Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

547 results about "Gravity flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

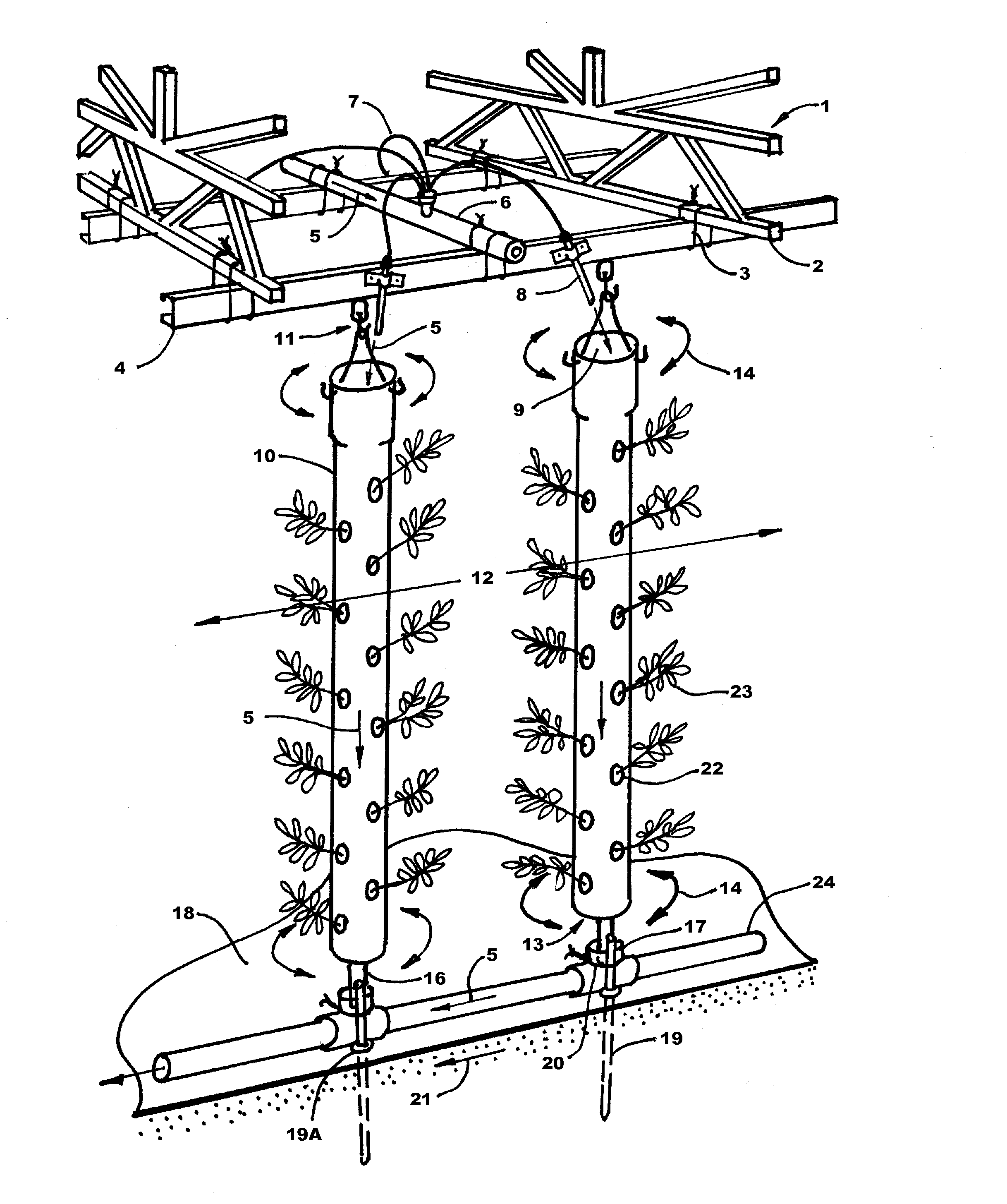

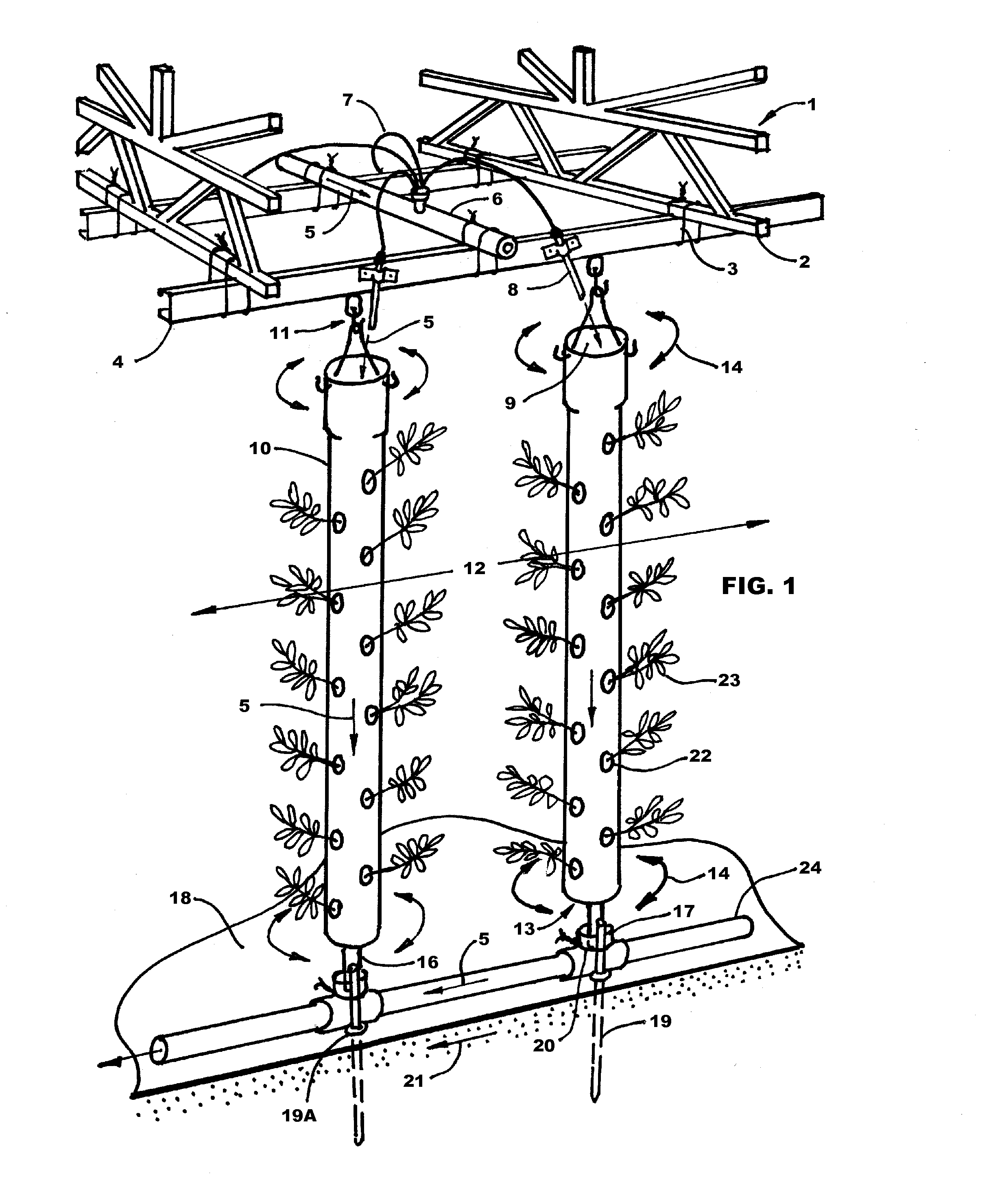

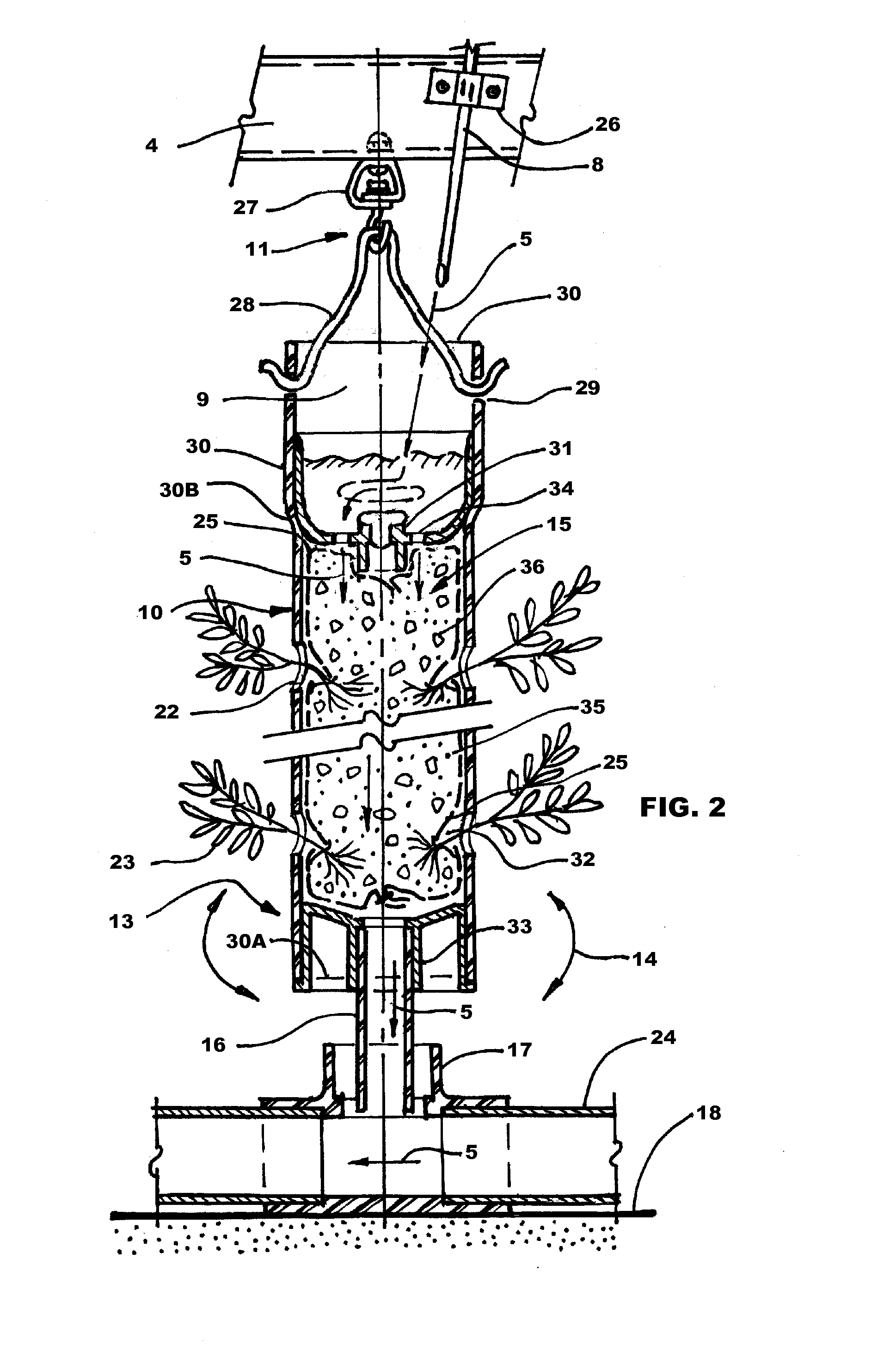

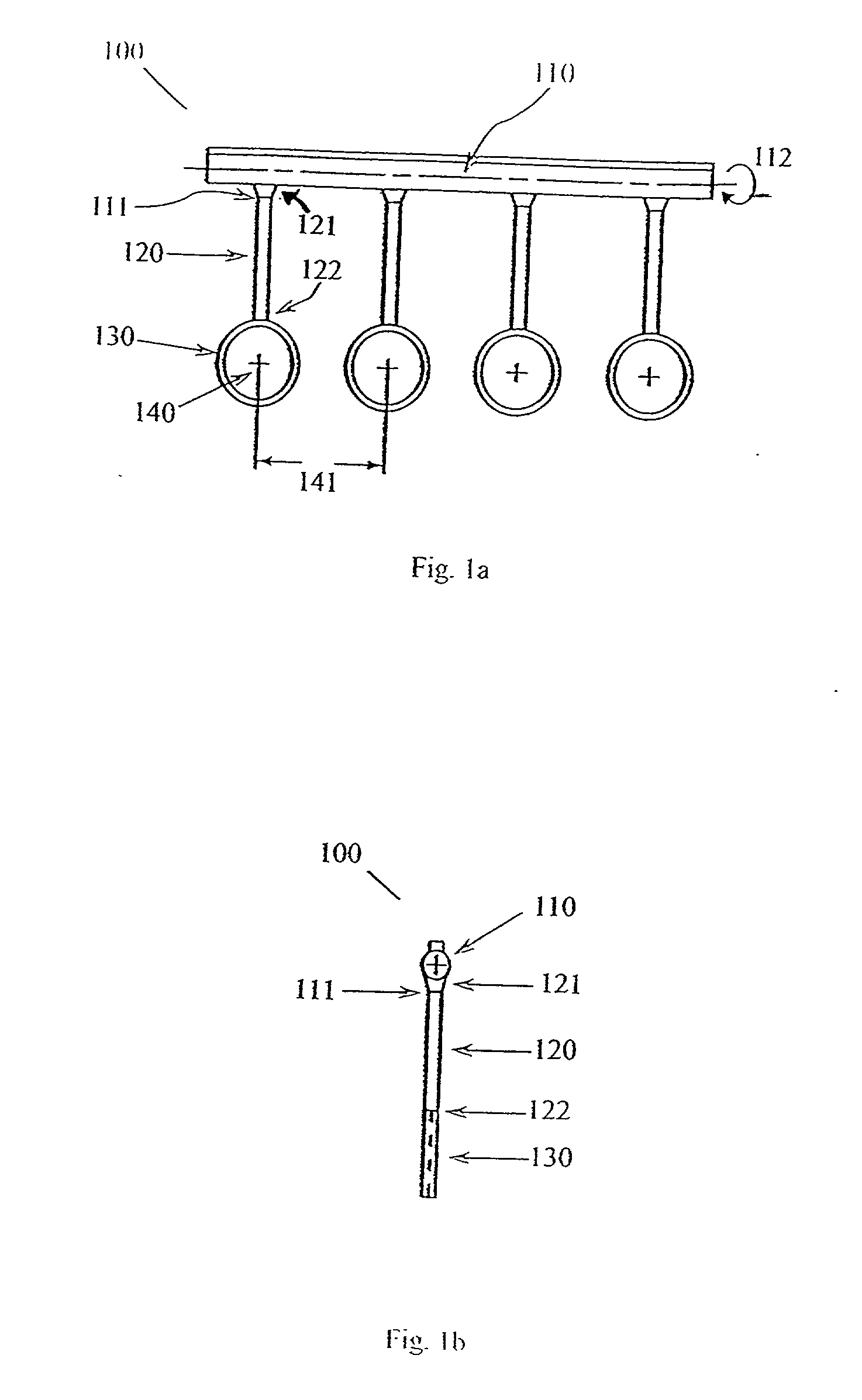

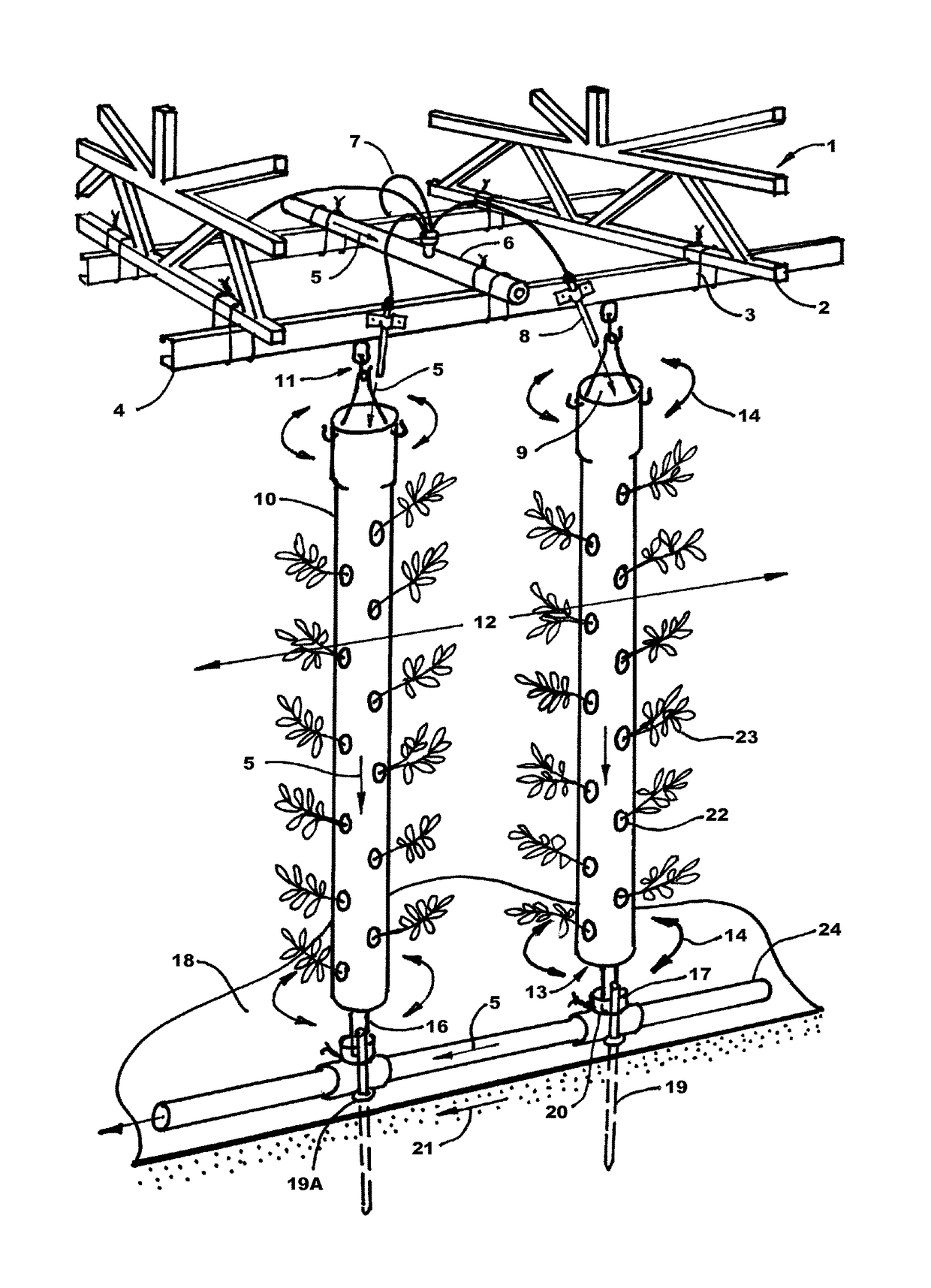

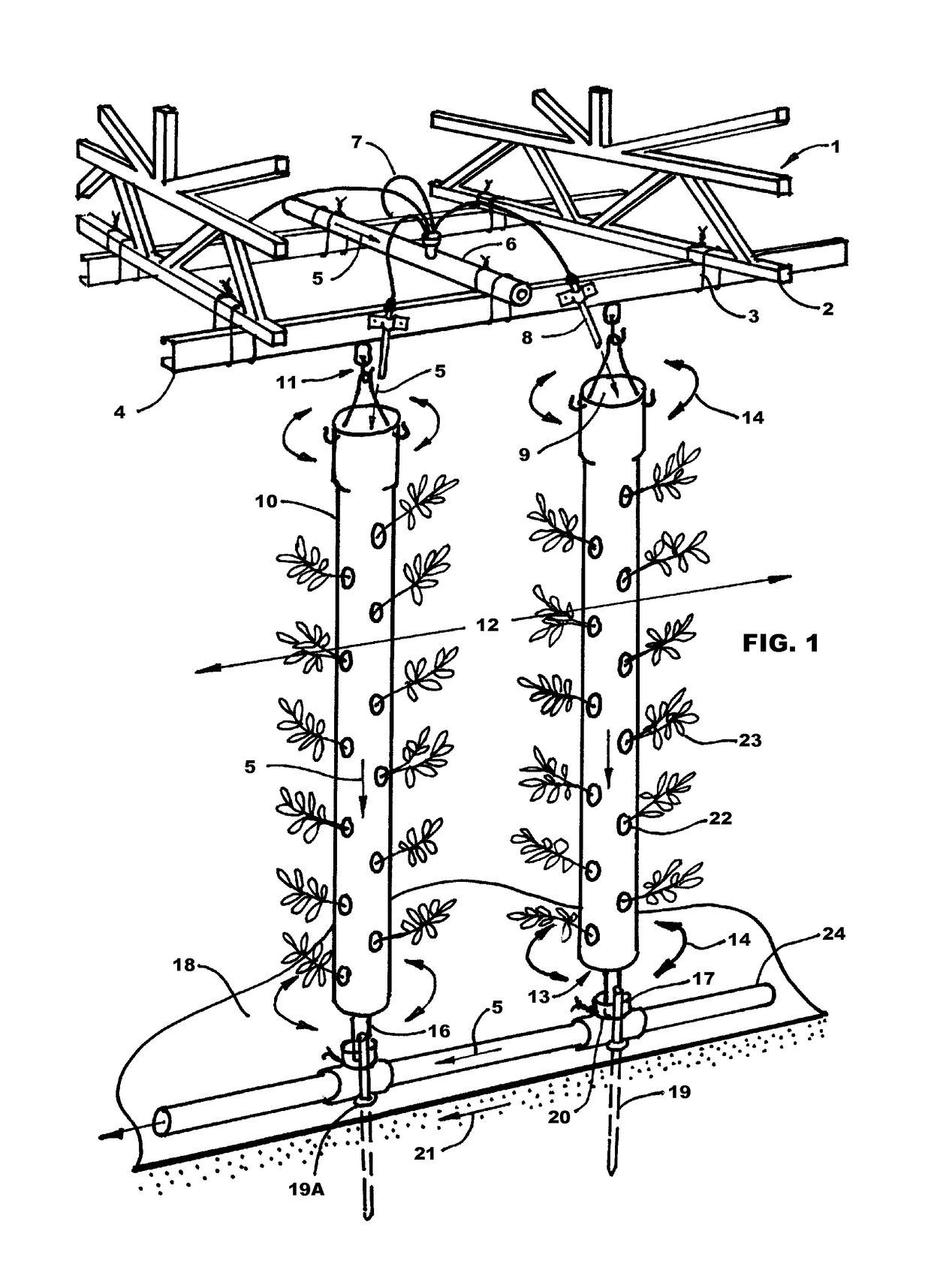

Light-weight modular adjustable vertical hydroponic growing system and method

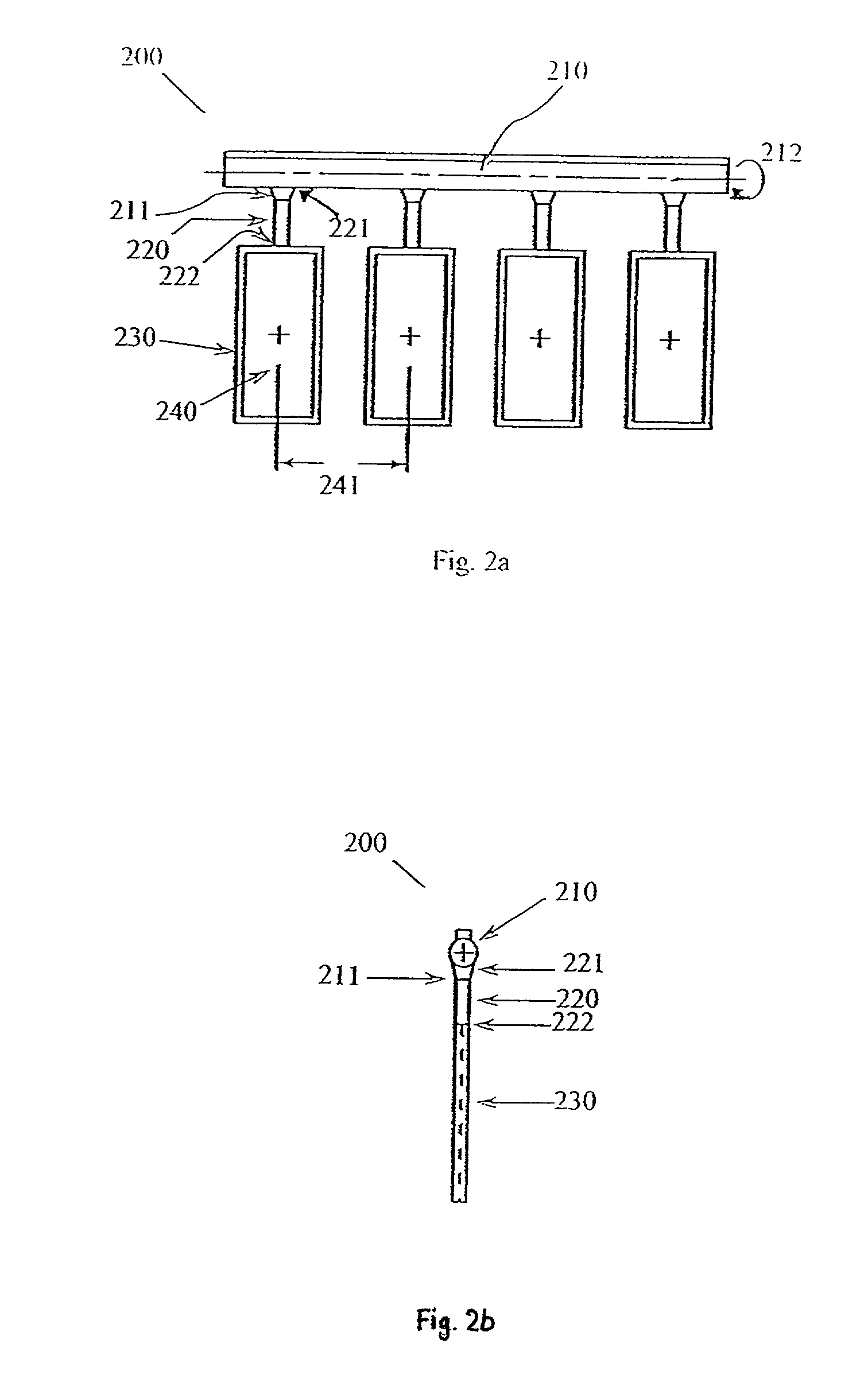

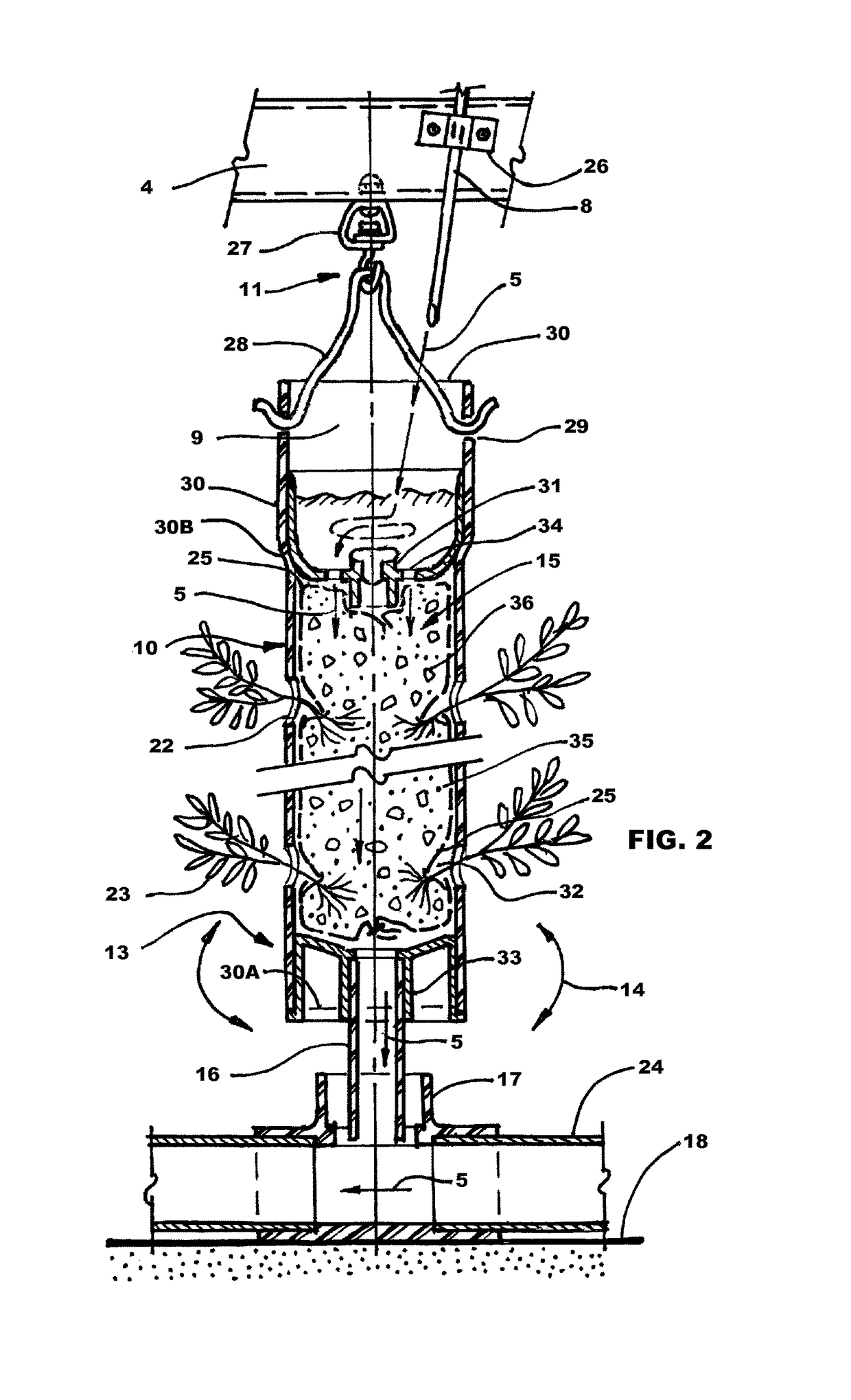

A light-weight, modular, adjustable vertical hydroponic growing system and method of Native American design for cultivation plants and beneficial soil organisms (BSO's) in symbiotic combination. Forest-like arrays of fully rotatable and demountable grow tubes are suspended within climate-moderating greenhouses, optionally from conveyor tracks. The tubes are filled with light-weight, porous 100% in-organic grow media predominately comprised of expanded volcanic or recycled glass granules. The grow tube arrays are provided with an insulated, overhead-mounted fertigation distribution system delivering metered intermittent flows from insulated mixing and holding tanks. The flows are recycled via an insulated return piping system to maintain cool fertigation temperatures near those of natural ground water. Fertigation supply mains provided with vortex flow induction devices impart rotational momentum to flows for delivery of uniform aerated fertigation to plants and BSO's via a combination of open-tube emitters and gravity flows within grow tubes.

