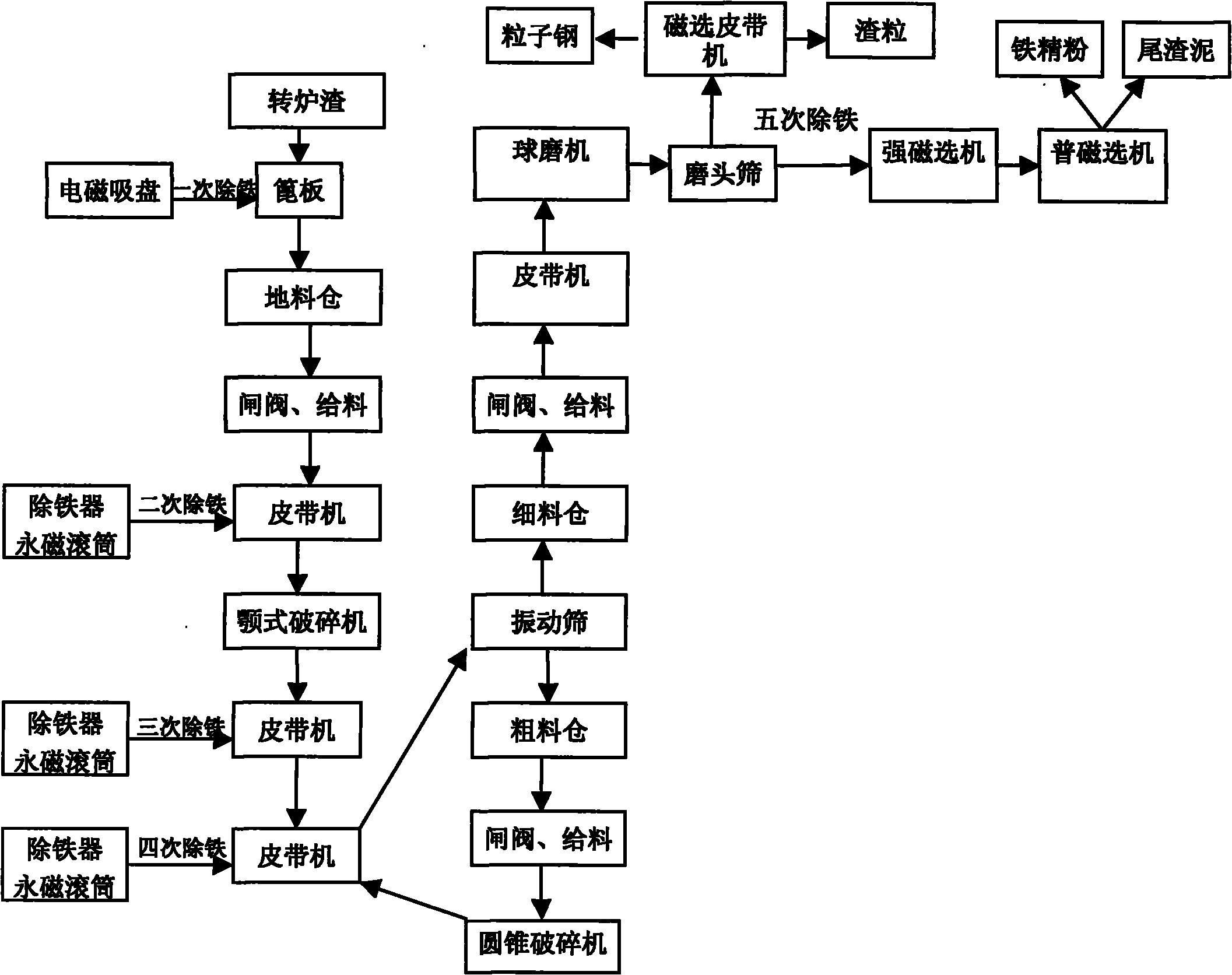

Method for recycling iron from steel slag

InactiveCN101864501AEasy to separateAvoid artificial unluckyRecycling and recovery technologiesProcess efficiency improvementSlagGranularity

The invention belongs to the field of recycling of steel slag, in particular to a method for recycling iron from steel slag. The method comprises the following steps of: (1) pouring steel slag into a grate plate with the length and the width of 180 mm respectively, leading the steel slag with granularity smaller than 180 mm to enter an underground material bin and carrying out first iron recycling on the steel slag with granularity larger than 180 mm by an electromagnetic sucking disk; (2) magnetically separating and crushing the steel slag with granularity smaller than 180 mm, wherein the crushed granularity is smaller than 60 mm; (3) magnetically separating the crushed steel slag; (4) screening by a vibrating screen, leading steel slag with granularity larger than 25 mm to enter a cone crusher for carrying out second crushing with the crushed granularity smaller than 25 mm, and magnetically separating; (5) grinding steel slag with granularity smaller than 25 mm, screening by a cylinder screen with granularity of 2 mm and remelting particle steel with granularity larger than 2 mm for utilizing; and after magnetically separating steel slag with granularity smaller than 2 mm by a wet magnetic separator, separating iron fine powder and tailings. The invention can recycle iron in the steel slag and reduce the iron content of the steel slag below 0.5 percent.