Owner:COLLINS FRED +1

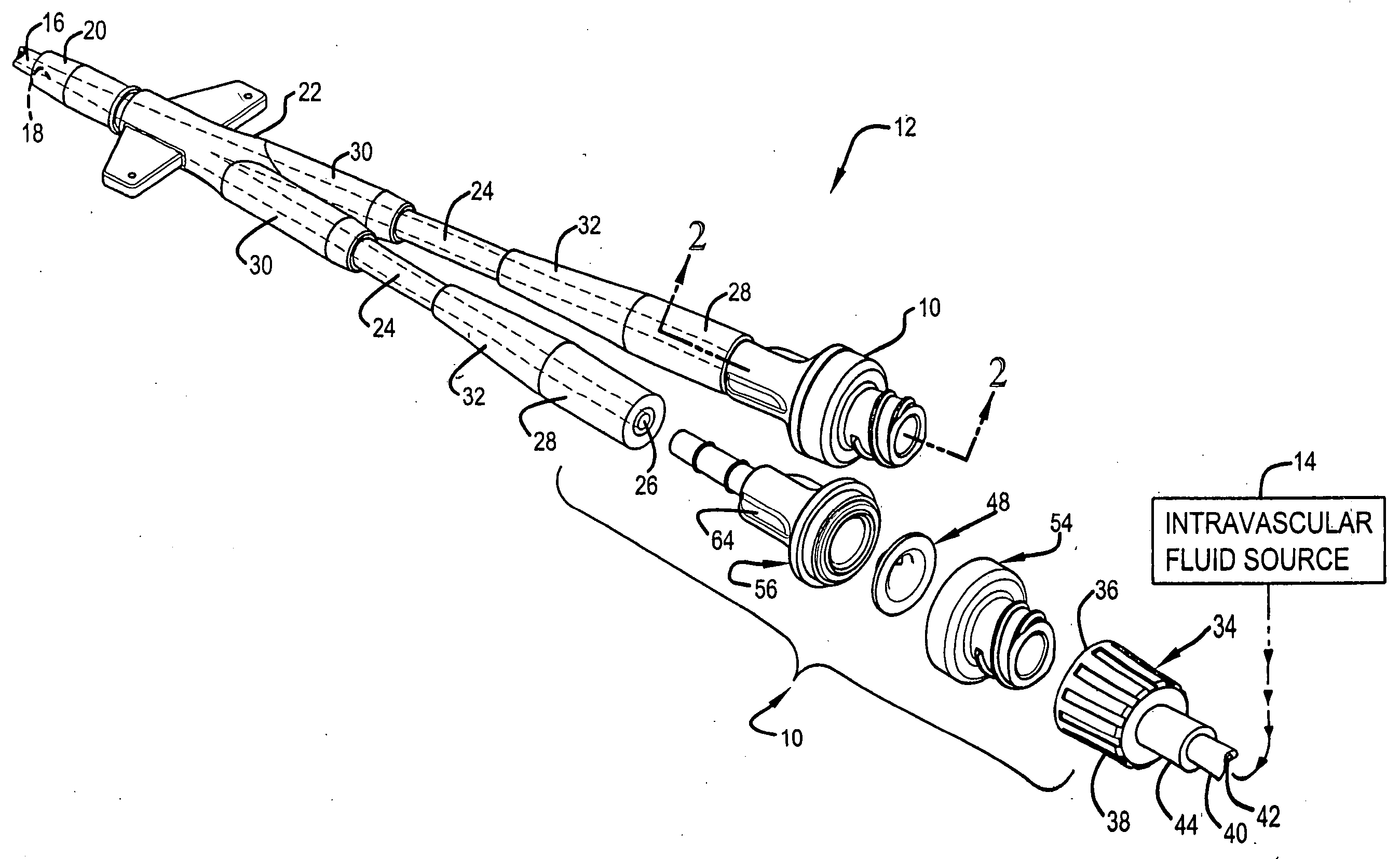

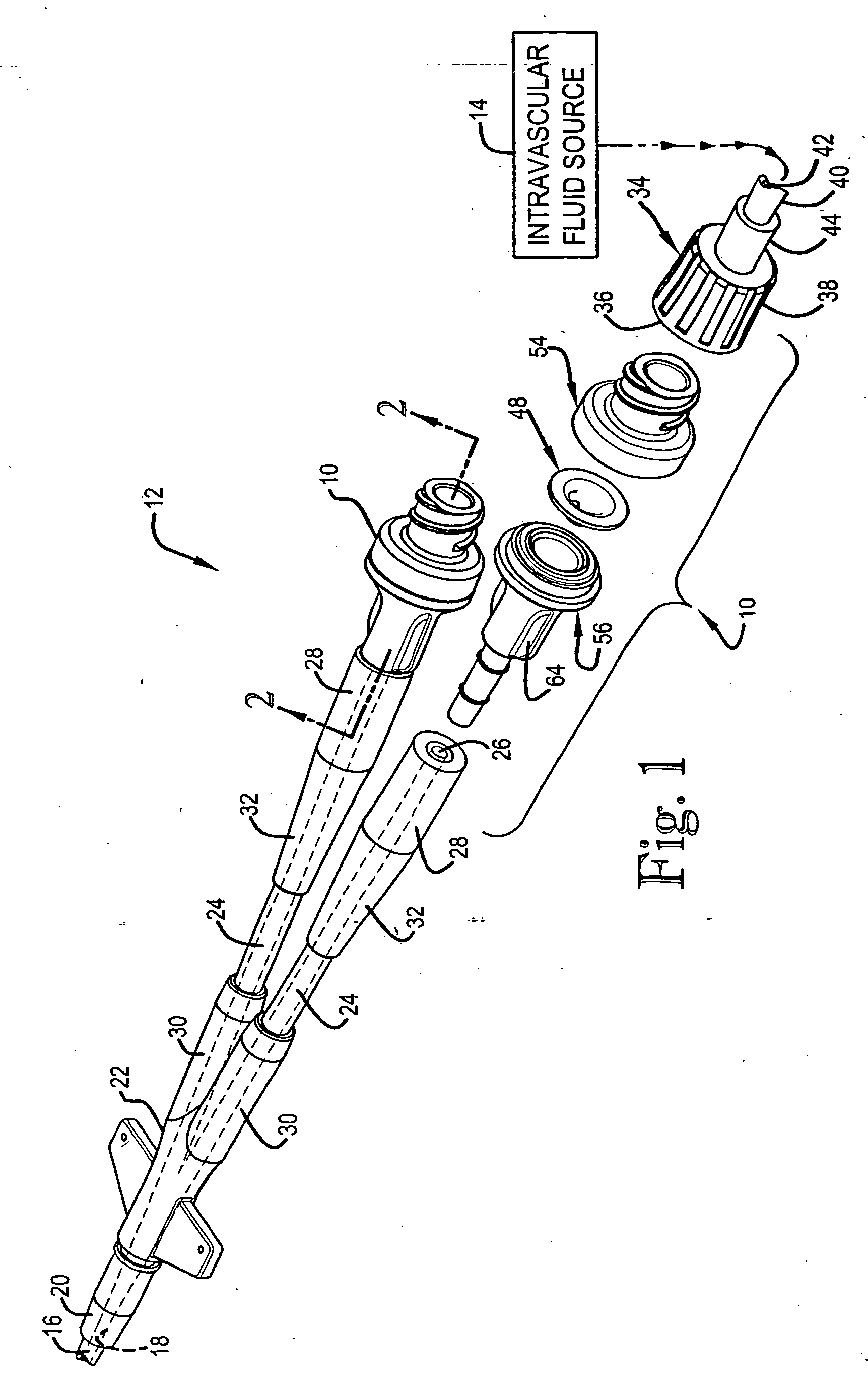

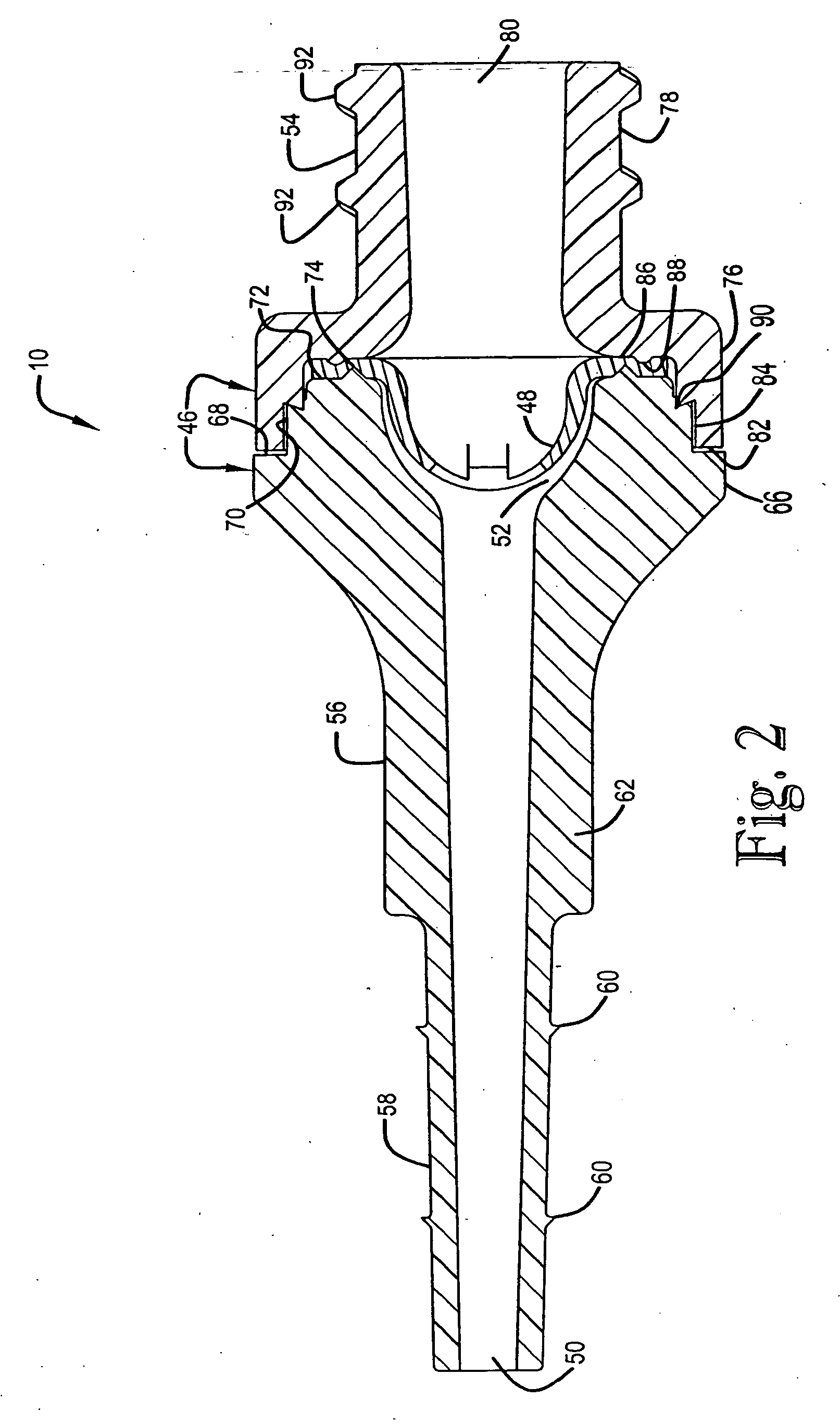

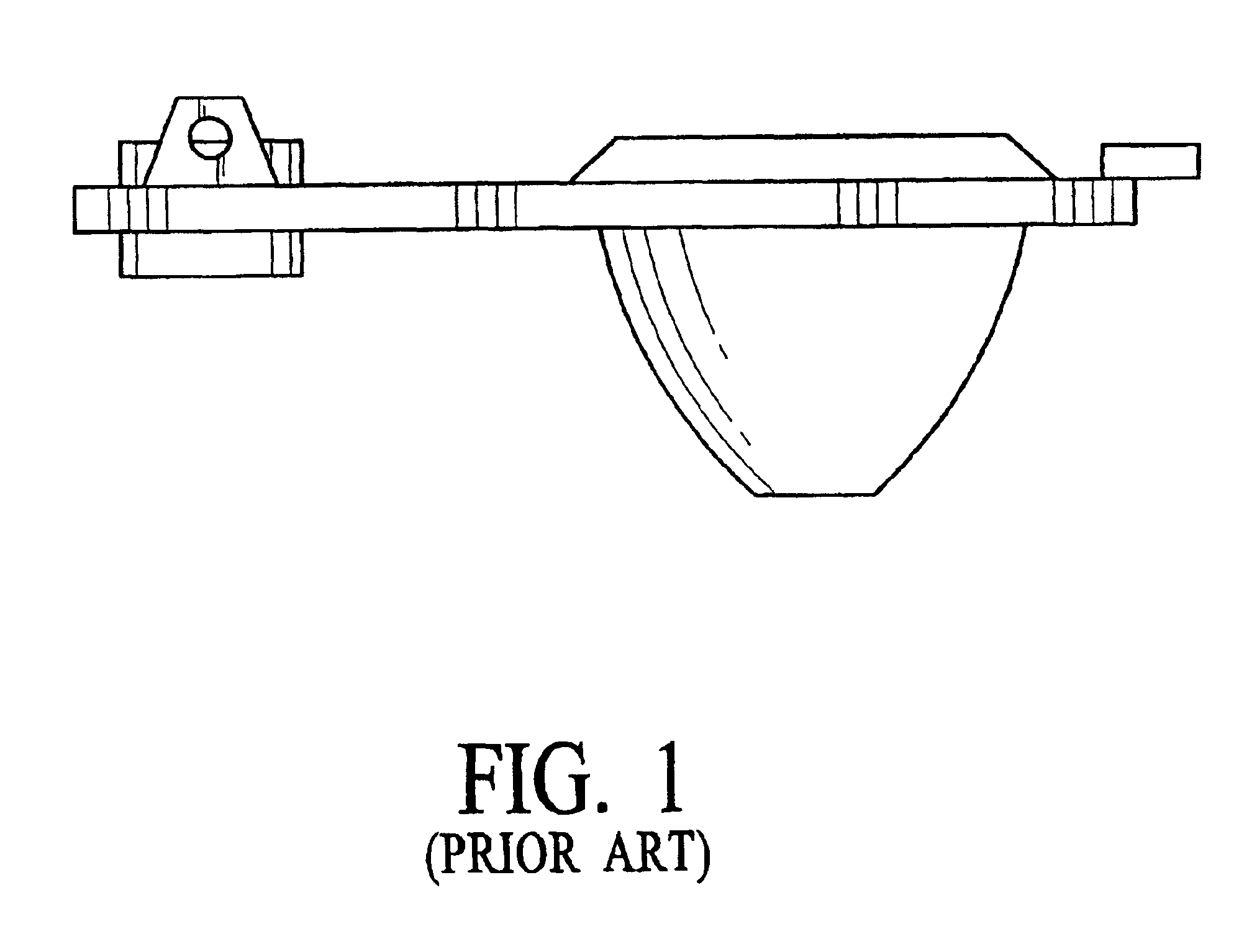

Pressure actuated flow control valve

InactiveUS20050010176A1Reducing total apical deflectionReduced cross-sectional thicknessIntravenous devicesTube connectorsInfusion catheterGravity flow

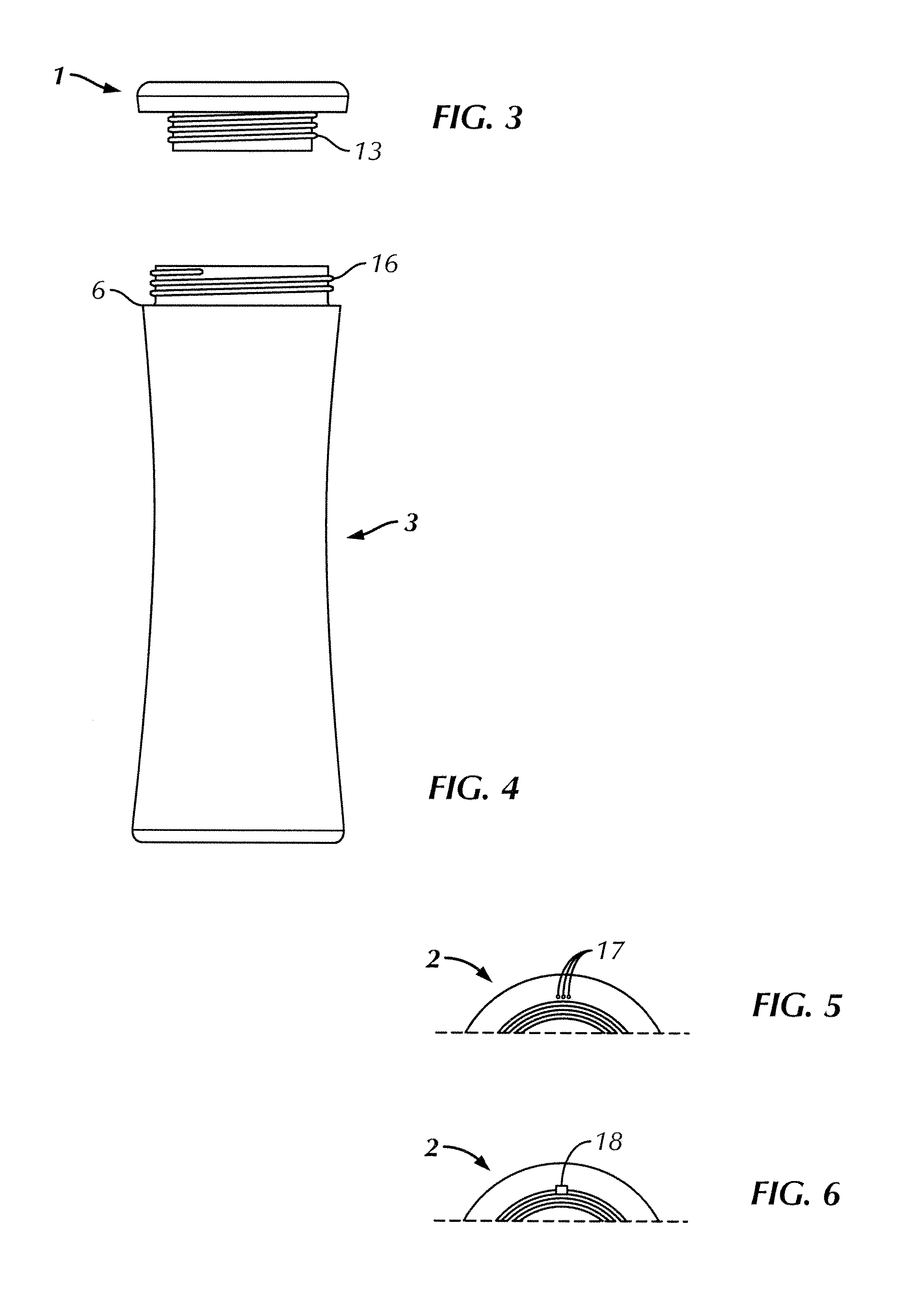

A pressure actuated flow control valve for an infusion catheter permits gravity flow of a liquid through the catheter and into a patient while resisting back flow of blood from the patient and into the catheter. The valve has a hemispherical body with an outstanding circumferential flange and a normally closed, diametric slit. The slit is longer on the convex outer surface than on the concave inner surface. Dome thickness diminishes in the area adjacent the slit, reducing total apical deflection upon collapse of the slit toward the concave surface. An inner orthogonal rib biases the slit closed. Upon application of a predetermined pressure, the slit opens toward the concave surface to permit forward fluid flow. At lower pressures, the slit closes to check fluid flow. Greater reverse pressure is required to collapse the slit toward the concave surface to permit reverse fluid flow.

Owner:DIKEMAN W CARY +1

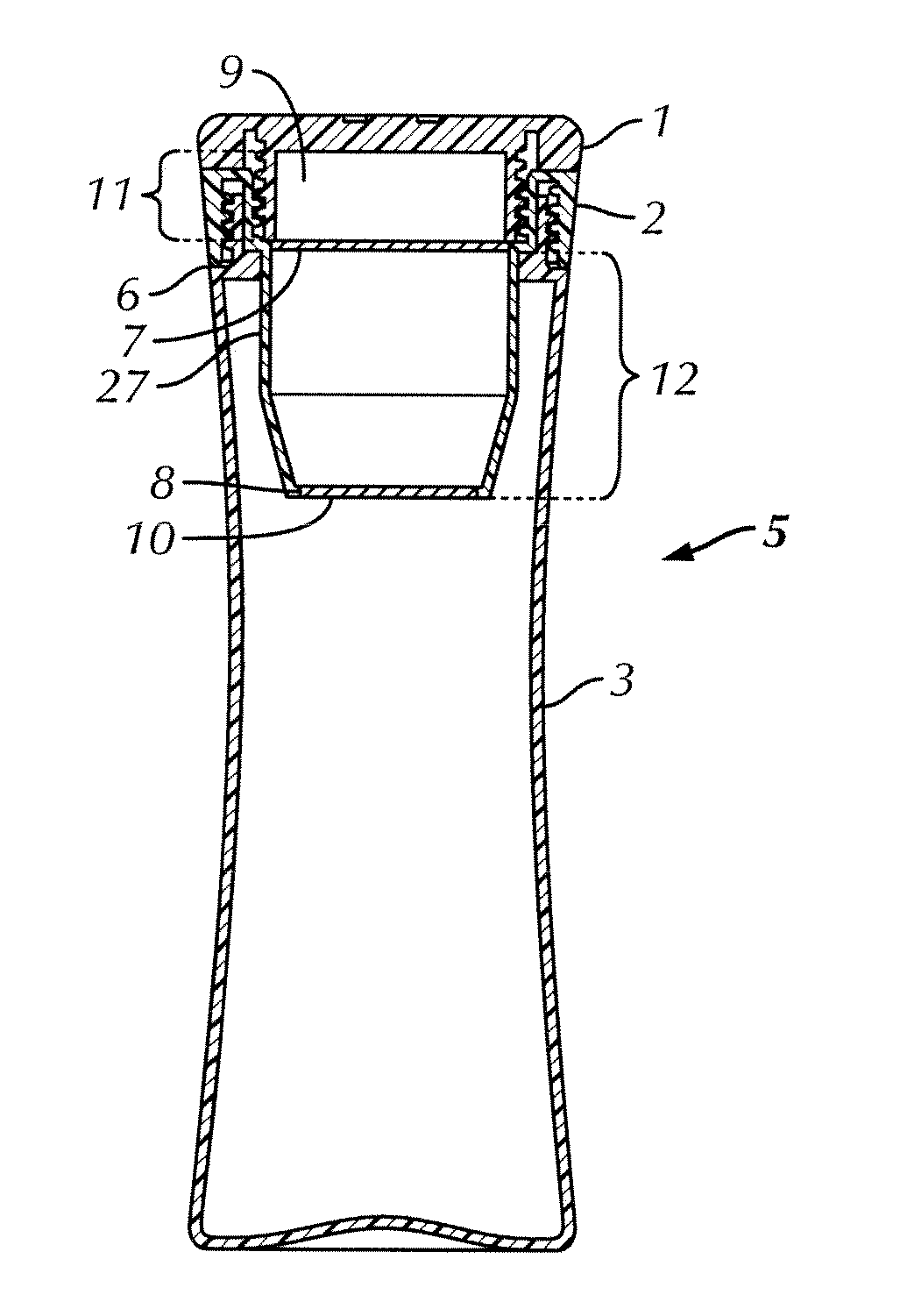

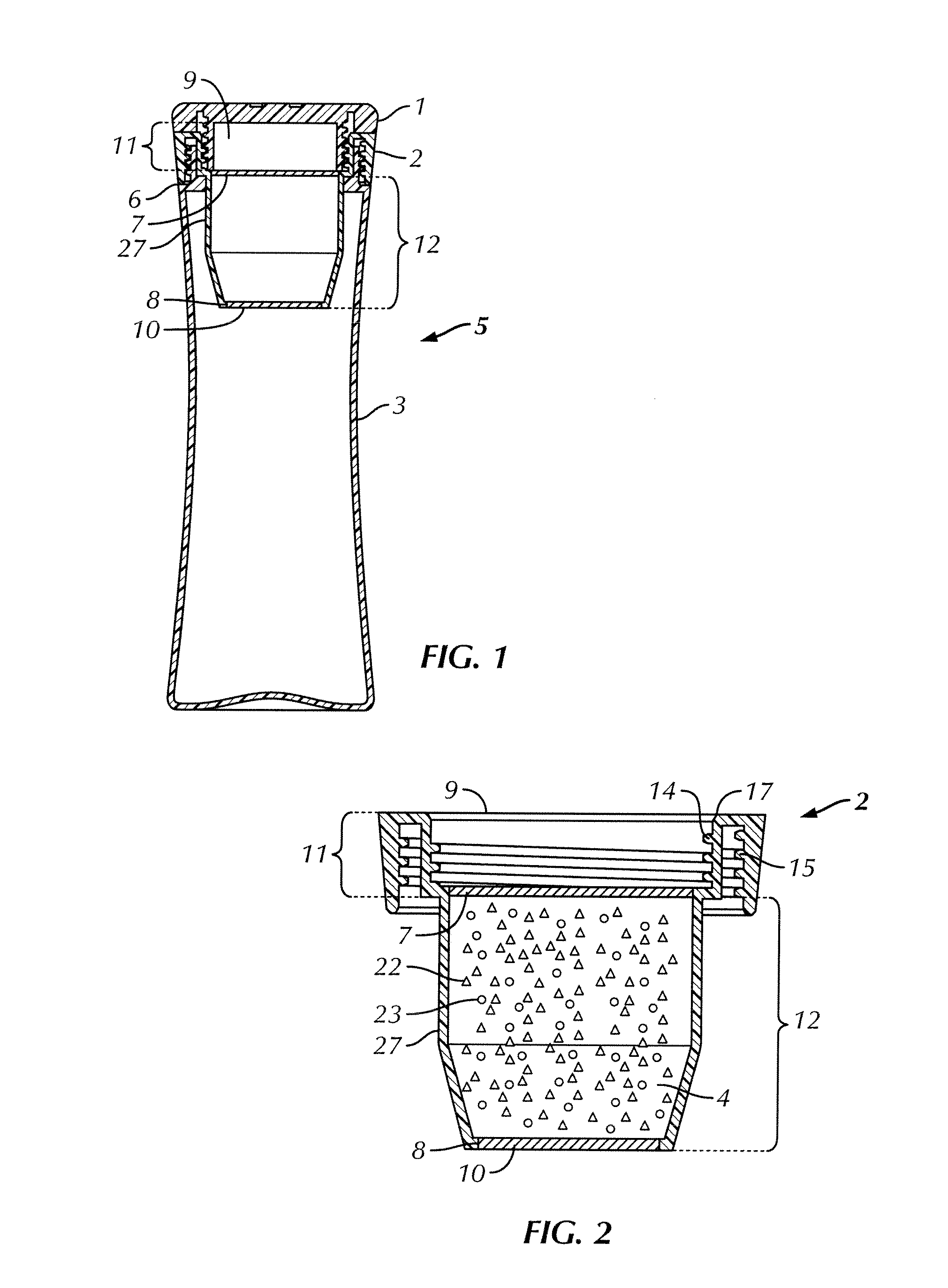

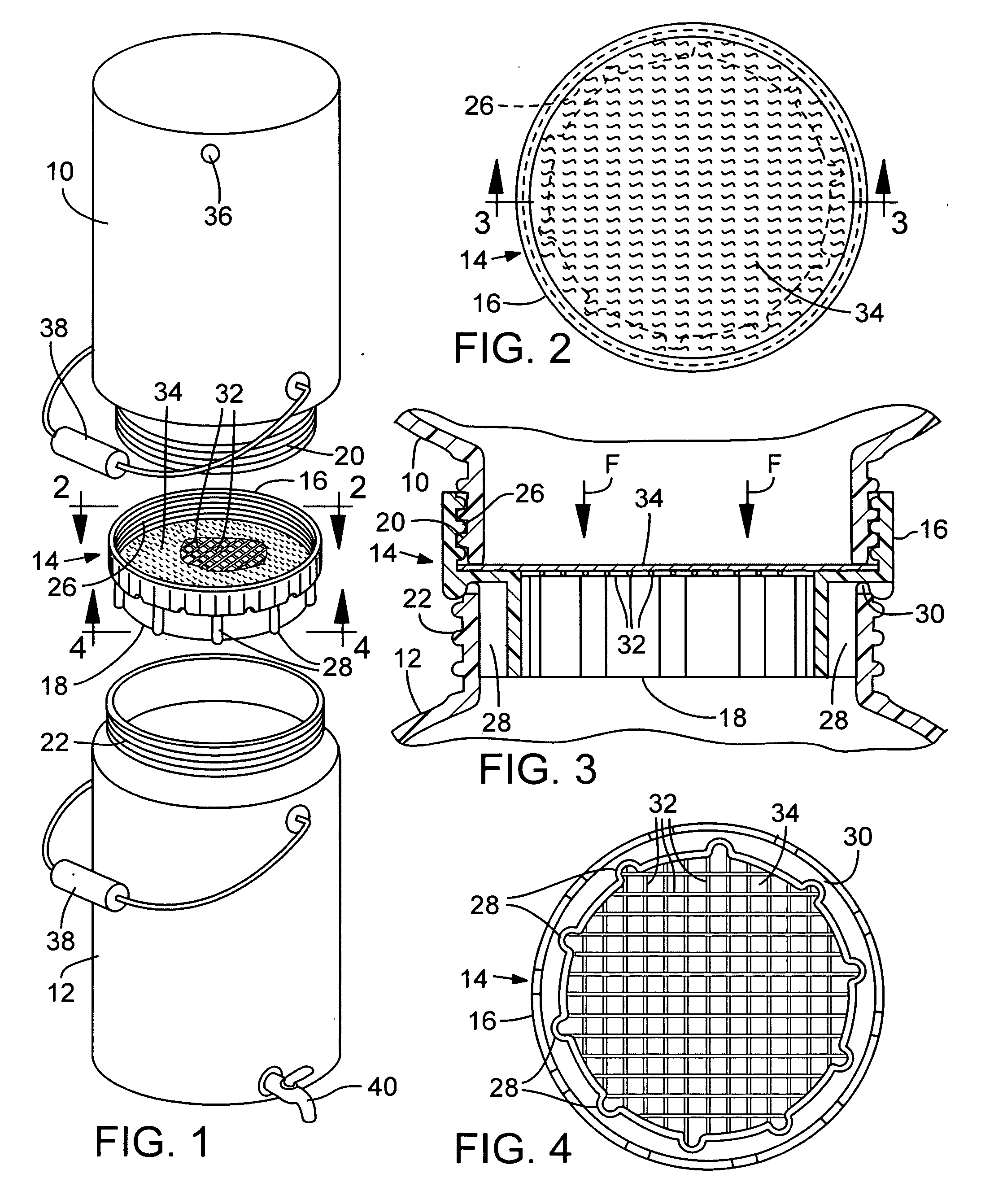

Filtering water bottle

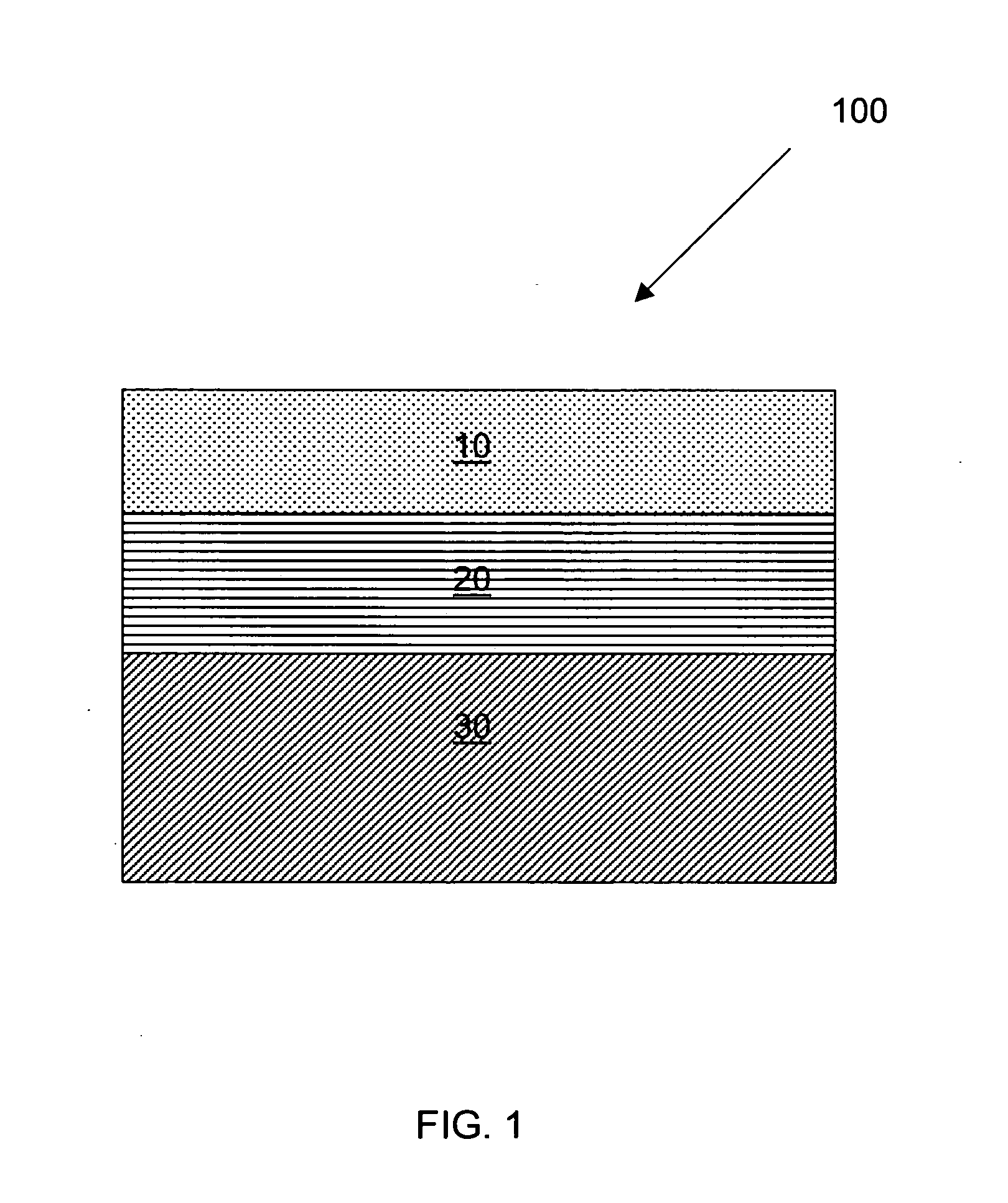

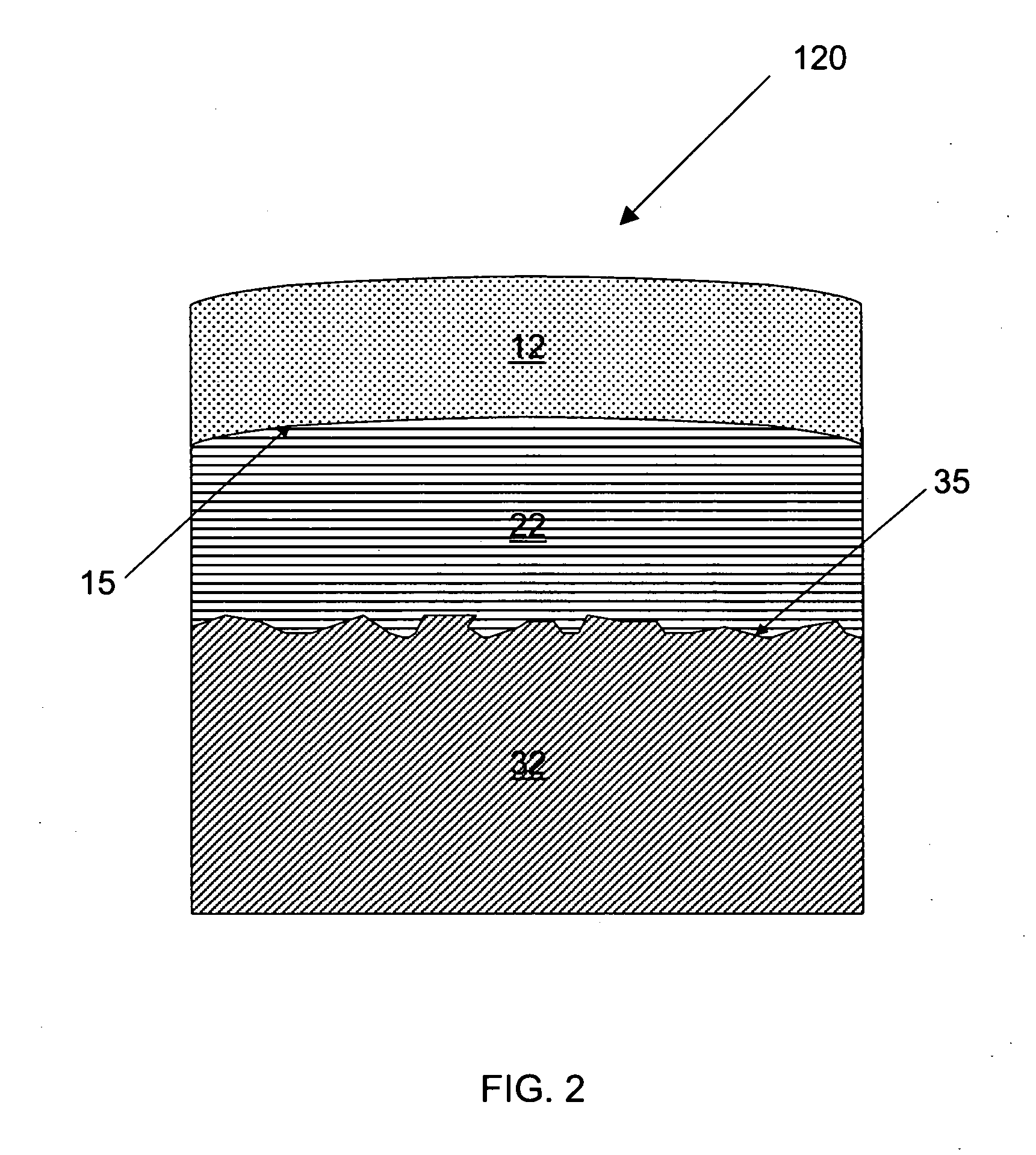

ActiveUS20120055862A1Improve filtering effectIncrease ratingsGeneral water supply conservationTreatment involving filtrationFiltrationGravity flow

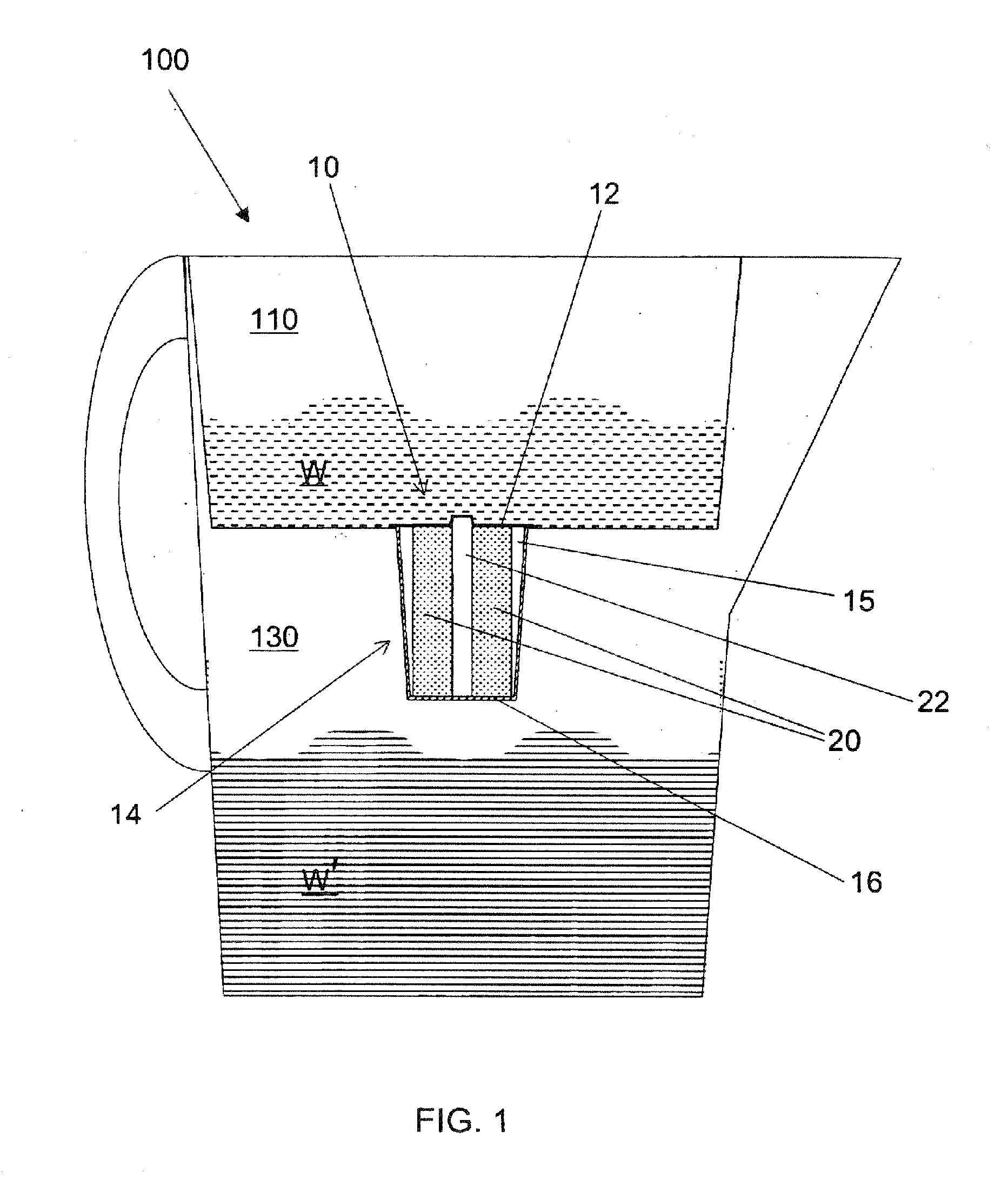

A portable, personal apparatus for treating drinking water comprises a generally tubular or cylindrical filter housing containing filtration media and water-permeable screen or mesh or felt or membrane or netting layer at the top and bottom ends of the filter. The design of the apparatus involves the bottle exterior and interior contouring to the filter and enables the efficient and rapid gravity flow of water in through the filter. The apparatus may be configured such that water is first passed through a top reservoir designed to receive water, followed by a porous mesh, followed by granular filtration and antimicrobial media agitated by turbulent motion of influent water, followed by a porous mesh before reaching a durable and reusable water containment vessel.