Owner:XINXING HEBEI ENG & RES INC

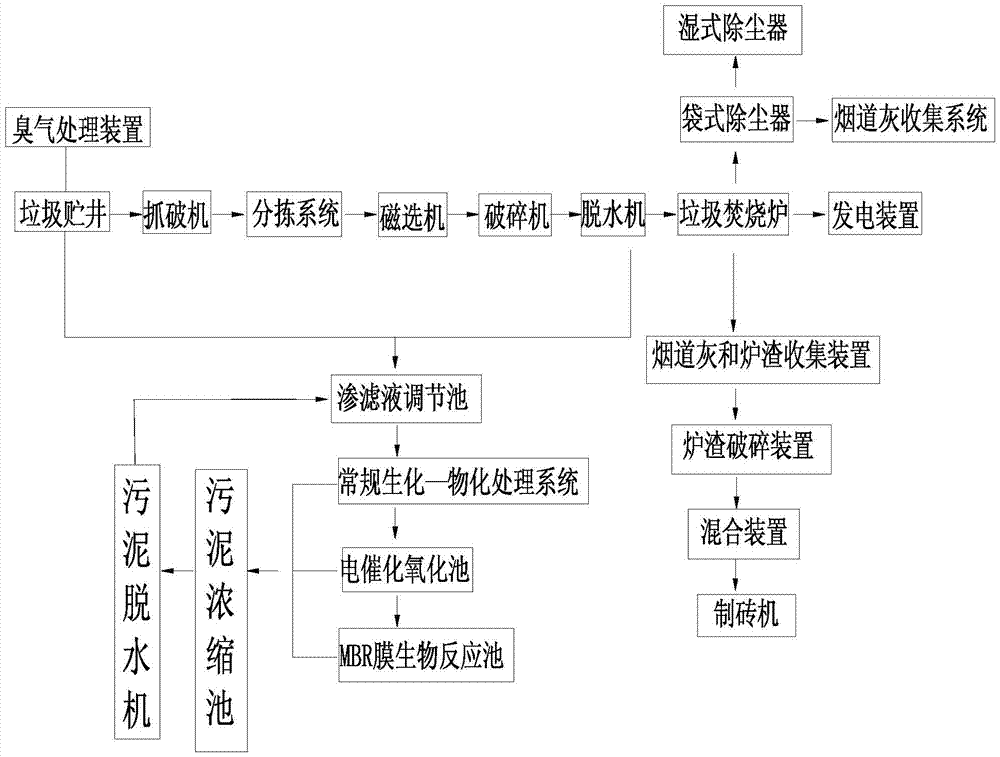

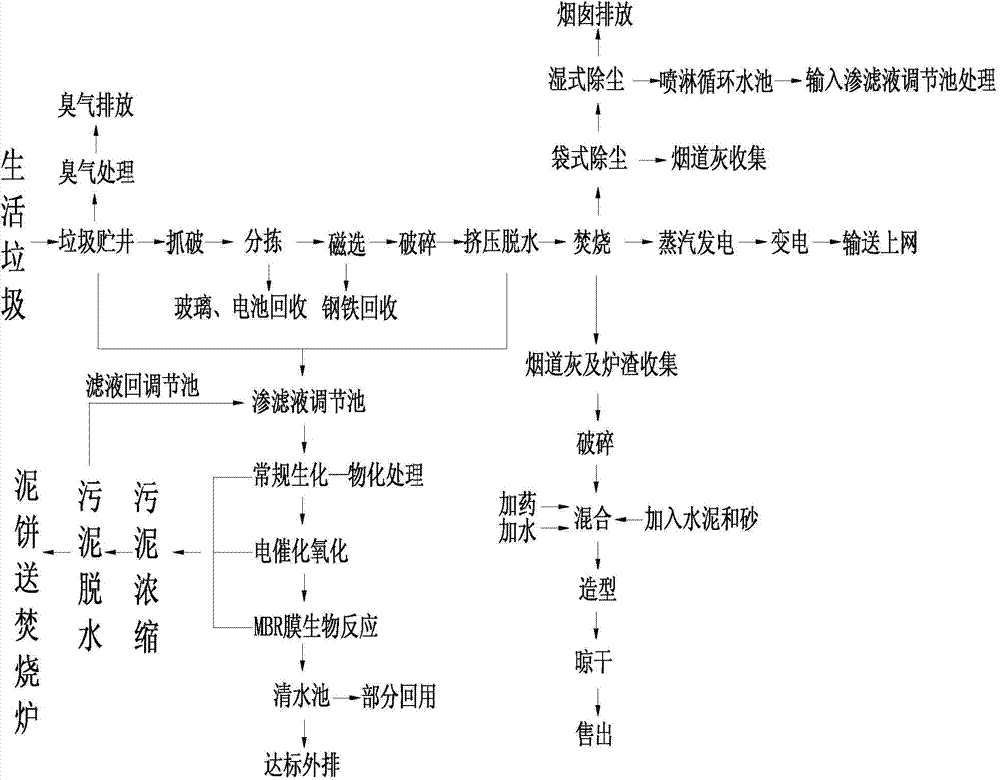

Environment-friendly device matched with efficient and pollution-free refuse incineration power generation and using technology thereof

ActiveCN103900090AGuaranteed normal processingReduce pollutionCombination devicesMultistage water/sewage treatmentSlagCollection system

The invention relates to the technical field of refuse incineration power generation and particularly discloses an environment-friendly device matched with efficient and pollution-free refuse incineration power generation and a using technology of the environment-friendly device matched with efficient and pollution-free refuse incineration power generation. On the basis of an existing refuse incineration power generation system, a pre-treatment system, a flue gas treatment system and a leachate treatment system are additionally arranged. The pre-treatment system comprises a scratching machine, a sorting system, a magnetic separator, a crusher and a dehydrator. The flue gas treatment system comprises a bag type dust collector and a wet type dust collector, and a slag outlet of the bag type dust collector is provided with a flue dust collecting system. A leachate adjusting pool is sequentially connected with a convectional biochemical-physicochemical treatment system, an electrocatalytic oxidation pool and a membrane biological reaction pool. Through the environment-friendly device matched with efficient and pollution-free refuse incineration power generation and the using technology of the environment-friendly device matched with efficient and pollution-free refuse incineration power generation, generation of dioxin precursors is greatly reduced or even eliminated, and therefore first, pollution is reduced, and second, waste treatment cost is reduced and the national emission standard can be reached. The environment-friendly device matched with efficient and pollution-free refuse incineration power generation has prominent innovation, the generating capacity is improved by more than 1.5 times, and the tough problem of environmental pollution is solved comprehensively and thoroughly.

Owner:深圳市宇力科技有限公司

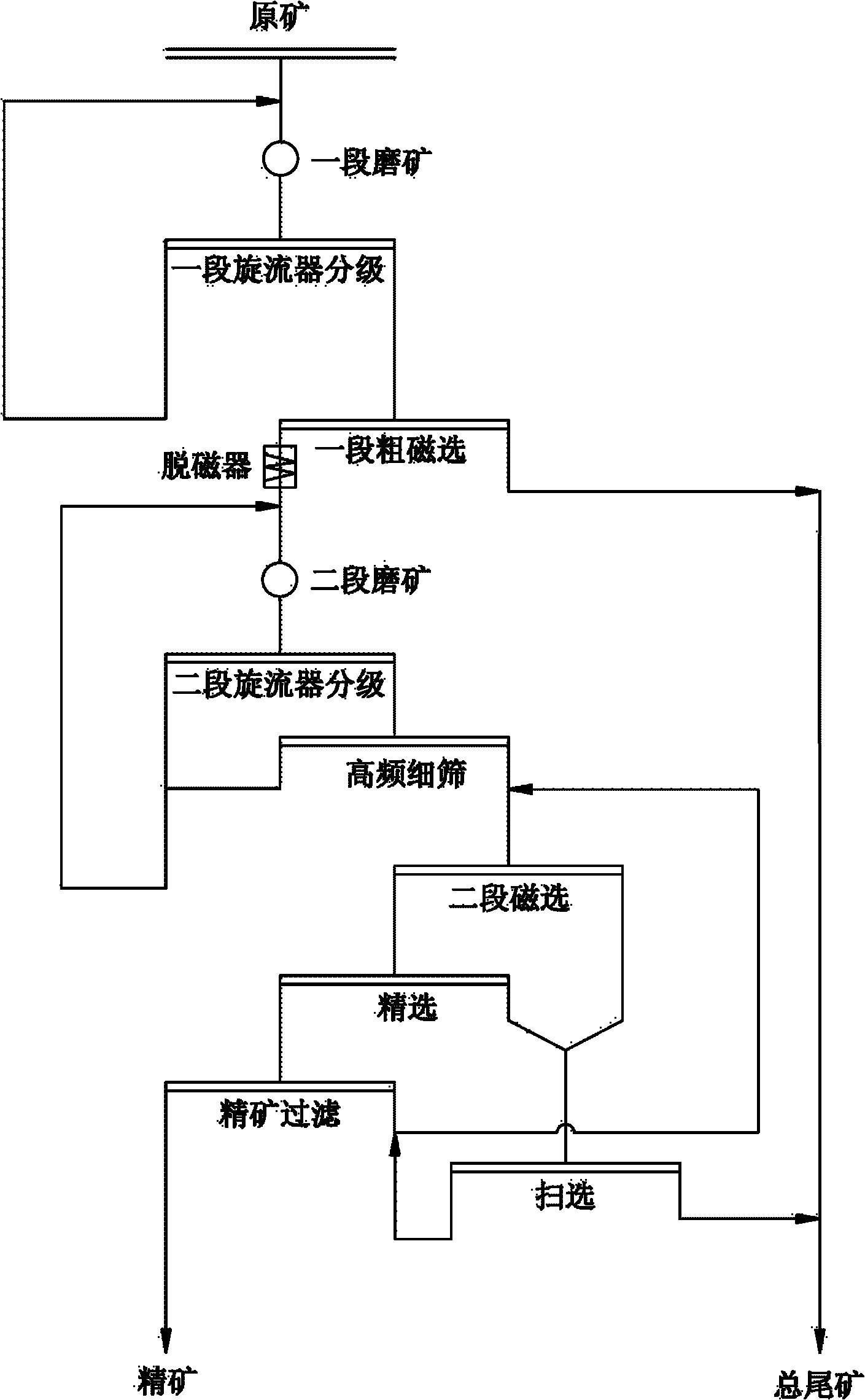

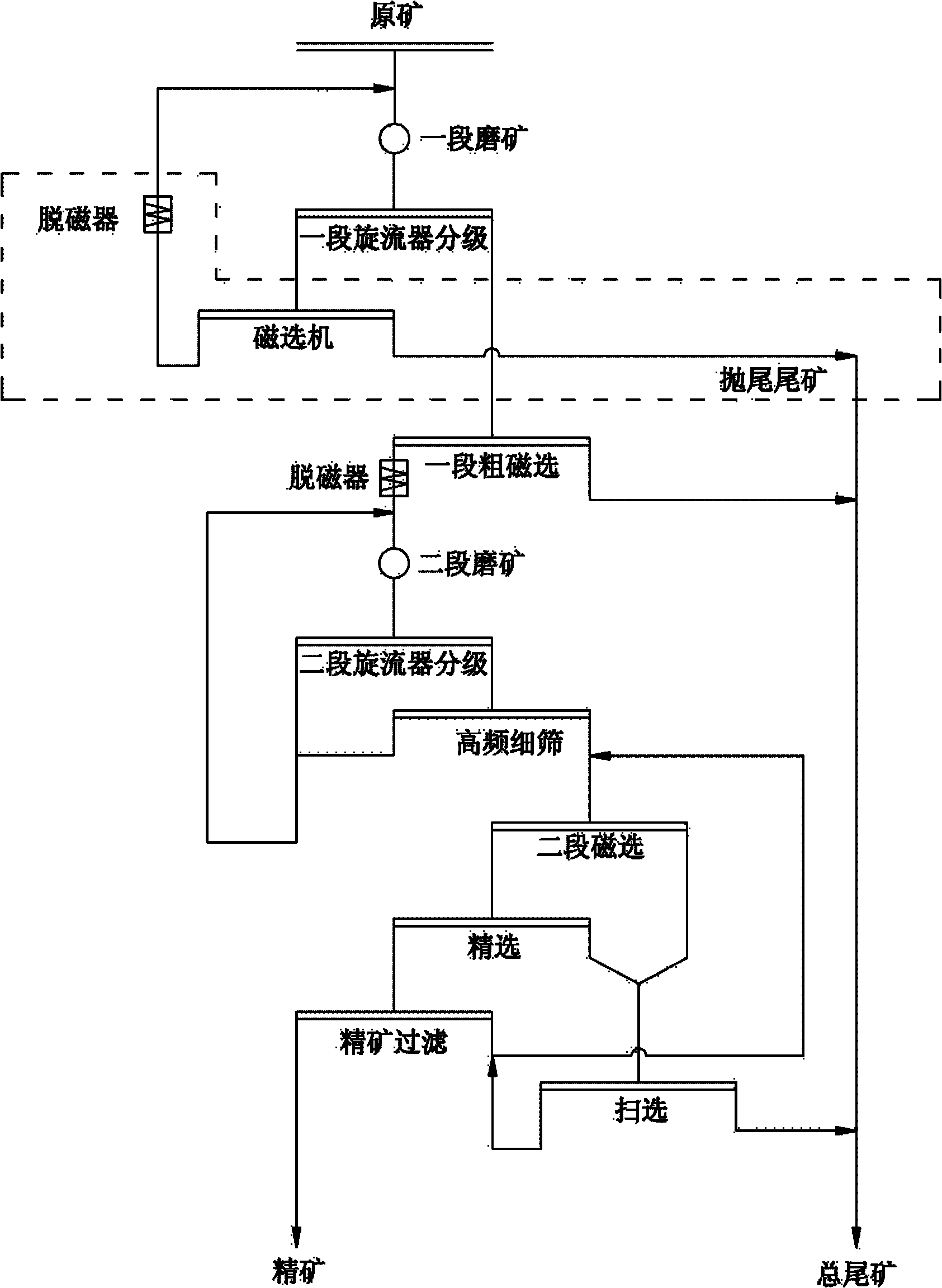

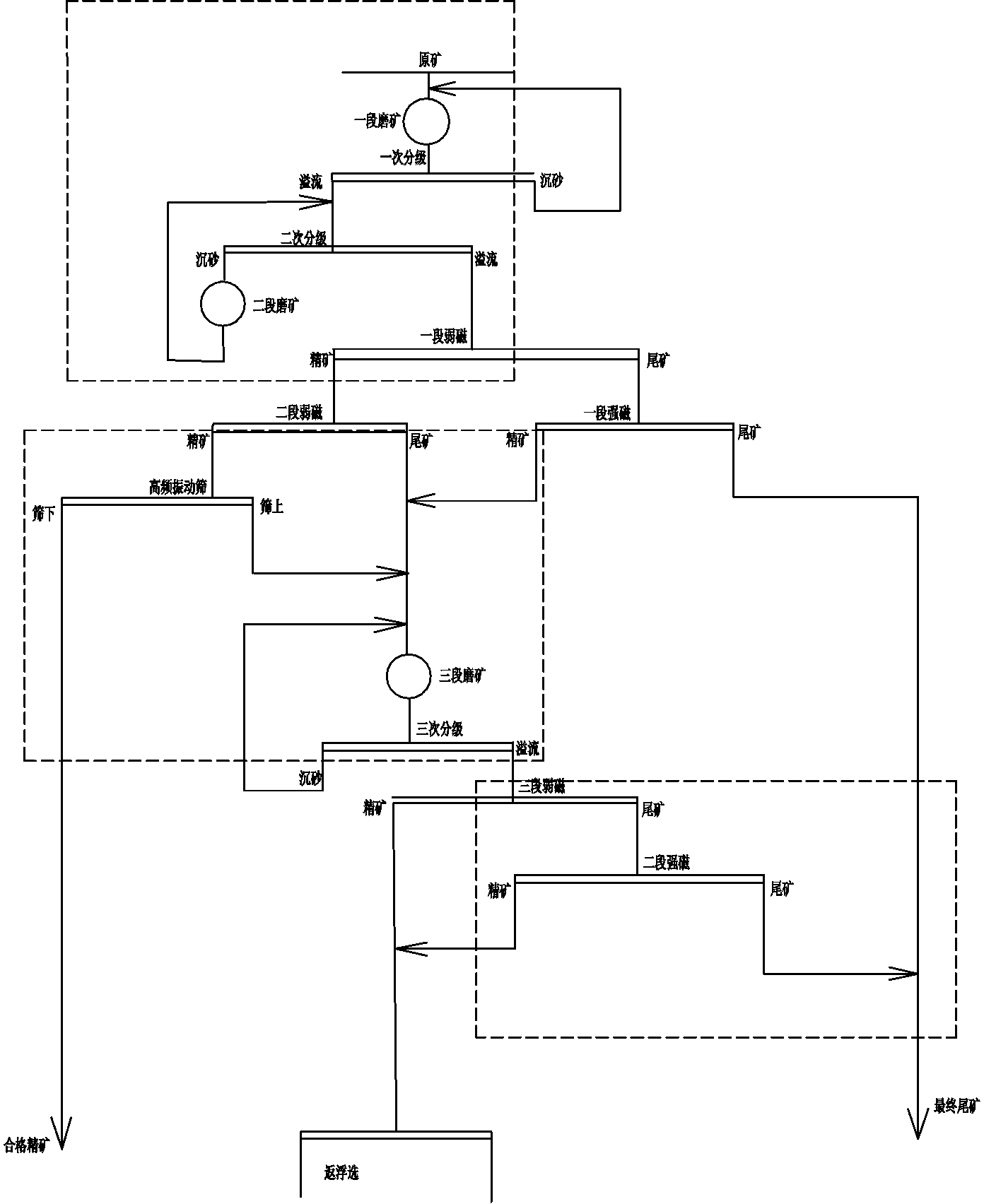

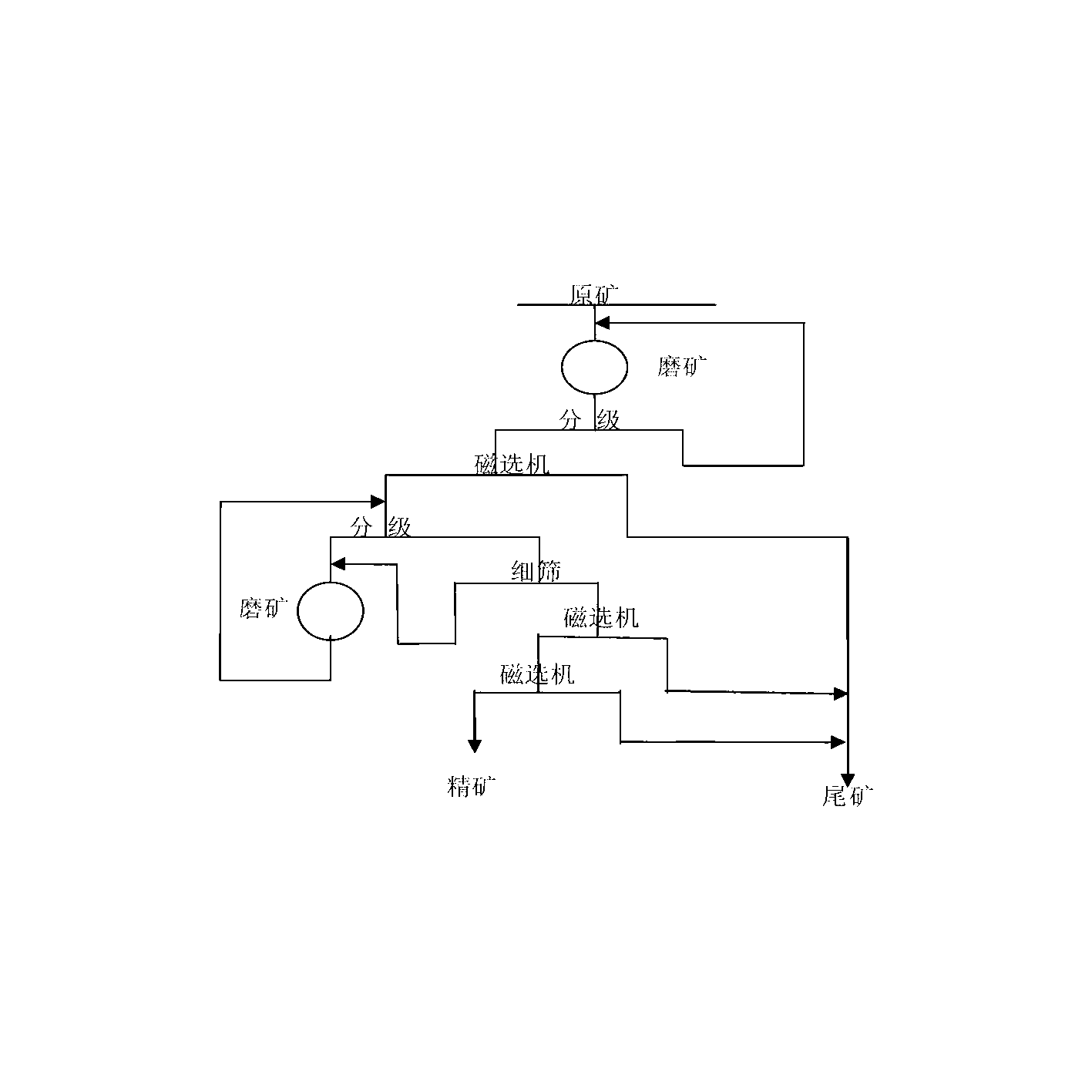

Mineral separation method for vanadium-titanium magnetite ores

The invention discloses a mineral separation method for vanadium-titanium magnetite ores. The mineral separation method comprises the following steps of: conveying raw vanadium-titanium magnetite ores to a primary grinding stage; conveying the crushed vanadium-titanium magnetite ores to a primary swirler for classification; conveying deposited sand of the primary swirler to a magnetic separator for magnetic separation, demagnetizing primary tail-ground refined ores subjected to magnetic separation, and returning to the primary grinding stage for grinding again, wherein the tail-ground tailings subjected to magnetic separation are final tailings; and sequentially performing primary rough magnetic separation, secondary grinding, secondary swirler classification, high-frequency fine screening classification, secondary magnetic separation, fine separation, sweeping, filtration and dehydration