Owner:INNOVA DYNAMICS +1

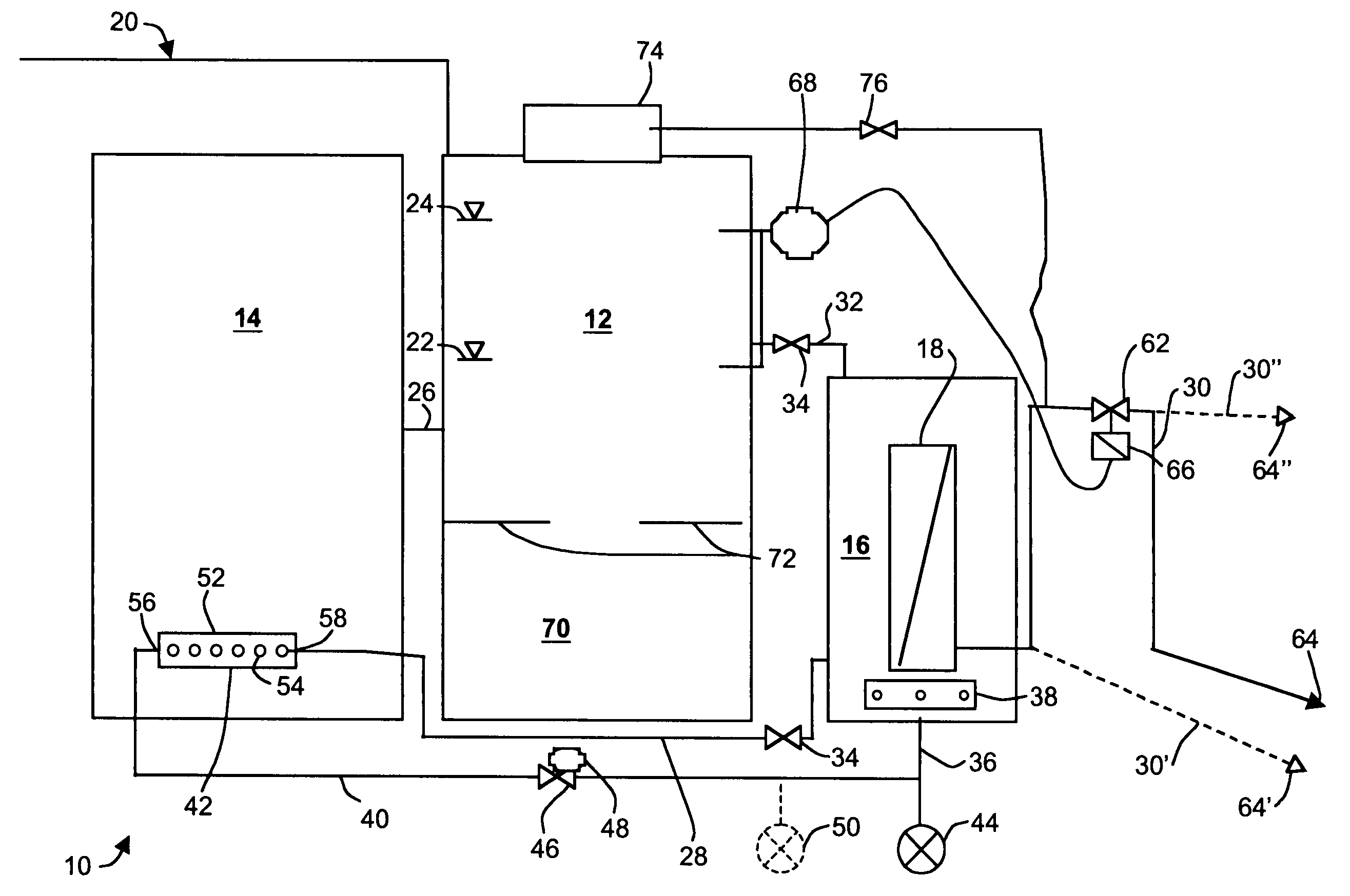

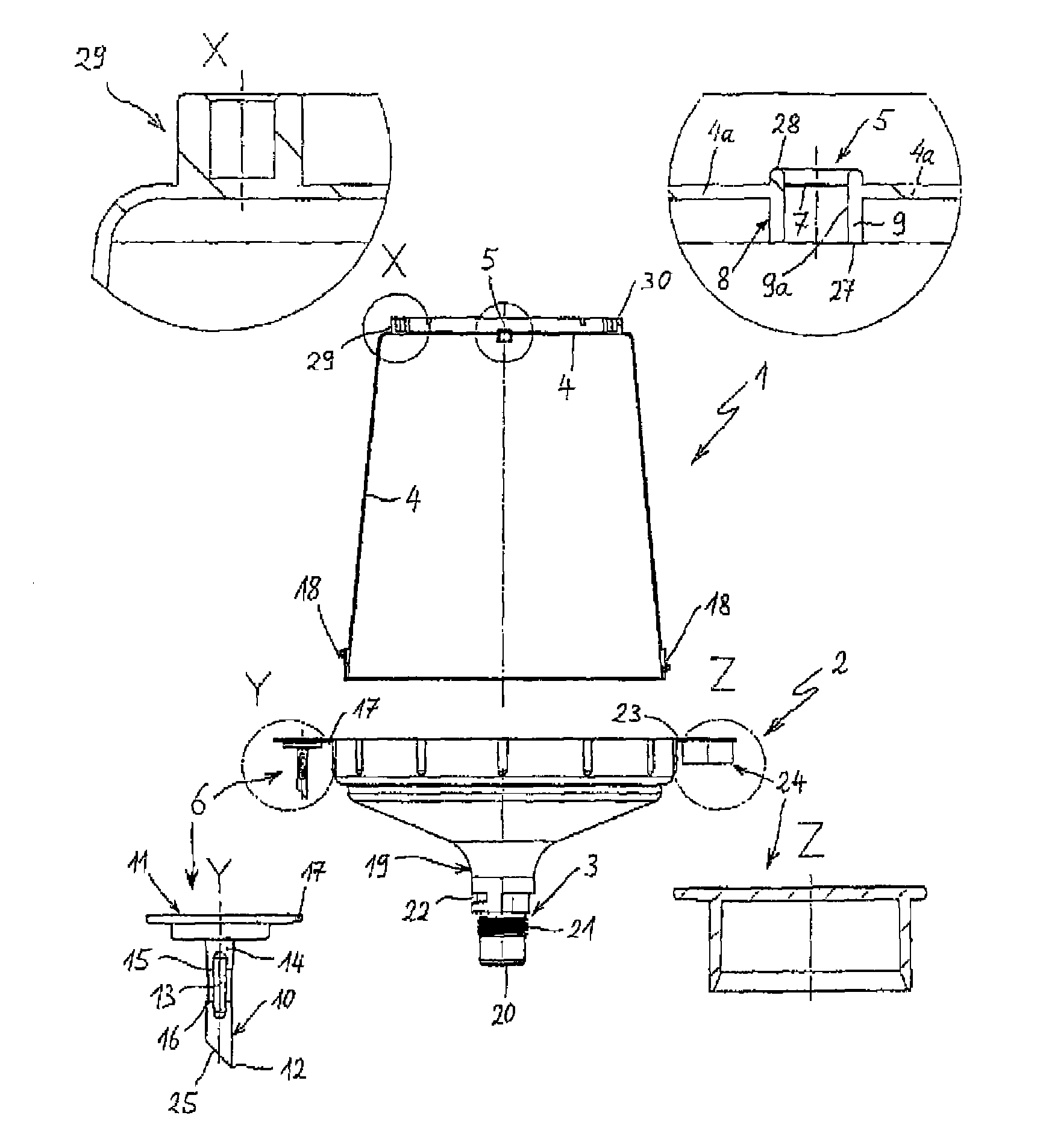

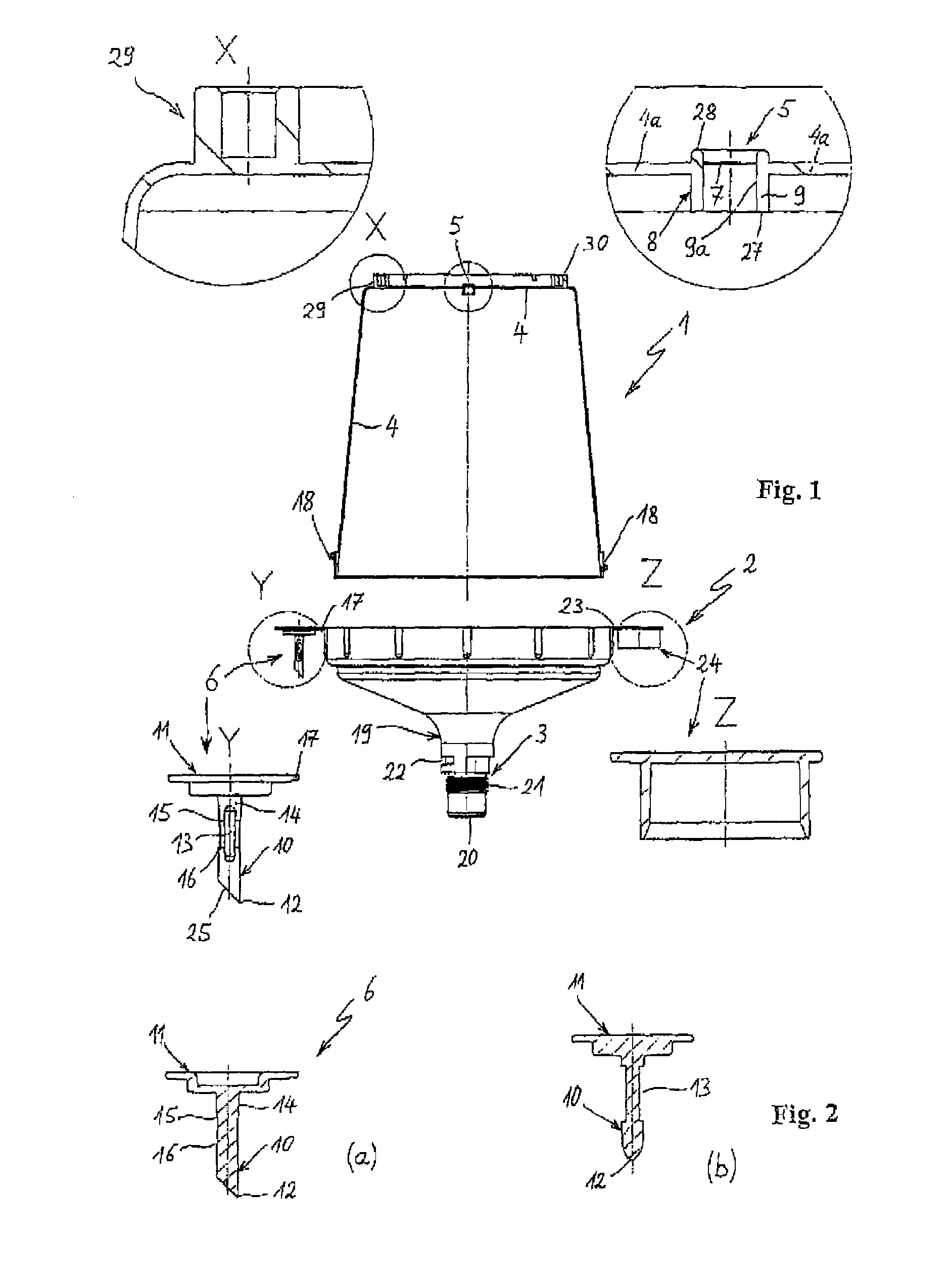

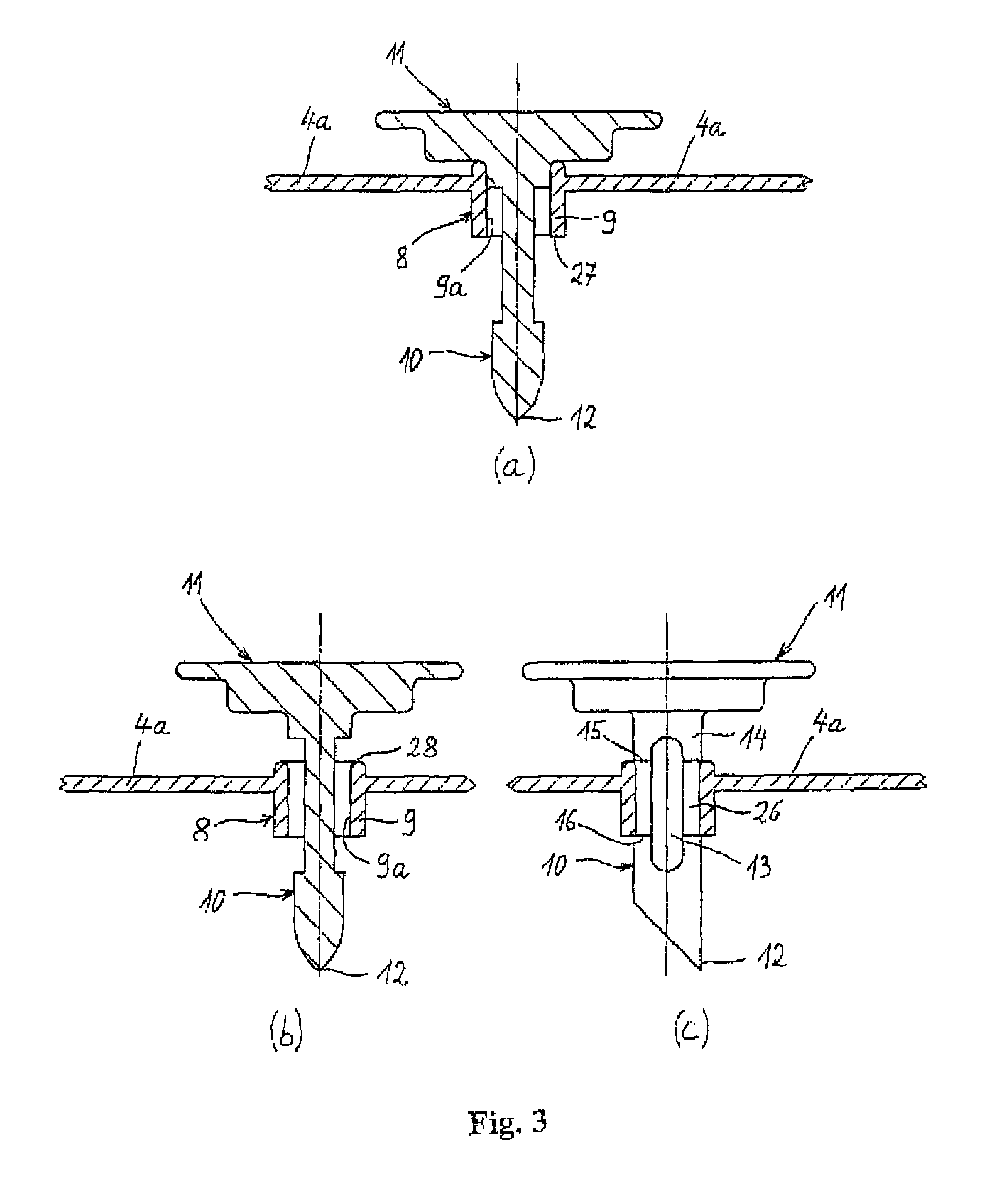

Membrane bioreactor, process and aerator

InactiveUS6863817B2Increase pressureEasy to moveTreatment using aerobic processesUsing liquid separation agentSiphonGravity flow

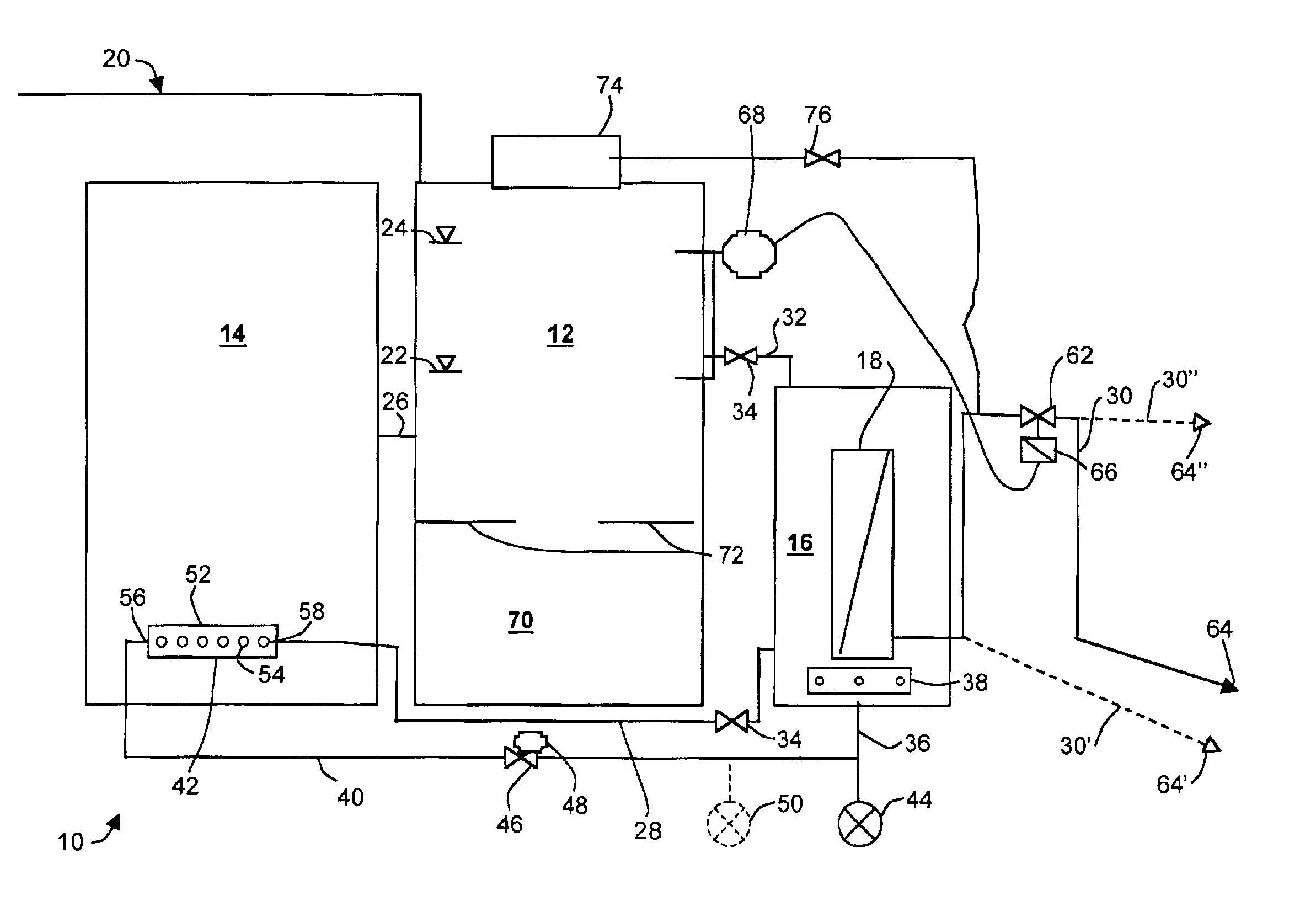

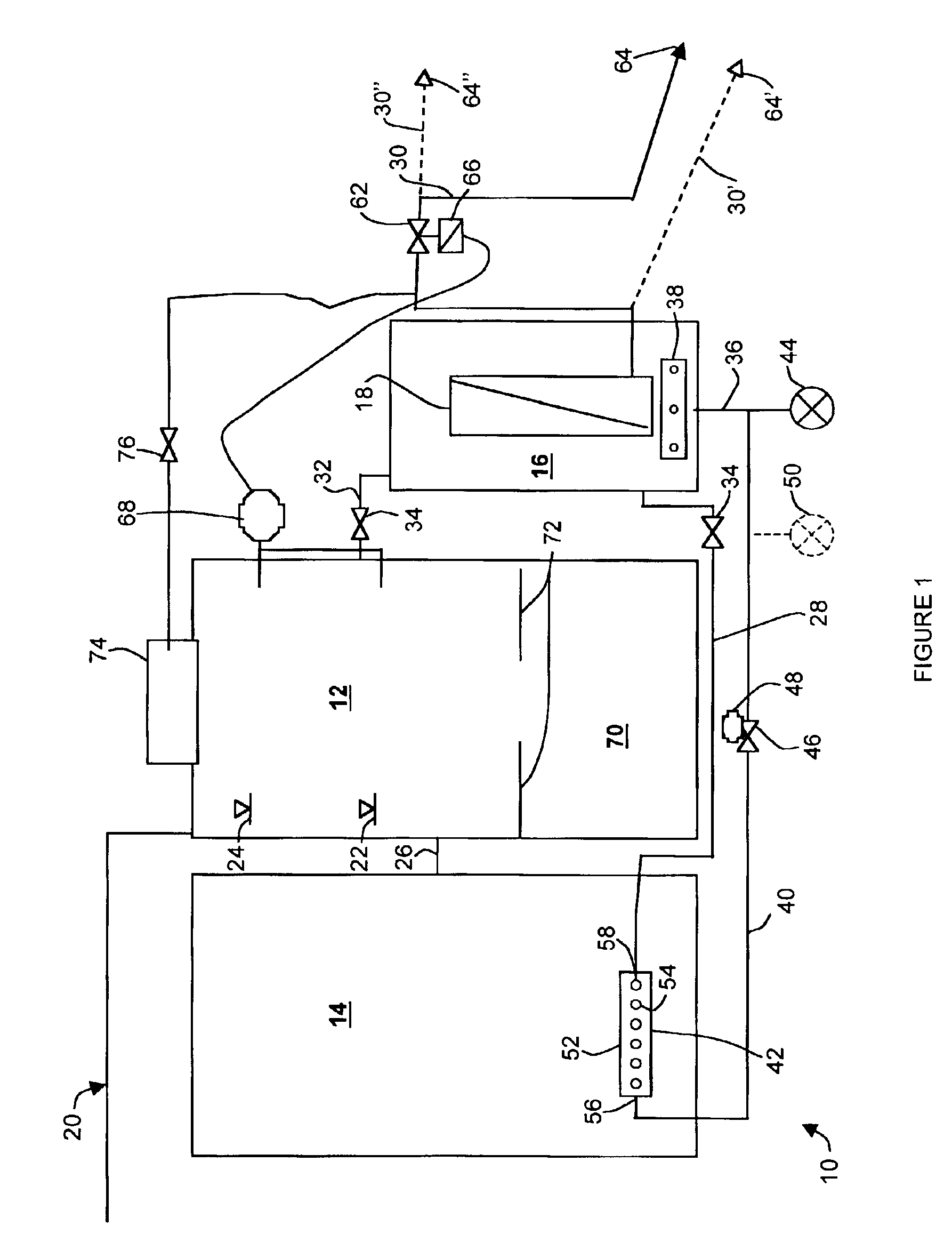

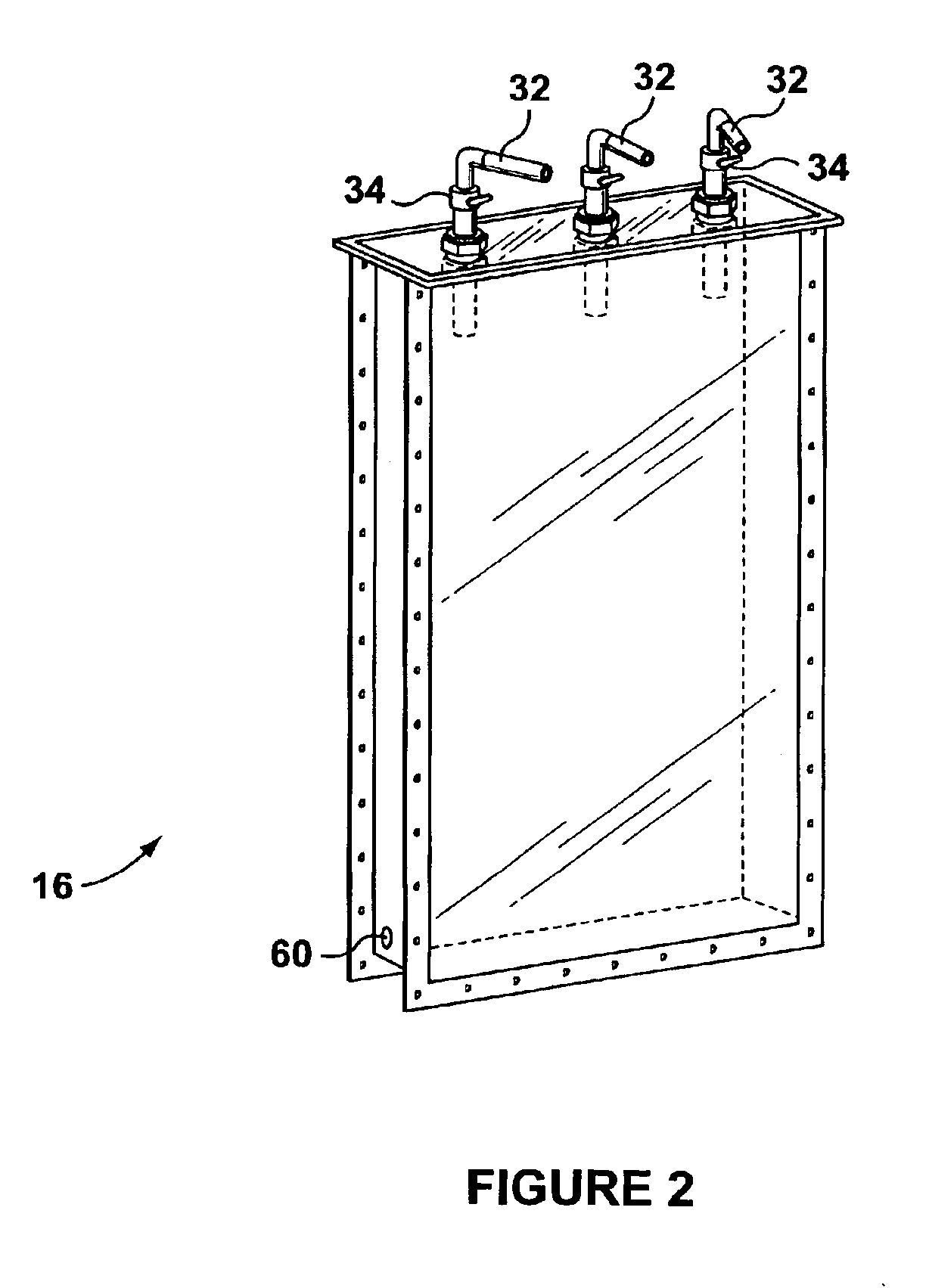

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON TECH PARTNESHIP

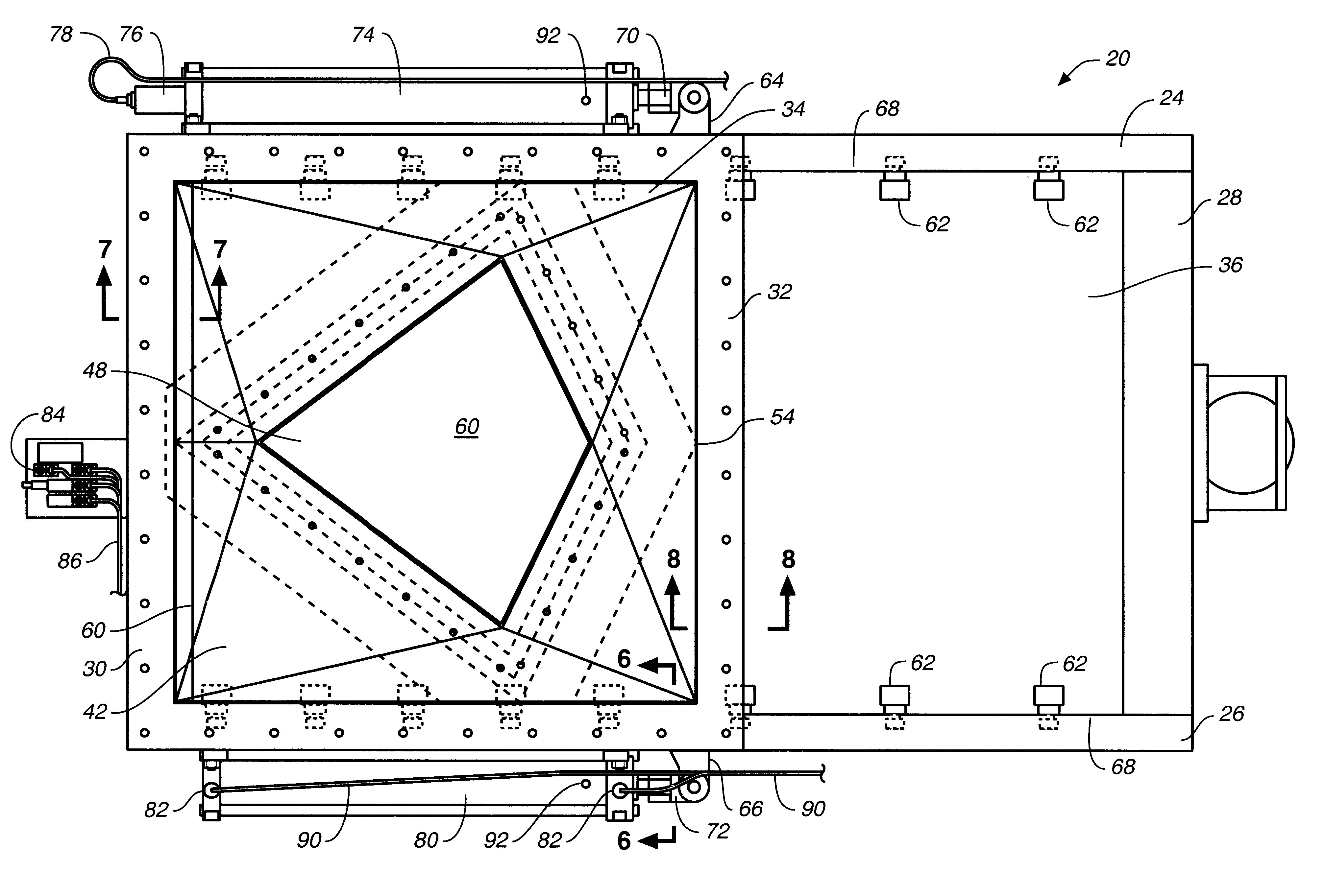

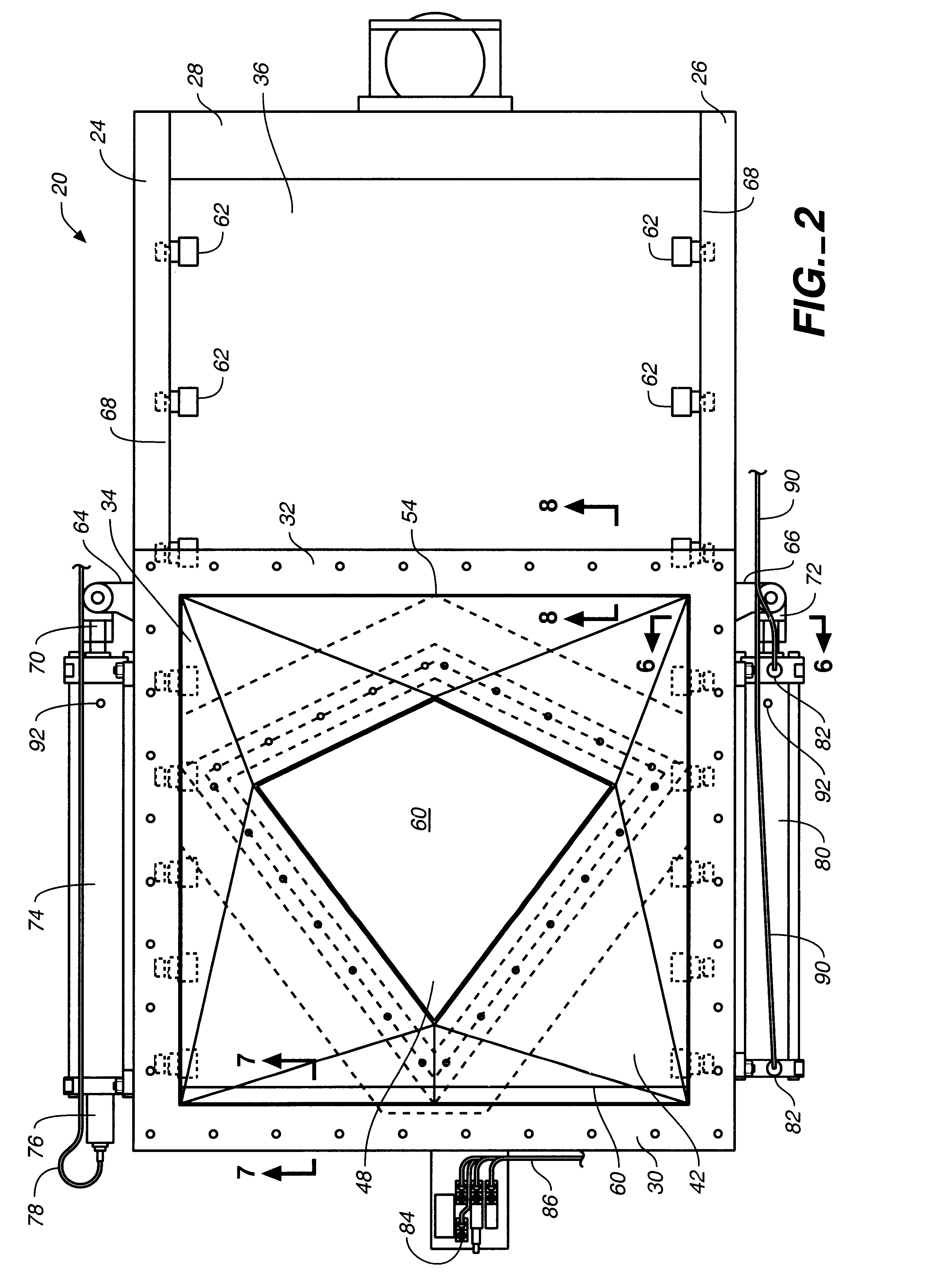

Gravity flow sludge load-out metering gate

InactiveUS6508387B1Easy to controlReduction in splashing and splatteringClosuresLiquid flow controllersSludgeEngineering

A gravity flow sludge load-out metering gate comprising a frame having longitudinal and horizontal frame rails and a transverse rail member which defines a gate front portion and a smaller gate rear portion. A sludge inlet funnel is positioned above the front portion for insertion into the interior of a hopper discharge outlet. In the preferred embodiment, the sludge inlet funnel is substantially square and has four triangular, tapering interior sides, which, when viewed from above define an asymmetrical four-pointed star, the interior configuration of which further defines an asymmetrical diamond-shaped sludge discharge orifice. Interior to the metering gate frame is a metering gate blade, slidingly positioned between a plurality of support rollers and a bulb seal, the gate operatively connected to electric, hydraulic, or pneumatic power.

Owner:RDP TECH

Membrane bioreactor, process and aerator

InactiveUS20050061725A1Easy to moveIncrease pressureWater treatment parameter controlMembranesSiphonEnvironmental engineering

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON ENVIRONMENTAL INC

Desulfurization process

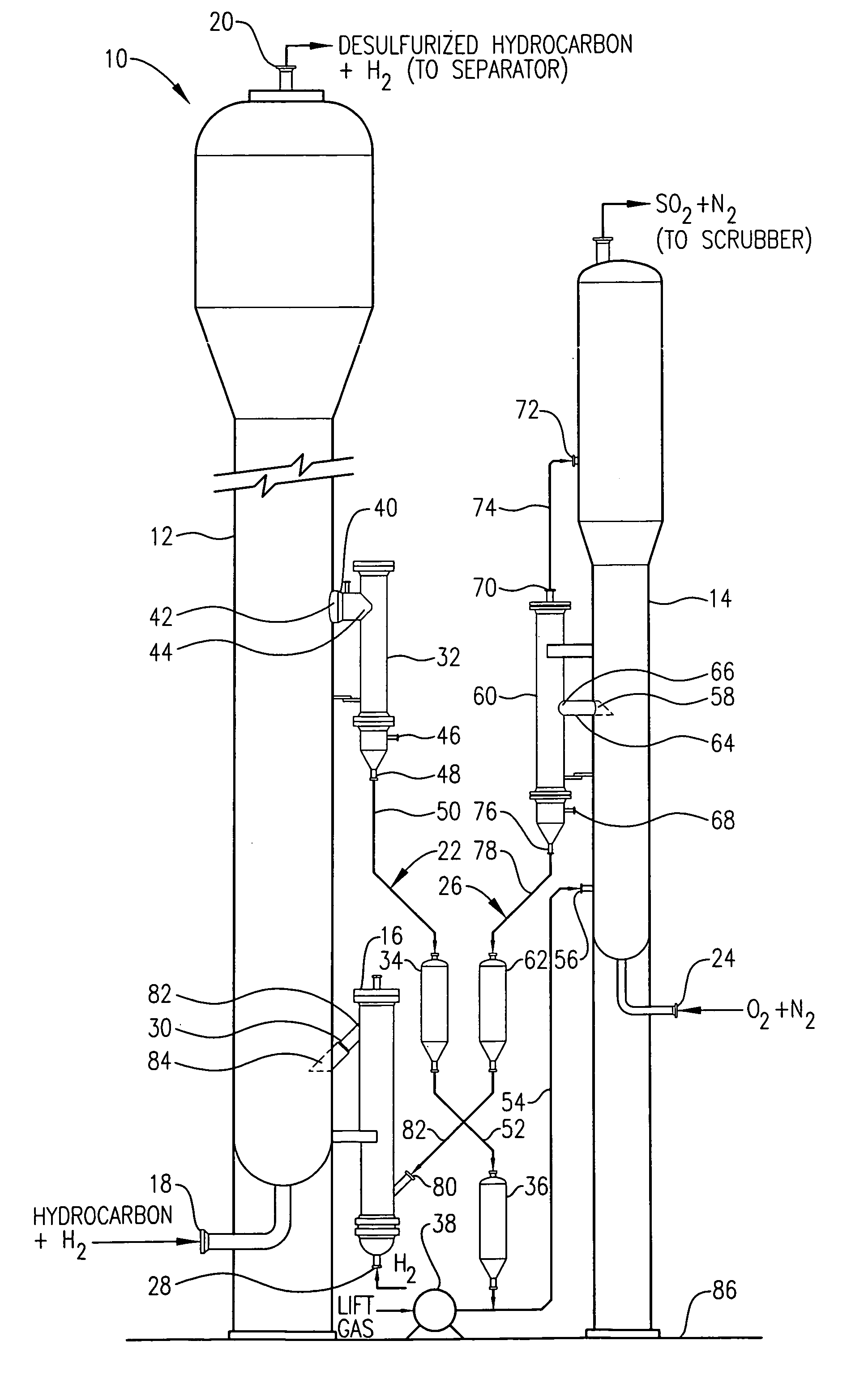

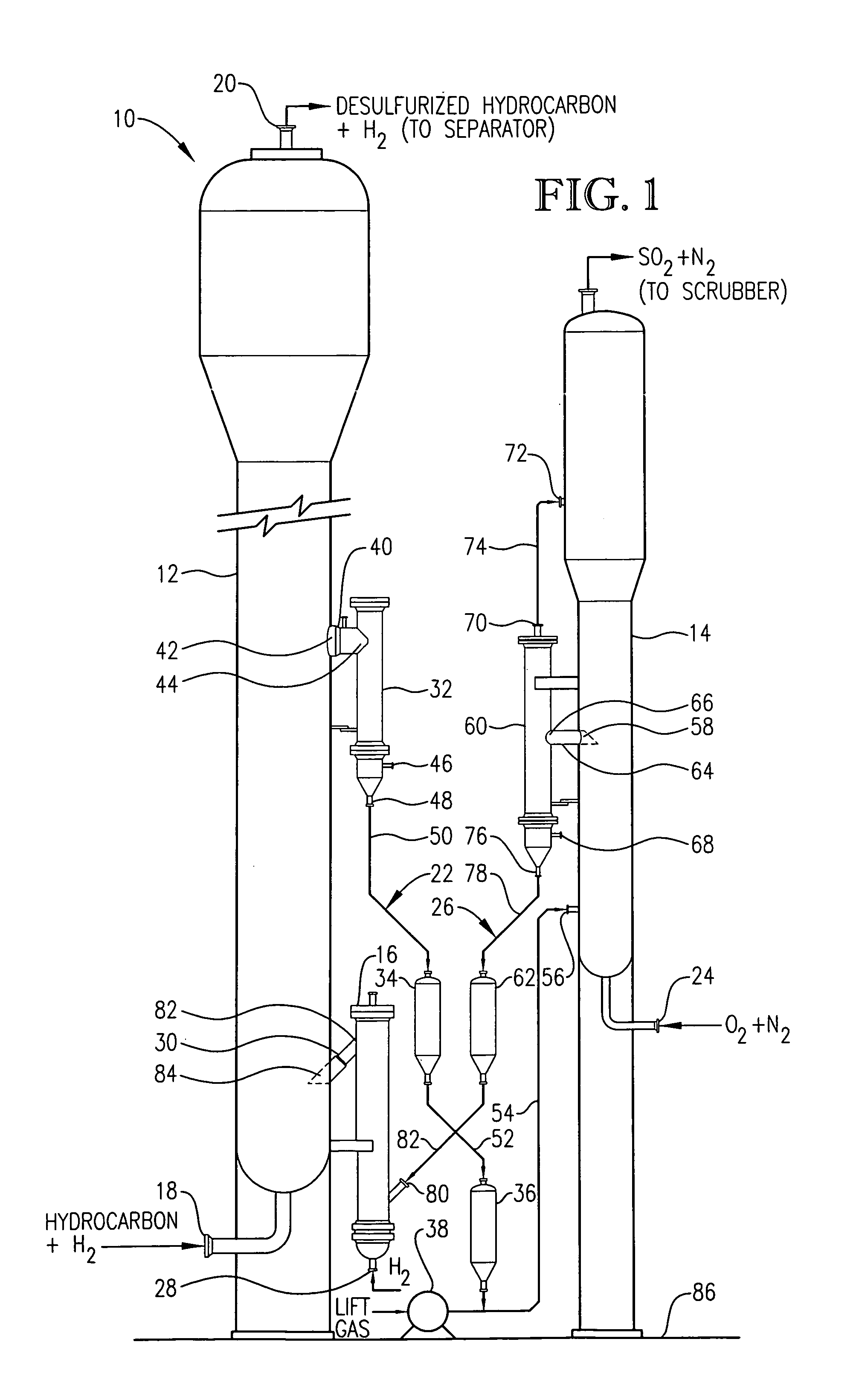

ActiveUS7182918B2Low costMinimizes attritionCombustible gas purificationFluidised-bed furnacesTransport systemFluidized bed

Owner:CHINA PETROCHEMICAL CORP

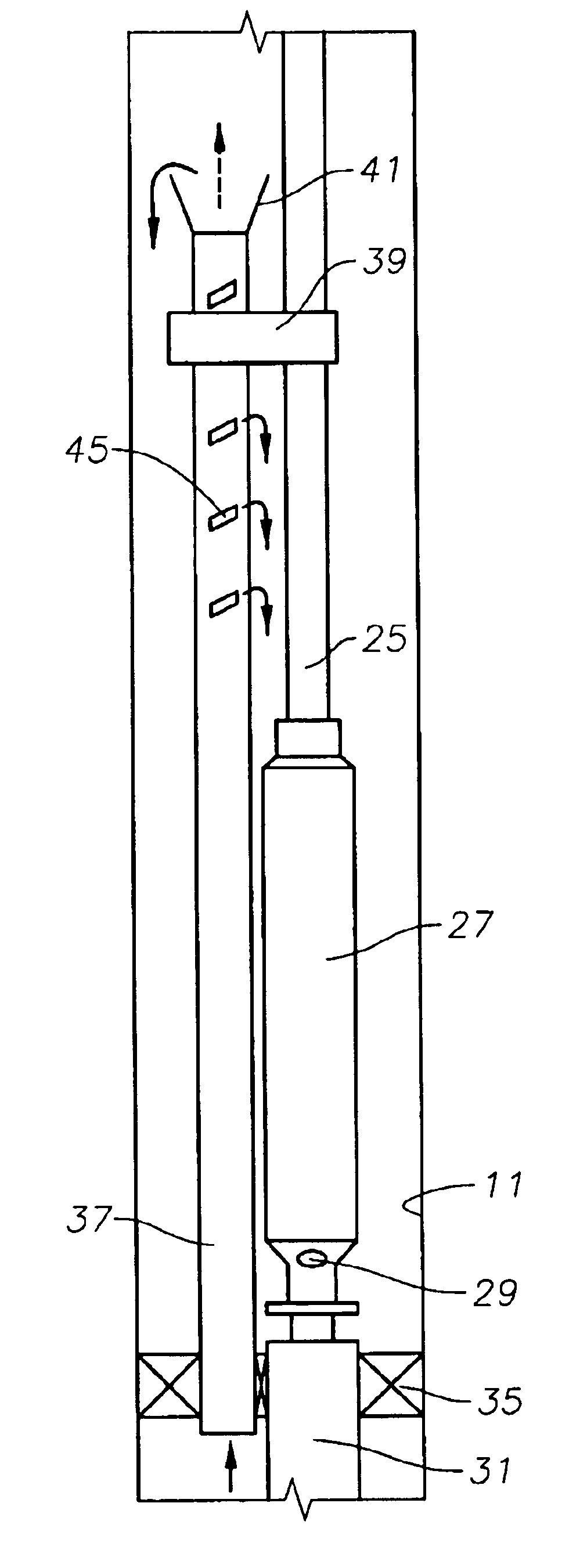

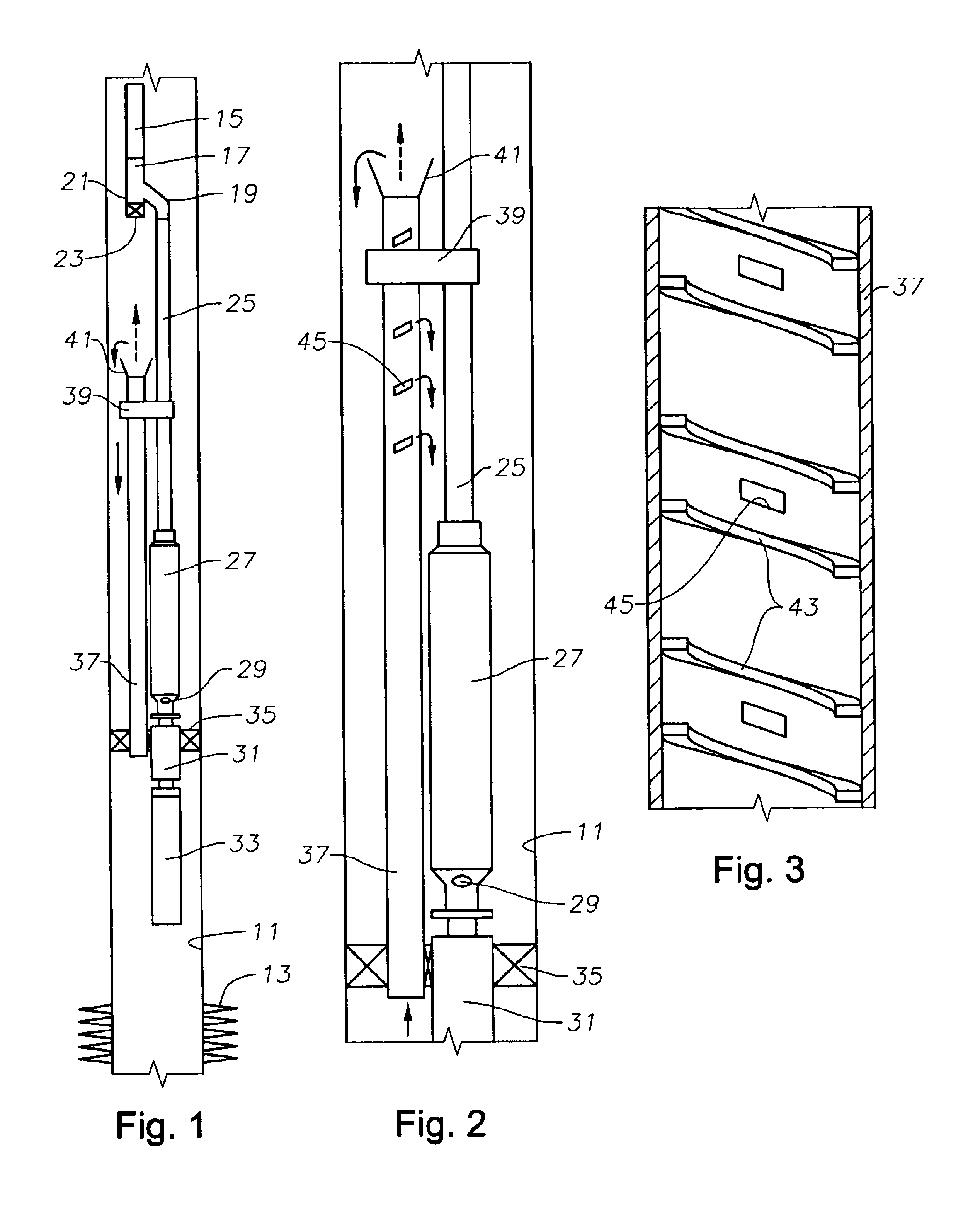

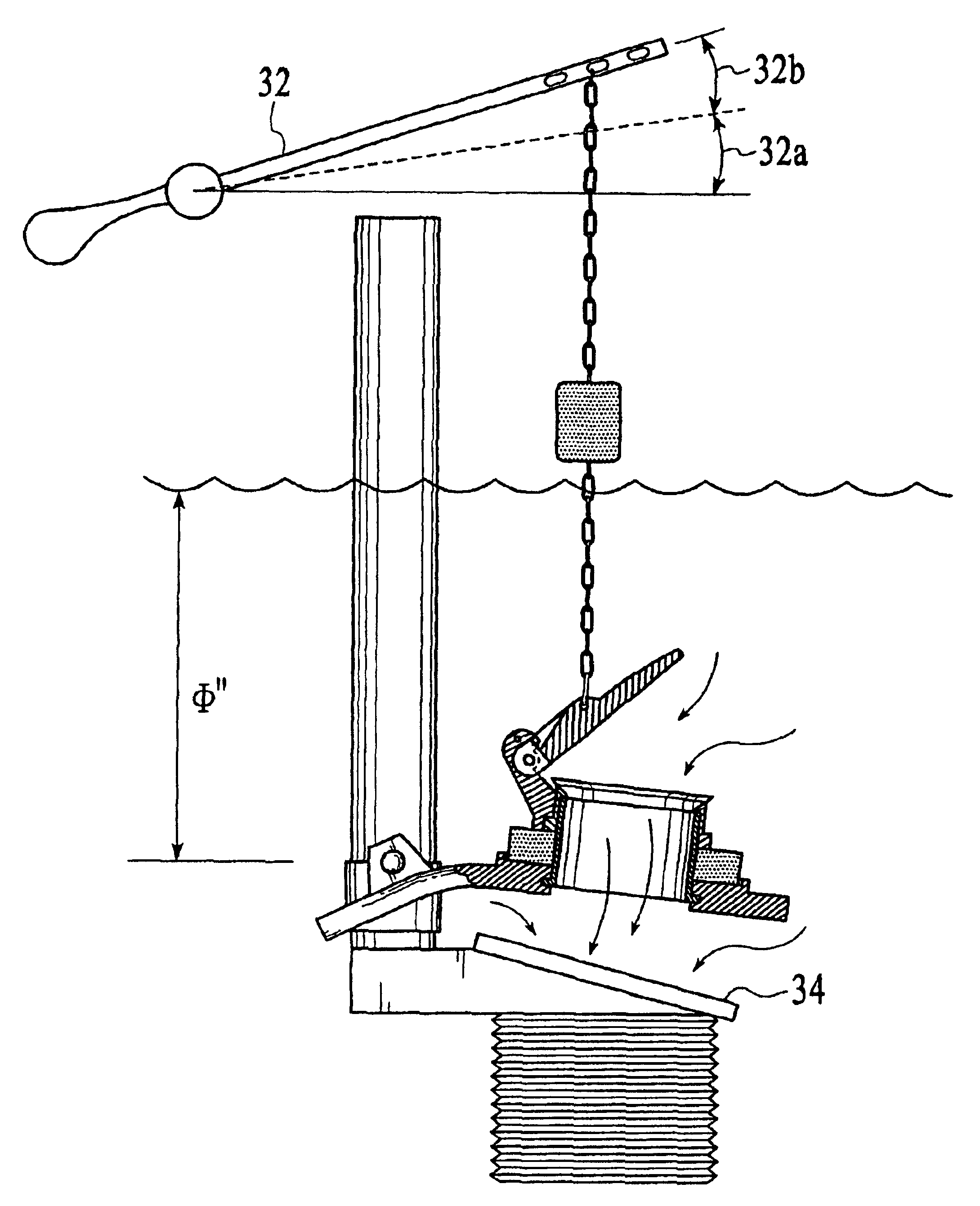

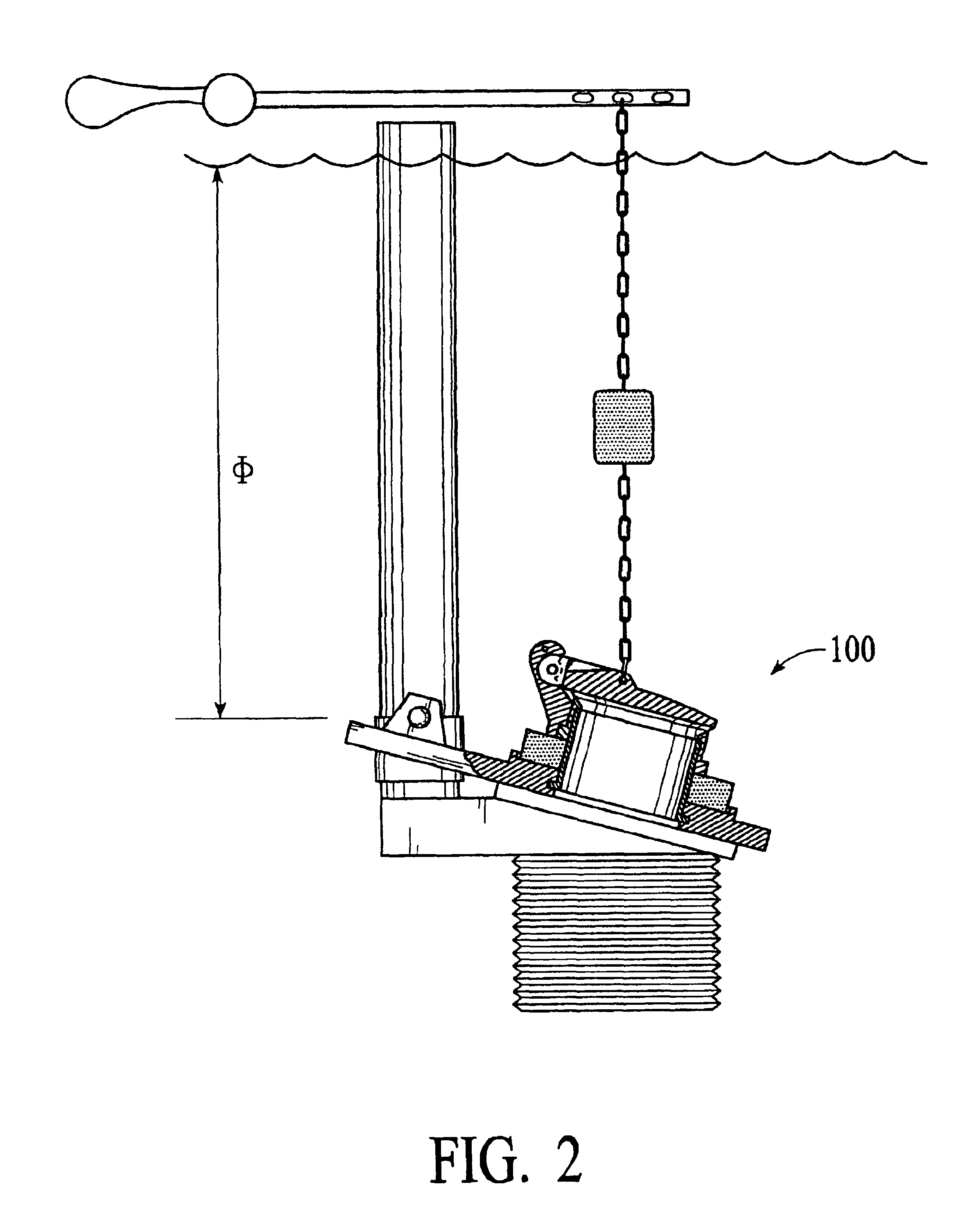

Riser pipe gas separator for well pump

A well pump has a riser gas separator for removing large slugs of gas prior to reentry into the pump. The riser extends upward from a barrier that is located in the well. The riser has an inlet that is located above an effective intake of the pump. Well fluid must turn to flow down to the pump, with gas separating by gravity flowing upward while the liquid flows downward. The downhole assembly has various configurations to assure that fluid flows past the motor for cooling.

Owner:BAKER HUGHES INC

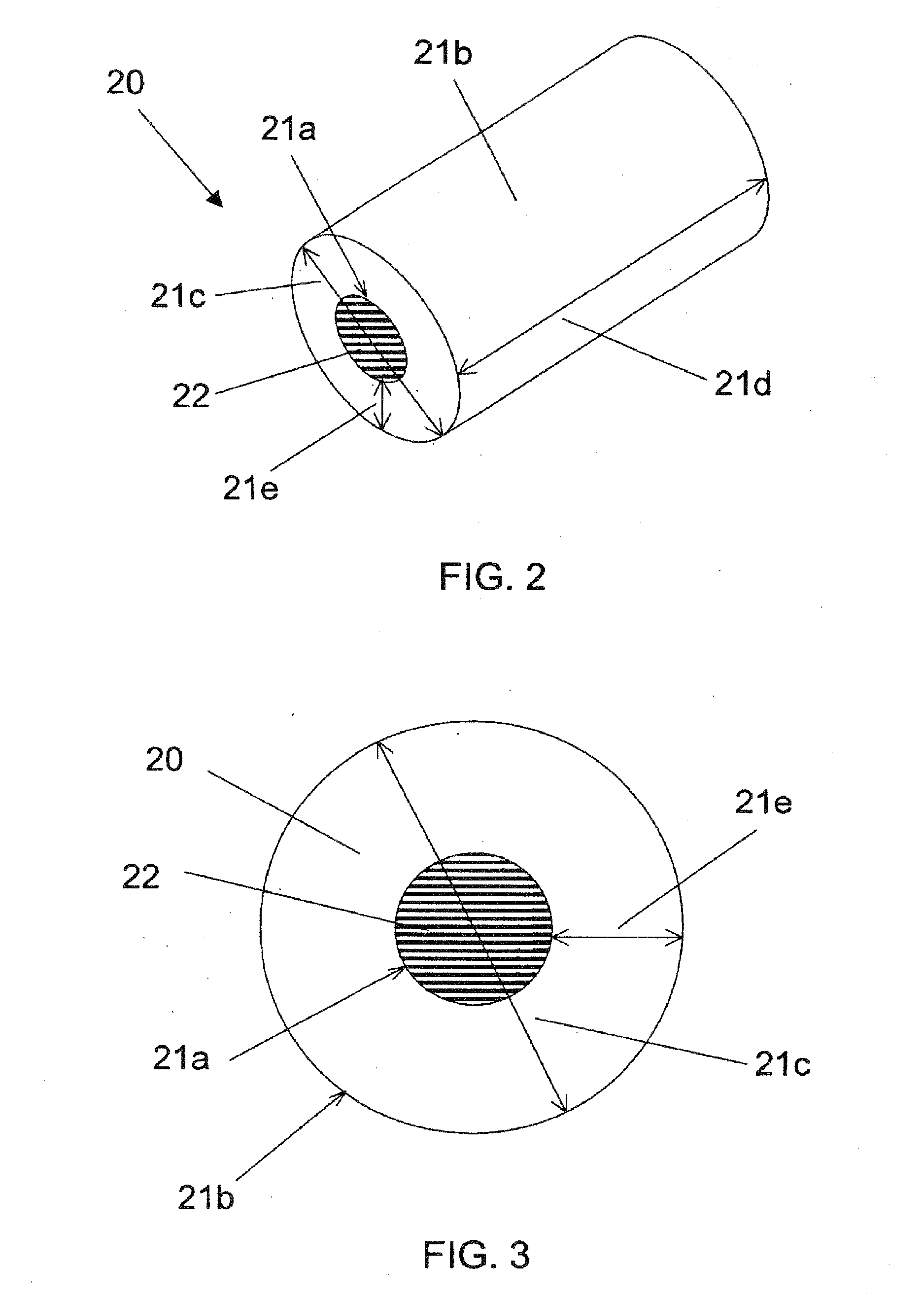

Gravity Flow Carbon Block Filter

A gravity fed carbon block water filter includes activated carbon particles; a binder material interspersed with the activated carbon particles; and a lead scavenger coupled to at least one of the activated carbon particles and binder material, the lead scavenger being for removing lead from water, where a lead concentration in a final liter of effluent water filtered by the filter is less than about 10 μg / liter after about 151 liters (40 gallons) of source water filtration, the source water having a pH of 8.5 and containing 135-165 parts per billion total lead with 30-60 parts per billion thereof being colloidal lead greater than 0.1 μm in diameter, and where the water has an average flow rate of at least 0.1 liter per minute through the filter with a head pressure of between approximately 0.1 and 1.0 psi.

Owner:BRITA LP

Gravitational flow purification system

InactiveUS20030203491A1Analysis using chemical indicatorsPreparing sample for investigationAmount of substanceMacromolecule

The present invention relates to a gravitational flow purification system. More particularly, the invention relates to a process for purifying or isolating one or more substances from samples comprising said substances. Even more particularly, the invention relates to purifying or isolating macromolecules from biological samples using a gravitational flow apparatus.

Owner:ALFA WASSERMANN INC

Paint reservoir system for a paint spray gun

ActiveUS7819341B2Simple and fast and uncomplicated formationLiquid flow controllersFire rescueWood shavingsThermodynamics

Owner:SATA GMBH & CO KG

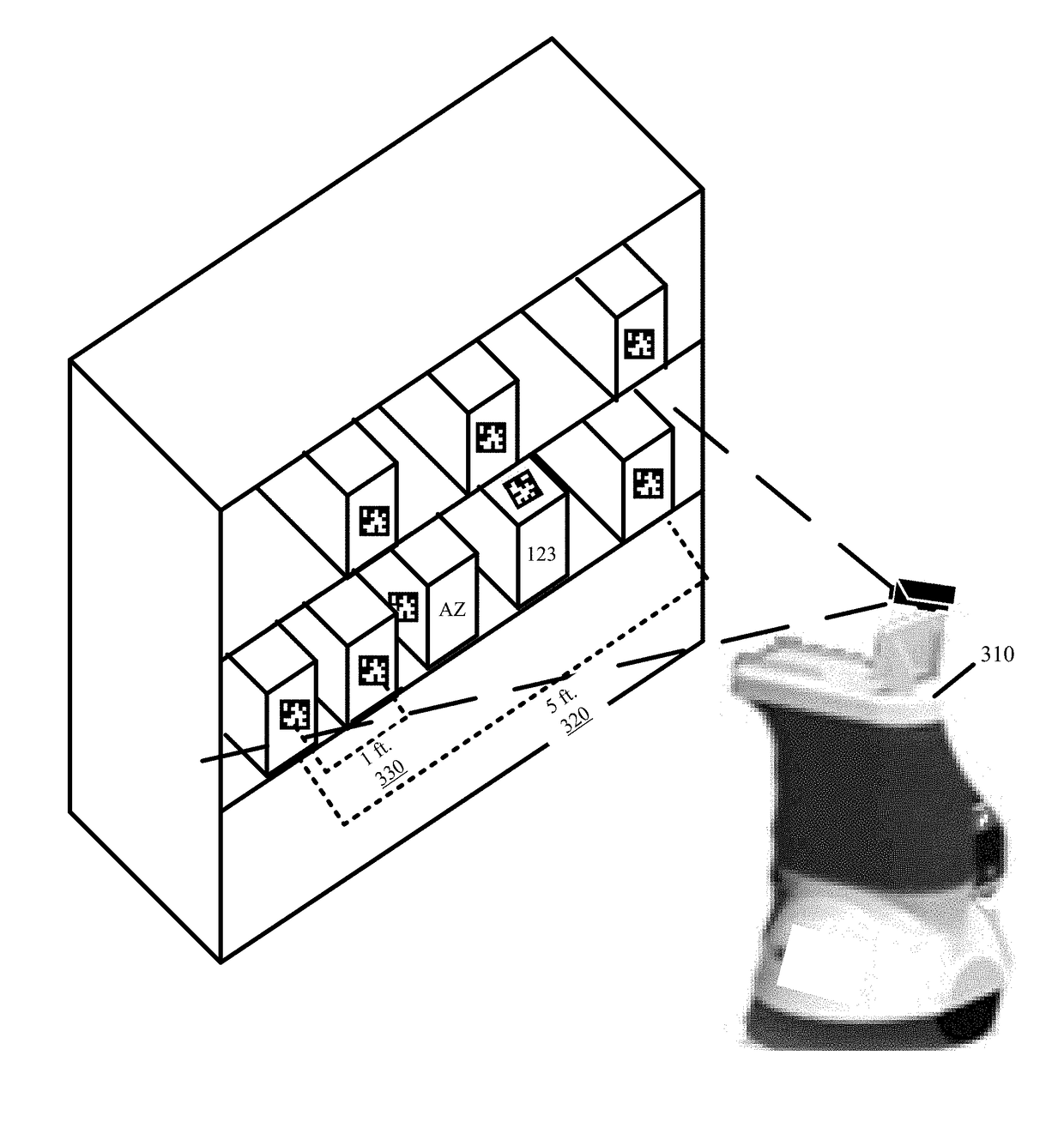

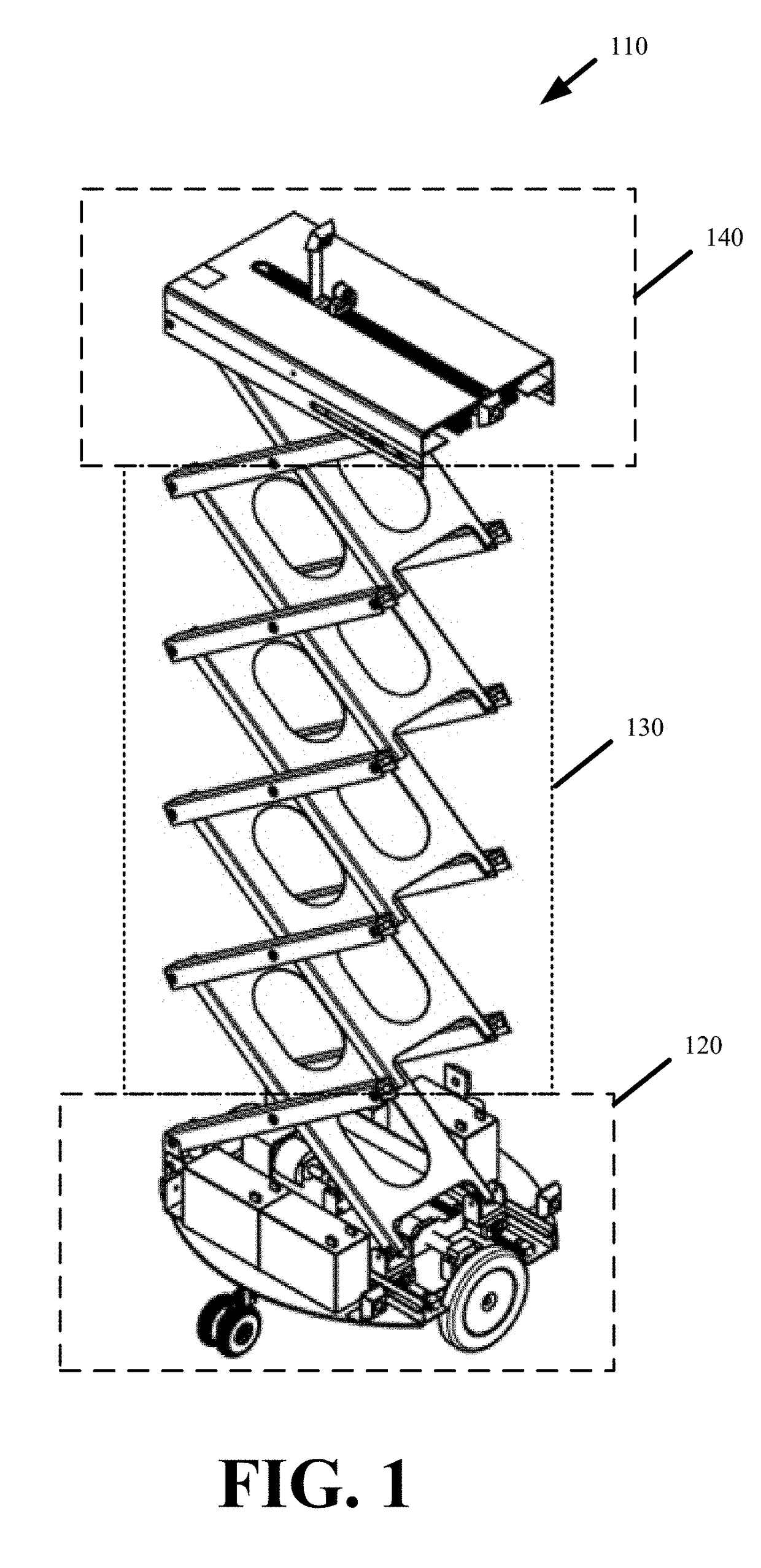

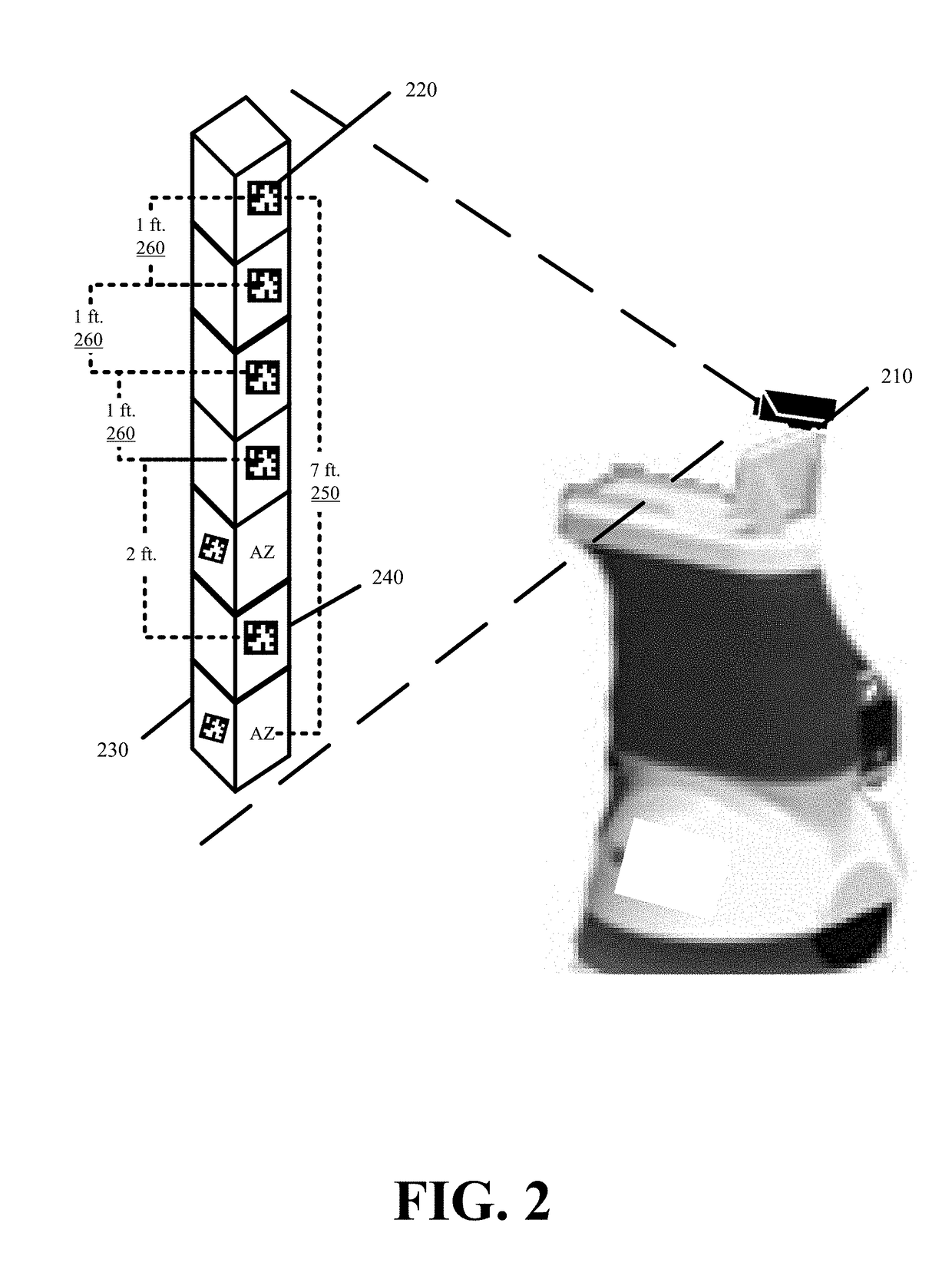

Inventory Management Robots

Provided are robots for managing inventory of arbitrary size, shape, weighted, or other distinct featured items. The robots dynamically and adaptively manage inventory for items stacked atop one another, items stacked behind one another, items that are horizontally arranged, items that are dispensed from a gravity flow dispenser, items that are dispensed from a back-to-front push dispenser, and items that are loosely contained within a bin. The robots have a sensory array from which dimensions of a particular arrangement and dimensions of a particular item in the particular arrangement can be calculated. The calculated dimensions can include length, width, or height of a particular arrangement and a particular item or force imposed by the particular arrangement and mass of the particular item. Based on these dimensions, the robots can dynamically track different item inventories without counting each individual item.