on overflowed ores of the primary swirler so as to obtain the vanadium-titanium magnetite ores and the final tailings. Compared with the prior art, the treatment capacity and the yield of a vanadium-titanium magnetite ore mineral separation system are improved, the raw ore machine time and the fine ore machine time are prolonged, and great economic benefit can be obtained.

Owner:PANGANG GRP MINING

Mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore

The invention relates to a mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore. The mineral processing process comprises steps as follows: raw ore containing the mixed ore of the magnetic iron ore and the hematite-limonite ore is smashed and then subjected to two-stage continuous ore grinding; overflowing ore of a secondary classifying cyclone is subjected to two-stage low-intensity magnetic separation and one-stage fine screening and separation in combination of a single magnetic separation, fine screening and regrinding process for processing magnetic ore; under the condition of rougher ground ore particles, a part of undersize qualified magnetite concentrate products are firstly obtained, the other part of oversize products are combined with one-stage high-intensity magnetic separator concentrate and two-stage low-intensity magnetic separator tailings to serve as middlings, and the middlings are subjected to three-stage ore grinding classification operation for regrinding and separation; and overflowing ore of a tertiary classifying cyclone is subjected to three-stage low-intensity magnetic separation and high-intensity magnetic separation, fine-grain qualified tailings are thrown again, three-stage low-intensity magnetic concentrate and two-stage high-intensity magnetic concentrate are combined to obtain mixed magnetic concentrate, the mixed magnetic concentrate is subjected to a reverse flotation process for separation, and a qualified flotation concentrate product is obtained. According to the mineral processing process, the mixed ore of the magnetic iron ore and the hematite-limonite ore with different dissemination particle sizes is reasonably processed, the qualified iron ore concentrate product is obtained, and the mineral processing process is economical, energy-saving and environment-friendly.

Owner:ANSTEEL GRP MINING CO LTD

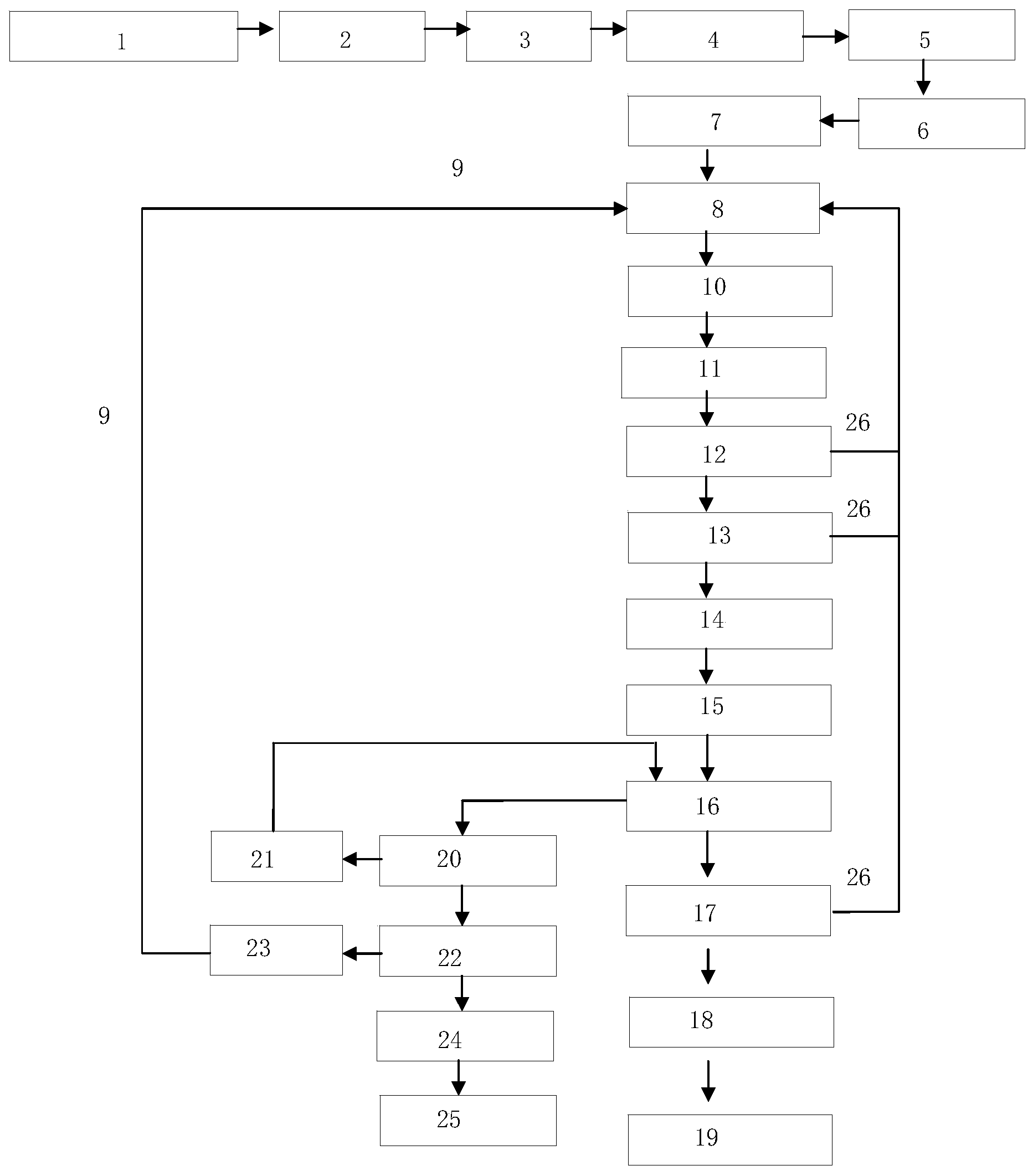

Magnetic Separator for Water Treatment System

InactiveUS20080073283A1Water/sewage treatment by magnetic/electric fieldsMagnetic separationWater treatment systemSludge

A magnetic separator for use in water treatment. Magnetic floc collected from water by the magnetic separator and delivered to a shearing device. Sheared slurry of magnetic seeds and sludge returned to same magnetic separator for extracting the seeds from the sludge and returning the seed to the water for reuse.