Owner:INVIA ROBOTICS INC

Water contaminant indicators

InactiveUS20050109683A1Detection of fluid at leakage pointMaterial analysis by observing effect on chemical indicatorWater treatment systemFiltration

A filtering device for a gravity-flow liquid treatment system includes a first filter component that can be either exposed or adjacent to a substantially transparent region in at least a portion of a filter housing. The first filter component is capable of providing a visual indication of exposure to at least one contaminant. The contaminants for which the first filter component can indicate exposure include particles, inorganic, and organic contamination. Particle contamination is indicated by a change in color of the first filter component through particle collection. Inorganic and organic contaminants are indicated by reaction with at least one agent capable of undergoing a color-change reaction in response to at least one contaminant. Water treatment systems and filtration devices that include at least one agent capable of undergoing a color-change reaction and thus give a visual indication of exposure to at least one contaminant for use in both gravity-driven and pressure-driven environments are also described.

Owner:THE CLOROX CO

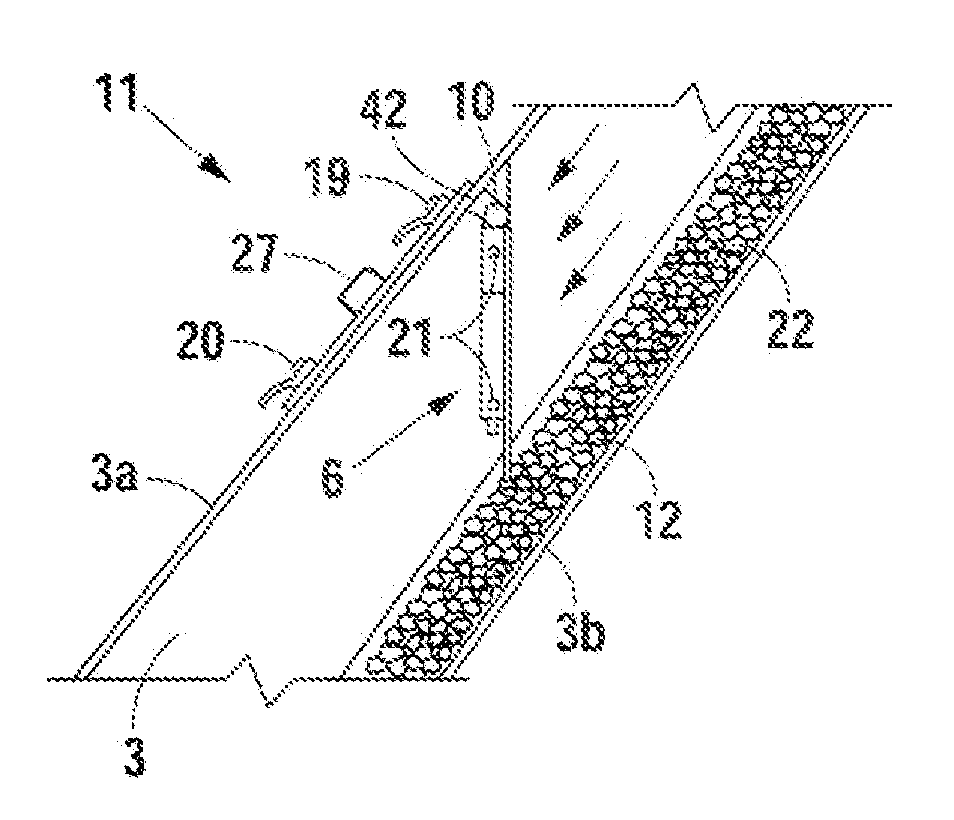

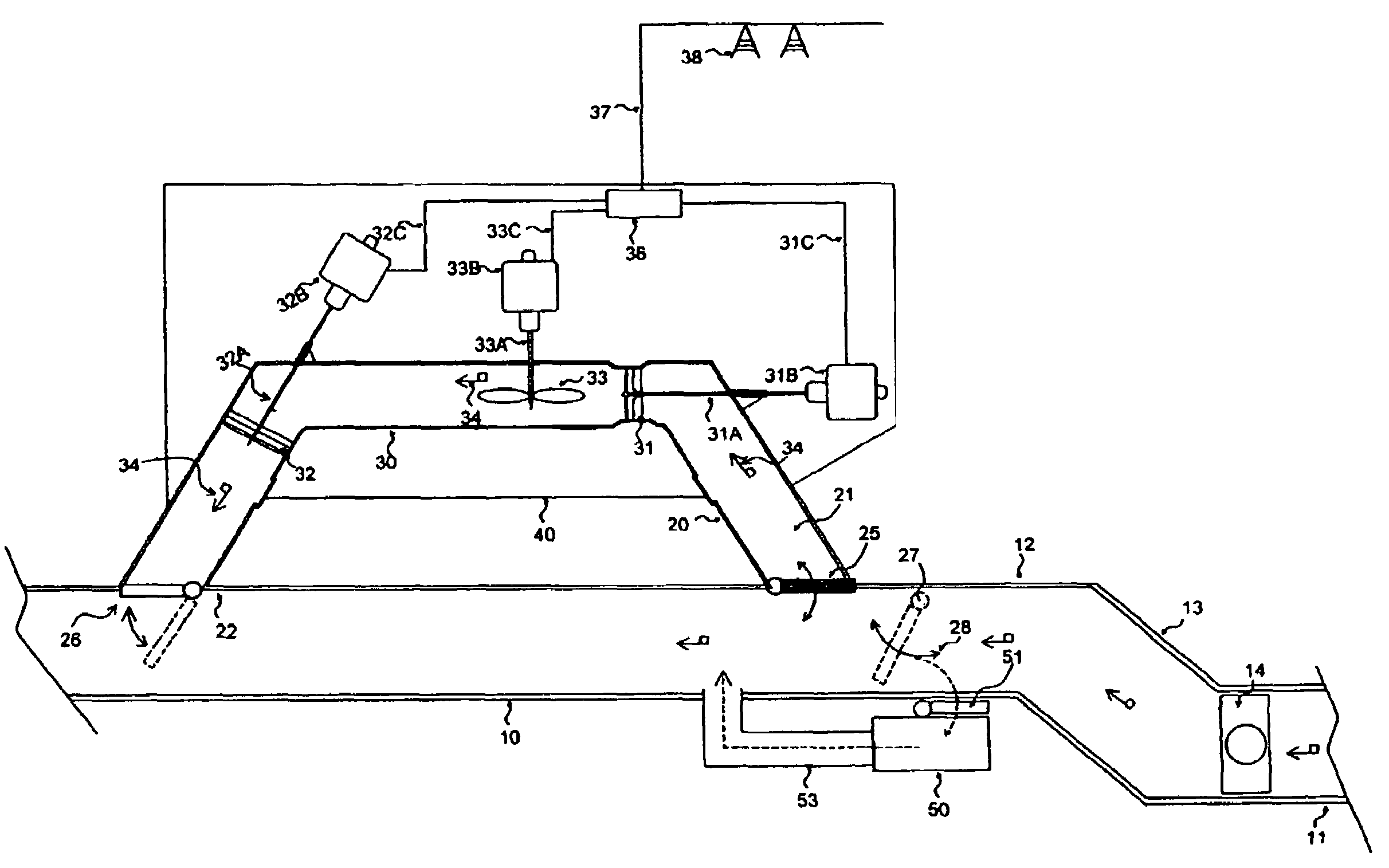

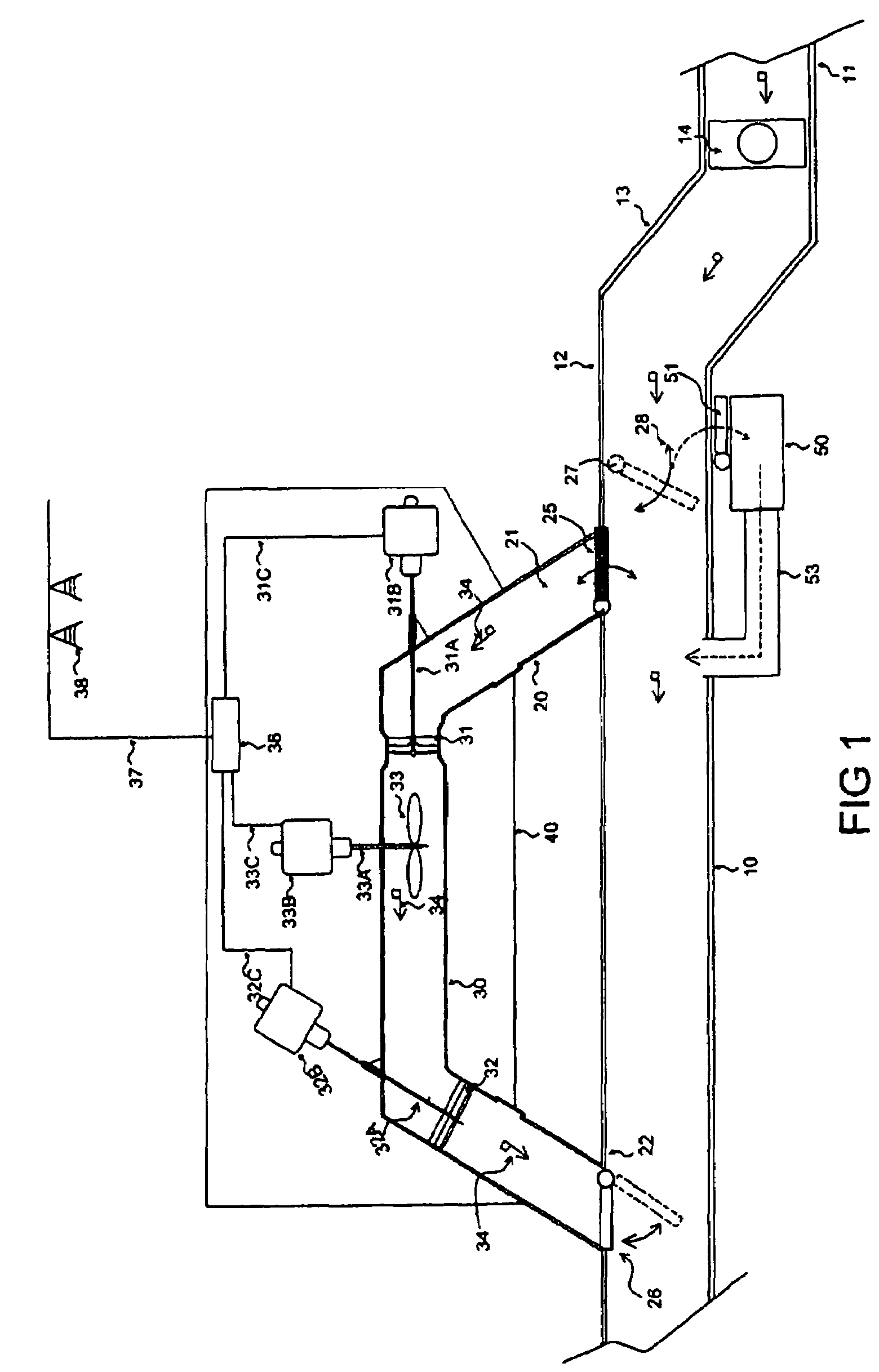

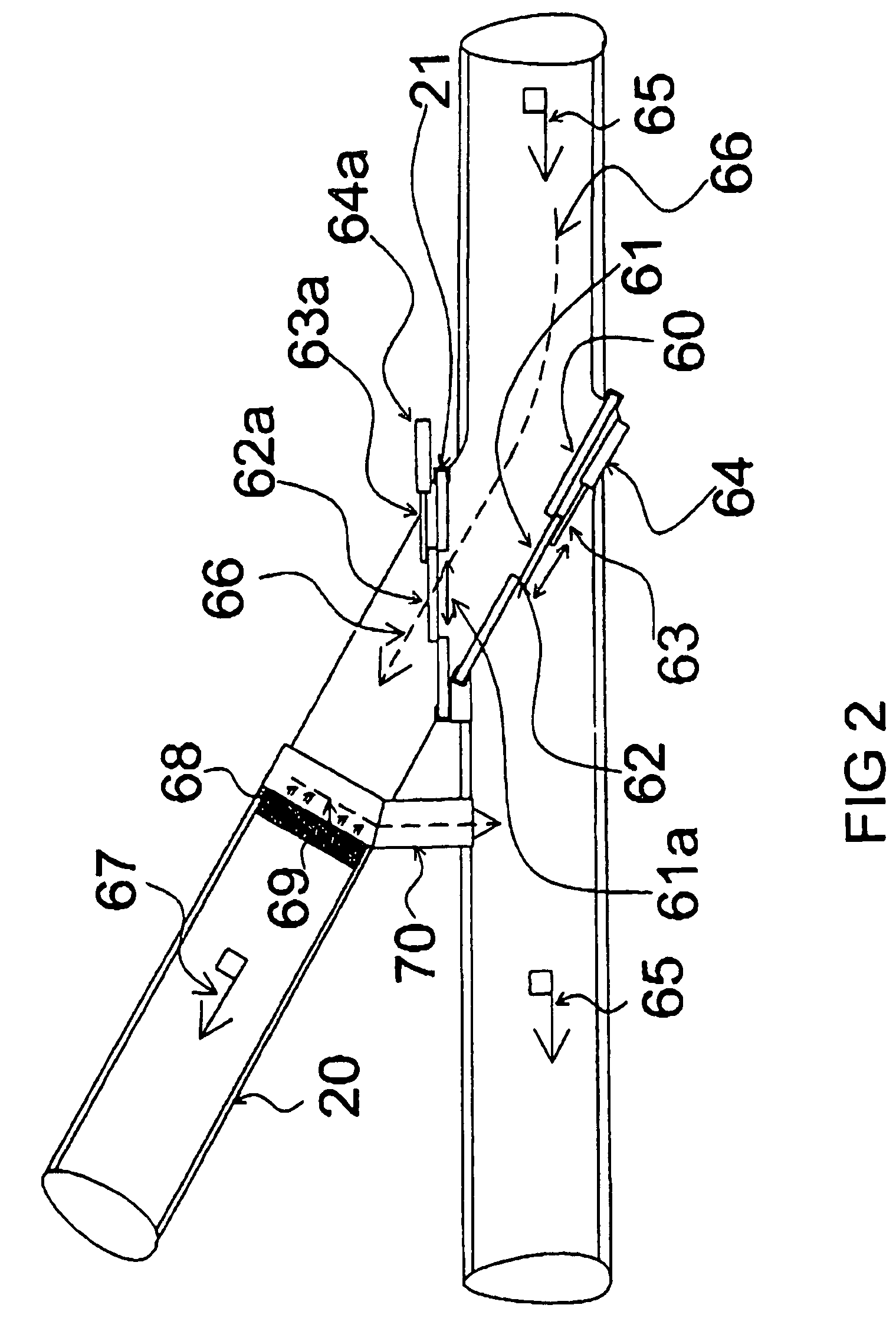

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

Waste water electrical power generating system with storage system and methods for use therewith

A method for selectively generating electrical power by using waste water gravity flow to generate electrical power includes attaching ends of a water flow diversion pipe to a waste water pipe. At least some of the waste water flowing by gravity through the waste water pipe is diverted into and through the diversion pipe and back into the waste water pipe. An electrical power generator is driven to generate electrical power in response to the waste water flowing through the diversion pipe. At least a portion of the electrical power generated by the at least one electrical power generator is stored and can be tapped later to supplement the output of the electrical power generator.

Owner:CRIPTONIC ENERGY SOLUTIONS

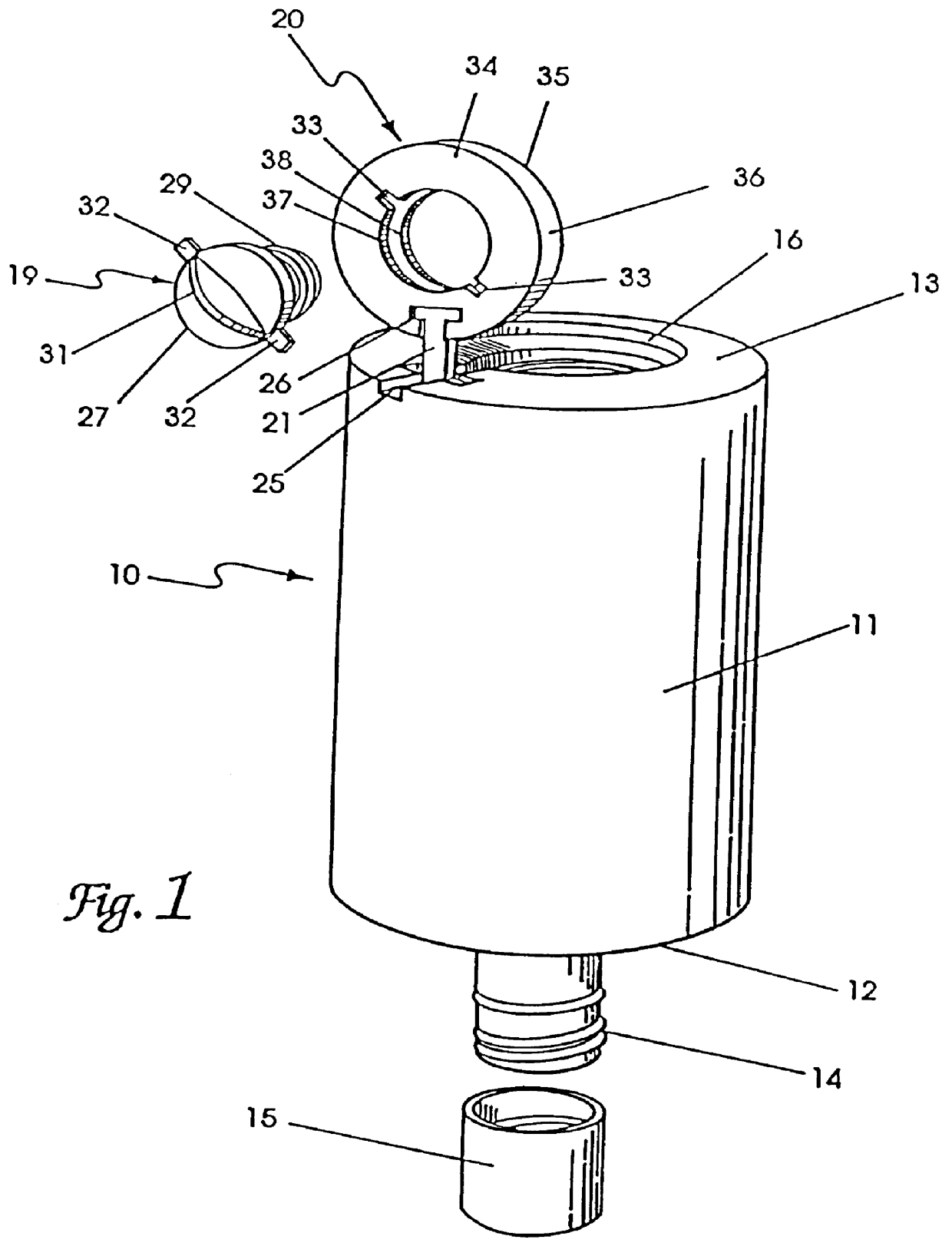

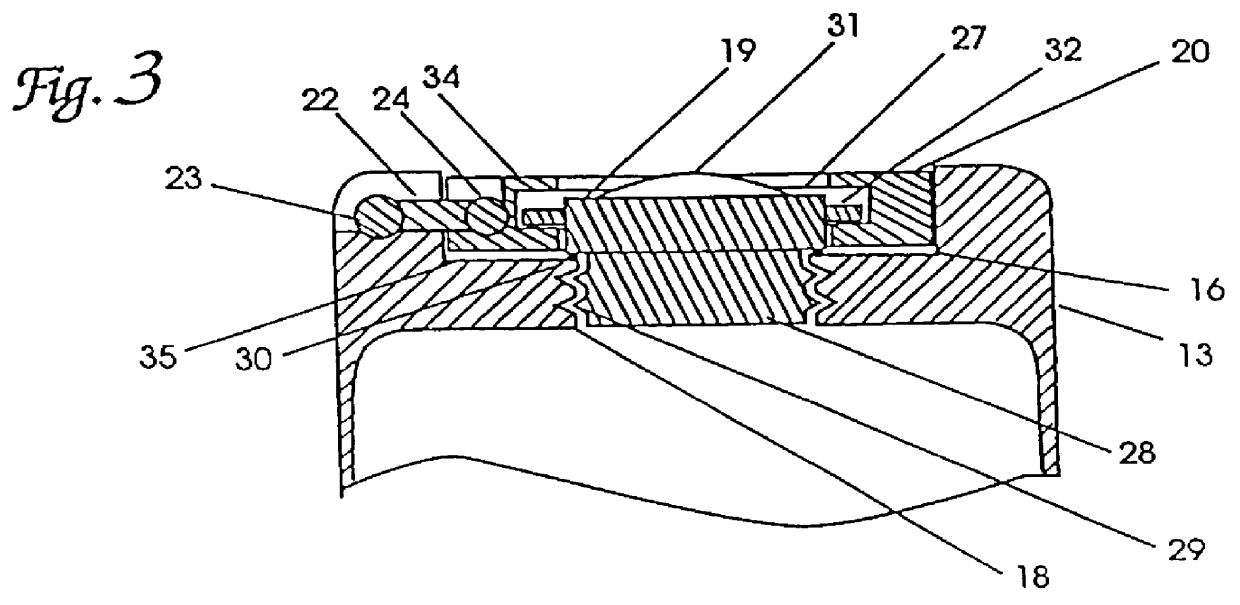

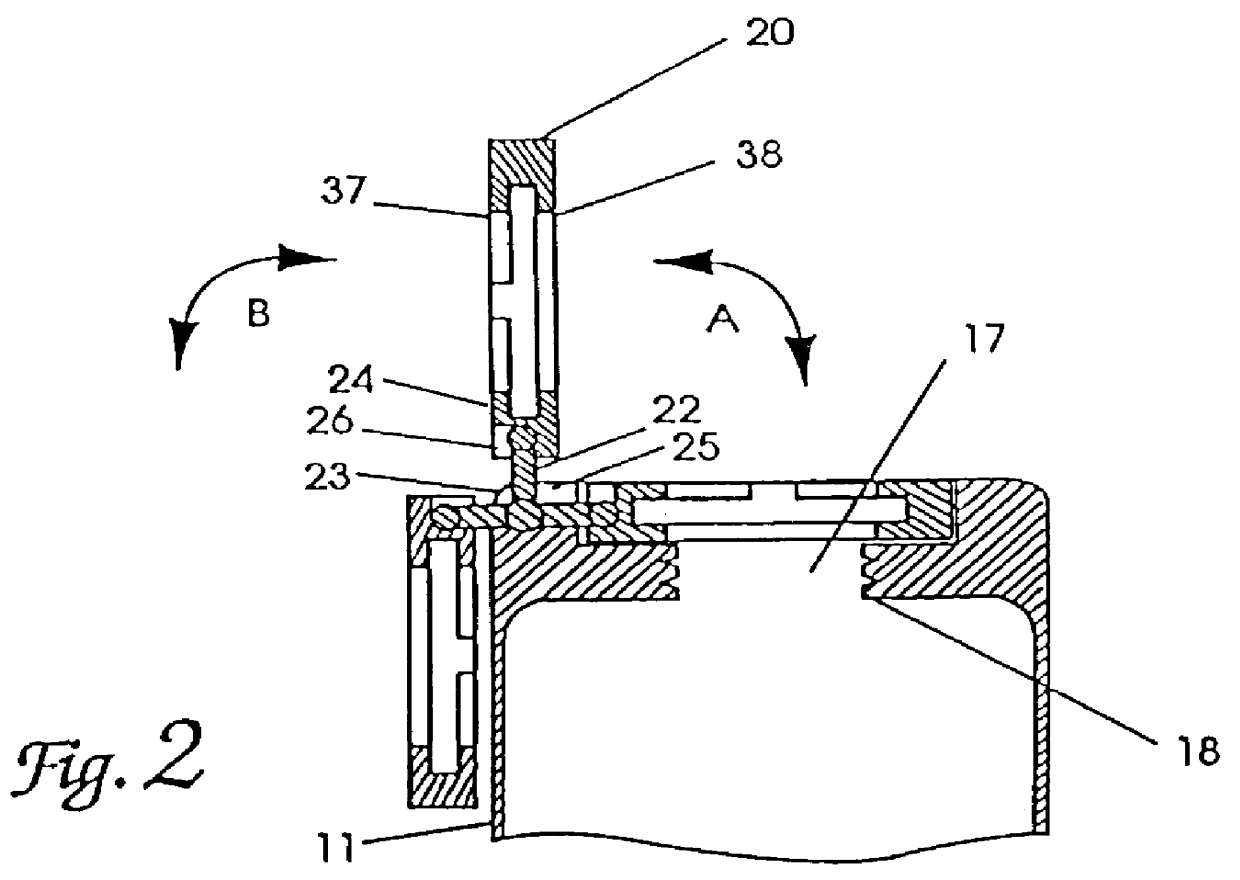

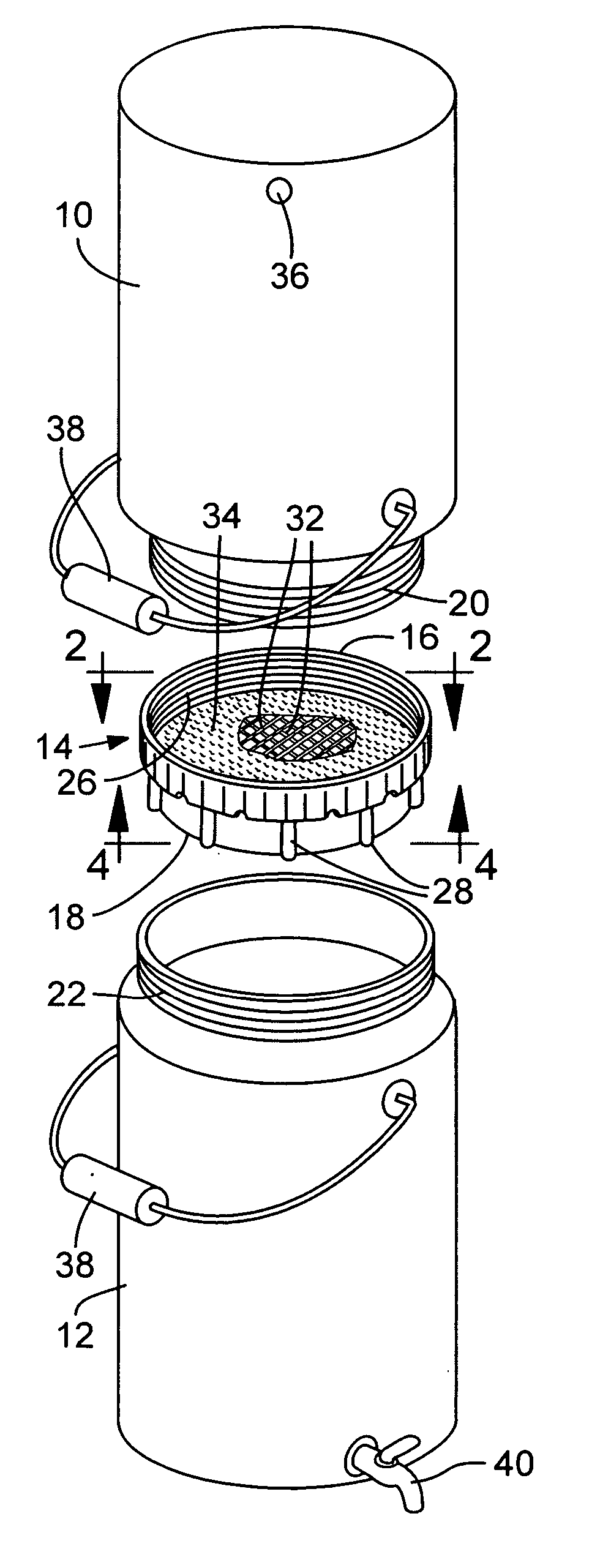

Dispensing container with top and bottom access ports and a dispensing manifold therefore

A dispensing container for viscous fluids formed of a tubular body having top and bottom surfaces with the top surface including a threaded outlet neck and the bottom surface including a recessed portion with a female threaded opening. The container is designed to operate in an upside-down manner to take advantage of gravity flow. A hanger ring is provided which pivots out of the recessed portion to suspend the container in an upside-down position. A plurality of bottles can be vertically supported by a dispensing manifold to yield different dispensing relationships.