Owner:CORT STEVEN L

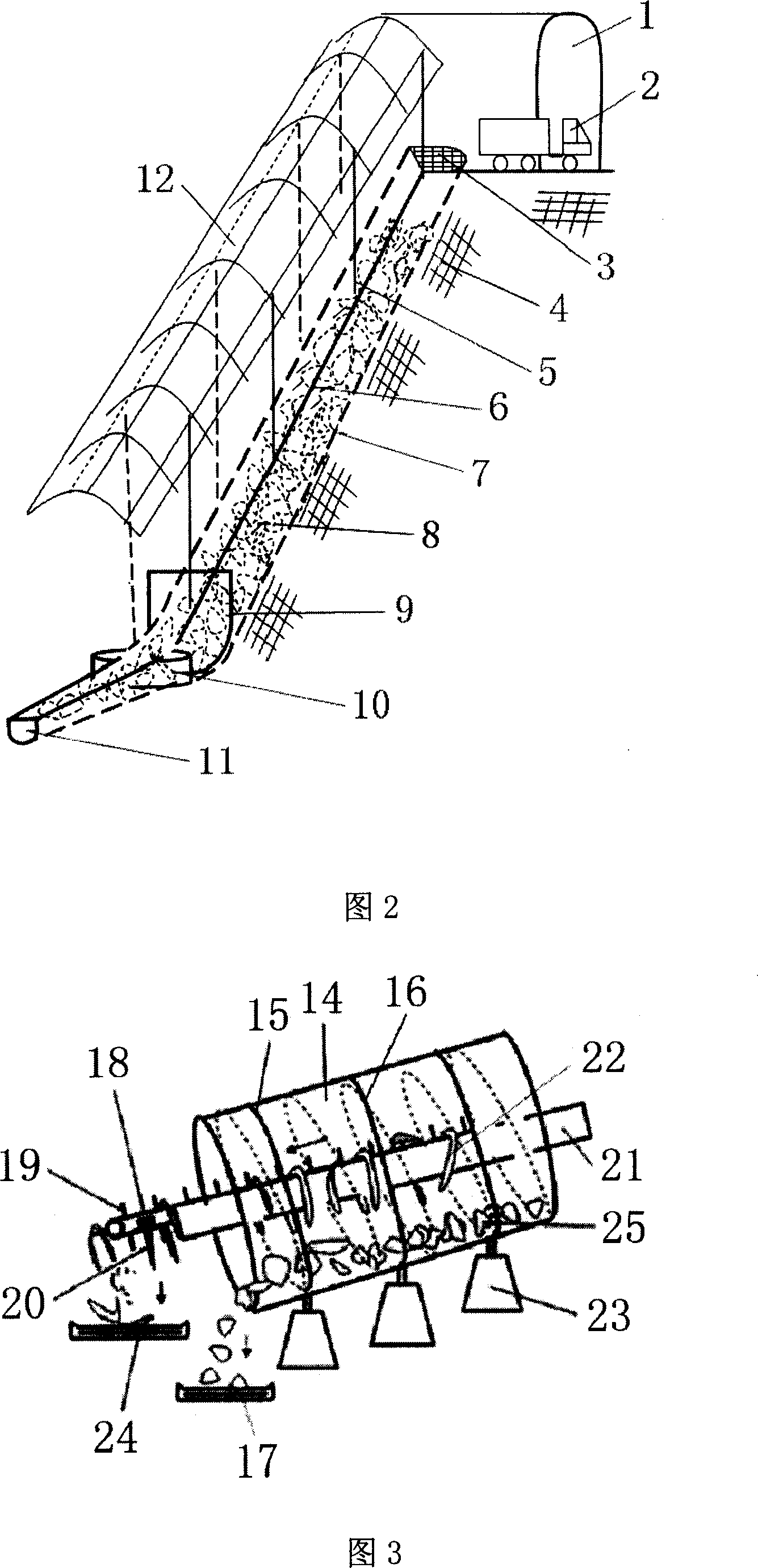

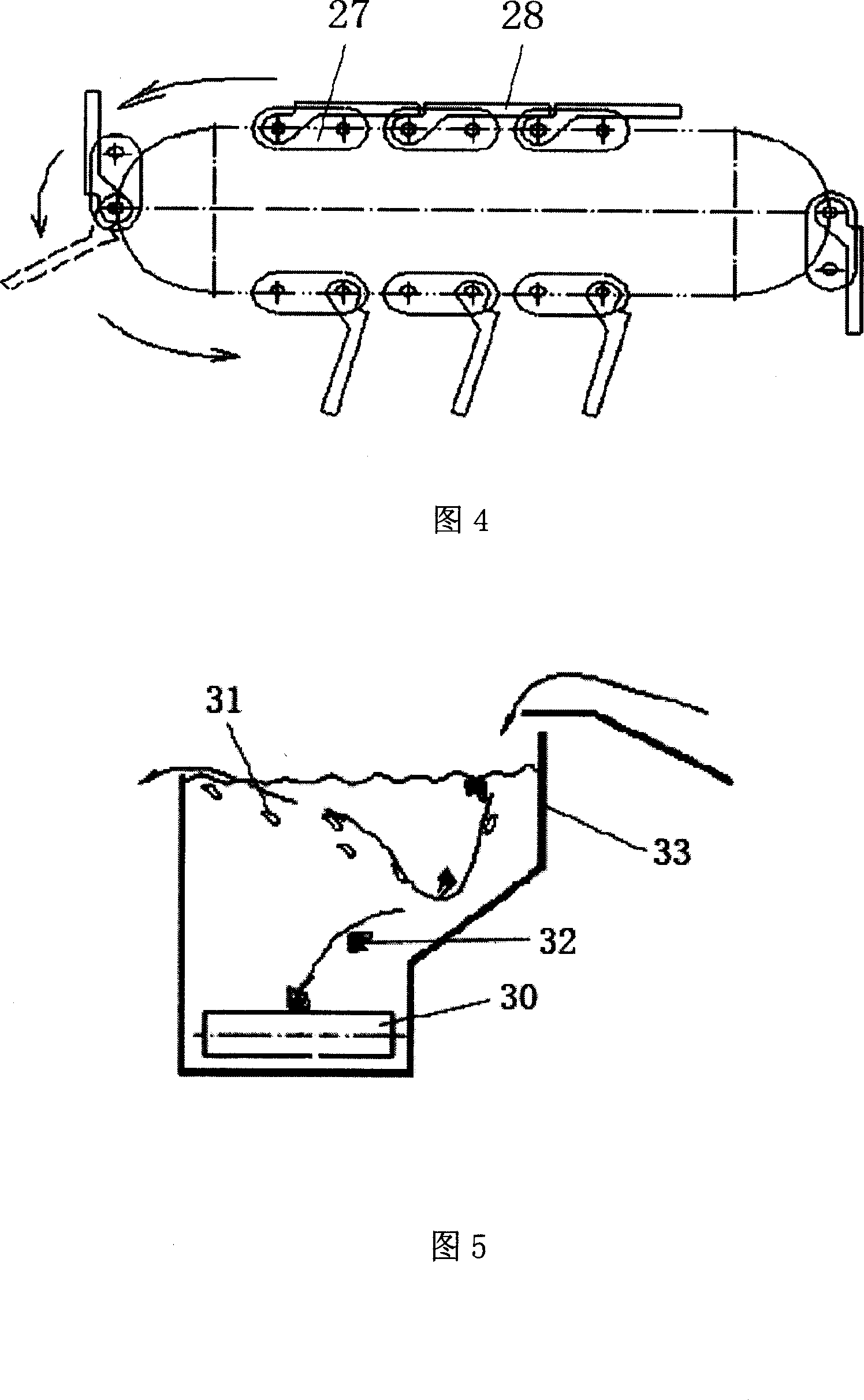

Technology for breaking, sorting and recycling household garbage incineration slag

ActiveCN103769287AImprove cleanlinessReduce frictional heatSolid waste disposalGrain treatmentsSlagFiltration

The invention relates to a technology for breaking, sorting and recycling household garbage incineration slag. The technology comprises the following steps: by utilizing gravitational potential energy and using water as a medium and circulating flow, vertically arranging an iron removal device, a hopper, a breaker, a magnetic separator, a jigger, screening equipment, a slag finished product collection tank, a sedimentation tank and the like which are equipment for treating the household garbage incineration slag in every link from high to low; injecting water and the garbage incineration slag into the breaker so as to form a material flow, obtaining slag materials with fine particles, light mass and optimized components through the breaker, the jigger and the screening equipment under the action of material gravity flow, filtering through the collection tank and the sedimentation tank and directly transporting the dried fine-grained slag finished product to a finished product warehouse finally; and reblending clear water obtained after sedimentation and filtration and the garbage incineration slag raw material so as to be recycled. The technology has the advantages that the exertion of gravitational potential energy is facilitated in a material treatment process, and the friction heat energy of the materials and the equipment is reduced; and the dust fog pollution in the treatment process is reduced, and environments are protected.

Owner:TONGXIANG TONGDE WALL BUILDING MATERIALS +2

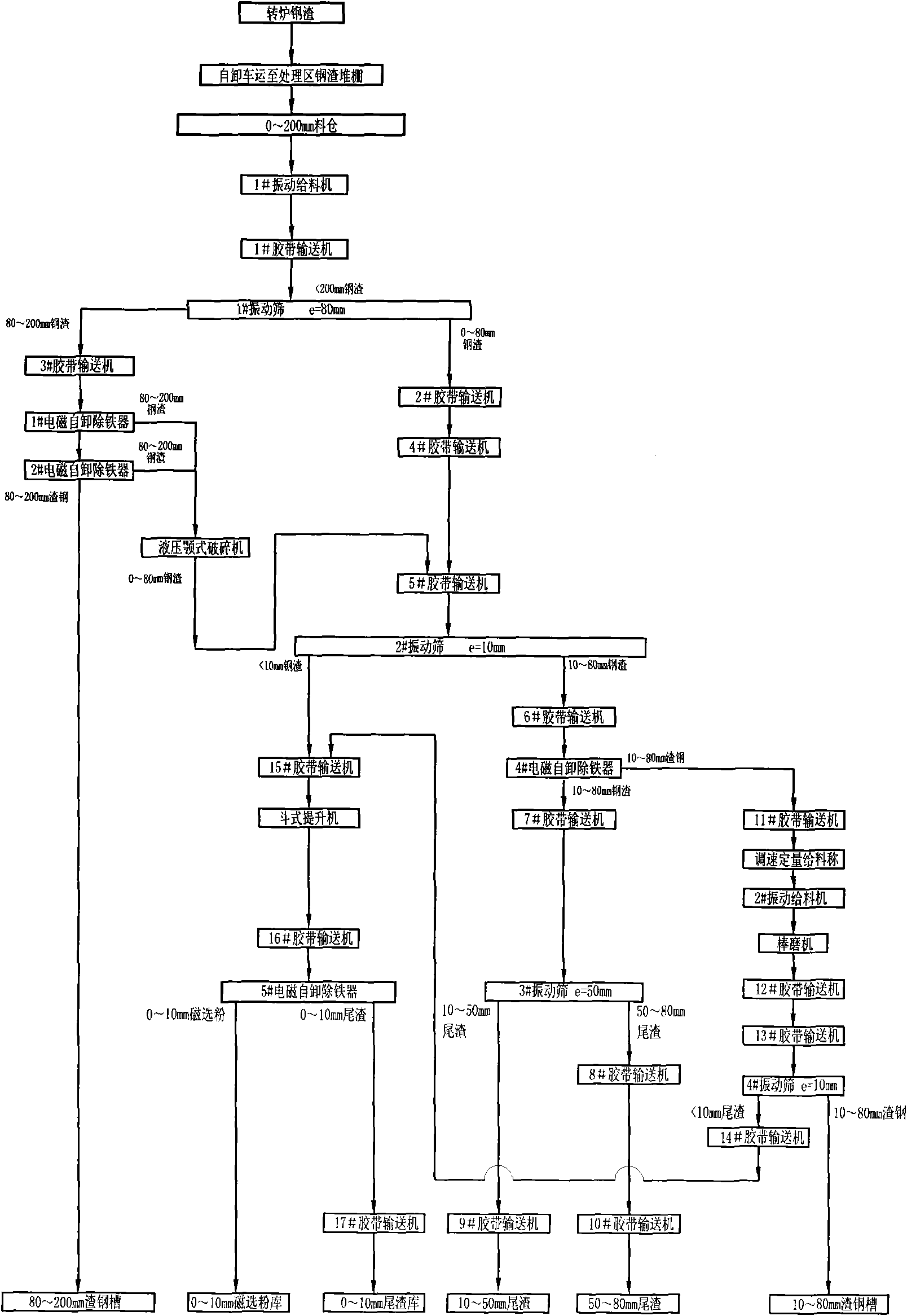

Optimized process for processing steel slag by magnetic separation

The invention relates to an optimized process for processing steel slag by magnetic separation, which is characterized by comprising the following steps: (1) screening steel slag by using a No.1 vibrating screen, separating out the steel slag and slag steel by using a No.1 magnetic separator to separate the oversize material, feeding the slag steel to a slag steel tank, and feeding the steel slagto a jaw crusher; (2) feeding the screen underflow of the No.1 vibrating screen and the discharge of the jaw crusher to a No.2 vibrating screen together, separating the oversize material by using a No.2 magnetic separator, feeding the separated slag steel to a rod mill, and stripping steel slag on the slag steel by the vibration effect of the rod mill; (3) feeding the steel slag separated out by the No.2 magnetic separator to a No.3 vibrating screen, feeding the oversize material to a large-size tailing storeroom, and feeding the screen underflow to a medium-size tailing storeroom; and (4) feeding the discharge of the rod mill to a No.4 vibrating screen, feeding the oversize material the iron content of which is no less than 90% to the slag steel tank, feeding the screen underflow to a No.3 magnetic separator, feeding the separated steel slag magnetic separation powder to a magnetic separation powder storeroom, and feeding the steel slag to a small-size tailing storeroom. By using theinvention, high-quality slag steel the iron content of which is more than 90% can be obtained, thereby fully recovering the iron in the steel slag.

Owner:鞍钢绿色资源科技有限公司

Ore dressing technology for treating vanadium titano-magnetite

ActiveCN102698871AReduce the amount of oreReduce processingMagnetic separationGrain treatmentsResource utilizationMagnetite

The invention relates to an ore dressing technology for treating vanadium titano-magnetite. The technology comprises the following steps of: feeding crushed raw ore into a ball mill in a primary milling and grading closed path, and feeding primary graded overflow containing 40 to 50 percent of milled powder with the granularity of 200 meshes into a rough magnetic separator, wherein tailings in the rough magnetic separator are final tailings; demagnetizing the concentrate in the rough magnetic separator, then feeding for secondary grading, feeding secondary graded return sand into a secondary ball mill, returning the discharged ore in the secondary ball mill for grading, and feeding secondary graded overflow containing 65 to 95 percent of milled powder with the granularity of 200 meshes into a magnetic separator, wherein the tailings in the magnetic separator are final tailings; and demagnetizing the concentrate in the magnetic separator, then feeding into a high-frequency vibrating mesh fine screen, returning the ore on the high-frequency vibrating mesh fine screen to the ball mill, feeding the powder below the fine screen into a magnetic separation column, and returning middling in the magnetic separation column for secondary grading, wherein the concentrate in the magnetic separation column is used as final concentrate. The technology has the advantages of effectively improving the grade and the recovery rate of the vanadium titano-magnetite, reducing the ore dressing energy consumption, improving the utilization rate of resources and reducing the production cost.

Owner:ANSTEEL GRP MINING CO LTD

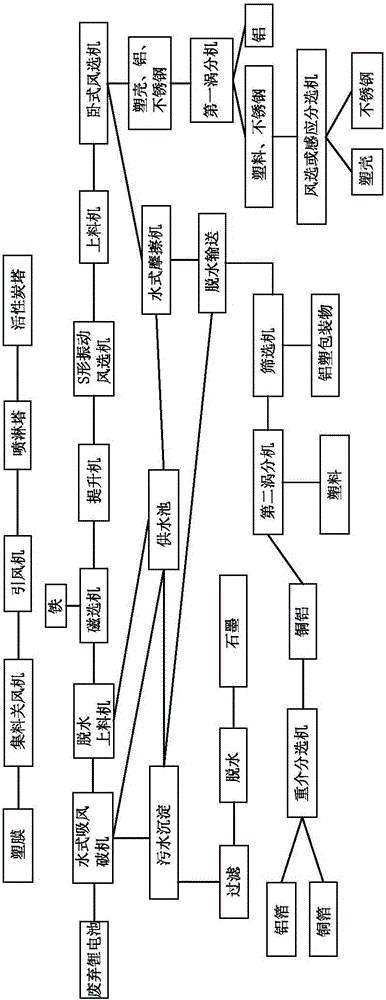

Method for smashing, detaching and recycling lithium battery

ActiveCN105811040AAvoid it happening againImprove processing efficiencyWaste accumulators reclaimingBattery recyclingCyclic processWater source

The invention relates to a method for smashing, detaching and recycling a lithium battery. Plastics, diaphragms, stainless steel, aluminium plastic films, aluminium, plastics, copper foils, aluminium foils, graphite and other materials are sorted from waste lithium batteries through a water type air-suction smashing machine, a magnetic separator, a horizontal type winnowing machine, a water-type friction machine, a first vortex separator, a second vortex separator and the like; the sorting purity can reach 94-99%; various kinds of harmful gases generated in the production process of the lithium batteries are processed by spray towers and activated carbon, and then the standardized gases are discharged; all the water required in the production process is recycled without an externally-discharged water source; and in addition, the water is precipitated, filtered and added with chemical drugs in the cycle process to carry out water treatment. According to the method, the waste batteries are not required to be pre-processed; instead, the waste batteries can be smashed, detached and recycled directly; therefore, the processing quality and processing efficiency of the waste batteries can be greatly improved; and in addition, pollutant emissions in the processing process can be effectively controlled.

Owner:哈尔滨巴特瑞资源再生科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com