Owner:SCOGGINS LESTER E

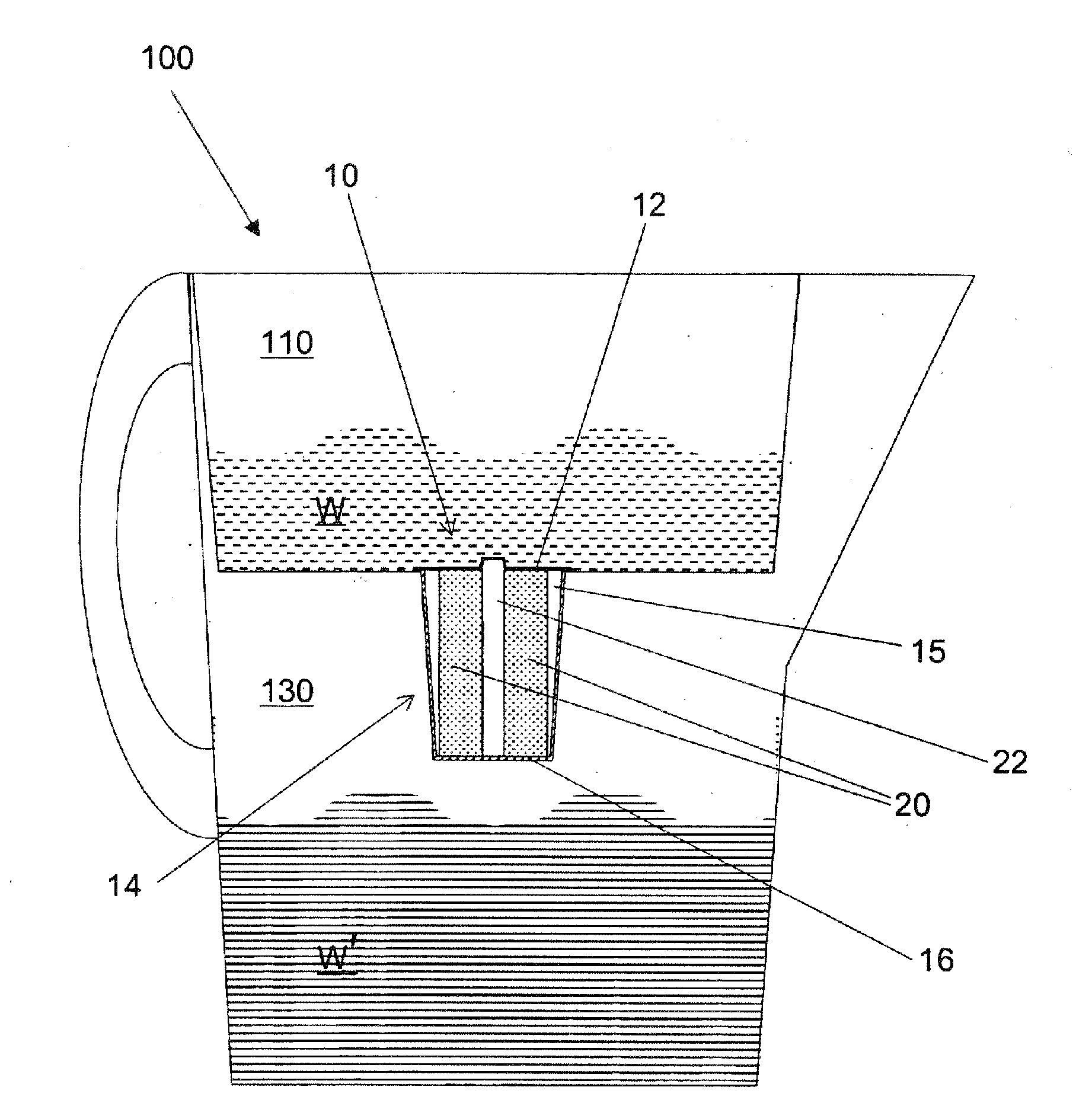

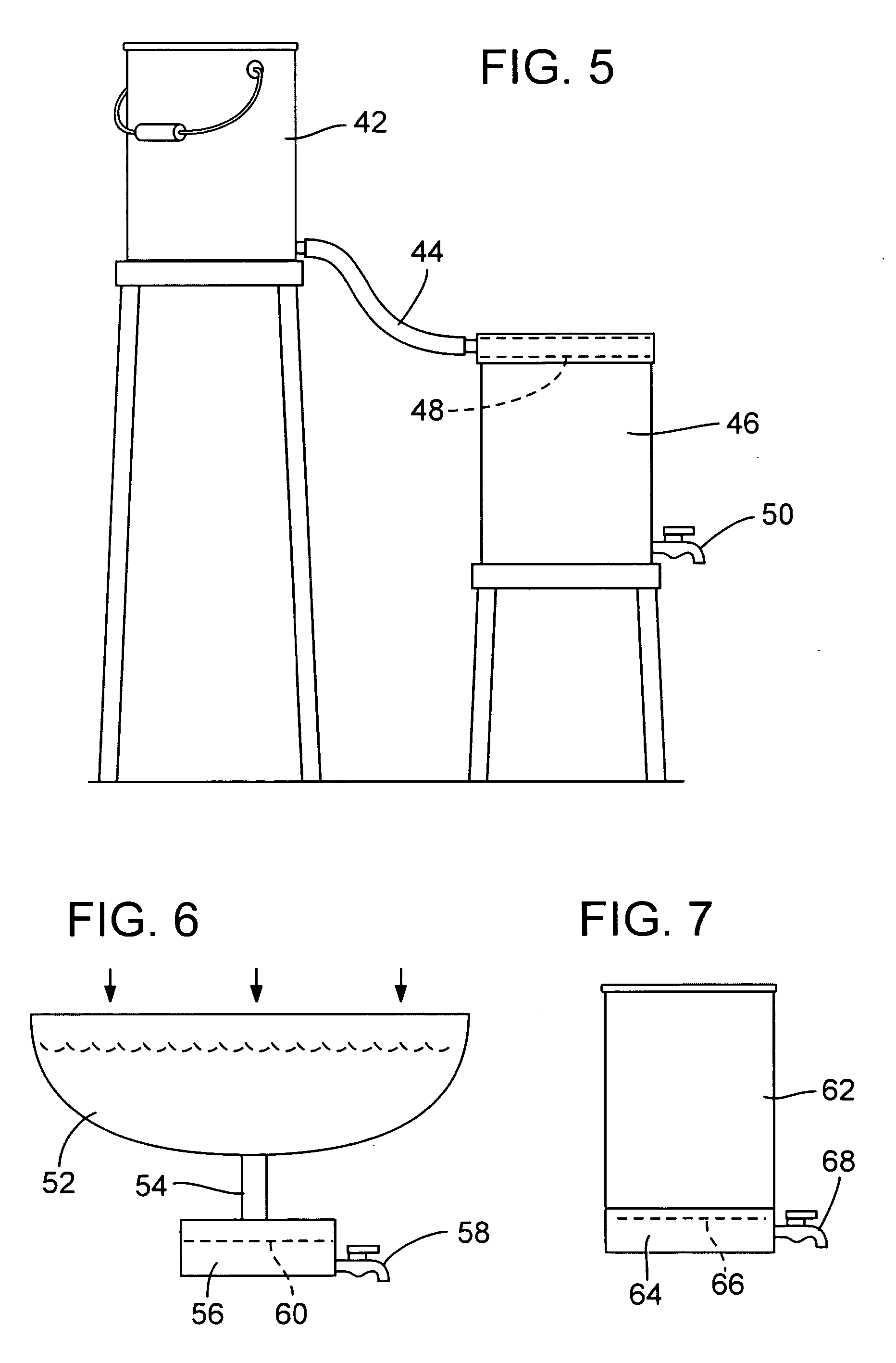

Water purification system

A system for providing purified drinking water for populations and persons having minimal access to modern water purification systems and therefore rely on water sources which contain microorganisms known to cause illness and death to large segments of such populations. Membranes are known which are pervious to water and impervious to the contaminants in such drinking water. The invention provides for gravity flow passage of water from the dirty (contaminated) water containment area to a clean (purified) water containment area and a filter including such a membrane whereby the flow of water has to penetrate through the membrane and in the process filters out the illness-producing microorganisms. The invention enables the use of commonly available jugs or jars requiring only a gravity flow passage between the jugs or jars and the filter contained in the passage.

Owner:GLOBAL WATER

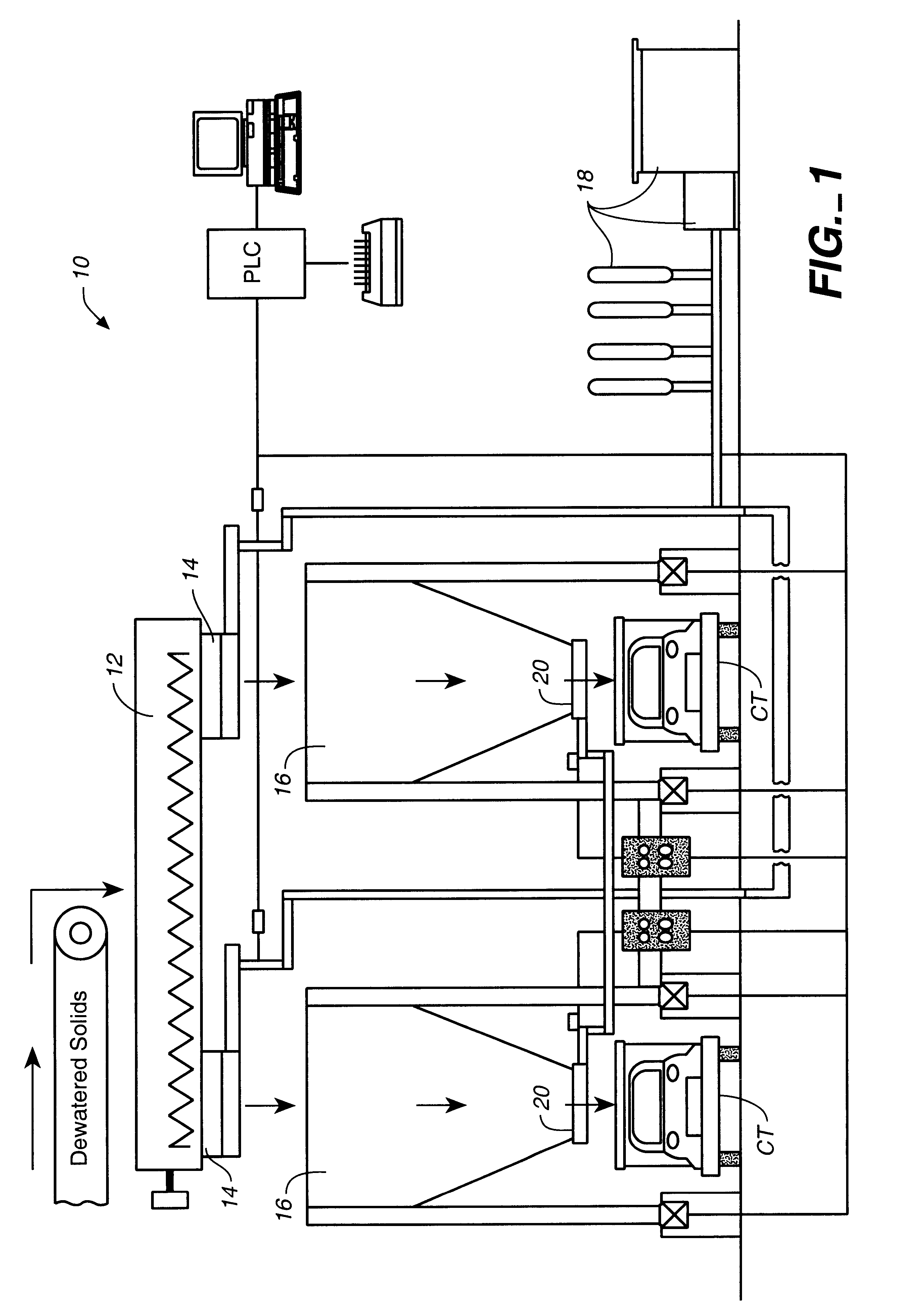

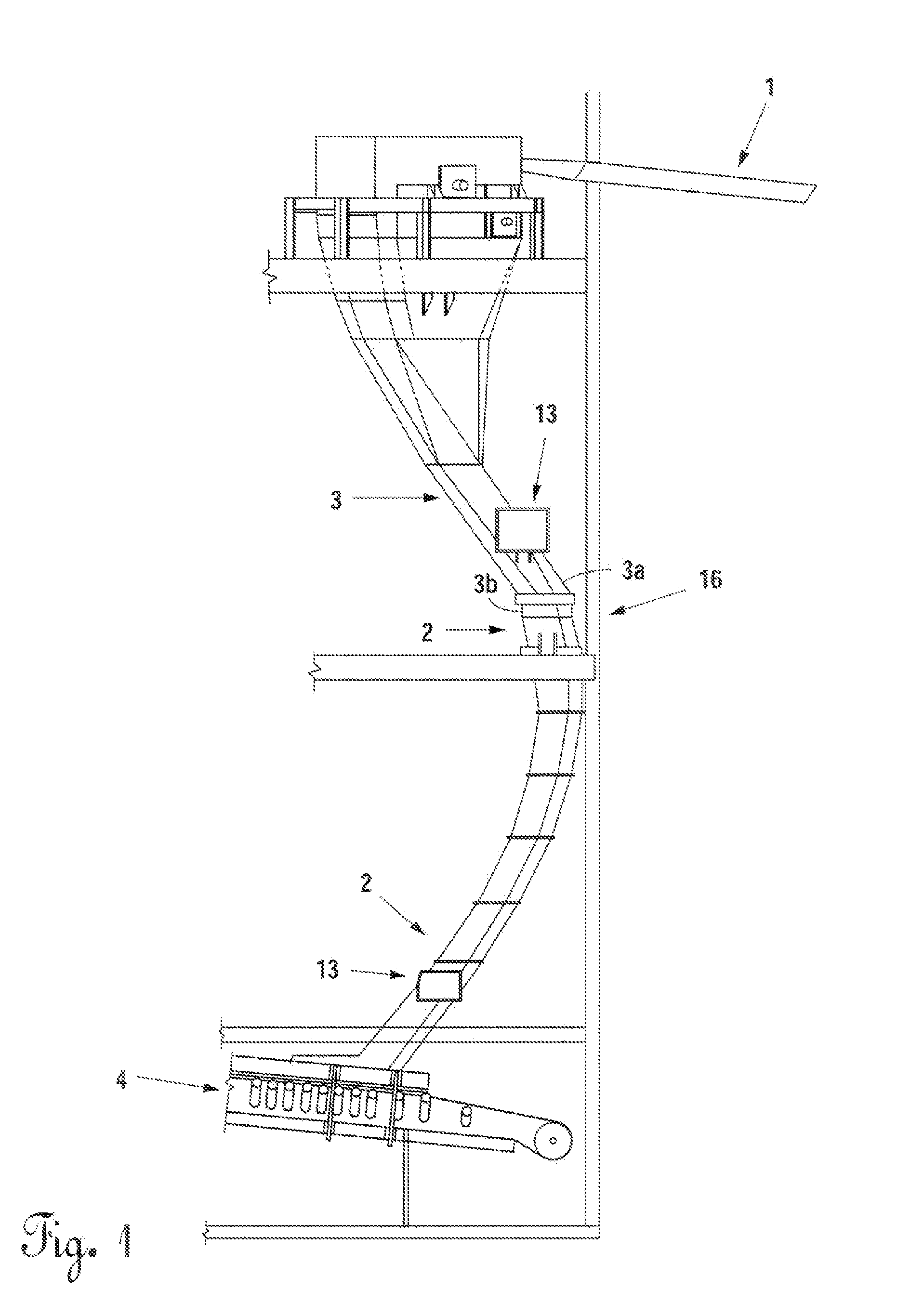

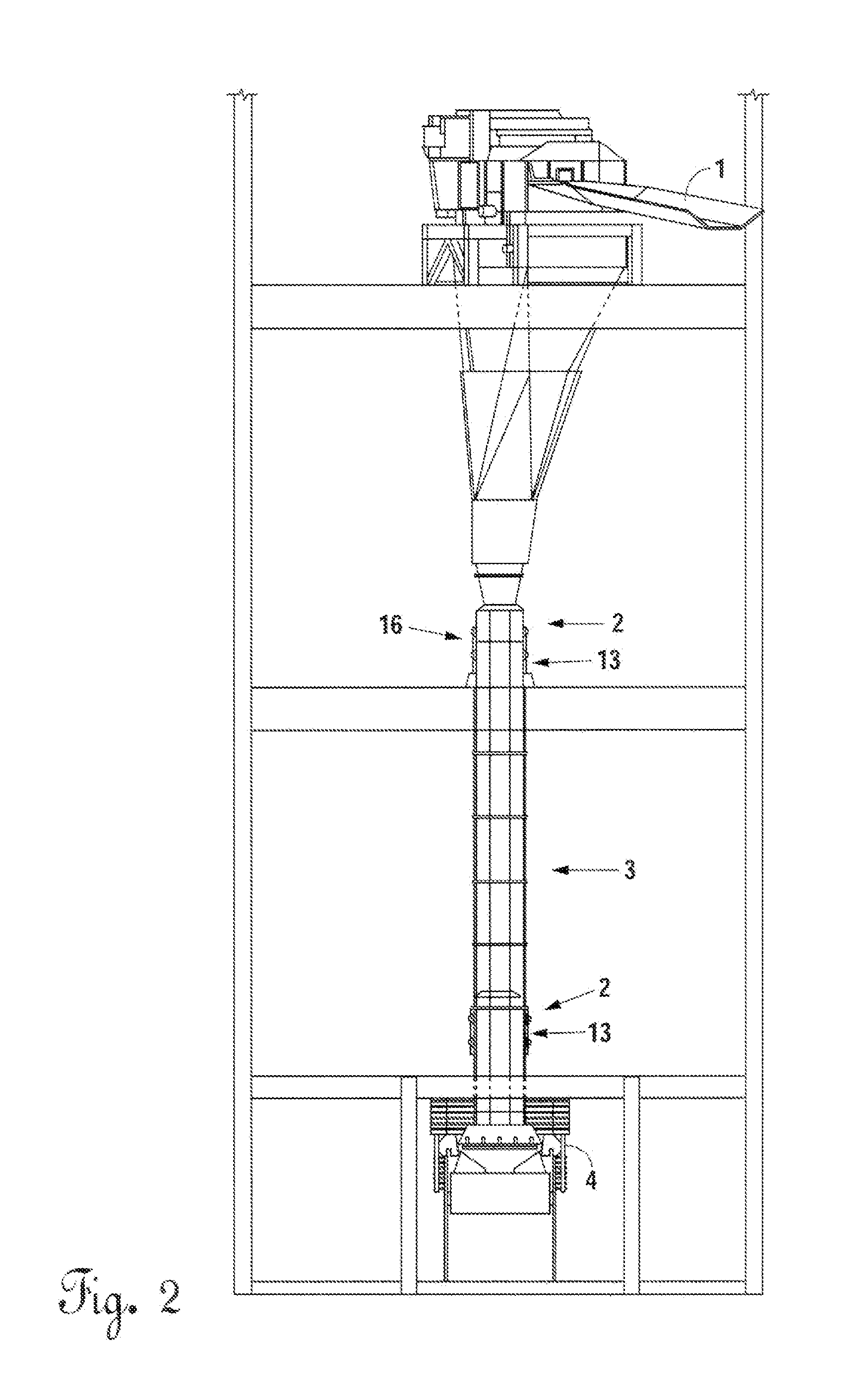

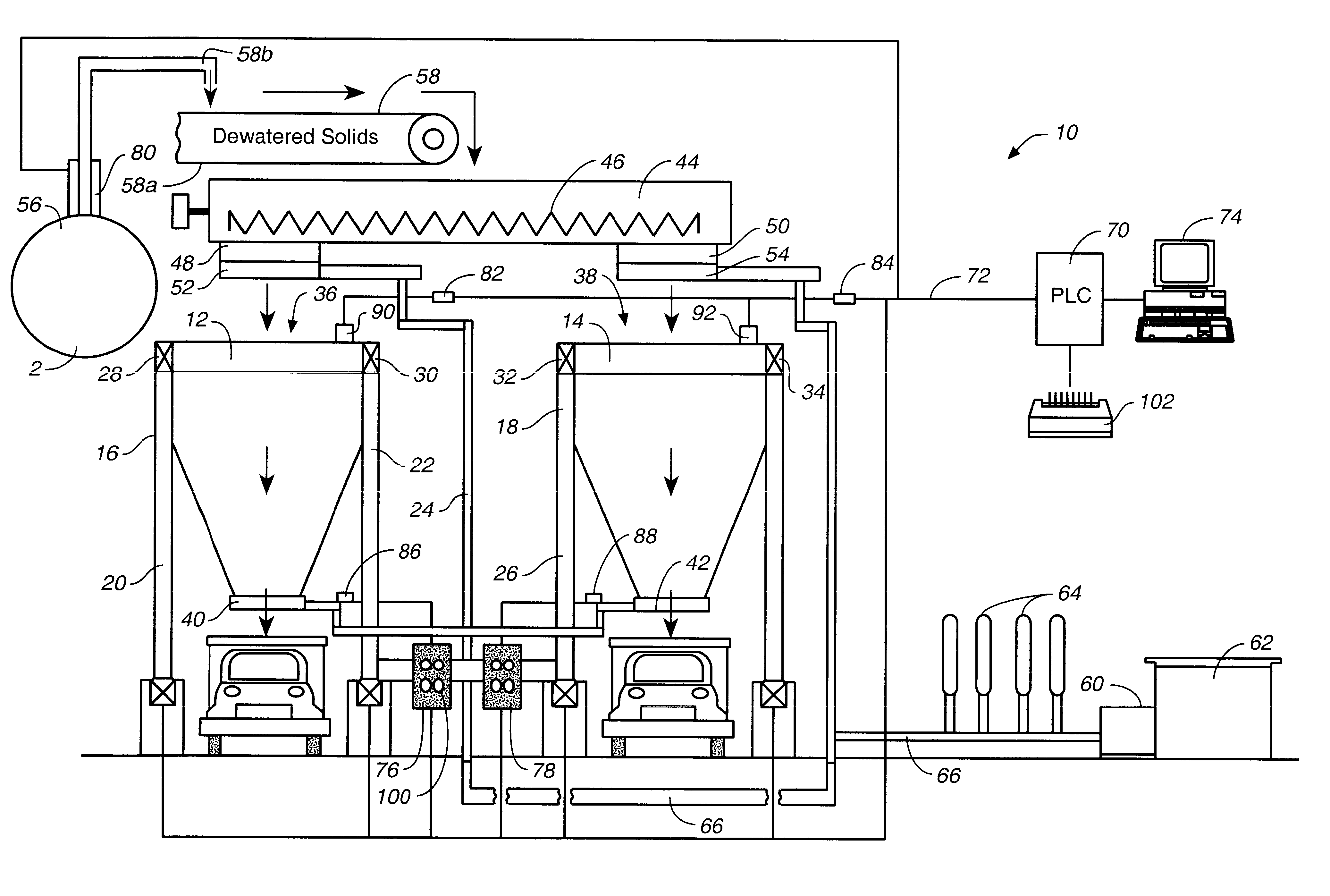

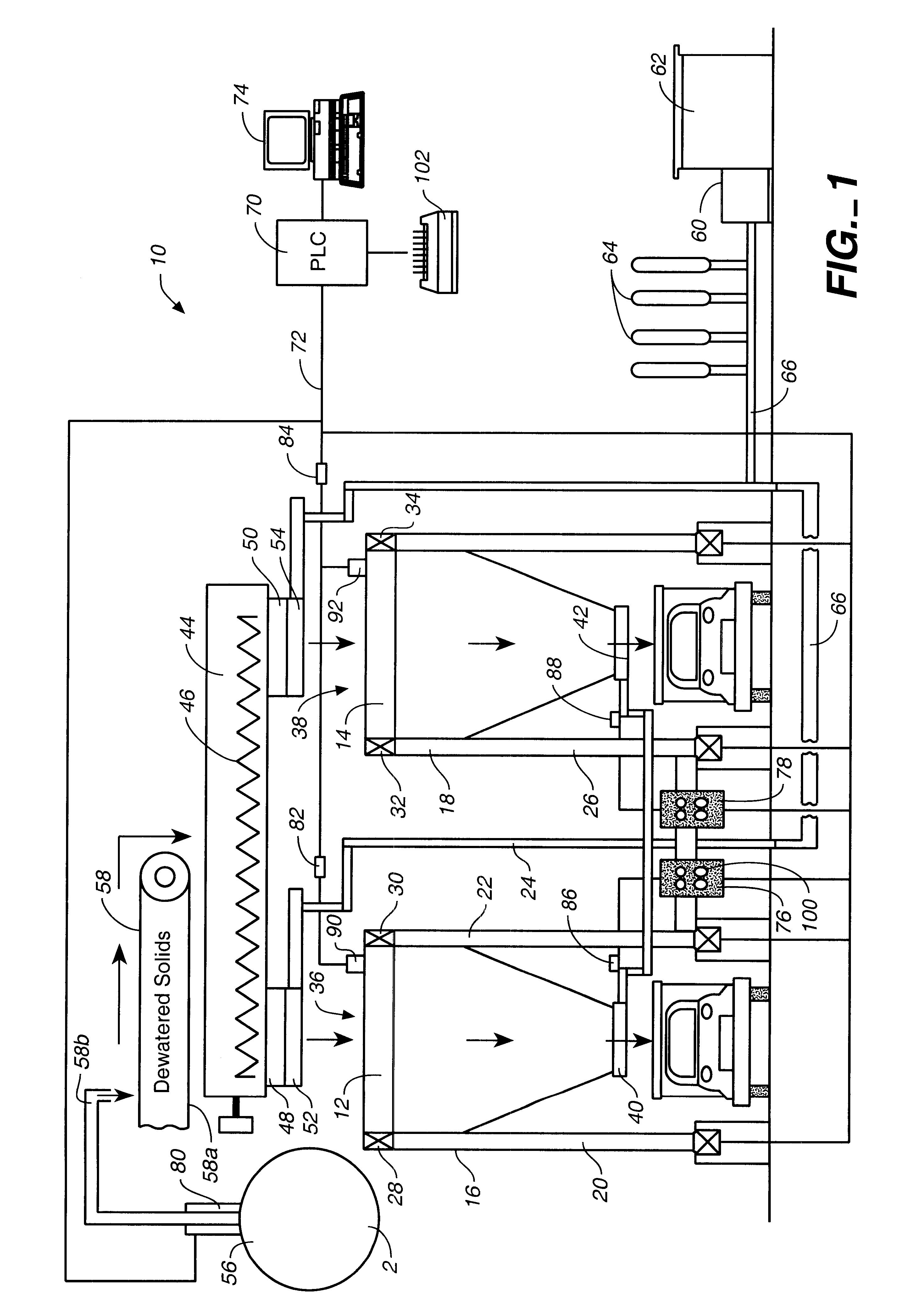

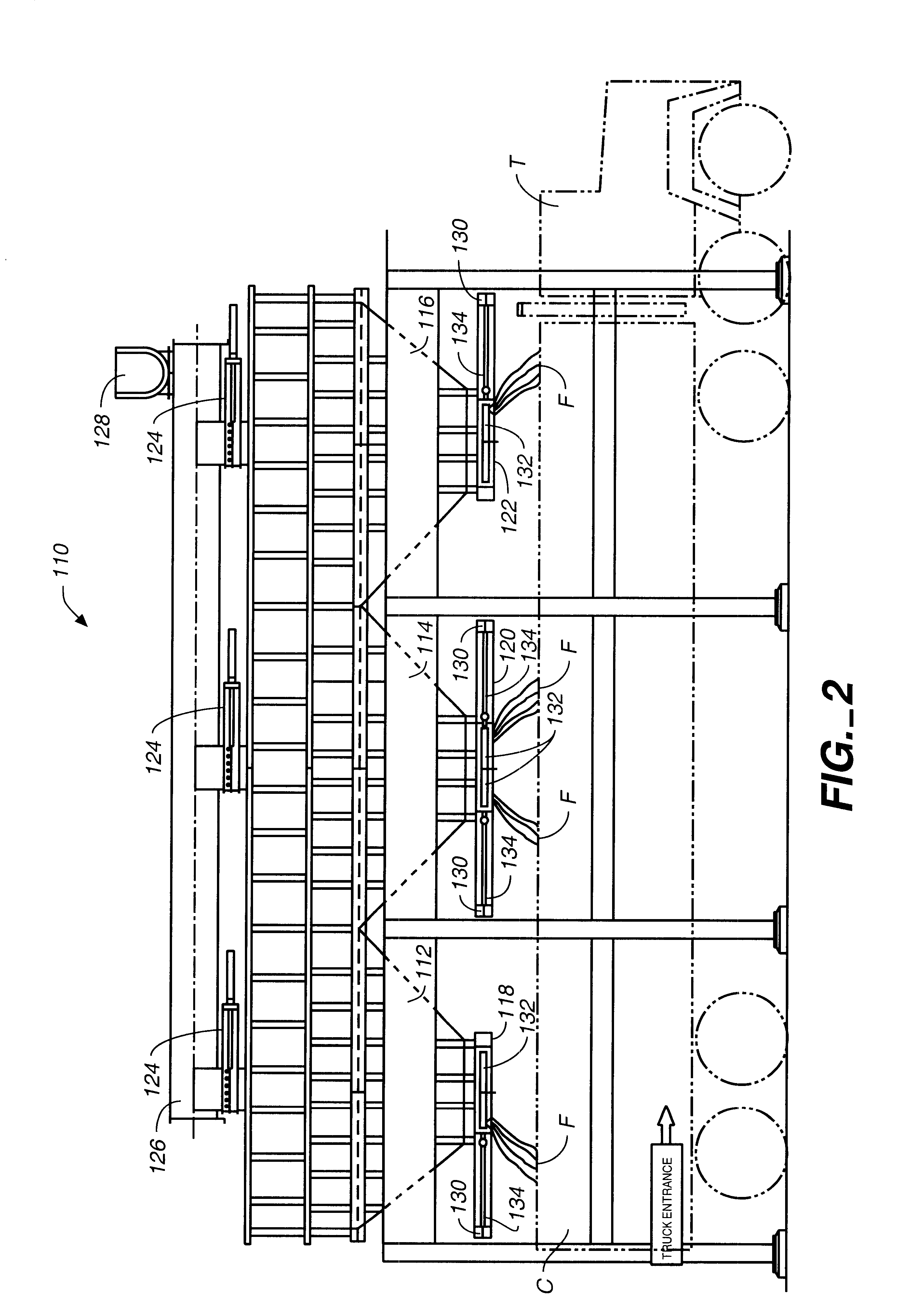

Gravity flow sludge load-out system

InactiveUS6447674B1Rapidly and accurately loading-out large volumeSettling tanks feed/dischargeCentrifugal force sediment separationWastewaterGravity flow

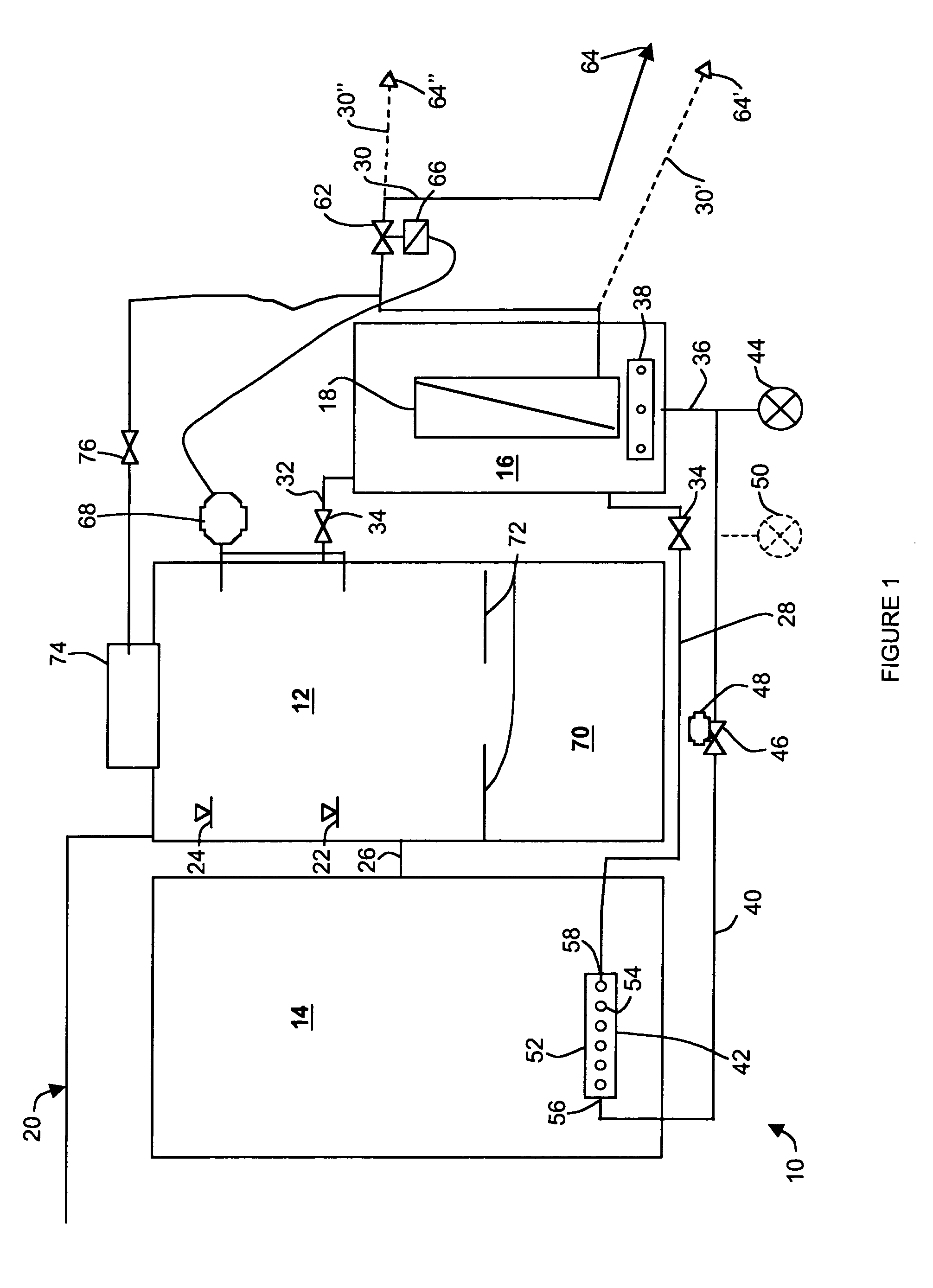

A gravity flow sludge load-out system for rapid and accurate loading-out of large volumes of treated biosolids from a wastewater dewatering plant, said system includes a plurality of hoppers 12, 14 supported by a main structure 16 having a plurality of vertical support members 20, each resting on a load cell 28, a sludge inlet at the tip of each hopper, and hydraulically controlled metering gates 40 at the bottom. A PLC 70 controls delivery of sludge from a dewatering facility, including e.g. a dewatering centrifuge 56, into the hoppers and then controls load-out of the sludge to a container truck by providing real-time monitoring of net sludge load-out and tight control of metering gates.

Owner:RDP TECH

Method for continuously preparing cellulose/ionic liquid solution

The invention discloses a method for continuously preparing fiber / ionic liquid solution. It comprises following steps: mixing fiber with ionic liquid solution into soft muddy shape, feeding said soft muddy mixture into feed port of screw extruder for continous dissolution, getting fiber / ionic liquid solution at outlet port of screw extruder. The metioned mixture contains no free ionic liquid solution, and does not possess property of gravity flow and deposition. The invention is characterized in that it employs screw extruder to process said muddy mixture, the solution efficiency of fiber can be increased and time can be reduced by making use of cutting action of extruder, and the degradation of fiber can be avoided. If extruding dissloution process and spinning / filming process can be matched together, the heating time for material can be identical, which will stabilize product quality.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

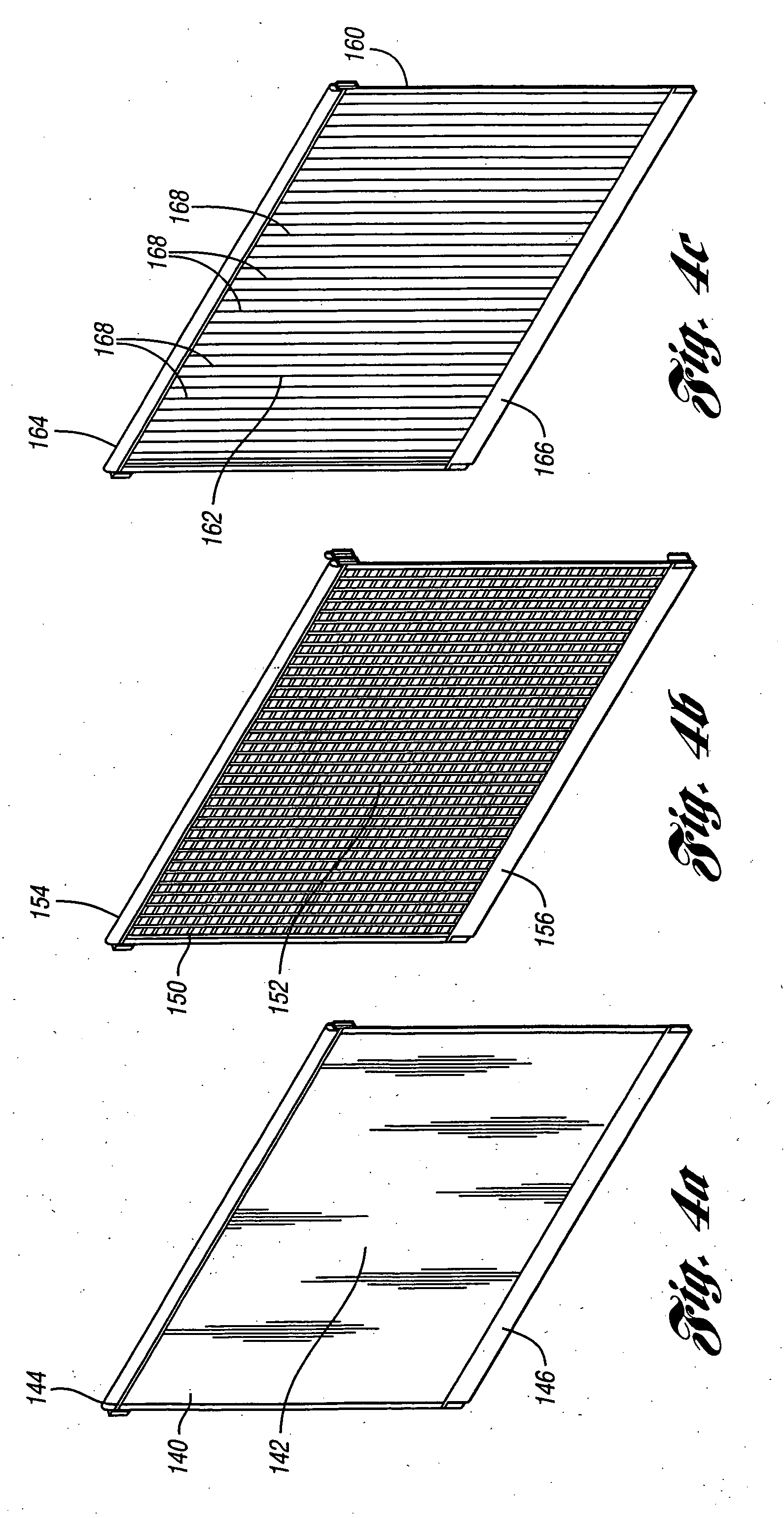

Family of stationary film generators and film support structures for vertical staged polymerization reactors

InactiveUS20060251547A1Liquid-gas reaction of thin-film typeChemical/physical/physico-chemical reactor detailsHigh fluxEngineering

Owner:EASTMAN CHEM CO

Water saving dual flush system of valving

A water saving dual flush system of valving assembly for toilet water-closets of the gravity flow type. This system of valving is designed to fit existing hardware in typical water-closets and convert single flush designs to dual flush water saving systems. Comprised of a flapper type bottom valve having a port located at a position above the discharge pipe of a common water-closet. The port edge of the bottom valve being molded to receive and mate to a flanged pipe end and thereby forming a watertight seal between the pipe and the bottom valve. A floatation collar being attached about the outside of the pipe. The upper end of the pipe having a upper valve seat sleeve attached. The upper valve seat sleeve being a slip-fit sleeve with a valve seat formed on the upper end and having a hinge portion incorporated on one side. The upper valve seat sleeve hinge is designed to mate to the upper valve and form together a hinged mount. The bottom end of the valve seat sleeve being flared to retain the floatation collar. The upper valve having a mating hinge mount attachment point to mate with the upper valve seat sleeve hinge. The upper valve being non-buoyant (depending on the application). The upper valve having a chain attachment point for flush actuation connection to the flush arm and thereby to the flush handle. The chain also having attached a float by which the upper valve is operatively adjusted.

Owner:PIPENBURG CHARLES G

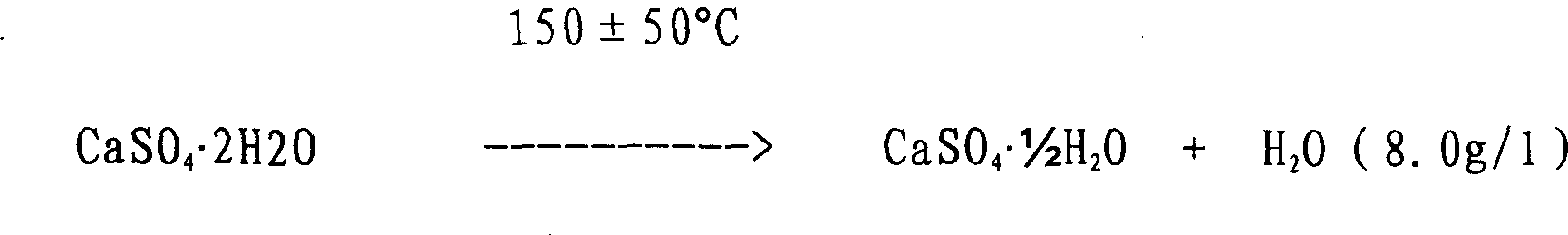

Gypsum base plastering mortar and gypsum base gravity flowing levelling mortar

A gypsum-based mortar for plastering is prepared from semi-hydrated gypsum, quartz sand, Ca(OH)2, powdered coal ash, slag, lime stone, hoolamite, volcanic dregs, haydite, polystyrene foam, expanded pearlite, zeolite, and ethene-vinyl acetate copolymer resin. Agypsum-based mortar for automatic leveling is prepared from semi- hydrated gypsum, quartz sand, Ca(OH)2, powdered coal ash, slag, lime stone, ethene-vinyl acetate copolymer resin, methyl hydroxyethyl (or hydroxypropyl) cellulose ether, sulfonated cyanuramide-formaldehyde resin and gluconate.

Owner:BEIJING SOULLEADER TECH DEV

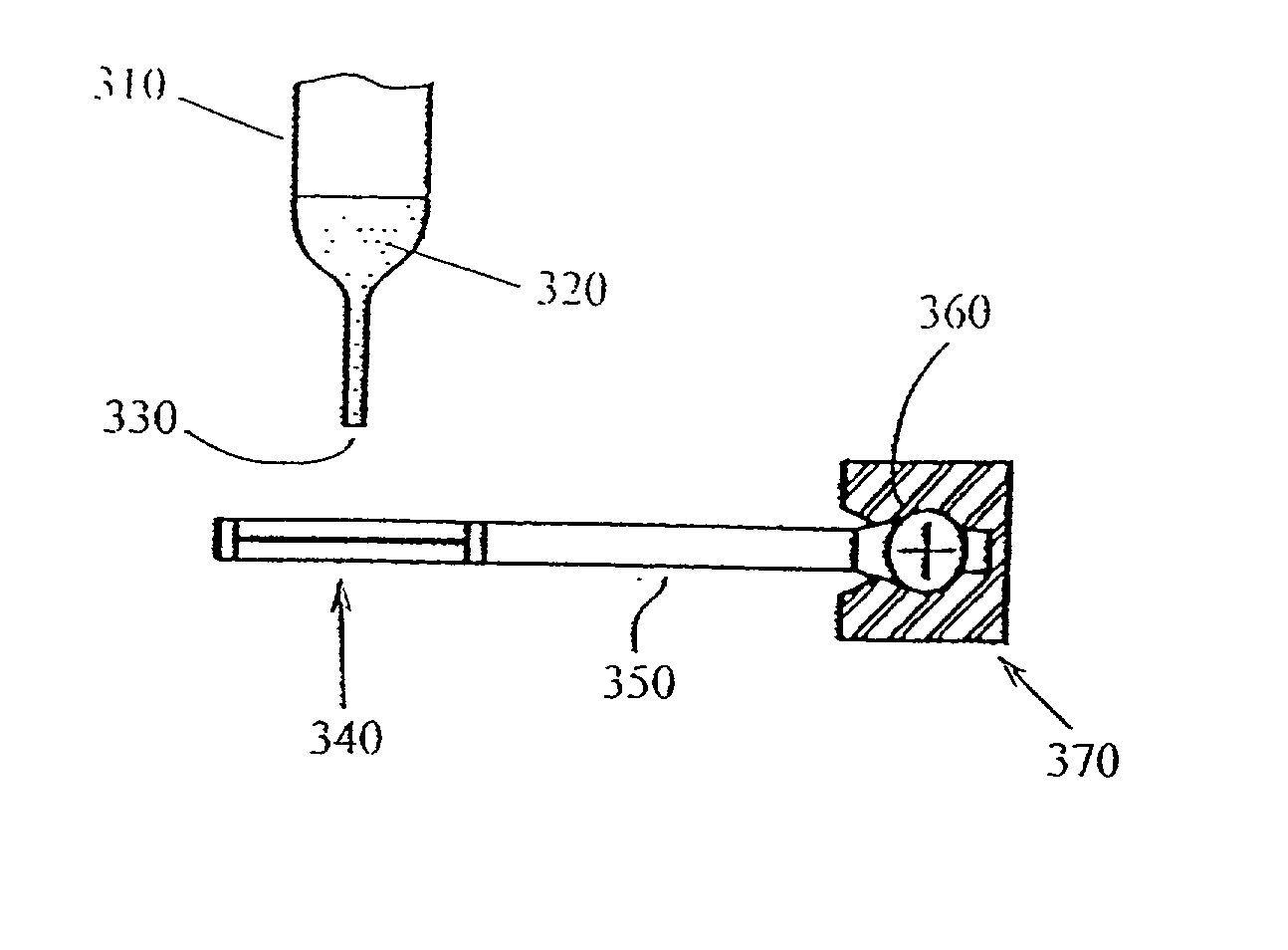

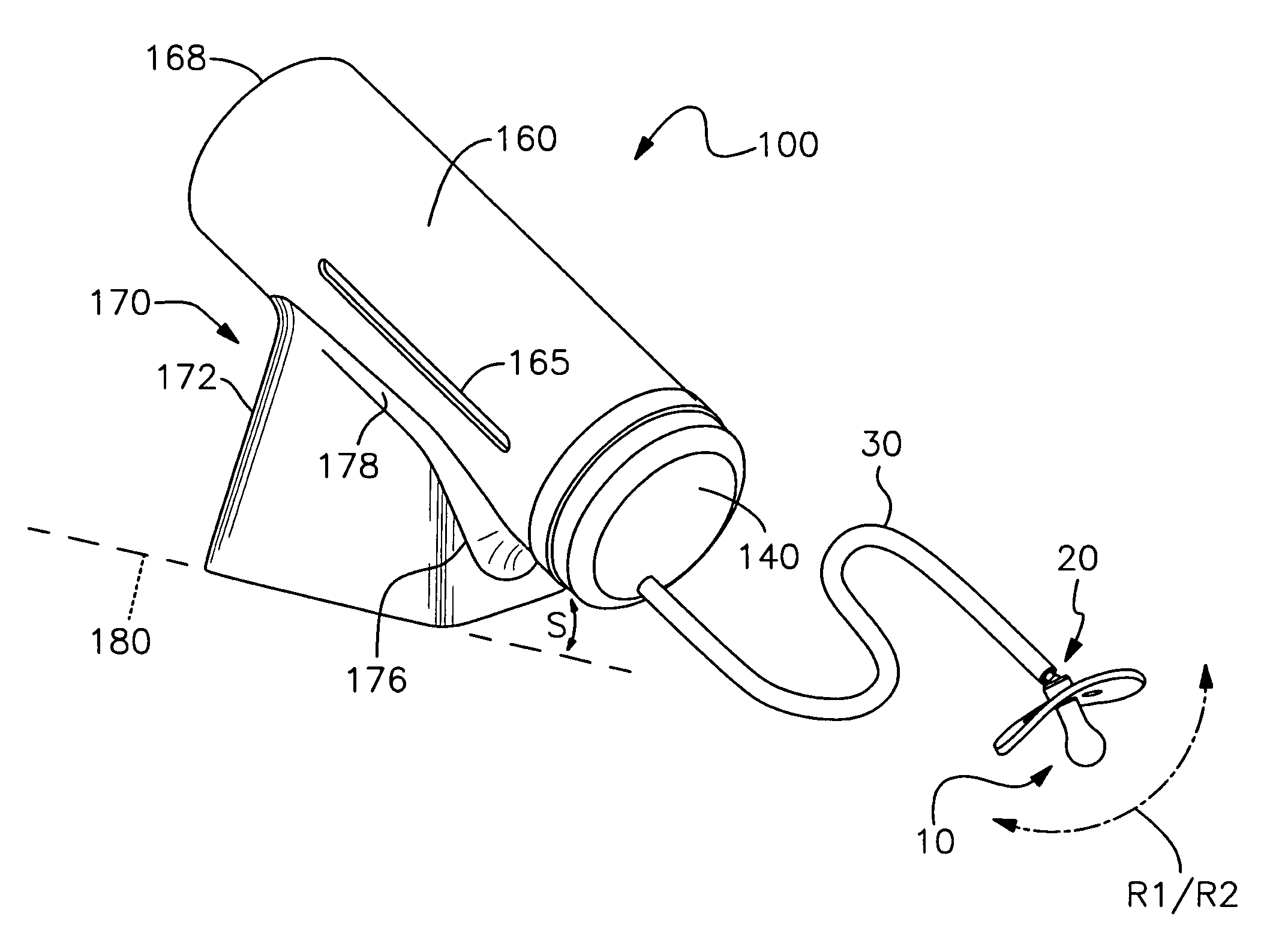

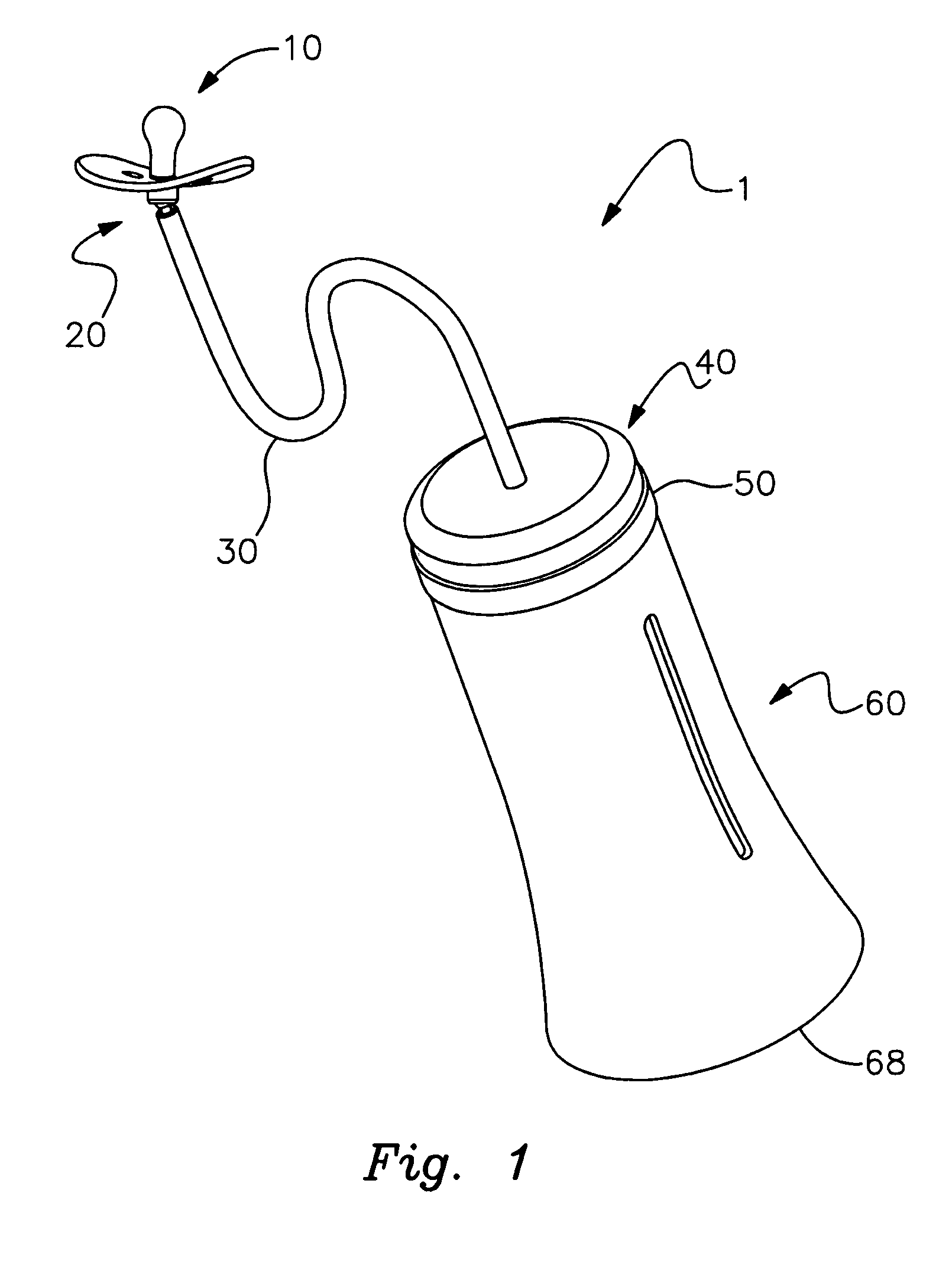

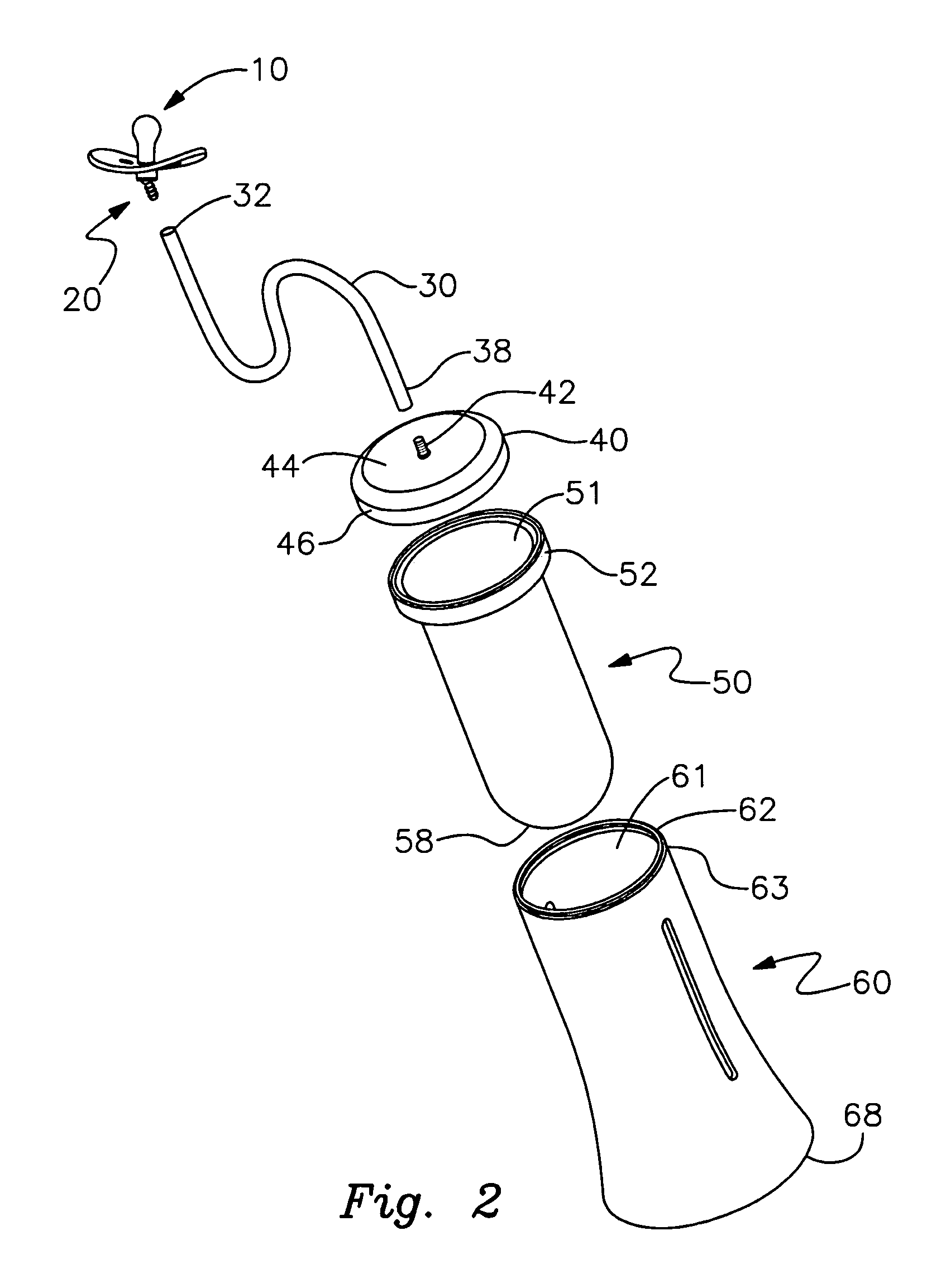

Nursing bottle with elongated tube and pivotable pacifier

InactiveUS6923332B1Firmly connectedEliminates physically supporting the bottle for infant feedingDispensing apparatusChildren furnitureGravity flowEngineering

A baby bottle feeding apparatus and method for assisting the feeding of a nursing infant by a bottle attached to an elongated feeding tube with pacifier end. The apparatus and method can include a pivotable connector such as a ball and socket connected between an elongated tube and the pacifier that can be rotated to selected positions without pinching off the tube for allowing ease of use by the nursing infant. The apparatus and methods can include additional assists such as allowing the liquid contents of the bottle to become more easily moveable by gravity flow. One embodiment can have a stand that orients the bottle up to approximately ninety degrees which can include forty five degrees when positioning the bottle on a support surface. Another embodiment allows for an interior wall inside the bottle to have a sloped portion so that laying the bottle on its side in a horizontal position still allows gravity to assist moving liquid contents within the bottle to the feeding infant.

Owner:THOMAS JEFF H

Technology for breaking, sorting and recycling household garbage incineration slag

ActiveCN103769287AImprove cleanlinessReduce frictional heatSolid waste disposalGrain treatmentsSlagFiltration

The invention relates to a technology for breaking, sorting and recycling household garbage incineration slag. The technology comprises the following steps: by utilizing gravitational potential energy and using water as a medium and circulating flow, vertically arranging an iron removal device, a hopper, a breaker, a magnetic separator, a jigger, screening equipment, a slag finished product collection tank, a sedimentation tank and the like which are equipment for treating the household garbage incineration slag in every link from high to low; injecting water and the garbage incineration slag into the breaker so as to form a material flow, obtaining slag materials with fine particles, light mass and optimized components through the breaker, the jigger and the screening equipment under the action of material gravity flow, filtering through the collection tank and the sedimentation tank and directly transporting the dried fine-grained slag finished product to a finished product warehouse finally; and reblending clear water obtained after sedimentation and filtration and the garbage incineration slag raw material so as to be recycled. The technology has the advantages that the exertion of gravitational potential energy is facilitated in a material treatment process, and the friction heat energy of the materials and the equipment is reduced; and the dust fog pollution in the treatment process is reduced, and environments are protected.

Owner:TONGXIANG TONGDE WALL BUILDING MATERIALS +2

Light-weight modular adjustable vertical hydroponic growing system and method

A light-weight, modular, adjustable vertical hydroponic growing system and method of Native American design for cultivation plants and beneficial soil organisms (BSO's) in symbiotic combination. Forest-like arrays of fully rotatable and demountable grow tubes are suspended within climate-moderating greenhouses, optionally from conveyor tracks. The tubes are filled with light-weight, porous 100% in-organic grow media predominately comprised of expanded volcanic or recycled glass granules. The grow tube arrays are provided with an insulated, overhead-mounted fertigation distribution system delivering metered intermittent flows from insulated mixing and holding tanks. The flows are recycled via an insulated return piping system to maintain cool fertigation temperatures near those of natural ground water. Fertigation supply mains provided with vortex flow induction devices impart rotational momentum to flows for delivery of uniform aerated fertigation to plants and BSO's via a combination of open-tube emitters and gravity flows within grow tubes.

Owner:COLLINS FRED +1

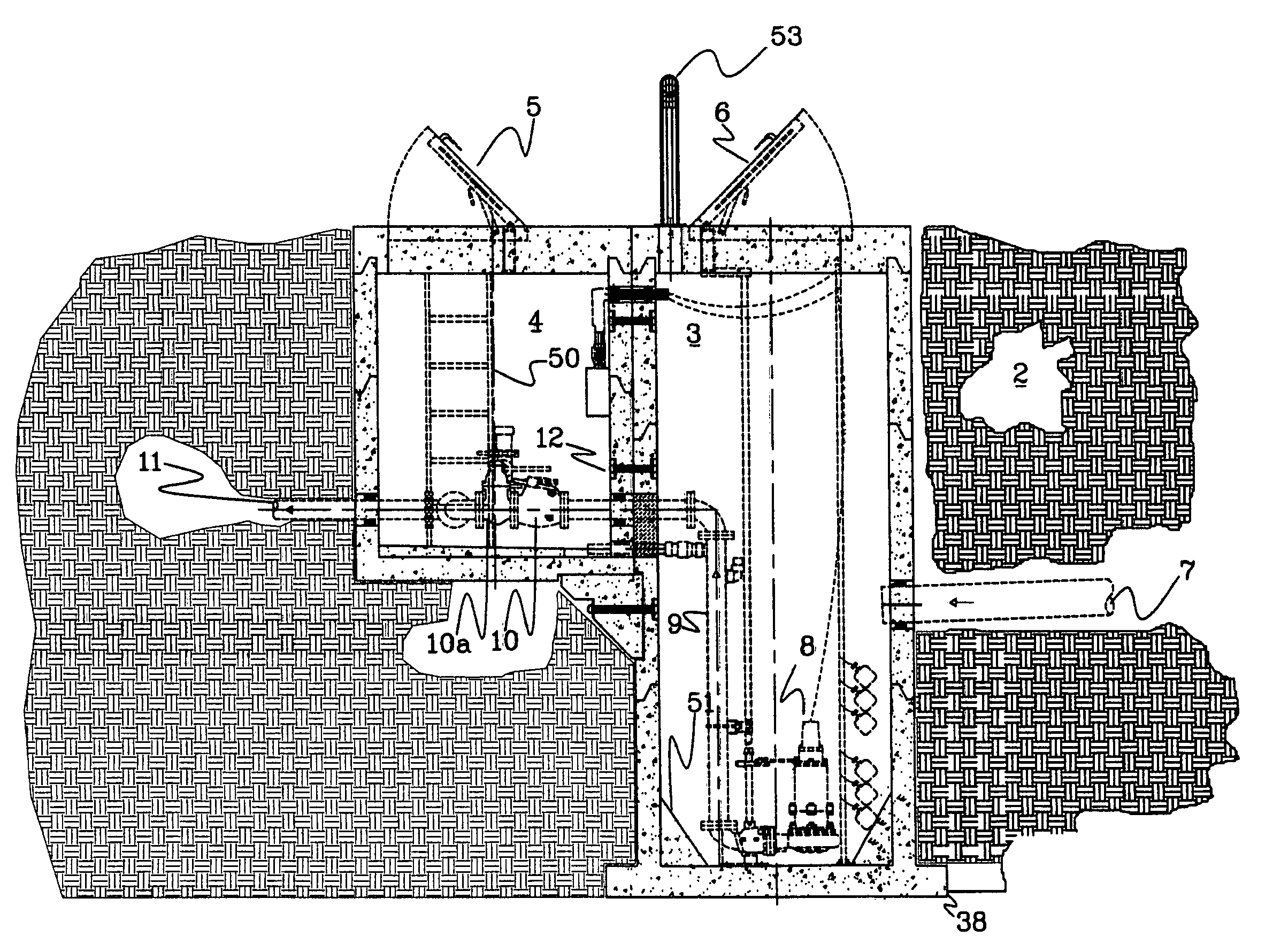

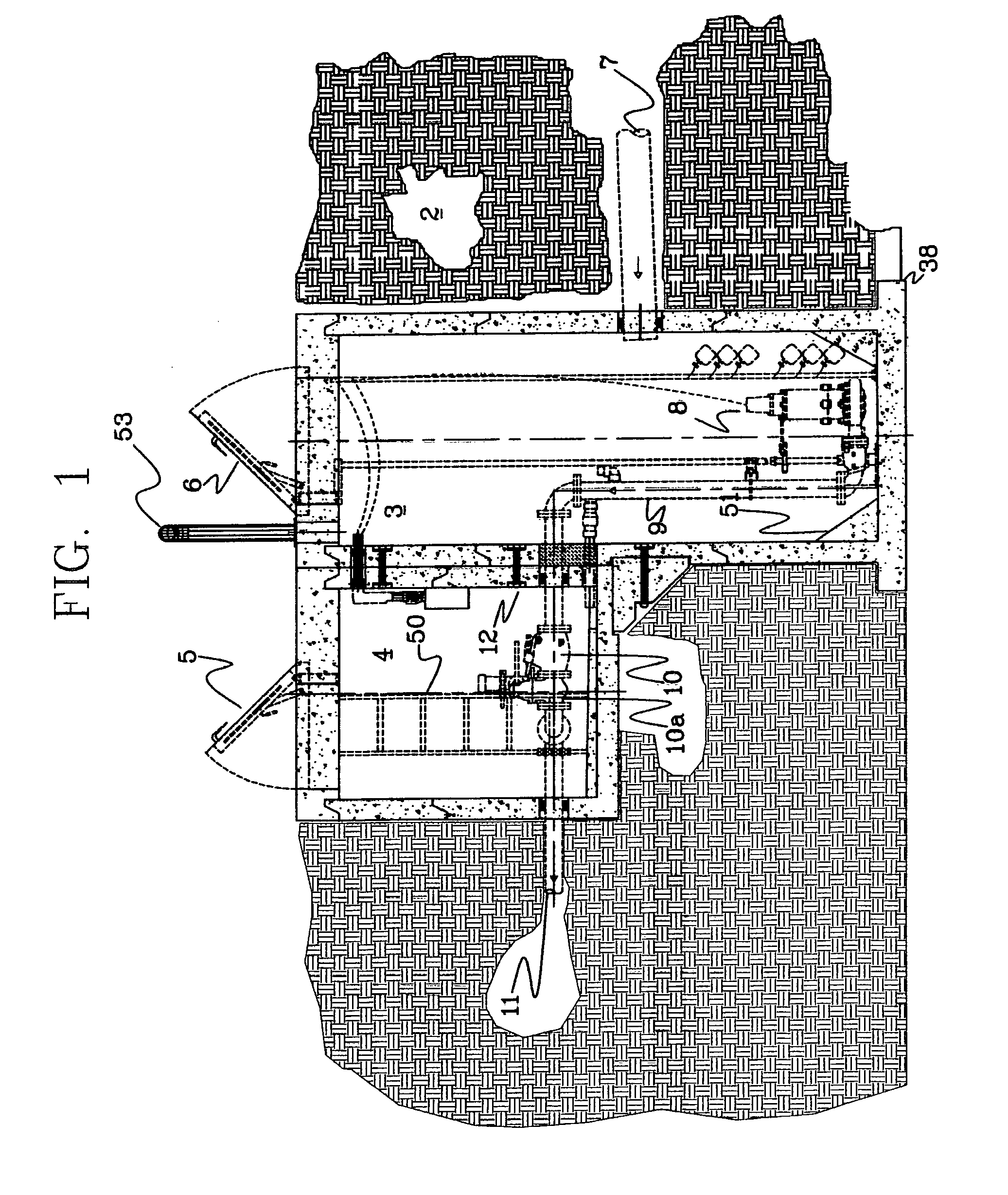

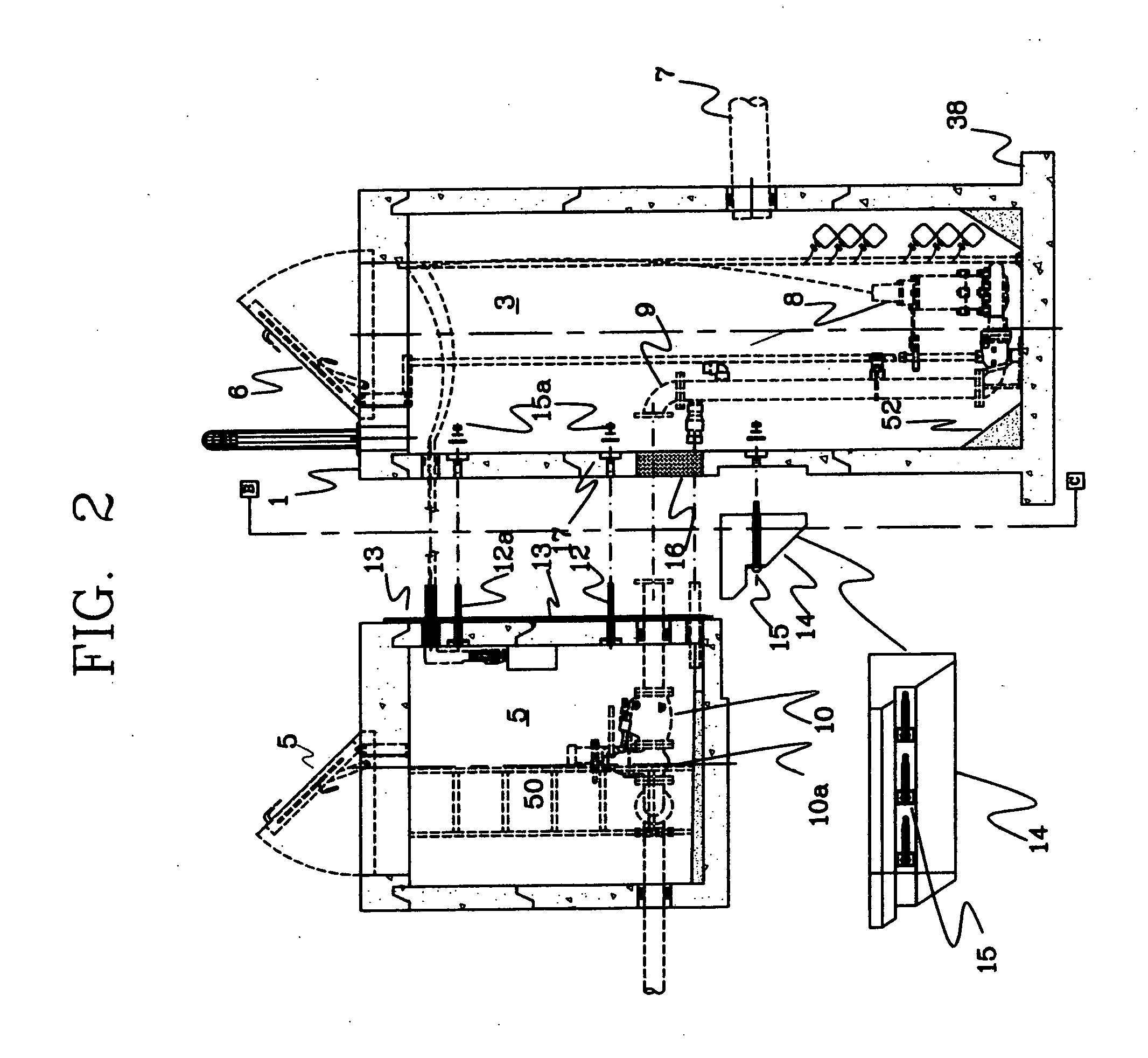

Unitary concrete pumping station for aqueous waste submersible pumping applications

InactiveUS7150290B1Easy to installShorten the timePump componentsPipeline systemsLiquid wasteStructural engineering

A unitary concrete structure pumping station useful in pumping waste fluids and the like during the passing of such materials from one part of a gravity flow waste system to another. This concrete structure is simple to install and use and many of the problems associated with conventional pumping stations are alleviated. The structure is comprised of several parts that can be made pre-assembled at the factory or assembled in the field prior to installation. By being a unitary structure this pumping station is resistant to movements within the earth and therefore less likely to incur line breaks.

Owner:ELECTRIC TECH

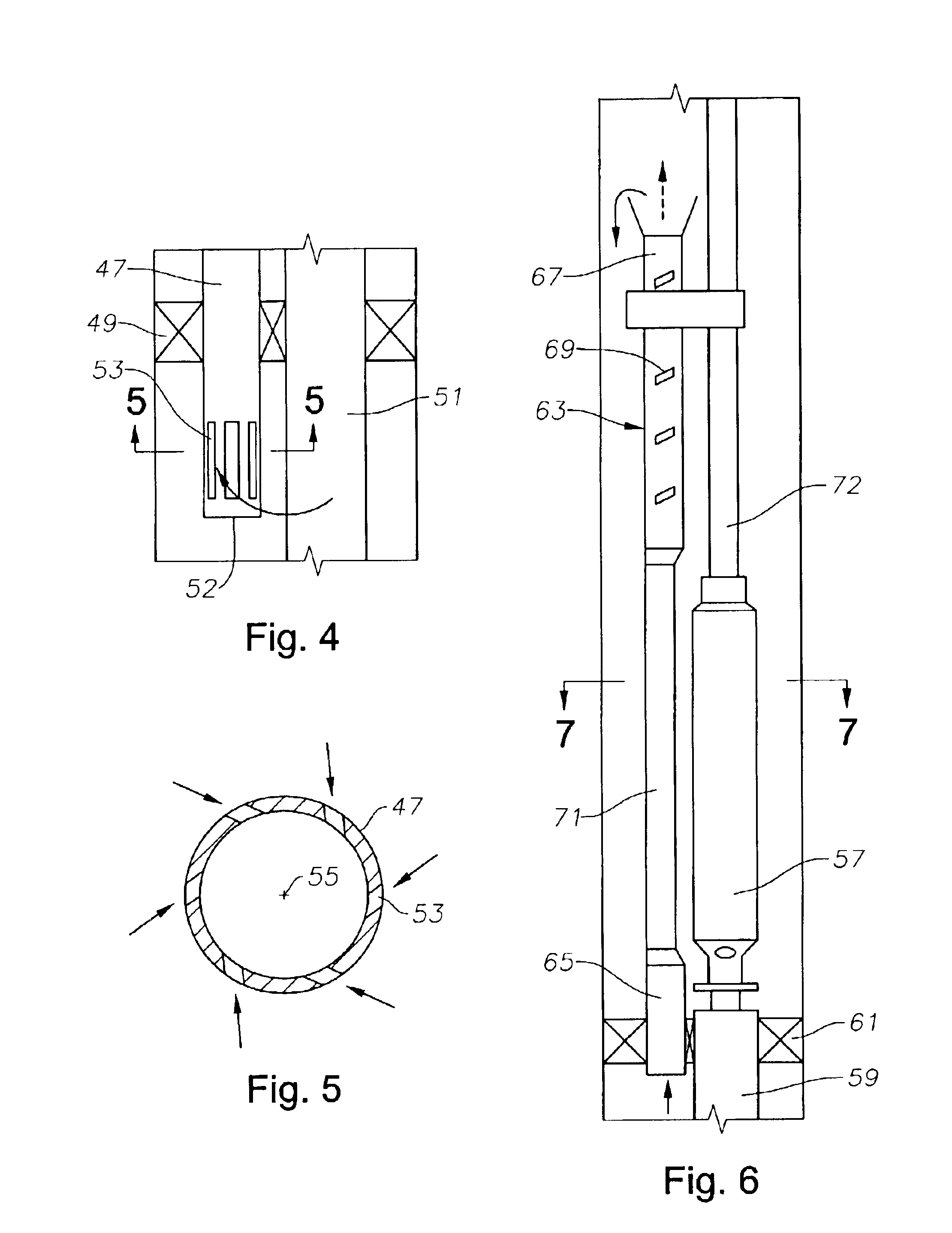

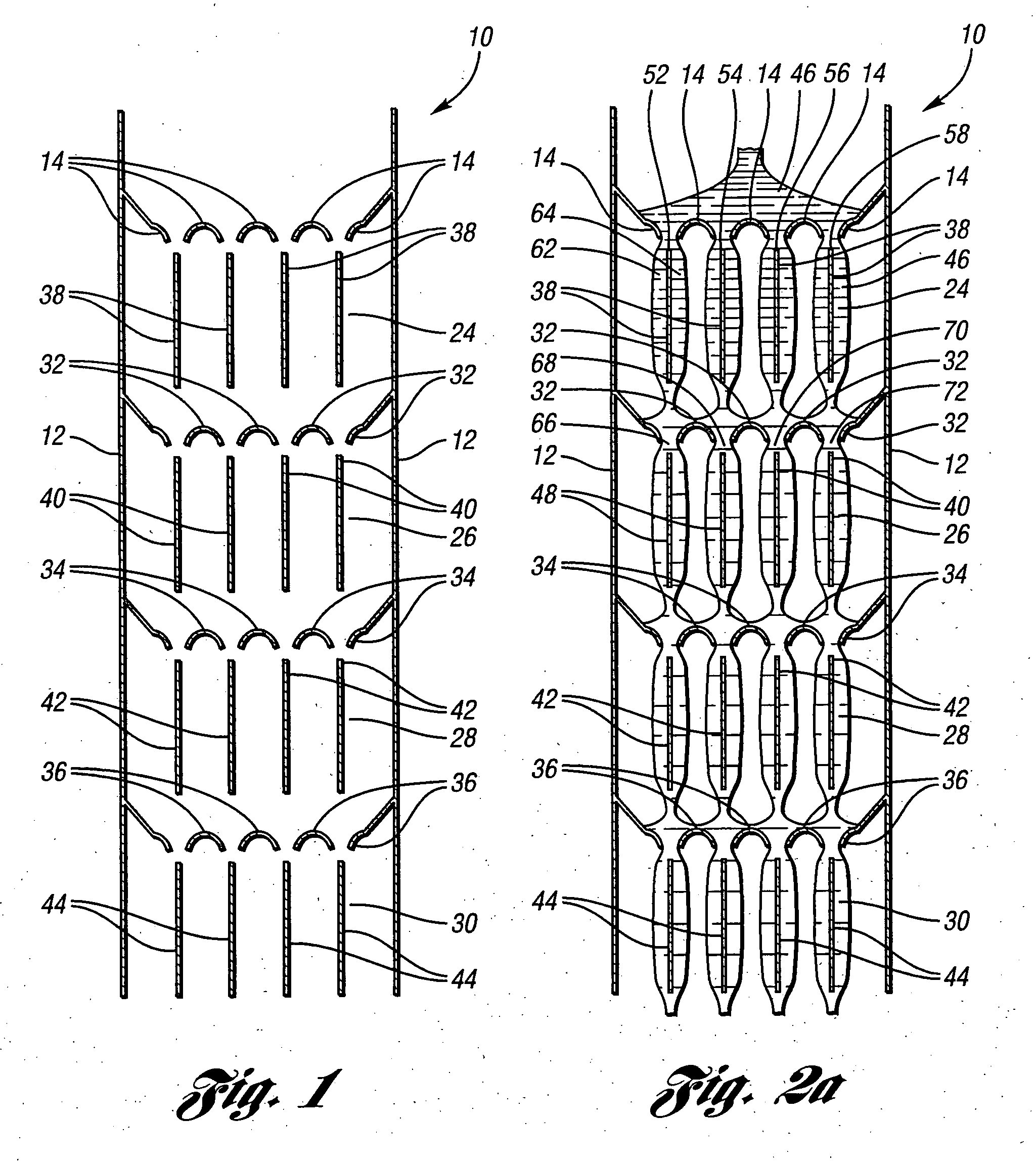

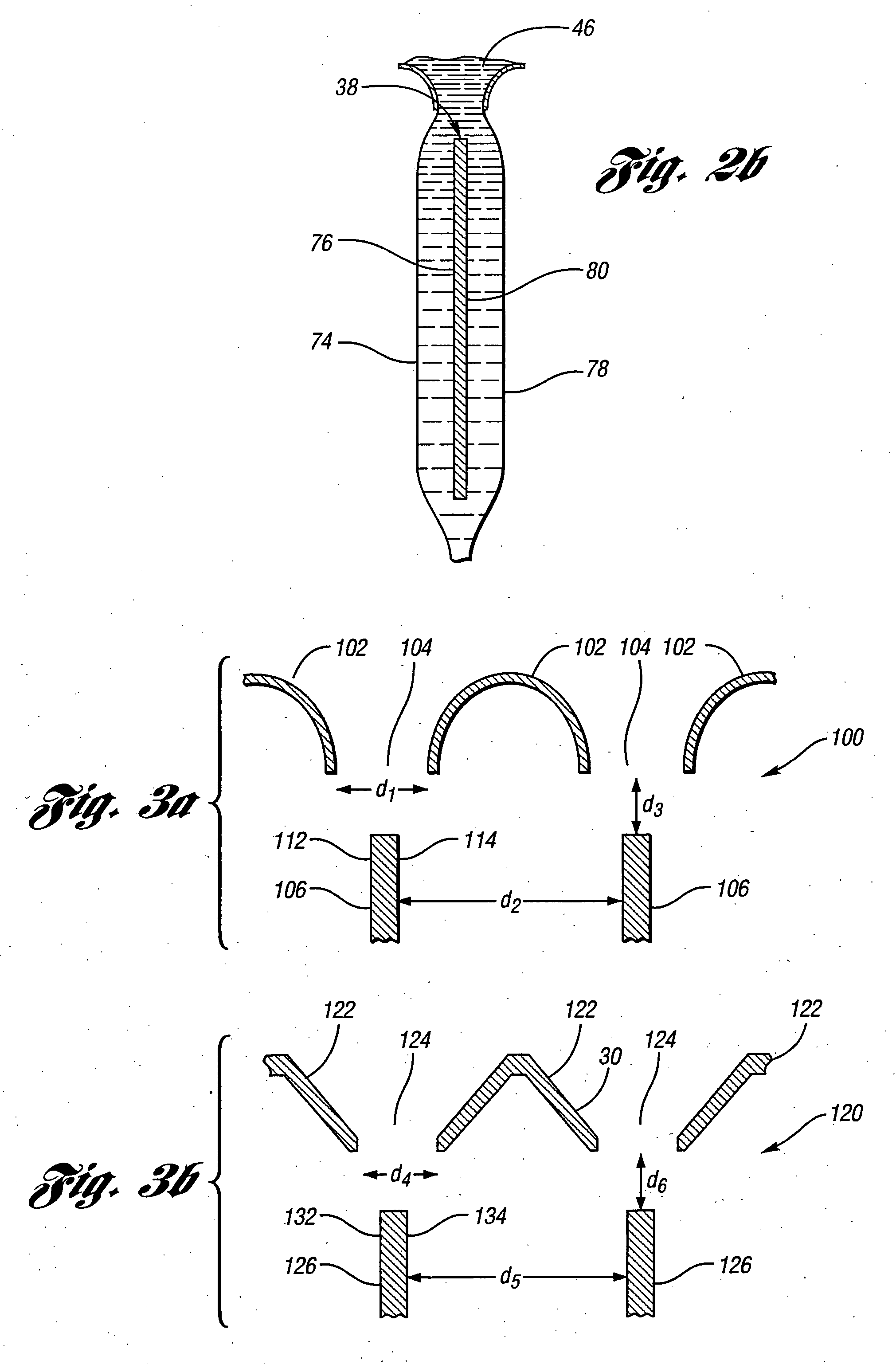

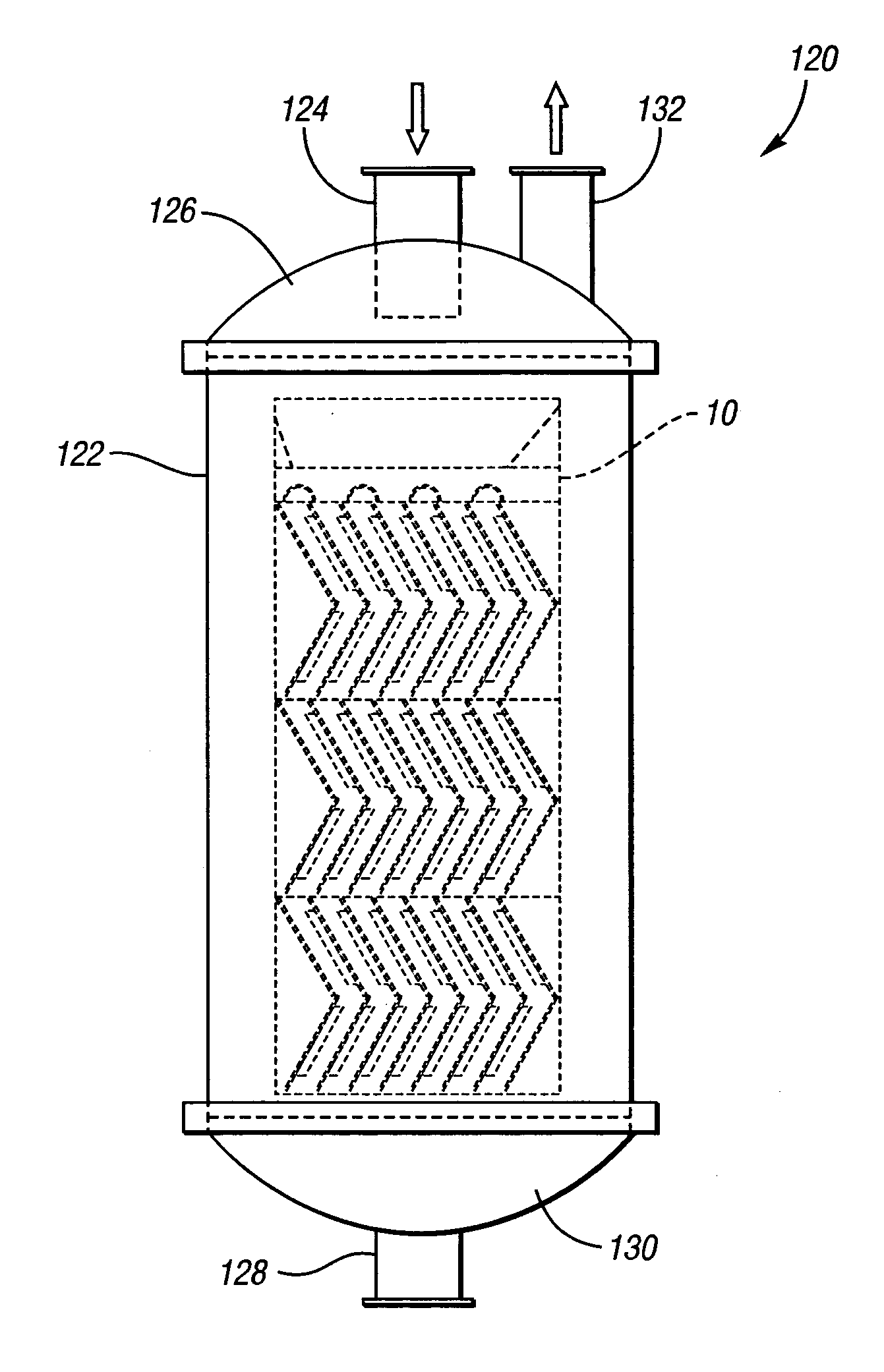

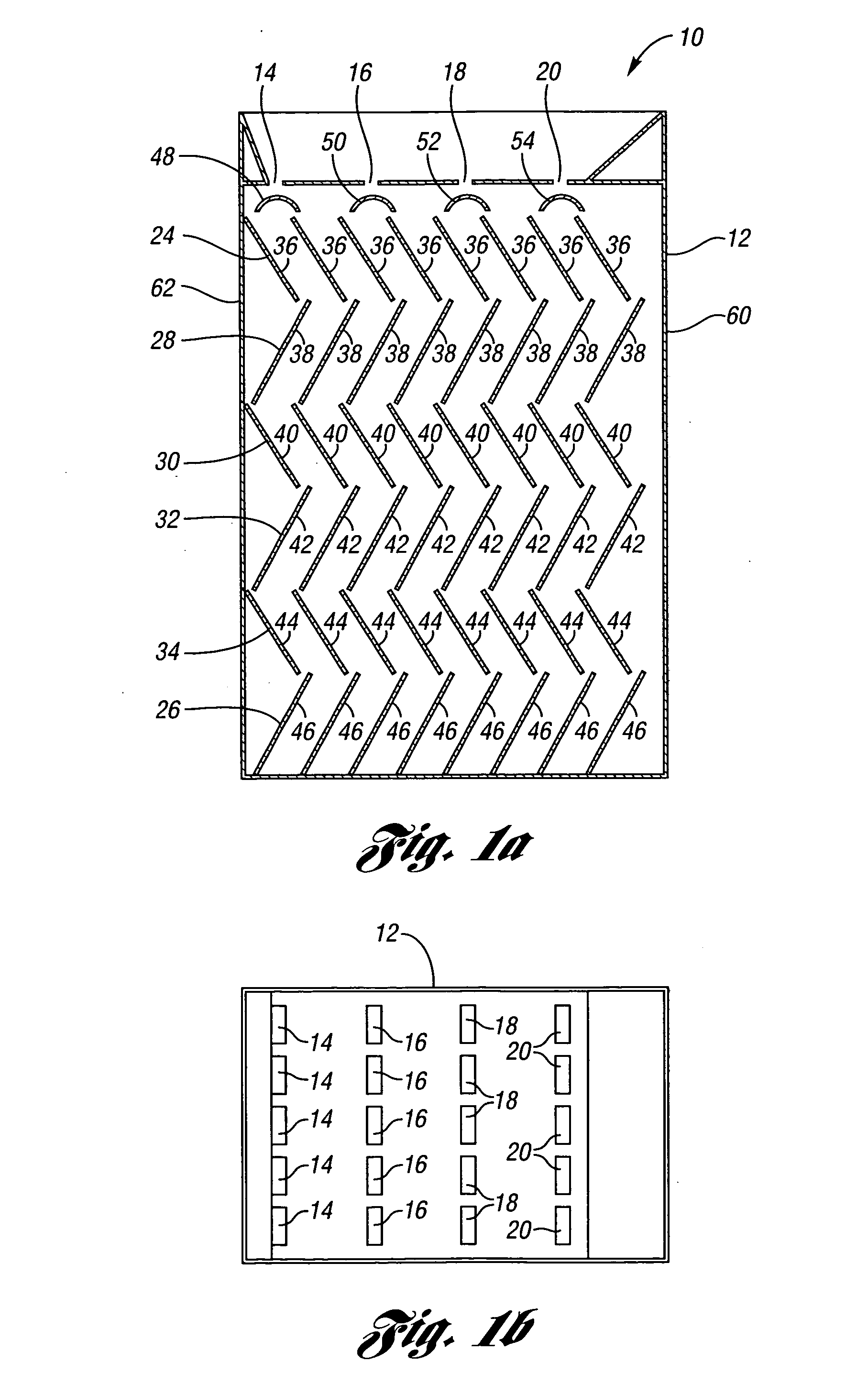

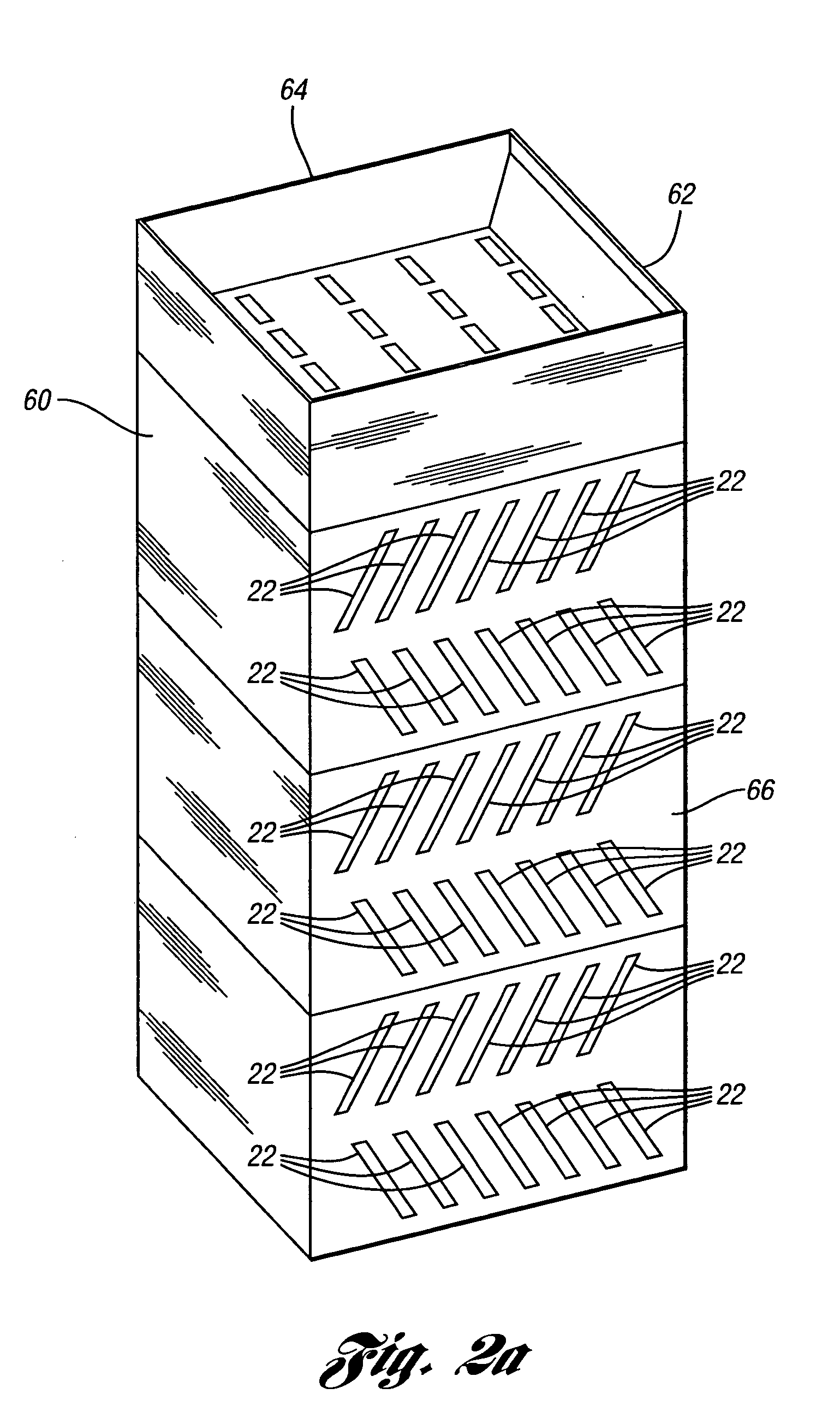

Baffle assembly module for vertical staged polymerization reactors

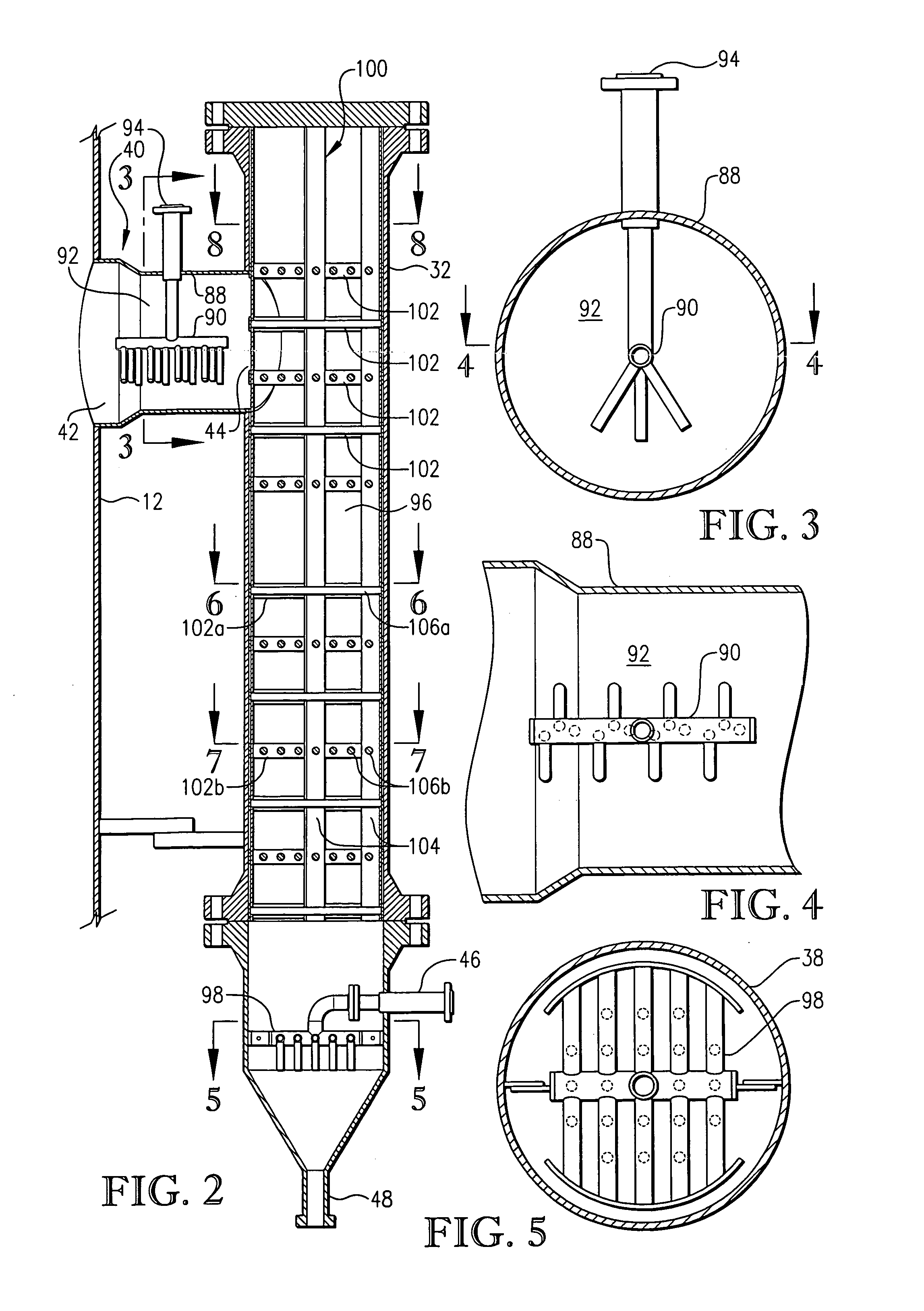

InactiveUS20060251546A1Increase exposureIncrease residence timeProcess control/regulationLiquid-gas reaction of thin-film typeGravity flowPolymer melt

The present invention provides an assembly for use in vertical, gravity flow driven polymerization reactors for combinations of high viscosity, high throughput, and shallow polymer depths. The baffle assembly module of the invention includes a support structure having a plurality of side openings. The side openings allow the escape of vapor liberated from the polymeric melt. The assembly further includes a feed splitter followed by two or more vertically arranged rows of baffle plates with the feed splitter and baffles sequentially positioned in the support structure. The plurality of parallel baffles in a row are angled such that when a polymeric melt contacts a given baffle the polymeric melt moves in a downward direction under the force of gravity. The arrangement of the rows is such that each row (except the lowest row) transfers the polymeric melt to a lower vertically adjacent row until reaching the last row of baffles in the module. According to the vertical arrangement of the components in the baffle assembly module and by stacking additional baffle assembly modules if needed within the reactor, the polymeric melt cascades down the vertical length of the reaction vessel interior. The present invention also provides a polymerization reactor that incorporates the assembly of the invention and a method of increasing the degree of polymerization of a polymer melt by using the assembly of the invention.

Owner:EASTMAN CHEM CO

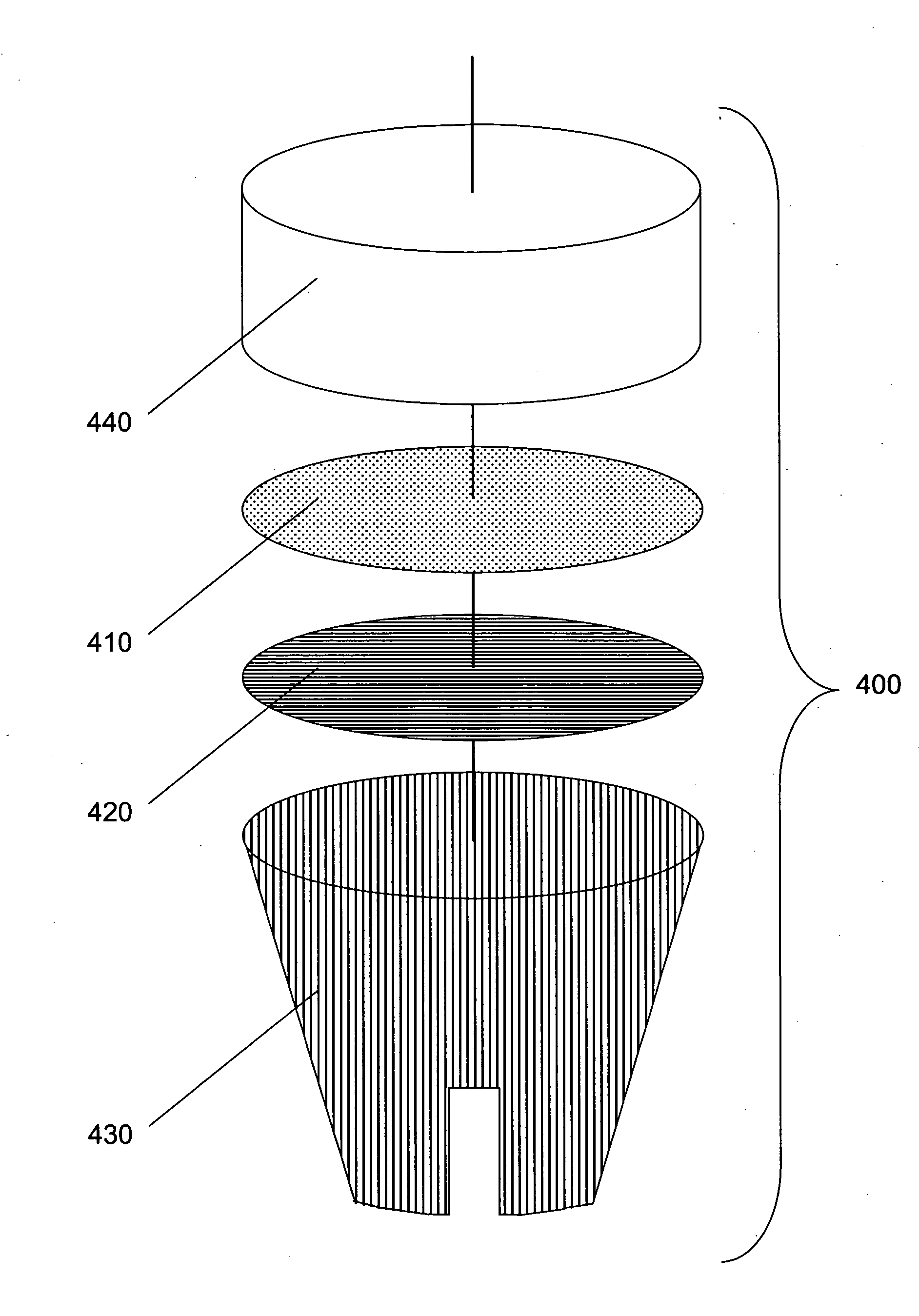

Gravity flow filter

A gravity-fed carbon block water filter in one embodiment includes a filter block comprising multiple sub-blocks each comprising filter media walls surrounding and defining a cavity for receiving fluid. Each of the sub-blocks is connected to at least one other of the sub-blocks by filter media of which the filter block is made. In one approach, the filter media includes about 20-90 wt % activated carbon, and about 5-50 wt % binder. In another approach, a lead concentration in a final liter of effluent water filtered by the filter is less than about 10 μg / liter after about 151 liters (40 gallons) of source water filtration, the source water having a pH of 8.5 and containing 135-165 ppb total lead with 30-60 ppb being colloidal lead greater than 0.1 μm in diameter. A gravity-fed water filter in other embodiments has no specified shape but achieves a FRAP factor of about 350 or less.

Owner:BRITA LP

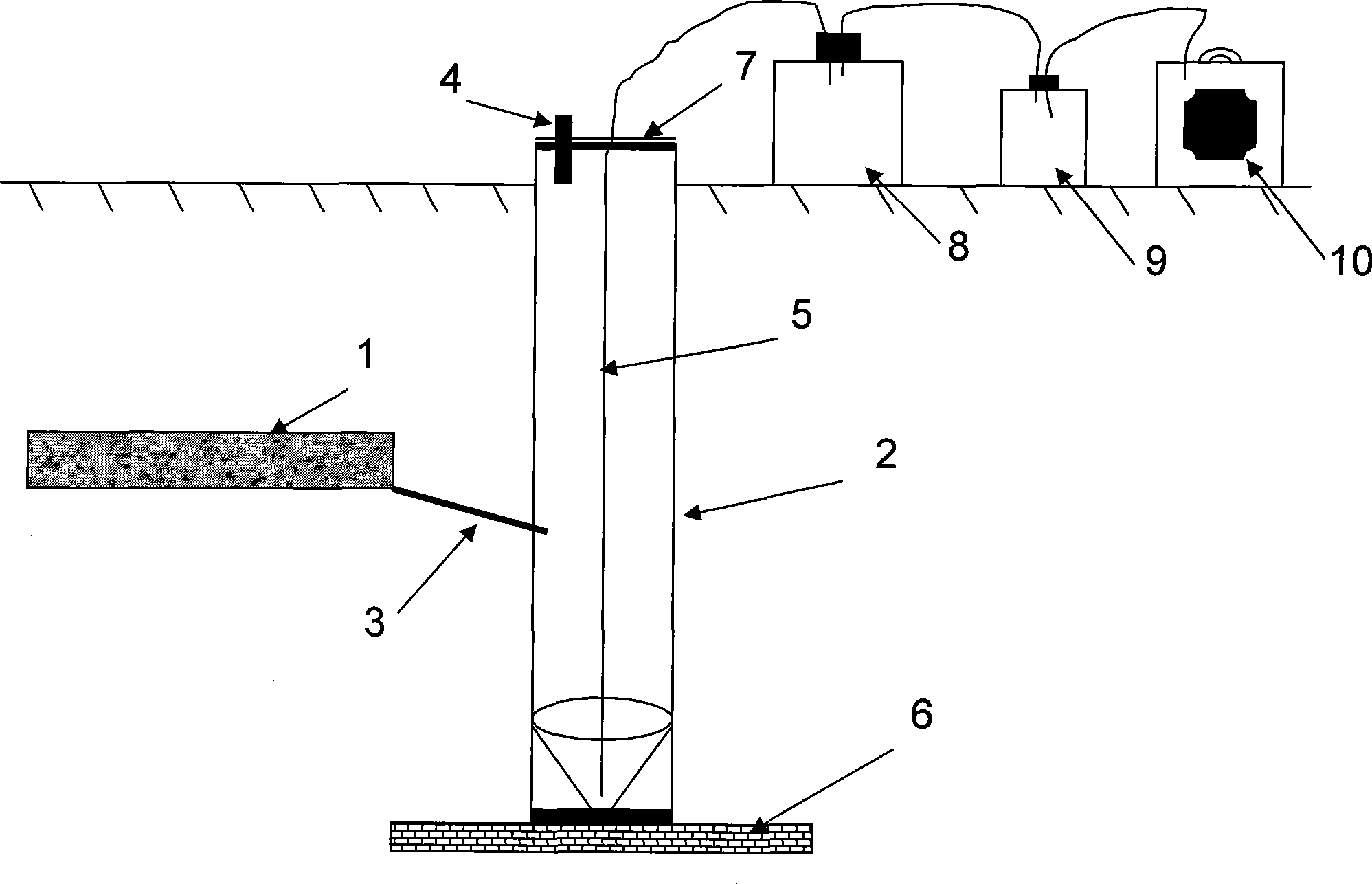

Gravity flow type farmland underground leaching liquor collecting device

InactiveCN101246094AGuaranteed leaching conditionUnrestricted installation depthWithdrawing sample devicesEarth material testingWater dischargePhosphor

The present invention discloses a self-flowing farmland underground drenching solution collecting device which belongs to the field for researching the environment science, agrology and plant nutriology. The device of the invention comprises an eluviation disk, a water-discharging pipe, a liquid-collecting pipe, a breathing pipe, a liquid drawing pipe, a sampling bottle, a buffering bottle and a vacuum pump; the eluviation disk is used for collecting the drenching solution; the liquid-collecting pipe is connected to the water outlet of the eluviation disk through the water-discharging pipe, the drenching solution in the eluviation disc can automatically flow into the liquid collecting tube; and the vacuum pump is used for extracting the drenching solution collected by the liquid-collecting pipe to the sampling bottle through the liquid drawing pipe under the buffering of the buffering bottle. Comparing with the prior art the invention has the characters of reasonable structure, convenient manufacturing, easy actualizing and the like, and the invention is especially suitable for monitoring the influence of the soil solutes of nitrogen, phosphor, agriculture chemicals and the like to the groundwater.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +4

Solvent-free polyurethane gravity flow self-leveling floor material and preparing method

ActiveCN101270259AImprove protectionReduce coating costTemporary pavingsPolyurea/polyurethane coatingsVegetable oilSolvent free

The invention provides solvent-free polyurethane self-leveling terrace material, which comprises A, B and C components. A consists of 20 to 60 percent of vibrin, 0.1 to 1 percent of defoamer, 1 to 5 percent of color paste, 5 to 20 percent of powdered zeolite, and10 to 40 percent of kaolin or silica flour. B is liquid MDI with NCO equivalent of 127. The solvent-free polyurethane self-levelling terrace material has the advantages that dehydrated castor oil is used to prepare vibrin instead of polyether and polyester polyol; castor oil belongs to vegetable oil with wide sources, and is renewable; vegetable oil is low in cost as raw material for preparing coating, and is innoxious, friendly to the environment with high hardness.

Owner:SHANGHAI YANGSEN SPECIALITY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com